Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298 results about "Communication industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Communications Industry. Overview. The communications industry is a multifaceted complex of technology, media, content, telephony, data, distribution, transport and other factors, including extensive federal, state and local regulation.

Rechargeable aluminum ion cell and preparation method thereof

InactiveCN104241596AImprove conductivityImprove thermal stabilityCell electrodesElectrolyte accumulators manufactureAluminum IonMetal foil

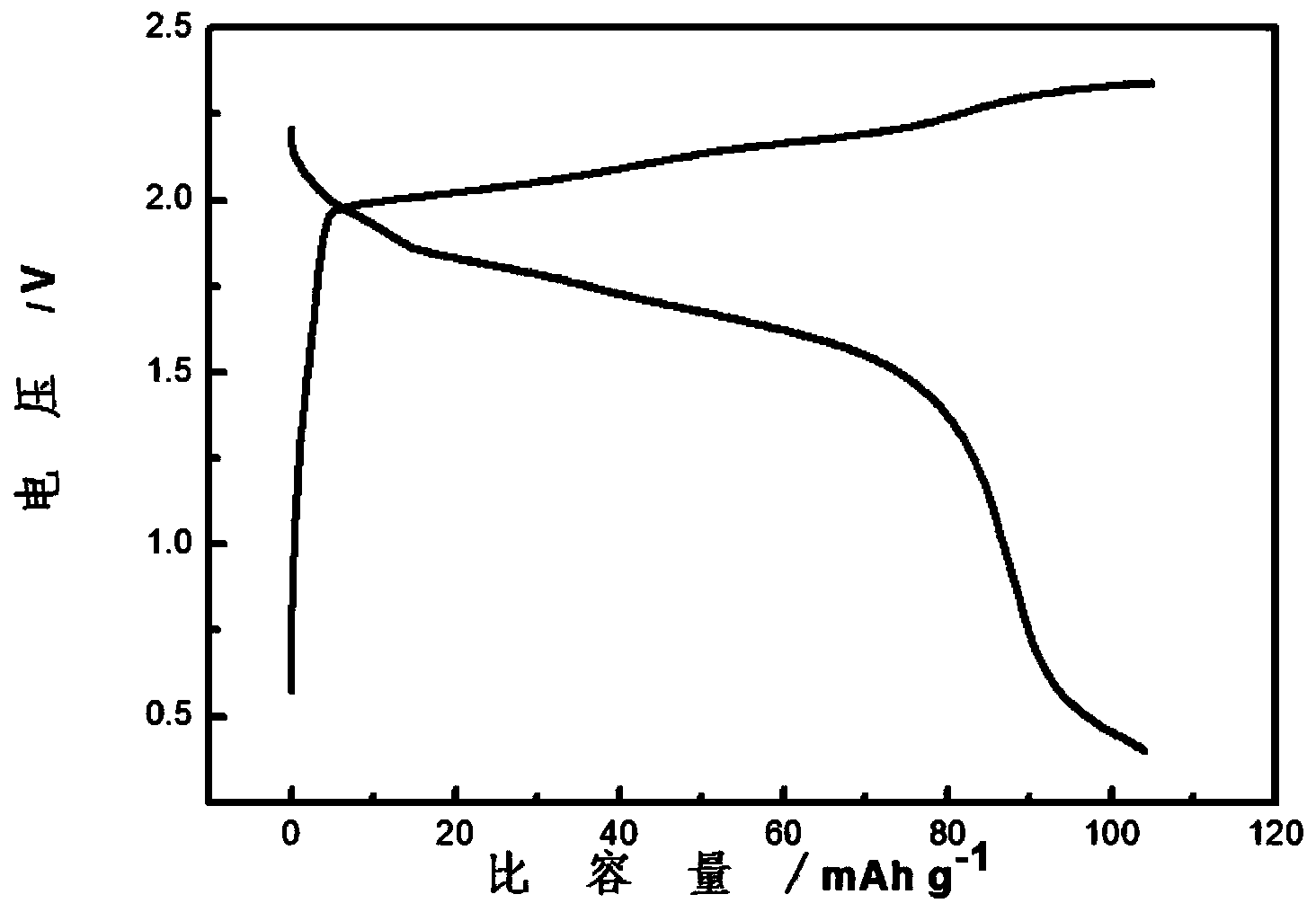

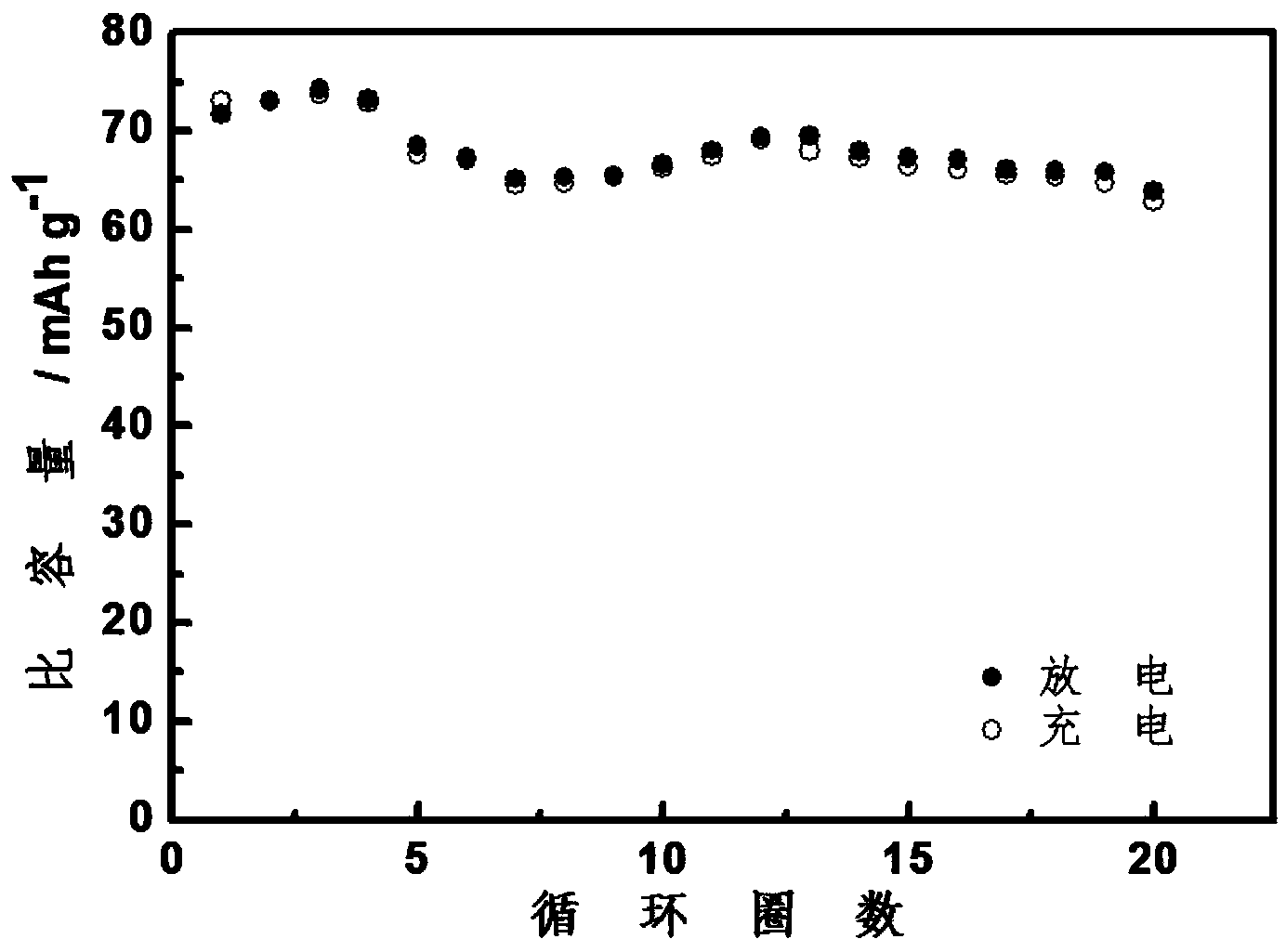

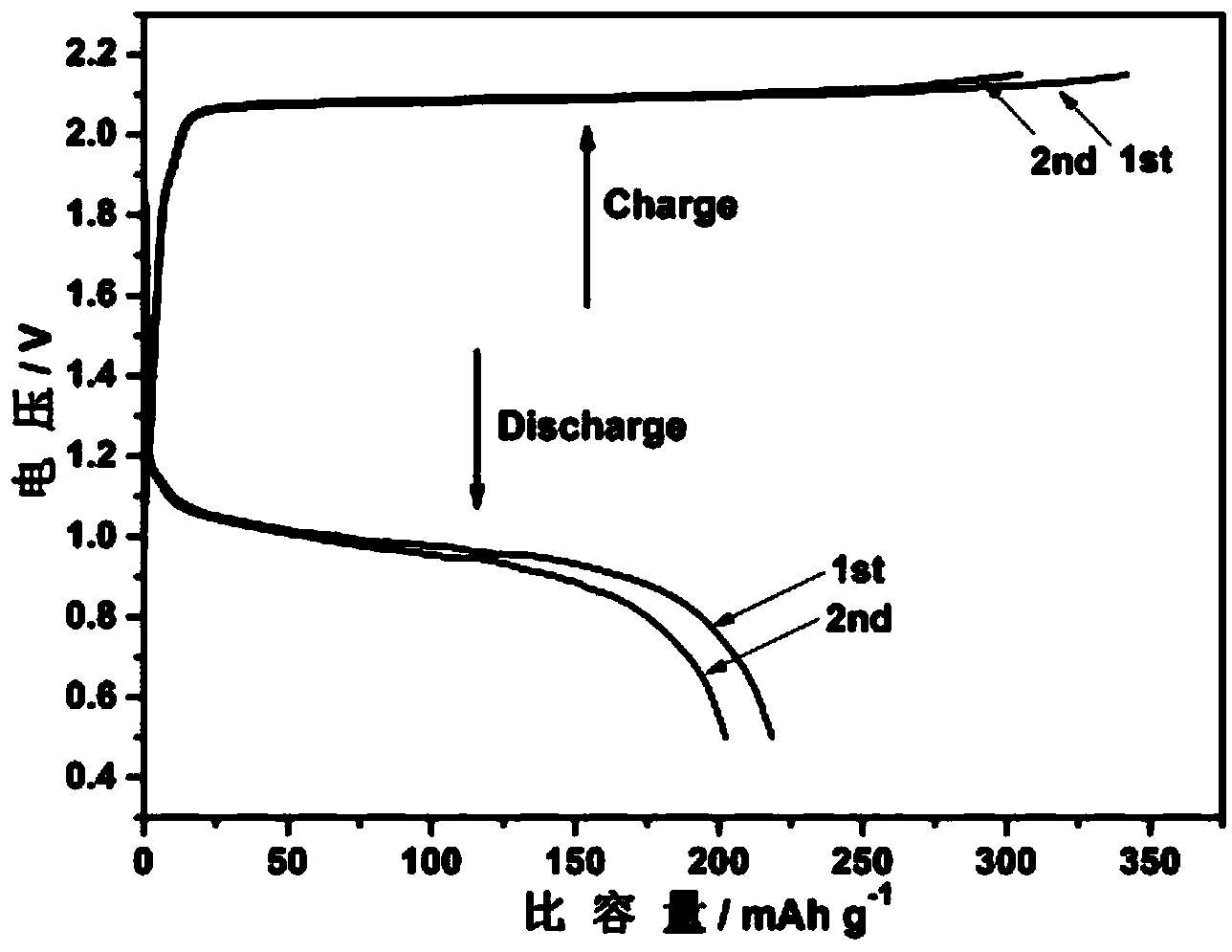

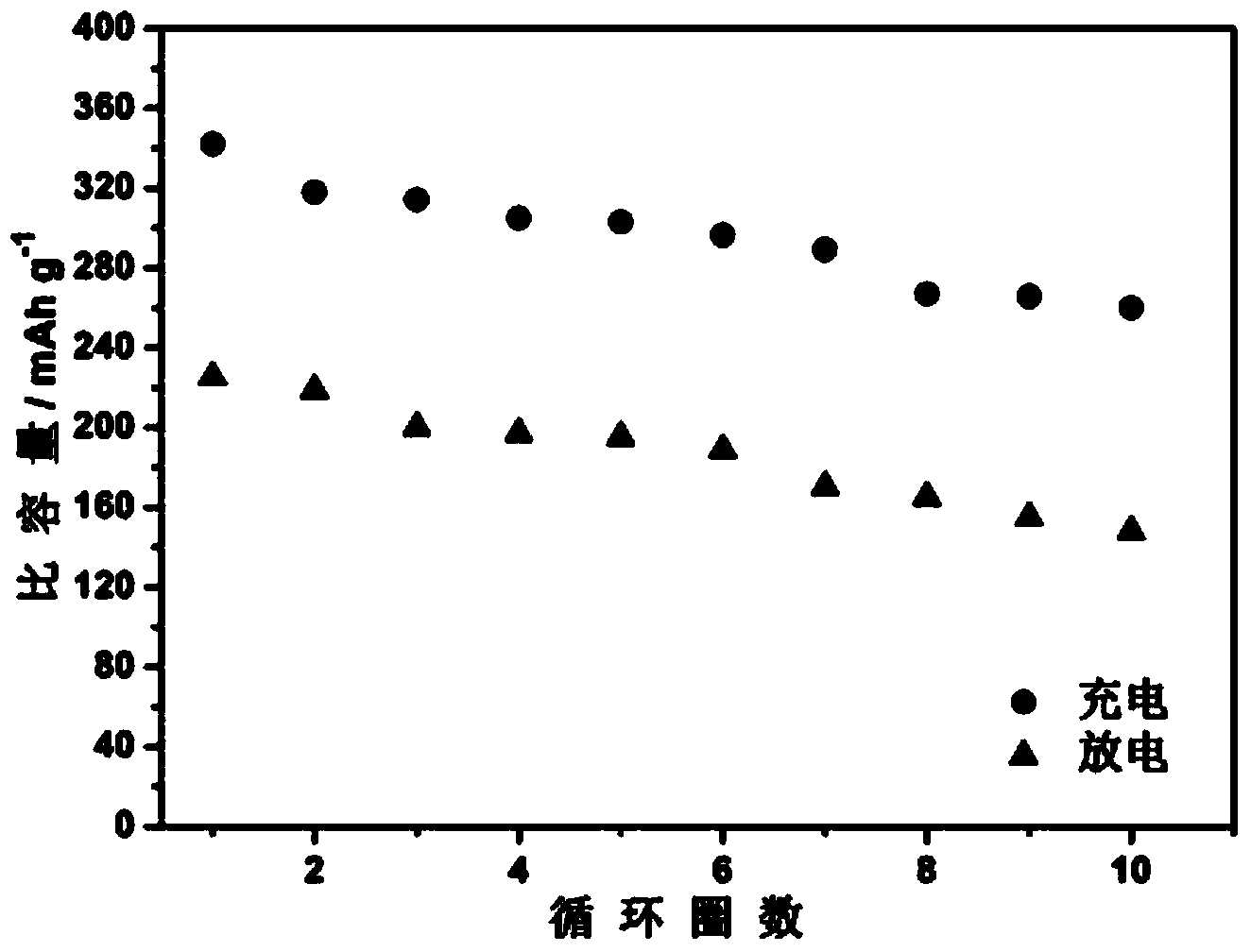

The invention discloses a rechargeable aluminum ion cell and a preparation method thereof and belongs to the field of energy reutilization. The cell comprises an anode, a cathode, a liquefied aluminum ion electrolyte and a diaphragm material, wherein the anode is made of graphite structure carbon material; the cathode is made of highly pure aluminum; the liquefied aluminum ion electrolyte is formed by mixing anhydrous aluminum chloride and 3-methyl imidazole compound; the molar ratio between the anhydrous aluminum chloride and the 3-methyl imidazole compound is from 1.1:1 to 1.6:1. The preparation process of the cell comprises the following steps: processing the graphite structure carbon material into laminar shapes; fixing the anode material with inertial metal foil as a current collector and covering the anode with the diaphragm material; washing highly pure aluminum cutting piece as the cathode; preparing the liquefied aluminum ion electrolyte which contains A13 plus ion capable of freely moving. The anode, the cathode and the liquefied aluminum ion electrolyte are assembled in a glove box to form the cell; the cell has the characteristics of high capacity and good circulating stability and is applicable to multiple fields such as electronic industry, communication industry and electric automobile.

Owner:UNIV OF SCI & TECH BEIJING +1

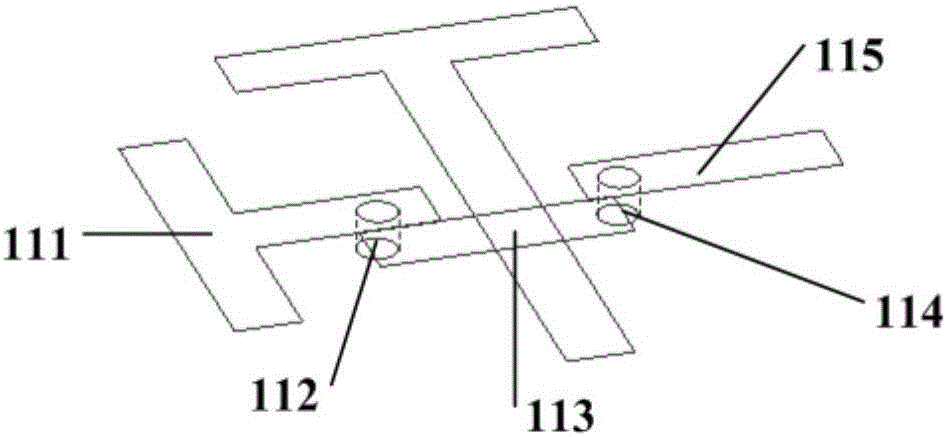

Low-profile dual-polarization dipole base station antenna loaded with AMC reflecting plate

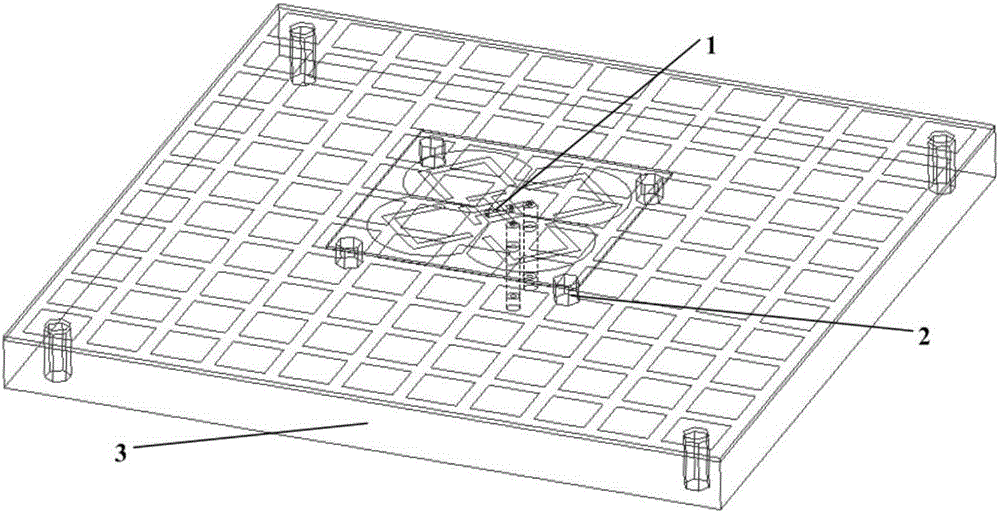

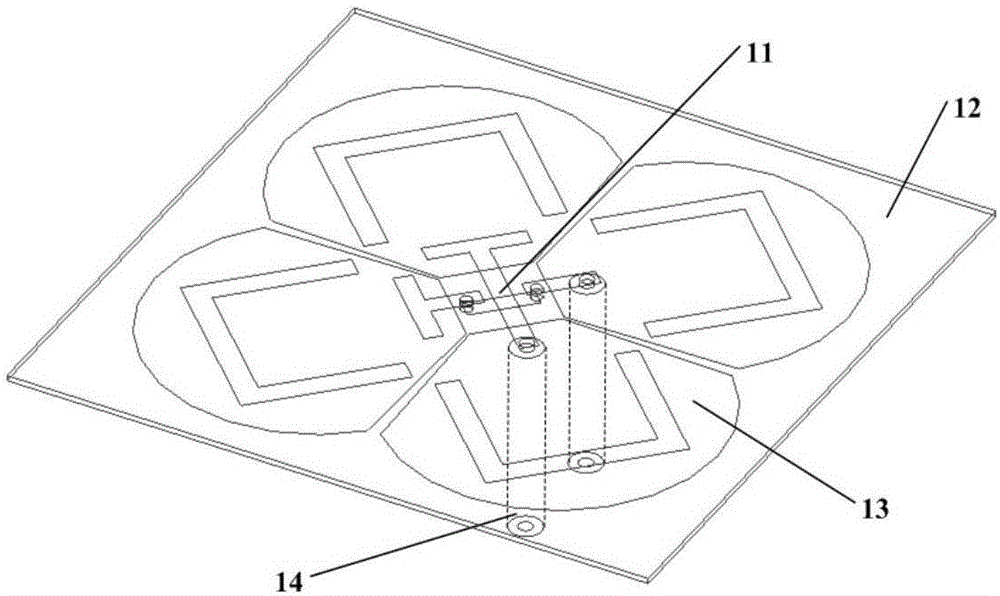

InactiveCN106785405AEasy to expandImprove isolationRadiating elements structural formsAntennas earthing switches associationCoaxial lineHigh isolation

The invention discloses a low-profile dual-polarization dipole base station antenna loaded with an AMC reflecting plate. The antenna comprises a dual-polarization planar dipole antenna, four plastic support columns and the AMC reflecting plate. The dual-polarization planar dipole antenna comprises coupling microstrip lines, an upper dielectric plate, a radiating structure and coaxial lines from top to bottom in sequence; the AMC reflecting plate comprises a rectangular patch, a lower dielectric plate, an air dielectric, metal support columns and a metal plate which are periodically arranged from top to bottom in sequence, the coupling microstrip lines and the radiating structure are located on the upper side and the lower side of the upper dielectric plate in the same placing direction, and + / -45-degree dual-polarization is achieved in a coaxial line feeding mode. The dual-polarization planar dipole antenna is fixed to the AMC reflecting plate through the plastic support columns. Accordingly, the AMC reflecting plate is adopted for replacing an original metal reflecting plate, the antenna profile height is lowered to 0.132 lambda 2.2 GHz from 0.264 lambda 2.2 GHz, and meanwhile the advantages of being wide in frequency band, high in isolation, low in cross polarization, low in cost and the like are reserved. The application requirement of the current communication industry is met, and the low-profile dual-polarization dipole base station antenna conforms to the development trend of miniaturization of current base station antennae and has practical reference value.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

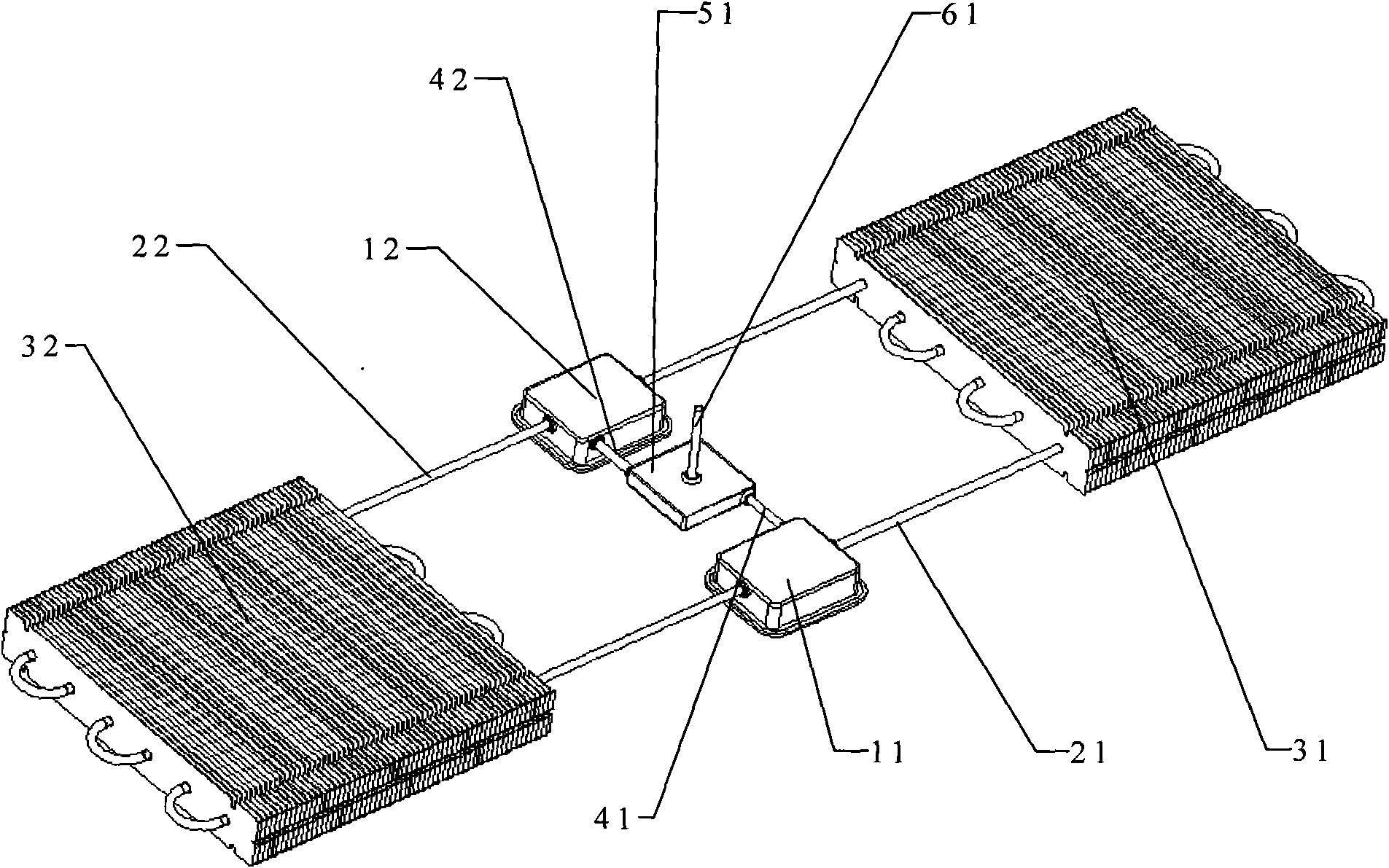

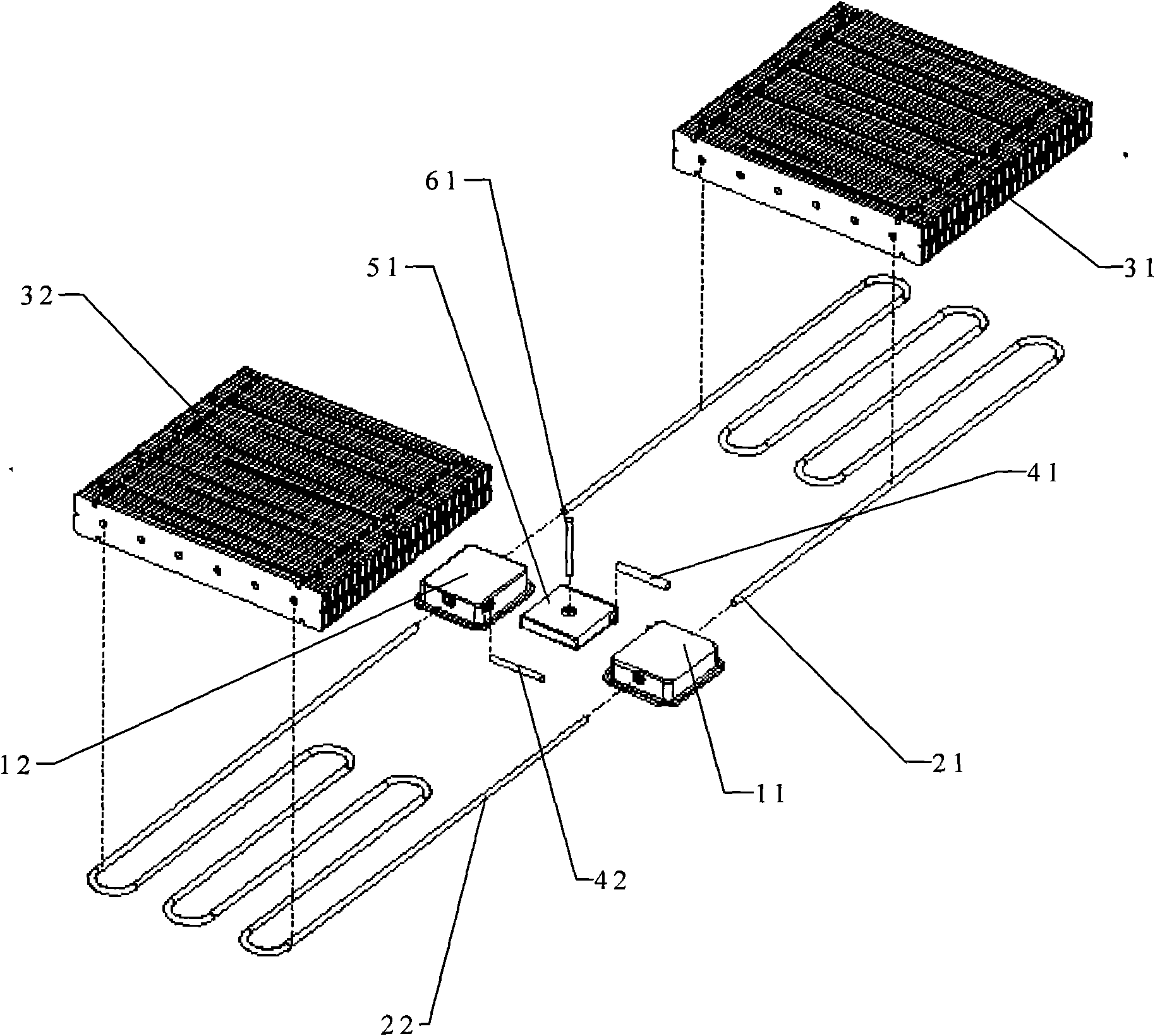

Heat radiating device and manufacturing process thereof

ActiveCN101478868ASave installation spaceEffective fitSemiconductor/solid-state device detailsSolid-state devicesHigh energyEffect light

Owner:BEIJING AVC TECH RES CENT

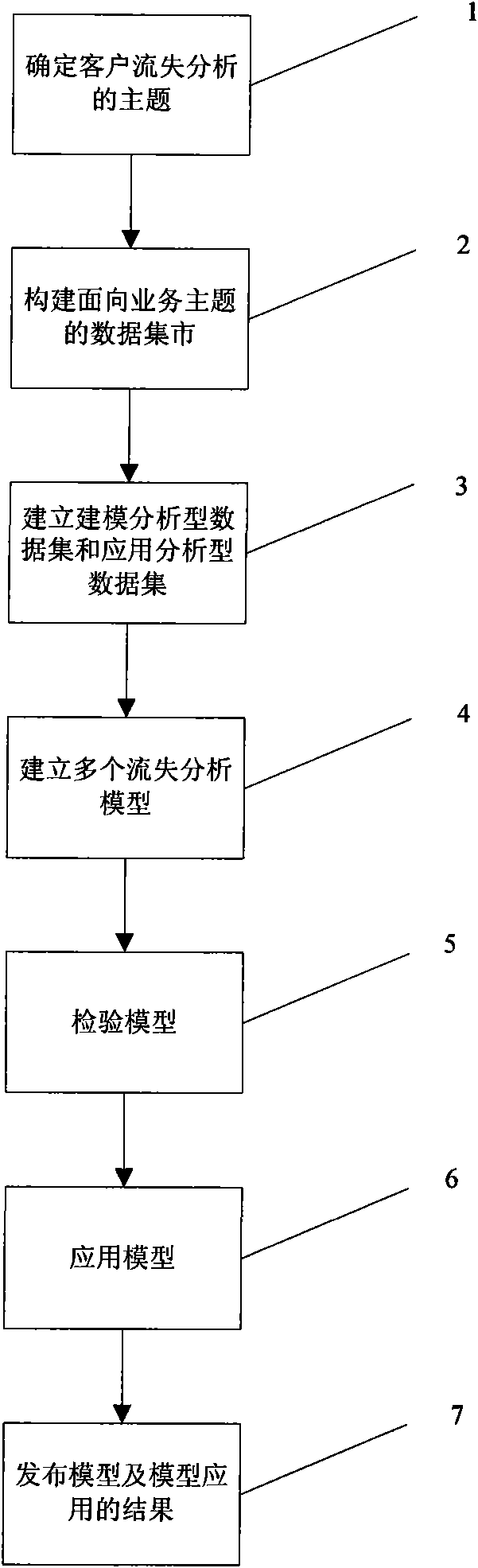

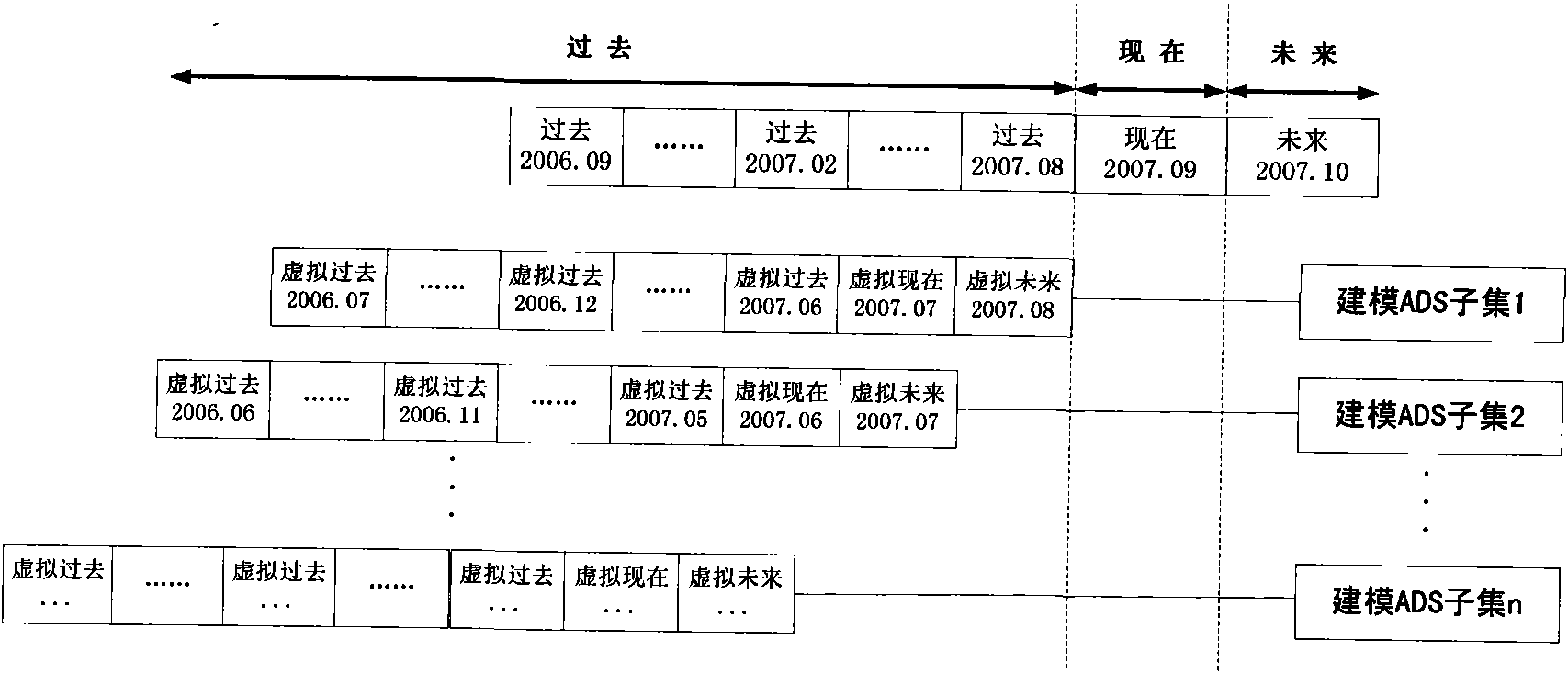

Method for analyzing customer churn of mobile communication service

InactiveCN101620692AChurn AnalysisSpecial data processing applicationsMarketingPaymentCustomer attrition

The invention relates to a method for analyzing customer churn of a mobile communication service. The method comprises the following steps of: connecting a data warehouse; scheduling a data mining tool to analyze information such as calling in the past period of time, customer service complaints or payment and the like of a churned customer; extracting behavior characteristics of the churned customer or a customer with the churning tendency; building a customer churn prediction model; applying the model to an actual customer service; acquiring customer churn prediction information; and providing support for the management decisions of enterprises. Compared with the prior art, the method can well analyze the customer churn for the mobile communication industry.

Owner:上海全成通信技术有限公司

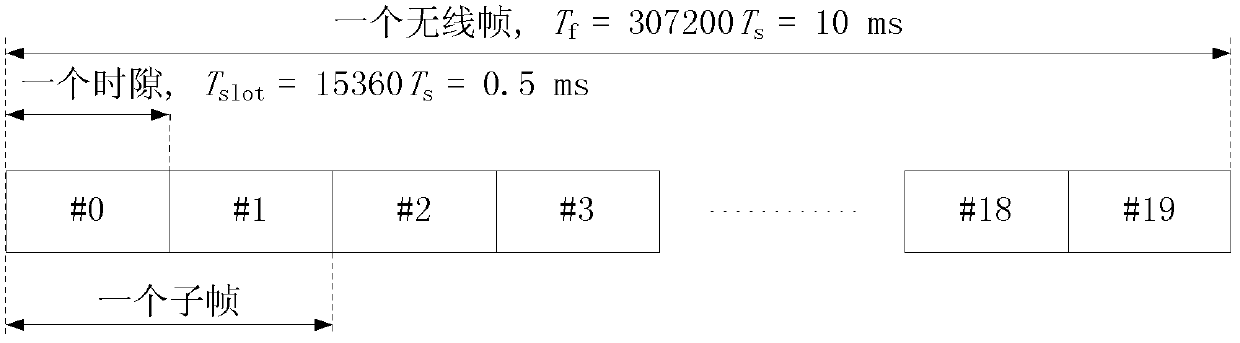

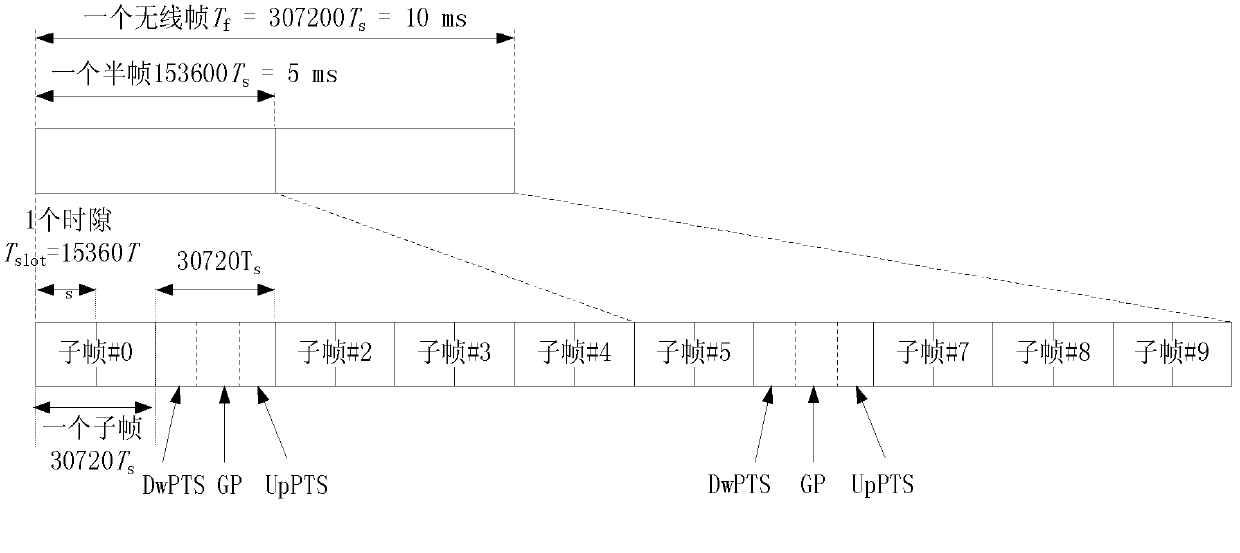

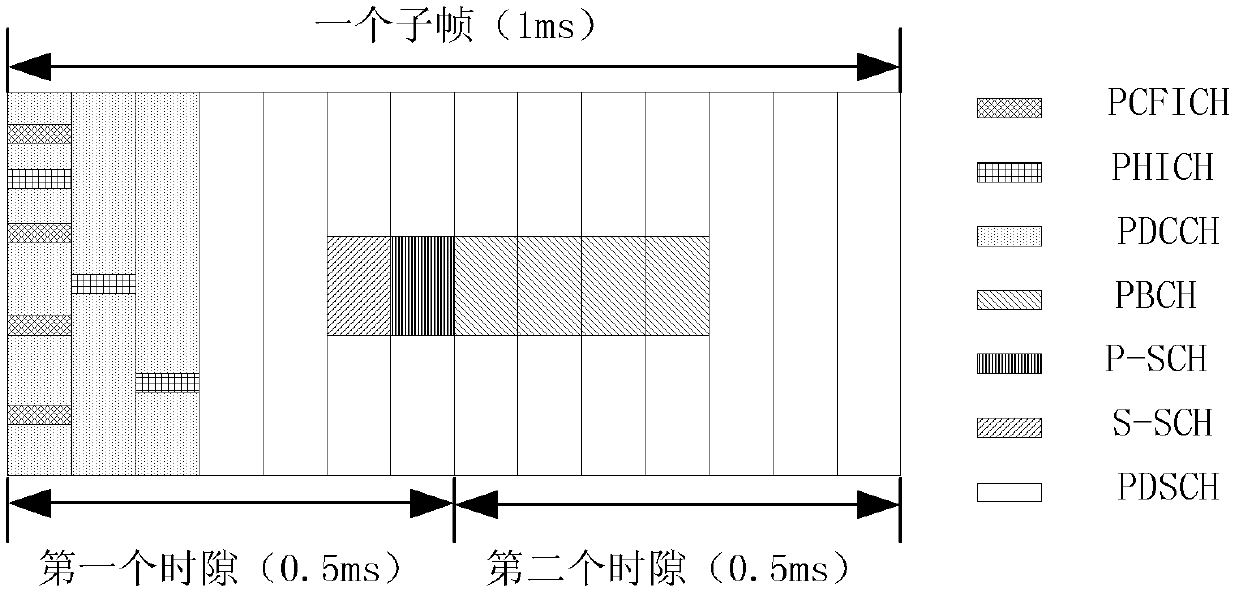

Method and device for sending synchronizing signals

InactiveCN103379079AReduced precision requirementsReduce power consumptionSynchronisation arrangementMulti-frequency code systemsCommunications systemCommunication industry

The invention discloses a method and device for sending synchronizing signals. The problem that system implementation cost is high due to an existing wireless communication standard is solved. The sending method is applied to a communication system applying an LTE series standard and comprises the steps that a network side network element generates enhanced synchronizing signals; the network side network element sends the enhanced synchronizing signals to an enhanced terminal, wherein the time-frequency resource used in the enhanced synchronizing signals is different from the time-frequency resource used in basic synchronizing signals. The device comprises a generating module and a sending module. According to the method and device for sending the synchronizing signals, a synchronizing channel of the LTE series standard is enhanced, the power consumption and the implement complexity of the terminal can be effectively lowered, cost is also lowered, and the demands of high-speed development data users and wireless communication industry future development can be better met.

Owner:ZTE CORP

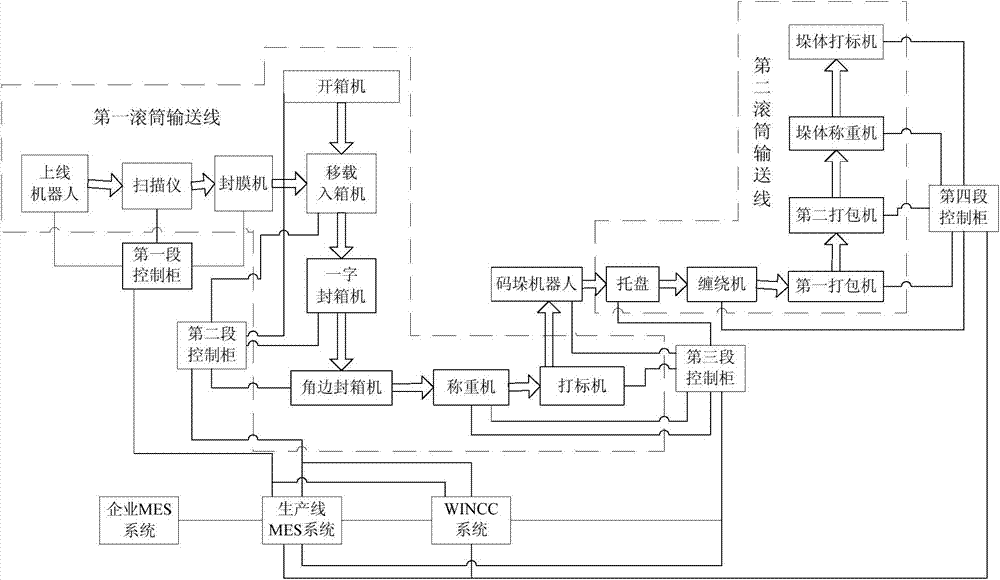

Intelligent flexible packaging production line for box type products

ActiveCN103935568ADynamic adjustment of process parametersWith intelligent line change functionPackaging automatic controlPackaging machinesWinding machineProduction line

The invention discloses an intelligent flexible packaging production line for box type products. The intelligent flexible packaging production line comprises a first roller conveying line, a second roller conveying line, a production line MES system, a WINCC system, a robot palletizer and four control cabinets. A scanner, a film sealing machine, a transferring boxing machine, a linear box sealing machine and a corner and edge box sealing machine are sequentially arranged between the feeding segment and the discharging segment of the first roller conveying line. A box body is arranged between the film sealing machine and the transferring boxing machine. A tray, a winding machine and a first packaging machine are sequentially arranged between the feeding segment and the discharging segment of the second roller conveying line. The robot palletizer is arranged between the feeding segment of the first roller conveying line and the discharging segment of the second roller conveying line. According to the intelligent flexible packaging production line for the box type products, the intelligent flexible packaging production line is compatible with the box type products with different appearances, procedures of feeding, film sealing, vacuum pumping, box opening, box entering, box sealing, weighing, packaging, stacking, marking, discharging and the like can be intelligently finished in a full-automatic mode. The intelligent flexible packaging production line for box type products is wide in application and suitable for packaging of many products in the communication industry.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Flexible heat conduction interface material with wave absorbing function and preparation method thereof

The invention relates to a flexible heat conduction interface material with a wave absorbing function, which comprises the following components in parts by mass: 100 parts of vinyl silicone oil, 100 to 1,000 parts of a heat conducting filler, 100 to 1,000 parts of a wave absorbing material, 1 to 50 parts of hydrogen-containing silicone oil, 0.01 to 1 part of a platinum catalyst, and 0.01 to 1 part of an inhibitor. The flexible heat conduction interface material has the advantages that a high-thermal-conductivity caulking interface is produced by a mixture prepared by mixing the vinyl silicone oil, the heat conducting filler, the wave absorbing material, the hydrogen-containing silicone oil, the platinum catalyst and the inhibitor; due to addition of the wave absorbing material, the mixture has an excellent electromagnetic parameter, and the electromagnetic parameter of the mixture can be achieved by regulating a particle size of micro particles of the wave absorbing material; and the flexible heat conduction interface material is beneficial to impedance matching and widening of an absorption band and can meet the requirements of the electron and communication industries for high-efficiency energy conduction and electromagnetic compatibility. In addition, the invention further provides a preparation method of the flexible heat conduction interface material with the wave absorbing function.

Owner:PINGHU ALLIED IND

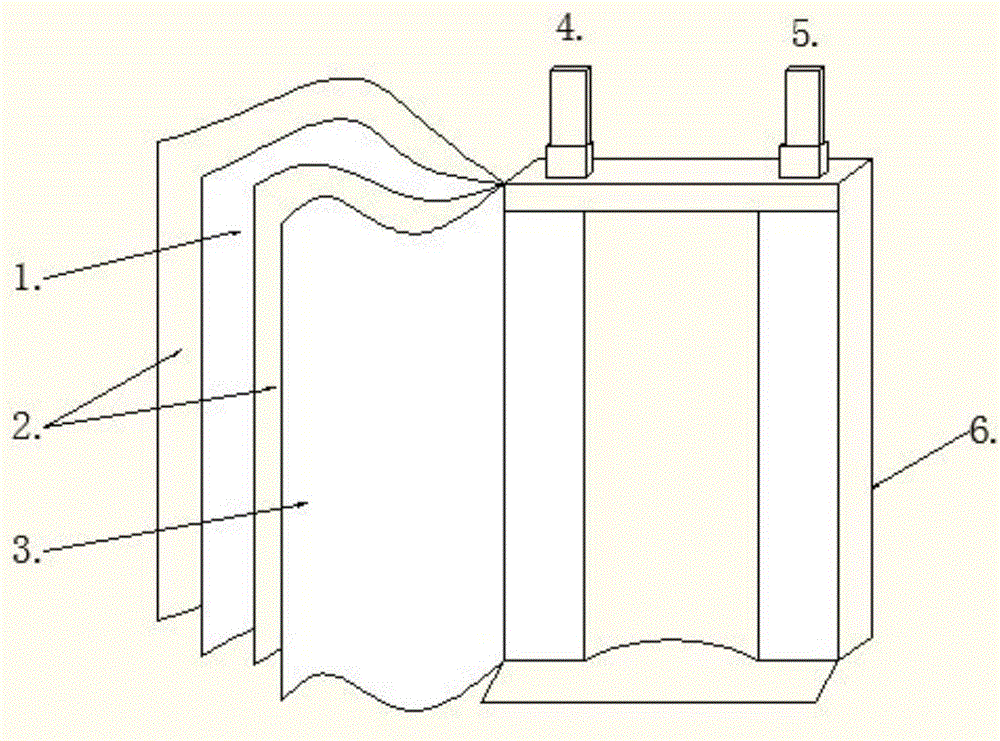

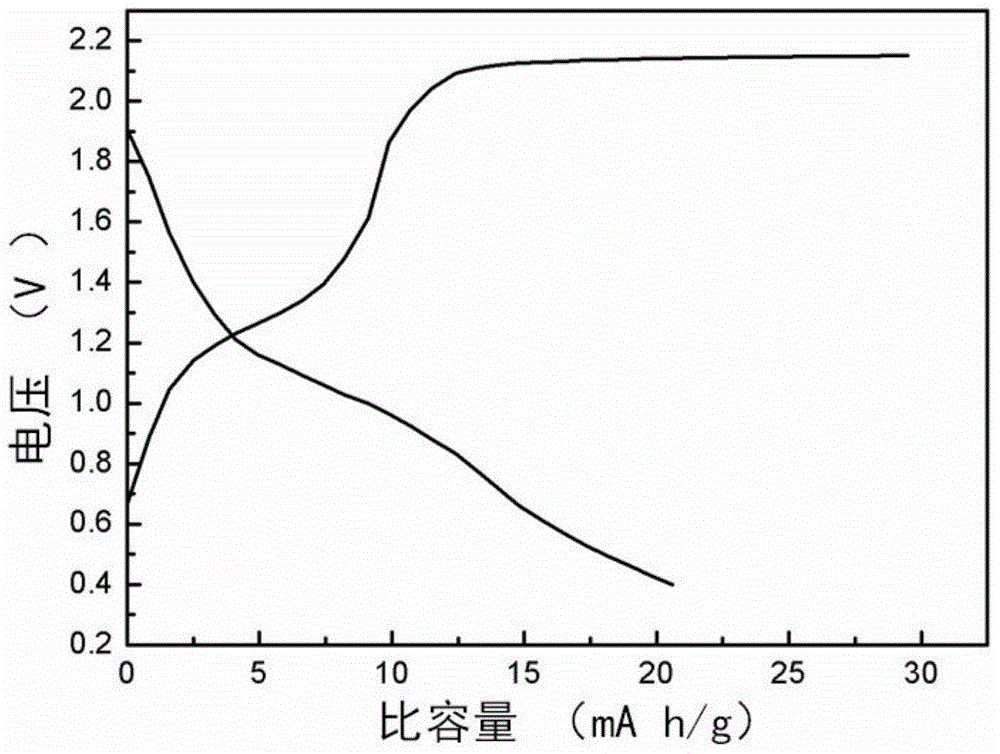

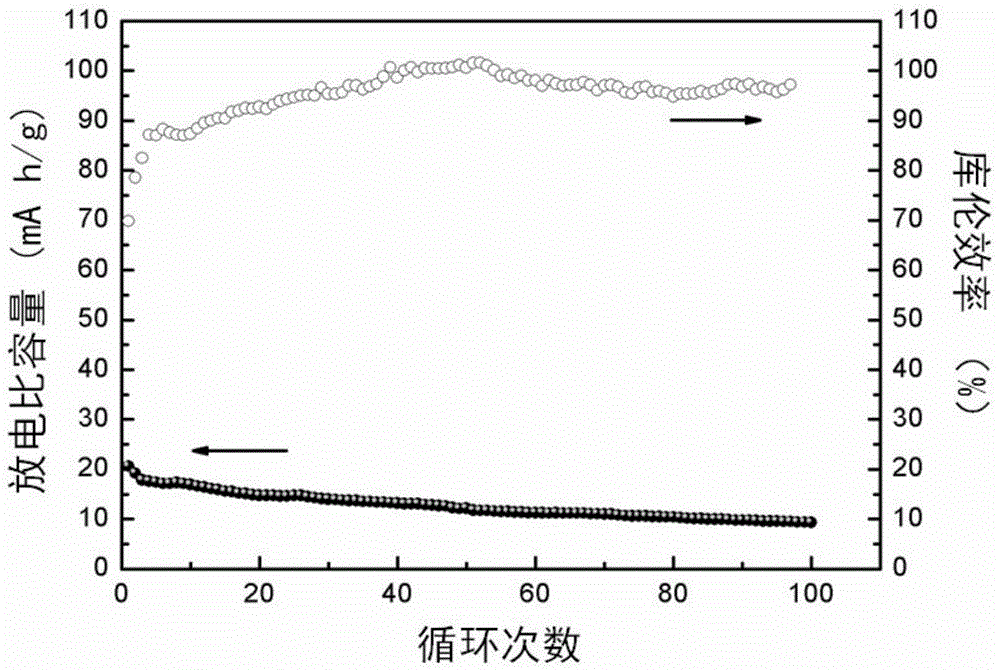

Rechargeable aluminum ion battery and preparation method thereof

InactiveCN104810544AAchieve practical purposesCell seperators/membranes/diaphragms/spacersFinal product manufactureAluminum IonShielding gas

The invention discloses a rechargeable aluminum ion battery and a preparation method thereof, and belongs to the technical field of batteries. The rechargeable aluminum ion battery can be widely used in the electronics industry and communications industry, and can also be used as a power battery for an electric vehicle. The invention provides a novel aluminum ion battery device, especially a soft bagged battery. The aluminum ion battery device adopts a membrane to separate the positive and negative electrodes of the aluminum ion battery, and uses an insulating soft bag to wrap the positive and negative electrodes of the aluminum ion battery; the enclosed battery is assembled in a shielding gas atmosphere, and only the positive and negative electrode leads which are conductive are exposed for being connected with an external circuit; according to different electrode making technologies, the battery can be assembled into square or round or other shapes. The soft bagged aluminum ion storage battery provided by the invention has the benefits that the capacity is high, the charge and discharge efficiency is high, the cycling stability is good, and the charge and discharge features are excellent; in addition, the electrode materials are extensive in source, and the battery is easy to prepare, low in cost, green and environment-friendly, and low in price.

Owner:UNIV OF SCI & TECH BEIJING +1

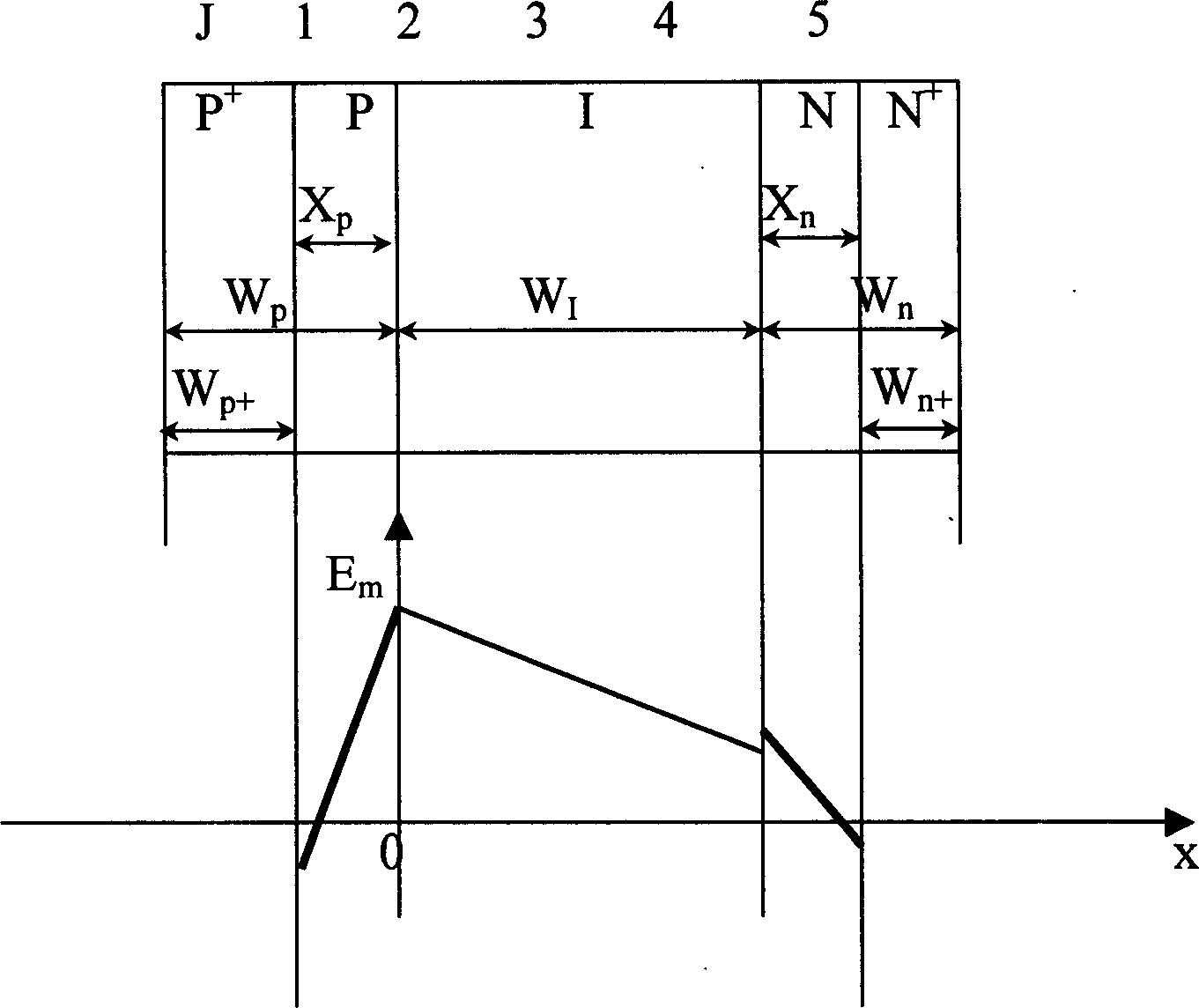

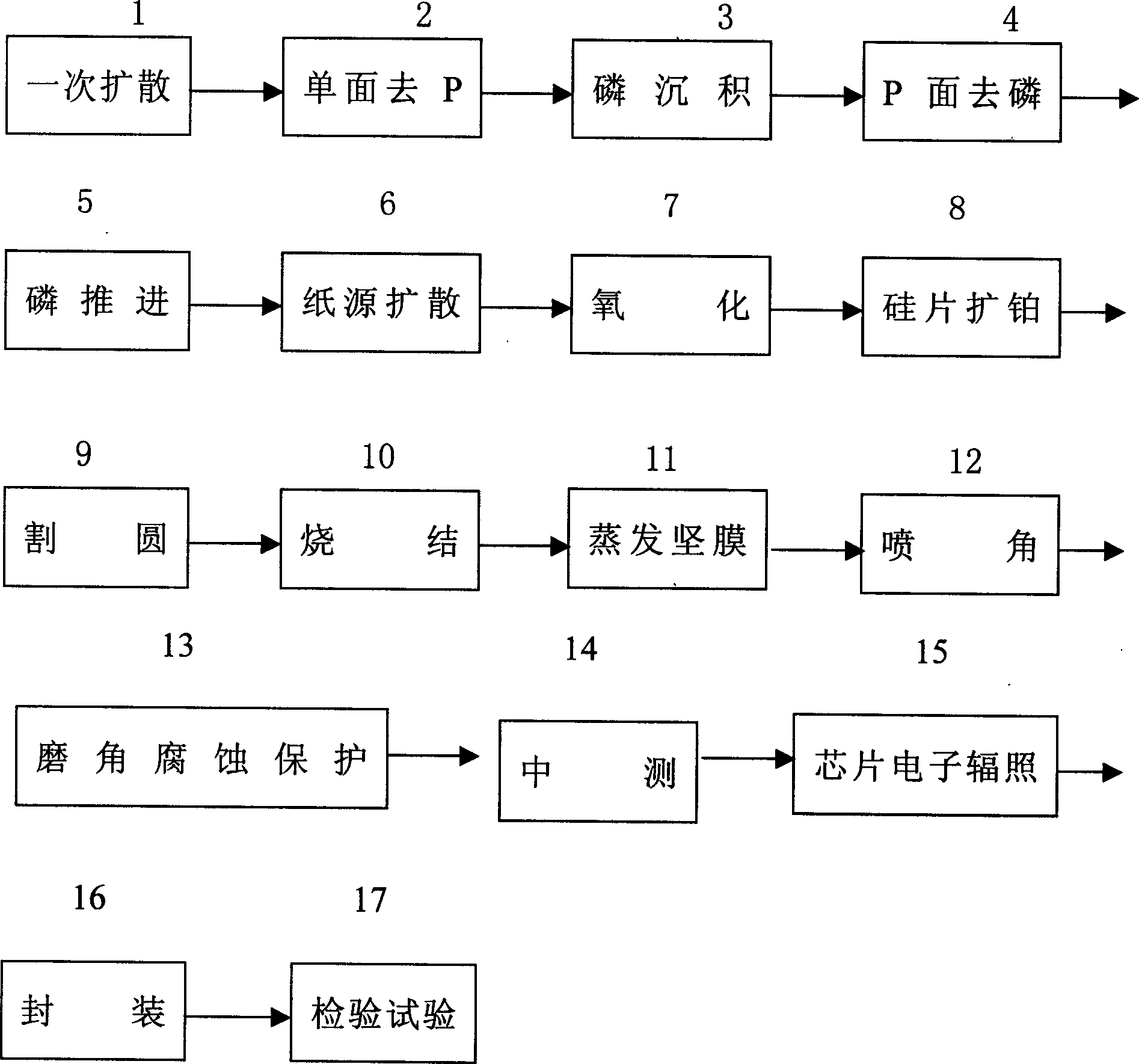

High-power quick soft-restoring diode and mfg technology thereof

InactiveCN1710707AAddressing Forward Voltage DropAddressing the reverse recovery featureSemiconductor/solid-state device manufacturingCommunication industryEngineering

The disclosed diode is as key part in semiconductor converter assembly of electric power. Structure of silicon chip is in P+PINN+ structure. In order to solve contradiction between forward voltage drop / backward recovery characteristic of diode and large power, following manufacturing steps are added: diffusion of paper source, oxidation, expansion of platinum on silicon chip, electron irradiation for chip etc. Thus, quick and soft backward recovery characteristic of the diode meets requirements of support devices in reverse parallel, absorption, follow current of high frequency arts in high-power such as fast thyristor, GTO, IGCT and IGBT. Power supply unit made from the disclosed diode is widely applicable to steel, petrochemical, electric power, railway and communication industries.

Owner:北京京仪椿树整流器有限责任公司

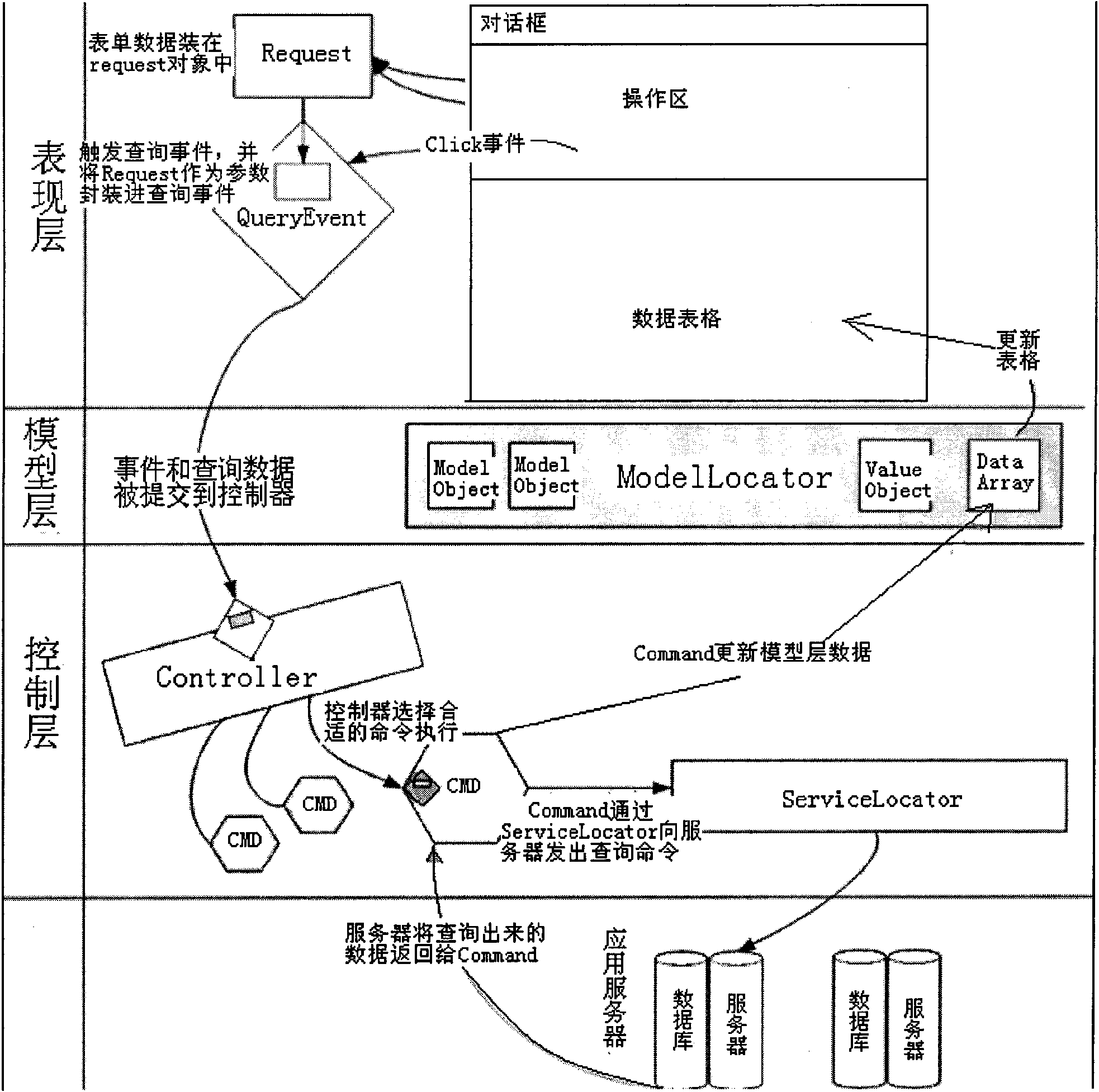

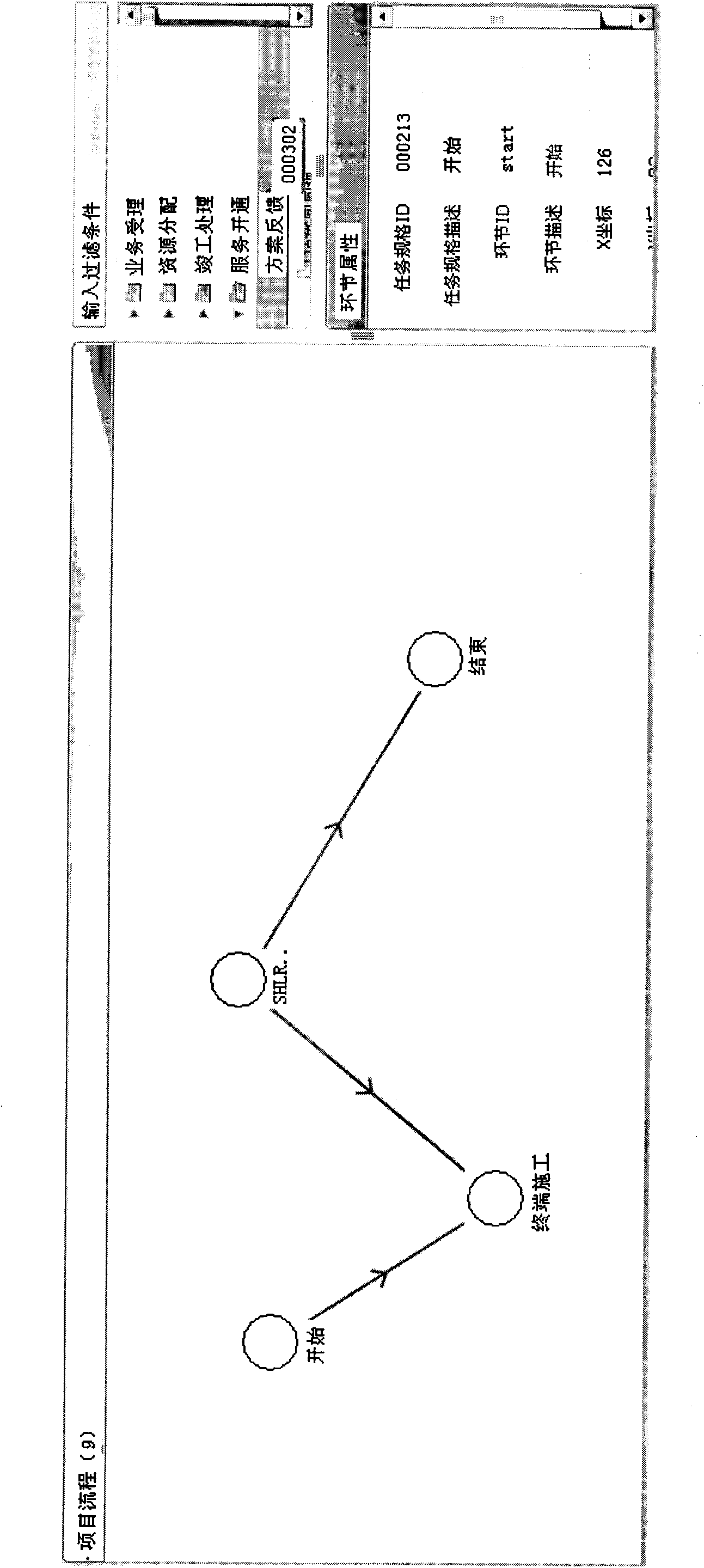

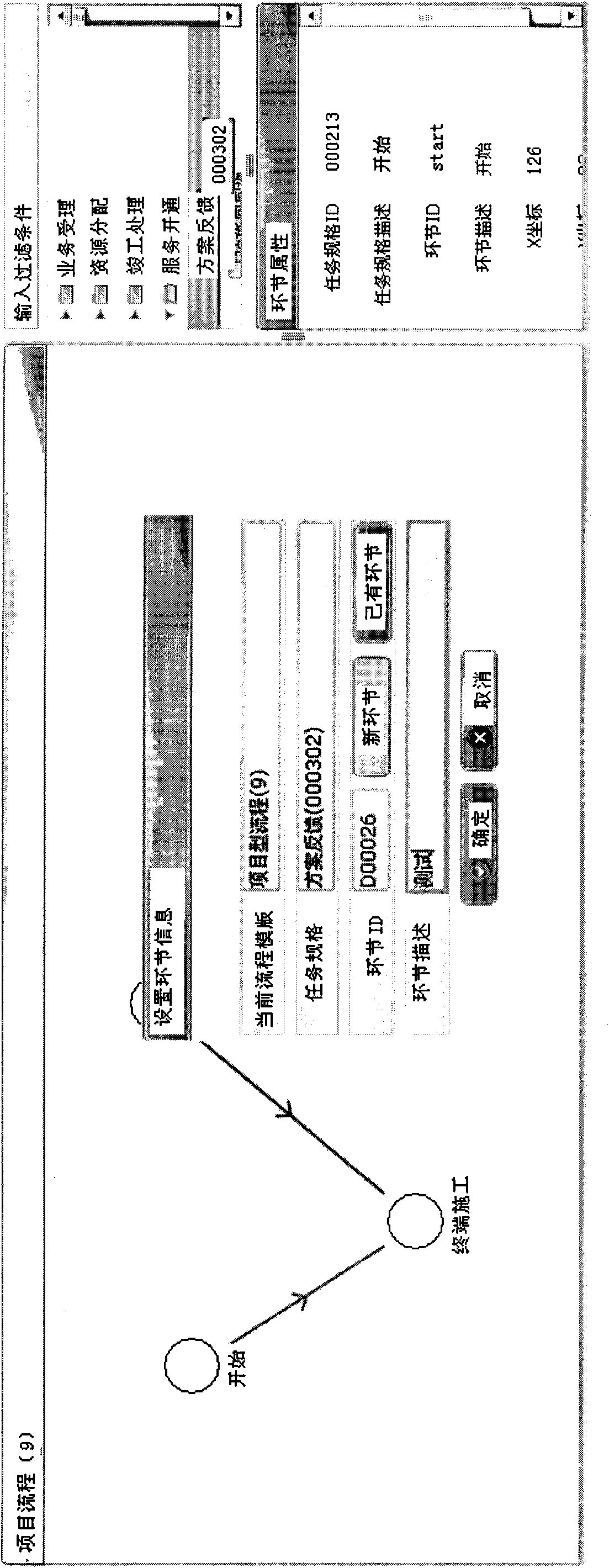

Graphic flow template drafting method under ARP frame

ActiveCN101587438AData processing applicationsSpecific program execution arrangementsGraphicsCollocation

A graphic flow template drafting method under ARP frame displays the flow diagram by means of complicated algorithm, based on the data model collocation, under the FLEX frame, refreshes the graphical interface by the ActionScript technology in real time and drifts the graphics on the WEB browser. The algorithm comprises following steps: a) drifting the flow diagram nodes; b) drifting the connection lines between the flow diagram nodes; c) supporting the node dragging; d) storing the flow diagram data. The data model comprises a route section information of the flow diagram and a coordinate information of the node on the flow diagram. The method supports the user to drag nodes, connects the nodes for drifting the flow template and displays the actual flow. The graphic display and the drifted flow diagram are easy to be accepted and understood and are directly applicable to the graphic display and drift of the flow template in the flow management platform, particularly to the workflow management platform in the electric communication industry.

Owner:LINKAGE SYST INTEGRATION

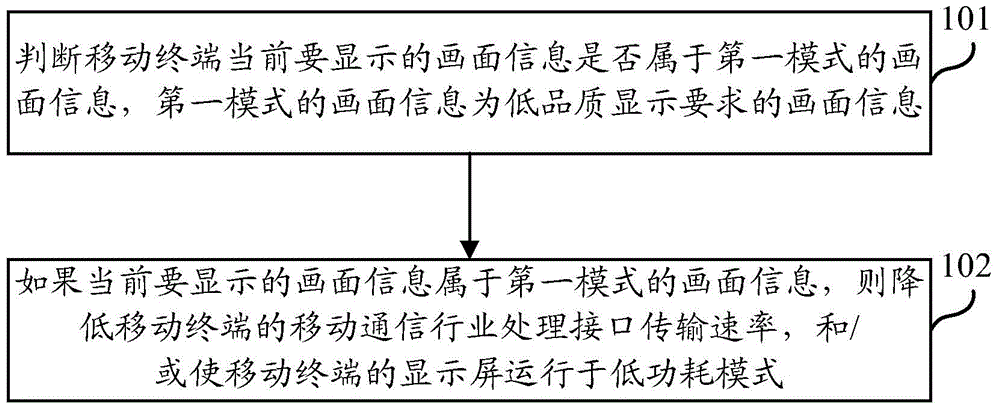

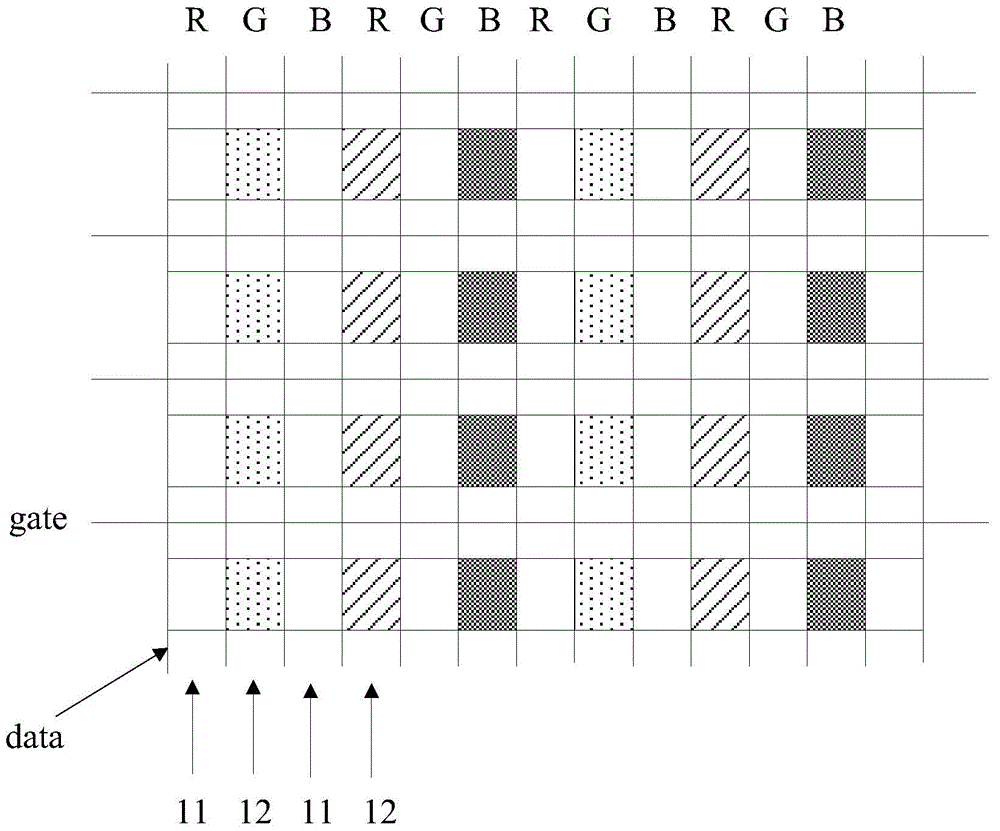

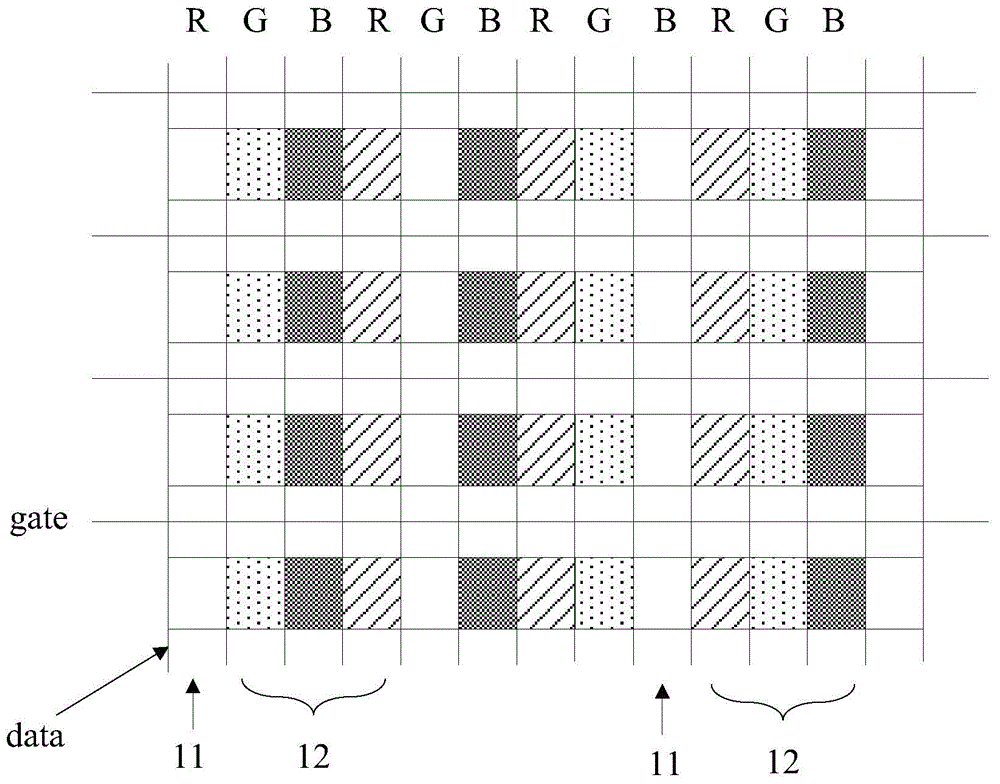

Method and system for reducing power consumption of mobile terminal

InactiveCN104933983AReduce power consumptionLow transfer ratePower managementCathode-ray tube indicatorsCommunication industryComputer terminal

The present invention discloses a method and a system for reducing power consumption of a mobile terminal, in order to solve the problem that the mobile terminal has high power consumption in a normal state. The method for reducing power consumption of the mobile terminal comprises the steps of: judging whether frame information to be displayed by the mobile terminal at present belongs to frame information of a first mode, wherein the frame information of the first mode is frame information with low quality display requirements; and reducing mobile communication industry processing interface transmission rate of the mobile terminal and / or enabling a display screen of the mobile terminal to operate in a low-power consumption mode if the frame information to be displayed by the mobile terminal at present belongs to the frame information of the first mode.

Owner:BOE TECH GRP CO LTD +1

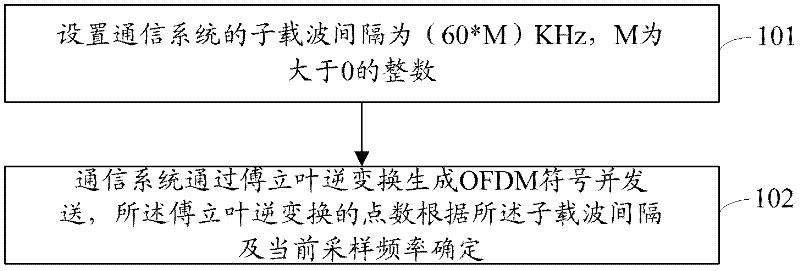

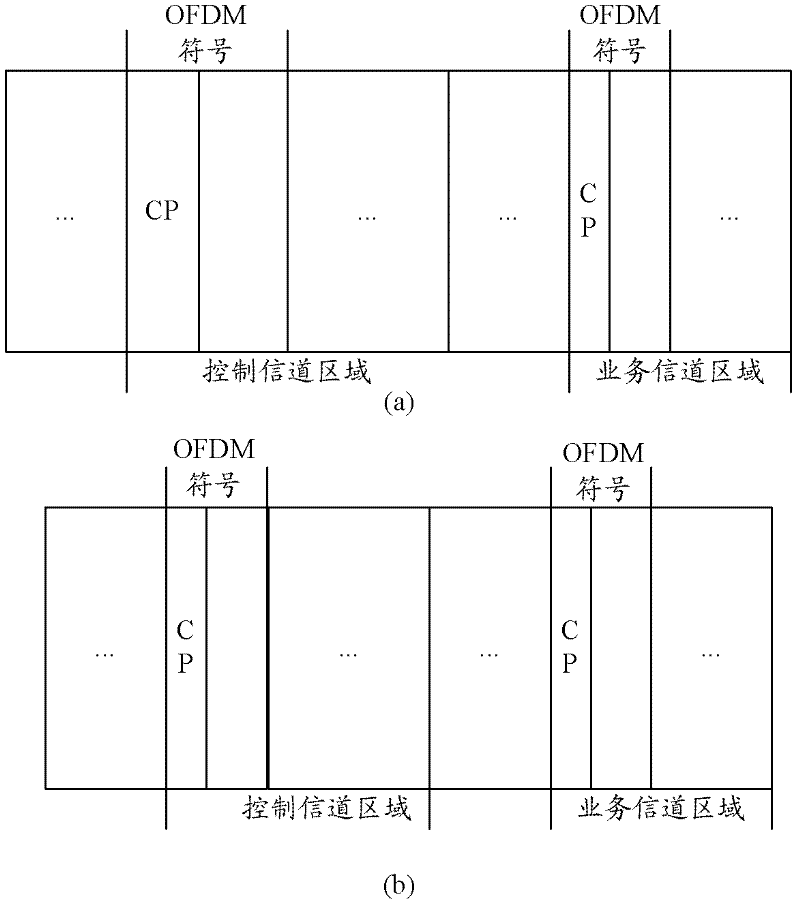

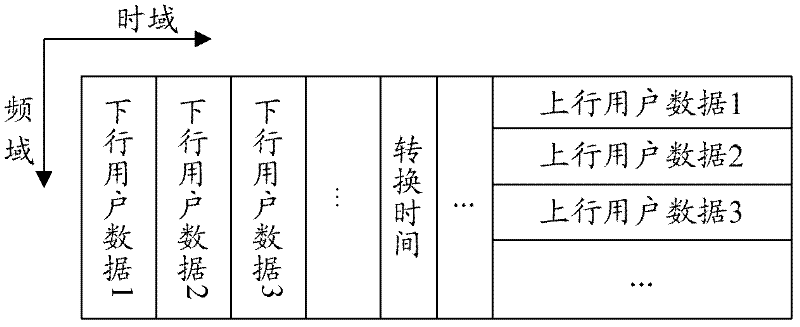

Method and device for setting and using key parameters in communication system

ActiveCN102299892ASolve the problem of poor reusability in hardware and software implementationImprove reusabilityMulti-frequency code systemsWireless communicationFast Fourier transformCommunications system

Disclosed is a data sending method in a wireless communication system. The method includes: setting the sub-carrier interval of a communication system as (60*M) KHz, with M being an integer greater than 0 (101); and the communication system generating an OFDM symbol by way of inverse fast Fourier transform and sending the same, wherein the points of the inverse fast Fourier transform operation are determined according to the sub-carrier interval and the current sampling frequency (102). Also disclosed is a data sending device in a wireless communication system, which can be compatible and shared with the existing cellular network standards or standards to be used, thereby providing a solution suitable for the cellular mobile field and nomadic / local wireless data access with low costs, greatly reducing the development or usage costs of the manufacturers and operators of the cellular device, which not only saves resources but also can meet the data user demand developing with high speed and the future development demand of the wireless communication industry.

Owner:ZTE CORP

Aluminum-ion battery using MoS2 as positive electrode material and preparation method of battery

ActiveCN104393290AGood chemical stabilityImprove thermal stabilityMaterial nanotechnologyFinal product manufactureAluminum IonDischarge efficiency

The invention provides an aluminum-ion battery using MoS2 as a positive electrode material and a preparation method of the battery, belongs to the technical field of batteries, can be widely applied to the fields of electronic industry and communications industry, and also can be taken as a power battery for an electric automobile. The aluminum-ion battery comprises a positive electrode active material, a negative electrode, a diaphragm material, a molten aluminum ion electrolyte solution and an electrolytic tank, wherein the positive electrode active material is MoS2, the negative electrode is a high-purity aluminum sheet, and the molten aluminum ion electrolyte solution is non-aqueous electrolyte solution containing Al3<+> ions. According to the aluminum-ion battery using the MoS2 as the positive electrode material and the preparation method of the battery, a provided aluminum-ion storage battery can be repeatedly charged and discharged, and has high capacity, high charging and discharging efficiency, good circulation stability and excellent charging and discharging features; in addition, the electrode material source is wide, the preparation method is easy, the cost is low, and the battery is green and environment-friendly and is low in price.

Owner:UNIV OF SCI & TECH BEIJING +1

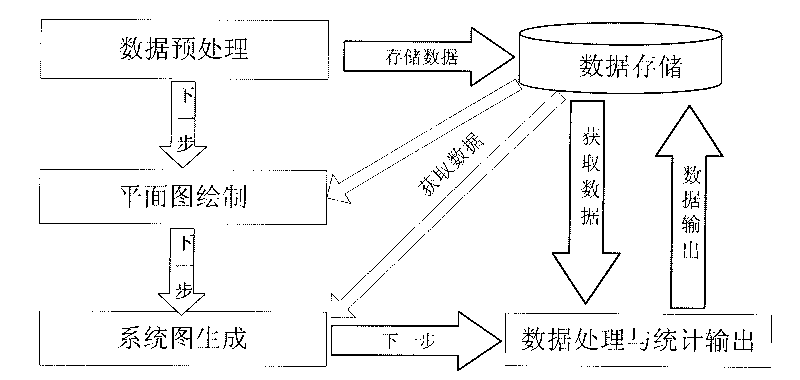

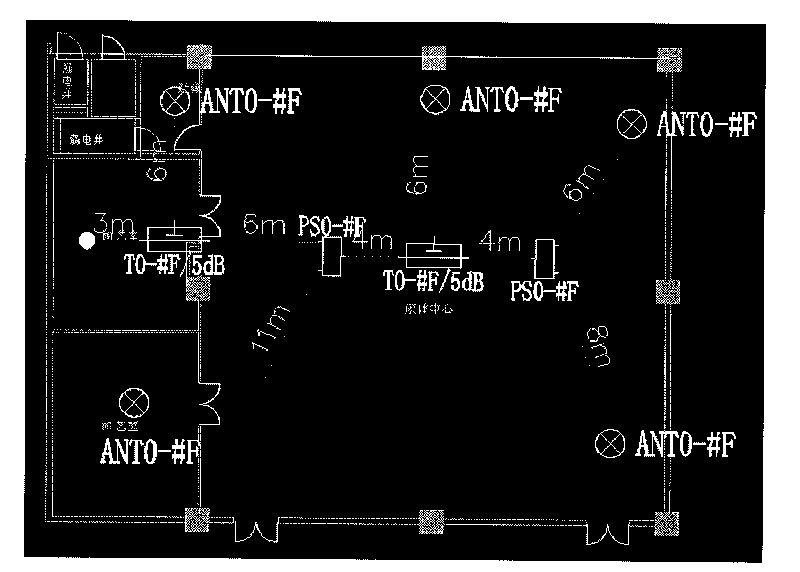

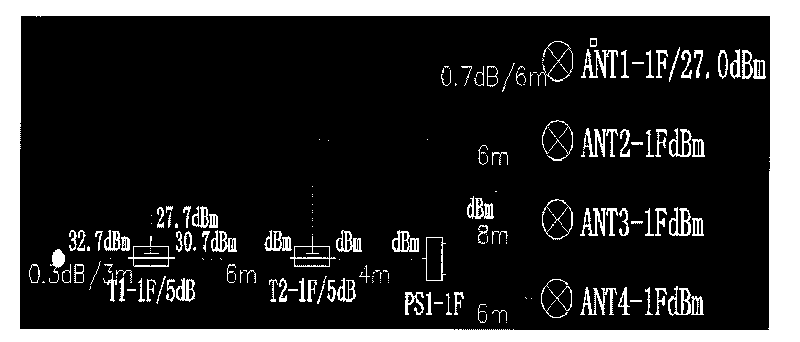

CAD platform-based indoor coverage designing method

InactiveCN101719175ASimple designEasy maintenanceSpecial data processing applicationsSystems designCommunication industry

The invention discloses a CAD platform-based indoor coverage designing method, which belongs to the technical field of wireless network communication indoor distribution in the communication industry. The method mainly comprises the steps of: 1) data preprocessing, 2) planar graph drawing, 3) system map drawing and 4) data processing and statistical output. The method has the characteristics of bringing great convenience to the system design of an indoor coverage network, improving the scheme designing work efficiency and accuracy of research staff, finishing the automatic design of an indoor distributed system, realizing a scheme for auditing the standard and high efficiency of operators, and bringing great convenience to later data management and later engineering maintenance.

Owner:GUANGZHOU TIANYUE ELECTRONICS TECH

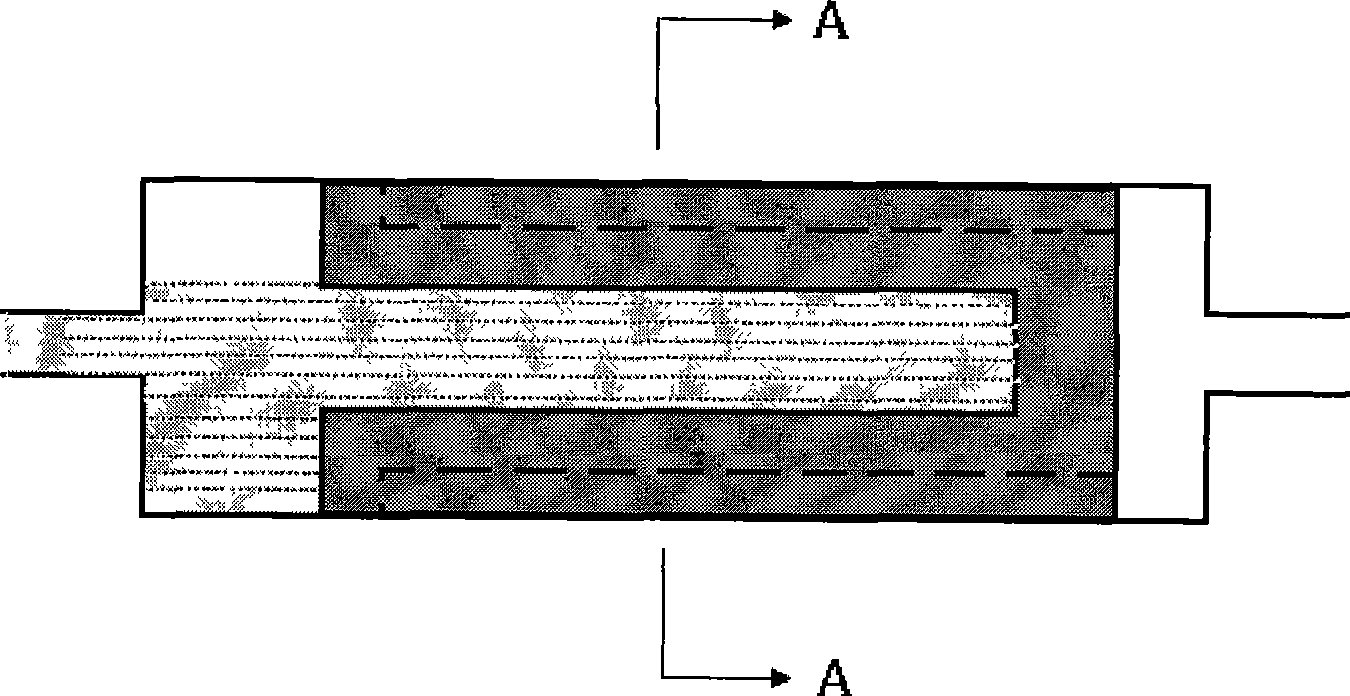

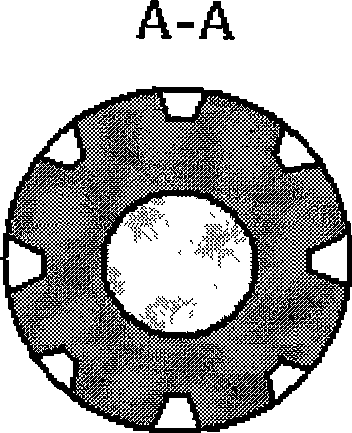

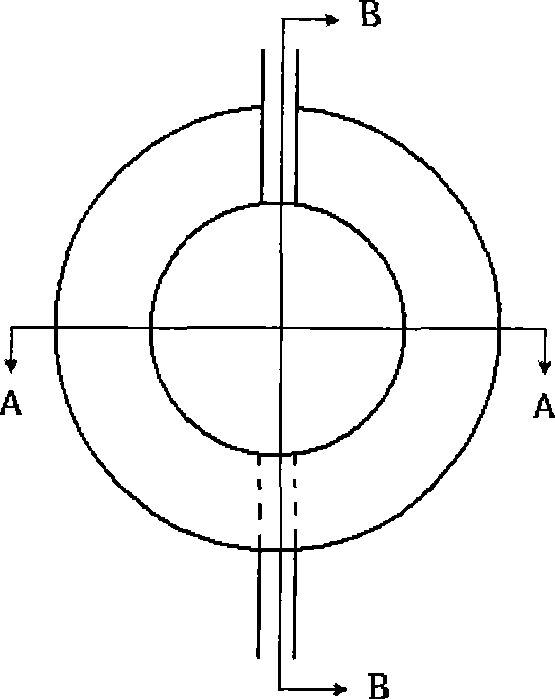

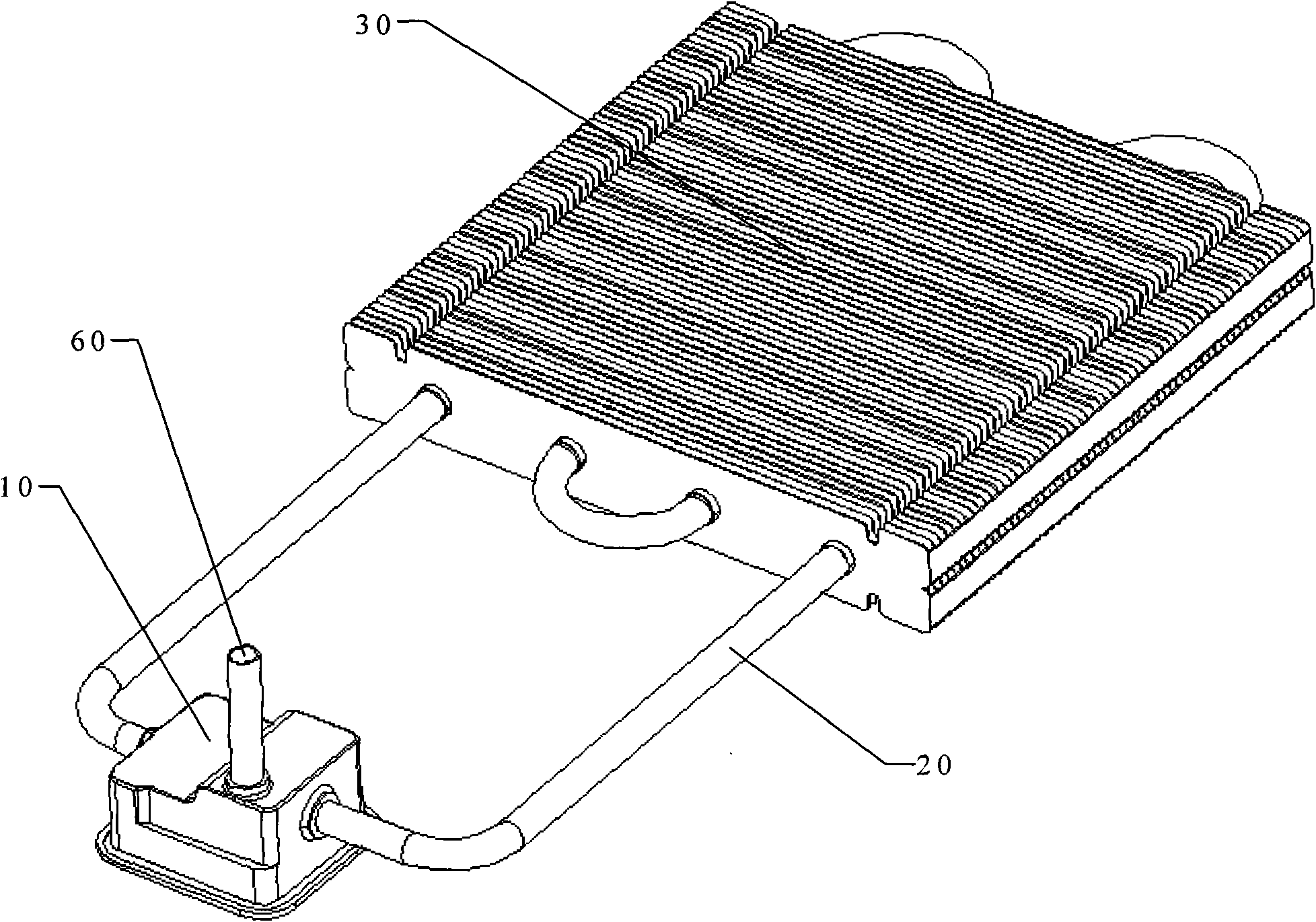

Serial-parallel type multi-evaporator loop heat pipe

InactiveCN101566442AMeet simultaneous heat dissipation requirementsAvoid disadvantagesSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHigh energy

A serial-parallel type multi-evaporator loop heat pipe comprises at least two groups of evaporators, at least two gas-liquid pipelines, at least two groups of condensers and at least one group of working fluid compensation chamber. The arrangement of a plurality of evaporators adopts a sequential serial-parallel type, namely the gas-liquid pipelines are used for connecting a back evaporator liquid inlet with a front steam outlet and connecting the steam outlet of the final evaporator with the first liquid inlet of the first evaporator; the gas-liquid pipeline is provided with the condenser; and the multi-group of the evaporators commonly use at least one group of working fluid compensation chambers that are connected with each other by the liquid compensation pipelines. The loop heat pipe can meet the simultaneous heat dissipation requirement of a plurality of heat sources, is mainly applicable to the heat dissipation of computer chips, and can be also used for the cooling of light-emitting diode lighting equipment, chips in communication industries and internal high-energy heating parts of military, medical and aerospace equipment.

Owner:BEIJING AVC TECH RES CENT

Lithium-ion battery with WS2 serving as positive electrode and preparation method of lithium-ion battery

InactiveCN104701541ALarge capacityCyclic stabilityFinal product manufactureCell electrodesAluminum IonCommunication industry

The invention discloses a lithium-ion battery with WS2 serving as a positive electrode and a preparation method of the lithium-ion battery and belongs to the field of lithium-ion batteries and the preparation method of the lithium-ion batteries. The lithium-ion battery comprises a positive electrode, a negative electrode, a diaphragm material and an aluminum ion electrolyte, wherein the positive active material is WS2; a negative electrode is a high-purity aluminum sheet; the electrolyte is aluminum ion electrolyte which is formed by mixing aluminum halide with a plurality of inorganic acid salts according to a ratio. The lithium-ion battery prepared by the method is stable in cycle performance, relatively wide in electrochemical window, continuous and high in coulombic efficiency and relatively wide in battery using temperature range; the lithium-ion battery can be widely applied to a plurality of fields such as portable electronic devices, electric vehicles, communication industry and aerospace.

Owner:UNIV OF SCI & TECH BEIJING

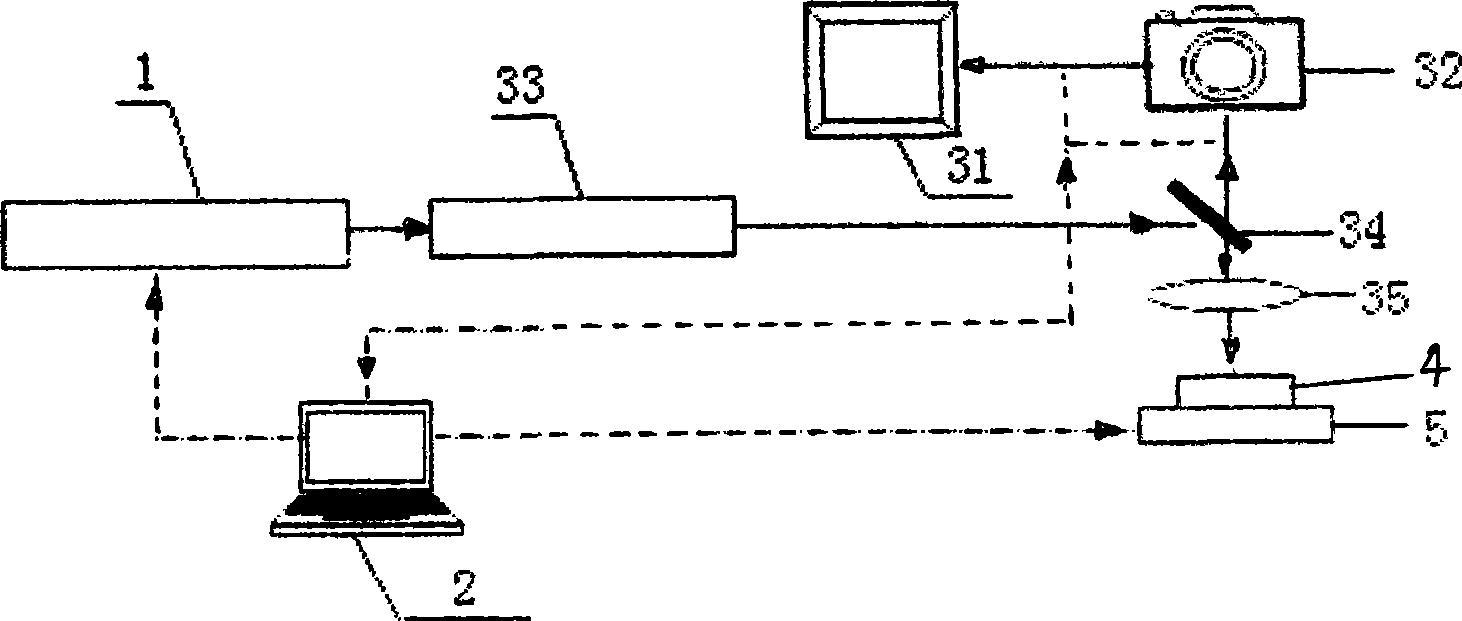

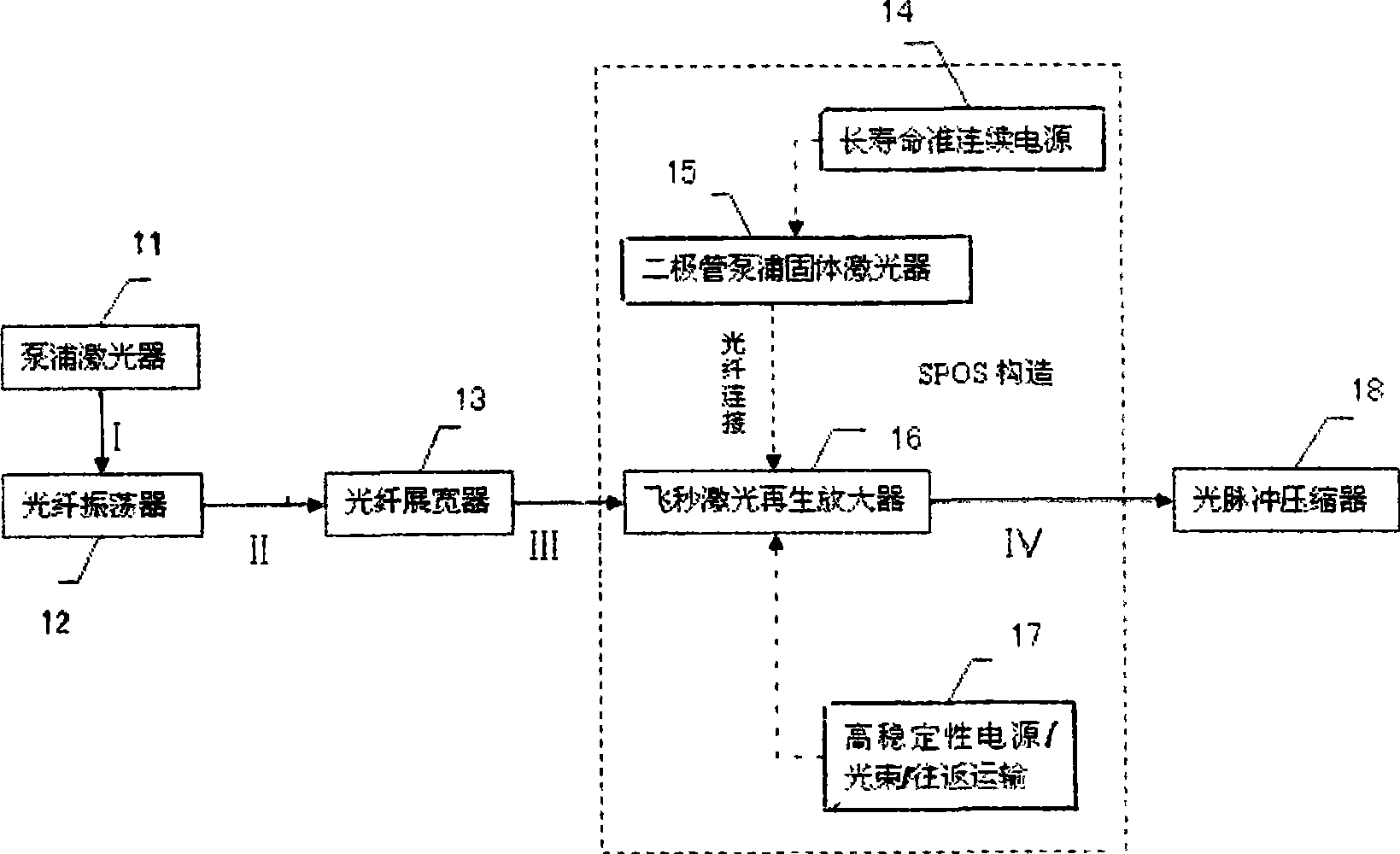

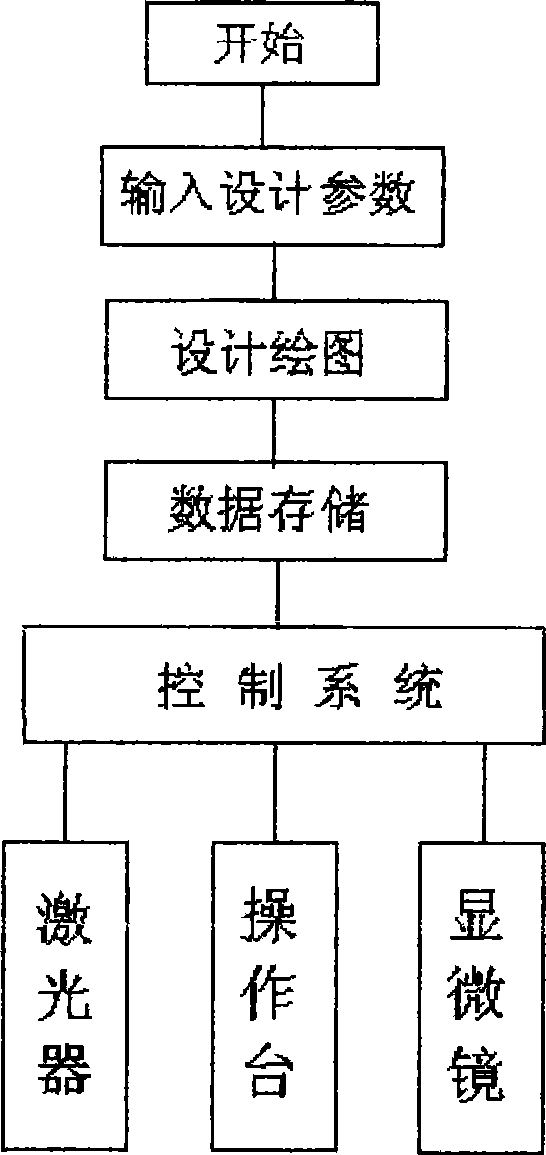

Micro-fine processing system of femtosecond laser for material surface modification

InactiveCN101480757AAvoid damageAchieve ultra-precision machiningLaser beam welding apparatusHeat-affected zoneFemto second laser

The invention discloses a micro-fine processing system for the surface modification of materials using femto-second laser, comprising a femto-second laser, a micro-light path system, a high-precision three-dimensional working platform and a control system host machine, wherein the femto-second laser acquires an emitted laser beam to focus and irradiate onto processed components on the three-dimensional working platform through the micro-light path system; the micro-light path system comprises a microscope for the observation of processing, a light batch system with a CCD monitor imaging unit, and the three-dimensional working platform is connected with the control system host machine in a control way. The micro-fine processing system uses the femto-second laser as a processing light source to precisely process the surface modification of material through the characteristics of unique ultra-short duration and ultra-strong peak power of the femto-second laser, the cooperation of the optical system and the high-precision three-dimensional working platform and the control of a software program in order to achieve the ultra-precise processing in the sub-micron level for no presence of heat affected zone during the processing and to provide a useful tool for automobile industry, semiconductor, communication industry, and the like needing the high-precision processing.

Owner:陕西午禾科技有限责任公司

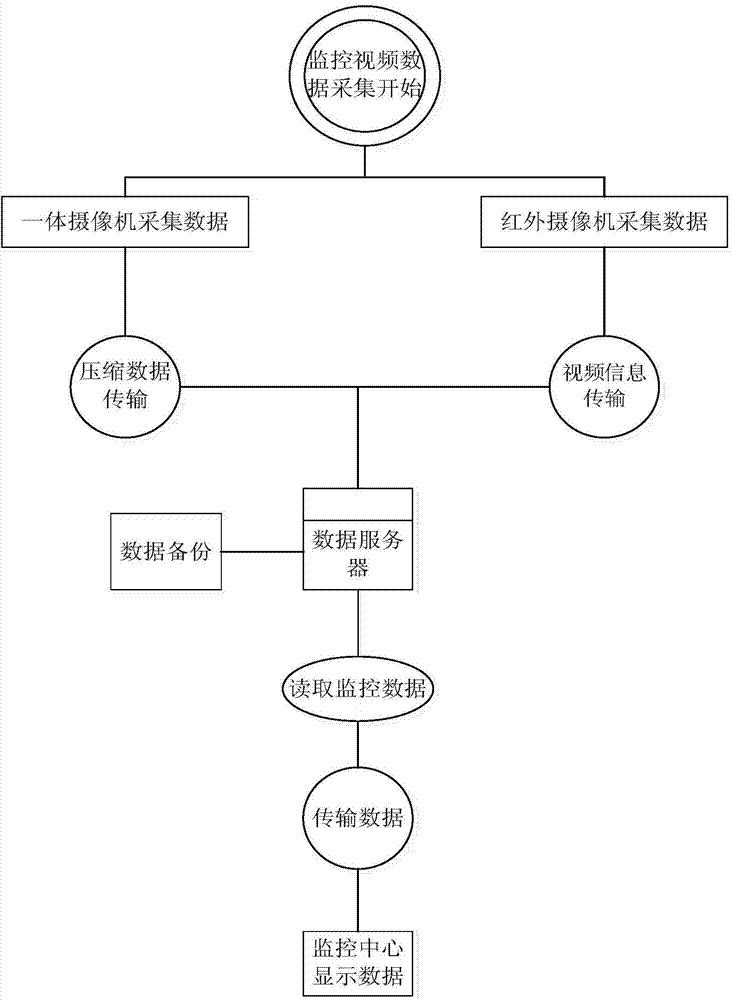

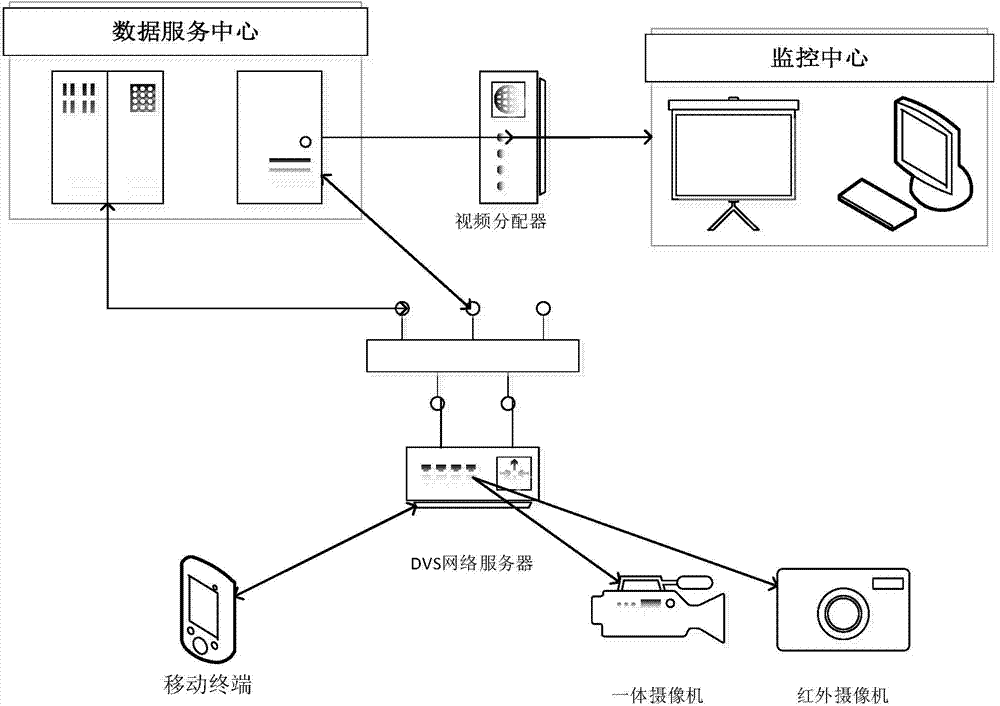

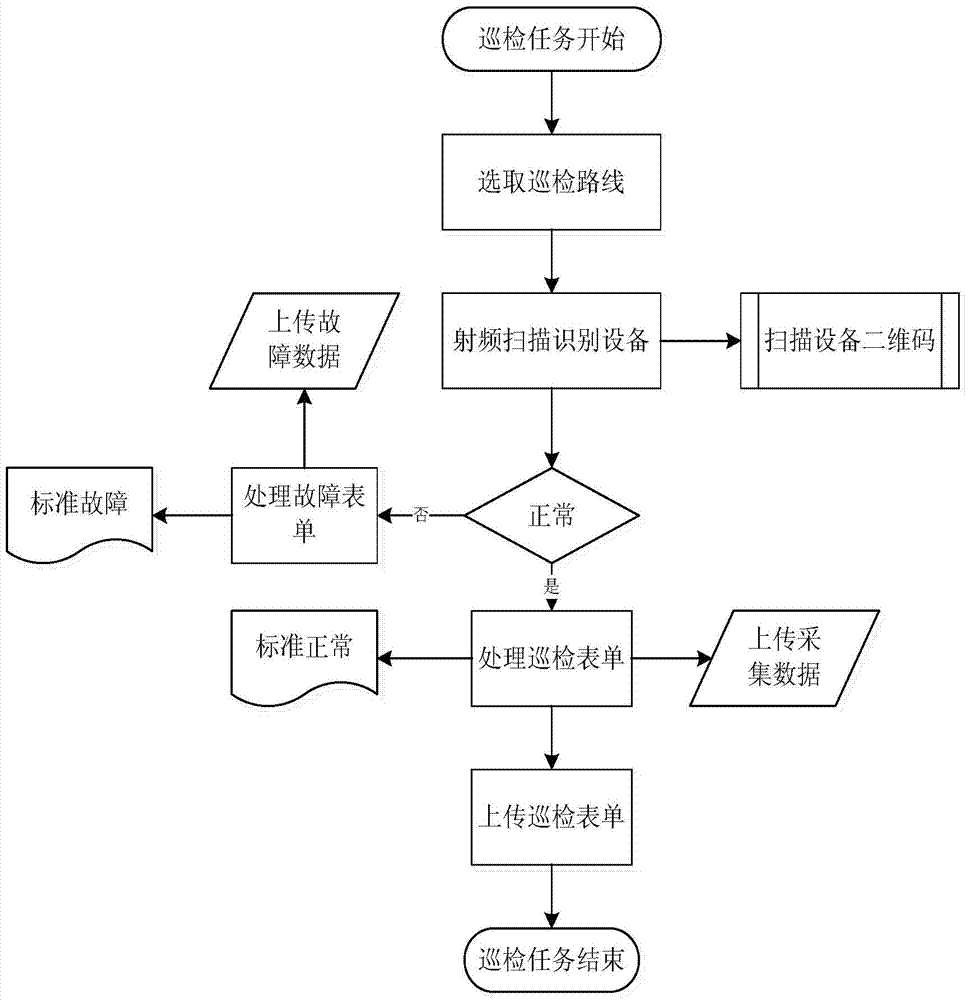

IPv6-based video monitoring and radio frequency identification two-dimensional code system in transformer station inspection

InactiveCN104850816AComprehensive hidden danger monitoringHidden danger monitoring is in placeData processing applicationsClosed circuit television systemsVideo monitoringData transformation

The invention relates to an IPv6-based video monitoring and radio frequency identification two-dimensional code system and method in transformer station inspection. The system is composed of a video monitoring module and a radio frequency identification two-dimensional code module; the video monitoring module is composed of a monitoring scheduling center and monitoring centers and monitoring devices at various levels from top to the bottom; and the radio frequency identification two-dimensional code module is composed of a two-dimensional code module, a radio frequency front end and a processing center. The system provided by the invention provides such video monitoring tasks as equipment monitoring, personnel operation monitoring, operation maintenance monitoring and the like for an electric power communication industry, and realizes regular in-place inspection examination of electric power equipment especially a transformer station, thereby being an important guarantee of safe and stable operation of a power system. Defects and faults can be timely discovered through the transformer station inspection, the video monitoring module employs an IPv6 communication protocol for network communication, and the data security and the data transformation performance are improved. The system provided by the invention is simple and complete and is good in expansion performance and reliable in operation, thereby having quite good popularization and application prospect.

Owner:CHINA ELECTRIC POWER RES INST +3

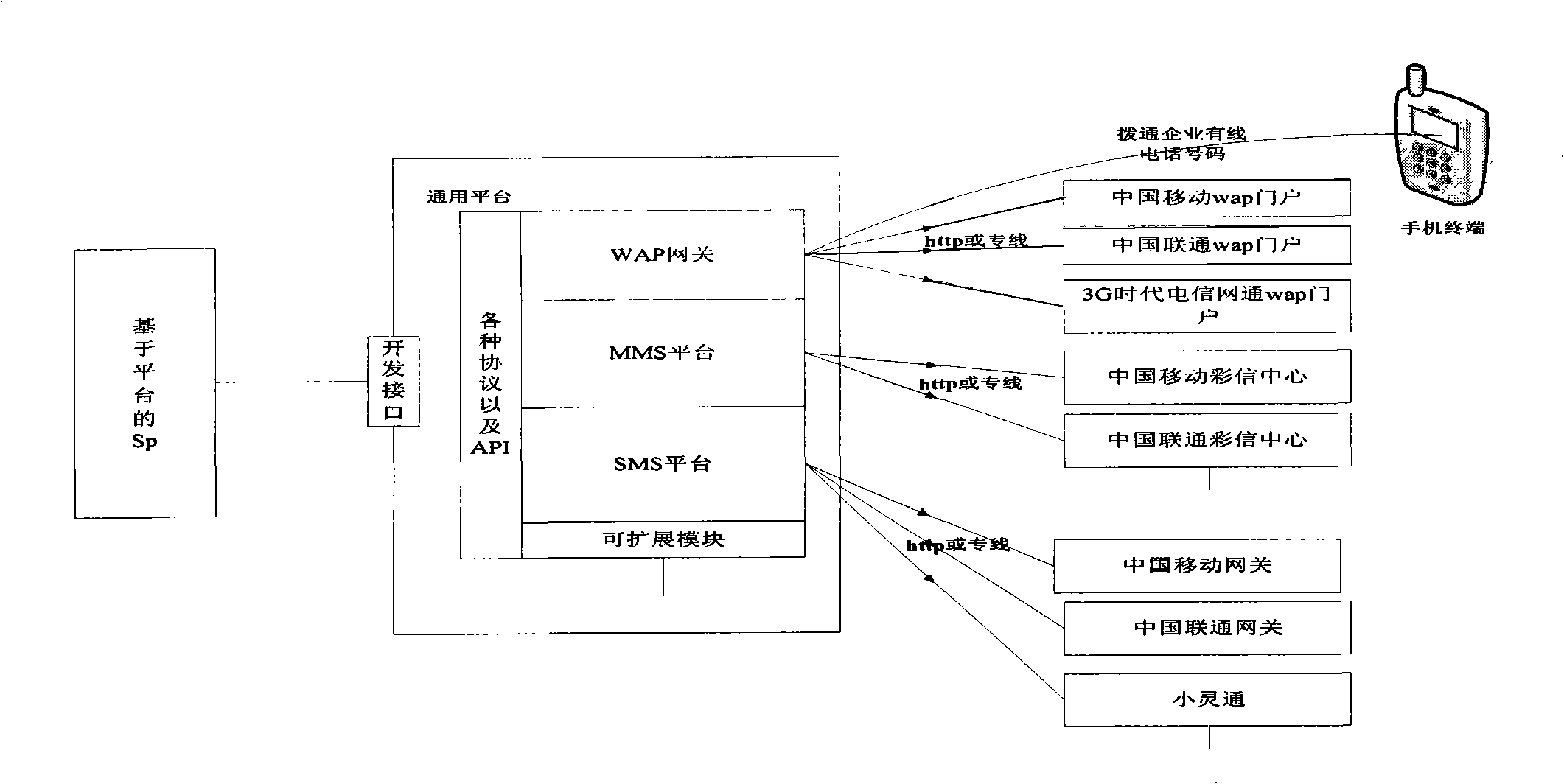

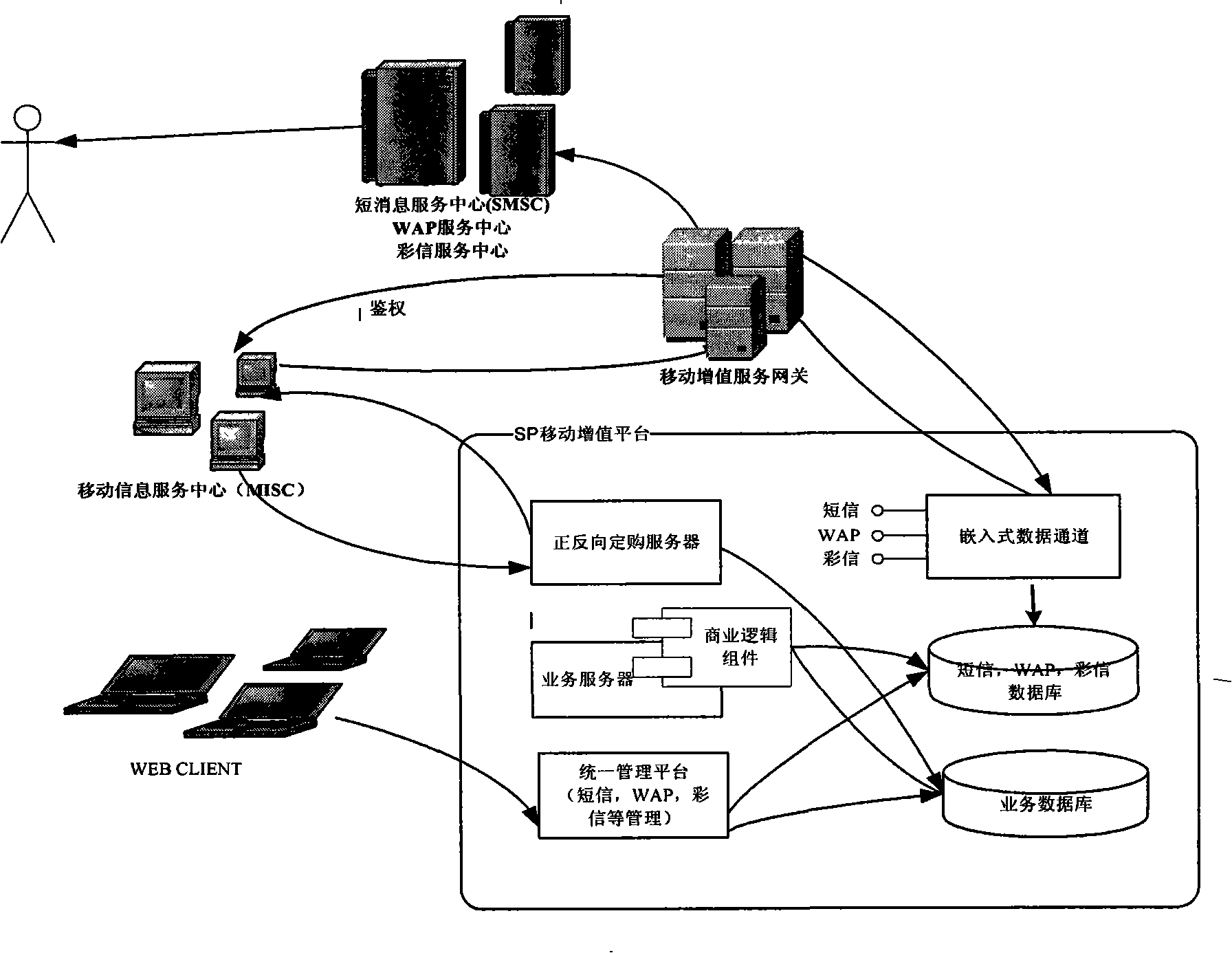

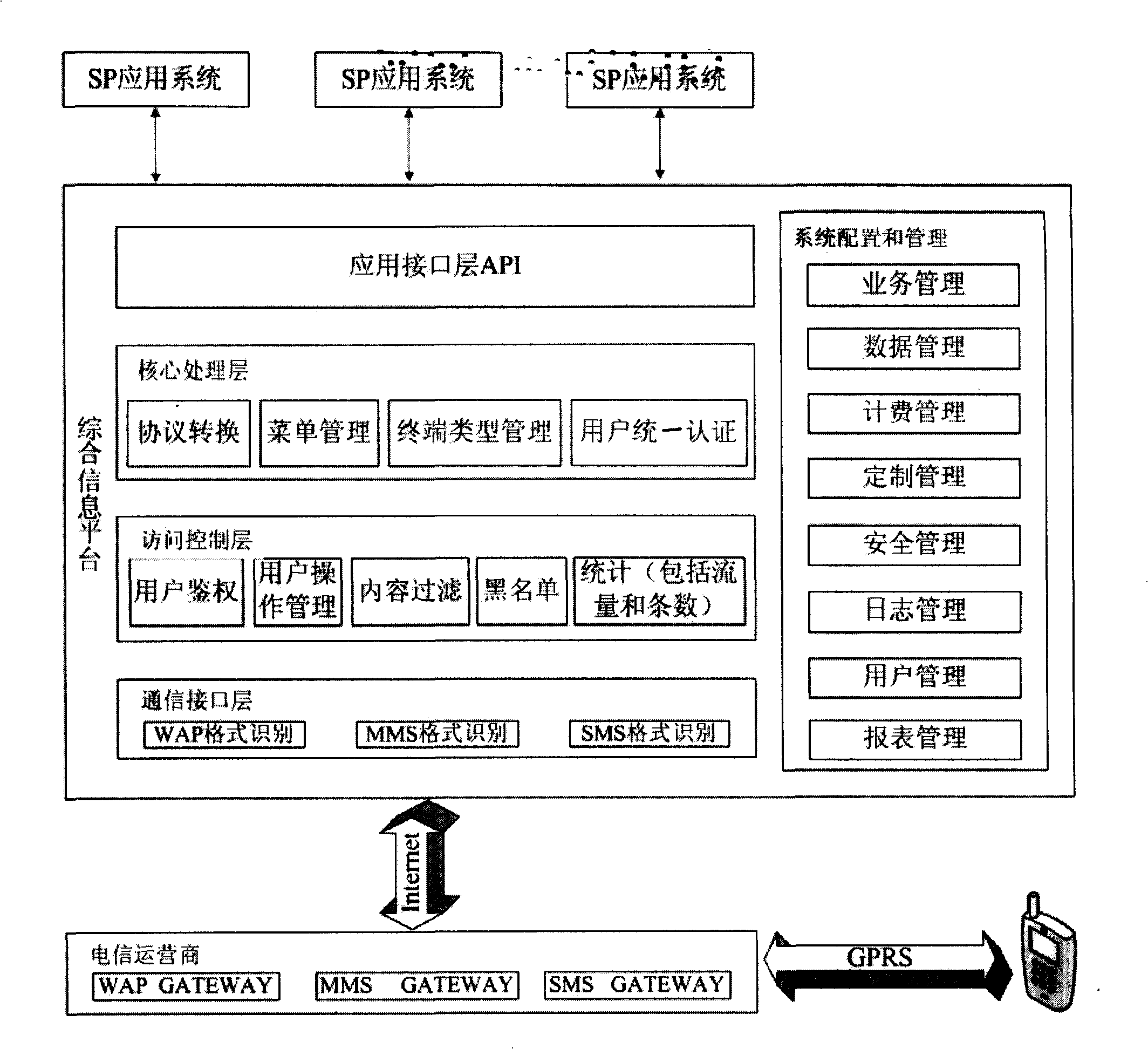

Embedded telecom value-added service gateway

InactiveCN101350963AEasy accessAvoid visitingRadio/inductive link selection arrangementsTransmissionCommunication interfaceMutual transformation

The invention discloses an embedded type telecommunication value-added service gateway, particularly comprising: (1) a communication interface module which is used for accomplishing information communication with various protocol gateways and providing a standard input for a core processing layer; (2) an access control module which is used for validating and controlling the legality of an accessed subscriber and controlling the access process of the subscriber; (3) a core processing module which is used for accomplishing mutual transformation of a specified application data format and a standard data format; (4) a system configuration management module which is used for managing a service in all portals providing an information value added service in mobile communication industry; (5) an application program interface module which is used for providing an interface for a back-end specified business application program and being responsible for a data communication process between two parties. The embedded type telecommunication value-added service gateway can be used as a data channel realizing message instant sending, support the access with various networks, realize a unified data access interface with various access modes such as SMS , WAP and MMS, and provide the unified access mode in the interface for a value added service provider.

Owner:NORTHWEST UNIV

Method for solving performance bottleneck of network management system in communication industry based on cloud computing technology

InactiveCN102624558AFix performance issuesSolve difficult system performance problemsData switching networksVirtualizationThird party

The invention provides a method for solving the performance bottleneck of a network management system in the communication industry based on a cloud computing technology. In the method, cloud computing is adopted to determine the guiding principle of the network management system. The method comprises the following steps of: 1) aiming at hardware and third-party software, a mainstream virtualization technology which supports unified cloud computing implementation mode is adopted, and 2) aiming at system software, a design mode adaptive to distributed deployment is adopted; and in terms of three levels (hardware, middleware and application software), the cloud computing technology is utilized to effectively solve the performance problem of the network management system; Based on a cloud computing architecture design and a deployment application system, the system performance problem which is hardly solved by a traditional system can be effectively solved; and simultaneously, by utilizing cloud computing, the advantages in the aspects of low cost, high expansibility and the like can be achieved, and from the macroscopic view, great problems can be solved by utilizing existing technologies without spending great time in processing certain technical details.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

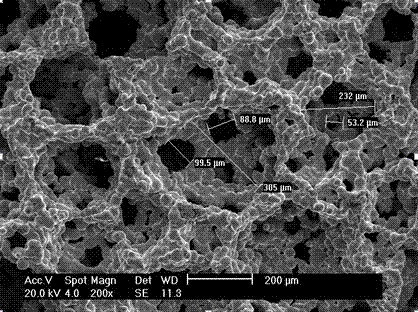

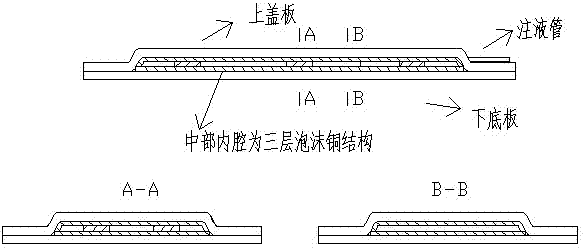

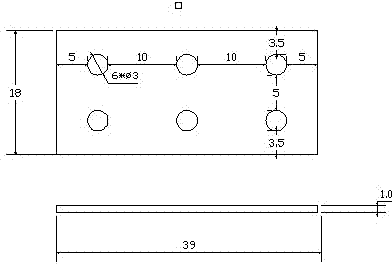

Method for manufacturing uniform-heating plate with foam copper as liquid absorption core

The invention discloses a method for manufacturing a uniform-heating plate with foam copper as a liquid absorption core. The foam copper which is manufactured in a grading manner and has the different thicknesses and the porosity is sintered on an upper cover plate and a lower bottom plate manufactured through copper plates or copper foil of the corresponding different thicknesses, and through welding, vacuumizing, liquid injecting and packaging, the uniform-heating plate is manufactured. A cylindrical foam copper supporting column which is manufactured in a grading manner and has a certain thickness(generally larger than or equal to 0.8mm) is adopted by a middle steam cavity, rapid flowing of gas-liquid phase media is ensured, and medium phase change circulation speed is increased; and the foam copper which is manufactured in a grading manner is provided with a good capillary structure, and is uniform in pore structure distributing and high in porosity. The uniform-heating plate with foam copper as the liquid absorption core has the advantages of being high in heat dissipation efficiency, small in weight, suitable for manufacturing an ultra-thin structure, and capable of meeting the requirement of semiconductor electronic equipment with the high heat flow density for high heat conduction efficiency and miniaturization. The uniform-heating plate is low in manufacturing cost, high in manufacturing precision and suitable for purposes of heat radiation of a computer chip, cooling of high-energy electronic chips or photoelectric chips or radio frequency chips of the wireless or wire communication industry and the like.

Owner:JIANGSU KAIWEIDI TECHNOLOGY CO LTD

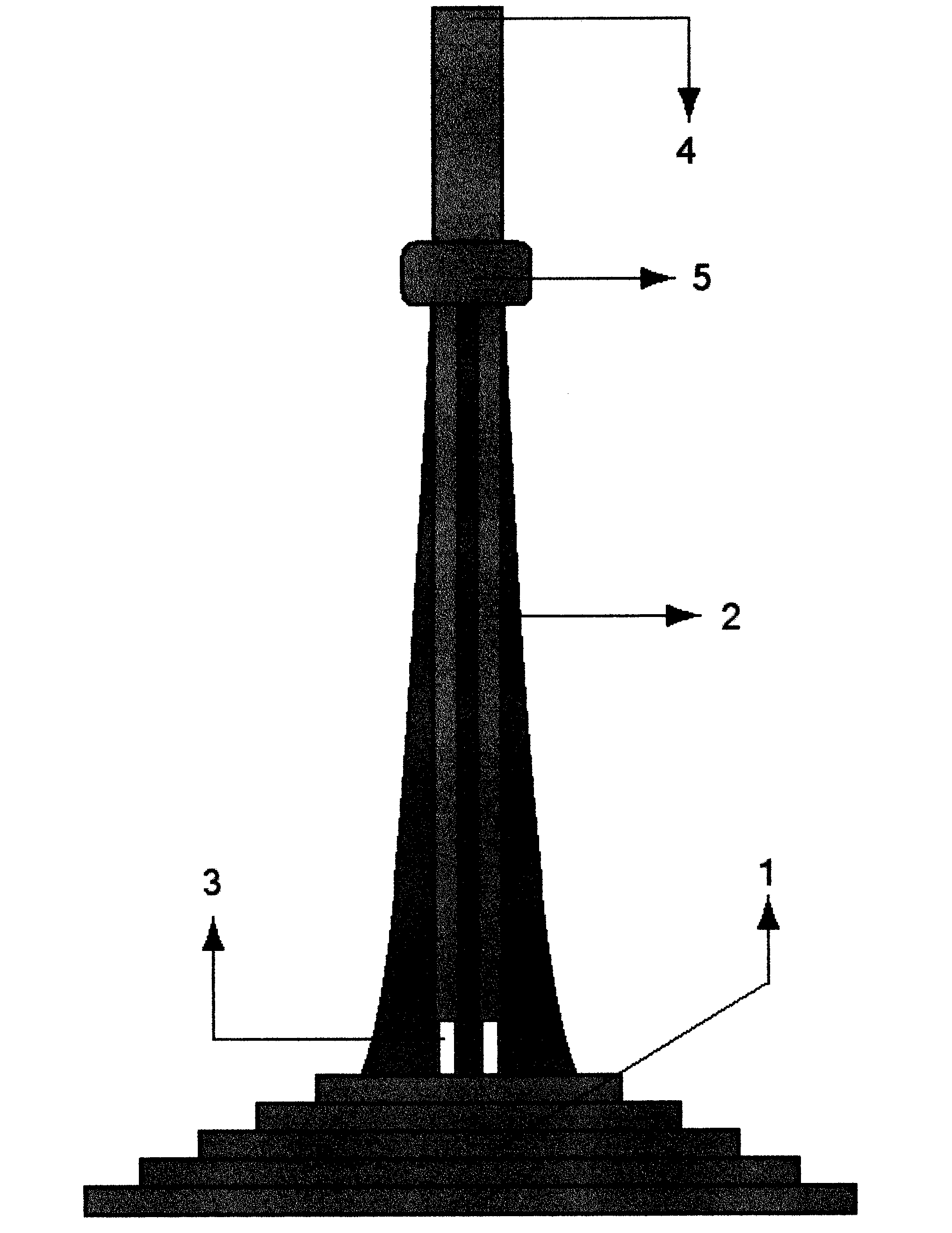

Method and equipment for carrying out air conditioning on natural environment by applying chimney type air guide tower

InactiveCN102027869AIncrease dissolved oxygenPromote growthWeather influencing devicesDiseaseAir conditioning

The invention relates to a method for continuously drawing humid and hot air on the ground according to the chimney effect by utilizing a chimney type air guide tower so that the humid and hot air rapidly floats to break the up-and-down convection of the humid and hot air and dry and cold air by the greenhouse effect and achieve the aims of controlling ground air temperature and humidity, reducing carbon dioxide and dust concentration in ground air and artificially raining and environmental air conditioning equipment. The application of the technology realizes the aim that people reform nature by utilizing nature. The method and the equipment can be used for controlling the temperature and the humidity of urban ground air and carrying out artificial rainfall and also used for preventing great loss on agriculture, forestry, electric industry, communication industry, and the like by natural disasters, such as strong wind, rainstorm, thunder, lightning, hail, and the like due to strongly convective weather; meanwhile, cool weather is more beneficial to the growth of crops and prevents damage by diseases and insects. In the aspect of fishery, the invention can improve the oxygen dissolving amount of a pond and prevent the generation of the phenomenon of fish dead by pond turn-over; meanwhile, cool water temperature is more beneficial to the growth of aquatic animals and plants.

Owner:胡永生

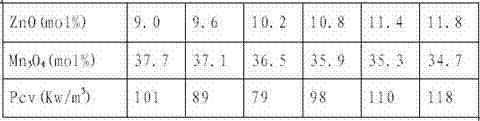

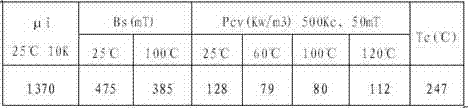

Wide-temperature, high-frequency and low-power-consumption manganese zinc iron oxidation material and method for manufacturing same

ActiveCN102924070AImprove high frequency performanceUniform oxygen contentCommunication industryHome appliance

The invention discloses a wide-temperature, high-frequency and low-power-consumption manganese zinc iron oxidation material and a method for manufacturing the same. The material comprises, by molar percentage, 50.5% to 55.0% of Fe2O3, 7.0% to 11.5% of ZnO, 30.5% to 38.5% of Mn3O4 and additive compositions of Si02, Ca0, Nb205, Zr02, TiO2, NiO and Ta2O5. The method for manufacturing the material comprises steps of: fixing a molar percentage content of the Fe2O3 and fixing contents of the ZnO and the Mn3O4; performing ball-milling for 45 minutes; pre-sintering materials after ball-milling in a rotary kiln; and performing sanding for 2 hours so that powder grain sizes are in a range from 1.0 mu m to 1.2 mu m, adding additives and the like. According to the wide-temperature, high-frequency and low-power-consumption manganese zinc iron oxidation material and the method for manufacturing the same, excellent high-frequency performances are provided for the material, demands of users for temperature characteristics are considered simultaneously, and magnetic cores of a large amount of imported magnetic cores of PC50 and 3F4 and the like in prior home appliance and communication industries can be replaced.

Owner:眉山市宇泰电子设备有限公司

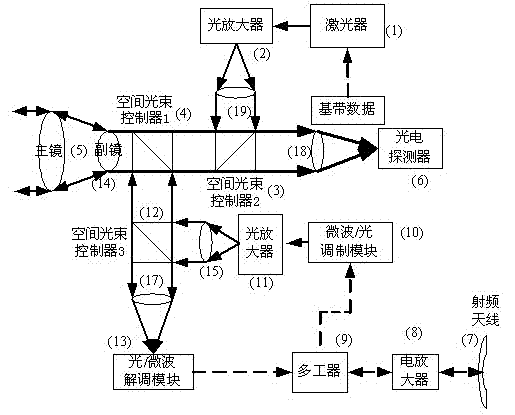

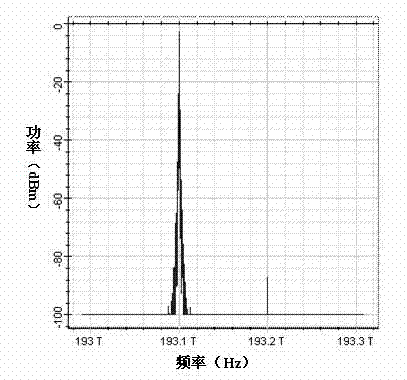

Space-borne microwave and laser communication link integrating system and application method

InactiveCN103117803AImprove unityReduce volumeSatellite communication transmissionSoftware engineeringCommunication link

The invention discloses a space-borne microwave and laser communication link integrating system and an application method. The integrating system comprises a laser, light amplifiers, a convergent lens, a light beam controller, an optical antenna, a photoelectric detector, a microwave / light demodulator, a light / microwave demodulator, a multiplexer, an electricity amplifier and a radio frequency antenna. The application method includes that a digital signal is modulated to a light area via the laser; an optical signal is coupled to the optical antenna for transmitting via light beam coupling; the optical signal is received and coupled to the photoelectric detector by the optical antenna; the optical signal is received by the optical antenna, processed by the light beam controller, coupled to the light / microwave demodulator, and converted into a microwave signal, the microwave signal is amplified by the electricity amplifier and coupled to the radio frequency antenna for transmitting; the microwave signal is received by the radio frequency antenna, amplified by the electricity amplifier and input to the multiplexer to realize microwave signal combination, then is modulated to the light area via the microwave / light demodulator; and finally the combined signal is coupled to the optical antenna for transmitting via the light beam controller. The space-borne microwave and laser communication link integrating system is small in size, low in energy consumption, and can be widely used in military and civil space-borne communication industry.

Owner:AIR FORCE UNIV PLA

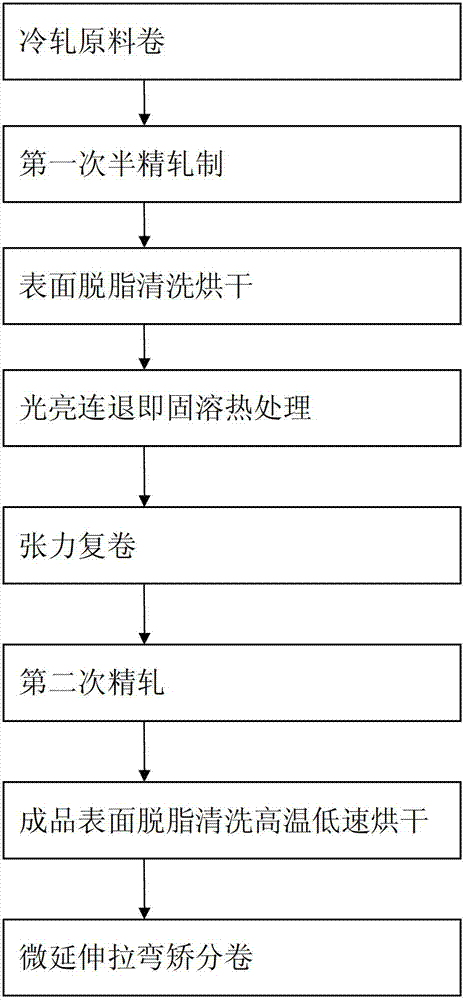

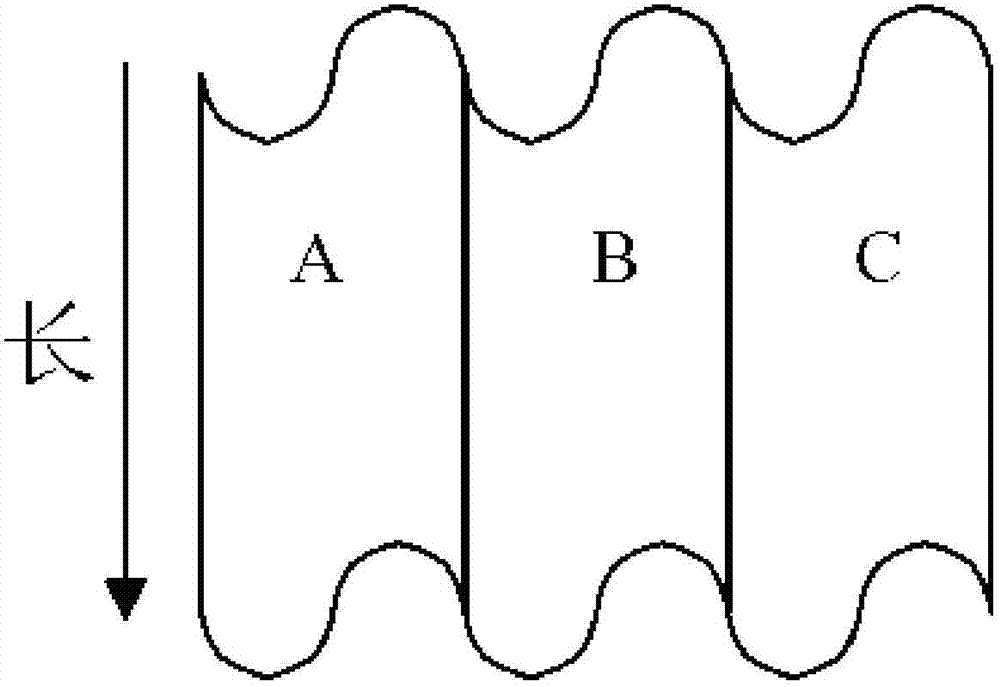

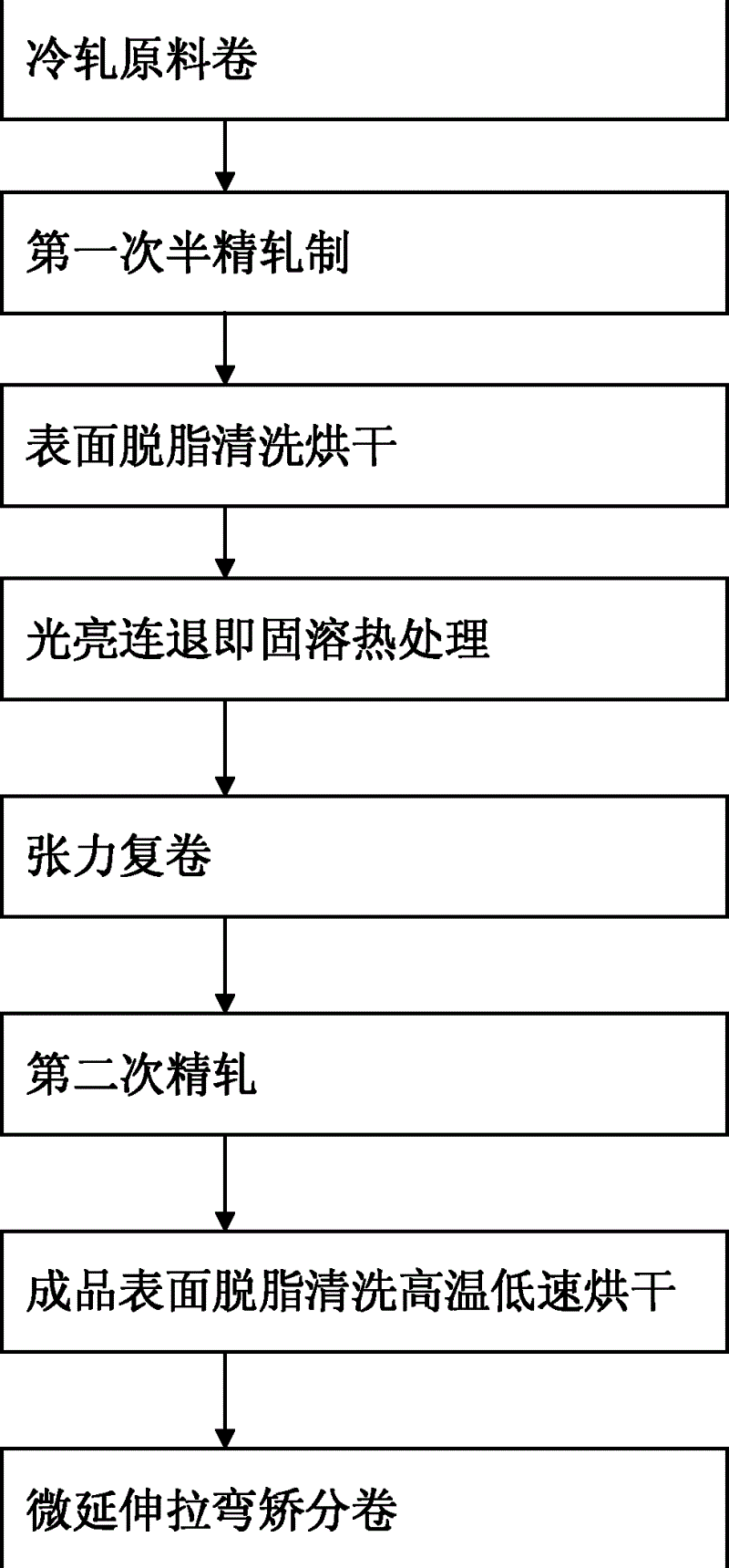

Partially-etched precision stainless steel strip used in communication industry as well as production process and application thereof

ActiveCN102699019AAvoid deformationMeet production requirementsTension/compression control deviceMetal rolling arrangementsCommunication industrySurface roughness

The invention relates to a production method of a partially-etched precision stainless steel strip, which comprises the following steps: semi-finish rolling; degreasing, washing and drying; solution heat treatment; tension rewinding; finish rolling; degreasing, cleaning and drying; micro extending, straightening and bundling. Due to the implementation of the technical scheme of the production process, the product has high thickness tolerance precision, low fluctuation, smooth surface, uniform surface roughness and no surface color difference. The plate is flat, has stable mechanical performance, is not easy to deform after being partially etched and can met the needs of producing the intelligent mobile phones in the communication industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

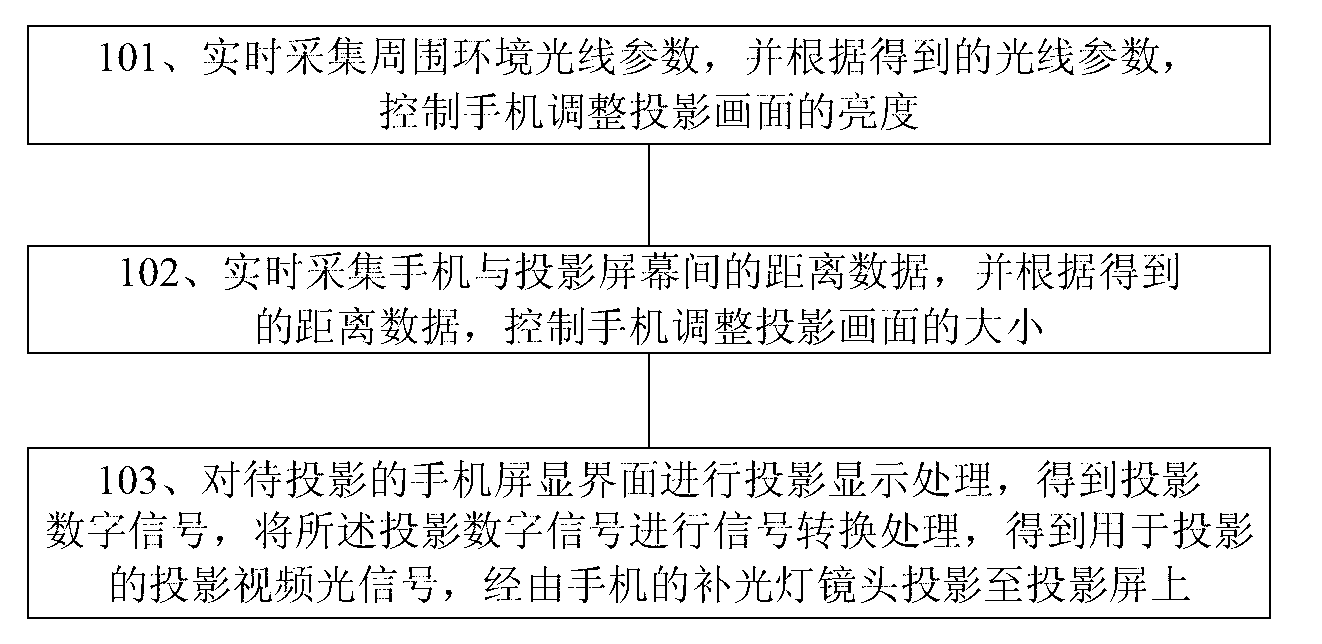

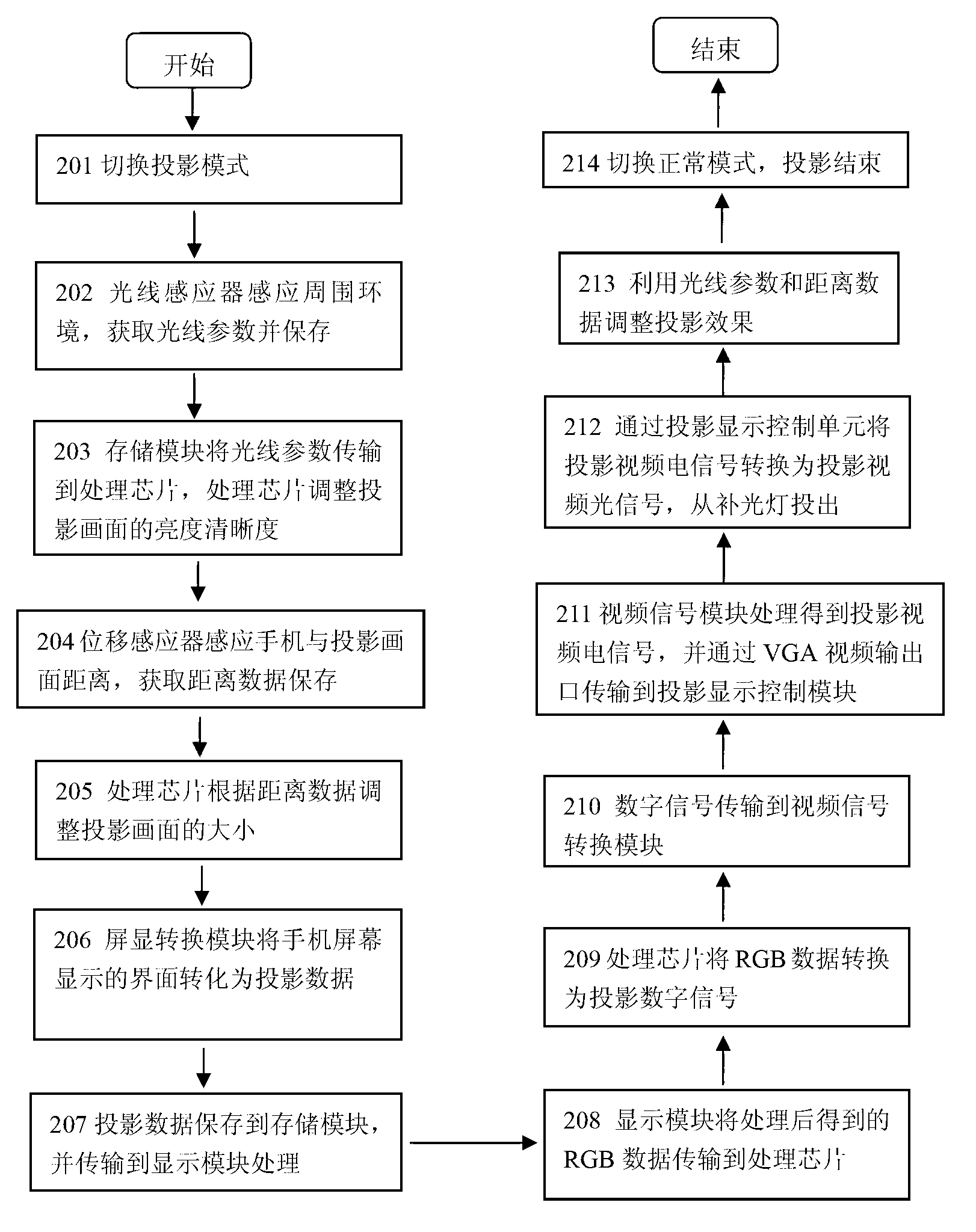

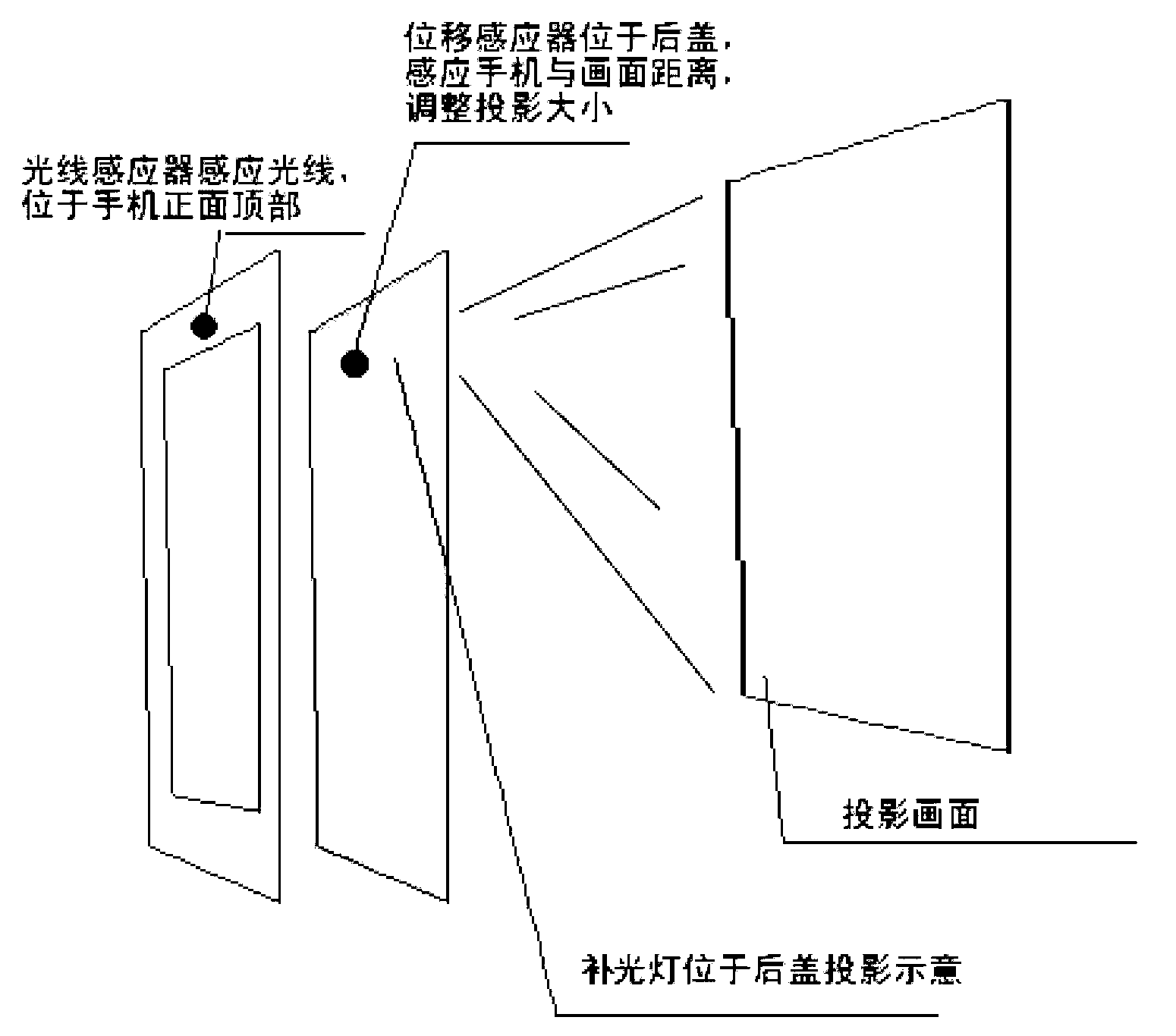

Method and device for projecting by light-compensating lamp of mobile phone

InactiveCN103019004AEasy to moveImprove real-time performanceTelevision system detailsProjectorsCamera lensCommunication industry

The invention discloses a method and a device for projecting by a light-compensating lamp of a mobile phone, relating to the sensing technology and the photographing-projecting technology in the communication industry. The method comprises the following steps of: acquiring the light ray parameters of an ambient environment in real time, and controlling the mobile phone to adjust the brightness of the projected picture according to the obtained light ray parameters; acquiring the distance data between the mobile phone and a projecting screen in real time, and controlling the mobile phone to adjust the size of the projected picture according to the obtained distance data; and performing projecting display processing on the to-be-projected mobile phone screen display interface to obtain a projecting digital signal, performing signal conversion processing on the projecting digital signal to obtain a projecting video light signal for projecting, and projecting onto the projecting screen via the lens of the light-compensating lamp of the mobile phone. In the method and the device disclosed by the invention, the mobile phone is utilized for projecting without the need of connecting a projector, thus improving the mobile working capacity of the mobile phone.

Owner:ZTE CORP

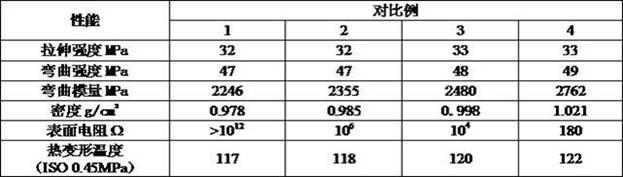

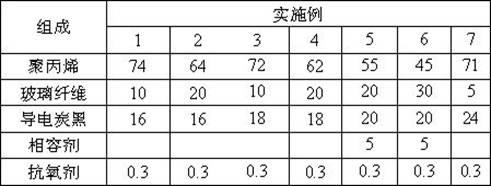

Heat-resistant conductive polypropylene composite material and preparation method thereof

The invention discloses a heat-resistant conductive polypropylene composite material and a preparation method thereof; the heat-resistant conductive polypropylene composite material comprises components in parts by mass: 45-75 parts of polypropylene, 5-30 parts of glass fiber and 16-24 parts of conductive carbon black. The composite material takes polypropylene as matrix resin and is prepared by a one-step melt kneading method; the glass fiber and the conductive carbon black have an obvious conductive synergistic effect, so that the composite material has excellent rigidity, heat resistance and good electrical conductivity; and the surface resistance is not higher than 109W, so that the composite material can be applied to a package and a chip carrier with anti-static requirement as well as a motor vehicle and the information and communication industry with electromagnetic shielding requirement.

Owner:KINGFA SCI & TECH CO LTD +1

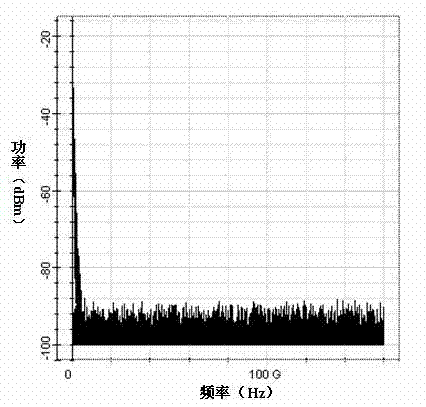

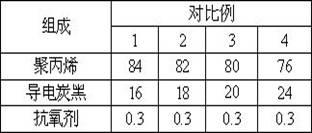

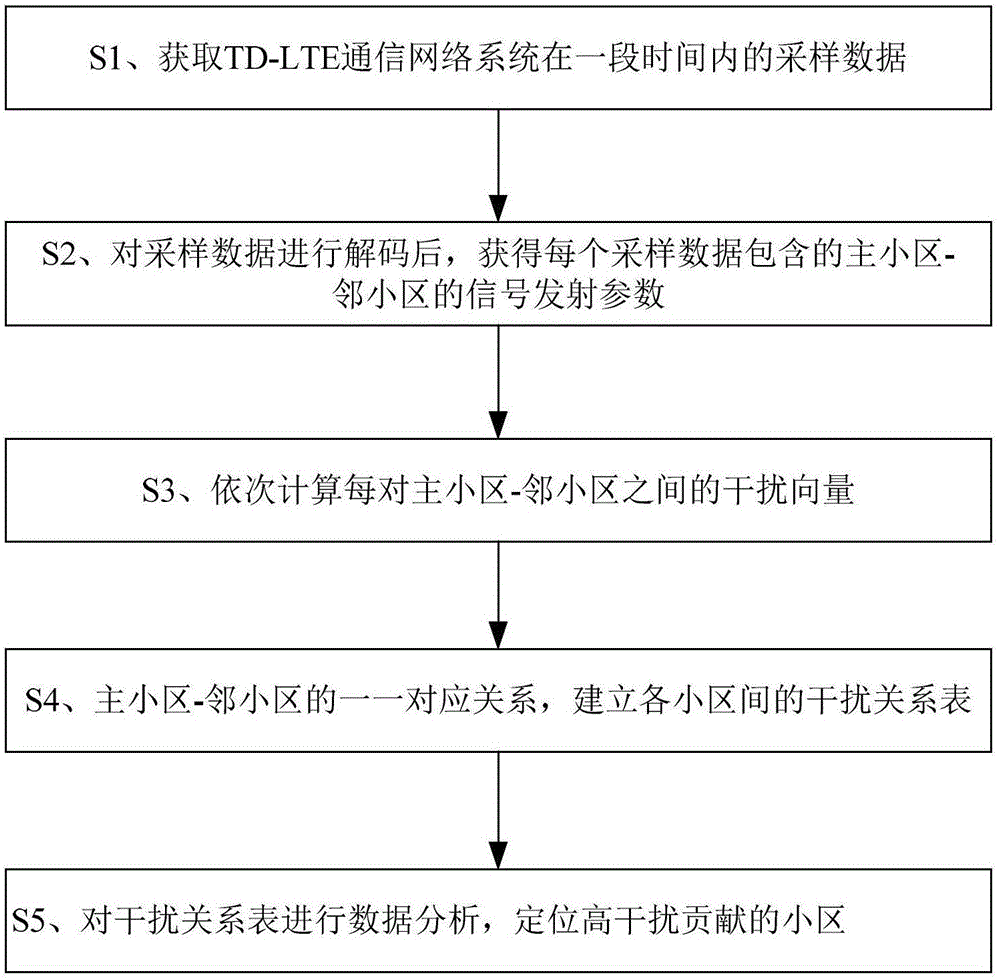

Method for positioning TD-LTE intra-system interference

ActiveCN105163344AReduce consumptionHigh precisionWireless communicationTime-Division Long-Term EvolutionCommunication industry

The present invention discloses a method for positioning TD-LTE (Time Division-Long Term Evolution) intra-system interference, comprising the following steps: S1, acquiring data sampled by a TD-LTE communication network system within a period of time; S2, after decoding the sampled data, acquiring a signal emission parameter of a main cell-a neighbor cell included in each sampled data; S3, calculating an interference vector between each pair of the main cell-the neighbor cell successively; S4, forming an interference relation table among each cell according to the corresponding relation of the main cell-the neighbor cell; and S5, carrying out data analysis on the interference relation table, and positioning cells with high interference contribution. The method of the present invention can position high interference cells based on real-time sampled data of a TD-LTE network without considering affects of station structural characteristics; the calculation method is simple, the resource consumption is low, the precision is high, the output results are comprehensive, accurate and quantitative, and so the method can be widely applicable for mobile communication industry.

Owner:DINGLI COMM

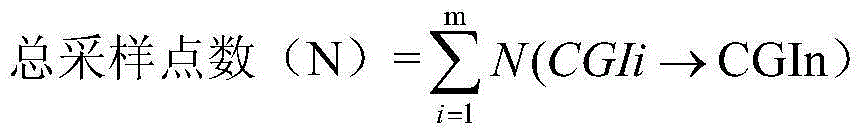

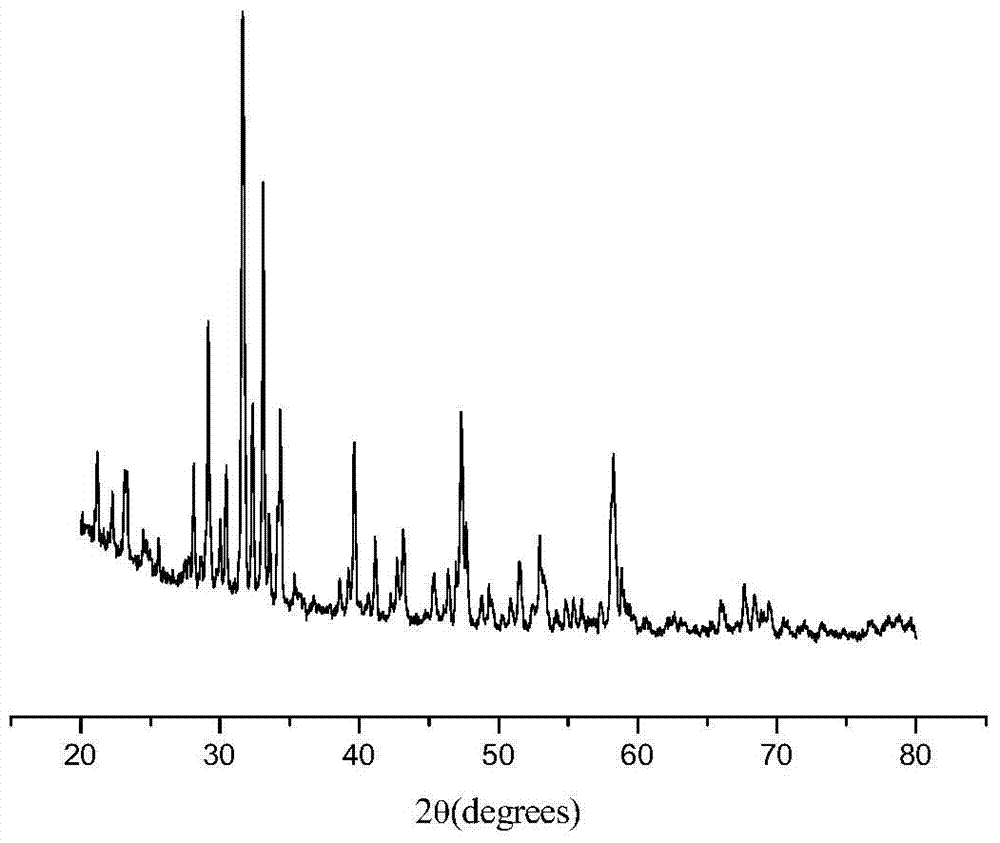

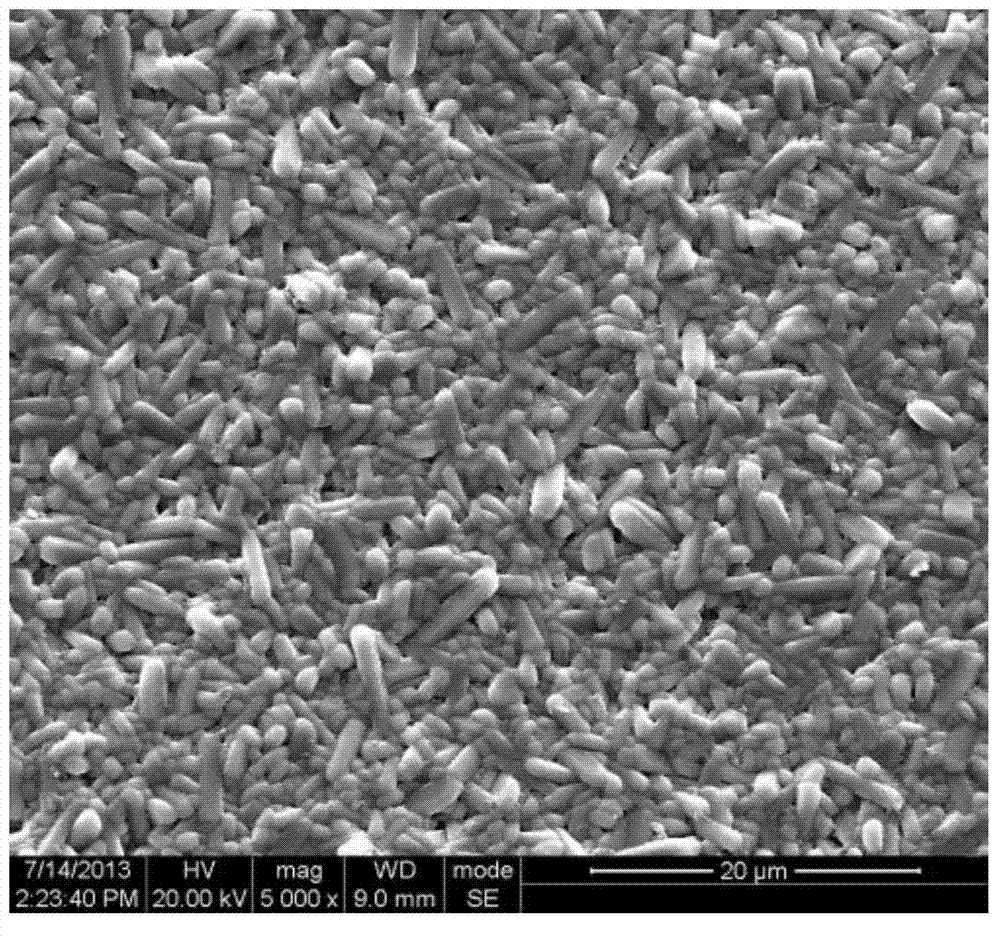

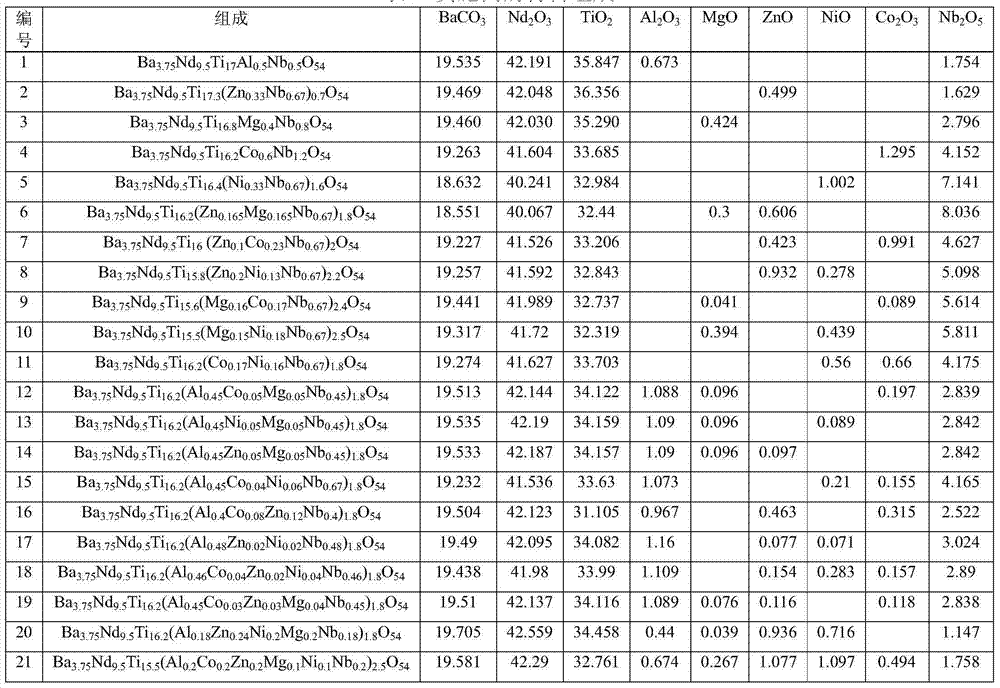

B-substituted BNT microwave dielectric ceramic material and preparation method

A B-substituted BNT microwave dielectric ceramic material and its preparation method belong to the technical field of a functional material. The general chemical formula of the microwave dielectric ceramic material is Ba3.75Nd9.5Ti18-y(M,N)yO54, wherein y is less than or equal to 2.5 and greater than or equal to 0.6; the microwave dielectric ceramic material is prepared by steps of: burdening BaO, Nd2O3, TiO2, oxides of metallic elements M and N according to mole ratio of the general chemical formula, carrying out ball-milling, presintering and sintering; an oxide of the element M is Nb2O5; and an oxide of the element N is one or more compounds selected from Al2O3, MgO, ZnO, Co2O3 and NiO. According to the invention, simultaneous substitution of high and low valence elements is carried out in the B position of Ba6-3xNd8+2xTi18O54. The microwave dielectric ceramic material prepared by a one-step synthesis process has high dielectric constant, low loss characteristic and low frequency-temperature coefficient, can meet requirements in the microwave communication industry, and is especially suitable for manufacturing of RFID tags.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

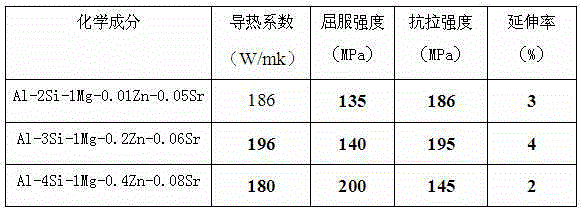

High-heat-conductivity corrosion-resistant die-cast aluminum alloy and preparing technique thereof

InactiveCN105112737AImprove thermal conductivityHigh corrosion resistance requirementsCommunication industryDie casting

The invention discloses high-heat-conductivity corrosion-resistant die-cast aluminum alloy. The high-heat-conductivity corrosion-resistant die-cast aluminum alloy comprises, by weight, 1.5%-5% of Si, 1.0%-3% of Mg, 0.01%-0.5% of Zn, 0.05%-0.1% of Sr and the balance aluminum and other impurity elements. The content of the other impurity elements is smaller than 0.005%. After pure aluminum is molten, corresponding intermediate alloy is added according to the composition proportion, refining is conducted at the temperature of 750 DEG C by means of a specialized refining agent, the temperature is decreased to 730 DEG C after stirring is conducted sufficiently, and standing is conducted for 10 min. An Al-Ti-B modificator is used for modification. According to the high-heat-conductivity corrosion-resistant die-cast aluminum alloy, at the temperature of 20 DEG C, the heat conductivity coefficient is 175-190 W / mk, the tensile strength of a die casting ranges from 170 MPa to 200 MPa, the yield strength ranges from 130 MPa to 145 MPa, the ductility is 2%-4%, and the high-heat-conductivity corrosion-resistant die-cast aluminum alloy can be applied to structural components, having high requirements for the heat conductivity coefficients and the corrosion resistance of materials, in the industries such as the automobile industry and the communication industry. Compared with conventional AD12 alloy, the high-heat-conductivity corrosion-resistant die-cast aluminum alloy has remarkable advantages on the aspect of the heat conductivity coefficient.

Owner:苏州慧驰轻合金精密成型科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com