Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1649 results about "Forward voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The forward voltage of an LED, VF, is the voltage that must be applied across the leads of the LED, from anode to cathode, in order for the LED to turn on. As you can see above, positive voltage must be applied across the LED from its anode to its cathode.

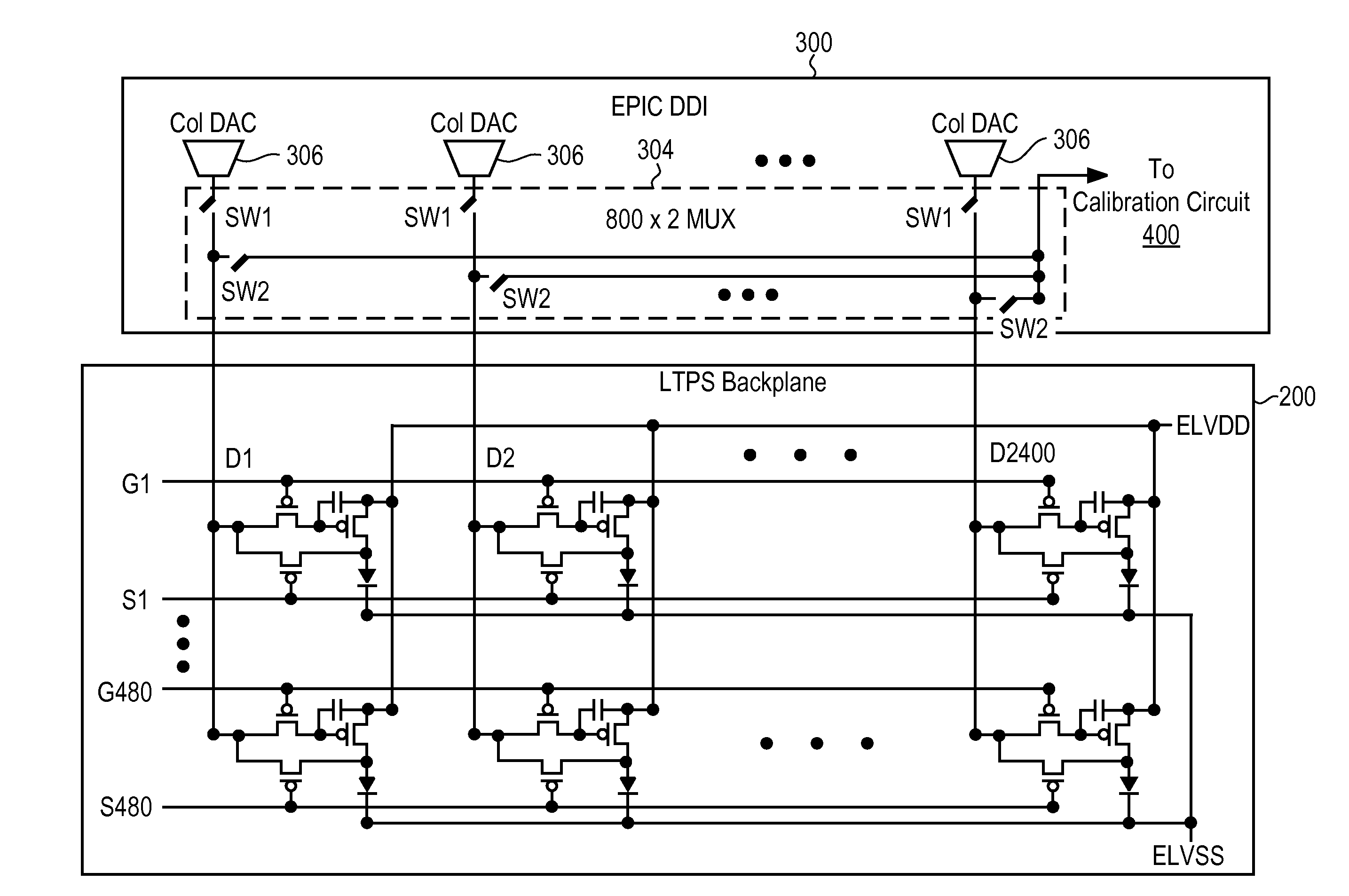

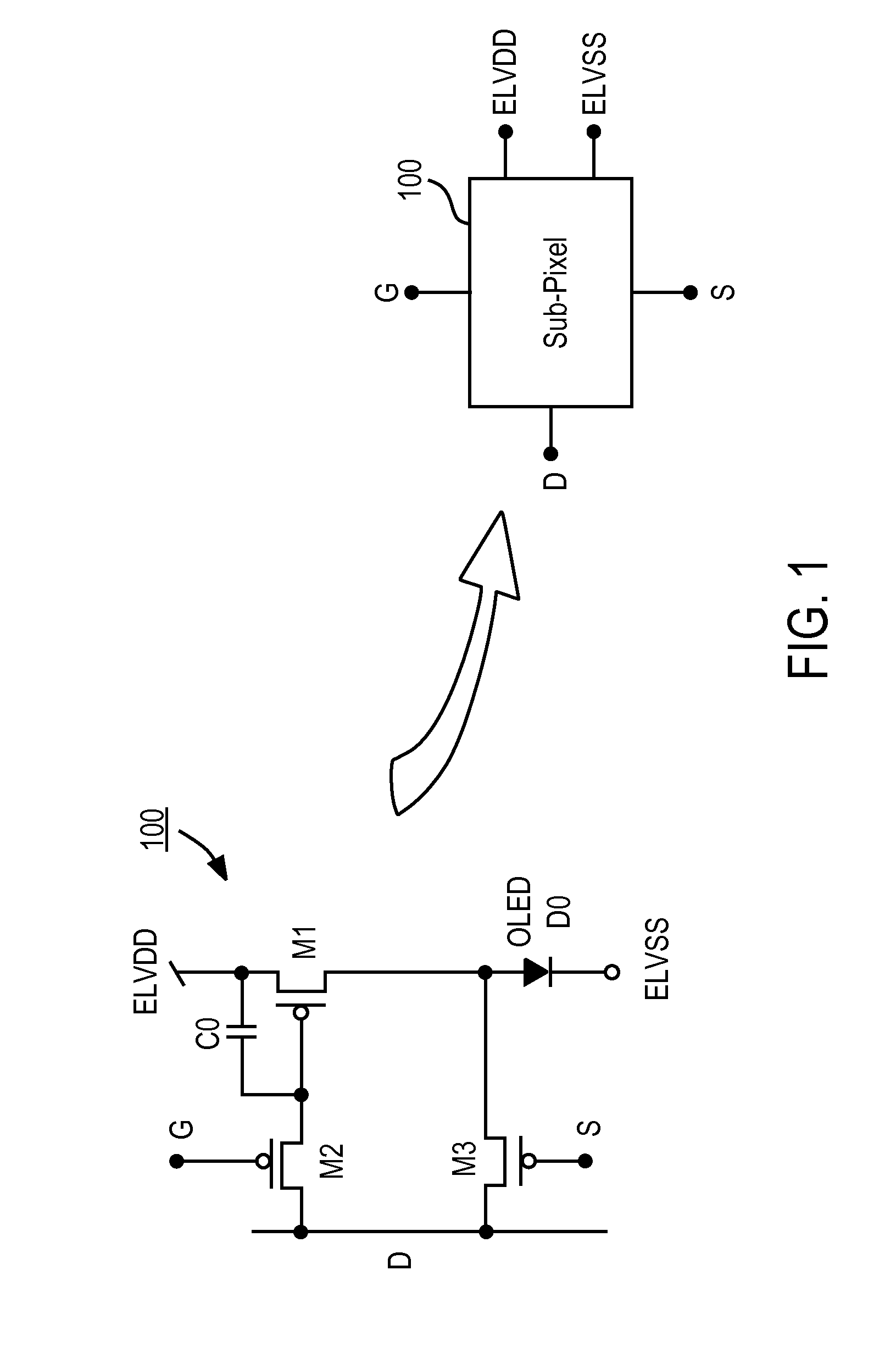

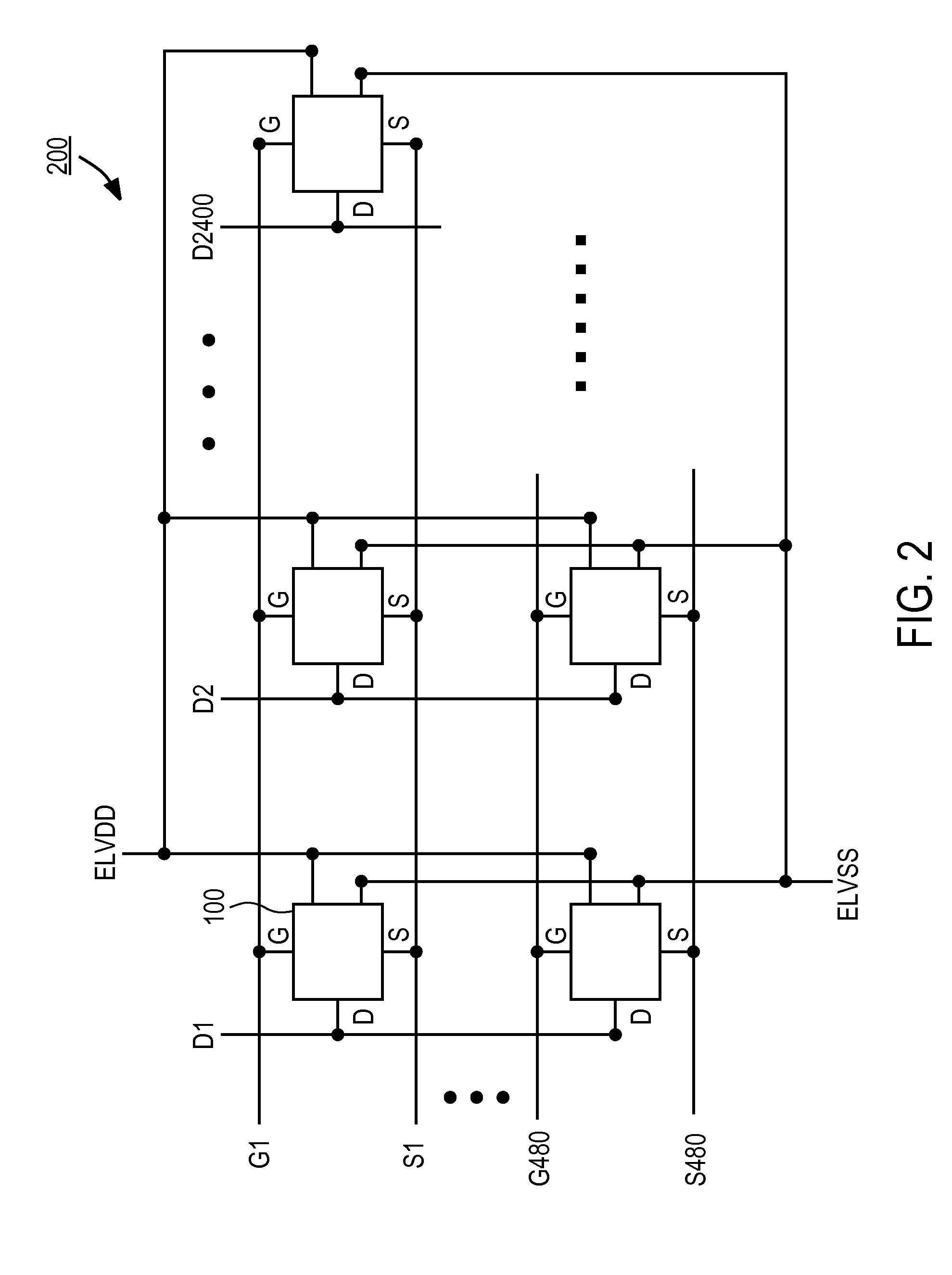

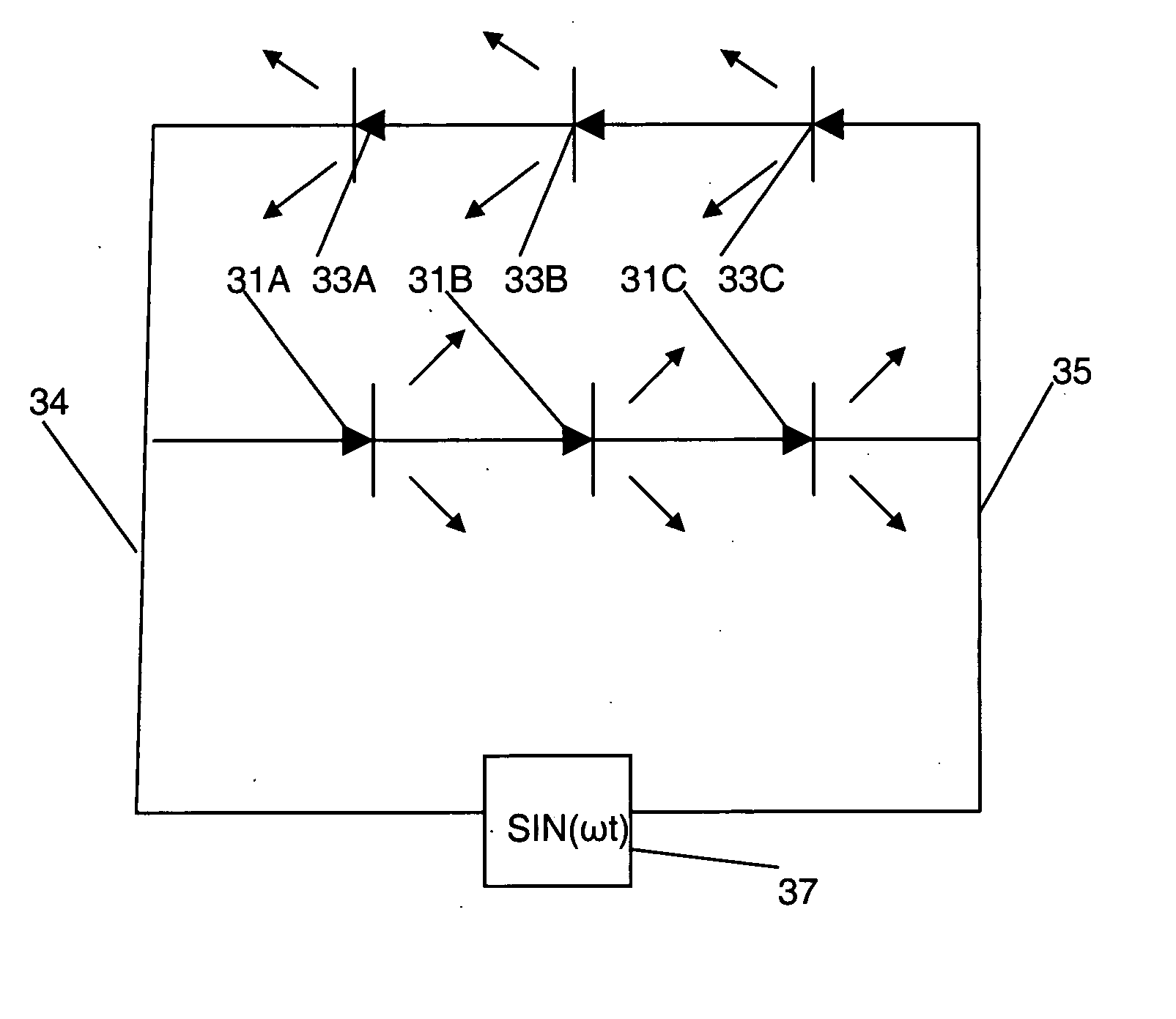

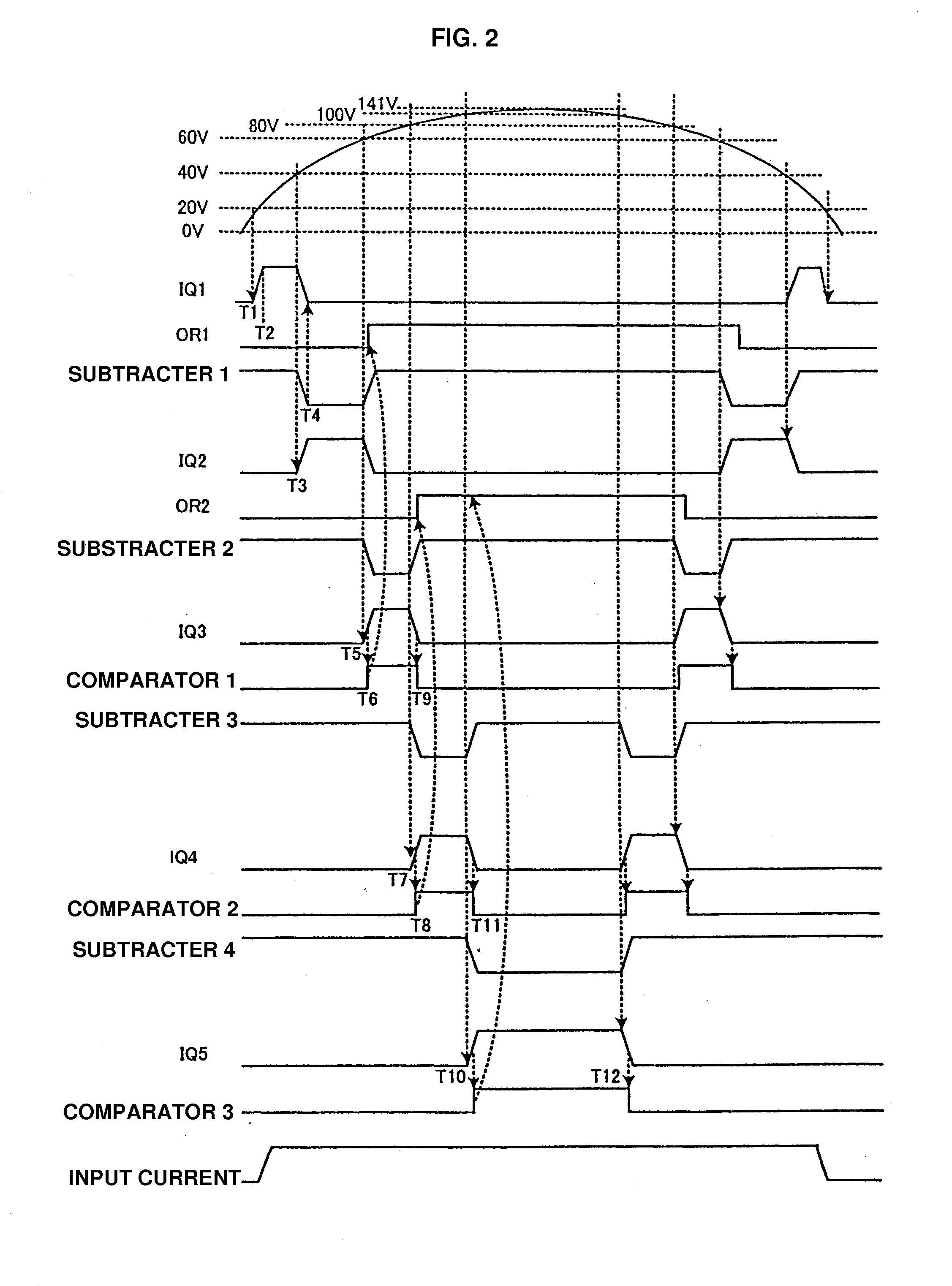

Correction of aging in amoled display

The data line voltage on the data line of the AMOLED sub-pixels is measured while the OLED is being driven by a reference current, in order to determine the age of the OLED in the sub-pixel. The pixel transistor serves as a current source for driving the OLED in the sub-pixel with the reference current. The data line voltage is substantially equal to the forward voltage VF(aged) of the aged OLED being driven at the reference current. The forward voltage VF (un-aged) of a reference (un-aged) OLED sub-pixel also measured at the reference current, and is subtracted from the measured OLED diode forward voltage VF (aged) to obtain their difference ΔVF=VF(aged)−VF(un-aged). ΔVF is an indicator of the age of the OLED in the sub-pixel, and is used as an index to a look-up-table that stores the corresponding aging offset data for generating the incremental pixel current needed to maintain constant luminance in the aged OLED pixel.

Owner:SILICONFILE TECH INC

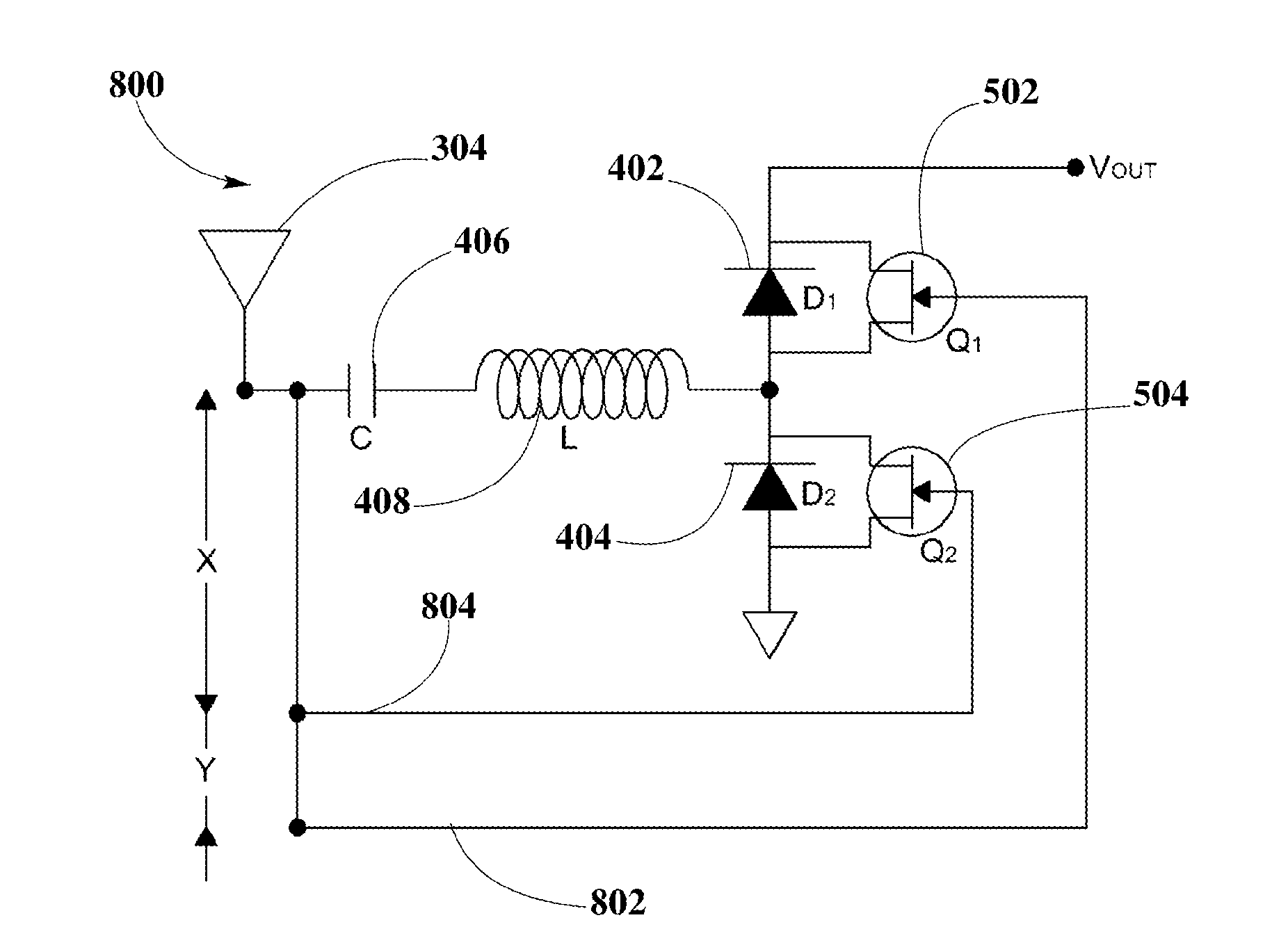

Synchronous Rectifier Design for Wireless Power Receiver

InactiveUS20150326143A1Lower forward voltage dropImprove efficiencyBatteries circuit arrangementsAc-dc conversion without reversalDelay-locked loopSwitching frequency

Synchronous rectifier circuit topologies for a wireless power receiver receiving a supply of power from a wireless transmitter are disclosed. The synchronous rectifier circuit topologies include a half-bridge diode-FET transistor rectifier for rectifying the wireless power into power including a DC waveform, using a control scheme that may be provided by a delay-locked loop clock, or phase shifters, or wavelength links to control conduction of FET transistors in the synchronous rectifier circuit topology, and maintaining a constant switching frequency to have the diodes, coupled to FET transistors, to allow current to flow through each one respectively at the appropriate timing, focusing on high conduction times. The synchronous rectifier circuit topologies may enable power transfer of high-frequency signals at enhanced efficiency due to significant reduction of forward voltage drop and lossless switching.

Owner:ENERGOUS CORPORATION

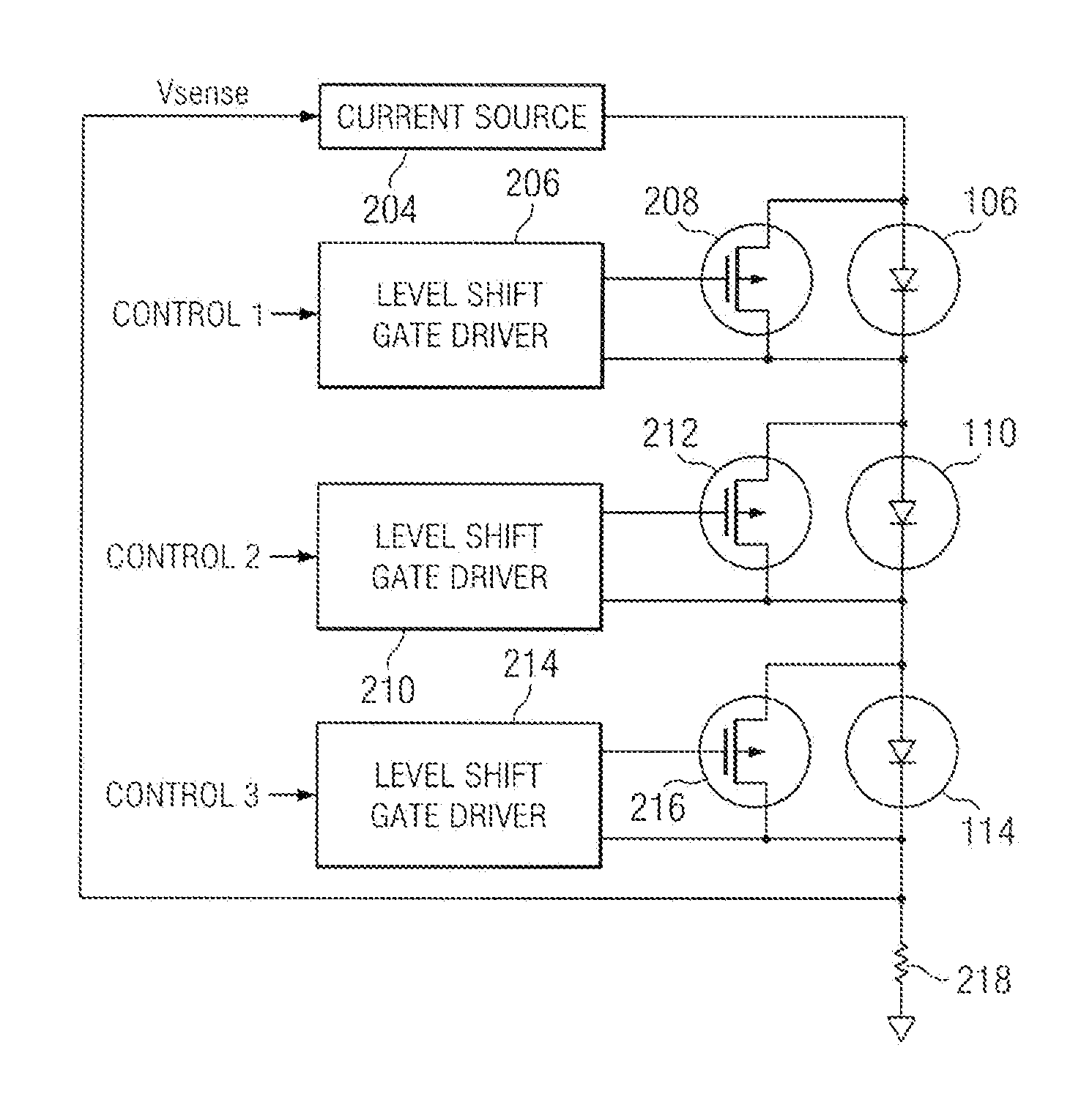

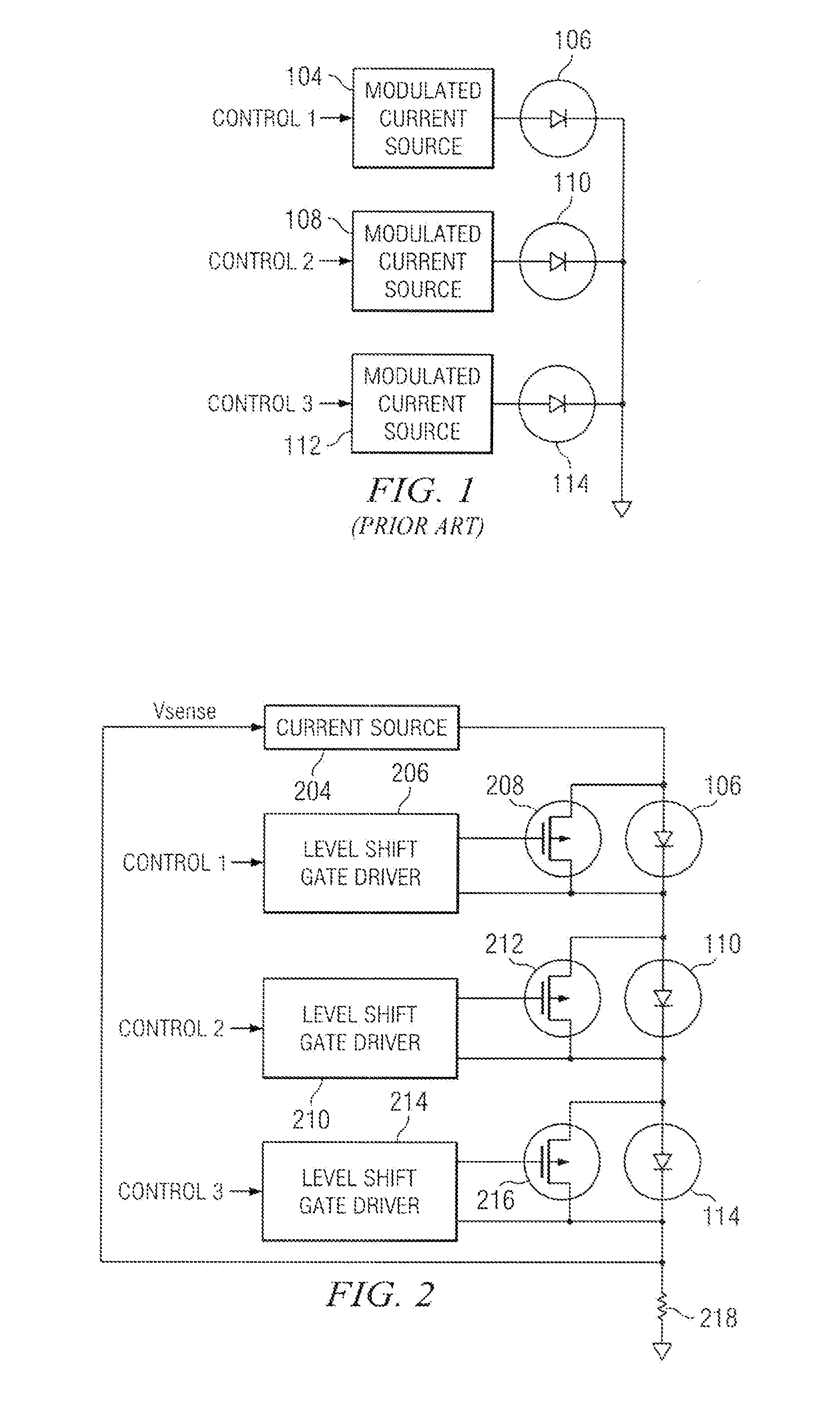

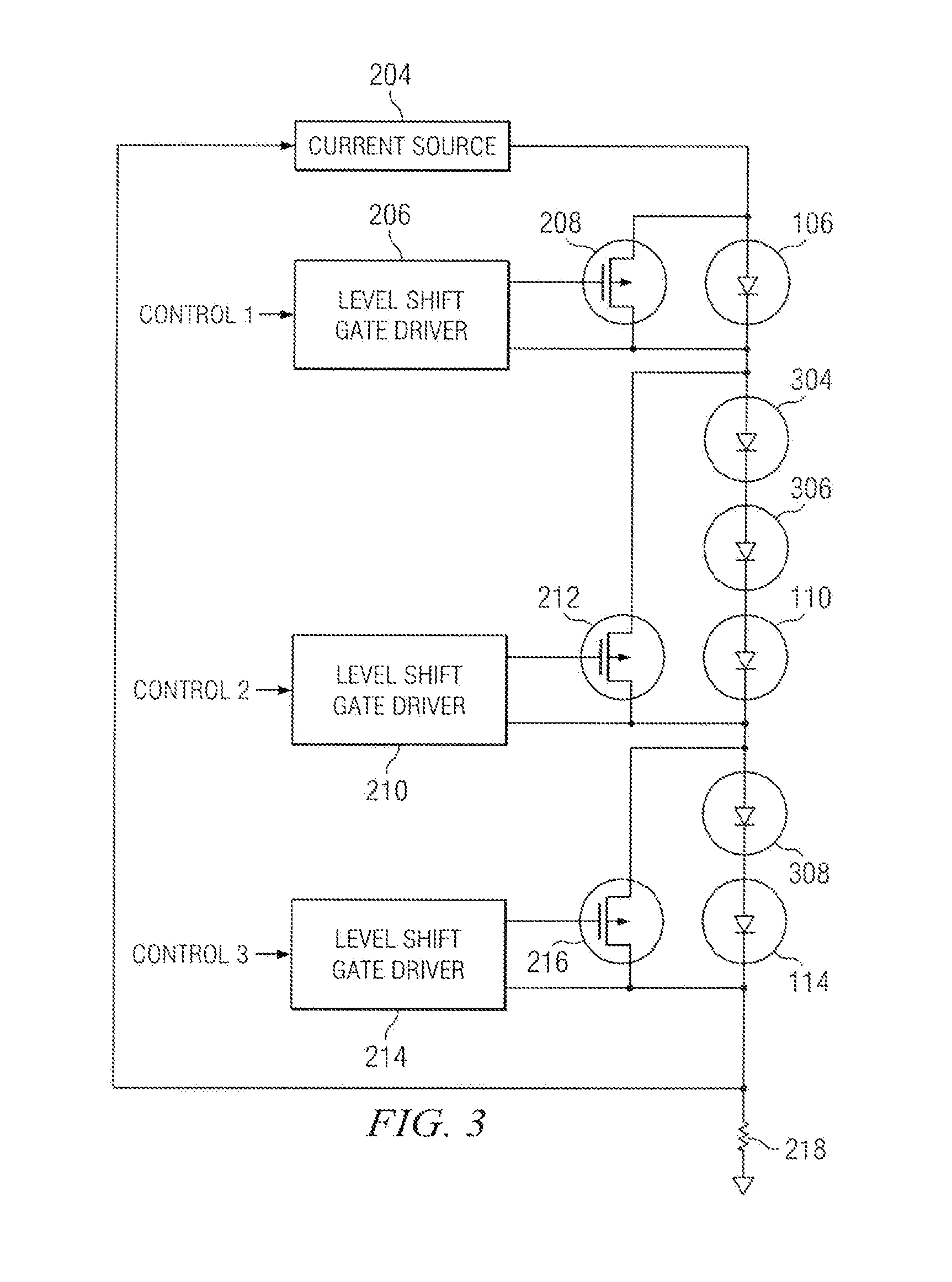

Highly efficient series string LED driver with individual LED control

ActiveUS20070257623A1Reduce power consumptionIncrease brightnessElectrical apparatusElectroluminescent light sourcesControl signalEngineering

A current source generates, with high efficiency, a current that is substantially constant over a wide range of output voltages. This current is injected into the first end of a series-connected string (hereinafter referred to as string) of LEDs, with the second end of the string connected through a resistor to ground. The voltage developed across this resistor, which is a measure of current flow in the series string, is fed back to the current source, wherein feedback maintains nearly constant current output over a wide range of output voltages. A switch, such as a field effect transistor (FET) is placed in parallel with each LED in the string. A level shift gate driver couples a pulse width modulated control signal to the gate of each FET. When the FET across a particular LED is on, substantially all the current flows through the FET rather than the LED, and little or no light is emitted. Because the one resistance of the FET is very low, the power dissipated in the FET (current squared times resistance) is also very low. With the FET turned on, the forward voltage drop of the LED it is controlling drops to near zero, since little current is flowing through the LED. However, because the current source is designed to provide constant current over a wide range of output voltages, the current flow through the other LEDs in the series string changes little. When the FET is turned off, substantially all of the current flows through the associated LED, turning it on. By modulating the duty cycle of each FET, the brightness of each associated LED may be varied smoothly over its full range.

Owner:TEXAS INSTR INC

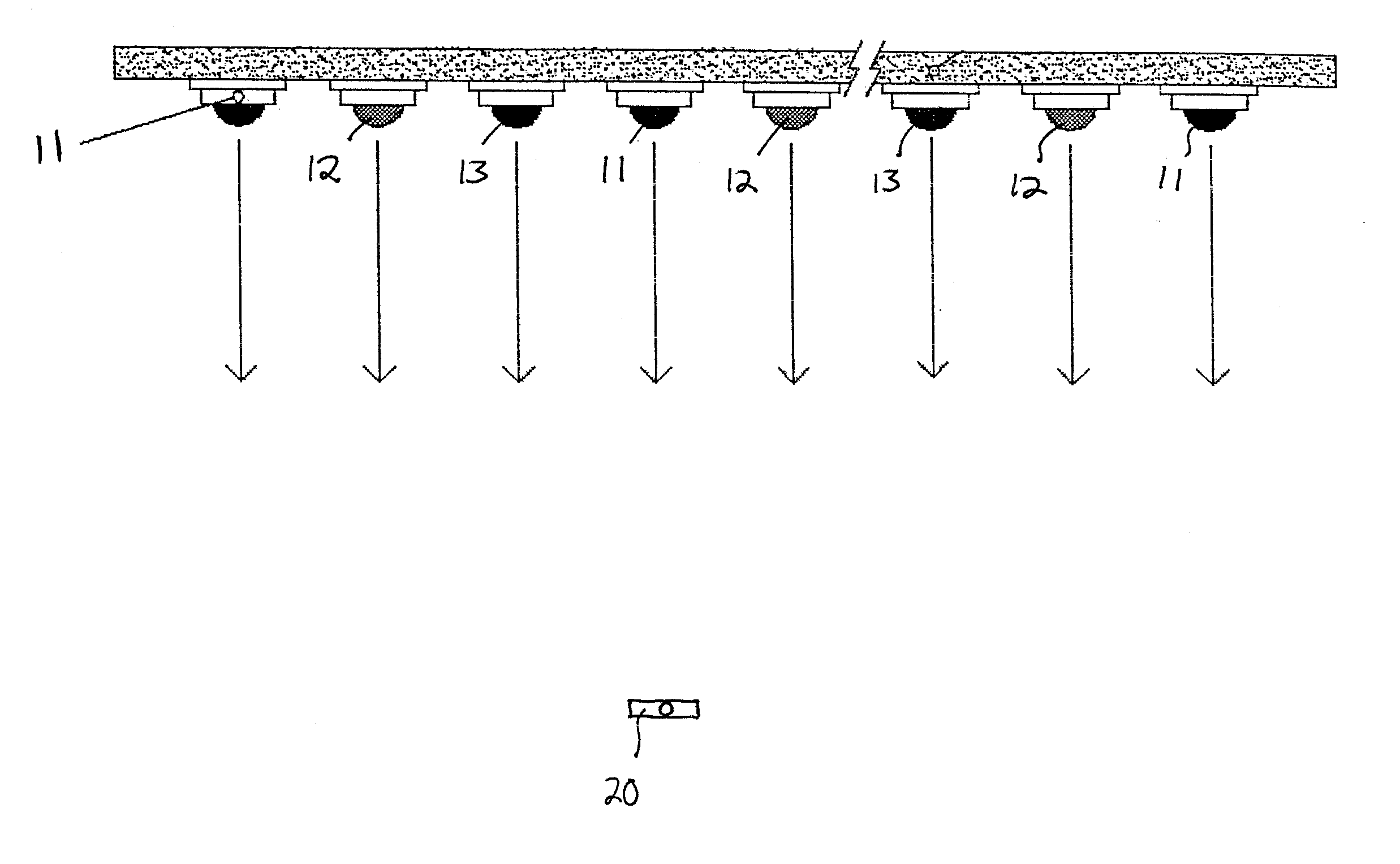

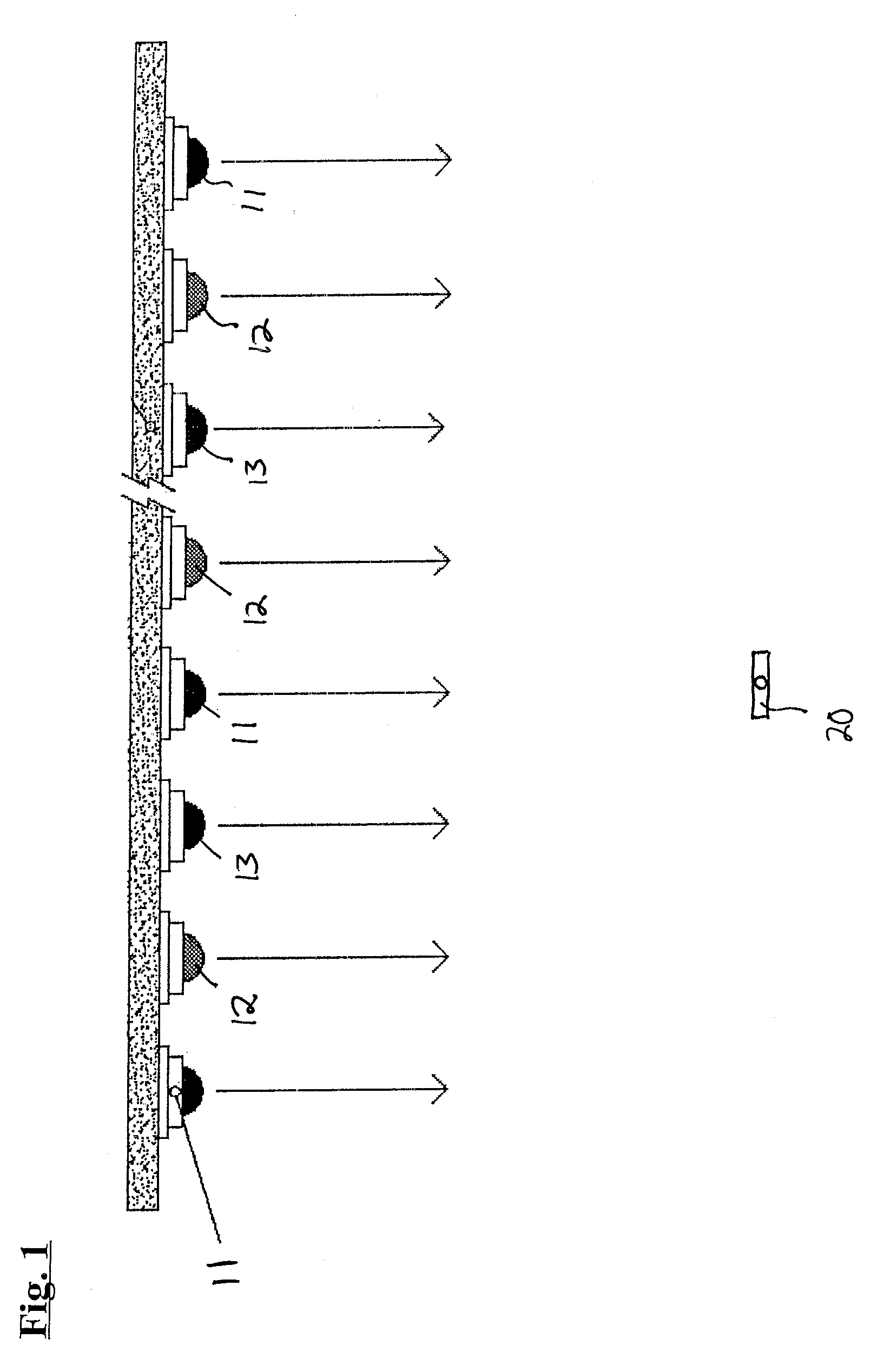

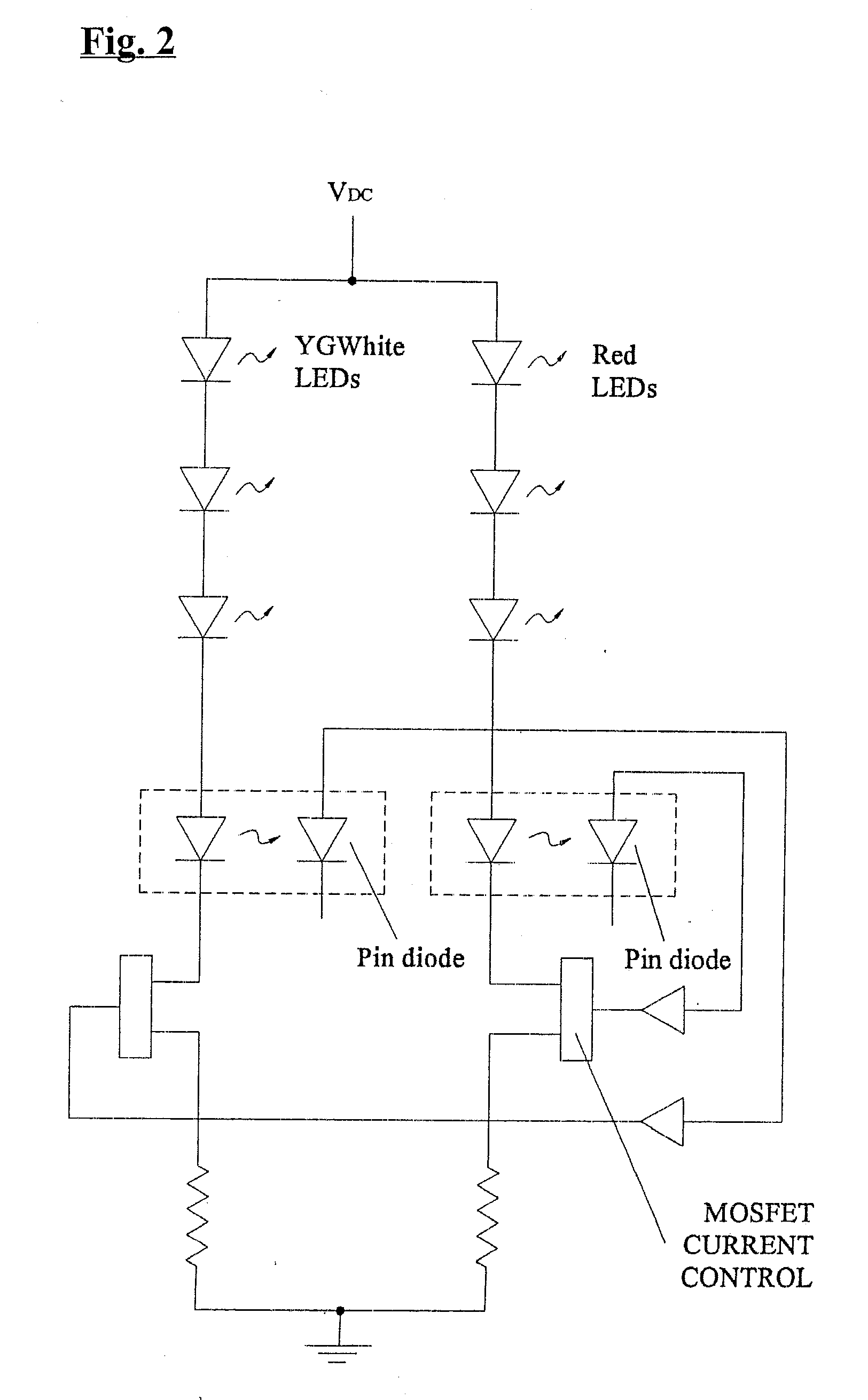

Lighting device with color control, and method of lighting

ActiveUS20070278974A1Electroluminescent light sourcesSemiconductor lamp usageEffect lightForward voltage

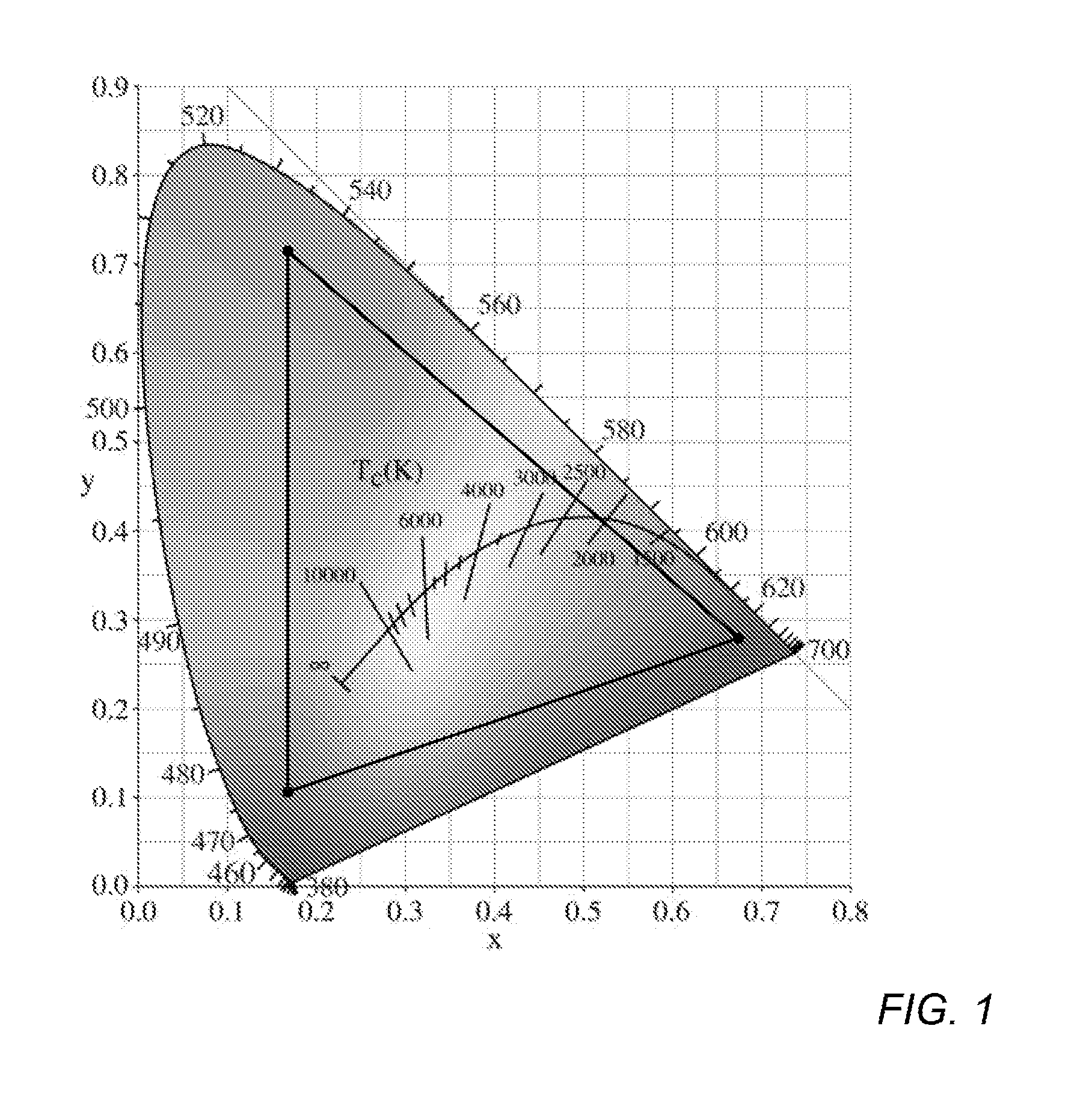

A lighting device comprising a group of one of more illumination solid state light emitters, a reference solid state light emitter and a reference sensor which detects an intensity of the reference solid state light emitter. Each of the emitters (1) has an illumination which is spaced from a first point by a delta u′, v′ distance on a 1976 CIR diagram of not more than 0.015, and / or (2) has a forward voltage temperature dependence which is within 5% of a first forward voltage temperature dependence. In addition, a lighting device comprising one or more illumination solid state light emitters, a reference solid state light emitter and a sensor which comprises at least two areas of individual sensors. Also, methods of lighting.

Owner:IDEAL IND LIGHTING LLC

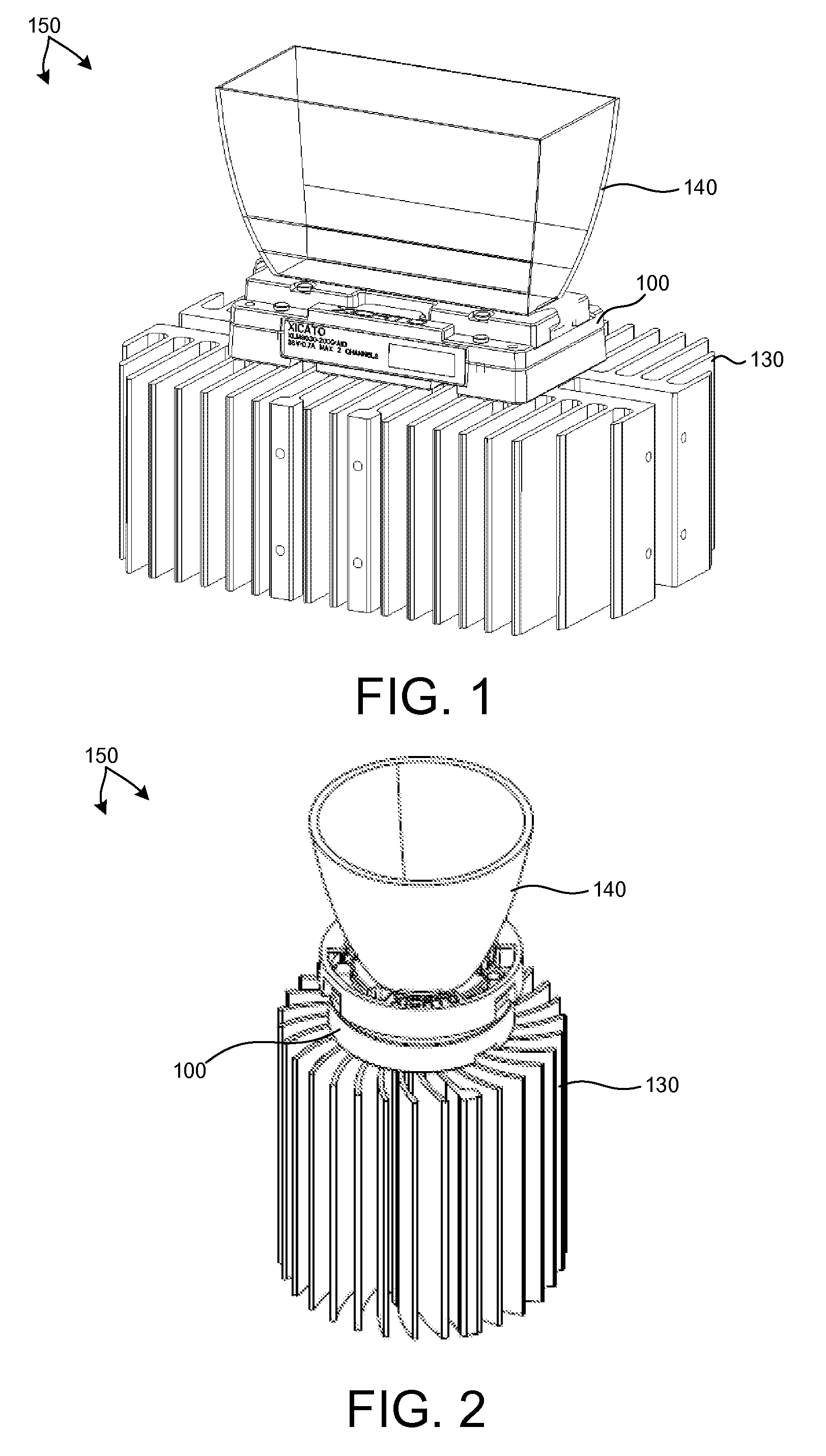

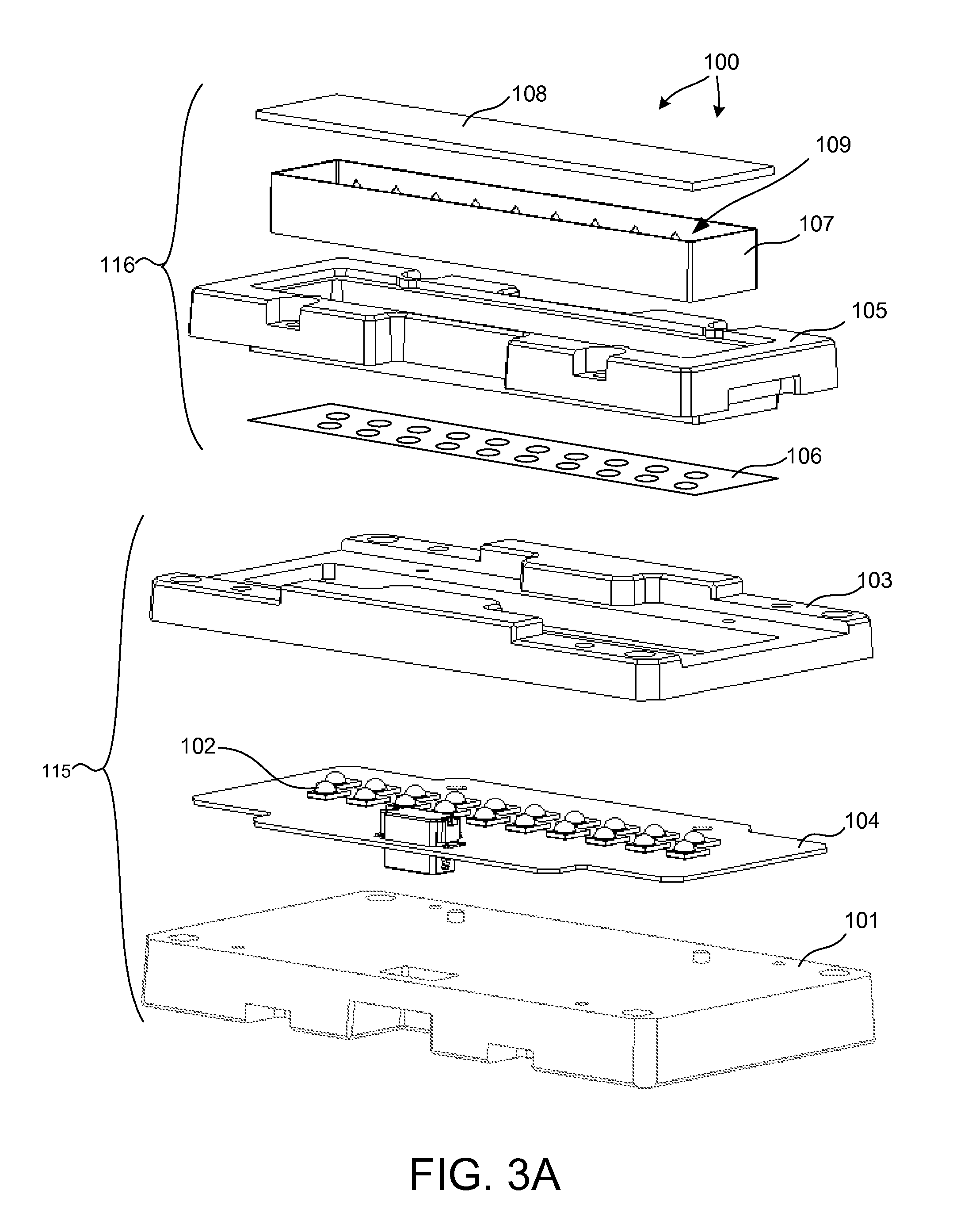

Led-based illumination module on-board diagnostics

ActiveUS20110254554A1Light source combinationsElectrical apparatusLight-emitting diodeOperant conditioning

A light emitting diode (LED) based illumination module performs on-board diagnostics. For example, diagnostics may include estimating elapsed lifetime, degradation of phosphor, thermal failure, failure of LEDs, or LED current adjustment based on measured flux or temperature. The elapsed lifetime may be estimated by scaling accumulated elapsed time of operation by an acceleration factor derived from actual operating conditions, such as temperature, current and relative humidity. The degradation of phosphor may be estimated based on a measured response of the phosphor to pulsed light from the LEDs. A thermal failure may be diagnosed using a transient response of the module from a start up condition. The failure of LEDs may be diagnosed based on measured forward voltage. The current for LEDs may adjusted using measured flux values and current values and a desired ratio of flux values. Additionally, the LED current may be scaled based on a measured temperature.

Owner:SBC XICATO CORP

Solid state lighting device

InactiveUS20060038542A1Effectively white lightEffective lightingElectroluminescent light sourcesSolid-state devicesLow voltageEngineering

A light assembly for use with a low voltage power source. The light assembly semiconductor photo-emitters are electrically in series with a higher forward voltage drop than the associated low voltage power supply. To provide the necessary voltage the light assembly includes a current regulated step-up DC / DC converter. The semiconductor photo-emitters that are electrically in series are in the form of a monolithic light emitting diode array with a plurality of light emitting diode elements electrically and mechanically in series with a conductive, rigid bond region between the cathode region of the first light emitting diode element and the anode region of the second light emitting diode element. The first and second light emitting diode elements may differ in band gaps to emit different colors, that are additive to a non-primary color, such as white.

Owner:TESSERA INC

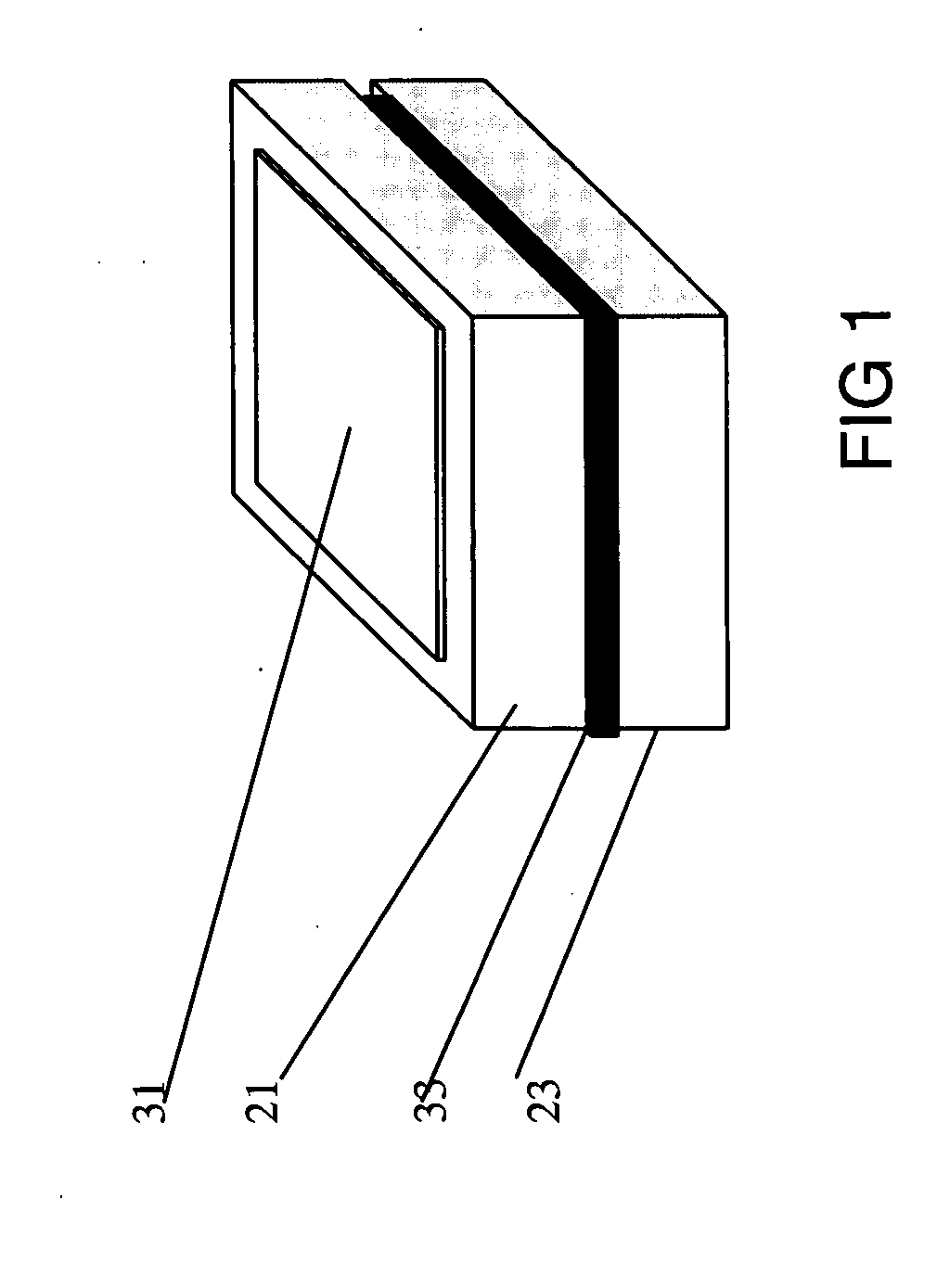

Diode-Like Composite Semiconductor Device

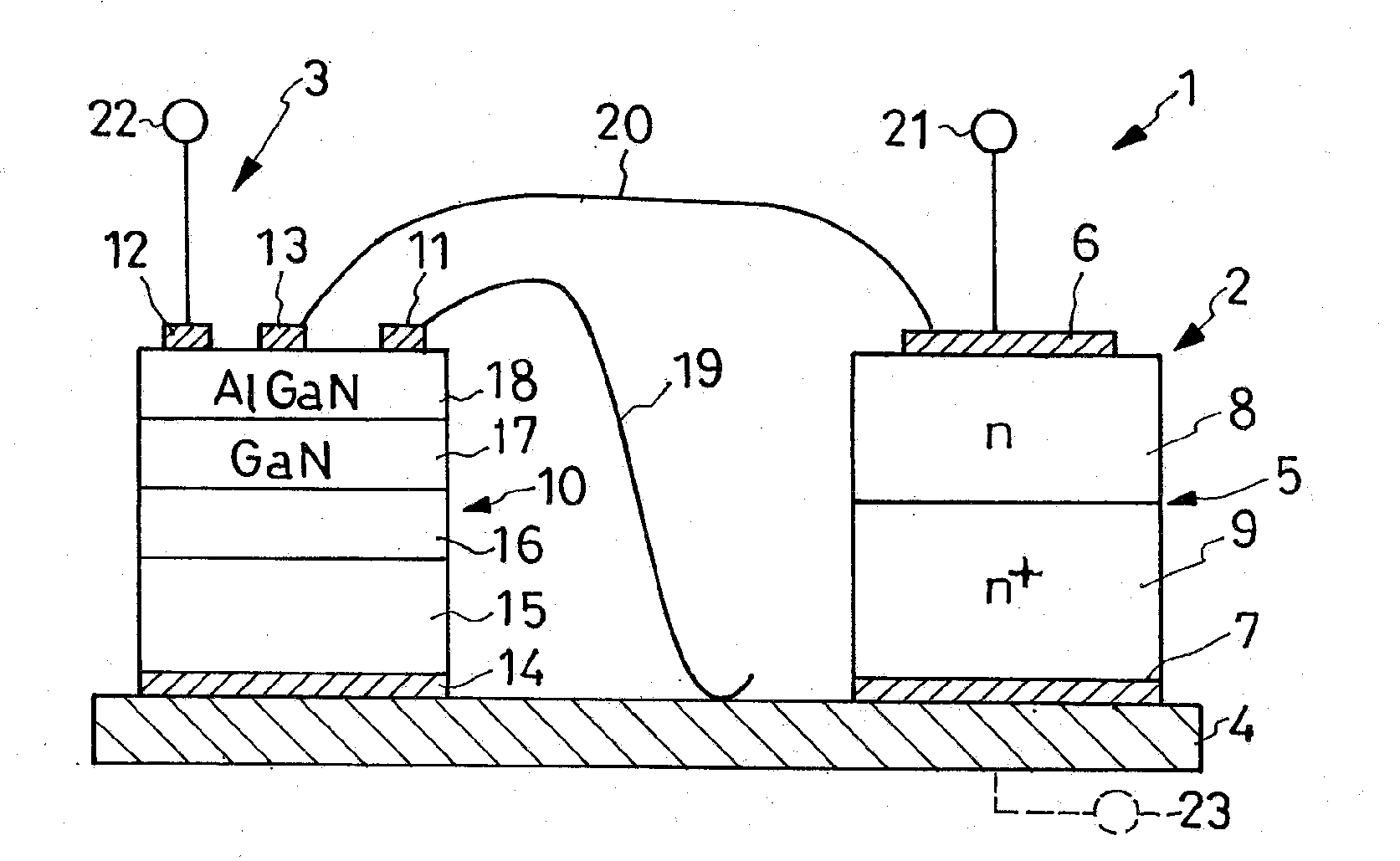

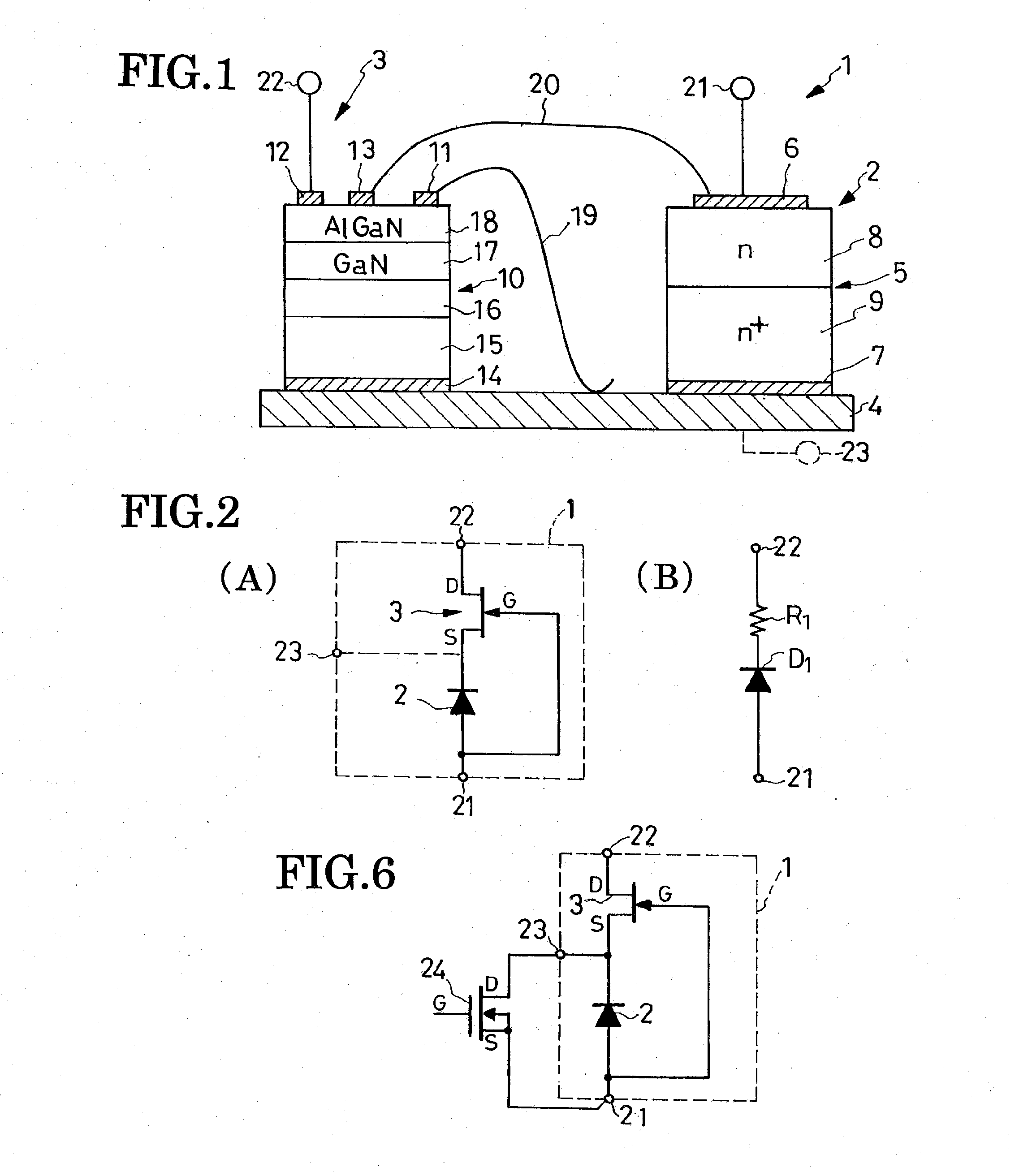

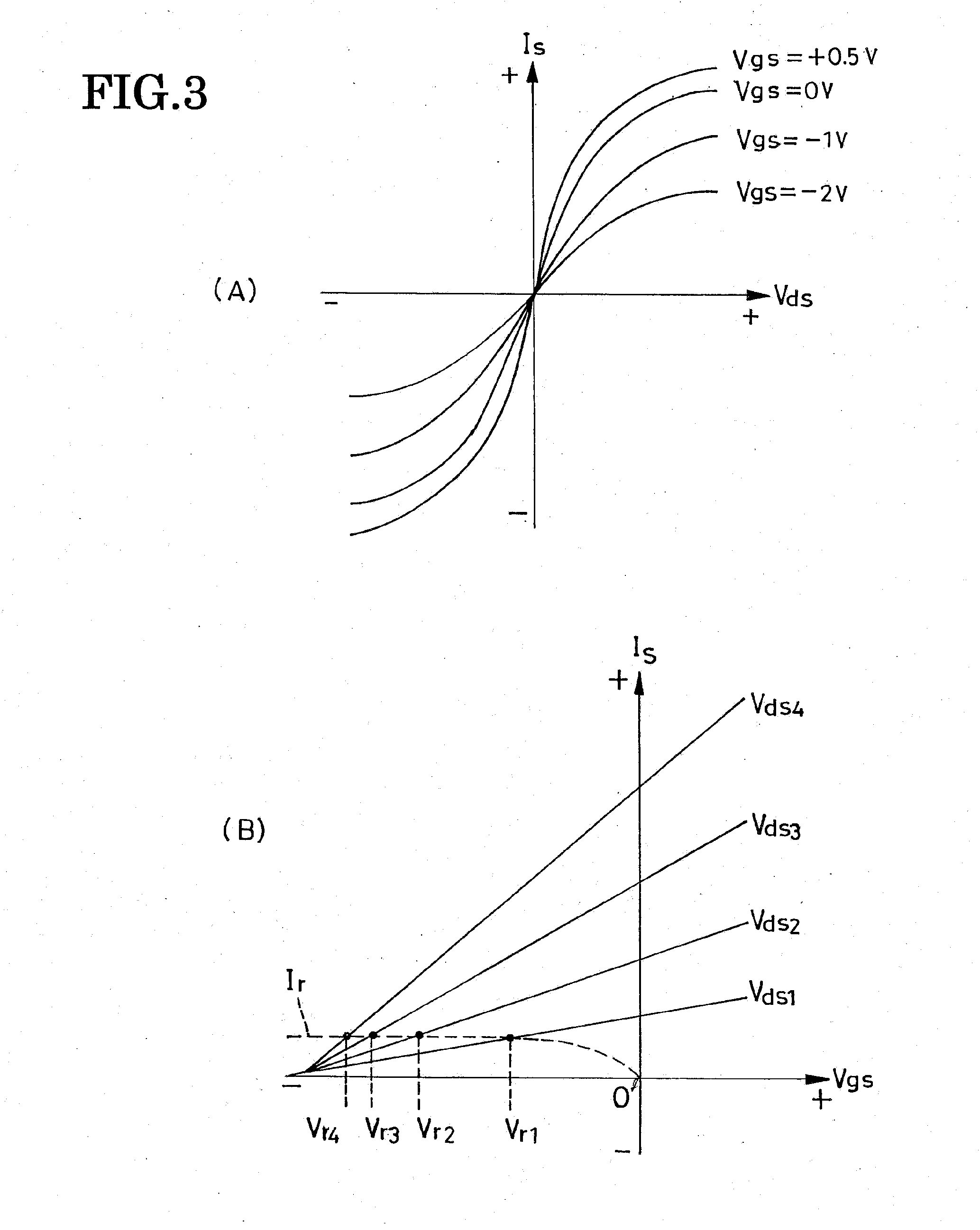

ActiveUS20080191216A1Minimal current capacityPrevent excess flowSolid-state devicesElectronic switchingSchottky barrierCompressive strength

A silicon-made low-forward-voltage Schottky barrier diode is serially combined with a high-antivoltage-strength high-electron-mobility transistor made from a nitride semiconductor that is wider in bandgap than silicon. The Schottky barrier diode has its anode connected to the gate, and its cathode to the source, of the HEMT. This HEMT is normally on. The reverse voltage withstanding capability of the complete device depends upon that between the drain and gate of the HEMT.

Owner:SANKEN ELECTRIC CO LTD

System, apparatus, and method for driving light emitting diodes in low voltage circuits

InactiveUS6995518B2Electrical apparatusStatic indicating devicesLow voltage circuitsLight-emitting diode

A system, apparatus, and method for allowing LED operation in circuits operating with power supply levels that are below the forward voltage limits of the LED. A first level of a modulated voltage signal is applied to charge a voltage increasing component in a first phase of operation. A second level of the modulated voltage signal is then summed with the voltage stored across the voltage increasing component to provide adequate forward potential across Light Emitting Diode (LED) for illumination. The second level of modulated voltage is also used to provide a source of constant forward current to be conducted by LED when in its luminescent state.

Owner:ADEMCO INC

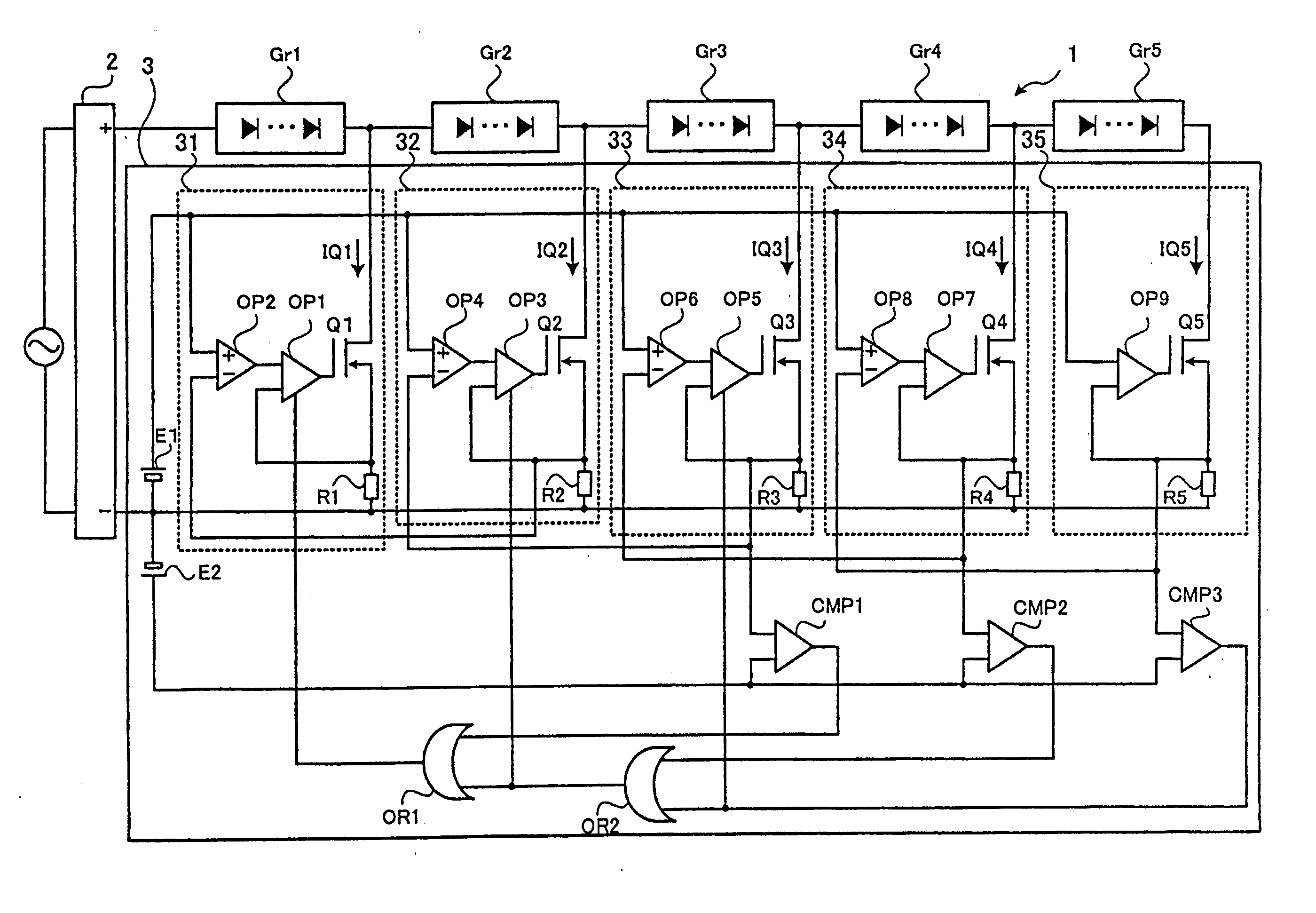

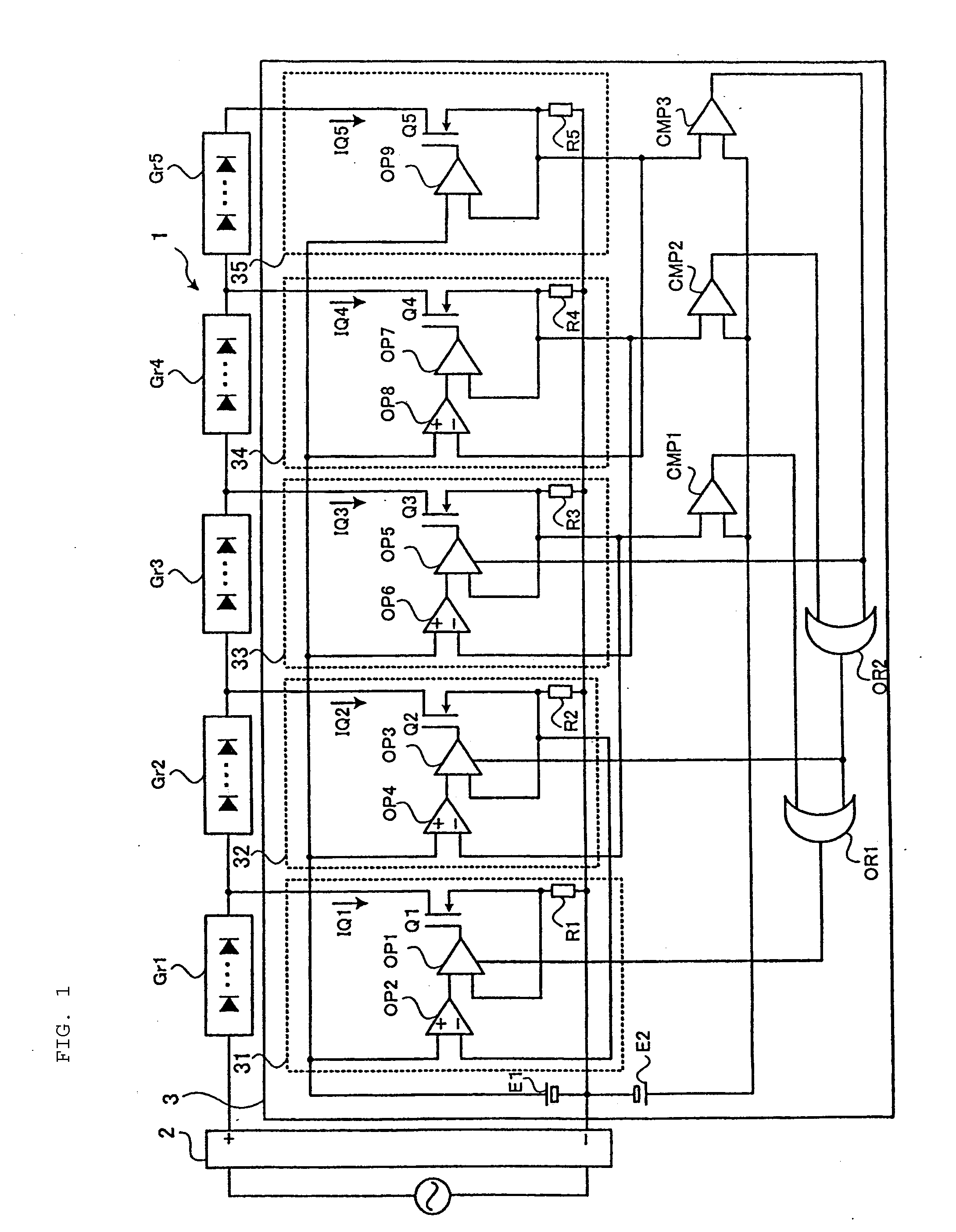

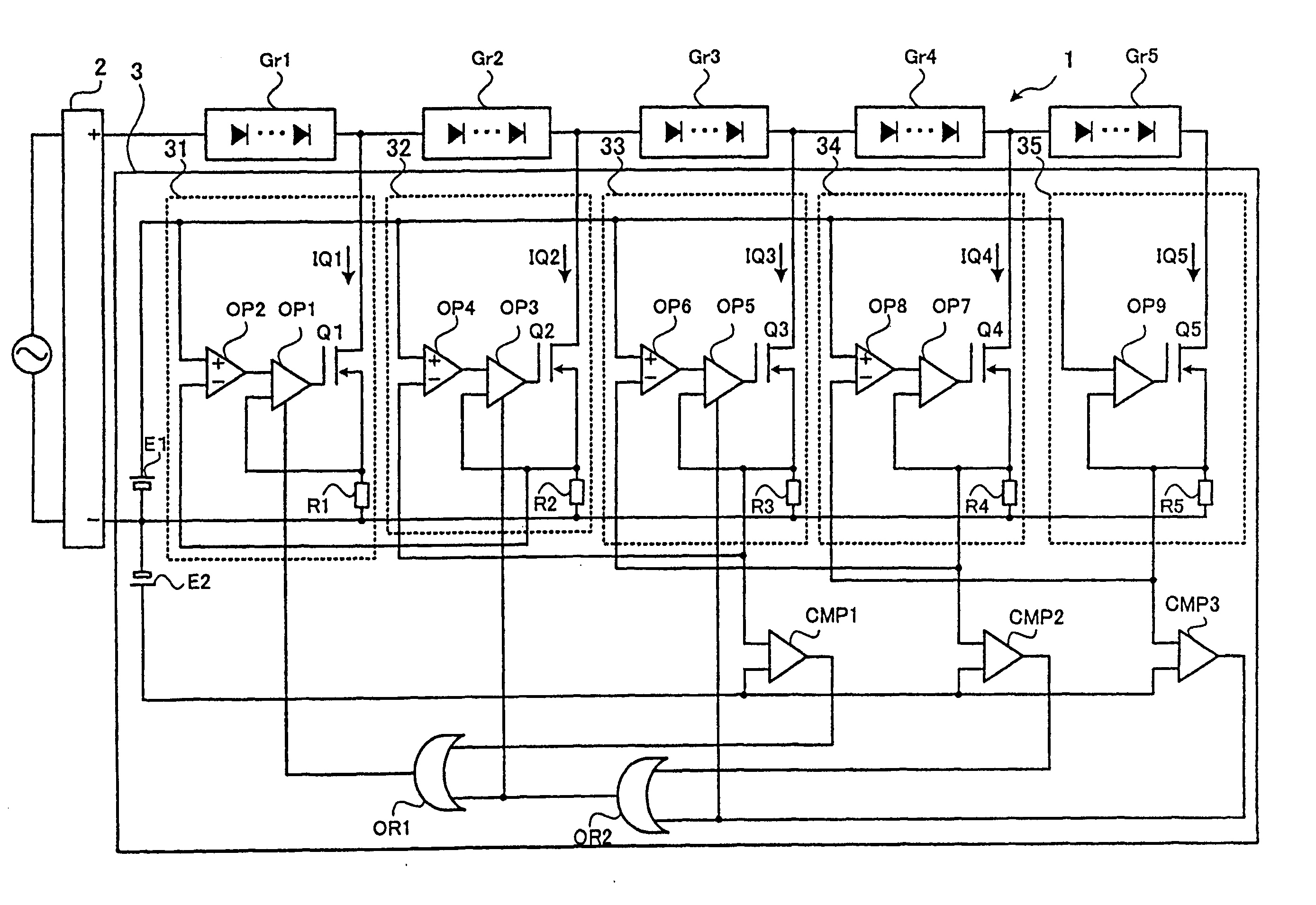

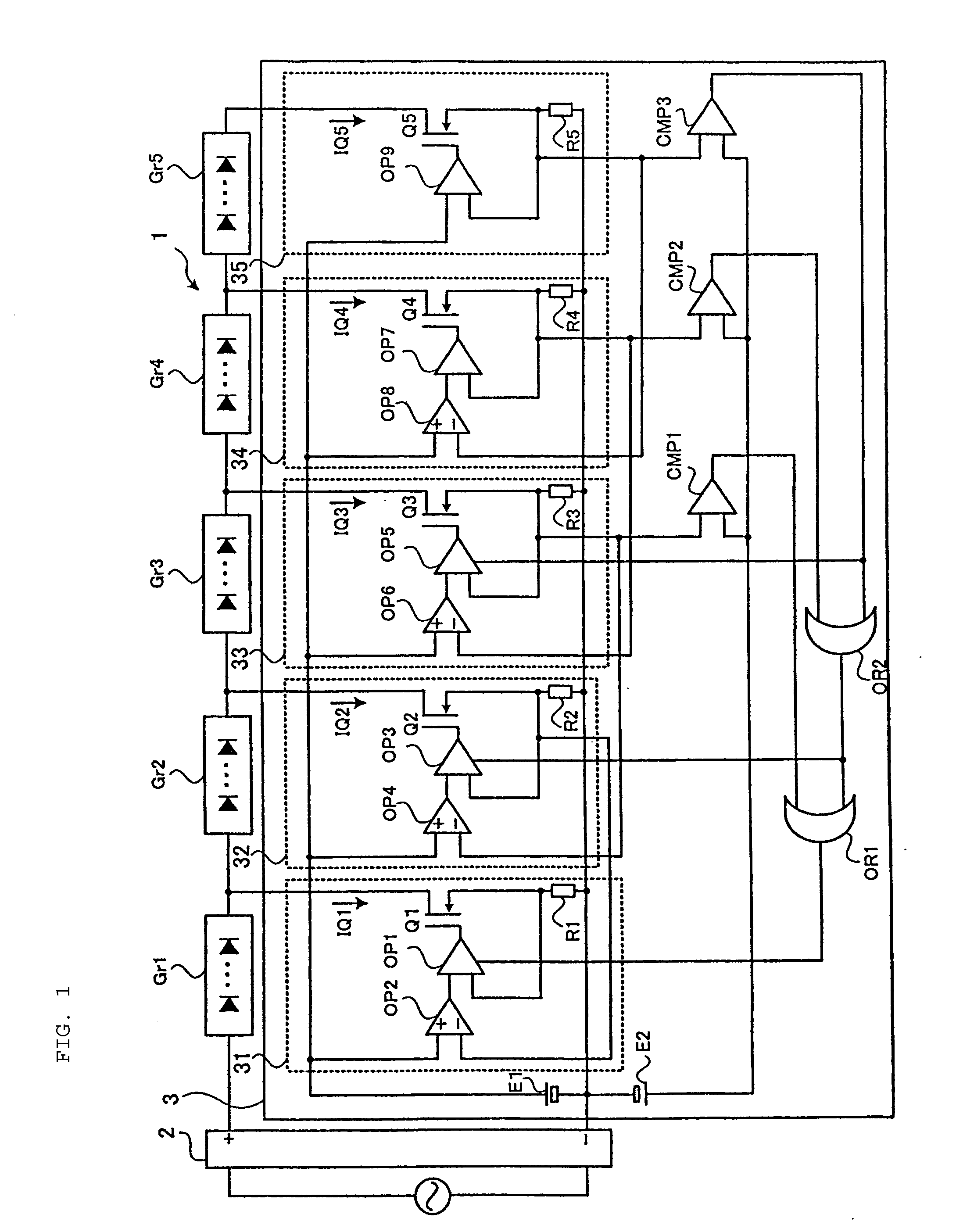

LED drive device, LED drive method and lighting system

InactiveUS20100194298A1Efficient switchingSmooth switchingElectrical apparatusElectroluminescent light sourcesDriver circuitEngineering

Owner:FUJI ELECTRIC CO LTD

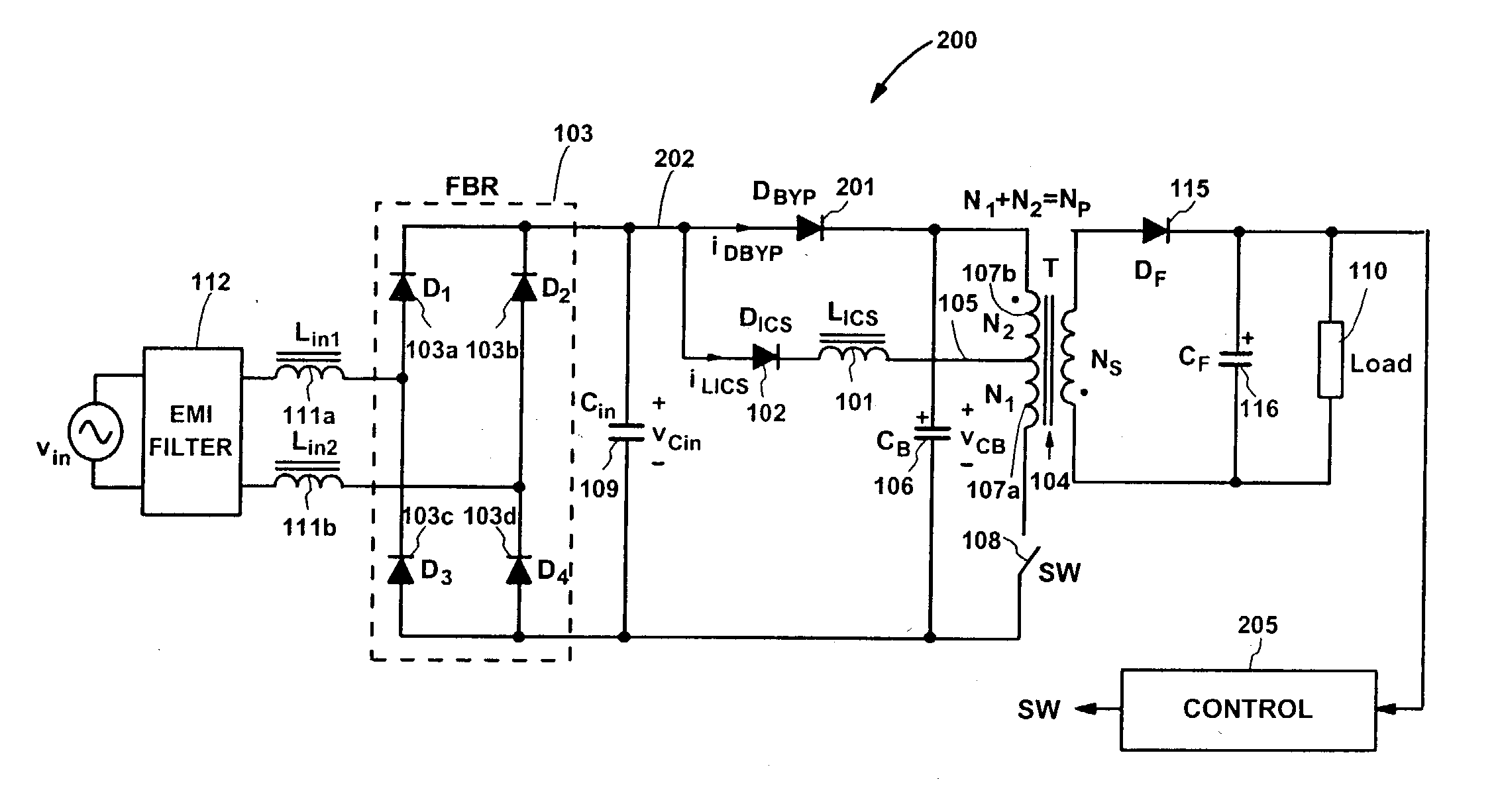

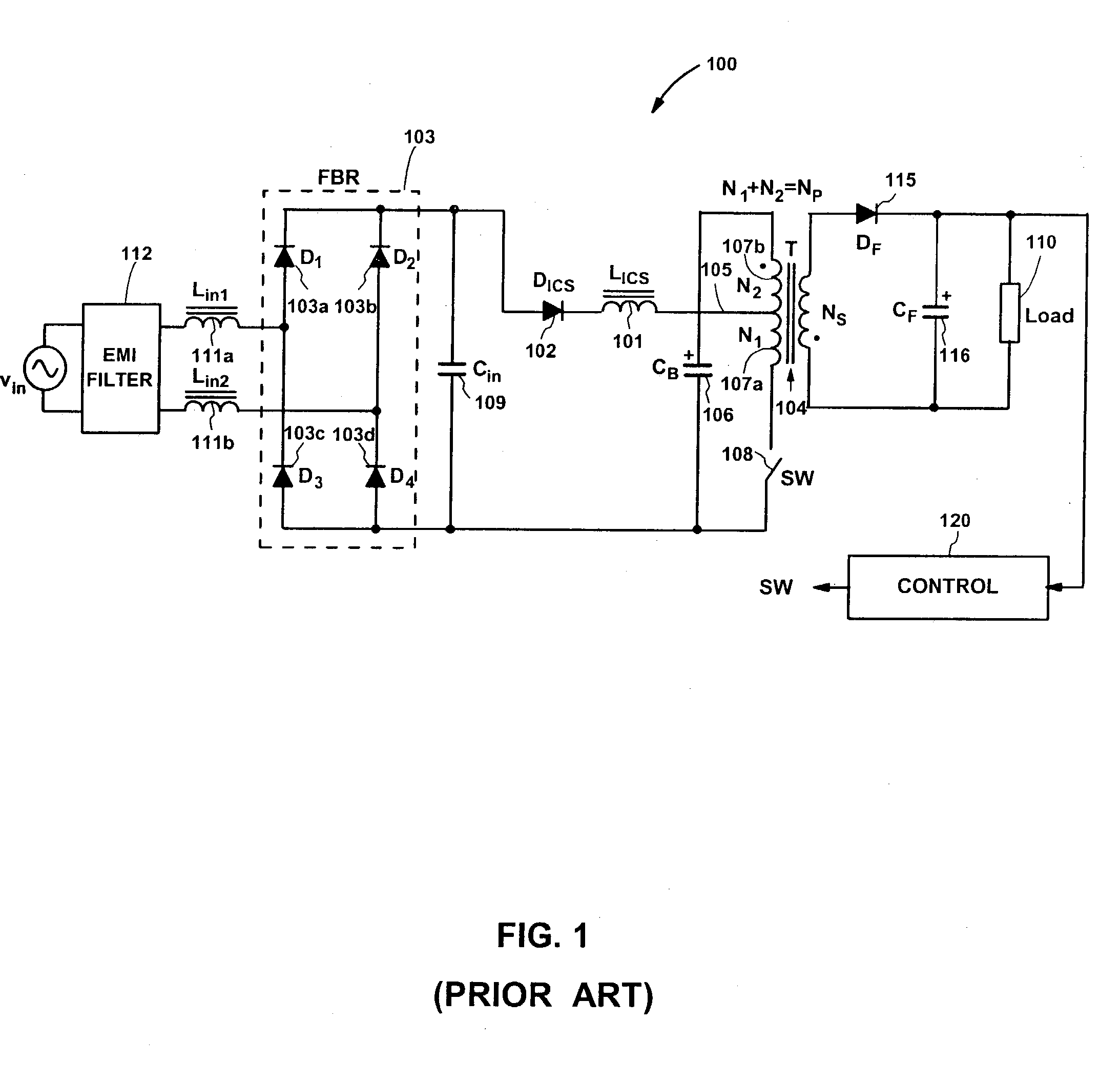

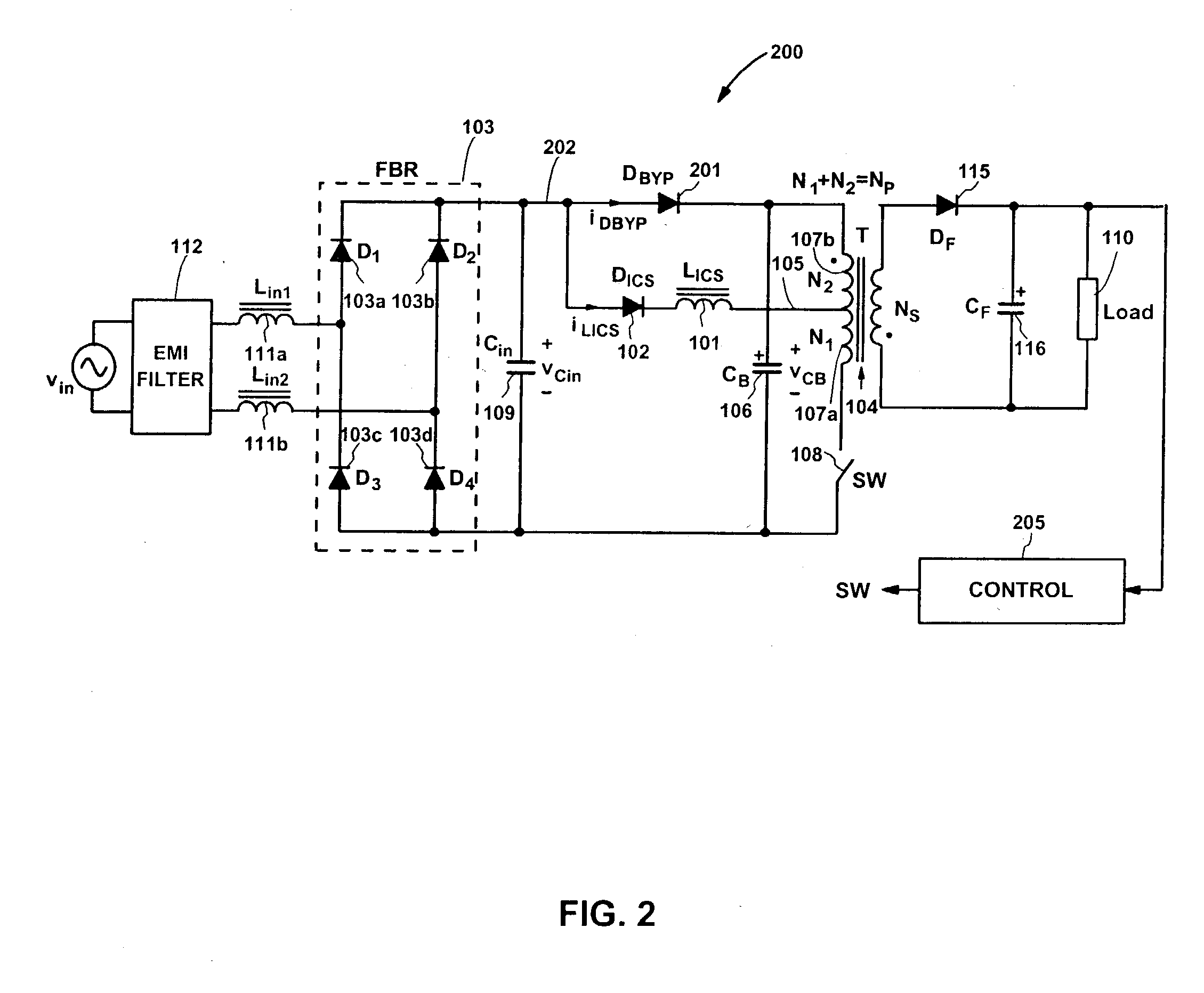

AC/DC flyback converter

ActiveUS20040252529A1Reduce conduction lossImprove efficiencyEfficient power electronics conversionApparatus with intermediate ac conversionSingle stageFull bridge

A single-stage input-current-shaping (S<2>ICS) flyback converter achieves substantially reduced conduction losses in the primary side of the S<2>ICS flyback converter by connecting a bypass diode between the positive terminal of a full-bridge rectifier and the positive terminal of an energy-storage capacitor. An effective current interleaving between an energy-storage inductor and the bypass diode is thus obtained in the S<2>ICS flyback converter around the peak of the rectified line voltage, resulting in a significantly reduced input-current ripple and reduced current stress on the switch. Further, by rearranging the rectifiers in the ICS part of the S<2>ICS flyback converter in such a way that the energy-storage capacitor and the ICS inductor are connected to the ac line voltage through only two rectifiers, one diode forward-voltage drop is eliminated, which results in a substantially reduced conduction loss in the primary-side rectifiers.

Owner:DELTA ELECTRONICS INC

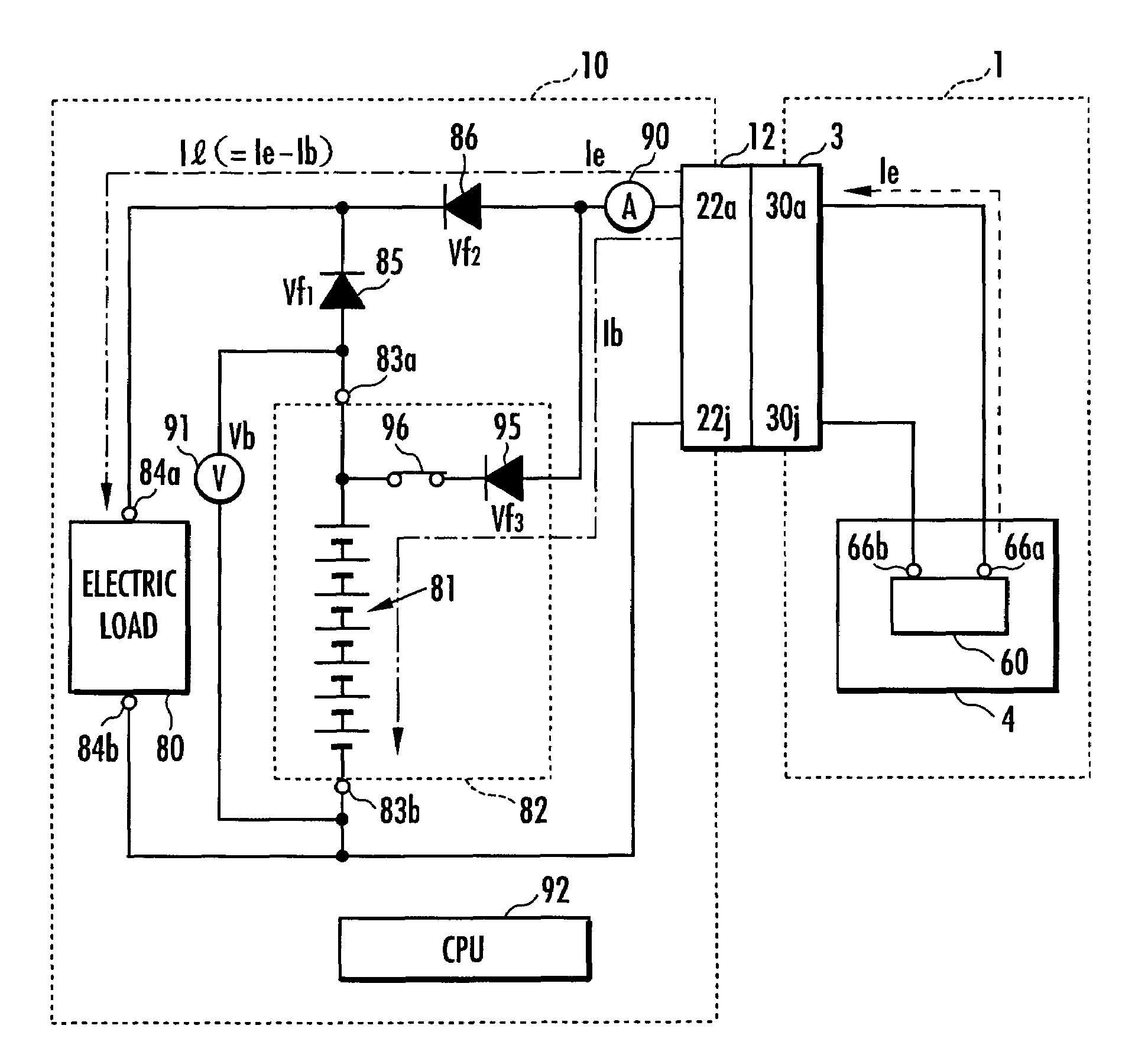

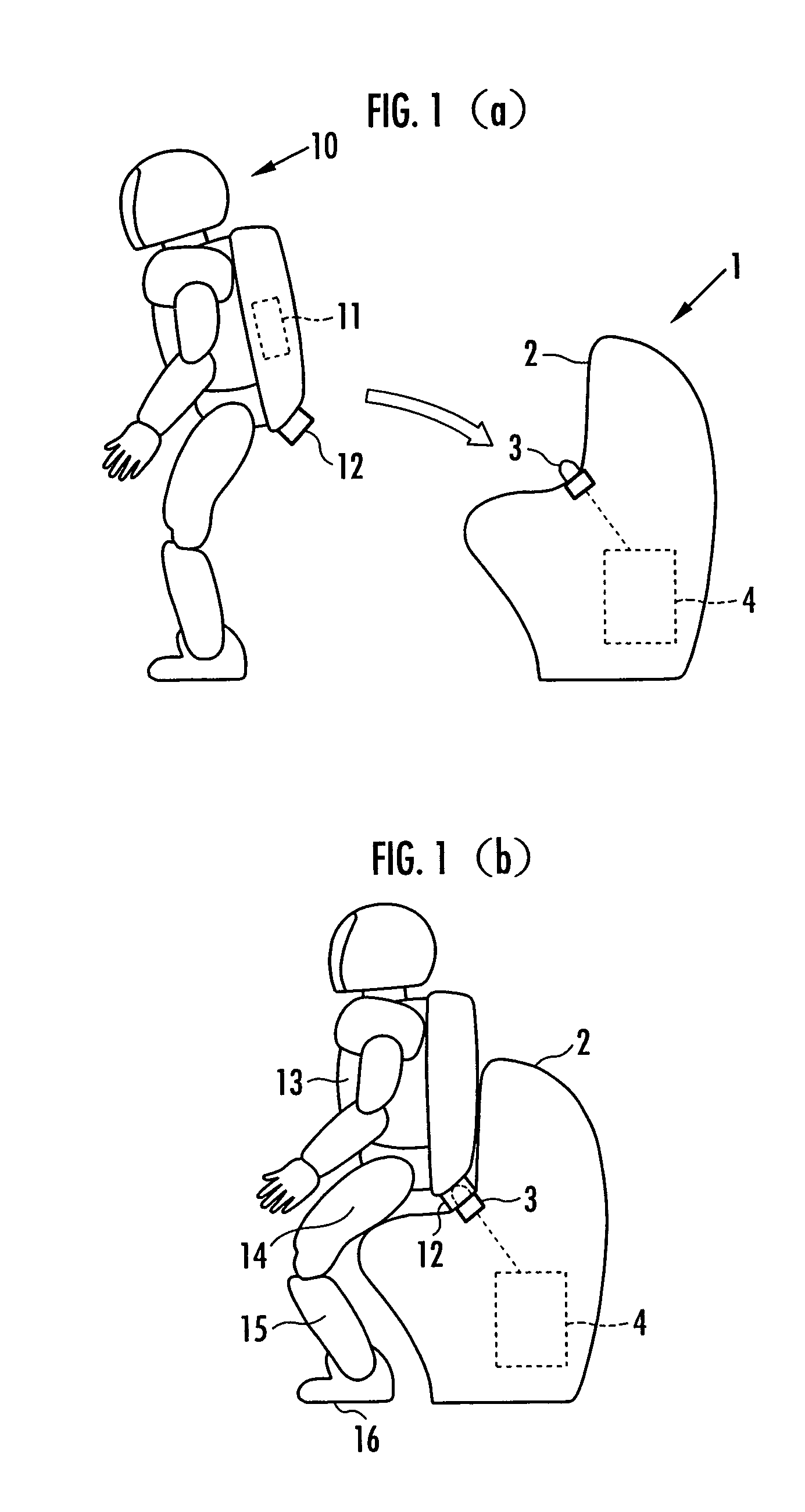

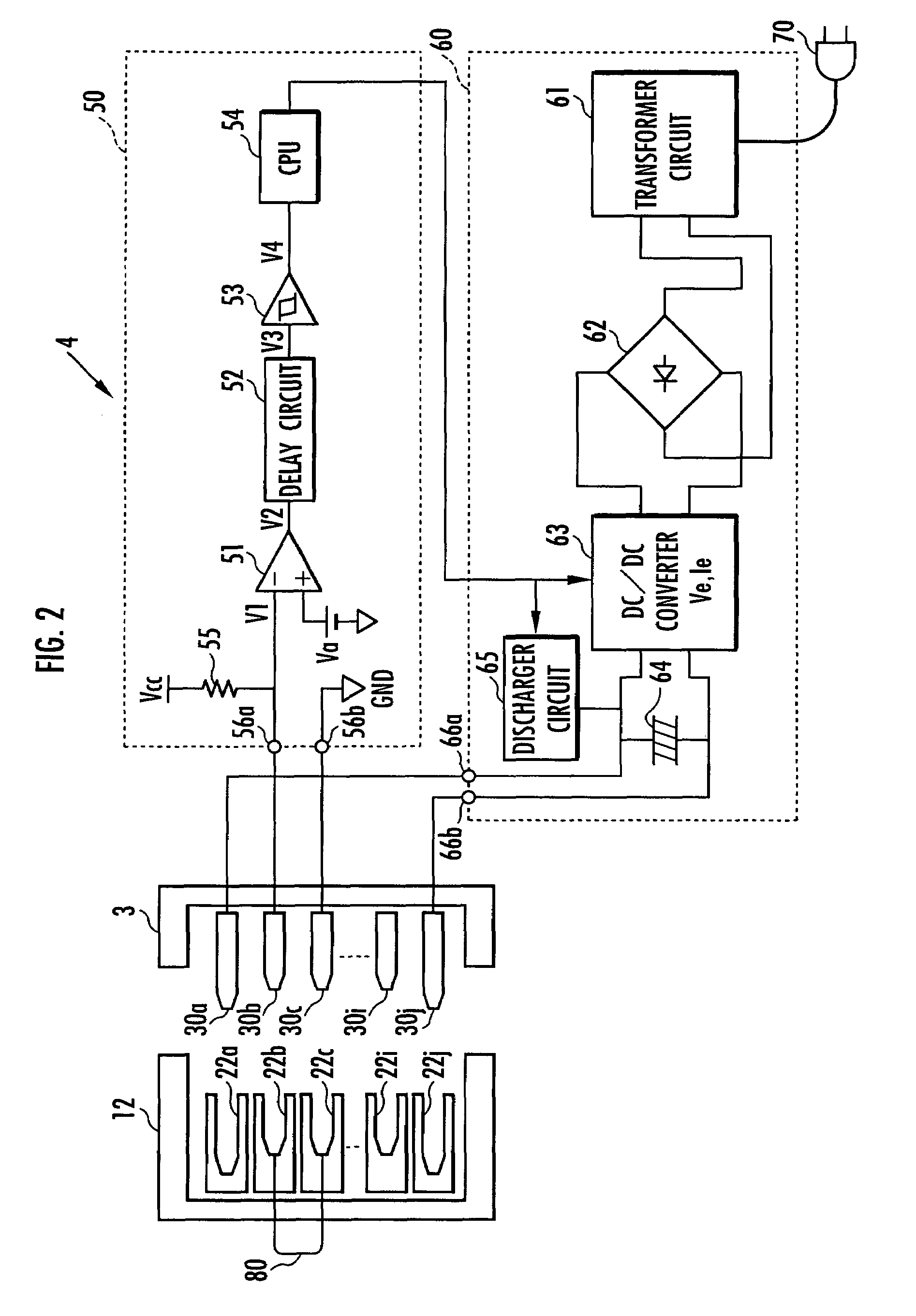

Charging system for legged walking robot

An inexpensive charging system with a simple construction can supply charging current to a battery of a legged walking robot while maintaining the supply of required current to an electric load of the legged walking robot by an external power source. The charging system includes a connection circuit having a first, a second diode, a third diode, and a circuit that brings various negative electrode and a negative input terminal of the electric load into conduction, and an output electric power controller that sets an output voltage of the external power source to be higher than a total voltage of a voltage across electrodes of the battery when the battery is fully charged and a forward voltage of the third diode, while setting a current of the external power source that can be output to be larger than a required current of the electric load.

Owner:HONDA MOTOR CO LTD

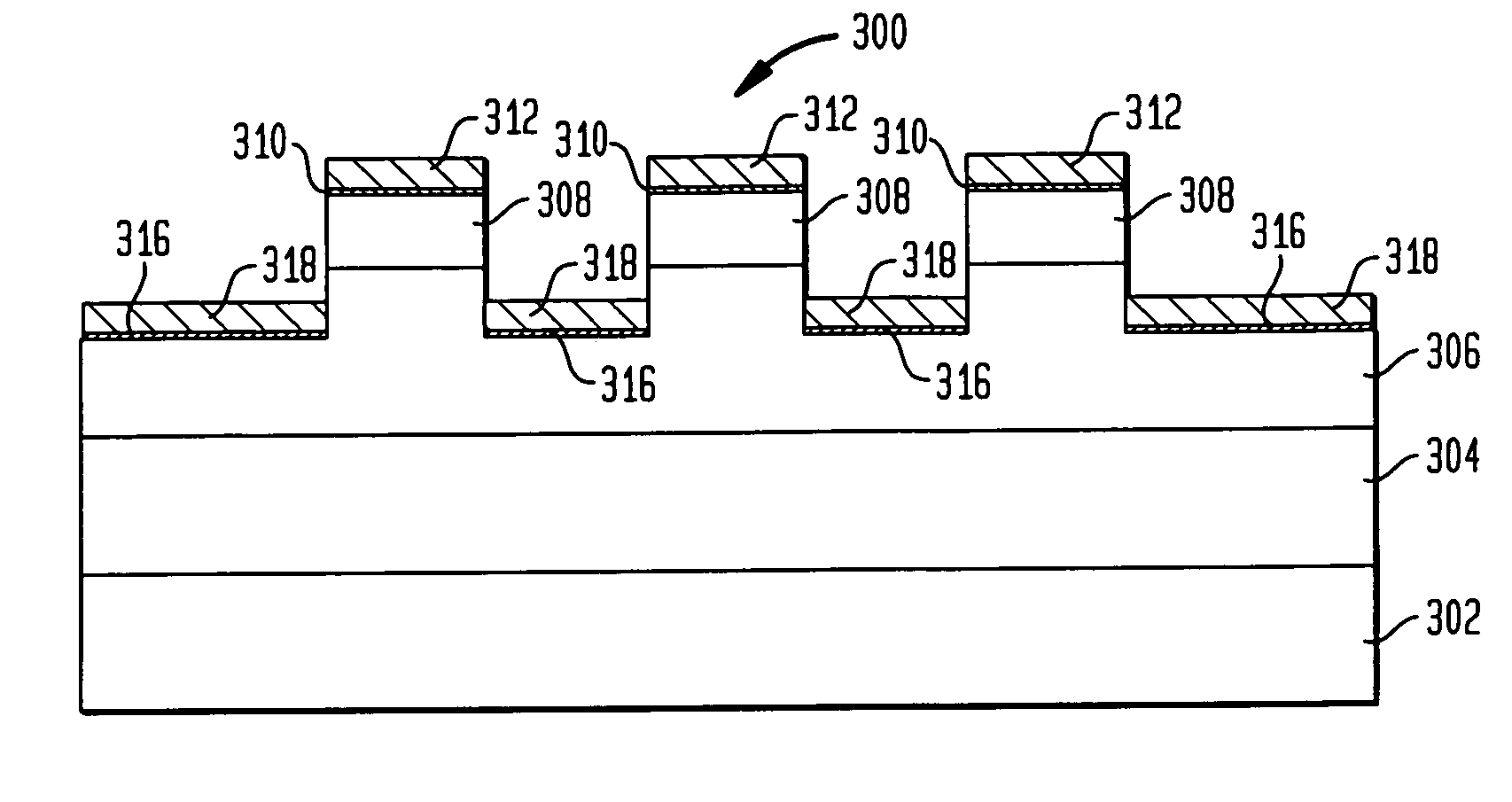

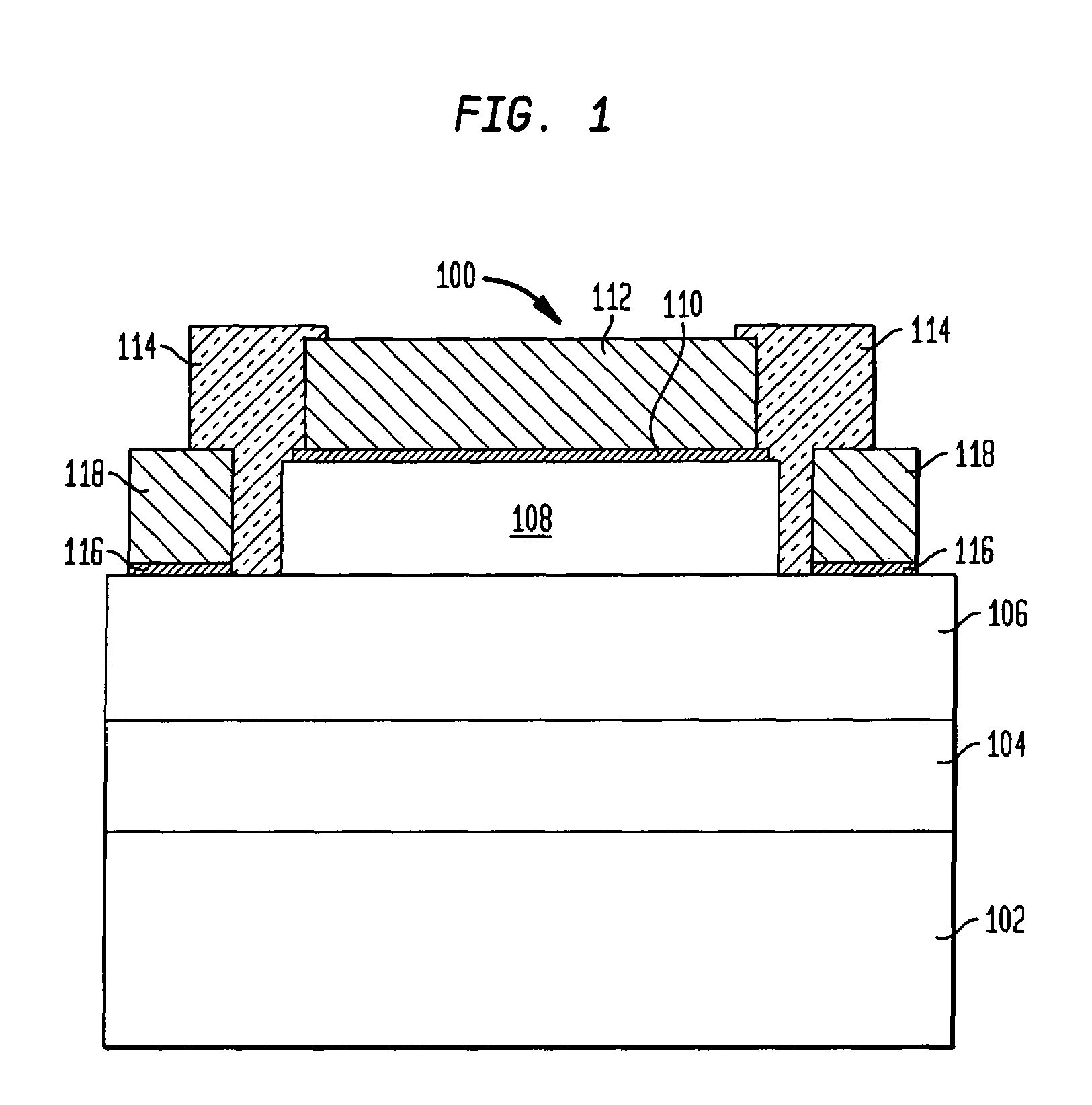

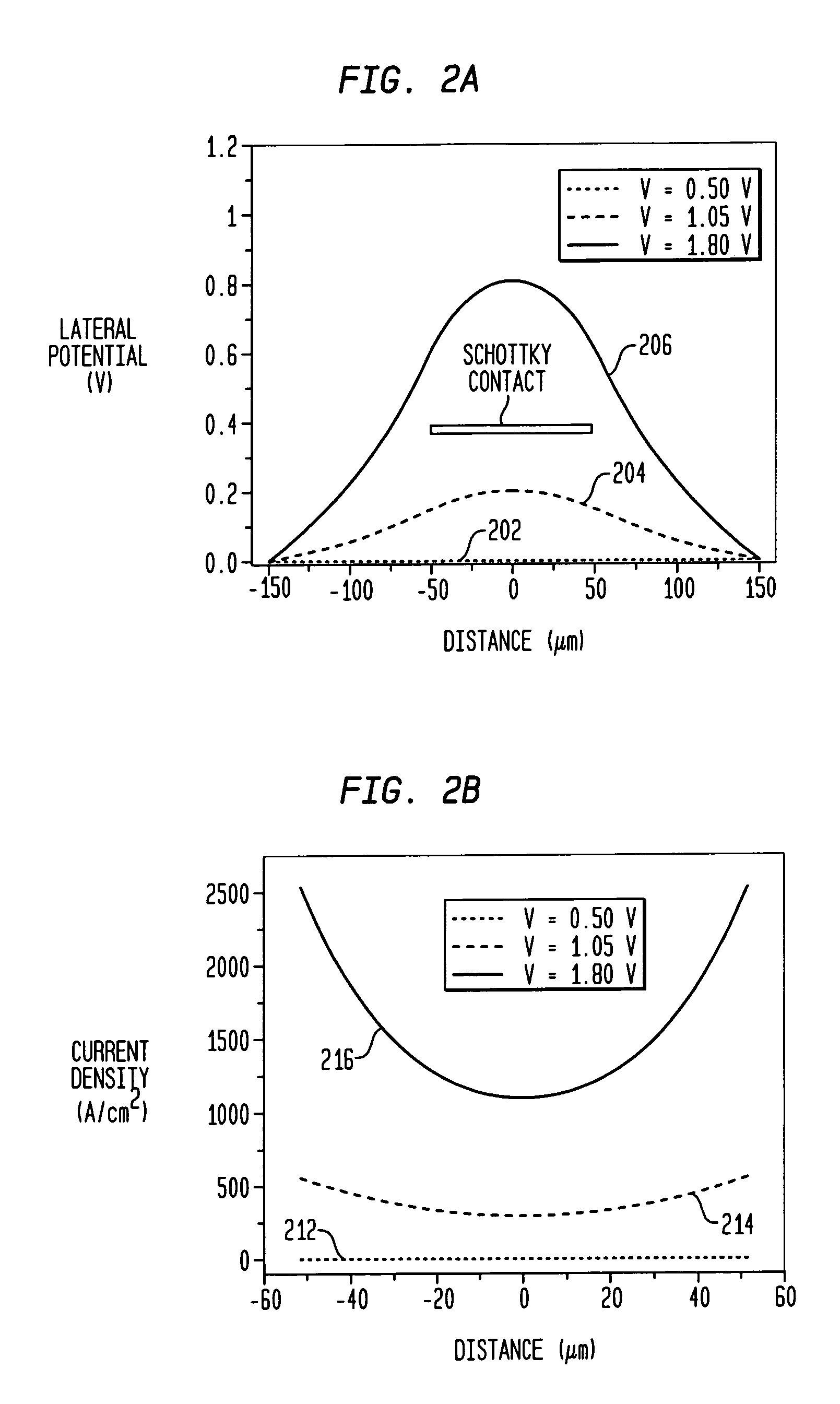

Lateral conduction Schottky diode with plural mesas

ActiveUS7084475B2Reduce heat buildupSolid-state devicesSemiconductor/solid-state device manufacturingPath lengthOhmic contact

A lateral conduction Schottky diode includes multiple mesa regions upon which Schottky contacts are formed and which are at least separated by ohmic contacts to reduce the current path length and reduce current crowding in the Schottky contact, thereby reducing the forward resistance of a device. The multiple mesas may be isolated from one another and have sizes and shapes optimized for reducing the forward resistance. Alternatively, some of the mesas may be finger-shaped and intersect with a central mesa or a bridge mesa, and some or all of the ohmic contacts are interdigitated with the finger-shaped mesas. The dimensions of the finger-shaped mesas and the perimeter of the intersecting structure may be optimized to reduce the forward resistance. The Schottky diodes may be mounted to a submount in a flip chip arrangement that further reduces the forward voltage as well as improves power dissertation and reduces heat generation.

Owner:POWER INTEGRATIONS INC

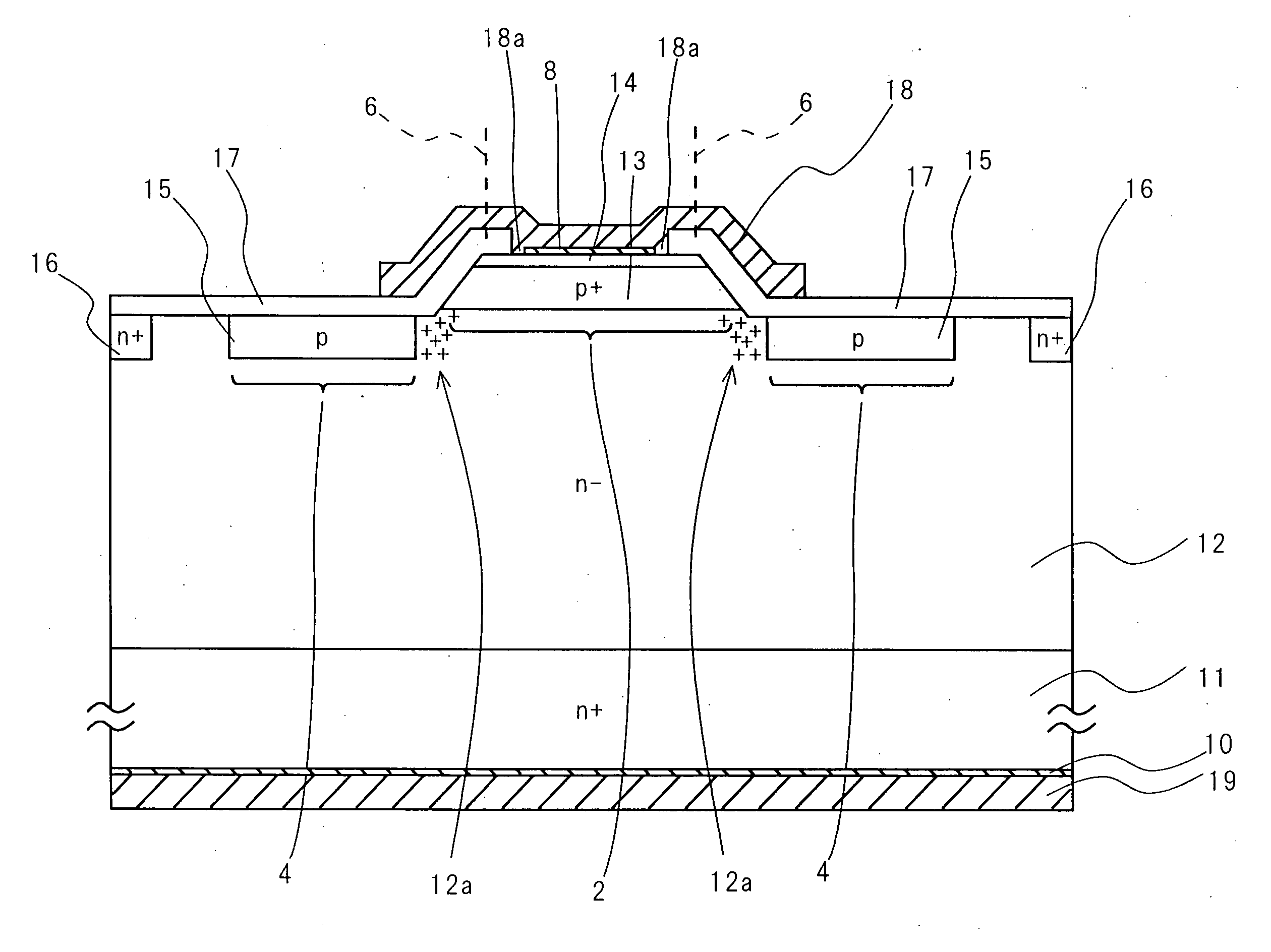

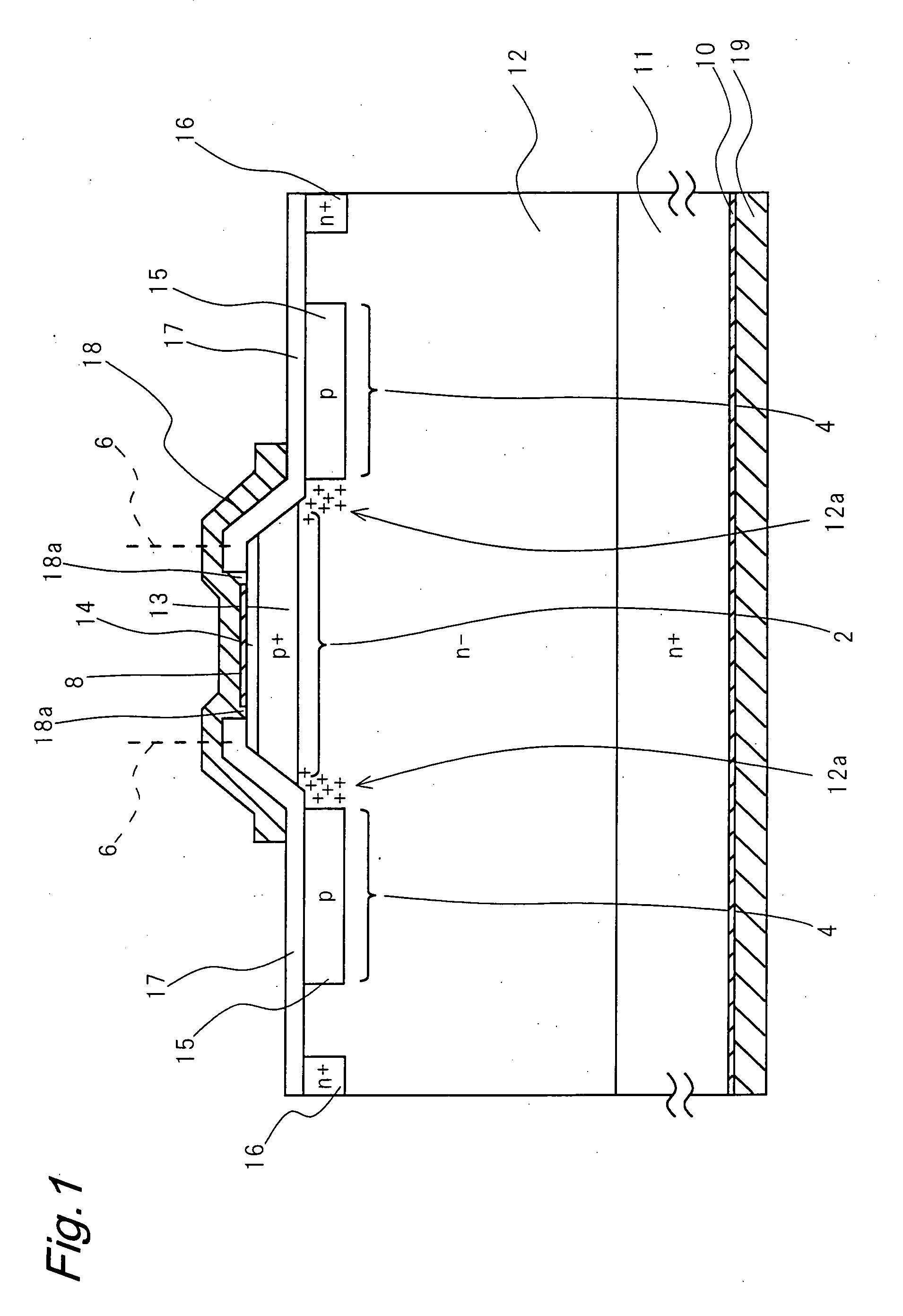

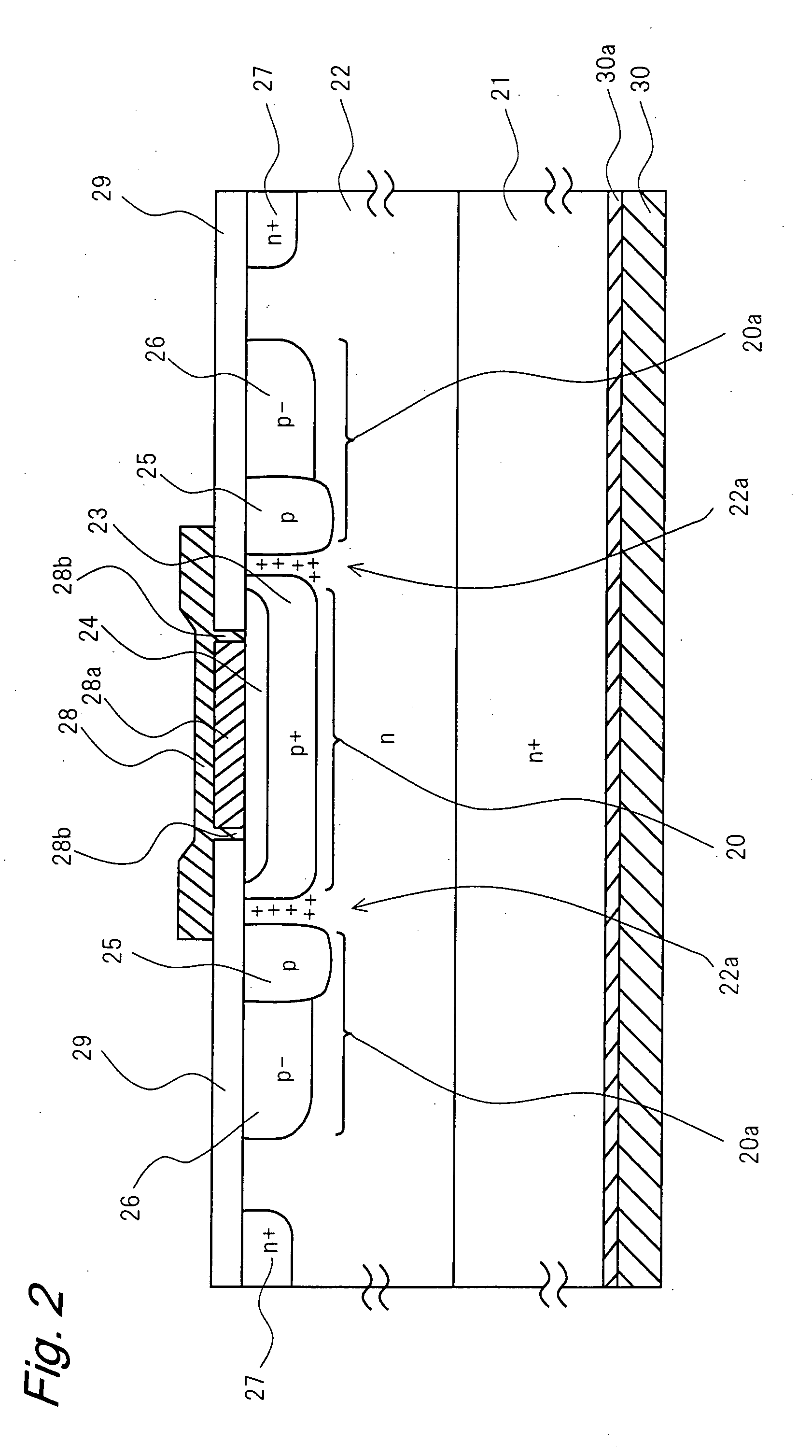

High-withstand voltage wide-gap semiconductor device and power device

InactiveUS20070170436A1Rise in forward-direction voltageExpansion can be suppressedThyristorWide gap semiconductorsBroadband

A semiconductor device with high withstand voltage, reduced forward-direction voltage degradation, long lifetime and high reliability, is provided. A junction between the drift layer and anode layer of a bipolar semiconductor device and an electric field relaxation layer are formed at a distance from each other, and an edge portion of the anode is opposed to the semiconductor region between the junction and the electric field relaxation layer, with an insulating film intervening. When reverse-biased, due to the electric field effect imparted to the drift layer between the junction and the electric field relaxation layer from the electrode, with the insulating film intervening, the junction and electric field relaxation layer are electrically connected, and electric field concentration at the junction edge portion is relaxed. When forward-biased, the junction and electric field relaxation layer are electrically isolated, and forward-direction current flows only through the junction.

Owner:THE KANSAI ELECTRIC POWER CO

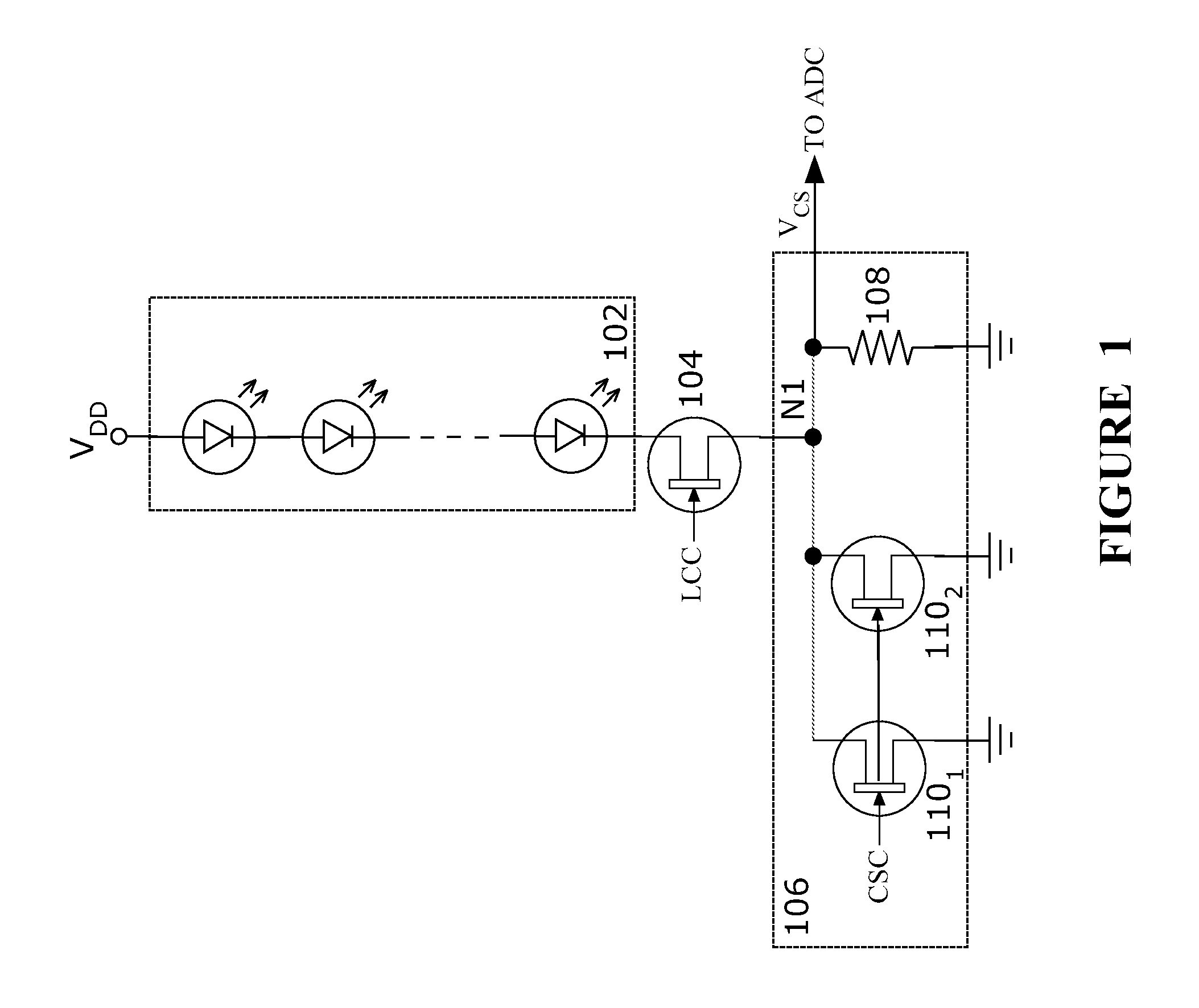

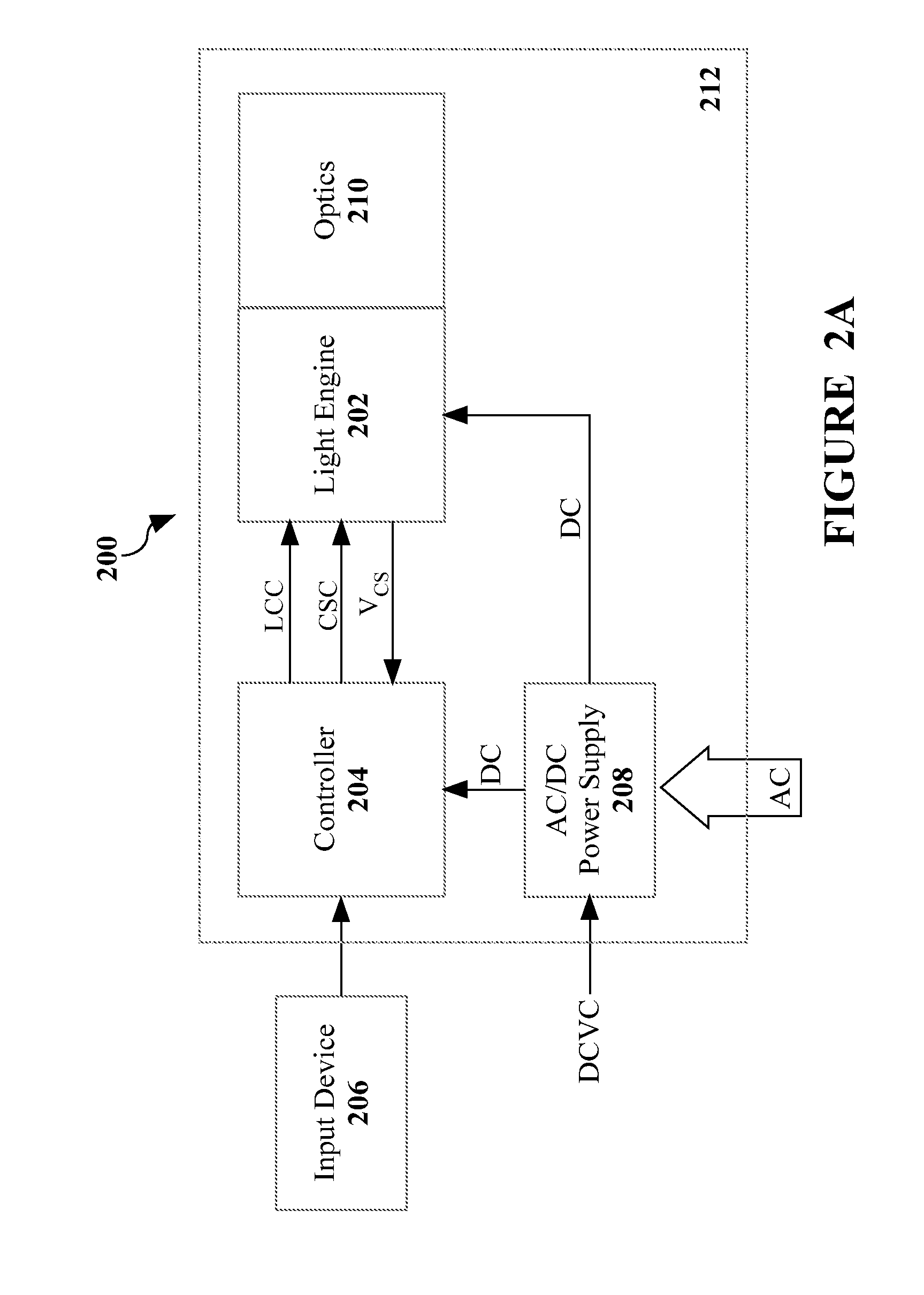

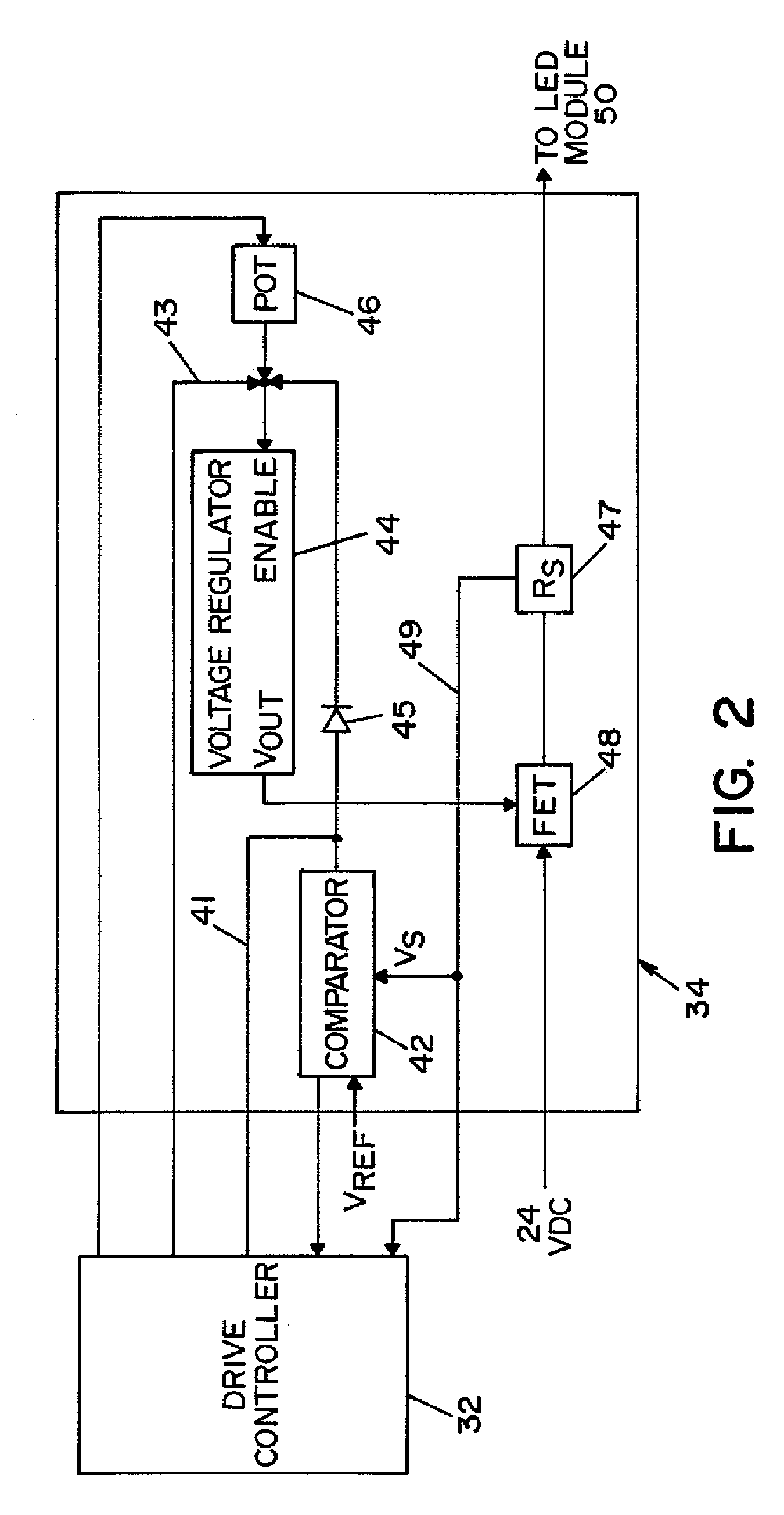

Circuits for sensing current levels within a lighting apparatus incorporating a voltage converter

ActiveUS20130009561A1Reduce resistanceElectrical apparatusElectrical measurement instrument detailsVoltage converterElectrical resistance and conductance

Circuits for sensing current levels within an apparatus are disclosed. In specific cases, a constant voltage power supply is used to power an LED lighting apparatus in which there are uncertainties within the forward voltages of the LEDs, which in turn creates uncertainty with respect to the current level flowing through the LEDs. To manage these uncertainties, the current flowing through the LEDs is measured by determining a voltage level across a known resistor and calculating the current level. To prevent the known resistor from causing a significant reduction in the efficiency of the overall light engine, the circuit includes one or more transistors in parallel with the known resistor to reduce the effective resistance in the LED circuit during times that the current is not being sensed.

Owner:ARKALUMEN

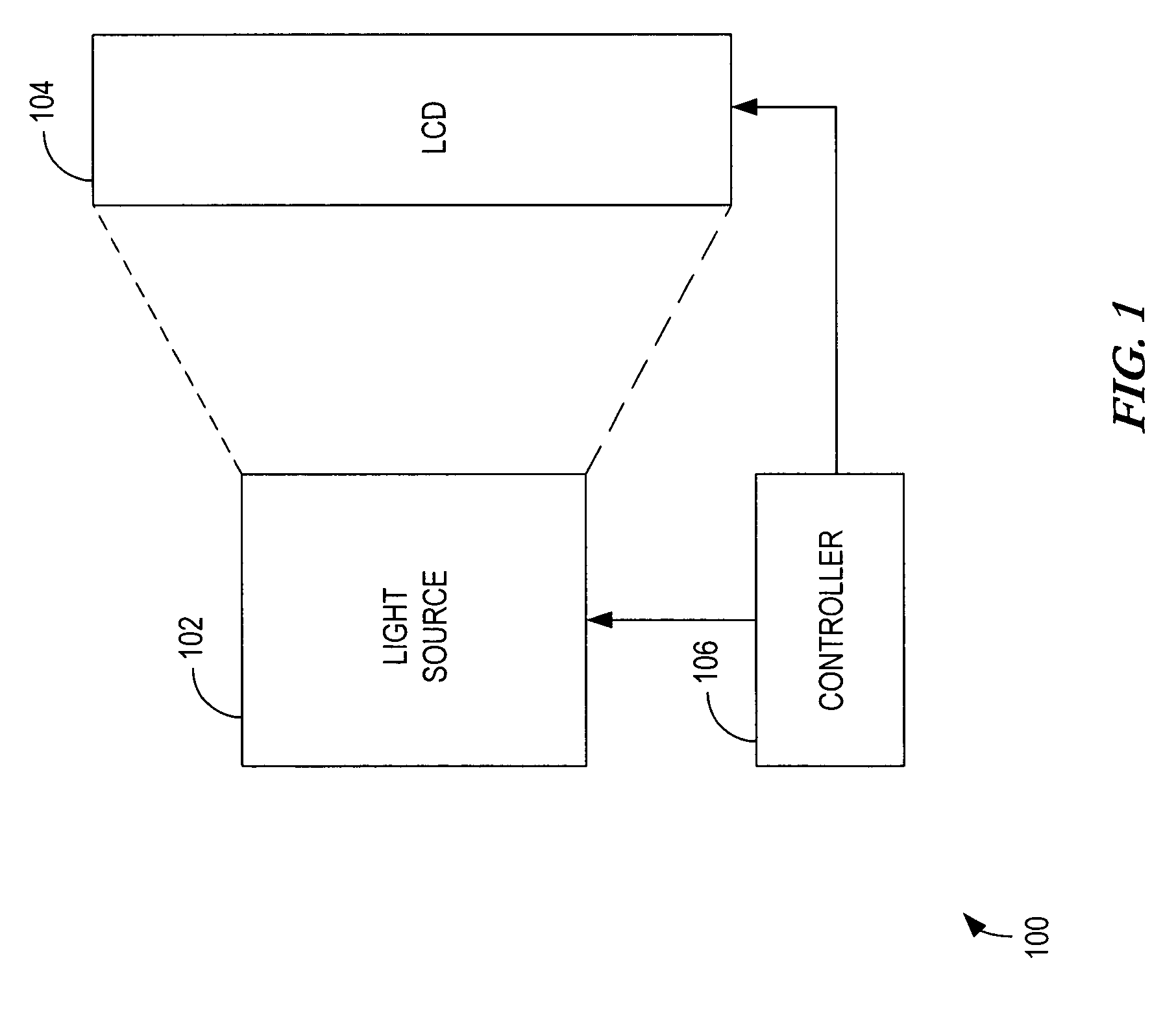

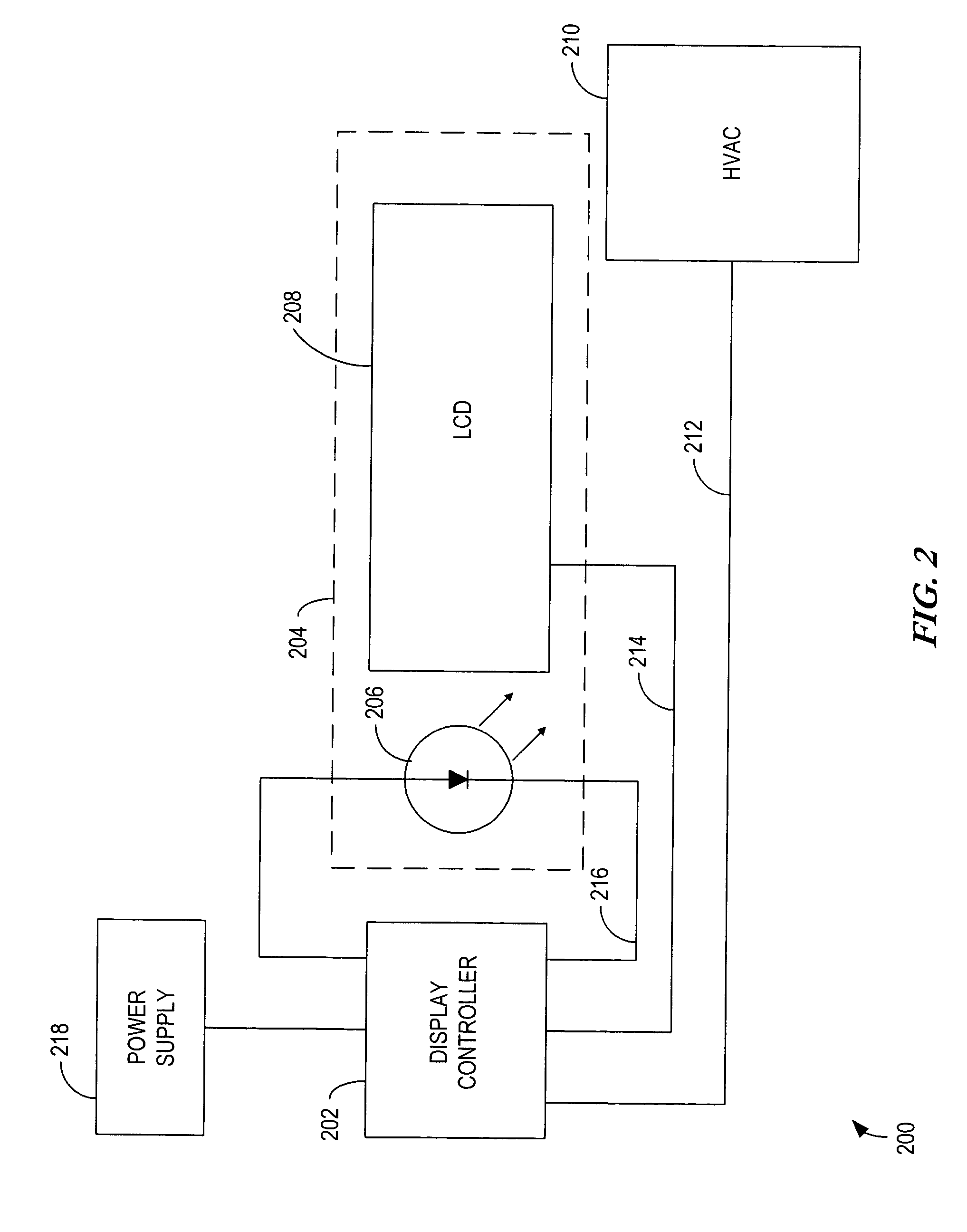

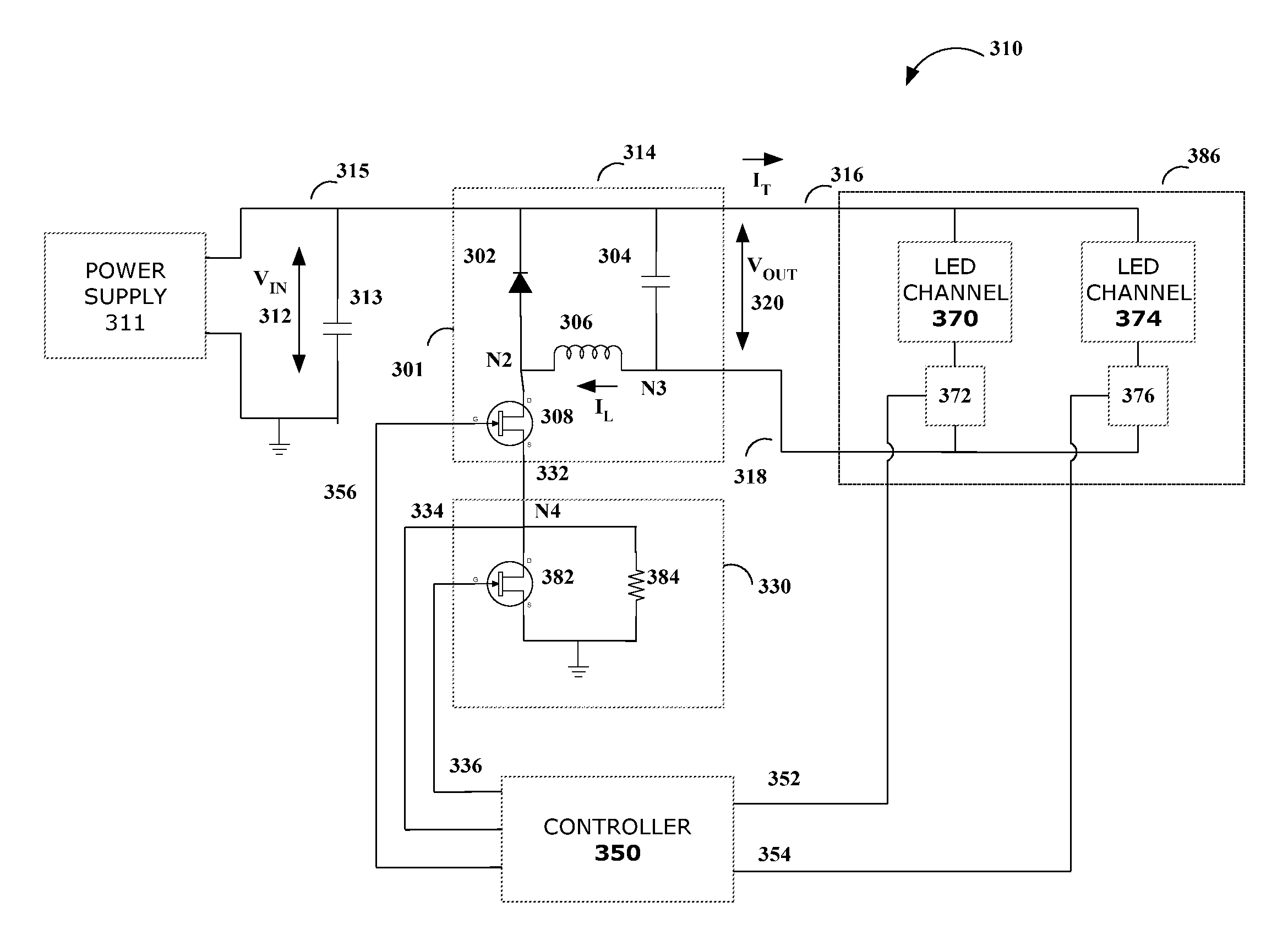

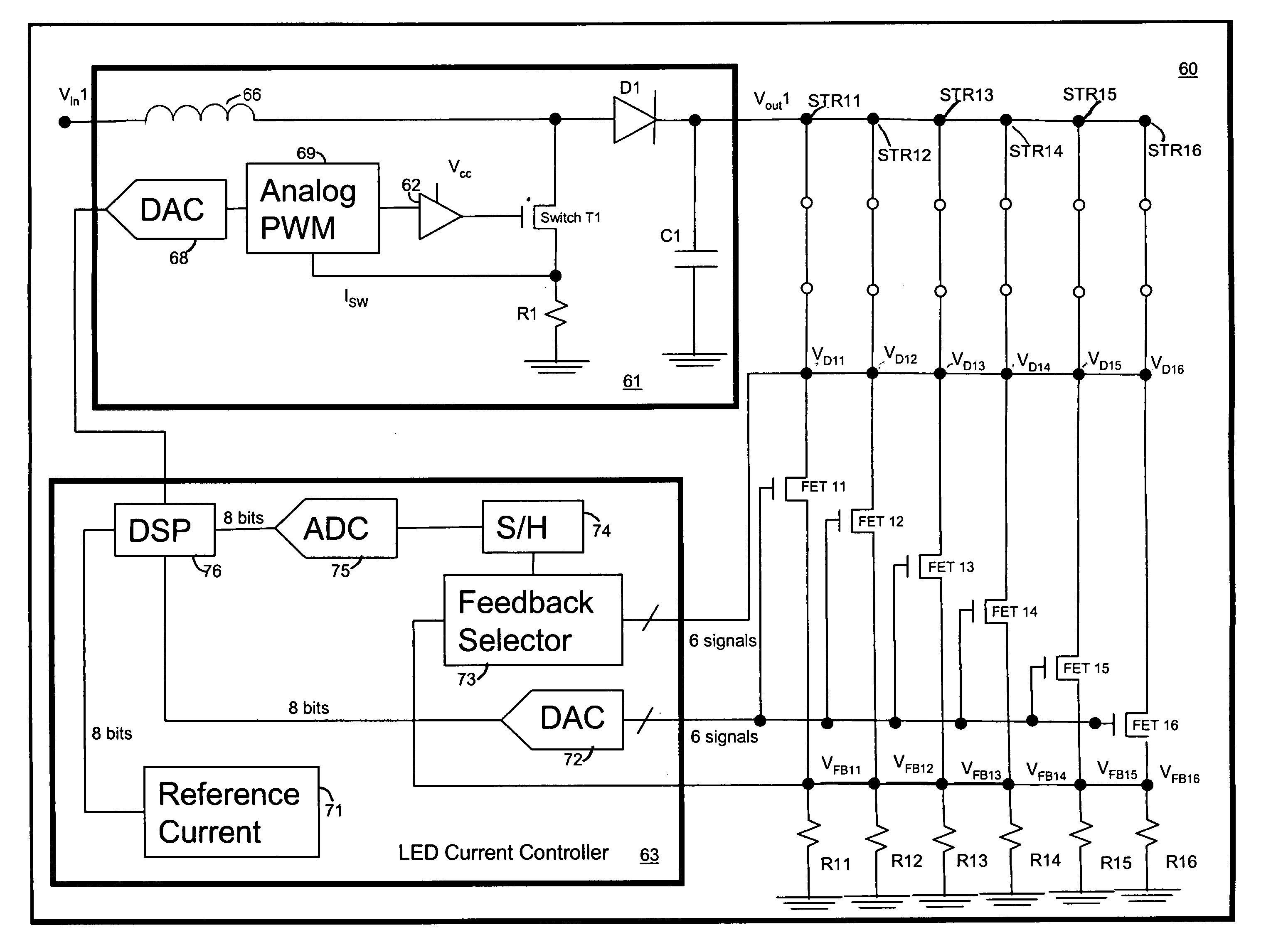

System and method for controlling a multi-string light emitting diode backlighting system for an electronic display

The present invention relates to displays that use LED strings for backlighting. A lead string is provided with continuous drive voltage and the non-lead strings are provided with pulsed drive pulses. The string having the highest forward voltage is selected as the lead string. Feedback information indicative of the currents flowing through the non-lead strings is used to determine the duty cycles of the voltage pulses provided to drive the non-lead strings. The non-lead strings are controlled using pulsed drive voltages to minimize power dissipation in the circuit.

Owner:ATMEL CORP

LED drive device, LED drive method and lighting system

InactiveUS8164276B2Efficient switchingSmooth switchingElectrical apparatusElectroluminescent light sourcesDriver circuitDrain current

Owner:FUJI ELECTRIC CO LTD

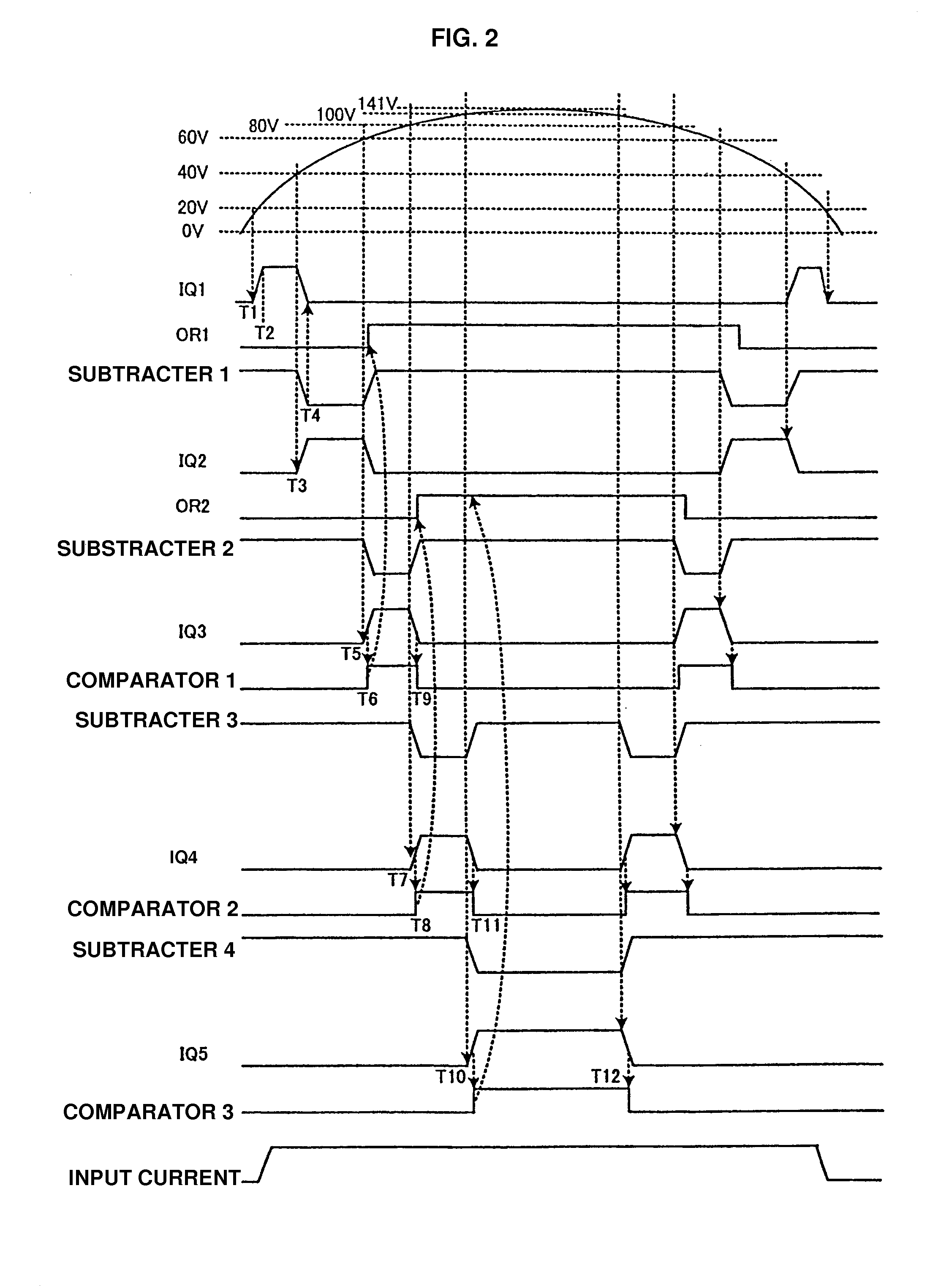

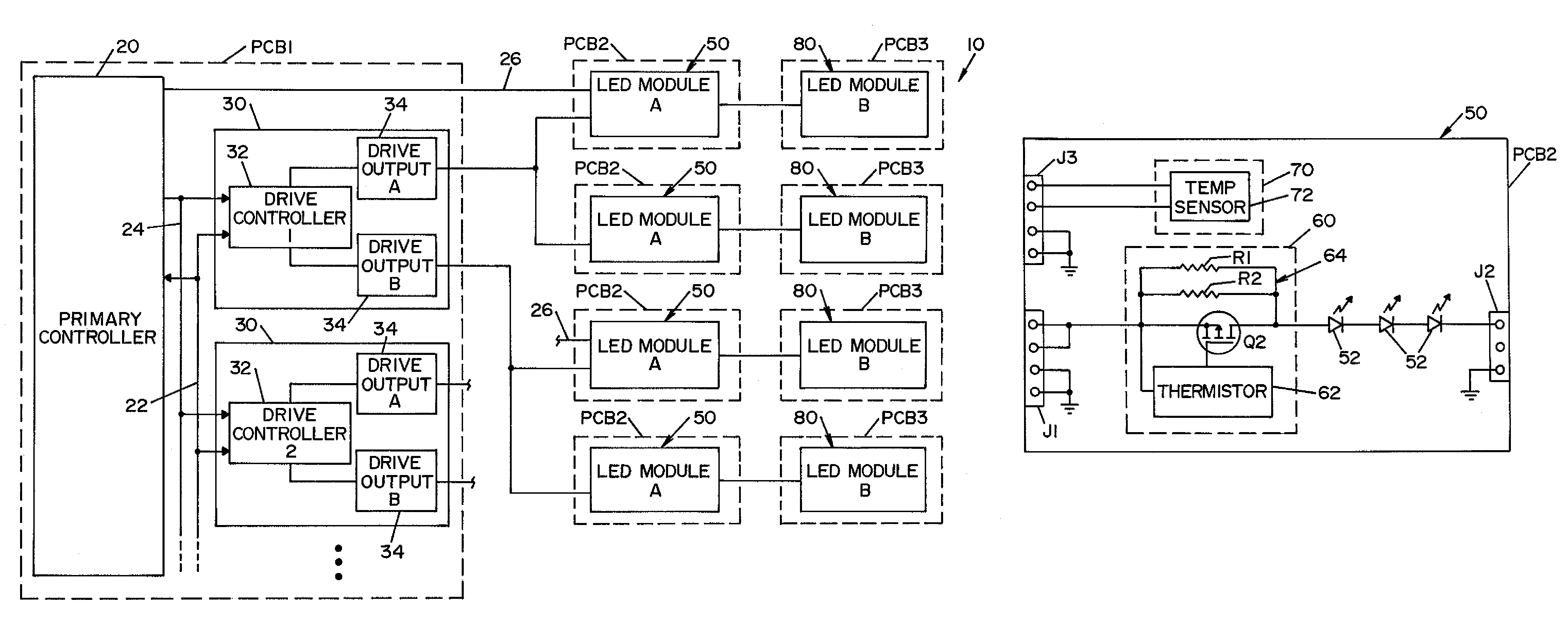

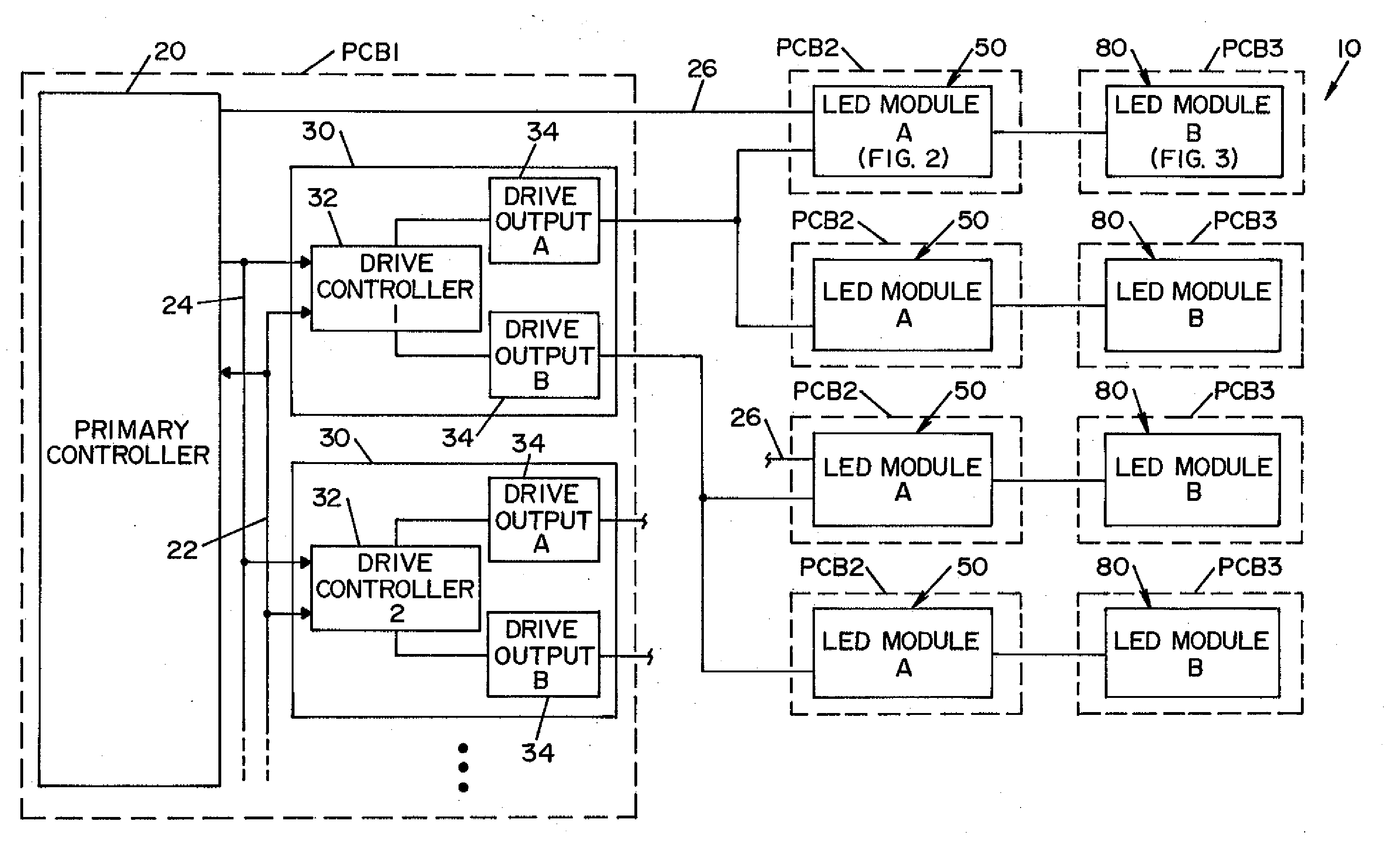

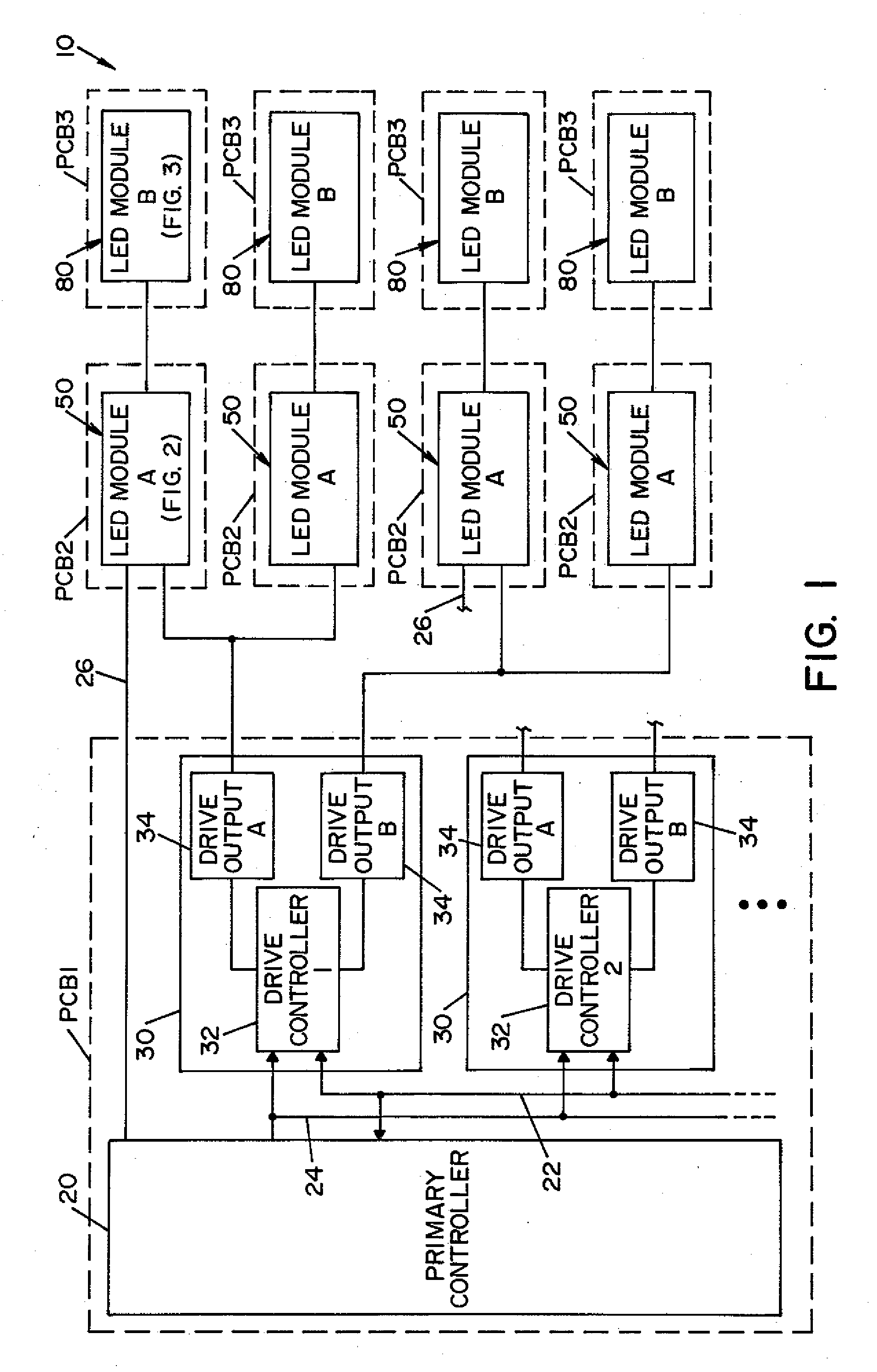

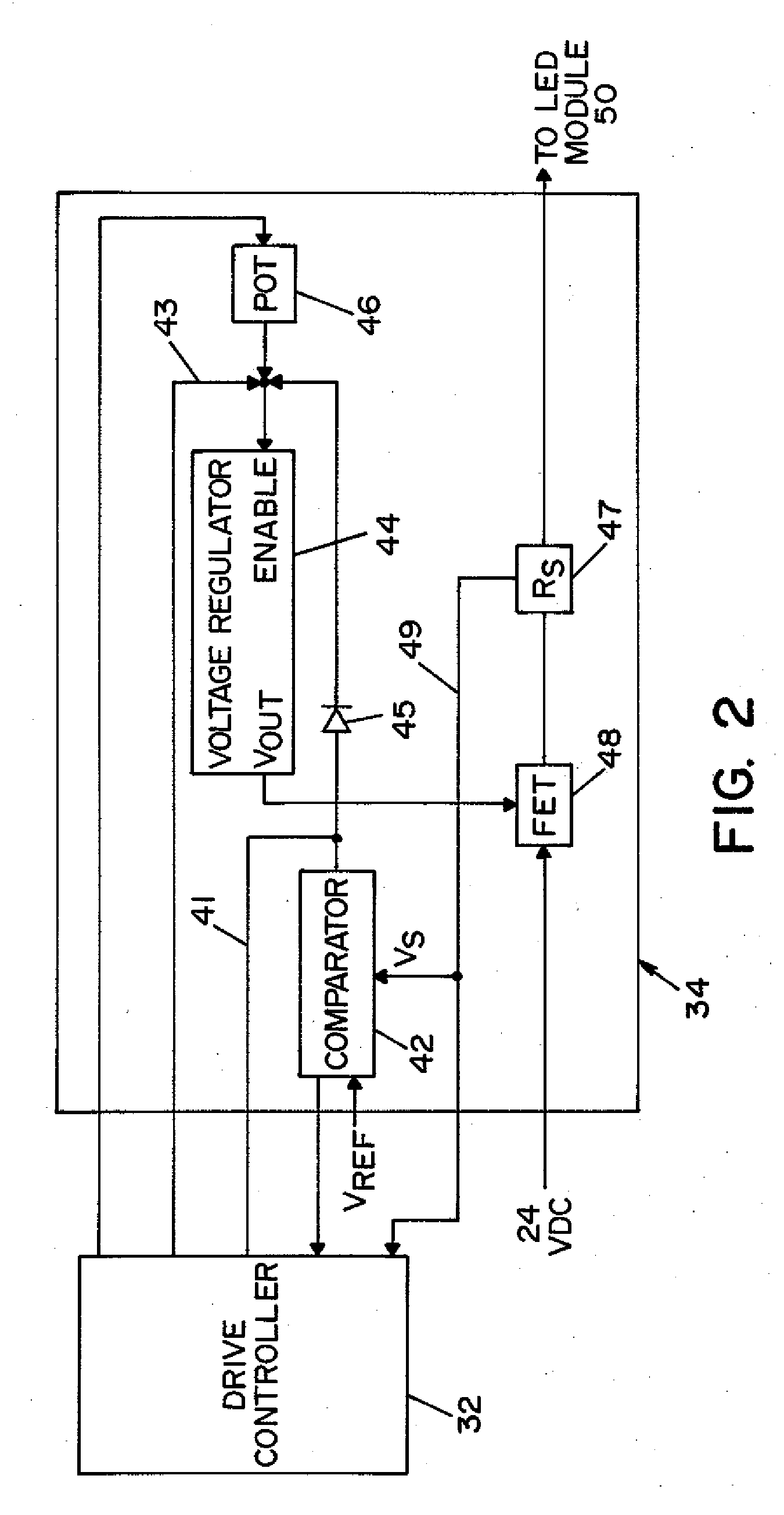

Lighting control system having temperature compensation and trim circuits

ActiveUS7701151B2Compensation effectUniform light outputElectrical apparatusElectroluminescent light sourcesEffect lightForward voltage

A lighting control system suitable for a surgical lighting device. The lighting control system includes circuitry that compensates for the effects of temperature changes in a lighting device, and that compensates for forward voltage variations among LED lighting modules to provide substantially uniform light output.

Owner:AMERICAN STERILIZER CO

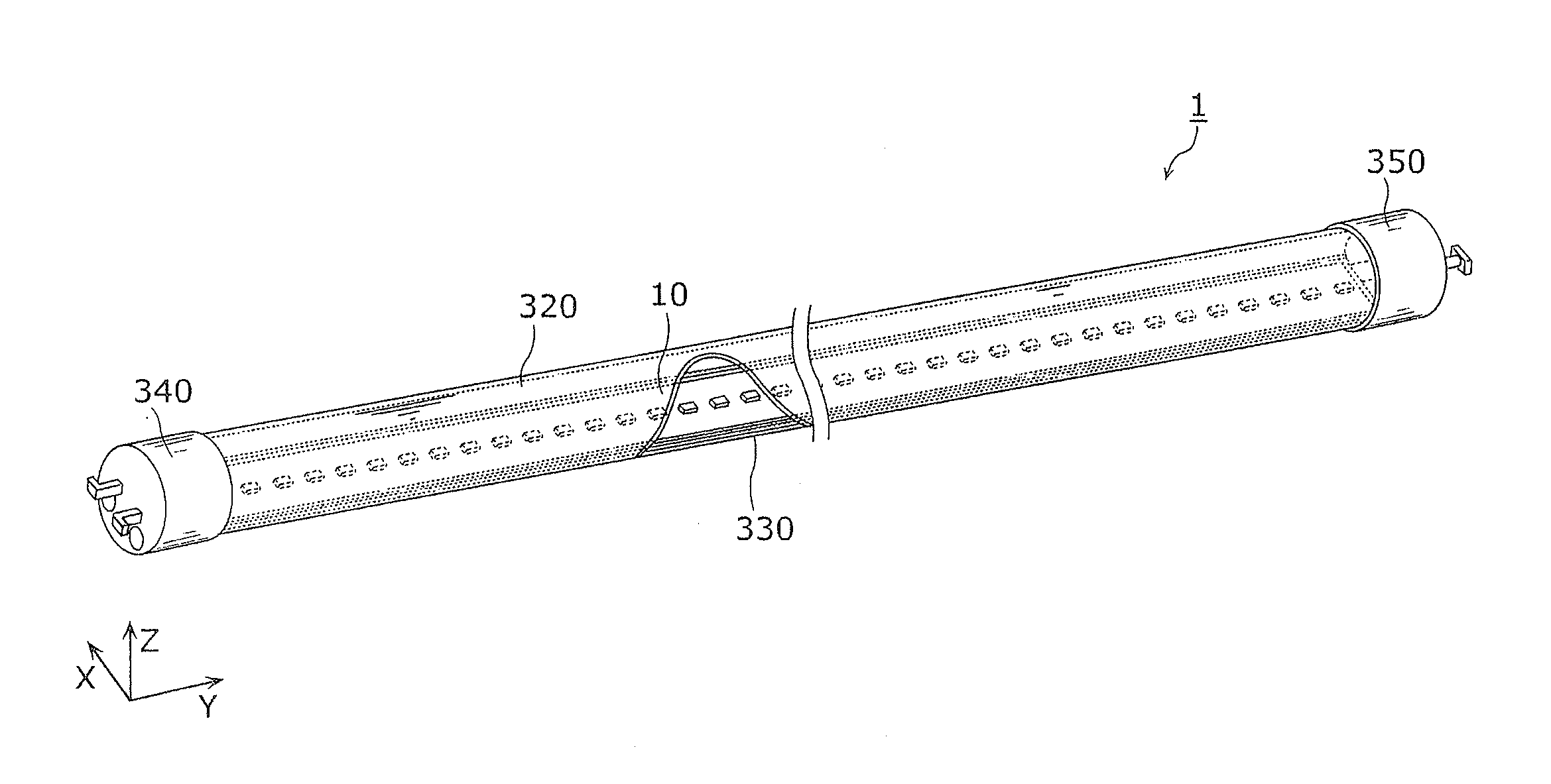

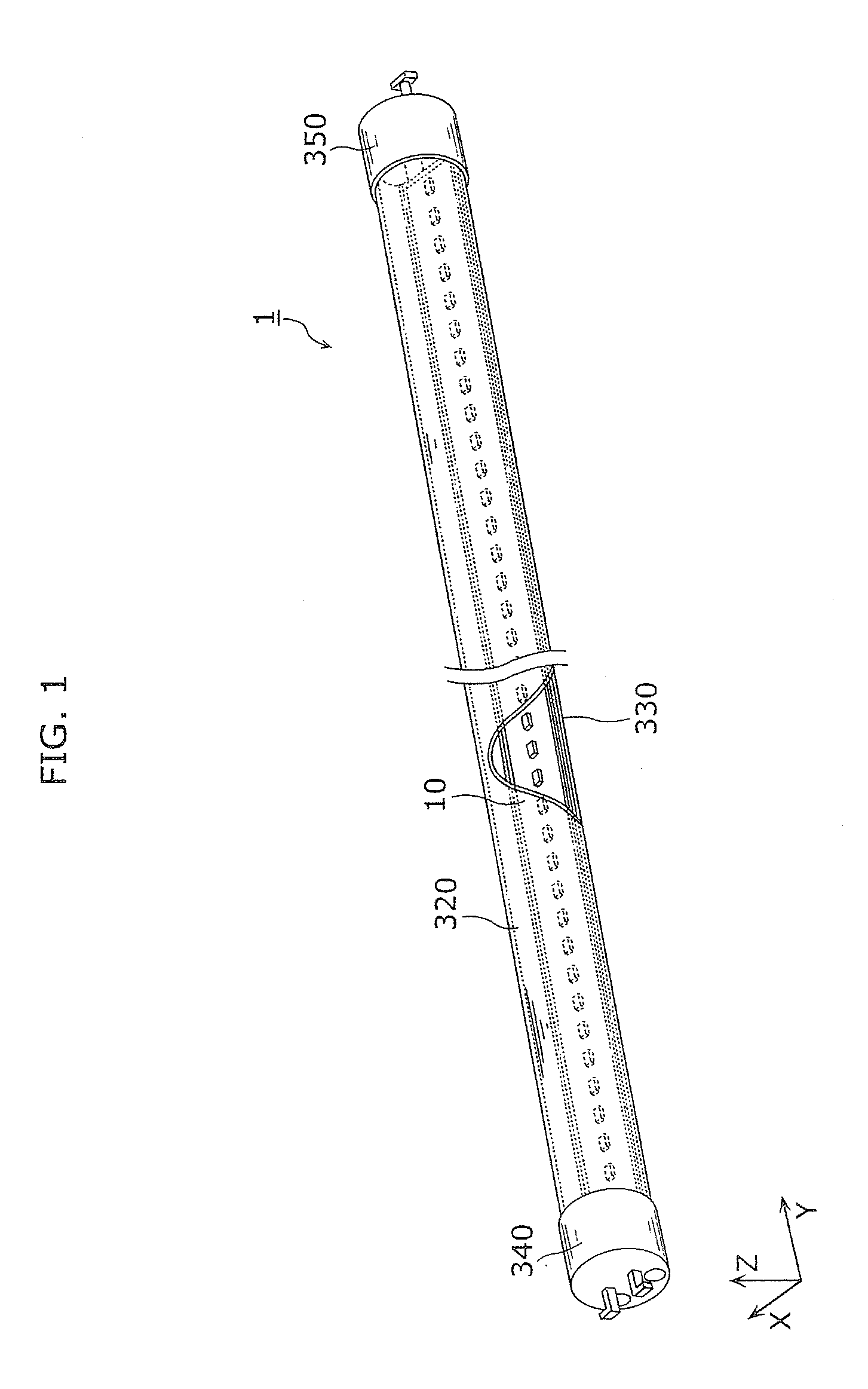

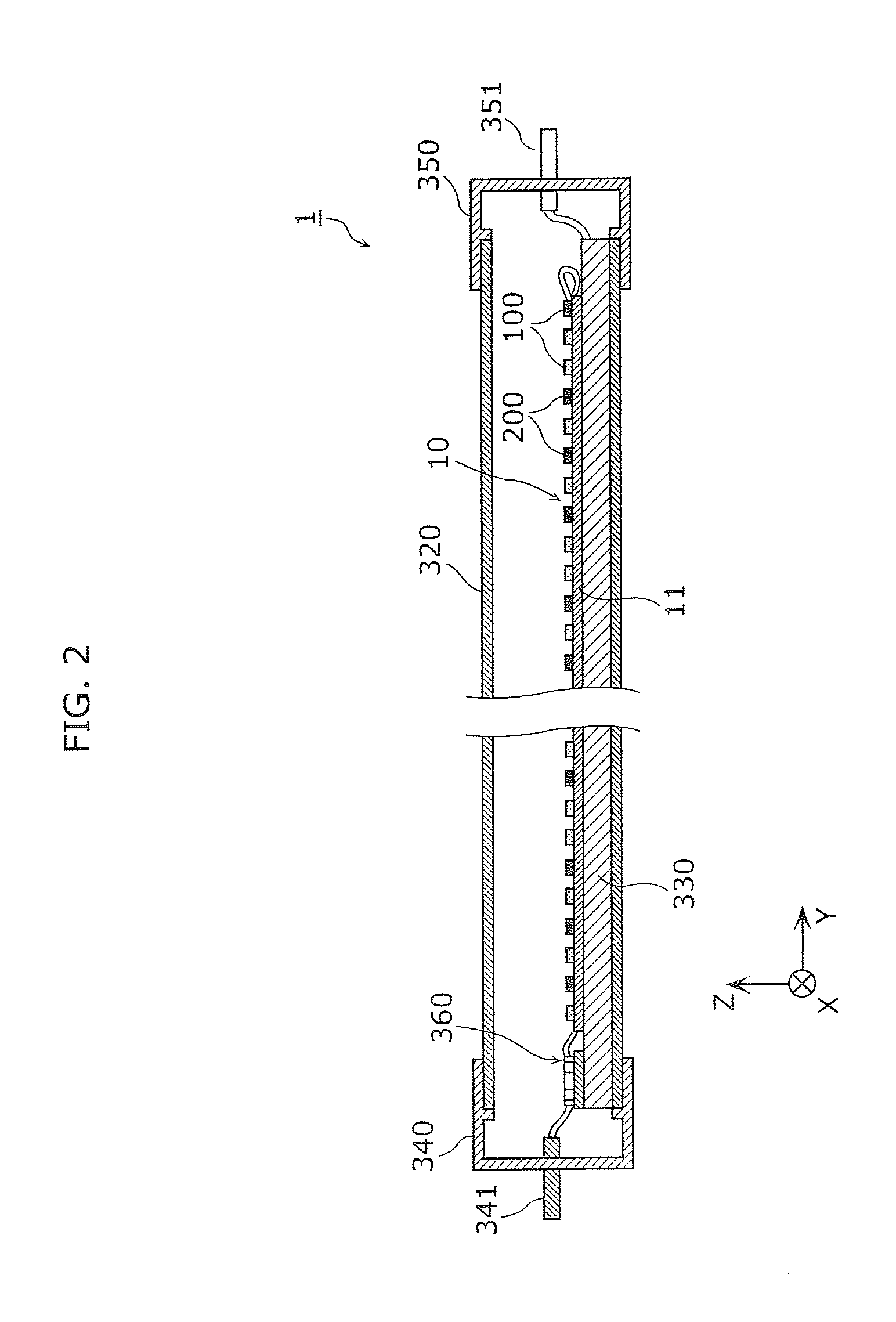

Lighting source and lighting apparatus

ActiveUS20150077001A1Changing brightnessChanging consumptionElectrical apparatusElectroluminescent light sourcesLight equipmentConstant power

A straight tube LED lamp according to one aspect of the present invention includes: a first LED array including first LED elements connected in series; a second LED array that includes second LED elements connected in series, and emits light having a different emission color from an emission color of the first LED array; a FET switch provided in a path through which current flows to the second LED array; and a constant power output circuit that outputs power without changing a total value of the power, wherein the number of the first LED elements connected in series is greater than the number of the second LED elements connected in series, a total forward voltage of the first LED array is greater than a total forward voltage of the second LED array, and the first LED elements are in alignment with the second LED elements.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

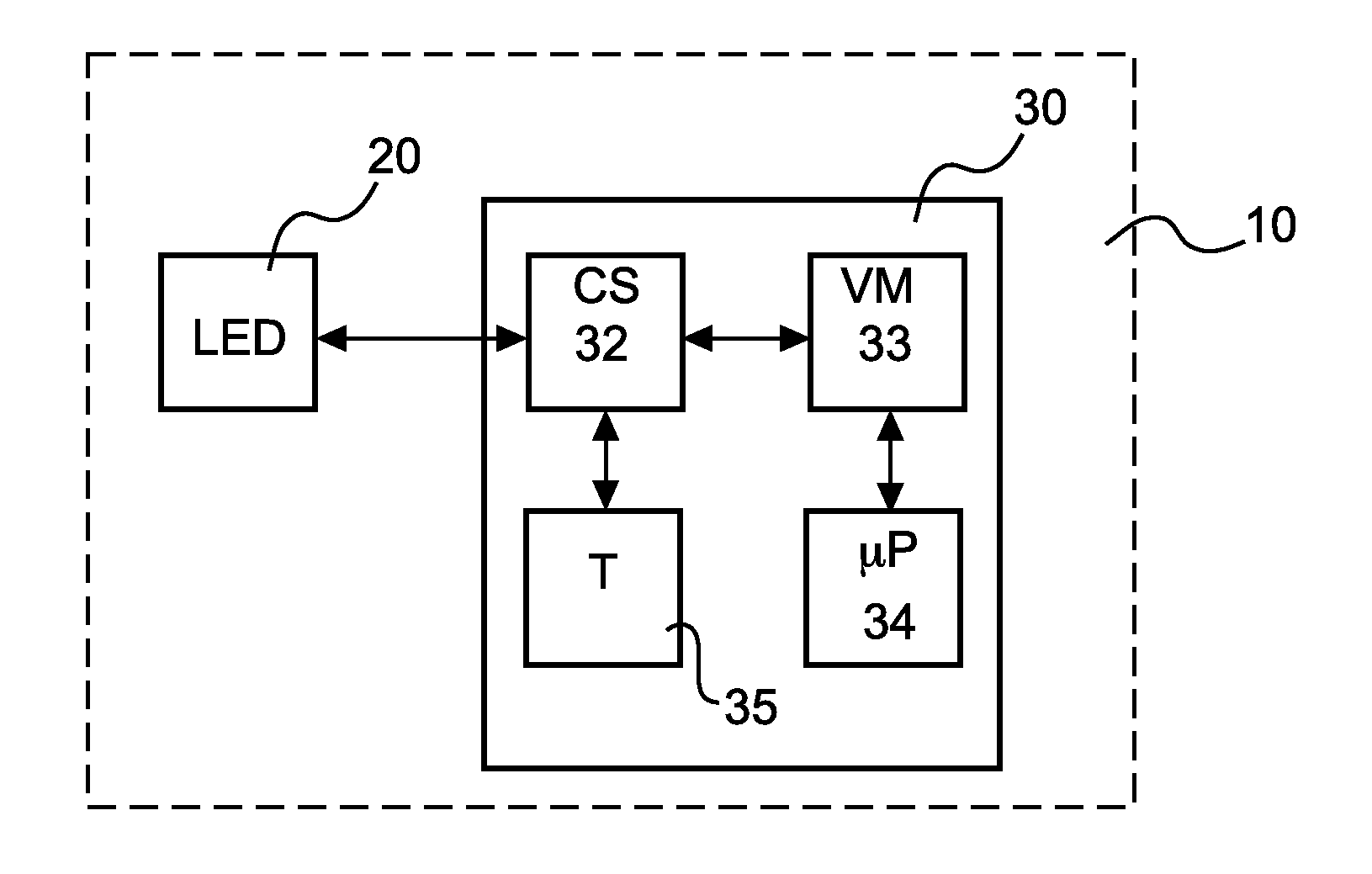

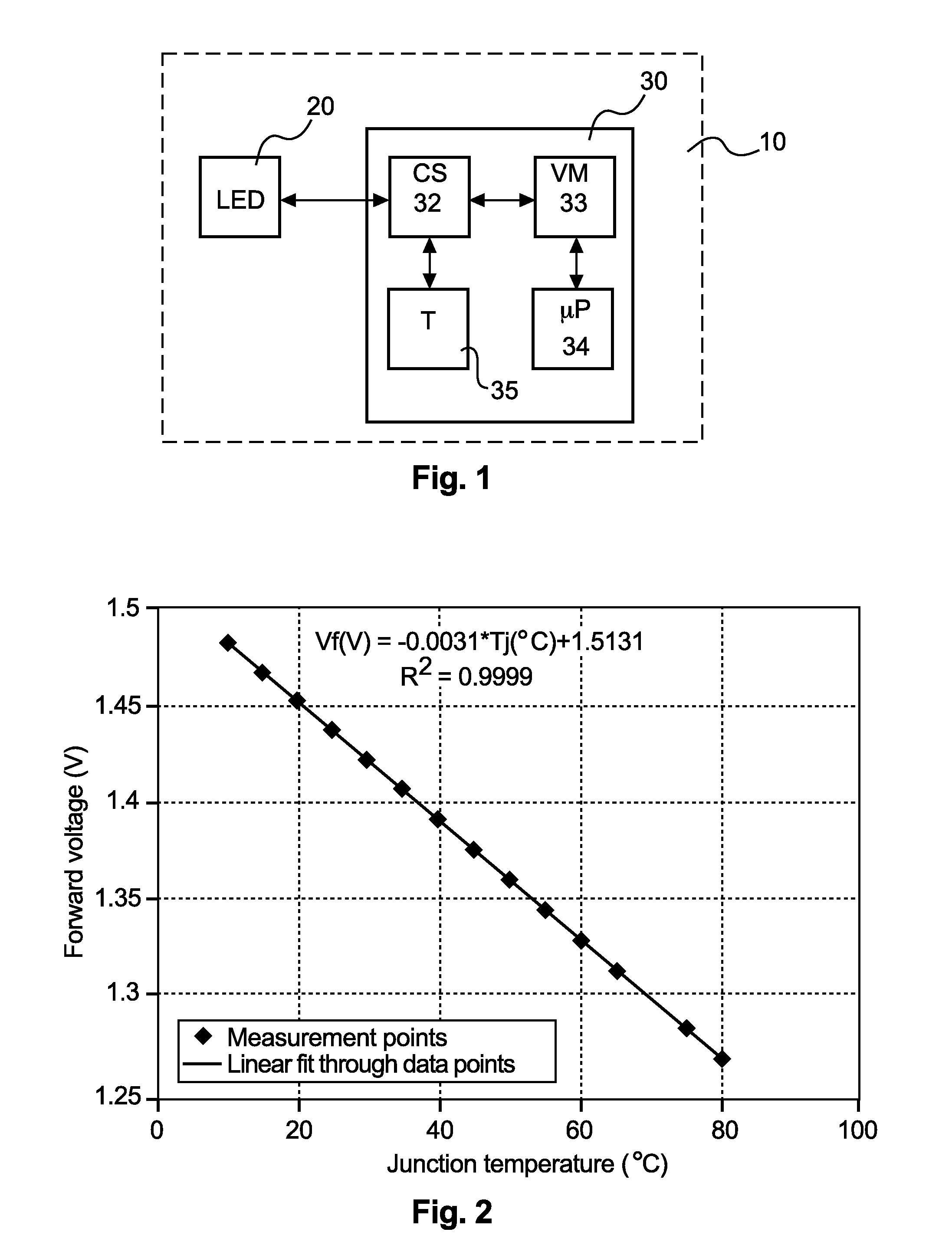

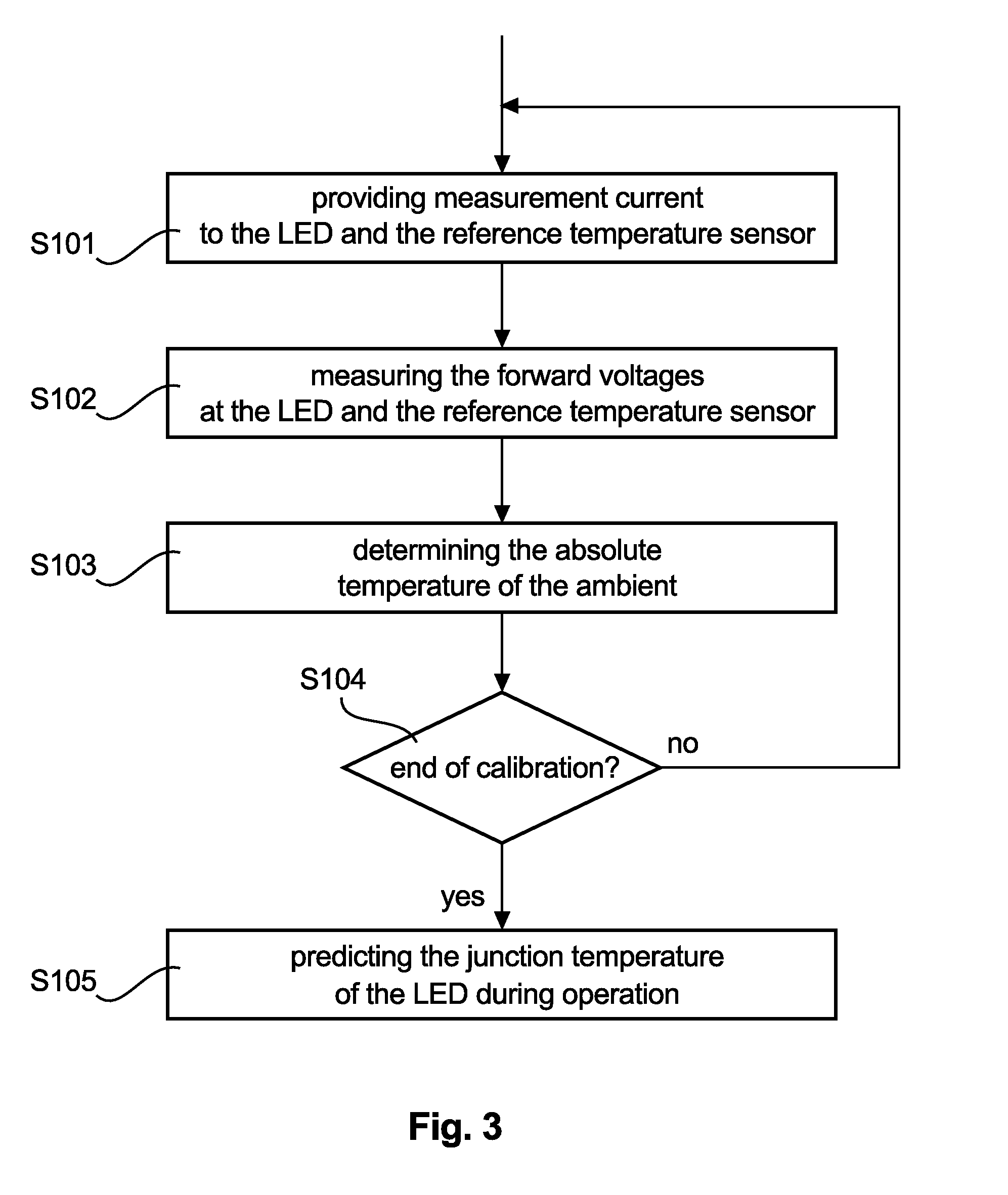

Self-calibration circuit and method for junction temperature estimation

InactiveUS20110150028A1Accurate and fast junction temperature measurementAccurate and fast junction temperatureThermometer detailsElectrical apparatusJunction temperatureEngineering

The present invention relates to a calibration circuit, computer program product, and method of calibrating a junction temperature measurement of a semiconductor element, wherein respective forward voltages at junctions of the semiconductor element and a reference temperature sensor are measured, and an absolute ambient temperature is determined by using the reference temperature sensor, and the junction temperature of the semiconductor element is predicted based on the absolute ambient temperature and the measured forward voltages.

Owner:NXP BV

LED circuit arrangement

ActiveUS20130200812A1Increase luminous fluxEasy to set upElectrical apparatusElectroluminescent light sourcesLow voltageEngineering

The invention relates to a LED circuit arrangement (1) with at least a voltage input (4), adapted to provide an operating voltage, a reactive element (6) connected in series with said voltage input (4) and a LED light source (3). To enable the LED circuit arrangement (1) to be driven at an operating voltage, the LED light source (3) comprises a first and a second LED unit (8, 9), each having one light emitting diode, controllable switching means (10) to connect said LED units (8, 9) with said reactive element (6) in a low voltage mode and a high voltage mode and a control unit (12). The LED light source (3) shows a first forward voltage in said low voltage mode and a second forward voltage in said high voltage mode, said second forward voltage being higher than said first forward voltage. The control unit (12) is adapted to control the current through the LED light source (3) by setting the switching means (10) to said low voltage mode when the current, supplied to the LED light source (3), corresponds to a first threshold value (30) and by setting the switching means (10) to the high voltage mode when said supplied current corresponds to a second threshold value (31).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

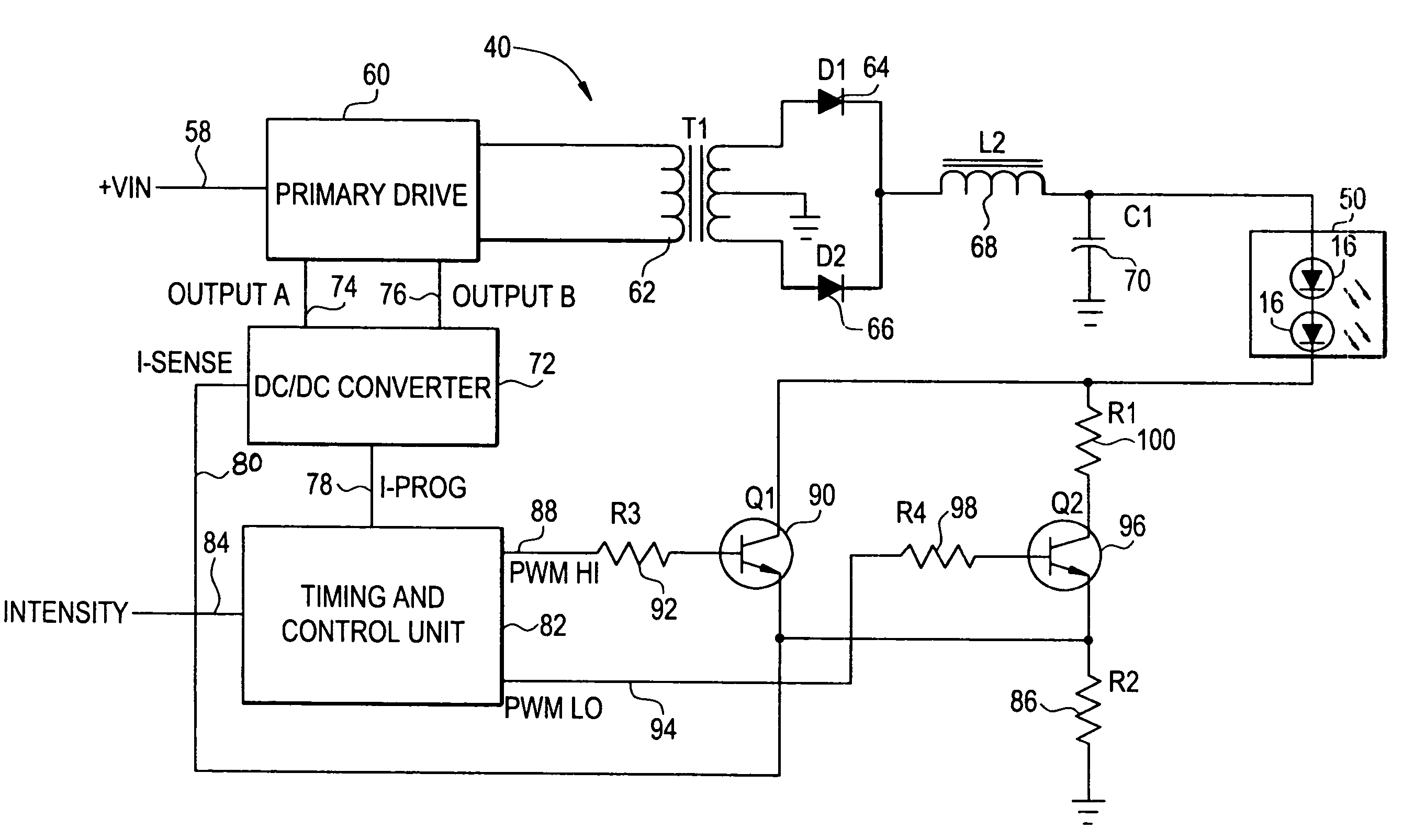

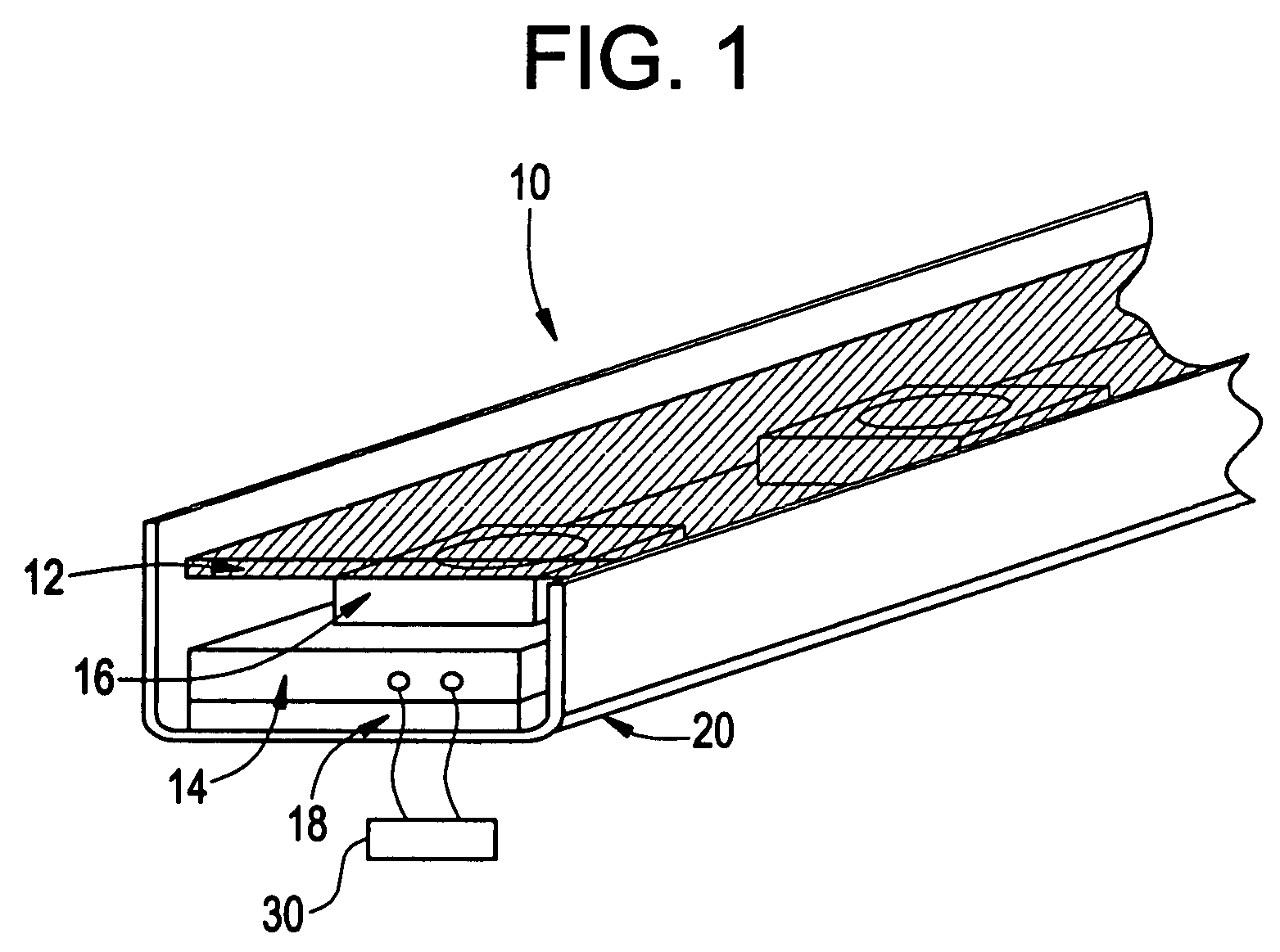

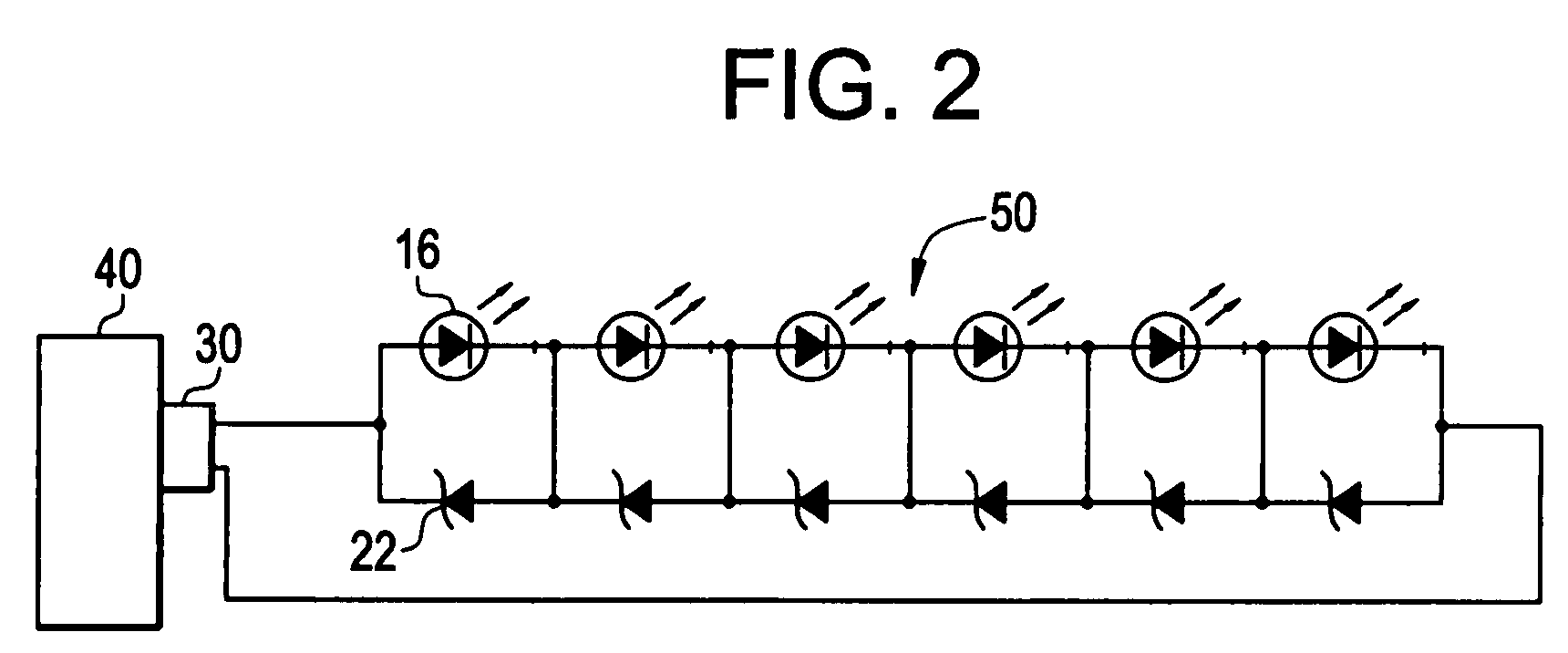

Method, apparatus, and system for driving LED's

InactiveUS7579786B2Static indicating devicesElectroluminescent light sourcesControl signalDisplay device

A method and apparatus for driving LED's is disclosed, comprising the steps of receiving a desired intensity value, wherein the desired intensity value represents the desired intensity for the LED's; generating a first switching control signal, wherein the first switching control signal is a pulse width modulated signal whose duty cycle is based on the desired intensity value; switching the LED's on and off based on the first switching control signal, wherein the switching takes place when the desired intensity value is less than a first desired intensity value threshold; generating a desired constant current value based on the desired intensity value, wherein the desired constant current value represents the value of the desired constant current to drive the LED's; determining an actual constant current value, wherein the actual constant current value represents the value of the actual constant current driving the LED's; comparing the actual constant current value with the desired constant current value; and adjusting the output of the primary drive of the LED's so that the actual constant current value is equal to the desired constant current value. A system for providing LED backlighting of a display is also disclosed, comprising a first constant current source driver, wherein the constant current source driver comprises a primary drive and a step-up circuit; a first series connection of LED's, wherein the LED's are driven by the first constant current driver; and wherein the first constant current source provides a forward voltage of 42 volts or greater to drive the first series connection of LED's.

Owner:APPLIED CONCEPTS

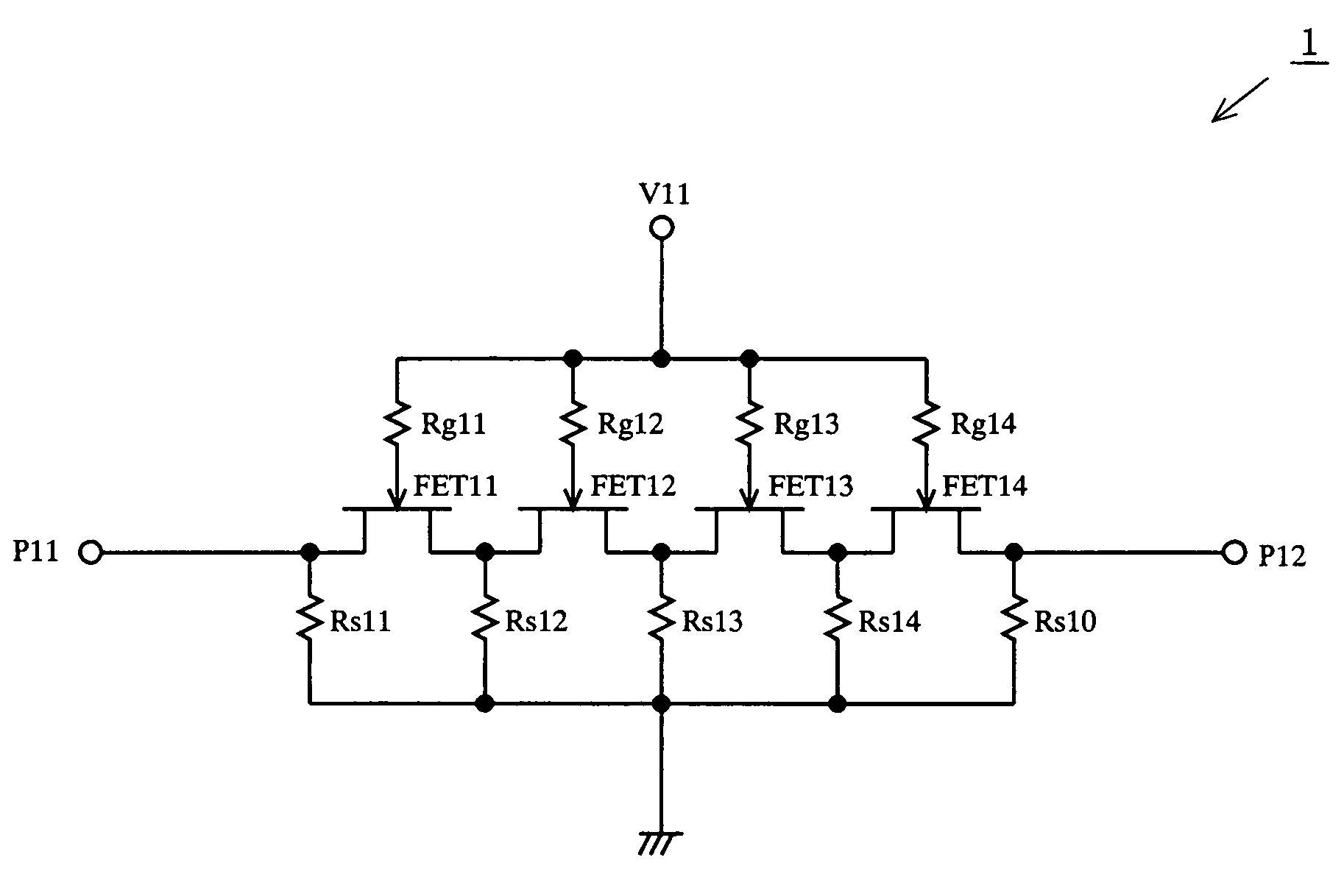

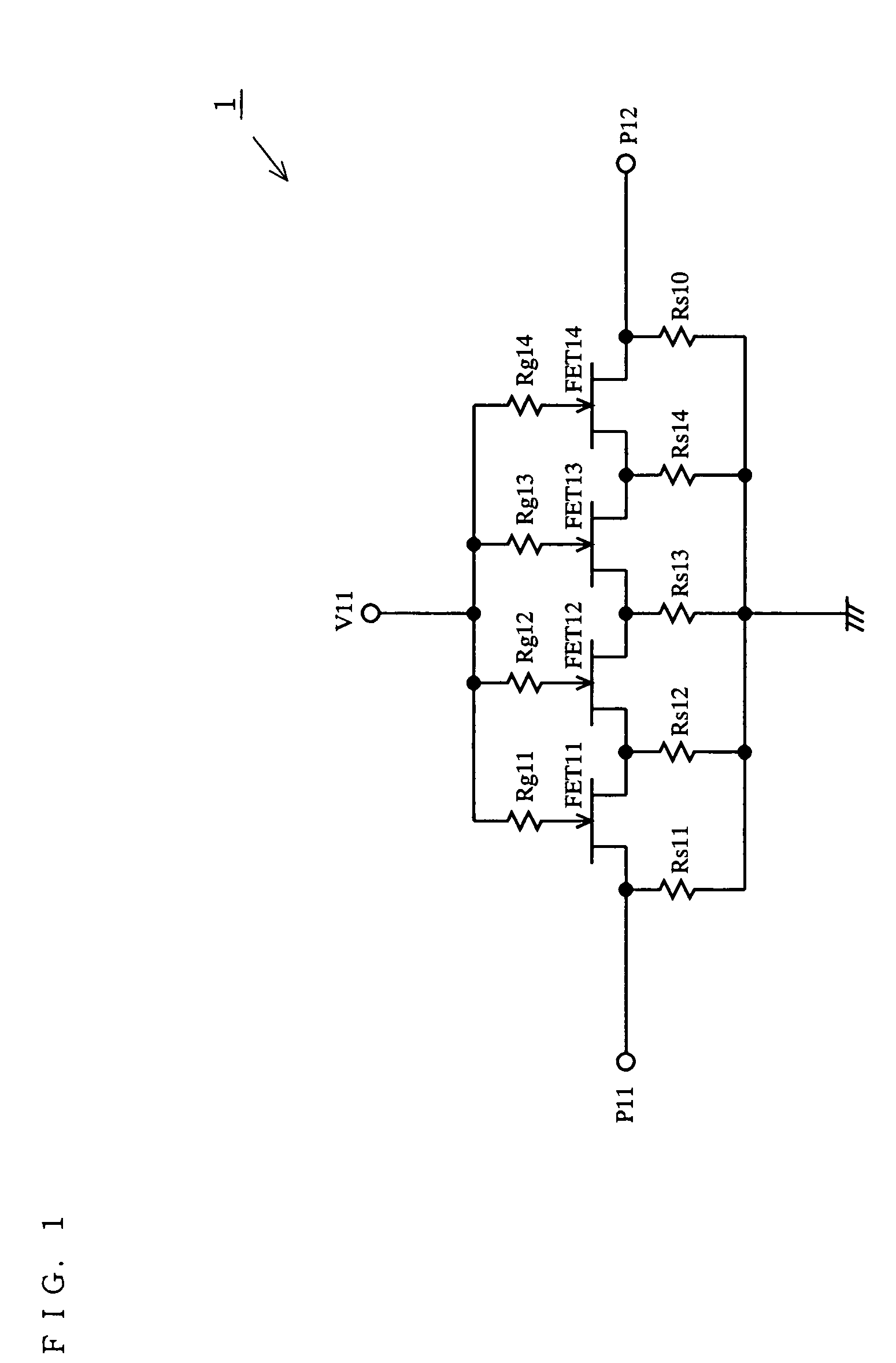

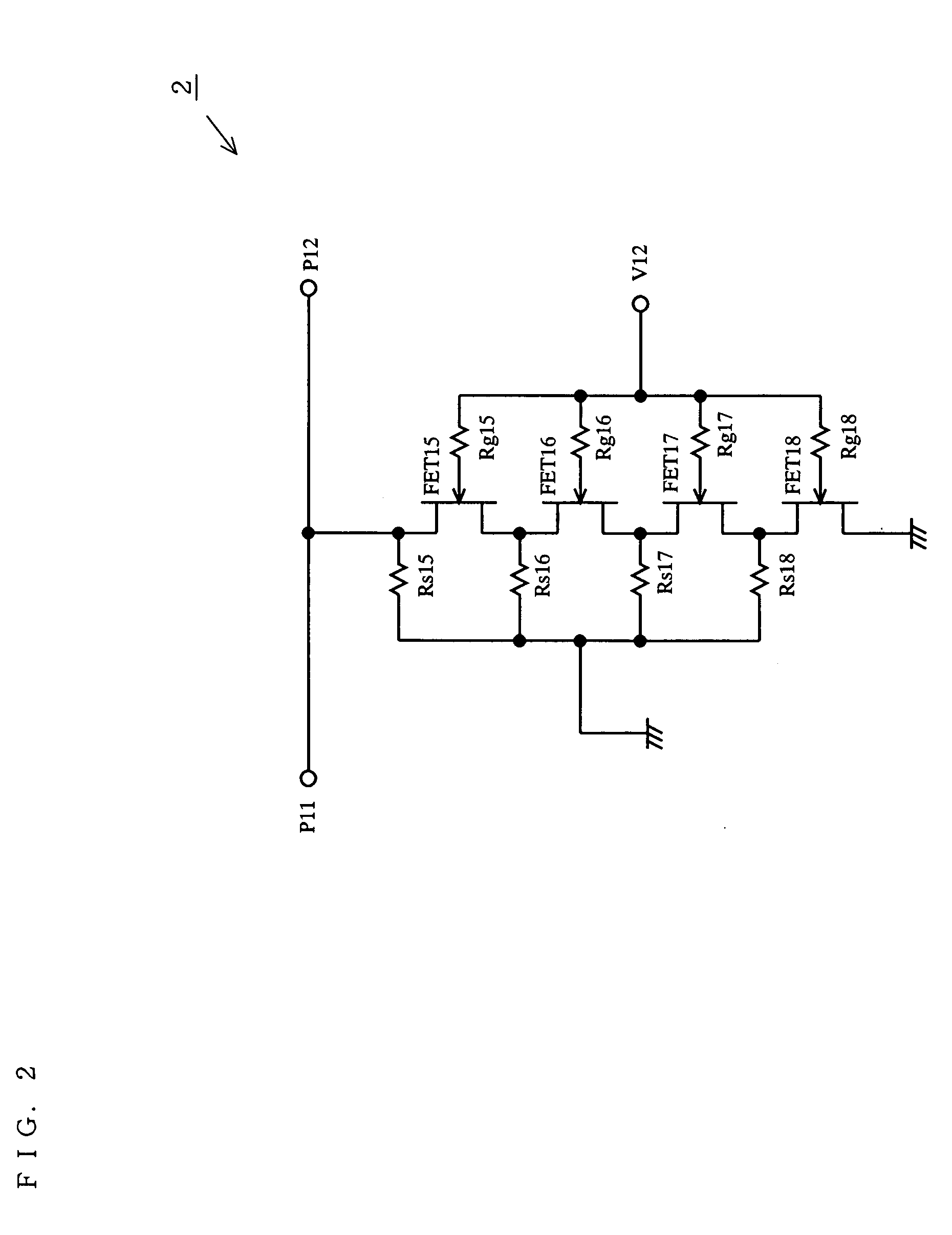

Radio frequency switching circuit, radio frequency switching device, and transmitter module device

InactiveUS20070290744A1Desirable radio frequency characteristicDesirable endurancePower amplifiersSolid-state devicesHigh pressureWide band

The present invention provides an inexpensive radio frequency switching circuit having desirable radio frequency characteristics over a wide band and desirable endurance against the inflow of a high voltage signal such as an electrostatic surge. Either a negative bias voltage or a positive bias voltage being greater than or equal to 0V and less than or equal to a Schottky forward voltage is used for the control terminals V11 and V12 for controlling FETs 11 to 18 and FETs 21 to 28 so as to turn ON / OFF the path extending from the first input / output terminal P11 to the second input / output terminal P12 and the path extending from the first input / output terminal P11 to the third input / output terminal P13. Thus, it is possible to eliminate the need for DC cut capacitors.

Owner:PANASONIC CORP

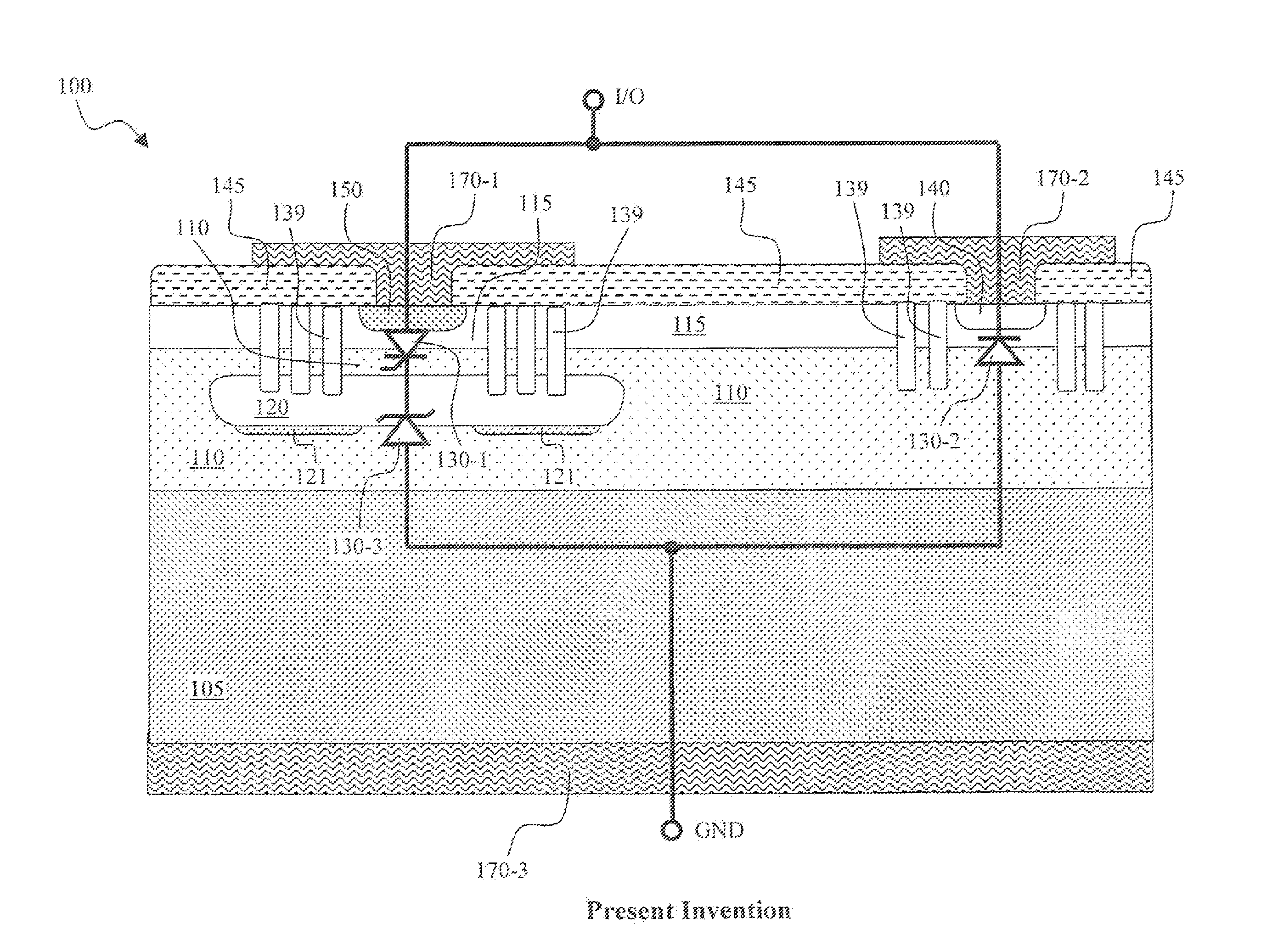

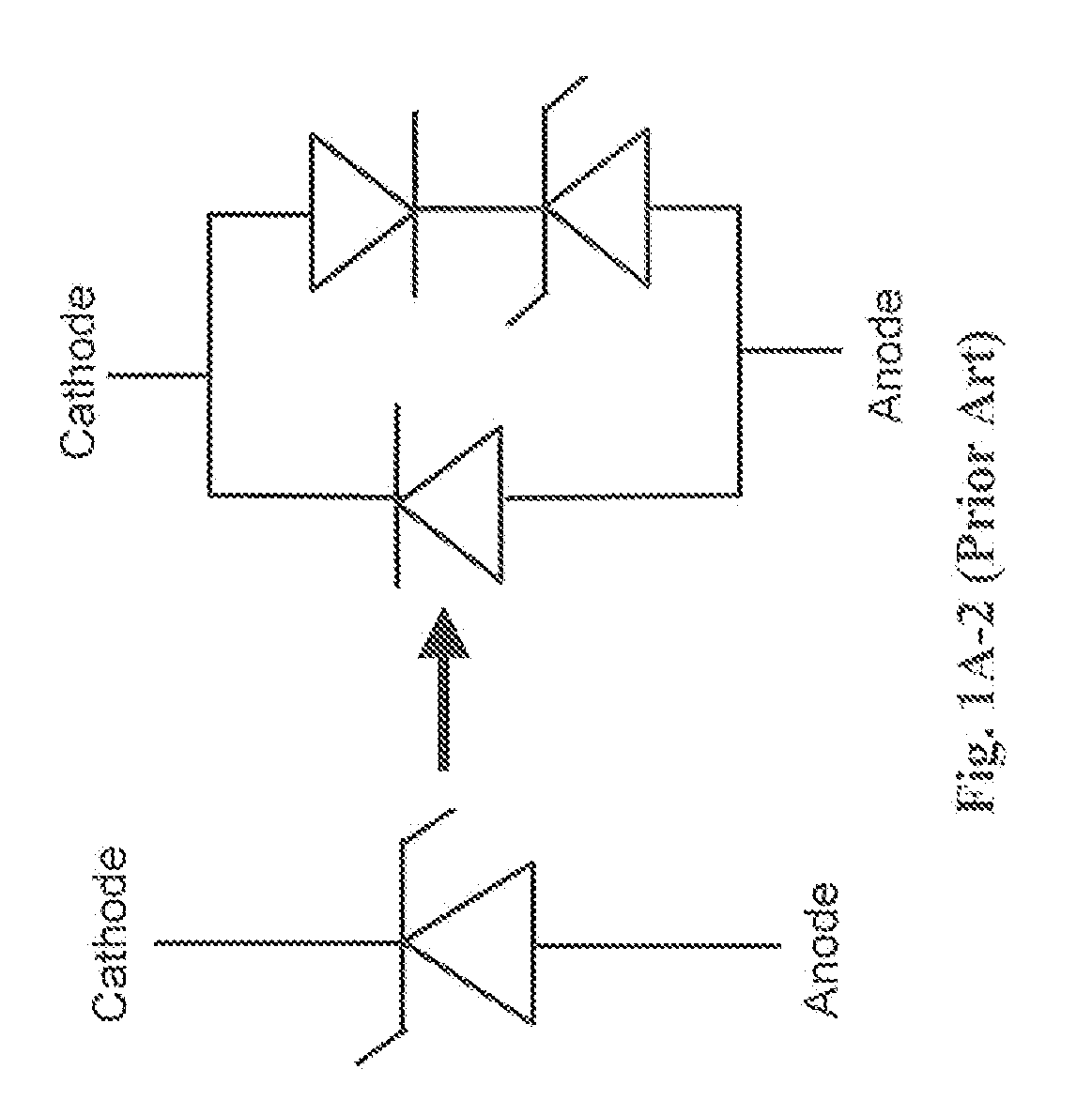

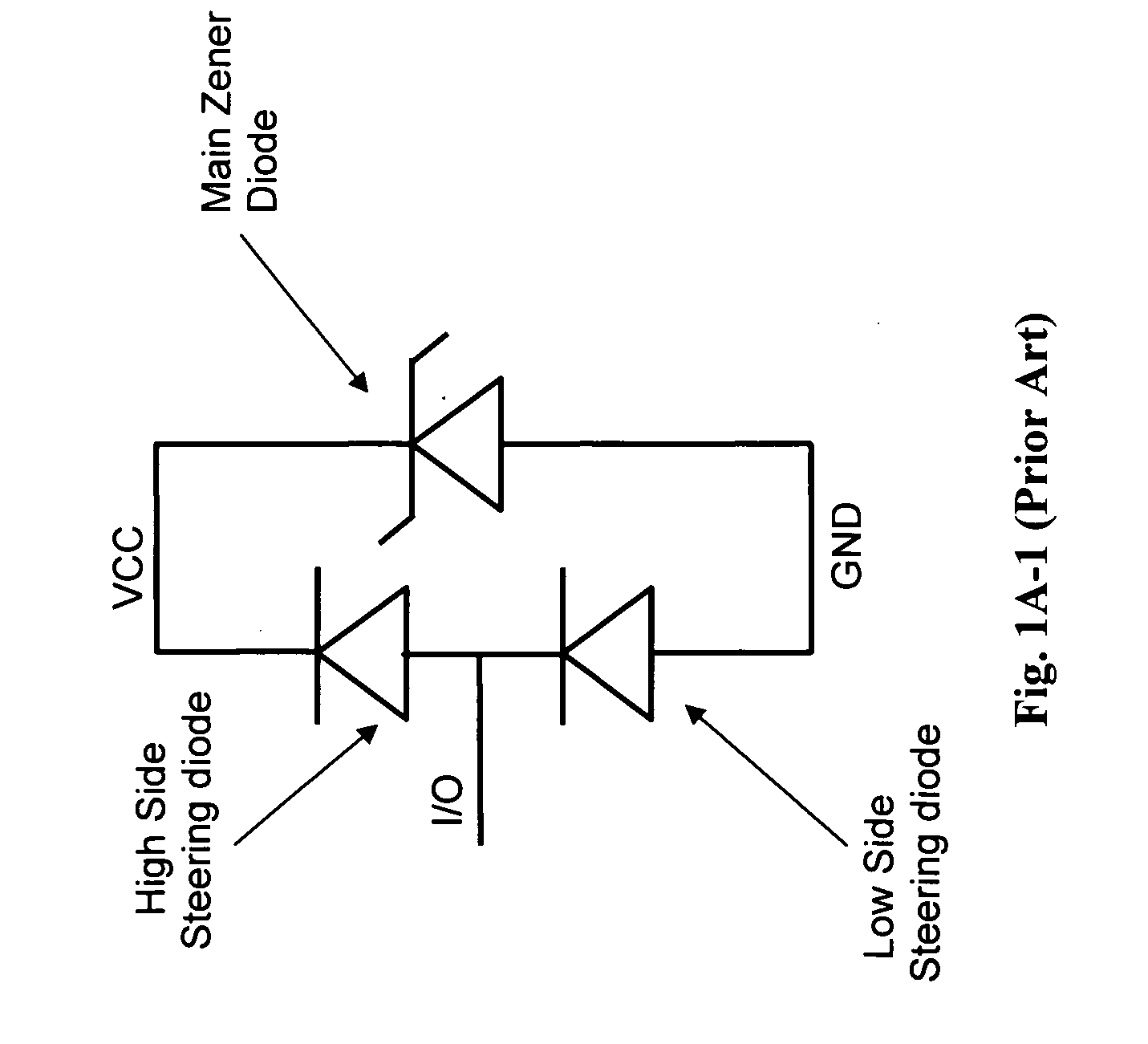

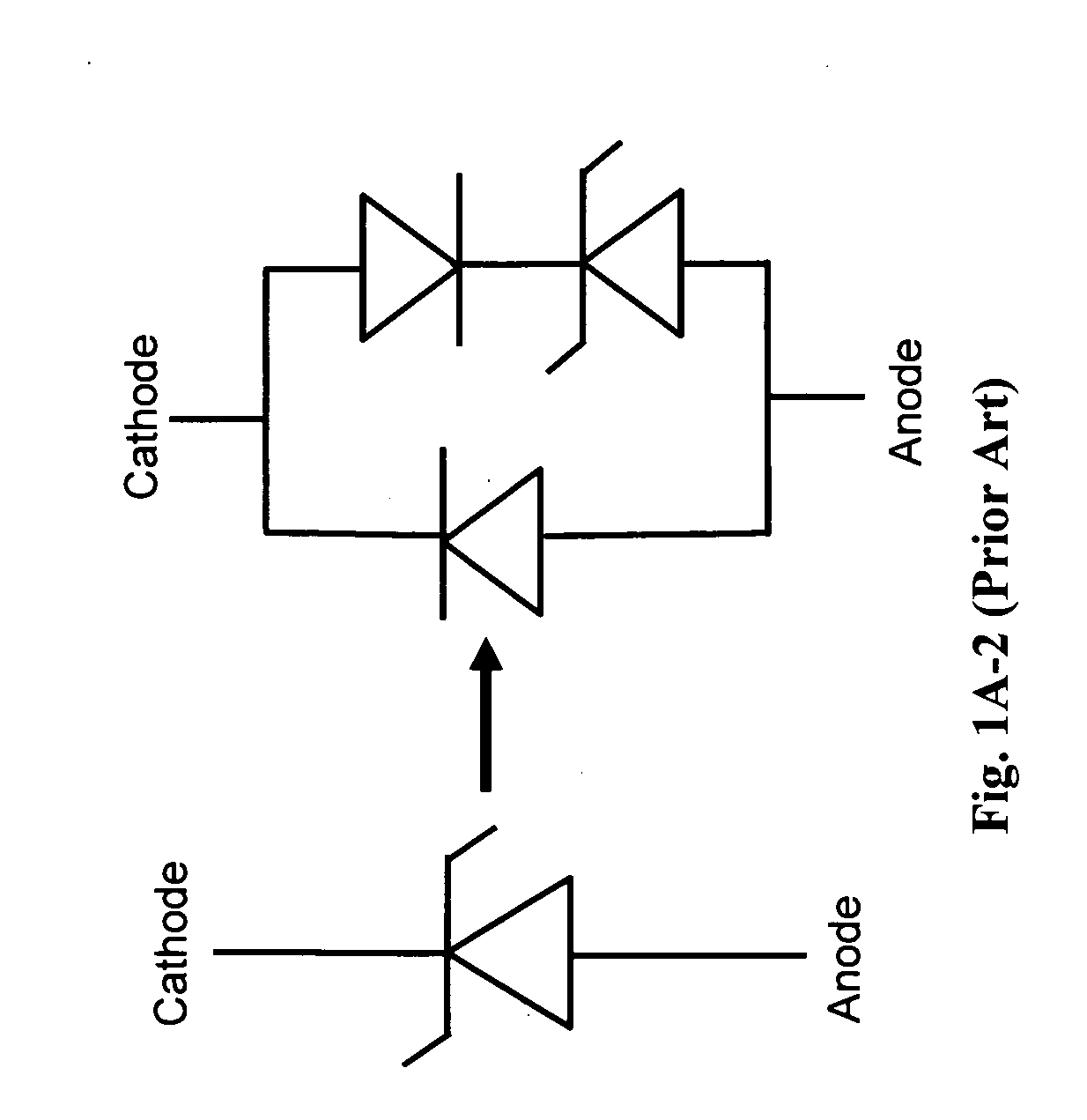

Tvs with low capacitance & forward voltage drop with depleted scr as steering diode

A transient-voltage suppressing (TVS) device disposed on a semiconductor substrate of a first conductivity type. The TVS includes a buried dopant region of a second conductivity type disposed and encompassed in an epitaxial layer of the first conductivity type wherein the buried dopant region extends laterally and has an extended bottom junction area interfacing with the underlying portion of the epitaxial layer thus constituting a Zener diode for the TVS device. The TVS device further includes a region above the buried dopant region further comprising a top dopant layer of a second conductivity type and a top contact region of a second conductivity type which act in combination with the epitaxial layer and the buried dopant region to form a plurality of interfacing PN junctions constituting a SCR acting as a steering diode to function with the Zener diode for suppressing a transient voltage.

Owner:ALPHA & OMEGA SEMICON INC

TVS with low capacitance & Forward voltage drop with depleted SCR as steering diode

A transient-voltage suppressing (TVS) device disposed on a semiconductor substrate of a first conductivity type. The TVS includes a buried dopant region of a second conductivity type disposed and encompassed in an epitaxial layer of the first conductivity type wherein the buried dopant region extends laterally and has an extended bottom junction area interfacing with the underlying portion of the epitaxial layer thus constituting a Zener diode for the TVS device. The TVS device further includes a region above the buried dopant region further comprising a top dopant layer of a second conductivity type and a top contact region of a second conductivity type which act in combination with the epitaxial layer and the buried dopant region to form a plurality of interfacing PN junctions constituting a SCR acting as a steering diode to function with the Zener diode for suppressing a transient voltage.

Owner:ALPHA & OMEGA SEMICON INC

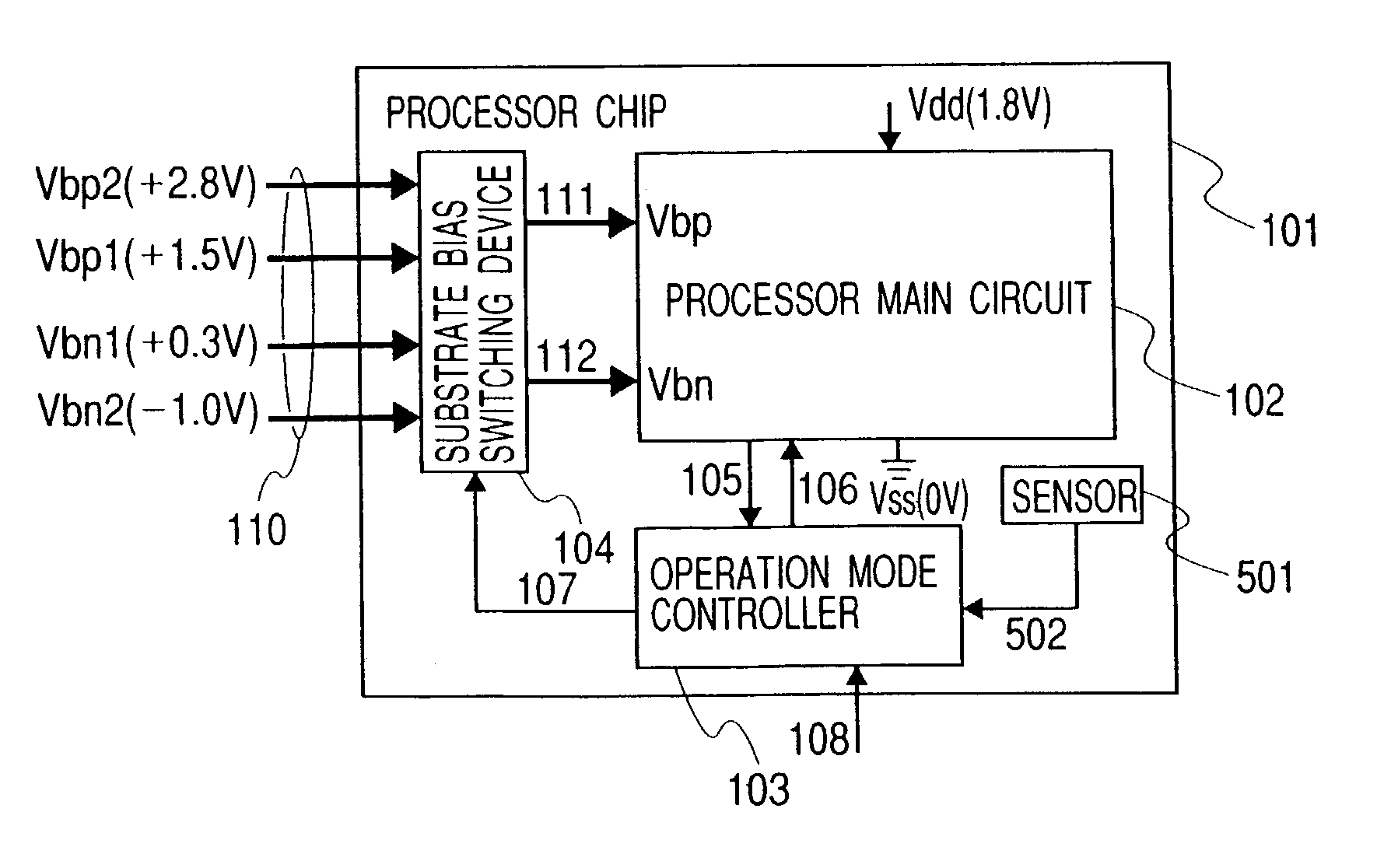

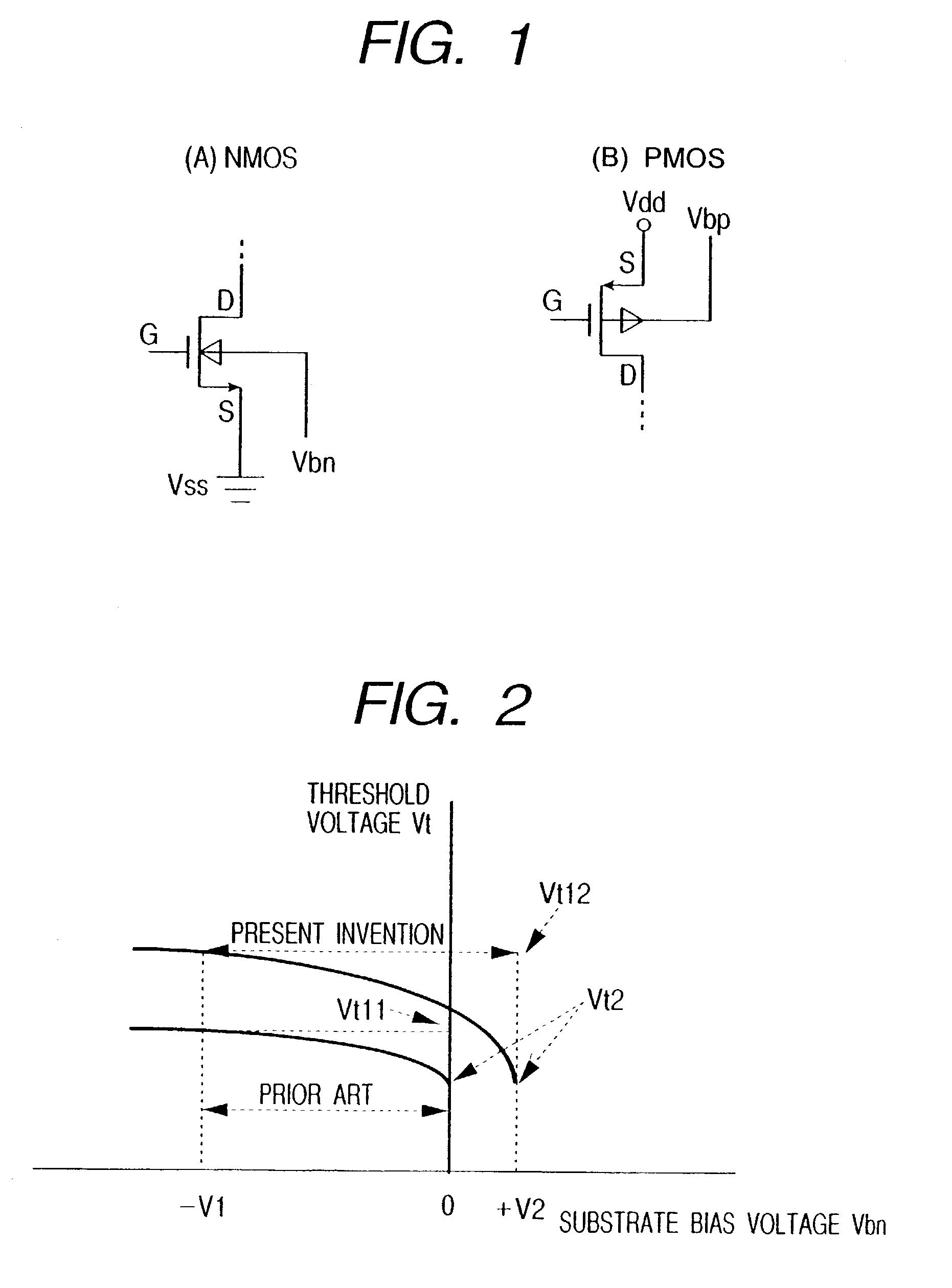

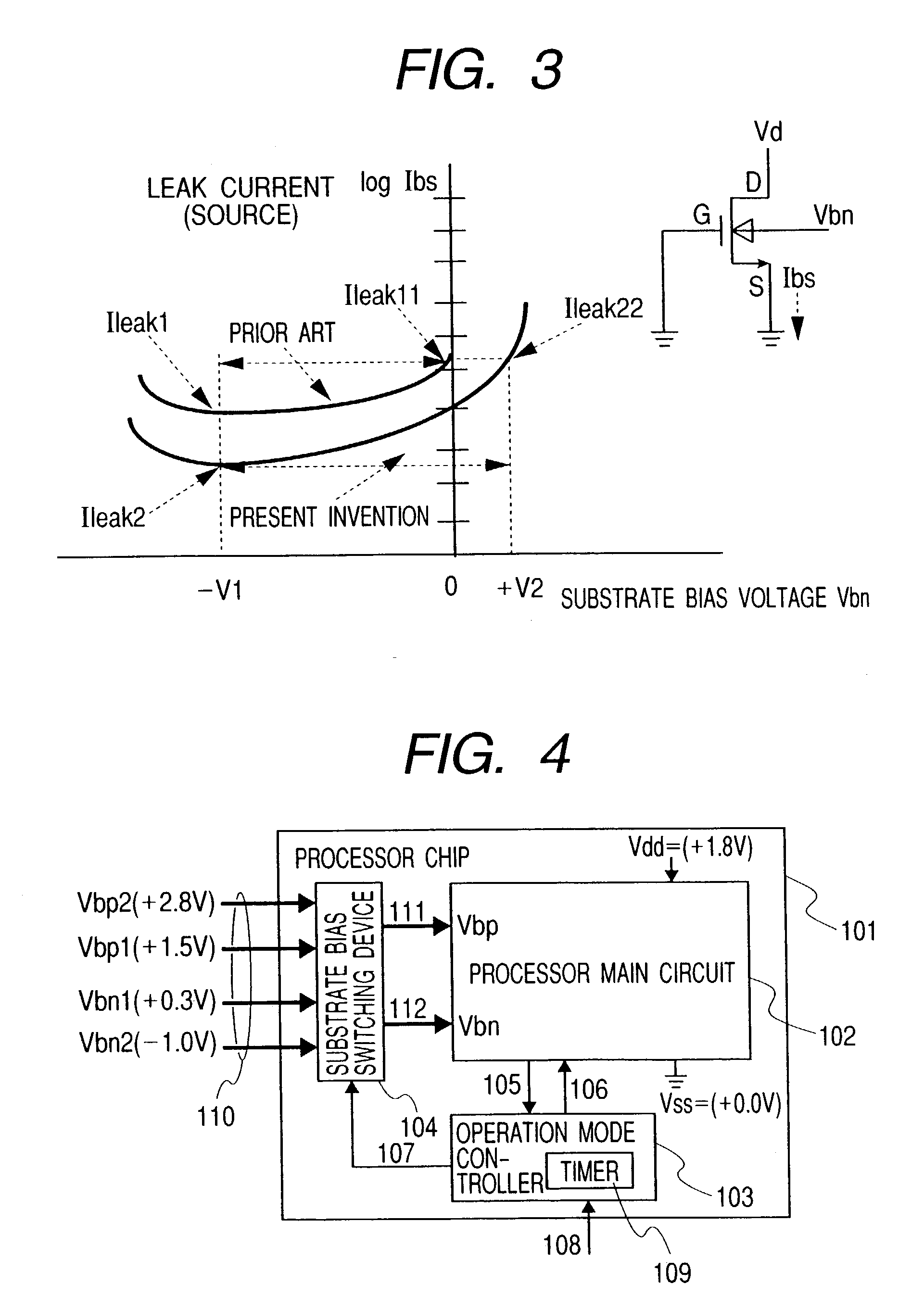

Method of setting back bias of MOS circuit, and MOS integrated circuit

In a MOS circuit comprising a plurality of MOSFETs constituting a digital circuit, an input signal is supplied to the digital circuit, and a first back bias voltage is supplied to a semiconductor substrate or a semiconductor well region in which the MOSFETs are formed, so that a pn junction between the semiconductor substrate or the semiconductor well region and a source region is brought to a forward voltage. In a non-operating state in which a circuit operation is suspended by the input signal supplied to the digital circuit as a fixed level, a second back bias voltage is applied to the semiconductor substrate or the semiconductor well region so that the pn junction between the semiconductor substrate or the semiconductor well region and the source region is brought to a reverse voltage.

Owner:RENESAS ELECTRONICS CORP

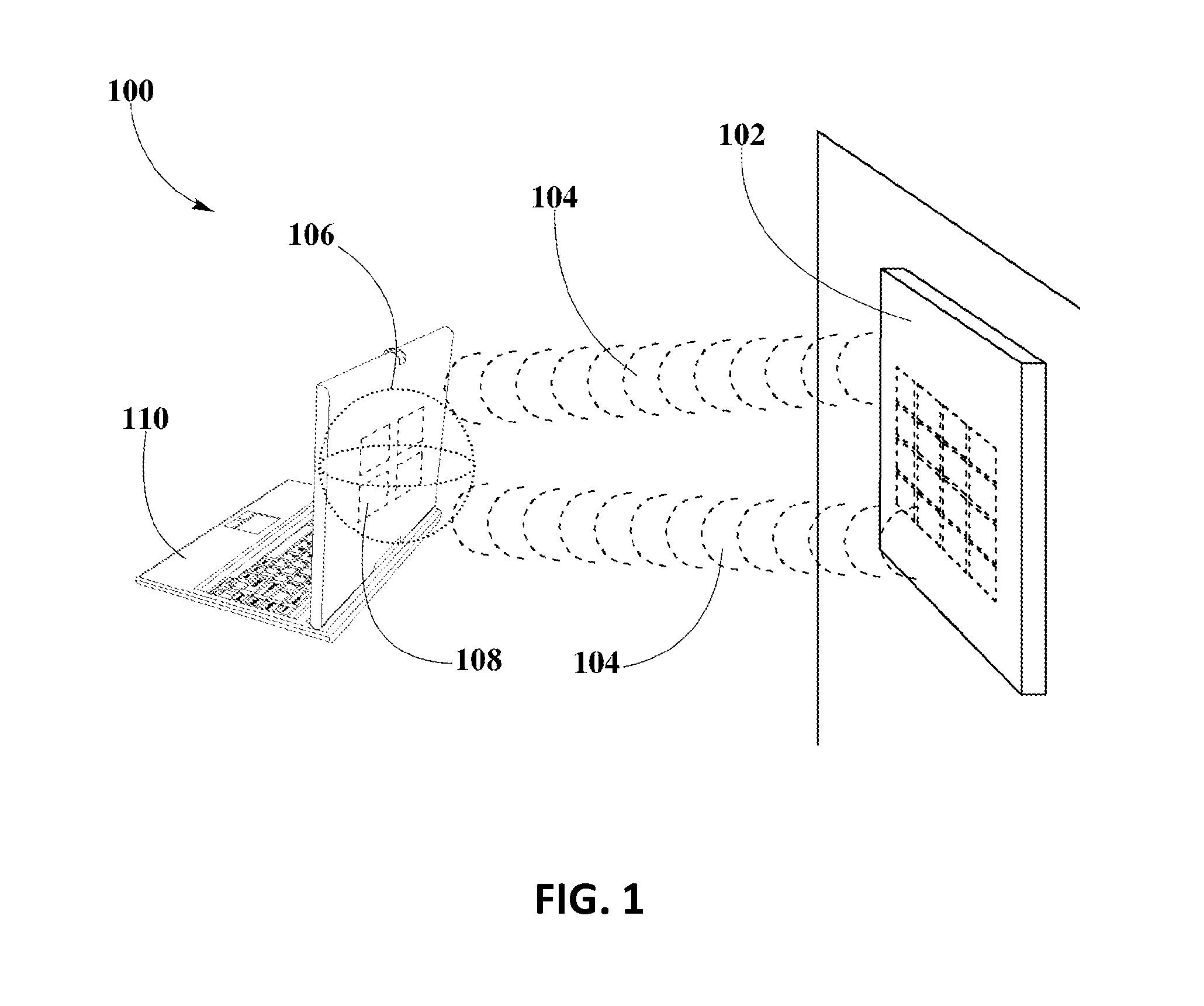

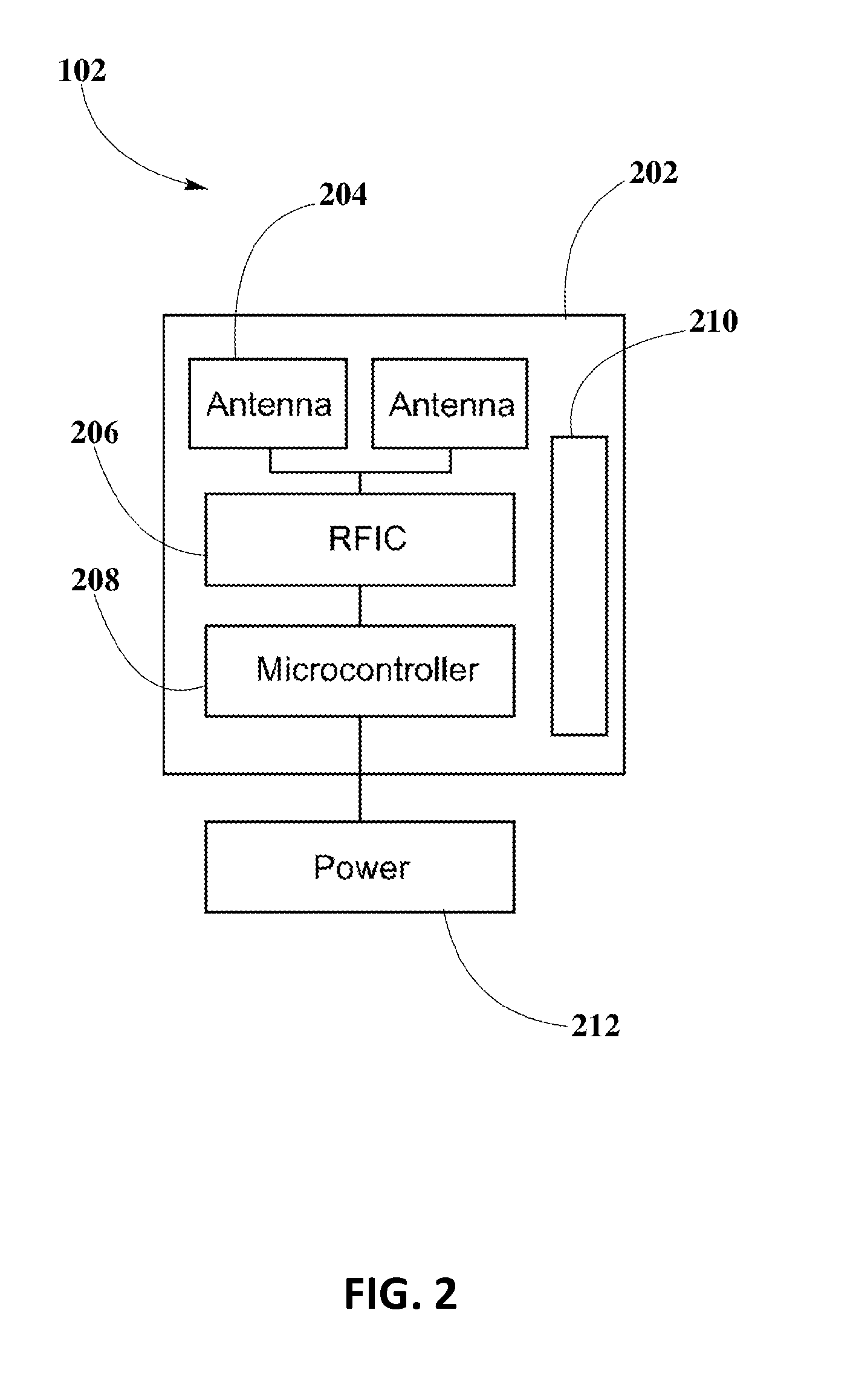

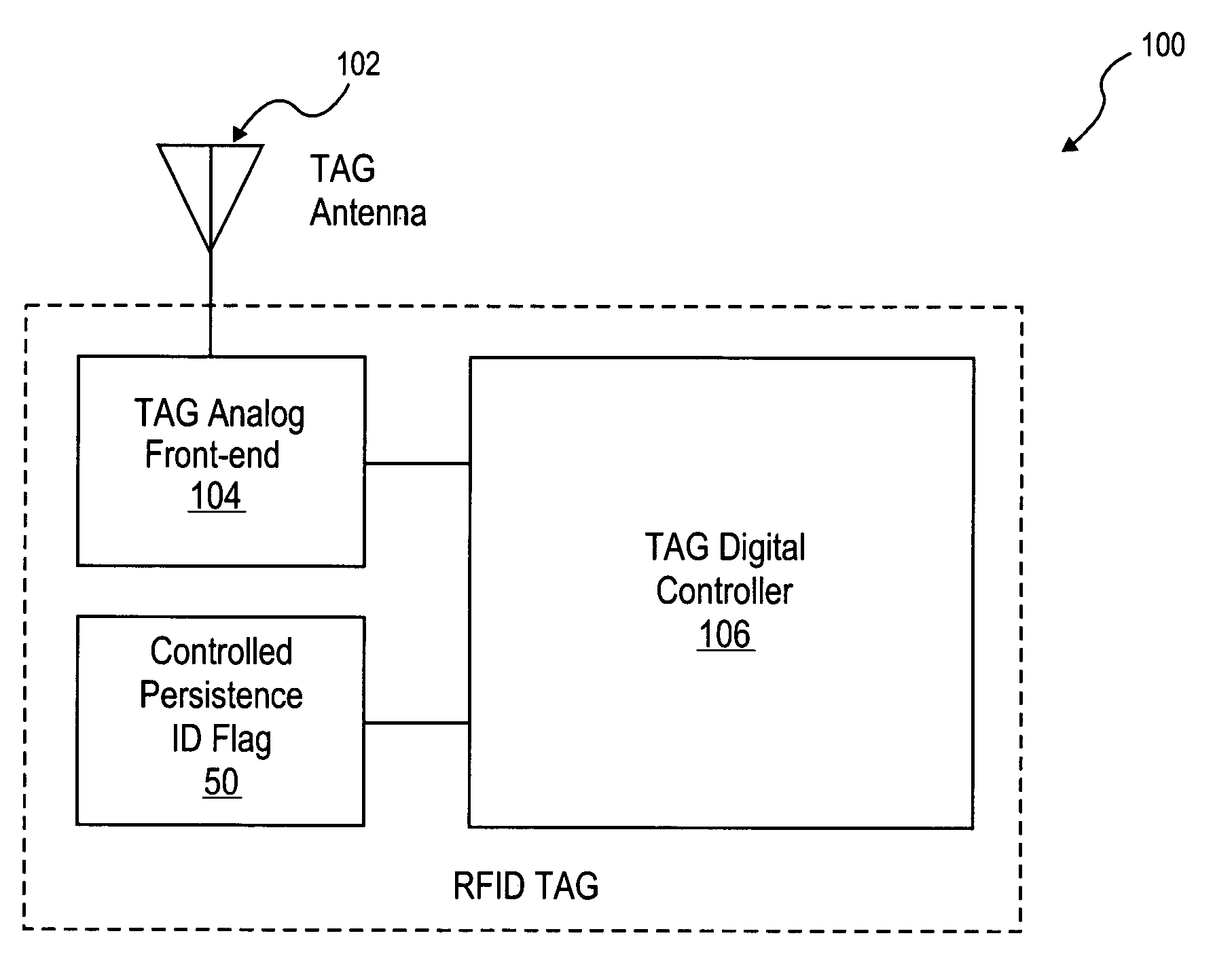

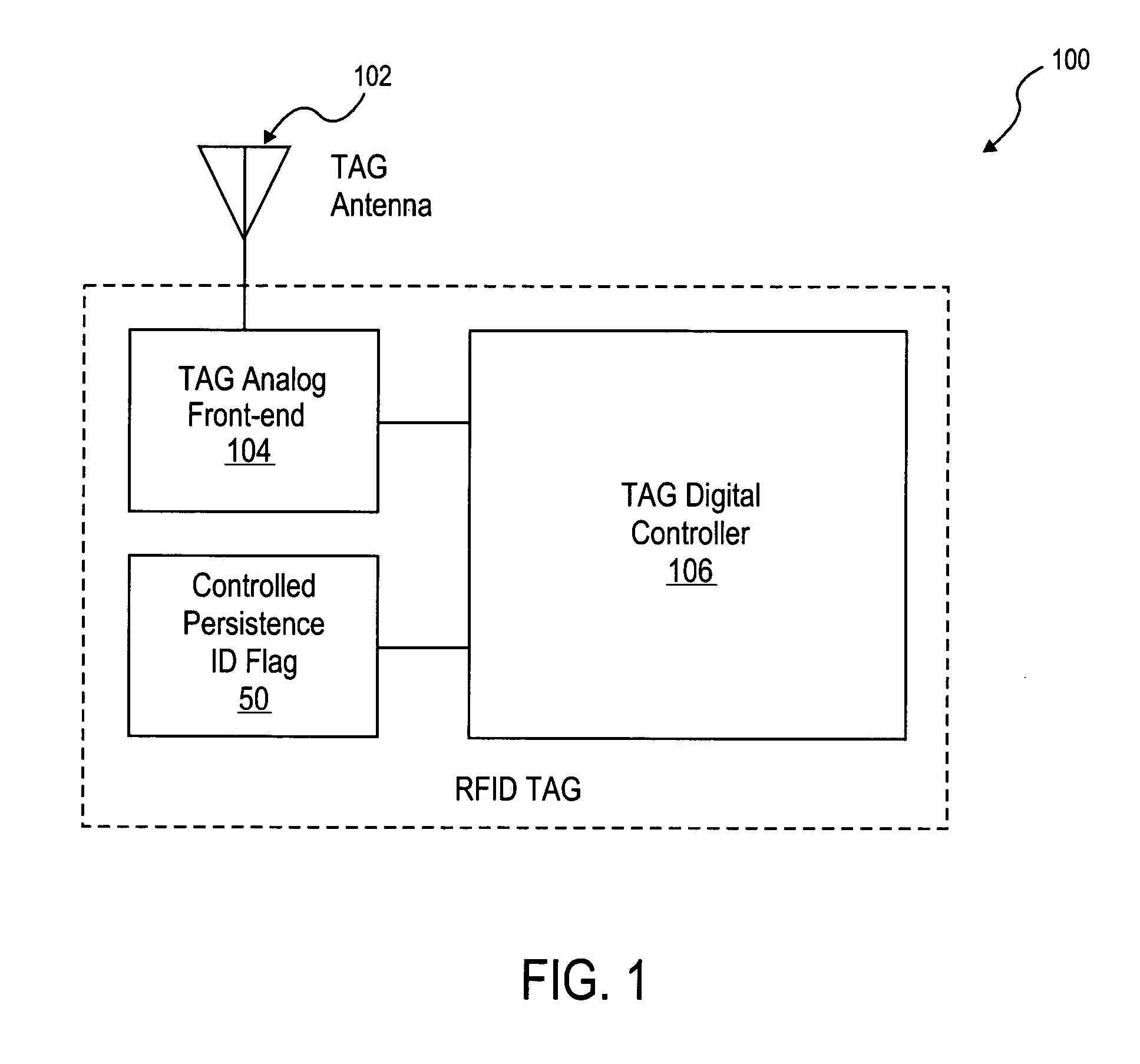

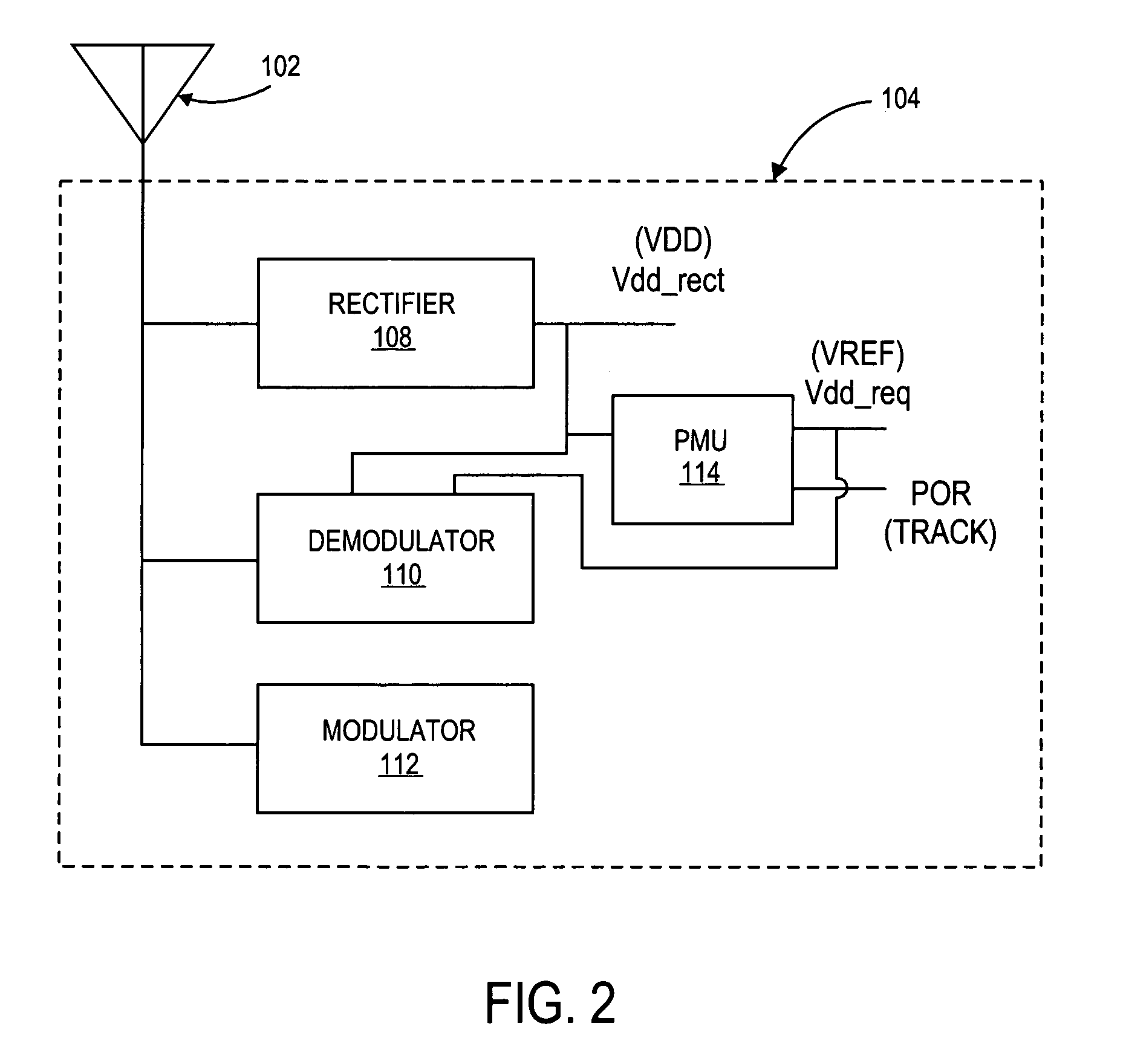

Method and apparatus for controlled persistent ID flag for RFID applications

A Radio-Frequency Identification (RFID) transponder is provided. The RFID transponder may include a basic ID flag circuit having a VDD voltage node, an output voltage node, and a capacitor coupled to the VDD voltage node and the output voltage node to store an ID flag. The persistence duration of the state of the ID flag is controlled by maintaining a charge and leakage circuit. The charge and leakage circuit includes an NMOS device having a source, a drain and a gate, the source node of the NMOS device being coupled to the capacitor and the drain node of the NMOS device being coupled to a first CMOS inverter. The first CMOS inverter is powered by a regulated supply voltage such that the voltage on the capacitor is not dependent on the forward voltage drop of the NMOS device.

Owner:IMPINJ

Lighting control system for a lighting device

ActiveUS20090102396A1Compensation effectUniform light outputElectrical apparatusElectroluminescent light sourcesLight equipmentEffect light

A lighting control system suitable for a surgical lighting device. The lighting control system includes circuitry that compensates for the effects of temperature changes in a lighting device, and that compensates for forward voltage variations among LED lighting modules to provide substantially uniform light output.

Owner:AMERICAN STERILIZER CO

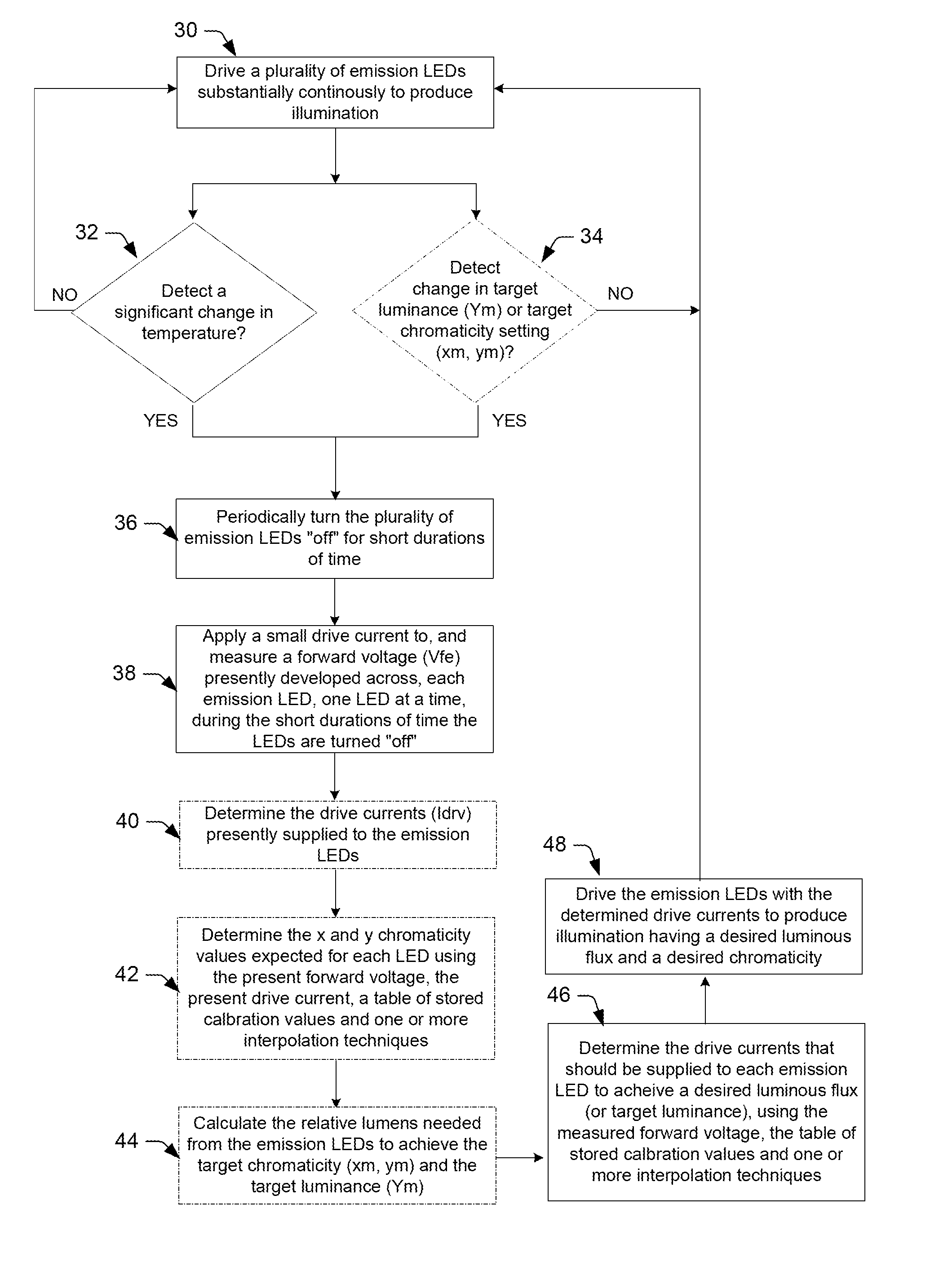

Illumination Device and Method for Controlling an Illumination Device over Changes in Drive Current and Temperature

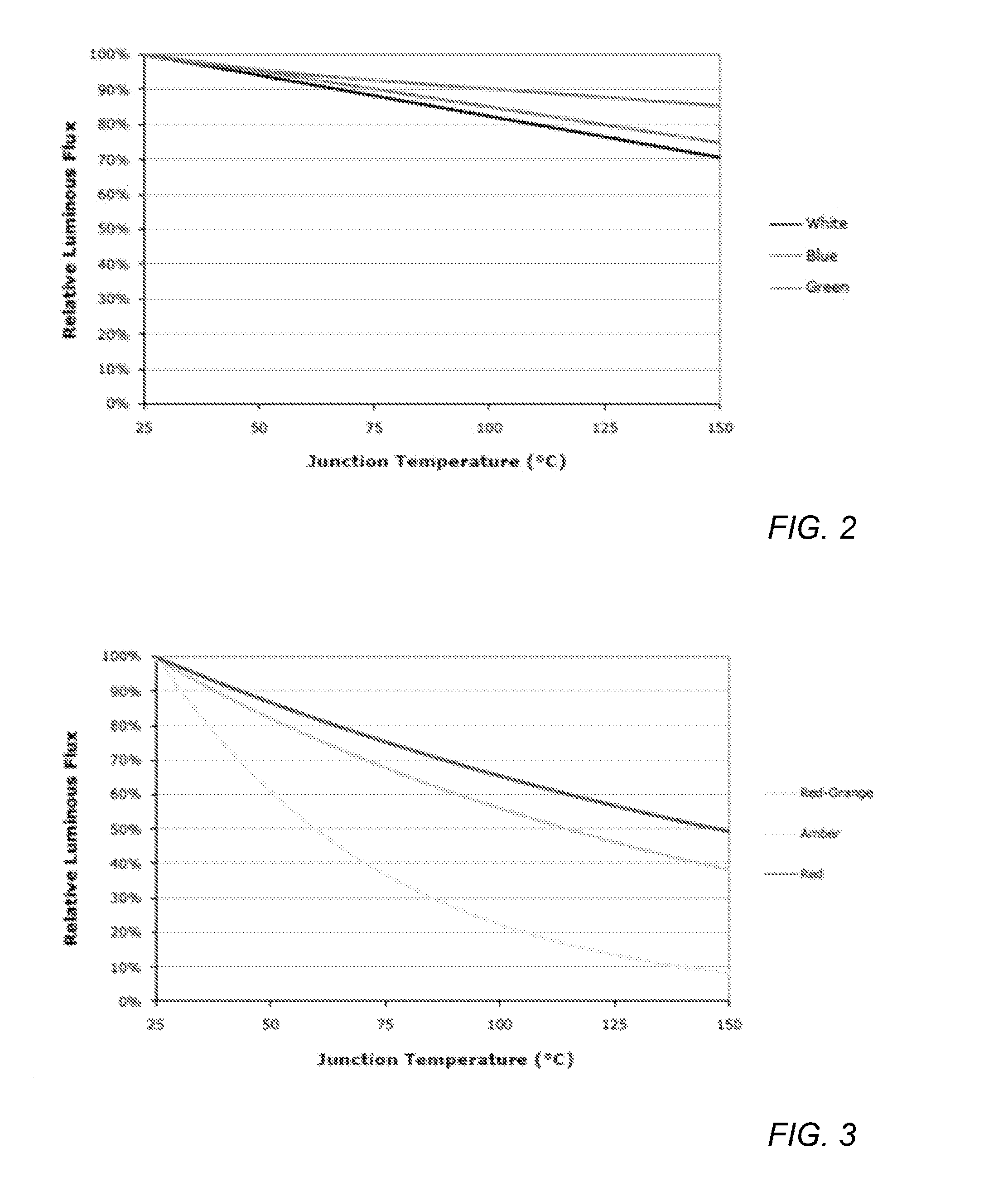

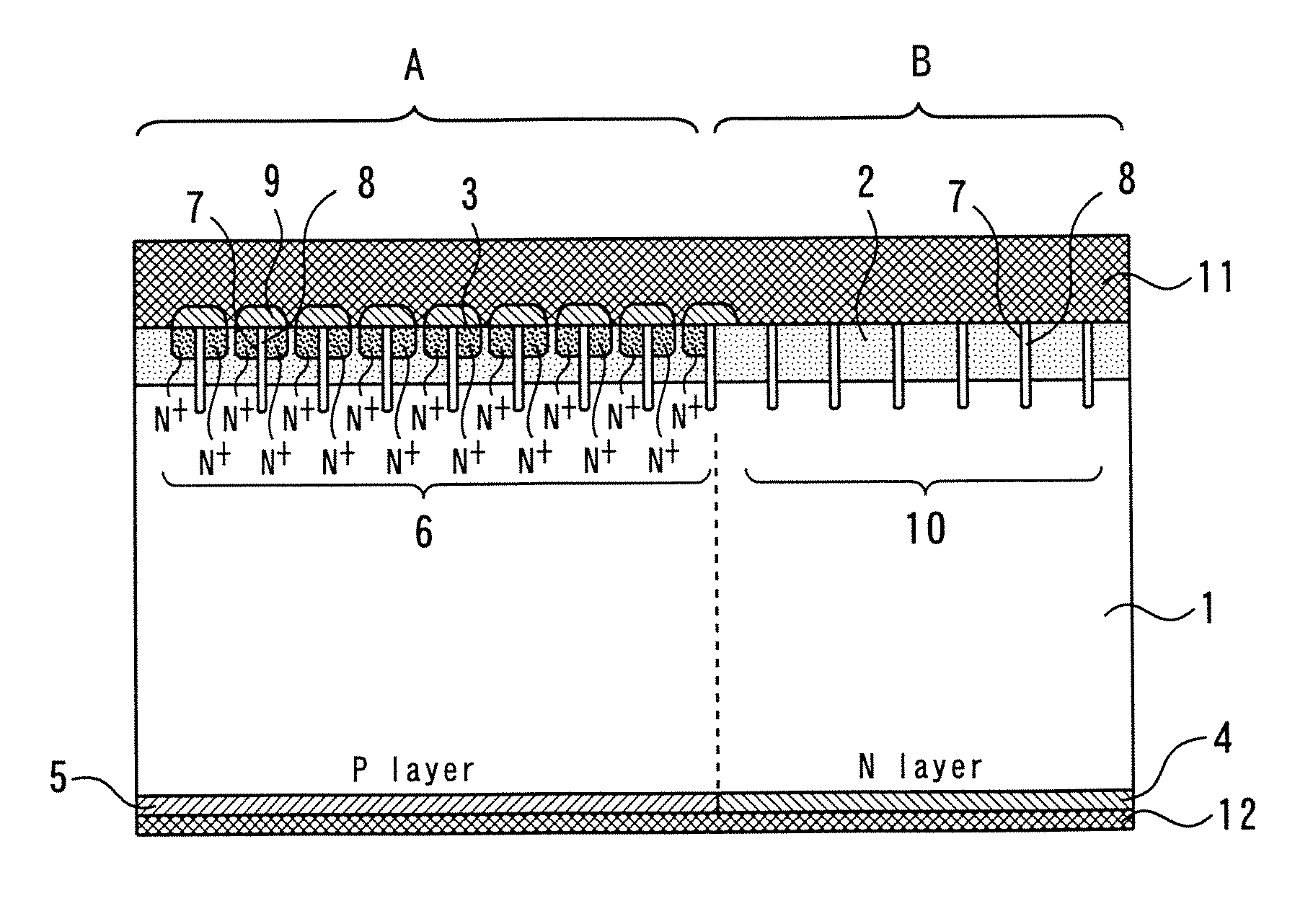

An illumination device and method is provided herein for controlling individual light emitting diodes (LEDs) in an LED illumination device, so that a desired luminous flux and a desired chromaticity of the device can be maintained over changes in drive current and temperature. According to one embodiment, the illumination device comprises a plurality of emission LEDs, a storage medium, an LED driver and receiver circuit and a control circuit. The storage medium may store a table of calibration values correlating forward voltage and drive current to chromaticity and luminous flux at a plurality of temperatures for each of the plurality of emission LEDs. The LED driver and receiver circuit may apply respective drive currents to the emission LEDs to produce substantially continuous illumination, and may periodically turn the emission LEDs off to measure operating forward voltages that develop across each emission LED. The control circuit may determine whether a target luminance setting or a target chromaticity setting for the illumination device has changed, and if so, may determine new respective drive currents needed to achieve the target luminance setting and the target chromaticity setting using the operating forward voltages measured across each emission LED, the table of calibration values and one or more interpolation techniques.

Owner:LUTRON TECH CO LLC

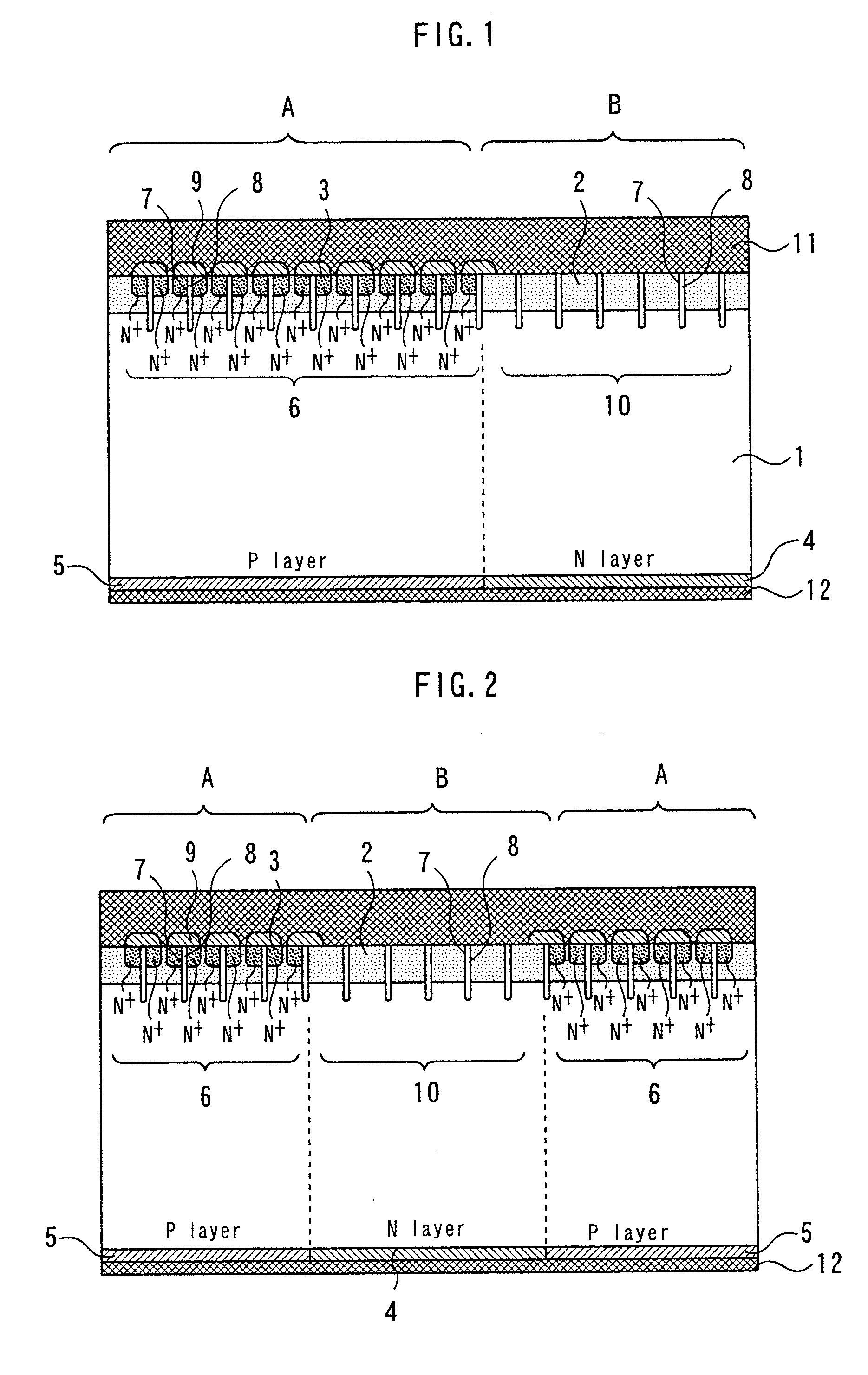

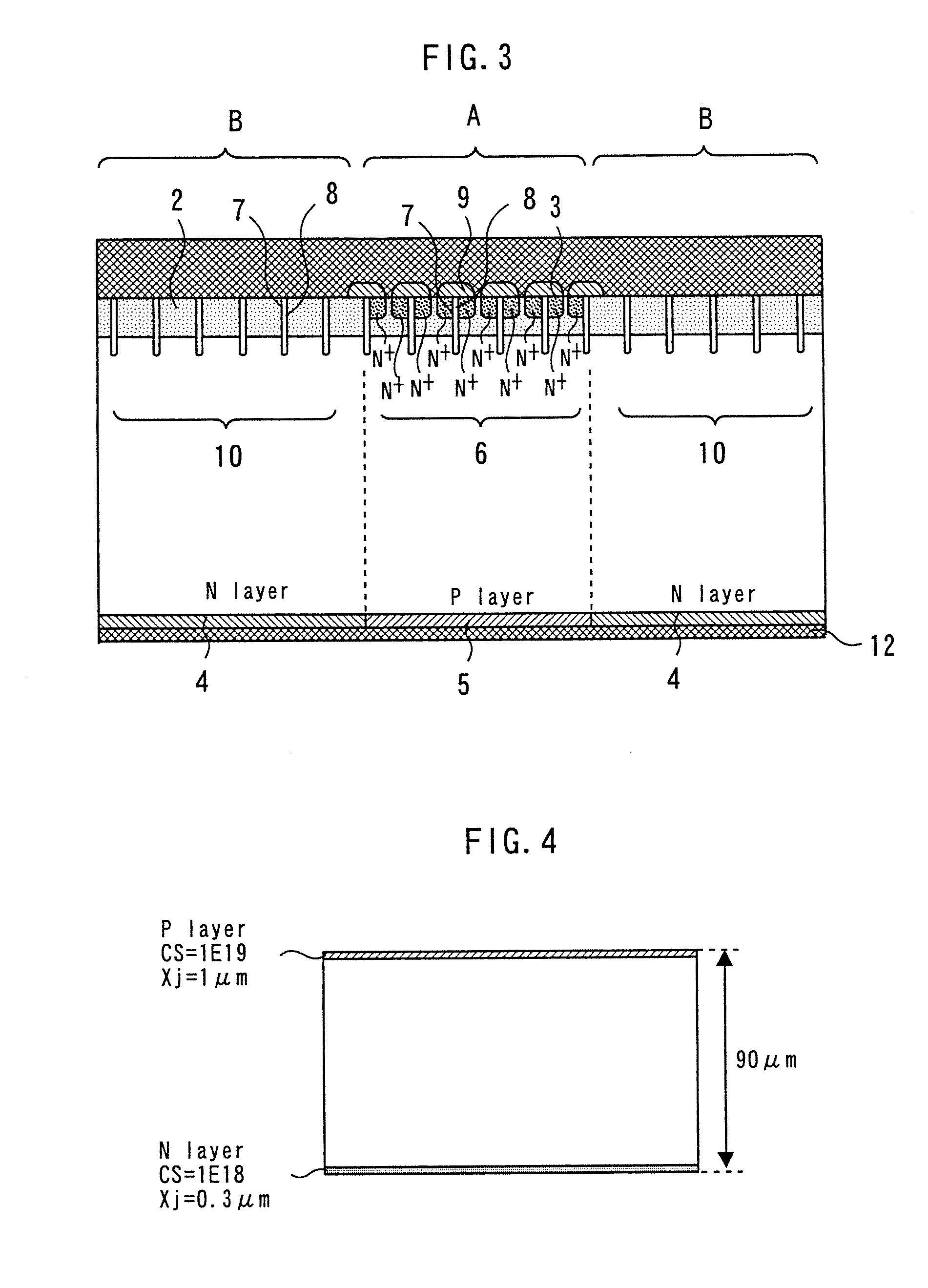

Insulated gate semiconductor device and method for manufacturing the same

ActiveUS20080048295A1Improve featuresTransistorSemiconductor/solid-state device manufacturingForward voltageSemiconductor

There is provided a structure wherein an emitter layer 3 is provided in the region A on the first major surface side of a semiconductor substrate 1, and emitter layer 3 is not provided in the region b. There is provided a structure wherein a collector P layer 5 is provided in the region A on the second major surface side of a semiconductor substrate 1, and a cathode N layer 4 is provided in the region B. Specifically, there is provided a structure wherein IGBTs are composed in the region A, and diodes are composed in the region B. By the above-described structure, ON characteristics when the gate is turned on can be improved while suppressing the elevation of the forward voltage Vf and the recovery current of the diodes.

Owner:MITSUBISHI ELECTRIC CORP

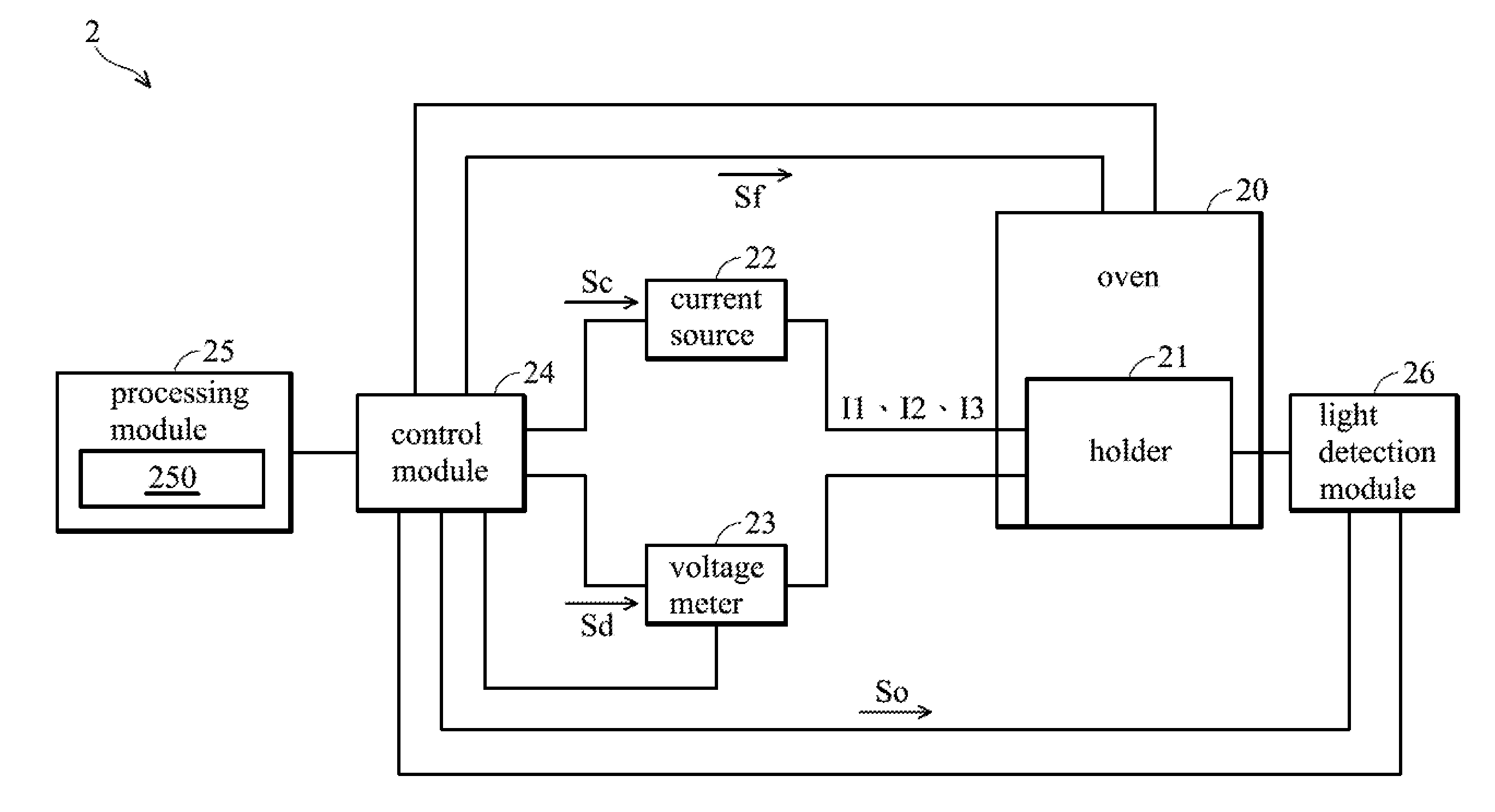

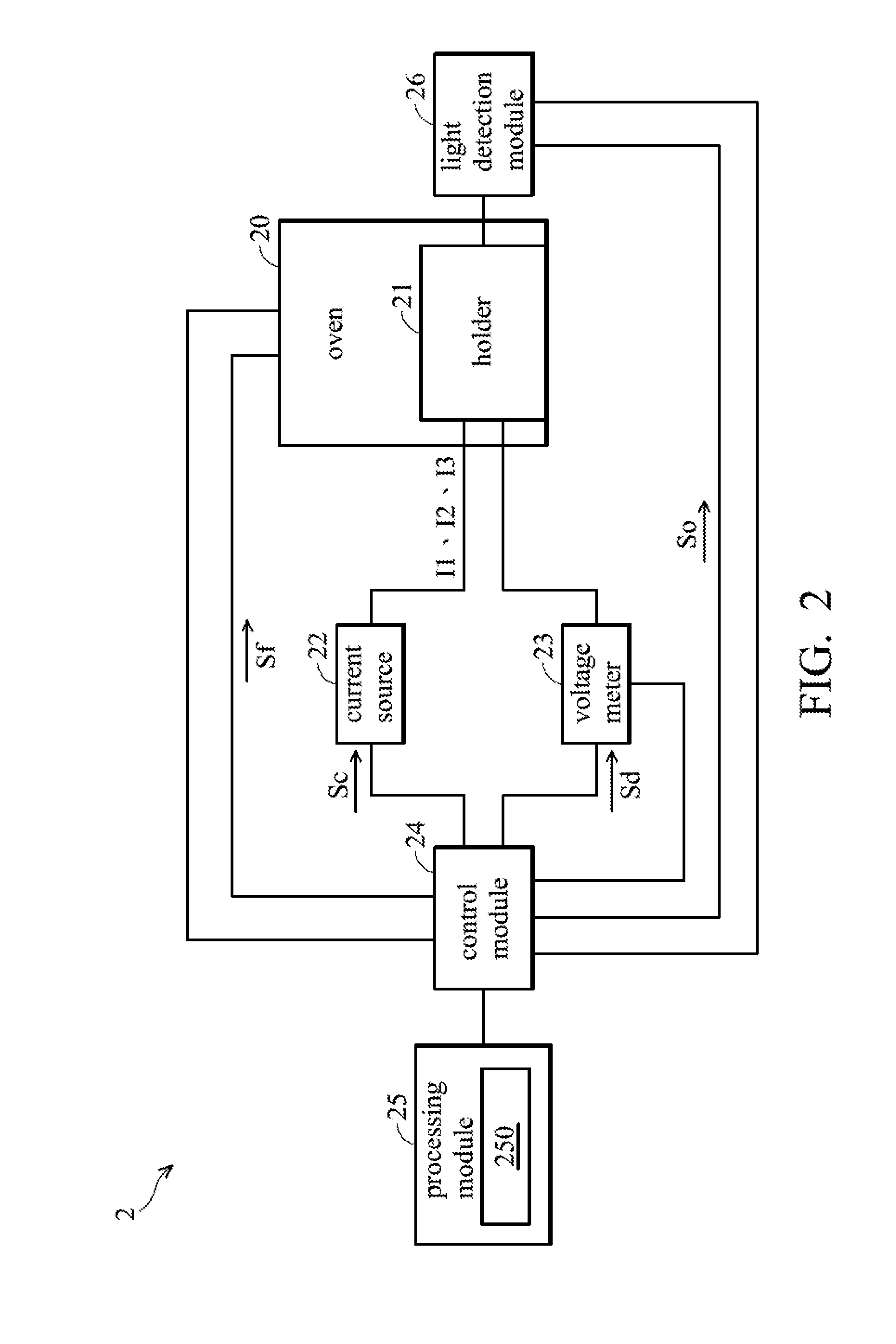

Devices And Methods For LED Life Test

A life test device comprises an oven, a current source, a voltage meter, a control module, and a process module. A light-emitting diode (LED) is disposed in the oven. The temperature of the oven is gradually changed in a first period and remains at a set temperature in a second period. The current source provides a first current and a second current to the LED. The voltage meter measures forward voltages of the LED. The control module controls the current source to output the first or second current to the LED and controls the voltage meter to measure the forward voltages of the LED. The process module calculates a junction temperature of the LED according to the forward voltages and a variation relationship formula between the forward voltages and the temperature of the oven.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com