Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

996results about "Diode testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

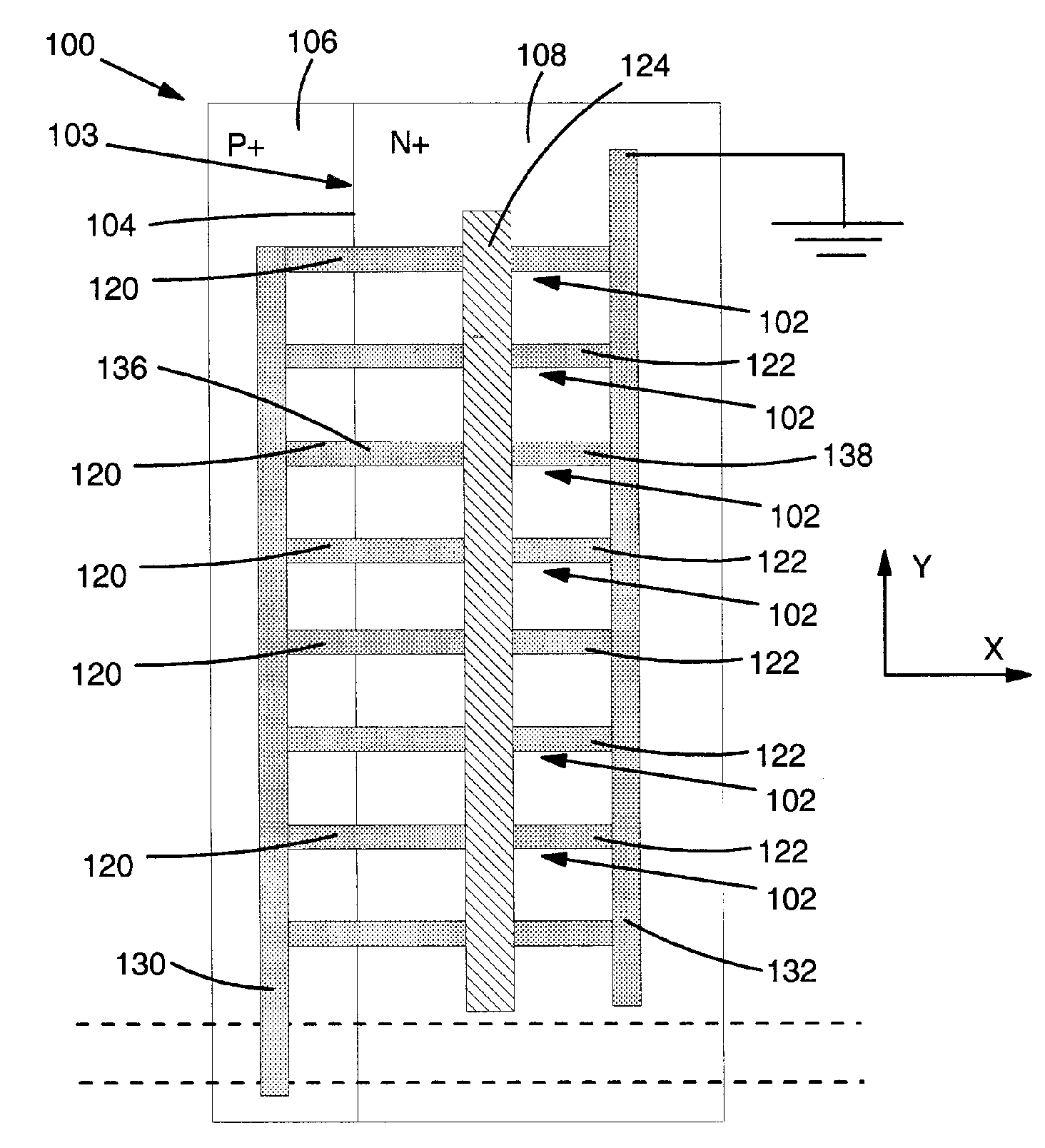

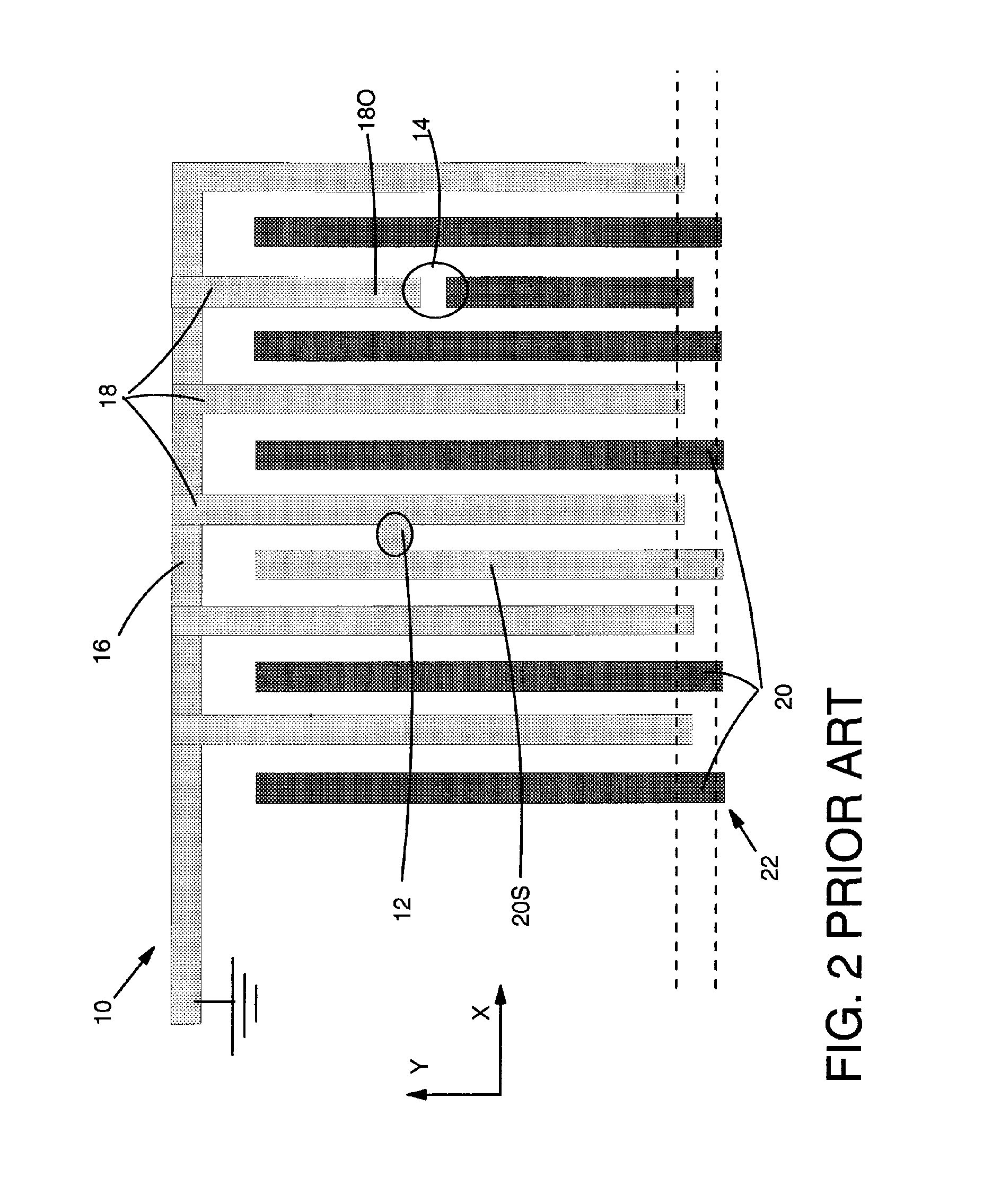

Buried short location determination using voltage contrast inspection

Structure and methods of determining the complete location of a buried short using voltage contrast inspection are disclosed. In one embodiment, a method includes providing a test structure having a PN junction thereunder; and using the PN junction to determine the location of the buried short using voltage contrast (VC) inspection. A test structure may include a plurality of test elements each having a PN junction thereunder, wherein a location of the buried short within the test structure can be determined using the PN junction and the VC inspection. The PN junction forces a change in illumination brightness of a test element including the buried short, thus allowing determination of the complete location of a buried short.

Owner:GLOBALFOUNDRIES INC

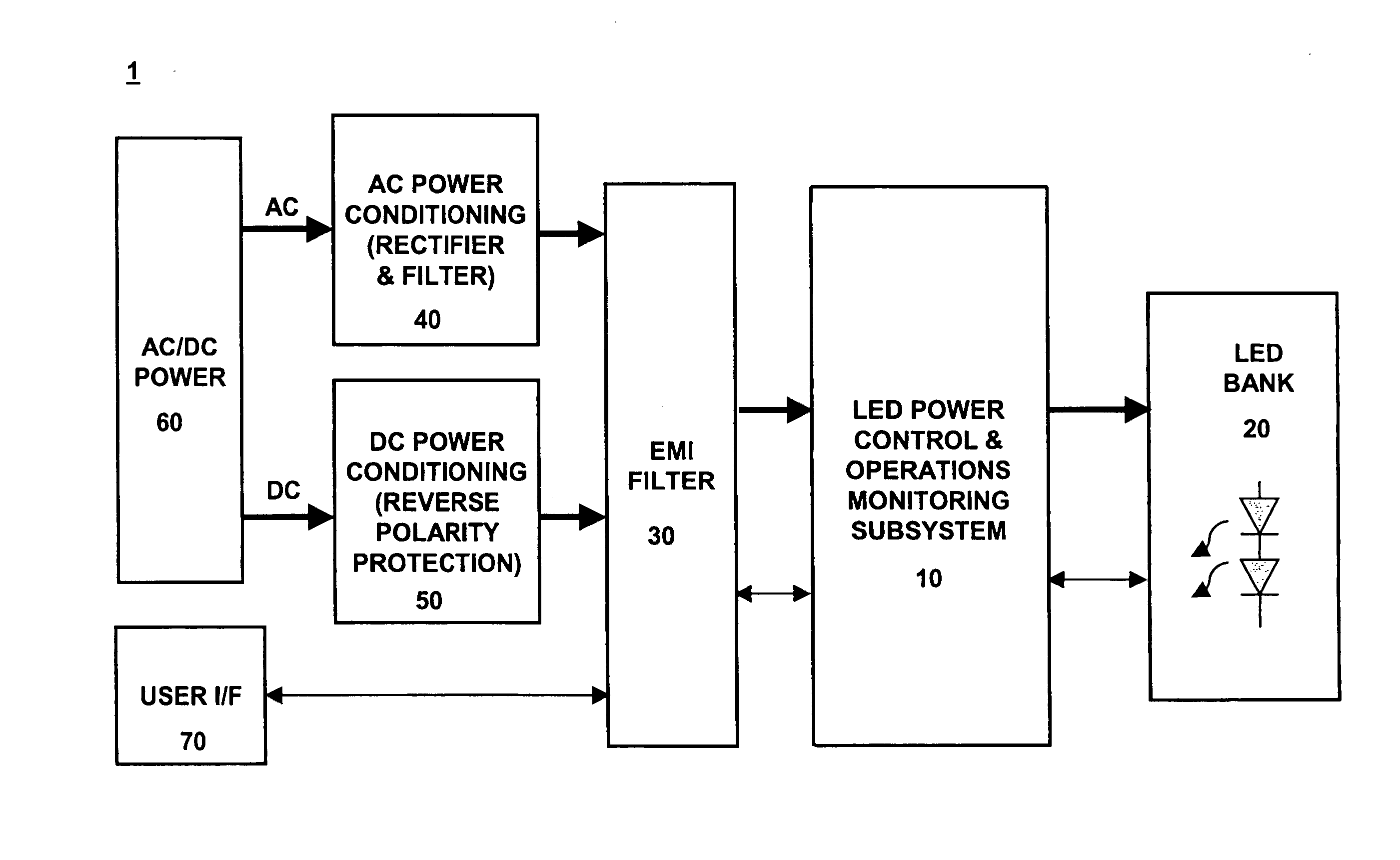

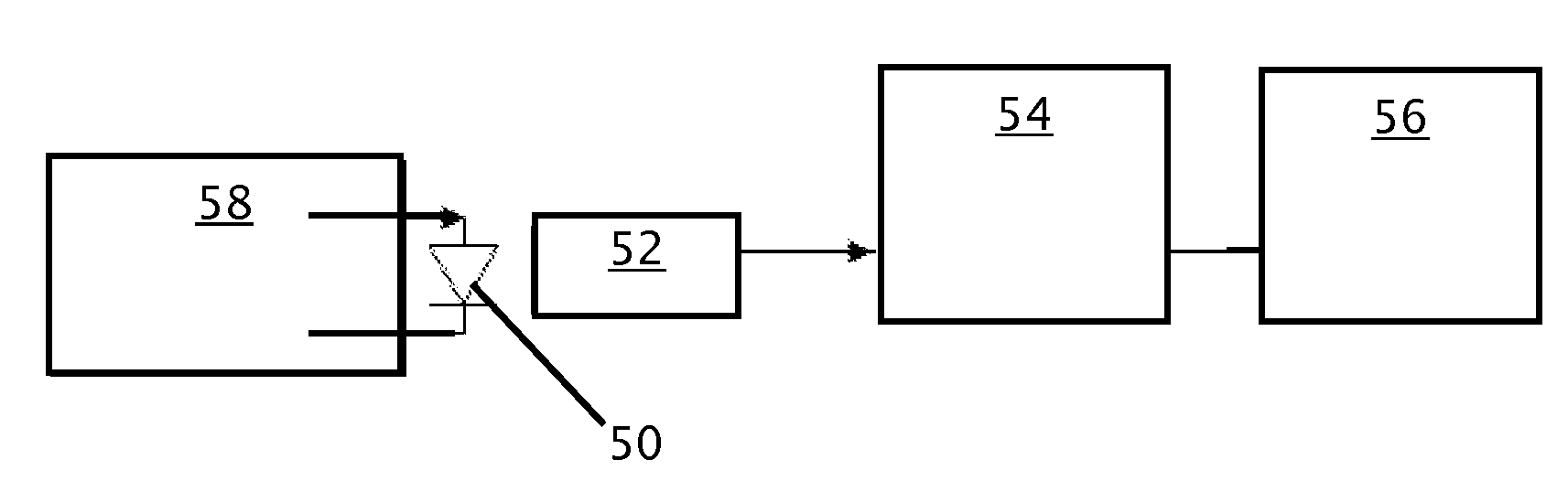

Aerospace light-emitting diode (LED)-based lights life and operation monitor compensator

ActiveUS20070040696A1Electrical apparatusStatic indicating devicesEngineeringUltimate tensile strength

A system (10) and method for monitoring the operational life and / or performance of one or more light-emitting diodes (LEDs) (20) based on sensed parameters are disclosed. The remaining life of each LED may be predicted by counting the clock cycles during which the LED-based light is activated. LED current and / or temperature measurements may be used to control the clock signal and, thus, to compensate the predicted life value. Furthermore, operational characteristics of the LED-based light may be monitored based on LED current and / or voltage measurements. Such characteristics may include performance (e.g., intensity) and failure conditions (e.g., open or short circuits).

Owner:HONEYWELL INT INC

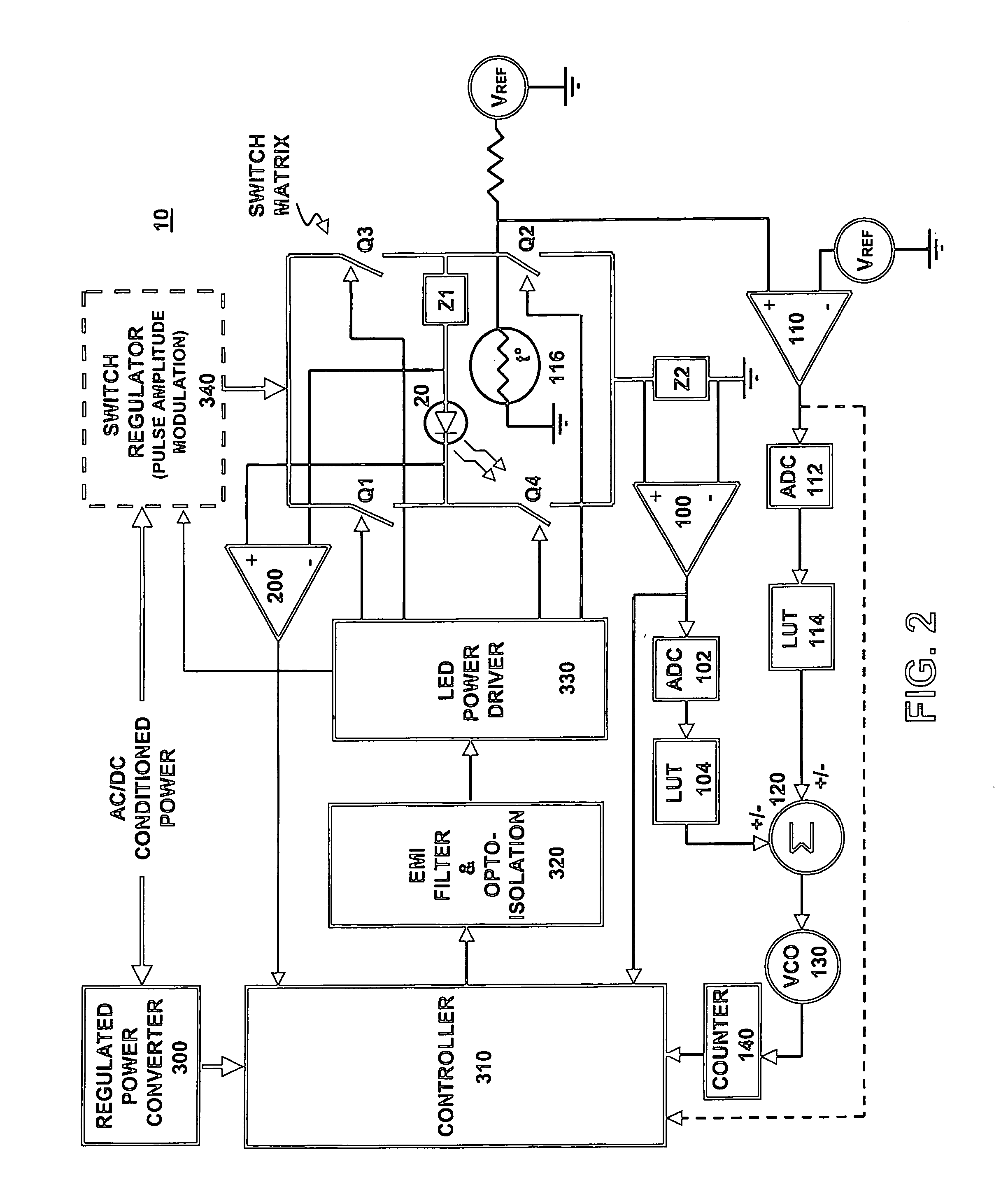

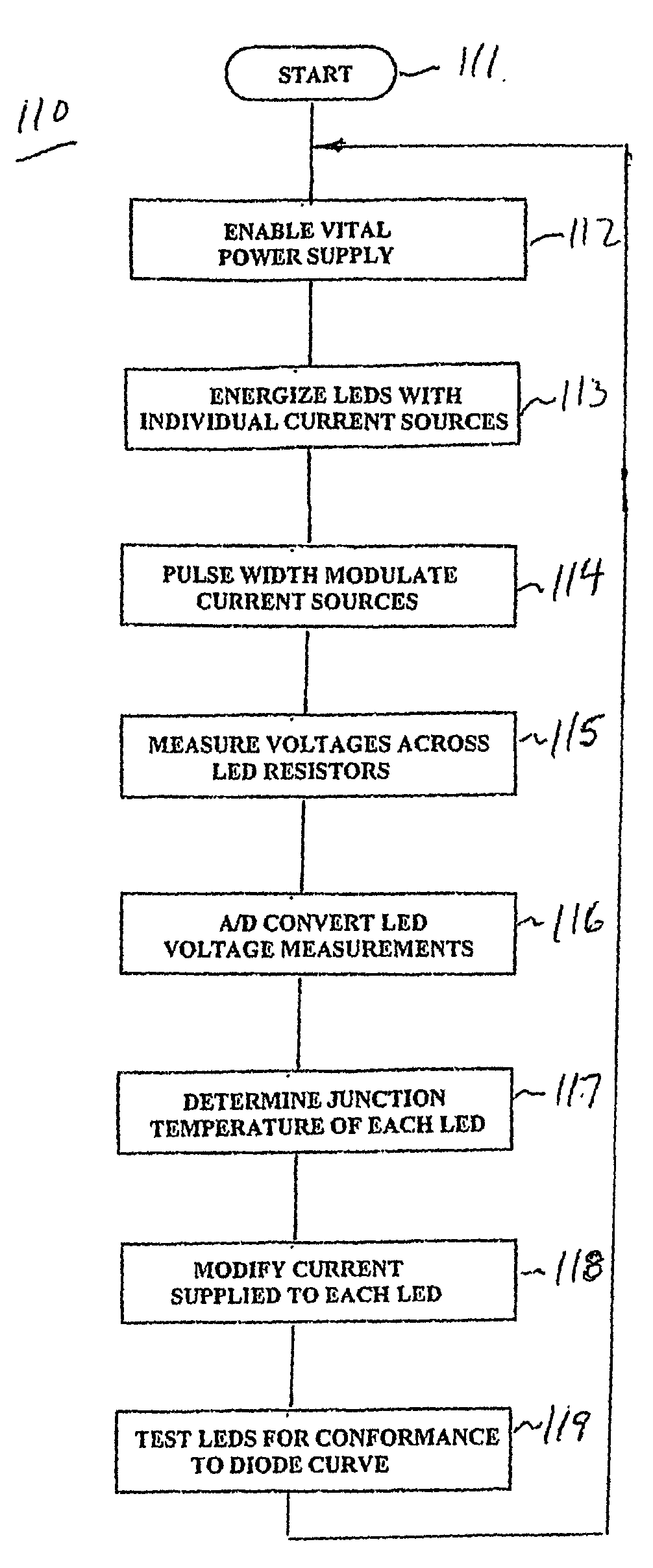

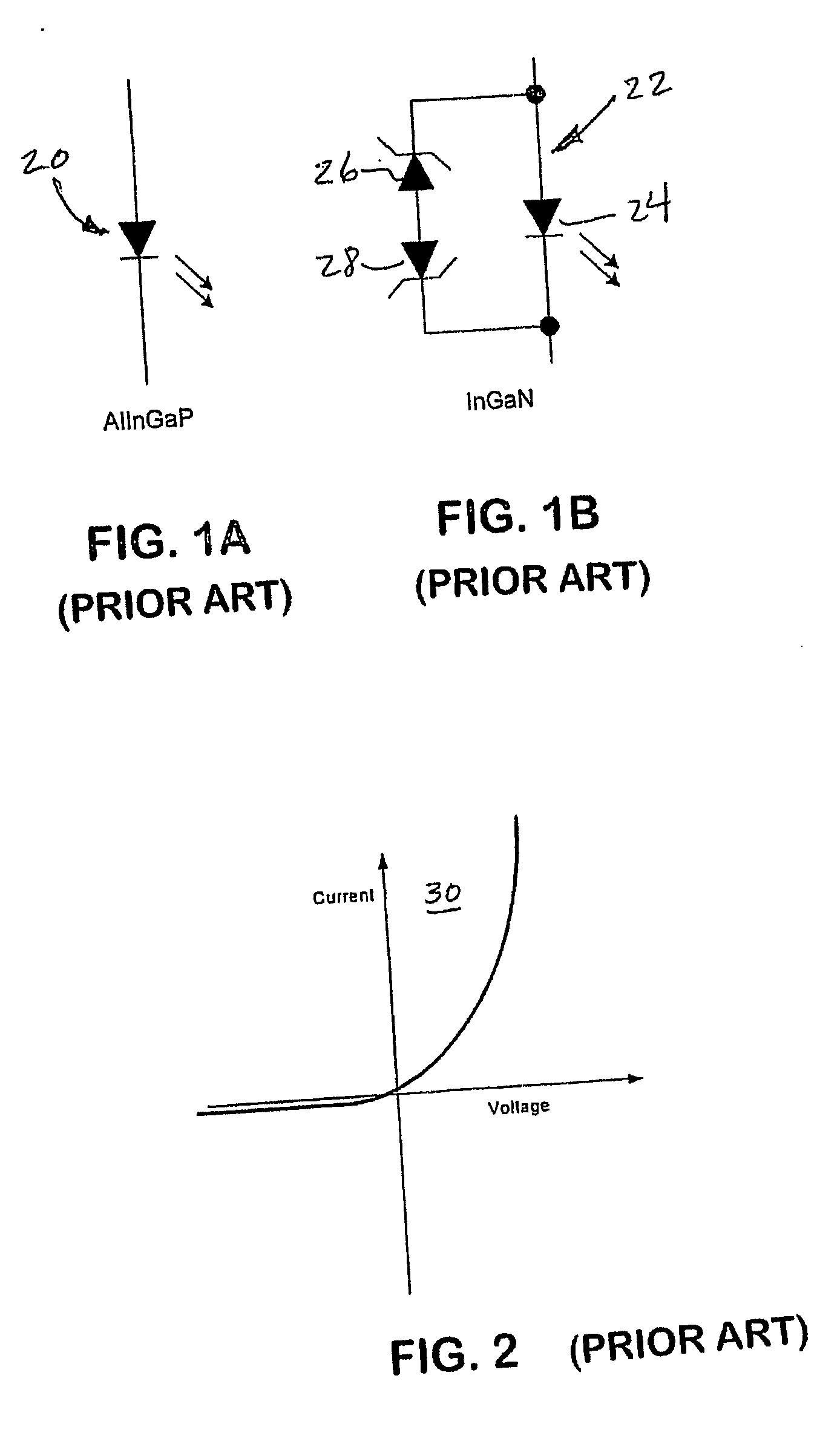

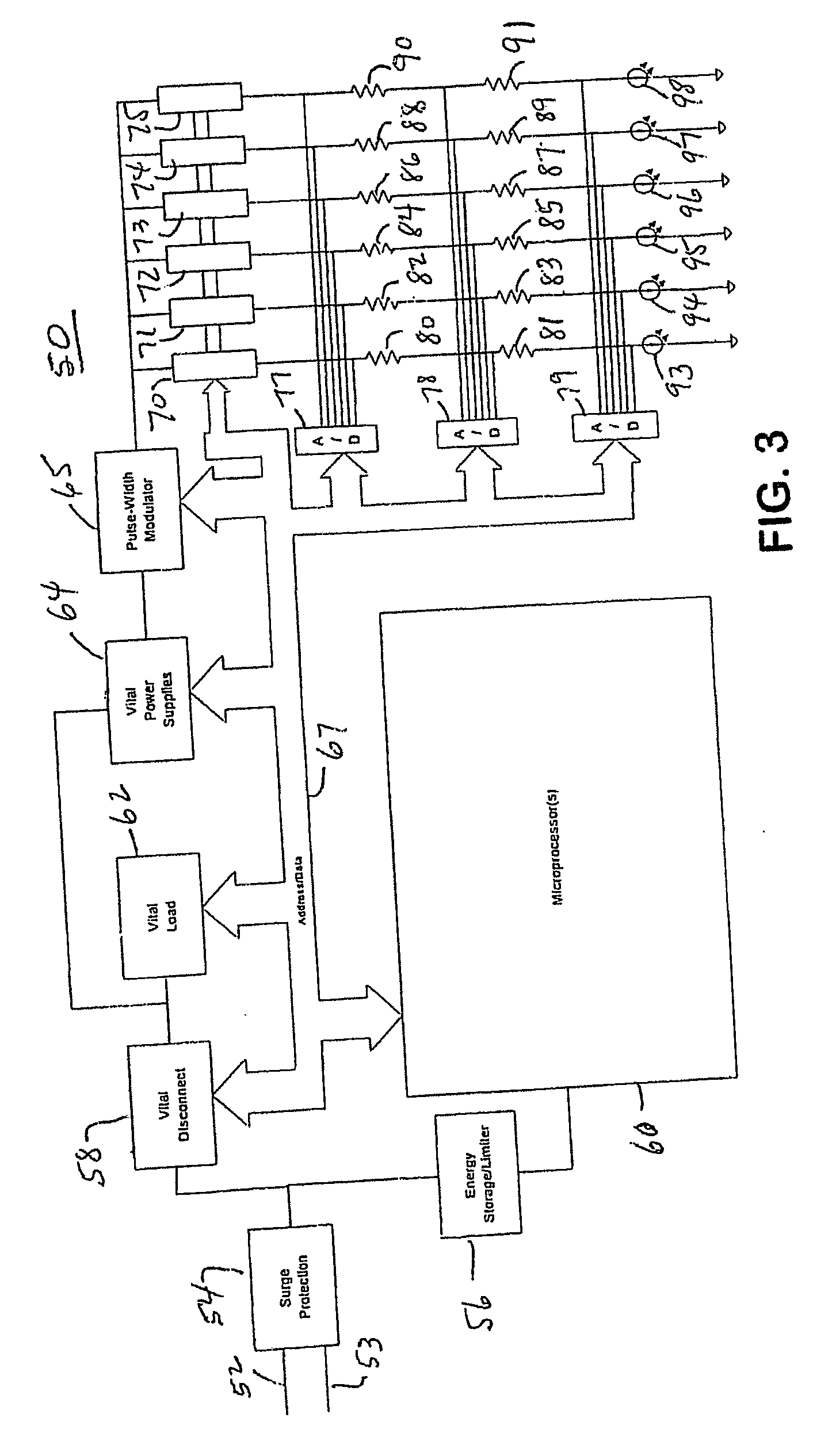

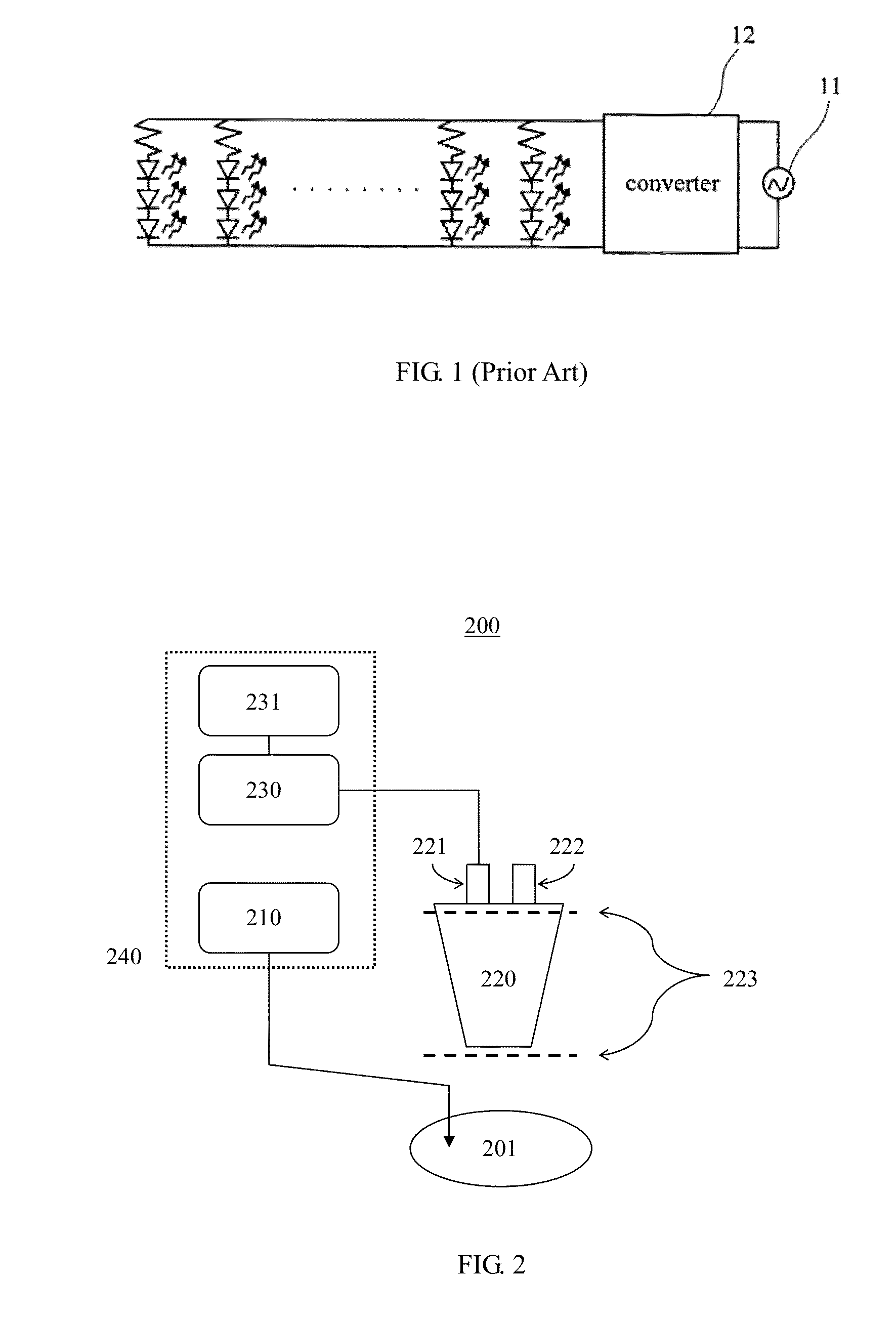

Wayside LED signal for railroad and transit applications

InactiveUS20050062481A1Sufficient energySufficient energy storageVisible signalsElectrical apparatusJunction temperatureData treatment

A LED signal lamp that monitors, controls and tests the operational status of a plurality of LEDs. A separate current source is provided for each LED and resistors are in series between the current sources and LEDs. Analog-to-digital converters monitor the voltages at the resistors and LEDs and convert the voltages to digital form for a data processor. The data processor determines the junction temperature of each LED, controls the amount of current supplied to each LED and tests the operational status of each LED by matching its characteristics to a known diode curve. A pulse-width modulator provides further control of the amount of power supplied to the current sources. The data processor further controls a vital disconnect and a vital load. An energy storage / limiter circuit stores energy for the data processor during the absence of normal power input. Related methods of monitoring, controlling and testing such an LED system are also disclosed.

Owner:SAFETRAN SYST CORP CORP

Aerospace light-emitting diode (LED)-based lights life and operation monitor compensator

A system (10) and method for monitoring the operational life and / or performance of one or more light-emitting diodes (LEDs) (20) based on sensed parameters are disclosed. The remaining life of each LED may be predicted by counting the clock cycles during which the LED-based light is activated. LED current and / or temperature measurements may be used to control the clock signal and, thus, to compensate the predicted life value. Furthermore, operational characteristics of the LED-based light may be monitored based on LED current and / or voltage measurements. Such characteristics may include performance (e.g., intensity) and failure conditions (e.g., open or short circuits).

Owner:HONEYWELL INT INC

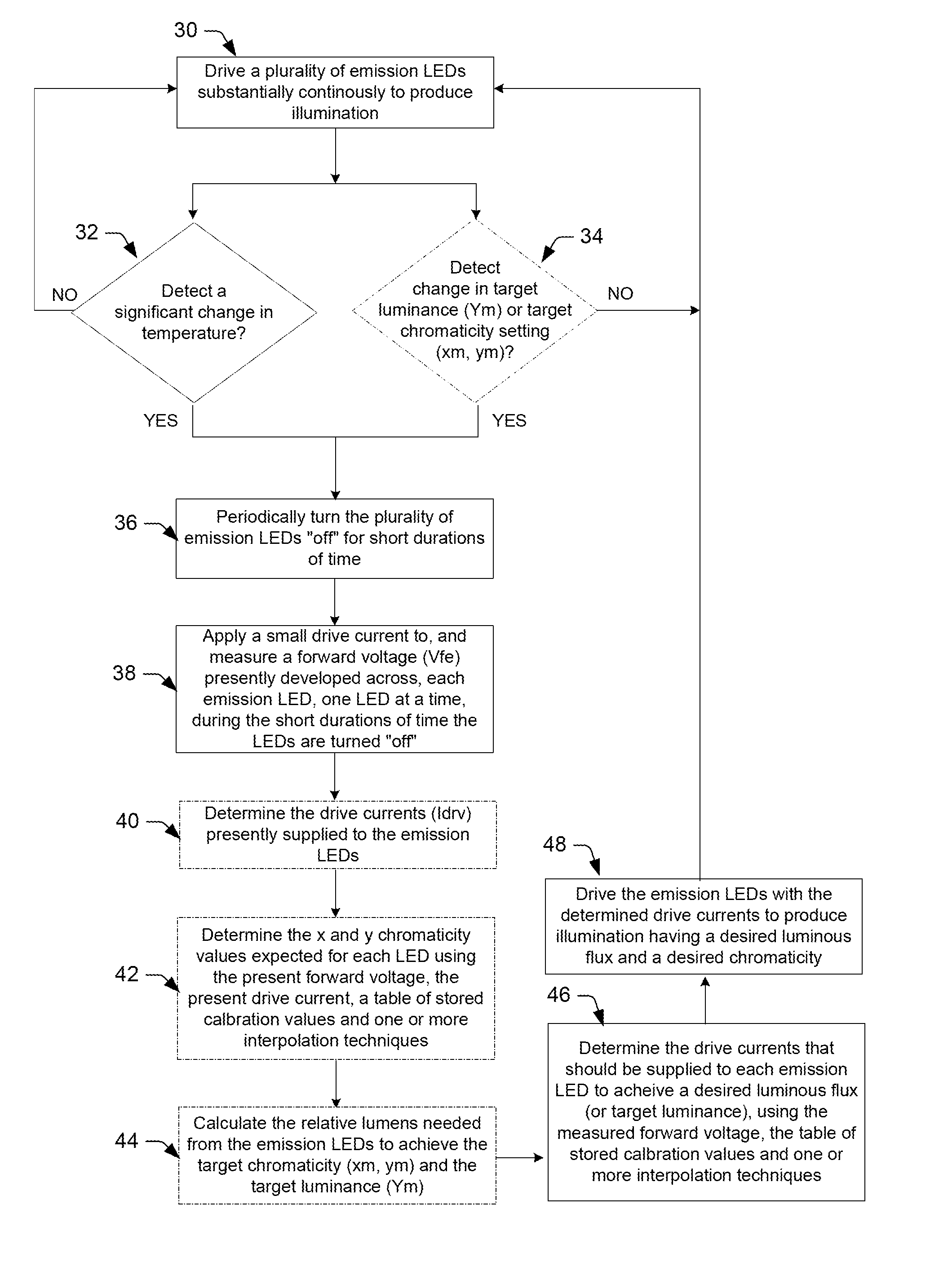

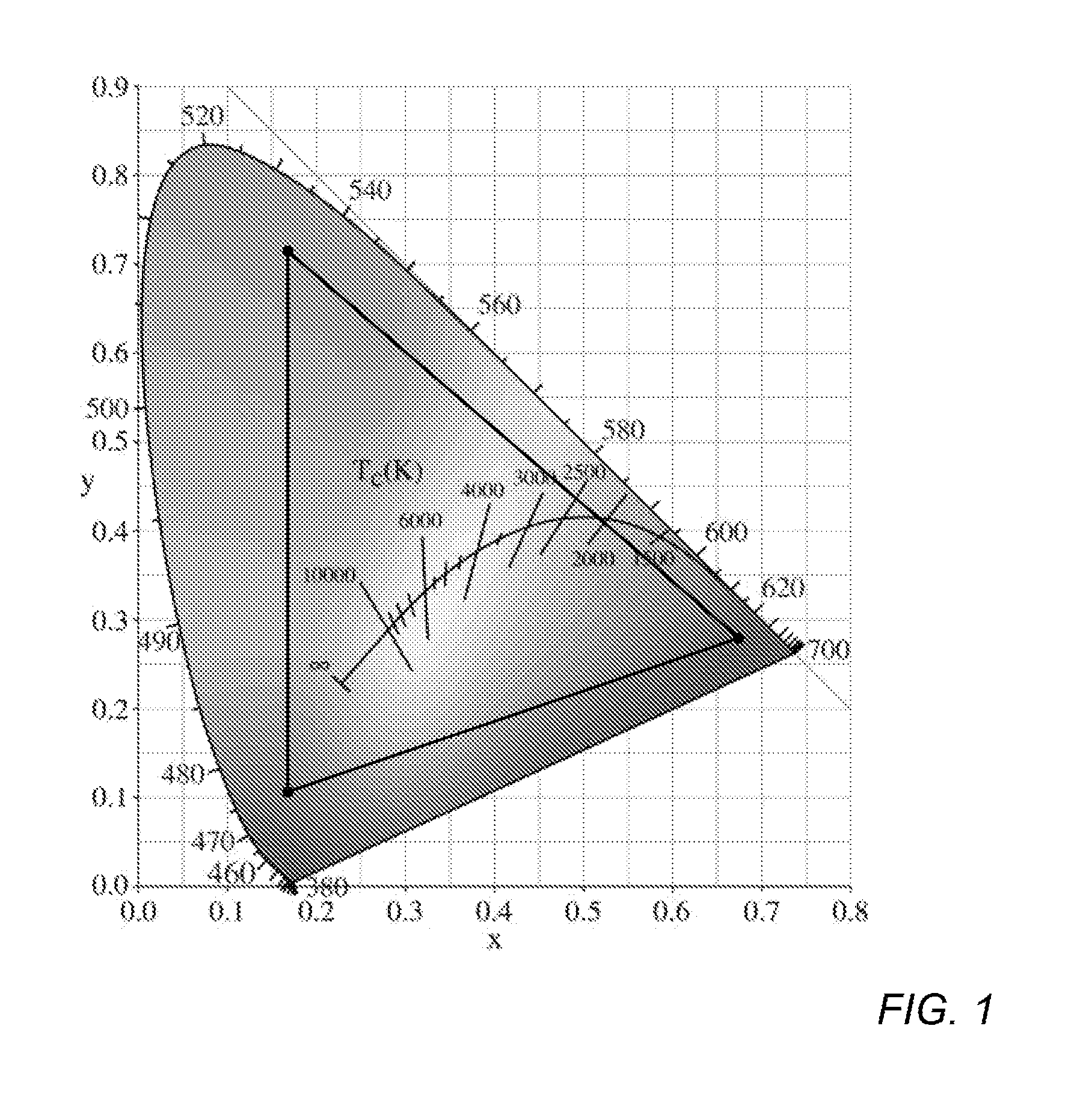

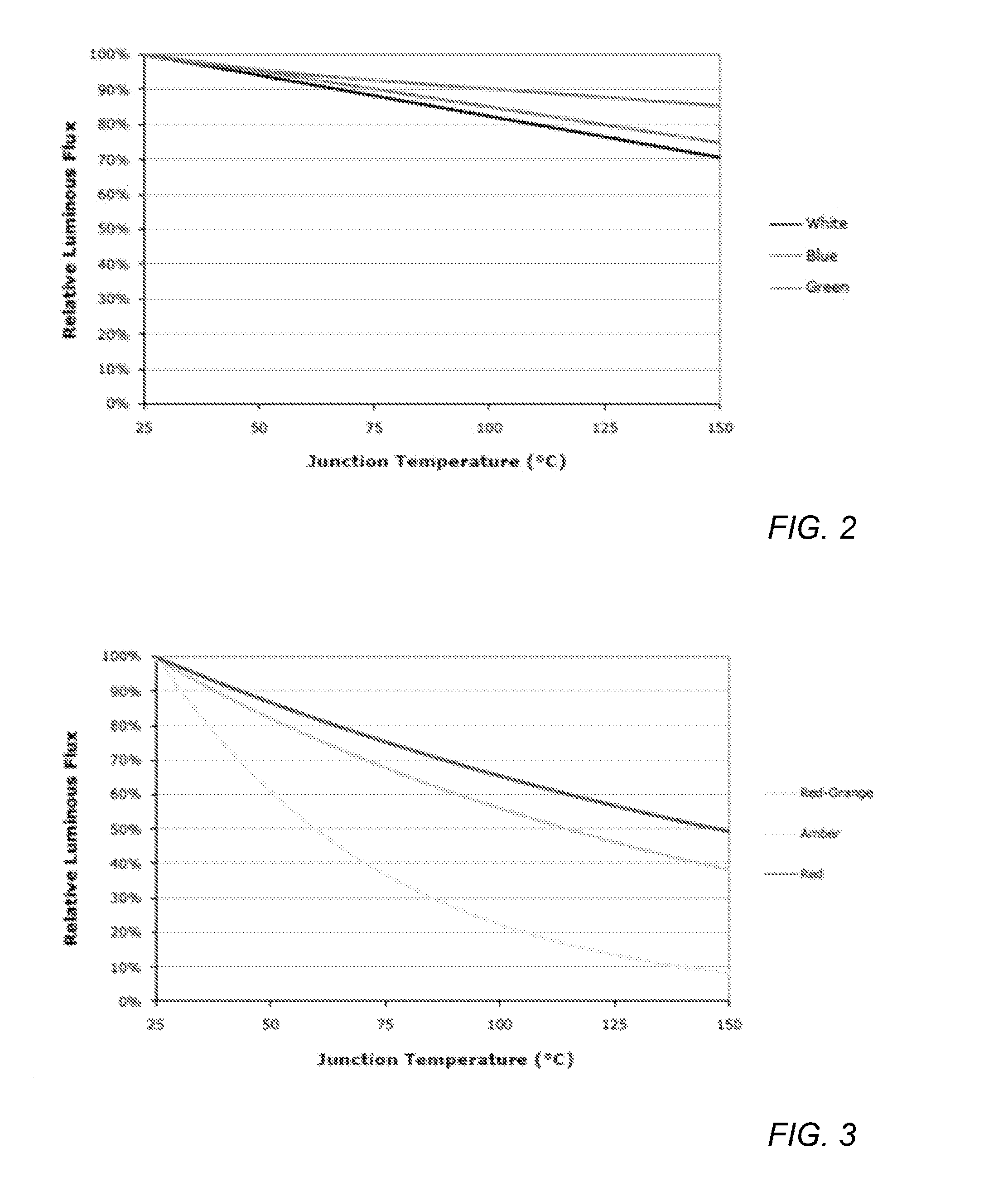

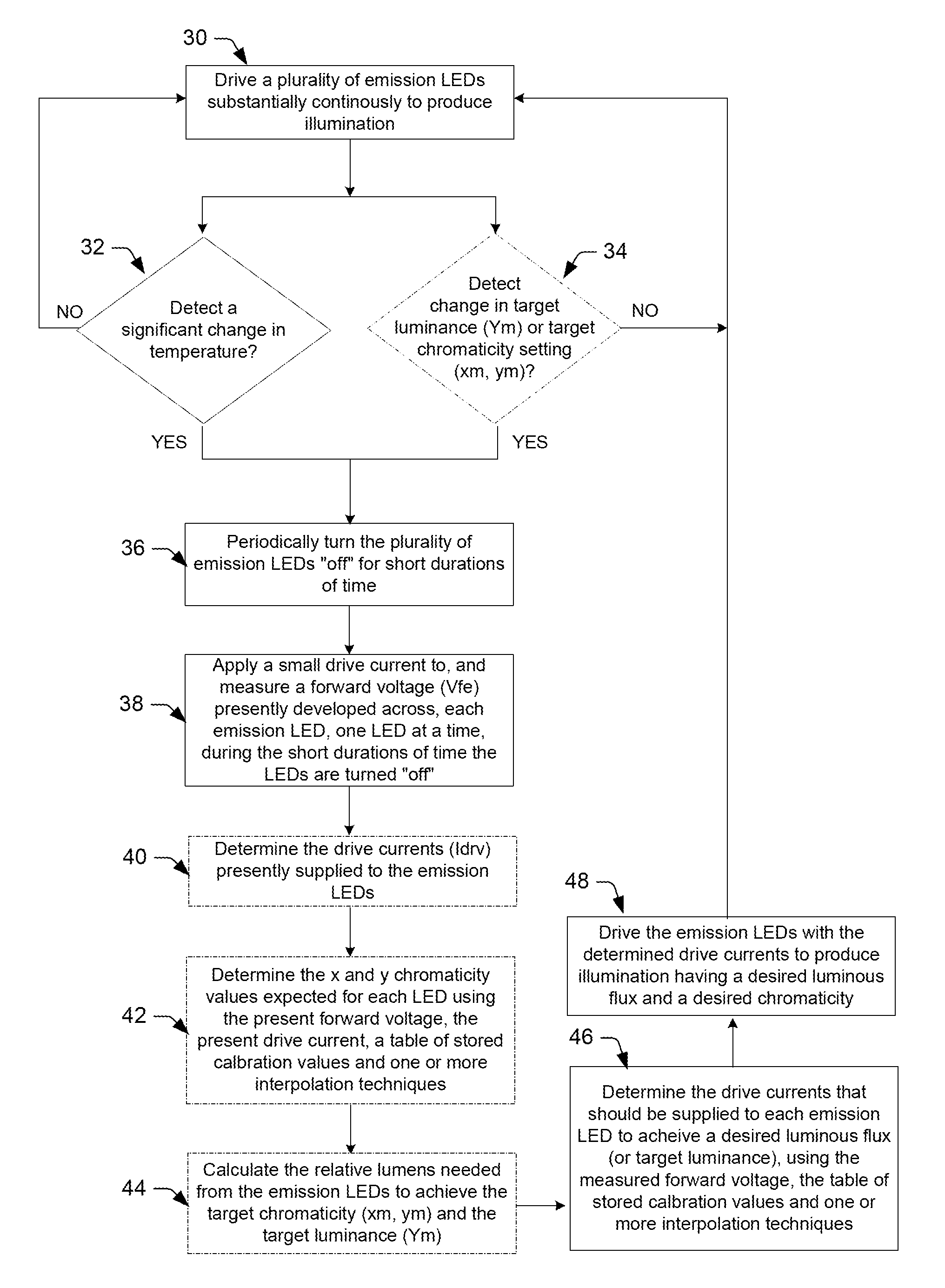

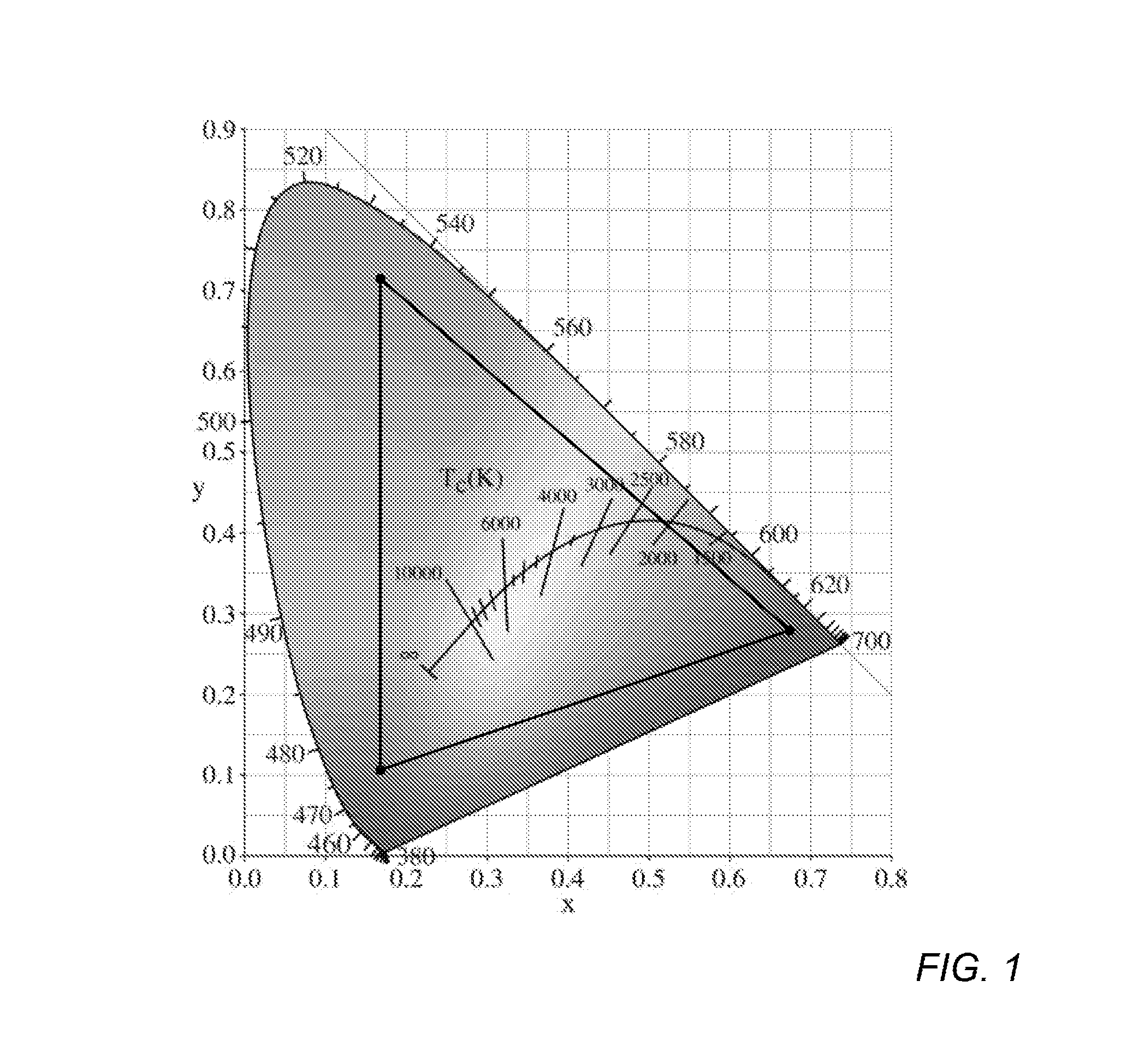

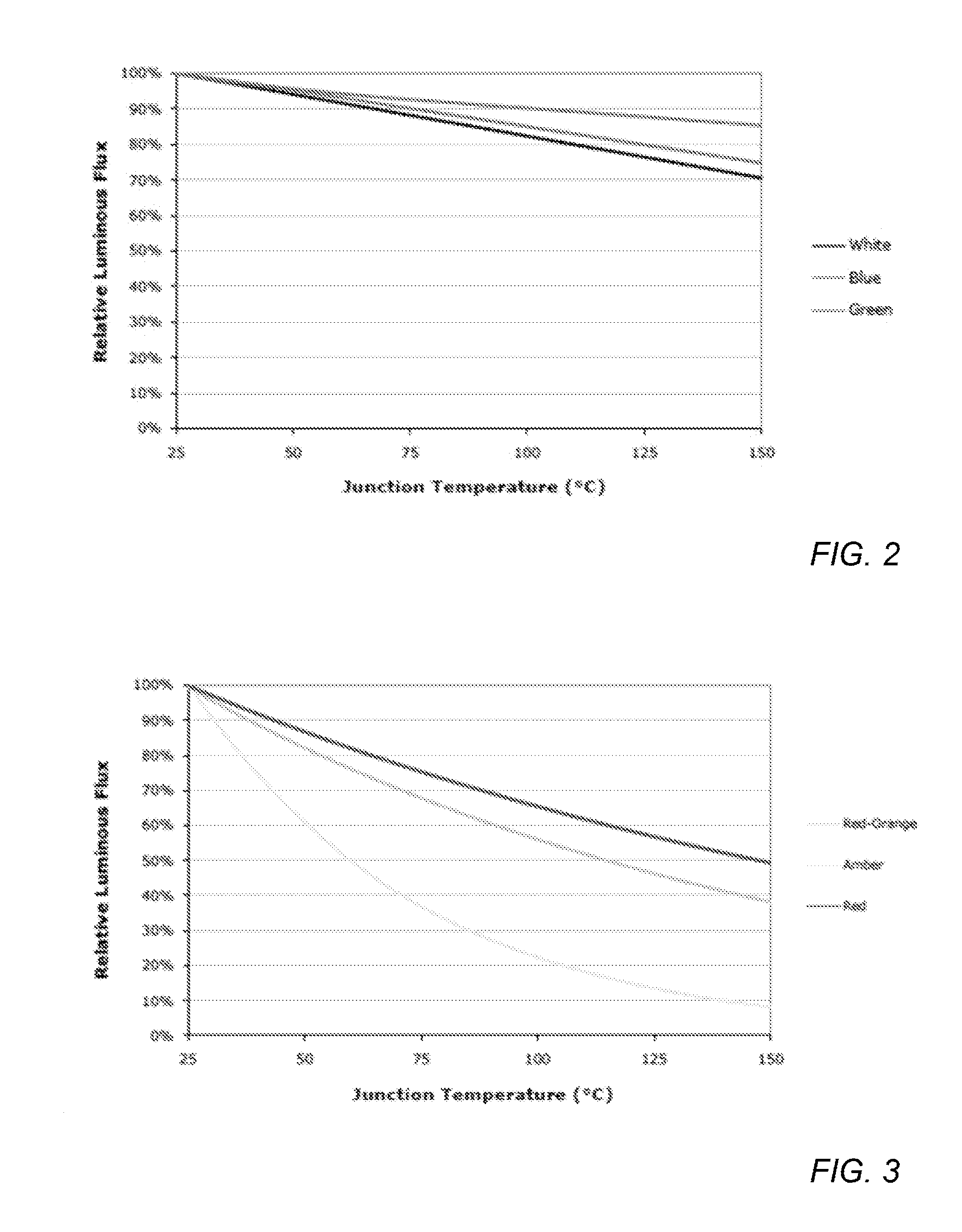

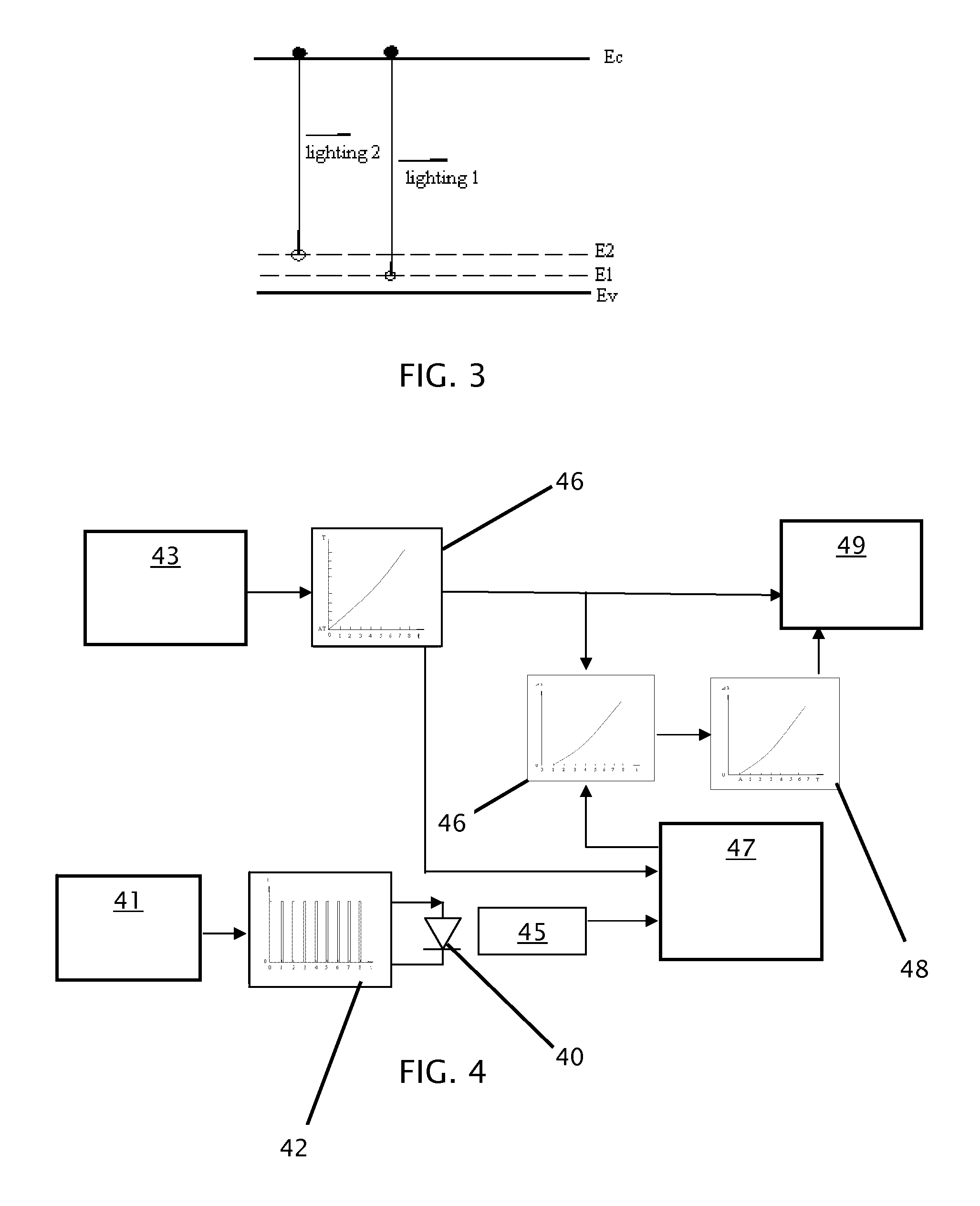

Illumination Device and Method for Controlling an Illumination Device over Changes in Drive Current and Temperature

An illumination device and method is provided herein for controlling individual light emitting diodes (LEDs) in an LED illumination device, so that a desired luminous flux and a desired chromaticity of the device can be maintained over changes in drive current and temperature. According to one embodiment, the illumination device comprises a plurality of emission LEDs, a storage medium, an LED driver and receiver circuit and a control circuit. The storage medium may store a table of calibration values correlating forward voltage and drive current to chromaticity and luminous flux at a plurality of temperatures for each of the plurality of emission LEDs. The LED driver and receiver circuit may apply respective drive currents to the emission LEDs to produce substantially continuous illumination, and may periodically turn the emission LEDs off to measure operating forward voltages that develop across each emission LED. The control circuit may determine whether a target luminance setting or a target chromaticity setting for the illumination device has changed, and if so, may determine new respective drive currents needed to achieve the target luminance setting and the target chromaticity setting using the operating forward voltages measured across each emission LED, the table of calibration values and one or more interpolation techniques.

Owner:LUTRON TECH CO LLC

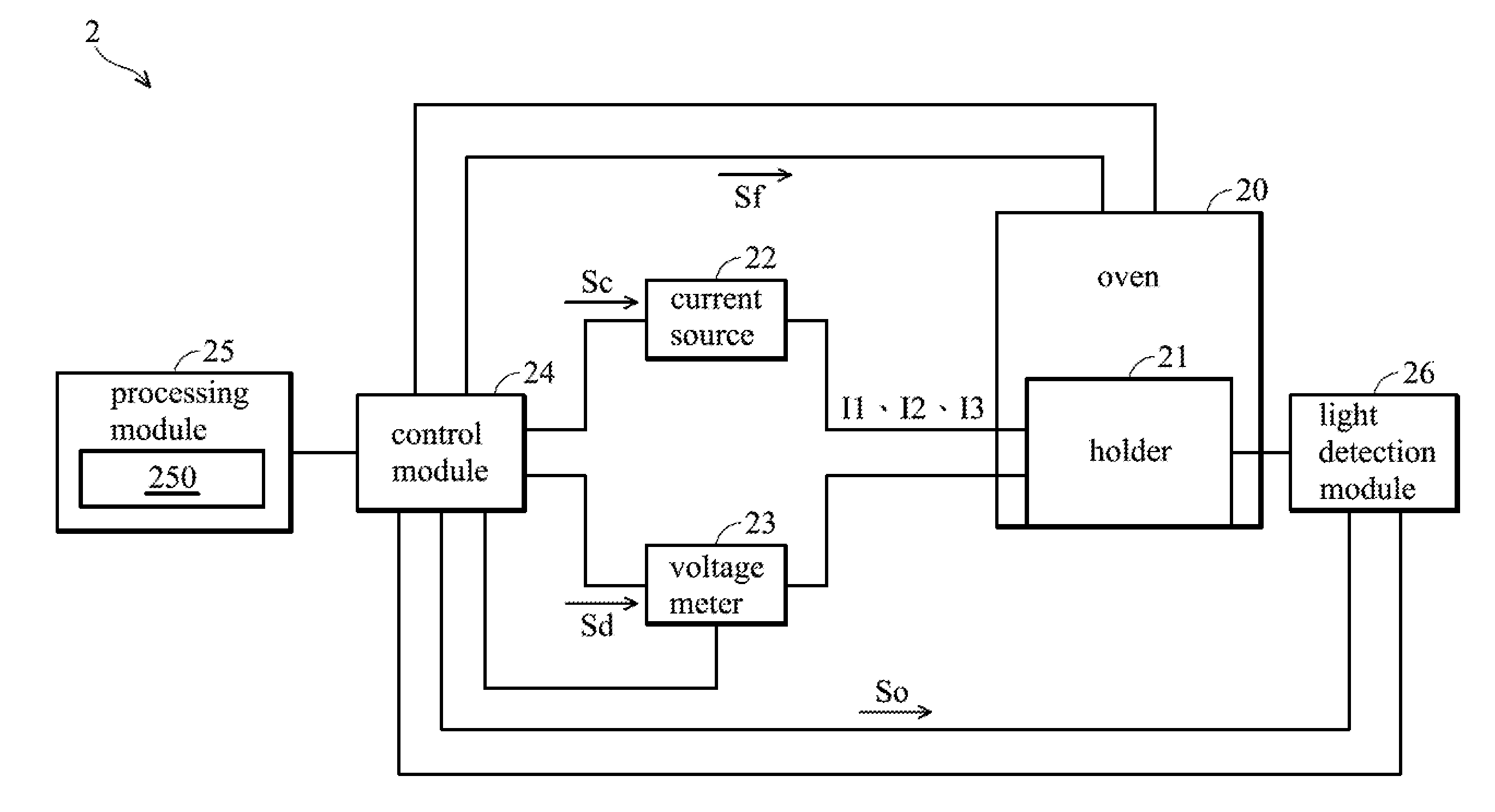

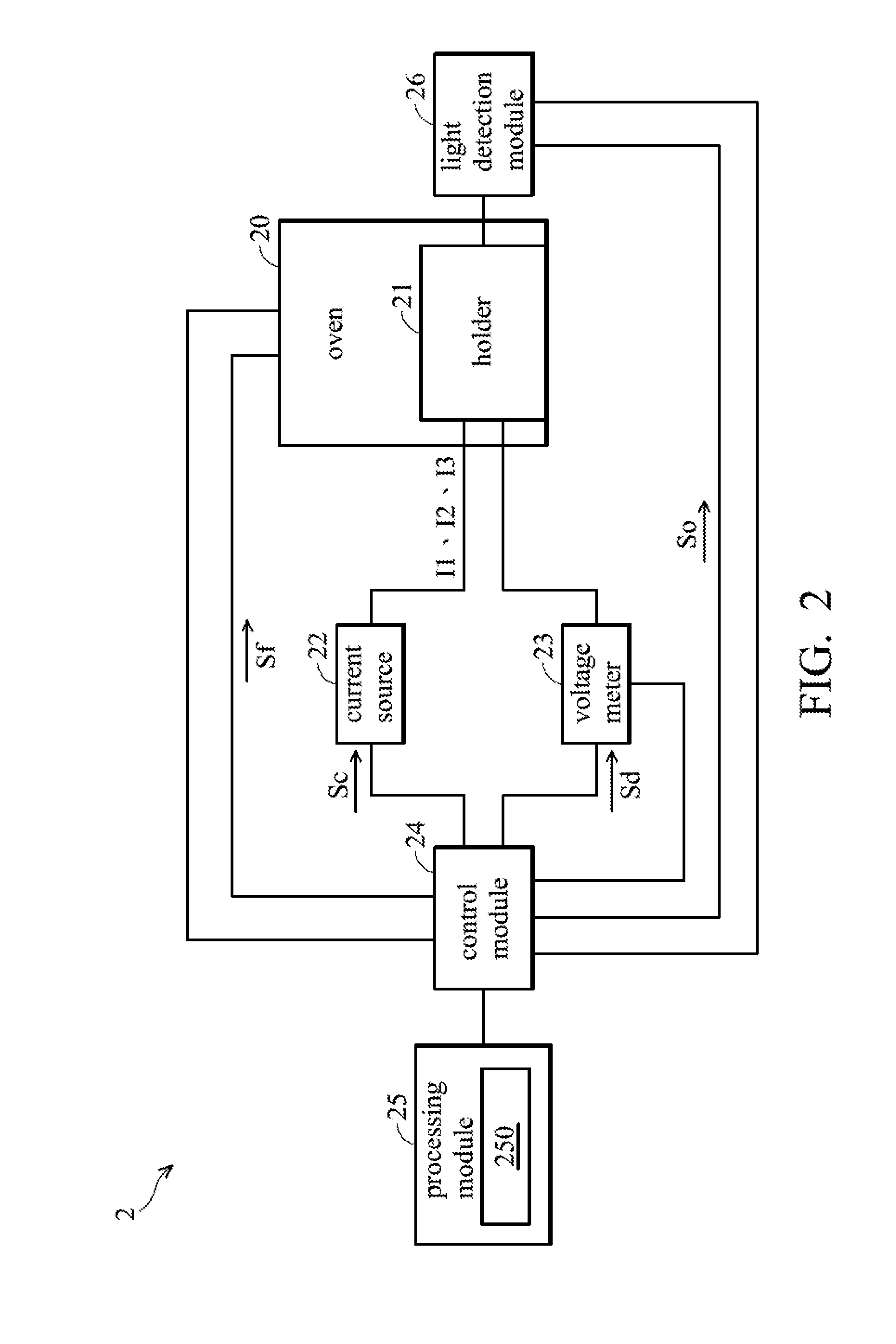

Devices And Methods For LED Life Test

A life test device comprises an oven, a current source, a voltage meter, a control module, and a process module. A light-emitting diode (LED) is disposed in the oven. The temperature of the oven is gradually changed in a first period and remains at a set temperature in a second period. The current source provides a first current and a second current to the LED. The voltage meter measures forward voltages of the LED. The control module controls the current source to output the first or second current to the LED and controls the voltage meter to measure the forward voltages of the LED. The process module calculates a junction temperature of the LED according to the forward voltages and a variation relationship formula between the forward voltages and the temperature of the oven.

Owner:IND TECH RES INST

Illumination device and method for controlling an illumination device over changes in drive current and temperature

An illumination device and method is provided herein for controlling individual light emitting diodes (LEDs) in an LED illumination device, so that a desired luminous flux and a desired chromaticity of the device can be maintained over changes in drive current and temperature. According to one embodiment, the illumination device comprises a plurality of emission LEDs, a storage medium, an LED driver and receiver circuit and a control circuit. The storage medium may store a table of calibration values correlating forward voltage and drive current to chromaticity and luminous flux at a plurality of temperatures for each of the plurality of emission LEDs. The LED driver and receiver circuit may apply respective drive currents to the emission LEDs to produce substantially continuous illumination, and may periodically turn the emission LEDs off to measure operating forward voltages that develop across each emission LED. The control circuit may determine whether a target luminance setting or a target chromaticity setting for the illumination device has changed, and if so, may determine new respective drive currents needed to achieve the target luminance setting and the target chromaticity setting using the operating forward voltages measured across each emission LED, the table of calibration values and one or more interpolation techniques.

Owner:LUTRON TECH CO LLC

Testing of leds

InactiveUS20110084701A1Improve aging performanceShorten the timeElectrical apparatusDiode testingAccelerated agingElectrical and Electronics engineering

A method of determining the ageing characteristics of an LED comprises applying a current stress pulse to the LED. The LED is monitored to determine when the thermal heating induced by the current stress pulse has been dissipated to a desired level. The operational characteristics of the LED are then measured before applying the next stressing pulse.This method accelerates the effect of aging in a reproducible way and therefore is able to greatly reduce the time needed for a reliability test.

Owner:NXP BV

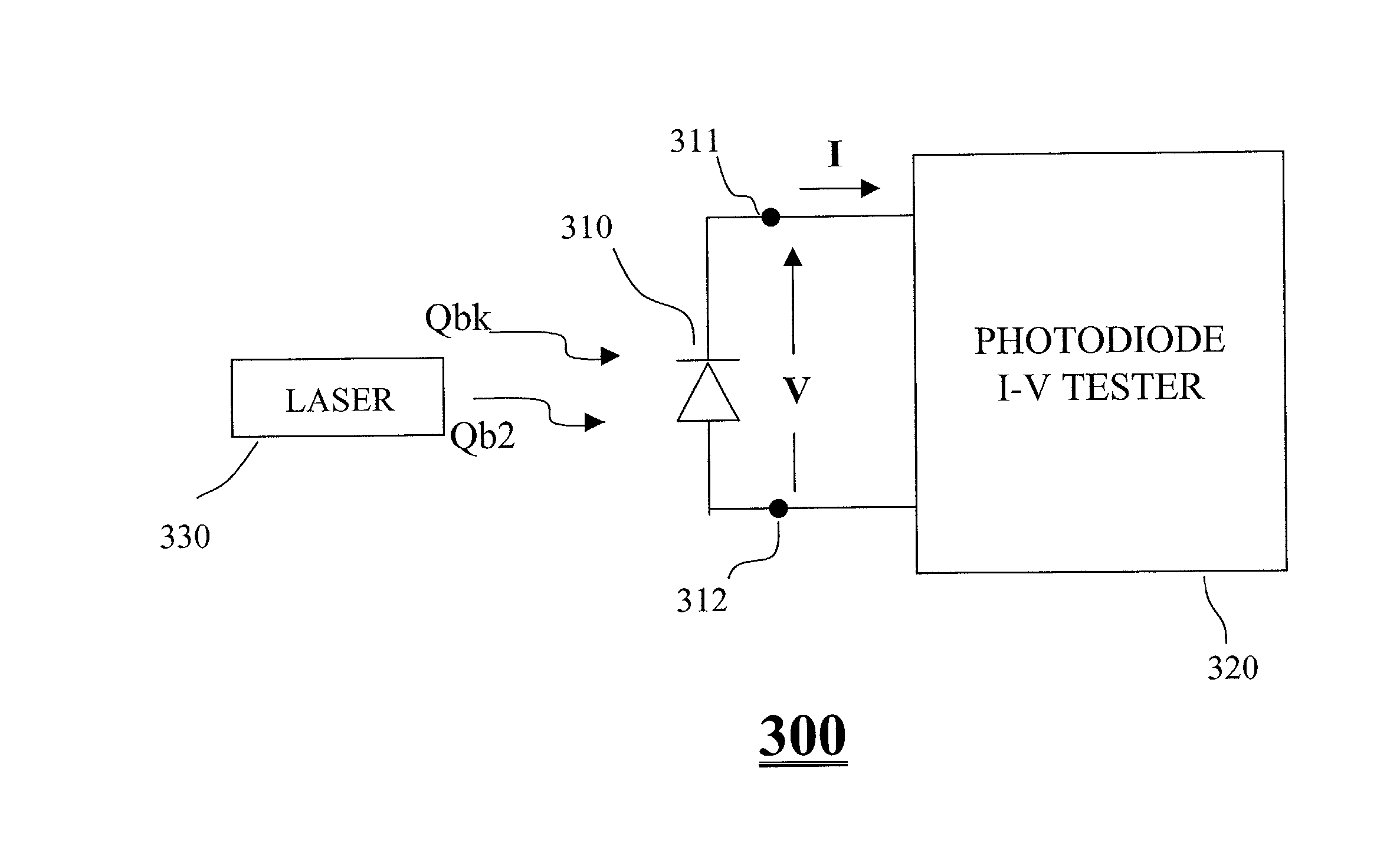

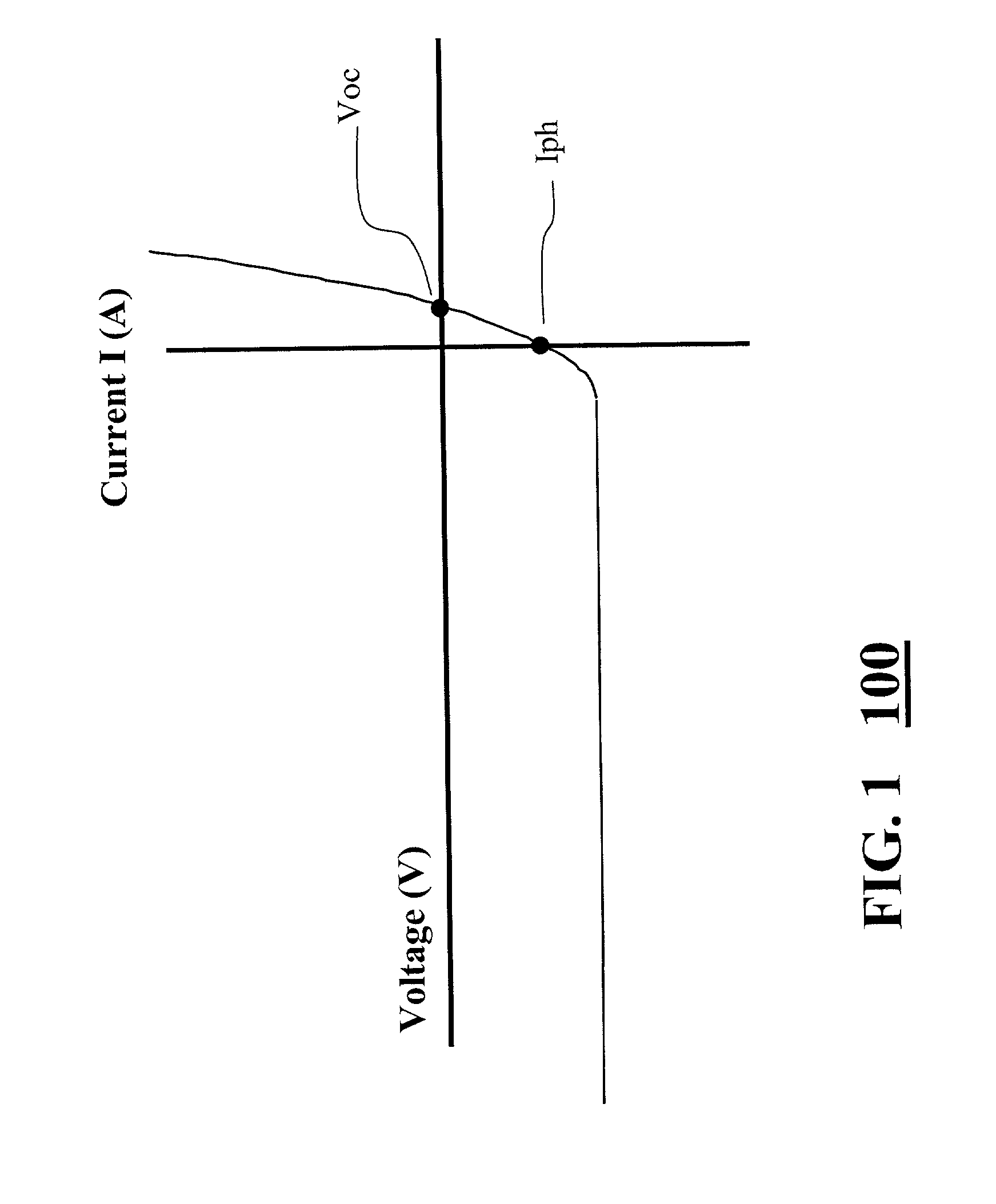

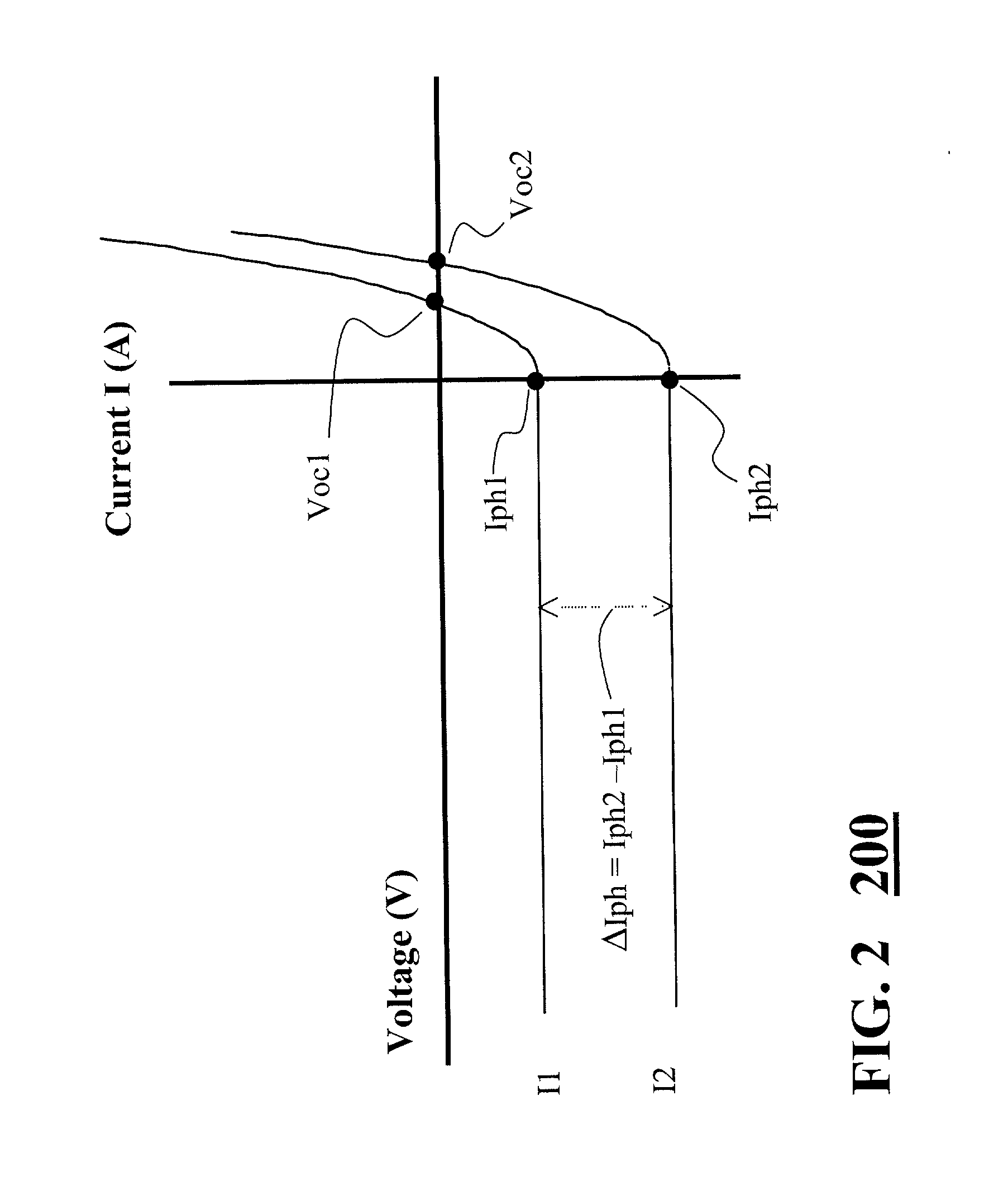

Method for determining photodiode performance parameters

One or more photodiode performance parameters for a photodiode are determined by first determining four data points Iph1, Voc1, Iph2, and Voc2, where Iph1 is a first short-circuit current, and Voc1 is a first open-circuit voltage, for the photodiode under a first illumination condition, and Iph2 is a second short-circuit current, and Voc2 is a second open-circuit voltage, for the photodiode under a second illumination condition. Then, at least one photodiode performance parameter for the photodiode is determined as a function of said four data points.

Owner:APPLIED OPTOELECTRONICS

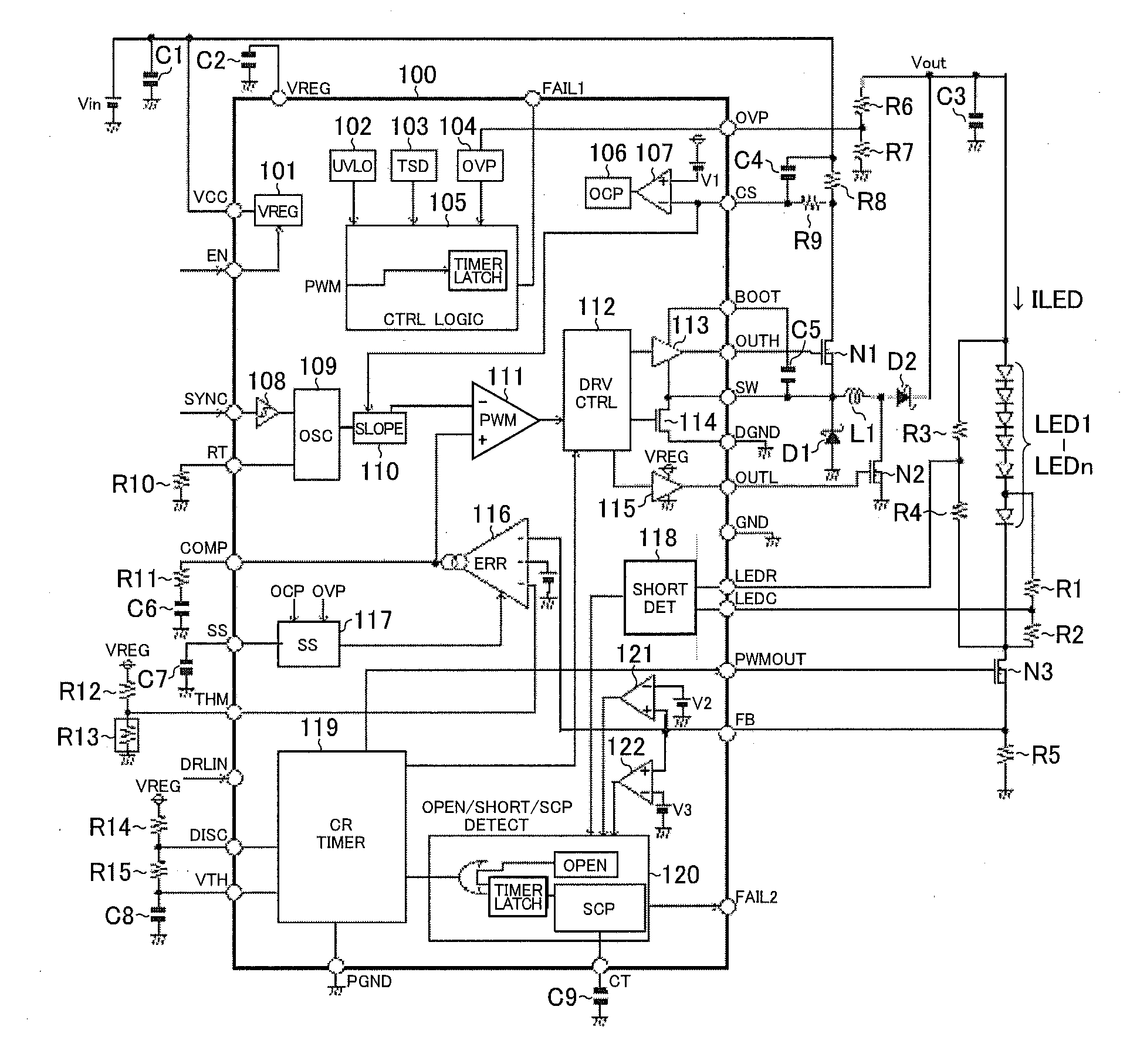

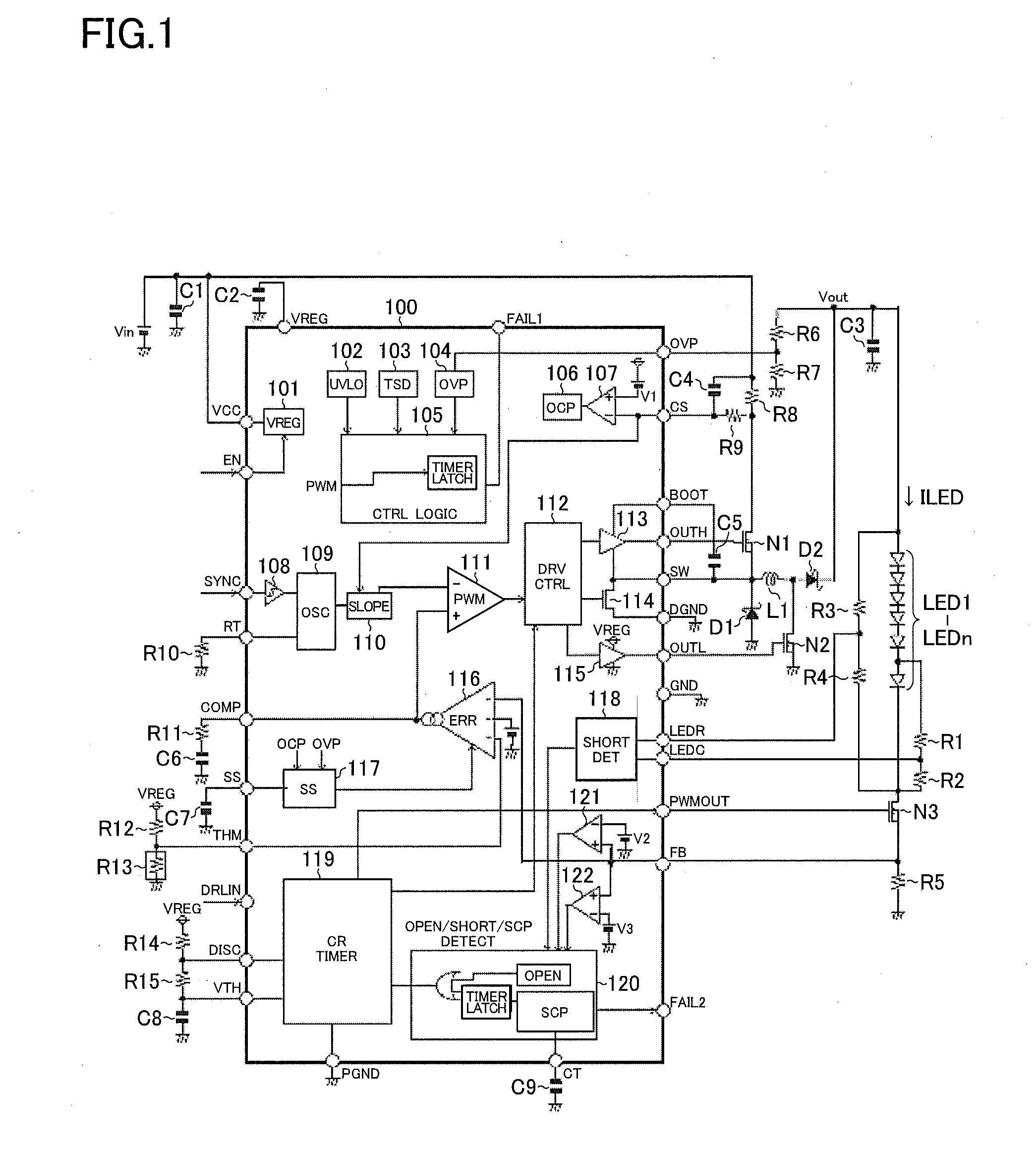

LED short-circuit detection circuit, LED drive device, LED lighting device, and vehicle

An LED short-circuit detection circuit produces an LED short-circuit detection signal by monitoring an LEDC terminal voltage (a first voltage obtained at a chip-to-chip node in a row of LED chips, or a divided voltage thereof) and an LEDR terminal voltage (a second voltage obtained by dividing the end-to-end voltage of the row of LED chips).

Owner:ROHM CO LTD

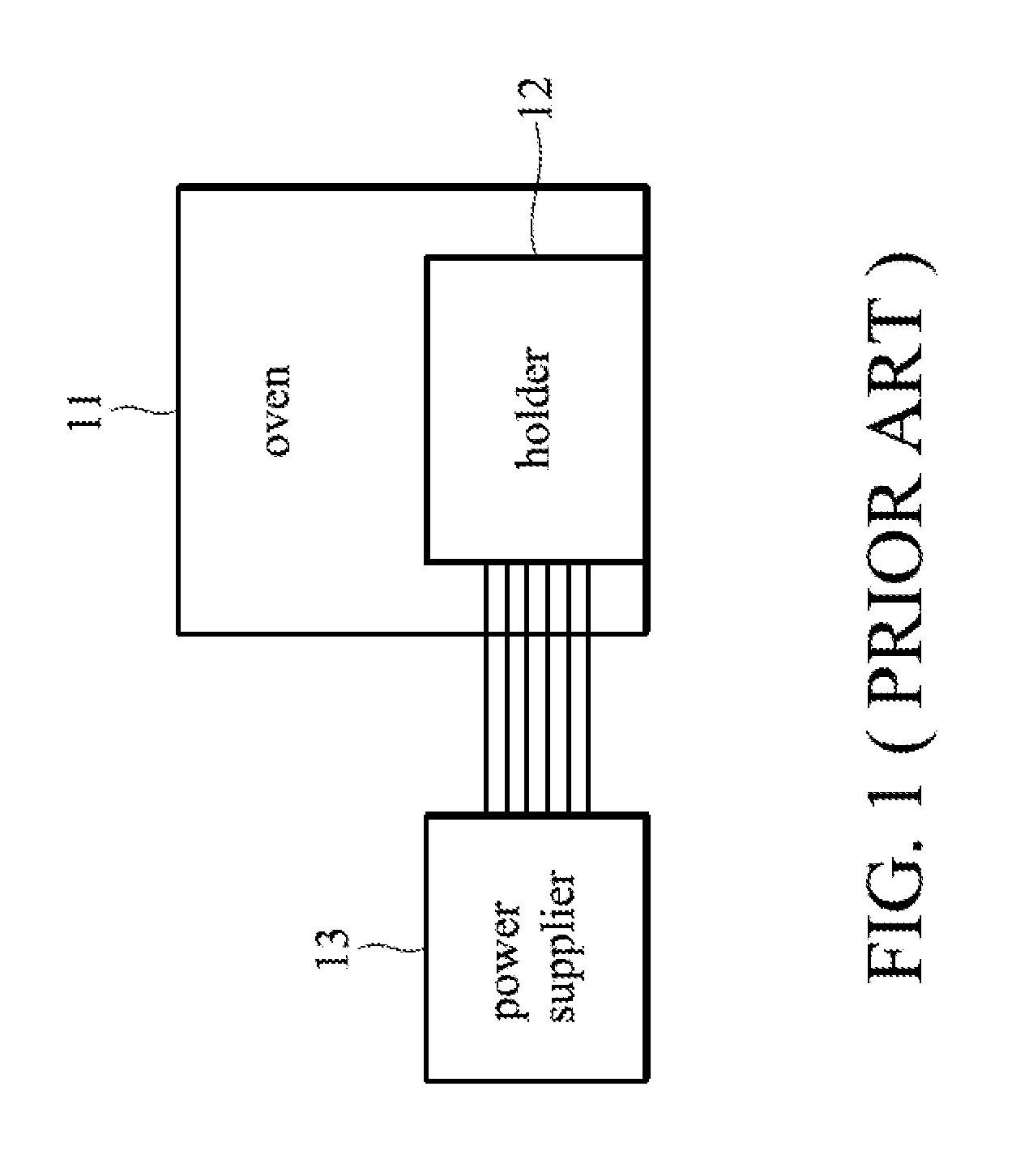

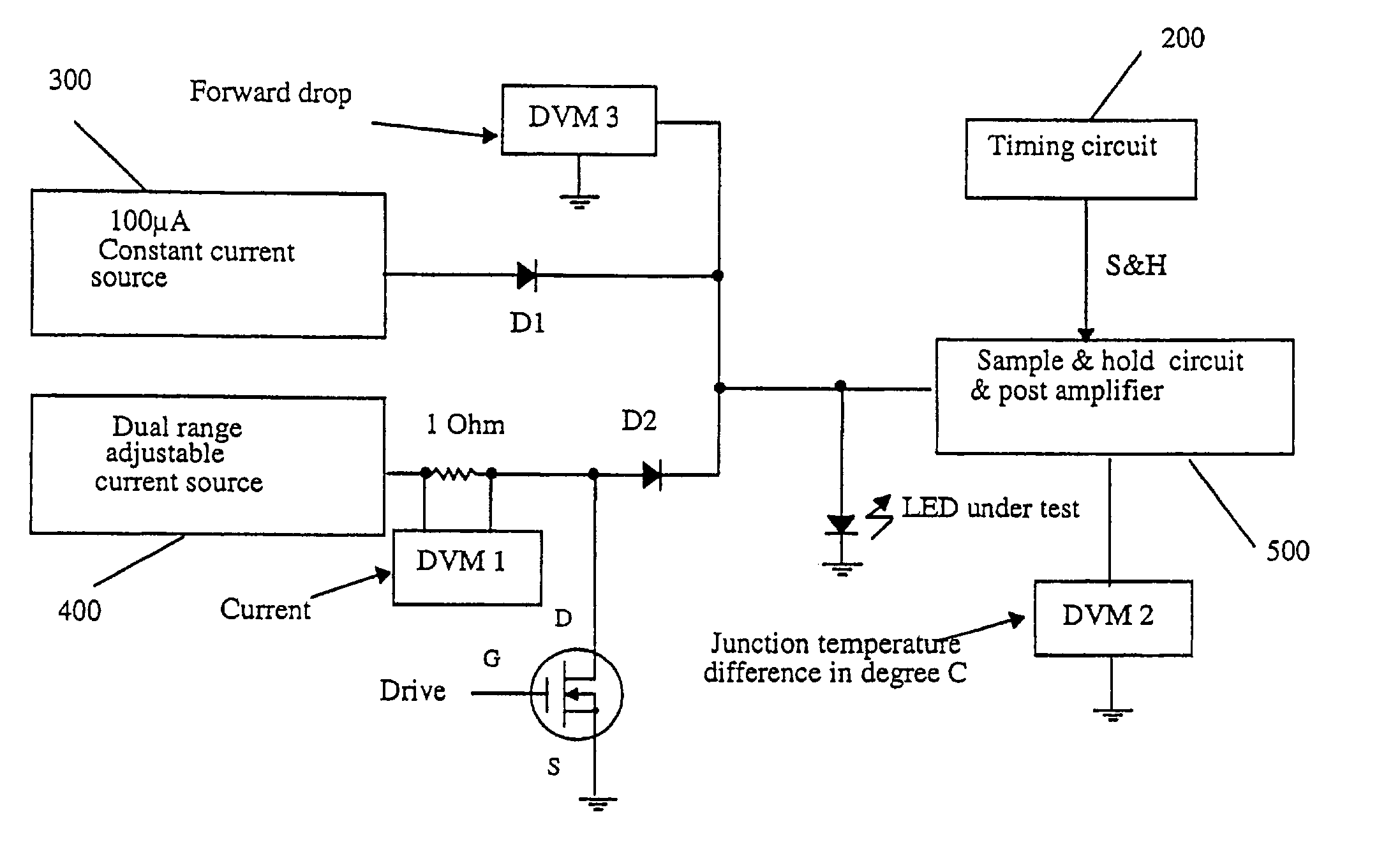

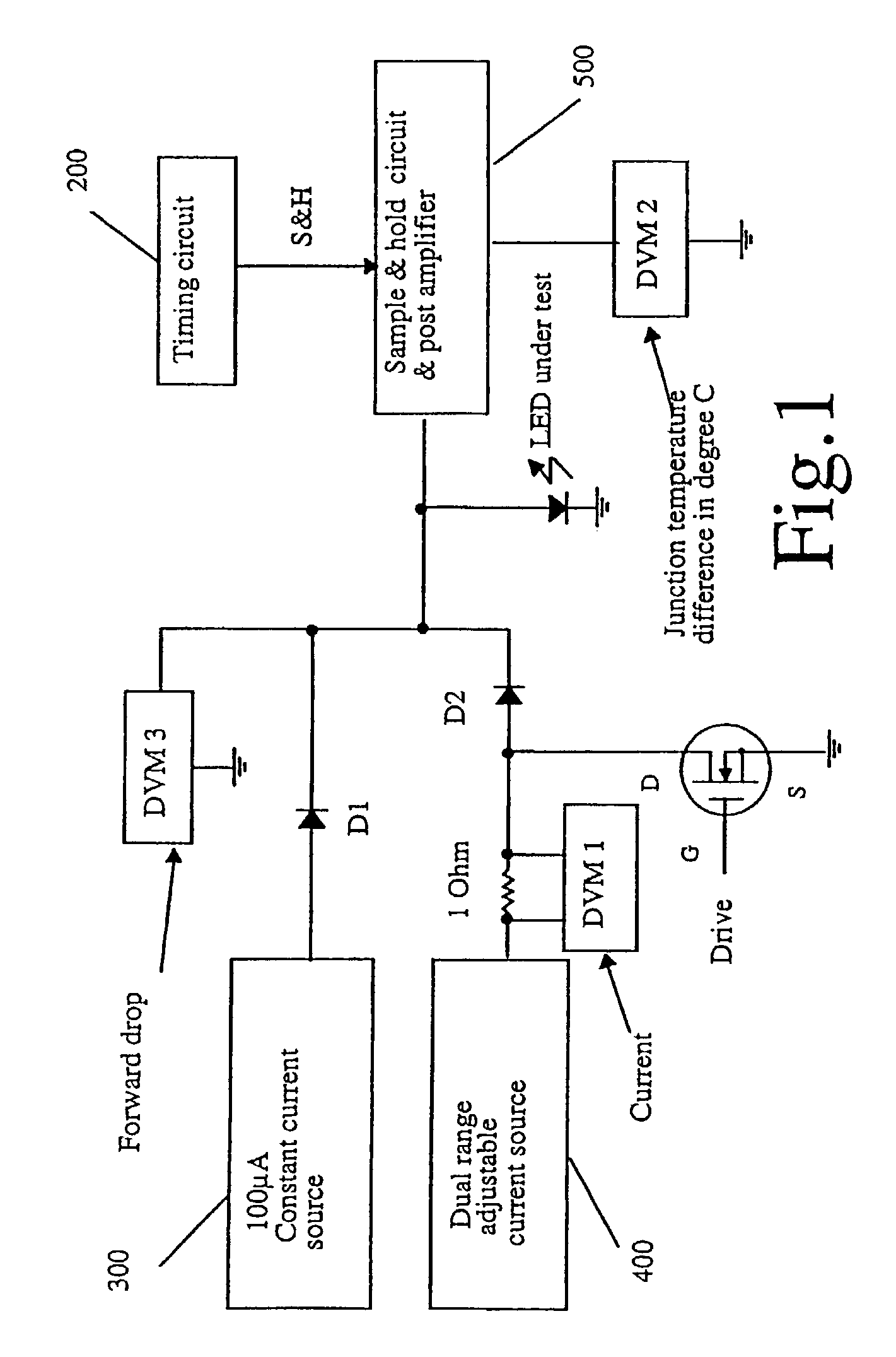

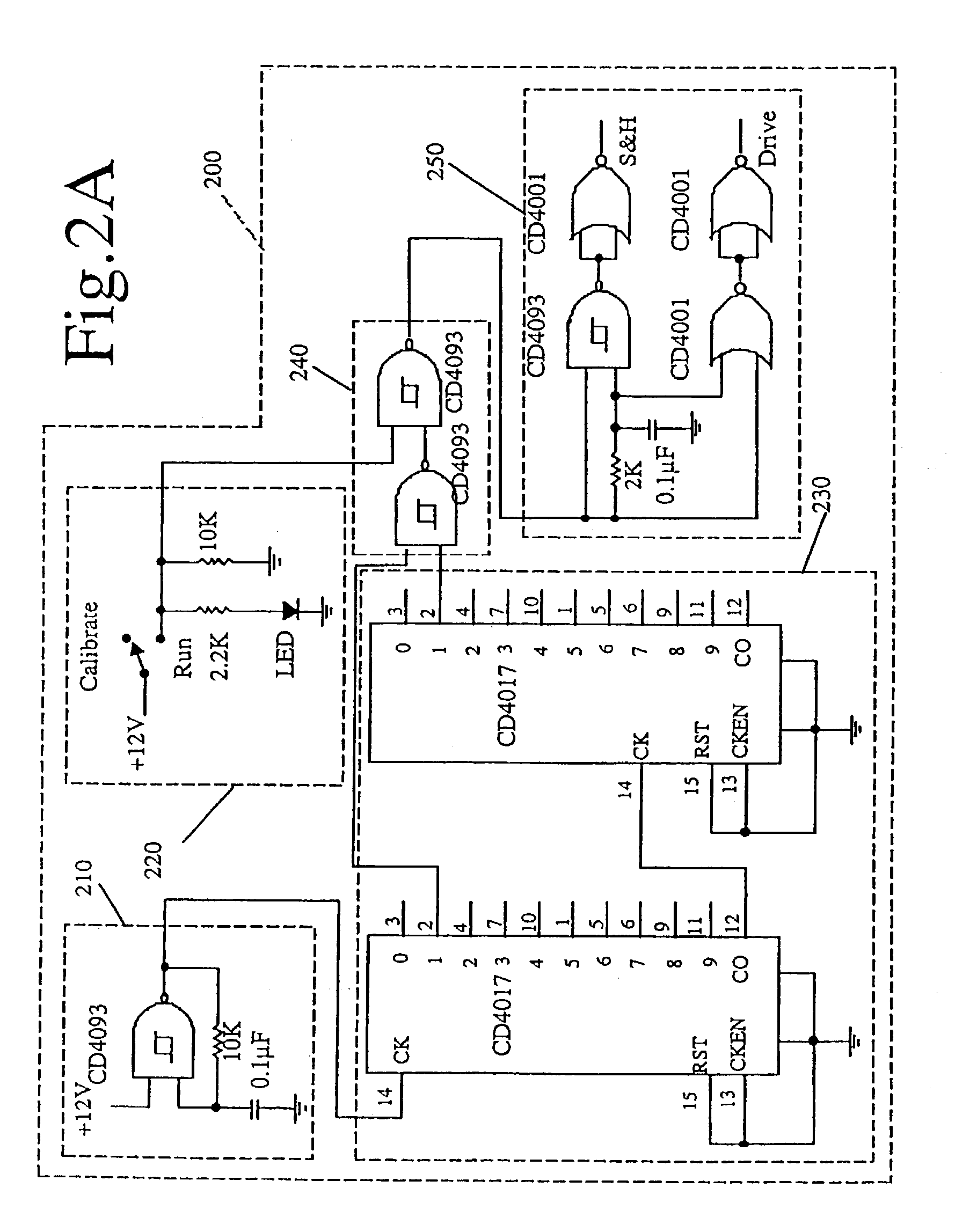

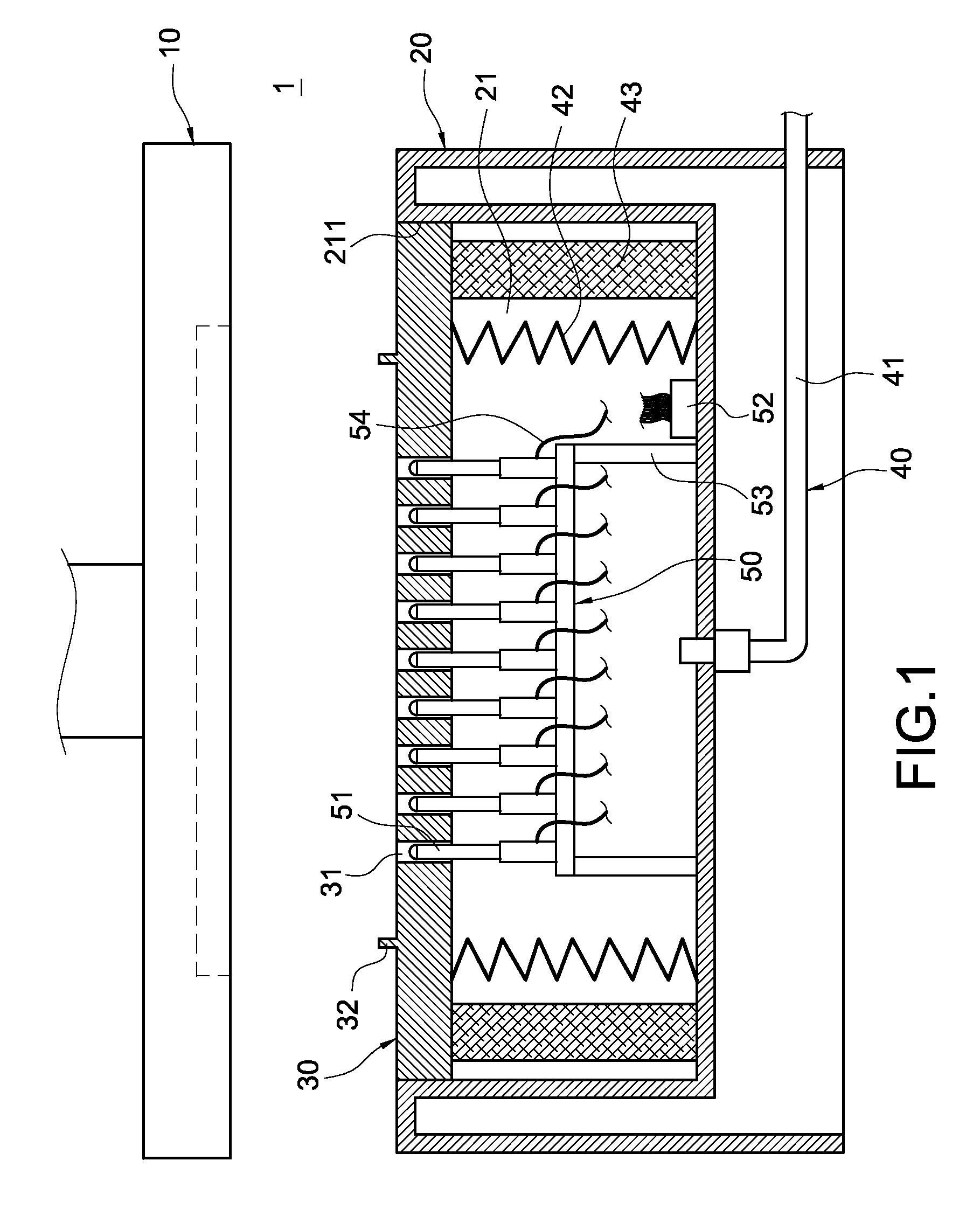

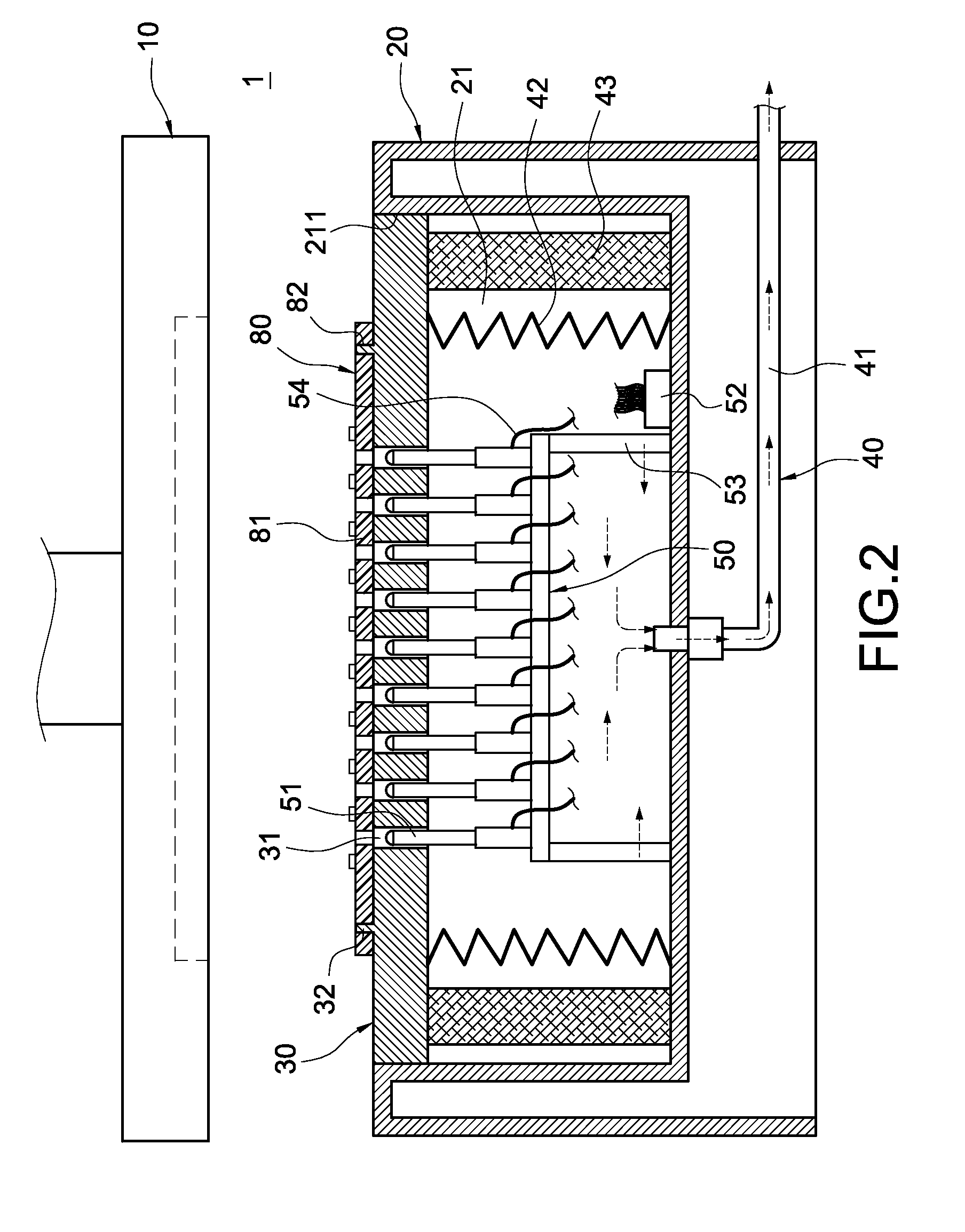

LED junction temperature tester

InactiveUS7052180B2Diode testingSemiconductor/solid-state device detailsJunction temperatureLinear relationship

An instrument measures the LED junction temperature directly by taking advantage of the linear relationship between the forward current driven through the LED, the forward drop of the LED, and the junction temperature to determine the LED junction temperature.Calibration is conducted by placing two LEDs from the same family in ambient temperature and passing a small test current through each of the LEDs to obtain the forward drop of the LED at ambient temperature. The LED under test is then placed in an environmentally-controlled chamber where the temperature is raised a known amount above ambient temperature. Known low and high voltage values are associated with the ambient temperature and the environmental chamber temperature, causing the LED under test becomes a calibrated thermometer that can measure its own junction temperature due to the linear relationship between the forward drop and the junction temperature.

Owner:SHIH KELVIN

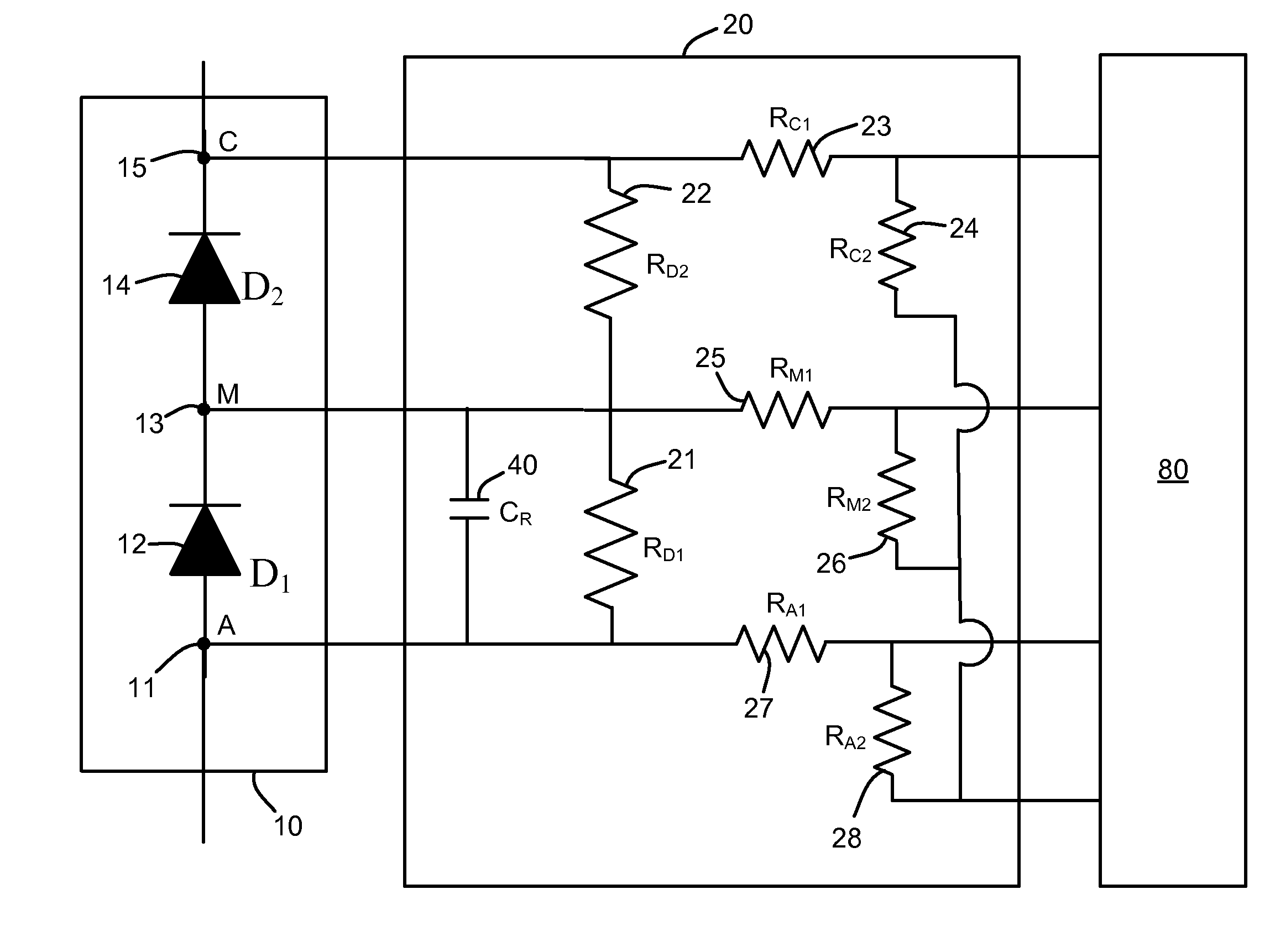

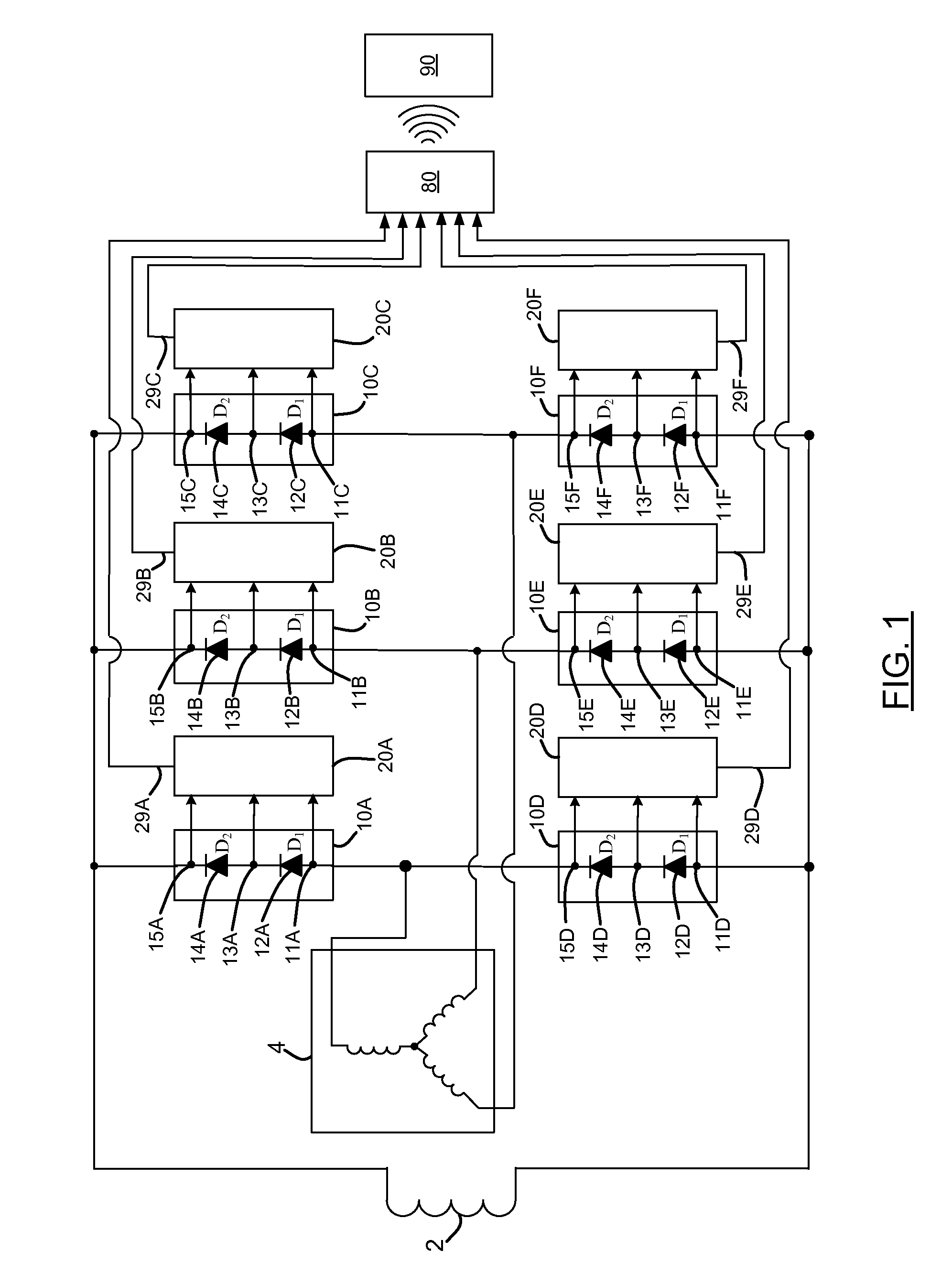

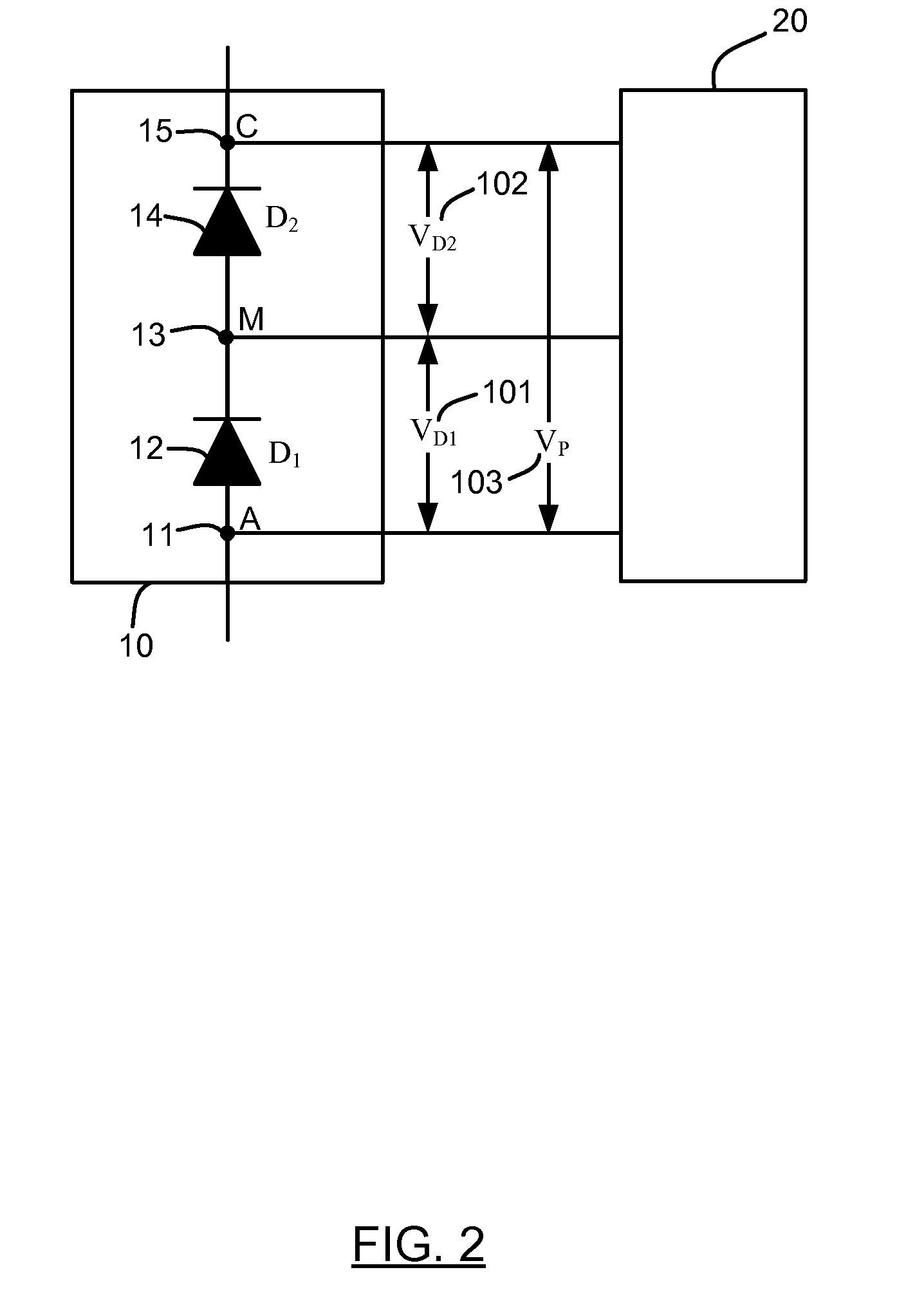

Method and apparatus for fault detection of series diodes in rectifiers

ActiveUS20110216449A1Minimize potentialEasy to detectDiode testingEmergency protective arrangements for limiting excess voltage/currentReverse recoveryEngineering

A method and apparatus for fault detection of series diodes in rectifiers is disclosed, wherein the voltages across one or both of the individual diodes, and / or the voltage across the pair of diodes are measured to determine a ratio between two of those voltages. The ratio is then analyzed to determine if a fault (e.g., a short circuit or an open circuit) is present. In some embodiments, circuitry can be included to compensate for the normal variations in diode characteristics (e.g., reverse leakage current, reverse recovery charge) between the pair of series diodes to minimize the potential for erroneous fault detection.

Owner:ACCUMETRICS INC +1

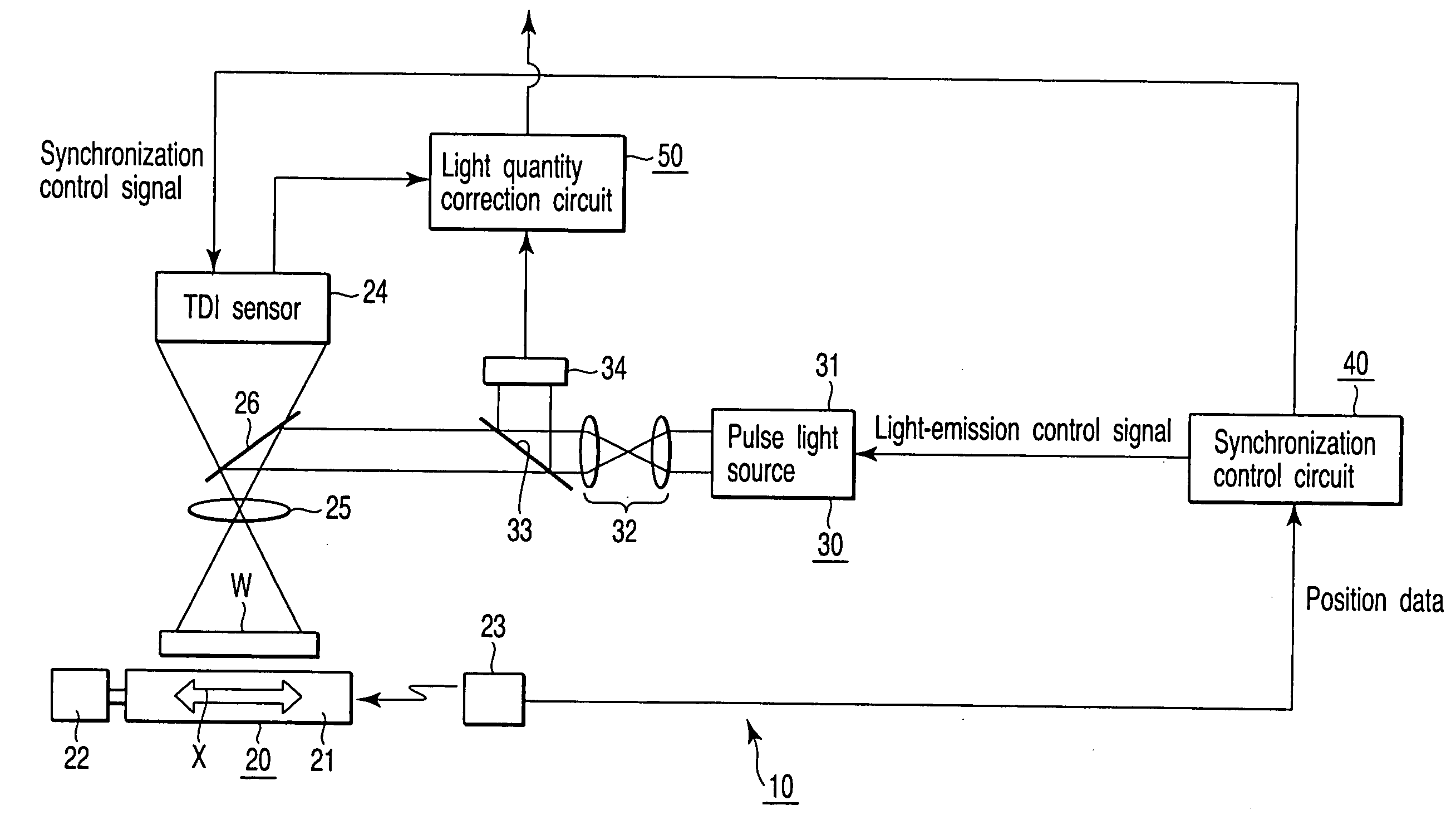

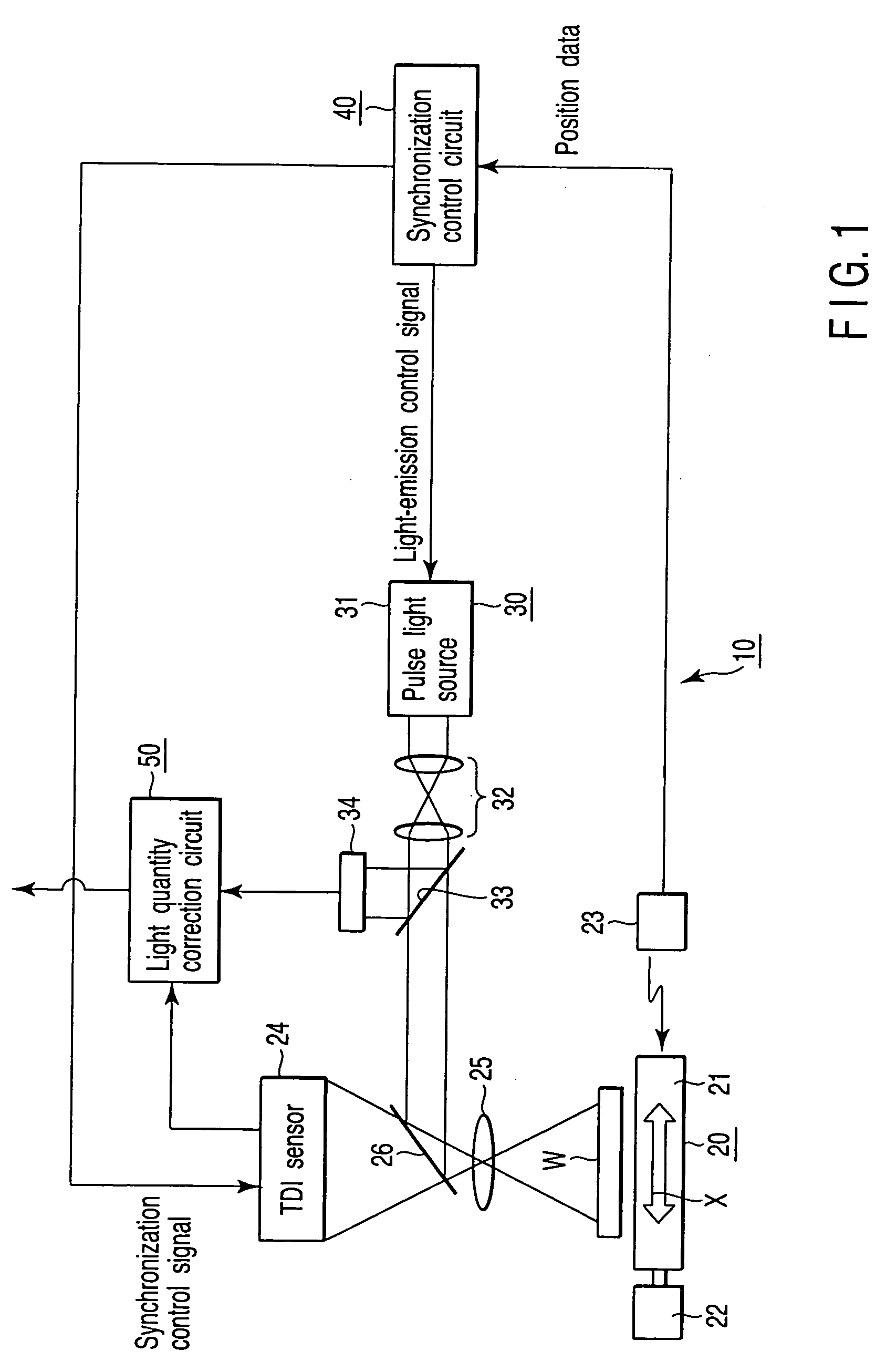

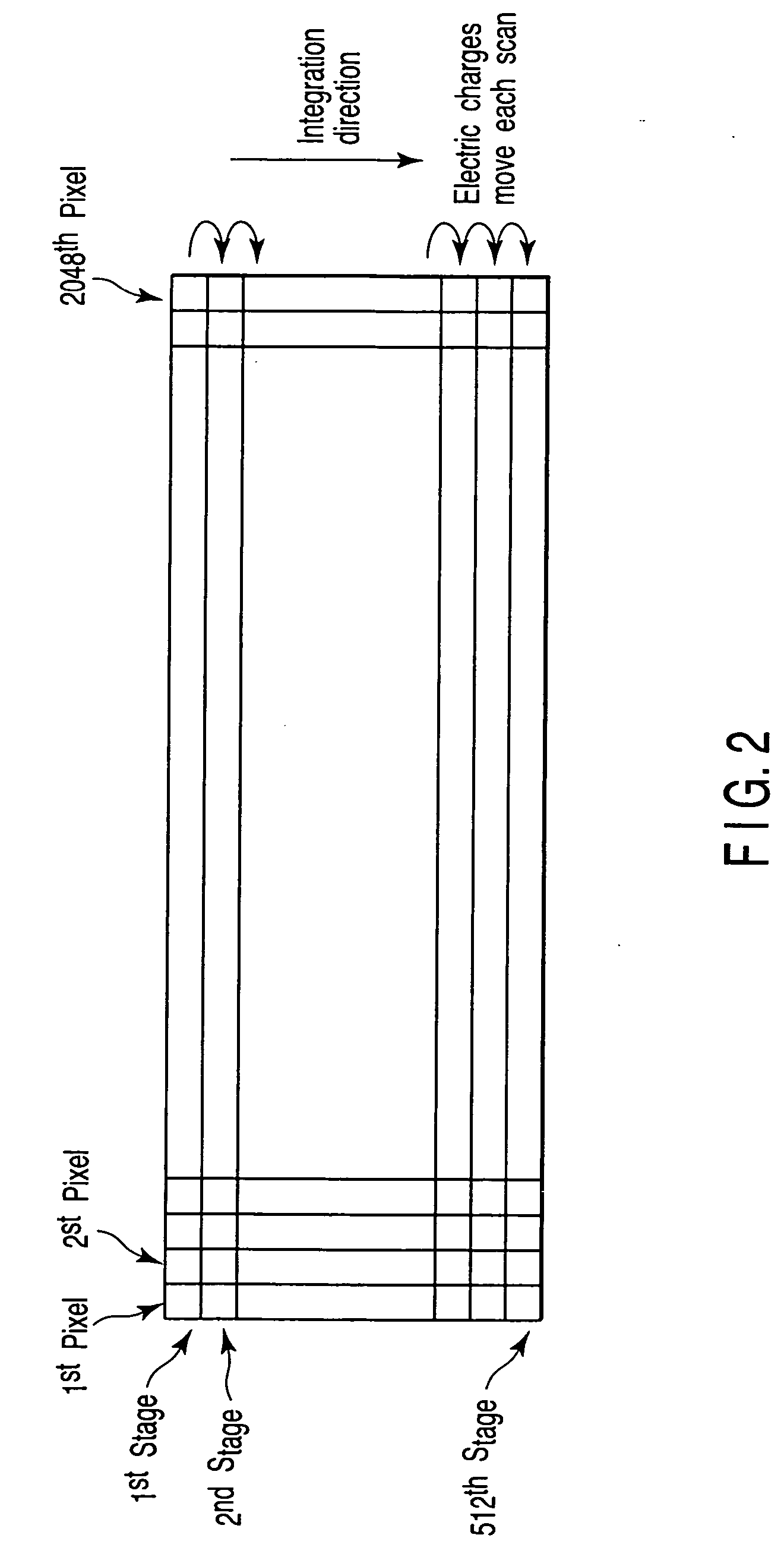

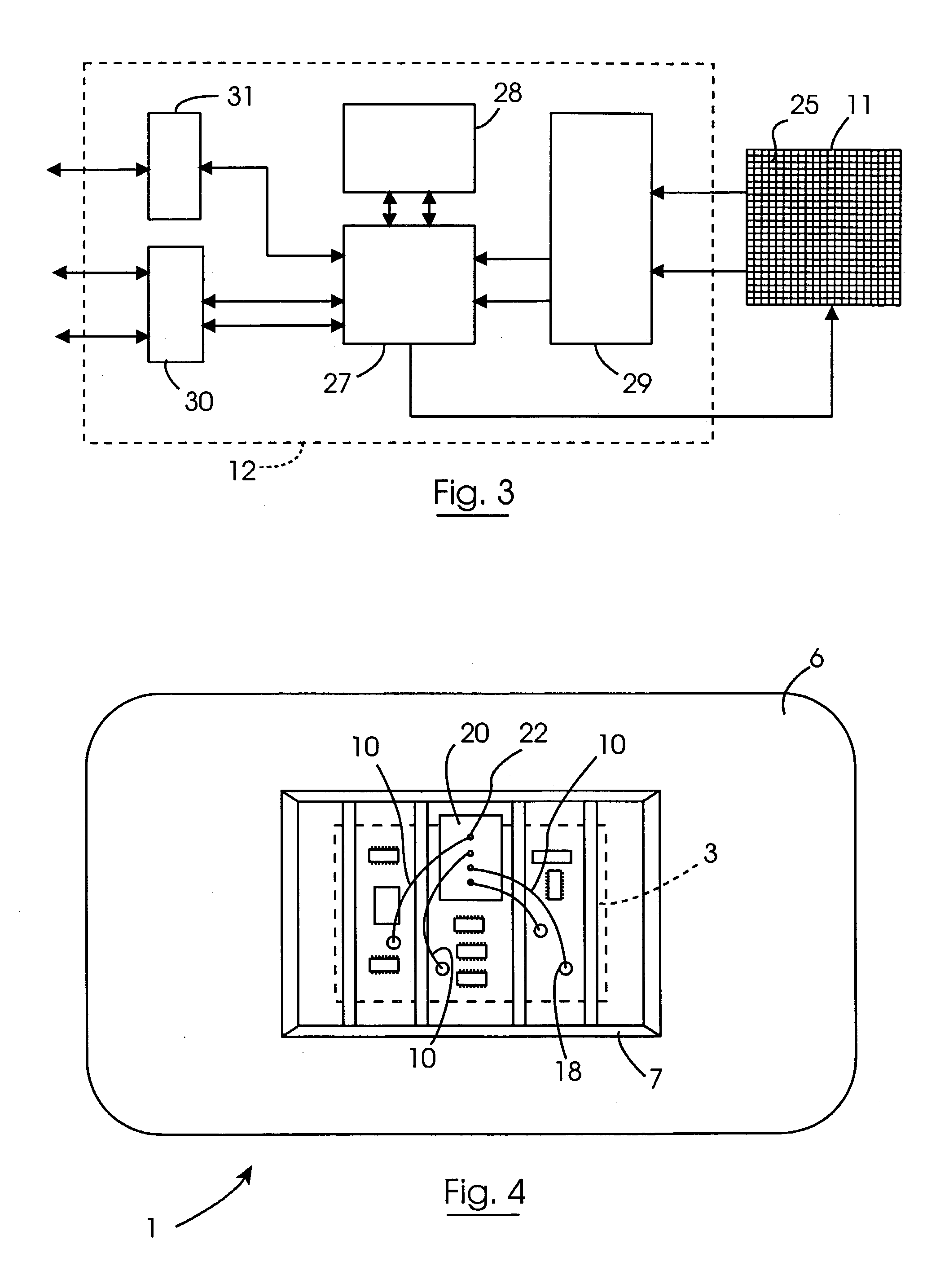

Image input apparatus and inspection apparatus

InactiveUS20050196059A1Enter exactlySemiconductor/solid-state device testing/measurementDiode testingElectricityControl circuit

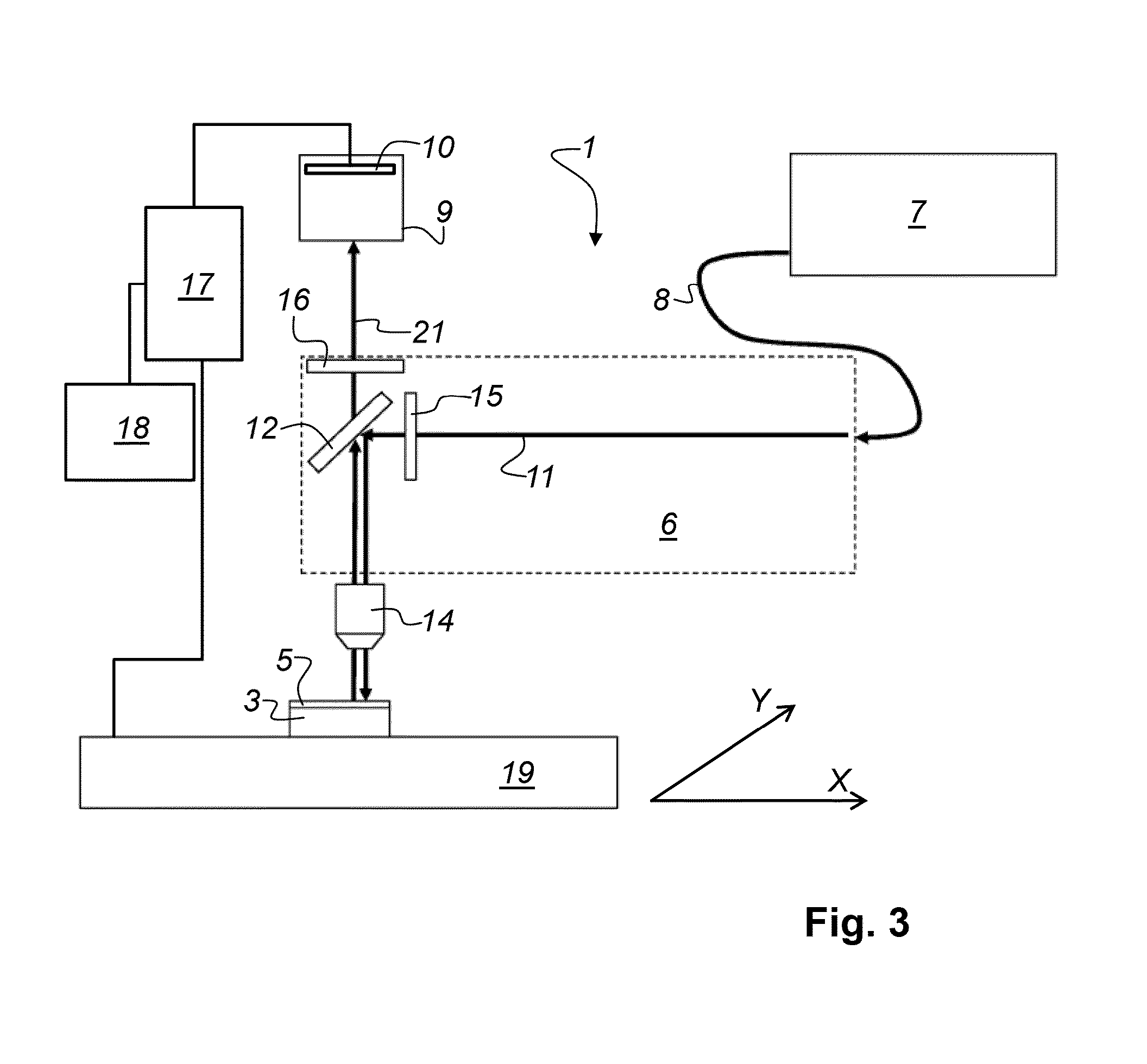

An image input apparatus for inputting an image of an object and outputting the image as an electric signal, the image input apparatus comprises a stage which supports the object, a laser interferometer which measures a position of the stage, a light source which emits a pulse light, an illumination optical system which irradiates the object with an illuminating light, a sensor which converts an image-formed optical image into an electric image signal, an imaging optical system which forms an image of the object on the sensor, a synchronization control circuit which controls a light-emission interval of the light source and synchronization of the sensor on the basis of position information of the laser interferometer, a light quantity monitor which measures a quantity of light, and a light quantity correction circuit which corrects the electric image signal on the basis of an output of the light quantity monitor.

Owner:KK TOSHIBA +1

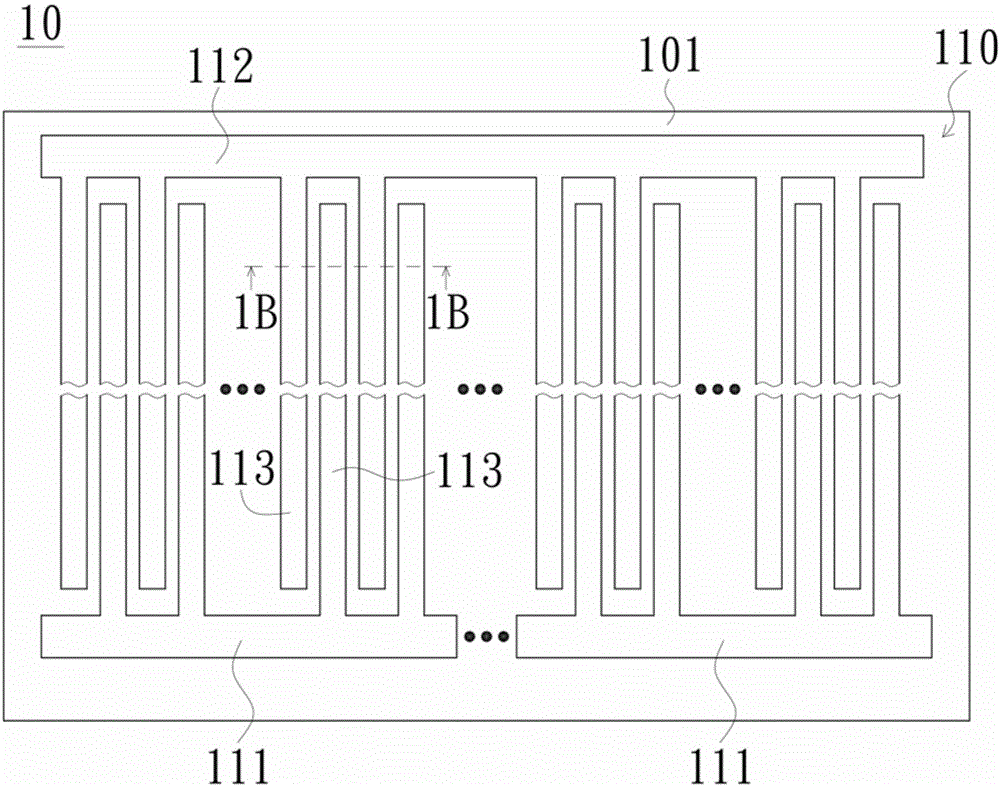

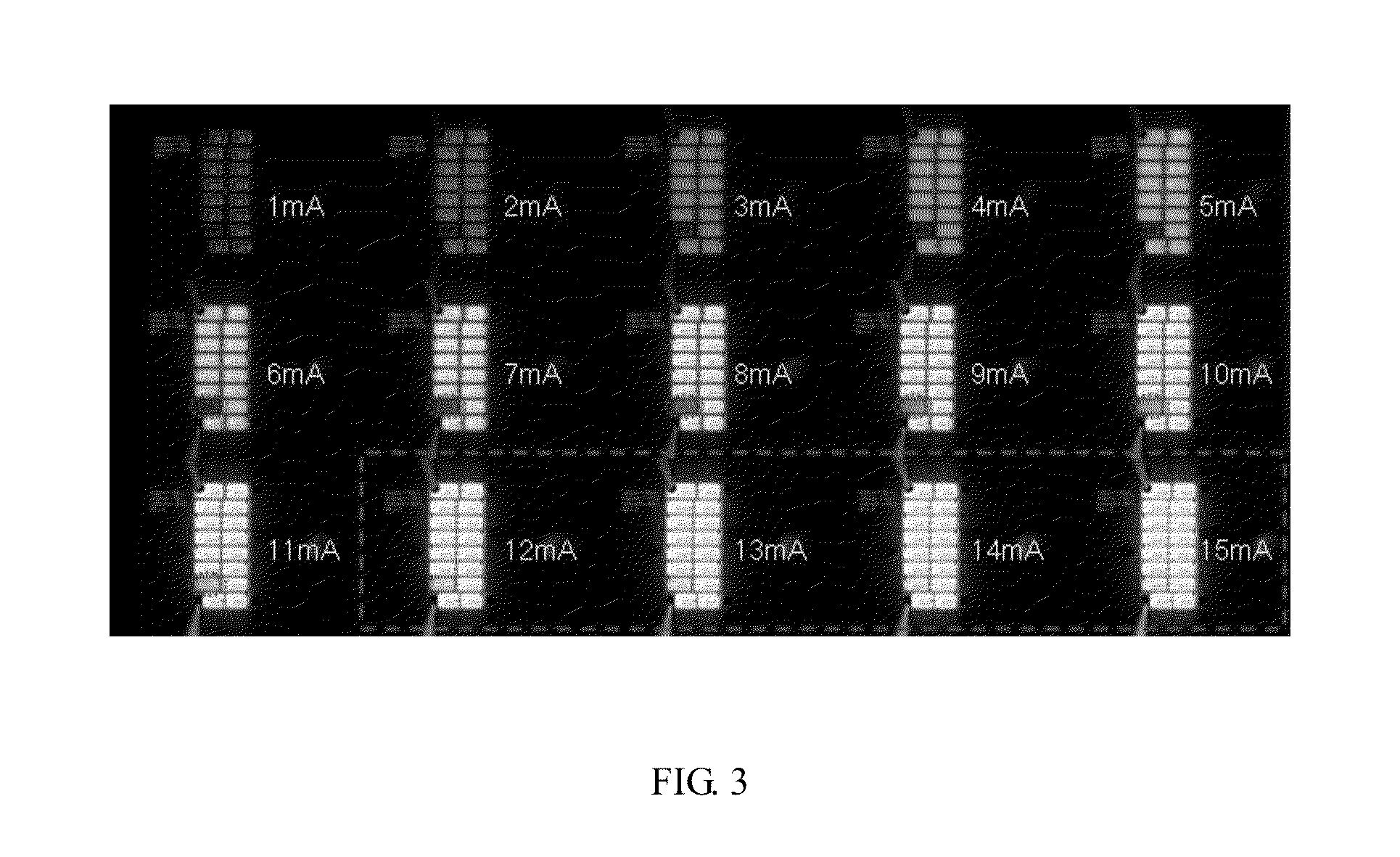

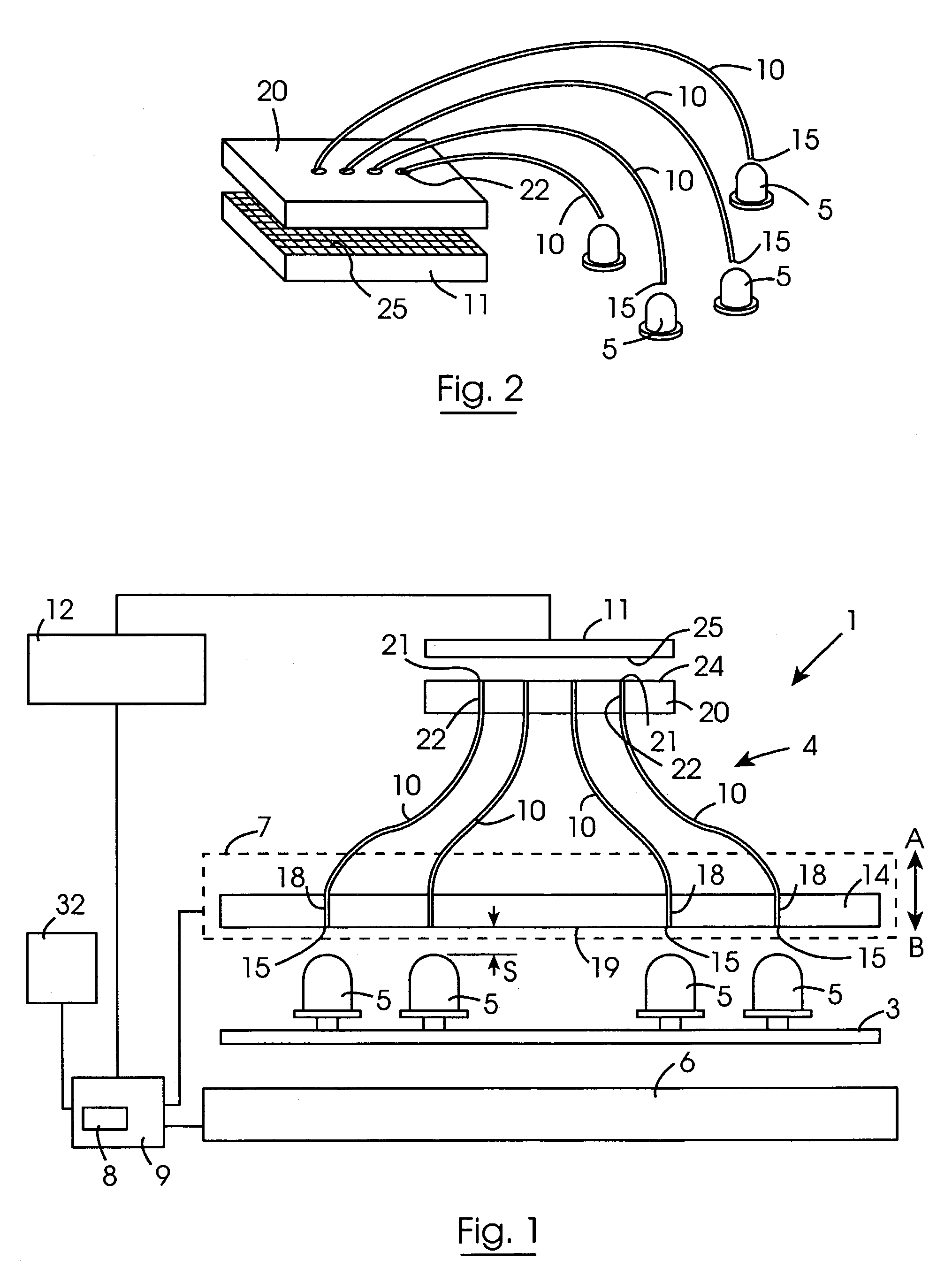

Light emitting diode (LED) test apparatus and method of manufacture

ActiveUS20180259570A1Charge coupling efficiencyEfficient Functional TestingSemiconductor/solid-state device testing/measurementDiode testingElectricityQuantum efficiency

Embodiments relate to functional test methods useful for fabricating products containing Light Emitting Diode (LED) structures. In particular, LED arrays are functionally tested by injecting current via a displacement current coupling device using a field plate comprising of an electrode and insulator placed in close proximity to the LED array. A controlled voltage waveform is then applied to the field plate electrode to excite the LED devices in parallel for high-throughput. A camera records the individual light emission resulting from the electrical excitation to yield a function test of a plurality of LED devices. Changing the voltage conditions can excite the LEDs at differing current density levels to functionally measure external quantum efficiency and other important device functional parameters.

Owner:APPLE INC

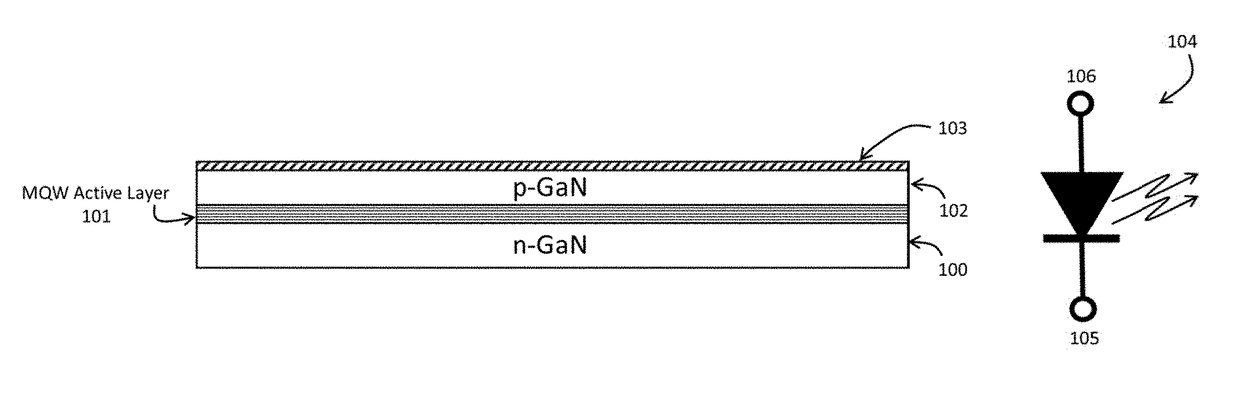

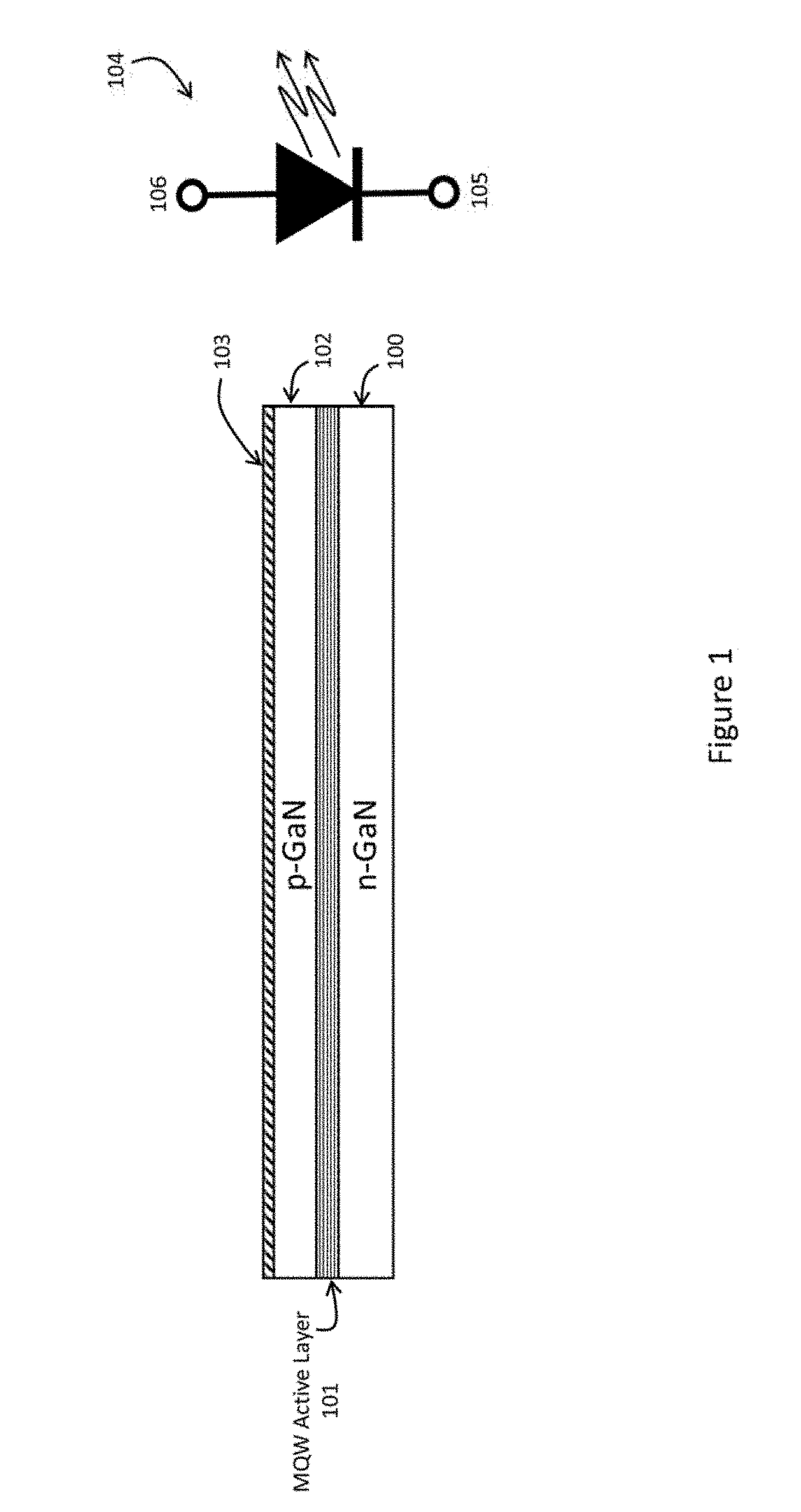

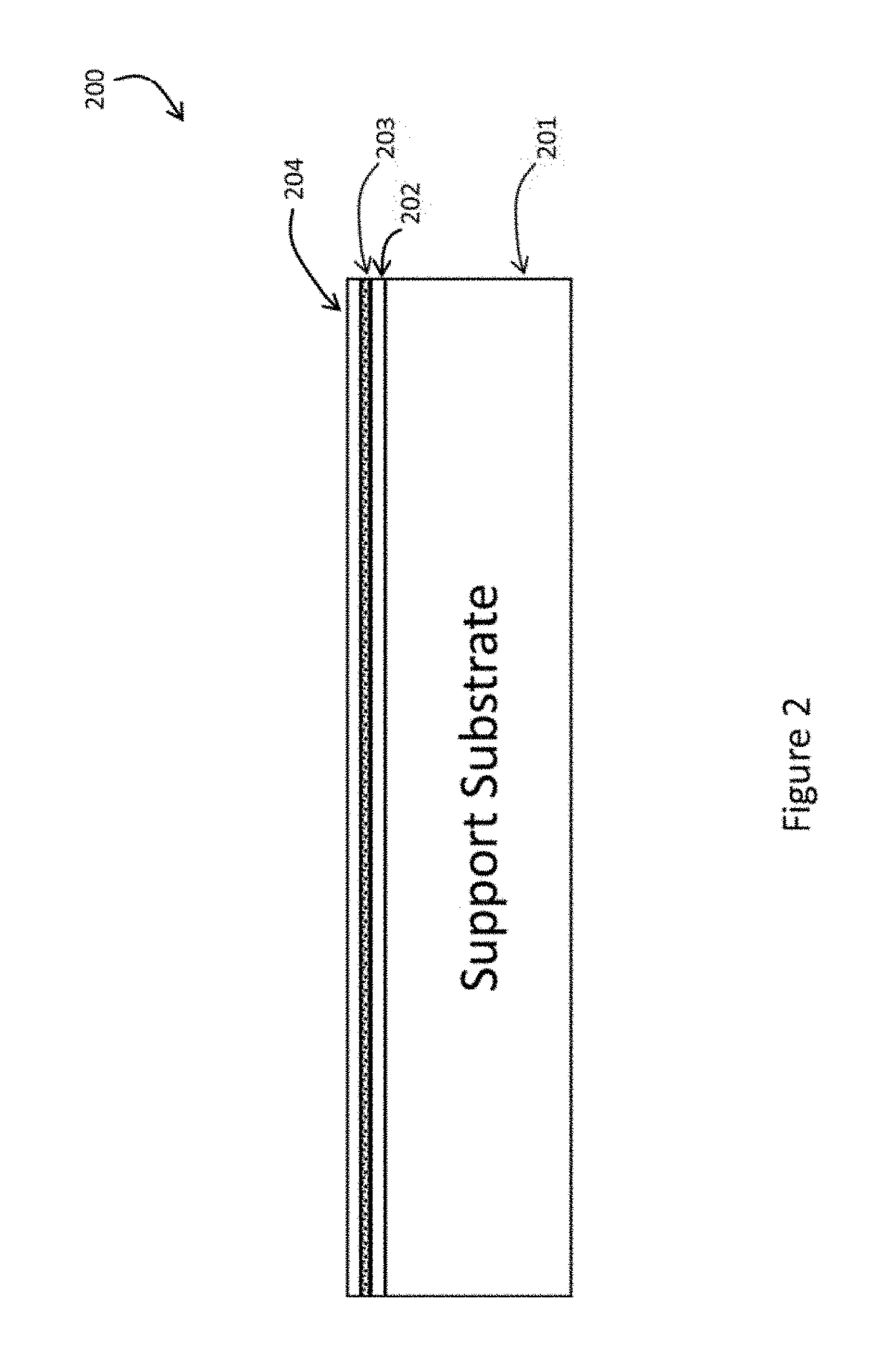

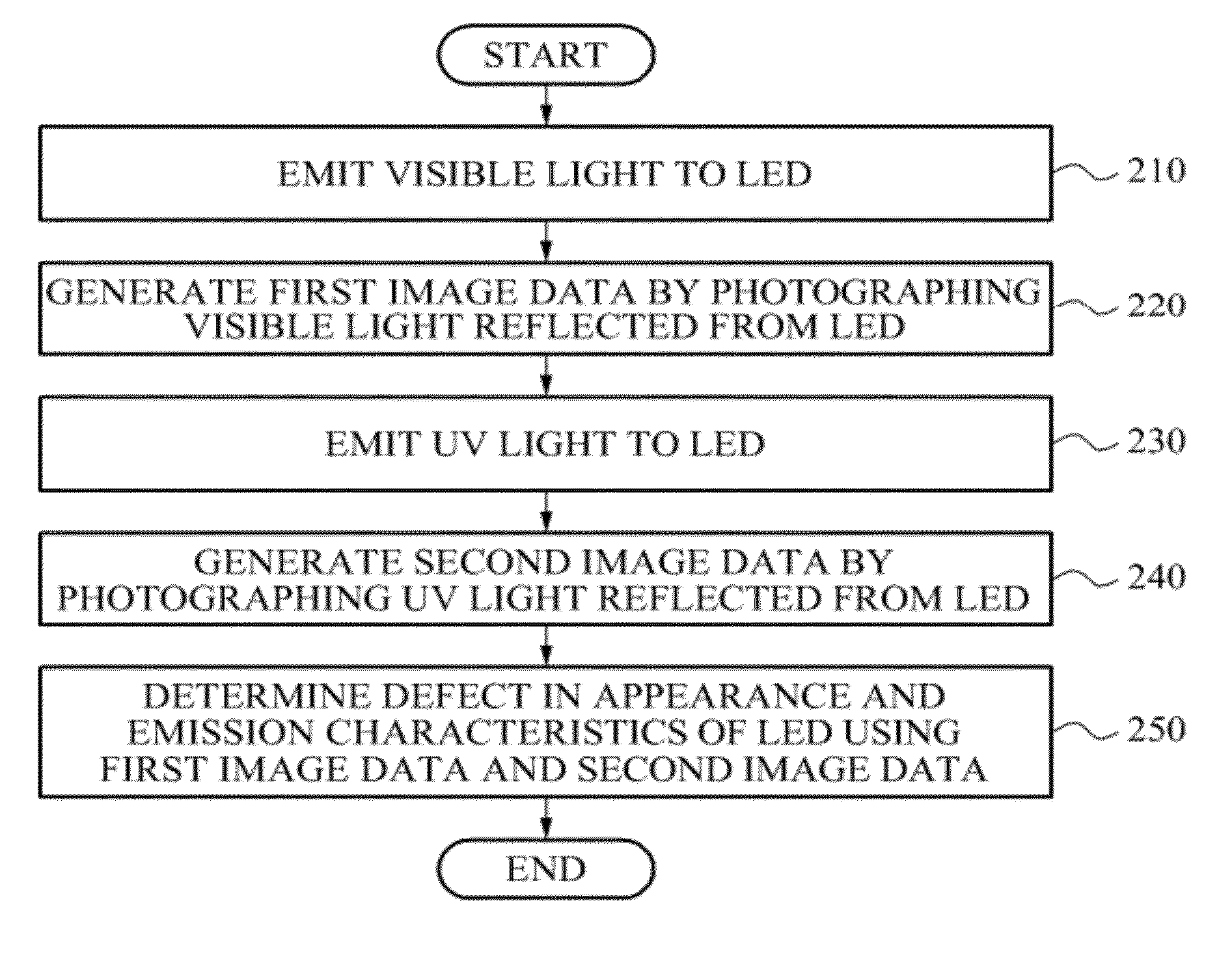

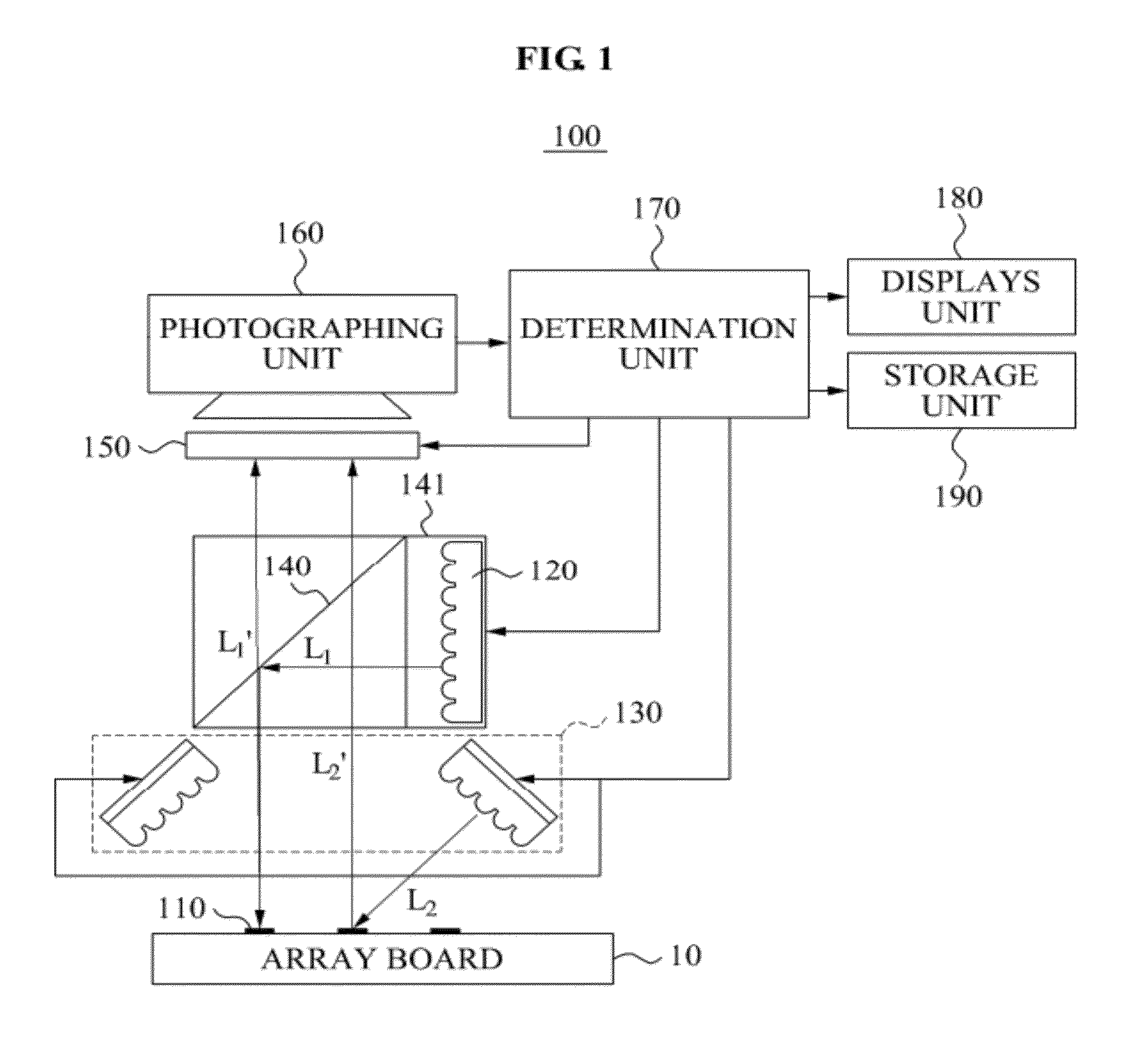

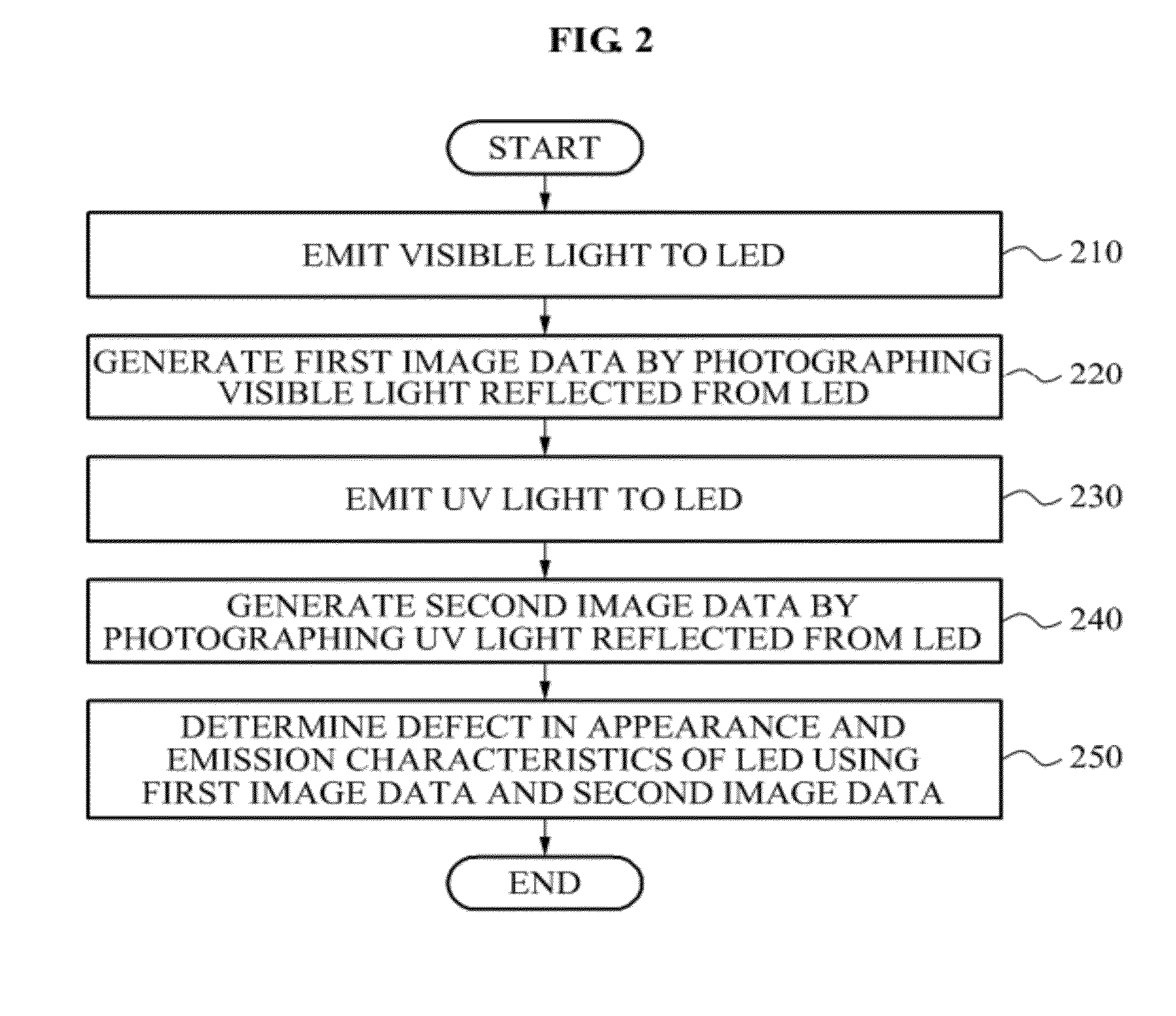

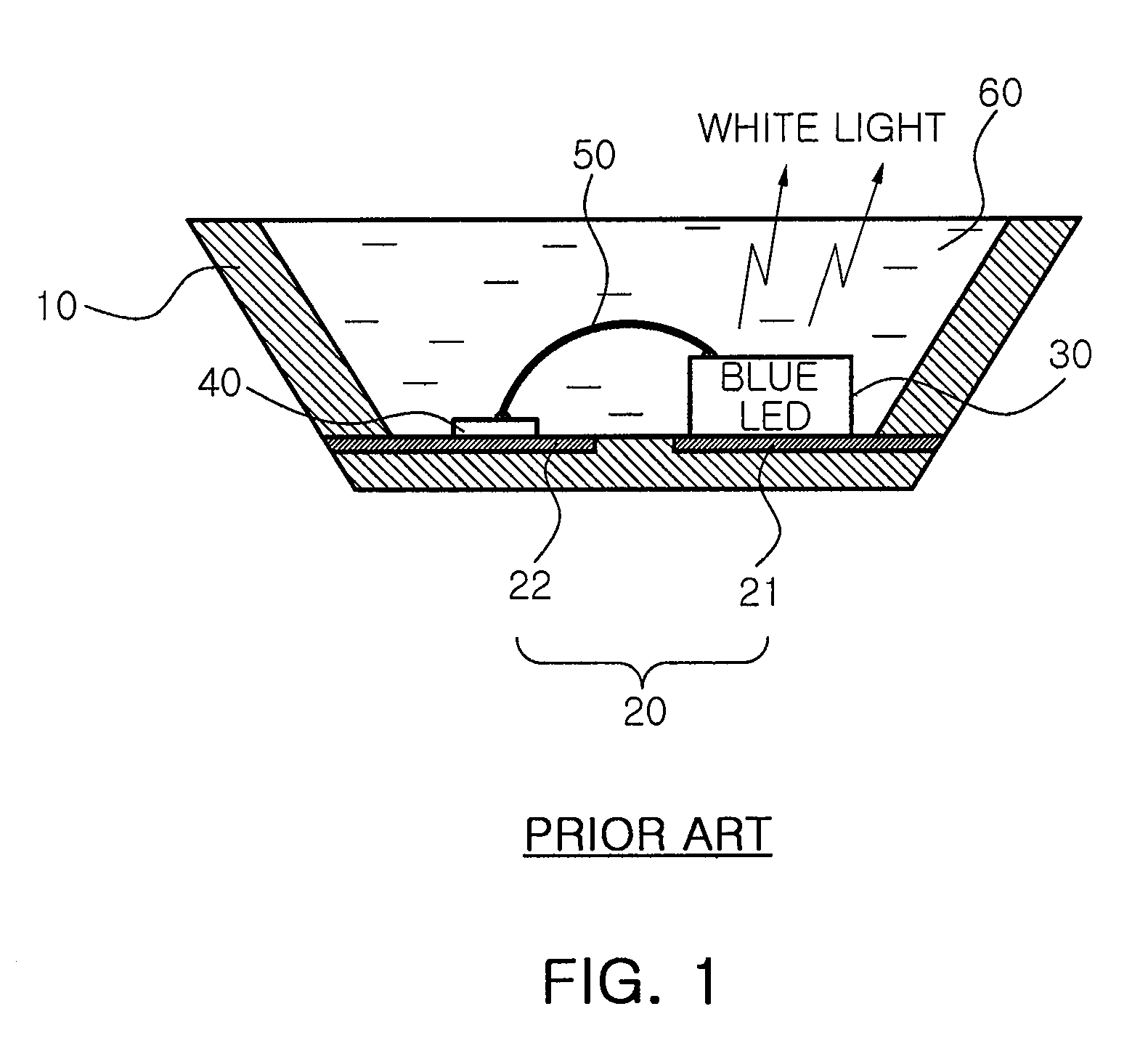

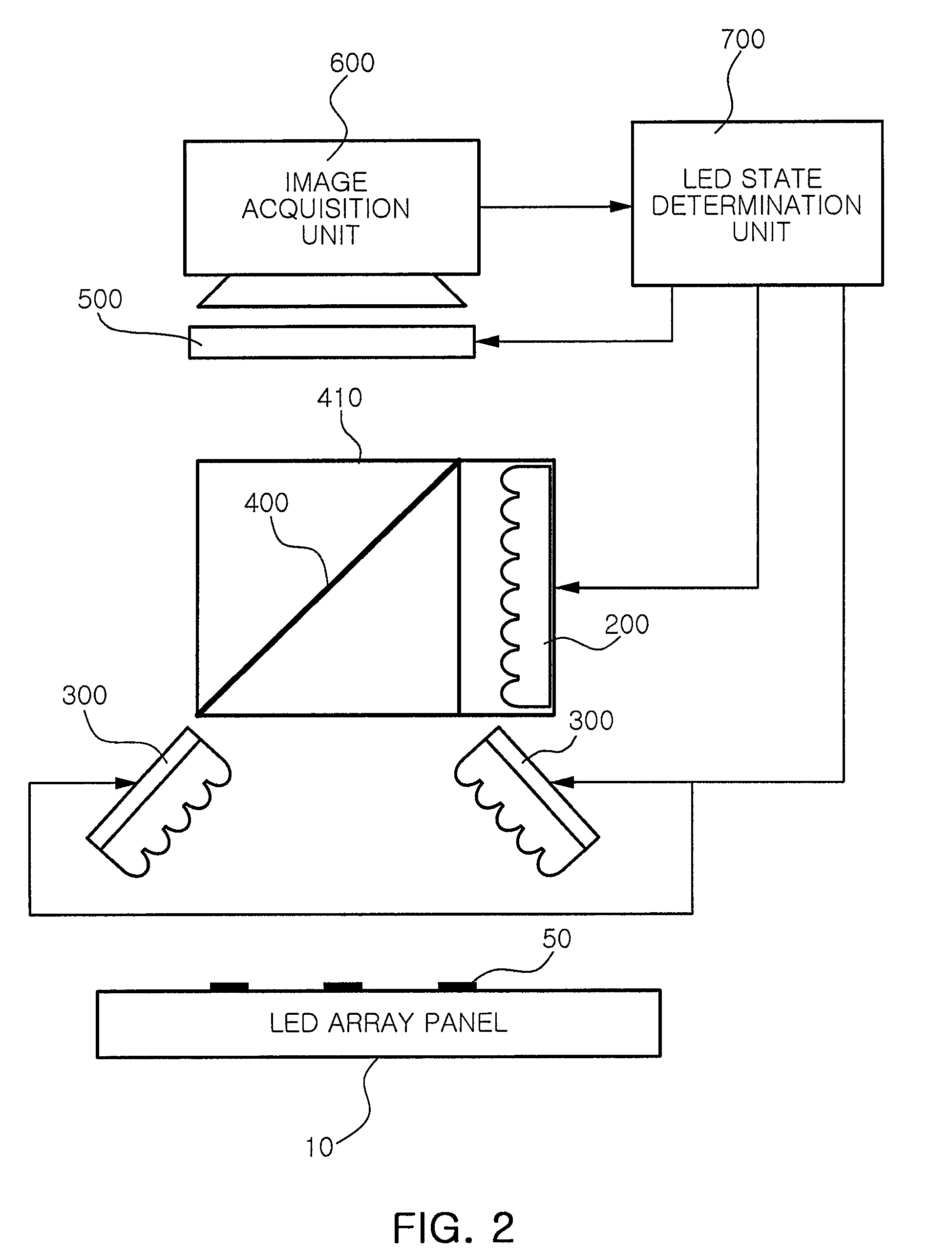

Apparatus for inspecting light emitting diode and inspecting method using said apparatus

ActiveUS20120249779A1Reduce inspection costsIncrease speedSemiconductor/solid-state device testing/measurementDiode testingPhosphorEffect light

A light emitting diode (LED) inspection apparatus includes at least one LED including a phosphor applied on an emission surface, a first lighting unit to emit visible light to the LED, a second lighting unit to emit ultraviolet (UV) light to the LED, a photographing unit to generate at least one first image data by photographing the visible light reflected from the LED and to generate at least one second image data by photographing the UV light reflected from the LED, and a determination unit to determine a defect in appearance and emission characteristics of the LED using the at least one first image data and second image data.

Owner:SAMSUNG ELECTRONICS CO LTD

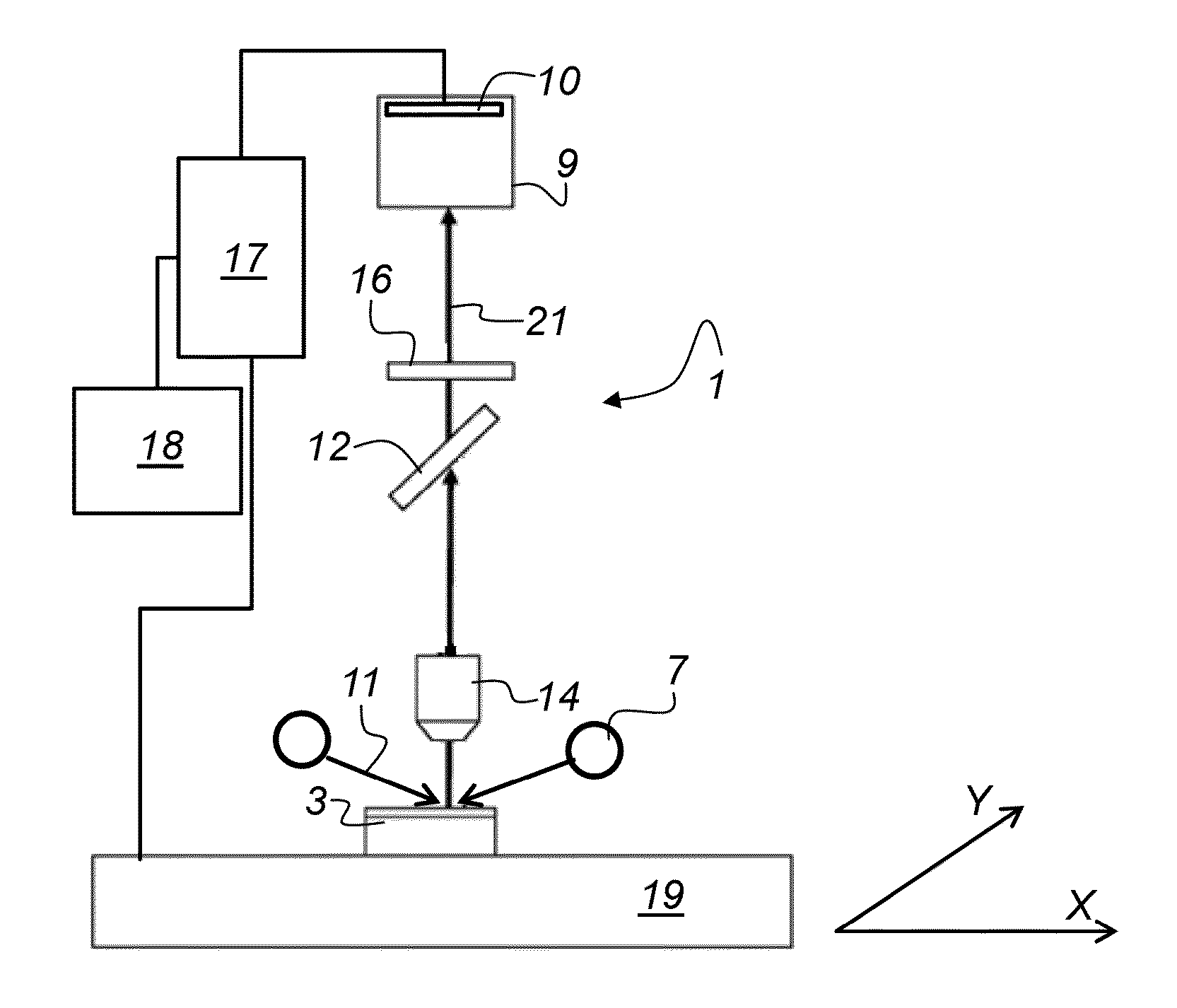

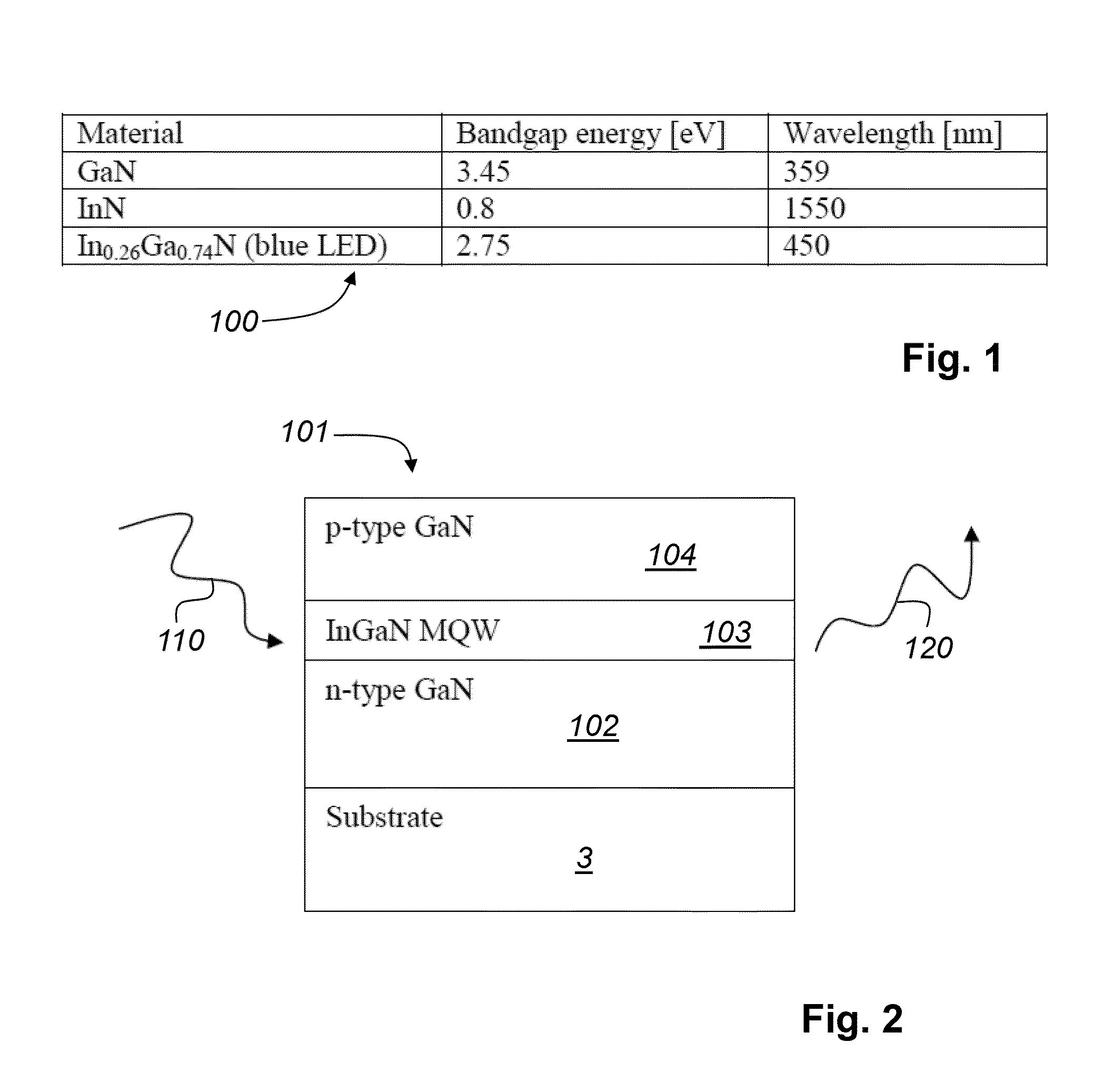

Method and apparatus for inspection of light emitting semiconductor devices using photoluminescence imaging

ActiveUS20130027543A1Quickly and reliably measureEasy to useDiode testingMaterial analysis by optical meansElectron holePhotoluminescence

A method and apparatus for the inspection of light emitting semiconductor devices. The semiconductor device is illuminated with a light source, wherein at least an area of the light emitting semiconductor is illuminated with a waveband of light. The waveband of light λA+λB can generate electron-hole pairs in the light emitting semiconductor to be inspected. Through an objective lens at least a part of the light λC emitted by the light emitting semiconductor is detected. The emitted light is captured with a sensor of a camera that is sensitive to wavelengths of the emitted light, wherein the wavelength of the emitted light is above the width of the waveband. The data of the emitted light, captured with the sensor, are transmitted to a computer system for calculating inspection results of the light emitting semiconductor.

Owner:KLA TENCOR TECH CORP

Miniature light-emitting component and manufacturing method thereof

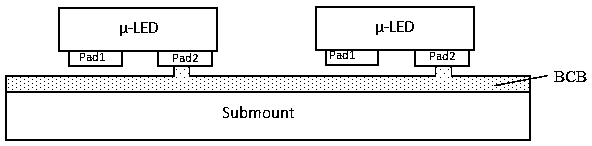

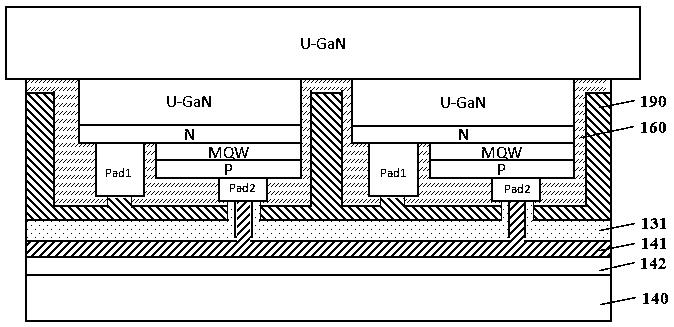

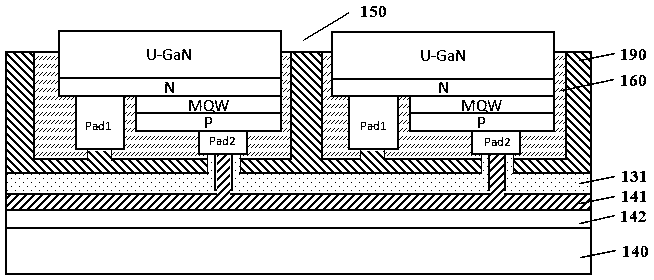

ActiveCN108417682ADoes not affect transfer processDiode testingSolid-state devicesEngineeringActive layer

The invention discloses a miniature light-emitting component and a manufacturing method thereof. A support pillar of a pinhole electrode is formed by a conductive substrate and insulation isolation, and a common-electrode parallel connection is used. A modular metal sacrificial layer is used as a test electrode to realize a huge amount of measurement of the miniature light-emitting component. Theminiature light-emitting component comprises: an epitaxial stack successively comprising a first type of semiconductor layer, an active layer, a second type of semiconductor layer and having oppositefirst and second surfaces; a first electrode formed on the second surface on the epitaxial stack and connected to the first type of semiconductor layer; a second electrode formed on the second surfaceof the epitaxial stack and connected to the second type of semiconductor layer; and first connection regions disposed on the surface of the first electrode and the second electrode. The first connection regions can be distinguished from other regions of the electrode where it is located from the surface topography or appearance color.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

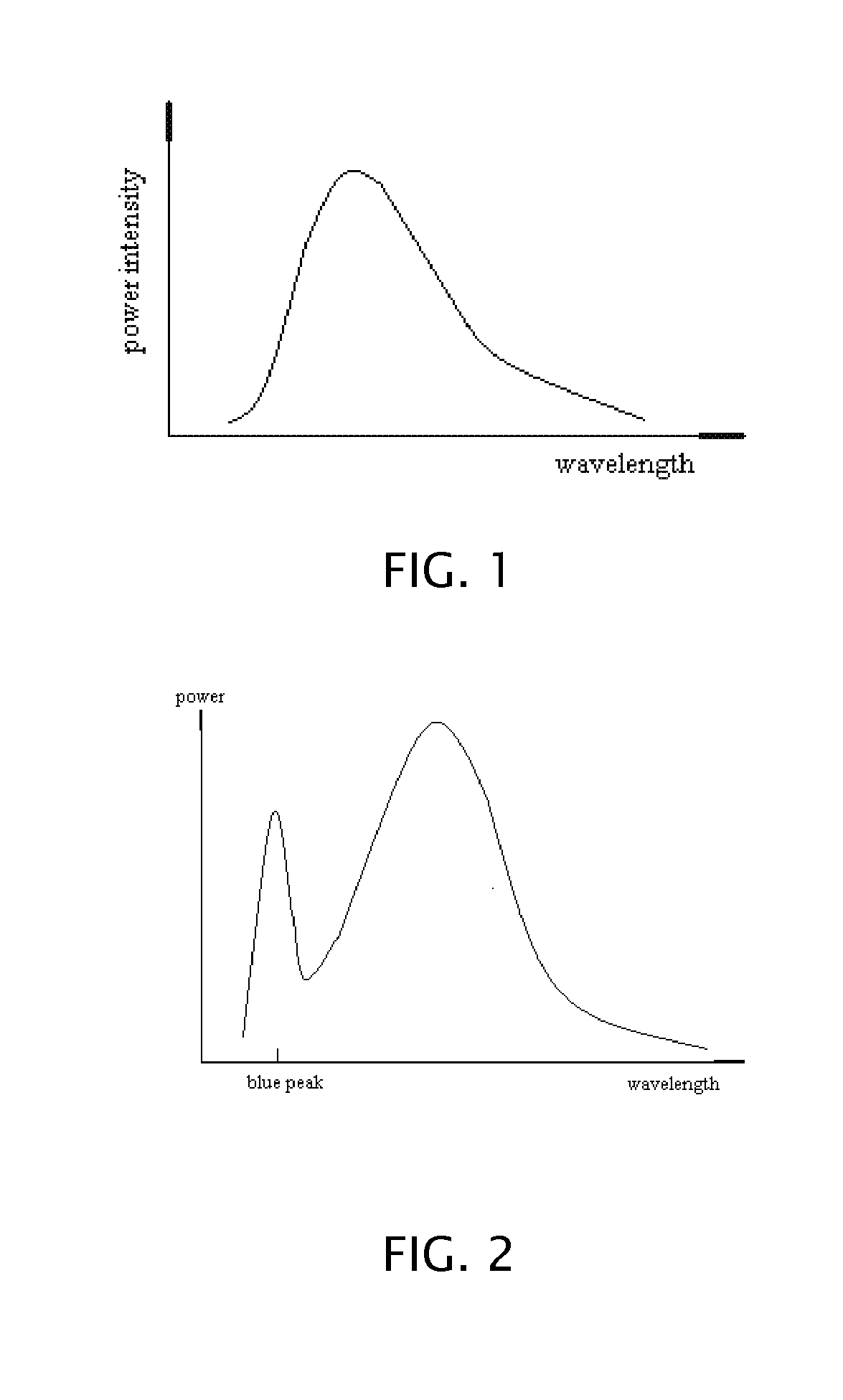

METHOD AND TESTING EQUIPMENT FOR LEDs AND LASER DIODES

ActiveUS20080205482A1Simple and quick procedureSimple methodDiode testingThermometers using electric/magnetic elementsFailure rateJunction temperature

The present invention is a non-invasive method and associated apparatus for determining the junction temperature for an LED or laser diode (collectively “LED”). First a sample LED is placed in a heat chamber and the change of the LED's peak wavelength is recorded over time, as is the change in the temperature in the heat chamber. Since the heat chamber supplies the major component to the junction temperature, dwarfing the other components, it is a reasonable proxy for true junction temperature. The data is compiled to determine change of peak wavelength as a function of temperature and that function can then be used to determine junction temperature of similar LEDs that are installed in a system or manufactured. The invention may also be used to measure other useful data, such as power, output power changing with the junction temperature and intensity of the LED over time and may be used to estimate failure rate.

Owner:EPISTAR CORP

Transition loading plate device, display panel and manufacture method, minisize light-emitting member detection method

ActiveCN106373895AImprove yieldSemiconductor/solid-state device testing/measurementDiode testingInsulation layerProtection layer

The inventio discloses a transition loading plate device, s display panel and s manufacture method, and a minisize light-emitting member detection method. The transition plate device manufacture method comprises steps of forming a circuit layer, forming a support layer which has a plurality of openings exposing the circuit layers; the protection layer is formed on the support layer and covers the support layer and the circuit layer which is exposed by the opening; a pattern layer is adhered to the protection layer; at least one minisize light emitting member is adhered to the pattern layer; an insulation layer is formed on the protection layer ad the minisize light emitting member; after that, the protection layer and the insulation layer are removed in order to form a plurality of contact holes; then, a lead layer is formed on the insulation layer; and the light-emitting member and the circuit layer are electrically connected through the contact holes. Besides, the invention also discloses a transition loading plate device, a method for detecting the minisize light-emitting member, a display panel and a manufacture method for the same.

Owner:AU OPTRONICS CORP

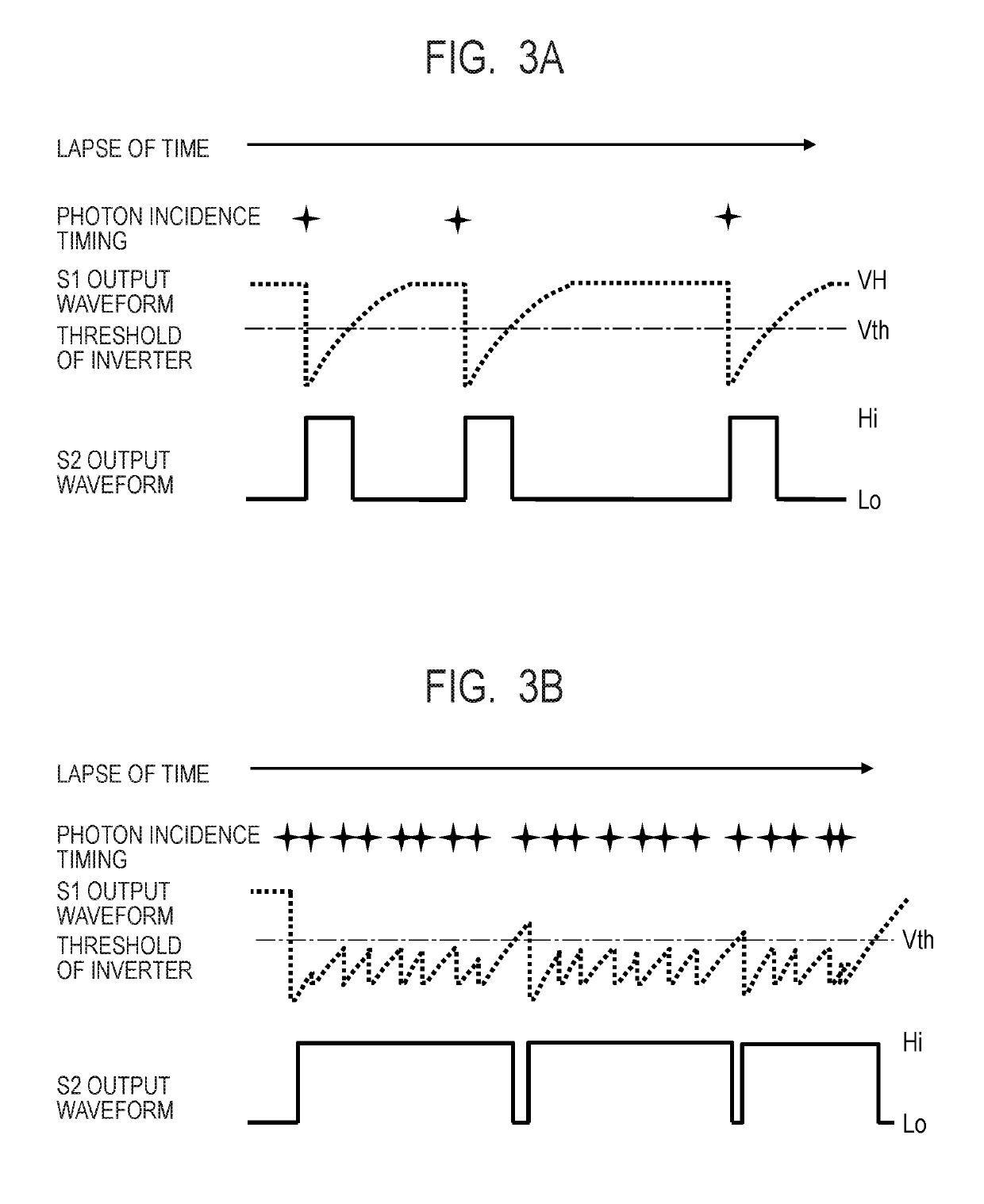

Photo-detection device, imaging apparatus, and imaging system

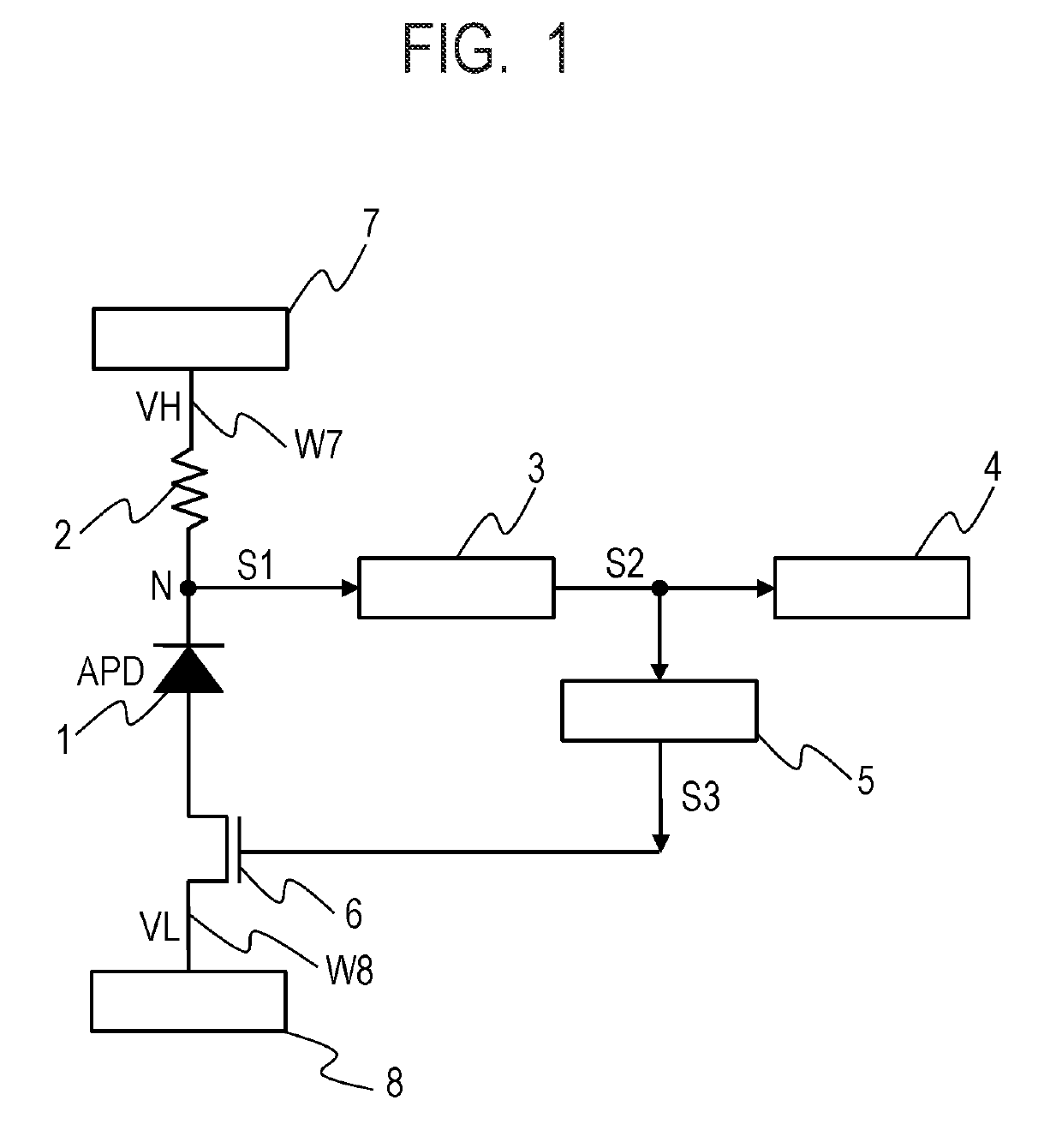

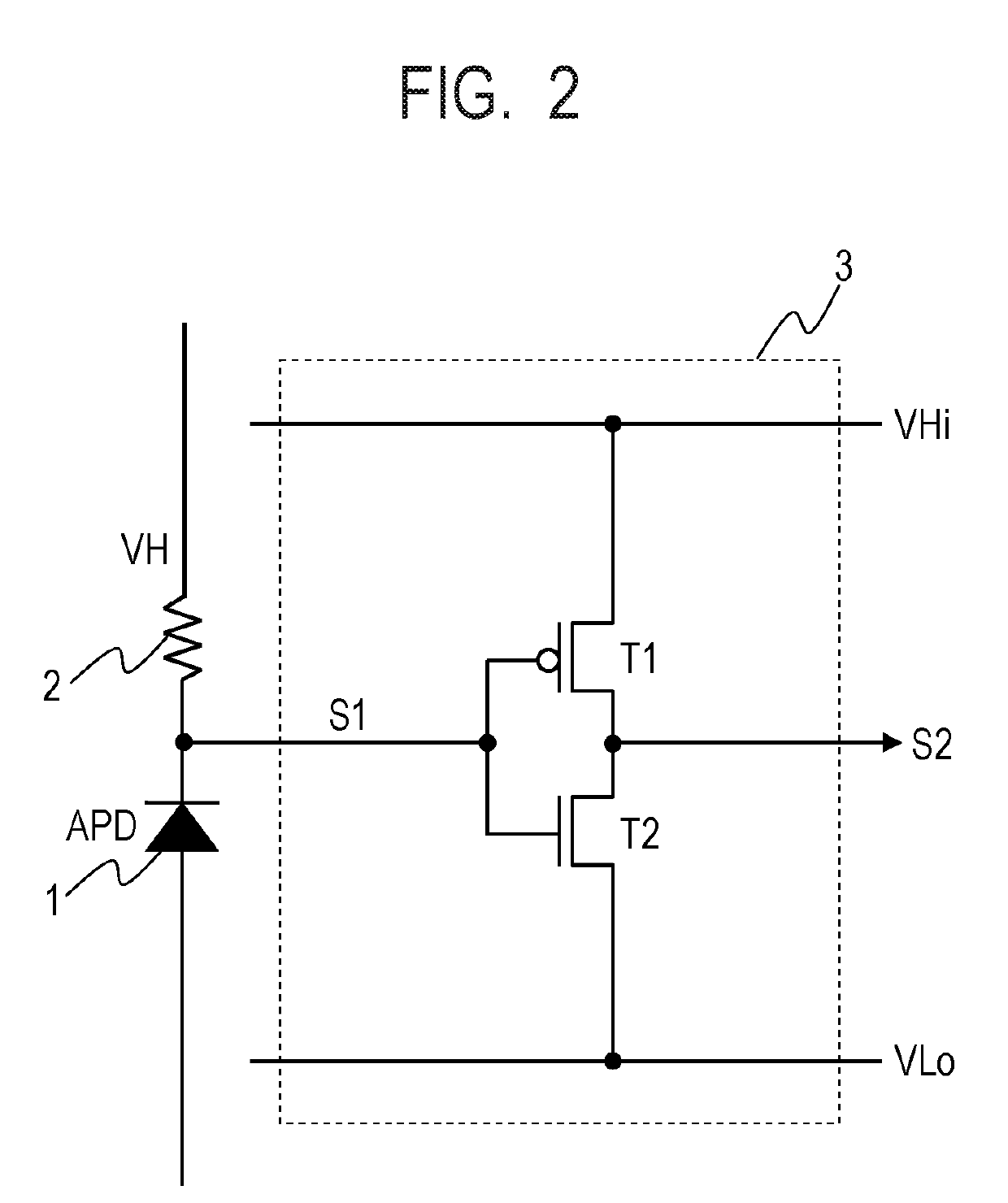

A photo-detection device includes an APD, a current detecting unit to which a signal via a first terminal of the APD is input, a load element connected to a node between the APD and the current detecting unit, a quench signal generating unit to which a signal from the current detecting unit is input and which outputs a quench signal, and a switch connected to a second terminal of the APD and a first wiring line to which first potential is supplied. The node is connected via the load element to a second wiring line to which second potential different from the first potential is supplied, and the quench signal generating unit generates a one-shot pulse signal as the quench signal based on the signal from the current detecting unit and causes the quench signal to be input to the switch.

Owner:CANON KK

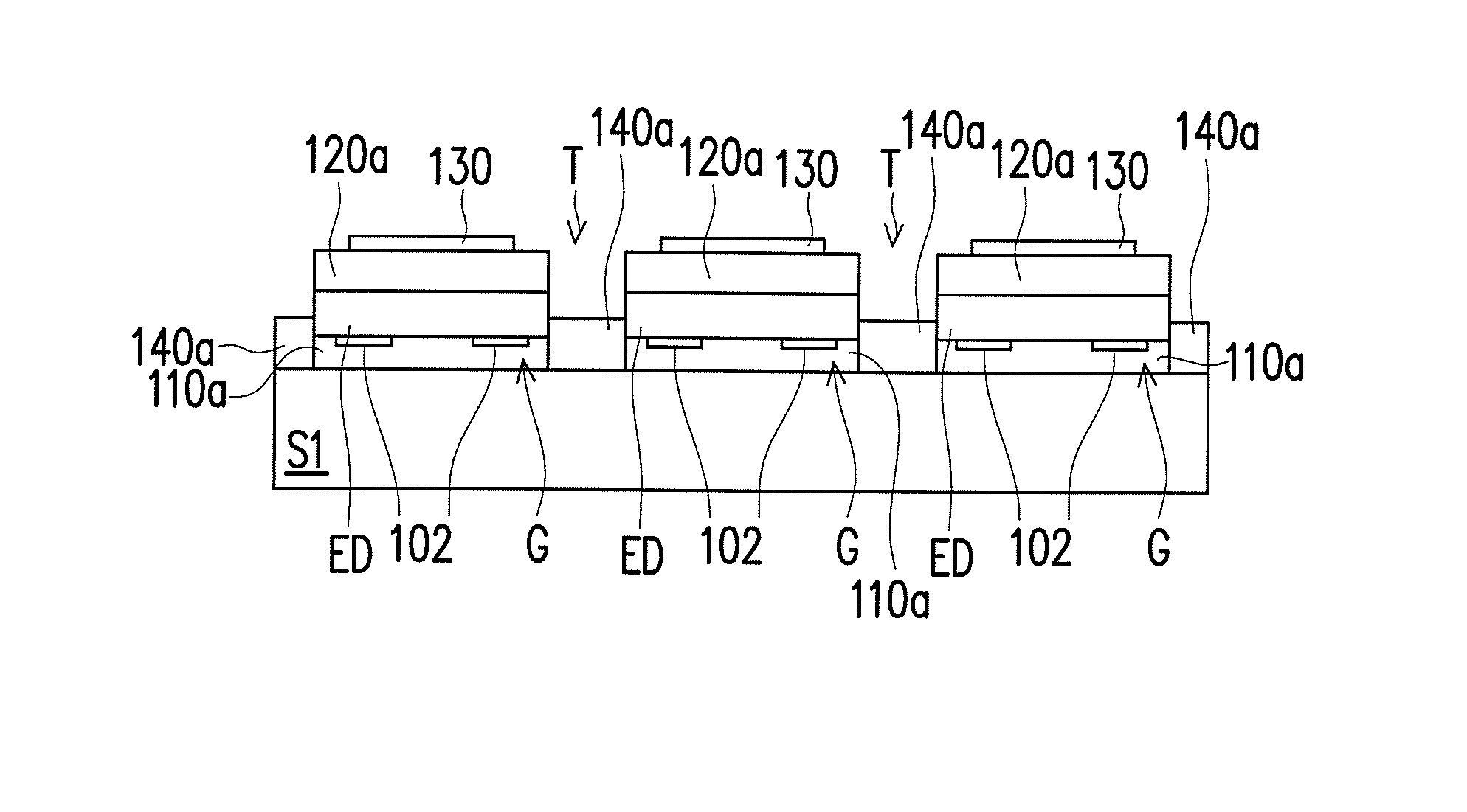

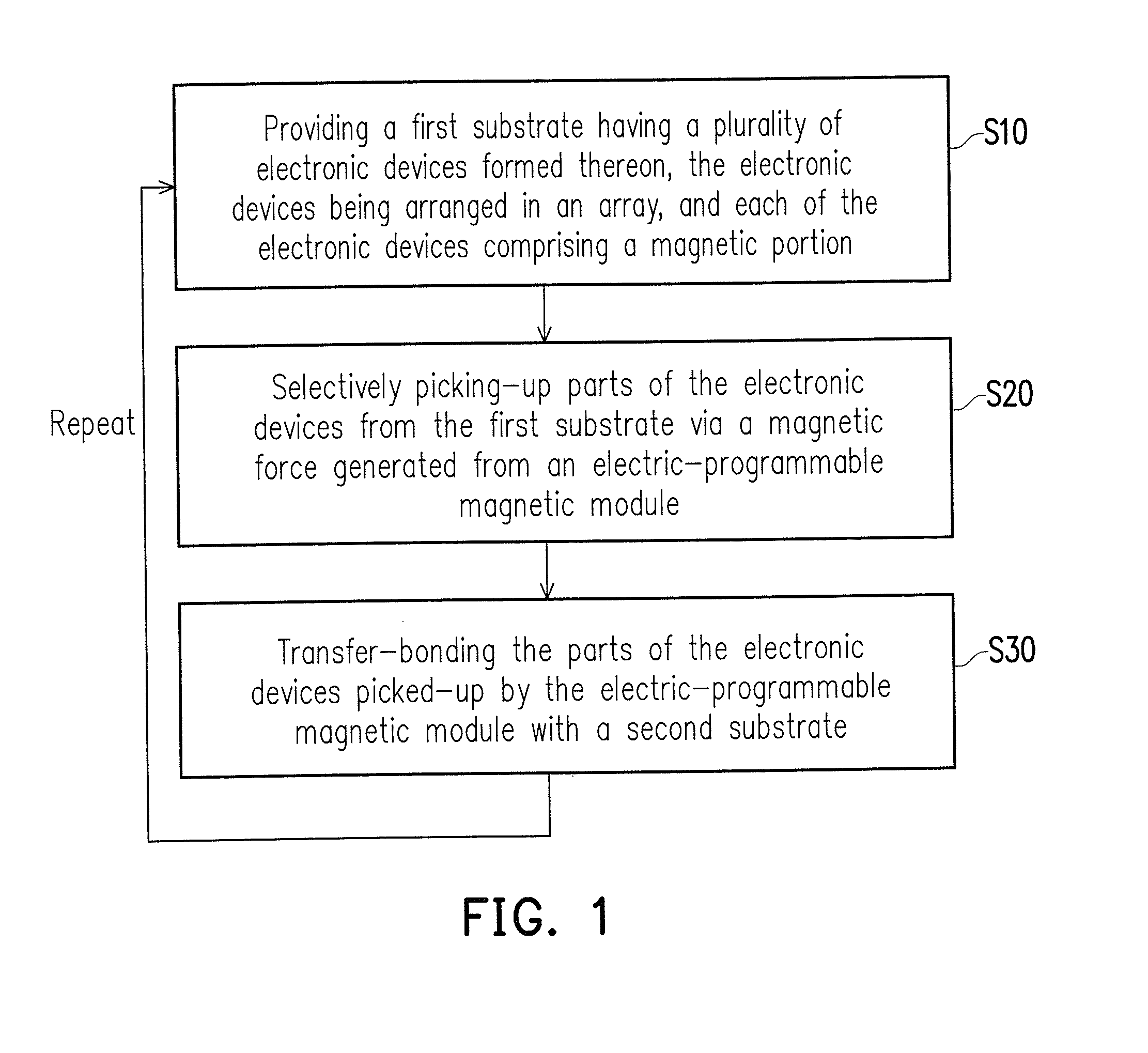

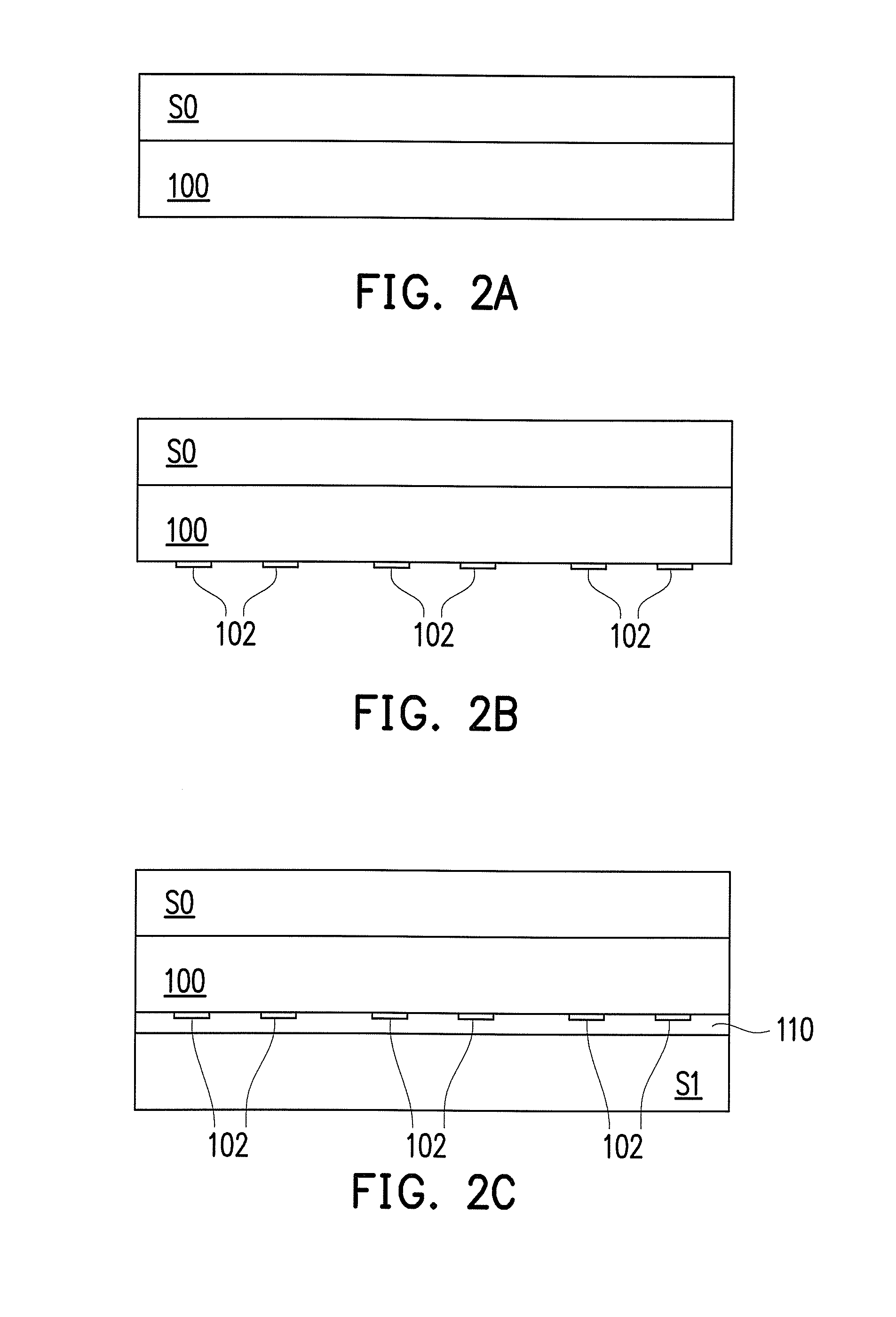

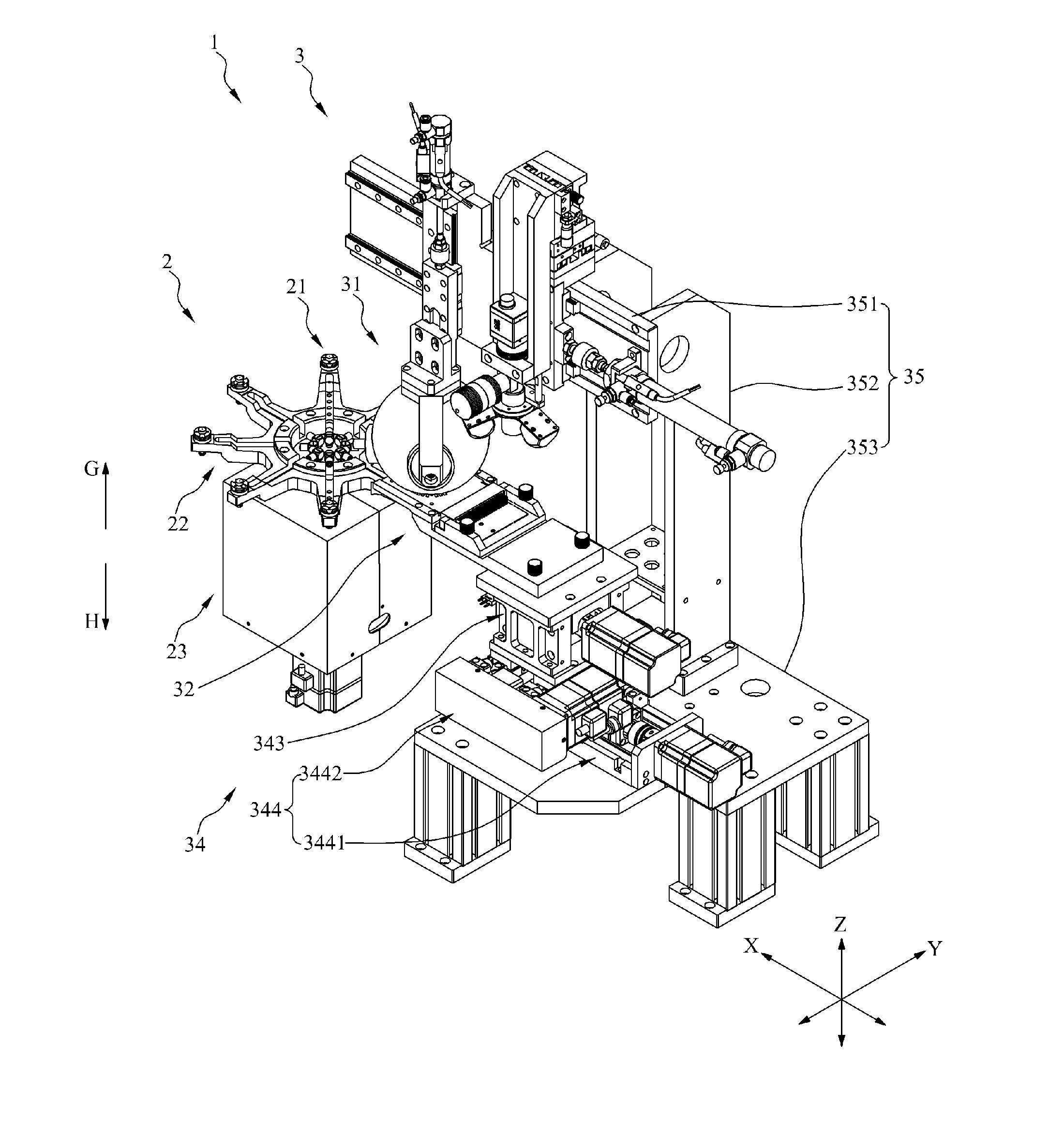

Electric-programmable magnetic module and picking-up and placement process for electronic devices

ActiveUS20160172253A1Electromagnets without armaturesSemiconductor/solid-state device testing/measurementMagnetic tension forceDevice form

Owner:PLAYNITRIDE +1

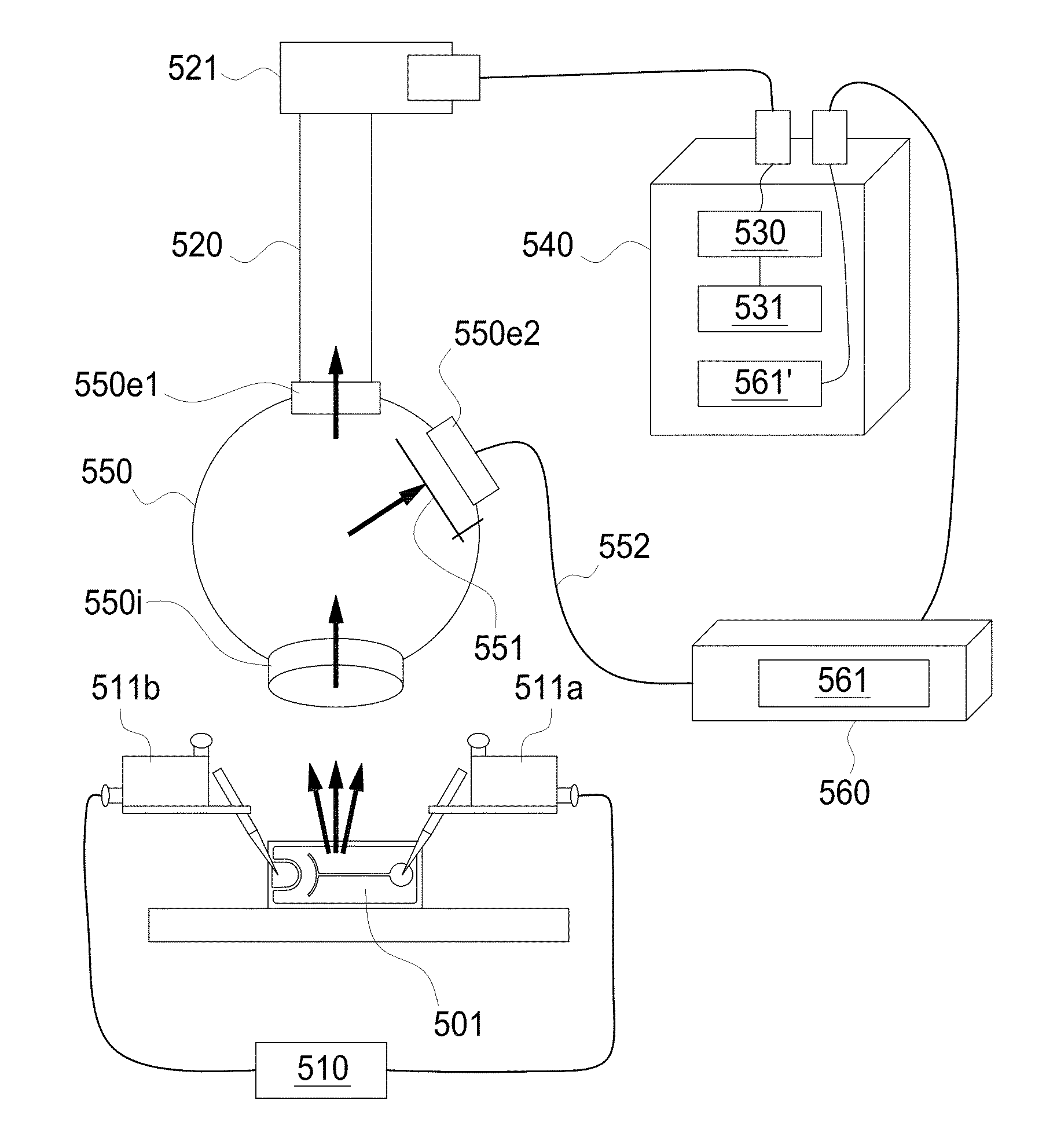

Method and apparatus for testing light-emitting device

Disclosed is a method for testing a light-emitting device comprising the steps of: providing an integrating sphere comprising an inlet port and a first exit port; disposing the light-emitting device close to the inlet port of the integrating sphere; providing a current source to drive the light-emitting device to form an image of the light-emitting device in driven state; providing an image receiving device and to receive the image of the light-emitting device, wherein the image receiving device is connected to the first exit port of the integrating sphere; and determining a luminous intensity of the light-emitting device according to the image. An apparatus for testing a light-emitting device is also disclosed. The apparatus for testing a light-emitting device comprises: an integrating sphere comprising an inlet port and a first exit port, wherein the light-emitting device is disposed close to the inlet port of the integrating sphere; an image receiving device connected to the first exit port of the integrating sphere for receiving an image of the light-emitting device; and a processing unit coupled to image receiving device for determining a luminous intensity of the light-emitting device.

Owner:EPISTAR CORP

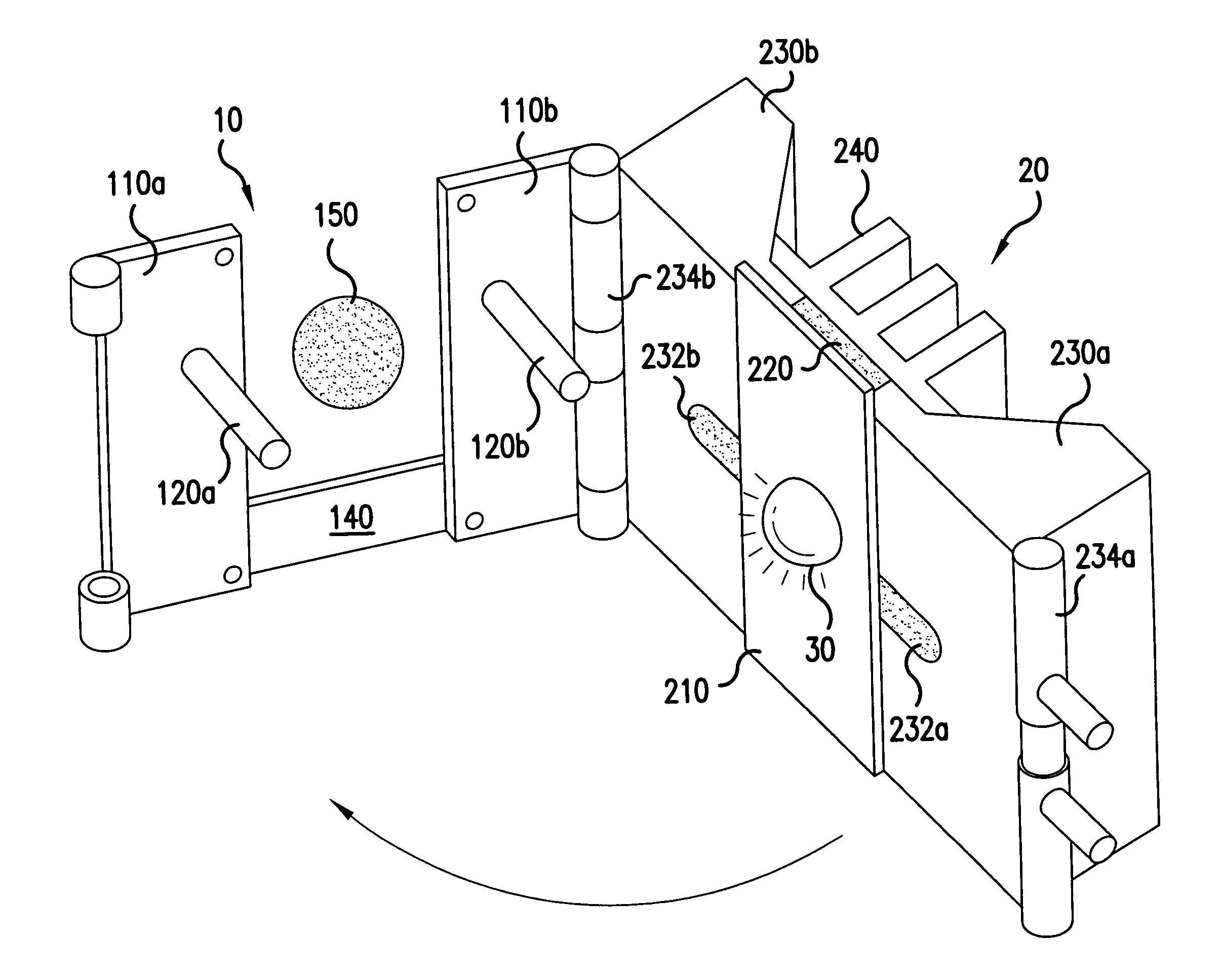

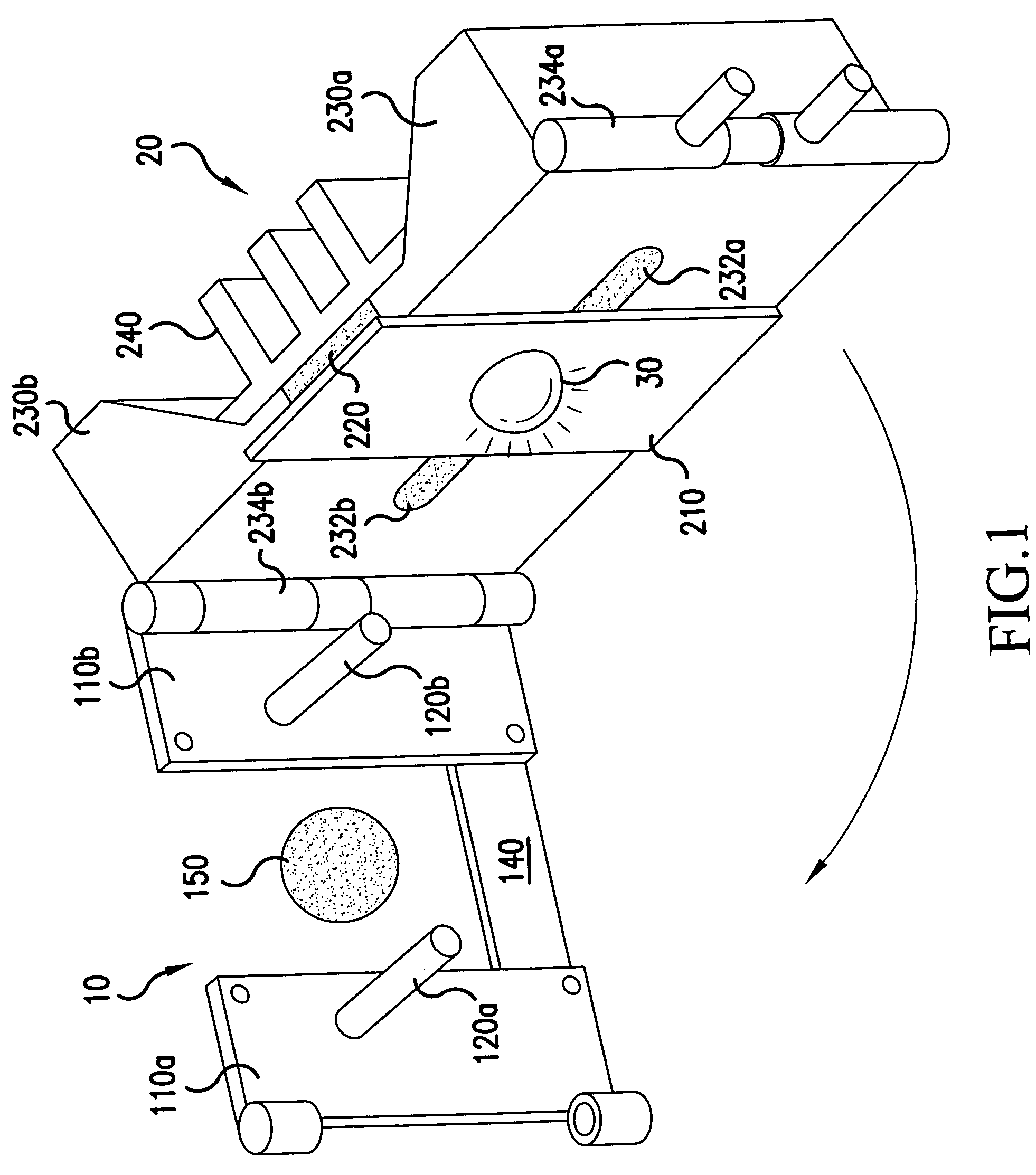

Quick attachment fixture and power card for diode-based light devices

InactiveUS7030642B2Fixed securityLoosening of the LT fit can be eliminatedDiode testingPhotometryRepeat testingFastener

A quick attachment device for use in the repeated testing of diode light sources (30) includes a quick attachment module (10) having a fixed location with respect to a testing position (150) for the diodes (30), and a mounting assembly (20) on which each diode (30) is mounted during testing. The quick attachment module (10) includes a quick disconnect fastener and two locating pins (120a and 120b) for securing the mounting assembly (20) for testing, where the two locating pins (120a and 120b) have a locational transition fit connection with the mounting assembly (20). The mounting assembly (20) may further include a thermal-electric cooling device (260) for cooling the diode light sources (30) during testing.

Owner:HONEYWELL INT INC

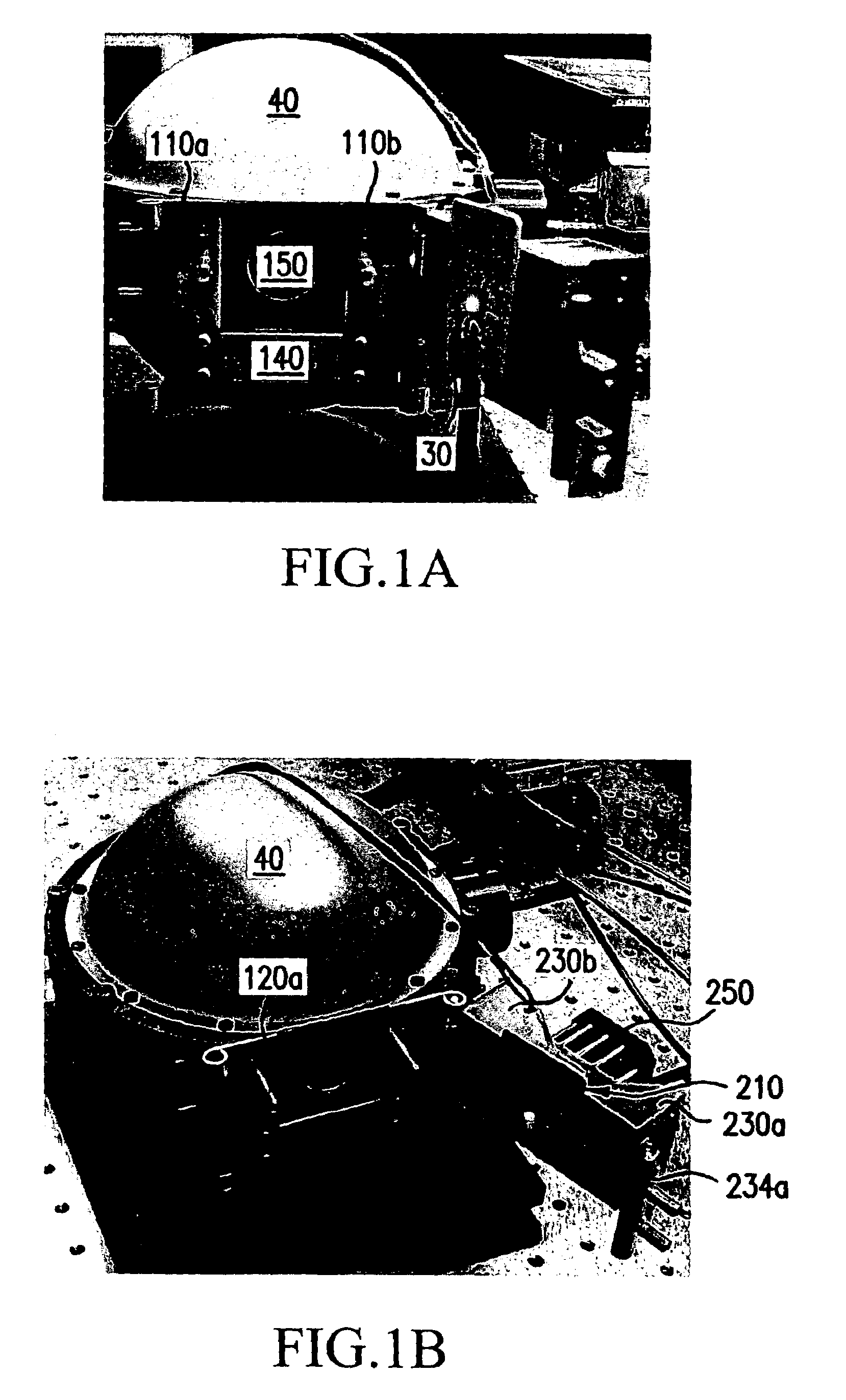

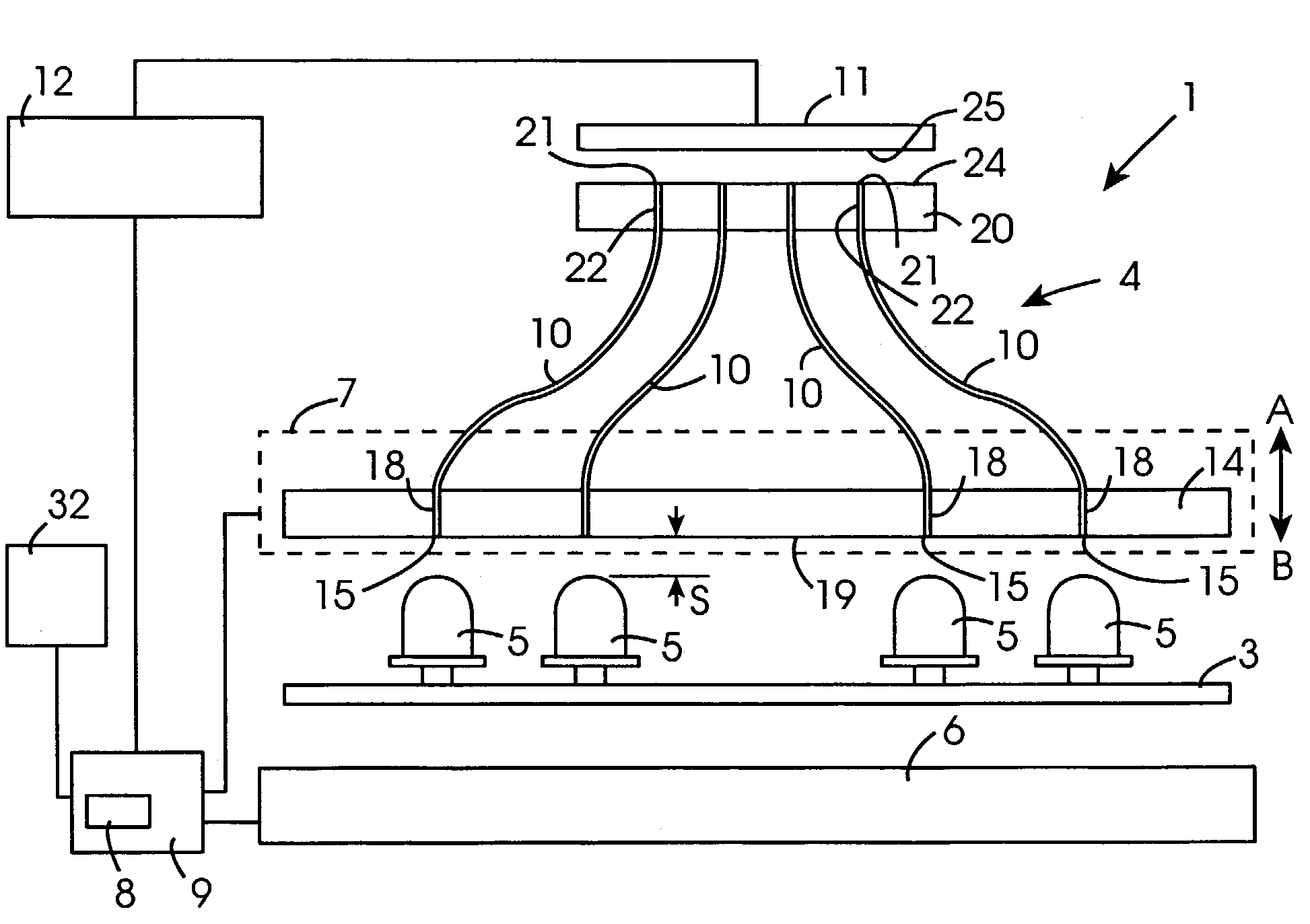

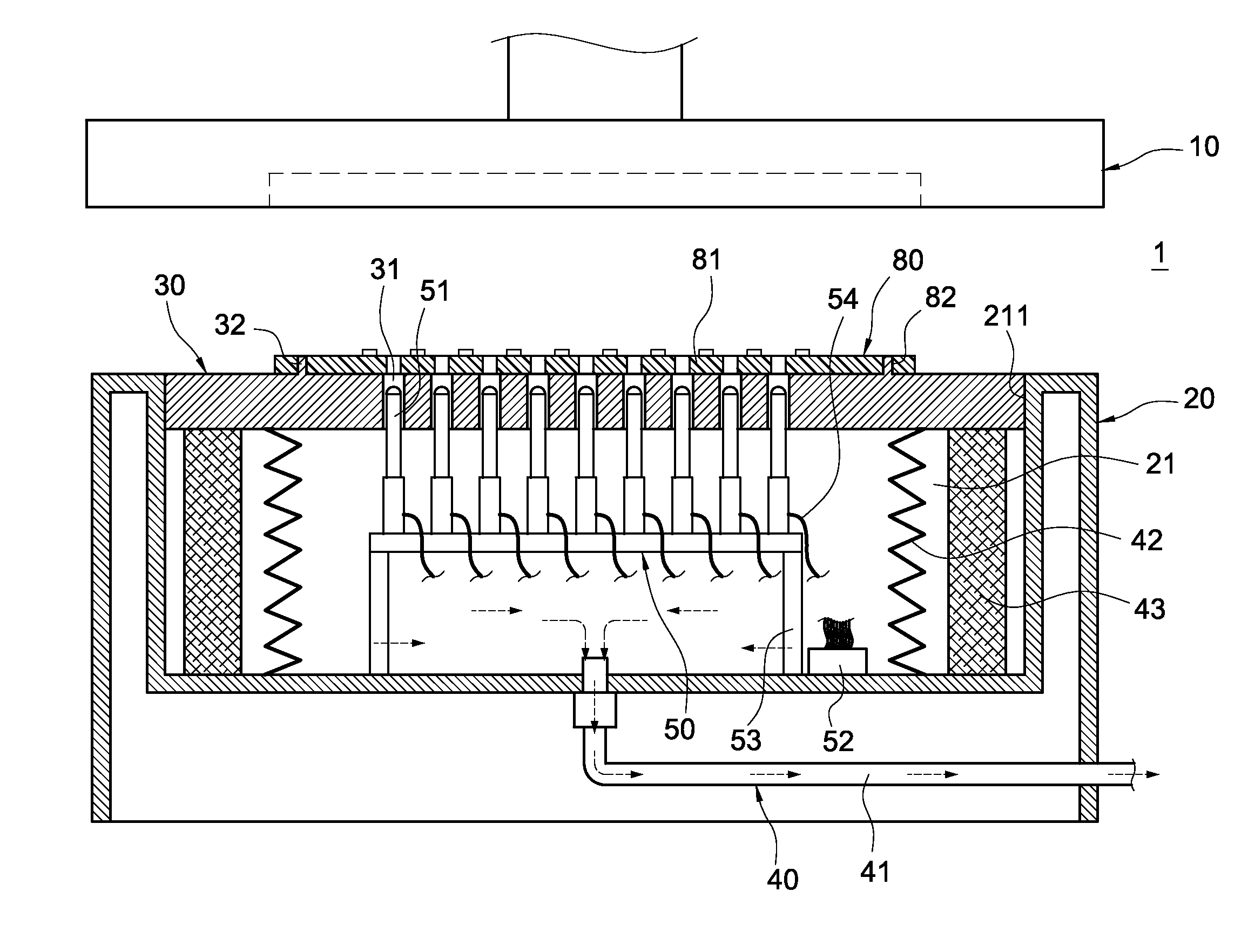

Apparatus for testing a light emitting device, and a method for testing light emitting devices

InactiveUS7056000B2Simple and inexpensiveAvoid the needSolid-state devicesMaterial analysis by optical meansEngineeringControl circuit

A text fixture (1) comprises apparatus (4) for verifying the color and brightness of light emitted from LEDs (5) of a printed circuit board (3). A base (6) of the fixture (1) supports the printed circuit board (3) during testing. A mounting panel (14) locates ends (15) of a plurality of optical fibers (10) adjacent the LEDs (5) on the printed circuit board (3), and ends (21) of ht optical fibers (10) are terminated in a terminating panel (20) adjacent an image sensing panel (11). The image sensing panel (11) comprises an array of individually addressable light and color sensitive pixels (25) onto which light from the optical fibers (10) is incident. An analysing circuit (12) scans the pixels (25) for determining the brightness values and the tristimulus values of the incident light, and a control circuit (9) compares the tristimulus values and brightness values with reference tristimulus and brightness values for verifying the color and brightness of the light emitted by the respective LEDs (5).

Owner:VIVEEN

Testing method for LED module

InactiveUS7812624B1Shorten the timeEfficient testingDiode testingSolid-state devicesElectricityEngineering

A testing method for a LED module and its associated elements includes the steps of: providing a LED module on which a plurality of light-emitting diodes is arranged; providing an integration detector, and mounting it above the LED module; providing an electrically conducting means having a plurality of conductive terminals and an electronic signal connector electrically connected to the conductive terminals; electrically connecting the light-emitting diodes with the conductive terminals; using the electronic signal connector to change the ON / OFF states of the electrical signals of the light-emitting diodes and the conductive terminals; and detecting the photo-electrical properties of each light-emitting diode via the integration detector.

Owner:HIGH POWER LIGHTING CORP

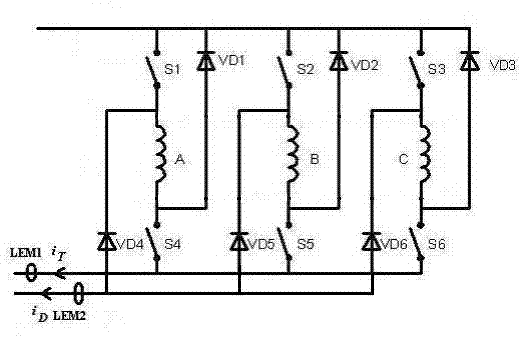

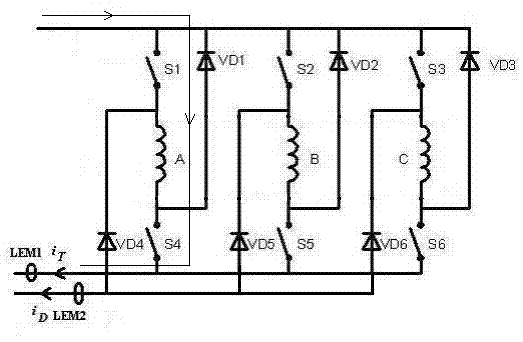

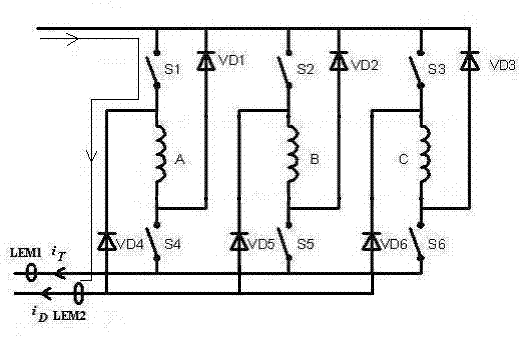

Fault diagnosis method for switch reluctance motor dual-switch power converter fly-wheel diode

ActiveCN103091598AQuick checkRapid identificationDiode testingPower supply testingEngineeringFlyback diode

Owner:CHINA UNIV OF MINING & TECH

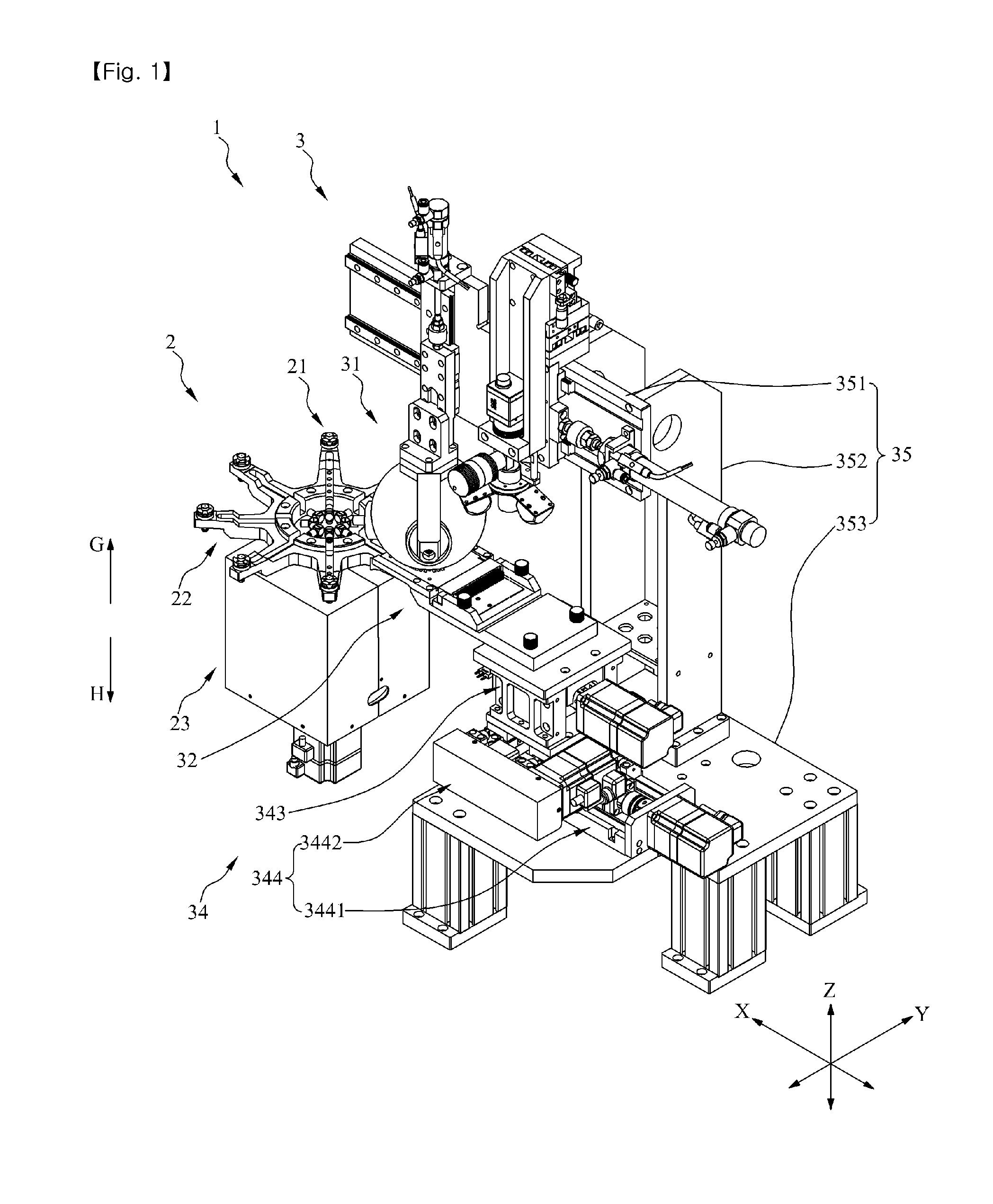

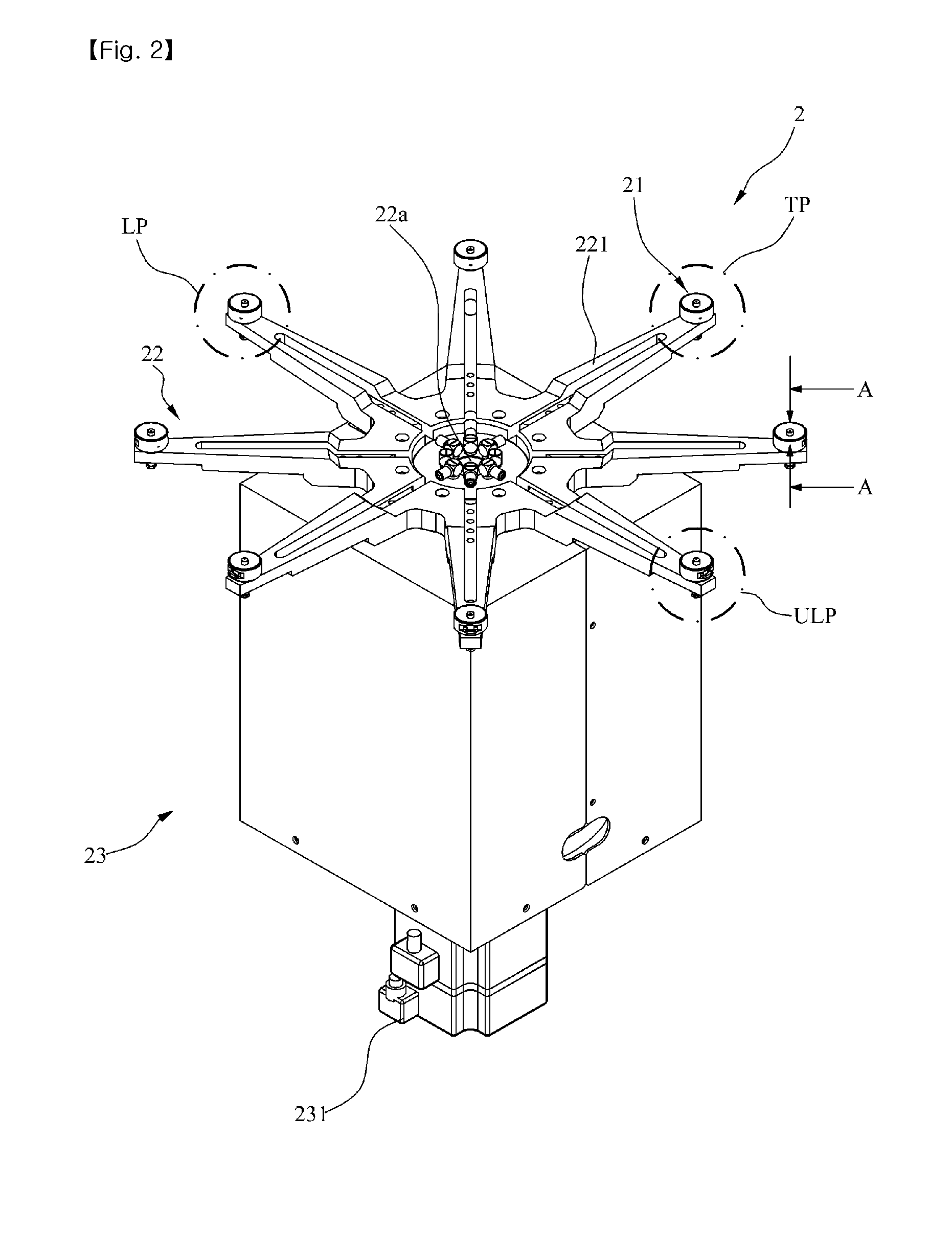

LED chip testing device

The present invention provides an LED chip testing device that measures characteristics of an LED chip.The LED chip testing device includes: a rotation member that supports the LED chip and rotates the LED chip to a testing position where the characteristics of the LED chip are tested; and a tester installed next to the rotation member and serving to measure the characteristics of the LED chip at the testing position.

Owner:QMC

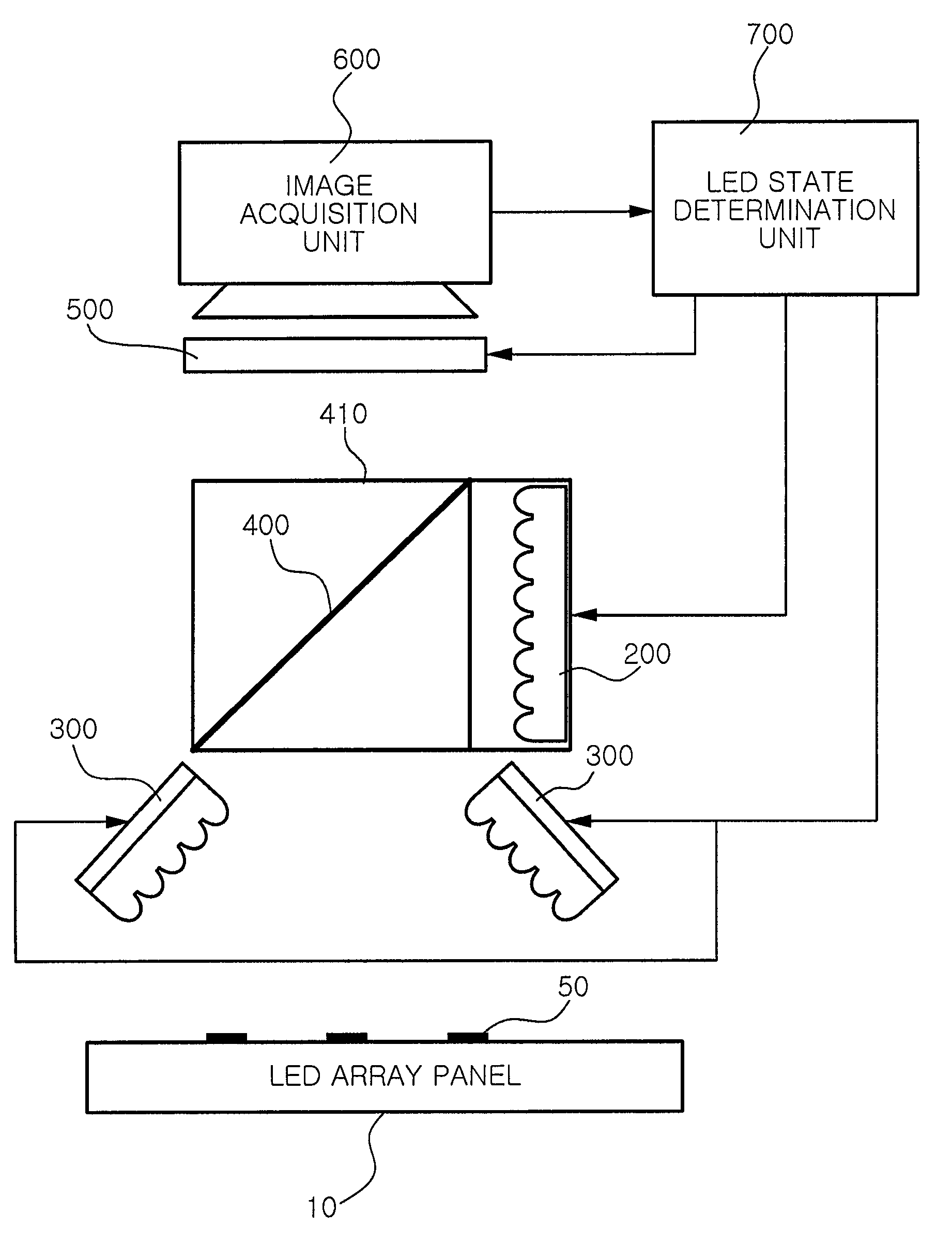

LED testing apparatus and testing method thereof

There is provided an LED testing apparatus. An LED testing apparatus according to an aspect of the invention may include: a first lighting unit generating first light and irradiating the first light onto an LED having an encapsulant including a fluorescent material excited by the first light to emit light having a longer wavelength than the first light; a second lighting unit generating second light having a longer wavelength than the first light to irradiate the second light onto the LED; an image acquisition unit receiving the light emitted from the fluorescent material and the second light reflected off the LED to acquire images of the LED; and an LED state determination unit determining whether the LED is acceptable or defective using the images of the LED acquired by the image acquisition unit.There is further provided an LED testing method using the LED testing apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

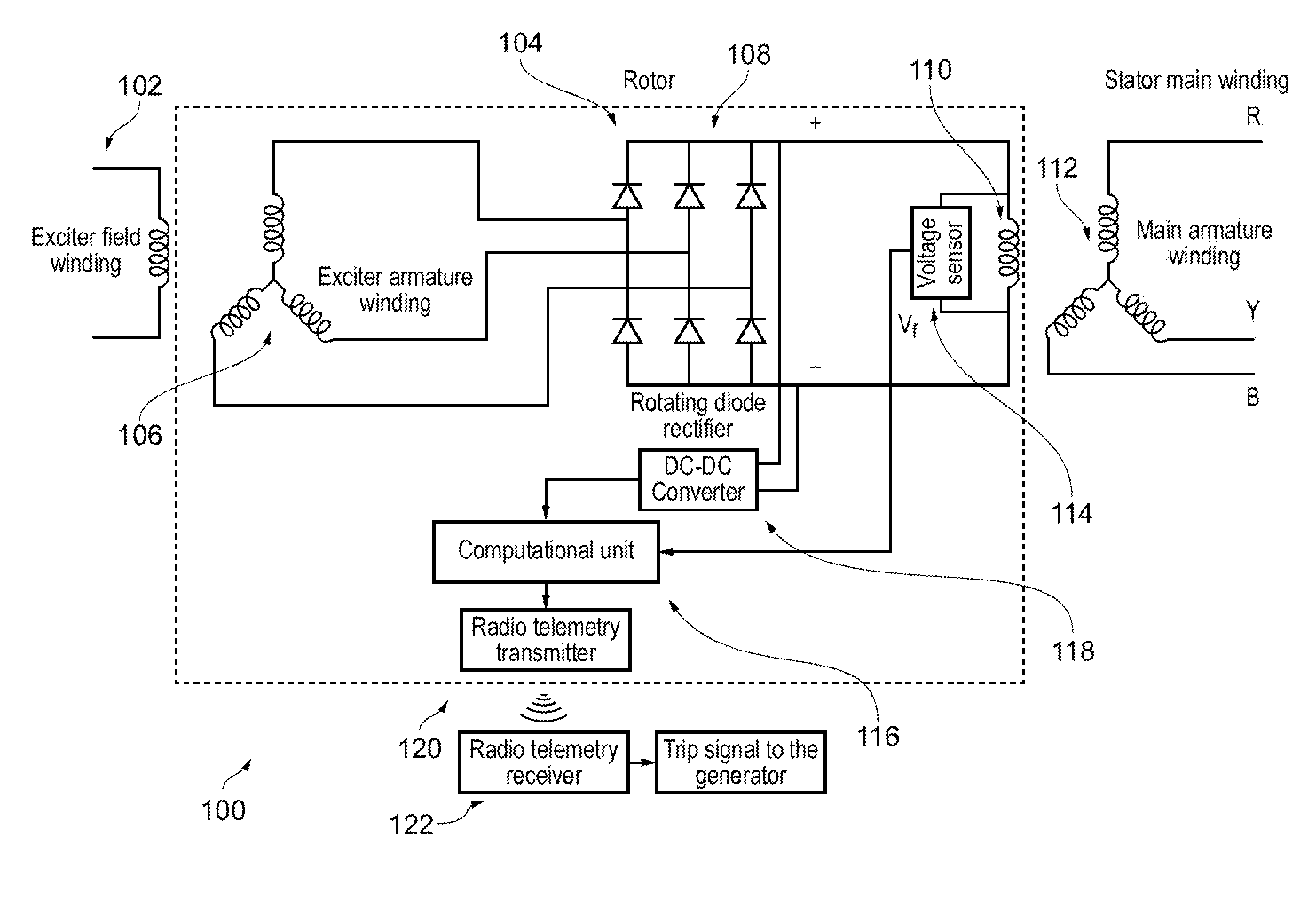

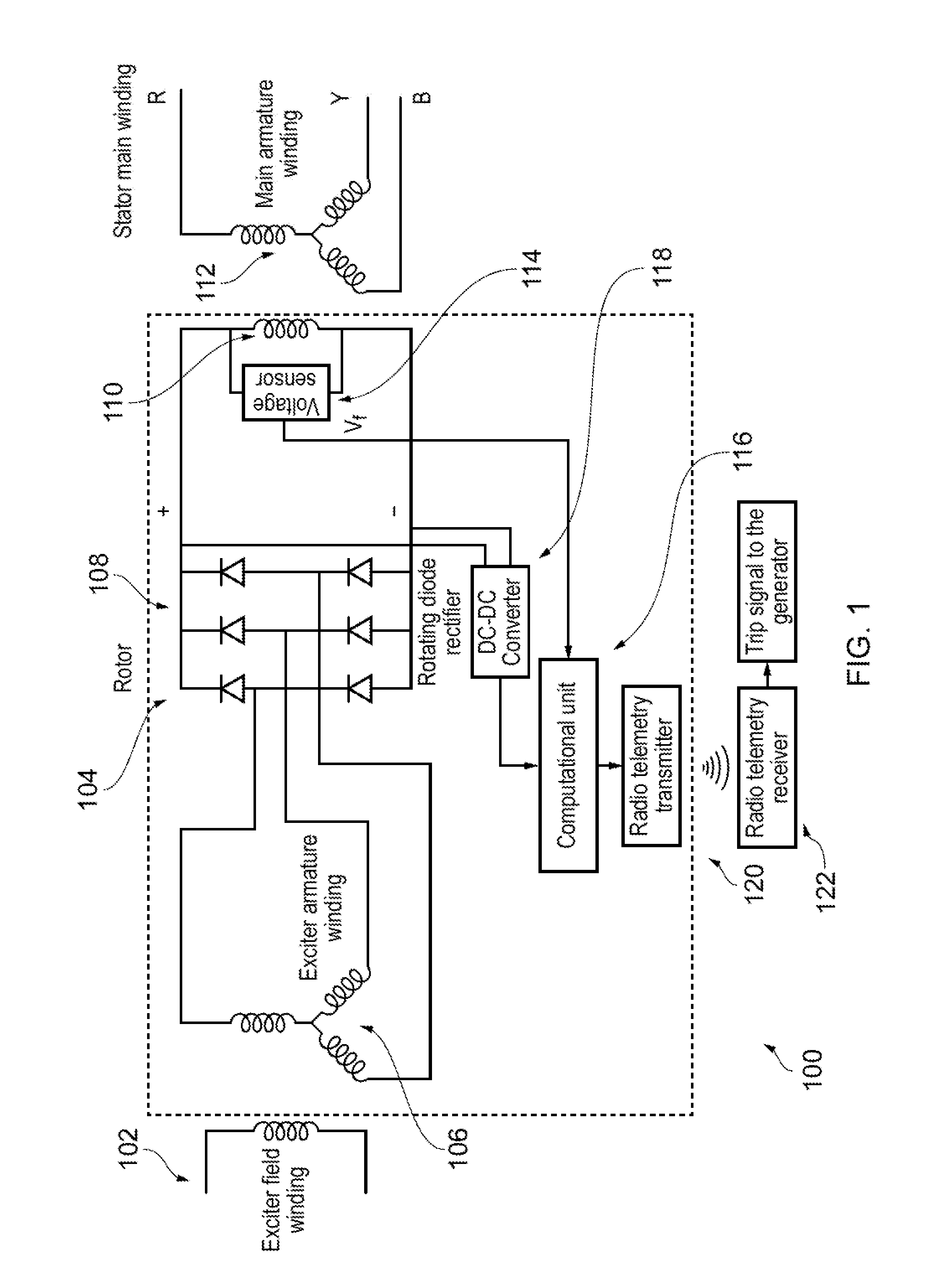

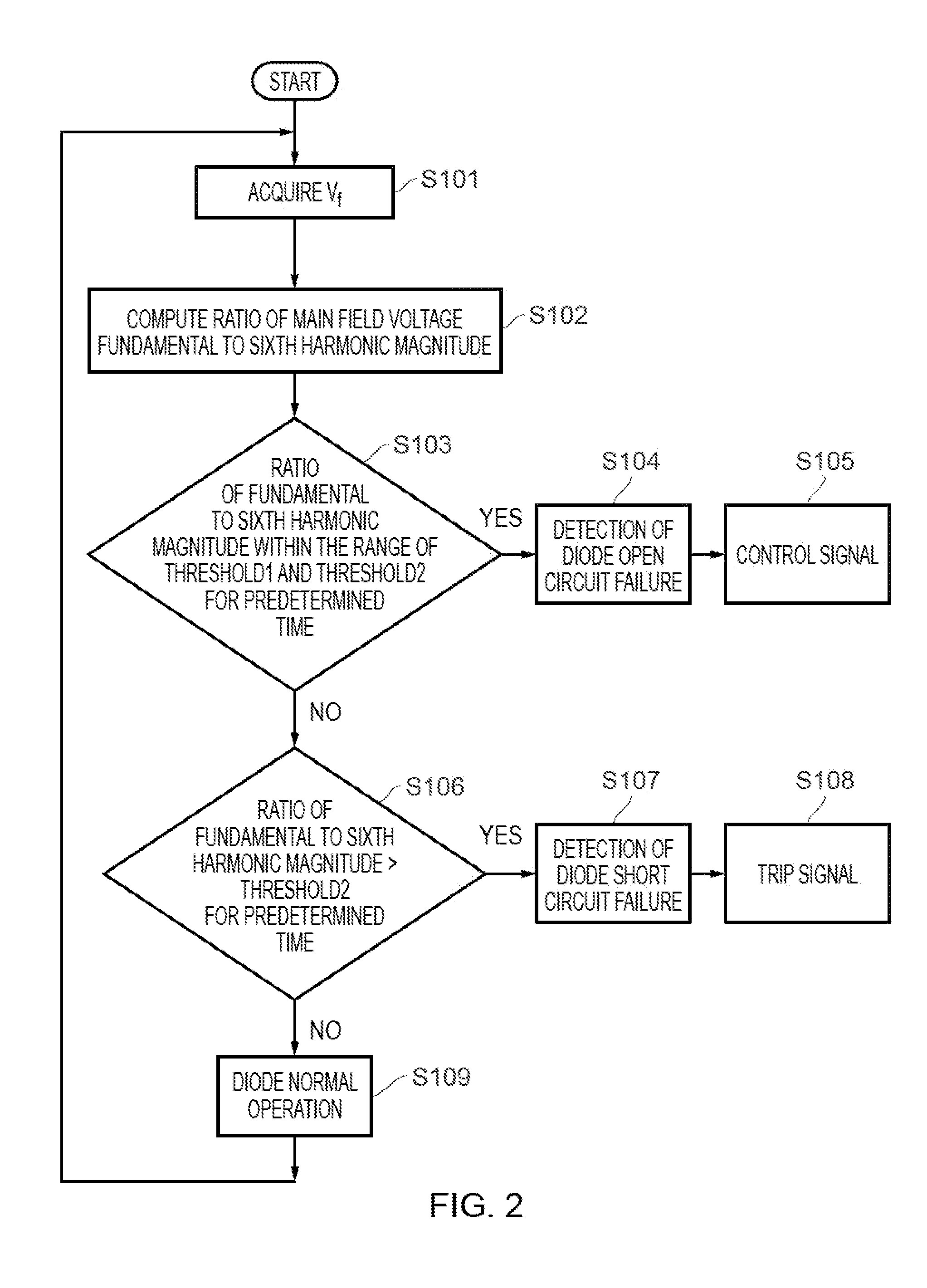

Rectifier diode fault detection in brushless exciters

ActiveUS20150198655A1Accurately and quickly detectedDiode testingEmergency protective circuit arrangementsVoltage amplitudeHarmonic

A method of detecting a diode fault in an AC signal rectifier circuit,the AC signal rectifier circuit including a plurality of diodes, and being arranged to supply a rectified output voltage to a load, wherein the method includes the steps ofderiving an operating value indicative of the ratio of the voltage magnitudes of a first harmonic frequency and another harmonic frequency of the rectified output voltage across the load; anddetermining whether a fault has occurred in one or more diodes on the basis of the derived operating value.The first harmonic frequency is preferably the fundamental harmonic frequency, and / or the another harmonic frequency is preferably the 6th harmonic frequency.

Owner:ROLLS ROYCE PLC

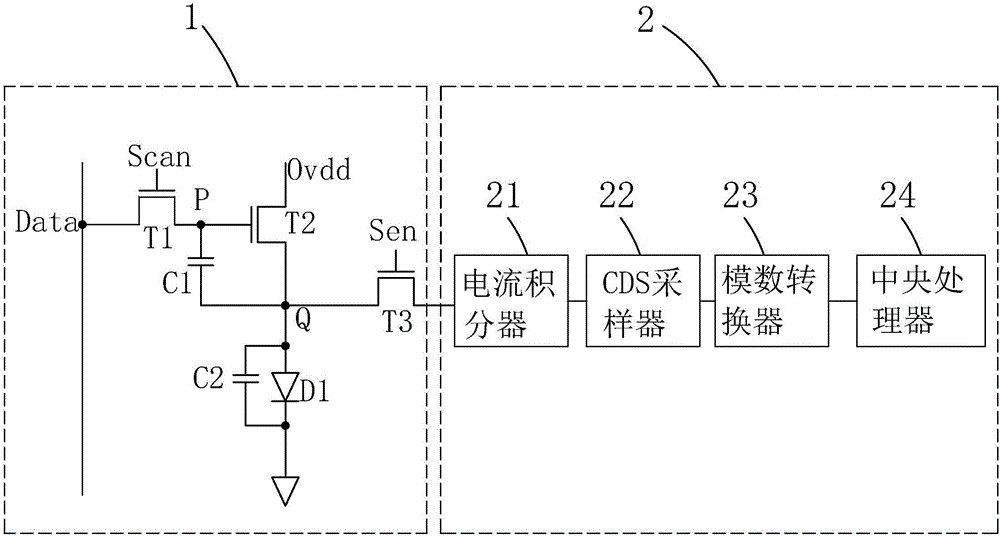

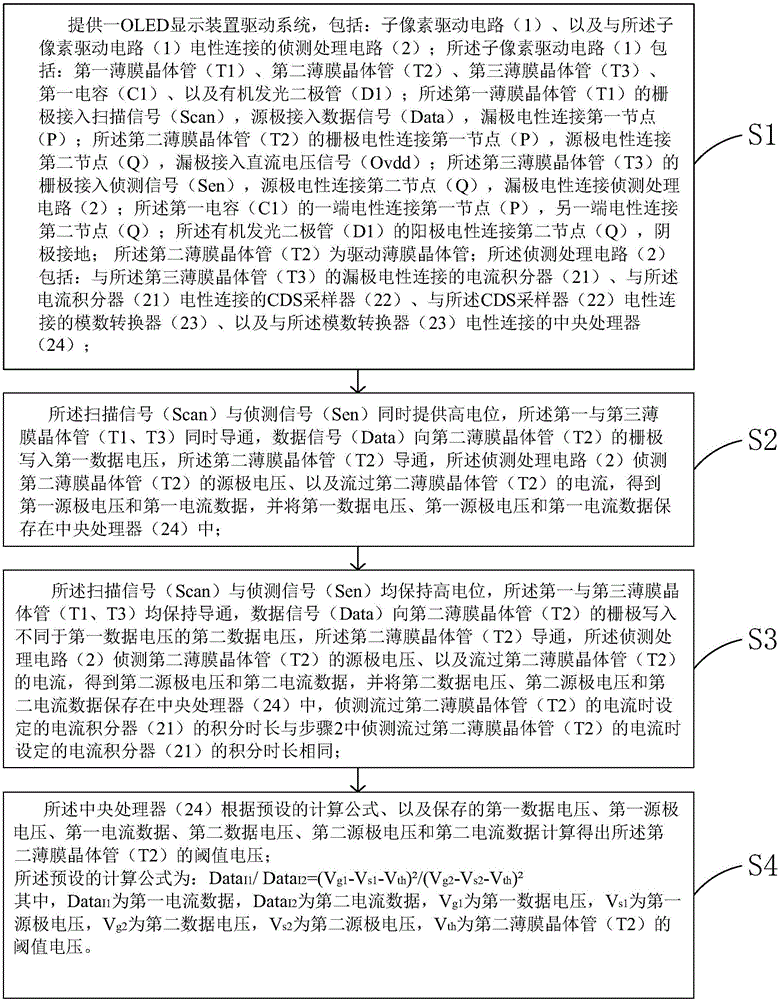

Threshold voltage detection method of OLED (organic light emitting diode) driver thin film transistor

ActiveCN106782320AImprove display qualityAccurate acquisition of threshold voltageCurrent/voltage measurementDiode testingDisplay deviceEngineering

The invention provides a threshold voltage detection method of an OLED (organic light emitting diode) driver thin film transistor. According to the method, by setting data signals, two different data voltages are offered, so that two different gate-source voltages are formed by virtue of the driver thin film transistor; then, by virtue of an external detection processing circuit, currents, passing through the driver thin film transistor under two different gate-source voltages, are detected; and by virtue of the two gate-source voltages, two current data and a calculating formula based on a driver thin film transistor current formula, a threshold voltage of the OLED driver thin film transistor is calculated by virtue of a central processing unit; therefore, the threshold voltage of the driver thin film transistor of each pixel in an OLED display device can be accurately acquired, and subsequently, a threshold voltage compensating effect of the OLED driver thin film transistor is improved and OLED display quality is enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com