Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13102 results about "Compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

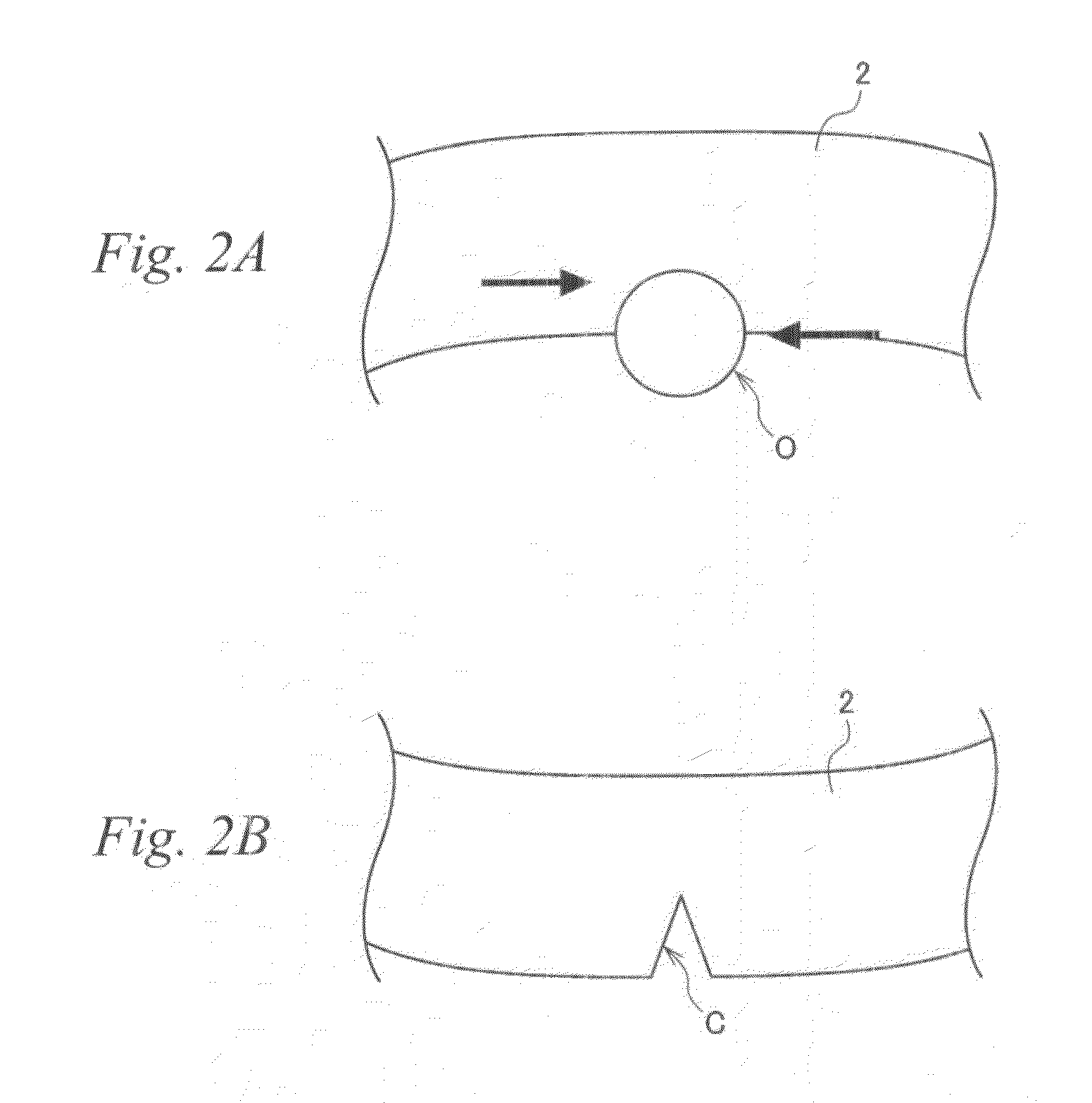

Compressive strength or compression strength is the capacity of a material or structure to withstand loads tending to reduce size, as opposed to tensile strength, which withstands loads tending to elongate. In other words, compressive strength resists compression (being pushed together), whereas tensile strength resists tension (being pulled apart). In the study of strength of materials, tensile strength, compressive strength, and shear strength can be analyzed independently.

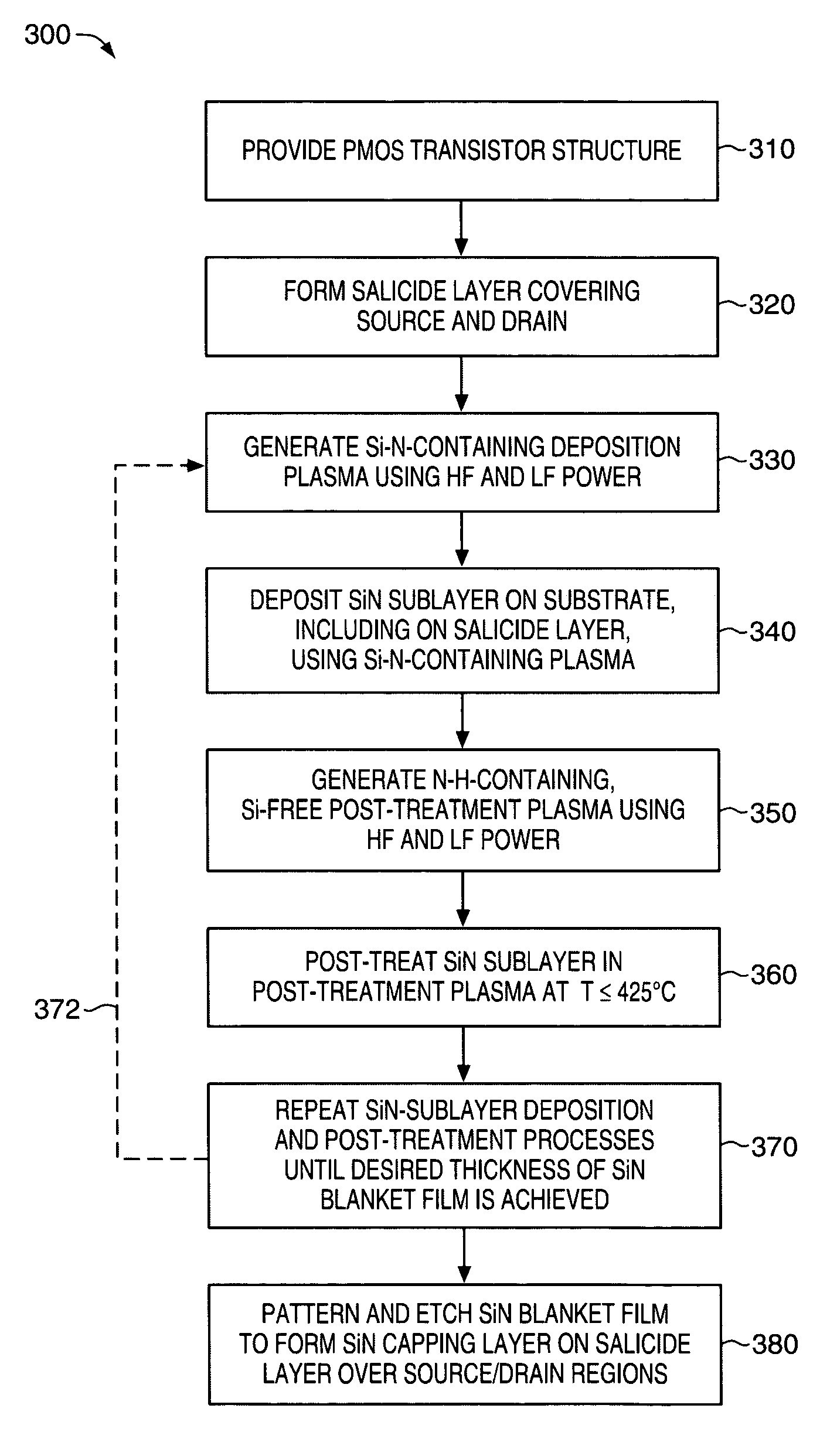

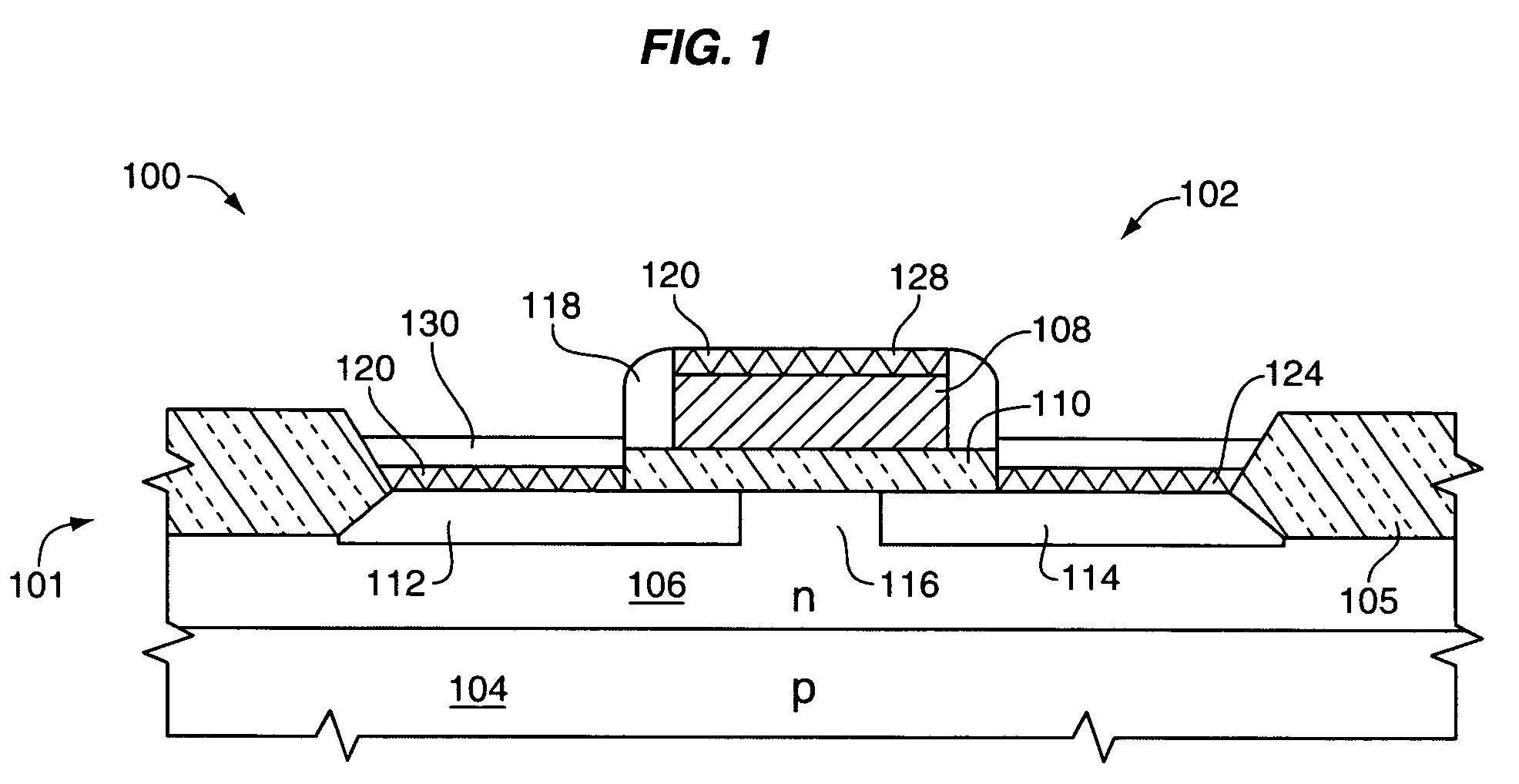

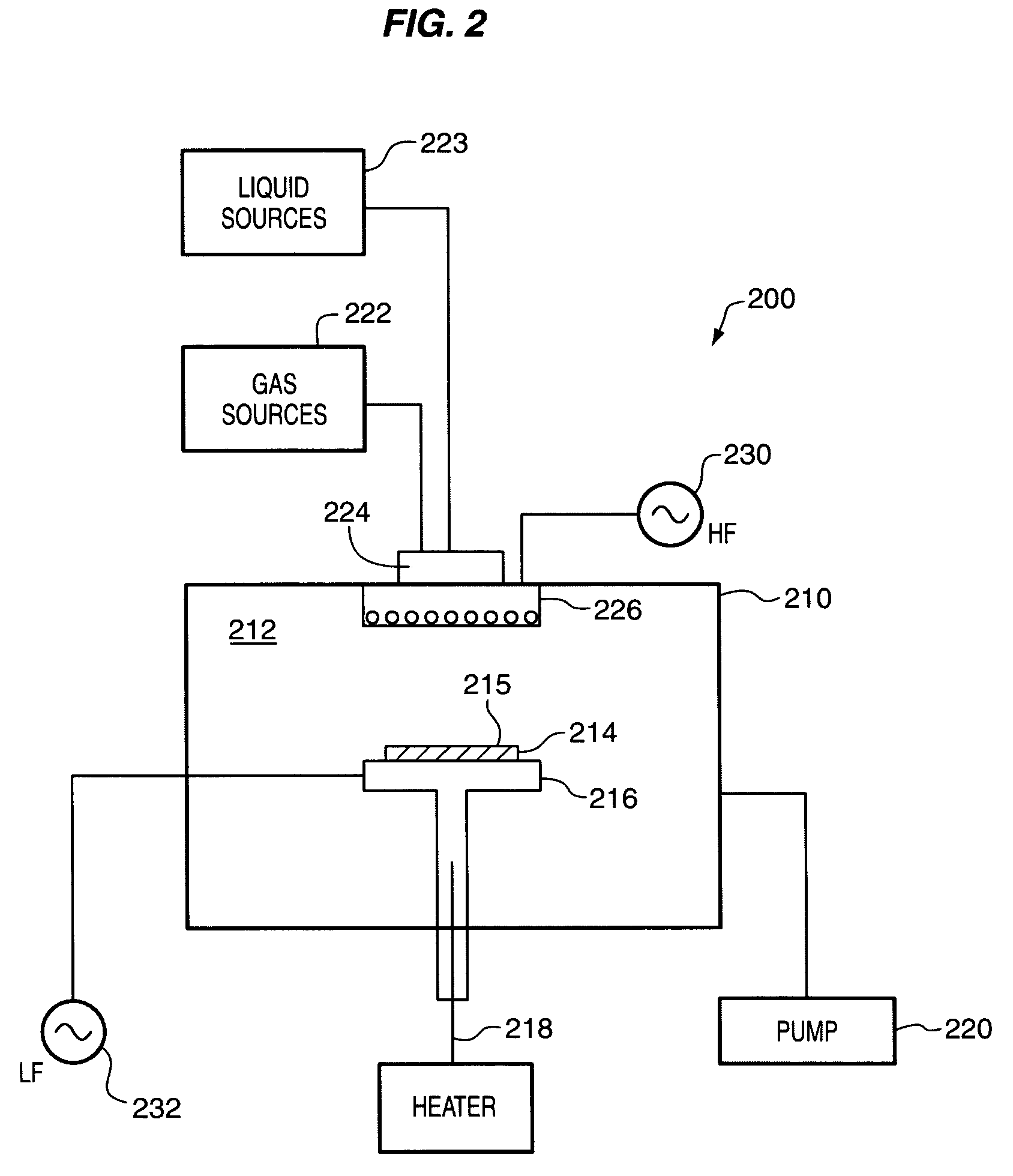

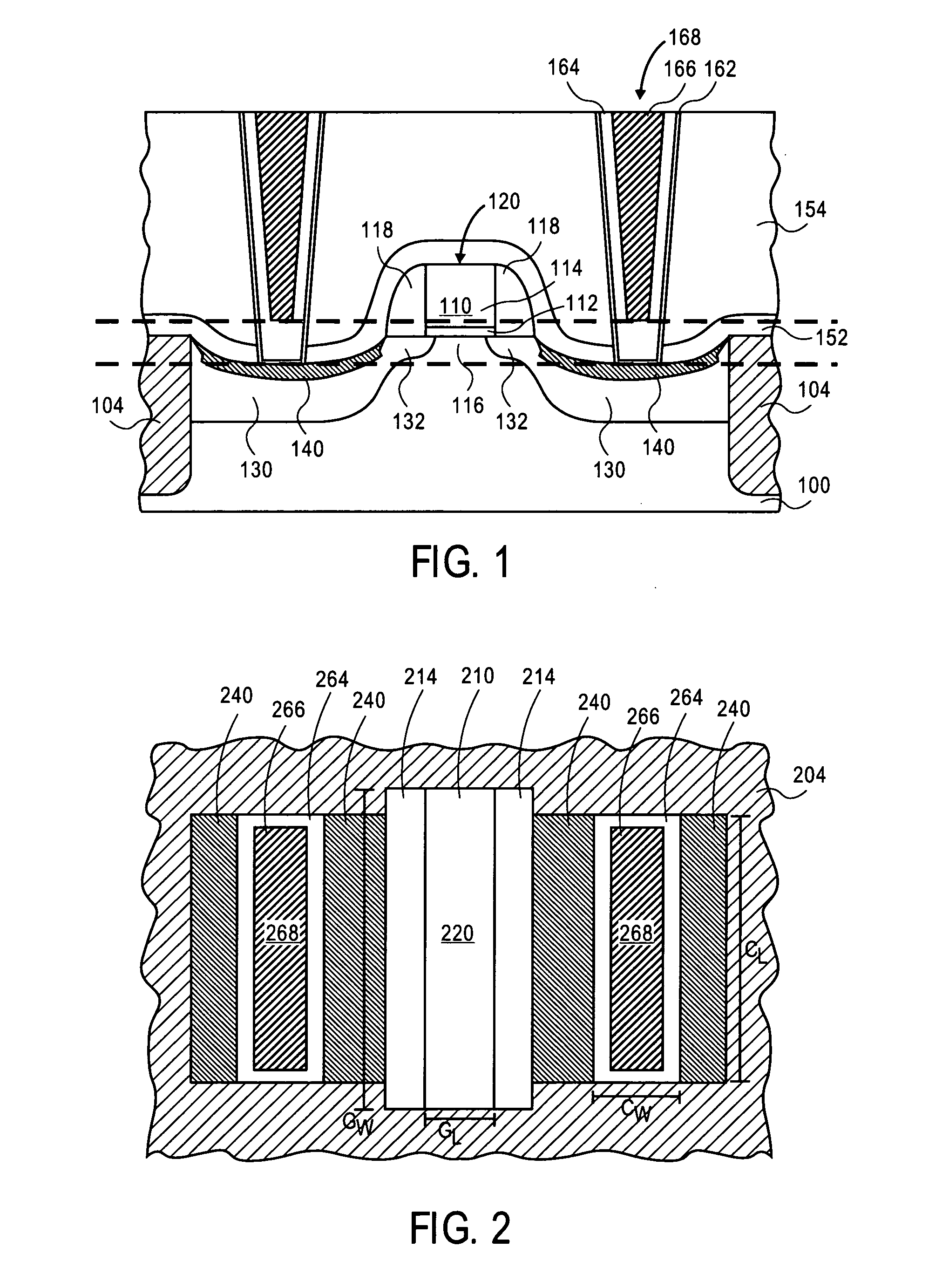

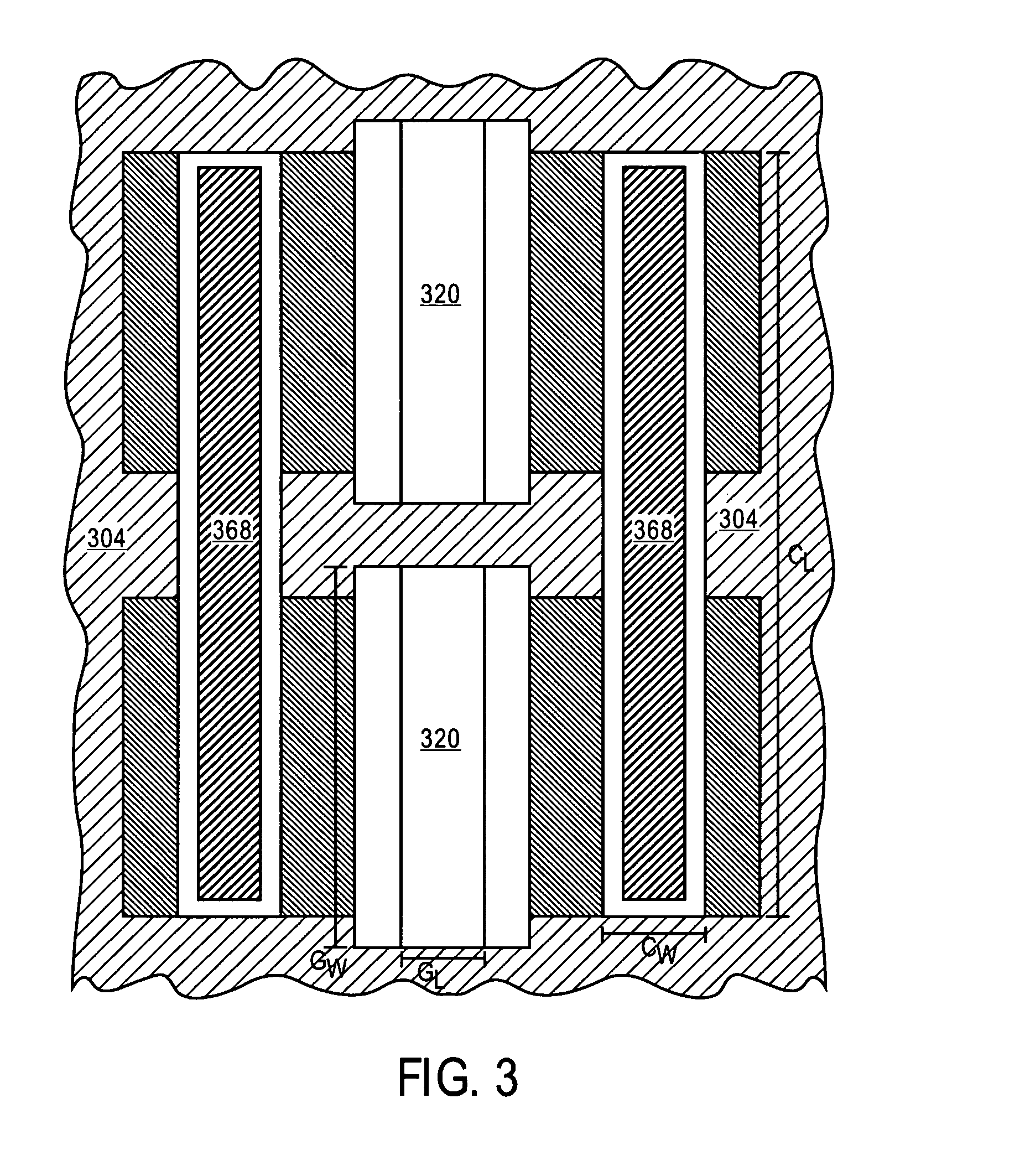

PMOS transistor with compressive dielectric capping layer

ActiveUS7214630B1Preserving material qualityImprove performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSalicideOxidation state

A salicide layer is deposited on the source / drain regions of a PMOS transistor. A dielectric capping layer having residual compressive stress is formed on the salicide layer by depositing a plurality of PECVD dielectric sublayers and plasma-treating each sublayer. Compressive stress from the dielectric capping layer is uniaxially transferred to the PMOS channel through the source-drain regions to create compressive strain in the PMOS channel. To form a compressive dielectric layer, a deposition reactant mixture containing A1 atoms and A2 atoms is provided in a vacuum chamber. Element A2 is more electronegative than element A1, and A1 atoms have a positive oxidation state and A2 atoms have a negative oxidation state when A1 atoms are bonded with A2 atoms. A deposition plasma is generated by applying HF and LF radio-frequency power to the deposition reactant mixture, and a sublayer of compressive dielectric material is deposited. A post-treatment plasma is generated by applying HF and LF radio-frequency power to a post-treatment gas that does not contain at least one of A1 atoms and A2 atoms. Compressive stress in the dielectric sublayer is increased by treating the sublayer in the post-treatment plasma. Processes of depositing a dielectric sublayer and post-treating the sublayer in plasma are repeated until a desired thickness is achieved. The resulting dielectric layer has residual compressive stress.

Owner:NOVELLUS SYSTEMS

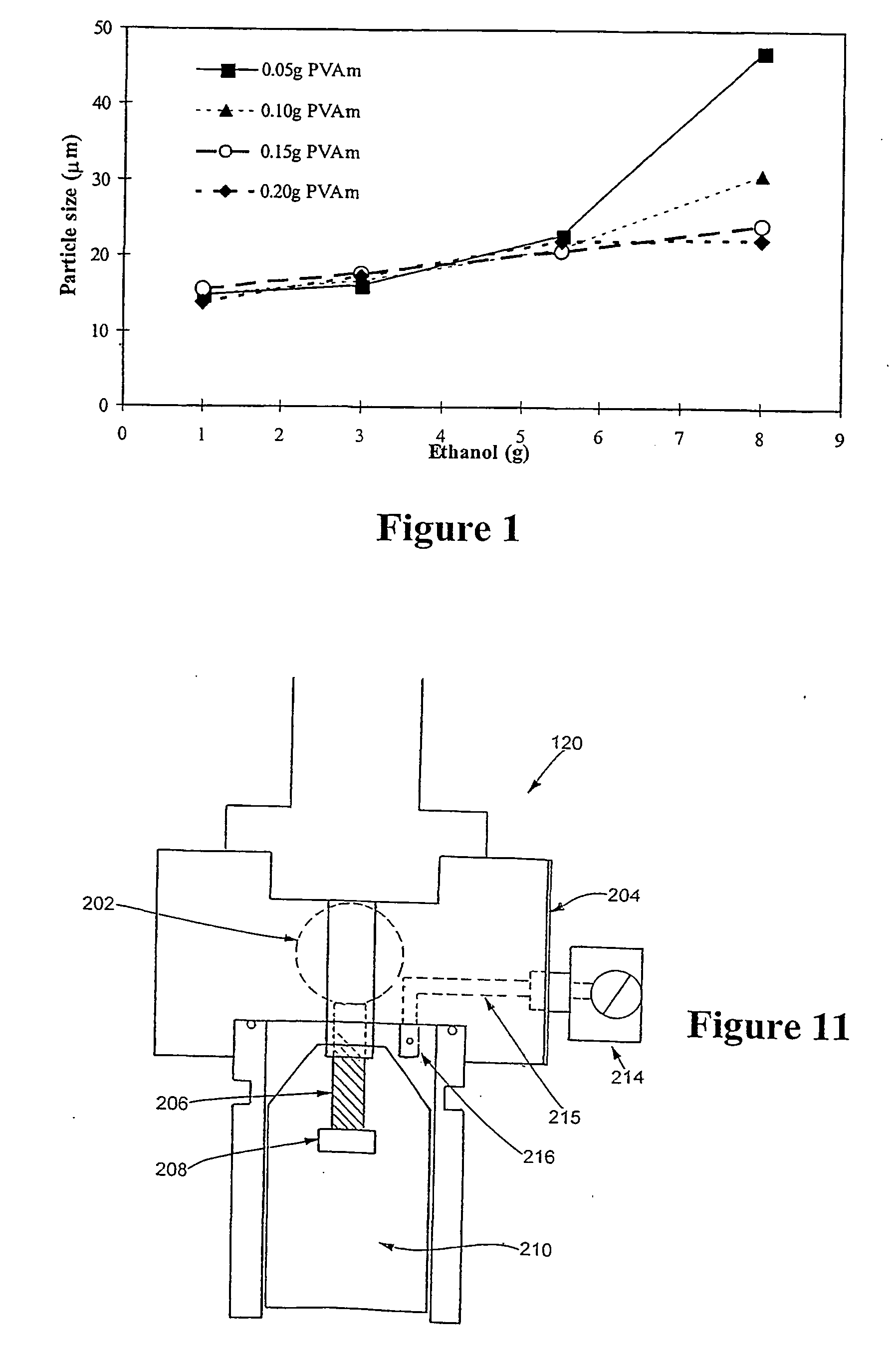

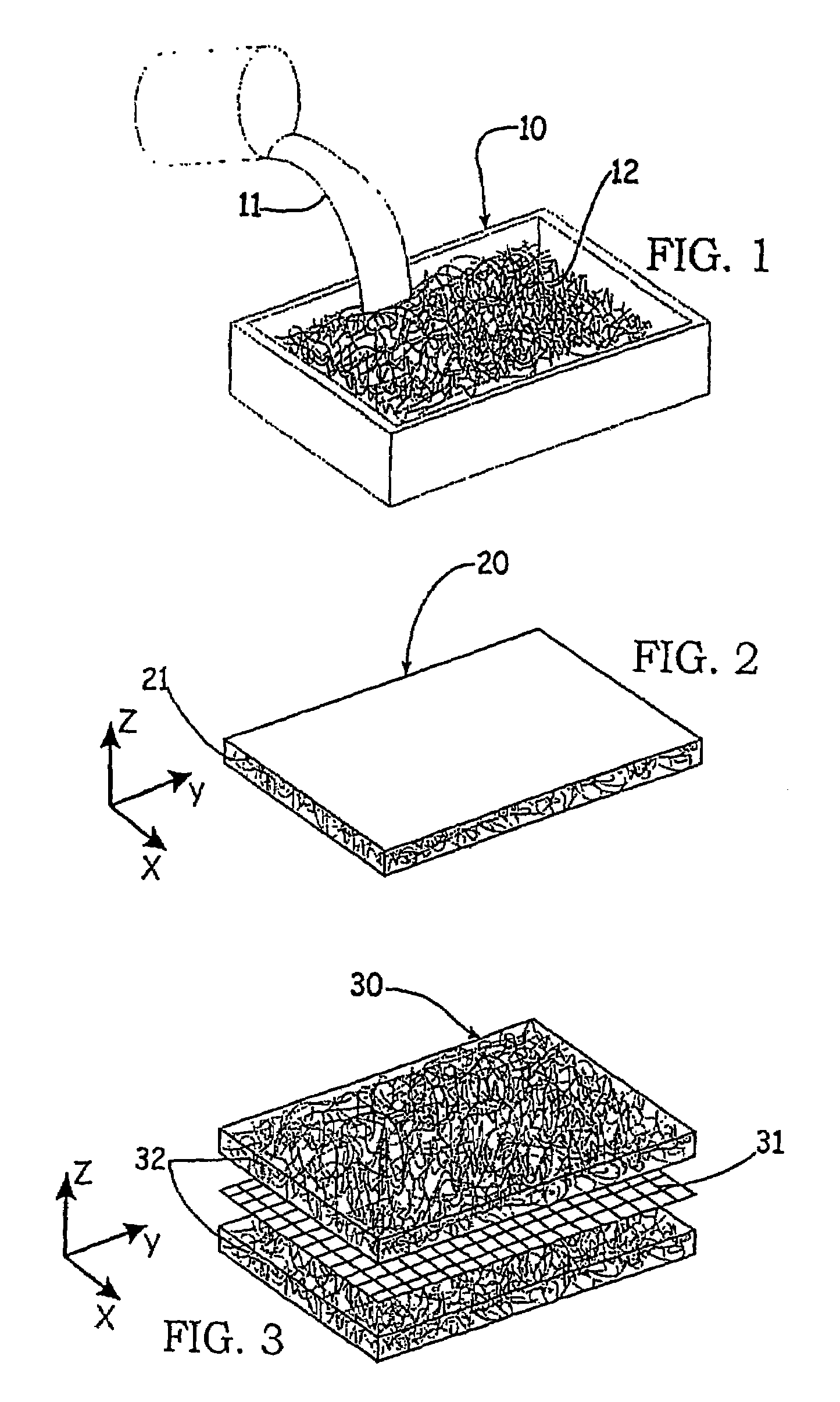

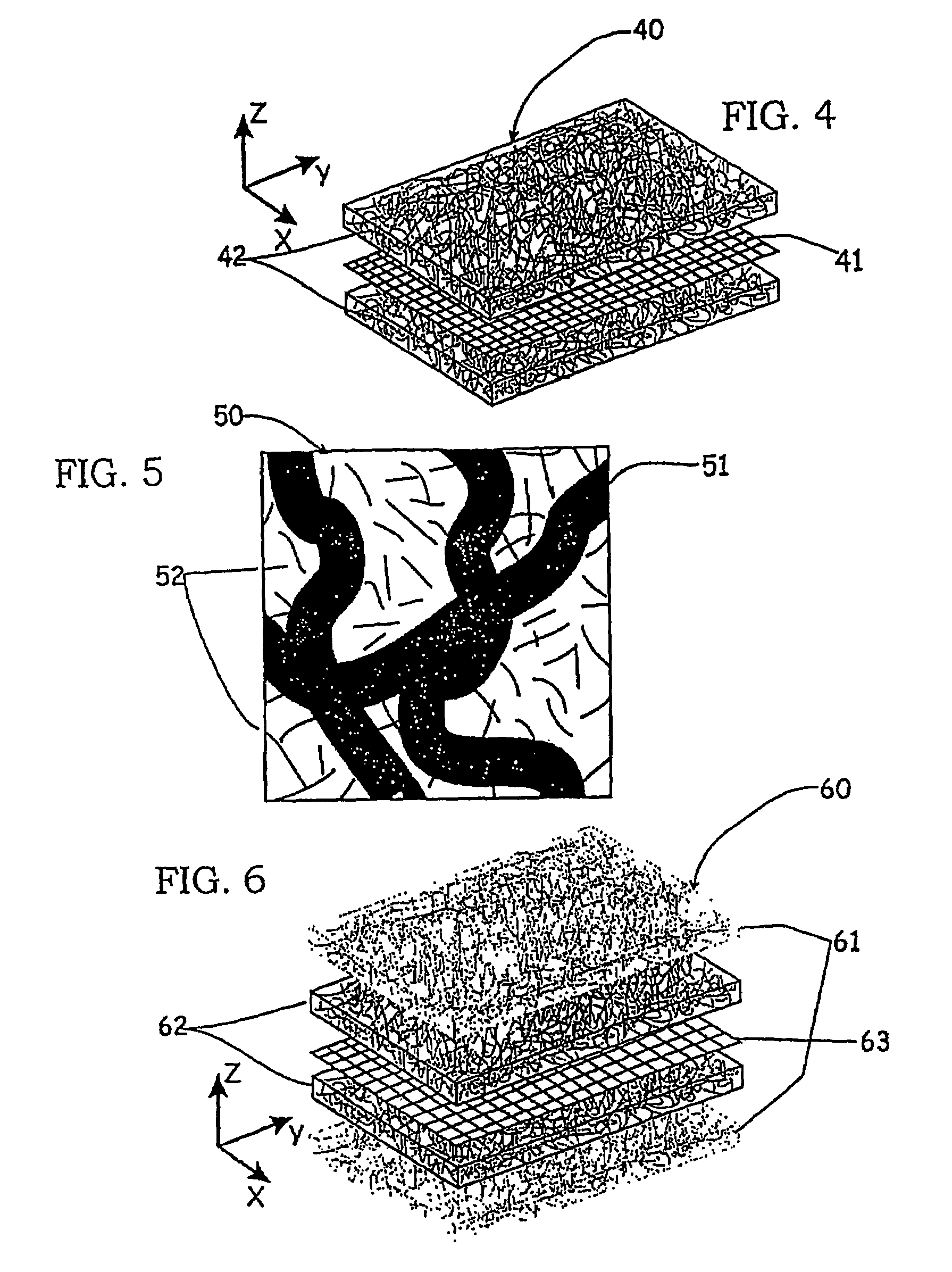

Structural and other composite materials and methods for making same

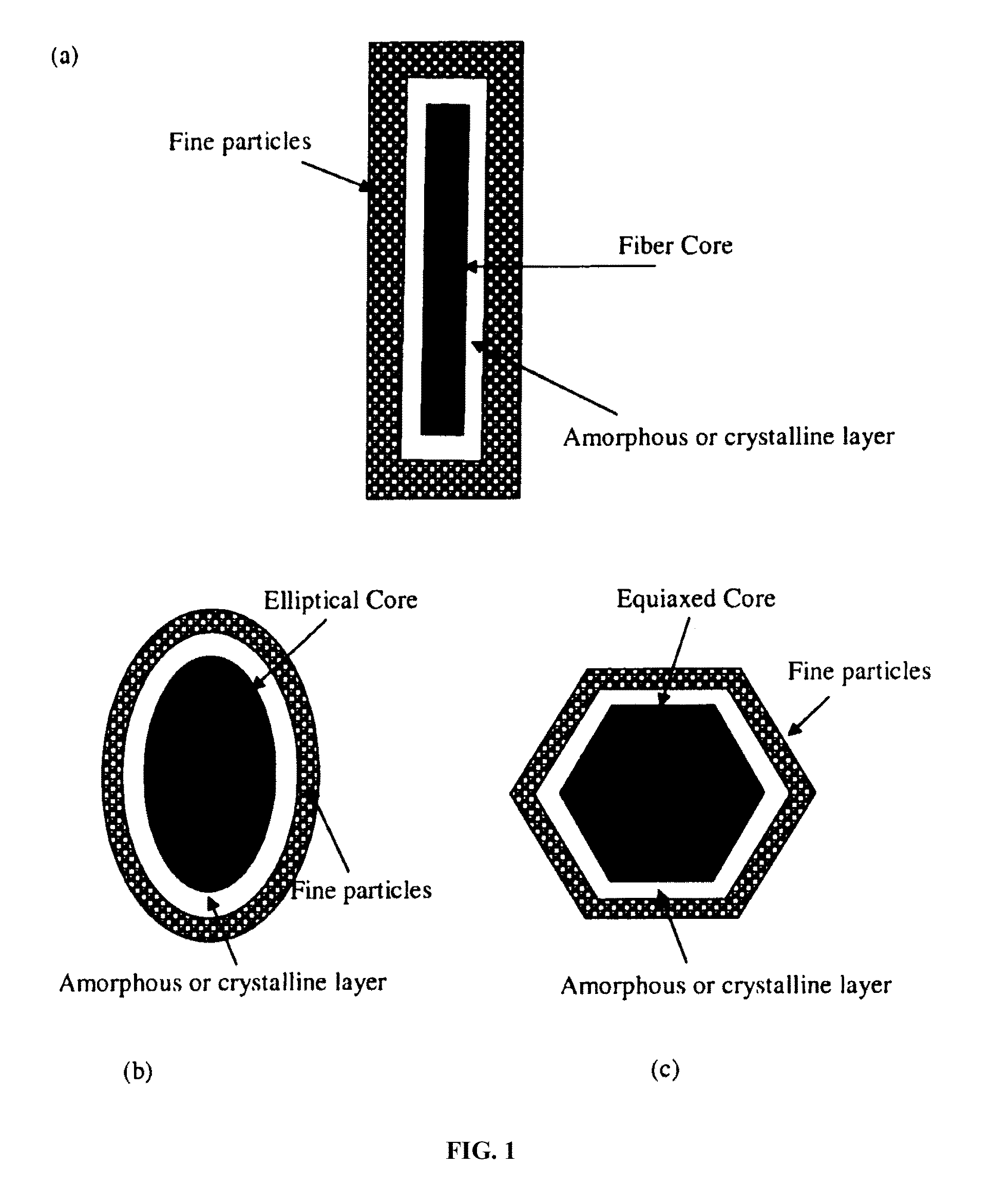

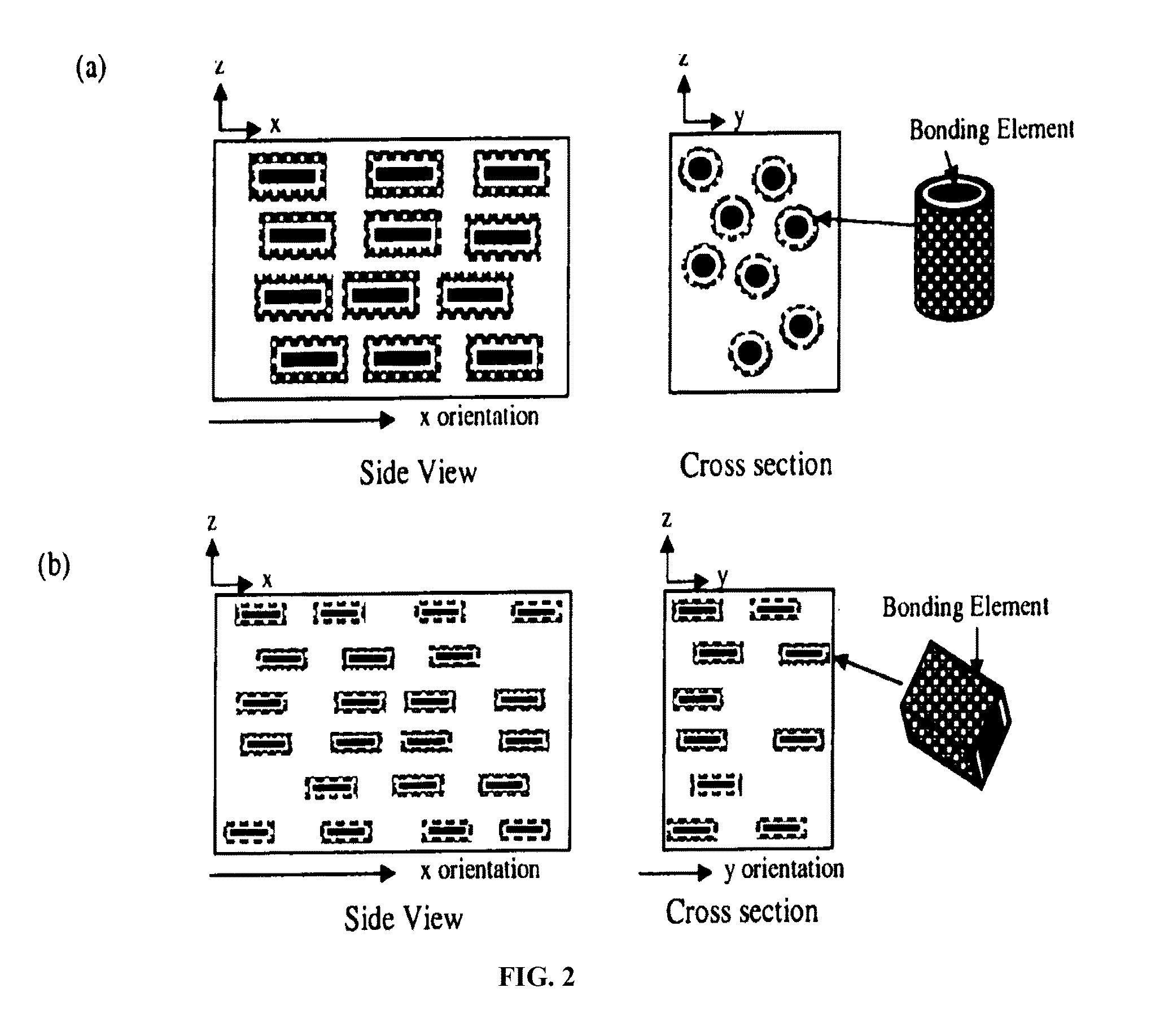

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

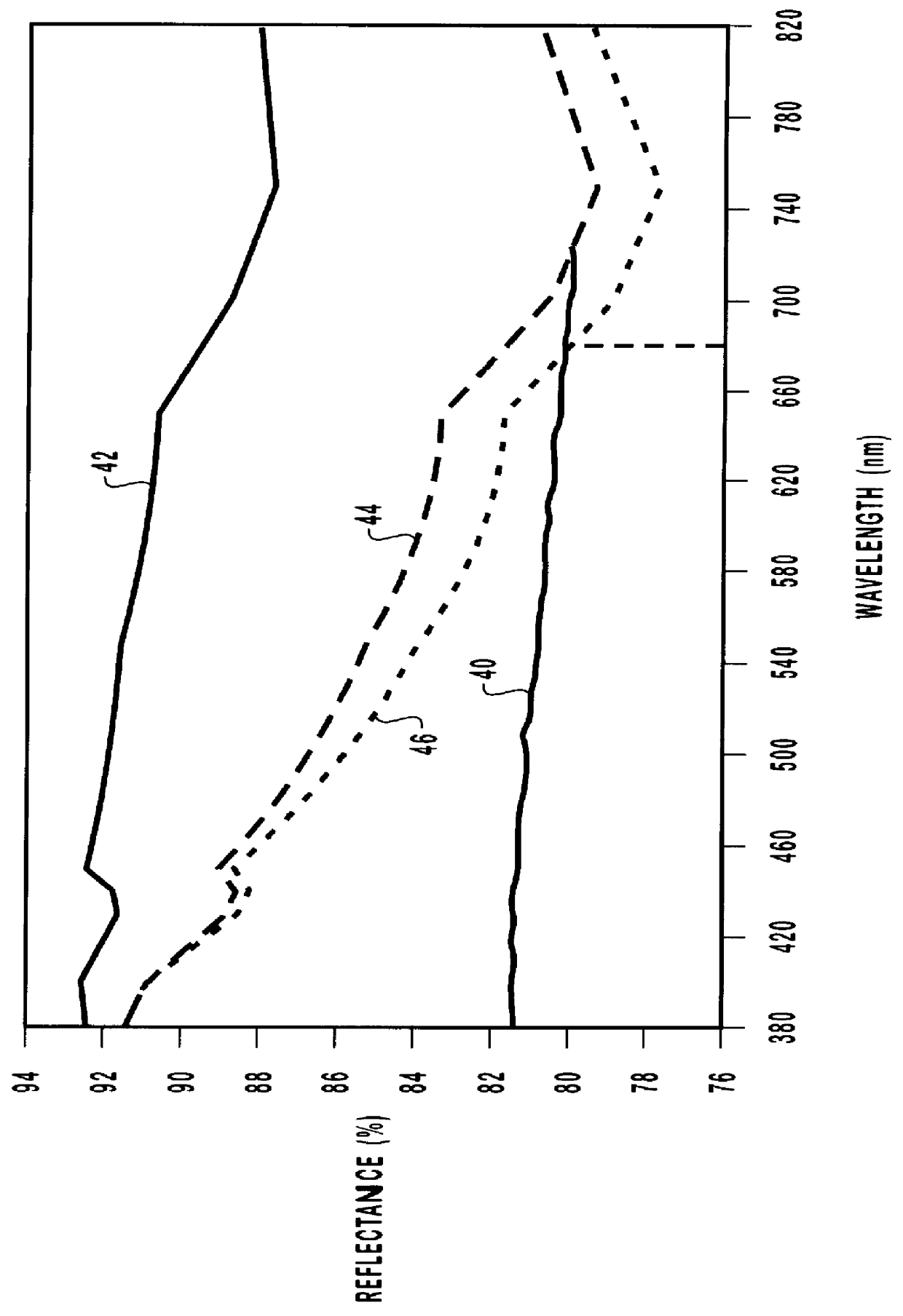

Bright metal flake based pigments

InactiveUS6150022AGood specular reflectance characteristicPigment preparation by PVD/CVD methodsSynthetic resin layered productsDielectricReflectivity

A flake-based pigment is provided having improved specular reflectance characteristics in the visible wavelength range. The flake-based pigment has a plurality of core flake sections each formed of a central reflector layer and dielectric support layers on opposing sides of the reflector layer. The resulting core flake section is a very thin three-layered structure that exhibits a uniaxial compressive strength much greater than a corresponding uniaxial tensile strength. This structure provides the benefits of rigidity and brittle fracture during manufacturing and application processes, which ultimately provides favorable planar and specular reflectance characteristics for the pigment in the visible wavelength range. A variety of outer coating layers can be formed around the core flake sections, such as various dielectric and absorber layers having thicknesses dependent upon the desired optical characteristics of the pigment.

Owner:JDS UNIPHASE CORP

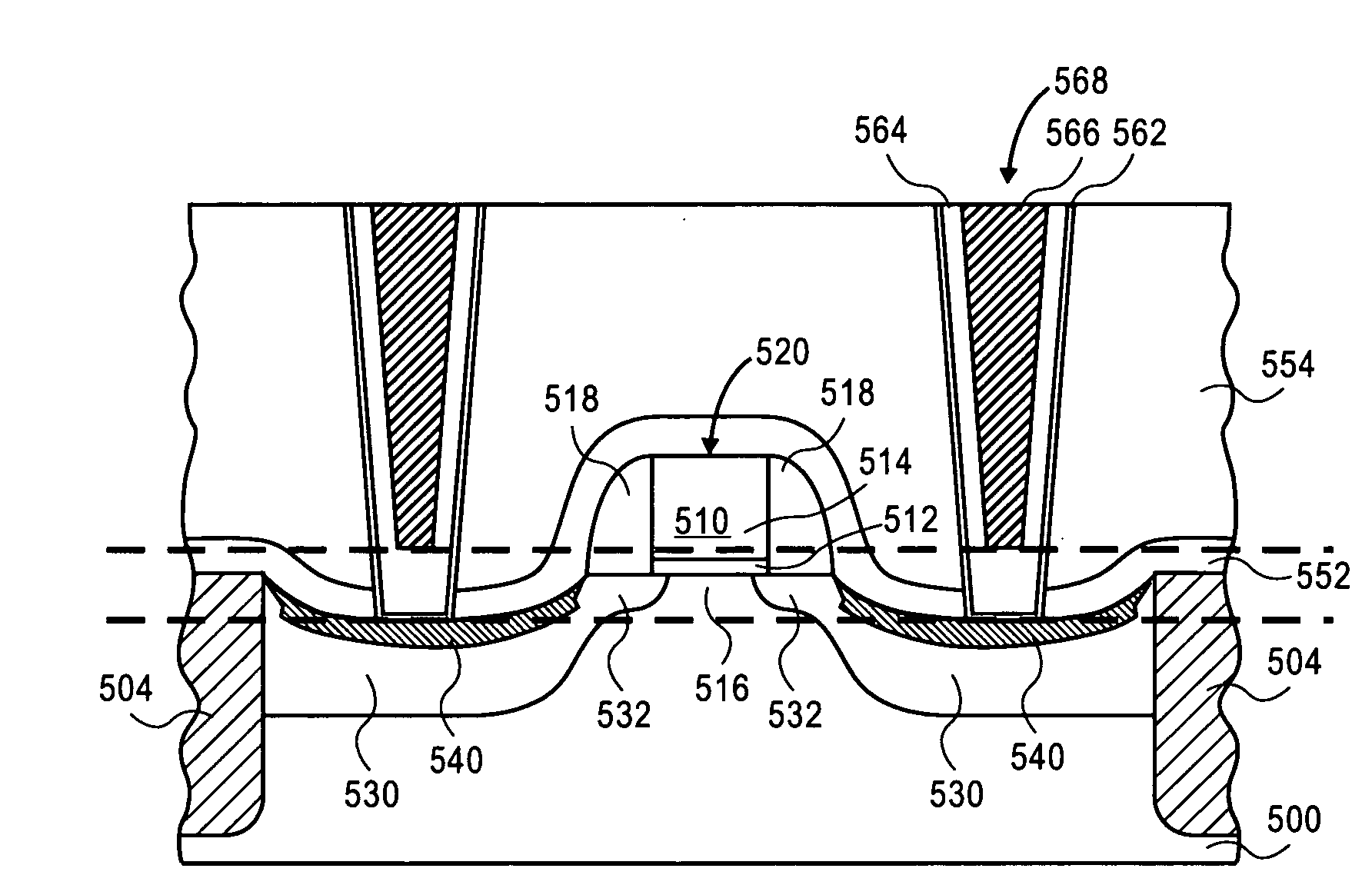

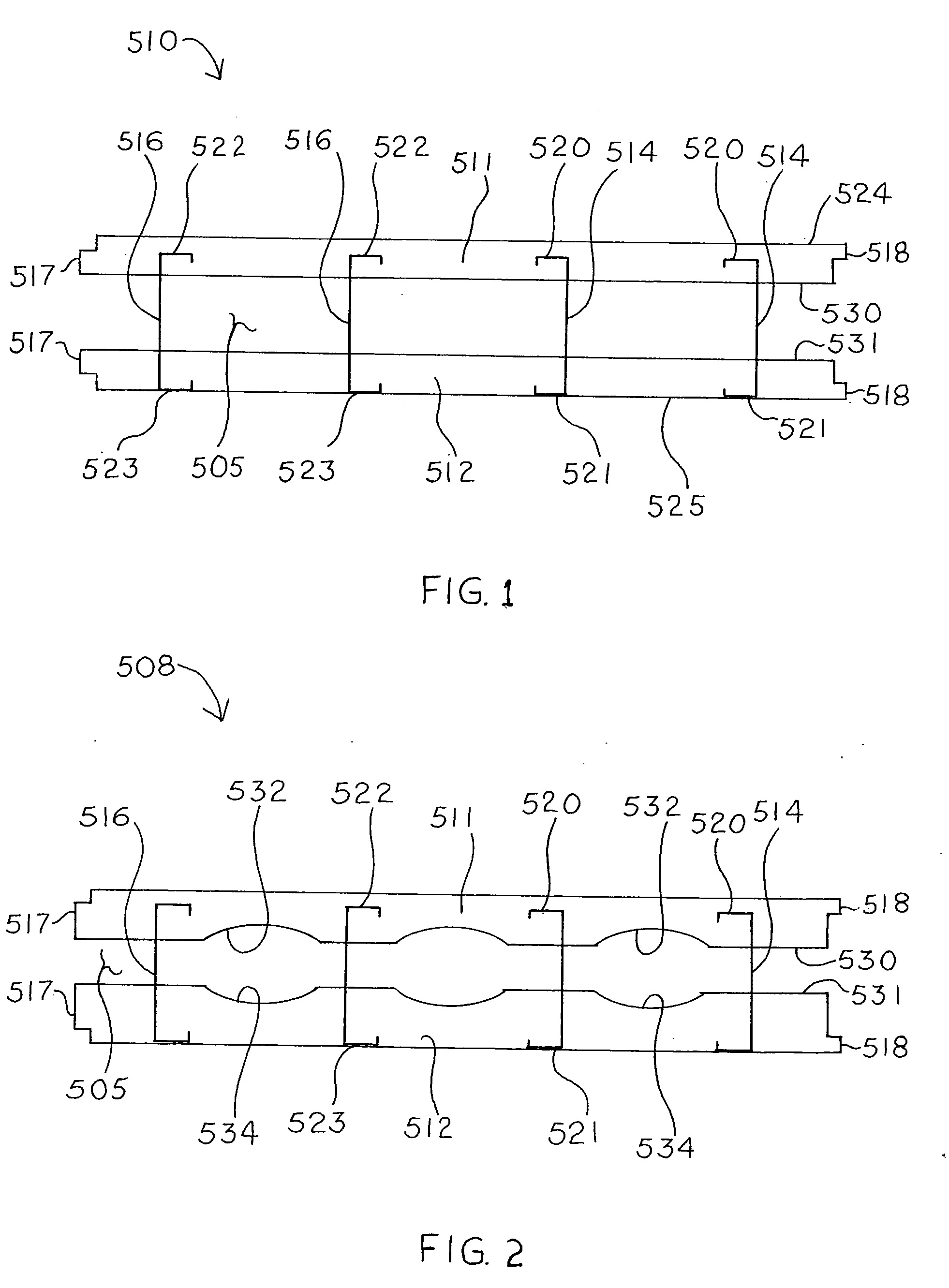

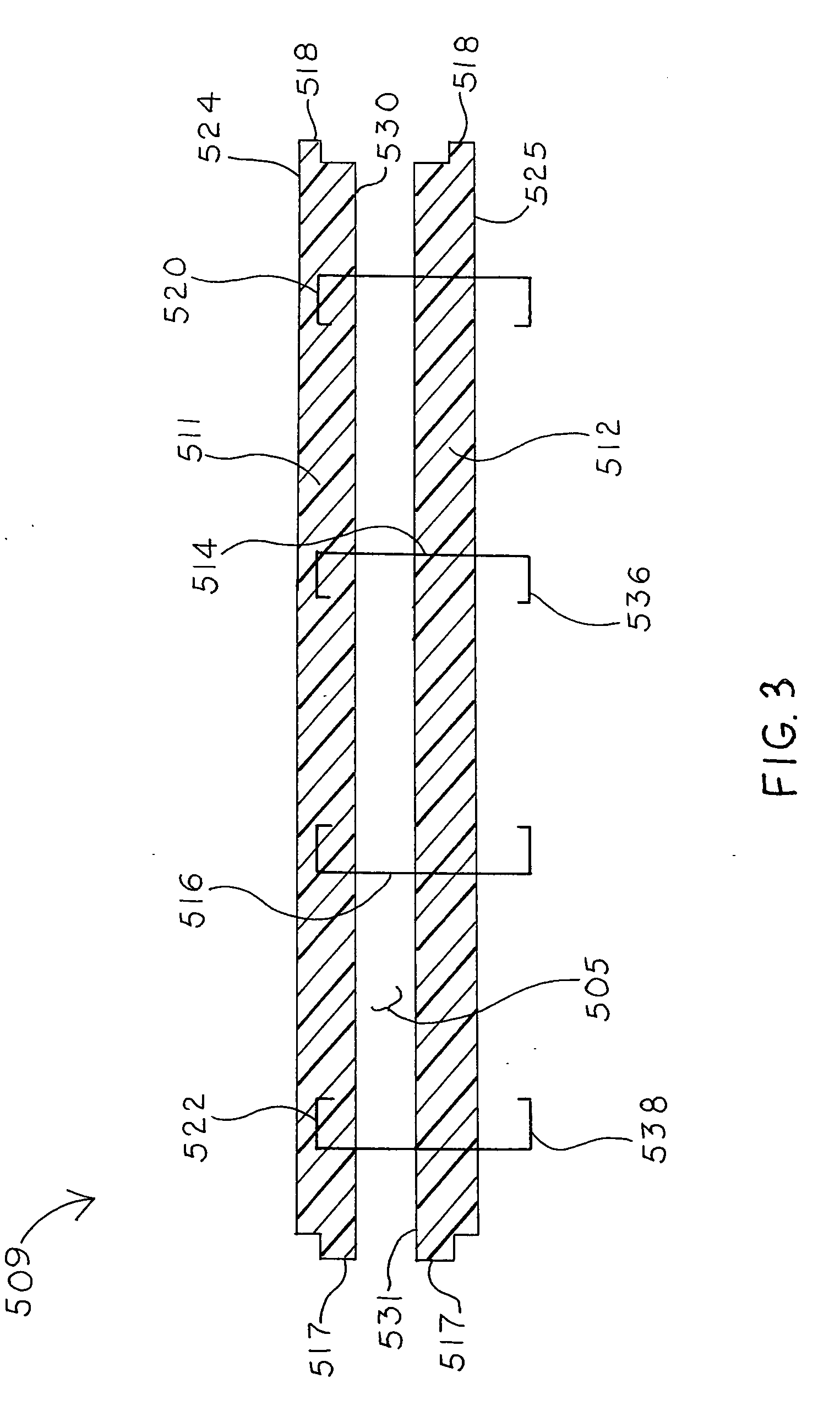

Stressed barrier plug slot contact structure for transistor performance enhancement

ActiveUS20080157208A1TransistorSemiconductor/solid-state device detailsStress inducedPerformance enhancement

A method for forming a slot contact structure for transistor performance enhancement. A contact opening is formed to expose a contact region, and a slot contact is disposed within the contact opening in order to induce a stress on an adjacent channel region. In an embodiment, a stress inducing barrier plug is disposed within a portion of the contact opening and the remainder of the contact opening is filled with a lower resistivity contact metal. By selecting the proper materials and deposition parameters, the slot contact can be tuned to induce a tensile or compressive stress on the adjacent channel region, thus being applicable for both p-type and n-type devices.

Owner:INTEL CORP

Bright metal flake

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

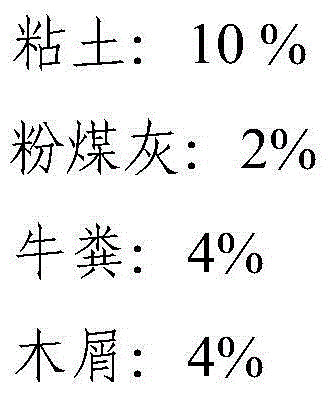

Ceramsite water permeable brick and preparation method thereof

The invention provides a ceramsite water permeable brick, which comprises the following components by weight: 80-100 parts of ceramsite, 10-15 parts of silicon sand, 20-40 parts of cement, a setting accelerator accounting for 2-4% of the weight of the ceramsite, and a water reducing agent accounting for 2-4% of the weight of the ceramsite. According to the invention, silicon sand dust made ceramsite is combined with a small quantity of cement, the setting accelerator, the water reducing agent and a silicon sand fabric to manufacture the ceramsite water permeable brick. One the one hand, the water permeable brick has a beautiful appearance, and on the other hand it combines the lightweight and high strength characteristics of ceramsite. At the same time, ceramsite is round stone rather than polygonal, and usually the gap between round objects is larger than that between polygonal objects, so that the prepared water permeable brick has good permeability effect. The water permeable brick prepared by the method has compressive strength of greater than or equal to 30Mpa and a permeability coefficient of greater than or equal to 0.05cm / s, and the other properties of the brick meet the JCT945-2005 industrial standard.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

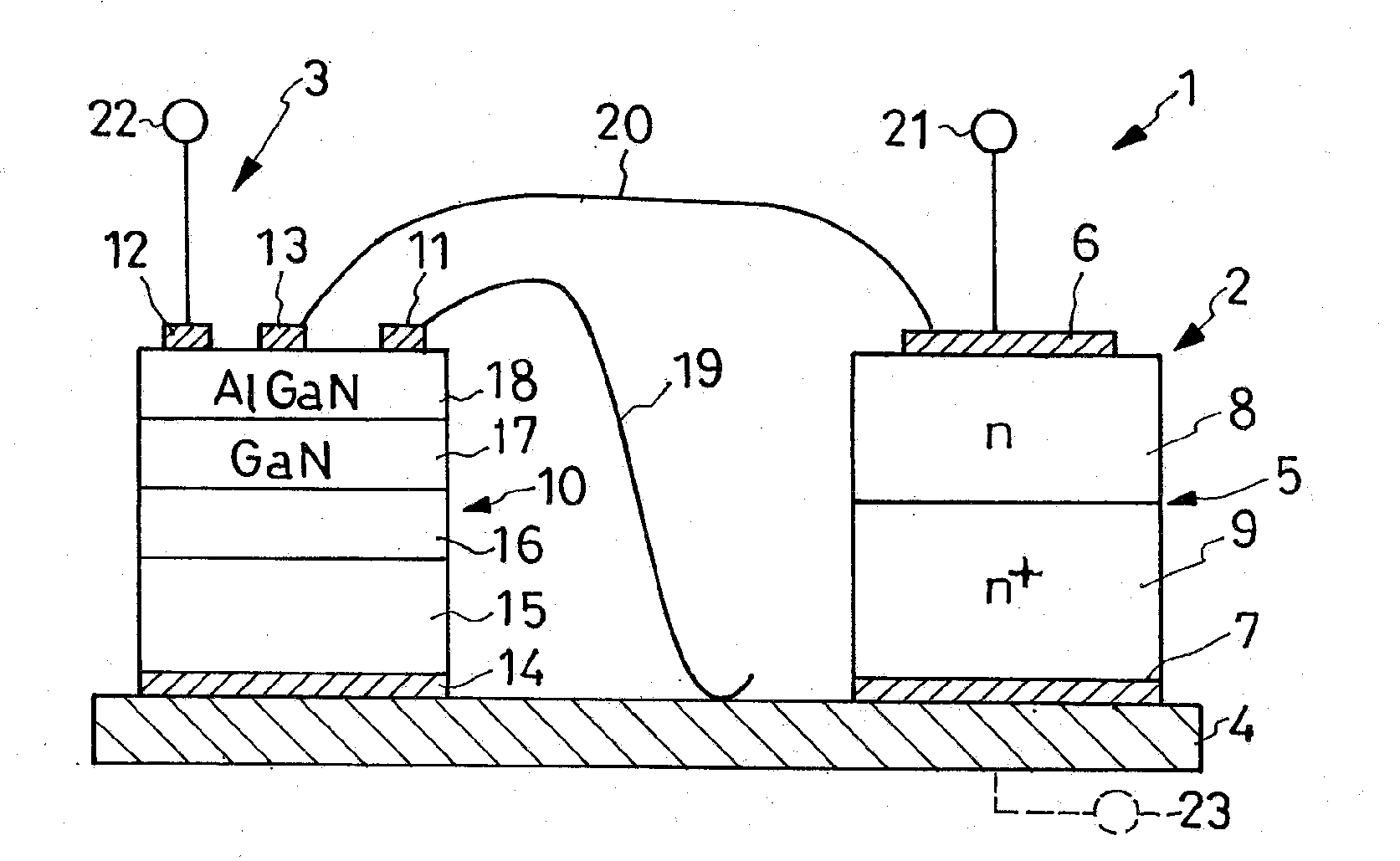

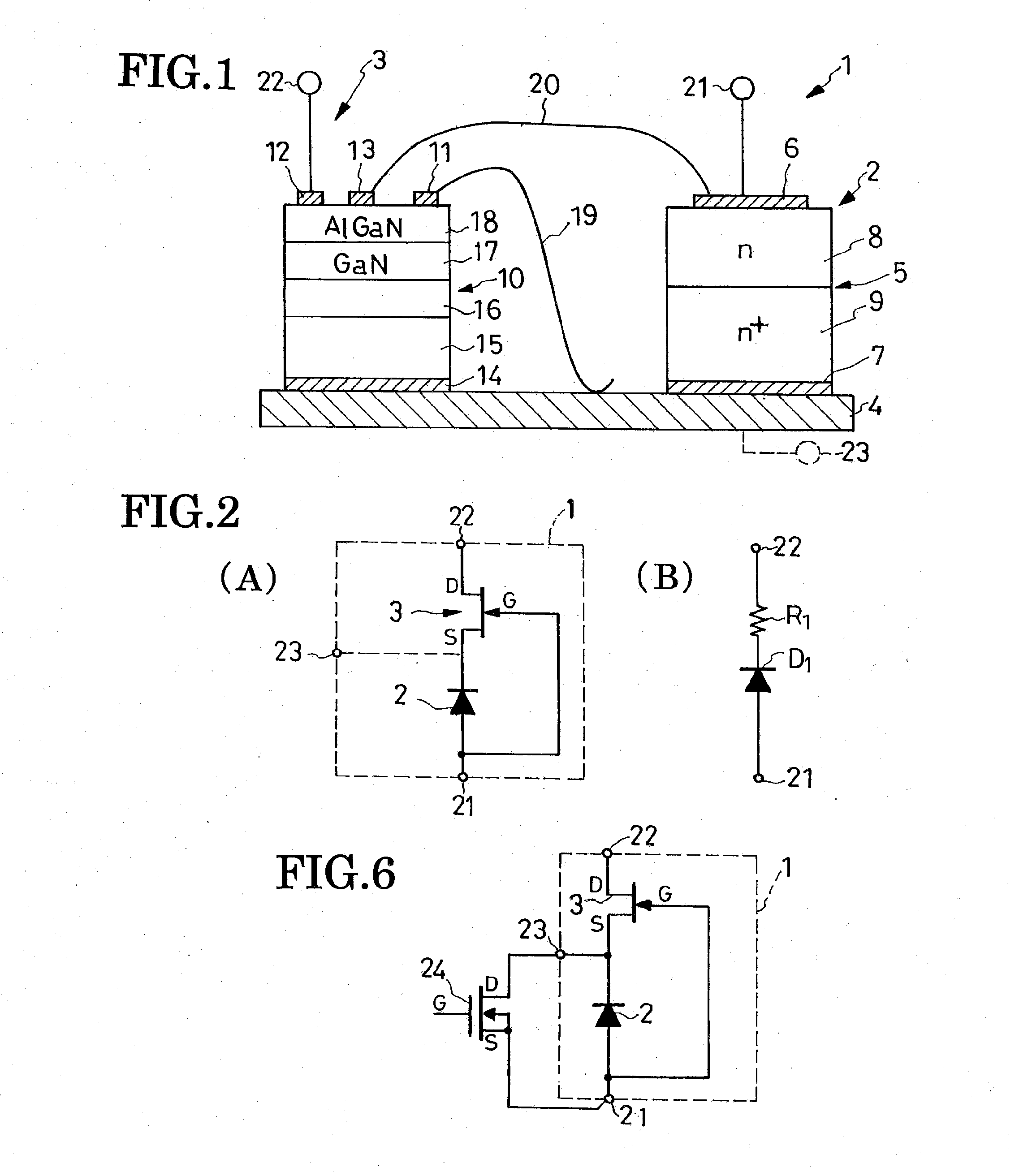

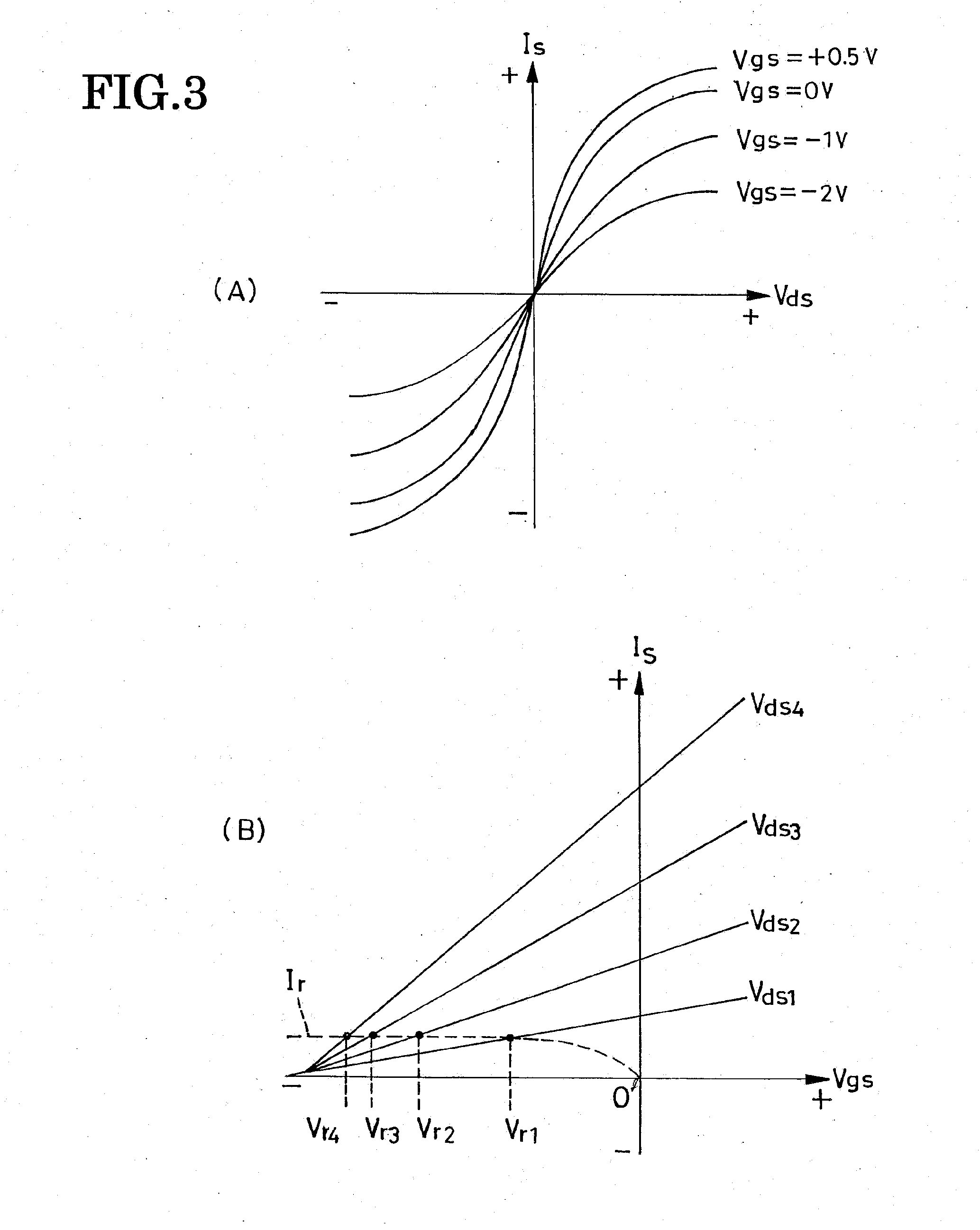

Diode-Like Composite Semiconductor Device

ActiveUS20080191216A1Minimal current capacityPrevent excess flowSolid-state devicesElectronic switchingSchottky barrierCompressive strength

A silicon-made low-forward-voltage Schottky barrier diode is serially combined with a high-antivoltage-strength high-electron-mobility transistor made from a nitride semiconductor that is wider in bandgap than silicon. The Schottky barrier diode has its anode connected to the gate, and its cathode to the source, of the HEMT. This HEMT is normally on. The reverse voltage withstanding capability of the complete device depends upon that between the drain and gate of the HEMT.

Owner:SANKEN ELECTRIC CO LTD

Expandable microspheres for foam insulation and methods

InactiveUS20050079352A1Use in some applicationHigh of encapsulationLiquid surface applicatorsGlass/slag layered productsPolymer scienceFoaming agent

Hollow thermoexpandable particles or microspheres are provided that contain hydrocarbon blowing agents and have a shell polymer that can be softened at the onset of the expansion temperature and solidified at a higher temperature (thermoset) in an expanded state. Preferably, the microspheres have a shell of thermally expandable and thermally crosslinkable polymer and a hollow interior that contains a hydrocarbon liquid that boils at a temperature below the heat activated crosslinking temperature of the polymer shell. The crosslinking of the shell polymer during or after expansion, which is heat activated at an elevated temperature, can solidify the shell polymer and, then, maintain the expanded volume of the microspheres. The thermoexpandable thermoset polymer particles are useful in insulation, packaging, for making foam materials such as polyurethane or polyisocyanurate rigid foams. The invented thermoset microspheres can substantially improve the close cell percentage and compressive strength of the foam materials and make the foam manufacturing less hazardous.

Owner:IP RIGHTS +1

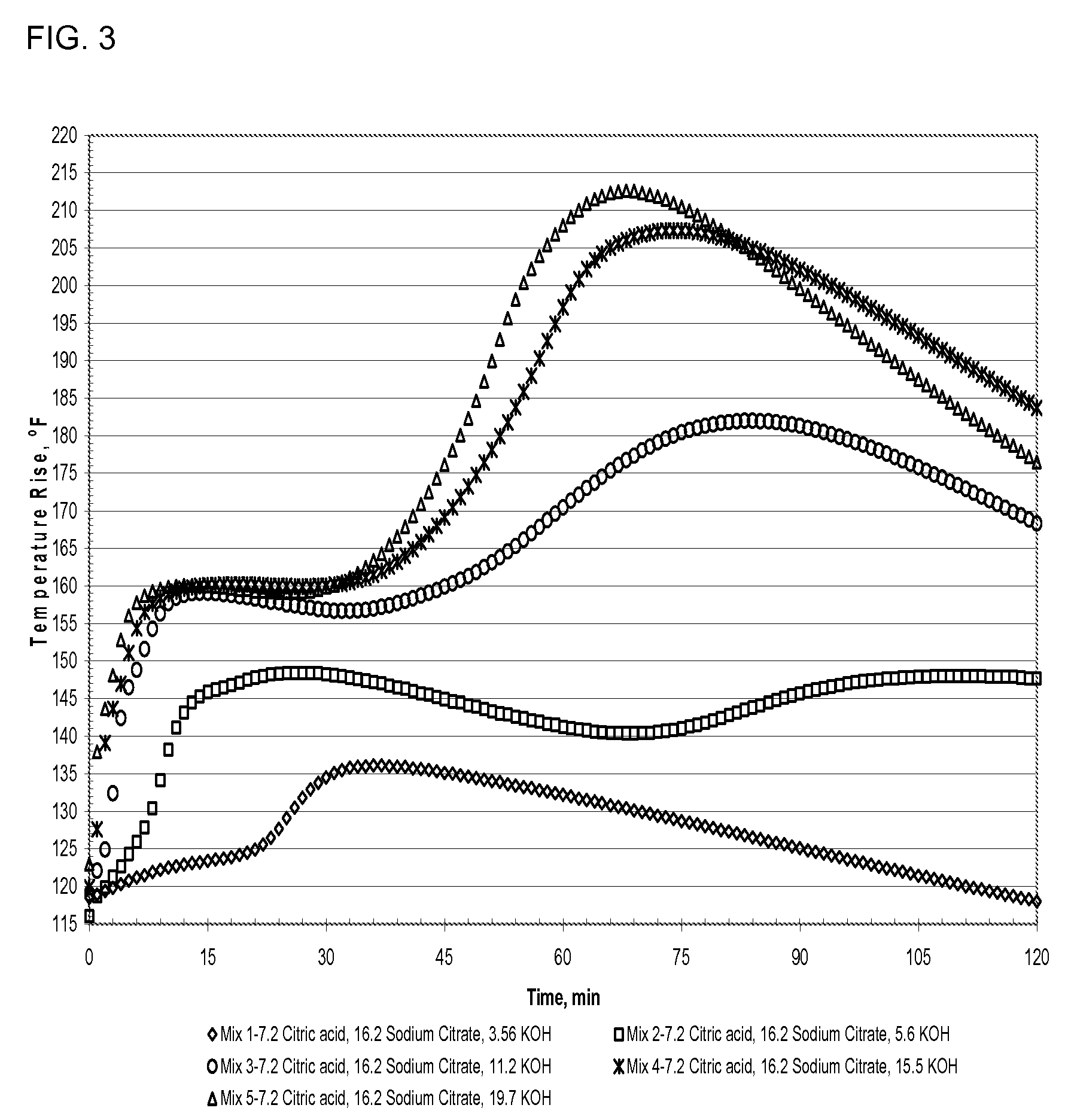

Fly ash based lightweight cementitious composition with high compressive strength and fast set

InactiveUS20100071597A1Quick SetupEnhanced early and final compressive strengthSolid waste managementPolymer scienceCompressive strength

A method of making a rapid setting lightweight cementitious composition with improved compressive strength for products such as boards is disclosed. The method mixes fly ash, alkali metal salt of citric acid and lightweight aggregate with water. Compositions which include fly ash, alkali metal salts of citric acid and lightweight aggregate are also disclosed.

Owner:UNITED STATES GYPSUM CO

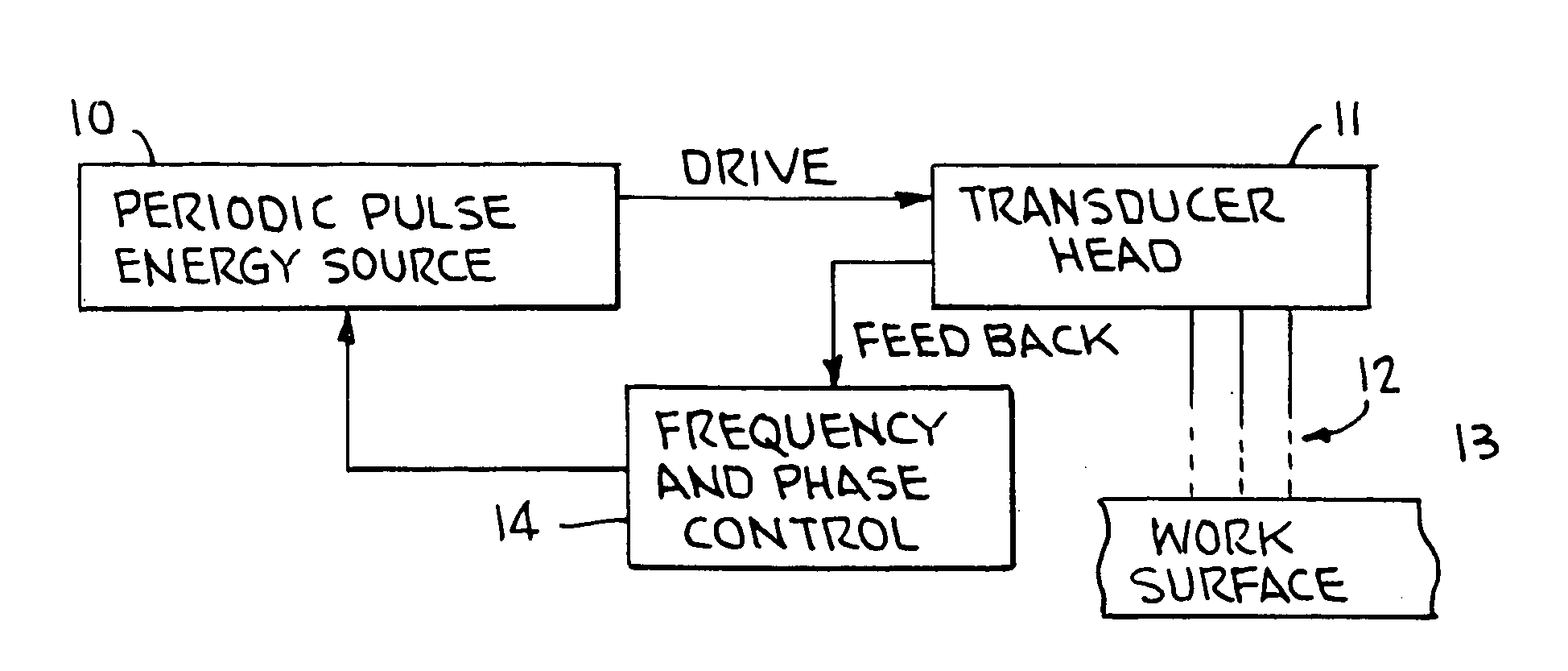

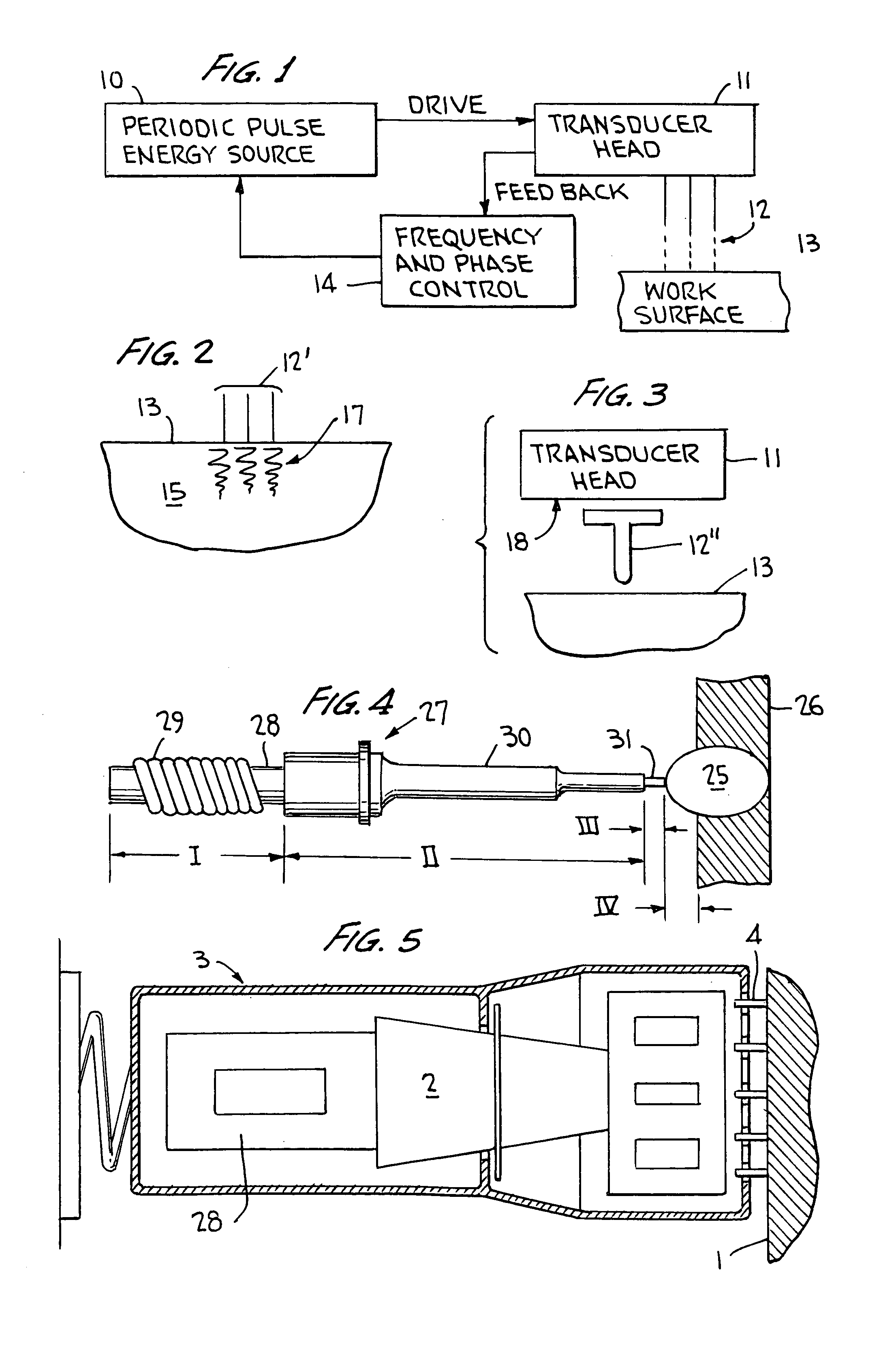

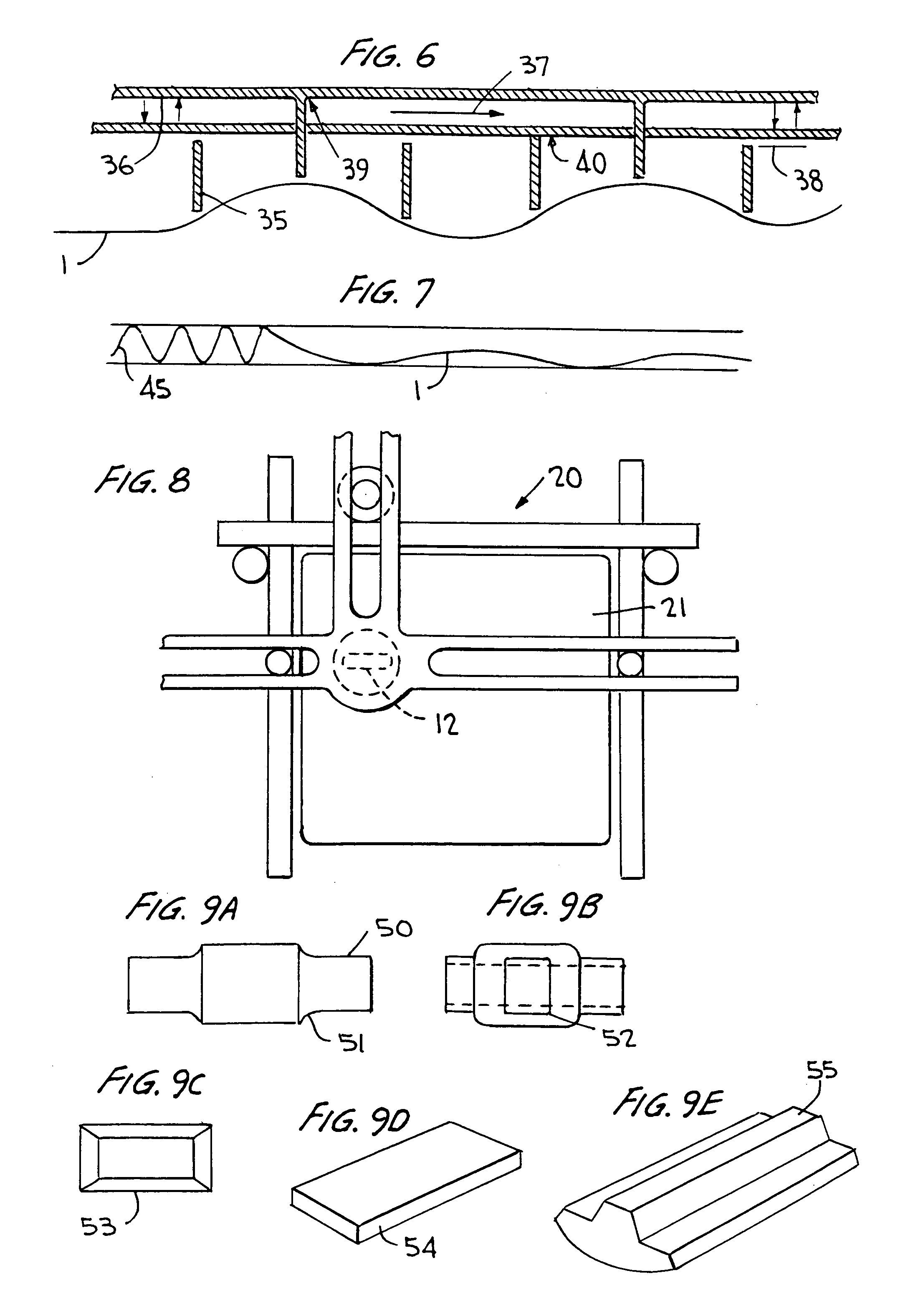

Ultrasonic impact machining of body surfaces to correct defects and strengthen work surfaces

InactiveUS6932876B1Improve power transfer efficiencyEfficient transferMechanical vibrations separationFurnace typesUltrasonic sensorPeriodic oscillation

Metallic workpieces of diverse shapes having work surfaces which are deformed at the surface and adjacent sub-surface layers by surface impact from ultrasonic transducers employing freely axially moving impacting elements propelled and energized by a transducer oscillating surface vibrating periodically at an ultrasonic frequency. The impacting elements are propelled in a random aperiodic and controlled impact mode at different phases of the periodic oscillation cycles. The transducer may be portable and provides a series of mechanically interconnected stages having mechanical resonances harmonically related as a multiple of the primary ultrasonic frequency and have matched stage resistances under instantaneous loading when the impact elements are driven by the transducer oscillating surface into the surface of the workpiece. This mode of operation produces Q-factor amplification of the input ultrasonic power oscillator energy at the impact needles and high propulsion velocities making it possible to machine metallic workpiece bodies to greater depths for compressing the metal to increase compressive strength of the workpiece work surfaces to substantially the ultimate material strength. The impact machining is done at ambient temperatures.

Owner:PROGRESS RAIL SERVICES

Epoxy resin composition for fiber-reinforced composite material prepreg, and fiber-reinforced composite material

The present invention relates to an epoxy resin composition for a fibre reinforced composite material, which is thermosetting resin composition where the glass transition temperature Tg of the cured material obtained by heating for 2 hours at 180° C. is at least 150° C., and the modulus of rigidity G'R in the rubbery plateau in the temperature region above the aforesaid Tg is no more than 10 MPa. In accordance with the present invention, it is possible to provide a fibre-reinforced composite material which is outstanding in its resistance to hot-wet environmental condition, impact resistance, and strength characteristics such as tensile strength and compression strength, and furthermore it is possible to provide a thermosetting resin composition and a prepreg outstanding in terms of their peel strength to a honeycomb core.

Owner:TORAY IND INC

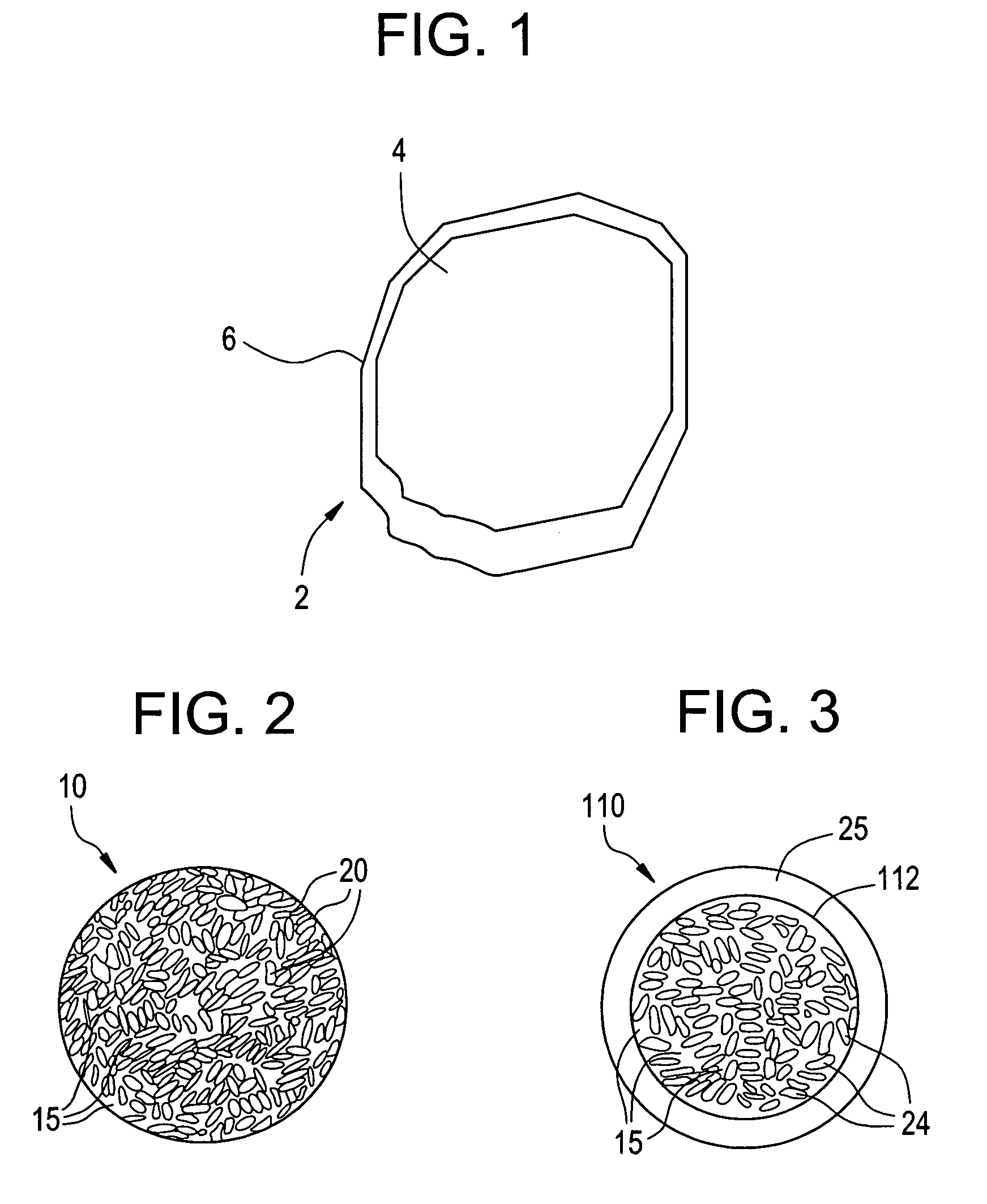

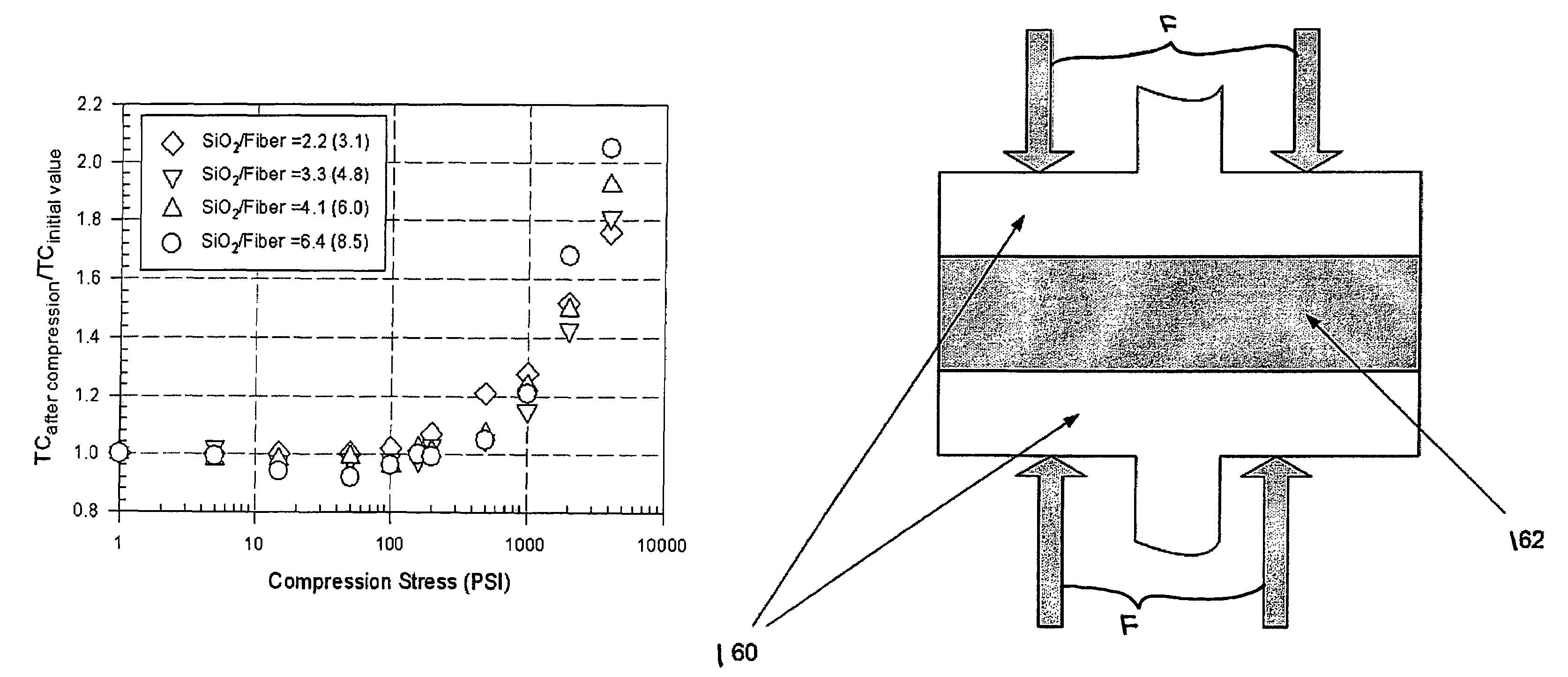

Particulate material containing thermoplastics and methods for making and using the same

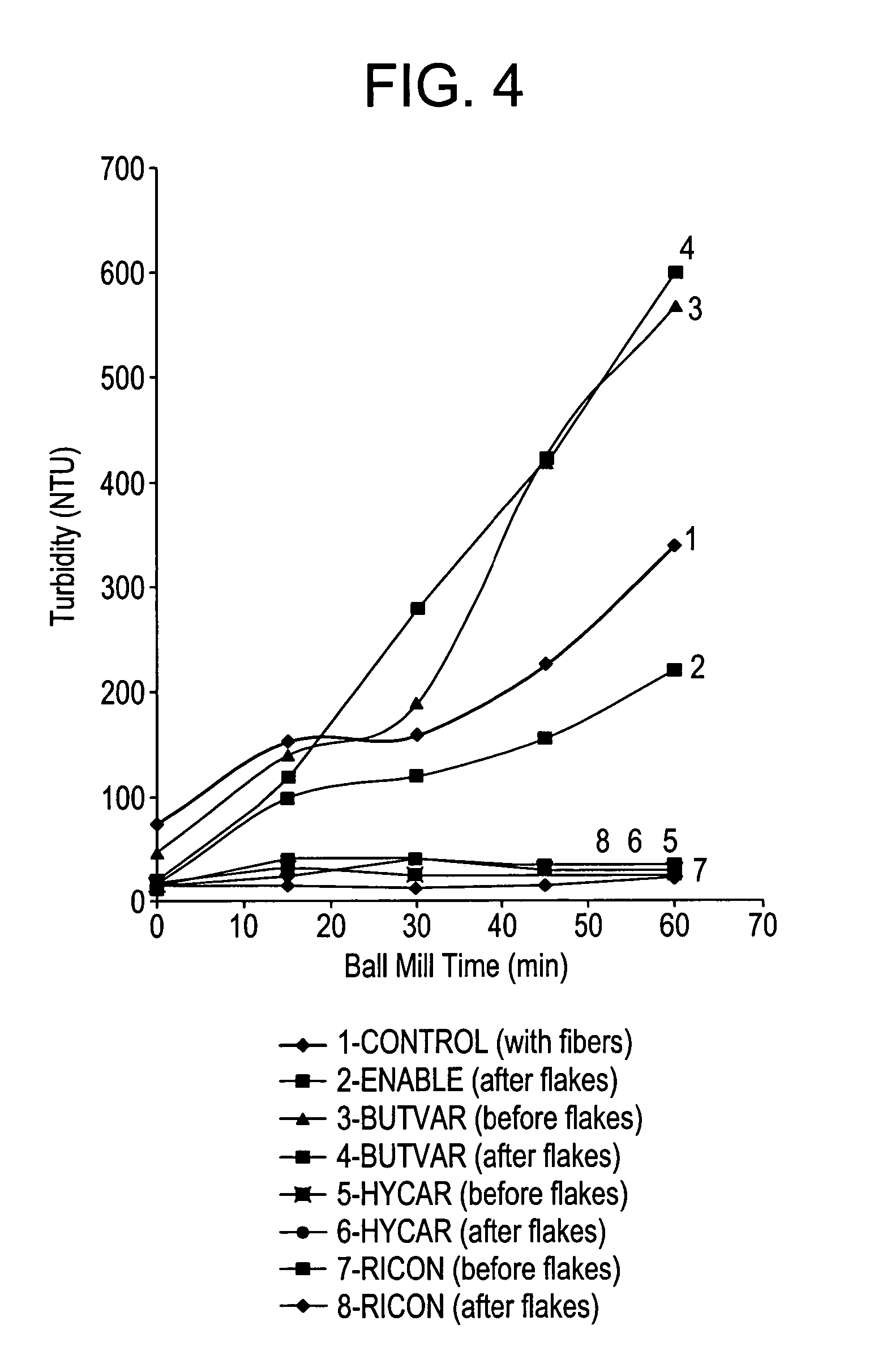

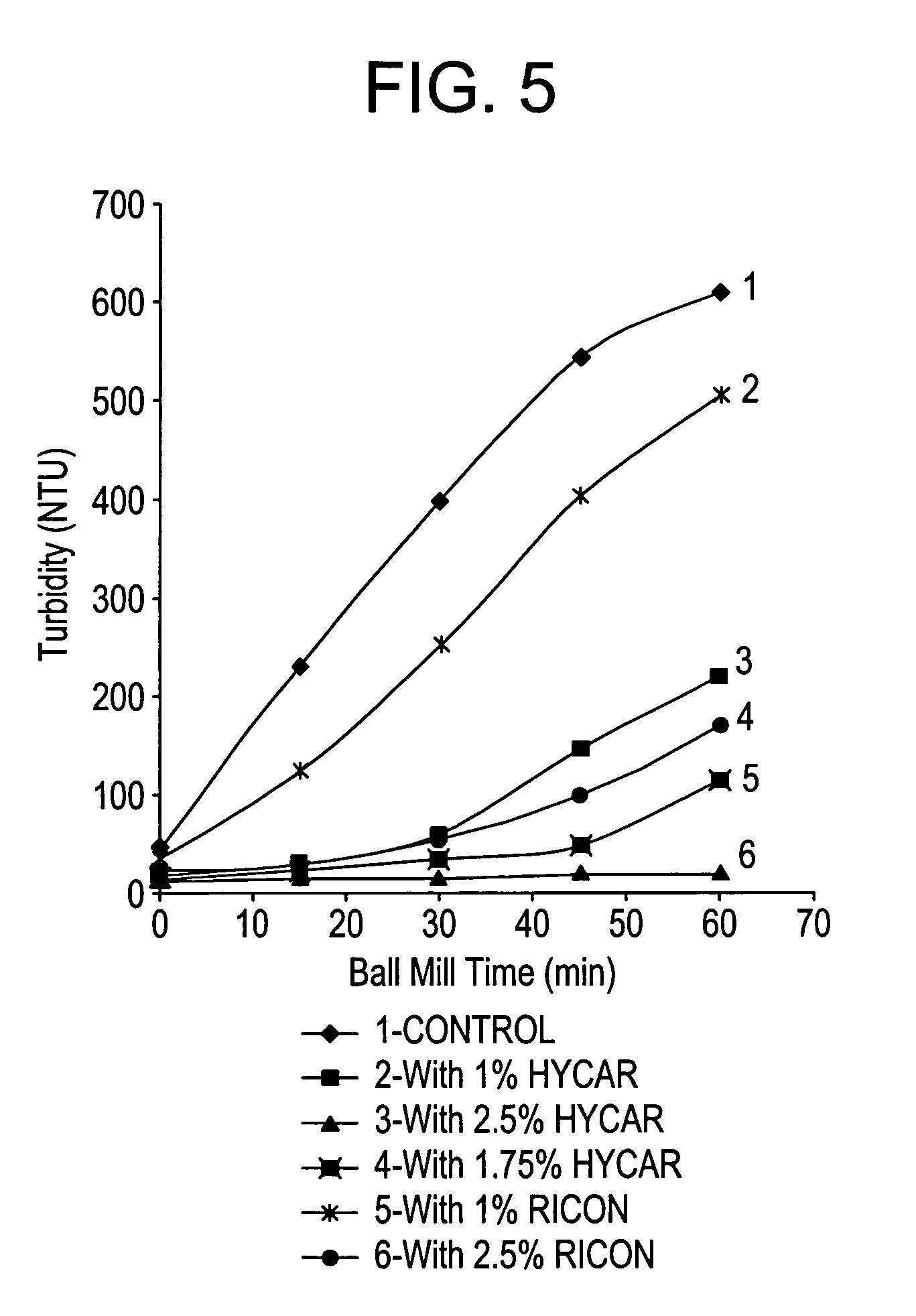

ActiveUS7270879B2Trend downImprove abilitiesPretreated surfacesGlass/slag layered productsParticulatesThermoplastic

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

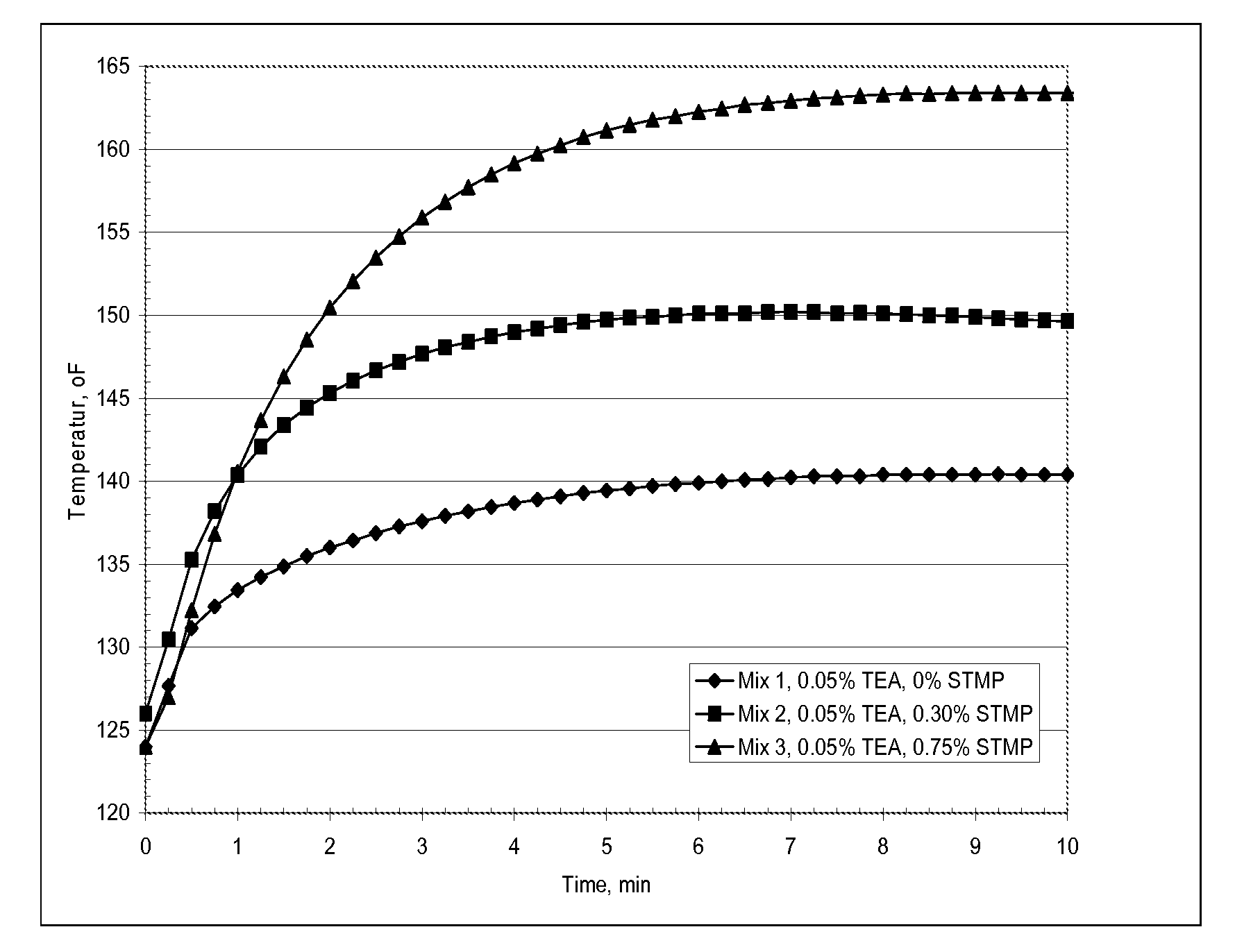

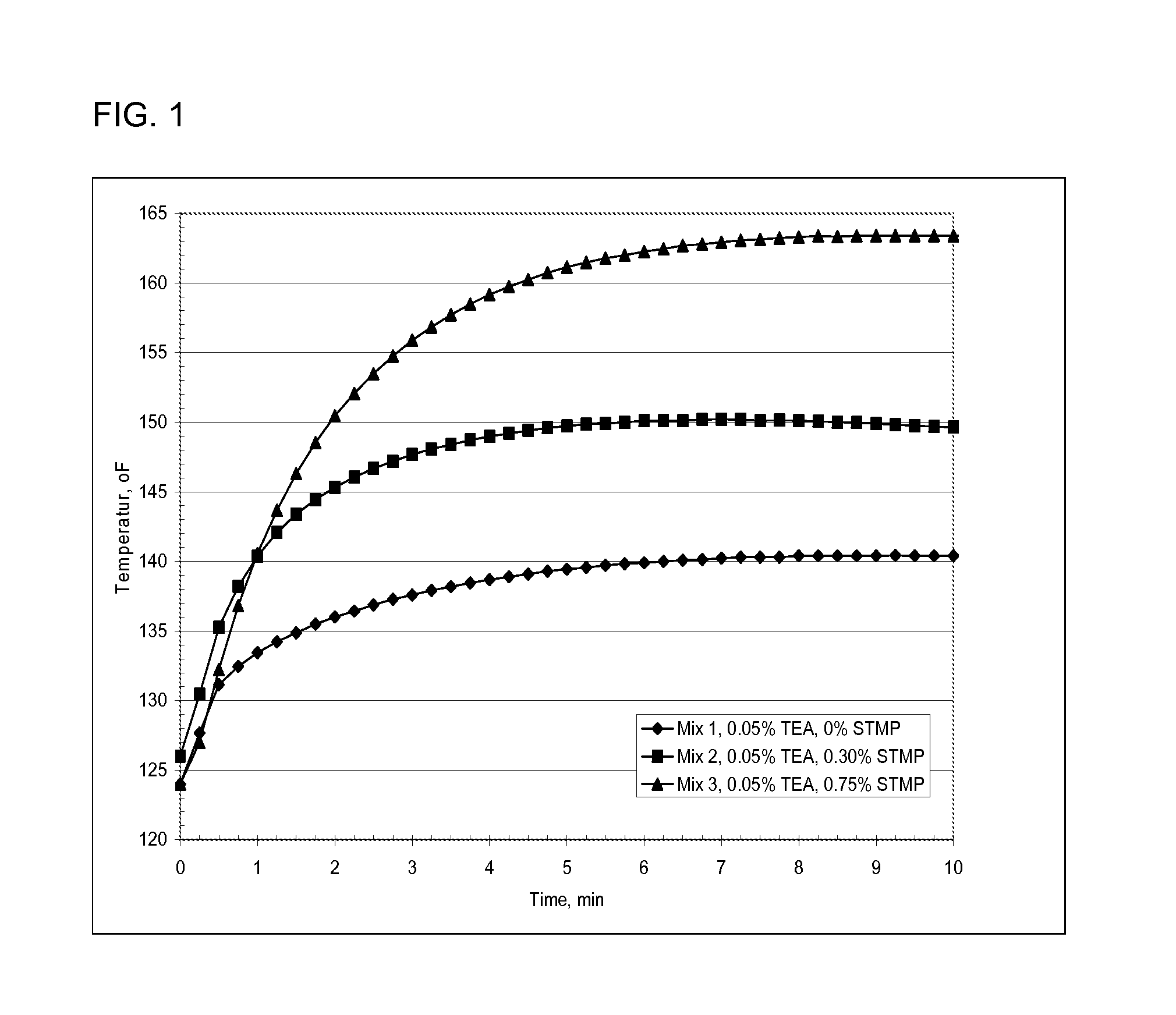

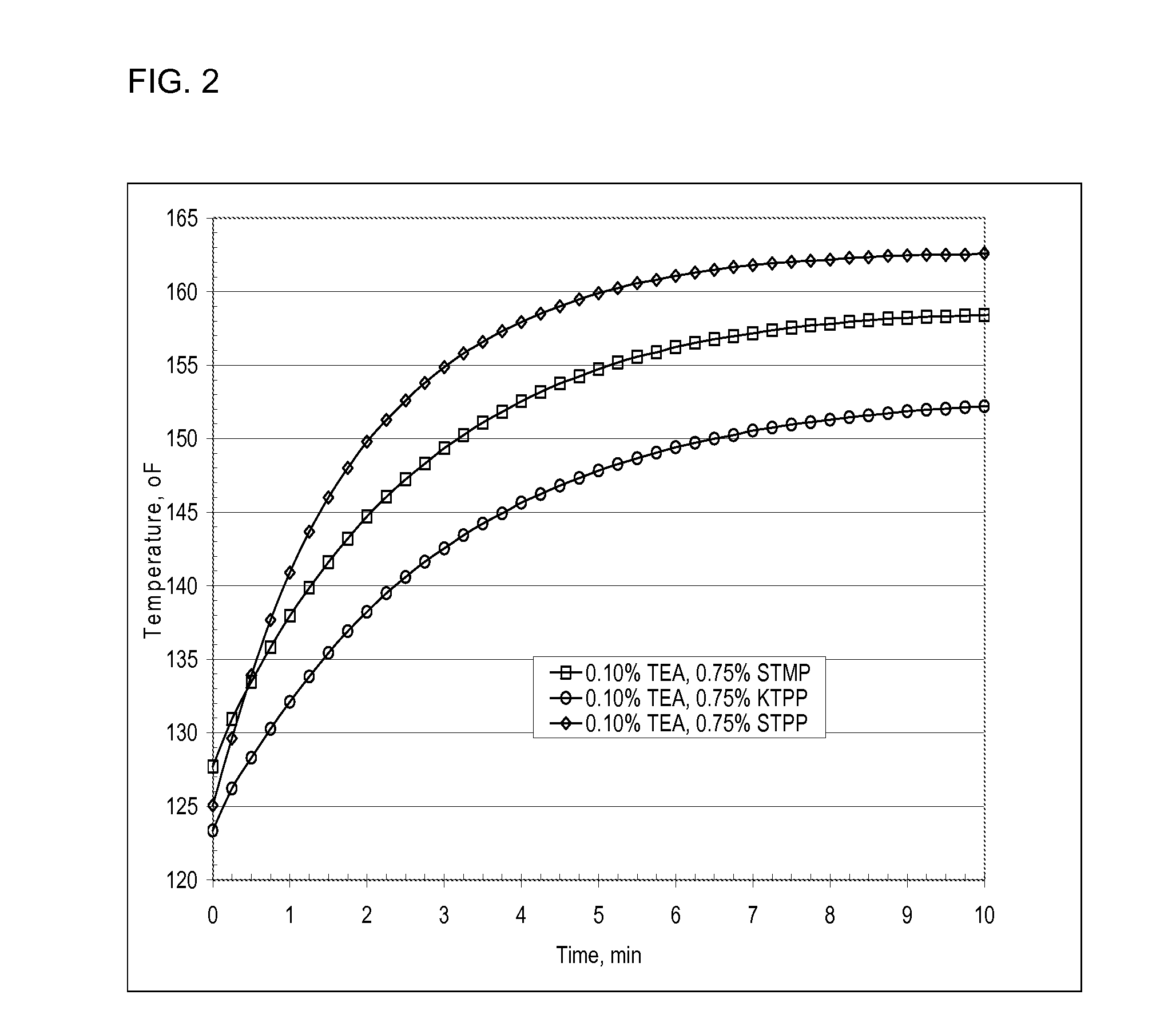

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS7670427B2Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

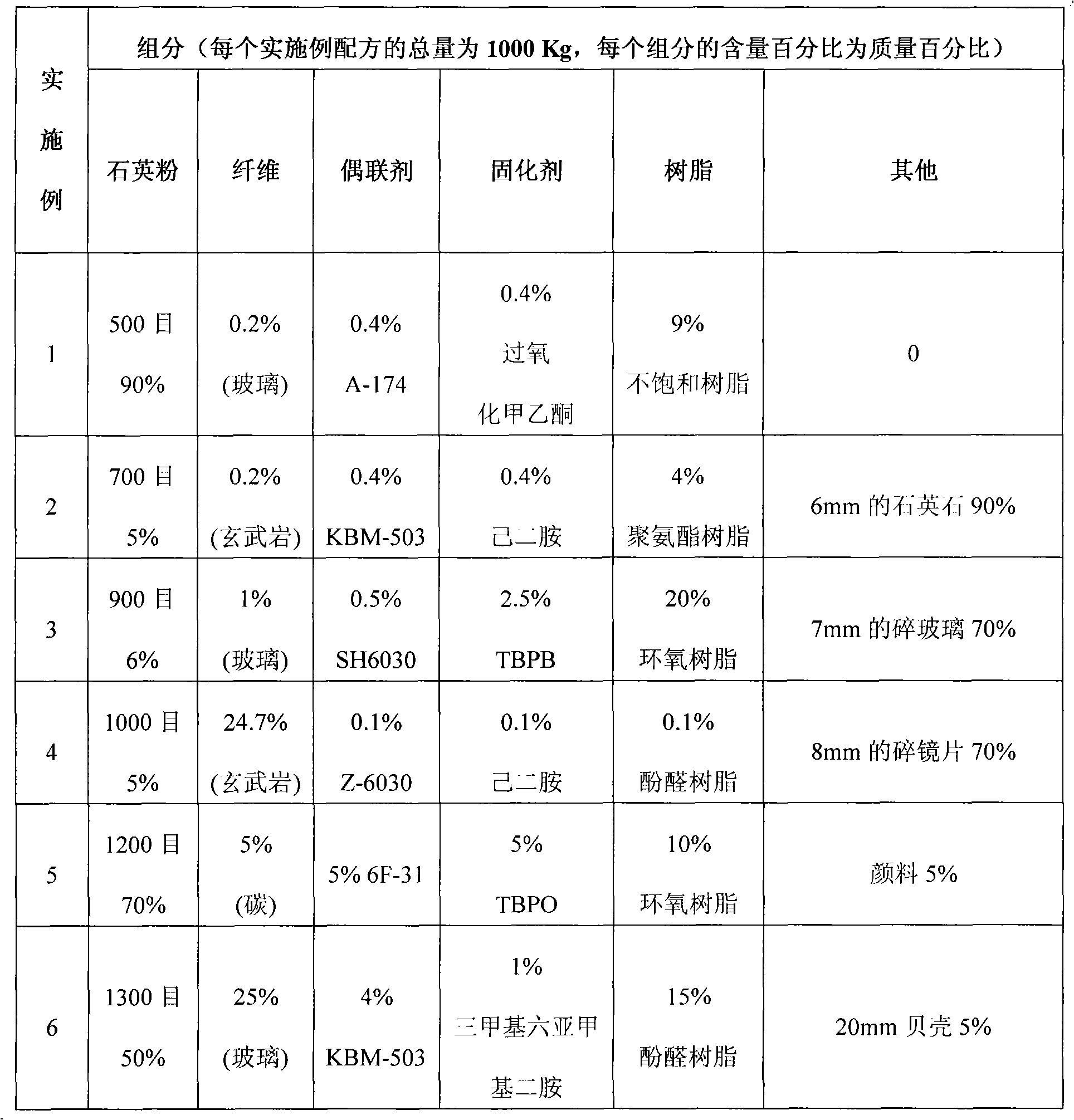

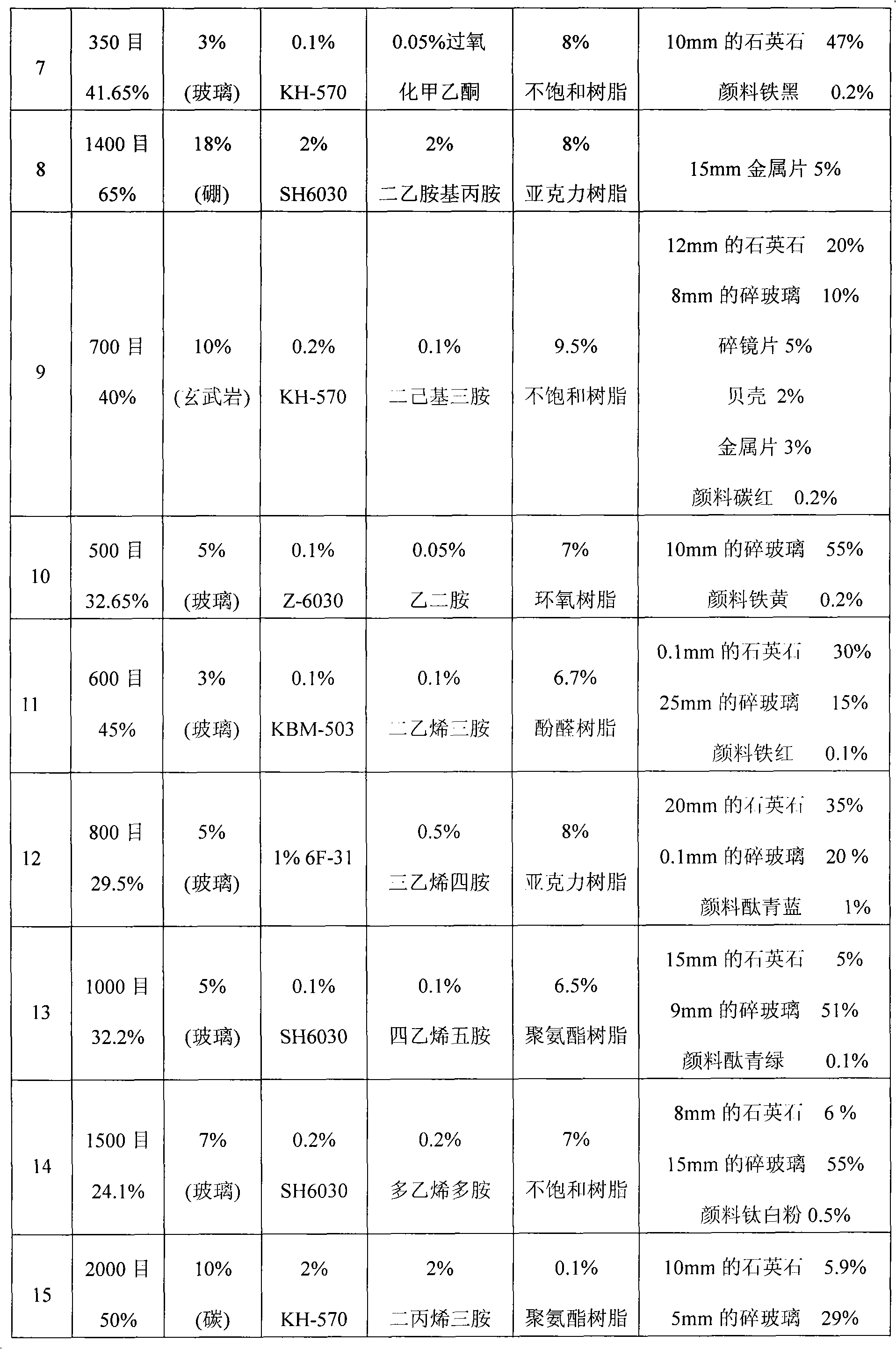

Artificial quartz in lump and fabrication technology thereof

The invention discloses a man-made quartz stone, which comprises 0 to 90 percent of quartz stone, 5 to 90 percent of silica flour, 1 to 25 percent of fiber, 0.1 to 20 percent of resin, 0.1 to 5 percent of a coupling agent, 0.1 to 5 percent of a curing agent, 0 to 70 percent of cullet, 0 to 70 percent of broken glass block, 0 to 5 percent of paint, 0 to 5 percent of shell, 0 to 5 percent of metal sheet by mass. The tear resistance, the compressive strength and the buckling strength of the man-made quartz stone are significantly improved compared with the prior man-made quartz stone. The invention further relates to a manufacturing process for a man-made quartz stone plate or block and vessel.

Owner:张璐 +1

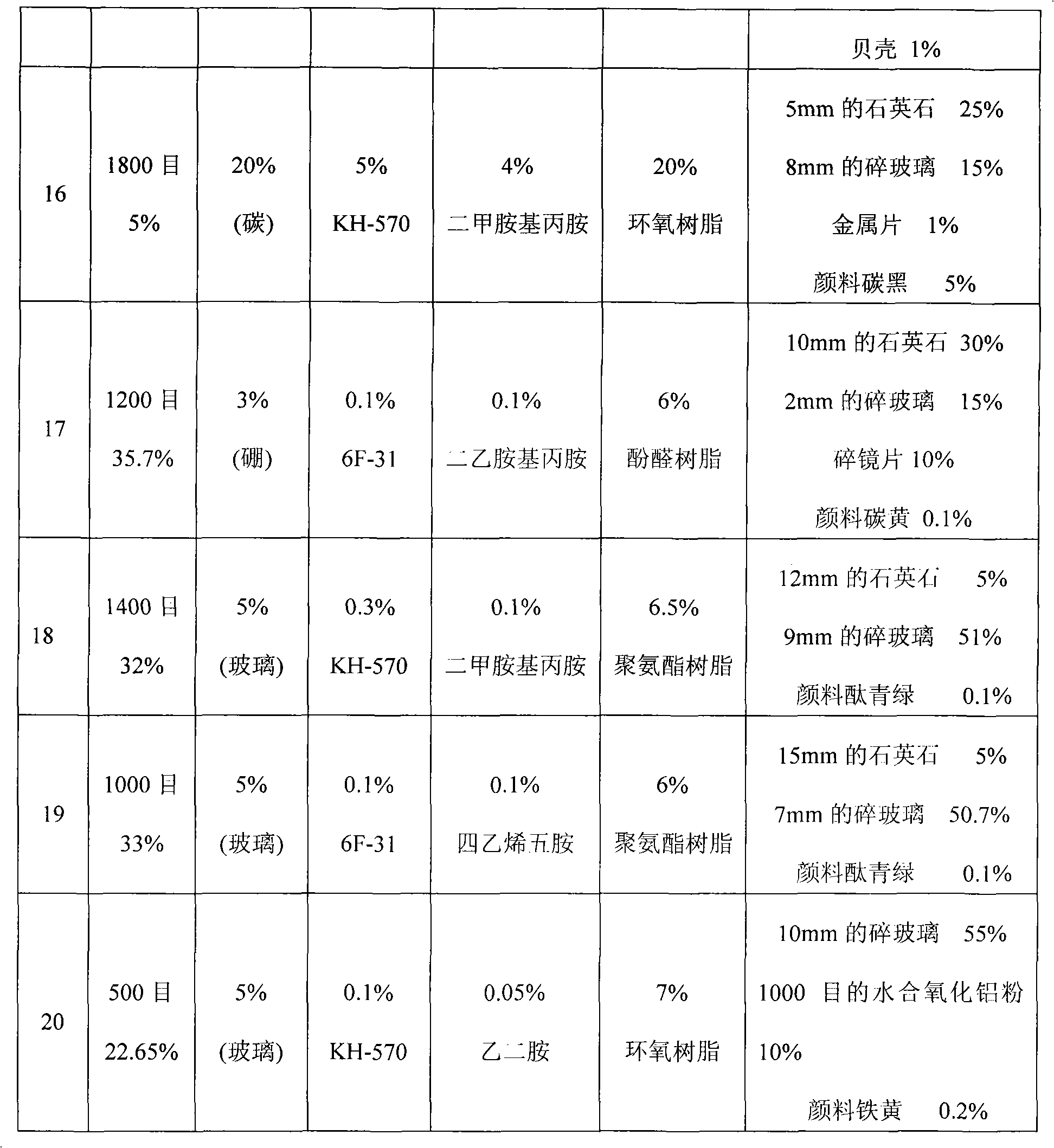

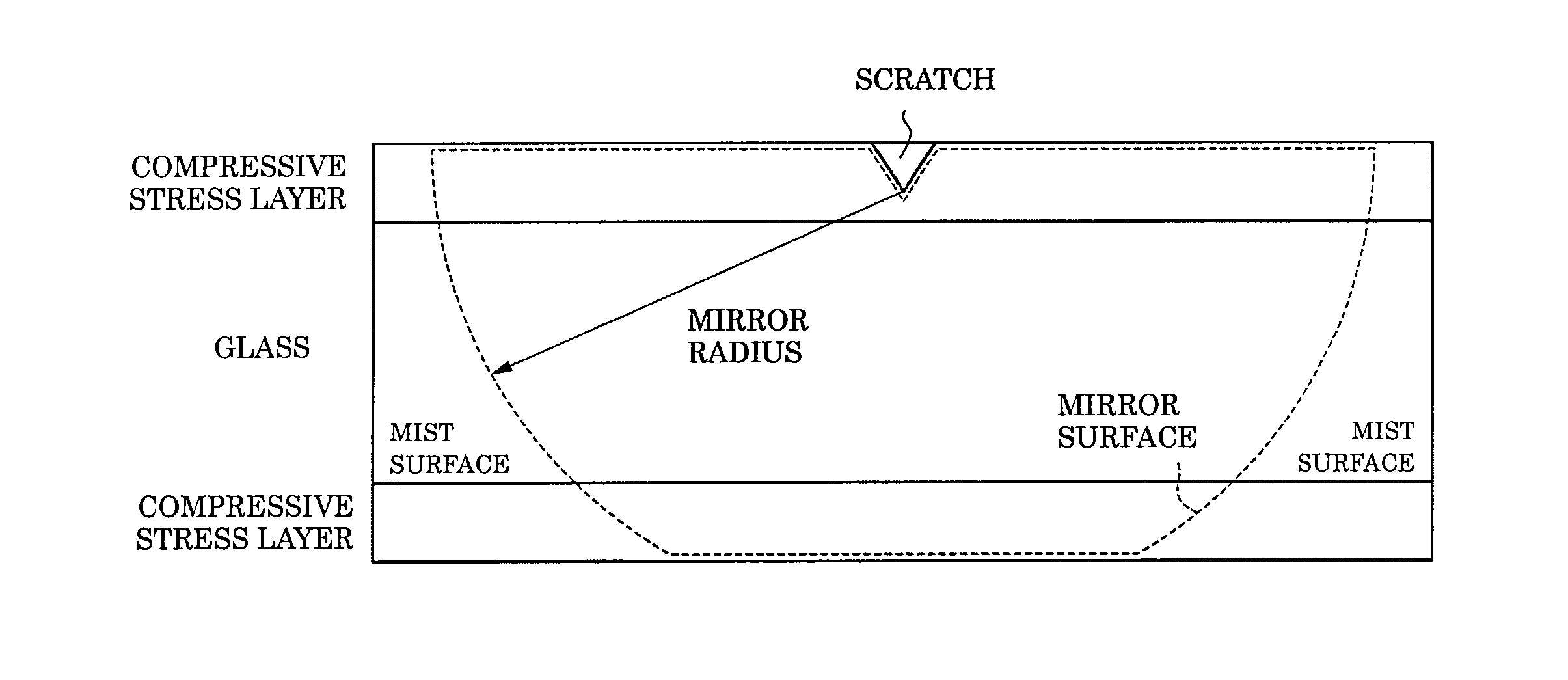

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

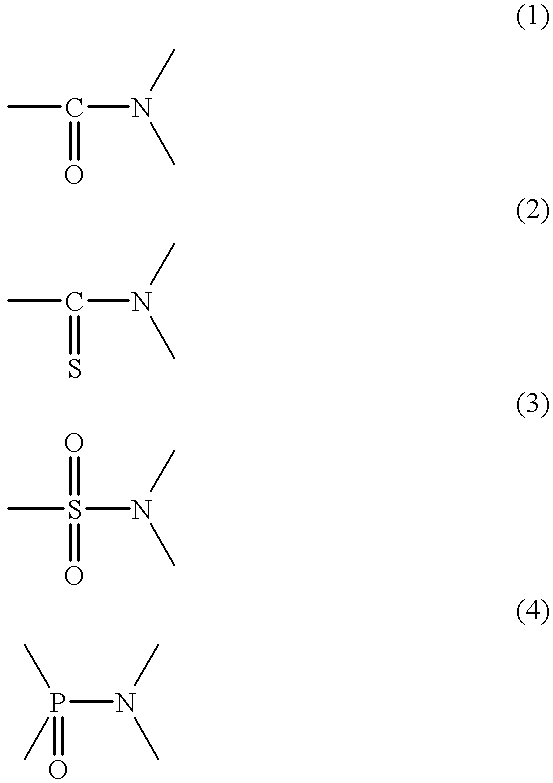

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

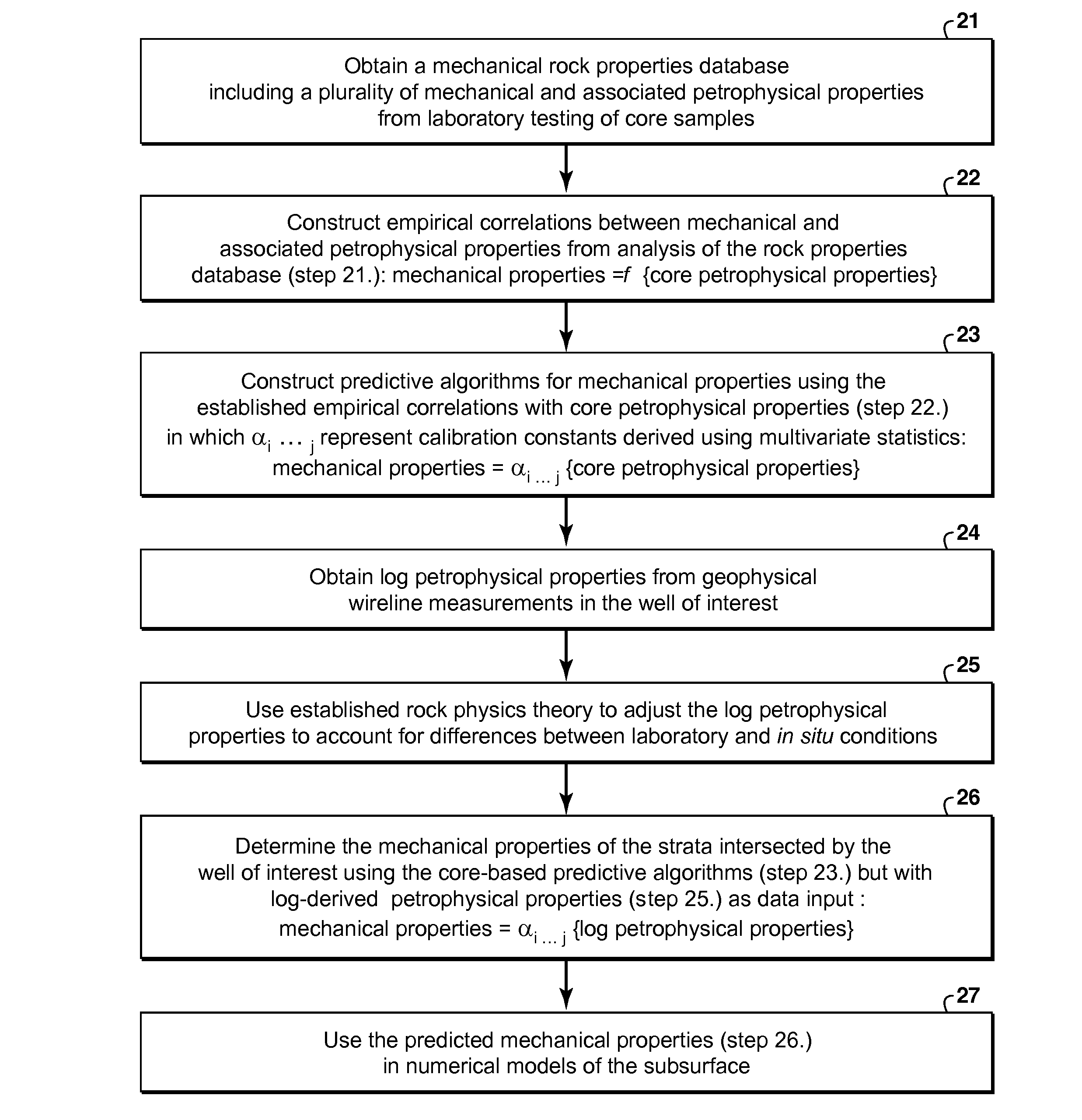

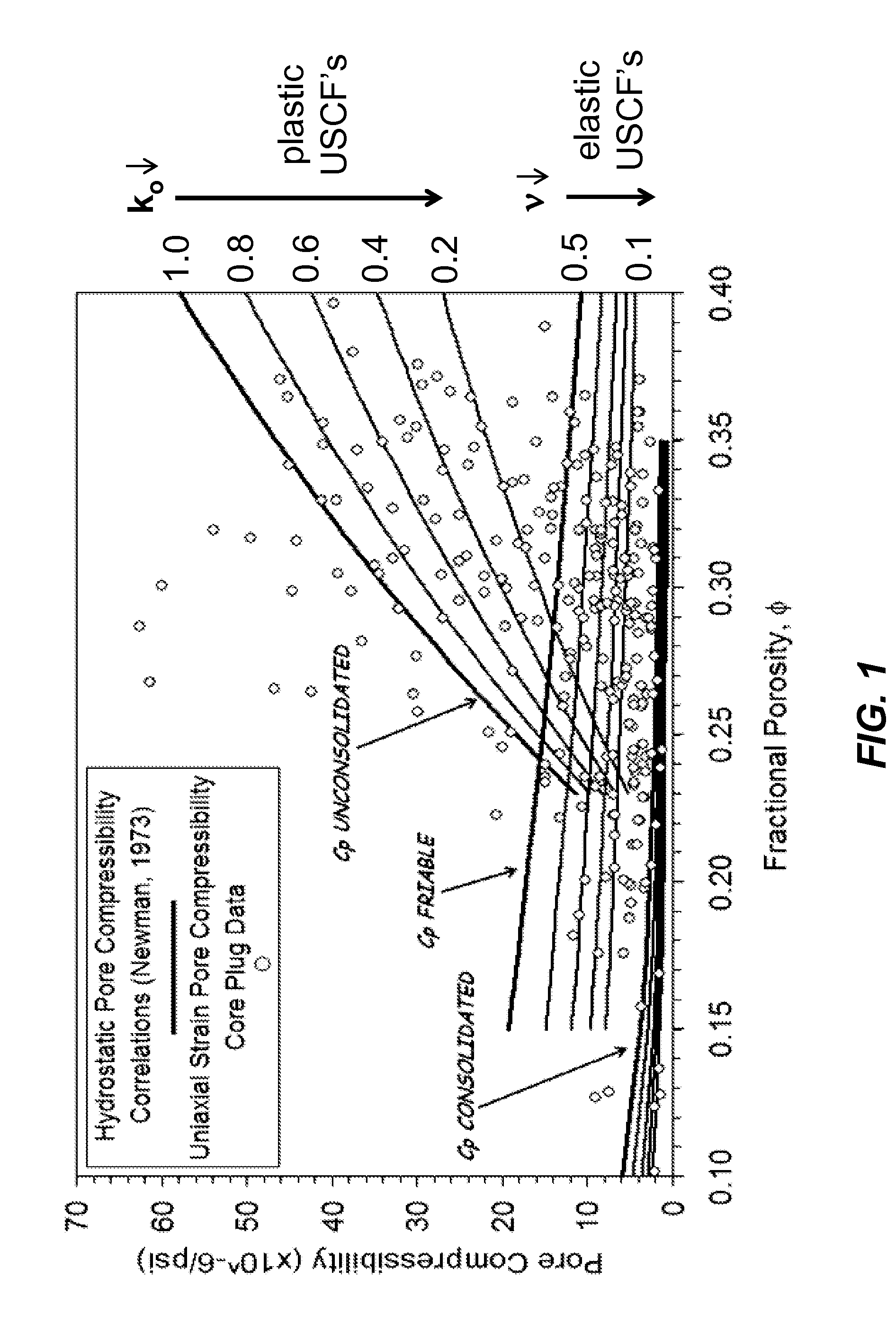

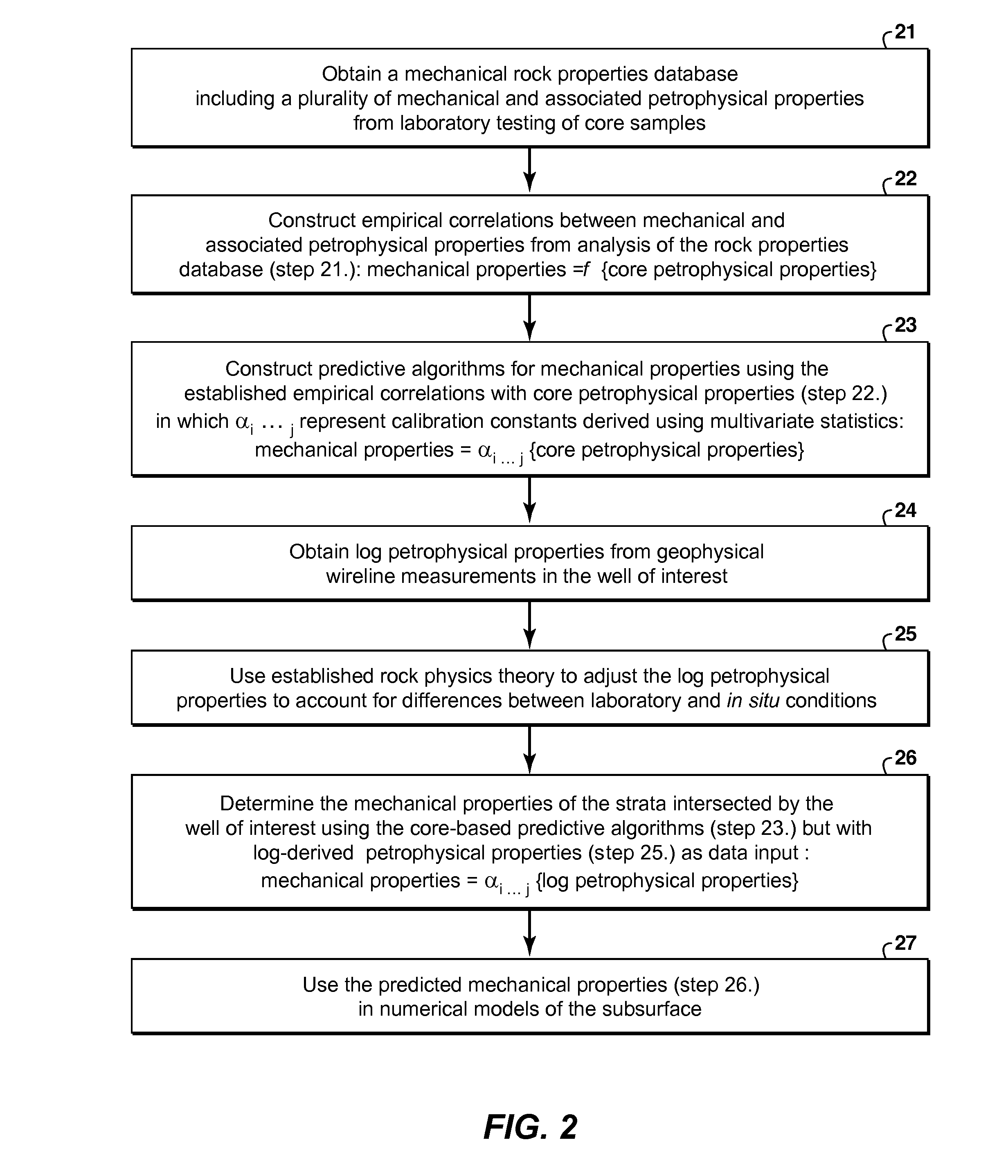

Petrophysical Method For Predicting Plastic Mechanical Properties In Rock Formations

InactiveUS20110015907A1Computation using non-denominational number representationGeological measurementsLithologyGeographic regions

Method for prediction of mechanical properties used in the description of large-strain plastic deformation for any subsurface rock strata of interest. The method is not specific to any geographic region, geological environment or subsurface depth interval, nor is it constrained to a specific lithology or plastic mechanical property. Predictive algorithms for triaxial compressive strength and rock compressibility are derived (23) from a mechanical properties database (21), and used to predict subsurface variation in mechanical properties such as rock strength or rock compressibility, with petrophysical properties generated from, for example, geophysical wireline logs as input to the algorithms (26).

Owner:EXXONMOBIL UPSTREAM RES CO

High strength, nanoporous bodies reinforced with fibrous materials

ActiveUS7560062B2High modulusHigh strengthLayered productsOrnamental structuresFlexural strengthHigh intensity

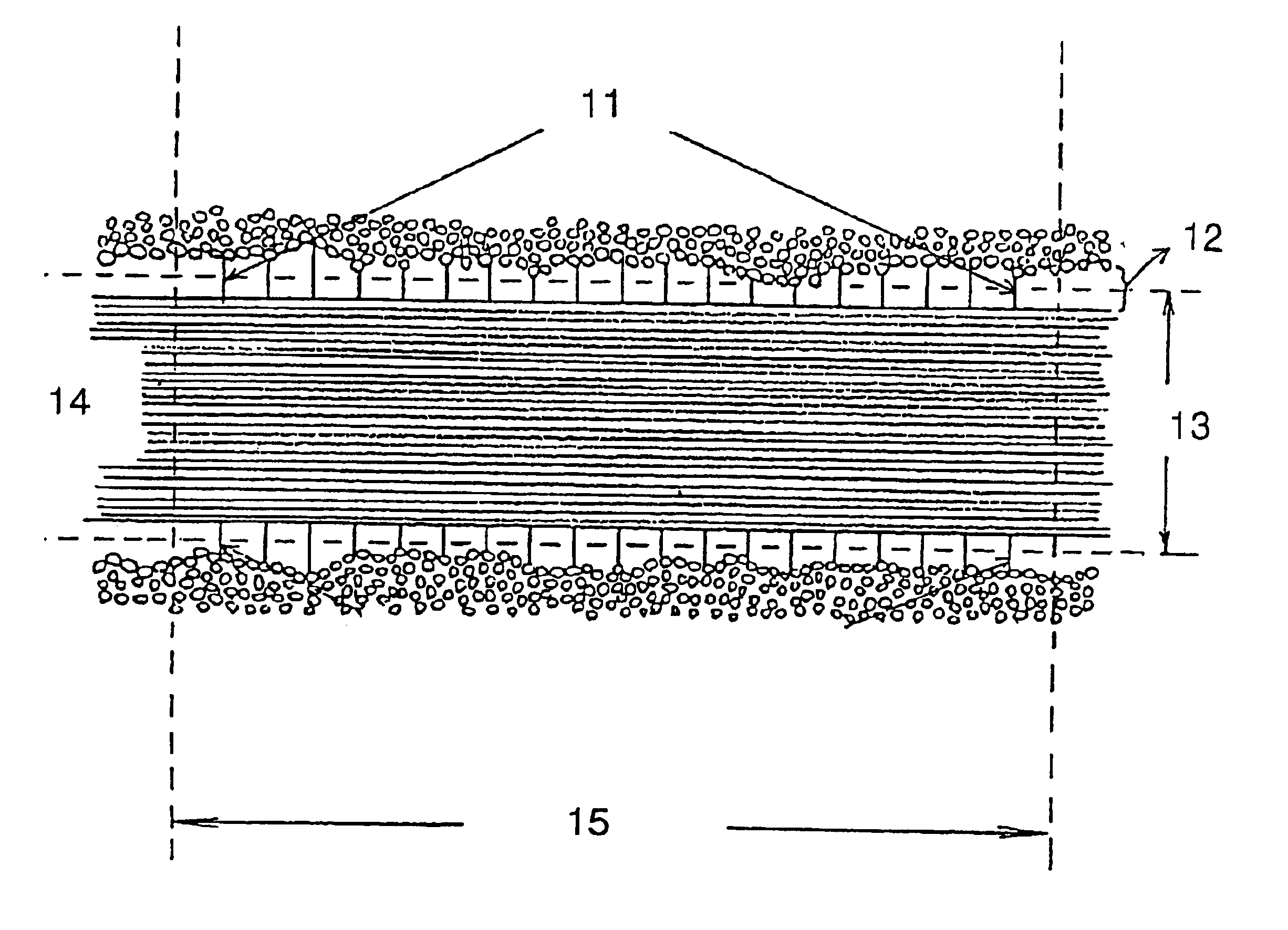

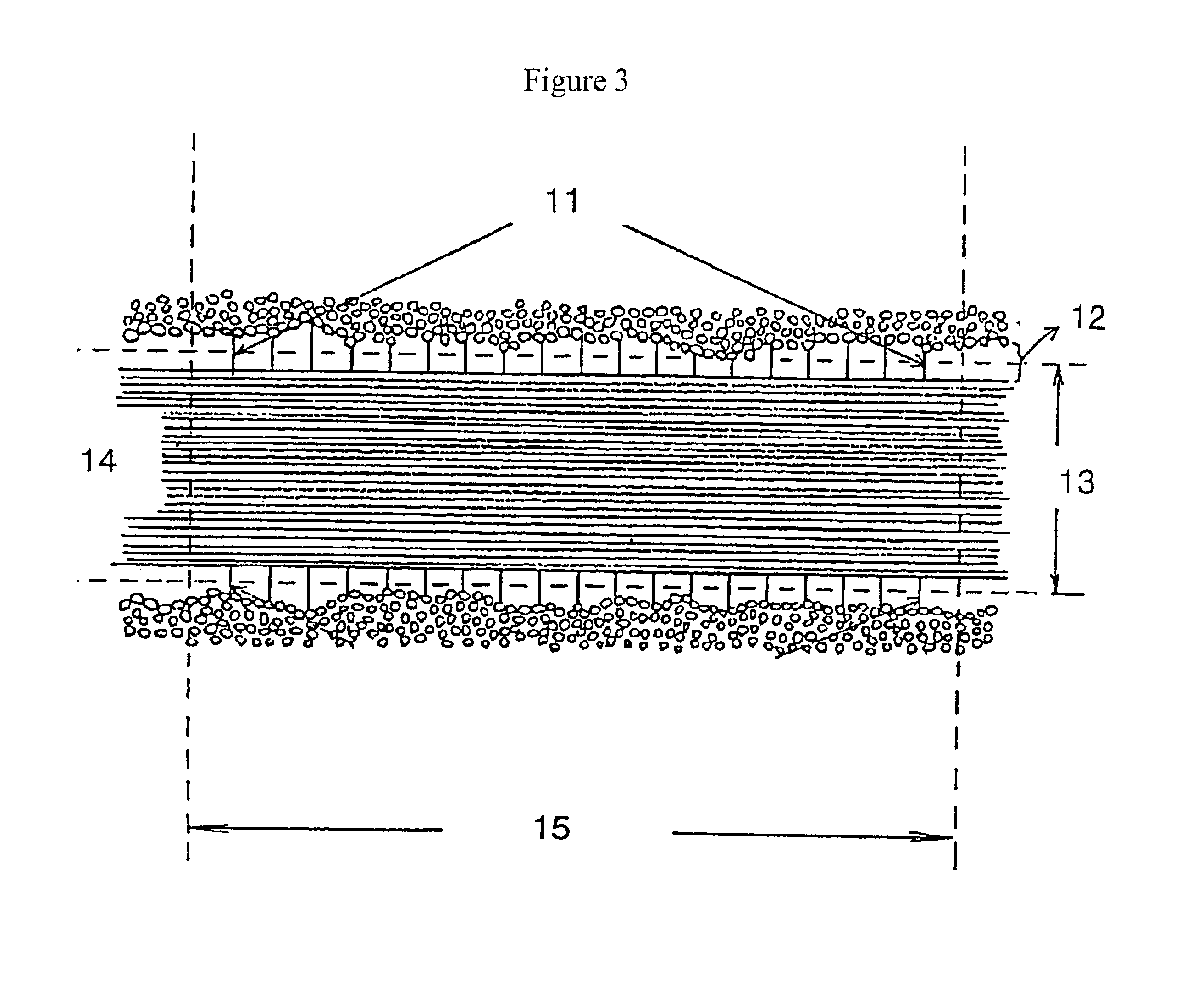

This invention discloses improvements that can be achieved in thermal or mechanical performance of aerogel composites via densification. Densified aerogels and aerogel composites can display higher compressive strength, modulus, flexural strength, and maintains or insubstantially increases the thermal conductivity relative to the pre-densified form. In the special case of fiber reinforced aerogel composites densification via mechanical compression can prove highly beneficial.

Owner:ASPEN AEROGELS INC

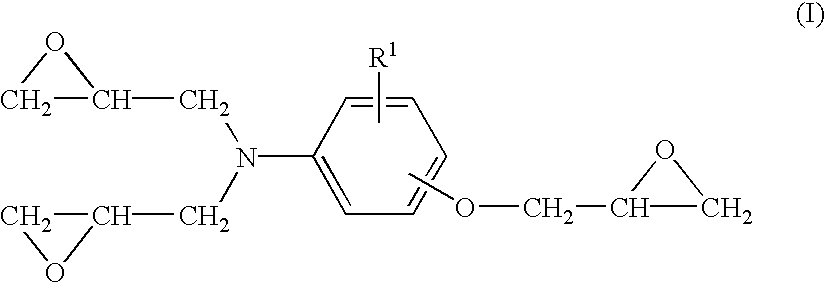

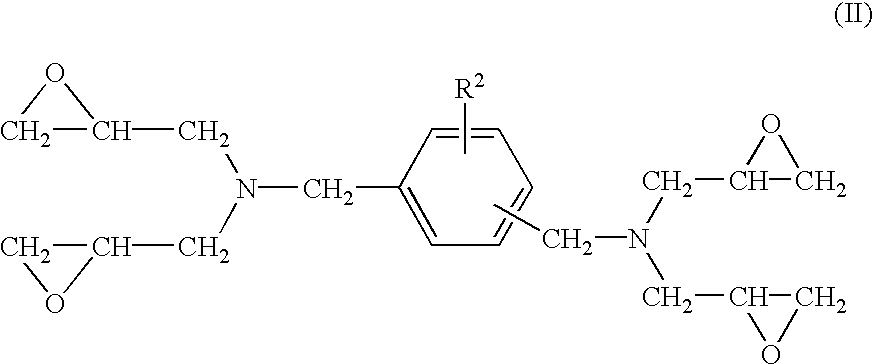

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

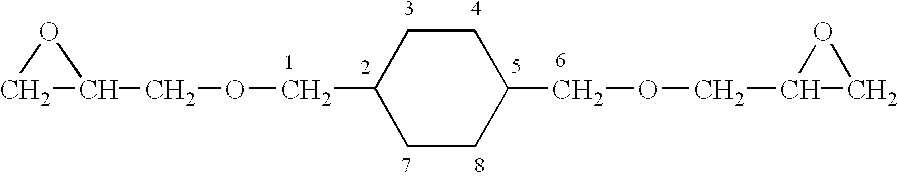

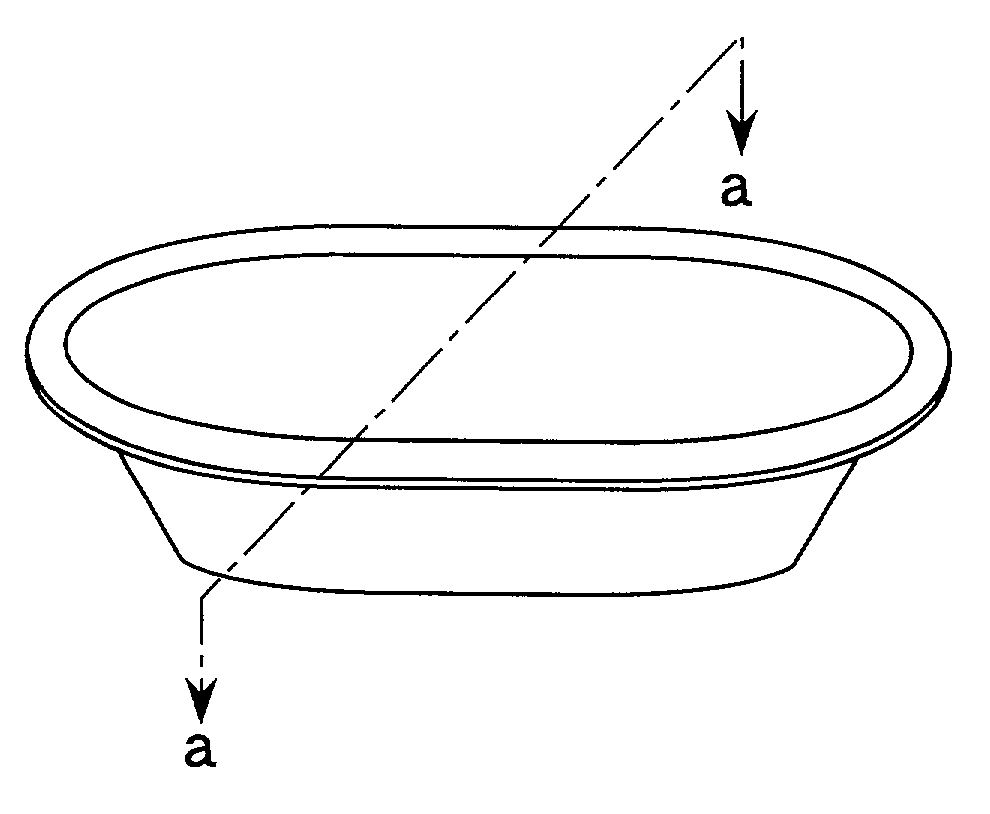

Molding base paper and molded paper vessel produced from it

InactiveUS20020012759A1Mechanical working/deformationSpecial paperCompressive strengthUltimate tensile strength

A molding base paper used for forming paper vessels such as a cup or tray for foods and various industrial products is disclosed which satisfies the following conditions (1) to (4): (1) a tensile strength (JIS-P 8113) of at least 2.0 kN / m, (2) an elongation at break (JIS-P 8113) of at least 1.5%, (3) a critical compression stress, defined by the following formula, in the range of 1 to 10 MPa: <paragraph lvl="0"><in-line-formula>critical compression stress=A / B < / in-line-formula>wherein A represents the compression strength determined by JIS-P 8126, and B represents the area of loaded part of the test piece in the determination of the compression strength, and (4) an amount of the compression deformation, caused by applying compression stress of 20 kgf / cm2in thickness direction, of at least 10 %. The paper vessels are prepared by controlling the water content of the molding base paper at 10 to 20% and then drawing the molding base paper at 100 to 150° C.

Owner:OJI PAPER CO LTD

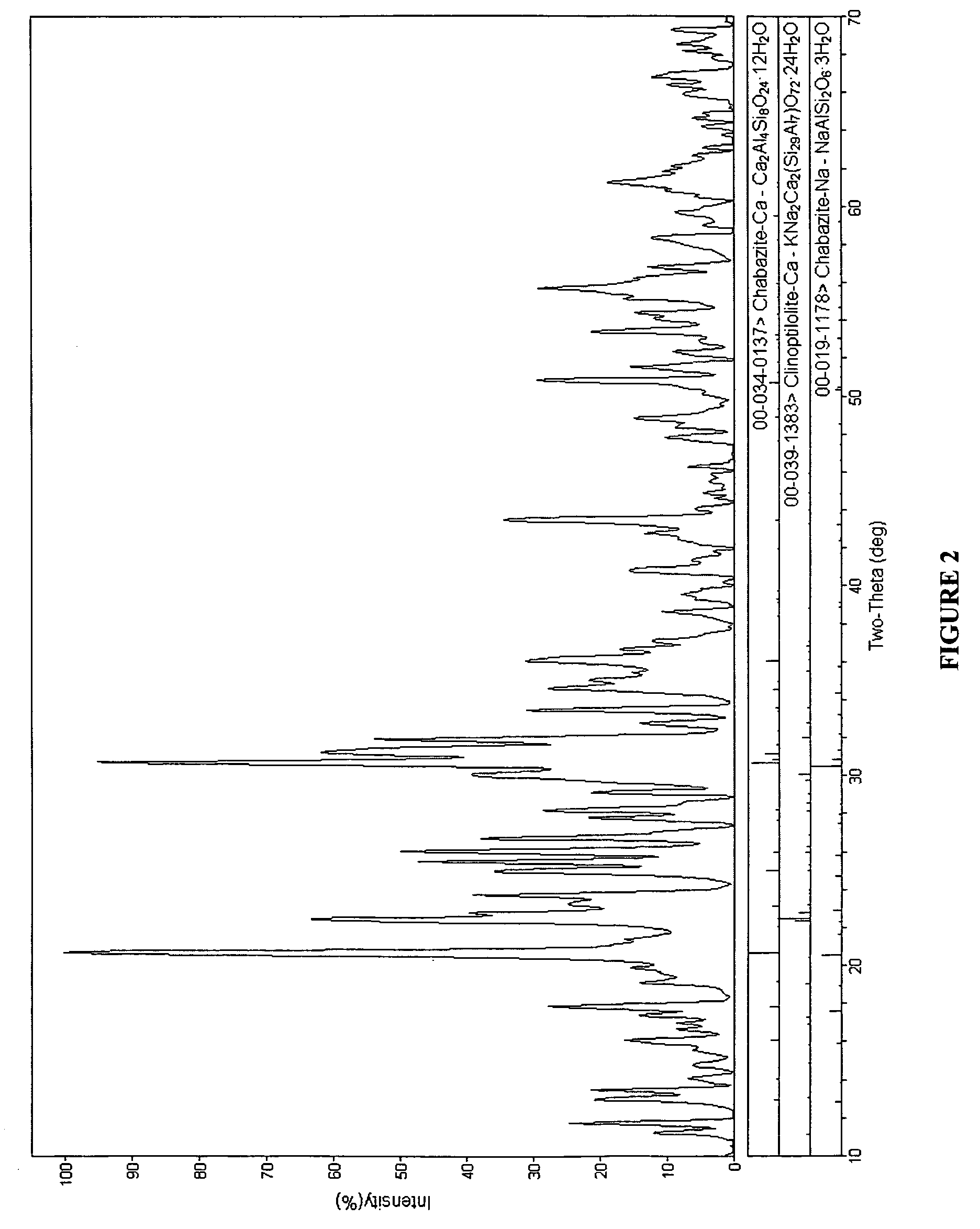

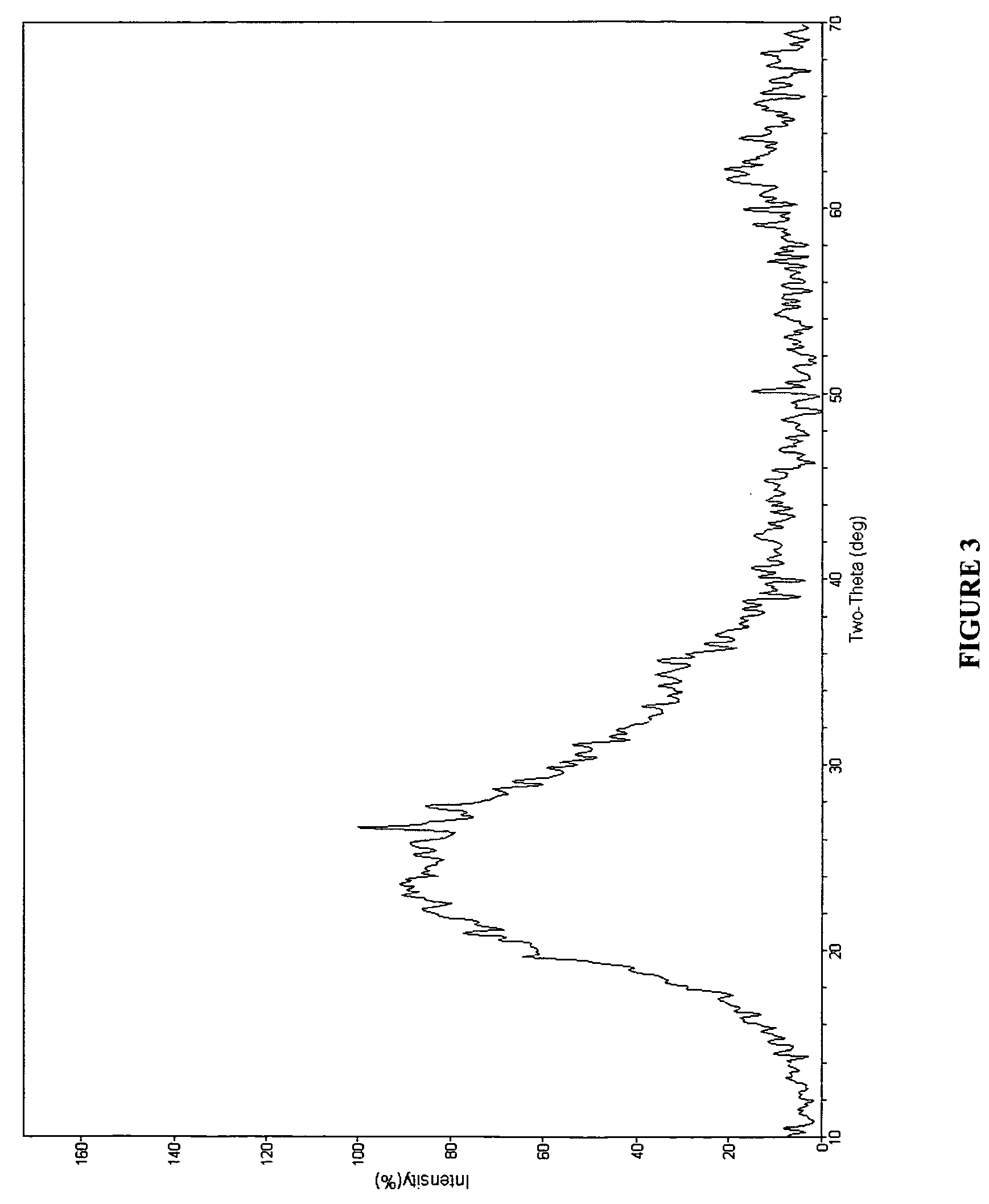

Pumice containing compositions for cementing a well

A cement composition comprises fine pumice particles, for use in cementing subterranean wells, and oil and gas wells in particular. The pumice containing cement blends feature enhanced compressive strength, and favorable compressive strength to Young's Modulus ratios. Lightweight cement blends containing pumice, and their use in cementing oil and gas wells are also described.

Owner:SANJEL ENERGY SERVICES INC

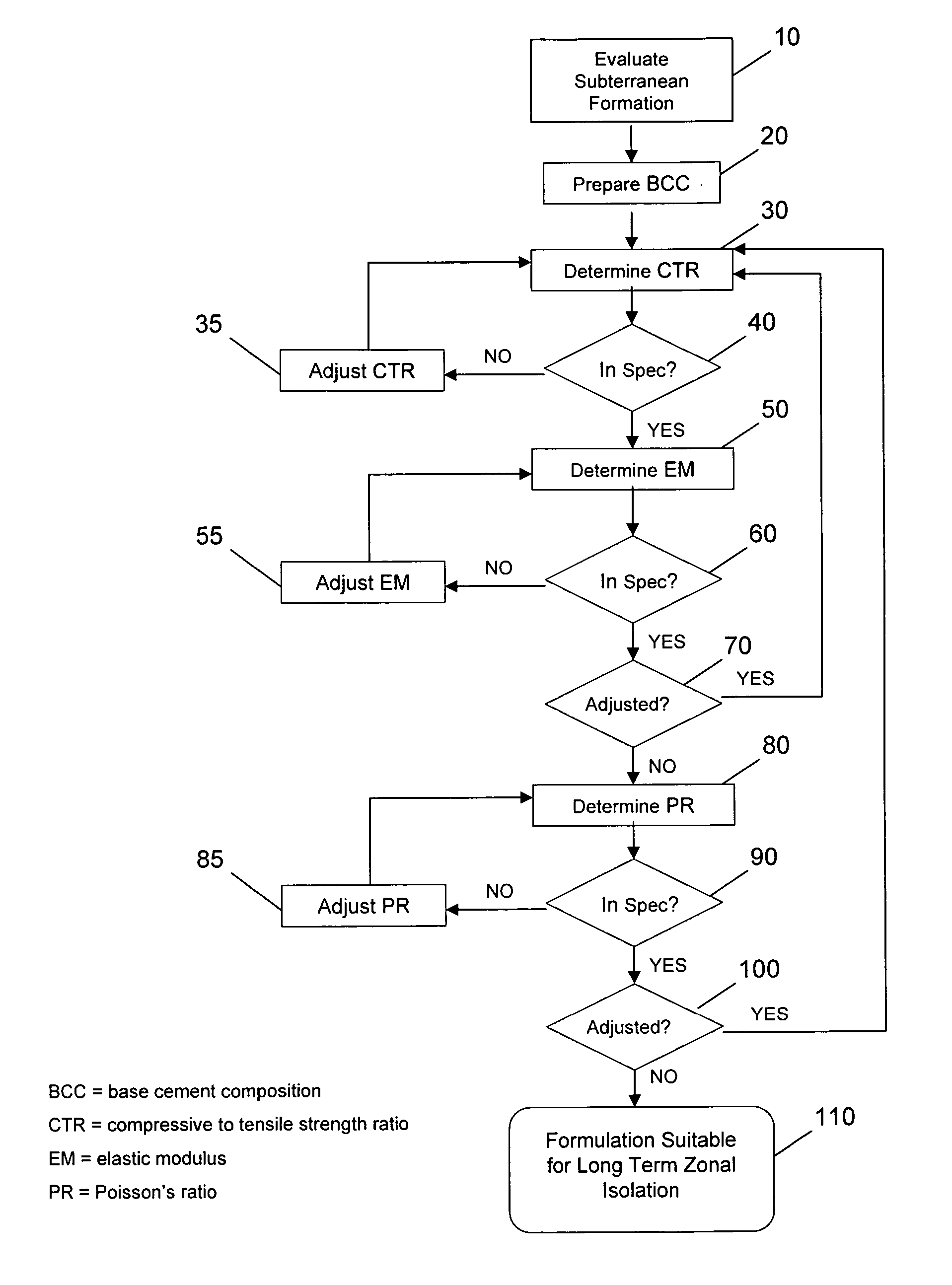

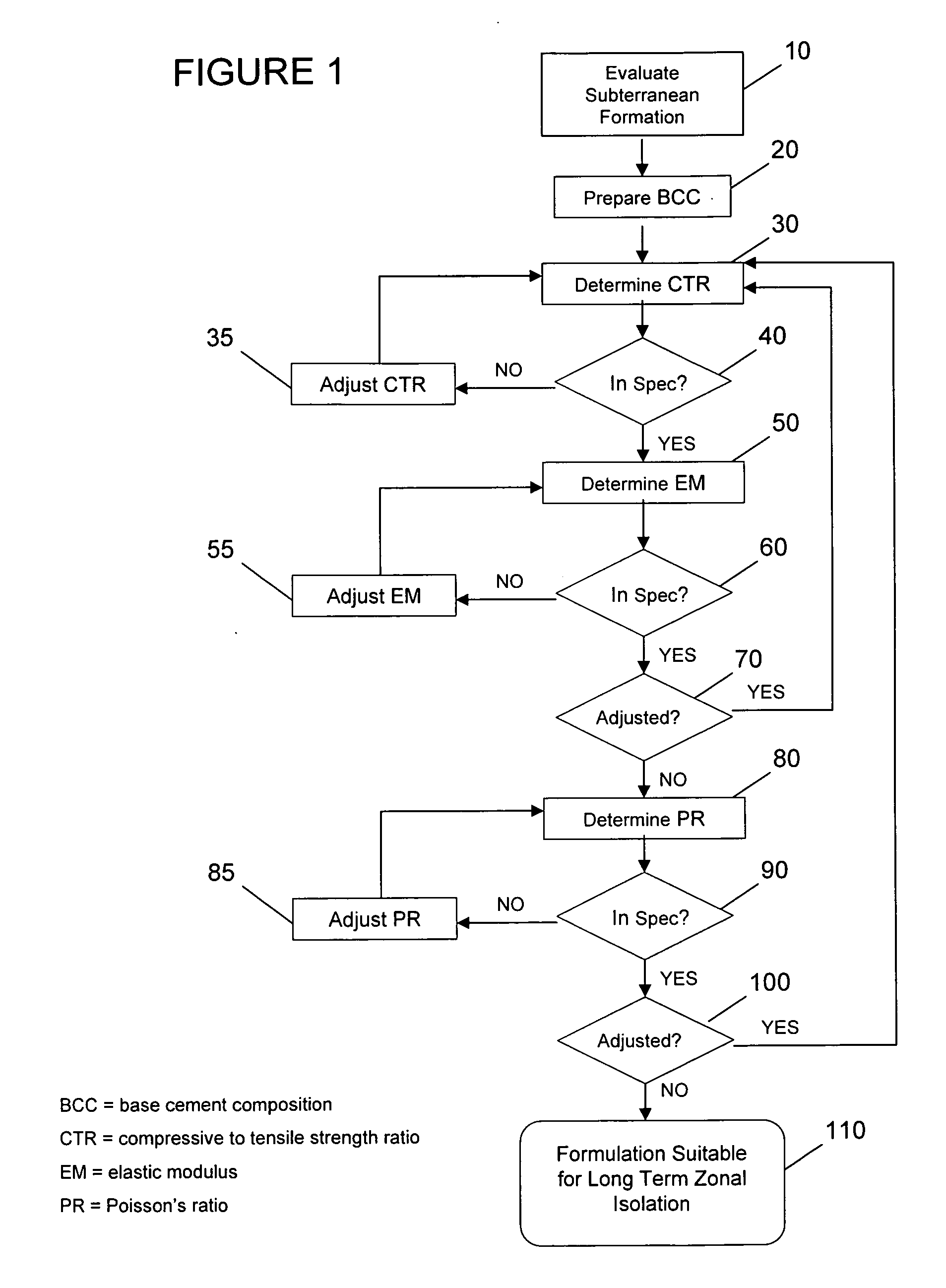

Methods of formulating a cement composition

A method of cementing a wellbore in a subterranean formation, comprising formulating a cement composition that may be suitable for long-term zonal isolation of the subterranean formation by evaluating a subterranean formation, preparing a base cement composition, determining the compressive strength of the base cement composition, determining the tensile strength of the base cement composition, and adjusting the ratio of compressive strength to tensile strength as need to within a first optimizing range to form a first optimized cement composition, and placing the optimized cement composition in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

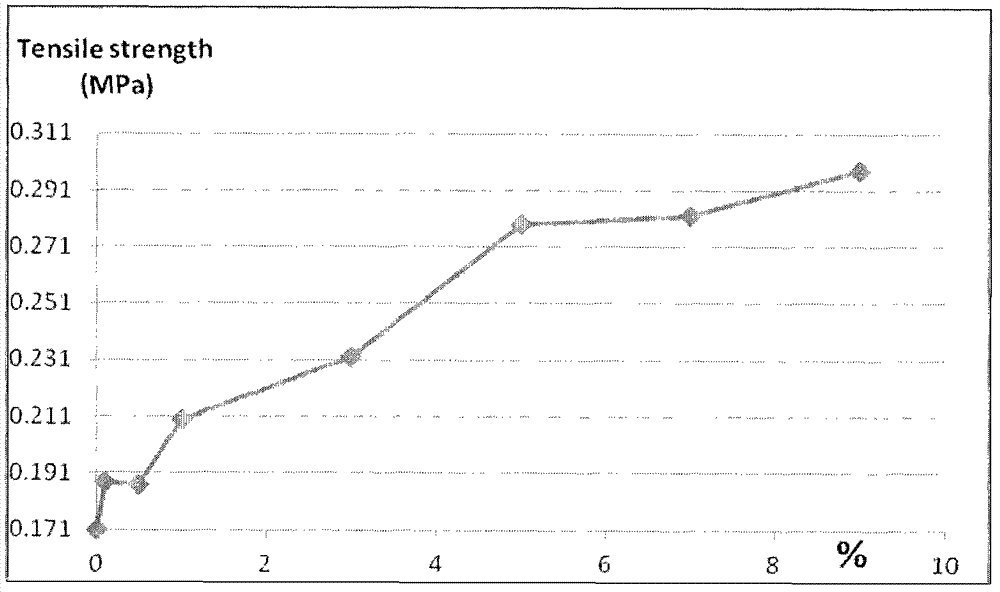

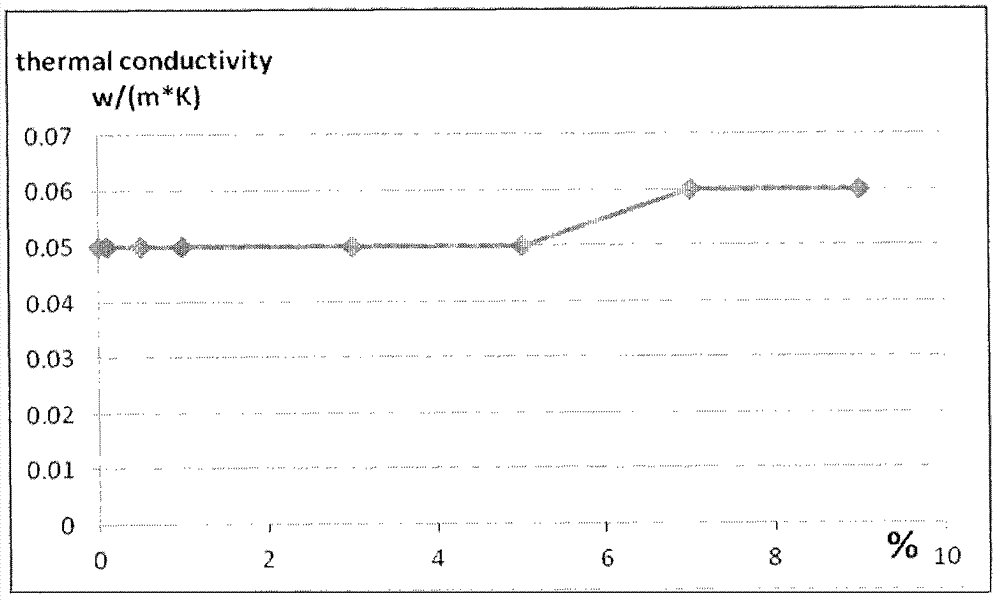

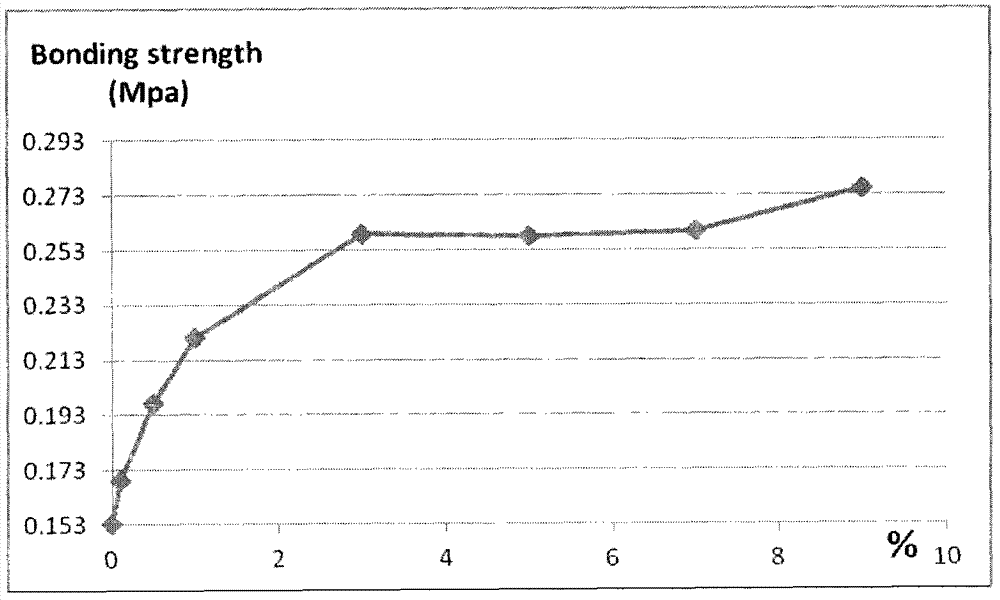

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

Coated and cured proppants

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

Lightweight compositions and articles containing such

A lightweight cementitious composition containing from 22 to 90 volume percent of a cement composition and from 10 to 78 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles and can be included as a layer on wall panels and floor panels and can be used in insulated concrete forms. Aspects of the lightweight cementitious composition can be used to make lightweight structural units.

Owner:SYNTHEON

Lightweight wall plaster

InactiveCN101691292AReduce lossWith thermal insulationSolid waste managementPlasterworkThermal insulation

The invention discloses a lightweight wall plaster which comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive, wherein the inorganic cementing material is a desulfurized plaster or a building plaster. The lightweight wall plaster is a single-component dry mixed material produced by a factory and can be used on a construction site by only adding water for stirring, the lightweight wall plaster has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional plastering mortar to be plastered on inner sides of external walls, partition walls, room separating walls, ceilings and other occasions and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

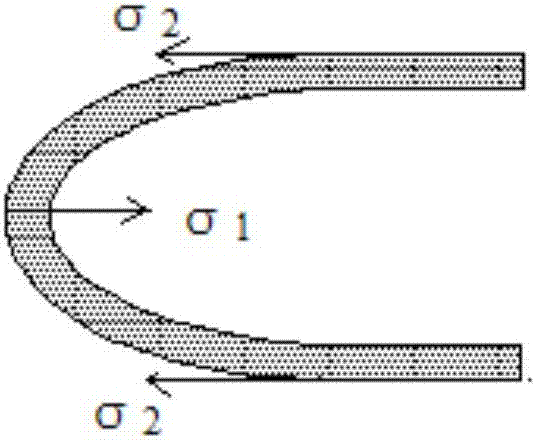

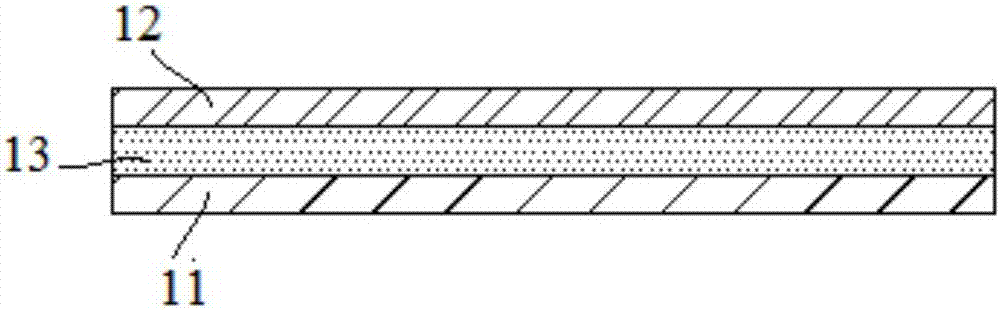

Flexible module and flexible display panel

ActiveCN107230429AImprove bending resistanceEven by forceSolid-state devicesIdentification meansEngineeringCompressive strength

The invention discloses a flexible module and a flexible display panel. The flexible module comprises a first flexible module part, a second flexible module part and a bonding part. The flexible module comprises a bent region and a non-bent region. A bent shaft of the flexible module stretches in the bent region in the first direction. The bent region comprises a first bent region body and a second bent region body. In the second direction, the distance between the first bent region body and the bent shaft is smaller than the distance between the second bent region body and the bent shaft, and the first direction is vertical to the second direction. A first bonding material is adopted for the first bent region body, a second binding material is adopted for the second bent region, a third bonding material is adopted for the non-bent region, the compressive strength of the first bonding material and the compressive strength of the second bonding material are both larger than that of the third bonding material, the tensile strength of the first bonding material and the tensile strength of the second bonding material are smaller than that of the third bonding material, and the elasticity modulus of the first bonding material is smaller than that of the second bonding material. The flexible module is high in overall mechanical strength and high in anti-bending performance.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

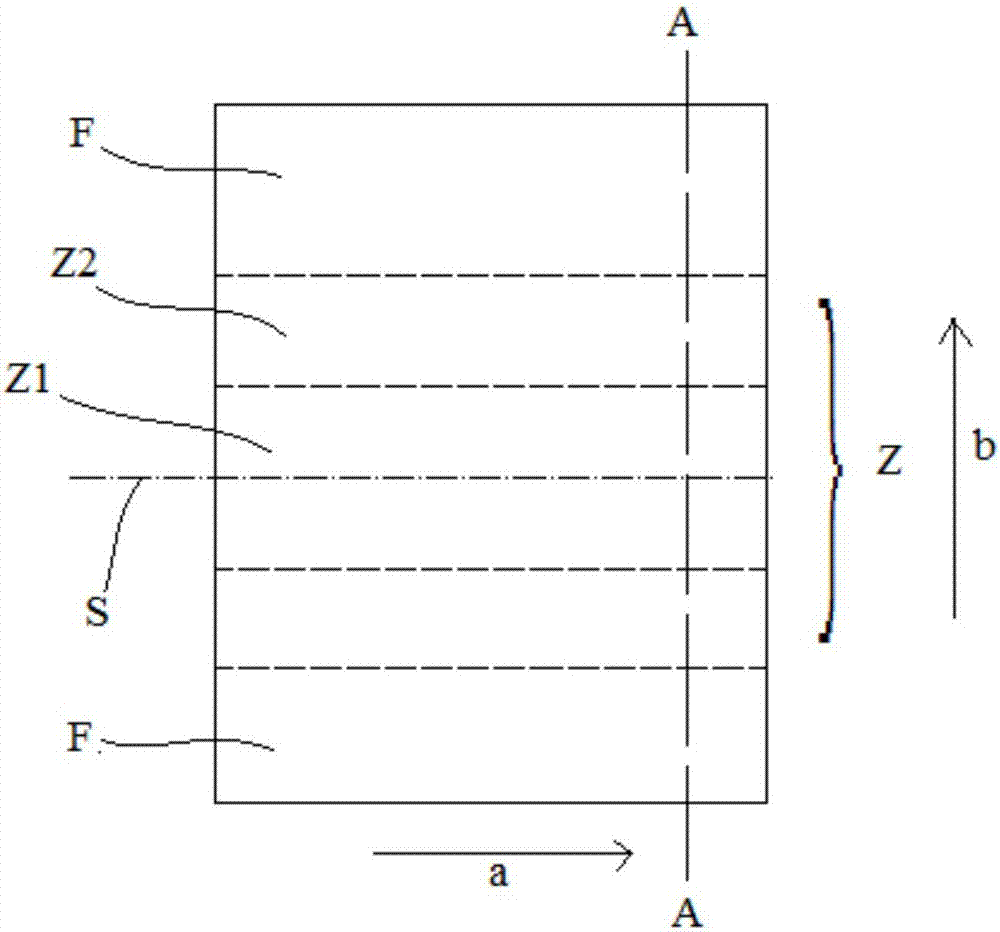

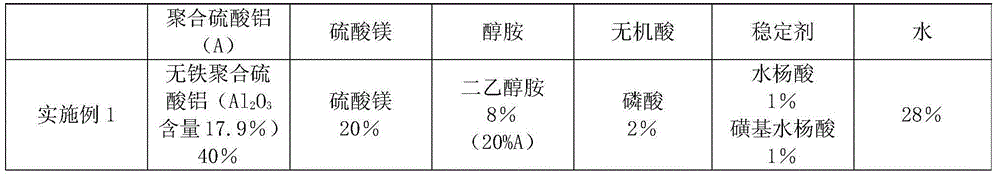

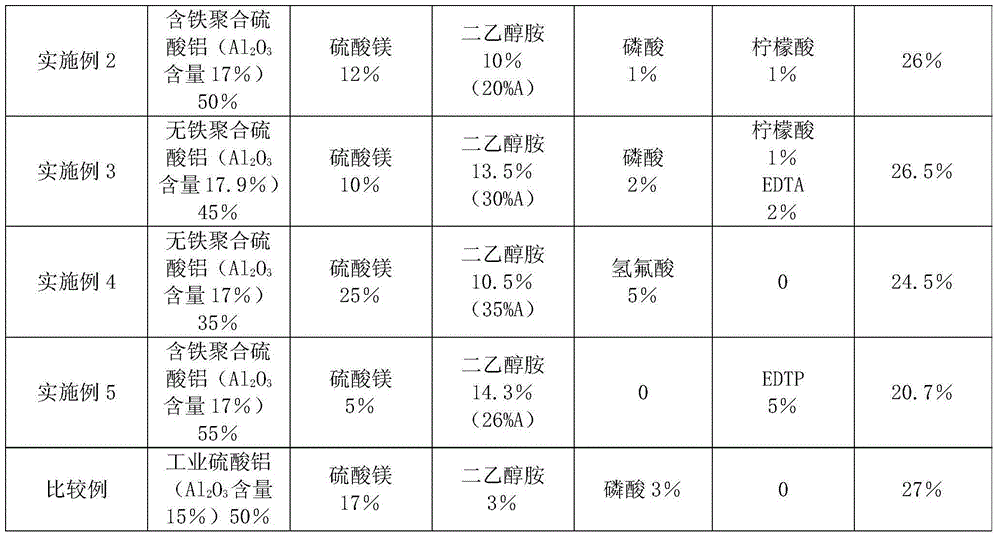

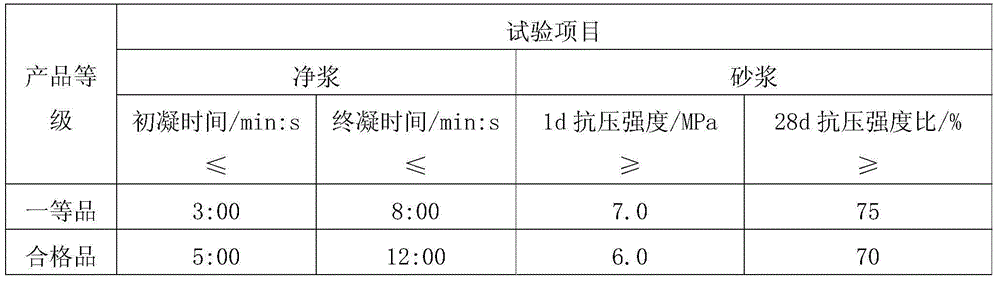

Alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate and its preparation method

The invention discloses an alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate. The liquid setting accelerator comprises the following raw materials by weight: 35-55% of polyaluminium sulfate, 5-25% of magnesium sulfate, alcohol amine accounting for 15-30% of the polyaluminum sulfate, 0-5% of an inorganic acid, 0-5% of a stabilizer, and the balance water. The liquid setting accelerator provided by the invention can be used in the wet jetting industry of sprayed concrete, belongs to alkali and chlorine-free liquid setting accelerators, has a stable period of more than 6 months, a 28d compressive strength ratio of greater than 100%, and good adaptability to different cement. When the dosage is 4.5%, the technical requirements of the JC477-2005 ''setting accelerators for sprayed concrete'' can be satisfied. The liquid alkali-free setting accelerator has superior performance, and can be widely used in tunnels, bridges, first-aid repair and other projects.

Owner:CHINA BUILDING MATERIALS ACAD

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com