Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8277 results about "Perlite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

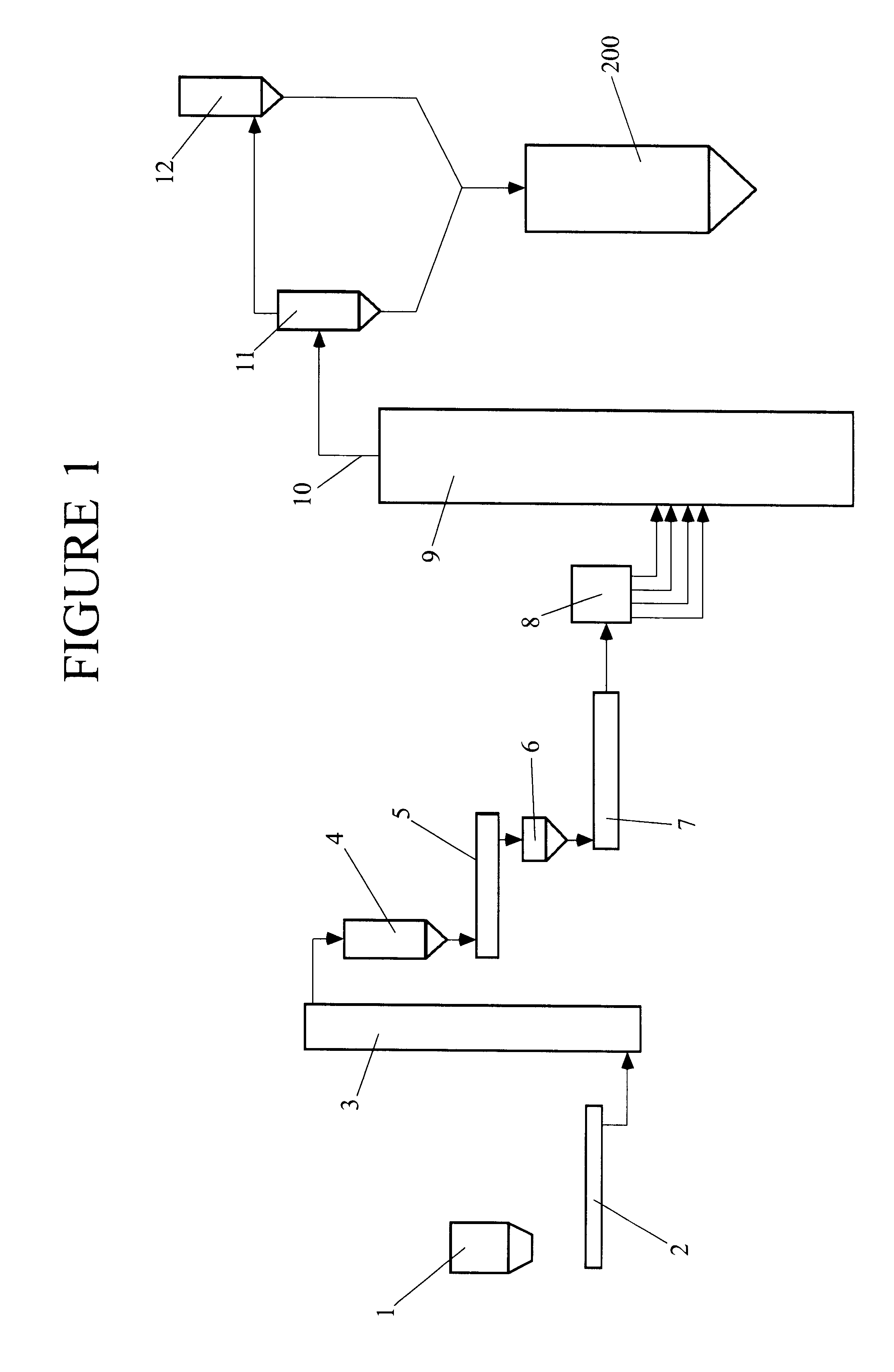

Perlite is an amorphous volcanic glass that has a relatively high water content, typically formed by the hydration of obsidian. It occurs naturally and has the unusual property of greatly expanding when heated sufficiently. It is an industrial mineral and a commercial product useful for its low density after processing.

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

Beverage cartridge and method for beverage formation using filter aid

InactiveUS20110076361A1Speed up circulationReduce cloggingTea extractionBeverage vesselsParticulatesCellulose

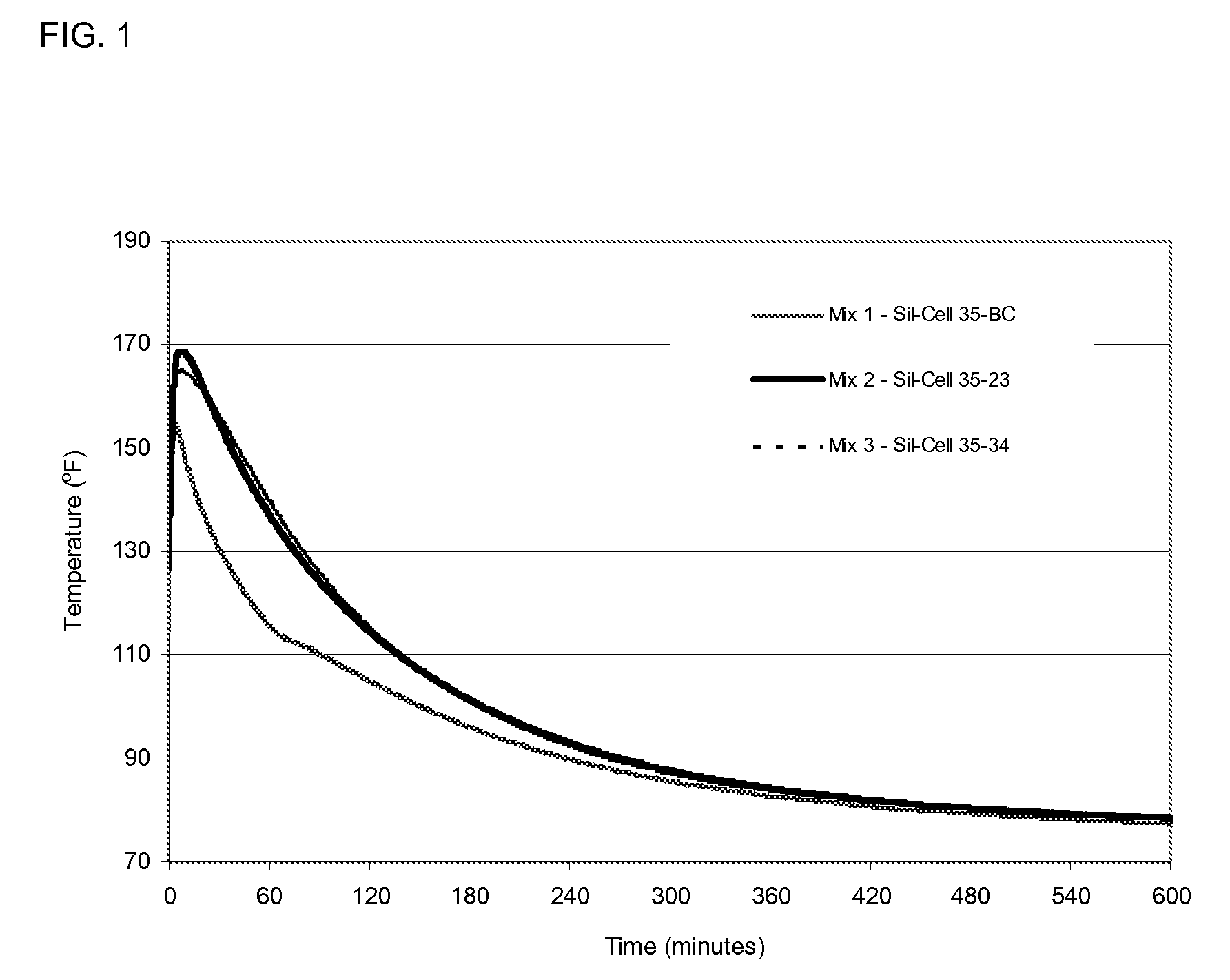

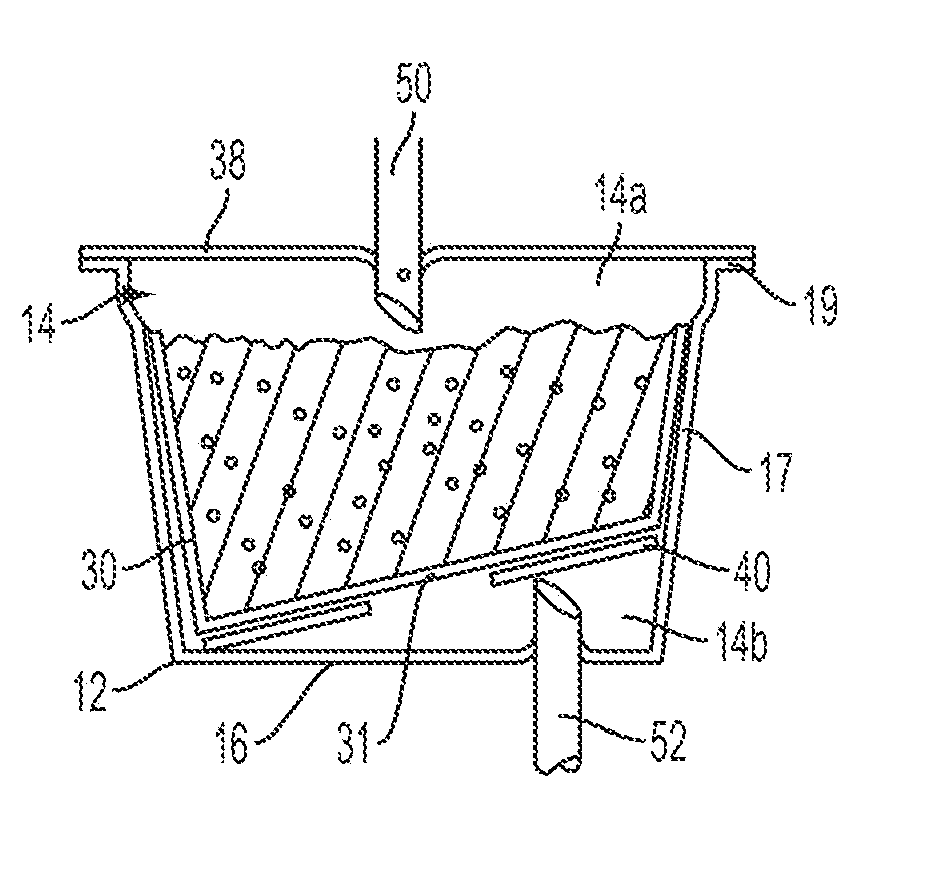

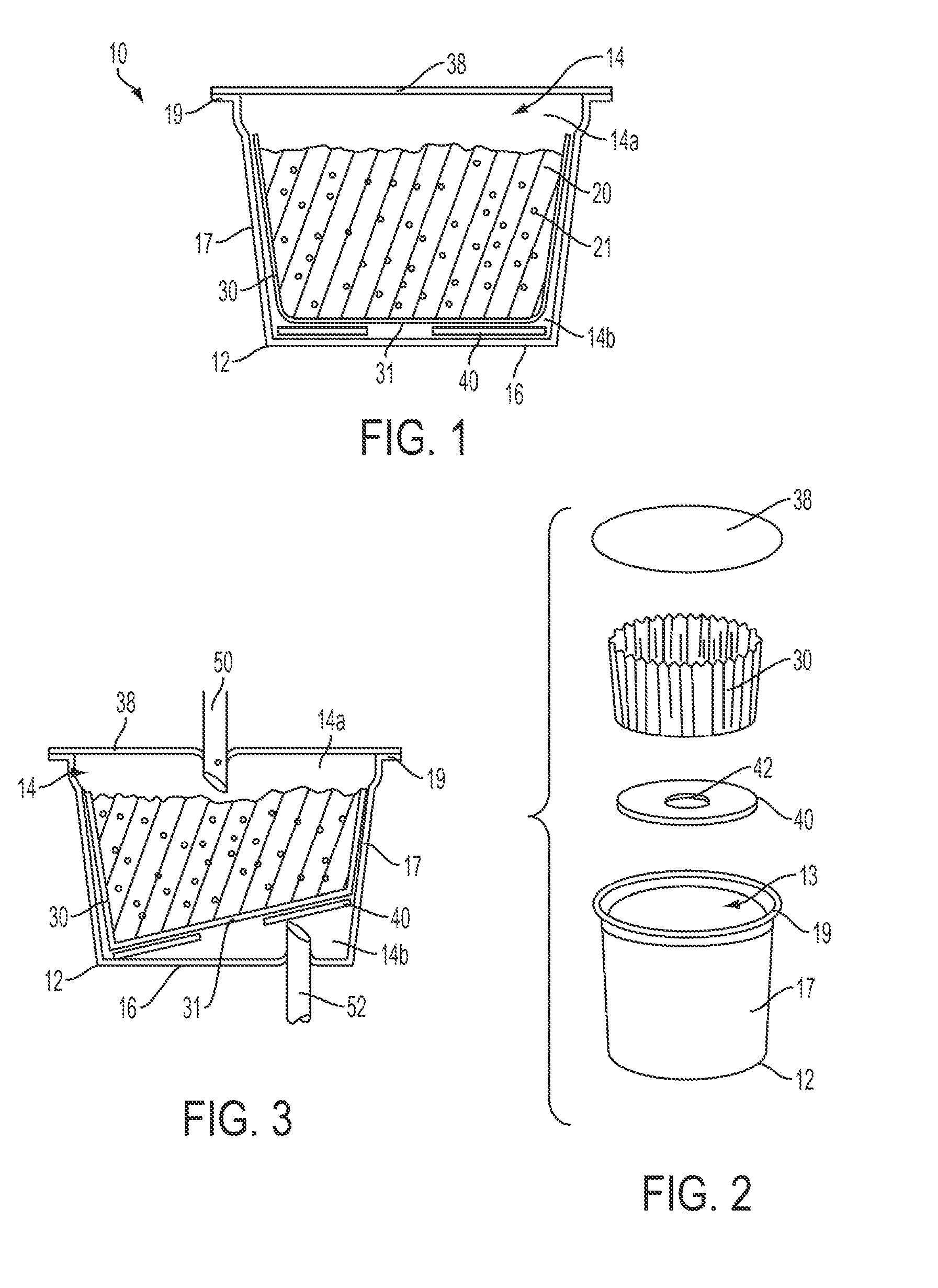

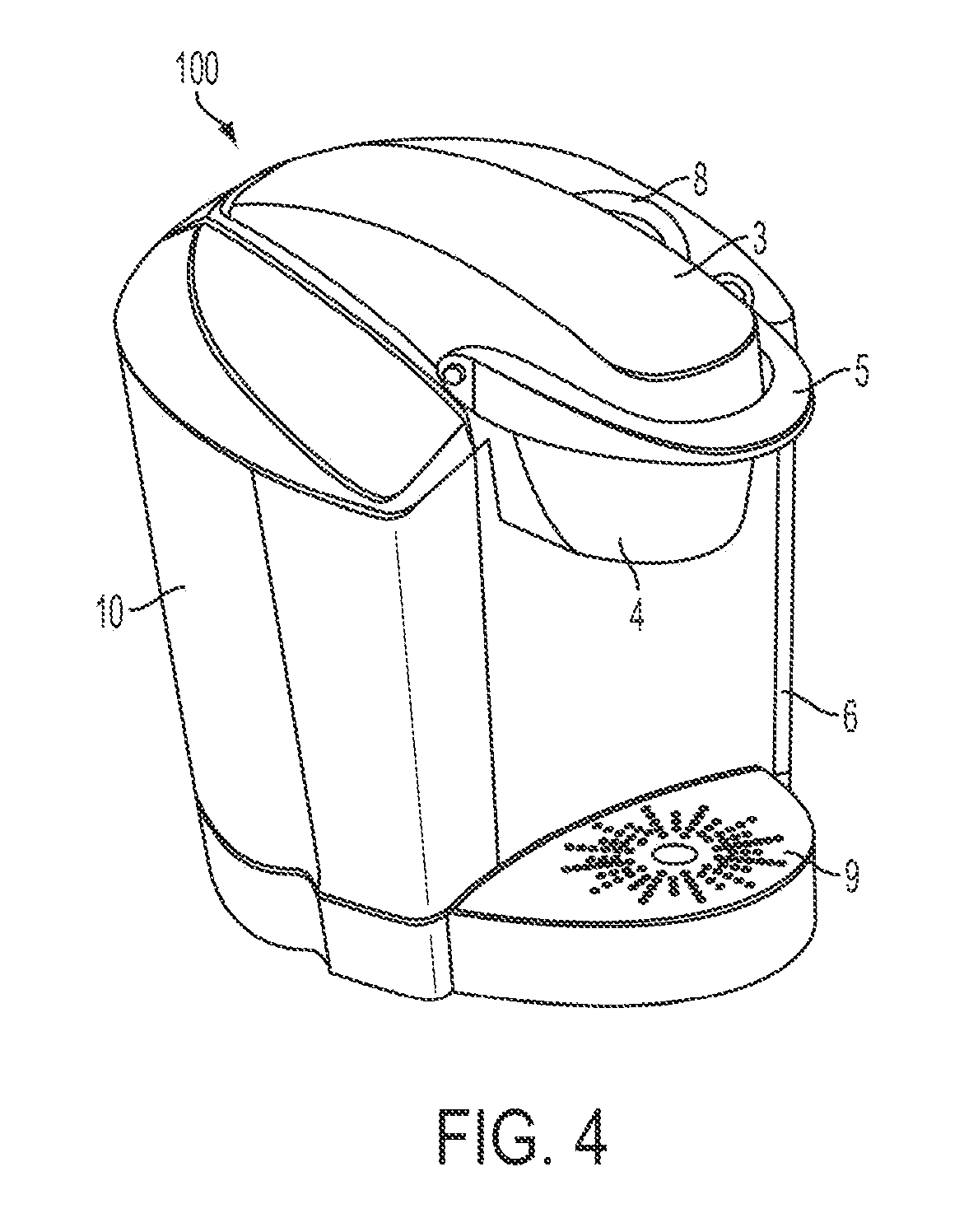

A method and apparatus for forming a beverage involves the use of a filter aid, e.g., that is provided in a beverage cartridge with a beverage medium in a dry state. In one embodiment, a cartridge including a dried fruit material may also include a filter aid, such as perlite, diatomaceous earth or cellulose, that is mixed together with the fruit material. The filter aid may assist in flow through the beverage medium or through a filter, e.g., by helping prevent the clogging of pores of a filter used to remove particulate from a beverage formed by interaction of the beverage medium with water introduced into the cartridge. Thus, the filter aid may permit the use of some beverage media that would otherwise clog a filter and / or prevent proper dissolution of materials in the beverage media without the filter aid.

Owner:GREEN MOUNTAIN COFFEE ROASTERS INC

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

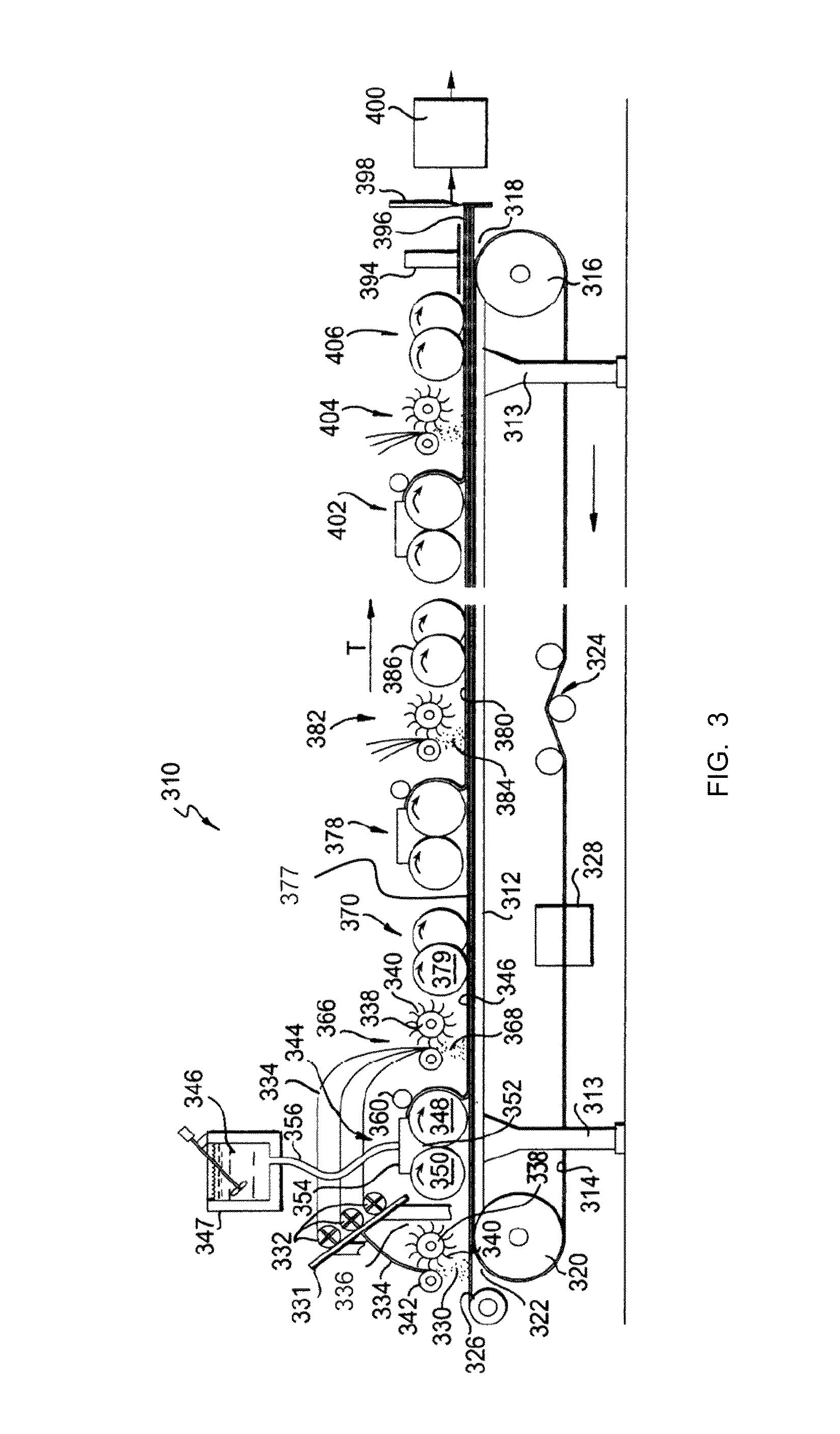

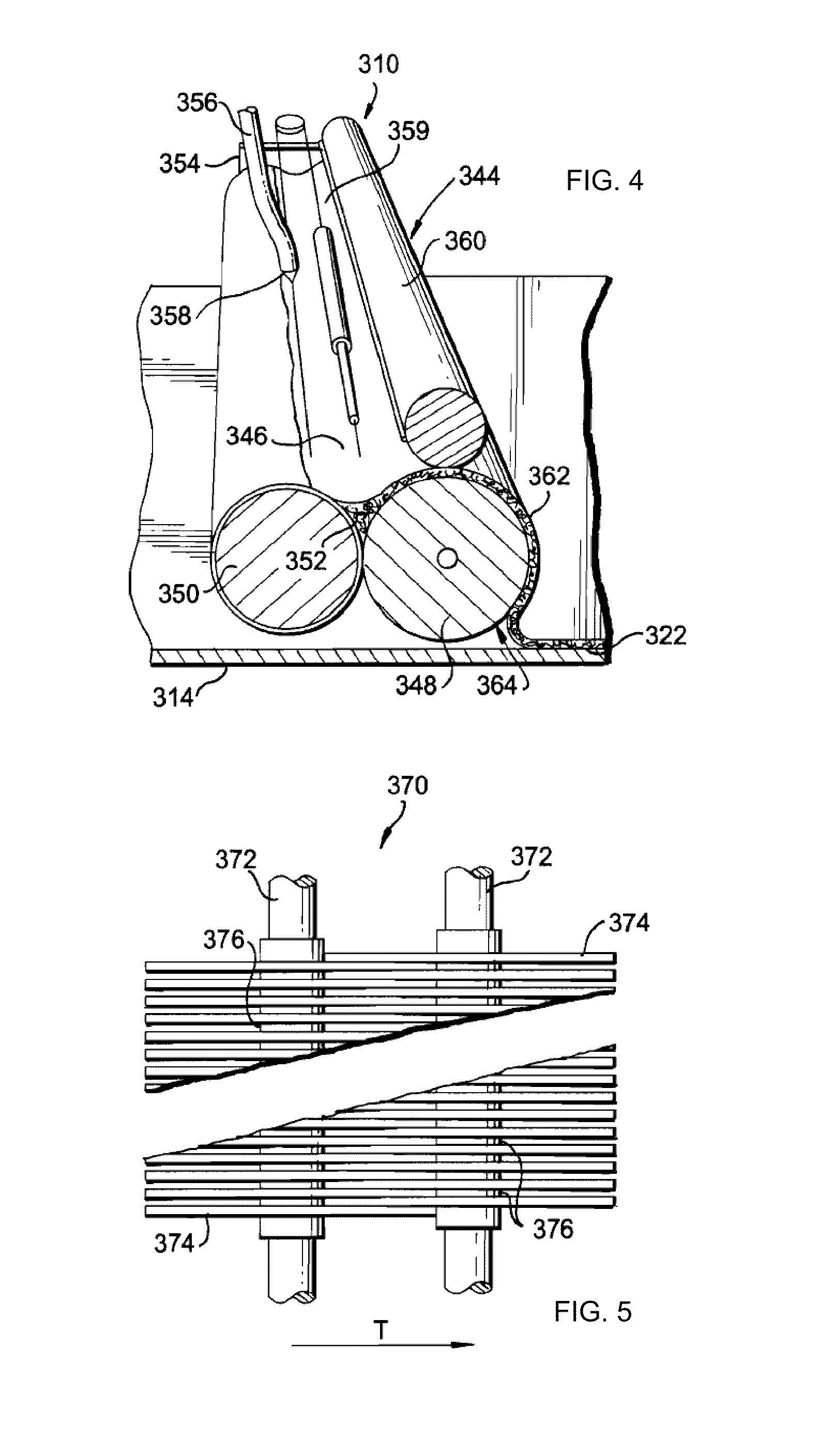

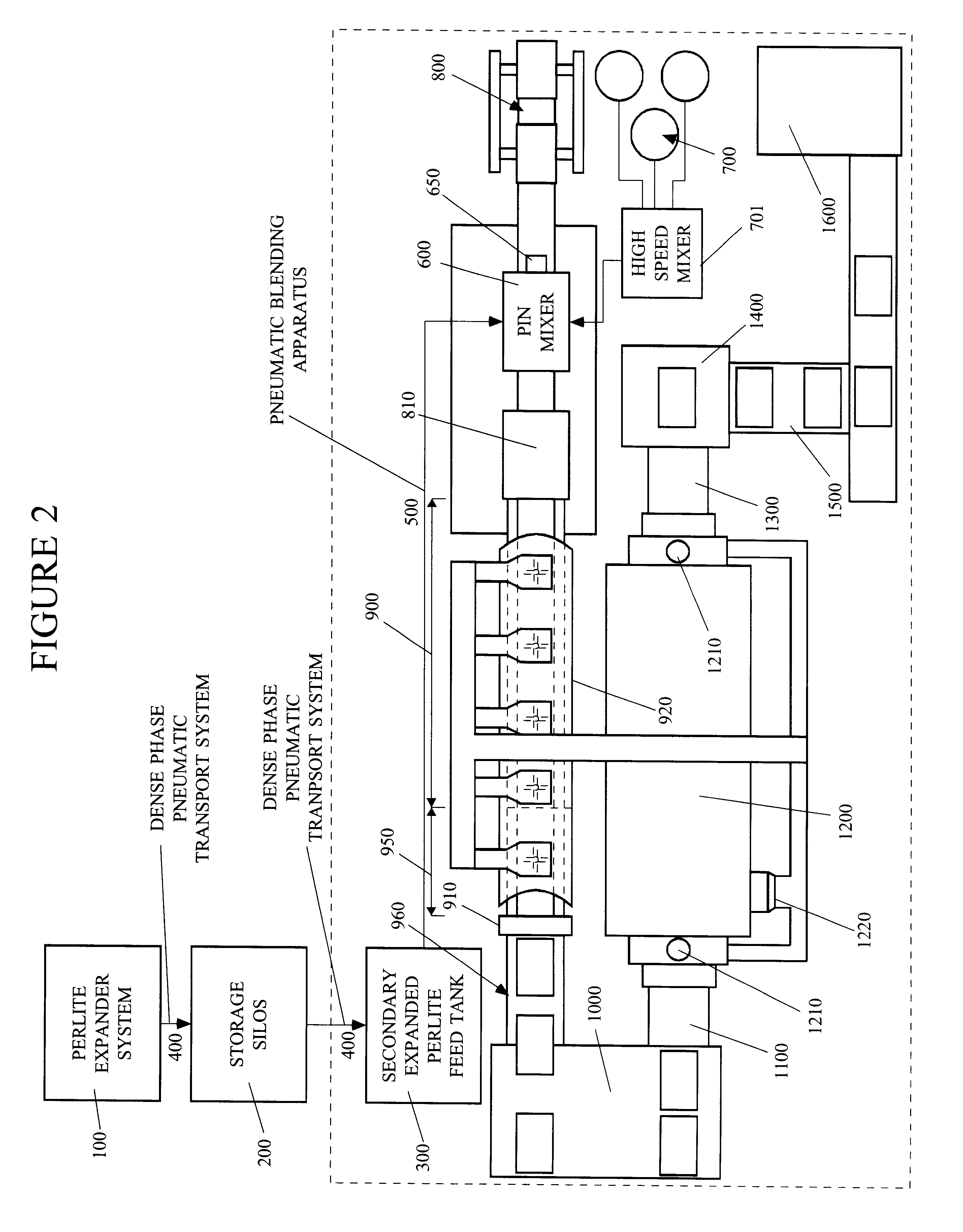

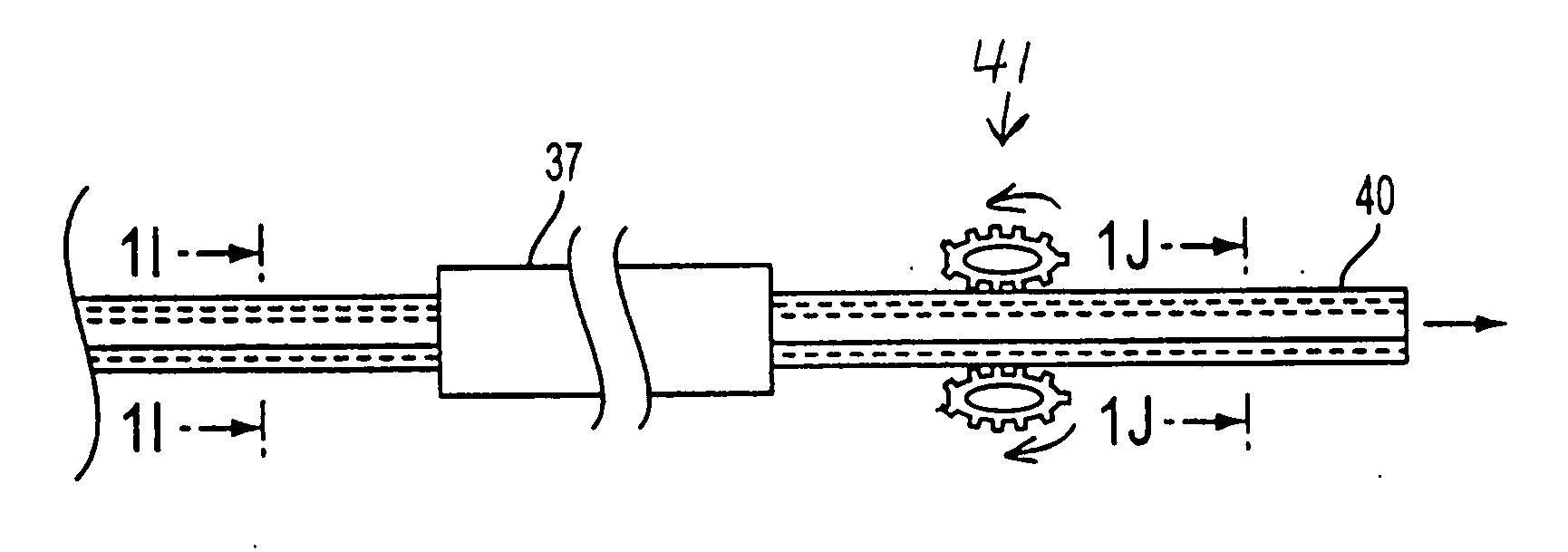

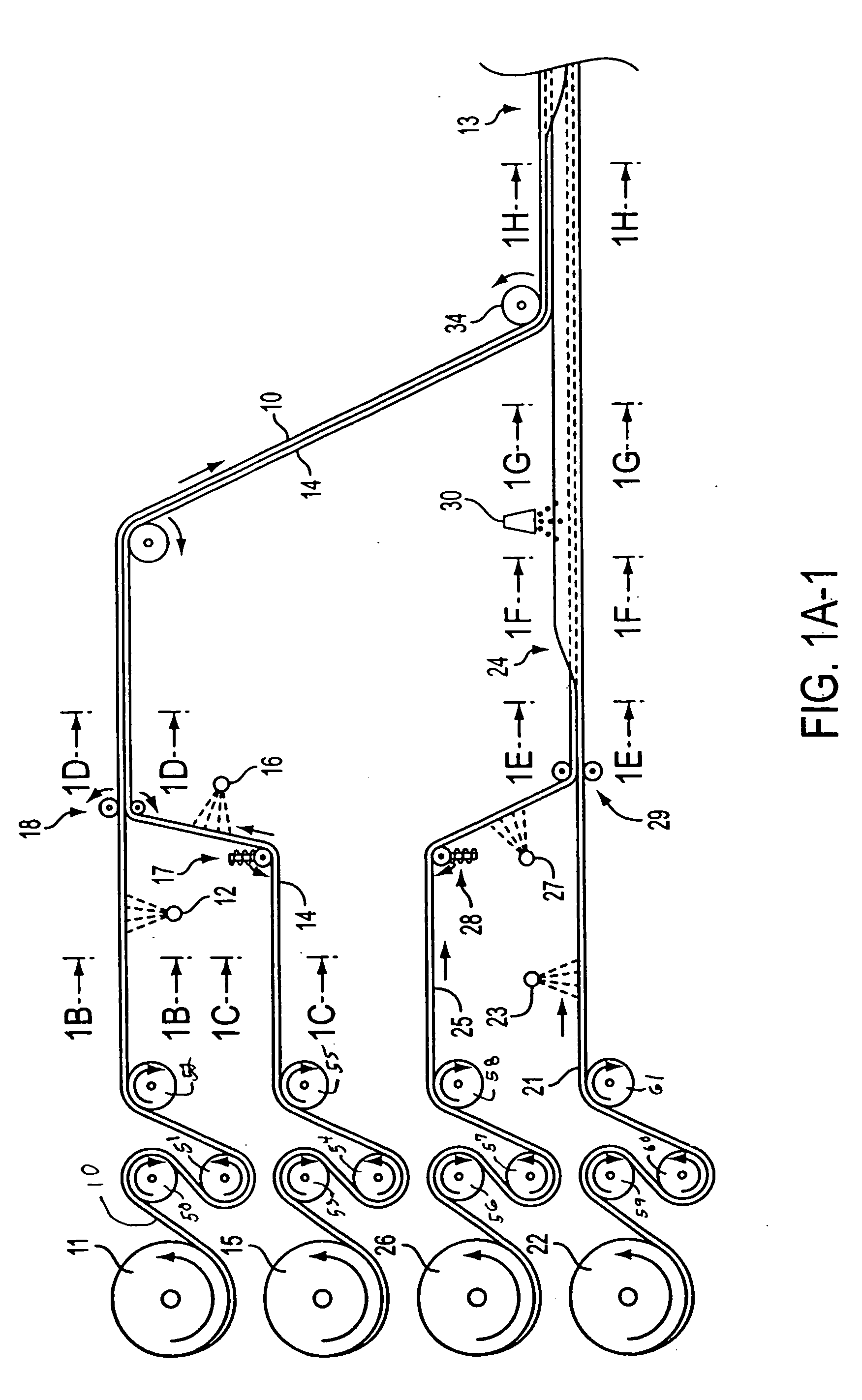

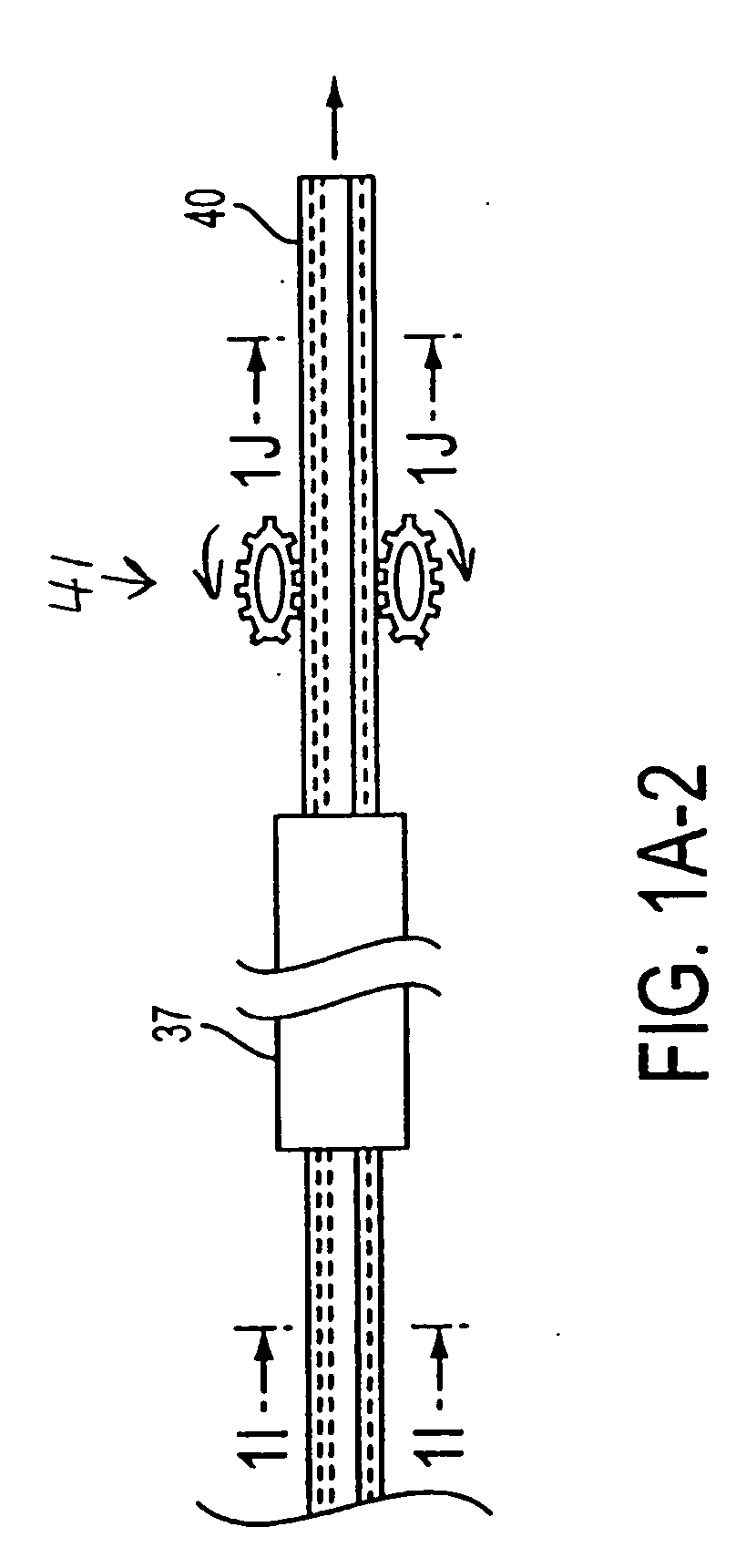

Strengthened, light weight wallboard and method and apparatus for making the same

InactiveUS6319312B1Easy to optimizeReduce amountConstruction materialCeramic shaping plantsSingle plateFlexural strength

A novel wallboard composition is disclosed comprising a unique combination of synthetic binders selected for their ability to establish a strengthened permanent bond in the final dry state for use in a wallboard composition comprising primarily gypsum, and in a wallboard composition comprising an expanded mineral such as Perlite which largely reduces the amount of gypsum over current gypsum wallboard formulations, thus reducing the weight while maintaining the strength of the wallboard structure. In a preferred embodiment, the lightweight, strengthened wallboard of the present invention also comprises an optional covering veneer that is applied to the top ply of the face paper to provide increased strength, moisture resistance, and fire retardency, and the back paper top ply is treated to provide increased flexural strength. Additionally, this invention relates to the unique manufacturing process to produce the wallboard composition of the present invention in order to create a lightweight, strengthened, moisture resistant, and fire retardant wallboard used to cover walls and ceilings in construction applications. Still further, this invention relates to the apparatus for manufacturing the wallboard composition of the present invention, including a method and apparatus for economically converting a standard gypsum wallboard manufacturing facility into a facility for manufacturing wallboard of the present invention.

Owner:INNOVATIVE TECH ENTERPRISES

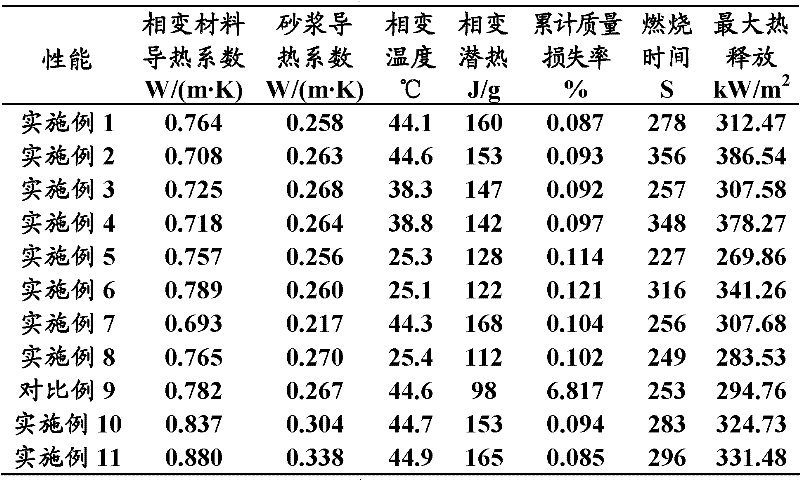

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

Zeolite colored coating powder having air-purifying function

InactiveCN105272114ASolving difficult-to-disperse reunionsImprove the bactericidal effectPorosityPyrophosphate

The invention discloses zeolite colored coating powder having an air-purifying function. According to the technical scheme, the zeolite colored coating powder having the air-purifying function is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the zeolite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, after spraying, a coating is hard, the porosity is high, the specific surface area is large, adhesion is strong, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

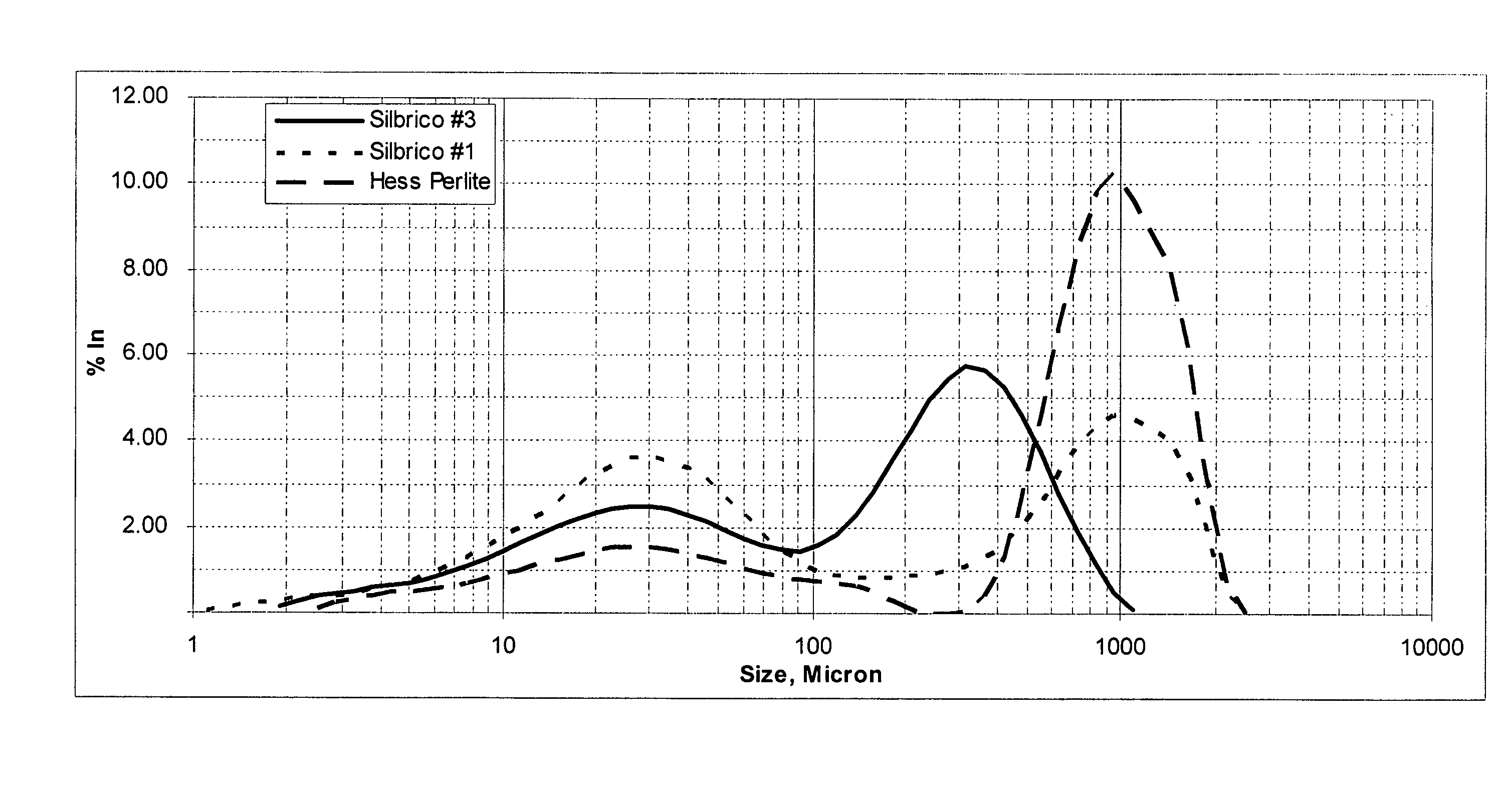

Micronized perlite filler product

ActiveUS20060075930A1High blue lightness brightnessLow oil absorptionCoatingsPlastic filmFiller - product

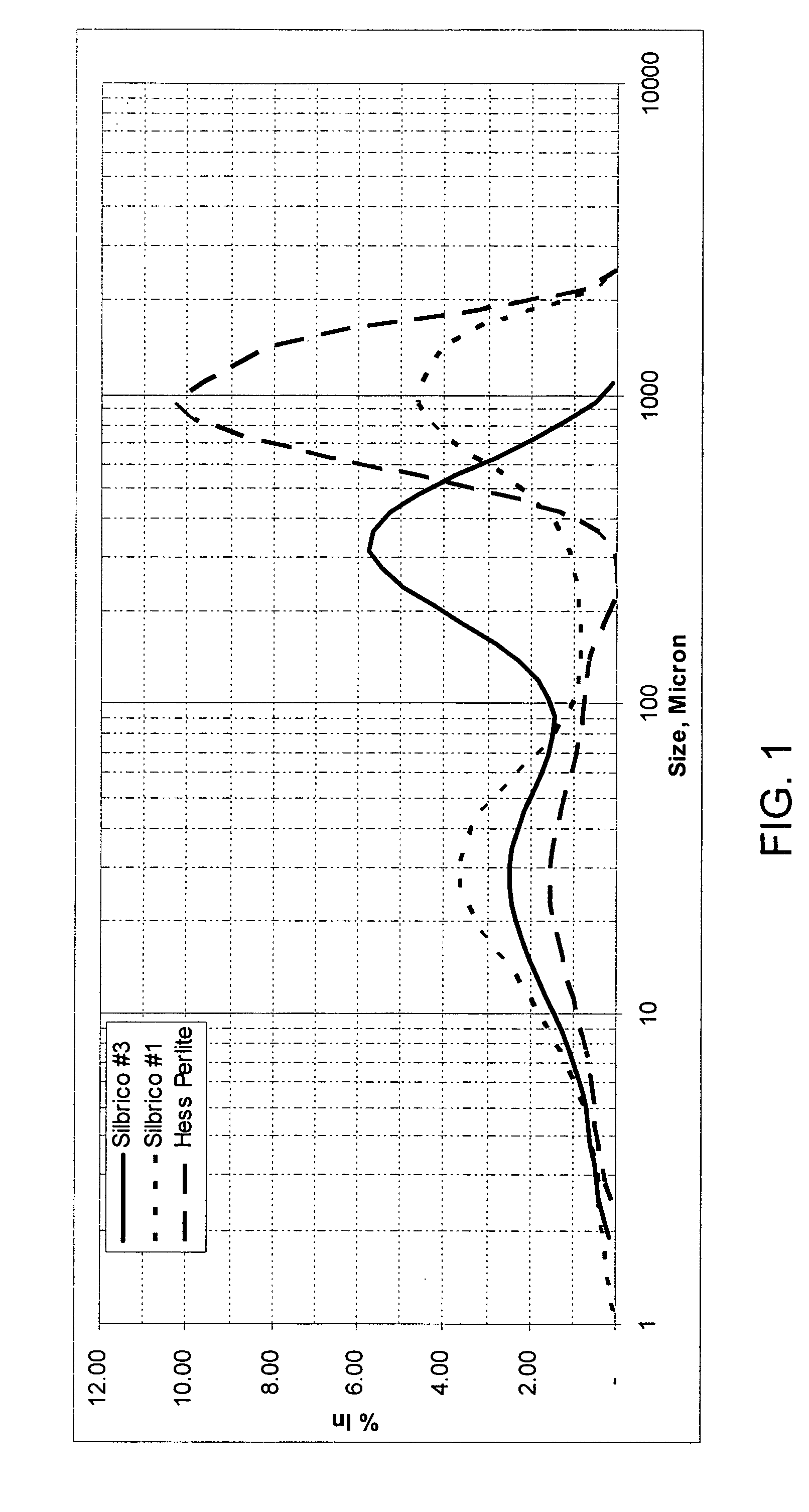

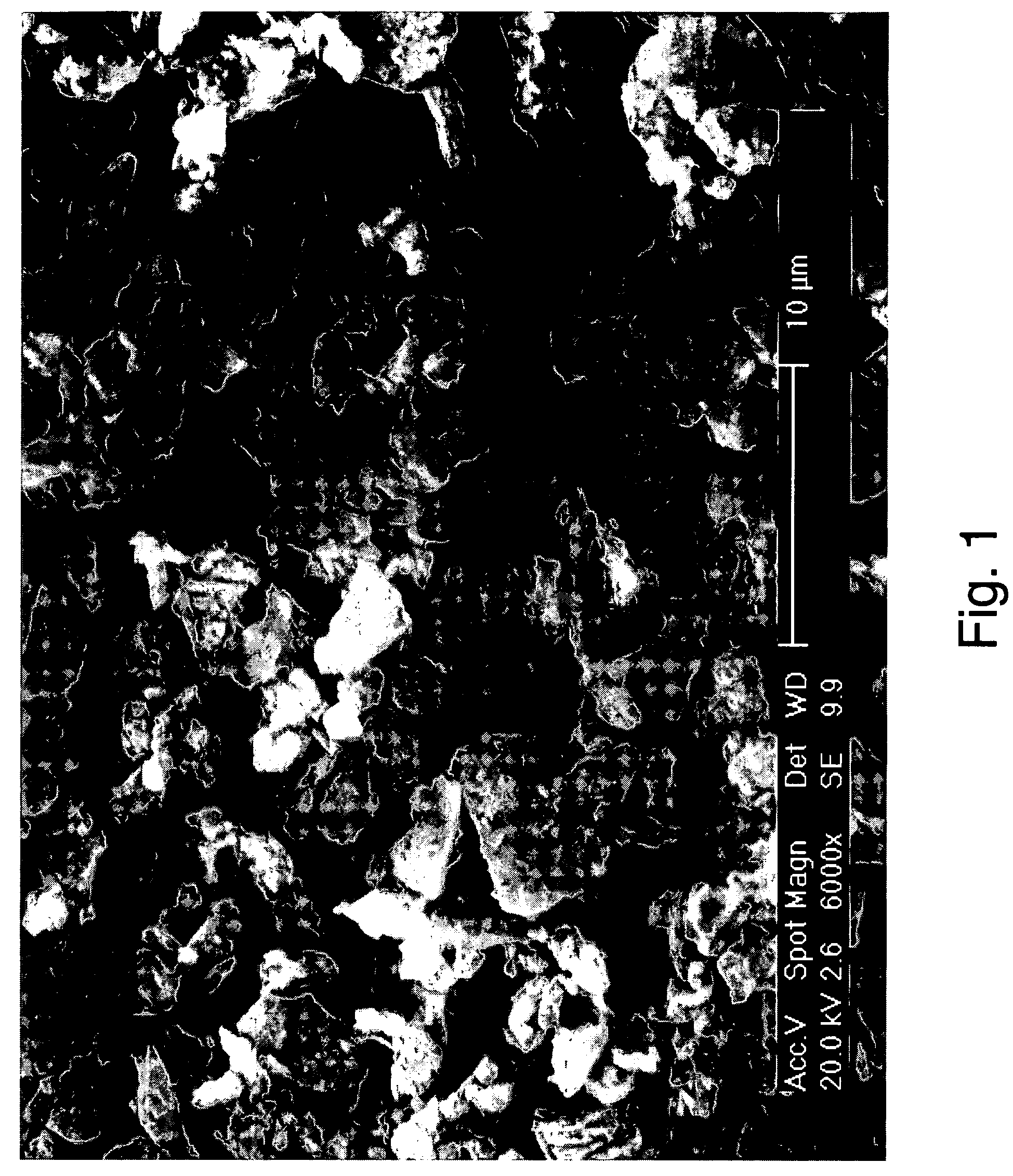

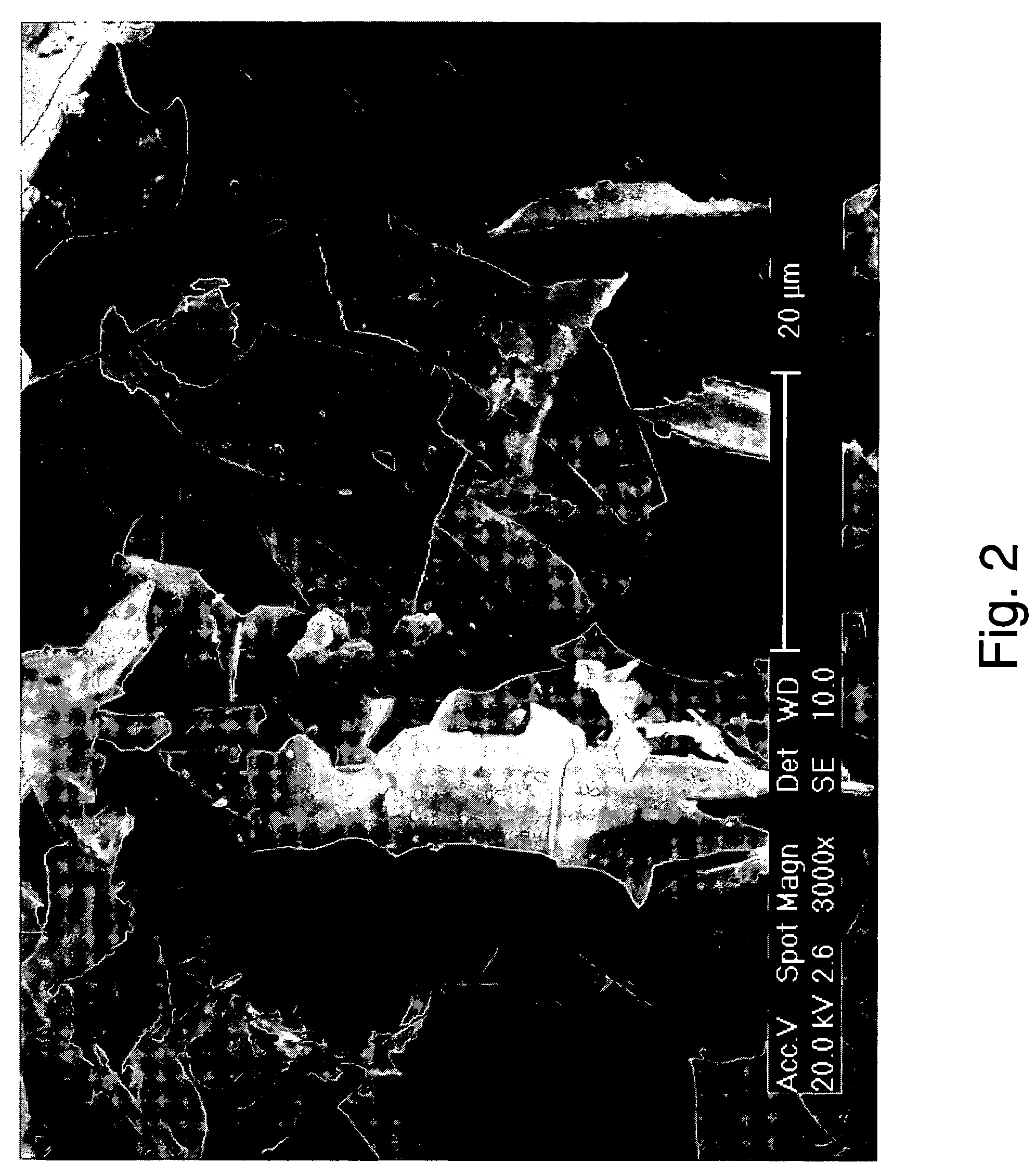

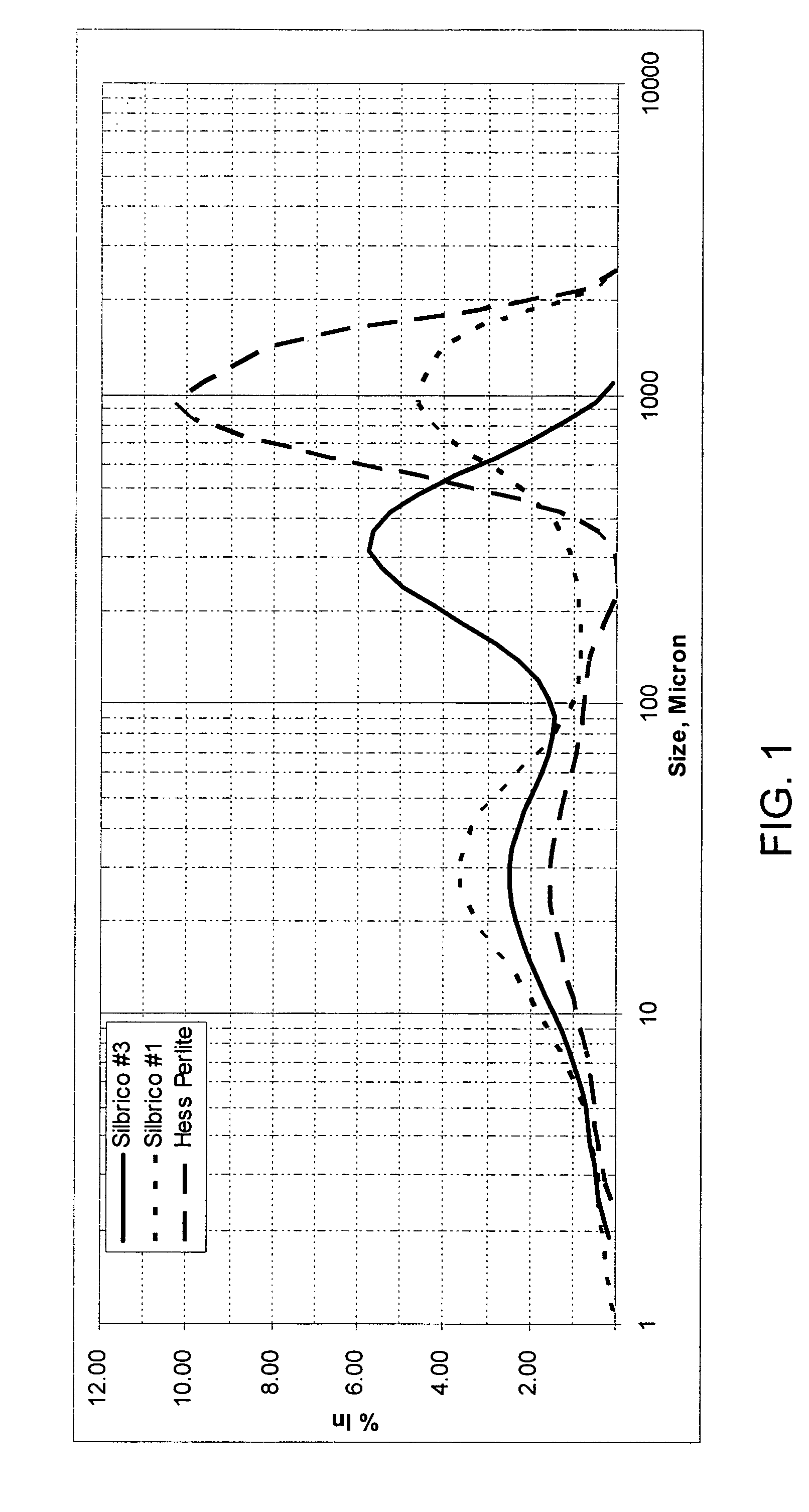

Micronized perlite filler product, methods of producing the micronized expanded perlite products, and methods of use thereof are provided. The micronized expanded perlite product has, for example, a small median particle size (for example, less than 11 microns), a high blue light brightness (for example, higher than 84) and low oil absorption (for example, less than 70 percent in volume). The micronized expanded perlite product may be used in a variety of applications such as anti-block filler in plastic films and reinforcement filler in polymers.

Owner:IMERYS USA INC

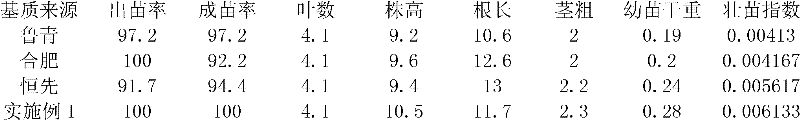

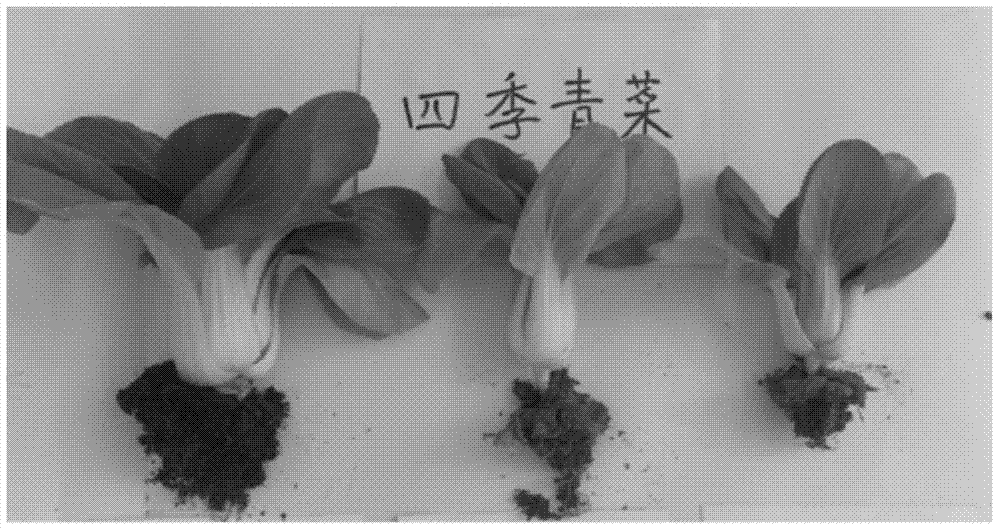

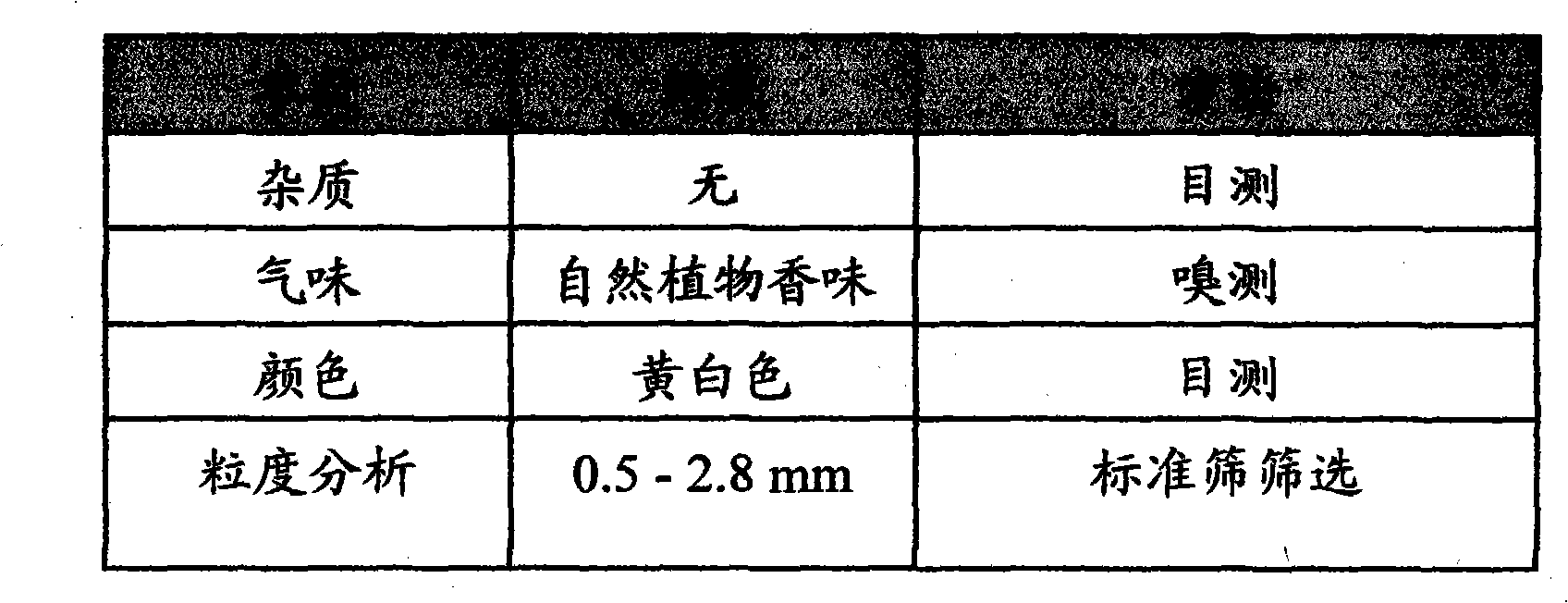

Seedling substrate for soilless culture for vegetables

ActiveCN102432394AHigh in potassiumRich in trace elementsBio-organic fraction processingAgriculture gas emission reductionPorosityBiology

The invention discloses a seedling substrate for vegetables, belonging to the technical field of soilless culture. The substrate formula comprises the following components based on volume ratios: 10-40% of fermented vinegar dreg, 5-30% of fermented cassava dreg, 5-30% of plant ash, 5-30% of perlite, 5-30% of vermiculite and 10-25% of turf. The water content of the substrate is not bigger than 50%, and the total porosity of the substrate is 65-95%, and the total nutrient content of the substrate (N+P2O5+K2O) is 3-5%, and the grain diameter of the substrate is 0.1-4.9 mm, and the volume weight of the substrate is 0.2-0.8 g / cm3, and the gas-water ratio of the substrate is 1: 2-4, and the EC (elastic coefficient) value of the substrate is 1-3 and the pH value of the substrate is 5.8-7.5. The seedling substrate for soilless culture for vegetables mainly uses organic wastes as raw materials, and produces seedling substrate by high temperature fermentation treatment, and changes wastes into wealth, and turns harm into good. The invention has a low production cost, a light weight and complete nutrients such that it is suitable for growth and development for vegetable seedlings, and is a good substrate for soilless culture industrialized tray seedling for vegetables.

Owner:江苏培蕾基质科技发展有限公司

Biological seedling growing matrix

The invention provides a new crop seedling growing matrix, wherein the pH value of the seedling growing matrix is 6.0-6.5. The seedling growing matrix comprises the components by the weight percentage: 50%-80% of an inorganic matrix, and 15-30% of an organic matrix, wherein the organic matrix includes a composition of peat, fermented cattle manure, fermented pig manure, plant ash and an additional organic matrix, and the inorganic matrix includes a composition of vermiculite, perlite and an additional inorganic matrix and is composed of inorganic matrix particles with different particle sizes. The seedling growing matrix provided by the invention has relatively high total porosity and maximum water holding capacity, and is higher in aeration porosity ratio, more reasonable in water-gas ratio, small in bulk density and convenient to transport and use. The seedling growing matrix provided by the invention has the advantages of wide range and many types of applicable crops, high germination rate, less morbidity and good seedling growth vigor.

Owner:上海宇强品牌策划有限公司 +1

Filterable composite adsorbents

InactiveUS6712974B1Increase profitImprove filtering effectLighting and heating apparatusSolid sorbent liquid separationAlkaline earth metalFiltration

This invention relates to filterable composite adsorbents comprising one or more adsorbent components and one or more filtration components, and methods for preparing and using same. More particularly, this invention pertains to filterable composite adsorbents and filterable composite adsorbent products which are suitable for use in filtration applications, and which comprise one or more microparticulate or colloidal adsorbent components selected from the group consisting of silica gel, fumed silica, neutral clay, alkaline clay, zeolite, solid catalyst, alumina, adsorbent polymer, alkaline earth silicate hydrate, and combinations thereof, which bear the property of adsorption, which are intimately bound to one or more functional filtration components selected from the group consisting of biogenic silica (e.g., diatomite, rice hull ash, sponge spicules), natural glass (e.g., expanded perlite, pumice, expanded pumice, pumicite, expanded obsidian, expanded volcanic ash), buoyant glass, buoyant polymer, cellulose, and combinations thereof, which bear a distinguishing porous and intricate structure and buoyancy suitable for filtration.

Owner:IMERYS USA INC

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

Crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and preparation method

ActiveCN106699026AStrong adaptability to high alkaline environmentAdaptableOn/in inorganic carrierWater reducerMechanical property

The invention discloses crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and a preparation method. The crack self-remediation regenerated concrete comprises components, namely, expanded perlite carried with urease production microorganisms, cement, stone, sand, silica fume, water, urea, calcium chloride, a urease production microorganism suspension and a water reducing agent. The urease production microorganisms are adopted as a concrete crack remediation agent, urease can be generated through metabolism through the urease production microorganisms, and the urea can be decomposed into NH4<+> and CO3<2+>, and furthermore the calcium carbonate can be mineralized and deposited to remedy cracks. In the preparation process, a part of the crack remediation agent is directly mixed with the concrete, then cracks and holes in regenerated crude aggregate self and weak adhesion areas between regenerated aggregate and a new cement stone base can be remedied, and thus the mechanical property of the regenerated concrete can be improved; meanwhile, the other part of the crack remediation agent is firstly adsorbed into an expanded perlite carrier and is further mixed into the concrete, then the crack self-remediation property of the regenerated concrete in the service period can be improved, and thus the anti-penetrability performance and the durability of the regenerated concrete can be improved.

Owner:TAIYUAN UNIV OF TECH

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

Cat litter and making method thereof

InactiveCN102150627AEnhanced adsorption and deodorization abilityImprove deodorization abilityAnimal housingSodium BentoniteSilica gel

The invention discloses cat litter comprising a composition prepared from the following components in percent by weight: 50-80% of inorganic clay, 5-15% of silica gel, 5-20% of organic substrate and 8-20% of mineral matter, wherein the inorganic clay is selected from one or a mixture of attapulgite, bentonite, kaolinite and sepiolite; the organic substrate is selected from one or a mixture of corncob, corn, wheat, clover, peanut hull, walnut shell, pine wood shavings and broadleaved tree wood shavings; and the mineral matter is selected from one or a mixture of perlite, diatomite, pumice and other low-density mineral matters. The cat litter disclosed by the invention has the following advantages of largely strengthened adsorption deodorization capacity due to the addition of the silica gel component, stronger deodorization capacity by utilizing the adsorbability of natural materials, natural fragrance, small weight and strong caking capability, in particular no dust and easiness for treatment; and the cat litter disclosed by the invention is 40% lighter than the traditional bentonite cat litter.

Owner:QINGDAO FRANK FINE CHEM

Acoustical gypsum board panel and method of making it

ActiveUS20080299413A1Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

The acoustical product of the present invention comprises an acoustical product including a matrix of calcium sulfate dihydrate crystals and expanded perlite distributed throughout the matrix. The expanded perlite has a particle size distribution with at least 10% of the perlite having a particle diameter of 700 microns or more, and the amount of expanded perlite to calcium sulfate dihydrate is about 35% to about 75% by weight, based upon the dry weight of the calcium sulfate dihydrate. A dispersing agent and glass fibers having a particle length of about ¼ inch to about 1 inch are dispersed throughout the gypsum matrix.

Owner:UNITED STATES GYPSUM CO

Inorganic heat-insulating dry powder mortar

The invention relates to inorganic heat-insulating dry powder mortar, which comprises the following components in percentage by weight: 30 to 95 percent of inorganic gelled material, 5 to 70 percent of lightweight aggregate and 0 to 10 percent of additive, wherein the inorganic gelled material comprises 75 to 90 weight percent of desulfuration gypsum and 10 to 25 weight percent of cement; the lightweight aggregate is hydrophobic expanded perlite or vitrified micro bubbles or a mixture of the hydrophobic expanded perlite and the vitrified micro bubbles; and the additive comprises a composite retarder, a water retention agent, a thickening agent, a cementing compound and a reinforcing agent. The inorganic heat-insulating dry powder mortar can replace cement mortar and mixed mortar, is applied to non-humid wall surfaces such as the inner side of an outer wall, a separating wall, an inner partition wall, a ceiling and the like, has the characteristics of heat preservation, heat insulation, crack resistance, fire prevention, ageing resistance, environmental protection, biological bite corrosion prevention and the like, and can improve the heat-preserving and heat-insulating performanceof wall bodies.

Owner:谢日清

Strengthened, light weight wallboard and method and apparatus for making the same

A novel wallboard composition is disclosed comprising a unique combination of synthetic binders selected for their ability to establish a strengthened permanent bond in the final dry state for use in a wallboard composition comprising primarily gypsum, and in a wallboard composition comprising an expanded mineral such as Perlite which largely reduces the amount of gypsum over current gypsum wallboard formulations, thus reducing the weight while maintaining the strength of the wallboard structure. In a preferred embodiment, the lightweight, strengthened wallboard of the present invention also comprises an optional covering veneer that is applied to the top ply of the face paper to provide increased strength, moisture resistance, and fire retardency, and the back paper top ply is treated to provide increased flexural strength. Additionally, this invention relates to the unique manufacturing process to produce the wallboard composition of the present invention in order to create a lightweight, strengthened, moisture resistant, and fire retardant wallboard used to cover walls and ceilings in construction applications. Still further, this invention relates to the apparatus for manufacturing the wallboard composition of the present invention, including a method and apparatus for economically converting a standard gypsum wallboard manufacturing facility into a facility for manufacturing wallboard of the present invention.

Owner:INNOVATIVE TECH ENTERPRISES

Servicing a wellbore with wellbore fluids comprising perlite

Owner:HALLIBURTON ENERGY SERVICES INC

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

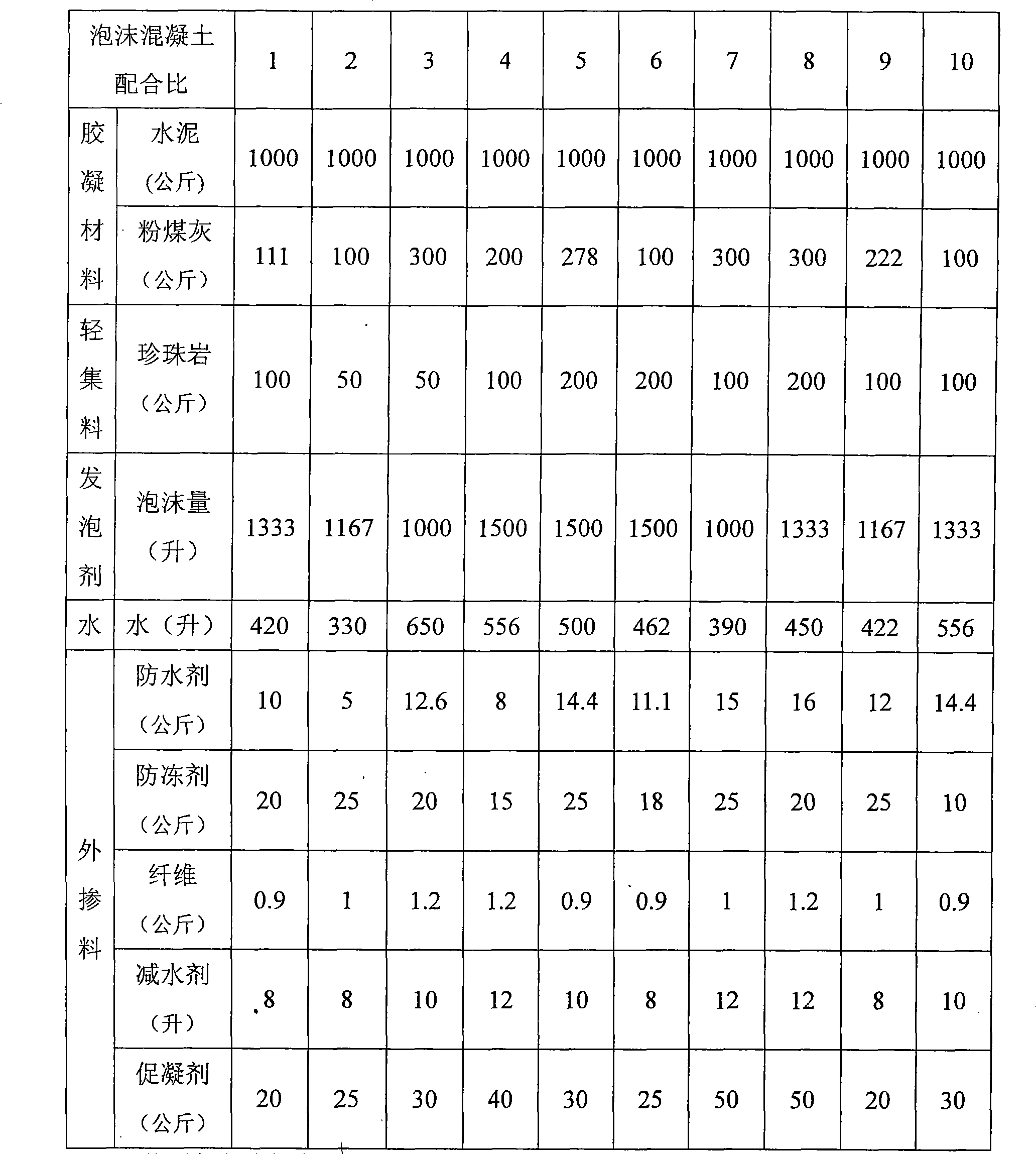

Foam concrete and preparing process thereof

InactiveCN101497533AHigh strengthLight weightCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting and molding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heat insulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Method utilizing expanded perlite to produce vacuum insulated plate

ActiveCN102717578ALow thermal conductivityLow priceLaminationLamination apparatusHigh resistanceFiber

The invention relates to a method utilizing expanded perlite to produce a vacuum insulated plate. The fabrication process of the method comprises the following steps of: burdening: putting the expanded perlite, an auxiliary material, fiber and a vacuum active stabilizing agent into a mixing machine to be fully mixed; drying: drying the uniformly stirred mixture; core material forming: putting the dried materials and a getter into a mould, and putting the mould into a pressing machine for pressure forming; package: taking out a pressure-formed core plate from the mould, packing a layer of non-woven fabric at the periphery of the core plate so as to obtain the core plate of the vacuum insulated plate for buildings; putting the core plate into a high-resistance gas membrane bag, vacuumizing with the vacuum degree of 0.02-20Pa, and then sealing. The method has the advantages that the sound absorption of the expanded perlite is good, and the own coefficient of thermal conductivity of the expanded perlite is low; the mixing of the auxiliary material, the fiber and the perlite can form a high-performance thermal-protective layer among perlite particles, and further the thermal insulation properties and the strength are increased; and the expanded perlite is an inorganic materials and is not easy to burn.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

Cutting propagation method for hard branch of Sabina przewalskii

InactiveCN101243760AShort breeding cycleNeat emergenceCultivating equipmentsHorticulture methodsGreenhousePeat

The invention discloses a method of hardwood cutting propagation of Qilian Juniper, which is characterized in that, annual hardwood of the Qilian Juniper having the age ranges from seven years to ten years is cut as branches; the average length of the branches ranges from 14.0cm to 18.0cm; the average diameter of the branches ranges from 3.0mm to 5.0mm; on the last ten days of April of each year, the branches are inserted into a greenhouse for seedling; the cutting medium is the mixture of peat and perlite mixed according to the proportion of 1:1; the cutting medium is firstly formed into a medium sausage having the length ranging from 13cm to 16cm; then the cutting medium is put in a 58 x 32cm tray and is put on the cutting bed in the greenhouse. The breeding of Qilian Juniper is realized by the method of hardwood cutting propagation. The method has the advantages of reduced seedling period of Qilian Juniper, saved cost and remarkable effect.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

Acoustical gypsum board panel and method of making it

ActiveUS8057915B2Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

Owner:UNITED STATES GYPSUM CO

Melon raise seedling or stalk cultivation ground mass and method for manufacturing same

InactiveCN101248738ASeedlings grow wellLow costBio-organic fraction processingOrganic fertiliser preparationLivestock manureDiammonium phosphate

The invention relates to a medium for culturing fruits and vegetables or cultivating straw, which is characterized in that the medium consists of materials of the following volume proportion: 35-80 percent of straw leavening, 0.2-0.5 percent of chemical fertilizer, and 19.5-64.8 percent of base material, wherein, the base material is one or more of grass carbon, perlite or vermiculite, or either grass carbon or river sand. The invention provides a manufacturing method for the medium culturing fruits and vegetables or cultivating straw, which includes: 1) fermentation of the straw; 2) proportioning of materials. The manufacturing method adds a small amount of excrement of animals and even ferments with organic material-decomposing agent; the decomposed mixture is mixed with the grass carbon and fertilizer (three-element compound fertilizer or carbamide, ordinary superphosphate, diammonium phosphate) according to certain proportion to prepare the seedling culture or cultivation medium; the growth of the fruit and vegetable seedlings are good, the cost is reduced and the dependence on mineral is reduced at the same time.

Owner:山东商道生物科技股份有限公司

Method for planting edible fungi and producing artificial grass peat by using cabo

The invention provides a comprehensive utilization method for planting edible fungi and producing artificial grass peat by using waste cabo generated in a tobacco threshing redrying plant as main raw materials. Raw materials forming culture materials are as follows: 60-100 parts of cabo and 1-5 parts of lime or / and plaster; and 1-40 parts of accessories also can be added. A bag cultivation methodis perfectly selected for a planting process, comprising the steps of dosing, bagging, sterilizing, inoculating, culturing and the like. After the harvest, waste residue of the culture materials containing the cabo is directly crushed to be in a puffy fiber, scrap, or powder state , or is crushed after being fermented and decomposed, and then is dried to obtain the artificial grass peat product. The artificial grass peat is mixed with packing materials such as perlite, roseite and the like to obtain plant culture substrate. The invention has centralized and stable raw materials so as to be beneficial to the massive production; the production cost is 1 / 3 lower than the common method; the planted edible fungi is large and thick, green and safe; and the artificial grass peat is prepared by the waste residue so as to realize high-efficiency comprehensive utilization of the waste cabo.

Owner:ZHENGZHOU UNIV

Composite structural material and method of making same

InactiveUS20070113759A1Conserve costIncrease the proportionSynthetic resin layered productsPaper/cardboard layered productsPolyesterEpoxy

A composite structural material suitable, for example, as a replacement for wooden boards, is disclosed. It comprises a dimensionally stable core material ensheathed in a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one layer of parallel cords (19) bonded to at least one layer of a rigidified web material (10) selected from the group consisting of paper and cloth. Suitable core materials include polyurethane foam (38), optionally filled with particles (32) of granulated rubber, expanded perlite, expandable polymer beads, and / or glass microspheres. The parallel cords (19) preferably are supplied in the form of a strip of polyester cloth, as the warp cords thereof. The web material (10) preferably is kraft paper that is rigidified with an epoxy resin.

Owner:CODA CAPITAL MANAGEMENT GROUP

Process for material treatment

InactiveUS20070059199A1Solid waste managementIon-exchanger regenerationThermal treatmentMaterials science

The invention discloses a process for material treatment, which includes the step of subjecting used siliceous material to heat to obtain treated siliceous material. The process may be used to recycle used siliceous material. The invention also discloses a material treatment apparatus for treating used siliceous material, which includes heating means for heating used siliceous material to obtain treated siliceous material. The used siliceous material may be perlite and / or diatomaceous earth.

Owner:LABUSCHAGNE FRANCOIS JACQUES

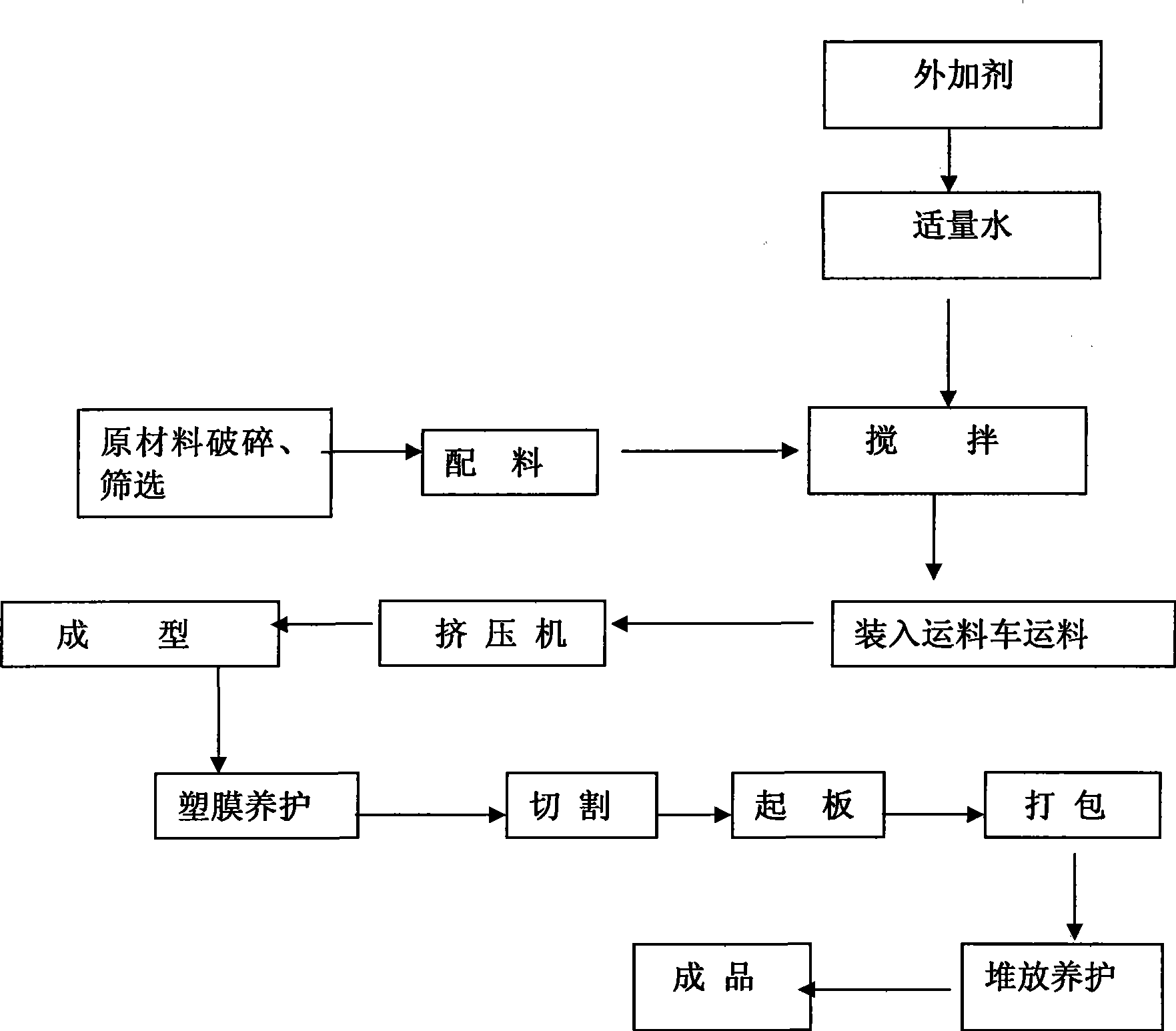

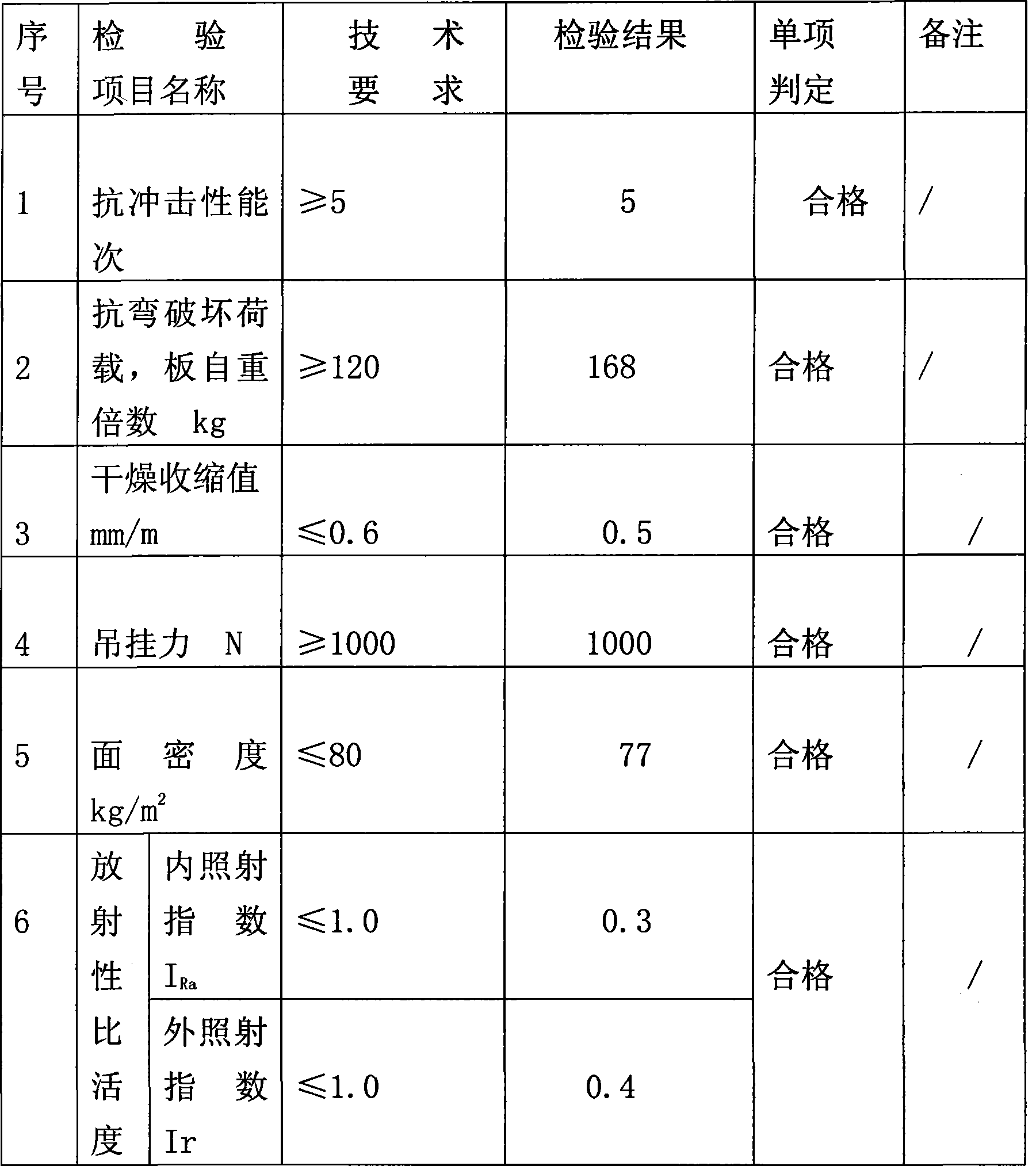

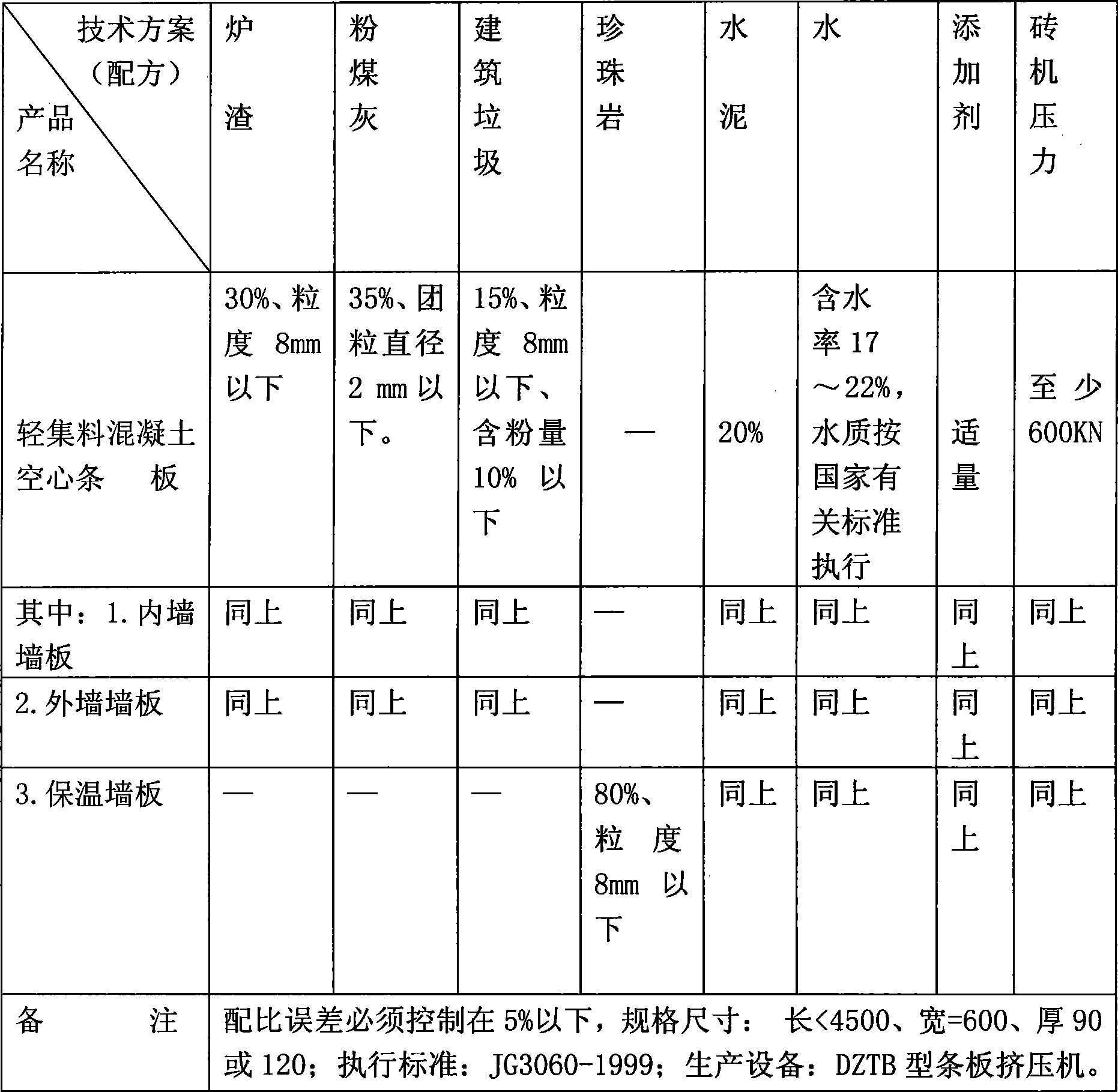

Light wall board and manufacturing technology thereof

InactiveCN101423368AFast constructionIncrease typeSolid waste managementManufacturing technologySlag

The invention provides a light wall slab, which is producing by the following materials in weight percentage: 30 percent of slag with the grain size of less than 8mm, 35 percent of fly ash with the pellet diameter of less than 2mm, 15 percent of construction waste with the grain size of less than 8mm and the power content of less than 10 percent, and 20 percent of cement; moreover, a water reducing agent, a water repellent and an accelerating agent are added into the materials, and water of which the weight accounts for the total weight of the slag, the fly ash, the construction waste and the cement dry material is between 17 and 22 percent is added into the mixture; and the production process comprises the following: crushing raw materials, screening, preparing materials, mixing and stirring the materials, extruding by a slat extruder, curing, cutting, lifting the slab and pile-curing. The light wall slab has the advantages of improving the construction speed of single buildings, saving energy, increasing usable floor areas, meeting building requirements on various levels and prompting the wall material to develop towards industrialization and modernization of the housing industry. The light wall slab can promote the development of internal wall slabs and external wall slabs, and increase types of heat preservation wall slabs. Compared with expanded perlite, the sound insulation property of the industrial residue light aggregate wall slab is improved by more than 30 percent.

Owner:丁志强

Coated perlite flakes

The present disclosure relates to a method of making coated perlite flakes comprises: (i) providing perlite flakes; (ii) applying a layer of tin oxide on the perlite flakes to obtain tin oxide coated perlite flakes; (iii) applying a layer titanium dioxide on the tin oxide coated perlite flakes obtained in step (ii) to obtain titanium dioxide and tin oxide coated perlite flakes; and (iv) applying a layer of iron oxide to the titanium dioxide and tin oxide coated perlite flakes to obtain the coated perlite flakes. The present disclosure also relates to coated perlite flakes comprising: perlite flakes with layer of tin oxide, then a layer of titanium dioxide, and then a layer of iron oxide.

Owner:SUN CHEMICAL BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com