Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4490 results about "Fumed silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fumed silica (CAS number 112945-52-5), also known as pyrogenic silica because it is produced in a flame, consists of microscopic droplets of amorphous silica fused into branched, chainlike, three-dimensional secondary particles which then agglomerate into tertiary particles. The resulting powder has an extremely low bulk density and high surface area. Its three-dimensional structure results in viscosity-increasing, thixotropic behavior when used as a thickener or reinforcing filler.

Storage stable compositions of biological materials

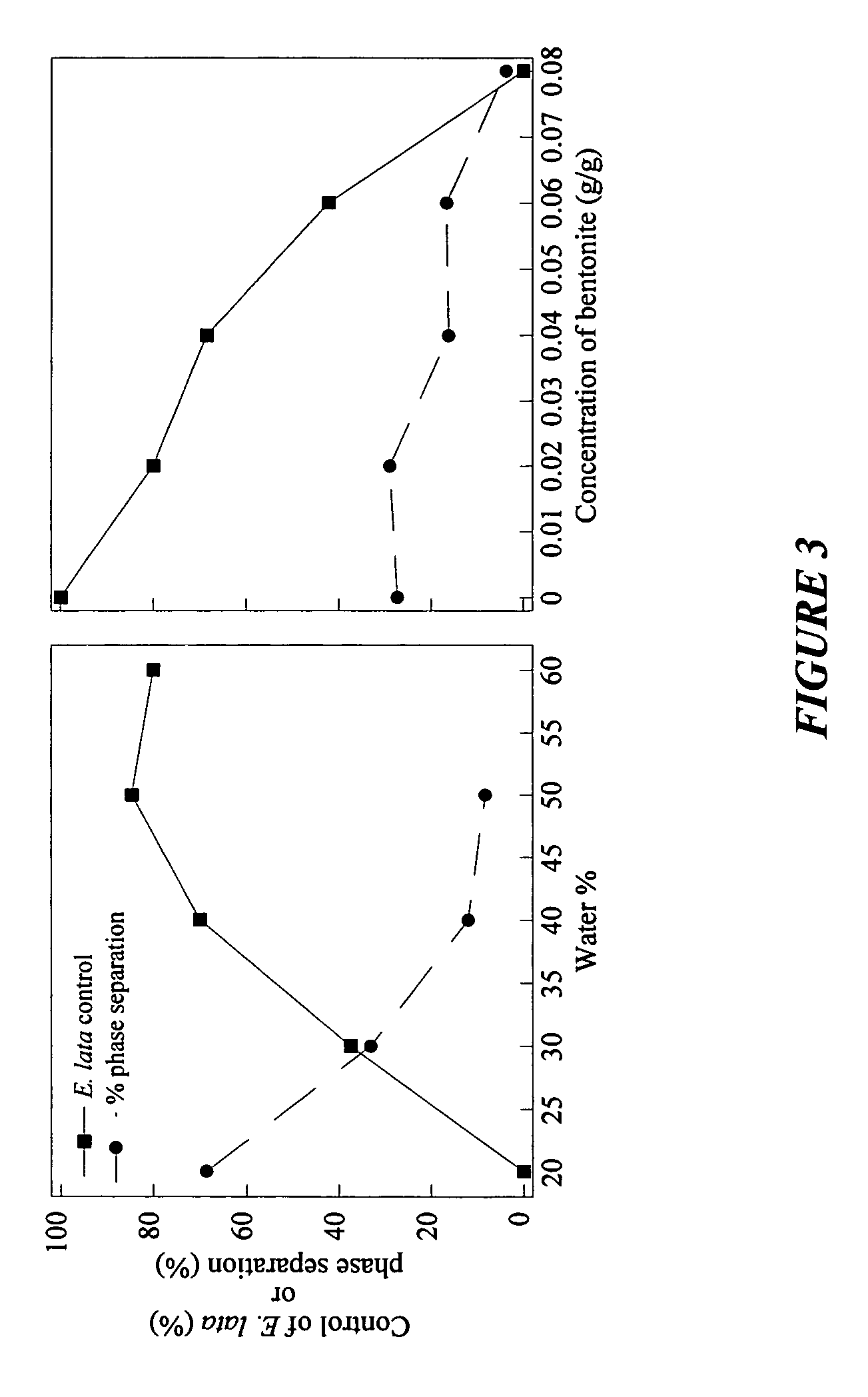

Storage stable compositions of biological materials, including bioactive biological materials are provided in the form of a water-in-oil emulsion, comprising:(a) cellular material selected from living and / or dormant prokaryotic and / or eukaryotic cells and tissues, the cellular material being compatible with water-in-oil emulsions;(b) one or more oils selected from vegetable oils and fish oils;(c) an oil-soluble nonionic polymeric surfactant having a molecular weight of from about 2500 to about 15000; and(d) water.The compositions may also contain a thickener such as a hydrophobic fumed silica or bentonite.Compositions may be used for various purposes, depending on the contained biological material. Specific examples include compositions containing Fusarium lateritium control of Eutypa lata in plant wounds made by cutting or pruning, and compositions containing Lagenidium giganteum for control of mosquitoes.

Owner:RGT UNIV OF CALIFORNIA

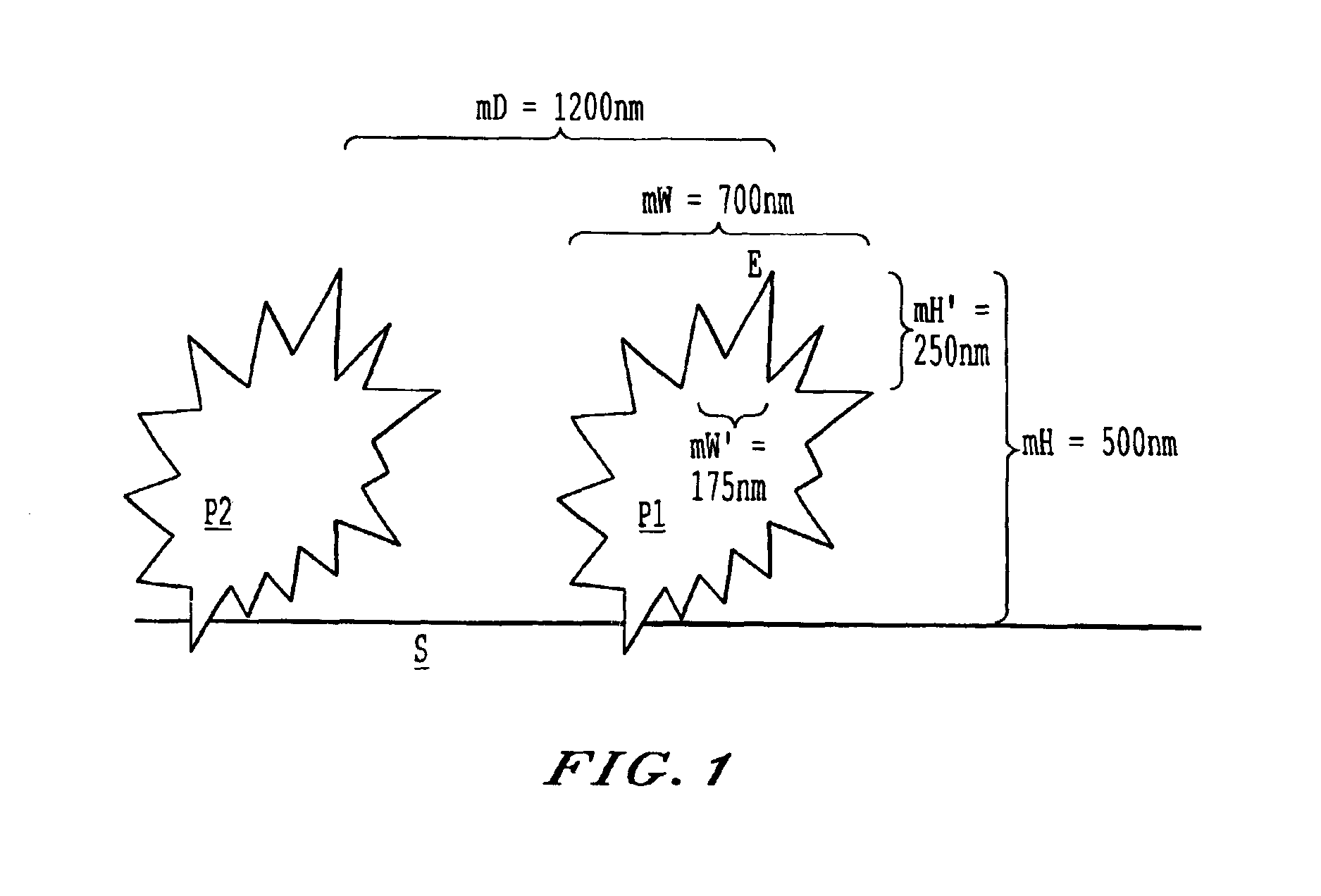

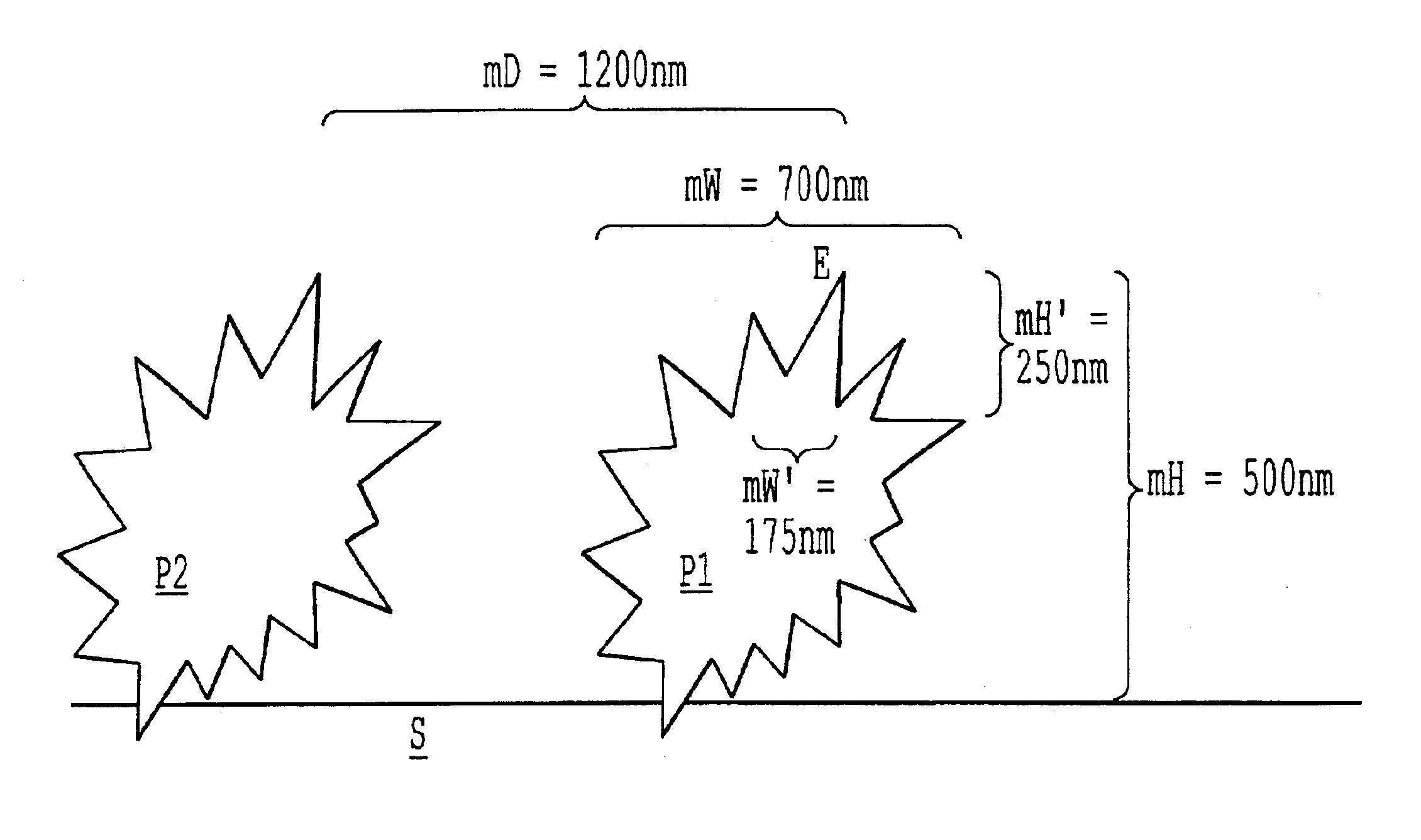

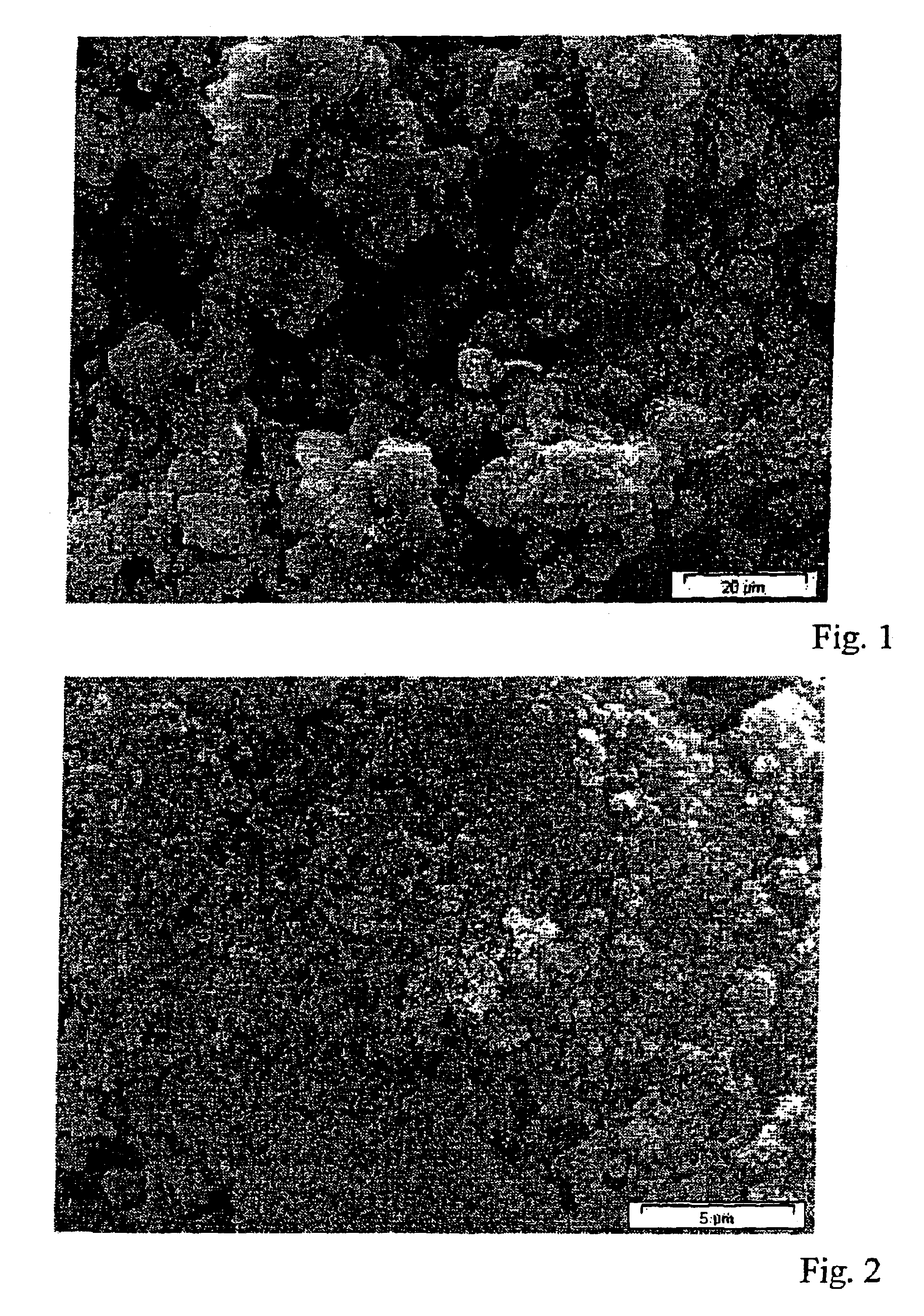

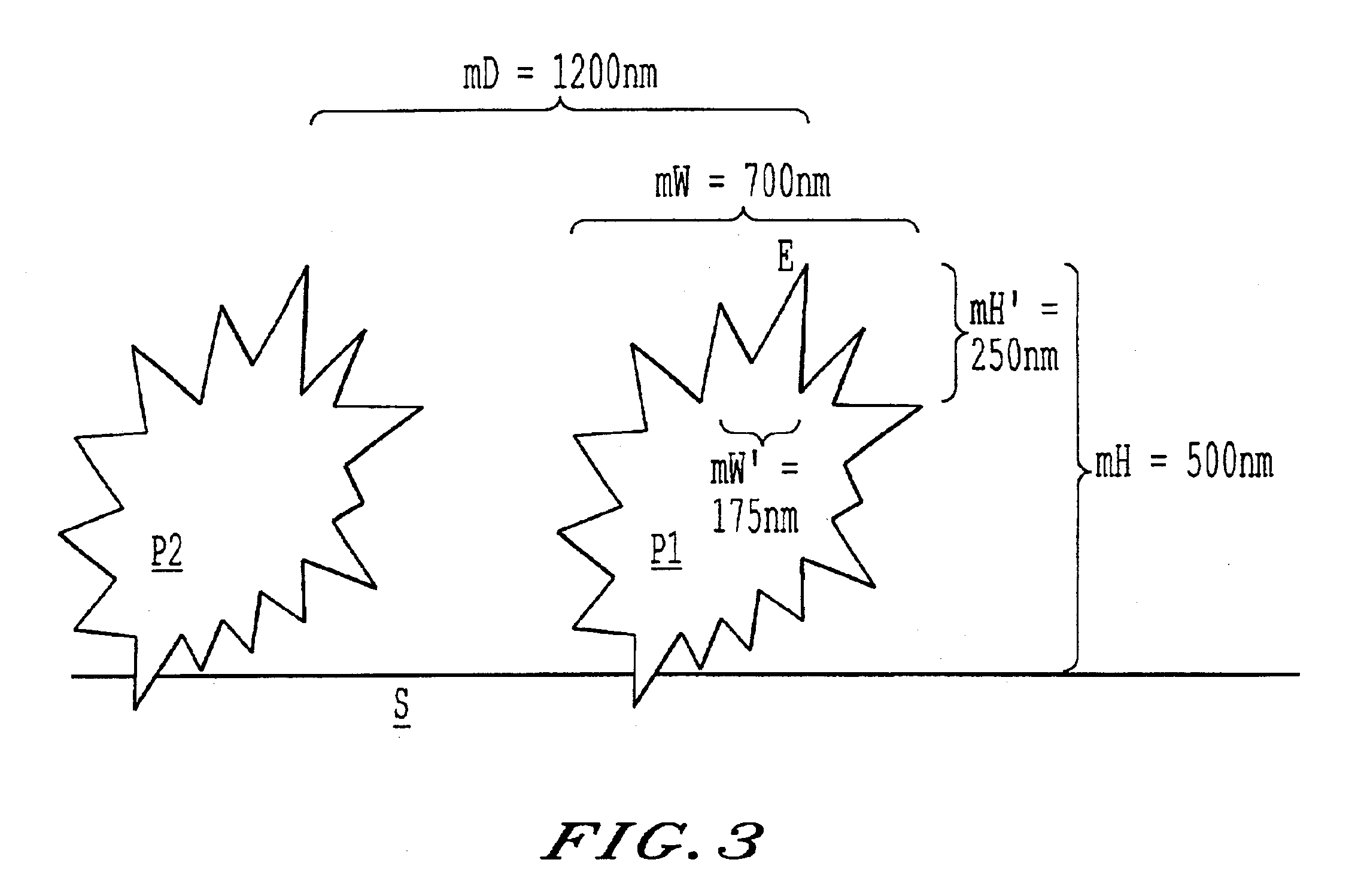

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

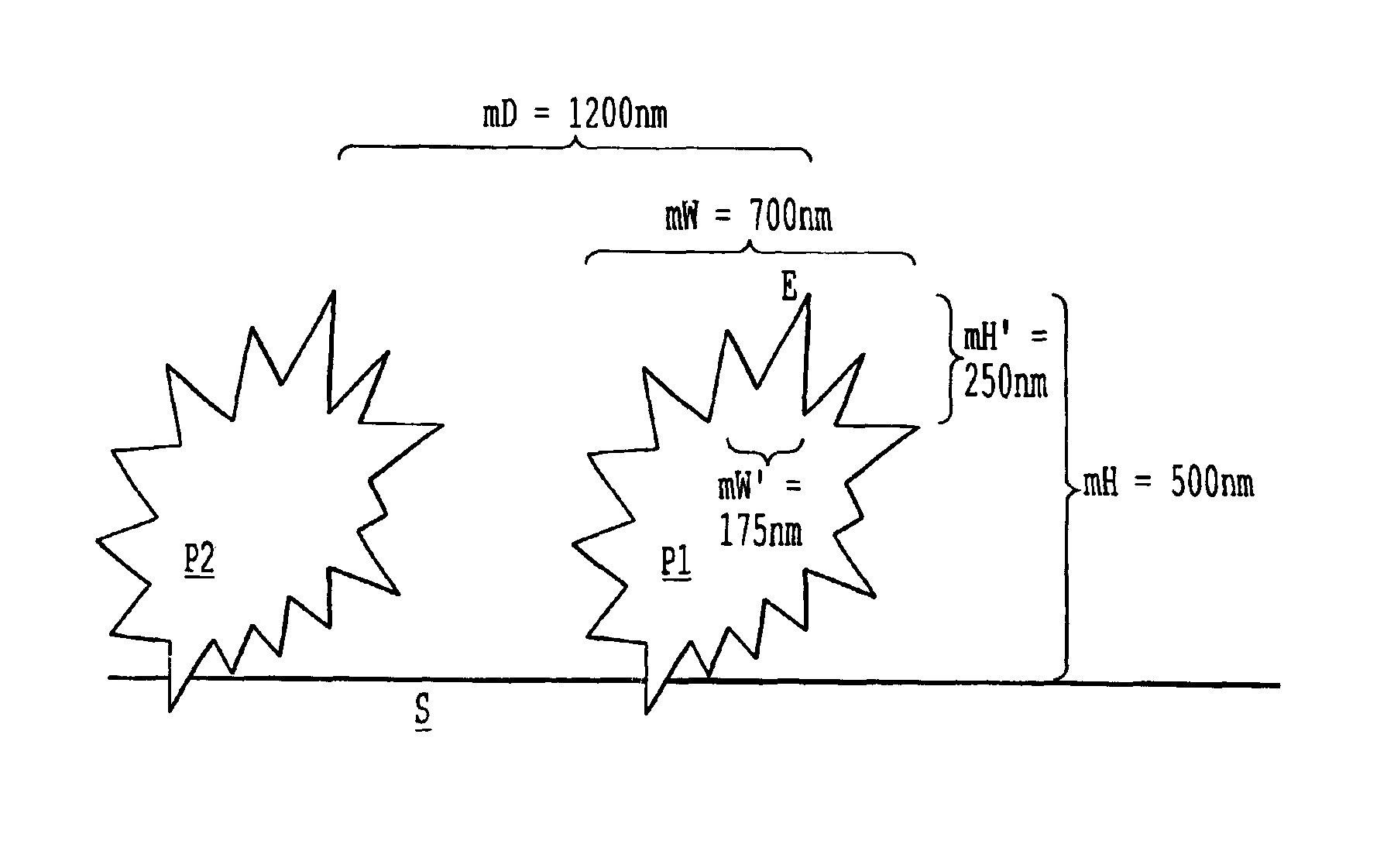

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6858284B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresMeth-Gas phase

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises an at least partially hydrophobic surface formed from structure-forming particles of hydrophobic fumed silica having elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm adhered to the surface by way of a viscous, curable carrier material selected from the group consisting of polyurethane, polyurethane acrylates, silicone acrylates and singly and / or multiply unsaturated (meth)acrylates applied to the surface, which is sufficient to bond the structure forming particles without substantial wetting of the particles by the carrier material while retaining the fissured structure of elevations and depressions of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

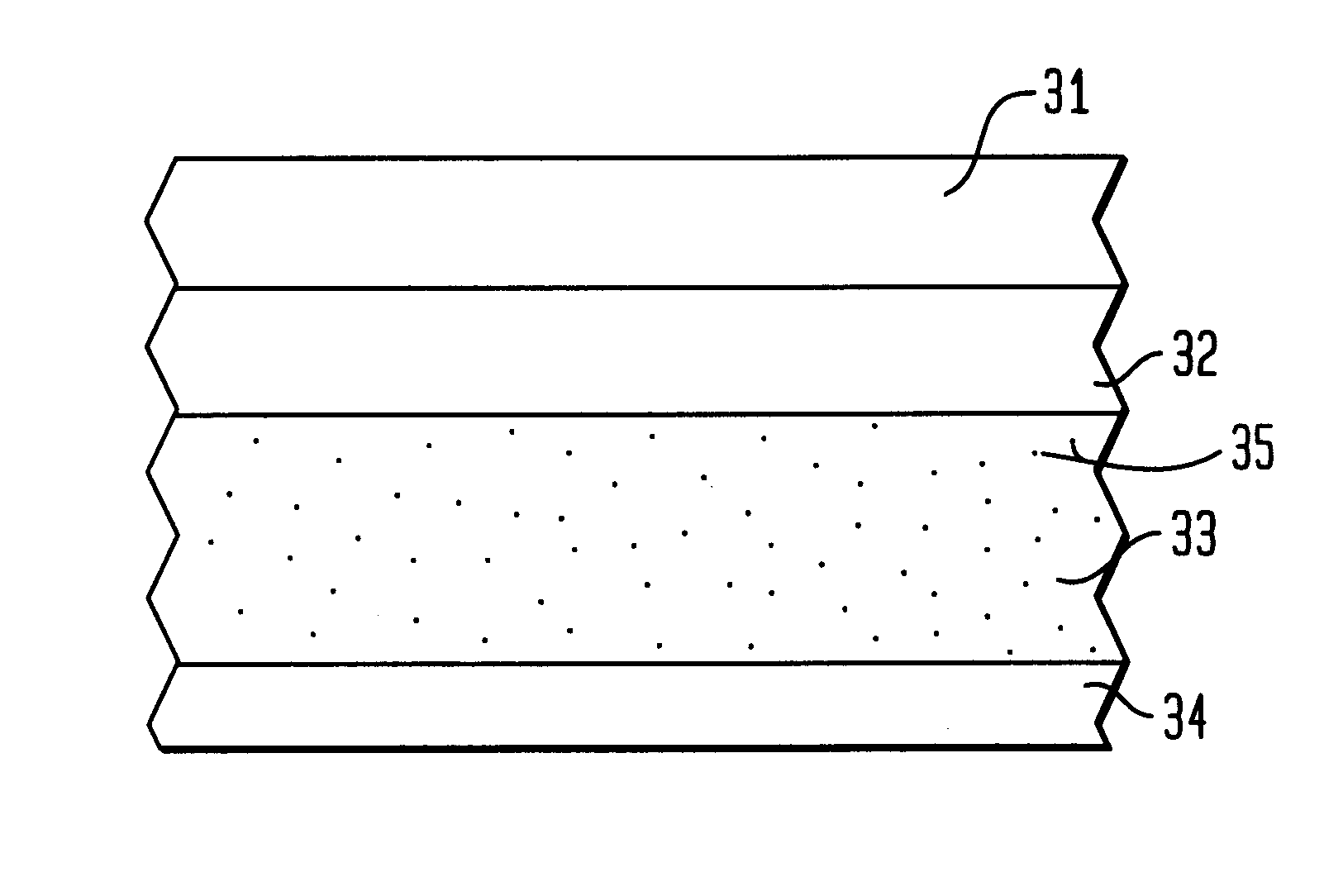

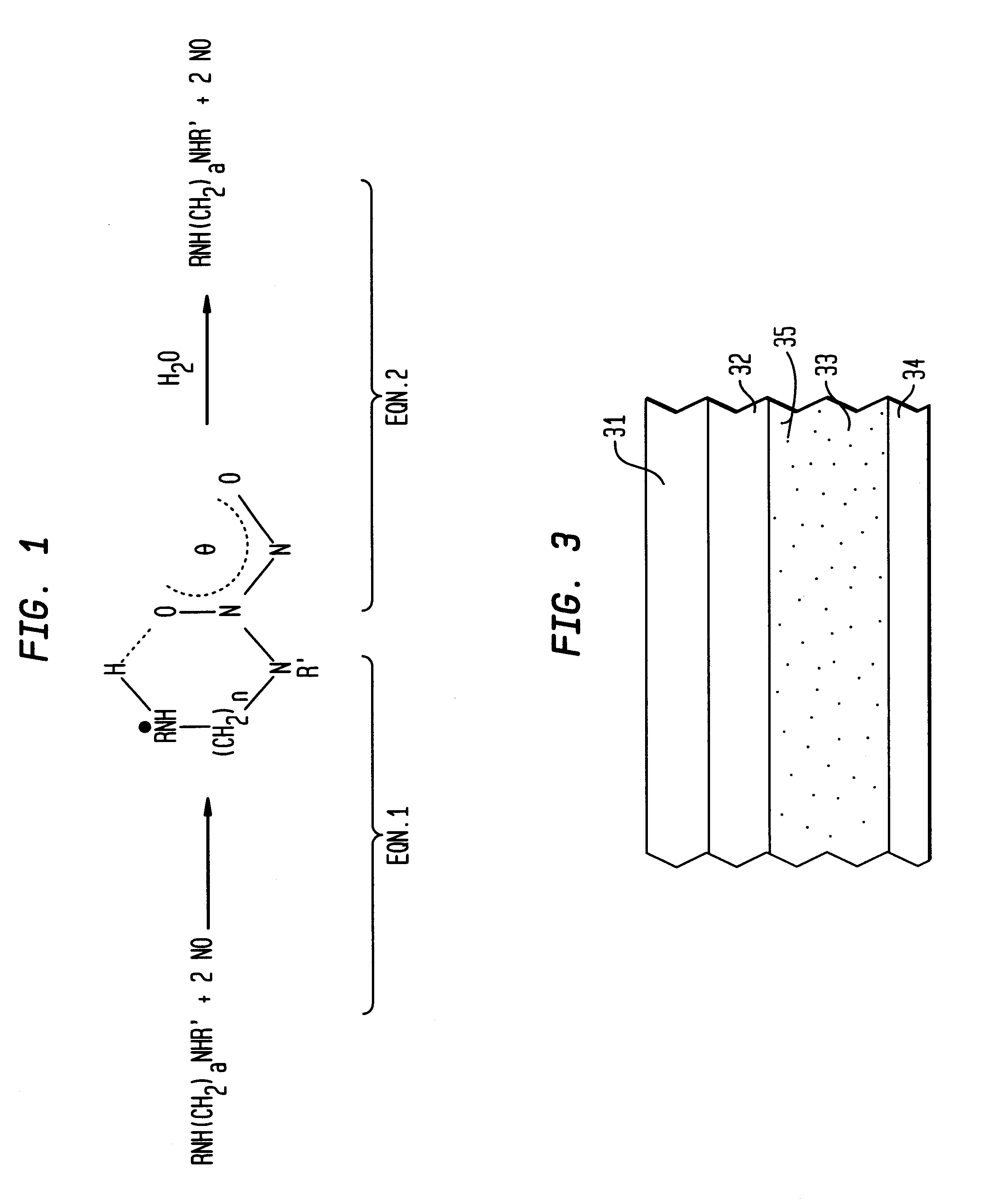

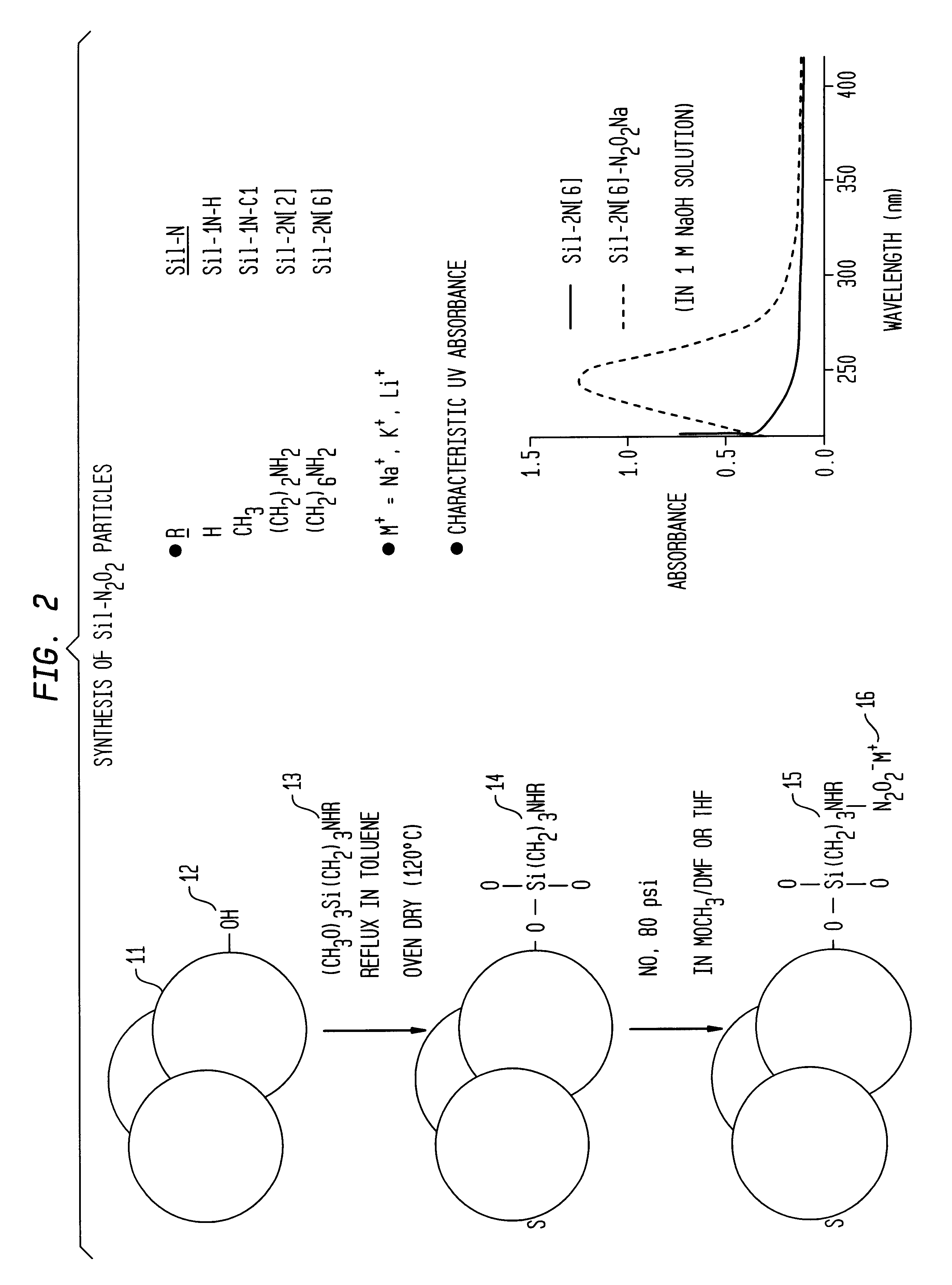

Nitric oxide-releasing polymers incorporating diazeniumdiolated silane derivatives

InactiveUS6841166B1Reduce activationReduce aggregationBiocideInorganic active ingredientsPolymeric surfaceSilanes

Biocompatible polymeric materials capable of providing in situ release of nitric oxide (NO) included diazeniumdiolated fumed silica as a filler in a multilayer polymer structure to release NO upon contact with water (blood). The blood-contacting polymer surface is preferably multi-layered so that the NO-releasing layer, containing the diazeniumdiolated fumed silica, is shielded from blood contact by one or more top (or base) coats. When in contact with blood, the NO released at the surface of the polymer prevents platelet activation and adhesion to the surface, thereby reducing platelet consumption, risk of thrombus formation and other clinical complications associated with interactions between blood and foreign materials.

Owner:RGT UNIV OF MICHIGAN

Interlayer films for laminated glazing containing silica with specific refractive index

InactiveUS20100124647A1Improve mechanical propertiesSynthetic resin layered productsAbsorbent padsPolymer sciencePolyvinyl alcohol

Interlayer films useful for laminated glass contain a polyvinyl acetal (A), at least on plasticizer (B), fumed silica (C) and at least one basic compound (D), wherein the difference of refractive index between fumed silica (C) and plasticized polyvinyl acetal (A+B) is 0.015 or less, and the weight ratio of C / (A+B) is 2.7-60 / 100.

Owner:KURARAY EURO GMBH +1

Method for producing methanol, dimethyl ether, derived synthetic hydrocarbons and their products from carbon dioxide and water (moisture) of the air as sole source material

InactiveUS7378561B2High activityImprove surface activityOrganic compound preparationOrganic chemistry methodsNano structuringWater source

A method for producing methanol and dimethyl ether using the air as the sole source of materials is disclosed. The invention relates to a method for separating the water (i.e., the moisture in the air) and carbon dioxide content of atmospheric air for their use in the subsequent production of methanol, dimethyl ether and derived synthetic hydrocarbons as products. The method includes the conversion of carbon dioxide and water under conditions sufficient to produce methanol and / or dimethyl ether. Methanol and / or dimethyl ether can be used as fuel or fuel additives or further converted to synthetic hydrocarbons and their products. Carbon dioxide is captured on a suitable absorbent, preferentially polyethyleneimine supported on nano-structured fumed silica. The process can also involve hydrogenation with hydrogen produced by electrolysis of water obtained from the air or from any other water source. Methanol can be dehydrated to produce dimethyl ether or further processed to produce synthetic hydrocarbons, polymers, and products derived from them by other known methods.

Owner:UNIV OF SOUTHERN CALIFORNIA

Adsorbent-Containing Hemostatic Devices

InactiveUS20070154510A1Minimal clean-upGood coagulationNon-adhesive dressingsPlastersFiberMontmorillonite

The present invention utilizes a combination of a porous carrier and inorganic material is selected from the group consisting of diatomaceous earth, glass powder or fibers, precipitated or fumed silica, kaolin and montmorillonite clays, and Ca exchanged permutites to make a more effective hemostatic device to treat wounds in mammalian animals. These hemostatic devices provide a lower heat rise to the skin as compared to direct application of zeolites to the skin.

Owner:HONEYWELL INT INC

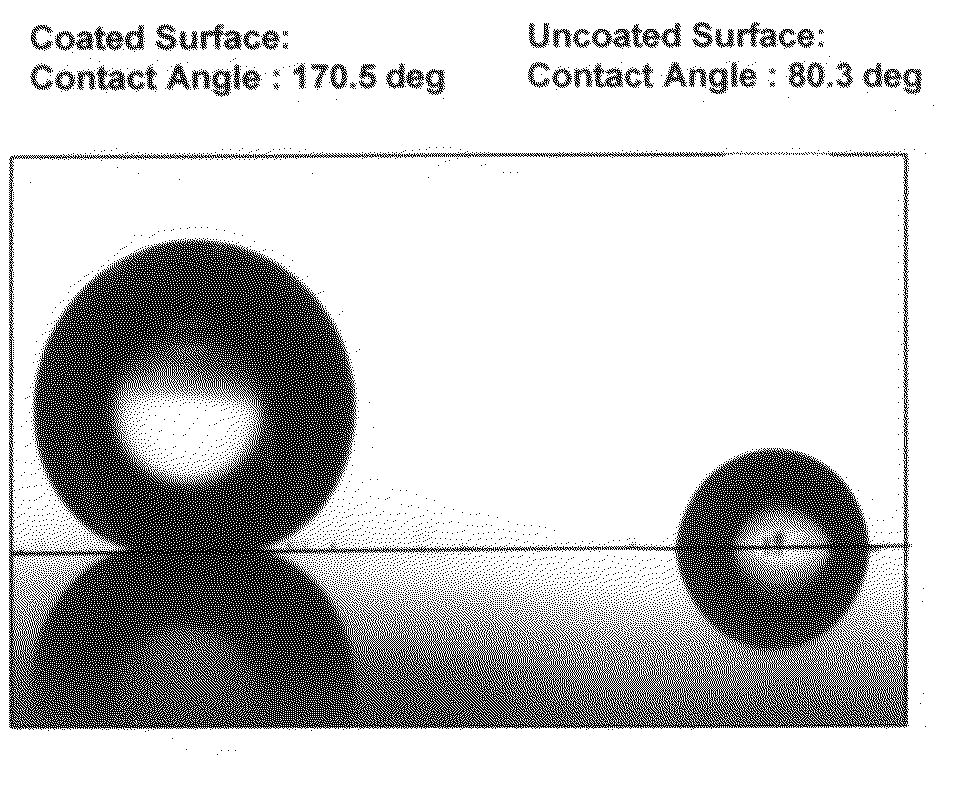

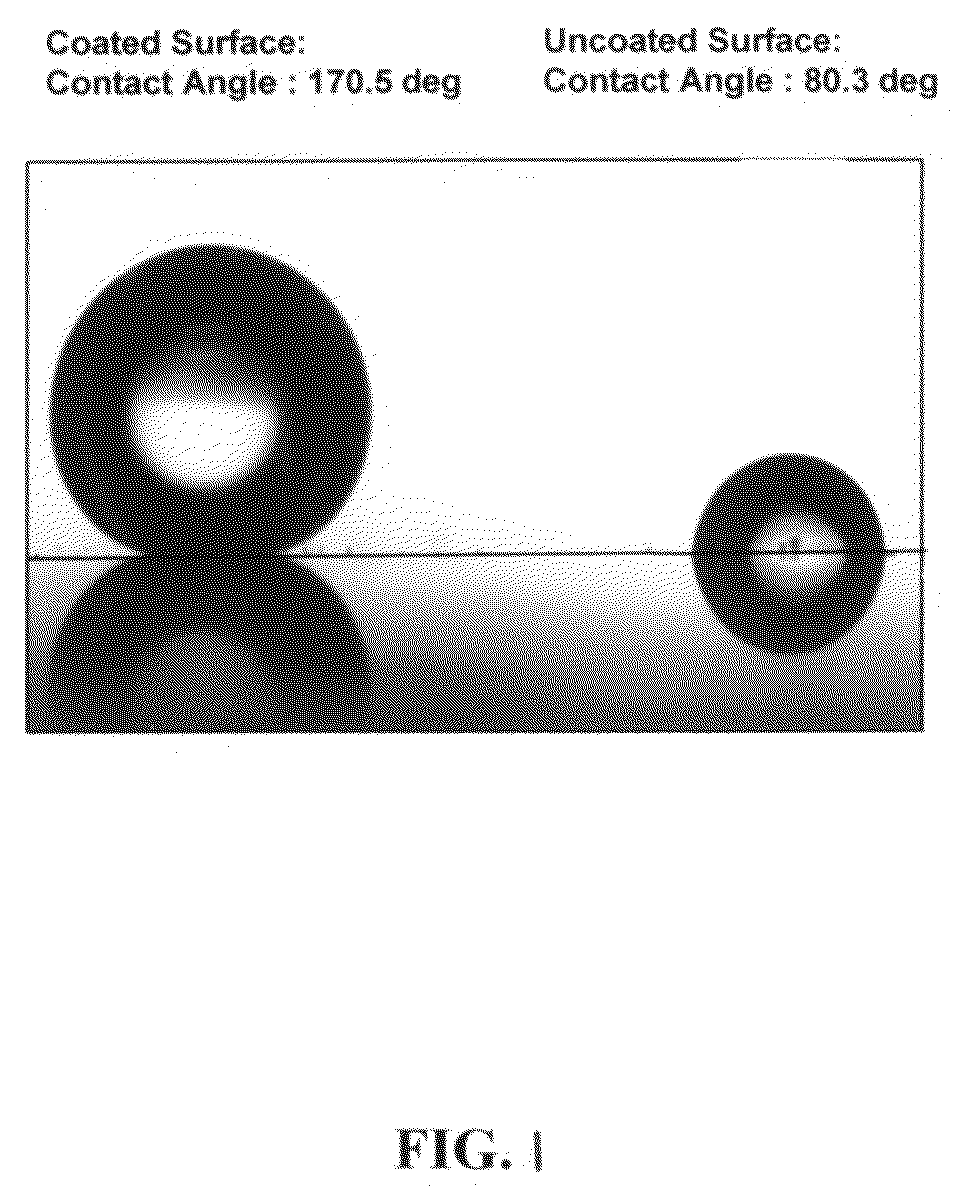

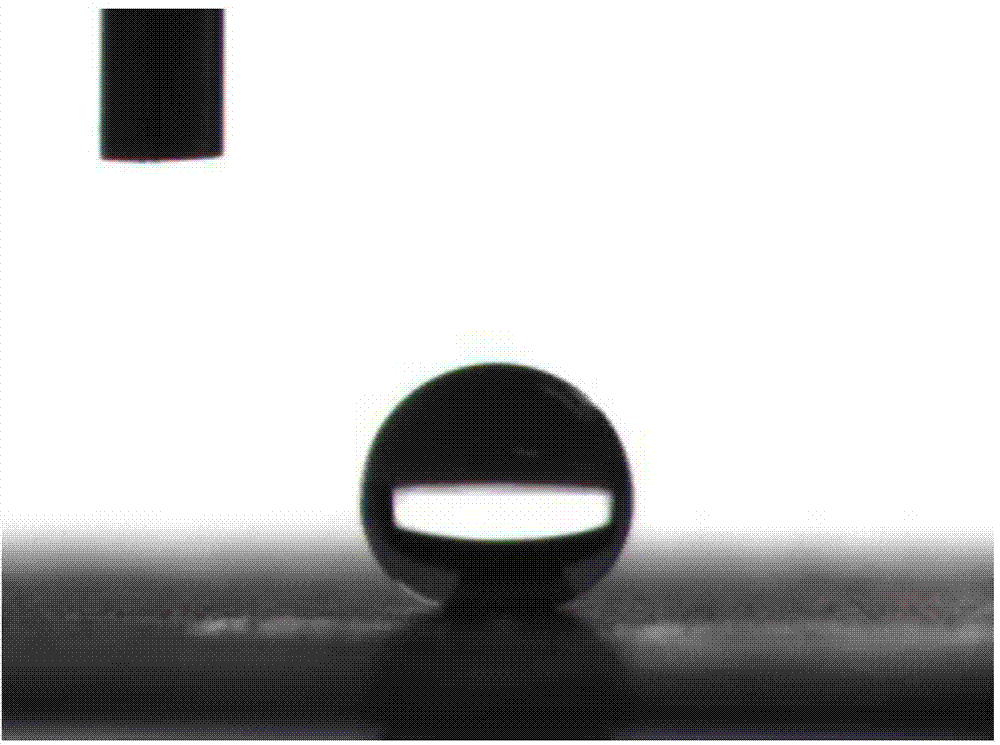

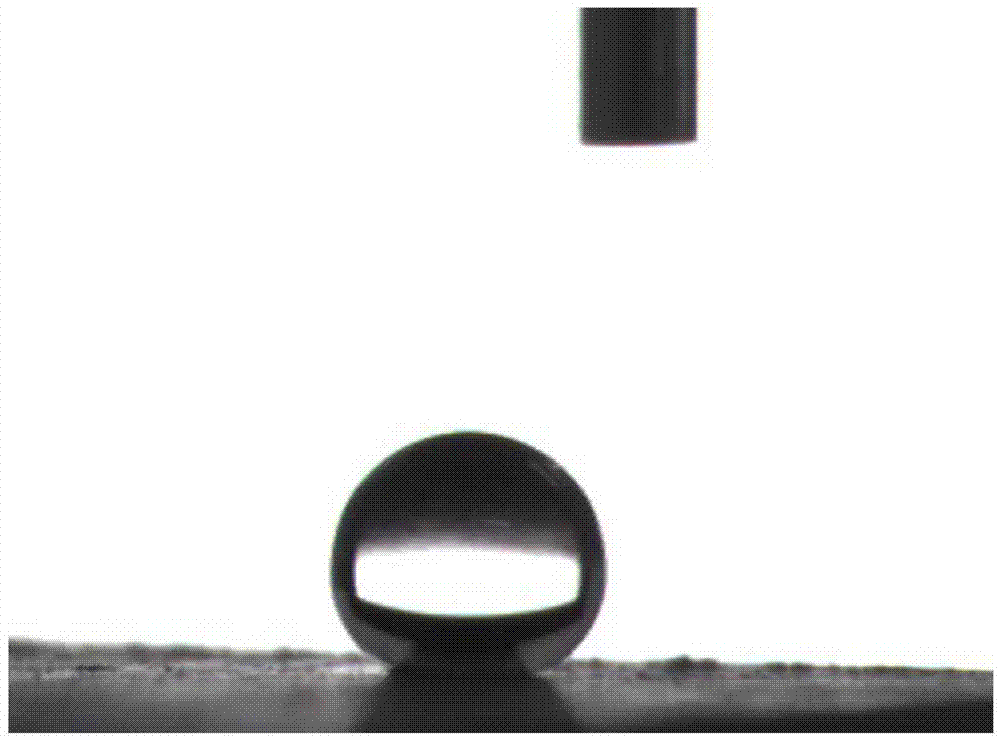

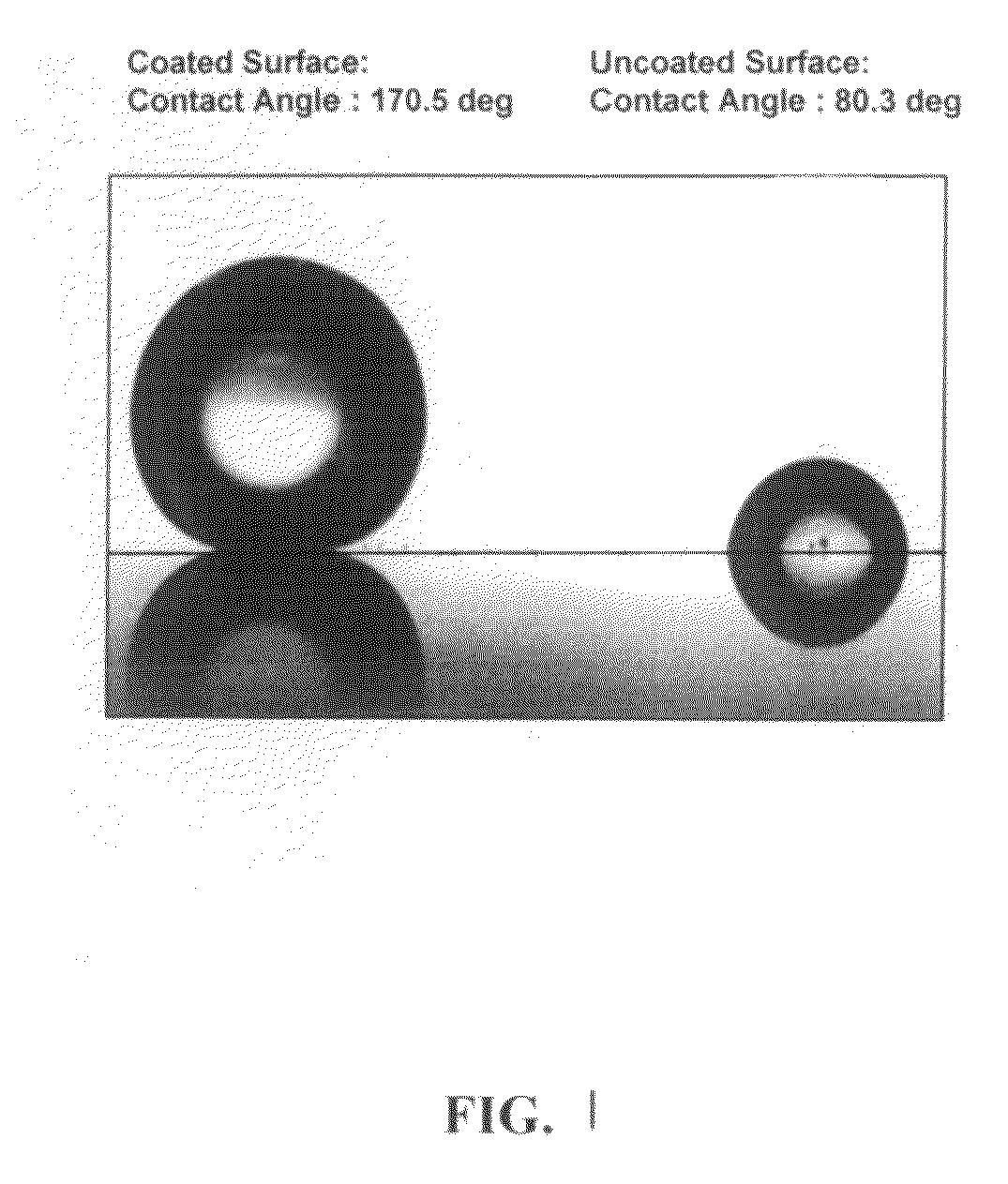

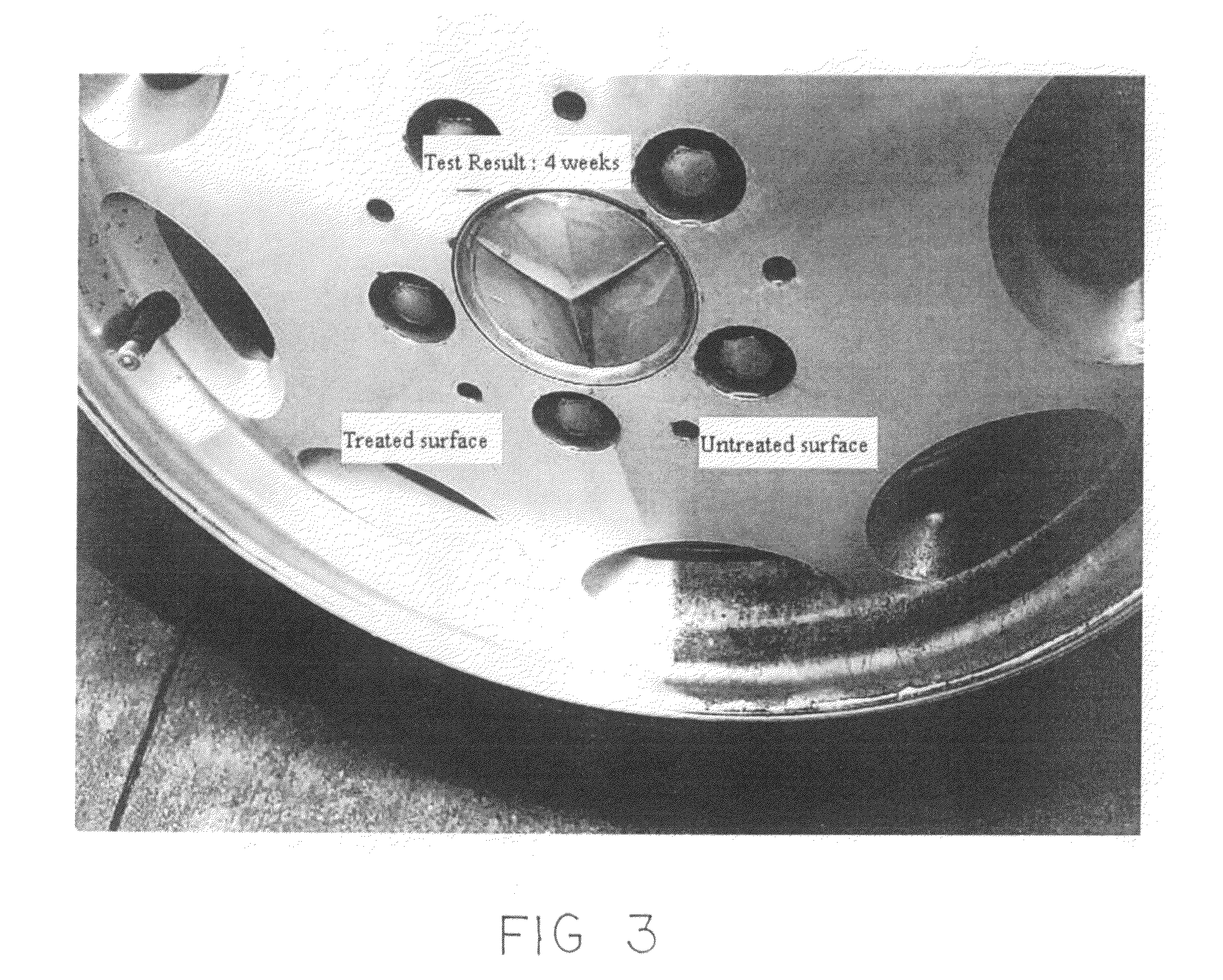

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

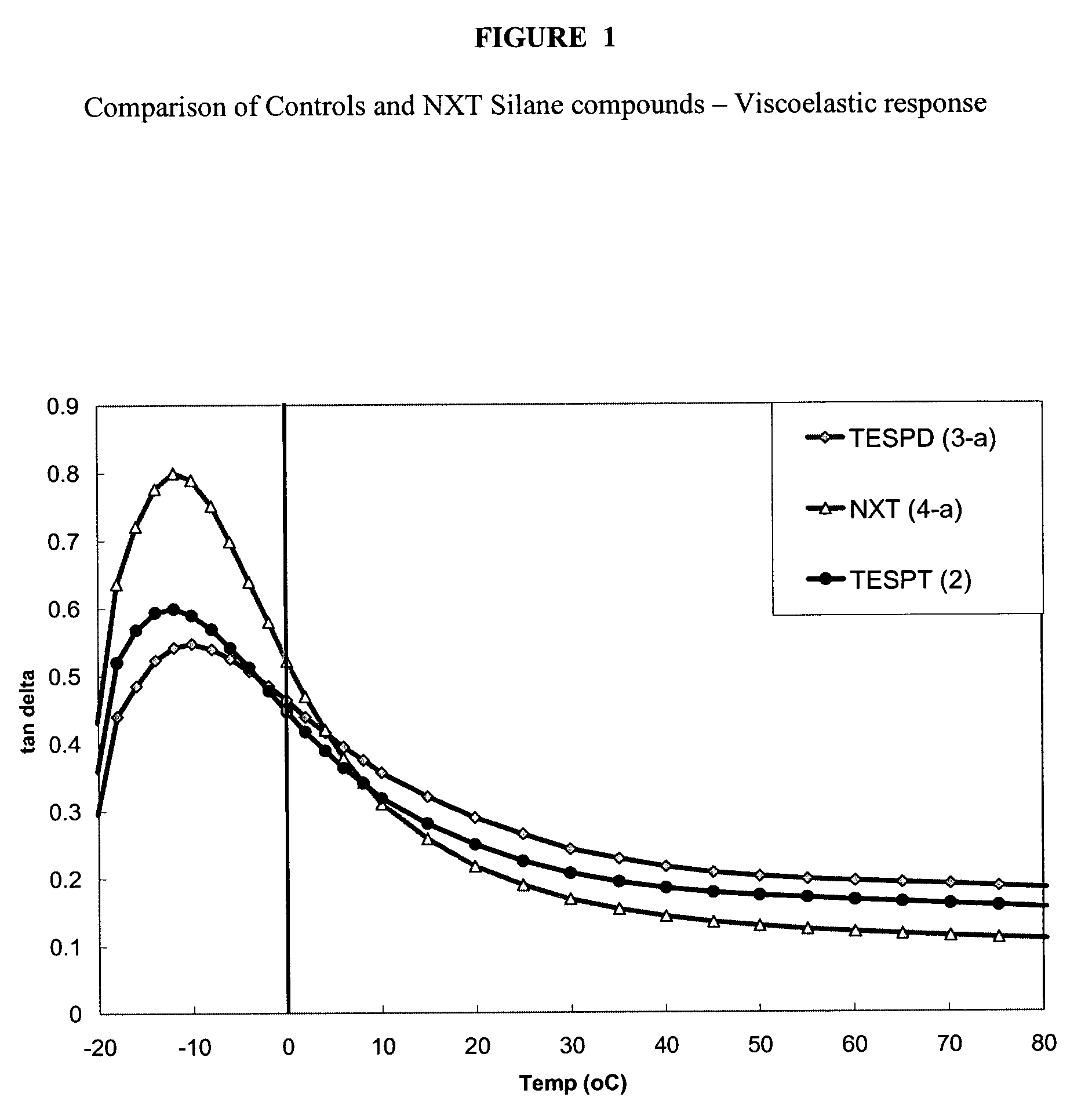

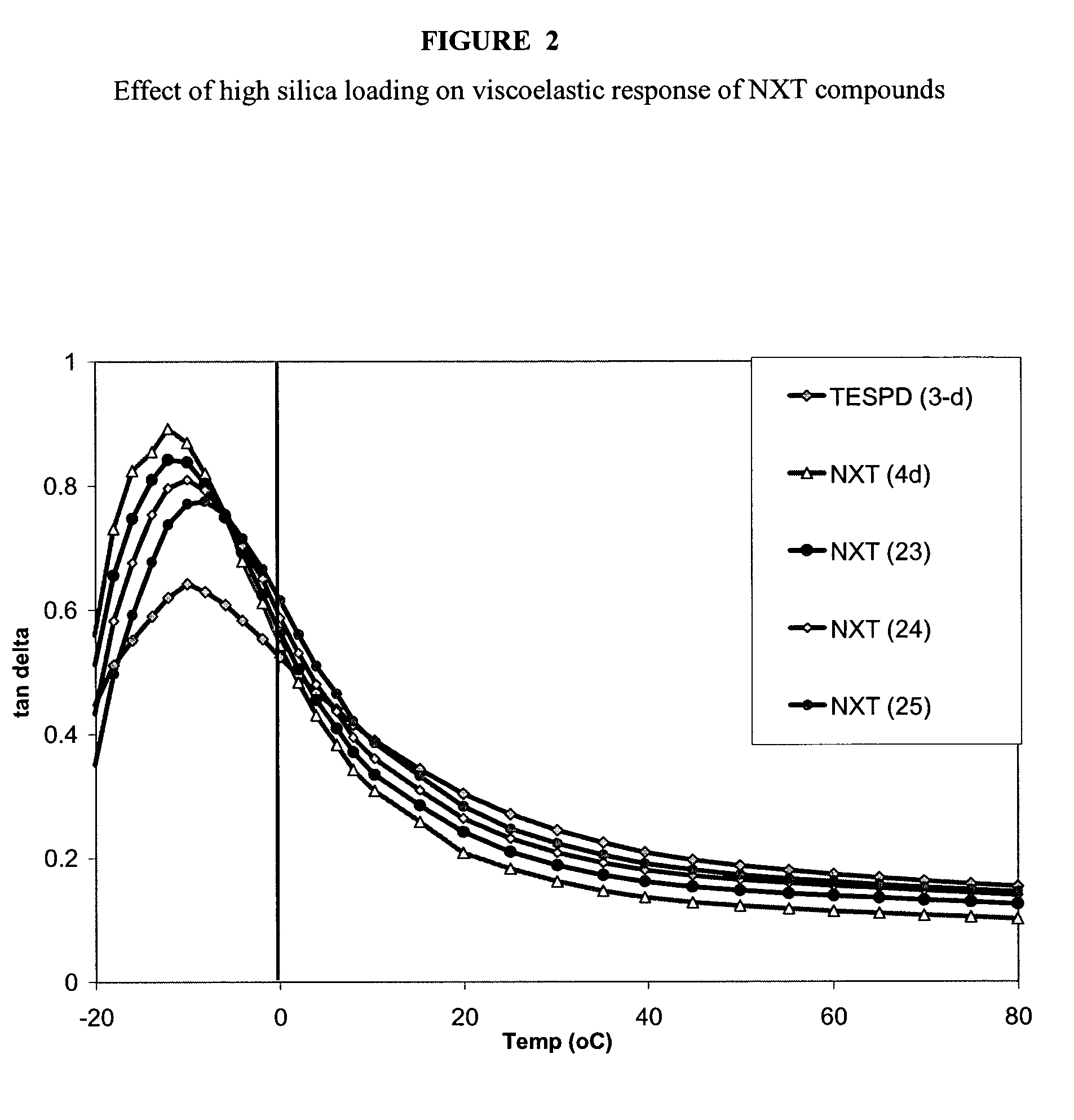

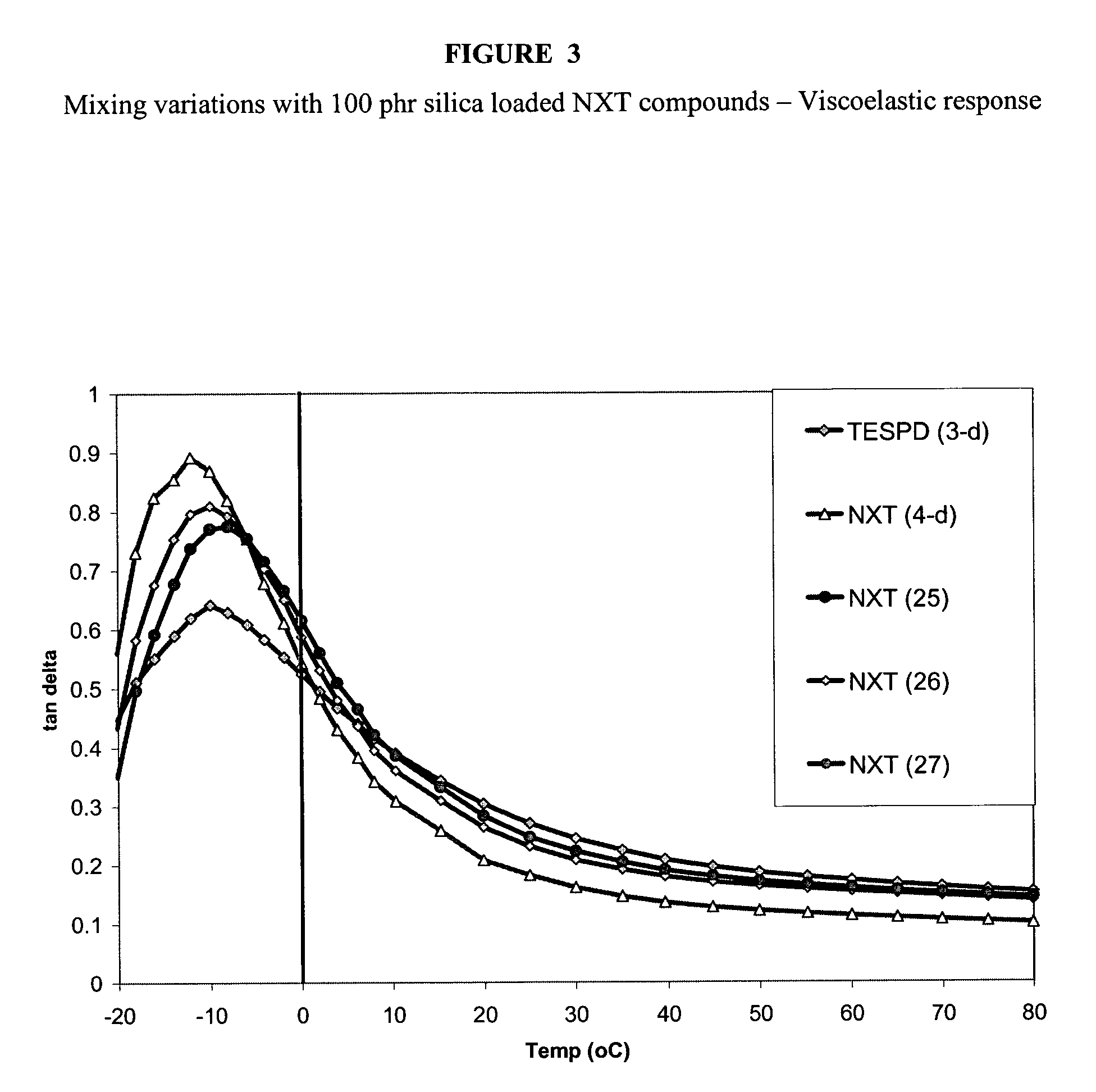

Silica-rubber mixtures having improved hardness

InactiveUS20050277717A1Eliminates and reduces filler network effectReduce hardnessSpecial tyresSilanesOrganic group

A method for increasing the hardness of silica / rubber mixtures is disclosed wherein the method comprises blending with said mixture at least one silane and a hardness-increasing amount of at least one member selected from the group consisting of thixotropic fumed silica; precipitated silica; an MQ resin wherein Q is SiO4 / 2, M is R1R2R3SiO1 / 2, and R1, R2, and R3 are the same or different functional or non-functional organic groups; carbon black; a thermoplastic resin; and a thermosetting resin.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Filterable composite adsorbents

InactiveUS6712974B1Increase profitImprove filtering effectLighting and heating apparatusSolid sorbent liquid separationAlkaline earth metalFiltration

This invention relates to filterable composite adsorbents comprising one or more adsorbent components and one or more filtration components, and methods for preparing and using same. More particularly, this invention pertains to filterable composite adsorbents and filterable composite adsorbent products which are suitable for use in filtration applications, and which comprise one or more microparticulate or colloidal adsorbent components selected from the group consisting of silica gel, fumed silica, neutral clay, alkaline clay, zeolite, solid catalyst, alumina, adsorbent polymer, alkaline earth silicate hydrate, and combinations thereof, which bear the property of adsorption, which are intimately bound to one or more functional filtration components selected from the group consisting of biogenic silica (e.g., diatomite, rice hull ash, sponge spicules), natural glass (e.g., expanded perlite, pumice, expanded pumice, pumicite, expanded obsidian, expanded volcanic ash), buoyant glass, buoyant polymer, cellulose, and combinations thereof, which bear a distinguishing porous and intricate structure and buoyancy suitable for filtration.

Owner:IMERYS USA INC

Hydrophobic self-cleaning coating compositions

InactiveUS20090018249A1Reduce icingInexpensive comparedOther chemical processesSpecial tyresEvaporationSolvent

A hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface forming creating a wet and dry dirt repellent coating on the surface. The coating utilizes hydrophobic nanoparticles of fumed silica and / or titania in a solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. Virtually transparent coating are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. One preferred coating composition utilizing an effective amount of a treated fumed silica in a solvent forms a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The self-cleaning coating composition imparts a degree of hydrophobicity to a surface so that the treated surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher.

Owner:ASHLAND LICENSING & INTPROP LLC

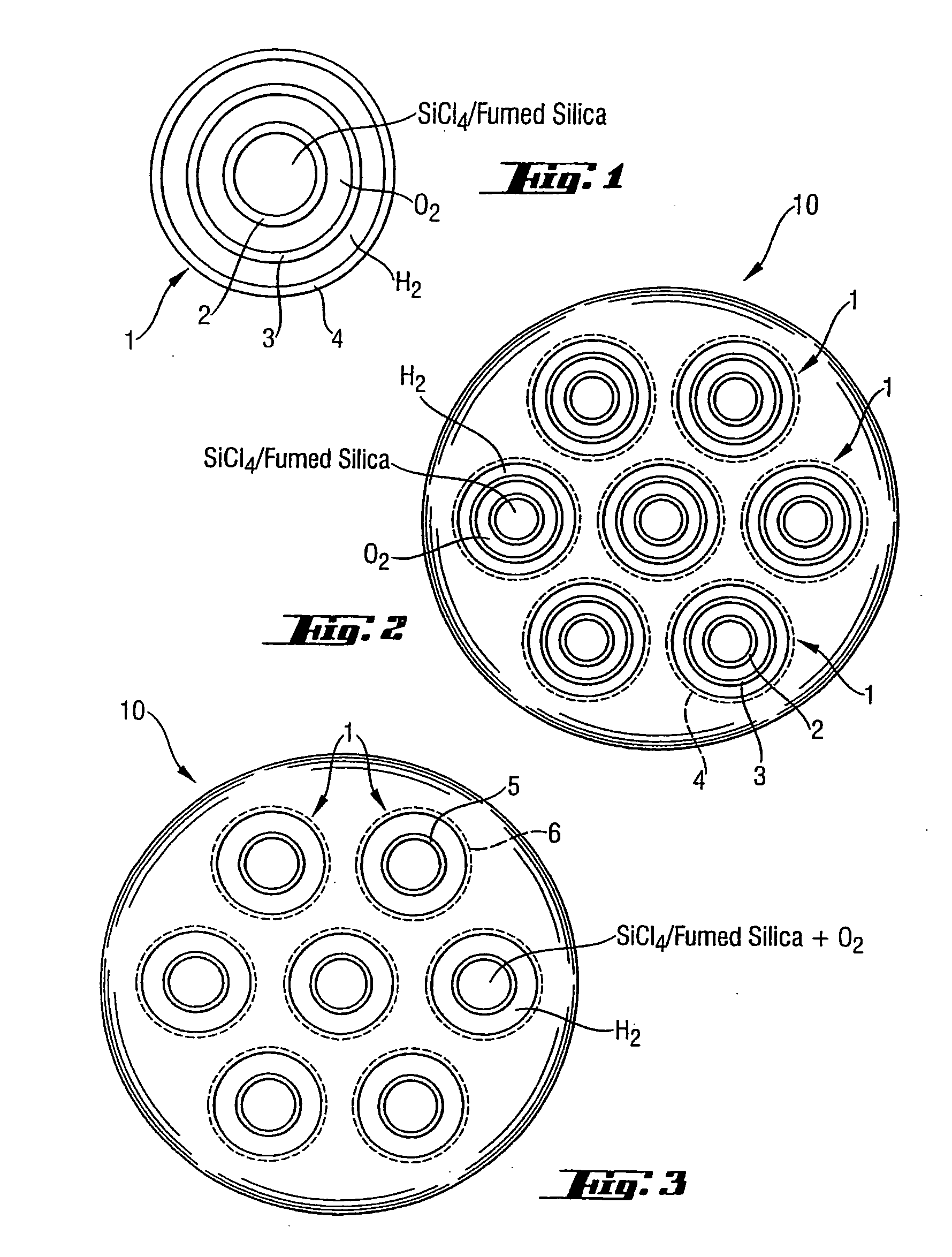

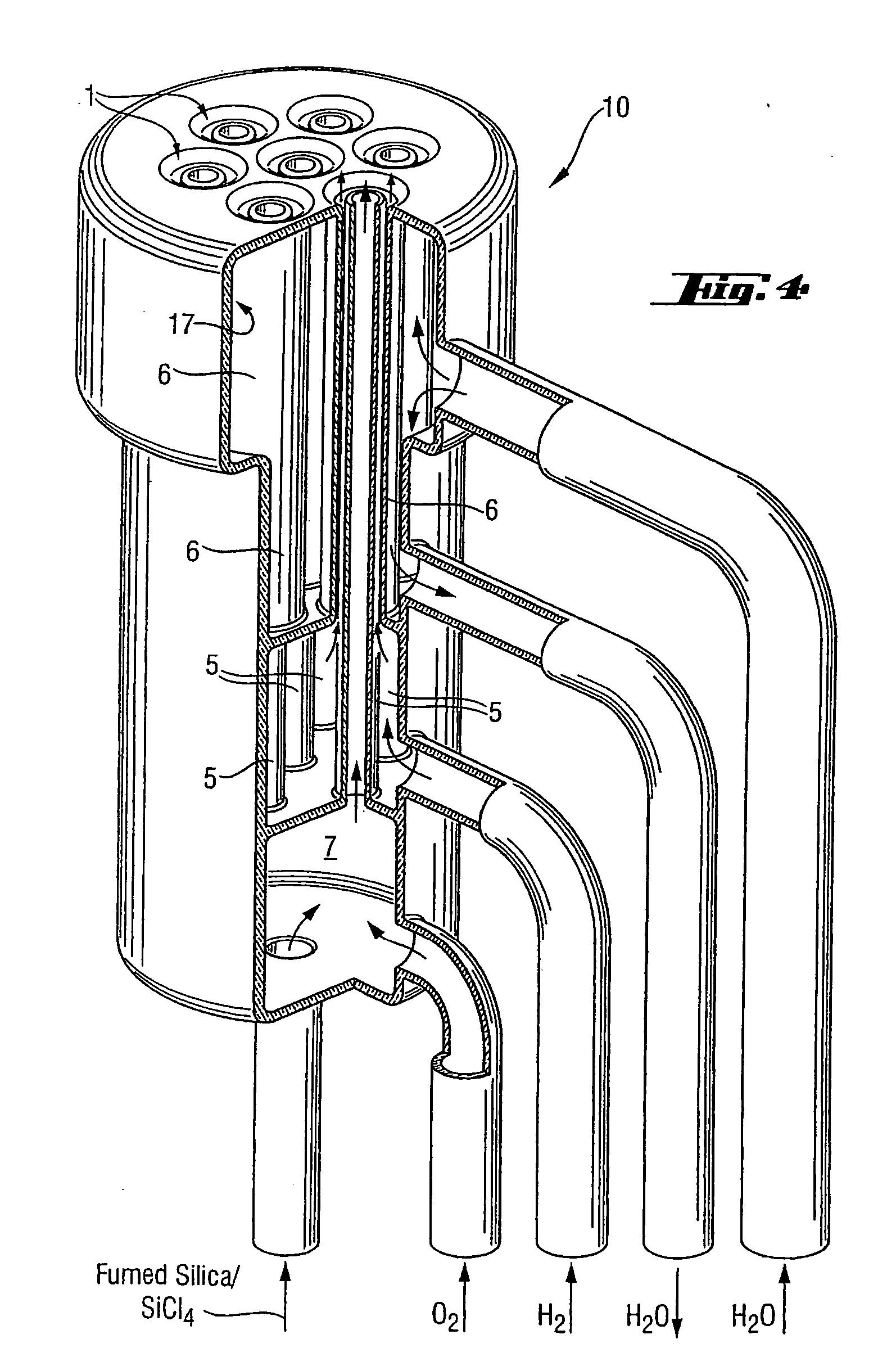

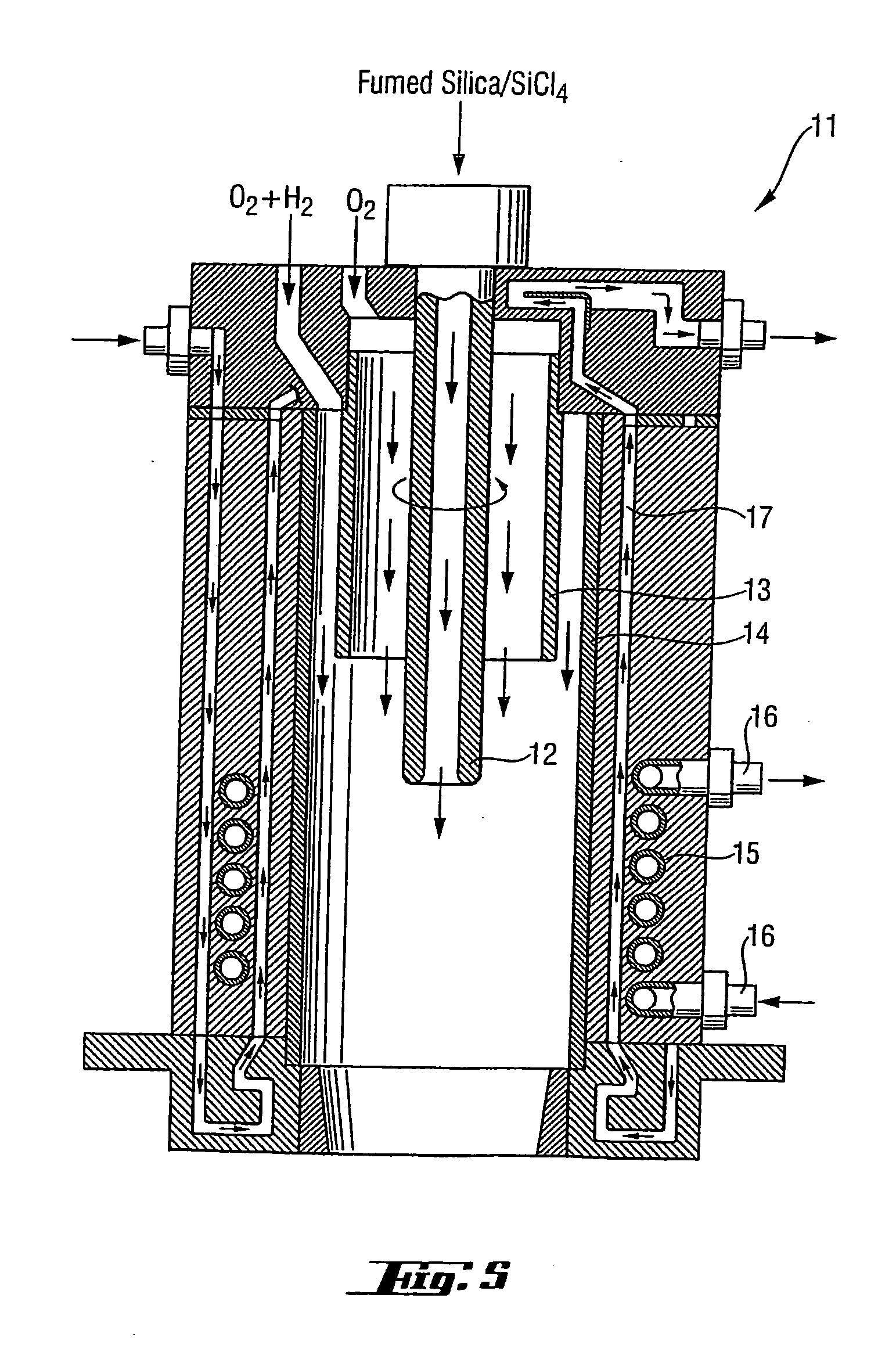

High-purity silica powder, and process and apparatus for producing it

Use of a flame hydrolysis apparatus for preparing fumed silica particles or a plasma torch apparatus for sintering fumed silica particles to fused silica particles is capable of producing highly pure silica with non-silicon metal impurities less than 500 pb, when at least an inner nozzle is constructed of a silicon-containing material having a low level of non-silicon metal impurities. Preferably, all surfaces in the respective apparatus which contact silica are of similar construction. The silica contains a low level of impurities as produced, without requiring further purification.

Owner:WACKER CHEM GMBH

Hydrophobic self-cleaning coating compositions

InactiveUS20080221009A1Not to damageEfficient use ofNon-ionic surface-active compoundsNon-surface-active detergent compositionsEvaporationEngineering

A super hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The super hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or some abrasion resistance not found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the super hydrophobic self-cleaning coating composition result in a clear coating or in some cases a translucent dirt repellant film for coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent. At least one preferred coating composition comprising an effective amount of a treated fumed silica in a solvent resulting in a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

Water based hydrophobic self-cleaning coating compositions

InactiveUS20090064894A1Efficient use ofWater-repelling agents additionSemiconductor/solid-state device manufacturingWater basedHydrophobic silica

A coating composition comprising hydrophobic particles having an average size of between 7 nm and 4,000 nm and a wetting agent for promoting dispersion of the hydrophobic particles in water. The hydrophobic particles may be oxides, such as silica, titania, or zinc oxide. In one embodiment, the hydrophobic particles comprise fumed silica. The coating composition may be brushed, spin coated, or dipped onto a surface. In one embodiment, once the coating composition dries, the coating formed thereby is characterized by a contact angle formed with a water droplet in excess of 165 degrees. A method of making a coating composition comprising providing hydrophobic particles having an average size of between 7 nm and 4,000 nm, mixing a wetting agent with the hydrophobic particles to form a paste, and dispersing the paste in water by mixing to form a mixture.

Owner:VALVOLINE LICENSING & INTPROP LLC

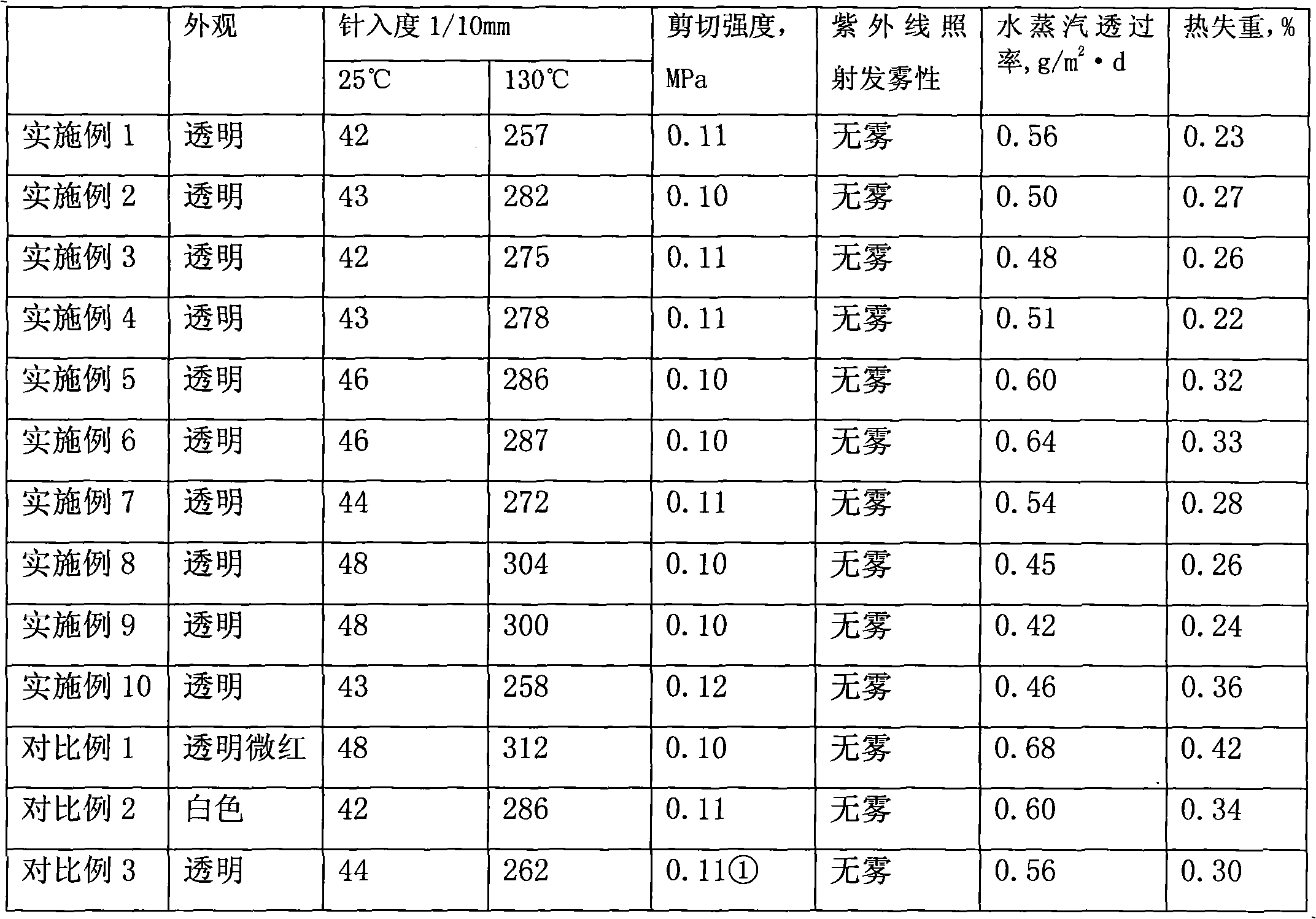

Transparent butyl hot-melt sealant and preparation method thereof

ActiveCN101805569AHigh strengthGood construction performanceNon-macromolecular adhesive additivesOther chemical processesSealantFumed silica

The invention relates to a transparent butyl hot-melt sealant, which is prepared with the following raw materials in parts by weight: 1-20 of butyl rubber, 10-80 of polyisobutylene, 5-30 of plasticizer, 3-10 of tackifier, 3-10 of softener, 0.1-5 of stabilizer, 5-30 of filler and 0.1-5 of adhesion promoting agent. The matching use of the butyl rubber and the polyisobutylene with different molecular weights facilitates the improvement of the strength and workability of the transparent butyl hot-melt sealant. The filler is selected from fumed silica or precipitated silica, which ensures the appearance transparency of the product. Due to the addition of the stabilizer and the strict control of the production process, the appearance transparency and the physical and chemical properties of the product are enhanced. The use of the active group substituted alkoxy silane as a coupling agent improves the adhesion of the product to glass, aluminum and other substrates.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

Cement compositions comprising improved lost circulation materials and methods of use in subterranean formations

The present invention relates to subterranean cementing operations and, more particularly, to cement composition that include improved lost circulation materials, and methods of using such cement compositions in subterranean formations. In certain exemplary embodiments, the improved lost circulation materials include inelastic particles of polyethylene, polystyrene and / or polypropylene. Optionally, the cement compositions also may include additives such as fly ash, a surfactant, a dispersant, a fluid loss control additive, a conventional lost circulation material, an generator, a retarder, a salt, a mica, fiber, a formation-conditioning agent, fumed silica, bentonite, expanding additives, microspheres, weighting materials, or a defoamer.

Owner:HALLIBURTON ENERGY SERVICES INC

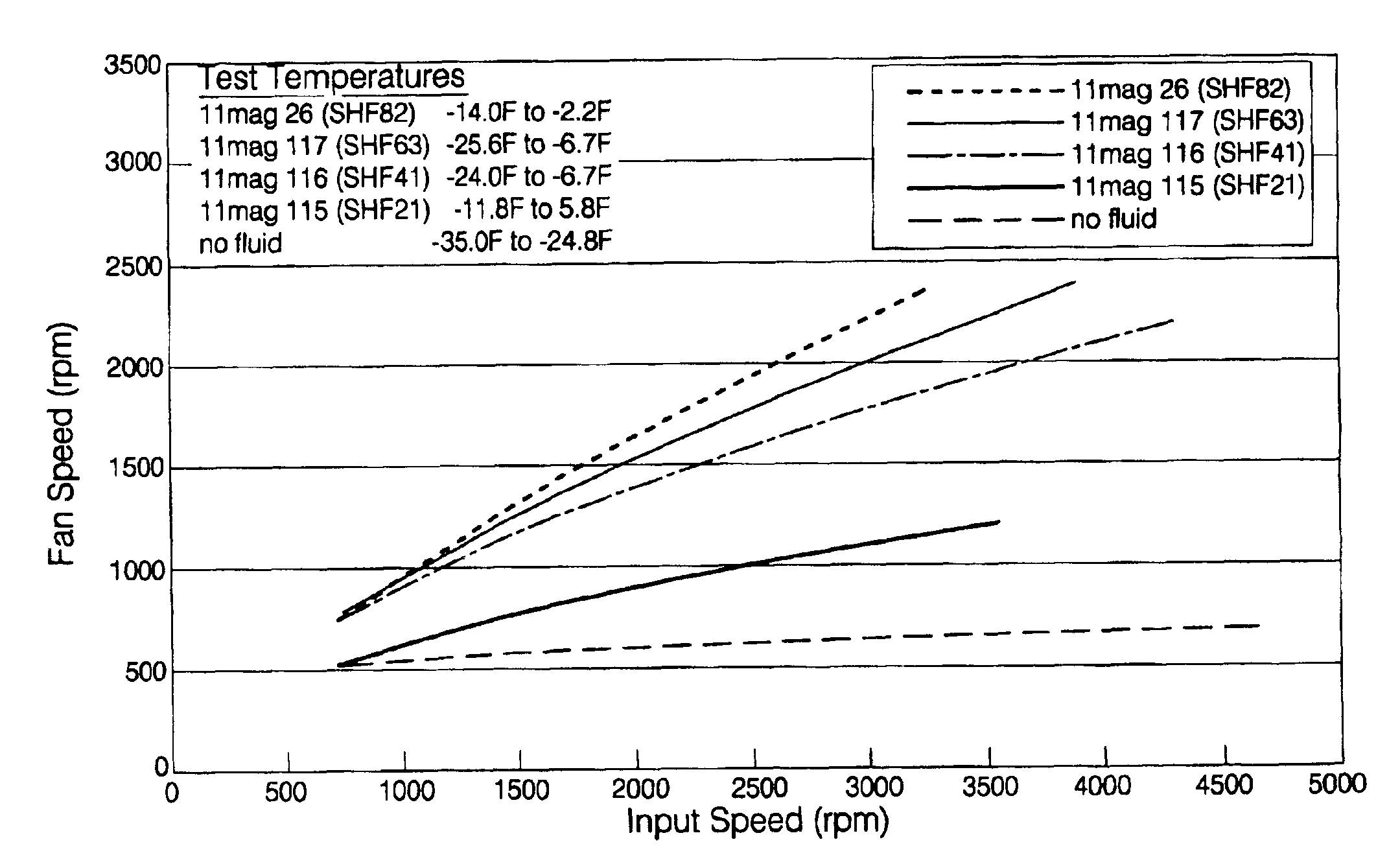

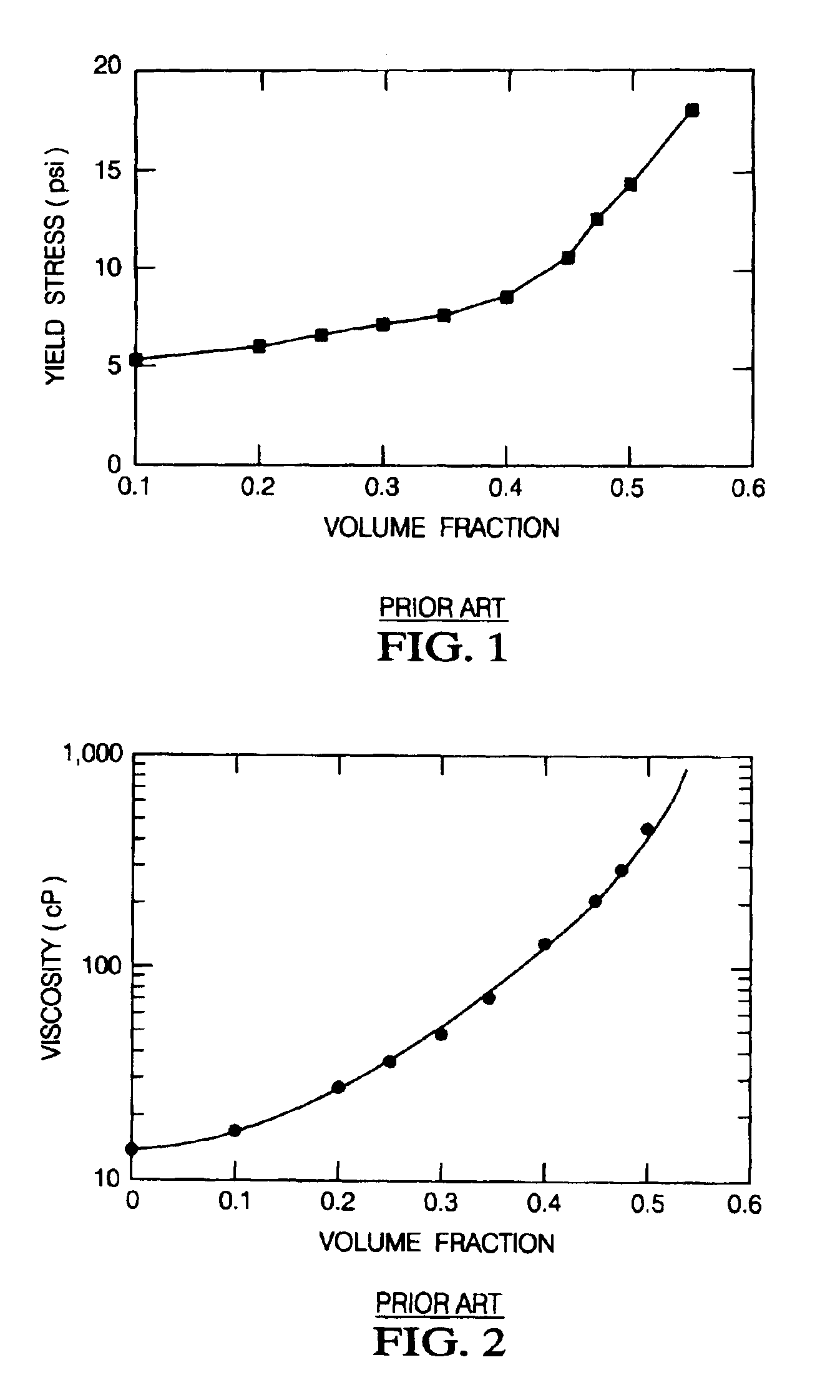

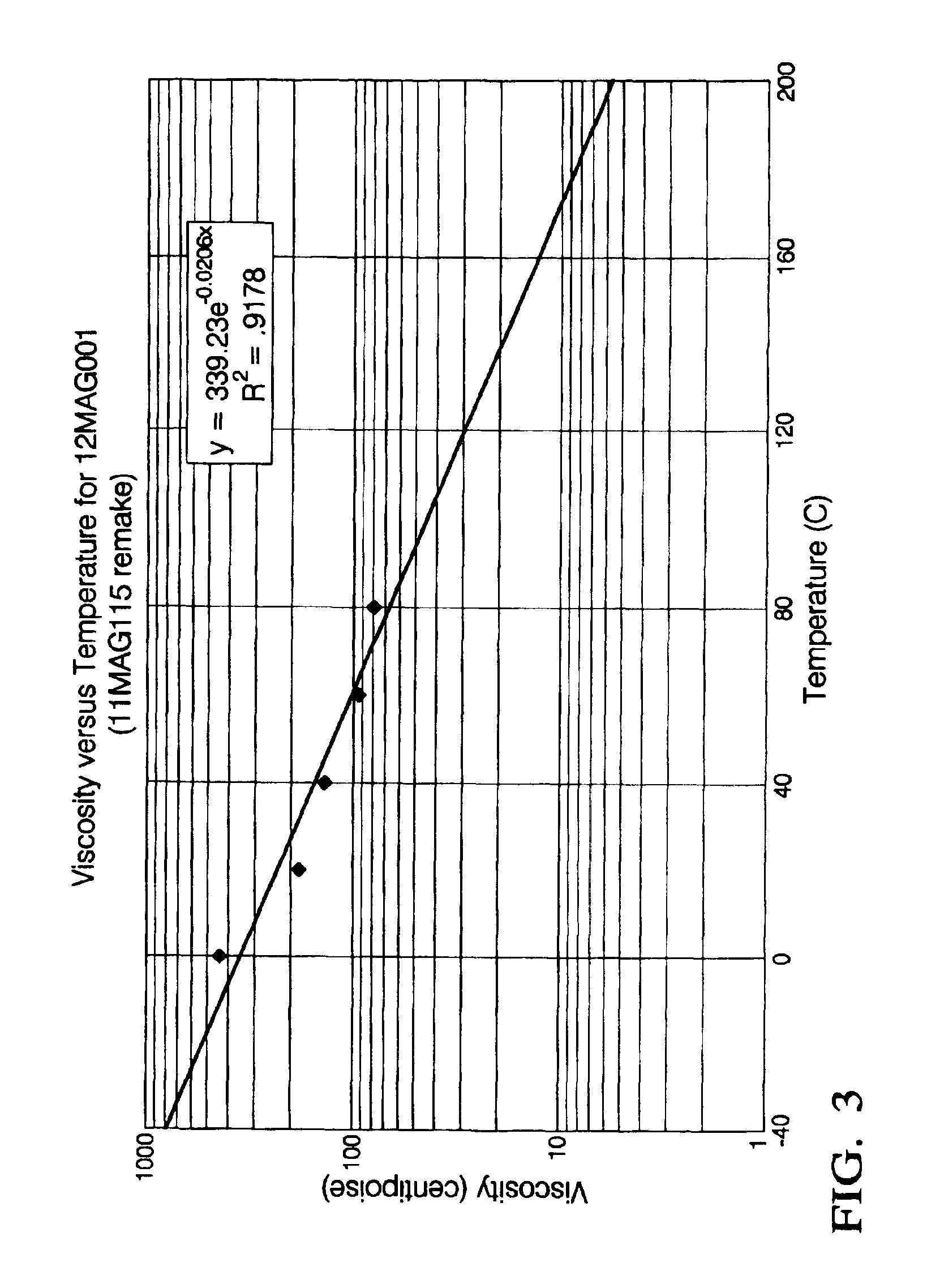

Magnetorheological fluids

InactiveUS6932917B2Increased durabilityLow viscosityOther chemical processesMagnetic liquidsMagnetorheological fluidCentrifugal force

One embodiment of the invention includes an MR fluid of improved durability. The MR fluid is particularly useful in devices that subject the fluid to substantial centrifugal forces, such as large fan clutches. A particular embodiment includes a magnetorheological fluid including 10 to 14 wt % of a hydrocarbon-based liquid, 86 to 90 wt % of bimodal magnetizable particles, and 0.05 to 0.5 wt % fumed silica.

Owner:GM GLOBAL TECH OPERATIONS LLC

Super-hydrophobic and oleophobic composite coating and preparation method thereof

InactiveCN104745045AImprove hydrophobicity and oleophobicityHydrophobic and oleophobicPretreated surfacesEpoxy resin coatingsGas phaseSolvent

The invention discloses a super-hydrophobic and oleophobic composite coating which comprises a super-hydrophobic and oleophobic primer coat layer and a super-hydrophobic and oleophobic finishing coat layer. The coating is characterized in that the super-hydrophobic and oleophobic finishing coat layer is located on the super-hydrophobic and oleophobic primer coat layer; the super-hydrophobic and oleophobic primer coat layer is coated by a super-hydrophobic and oleophobic primer coat which is a composition containing epoxy resin, an auxiliary A, extinction powder and a solvent; the super-hydrophobic and oleophobic finishing coat layer is coated by a super-hydrophobic and oleophobic finishing coat which is a composition containing fumed silica, an auxiliary B, an auxiliary C, a mixed solution A and a mixed solution B. Compared with the prior art, the super-hydrophobic and oleophobic composite coating disclosed by the invention not only has a super-hydrophobic performance, but also can resist greasy dirt and has a super-oleophobic performance as well as good wear resistance and stability; the preparation process is simple, and realization of industrialized production is facilitated.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

Hydrophobic coating compositions for drag reduction

Owner:VGP IPCO LLC

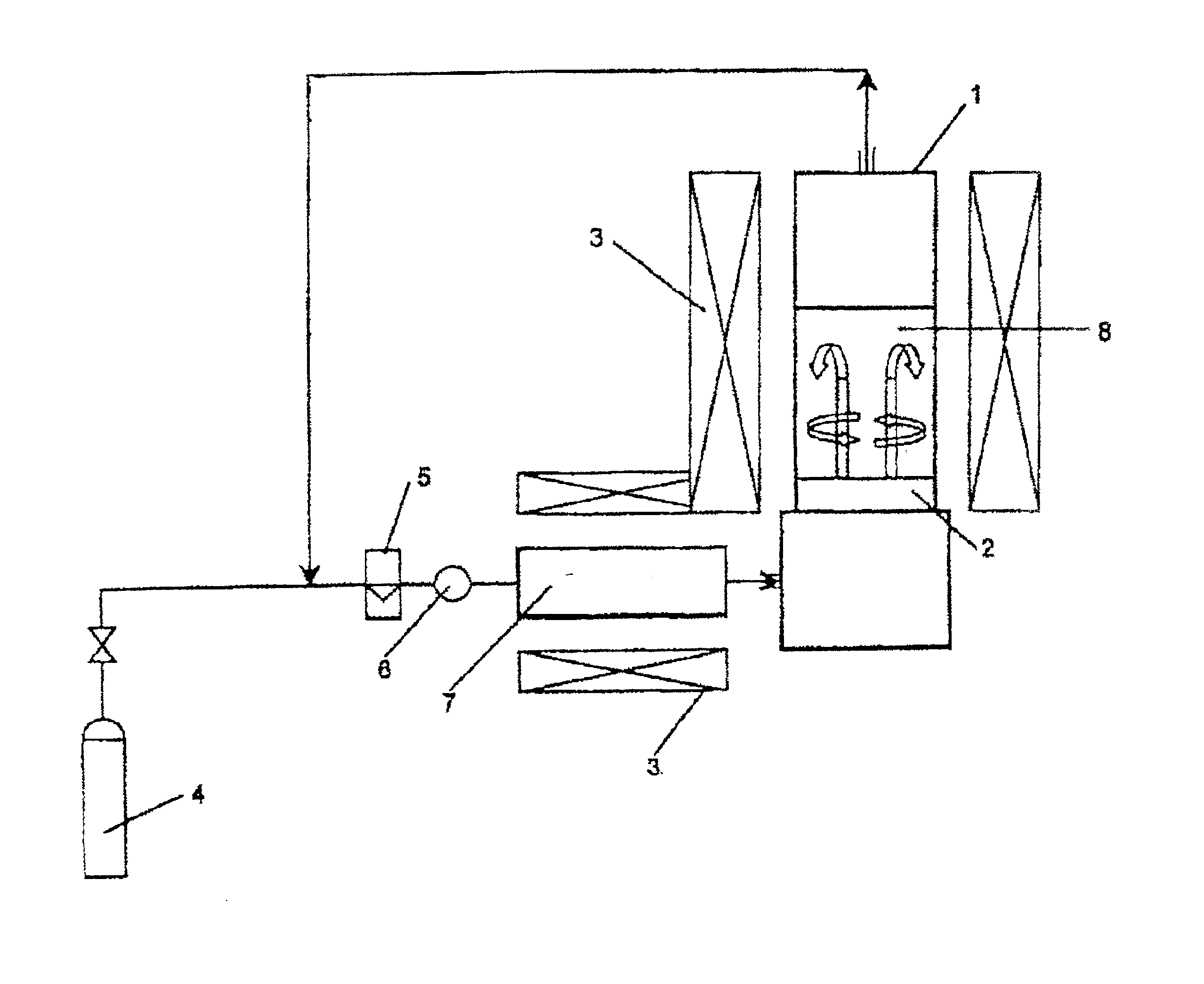

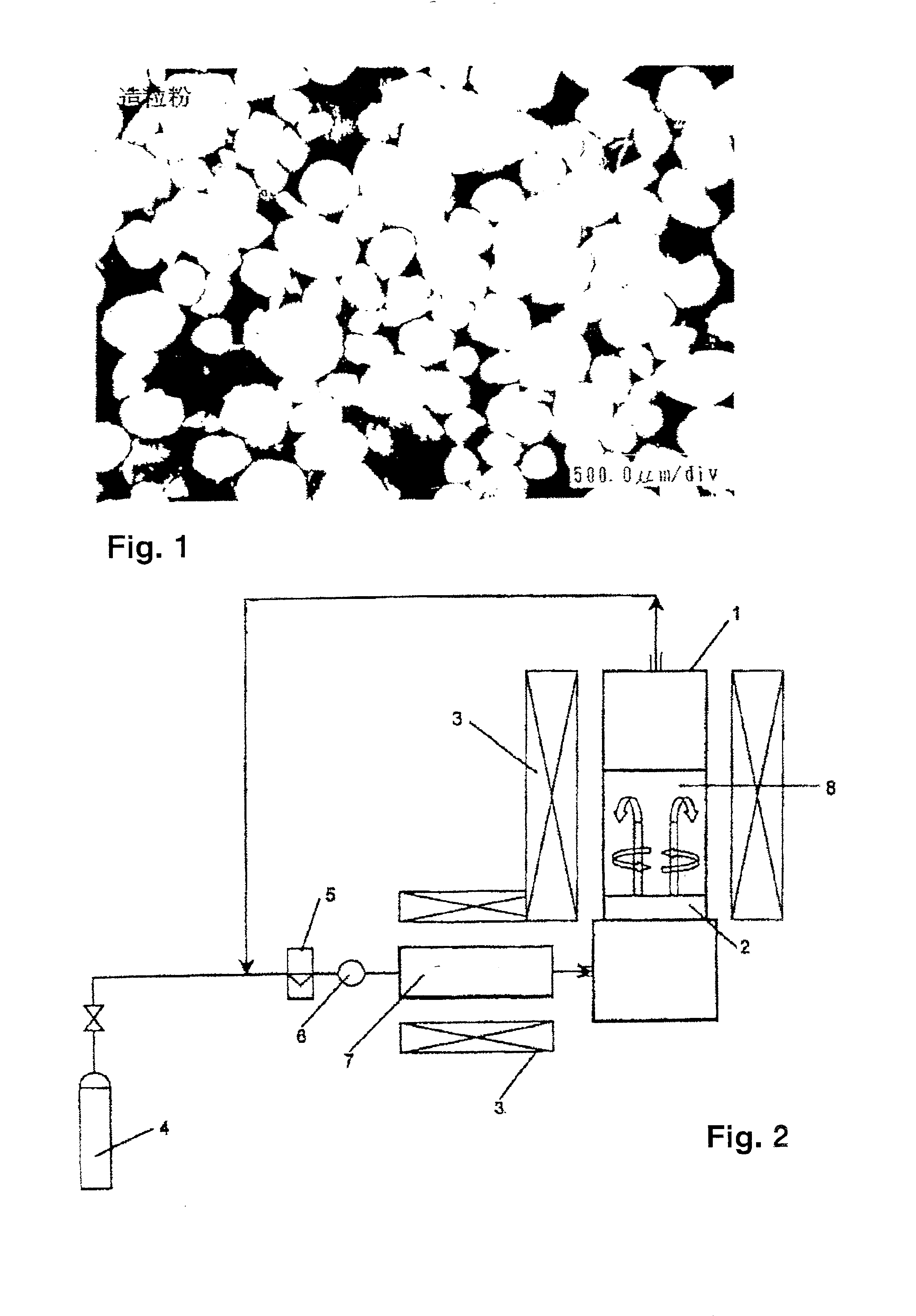

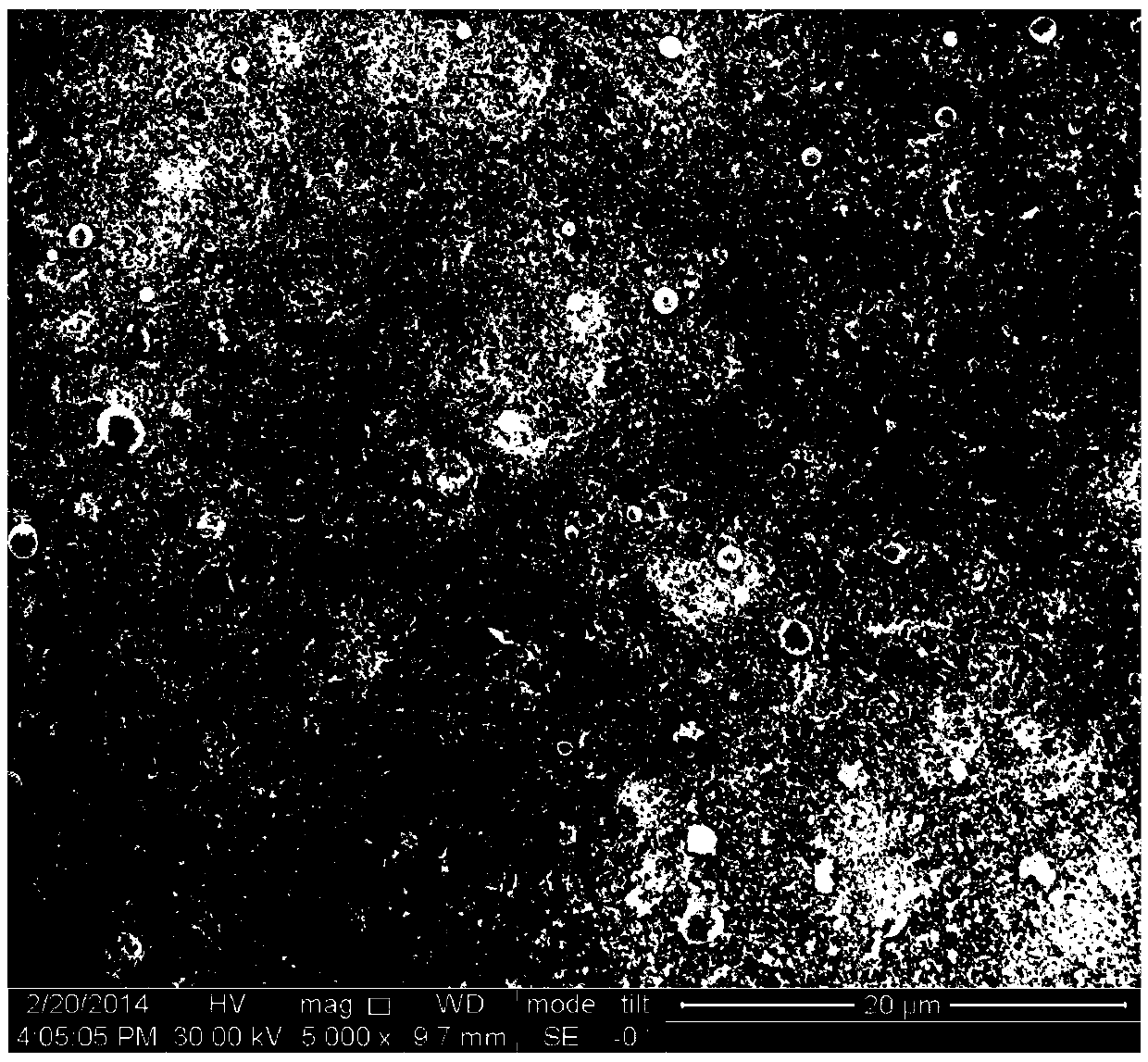

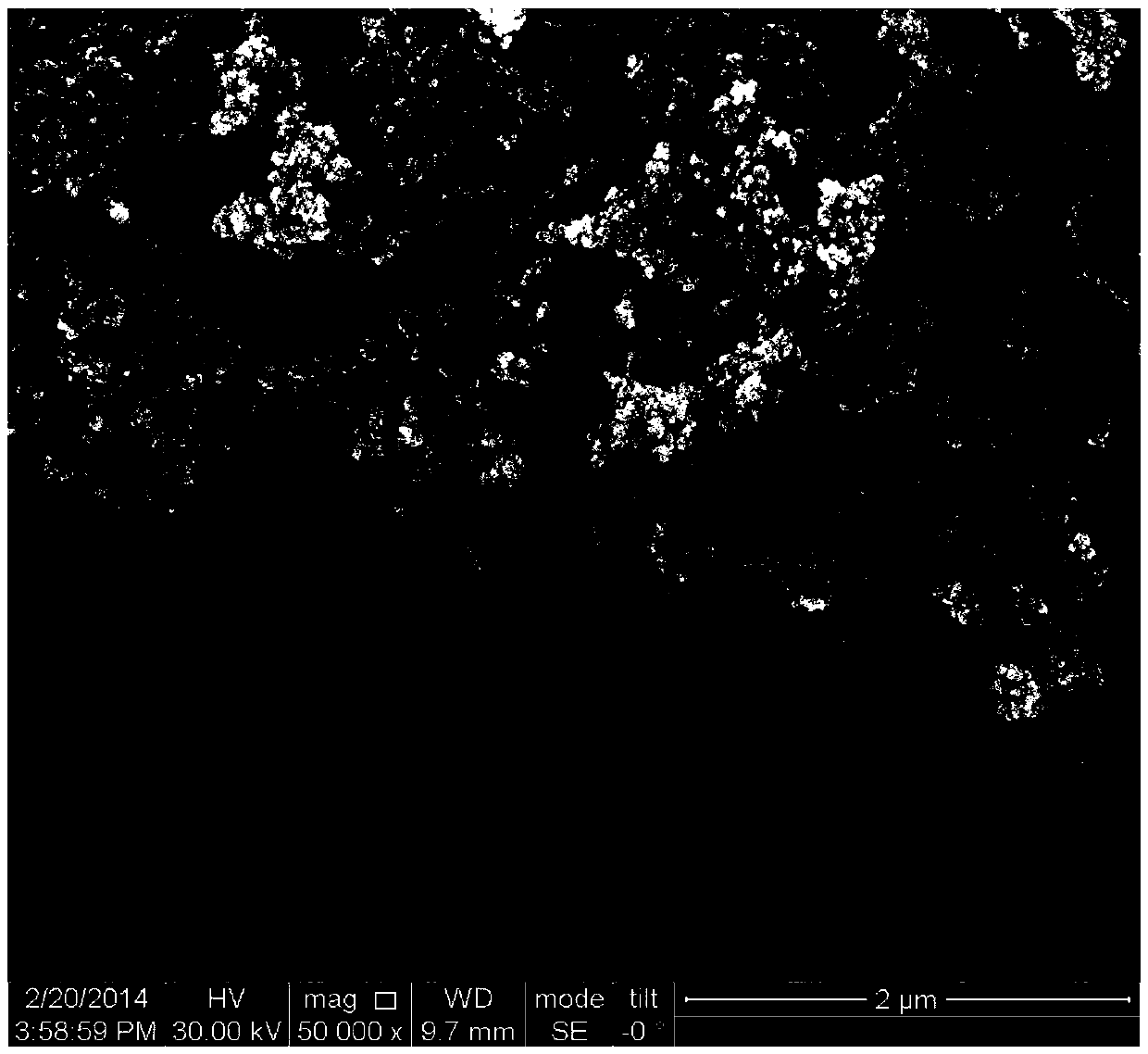

Porous silica granule, method for producing the same, and method for producing synthetic quartz glass powder using the porous silica granule

InactiveUS6849242B1Minimizes pore diameterHigh bulk densitySilicaGlass blowing apparatusMean diameterSlurry

The granule consists of individual granules approximately spherical in shape, having a pore volume of 0.5 cm3, a mean diameter of pores of 50 nm or less, a specific surface area of 100 m2 / g or less, and a bulk density of 0.7 g / cm3 or higher. It is produced by dispersing a fumed silica obtained by hydrolysis of a silicon compound into pure water to obtain a slurry, and drying the slurry. The granule is used for producing high purity synthetic quartz glass powder. The method further comprises: a first heat treatment under an oxygen-containing atmosphere, a second heat treatment in a temperature range of from 600 to 1100° C., and a third heat treatment in a temperature range of from 1100 to 1300° C. under an atmosphere containing hydrogen chloride; and a step of densification comprising calcining the product at a temperature not higher than 1500° C. under vacuum or in an atmosphere of gaseous hydrogen or gaseous helium. To calcine the powder without causing fusion adhesion of the particles, bubbling fluidization of said porous silica granule is conducted by supplying gaseous helium and calcining thereof in a temperature range of from 1000 to 1600° C.

Owner:HERAEUS QUARZGLAS +1

Transparent super-amphiphobic surface layer and layer-by-layer in-situ spraying reaction preparation method

ActiveCN105499092AImprove bindingIncreased superamphiphobiaSpecial surfacesEpoxy resin coatingsGas phaseSolvent

The invention relates to a transparent super-amphiphobic surface layer and a layer-by-layer in-situ spraying reaction preparation method. The method comprises the steps of sequentially spraying priming paint solutions and finishing paint solutions on a base body in a layer-by-layer in-situ mode through a spraying gun and by adopting the same spraying technology, sequentially spraying acetic acid water solutions of 1 wt.% and fluorine-silicane solutions of 0.1-2 wt.%, carrying out curing at normal temperature and then obtaining a transparent super-amphiphobic surface. The priming paint solutions are obtained by adding hydrophobic transparent resin and corresponding curing agents into soluble solvents and then dispersing the mixtures ultrasonically until the resin is completely dissolved; the finishing paint solutions are obtained by adding hydrophilic fumed silica into ethyl alcohol and forming solutions ultrasonically. According to the invention, the preparation technology for needed coatings is simple, the spraying technology is easy and convenient to operate, coatings are super-hydrophobic, super-oleophobic and highly transparent, and the application prospect is wide in the fields of solar panels, glasses and automobile windshield glass.

Owner:SOUTHEAST UNIV

Nano composite photocatalytic coating

InactiveUS20070000407A1Good anti-aging performanceNot perishableBiocideSolid waste managementAir cycleFungal microorganisms

A photocatalytic coating composition and method of coating articles, the composition containing solvents for rapid evaporation at room temperature, polyalkylphenylsiloxane, xylene, nano densified hydrophilic fumed silica, nanostructured composite photocatalyst powder and nano inorganic anti-bacteria powder. The coating may be applied by conventional coating methods to organic or inorganic structured surfaces where photocatalytic activity is desired, such as in a forced air-circulating environment. Once applied, the coating quickly dries to leave an adherent, flexible, durable, and long-lasting photocatalytic coating having a large surface area and exhibiting high surface activity against pathogens and pollutants such as bacteria, viruses, mold, fungi, and volatile organic compounds.

Owner:YORK INT CORP

Polishing composition and polishing method

InactiveUS20050205837A1Suitable for useOther chemical processesDecorative surface effectsColloidal silicaTetramethylammonium hydroxide

A polishing composition includes silicon dioxide, an alkaline compound, an anionic surfactant, and water. The silicon dioxide is, for example, colloidal silica, fumed silica, or precipitated silica. The alkaline compound is, for example, potassium hydroxide, sodium hydroxide, ammonia, tetramethylammonium hydroxide, piperazine anhydride, or piperazine hexahydrate. The anionic surfactant is at least one selected from a sulfonic acid surfactant, a carboxylic acid surfactant, and a sulfuric acid ester surfactant. The polishing composition can be suitably used in applications for polishing a silicon wafer.

Owner:FUJIMI INCORPORATED

Inkjet recording sheet

InactiveUS20020176970A1Improve abilitiesGood ink absorptionCoatingsThermographyPolyvinyl alcoholAcyl group

Disclosed is an inkjet recording sheet having a colorant-receiving layer on the surface of its support, in which the colorant-receiving layer contains at least one of compounds represented by the following general formula (1) and compounds represented by the following general formula (2), and contains a vapor-phase-process silica, a polyvinyl alcohol, a boron compound, and a mordant. In the formulae, R represents a saturated hydrocarbon group having from 1 to 12 carbon atoms, an unsaturated hydrocarbon group having from 1 to 12 carbon atoms, a phenyl group, or an acyl group, and n indicates an integer of 1 to 3. <paragraph lvl="0"><in-line-formula>RO(CH2CH2O)nH (1) < / in-line-formula><paragraph lvl="0"><in-line-formula>RO(CH2CH(CH3)O)nH (2) < / in-line-formula>

Owner:FUJIFILM HLDG CORP +1

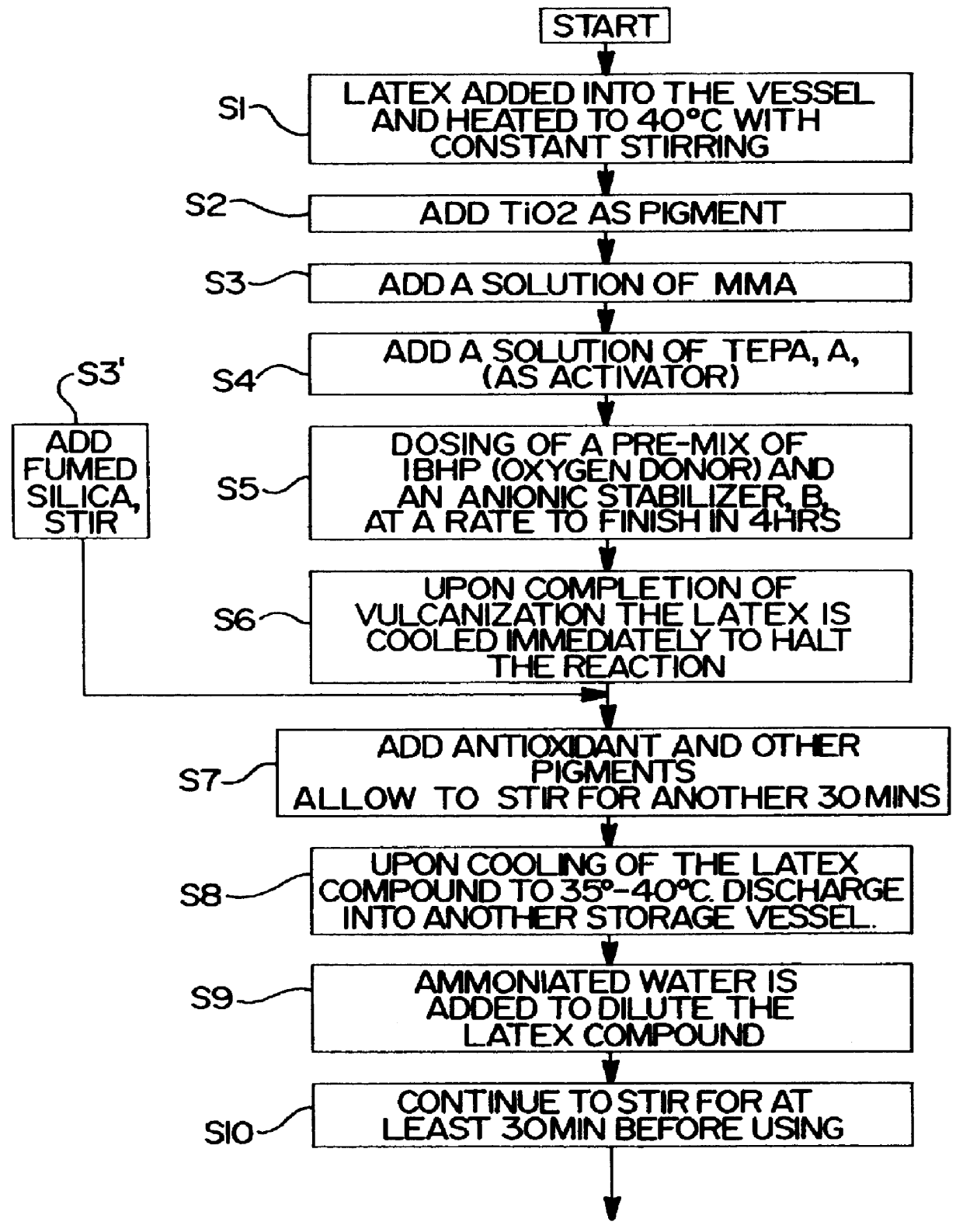

Thin-walled natural rubber latex material substantially free of sulfur and nitrosamines

InactiveUS6051320AEfficient processingEasy to useLayered productsGlovesMicrocrystalline waxGas phase

A thin walled natural rubber latex material is disclosed suitable for forming thin walled products including gloves, dental dams and shields, catheter tubing, penrose surgical drains, finger cots, coverings for body parts, and the like. The thin walled material is formed from a latex emulsion containing natural rubber, sulphur-free, oxygen-donating curing agents, and a strength enhancing agent which may be an inorganic substance such as fumed silica and / or an organic substance such as monomers and polymers of families of acrylics and esters. The emulsion also preferably includes microcrystaline wax as an oxygen barrier, and the material is also provided with a heat resistant and water resistant coating which blocks transfer of latex proteins from the material and enhances slip of the material.

Owner:HAU HO TEON +1

Inorganic Coagulation Accelerators for Individuals taking Platelet Blockers or Anticoagulants

InactiveUS20090047366A1Good coagulationAccelerate blood clottingBiocideInorganic non-active ingredientsMolecular sieveMontmorillonite

The present invention is a method to accelerate the coagulation of blood through the application of inorganic materials to the wound of a patient on anticoagulant or platelet blocker therapy. The method comprises contacting such wounds with a substance selected from the group consisting of zeolitic molecular sieves and non-zeolitic molecular sieves, diatomaceous earth, glass powder or fibers, precipitated or fumed silica, kaolin and montmorillonite clays and Ca exchanged permutites.

Owner:HONEYWELL INT INC

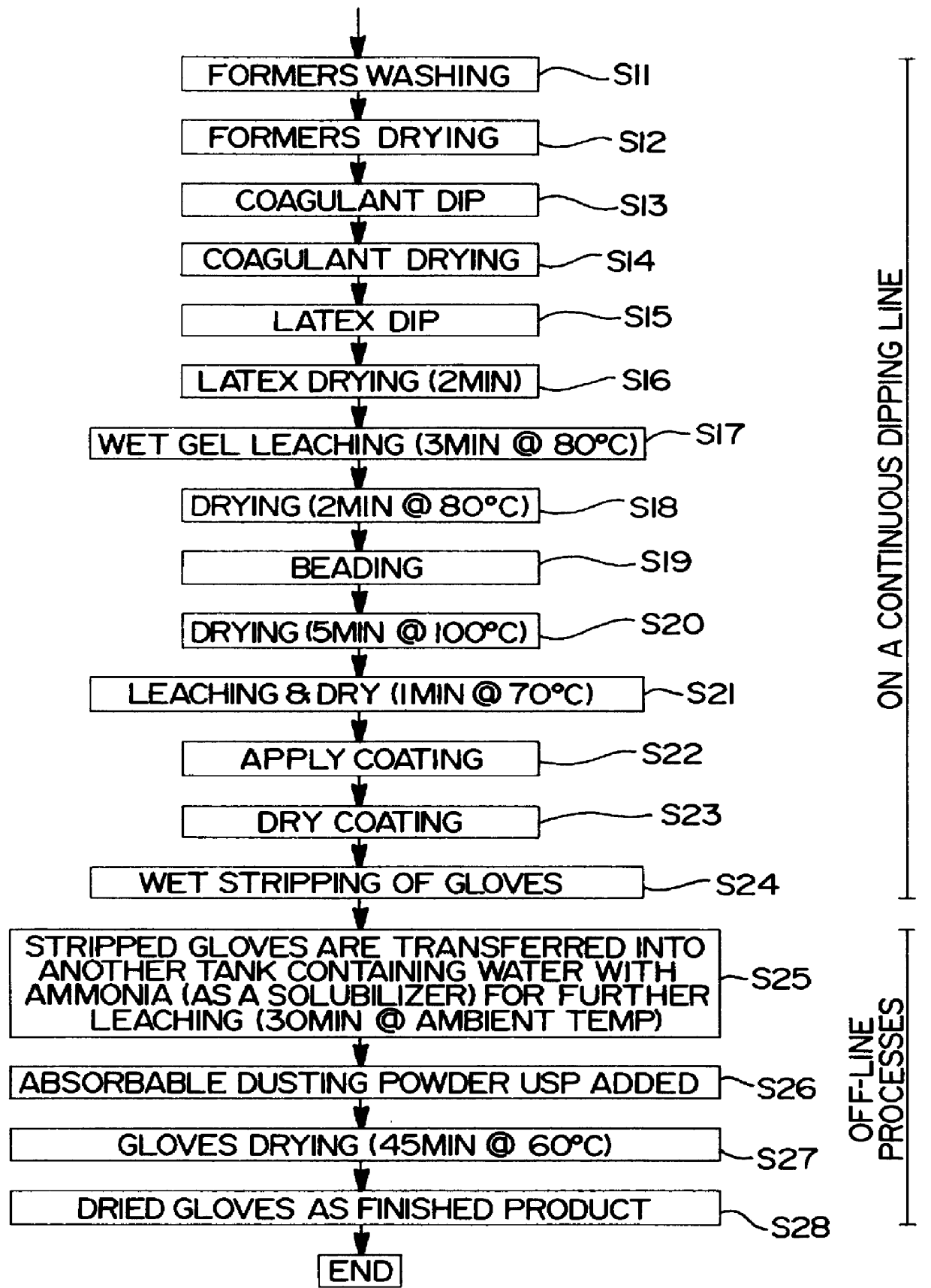

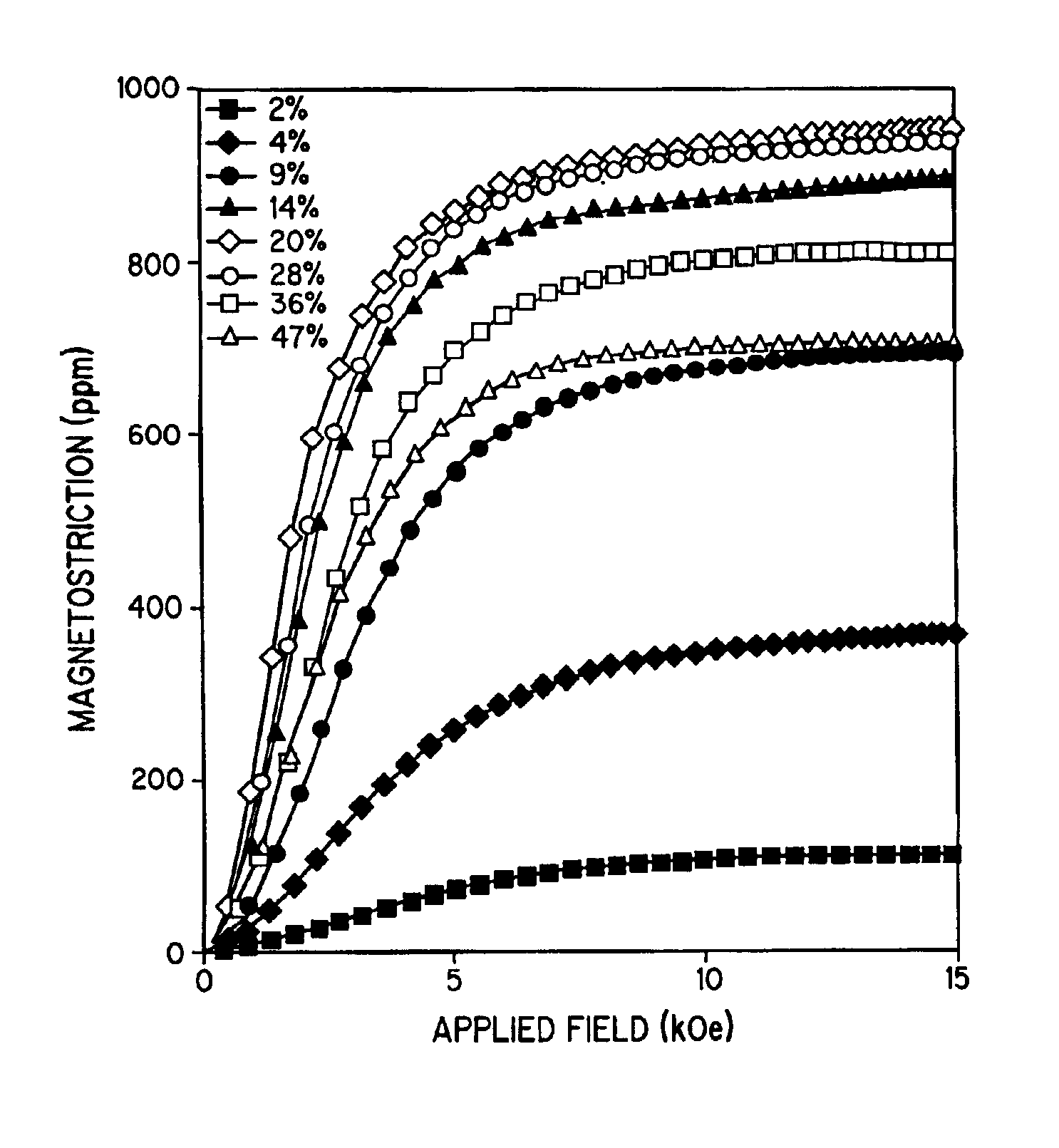

Composites with large magnetostriction

InactiveUS6849195B2Inorganic material magnetismMagnetostrictive material selectionResin matrixSilicon dioxide

A magnetostrictive composite having large magnetostriction by virtue of 2-50 vol. % magnetostrictive particles dispersed throughout a resin matrix formed from a thermosetting resin, an amine curing agent, fumed silica and a flexibilizing agent, wherein the magnetostrictive particles are aligned in the direction of their magnetic easy axes by the presence of a magnetic field prior to or during curing of the resin matrix. In an exemplary embodiment, an epoxy-Terfenol composite is formed by mixing an epoxy resin, fumed silica, a cycloaliphatic amine curing agent, and a flexibilizing agent that is a flexible diepoxide of EEW 390-470 or a mixture of a high molecular weight polyamine of MW 2000-5000 and a low molecular weight polyamine of MW 230-450 with Terfenol particles and curing the mixture in the presence of a magnetic field.

Owner:DELPHI TECH INC

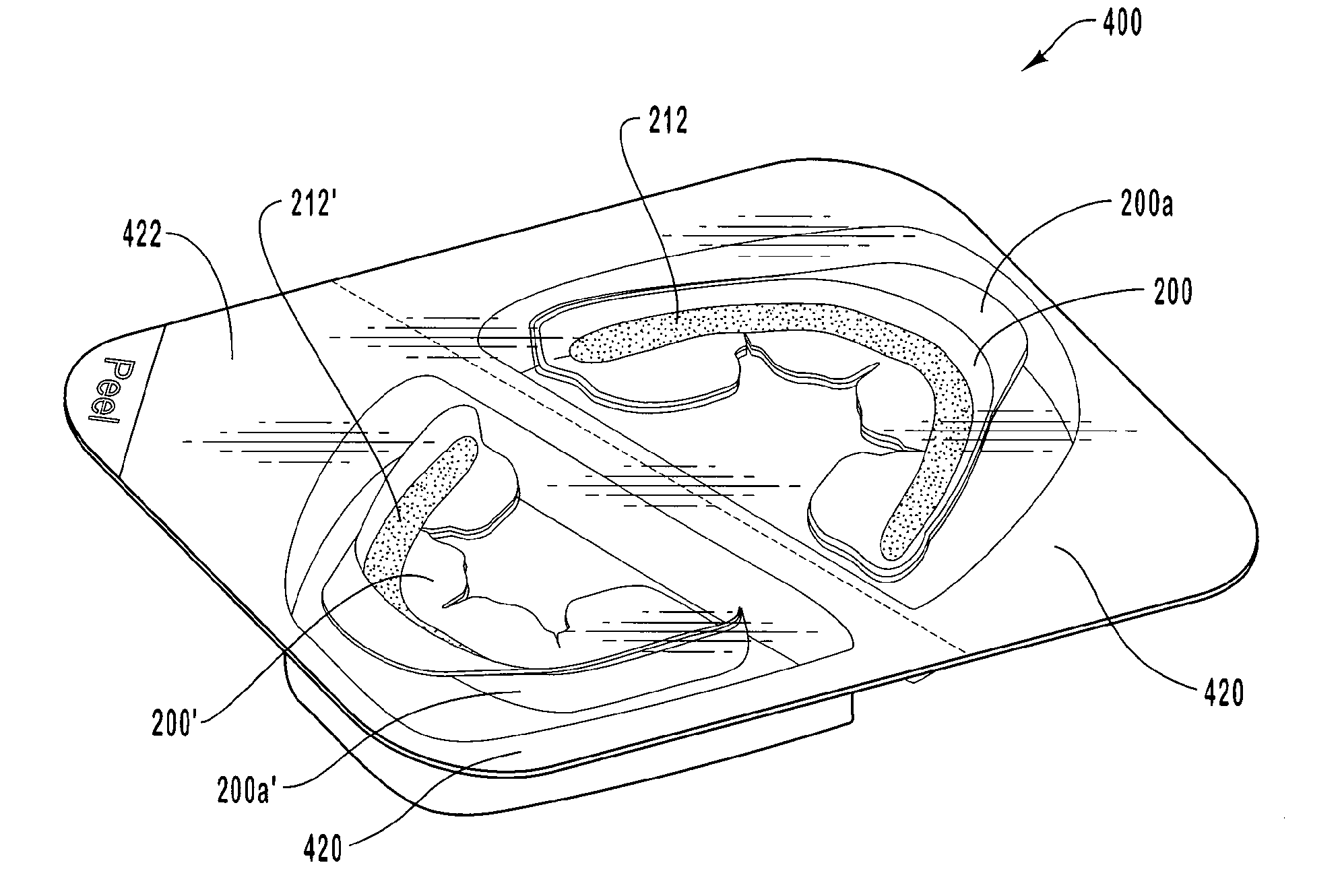

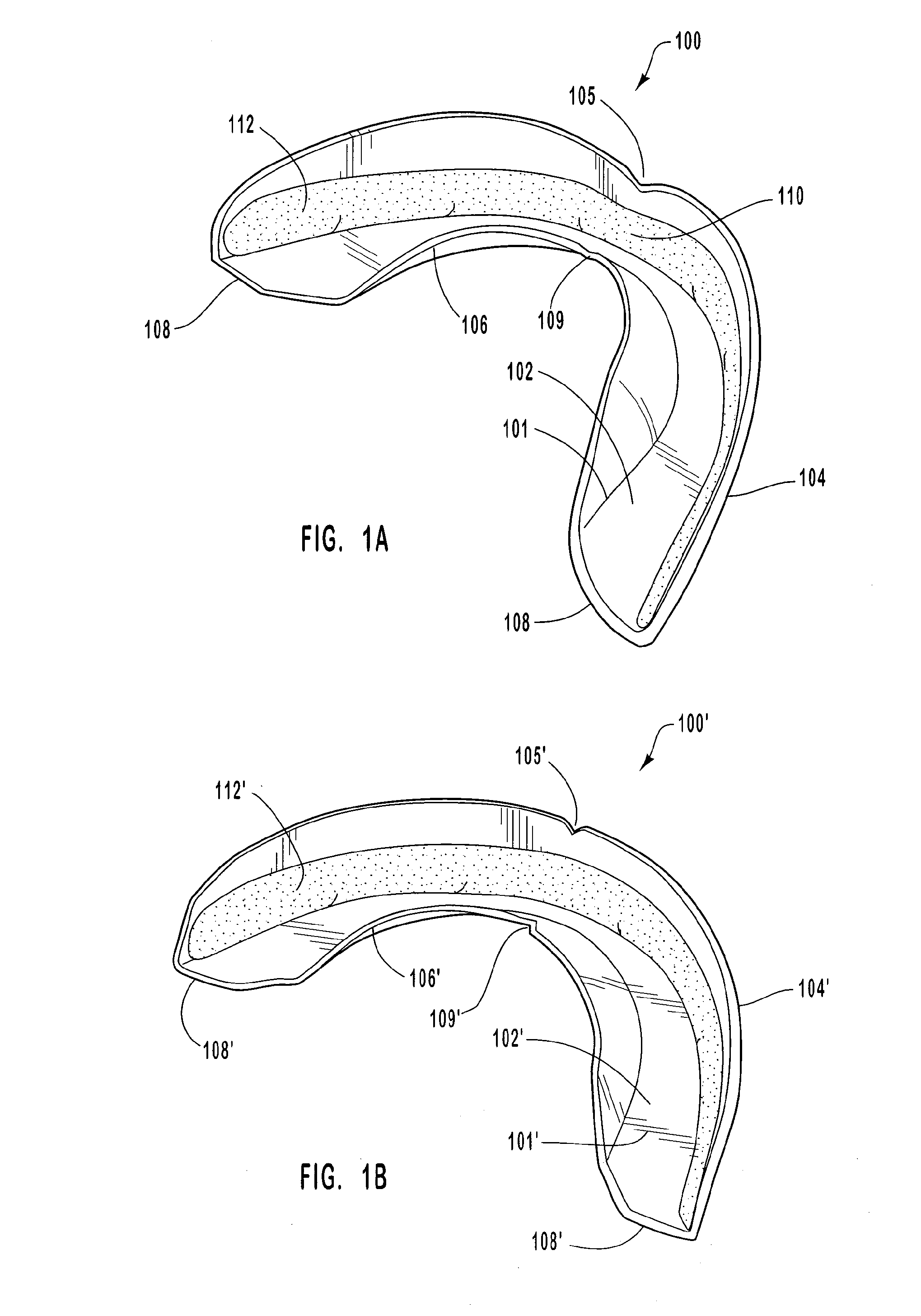

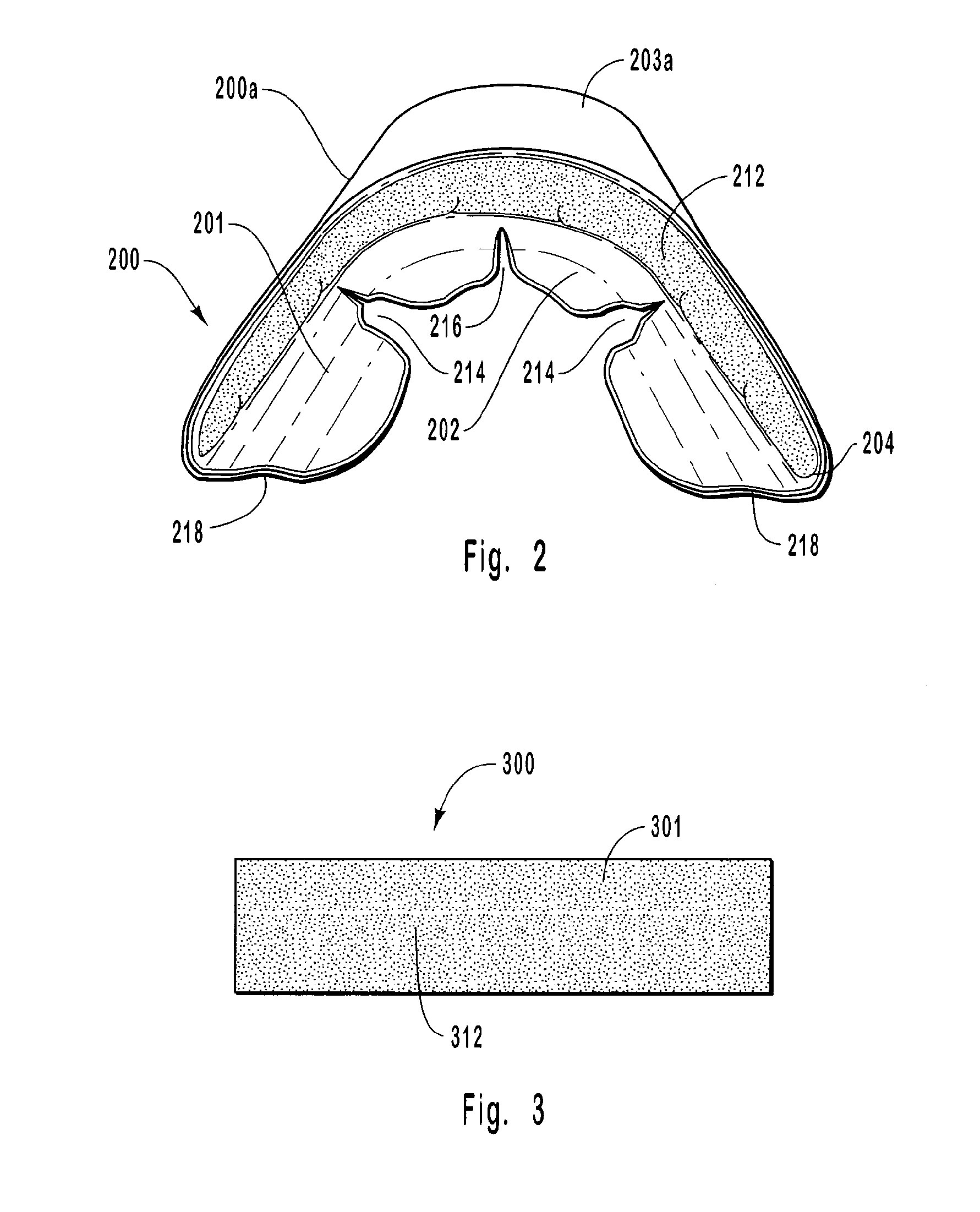

Dental bleaching compositions having long-term rheological stability and devices, kits and methods that utilize such compositions

ActiveUS20080025925A1Improve adhesionReduce stringinessCosmetic preparationsToilet preparationsHigh concentrationPolyethylene oxide

Dental bleaching compositions include a dental bleaching agent, a generally linear high molecular weight (i.e., greater than about 500,000) polyvinyl pyrrolidone (PVP) and / or polyethylene oxide (PEO) tissue adhesion agent included in amount that imparts a high level of adhesiveness, a rheology-modifying agent such as fumed silica or fumed alumina that reduces or eliminates stringiness otherwise caused by the high molecular weight PVP and / or PEO, and a solvent or carrier. Dental bleaching compositions may include carboxypolymethylene instead of or in addition to PVP and / or PEO, wherein the fumed silica or fumed alumina increases long-term rheological stability even in the presence of a high concentration of dental bleaching agent. Dental treatment devices including a barrier layer and a quantity of the dental bleaching composition positioned adjacent to the barrier layer.

Owner:ULTRADENT PROD INC

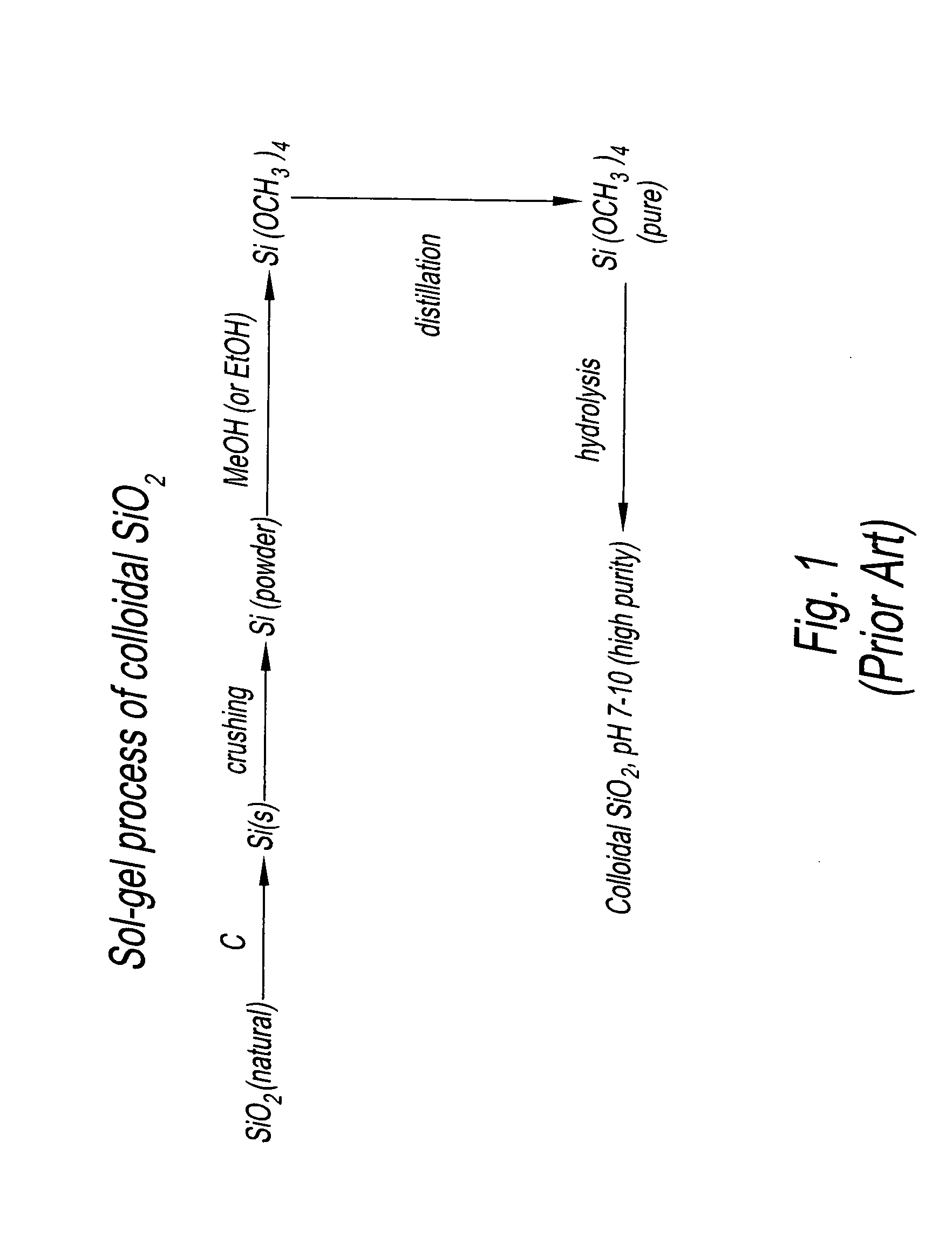

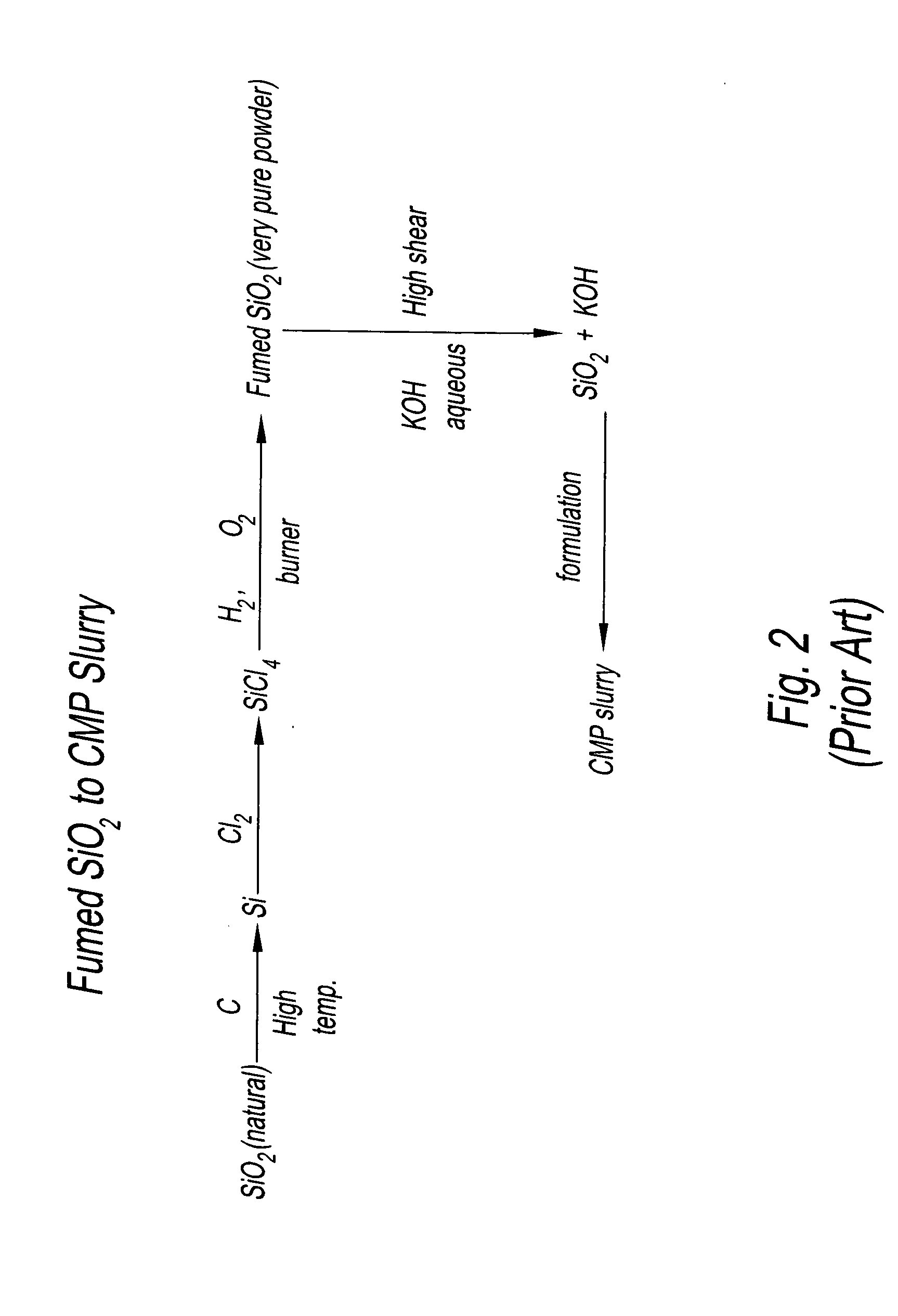

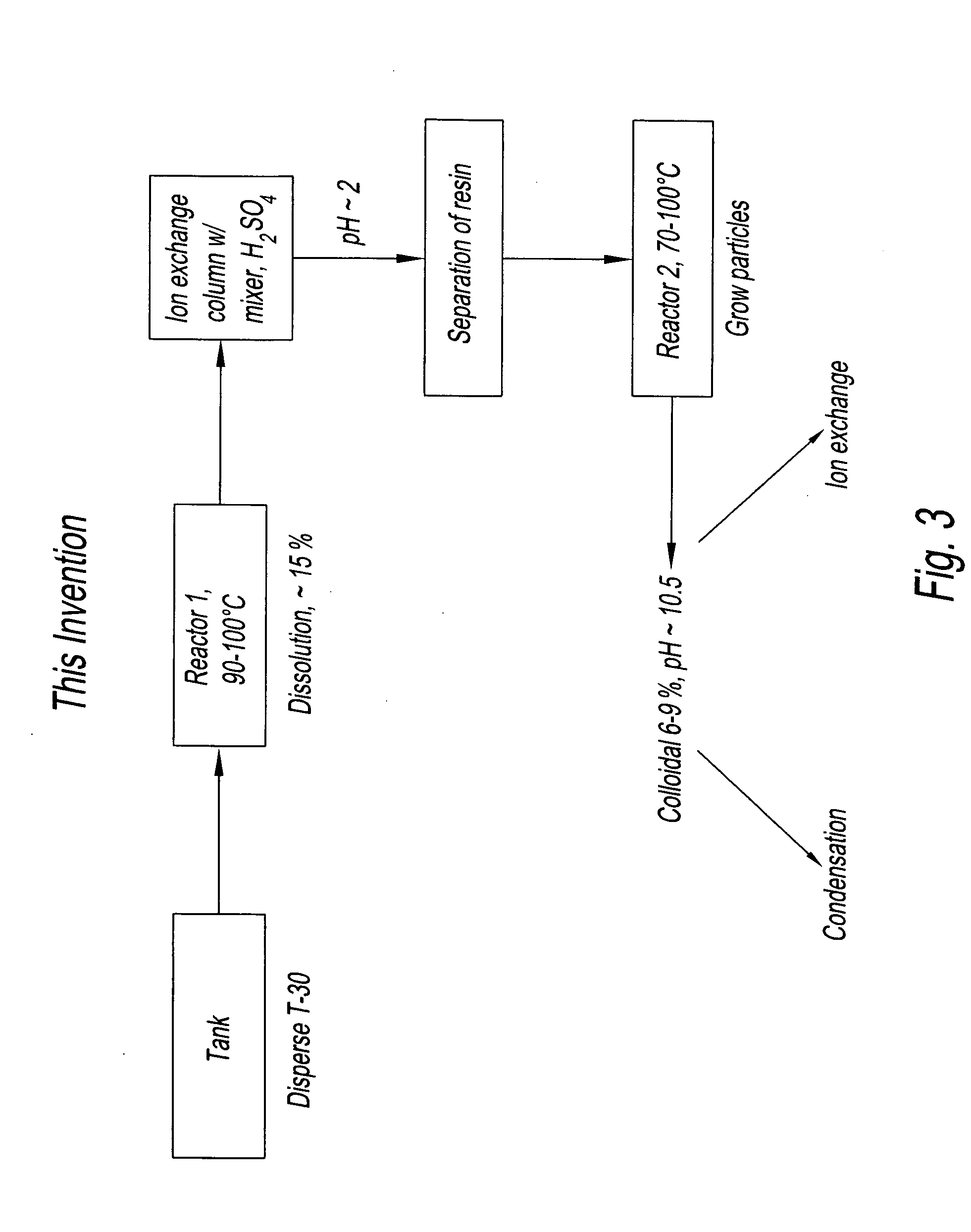

Fumed silica to colloidal silica conversion process

InactiveUS20060283095A1Low to moderate costHigh rateMagnesium silicatesPigmenting treatmentColloidal silicaSilicic acid

A method of manufacturing a colloidal silica dispersion, by dissolving a fumed silica in an aqueous solvent having an alkali metal hydroxide to produce an alkaline silicate solution; removing the alkali metal via ion exchange to produce a silicic acid solution; adjusting the temperature, concentration and pH of the silicic acid solution to values sufficient to initiate nucleation and particle growth at elevated temperatures; and cooling the silicic acid solution at a rate sufficient to produce the colloidal silica dispersion. The colloidal silica particles in the colloidal silica dispersion have a mean particle size about 2 nm to about 100 nm. Also provided is a method of chemical mechanical polishing a surface of a substrate by contacting the substrate and a composition having a plurality of colloidal silica particles according to the present invention and a medium for suspending the particles. The contacting is carried out at a temperature and for a period of time sufficient to planarize the substrate.

Owner:PLANAR SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com