Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362 results about "Creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally increases as they near their melting point.

Creep resistance magnesium alloy and preparation method thereof

A kind of alloy, which is anti-squirming, and the components of it and the weight percent of them is: 1.5-10%Y, 0.15-2.0%Zr, 0.3-2.0%Nd, 2.5-8%Gd, and one kind or several kinds of components among Sm, Dy, Tb, Ho, Er, Tm and Eu is also contained, the other is Mg. the following steps are contained in the method: (1) To prepare material (2) To improve the temperature of warm-up stove and melting stove (3) To warm up the material (4) To melt the purified magnesium ingots in batches (5) To melt the other materials, which has been warmed up, in the Mg solution. (6) To distribute equably the alloy components in the Mg solution. (7) To make into casting ingot, cast, billet, board material, pipe material, model material, stick material, line material and all kinds of forged piece. The Mg alloy can fulfill the need owing a higher mechanics performance and anti-squirming performance under high temperate, and the anti-causticity performance is higher than the Mg in existence.

Owner:GRIMAT ENG INST CO LTD

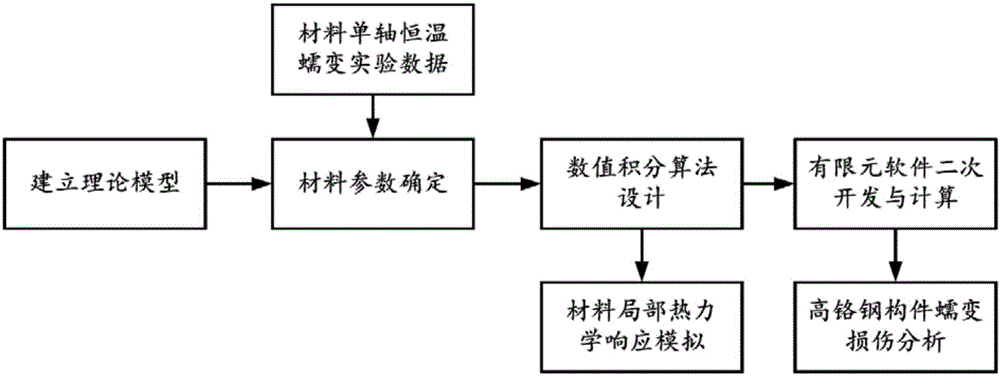

High-temperature creep deformation prediction and creep damage analysis method for high-chrome steel component

InactiveCN106529017AAccurate predictionAchieving Precise ForecastingGeometric CADDesign optimisation/simulationSecurity designEngineering

The invention discloses a high-temperature creep deformation prediction and creep damage analysis method for a high-chrome steel component. The method comprises the following steps of: establishing a theoretical model, determining material parameters, designing a numerical integration algorithm, carrying out the secondary development of finite element software, carrying out the creep damage analysis of the component and the like. Compared with an existing technical scheme, the method disclosed by the invention is characterized in that a great improvement is carried out, the accurate prediction of the creep behavior and the creep damage of the high-chrome steel component can be realized, and therefore, the method has an important application value in the fields of the security design and the residual life evaluation of high-temperature high-pressure components in a supercritical generator set.

Owner:SOUTH CHINA UNIV OF TECH

Mn-containing creep-resisting rolled zinc alloy belt material and preparation method thereof

InactiveCN101906555AOutstanding advantagesHighlight positive effectsRoll mill control devicesMetal rolling arrangementsRare-earth elementManganese

The invention relates to a Mn-containing creep-resisting rolled zinc alloy belt material. The material comprises the following components in percentage by weight: 0.5 to 3.0 percent of copper, 0.01 to 2.0 percent of manganese, 0.05 to 0.3 percent of titanium and the balance of zinc and less than 0.05 percent of impurities. An alloy component can also contain the following component in percentage by mass: 0.01 to 0.5 percent of X, wherein the X is at least one of aluminum and rare earth elements (Ce+La). A method for preparing the material comprises the following steps of: smelting by a protective covering method and adding alloy elements in the forms of pure zinc, Zn-Cu, Zn-Ti, Cu-Mn, pure aluminum and Ce+La composite rare earth, wherein a smelting temperature is between 650 and 740 DEG C; pouring at the temperature of between 420 and 480 DEG C; uniformly annealing cast ingots at the temperature of between 350 and 380 DEG C for 6 to 10 hours; performing hot rolling for multiple times at the temperature of between 220 and 280 DEG C, wherein total deformation is between 60 and 95 percent; performing cold rolling, wherein the total deformation is between 50 and 80 percent; and after rolling, annealing at the temperature of between 180 and 200 DEG C for 2 to 3 hours. The alloy of the invention has high creep resistance, hot processing performance and mechanical property and is suitable for the fields of building decoration, transportation, instruments, meters and the like.

Owner:CENT SOUTH UNIV

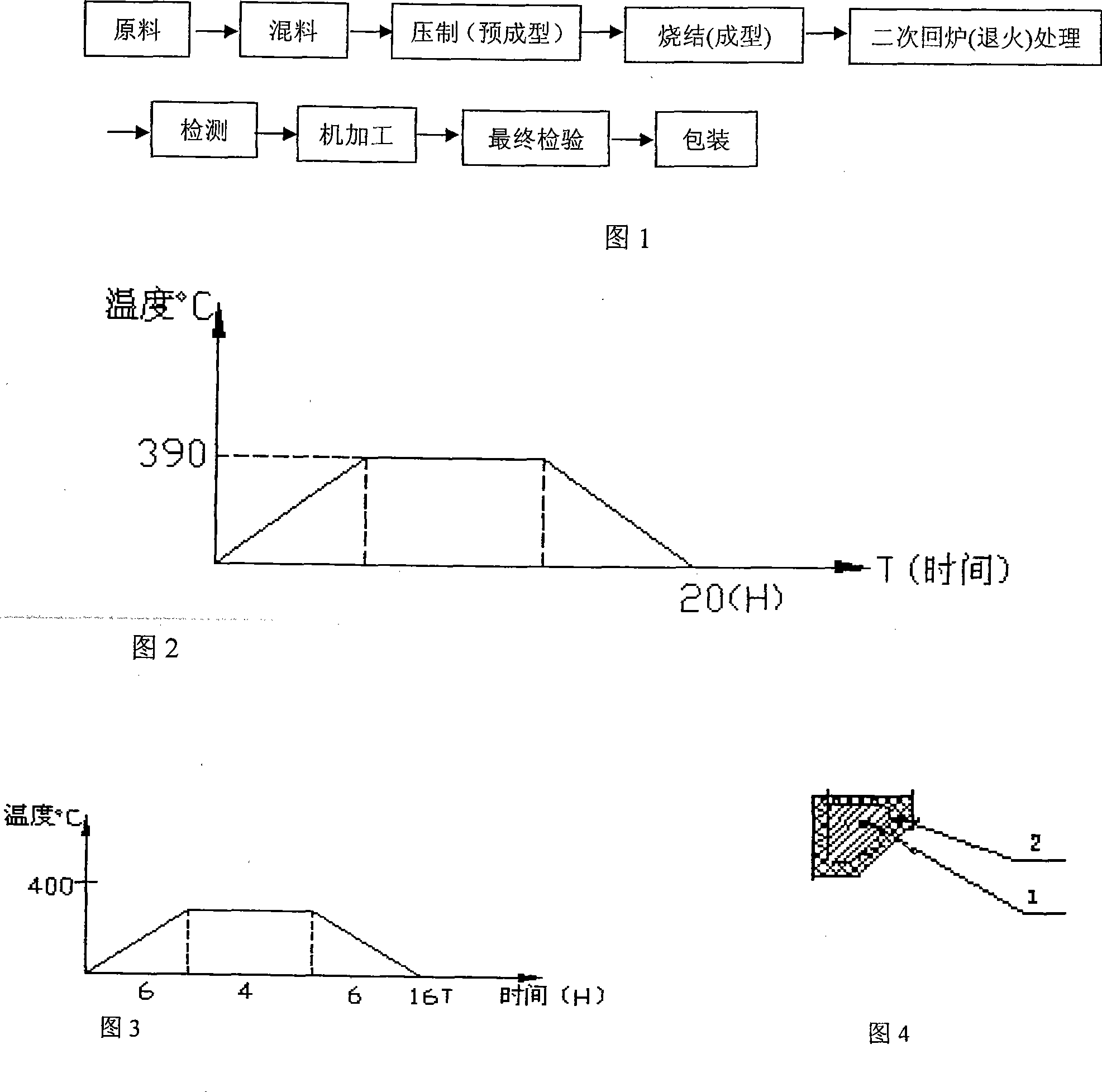

Poly(ether-ether-ketone) composite material, production method and application of sealing member

The invention relates to a polyether-ether-ketone composite material which consists of polyether-ether-ketone, nanoparticles, filling materials and addition agent materials. The composite material comprises 75 to 95 portions of polyether-ether-ketone powders, 5 to 10 portions of the nanoparticles, 10 to 20 portions of the filling materials and 2 to 5 portions of the additive agents by weight. The filling materials are glass fiber, carbon fiber, quartz powder and MoS2 or toner. A method of compression moulding forming adopted is that: materials is prepared according to the formula; materials are mixed: the materials prepared according to designed requirements poured into an automatic material mixing machine for evenly mixing, the mixing time is between 0.5 minute and 3 minutes, then compressing process is carried out, and the blended mixture is sent to a mould cavity for moulding. The material can be used for sealing materials products. Various valve sealing elements produced by the invention has properties of creep resisting, corrosion resistance, heat resistance and pressurization, etc.; the ability of pressurization and wear resistance of the material are improved, and at the same time the cost is lowered by 10 to 20 percent or even higher, thus being beneficial to using and promotion of the materials.

Owner:NANJING COMPTECH COMPOSITES CORP

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

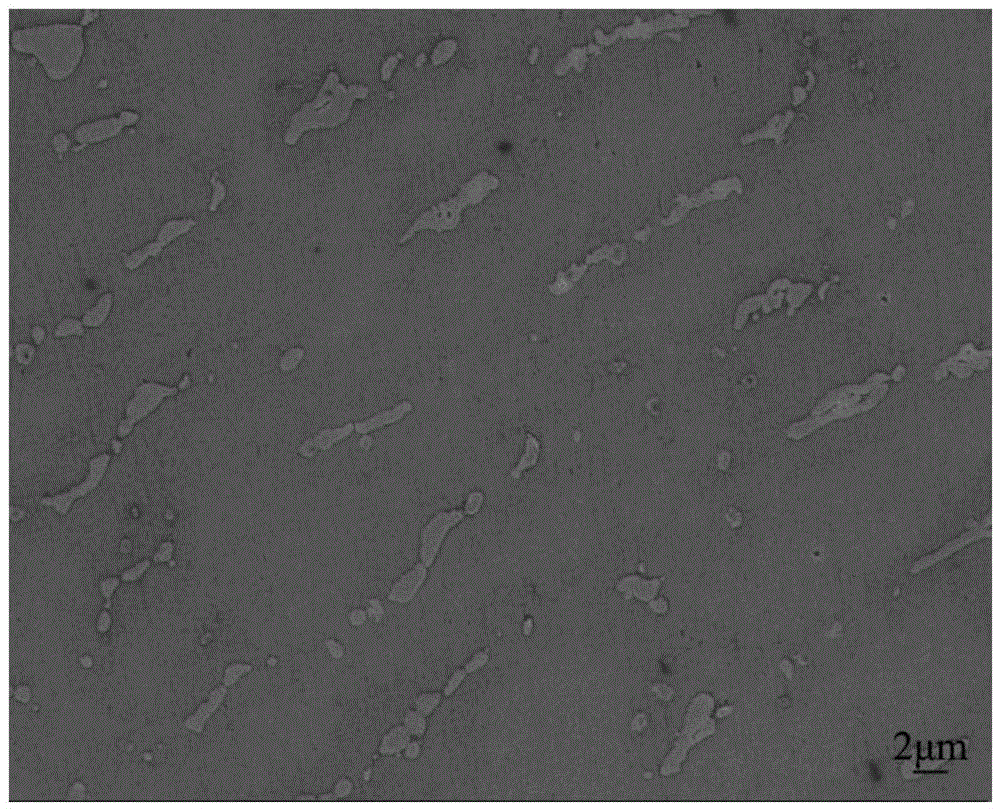

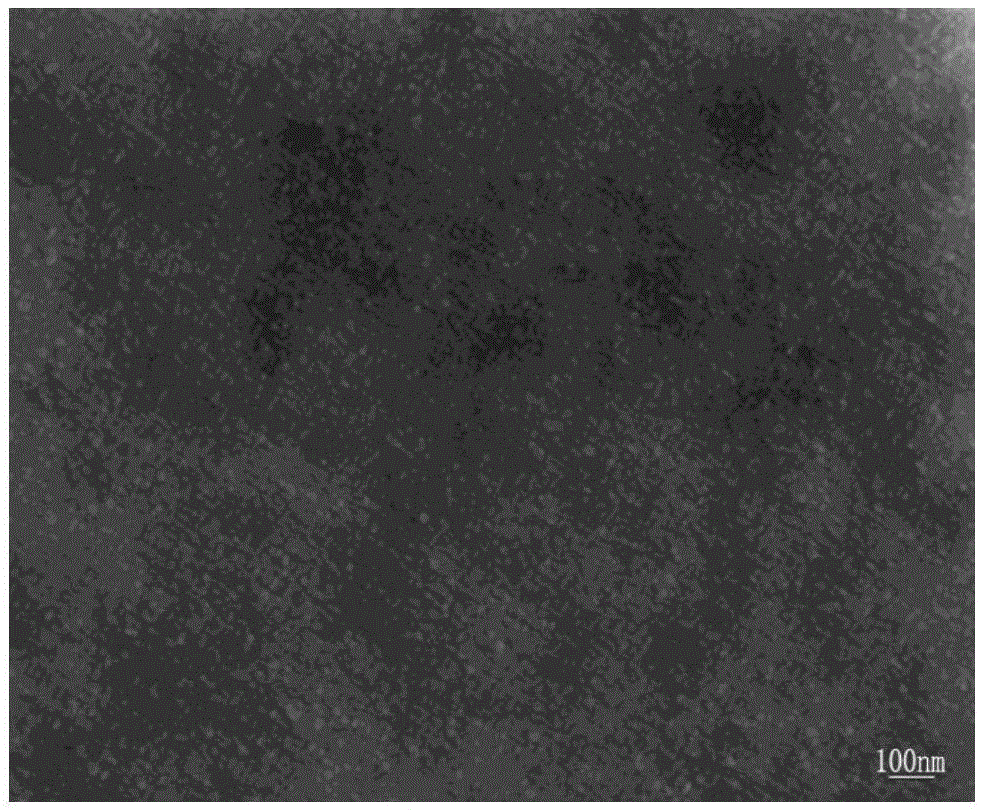

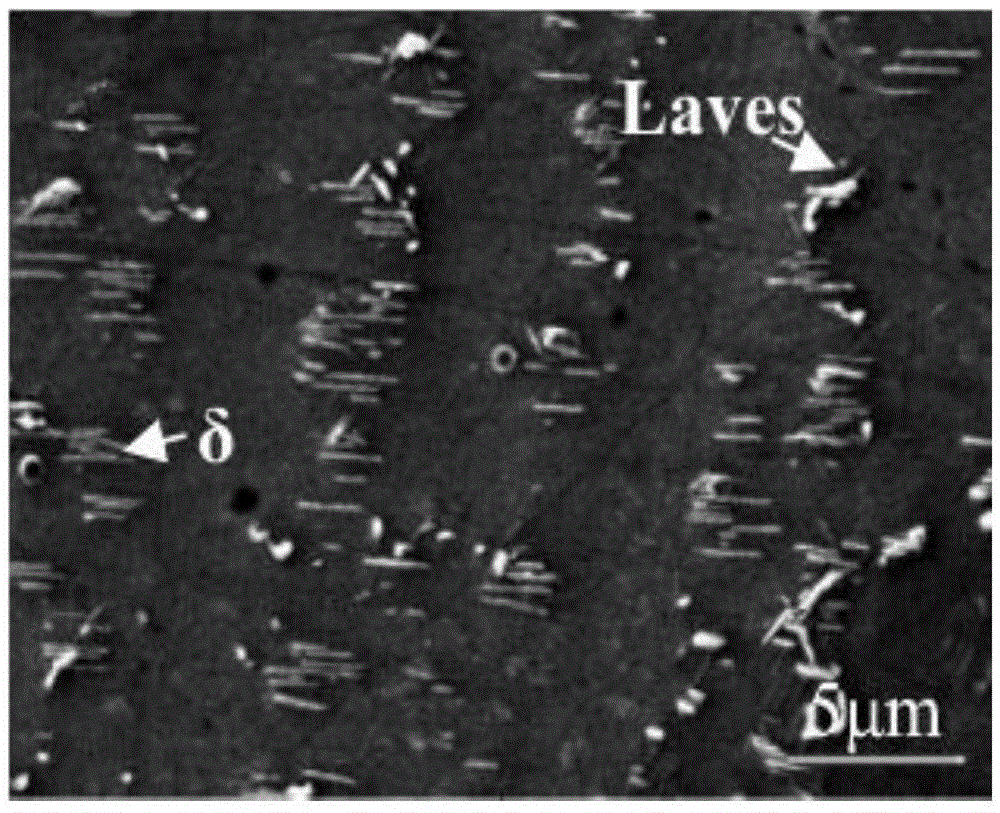

Preparation method of material increase manufactured nickel-based high-temperature alloy reserved with Laves phase

ActiveCN105543747AShorten the manufacturing cycleFast preparationMetallic material coating processesFree coolingSuperalloy

The invention provides a preparation method of a material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase. GH4169 high-temperature alloy with the Laves phase distributed in a dispersed particle shape is prepared through the preparation method, and compared with industrial forged and cast isometric crystal high-temperature alloy, the high-temperature mechanical properties, especially the high-temperature creep property, the high-temperature endurance life and the like are greatly improved. The preparation method comprises the following steps that firstly, in a processing rood, GH4160 high-temperature alloy powder or wire materials are processed through a high-energy beam heat source to be continuously melted and deposited on a base plate, so that the GH4169 high-temperature alloy reserved with the Laves phase is prepared; secondly, the prepared GH4169 high-temperature alloy reserved with the Laves phase is naturally cooled in the processing room and taken out after the temperature of the GH4169 high-temperature alloy is below 100 DEG C; and thirdly, two stages of heat treatment is conducted on the GH4169 high-temperature alloy which is taken out of the processing and reserved with the Laves phase in sequence, the first stage is completed by conducting heat preservation for 8-24 hours under the condition that the GH4169 high-temperature alloy is heated to the temperature of 700-740 DEG C, then the second stage is completed by cooling the GH4169 high-temperature alloy to the temperature below 600-640 DEG C along with a heat preservation furnace and then conducting heat preservation for eight hours, and finally air cooling is conducted till the indoor temperature is reached, so that the material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

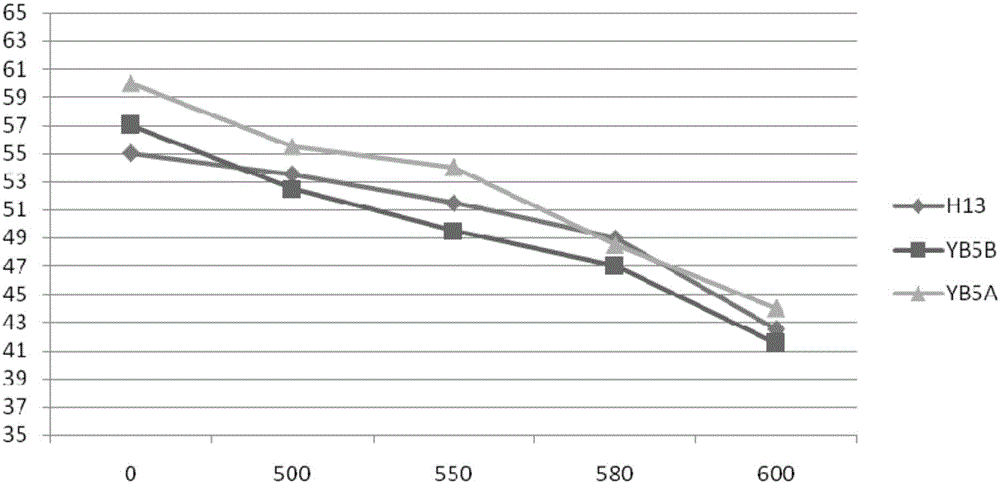

Cr5 series hot work die steel

The invention provides Cr5 series hot work die steel which comprises, by weight, 0.40-0.48% of C, 0.20-1.2% of Si, 0.40-0.80% of Mn, no more than 0.020% of P, no more than 0.010% of S, 4.80-5.50% of Cr, 1.40-2.0% of Ni, 0.80-1.50% of Mo, 0.50-0.70% of V, 0.50-1.00% of W, 0-0.75% of Co, 0.01-0.20% of Al, 0.02-0.20% of Nb, and the balance Fe. The chemical composition formula of the novel Cr5 series hot work die steel provided by the invention is recorded as the YB5 series, and compared with existing Cr5 series (H13) hot work die steel, the YB5 series die steel is higher in C content and Mn content and lower in Si content (YB5A and YB5C), Mo content and V content, and Ni, W, Co (YB5C) and Al (YB5A and YB5C) are added. Accordingly, the toughness of the steel is improved, and the high-temperature strength and creep resistance are improved.

Owner:YINGKOU SPECIAL STEEL FORGING

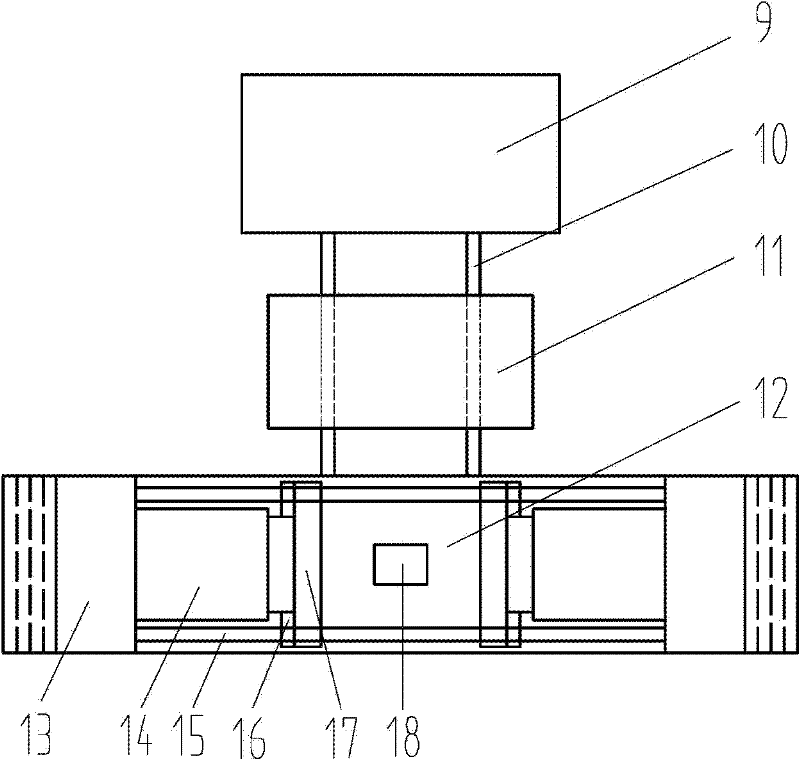

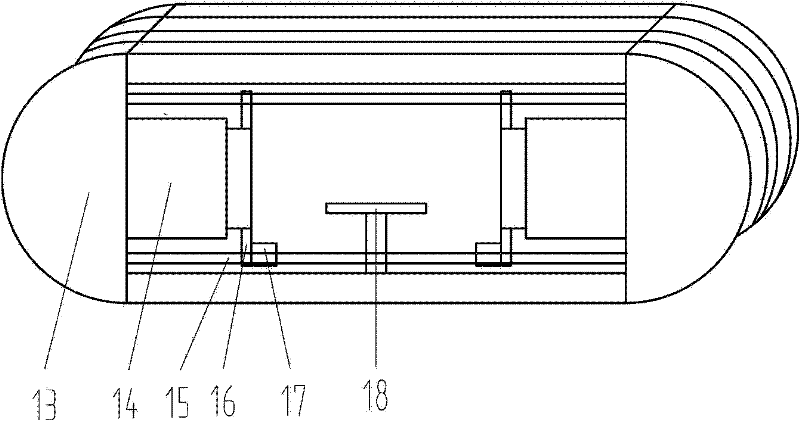

Device and method for testing material creep under coupling action of tensile stress and environment

InactiveCN103267682AUniform stressUniform stress distributionMaterial strength using tensile/compressive forcesTemperature controlInorganic salts

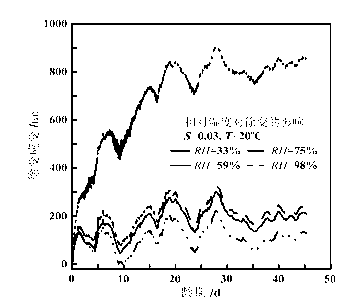

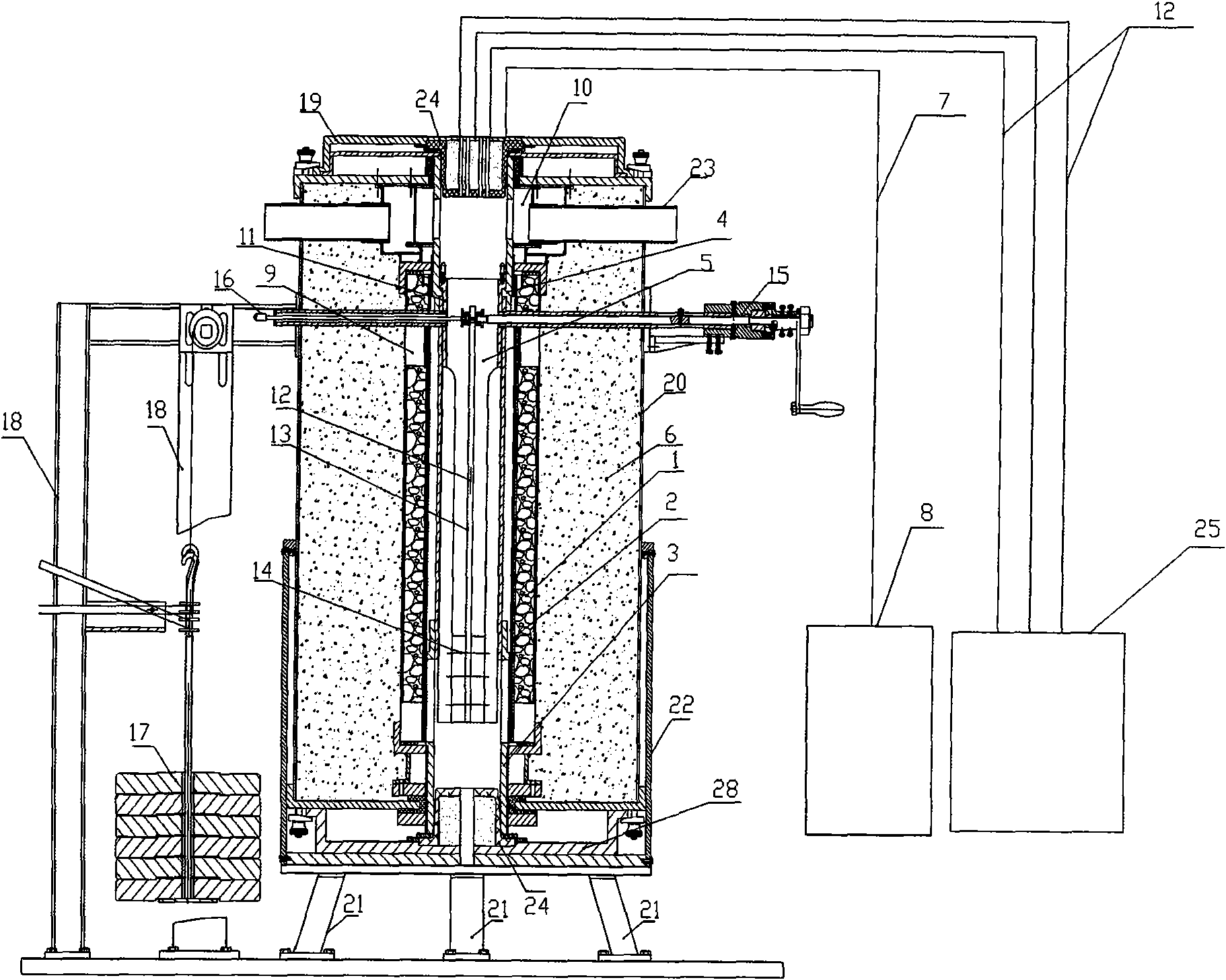

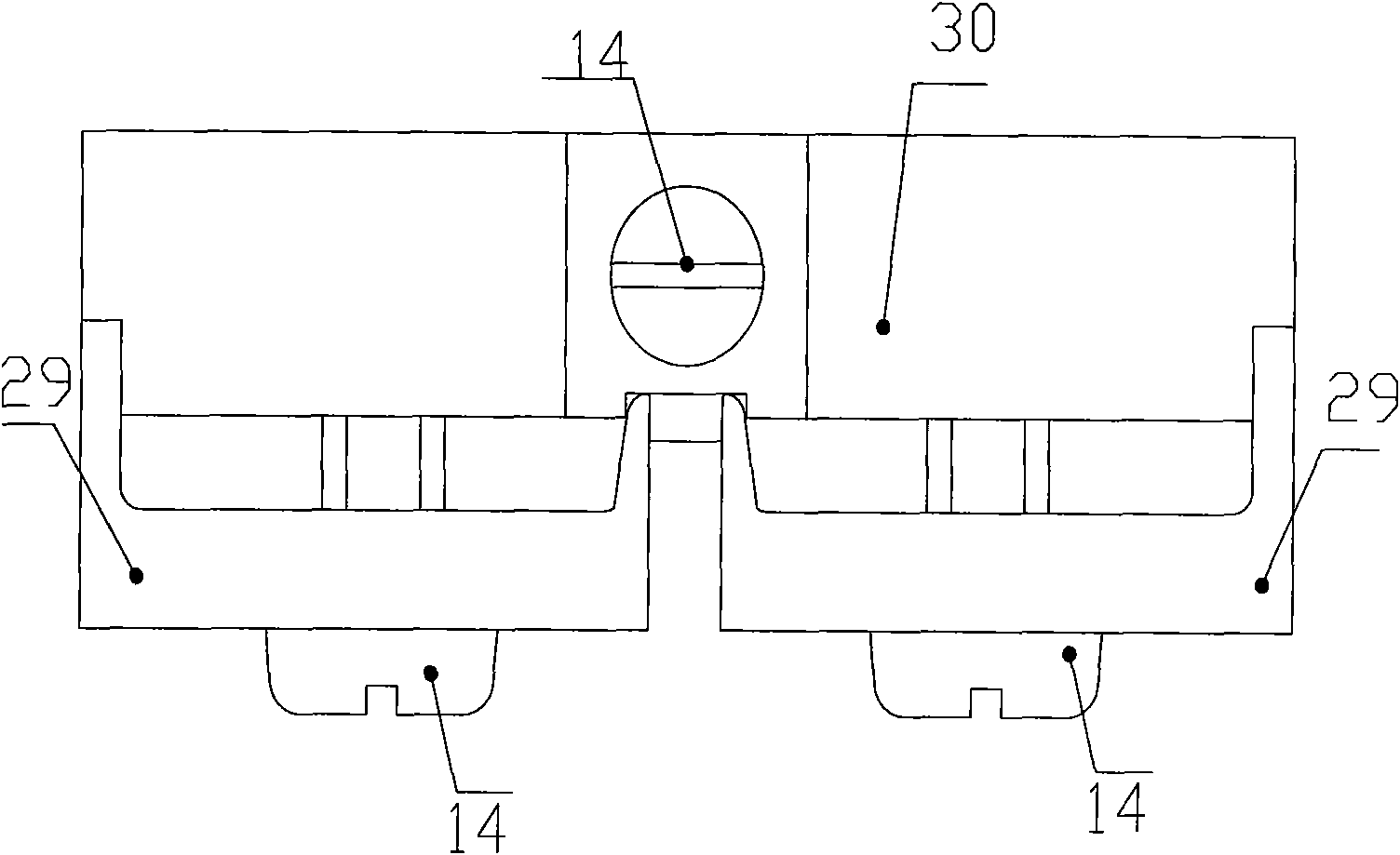

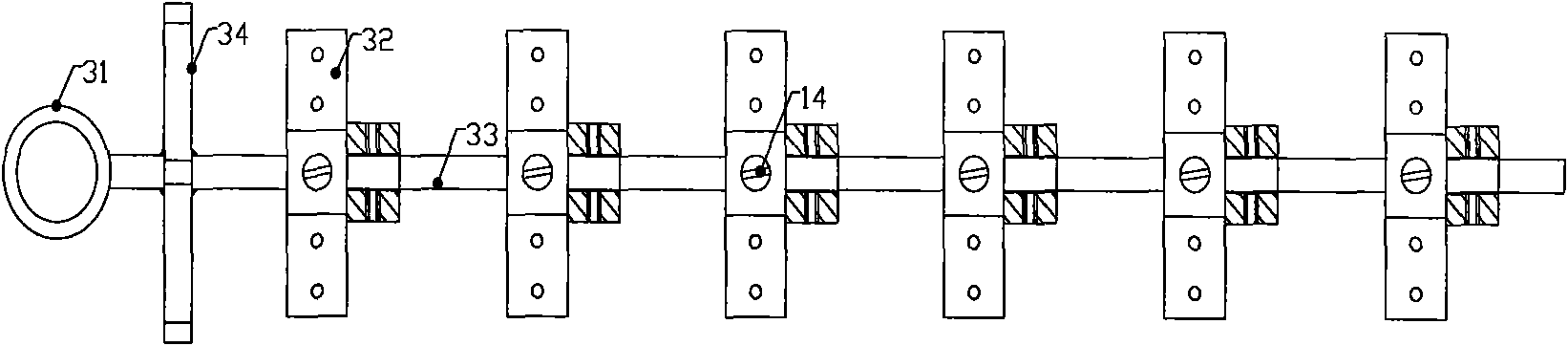

The invention discloses a device for testing material creep under the coupling action of tensile stress and the environment. The device comprises a support, a weight, a heating jacket, a container containing a saturated inorganic salt solution, a strain demodulator, a power supply, a temperature controller, a strain sensor and a test piece, wherein the support comprises a positioning plate, an upper spherical hinge, an upper clamping head, a supporting rod, a bearing plate, a base plate, a lower clamping head and a lower spherical hinge; the supporting rod is connected with the bearing plate through a sliding bearing; the test piece is embedded in a groove in the upper clamping head and a groove in the lower clamping head; the weight is positioned on the bearing plate; the heating jacket covers on the outer side of the support; the container is positioned between the support and the heating jacket; the strain sensor is adhered to the outer wall surface of the test piece; and the temperature controller is connected with the ring-shaped heating jacket. By adopting the device, the reliability of the test process can be improved, and the accuracy of results is ensured. Meanwhile, the invention also discloses a test method for the test device. The method is simple and easy to operate, and can keep that the test piece does not generate stress relaxation in the process of long-term load application, and the stress is uniformly distributed.

Owner:SOUTHEAST UNIV

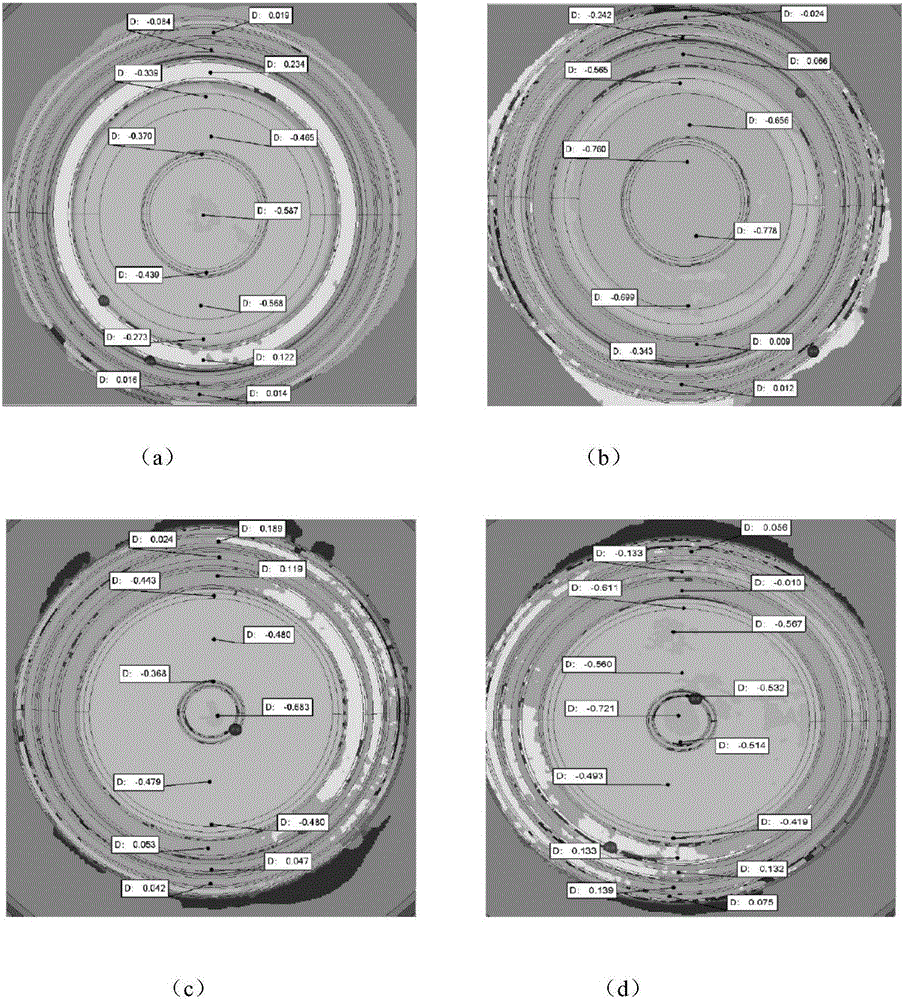

High temperature strain foil performance parameter tester and test method thereof

ActiveCN101614640AGood high temperature repeatabilityImprove test accuracyMaterial strength using tensile/compressive forcesSupporting systemTemperature control

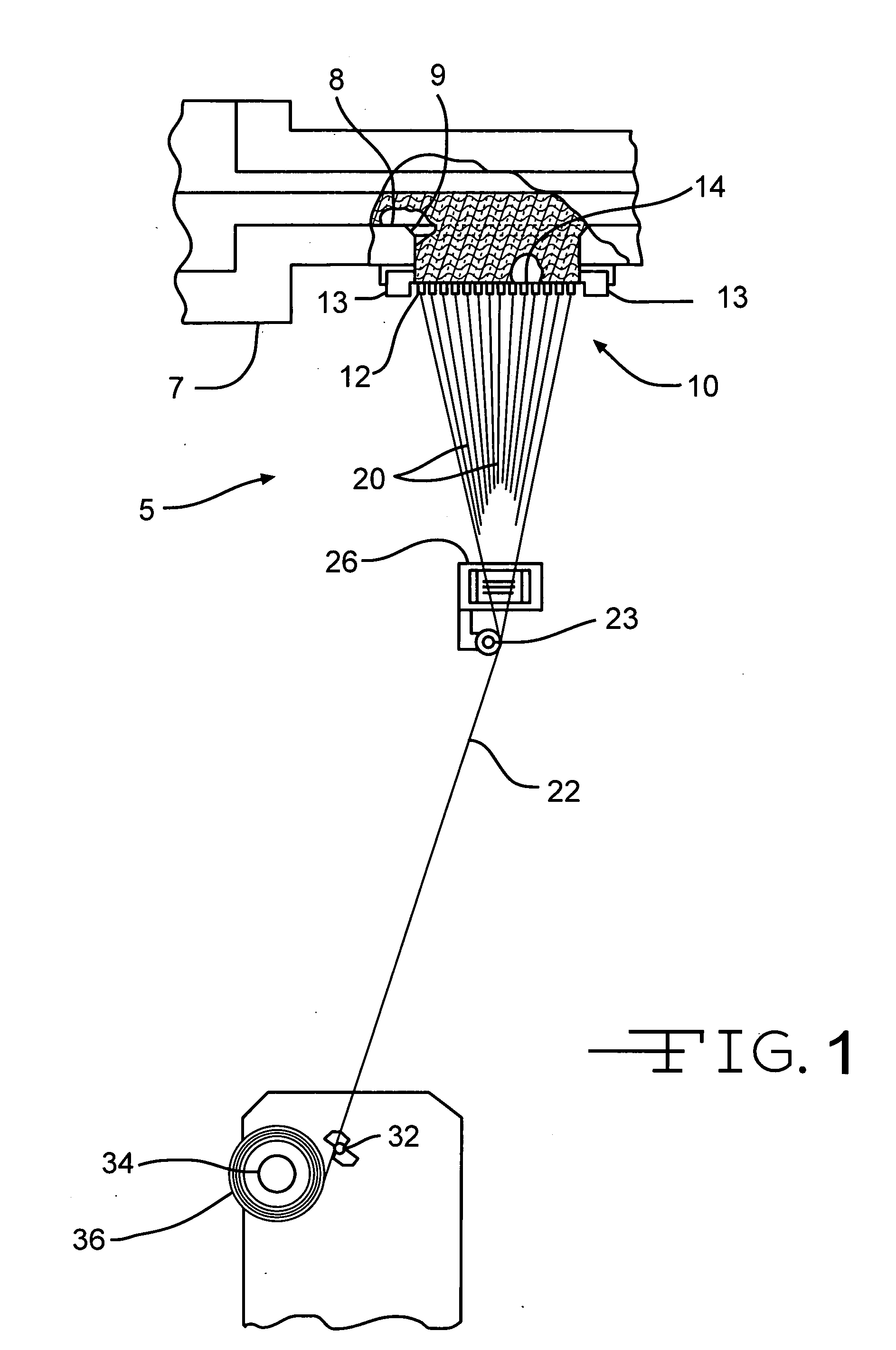

The invention provides a high temperature strain foil performance parameter tester and a test method thereof. The high temperature strain foil performance parameter tester is composed of a heating system, a heat preservation system, a temperature control system, a circulation system, a support system and a loading system. The tester and the test method of the invention can test technical parameters of the high temperature strain foil such as null shift, thermal output, thermal delay, mechanical delay, change of sensitivity coefficient with temperature, creep deformation of the high temperature strain foil, creep deformation of constant strength calibration beams made of measured target material and the like. The tester and the test method of the invention feature high test precision, good high temperature repeatability and reliable test results, thus providing data correction for long-term high temperature strain monitoring.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

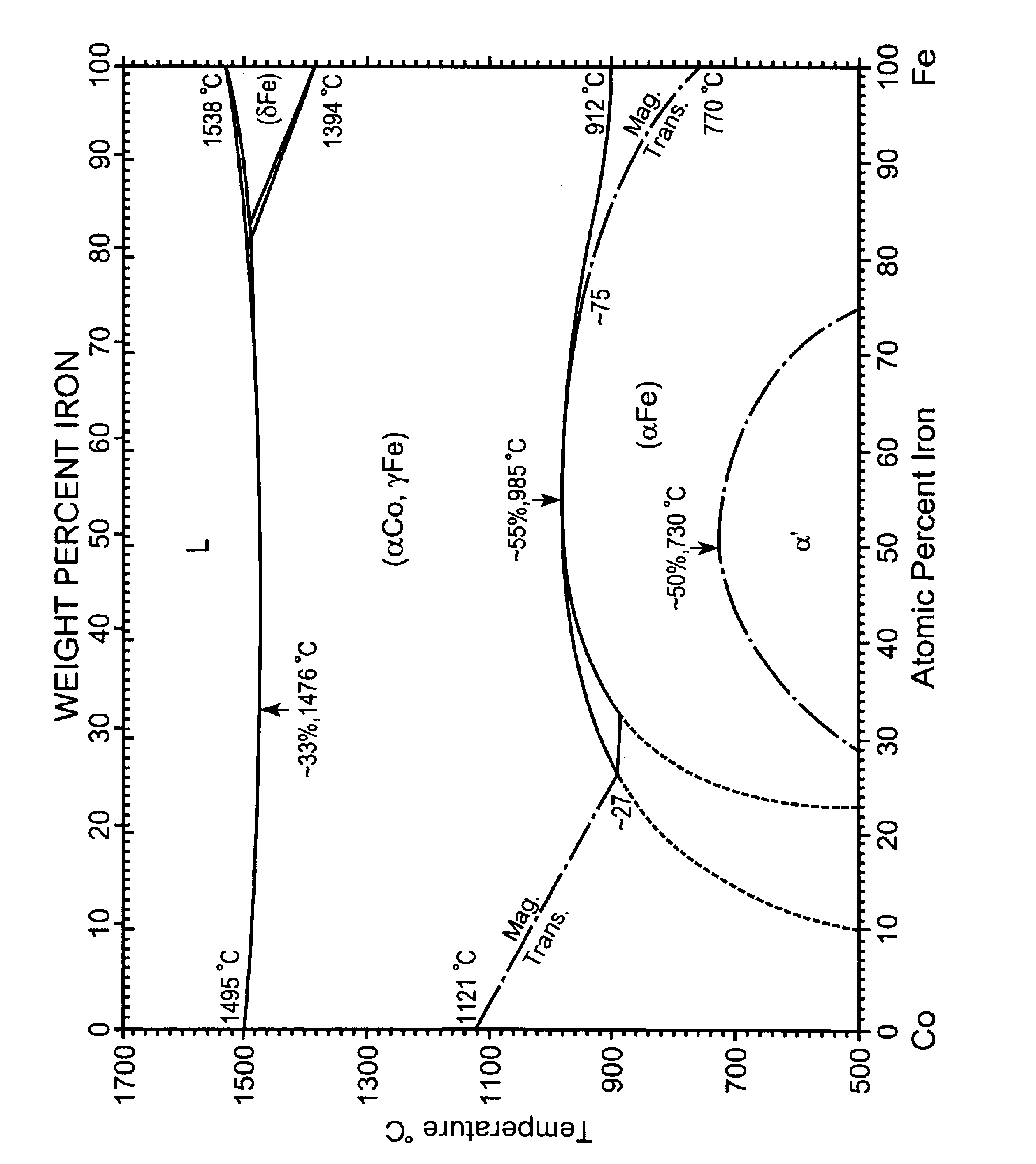

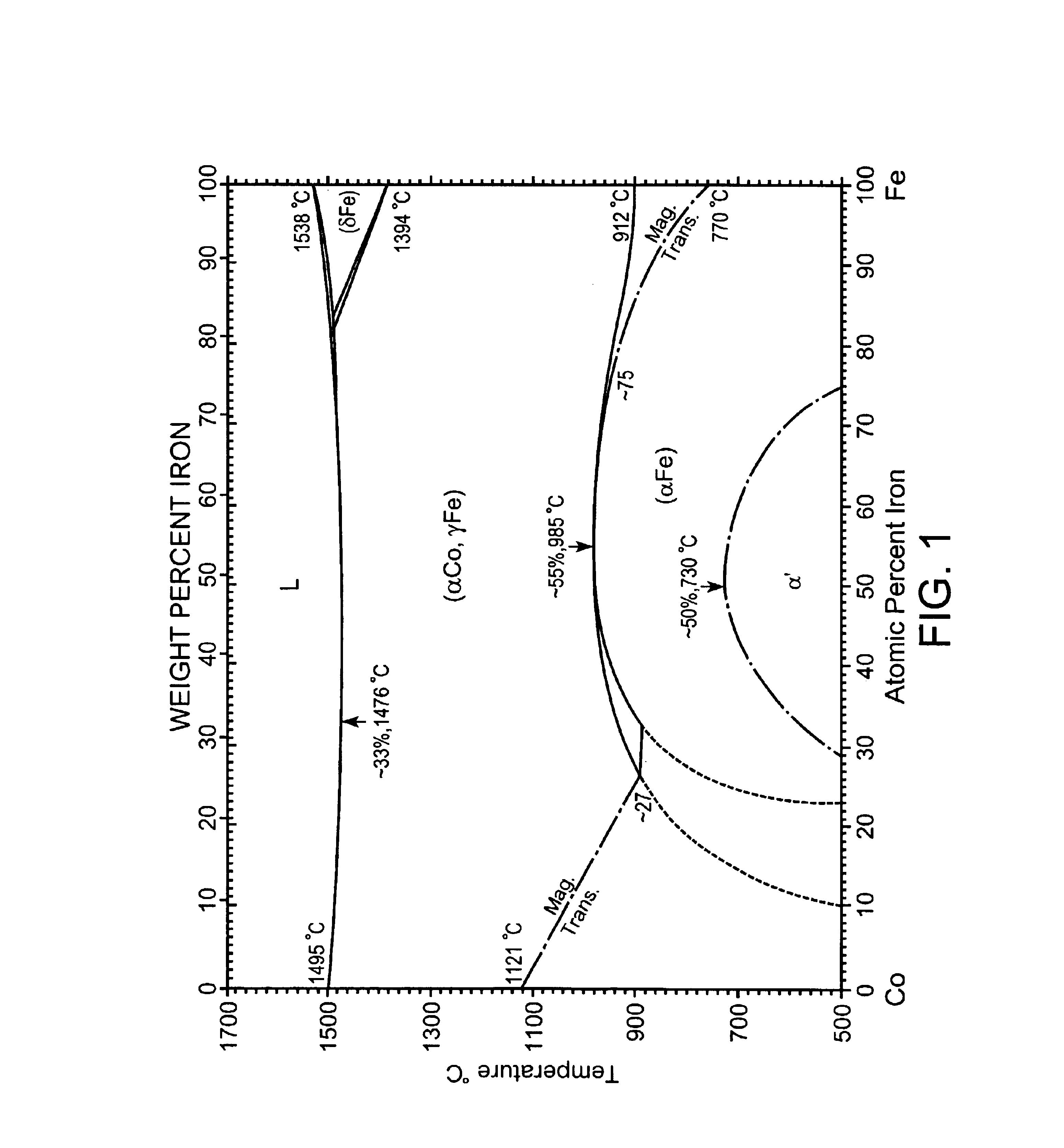

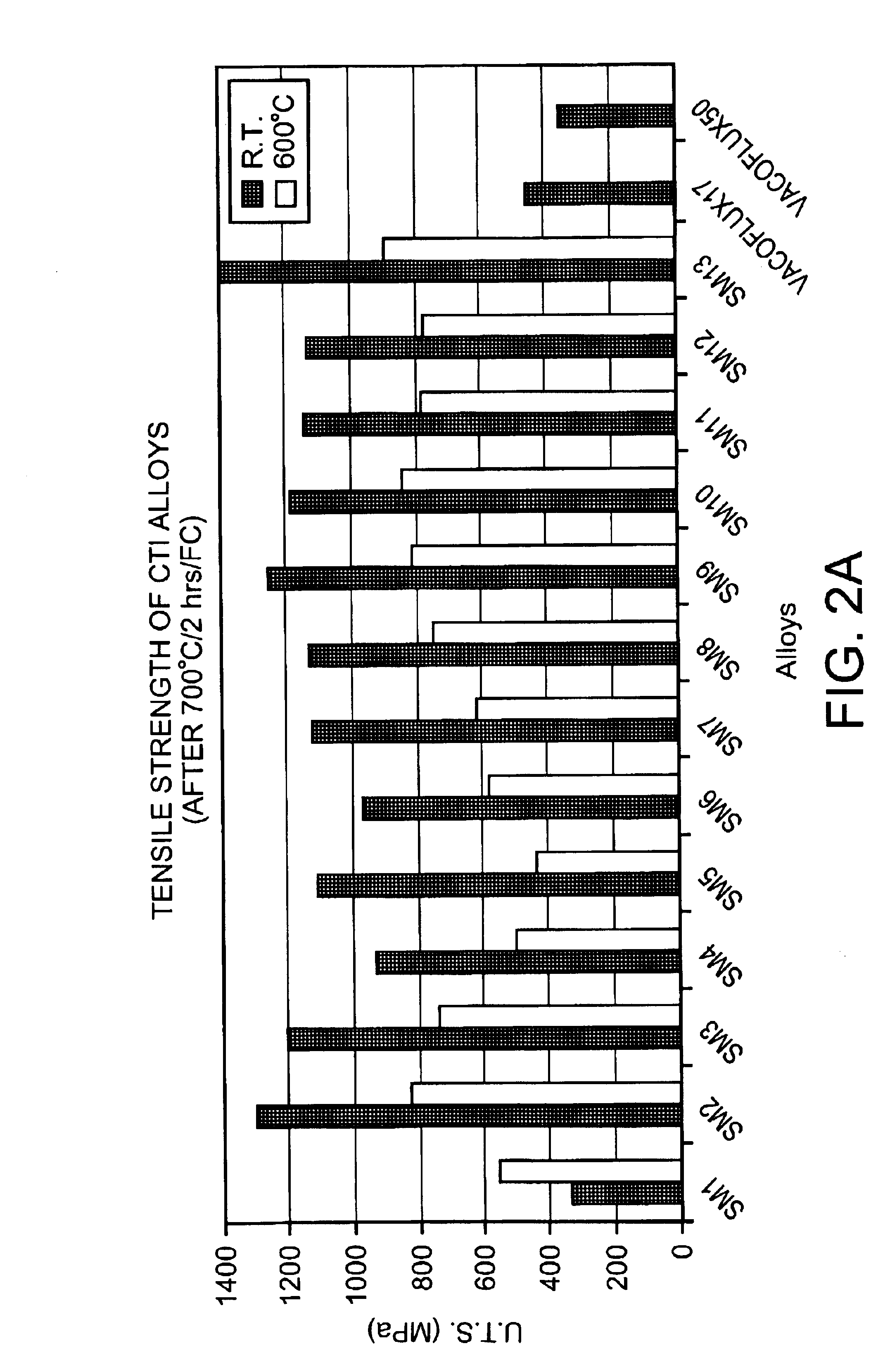

High-strength high-temperature creep-resistant iron-cobalt alloys for soft magnetic applications

A high strength and creep resistant soft magnetic Fe—Co alloy includes, in weight %, Fe and Co such that the difference between the Fe and Co is at least 2%, at least 35% Co, and 2.5%≦(V+Mo+Nb), wherein 0.4%≦Mo and / or 0.4%≦Nb. This alloy can further include B, C, W, Ni, Ti, Cr, Mn and / or Al. A vanadium-free high strength soft magnetic Fe—Co alloy includes, in weight %, Fe and Co such that the difference between the Fe and Co is at least 2%, and at least 15% Co, the alloy further satisfying (0.1%≦Nb and 0.1%≦W) or 0.25%≦Mn. This alloy can further include B, C, Ni, Ti, Cr and / or Al.

Owner:PHILIP MORRIS USA INC

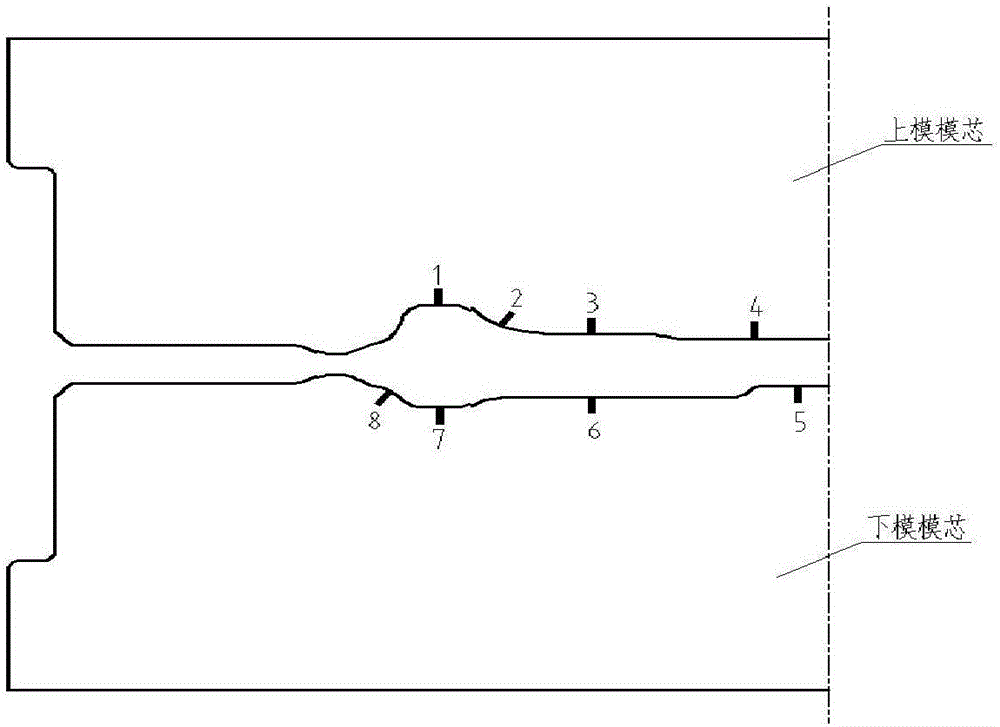

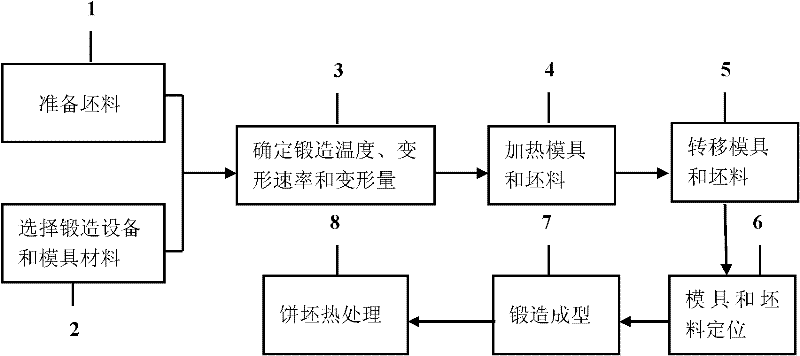

Quick isothermal forging method and device for preparing less-deformable alloy cake blank

ActiveCN102303083AReduce manufacturing costReduce the cost of forging processForging press detailsFlow stressHigh volume manufacturing

The invention discloses a quick isothermal forging method and device for preparing a less-deformable alloy cake blank. The device comprises a heating device, an automatic feeding device, a horizontal hydraulic forging device, a blank positioning device and a flame heating device. A mould material used by the device is a nickel-based alloy with creep strength which is higher than the flow stress of a forged high-temperature alloy under corresponding forging temperature and deformation rate. In the method, a homogenized electroslag remelting continuous directional solidification technology or other processes with maneuverability can be selected for preparing a high-alloyed less-deformable alloy directional solidification billet, as well as a fine grain billet prepared by adopting the processes, such as powder metallurgy and the like. The method and the device have the advantages of short production period, convenience for control and low cost, and are suitable for mass production of large-size high-clean and uniform tissue high-alloying less-deformable alloy cake blanks.

Owner:CENT IRON & STEEL RES INST

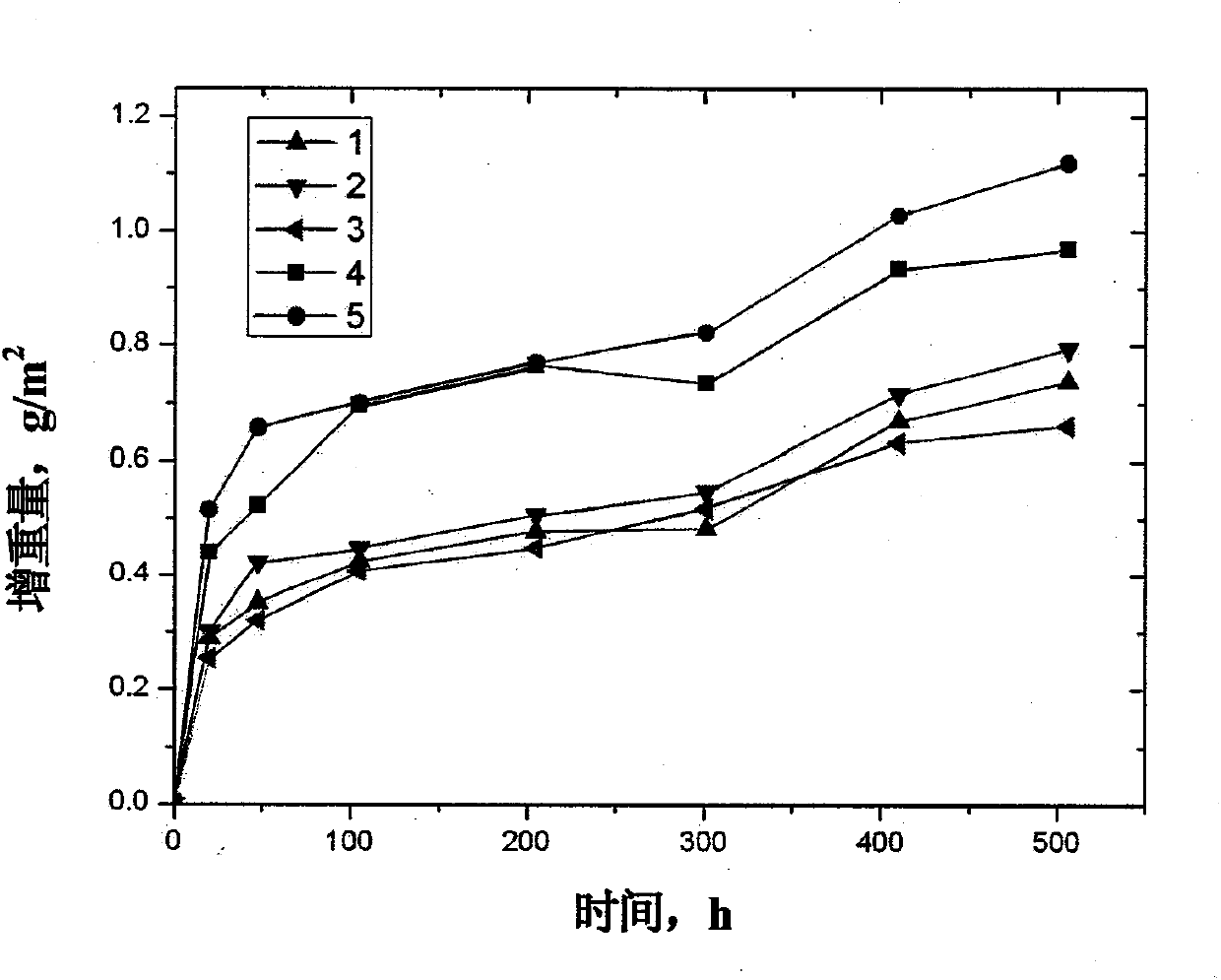

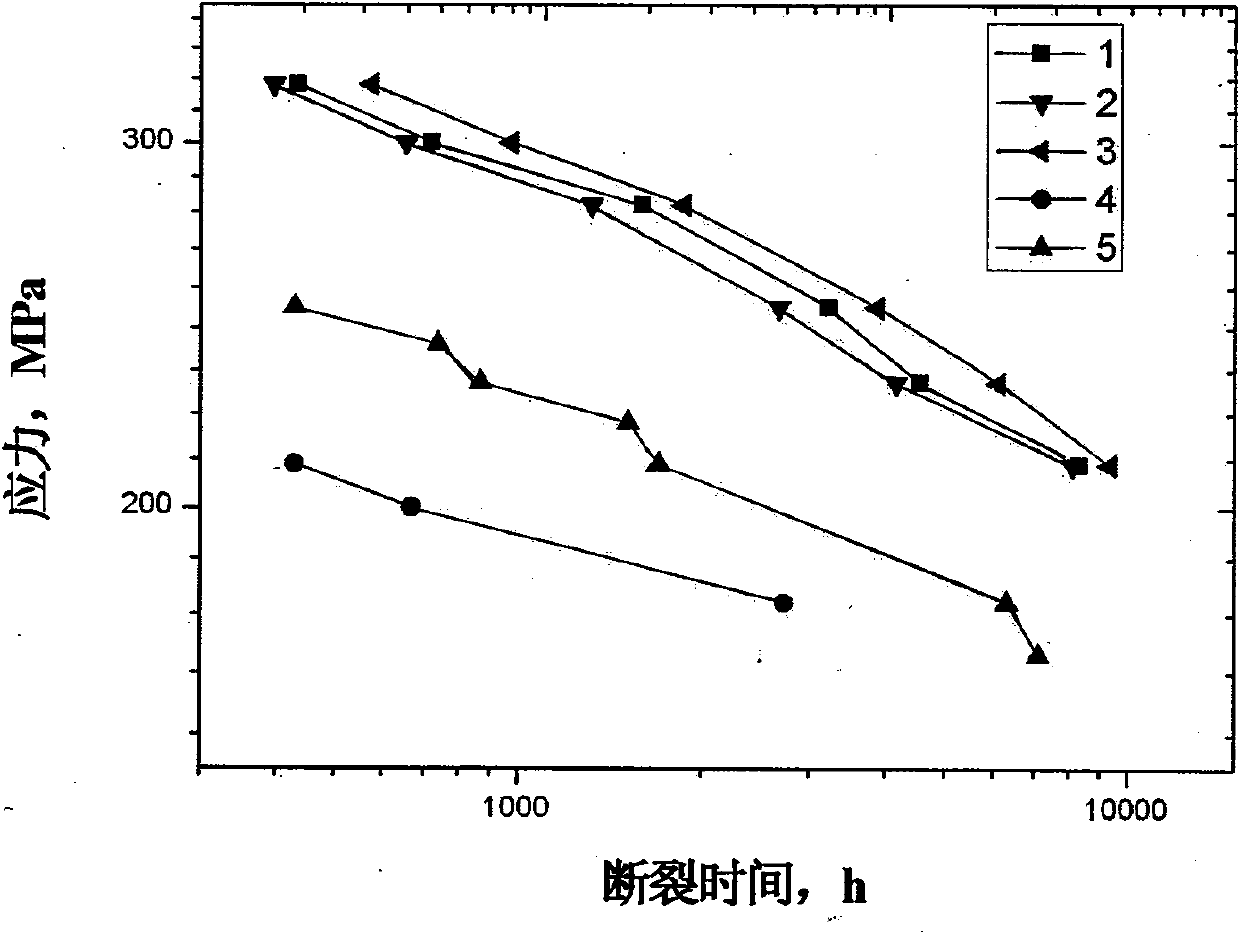

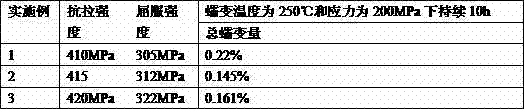

High-chromium martensitic heat-resistant steel and manufacturing method thereof

InactiveCN102086494AHigh strengthImprove antioxidant capacityOxidation resistantSolid solution strengthening

The invention belongs to the technical field of heat-resistant alloys, and particularly relates to high-chromium martensitic heat-resistant steel with high oxidation resistance and high creep resistance at a high temperature. The high-chromium martensitic heat-resistant steel is a novel structural material mainly applied to the manufacturing of high-pressure steam pipelines for super (ultra super)-critical thermal power stations. The steel comprises the following components in percentage by weight: 0.07 to 0.10 percent of C, 10.0 to 11.0 percent of Cr, 0.3 to 0.5 percent of Mo, 2.0 to 3.0 percent of W, 2.0 to 3.0 percent of Co (the content ratio of Co to W is more than or equal to 0.8 and is less than or equal to 1.2), 0.3 to 0.5 percent of Mn, 0.2 to 0.4 percent of Si, less than 0.5 percent of Ni, 0.001 to 0.006 percent of B, and the balance of Fe. In the high-chromium martensitic heat-resistant steel, by compoundly adding low molybdenum, high tungsten and high cobalt when the chromium content is increased and keeping the content ratio of cobalt to tungsten within a certain range, the coarsening of M23C6 which plays a role in precipitation strengthening in a microstructure can be inhibited, the content of delta-ferrite in the microstructure is effectively controlled to be lower than 5 percent (volume fraction), and the solid solution strengthening effect is greatly improved, so that the high-chromium martensitic heat-resistant steel which has both high oxidation resistance and high creep resistance at a high temperature and is used for thermal power stations is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

SiC-Si3N4 high temperature ceramic furnace bottom plate for annular furnace and preparation method thereof

InactiveCN102795859AImprove creep resistanceHigh temperature strengthThermal dilatationTemperature resistance

The invention relates to a SiC-Si3N4 high temperature ceramic furnace bottom plate for an annular furnace and a preparation method thereof; the preparation method comprises the following steps: on a basis of a total weight part of 100 parts, weighing 25-75 parts of Si powder and the balance of SiC powder; adding 3-8 parts of a sintering aid and 4-9 parts of a binder, wherein the sintering aid is Y2O3, or a mixture of Y2O3 and Al2O3; performing material mixing, molding, sintering, silicon immersion, and machining to prepare the SiC-Si3N4 high temperature ceramic furnace bottom plate for an annular furnace. The preparation method is simple in process and low in cost, and the obtained product has the characteristics of high temperature resistance, good creep resistance, large high-temperature strength, good thermal shock resistance, and the like, can meet working condition requirements for annular furnace production, and can effectively solve the problems of poor high temperature resistance of metal furnace bottom plates, furnace bottom plate bending deformation due to a large material high-temperature creep rate, furnace bottom plate cracking damage due to a large material thermal expansion rate, and low service life.

Owner:湖北红花高温材料股份有限公司

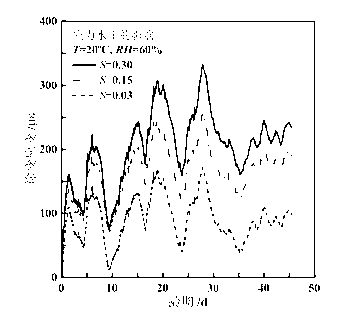

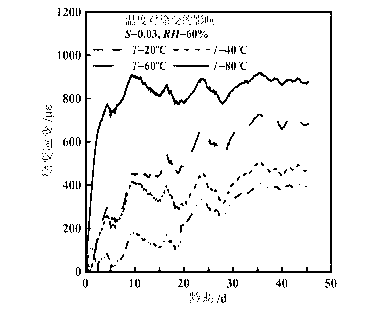

Operational method for measuring creep parameters and infiltration parameters of smashed rocks simultaneously

InactiveCN102620996ALow costEasy to operateMaterial strength using tensile/compressive forcesPermeability/surface area analysisAxial LoadingsAxial pressure

The invention relates to an operational method for measuring creep parameters and infiltration parameters of smashed rocks simultaneously, which realizes loading of axial pressure and infiltration pressure difference by the aid of a smashed rock creep-infiltration full-process coupling testing device. The operational method includes: firstly, determining initial height of rock in a cylinder before loading, starting an axial loading device then, starting an electric test pump to saturate rocks, applying axial load, injecting water to the rocks to infiltrate according to set water pressure, finally changing the axial load to perform the creep-infiltration test of the next-grade stress stage. The infiltration characteristic parameters are obtained by matching of a scatter diagram of hole pressure gradient and average infiltration speed and the Forchheimer formula, and the creep parameters are obtained by matching of Kelvin-Volgt creep model and an axial strain time curve. The operational method has the advantages that creep model during creep and infiltration full-process couple of the smashed rocks can be acquired, mutual affection of creep and infiltration can be indicated through the parameters, operation results can provide theoretical basis for theoretical analysis and numerical value simulation of creep-infiltration of the smashed rocks.

Owner:XUZHOU NORMAL UNIVERSITY

Micro alloyed oxide dispersion-strengthening ferrite steel and preparation method

The invention relates to a micro alloyed oxide dispersion-strengthening ferrite steel, wherein the chemical formula of the steel is Fe-(14-16)Cr-(1-3)W-(0.3-1.0)Ti-(0.3-0.6)Y2O3-(0.5-3)Cu. The preparation method of the steel comprises the following steps of: thermosetting and moulding after mixing and ball milling Fe-Cr-W, Ti, Y2O3 and Cu in proportion, or thermosetting and moulding after mixing ball milling powder and Fe-Cr-W alloy powder in the ratio of 1: (2-4), and then carrying out solution treatment or solution and ageing treatment, thus micro Cu alloyed oxide dispersion-strengthening ferrite steel is obtained. In the invention, Cu is introduced into a matrix lattice by mechanical alloying; nano-scale copper-rich second phase is precipitated from a matrix in the thermosetting, moulding and heat treatment process; and the strength and high-temperature creep resistance of alloy are greatly improved. The invention has the advantages of simple preparation process, short preparation period, low preparation cost and low impurity content, and is easy to operate. The prepared alloy has good room-temperature and high-temperature mechanical properties and is applicable to industrial production.

Owner:CENT SOUTH UNIV

Heat resisting casting magnesium alloy and preparation method thereof

The invention provides a heat-resistant cast magnesium alloy, which belongs to the technical field of metal material and comprises the following compositions in percentage by weight: 1.5 to 4.5 percent of yttrium, 0.4 to 1.5 percent of zinc, 0.2 to 0.7 percent of zirconium, impurity elements: less than 0.005 percent of ferrite, less than 0.015 percent of copper and less than 0.002 percent of nickel and the balance of magnesium. The heat-resistant cast magnesium alloy is low in cost and high in efficiency, has good tensile strength, yield strength and elongation, and meanwhile has perfect creep resistance property and good casting property.

Owner:SHANGHAI JIAO TONG UNIV

Composite high-temperature molybdenum disilicide-base material and preparation method thereof

InactiveCN101531519AImprove antioxidant capacityAdjust the coefficient of thermal expansionComposite substrateRoom temperature

The invention relates to a composite high-temperature molybdenum disilicide-base material and a preparation method thereof. The method can prepare the composite high-temperature material under lower production cost, which has the highest room temperature toughness equivalent to that of high-temperature alloys, higher high temperature intensity, high temperature creep resistant performance and certain plastic processing performance; the substrate of the composite high-temperature material is a composite substrate composed of MoSi2 and Si3N4, wherein the average crystal grain size of the MoSi2 is smaller than 2 microns, and the average grain diameter of the Si3N4 particulates is smaller than 1 microns. The method adopts the following technical proposal: Mo2N powder or powder of Mo5Si3 or Mo3Si are used as initial powder to obtain composite powder Mo3Si-Mo5Si3-Si3N4 or Mo5Si3-MoSi2-Si3N4 after being processed by siliconization or nitridation-siliconization, the composite powder is further enhanced and mixed with materials such as Si powder, SiC powder and the like, and is pressing molded, and then a blank is sintered under the temperature of 1415 to 1550 DEG C, and finally the sintered blank is plastic deformed, thus obtaining a required dense article of the composite high-temperature material.

Owner:李琎 +1

A Multiaxial Creep-Fatigue Prediction Method Based On ABAQUS

PendingUS20220026326A1Strong intuitivenessPracticalMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageElement model

The present invention discloses a multiaxial creep-fatigue prediction method based on ABAQUS, which comprises: S1: establishing an ABAQUS finite element model, and defining the viscoplastic constitutive equation of the material to be tested by means of the user subroutine UMAT; S2: determining the model parameters required by the viscoplastic constitutive equation; S3: establishing the fatigue damage calculation model and creep damage calculation model of the multiaxial stress-strain state of the material to be tested; S4: establishing an ABAQUS finite element model under the multiaxial stress-strain state, and calculating the stress-strain tensor of each cycle based on the defined viscoplastic constitutive equation and the model parameters; S5: calculating the equivalent stress and equivalent plastic strain by means of the user subroutine USDFLD, and superimposing the fatigue damage and creep damage of each cycle according to the linear cumulative damage criterion to obtain the crack initiation life of the material to be tested based on the fatigue damage calculation model and creep damage calculation model in combination with the stress-strain tensor.

Owner:EAST CHINA UNIV OF SCI & TECH

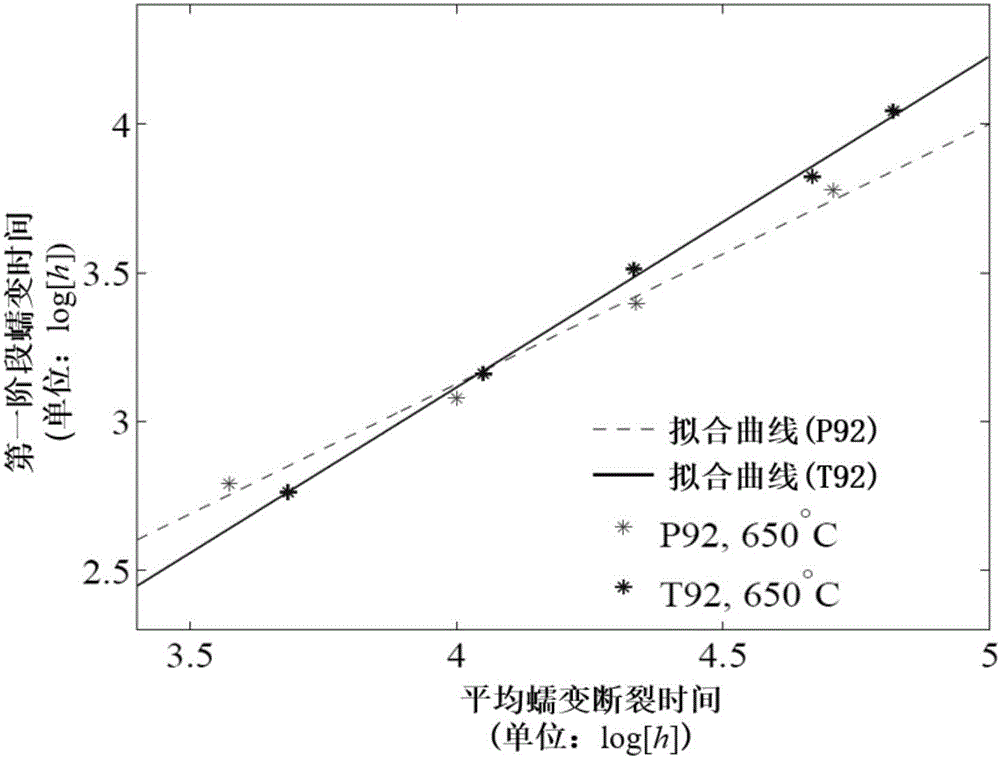

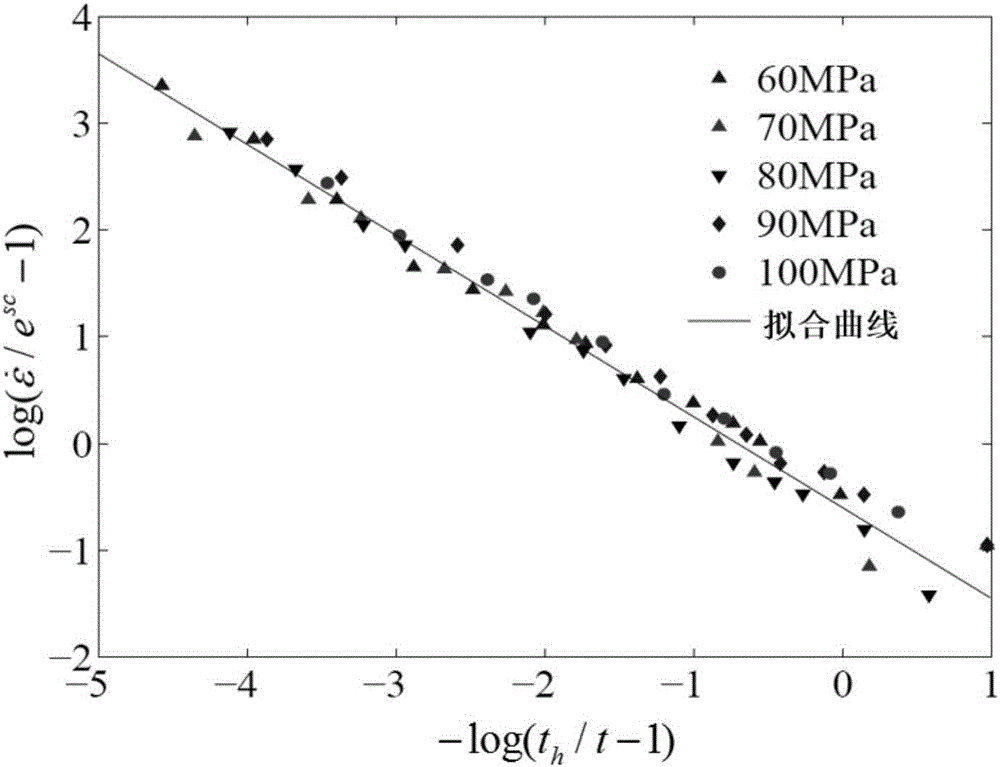

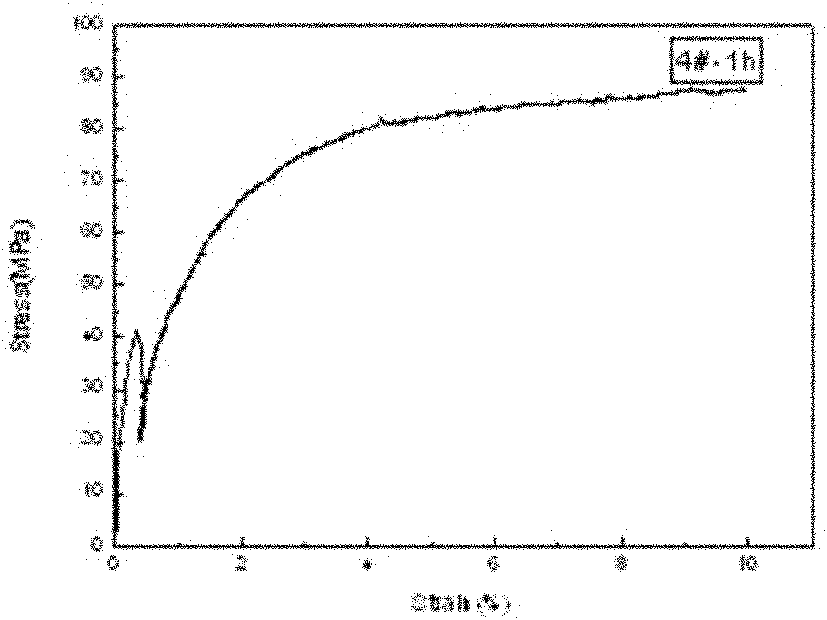

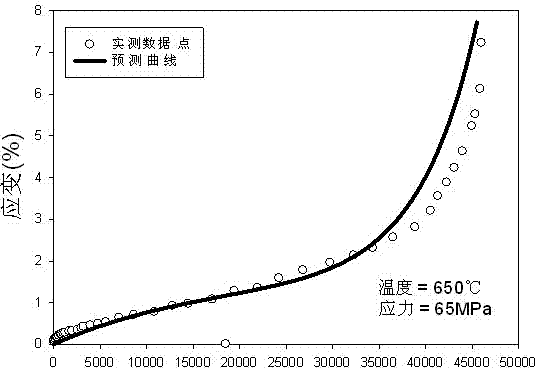

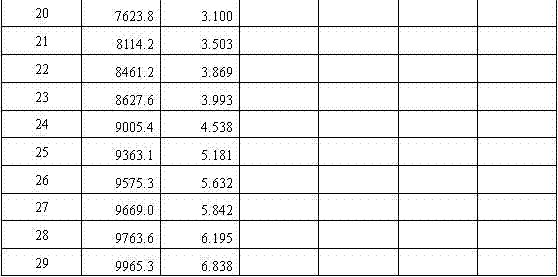

Method for evaluating creep performance of T/P92 steel

The invention discloses a method for evaluating creep performance of T / P92 steel. The method comprises the following steps of: (1) acquiring a plurality of pieces of strain data of a sample at temperature T and under strain sigma through high-temperature creep test for the creep performance under the conditions of temperature T and strain sigma; (2) selecting more than six groups of test conditions and performing the high-temperature creep test on a T / P92 steel sample until the sample is broken to acquire short-time strain data under each test condition; (3) fitting the short-time strain dataaccording to a theta parametric method model to acquire a material coefficient corresponding to each theta parameter; (4) extrapolating the theta parameter at the temperature T and under the strain sigma by using the material coefficient and the strain data; and (5) acquiring a creep curve equation of the T / P92 steel at the temperature T and under the strain sigma by using a result of the step (4), and thereby evaluating the creep performance of the corresponding steel grade. The result of the invention is excellently matched with the test data, so that the accuracy for predicting the third stage of a creep curve of the T / P92 steel by using the theta parameter method can be effectively improved. The method can be used for high-temperature duration test design and evaluation of long-time creep performance by using short-time test data.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

Alloy creep resistant heat resistant steel submerged arc welding stick

InactiveCN101983827ASimple designImprove creep strengthWelding/cutting media/materialsSoldering mediaChemical industryNuclear power

The invention discloses an alloy creep resistant heat resistant steel submerged arc welding stick, mainly comprising the following elements by percentage: 0.05 to 0.18% of C, 0.80 to 1.20% of Mn, 0.40 to 0.80% of Si, not more than 0.010% of S, not more than 0.35% of Cu, 2.20-3.80% of Cr, 0.40 to 0.80% of Ni, 0.8 to 1.40% of Mo, 0.90 to 1.30% of W, 0.30 to 0.80% of V, 0.20 to 0.50% of Ti, 0.08 to 0.16% of B, not more than 0.05% of Al, and balance of Fe. The alloy creep resistant heat resistant steel submerged arc welding stick is applied to the welding of heat-resisting steel 2.23 Cr-1Mo and 12CrMoWVB alloy hat-resisting steel, and SA-335P22 steel of a nuclear power boiler, a gas turbine generator, a high pressure steam pipe, a petroleum chemical industry and a nuclear power device at a working temperature of 600 DEG C. The welding process parameters of the alloy creep resistant heat resistant steel submerged arc welding stick comprise: a welding stick diameter is phi4.0mm, a coordinated welding agent is SJ101, a welding current is 550A, a welding voltage is 30V, and an inter-channel temperature is 135-165 DGC C. The alloy creep resistant heat resistant steel submerged arc welding stick can service for long-term under the high temperature of 600 DEG C without the occurrence of creep rupture phenomenon.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

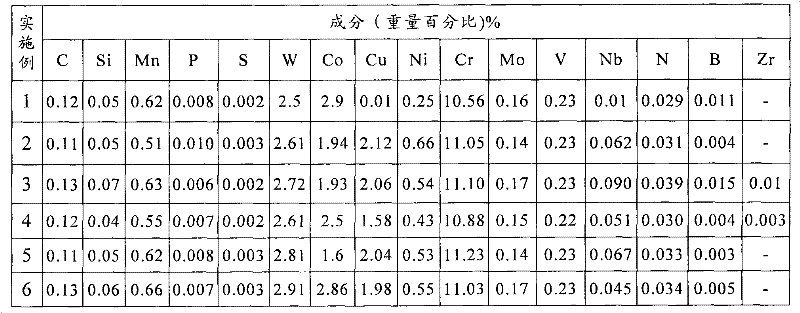

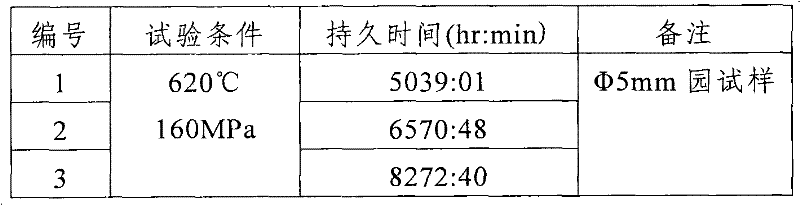

Ferrite heat resistant steel

The invention relates to ferrite heat resistant steel which comprises the following components (wt%): 0.10-0.15% of C; 0.02-0.1% of Si; 0.2-0.7% of Mn; 10.50-11.50% of Cr; 2.50-3.00% of W; 1.5-3.50% of Co; 0.01%-2.5% of Cu; 0.10-0.20% of Mo; 0.2-0.7% of Ni; 0.20-0.30% of V; not more than 0.10% of Nb; 0.001-0.015% of B; not more than 0.01% of Zr; 0.020-0.045% of N; not more than 0.030% of P; not more than 0.030% of S; and the balance of iron and inevitable impurities. An electrode bar is cast through vacuum induction smelting; after demolding of the electrode, heat preservation is performed at 670-710 DEG C for 16-20 hours; then the electrode is annealed, slowly cooled, and discharged from a furnace; after the electrode surface is cleaned, an electroslag ingot is formed by a CaF2.Al2O3.MgO slag system; the annealing temperature of the electroslag ingot is 740-780 DEG C; heat preservation is performed for 18-24 hours; the obtained ferrite heat resistant steel has excellent room-temperature and high-temperature mechanical properties; performance of a blade prepared by the steel, such as high-temperature strength, long-time strength, high-temperature creep deformation, and the like, meets the application requirements at a steam temperature of 620 DEG C and above.

Owner:宝钢特钢有限公司

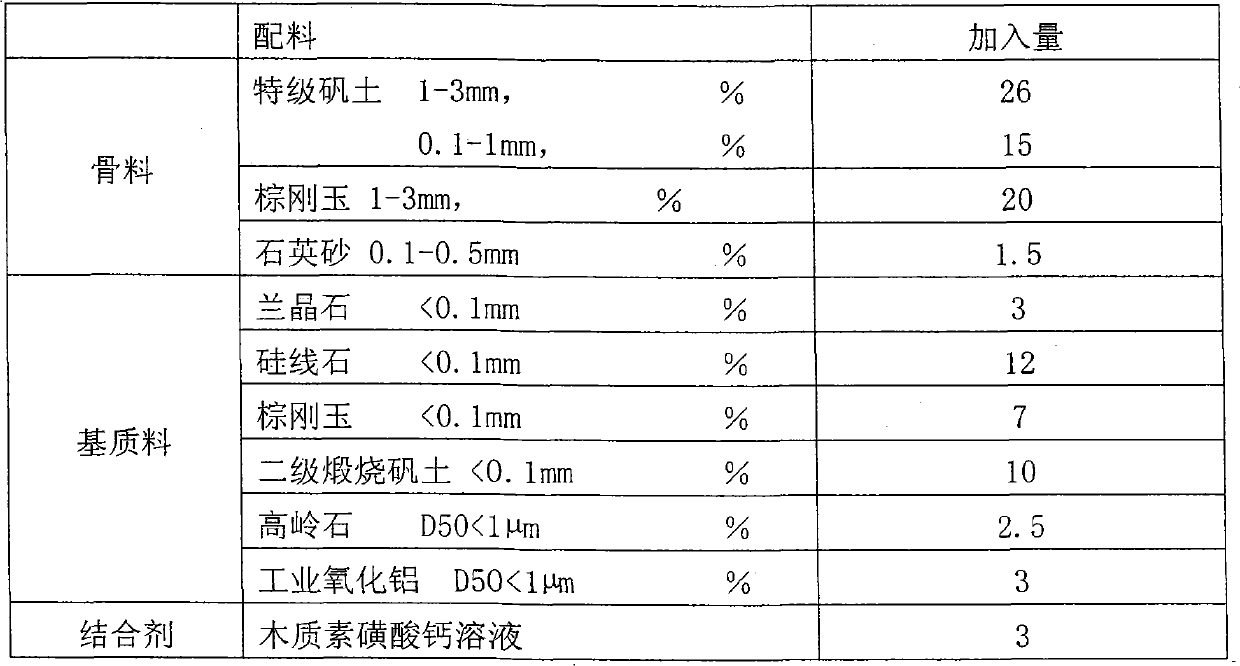

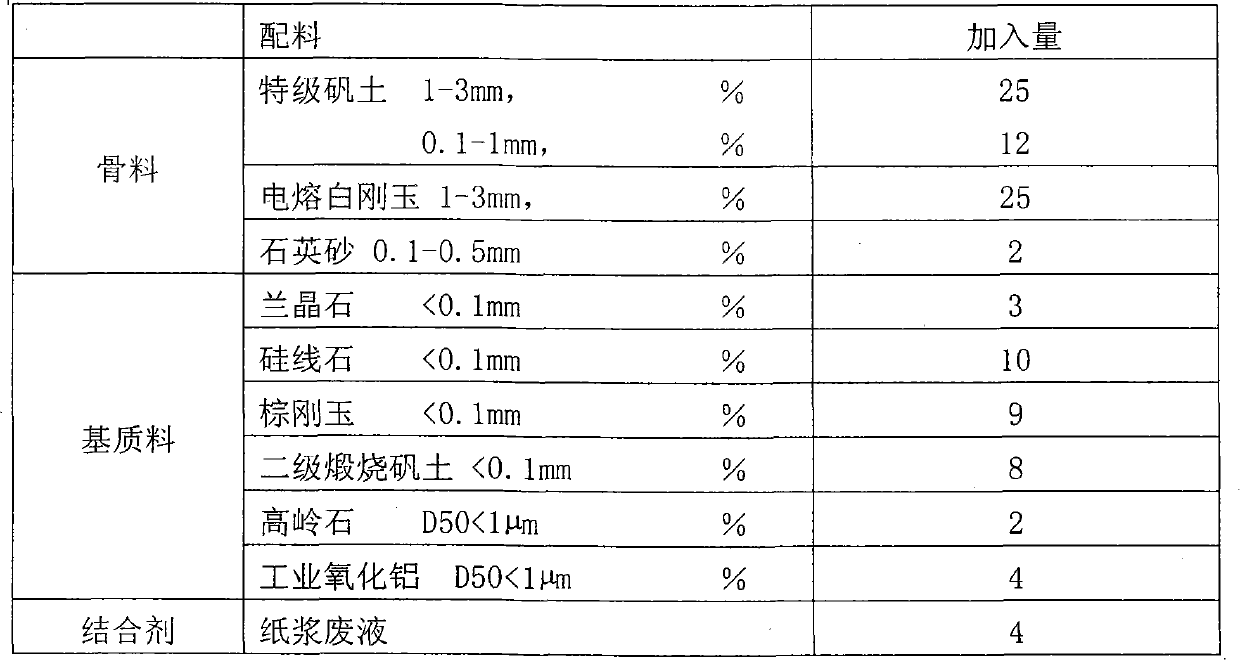

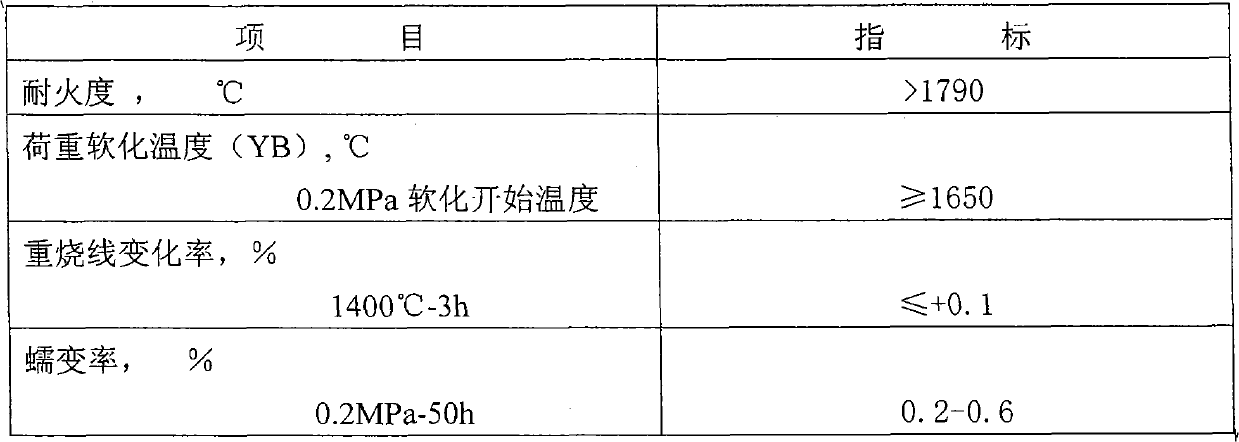

Bauxite-based low-creep mullite product

The invention provides a bauxite-based low-creep mullite product, which belongs to the field of fire-resistant materials. The bauxite-based low-creep mullite product is prepared by the following steps of: adding quartz sand, a sillimanite mineral, corundum, industrial aluminum oxide, kaolin and the like into high-alumina bauxite serving as a base material; proportioning, homogenizing, mixing, shaping and drying the mixture; and sintering the mixture at the temperature of 1,650 DEG C under the normal pressure to obtain the low-cost and high-grade bauxite-based low-creep mullite fire-resistant product. In the preparation, a composite technology route is adopted, the mineral composition is optimized and the mullitization during the production and use is effectively controlled, so the high-grade fire-resistant material product can be obtained, the superior high temperature performance of the mullite is brought into full play and the creep is small and the expansion is slight in the use of the product; and the preparation of the product can fully utilize the available resources of China, improve the comprehensive utilization value of the resources and optimize the product structure. The product can be widely applied to the parts, such as heat storage chambers, small furnaces, feeding ports, material passage systems and the like, of glass melting furnaces and other high temperature industrial furnaces.

Owner:山西高科耐火材料股份有限公司

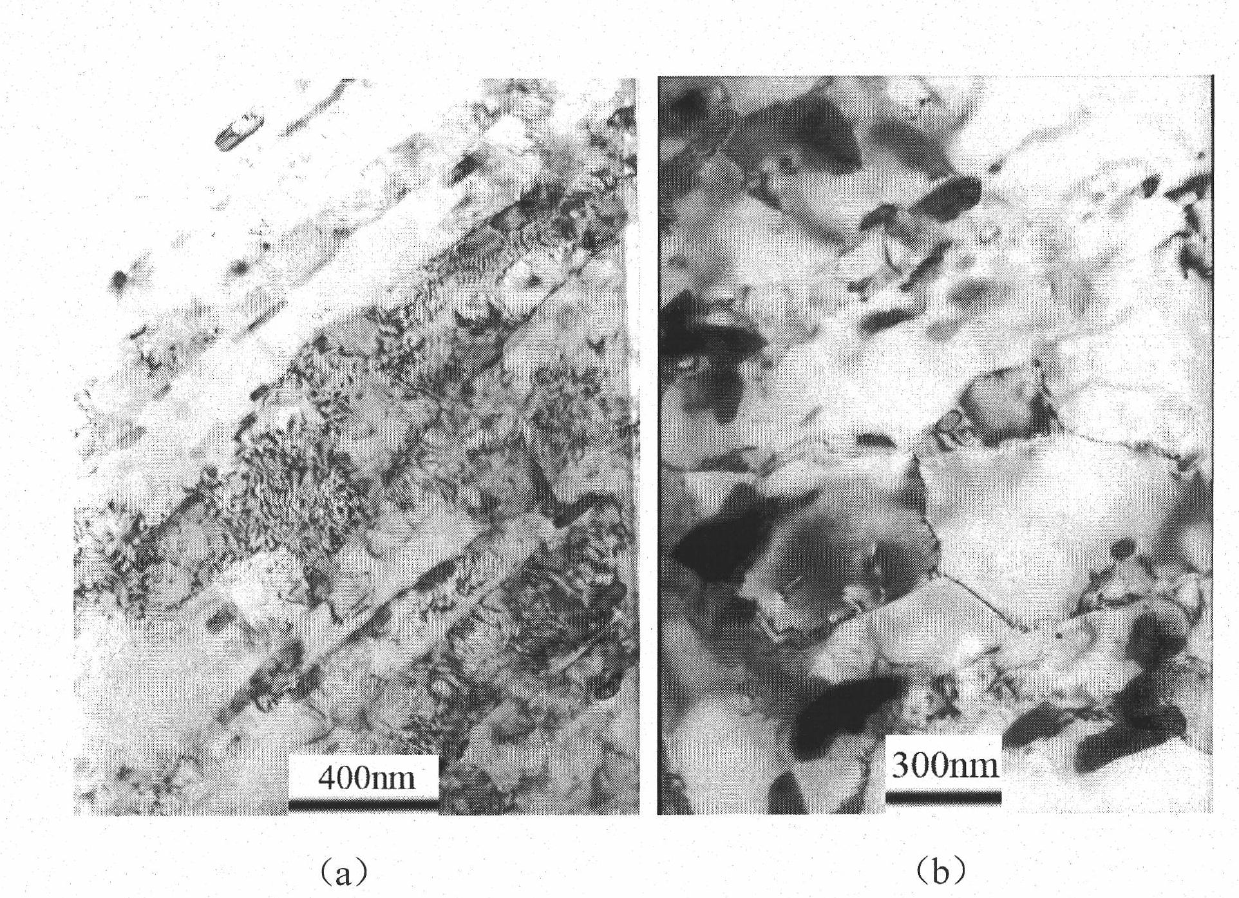

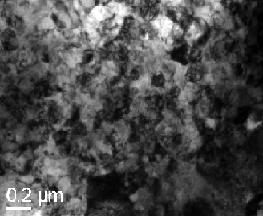

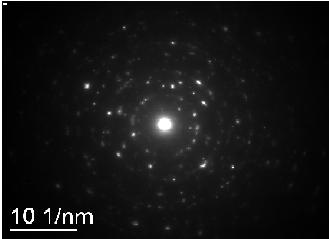

Preparation method of superfine grain nano-structure oxide dispersion strengthened steel

The invention discloses a preparation method of superfine grain nano-structure oxide dispersion strengthened steel. The preparation method comprises the following steps of: performing ball-milling mechanical alloying on alloy powder which is prepared by an atomization method or pure metal element powder in a corresponding constituent element ratio, metal Ti powder and Y2O3 powder in a nanometer scale in vacuum or under Ar gas protection so as to form solid solution alloy powder which is rich in supersaturated Y, Ti and O; and putting the supersaturated solid solution alloy powder into a mould, and performing solidification sintering in spark plasma sintering equipment so as to obtain the superfine grain nano-structure oxide dispersion strengthened steel, wherein sintering environment can be vacuum or inert gas; a sintering temperature is between 800 and 1,200 DEG C; heat preserving time is between 1 and 15min; and pressure is between 10 and 200MPa. The grain size of the alloy is refined from a micron level to a level which is equal to or less than 500 nanometers by the method, the characteristic microstructure and the irradiation resistance performance of the nano-structure oxide dispersion strengthened steel are maintained, and the alloy strength and the high temperature creep strength are greatly improved, so that the using requirement of core parts of an advanced nuclear reactor on the high temperature resistance and the irradiation resistance of materials are met.

Owner:NORTHEASTERN UNIV

Nanostructure-enhanced tin-silver-copper-base leadless compound solder and preparation thereof

InactiveCN101279405AImprove mechanical propertiesImprove reliabilityWelding/cutting media/materialsSoldering mediaManufacturing technologyTin-silver-copper

The invention relates to a tin, silver and copper based lead-free composite solder with enhanced nanometer-structure and a preparation method thereof, which belong to the technical field of the manufacturing of metal-based lead-free composite solders. The existing spreading process for SnSn-Ag-Cu series lead-free solder is characterized by poor processing performance, short creep rupture service life and high cost. The composite solder of the invention consists of 97 wt percent to 99 wt percent of commercial Sn-3.0Ag-0.5Cu solder paste and 1 wt % to 3 wt % of enhanced particles (POSS1, POSS2 or POSS3). The solder paste consists of 85 wt percent of Sn-3.0Ag-0.5Cu solder and 15 wt % of flux. The tin, silver and copper based lead-free composite solder with enhanced nanometer-structure is prepared by stirring and mixing the solder paste and enhanced particles according to the component concentration for 15 to 30 minutes. The composite solder of the invention has the advantages of good wettability and good creep rupture resistance, high shearing strength, excellent mechanical property, long creep rupture service life of the soldered joint and simple preparation process, etc.

Owner:BEIJING UNIV OF TECH

TiAl-based alloy material with excellent high-temperature property and preparation method thereof

InactiveCN101948967AGood high temperature performanceHigh temperatureOxidation resistantAluminium alloy

The invention introduces a TiAl-based alloy material with excellent high-temperature property. The TiAl-based alloy belongs to gamma-TiAl alloy and comprises the following chemical compositions in percentage by weight: 44.0 to 48.0 percent of Al, 3.0 to 5.0 percent of Nb, 0.1 to 3.0 percent of Mo, 0 to 0.8 percent of Ni, 0 to 0.8 percent of Si and the balance of Ti and inevitable impurities. A preparation method comprises a step of smelting and casting the materials in a vacuum consumable-electrode arc kish furnace or vacuum induction furnace, wherein a TiAl alloy ingot is subjected to vacuum melting or argon-filling melting first and then is cast in the casting process. Compared with the common TiAl alloy, the TiAl-based alloy material with excellent high-temperature property has higher usage temperature of up to 900 DEG C and has the advantages of good plasticity at room temperature, good creep-deformation resistance and oxidation resistance, good casting property, suitability for casting thin-wall components and great market prospect.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

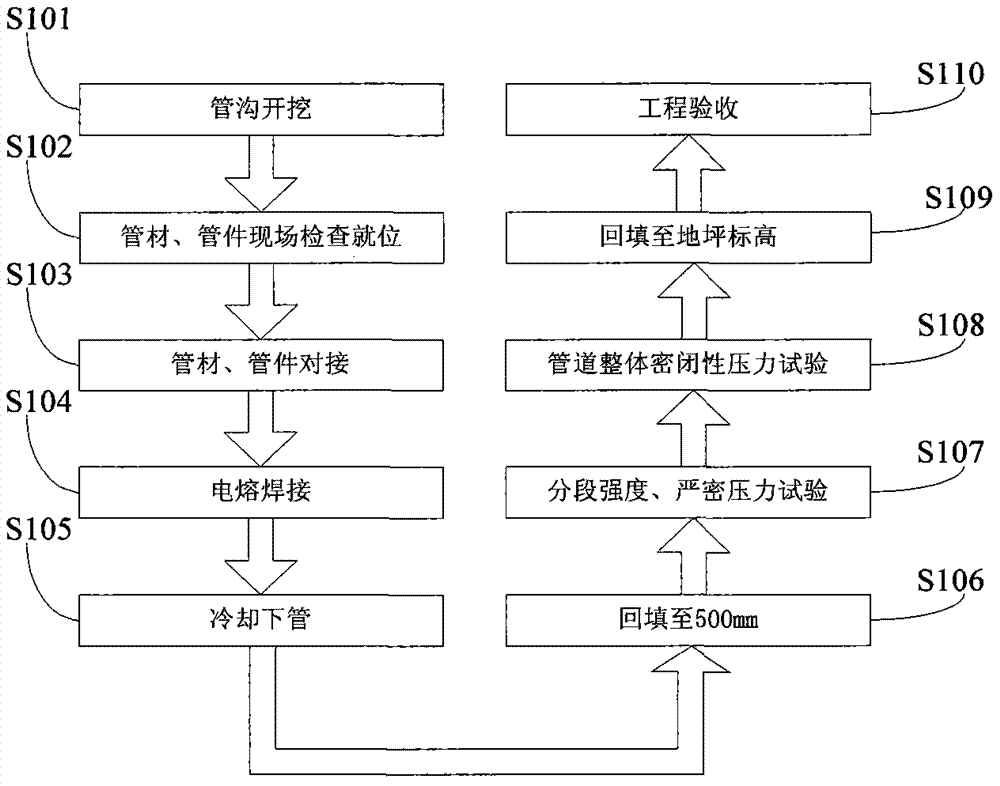

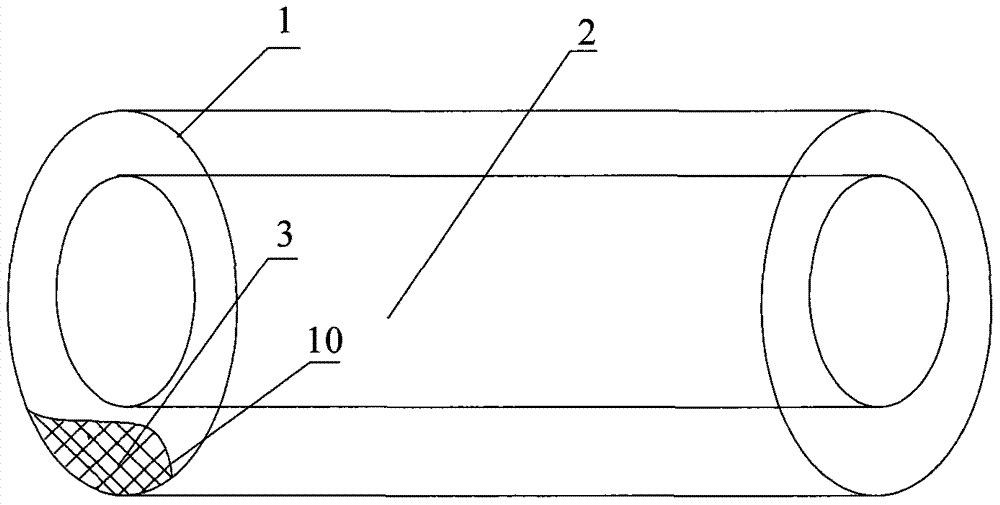

Construction method of steel wire mesh framework plastic composite pipe

InactiveCN103883797AComposite uniform and reliableSolve the interface peeling problemPipe laying and repairPipe fittingStructural engineering

The invention discloses a construction method of a steel wire mesh framework plastic composite pipe. The construction method includes the following steps that a pipe ditch is dug; a pipe and a pipe fitting are checked in place in an on-spot mode; the pipe and the pipe fitting are connected in a butt mode; electric smelting welding is performed; cooling and pipe underground-placing are performed; after a pipeline is installed and pipe laying and underground-placing are performed, primary backfilling to 500 mm is performed; the laid pipeline receives a segmented intensity and tight pressure test; an airtight pressure test is performed on a whole laid pipeline, after the pipeline is installed and pipe laying and underground-placing are performed, secondary backfilling to the grade level elevation is performed; acceptance of work is performed. The construction method of the steel wire mesh framework plastic composite pipe can effectively solve the interface stripping problem of steel-HDPE, a pipe end sealing technology which is extremely strictly required in the past can become convenient and reliable, the creep resistance is good, mechanical strength is durable, rigidity is high, shock resistance is good, size stability is good, moderate flexibility is achieved, and two materials of hard steel and flexible plastics are composited evenly and reliably.

Owner:WUHAI HIGHWAY ENG

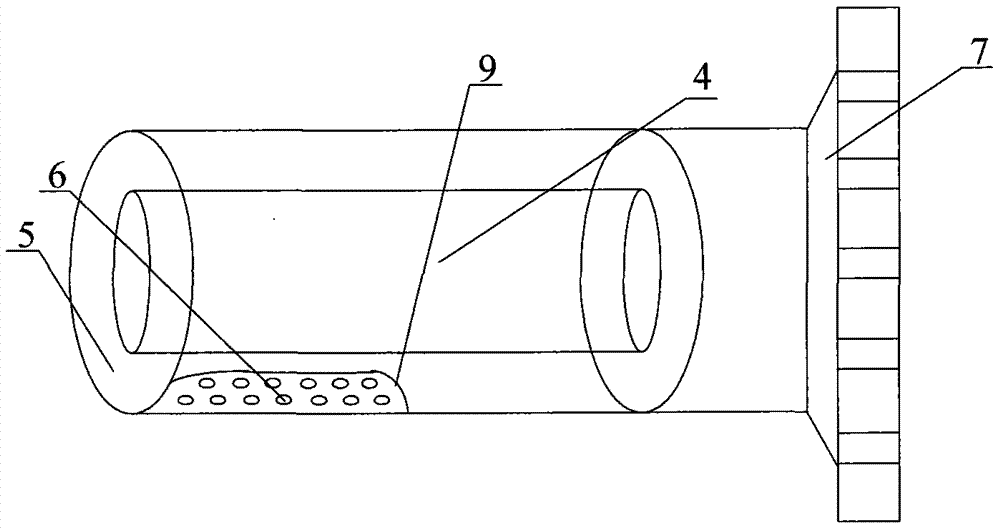

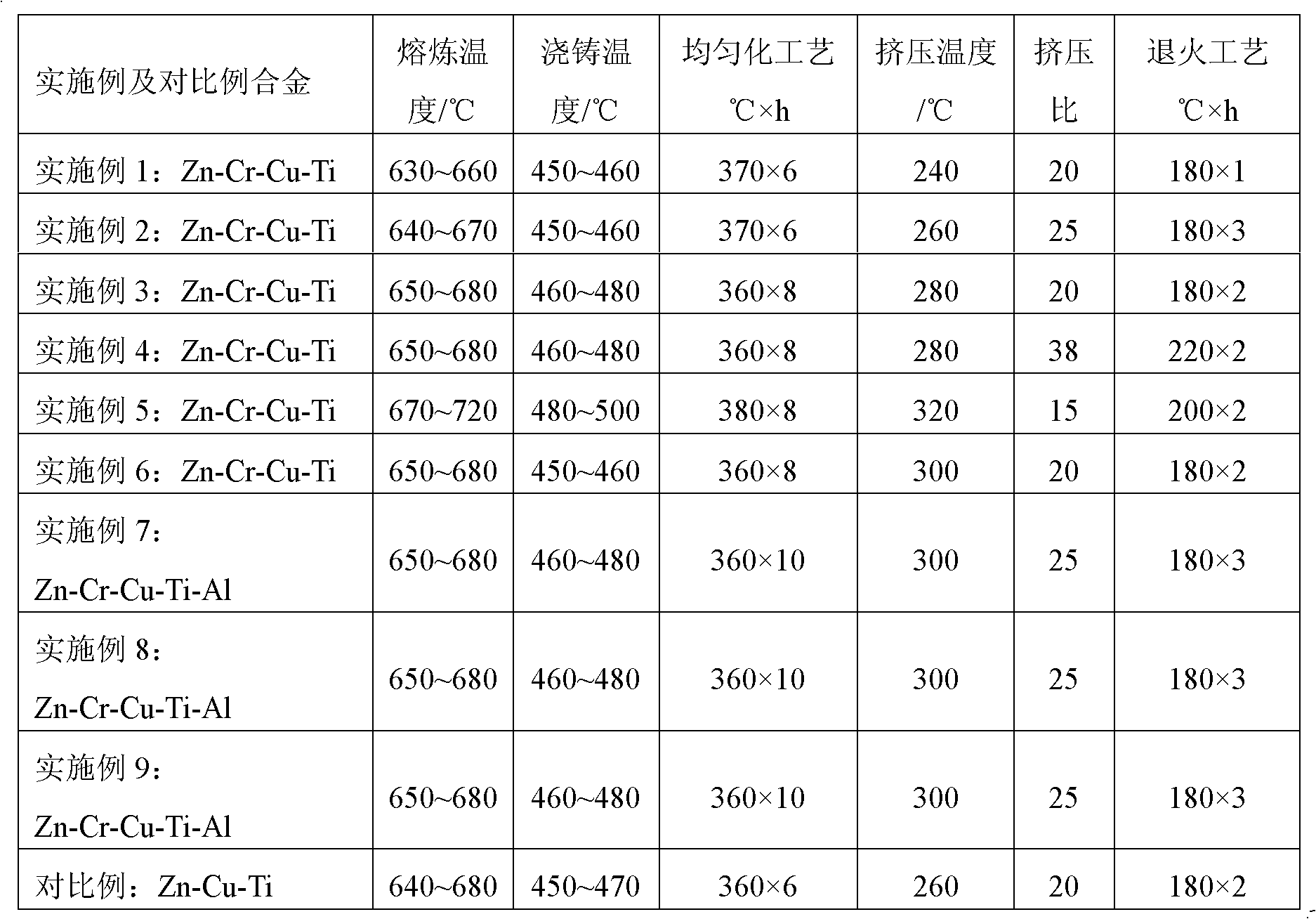

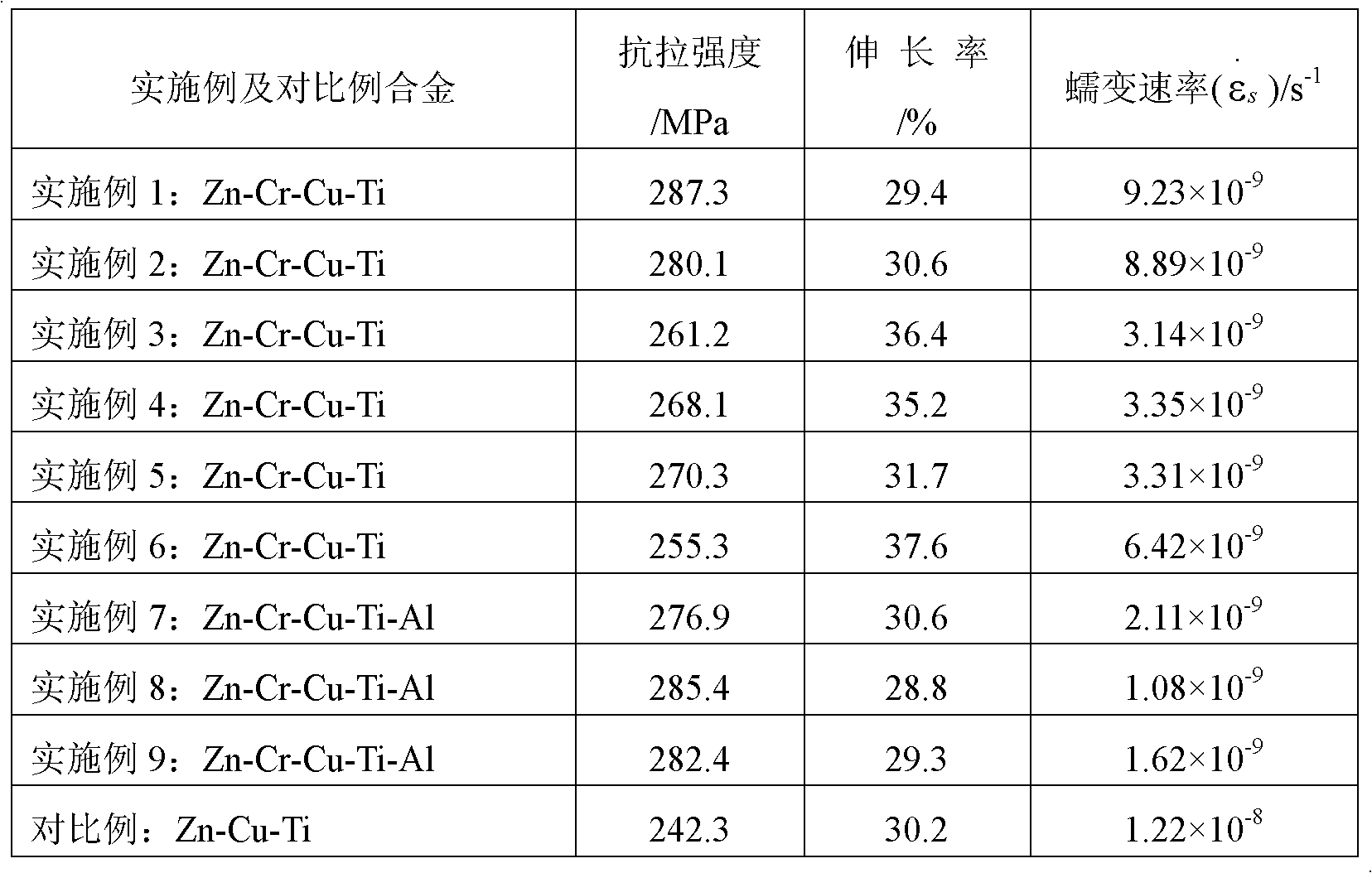

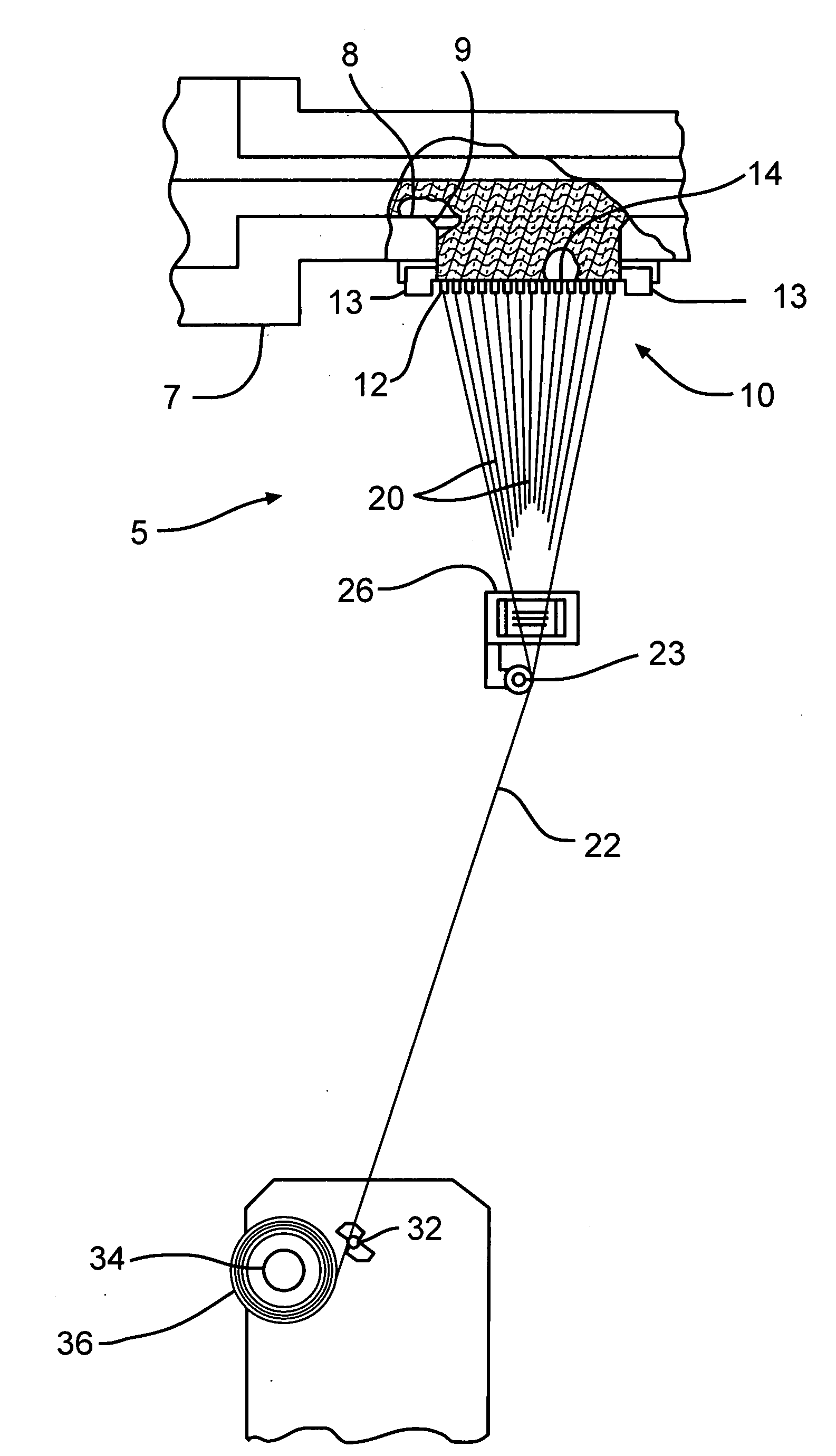

Cr-containing creep-resisting extruded zinc alloy and preparation method thereof

The invention discloses a Cr-containing creep-resisting extruded zinc alloy, belonging to the technical field of metal material manufacture. The alloy comprises the following components by mass percent: 0.05-3.0% of Cr, 0.5-2.5% of Cu, 0.1-0.3% of Ti and the balance of Zn and impurities which accounts for no more than 0.05% of the total amount. The alloy also can comprise 0.1-1.0% of Al by mass. The preparation method is implemented as follows: smelting by adopting a coverage protective method at the temperature of 630-720 DEG C, adding the alloy elements respectively in a form of pure Zn, pure Al and intermediate alloys of Cu-Cr, Zn-Cu and Zn-Ti, casting at the temperature of 450-500 DEG C after the alloy solution is mixed evenly, homogenizing ingots for 6-10h at the temperature of 360-380 DEG C, performing extrusion forming at the temperature of 240-320 DEG C with the extrusion ratio of 15-38, and annealing for 1-3h at the temperature of 180-220 DEG C. The invention has reasonable component proportioning, and the prepared zinc alloy is a deformation zinc alloy suitable for extrusion and has excellent creep resistance and combination properties.

Owner:CENT SOUTH UNIV

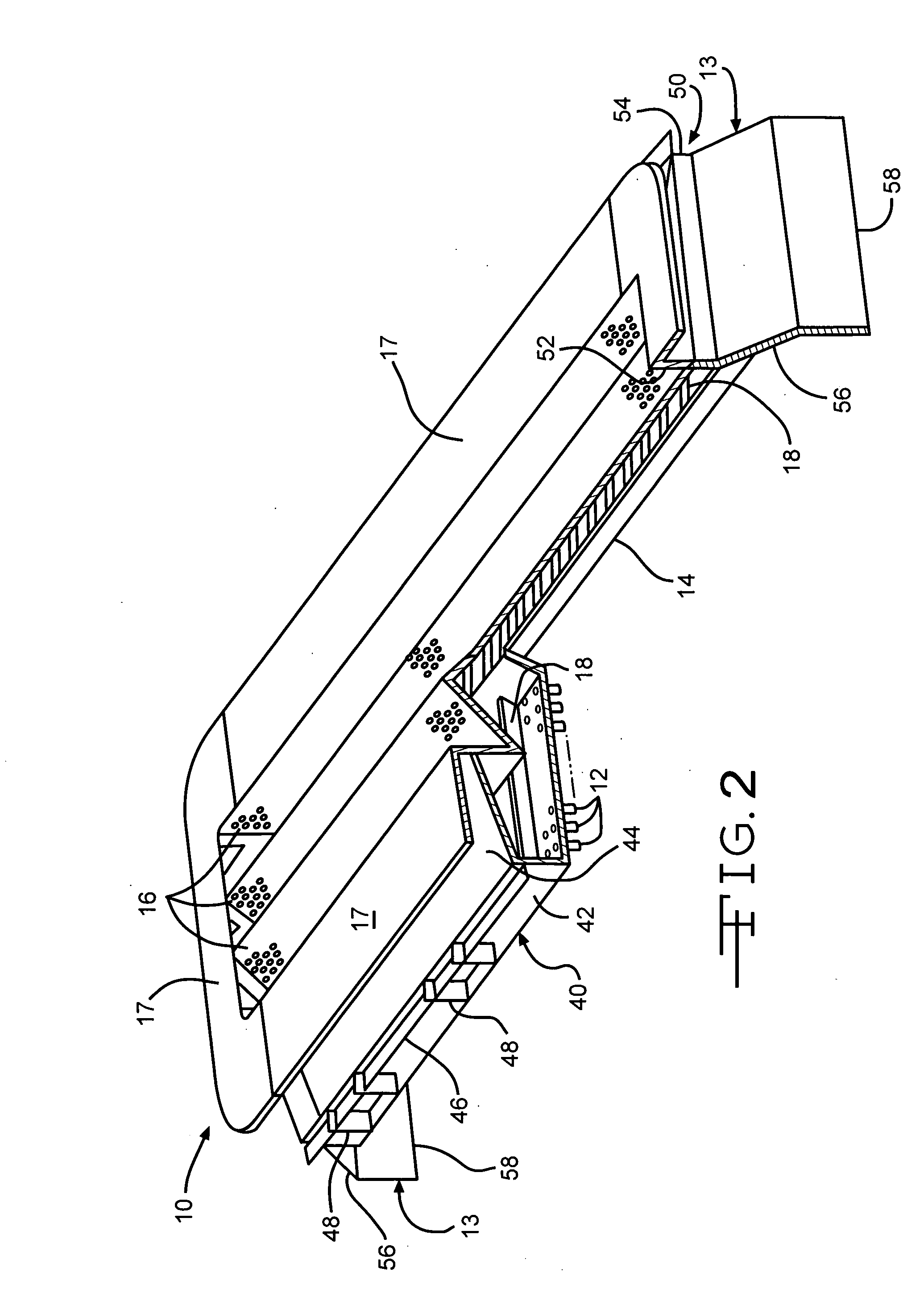

Palladium screens for bushing assembly

A filament forming apparatus has a bushing that includes a high palladium content screen along with structural components and non-structural components. The structural components are formed of a first material having a high creep strength and the ability to withstand corrosive effects of molten mineral materials. The non-structural components are formed of at least a second material that is different from the first material.

Owner:OCV INTELLECTUAL CAPITAL LLC

Nanoparticle reinforced creep-resistant magnesium alloy and preparation method thereof

The invention provides a nanoparticle reinforced creep-resistant alloy, which contains the following components in percentage by weight: 0.15-0.2 percent of Gd, 0.5-0.8 percent of Al, 1.1-1.26 percent of Zn, 0.3-0.4 percent of Ca, 0.1-0.3 percent of Sr, 0.2-0.6 percent of Nd, 0.4-0.55 percent of Zr, 0.8-0.9 percent of Sn, 0.05-0.15 percent of Be, 0.55-0.58 percent of Mn, 0.35-0.45 percent of Sb, 0.7-0.9 percent of Cu, 4-10 percent of SiC nanoparticles and the balance of Mg, wherein the diameters of the SiC nanoparticles are less than 100 nanometers. The invention further provides a preparation method of the alloy. The alloy has high mechanical property and high creep resistance.

Owner:广西北部湾粮油技术研究有限公司

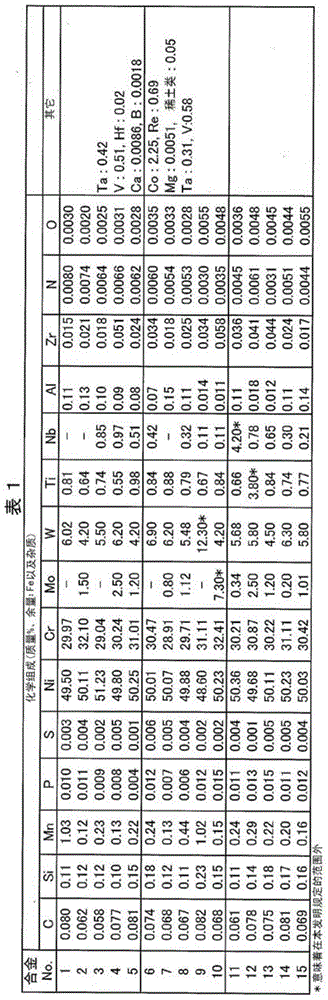

Method for manufacturing austenite series heat-resistant alloy pipe and austenite series heat-resistant alloy pipe manufactured by the method

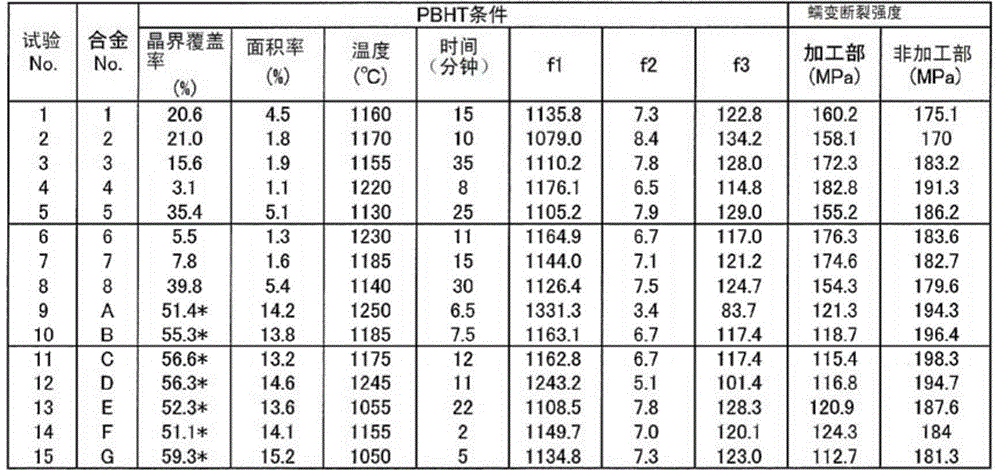

The invention provides a method for manufacturing an austenite series heat-resistant alloy pipe and an austenite series heat-resistant alloy pipe manufactured by the method, the austenite series heat-resistant alloy pipe is excellent in creep strength of hot working / cold working position after heat treatment. The method for manufacturing the austenite series heat-resistant alloy pipe comprises bending, expanding, hot working or cold working an alloy pipe after heat treatment to form a working portion, and after baking with the condition that the rate of coverage of carbonized matter in grain boundaries of the metallographic structure of the working portion and an intermetallic compound is below 50%, wherein the alloy pipe comprises chemical composition as following, by mass, 0.02 % to 0.13 % of C, less than 1 % of Si, less than 2 % of Mn, less than 0.03 % of P, less than 0.01 % of S, 25 % to 36 % of Cr, 40 % to 60 % of Ni, less than 0.3 % of Al, 2.0 % to 10.0 % of W, 0.05 % to 1.5 % of Ti, 0.002 % to 0.03 % of Zr, 0 % to 3 % of Mo, 0 % to 1.5 % of Nb, 0 % to 15 % of Co, 0 % to 0.05 % of Ca, 0 % to 0.05 % of Mg, 0 % to 0.2 % of rare earth element, 0 % to 0.2 % of Hf, 0 % to 0.2 % of B, 0 % to 1.5 % of V, 0 % to 2.0 % of Ta, 0 % to 3.0 % of Re, and the reminder comprising Fe and inevitable impurities.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com