Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43431 results about "Hot Temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Presence of warmth or heat or a temperature notably higher than an accustomed norm.

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

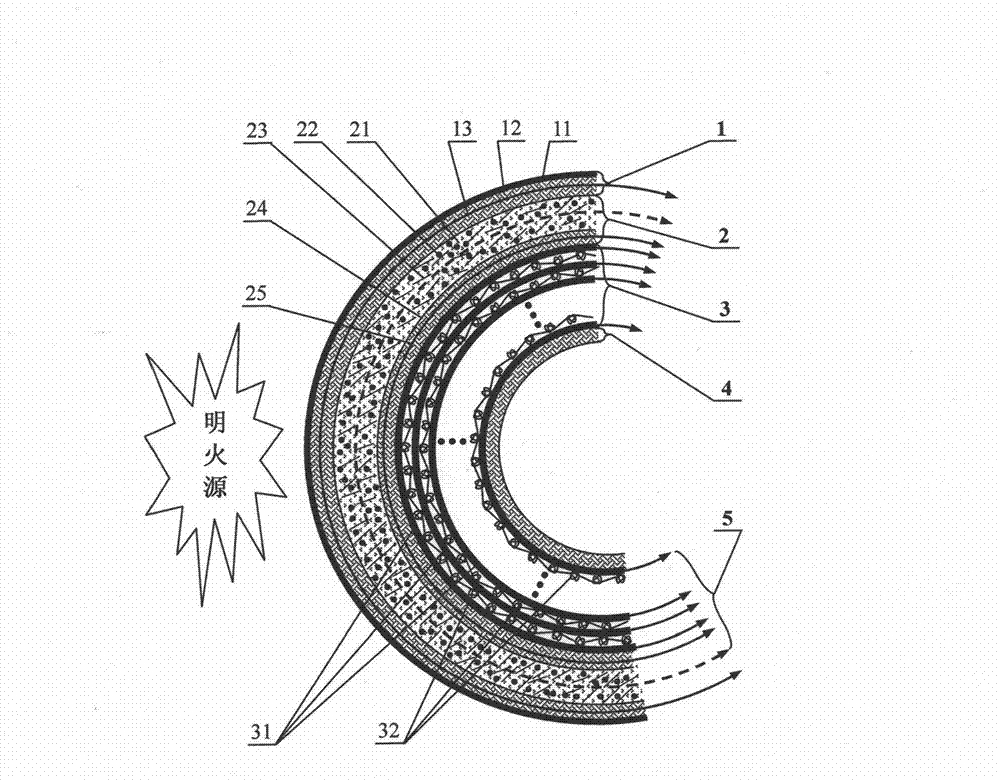

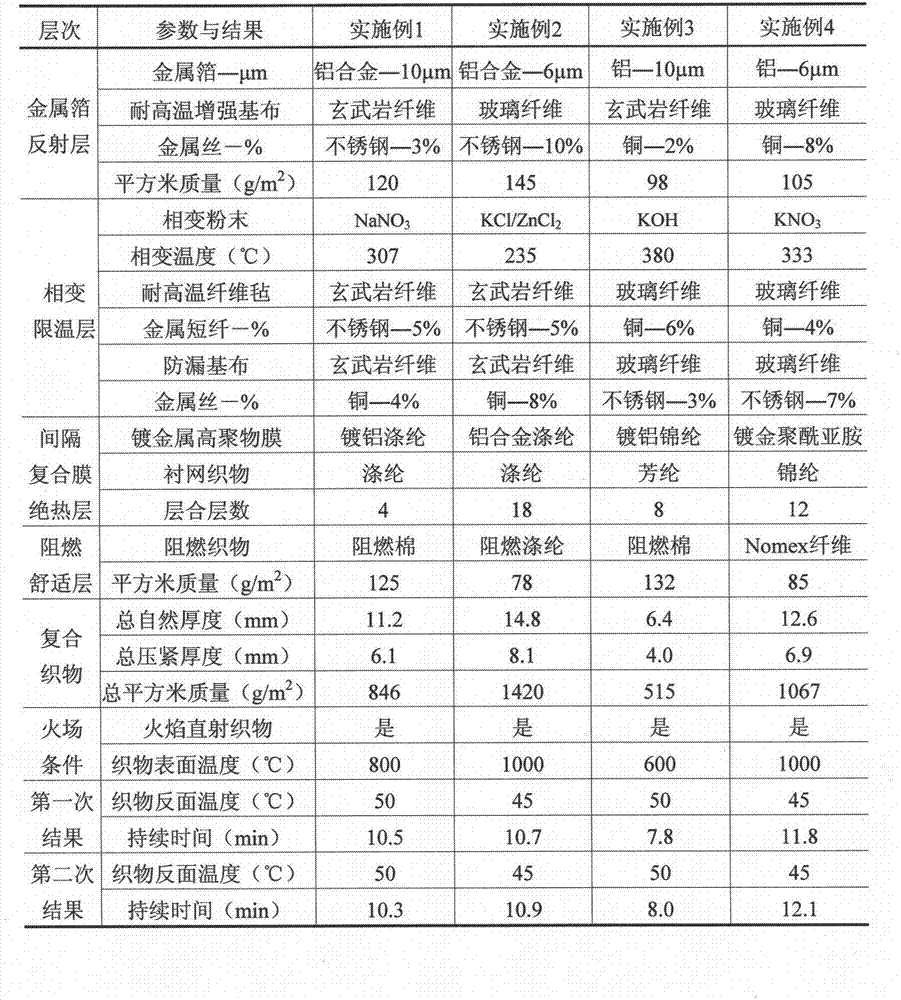

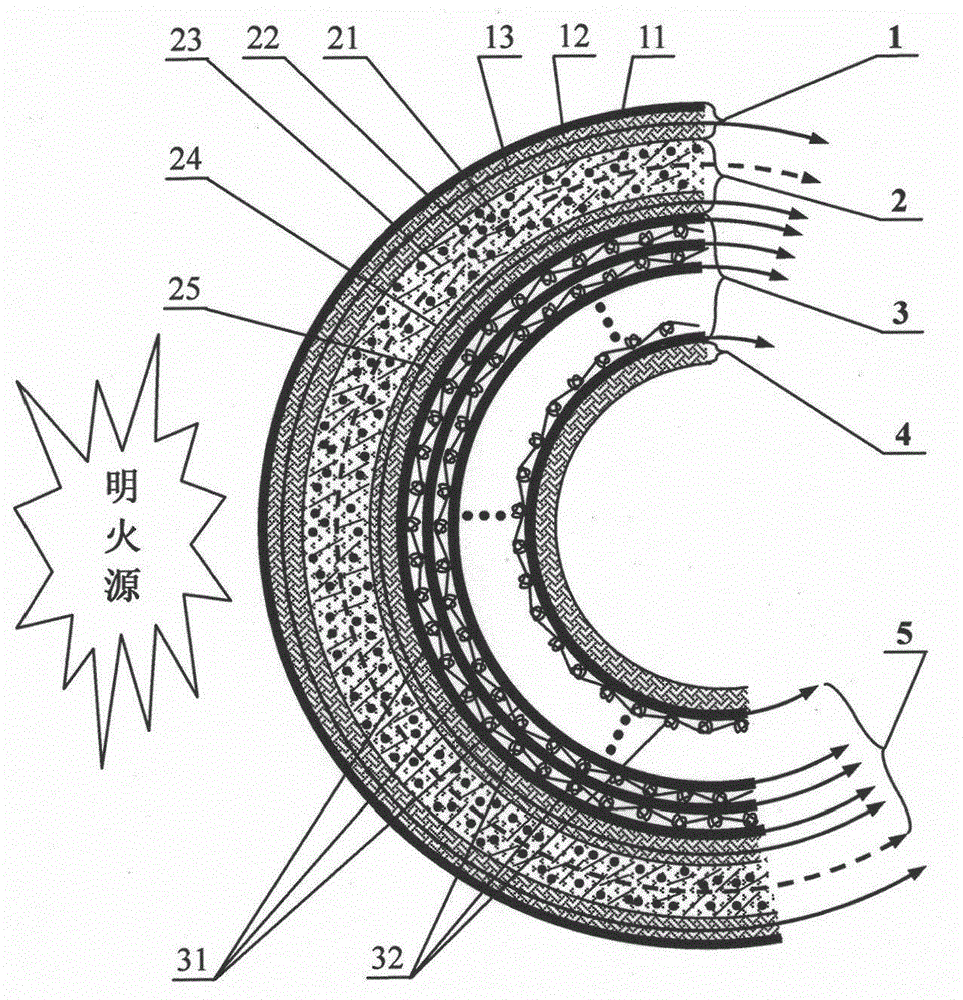

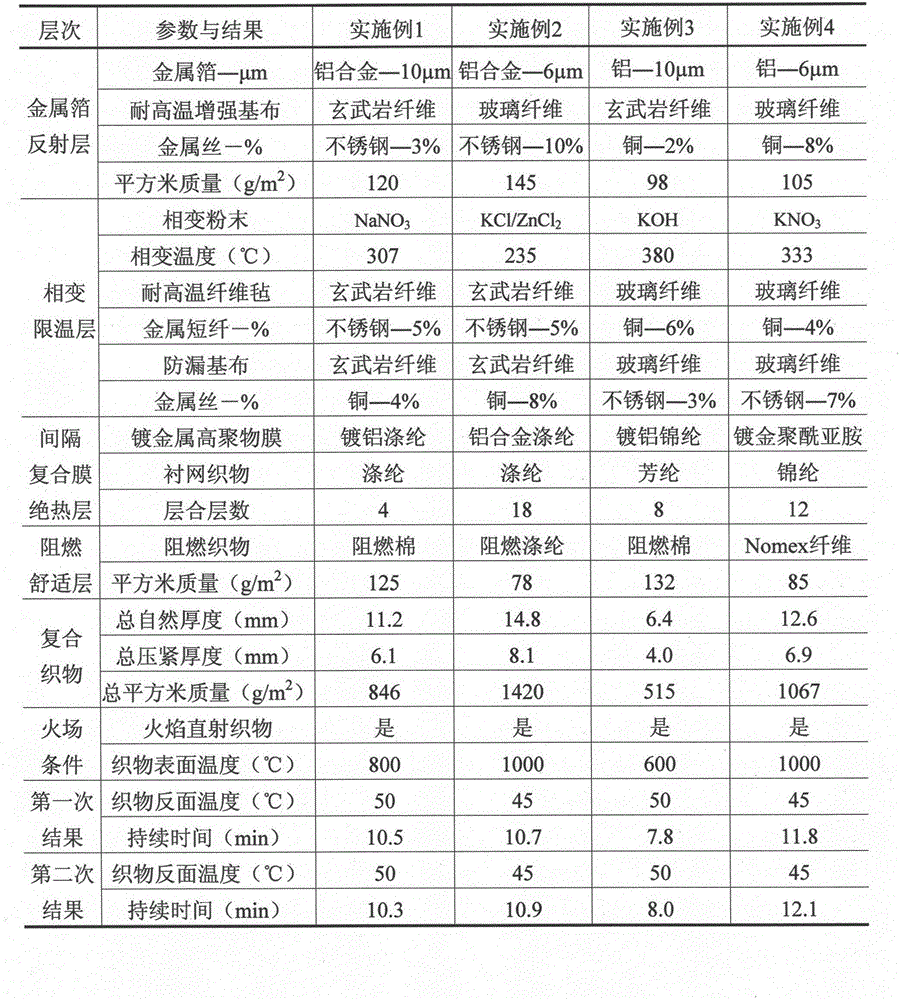

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

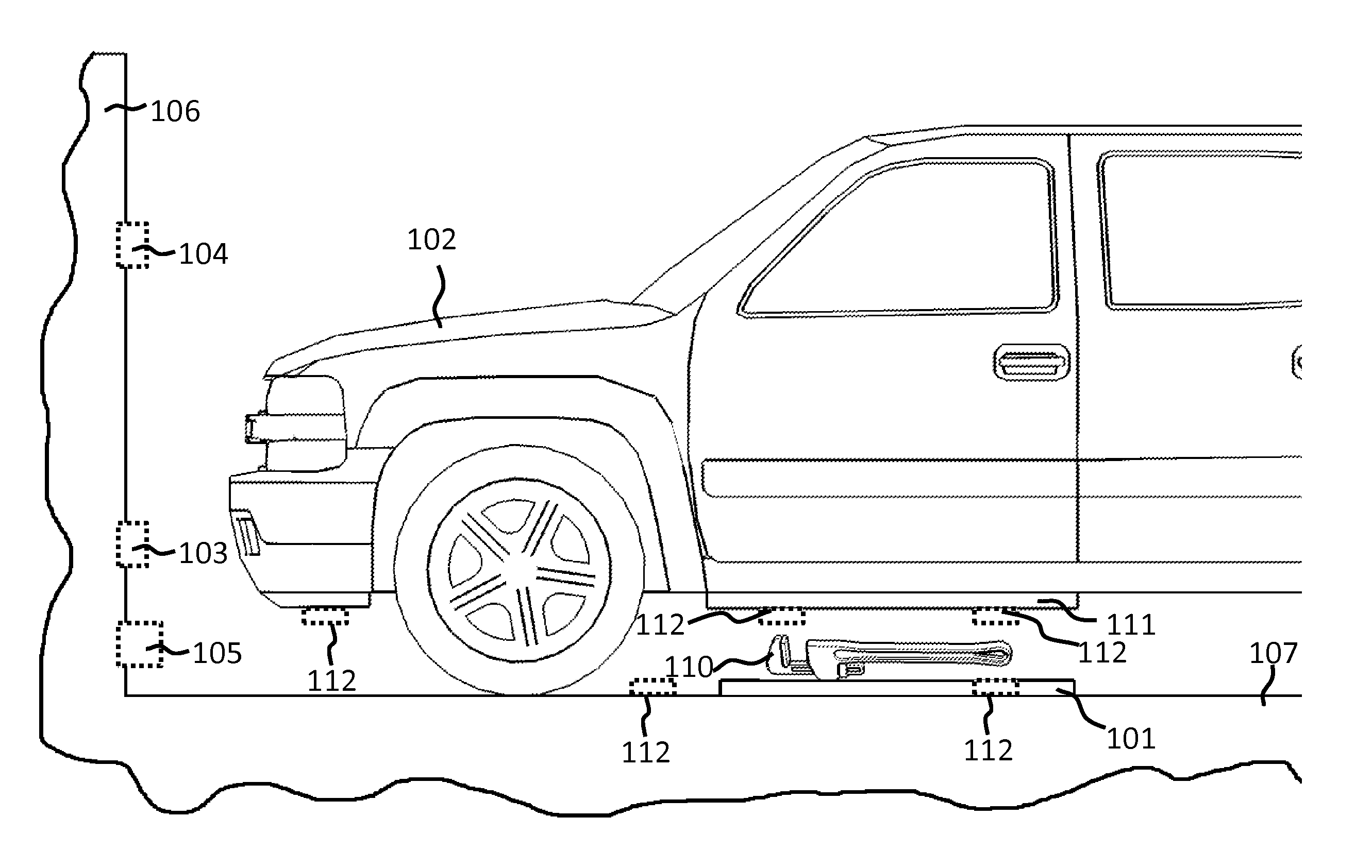

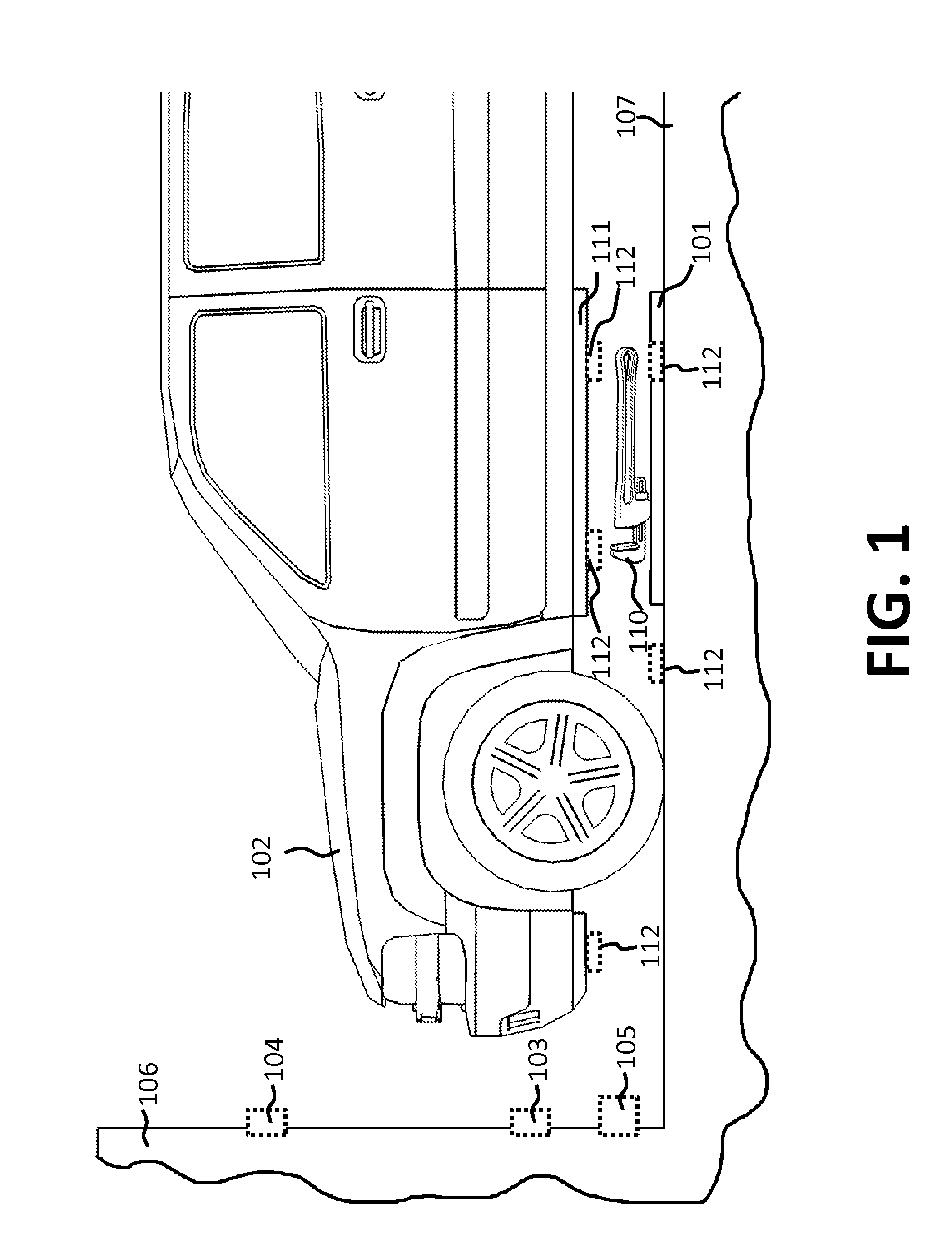

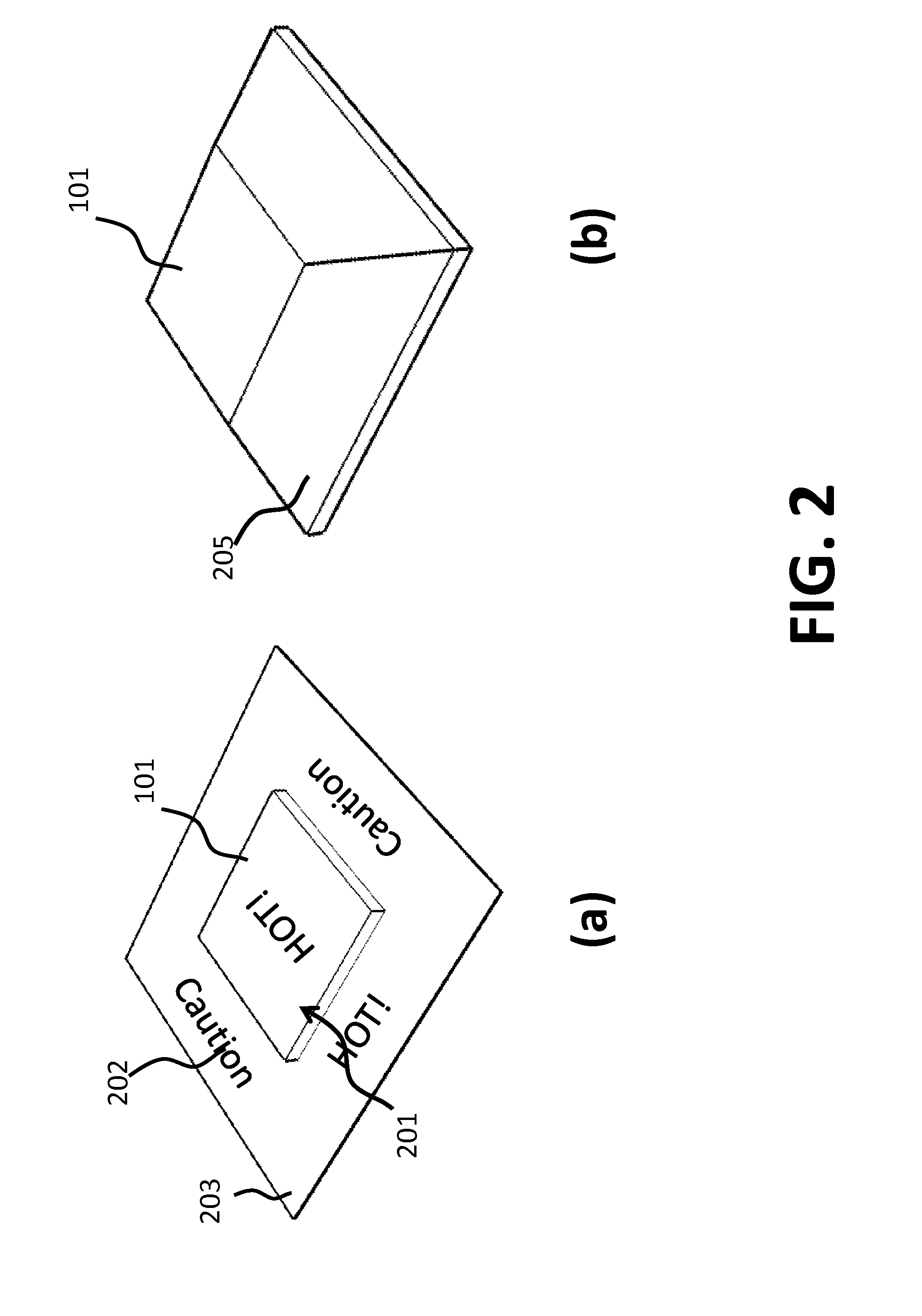

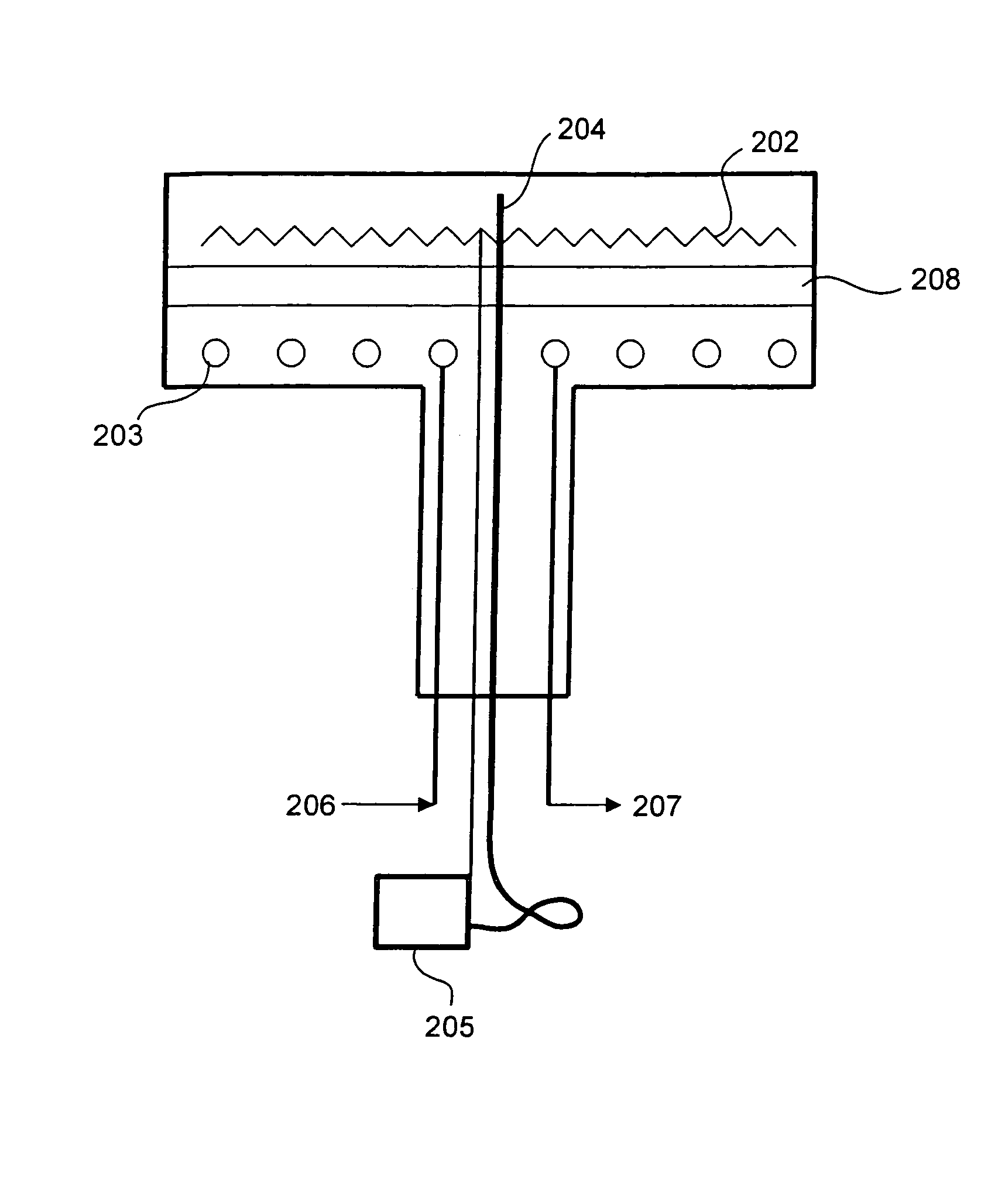

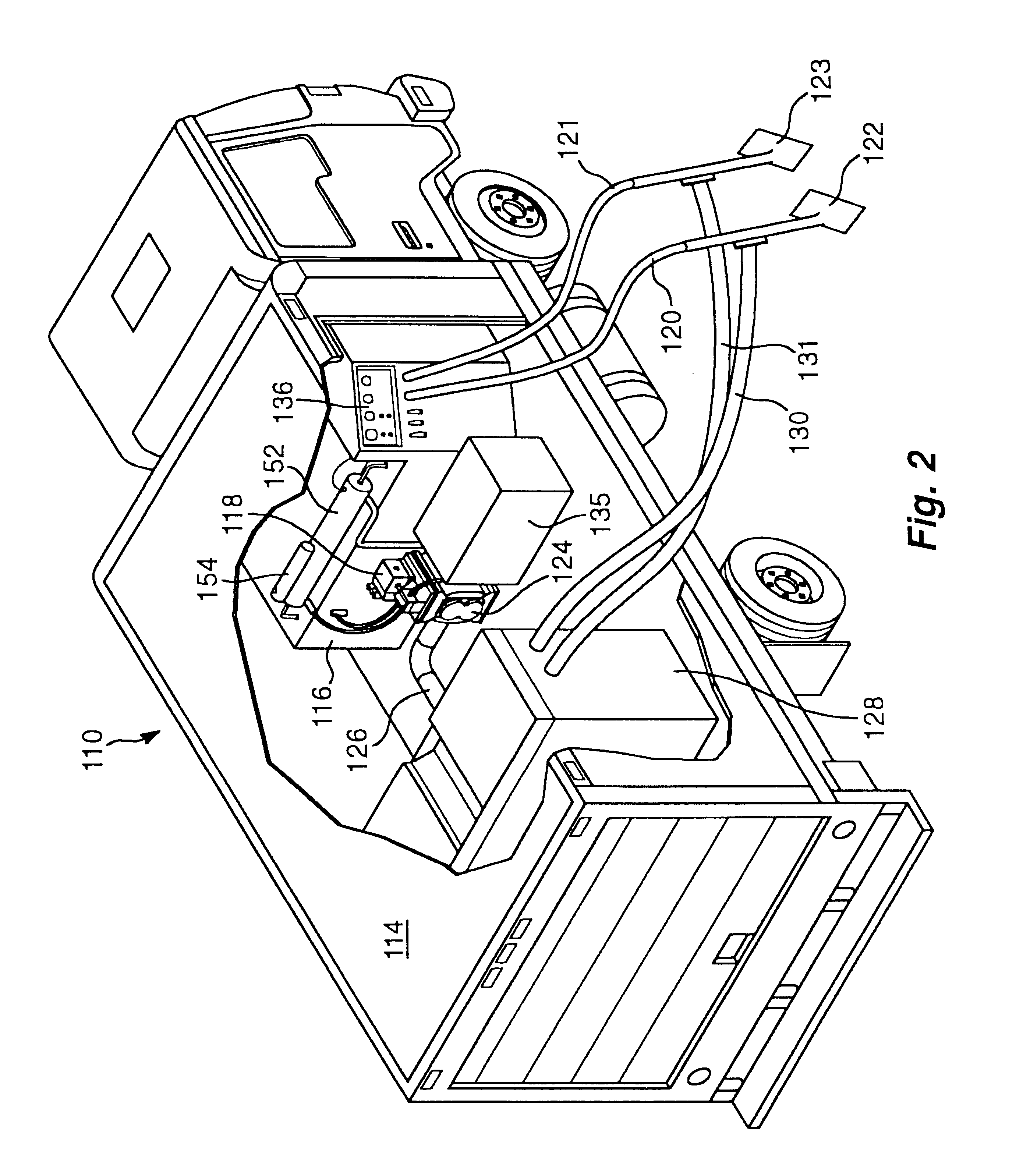

Vehicle charger safety system and method

InactiveUS20110074346A1Safety concern can be addressedFix security issuesMultiple-port networksBatteries circuit arrangementsForeign objectSystem identification

Wireless vehicle charger safety systems and methods use a detection subsystem, a notification subsystem and a management subsystem. The detection subsystem identifies a safety condition. The notification subsystem provides an indication of the safety condition. The management subsystem addresses the safety condition. In particular, undesirable thermal conditions caused by foreign objects between a source resonator and a vehicle resonator are addressed by sensing high temperatures, providing a warning and powering down a vehicle charger, as appropriate for the environment in which the charger is deployed.

Owner:WITRICITY CORP

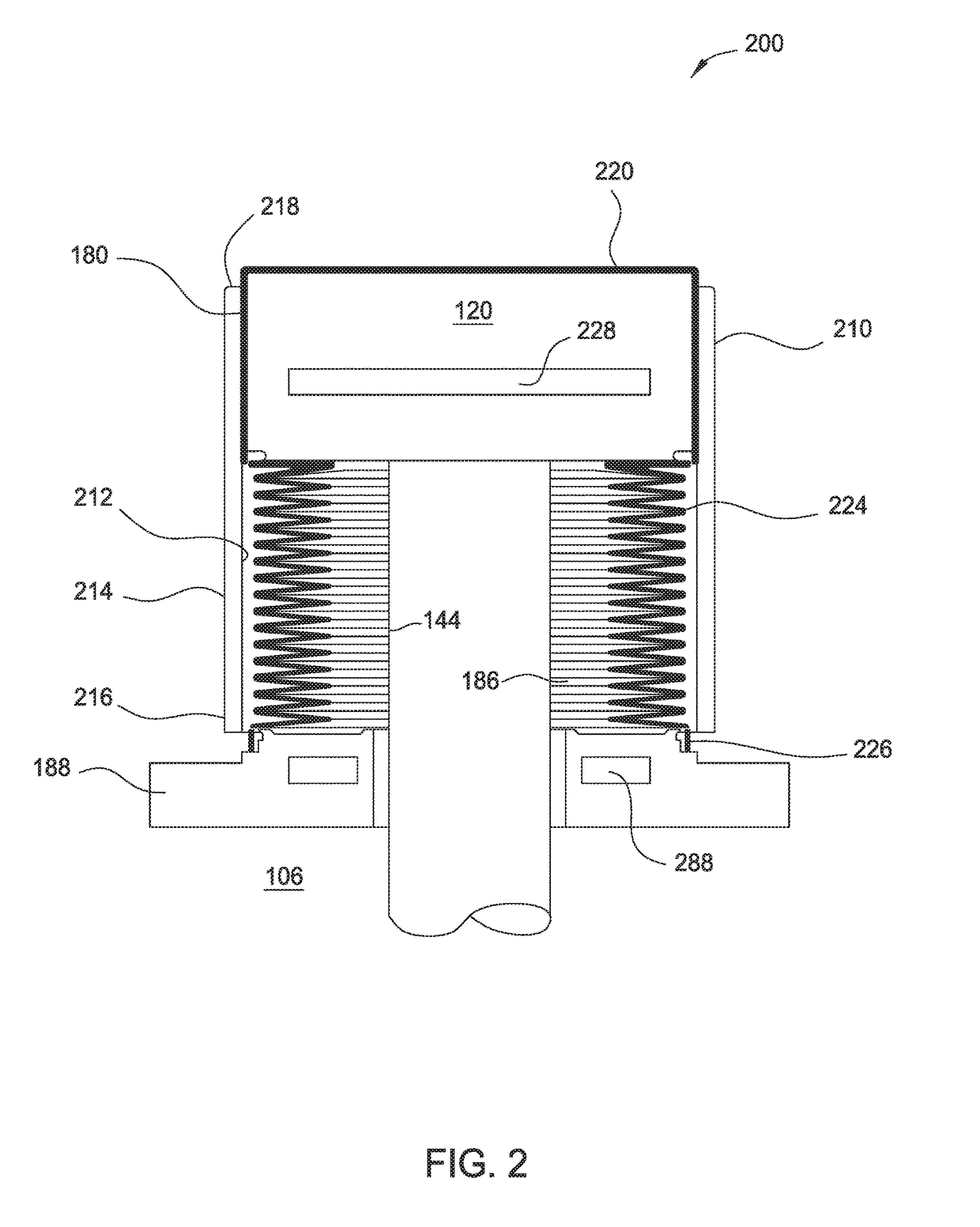

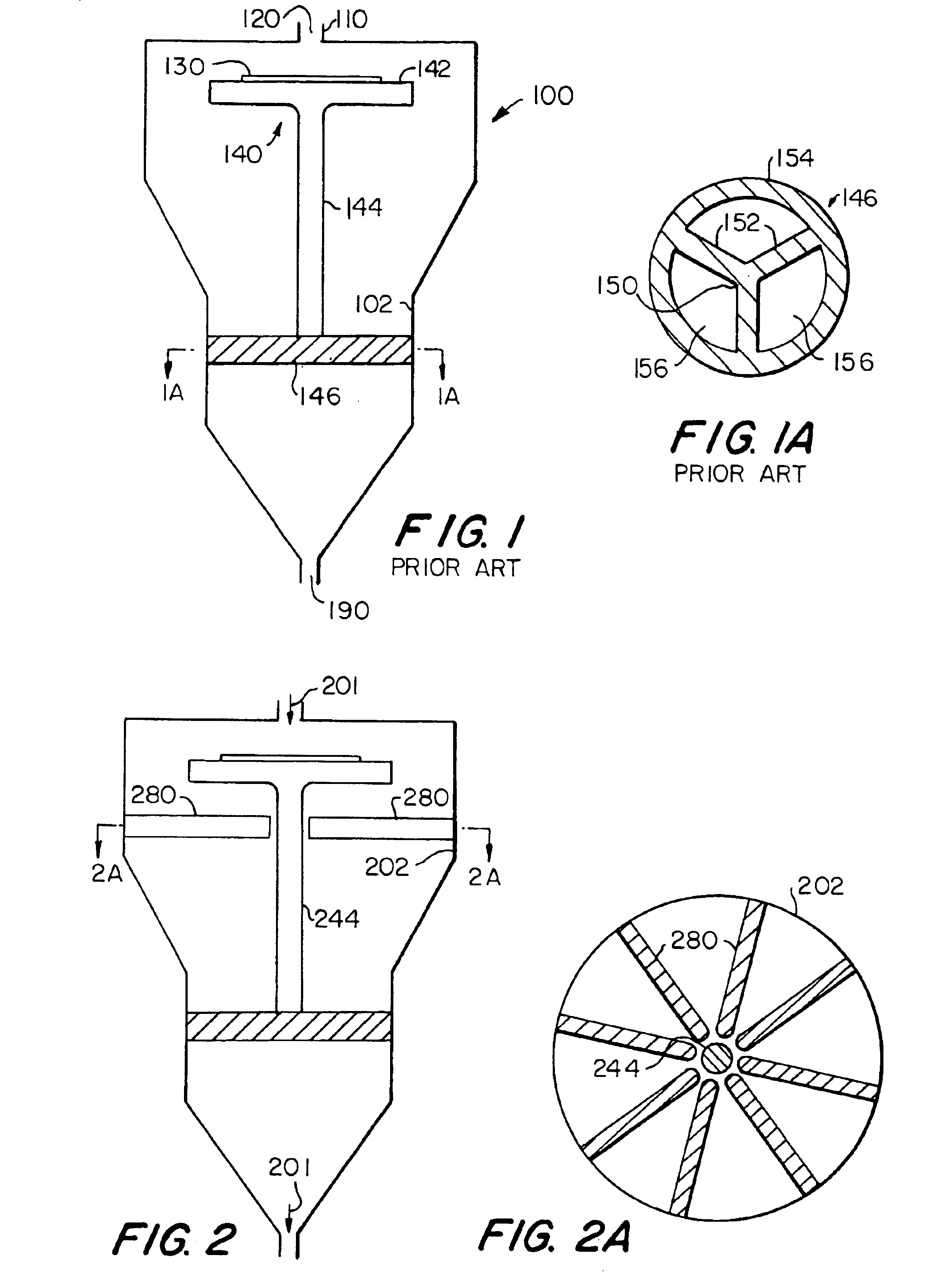

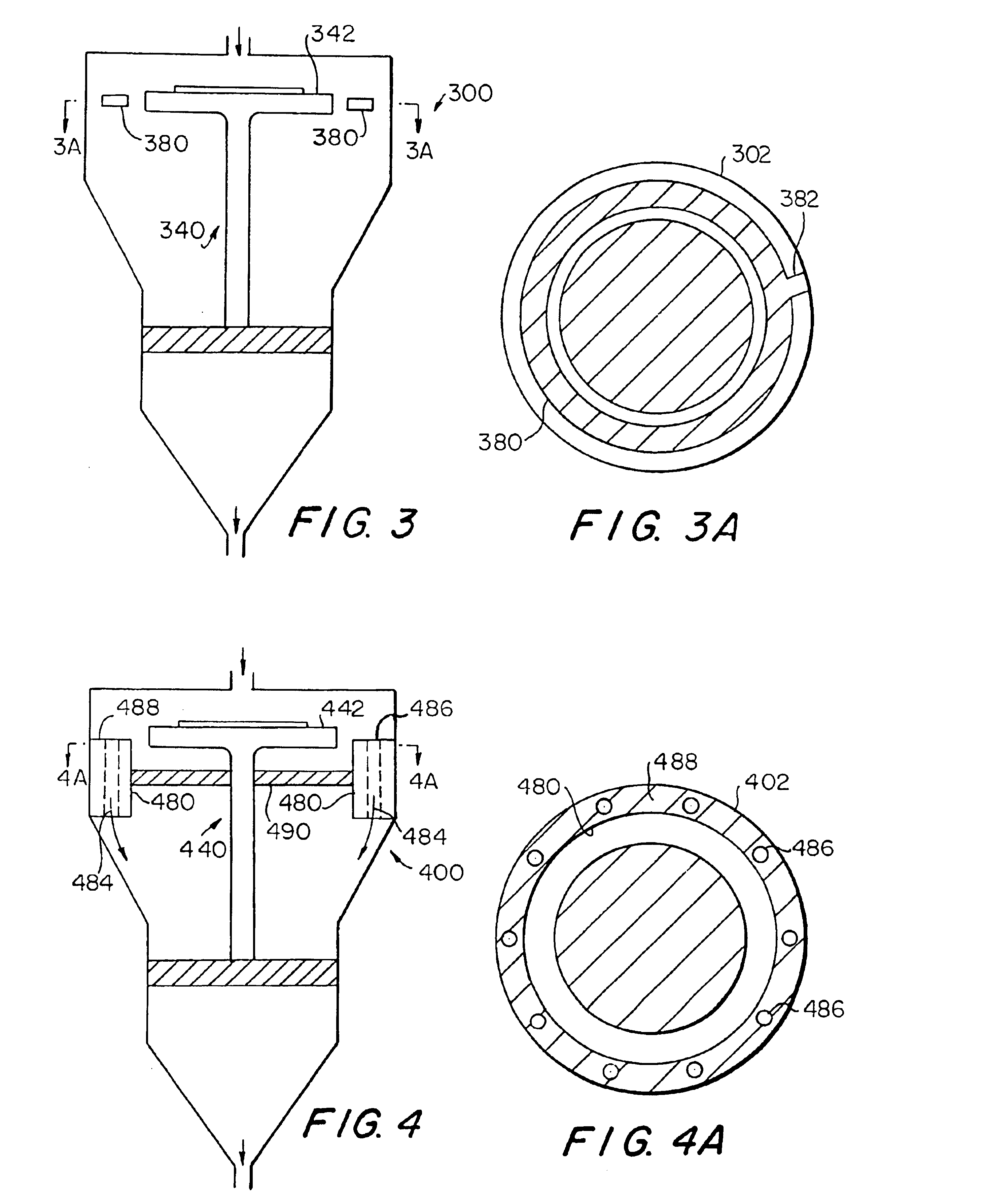

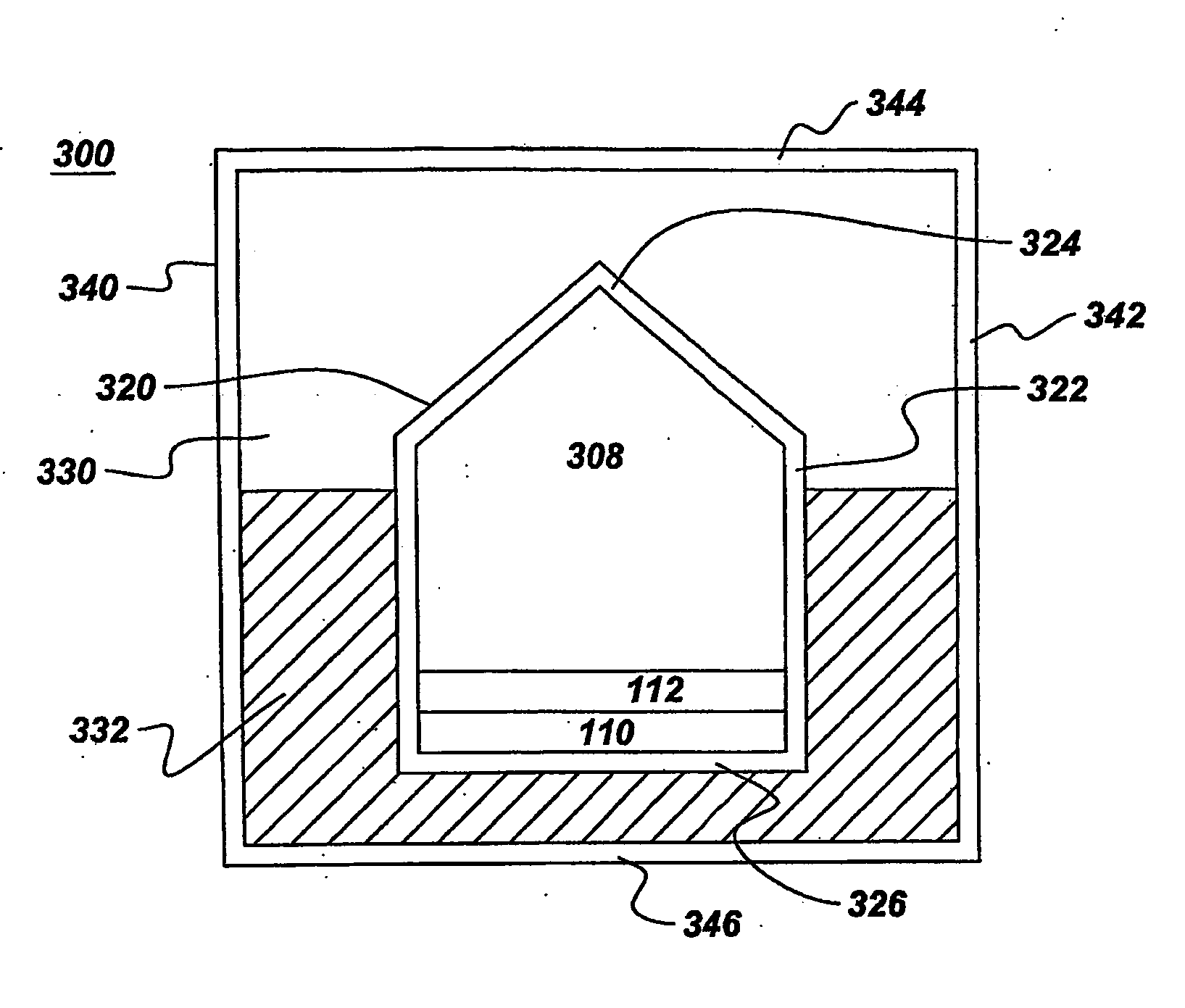

Cast pedestal with heating element and coaxial heat exchanger

ActiveUS7327948B1High-temperature gradientHeat resistantSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingHeat resistanceEngineering

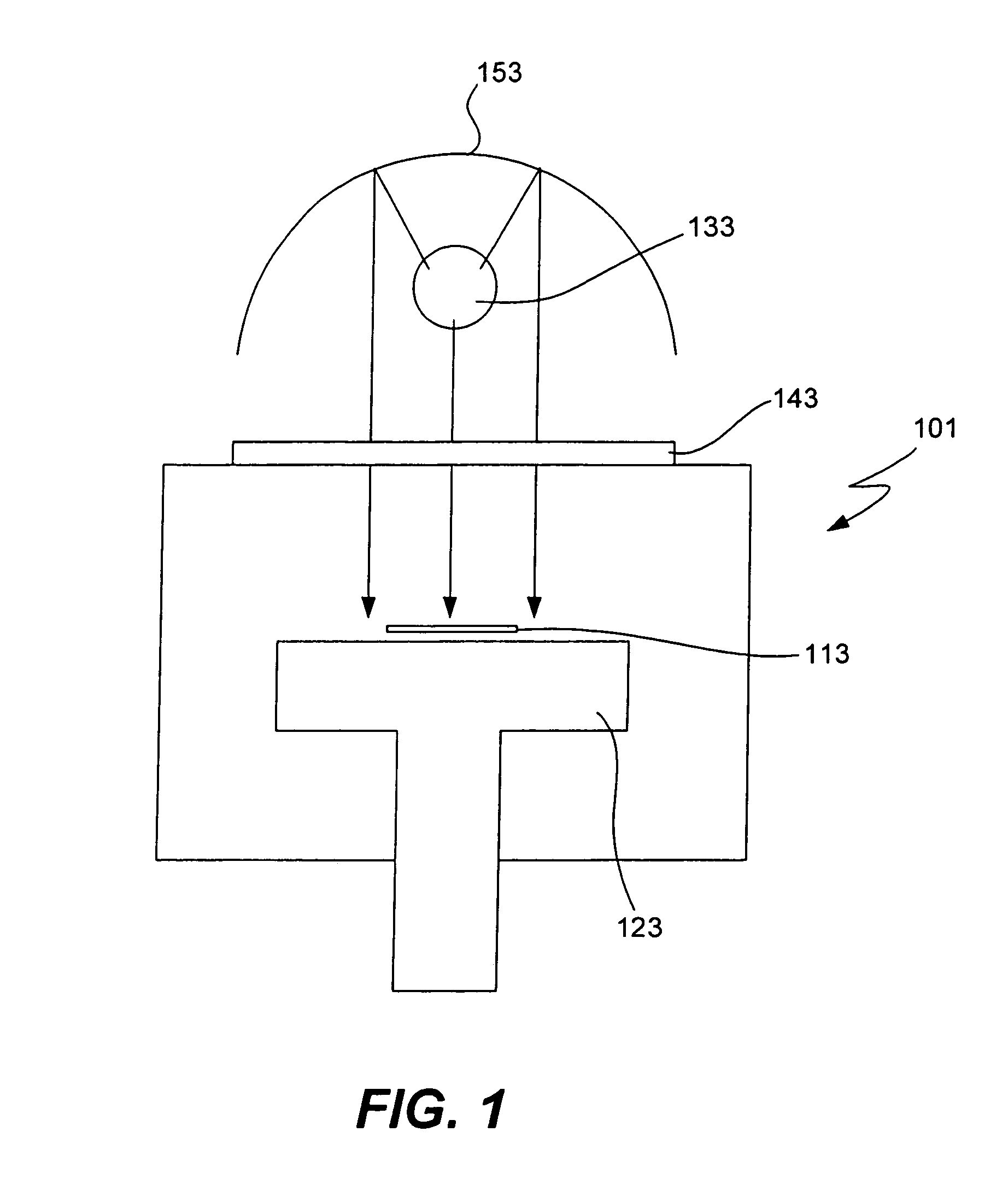

The present invention provides a heat transfer assembly that, when coupled to an object, is capable of keeping the object at a uniform elevated temperature while removing large amounts of heat from an external source. The assembly may be contained in a pedestal for use in a UV-cure chamber. The heat transfer assembly includes a heating element to control the wafer temperature and a cooling element to remove incident IR heat from the wafer and pedestal. A heat resistant layer having a calibrated heat resistance is located between the heating and cooling elements and between the wafer and the cooling elements. The heat resistant layer is able to sustain high temperature gradient from the wafer to the coolant so that the coolant does not boil while permitting enough heat to be conducted away from the wafer to maintain the desired set-point temperature.

Owner:NOVELLUS SYSTEMS

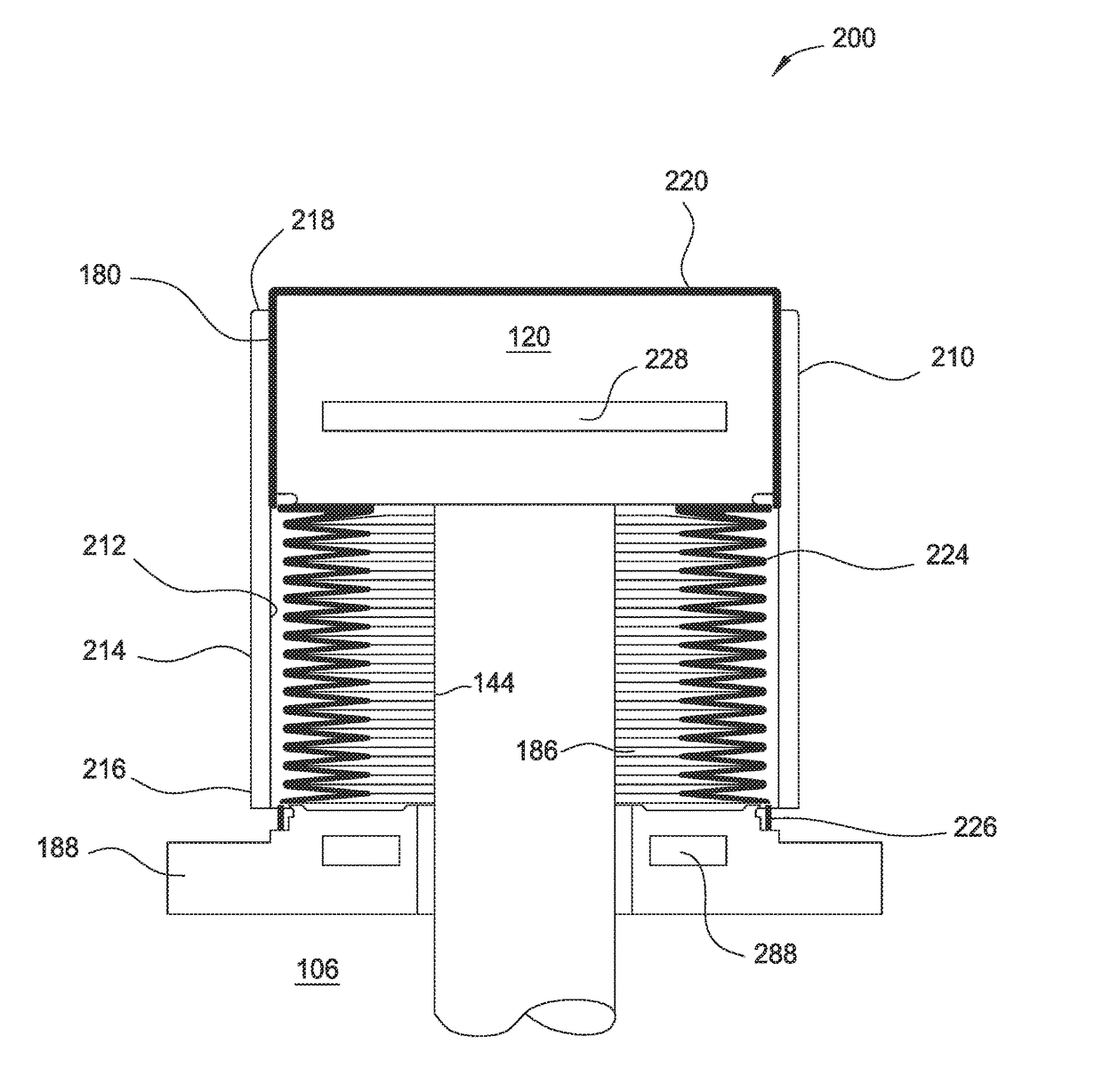

Composite heater and chill plate

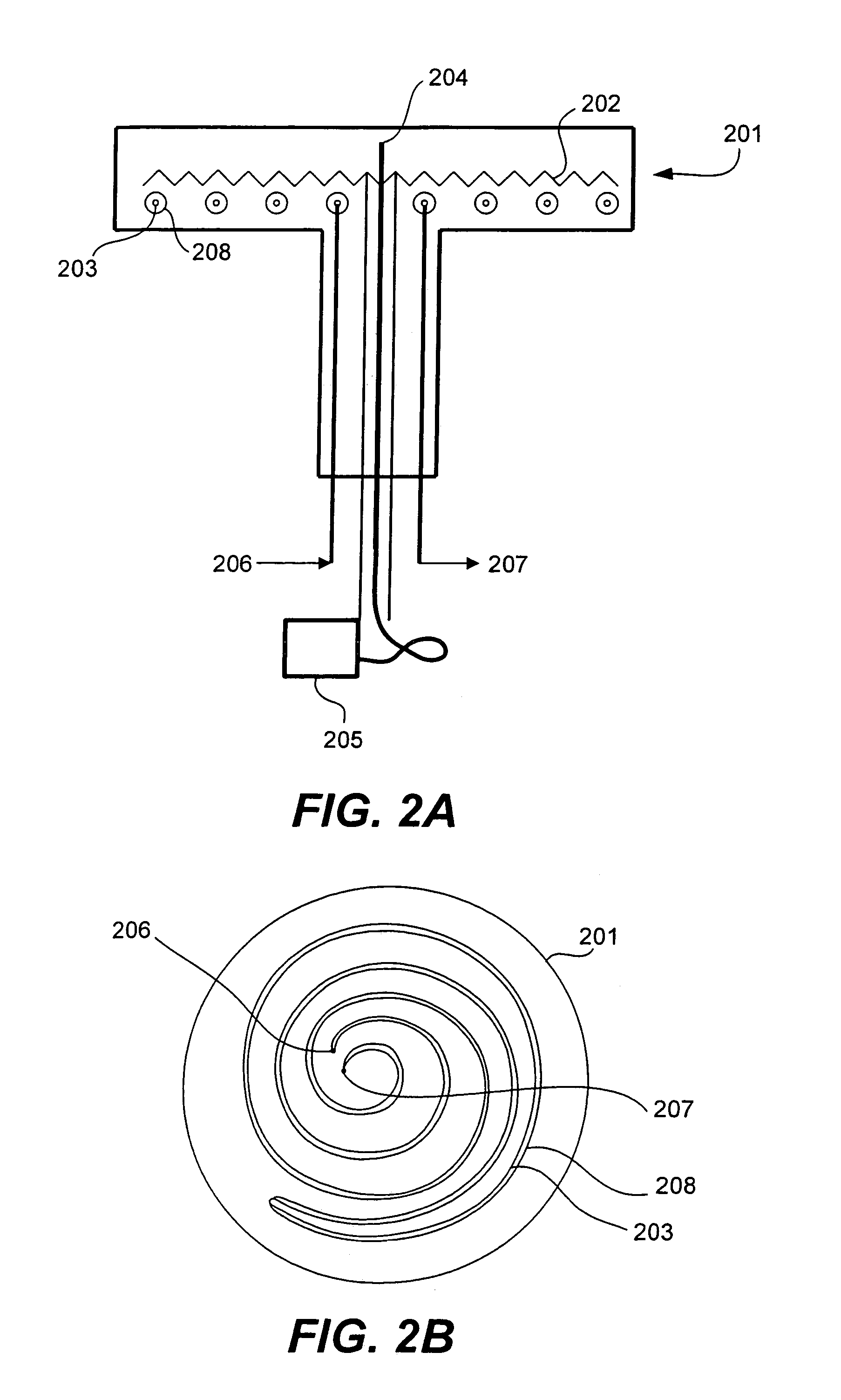

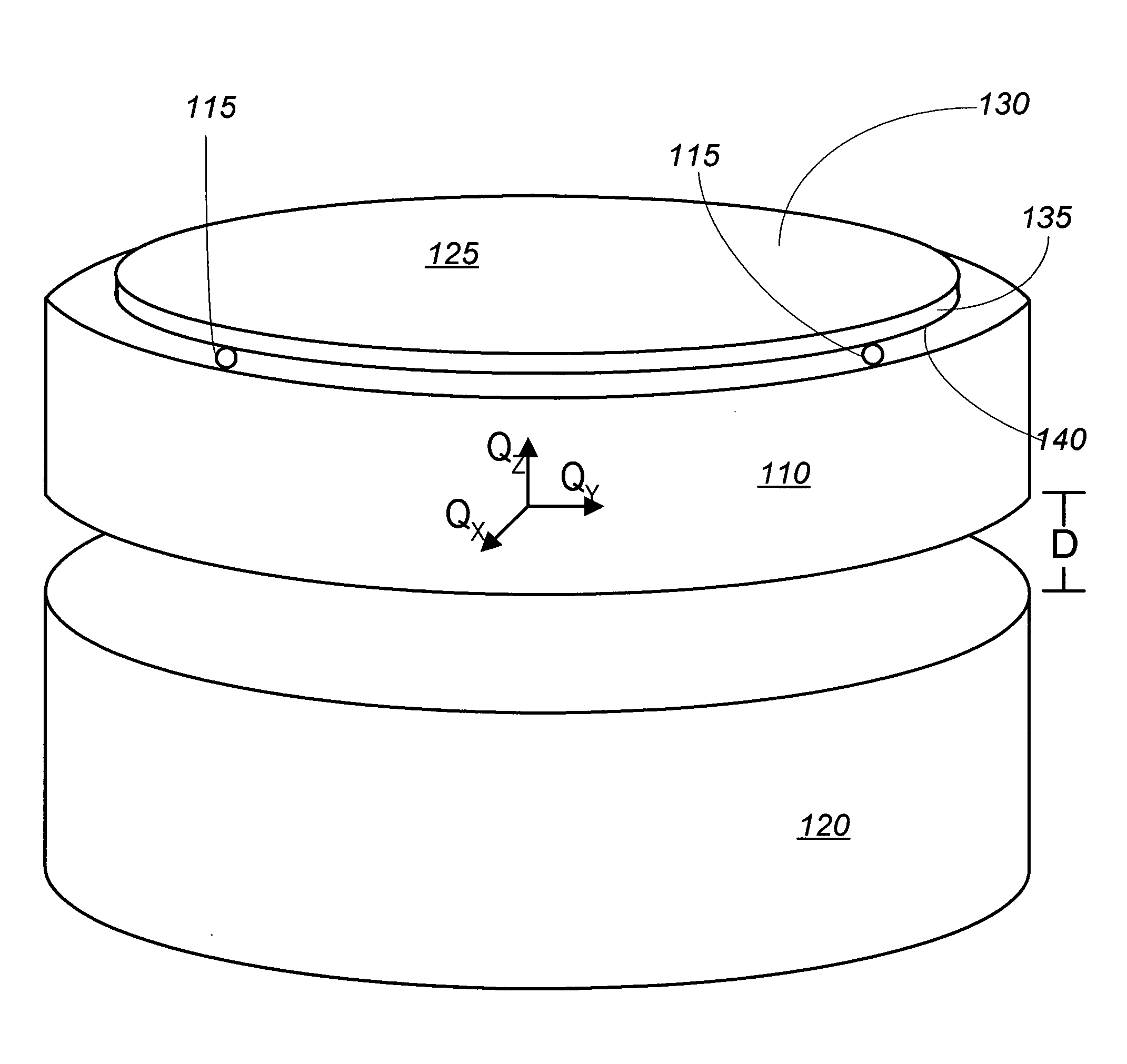

InactiveUS20070251456A1Highly controllable mannerHighly controllableSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringChiller

An integrated system for baking and chilling wafers includes a heater for heating a wafer to an elevated temperature, a chiller for cooling the wafer, and a shuttle operatively connected to the heater and the chiller for transferring the wafer between the heater and the chiller. The chiller further includes a low thermal mass wafer support for providing support to a bottom surface of a wafer and a chill plate coupled to the low thermal mass wafer support for cooling the wafer. The low thermal mass wafer support has a higher thermal conductivity in the plane parallel to the bottom surface of the wafer than in the direction perpendicular to the bottom surface of the wafer. The low thermal mass wafer support can further include a plurality of proximity pins for supporting the wafer.

Owner:SOKUDO CO LTD

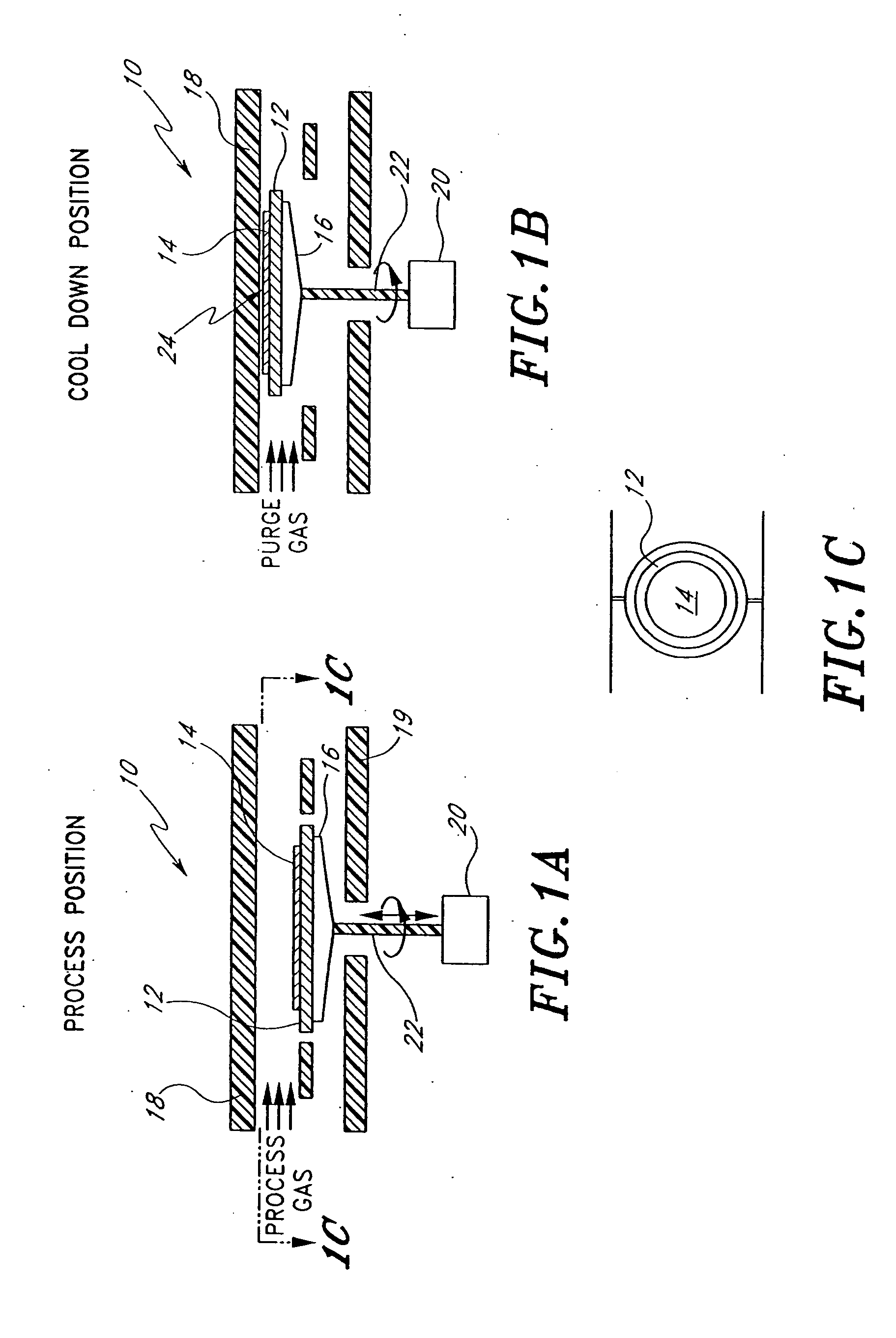

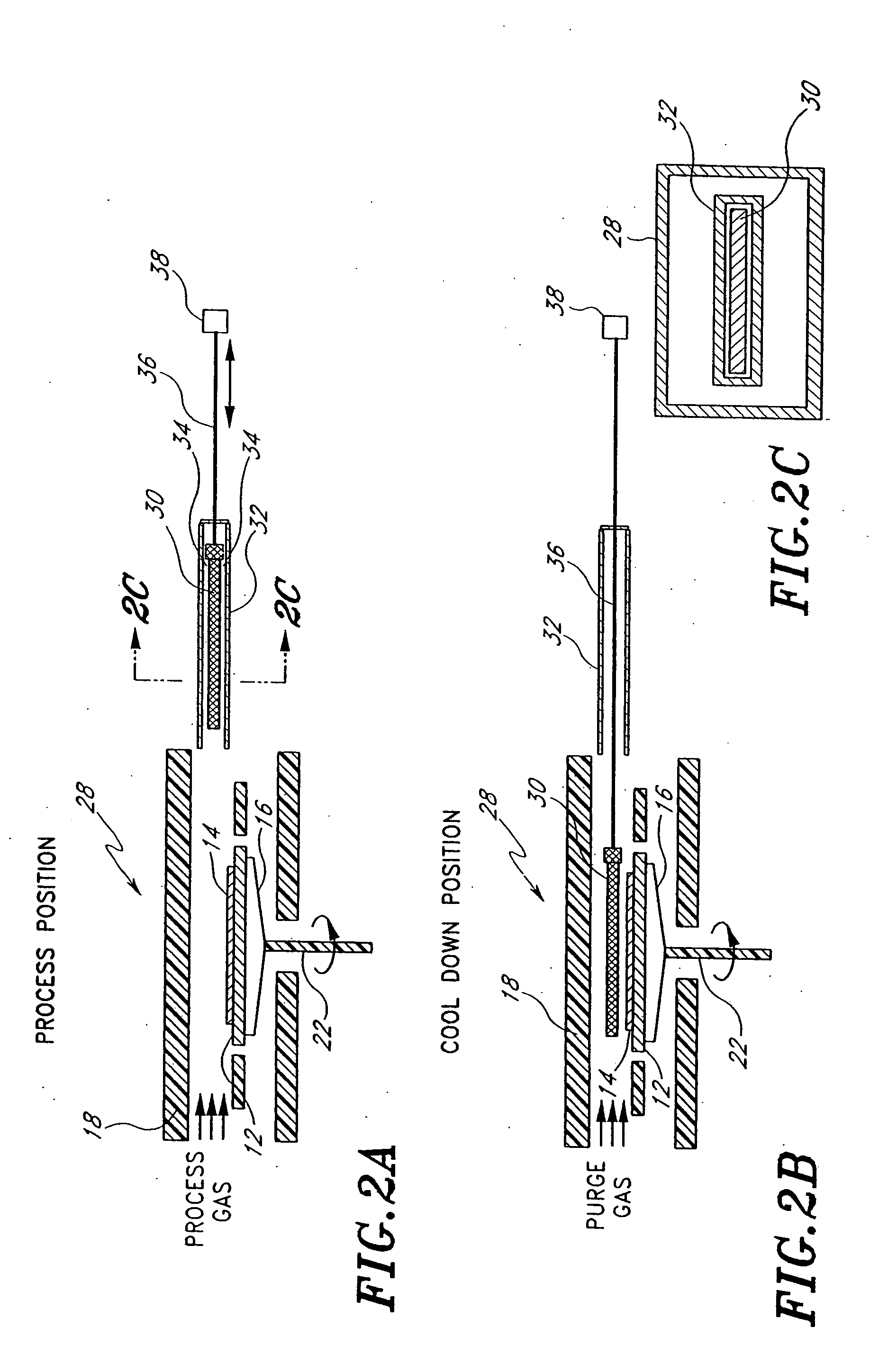

Apparatus for thermal treatment of substrates

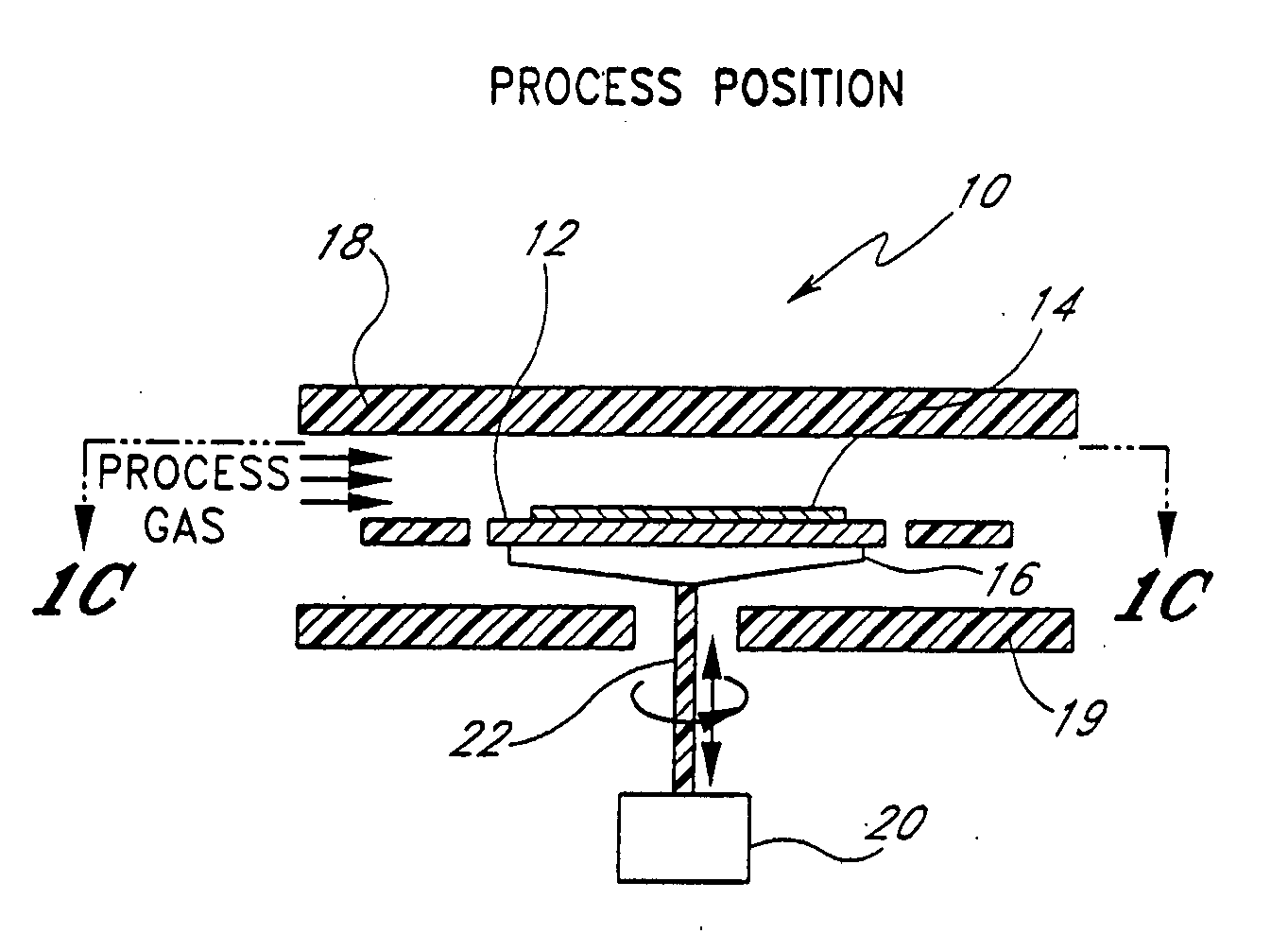

InactiveUS20050229855A1Short timeIncrease wafer throughputSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringCold plate

Methods and apparatuses are provided for cooling semiconductor substrates prior to handling. In one embodiment, a substrate and support structure combination is lifted after high temperature processing to a cold wall of a thermal processing chamber, which acts as a heat sink. Conductive heat transfer across a small gap from the substrate to the heat sink speeds wafer cooling prior to handling the wafer (e.g., with a robot). In another embodiment, a separate plate is kept cool within a pocket during processing, and is moved close to the substrate and support after processing. In yet another embodiment, a cooling station between a processing chamber and a storage cassette includes two movable cold plates, which are movable to positions closely spaced on either side of the wafer.

Owner:RAAIJMAKERS IVO

Corrosion control for chamber components

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

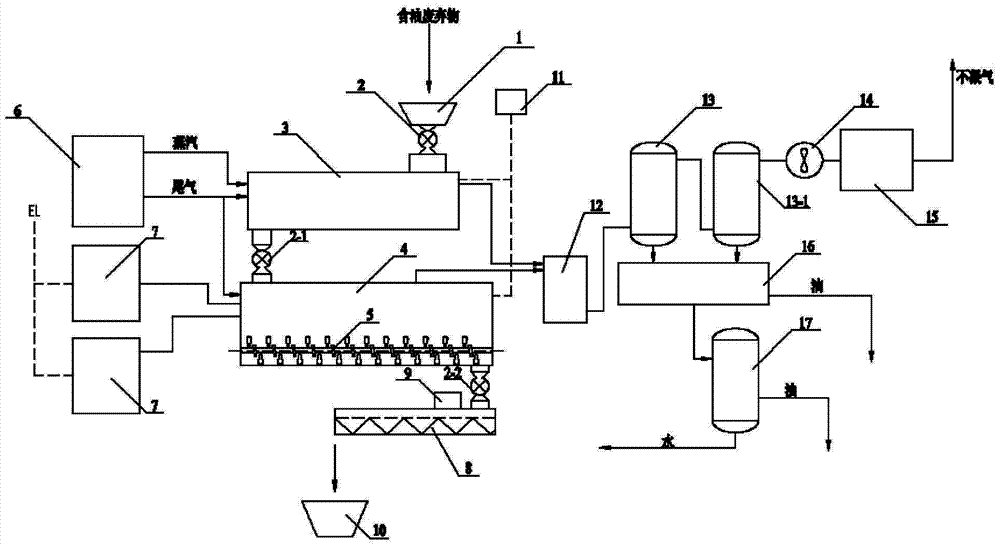

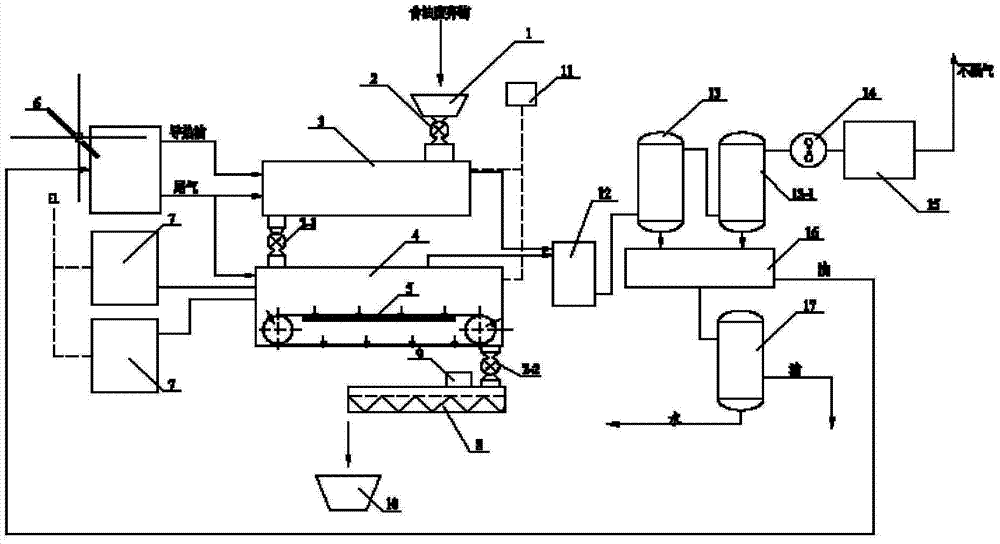

Industrial treatment method and industrial treatment device for oil field waste

ActiveCN103923670ALow boiling pointIncrease gasification rateElectrical coke oven heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisEnvironmental engineering

The invention provides an industrial treatment method for oil field waste. The industrial treatment method for oil field waste comprises the following steps: carrying out sampling analysis on the oil field waste, preheating to 80-300 DEG C by using high-temperature steam or conduction oil, then carrying out microwave pyrolysis treatment, controlling pressure at minus 5000 to minus 100 Pa, thus obtaining solid treatment substances and gas, condensing, separating and purifying the gas, and finally recycling so as to obtain water, oil and non-condensable gas. An industrial treatment device for oil field waste comprises a feed hopper, a dryer, a microwave heating cavity, a microwave generator, a heating device and a condensation separation purification device, wherein the feed hopper is connected to the dryer which is connected to the microwave heating cavity, a steam or conduction oil outlet of the heating device is connected to a steam or conduction oil outlet of the dryer; gas outlets of the dryer and the microwave heating cavity are connected to the condensation separation purification device; the microwave generator is connected to the microwave heating cavity. The industrial treatment method and the industrial treatment device have good treatment effects, high utilization rate of energy sources and good economical efficiency.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

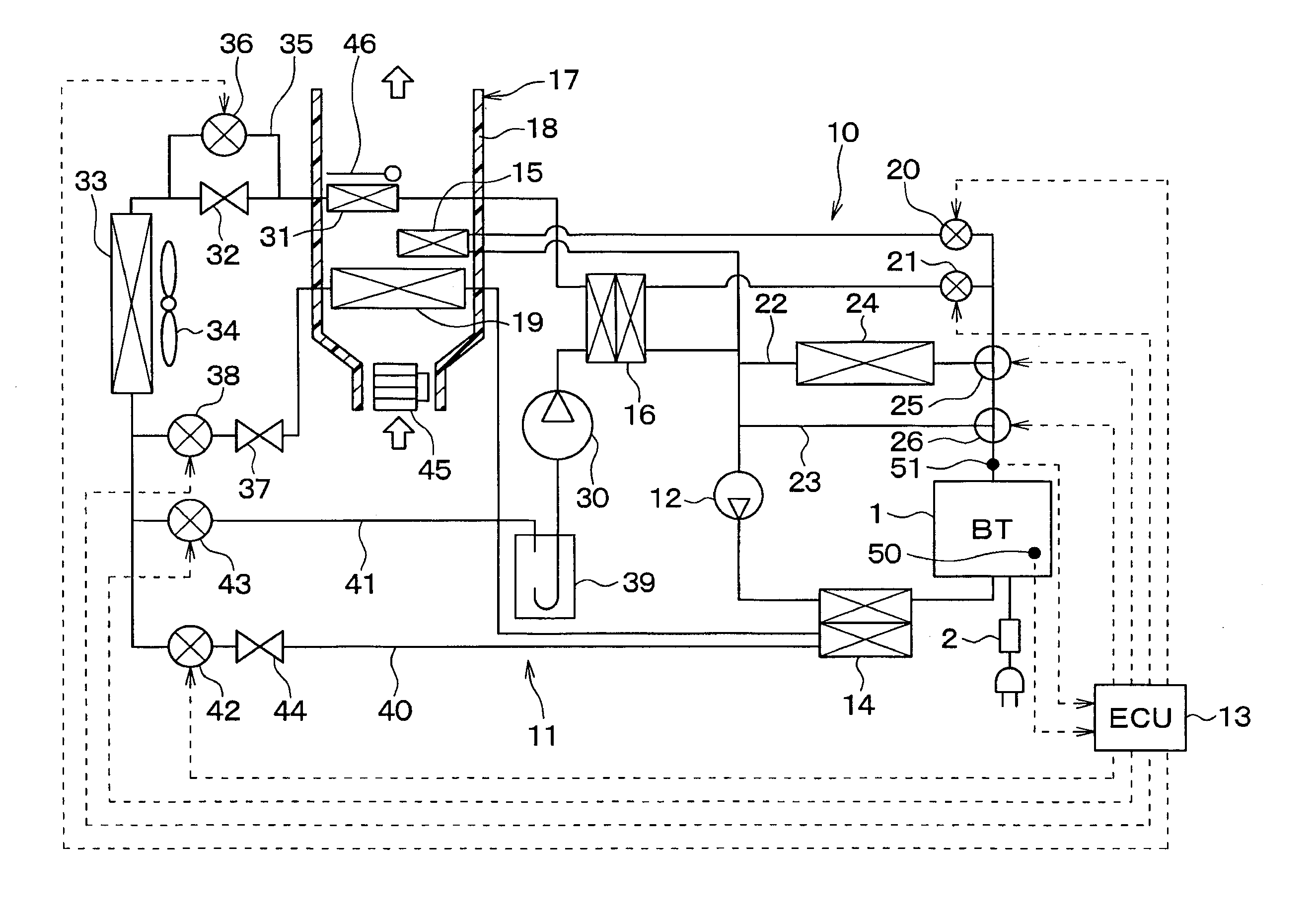

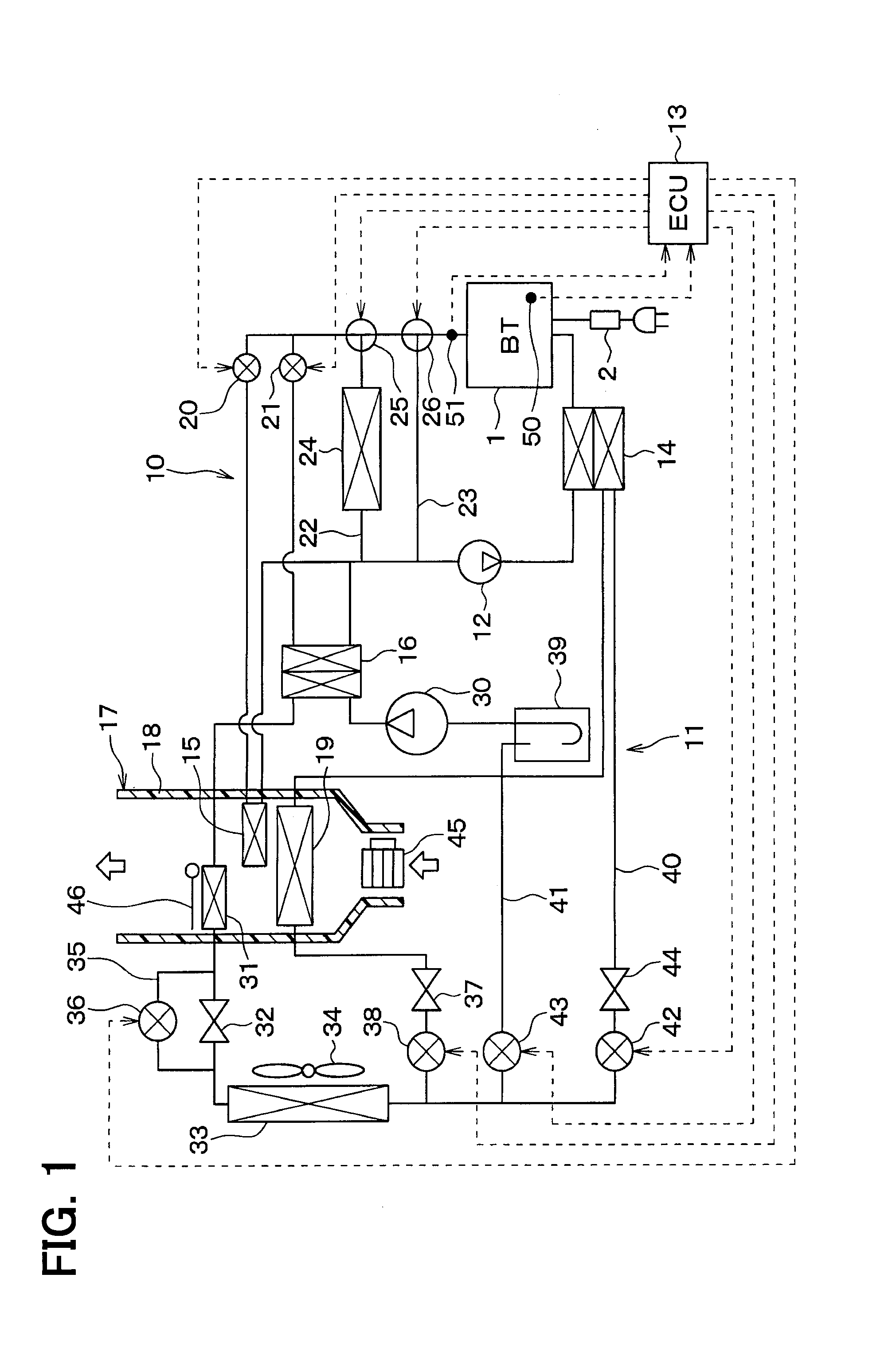

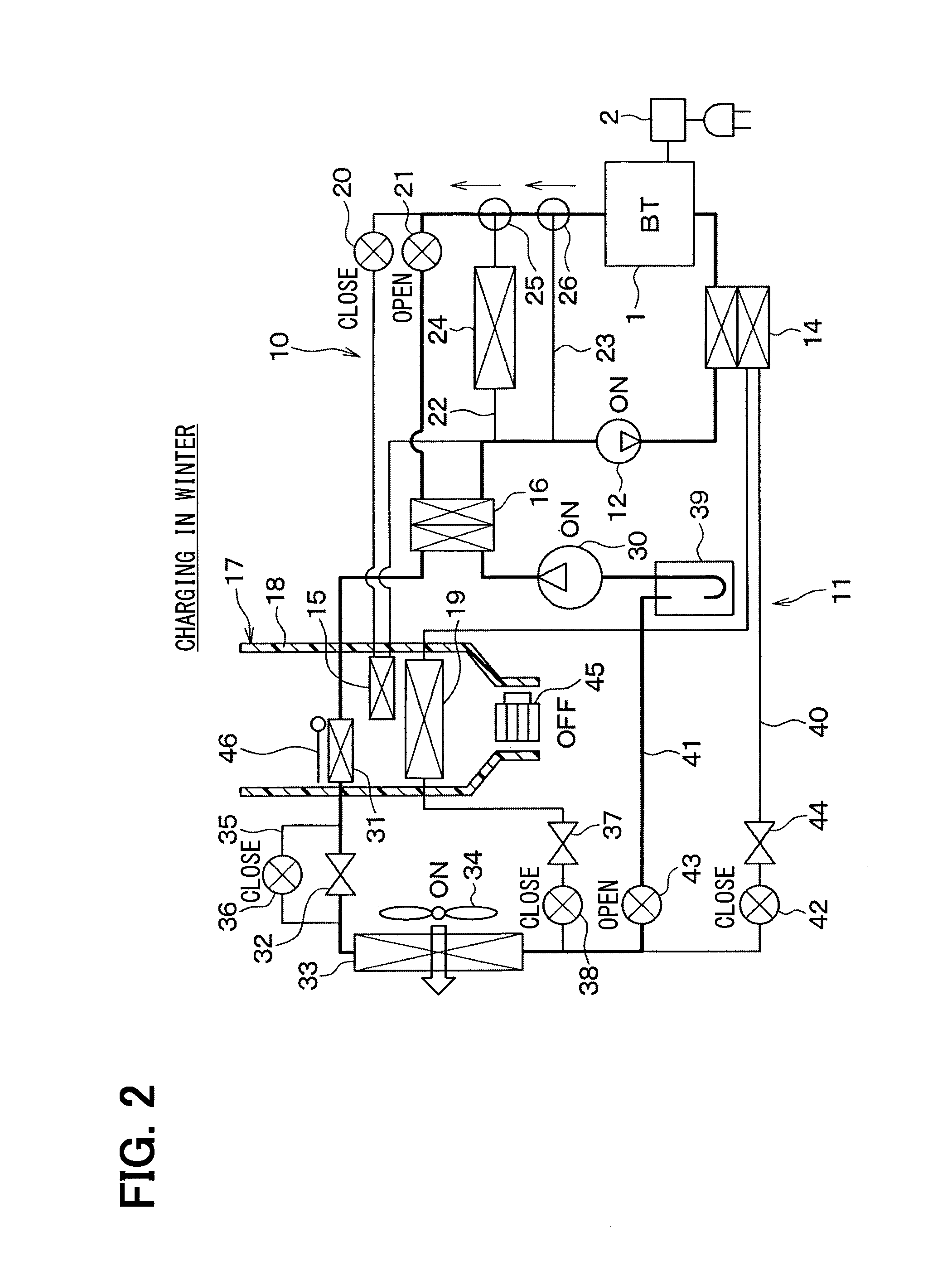

Vehicle temperature control apparatus and in-vehicle thermal system

InactiveUS20140041826A1Increase subcoolingImprove efficiencyTemperatue controlPower to auxillary motorsTemperature controlIn vehicle

A vehicle temperature control apparatus for controlling temperature of a temperature control object, which is at least one of inside air of a vehicle compartment and a vehicle component, includes a heat capacitive element capable of storing heat, a refrigeration cycle in which heat is absorbed from a low temperature side and is dissipated to a high temperature side, a heat exchanger that causes the heat capacitive element to exchange heat with refrigerant of the refrigeration cycle, and a heat dissipation portion which dissipates heat in the refrigerant of the refrigeration cycle to the temperature control object. Thus, a temperature control by using the heat capacitive element can be effectively performed.

Owner:DENSO CORP

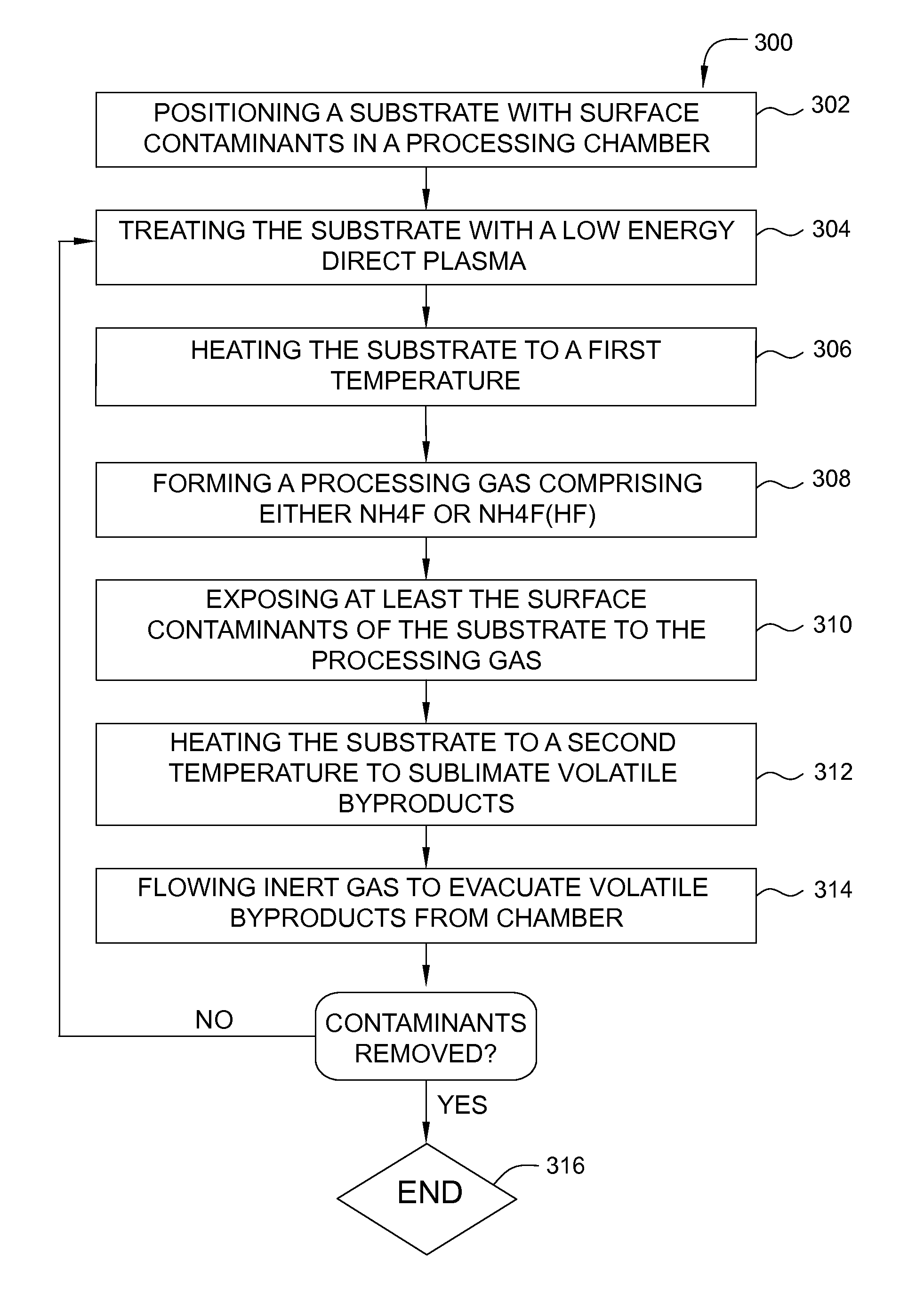

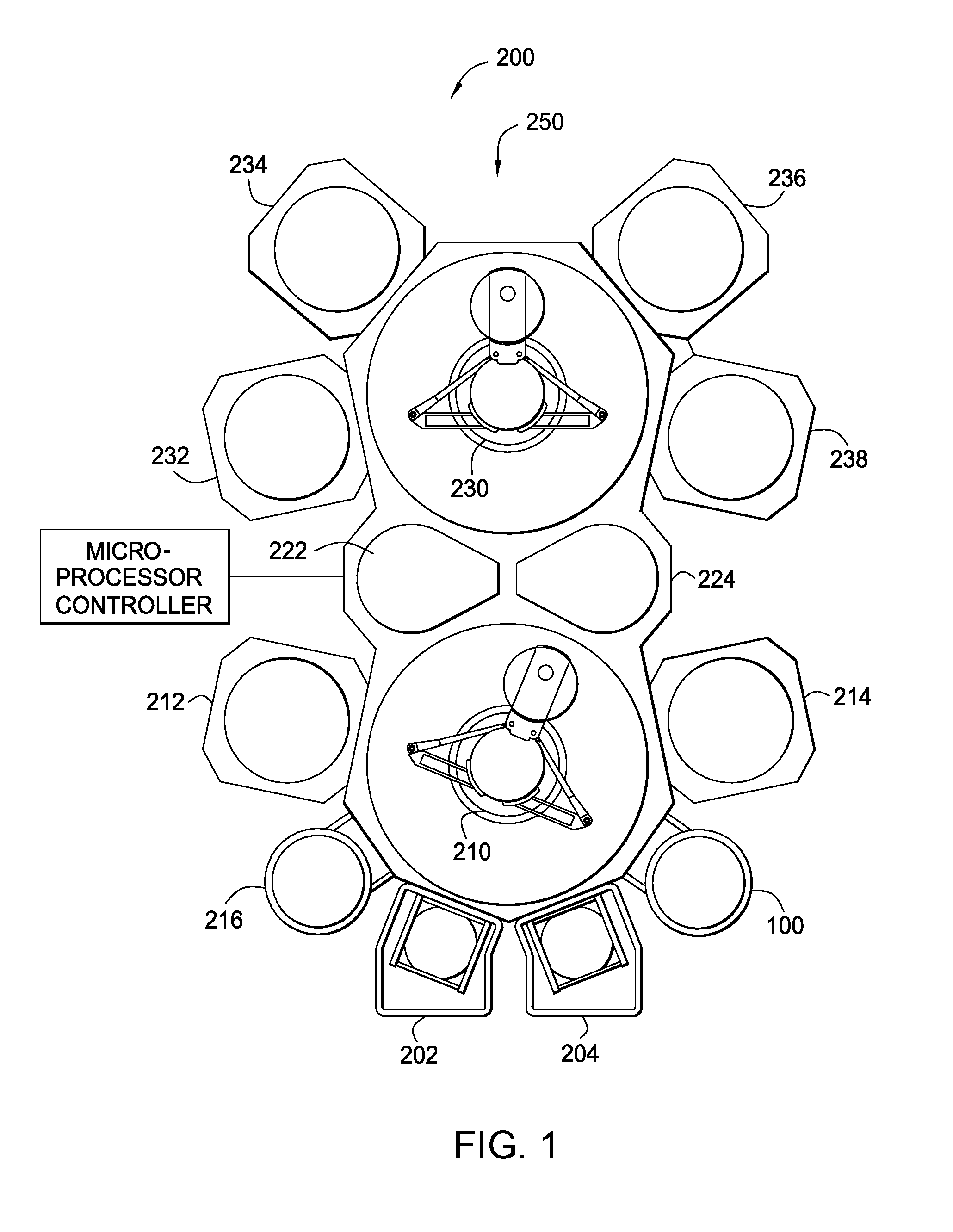

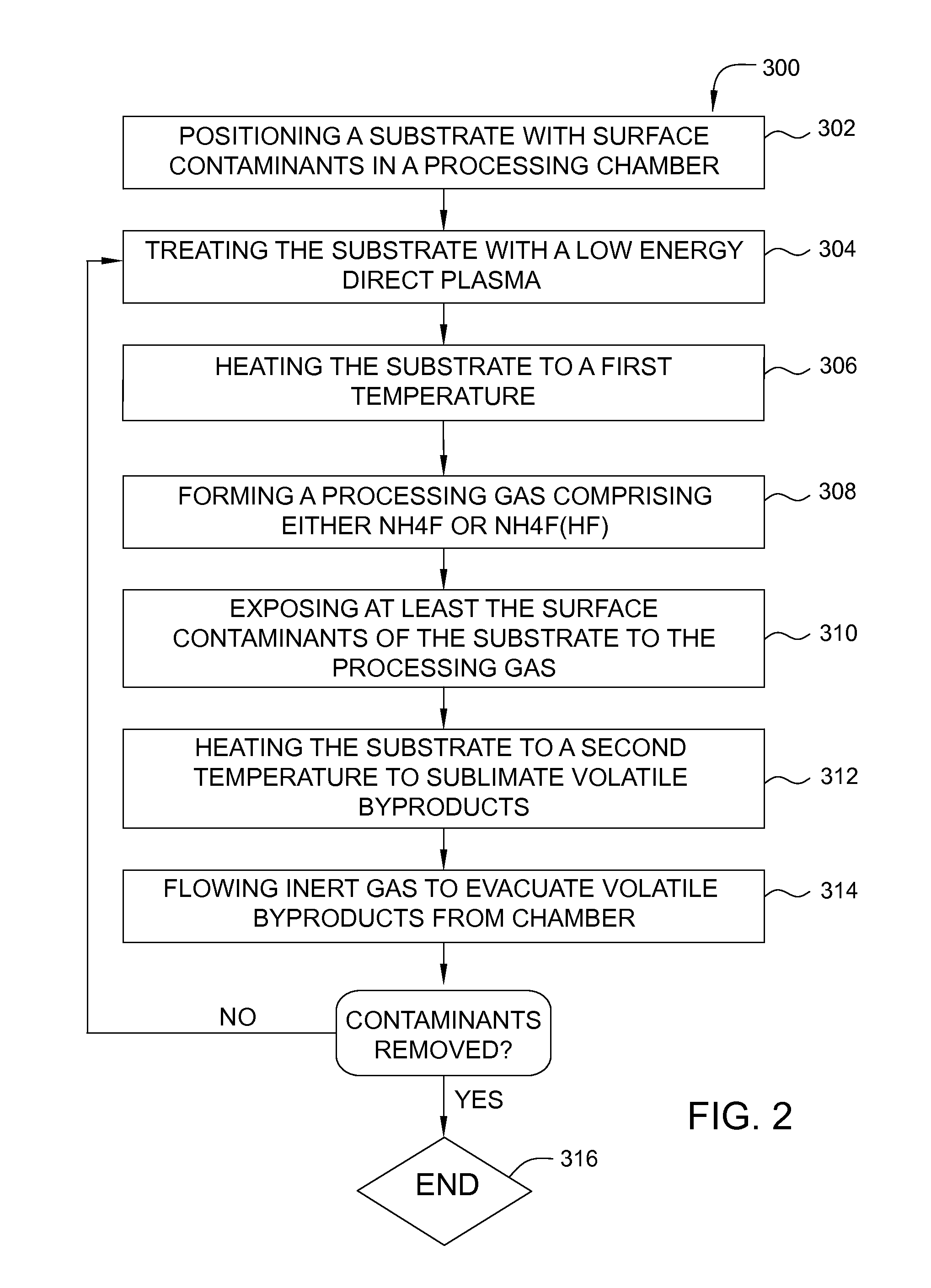

Directional sio2 etch using plasma pre-treatment and high-temperature etchant deposition

Methods for processing a substrate are described herein. Methods can include positioning a substrate with an exposed surface comprising a silicon oxide layer in a processing chamber, biasing the substrate, treating the substrate to roughen a portion of the silicon oxide layer, heating the substrate to a first temperature, exposing the exposed surface of the substrate to ammonium fluoride to form one or more volatile products while maintaining the first temperature, and heating the substrate to a second temperature, which is higher than the first temperature, to sublimate the volatile products.

Owner:APPLIED MATERIALS INC

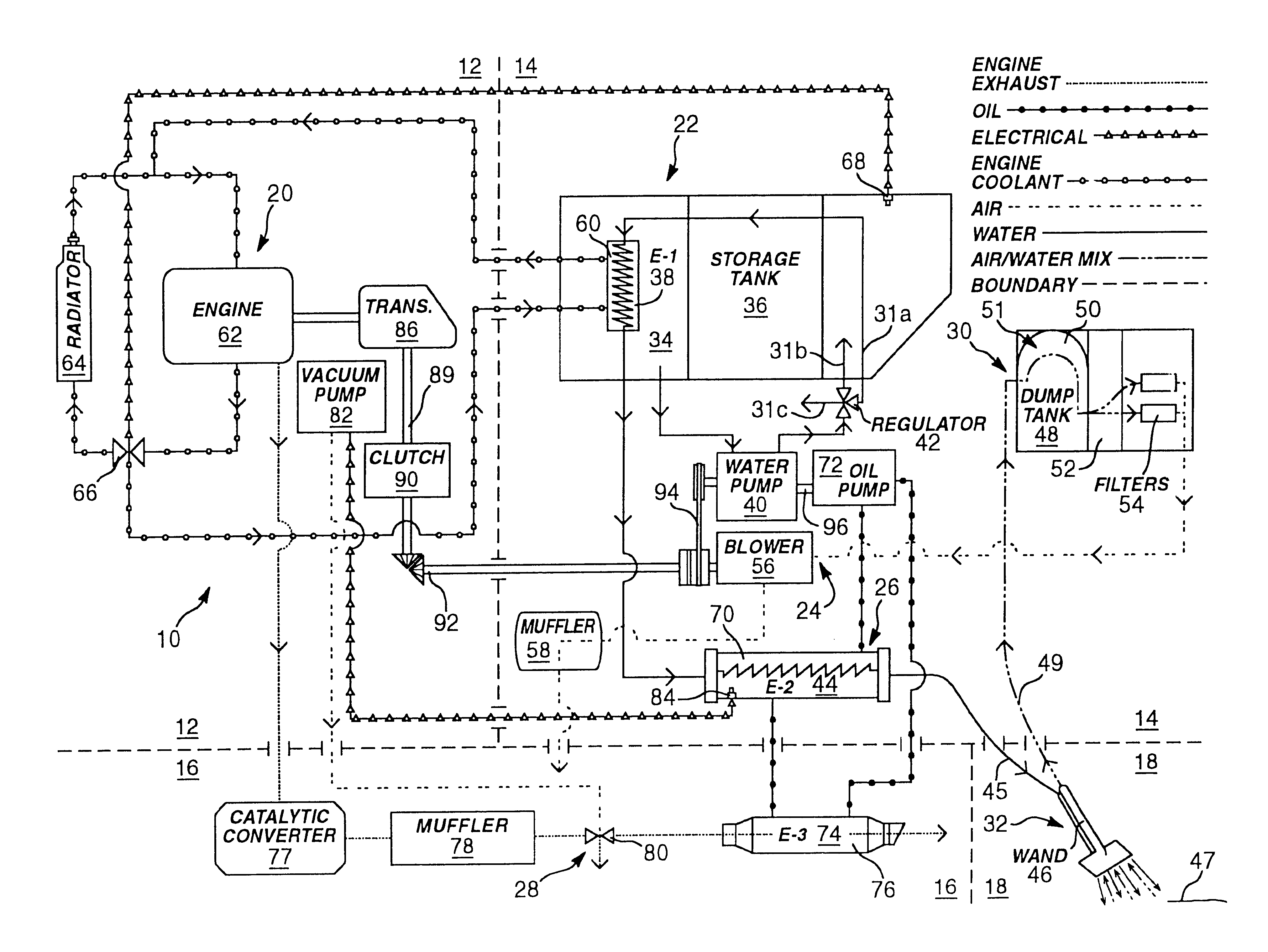

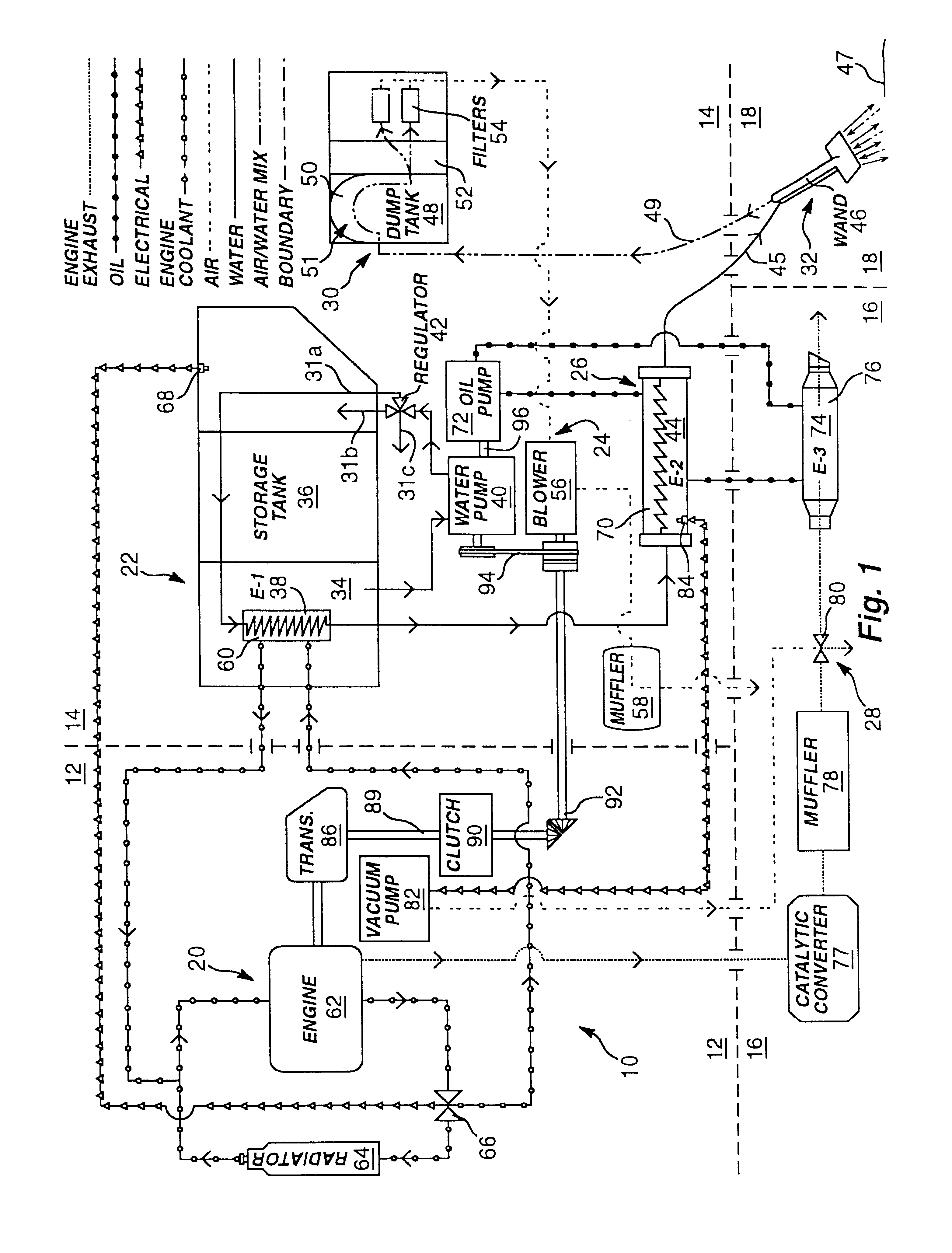

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

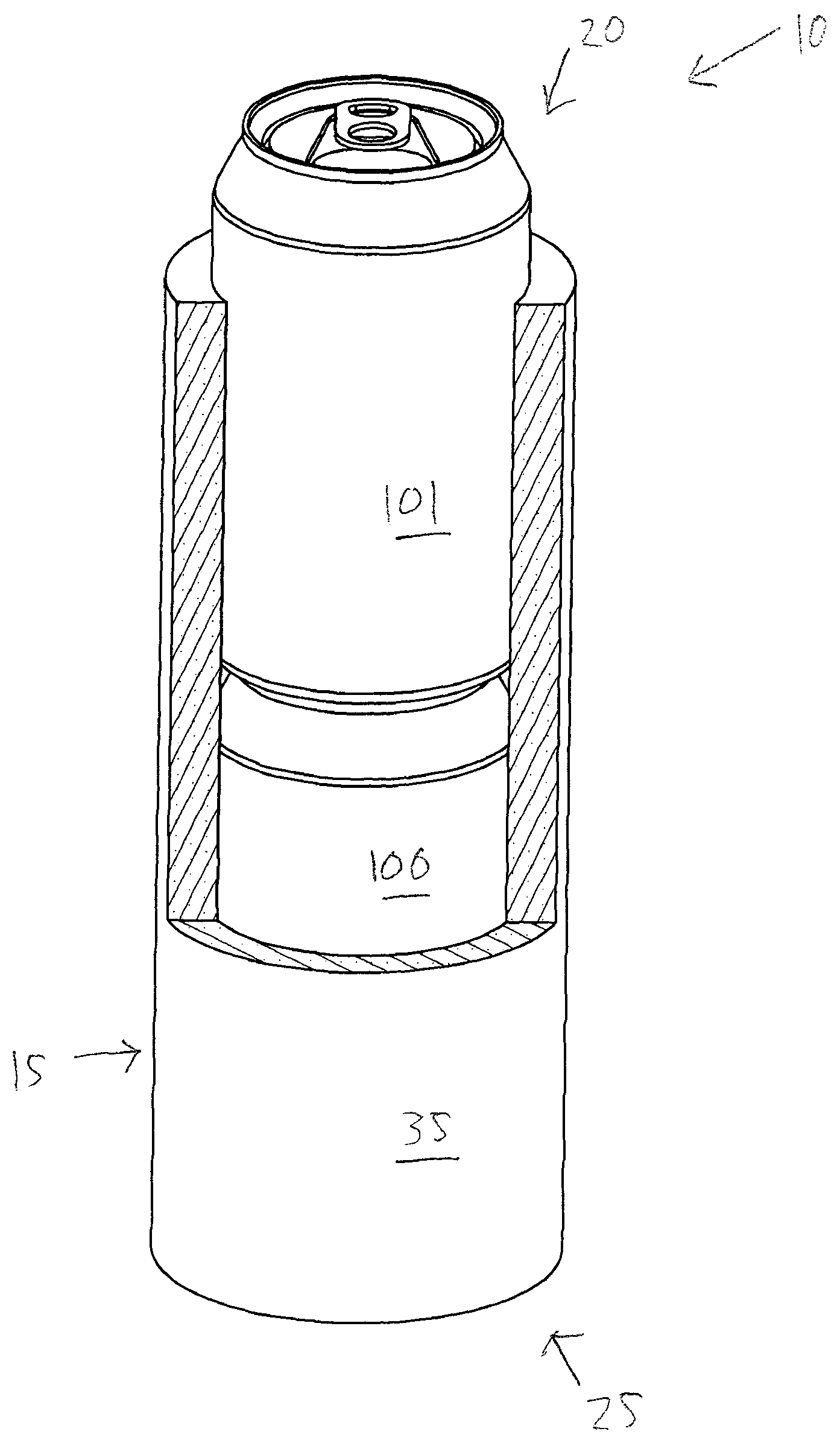

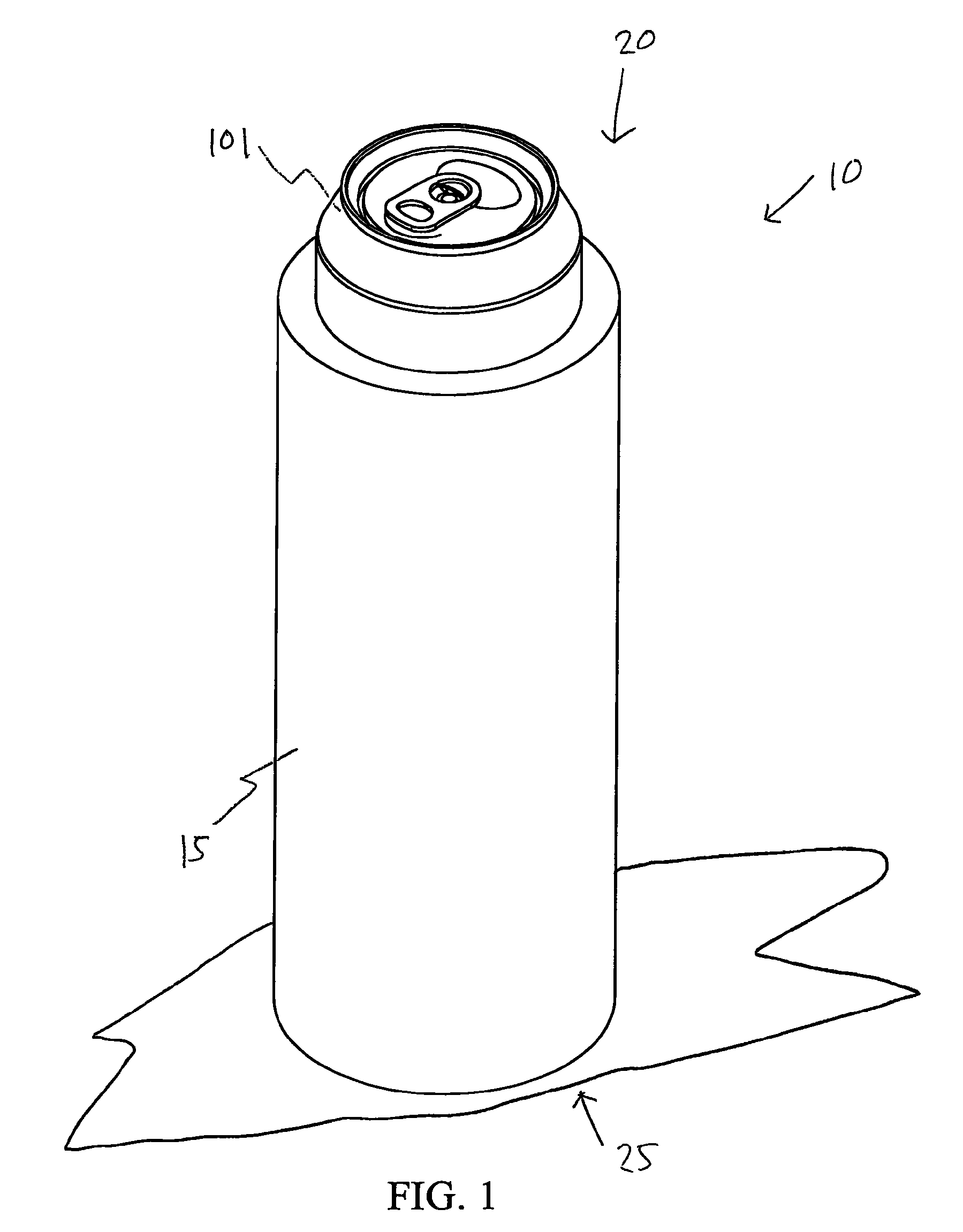

Beverage can holder and cooler technology

ActiveUS8720739B2Practical and reliable and efficientLighting and heating apparatusContainer/bottle contructionInterior spaceEngineering

A cooler for holding two cans, particular beverage cans containing beer, soft drinks or the like, in a stacked or tandem arrangement. The cooler holds the cans snuggly, keeping them safe from bumps and the like, and also insulates the cans to preserve cold or hot temperature of can contents as long as practicable. The cooler has a cylindrical configuration including a body with an open top, a closed bottom, and an interior space. The body has a cylindrical sleeve and a bottom, which is either in the form of a separate panel or unitary with the sleeve. The bottom has an aperture for preventing or reducing vacuum on the inside of the cooler.

Owner:DOUBLEUP

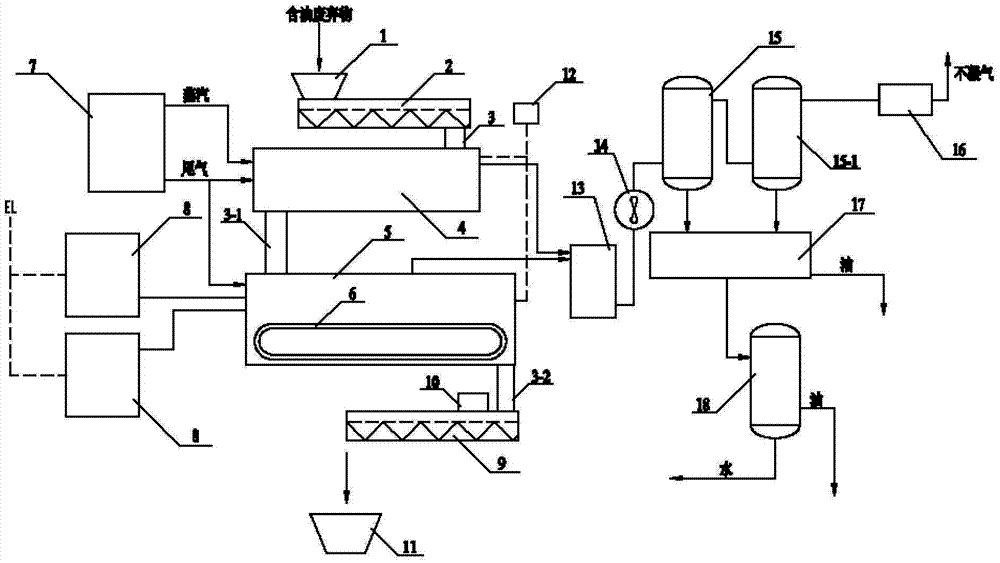

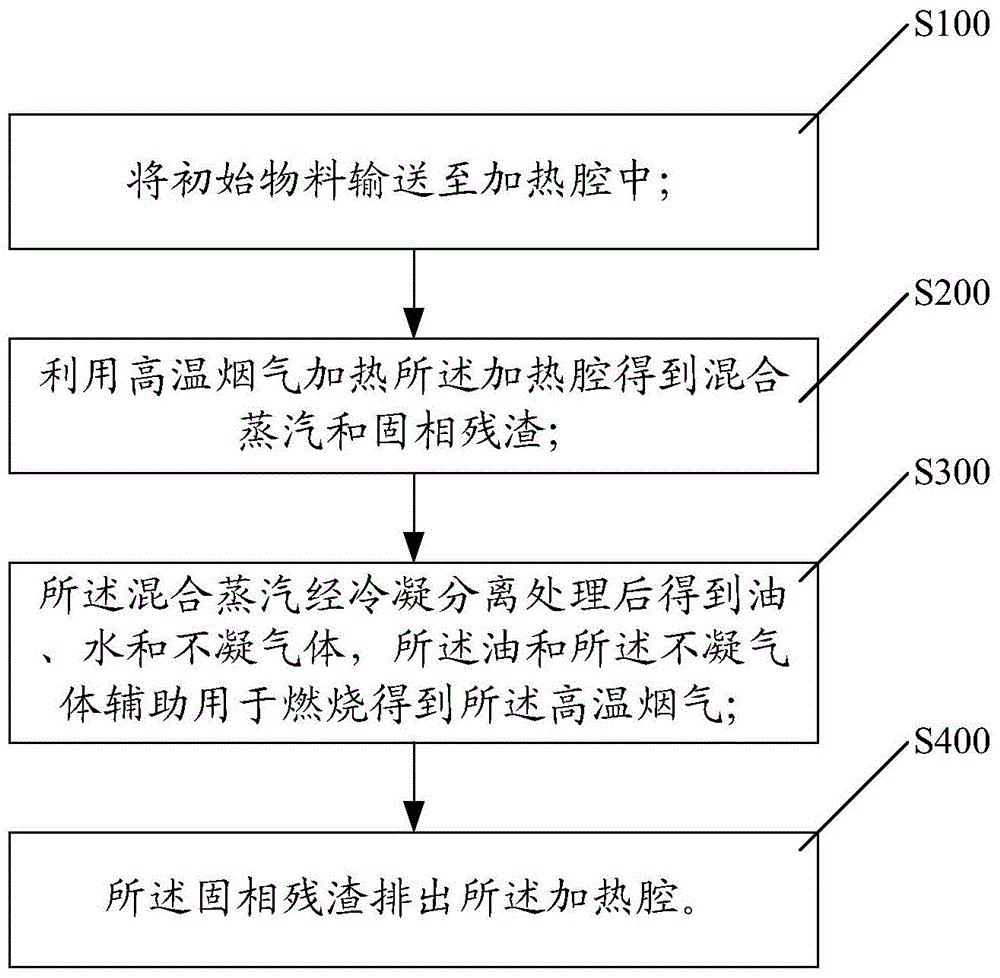

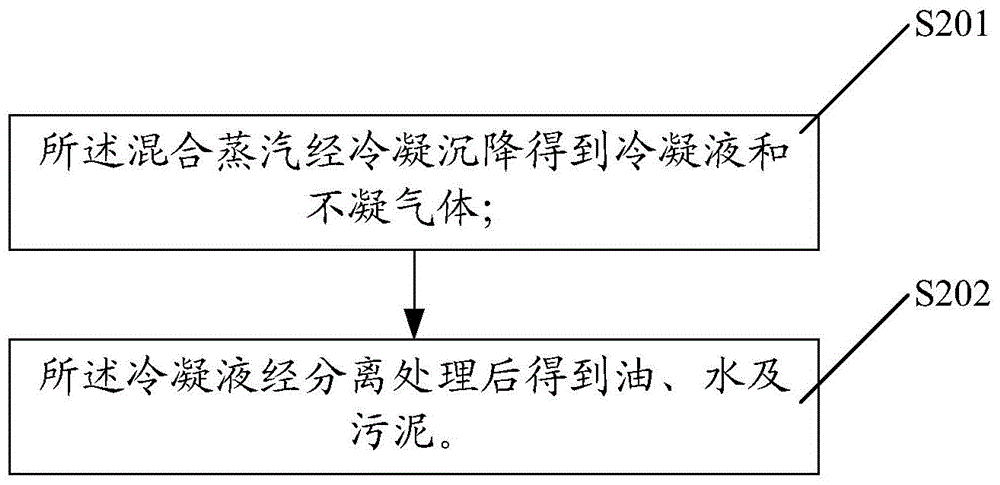

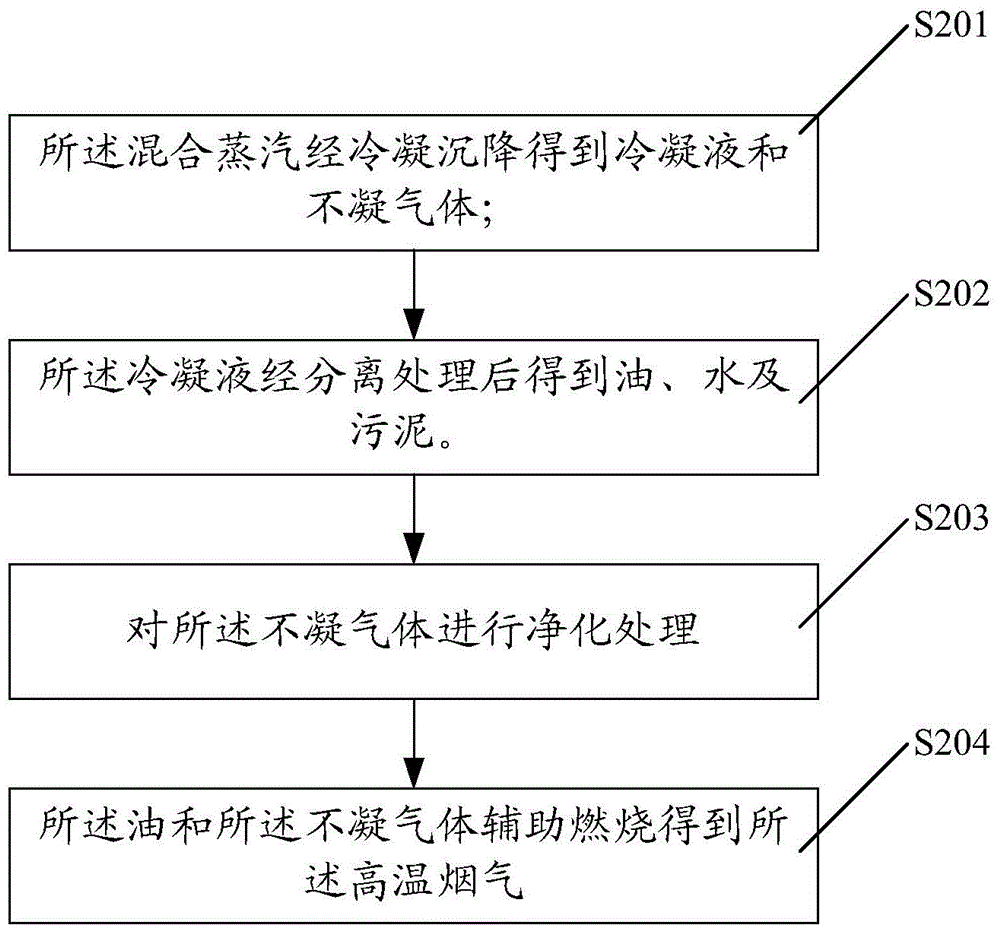

Method and system for processing oil field wastes

ActiveCN104150728AImprove versatilitySludge treatment by pyrolysisLiquid hydrocarbon mixture productionFlue gasDecomposition

The embodiment of the invention discloses a method and a system for processing oil field wastes. The method for processing the oil field wastes comprises the following steps: conveying initial materials to a heating cavity, and heating the heating cavity by using high-temperature flue gas, so as to obtain mixed steam and solid residues; carrying out condensation and separation on the mixed steam, so as to obtain oil, water and a noncondensable gas, wherein the oil and the noncondensable gas are used for combusting to obtain the high-temperature flue gas, and the solid residues are discharged out of the heating cavity. According to the method, the heating cavity is indirectly heated by using the high-temperature flue gas, so that the initial materials inside the heating cavity are subjected to thermal decomposition, solid residues free of oil, the noncondensable gas and oil are obtained from the mixed steam generated by thermal decomposition after a series of treatments, and then the noncondensable gas and oil are used for combusting to generate the high-temperature flue gas. Compared with the prior art, the method disclosed by the invention has the advantages that decomposition is carried out without adding a cracking agent, and thermal decomposition can be directly carried out on the oil field wastes in different regions, therefore, the method and the system are better in universality.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

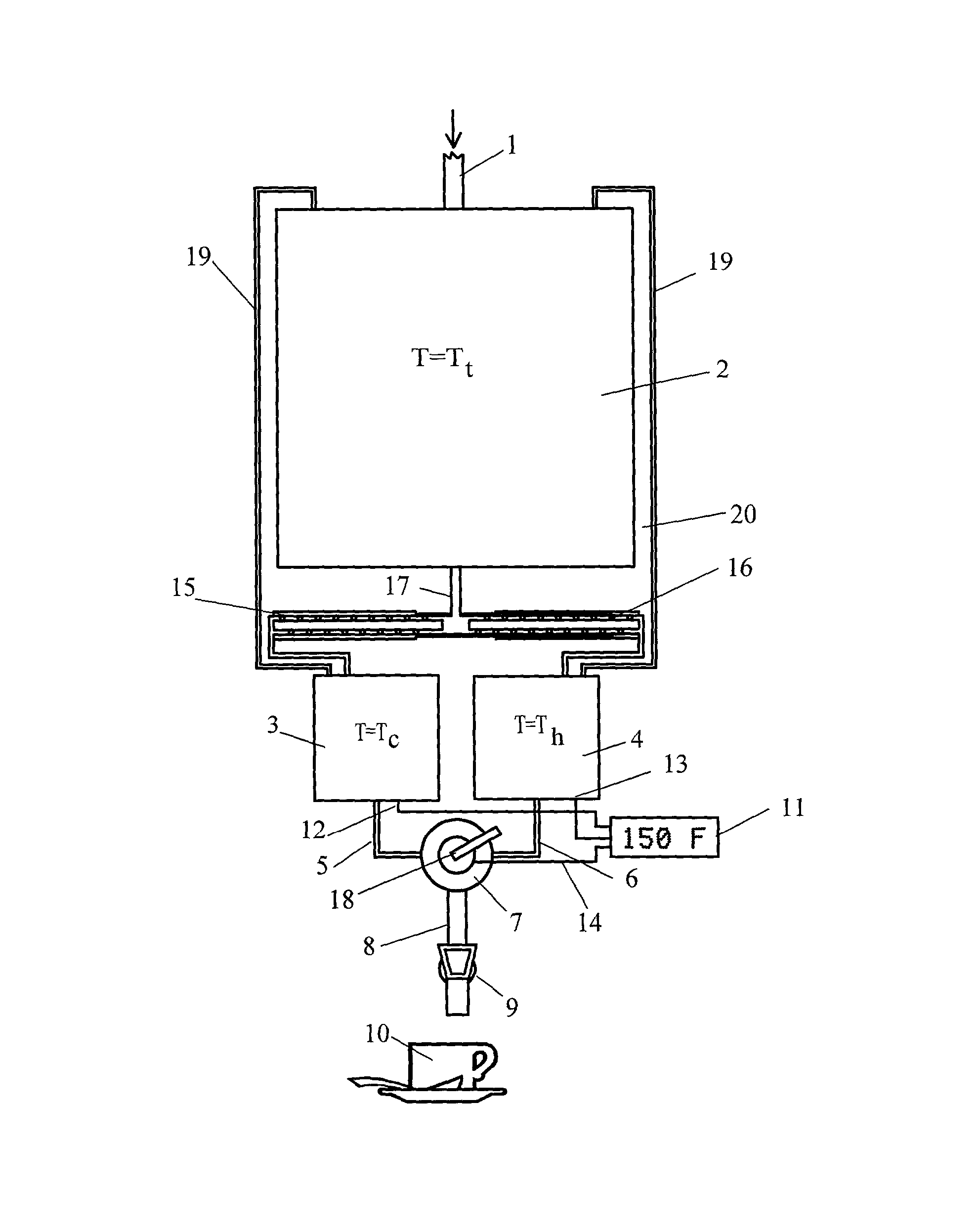

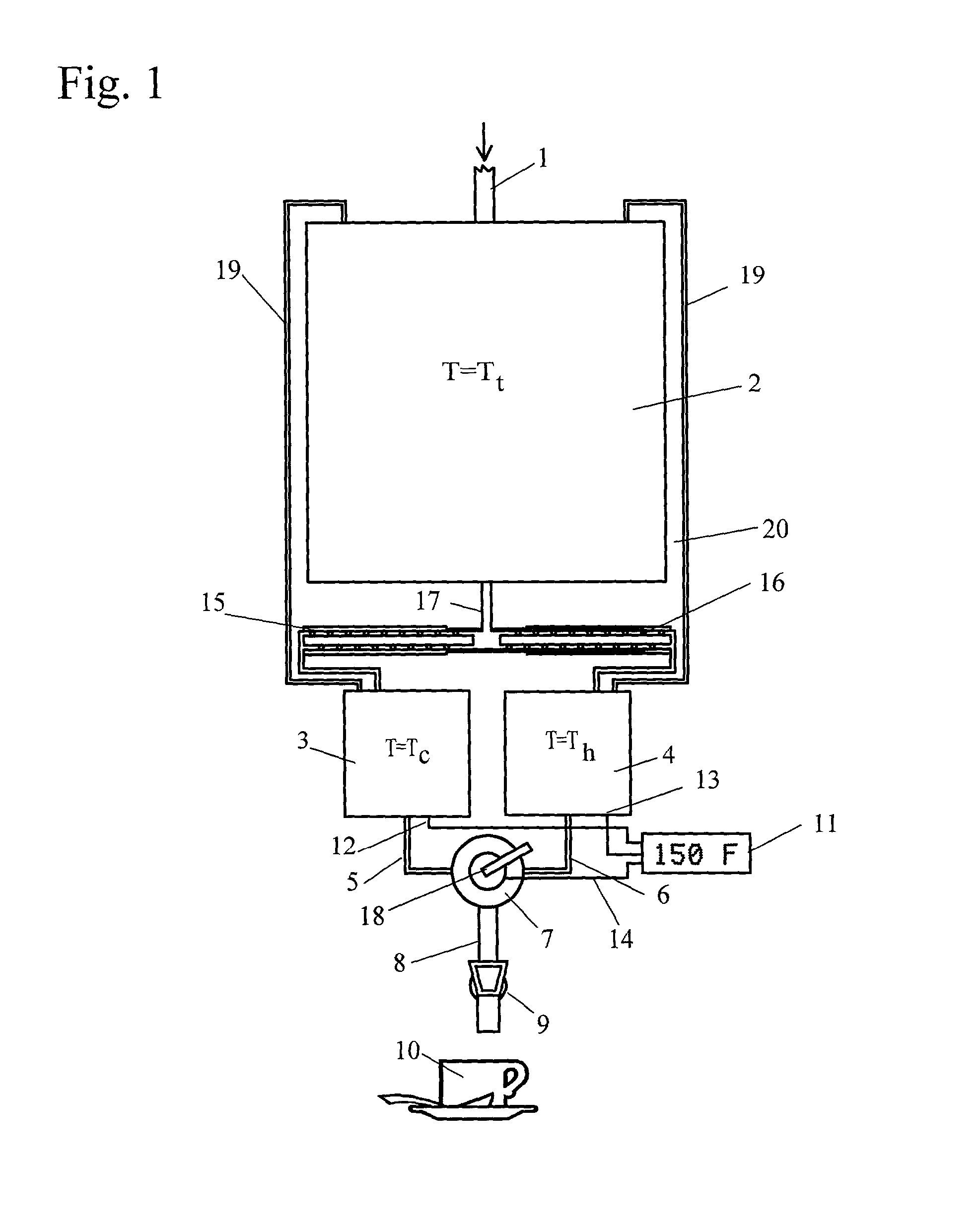

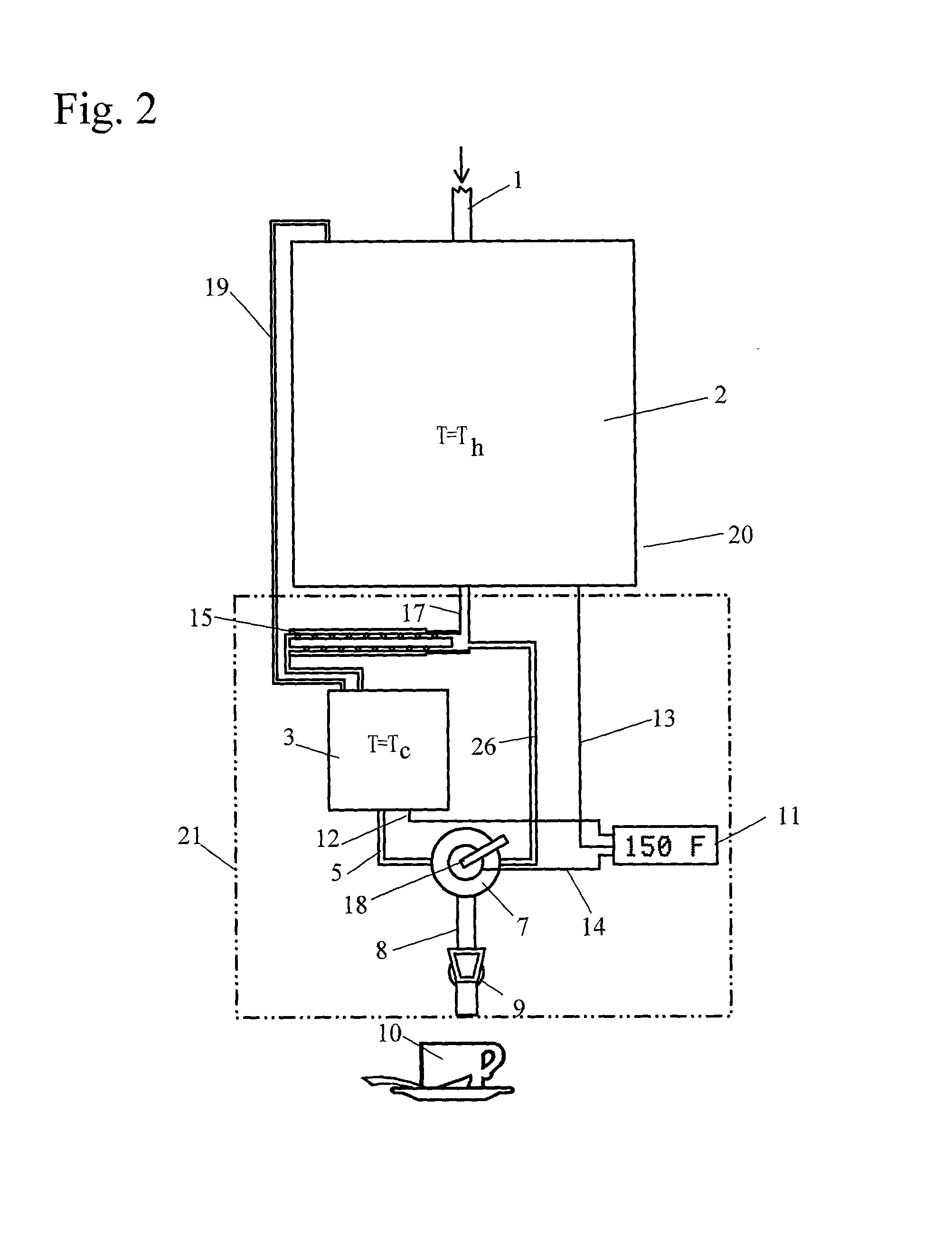

Beverage dispenser having selectable temperature

InactiveUS20020130137A1Extension of timeReduce the temperatureTemperature control without auxillary powerTemperature control with auxillary non-electric powerThermodynamicsProcess engineering

The present invention dispenses hot coffee or other beverage by the cup at a selected temperature, which can be varied from cup-to-cup. The beverage is brewed in a conventional way, and in one embodiment is stored in a conventional holding tank at elevated temperature. The holding tank communicates with two smaller reservoirs. A quantity of beverage is stored in a first reservoir at an elevated temperature, at or above the maximum desired dispensing temperature. A second quantity of beverage is cooled and stored in a second reservoir at a lower temperature, at or below the minimum desired dispensing temperature. When a cup of beverage is to be dispensed, the temperature is selected, and a quantity of beverage is dispensed from each of the reservoirs, proportioned so that the resulting dispensed beverage is at the selected temperature. In another embodiment, the first reservoir is omitted, and beverage from the holding tank provides the elevated temperature beverage for mixing. In several other embodiments, no cooling mechanism is needed. Instead, the holding tank is at a cooler temperature than the lowest vend temperature, and the beverage must be heated to the hot reservoir temperature and, in one embodiment, the cold reservoir temperature. In another embodiment, the holding tank functions as a cold reservoir. In still another embodiment requiring no heaters, the holding tank is eliminated, and the beverage is held in insulated chambers at the higher and lower temperatures.

Owner:GREENWALD TECH

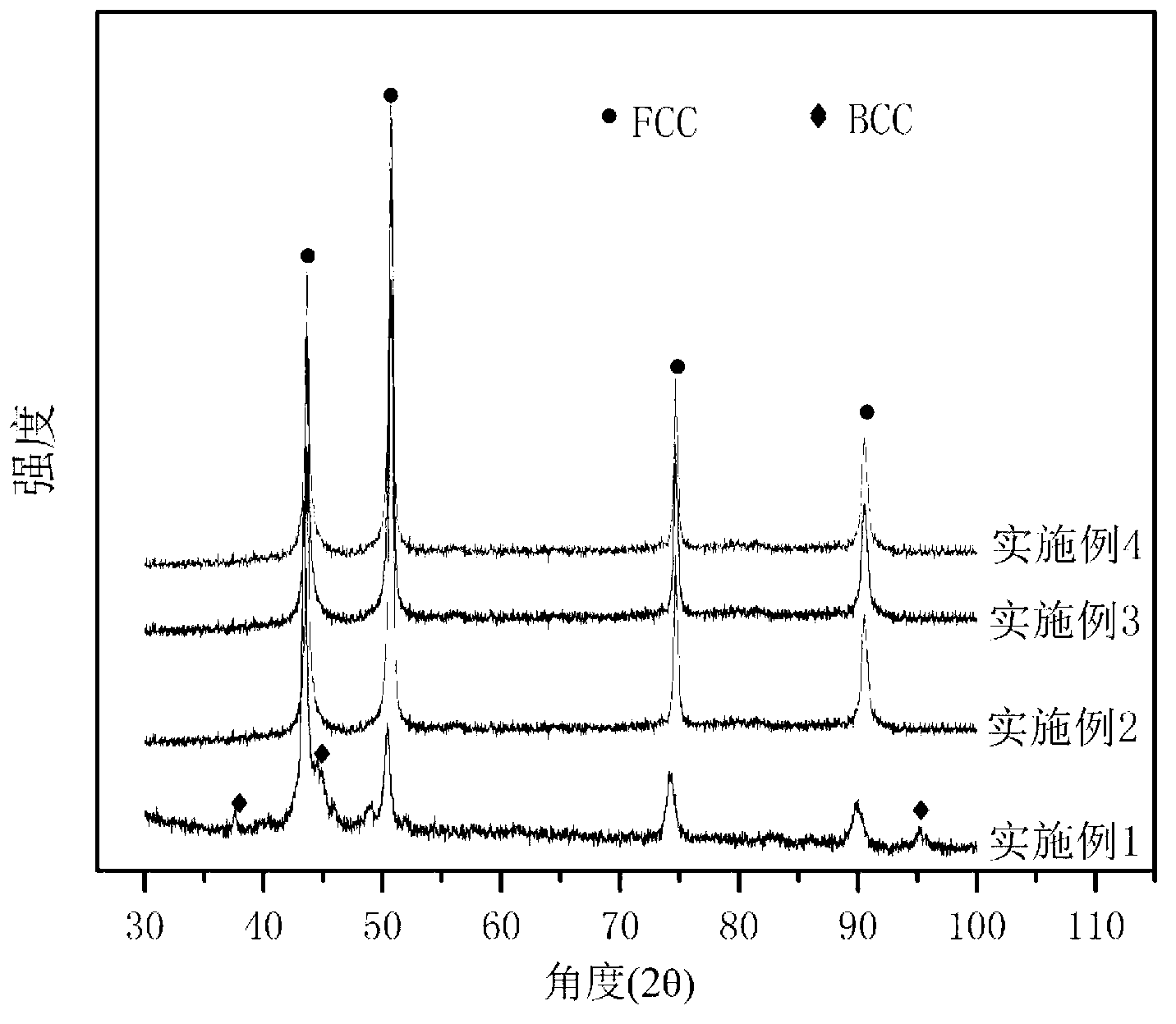

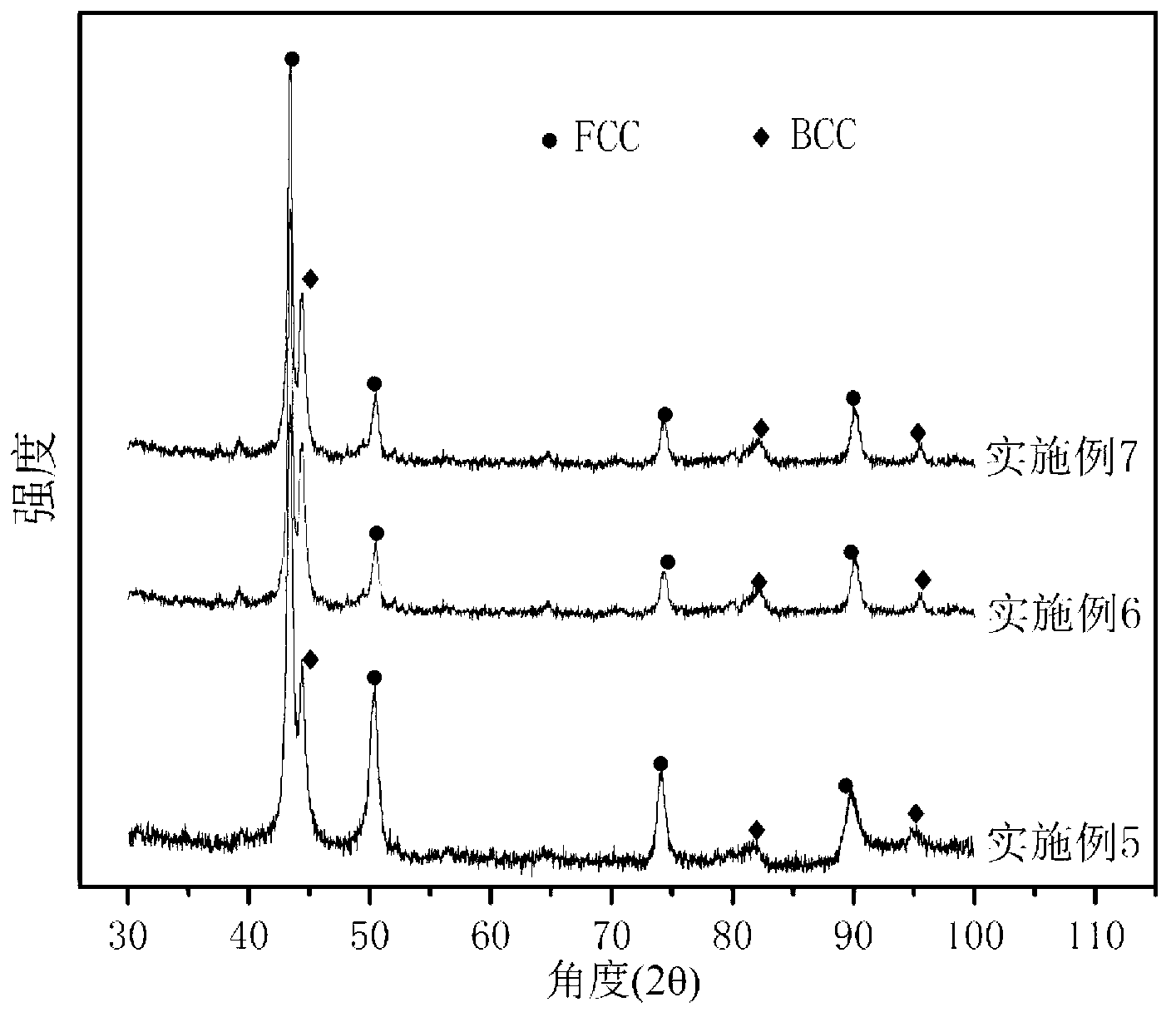

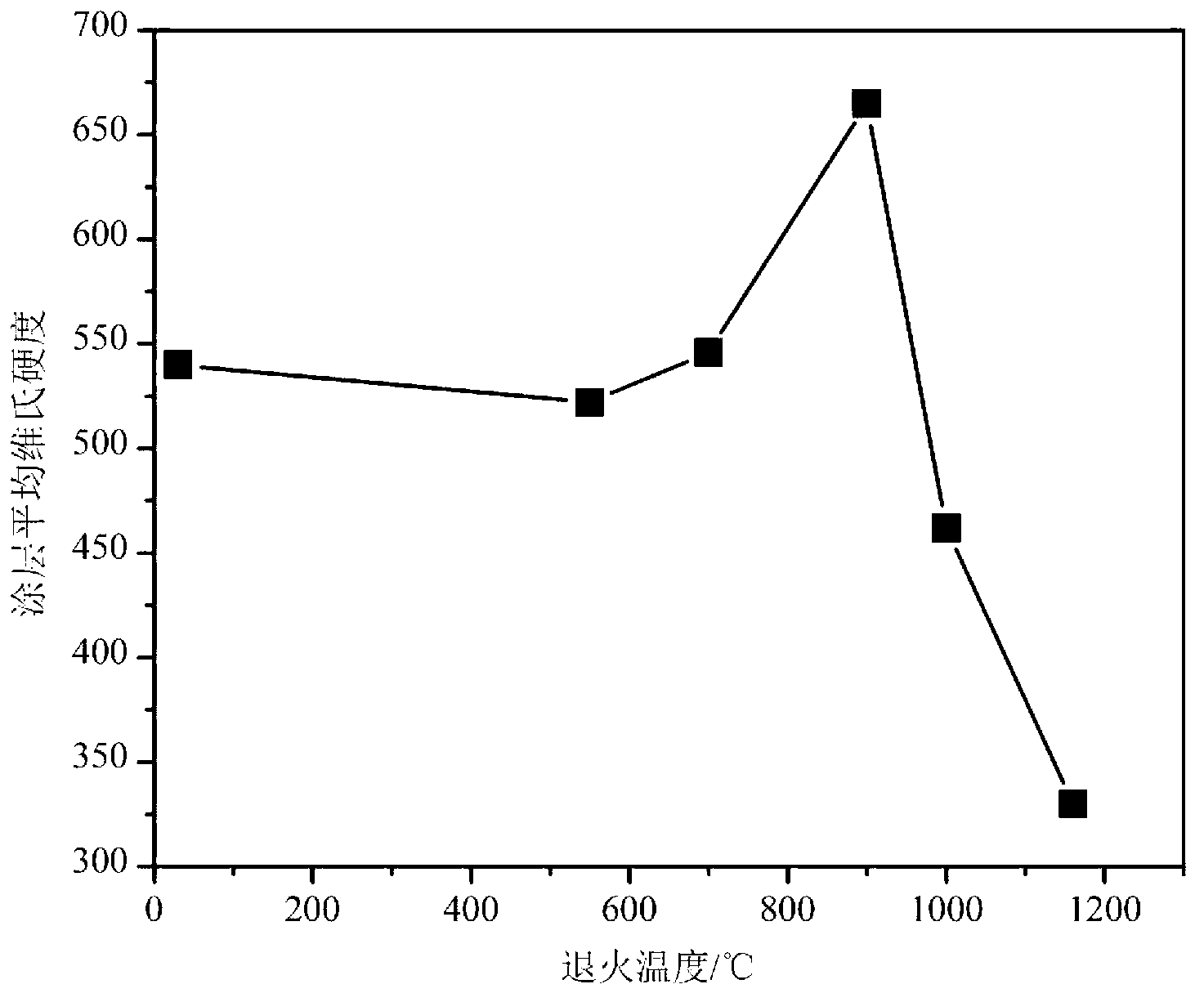

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

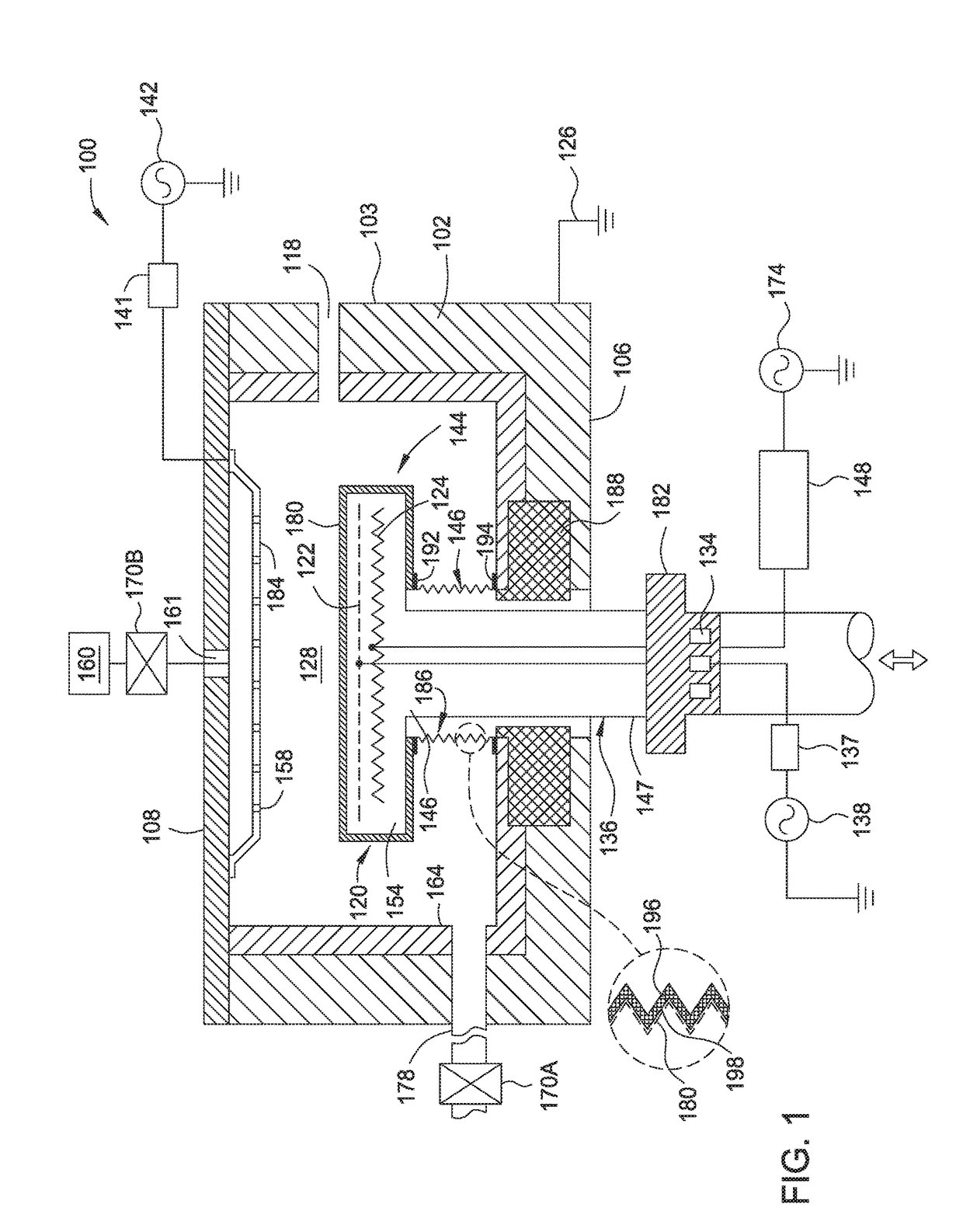

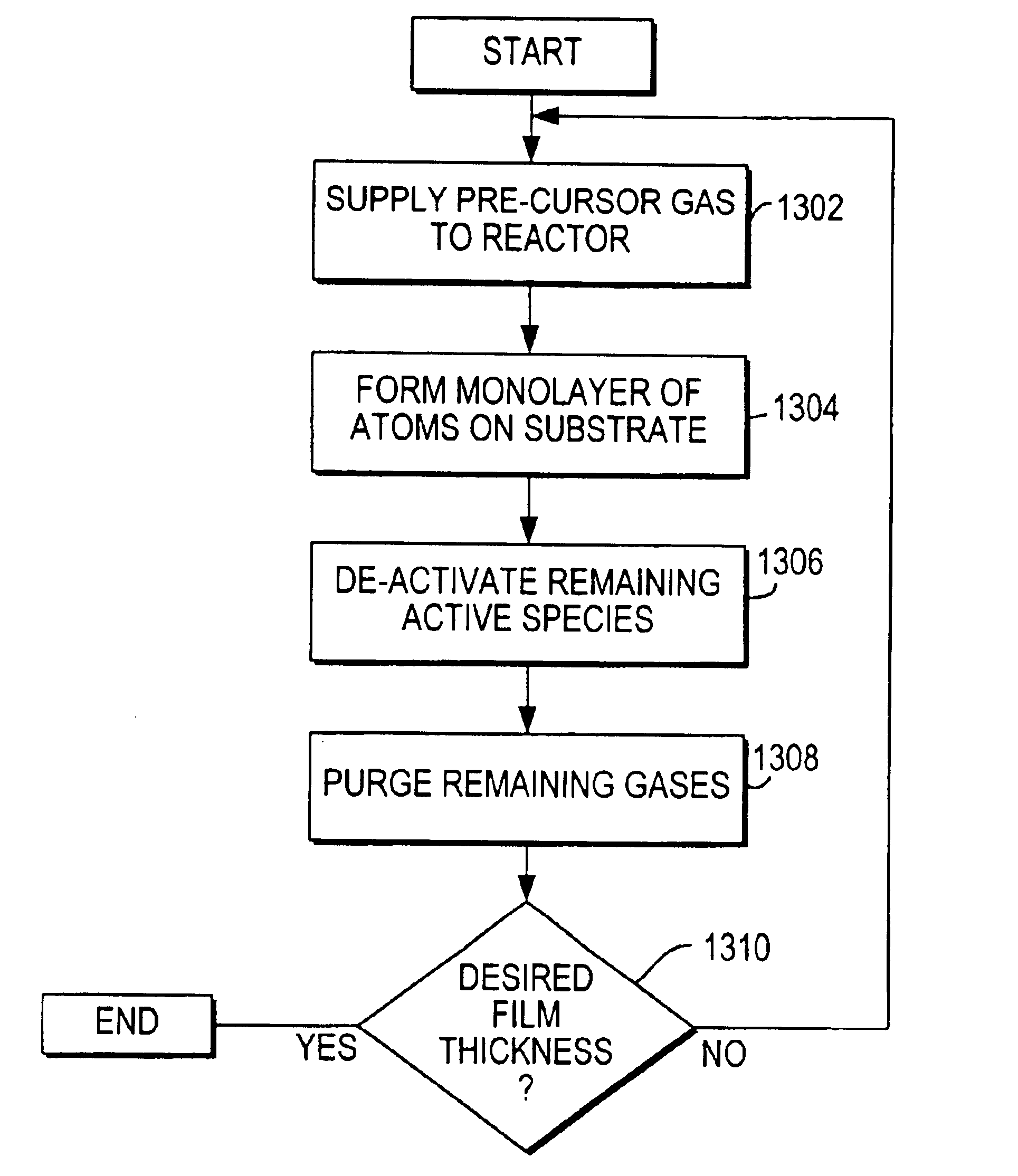

Insitu post atomic layer deposition destruction of active species

InactiveUS6844260B2Reduced purge timeImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasAtomic layer deposition

Systems and methods for insitu post atomic layer deposition (ALD) destruction of active species are provided. ALD processes deposit multiple atomic layers on a substrate. Pre-cursor gases typically enter a reactor and react with the substrate resulting in a monolayer of atoms. After the remaining gas is purged from the reactor, a second pre-cursor gas enters the reactor and the process is repeated. The active species of some pre-cursor gases do not readily purge from the reactor, thus increasing purge time and decreasing throughput. A high-temperature surface placed in the reactor downstream from the substrate substantially destroys the active species insitu. Substantially destroying the active species allows the reactor to be readily purged, increasing throughput.

Owner:MICRON TECH INC

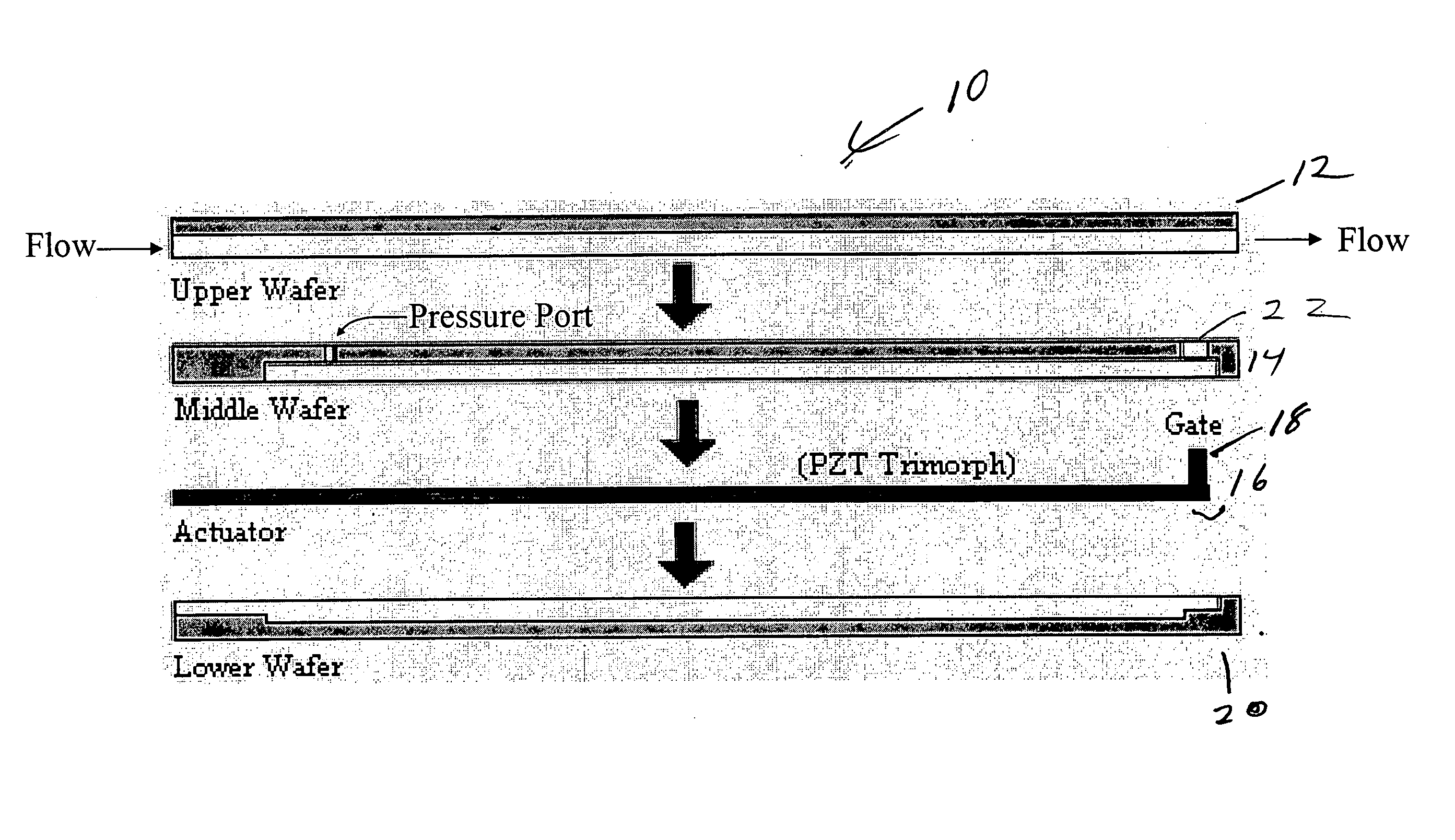

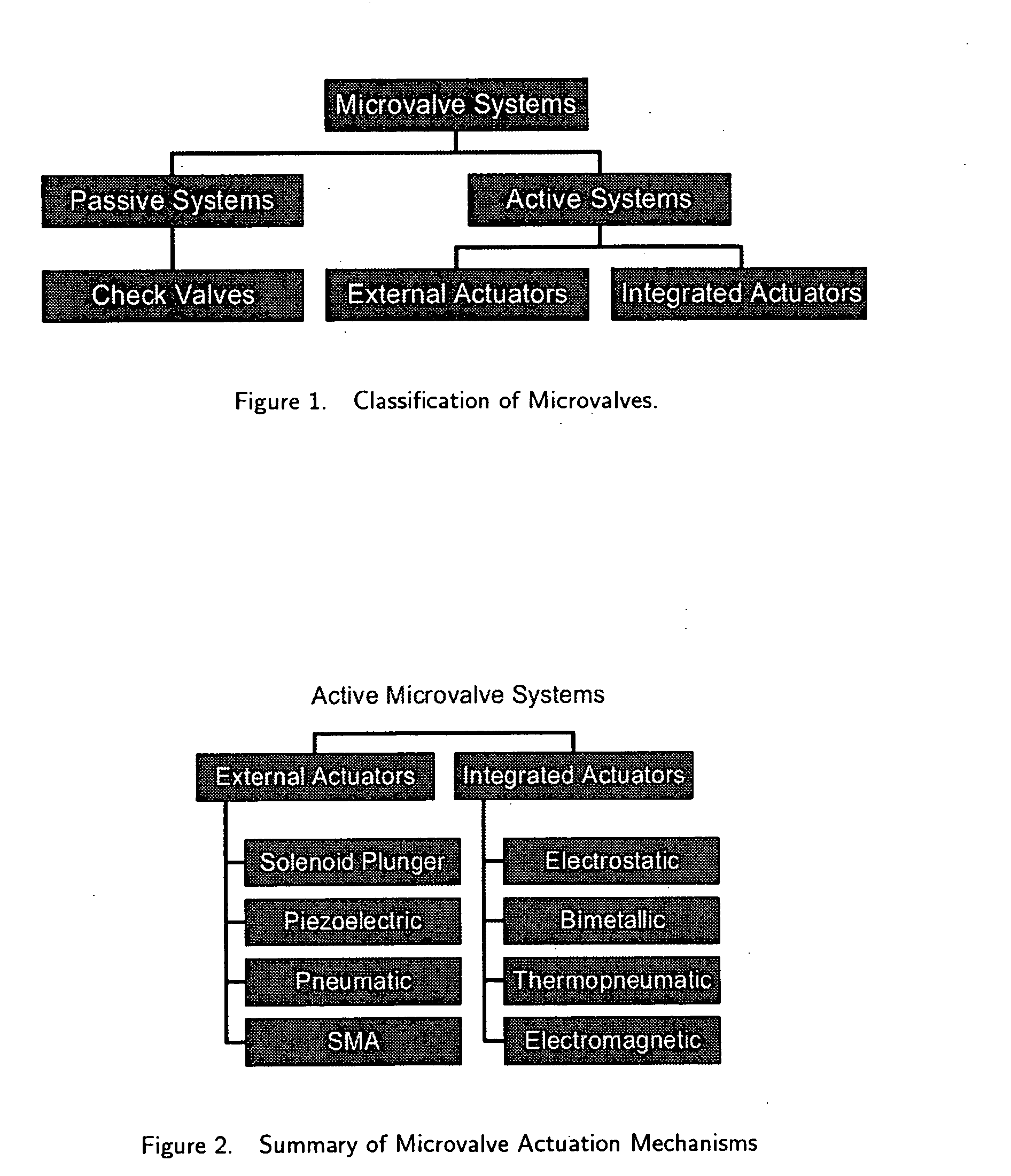

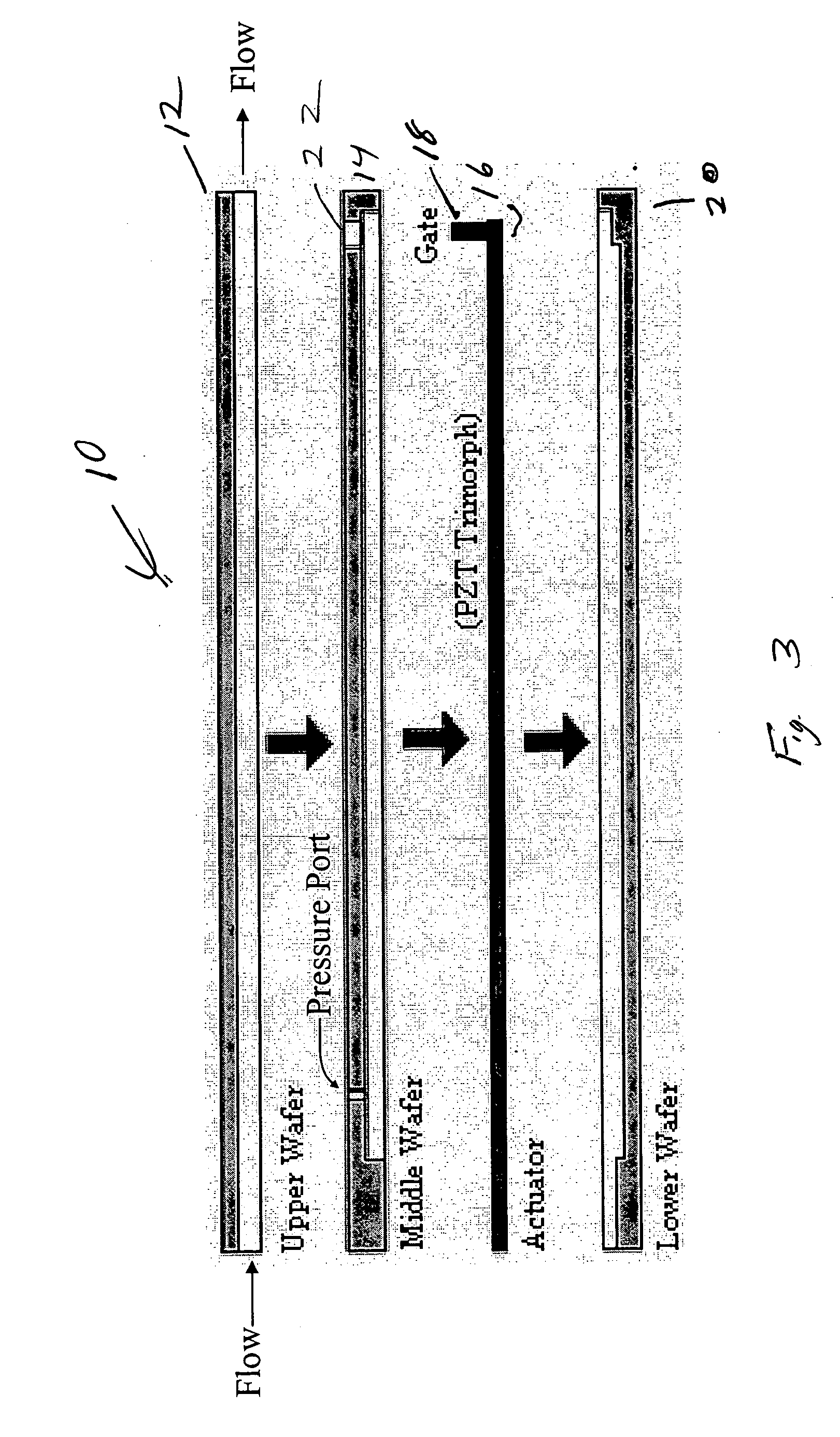

Piezoelectric axial flow microvalve

InactiveUS20040137300A1Operating means/releasing devices for valvesFinal product manufactureEpoxyPhotonics

This paper presents the fabrication and preliminary testing of a novel piezoelectric microvalve. Fabrication has three steps, which are the actuator fabrication, valve body fabrication and assembly of the microvalve. Fabricating an actuator involves cutting piezoelectric and brass beams, gluing the brass and piezoceramic beams into a trimorph sandwich structure, and curing them under pressure at elevated temperatures. Actuators are then wired either by using conductive epoxy or soldering. Valve body parts are constructed from single crystal silicon substrates using deep reactive ion etching (DRIE). DRIE is a subtractive process, whereby a mask is created on the surface of the stock, which will shield the parts that are not to be machined. Refinements in the actuator manufacturing process are made to increase the quality and decrease the fabrication time. Using a photonic probe, tip deflections of the actuators have been tested at various temperature and voltage levels. Currently, the valves are being assembled. Once assembled, multiple microvalves will undergo cold flow testing with air followed by extensive flow extensive flow testing at elevated temperatures with humidified hydrogen.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

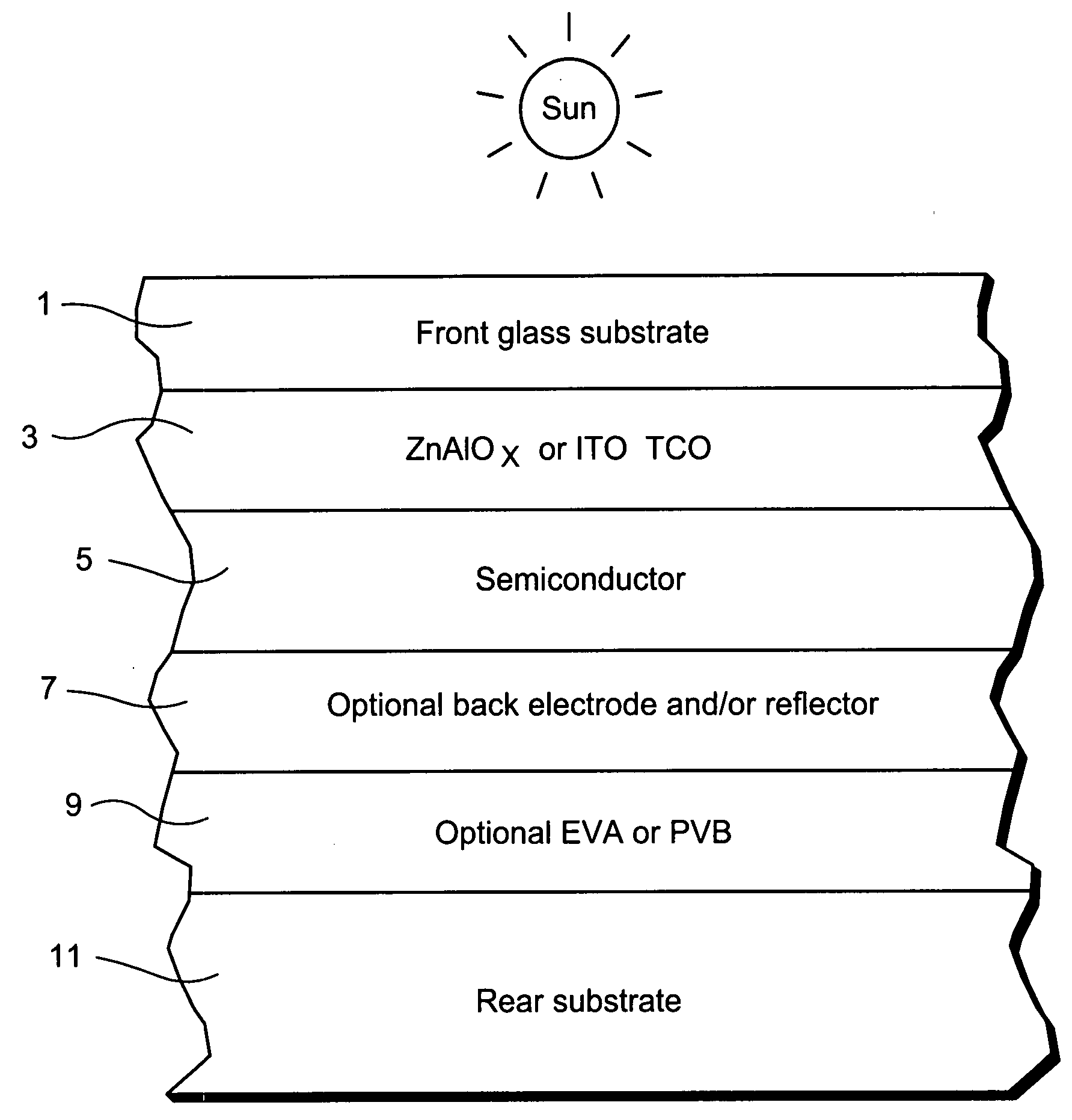

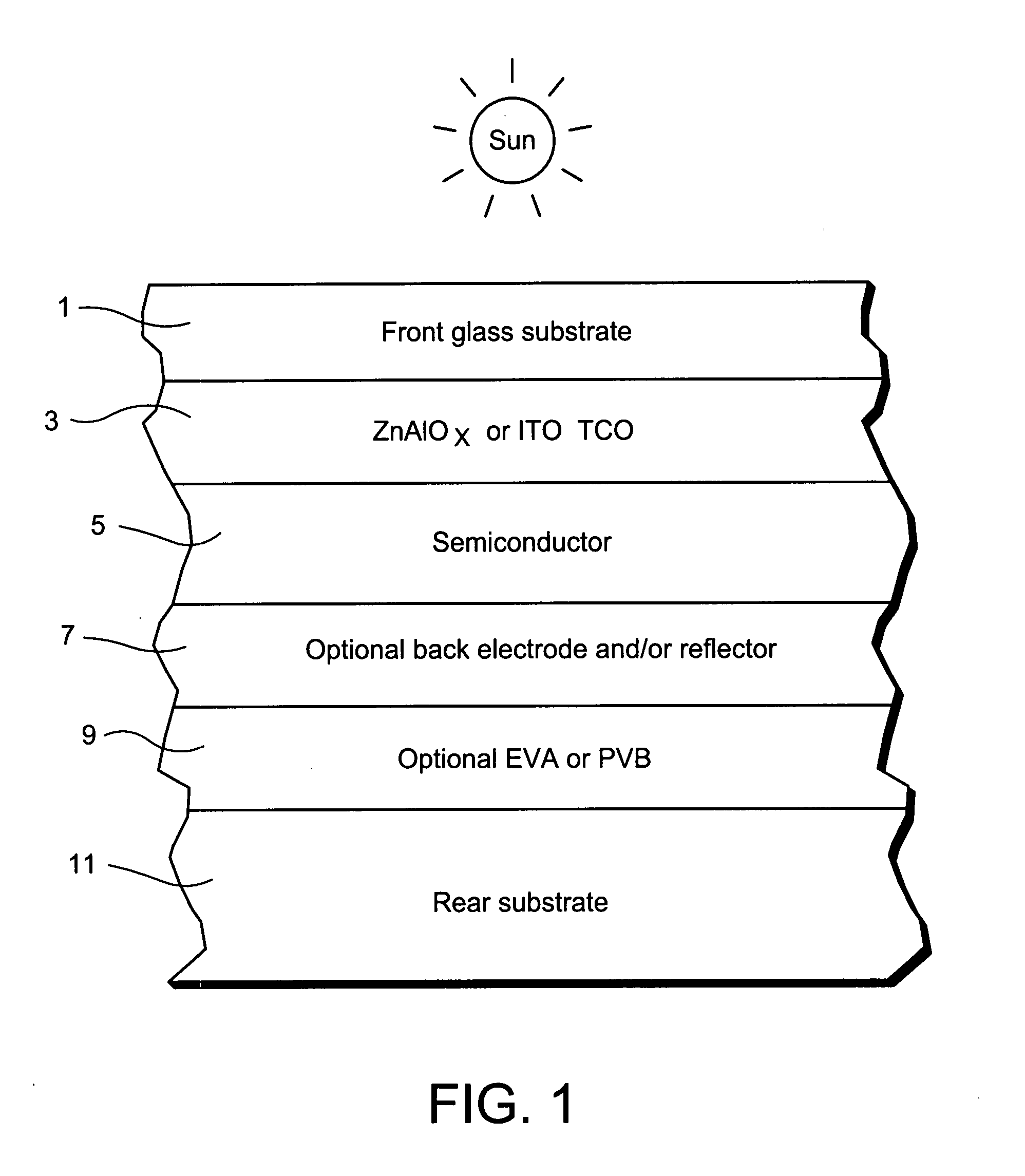

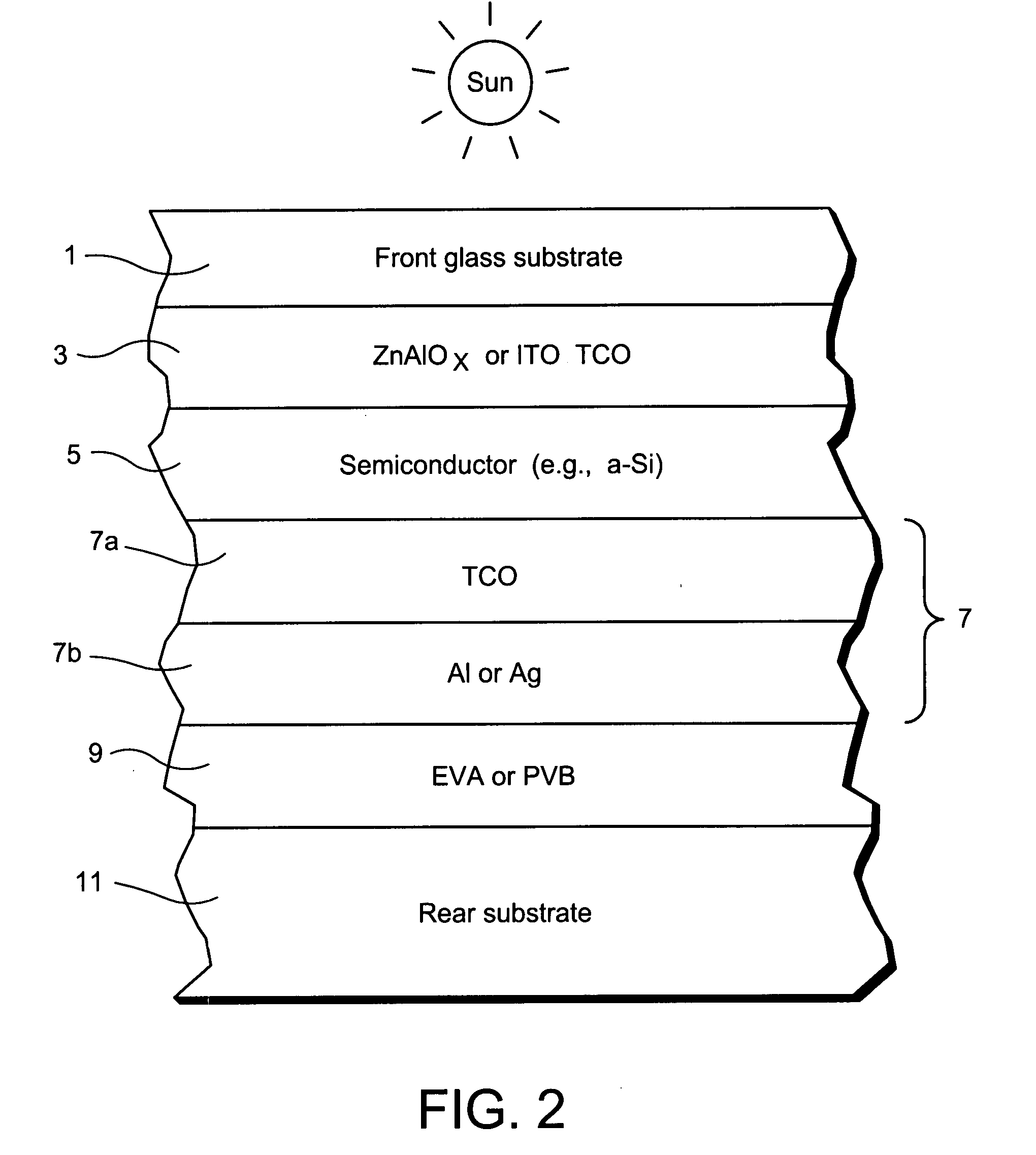

Method of making TCO front electrode for use in photovoltaic device or the like

InactiveUS20080169021A1Vacuum evaporation coatingSputtering coatingOptical propertyGaseous atmosphere

Certain example embodiments of this invention relate to an electrode (e.g., front electrode) for use in a photovoltaic device or the like. In certain example embodiments, a transparent conductive oxide (TCO) based front electrode for use in a photovoltaic device may be made by sputtering a ceramic target in a gaseous atmosphere tailored to optimize the electro-optical properties of the resulting TCO coating. For example, using a particular type of atmosphere in the sputtering process can permit the resulting TCO coating (e.g., of or including zinc oxide, zinc aluminum oxide, and / or ITO) to more readily withstand subsequent high temperature processing which may be used during manufacture of the photovoltaic device. Moreover, processing energy resulting from the high temperature(s) may also optionally be used to improve crystallinity characteristics of the TCO.

Owner:GUARDIAN GLASS LLC

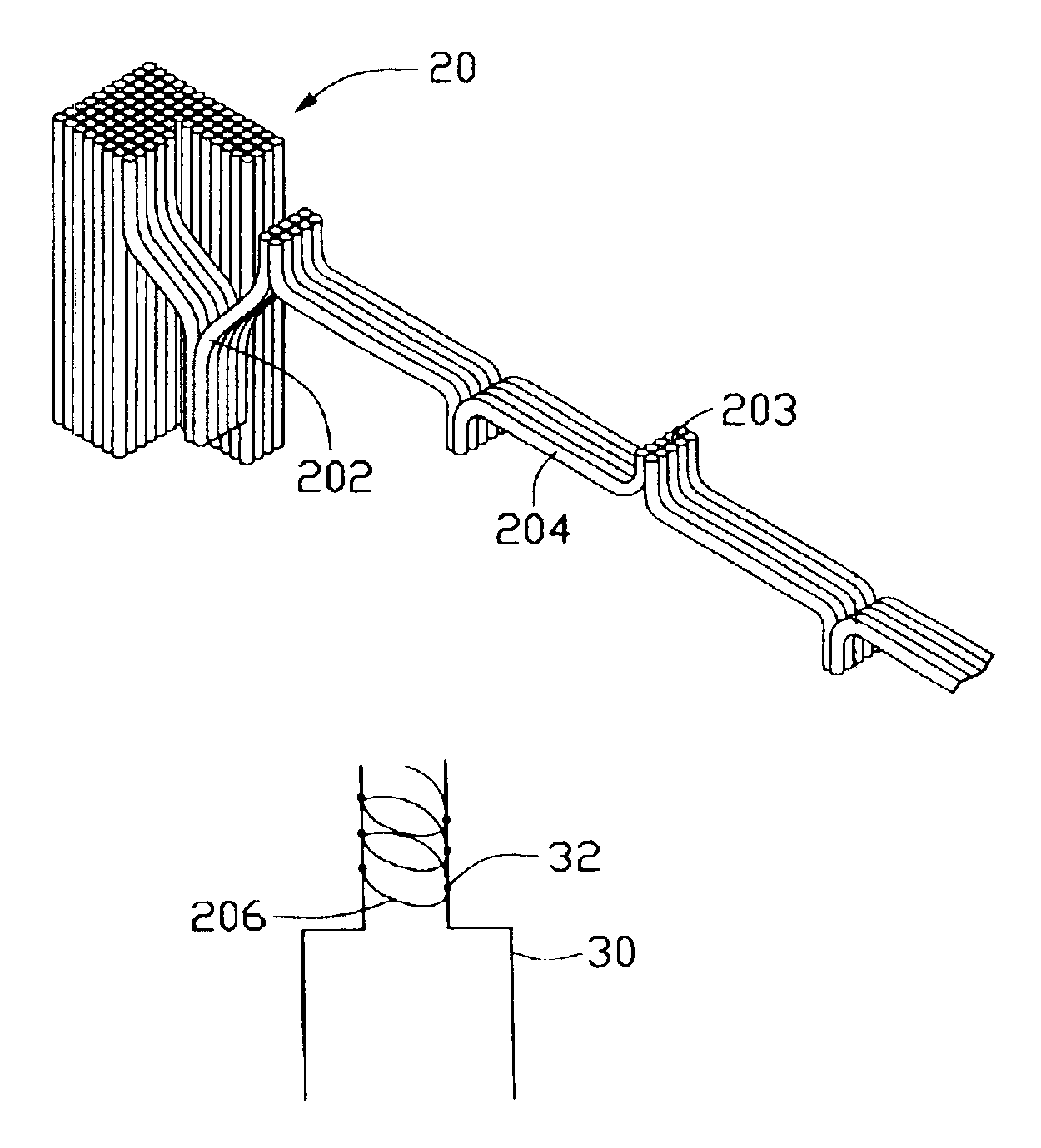

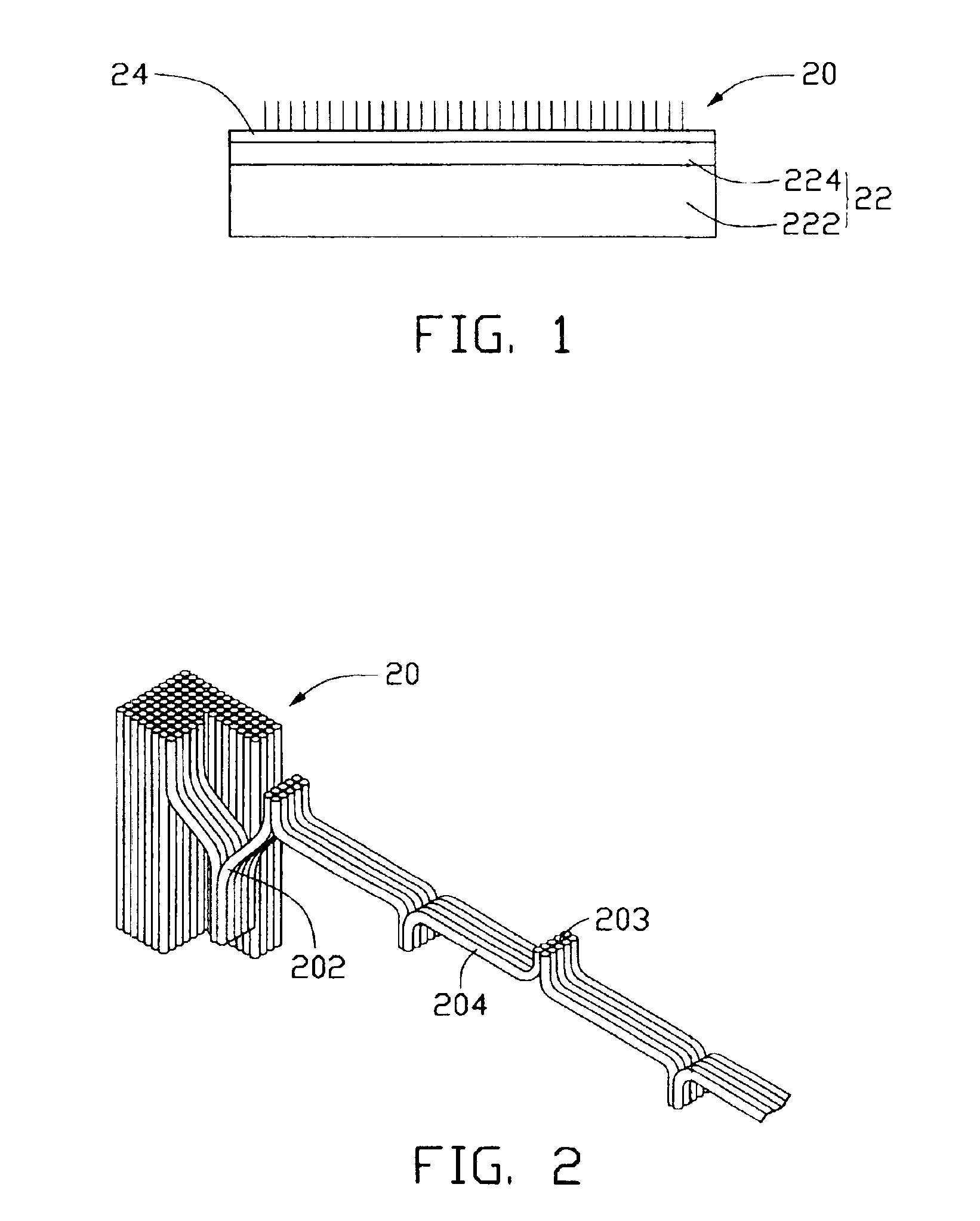

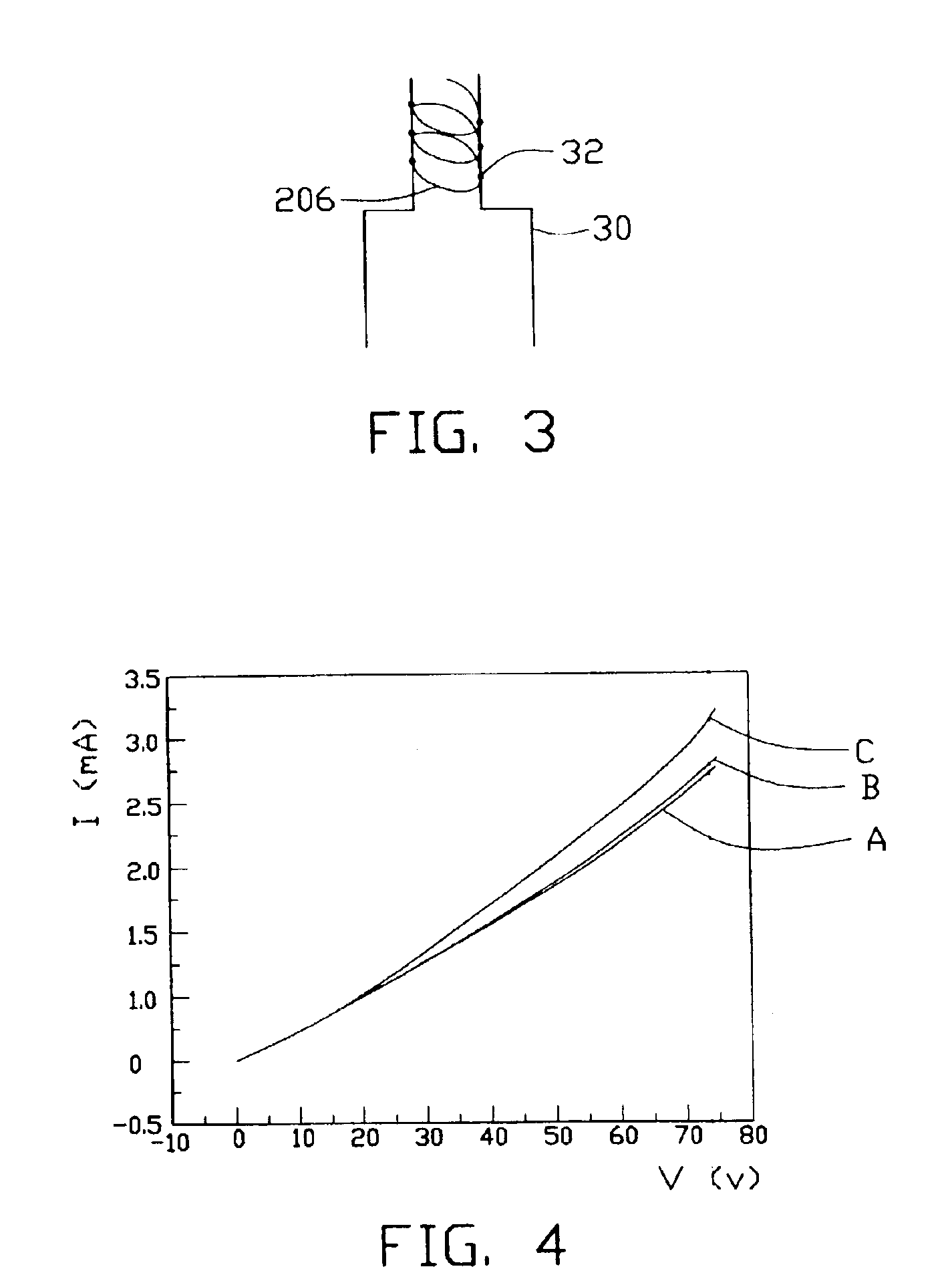

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

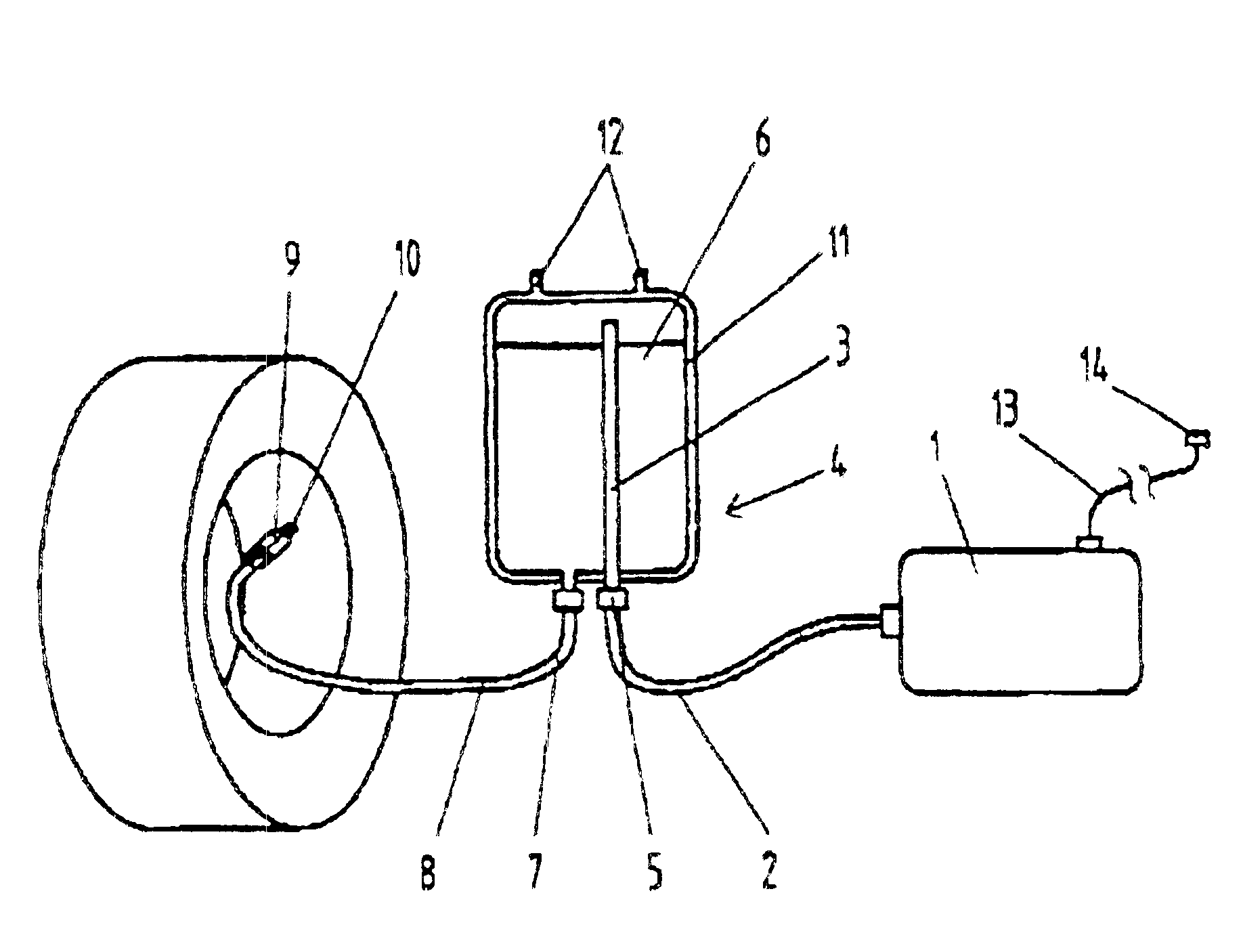

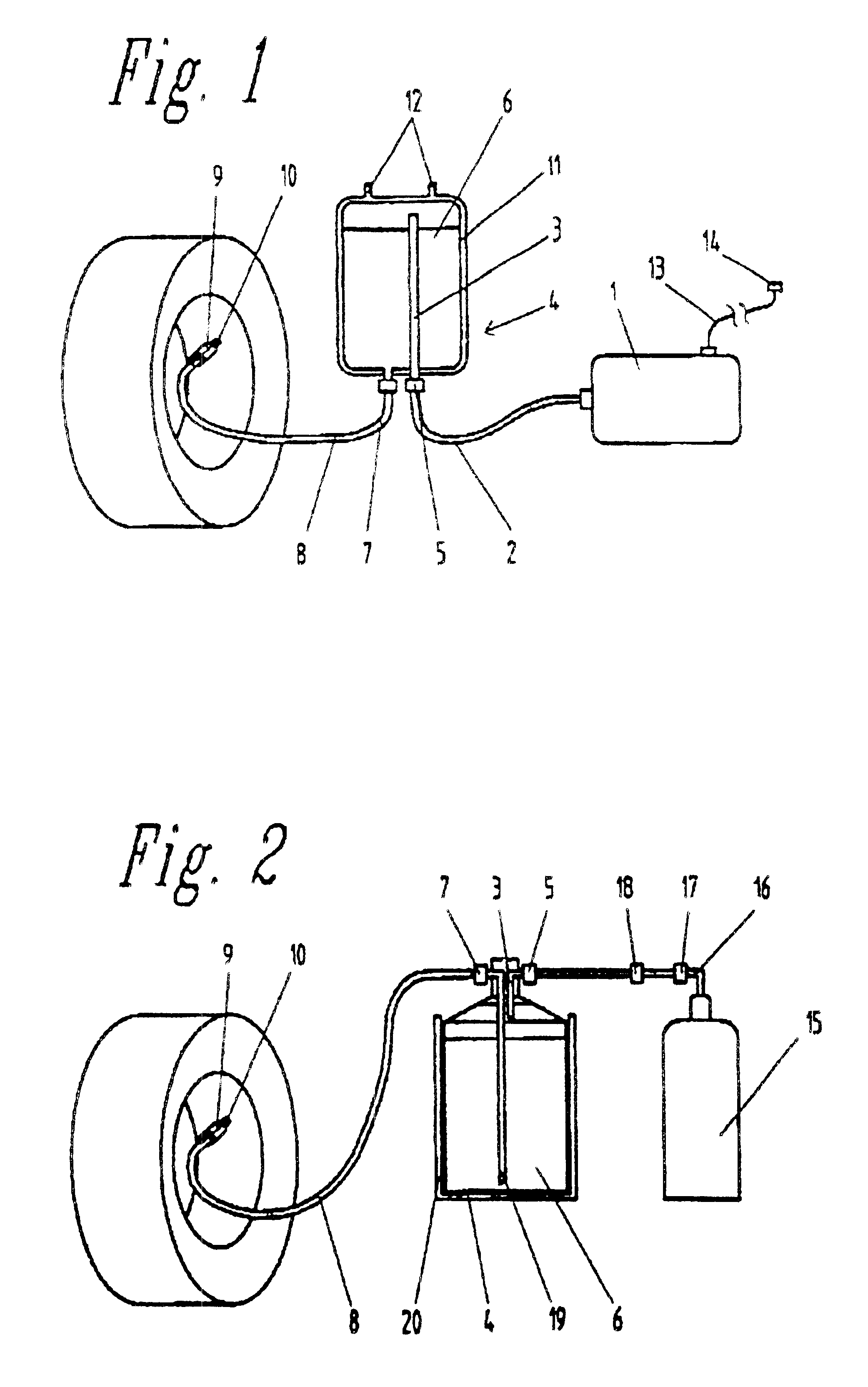

Preparation for sealing punctured tires and apparatus for the sealing and pumping up of tires

InactiveUS6889723B2Avoid easy removalImprove sealingLiquid surface applicatorsTyresSulfur hexafluorideEngineering

A sealing preparation for tire problems is proposed which seals in wet conditions, at low and high temperatures and with defects at the transition between the tread and the side wall of the tire. The sealing preparation contains natural rubber latex or a combination of rubber latex and compatible adhesive resin. Furthermore, various devices are proposed for introducing the sealing preparation into the tire and for the pumping up. An air compressor, or liquefied dinitrogenoxide, or sulphur hexafluoride are preferably used with these devices as a pressure source.

Owner:SUMITOMO RUBBER IND LTD

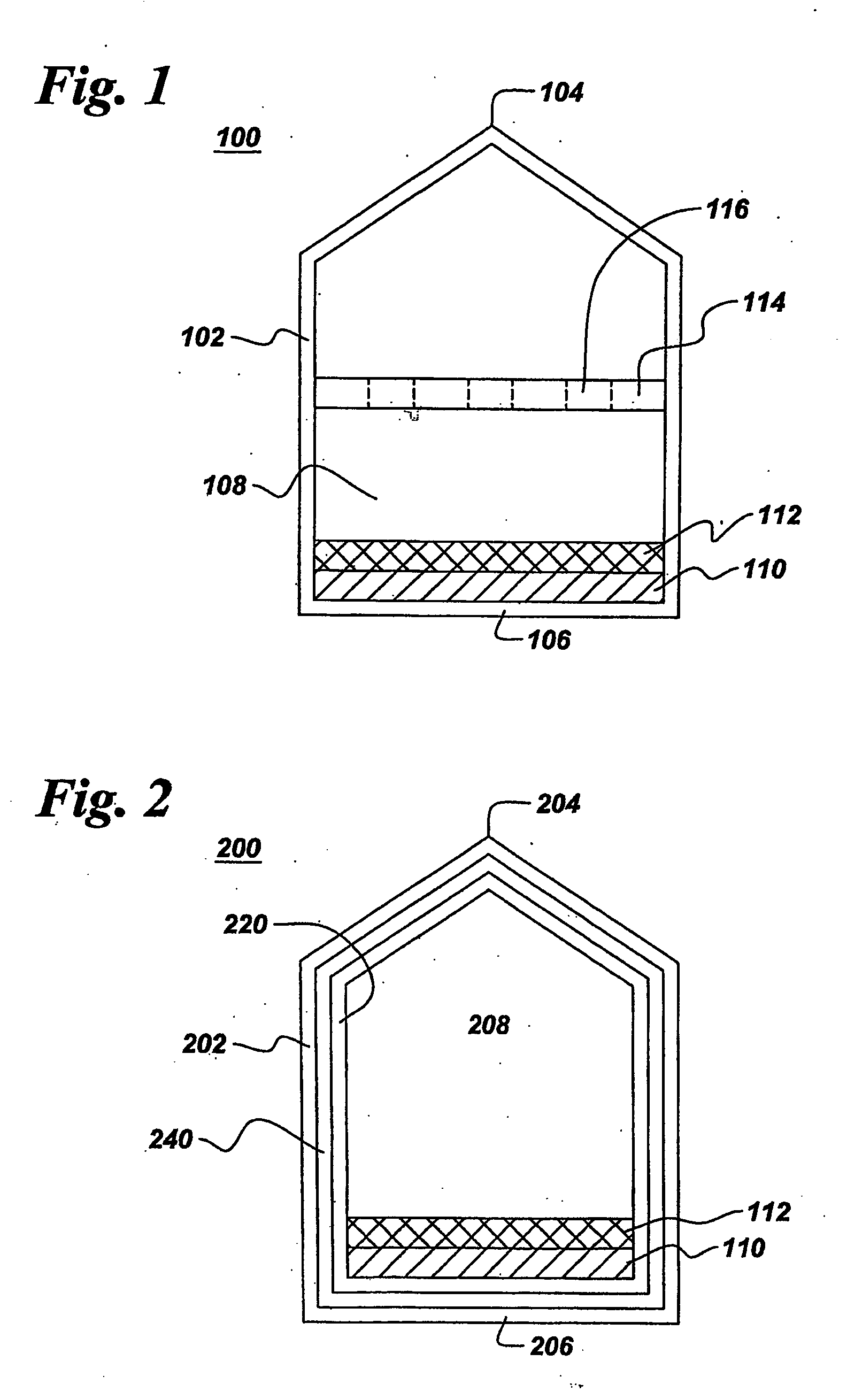

High temperature high pressure capsule for processing materials in supercritical fluids

InactiveUS20050152820A1From normal temperature solutionsUltra-high pressure processesHigh pressureSolvent

A capsule for containing at least one reactant and a supercritical fluid in a substantially air-free environment under high pressure, high temperature processing conditions. The capsule includes a closed end, at least one wall adjoining the closed end and extending from the closed end; and a sealed end adjoining the at least one wall opposite the closed end. The at least one wall, closed end, and sealed end define a chamber therein for containing the reactant and a solvent that becomes a supercritical fluid at high temperatures and high pressures. The capsule is formed from a deformable material and is fluid impermeable and chemically inert with respect to the reactant and the supercritical fluid under processing conditions, which are generally above 5 kbar and 550° C. and, preferably, at pressures between 5 kbar and 80 kbar and temperatures between 550° C. and about 1500° C. The invention also includes methods of filling the capsule with the solvent and sealing the capsule, as well as an apparatus for sealing the capsule.

Owner:SLT TECH

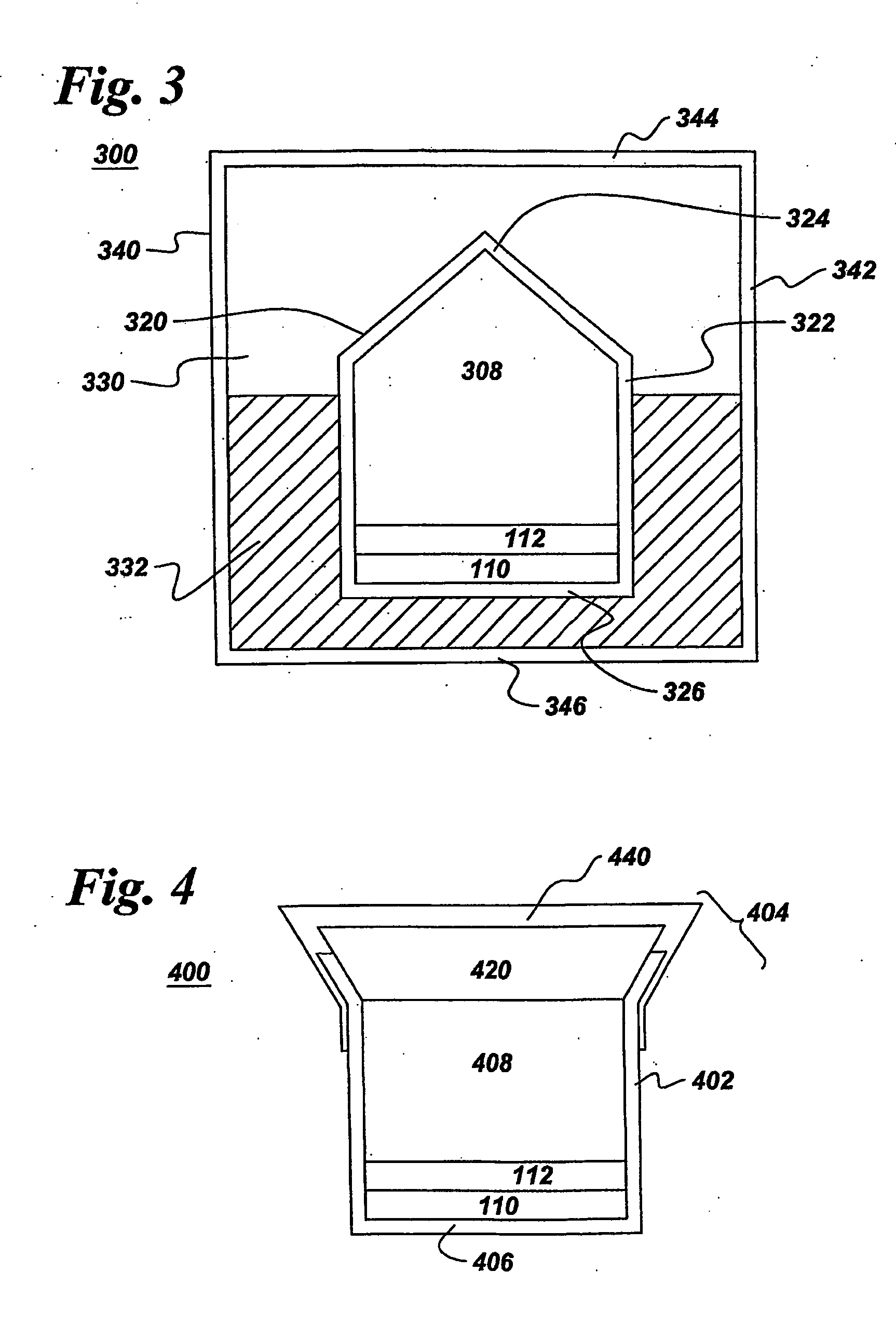

Fire extinguishing composition for generating fire extinguishing substance through chemical reaction among components at high temperature

The invention discloses a fire extinguishing composition for generating a fire extinguishing substance through chemical reaction among components at high temperature, which is characterized by comprising the following components in percentage by mass: 50 to 90 percent of flame retardant, 5 to 30 percent of oxidant, 5 to 10 percent of reducing agent and 0 to 10 percent of adhesive. During use, smoke and fire agents are taken as a heat source and power source, and by igniting the smoke and fire agents and utilizing the high temperature through combustion of the smoke and fire agents, the oxidant and the reducing agent in the fire extinguishing composition are reacted to generate an active fire extinguishing substance for extinguishing fire. Different from the traditional aerosol generating agent, the fire extinguishing composition does not need an external heat source, and does not combust. Compared with the traditional aerosol generating agent, the fire extinguishing composition is more high-efficiency and more safe.

Owner:YICHANG JI AN DUN FIRE FIGHTING TECH CO LTD

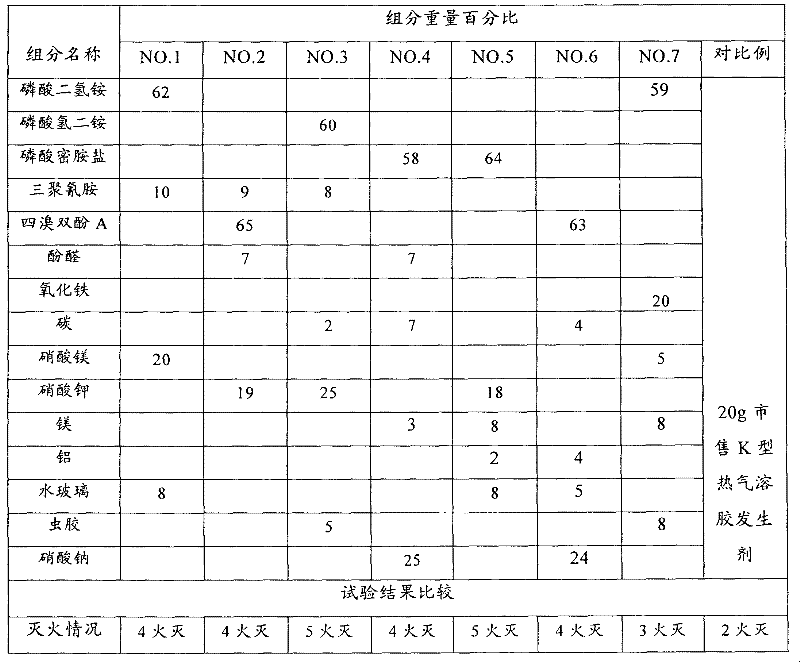

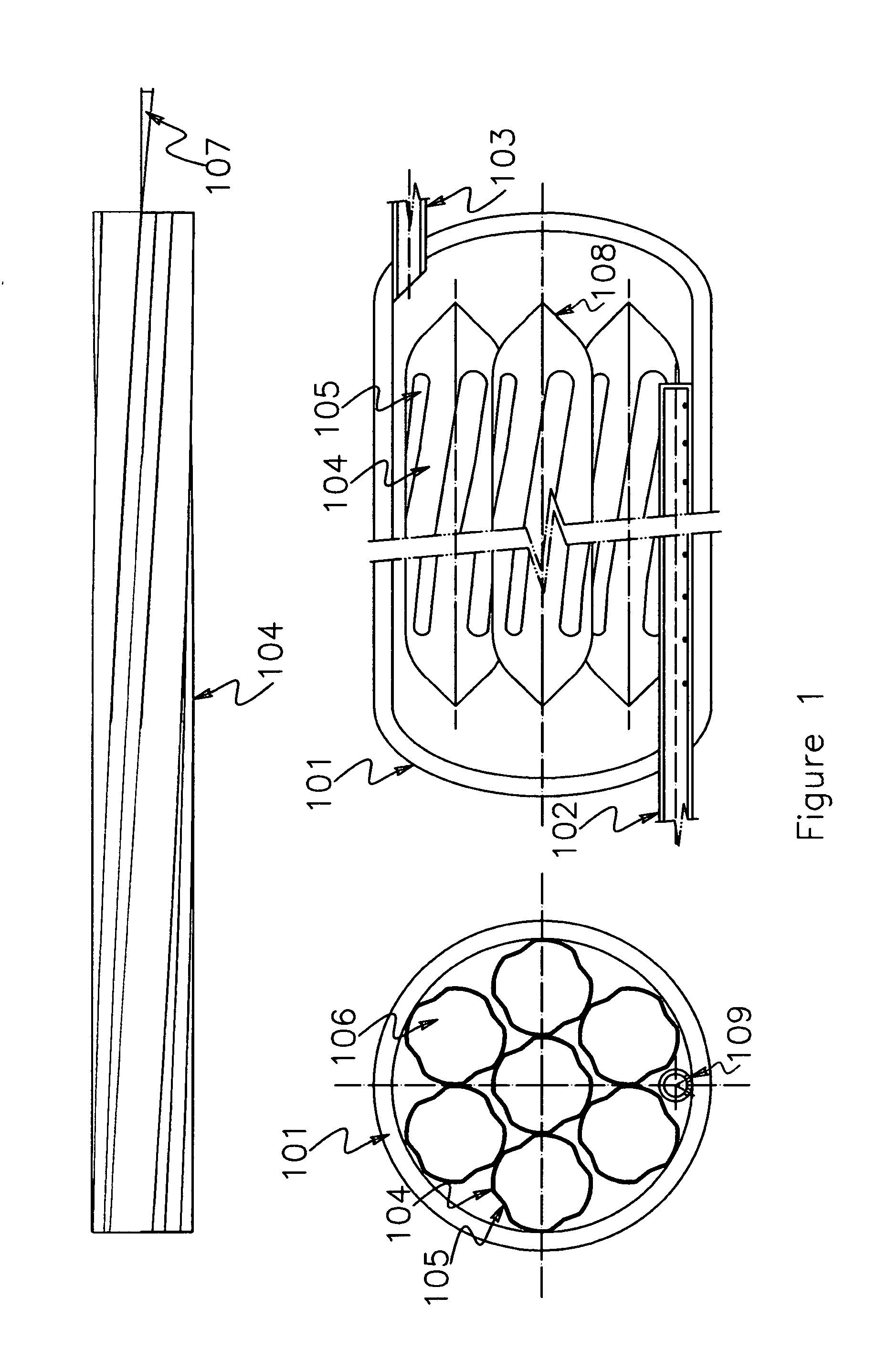

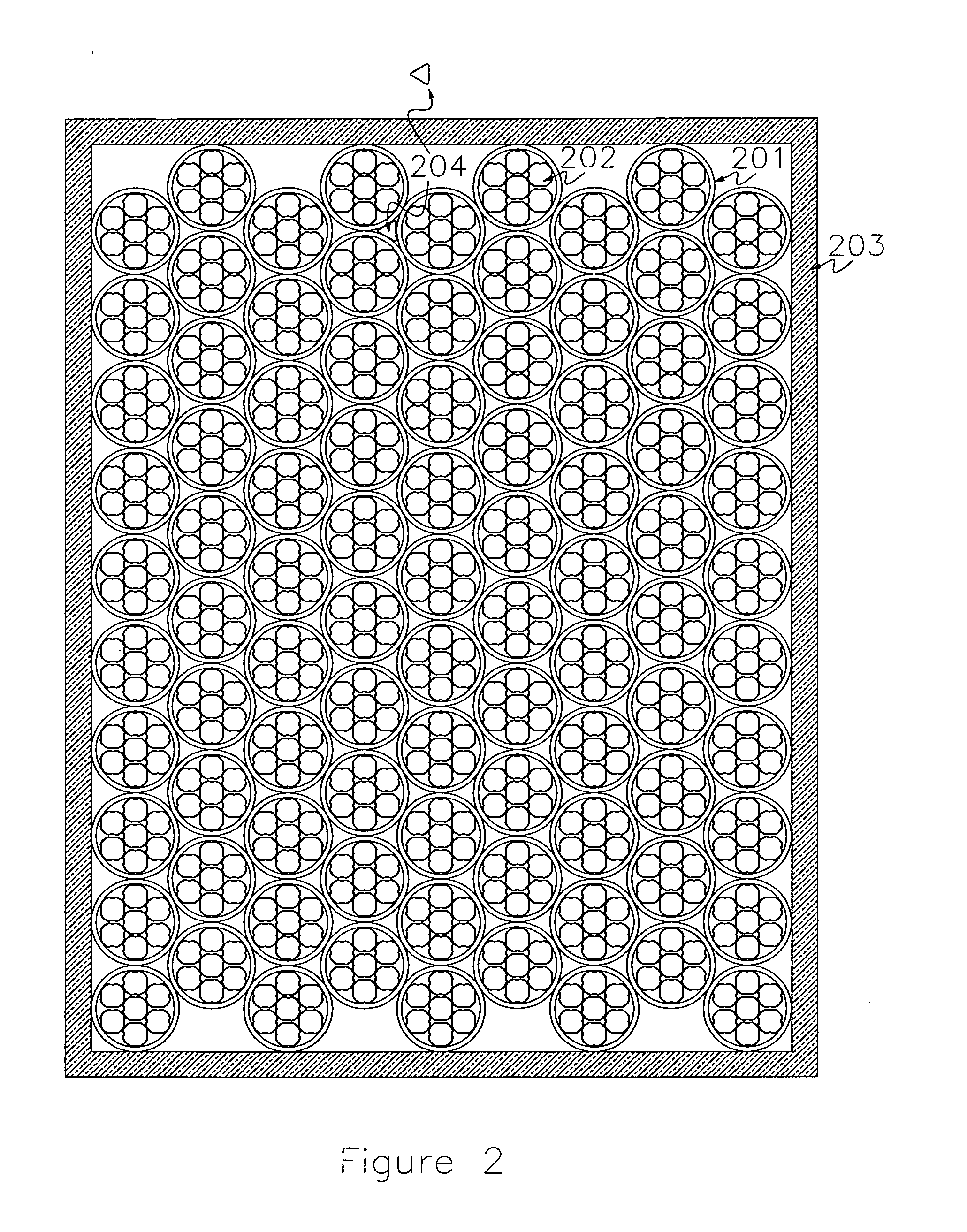

High temperature thermal energy storage system

InactiveUS20120055661A1Large lengthFrom solar energyHeat storage plantsThermal energyThermal energy storage

Owner:FEHER PETER

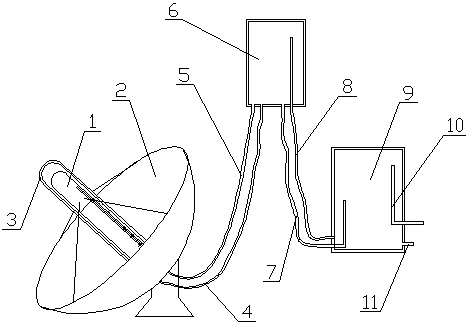

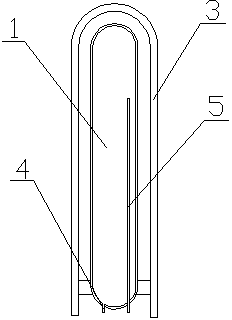

Solar energy storage and utilization device

InactiveCN104165347AAvoid lossImprove utilization efficiencySolar heating energySteam generation heating methodsWater storage tankHigh pressure water

A solar energy storage and utilization device comprises a metal inner container, a collecting lens, an energy storage tank and a water storage tank. A transparent vacuum tube is arranged outside the metal inner container; the bottom of the water storage tank and the bottom of the metal inner container are communicated through a water pipe I, the upper portion in the metal inner container and the bottom of the water storage tank are connected through a steam pipe I, and an exhaust pipe and a water supplementing pipe are arranged on the energy storage tank. According to the solar energy storage and utilization device, the transparent vacuum tube layer is arranged outside the metal inner container, received solar energy is stopped from being lost and thus the utilization rate of solar energy is substantially increased; meanwhile, the water storage tank and the energy storage tank are arranged so that solar energy received in good weather is stored in the energy storage tank in the form of high temperature and high pressure water and utilized in bad weather, the situation that an existing solar energy utilization device depends a lot on weather conditions is eliminated, and the application range of the solar energy utilization device is widened.

Owner:深圳市新浩建筑装饰工程有限公司

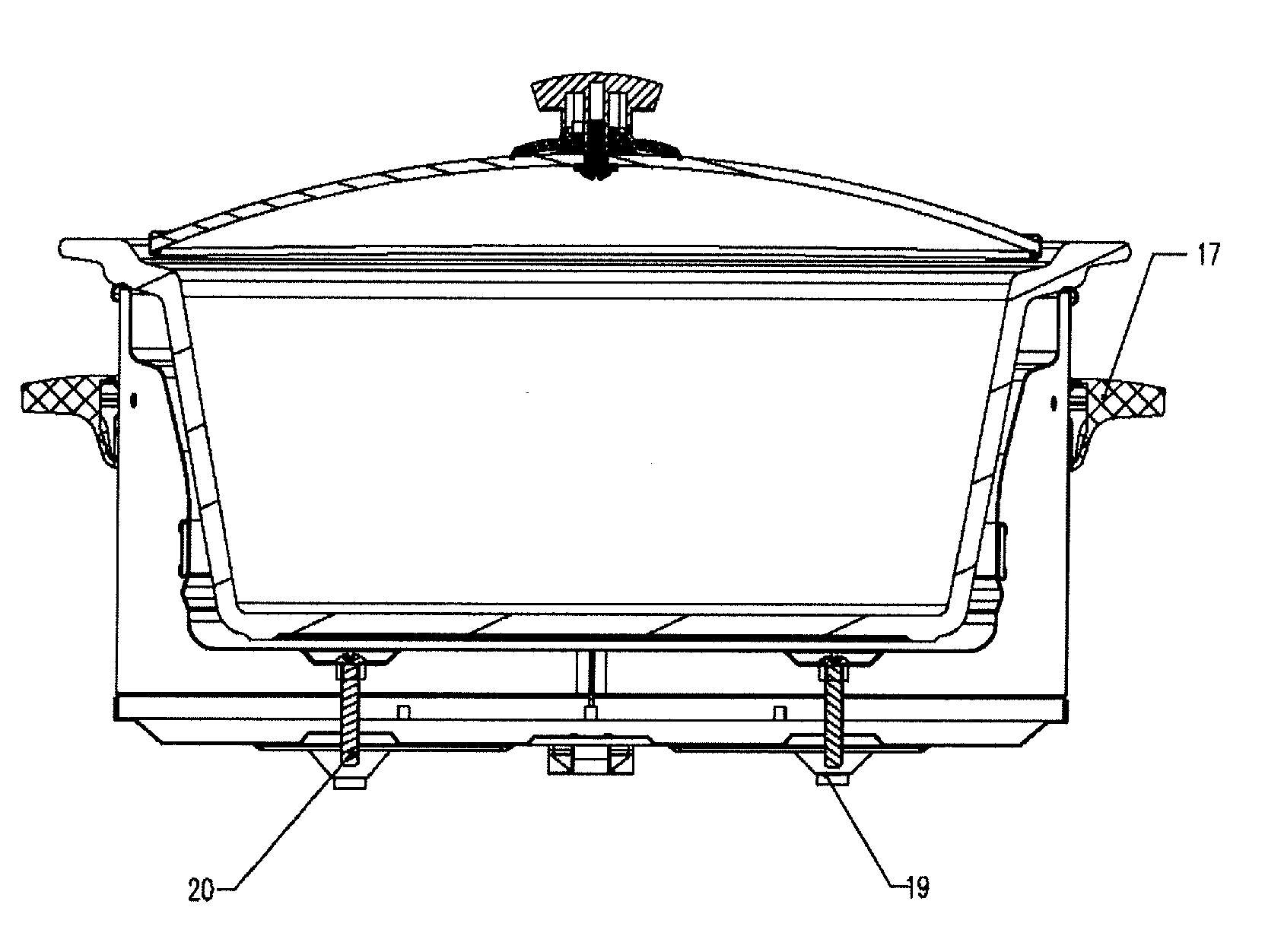

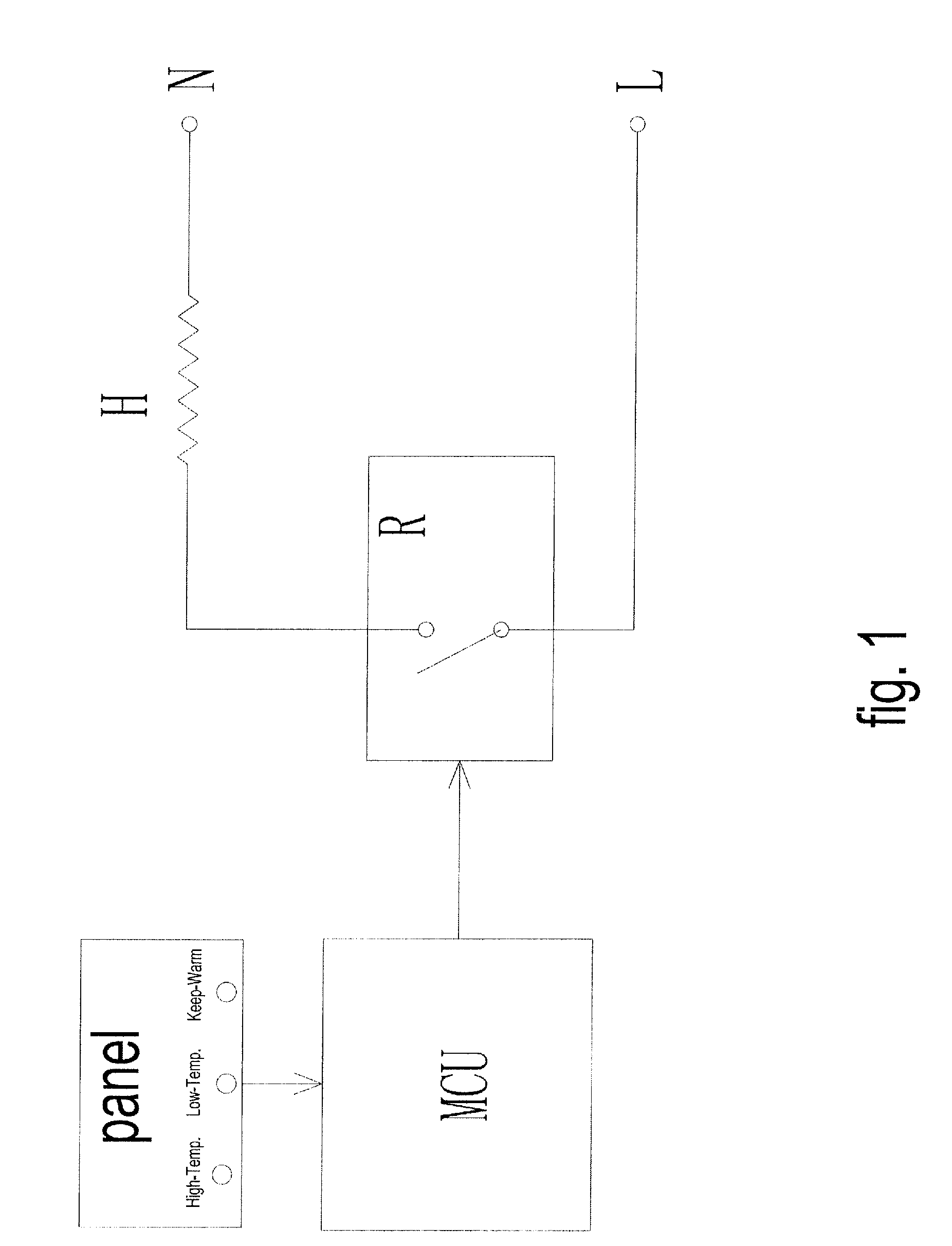

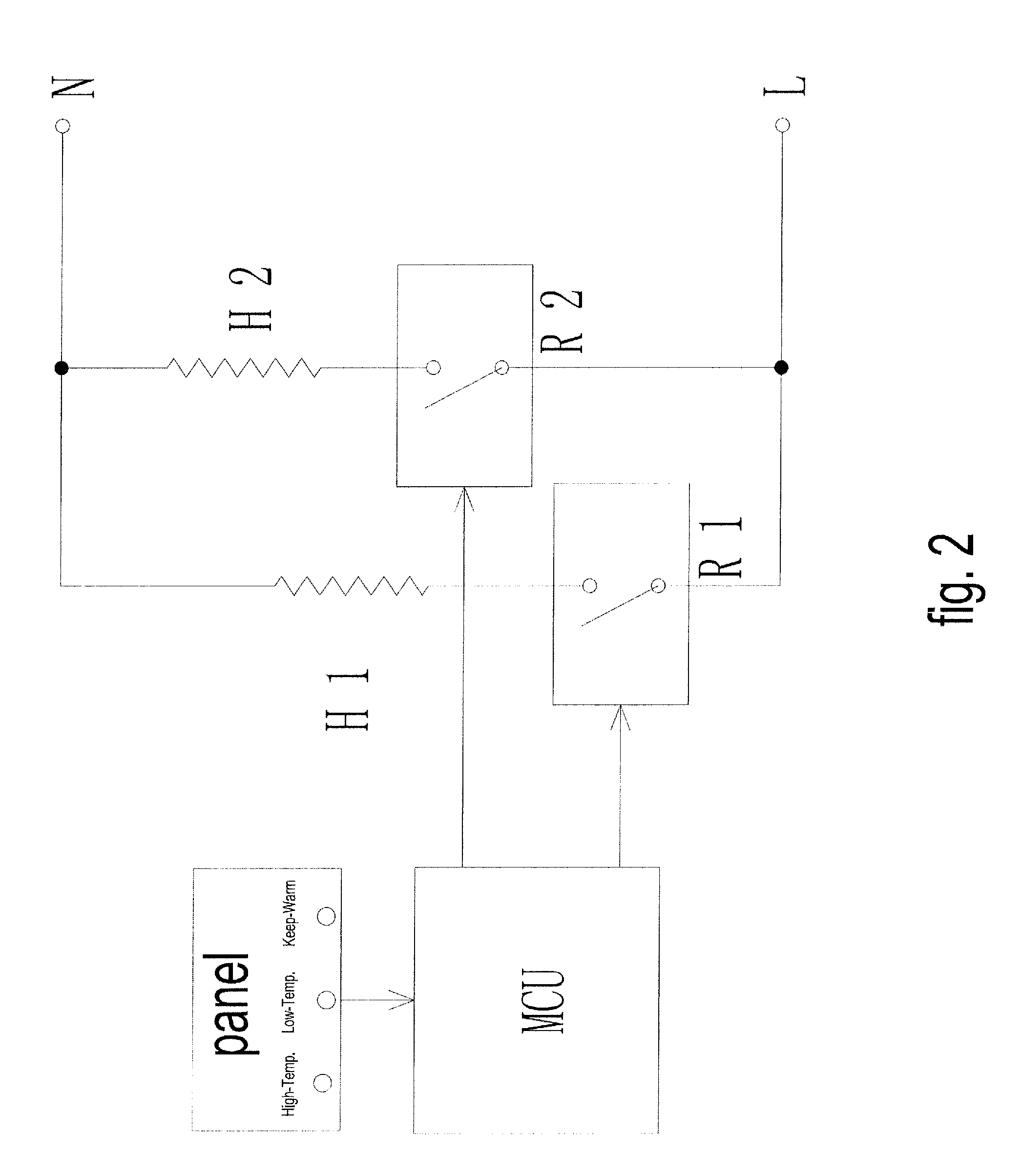

Electric slow-stewing cooker

InactiveUS20120048843A1Improve reliabilityLow costElectric heatingElectric heating for furnacesCookerElectricity

The present invention discloses an electric slow-stewing cooker which has three heating modes, namely high-temperature mode, low-temperature mode and keep-warm mode. The electric slow-stewing cooker of the present invention comprises an upper cover, a cooking container, a barrel-like housing, a base, a control panel, heating elements, a control circuit board (PCB) and a manual switch used for controlling the heating elements, and a power supply unit. The heating elements are divided into two portions with one portion being electrically connected to the manual switch to perform the function of the keep-warm mode and the other portion being electrically connected to the control circuit board to perform the function of both the high-temperature mode and the low-temperature mode. At the present invention only one relay switch is required for the electric slow-stewing cooker, which will result in relatively low cost, and the most frequently used keep-warm mode is controlled by a manual switch, which will result in a high reliability.

Owner:MIDEA GRP CO LTD

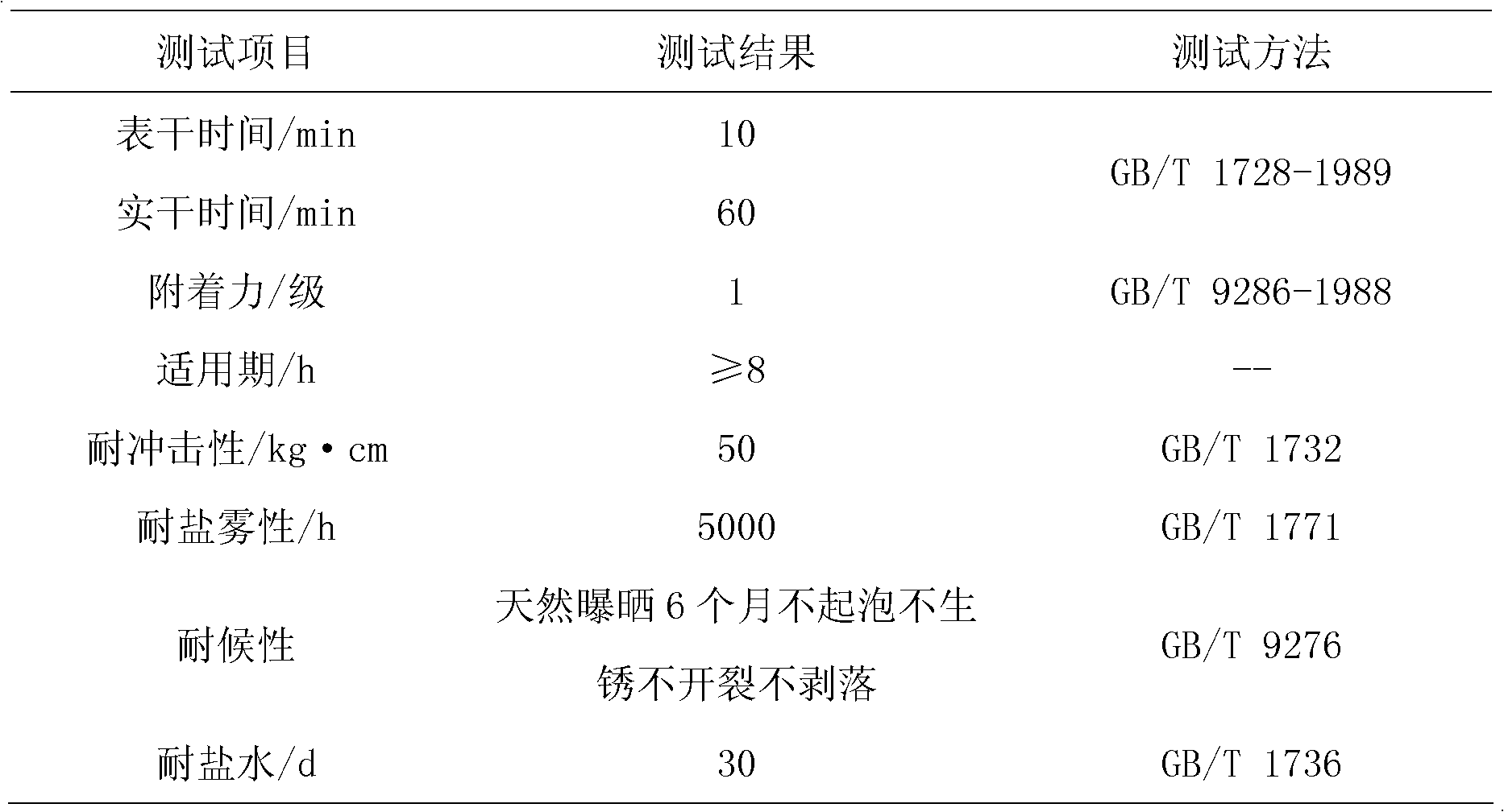

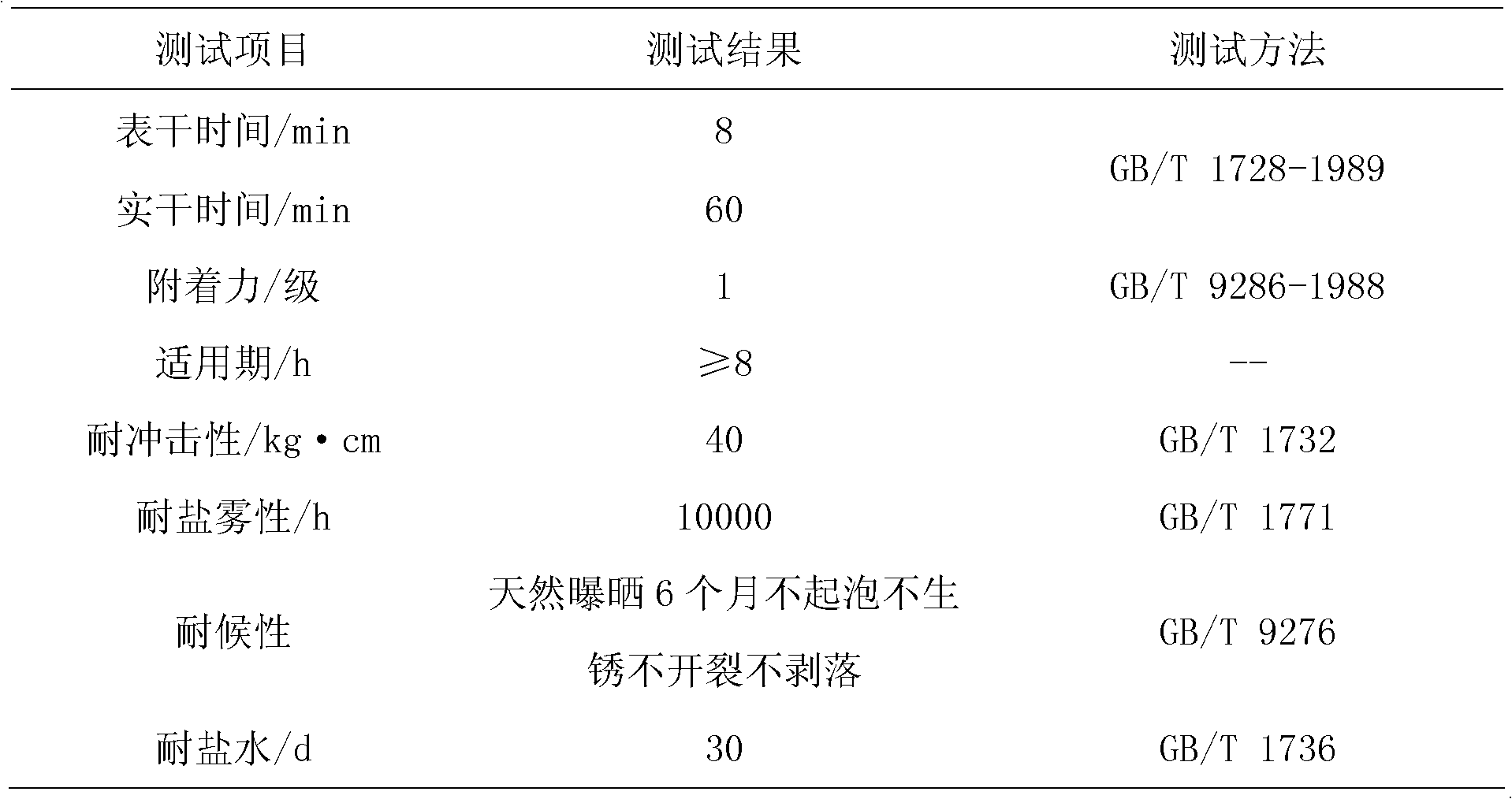

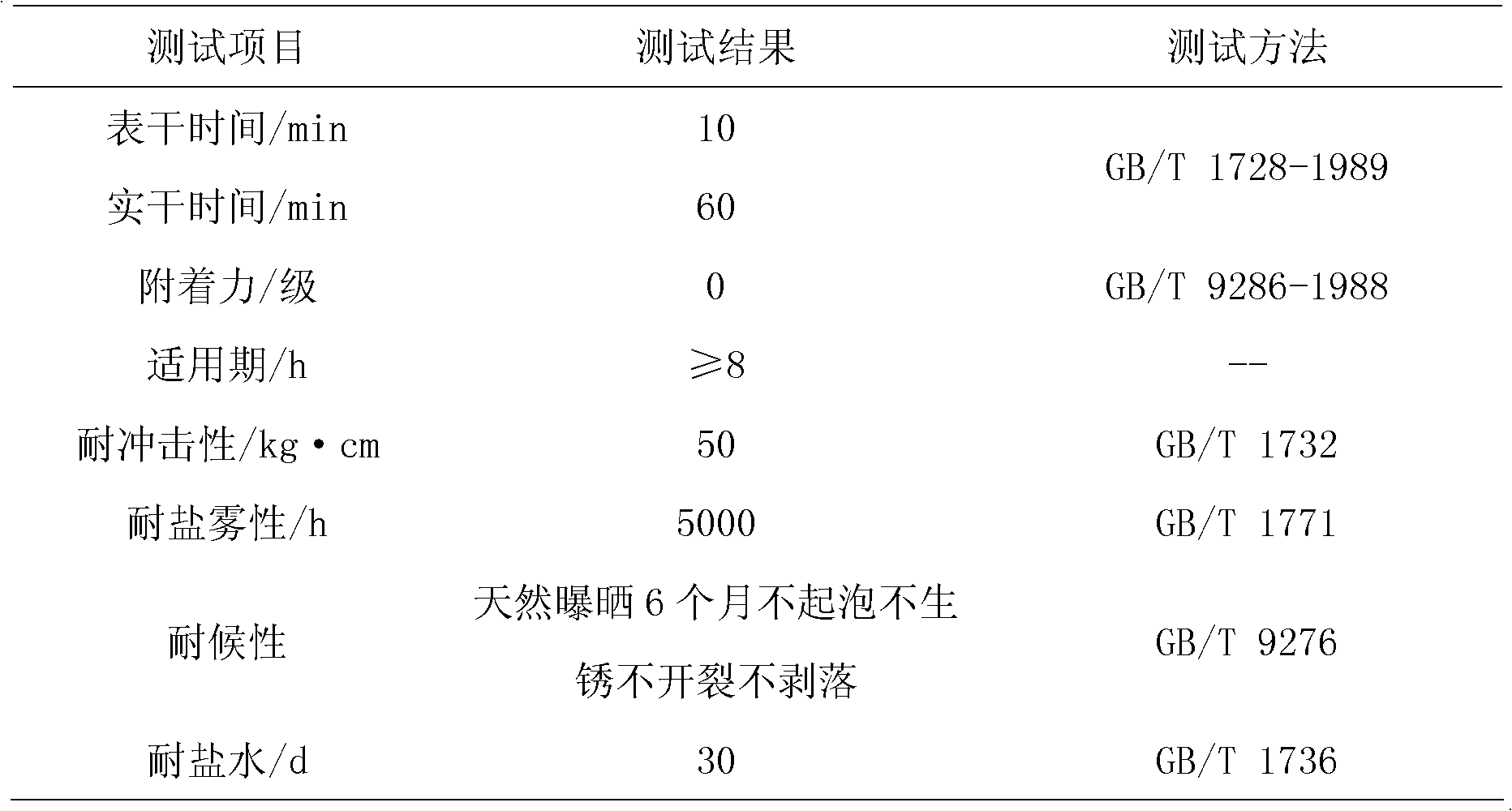

Waterborne room-temperature self-curing inorganic zinc rich coating

ActiveCN102146225AStrong adhesionHigh modulusAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceMaterials science

The invention discloses waterborne room-temperature self-curing inorganic zinc rich coating. The coating is prepared by uniformly mixing a prepared base stock and powder in a mass ratio of 1:1.5-3.5, wherein the process of preparing the base stock comprises the following steps of: adding 5 to 10 parts of water into alkali metal silicates solution with the mode number of 2.5 to 3.7 and stirring the mixture at low speed; then adding silica sol drops with the grain diameter of 7 to 20nm and the solid content of 25 to 32 percent, dripping 1 to 10 parts of silane coupling agent and adding 0.5 to 2parts of stabilizing agent; and filtering out precipitates to obtain the transparent base stock. The inorganic zinc rich coating has high drying speed and good early-period waterproofness and can resist to washing with certain pressure after being dried for 20 minutes, has good salt spray corrosion resistance due to the adoption of multiple anticorrosion mechanisms and can resist to the high temperature of 400 DEG C. Meanwhile, the constructability of the conventional waterborne inorganic zinc rich coating is greatly improved; and the corrosion resistance year limit can reach over 15 years. The paint is prepared at normal temperature under normal pressure and has low production cost. The environmental protection requirement is met.

Owner:SOUTH CHINA UNIV OF TECH +1

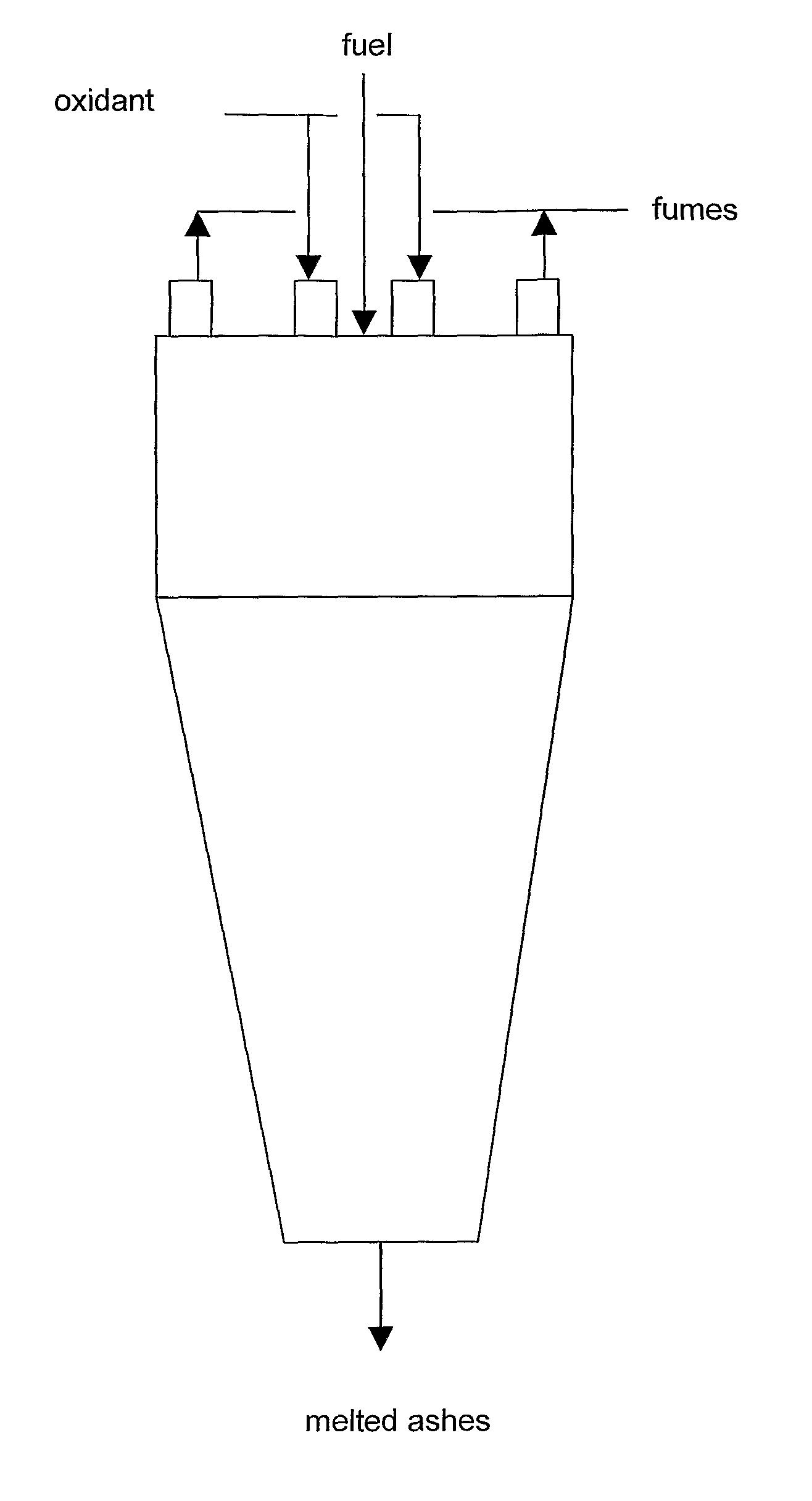

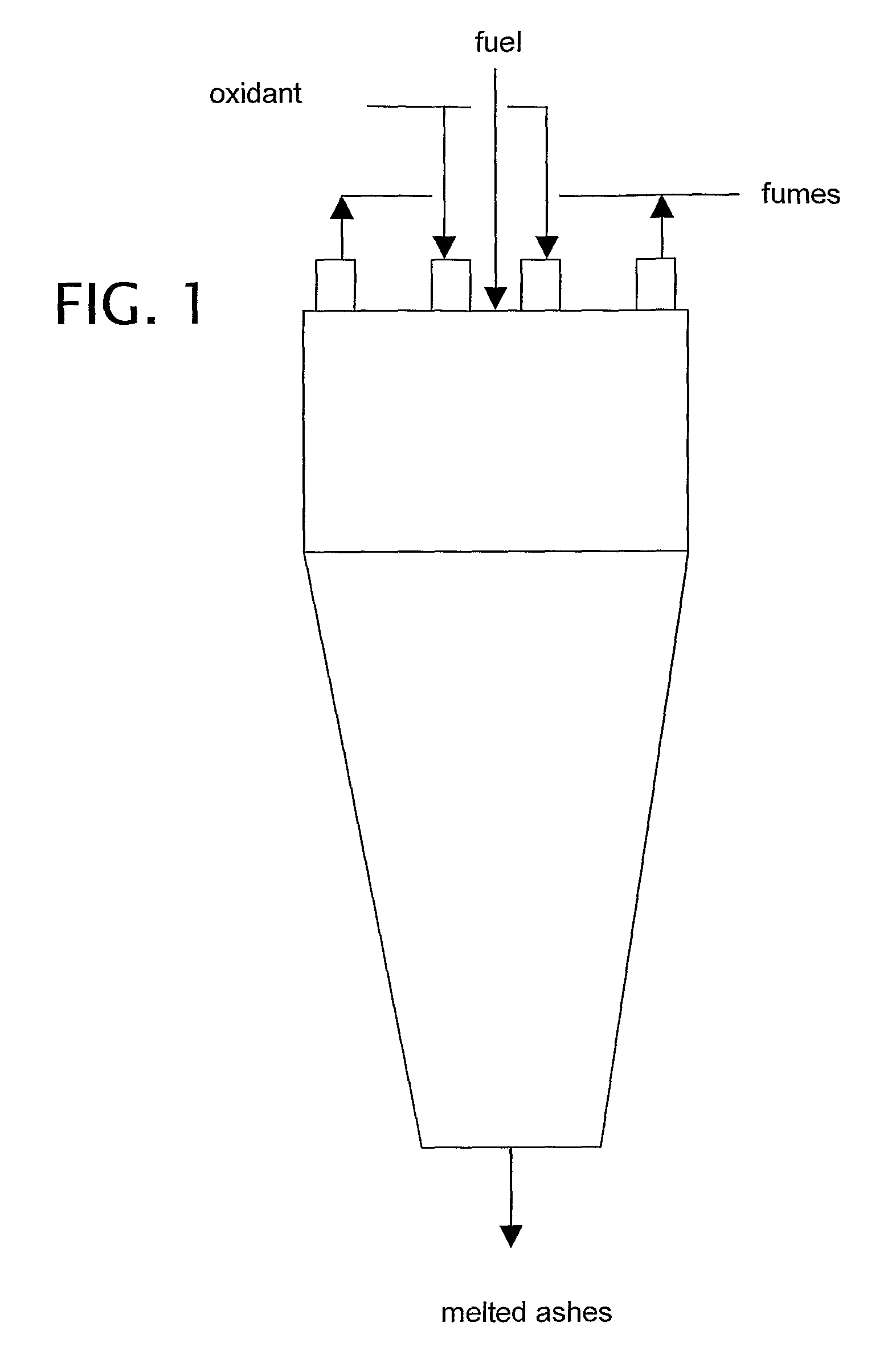

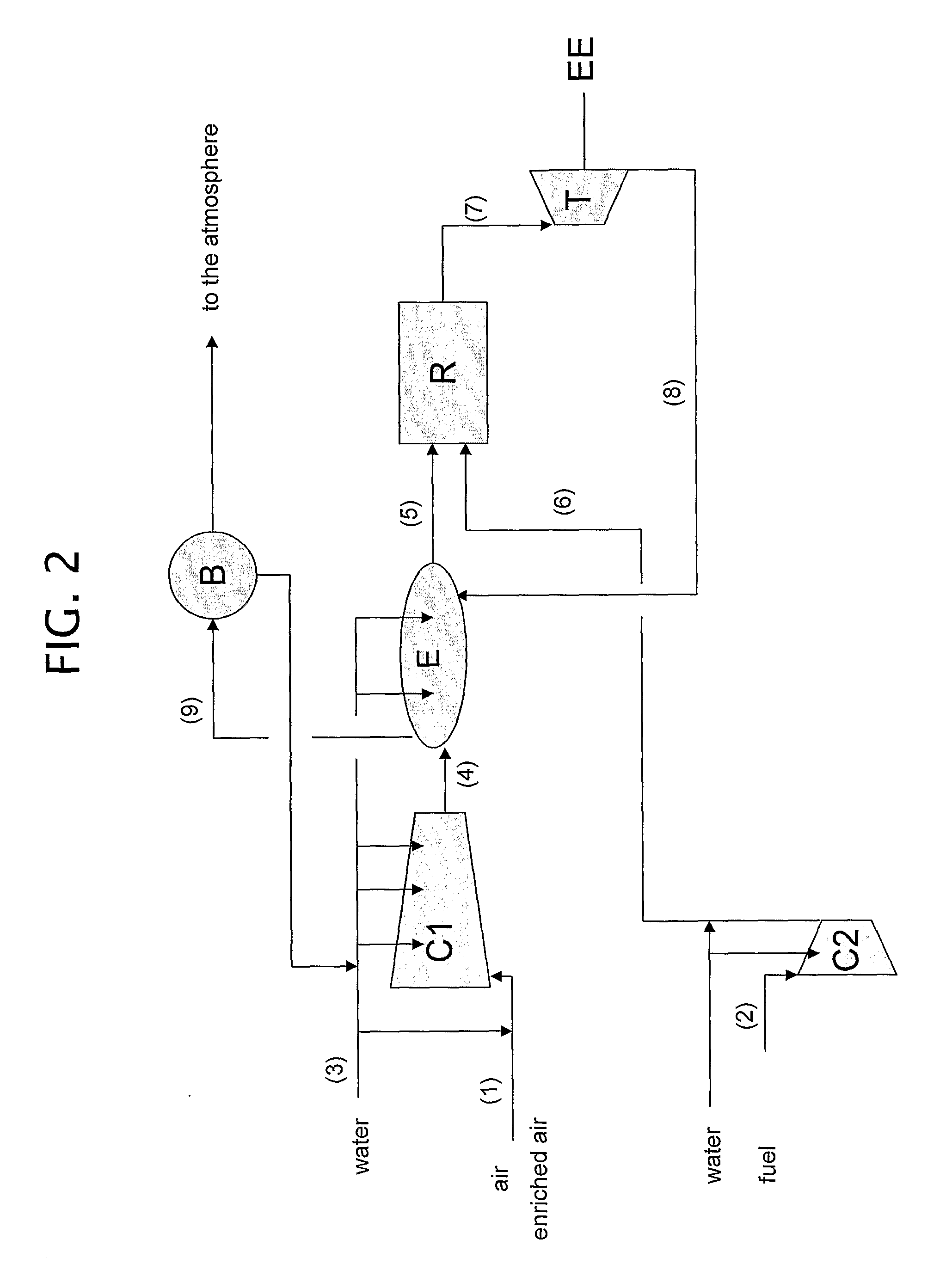

High-efficiency combustors with reduced environmental impact and processes for power generation derivable therefrom

A process for combusting solid liquid or gaseous fuels in a high temperature refractory-lined reactor with the aim of generating electric power comprises mixing at least one fuel with steam. The refactory material of the reactor and the opaque gases of the reaction environment bring about high power infrared radiation which substantially instantaneously preheats the reactants on input including said reactants being intrinsically transparent to infrared radiation (N2 / O2) but rendered opaque and thus absorbers of energy from infrared radiation thanks to dilution with steam. A high efficiency combustor is provided for carrying out the above-stated process.

Owner:ITEA SPA

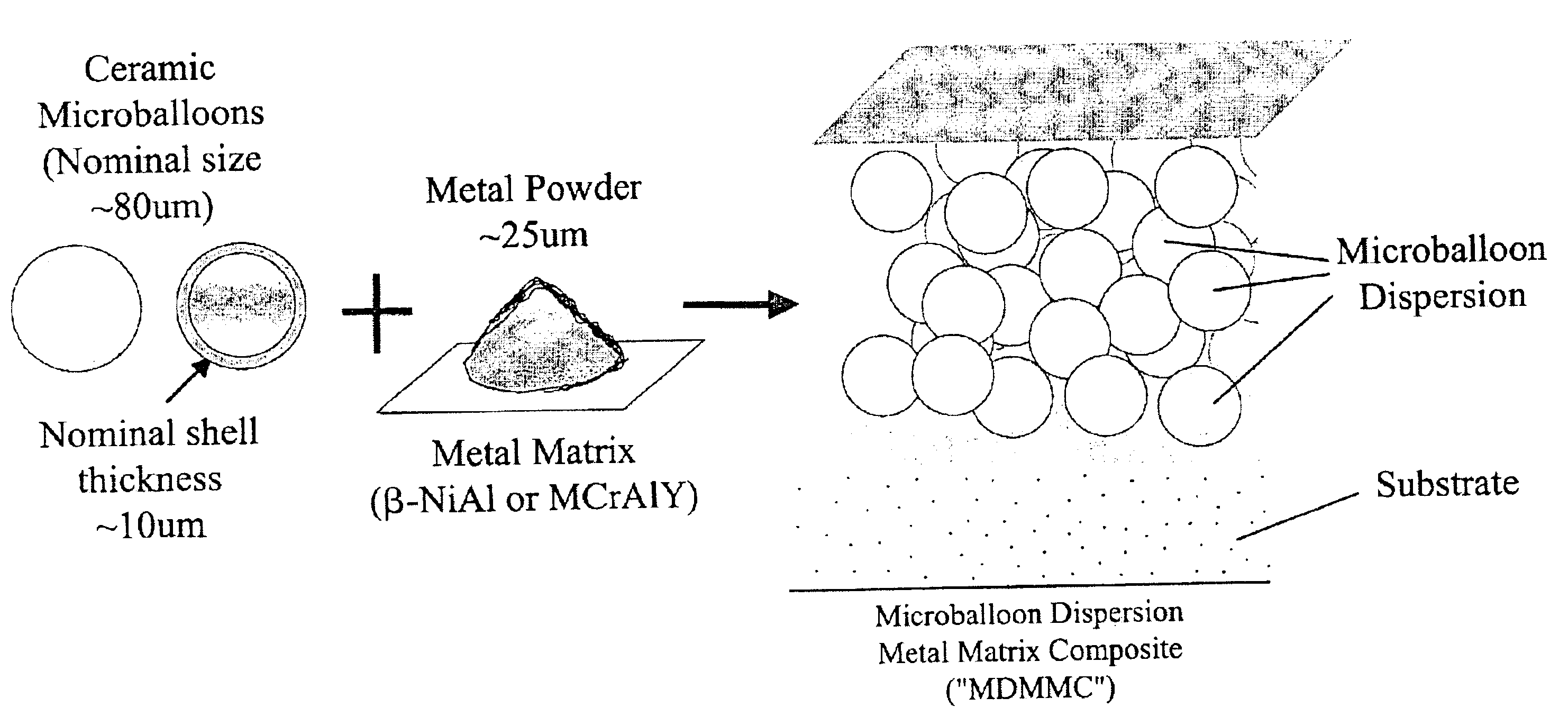

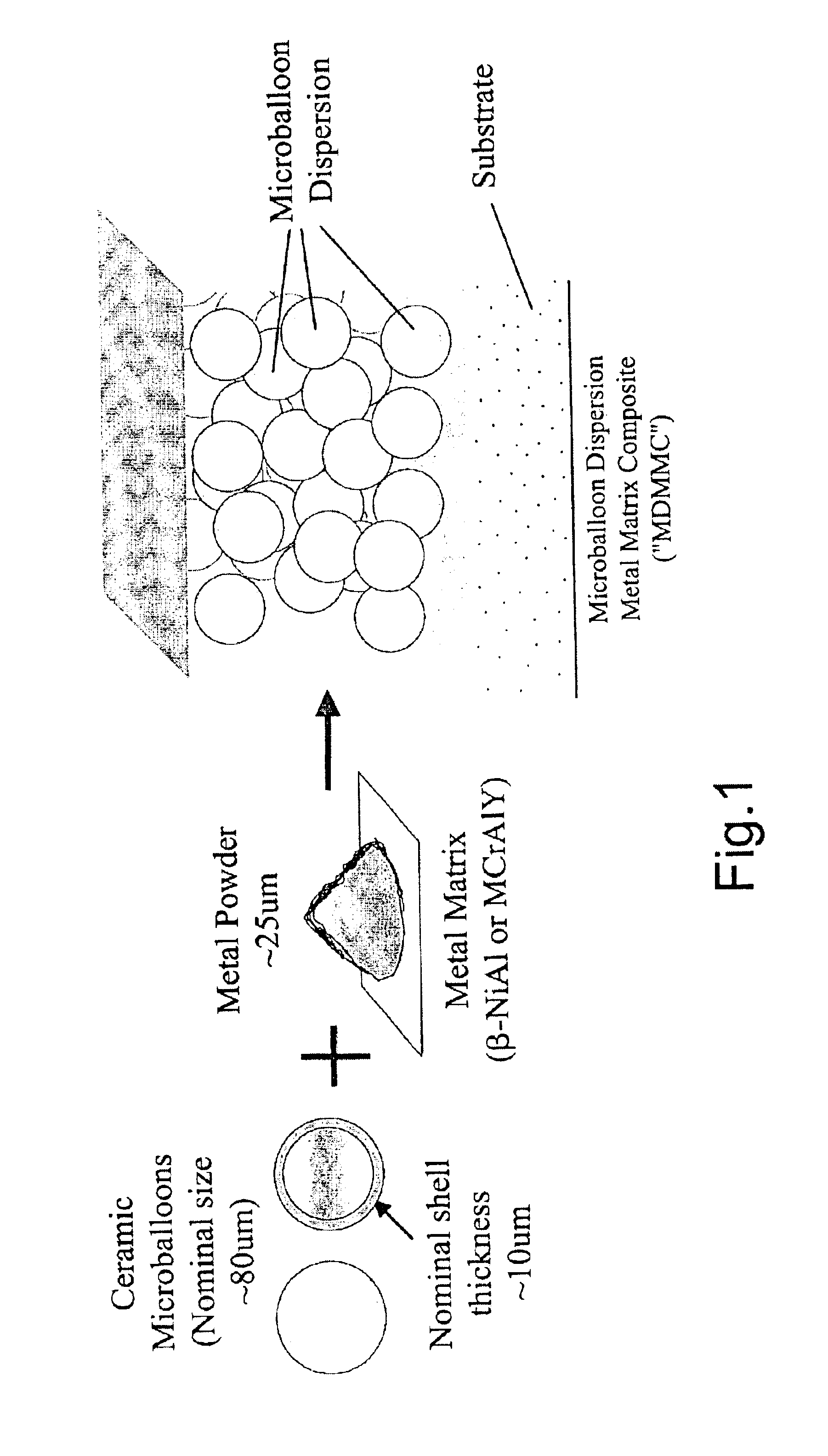

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

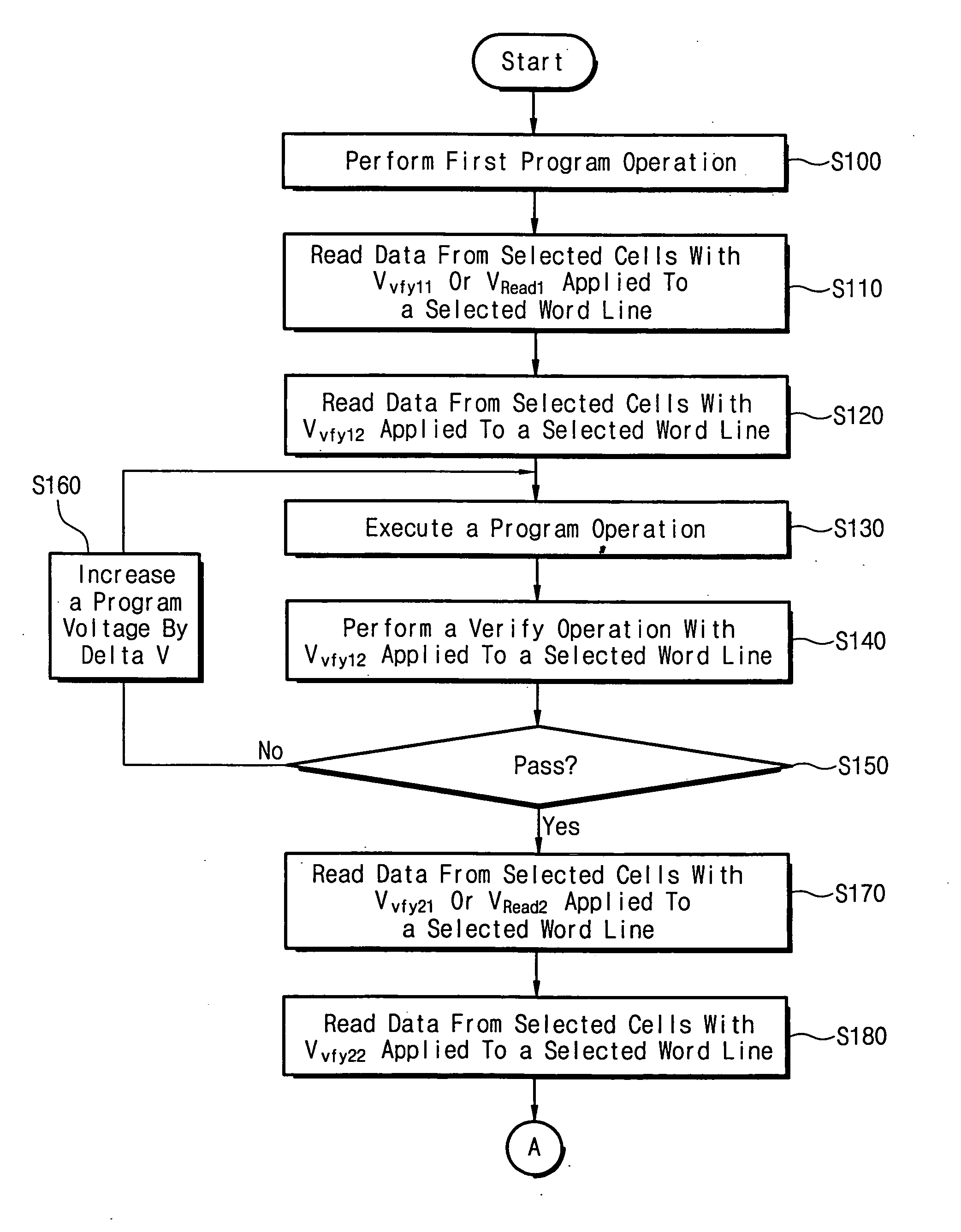

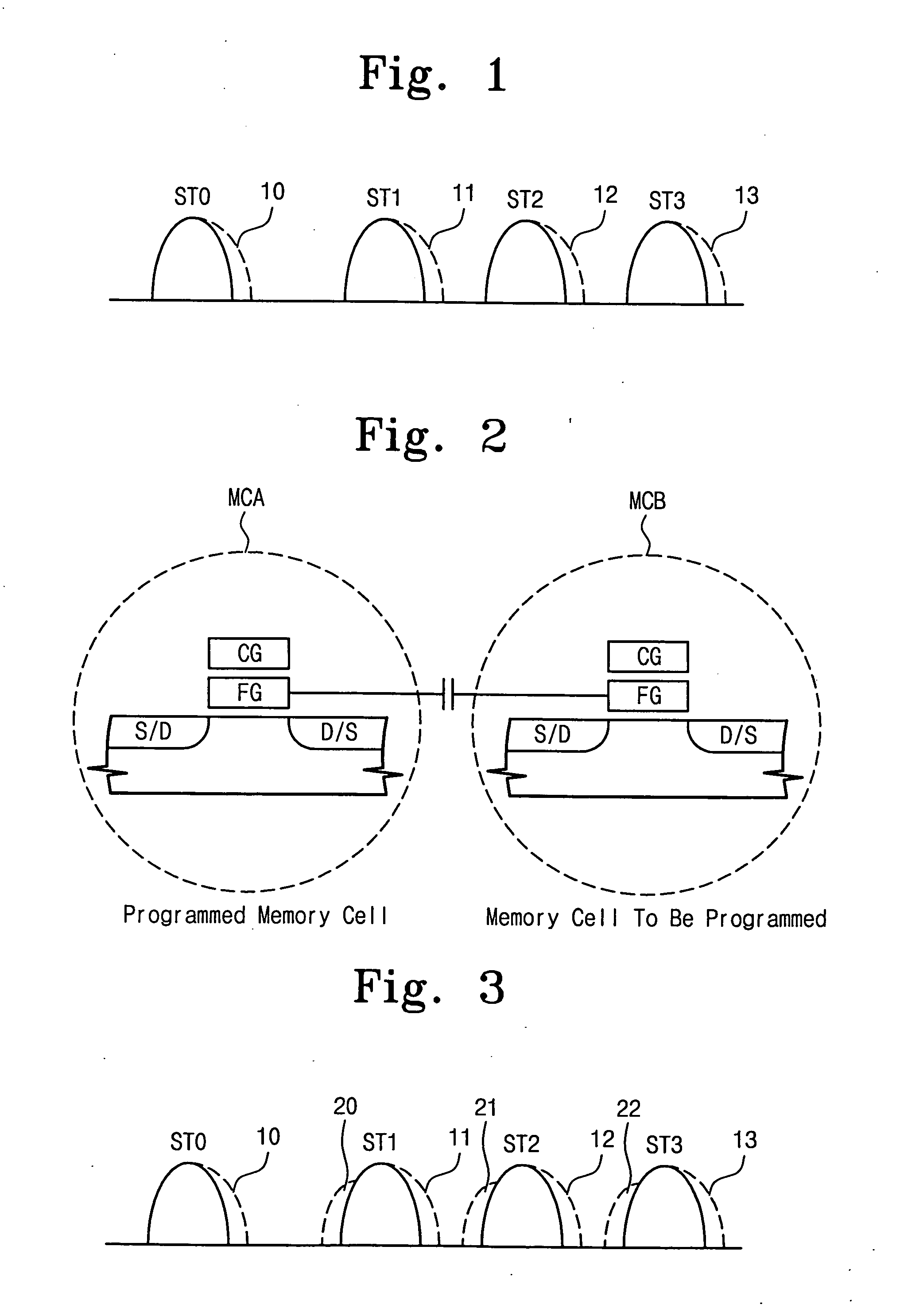

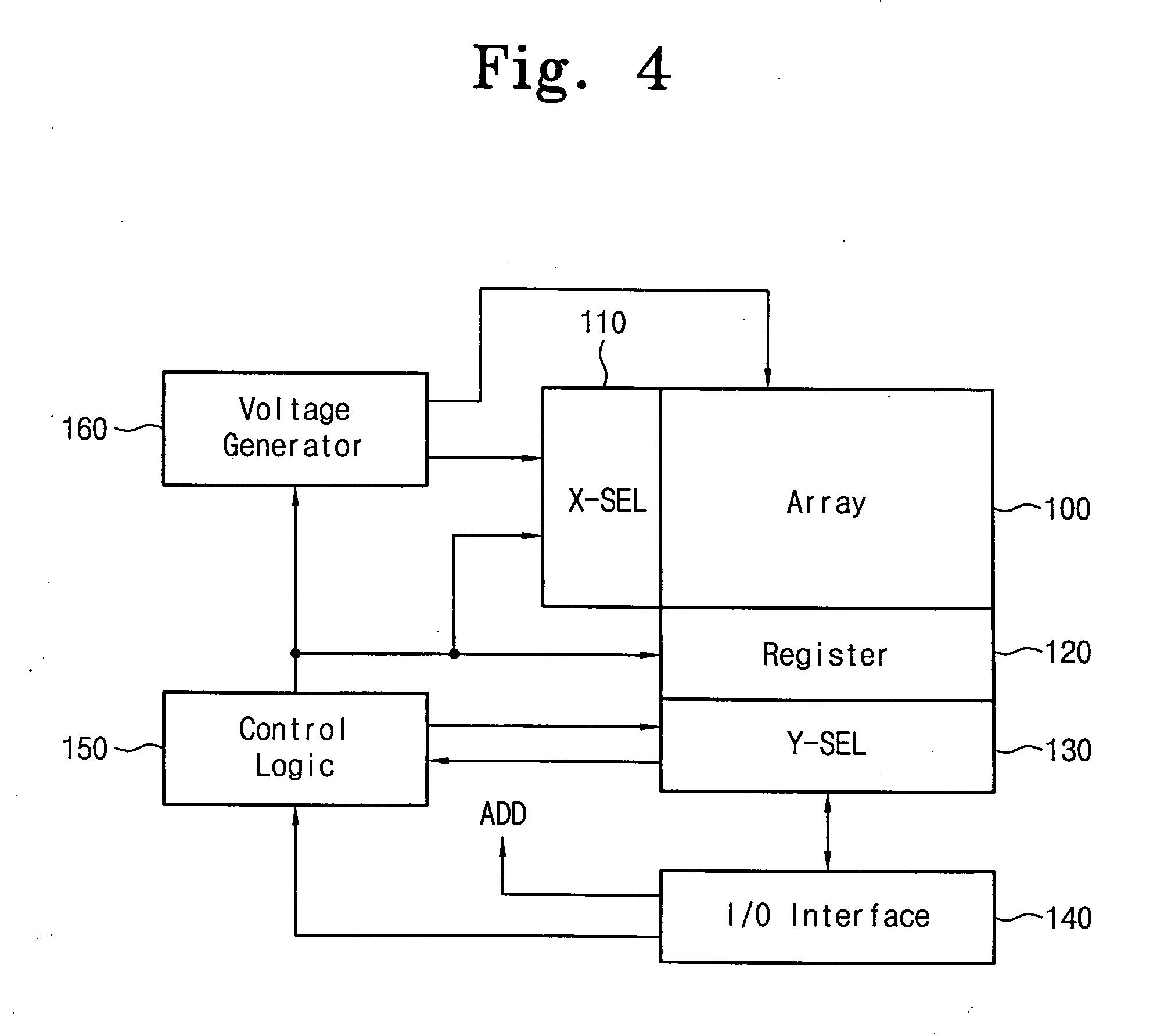

Programming method for flash memory capable of compensating reduction of read margin between states due to hot temperature stress

A program method of a flash memory device including a plurality of memory cells for storing multi-bit data indicating one of states. The program method includes programming memory cells selected to have one of the states by using multi-bit data; detecting programmed memory cells within a predetermined region of a threshold voltage distribution where the programmed memory cells having the respective states are distributed, wherein the predetermined region of the respective states is selected by one of a first verify voltage and a read voltage and a second voltage, the first verify voltage being lower than the second verify voltage and higher than the read voltage; and programming the detected memory cells to have a threshold voltage being equivalent to or higher than the second verify voltage corresponding to each of the states.

Owner:SAMSUNG ELECTRONICS CO LTD

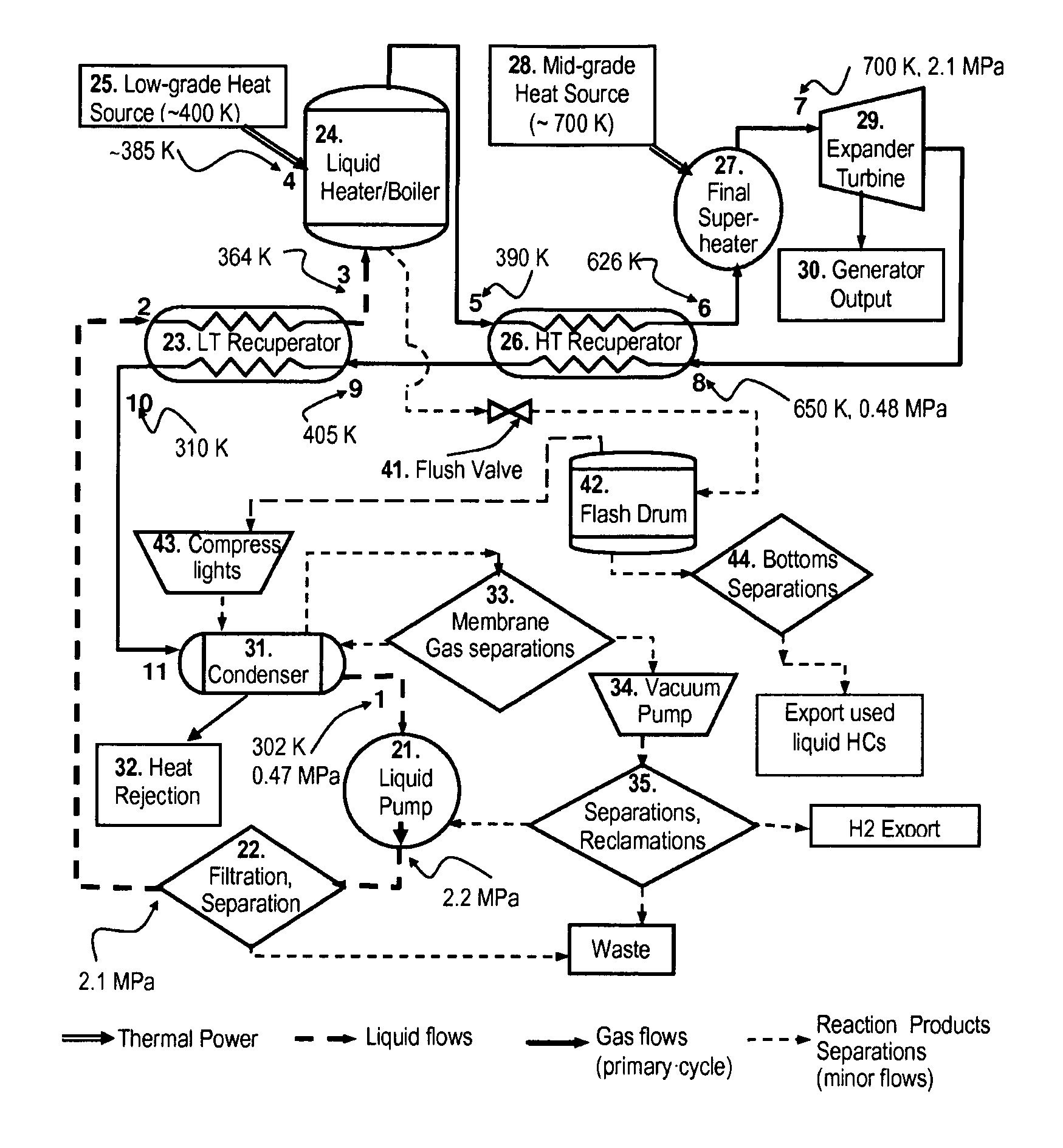

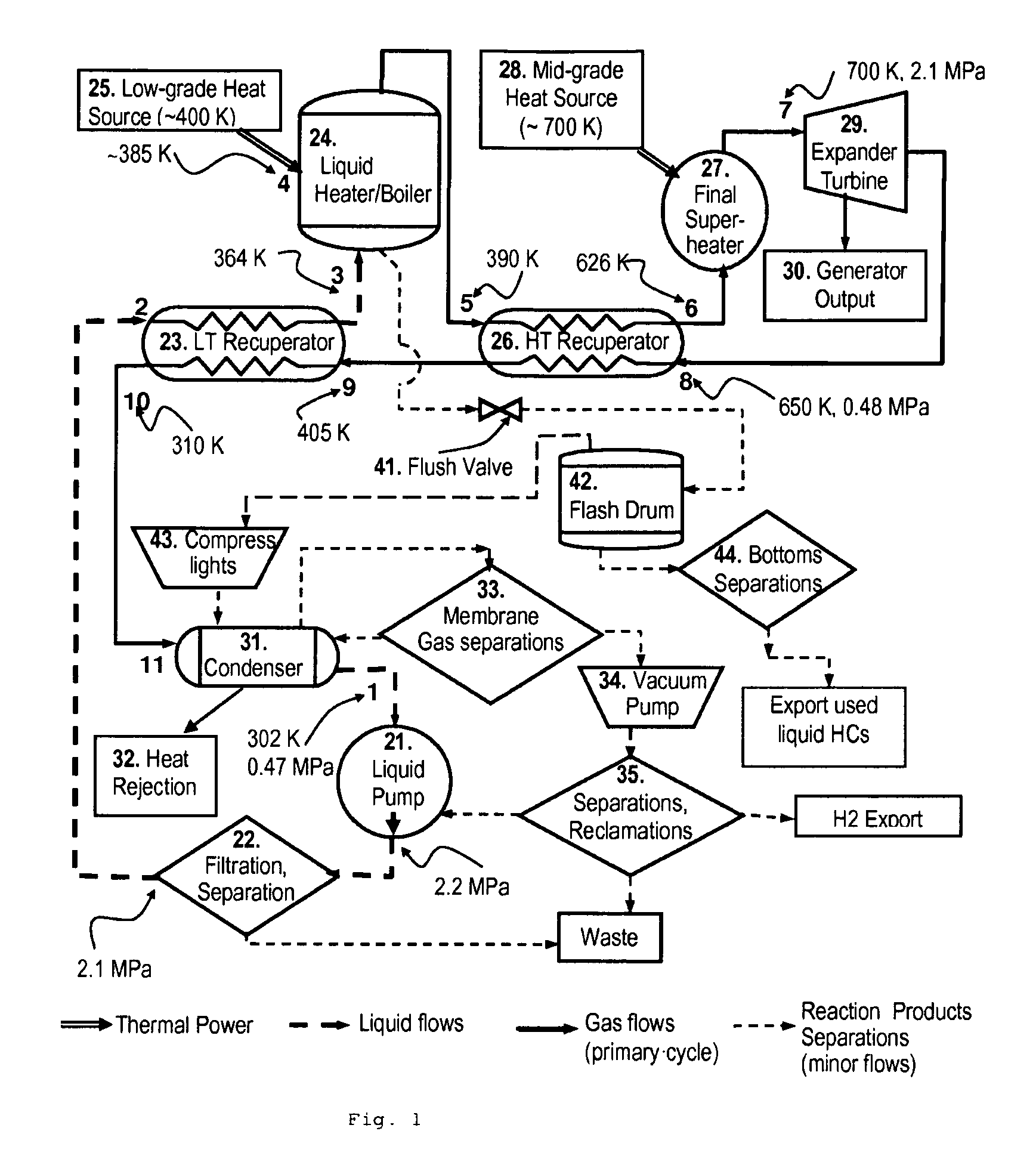

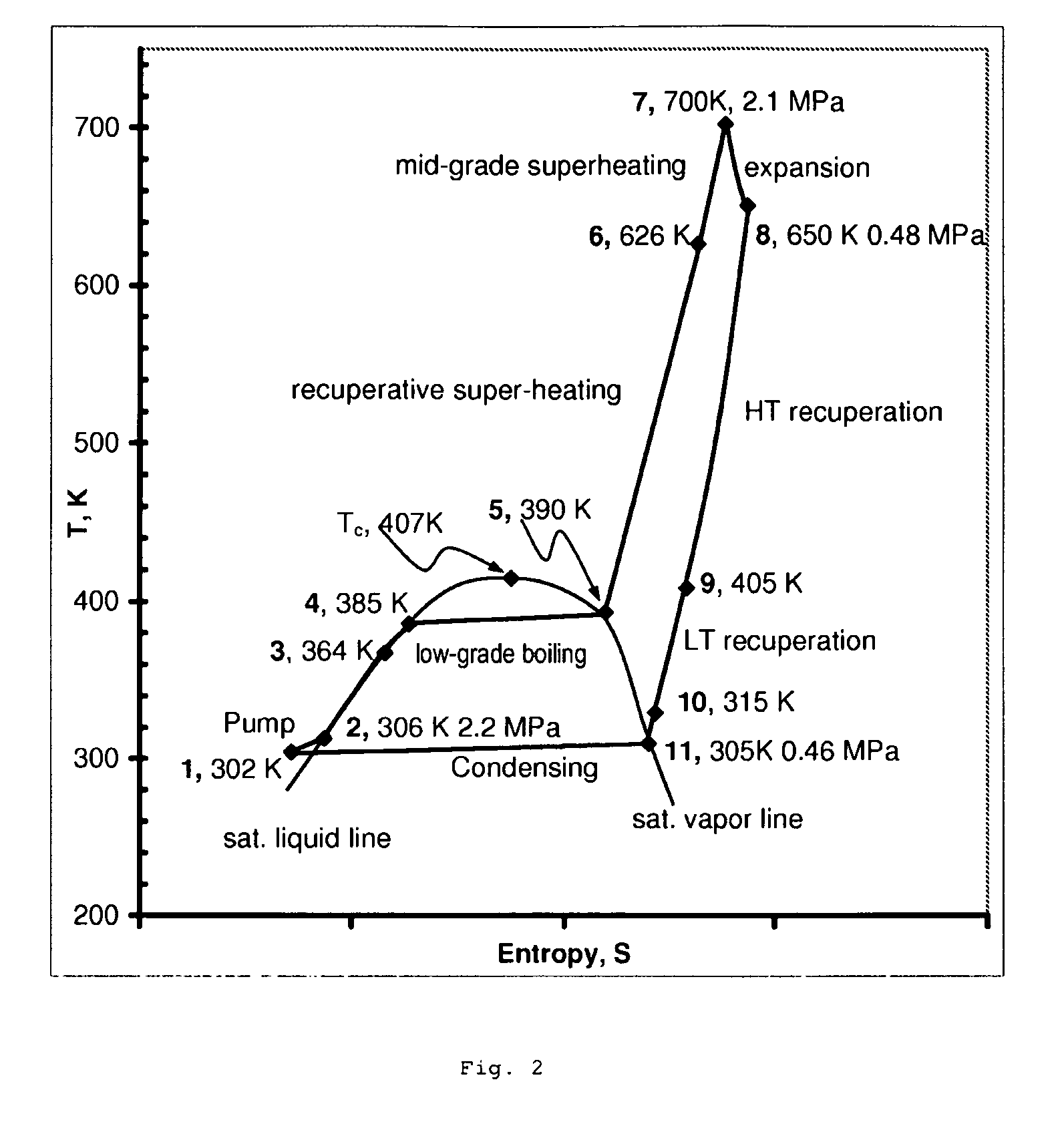

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com