Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10481 results about "Crystallinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystallinity refers to the degree of structural order in a solid. In a crystal, the atoms or molecules are arranged in a regular, periodic manner. The degree of crystallinity has a big influence on hardness, density, transparency and diffusion. In a gas, the relative positions of the atoms or molecules are completely random. Amorphous materials, such as liquids and glasses, represent an intermediate case, having order over short distances (a few atomic or molecular spacings) but not over longer distances.

Semiconductor device in which zinc oxide is used as a semiconductor material and method for manufacturing the semiconductor device

ActiveUS7501293B2Improve surface smoothnessHigh crystallinityTransistorLaser detailsSemiconductor materialsDevice material

A semiconductor device having excellent crystallinity and excellent electric characteristics includes a ZnO thin film having excellent surface smoothness. ZnO-based thin films (an n-type contact layer, an n-type clad layer, an active layer, a p-type clad layer, and a p-type contact layer) primarily including ZnO are formed sequentially by an ECR sputtering method or other suitable method on a zinc-polar surface of a ZnO substrate. A transparent electrode and a p-side electrode are formed by an evaporation method or other suitable method on a surface of the p-type contact layer, and an n-side electrode is formed on an oxygen-polar surface of the ZnO substrate.

Owner:MURATA MFG CO LTD

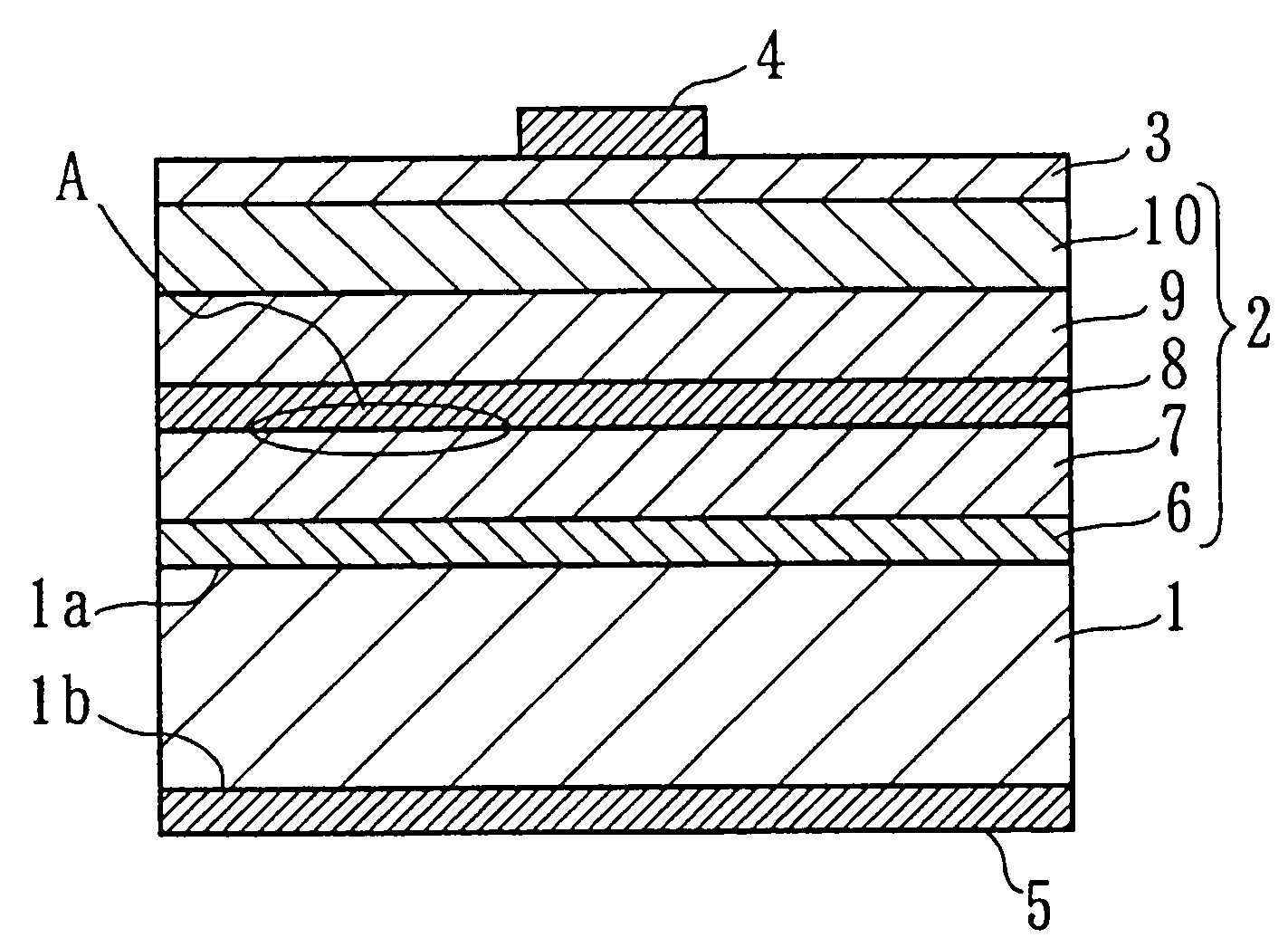

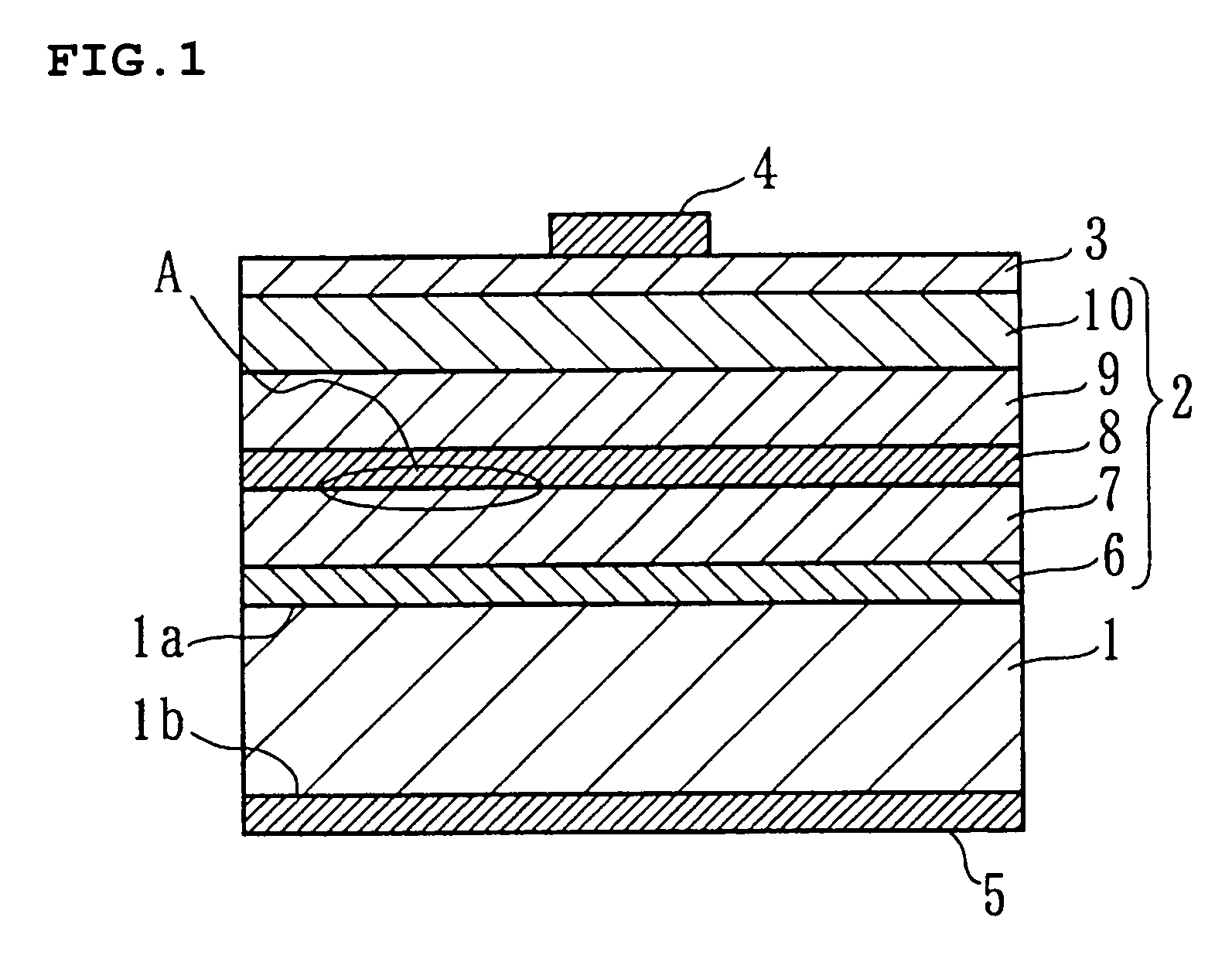

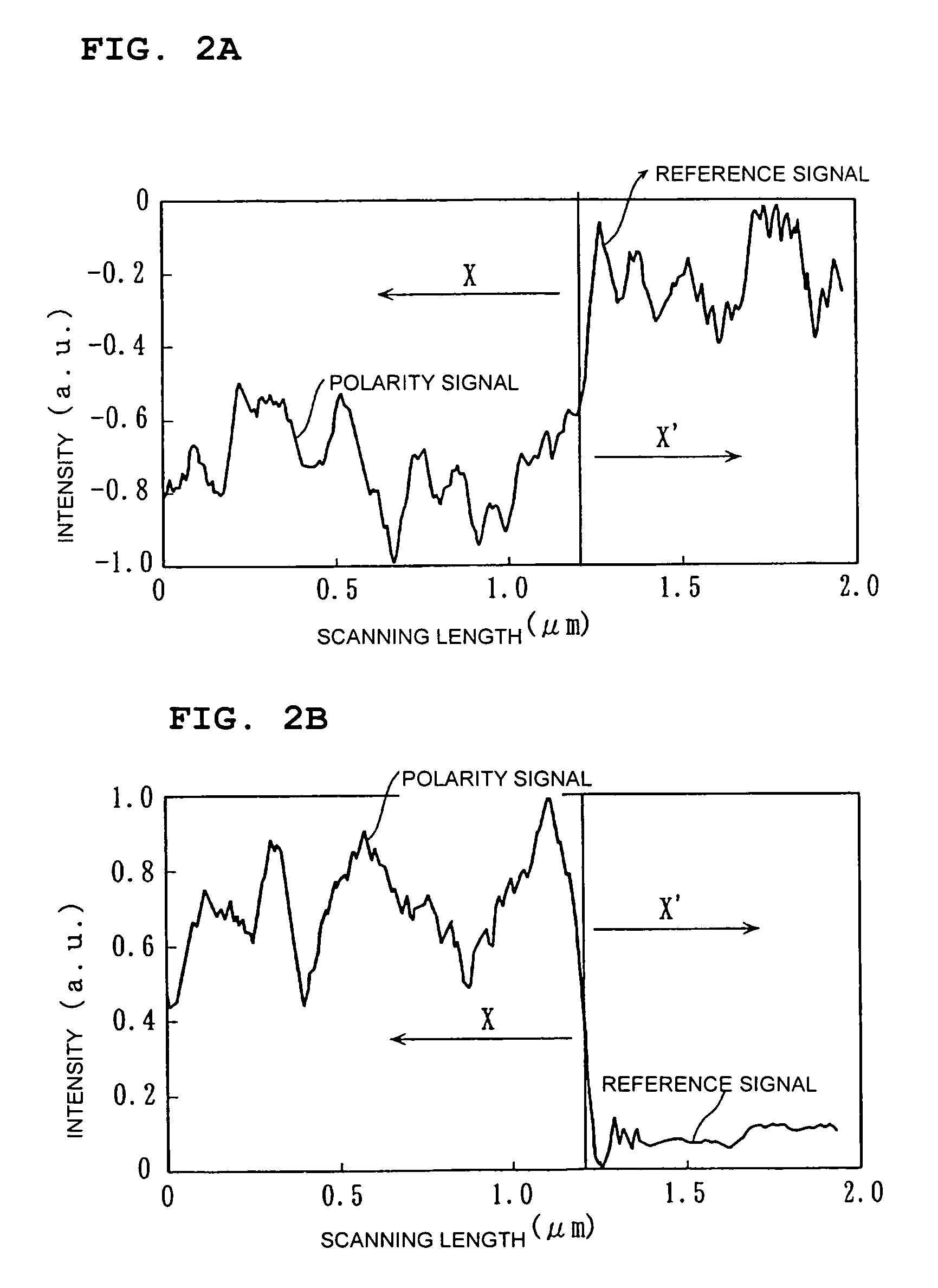

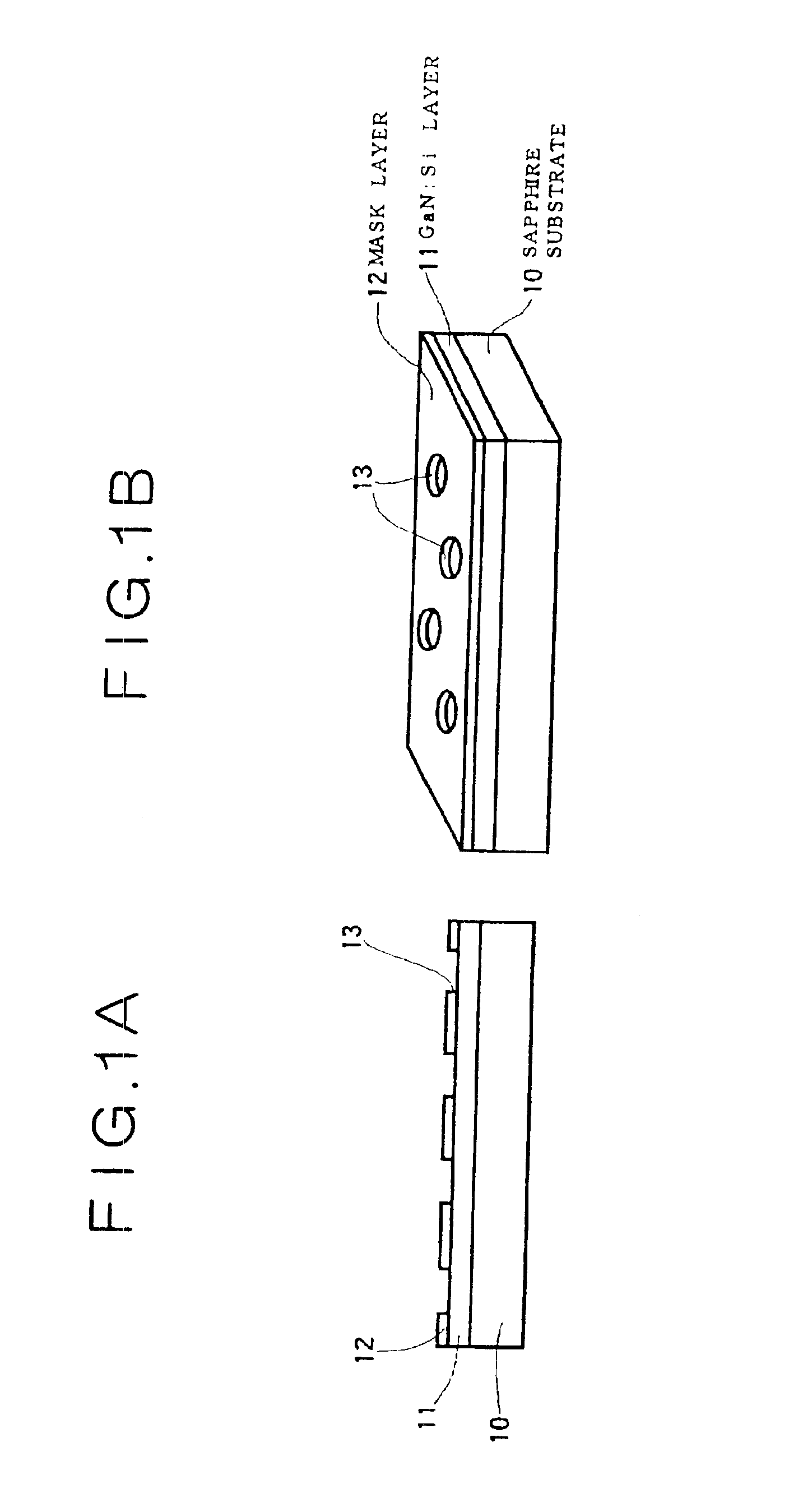

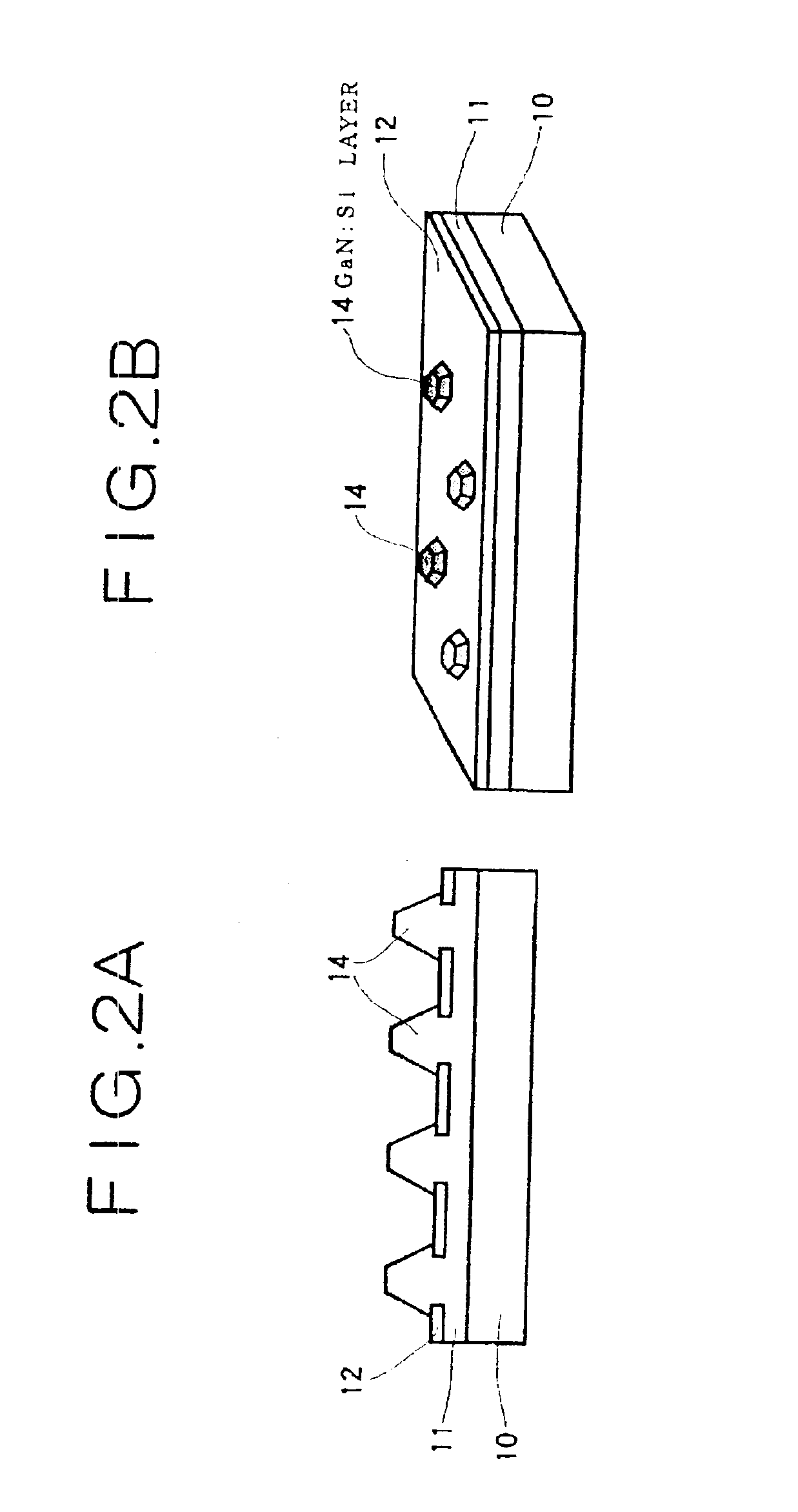

Semiconductor light-emitting device and semiconductor light-emitting device

InactiveUS7087932B2Well formedSolid-state devicesSemiconductor/solid-state device manufacturingCrystal planeCrystallinity

Owner:SAMSUNG ELECTRONICS CO LTD

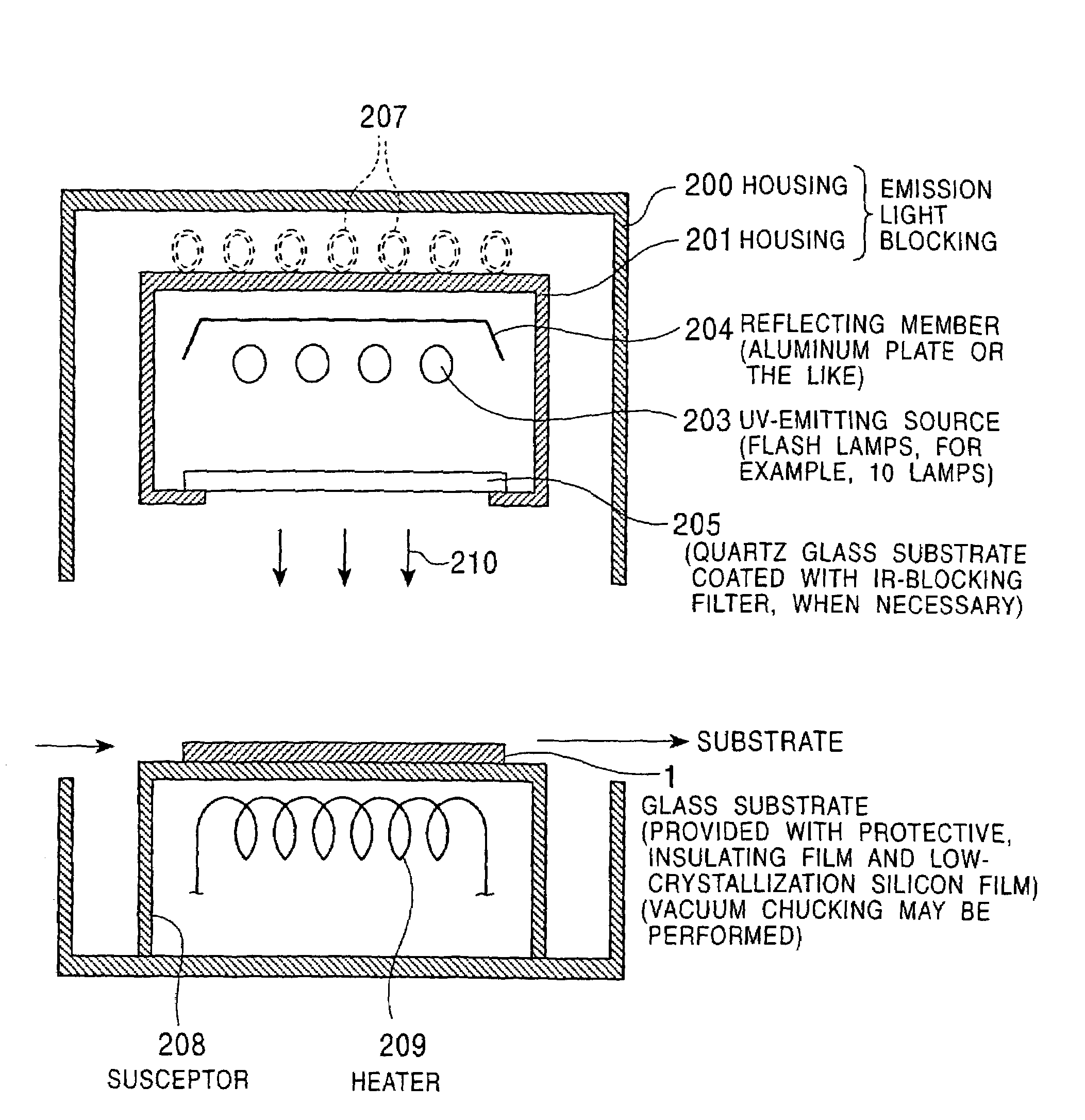

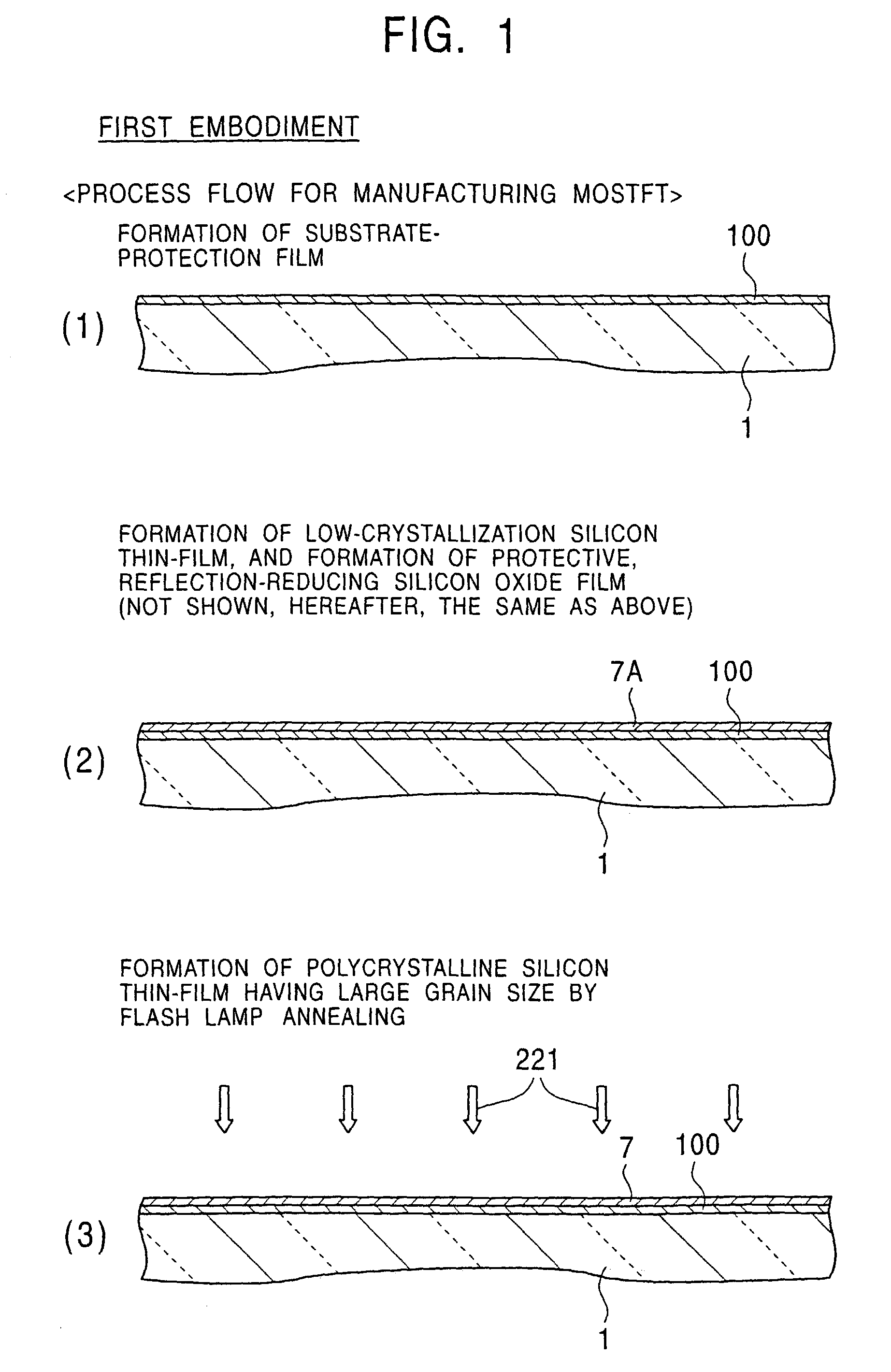

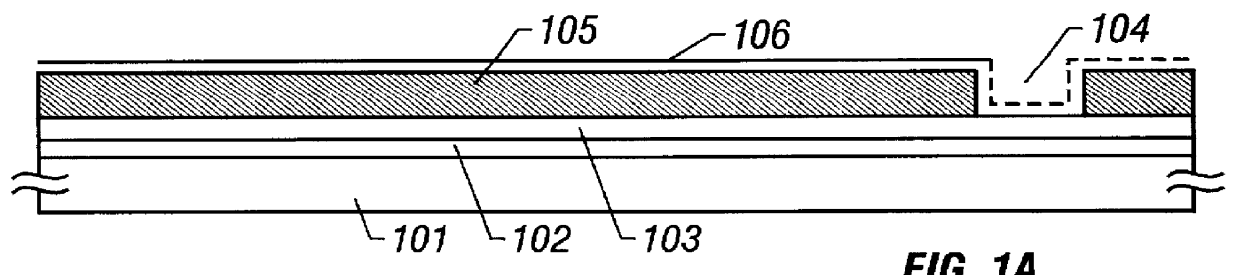

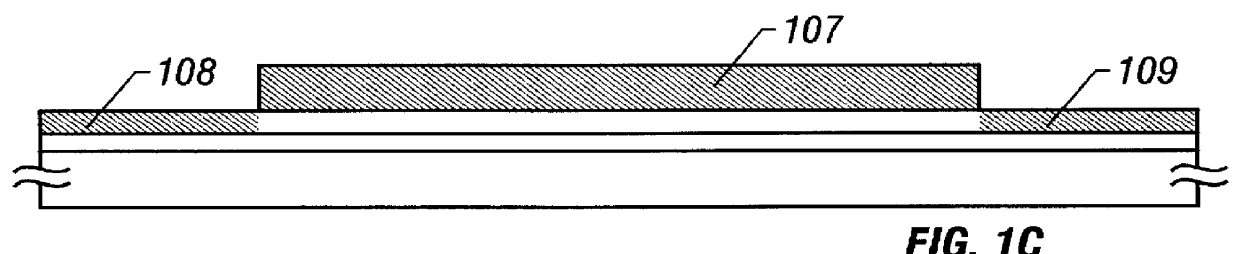

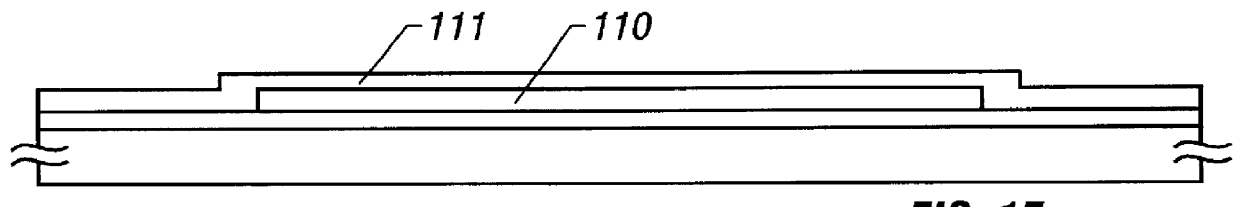

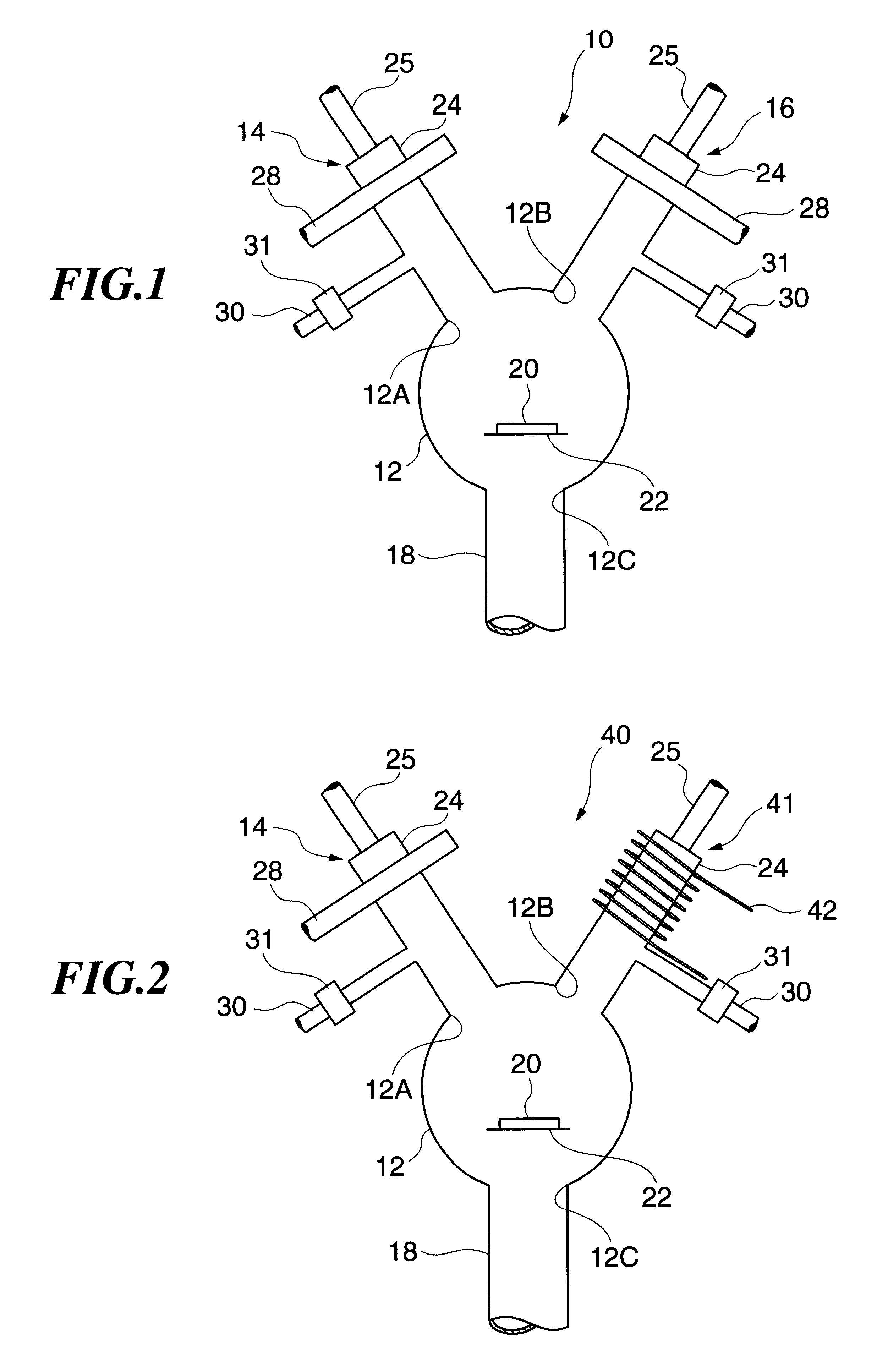

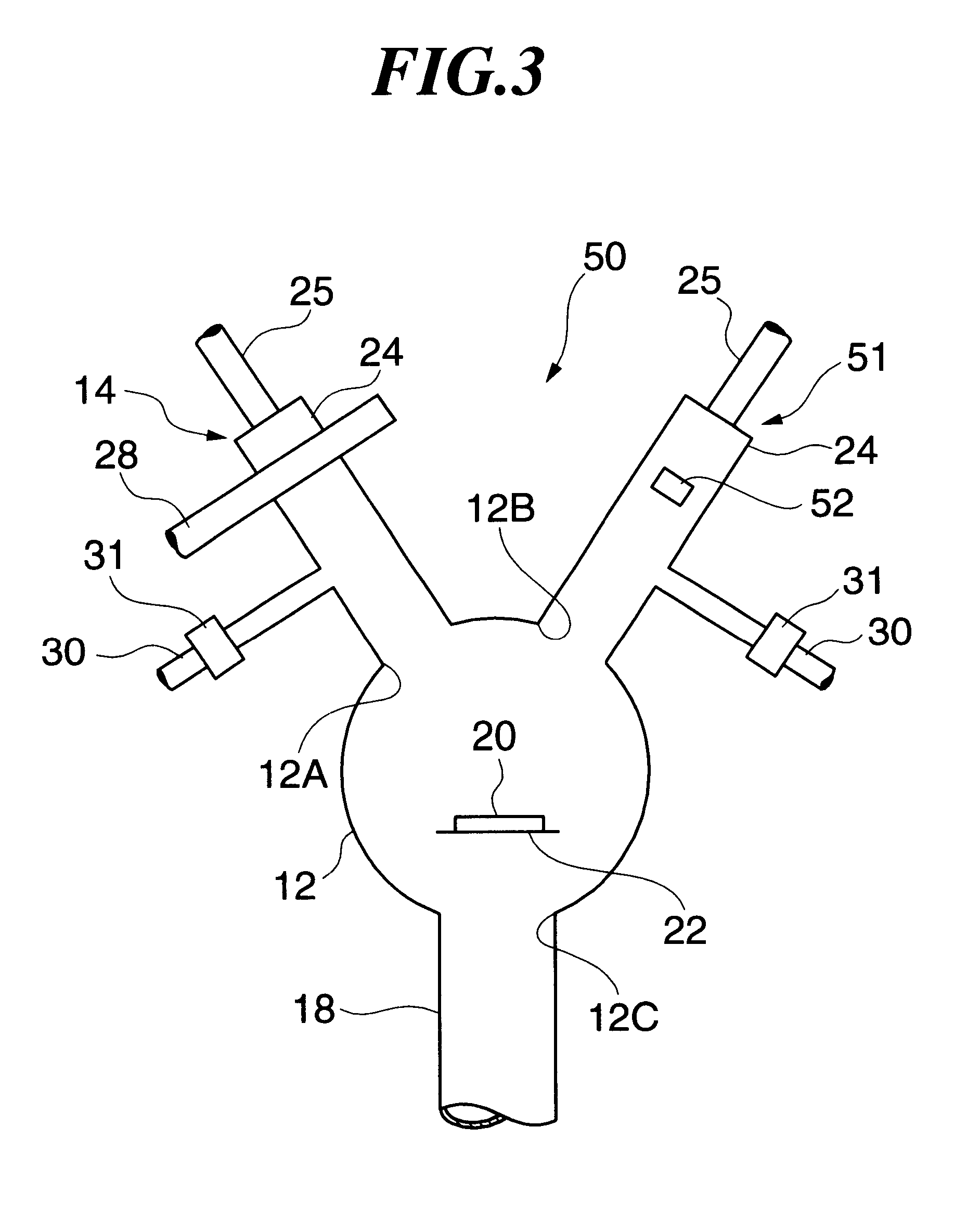

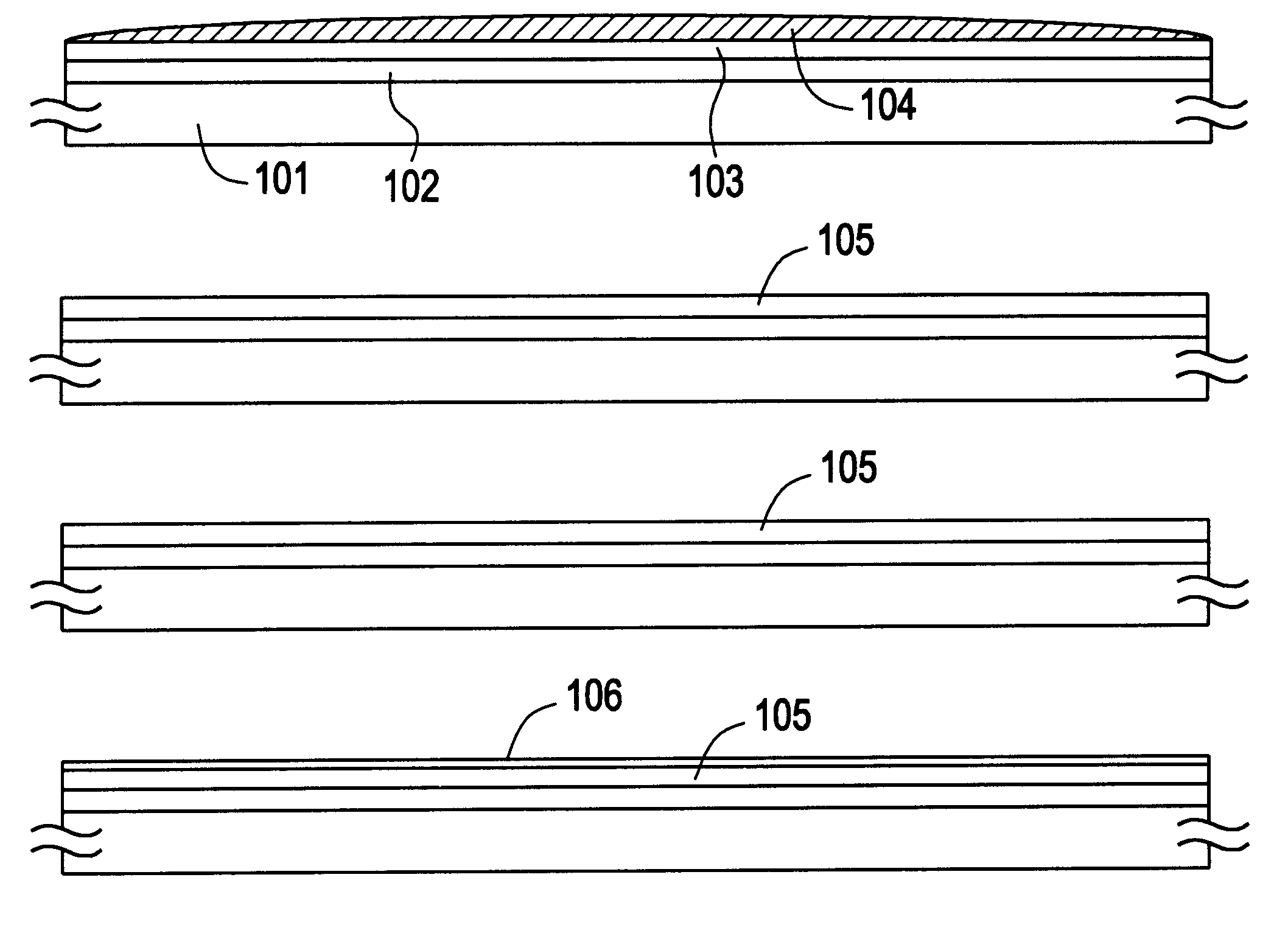

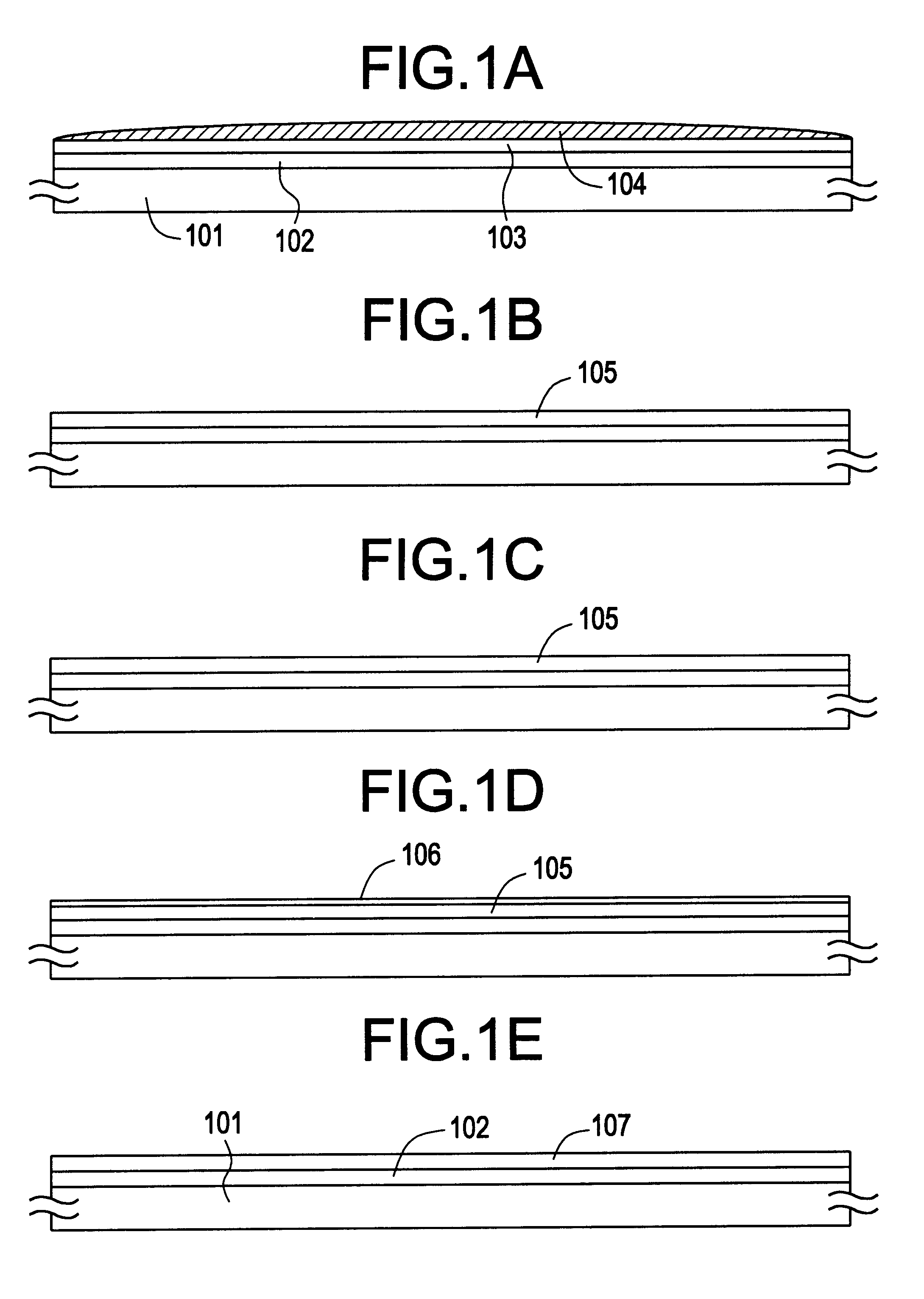

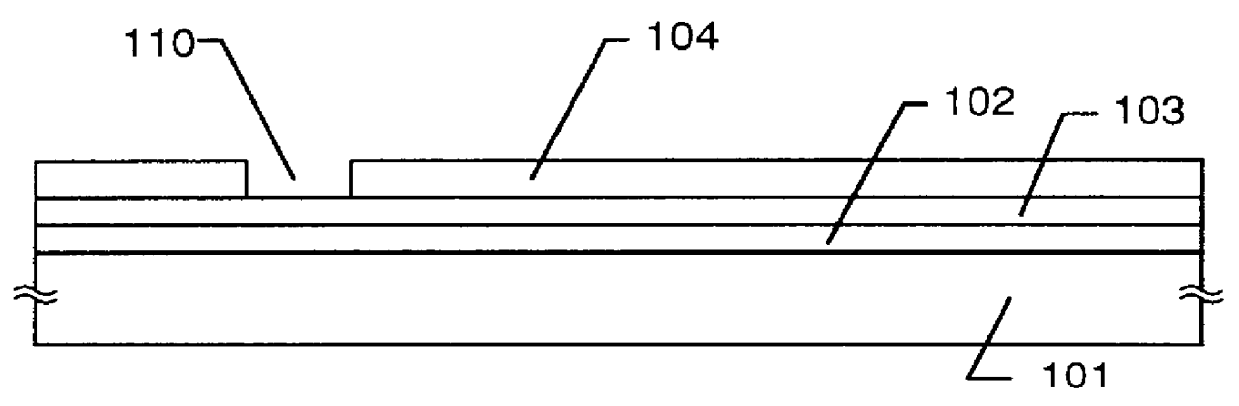

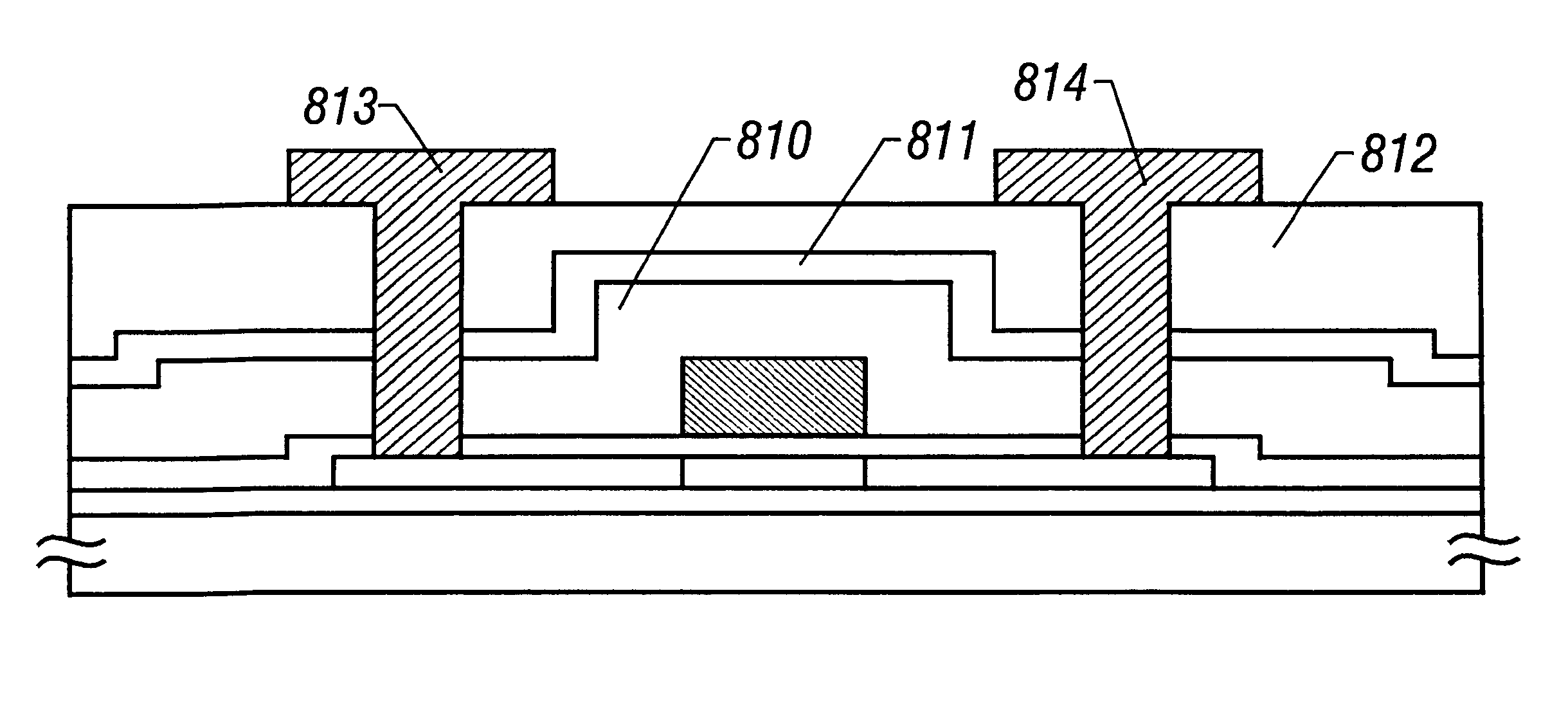

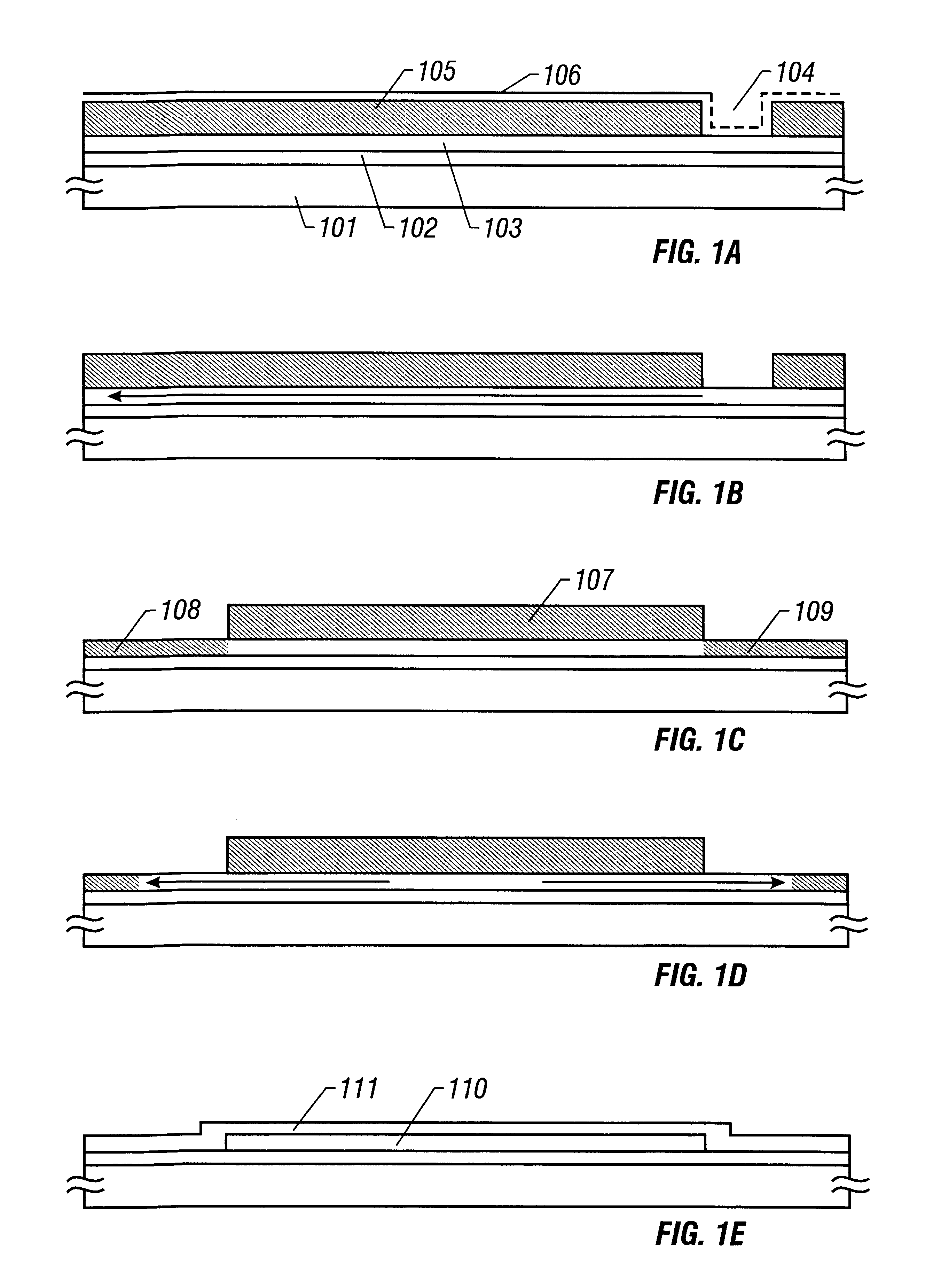

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

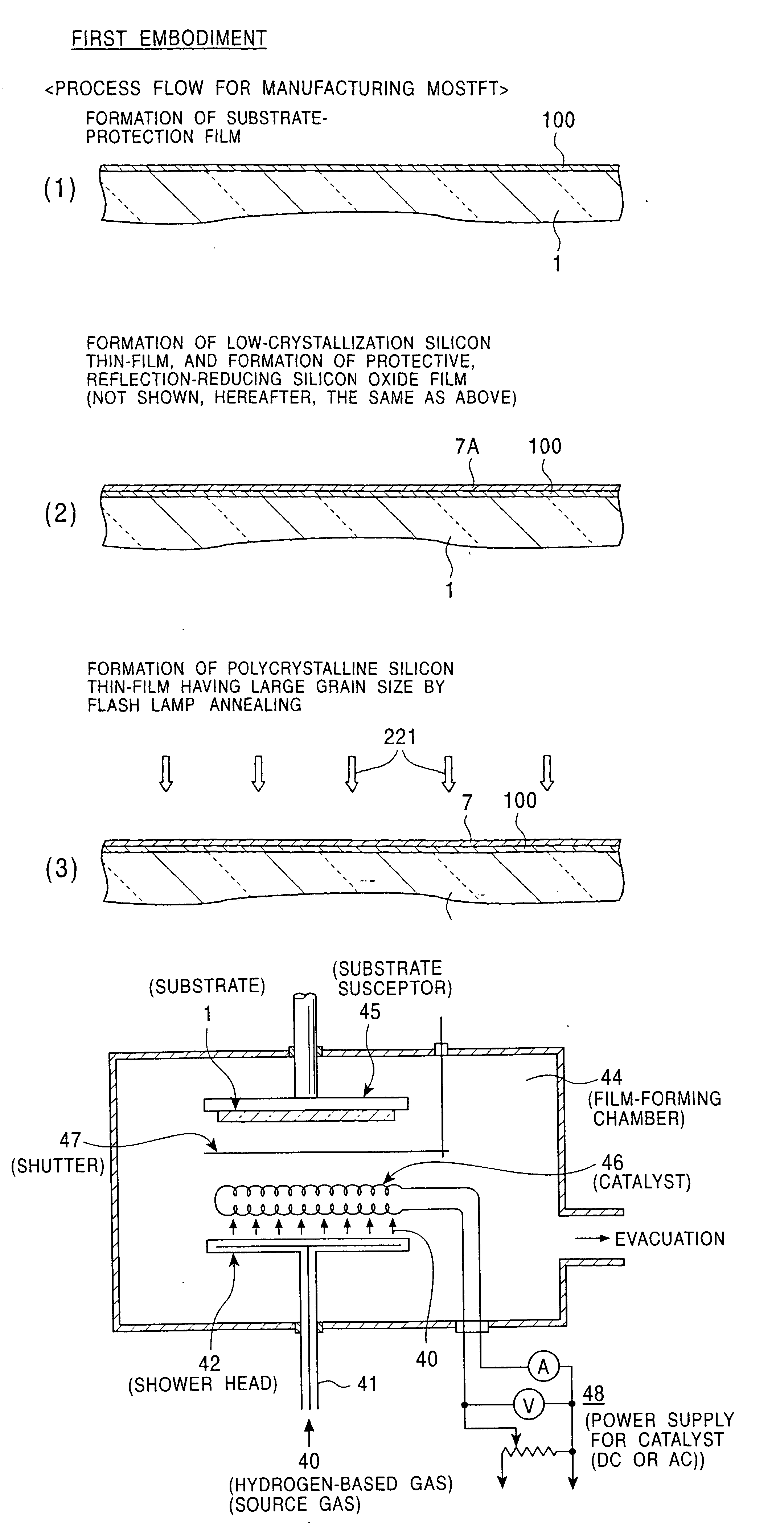

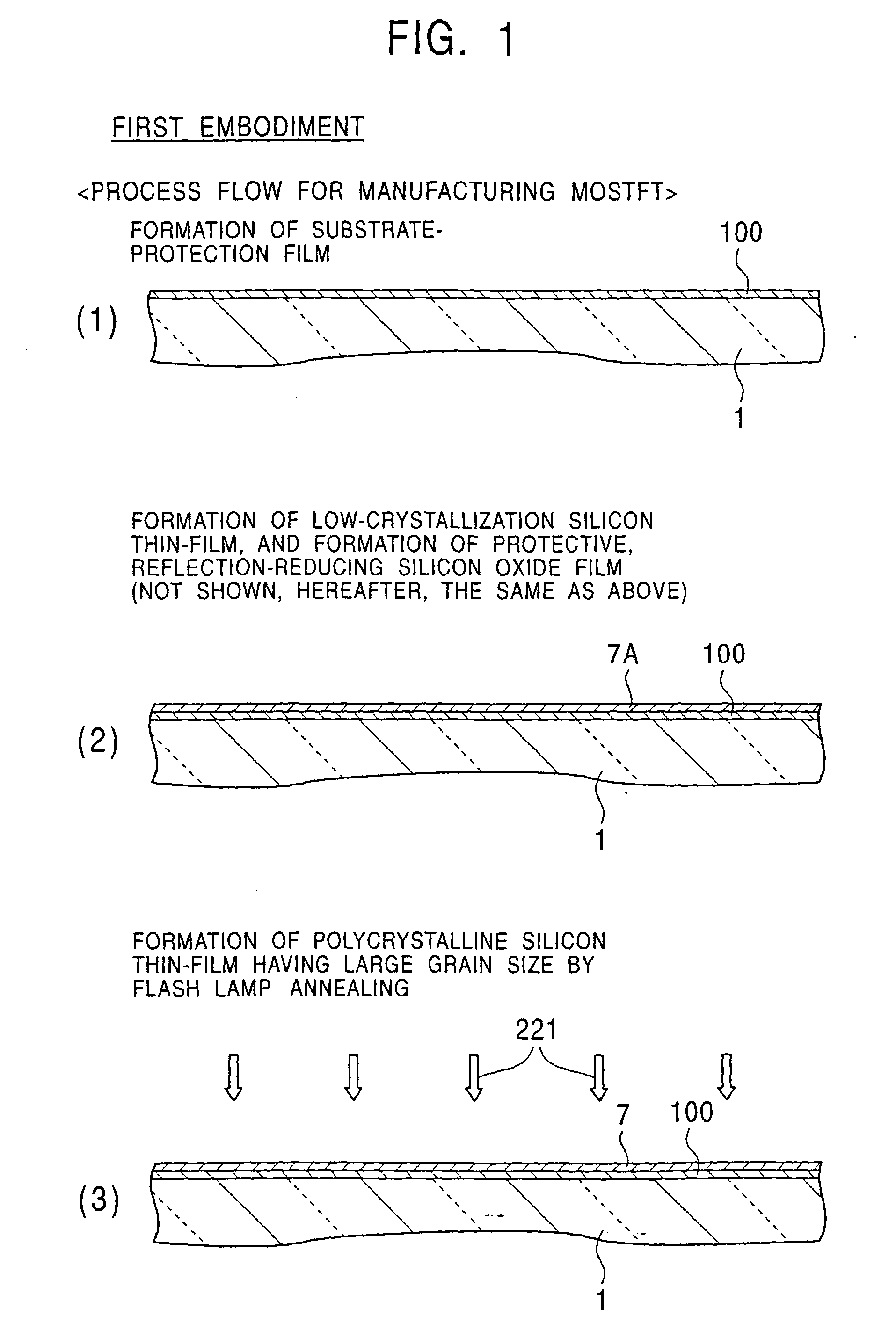

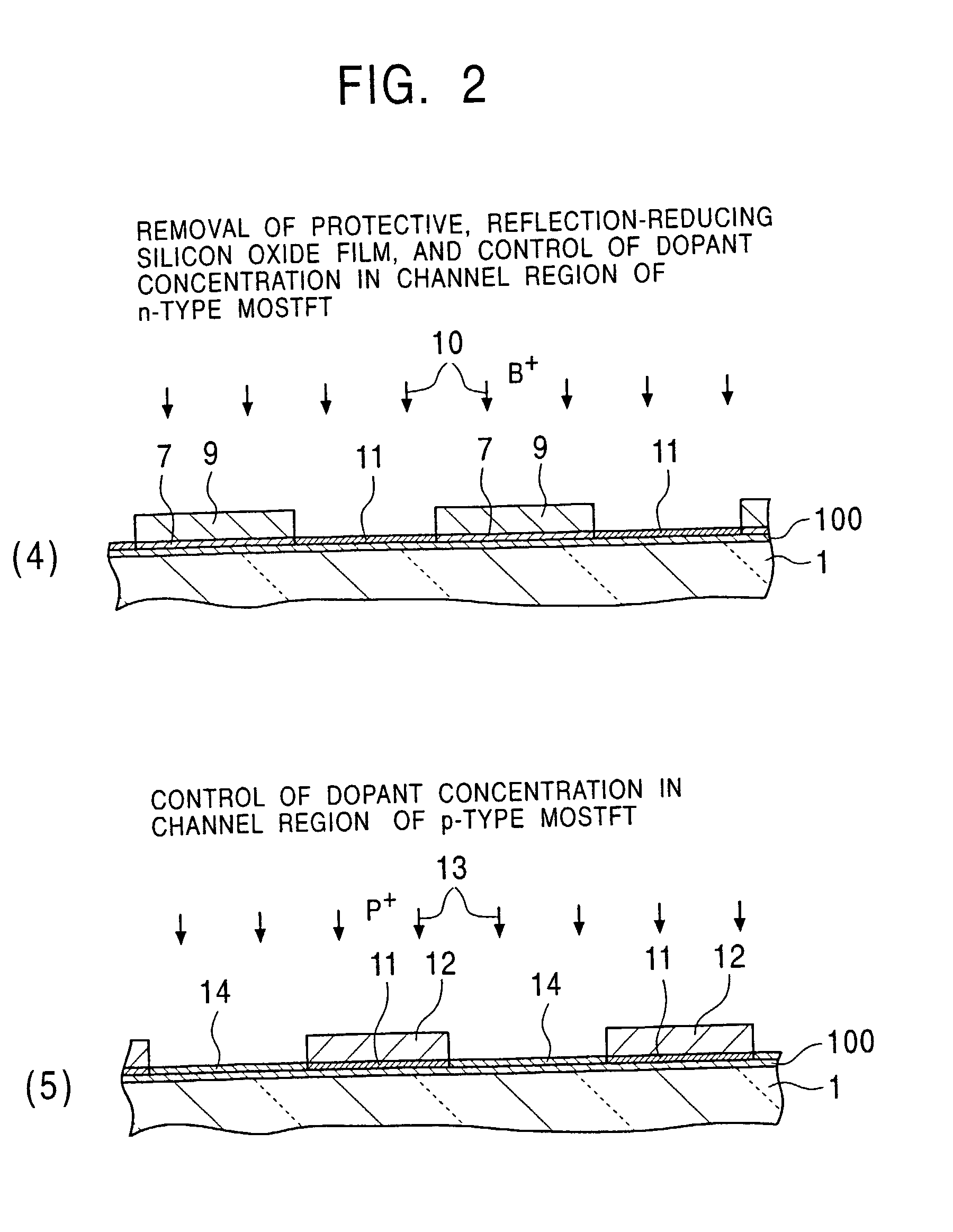

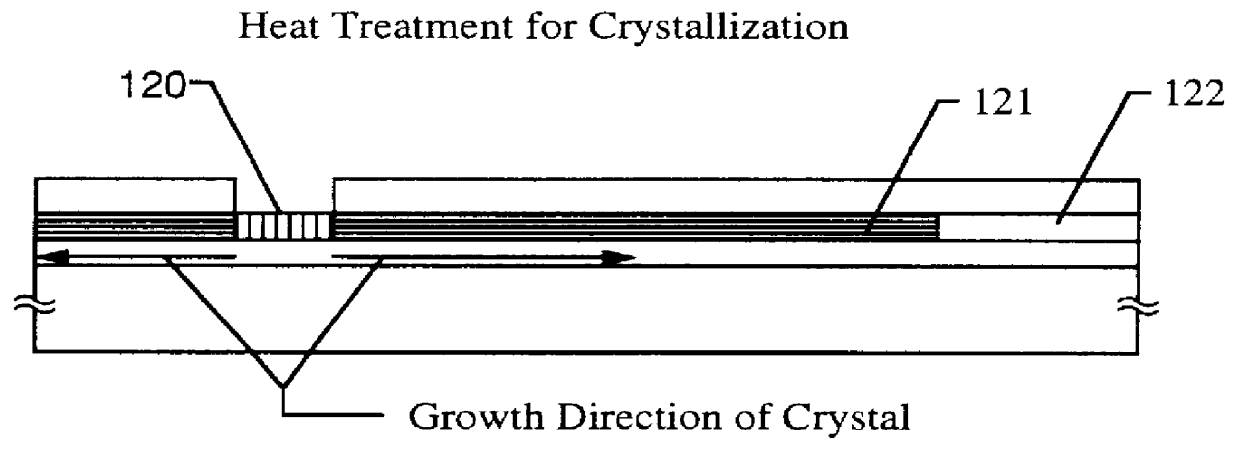

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

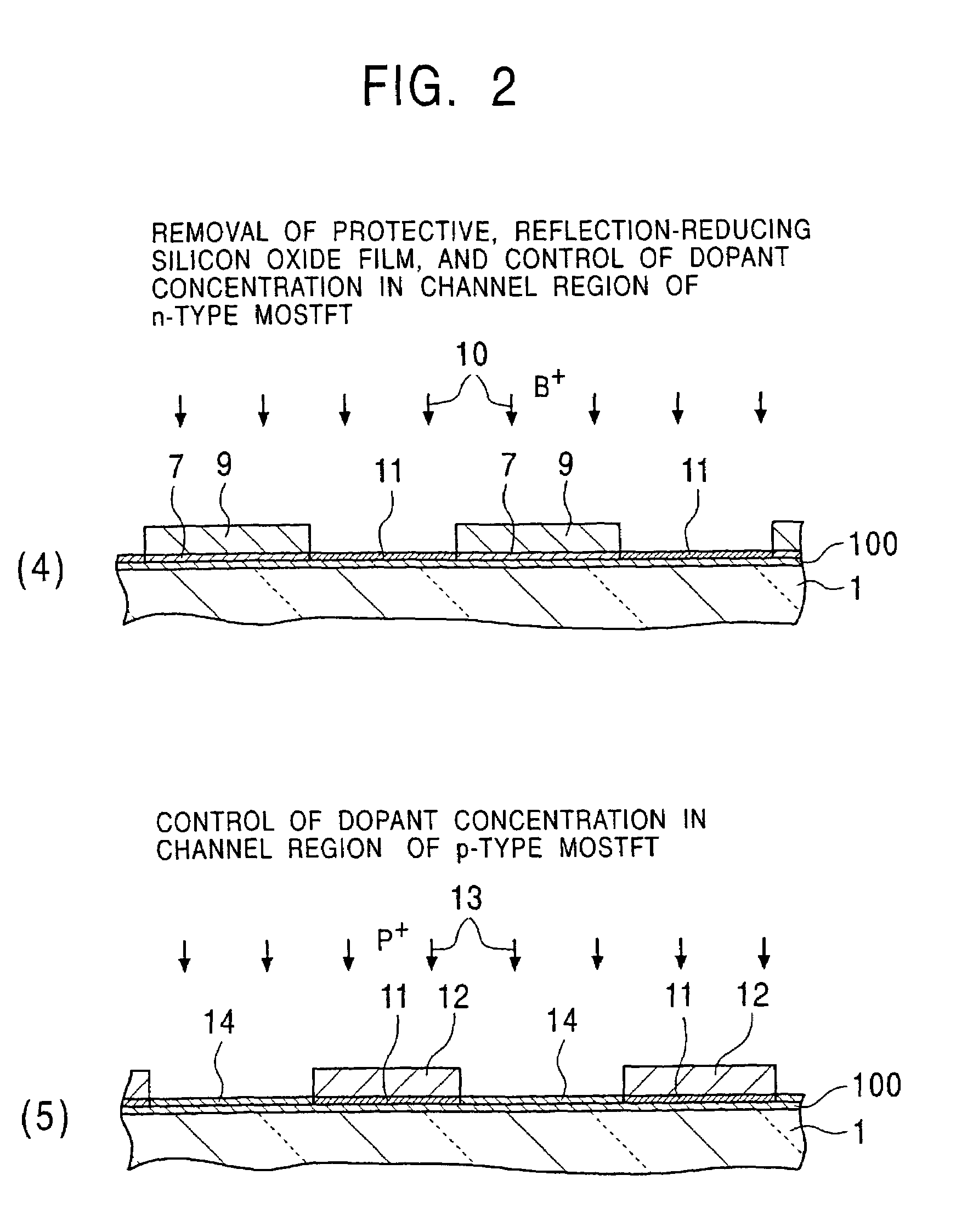

Method of manufacturing a semiconductor device

InactiveUS6165824ATransistorSemiconductor/solid-state device manufacturingCrystallinityCrystal growth

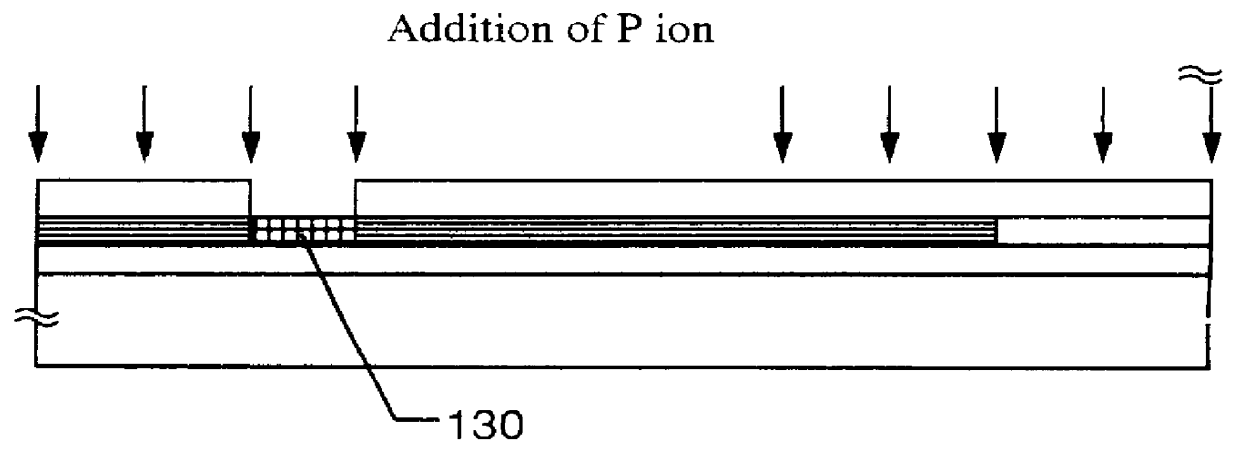

A crystal growth 301 is carried out by diffusing a metal element, and a nickel element is moved into regions 108 and 109 which has been doped with phosphorus. An axis coincident with the moving directions 302 and 303 of the nickel element at this time is made to coincide with an axis coincident with the direction of the crystal growth, and a TFT having the regions as channel forming regions is manufactured. In the path of the region where nickel moved, since high crystallinity is obtained in the moving direction, the TFT having high characteristics can be obtained by this way.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

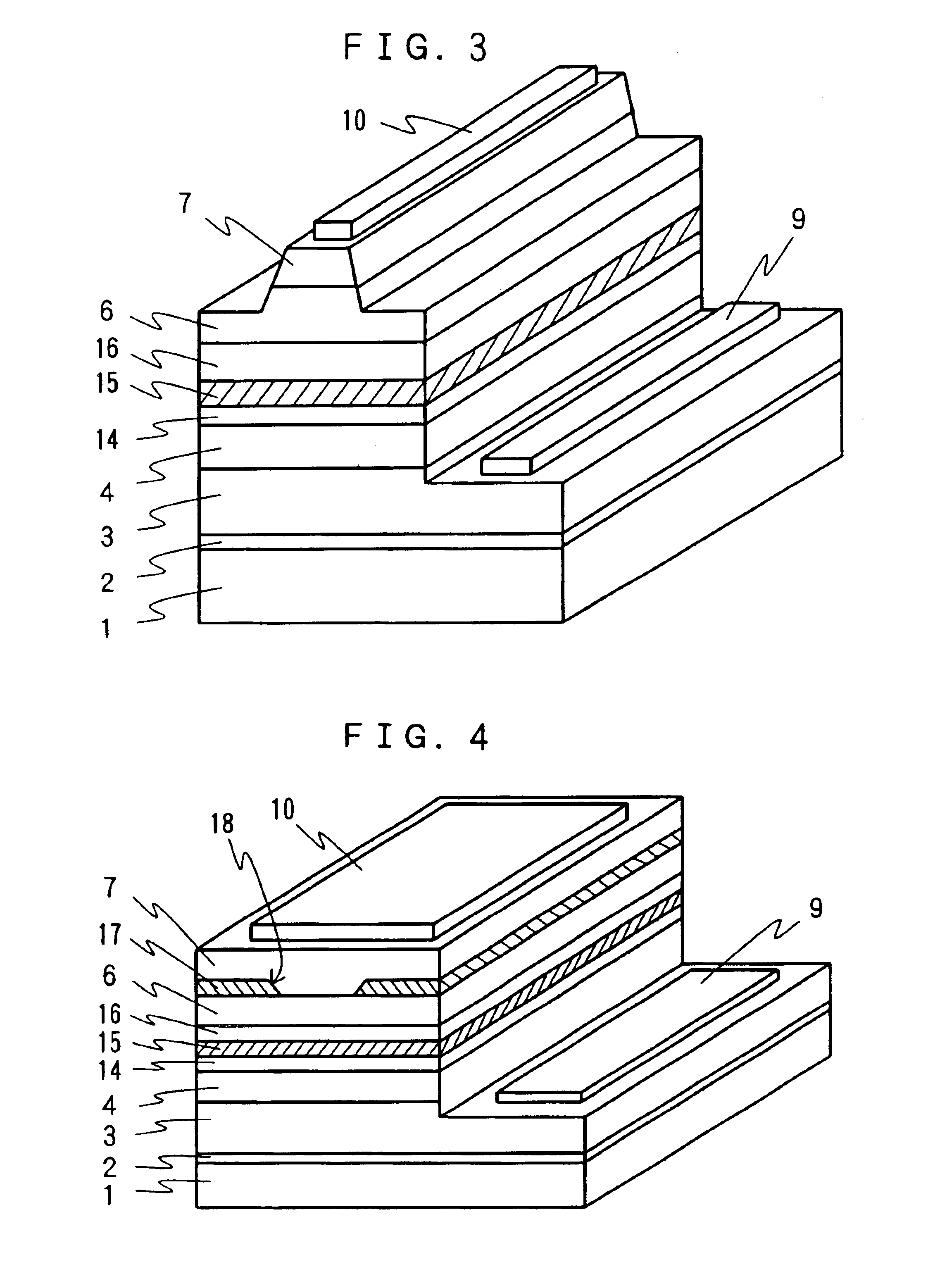

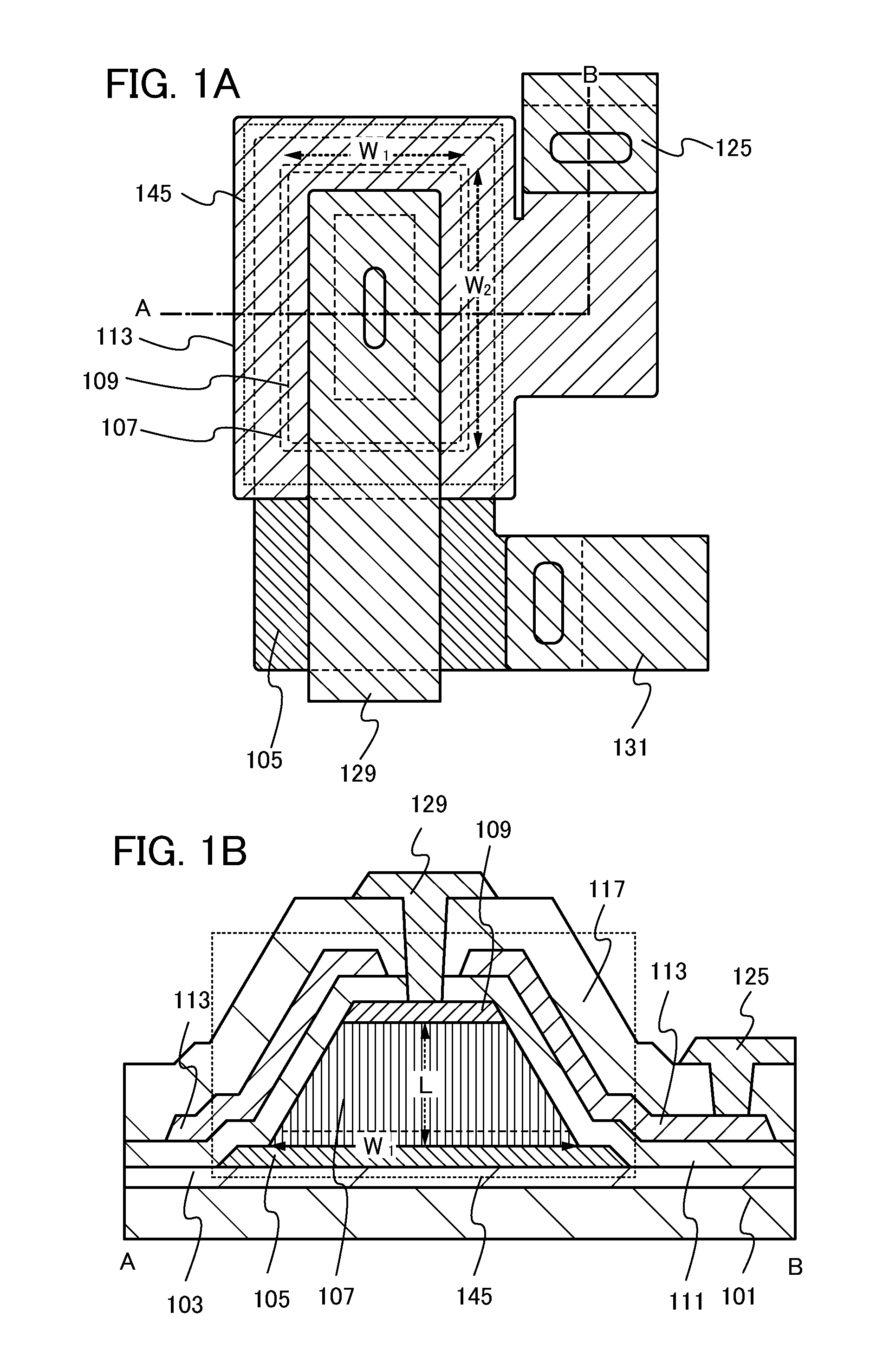

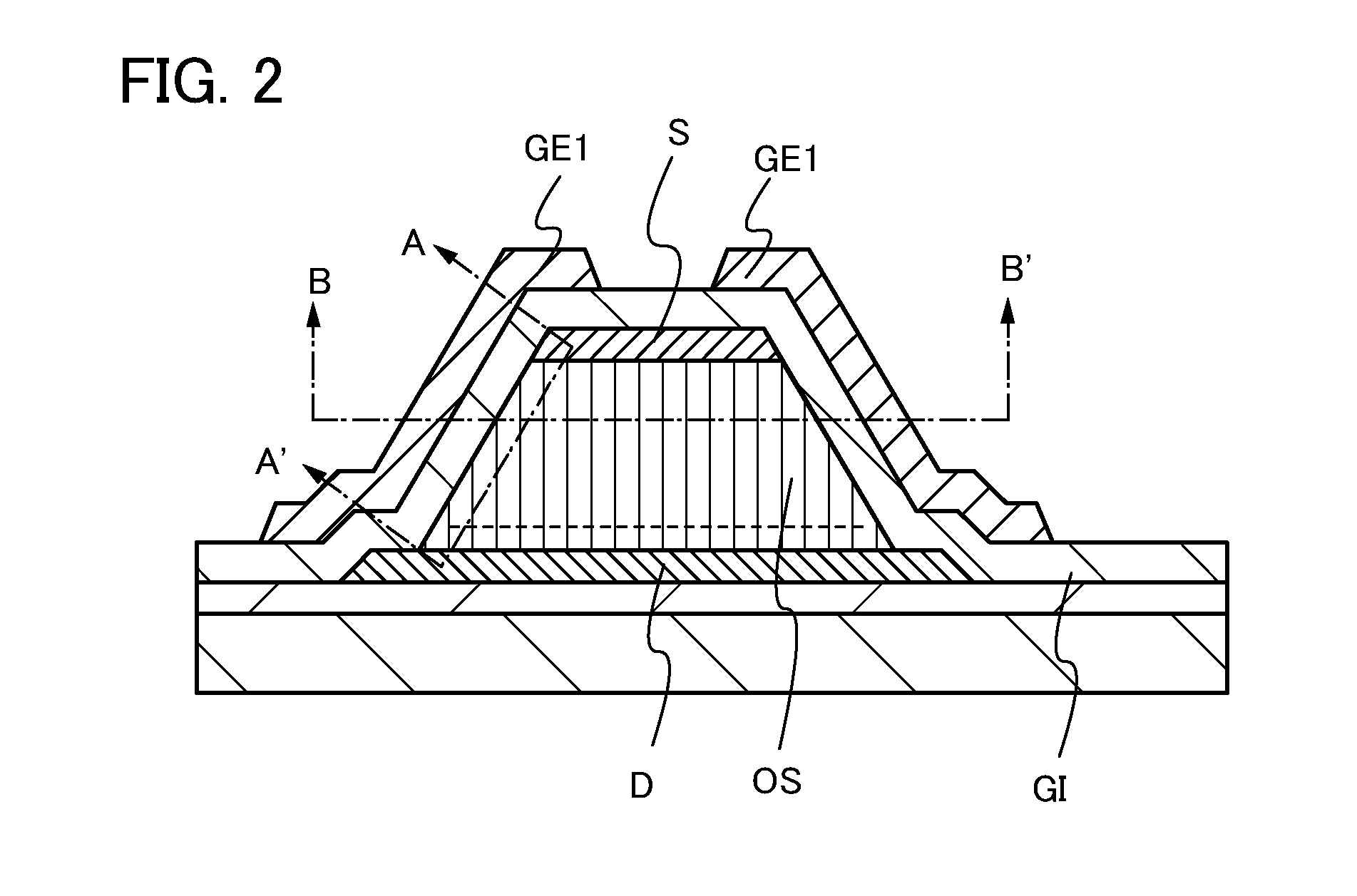

Semiconductor device and manufacturing method thereof

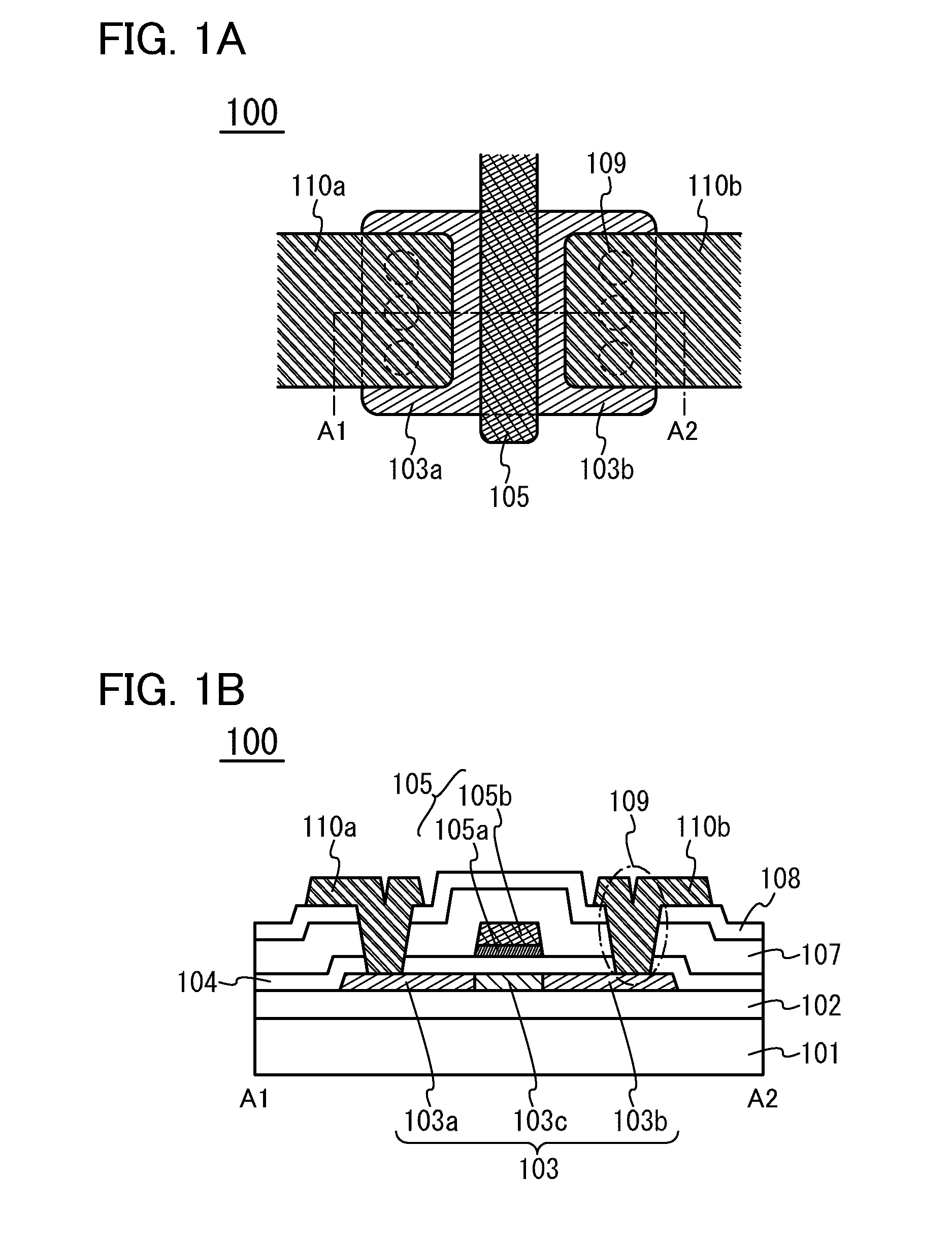

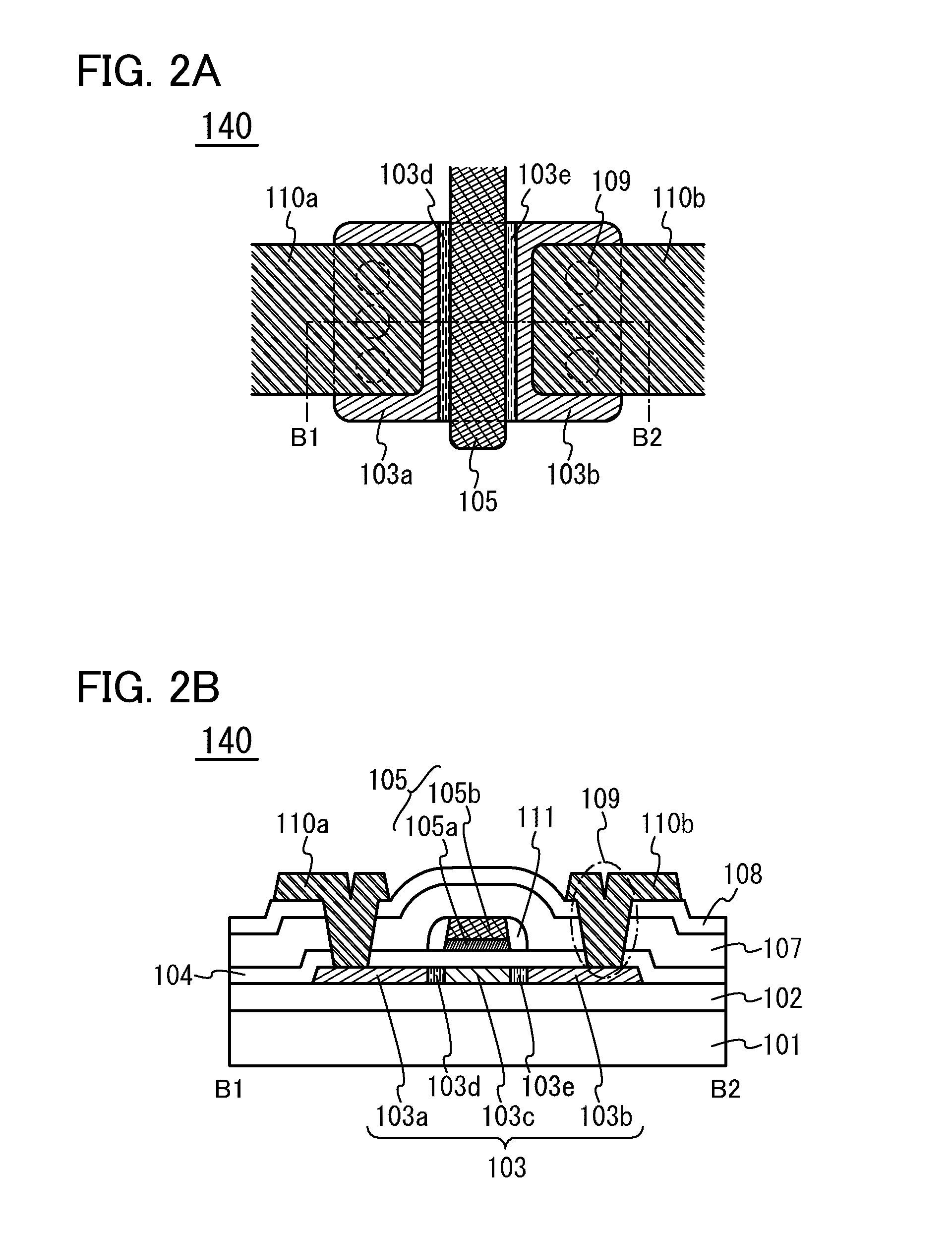

ActiveUS20120161126A1Reduce parasitic capacitanceIncrease speedTransistorSolid-state devicesDevice materialWurtzite crystal structure

A semiconductor device capable of high speed operation is provided. Further, a semiconductor device in which change in electric characteristics due to a short channel effect is hardly caused is provided. An oxide semiconductor having crystallinity is used for a semiconductor layer of a transistor. A channel formation region, a source region, and a drain region are formed in the semiconductor layer. The source region and the drain region are formed by self-aligned process in which one or more elements selected from Group 15 elements are added to the semiconductor layer with the use of a gate electrode as a mask. The source region and the drain region can have a wurtzite crystal structure.

Owner:SEMICON ENERGY LAB CO LTD

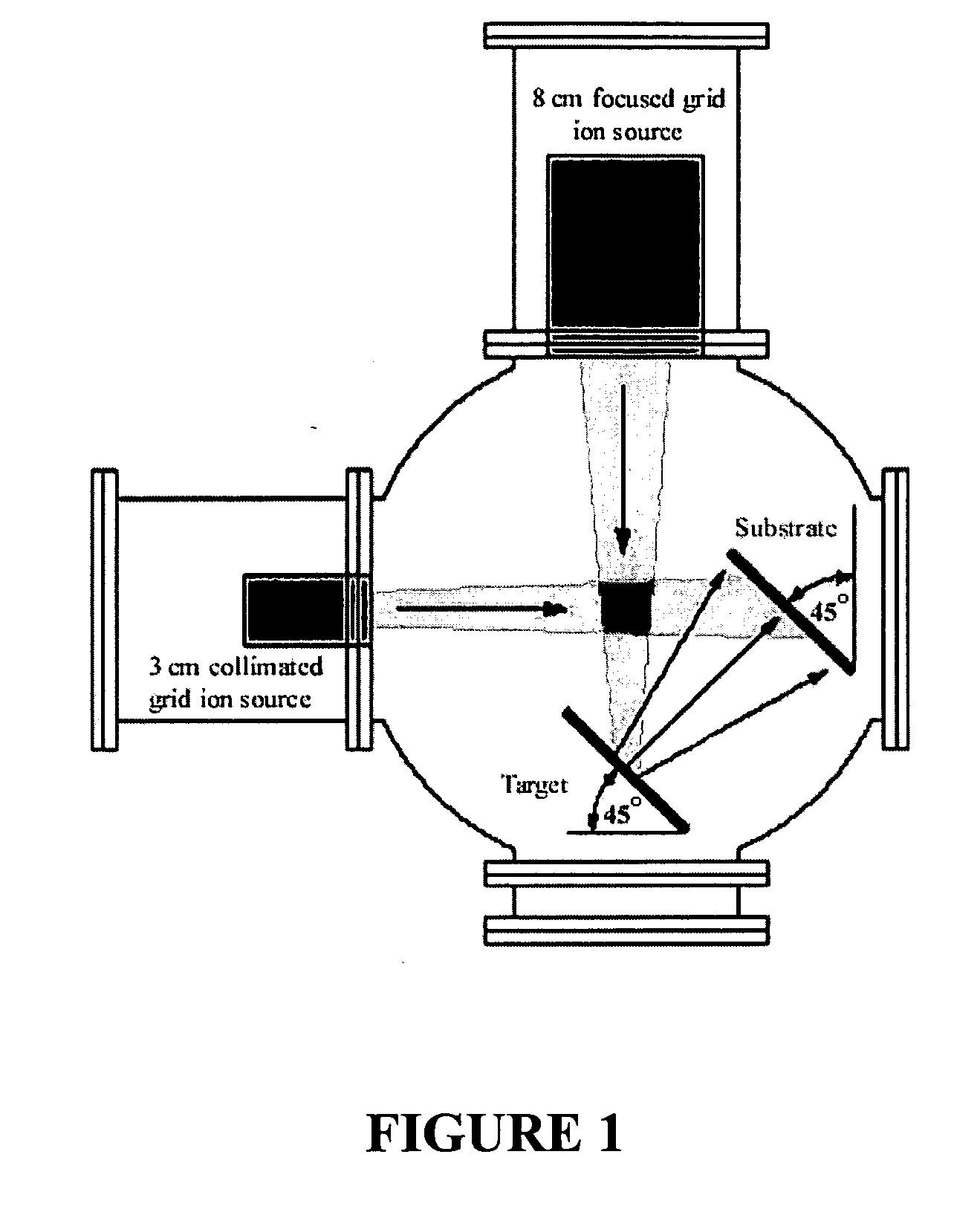

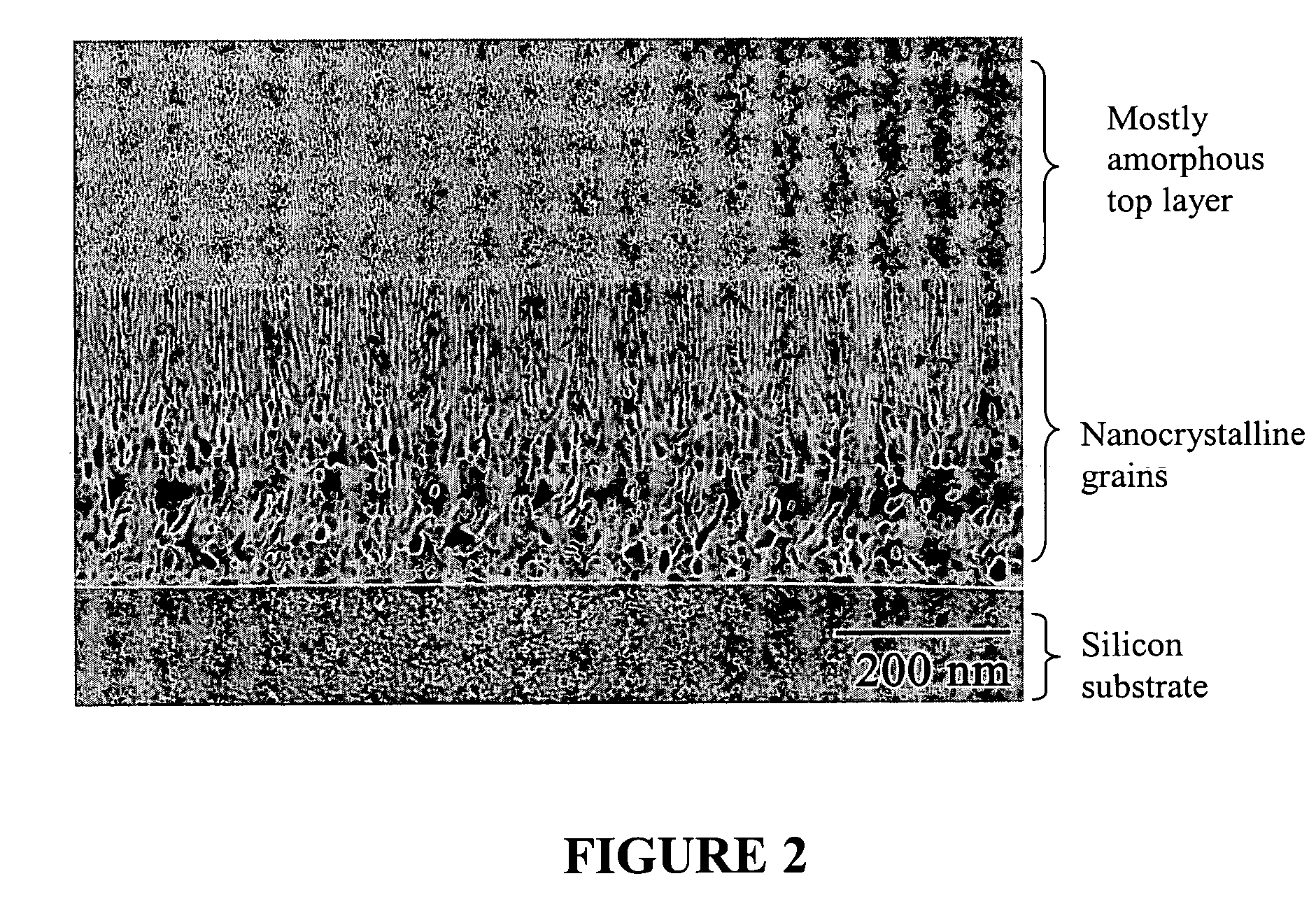

Rechargeable thin film battery and method for making the same

InactiveUS6982132B1Improve lithium ion mobilityHigh voltageElectrode thermal treatmentFinal product manufactureElectrical batteryHigh energy

A rechargeable, stackable, thin film, solid-state lithium electrochemical cell, thin film lithium battery and method for making the same is disclosed. The cell and battery provide for a variety configurations, voltage and current capacities. An innovative low temperature ion beam assisted deposition method for fabricating thin film, solid-state anodes, cathodes and electrolytes is disclosed wherein a source of energetic ions and evaporants combine to form thin film cell components having preferred crystallinity, structure and orientation. The disclosed batteries are particularly useful as power sources for portable electronic devices and electric vehicle applications where high energy density, high reversible charge capacity, high discharge current and long battery lifetimes are required.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

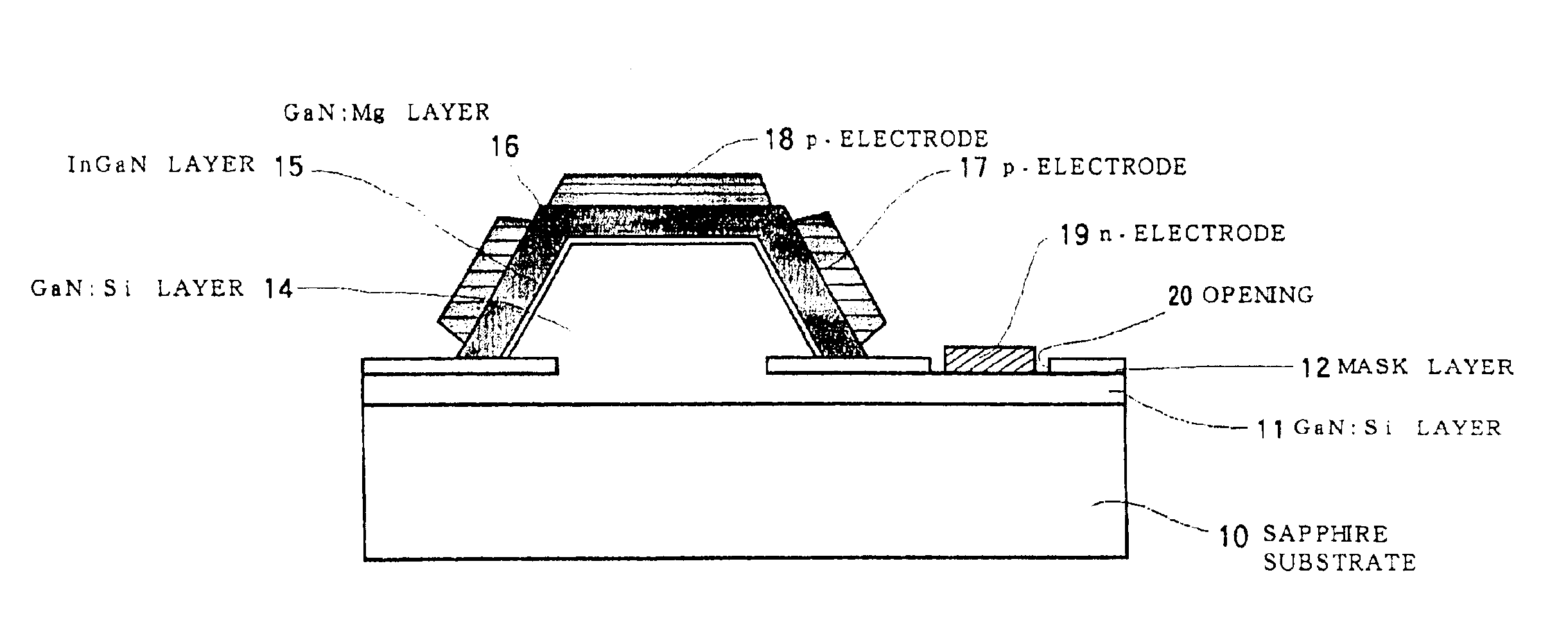

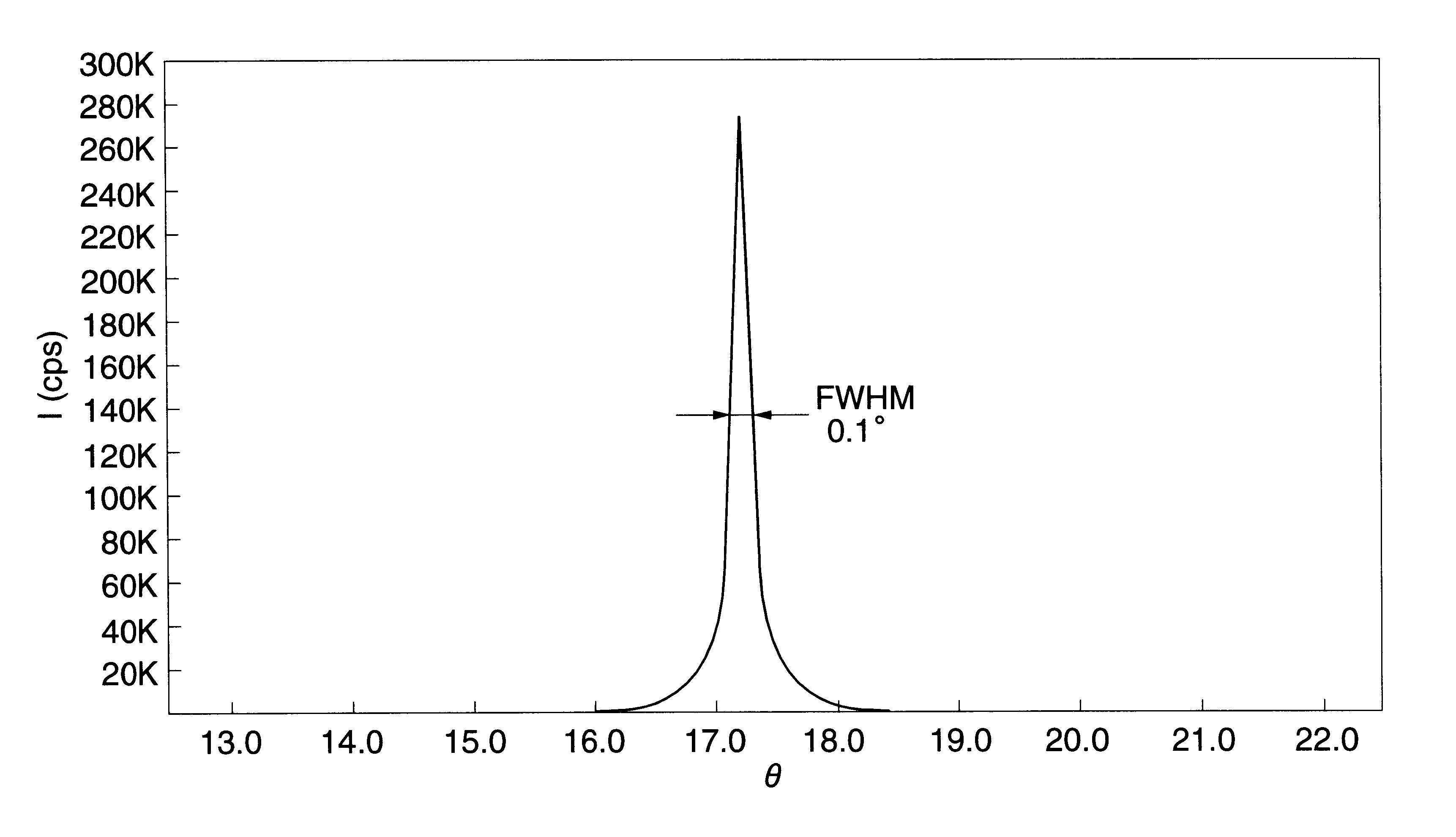

Nitride semiconductor device and method of manufacturing the same

A nitride semiconductor device of high quality and excellent crystallinity and the method of manufacturing the same, wherein a nitride series compound semiconductor having at least an element belonging to the group IIIA and nitrogen is grown directly on a substrate, X-ray diffraction peaks of the nitride series compound semiconductor consist only of the peaks from the C-face of the hexagonal system, and the half width of an X-ray rocking curve at (0002) peak in the C-surface is 0.2 degrees of less, and wherein the method includes a step of introducing an organic metal compound at least containing a group IIIA element and a plasma activated nitrogen source into a reaction vessel to grow a nitride series compound semiconductor on the surface of a substrate, in which the ratio for the amount of the group IIIA element and nitrogen atom supplied (ratio for the number of atoms) is group IIIA element: nitrogen atom=1:50,000 to 1:1,000,000.

Owner:FUJIFILM BUSINESS INNOVATION CORP

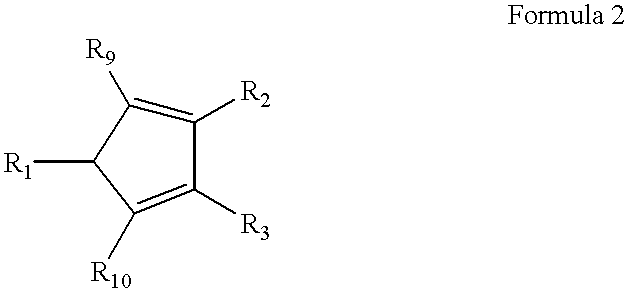

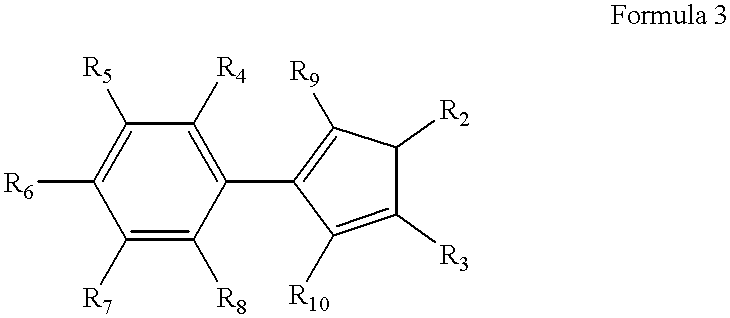

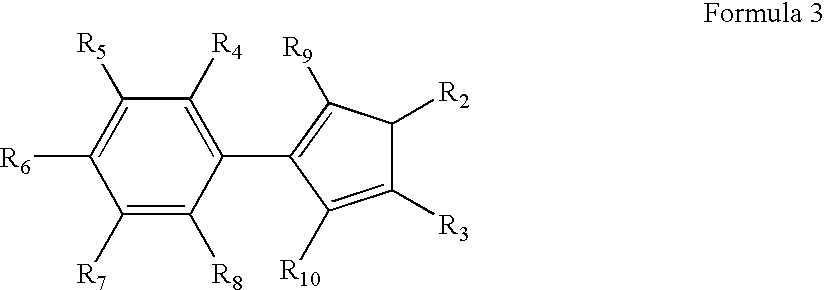

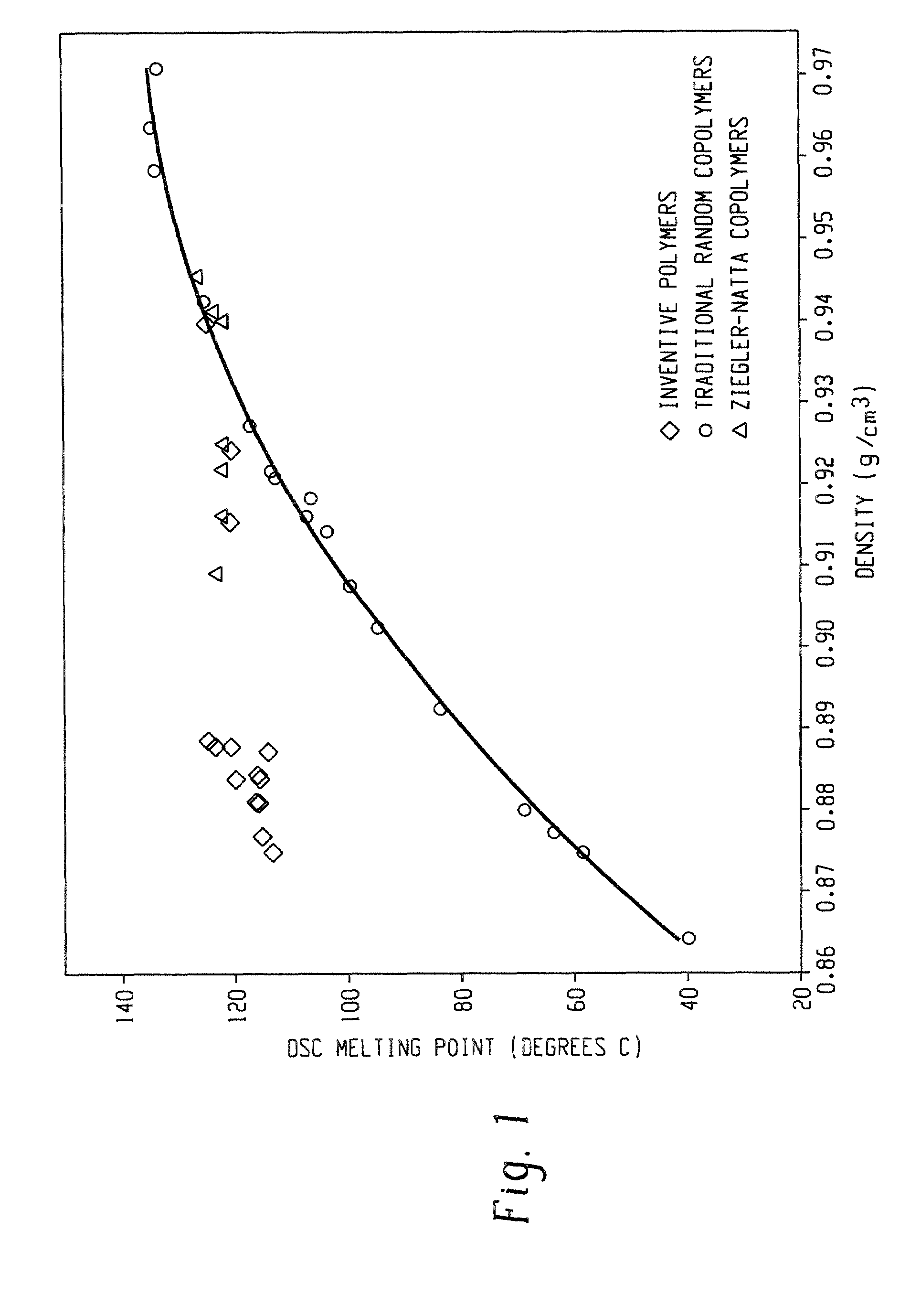

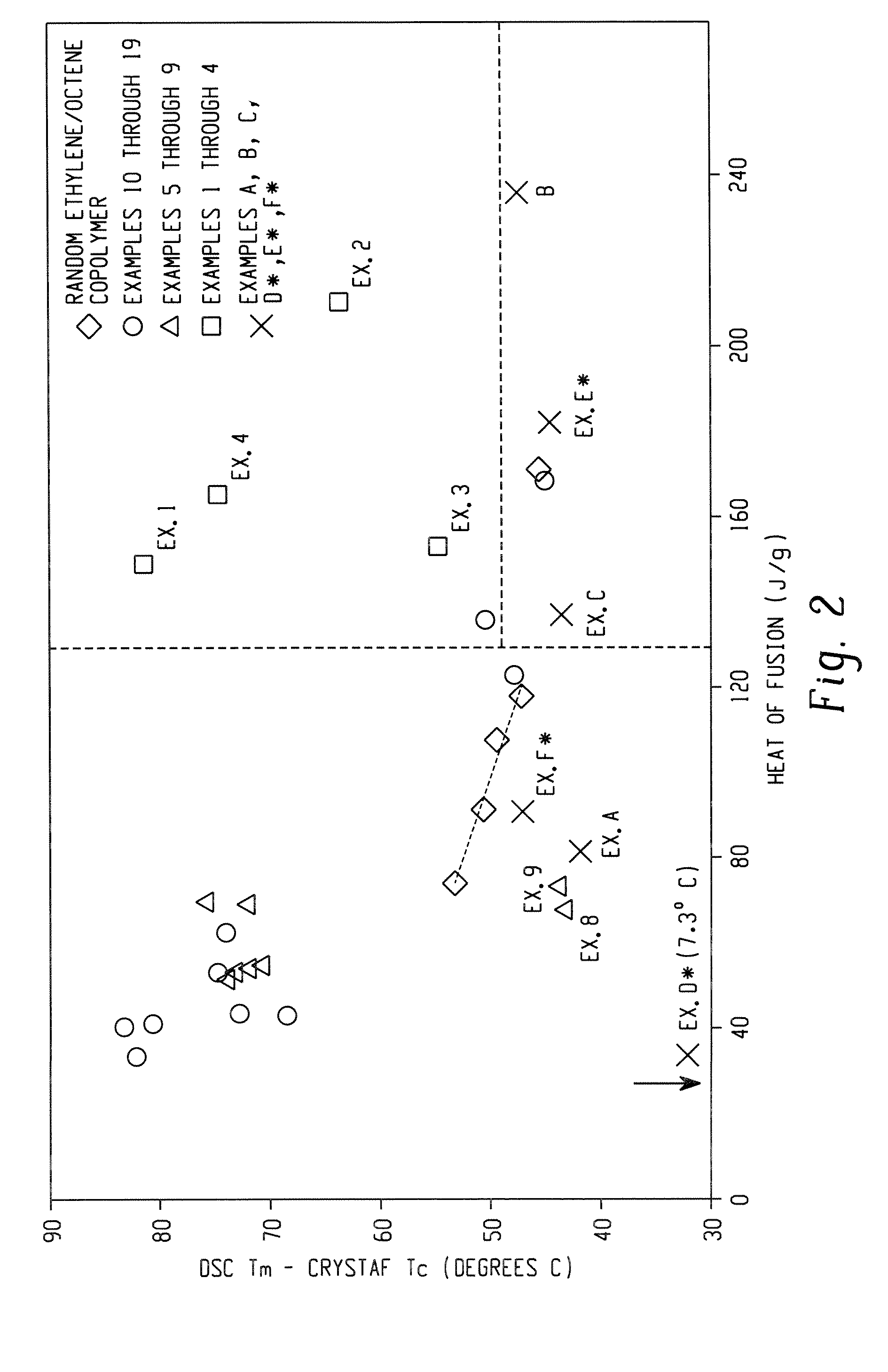

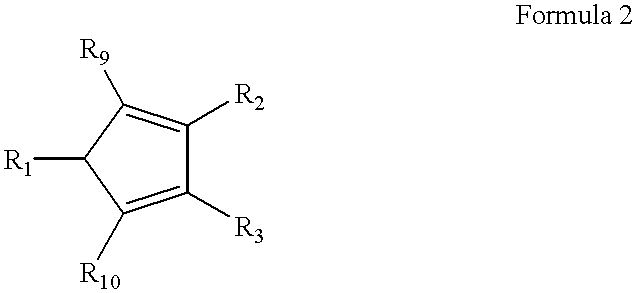

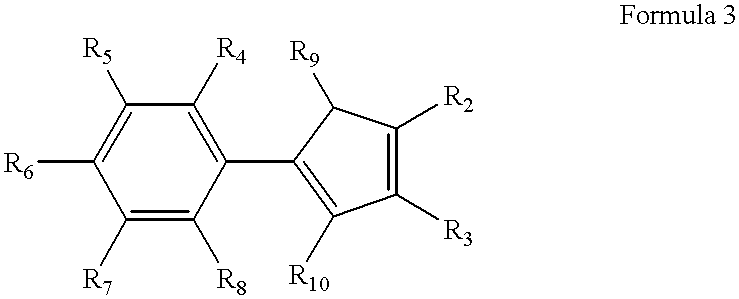

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6169151B1Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

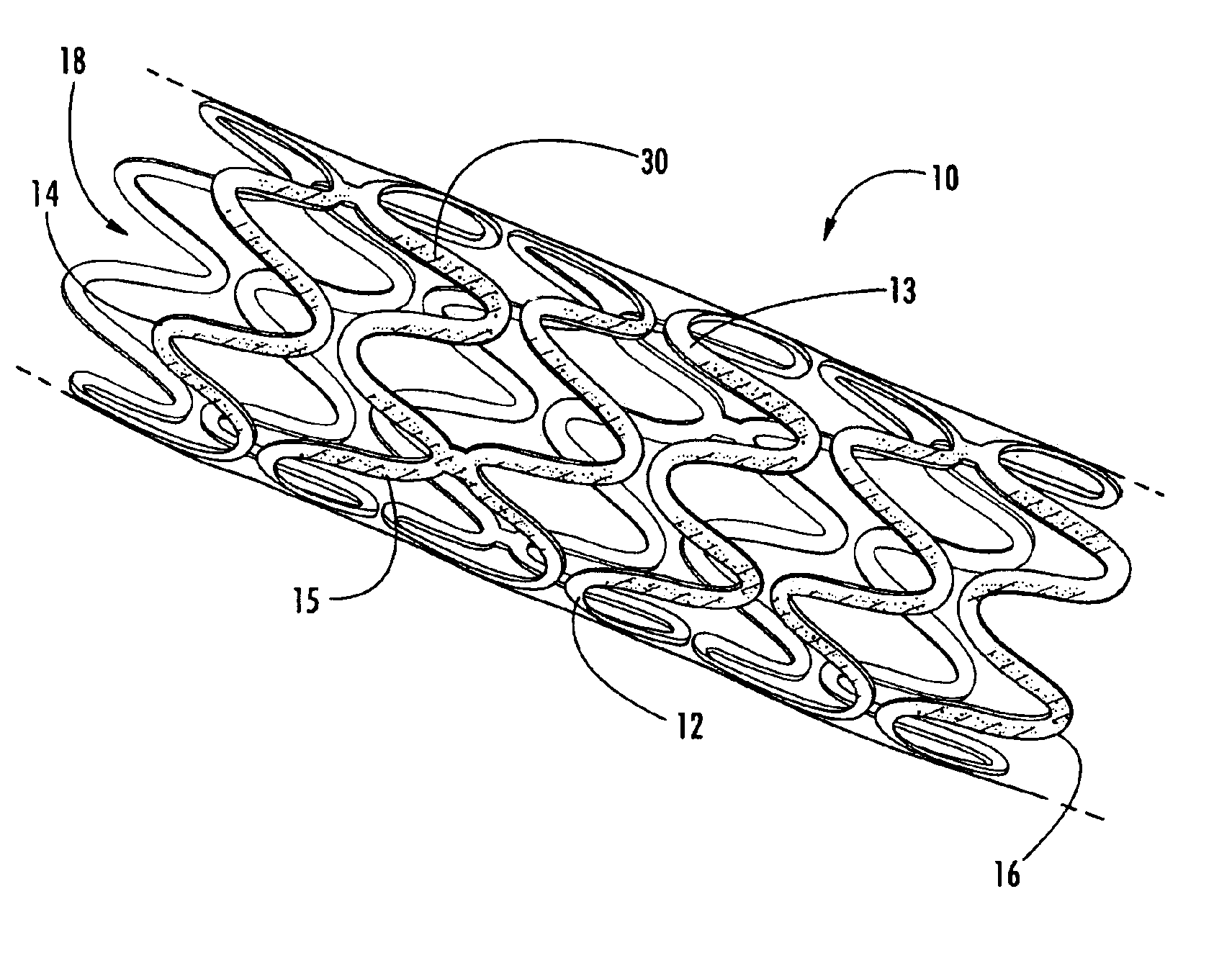

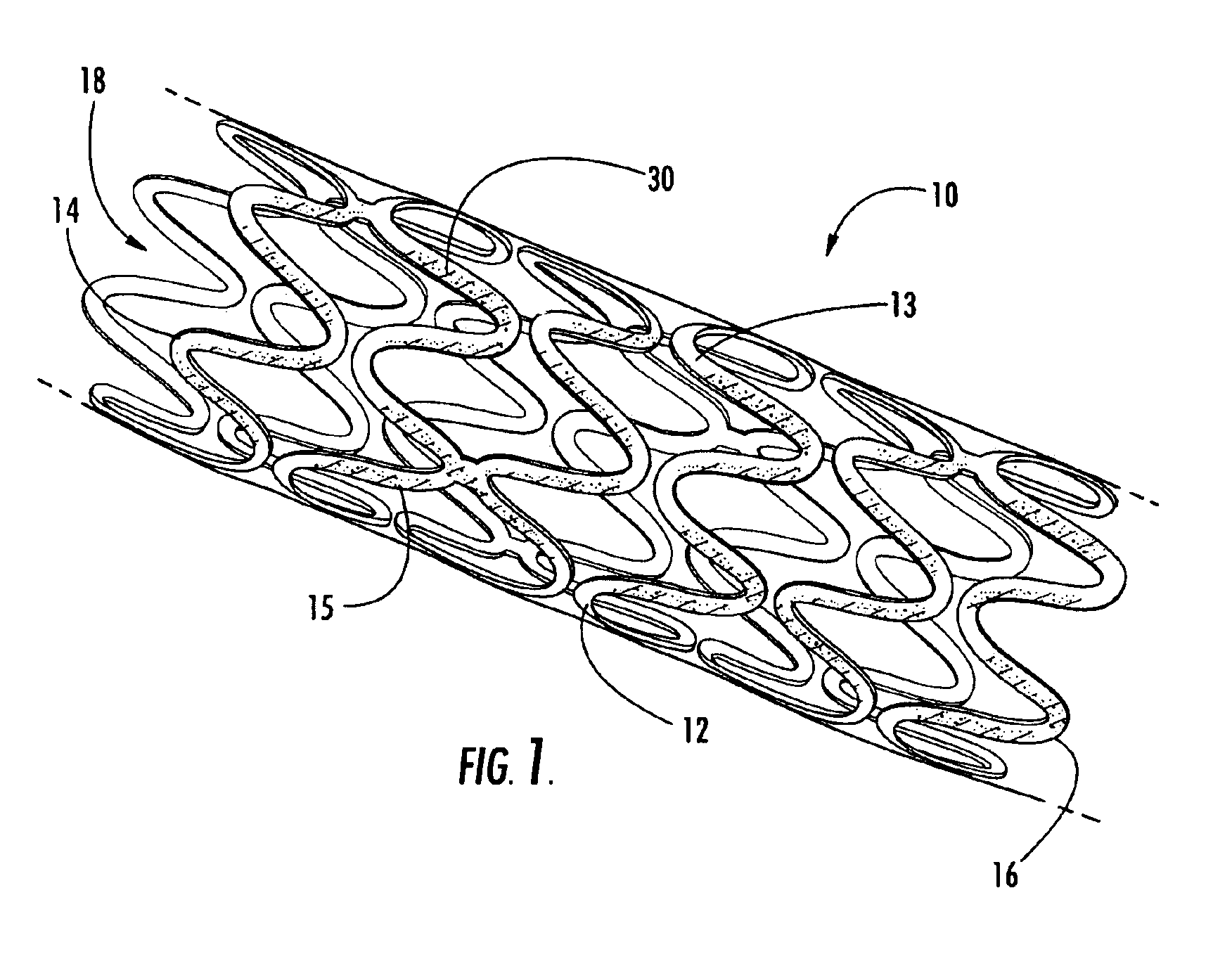

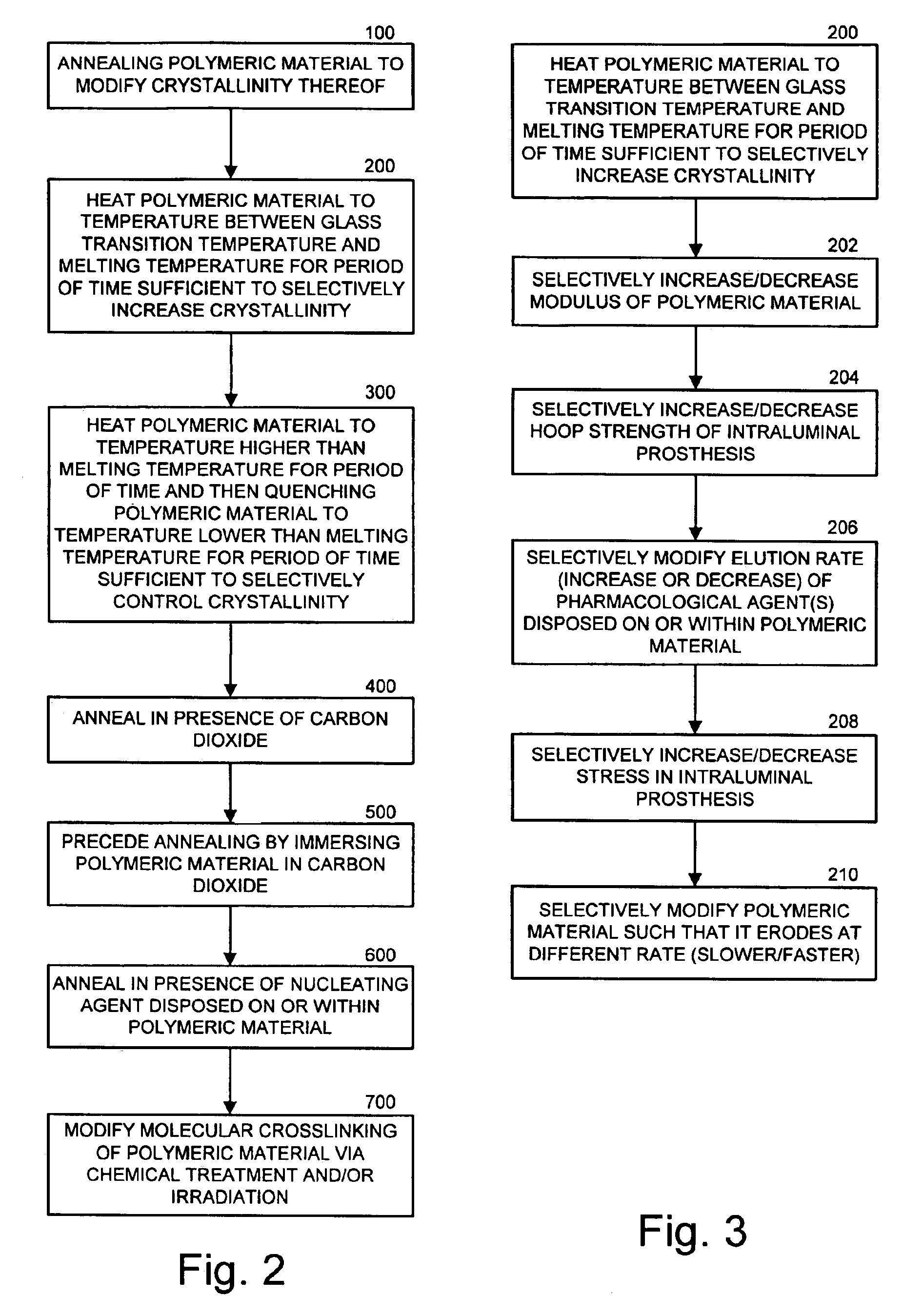

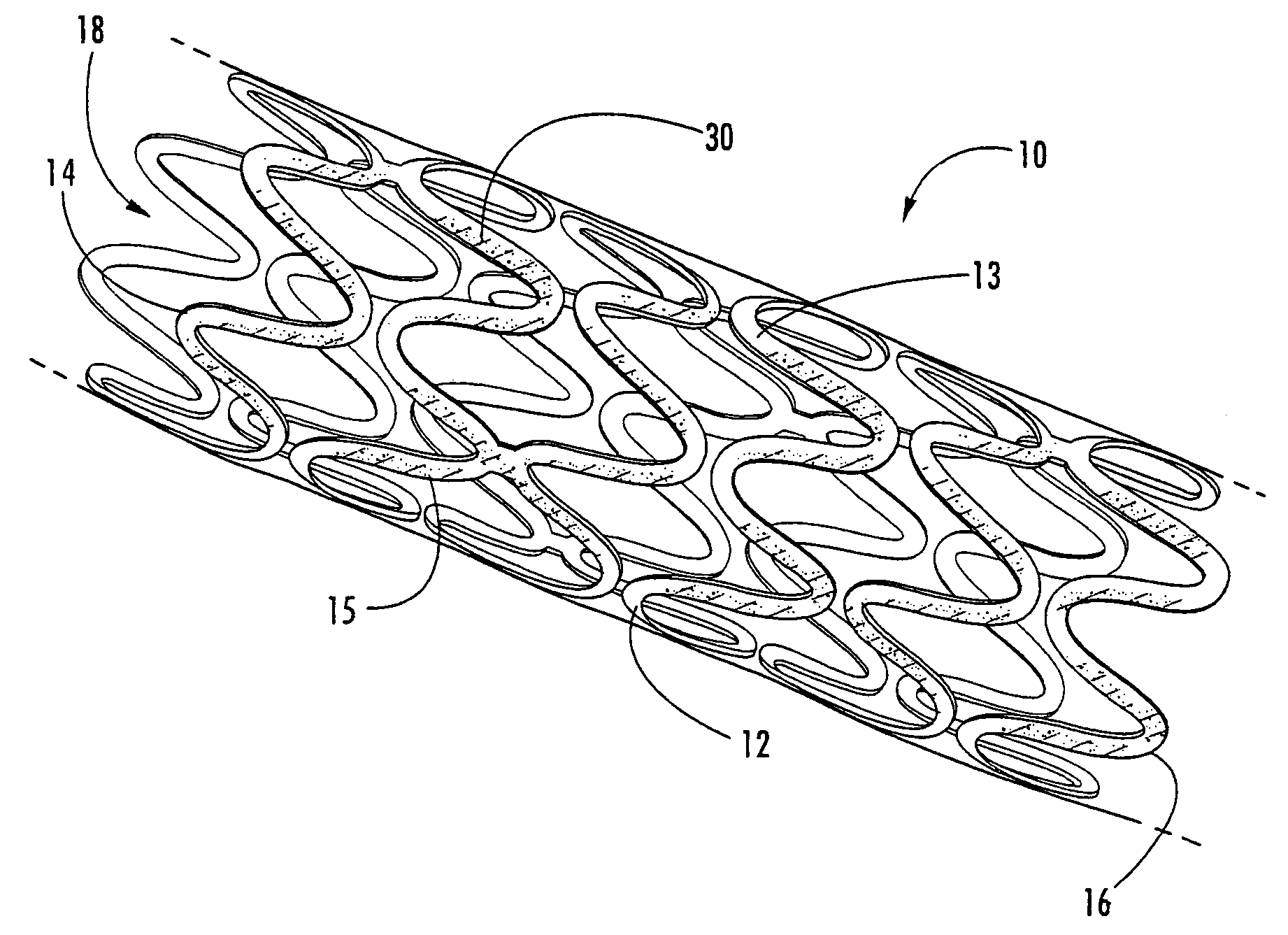

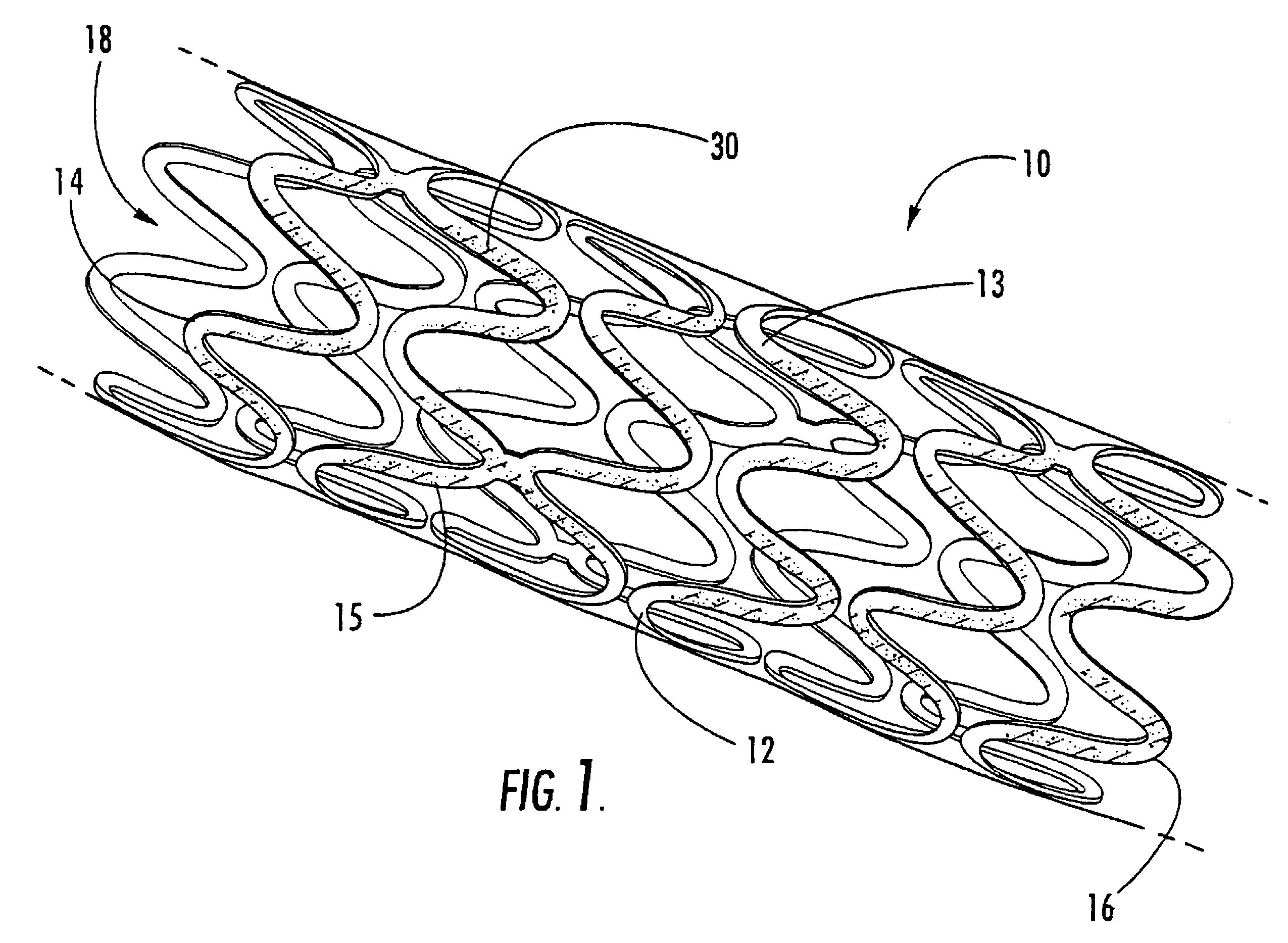

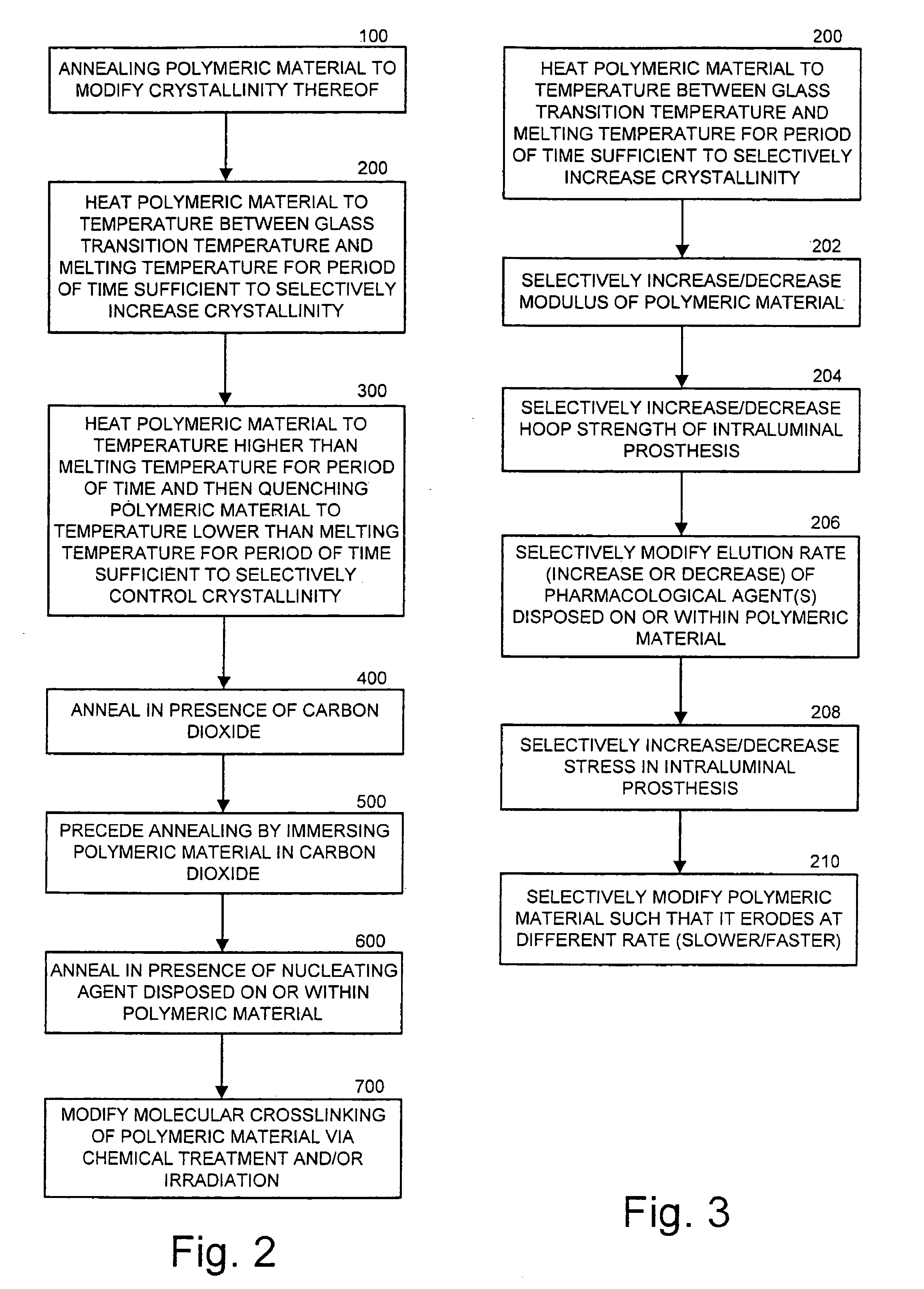

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

High melting thermoplastic elastomeric alpha-olefin polymers (PRE/EPE effect) and catalysts therefor

InactiveUS6559262B1Activity of fluxional unbridged metallocene polymerization catalystsHigh molecular weightGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

This invention relates generally to low ethylene insertions into I-olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point I-olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of I-olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. The amount of ethylene included in the reaction system can be selected and controlled to be so small as to result in essentially minimal (<2 mole %) incorporation of ethylene units into the resulting elastomeric polymer and the molecular weight may be increased. Amounts of ethylene to generate the PRE effect may be greater than 0.1 wt. % and preferably range up to about 2 wt. %. However, if a polymer with more ethylene is desired, additional ethylene may be incorporated into the polymerization feed, including up to 10 to about 50 mole % based on olefin units. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, I-olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. This effect is termed the EPE effect, for Elastomeric Property-Enhancing effect. The EPE amount of ethylene required to produce such elastomers typically overlaps the PRE activity-enhancing amount. Incorporation of up to about 5 mole % or more of ethylene typically will produce an elastomeric polymer using such catalyst systems. Typical useful amounts of incorporated ethylene include about 1 to 3 mole %. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80° C., preferably above 100° C., including in the range of from about 120° C. to about 140° C. and above. Novel flexible alpha-olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:BP CORP NORTH AMERICA INC

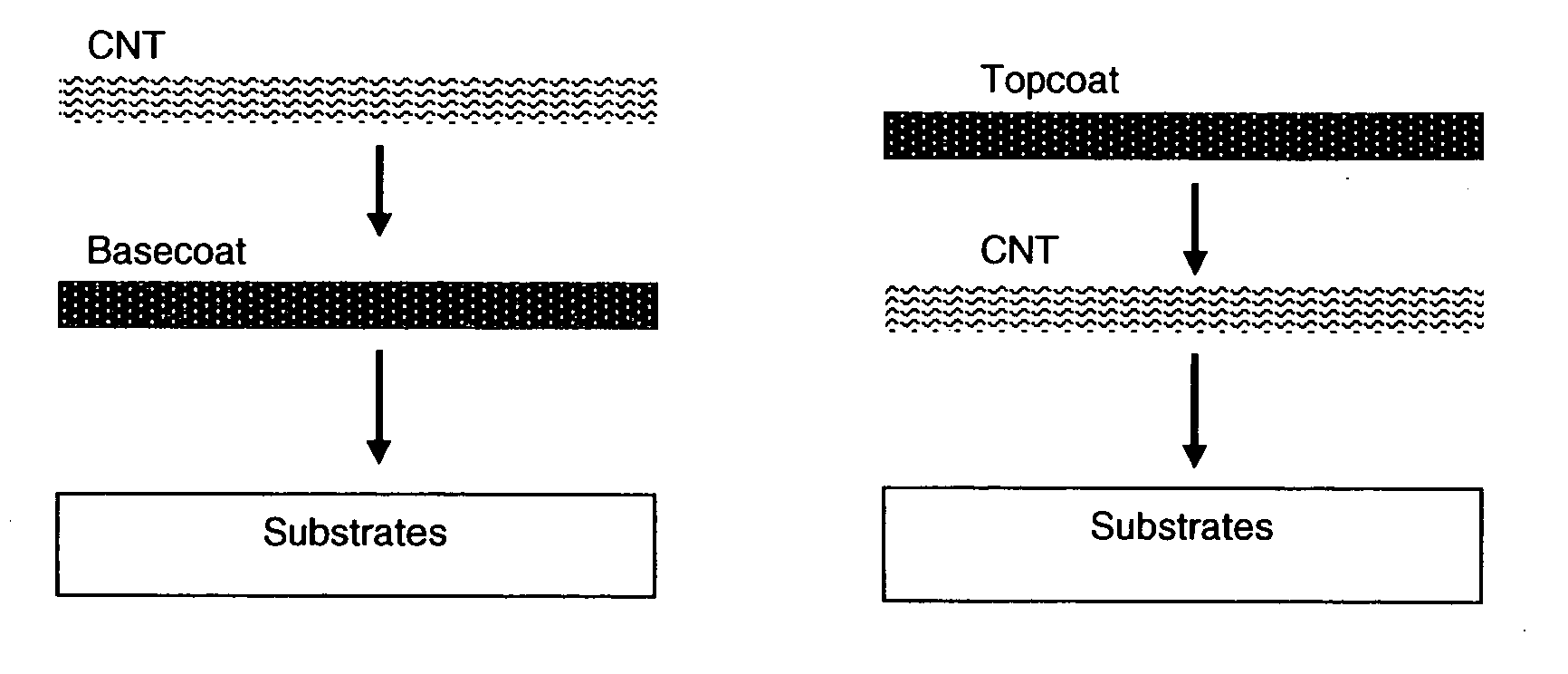

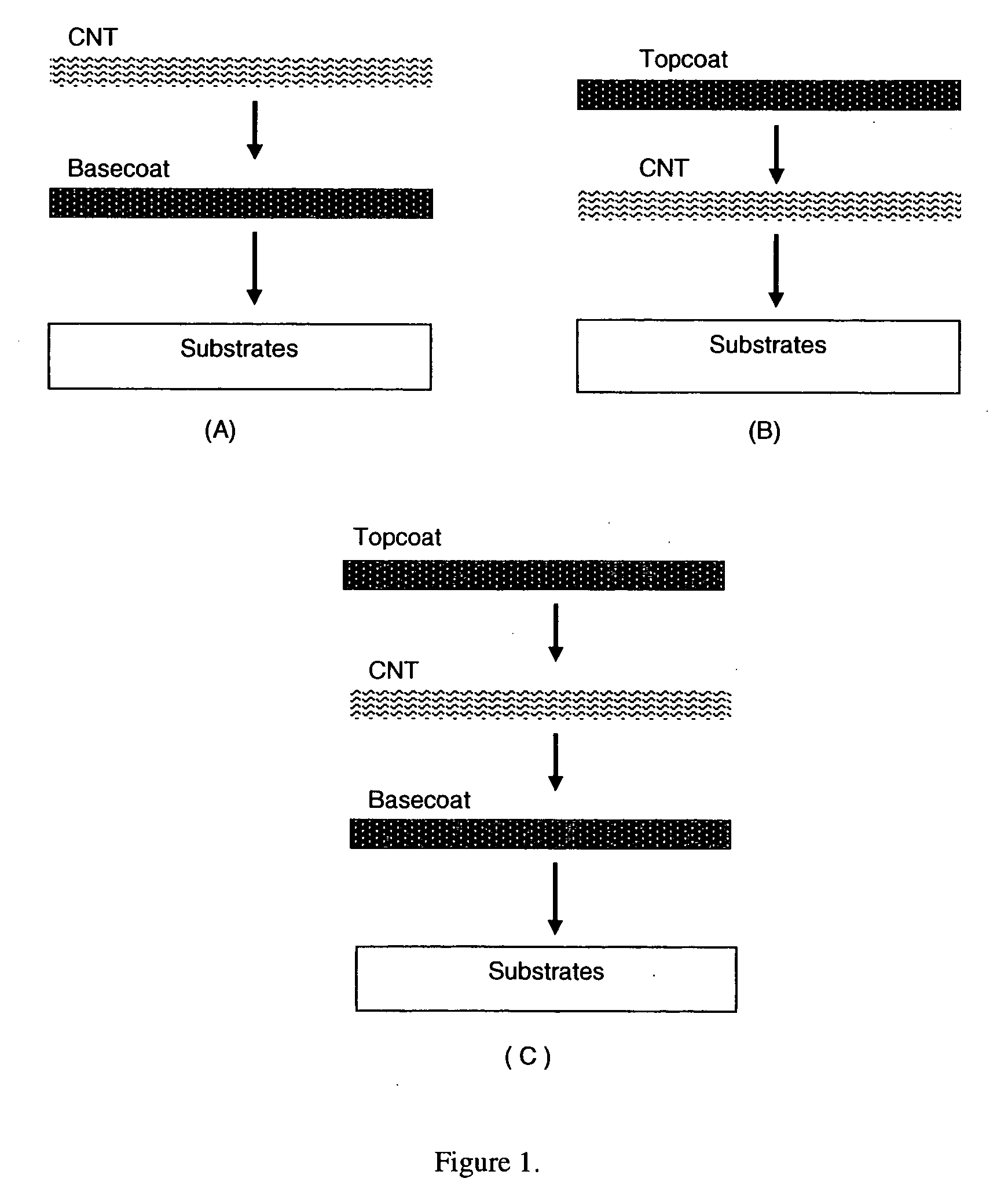

Fluoropolymer binders for carbon nanotube-based transparent conductive coatings

InactiveUS20060113510A1Reduce conductivityFunction increaseNanoinformaticsConductive materialThermoplasticOptical transparency

This invention relates to flexible, transparent and conductive coatings and films formed using carbon nanotubes (CNT) and, in particular, single wall carbon nanotubes, with polymer binders. Preferably, coatings and films are formed from carbon nanotubes applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or a combination thereof. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. A fluoropolymer containing binder, which is a solution of one fluoropolymer or a blend of fluoropolymers, which may be formulated with additives, is applied onto a carbon nanotube-based transparent conductive coating at nanometer level of thickness on a clear substrate such as PET and glass. The fluoropolymers or blend can be either semi-crystalline (with low level of crystallinity) or amorphous, preferably to be amorphous with low refraction index. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. This binder coating significantly improves optical transparency, and also maintain or increases conductivity of the CNT-based coating. With other benefits such as abrasion, thermal and moisture resistance, this binder coating and the resulting products is used for display and electronic applications.

Owner:EIKOS

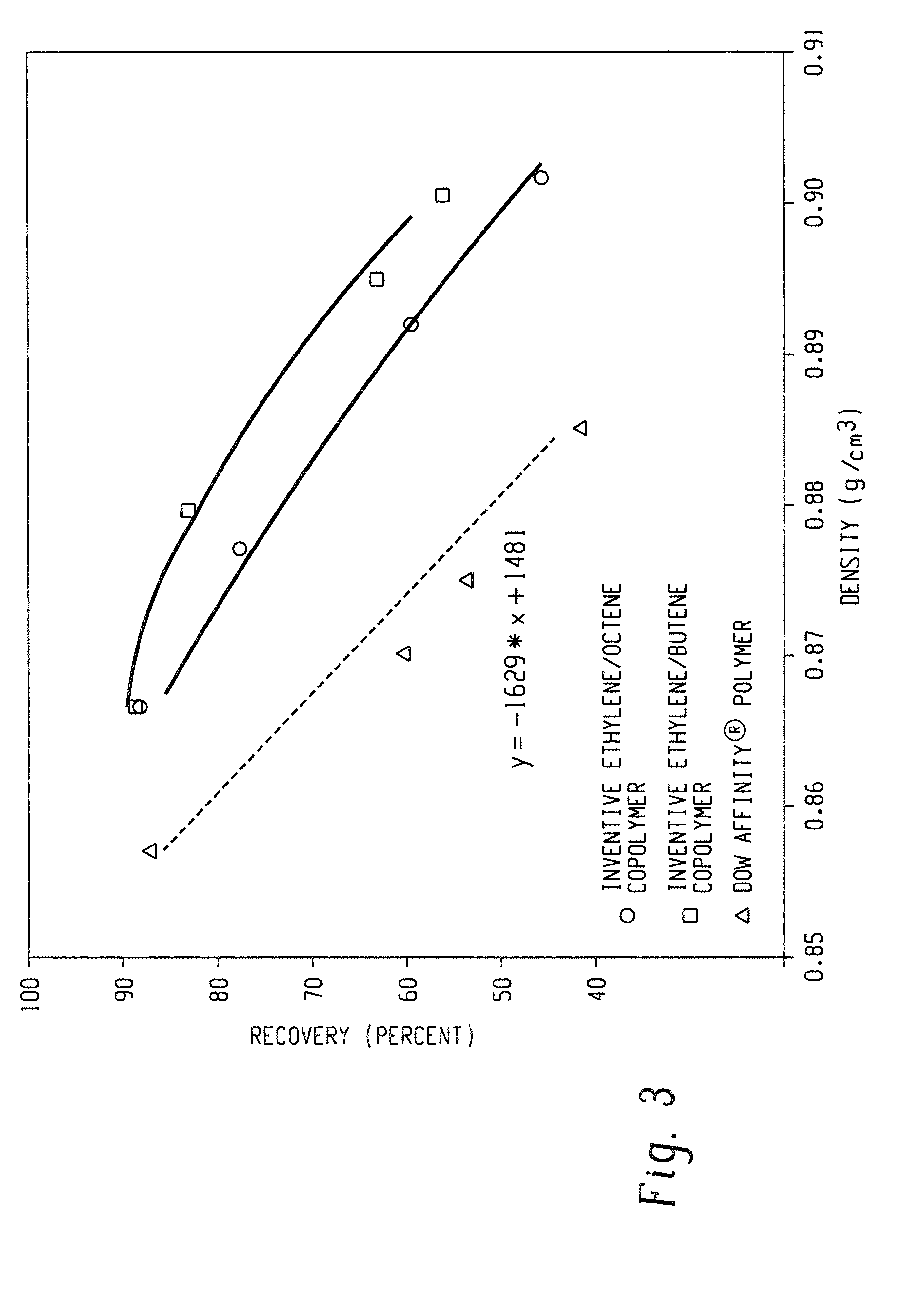

Multi-layer, elastic articles

The invention is an article comprising at least two layers, a low crystallinity layer and a high crystallinity layer. One or both layers is capable of being elongated so that a pre-stretched article is capable of being formed.

Owner:DOW GLOBAL TECH LLC

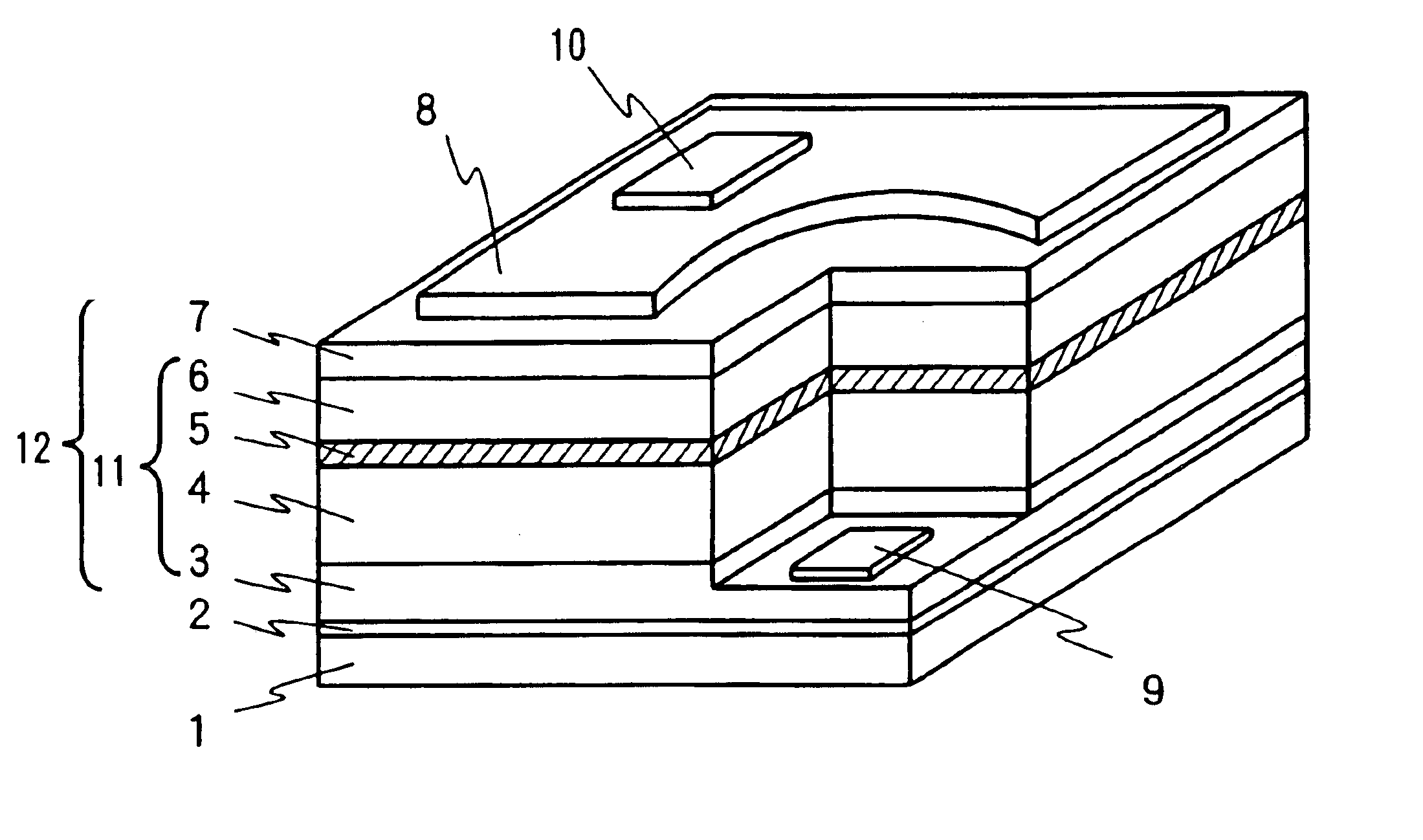

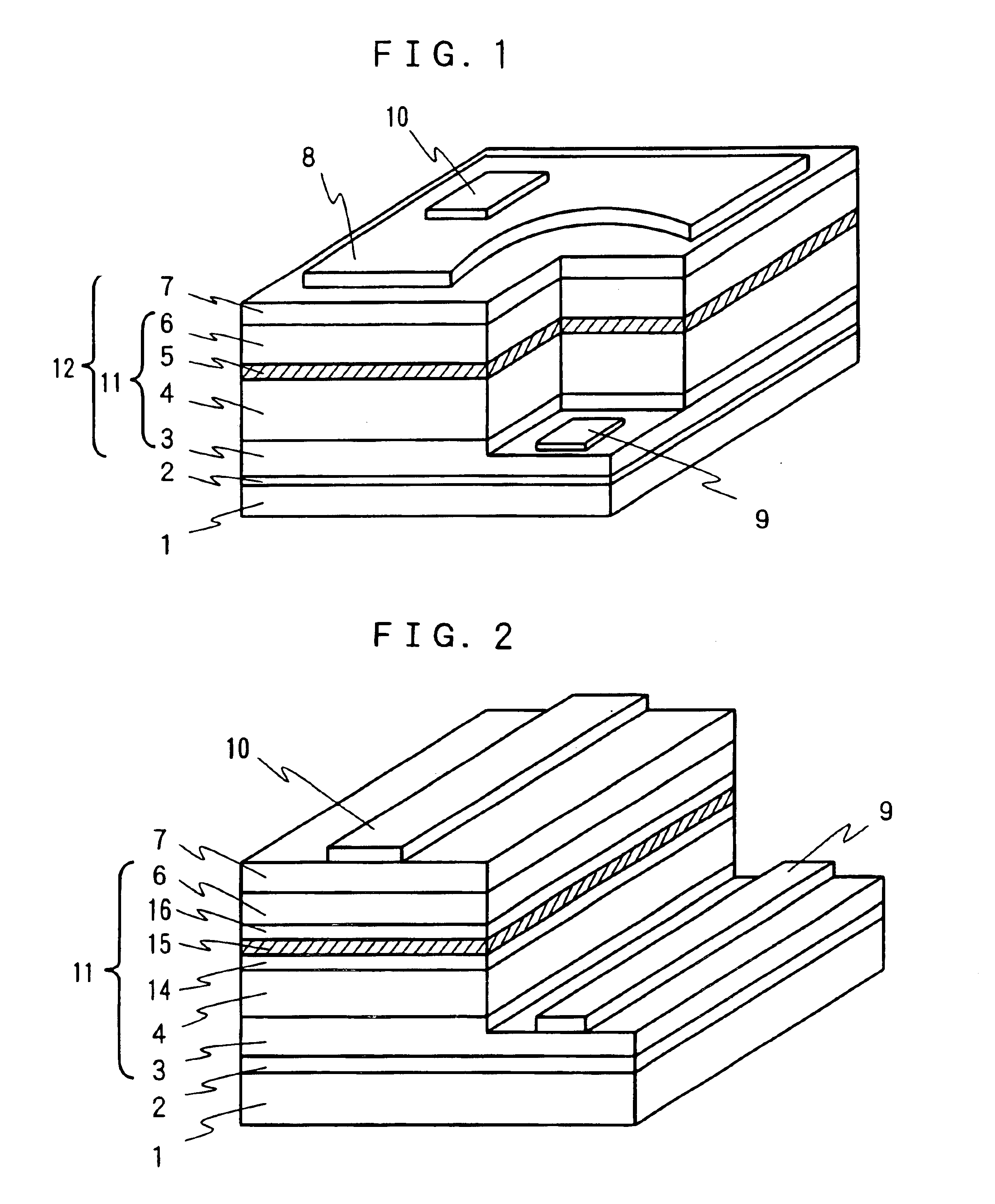

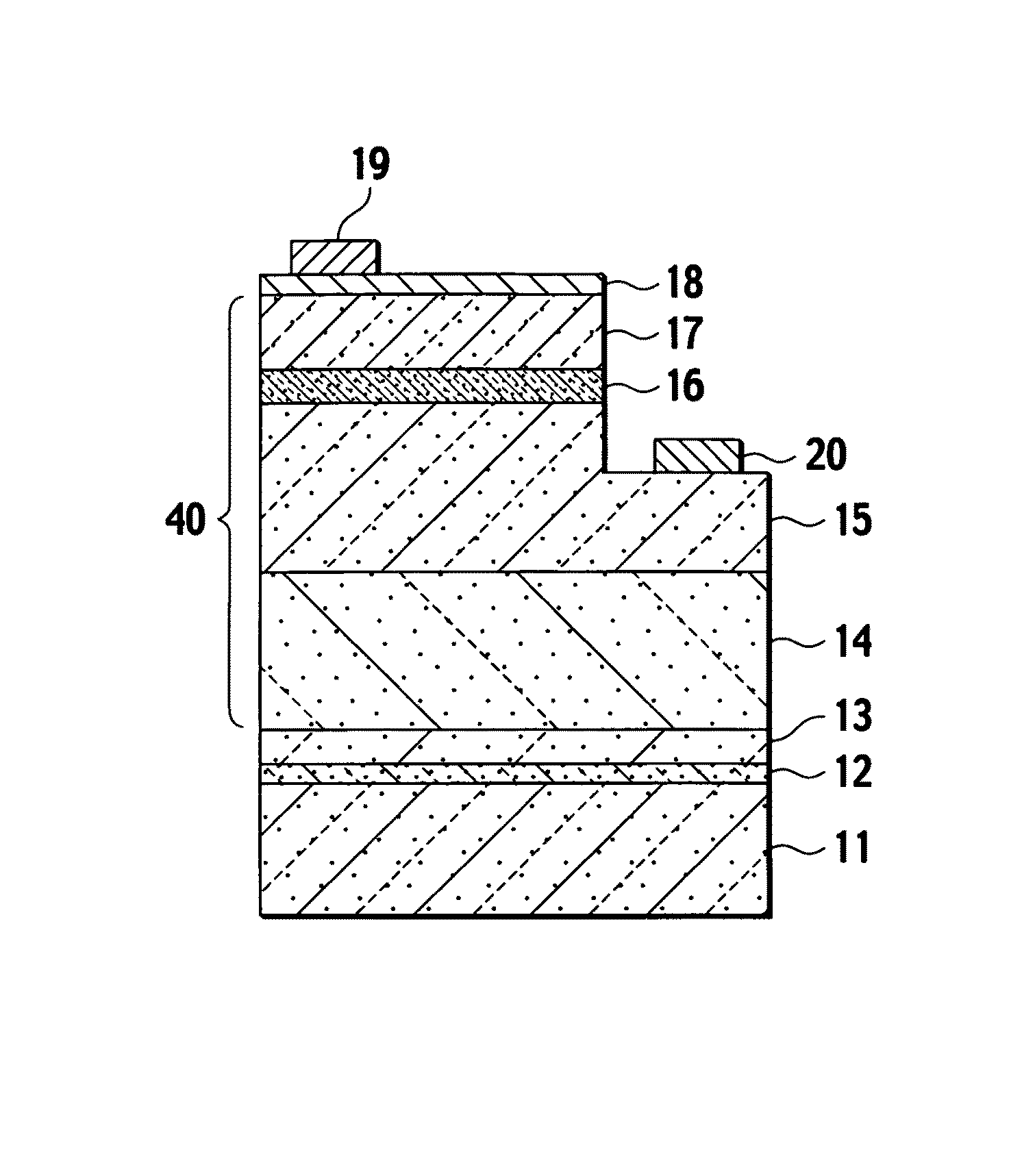

Semiconductor light-emitting device and method for manufacturing the same

InactiveUS7132691B1High crystallinityHigh light emitting efficiencyLaser detailsLaser active region structureCrystallinityActive layer

It has a structure in which an active layer (5) that emits light by electric current injection is sandwiched between an n-type cladding layer (4) and a p-type cladding layer (6) made of materials having a larger band gap than the active layer (5), wherein the active layer (5) is made, for example, of CdxZn1−xO (0≦x<1). It is further more preferable if the cladding layers (4), (6) are made, for example, of MgyZn1−yO (0≦y<1). This narrows the band gap of the ZnO materials, and an oxide semiconductor capable of being wet-etched, easy to handle with, and excellent in crystallinity can be used as a material for an active layer or a cladding layer of a semiconductor light emitting device such as a blue light emitting diode or a blue laser diode in which an active layer is sandwiched between cladding layers, so that a blue semiconductor light emitting device being excellent in light emission characteristics can be obtained.

Owner:ROHM CO LTD

Method for manufacturing semiconductor device

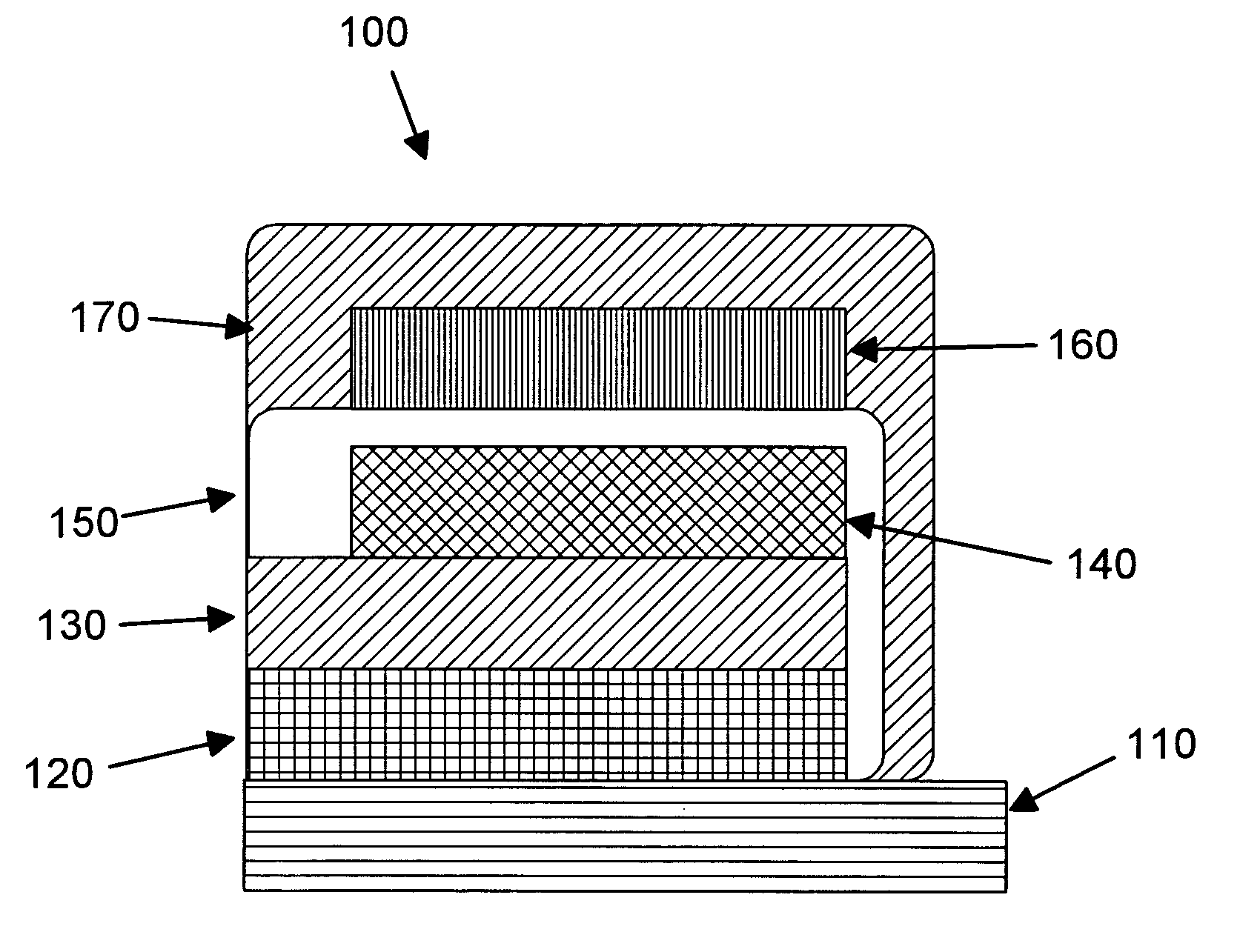

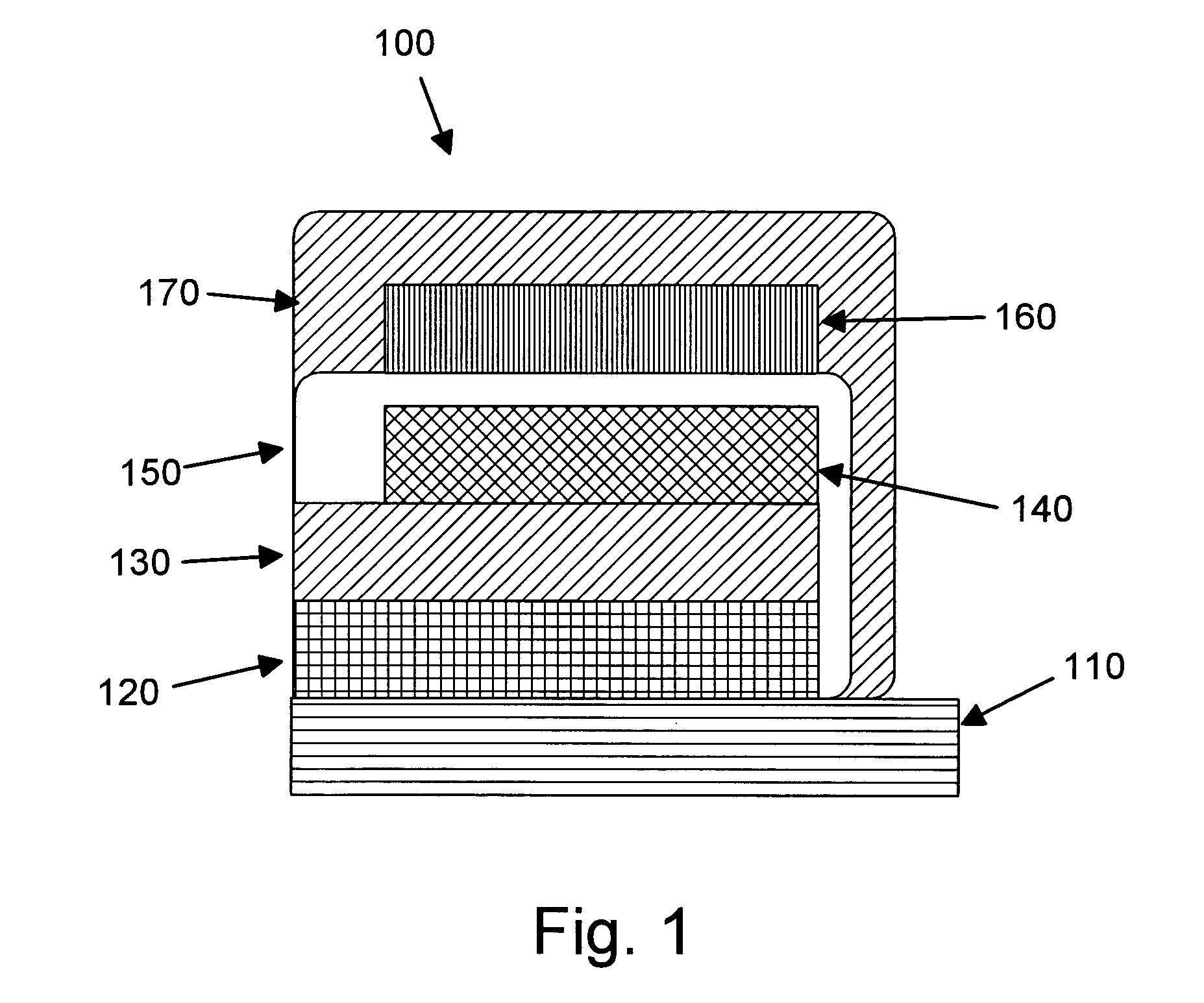

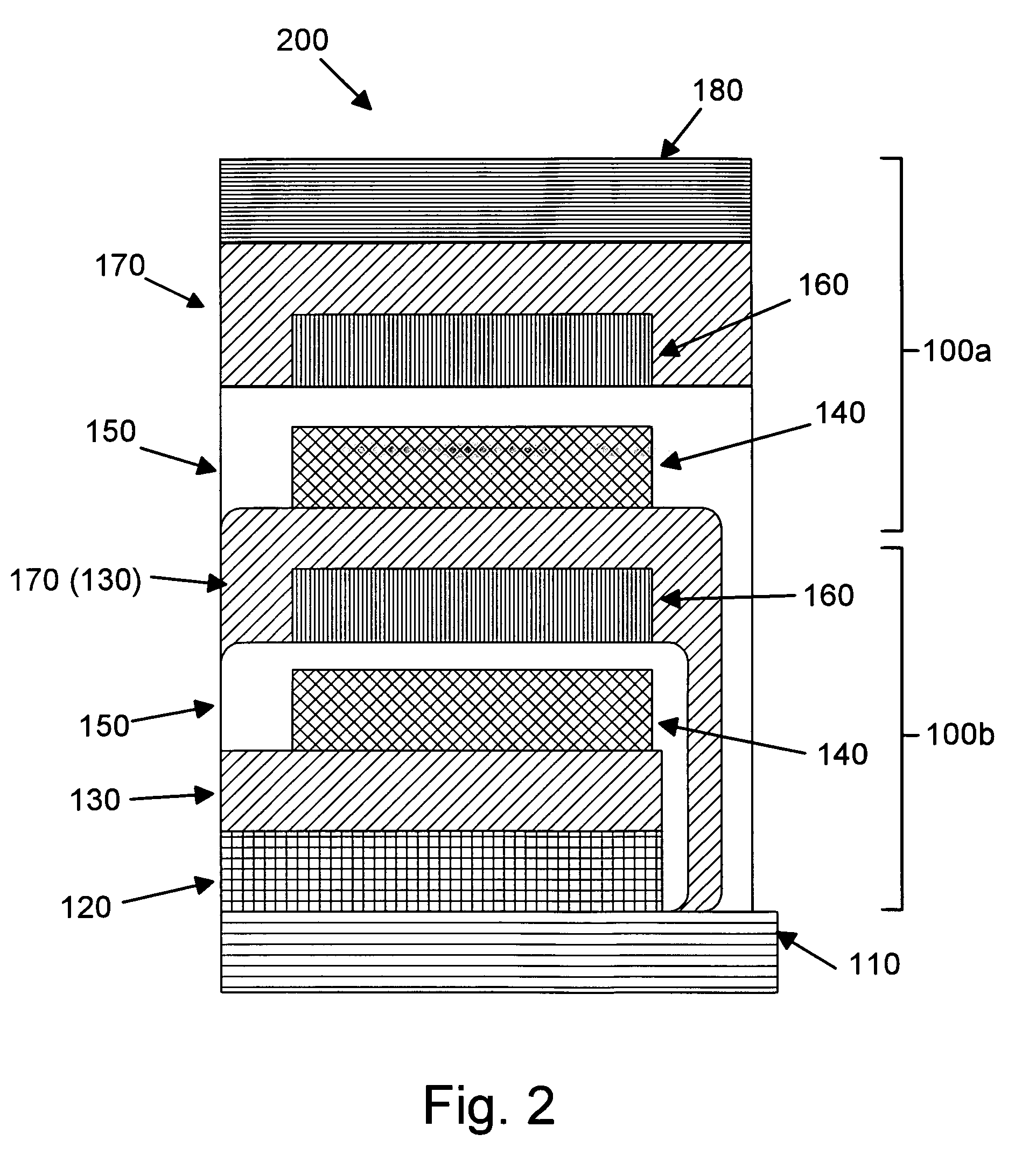

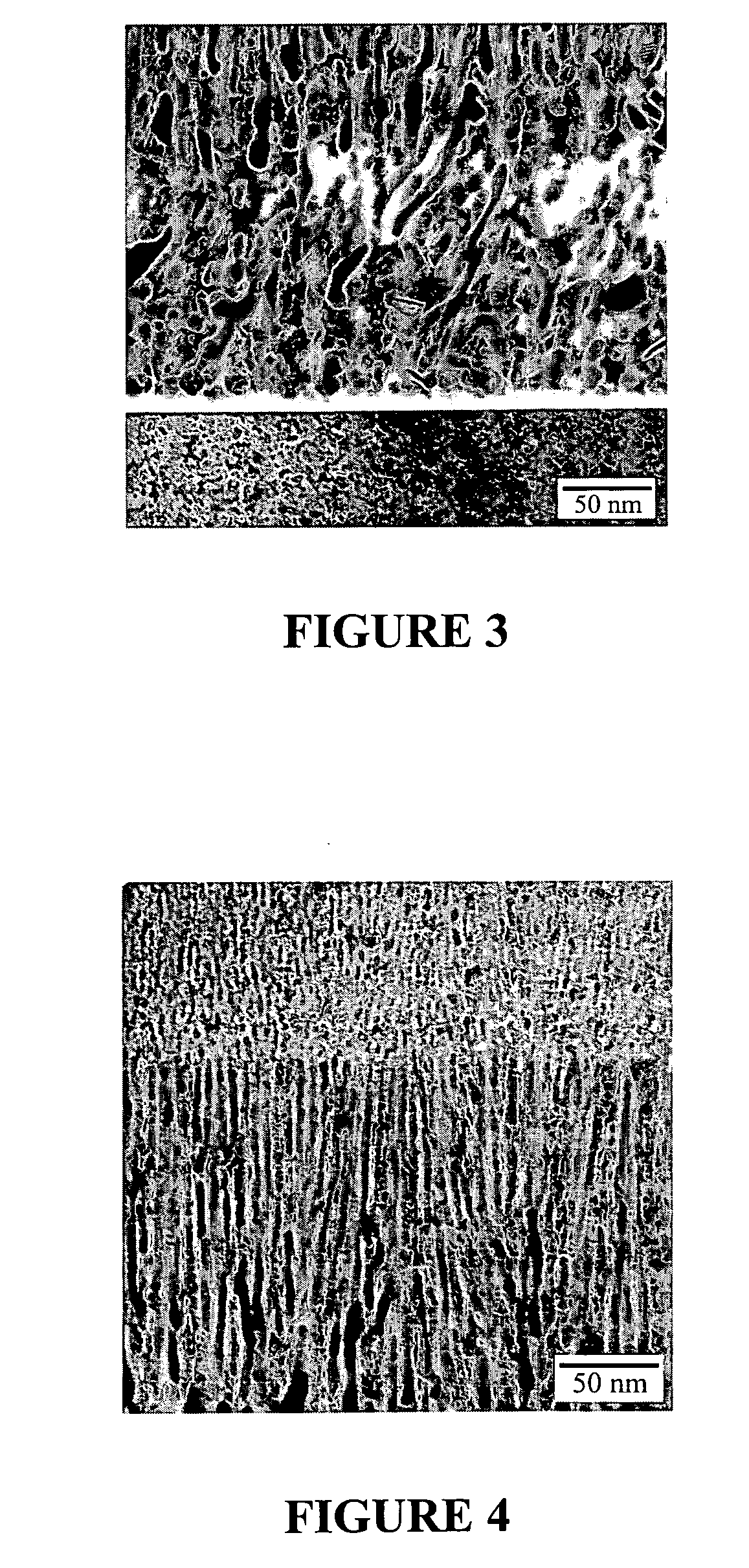

ActiveUS20110156026A1High field-effect mobilitySufficient performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSingle crystal

A larger substrate can be used, and a transistor having a desirably high field-effect mobility can be manufactured through formation of an oxide semiconductor layer having a high degree of crystallinity, whereby a large-sized display device, a high-performance semiconductor device, or the like can be put into practical use. A first multi-component oxide semiconductor layer is formed over a substrate and a single-component oxide semiconductor layer is formed thereover; then, crystal growth is carried out from a surface to an inside by performing heat treatment at 500° C. to 1000° C. inclusive, preferably 550° C. to 750° C. inclusive so that a first multi-component oxide semiconductor layer including single crystal regions and a single-component oxide semiconductor layer including single crystal regions are formed; and a second multi-component oxide semiconductor layer including single crystal regions is stacked over the single-component oxide semiconductor layer including single crystal regions.

Owner:SEMICON ENERGY LAB CO LTD

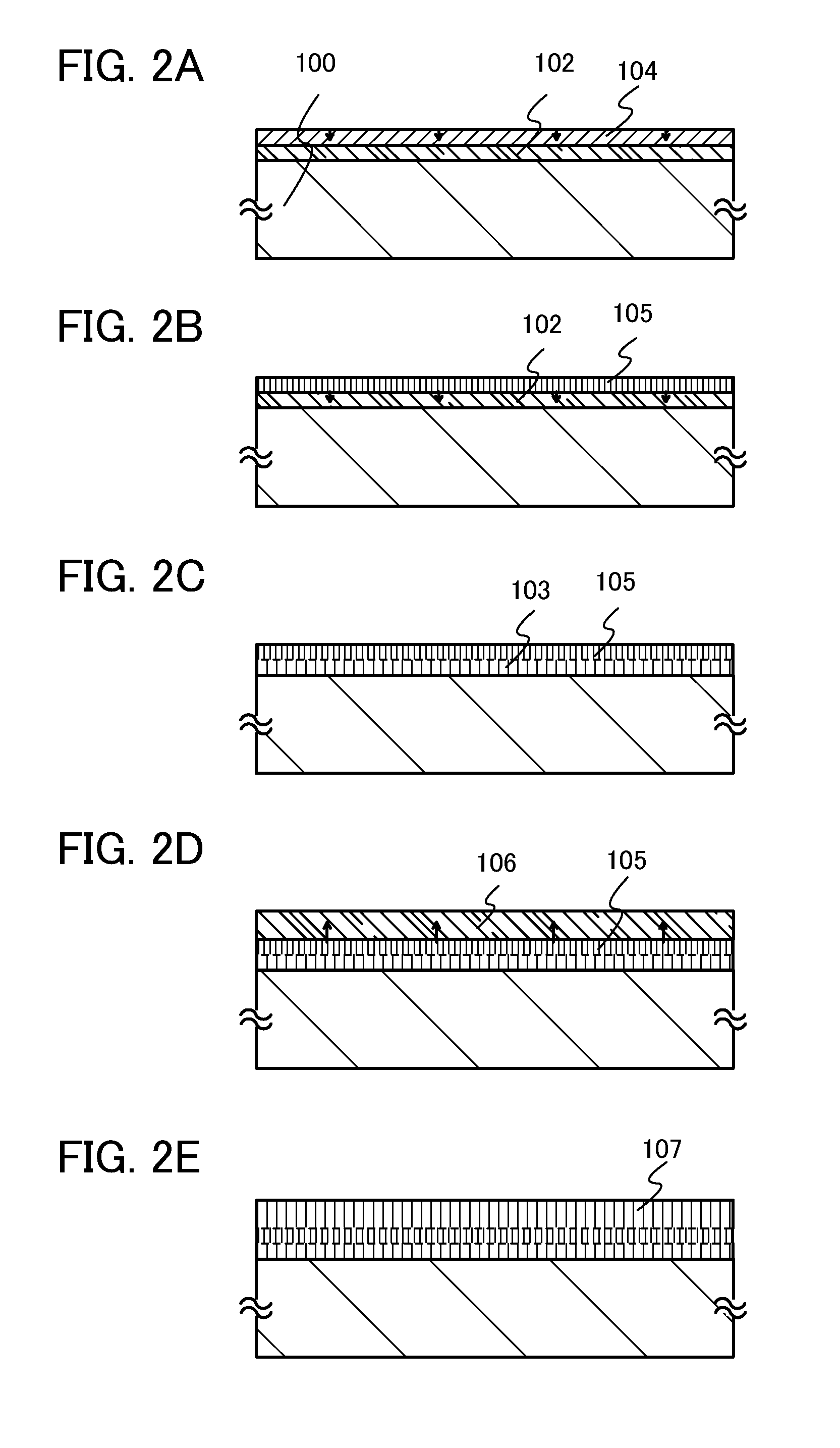

Method for fabricating a semiconductor device

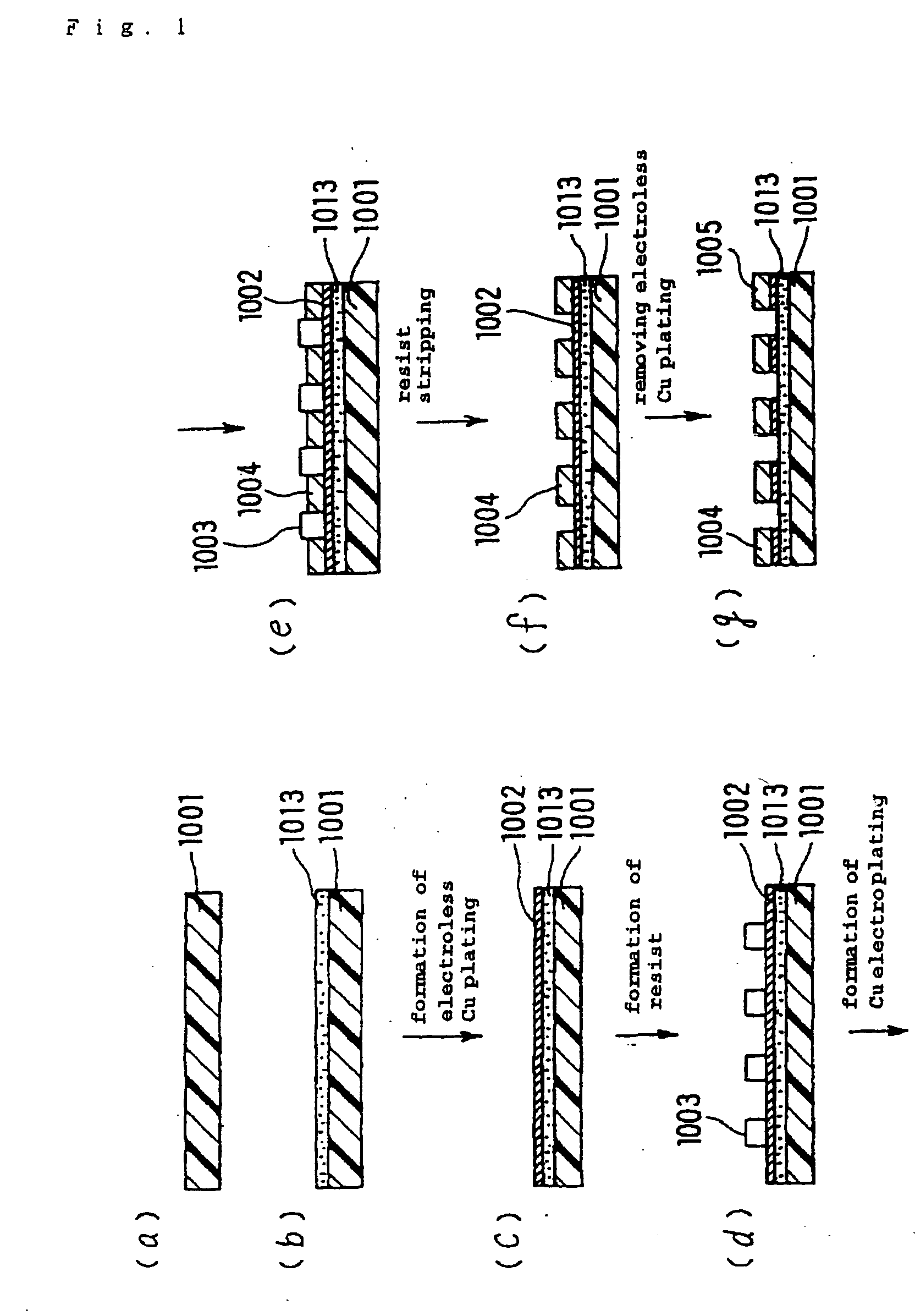

InactiveUS6180439B1Promote crystallizationReduce concentrationTransistorSolid-state devicesAtmospheric airLaser light

Concentration of metal element which promotes crystallization of silicon and which exists within a crystalline silicon film obtained by utilizing the metal element is reduced. A first heat treatment for crystallization is performed after introducing nickel to an amorphous silicon film 103. Then, laser light is irradiated to diffuse nickel element which is concentrated locally. After that, another heat treatment is performed within an oxidizing atmosphere at a temperature higher than that of the previous heat treatment. At this time, HCl or the like is added to the atmosphere. A thermal oxide film 106 is formed in this step. At this time, gettering of the nickel element into the thermal oxide film 106 takes place. Then, the thermal oxide film 106 is removed. Thereby, a crystalline silicon film 107 having low concentration of the metal element and a high crystallinity can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

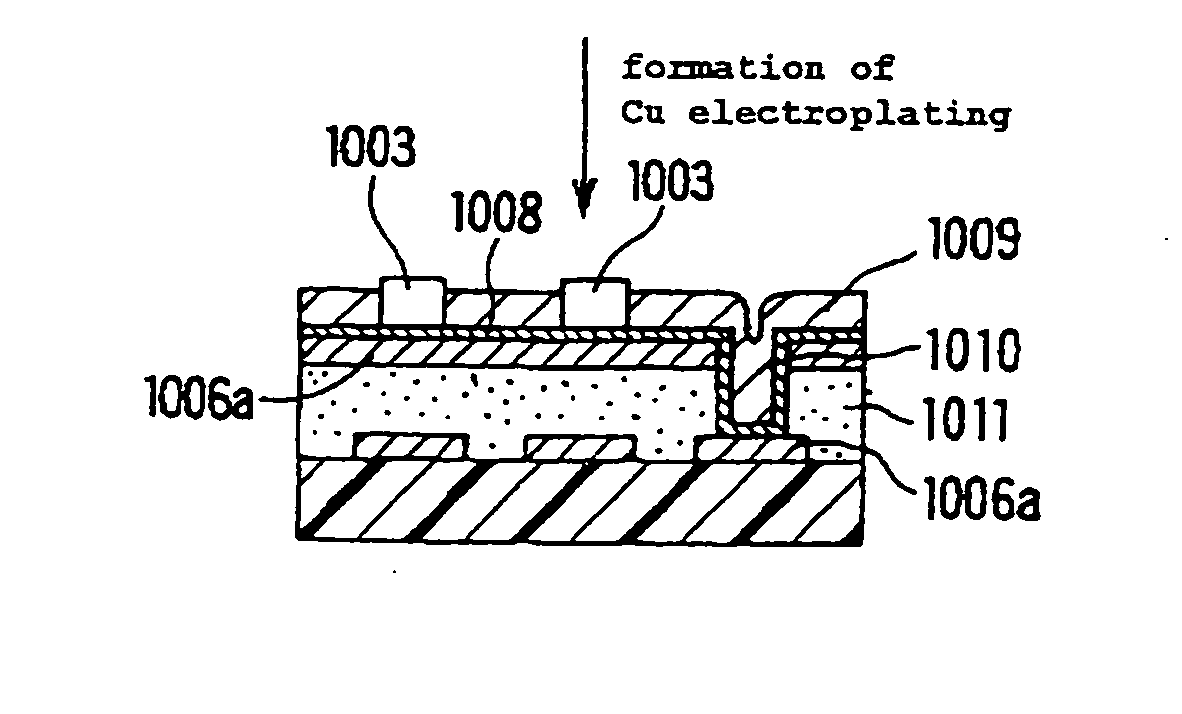

Printed wiring board and its manufacturing method

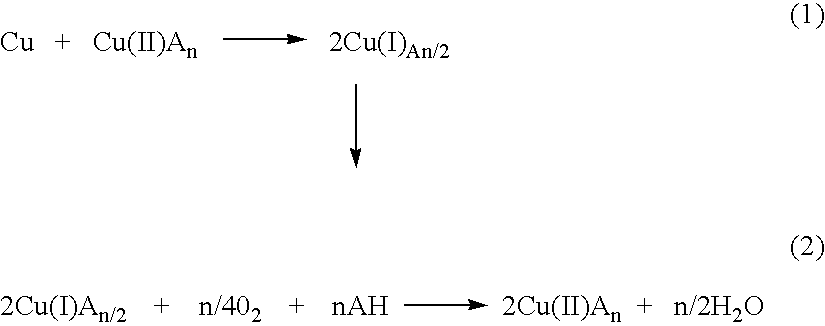

The present invention has for its object to provide a process for manufacturing multilayer printed circuit boards which is capable of simultaneous via hole filling and formation of conductor circuit and via holes of good crystallinity and uniform deposition can be constructed on a substrate and high-density wiring and highly reliable conductor connections can be realized without annealing. The present invention is related to a process for manufacturing multilayer printed circuit boards which comprises disposing an interlayer resin insulating layer on a substrate formed with a conductor circuit, creating openings for formation of via holes in said interlayer resin insulating layer, forming an electroless plated metal layer on said interlayer resin insulating layer, disposing a resist thereon, performing electroplating, stripping the resist off and etching the electroless plated metal layer to provide a conductor circuit and via holes, wherein the electroplating is performed intermittently using said electroless plated metal layer as cathode and a plating metal as anode at a constant voltage between said anode and said cathode.

Owner:IBIDEN CO LTD

Method of manufacturing nitride semiconductor and nitride semiconductor element

ActiveUS8709843B2Improve surface morphologyReduce layeringPolycrystalline material growthSemiconductor/solid-state device manufacturingSource materialCrystallinity

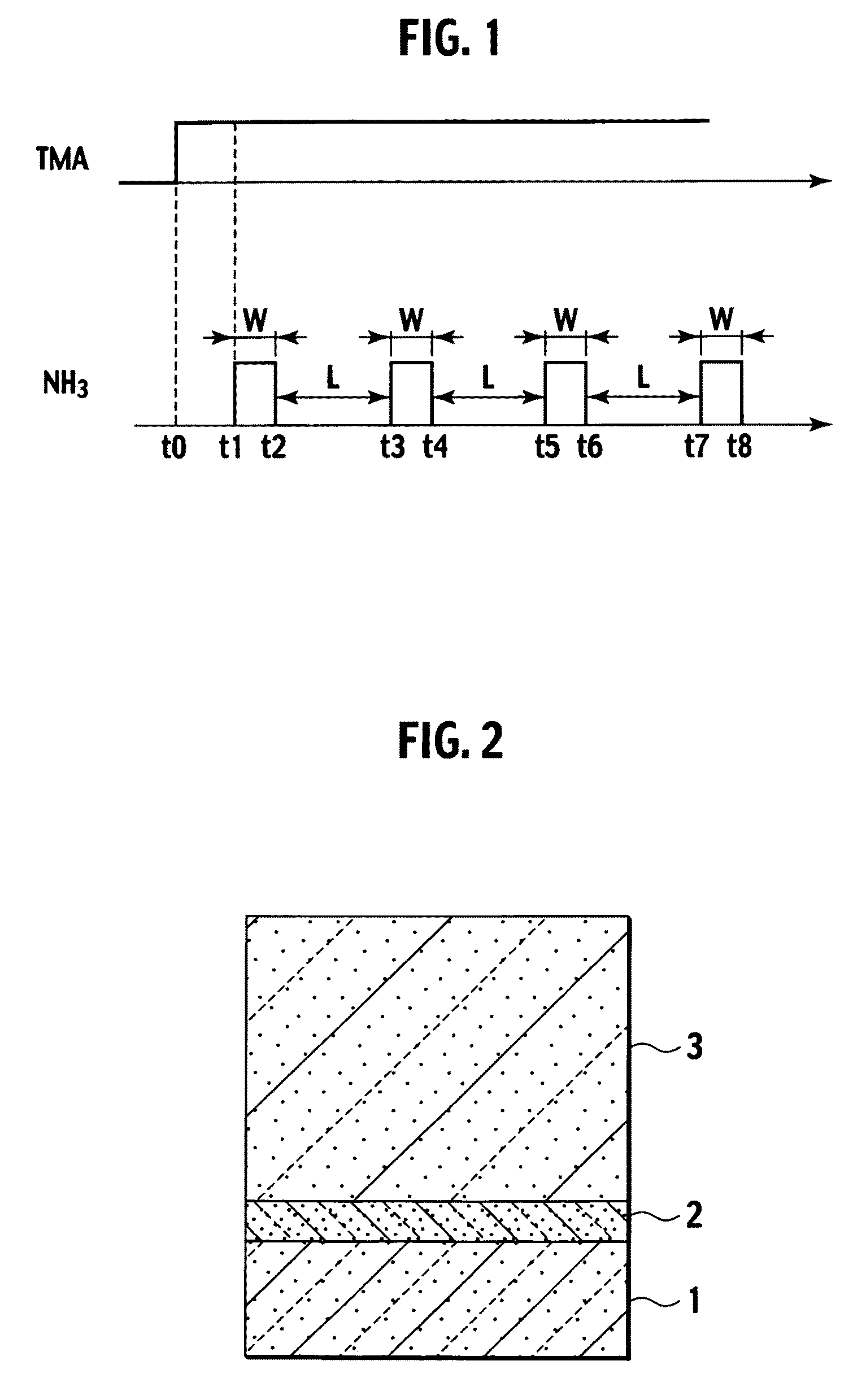

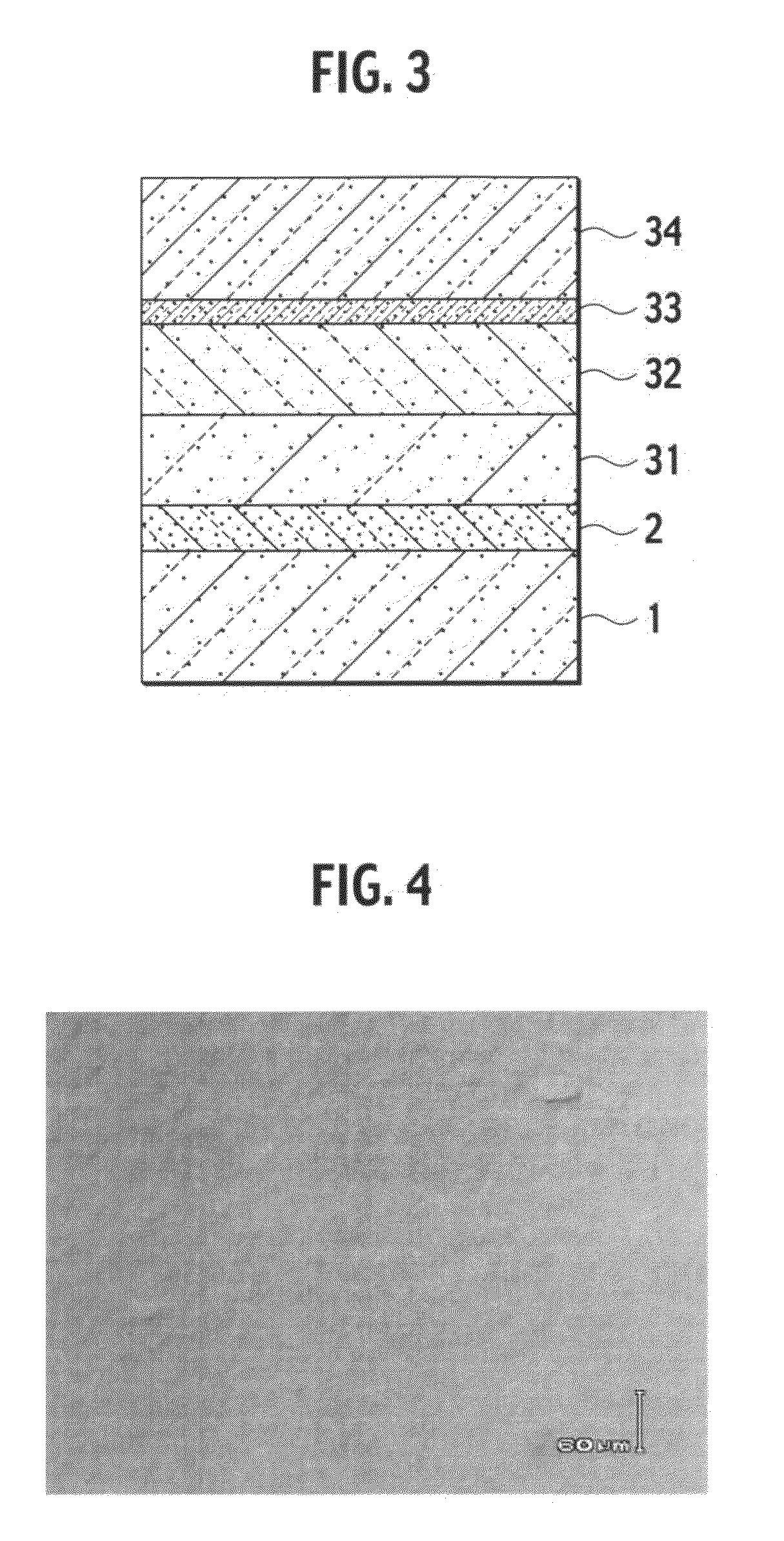

The present invention provides a method of manufacturing a nitride semiconductor capable of improving the crystallinity and the surface state of the nitride semiconductor crystal formed on top of a high-temperature AlN buffer layer. An AlN buffer layer is formed on top of a growth substrate, and then nitride semiconductor crystals are grown on top of the AlN buffer layer. In a stage of manufacturing the nitride semiconductor, the crystal of the AlN buffer layer is grown at a high temperature of 900° C. or higher. In addition, an Al-source material of the AlN buffer layer is started to be supplied first to a reaction chamber and continues to be supplied without interruption, and then a N-source material is supplied intermittently.

Owner:ROHM CO LTD

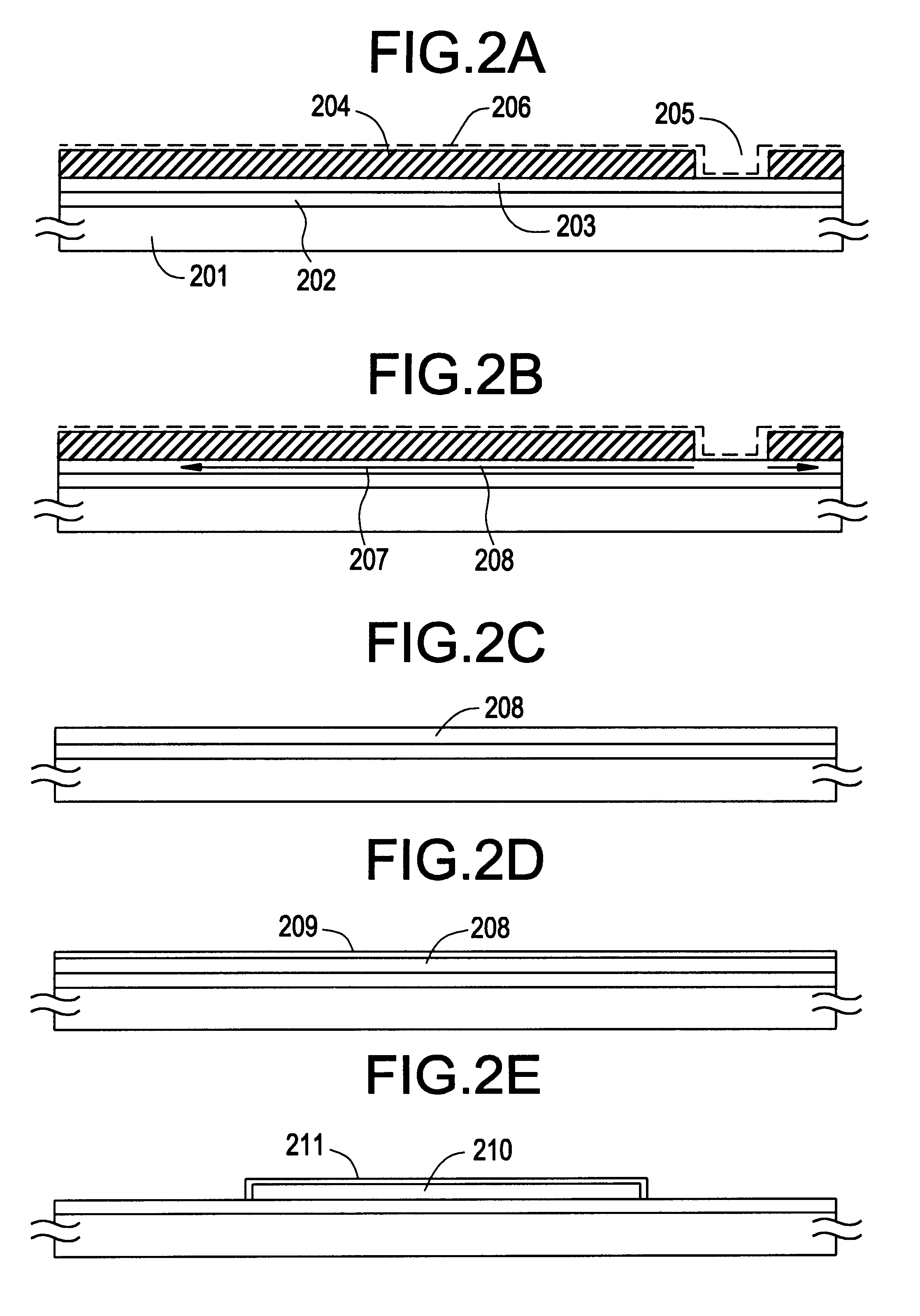

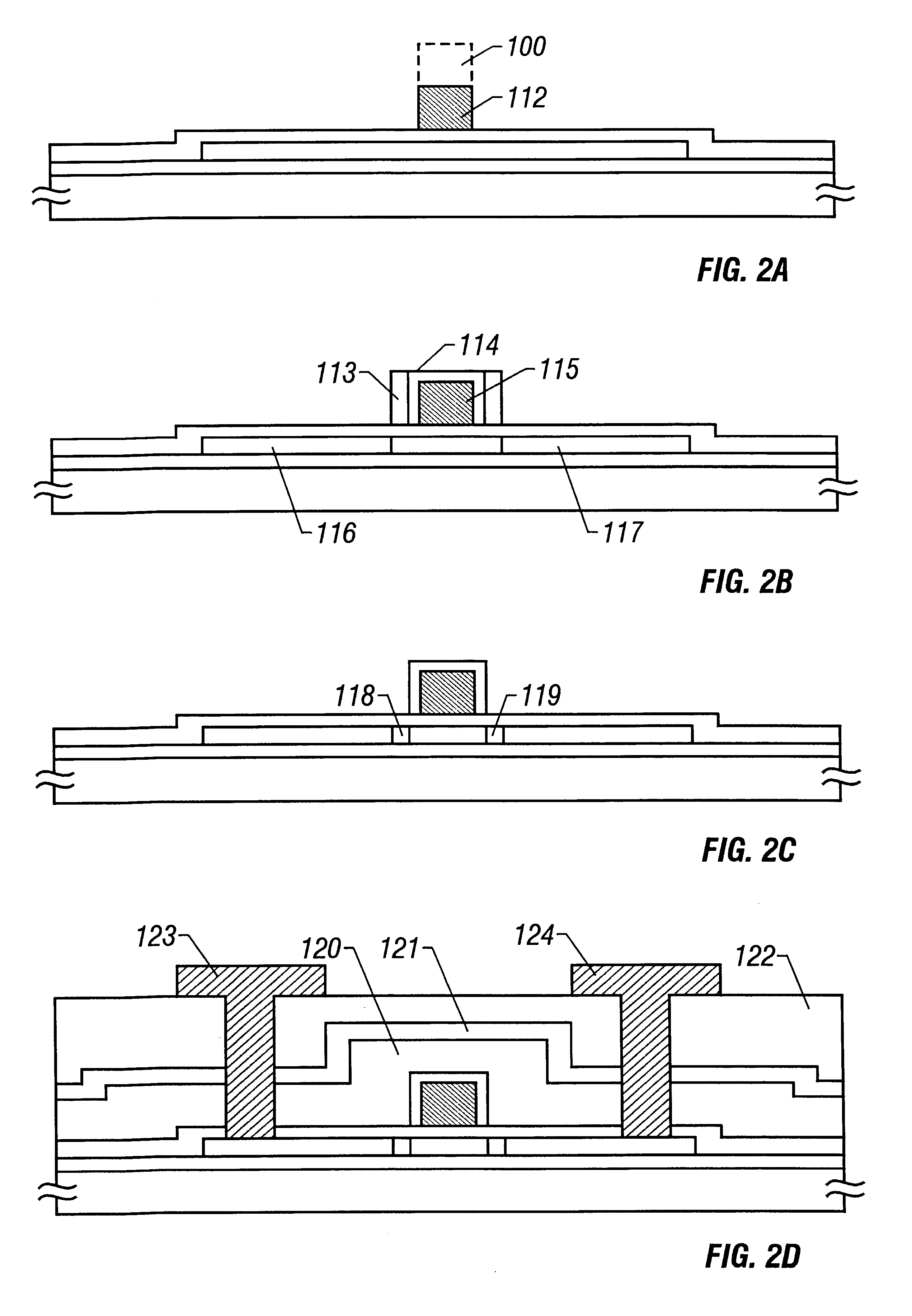

Method of manufacturing semiconductor devices using a crystallization promoting material

InactiveUS6066518AReduce concentrationPromote crystallizationTransistorSolid-state devicesCrystallinityThermal treatment

In a method of manufacturing a semiconductor device, an insulating film having an opening is formed on an amorphous film 103 containing silicon therein. After catalytic elements are introduced from the opening, the amorphous film 103 is crystallized. Thereafter elements (phosphorus) selected from Group XV are introduced from the opening, and then a heat treatment is conducted to obtain a film having crystallinity. Thereafter, a portion of the film containing silicon into which the catalytic elements and phosphorus is introduced are removed.

Owner:SEMICON ENERGY LAB CO LTD

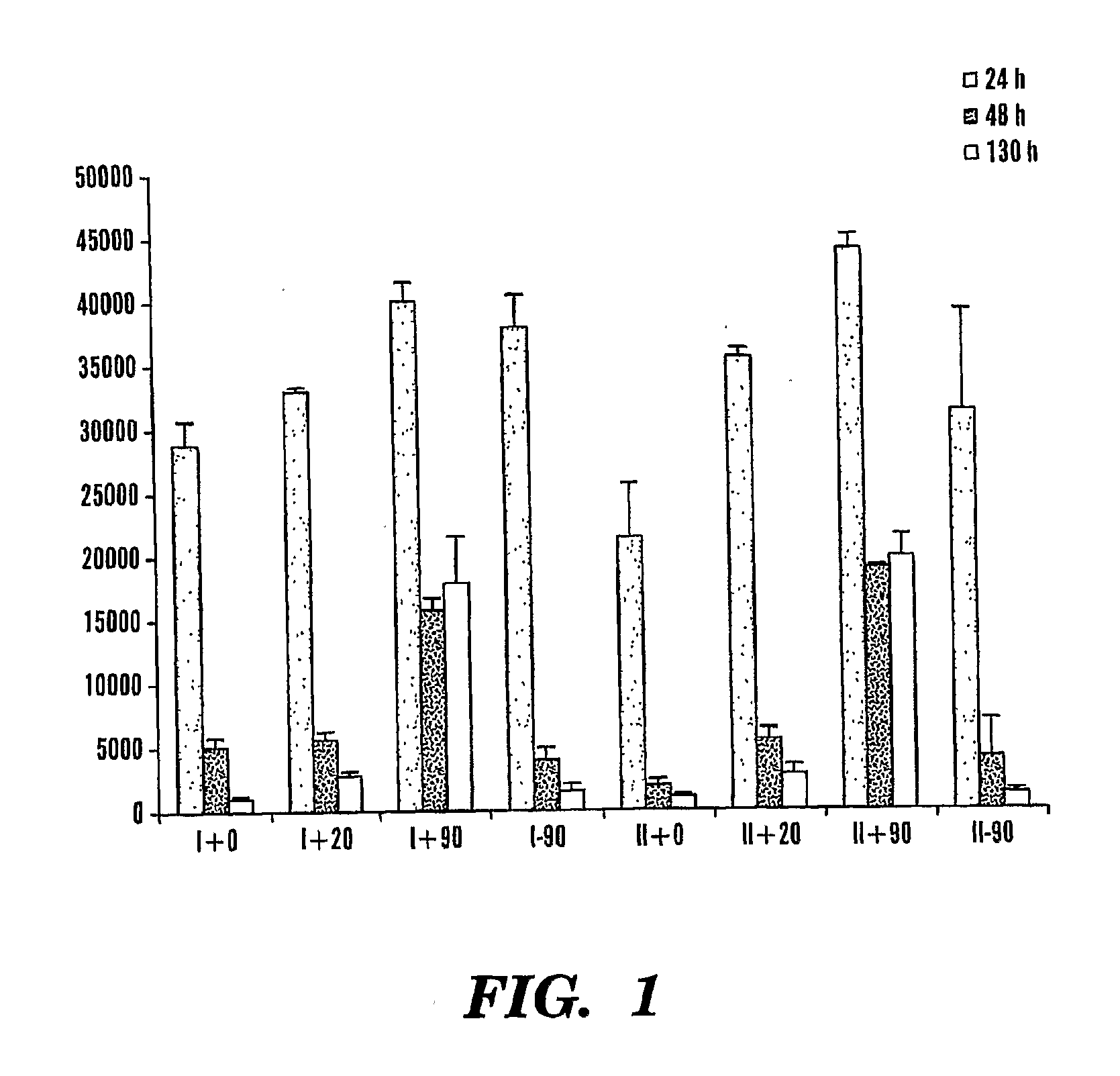

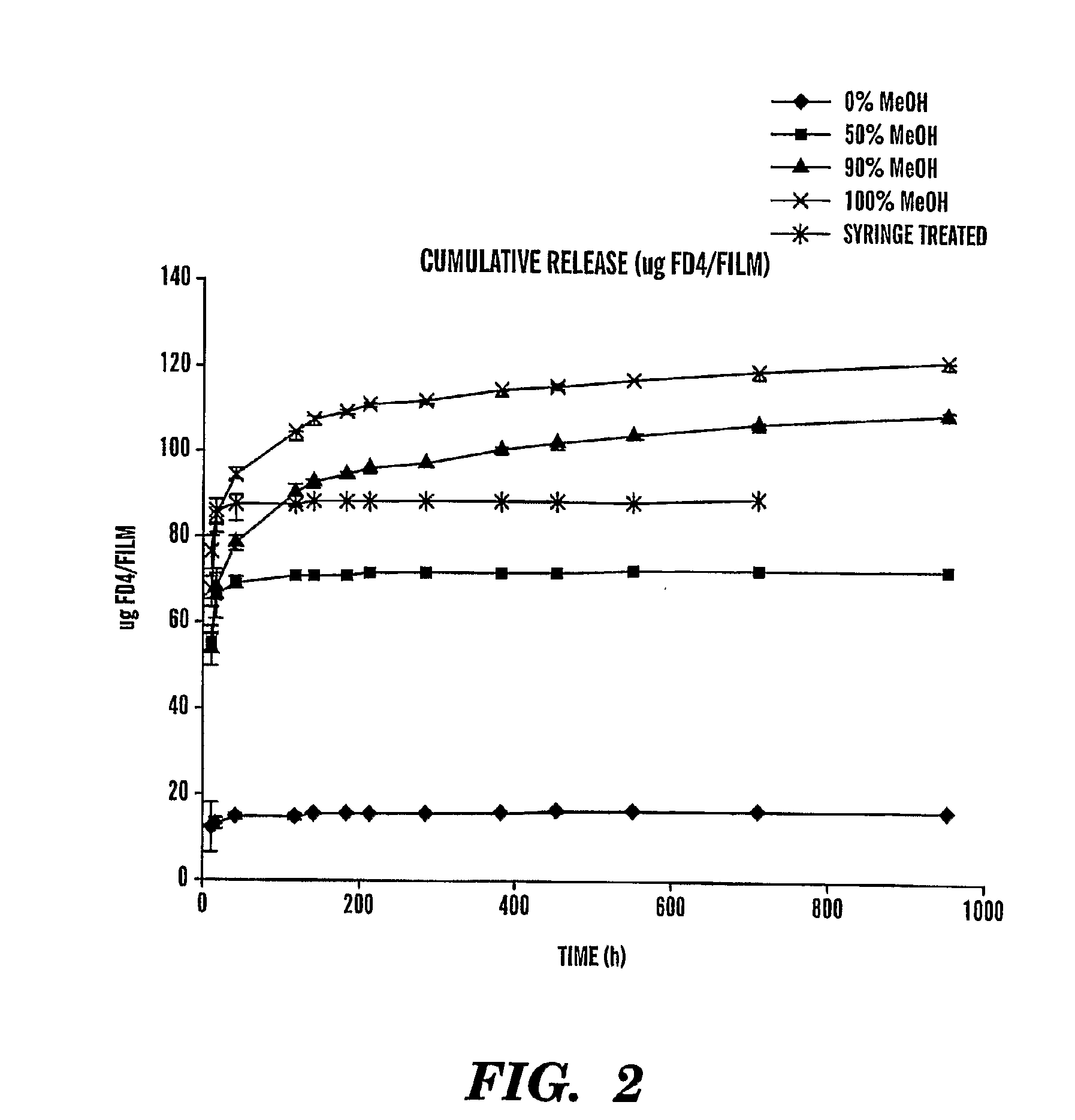

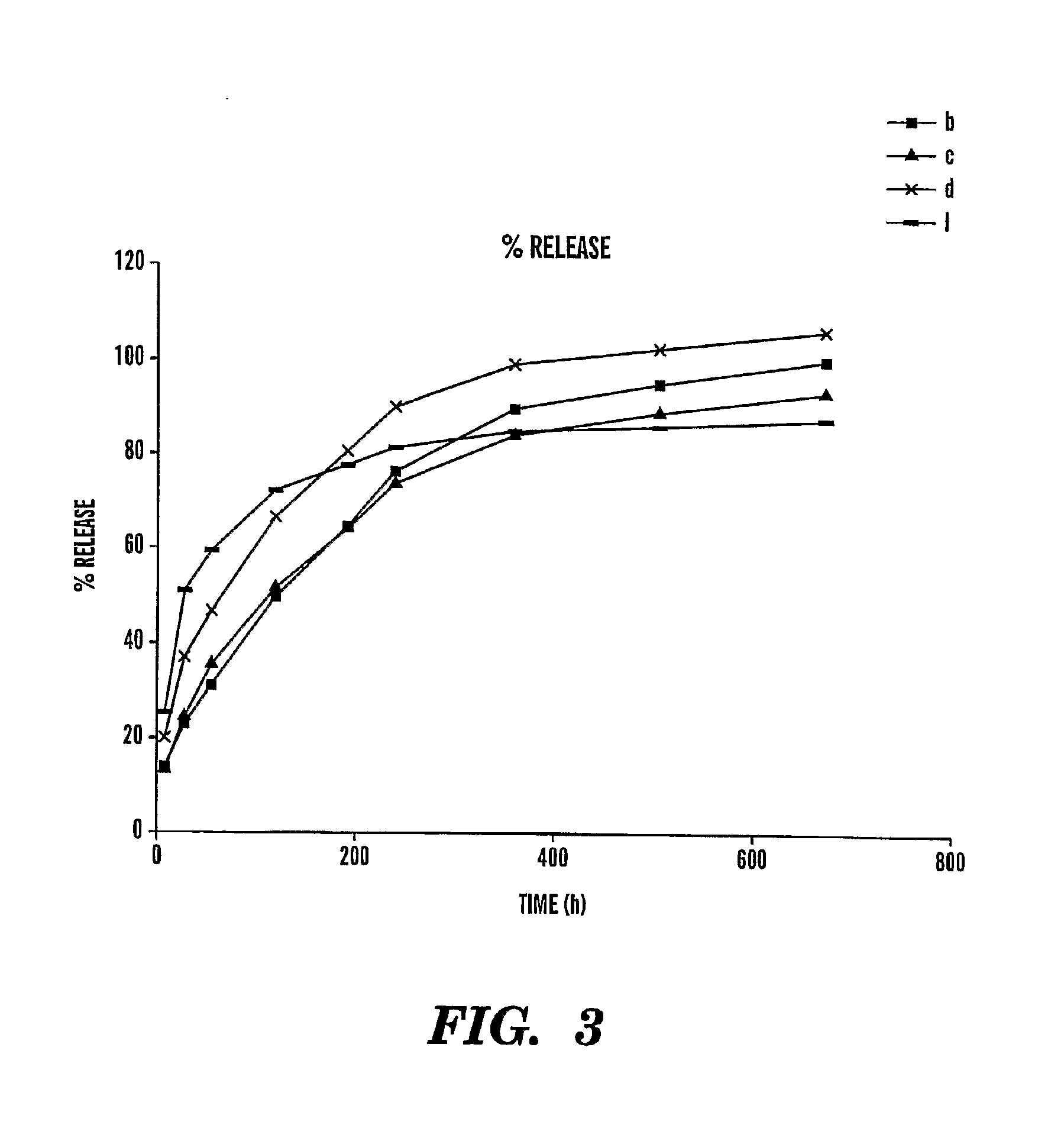

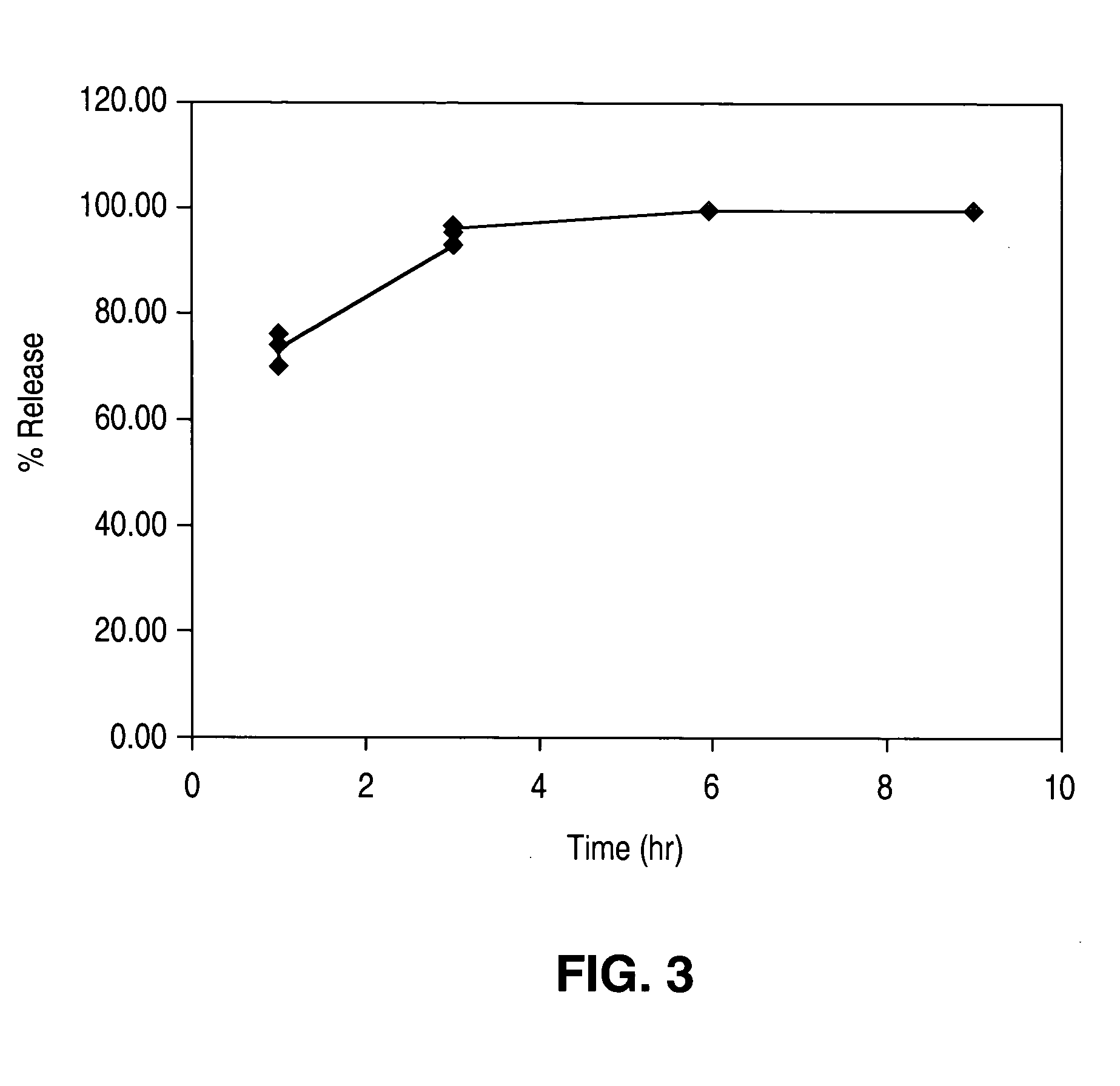

Silk-Based Drug Delivery System

ActiveUS20080085272A1High crystallinityIncrease liquid crystlallinityAntibacterial agentsOrganic active ingredientsCrystallinityDelivery system

The present invention provides for novel sustained release silk-based delivery systems. The invention further provides methods for producing such formulations. In general, a silk fibroin solution is combined with a therapeutic agent to form a silk fibroin article. The article is then treated in such a way as to alter its conformation. The change in conformation increases its crytallinity or liquid crystallinity, thus controlling the release of a therapeutic agent from the formulation. This can be accomplished as single material carriers or in a layer-by-layer fashion to load different therapeutic agents or different concentrations of these agents in each layer.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV +1

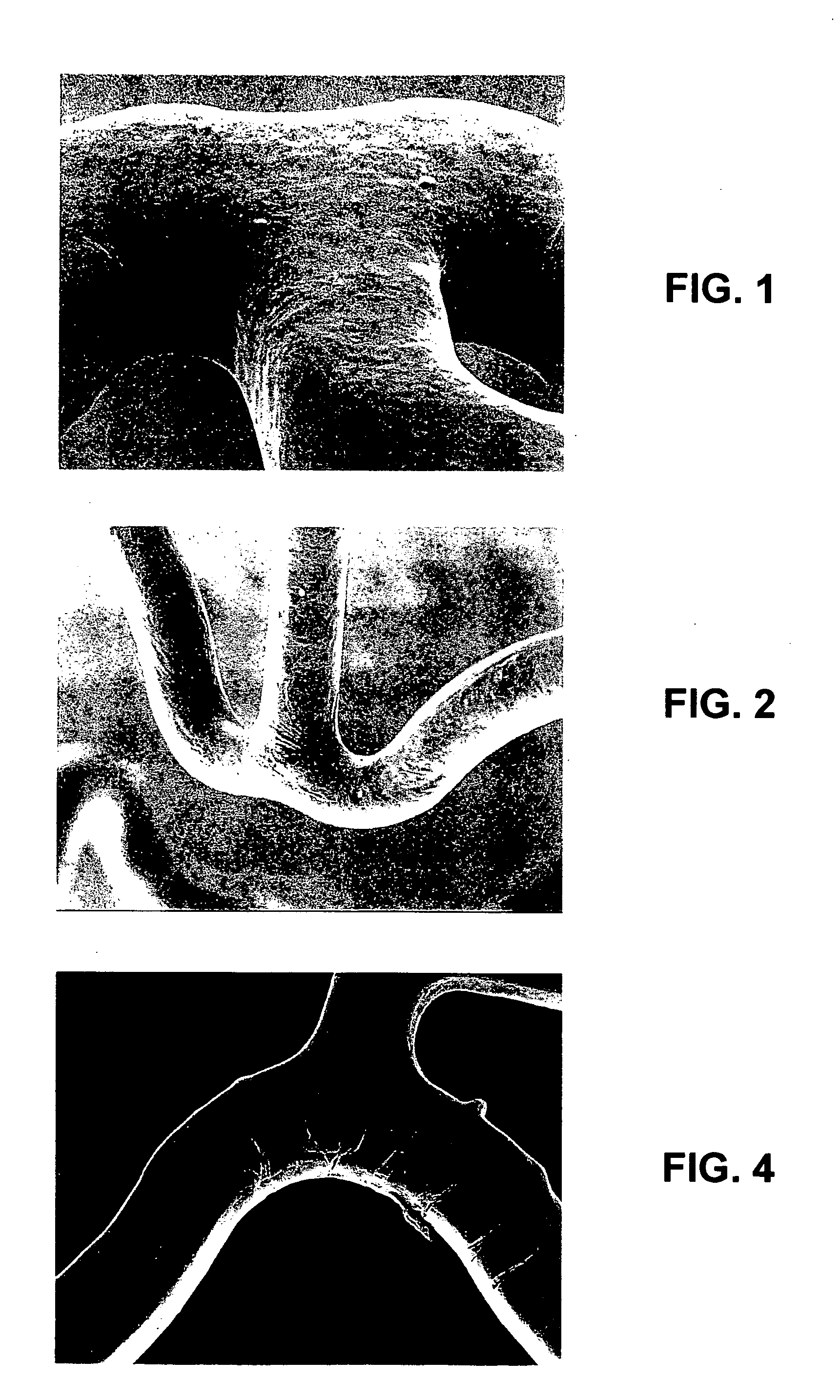

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

InactiveUS7919162B2High modulusEnhanced hoop strengthStentsSynthetic resin layered productsProsthesisCrystallinity

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6518378B2Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerPolyolefin

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:BP AMOCO CORP +1

Method of manufacturing a semiconductor device

InactiveUS6479333B1TransistorSemiconductor/solid-state device manufacturingCrystallinityCrystal growth

A crystal growth 301 is carried out by diffusing a metal element, and a nickel element is moved into regions 108 and 109 which has been doped with phosphorus. An axis coincident with the moving directions 302 and 303 of the nickel element at this time is made to coincide with an axis coincident with the direction of the crystal growth, and a TFT having the regions as channel forming regions is manufactured. In the path of the region where nickel moved, since high crystallinity is obtained in the moving direction, the TFT having high characteristics can be obtained by this way.

Owner:SEMICON ENERGY LAB CO LTD

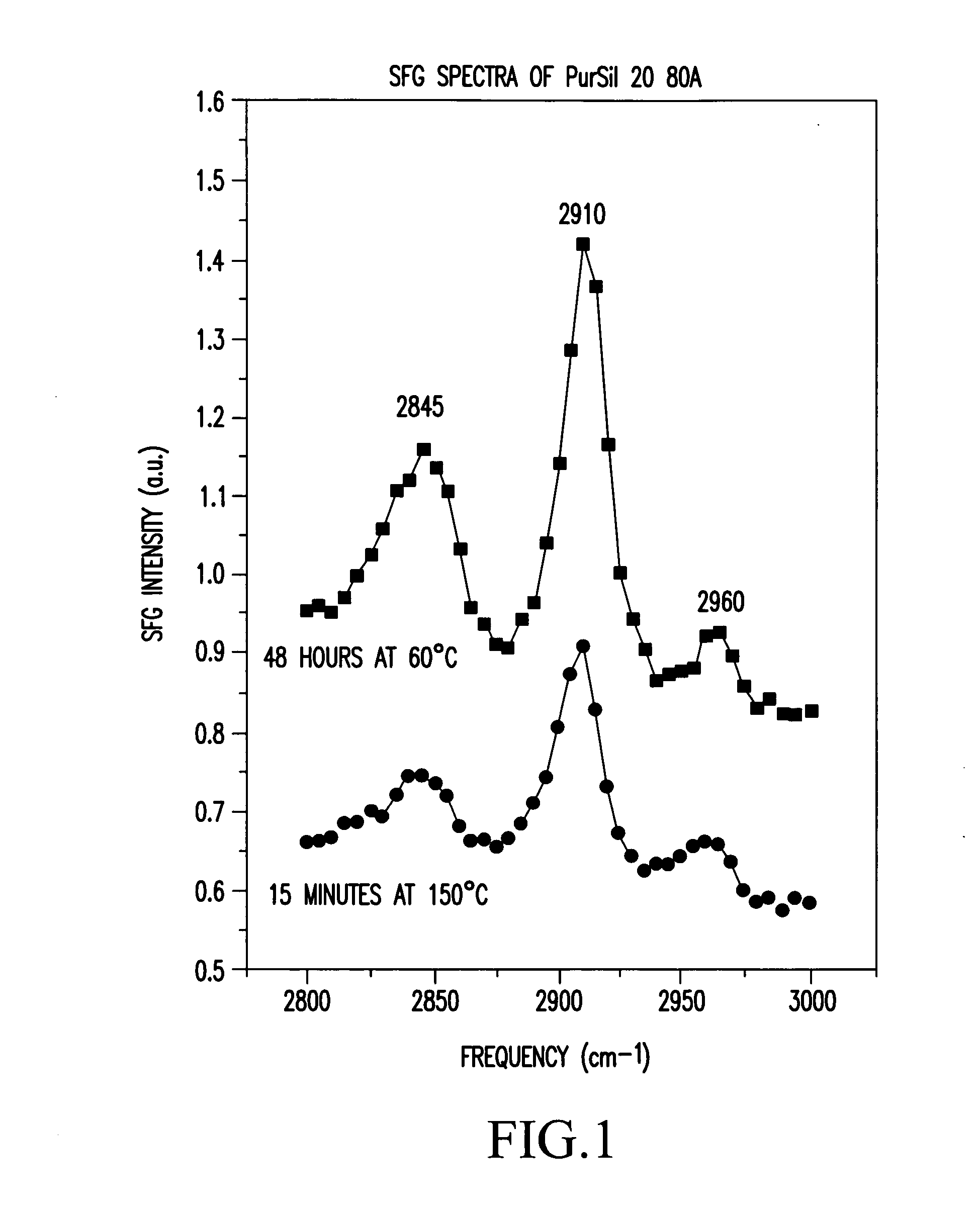

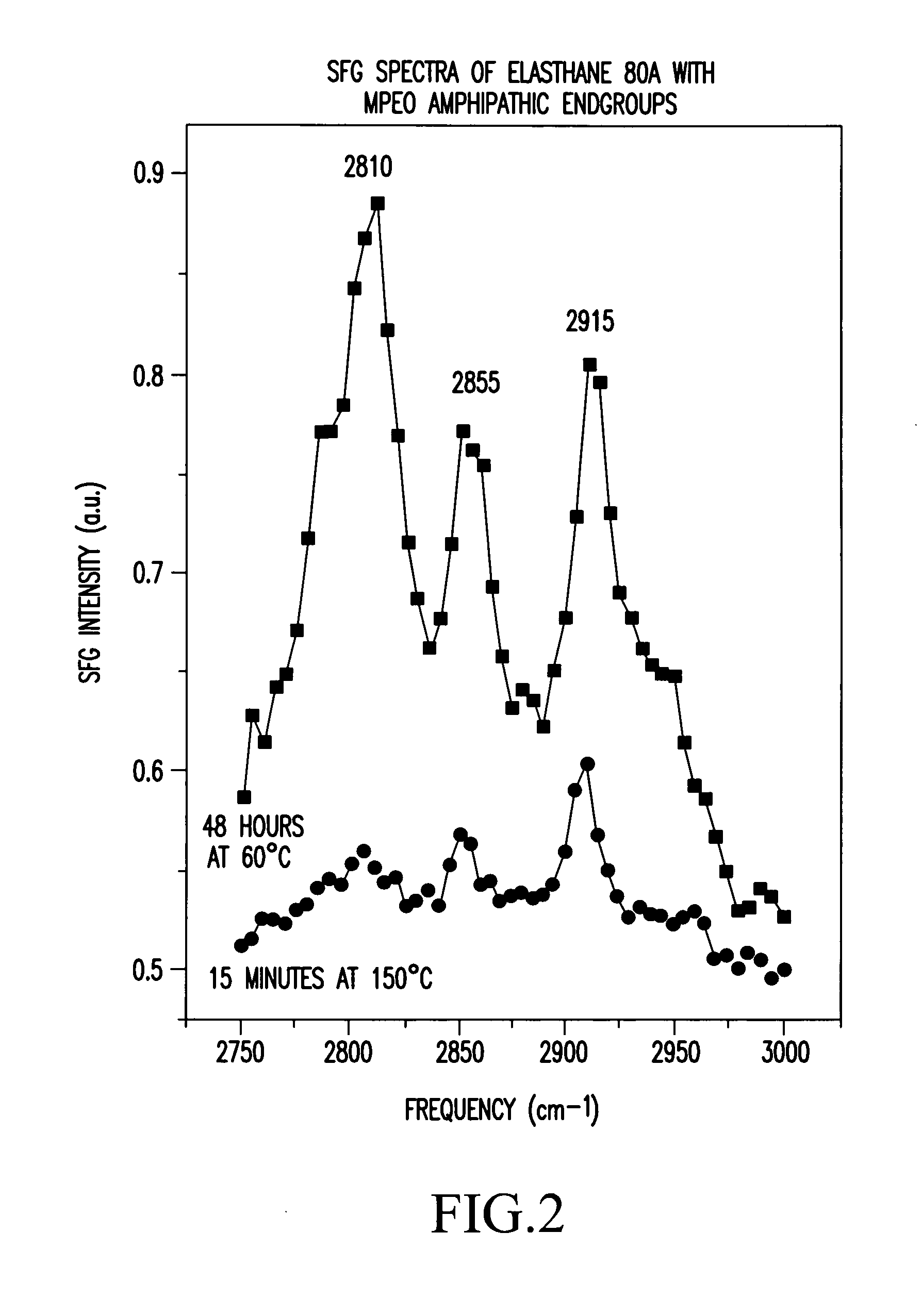

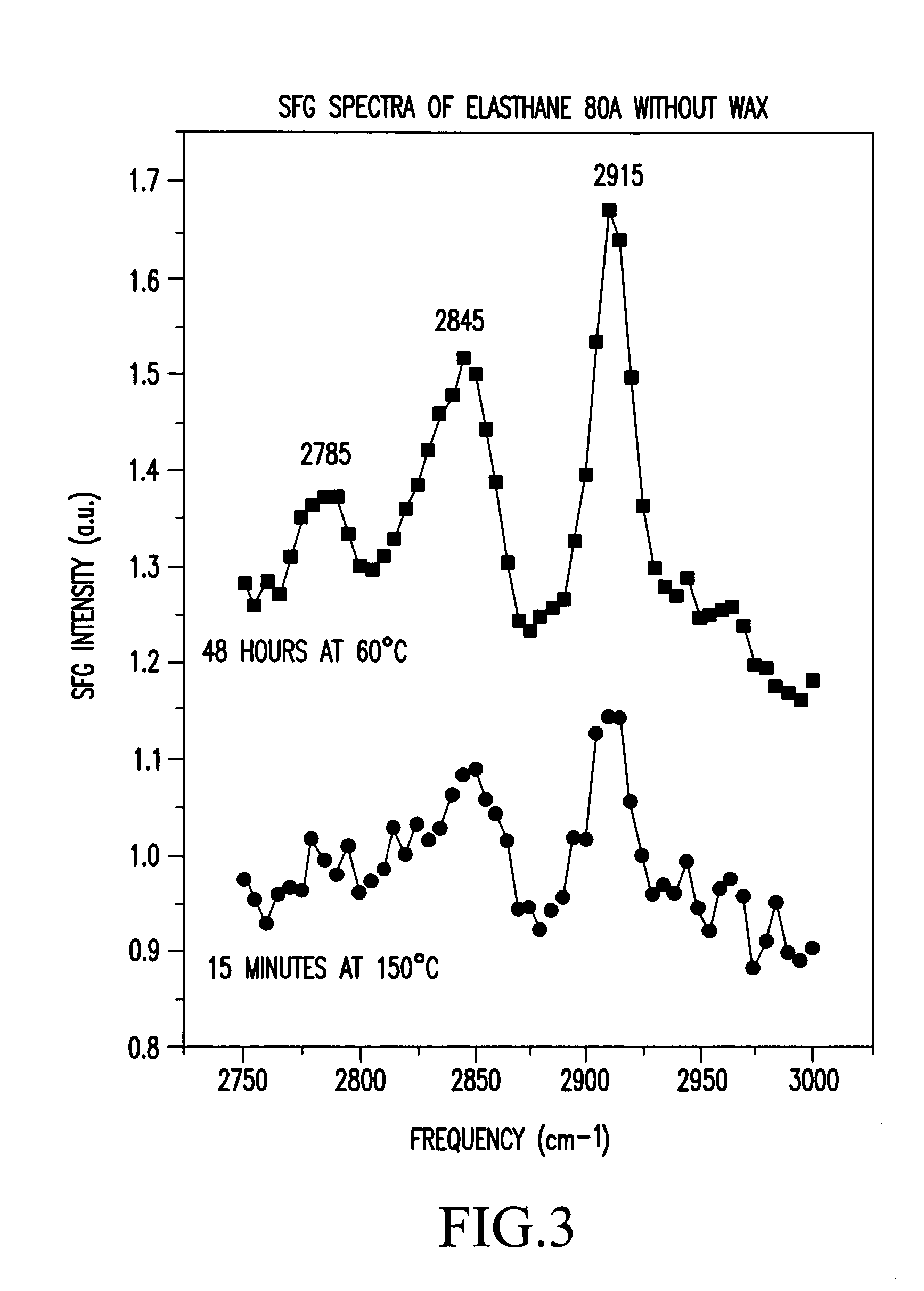

Control of polymer surface molecular architecture via amphipathic endgroups

ActiveUS20050282997A1Promote resultsReduce signal to noise ratioSurgeryCatheterPolymeric surfacePolyethylene oxide

Polymers whose surfaces are modified by endgroups that include amphipathic surface-modifying moieties. An amphipathic endgroup of a polymer molecule is an endgroup that contains at least two moieties of significantly differing composition, such that the amphipathic endgroup spontaneously rearranges its positioning in a polymer body to position the moiety on the surface of the body, depending upon the composition of the medium with which the body is in contact, when that re-positioning causes a reduction in interfacial energy. An example of an amphipathic surface-modifying endgroup is one that has both a hydrophobic moiety and a hydrophilic moiety in a single endgroup. For instance, a hydrophilic poly(ethylene oxide) terminated with a hydrophilic hydroxyl group is not surface active in air when the surface-modifying endgroup is bonded to a more hydrophobic base polymer. If the hydroxyl group on the oligomeric poly(ethylene oxide) is replaced by a hydrophobic methoxy ether terminus, the poly(ethylene oxide) becomes surface active in air, and allows the poly(ethylene oxide) groups to crystallize in the air-facing surface. In this example, immersion in water destroys the crystallinity as the poly(ethylene oxide) sorbs water and the hydrophobic methoxy group retreats below the surface of the polymer. Also disclosed are methods and articles of manufacture that make use of these polymers.

Owner:THE POLYMER TECH GROUP

Coatings for implantable devices including biologically erodable polyesters and methods for fabricating the same

A medical article comprising an implantable substrate having a coating is disclosed, the coating comprising a biologically erodable polymer having the glass transition temperature below about −50° C. The biologically erodable polymer can be blended with a polymeric additive which either has the glass transition temperature of about −50° C. or higher, or a degree of crystallinity greater than that of the first polymer.

Owner:ABBOTT CARDIOVASCULAR

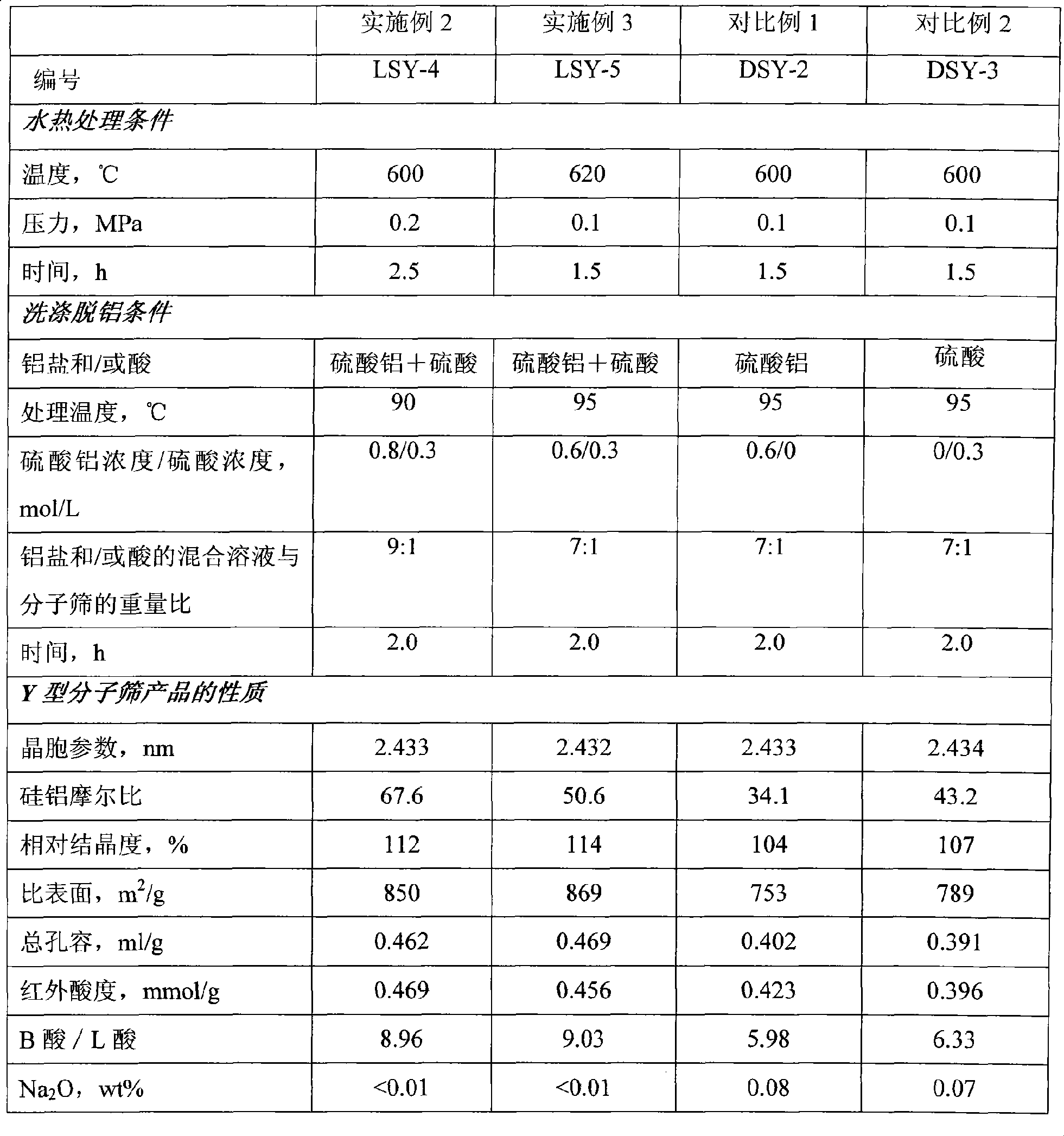

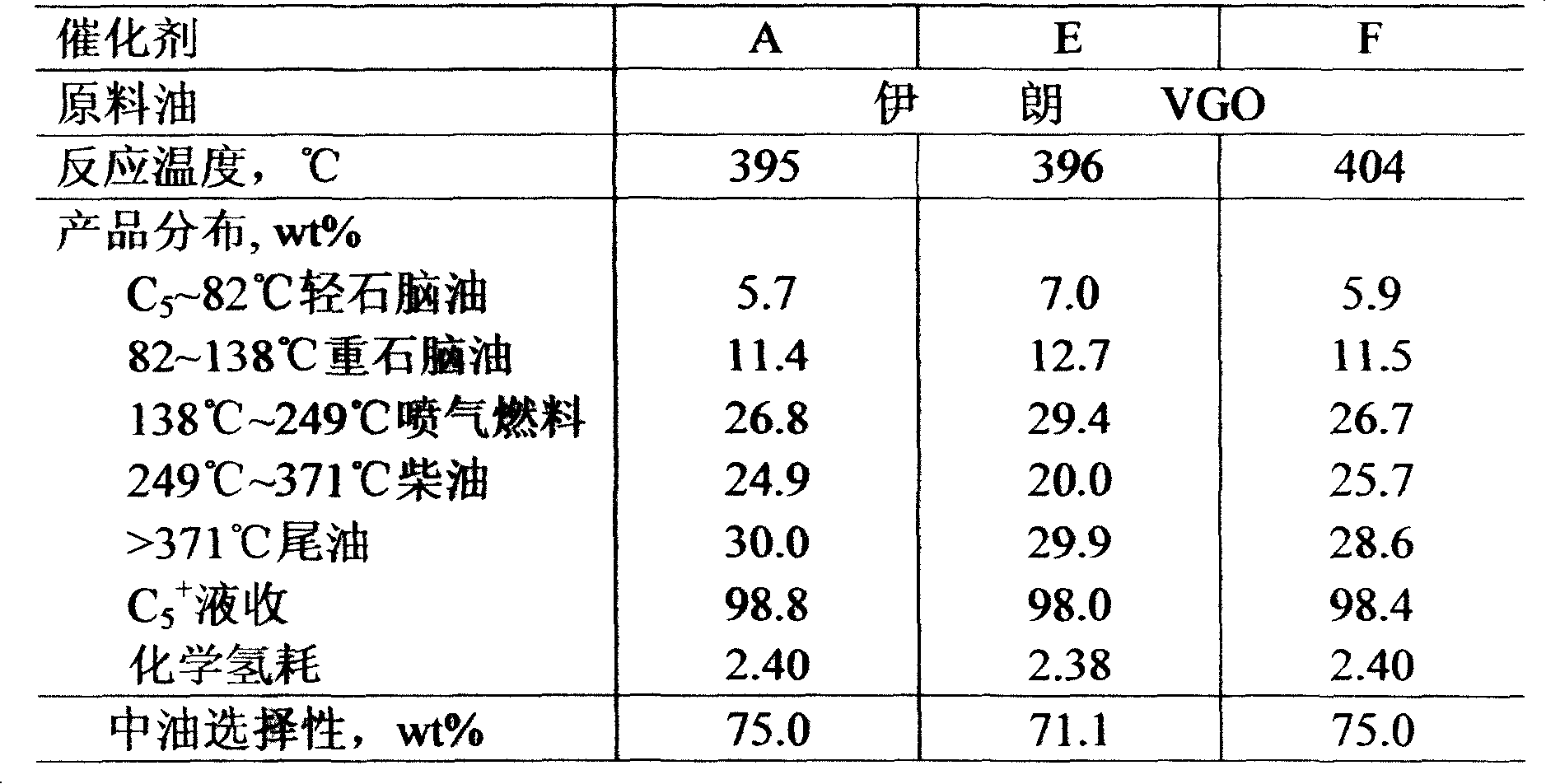

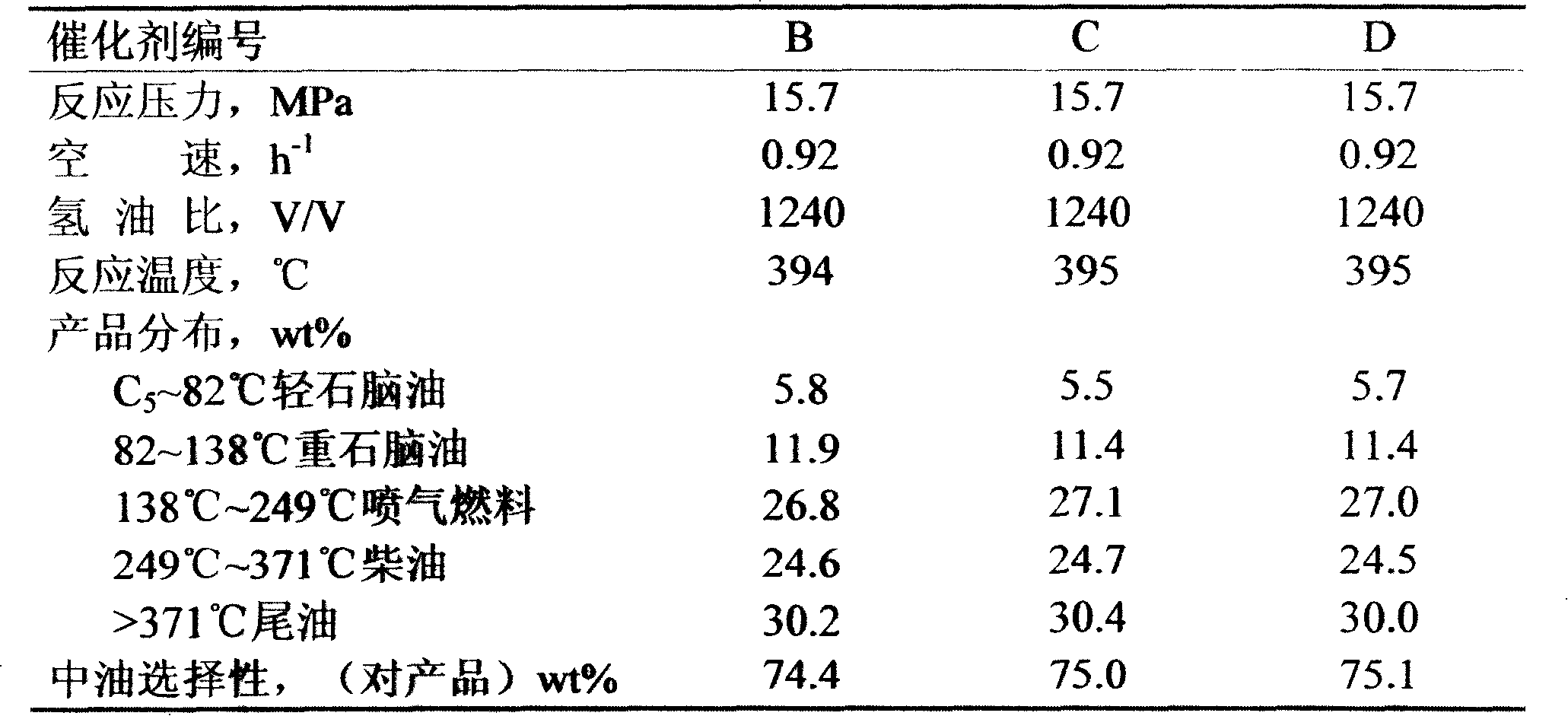

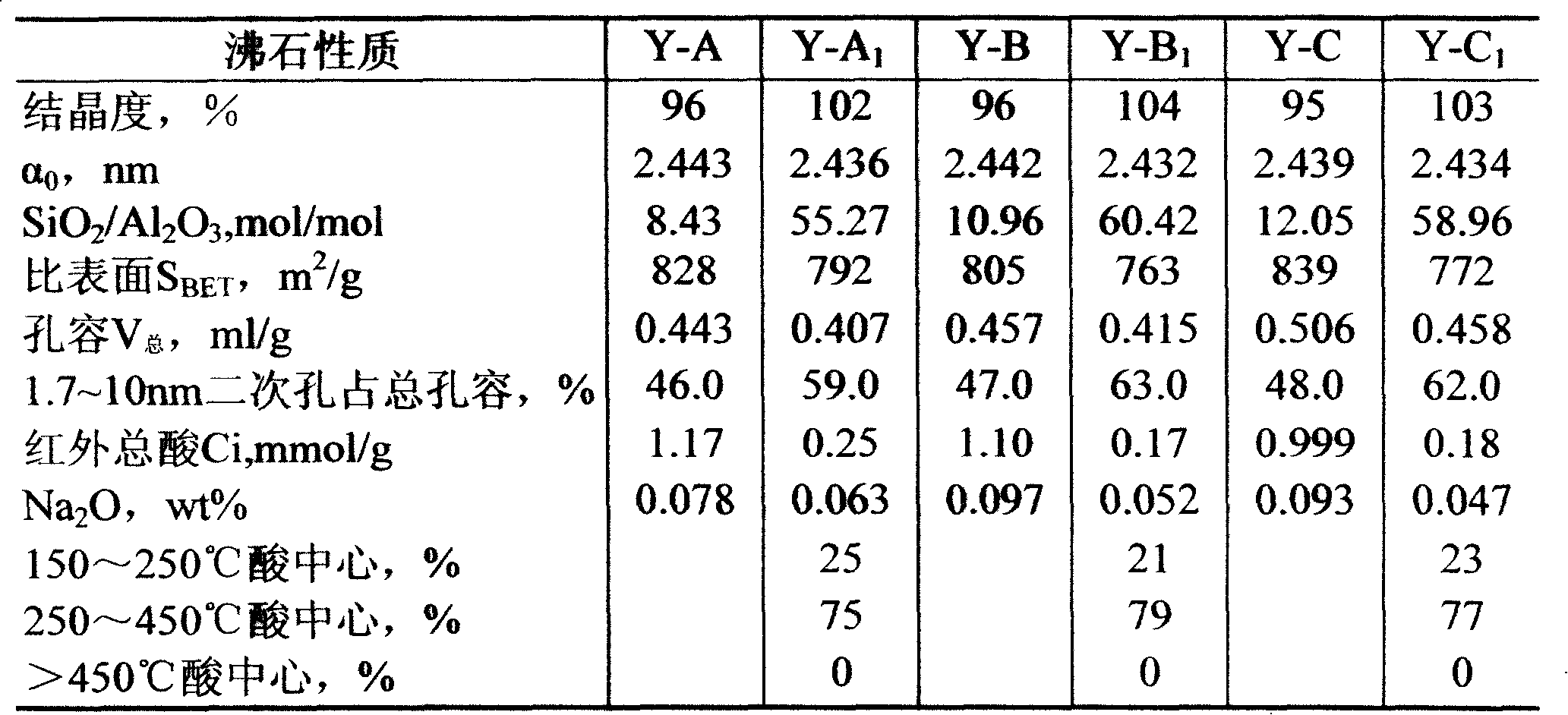

Hydrocracking catalyst and preparation method thereof

ActiveCN101380589AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingCrystallinityCell parameter

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Functionally graded biocompatible coating and coated implant

ActiveUS20060210494A1Degree of reductionDental implantsCosmetic preparationsCalcium biphosphateCalcium phosphate coating

The present invention provides a biocompatible coating comprising calcium phosphate that is functionally graded across the thickness of the coating. The coating, which preferably includes hydroxyapatite, is particularly useful for coating implants, such as dental or orthopedic implants. The functionally graded coating is generally crystalline near the interface with the surface of the implant, with crystallinity and crystal diameter decreasing toward the outer layer of the coating. The invention further provides methods for preparing a coated implant comprising a functionally graded calcium phosphate coating thereon.

Owner:NORTH CAROLINA STATE UNIV

Wound dressing material containing silk fibroin and sericin as main component and method for preparing same

There is provided a novel wound dressing material which has biocompatibility and infection controllability as essential properties required for such a material, especially excellent flexibility and water absorption properties, thereby accelerating smooth regeneration of a skin defect without stripping off the regenerating skin while removing the material from the skin. A healing agent is added to the wound dressing material which comprises an amorphous film of a crystallinity below 10% and contains fibroin and sericin as a main component.

Owner:NAT INST OF AGROBIOLOGICAL SCI +1

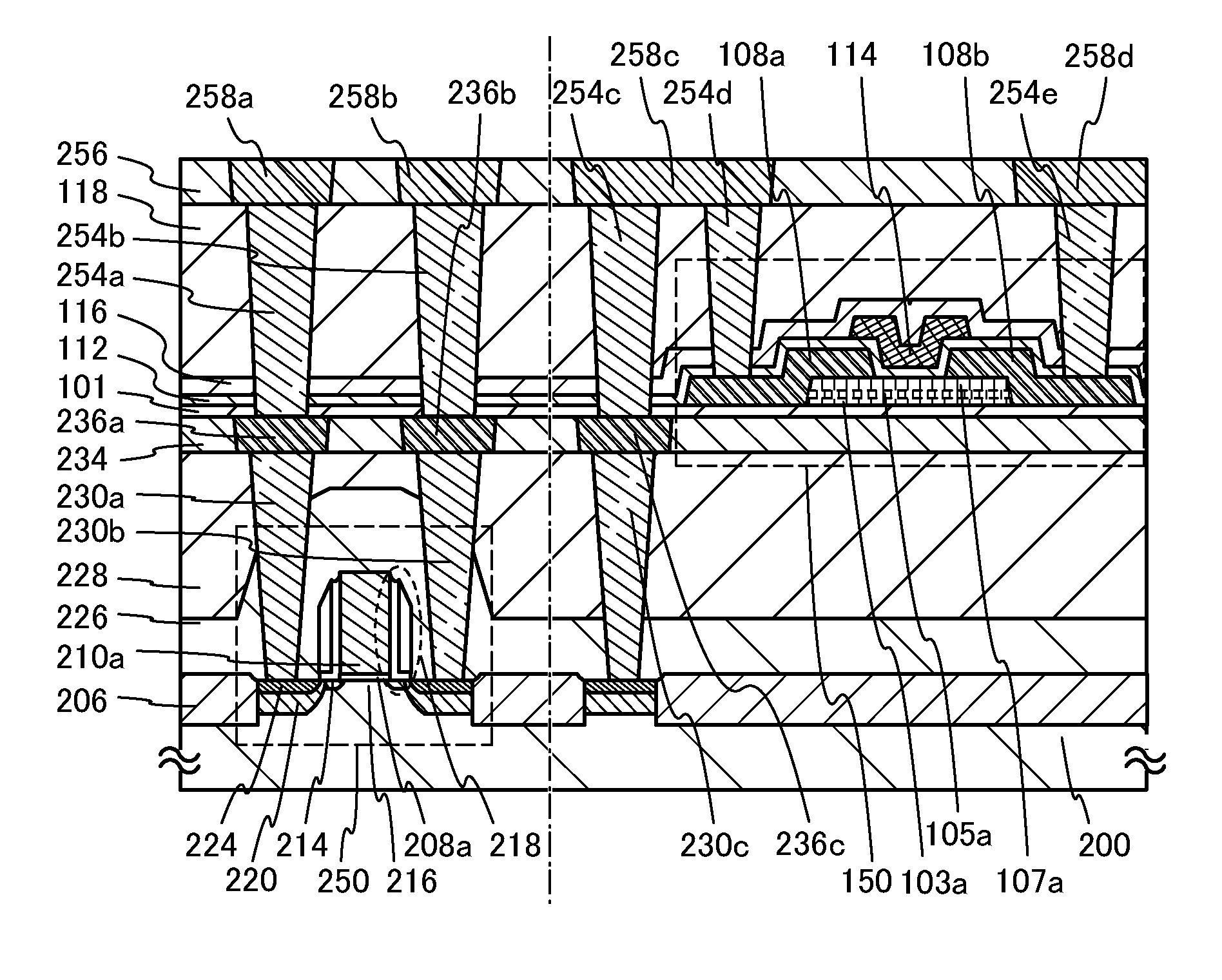

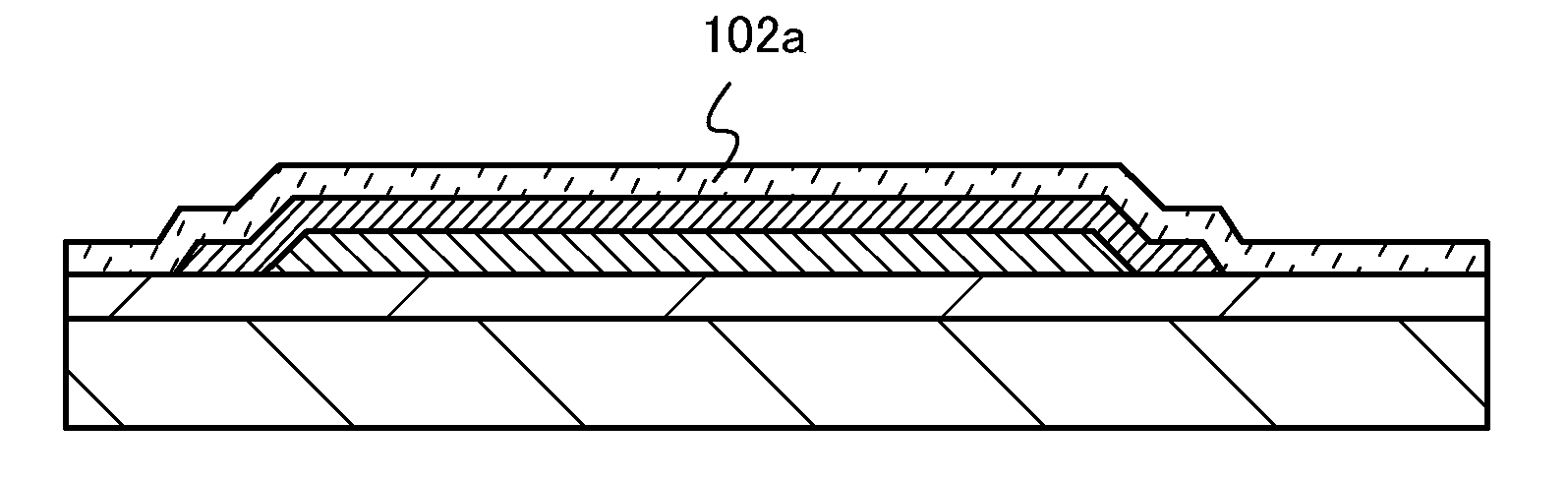

Semiconductor device and method for manufacturing the same

ActiveUS20110127522A1High on-off ratioHigh puritySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsElectron donor

Objects are to provide a semiconductor device for high power application in which a novel semiconductor material having high productivity is used and to provide a semiconductor device having a novel structure in which a novel semiconductor material is used. The present invention is a vertical transistor and a vertical diode each of which has a stacked body of an oxide semiconductor in which a first oxide semiconductor film having crystallinity and a second oxide semiconductor film having crystallinity are stacked. An impurity serving as an electron donor (donor) which is contained in the stacked body of an oxide semiconductor is removed in a step of crystal growth; therefore, the stacked body of an oxide semiconductor is highly purified and is an intrinsic semiconductor or a substantially intrinsic semiconductor whose carrier density is low. The stacked body of an oxide semiconductor has a wider band gap than a silicon semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com