Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Enhanced hoop strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

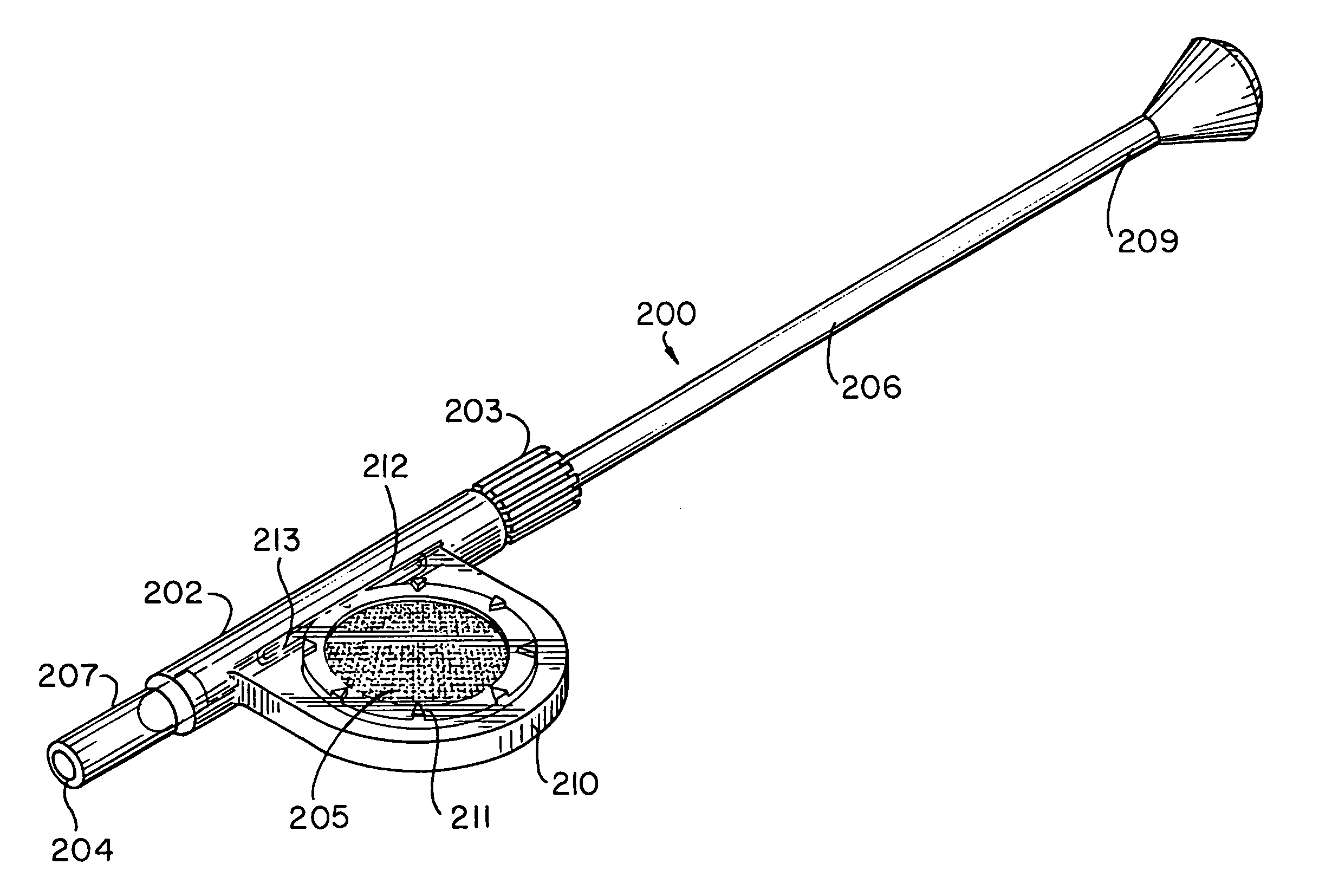

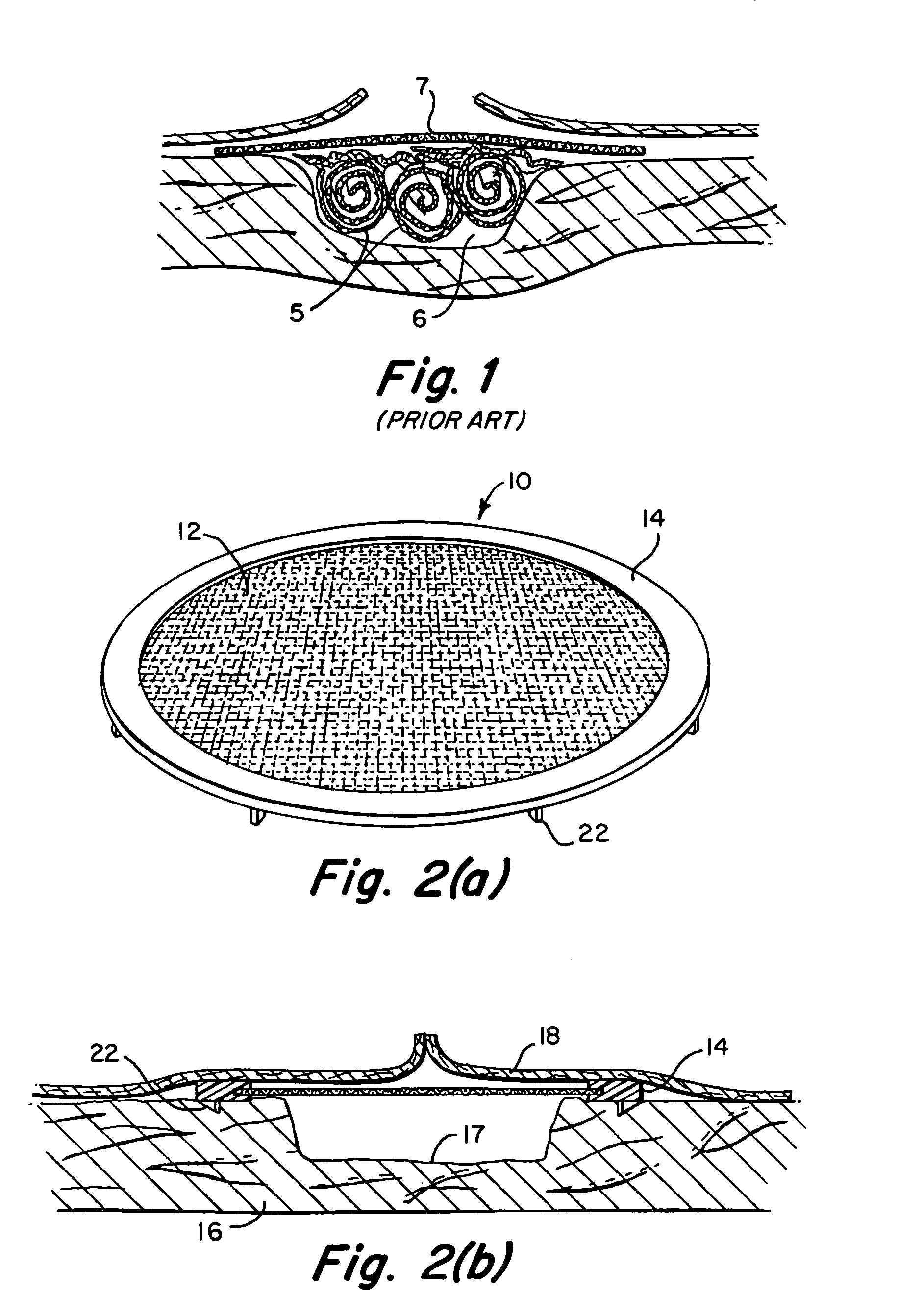

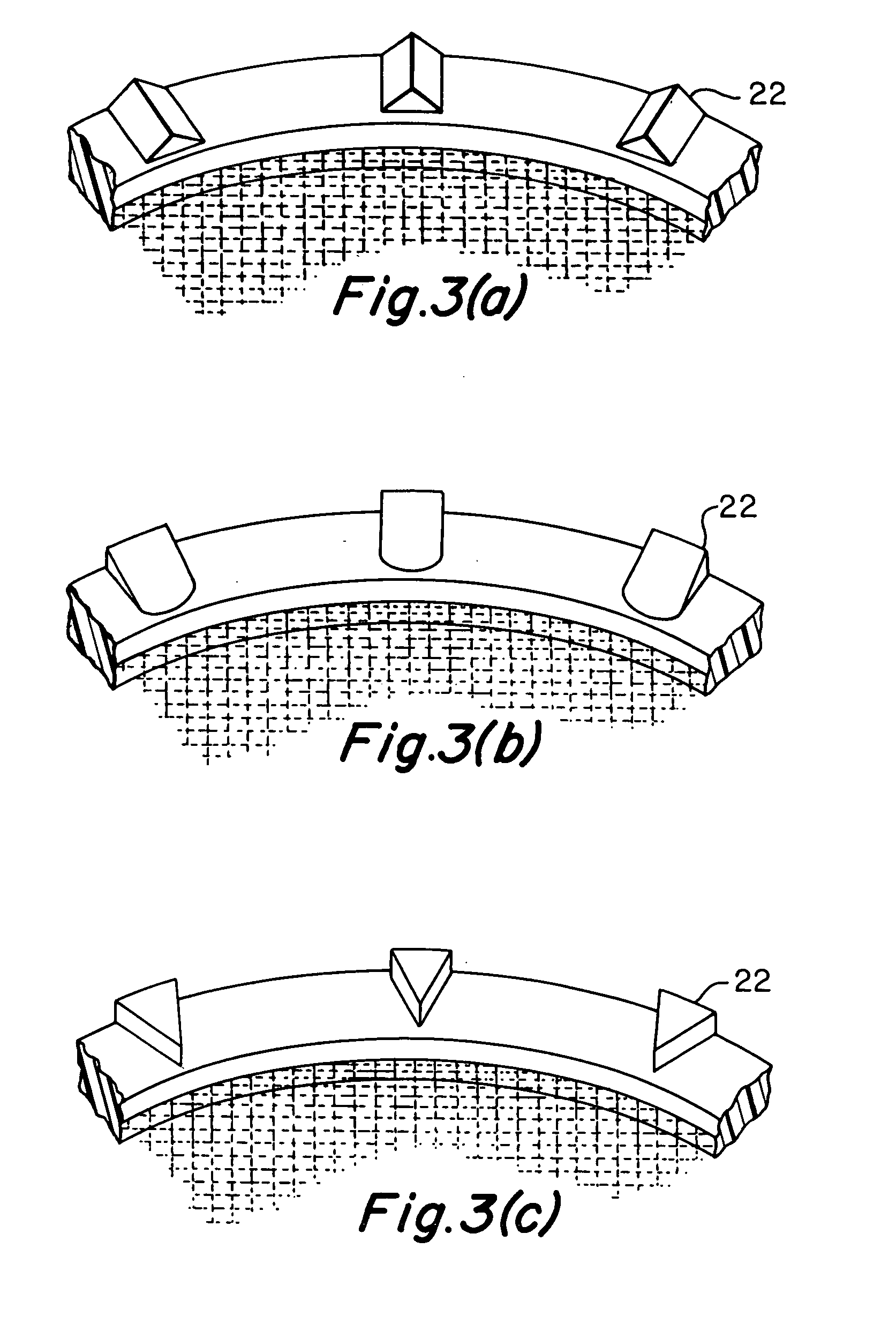

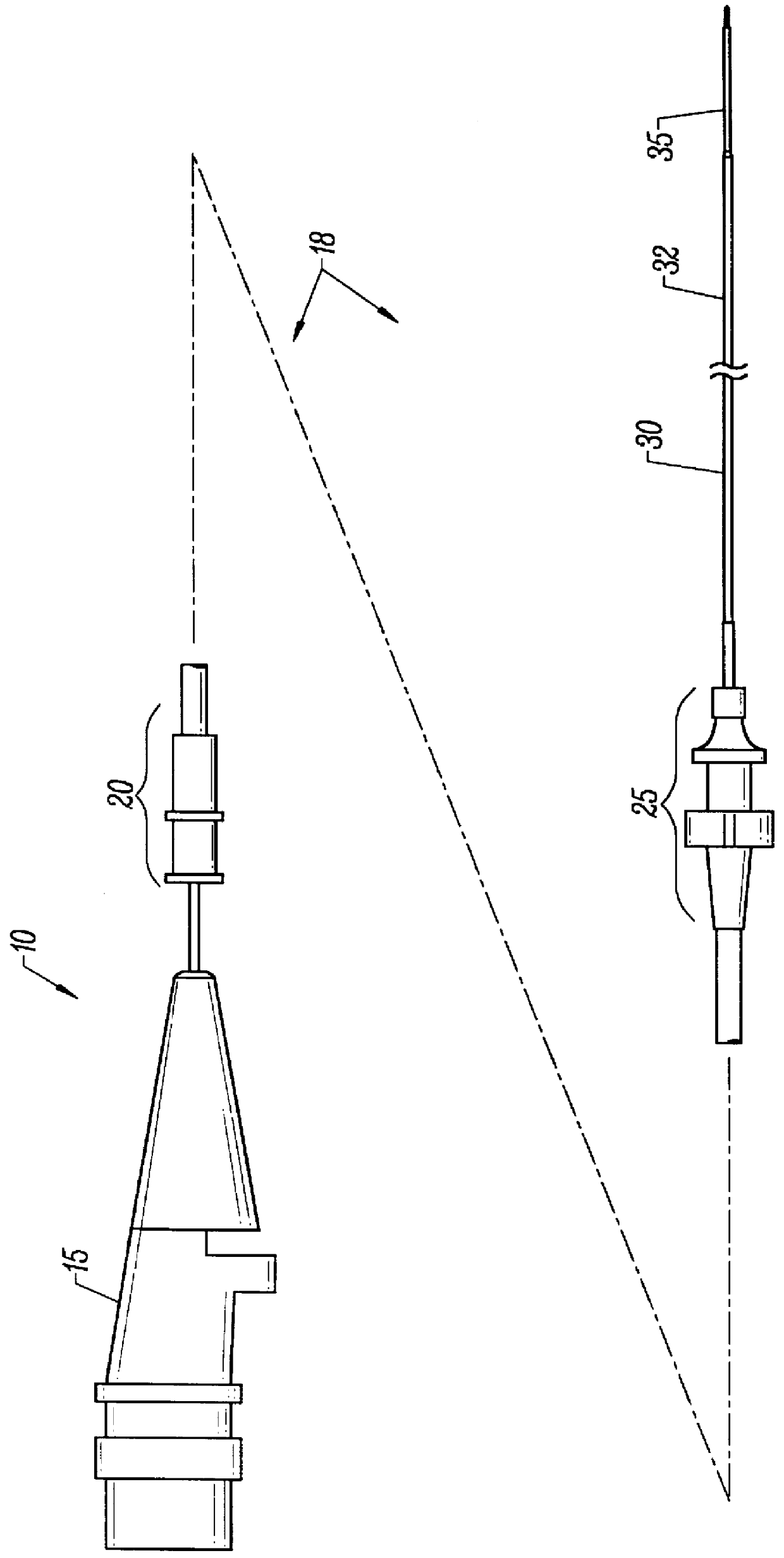

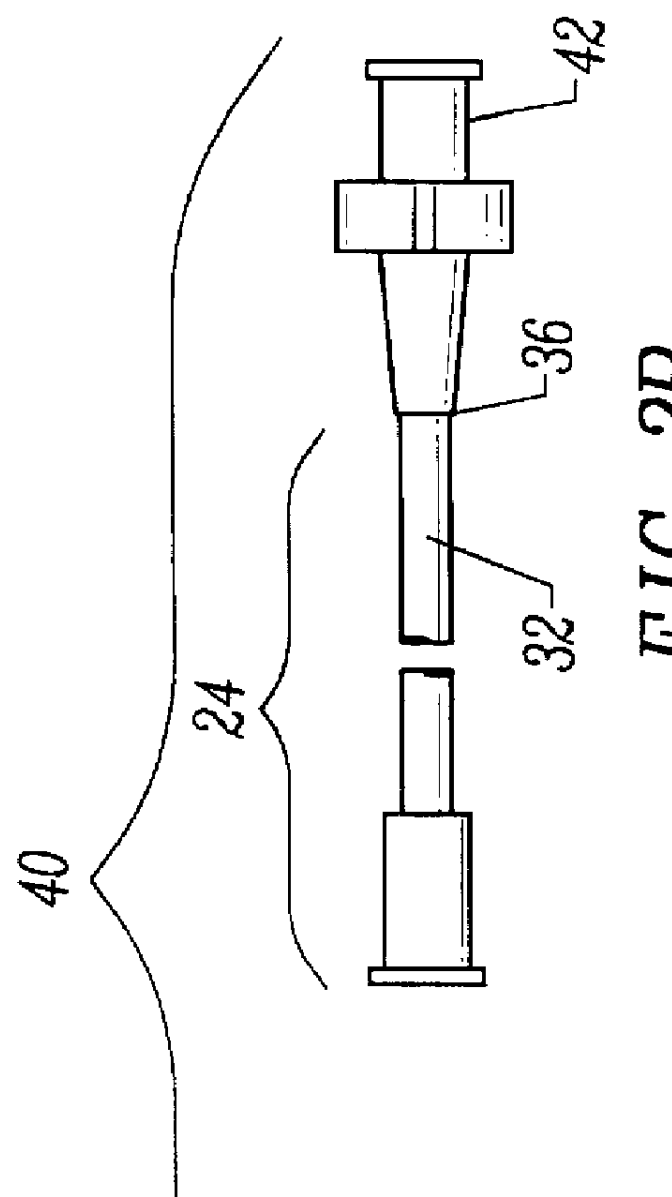

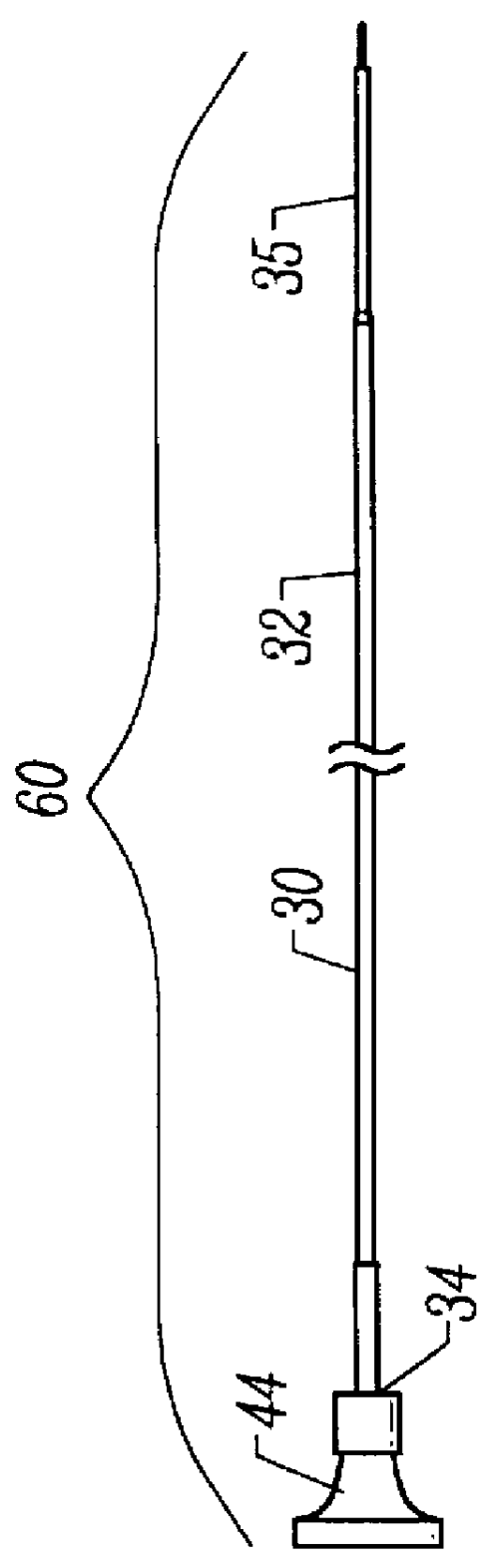

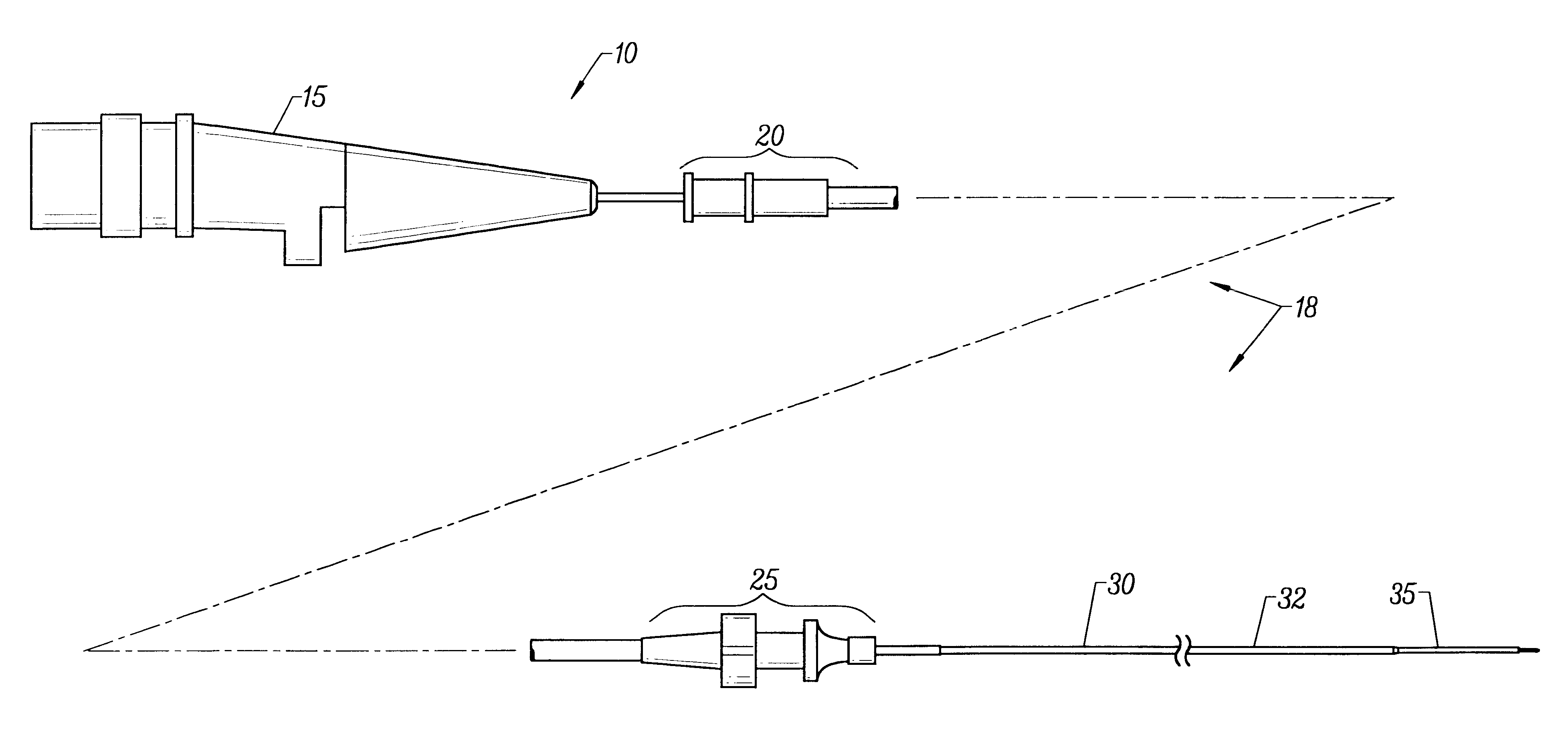

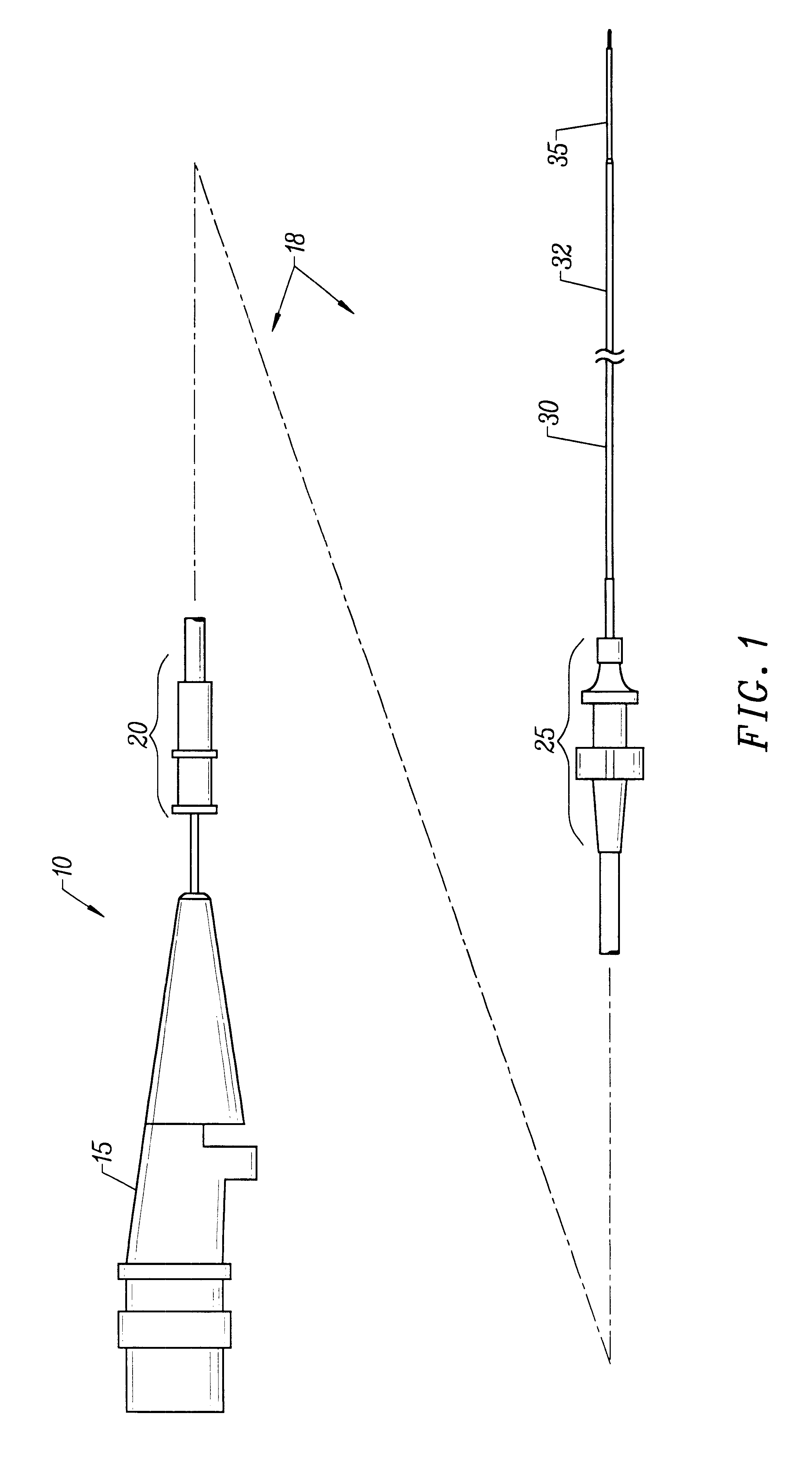

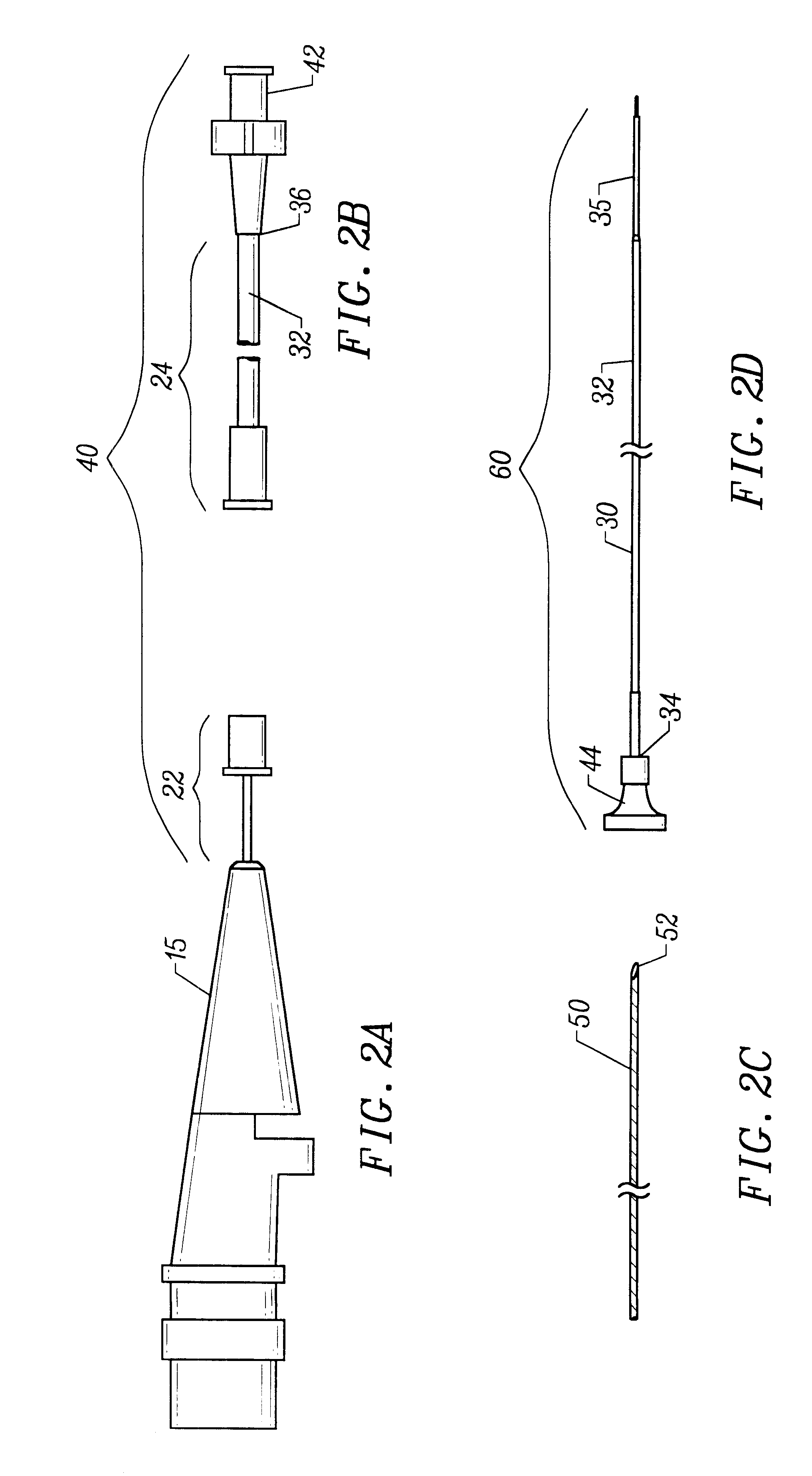

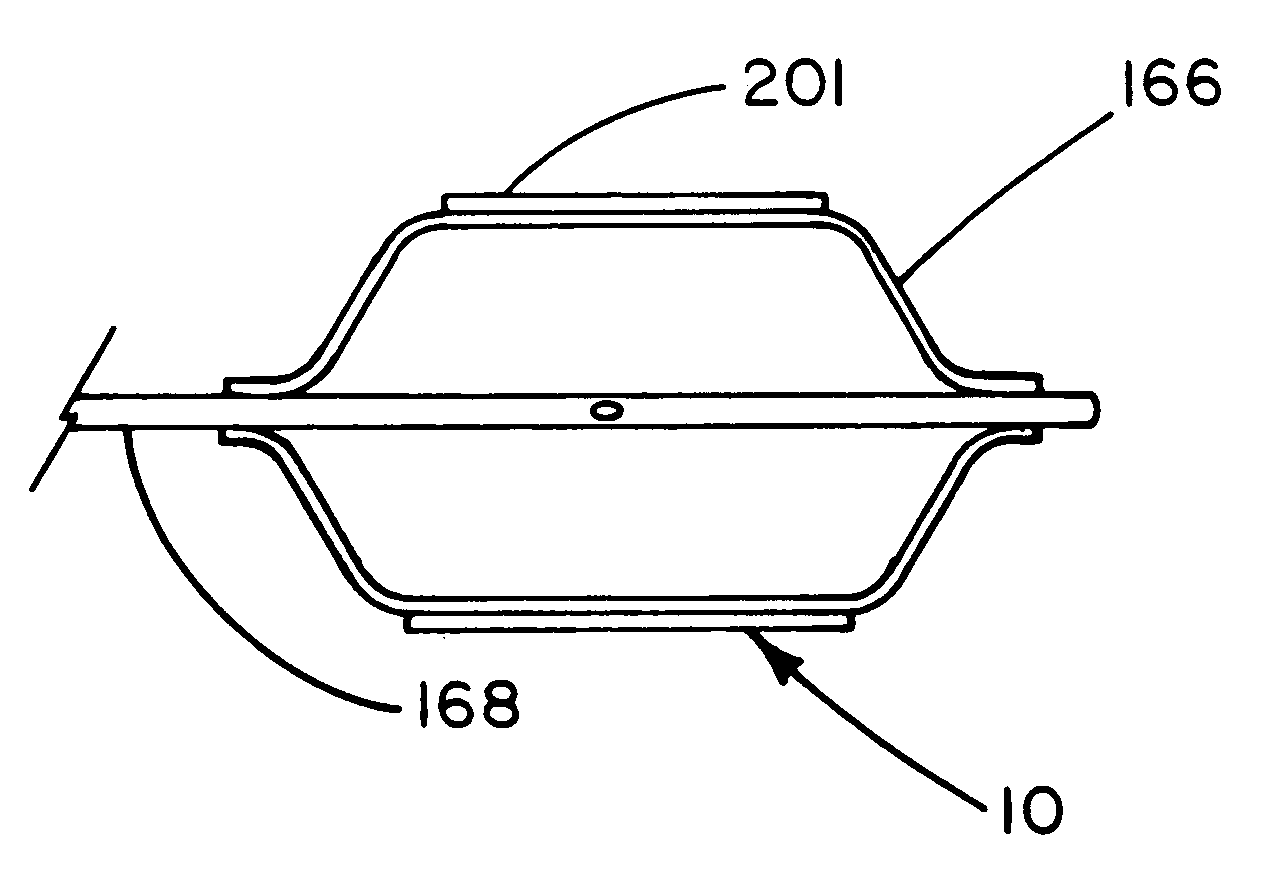

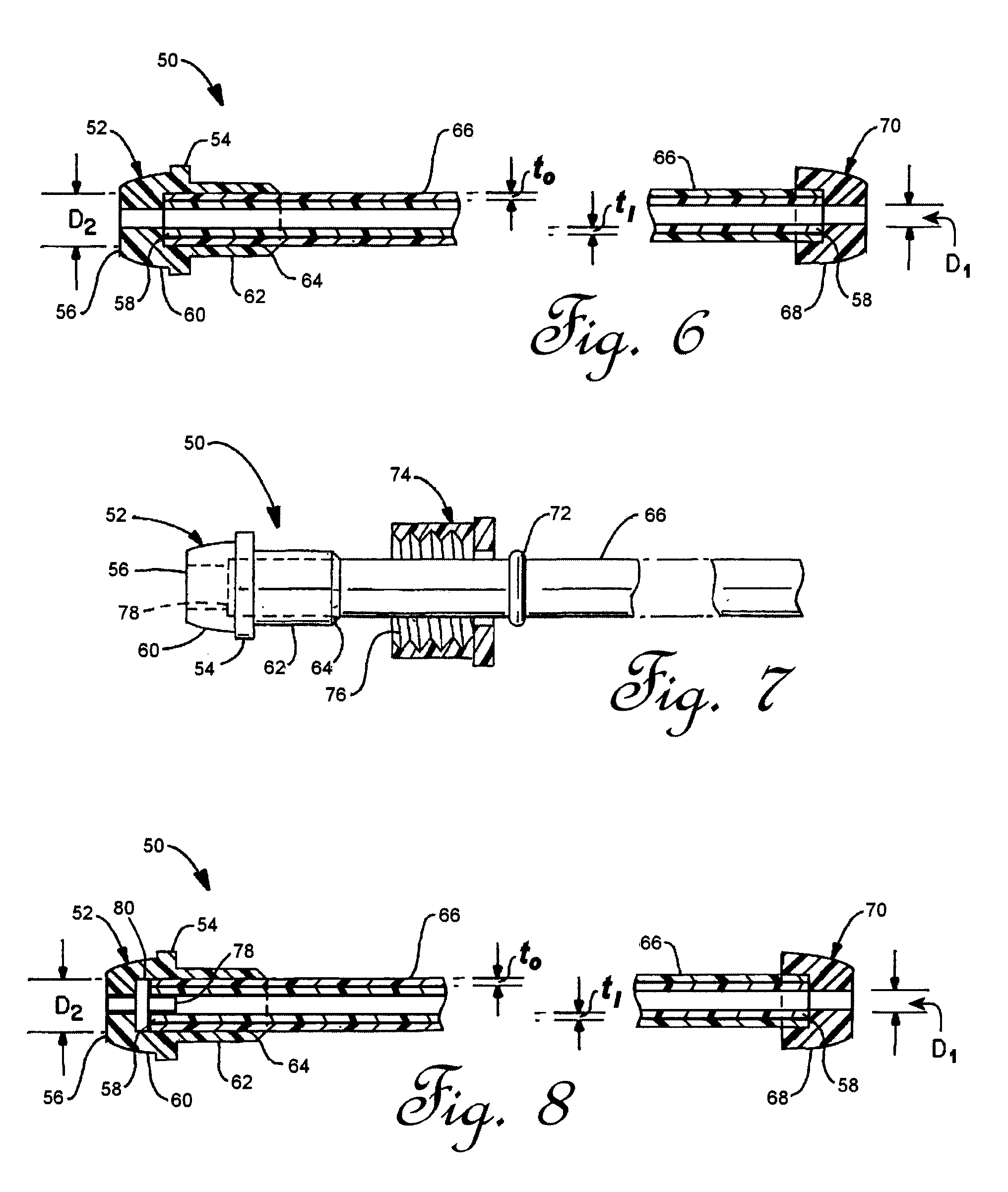

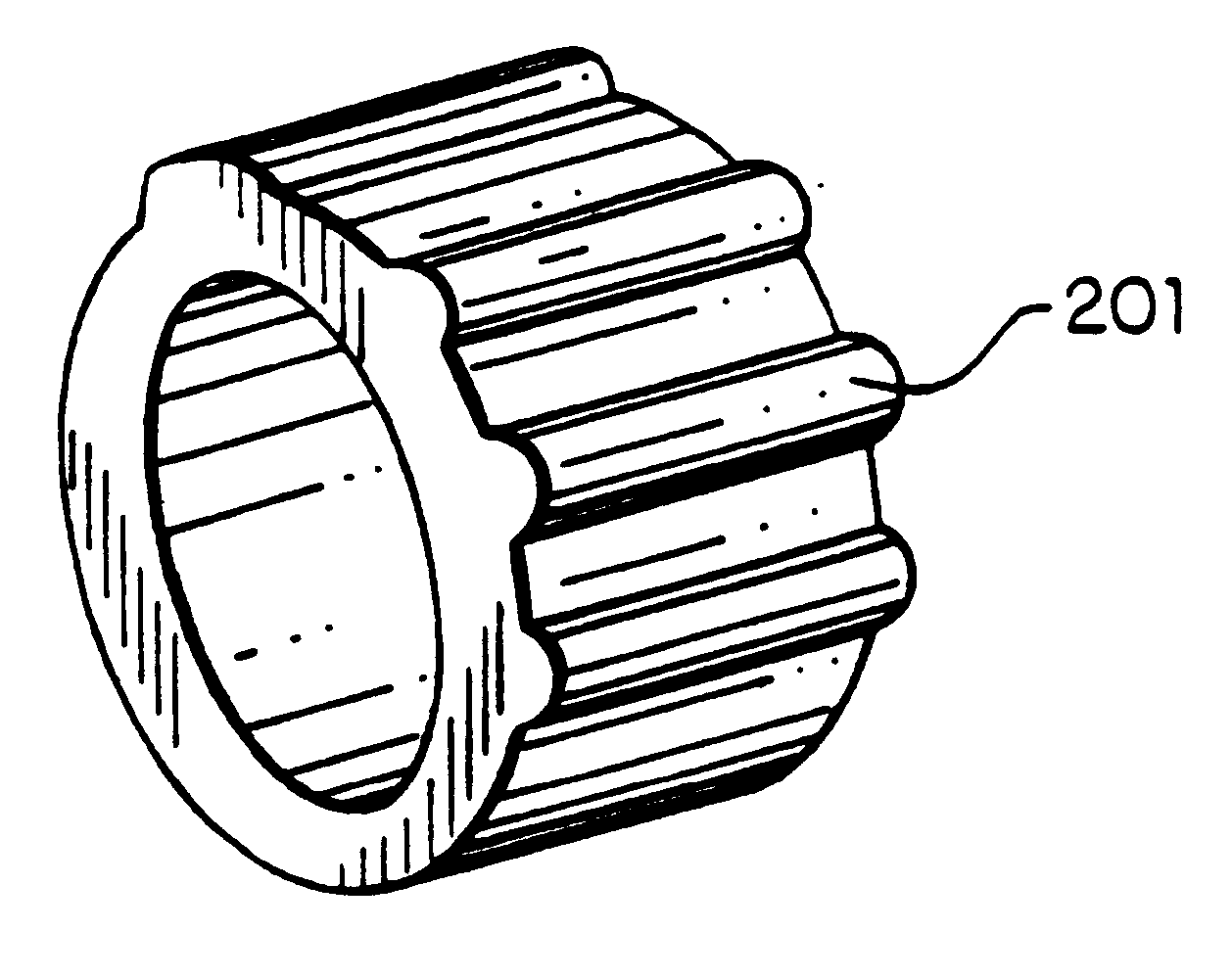

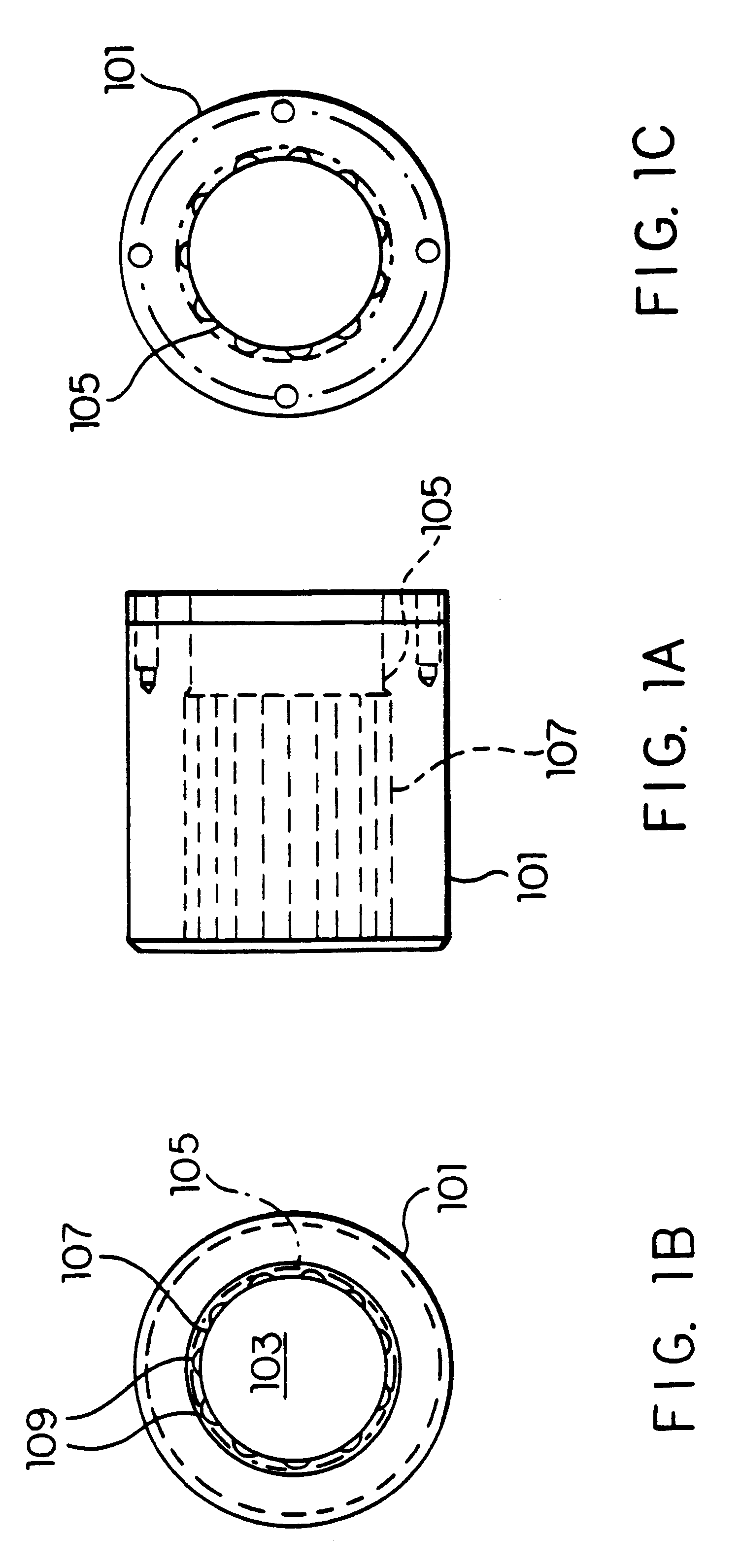

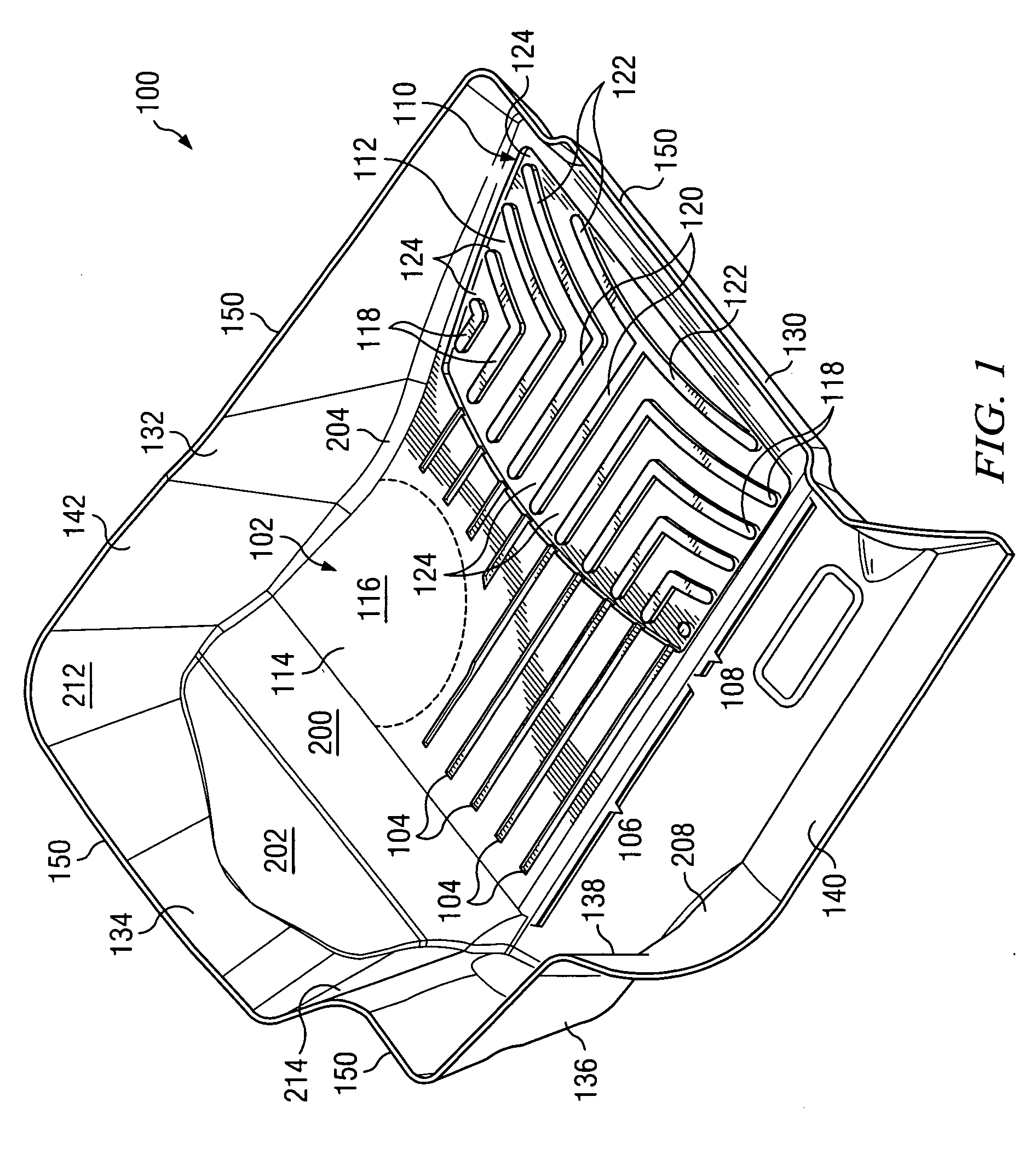

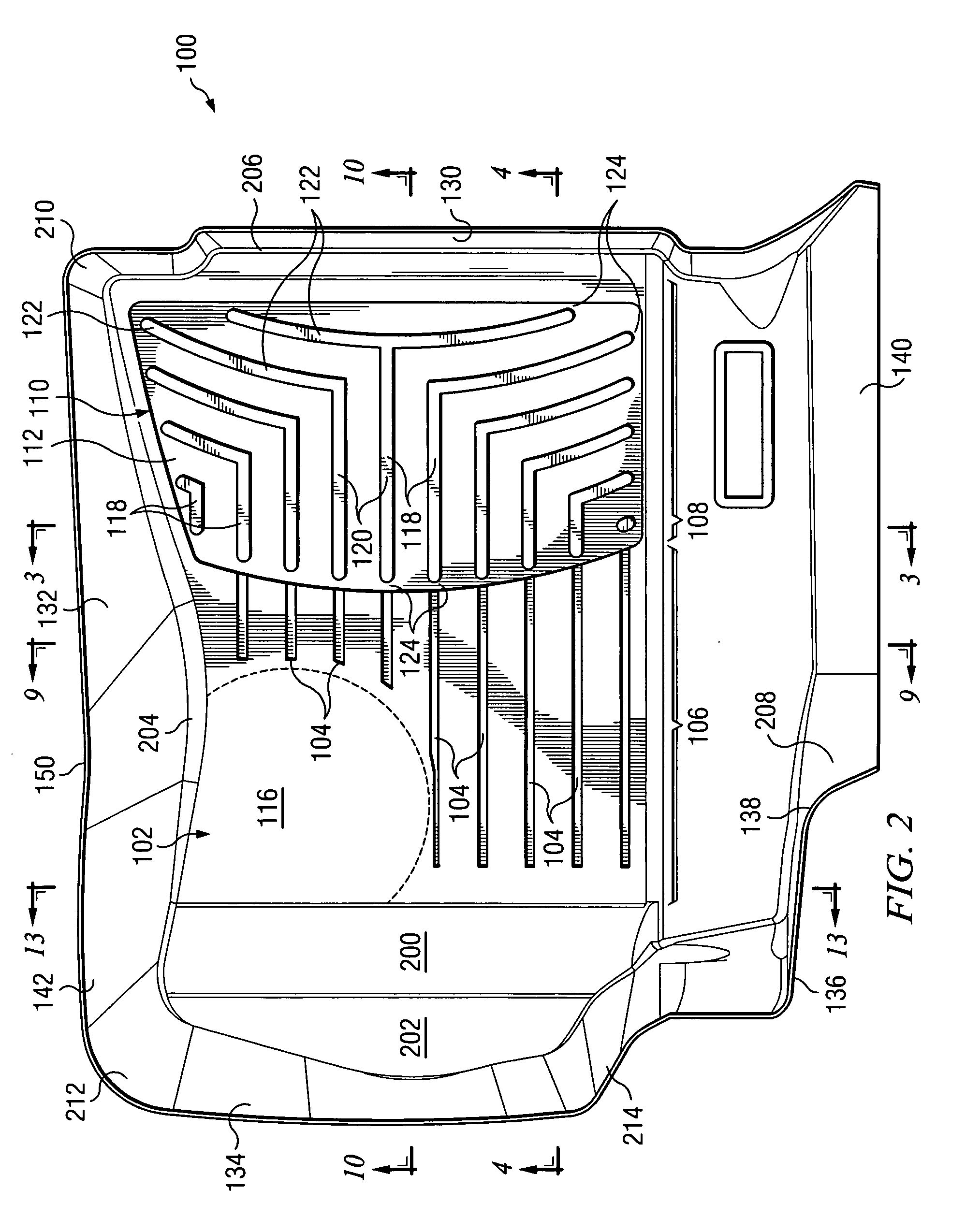

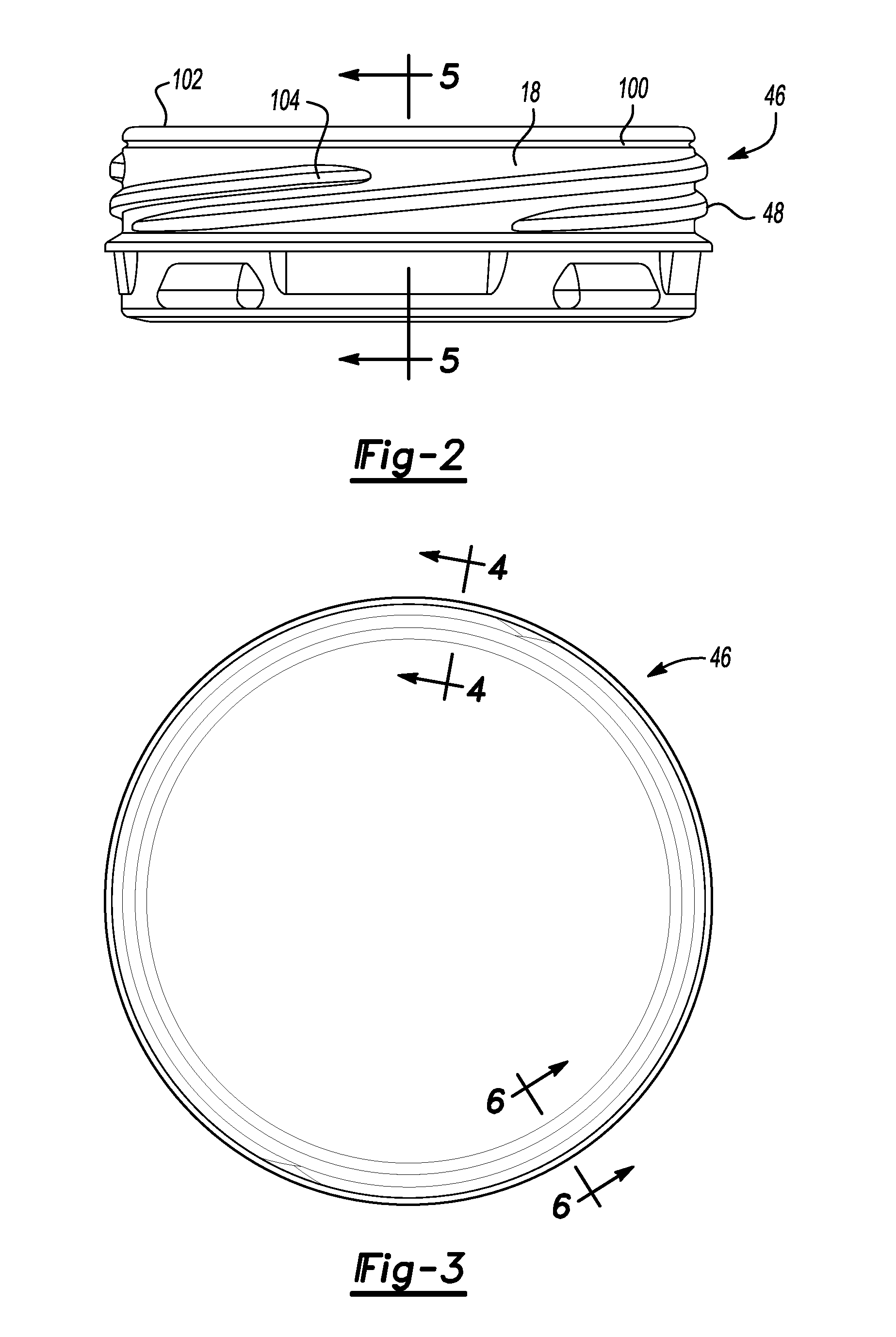

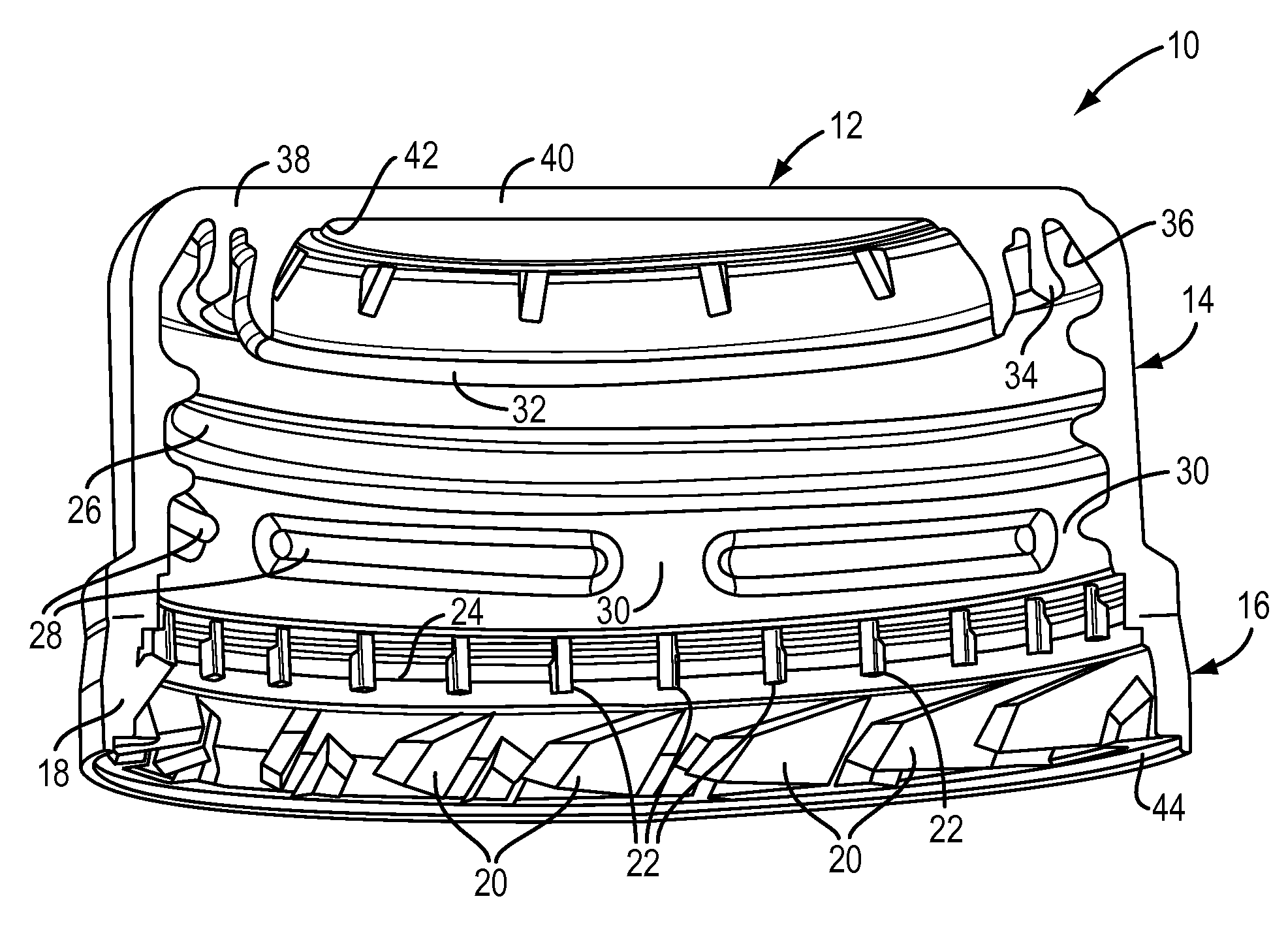

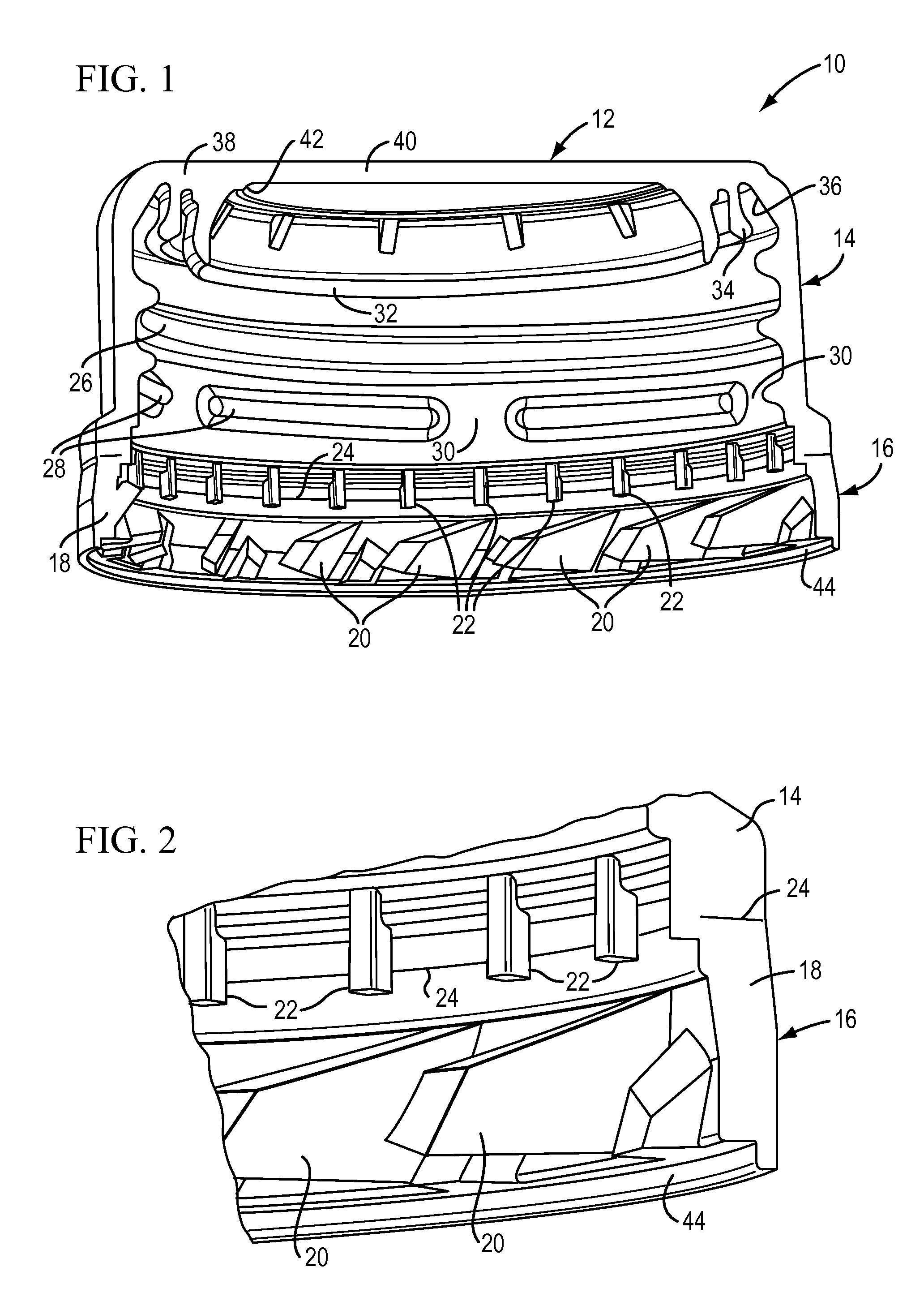

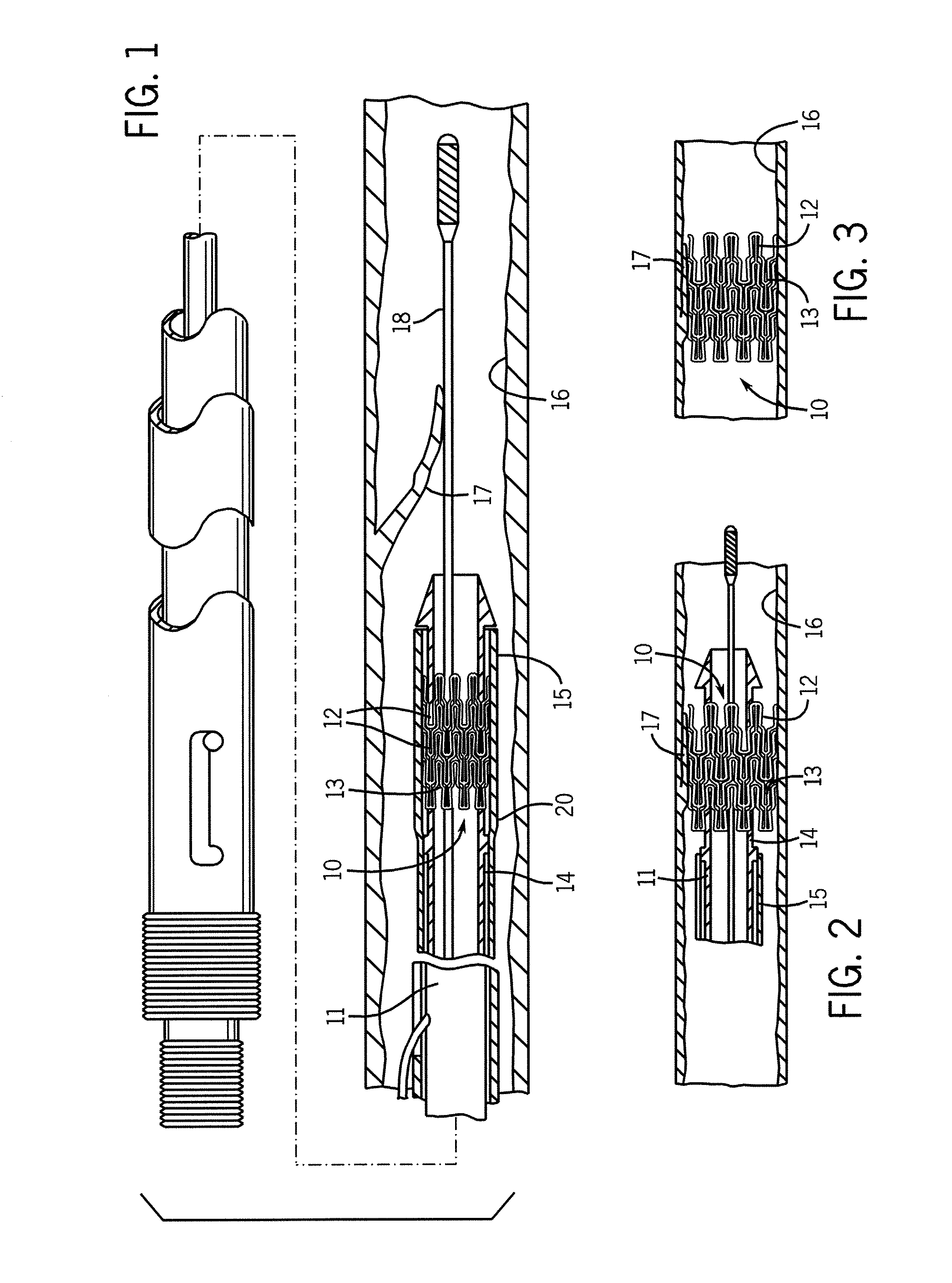

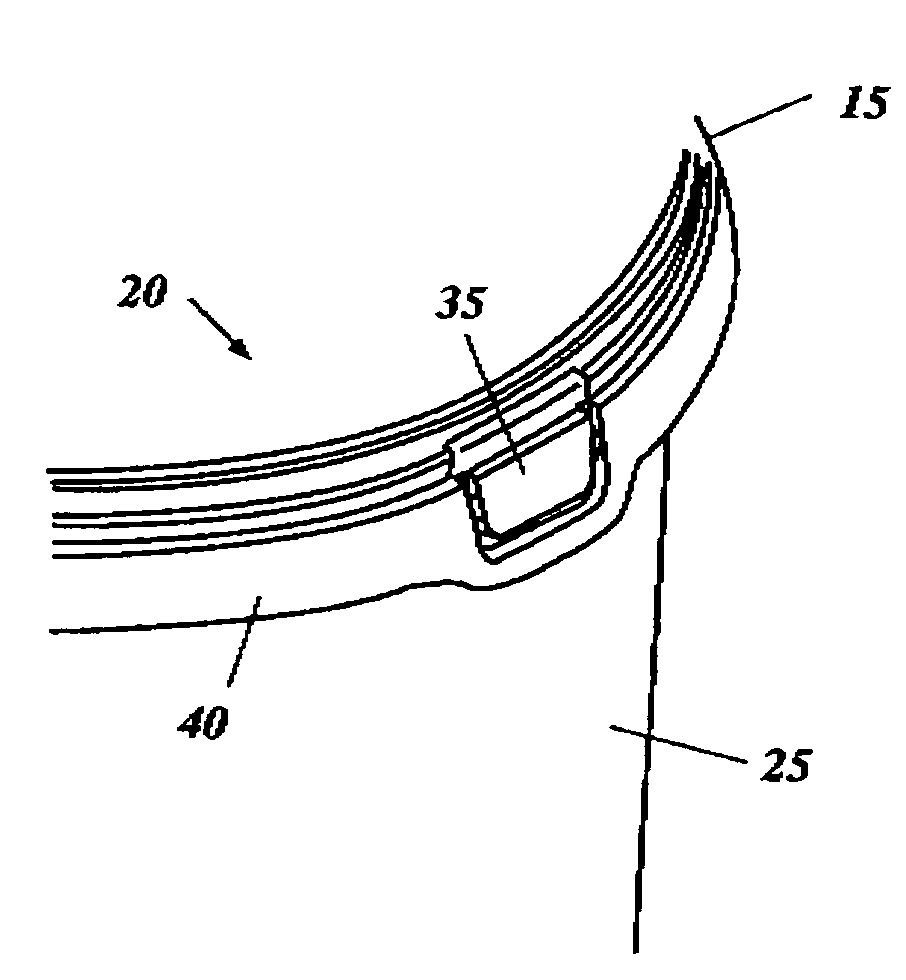

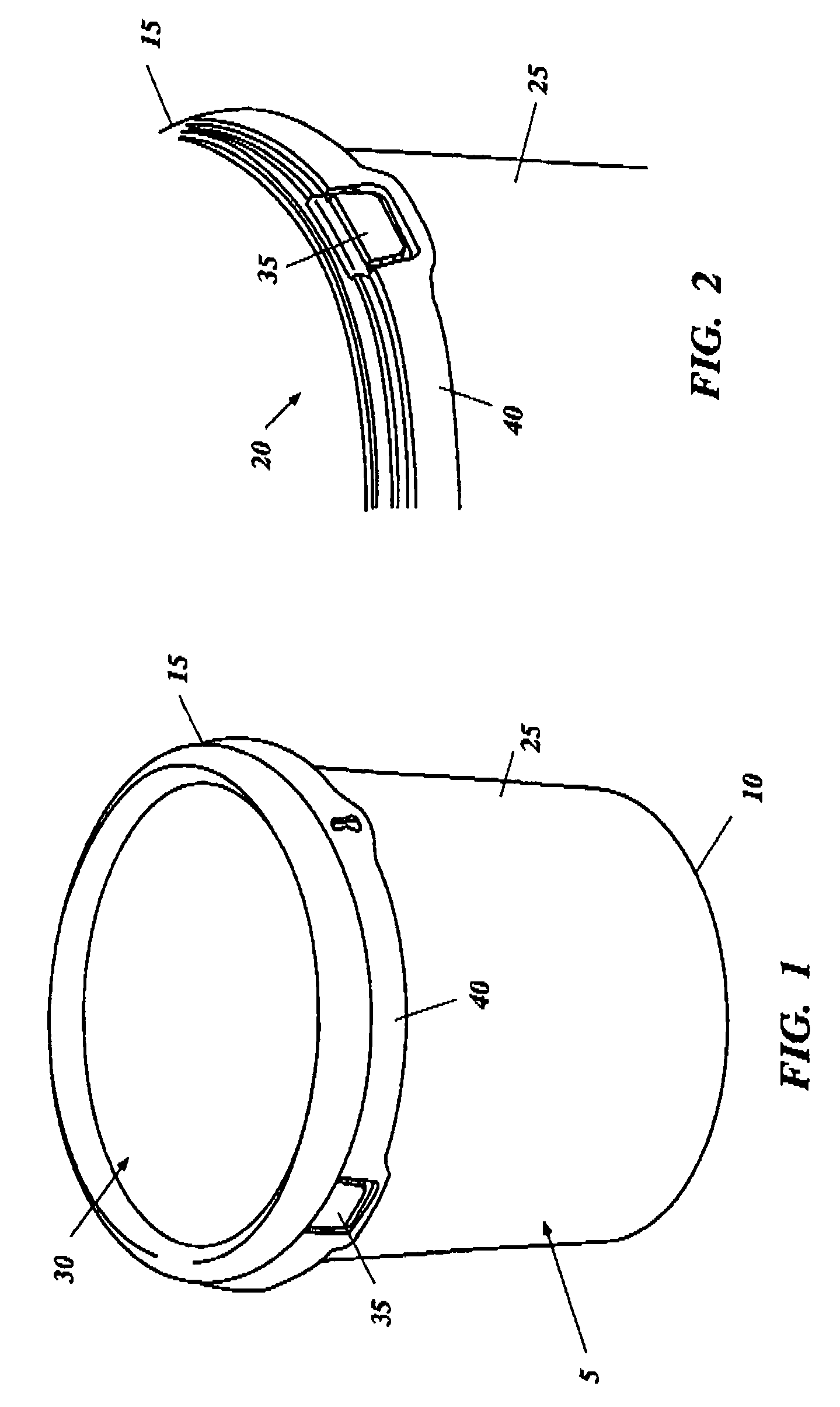

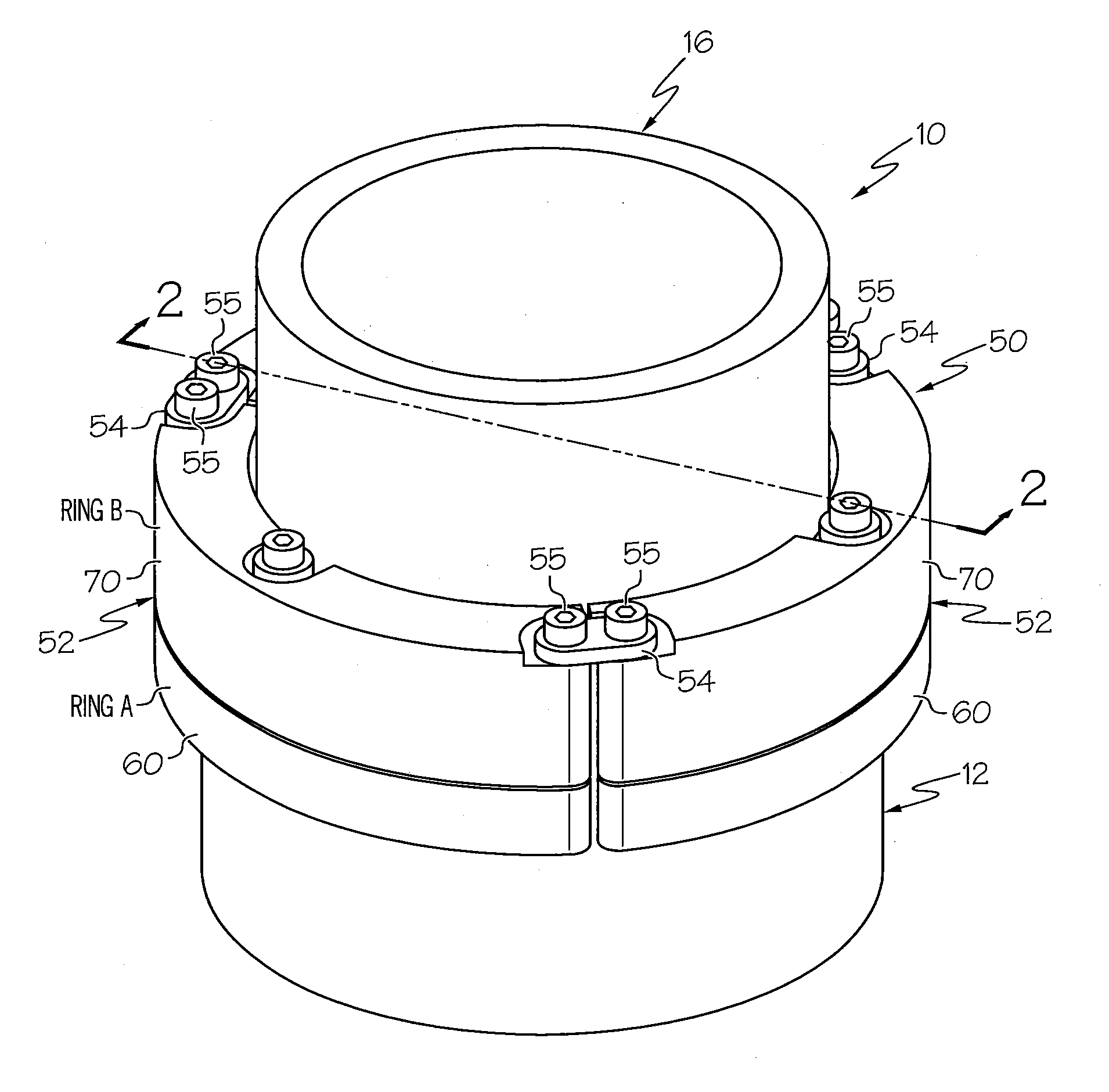

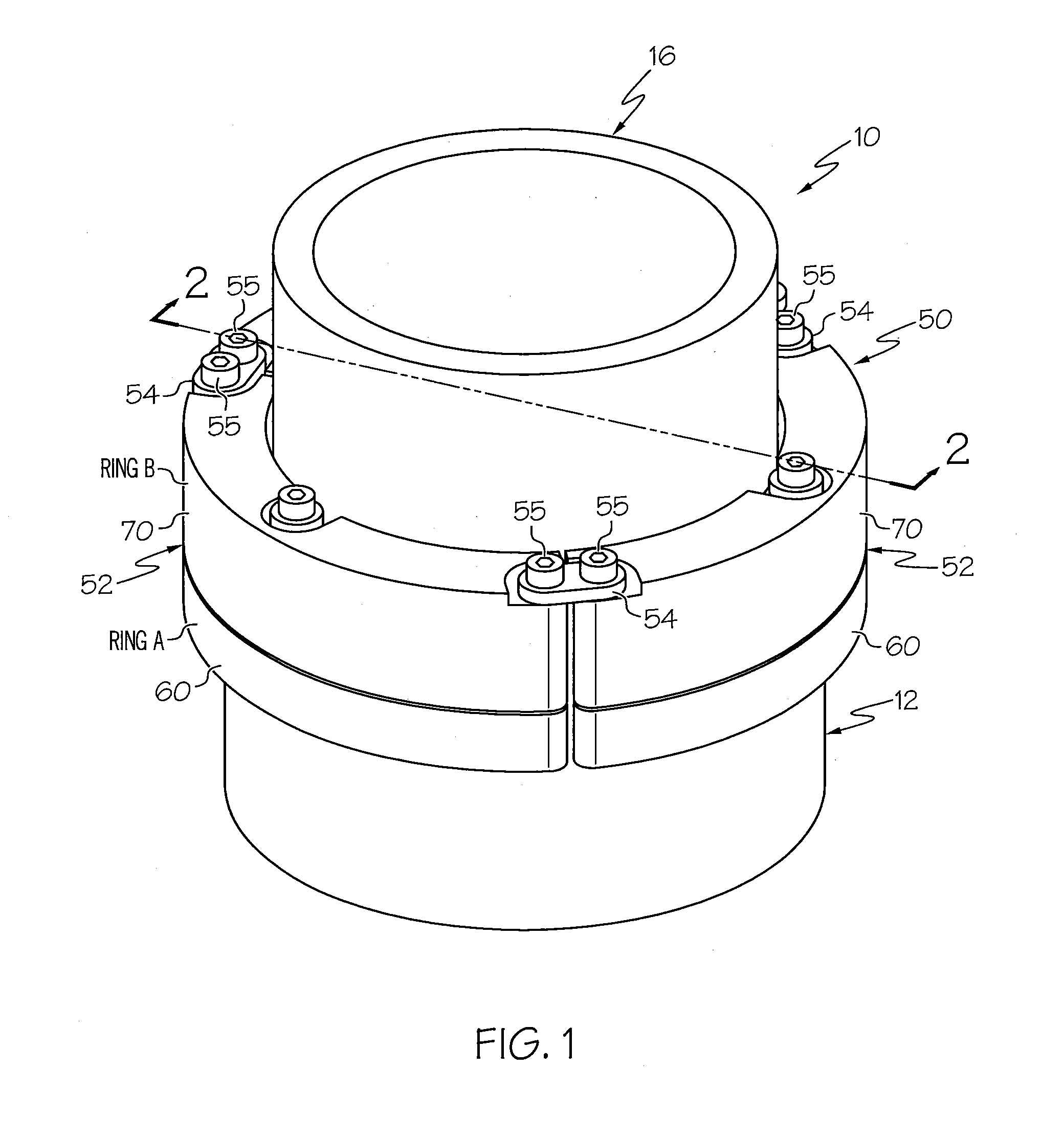

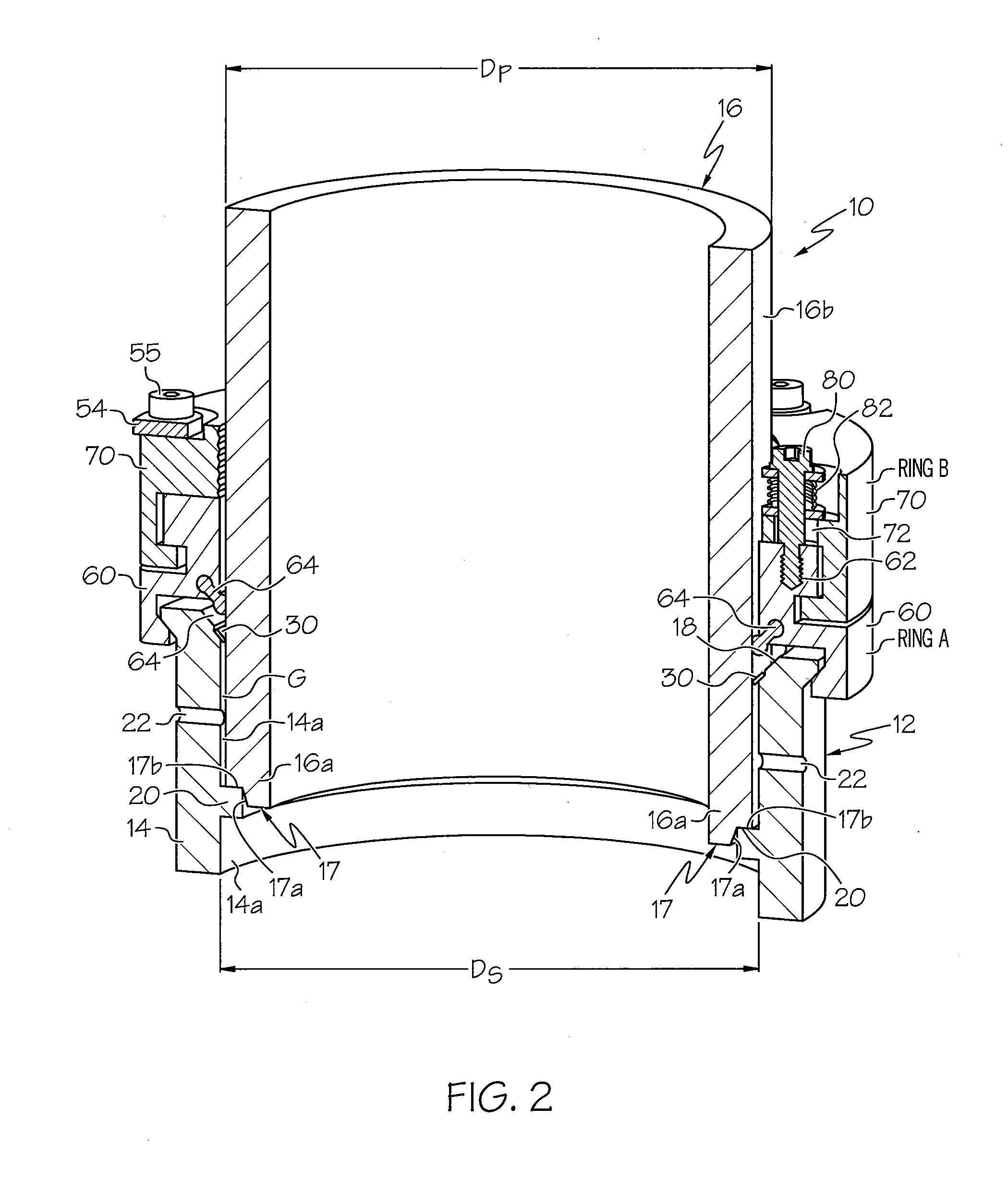

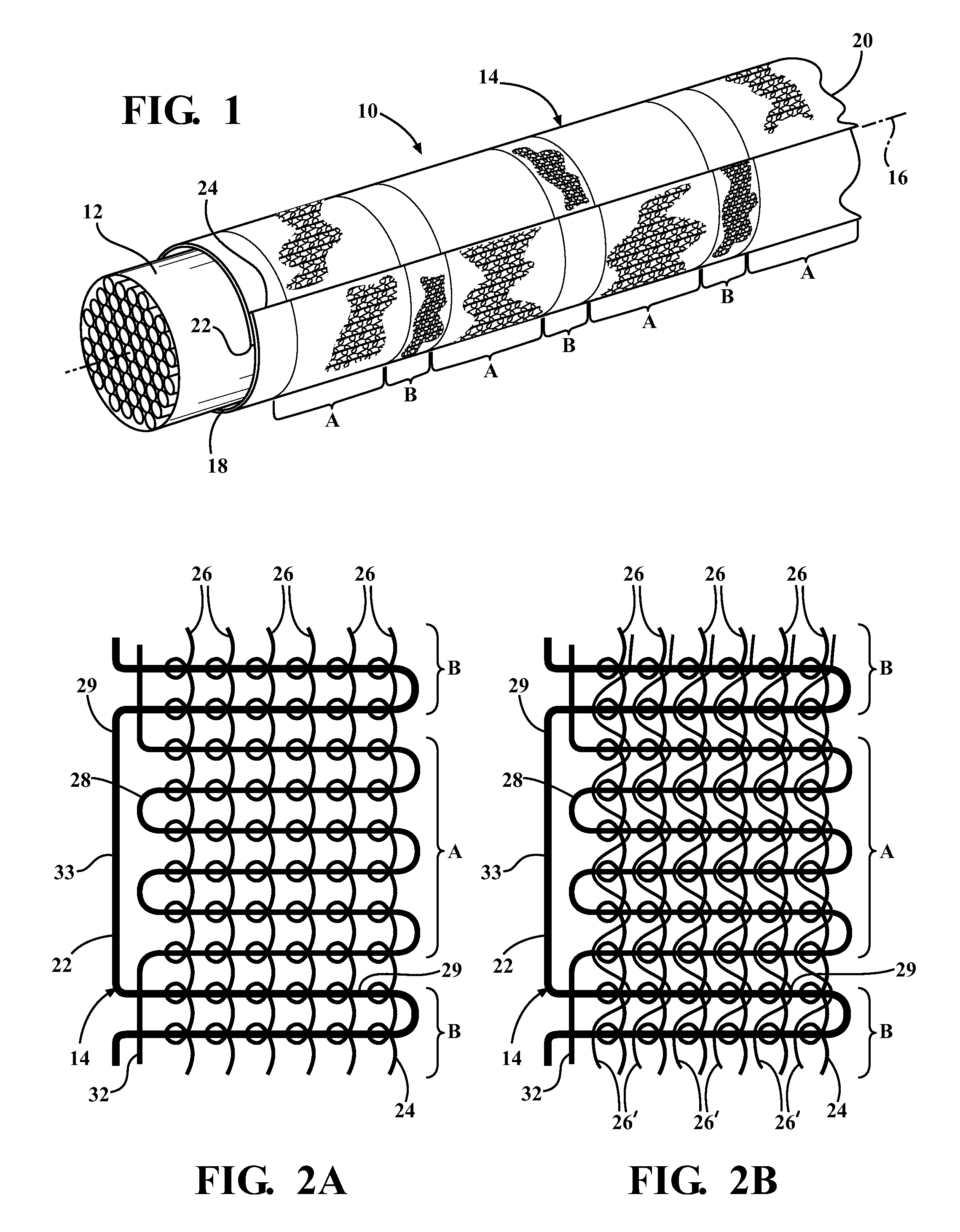

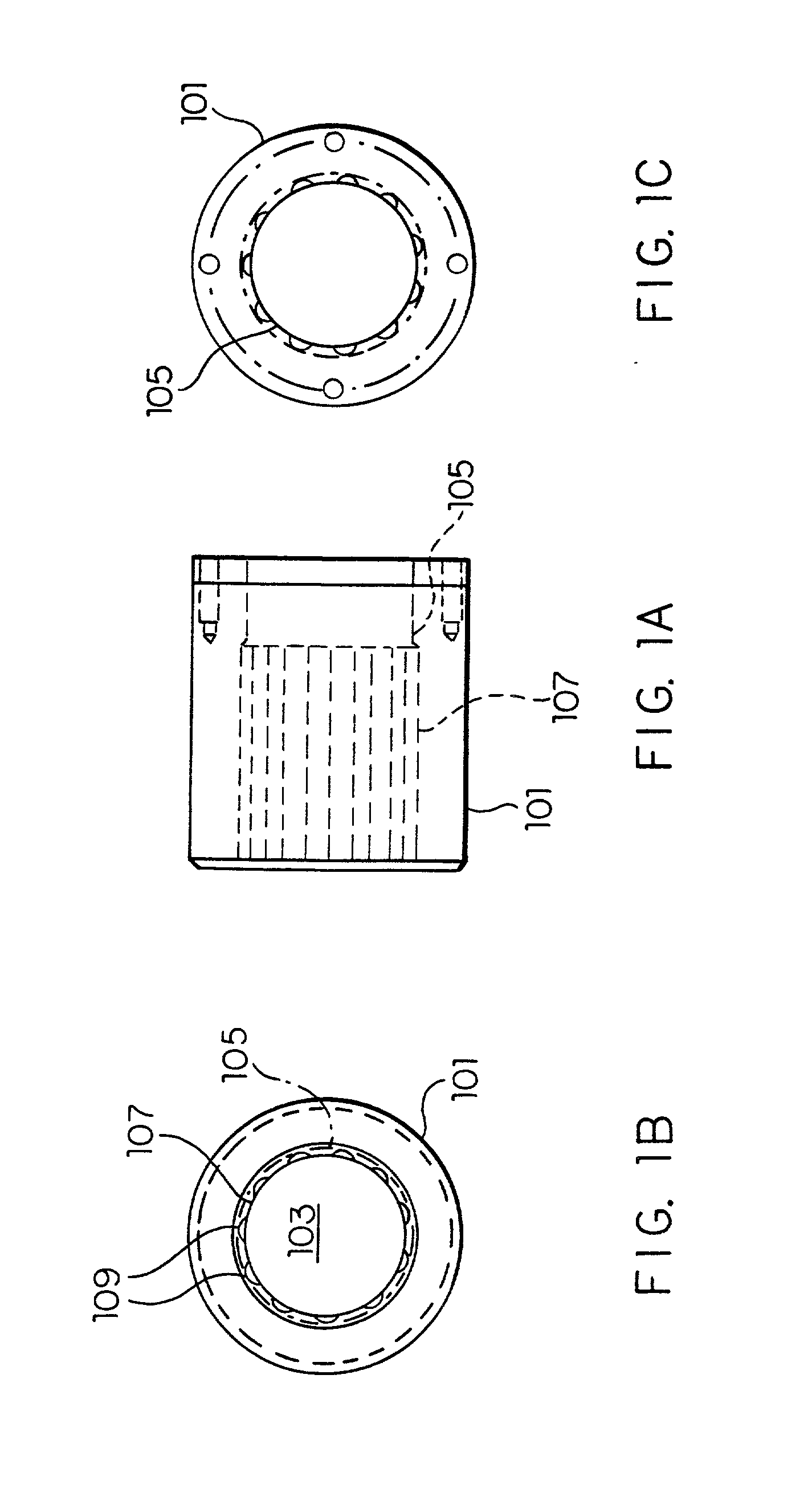

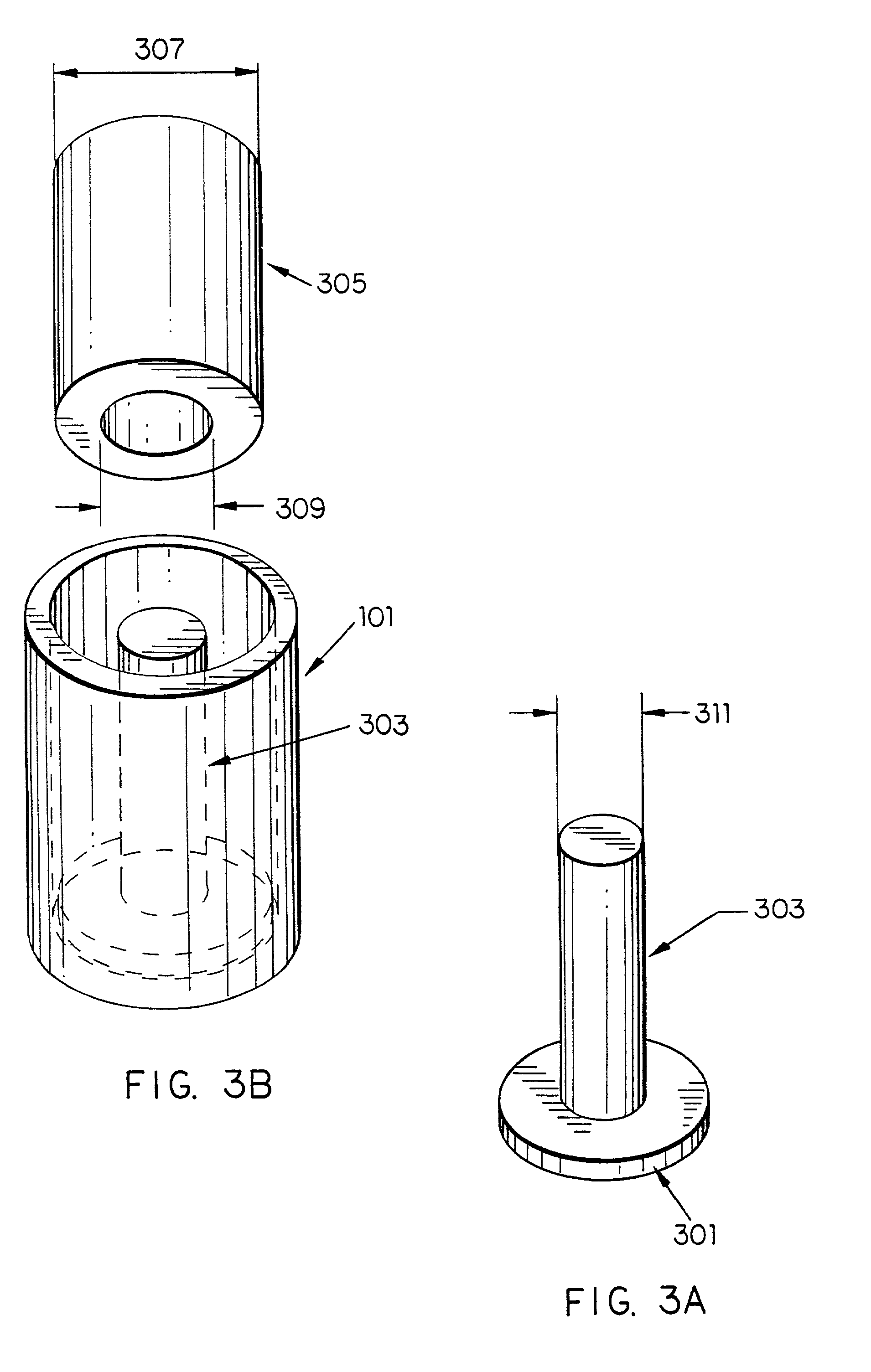

Implantable prosthesis and method and apparatus for loading and delivering an implantable prosthesis

InactiveUS6926723B1Easy to operateEnhanced hoop strengthProsthesisWound clampsLong axisBiomedical engineering

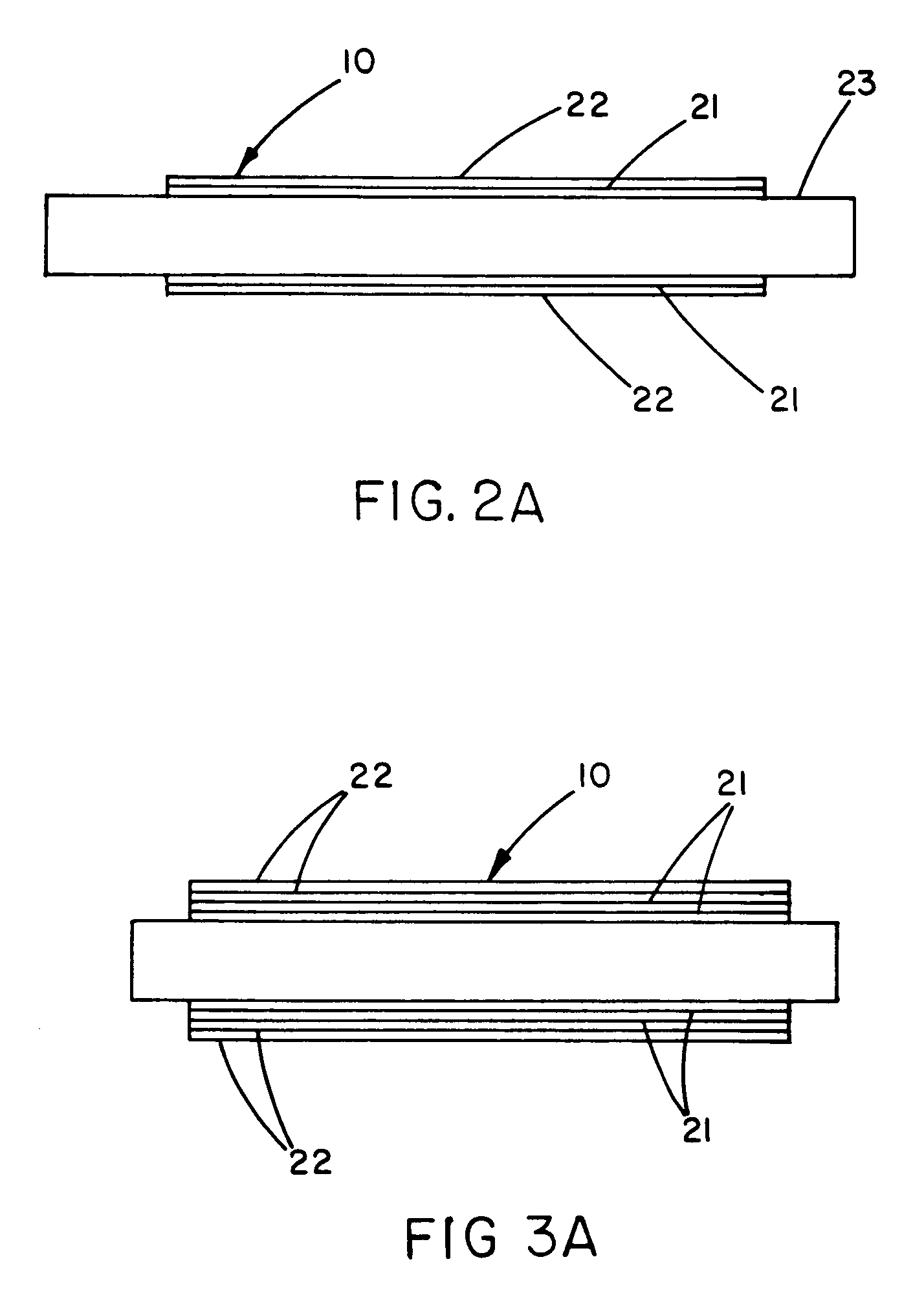

An implantable prosthesis and device and method for loading and delivering the implantable prosthesis to a trocar cannula. The implantable prosthesis includes a body portion sufficient to extend across and occlude a defect opening and a semi-rigid ring for supporting the body portion. The implantable prosthesis may be provided with a sufficient hoop strength to prevent the body portion from collapsing into the defect opening. A loading and delivery tool includes a main body with a lumen sized to collapse the implantable prosthesis. An elongated shaft is rotatable to wind the implant into a slender configuration and axially moveable to advance the rolled-up implant into the trocar cannula. A cartridge extends from the main body and holds the implant in a normal expanded configuration.

Owner:CR BARD INC

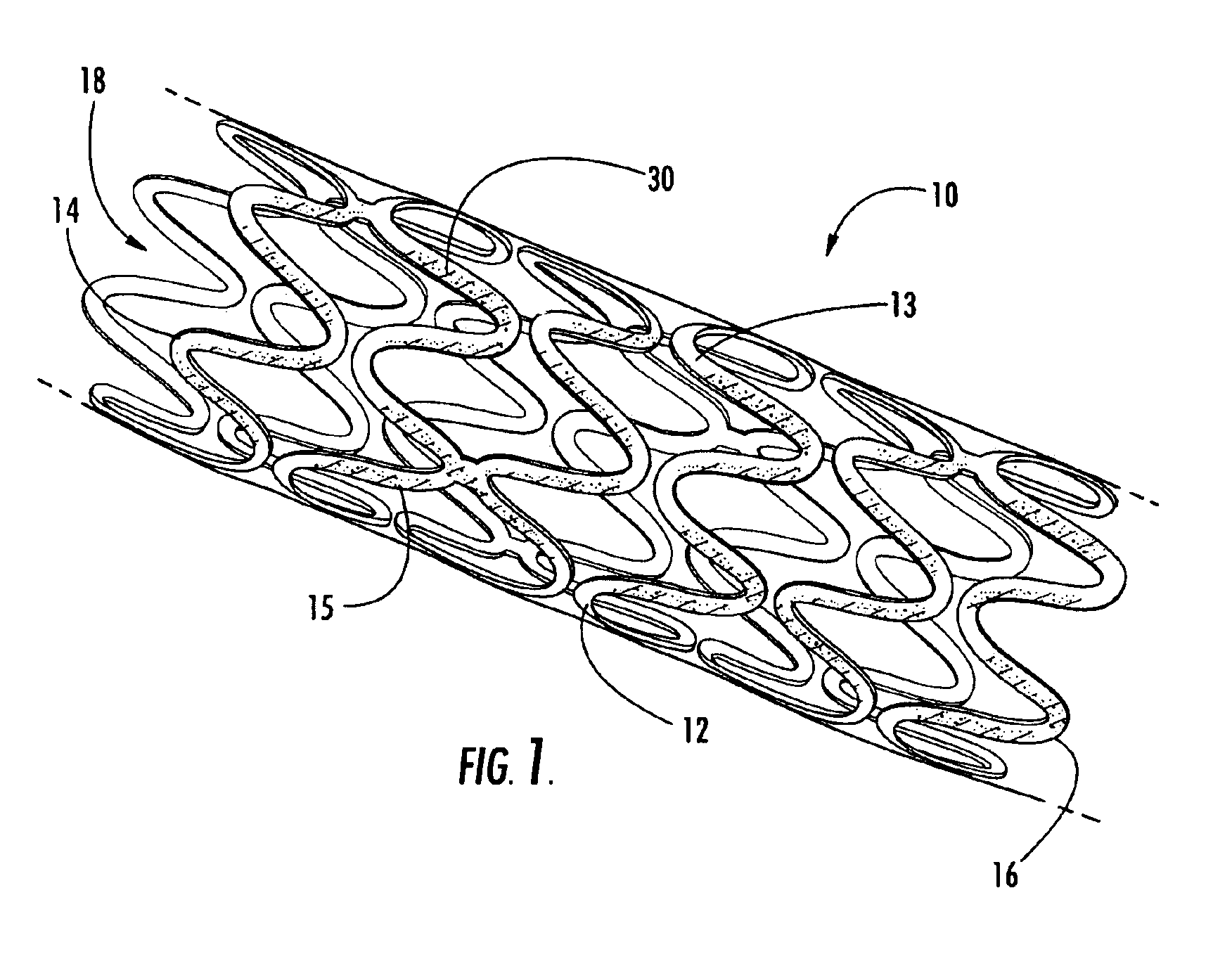

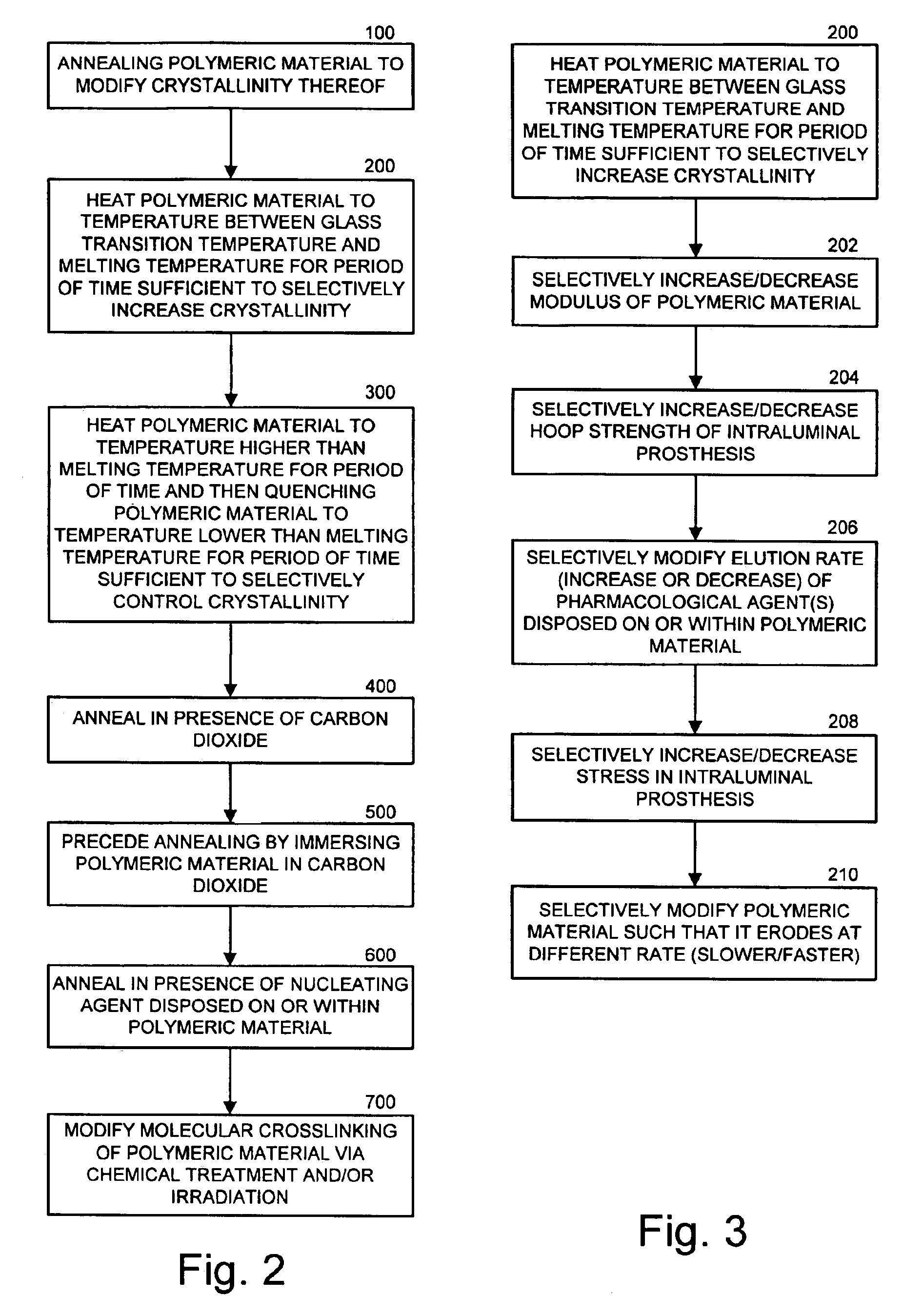

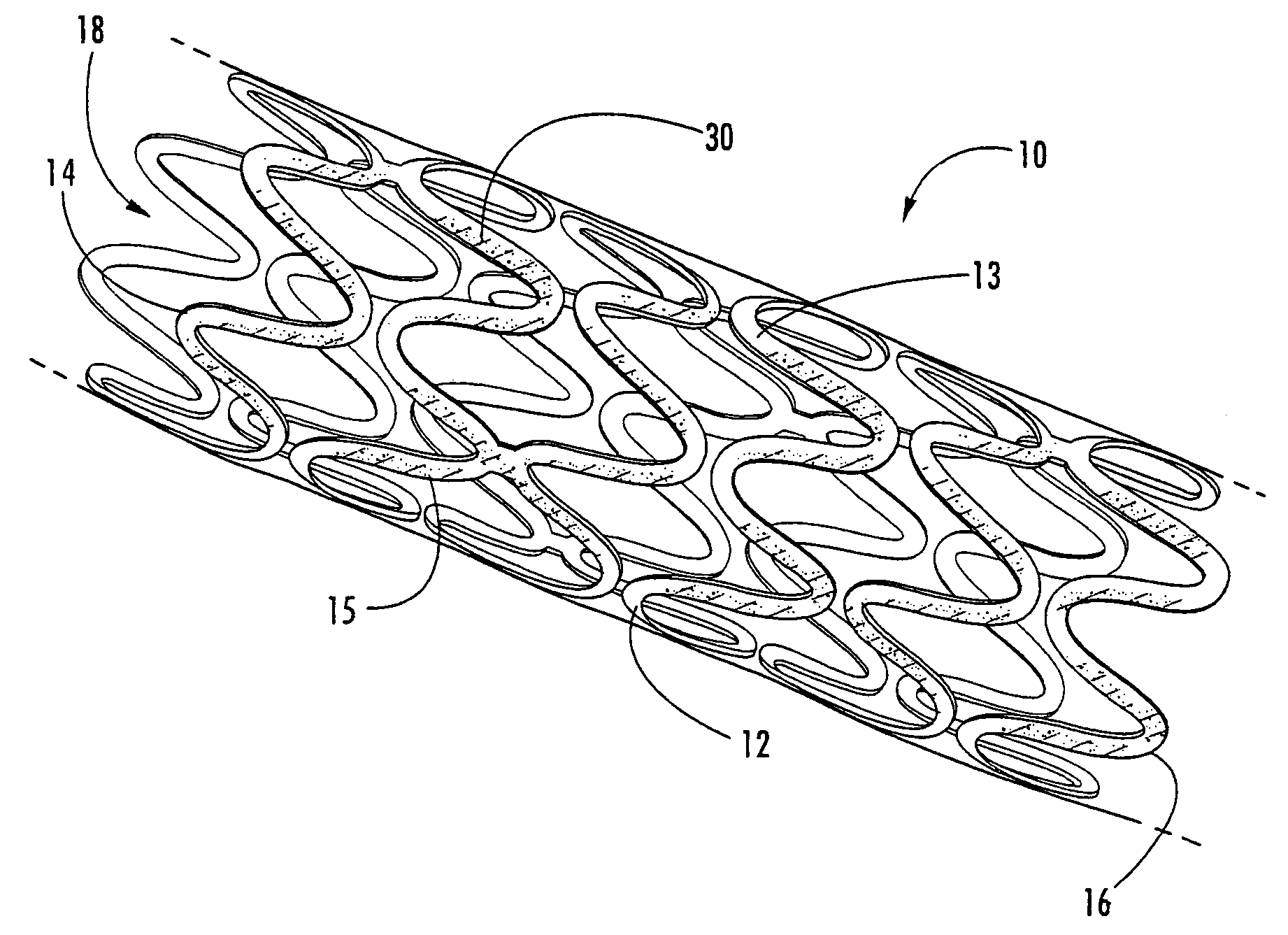

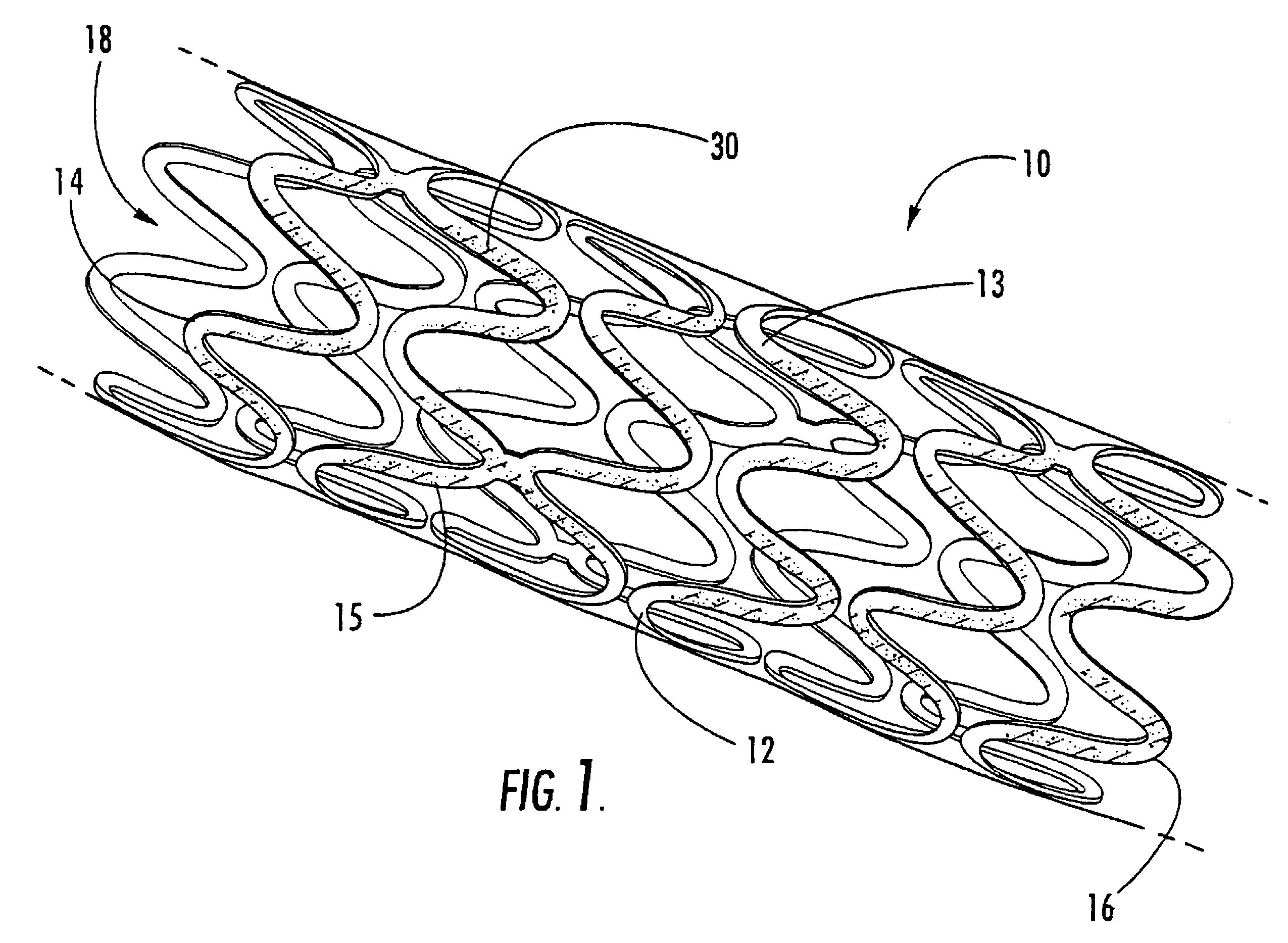

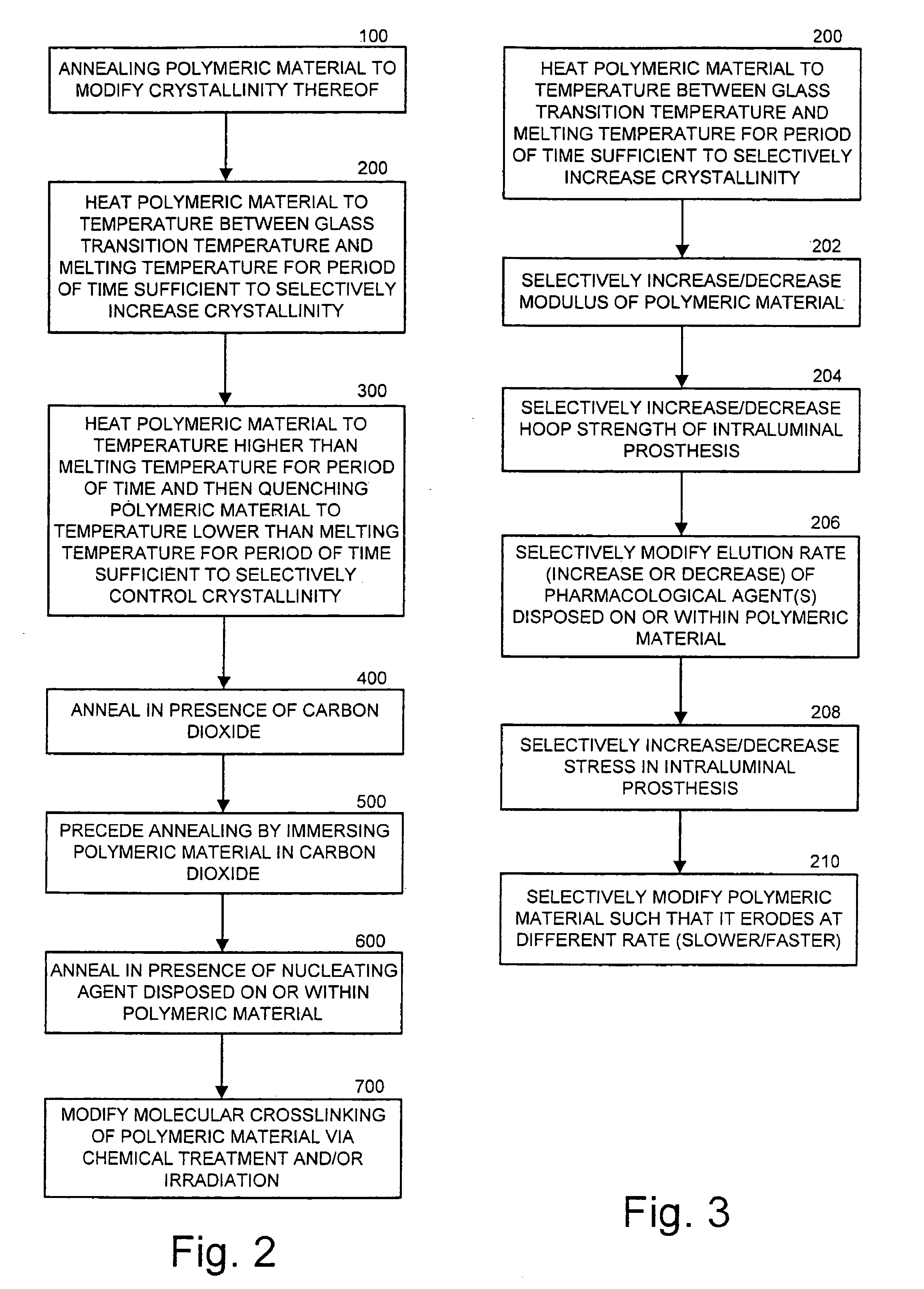

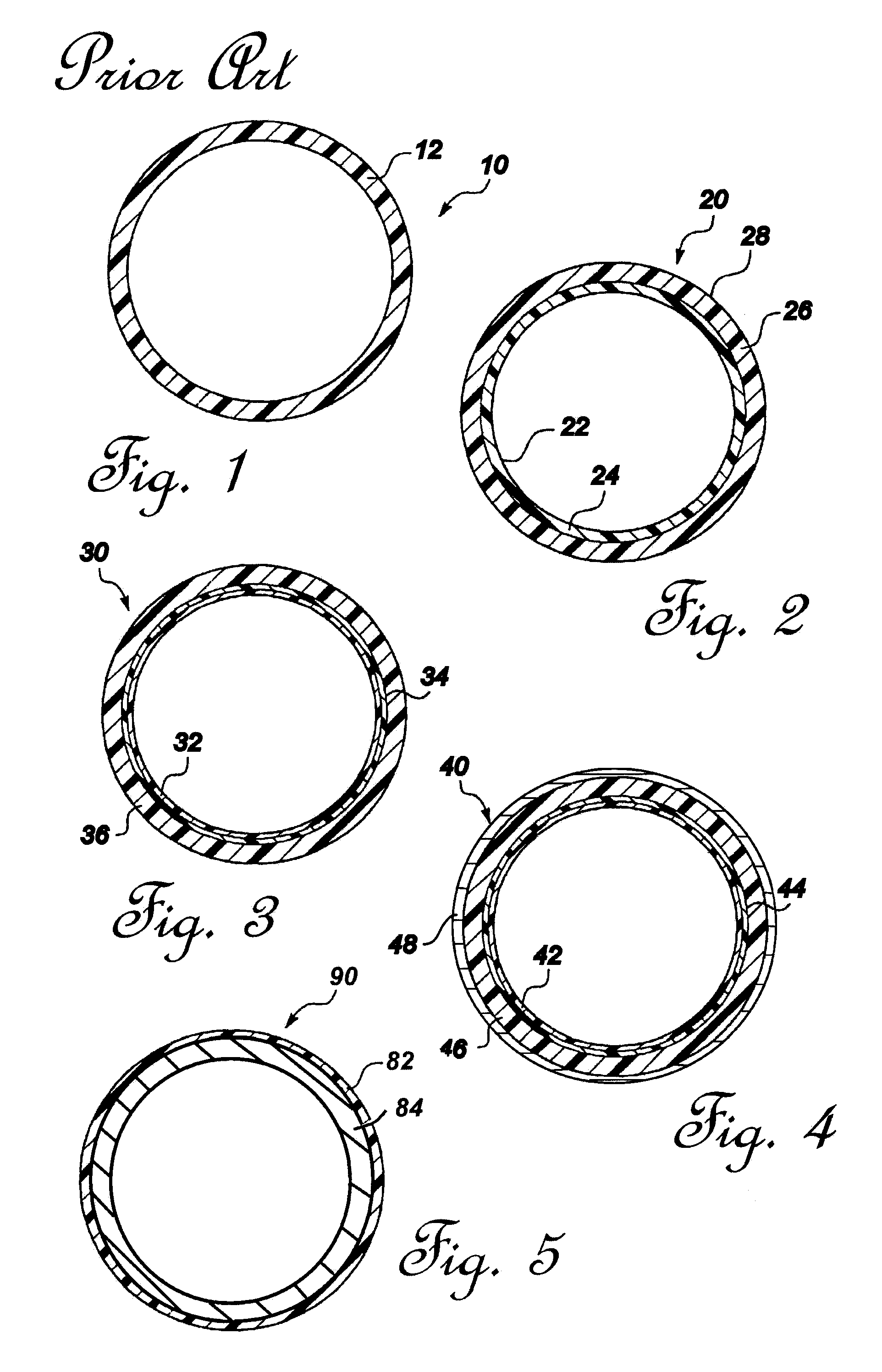

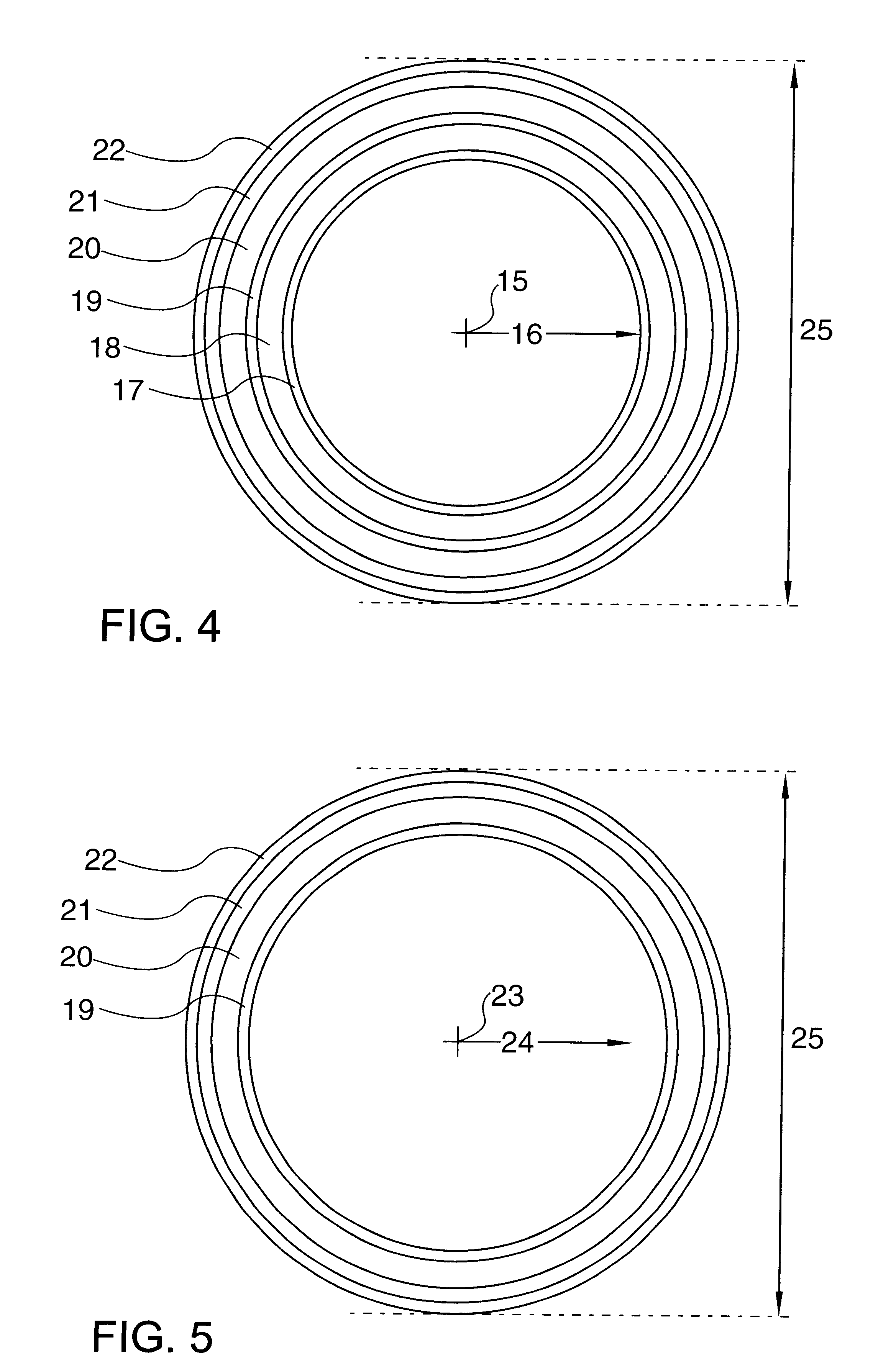

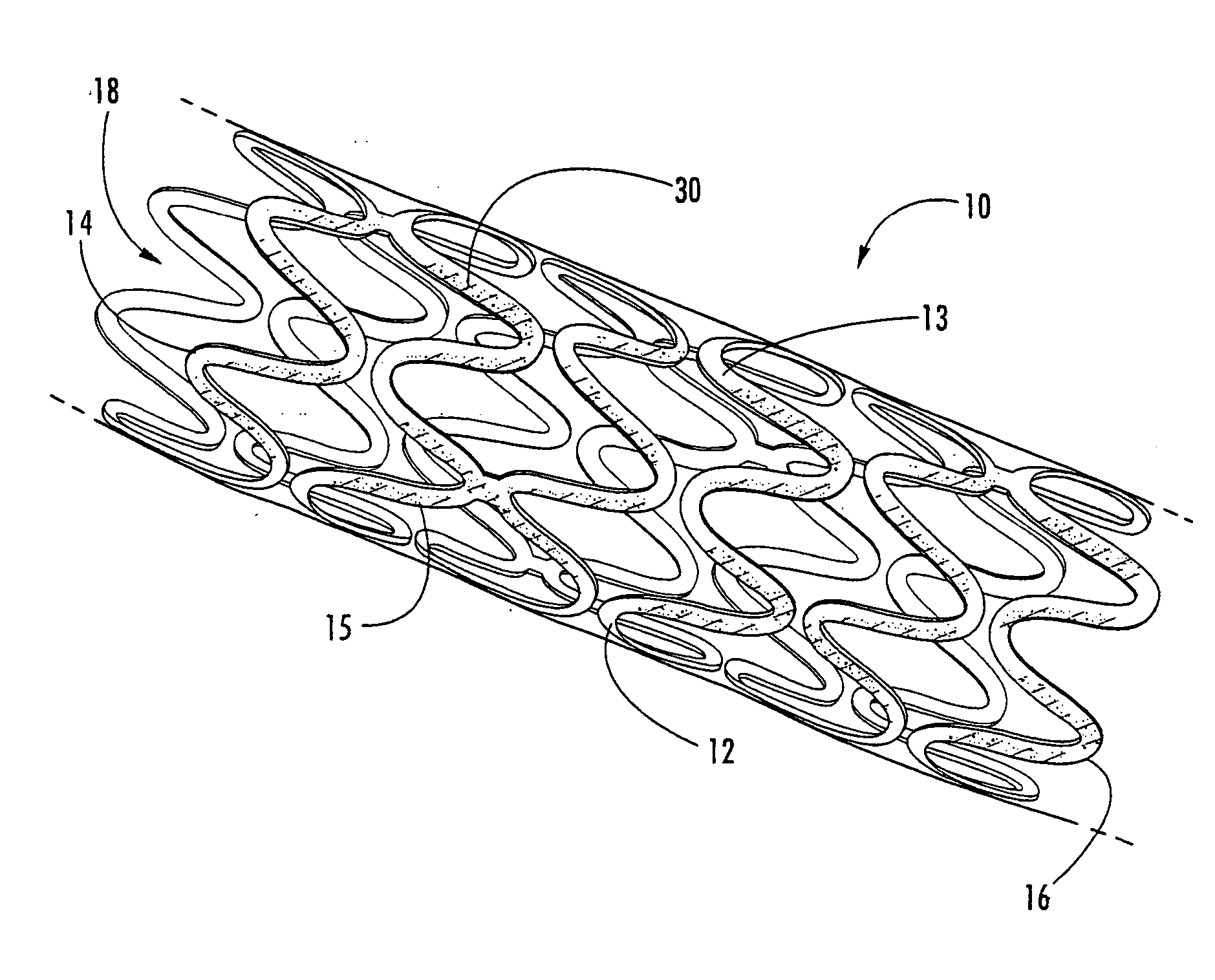

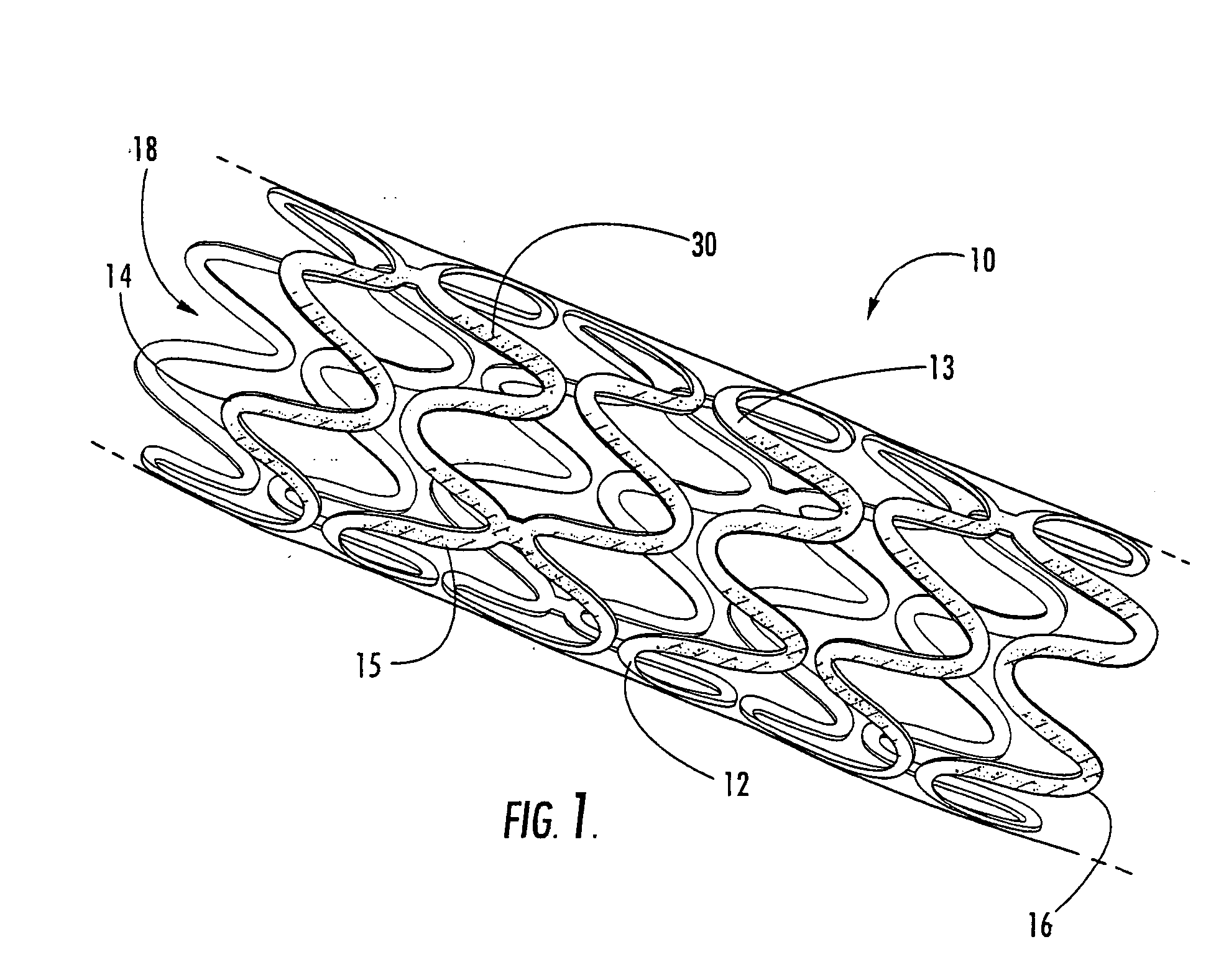

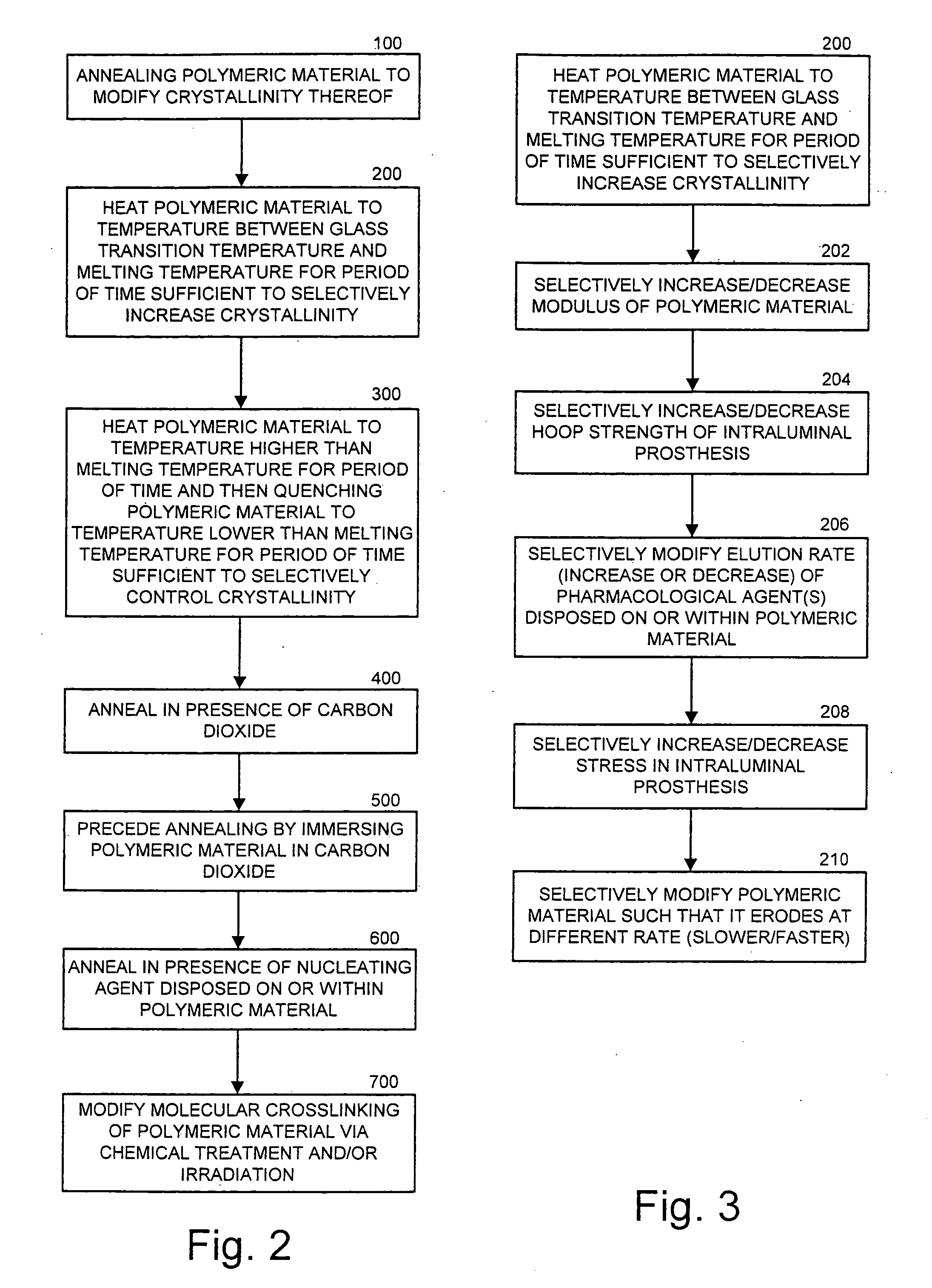

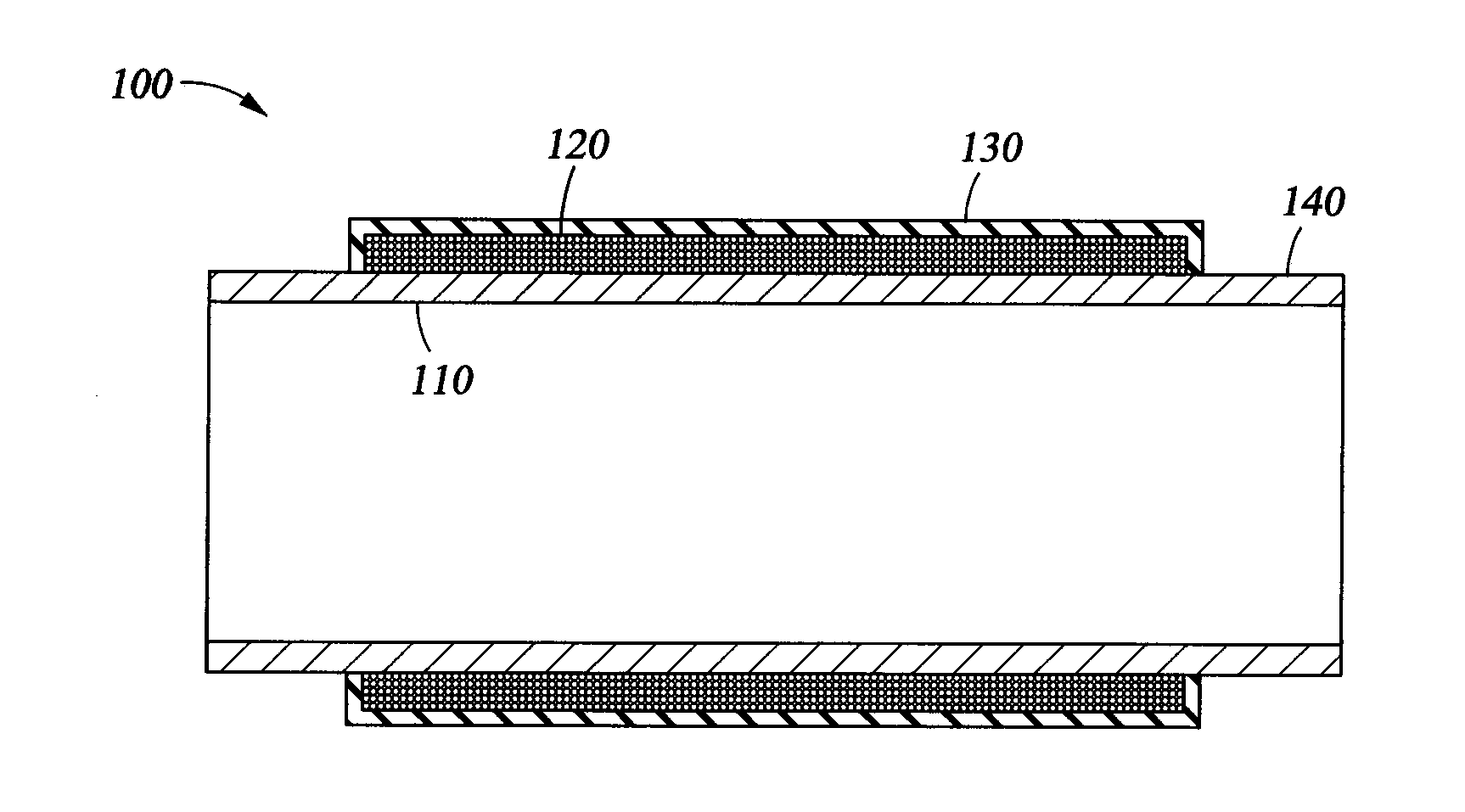

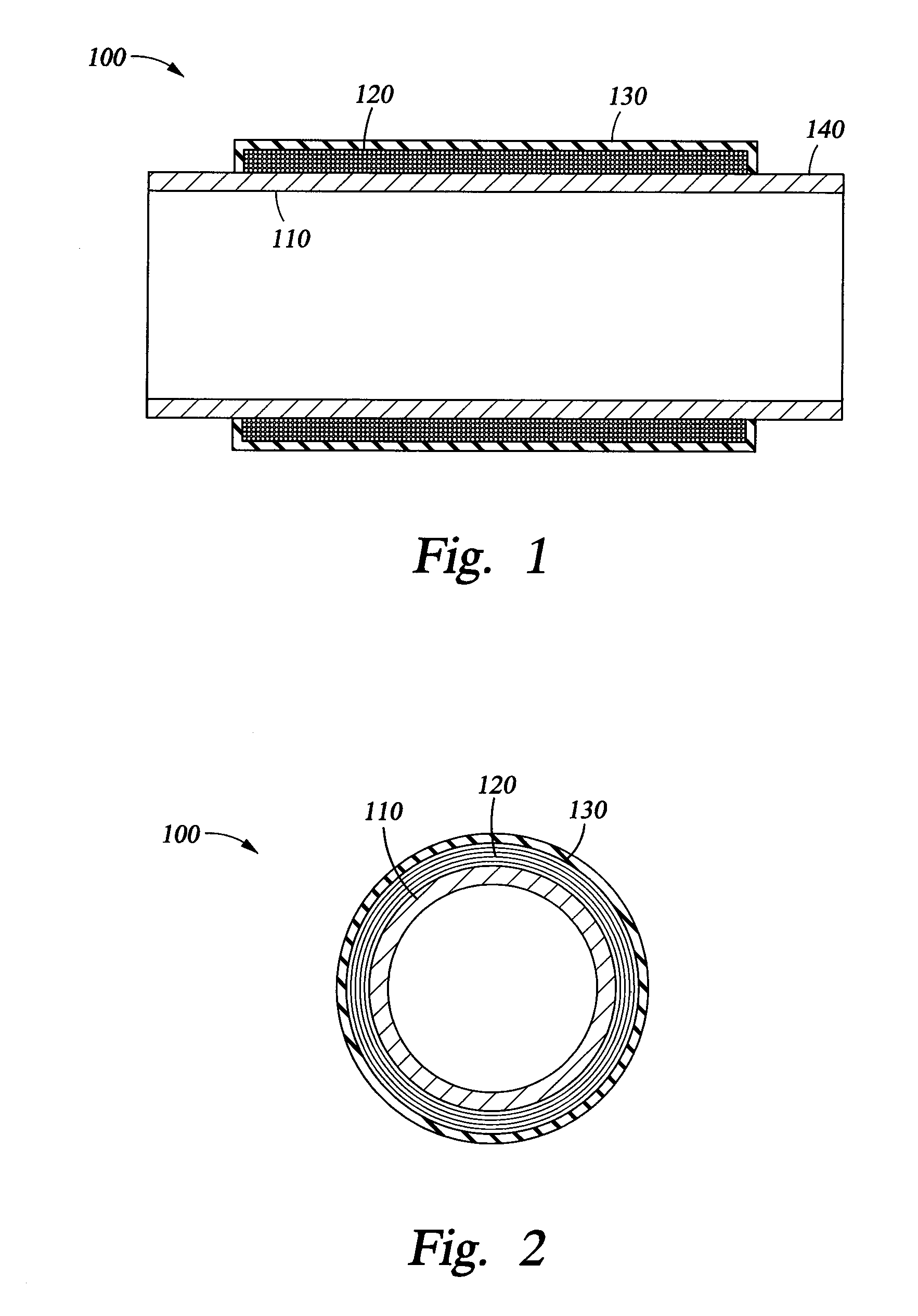

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

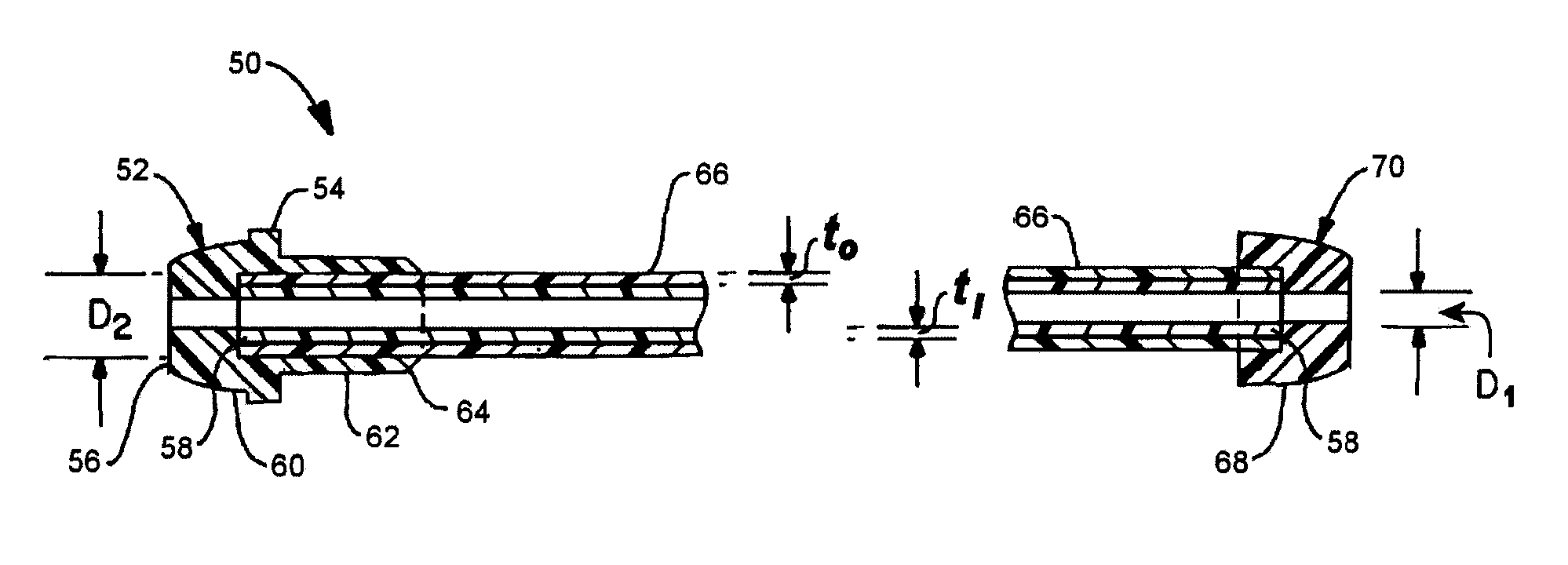

Catheher system having connectable distal and proximal portions

InactiveUS6050949AEnhanced hoop strengthBending stiffnessUltrasonic/sonic/infrasonic diagnosticsSurgeryPlastic materialsUltrasonic imaging

A vascular catheter system comprises a catheter body having a proximal and distal portion and a single common lumen therebetween. The catheter body includes a first connector secured to the distal end of the proximal portion and a second connector secured to the proximal end of the distal portion. The connectors can be selectively connected to each other to join the lumens of the proximal and distal portions together in a continuous, axially fixed relationship. Disposed within the lumens, when the proximal and distal portions are joined together, is a drive cable. The drive cable may be movably, rotatable about its own longitudinal axis and carries at its distal end, a work element, which is typically an ultrasonic imaging transducer or interventional device. The lumen carrying the cable will be sufficiently large along a proximal portion to permit preferential collapse of the cable should rotation of the distal end become impeded. The catheter body may be made of a polymer or plastic material, such as polyetheretherketone (PEEK), which provides adequate bonding stiffness and resistance to kinking from large hoop stresses.

Owner:BOSTON SCI SCIMED INC

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

InactiveUS7919162B2High modulusEnhanced hoop strengthStentsSynthetic resin layered productsProsthesisCrystallinity

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

System and method for intraluminal imaging

InactiveUS6364841B1Enhanced hoop strengthBending stiffnessUltrasonic/sonic/infrasonic diagnosticsSurgeryUltrasonic imagingPlastic materials

A vascular catheter system comprises a catheter body having a proximal and distal portion and a single common lumen therebetween. The catheter body includes a first connector secured to the distal end of the proximal portion and a second connector secured to the proximal end of the distal portion. The connectors can be selectively connected to each other to join the lumens of the proximal and distal portions together in a continuous, axially fixed relationship. Disposed within the lumens, when the proximal and distal portions are joined together, is a drive cable. The drive cable may be movably, rotatable about its own longitudinal axis and carries at its distal end, a work element, which is typically an ultrasonic imaging transducer or interventional device. The lumen carrying the cable will be sufficiently large along a proximal portion to permit preferential collapse of the cable should rotation of the distal end become impeded. The catheter body may be made of a polymer or plastic material, such as polyetheretherketone (PEEK), which provides adequate bonding stiffness and resistance to kinking from large hoop stresses.

Owner:BOSTON SCI LTD +1

Thin-wall polytetrafluoroethylene tube

A thin-wall PTFE (polytetrafluoroethylene) tube in the form of a tube of porous expanded PTFE film wherein the porous PTFE film has a microstructure containing a multiplicity of fibrils. The thin-wall tube is used in a non-porous embodiment as the balloon portion of a balloon catheter. The thin-wall tube is not elastomeric; however, because of the thinness, strength and flexibility of the tube, it may be inserted into a body conduit in a collapsed state and then deployed from a catheter and inflated up to the maximum diameter of the thin-wall tube. The porous PTFE film is provided with a continuous layer of adhesive to provide the non-porous tube; the adhesive is preferably a thermoplastic and more preferably a thermoplastic fluoropolymer such as fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

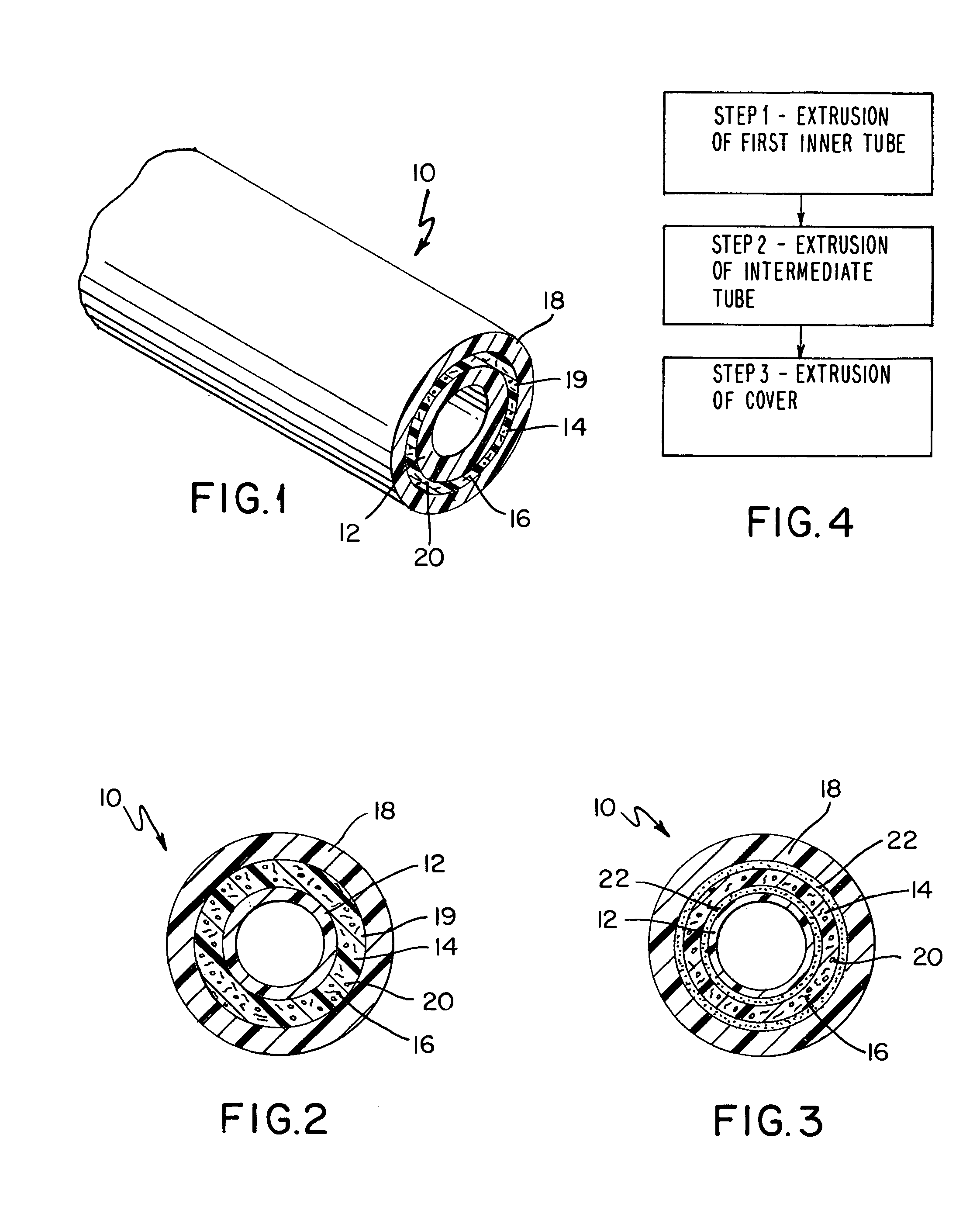

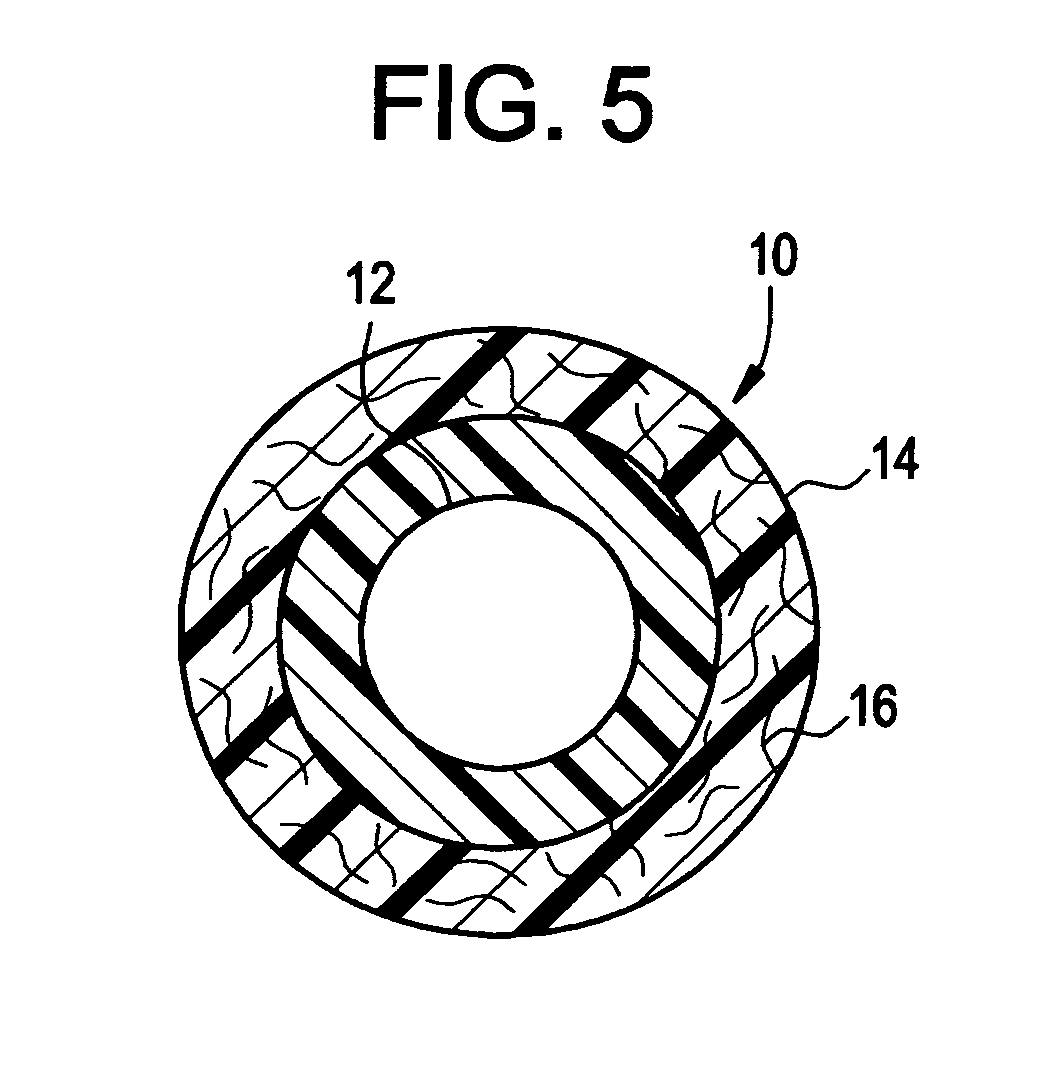

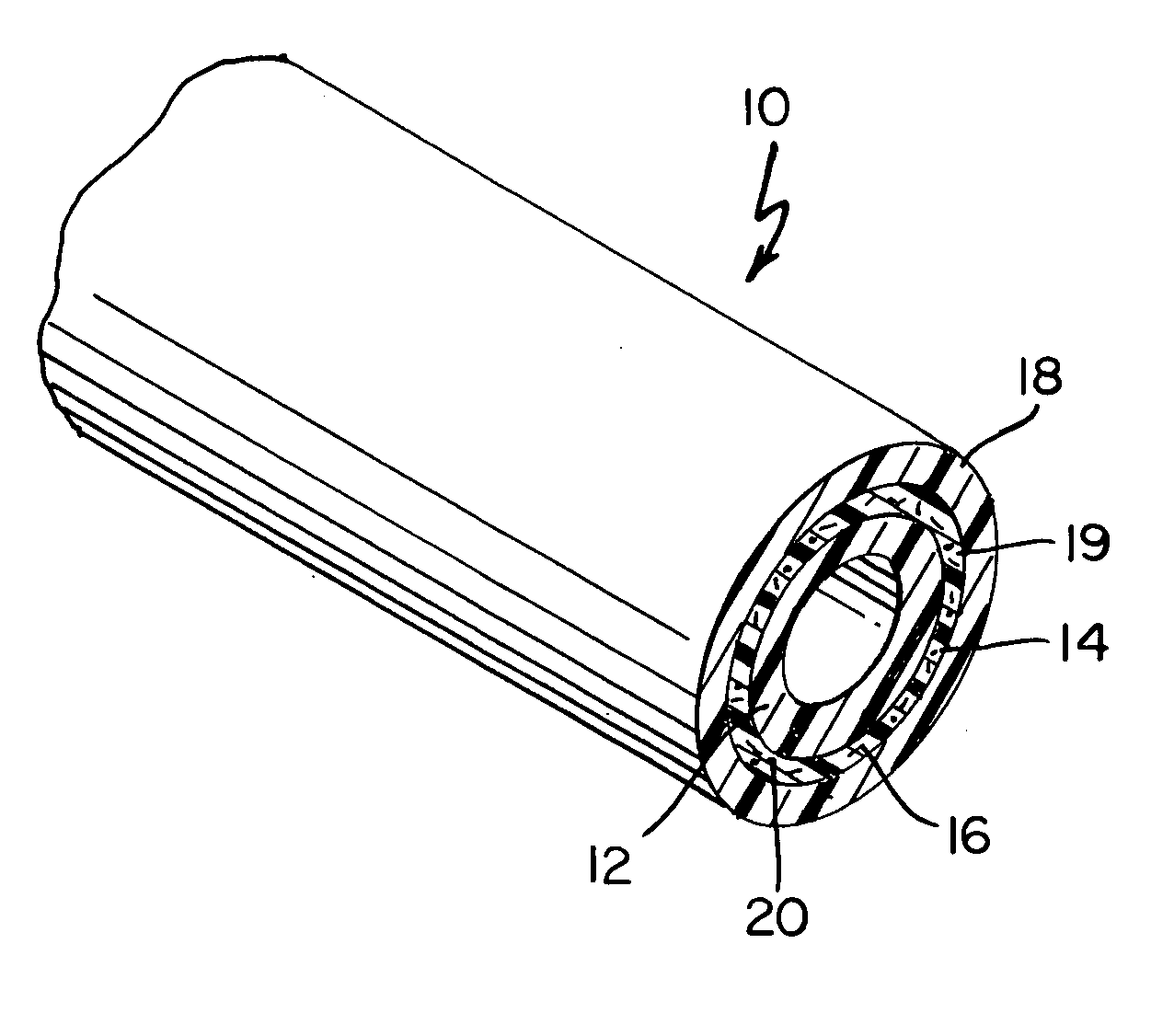

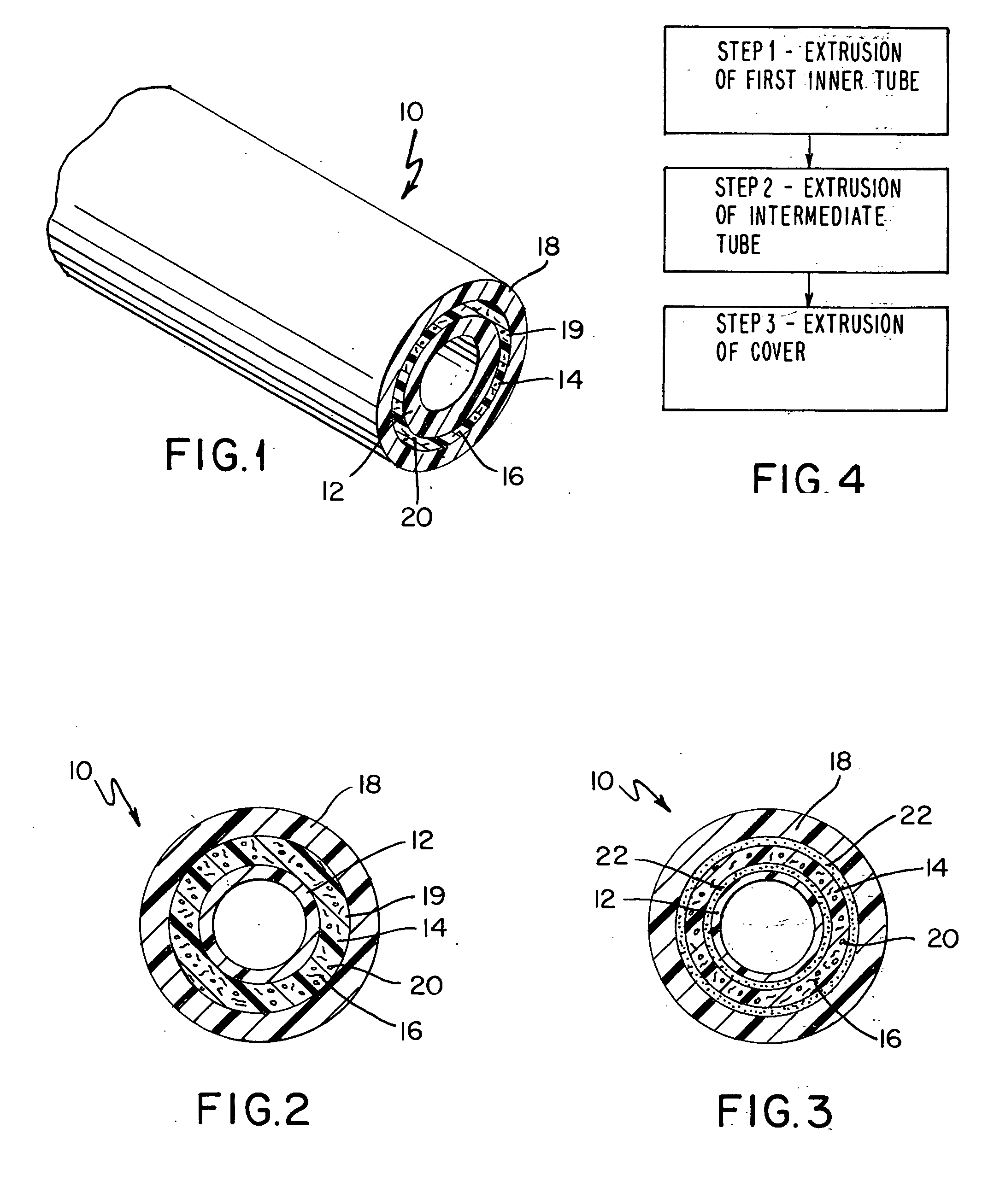

Multilayer tubes

InactiveUS20070051418A1Reduced flexibilityReduce wall thicknessFlexible pipesRigid pipesThermoplastic elastomerEngineering

The invention described relates to a composition for a multilayer tube having an inner and an outer layer. Preferably the inner layer of the tube has at least one at least partially crosslinked, preferably polyethylene, which is less flexible than the adjacent more flexible outer layer, which is preferably a thermoplastic elastomer. The inner and outer layers are typically coextruded during manufacture, with at least one overmolded end, preferably crosslinked, which generally has an internal diameter which is essentially the same as the internal diameter of the multilayer tube. The multilayer tube is typically crosslinked, preferably by electron beam.

Owner:ROWLES BRIAN A +1

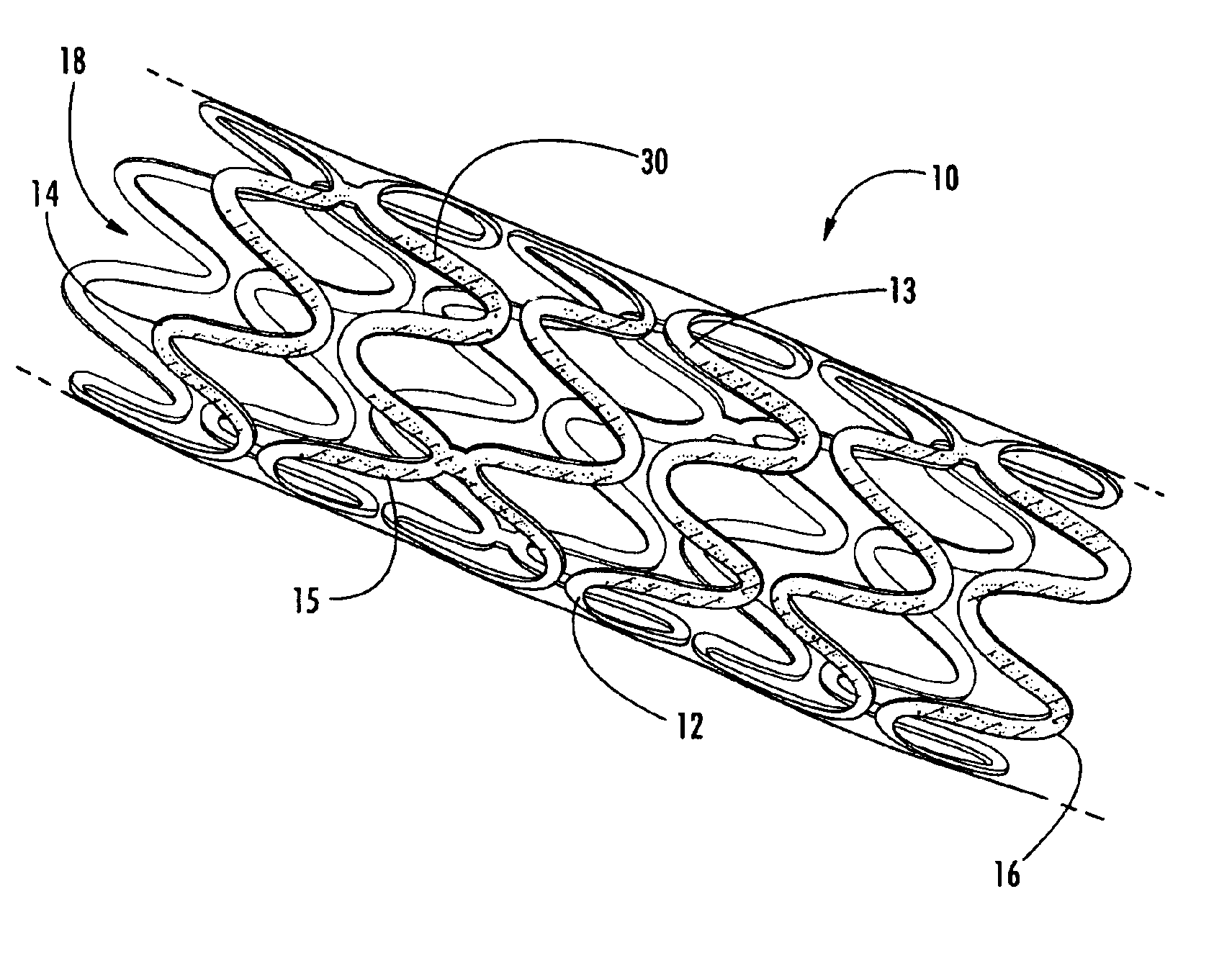

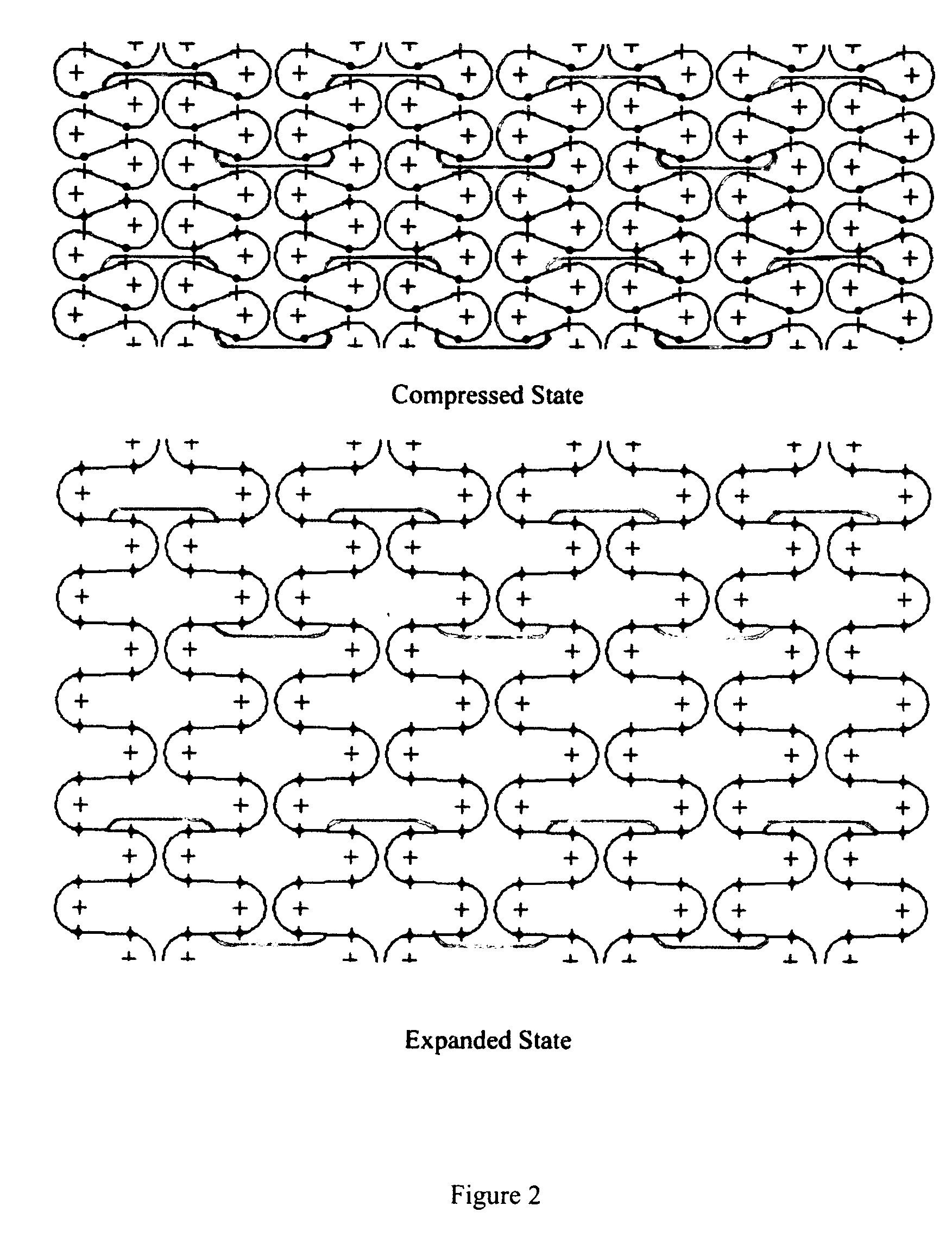

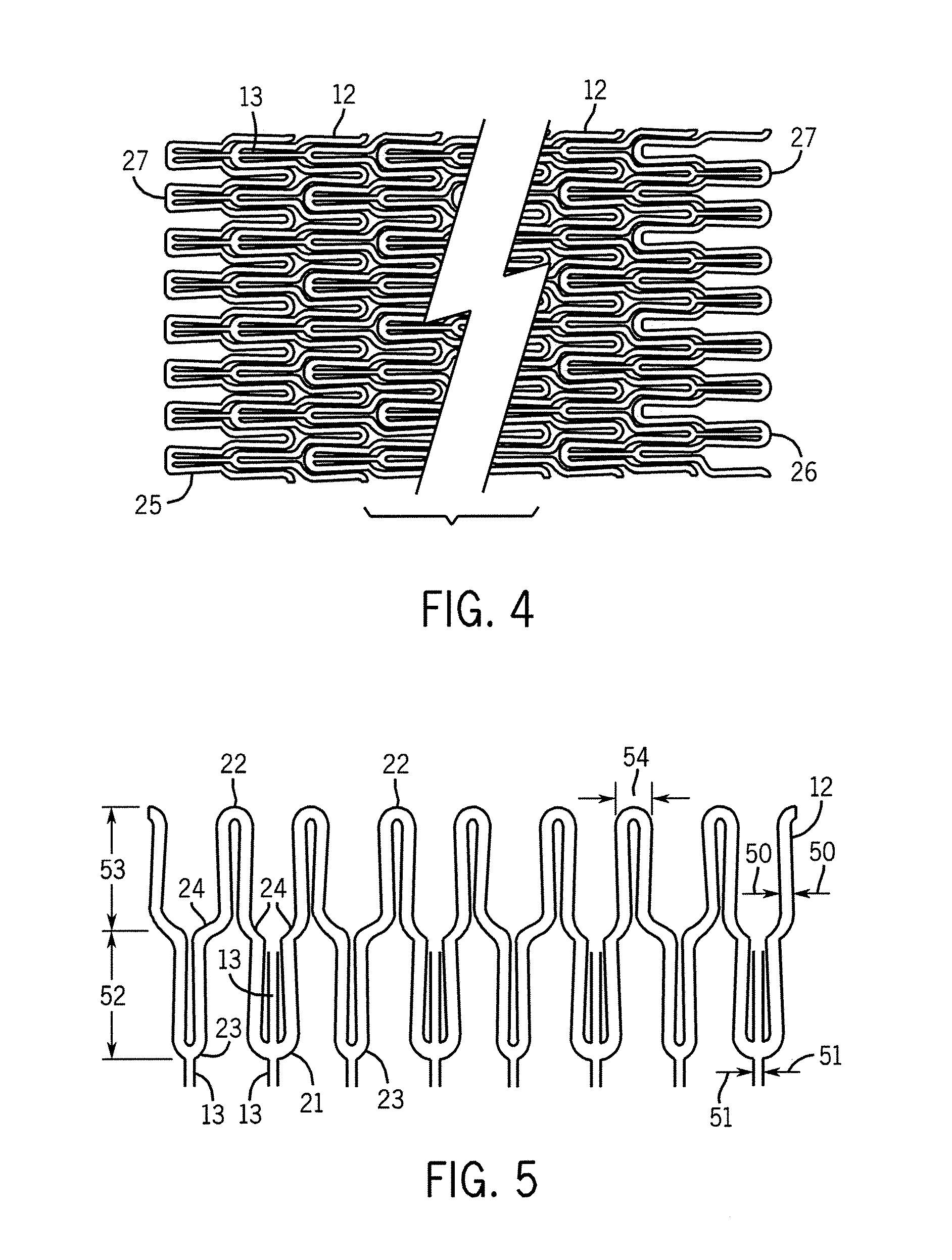

Expandable endovascular stent

InactiveUS20050080479A1Minimize amount of materialSubstantial longitudinal flexibility longitudinalStentsBlood vesselsStress concentrationPercent Diameter Stenosis

Disclosed herein is a tubular endovascular stent comprising a plurality of annular segments connected by one or more bridging elements. Each annular segment takes forms of periodic wavelets with a plurality of alternating symmetric peaks and valleys, preferably consisting of circular arc segments of large radii connected tangentially with straight segments to minimize stress concentration when the stent undergoes radial deformation, transverse to the longitudinal axis of the stent. The points of connection between the bridging elements and adjacent annular segments are so designed that deformations of the bridging elements remain negligible as the stent deforms radially, namely, the longitudinal dimension of the stent does not vary during the radial expansion or contraction of the stent. Hence, the radial strength and the longitudinal flexibility of the stent made according to the principles disclosed by the present invention can be independently controlled by the design parameters for the annular segments and bridging elements, without compromising the longitudinal dimensional stability of the stent. Since stress concentration and deformation in the stent can lead to restenosis, stent made from the invention disclosed here can reduce the probability of restenosis.

Owner:FENG JAMES Q +1

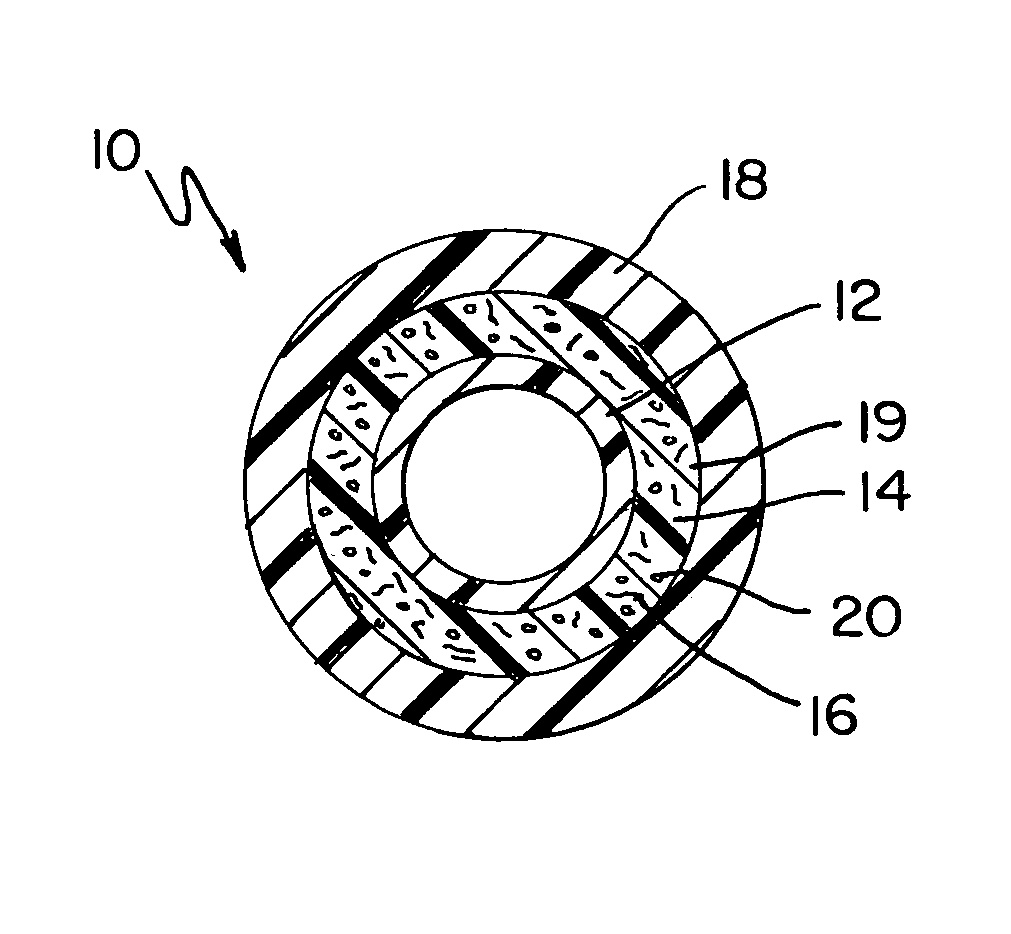

Multi-layered flexible tube

InactiveUS7281547B2Enhanced hoop strengthImprove adhesionSynthetic resin layered productsLaminationBiomedical engineeringPolymer architecture

Owner:FLUID ROUTING SOLUTIONS

Multi-layered flexible tube

InactiveUS20050170118A1Increase in production rateDecrease production cost and complexitySynthetic resin layered productsLaminationBiomedical engineeringPolymer architecture

Owner:FLUID ROUTING SOLUTIONS

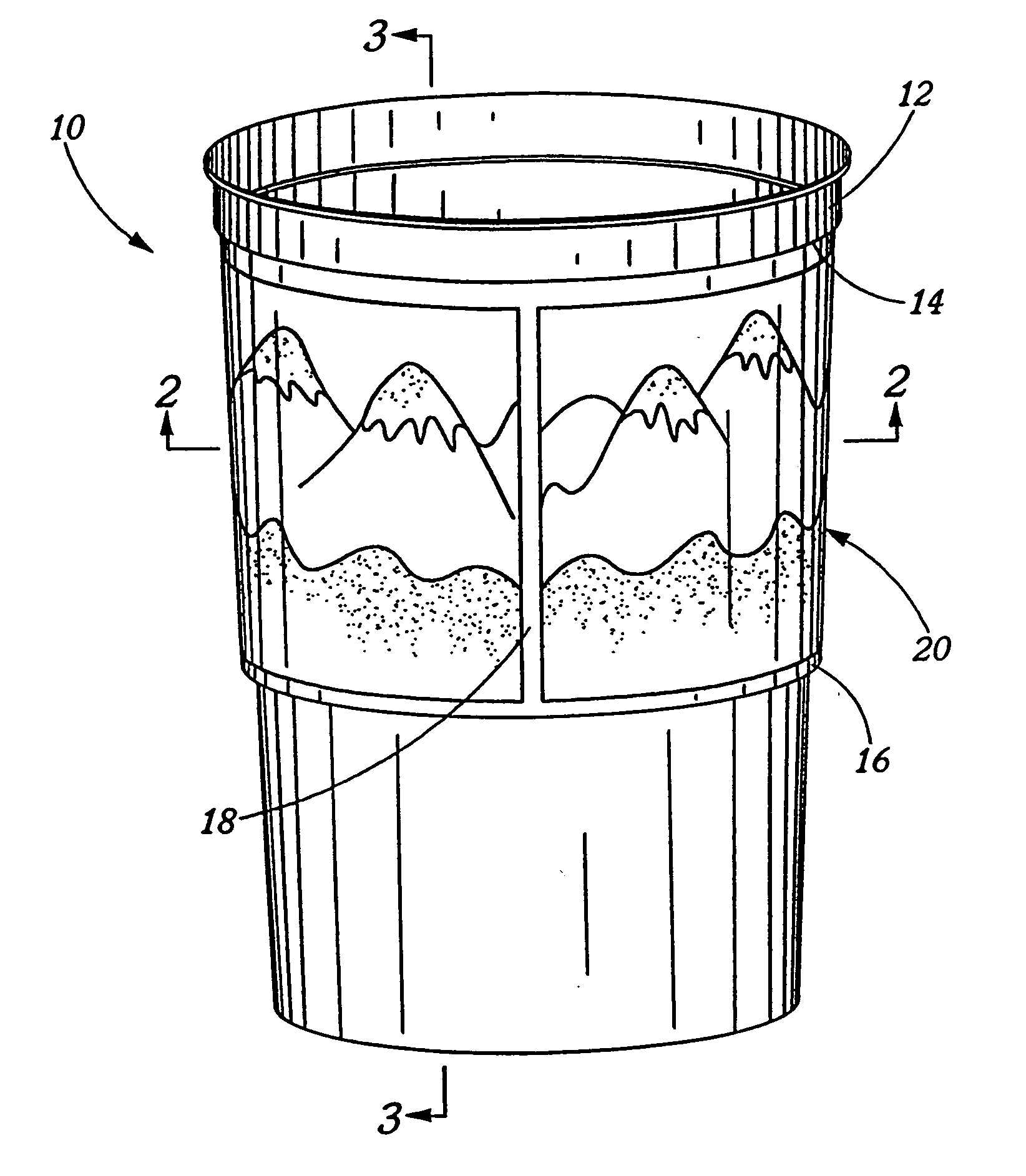

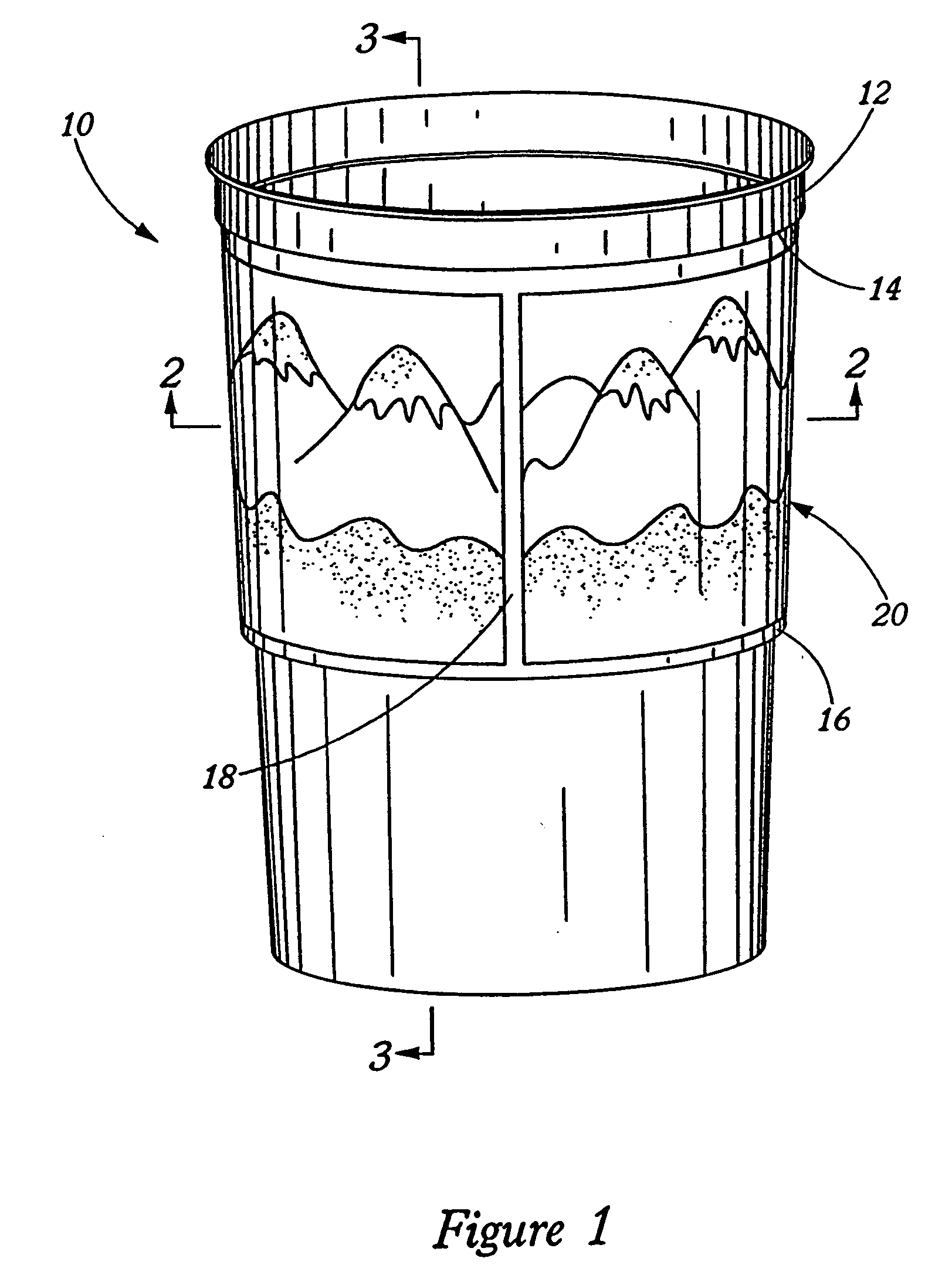

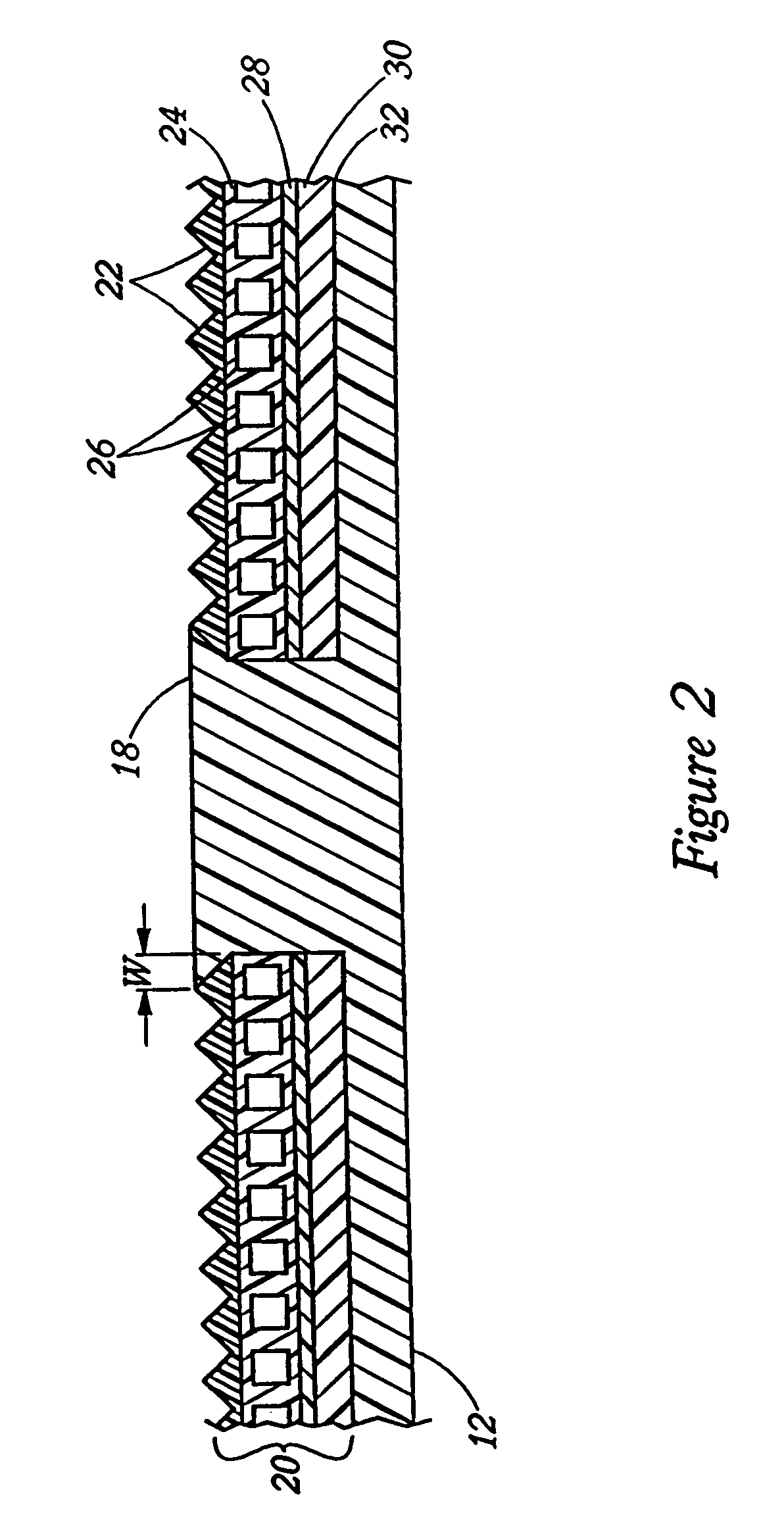

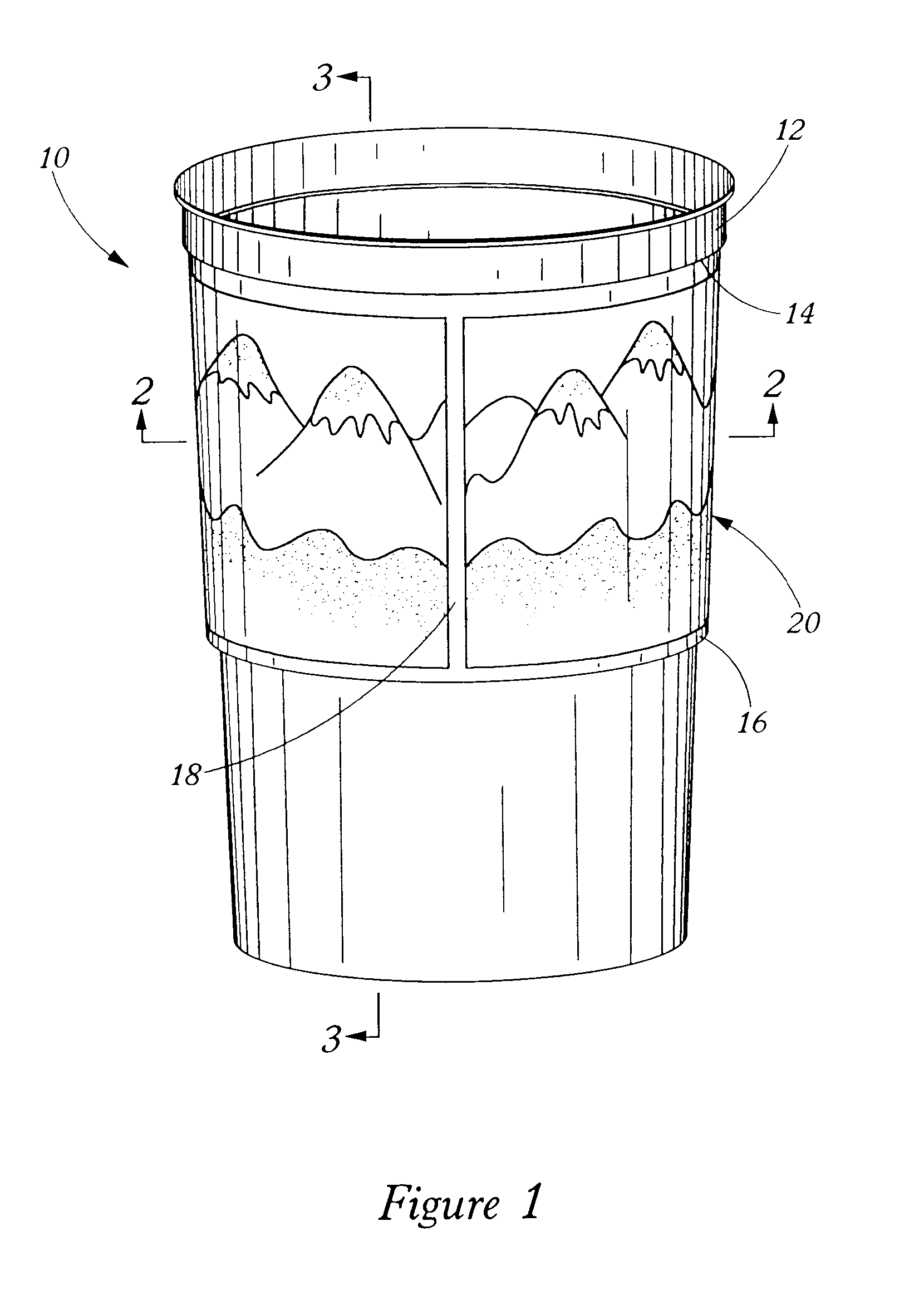

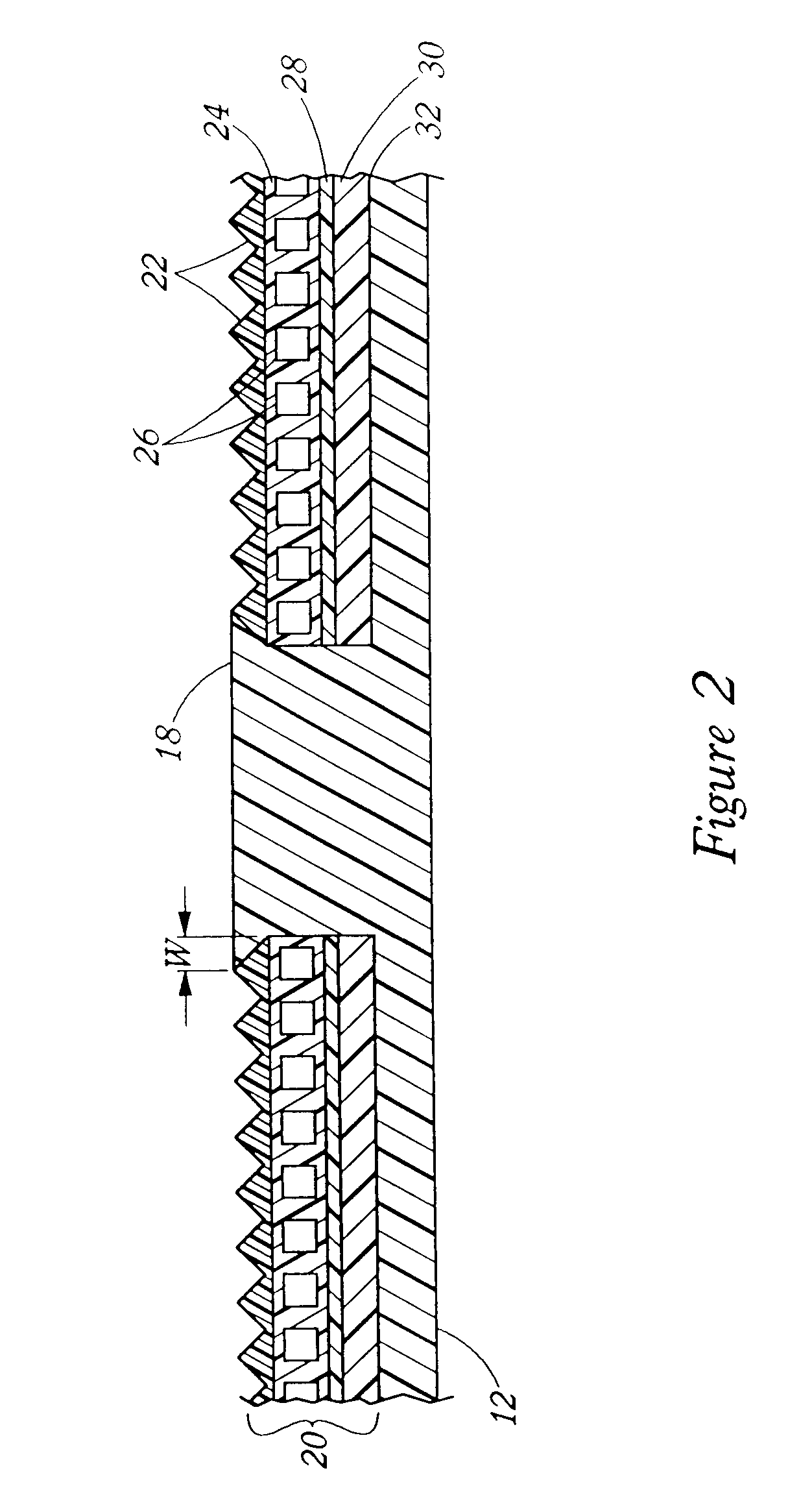

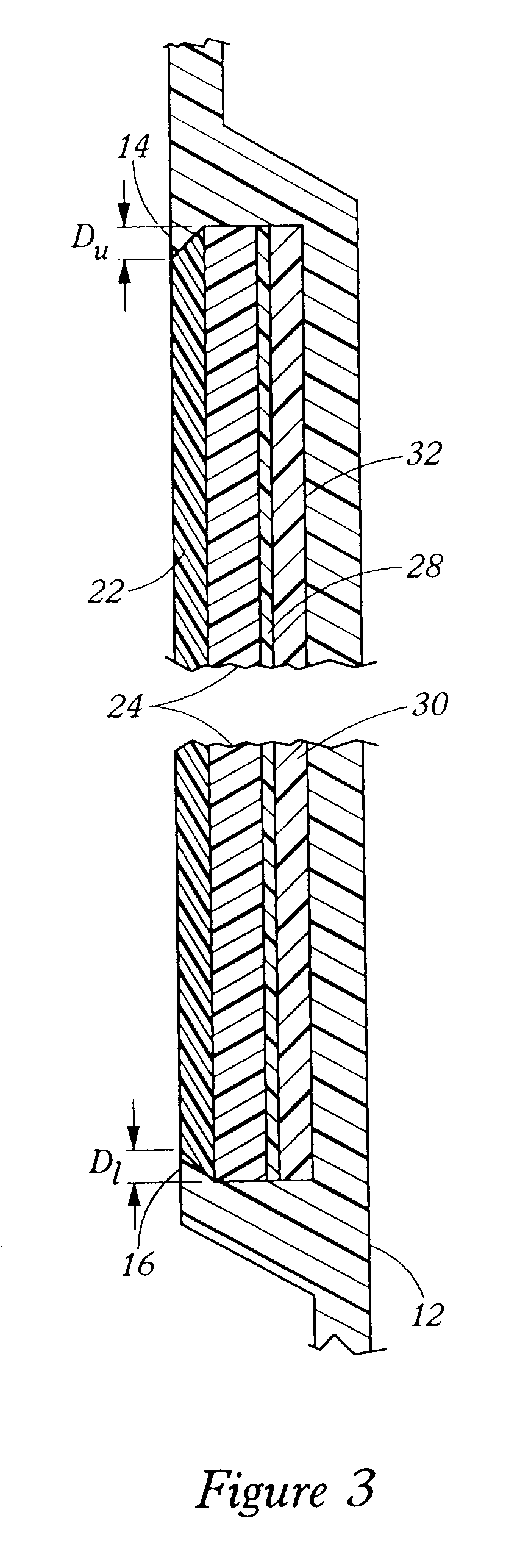

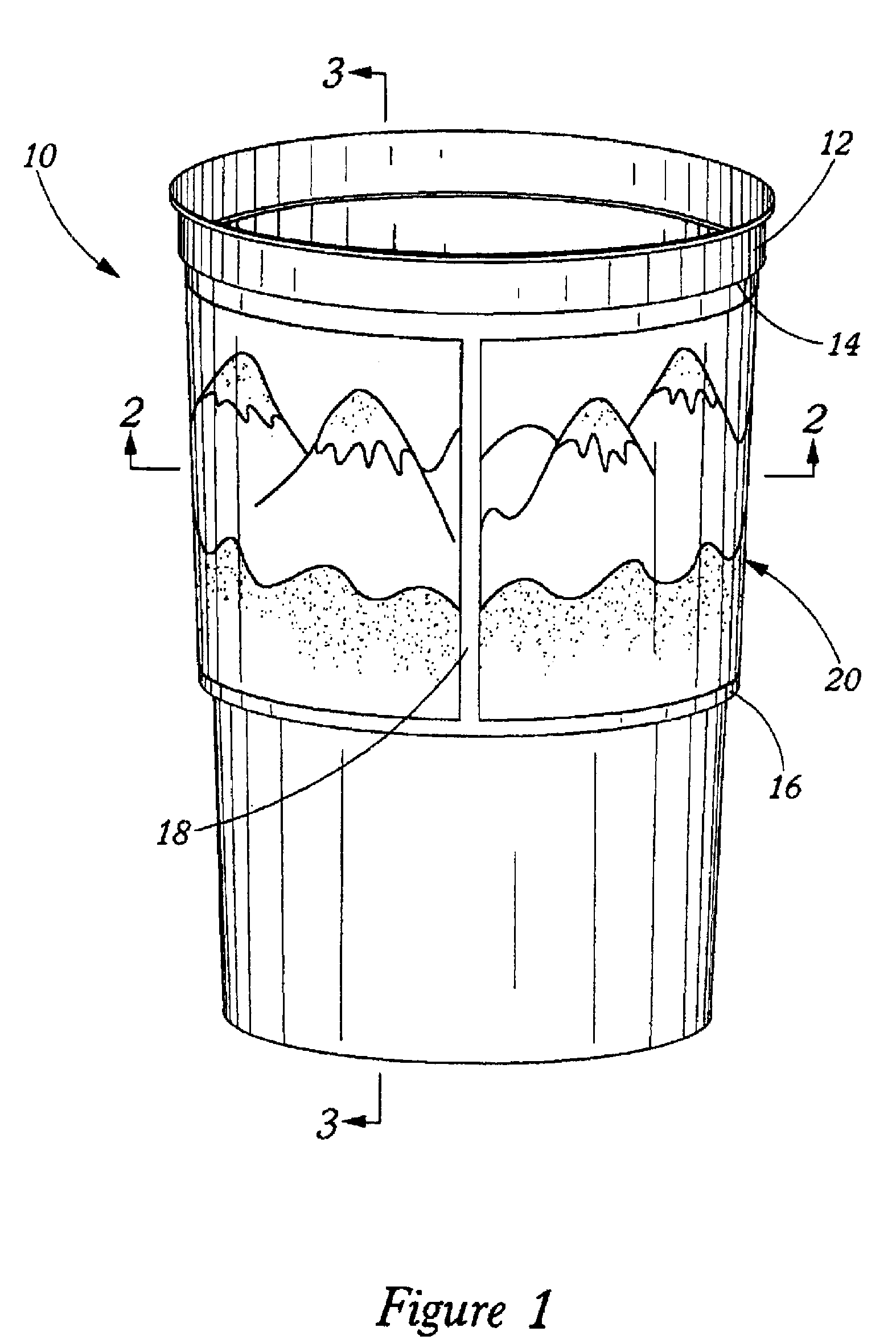

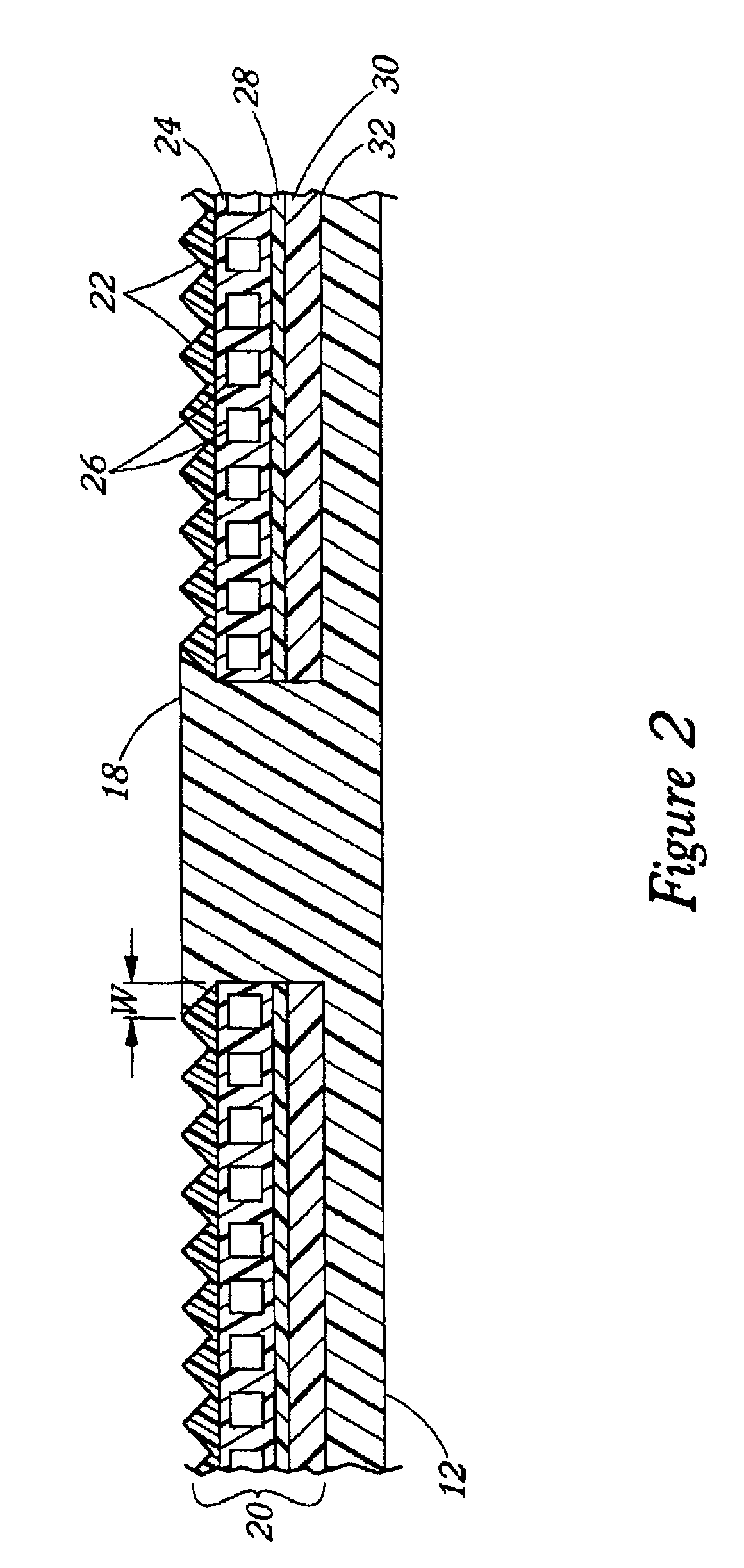

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

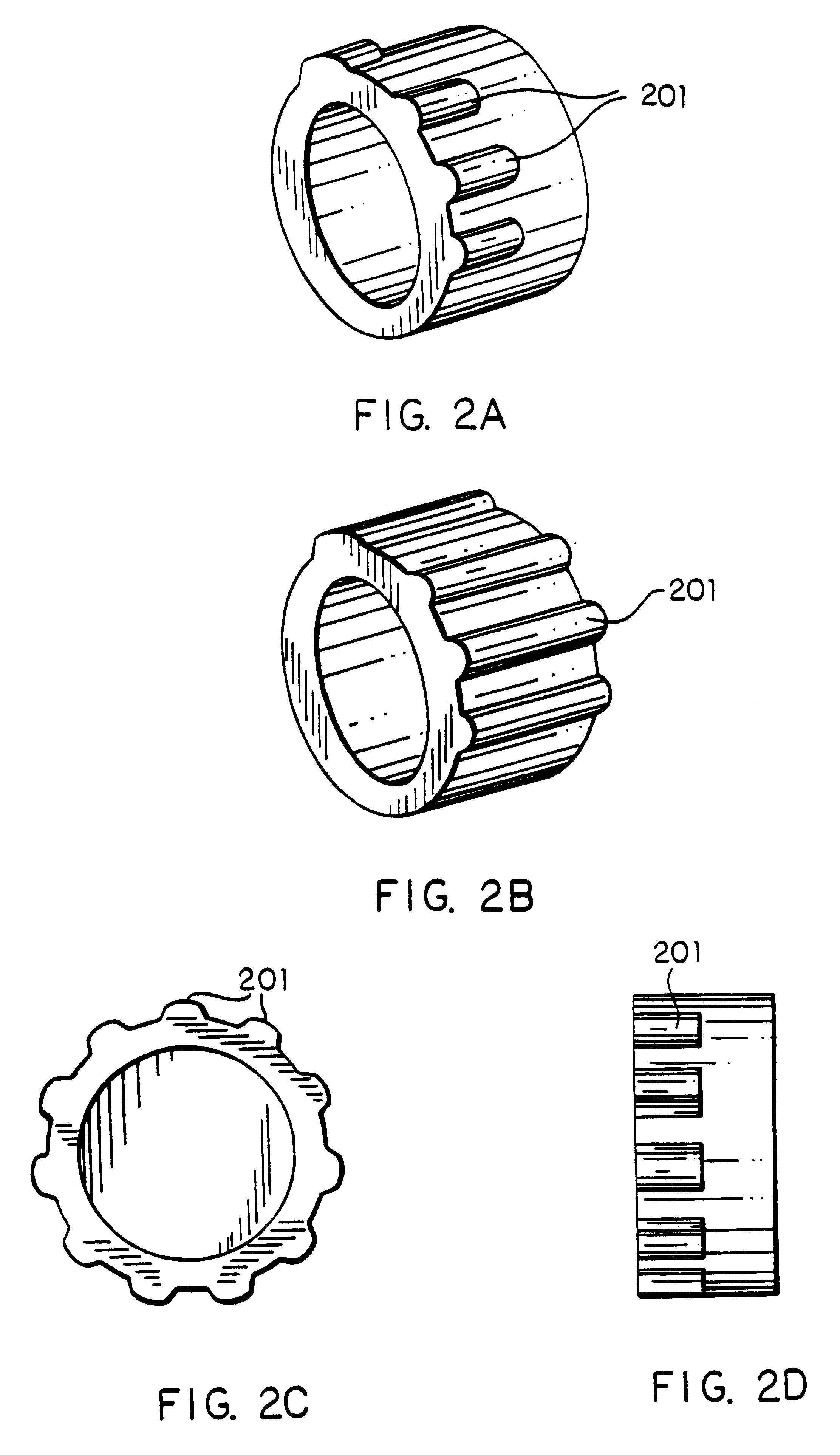

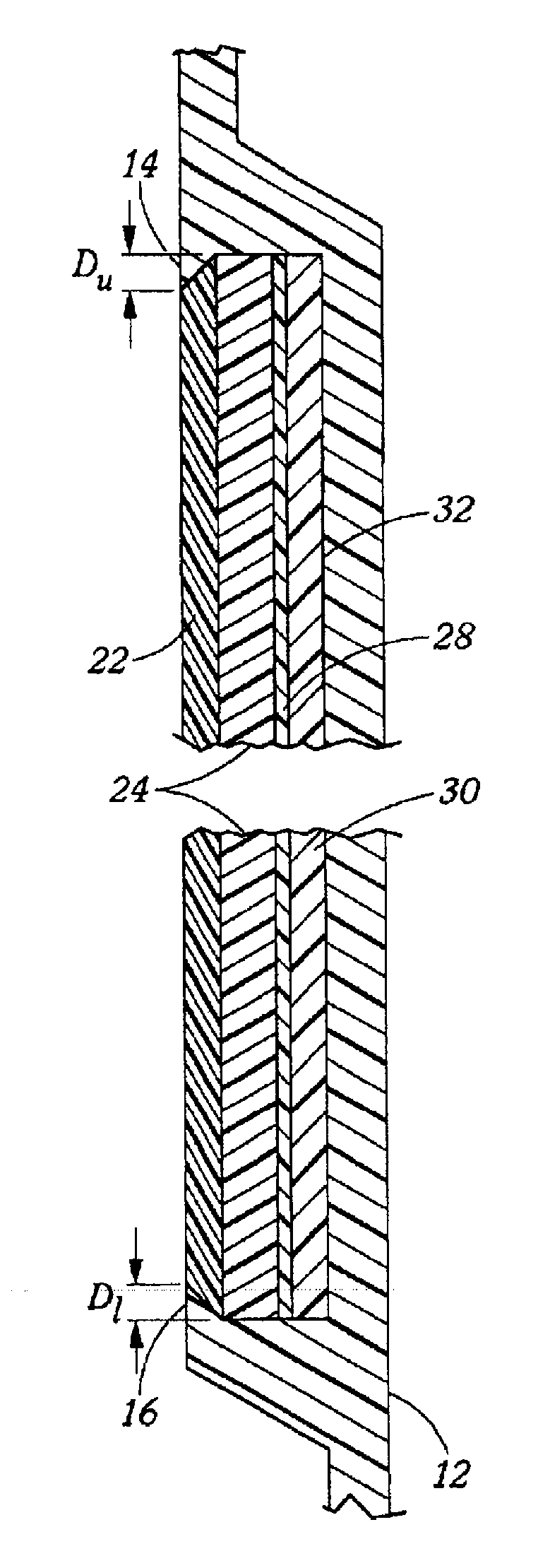

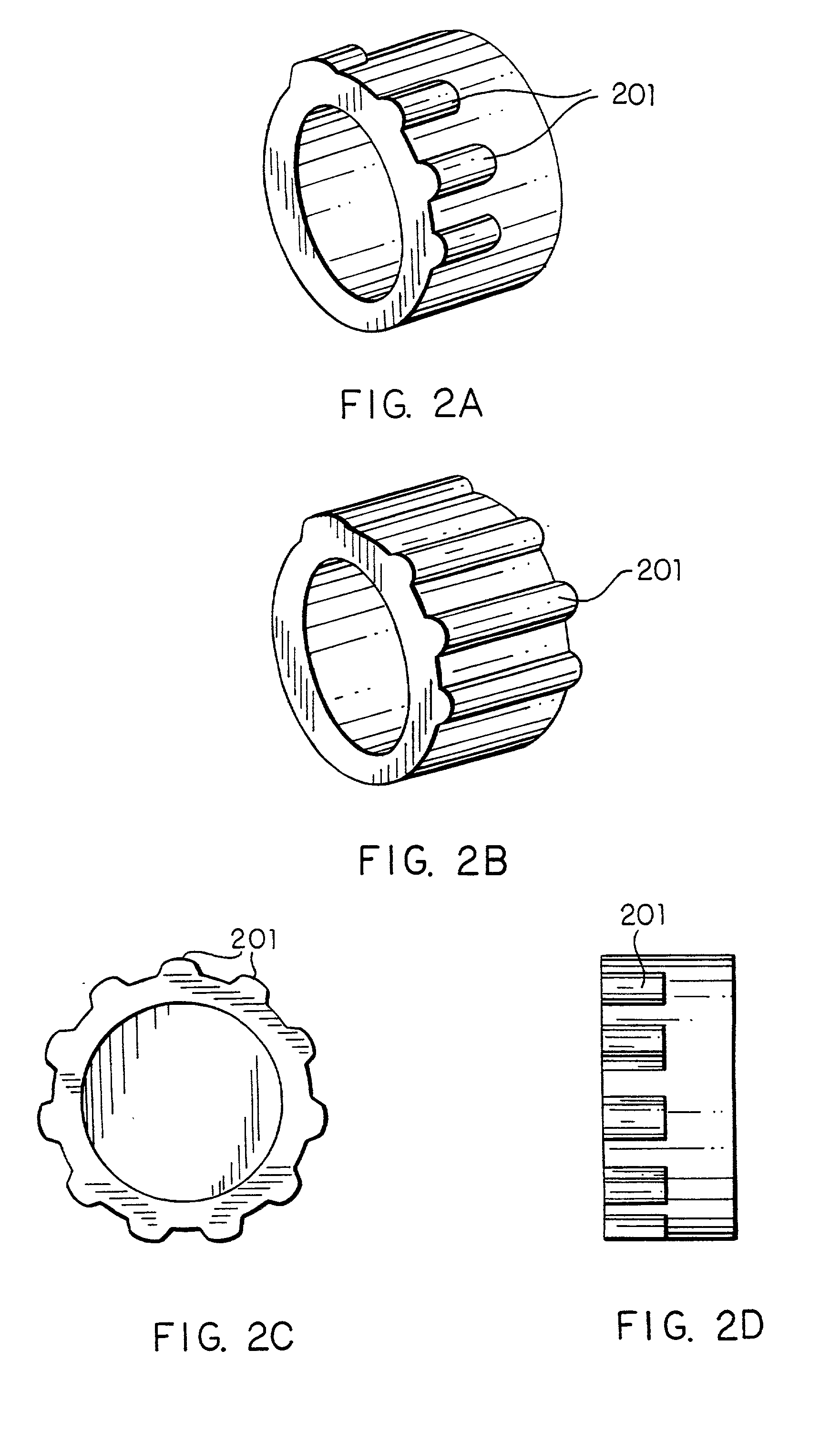

Filter with stiffening ribs

InactiveUS6277166B2Withstand explosive forceInexpensive and effectiveCombination devicesGas treatmentEngineeringVolumetric Mass Density

Annular wire mesh filters for airbag assemblies for passenger vehicles are provided with a series of ribs extending parallel with the axis of the annulus and along the outer wall. The ribs provide added strength to the filter. Also provided is a method of manufacturing the compressed mesh filter with a uniform density, and a molding tool (mold, mandrel, and plunger) for making the compressed mesh articles of this invention.

Owner:ACS TECH

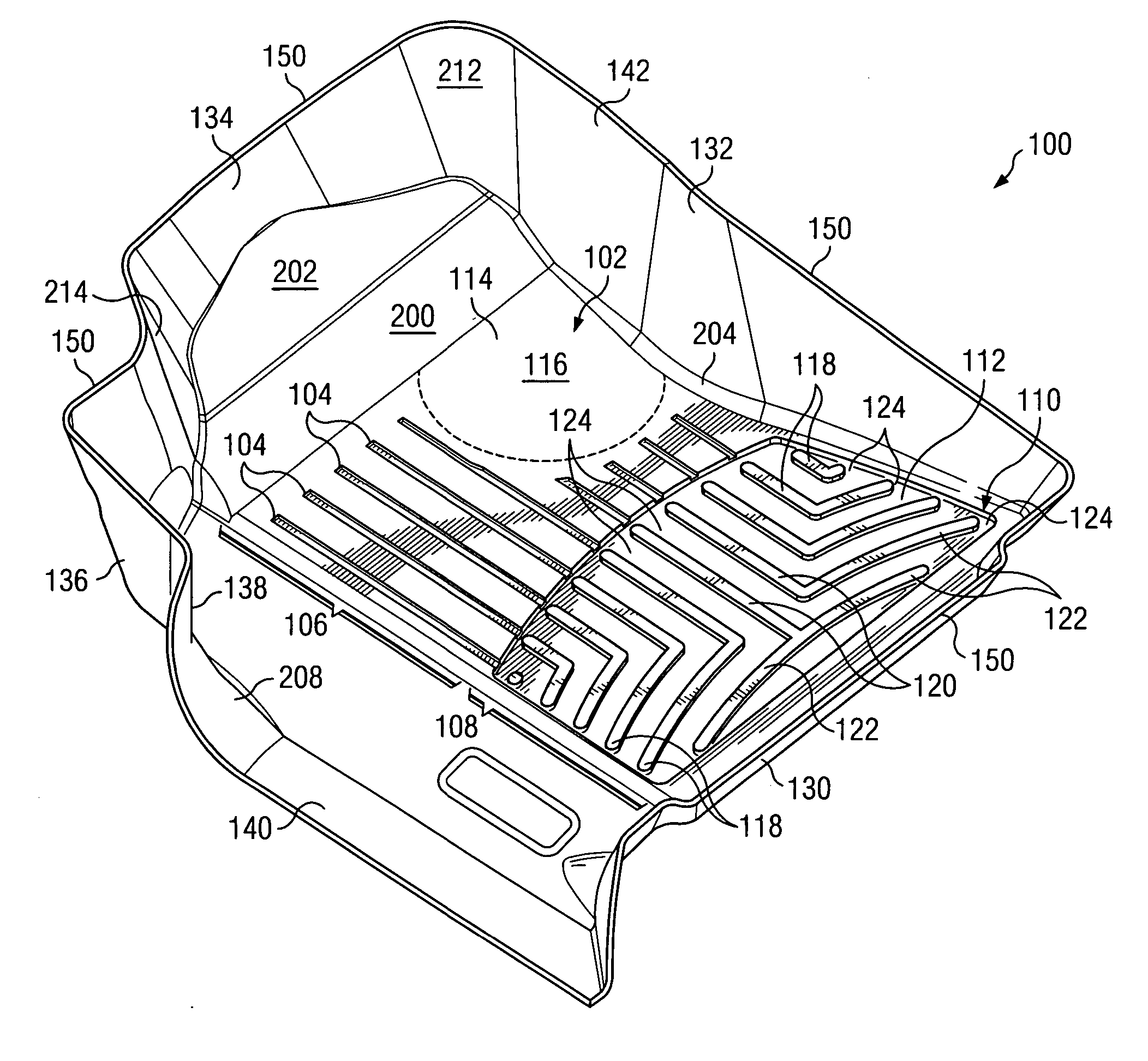

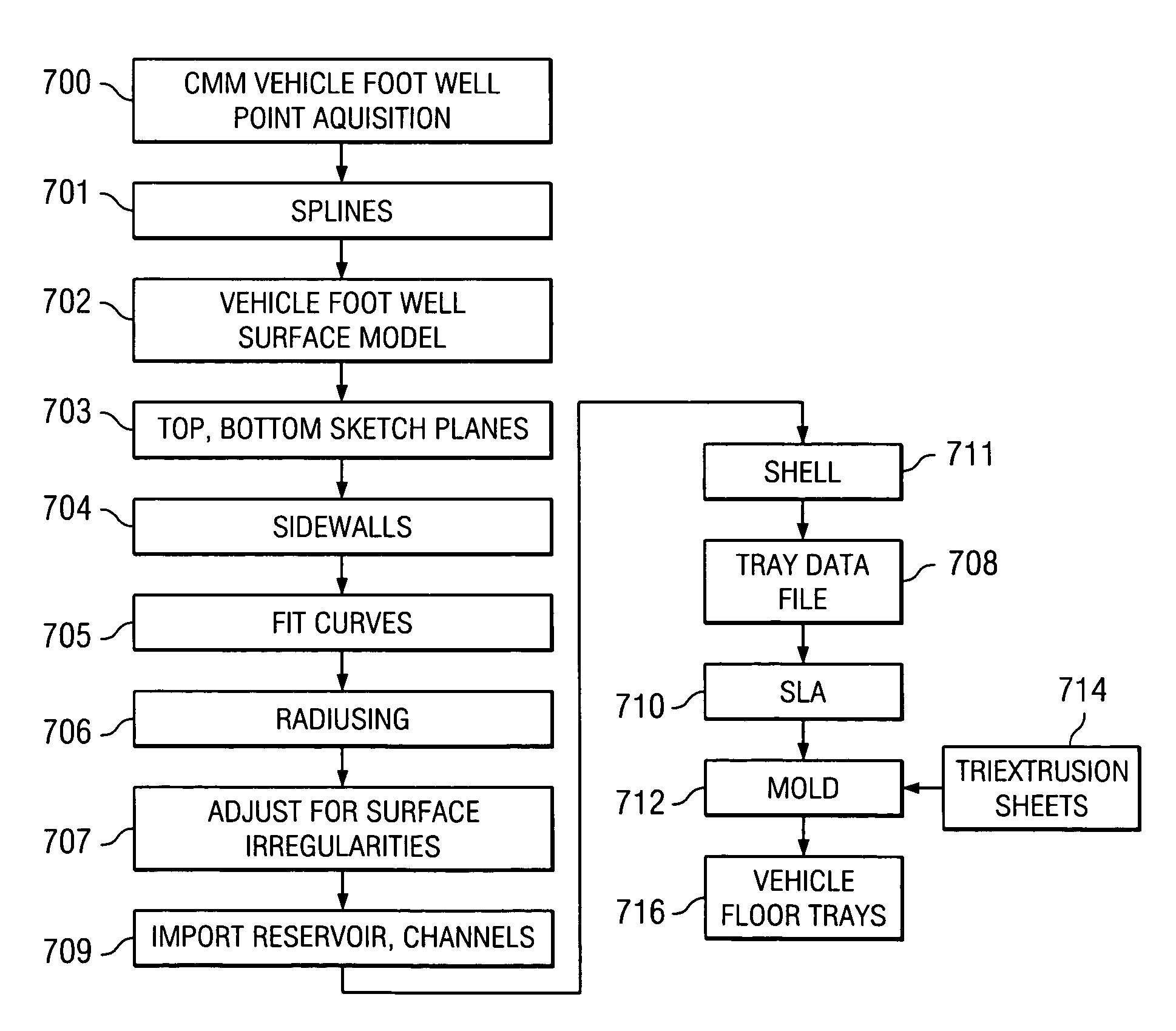

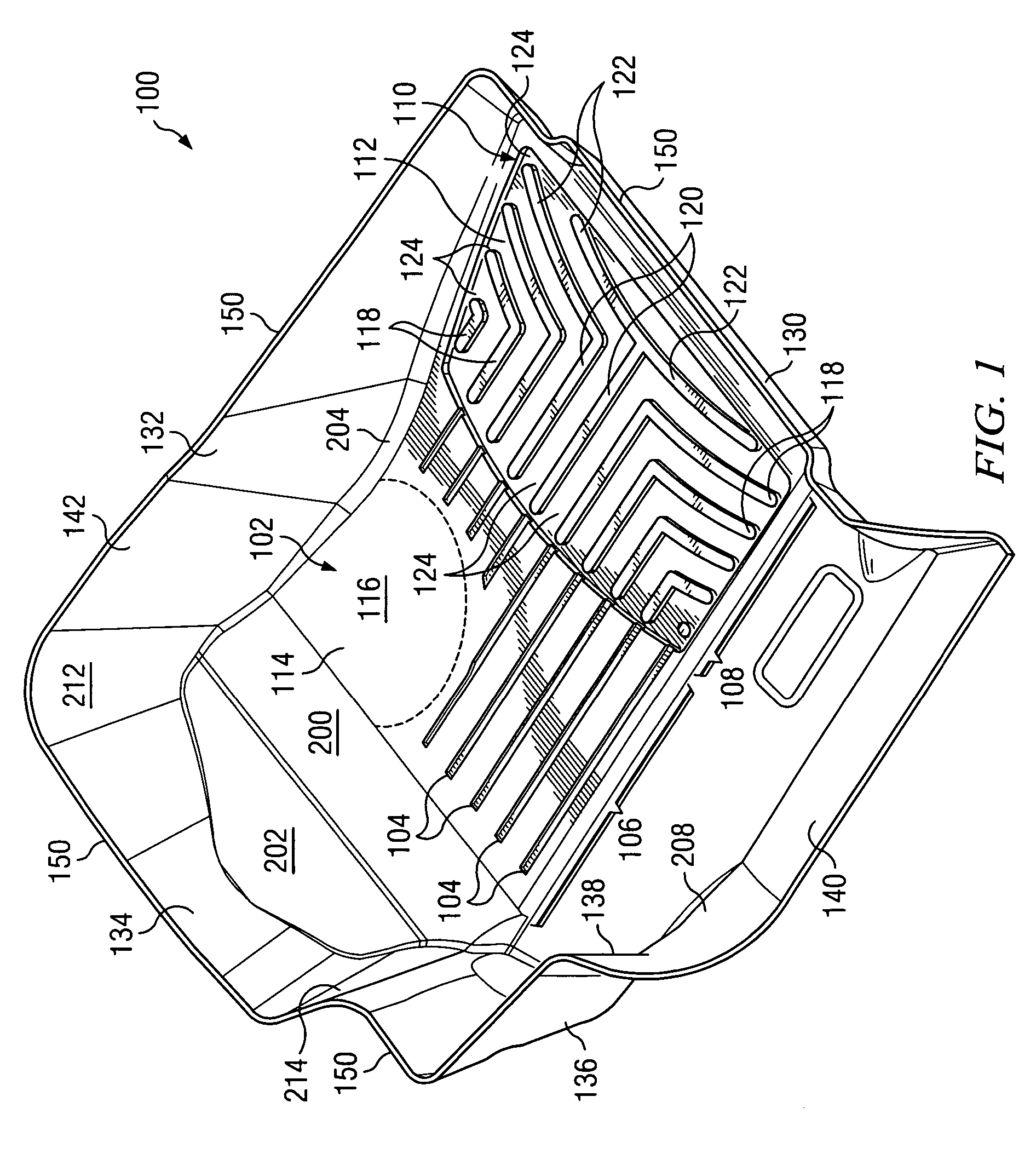

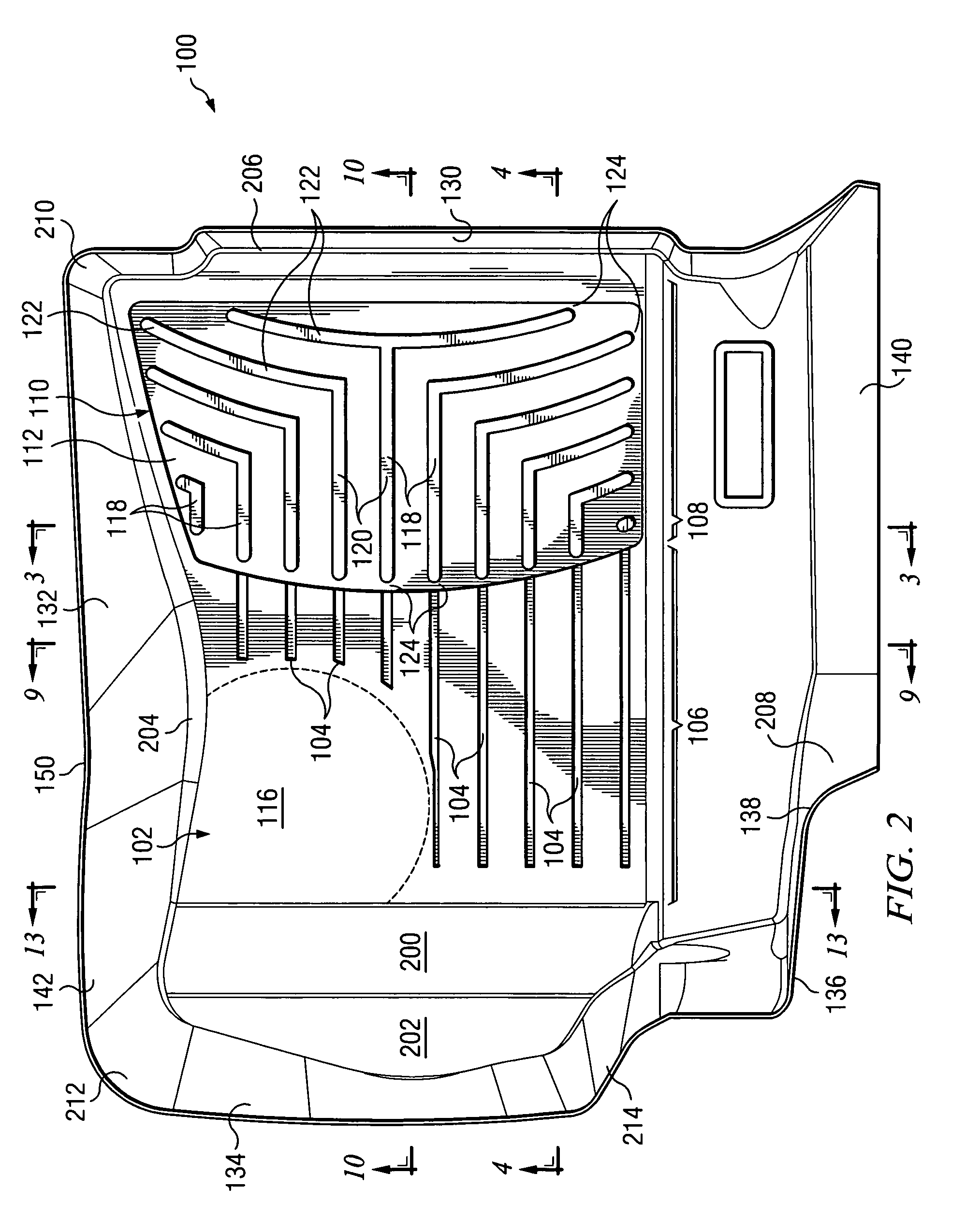

Close-conforming vehicle floor tray with reservoir

ActiveUS20060091695A1Improve fitGood physical propertiesAdditive manufacturing apparatusVehicle arrangementsEngineeringThermoplastic polymer

A vehicle floor tray is molded from a multiple extrusion thermoplastic polymer sheet such that it has high shear and tensile strength, an acceptable degree of stiffness and a high coefficient of friction on its upper surface. The floor tray design is digitally fitted to a foot well of a particular model of vehicle such that a lower surface of the tray is no more than one-half of an inch from a digitally acquired model of the foot well surface.

Owner:MACNEIL IP

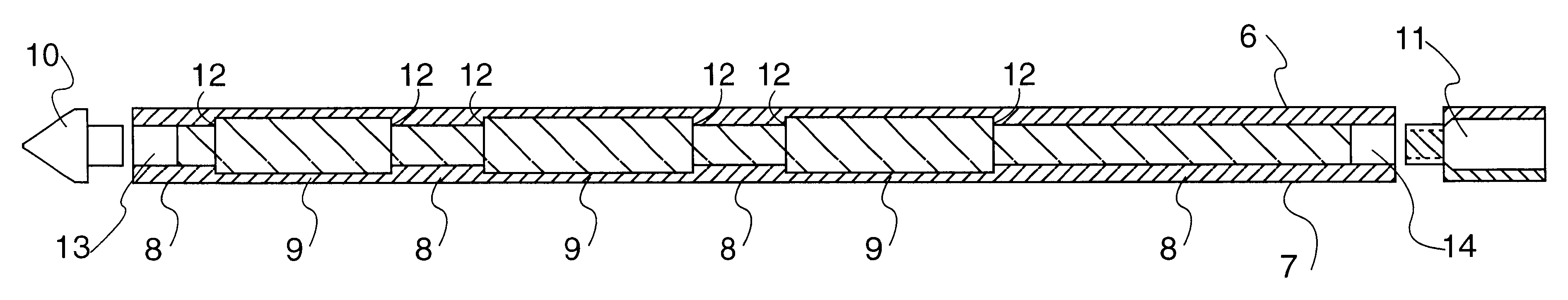

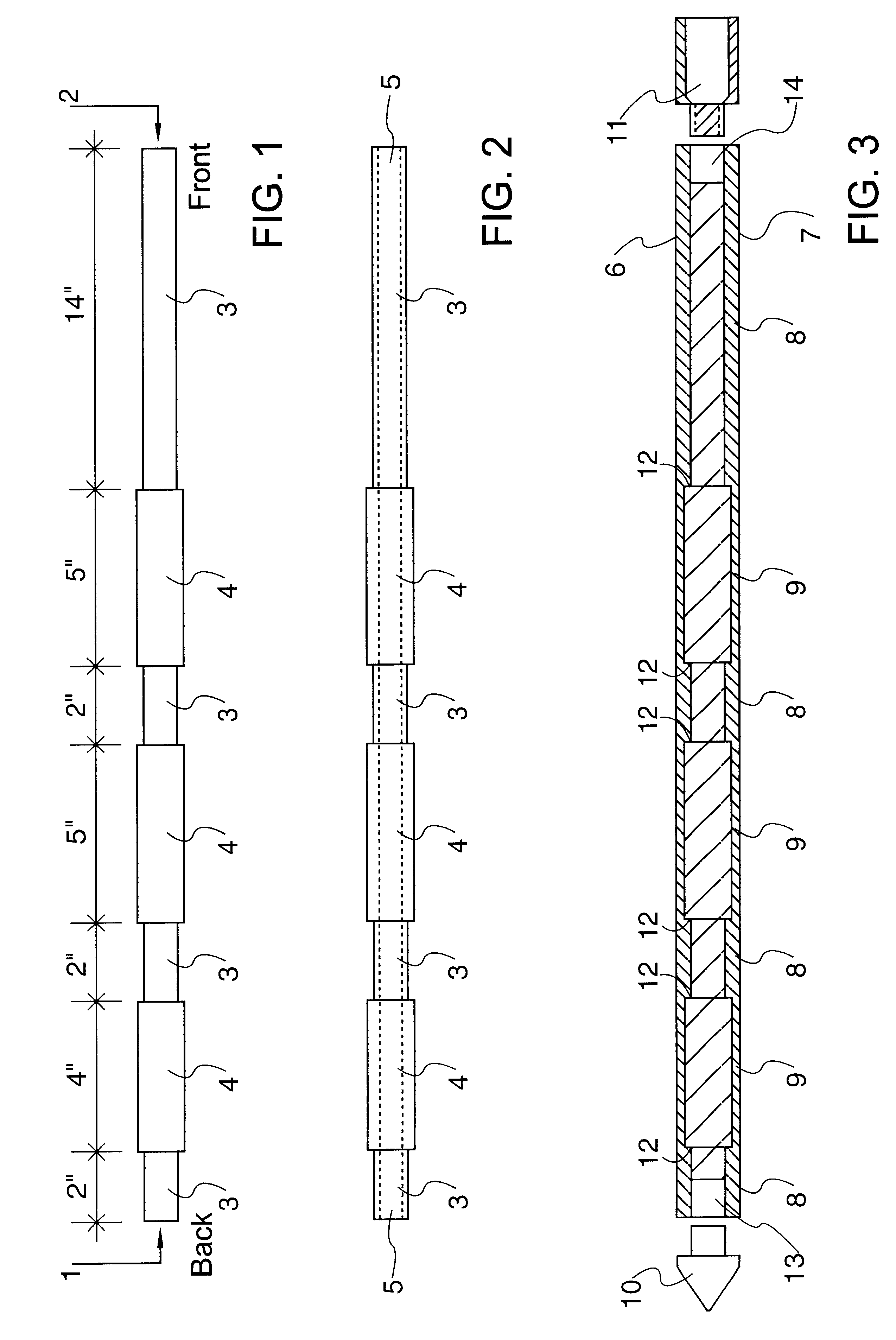

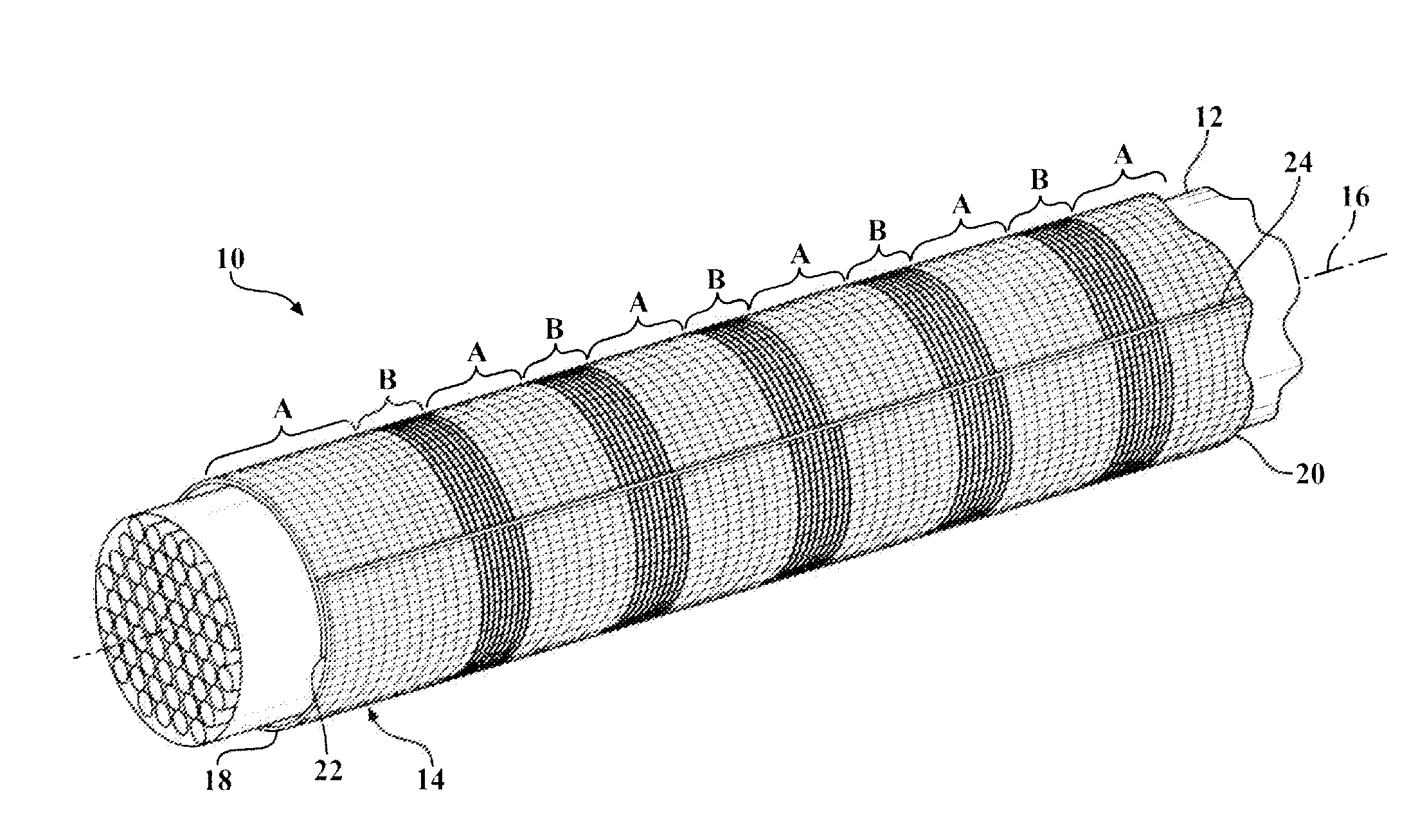

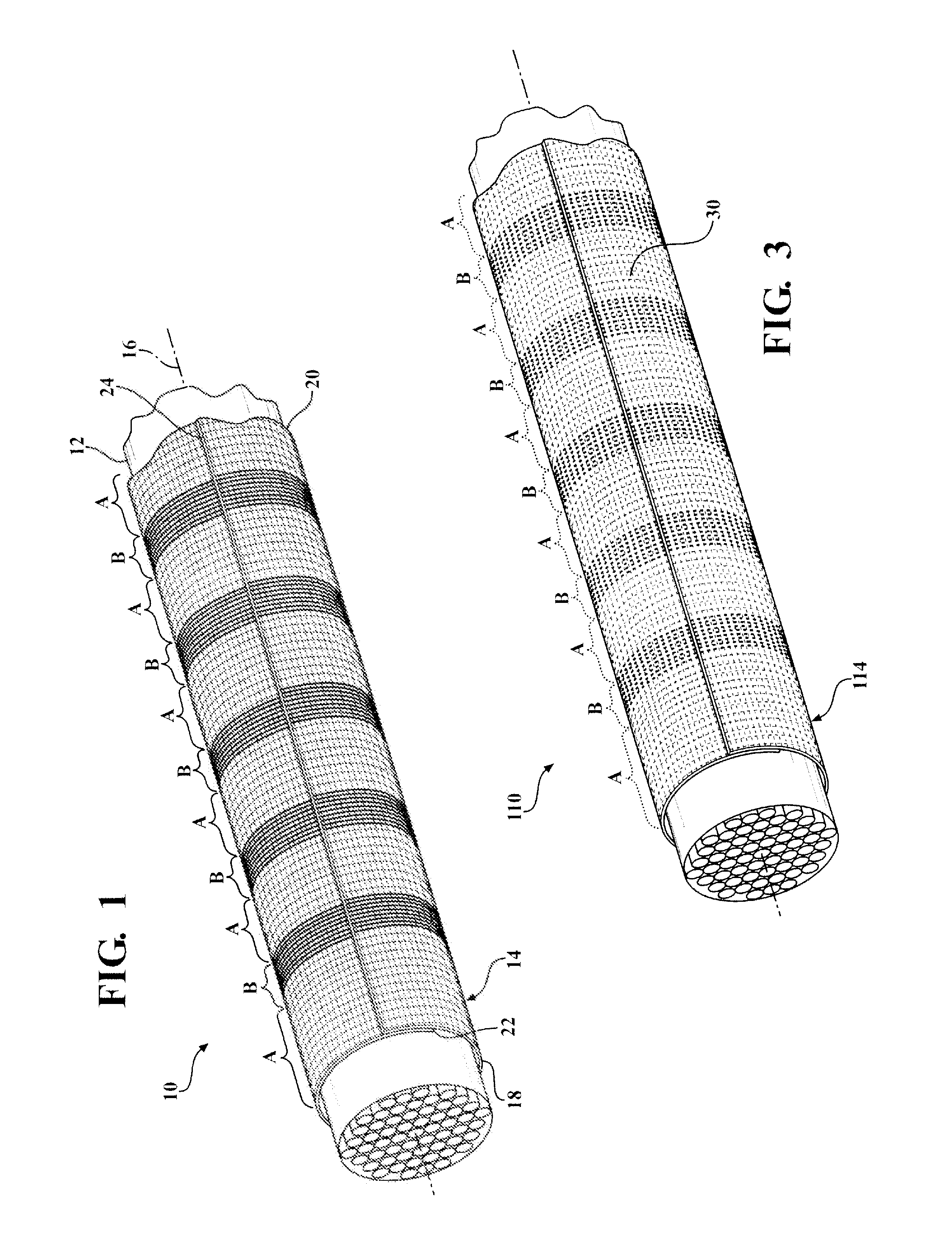

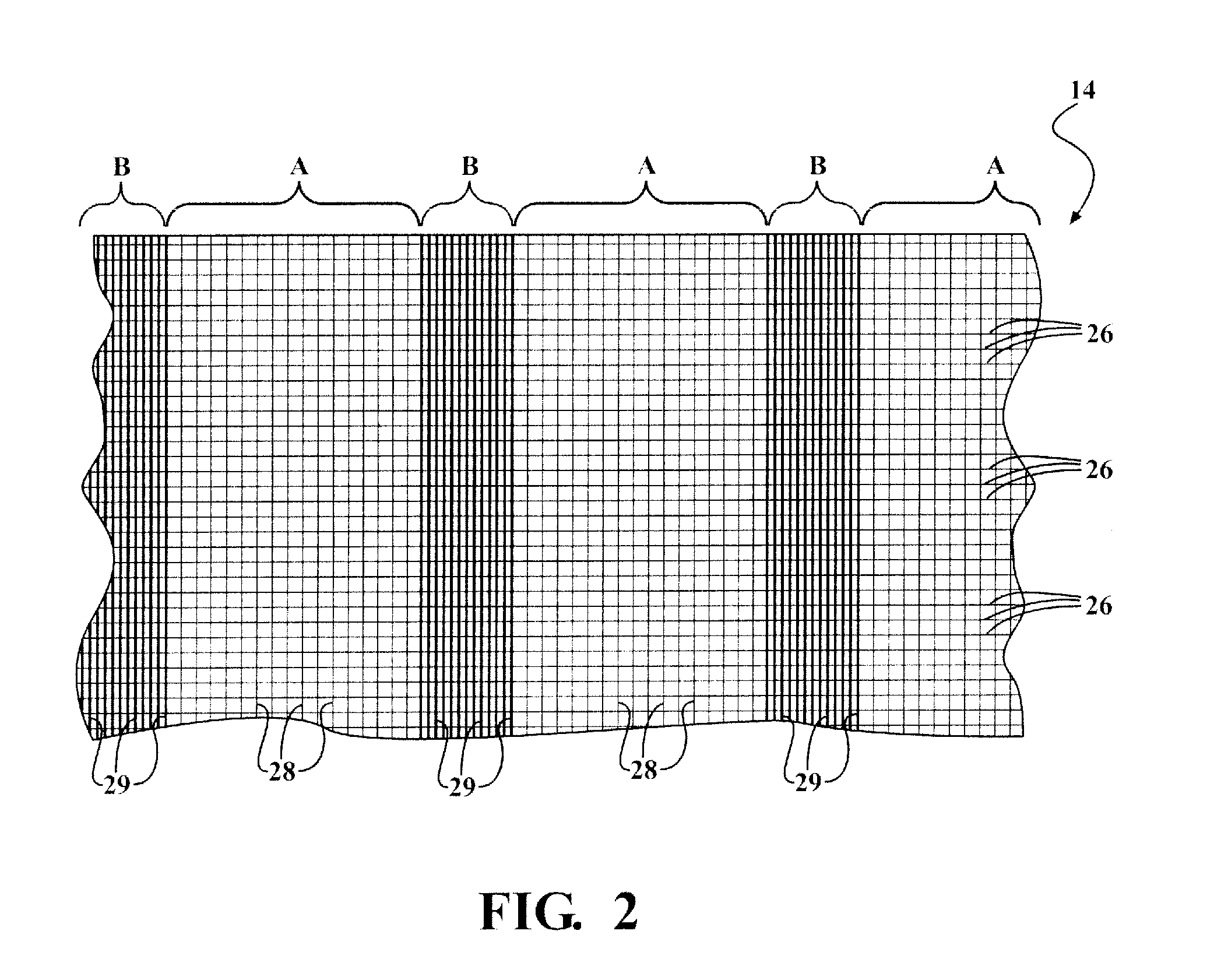

Weight-forward composite arrow shaft

InactiveUS6554725B1Significant stiffeningStrong rigidityAmmunition projectilesThrow gamesEngineeringUltimate tensile strength

An improved arrow shaft comprised of a core of substantially round, very lightweight, porous material, with the porous core having sections that have different diameters at various points along the length of the arrow shaft, with the lightweight core materials being overwrapped with different thickness' of reinforcing materials such that the resulting outside diameter of the finished arrow shaft has substantially parallel surfaces over the entire length of the shaft and the finished shaft has a substantially constant circumference and outside diameter along its entire length. The inventive composite arrow shaft incorporates different thickness' and weights of reinforcement materials, strategically placed along it's length, in a manner that results in providing, in an integral manner, proper front to back balance in the finished arrow, with the proper balance achieved by using the same weight point, point insert, nock, nock insert, and fletching materials, regardless of the length the shaft is cut off at. The preferred embodiment of the inventive arrow shaft includes end sections at each end that have greater thicknesses of reinforcement materials overlaying the core, than at other intermediate sections of the shaft, with the increased reinforcement materials at each end of the shaft serving to increase, in an integral manner, the strength of the shaft in these areas. The preferred embodiment of the inventive arrow shaft also includes at least one other section intermediate the end sections of the shaft that also has greater thicknesses of reinforcement materials along it's length than do some other sections of the shaft that are intermediate the additionally-reinforced end sections.

Owner:SCHAAR JOHN G

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

Close-conforming vehicle floor tray with reservoir

ActiveUS7444748B2Good physical propertiesIncrease coefficient of frictionVehicle arrangementsSuperstructure subunitsEngineeringUltimate tensile strength

A vehicle floor tray is molded from a multiple extrusion thermoplastic polymer sheet such that it has high shear and tensile strength, an acceptable degree of stiffness and a high coefficient of friction on its upper surface. The floor tray design is digitally fitted to a foot well of a particular model of vehicle such that a lower surface of the tray is no more than one-half of an inch from a digitally acquired model of the foot well surface.

Owner:MACNEIL IP

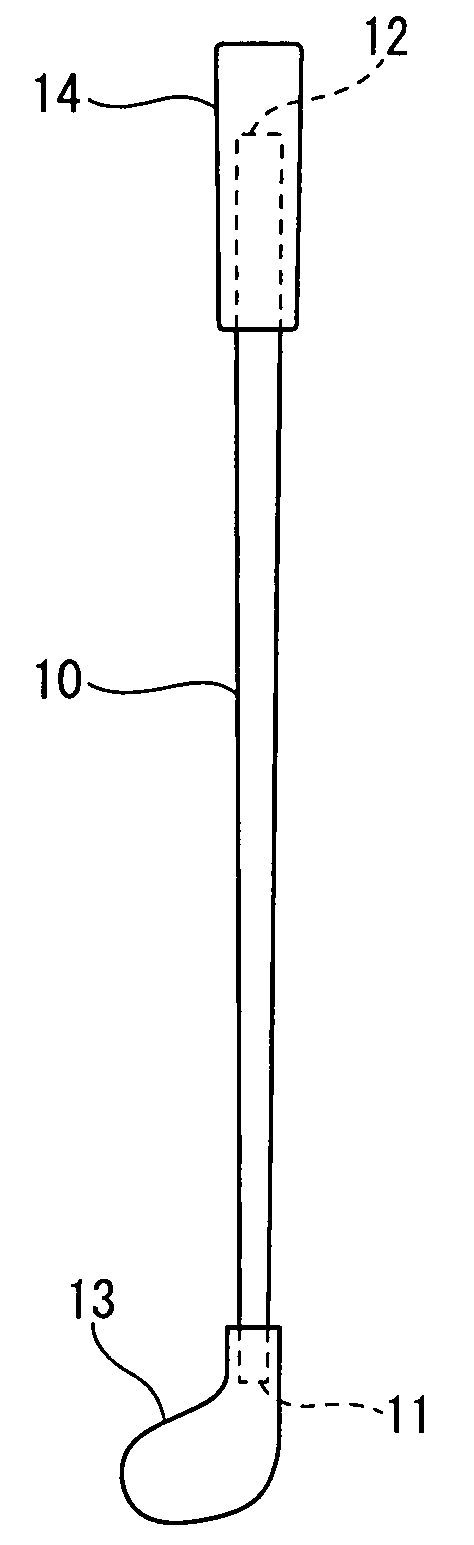

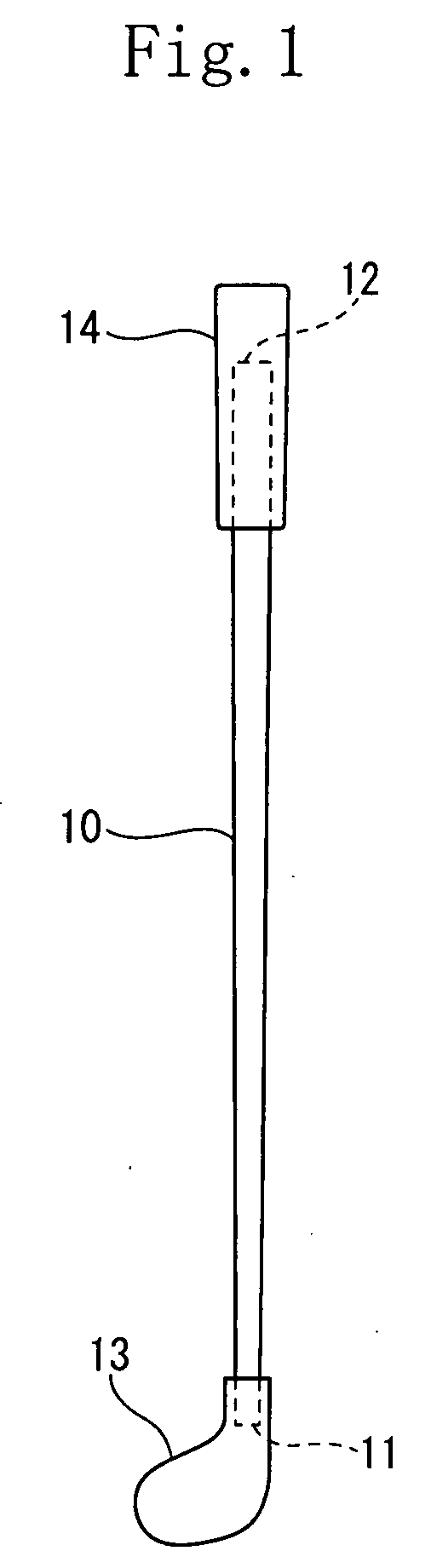

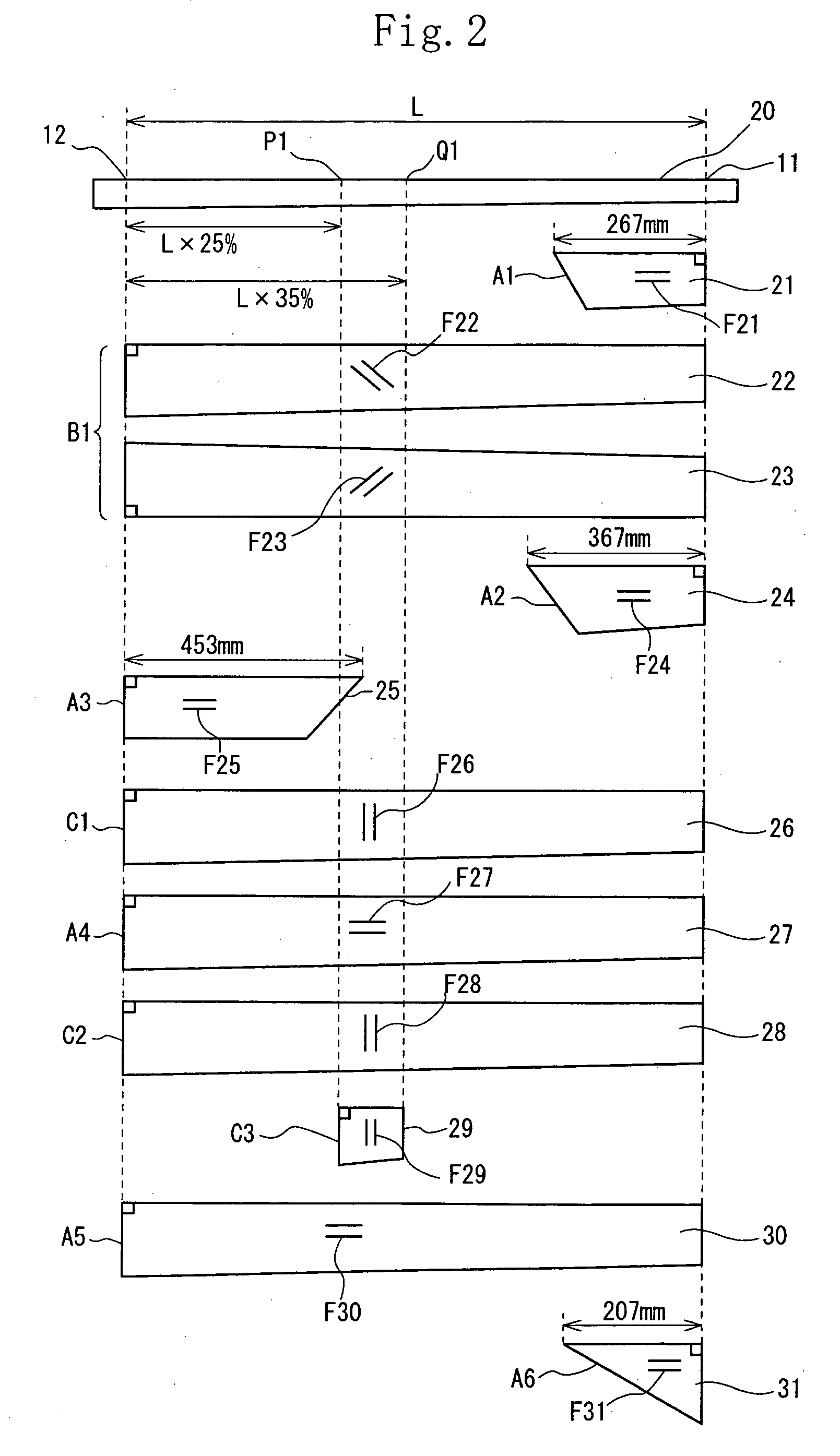

Golf club shaft

InactiveUS20090029792A1Enhance crush rigidityIncrease head speedGolf clubsRacket sportsEngineeringGolf club

A golf club shaft (10) having a weight not less than 30 g nor more than 60 g. The golf club shaft (10) includes a bias layer (B1) composed of a prepreg whose reinforcing fibers have an orientation angle of not less than ±10° nor more than 80° to an axis of the golf club shaft (10) and a straight layers (A1 through A6) each composed of a prepreg whose reinforcing fibers have an orientation angle within 0°±10° to the axis of the golf club shaft (10). At least one partial reinforcing hoop layer whose reinforcing fibers have an orientation angle of within 90°±10° to the axis of the golf club shaft (10) is disposed in only an important reinforcing region in a range from a point (P) spaced at 15% of a full length (L) of the golf club shaft (10) from a grip-side butt (12) thereof to a point (Q) spaced at 45% of the full length (L) of the golf club shaft (10) from the grip-side butt (12) thereof.

Owner:SUMITOMO RUBBER IND LTD

Finish horizontal reinforcing rib-ring force

Owner:AMCOR RIGID PLASICS USA LLC

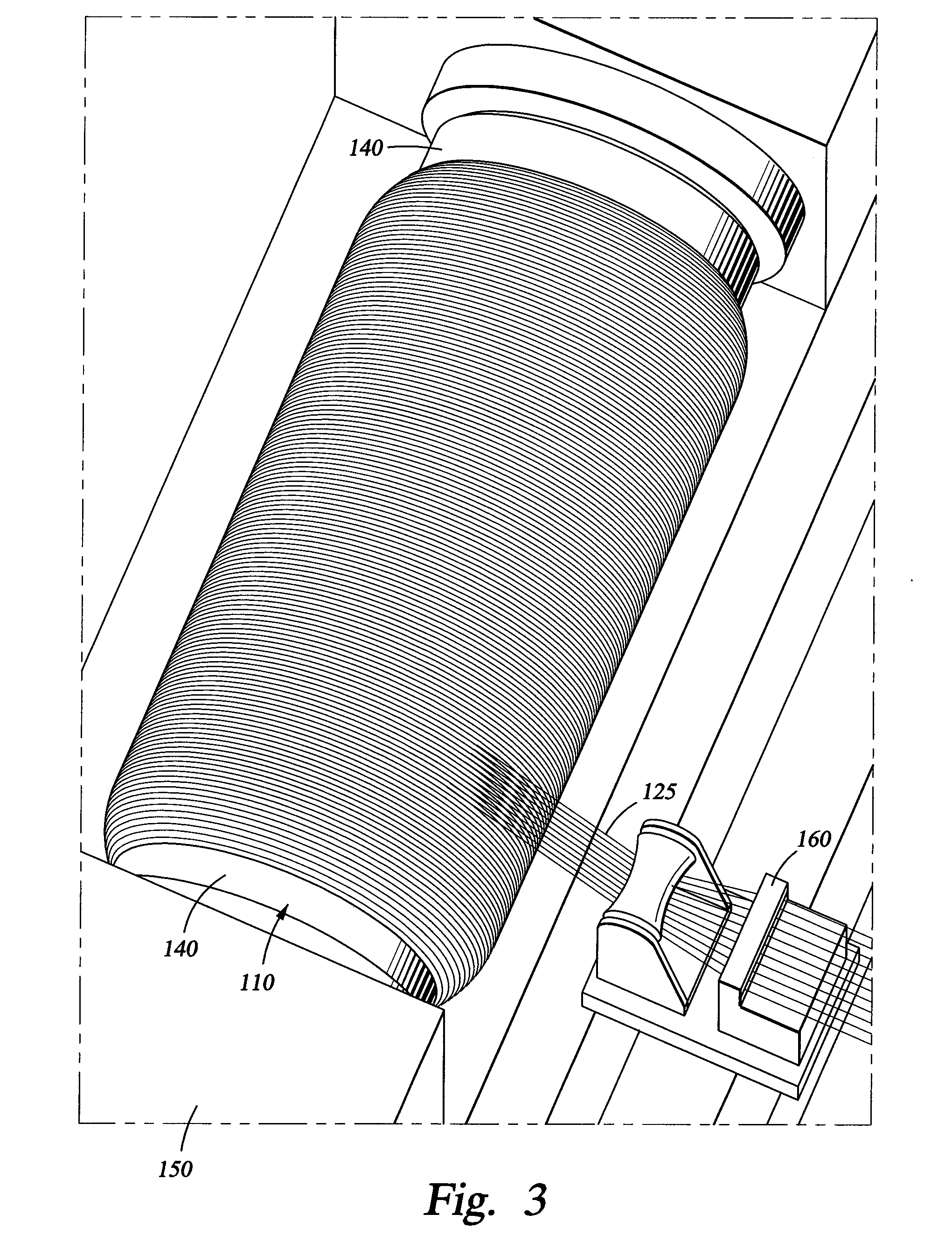

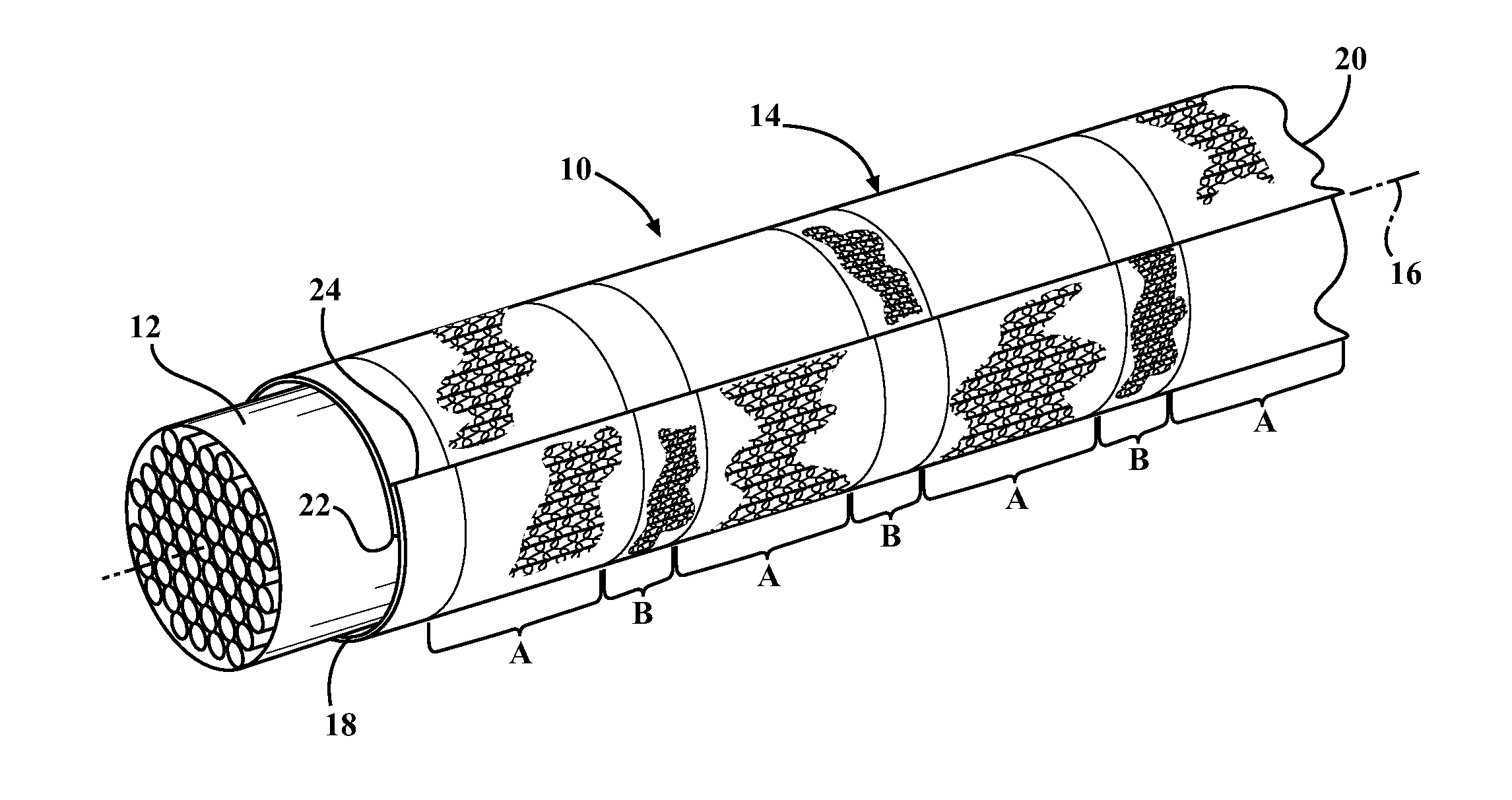

Dry fiber wrapped pipe

InactiveUS20080053554A1Increase hoop strengthEnhanced hoop strengthMetal rolling stand detailsAbrasion apparatusMetalFilament winding

A reinforced pipe section comprises a metal pipe, a layer of dry fibers disposed around the metal pipe, and an external liner covering the layer of dry fibers. A method of manufacturing a reinforced pipe section comprises wrapping a layer of dry fibers over a metal pipe, and covering the layer of dry fibers with an external liner, thereby forming a first dry fiber wrapped metal pipe. A method of reinforcing a degraded metal pipe comprises wrapping the degraded metal pipe with a layer of dry fibers to increase the hoop strength of the degraded metal pipe, and covering the layer of dry fibers with an external liner.

Owner:CONOCOPHILLIPS CO

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20040157011A1Efficient and economicalHigh qualityEnvelopes/bags making machineryWrappers shrinkageLens materialsPolyester

Abstract of the Disclosure A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:REIL JENNIFER +4

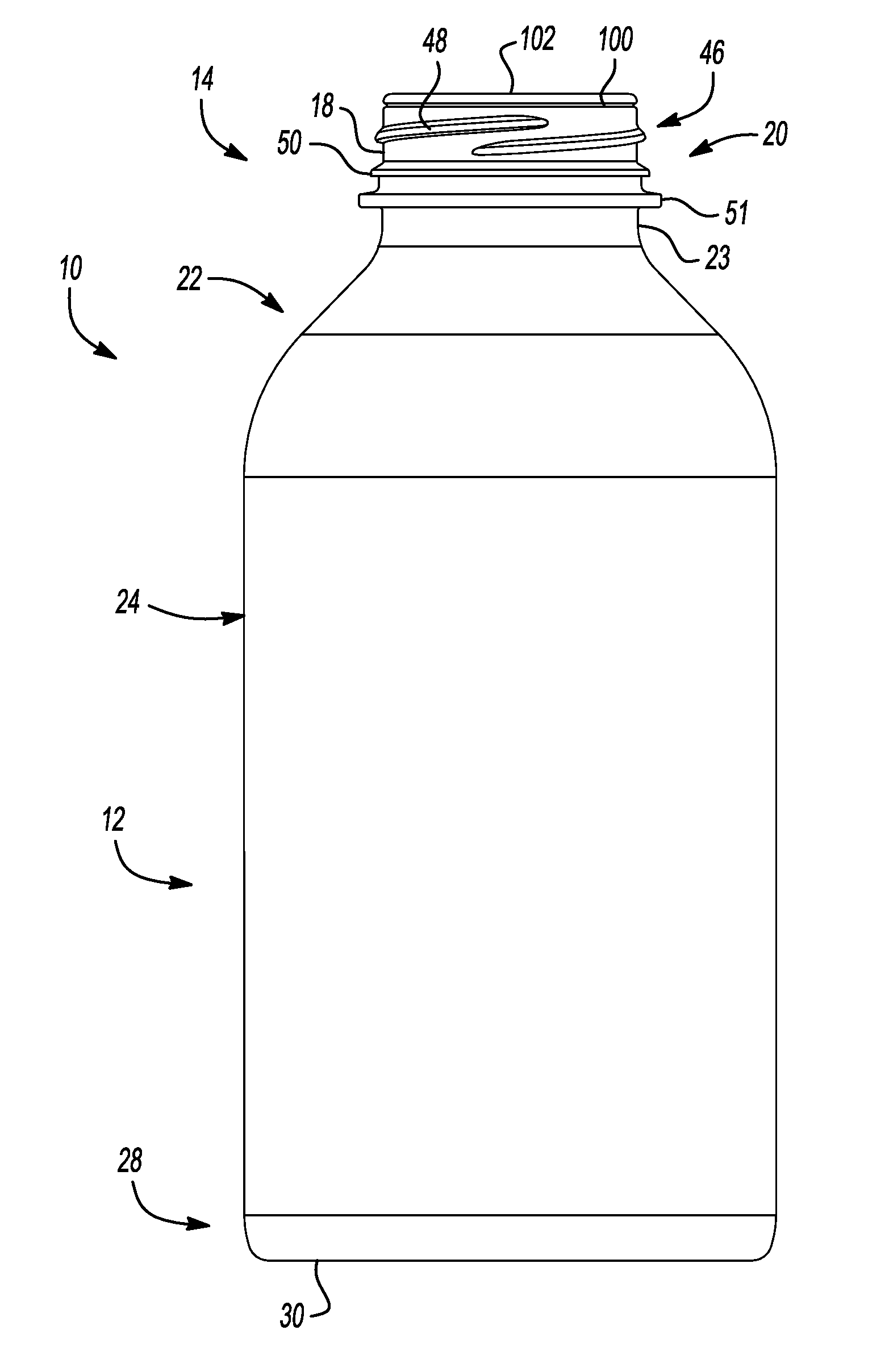

Plastic closure with enhanced performance

InactiveUS8485374B2Use minimizedEfficient and versatile useCapsClosure capsTamper resistanceEngineering

Owner:CLOSURE SYST INT INC

Methods of manufacturing plastic objects having bonded lenticular lens-sheets

InactiveUS20070132122A1Quality improvementEfficient and economicalOptical articlesContainer/bottle contructionPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

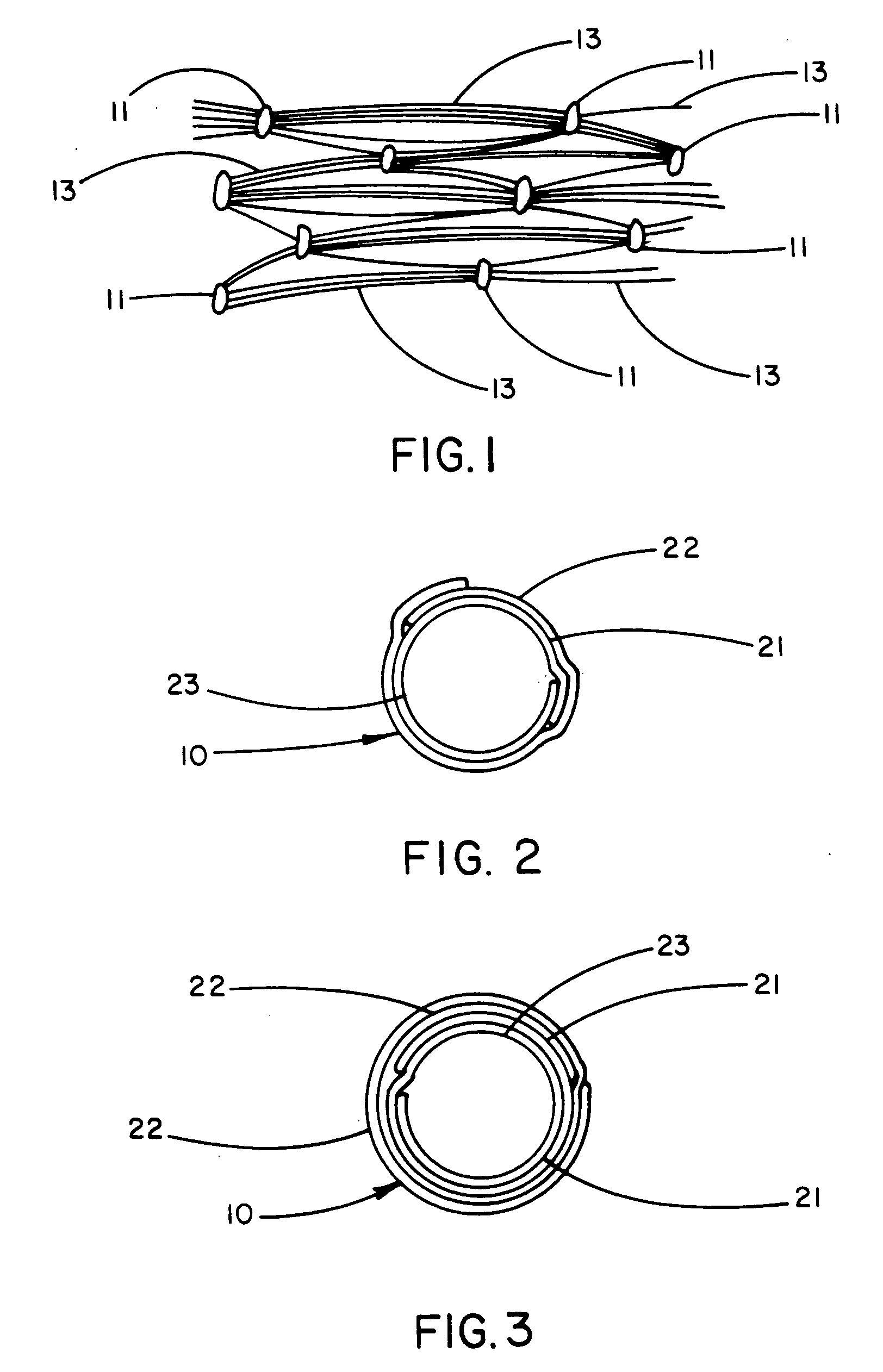

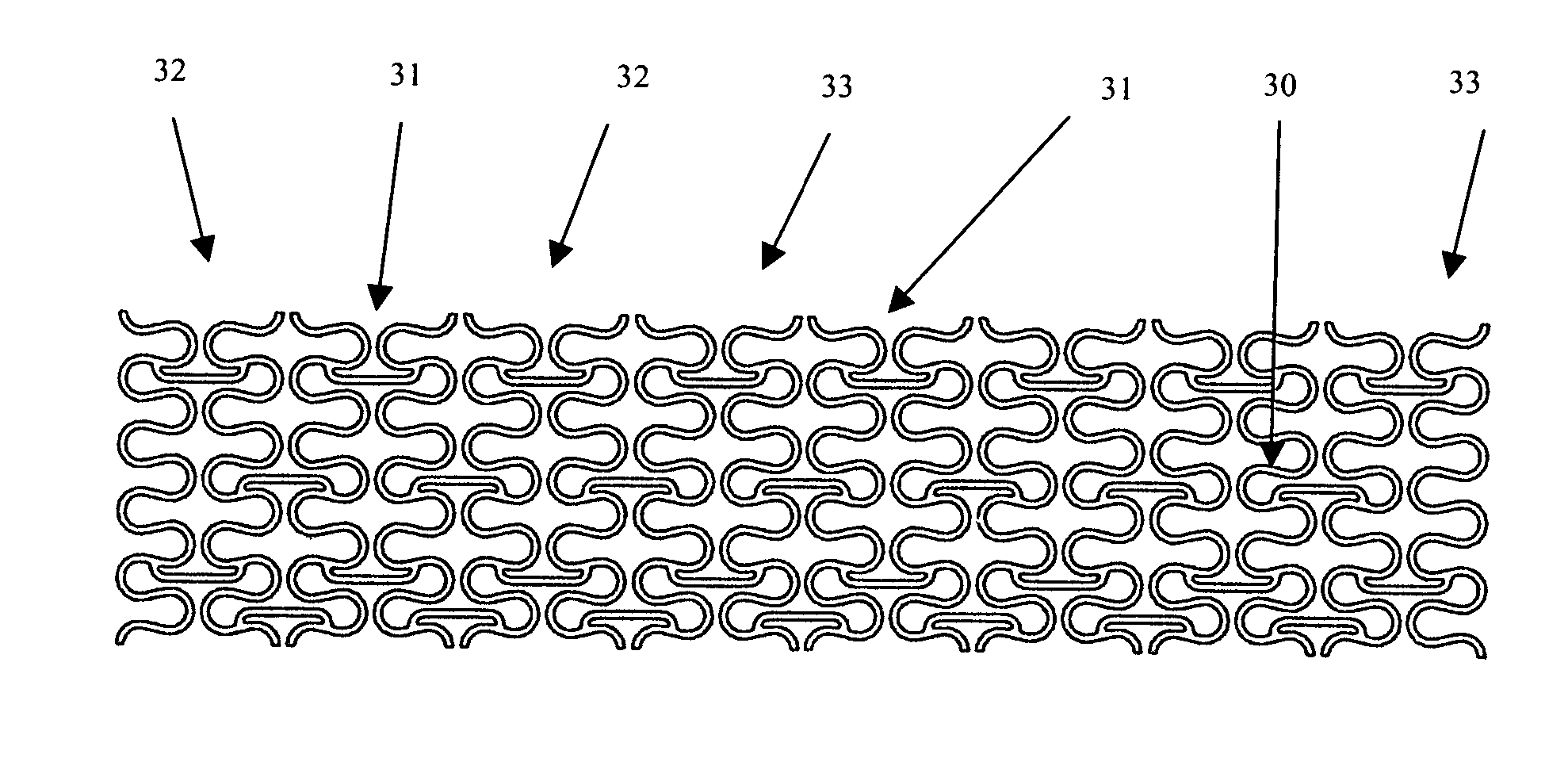

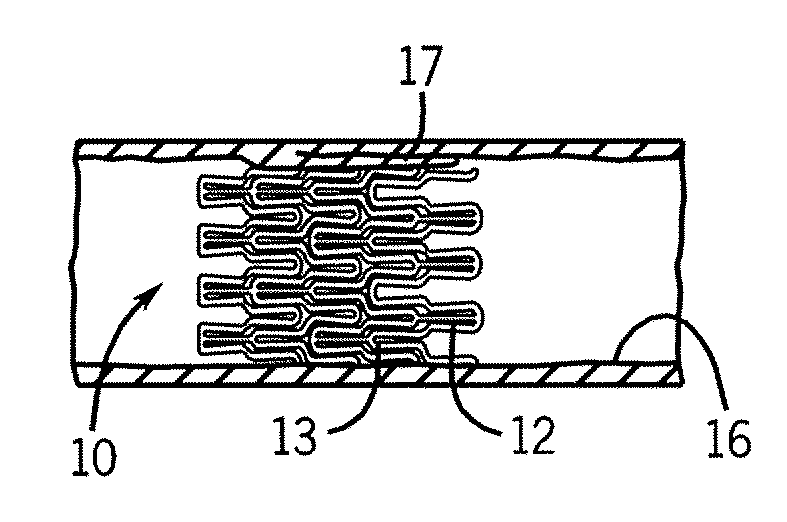

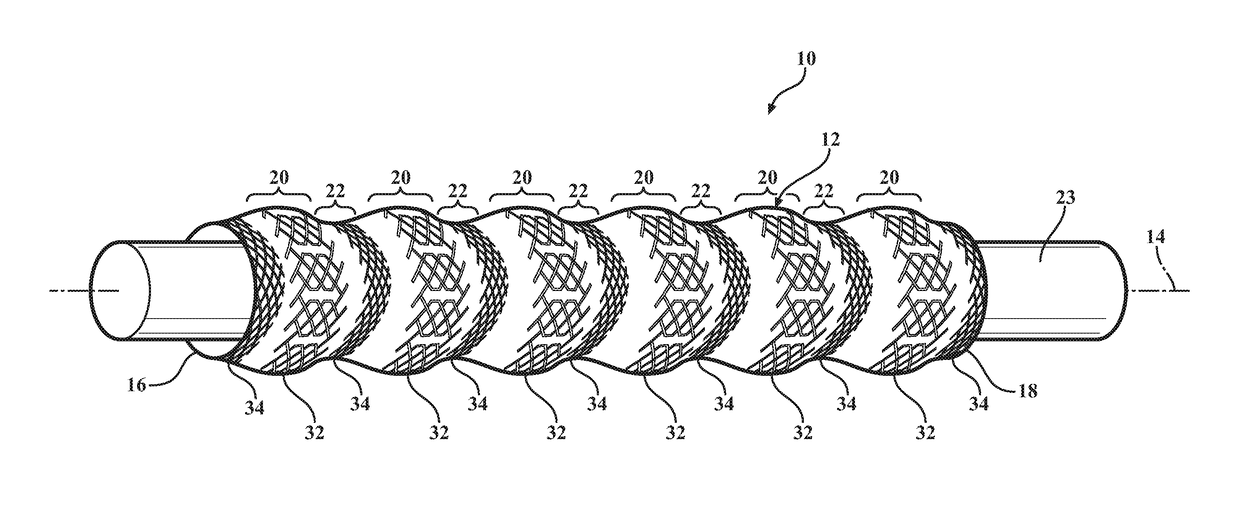

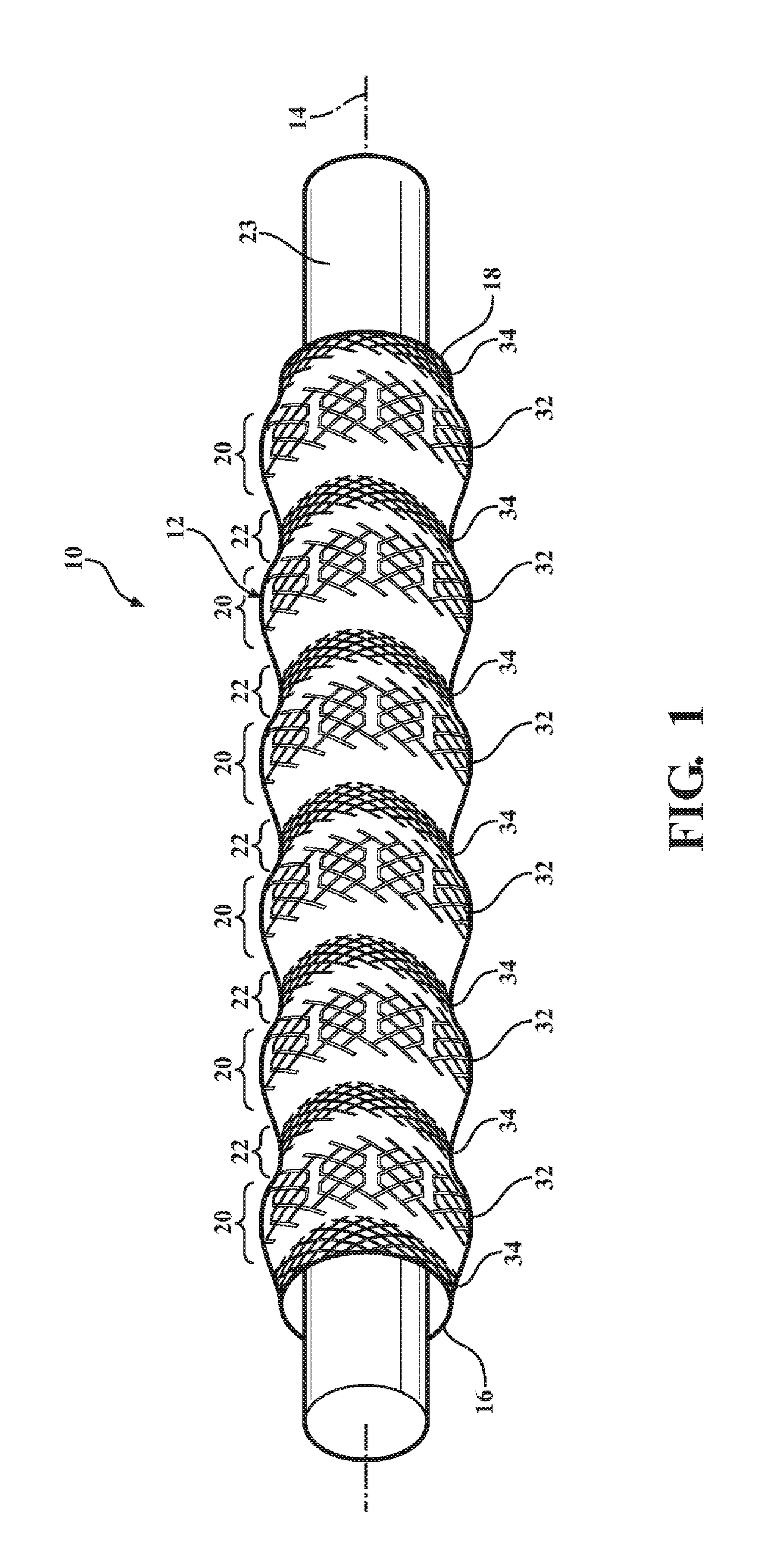

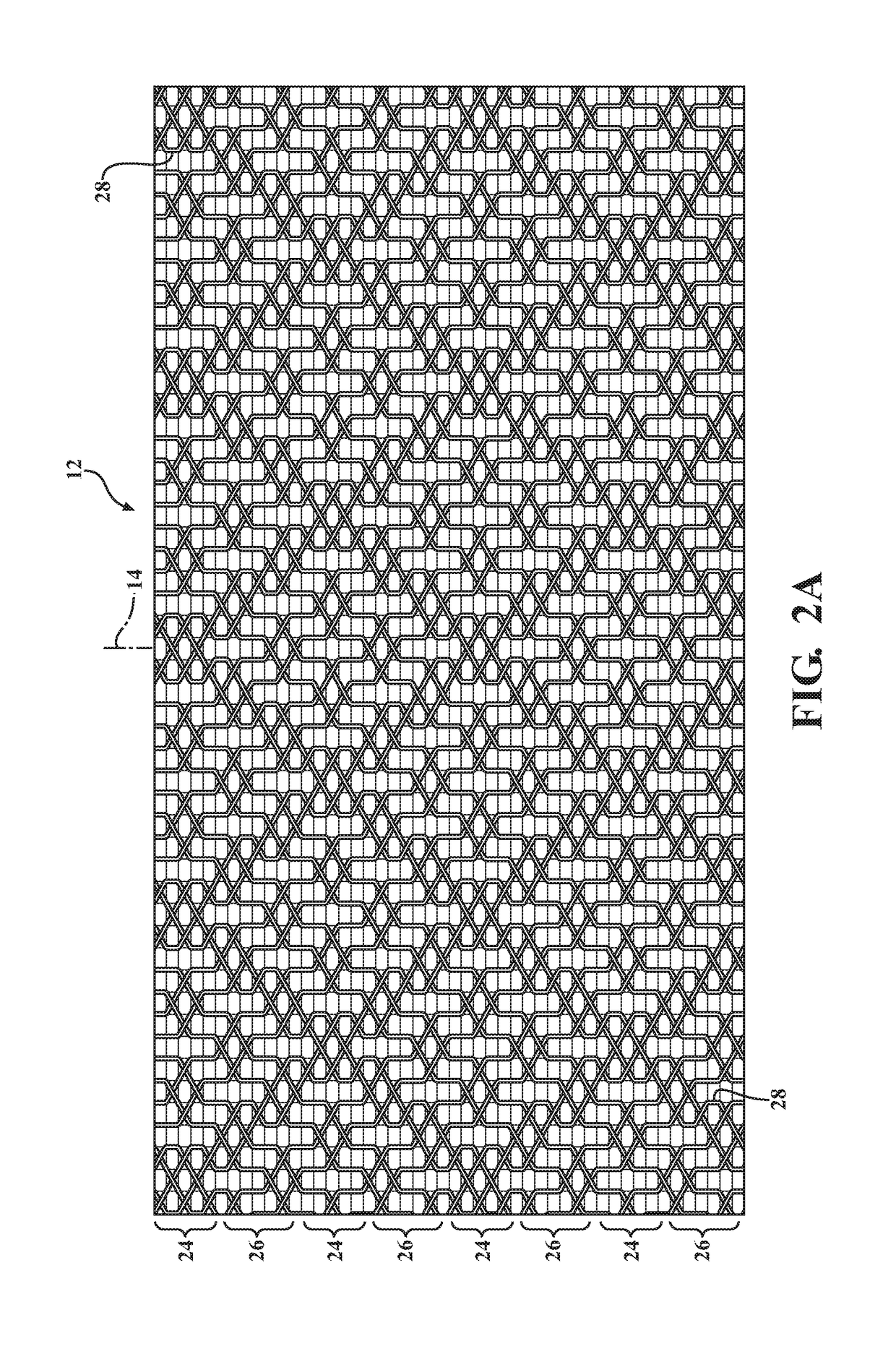

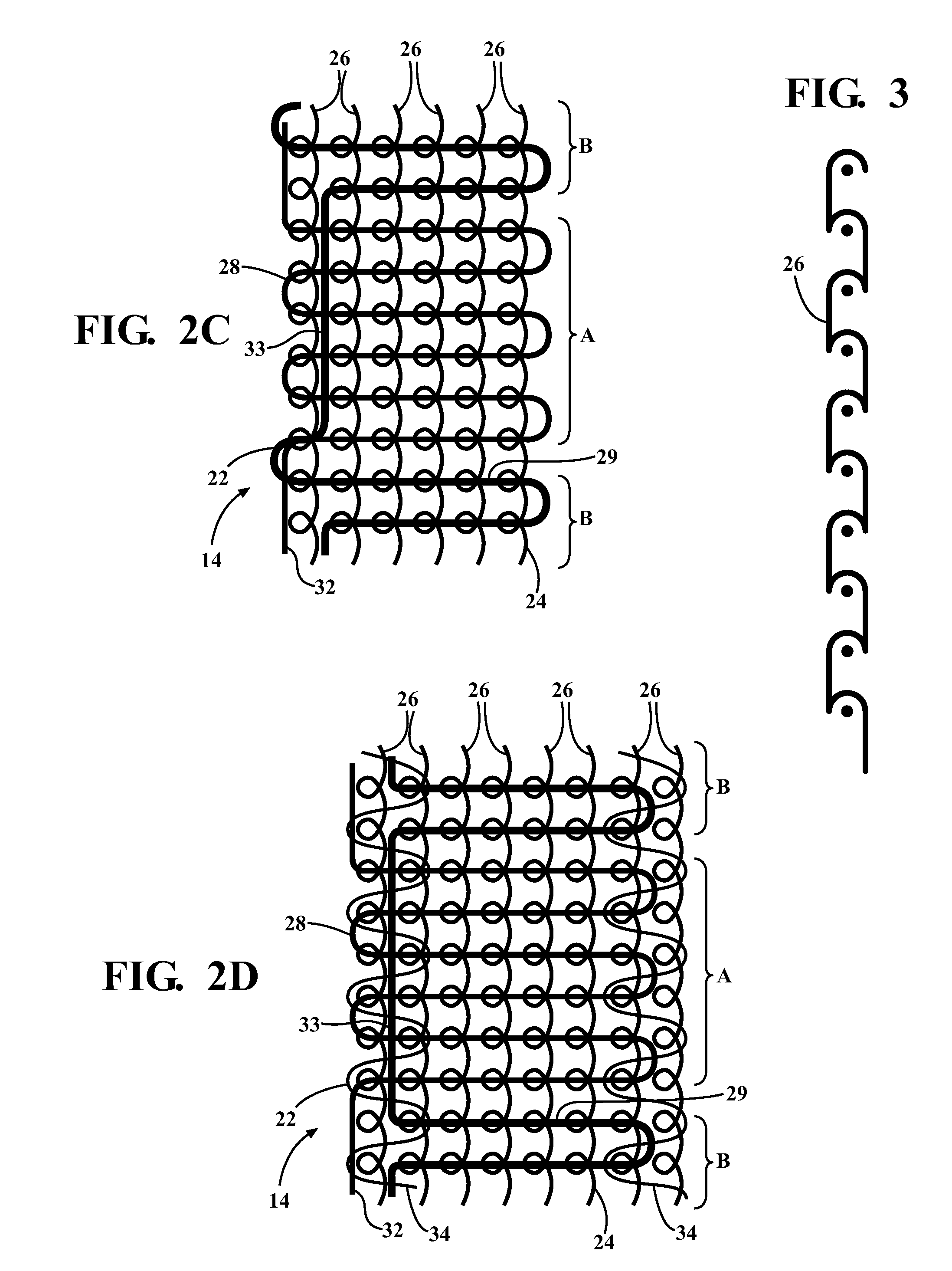

Non-Kinking Self-Wrapping Woven Sleeve and Method of Construction Thereof

ActiveUS20140220846A1Enhanced hoop strengthProvide resilienceProtective equipmentLayered productsArchitectural engineeringUltimate tensile strength

A wrappable textile sleeve and method of construction thereof is provided. The wrappable textile sleeve includes an elongate wall extending along a longitudinal axis between opposite ends with lengthwise extending edges extending parallel or substantially parallel with the longitudinal axis between the opposite ends. The wall is woven from lengthwise extending warp yarns and circumferentially extending weft yarns. The weft yarns form a plurality of discrete annular bands, with adjacent bands having weft yarns of different diameters to provide the wall with discrete enhanced hoop strength regions and with discrete enhanced flexibility regions, where the enhanced hoop strength and enhanced flexibility regions alternate in adjacent relation with one another.

Owner:FEDERAL MOGUL POWERTAIN LLC

Stent designs for use in peripheral vessels

ActiveUS20080051877A1Improve radiopacityHigh strengthStentsBlood vesselsMedicineUltimate tensile strength

Stent designs for use in peripheral vessels, such as the carotid arteries, are disclosed. The stents consist of a plurality of radially expandable cylindrical elements generally aligned on a common longitudinal stent axis and interconnected by one or more interconnecting members placed so that the stent is flexible in a longitudinal direction. The cylindrical elements are generally serpentine wave pattern transverse to the longitudinal axis between alternating valley portion and peak portions, the valley portion including alternating double-curved portions and U-shaped portions. The interconnecting members are attached to the double-curved portions to connect a cylindrical element to an adjacent cylindrical element and interconnecting members are attached to the U-shaped portions to connect the cylindrical element to the other adjacent cylindrical element. The designs include an eight crown and six crown stent which exhibit flexibility and sufficient radial strength to support the vessel.

Owner:ABBOTT LAB INC

Container and lid and related method

ActiveUS20080257886A1Enhanced hoop strengthInhibition of activationOpening closed containersCapsEngineeringCorrelation method

Owner:ROPAK CORP

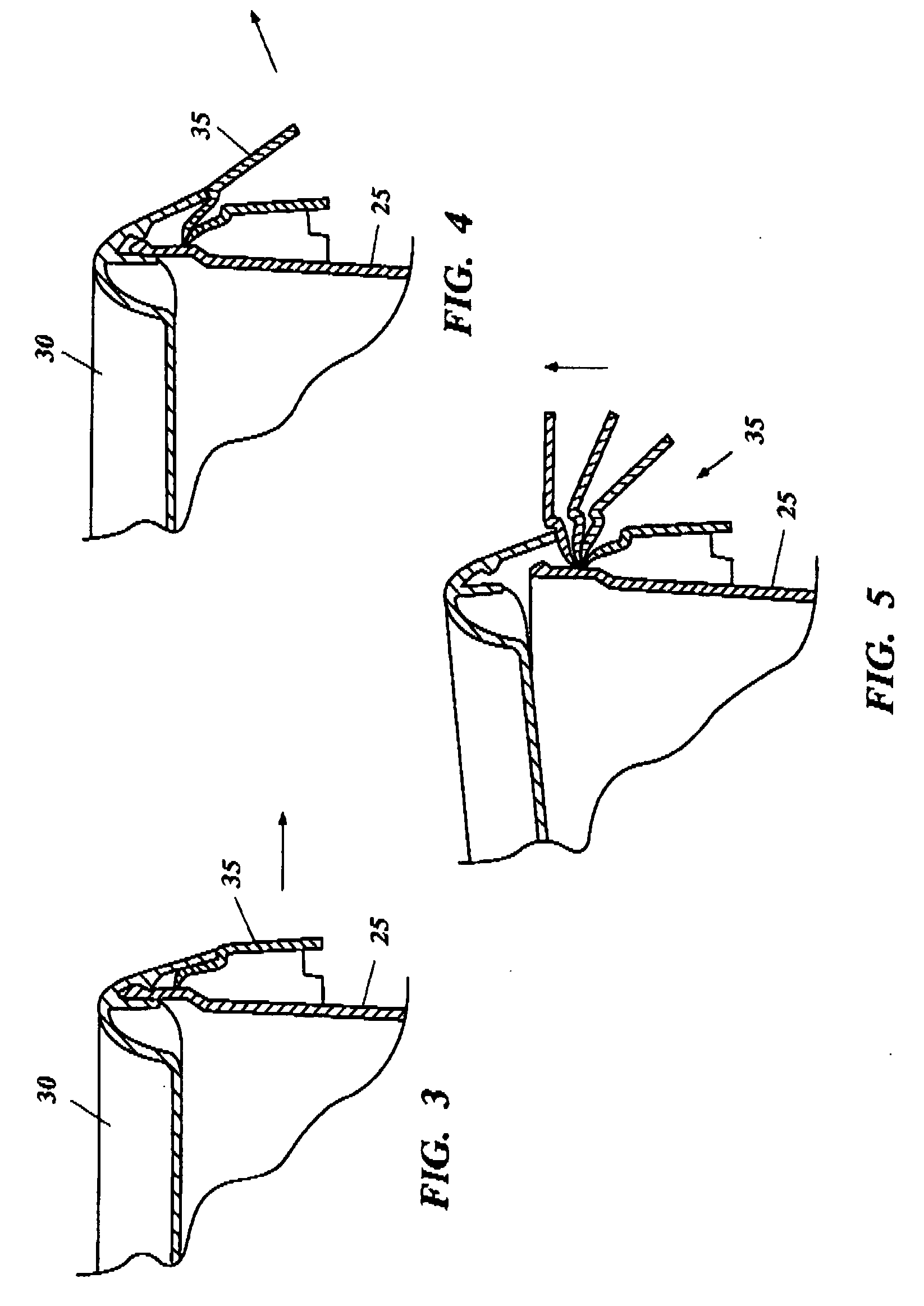

Braided textile sleeve with axially collapsible, Anti-kinking feature and method of construction thereof

ActiveUS20170137978A1Expand coverageIncrease flexibilityOrnamental textile articlesBraidYarnClosed loop

A protective textile sleeve and method of construction thereof are provided. The sleeve has a tubular wall of braided yarns extending lengthwise along a central longitudinal axis between opposite ends. At least some of the braided yarns including heat-set yarns, and the wall has a plurality of annular first regions forming generally convex ridges and a plurality of annular second regions forming generally concave valleys. The first regions alternate with the second regions along the central longitudinal axis. The first regions include a plurality of twisted yarns forming a plurality of closed loops, wherein at least some of the braided yarns pass through at least some of the closed loops within the first regions to enhance the radial stiffness and resistance of the wall to kinking.

Owner:FEDERAL MOGUL POWERTAIN LLC

Pipe Fitting Apparatus and Methods

ActiveUS20160091131A1Enhanced hoop strengthReduce hoop stressSleeve/socket jointsLaminationPipe fittingEngineering

A pipe fitting includes a tubular member comprising a socket and a centering device within the socket. The socket is configured to receive an end of a pipe section therein such that a gap exists between an outer surface of the pipe section and an inner surface of the socket. An annular pipe stop extends from the inner surface of the socket and is configured to matingly engage with the end of the pipe section. A pair of ports extend through the tubular member in circumferentially spaced-apart relationship and are in fluid communication with the gap. The centering device is configured to maintain a coaxial relationship between the pipe section and the socket and such that the gap is substantially circumferentially uniform. A removable and reusable clamp secures the pipe section within the socket as a bonding agent is extruded into the gap via one of the ports.

Owner:IPS WELD ON DIV

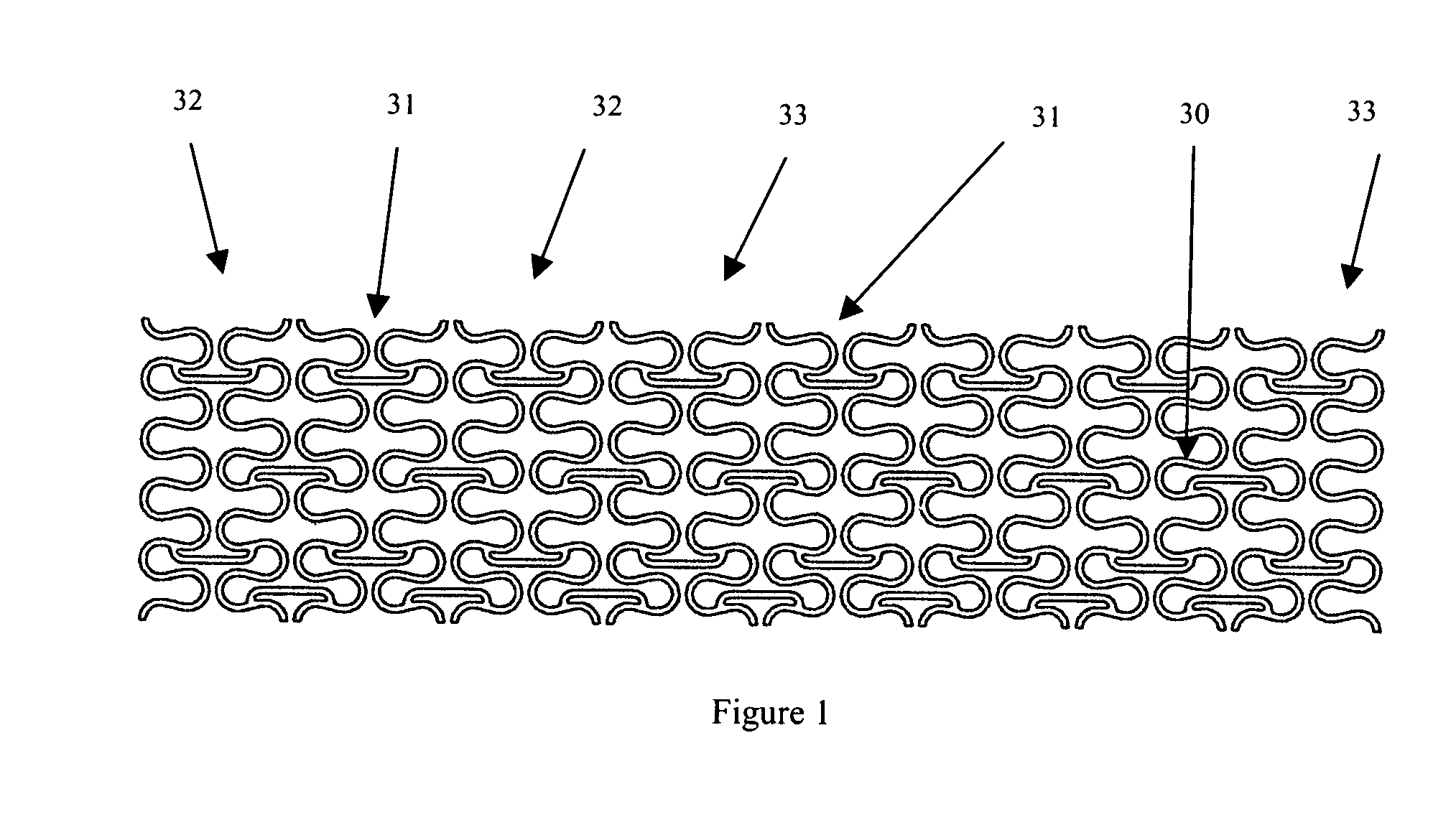

Non-kinking wrapple knit sleeve and method of construction thereof

ActiveUS20150233029A1Enhanced hoop strengthIncrease flexibilityOrnamental textile articlesWarp knittingEngineeringWeft yarn

A warp knit textile sleeve is provided. The sleeve has an elongate, wrappable wall extending along a longitudinal axis between opposite ends. The wall has opposite free edges extending lengthwise along the longitudinal axis between the opposite ends. The wall is knit from at least one warp yarn extending lengthwise between the opposite ends and a plurality of weft yarns extending circumferentially between the opposite free edges. The weft yarns form a plurality of discrete, annular bands alternating in adjacent relation along the longitudinal axis. The weft yarn of one of the adjacent bands has a first diameter and the weft yarn of the other of the adjacent bands has a second diameter, wherein the first diameter is less than the second diameter.

Owner:FEDERAL MOGUL POWERTAIN LLC

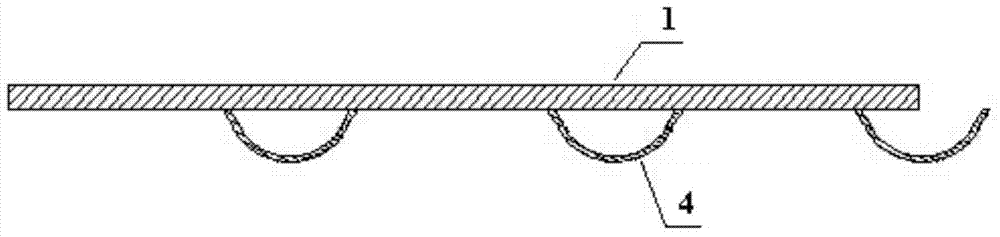

Spiral steel pipe with reinforcing rings and manufacturing method of spiral steel pipe

ActiveCN104266006ASolve the deformationEnhanced hoop strengthRigid pipesEngineeringUltimate tensile strength

The invention discloses a spiral steel pipe with reinforcing rings and a manufacturing method of the spiral steel pipe. The steel pipe comprises a spiral pipe body formed by spirally winding main steel strips; spiral joints are formed between the adjacent main steel strips of the spiral pipe body; the reinforcing rings are spirally wound on and locked to the outer wall or the inner wall of the spiral pipe body; at the spiral joints, the reinforcing rings are formed by bending narrow steel strips and the sections of the reinforcing rings are circular-arc-shaped, square or trapezoidal. The reinforcing rings are capable of enhancing the overall annular strength of the pipe, the thickness of the pipe can be reduced by more than a half, and the cost can be greatly reduced; meanwhile, the inertia moment of the circumferential section of the pipe is increased exponentially; as a result, the effect of the reinforcing rings is much better than that of a common reinforcement way, and consequently, the deformation problem of a large-diameter steel pipe, in particular a steel pipe of which the diameter is greater than 4m, during production is solved, and a steel pipe with an ultra-large diameter (10m or above) can be produced. Besides, the spiral joints formed between the adjacent sections of the spiral steel pipe are capable of surrounding the reinforcing rings so that the leakage protection at the joints can be strengthened.

Owner:NANJING LIANZHONG CONSTR ENG TECH

Filter with stiffening ribs

InactiveUS20010007189A1Withstand explosive forceInexpensive and effectiveCombination devicesGas treatmentAirbagWire mesh

Annular wire mesh filters for airbag assemblies for passenger vehicles are provided with a series of ribs extending parallel with the axis of the annulus and along the outer wall. The ribs provide added strength to the filter. Also provided is a method of manufacturing the compressed mesh filter with a uniform density, and a molding tool (mold, mandrel, and plunger) for making the compressed mesh articles of this invention.

Owner:ACS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com