Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2738 results about "Coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

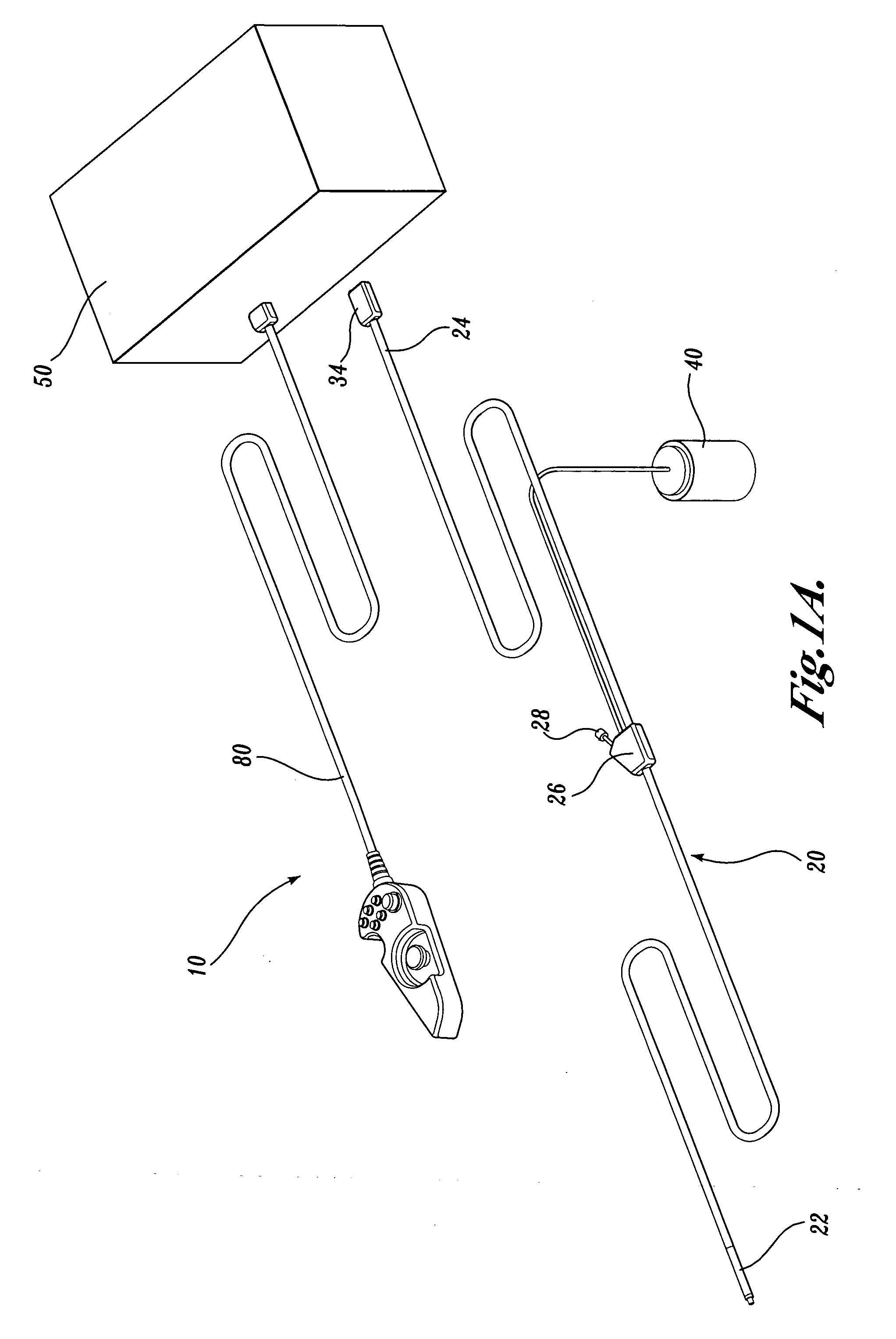

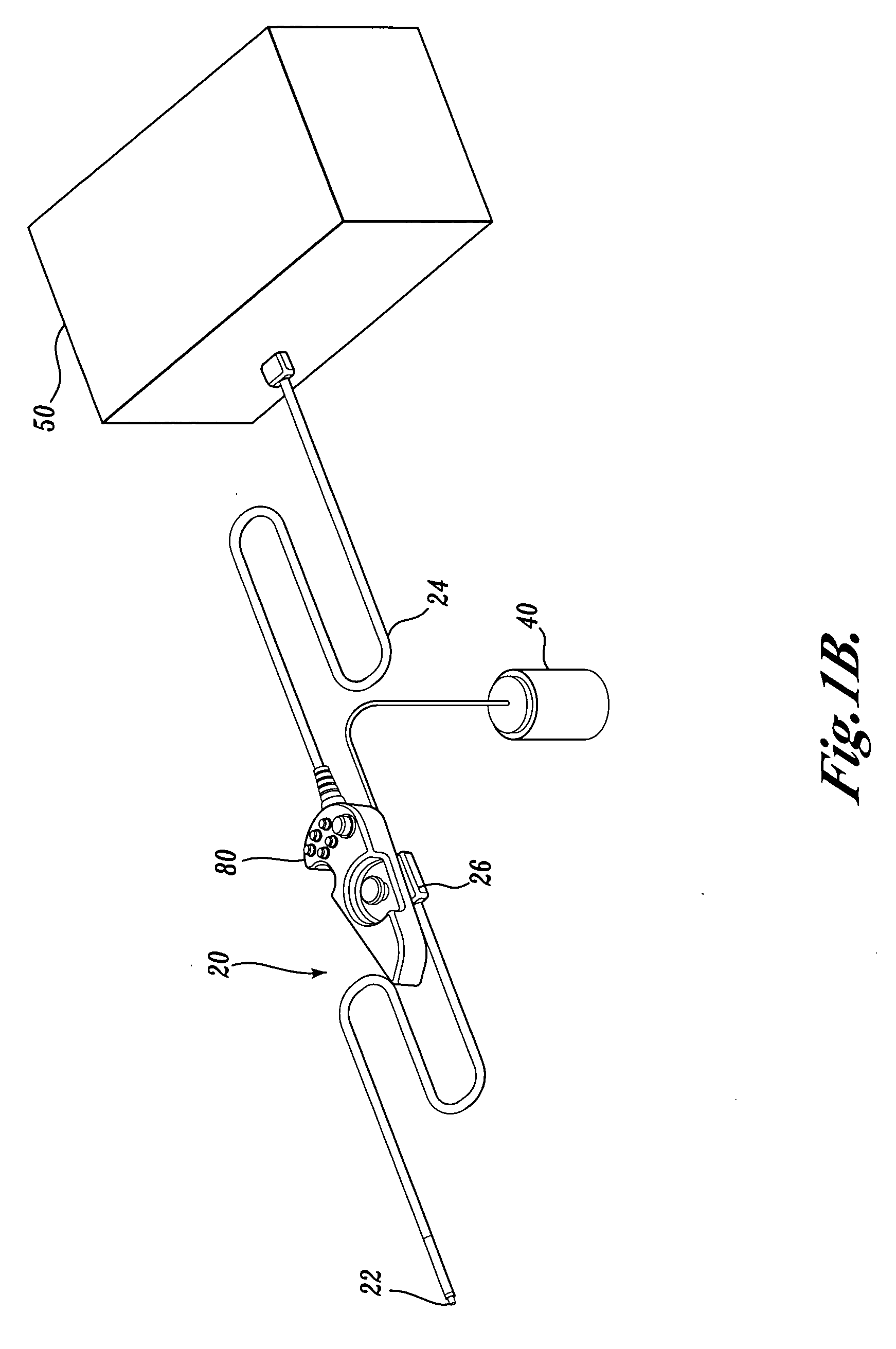

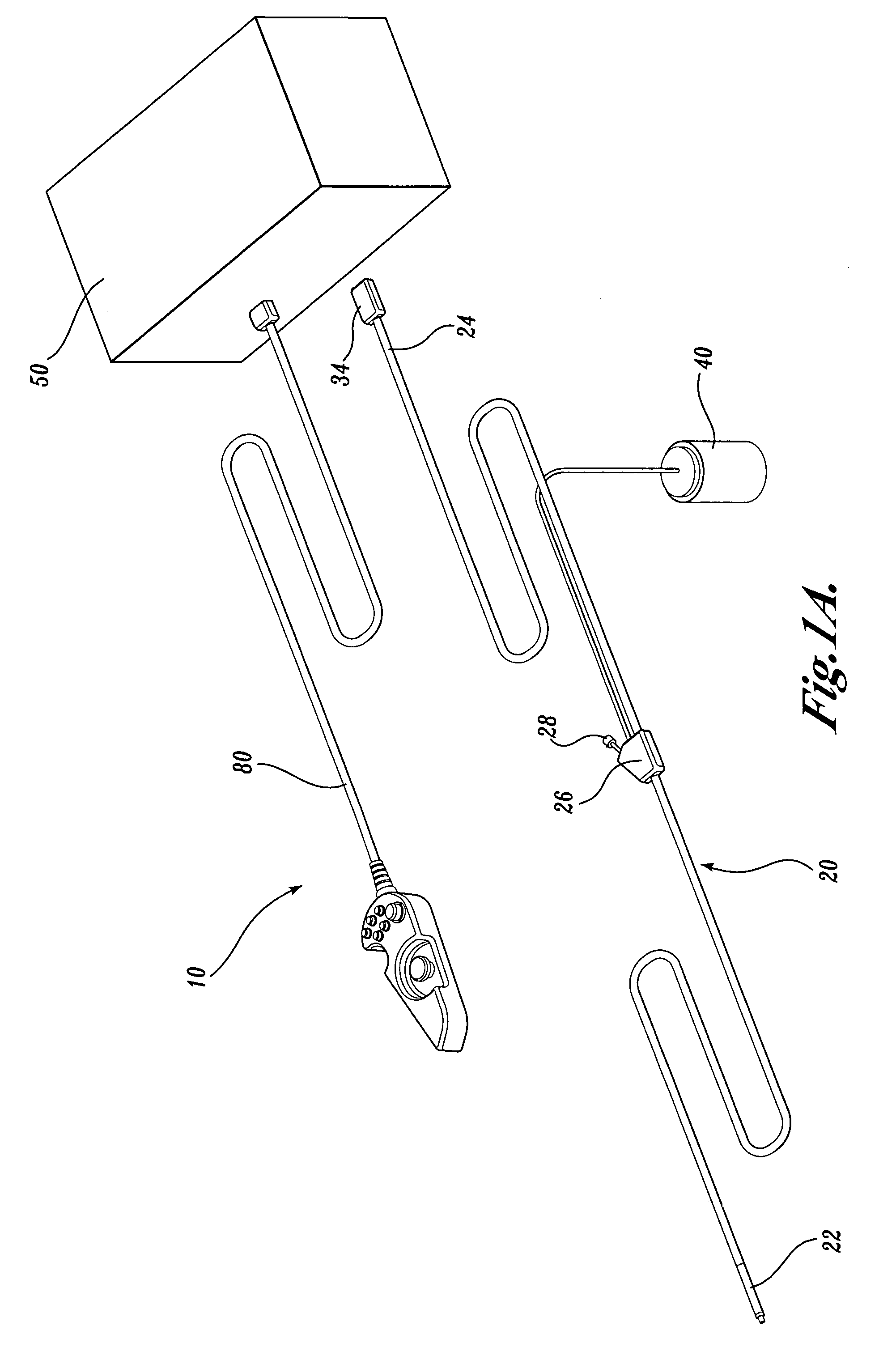

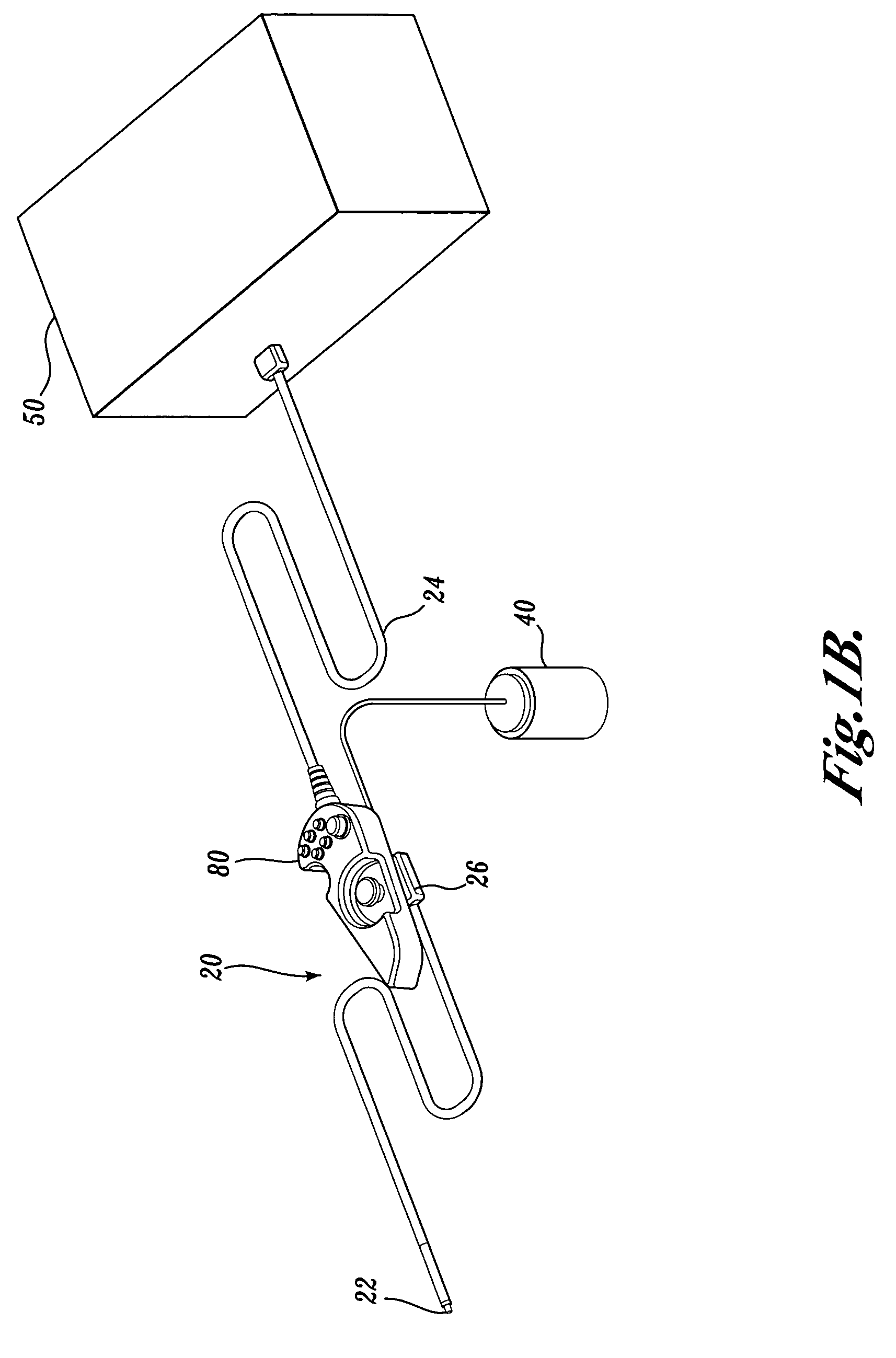

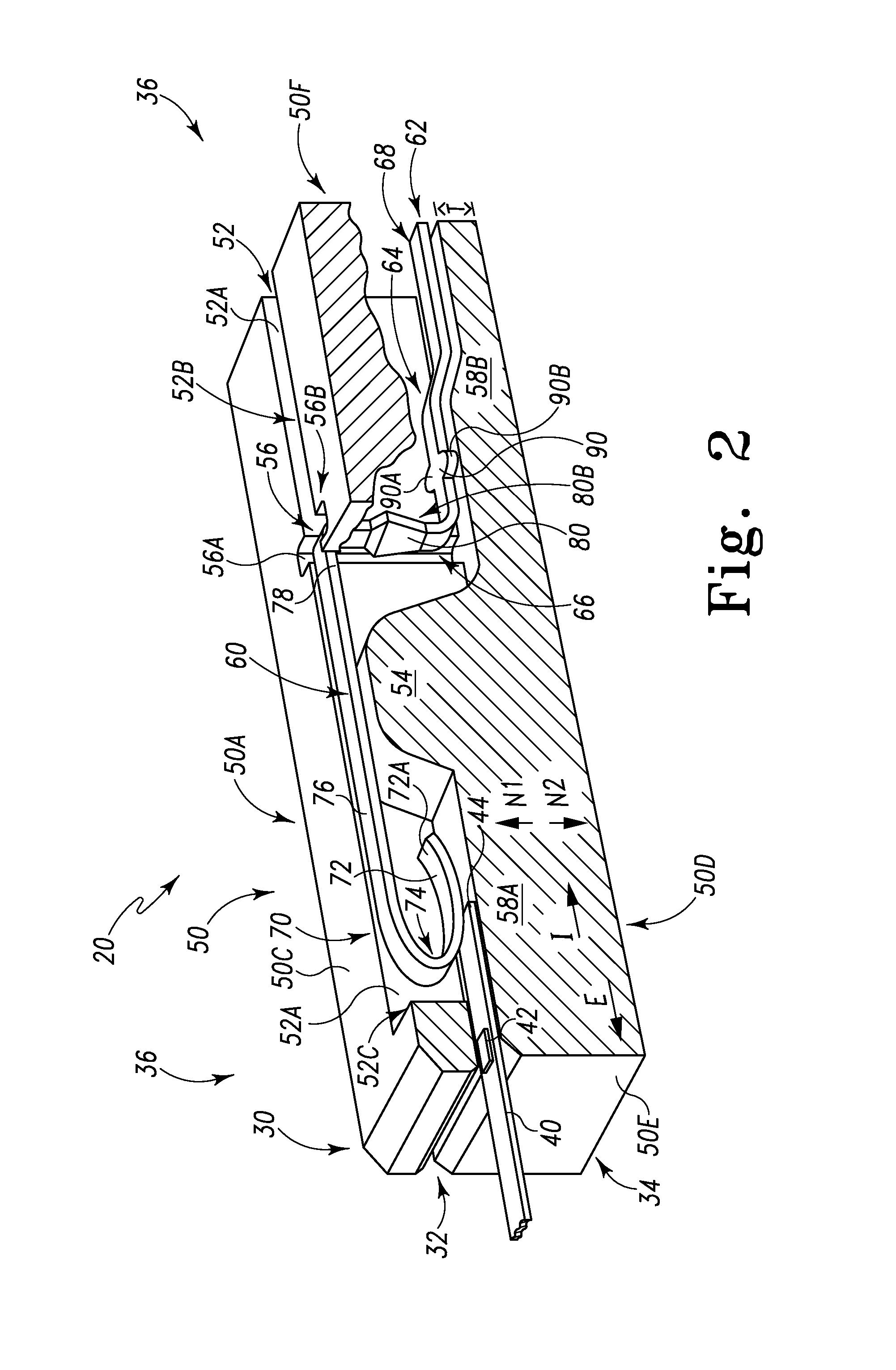

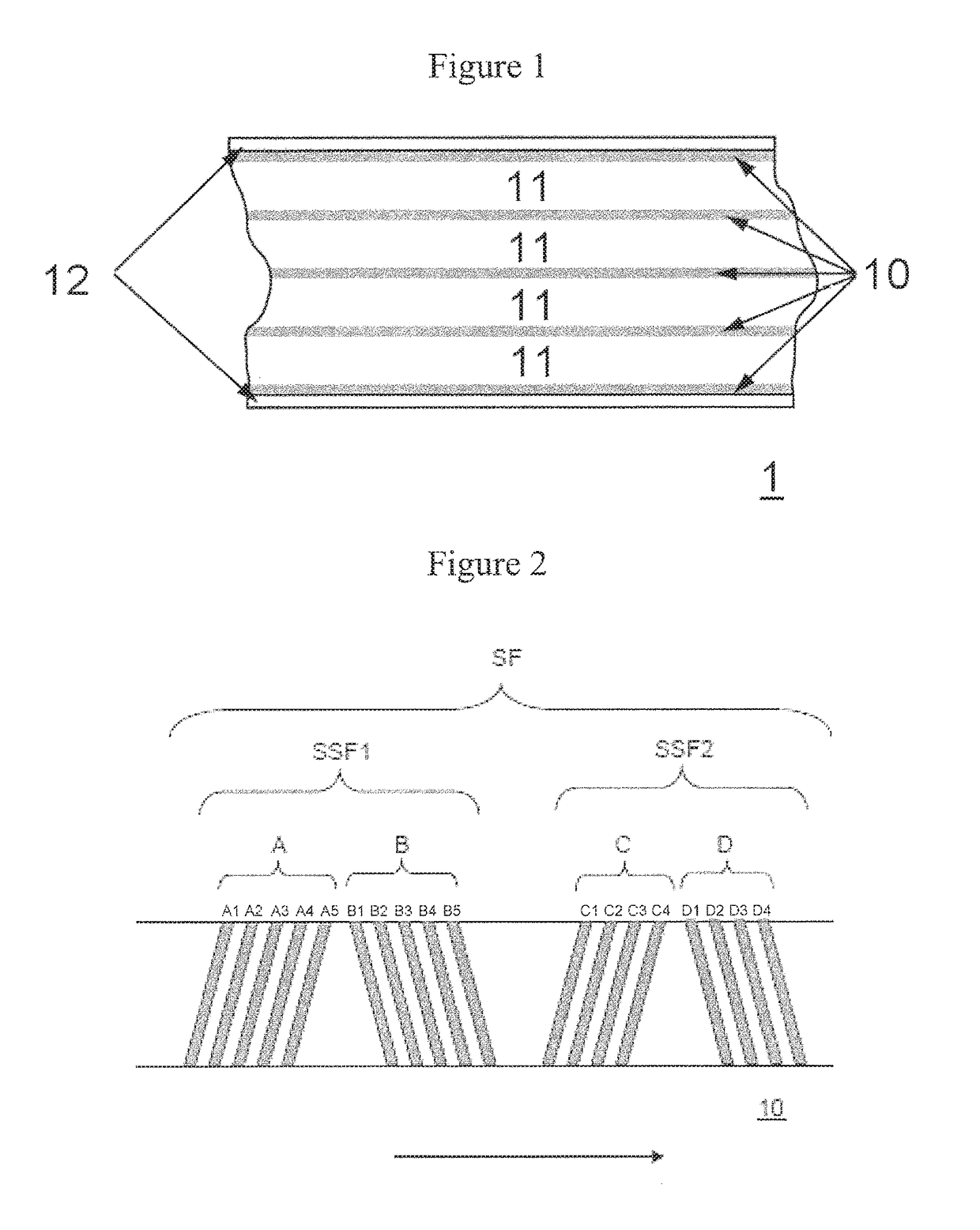

Single use endoscopic imaging system

An endoscopic imaging system includes a reusable control cabinet having a number of actuators that control the orientation of a lightweight endoscope that is connectable thereto. The endoscope is used with a single patient and is then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet. The endoscope is coated with a hydrophilic coating that reduces its coefficient of friction and because it is lightweight, requires less force to advance it to a desired location within a patient.

Owner:SCI MED LIFE SYST

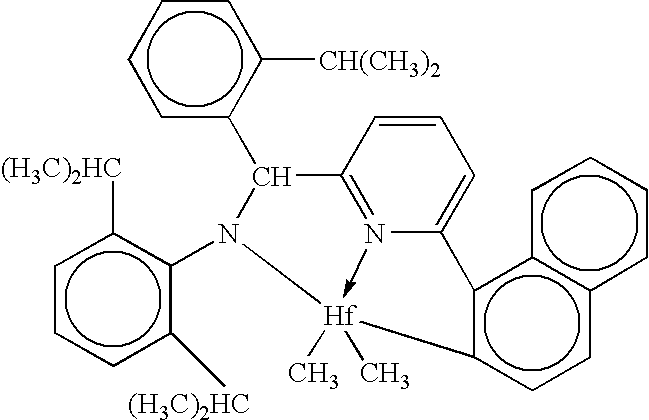

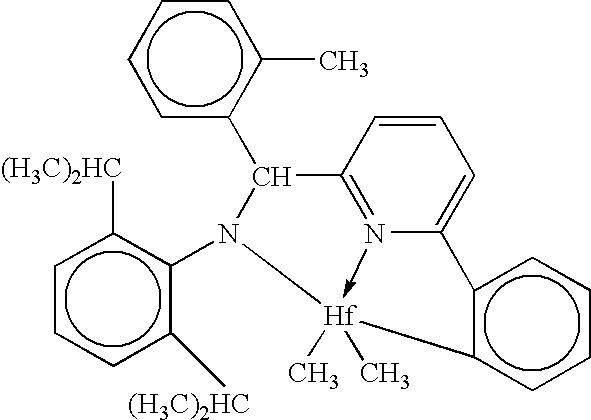

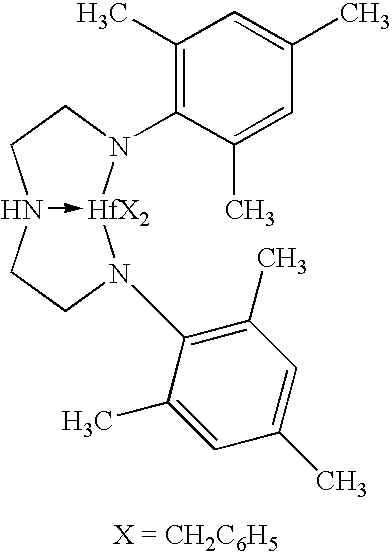

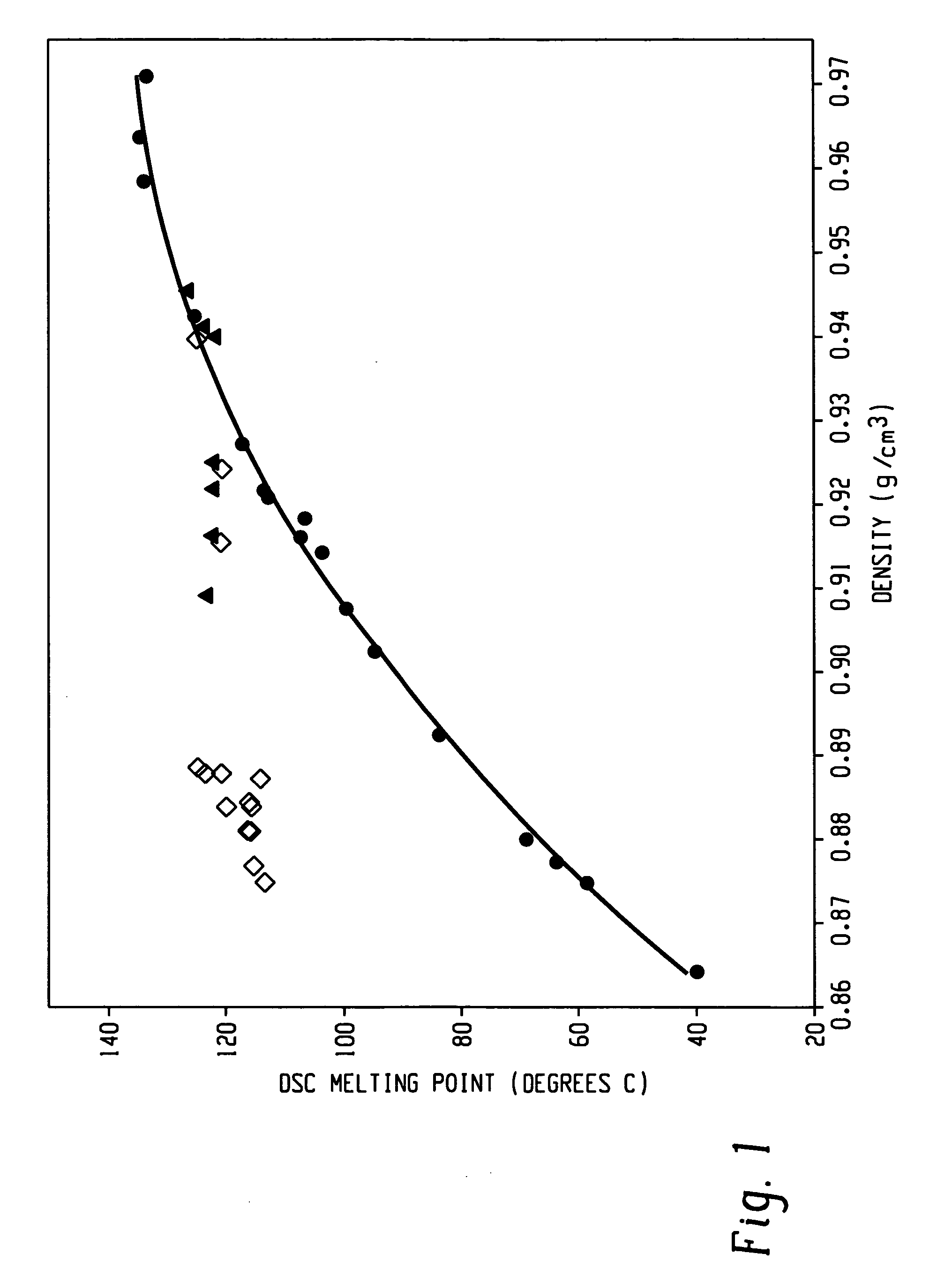

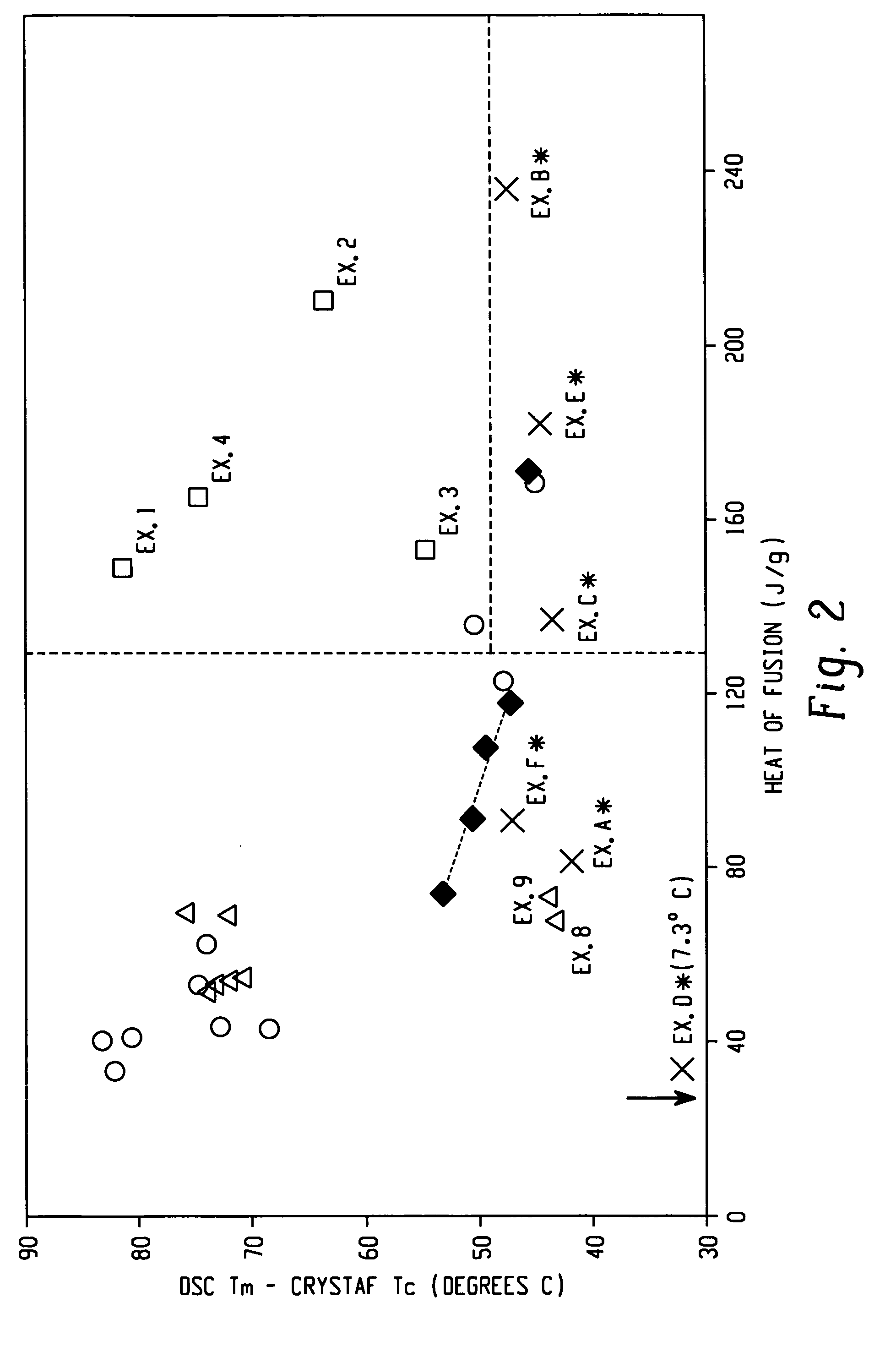

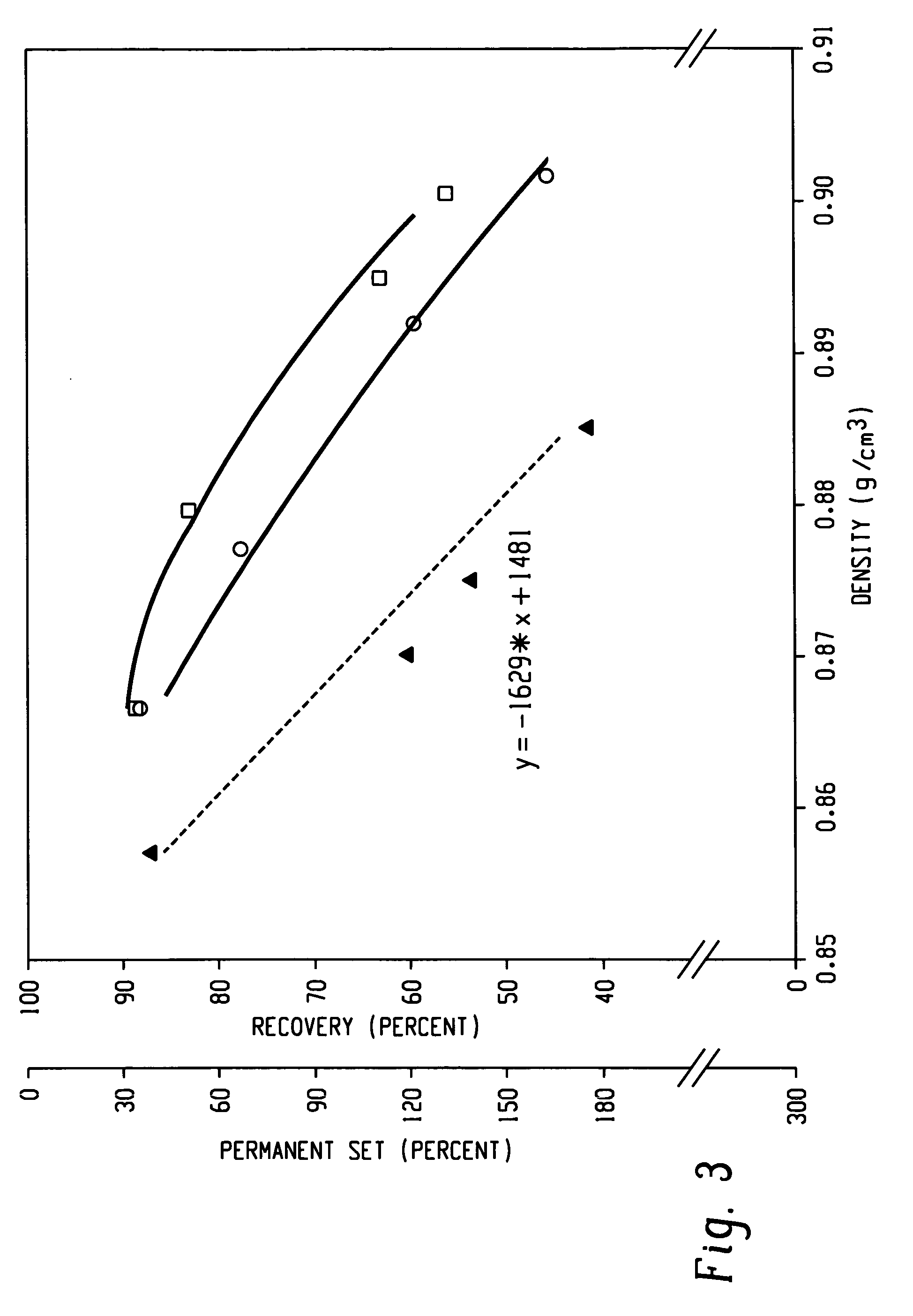

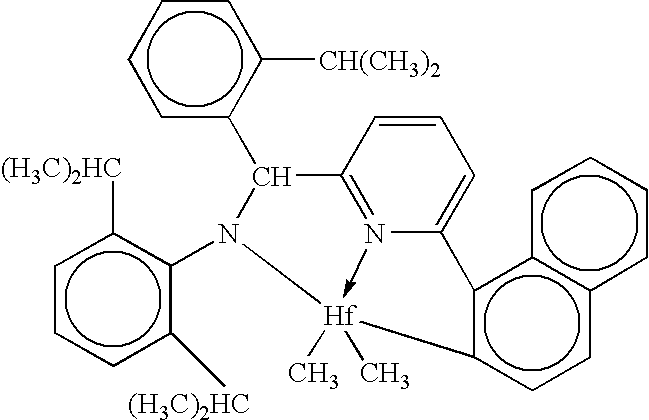

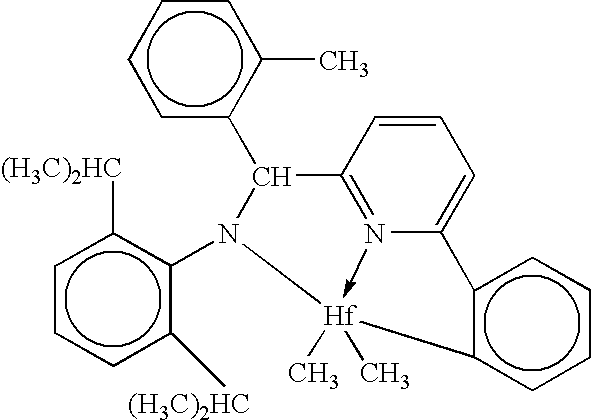

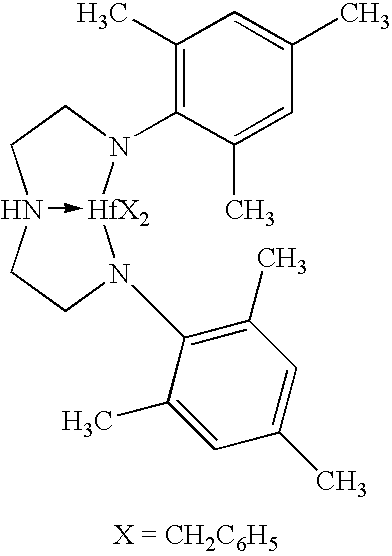

Fibers made from copolymers of propylene/alpha-olefins

ActiveUS7504347B2Monocomponent synthetic polymer artificial filamentWoven fabricsFiberVolumetric Mass Density

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629 (d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

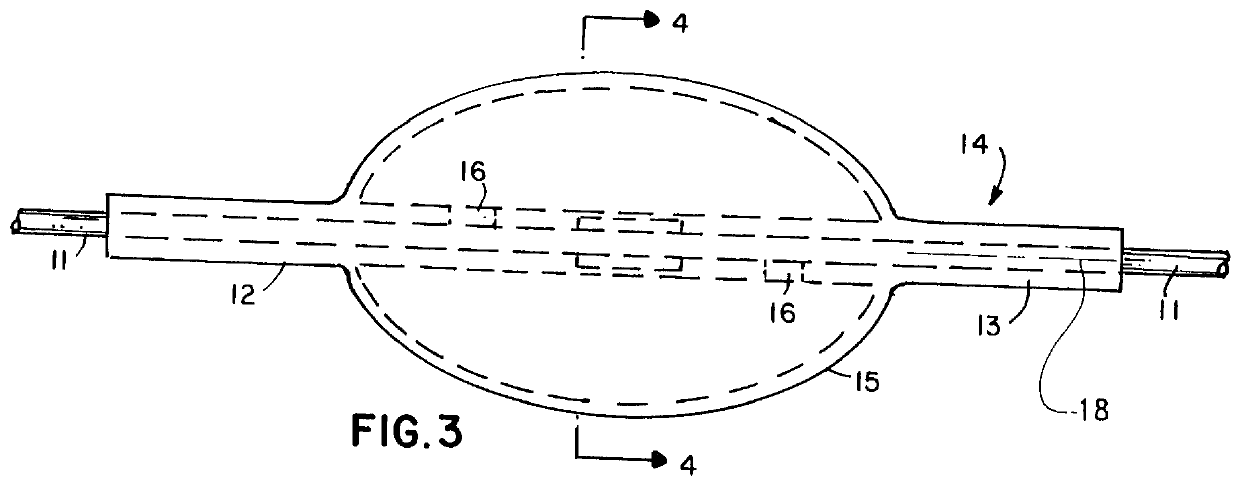

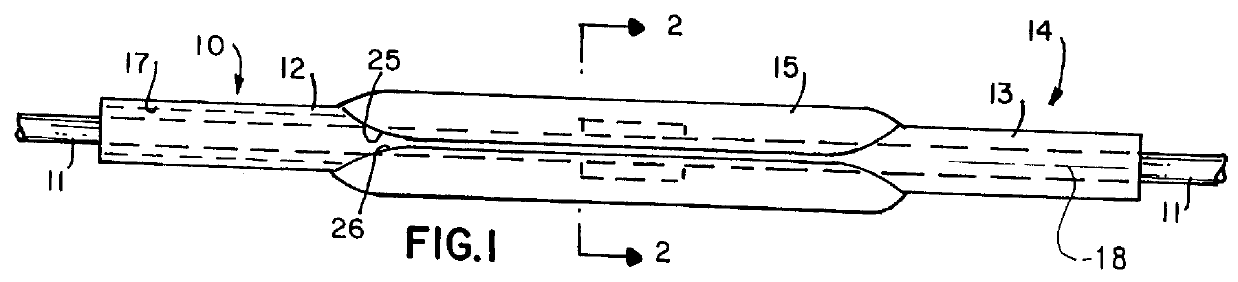

Balloon catheter

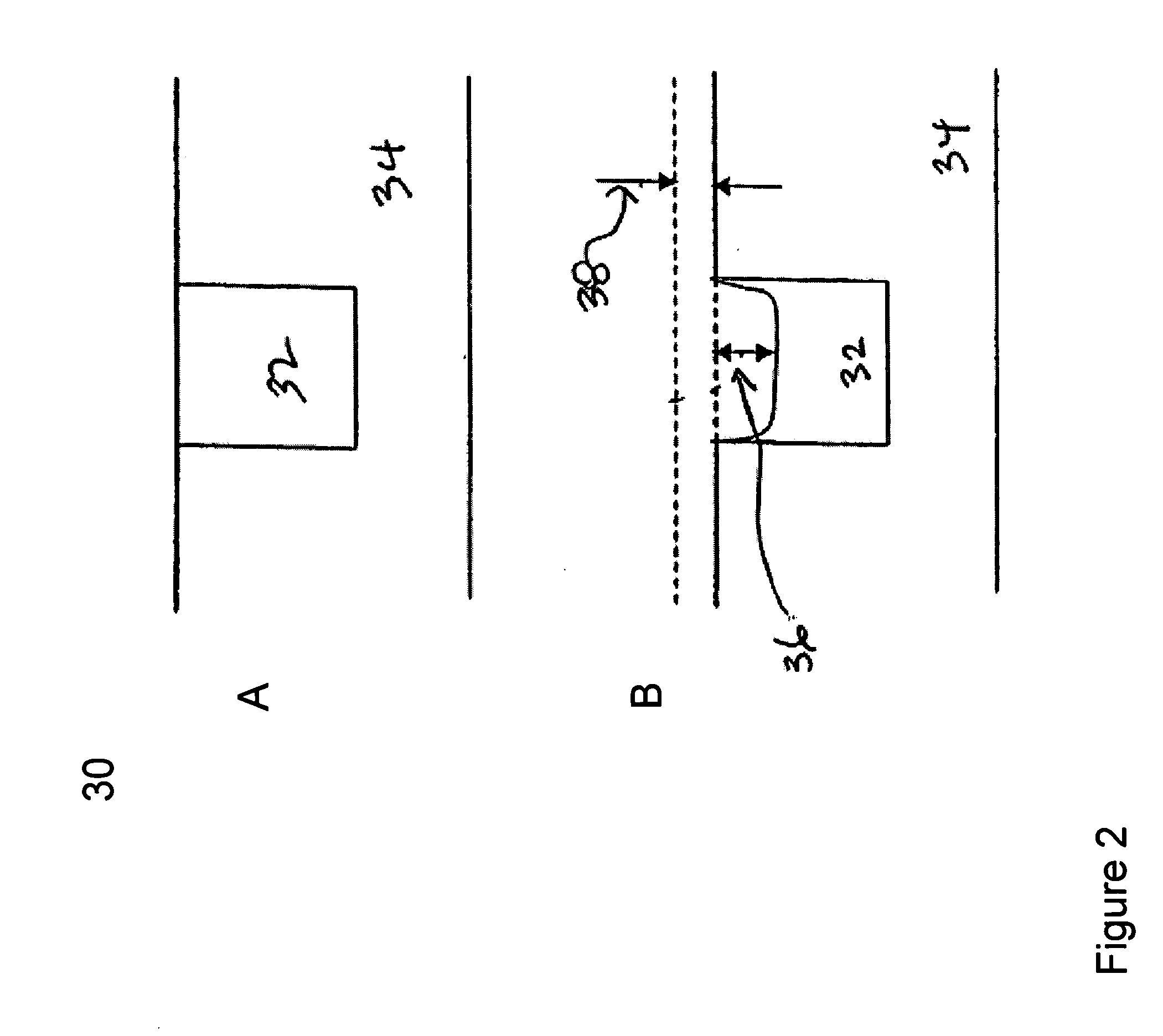

InactiveUS6010480AImprovement factorReduce coefficient of frictionStentsBalloon catheterBalloon catheterLesion

An expansible balloon catheter has at least a first exterior surface with a given coefficient of friction and a second exterior surface with a greater coefficient of friction. In a compact form only the first exterior surface is exposed to produce one coefficient of friction during transfer of the collapsed or uninflated balloon to and across a lesion. When inflated, the second surface dominates the first surface and produces a second coefficient of friction.

Owner:BOSTON SCI SCIMED INC

Fibers made from copolymers of ethylene/alpha-olefins

A fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

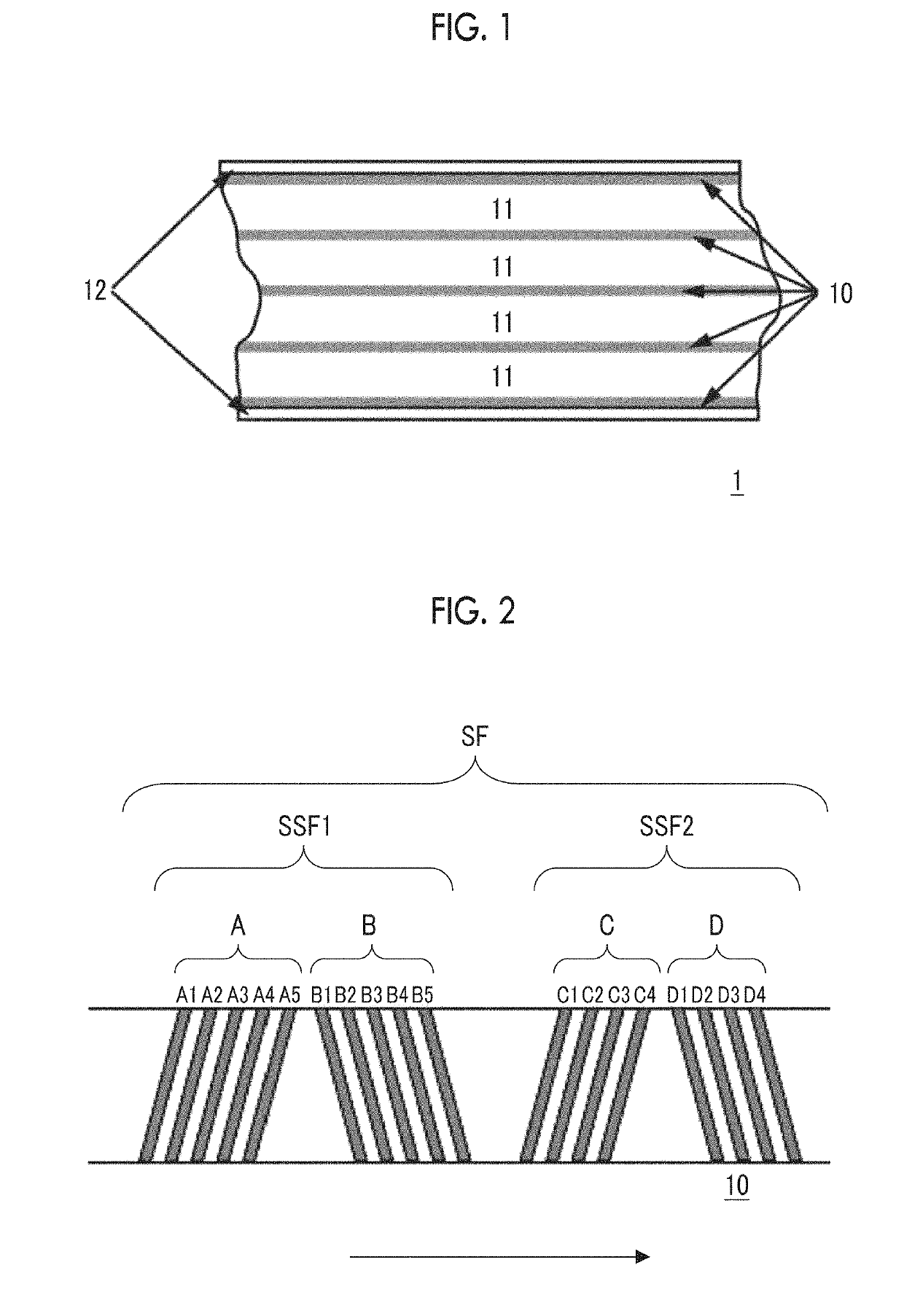

Optimized fiber optic cable suitable for microduct blown installation

A fiber optic cable with optical fibers stranded around a central strength member, and surrounded outer jacket made of a low coefficient of friction material and thinly constructed to show the profile of the stranded shape of the optical lines through the jacket, to thereby form a textured surface.

Owner:ALCATEL LUCENT SAS

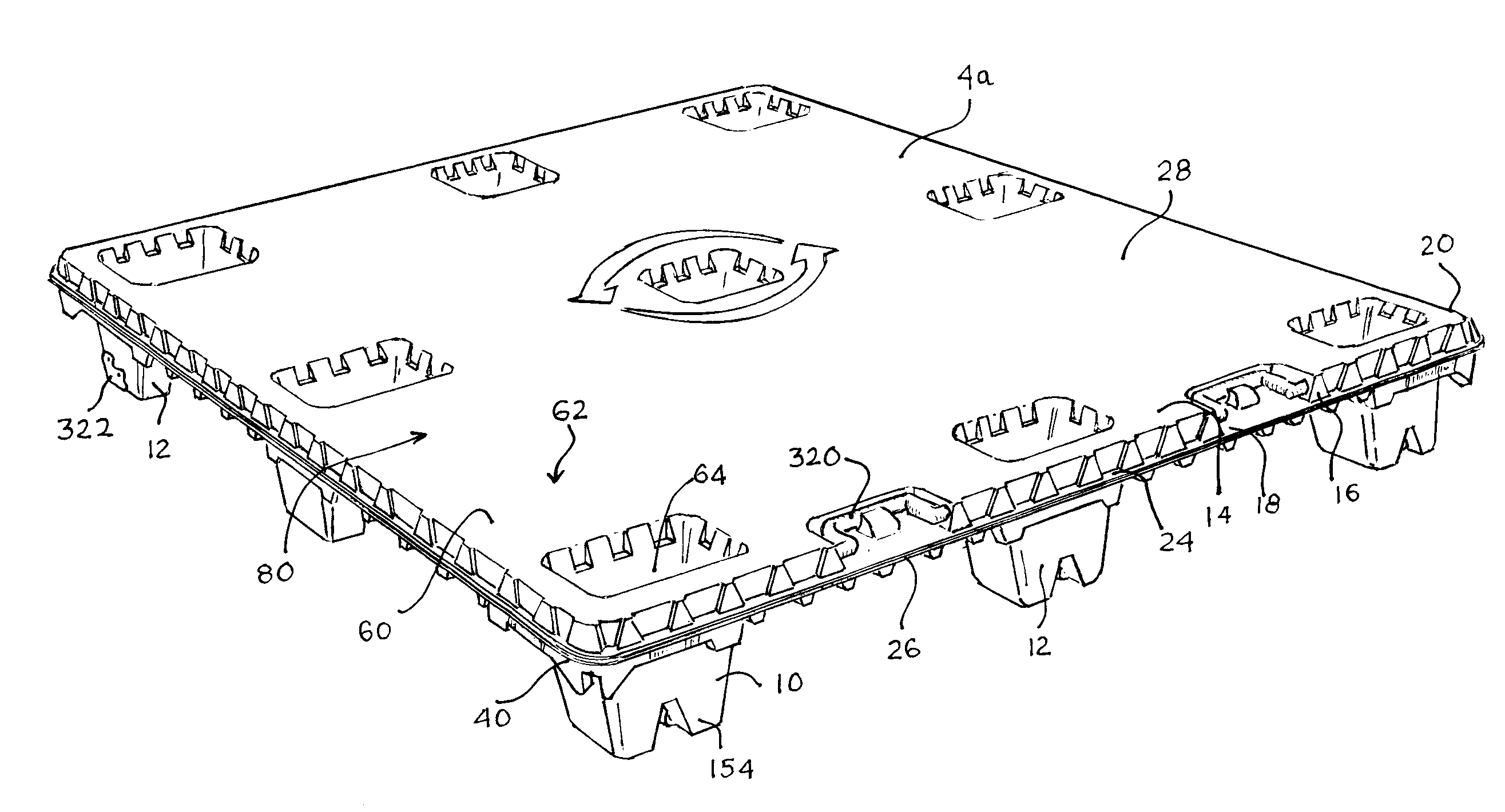

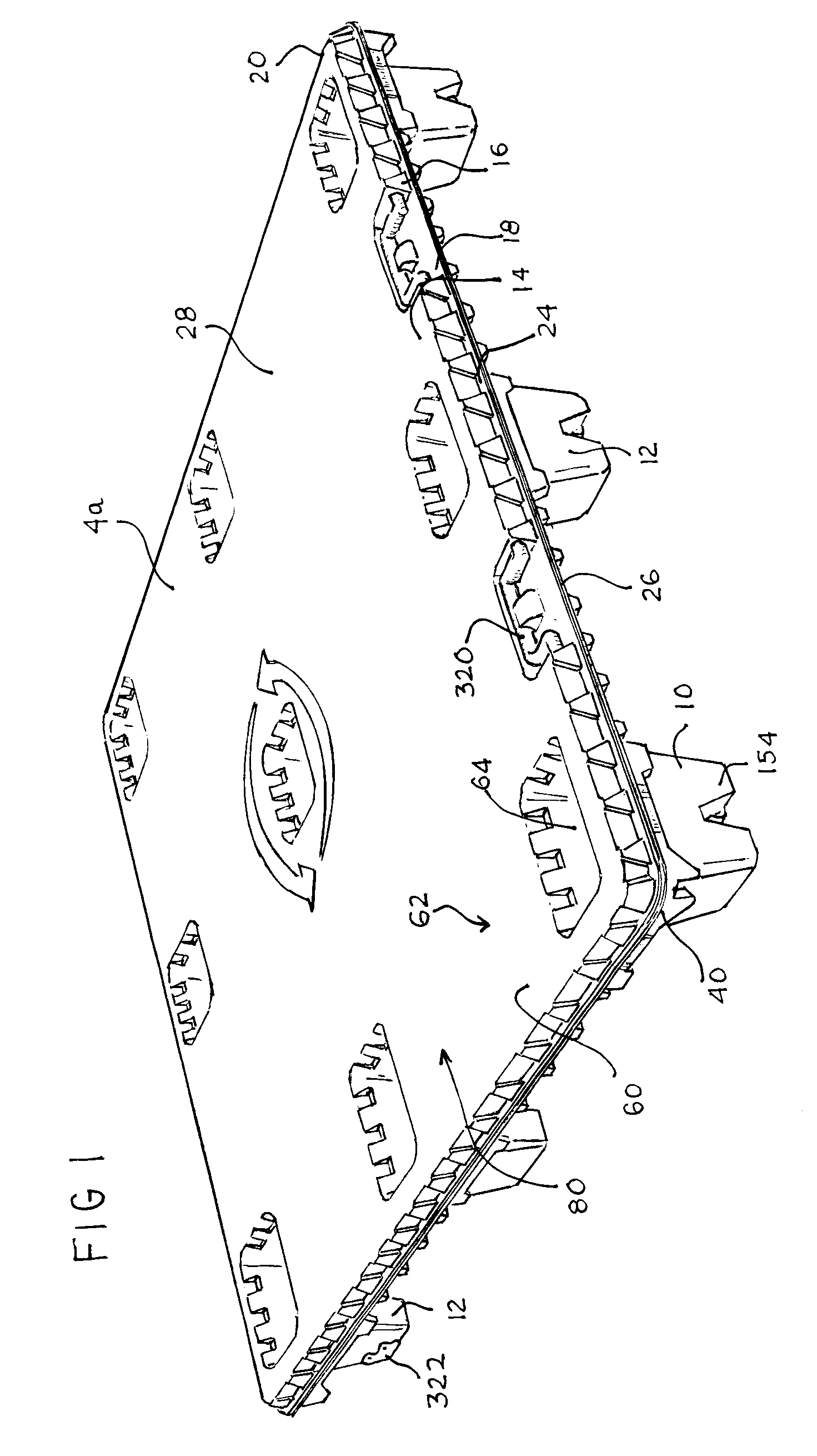

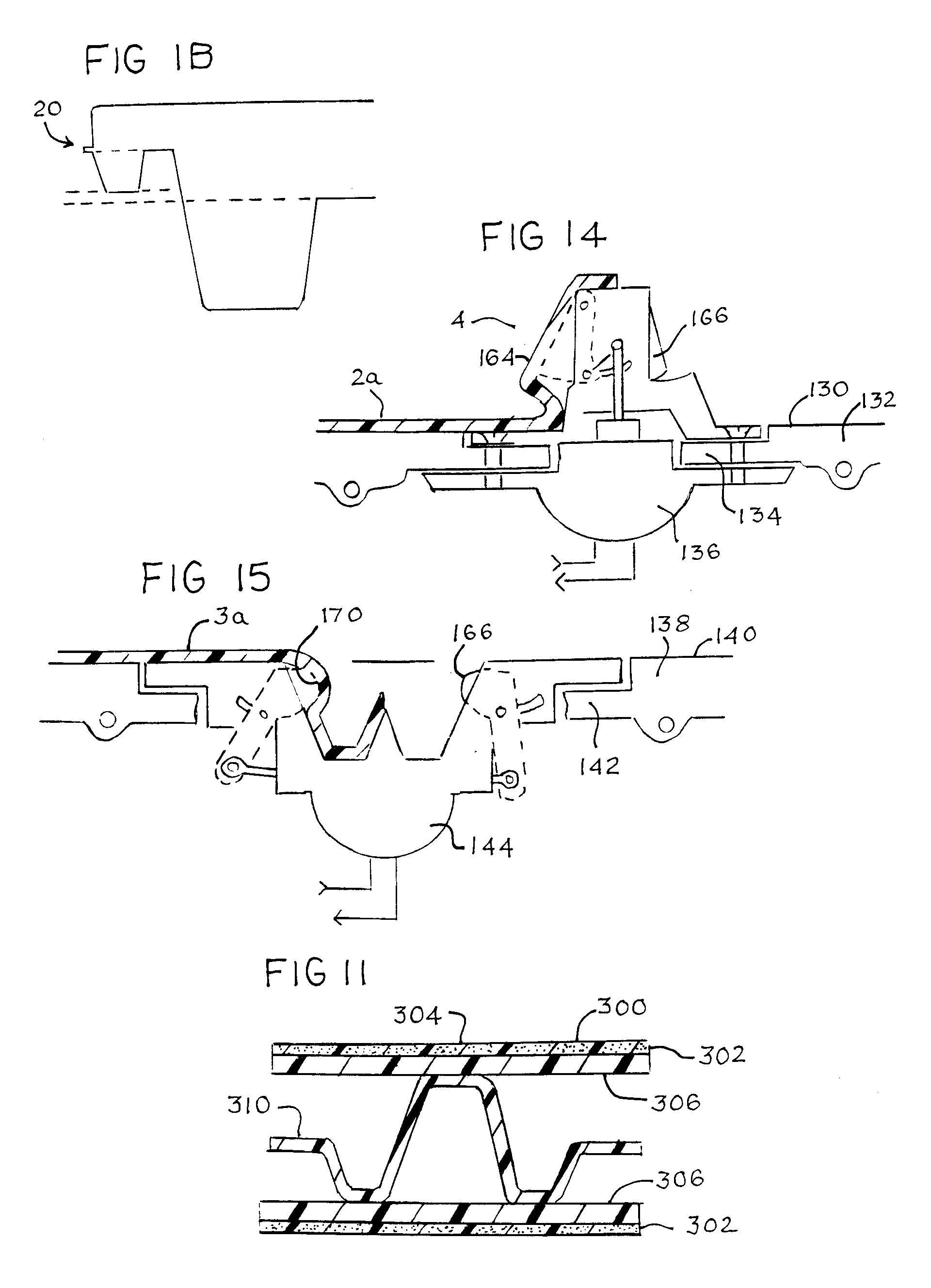

Thermoformed platform

Articles constructed of a plurality of scuffed sheets have improved sheet-to-sheet bond strength and surfaces with high coefficients of friction. Articles constructed out of three scuffed sheets include exterior intumescent polymeric surfaces resisting the spread of combustion flames and insulating the interior surfaces from the high temperature of fire. Articles include electronic apparatus sending an emergency 911 call to a remote monitoring station. Articles are advantageously reinforced with optional rigidifying structures without article modification. Members are joined with snap together features providing an assembled article. Articles include handles for ergonomic manipulation by workers. Articles include elements amenably receiving unitization accessories. The article improvements are demonstrated in the form of industrial platforms, particularly material handling pallets.

Owner:NEXTREME

Fibers made from copolymers of propylene/alpha-olefins

ActiveUS20060199006A1Monocomponent synthetic polymer artificial filamentWoven fabricsFiberAlpha-olefin

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

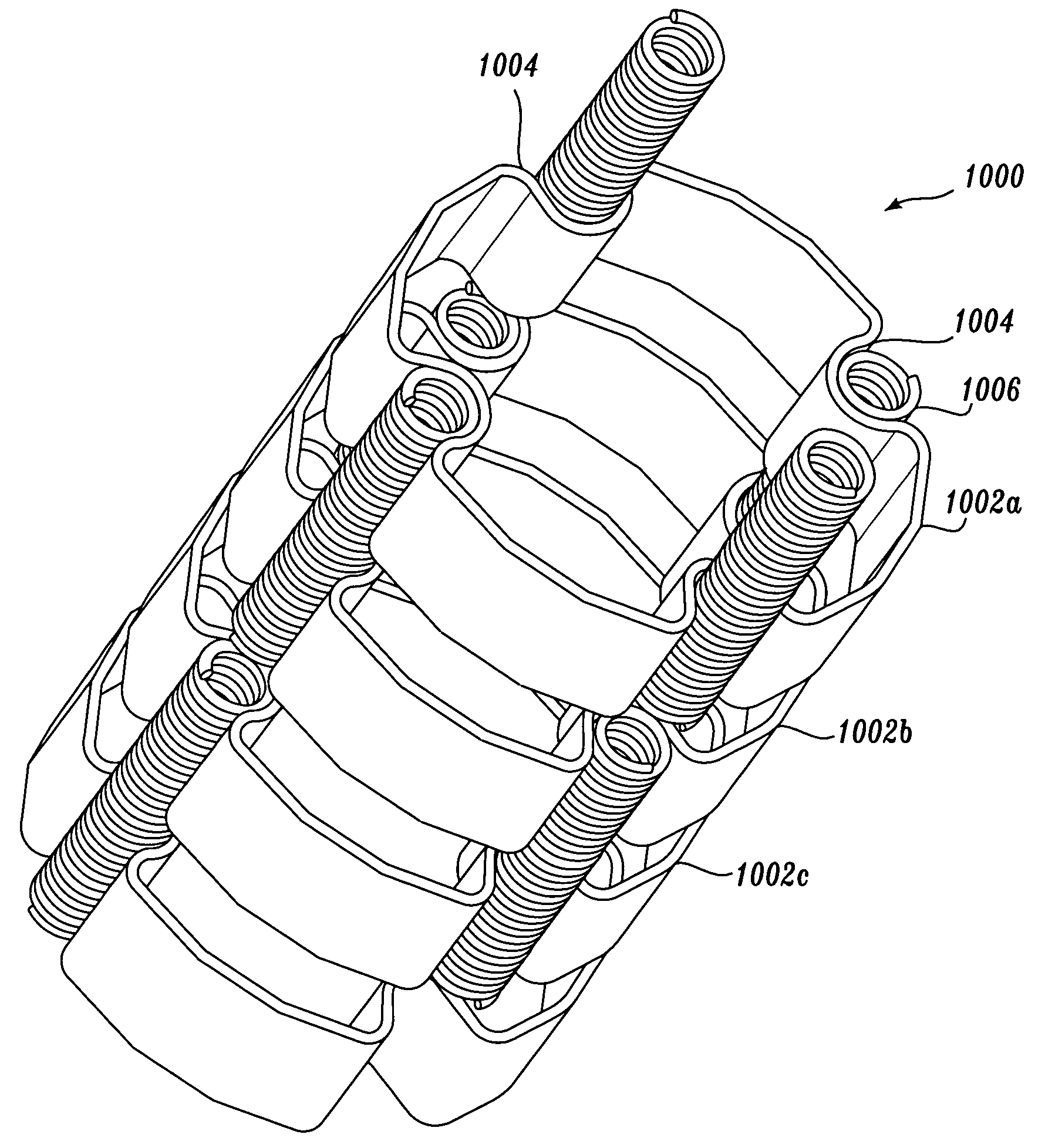

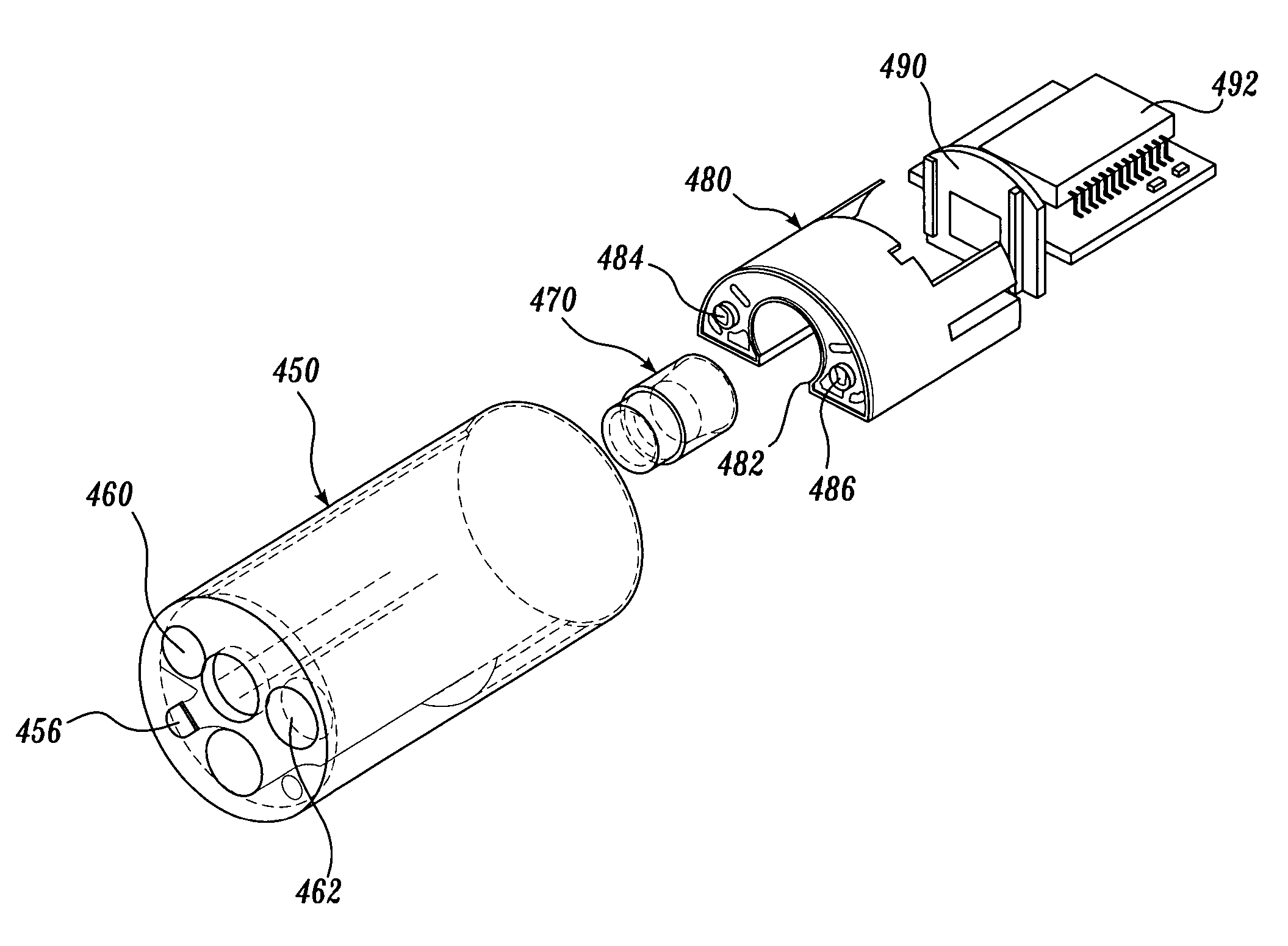

Endoscope with actively cooled illumination sources

ActiveUS7413543B2Inexpensive and easy to assembleRemove heatSurgeryEndoscopesHydrophilic coatingActive cooling

Owner:SCI MED LIFE SYST

Void-containing polyester shrink film

InactiveUS20050119359A1Improve performanceHigh opacitySynthetic resin layered productsLabelsPolyesterVolumetric Mass Density

Disclosed are polyester shrink films comprising a voiding agent dispersed within a continuous polyester phase. The voiding agent comprises at least one first polymer and at least one second polymer, in which the polymer components have selected physical properties such as glass transition temperature, melting point, tensile modulus, surface tension, and melt viscosity. The resulting shrink films have high opacity, a low coefficient of friction, lower density, low shrink force, and good printability. The films are useful for sleeve label and other shrink film applications, and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations. Also disclosed is a process for separating a void-containing polyester from a mixture of polymers.

Owner:SHELBY MARCUS DAVID +2

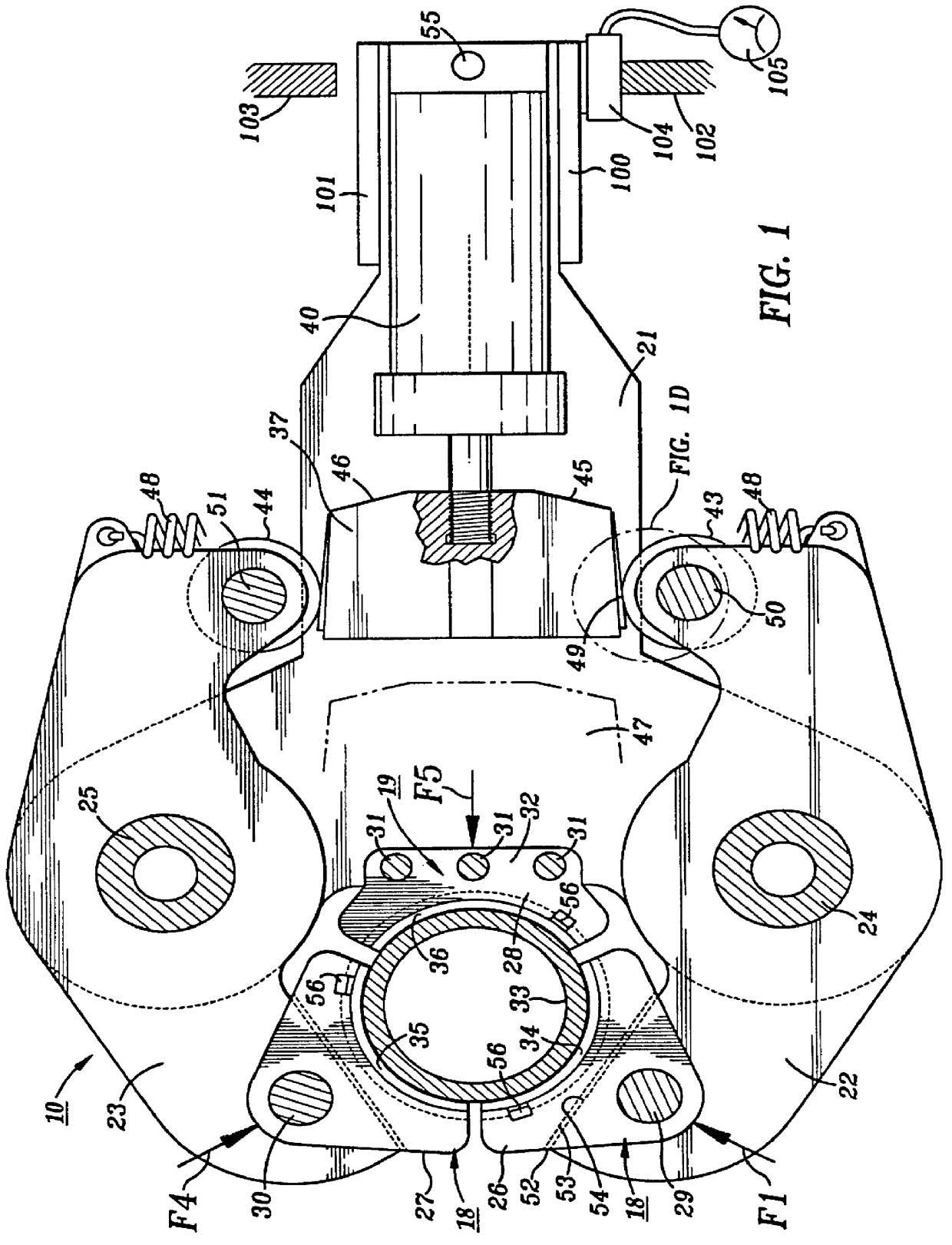

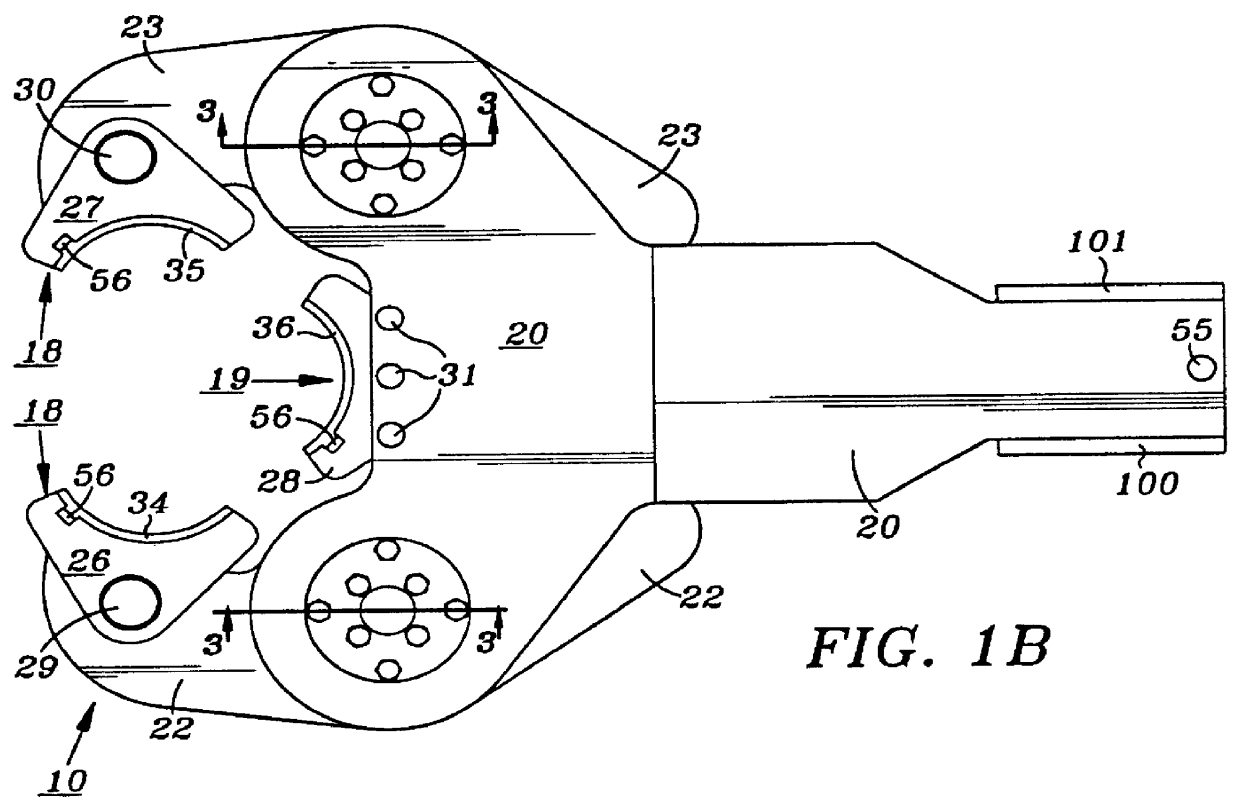

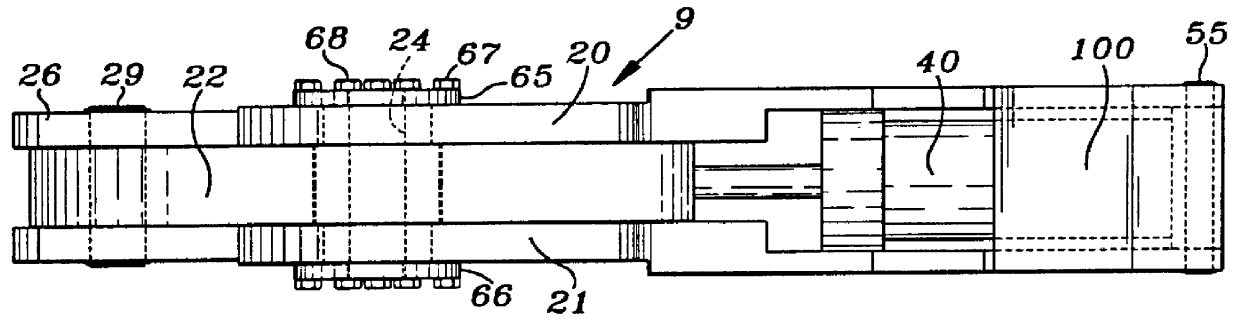

Gripping apparatus for power tongs and backup tools

Apparatus for gripping tubular members including self aligning gripping jaws with high coefficient of friction for resisting force applied to the elongated member to prevent rotation either clockwise or counterclockwise. Linear cams and cam rollers actuated by a fluid cylinder bring the gripping jaws to an elongated member, applying predetermined gripping force and retract the jaws for removal of the elongated member.

Owner:WESCH JR WILLIAM E

Radiation curable and jettable ink compositions

The present invention is directed to radiation curable and jettable ink compositions and particularly to such compositions which exhibit enhanced elongation, when cured at low doses, and are advantageously used, for example, in digital inkjet printing. The compositions include a polyfunctional component and a monofunctional monomer, and may optionally include an additional monofuctional component and / or chain transfer agent. The compositions have a viscosity at 25° C. of not greater than about 70 cP and are radiation curable to form a cured ink having an elongation of between about 40 and about 150%. In addition, the compositions, when cured at low dose, exhibit a tack free surface and a low coefficient of friction.

Owner:COLLINS INK CORP

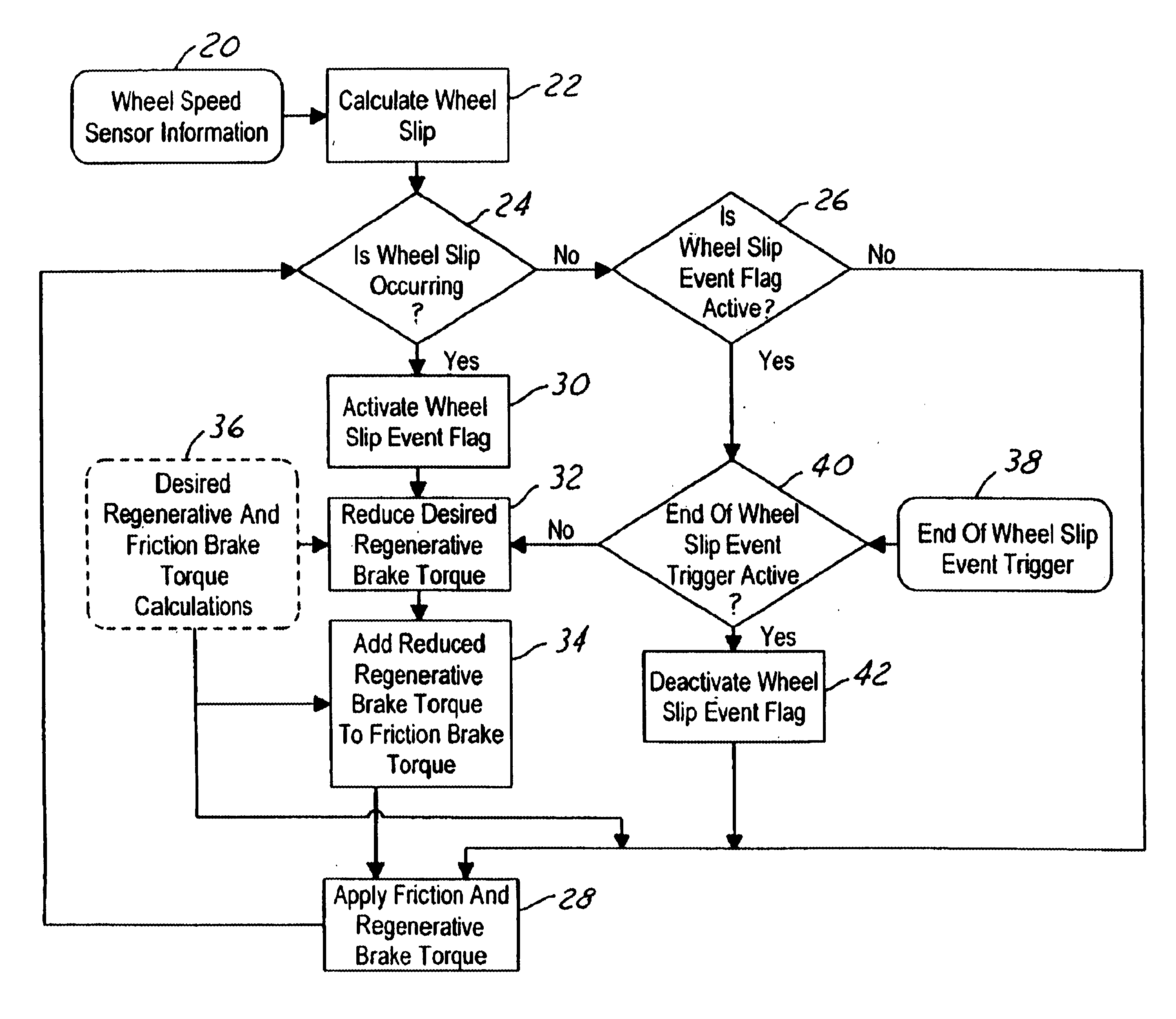

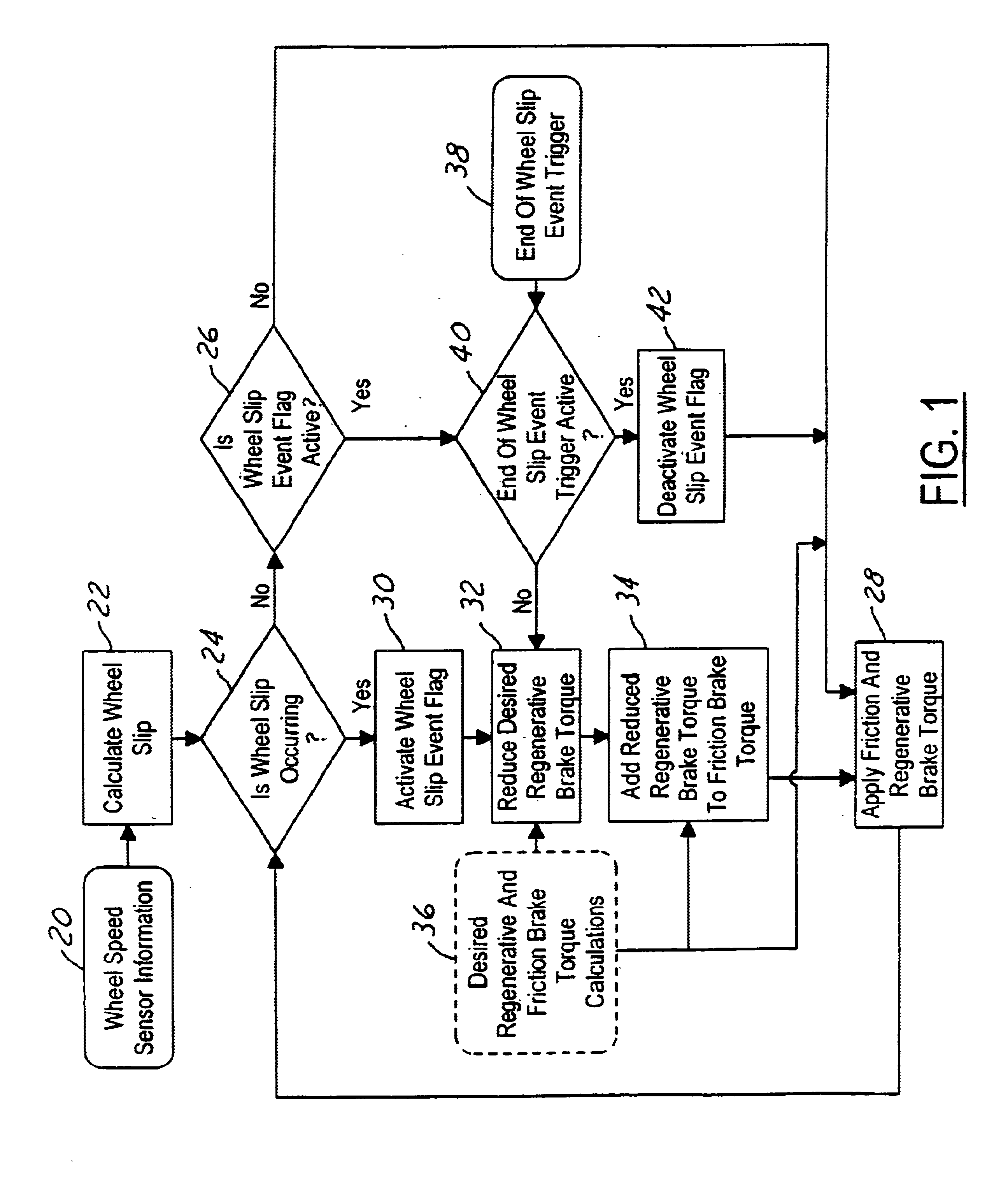

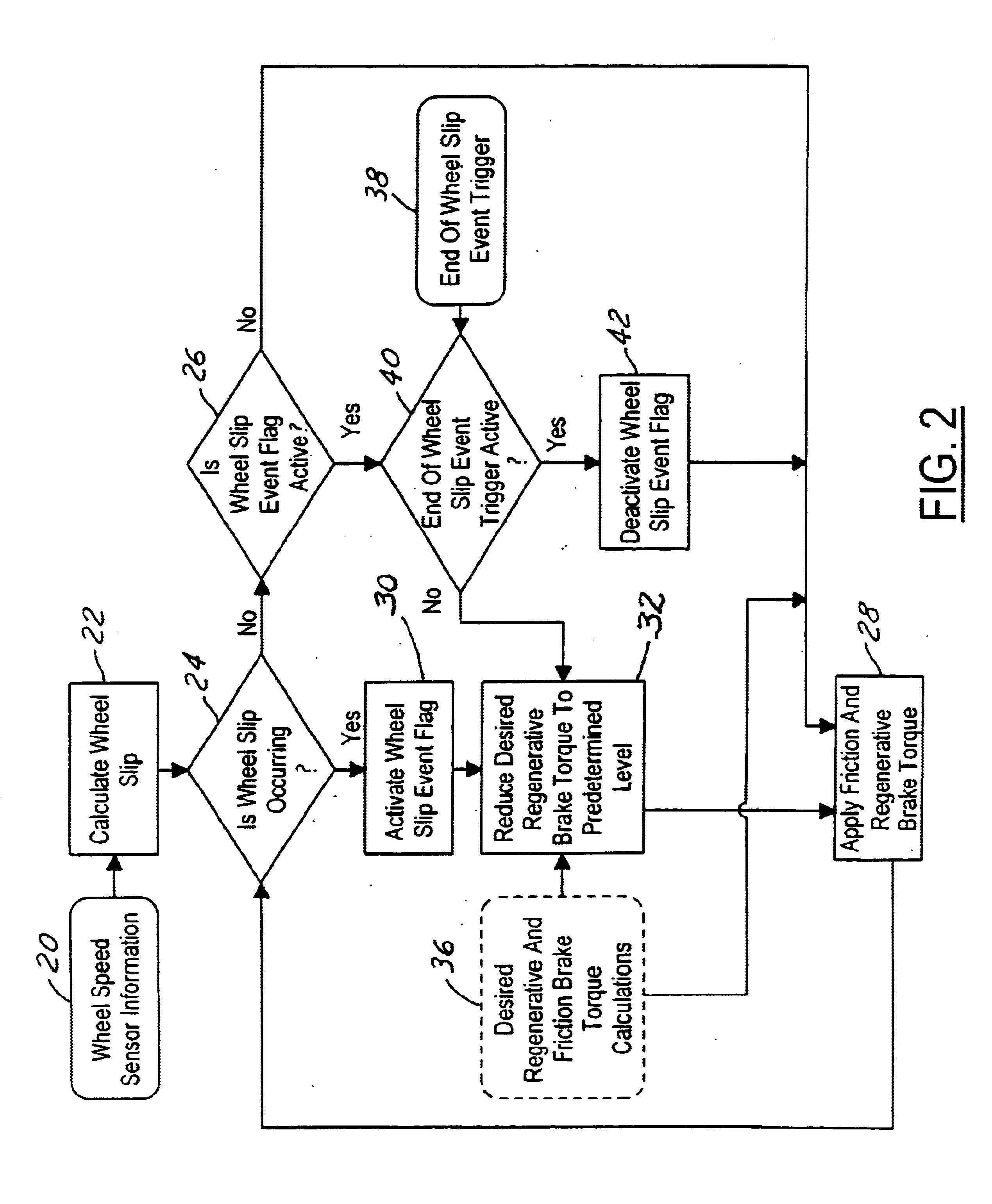

System and method for braking an electric drive vehicle on a low Mu surface

Strategies other than immediate elimination of regenerative braking (FIG. 2) are invoked when an incipient wheel lock-up is detected, the ABS becomes active, and / or incipient wheel slip is detected. The strategies include: reducing the regenerative braking torque as a function of the coefficient of friction of a surface on which the vehicle is traveling (FIG. 3); and adjusting regenerative braking in relation to the rate at which wheel slip is changing (FIG. 4). Some of the strategies may be applied on an individual wheel basis (FIG. 5), and some of the strategies may be applied in conjunction with operating friction brakes of the vehicle to apply at least some of the reduction in regenerative braking torque as friction brake torque (FIG. 1).

Owner:FORD GLOBAL TECH LLC

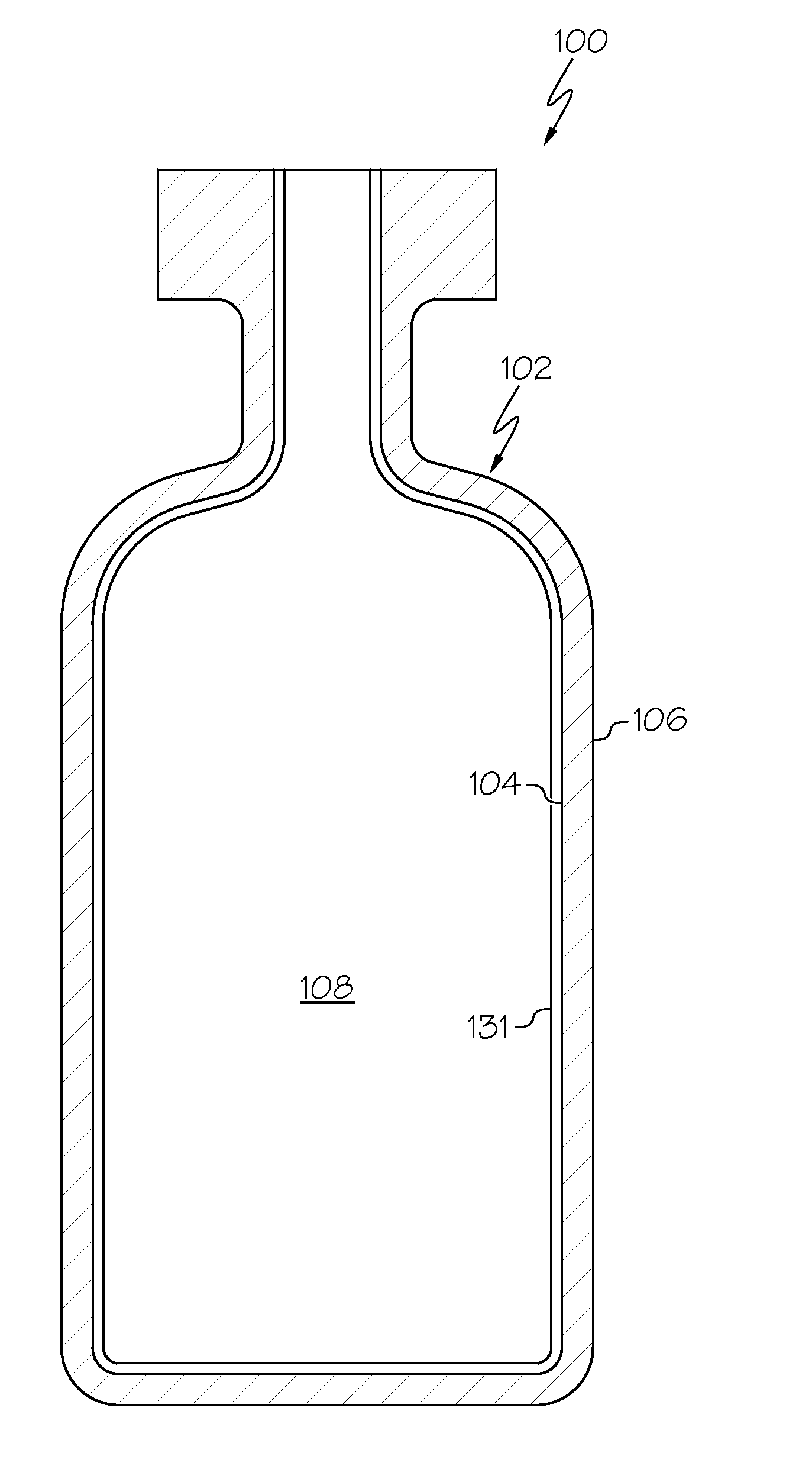

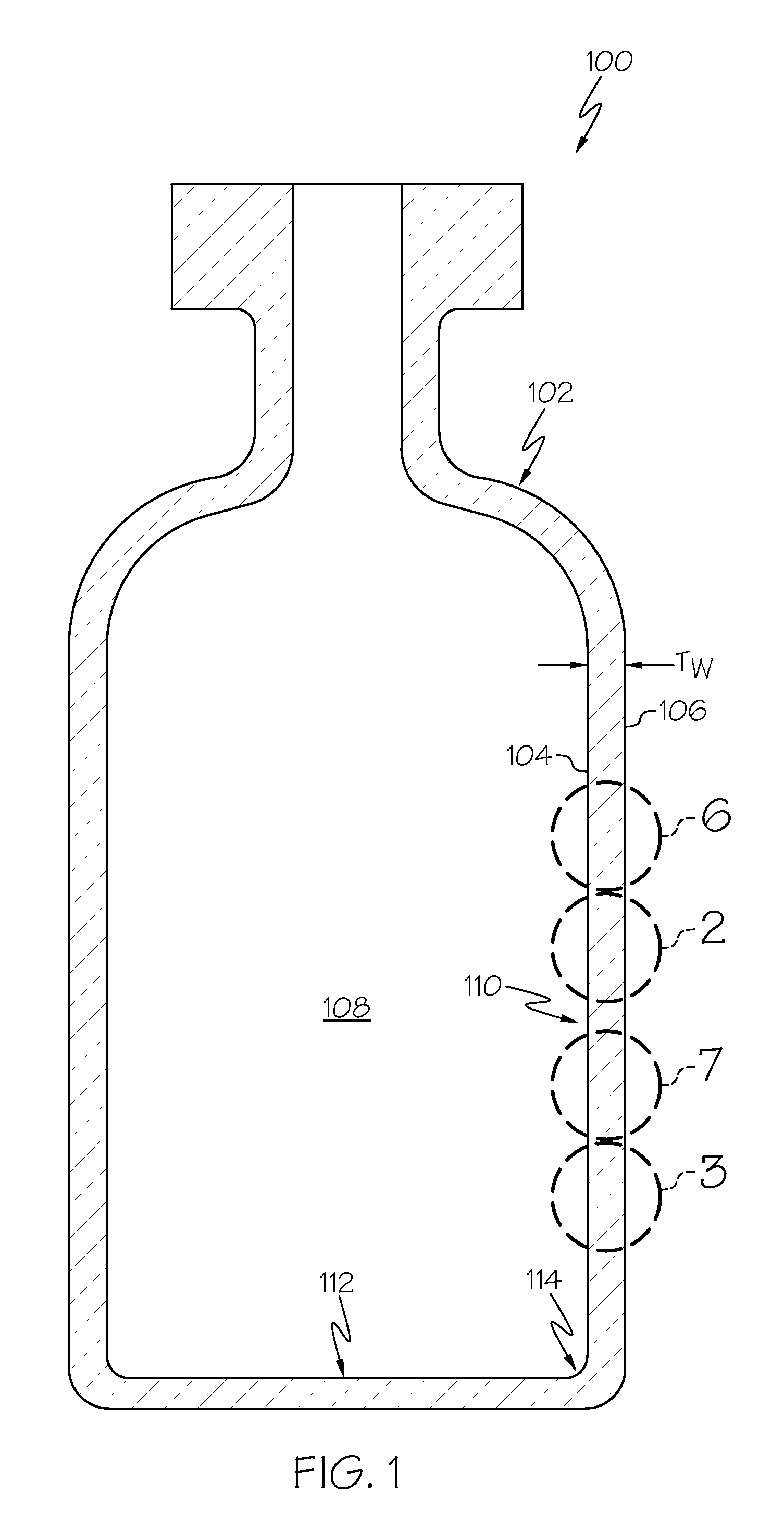

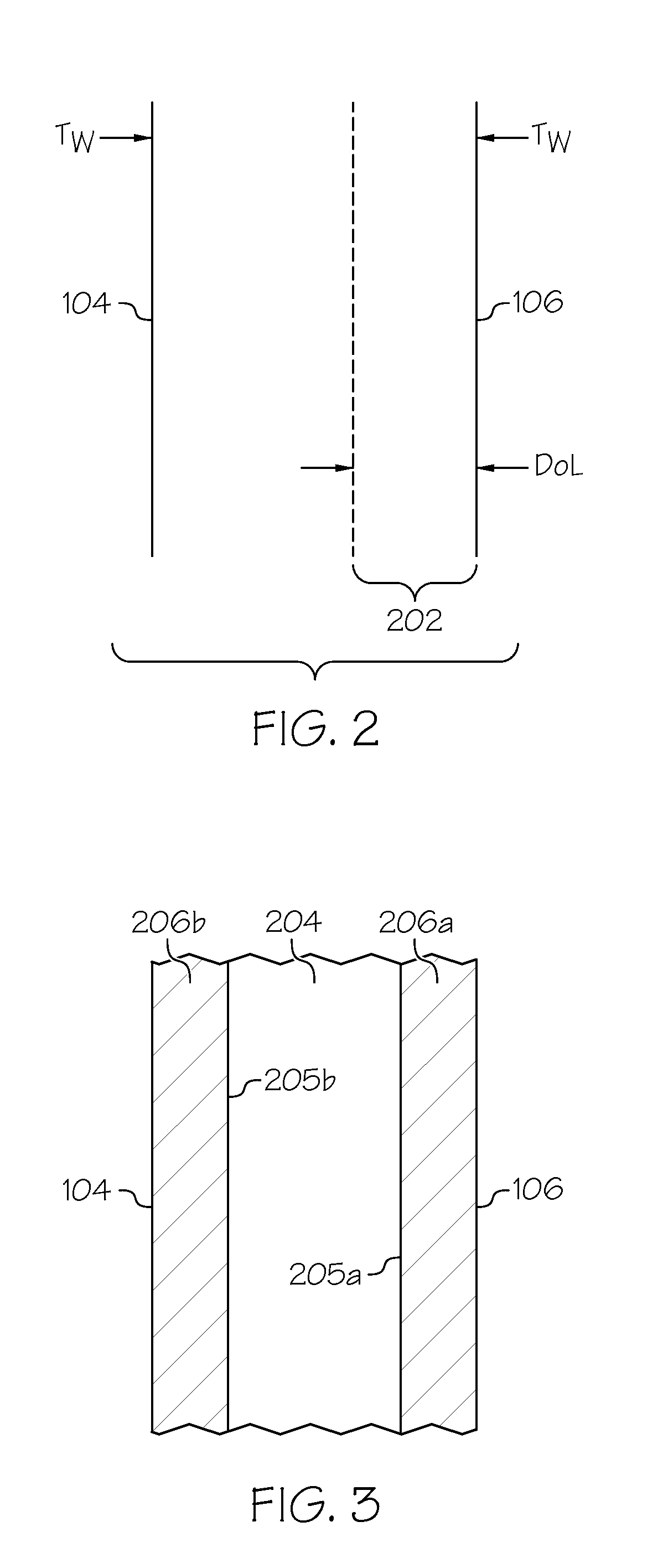

Strengthened glass containers resistant to delamination and damage

ActiveUS20140151370A1Pharmaceutical containersLarge containersUltimate tensile strengthMaterials science

The glass containers described herein are resistant to delamination, have improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. The body may also have a compressively stressed layer extending from the outer surface of the body into the wall thickness. The compressively stressed layer may have a surface compressive stress greater than or equal to 150 MPa. A lubricous coating may be positioned around at least a portion of the outer surface of the body, such that the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

Magnetic tape

ActiveUS20160093322A1Reduce coefficient of frictionImprove noiseRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

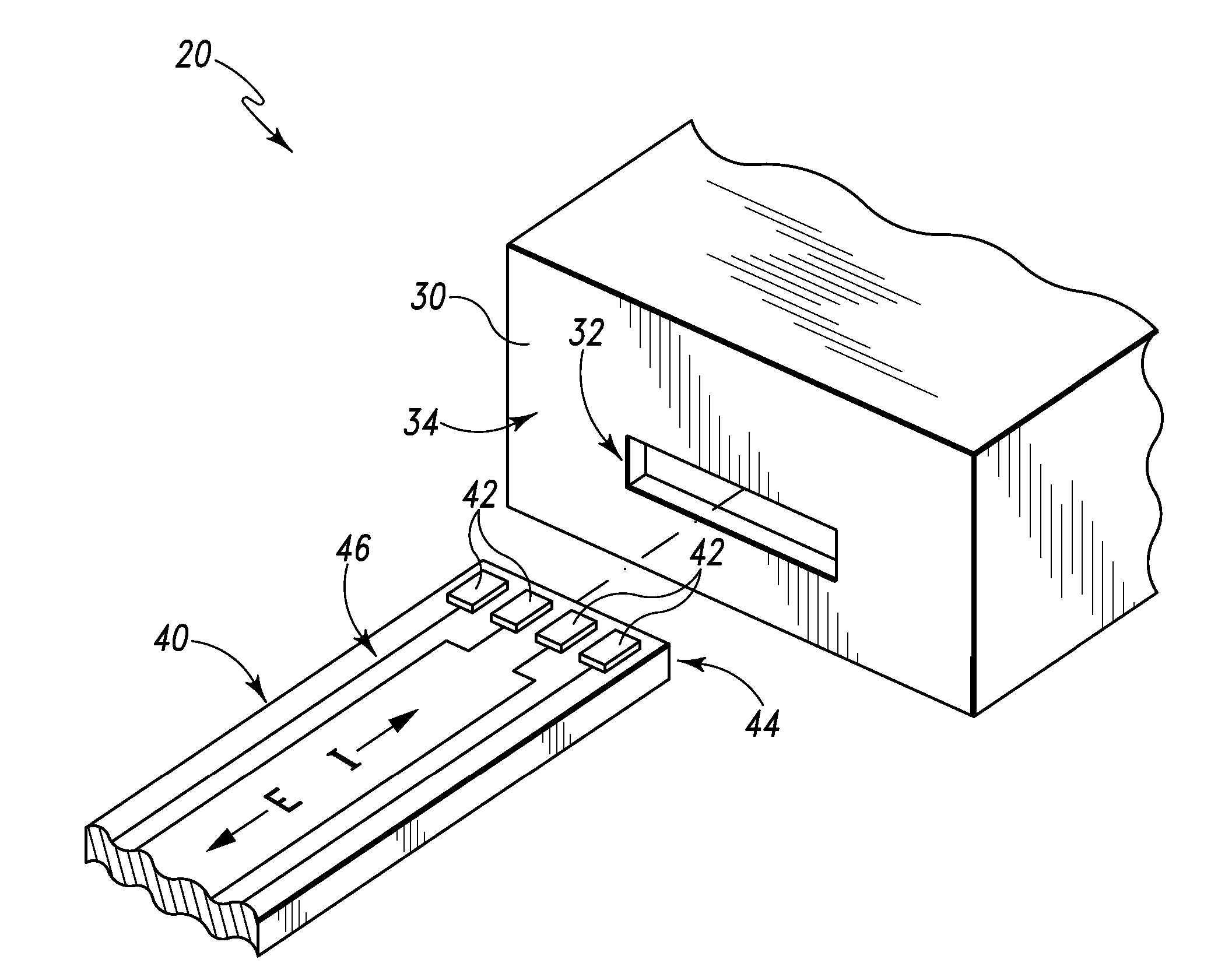

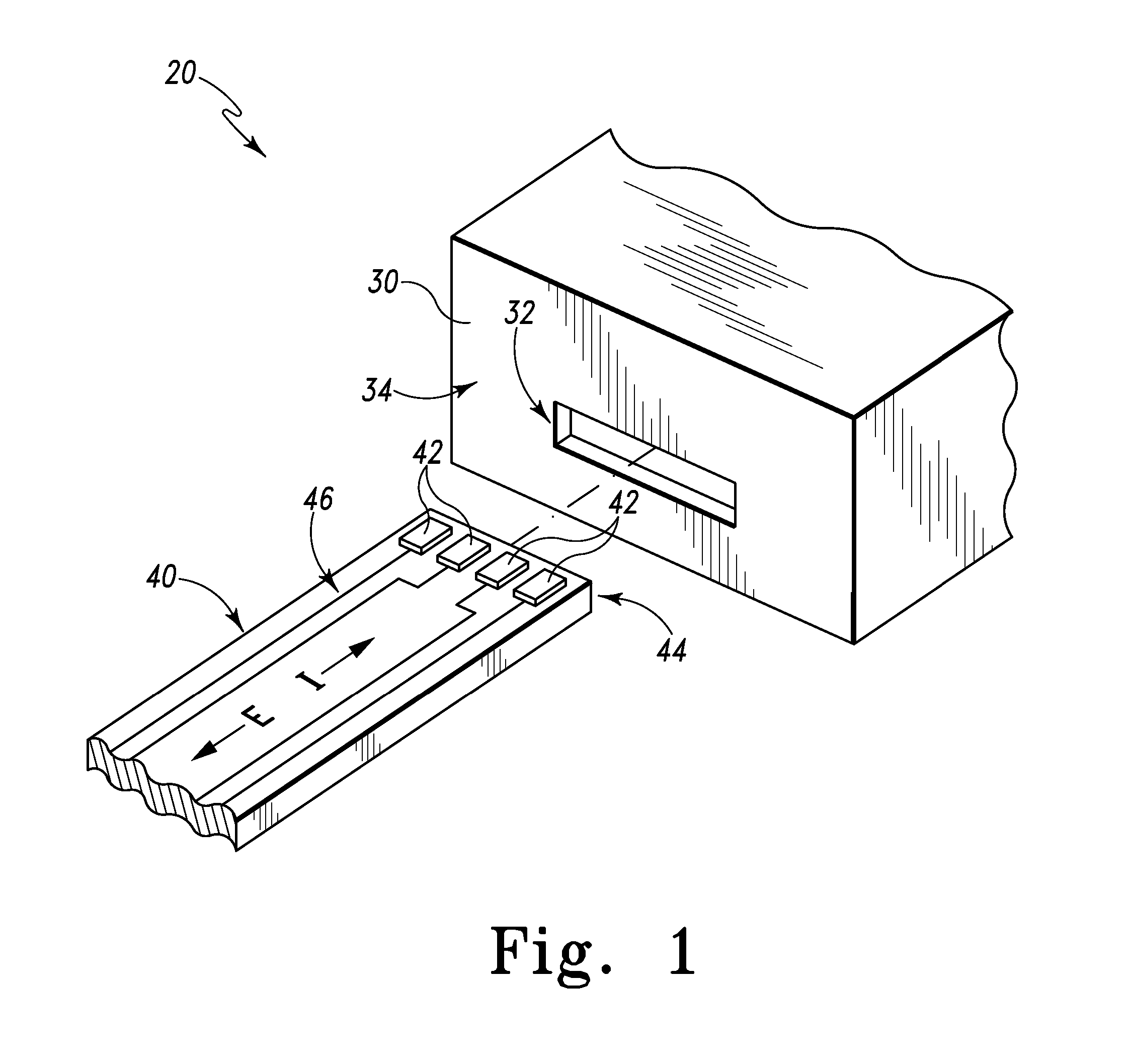

Biological testing system

ActiveUS20070249921A1Improve user experienceIncrease probabilityMaterial analysis by electric/magnetic meansDiagnostic recording/measuringElectrical resistance and conductanceContact pad

A connector for establishing electrical connection between a testing device and a test strip with a biological fluid thereon includes a contact pad on the test strip, and one or more contact wires in the testing device. When the strip is inserted into the testing device, part of the strip's end engages a contact portion of a contact wire and deflects it in a direction normal to the direction of insertion. In certain embodiments the radius of curvature (in the direction of insertion) of the contact portion is controlled to reduce abrasion of the strip by the wire. In other embodiments the radius of curvature (perpendicular to the direction of insertion) is controlled to reduce the abrasion of the strip by the wire. Sometimes the contact portion and / or contact pad is plated with a sacrificial material to reduce the coefficient of friction. In other embodiments various numbers of contacts receive the end of the strip substantially simultaneously, or are staggered in rows to distribute the resistance presented.

Owner:ROCHE DIABETES CARE INC

Magnetic tape

ActiveUS20170249963A1Improve featuresImprove surface smoothnessBase layers for recording layersTape carriersMagnetic tapeSurface roughness

The magnetic tape has a magnetic layer containing ferromagnetic powder, abrasive, and binder on a nonmagnetic support, wherein the centerline average surface roughness Ra measured on the surface of the magnetic layer is less than or equal to 1.8 nm, the contact angle for 1-bromonaphthalene that is measured on the surface of the magnetic layer falls within a range of 45.0° to 60.0°, and the coefficient of friction that is measured on the base portion of the surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

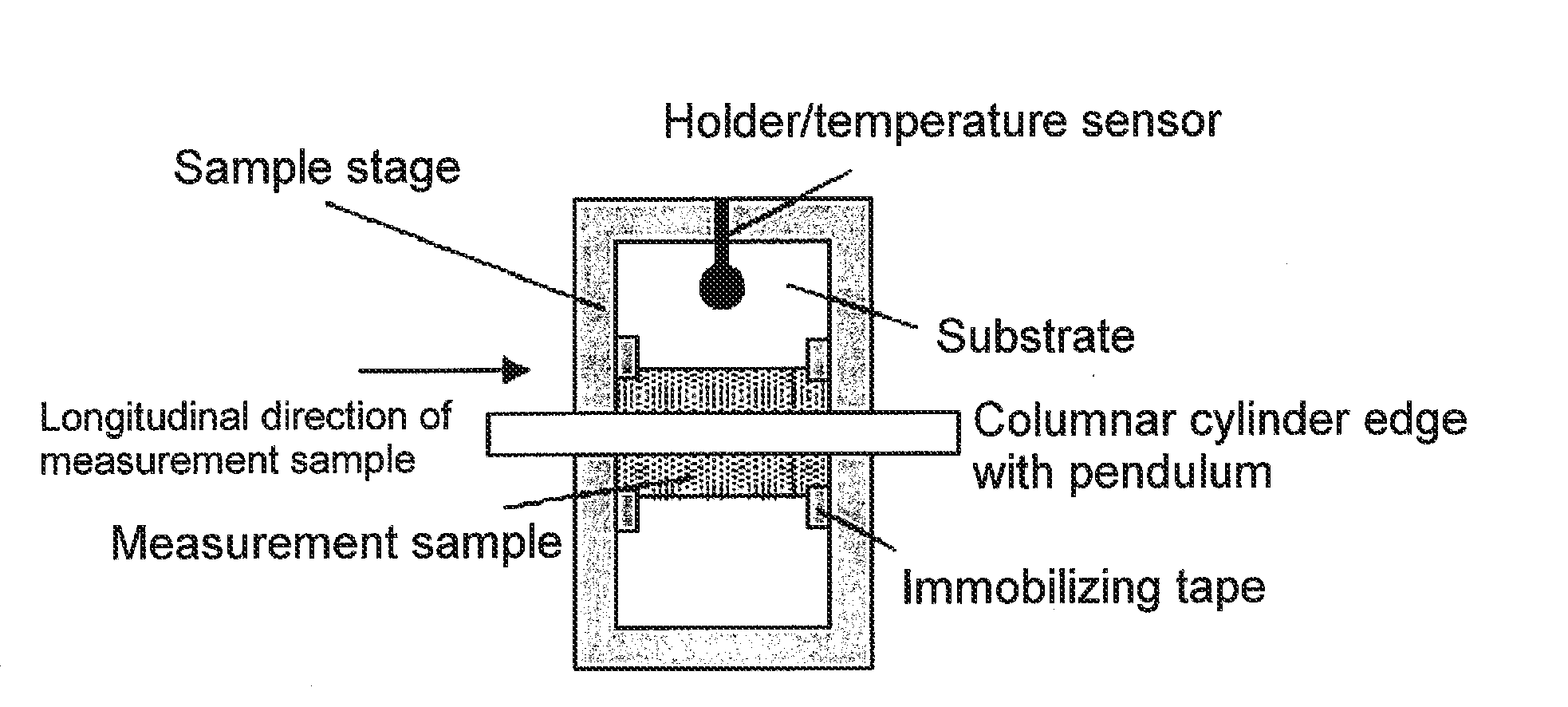

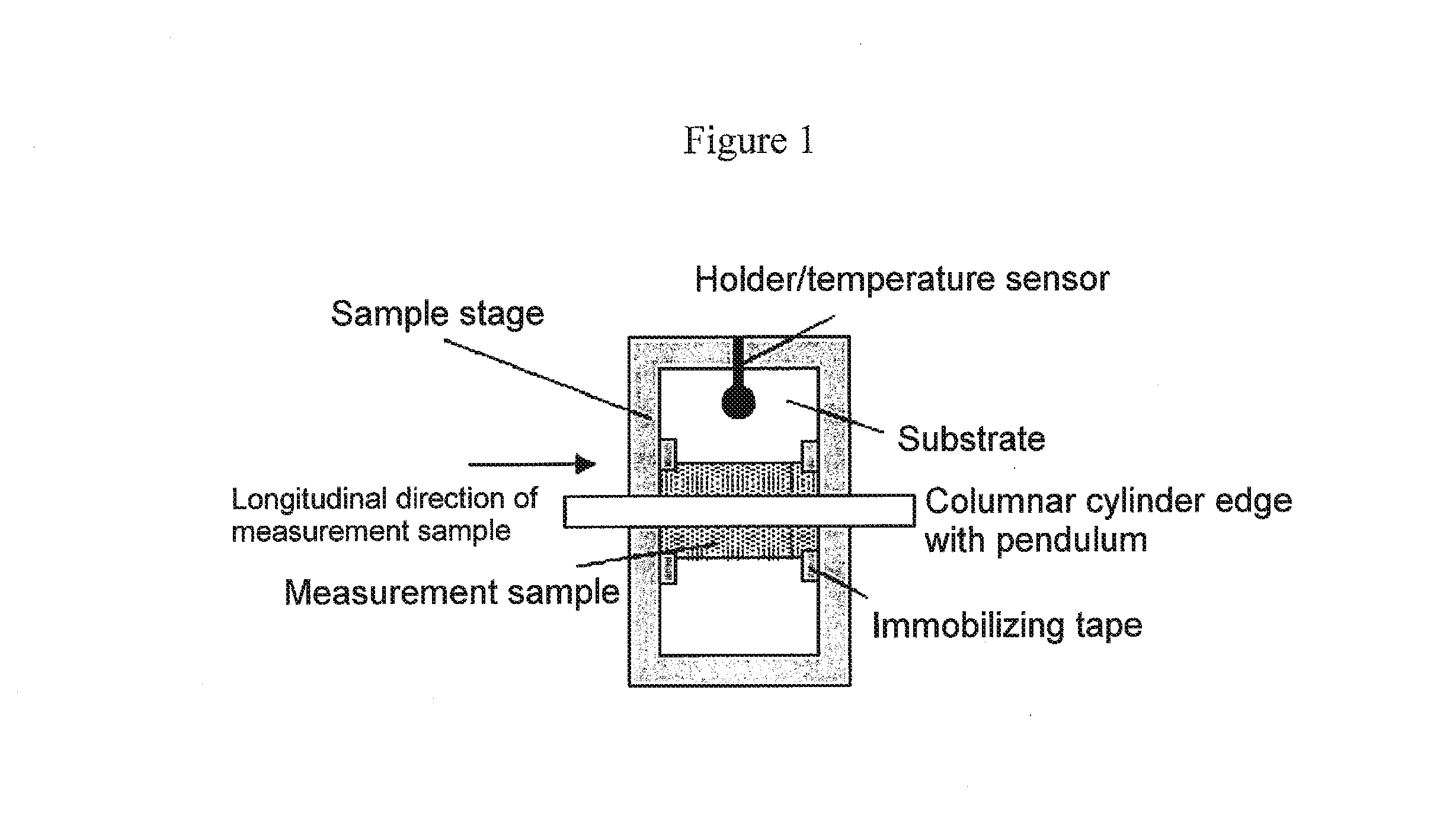

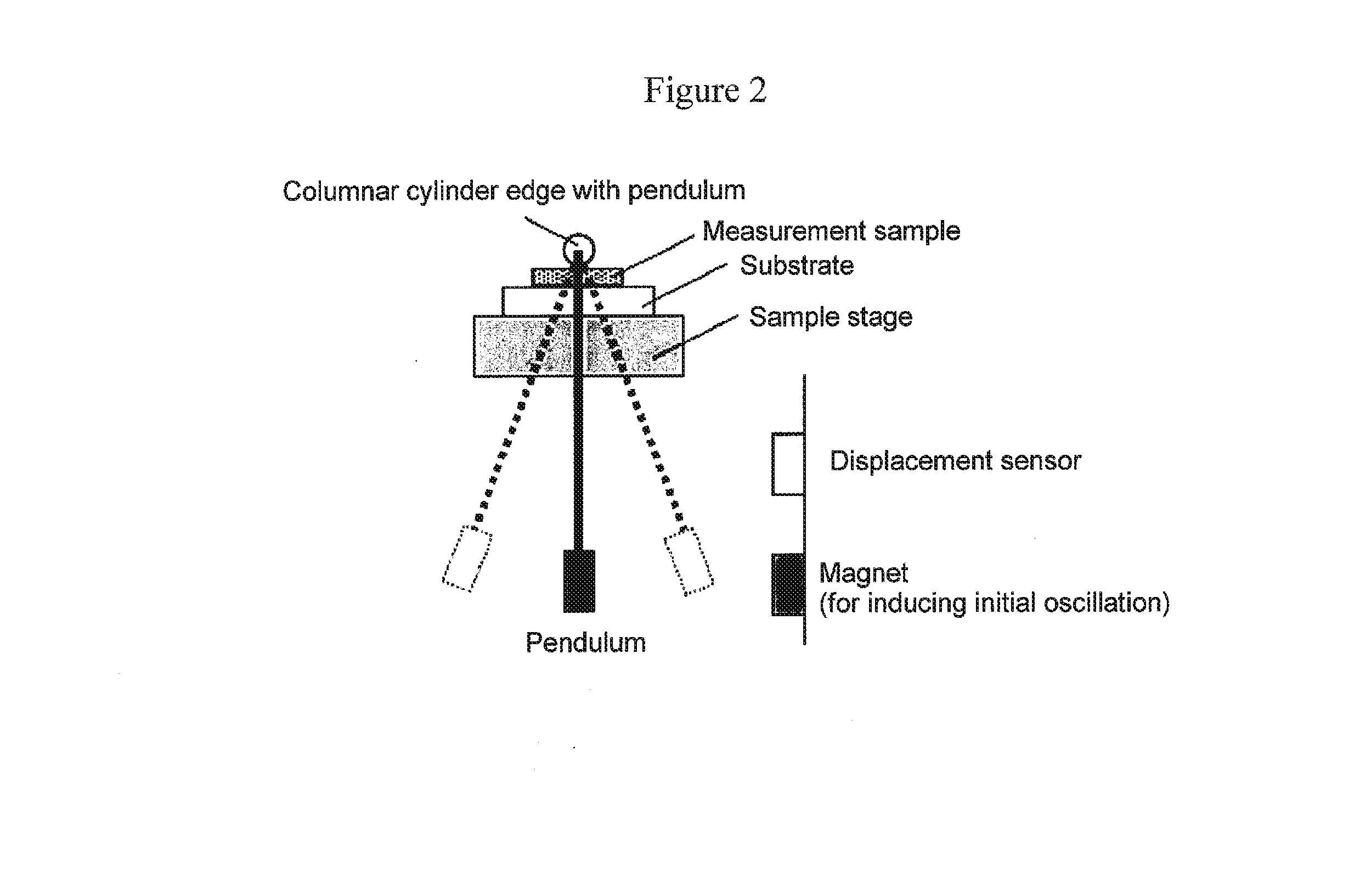

Magnetic tape having controlled surface properties of the magnetic layer and method of manufacturing the same

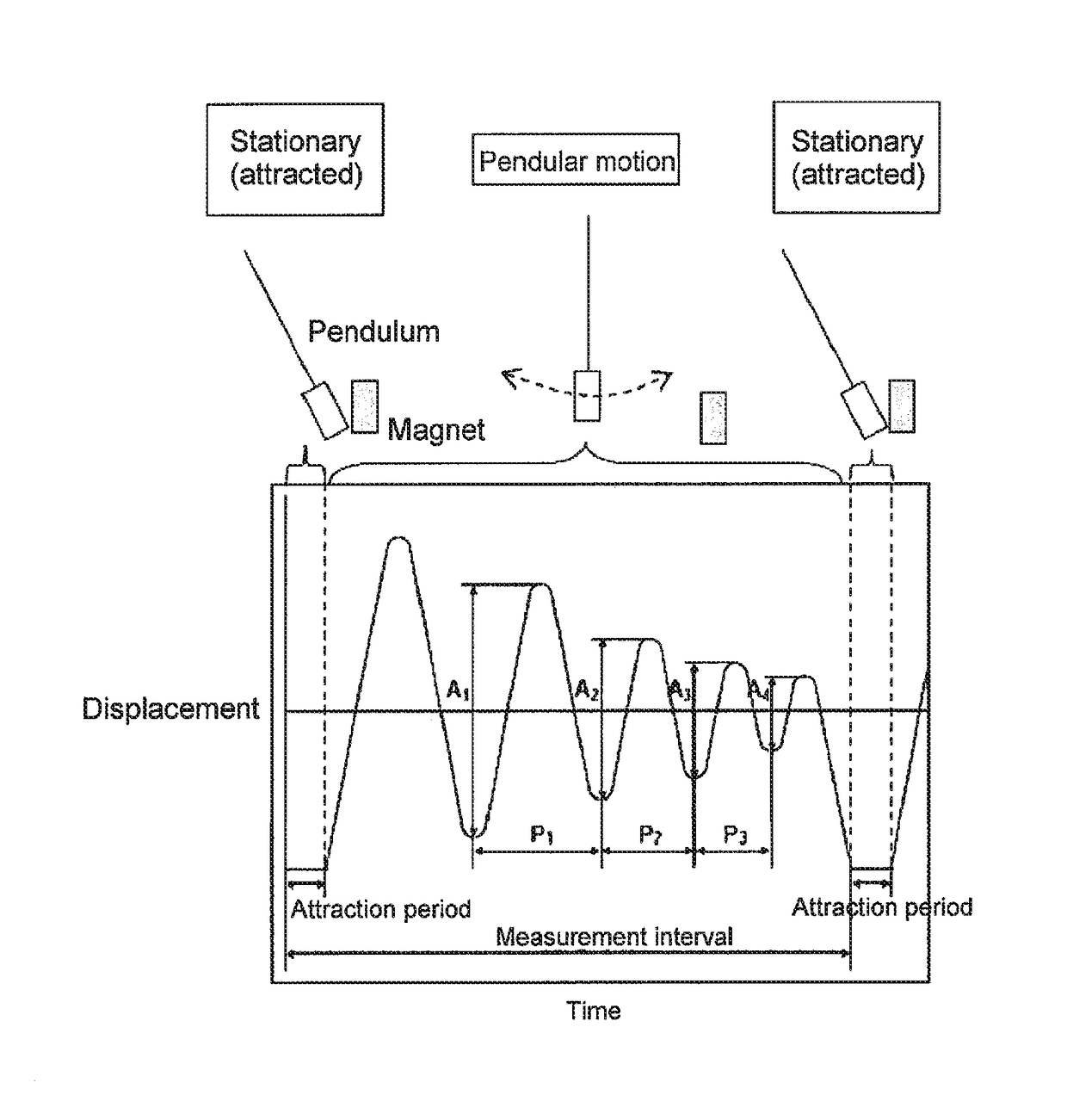

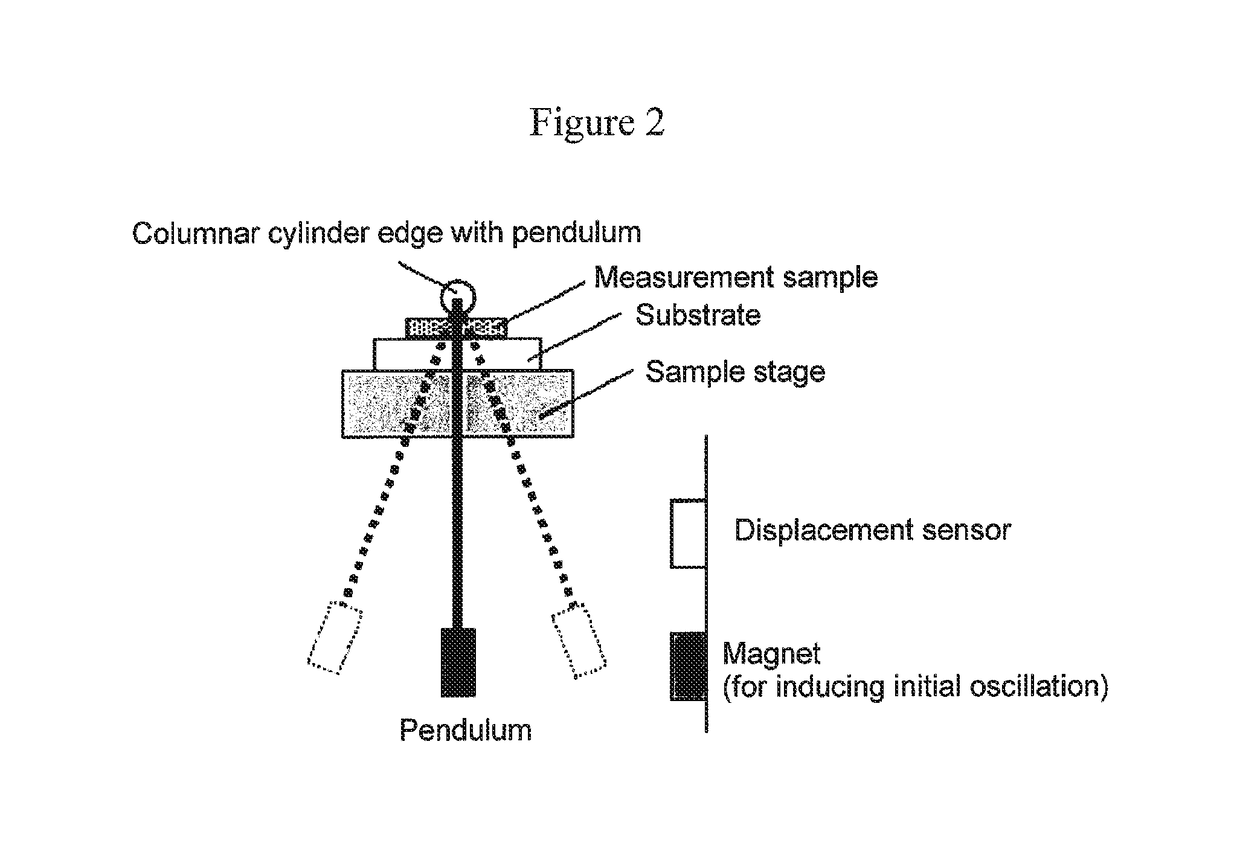

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and has a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein the combined thickness of the magnetic layer and the nonmagnetic layer is less than or equal to 0.80 μm; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the magnetic layer side of the magnetic tape is less than or equal to 0.050 and the coefficient of friction as measured on a base portion of the surface on the magnetic layer side is less than or equal to 0.35.

Owner:FUJIFILM CORP

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20190103134A1Excellent electromagnetic conversion characteristicAvoid it happening againMaterials with ironProtective coatings for layersIn planeX-ray

Provided are a magnetic recording medium, in which a magnetic layer includes ferromagnetic hexagonal ferrite powder, a binding agent, and an oxide abrasive, an intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic recording medium is 0.65 to 1.00, a coefficient of friction measured regarding a base portion of a surface of the magnetic layer is equal to or smaller than 0.30, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic recording medium.

Owner:FUJIFILM CORP

Magnetic recording medium

InactiveUS20130084470A1Good running durabilityGood dispersionMagnetic materials for record carriersRecord information storageInorganic particleNon magnetic

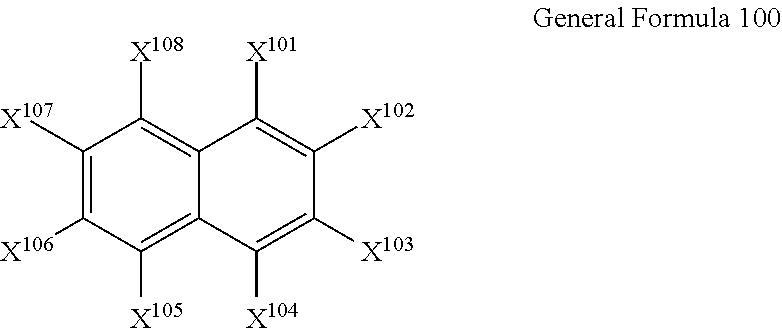

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer containing a ferromagnetic powder and a binder on a nonmagnetic support, wherein the ferromagnetic powder has a hexagonal ferrite structure, the magnetic layer comprises a coefficient of friction-lowering component in the form of nonmagnetic inorganic particles, and a compound in which a substituent selected from the group consisting of a hydroxyl group and a carboxyl group is directly substituted on an aromatic ring.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS9779772B1High precisionAccurate informationAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on a nonmagnetic support, wherein a timing based servo pattern is present on the magnetic layer, the centerline average surface roughness Ra that is measured on the surface of the magnetic layer is less than or equal to 1.8 nm, and the coefficient of friction that is measured on the base portion of the surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS10026430B2Improve noiseDeterioration of characteristicRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

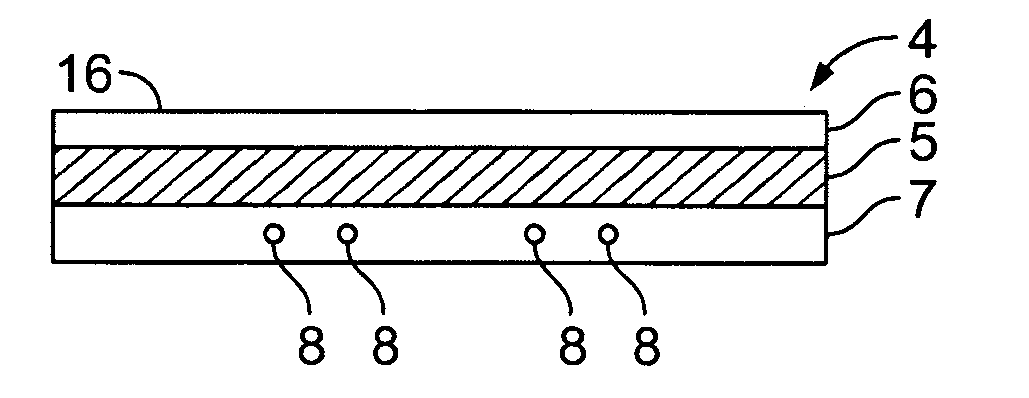

Photovoltaic-embedded surface

InactiveUS20050199282A1Transform energyGenerate electricity inexpensively and convenientlyPhotovoltaic supportsSolar heating energyElectricityElectrical conductor

An integrated solar power system that provides electricity to external electrical devices has a trafficable surface formed from a plurality of roadway panels arranged with respect to each other. Each roadway panel has a solar energy collector, a layer of translucent and protective material covering the solar energy collector, the material being sufficiently translucent to allow passage of light therethrough for absorption of light by said solar energy collector and sufficiently protective to withstand the loads and the impact of pedestrian and vehicular traffic and having a sufficient coefficient of friction to allow passage thereon of pedestrians and vehicles without slippage, and an electrical conductor for extracting electrical power from the solar energy collector. Each roadway panel may be modularly connected to others. The roadway panel provides solar energy to at least one external electrical device or solar power storage member.

Owner:OLEINICK ENERGY

Magnetic tape and method of manufacturing the same

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and has a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein the combined thickness of the magnetic layer and the nonmagnetic layer is less than or equal to 0.80 μm; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the magnetic layer side of the magnetic tape is less than or equal to 0.050 and the coefficient of friction as measured on a base portion of the surface on the magnetic layer side is less than or equal to 0.35.

Owner:FUJIFILM CORP

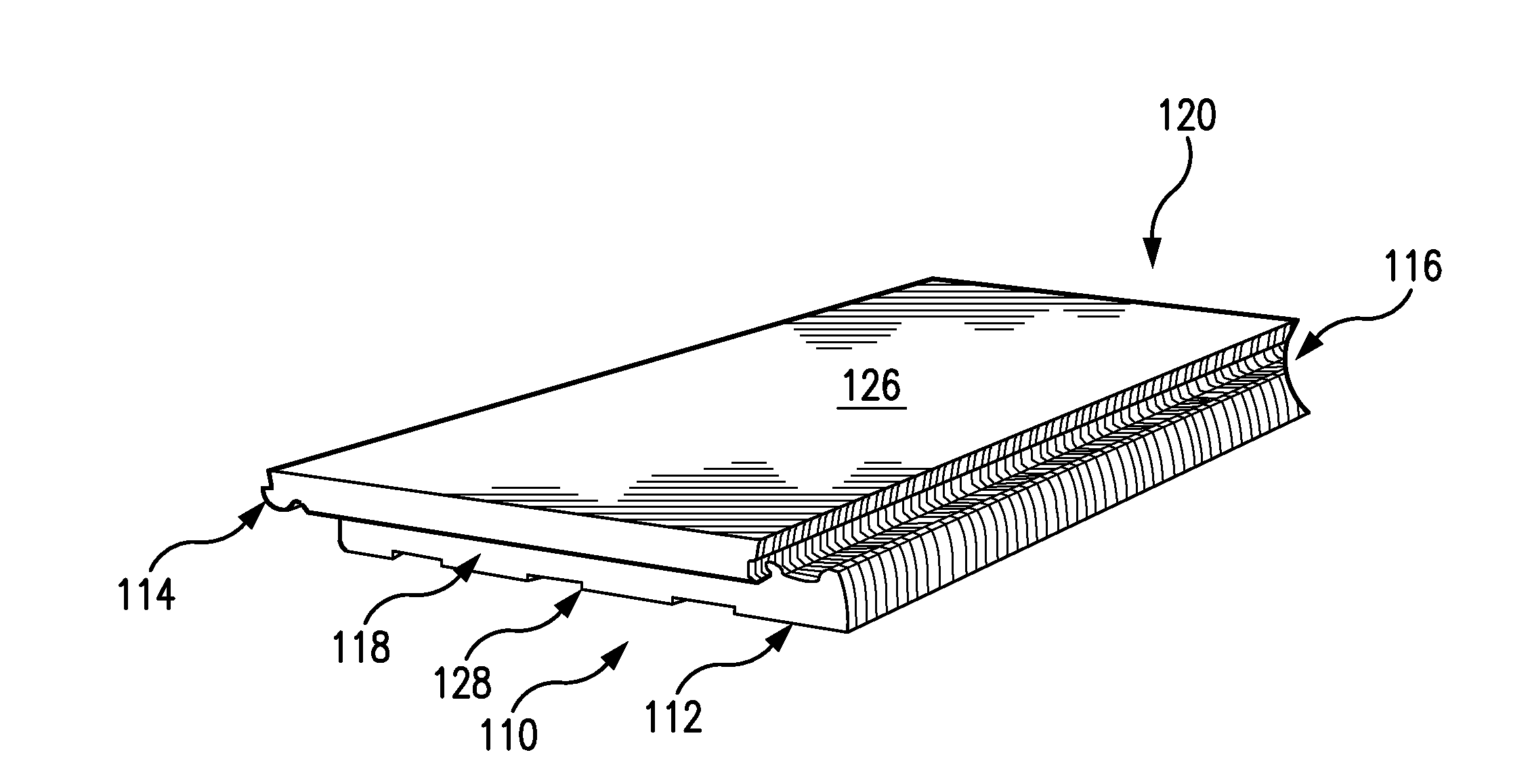

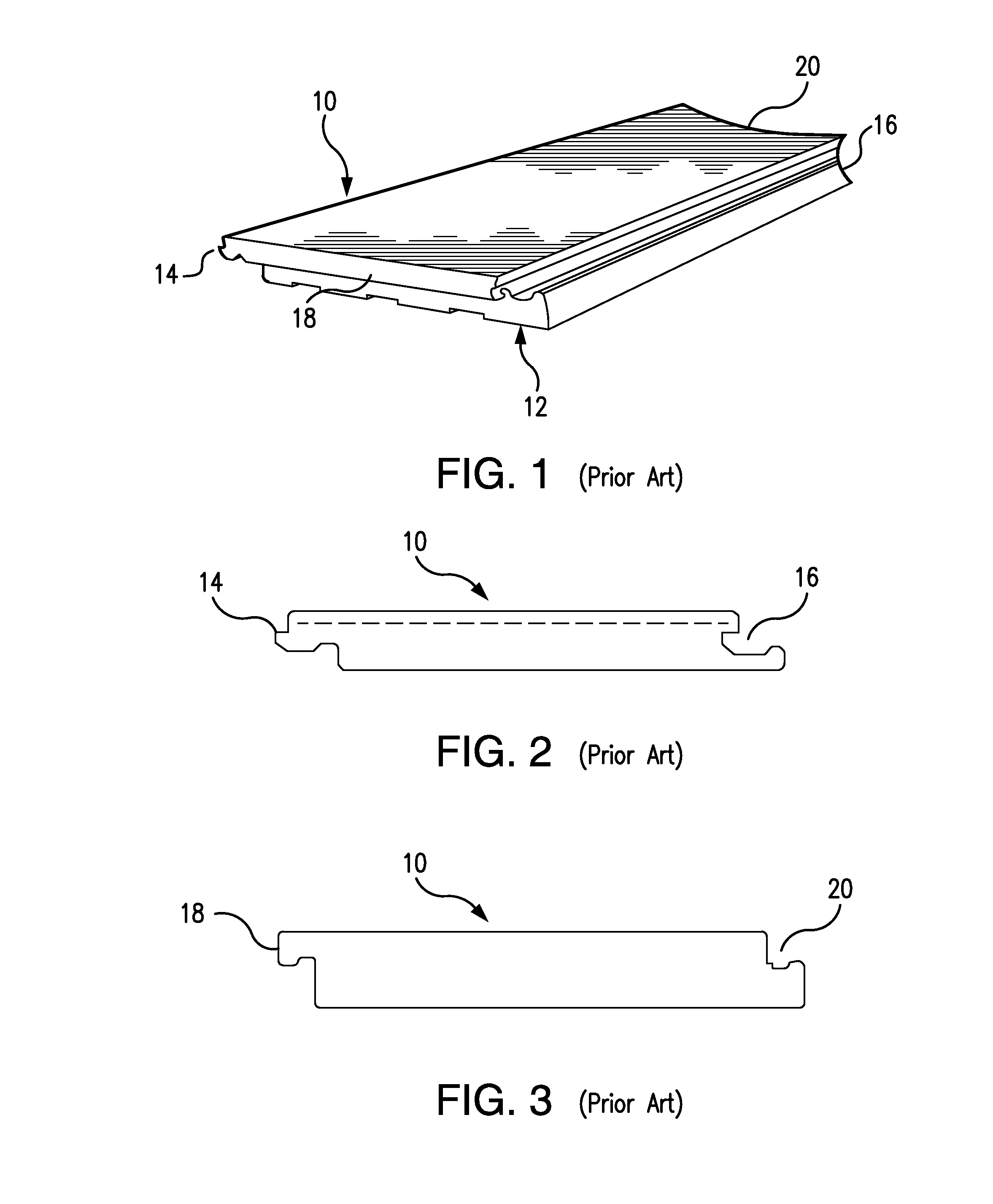

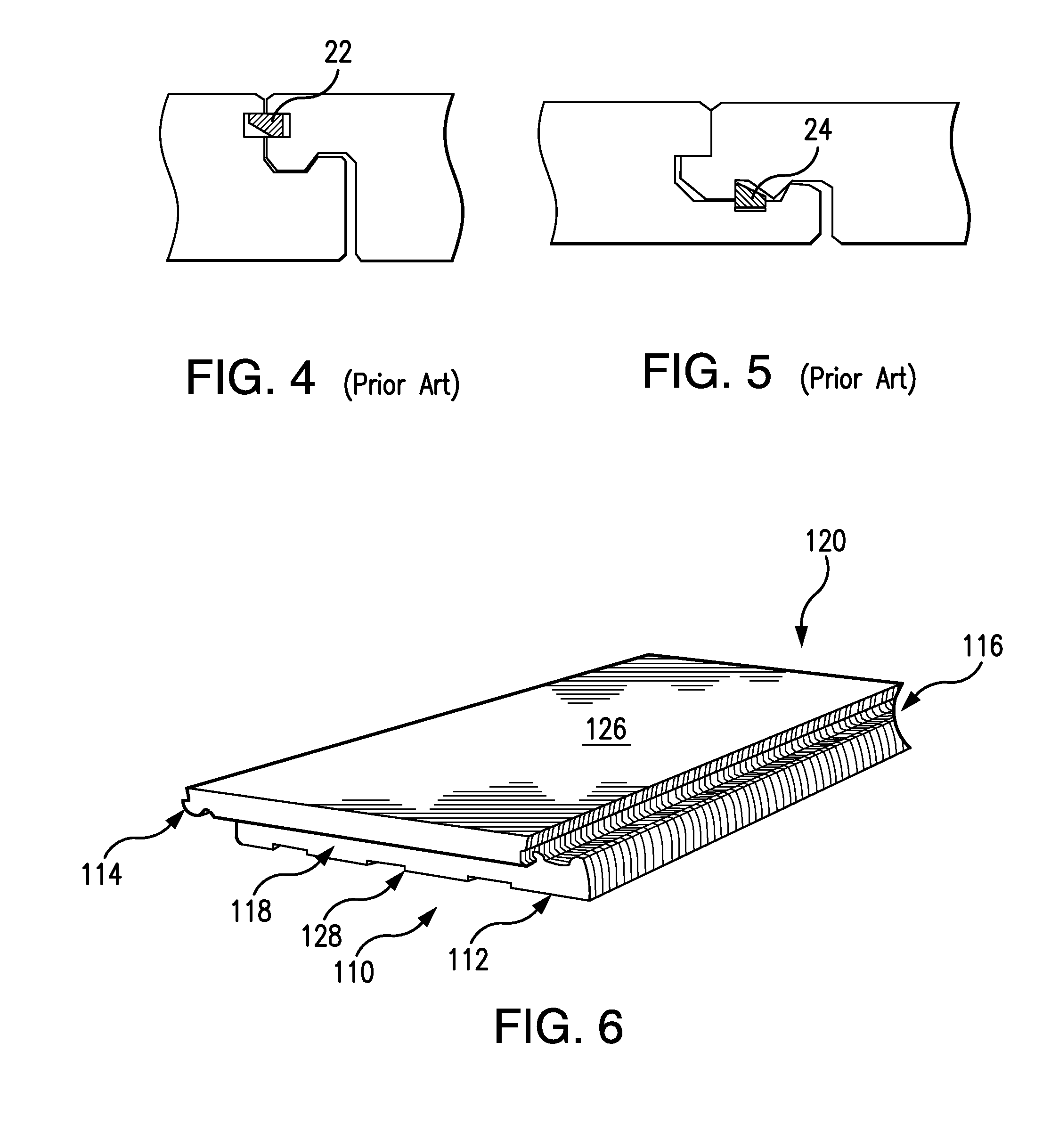

Non-squeaking wood flooring systems and methods

ActiveUS20130008118A1Avoid squeakingAvoid squeaking of the floorboardsFloorsLaminationTectorial membraneEngineering

Wood-based flooring systems with click-type interlocking joint systems include a protective film system covering the contact surfaces of the click system. The protective film system includes one or more sheets of a material with low moisture transmissivity and a low coefficient of friction. In this way, the contact surfaces of the click system are protected against undue humidity absorption and frictional rubbing to thereby avoid squeaking after installation. In some embodiments there are four film sheets covering the entirety of all four click surfaces, in others there is one film sheet covering the entirety of all four click surfaces, in others there is film covering the entirety of only the two longitudinal click surfaces, in others there is film covering the entirety of only the two tongue click surfaces, and in others there is film covering only the contact surfaces of the click surfaces.

Owner:CFL HLDG LTD

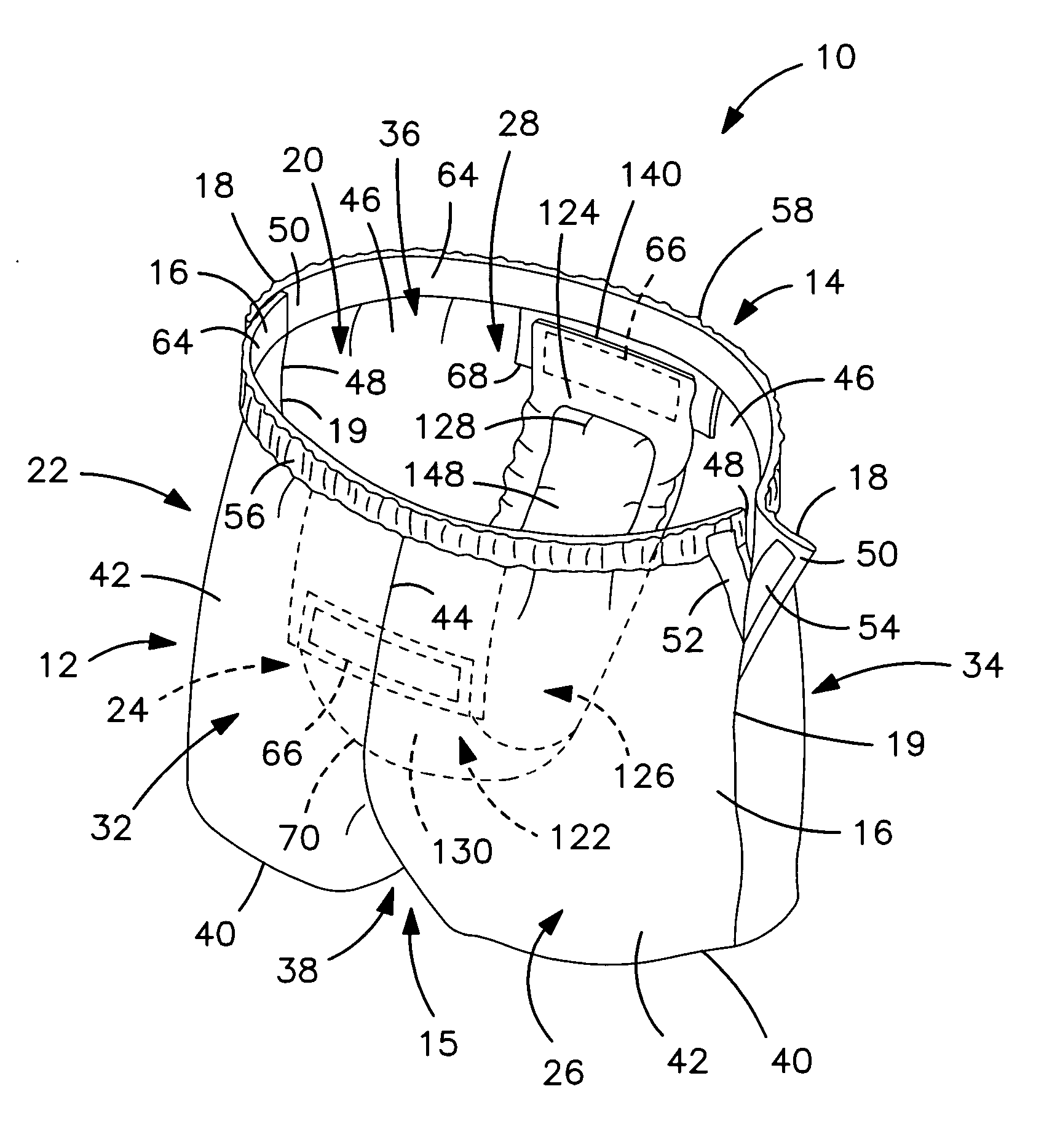

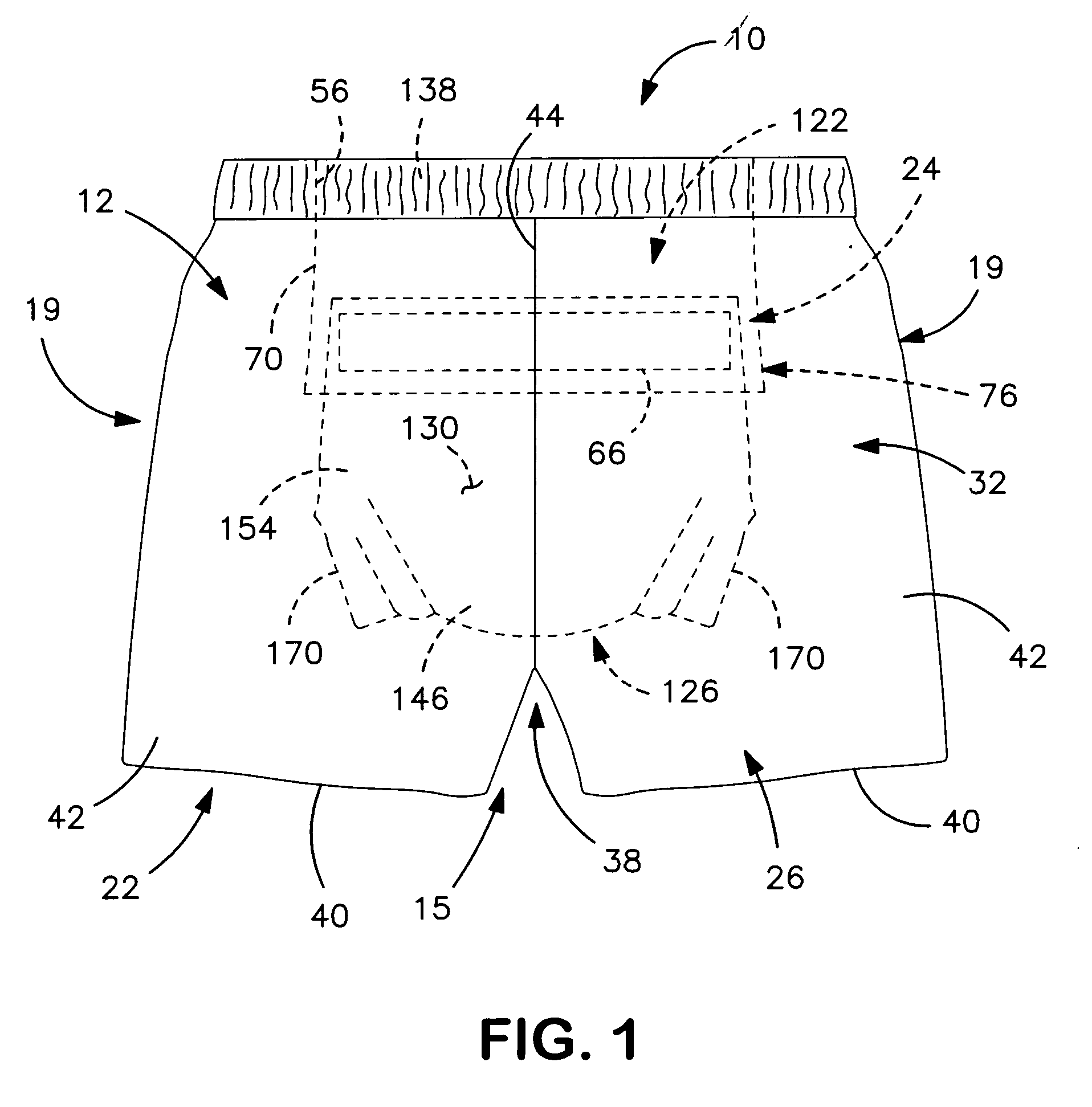

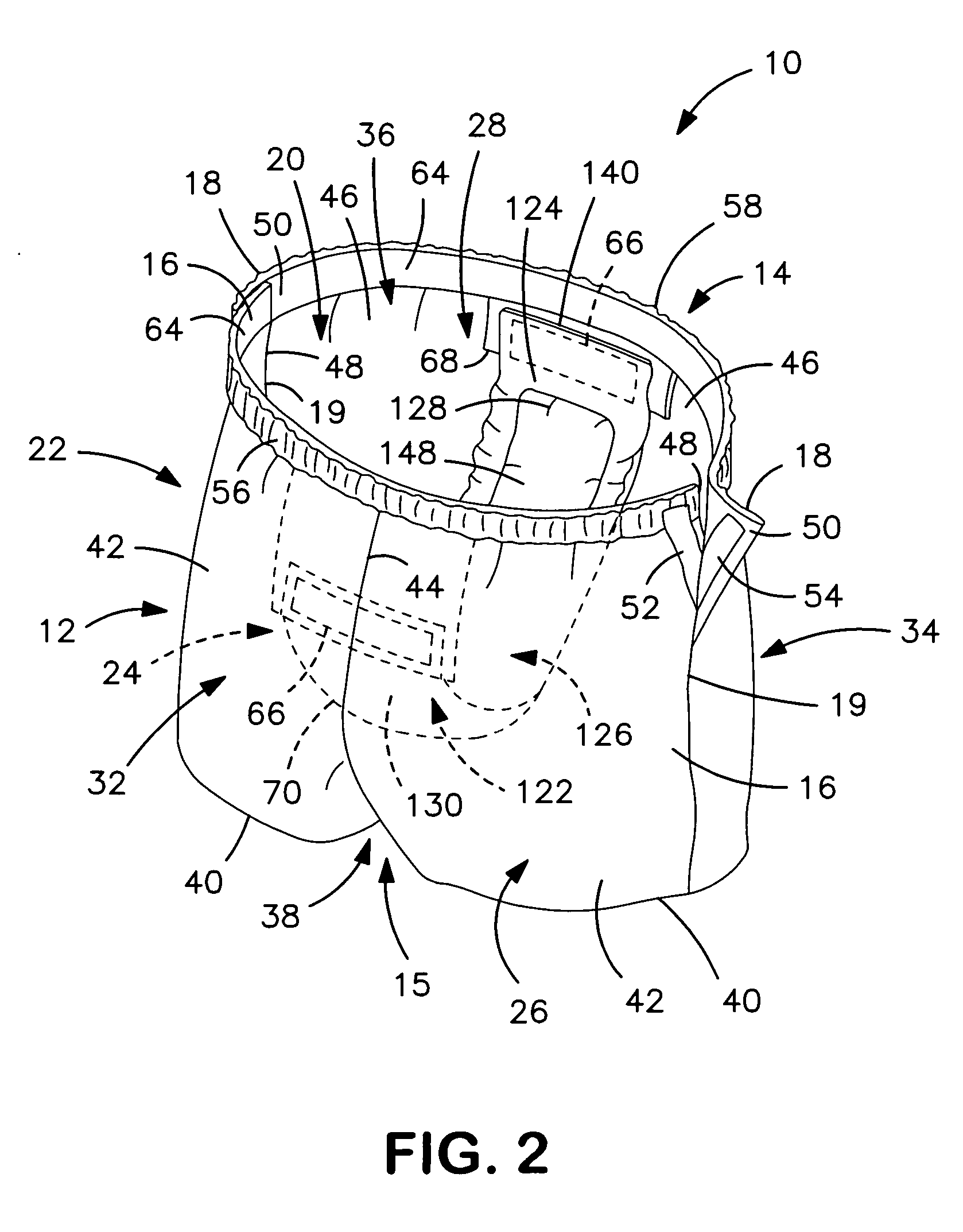

Garment having an outer shell that freely moves in relation to an absorbent assembly therein

InactiveUS20060247599A1Prevent twisting and bunchingPrevents twisting and bunchingAbsorbent padsBaby linensStandard bedControl material

An absorbent garment having a garment-like outer shell and an absorbent assembly positioned therein as disclosed. In particular embodiments, the outer cover of the absorbent assembly has a relatively low coefficient of friction with the interior side of the garment shell. In one embodiment, the garment shell may be constructed such that the coefficient of friction between the garment shell and the outer cover of the absorbent assembly is less than, such as at least 15 percent less than the coefficient of friction between the exterior side of the garment shell and an adjacent material. The adjacent material may include, for instance, a standard bed sheet material. By carefully controlling the frictional properties of the materials as described above, problems associated with bunching and twisting of the garment are minimized.

Owner:KIMBERLY-CLARK WORLDWIDE INC

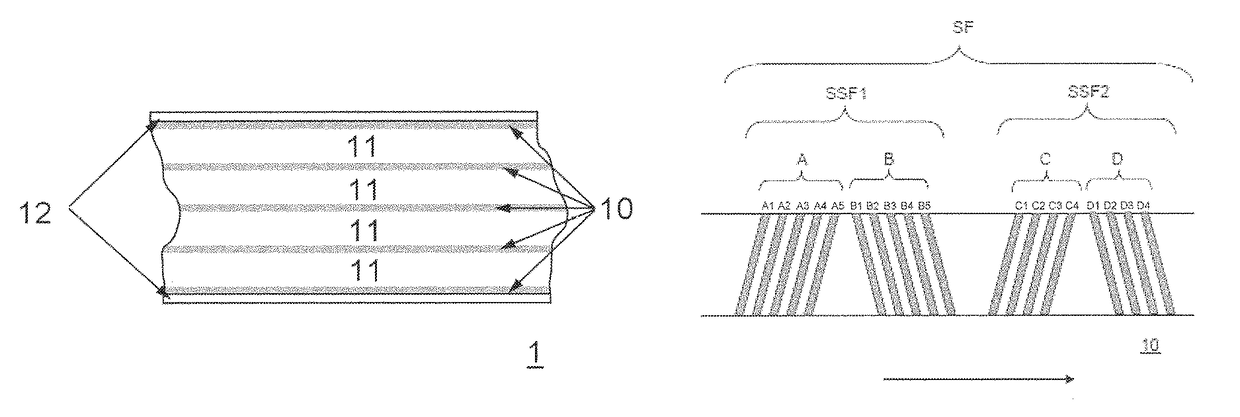

Magnetic tape device and head tracking servo method

ActiveUS20180182417A1Avoid it happening againImprove accuracyAlignment for track following on tapesRecord information storageMagnetic tapeEngineering

The magnetic tape device includes: a magnetic tape; and a servo head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the servo head is a magnetic head including a tunnel magnetoresistance effect type element as a servo pattern reading element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes a servo pattern, and a coefficient of friction measured regarding a base portion of a surface of the magnetic layer is equal to or smaller than 0.30.

Owner:FUJIFILM CORP

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

Magnetic tape, magnetic tape cartridge, and magnetic recording and reproducing device

ActiveUS20170178677A1Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

The magnetic tape includes a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and a magnetic layer containing ferromagnetic powder, abrasive, and binder on the nonmagnetic layer, wherein a thickness of the nonmagnetic layer is less than or equal to 0.50 μm, a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1, ΔSFD=SFD25° C.−SFD−190° C., is greater than or equal to 0.50, wherein, in Equation 1, SFD25° C. denotes a SFD as measured in the longitudinal direction of the magnetic tape in an environment with a temperature of 25° C., and SFD−190° C. denotes a SFD as measured in the longitudinal direction of the magnetic tape in an environment with a temperature of −190° C.

Owner:FUJIFILM CORP

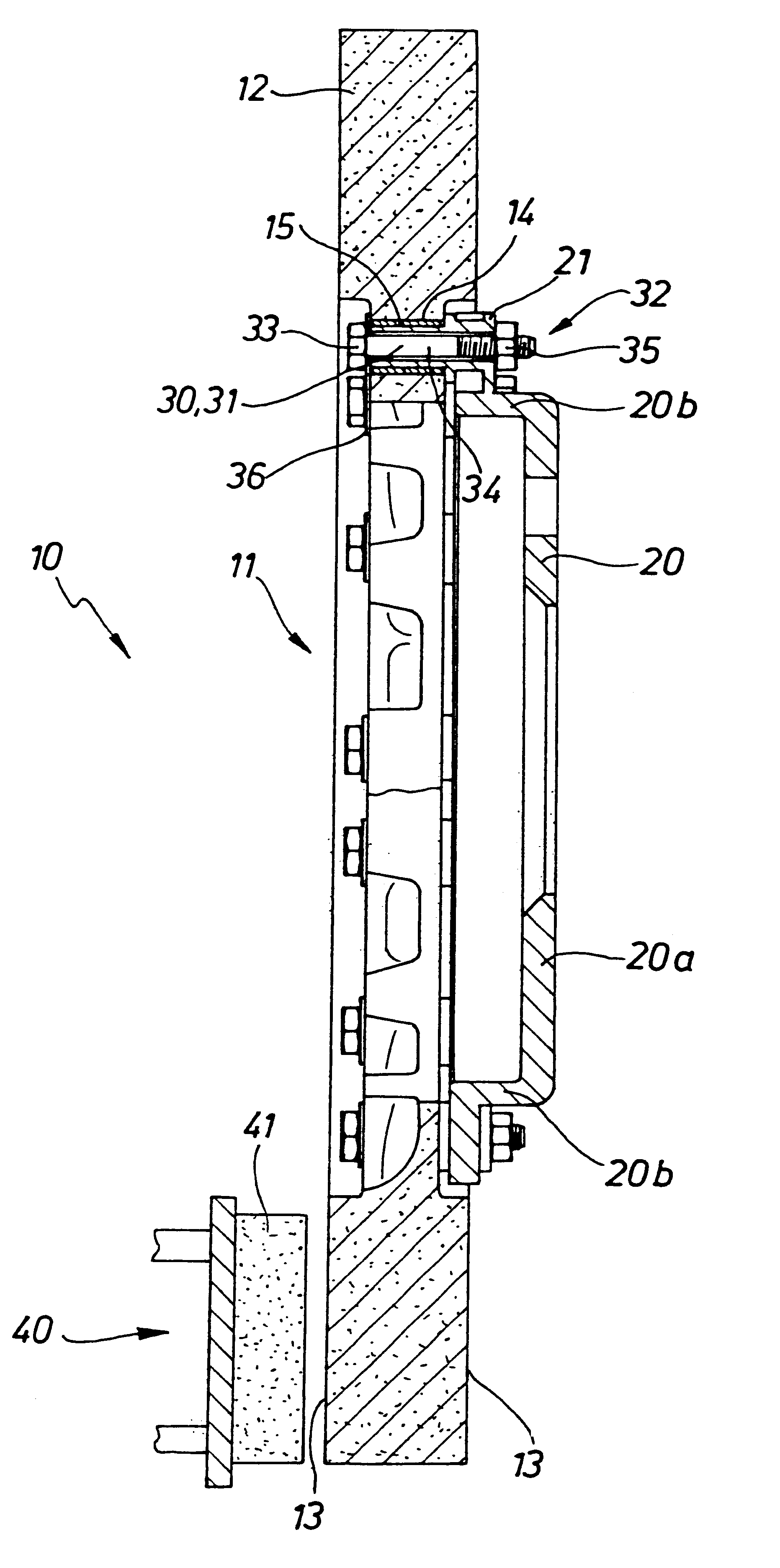

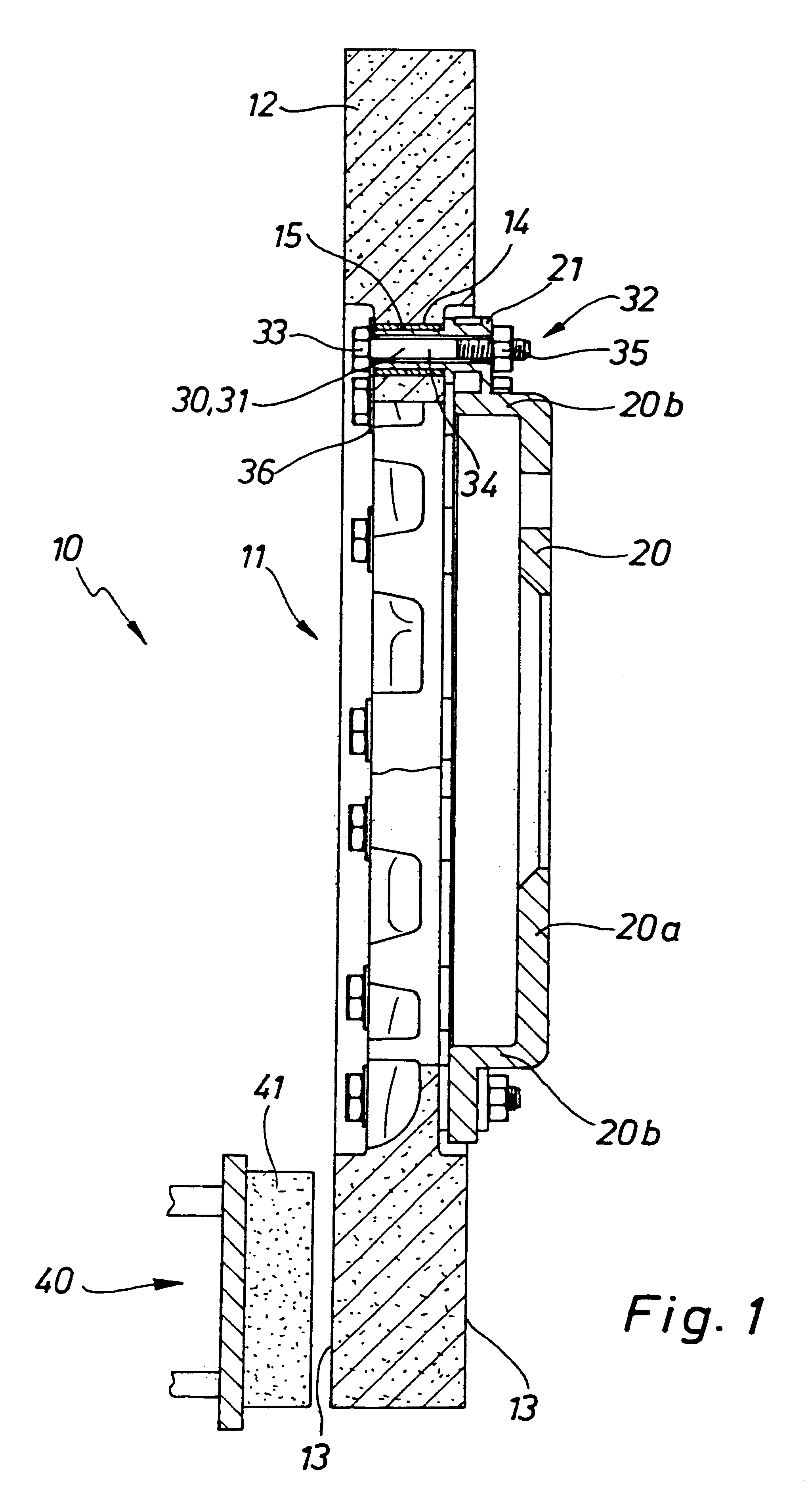

Brake unit

InactiveUS6302246B1Prolong lifeImprove flatnessBraking element arrangementsNoise/vibration controlEngineeringCeramic metal

A brake unit comprising at least one brake and at least one brake pad having at least one friction lining is described. The brake has a disk brake with a brake rotor made of a ceramic-metal composite (CMC) whose outer surface or surfaces at least partially form a friction surface for the at least one friction lining, and a disk brake cup that is mounted on the disk brake by way of one or more mounting elements. The friction surface of the disk brake has a hardness of approximately 1600 to 2500 HV, and the at least one friction lining has a coefficient of friction of approximately 0.3 to 0.5. The disk brake cup and / or the mounting elements form a corrosion-inhibiting attachment to the disk brake. The brake unit can be operated in corrosion-free fashion over a service life of at least approximately eight to 10 years or approximately 200,000 to 300,000 km.

Owner:FRENI BREMBO SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com