Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

570results about "Protective coatings for layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

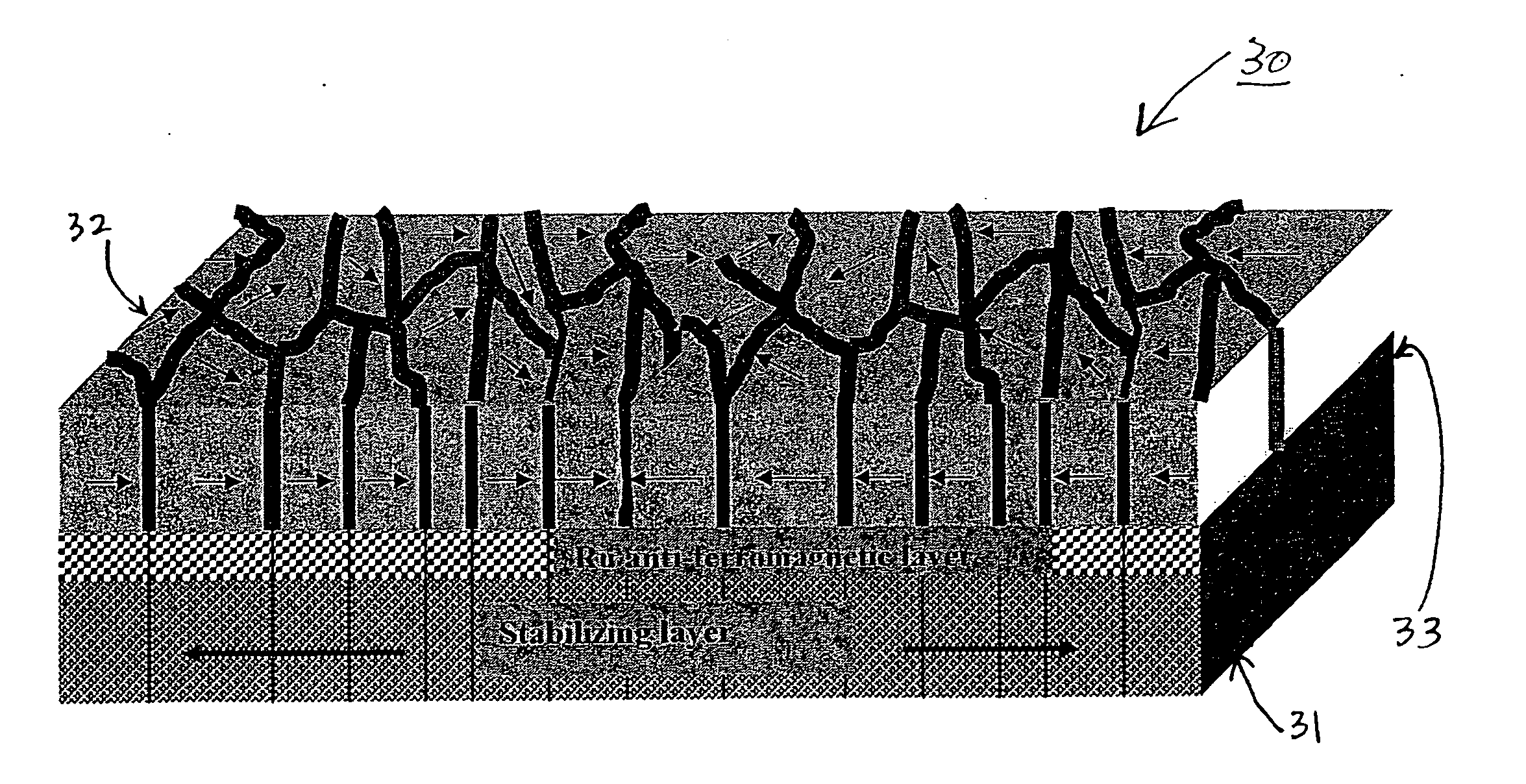

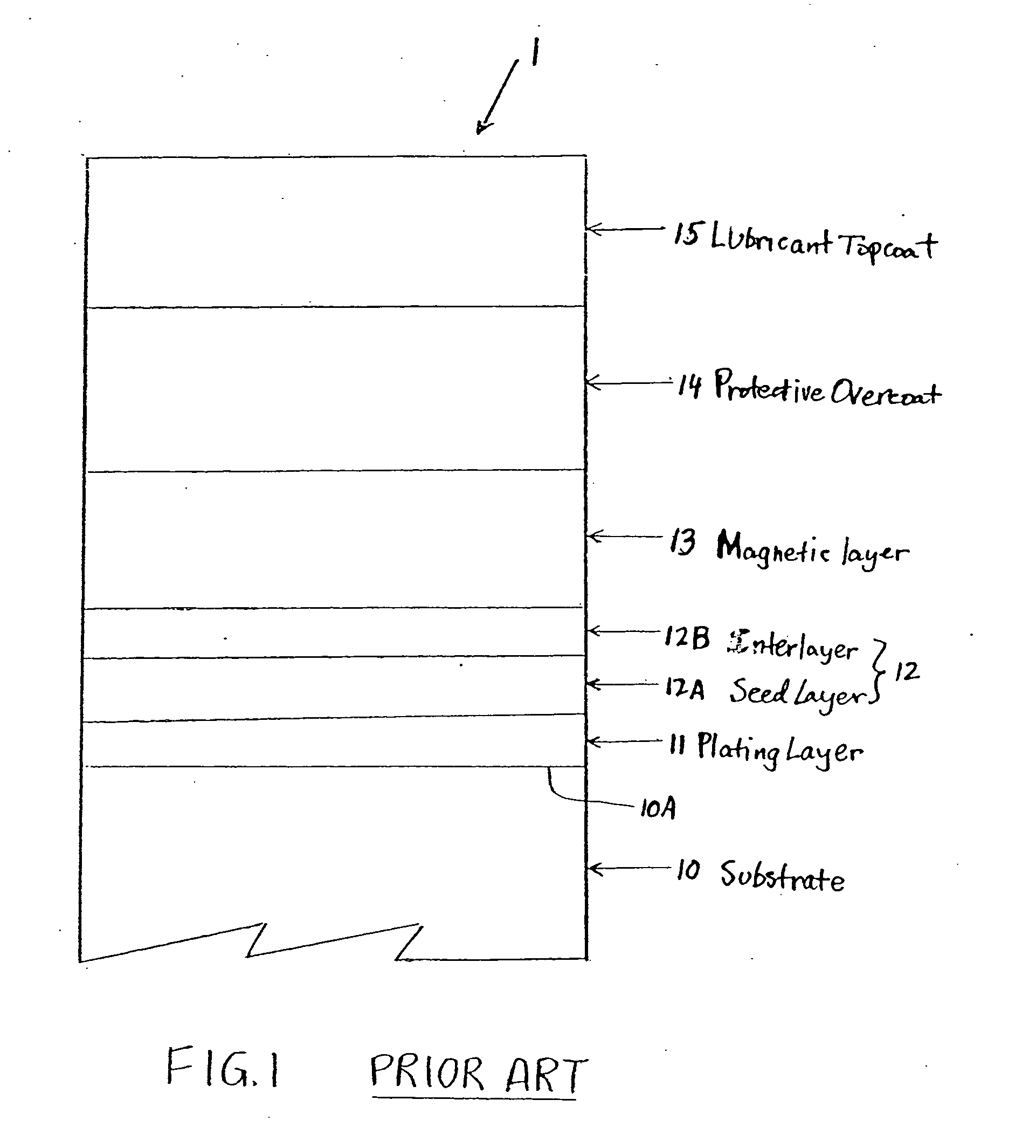

Anti-ferromagnetically coupled granular-continuous magnetic recording media

InactiveUS20050214585A1Improve performanceRaise the ratioProtective coatings for layersBase layers for recording layersAntiferromagnetic couplingEngineering

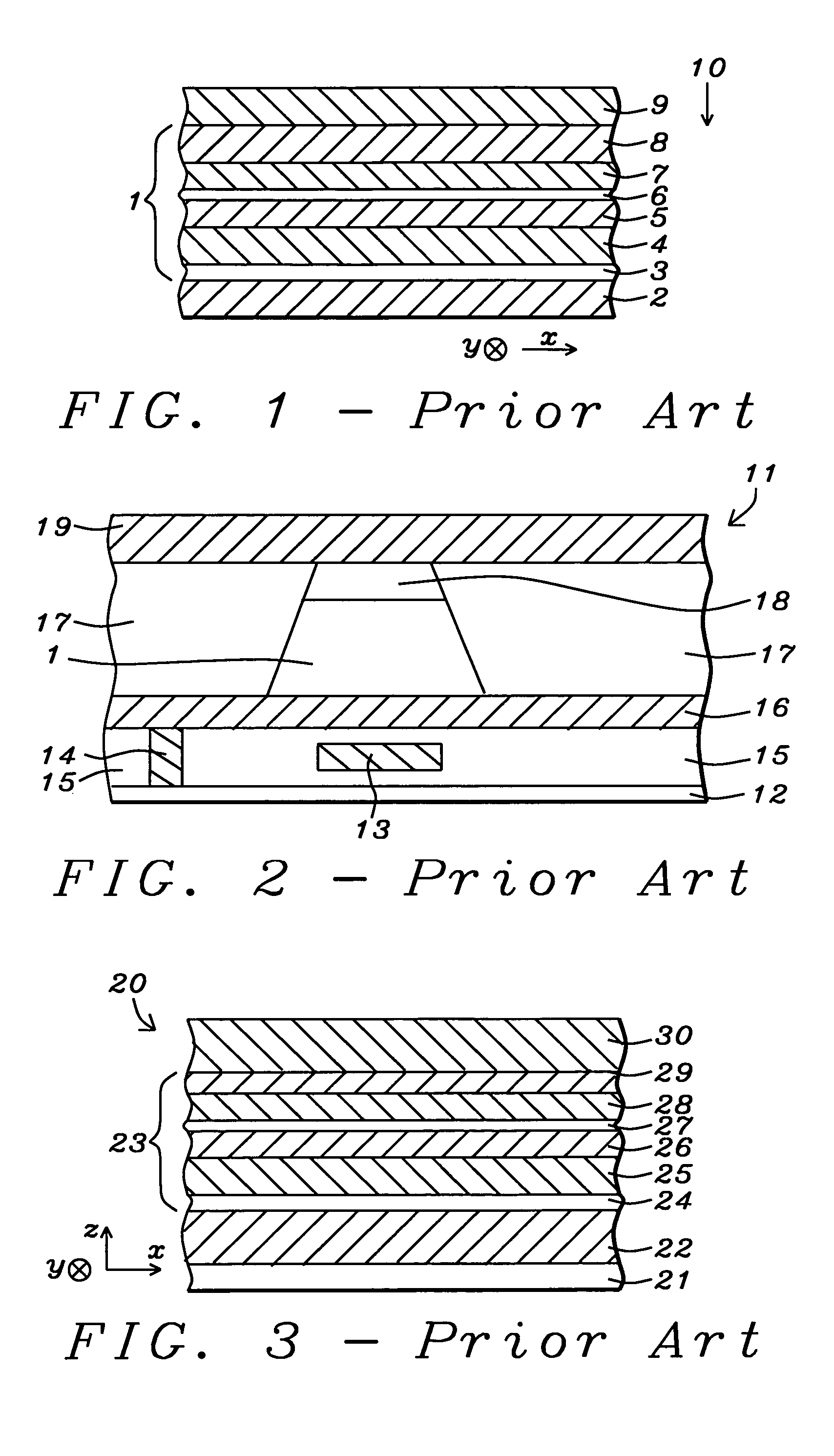

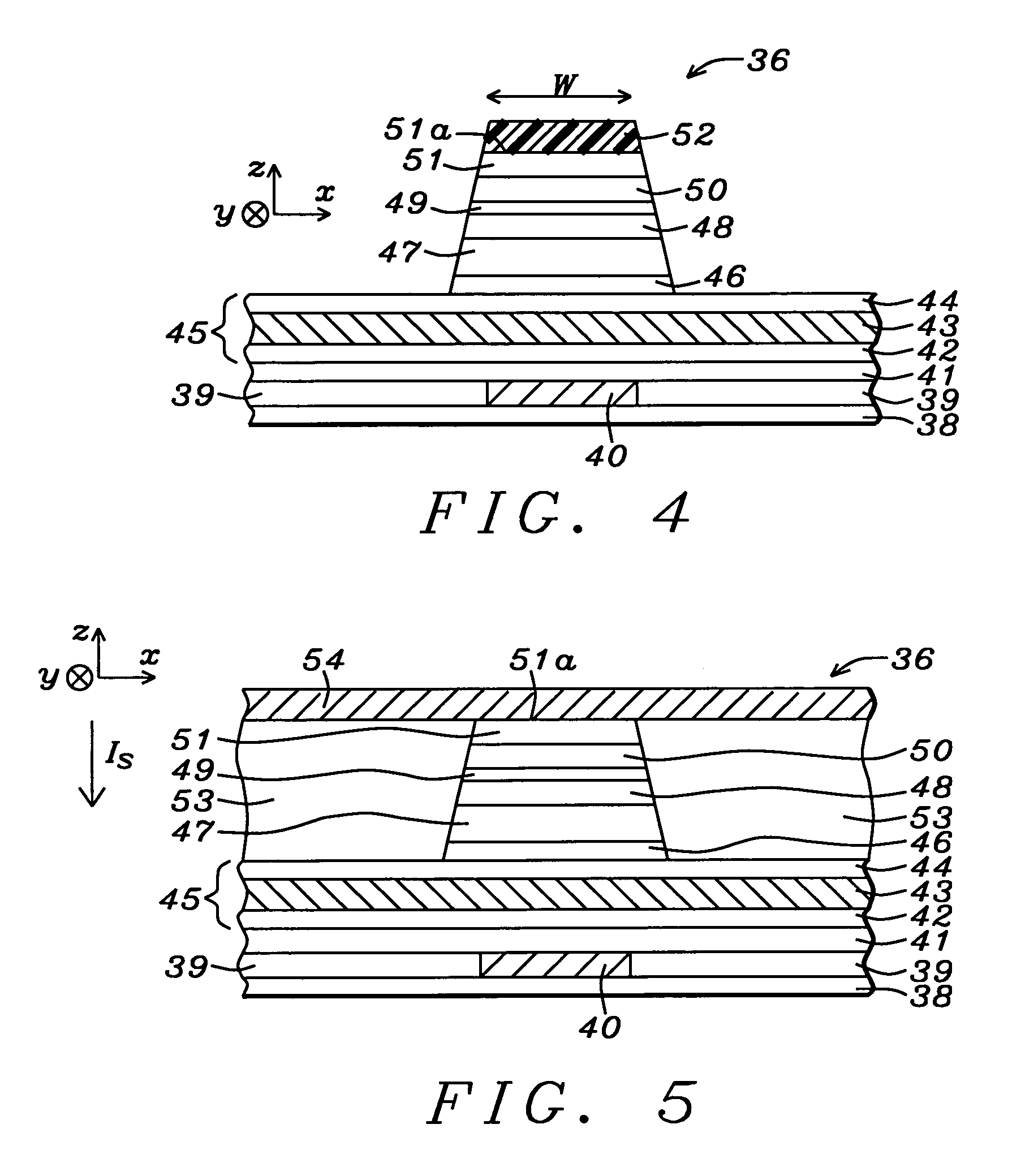

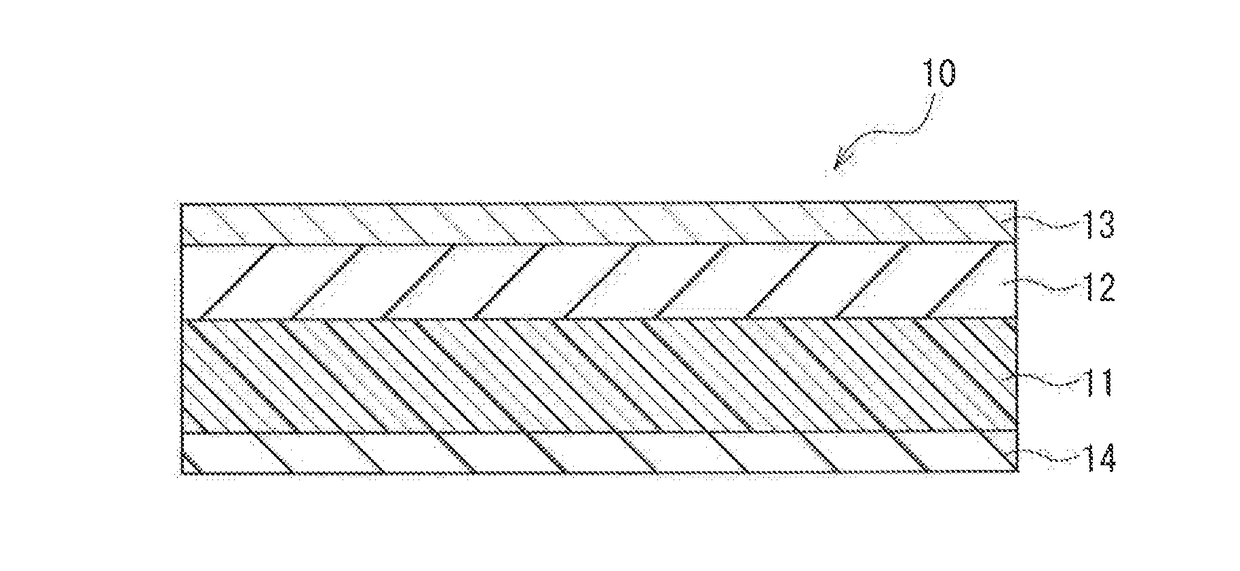

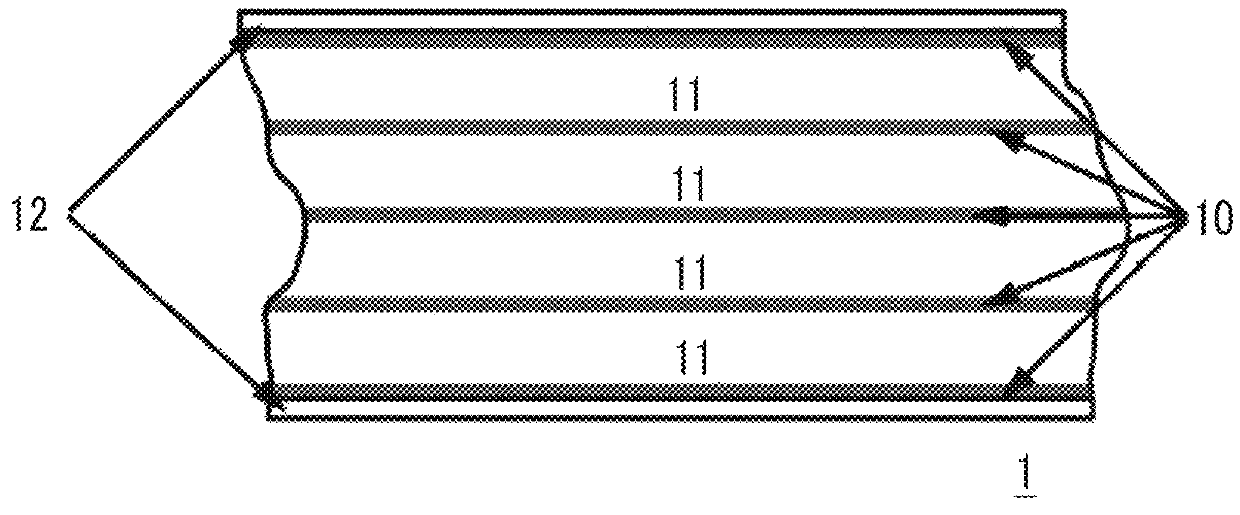

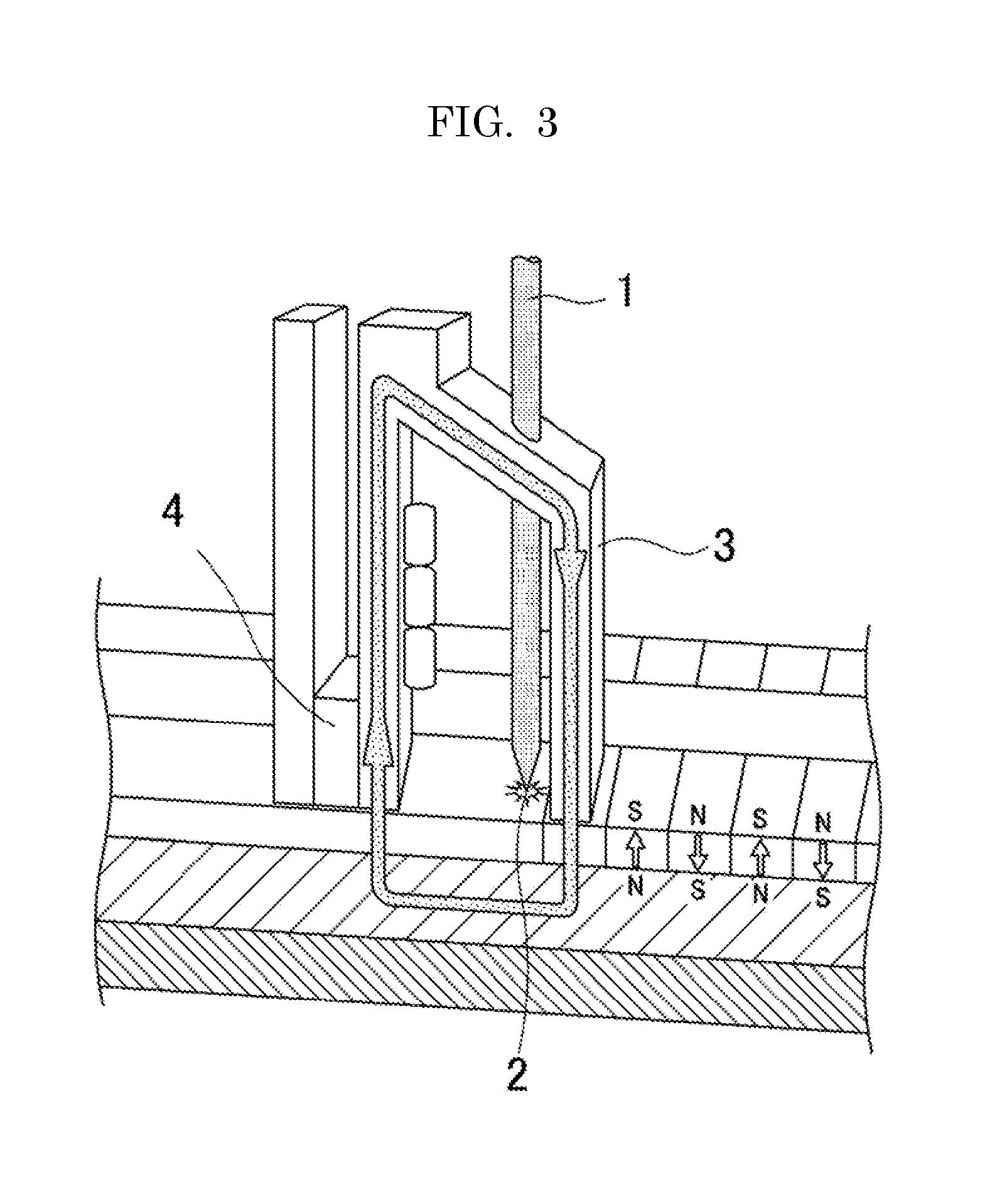

An anti-ferromagnetically coupled, granular-continuous (“AFC-GC”) magnetic recording medium having increased thermal stability, writability, and signal-to-medium noise ratio (“SMNR”), comprising a layer stack including, in sequence from a surface of a non-magnetic substrate: (a) a continuous ferromagnetic stabilizing layer; (b) a non-magnetic spacer layer; and (c) a granular ferromagnetic recording layer; wherein: (i) the continuous ferromagnetic stabilizing and granular ferromagnetic recording layers are anti-ferromagnetically coupled across the non-magnetic spacer layer, the amount of anti-ferromagnetic coupling preselected to ensure magnetic relaxation after writing; (ii) lateral interactions in the granular, ferromagnetic recording layer are substantially completely eliminated or suppressed; and (iii) the exchange coupling strength in the continuous, ferromagnetic stabilizing layer is preselected to be slightly larger than the strength of the anti-ferromagnetic coupling provided by the non-magnetic spacer layer to thereby enhance thermal stability of the recording bits.

Owner:SEAGATE TECH LLC

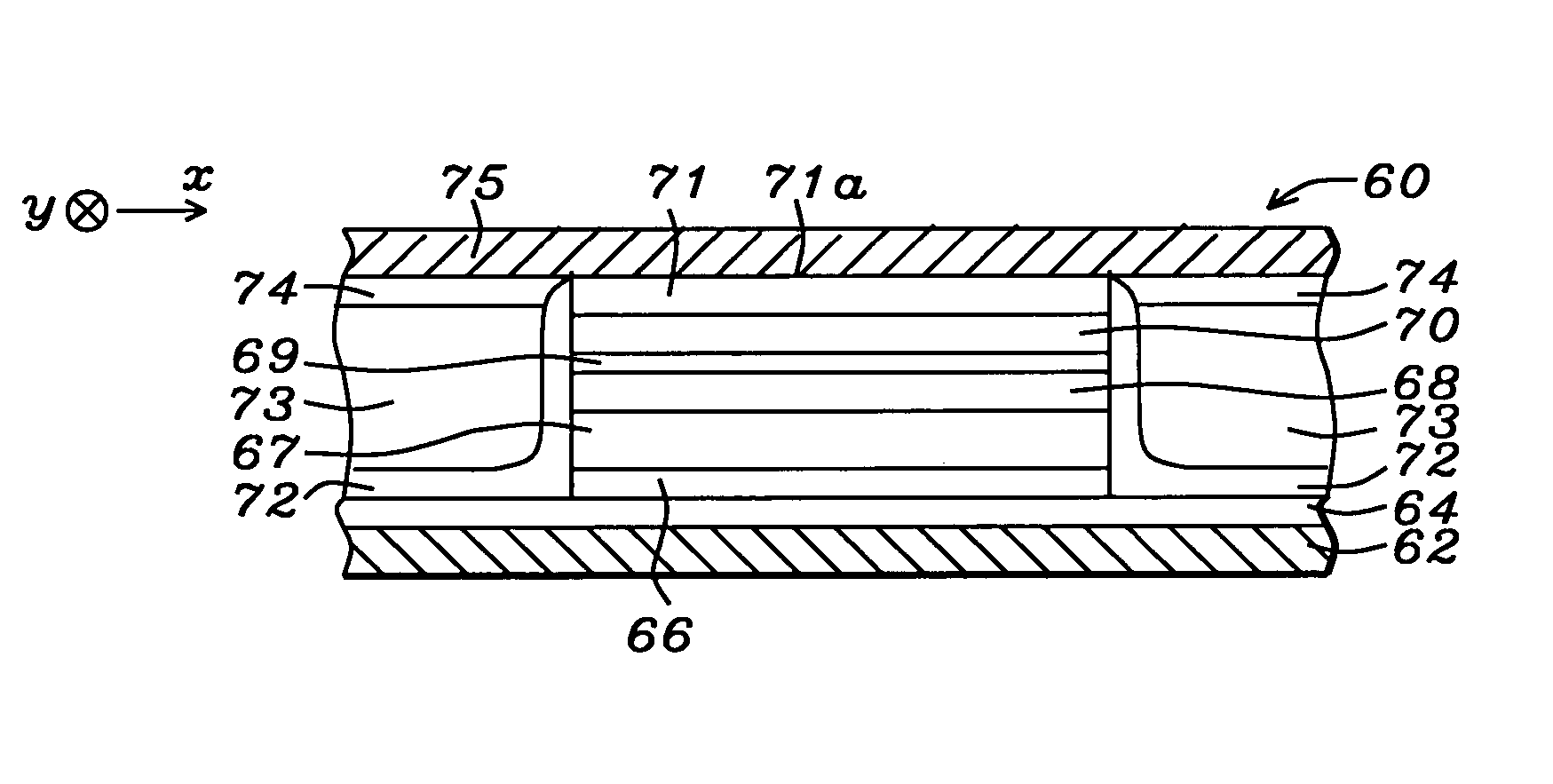

Capping structure for enhancing dR/R of the MTJ device

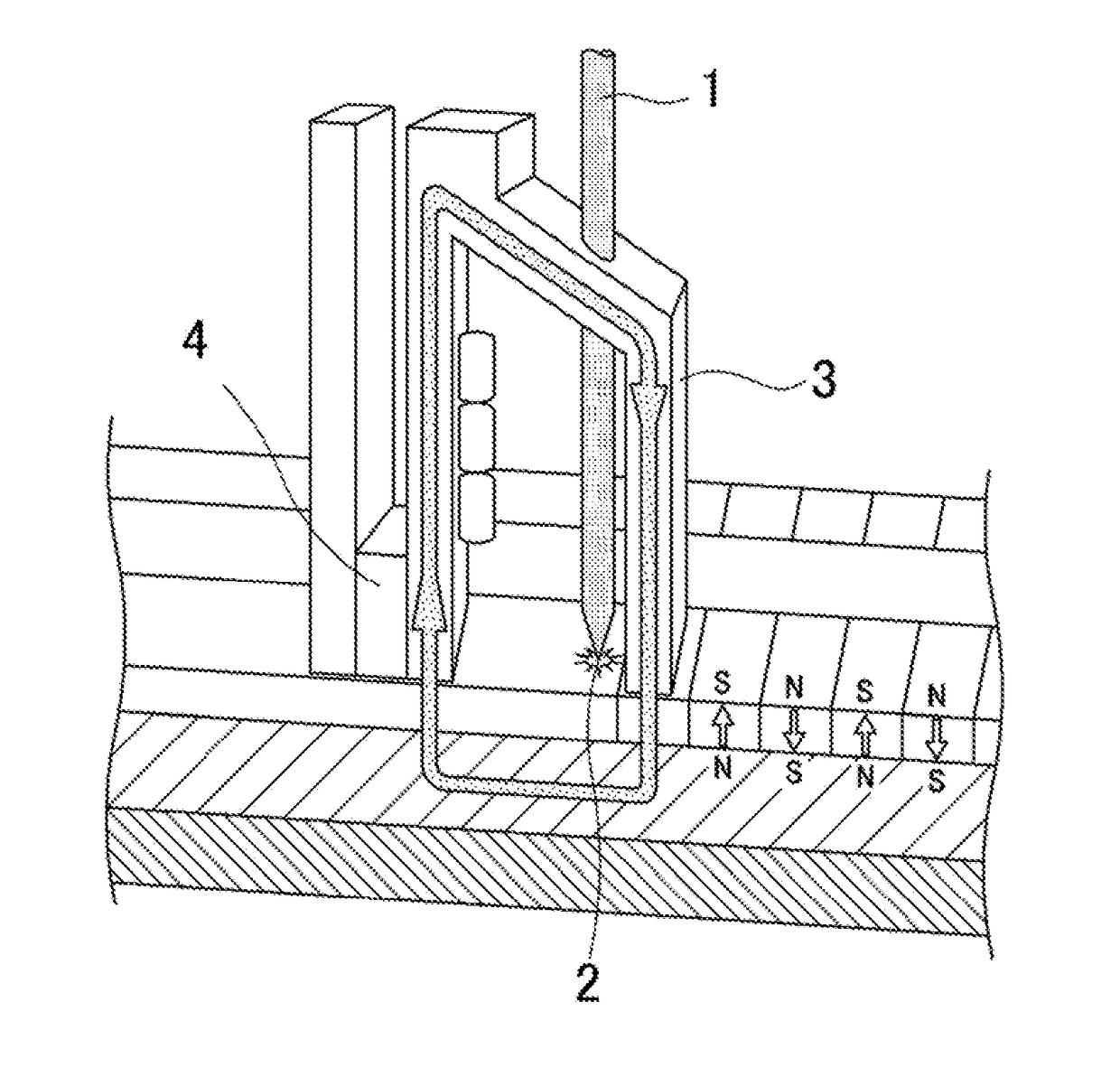

An MTJ in an MRAM array or in a TMR read head is comprised of a capping layer with a lower inter-diffusion barrier layer, an intermediate oxygen gettering layer, and an upper metal layer that contacts a top conductor. The composite capping layer is especially useful with a moderate spin polarization free layer such as a NiFe layer with a Fe content of about 17.5 to 20 atomic %. The capping layer preferably has a Ru / Ta / Ru configuration in which the lower Ru layer is about 10 to 30 Angstroms thick and the Ta layer is about 30 Angstroms thick. As a result, a high dR / R of about 40% is achieved with low magnetostriction less than about 1.0 E−6 in an MTJ in an MRAM array. Best results are obtained with an AlOx tunnel barrier layer formed by an in-situ ROX process on an 8 to 10 Angstrom thick Al layer.

Owner:HEADWAY TECH INC +1

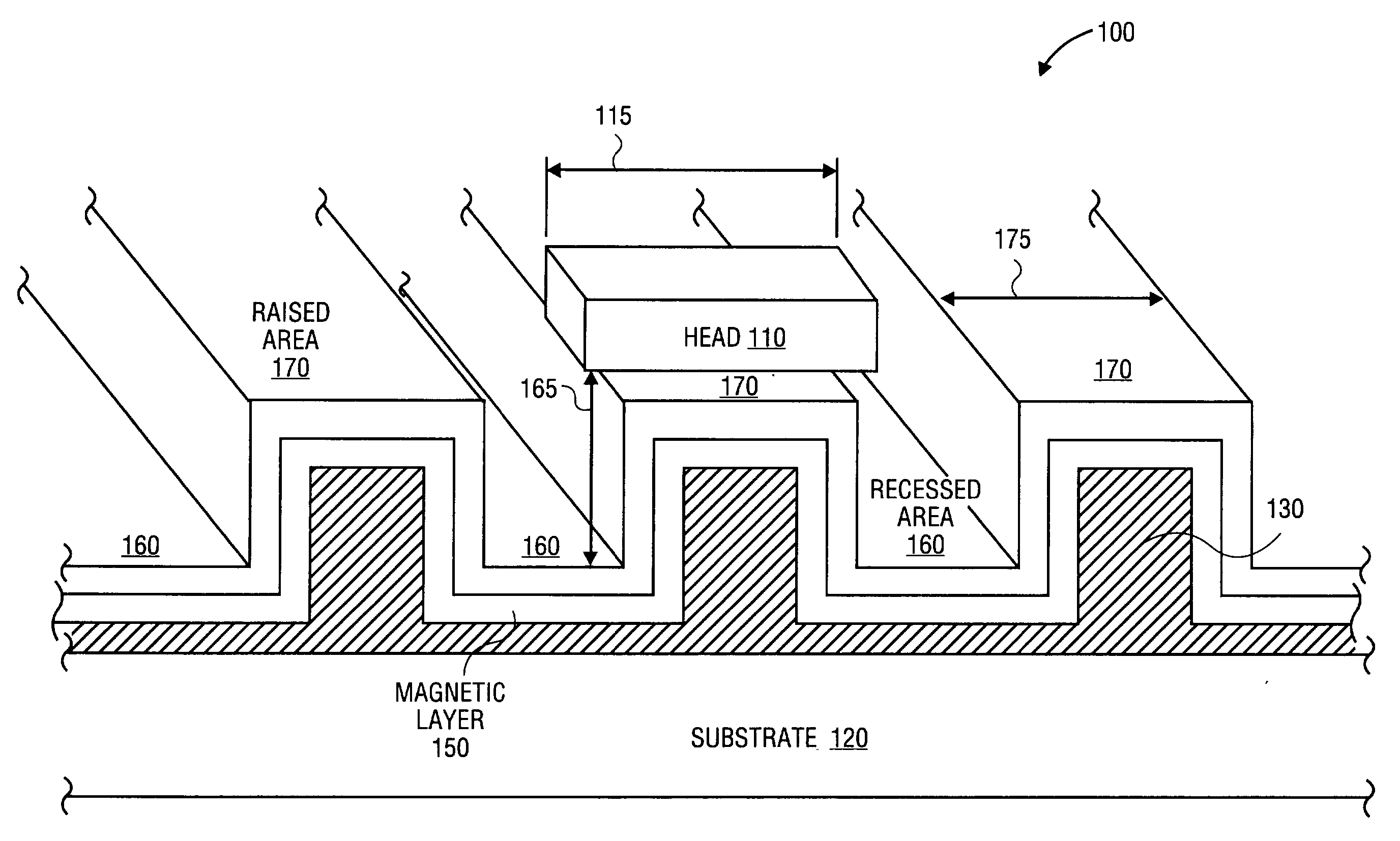

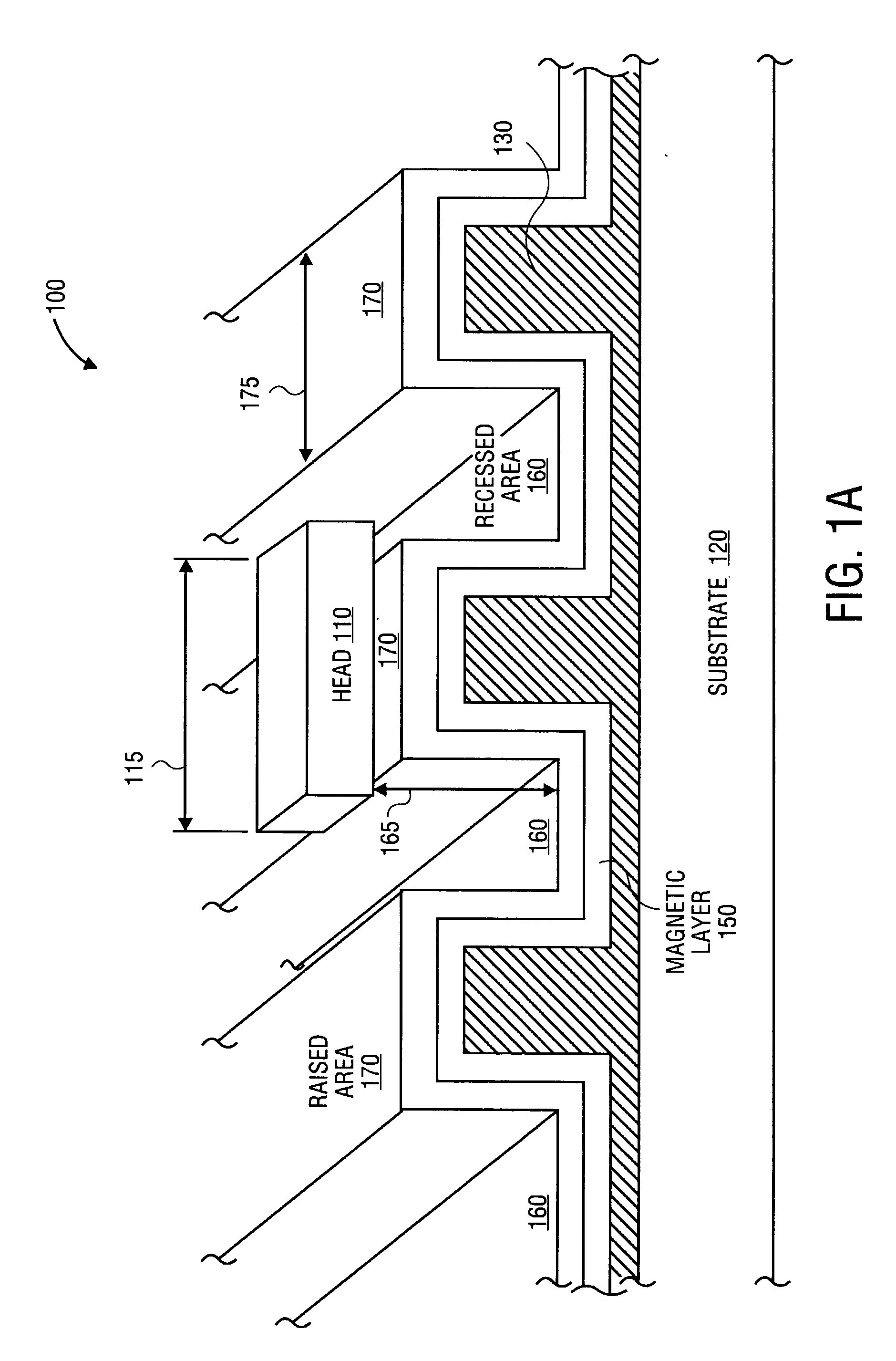

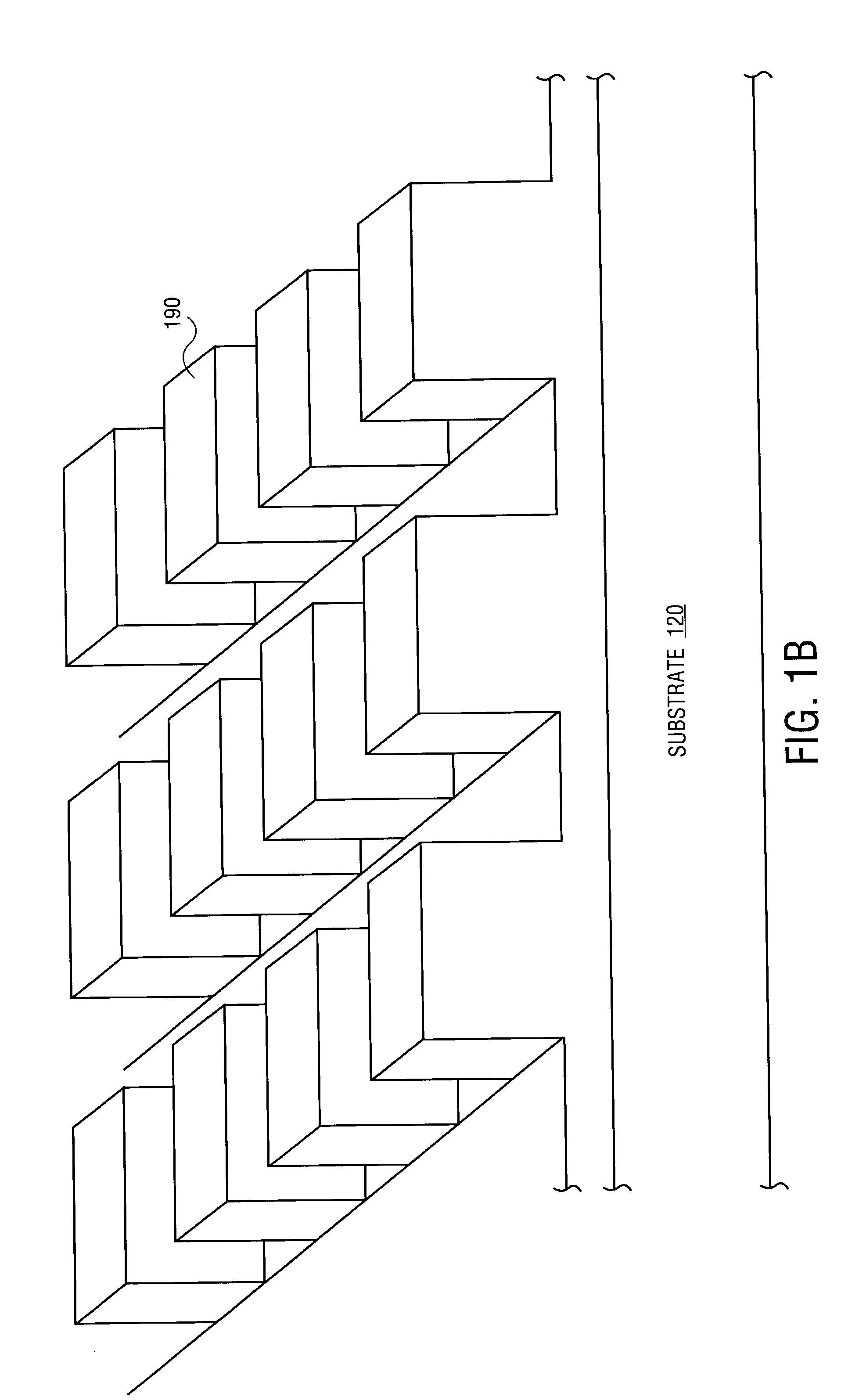

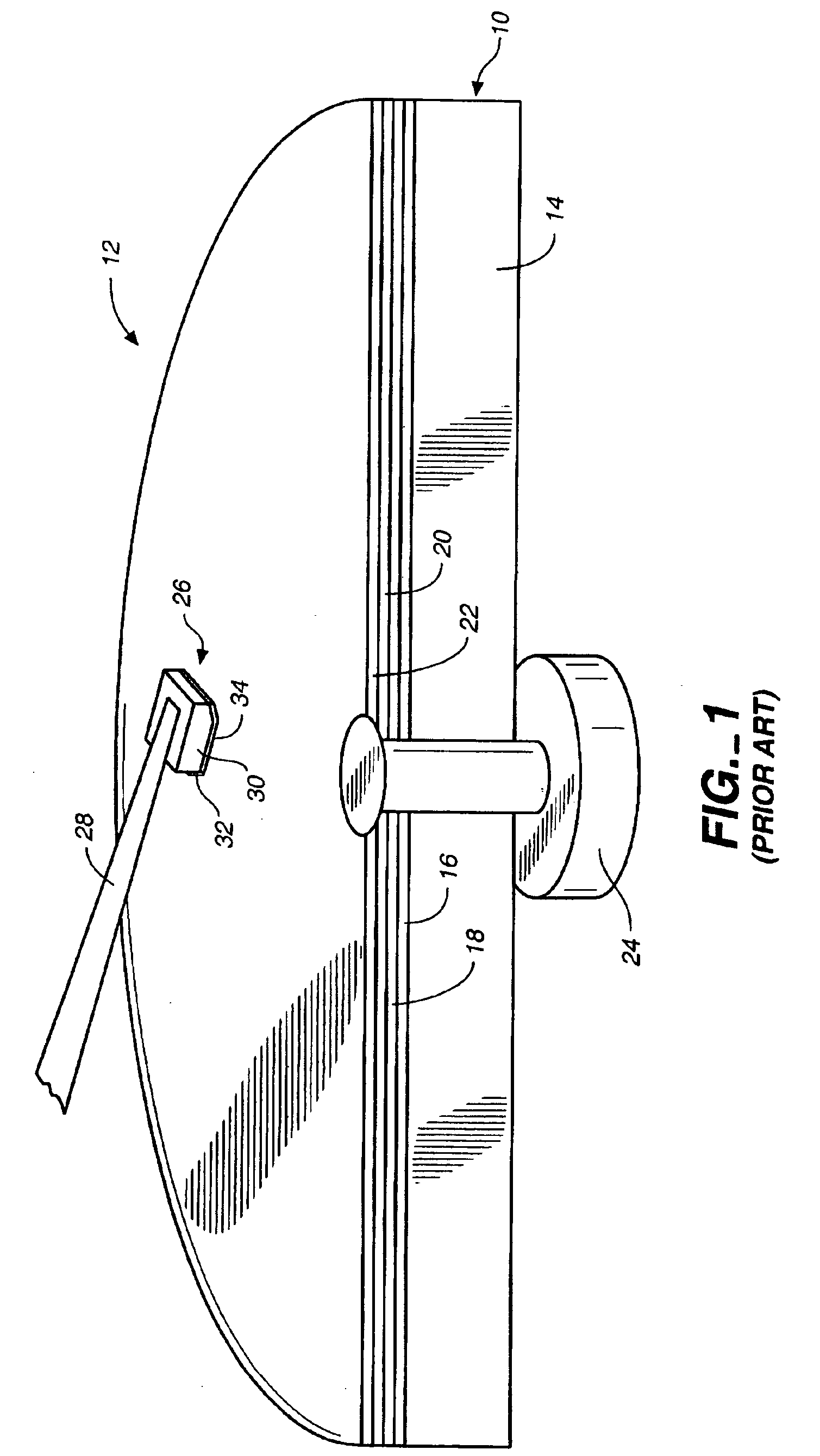

Magnetic discrete track recording disk

InactiveUS20050036223A1Protective coatings for layersBase layers for recording layersComputer science

Owner:KOMAG

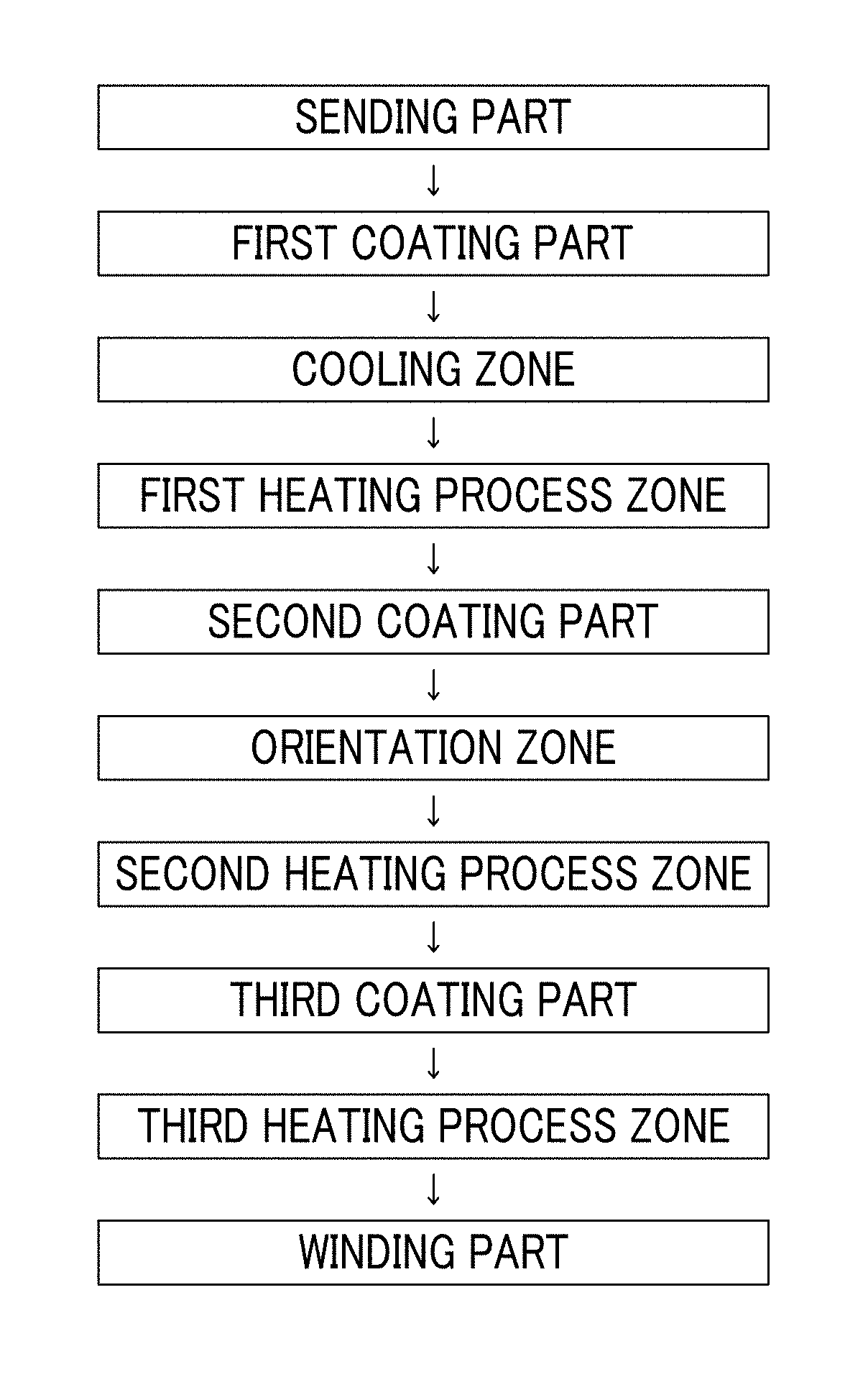

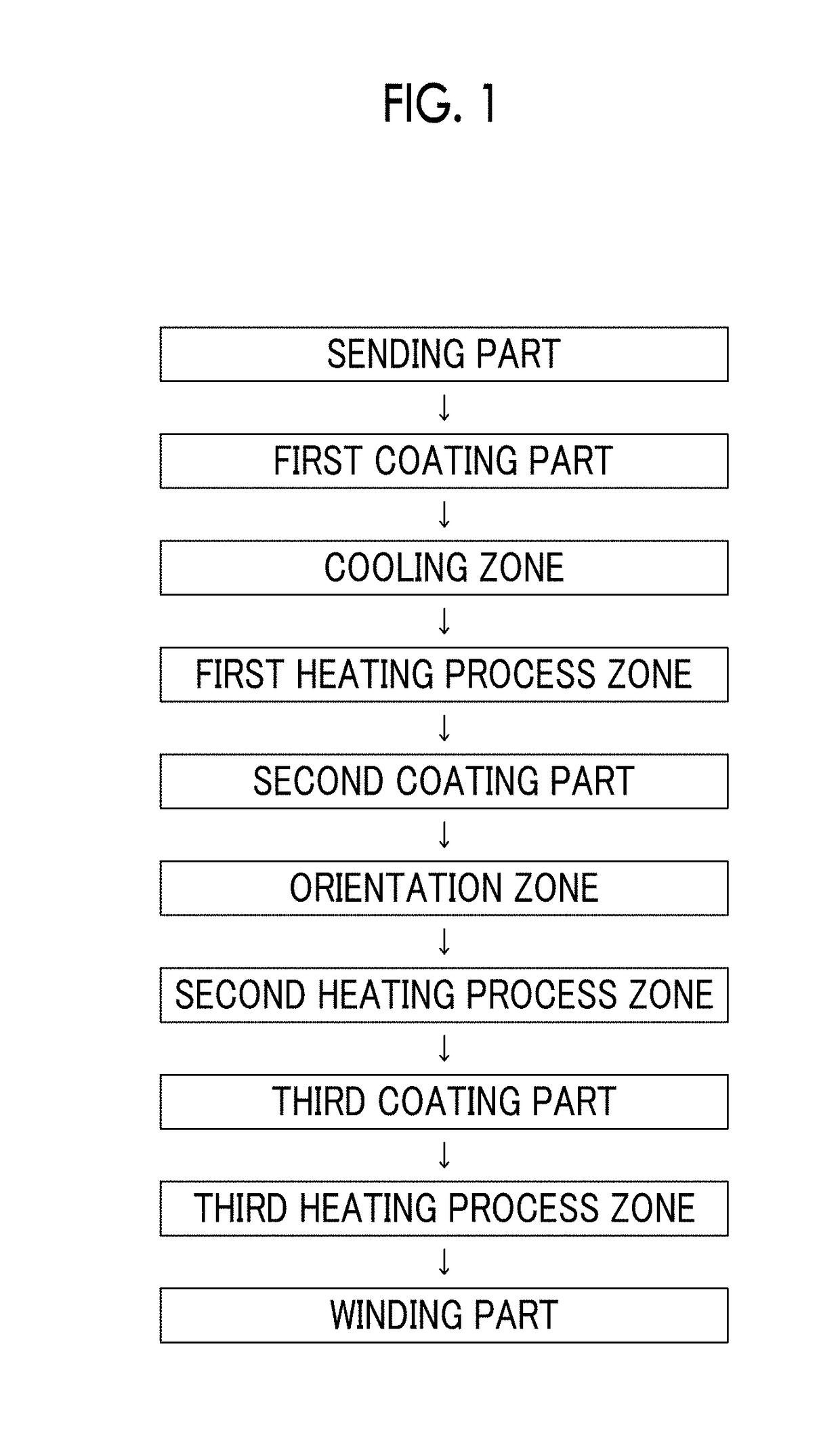

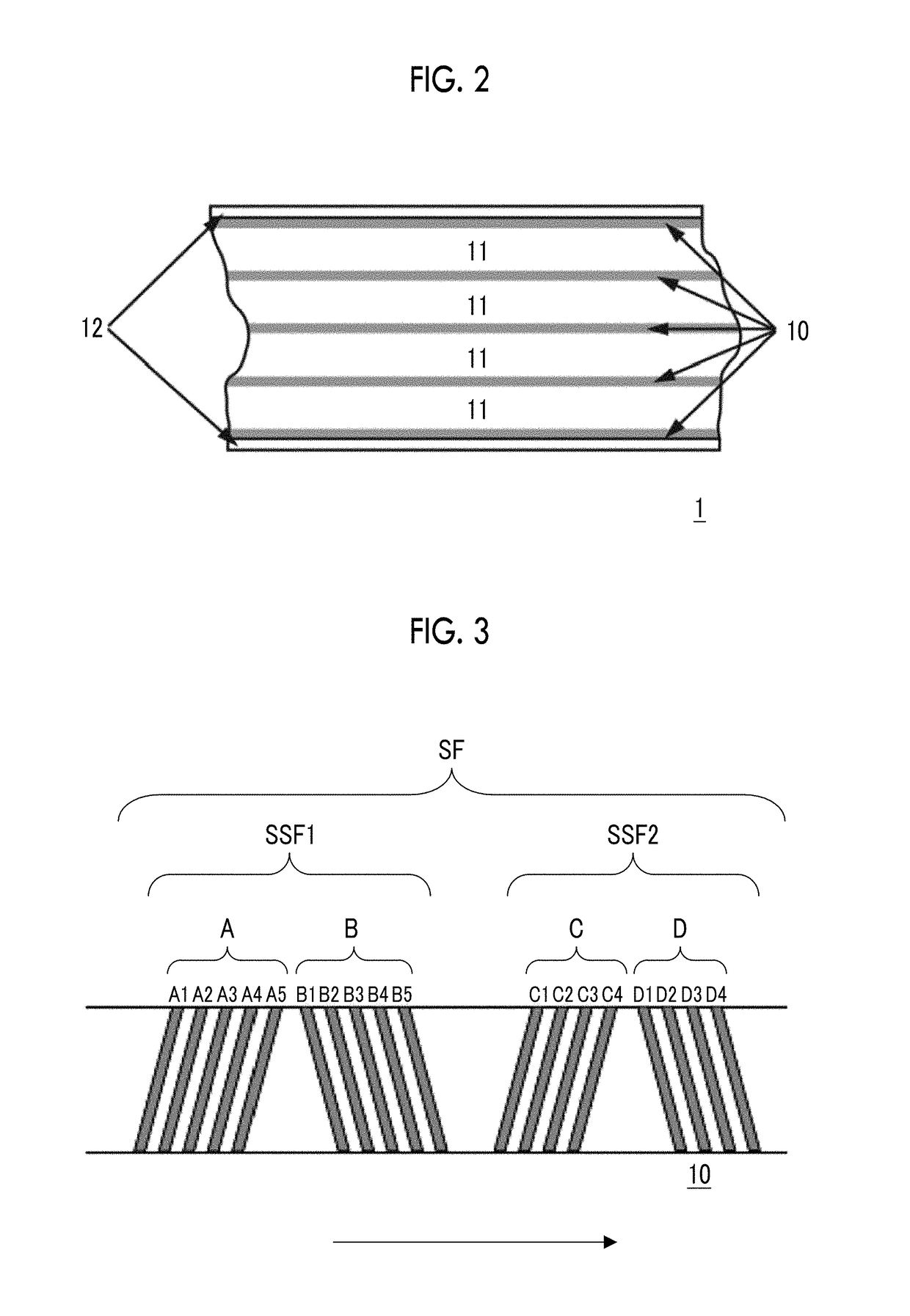

Magnetic tape device and head tracking servo method

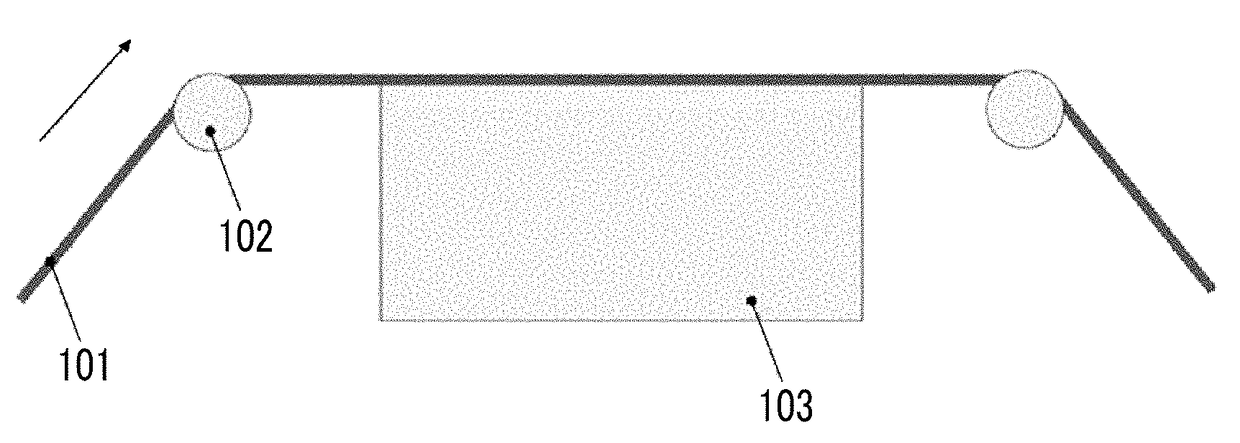

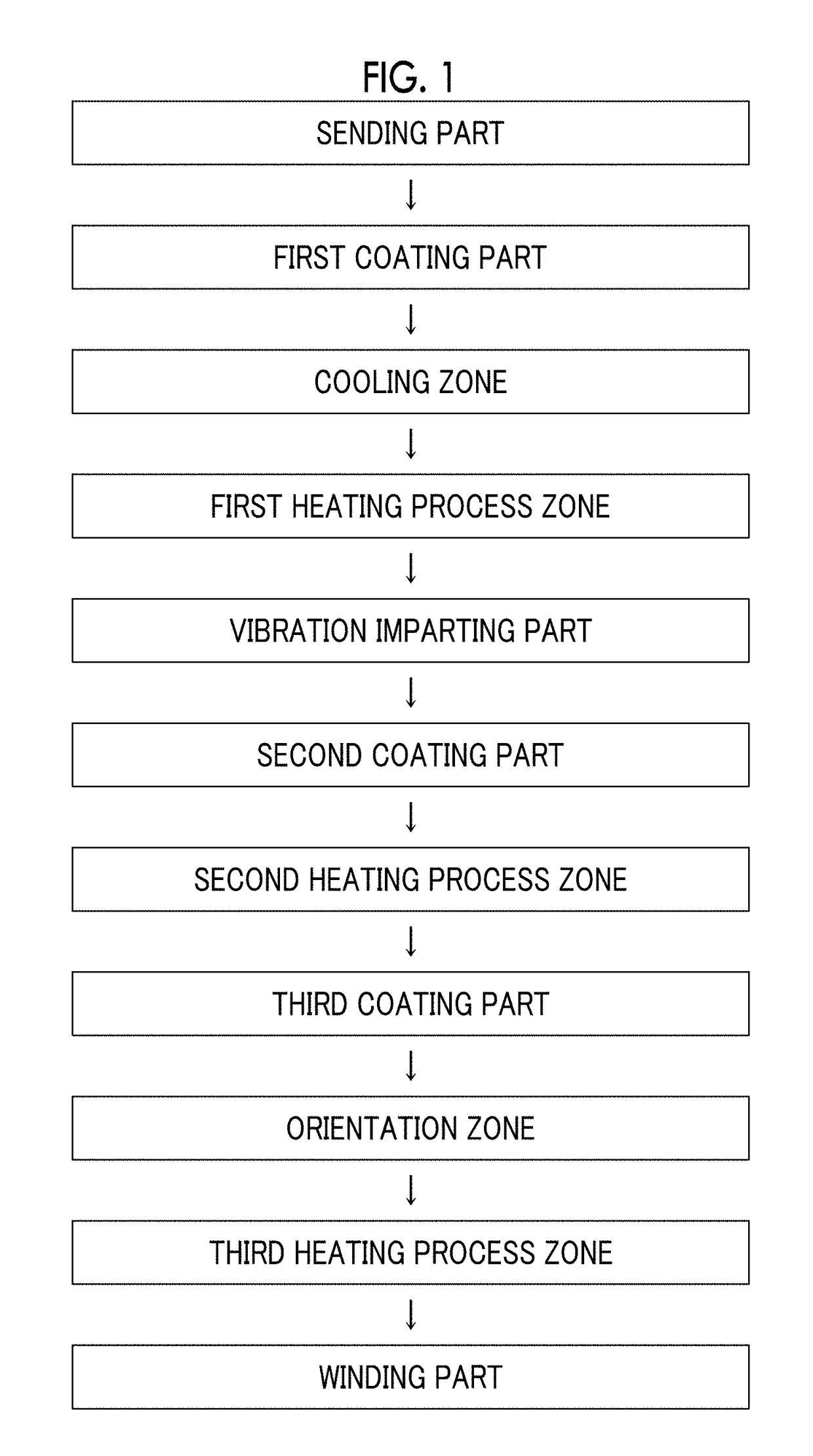

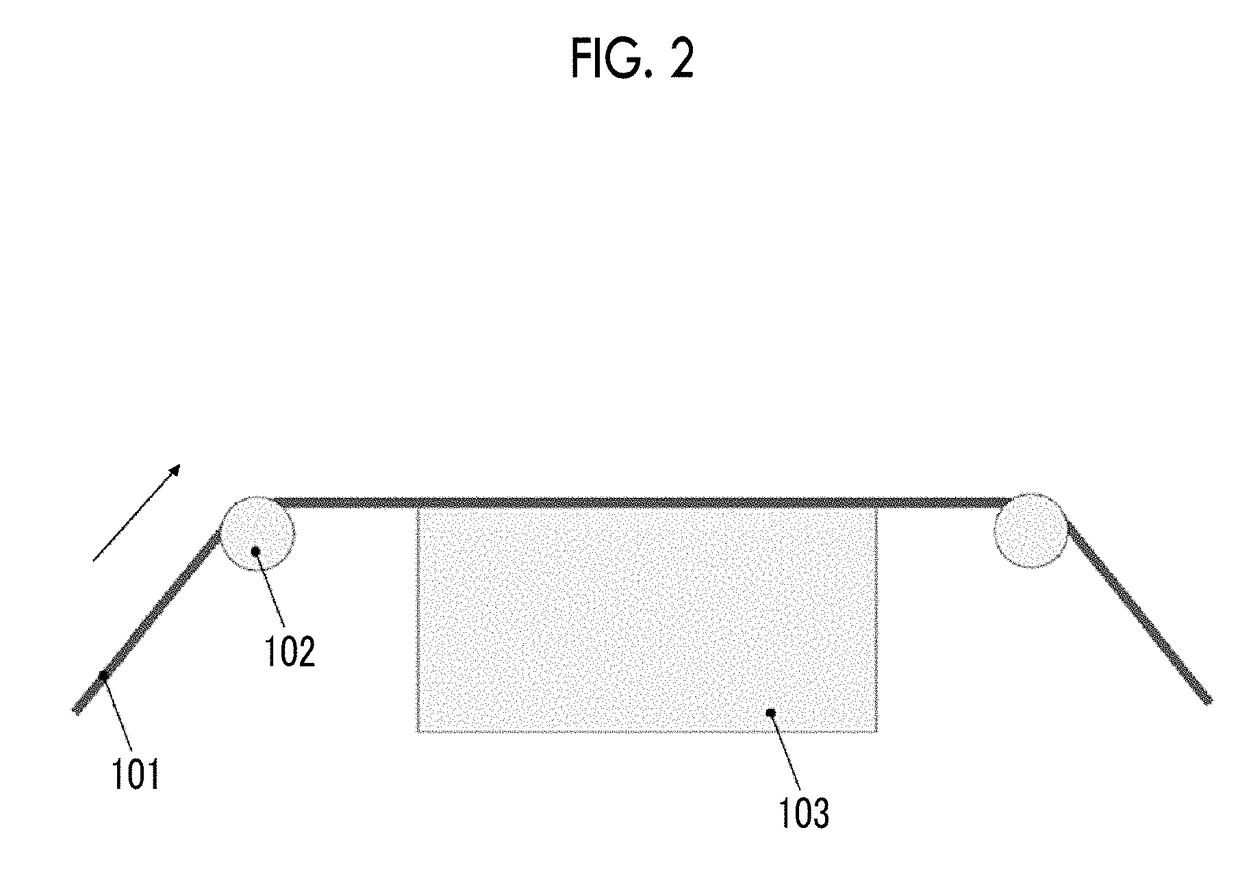

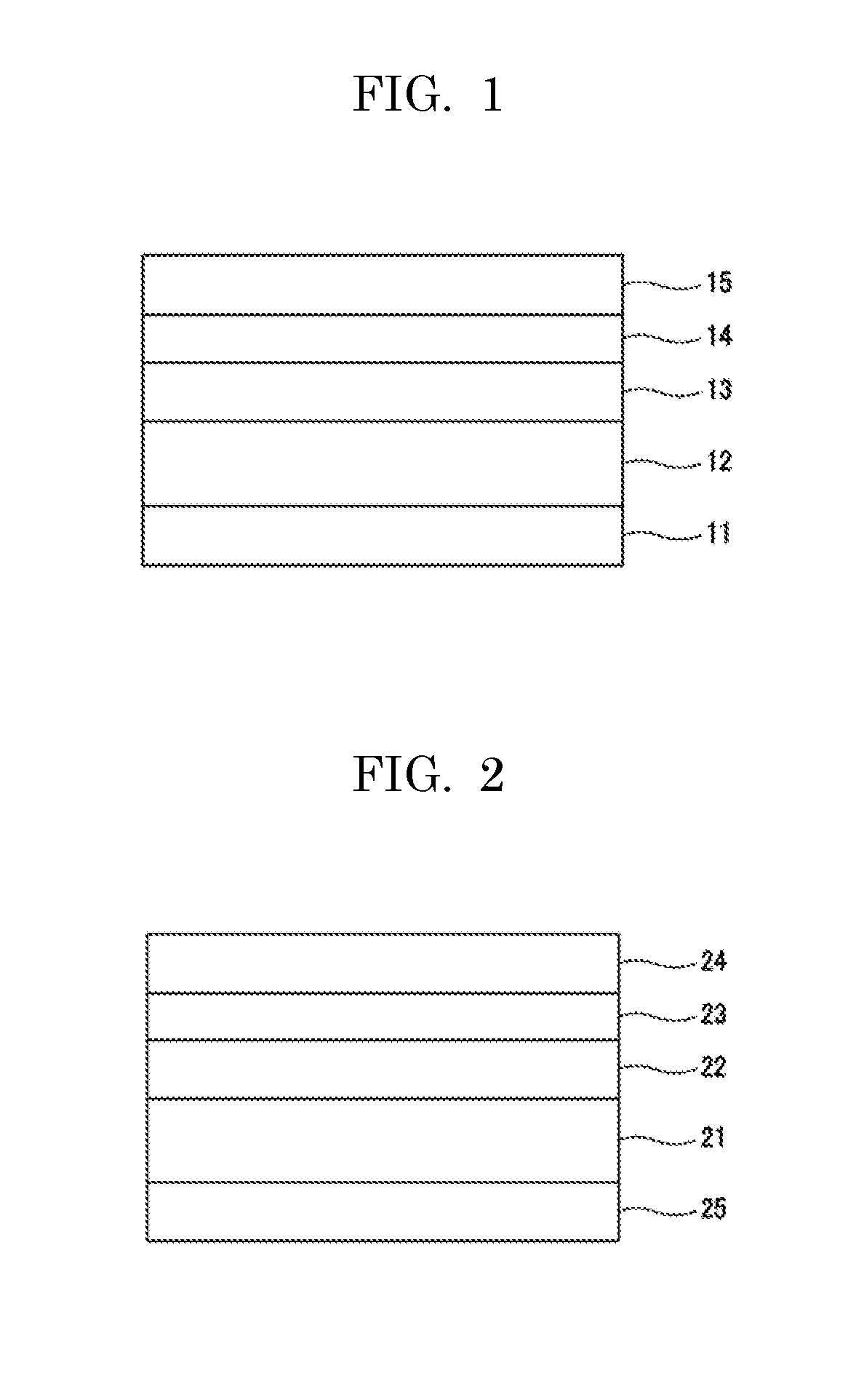

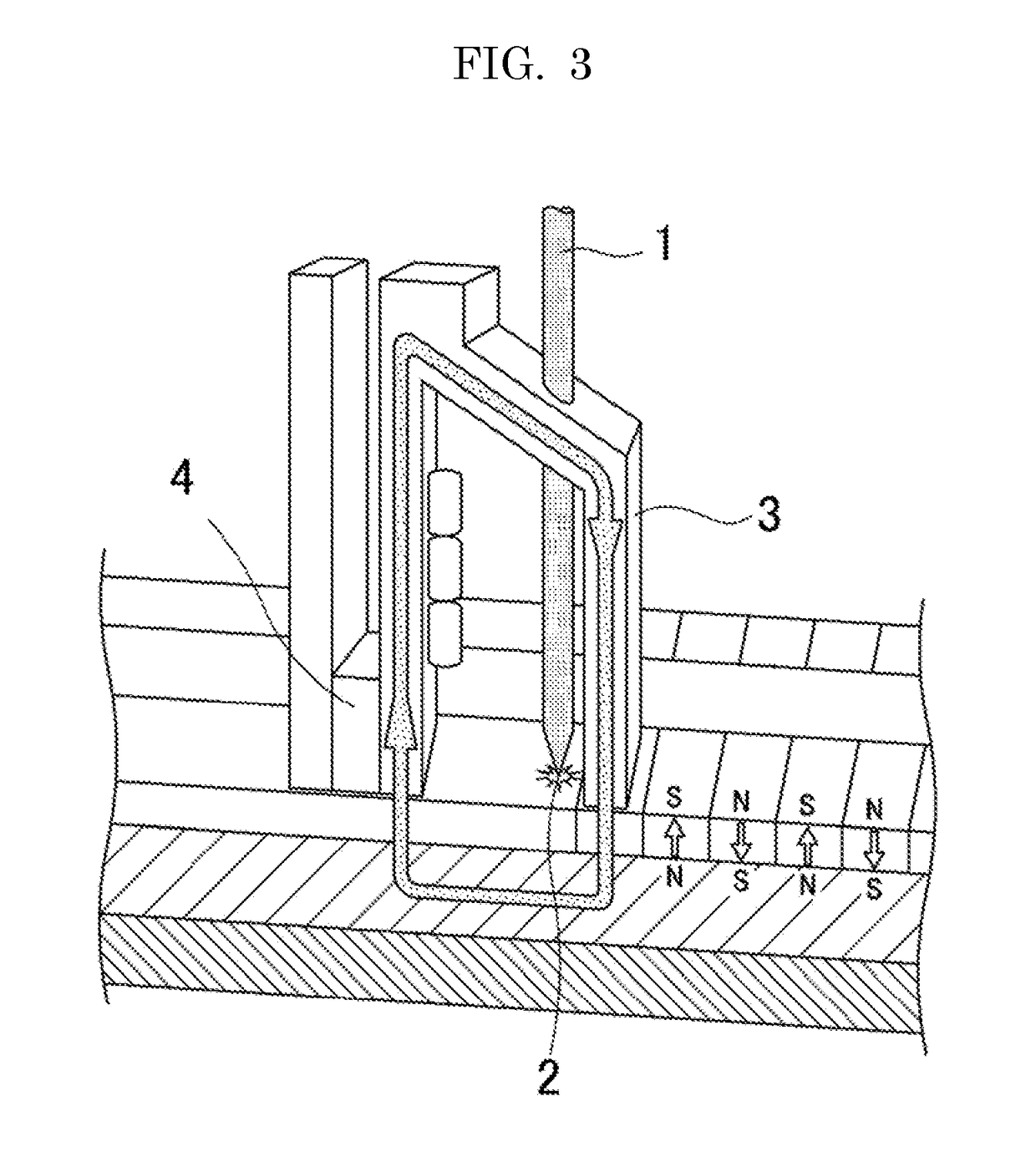

ActiveUS9984716B1Avoid it happening againImprove accuracyProtective coatings for layersTape carriersMagnetic tapeX-ray

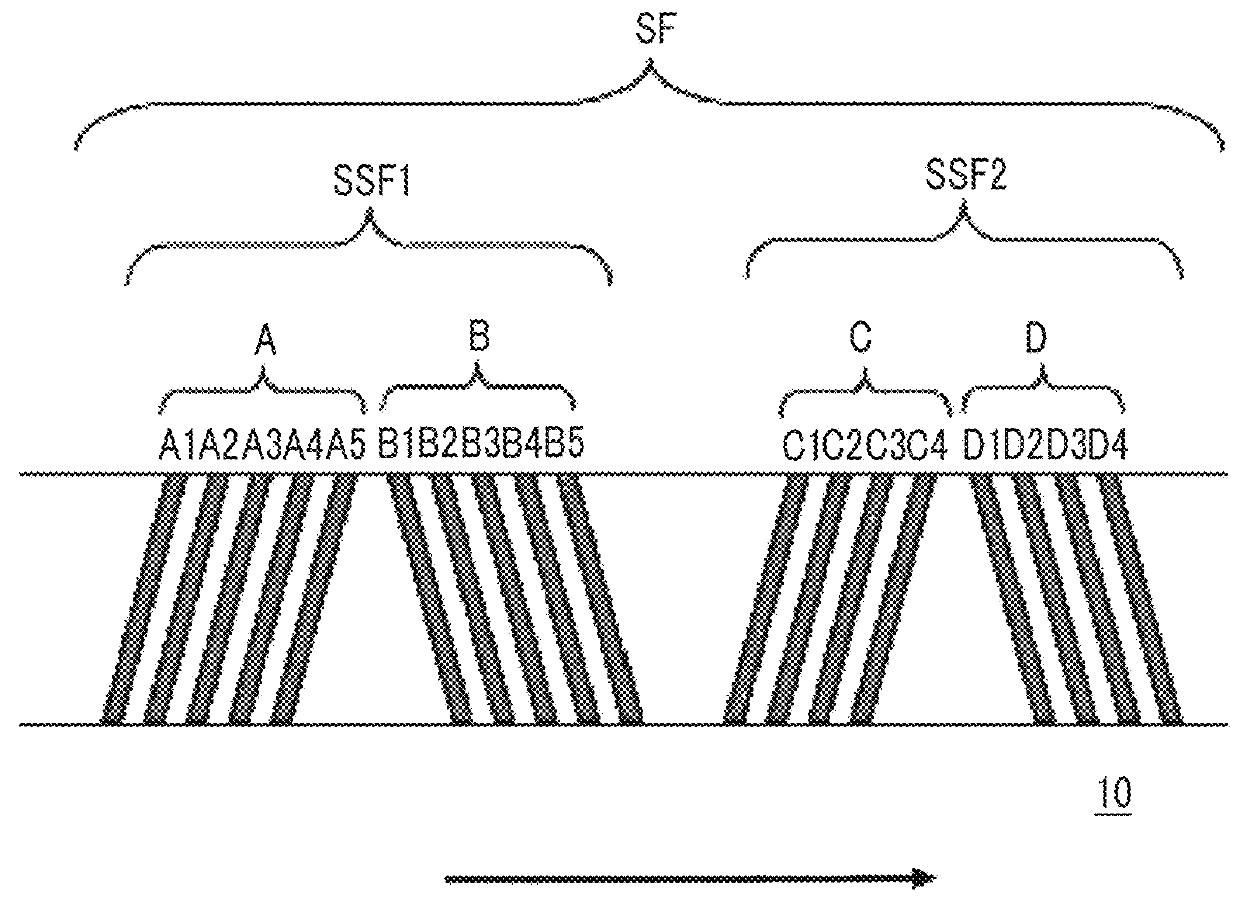

The magnetic tape device includes: a magnetic tape; and a servo head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the servo head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes a servo pattern, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on a surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20190103134A1Excellent electromagnetic conversion characteristicAvoid it happening againMaterials with ironProtective coatings for layersIn planeX-ray

Provided are a magnetic recording medium, in which a magnetic layer includes ferromagnetic hexagonal ferrite powder, a binding agent, and an oxide abrasive, an intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic recording medium is 0.65 to 1.00, a coefficient of friction measured regarding a base portion of a surface of the magnetic layer is equal to or smaller than 0.30, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic recording medium.

Owner:FUJIFILM CORP

Magnetic tape

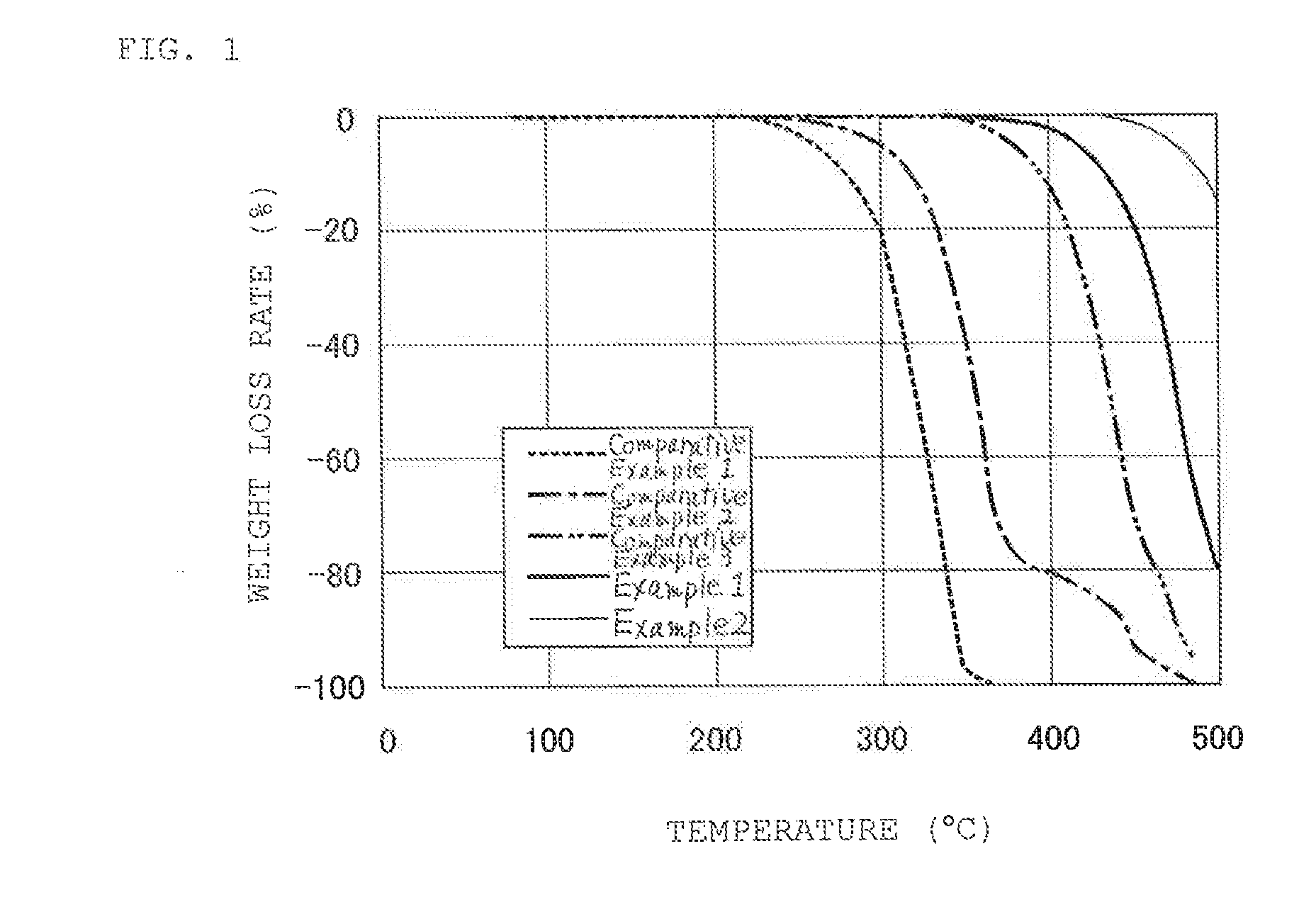

ActiveUS20170372741A1Improve running stabilitySuitable compatibilityProtective coatings for layersRecord information storageMagnetic tapeX-ray

Provided is a magnetic tape in which a thickness of a back coating layer is equal to or smaller than 0.20 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees, is equal to or greater than 35 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic recording medium

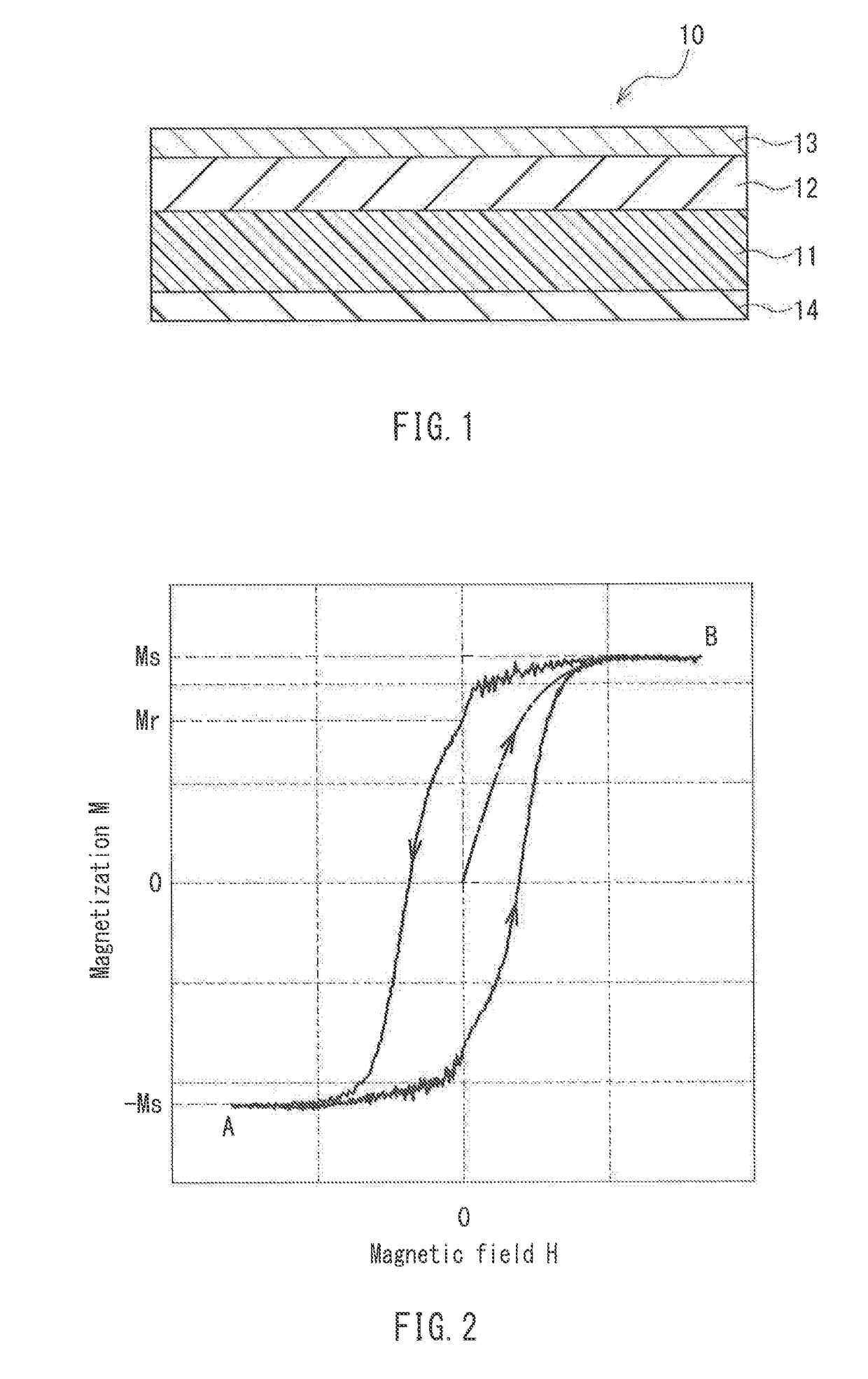

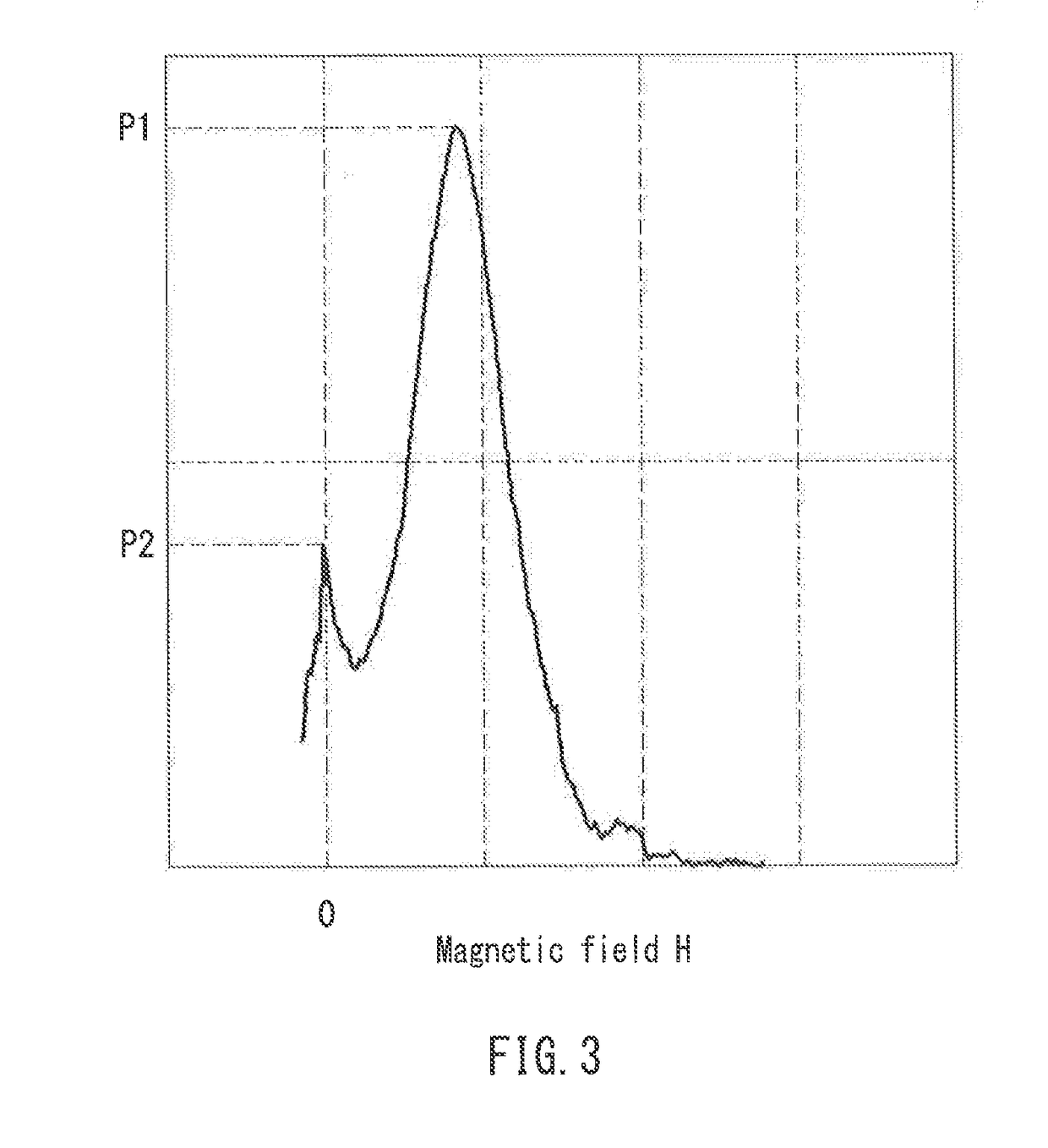

ActiveUS20170221513A1Increased durabilityHigh outputProtective coatings for layersRecord information storageHysteresisNon magnetic

A magnetic recording medium of the present invention includes a non-magnetic substrate, and a magnetic layer containing a magnetic powder. The magnetic powder is constituted by an ε-iron oxide powder. The magnetic layer has a squareness in a thickness direction of 0.65 or more. In a differential curve obtained by differentiating a hysteresis curve in the thickness direction of the magnetic layer, two or more peaks are present. In a case where, out of peaks in the same direction among the above-described peaks, a local maximum of a largest peak in a magnetic field range of +500 oersted [Oe] or more is taken as P1 and a local maximum of a largest peak in a magnetic field range of −500 oersted [Oe] or more and less than +500 oersted [Oe] is taken as P2, a relationship below is satisfied:0.25≦P2 / P1≦0.60.

Owner:MAXELL HLDG LTD

Magnetic tape device and head tracking servo method

ActiveUS10008230B1Improve accuracyExact reproductionProtective coatings for layersFilamentary/web record carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes: a magnetic tape; and a servo head, in which the servo head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester on the non-magnetic support, the magnetic layer includes a servo pattern, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the magnetic layer after performing the vacuum heating with respect to the magnetic tape and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 9.0 nm.

Owner:FUJIFILM CORP

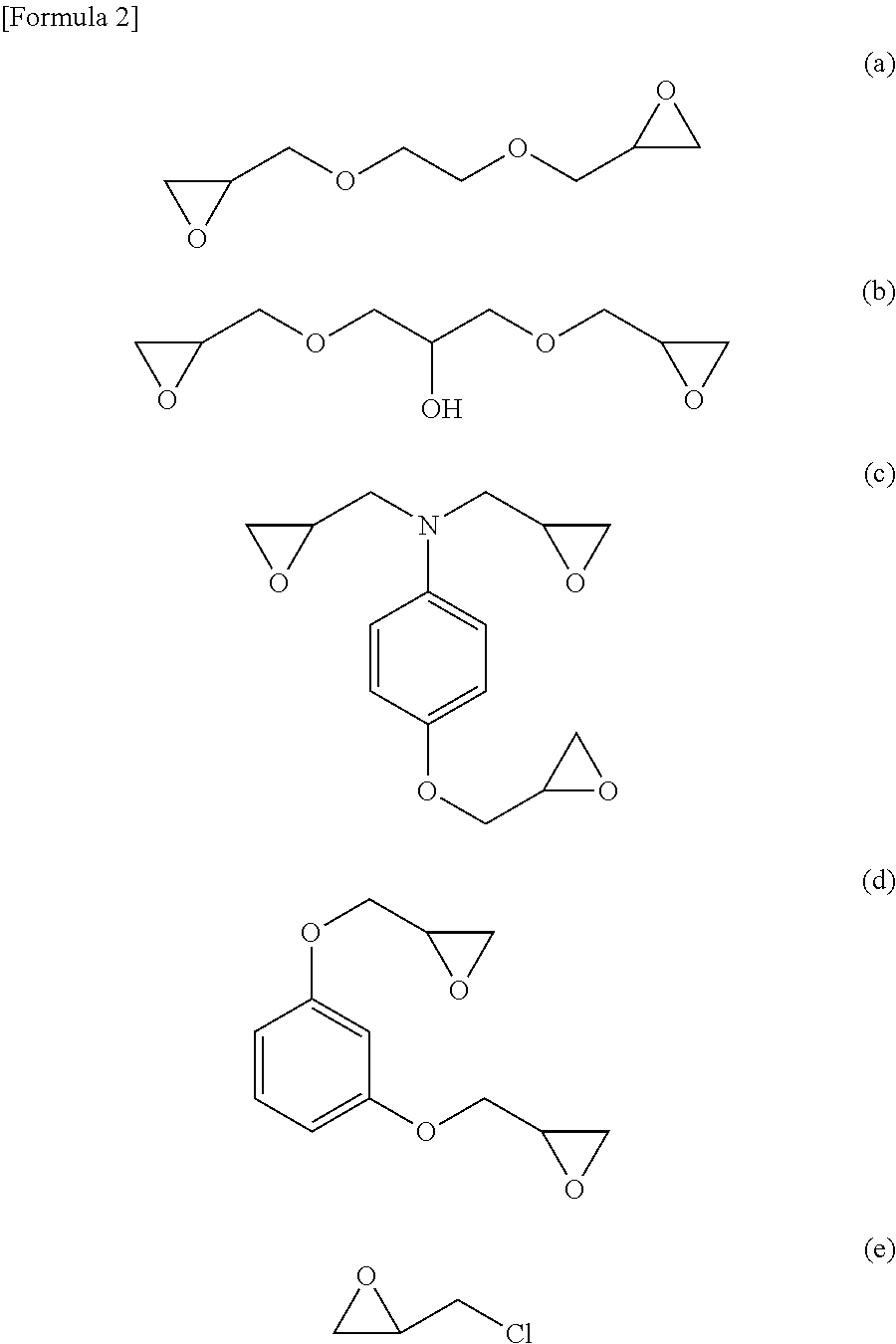

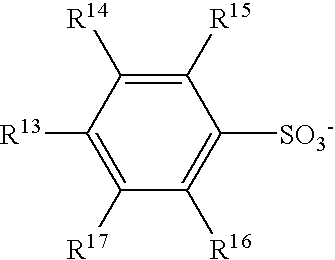

Ionic liquid, lubricant, and magnetic recording medium

ActiveUS20170058227A1Improve the lubrication effectMaintain good propertiesProtective coatings for layersRecord information storageConjugate acidIonic liquid

A lubricant including an ionic liquid, which includes a conjugate acid (B+) and a conjugate base (X−), and is protic, wherein the conjugate acid includes a straight-chain hydrocarbon group having 10 or more carbon atoms, and wherein the conjugate base is represented by the following general formula (1):where n is an integer of from 0 to 6 in the general formula (1).

Owner:DEXERIALS CORP

Ionic liquid, lubricant, and magnetic recording medium

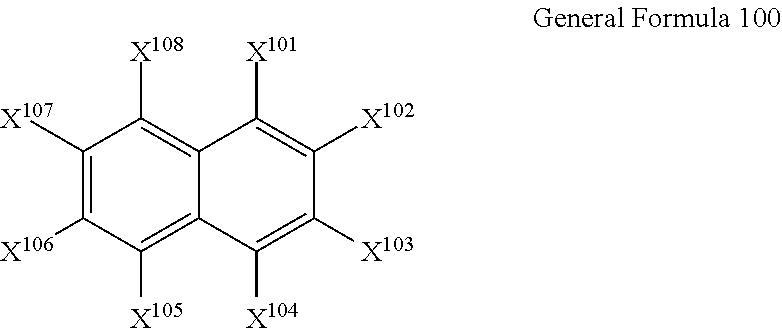

ActiveUS20170130156A1Improve the lubrication effectMaintain good propertiesOrganic chemistryProtective coatings for layersBenzeneHydrogen atom

A lubricant including: an ionic liquid, which includes a conjugate acid (B+) and a conjugate base (X−), and is protic, wherein the ionic liquid is represented by the following general formula (1), and wherein the conjugate base is a conjugate base of sulfonic acid, a conjugate base of sulfonimide, or a conjugate base of trisulfonylmethide:where R1 and R2 each represent a hydrogen atom or R1 and R2 form a benzene ring together with carbon atoms to which R1 and R2 are bonded, R3 represents a to straight-chain hydrocarbon group having 10 or more carbon atoms, and R4 represents a hydrogen atom or a hydrocarbon group in the general formula (1).

Owner:DEXERIALS CORP

Magnetic tape

ActiveUS20180240488A1Avoid it happening againAvoid edge damageProtective coatings for layersTape carriersMagnetic tapeNon magnetic

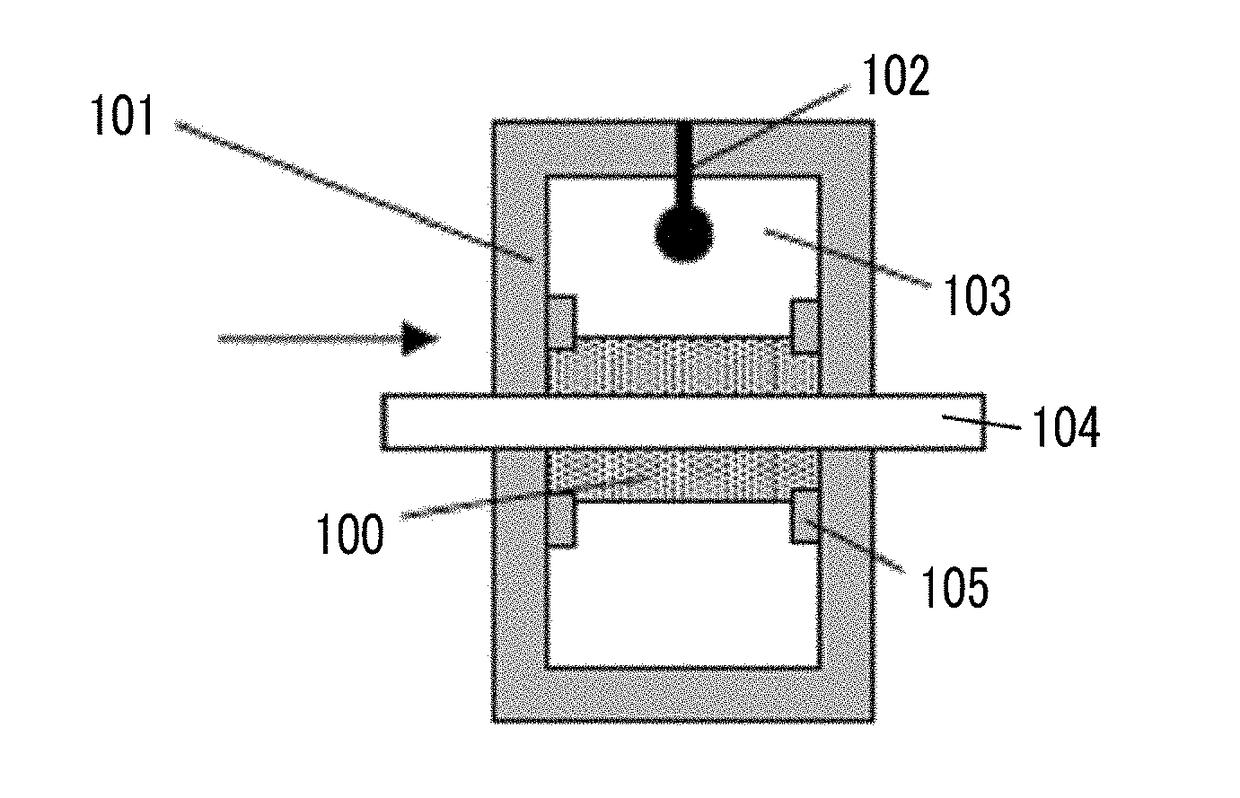

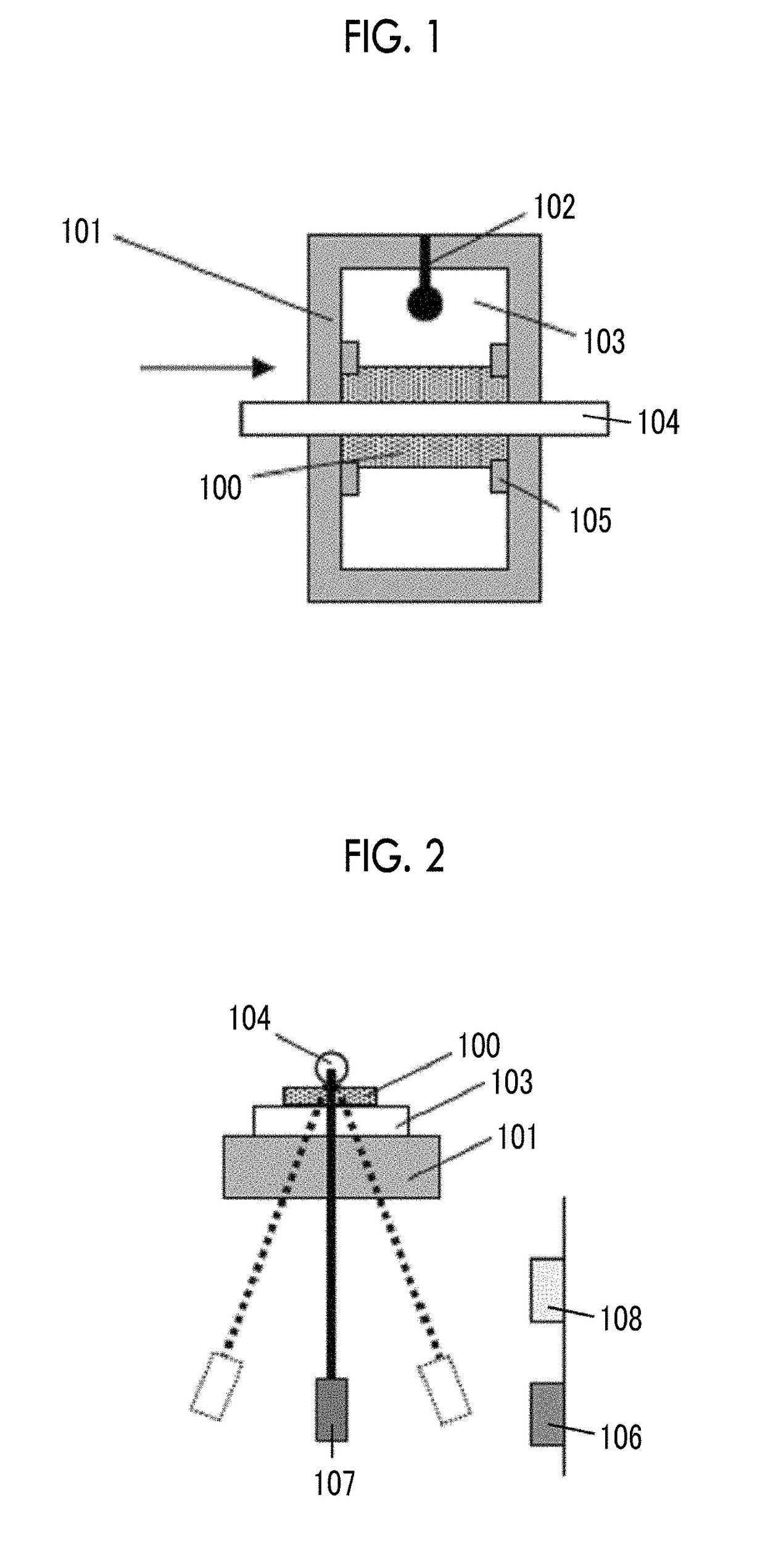

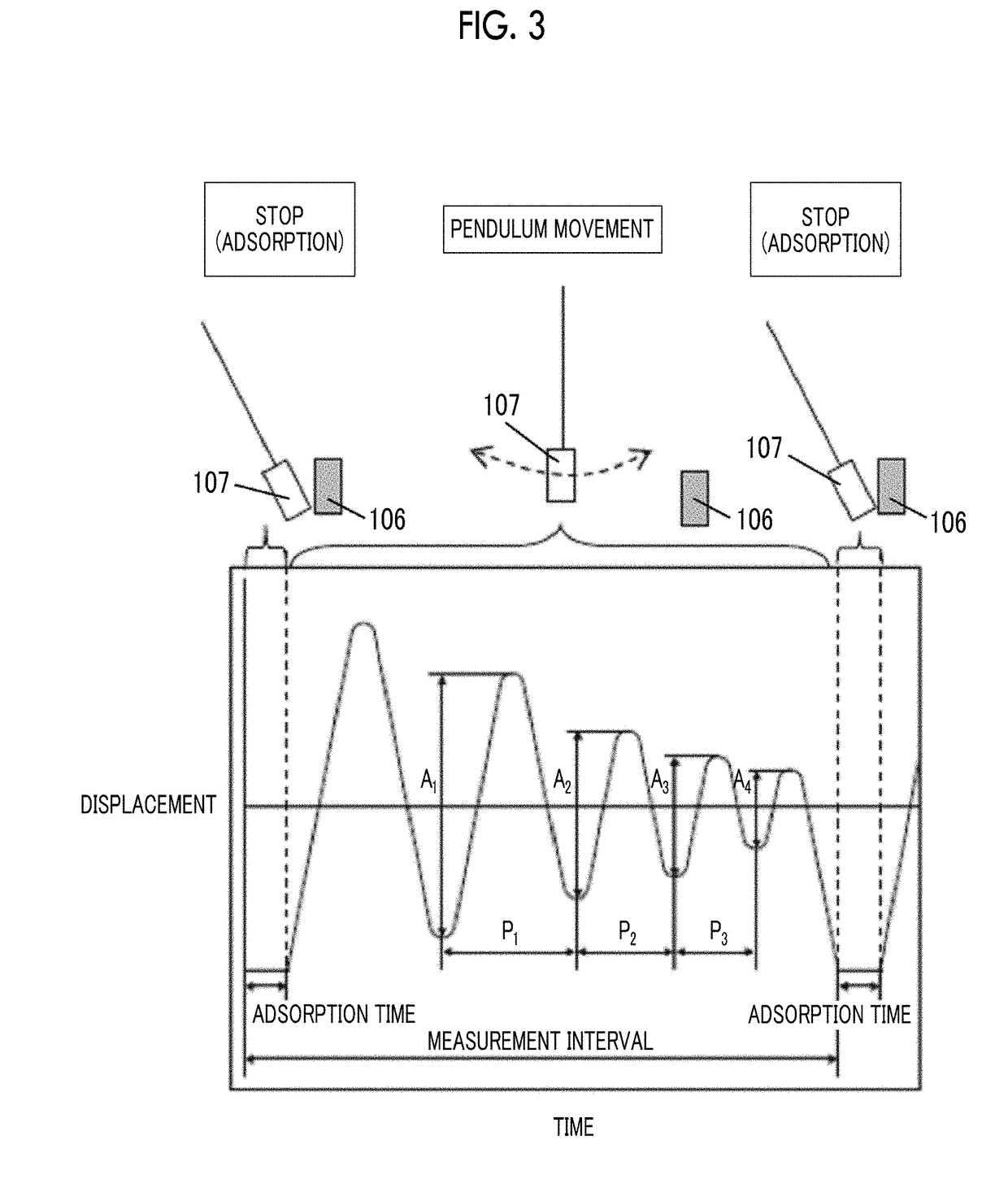

The magnetic tape includes a non-magnetic support; a magnetic layer including ferromagnetic powder and a binding agent on one surface side of the non-magnetic support; and a back coating layer including non-magnetic powder and a binding agent on the other surface side of the non-magnetic support, in which a thickness of the back coating layer is equal to or smaller than 0.30 μm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the back coating layer is equal to or smaller than 0.060, and a contact angle with respect to 1-bromonaphthalene measured regarding a surface of the back coating layer is 15.0° to 30.0°.

Owner:FUJIFILM CORP

Lubricant for magnetic disk and magnetic disk

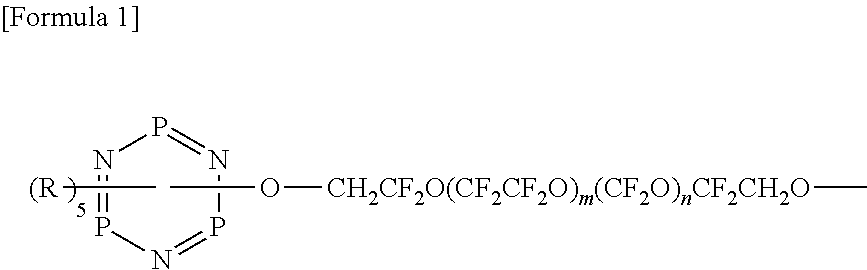

InactiveUS20120276417A1Improve heat resistanceHigh heat resistanceProtective coatings for layersMagnetic materials for record carriersHeat-assisted magnetic recordingPerfluoropolyether

A lubricant for a magnetic disk that is excellent in heat resistance and is suitably used in a magnetic disk to be mounted on a magnetic recording device of a thermally assisted magnetic recording system and a magnetic disk provided with a lubricant layer containing this lubricant. The lubricant for a magnetic disk contains a compound where perfluoropolyether groups each having a perfluoropolyether main chain in its structure and a phosphazene ring at an end are linked to each other through a linking group. The linking group is an aliphatic group or a phosphazene ring. In a magnetic disk having at least a magnetic recording layer, a protective layer, and a lubricant layer on a substrate, the lubricant layer contains the lubricant for a magnetic disk.

Owner:WESTERN DIGITAL TECH INC

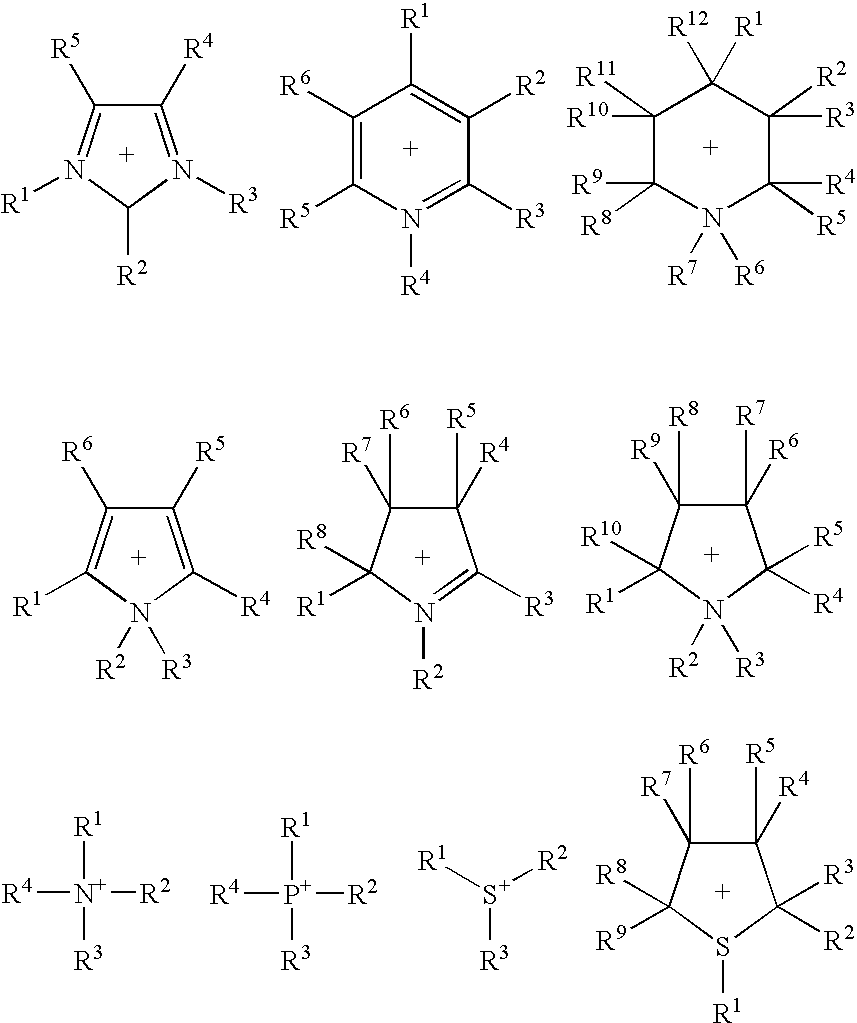

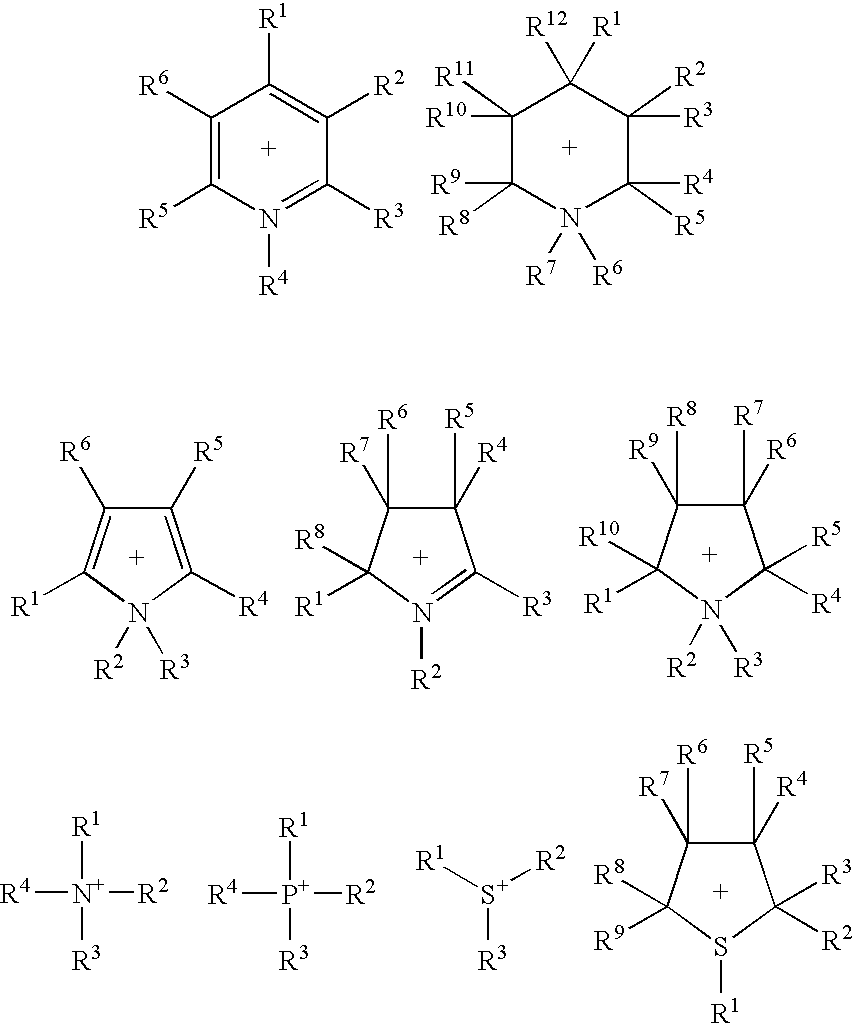

Lubricating oil

InactiveUS20070027038A1Low vapor pressureImprove heat resistanceOrganic chemistryProtective coatings for layersHeat resistanceBase oil

The invention provides a lube oil which exhibits low vapor pressure despite having low viscosity, is non-flammable, exhibits excellent heat resistance, has tribological characteristics equivalent to those of conventional hydrocarbon-based lube oils, and can be used for a long time under very severe conditions such as high temperature and vacuum. The lube oil contains, as a base oil, an ionic liquid formed of a cation and an anion and having an ion concentration of 1 mol / dm3 or more.

Owner:IDEMITSU KOSAN CO LTD +1

Magnetic disk comprising a first carbon overcoat having a high SP3 content and a second carbon overcoat having a low SP3 content

InactiveUS6855232B2Increase contentResists wearLayered productsVacuum evaporation coatingCarbon layerPerfluoropolyether

A method for making a magnetic disk comprises forming first and second protective carbon layers on a magnetic layer. The first protective carbon layer is predominantly SP3 carbon. The second protective carbon layer comprises about 50% or less SP3 carbon. The second protective carbon layer is very thin, e.g. between 0.1 and 1.0 nm thick. A lubricant layer (e.g. a perfluoropolyether lubricant) is applied to the second protective carbon layer. The second protective carbon layer facilitates improved cooperation between lubricant and the disk.

Owner:WESTERN DIGITAL TECH INC

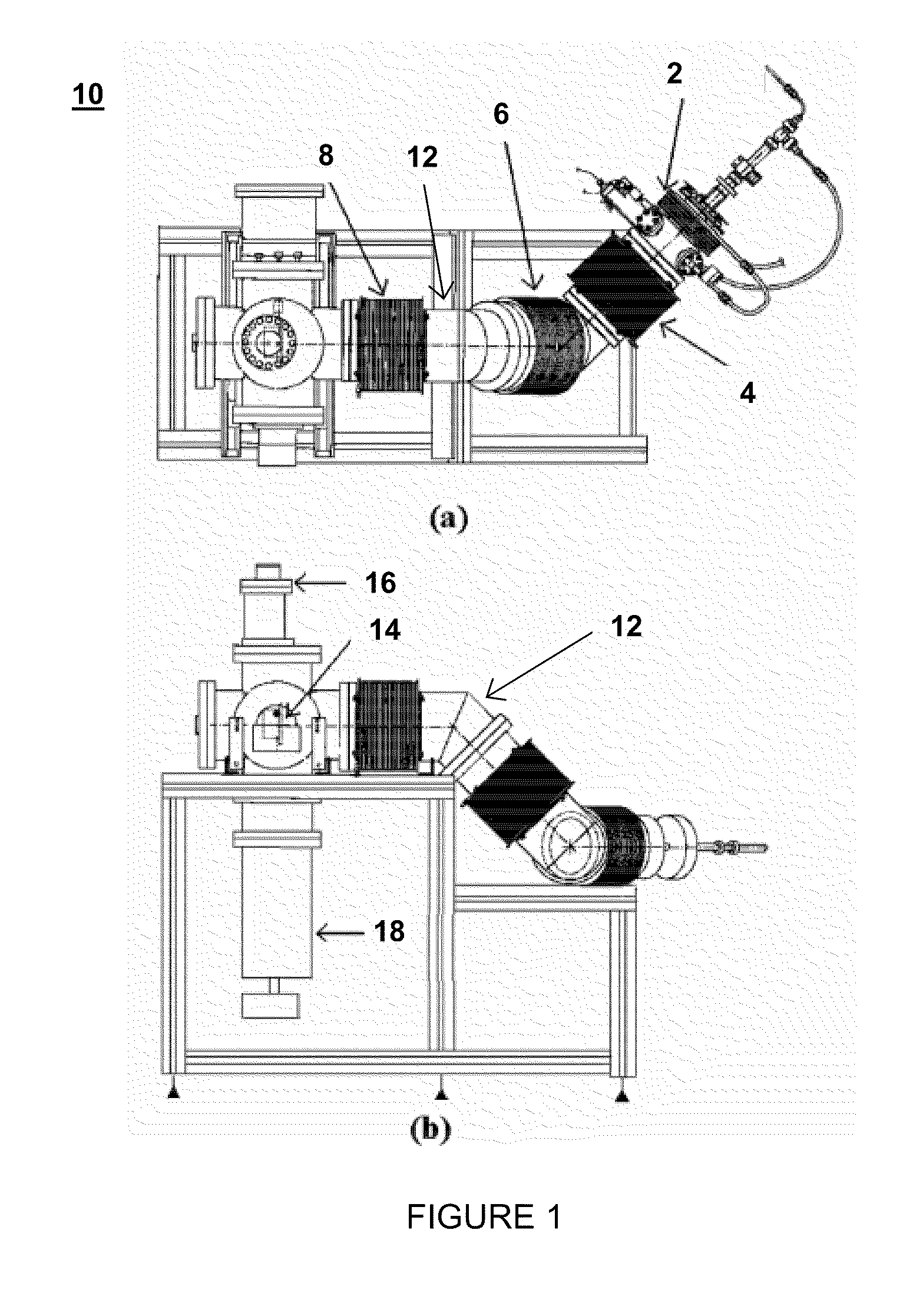

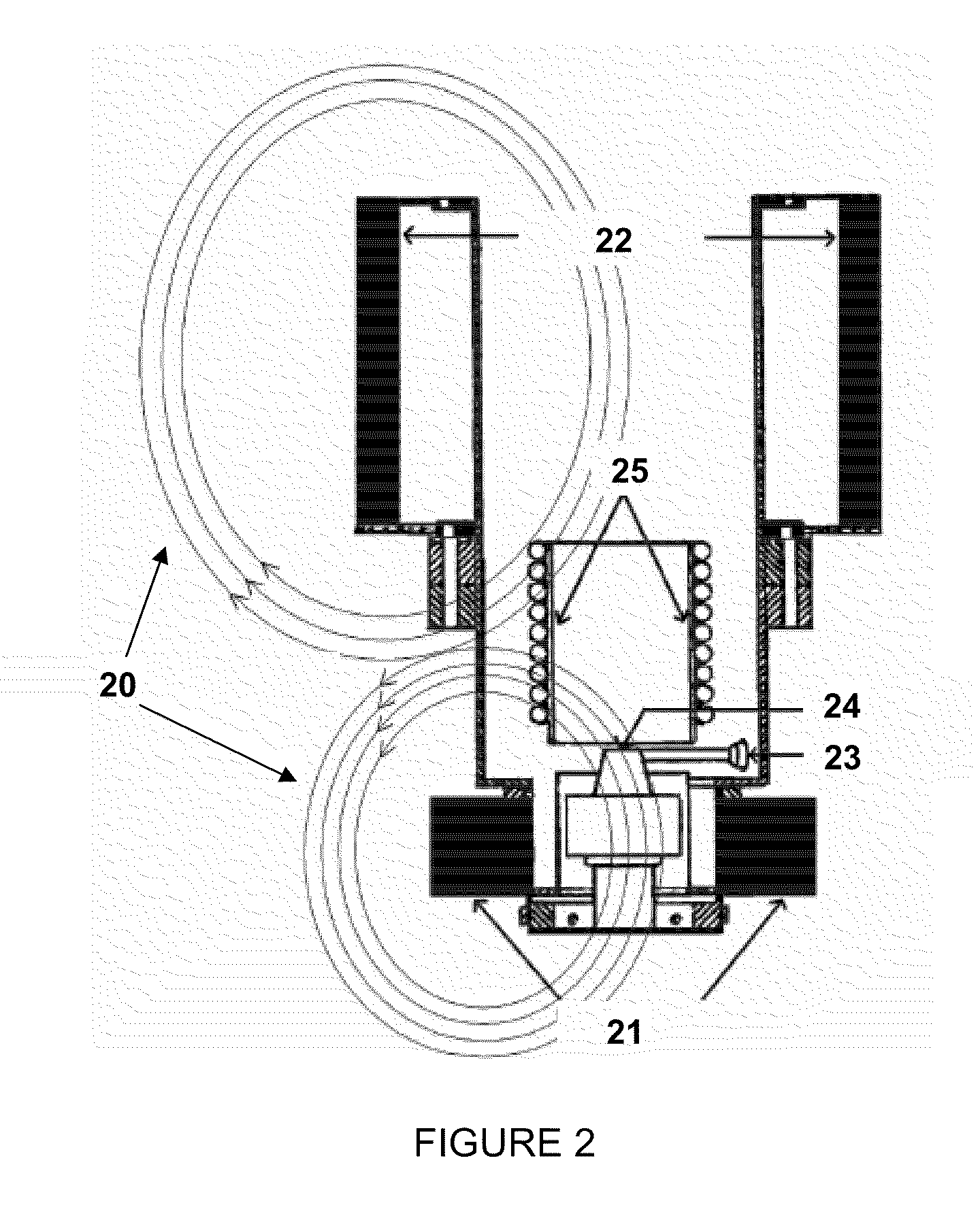

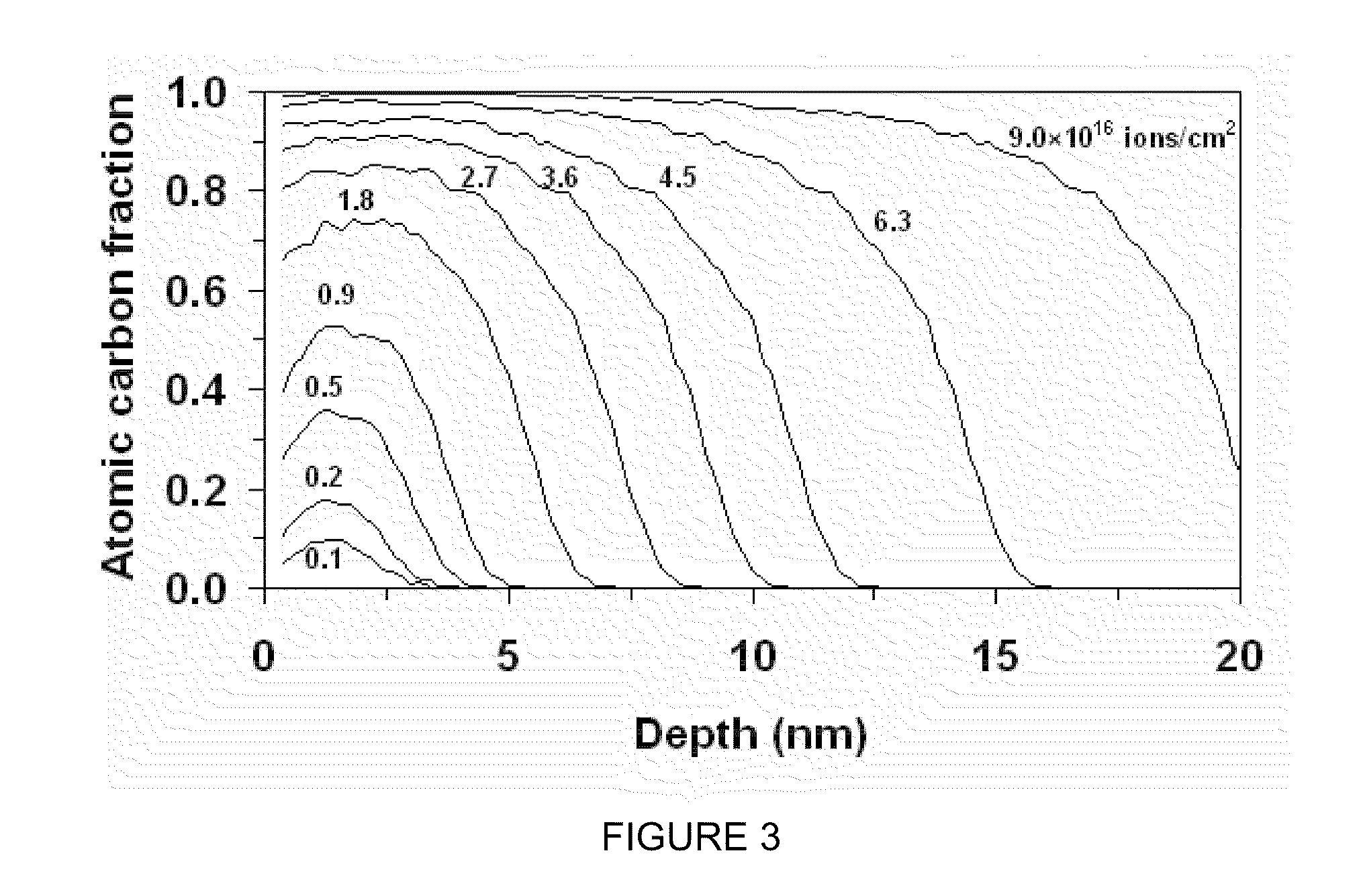

Systems and Methods for Surface Modification by Filtered Cathodic Vacuum Arc

InactiveUS20100190036A1Protective coatings for layersElectric discharge tubesSurface modificationMaterials science

Provided are filtered cathodic vacuum arc systems useful for modifying a surface of a substrate (e.g. depositing a thin film of a material onto a surface of a substrate and / or implanting a material into the near-surface region of a substrate). The systems are configured to stabilize a do arc discharge plasma from an arc source. Also provided are methods for modifying a surface of a substrate, which in some cases includes depositing a material onto a surface of a substrate, in some cases includes implanting a material into the near-surface region of a substrate, and in some cases includes both depositing a material onto a surface of a substrate and implanting a material into the near-surface region of a substrate using the subject cathodic arc systems. In addition, magnetic recording media produced by the subject systems and methods are provided.

Owner:NAT UNIV OF SINGAPORE +1

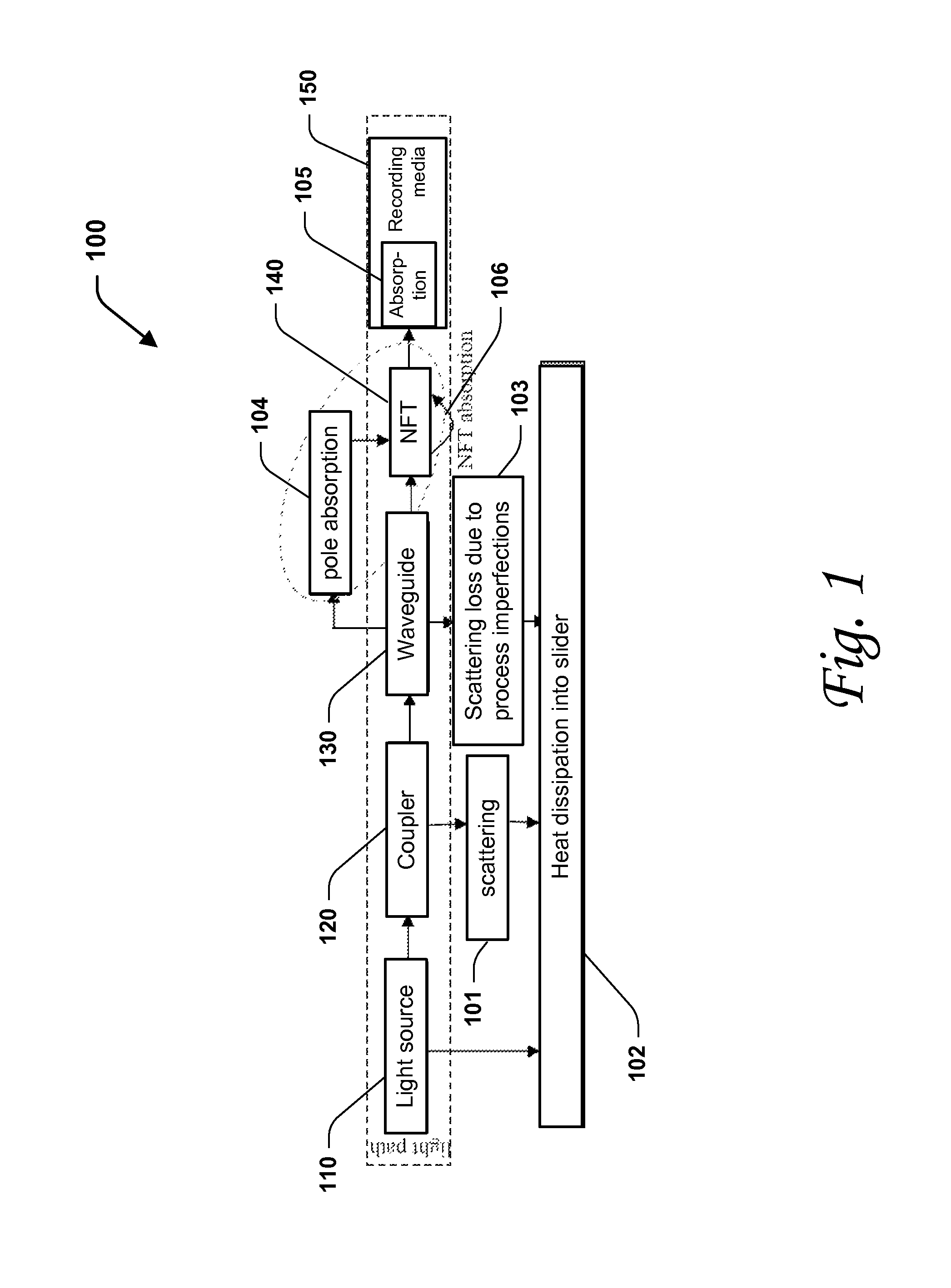

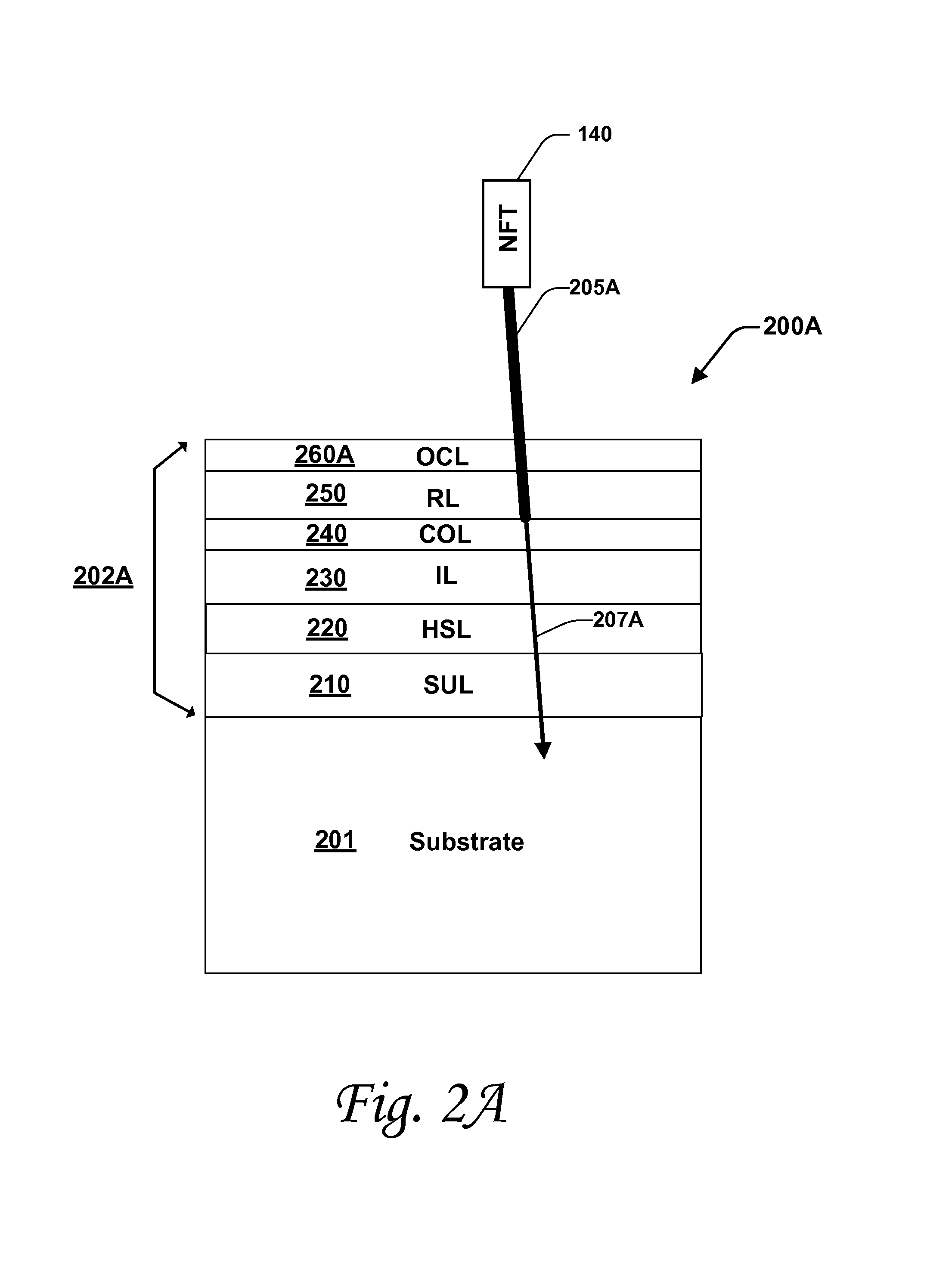

Absorption enhanced media for energy assisted magnetic recording

ActiveUS8570844B1Improve energy absorptionEnhanced electromagnetic absorptionDifferent record carrier formsCombination recordingOptoelectronicsElectromagnetic radiation

A magnetic recording media is disclosed. The media comprises a substrate, a recording layer disposed over the substrate, and a metallic layer disposed between the recording layer and the substrate. The recording layer is configured to receive an electromagnetic radiation, absorb a first portion of the electromagnetic radiation, and transmit a second portion of the electromagnetic radiation. The metallic layer comprises a non-magnetic metal and configured to reflect at least some of the second portion of the electromagnetic radiation towards the recording layer.

Owner:WESTERN DIGITAL TECH INC

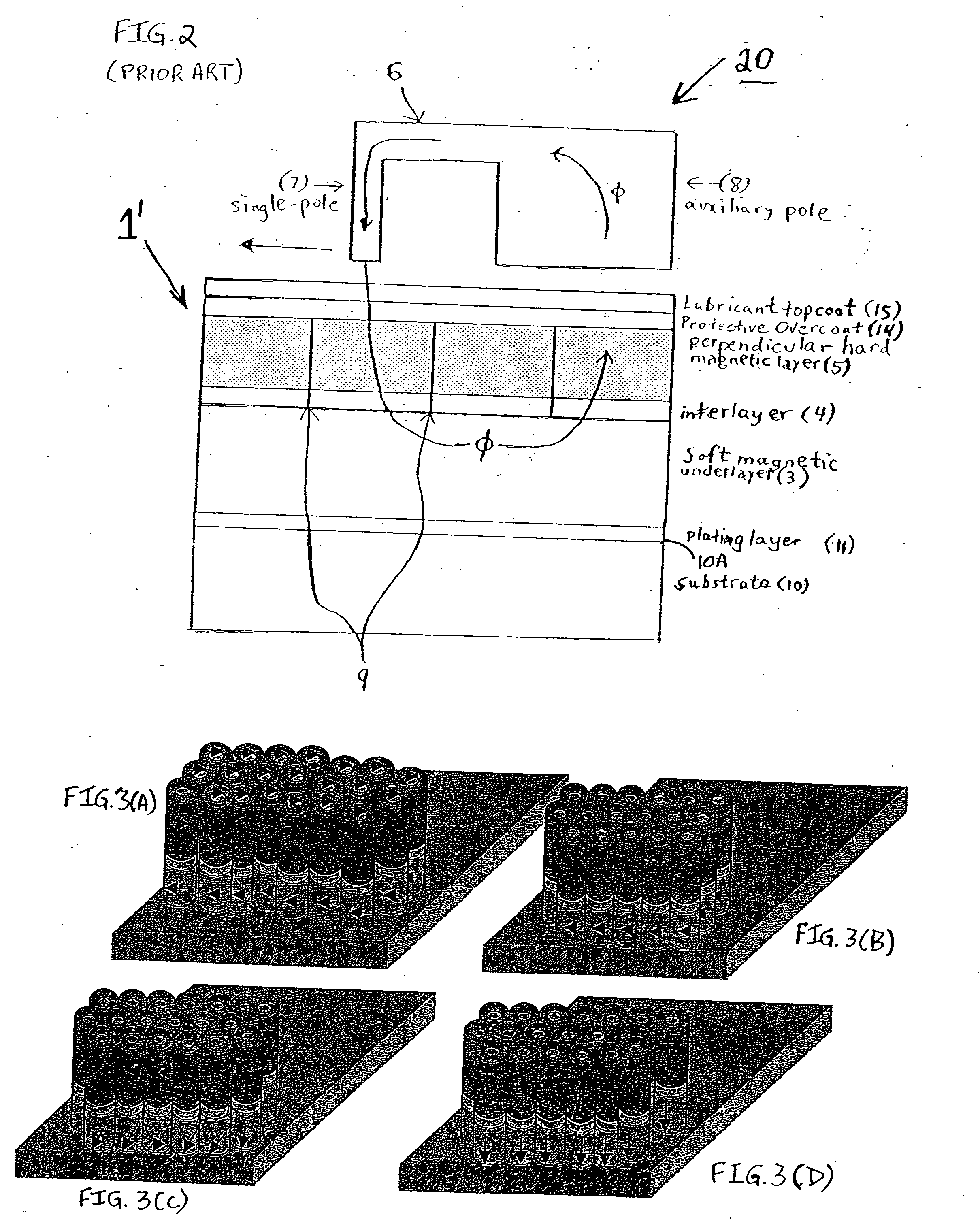

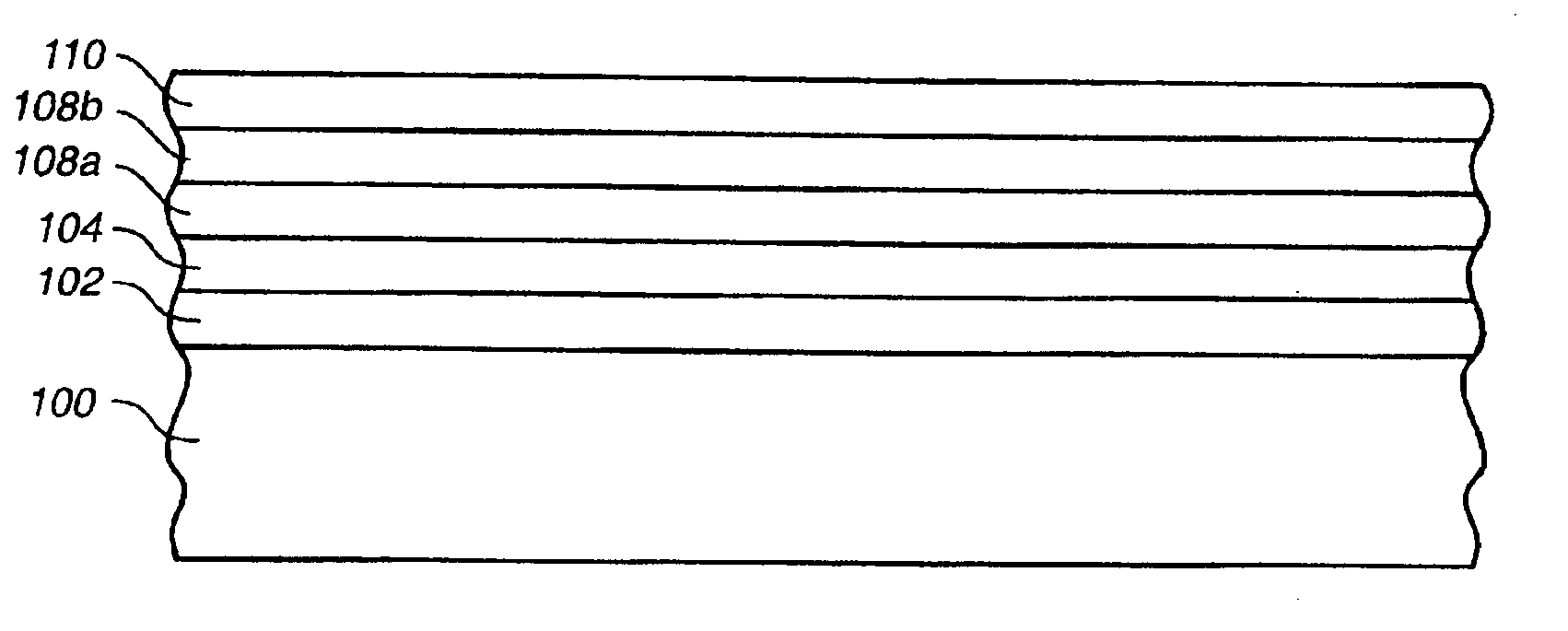

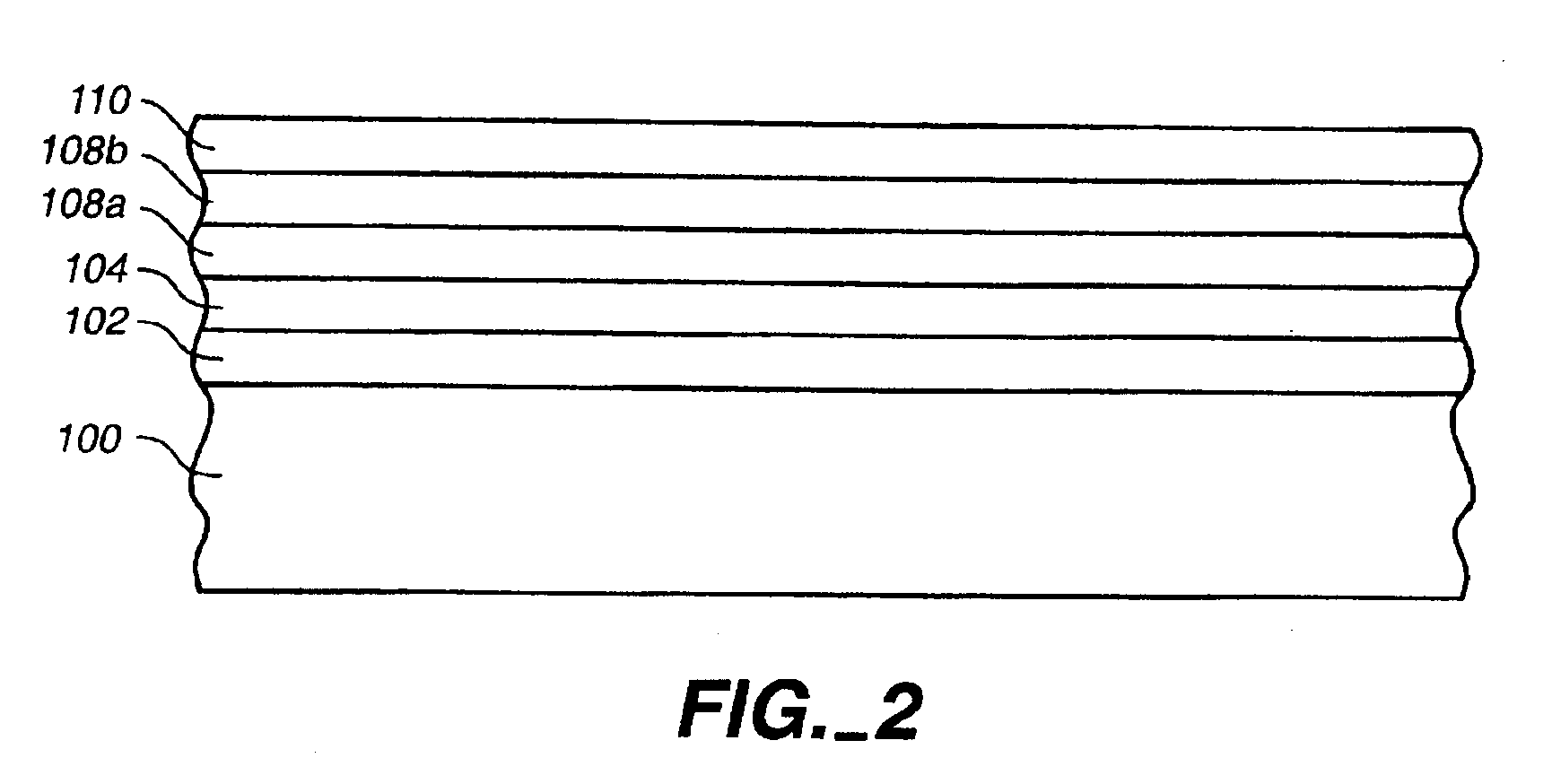

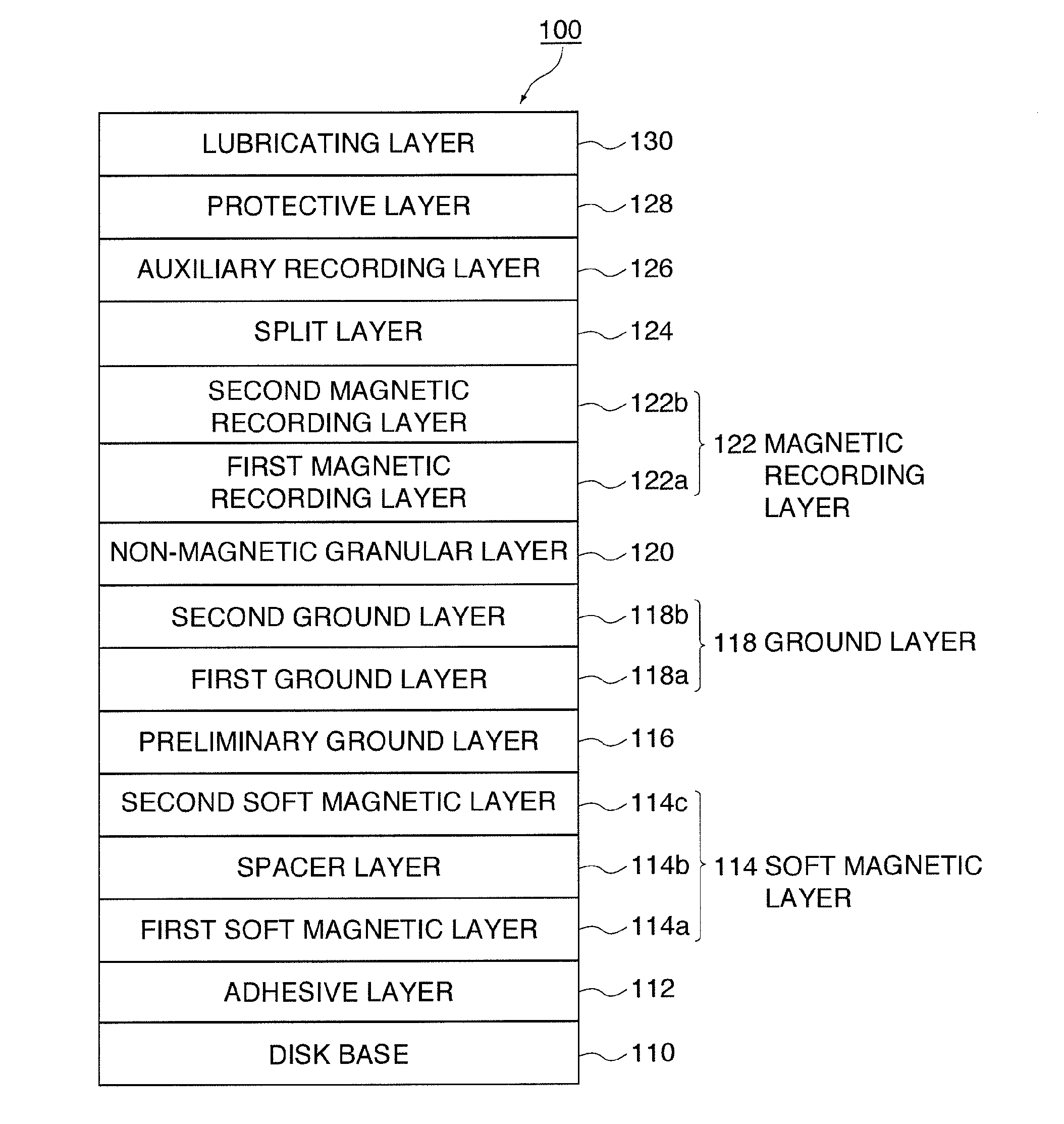

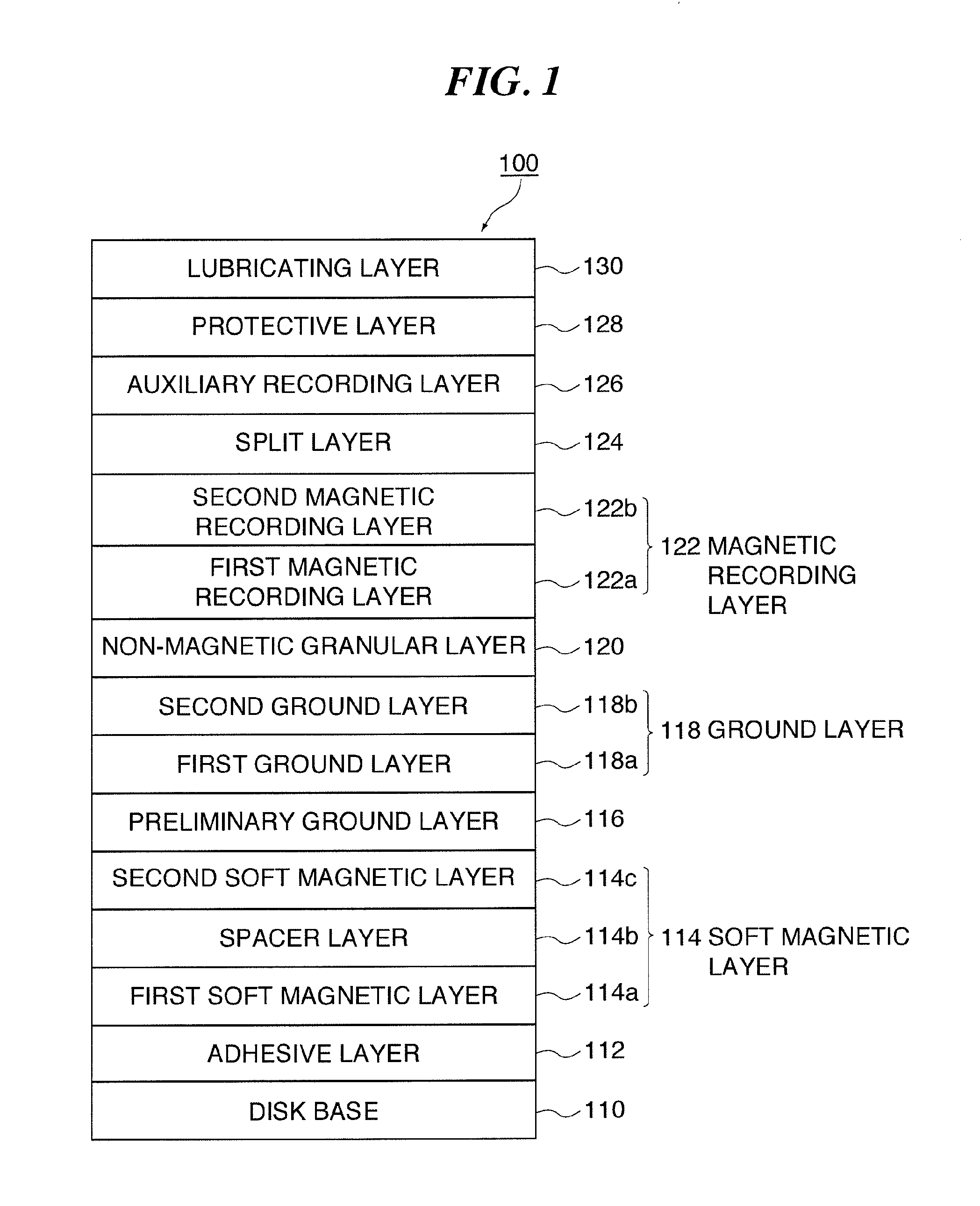

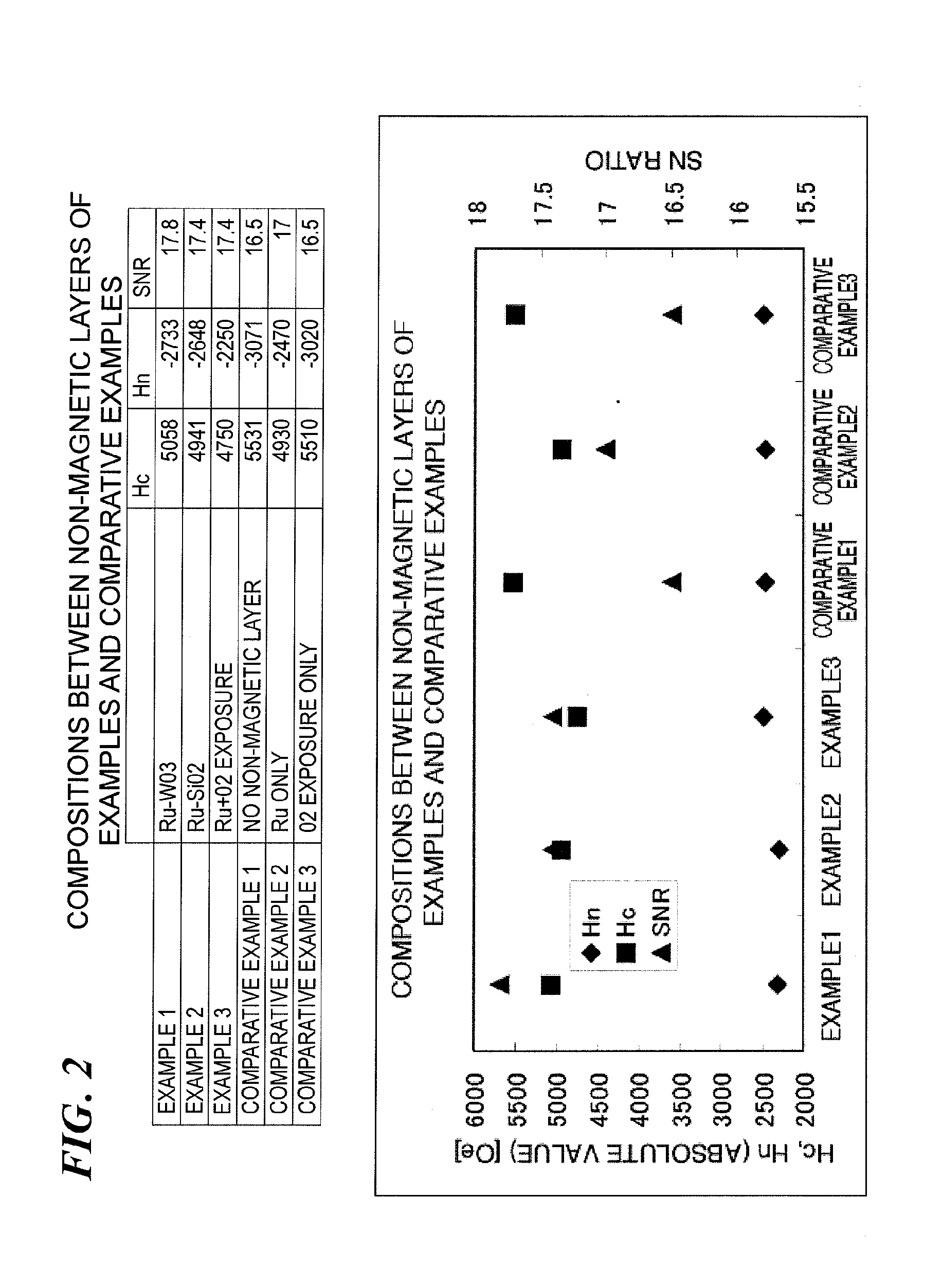

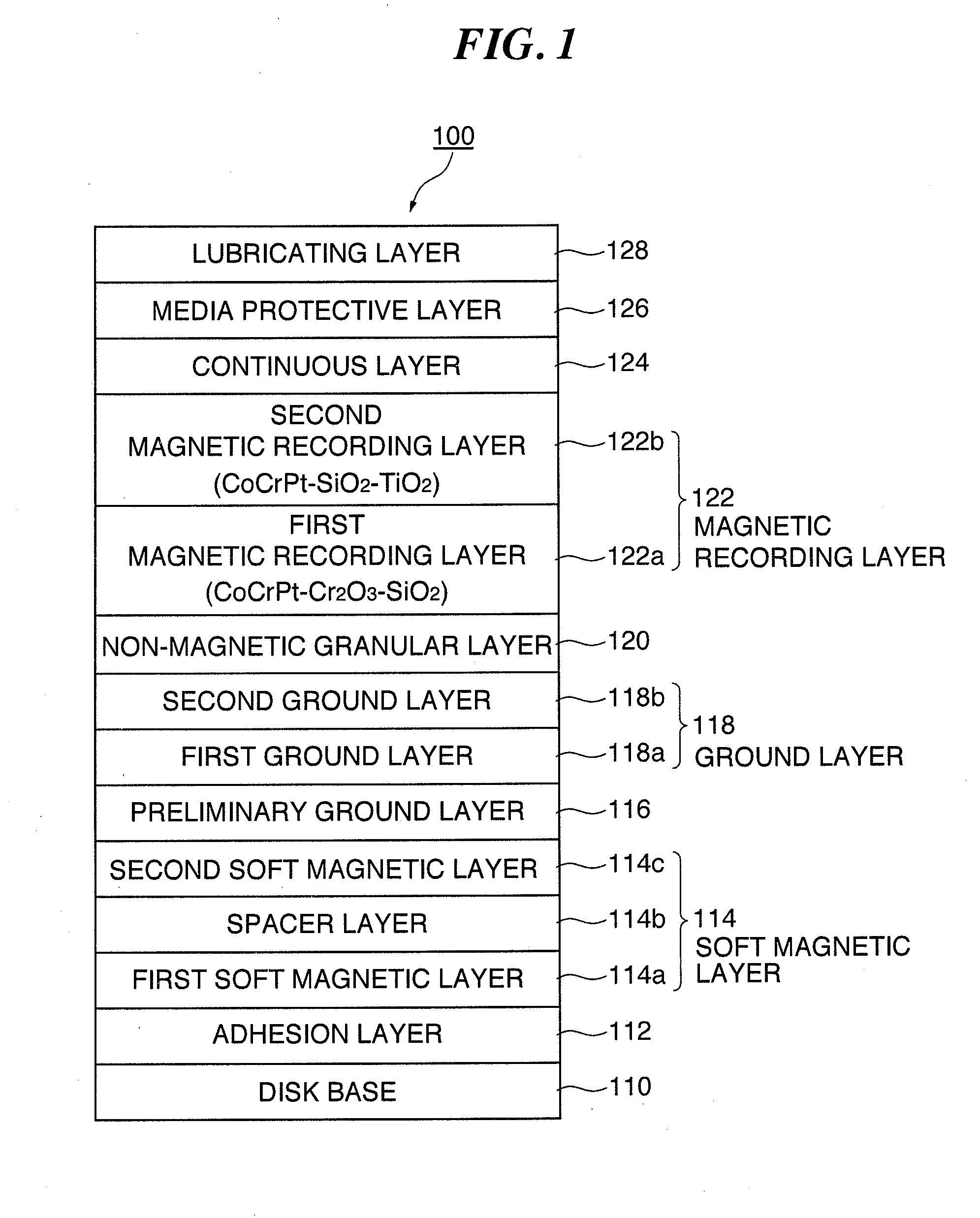

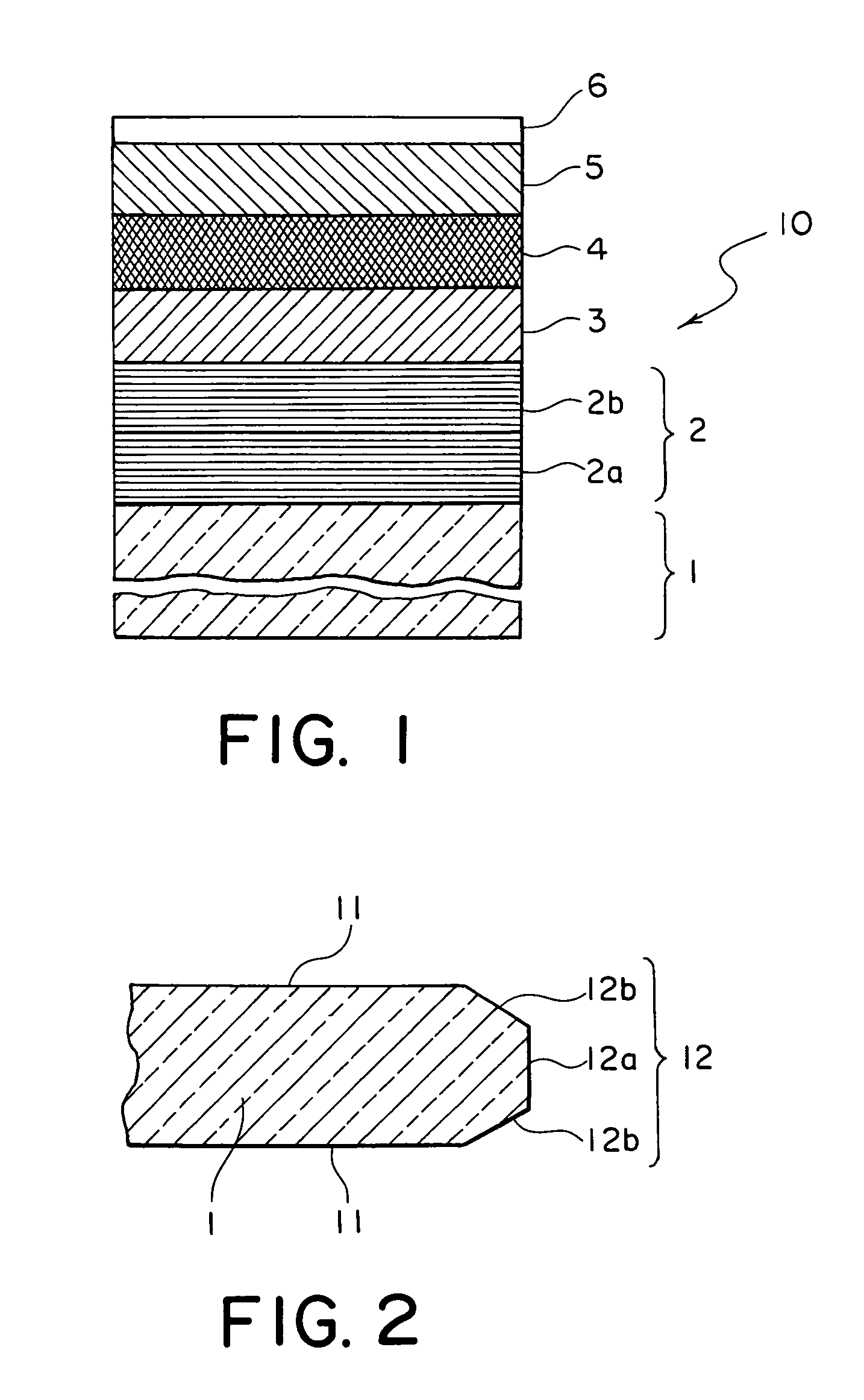

Perpendicular magnetic recording medium and process for manufacture thereof

ActiveUS20110212346A1Improve coercive forceIncrease forceProtective coatings for layersPretreated surfacesIn planeRecording density

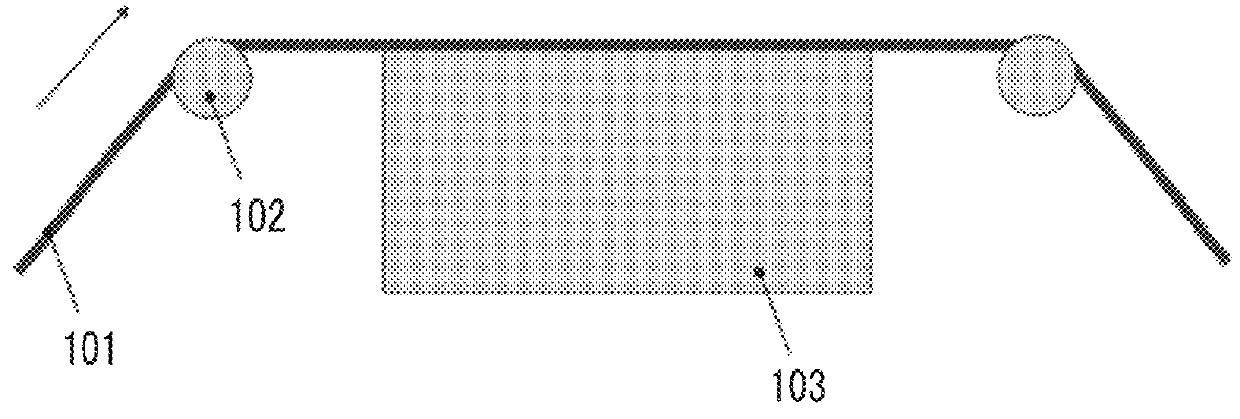

An object of the present invention is to provide a perpendicular magnetic recording medium the SNR of which is improved by reducing noise thought to be due to an auxiliary recording layer so that a higher recording density can be achieved, and a method of manufacturing the same.In order to achieve the above object, a representative configuration of a perpendicular magnetic recording medium 100 according to the present invention includes, on a base, at least a magnetic recording layer 122 having a granular structure in which a non-magnetic grain boundary portion is formed between crystal particles grown in a columnar shape; a non-magnetic split layer 124 disposed on the magnetic recording layer 122 and containing Ru and oxygen; and an auxiliary recording layer 126 that is disposed on the split layer 124 and that is magnetically approximately continuous in an in-plane direction of a main surface of the base 110.

Owner:WESTERN DIGITAL TECH INC

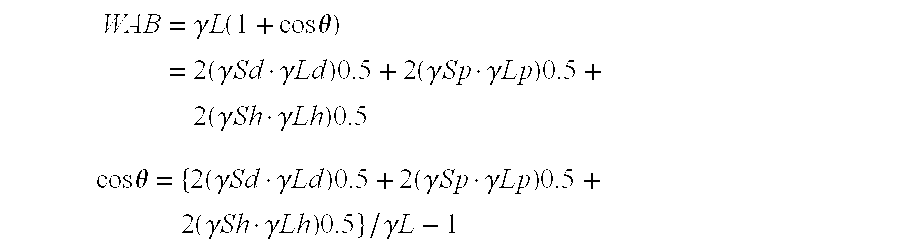

Solid body surface evaluation method, magnetic disk evaluation method, magnetic disk, and manufacturing method thereof

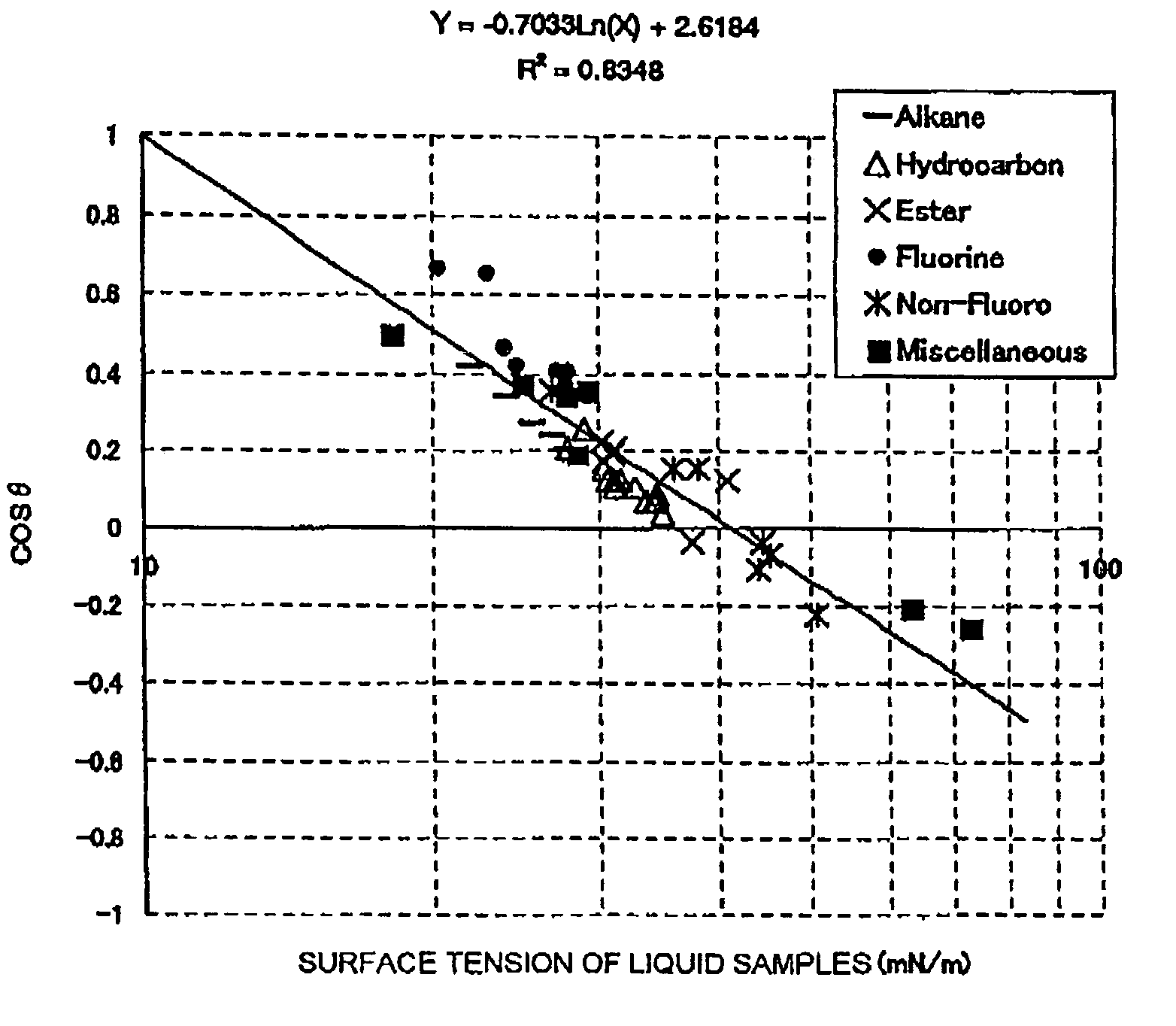

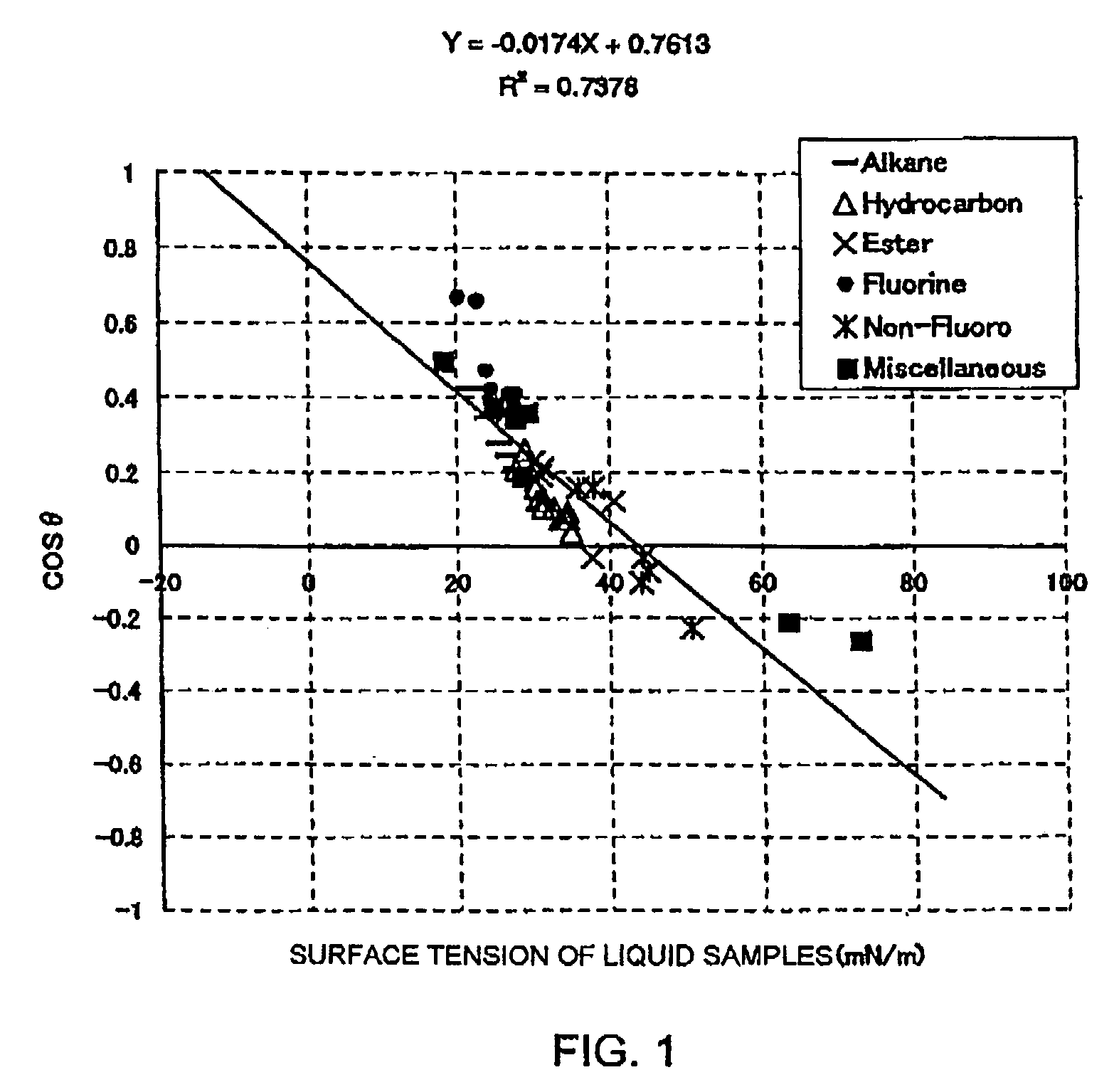

InactiveUS7174775B2Effective tensionSolve the real problemVehicle testingElectronic circuit testingBiomedical engineeringBody surface

In a method of evaluating surface tension of a solid body surface, selection is made of at least three liquid samples having different surface tensions, and contact angles between the respective liquid samples and the solid body surface are measured. Thereby, a correlation between cosines (Y) of the contact angles and surface tensions (X) of the liquid samples is derived as a logarithmic function. Surface tension of the solid body surface is evaluated by the use of a value of X that is calculated by substituting 1 for Y in the correlation. When evaluated by the foregoing evaluation method, a magnetic disk has a surface where the value of X, when 1 is substituted for Y, is greater than 0 and no greater than 17 mN / m.

Owner:WD MEDIA SINGAPORE PTE

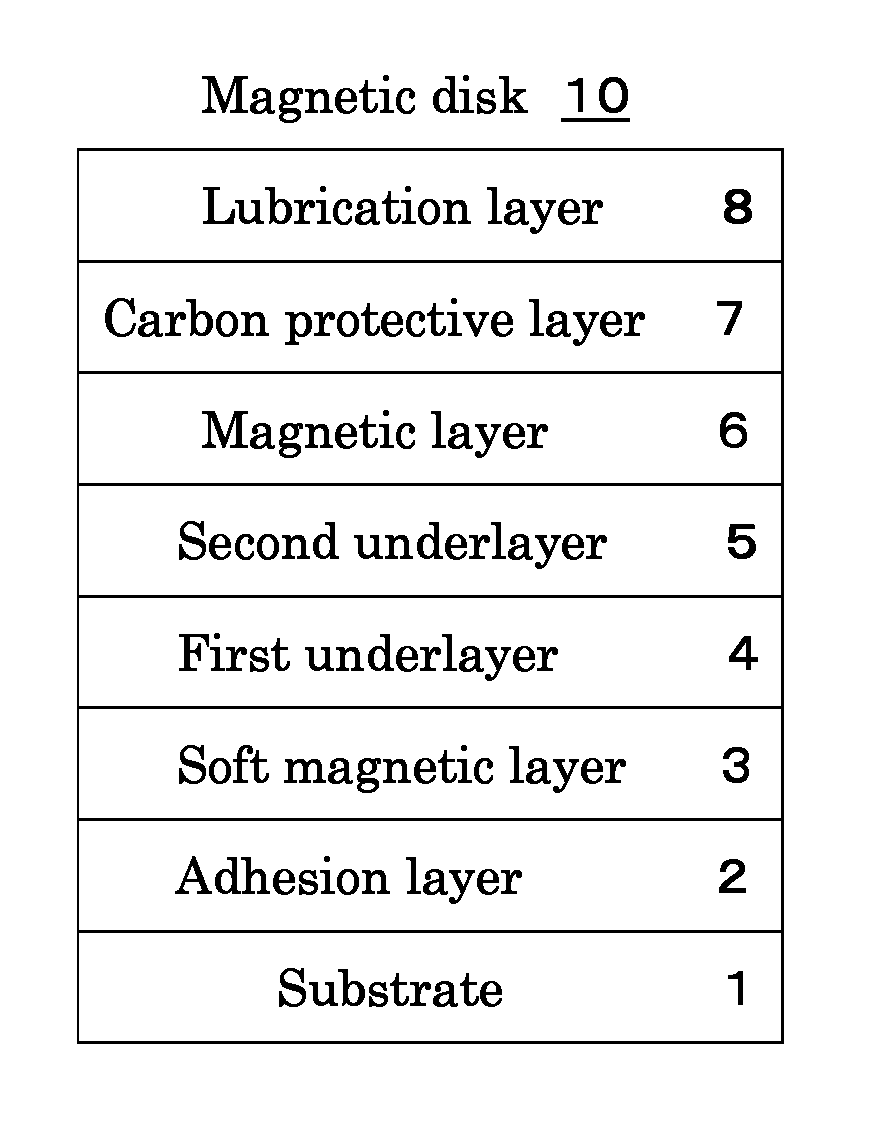

Magnetic disk and method of producing the same

ActiveUS7166319B2Excellent in LUL durabilityAvoid it happening againProtective coatings for layersRecord information storageAlcoholGas phase

A magnetic disk includes a substrate on which a nonmagnetic metal layer, a magnetic layer, a carbon-based protection layer, an alcohol-based coupling layer, and a lubrication layer successively formed thereon. The lubrication layer contains a hydroxyl- or a carboxyl-modified compound as a lubricating material. The alcohol-based coupling layer contains, for example, lower alcohol as a main component and is deposited on the carbon-based protection layer, for example, by vapor deposition. The alcohol-based coupling layer may be replaced by a layer containing lower alcohol. The carbon-based protection layer may be deposited by plasma CVD.

Owner:WESTERN DIGITAL TECH INC

Magnetic disk and method of manufacturing same

Owner:WD MEDIA SINGAPORE PTE

Lubricating compositions containing aromatized 1,2-dihydro-2,2,4-trimethylquinoline polymers

InactiveUS6235686B1Improve performanceOrganic chemistryProtective coatings for layersPolymerBase oil

Lubricating compositions containing a major amount of a base oil and an effective amount of an additive component having at least one compound of formula (I):where R is one of the following radicals, methyl, ethyl, n-propyl, i-propyl or a combination thereof, and n=0-8. In a preferred embodiment, R is a methyl radical and n=2-3. The lubricating compositions provide improved lubricating performance, particularly by inhibiting oxidation and improving thermal stability.

Owner:VANDERBILT CHEM LLC

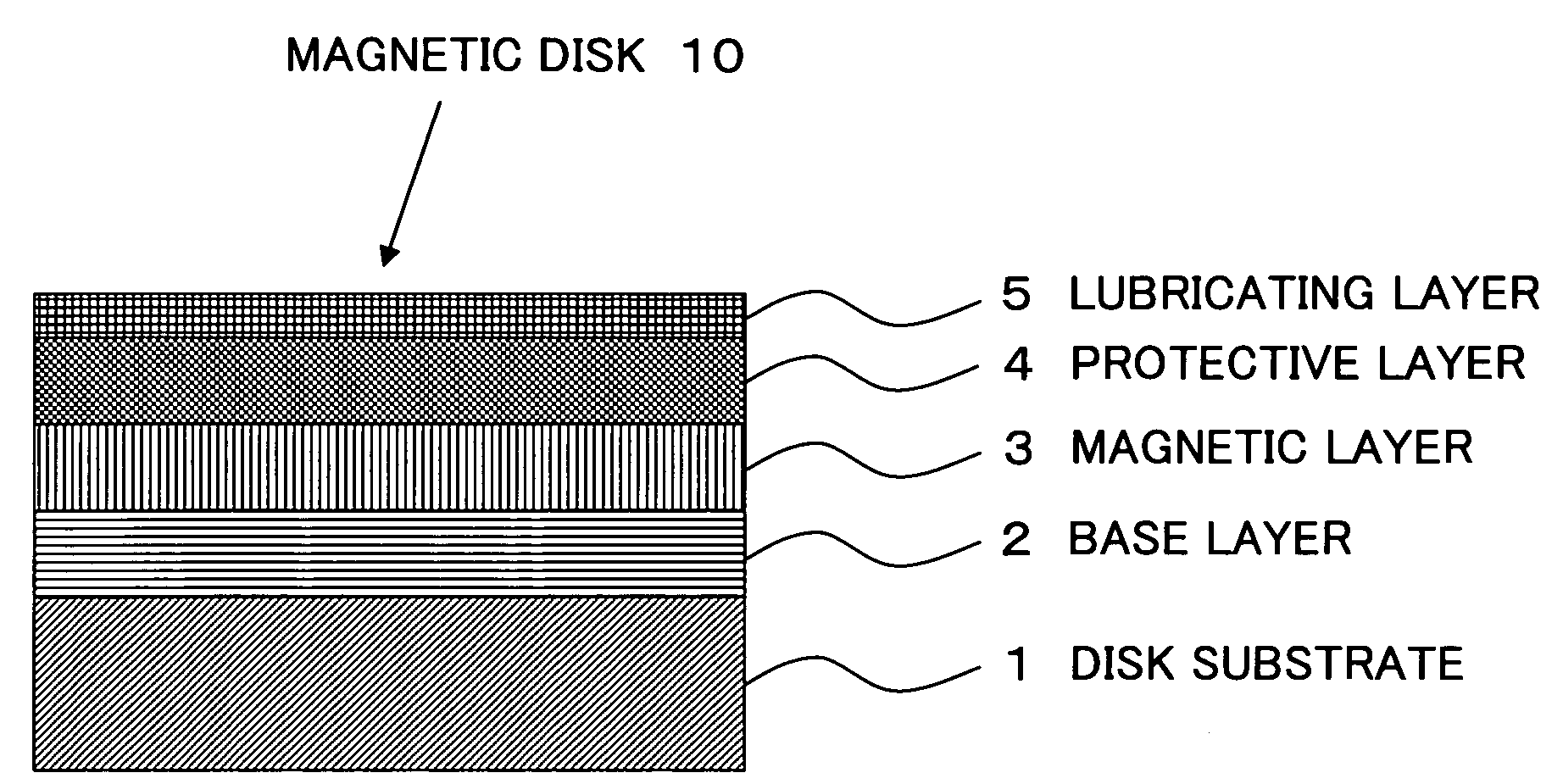

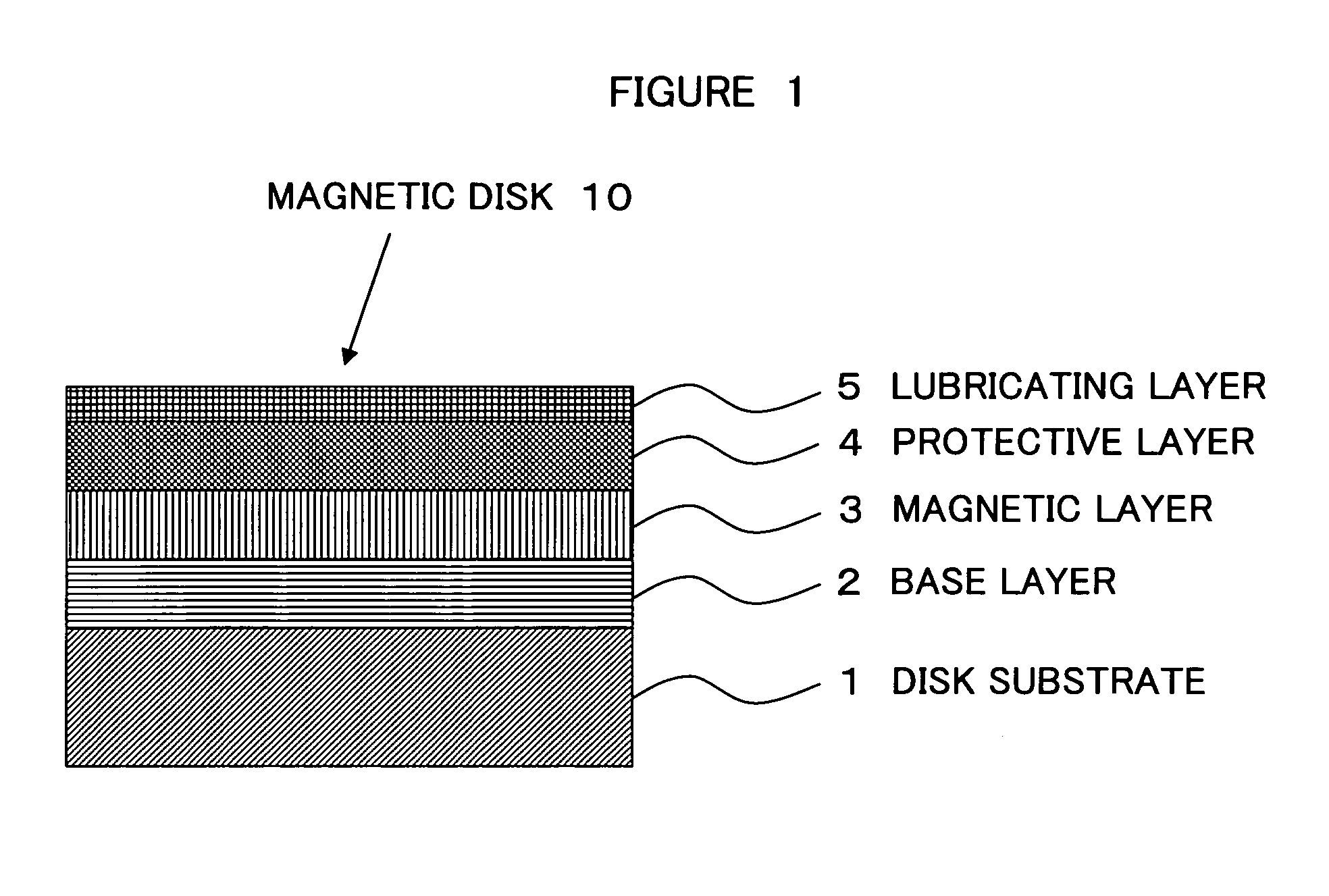

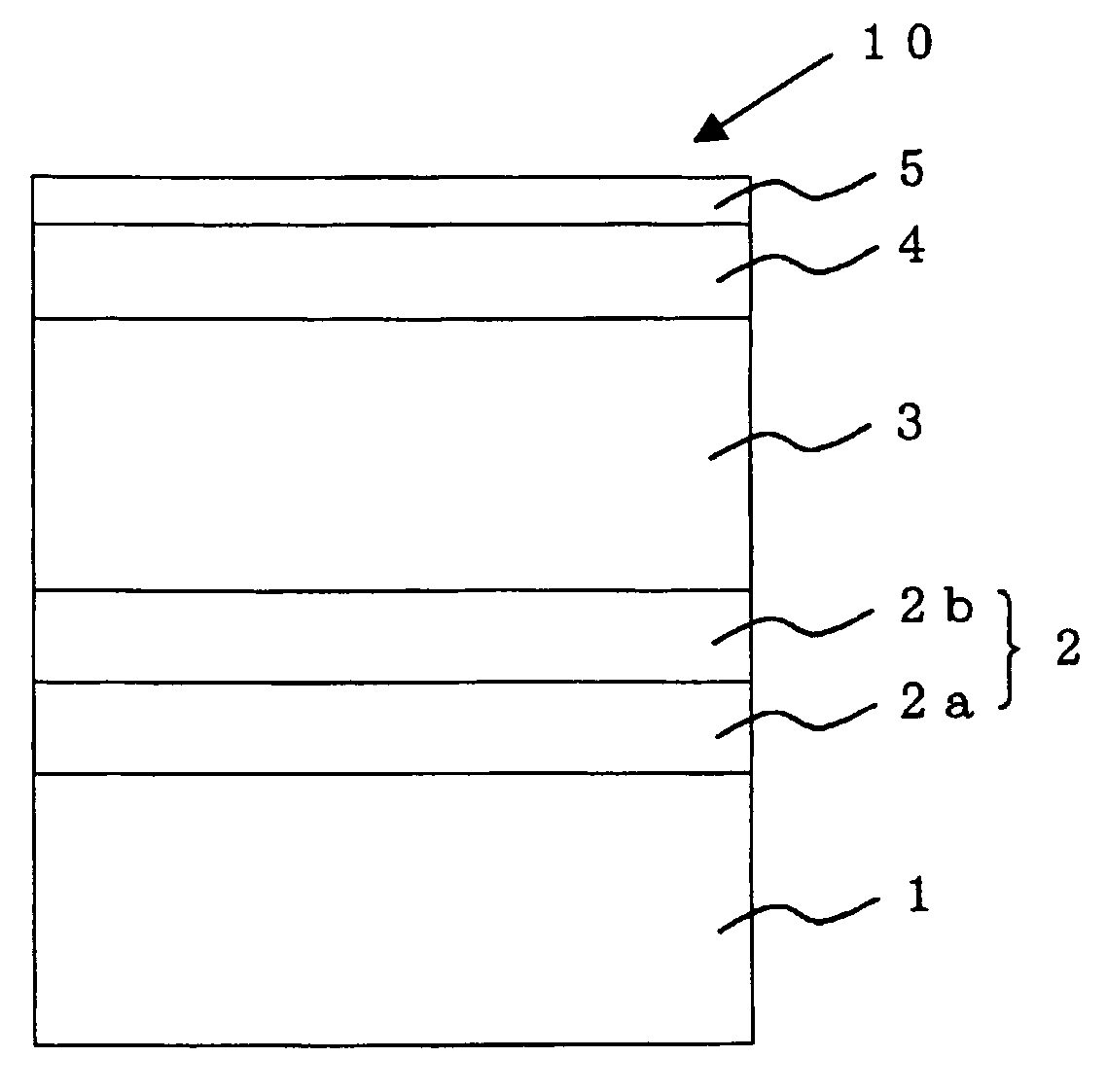

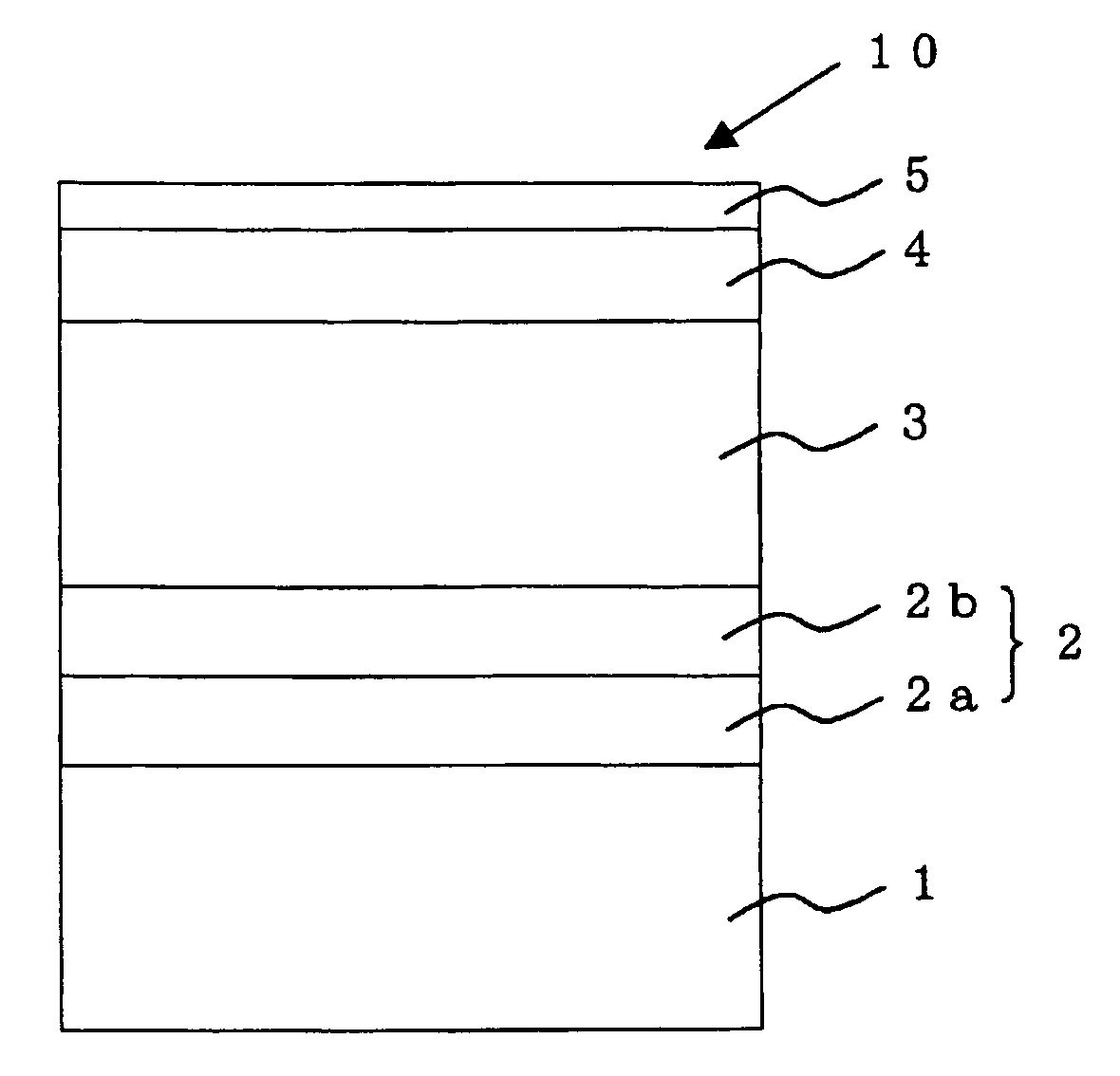

Magnetic recording medium

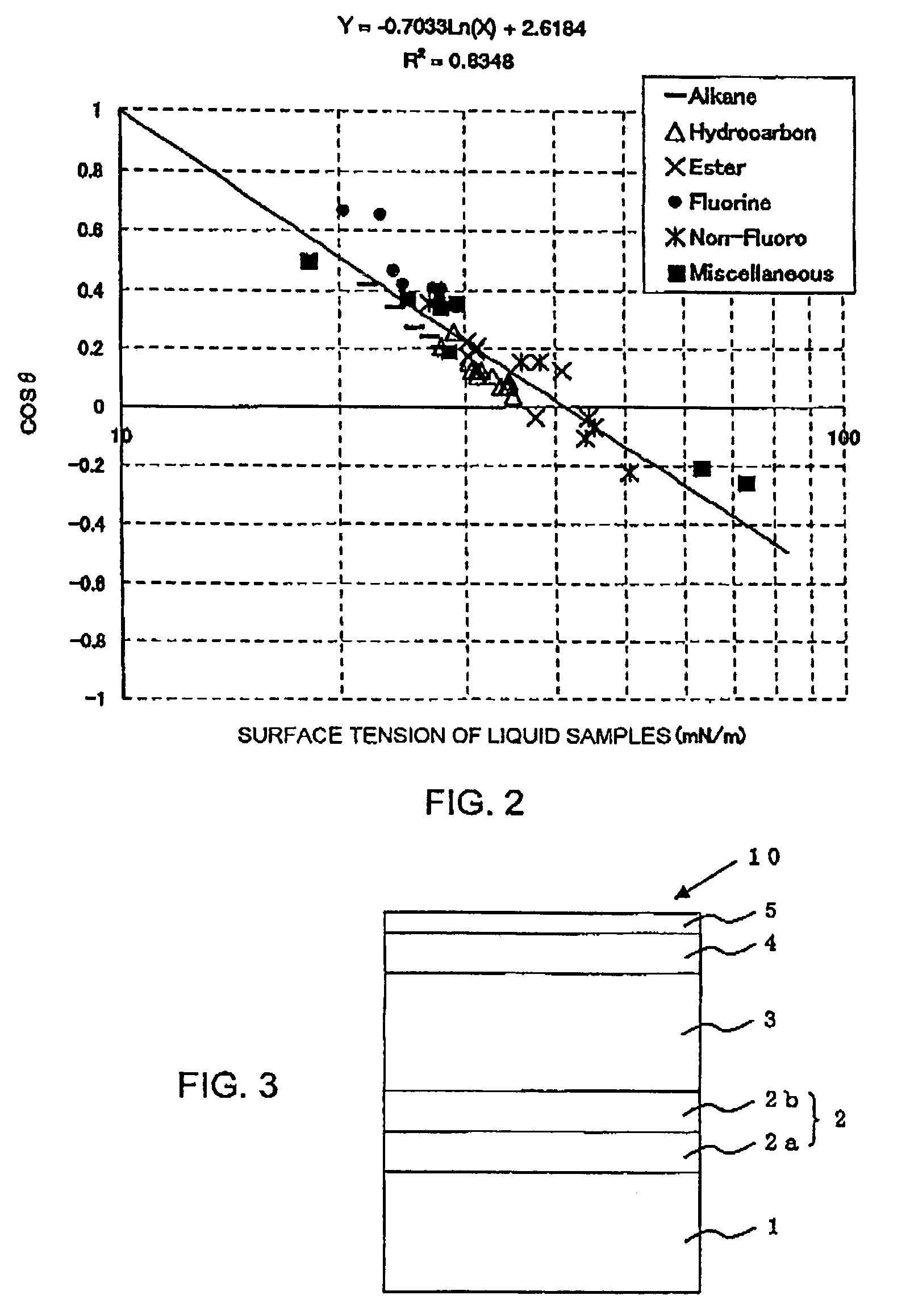

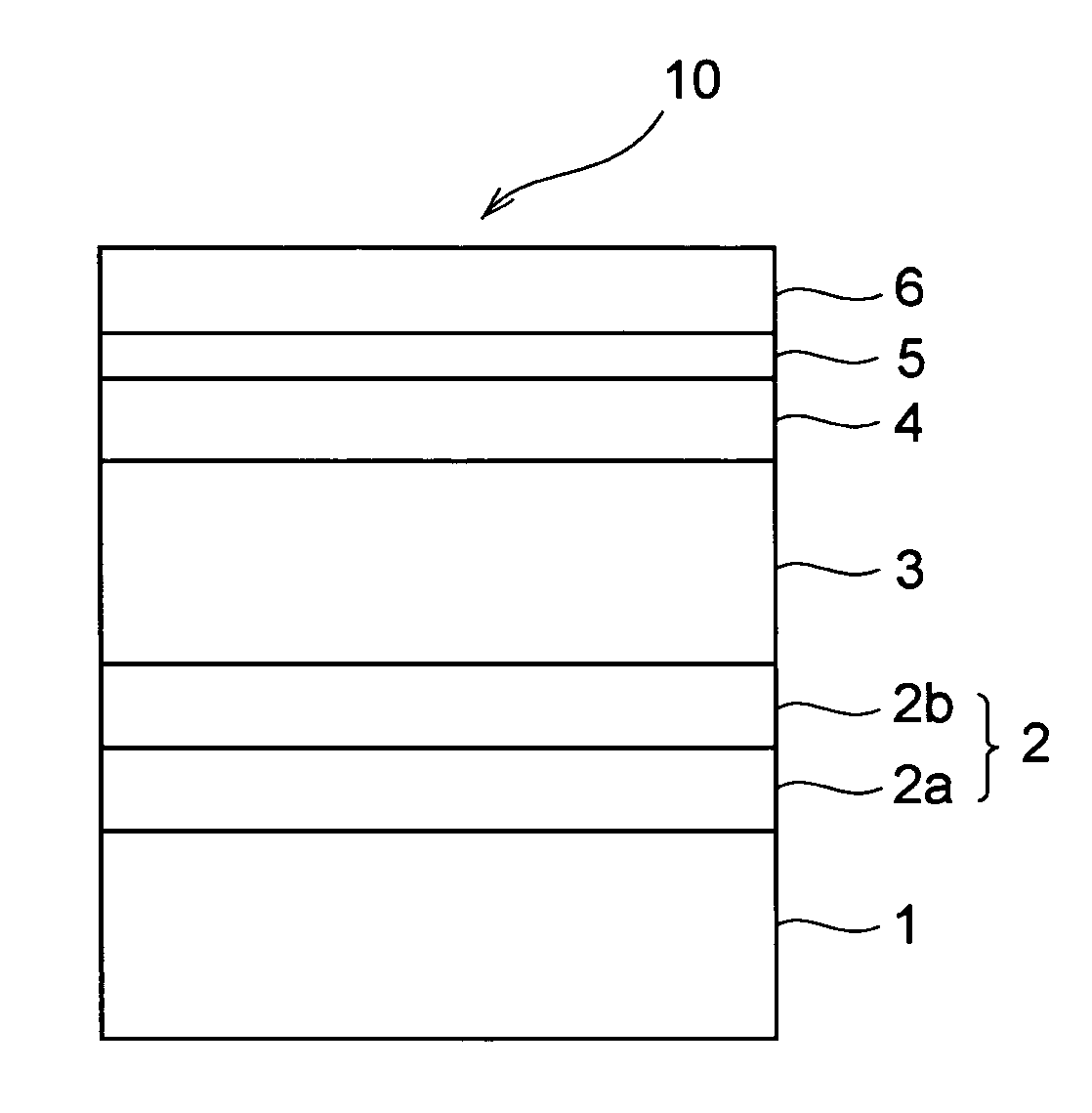

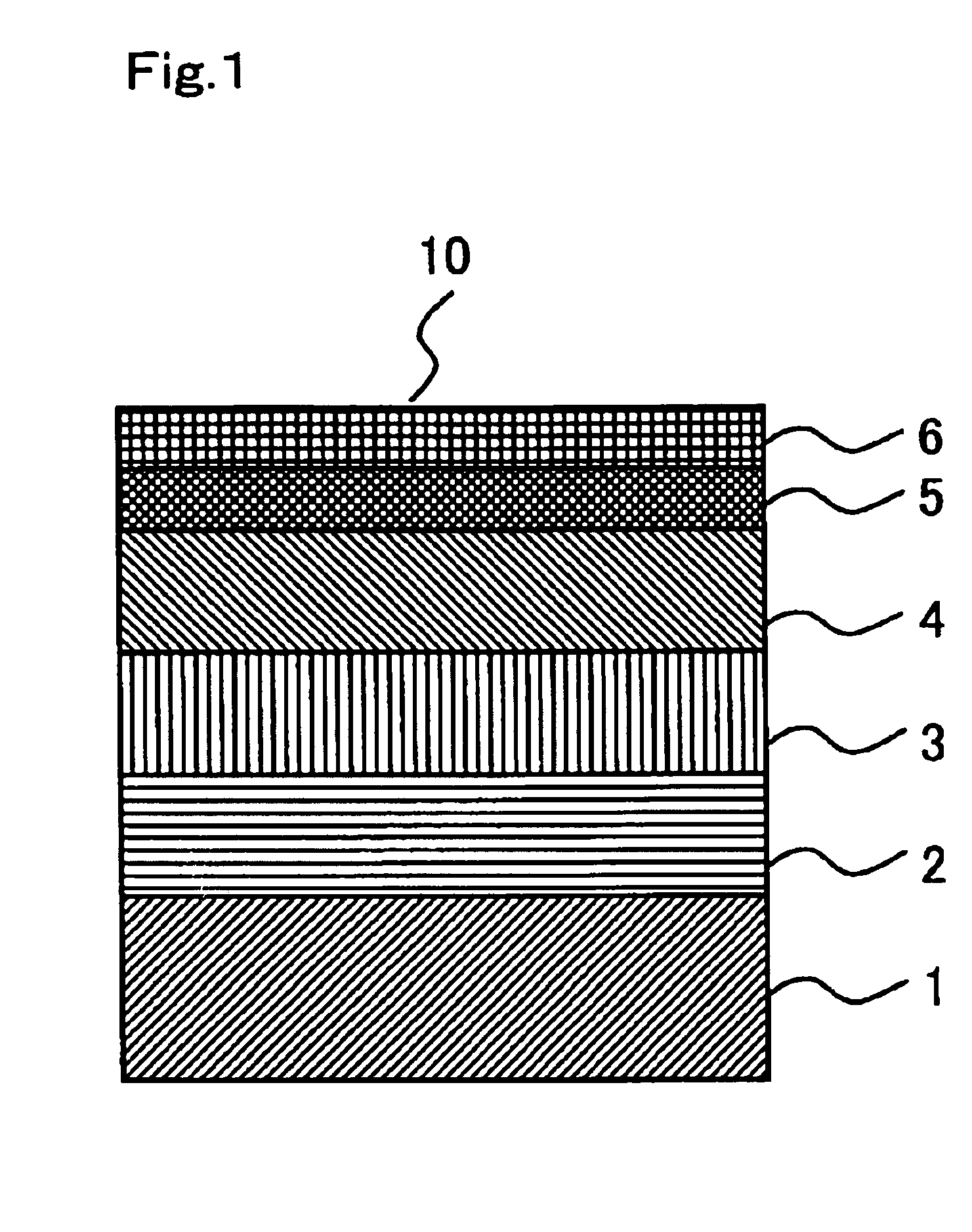

InactiveUS6946191B2Inhibit migrationSuppressing adhesionProtective coatings for layersLayered productsHydrogenNitrogen

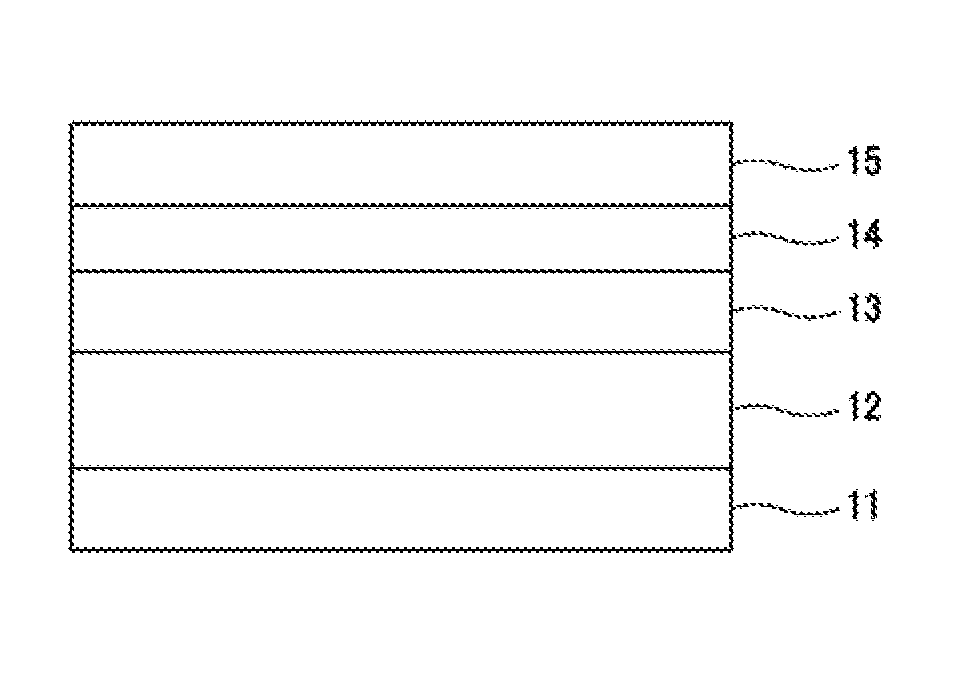

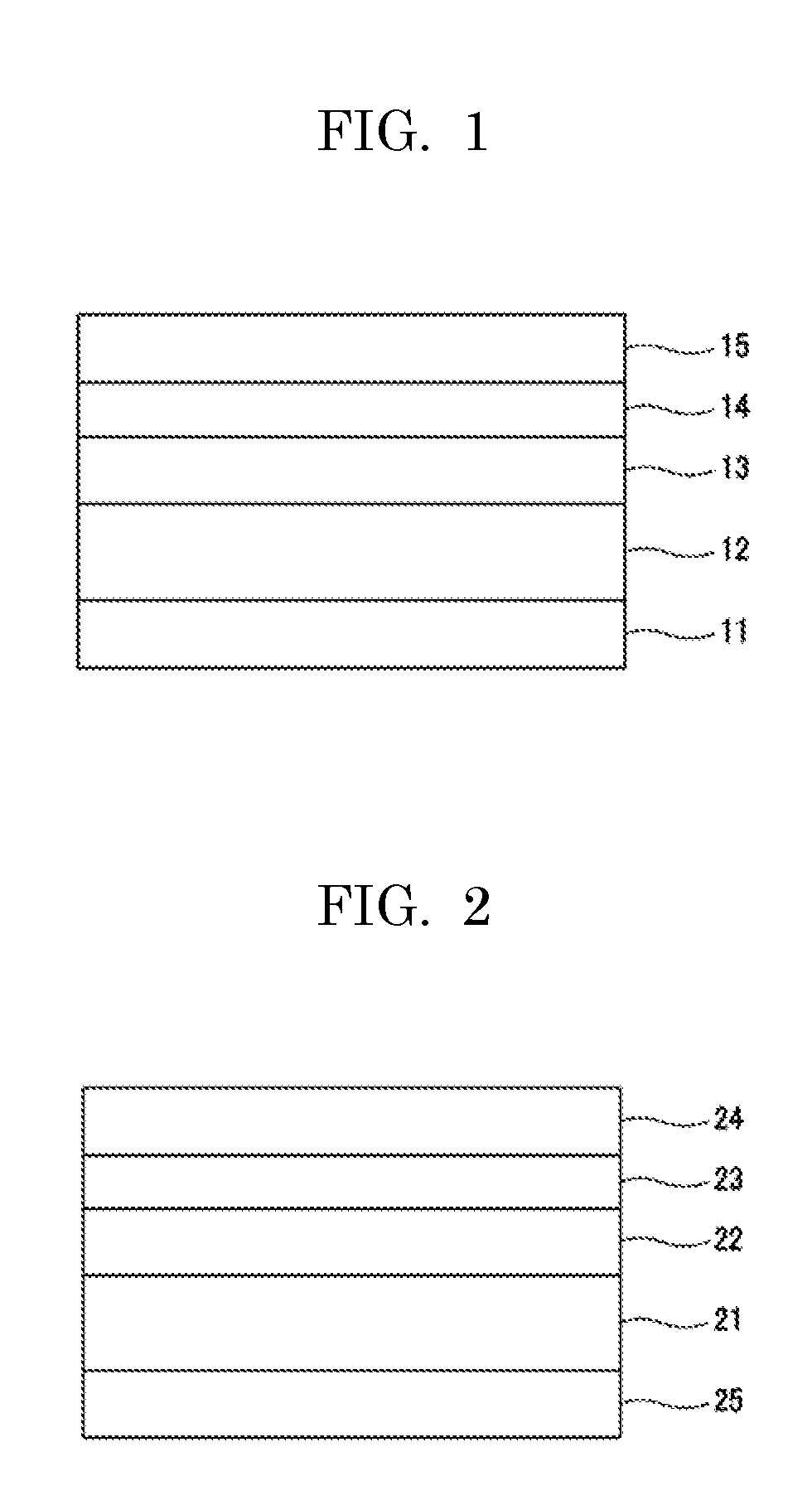

In a magnetic recording medium which comprises a substrate (1), a magnetic layer (3) formed on the substrate, a carbon-based protection layer (4) comprising carbon and formed on the magnetic layer, and a lubrication layer (5) formed on the carbon-based protection layer, the carbon-based protection layer comprises a hydrogenated carbon protection layer (4a) facing the magnetic layer and a nitrogenated carbon protection layer (4b) facing the lubrication layer. The hydrogenated carbon protection layer (4a) comprises carbon and hydrogen. The nitrogenated carbon protection layer (4b) includes no hydrogen but comprises carbon and nitrogen.

Owner:WD MEDIA SINGAPORE PTE

Magnetic disk and manufacturing method thereof

InactiveUS7722968B2Improve securityEfficient preparationProtective coatings for layersRecord information storageHydrogenFree energies

In a magnetic disk having a magnetic layer, a protection layer, and a lubrication layer formed on a substrate in this order, a surface free energy γS of a surface of the magnetic disk derived by an extended Fowkes equation is greater than 0 and no greater than 24 mN / m. γSd (dispersion force component of surface free energy) forming the surface free energy γS is greater than 0 and no greater than 17 mN / m, γSp (dipole component of surface free energy) forming the surface free energy γS is greater than 0 and no greater than 1 mN / m, and γSh (hydrogen bonding force component of surface free energy) forming the surface free energy γS is greater than 0 and no greater than 6 mN / m.

Owner:WD MEDIA SINGAPORE PTE

Method of producing a perpendicular magnetic recording medium and perpendicular magnetic recording medium

InactiveUS20140011054A1Solve the lack of durabilitySolve the lack of resistanceProtective coatings for layersRecord information storageBond densityMoisture resistance

Owner:WD MEDIA SINGAPORE PTE

Magnetic disk and manufacturing method thereof

ActiveUS20120127599A1Guaranteed uptimeImprove reliabilityDriving/moving recording headsProtective coatings for layersEnvironmental resistanceCompound a

A magnetic disk is provided which is excellent in durability of the magnetic disk or particularly in LUL durability and CFT characteristics and has high reliability under a decreased floating amount of the magnetic head accompanying the recent rapid increase in a recording density and extremely severe environmental resistance accompanying diversification of the applications.The magnetic disk of the present invention is a magnetic disk having at least a magnetic layer, a carbon protective layer, and a lubrication layer sequentially provided on a substrate, and the lubrication layer is a film formed by a lubricant that contains two types of compounds having a perfluoropolyether main chain in the structure, a molecular weight distribution of the two types in total being within a range of 1 to 1.2, the two types of compounds including a compound a having a hydroxyl group at the end and a compound b having a number average molecular weight smaller than the number average molecular weight of the compound a and not more than 1500, and a content of the compound b in the two types of compounds being not more than 10%.

Owner:WESTERN DIGITAL TECH INC

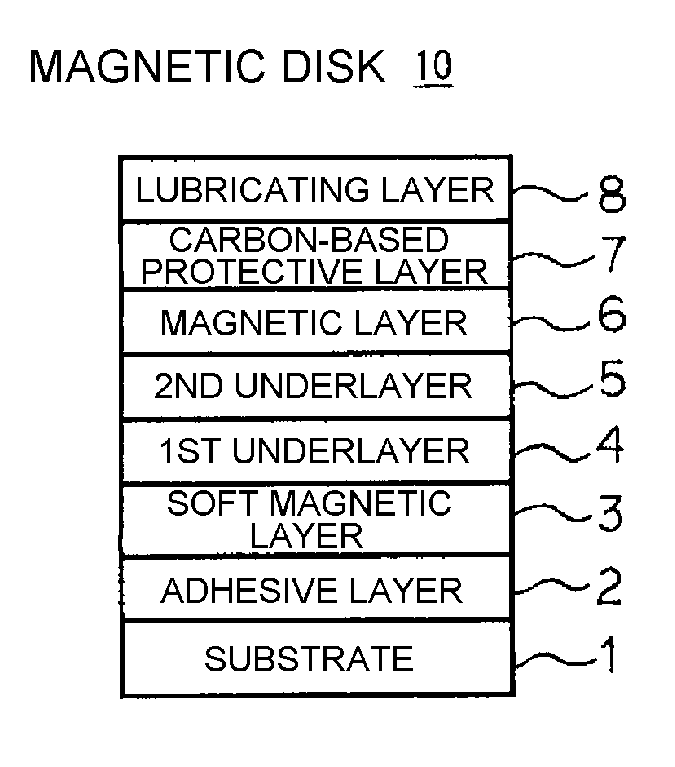

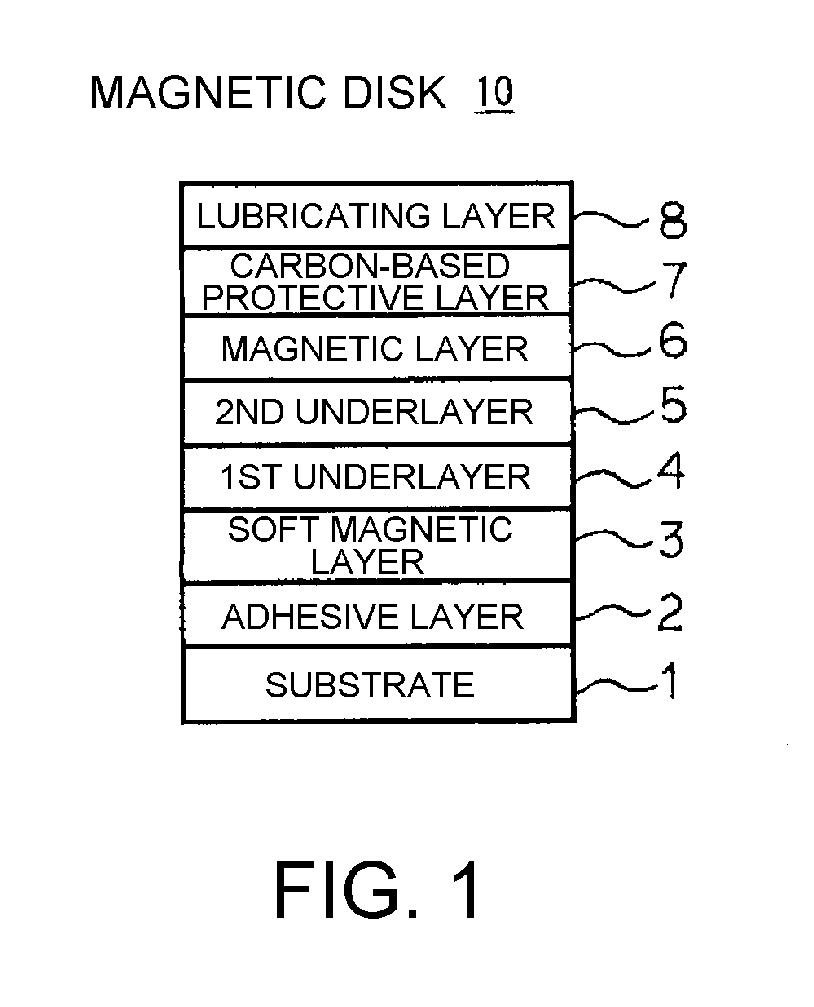

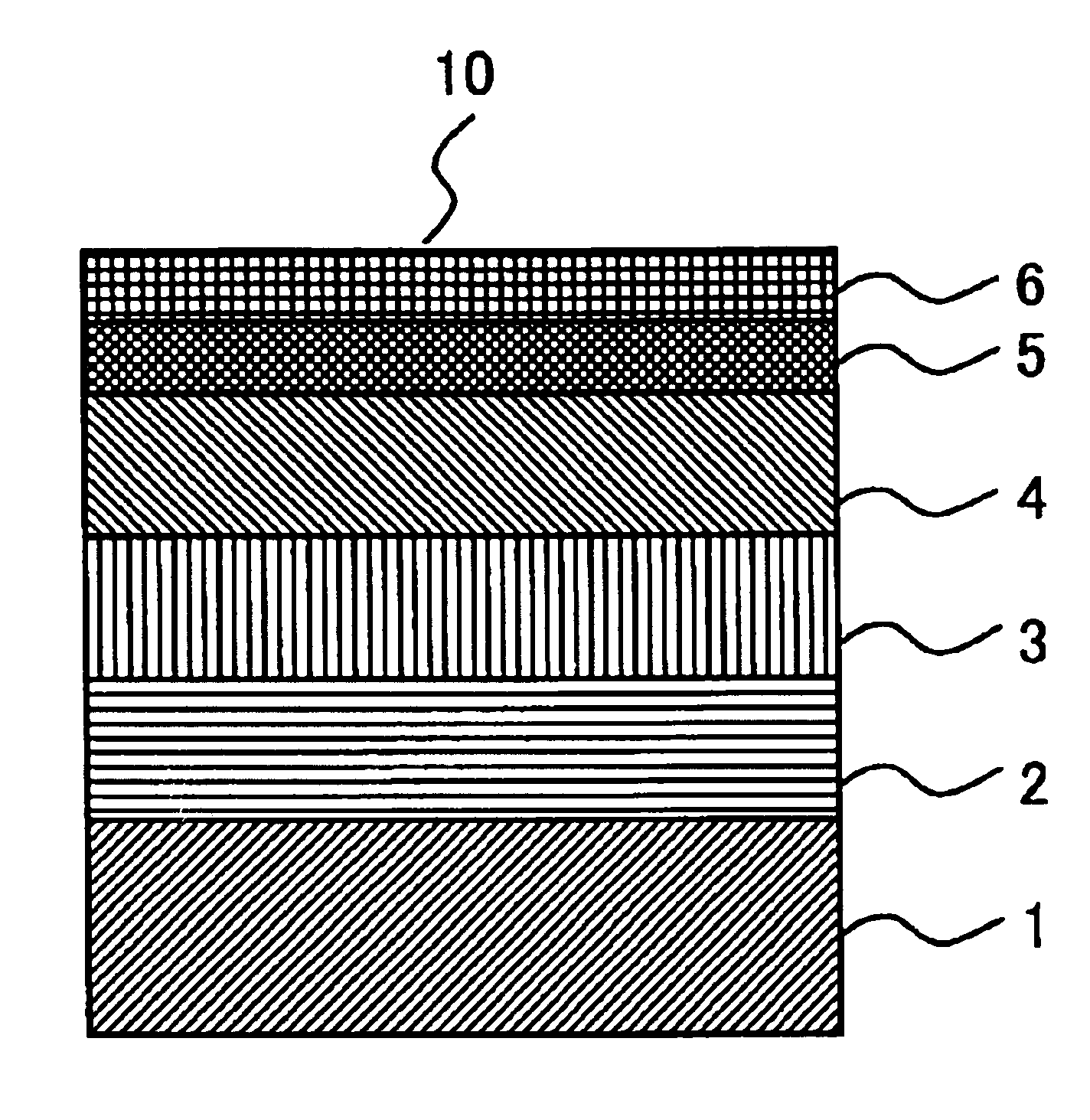

Magnetic disk and method of manufacturing the same

InactiveUS20100304186A1Maintain good propertiesImprove reliabilityProtective coatings for layersRecord information storagePerfluoropolyetherBackbone chain

Provided is a magnetic disk comprising a lubricating layer formed of a lubricant. The lubricant constituting the lubricating layer has excellent properties, for example, excellent fluidity, surface energy, and CFT properties. By virtue of the excellent properties, the magnetic disk has a high level of reliability despite a low flying height of a magnetic head due to a recent rapid increase in recording density and a very severe environment resistance requirement due to diversification of applications. The magnetic disk comprises a substrate and at least a magnetic layer, a protective layer, and a lubricating layer provided in that order over the substrate. The lubricating layer is formed of a lubricant that is a mixture of a specific perfluoropolyether lubricant with a lubricant formed of a compound comprising perfluoropolyether groups having a perfluoropolyether main chain in the structure thereof and having a hydroxyl group at the end thereof, the perfluoropolyether groups being bonded to each other through a divalent linking group having at least two hydroxyl groups in the structure thereof.

Owner:WESTERN DIGITAL TECH INC

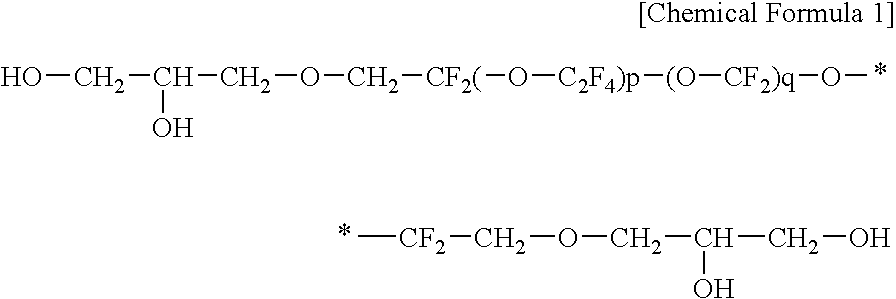

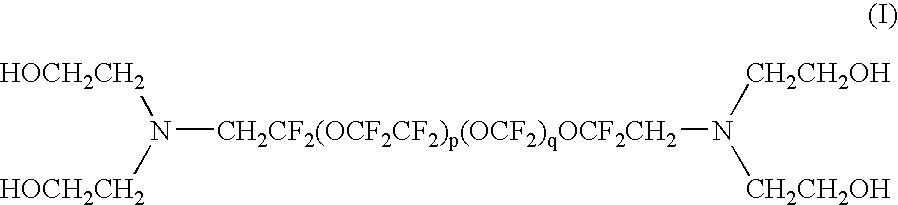

Magnetic recording disk and process for manufacture thereof

ActiveUS7045215B2Improve the lubrication effectImprove adhesionProtective coatings for layersSynthetic resin layered productsPerfluoropolyetherEther

A magnetic recording disk has a high-adhesion lubricant layer that permits an operation at an extremely low level of flying height of 12 nm or less without troubles and which is capable of preventing the migration at a high-speed rotation, and comprises a substrate, a magnetic layer formed on the substrate, a protective layer formed on the magnetic layer and a lubricant layer formed on the protective layer, the lubricant layer containing a compound (A) of the general formula (I), wherein each of p and q is an integer of 1 or more, anda compound (B) having a perfluoropolyether main chain having two end moieties each of which contains a carbon atom or an oxygen atom to which a hydroxyl-containing hydrocarbon group that optionally contains ether bond(s) is bonded, and a process for the manufacture thereof is provided.

Owner:WESTERN DIGITAL TECH INC

Manufacturing method of magnetic recording medium

InactiveUS20120196049A1Improve corrosion resistanceImprove mechanical durabilityProtective coatings for layersRecord information storageNitrogen gasChemical vapor deposition

A manufacturing method of a magnetic recording medium provided with a protective layer excellent in corrosion resistance, mechanical durability, adhesion with a lubrication layer, and floating stability of a head even if the film thickness is reduced is provided. This is a manufacturing method of a magnetic recording medium in which at least a magnetic layer, a carbon protective layer, and a lubrication layer are sequentially provided on a substrate, and said carbon protective layer is provided with a lower layer formed on the magnetic layer side and an upper layer formed on the lubrication layer side. The lower layer is formed by a chemical vapor deposition (CVD) method using hydrocarbon gas and then, the upper layer is formed by using mixed gas of hydrocarbon gas and nitrogen gas and then, treatment which nitridizes the surface of the upper layer is applied.

Owner:WD MEDIA SINGAPORE PTE

Perpendicular magnetic recording medium and method of manufacturing the same

A vertical magnetic recording disc (100) includes a base (10), a magnetic recording layer (22), and a medium protection layer (26). The magnetic recording layer (22) is a ferromagnetic layer having a granular structure where a granular portion is formed. The medium protection layer (26) contains nitrogen (N) atoms and carbon (C) atoms with a number ratio (N / C) in a range from 0.050 to 0.150. In a Raman spectrum obtained by exciting the medium protection layer (26) by argon ion laser light of wavelength 514.5 nm, from which a fluorescence is removed, the peak ratio Dh / Gh is in a range from 0.70 to 0.95, when a D peak Dh appearing in the vicinity of 1350 cm−1 is separated from G peak Gh appearing in the vicinity of 1520 cm−1 by the Gauss function.

Owner:HOYA CORP +1

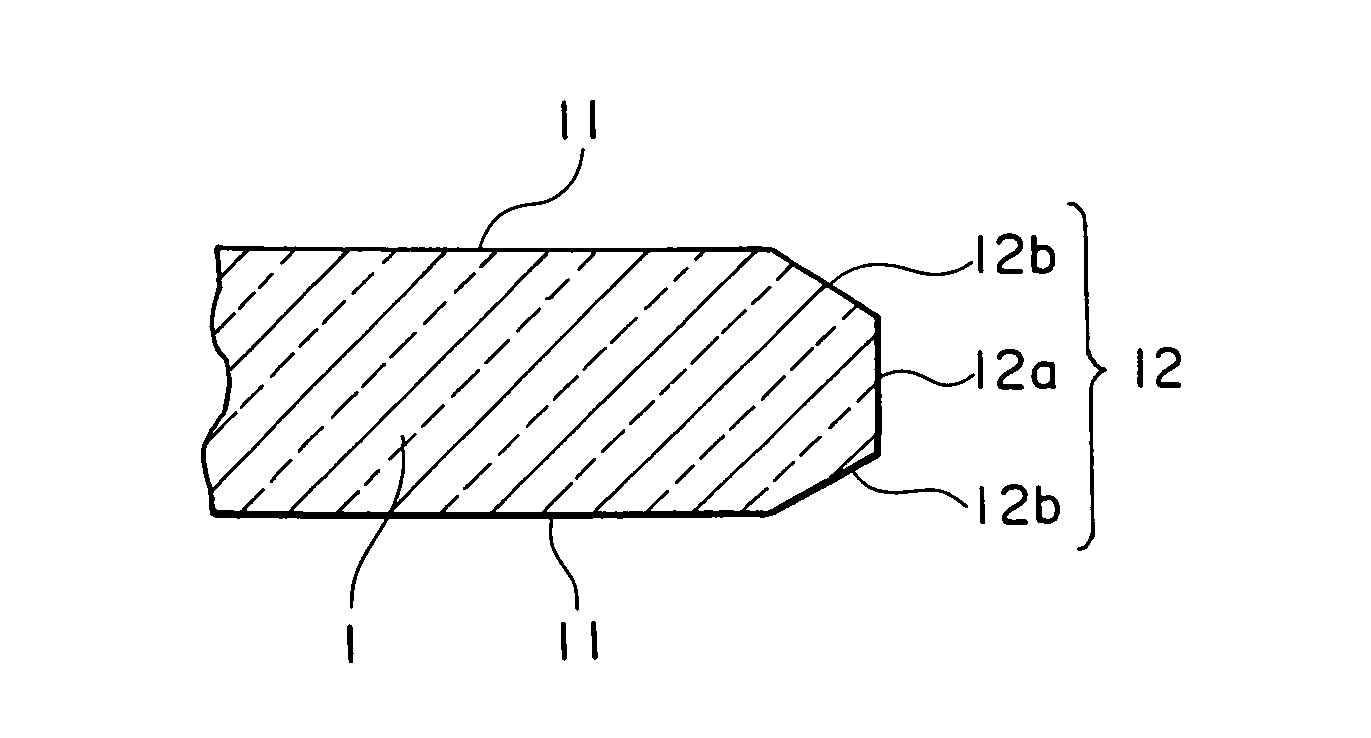

Magnetic disk and manufacturing method thereof

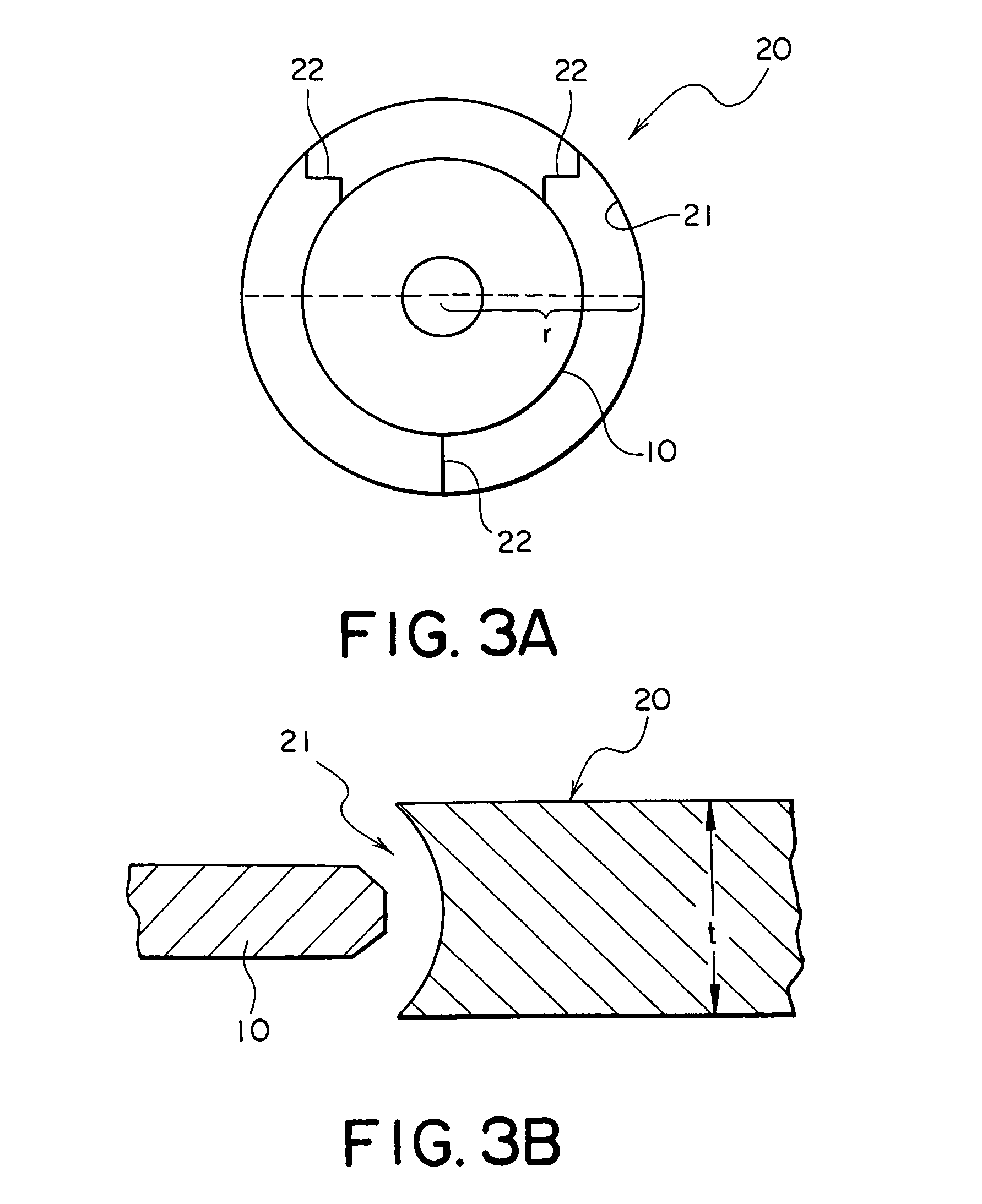

ActiveUS7736768B2Satisfy safety performance requirementsEasy to produceProtective coatings for layersMagnetic materials for record carriersEngineeringMagnetic layer

A magnetic disk comprises a magnetic layer and a protective layer sequentially formed on a disk-shaped substrate and has a principal surface to which data is recorded, and a side surface portion both of which are coated with the protective layer. The protective layer on the side surface portion is thinner than the protective layer on the principal surface. Preferably, the side surface portion includes a side wall surface, and a chamfered surface lying between the side wall surface and the principal surface, and at least the protective layer on the chamfered surface is thinner than the protective layer on the principal surface.

Owner:WESTERN DIGITAL TECH INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com