Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1102results about How to "Solve the lack of resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

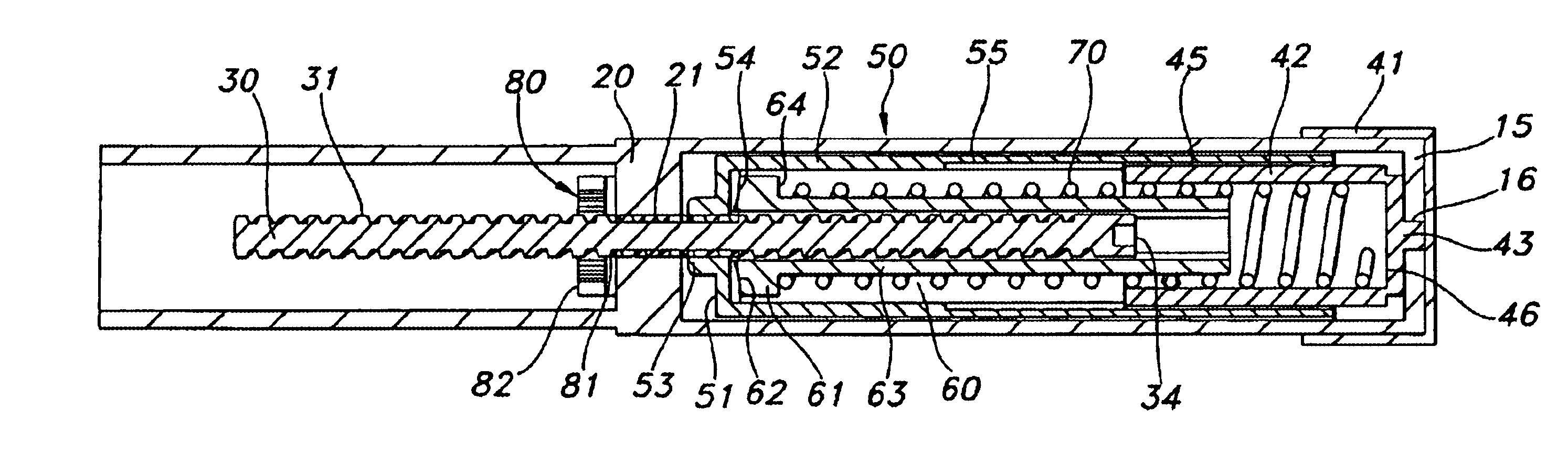

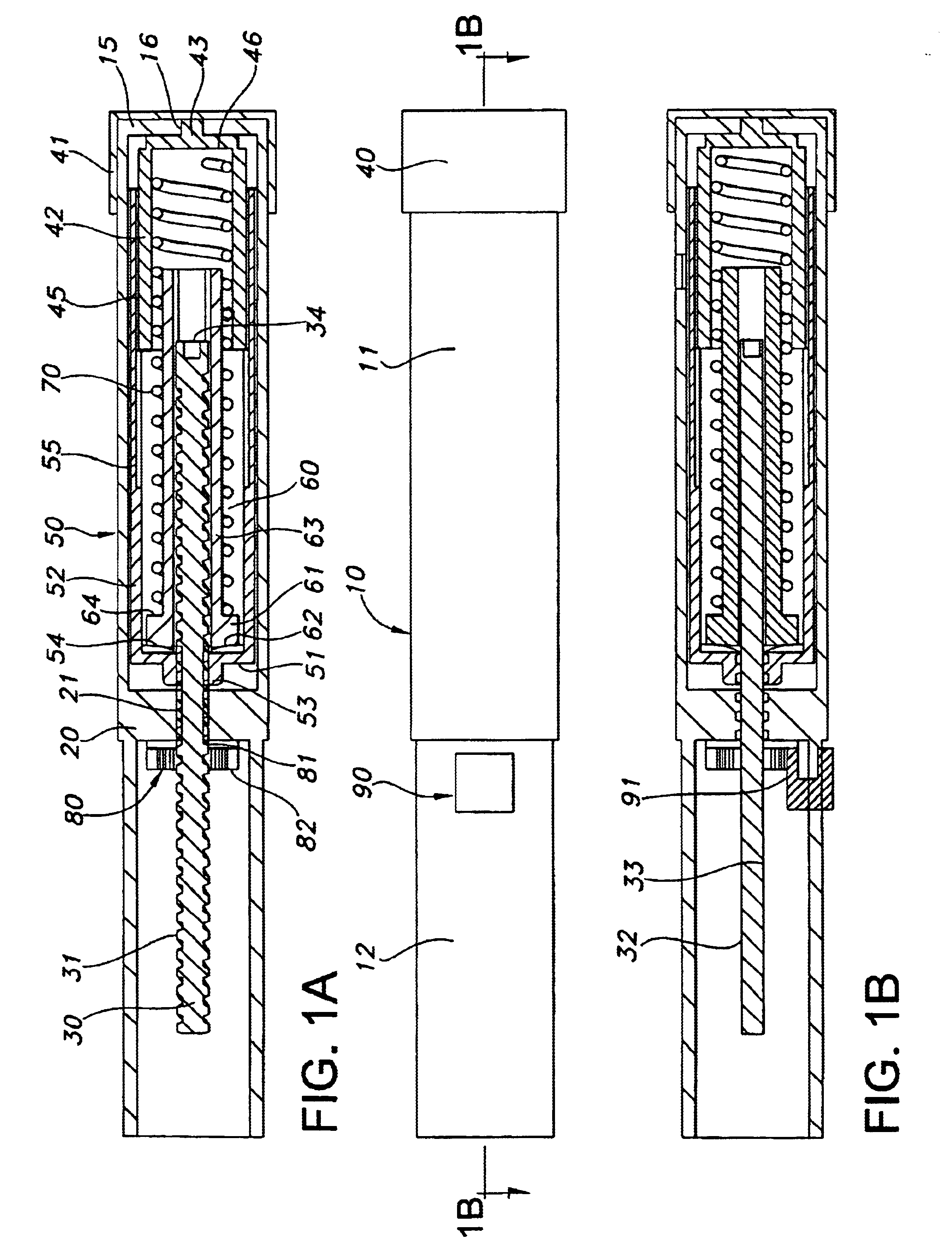

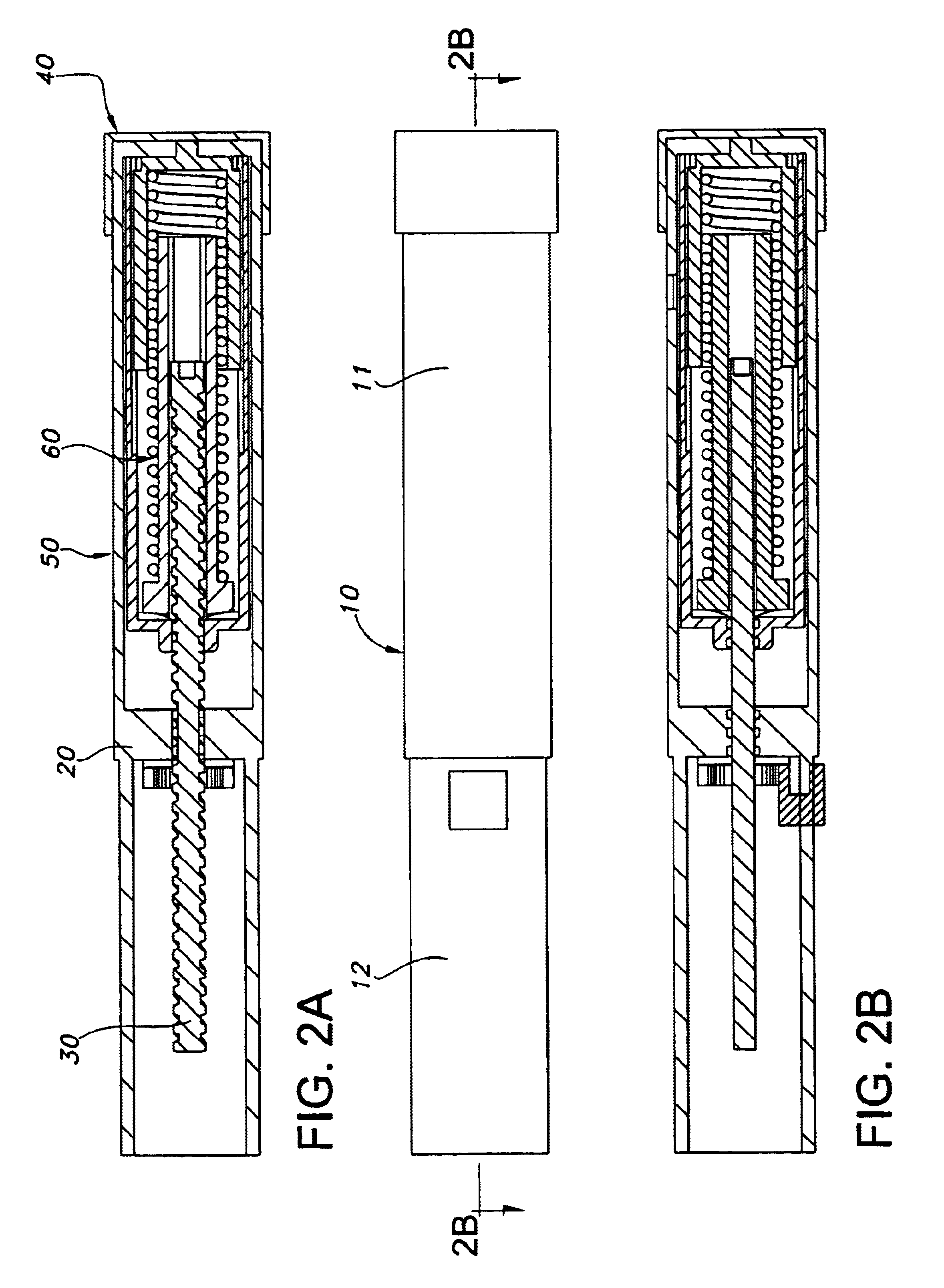

Automatic injection device with reset feature

InactiveUS6899699B2Solve the lack of resistanceEasy to solveAmpoule syringesAutomatic syringesInjection deviceBiomedical engineering

The present invention relates to a dose setting and expelling device comprising a drive member and a dose setting mechanism which simultaneously sets a given dose and stores the energy necessary for a subsequently driving the drive member in order to expel a dose of medicine from an injection device. According to the invention the dose setting mechanism allows adjustment in both directions, such that a given set dose can be reduced or cancelled by reversing the input motion, typically by rotating a setting member backwardly, this in contrast to the known devices which either requires an additional release mechanism or which cannot be reversed at all.

Owner:NOVO NORDISK AS

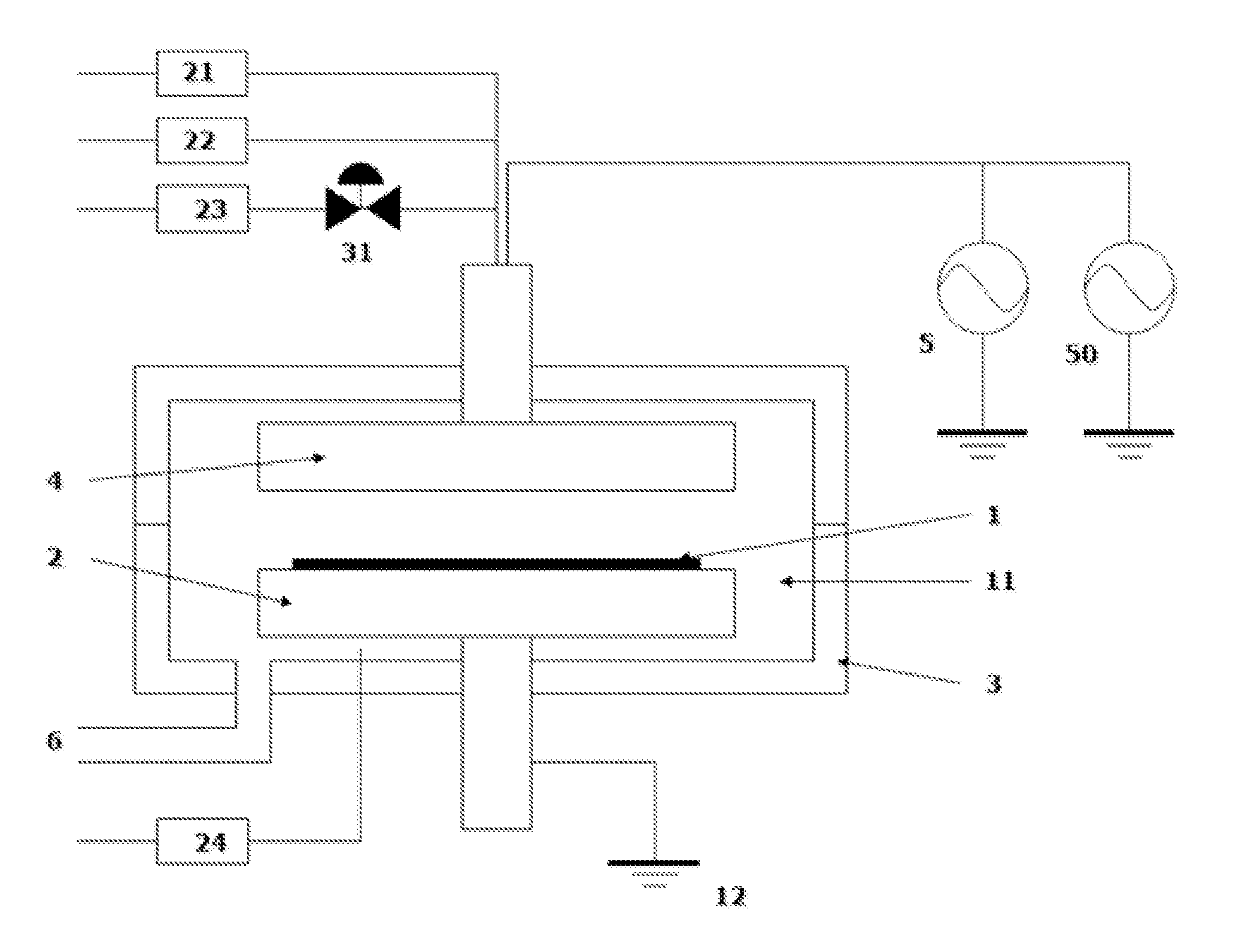

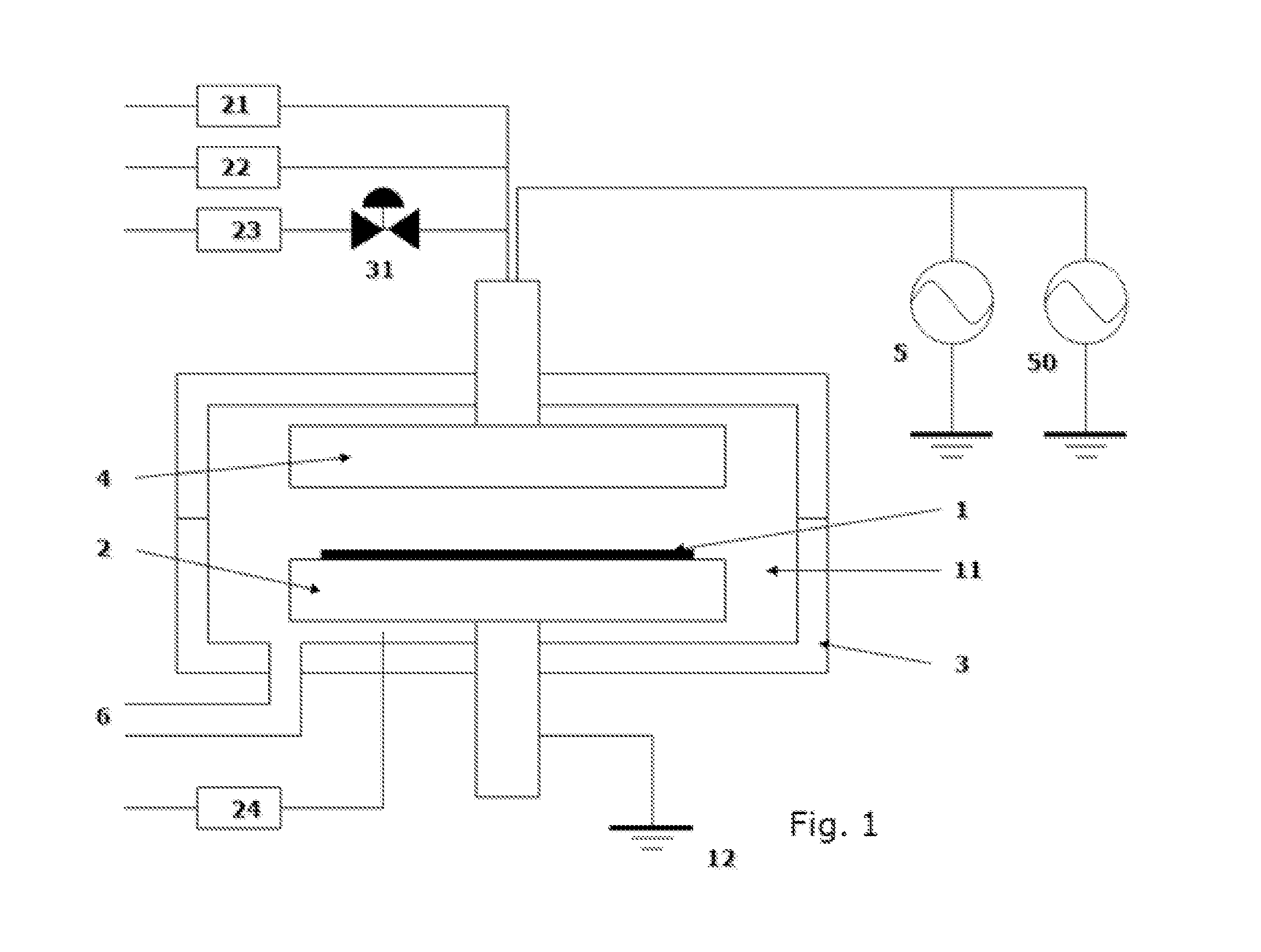

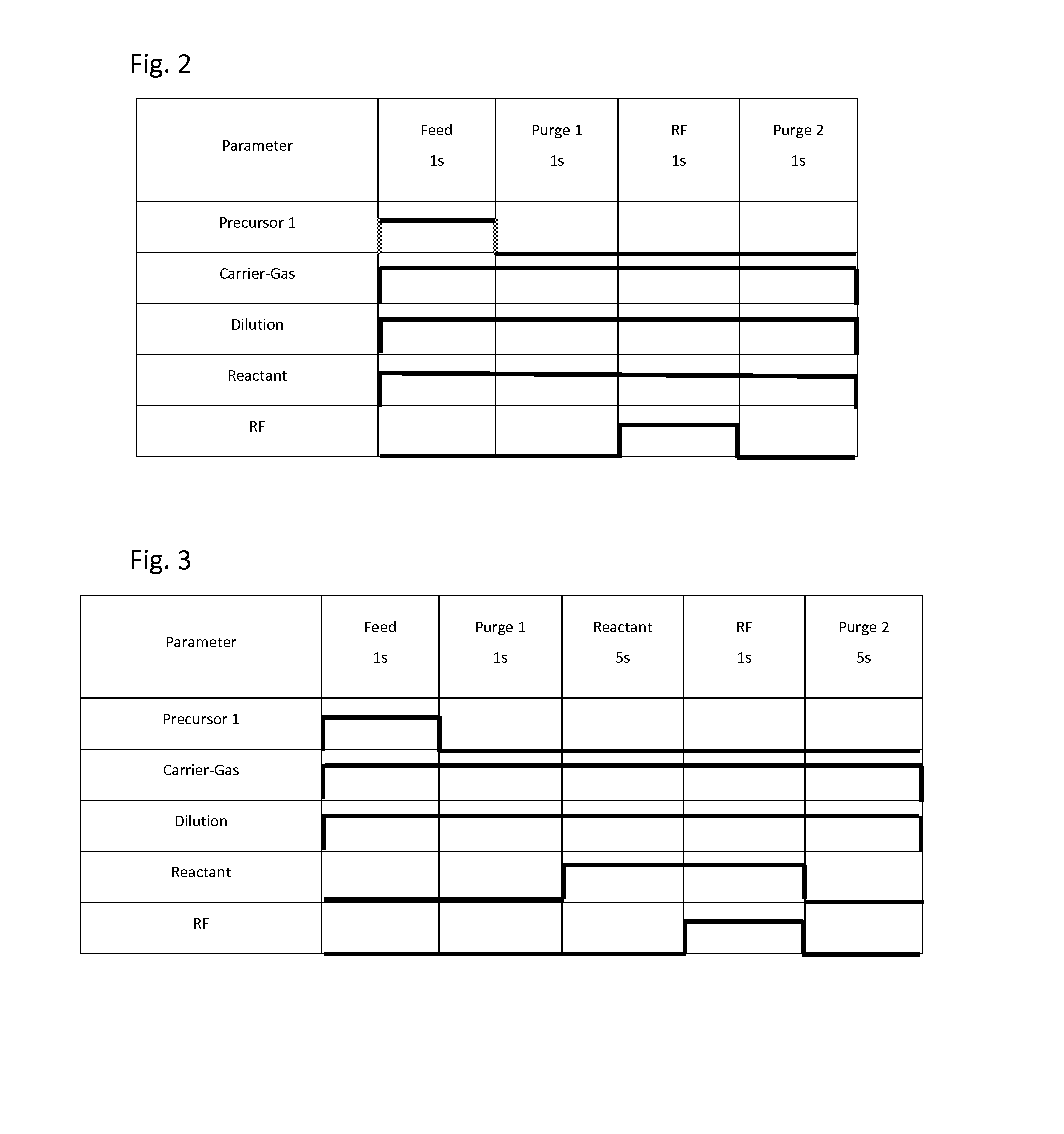

Method for depositing metal-containing film using particle-reduction step

InactiveUS20160168699A1Reduce surface roughnessSolve the lack of resistanceChemical vapor deposition coatingPlasma techniqueAMINO BASENitride

A method for forming a metal oxide or nitride film on a substrate by plasma-enhanced atomic layer deposition (PEALD), includes: introducing an amino-based metal precursor in a pulse to a reaction space where a substrate is placed, using a carrier gas; and continuously introducing a reactant gas to the reaction space; applying RF power in a pulse to the reaction space wherein the pulse of the precursor and the pulse of RF power do not overlap, wherein conducted is at least either step (a) comprising passing the carrier gas through a purifier for reducing impurities before mixing the carrier gas with the precursor, or step (b) introducing the reactant gas at a flow rate such that a partial pressure of the reactant gas relative to the total gas flow provided in the reaction space is 15% or less.

Owner:ASM IP HLDG BV

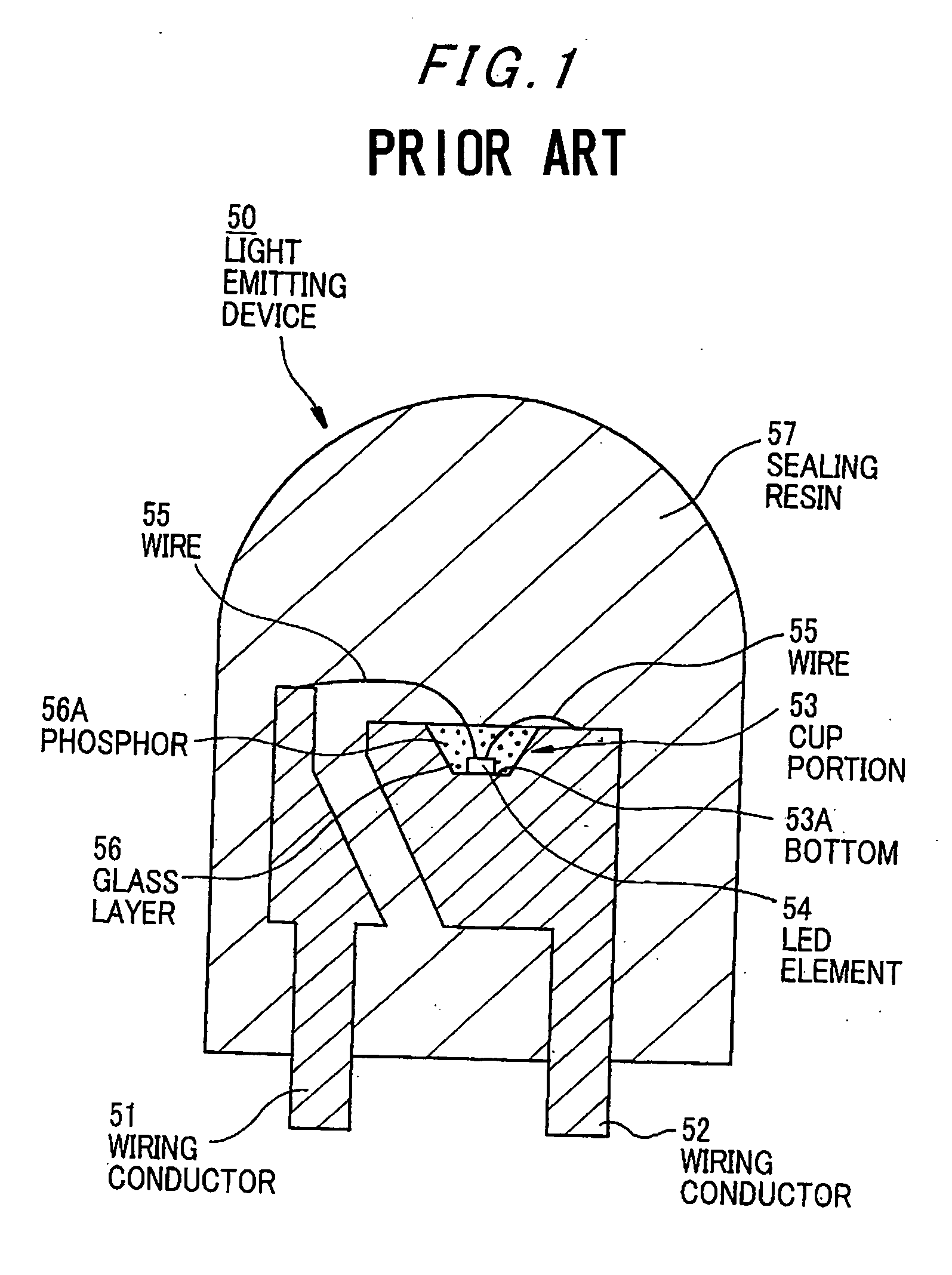

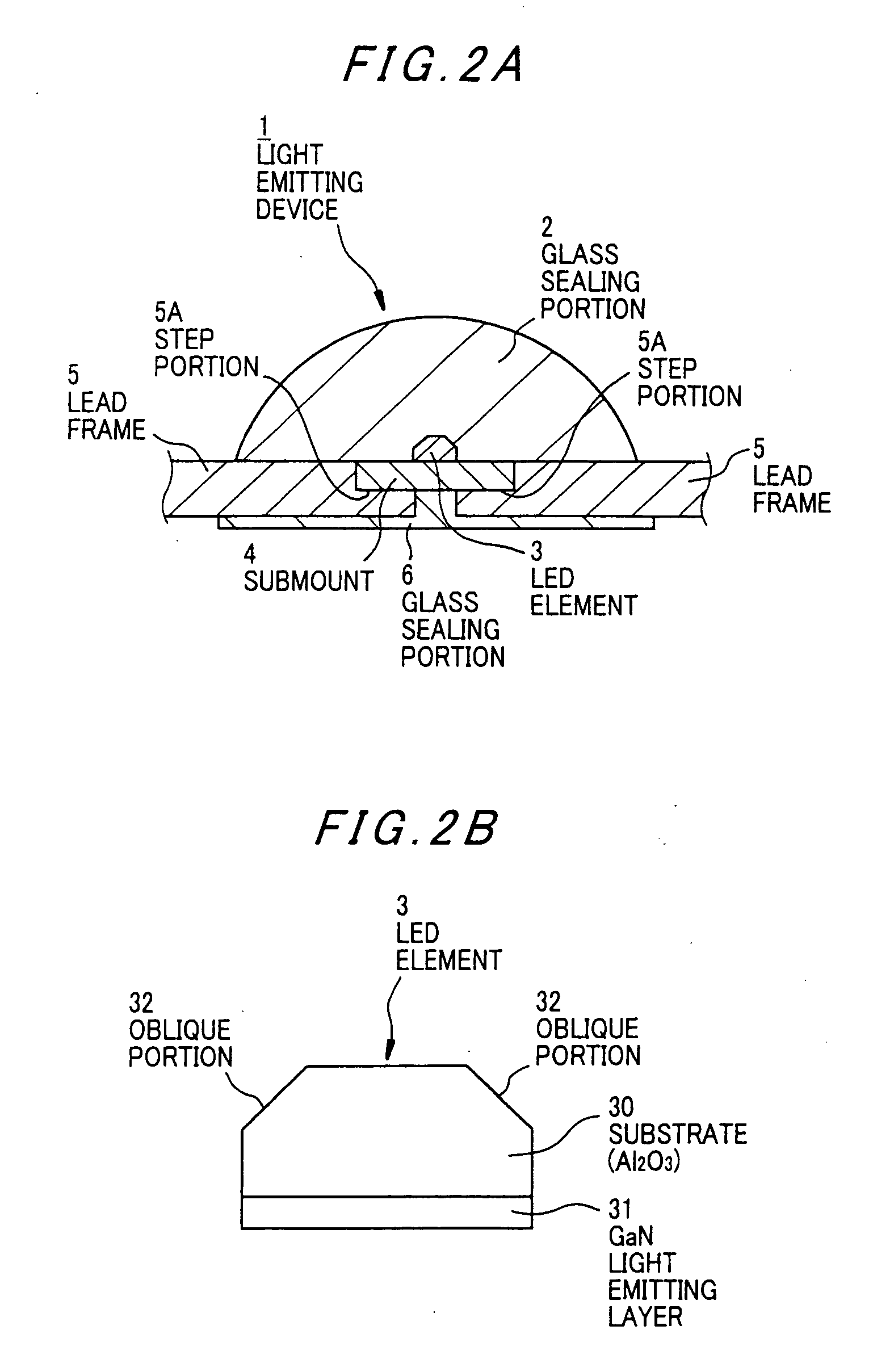

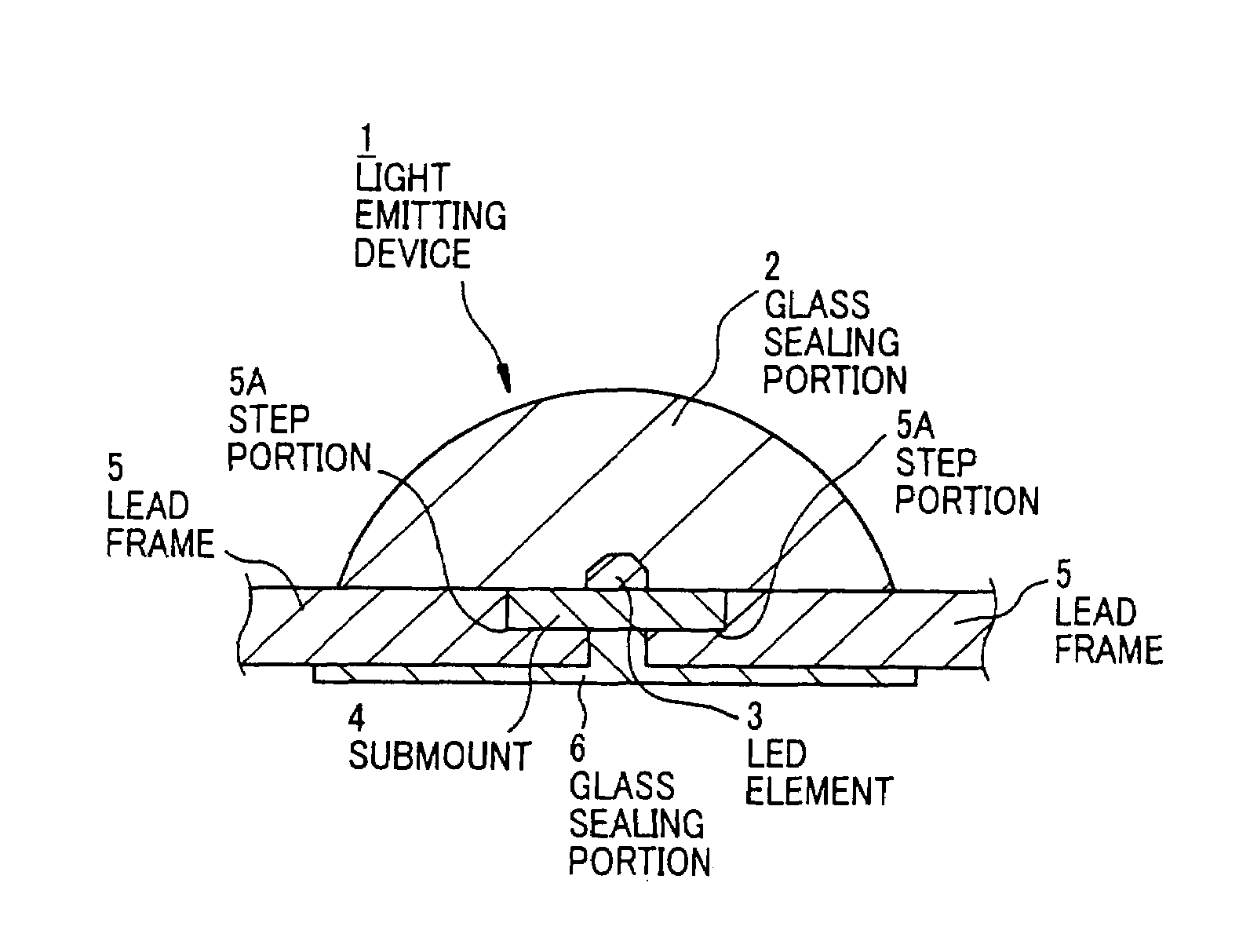

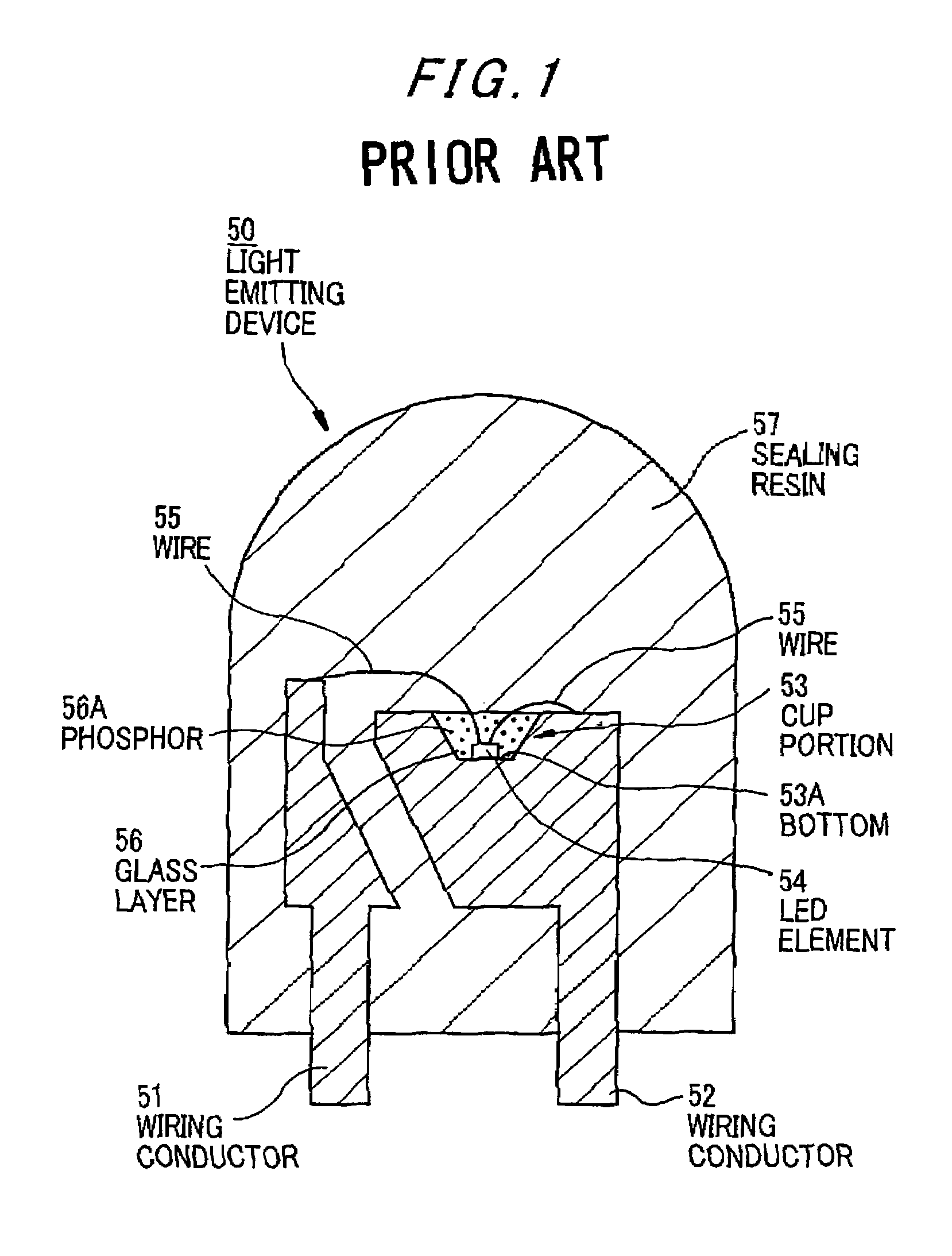

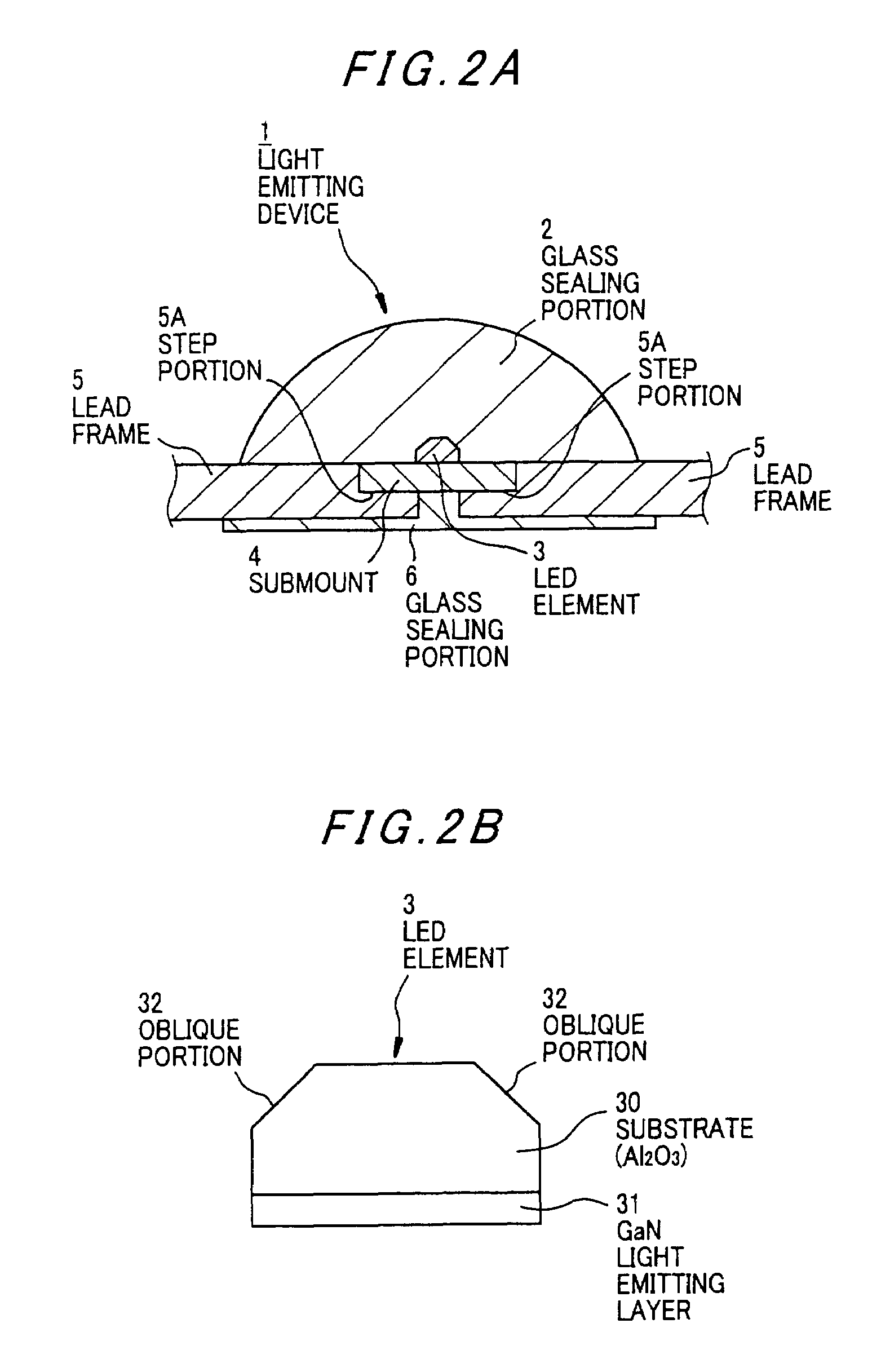

Light emitting device

ActiveUS20060012299A1Avoiding pressure injuriesDifference in stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

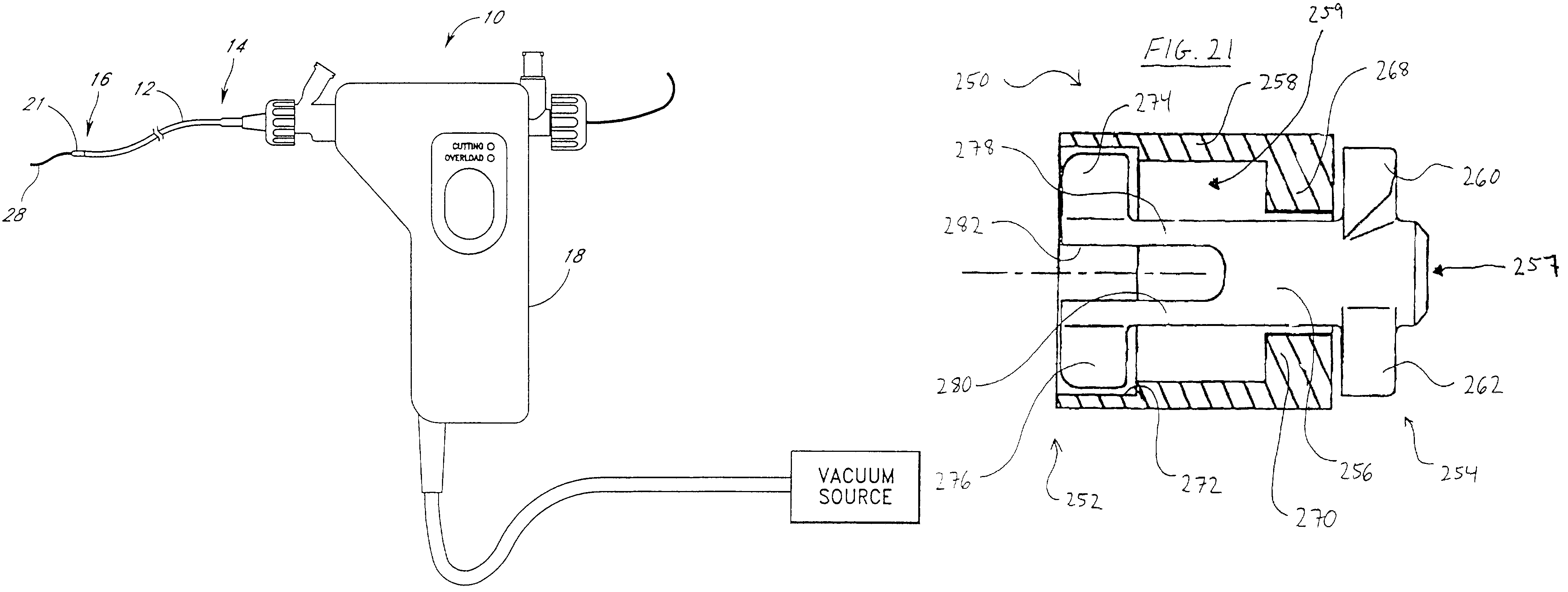

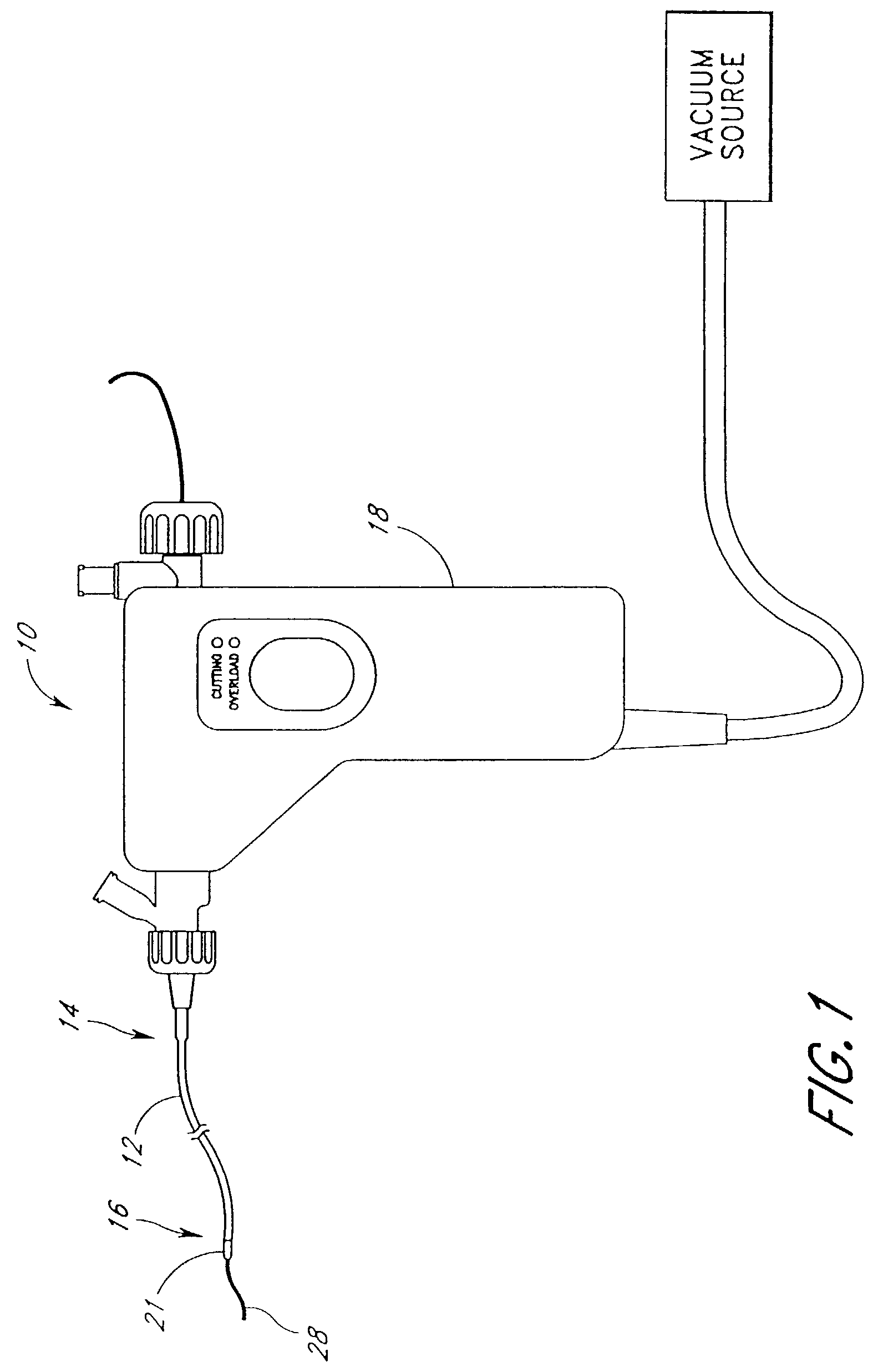

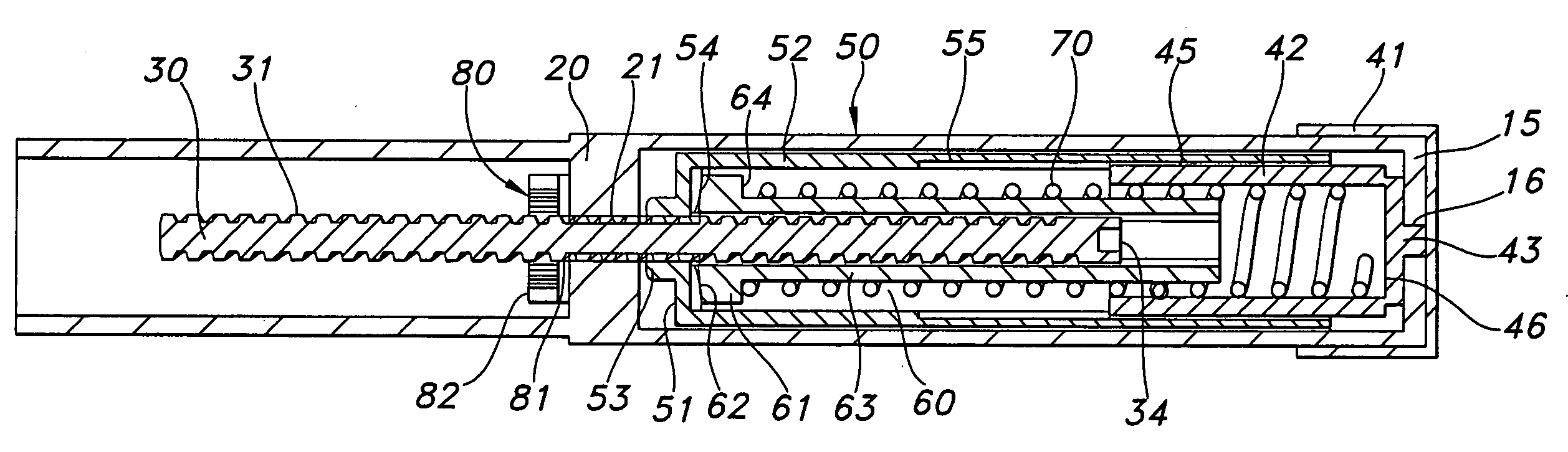

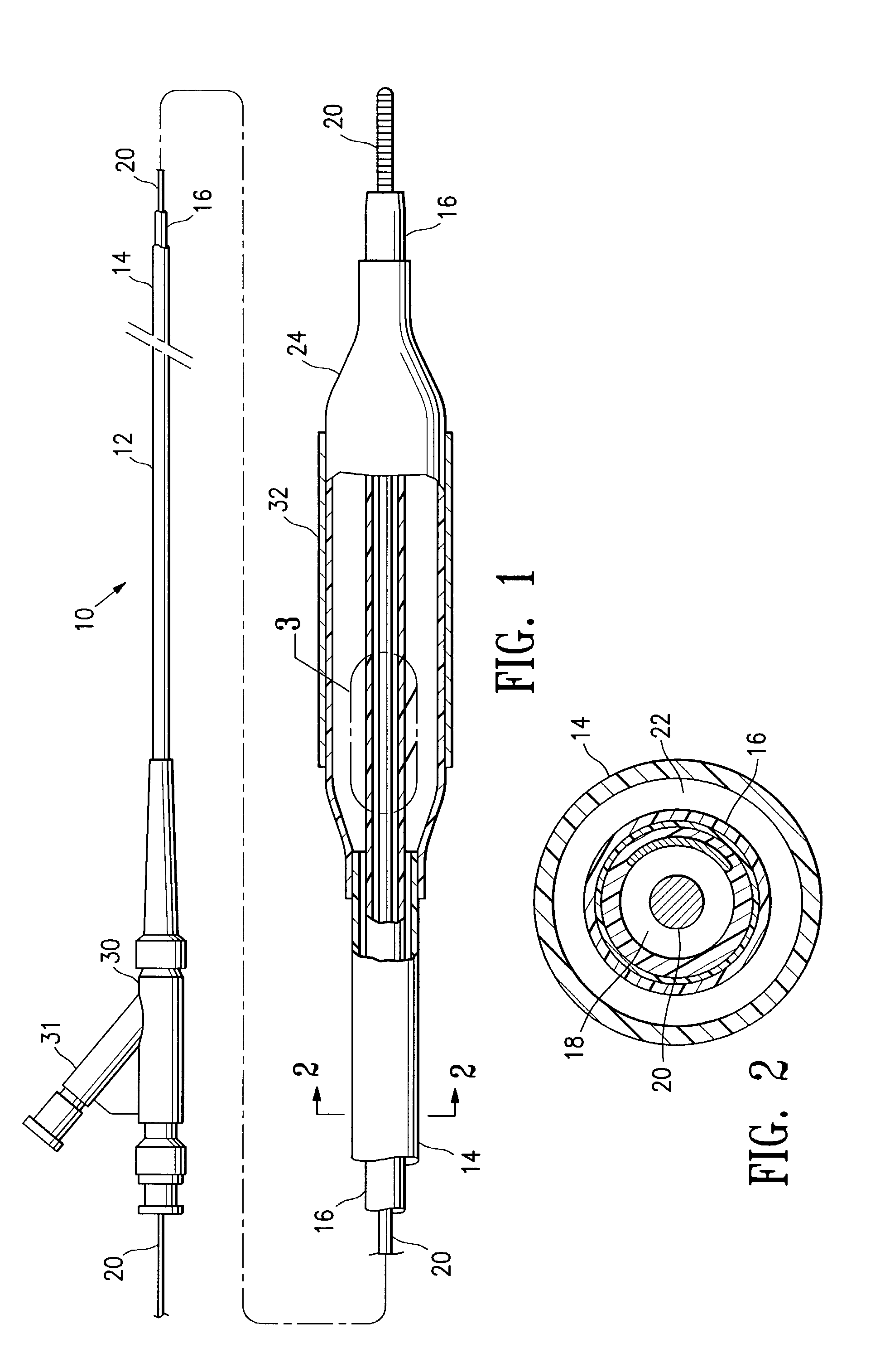

Neuro thrombectomy catheter

InactiveUS7235088B2Small outer diameterSufficient pushabilityCannulasExcision instrumentsThrombusEngineering

An elongate tubular body extends between a rotatable cutter and a control. The cutter is connected to the control with a rotatable element. A vacuum is applied through an annular passage defined between the tubular body and the rotatable element. The tubular body has a sufficiently small outside diameter and sufficient kink resistance and pushability to navigate through arteries such as the internal carotid artery.

Owner:TYCO HEALTHCARE GRP LP

Conductive, plasma-resistant member

InactiveUS20070248832A1Improve corrosion resistanceSuppress particle contaminationMolten spray coatingNatural mineral layered productsDisplay deviceFlat panel display

An electrically conductive, plasma-resistant member adapted for exposure to a halogen-based gas plasma atmosphere includes a substrate having formed on at least part of a region thereof to be exposed to the plasma a thermal spray coating composed of yttrium metal or yttrium metal in admixture with yttrium oxide and / or yttrium fluoride so as to confer electrical conductivity. Because the member is conductive and has an improved erosion resistance to halogen-based corrosive gases or plasmas thereof, particle contamination due to plasma etching when used in semiconductor manufacturing equipment or flat panel display manufacturing equipment can be suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

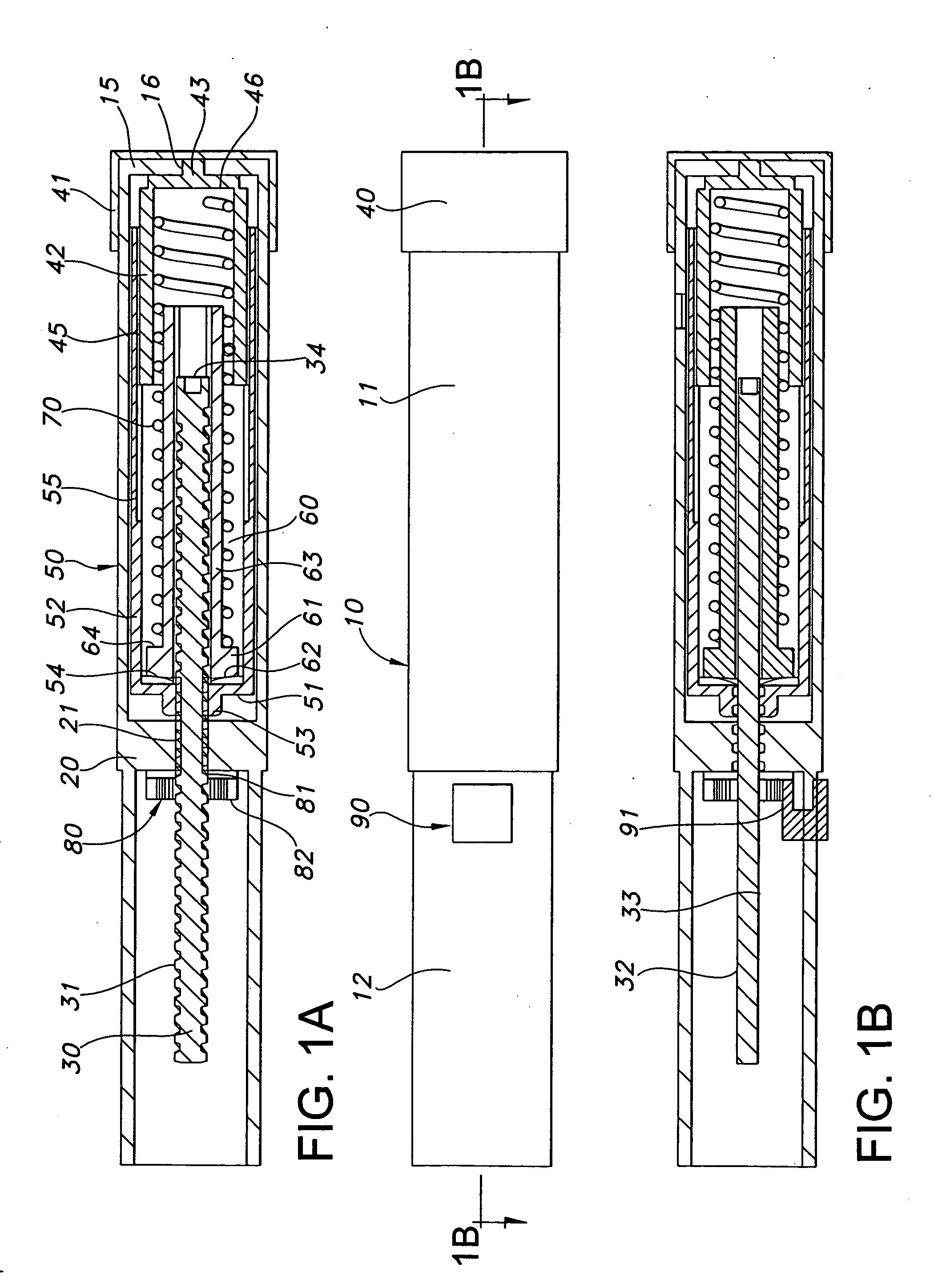

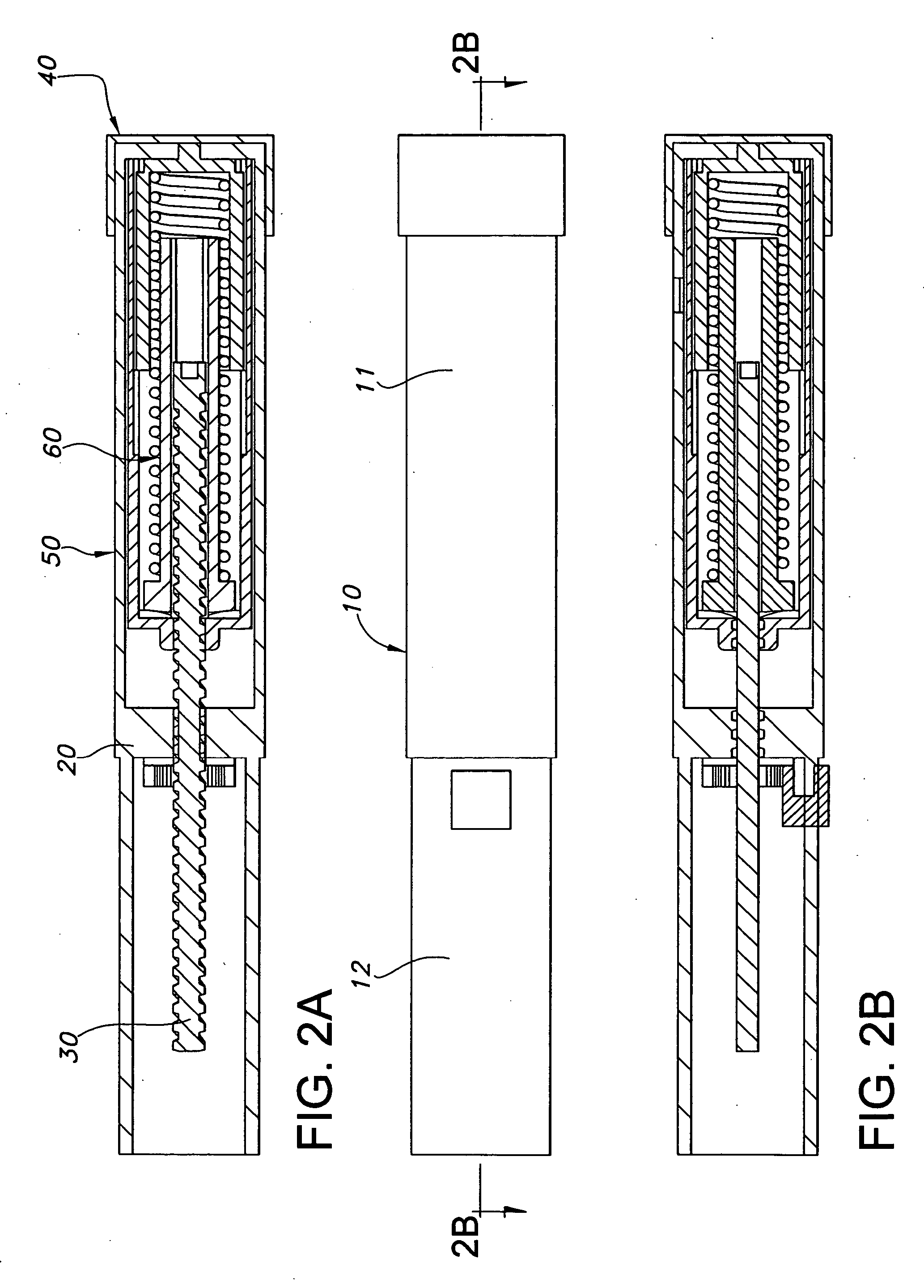

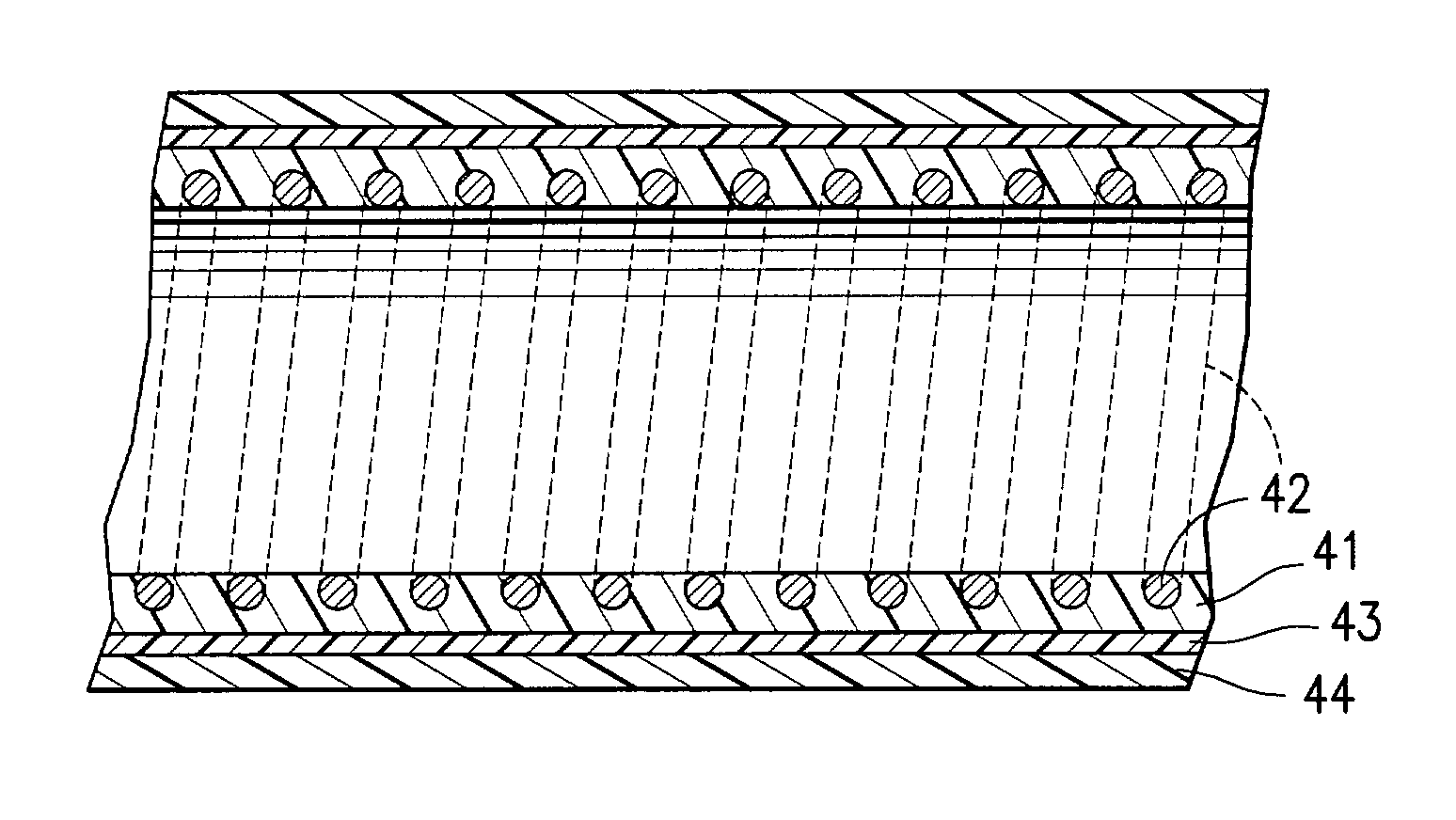

Automatic injection device with reset feature

InactiveUS20050055011A1Sufficient resistanceEasily overcomeAmpoule syringesAutomatic syringesBiomedical engineeringInjection device

The present invention relates to a dose setting and expelling device comprising a drive member and a dose setting mechanism which simultaneously sets a given dose and stores the energy necessary for a subsequently driving the drive member in order to expel a dose of medicine from an injection device. According to the invention the dose setting mechanism allows adjustment in both directions, such that a given set dose can be reduced or cancelled by reversing the input motion, typically by rotating a setting member backwardly, this in contrast to the known devices which either requires an additional release mechanism or which cannot be reversed at all.

Owner:NOVO NORDISK AS

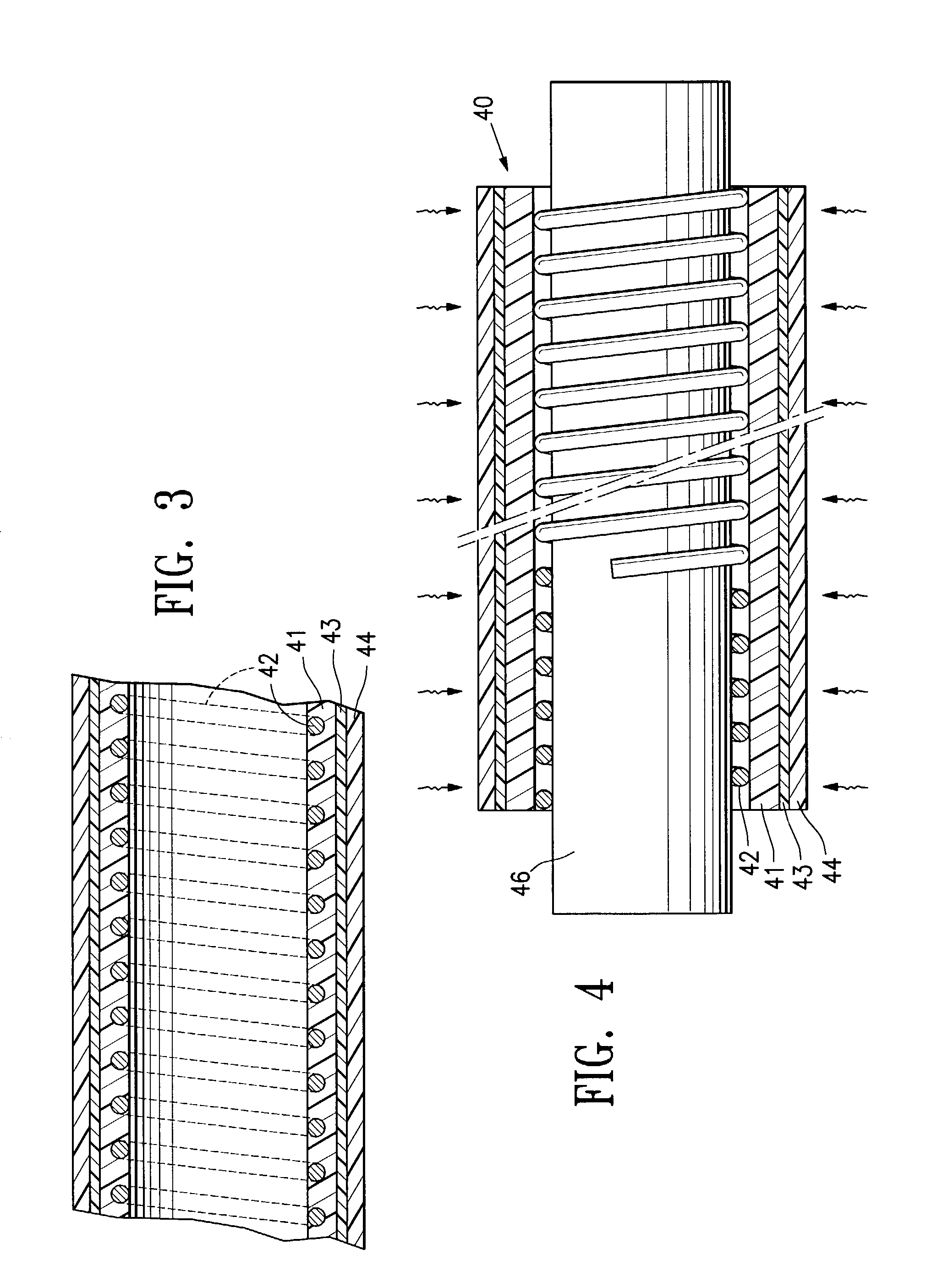

Coil reinforced multilayered inner tubular member for a balloon catheter

A catheter having an elongated shaft formed of a polymeric tubular member with at least a section having a lubricious inner layer defining the guidewire lumen, a coiled support member at least partially embedded in the lubricious inner layer, and an outer layer on an outer surface of at least a distal portion of the lubricious inner layer. In a presently preferred embodiment, the coil supported polymeric tubular member forms an inner tubular member of a balloon catheter.

Owner:ABBOTT CARDIOVASCULAR

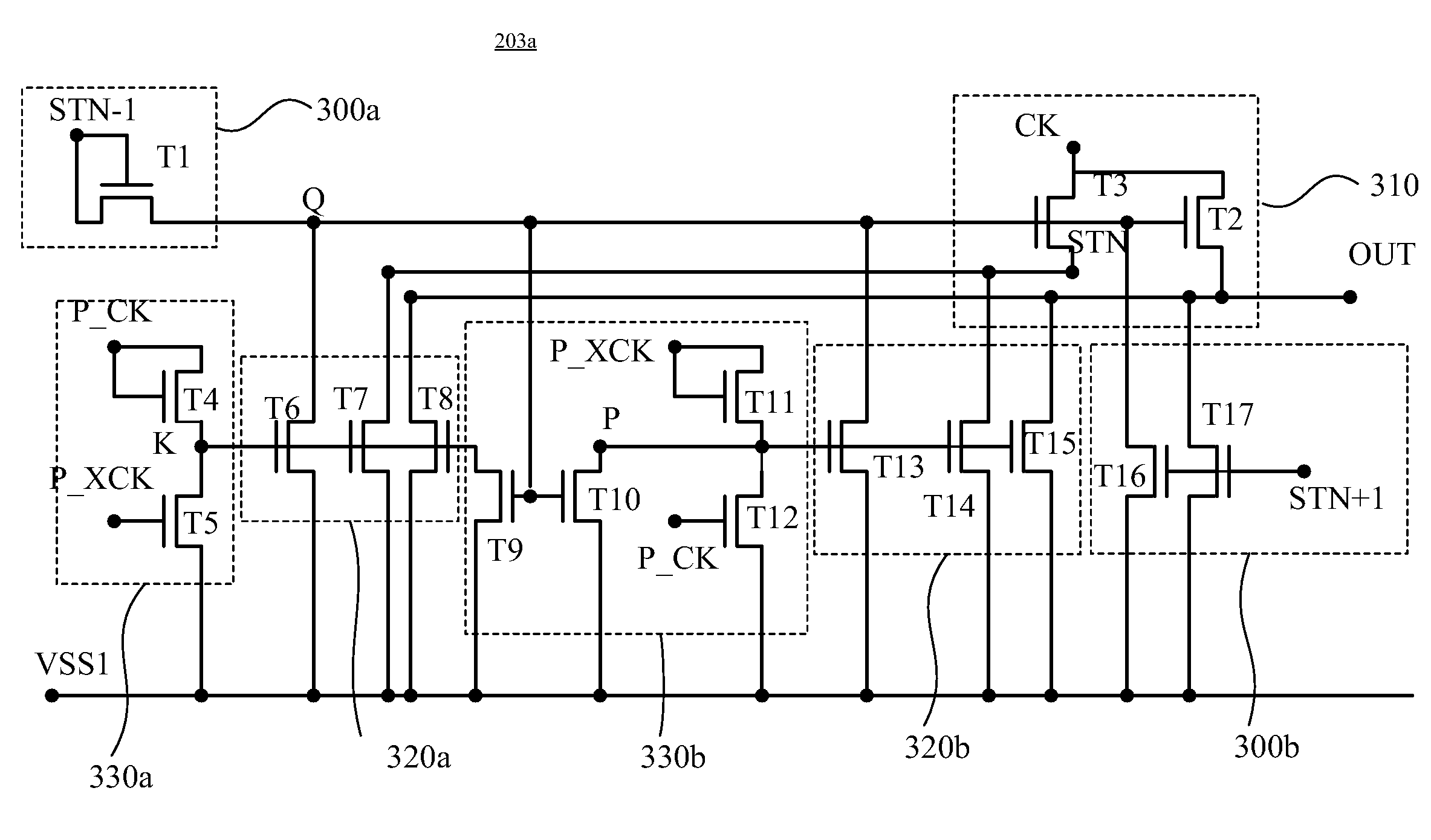

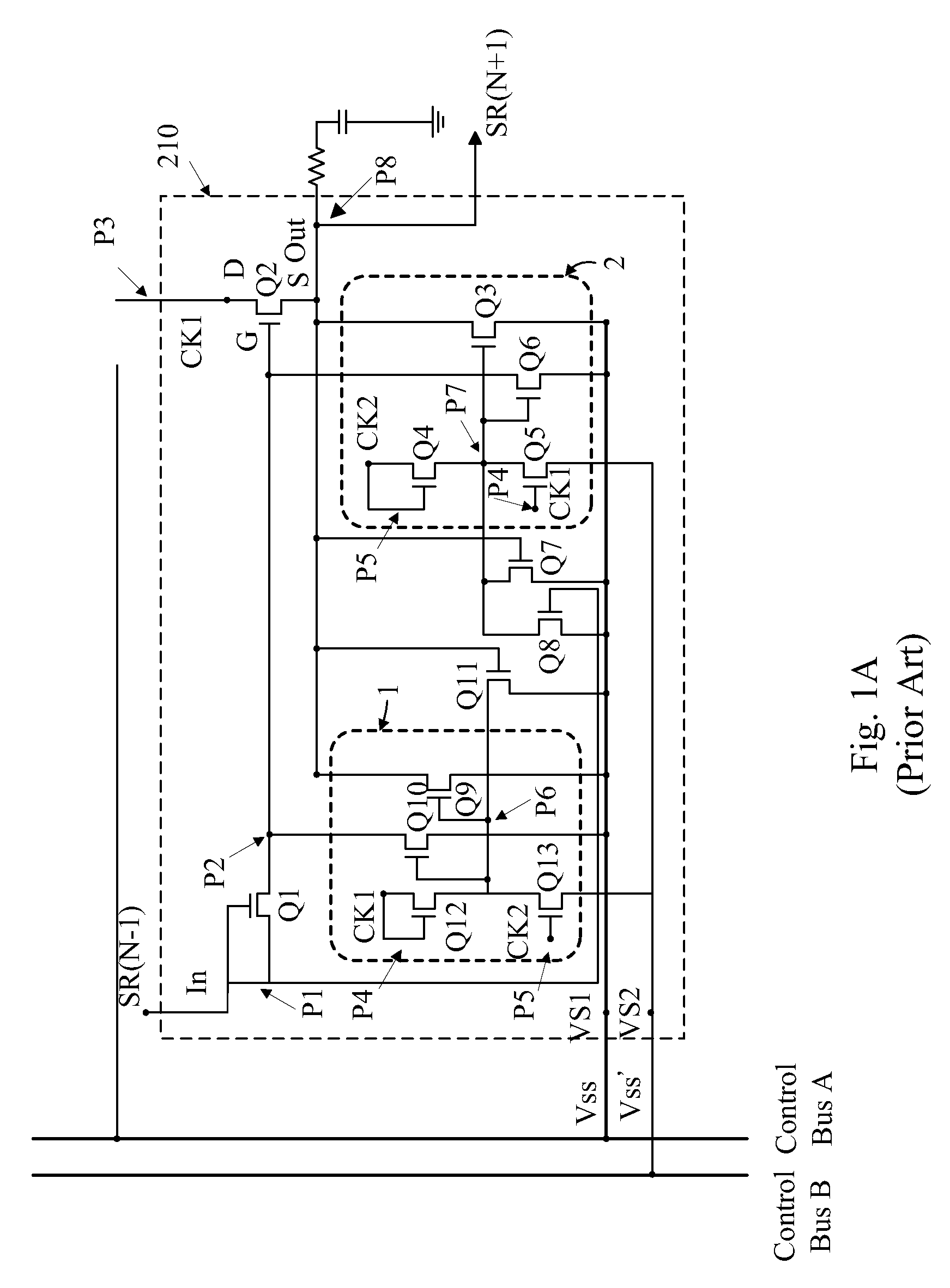

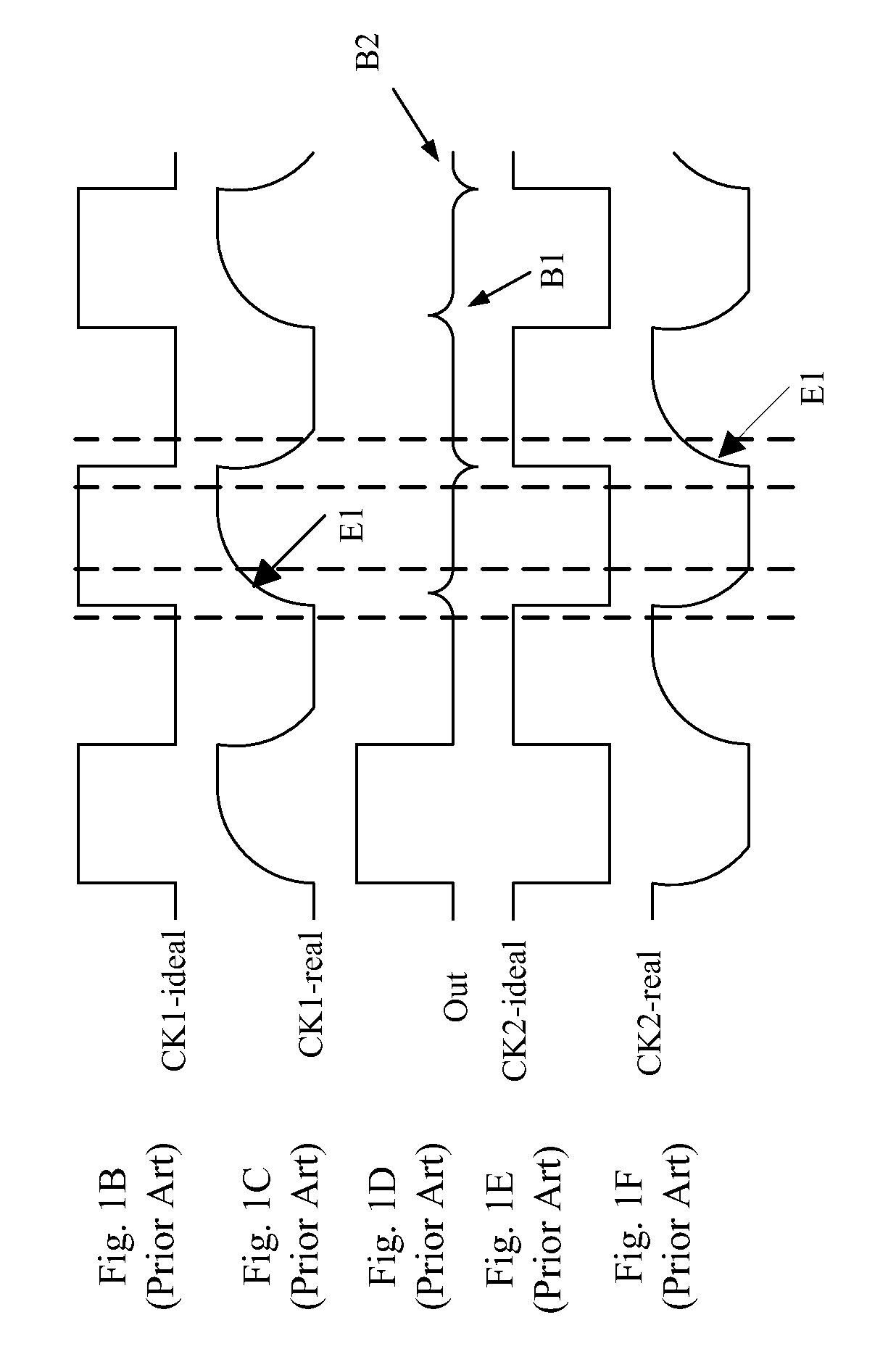

Shift register and shift register unit for diminishing clock coupling effect

ActiveUS20090304138A1Optimize outputOptimize waveform outputStatic indicating devicesDigital storageWave shapeEngineering

A shift register and a shift register unit for diminishing clock coupling effect are introduced herein. Each stage shift register unit includes at least one pull-up driving module, a pull-up module, at least one pull-down module and a pull-down driving module. Before a waveform of either a first clock signal or a second clock signal employed by the pull-up module transits into a rising edge, the pull-down driving module employs a first periodic signal to turn on the pull-down module in advance for a specific period, and / or before the waveform of the first or second clock signal employed by the pull-up module transits into a falling edge, the pull-down driving module employs a second periodic signal to turn off the pull-down module in advance for a specific period. Accordingly, the pull-down module can gain a sufficient capability against the clock coupling effect so as to optimize the waveform outputted from the shift register unit.

Owner:AU OPTRONICS CORP

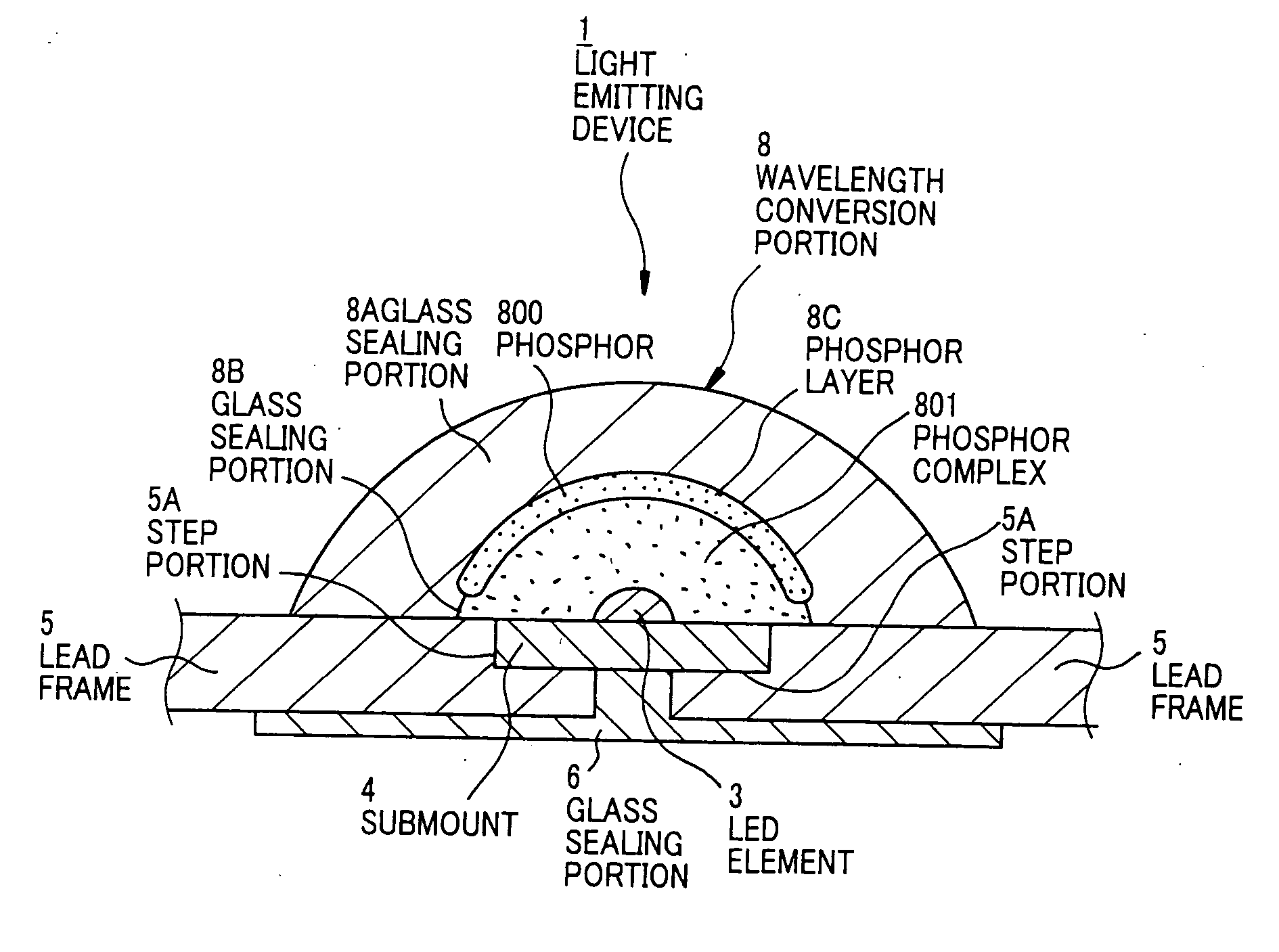

Light emitting device provided with a submount assembly for improved thermal dissipation

ActiveUS7391153B2Lowing of residual bubbleReduce internal stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

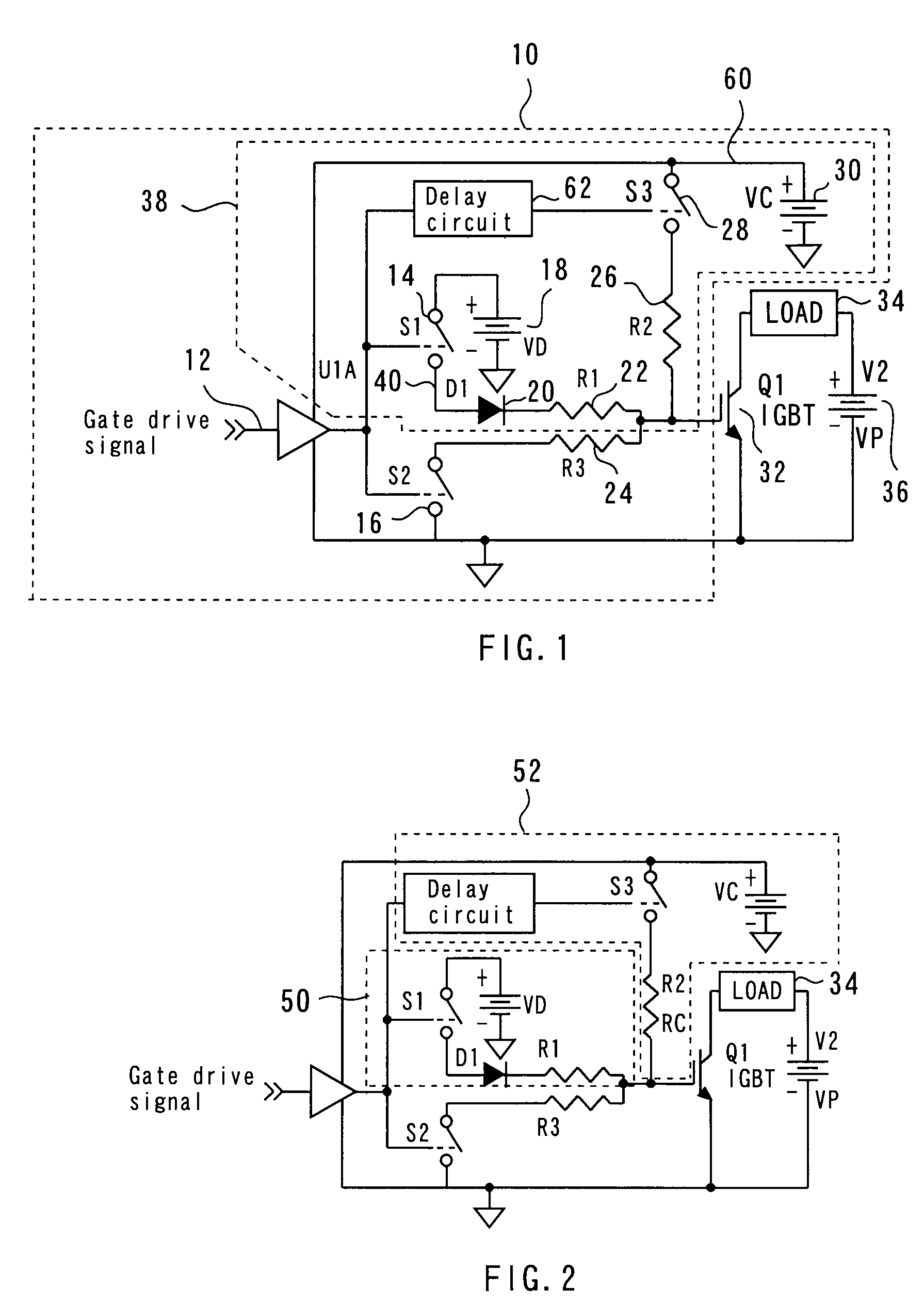

Gate drive circuit

ActiveUS20090066402A1Solve the lack of resistanceImprove homeostasisReliability increasing modificationsElectronic switchingPower switchingEngineering

A gate drive circuit includes a turn-on side circuit for turning on a gate of a power switching device, the turn-on side circuit including a first turn-on side power supply circuit and a second turn-on side power supply circuit, the first turn-on side power supply circuit including: a first turn-on voltage source for supplying a first turn-on voltage; first turn-on wiring; and a first turn-on switch connected in the first turn-on wiring and controlled by a gate drive signal; and the second turn-on side power supply circuit including: a second turn-on voltage source for supplying a second turn-on voltage applied to the gate of the power switching device to set the power switching device in a steady (on) state; second turn-on wiring; a second turn-on switch connected in the second turn-on wiring; and a turn-on side delay circuit for delaying the gate drive signal and passing it to the second turn-on switch.

Owner:MITSUBISHI ELECTRIC CORP

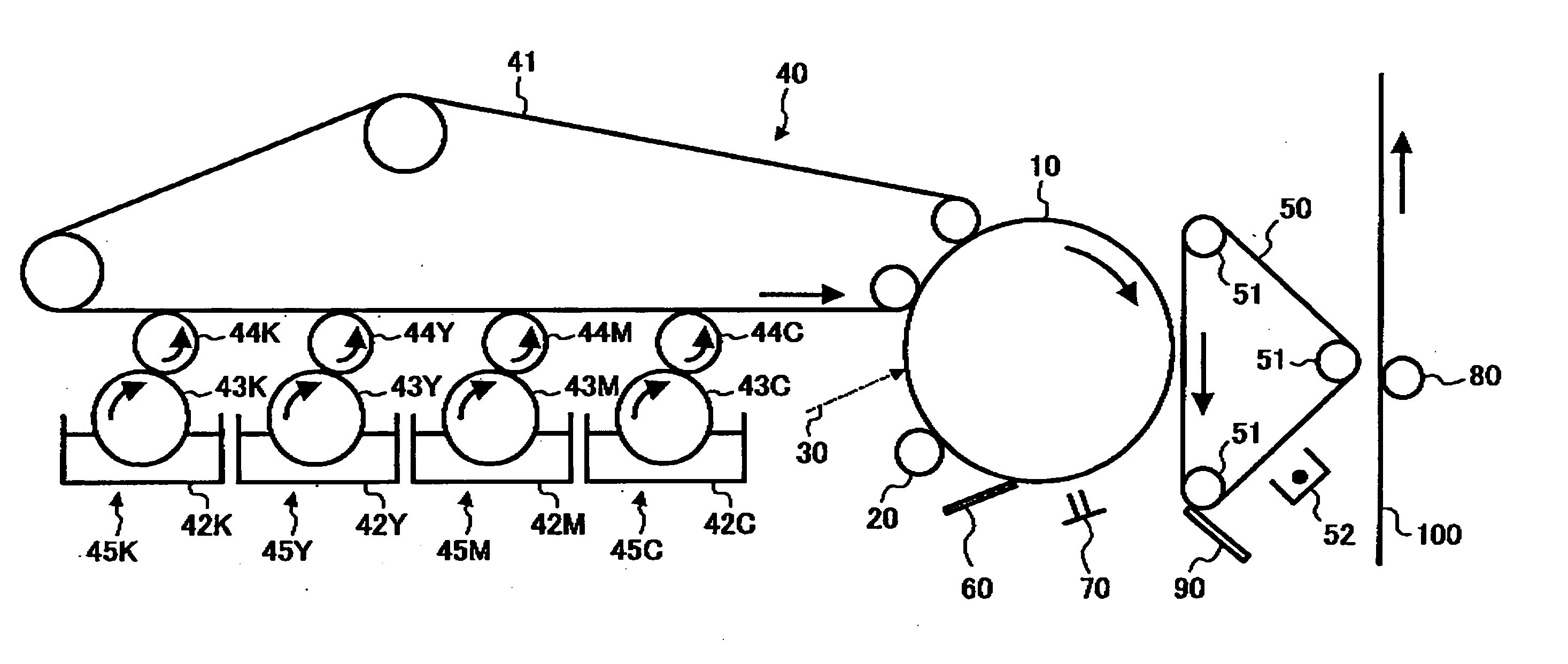

Toner, developer, image forming apparatus and image forming method

ActiveUS20050089786A1Sufficient resistance frictionSufficient glossinessDevelopersElectrographic process apparatusImage formationPolymer chemistry

Owner:RICOH KK

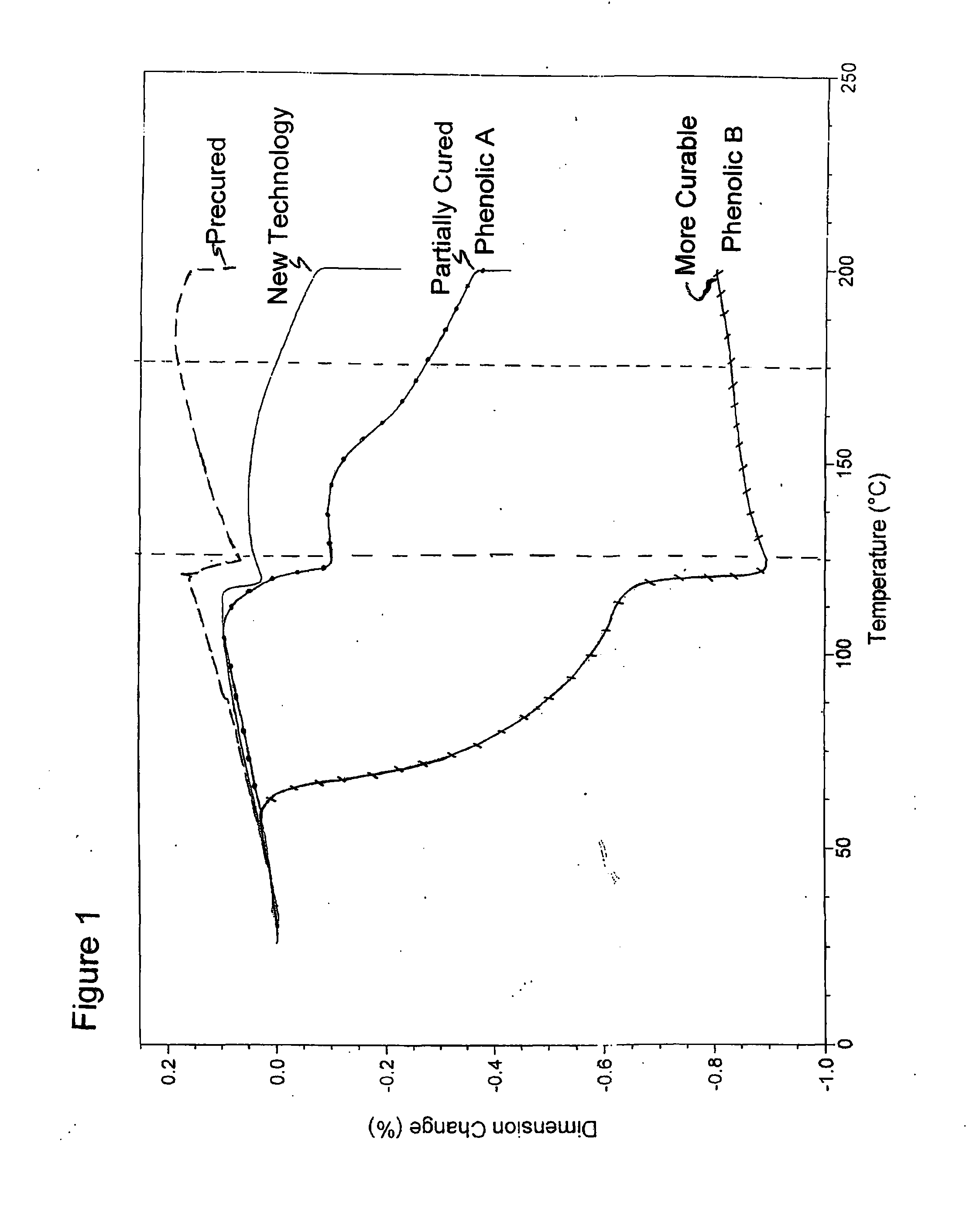

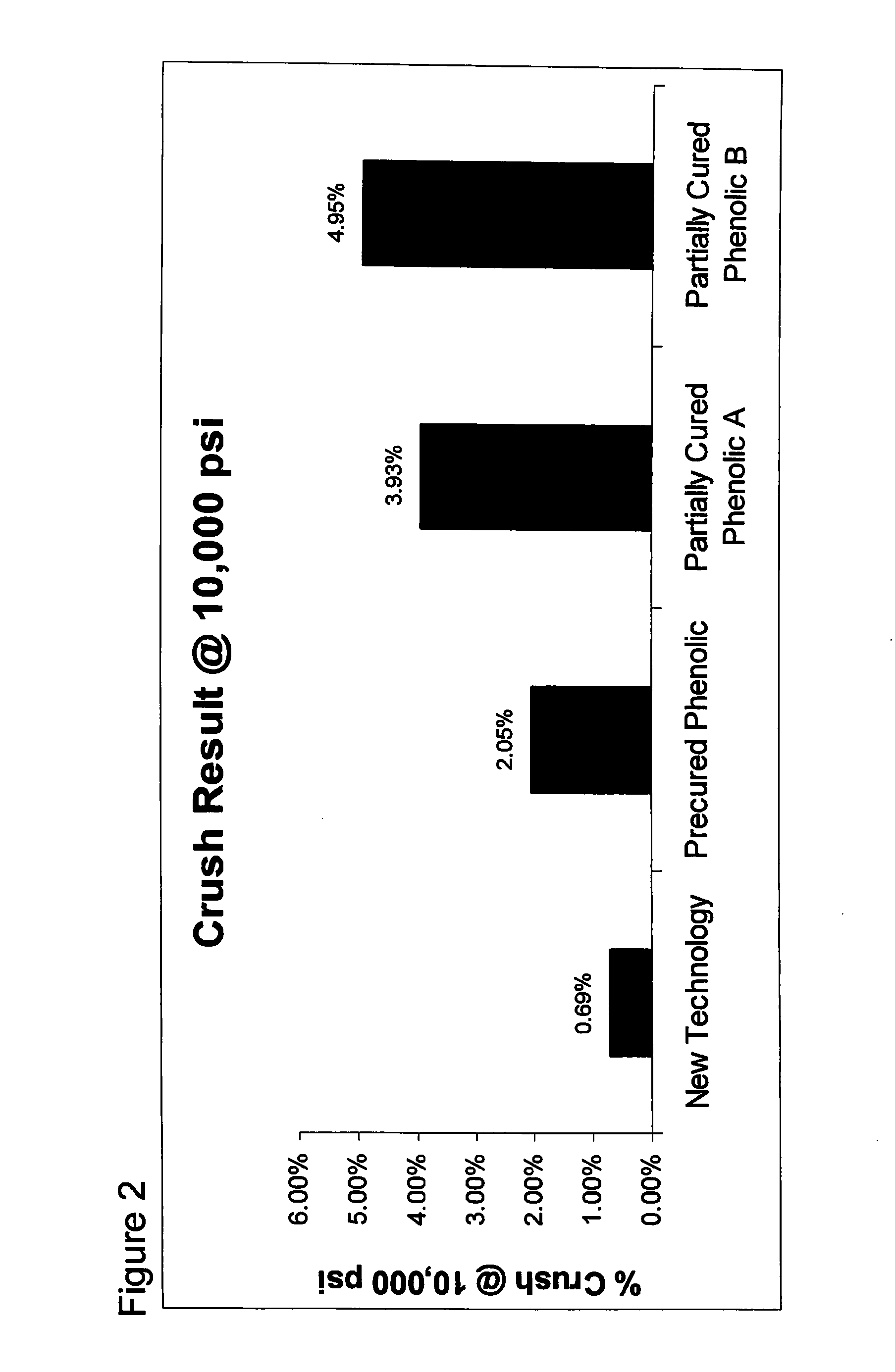

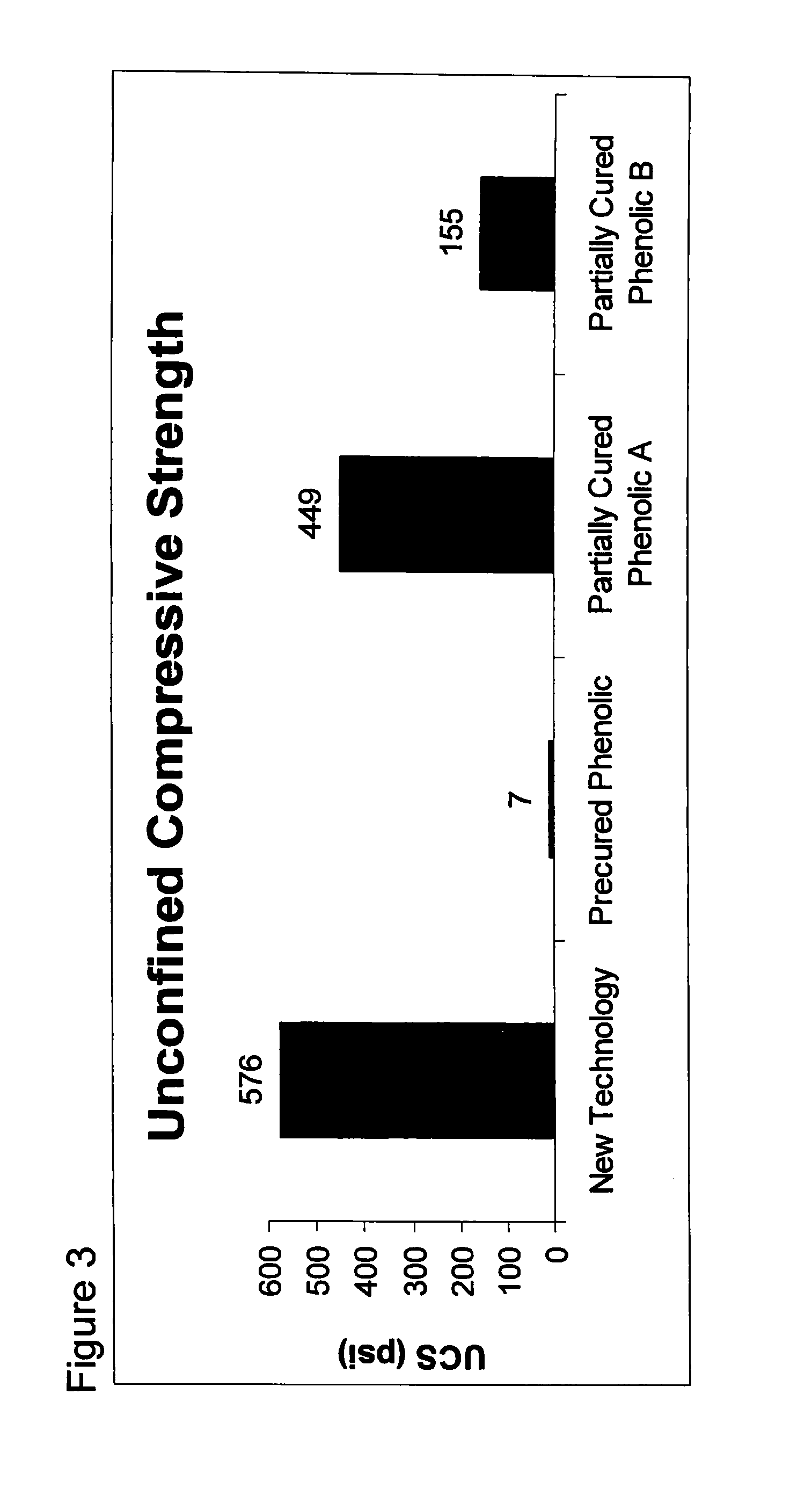

Coated and cured proppants

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

Thin stator, eccentric motor and axial air-gap brushless vibration motor equipped with the same

InactiveUS20080018187A1Sufficient starting torqueInfluence of bracket magnetic force can be suppressedMagnetic circuit stationary partsMechanical energy handlingDetentAir core

A stator includes a bracket having a shaft bearing portion at a center, a stator base including a flexible printed wiring board outwardly attached to the shaft bearing portion, single-phase air-armature coils disposed on the stator base, and a drive circuit member disposed on the stator base so as not to overlap with the single-phase air-core armature coils. The bracket has a through hole at the section corresponding to the bottom of the drive circuit member. The stator base is embedded at least partly in the thickness direction in the through hole and fixed using a resin, and a detent torque generation member is contained in, and is no thicker than, the stator base.

Owner:TOKYO PARTS IND CO LTD

Method for polymerization of an alpha -olefin

InactiveUS6066702AHigh reactivityEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorAlpha-olefin

A method for polymerization or copolymerization of alpha -olefin, characterized in that the polymerization is performed using a solid complex titanium catalyst comprising magnesium, a halogen-containing titanium compound, and internal electron donors; organometallic compounds of metals belonging to Groups I and III on the periodic table of elements; and, as external electron donors, a mixture of three or more kinds of organic silicon compounds, from which homopolyolefins having MFR less than 5, MFR in the range from 5 to 20, and MFR greater than 20 are polymerized under the same polymerization conditions. By use of the present invention it is possible to produce an olefin polymer with high stereoregularity, broad molecular weight distribution, and good fluidity, at high rates of yield.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

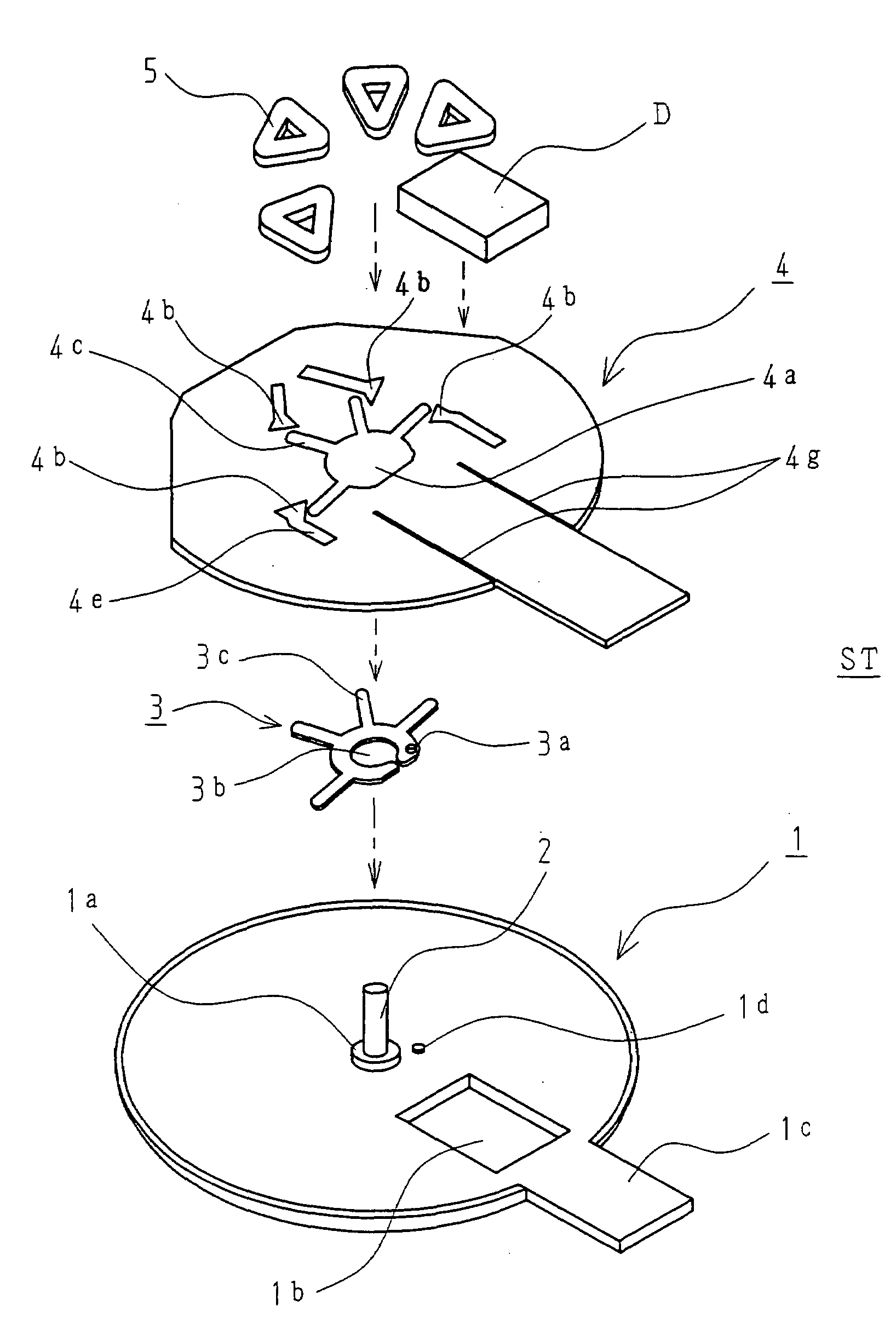

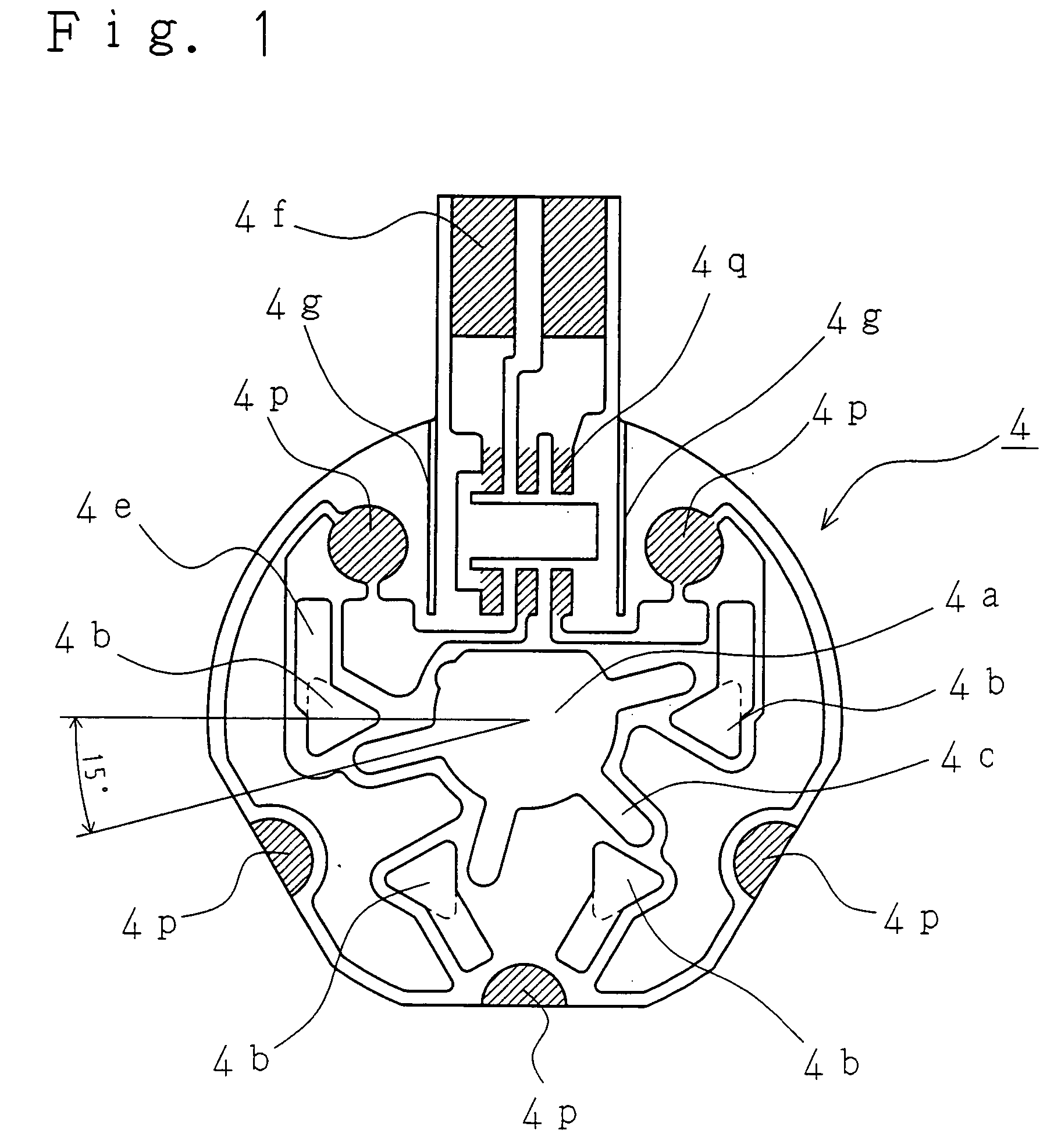

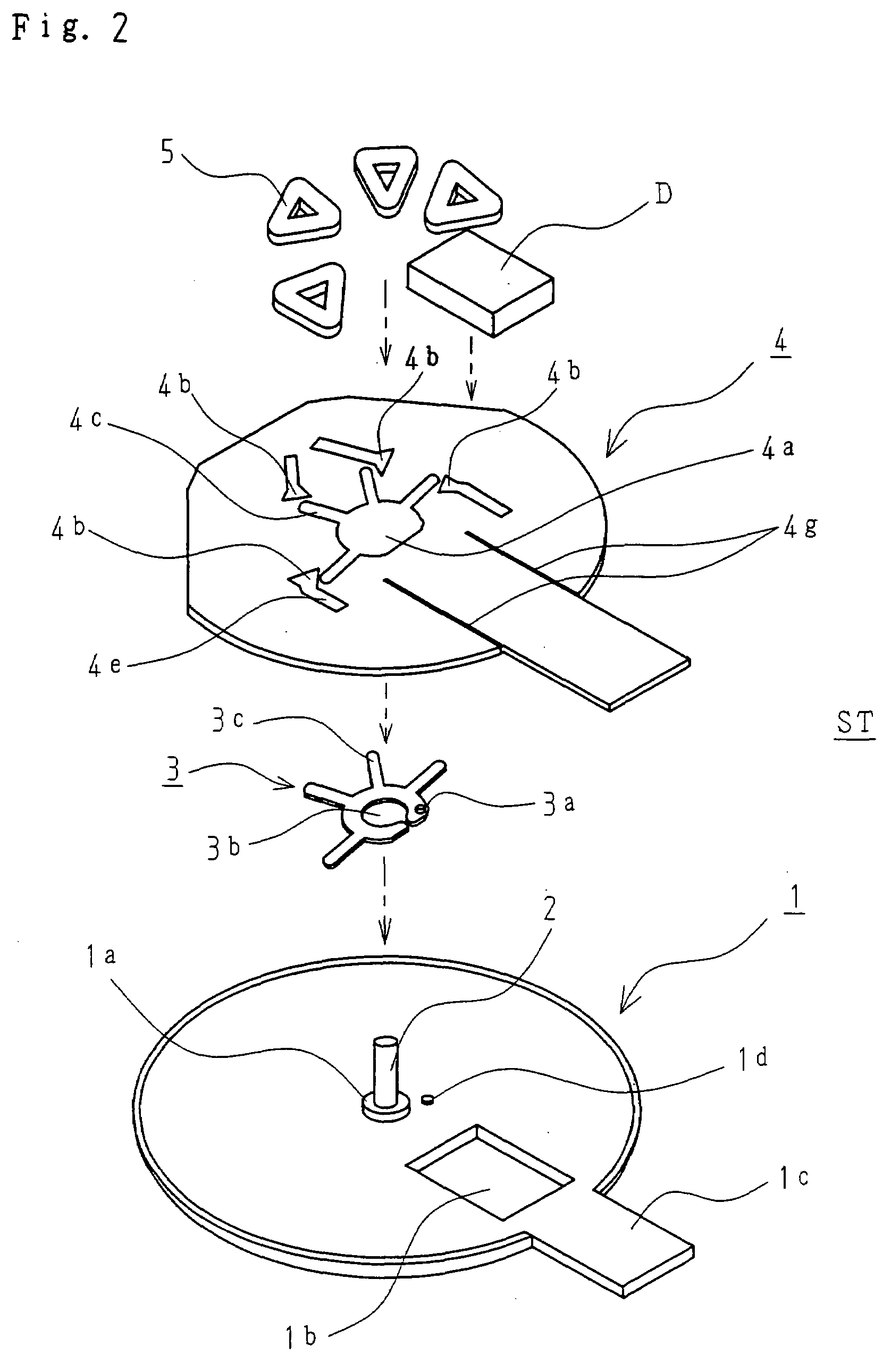

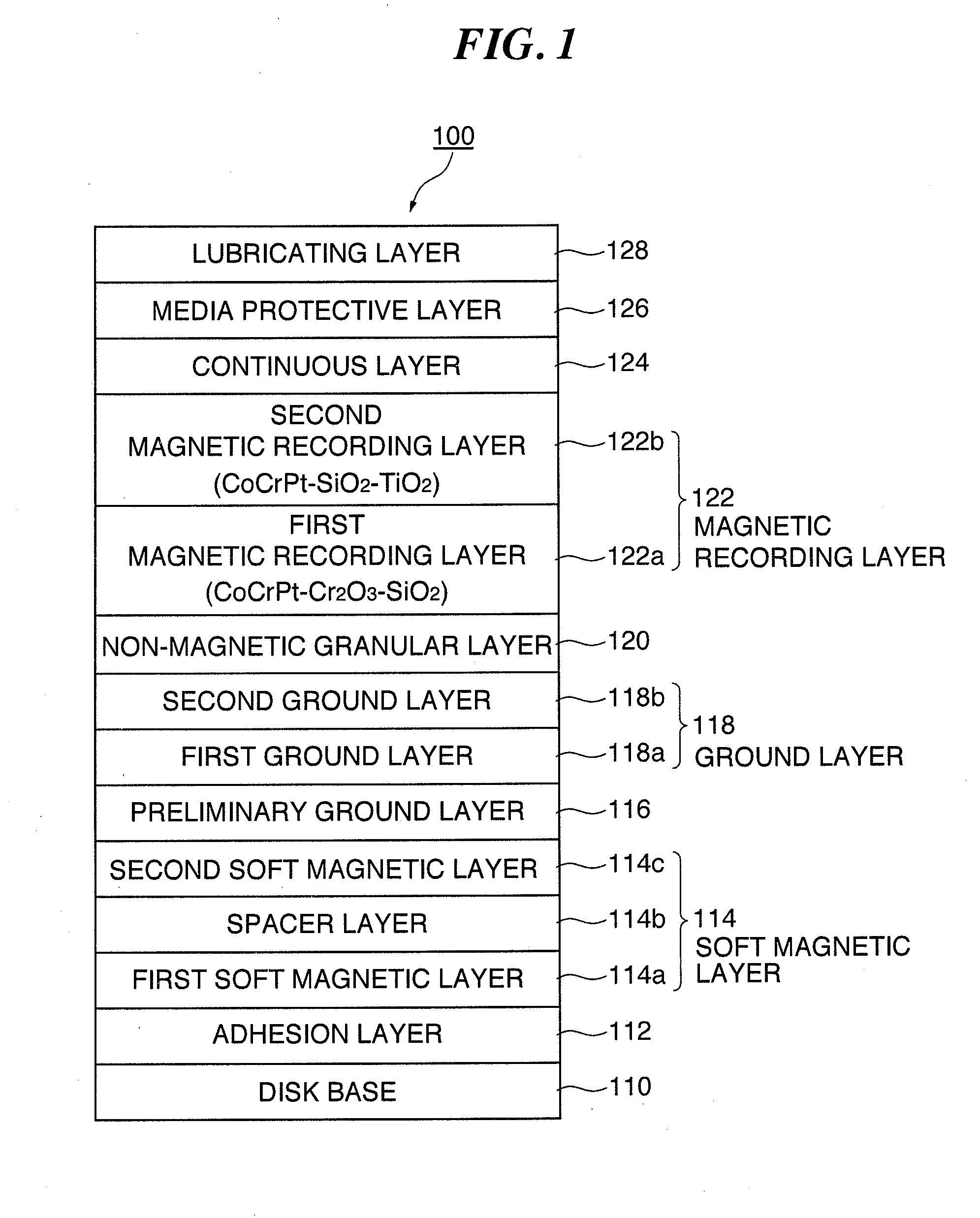

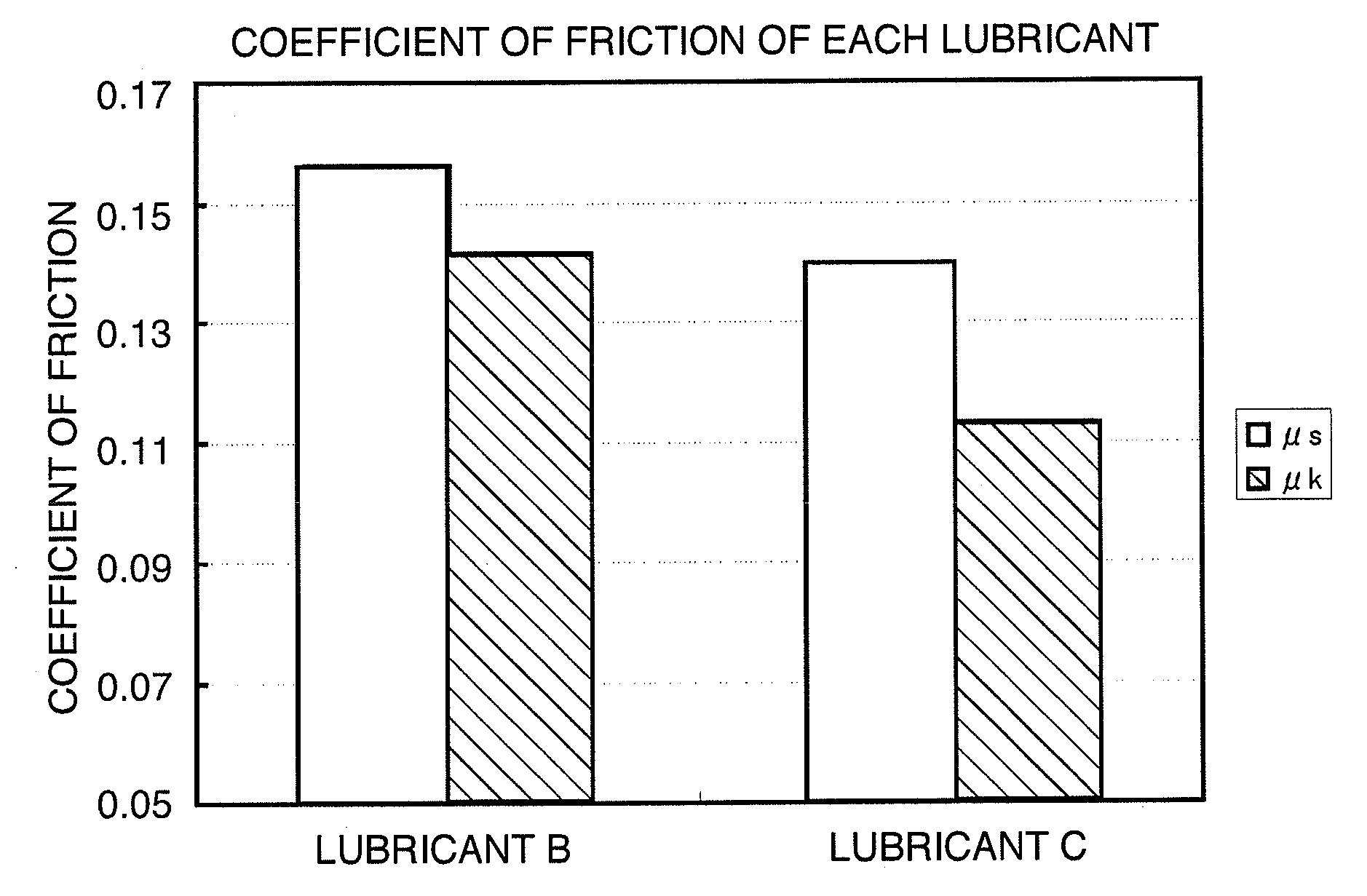

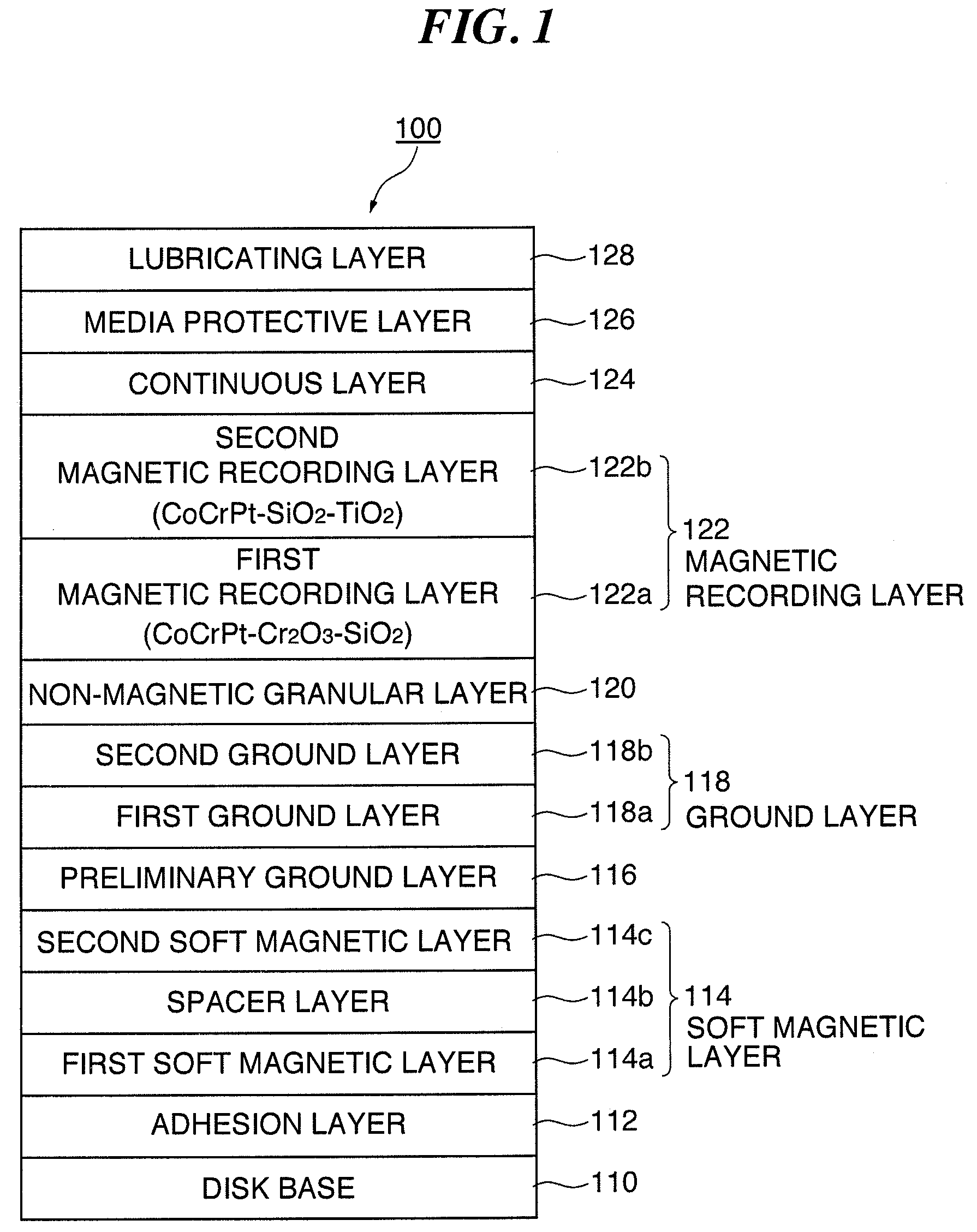

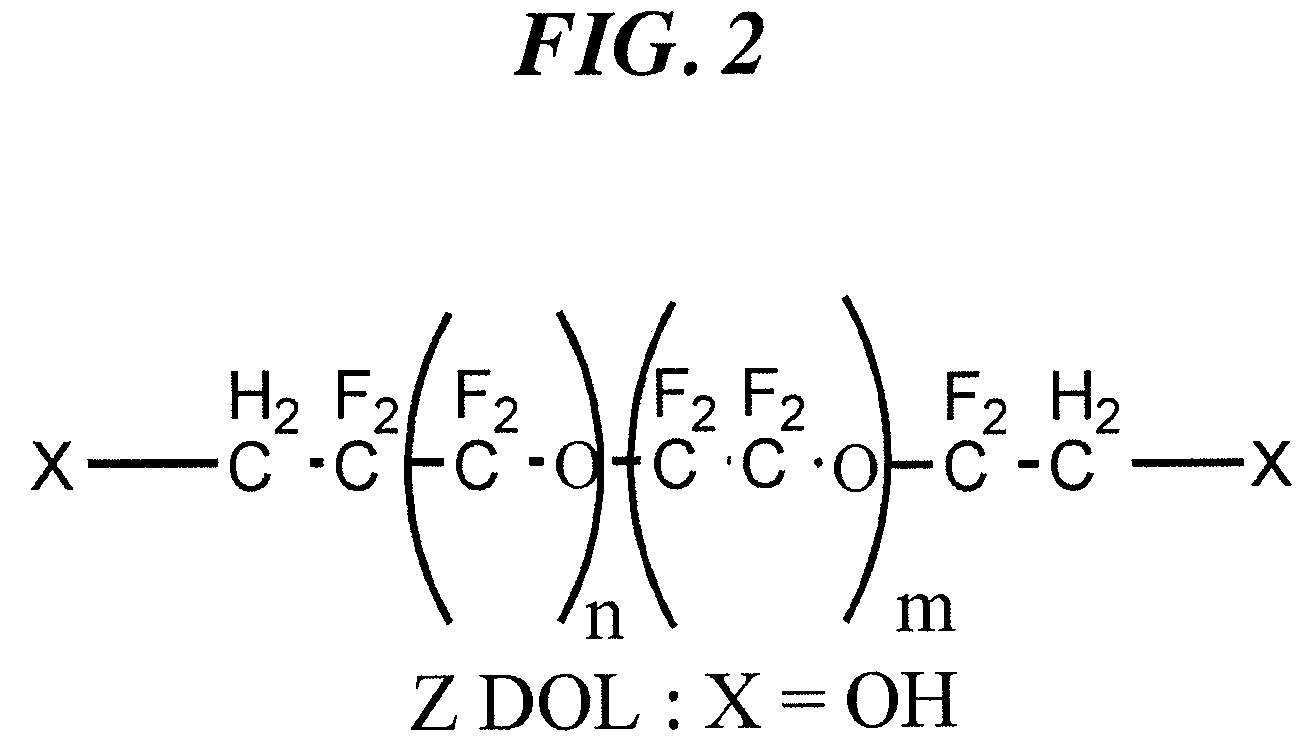

Method of producing a perpendicular magnetic recording medium and perpendicular magnetic recording medium

InactiveUS20140011054A1Solve the lack of durabilitySolve the lack of resistanceProtective coatings for layersRecord information storageBond densityMoisture resistance

Owner:WD MEDIA SINGAPORE PTE

Method of producing a perpendicular magnetic recording medium and perpendicular magnetic recording medium

InactiveUS8623529B2Solve the lack of durabilitySolve the lack of resistanceMagnetic materials for record carriersRecord information storageBond densityMoisture resistance

An object of the present invention is to provide a perpendicular magnetic recording medium including a suitable lubricating layer with sufficient durability, moisture resistance, and contamination resistance and also maintaining an R / W characteristic. In a typical structure of the present invention, a method of manufacturing a perpendicular magnetic recording medium 100 including a magnetic recording layer 122, a medium protective layer 126, and a lubricating layer 128 in this order on a base 110 includes: a CF bond density measuring step of measuring a CF bond density of a lubricant; and a lubricating layer forming step of forming a lubricating layer with the lubricant when the measured CF bond density is 2.0×1022 to 2.7×1022 atoms / cm3.

Owner:WD MEDIA SINGAPORE PTE

Neuro thrombectomy catheter

InactiveUS20060259052A1Small outer diameterSufficient kink resistanceCannulasExcision instrumentsThrombusEngineering

An elongate tubular body extends between a rotatable cutter and a control. The cutter is connected to the control with a rotatable element. A vacuum is applied through an annular passage defined between the tubular body and the rotatable element. The tubular body has a sufficiently small outside diameter and sufficient kink resistance and pushability to navigate through arteries such as the internal carotid artery.

Owner:TYCO HEALTHCARE GRP LP

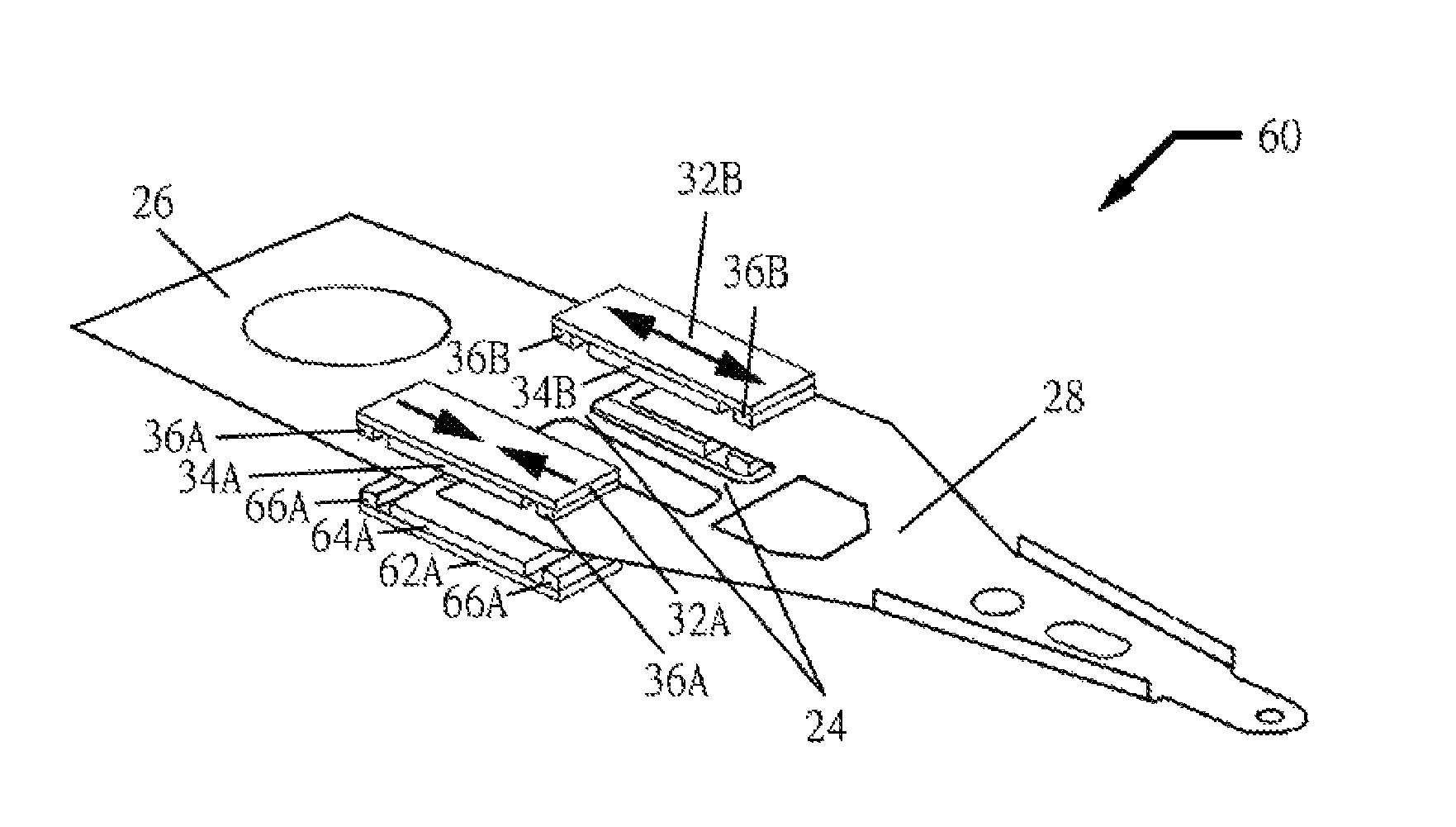

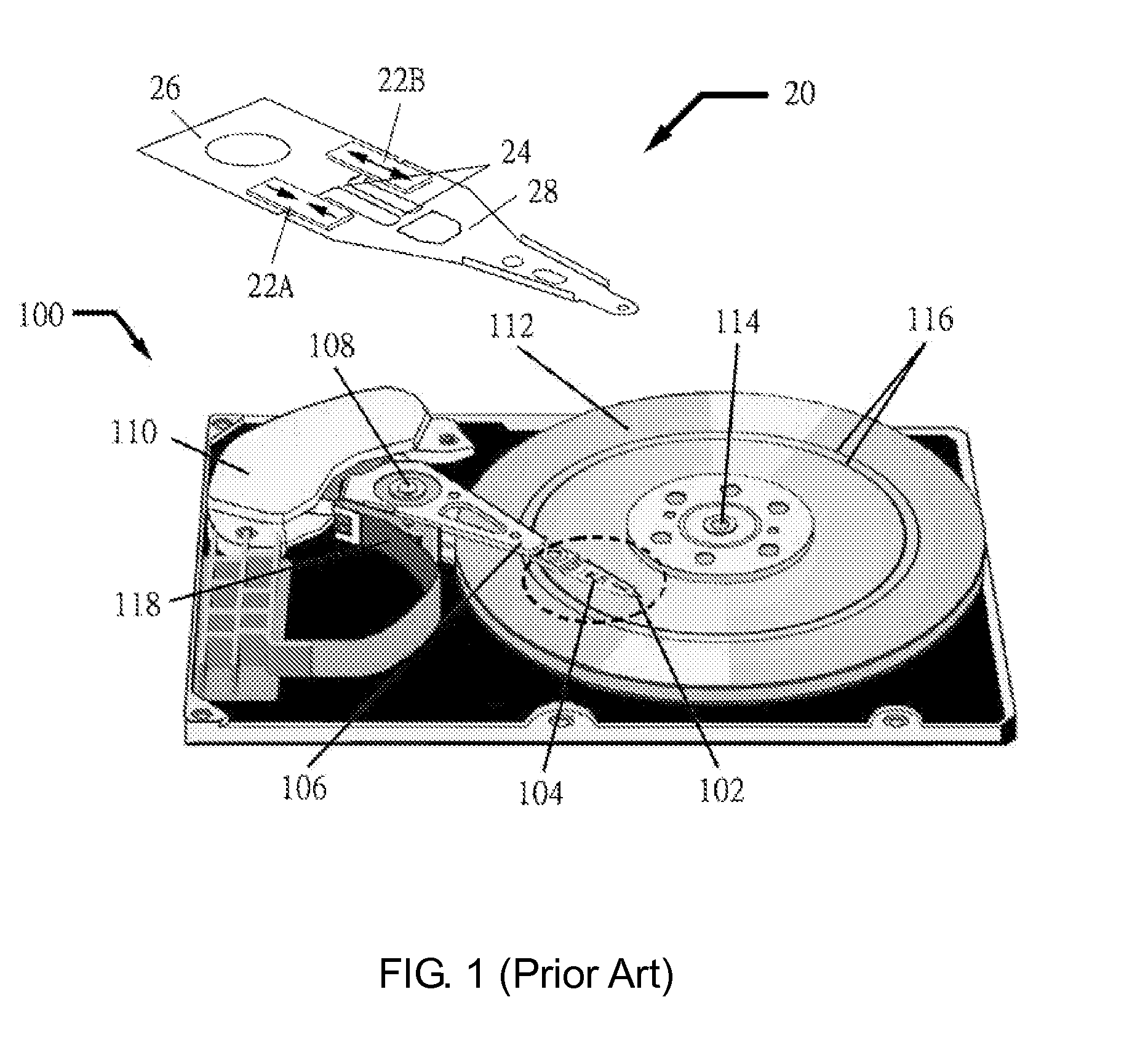

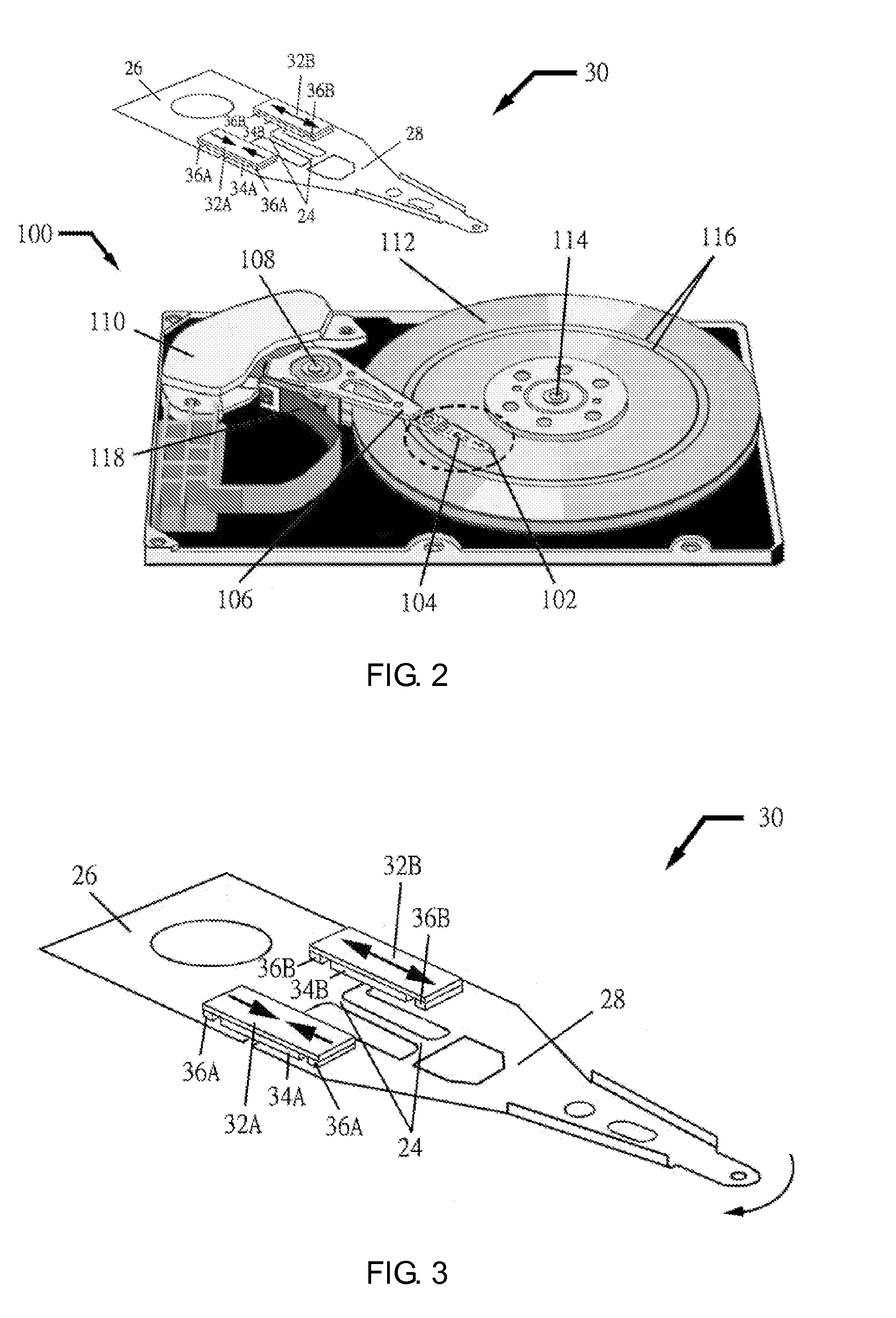

Piezoelectric actuated suspension with passive damping in hard disk drives

ActiveUS7983008B2Precise positioningSufficient shock resistanceArm with actuatorsRecord information storageViscoelastic dampingHard disc drive

A piezoelectric actuated suspension with passive damping is disclosed for precision positioning of hard disk drive while reducing undesired shock vibrations. Along the longitudinal axis of an etched suspension, two piezoelectric actuators dispose near the base plate to provide a push-pull motion. The actuators have two main portions. The first portion is piezoelectric elements to provide active positioning. The second portion is viscoelastic damping layers underneath the piezoelectric elements for passive damping. The complementary parts such as stiff edge elements and optional soft boundary covers are used to enhance the actuating abilities of the actuators and prevent any contaminants of the viscoelastic layers from going into the clean sealed chamber of the hard disk drive, respectively. The present invention further relates to a dual-stage servo system in a hard disk drive for fine positioning of the read / write head and better shock resistance via the piezoelectric actuated suspension with passive damping.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

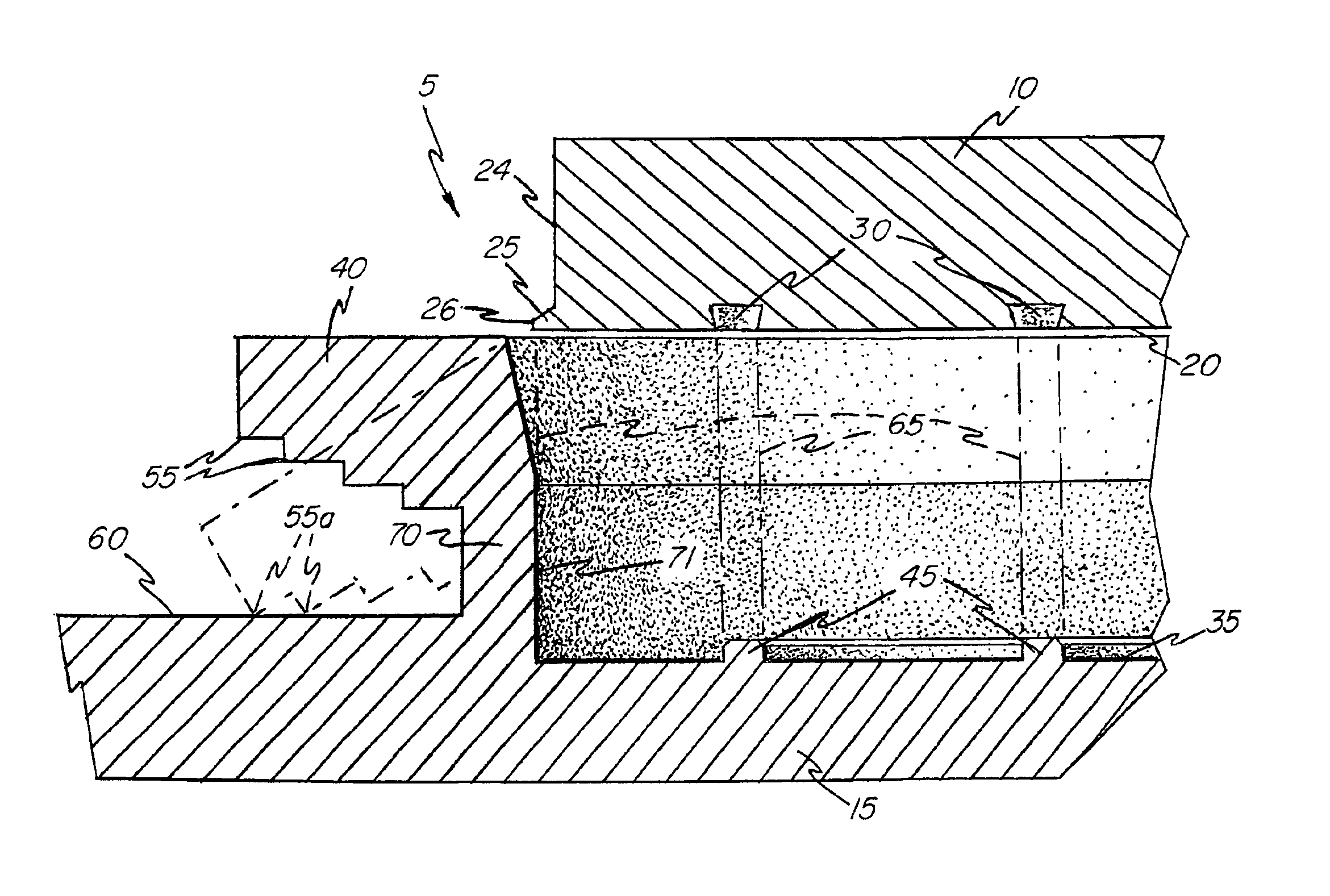

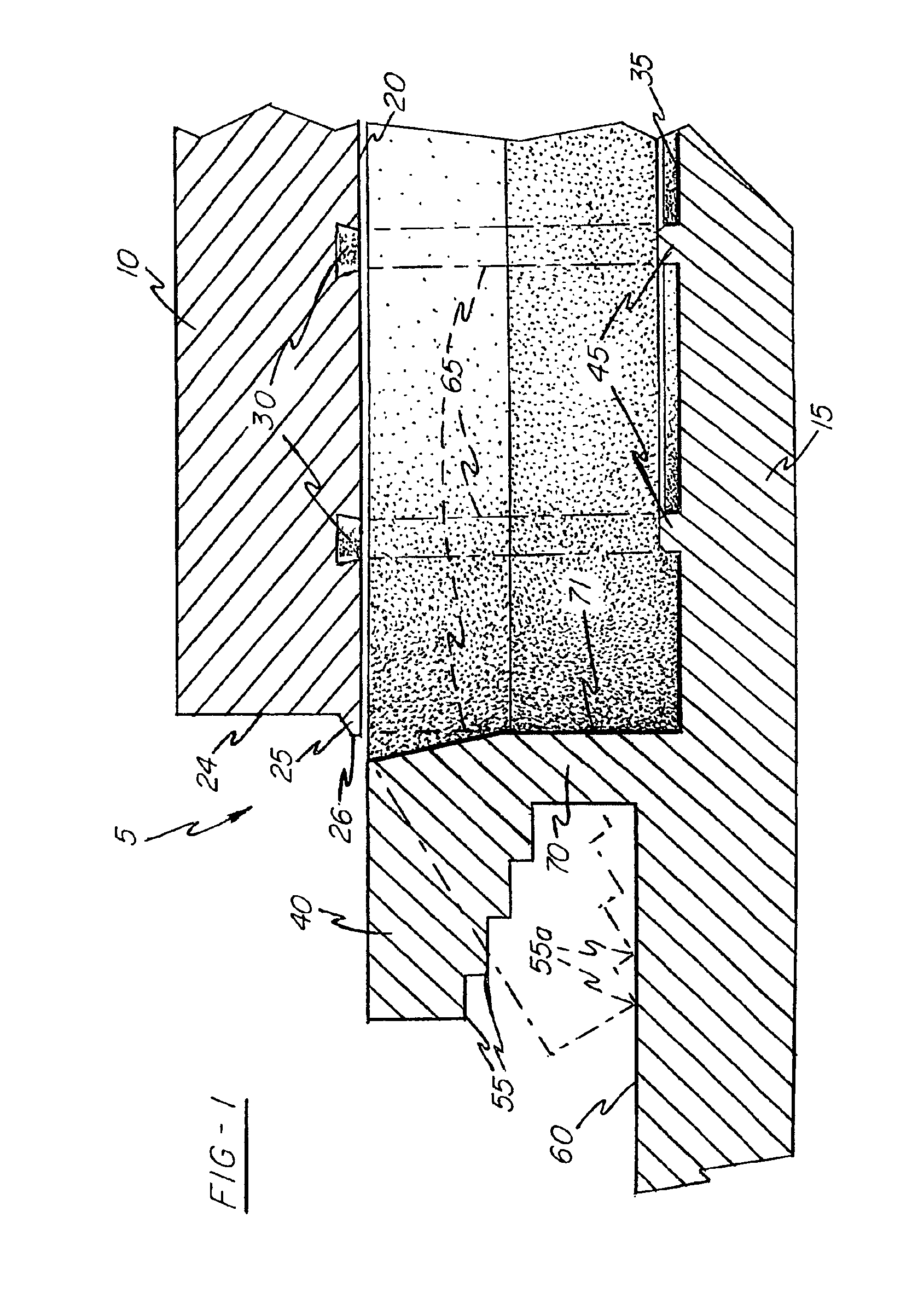

Low temperature sputter target/backing plate method and assembly

InactiveUS7146703B2Firmly connectedSolve the lack of resistanceCellsElectric discharge tubesBond interfaceBond strength

A sputtering target and a backing plate are diffusion-bonded with or without an insert or inserts interposed there-between so as to have a solid phase diffusion-bonded interface. The sputtering target substantially maintains its metallurgical characteristic and properties even though it has been diffusion-bonded to the backing plate. The solid-diffusion bonding of the target and backing plate, is achieved at a low temperature and pressure and results in interdiffusion of constituent atoms to attain high adhesion and bond strength without attendant deterioration or large deformation of the target material, while inhibiting the crystal growth in the target material. The bond undergoes no abrupt decrease in bond strength upon elevation of the service temperature. One hundred percent bonding is achieved with non-bonded portions such as pores left along the interface.

Owner:TOSOH SMD

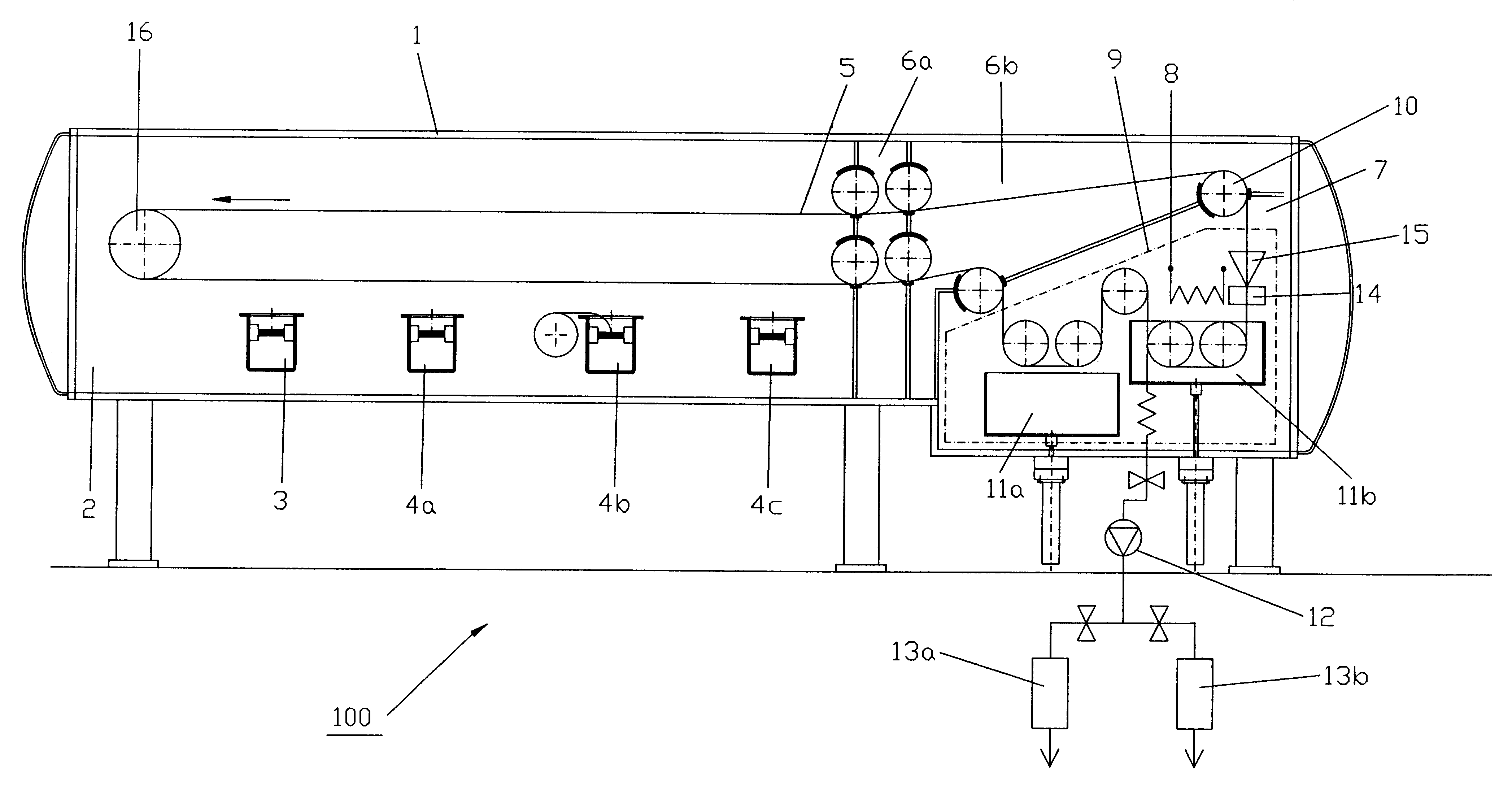

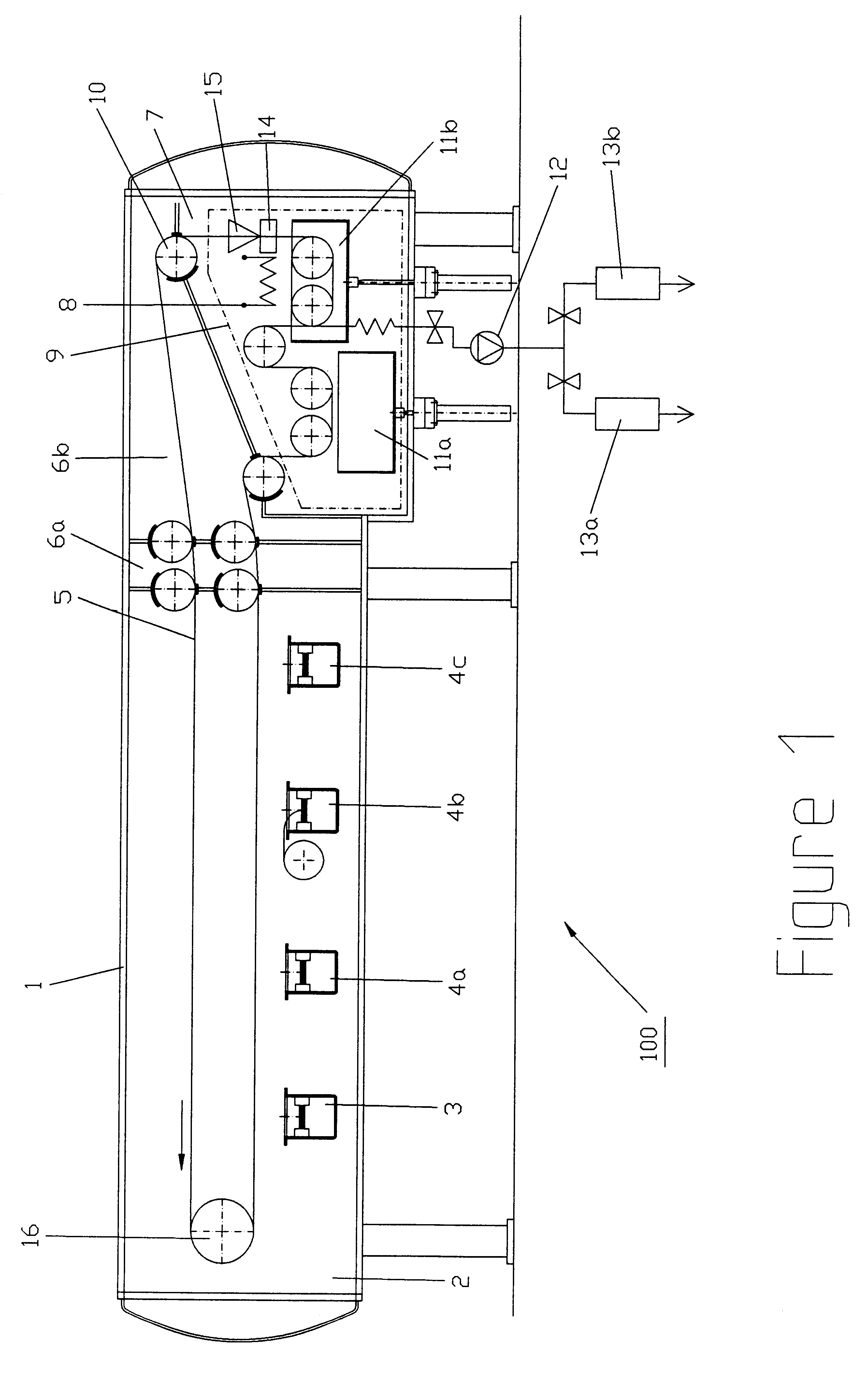

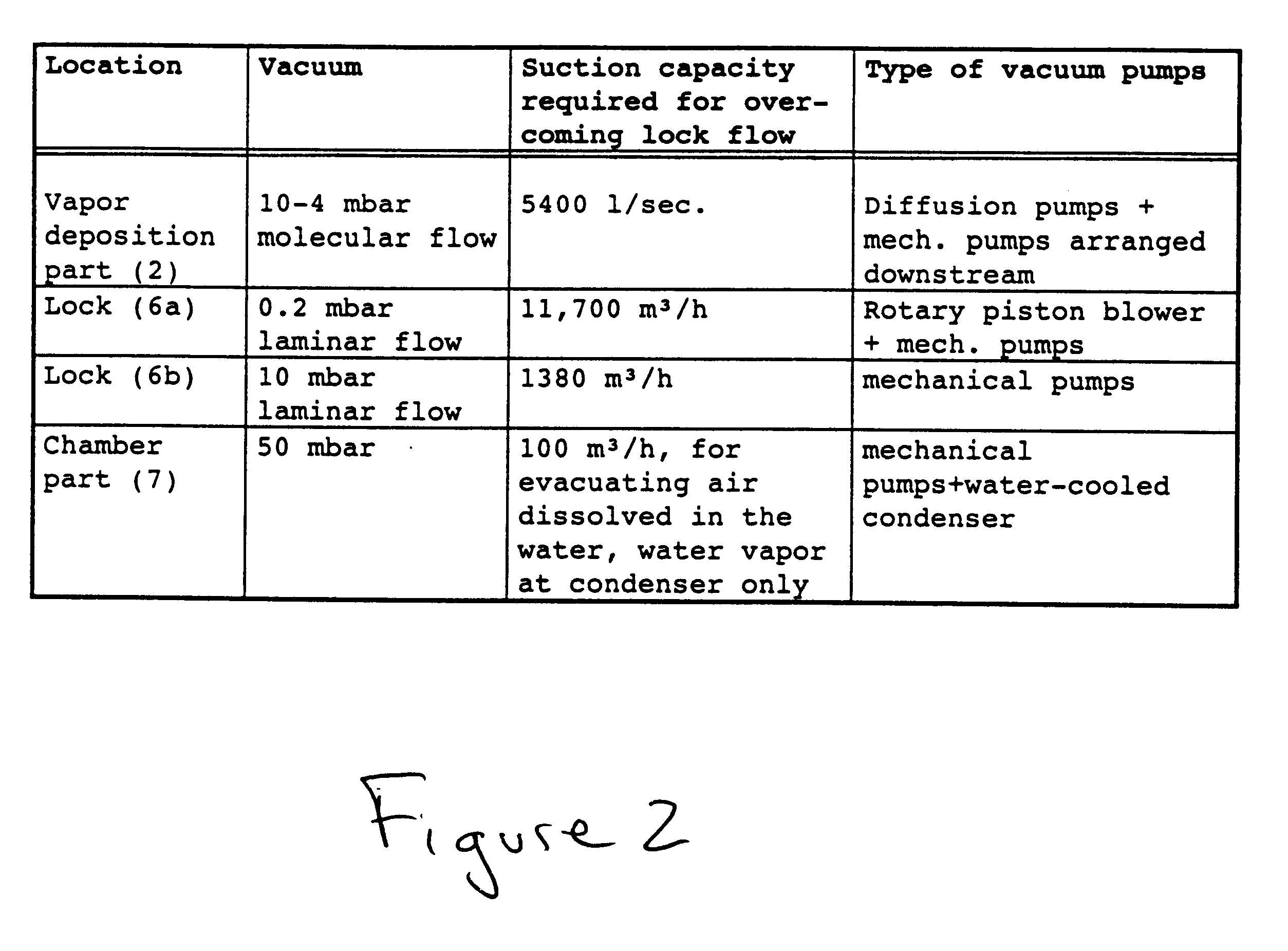

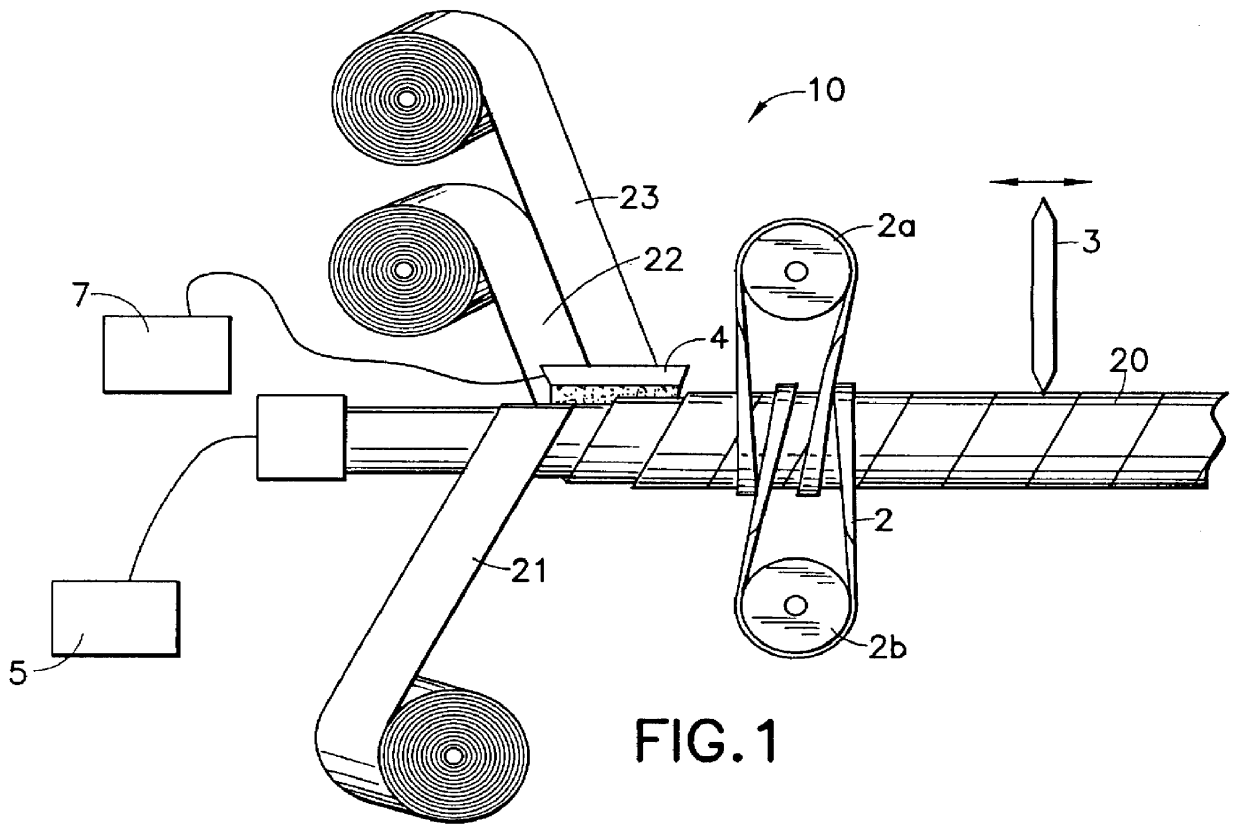

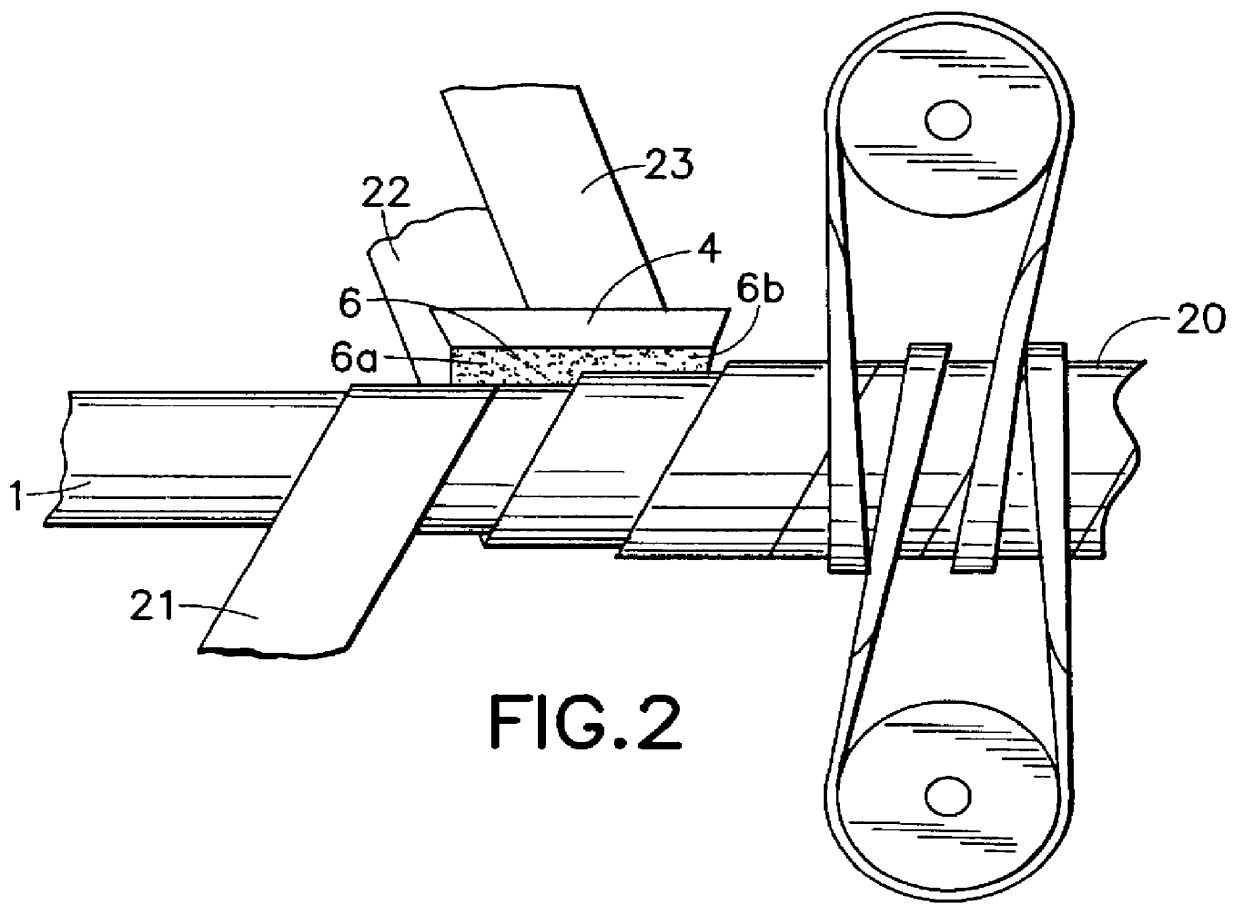

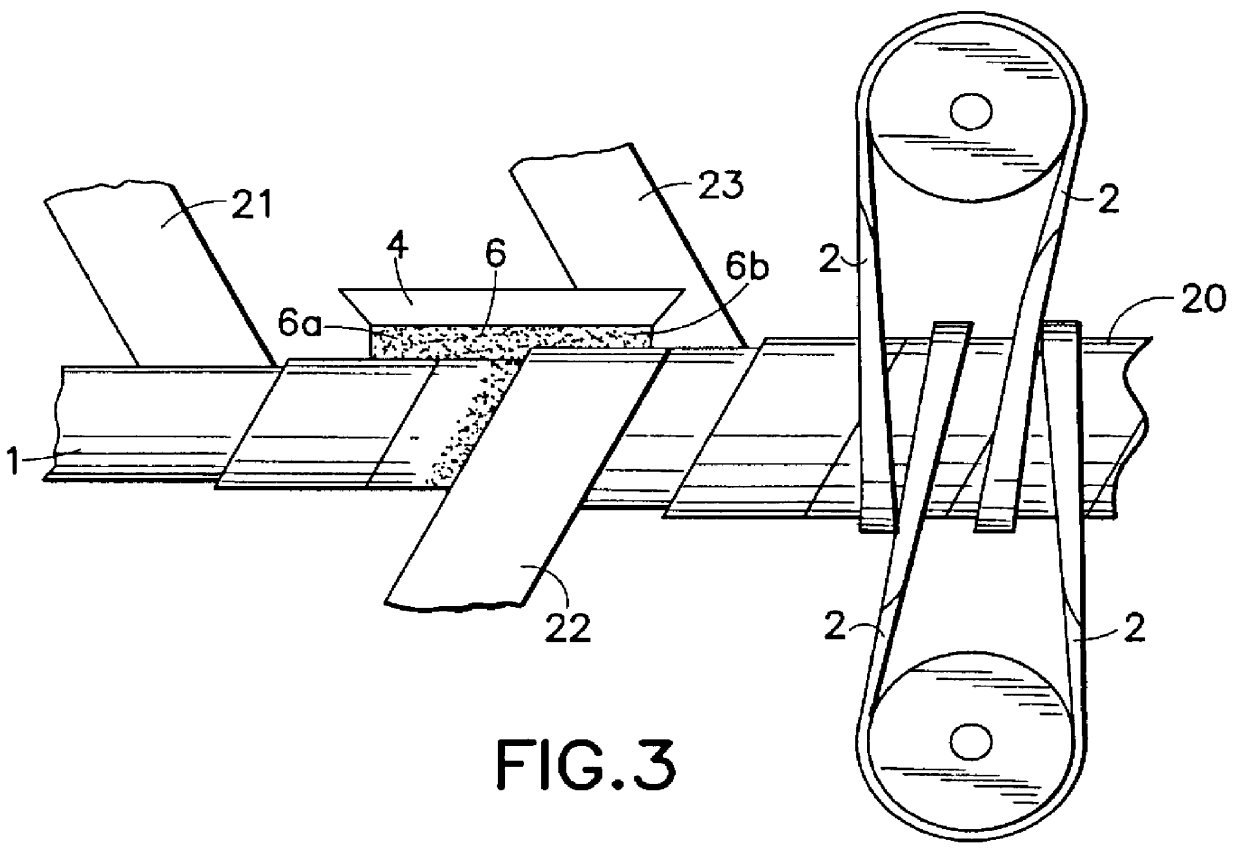

Apparatus and method for producing plane-parallel flakes

InactiveUS6270840B1Increase productionLow production costTransportation and packagingPigment preparation by PVD/CVD methodsAlcoholFluoride

An apparatus and method technique for producing plane-parallel flakes is disclosed. In a preferred embodiment, the present invention is realized through a multi-chamber apparatus for producing plane-parallel flakes from layers vapor deposited in vacuum on an endlessly circulating substrate. The present invention includes the sequential steps of: vapor deposition of a separating agent layer in high vacuum on the endlessly circulating substrate; vapor deposition of one or more layers of metal, oxides, fluorides, and nitrides in high vacuum on the separating agent layer; and stripping the vapor deposited layers from the endlessly circulating substrate under low vacuum. The vapor deposited layers are subsequently present in a separate vacuum stage separated from the vapor deposition chamber by dynamic locks as a suspension of fine flakes in a mixture of solvent. and separating agent. The suspension may continuously or intermittently be transferred out of the separate vacuum stage for further processing. The solvent may be water in a vacuum environment of more than 20 mbar or secondary or tertiary alcohols at more than 0.05 mbar.

Owner:CIBA SPECIALTY CHEM CORP +1

Ink composition and ink jet recording method using the same

ActiveUS20080028980A1Sufficient weather resistanceImprove ink adhesionMeasurement apparatus componentsDuplicating/marking methodsWeather resistancePlastic film

An ink composition containing an aprotic polar solvent, a thermoplastic resin, a pigment, a cyclic amide, a surfactant, and water and is printable on a recording surface that is a plastic film. The ink composition is capable of forming a record, having high weather resistance properties such as adhesion, scratch resistance, and water resistance, on a recording surface that is a plastic film.

Owner:SEIKO EPSON CORP

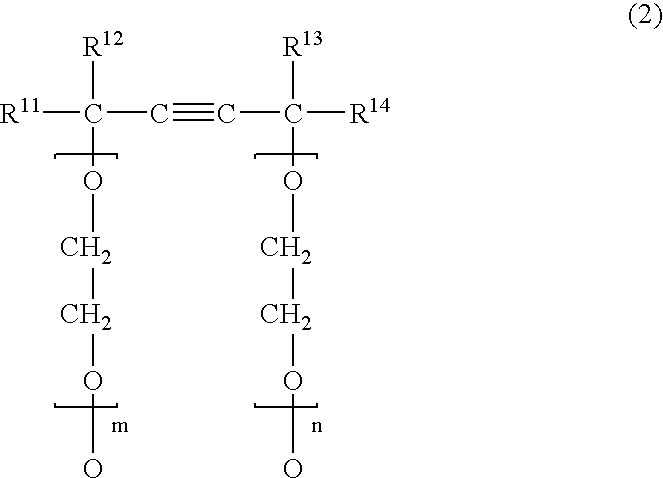

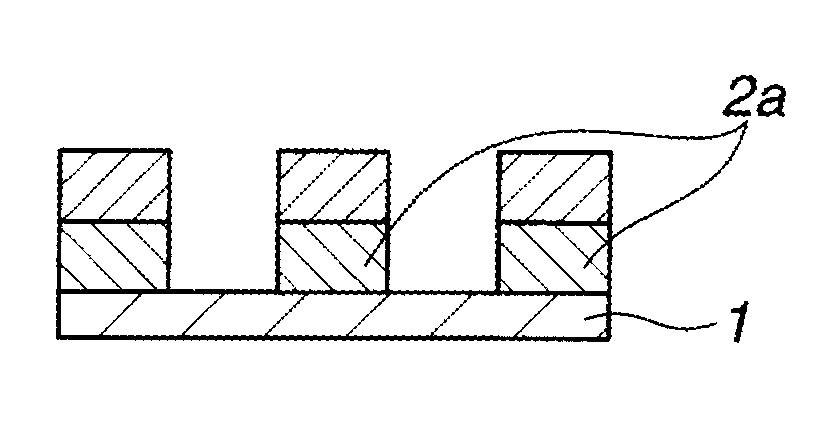

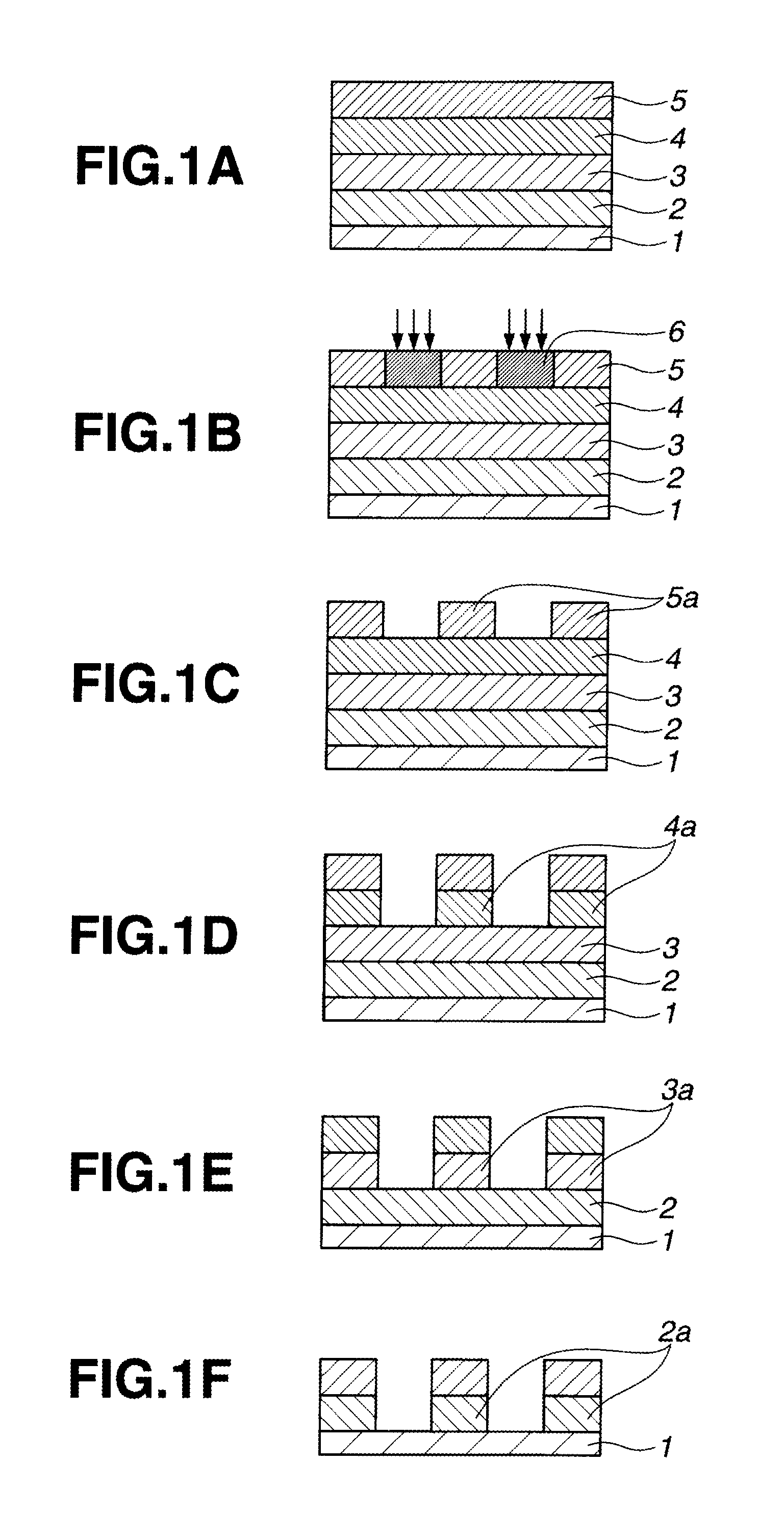

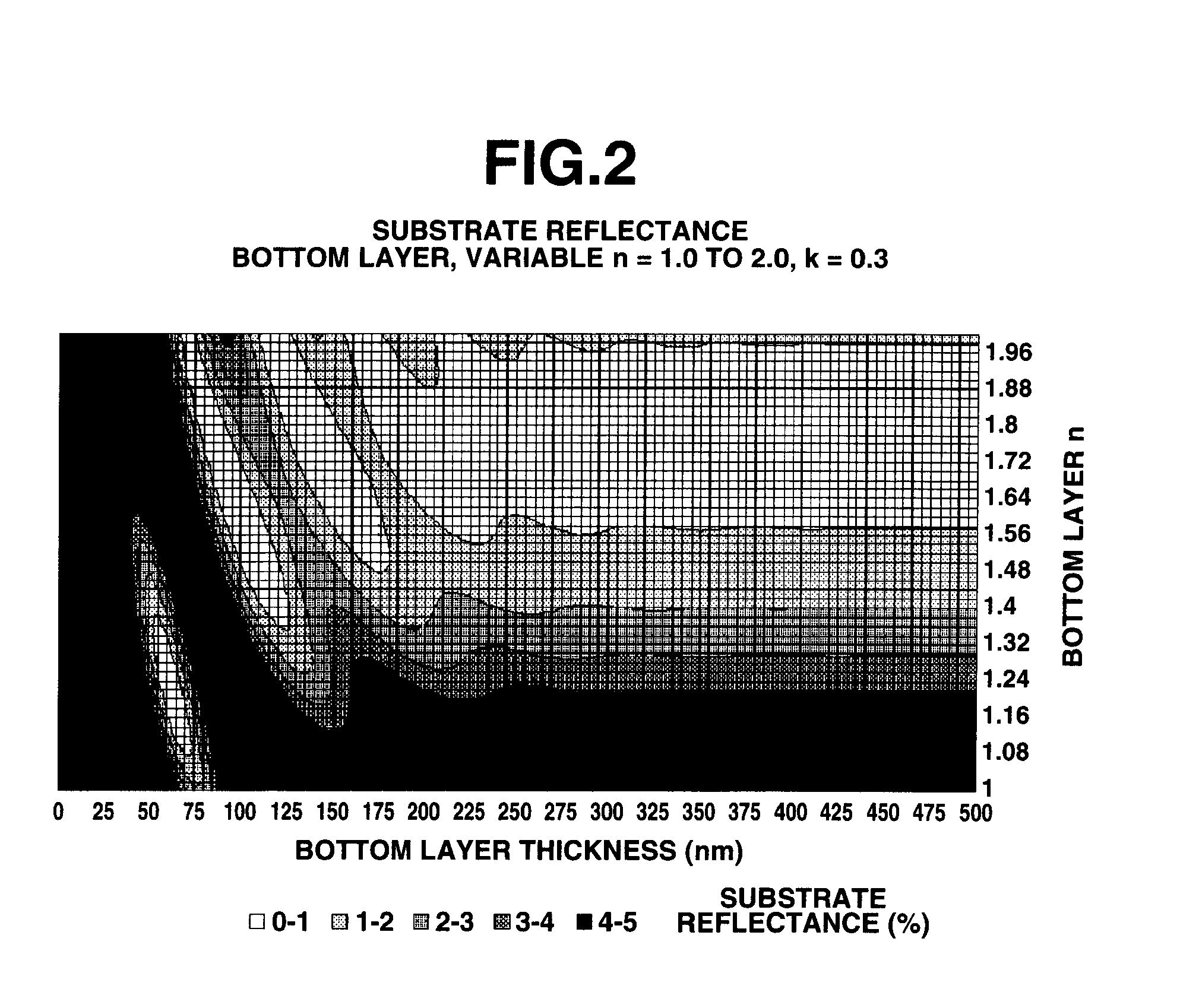

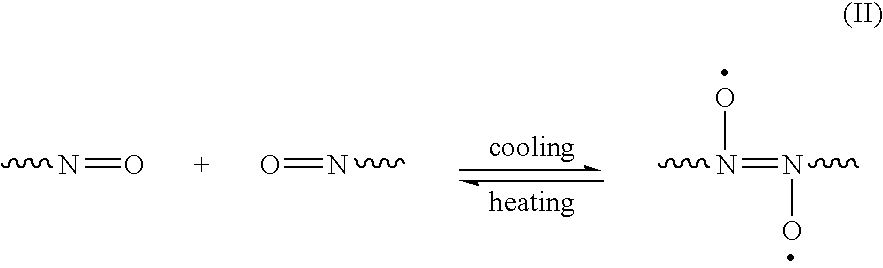

Naphthalene derivative, resist bottom layer material, and patterning process

ActiveUS20120064725A1Excellent etch resistanceMinimizing outgassingOrganic chemistryOrganic compound preparationBenzeneResist

A naphthalene derivative having formula (1) is provided wherein An and Art denote a benzene or naphthalene ring, and n is such a natural number as to provide a weight average molecular weight of up to 100,000. A material comprising the naphthalene derivative or a polymer comprising the naphthalene derivative is spin coated to form a resist bottom layer having improved properties. A pattern forming process in which a resist bottom layer formed by spin coating is combined with an inorganic hard mask formed by CVD is available.

Owner:SHIN ETSU CHEM IND CO LTD

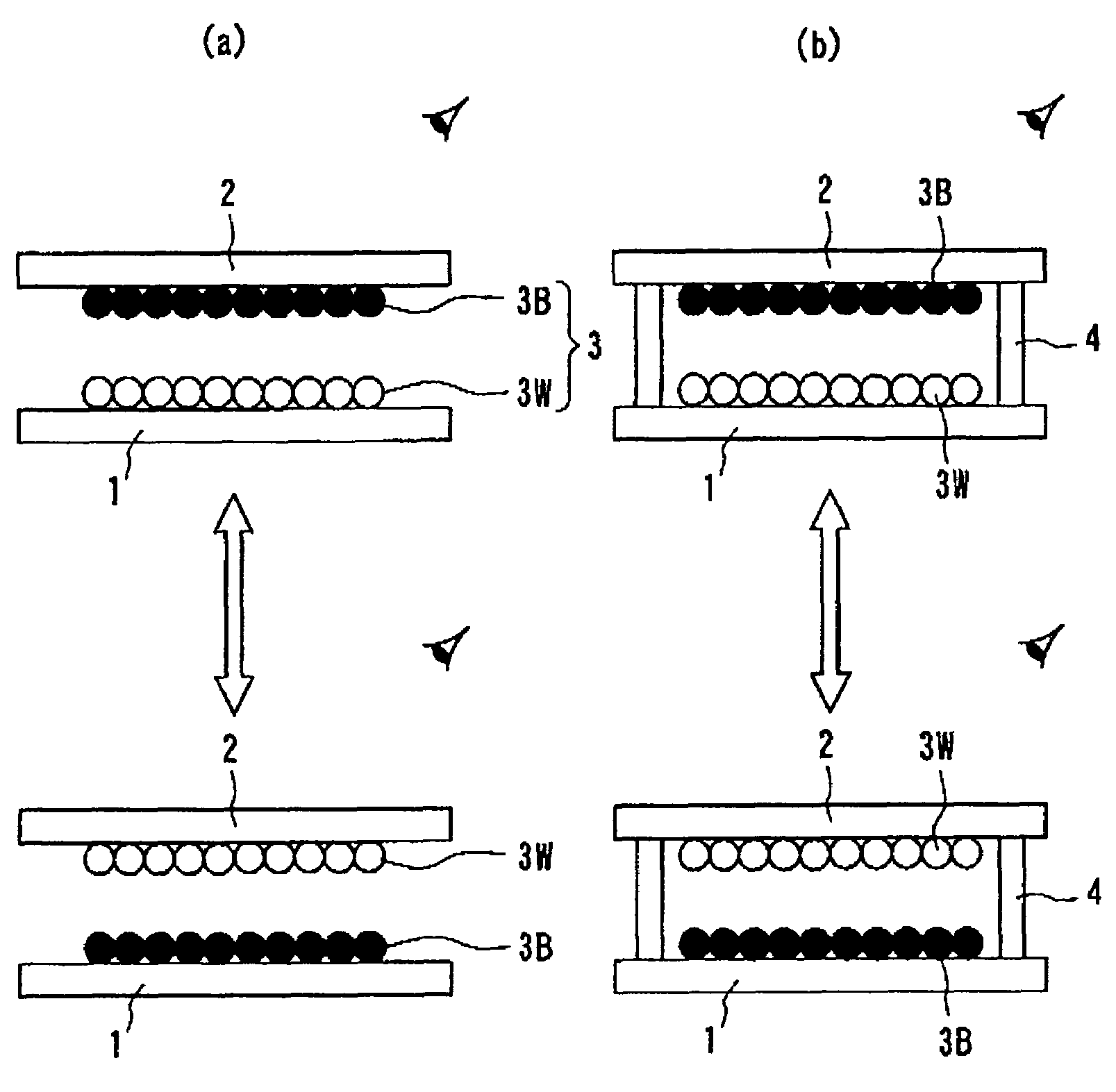

White color particles for display media and information display device utilizing them

InactiveUS7639417B2Improve reflectivityIncrease contrastStatic indicating devicesNon-linear opticsHeat resistanceTitanium oxide

Owner:BRIDGESTONE CORP

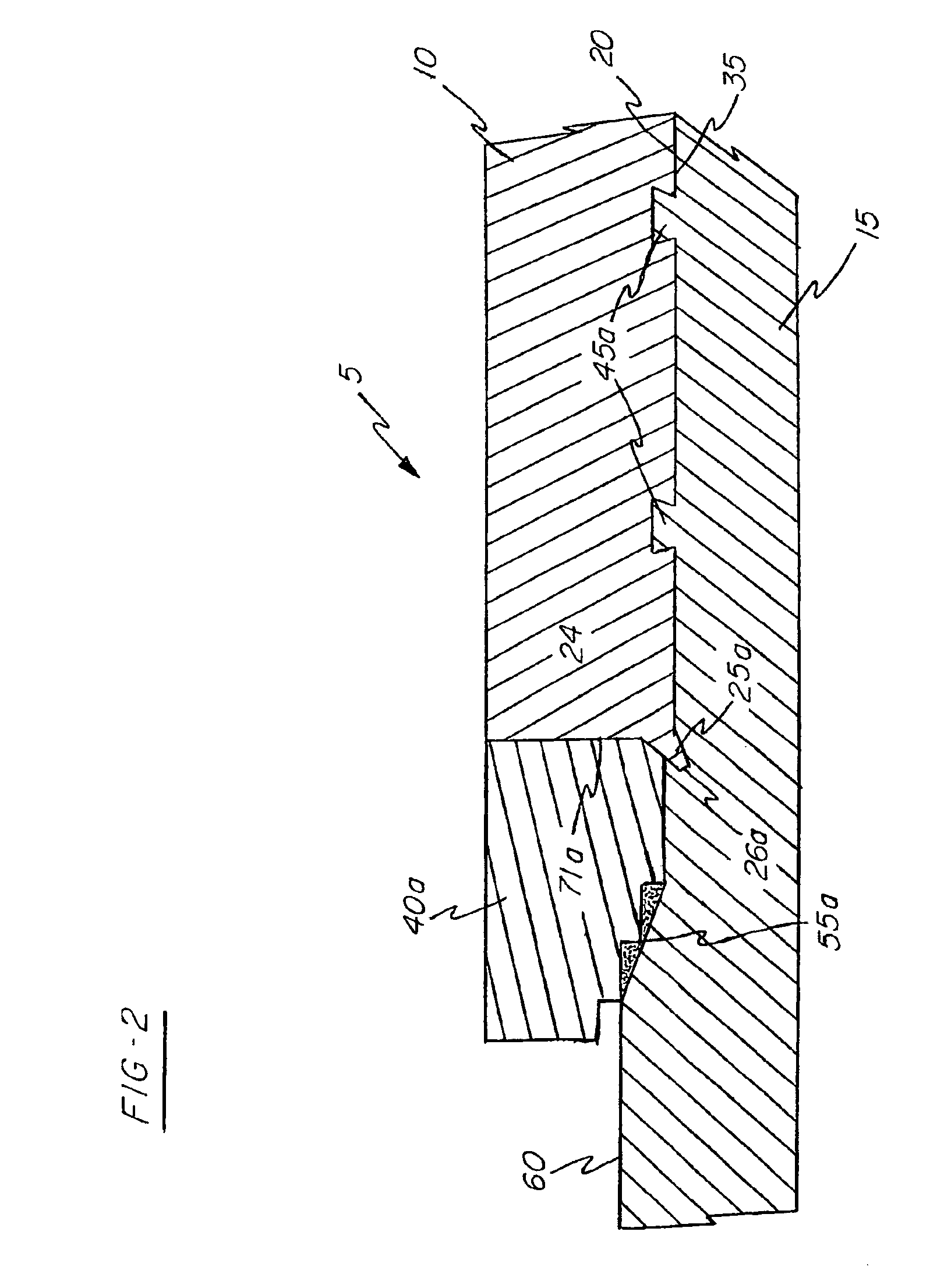

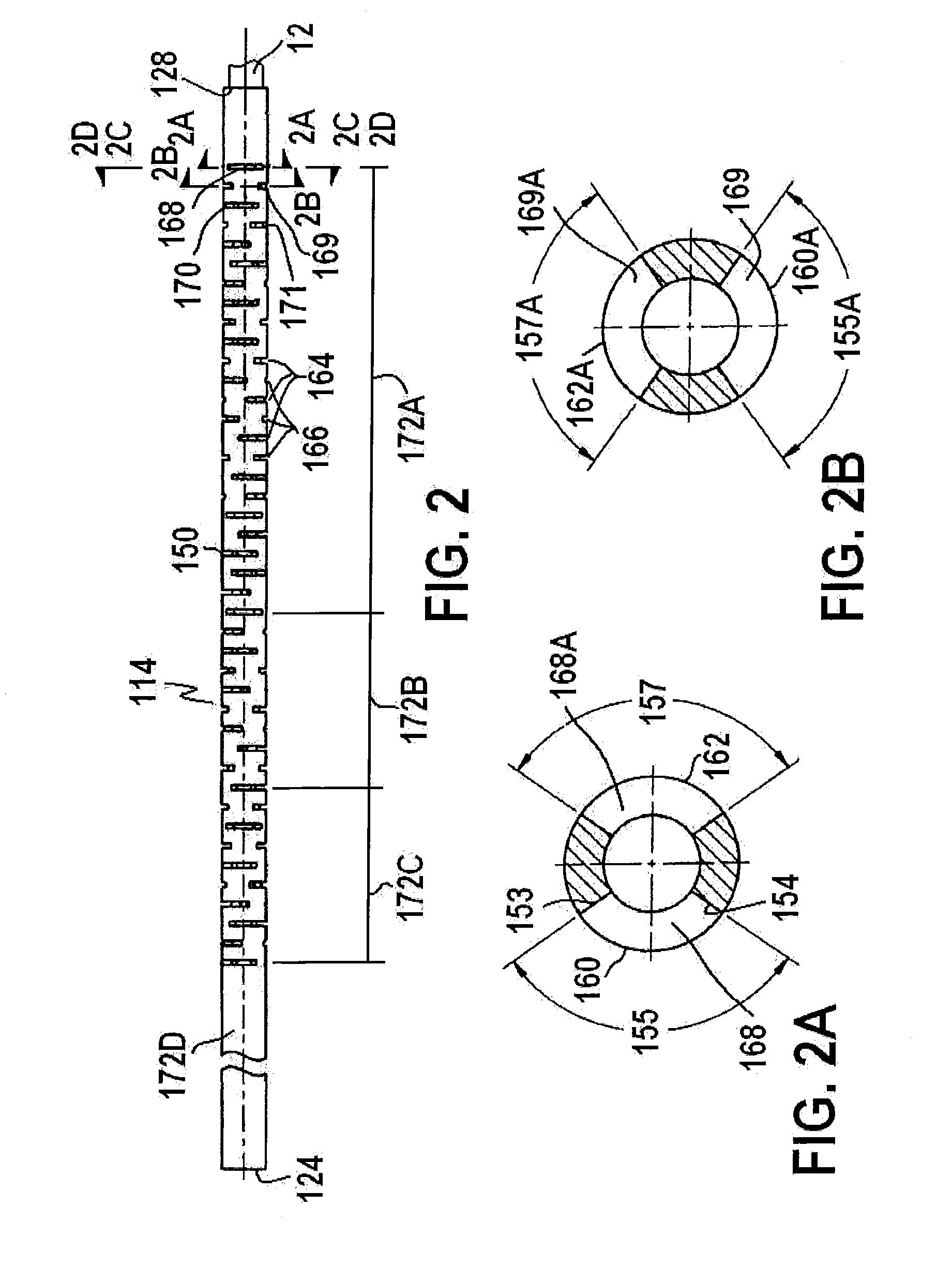

Methods for manufacturing a paint roller with integrated core and cover

InactiveUS6159134ASimple processQuality improvementLiquid surface applicatorsMetal rolling stand detailsPolypropylenePaint roller

A reusable multi-strip laminate paint roller and method for manufacturing the same. The method comprising steps of: advancing a first strip of polypropylene material about a mandrel; advancing a second strip of polypropylene about a mandrel in offset relation to the first strip; advancing a cover about the second strip of polypropylene; providing a first adhesive layer (preferably a liquefied polypropylene) between the first and second strips of polypropylene; providing a second adhesive layer between the second strip of polypropylene and the cover; and applying a compressing force upon the cover urging the cover toward the second strip and simultaneously urging the second strip toward the first strip, thereby creating the continuous laminated paint roller. After forming of the continuously paint roller it is moved towards a cutter by a helical drive belt system. The continuously formed roller is then preferably cut into lengths for movement to a finishing station, and then cut into finished size paint rollers.

Owner:SEKAR CHANDRA

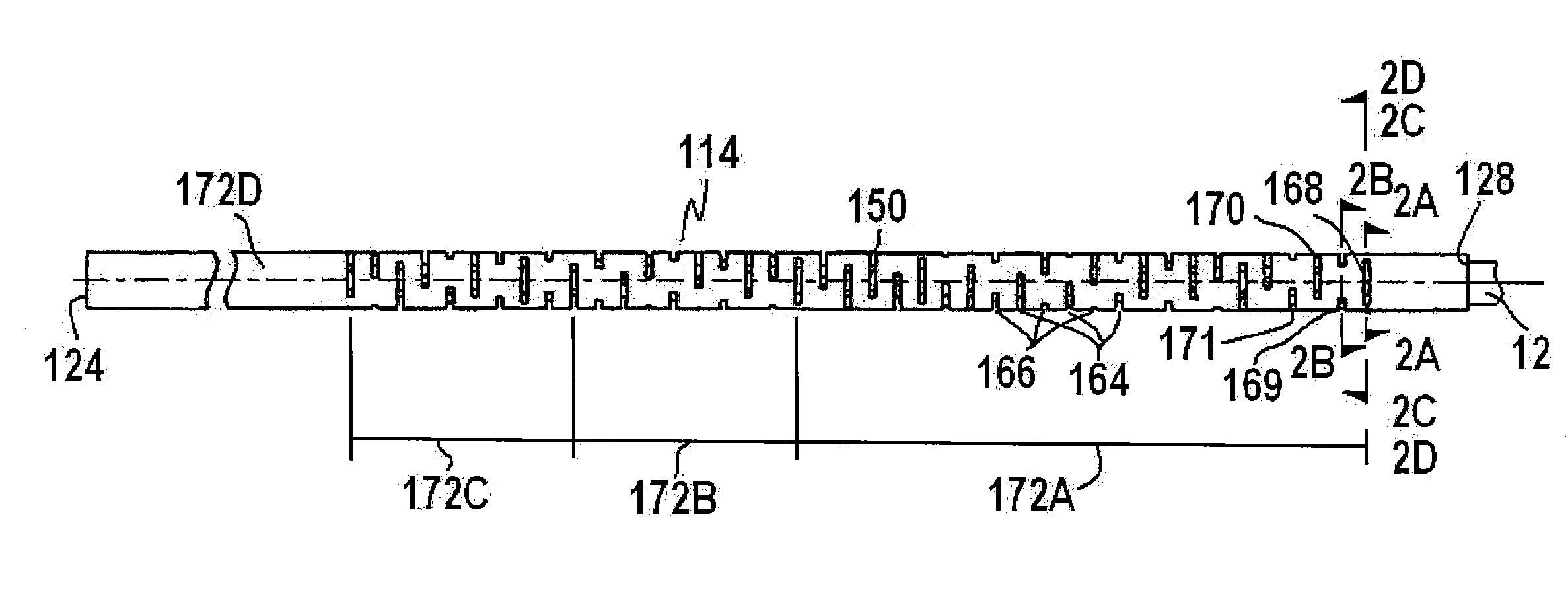

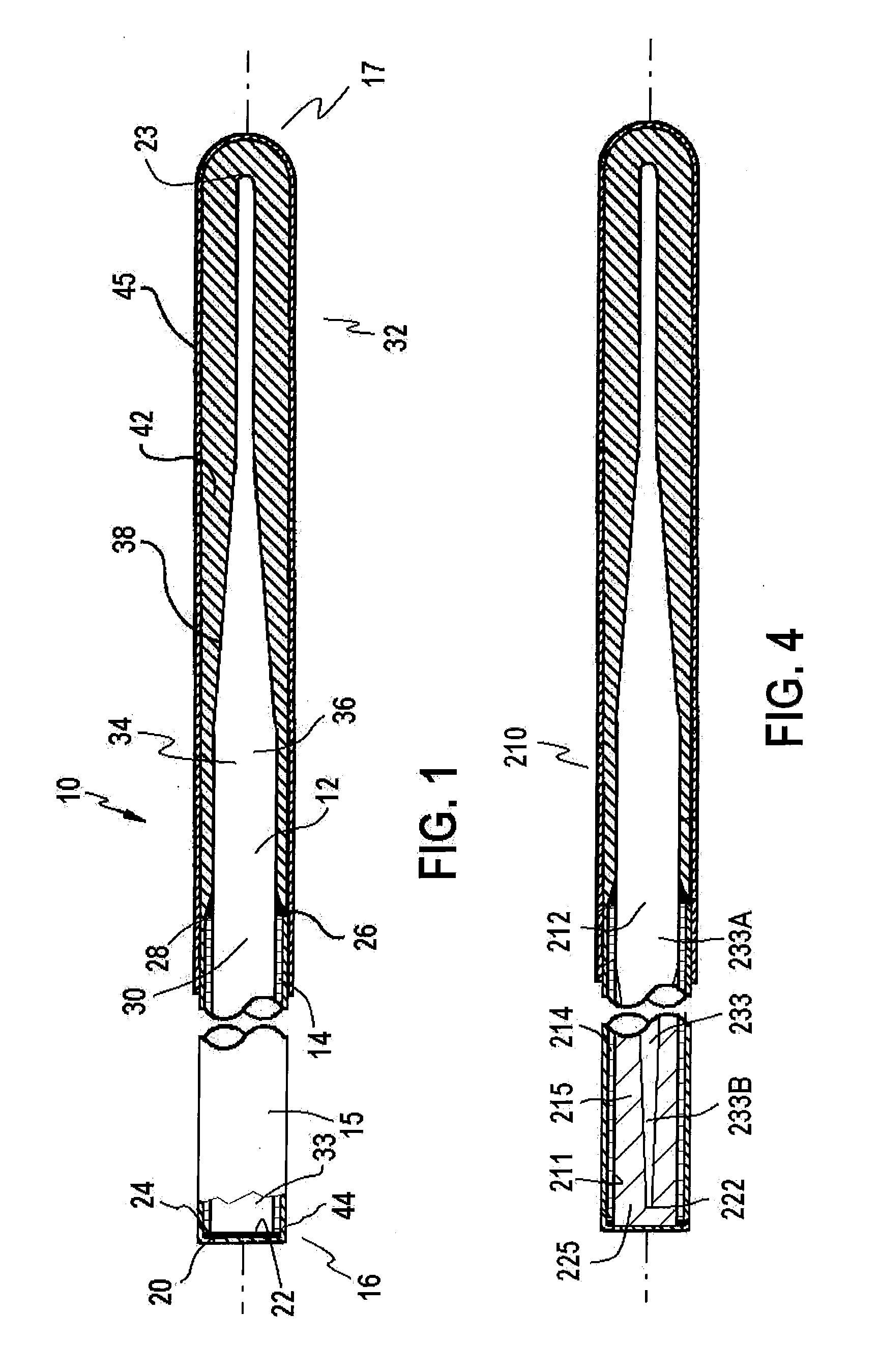

Wire guide with cannula

InactiveUS20110160680A1Solve the lack of flexibilitySolve the lack of resistanceGuide wiresAbsorbent padsMedical treatmentSurgical device

The present invention generally relates to a medical surgical device and specifically a wire guide for percutaneous placement within a body lumen. The wire guide includes an elongated mandrel having sufficient flexibility and kink resistance and a cannula having a stiffness greater than the mandrel stiffness for sufficient pushability. The mandrel extends through the cannula and has a portion extending distal thereto to form a distal tip of the wire guide. The wire guide can further include a slotted cannula to improve the flexibility of the wire guide at the proximal portion of the wire guide. The slots can be arranged in various patterns for increased flexibility along the longitudinal length of the cannula, as well as increased circumferential flexibility along the wire guide. The mandrel may also have a proximally tapered portion to improve the flexibility of the wire guide at the proximal portion of the wire guide.

Owner:COOK INC

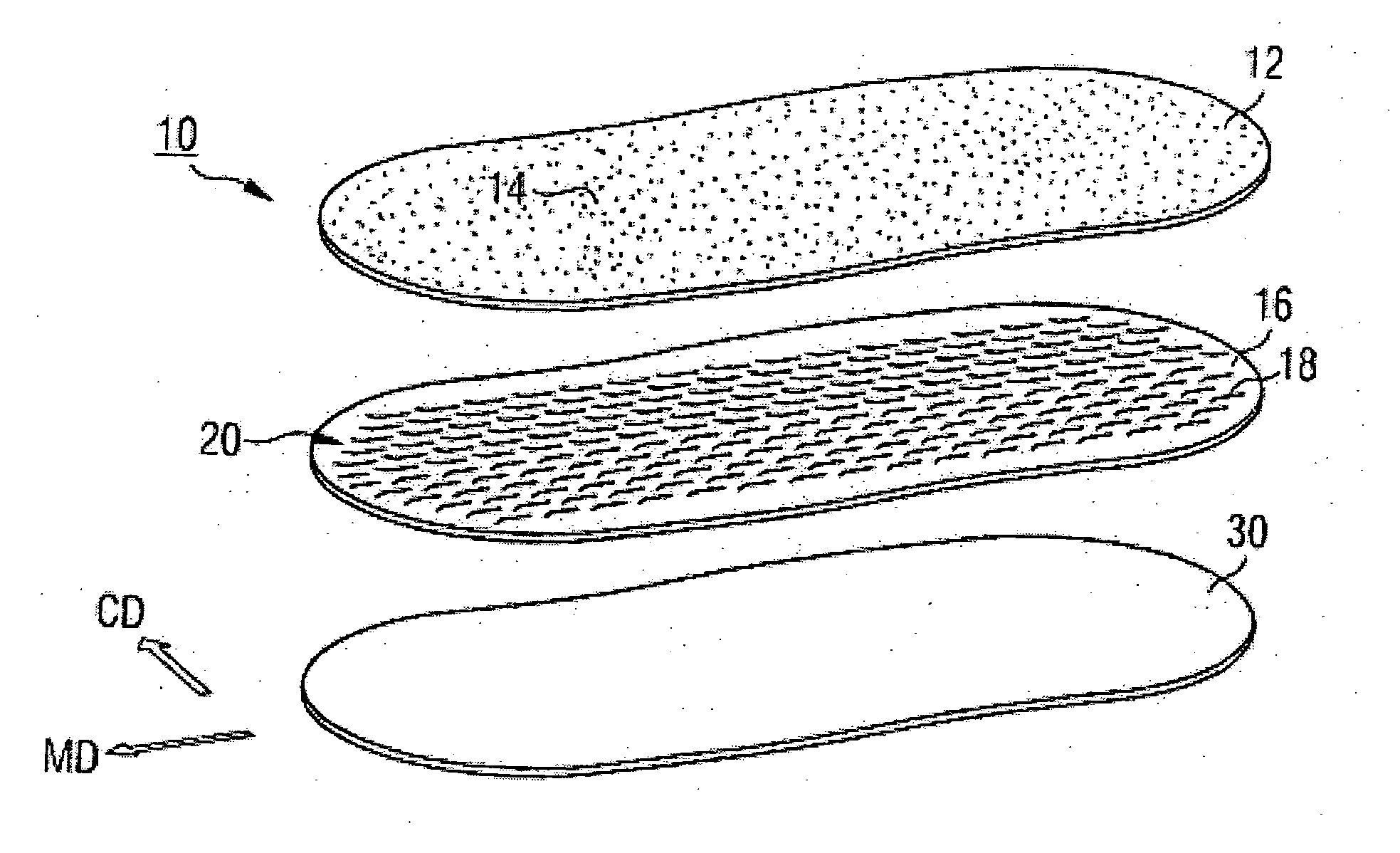

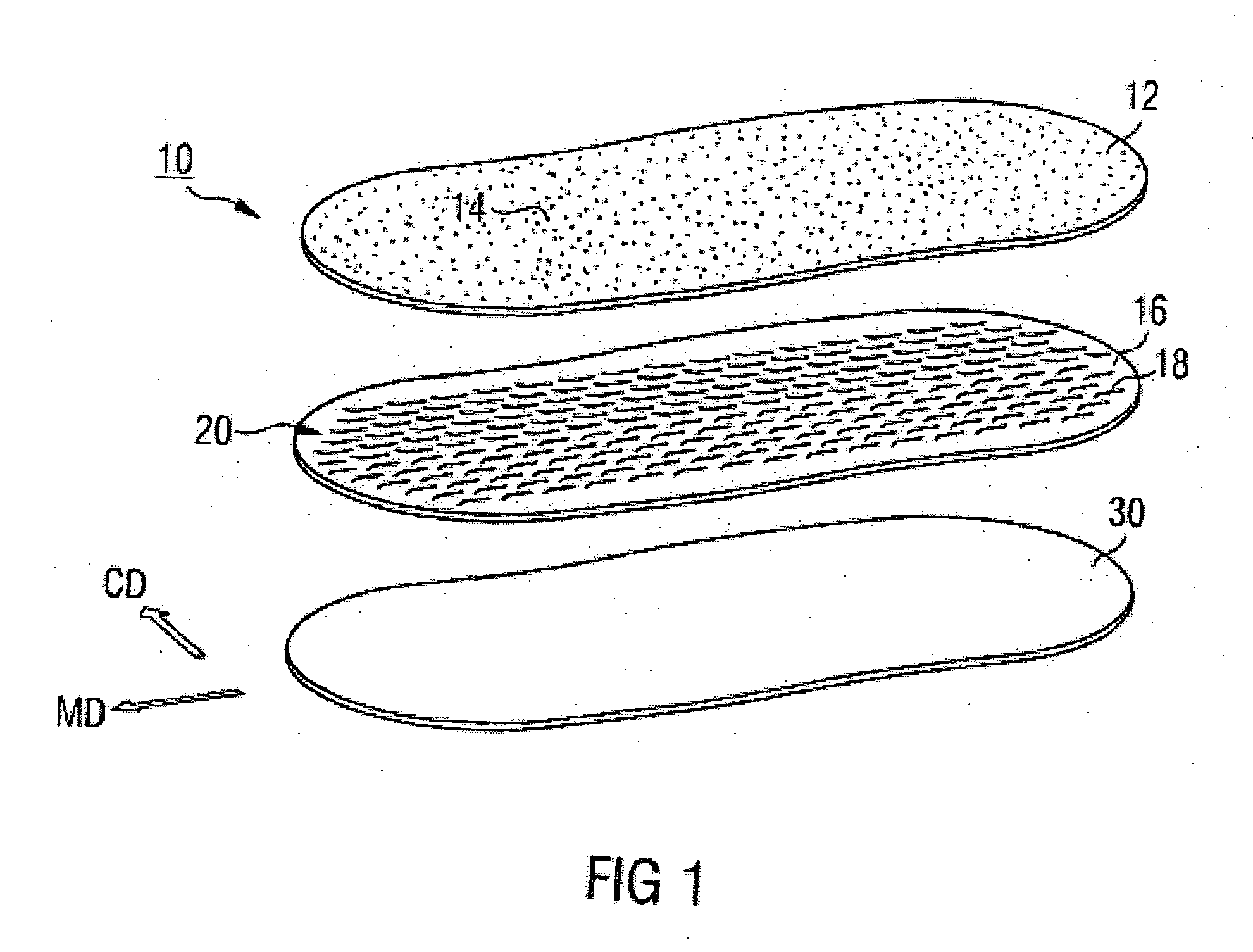

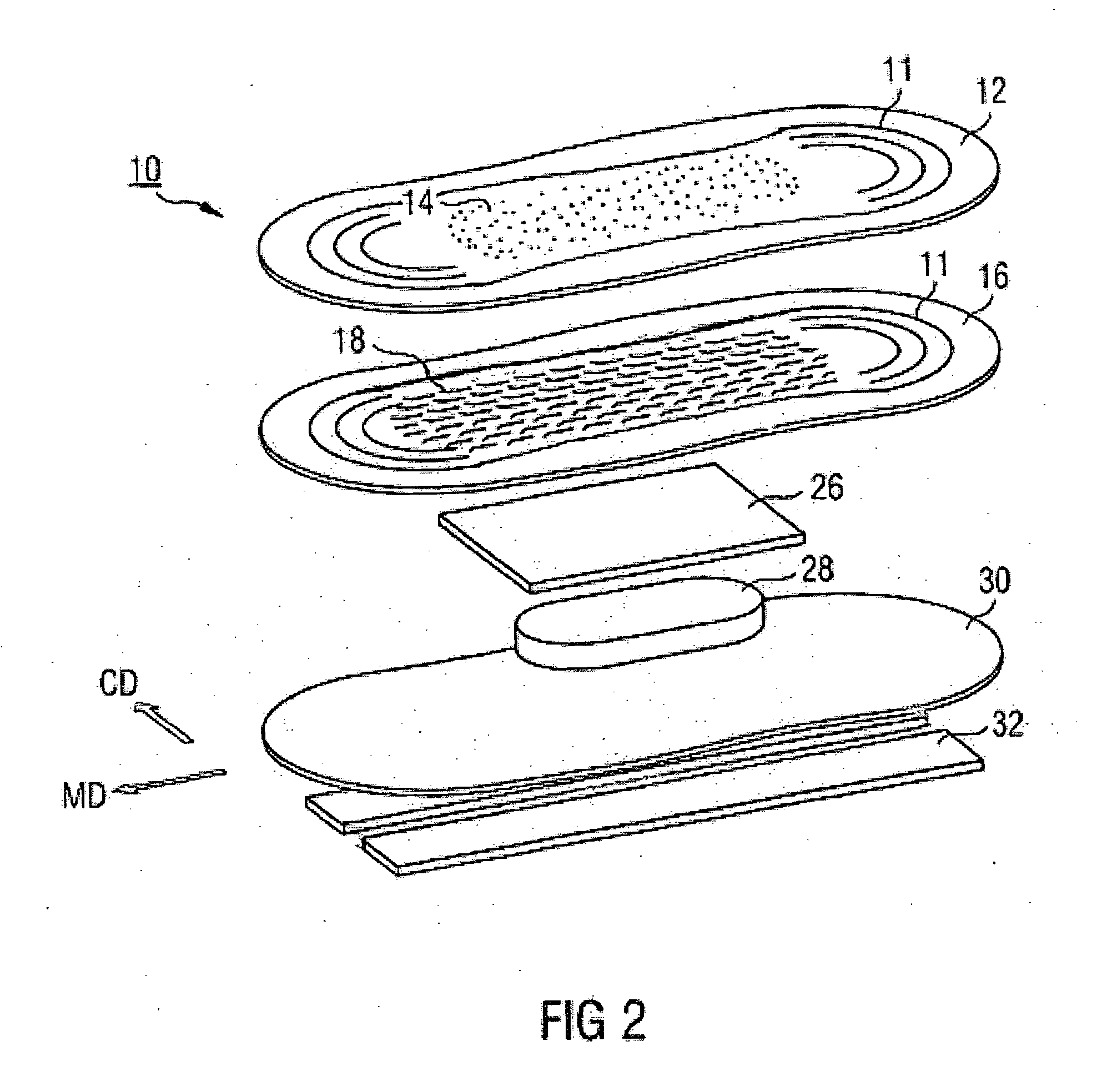

Extensible absorbent core and absorbent article

InactiveUS20060047257A1Improve fitEfficiently utilizes absorbent capacity of absorbentBaby linensTamponsMulti materialFiber layer

The present invention provides an absorbent article, such as a sanitary napkin or catamenial napkin, wherein the absorbent article has a longitudinal direction and a lateral direction, the absorbent article has: a) a liquid-permeable top layer, wherein the top layer has an extensibility in lateral direction of at least 30% to 70% at 4N / 50 mm, b) a liquid-impermeable backing layer laminated to the top layer, wherein the backing layer has a higher extensibility in lateral direction than in longitudinal direction and the extensibility in lateral direction is at least between 5% and 40% at 4N / 50 mm, and c) an absorbent core positioned between the top layer and the backing layer, wherein the absorbent core has a plurality of non-linear slits and / or linear slits at an acute angle relative to the longitudinal direction through the absorbent core. The absorbent core may be a variety of materials, however one particular example is an absorbent core with a layer of material having a basis weight of between 20 g / m2 to 1000 g / m2 and is an airlaid fiber layers, coform fiber layers, meltblown fiber layers or laminates thereof and laminates of airlaid fiber layers, coform fiber layers or meltblown fiber layers or laminates thereof with a nonwoven support. The absorbent core generally will have a ratio of tensile strength in longitudinal direction and resistance to tear in lateral direction has a value in the range from 3.5:1 to 6:1. The invention further provides a punching die for forming slits in an nonwoven absorbent core material and a process for forming an absorbent article using said punching die.

Owner:KIMBERLY-CLARK WORLDWIDE INC

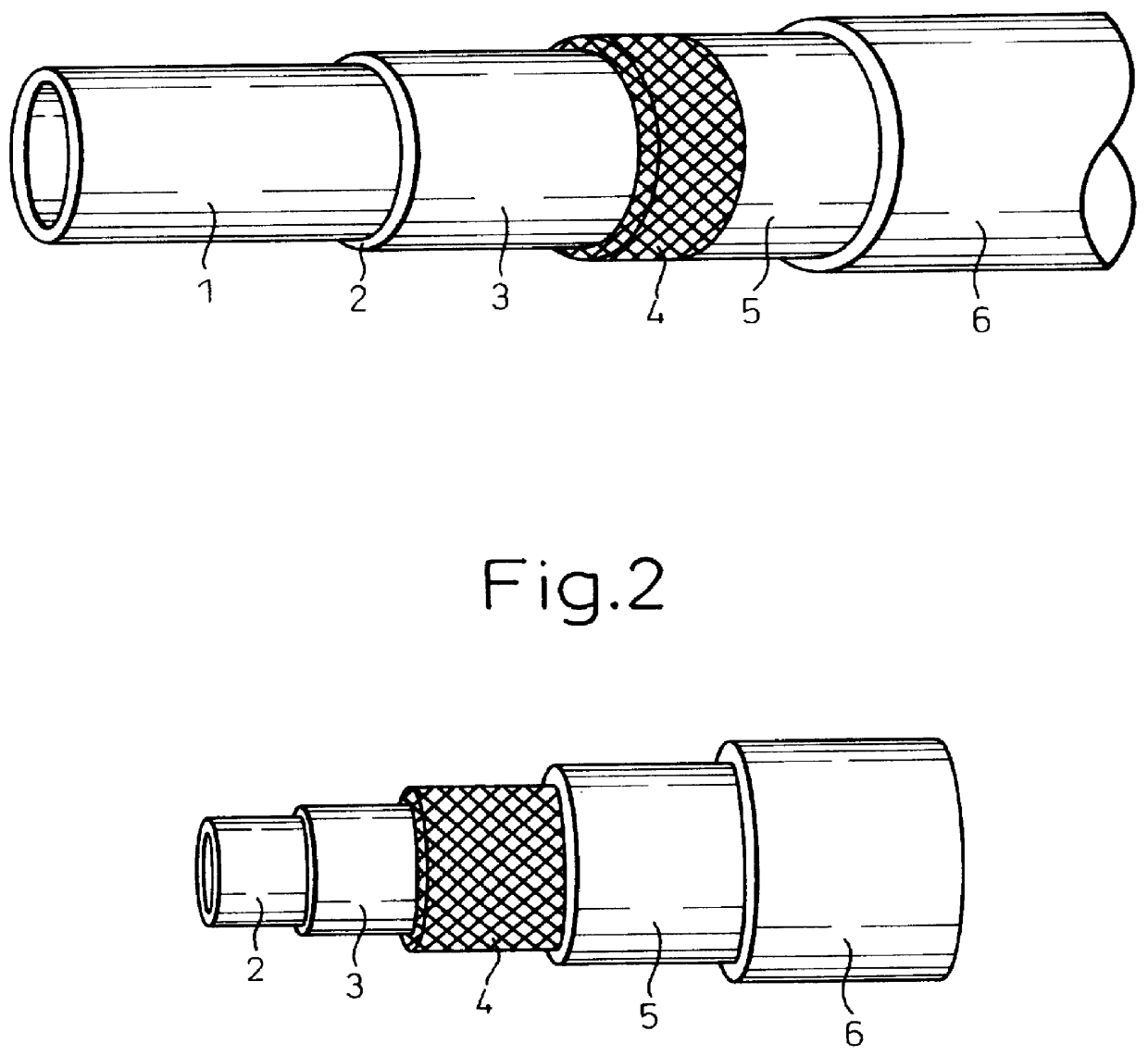

Thermoplastic elastomer composition, hose comprising thermoplastic elastomer composition and process of production thereof

InactiveUS6166143AImprove compatibilitySolve the lack of flexibilityClosuresClosure using stoppersThermoplasticCross-link

PCT No. PCT / JP97 / 03987 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20068 PCT Pub. Date May 14, 1998A thermoplastic elastomer composition containing a component (A) (thermoplastic polyolefin resin), component (B) (epoxy-group-containing ethylene acrylic ester copolymer rubber), and component (C) (acid-modified polyolefin resin) comprising a continuous phase of the component (A) in which the component (B) is dispersed as a dispersed phase and is cross-linked by a peroxide; a thermoplastic elastomer composition comprising a continuous phase of a thermoplastic polyolefin resin (A) and a dispersed phase of an epoxy-group-containing ethylene-acrylic ester copolymer rubber component (B) and acrylonitrile butadiene rubber component (C), which is dynamically cross-linked; and a hose having an inner tube, at least one reinforcing layer, and an outer cover, wherein the inner tube and the outer cover contain a thermoplastic elastomer composition comprised of a thermoplastic resin in which is blended an at least partially cross-linked elastomer component, the reinforcing layer is a brass-plated wire, and the reinforcing layer and inner tube and the reinforcing layer and outer cover have between them a maleic-acid-modified polyolefin thermoplastic resin.

Owner:YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com