Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7182 results about "Organic Silicon Compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

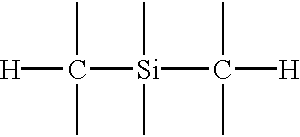

Organosilicon chemistry is the corresponding science of their preparation and properties. Most organosilicon compounds are similar to the ordinary organic compounds, being colourless, flammable, hydrophobic, and stable to air. Silicon carbide is an inorganic compound.

Organosilicon compounds

InactiveUS6849754B2Improve bindingAvoid large quantitiesSilicon organic compoundsOrganic chemistry methodsAlcoholSilanes

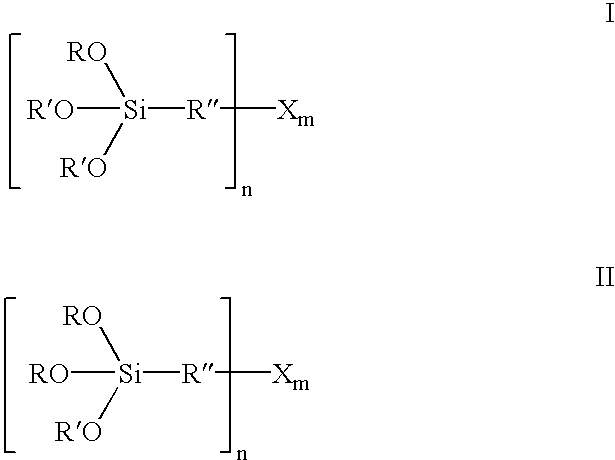

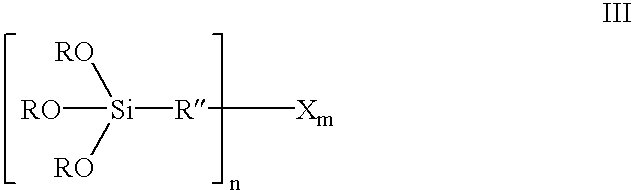

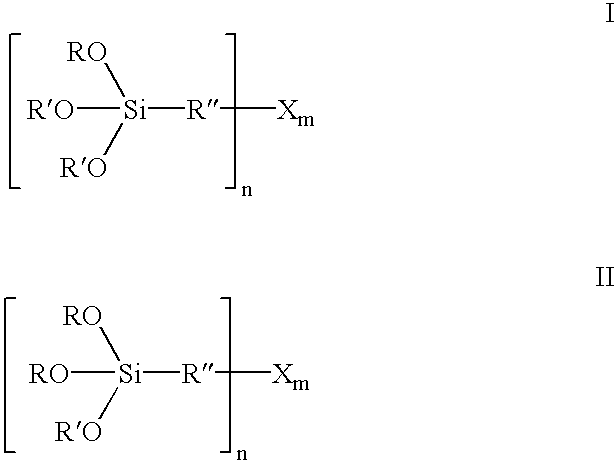

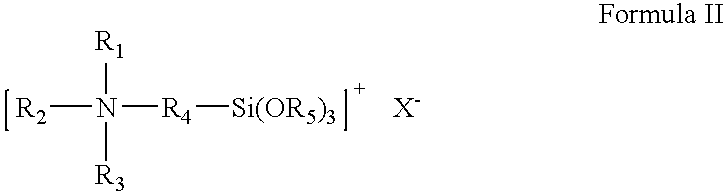

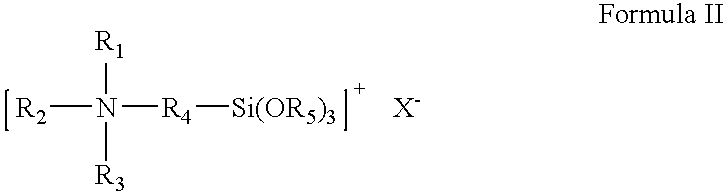

Organosilicon compounds of the general formula I and / or II are produced by reacting silanes of the general formula III with alcohols of the general formula R′—OH, with elimination of R—OH, wherein R—OH may be continuously separated from the reaction mixture by distillation. The organosilicon compounds may be used in rubber mixtures. Compounds, such as rubbers, produced using such organosilicon compounds.

Owner:EVONIK DEGUSSA GMBH

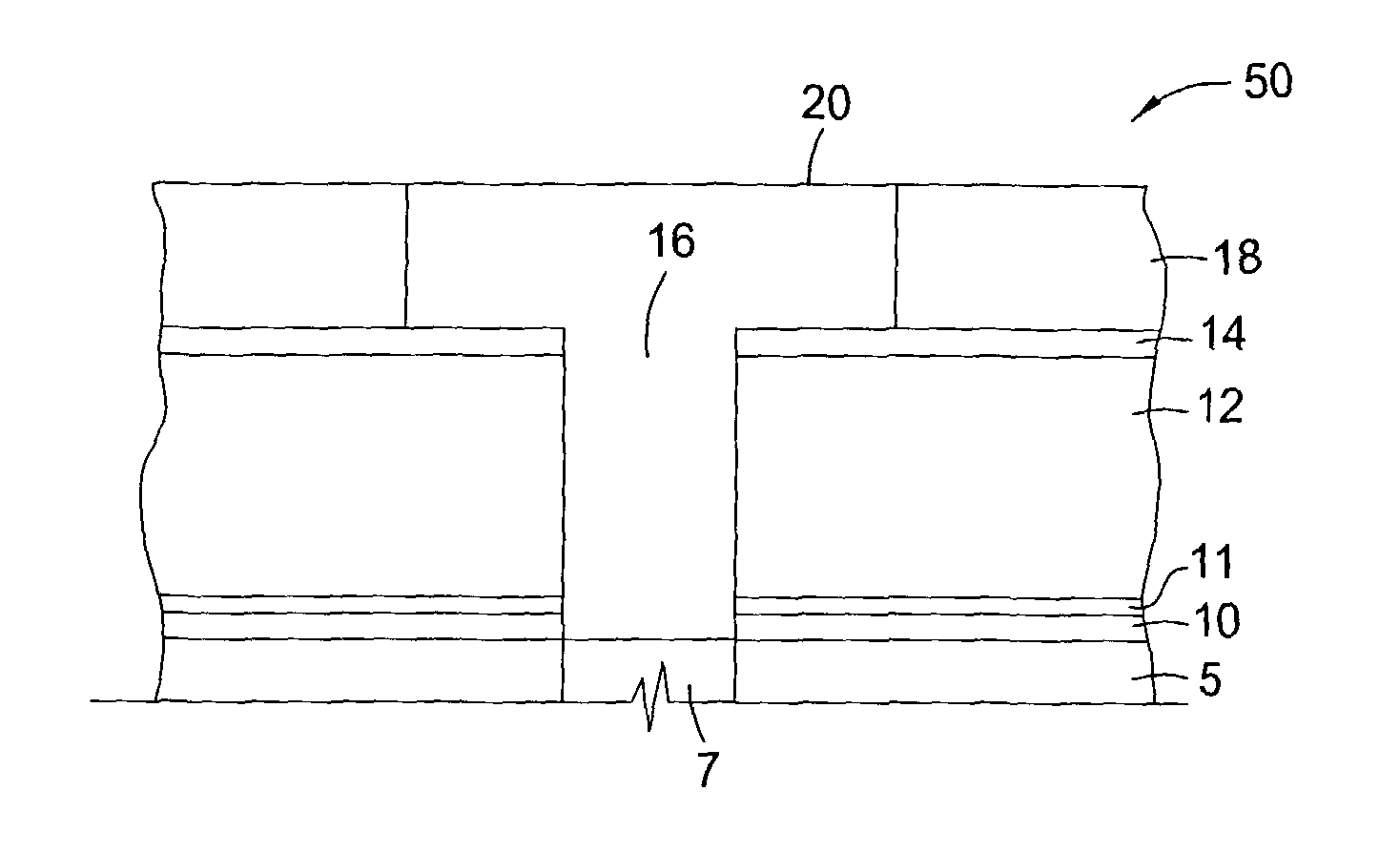

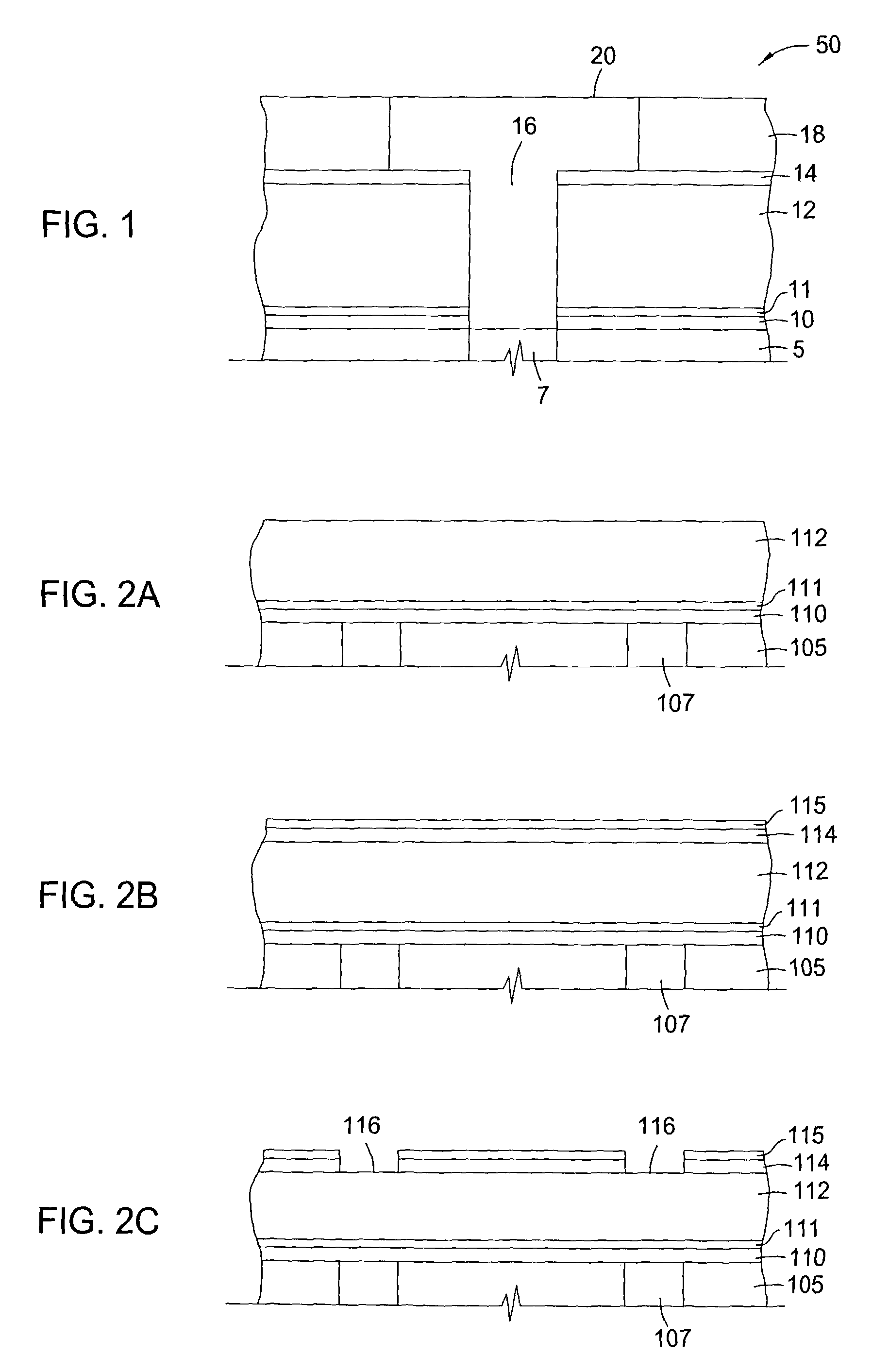

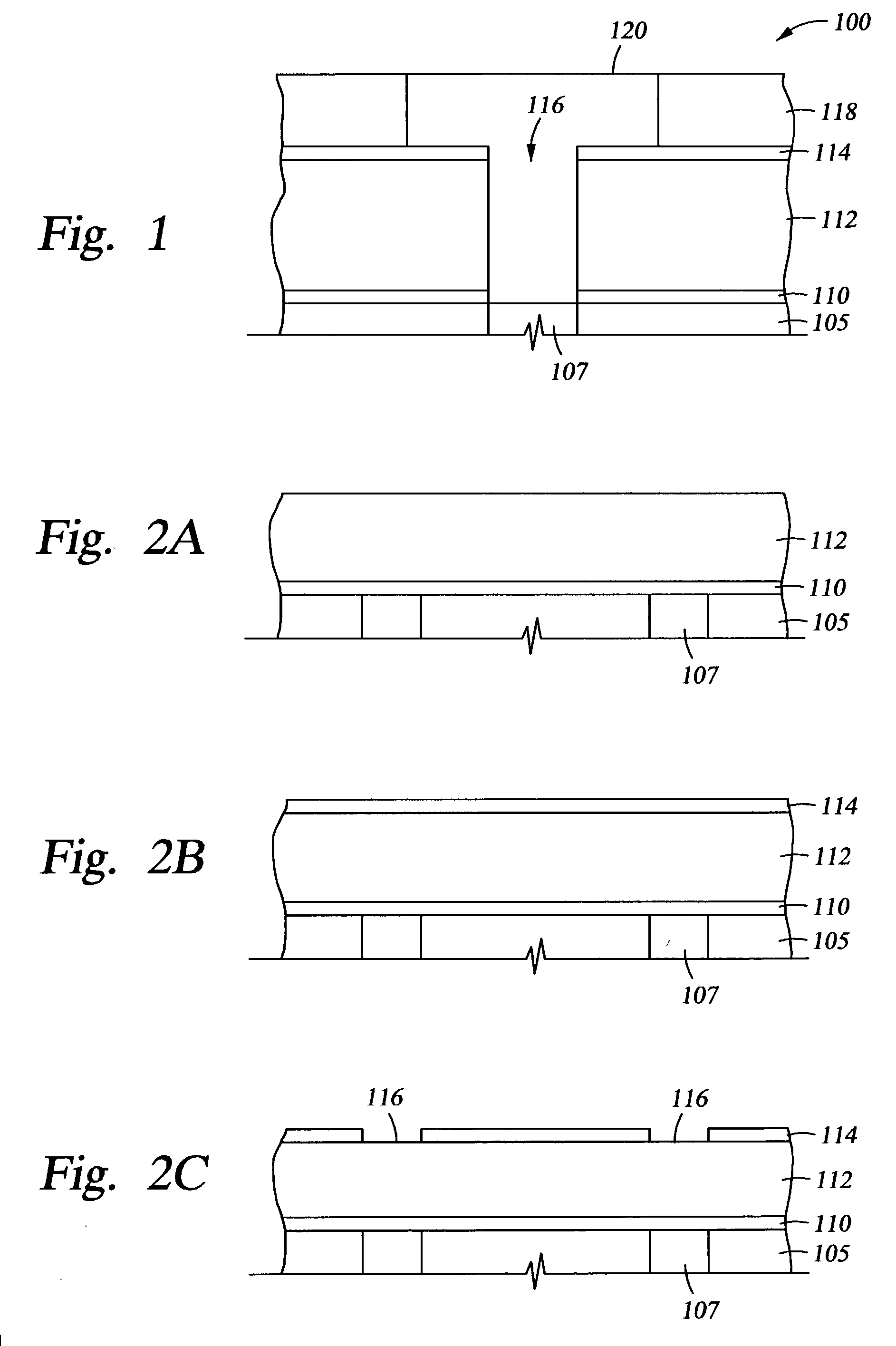

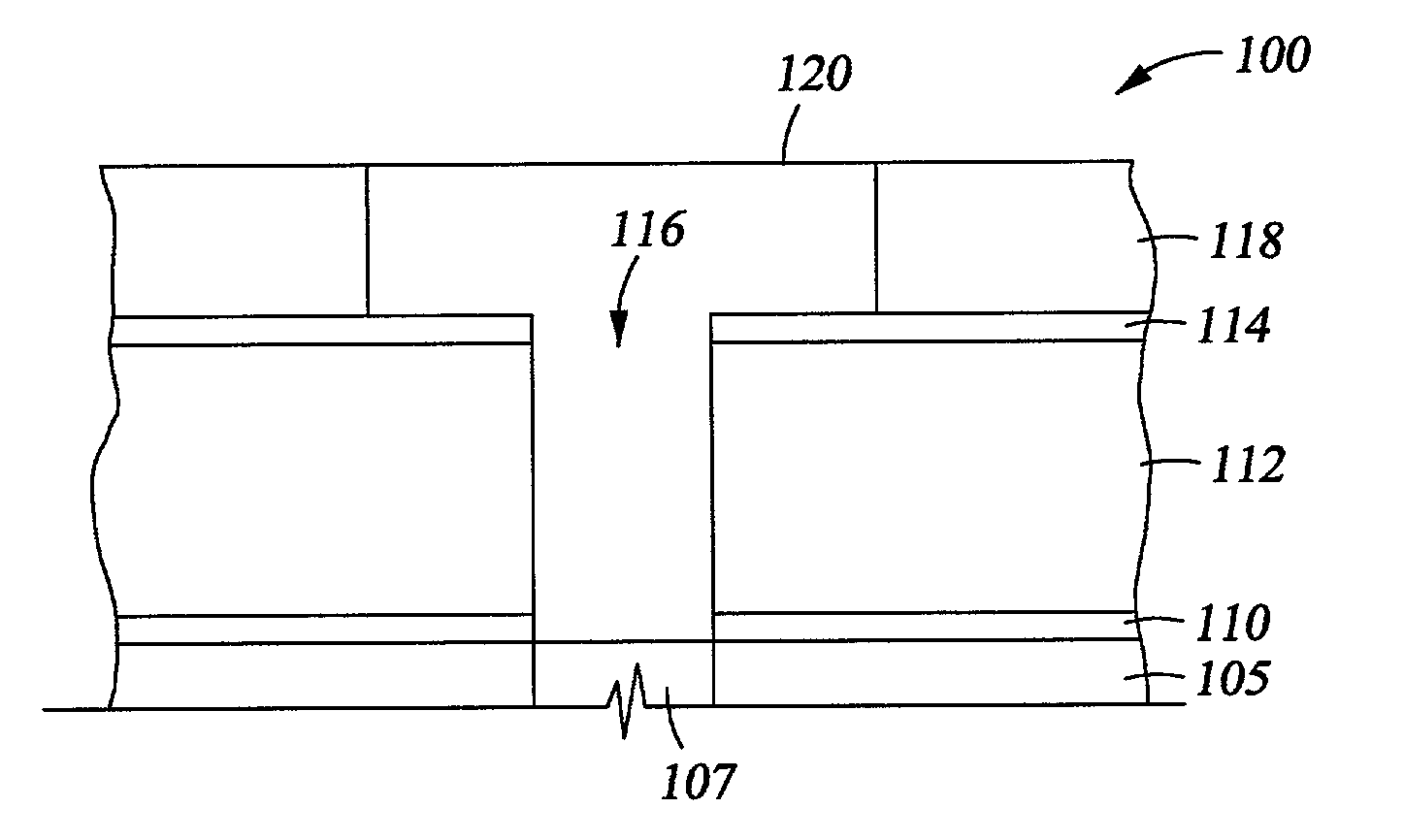

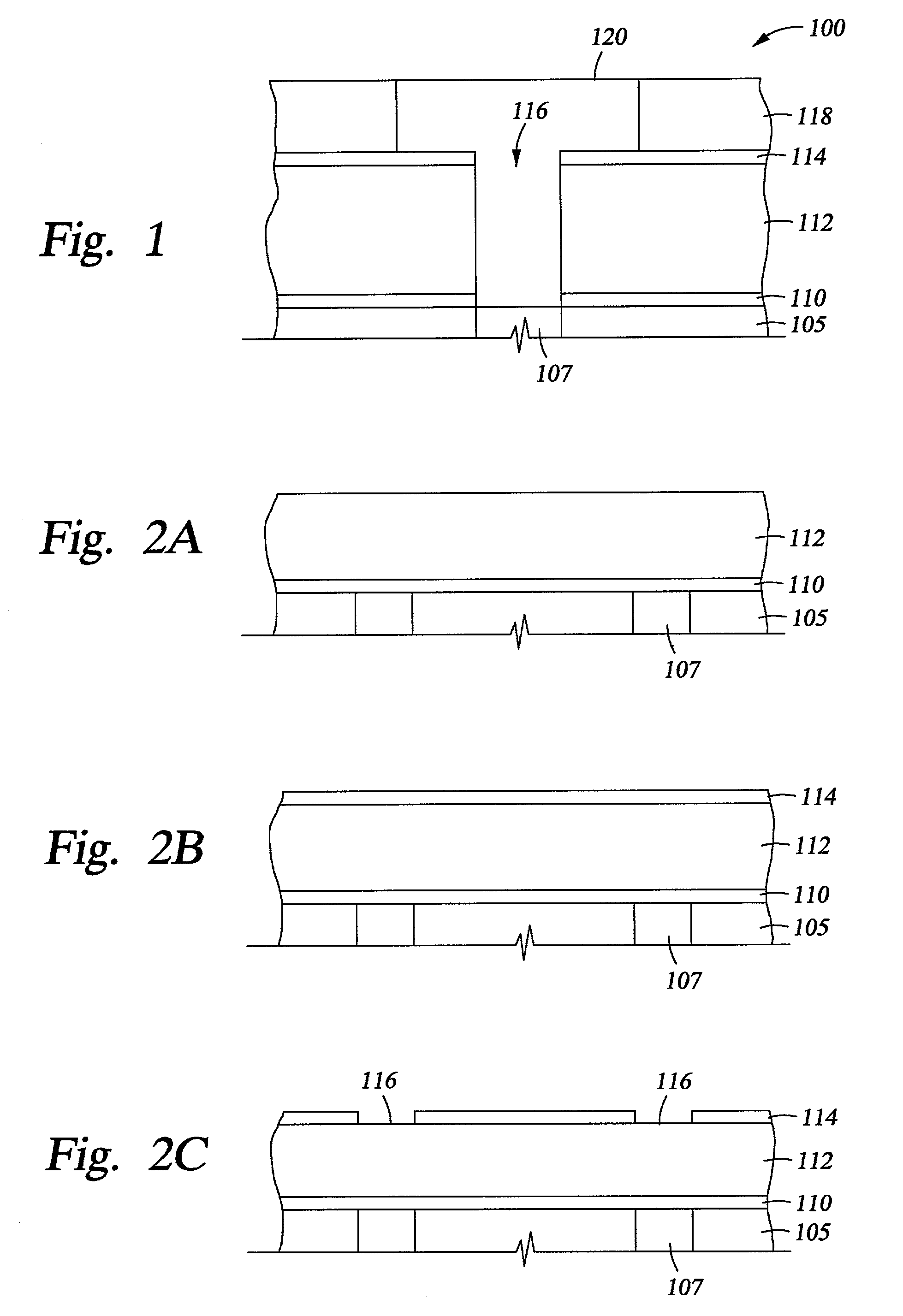

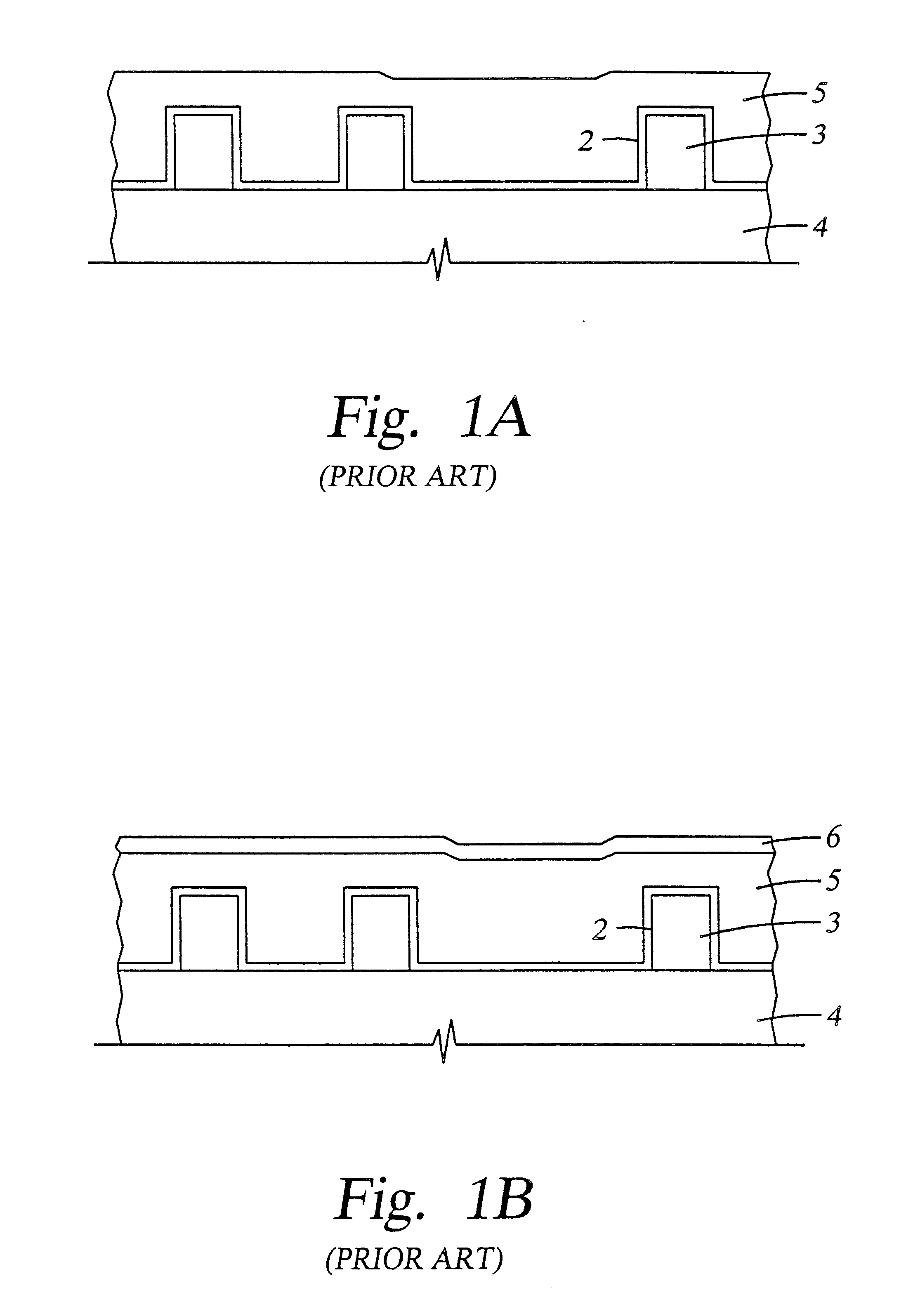

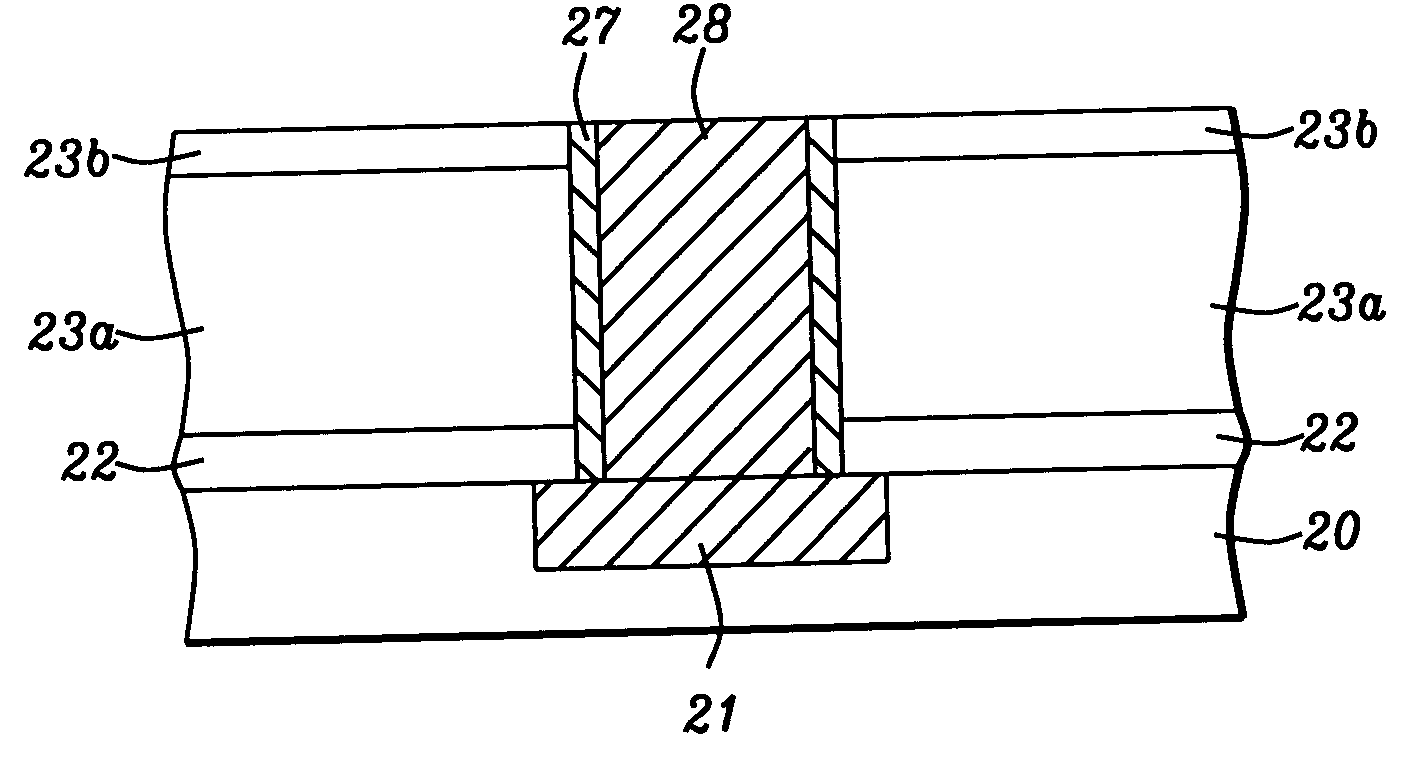

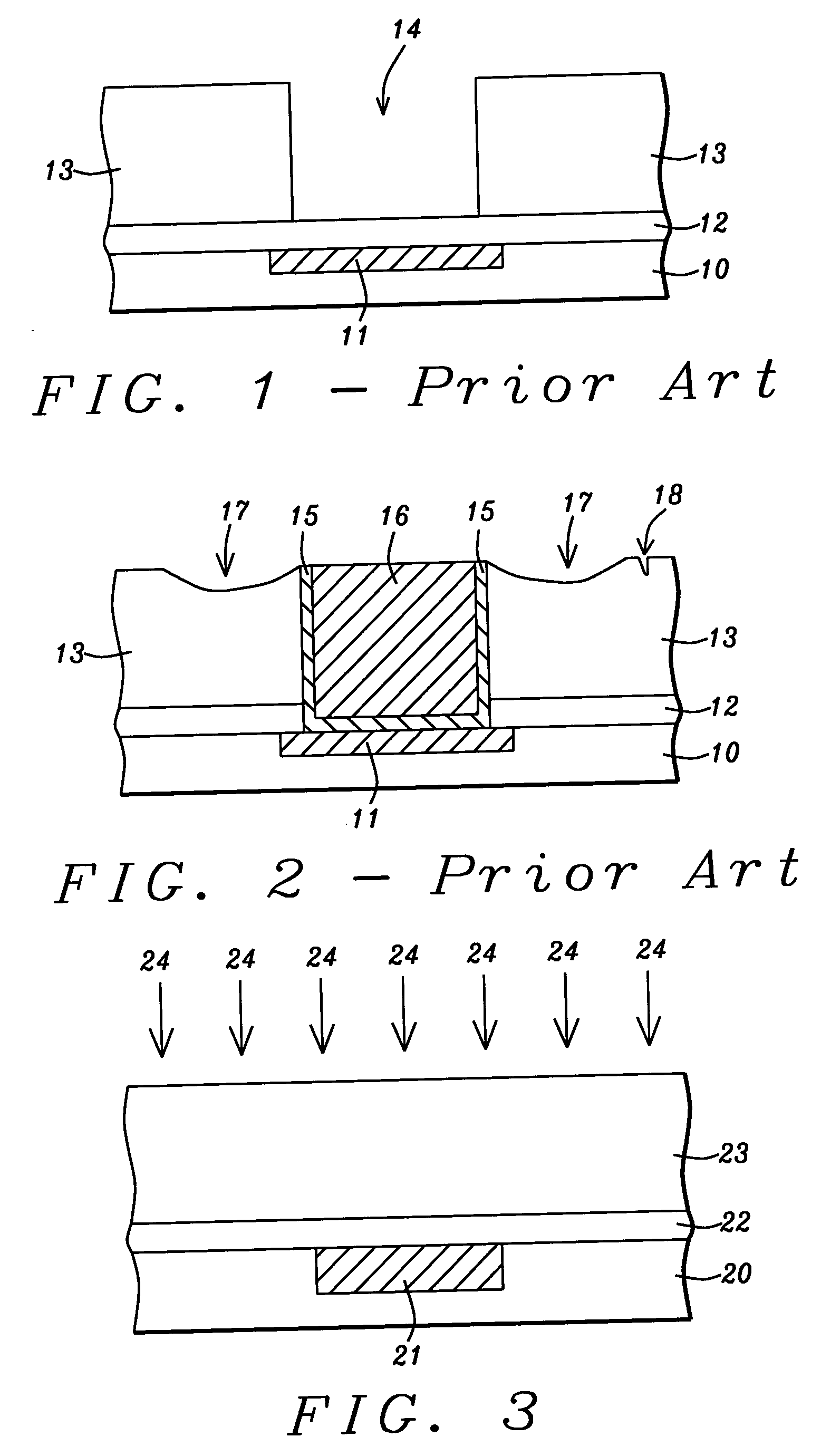

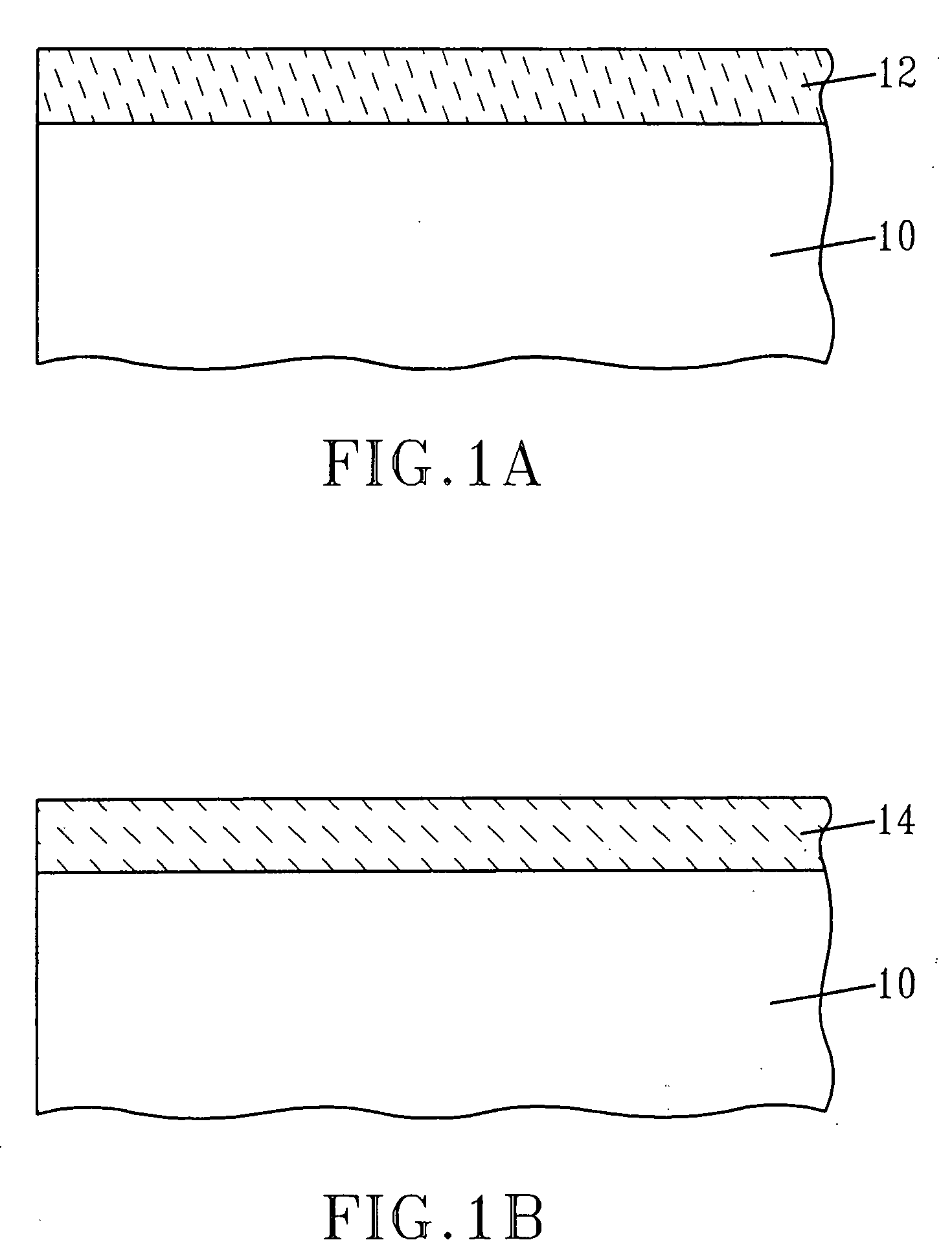

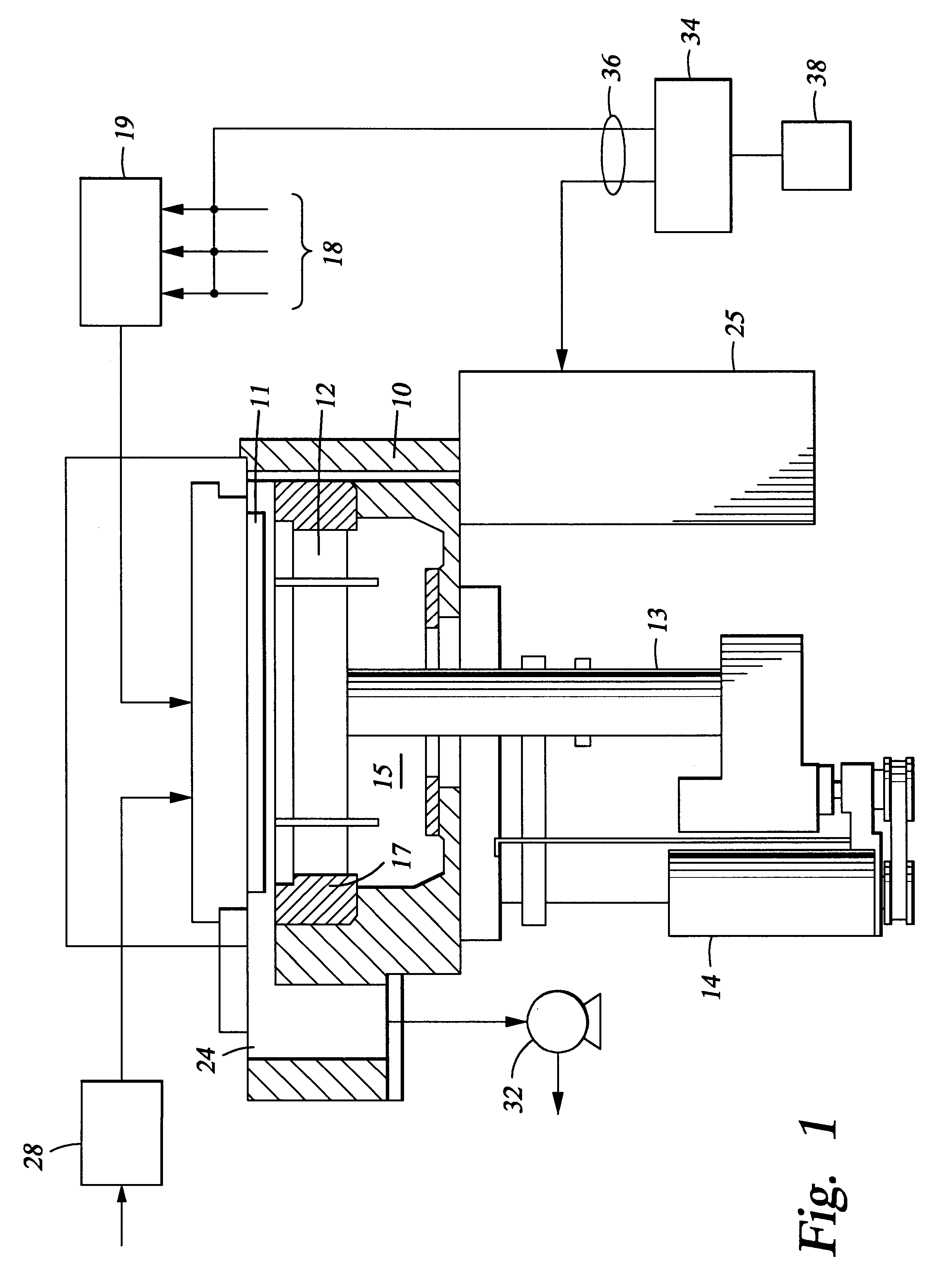

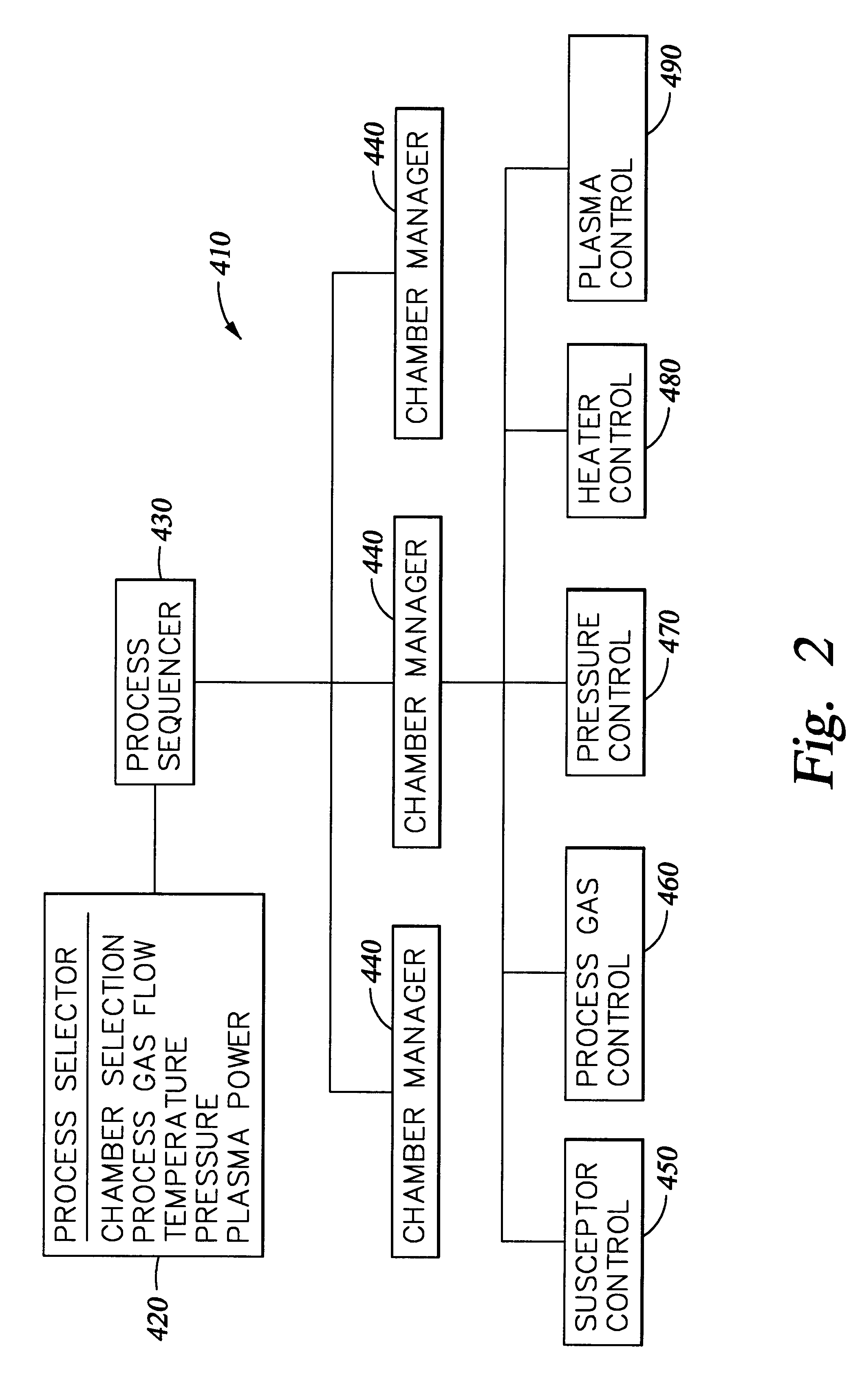

Formation of a liquid-like silica layer by reaction of an organosilicon compound and a hydroxyl forming compound

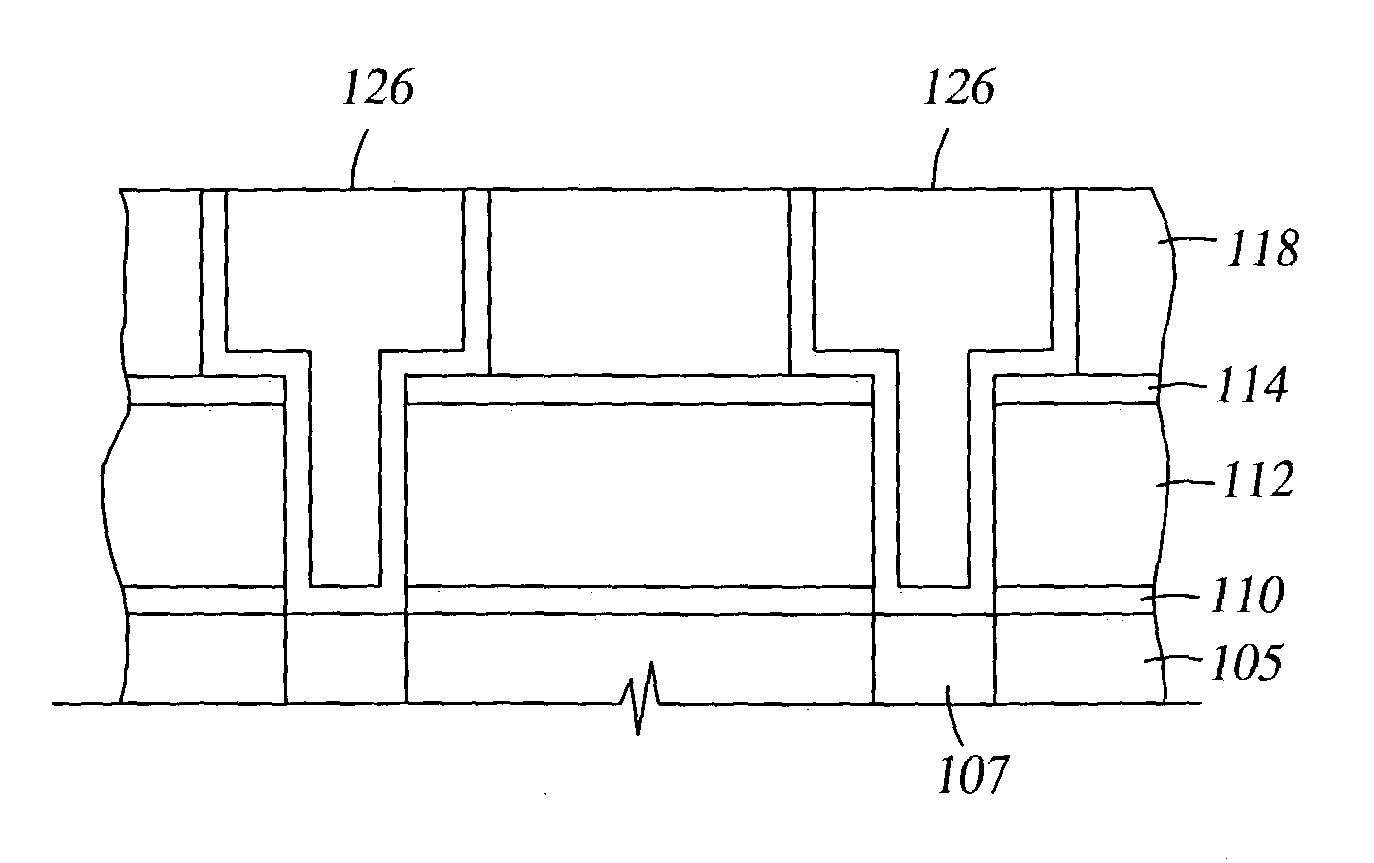

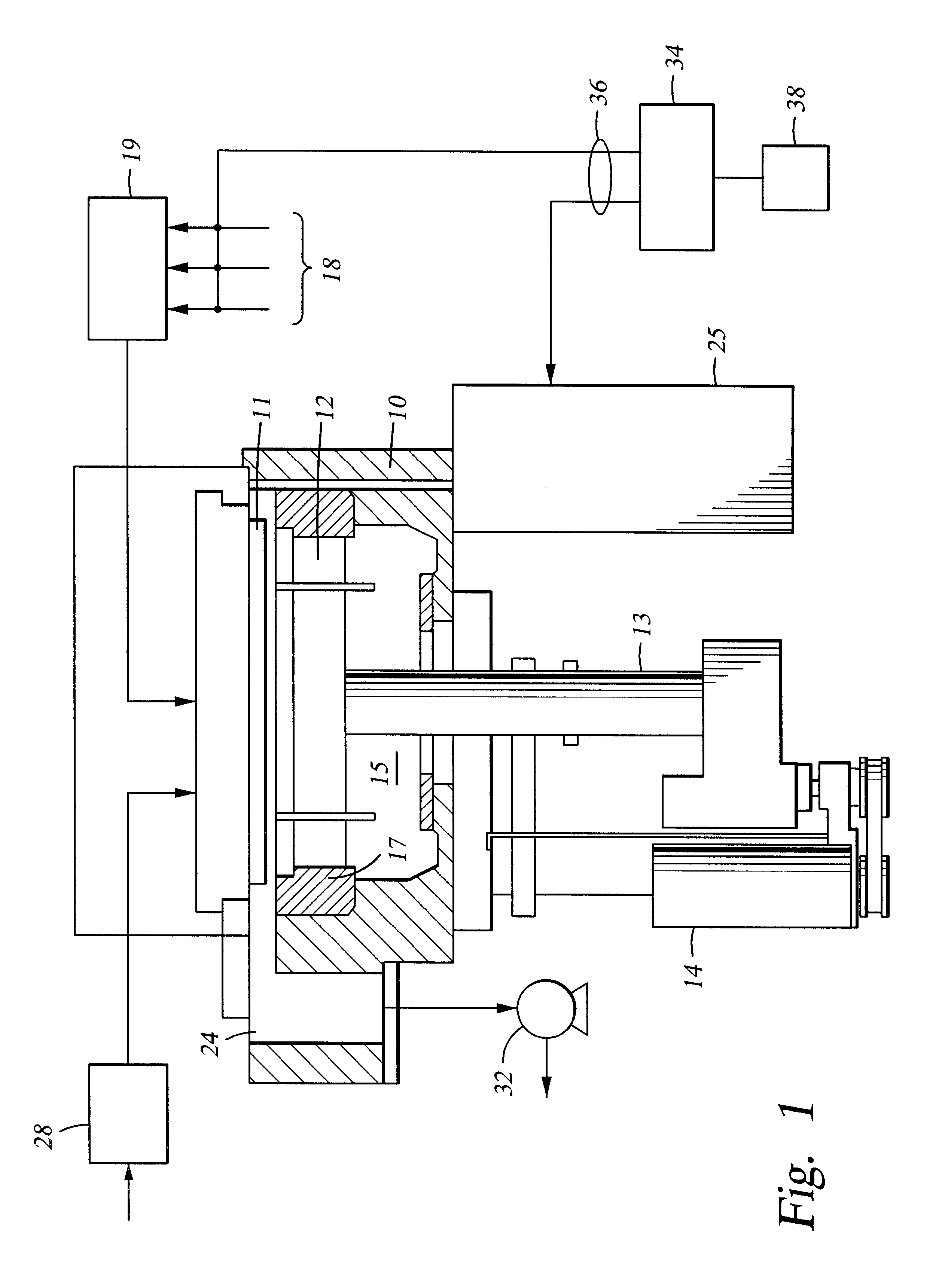

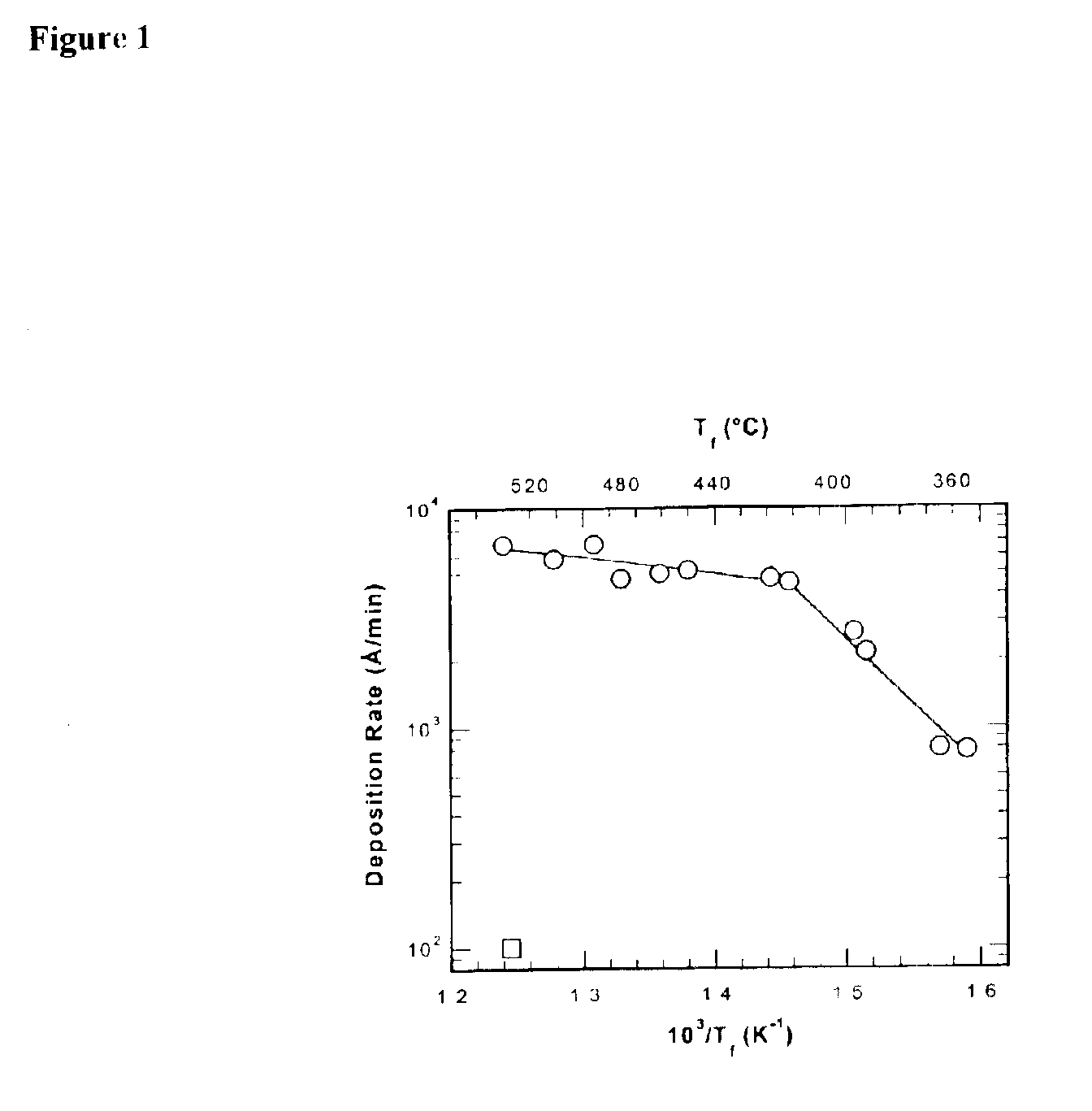

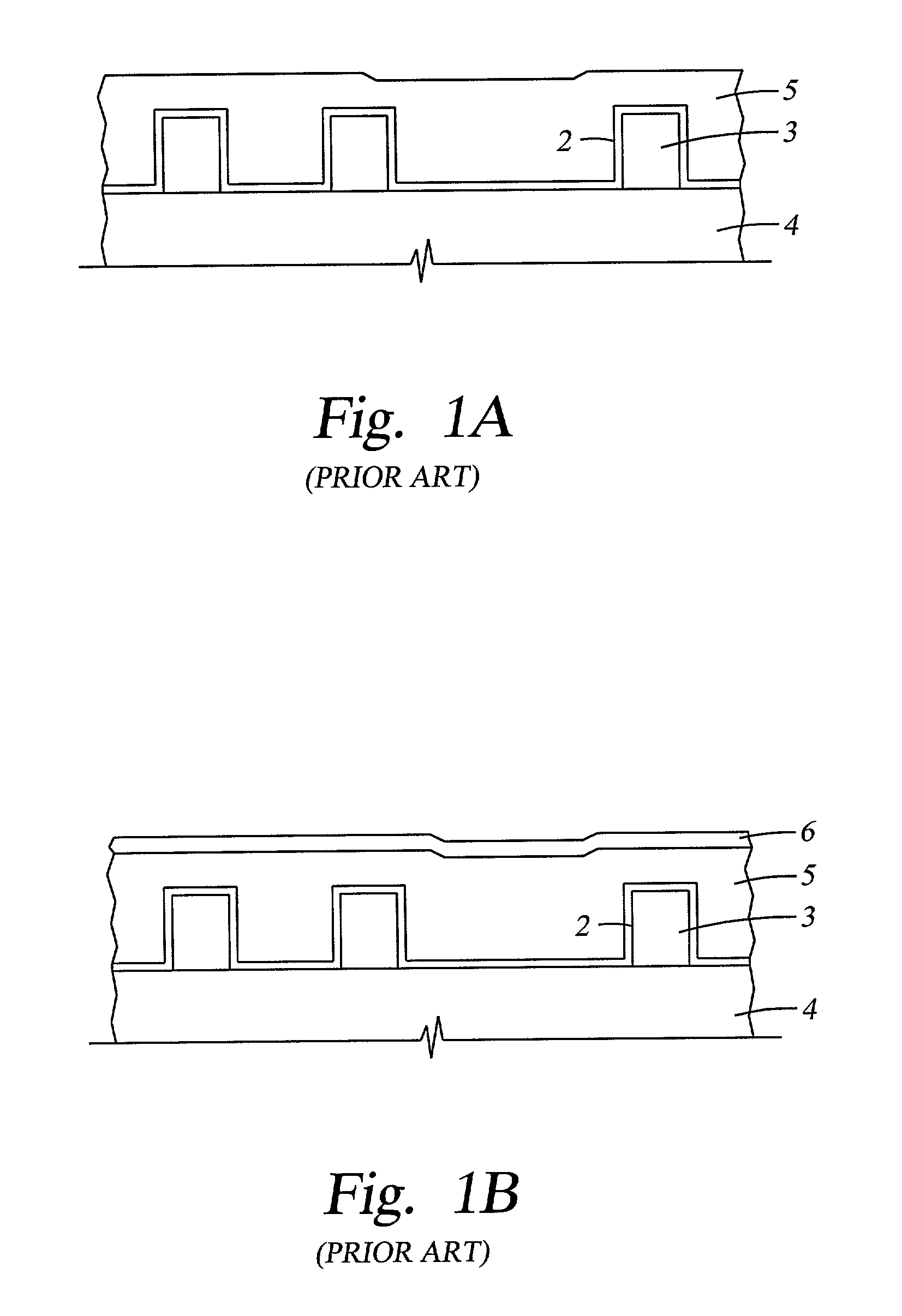

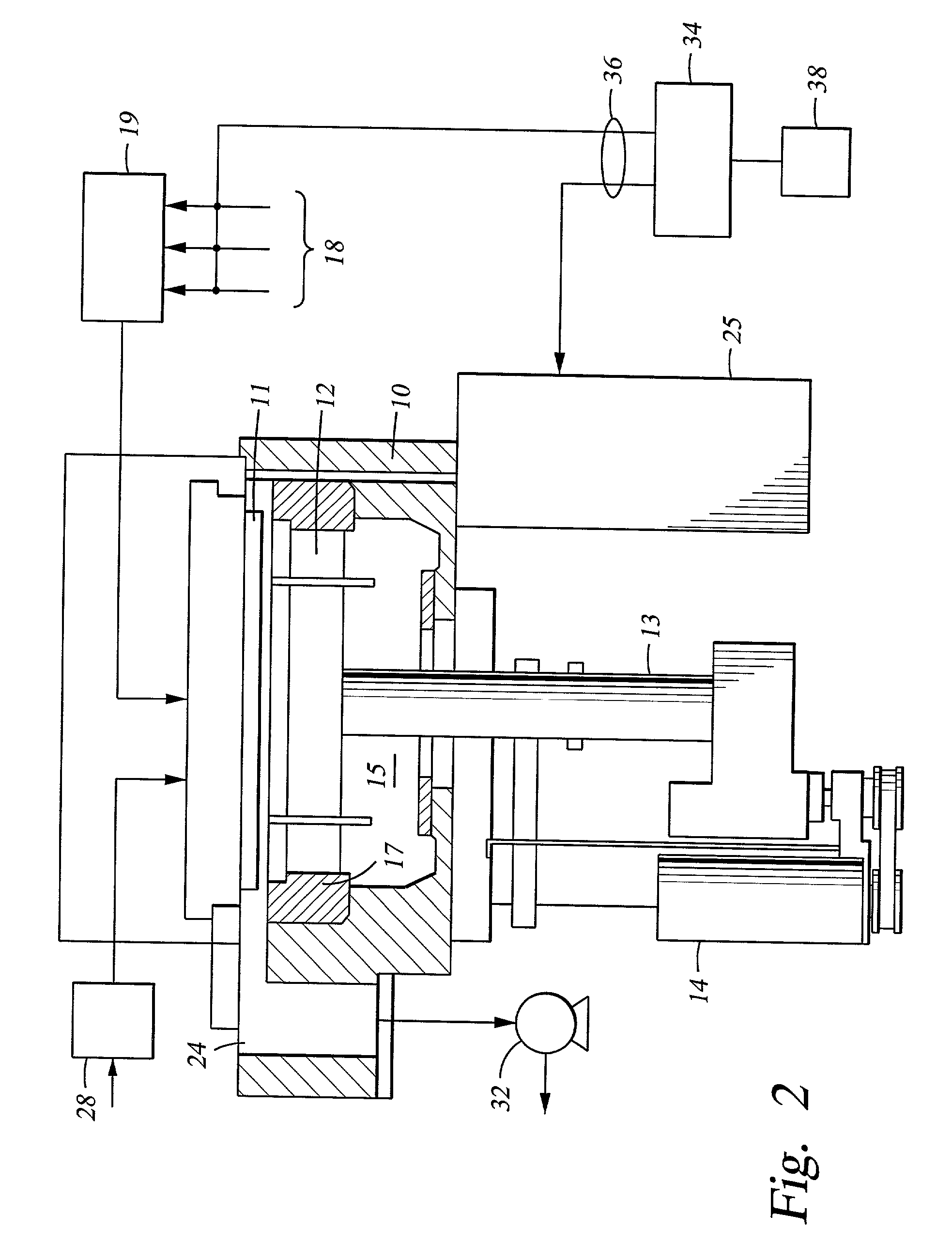

InactiveUS6413583B1Semiconductor/solid-state device detailsSolid-state devicesSilicon oxideSilicon dioxide

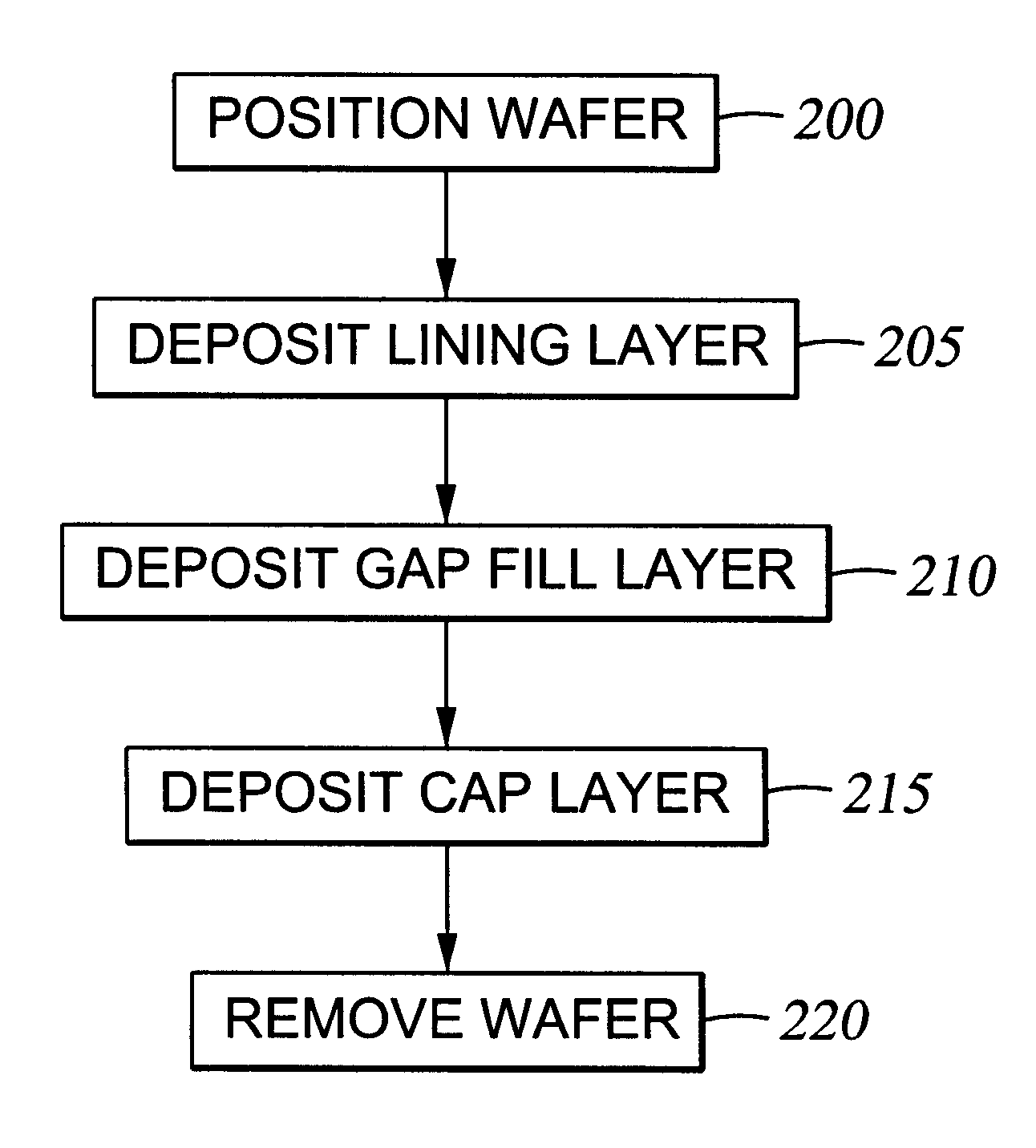

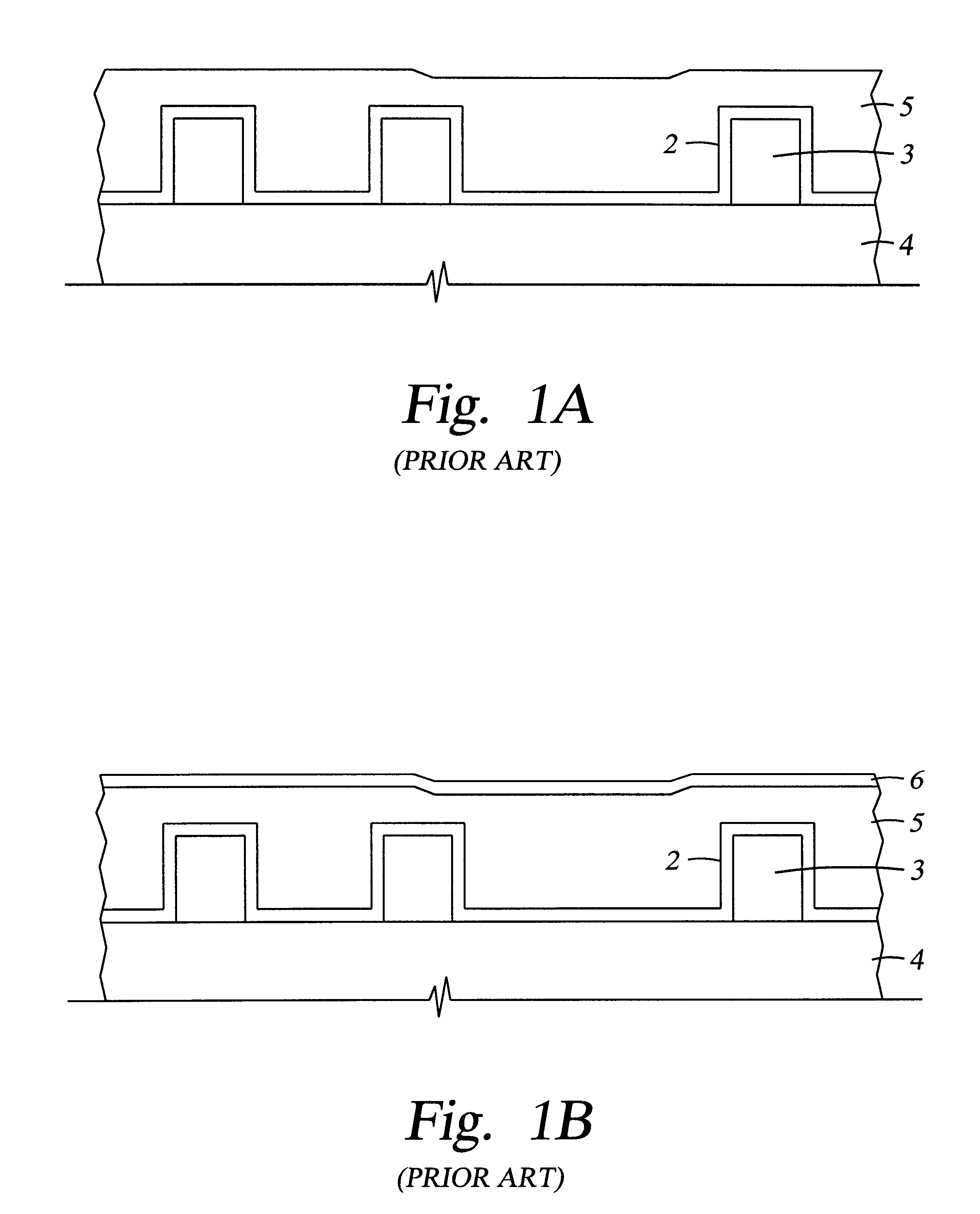

A method for depositing silicon oxide layers having a low dielectric constant by reaction of an organosilicon compound and a hydroxyl forming compound at a substrate temperature less than about 400° C. The low dielectric constant films contain residual carbon and are useful for gap fill layers, pre-metal dielectric layers, inter-metal dielectric layers, and shallow trench isolation dielectric layers in sub-micron devices. The hydroxyl compound can be prepared prior to deposition from water or an organic compound. The silicon oxide layers are preferably deposited at a substrate temperature less than about 40° C. onto a liner layer produced from the organosilicon compound to provide gap fill layers having a dielectric constant less than about 3.0.

Owner:APPLIED MATERIALS INC

Method of making low kappa dielectric inorganic/organic hybrid films

InactiveUS6068884AImprove thermal stabilityLow dielectric constantLayered productsSemiconductor/solid-state device detailsThermal chemical vapor depositionSemiconductor

A method of depositing a dielectric film exhibiting a low dielectric constant in a semiconductor and / or integrated circuit by chemical vapor deposition (CVD) is provided. The film is deposited using an organosilicon precursor in a manner such that the film is comprised of a backbone made substantially of Si-O-Si or Si-N-Si groups with organic side groups attached to the backbone.

Owner:APPLIED MATERIALS INC

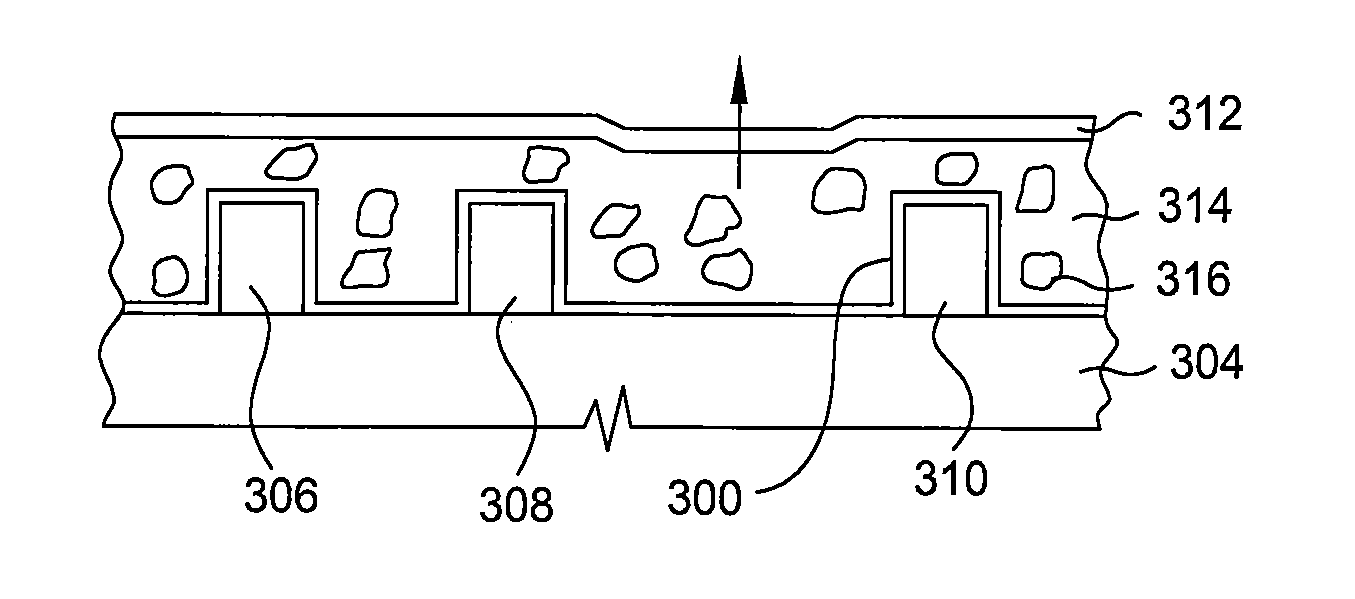

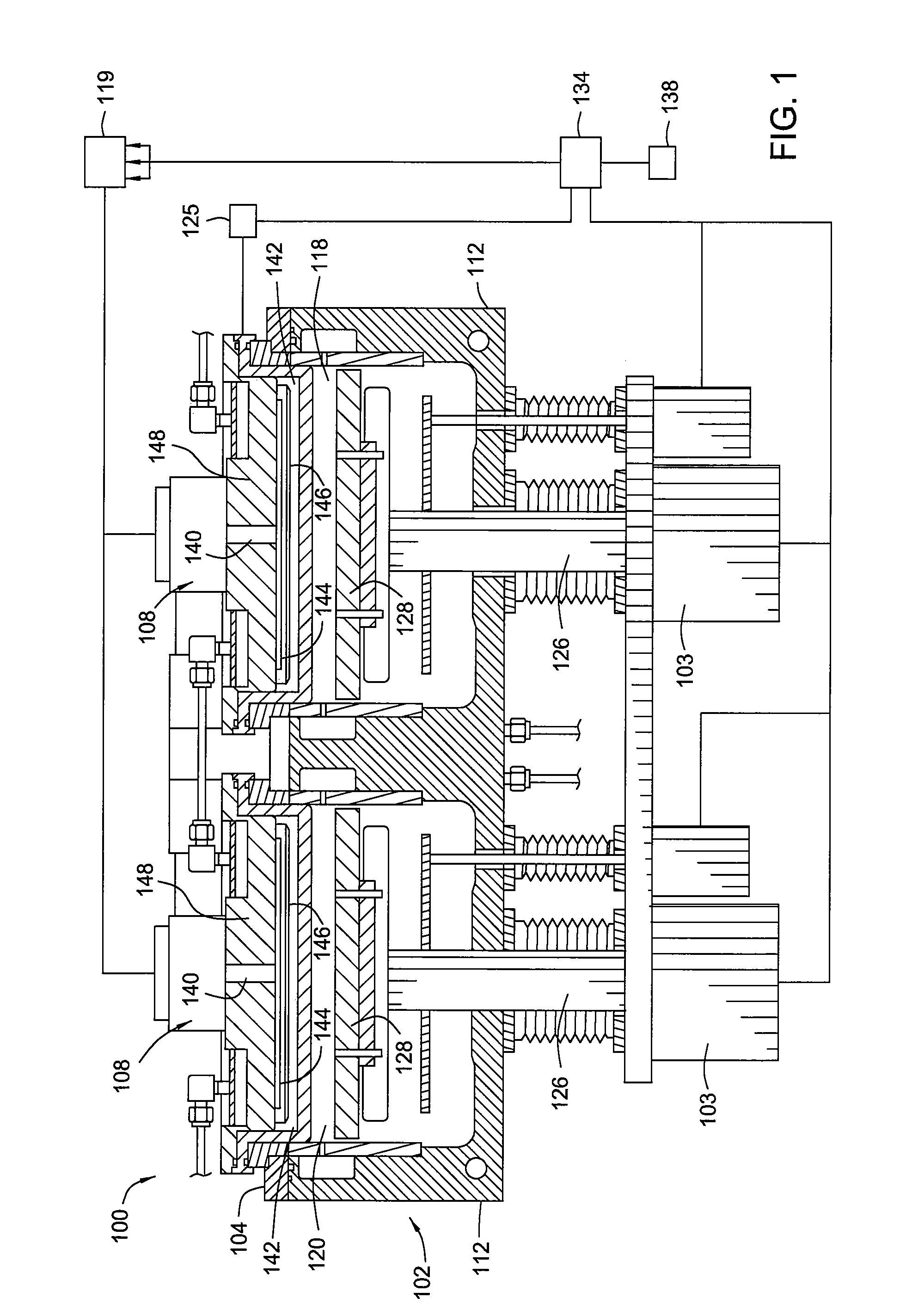

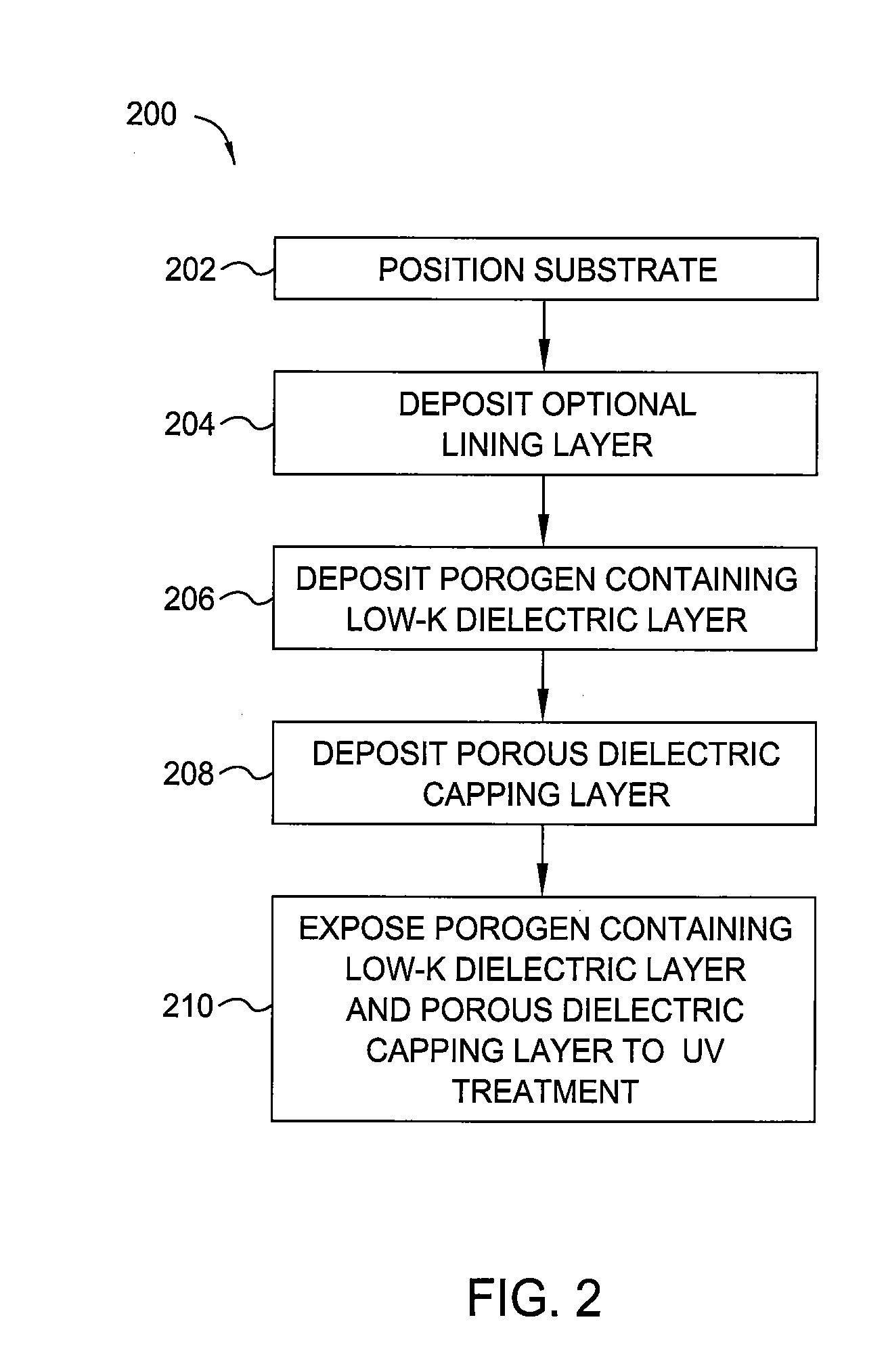

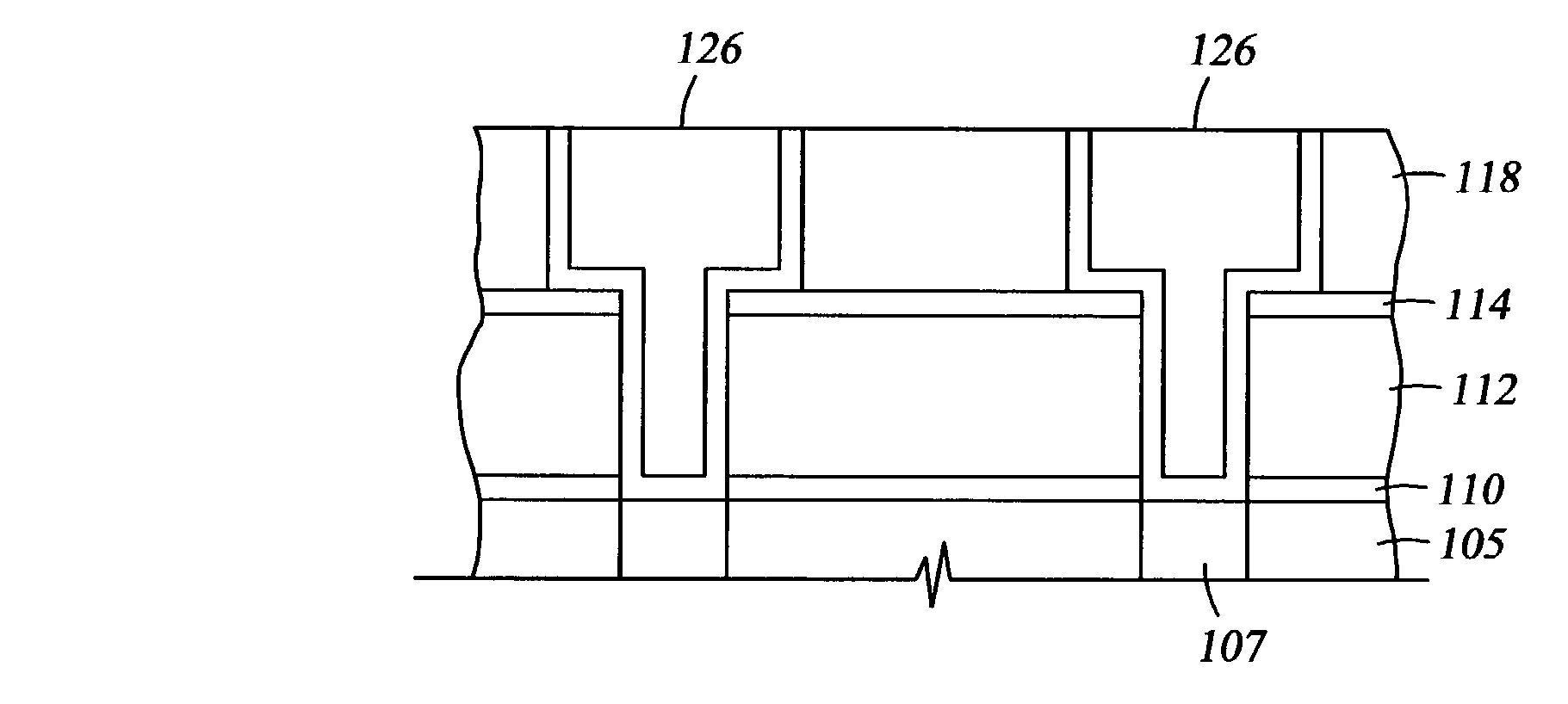

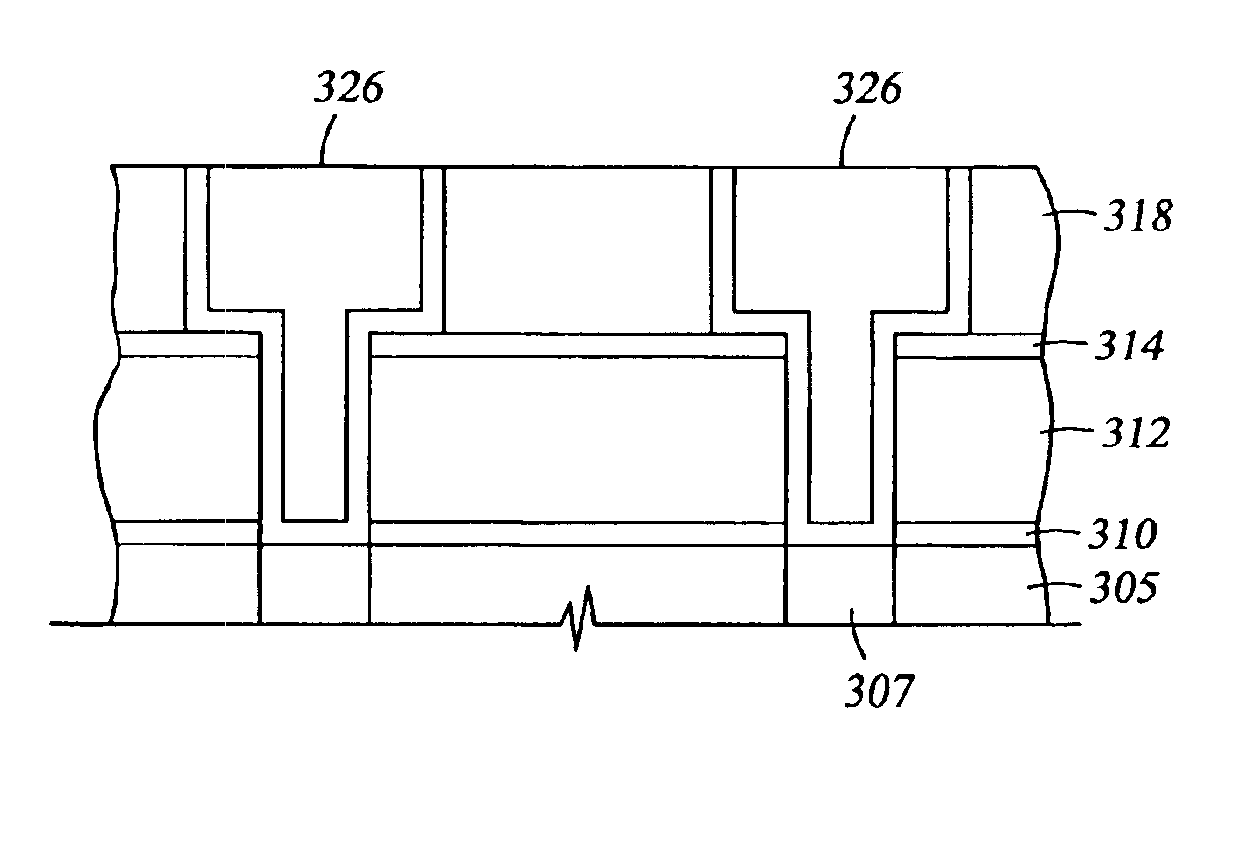

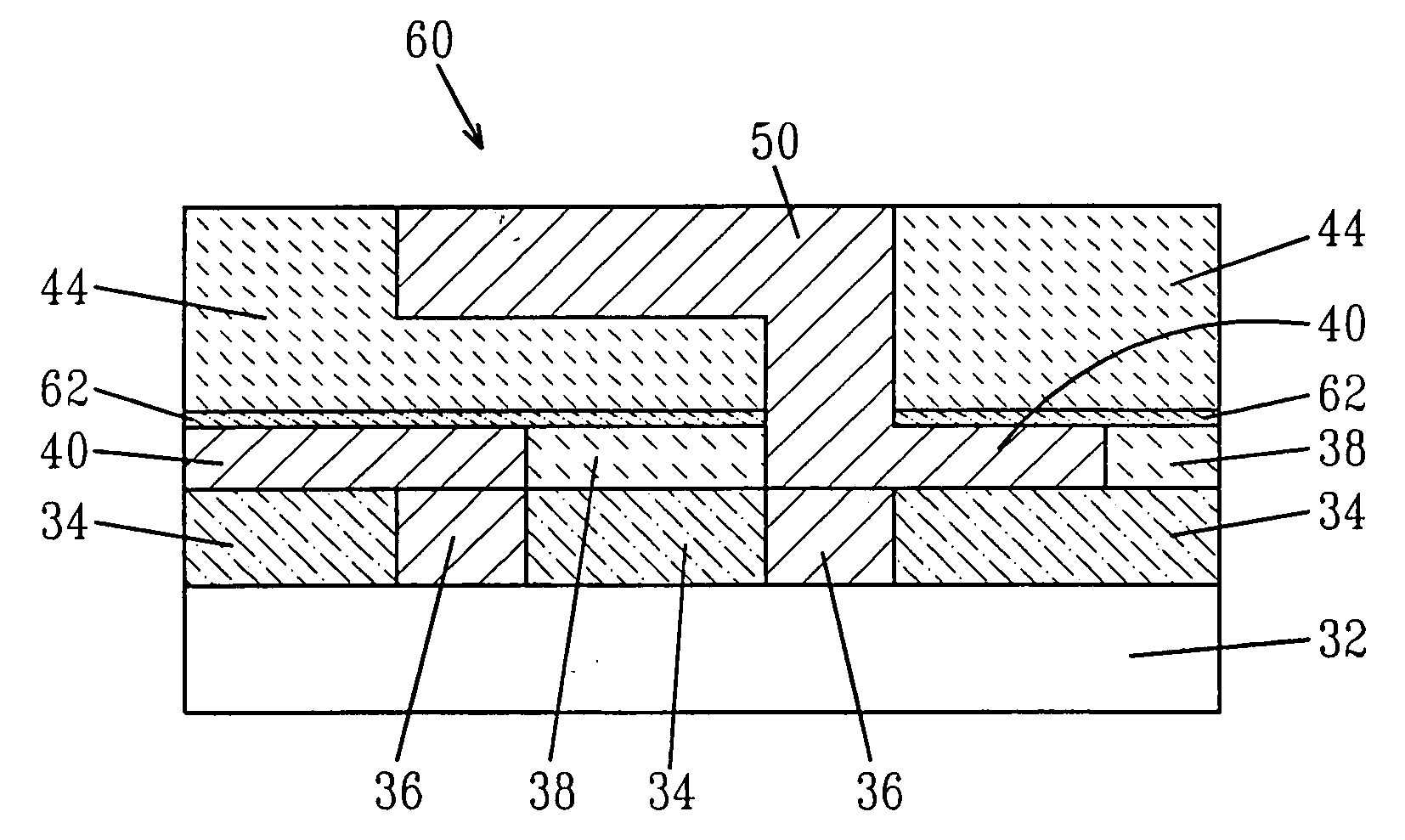

In-situ low-k capping to improve integration damage resistance

InactiveUS20120156890A1Solid-state devicesSemiconductor/solid-state device manufacturingProcess regionOxygen

A method and apparatus for forming low-k dielectric layers that include air gaps is provided. In one embodiment, a method of processing a substrate is provided. The method comprises disposing a substrate within a processing region, reacting an organosilicon compound, with an oxidizing gas, and a porogen providing precursor in the presence of a plasma to deposit a porogen containing low-k dielectric layer comprising silicon, oxygen, and carbon on the substrate, depositing a porous dielectric capping layer comprising silicon, oxygen and carbon on the porogen containing low-k dielectric layer, and ultraviolet (UV) curing the porogen containing low-k dielectric layer and the porous dielectric capping layer to remove at least a portion of the porogen from the porogen containing low-k dielectric layer through the porous dielectric capping layer to convert the porogen containing low-k dielectric layer to a porous low-k dielectric layer having air gaps.

Owner:APPLIED MATERIALS INC

Two-layer film for next generation damascene barrier application with good oxidation resistance

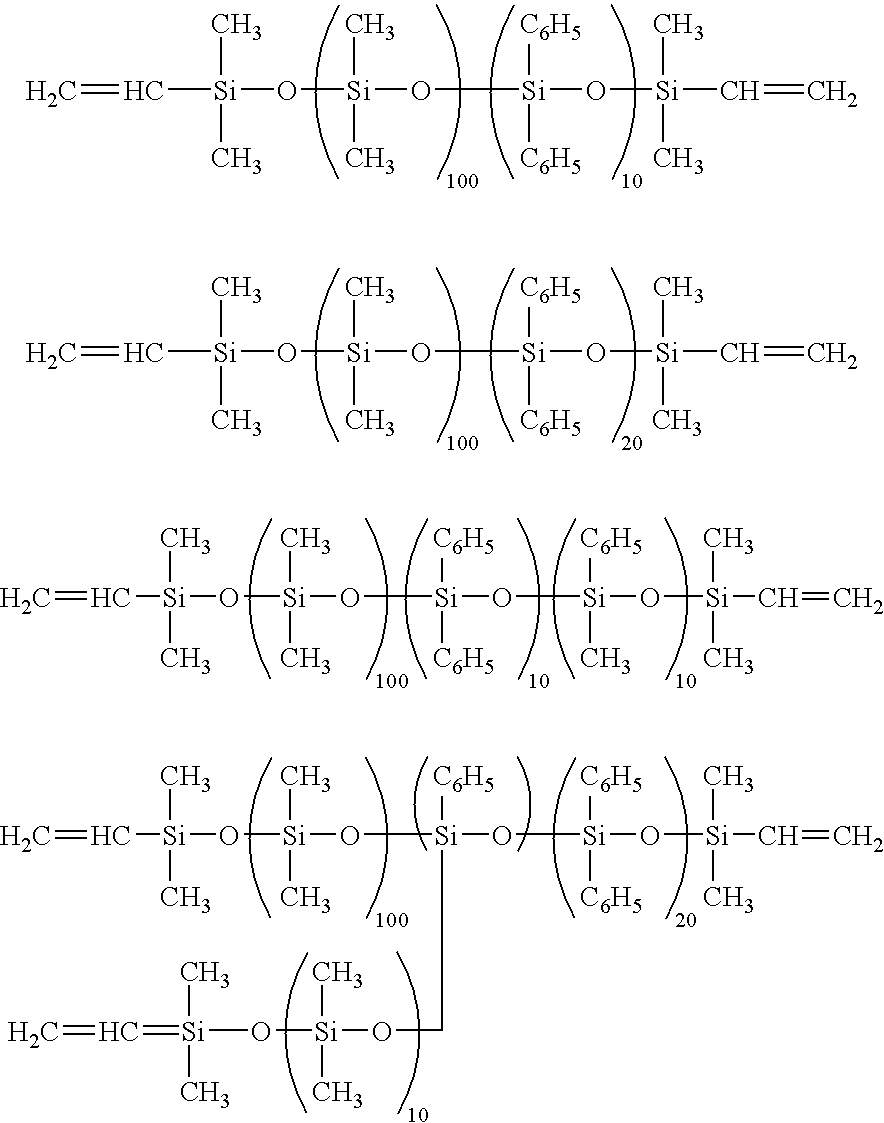

InactiveUS7749563B2Low dielectric constantLiquid surface applicatorsSemiconductor/solid-state device manufacturingOxygenPhenyl group

A method is provided for processing a substrate including providing a processing gas comprising an organosilicon compound comprising a phenyl group to the processing chamber, and reacting the processing gas to deposit a low k silicon carbide barrier layer useful as a barrier layer in damascene or dual damascene applications with low k dielectric materials. A method is provided for depositing a silicon carbide cap layer that has substantially no phenyl groups attached to silicon atoms from a processing gas comprising an oxygen-free organosilicon compound on a low k silicon carbide barrier layer.

Owner:APPLIED MATERIALS INC

Method of depositing dielectric materials in damascene applications

InactiveUS20030129827A1Semiconductor/solid-state device detailsSolid-state devicesMetallurgyProduct gas

Methods are provided for depositing an oxygen-doped dielectric layer. The oxygen-doped dielectric layer may be used for a barrier layer or a hardmask. In one aspect, a method is provided for processing a substrate including positioning the substrate in a processing chamber, introducing a processing gas comprising an oxygen-containing organosilicon compound, carbon dioxide, or combinations thereof, and an oxygen-free organosilicon compound to the processing chamber, and reacting the processing gas to deposit an oxygen-doped dielectric material on the substrate, wherein the dielectric material has an oxygen content of about 15 atomic percent or less. The oxygen-doped dielectric material may be used as a barrier layer in damascene or dual damascene applications.

Owner:APPLIED MATERIALS INC

Method of improving stability in low k barrier layers

InactiveUS20040137756A1Decorative surface effectsSemiconductor/solid-state device detailsHydrogenPhenyl group

A method is provided for processing a substrate including providing a processing gas comprising hydrogen gas and an organosilicon compound comprising a phenyl group to the processing chamber, and reacting the processing gas to deposit a low k silicon carbide barrier layer useful as a barrier layer in damascene or dual damascene applications with low k dielectric materials.

Owner:APPLIED MATERIALS INC

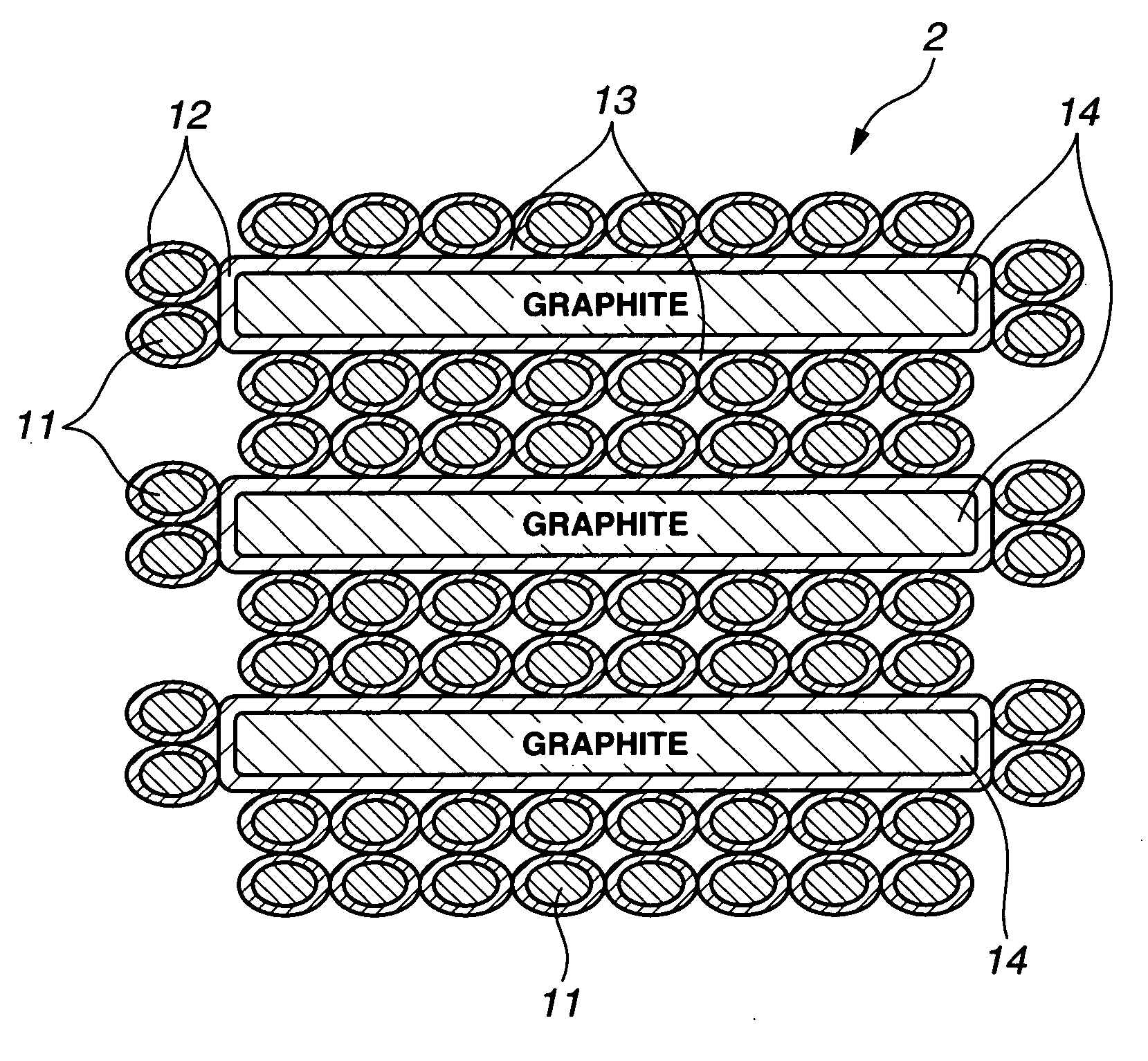

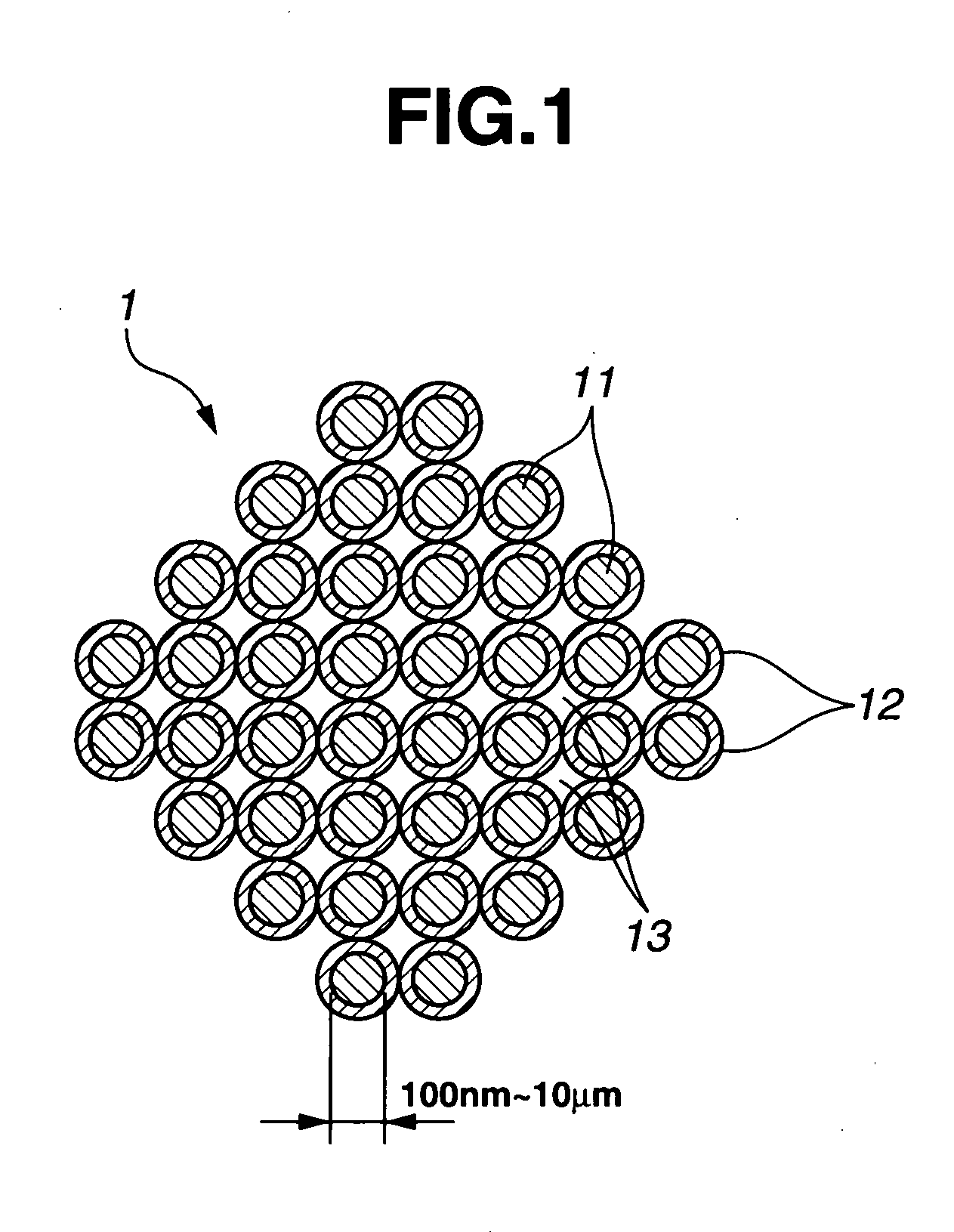

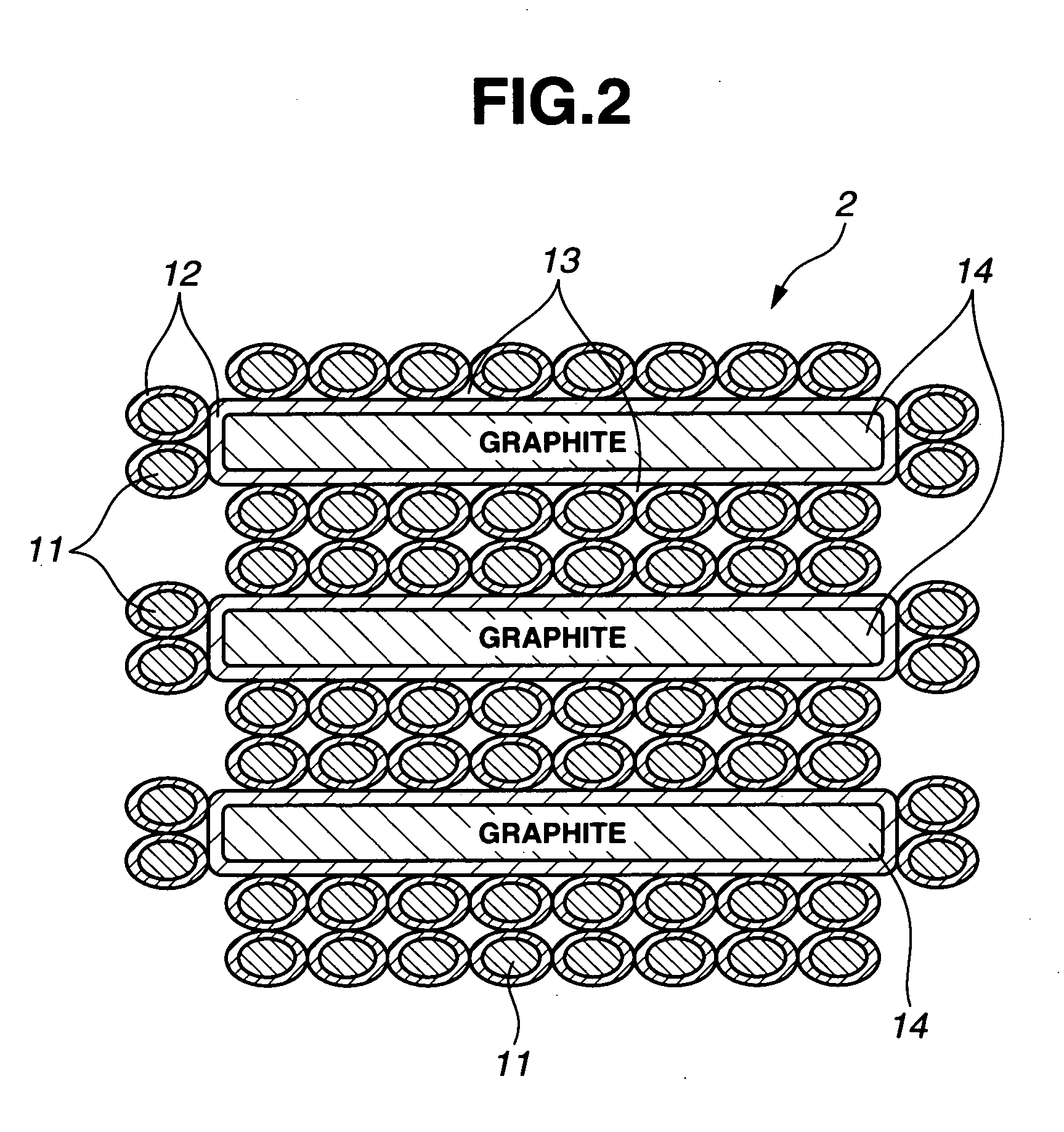

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS20050214644A1Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

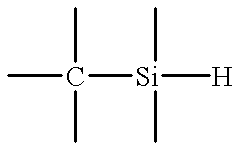

Method of depositing low k films using an oxidizing plasma

InactiveUS6593247B1Semiconductor/solid-state device detailsSolid-state devicesTrimethylsilaneSilicon oxide

A silicon oxide layer is produced by plasma enhanced oxidation of an organosilicon compound to deposit films having a carbon content of at least 1% by atomic weight. Films having low moisture content and resistance to cracking are deposited by introducing oxygen into the processing chamber at a flow rate of less than or equal to the flow rate of the organosilicon compounds, and generating a plasma at a power density ranging between 0.9 W / cm2 and about 3.2 W / cm2. An optional carrier gas may be introduced to facilitate the deposition process at a flow rate less than or equal to the flow rate of the organosilicon compounds. The organosilicon compound preferably has 2 or 3 carbon atoms bonded to each silicon atom, such as trimethylsilane, (CH3)3SiH. An oxygen rich surface may be formed adjacent the silicon oxide layer by temporarily increasing oxidation of the organosilicon compound.

Owner:APPLIED MATERIALS INC

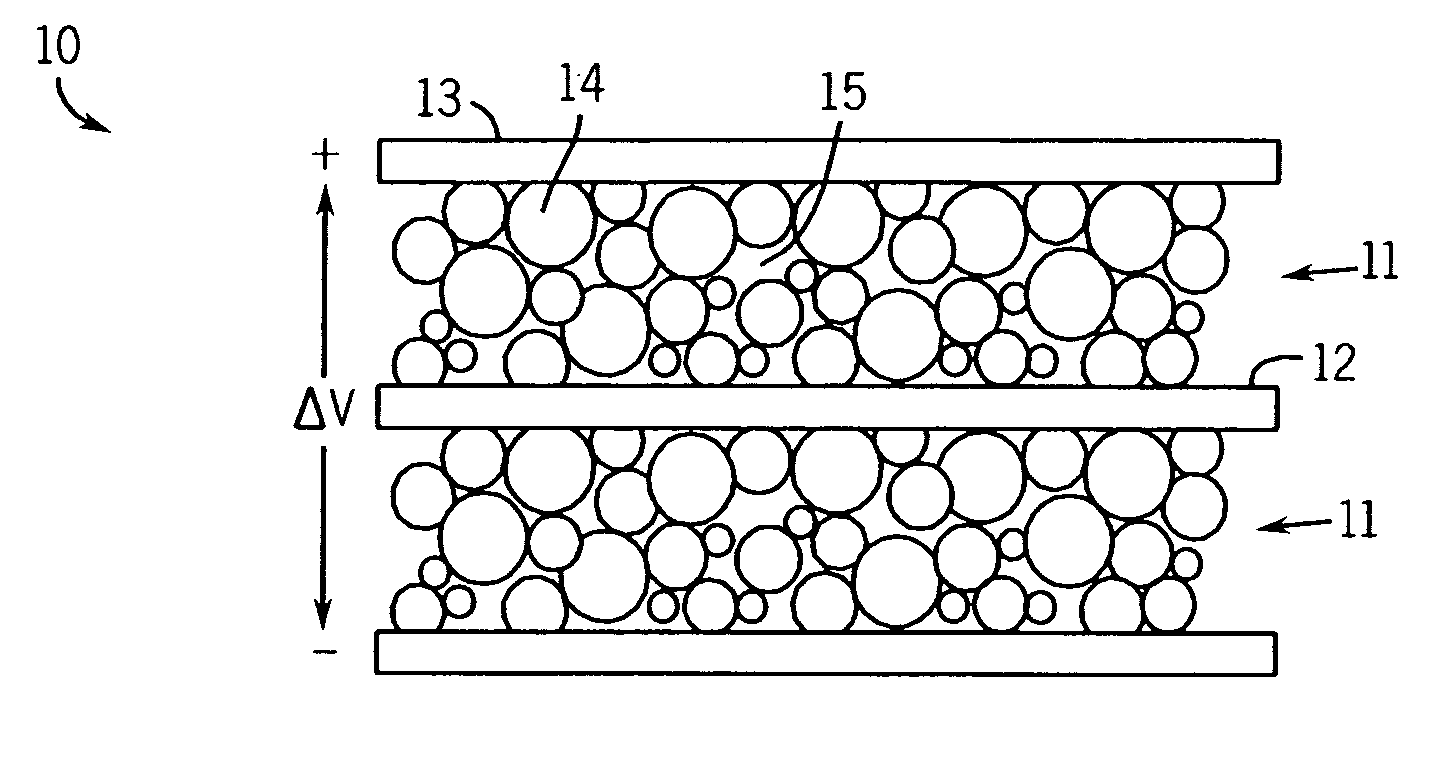

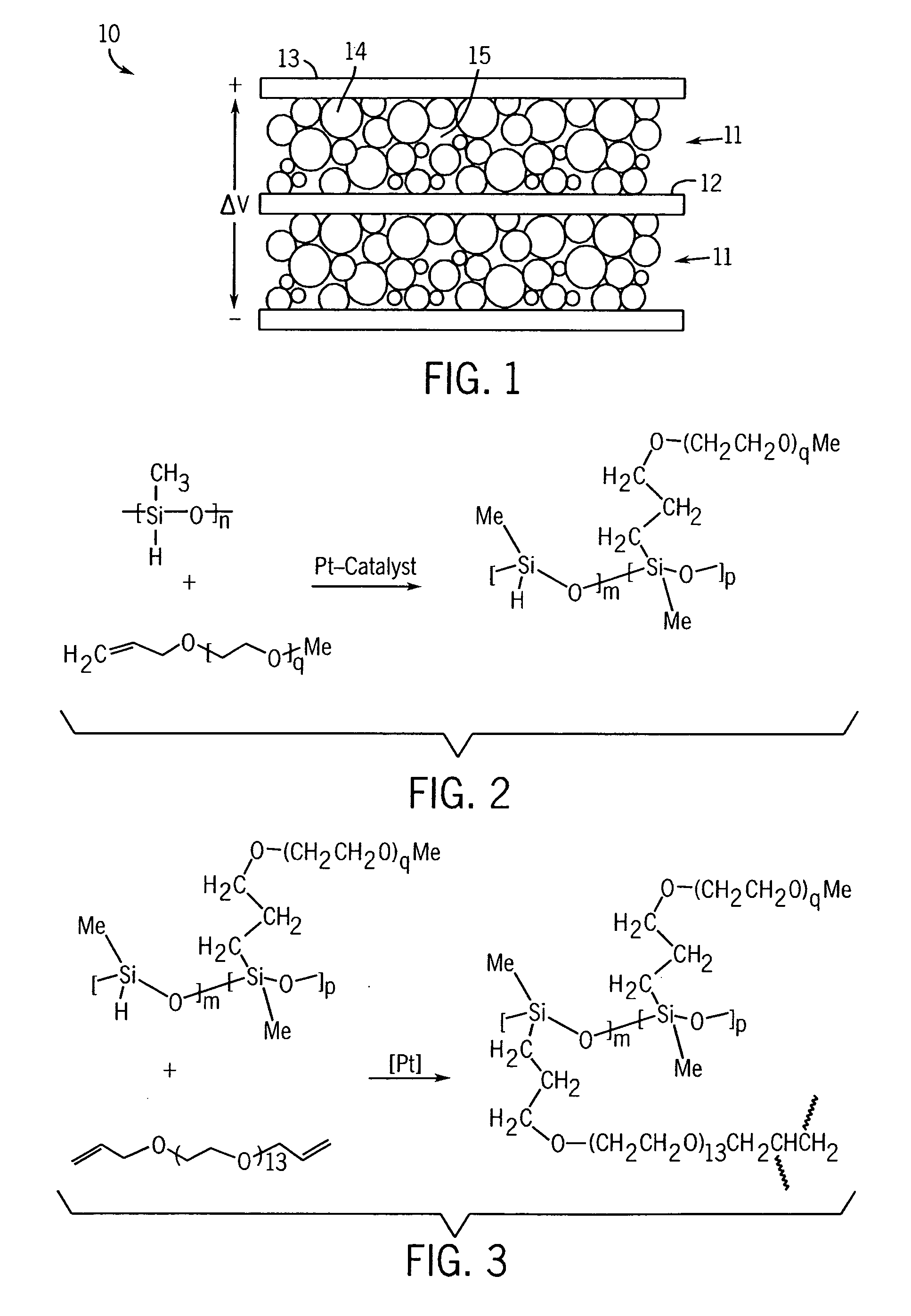

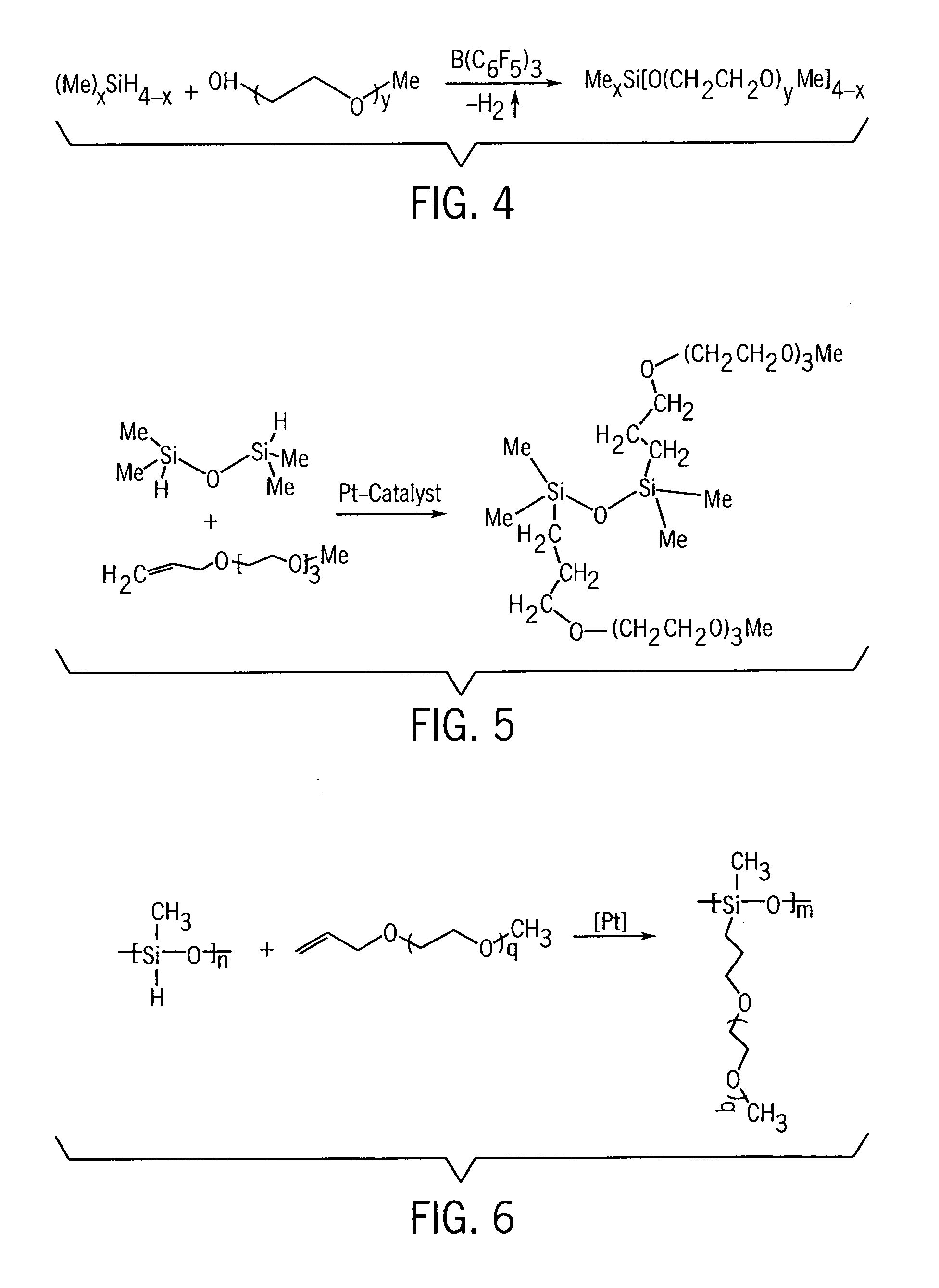

Electrochemical double-layer capacitor using organosilicon electrolytes

ActiveUS20070076349A1Simple processStable storageHybrid capacitor electrolytesLiquid electrolytic capacitorsPorous carbonElectrochemical double layer capacitor

Owner:WISCONSIN ALUMNI RES FOUND

Method of depositing low k barrier layers

InactiveUS20030068881A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPhenyl groupOrganosilicon

A method is provided for processing a substrate including providing a processing gas comprising an organosilicon compound comprising a phenyl group to the processing chamber, and reacting the processing gas to deposit a low k silicon carbide barrier layer useful as a barrier layer in damascene or dual damascene applications with low k dielectric materials.

Owner:APPLIED MATERIALS INC

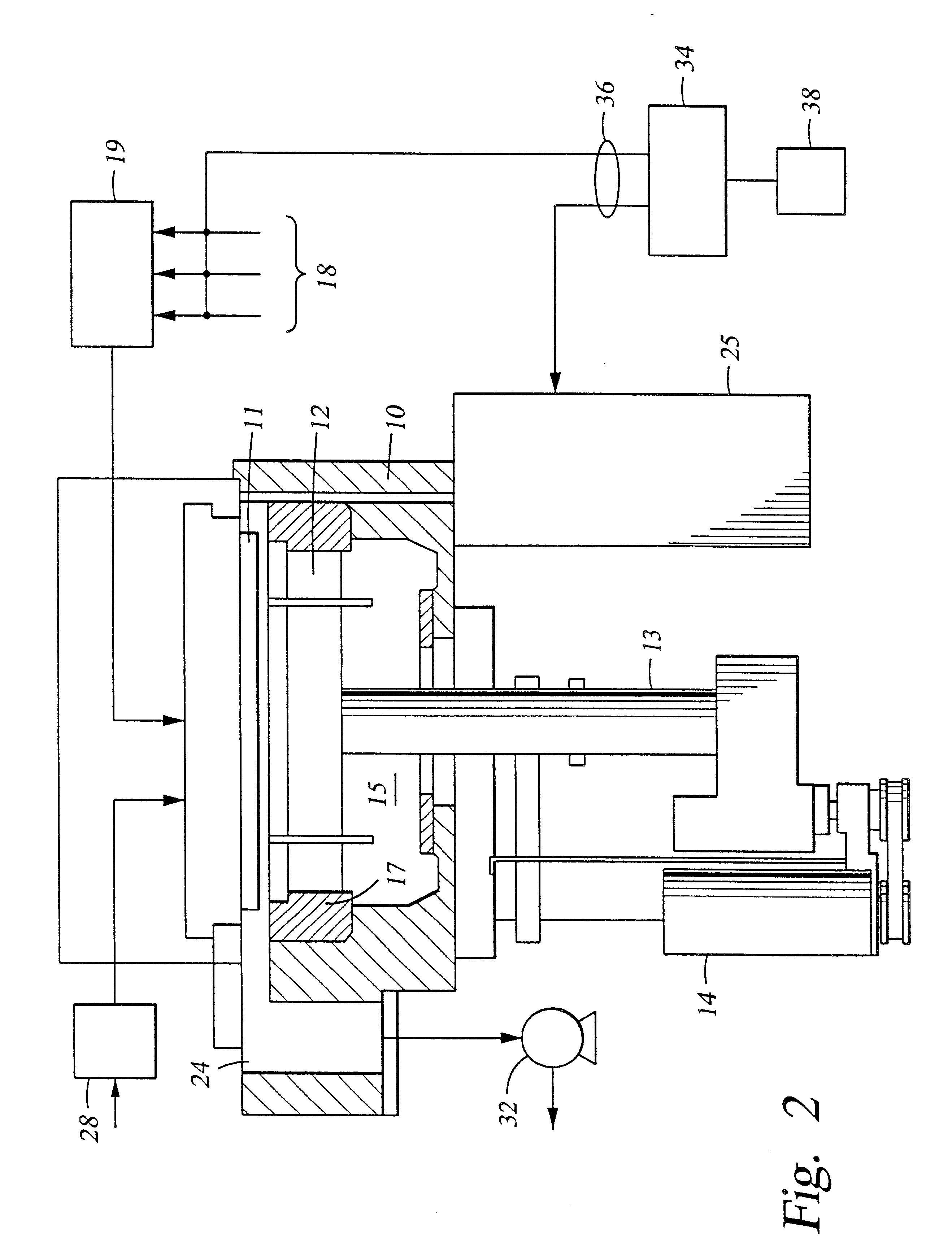

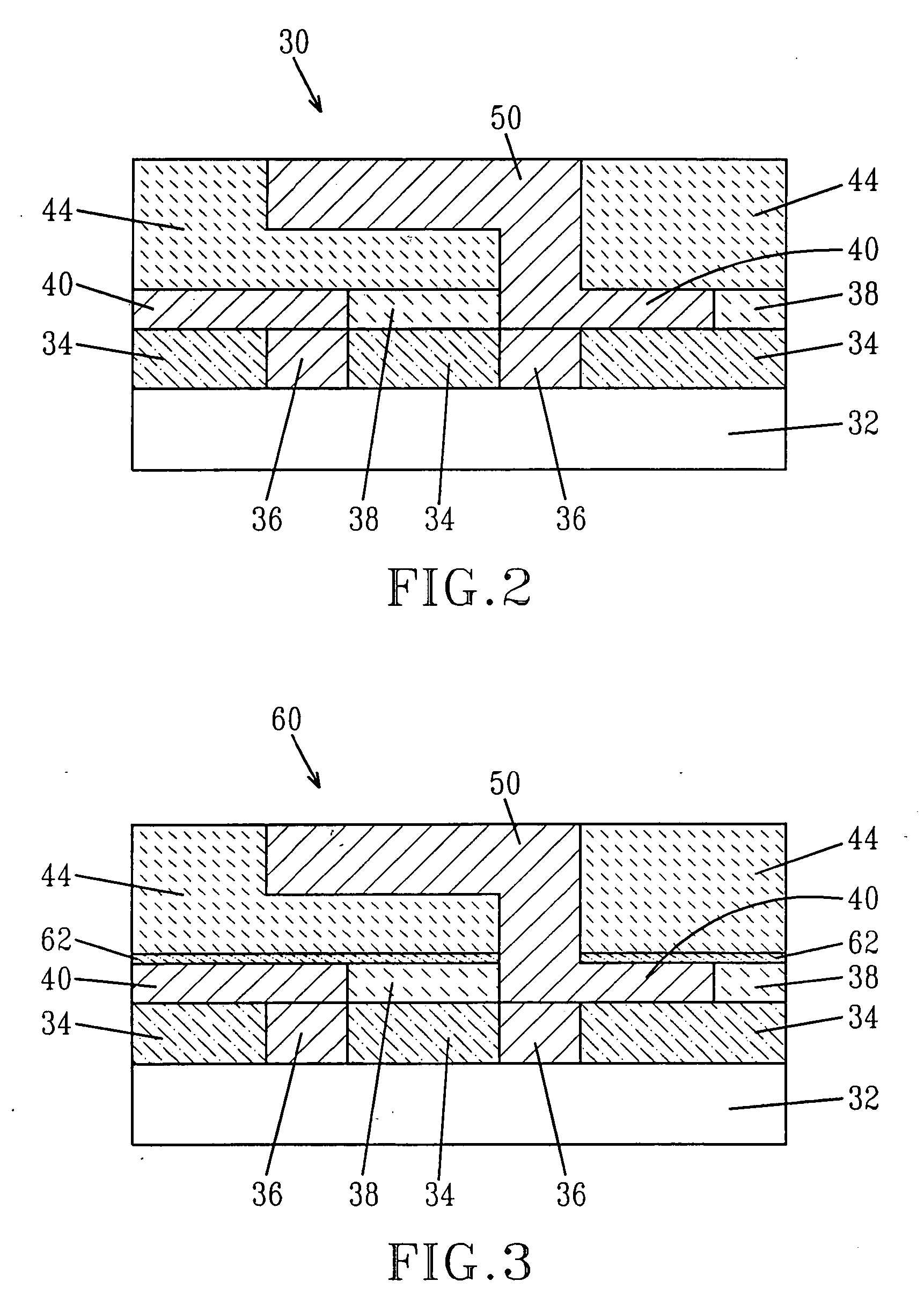

Plasma processes for depositing low dielectric constant films

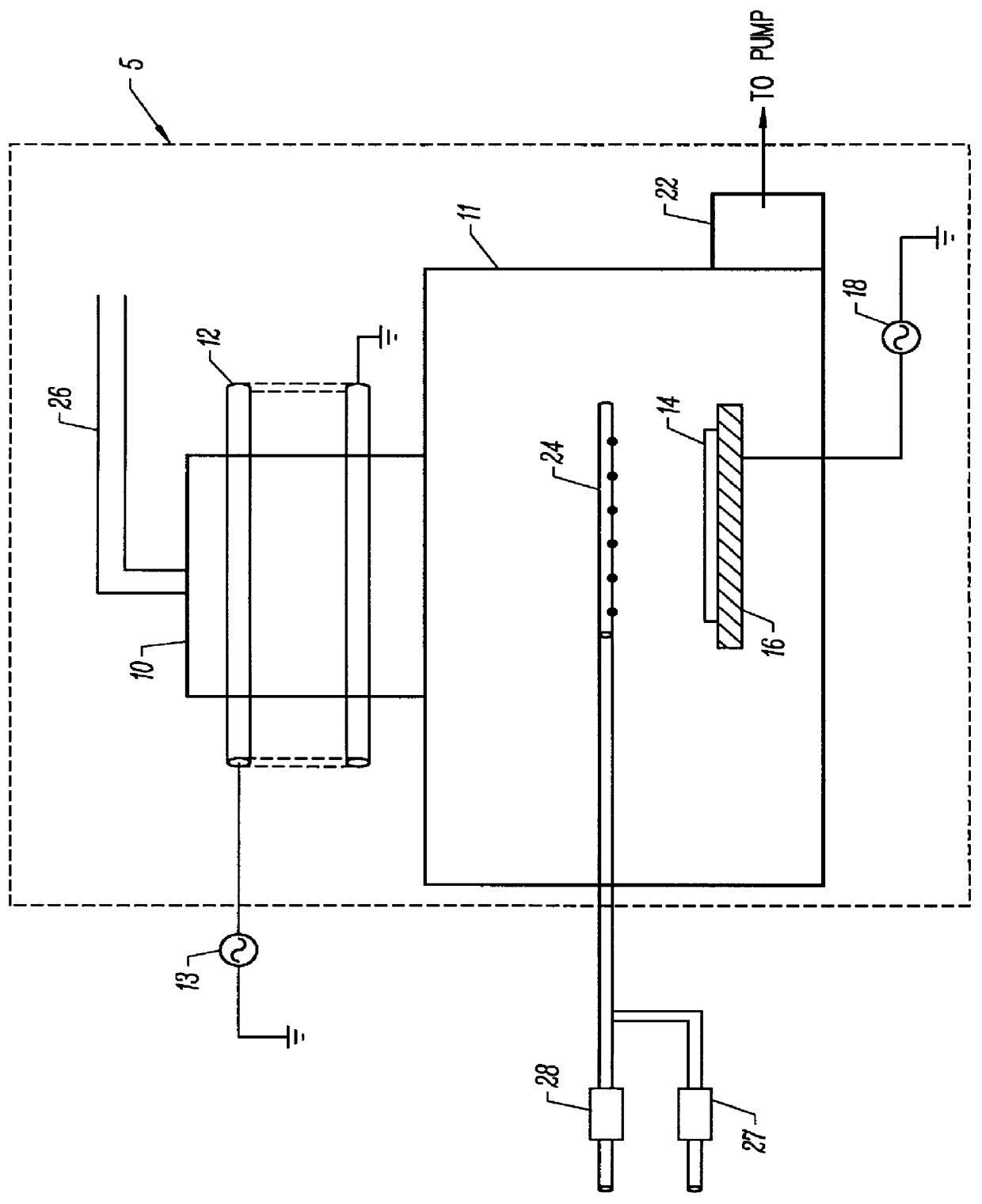

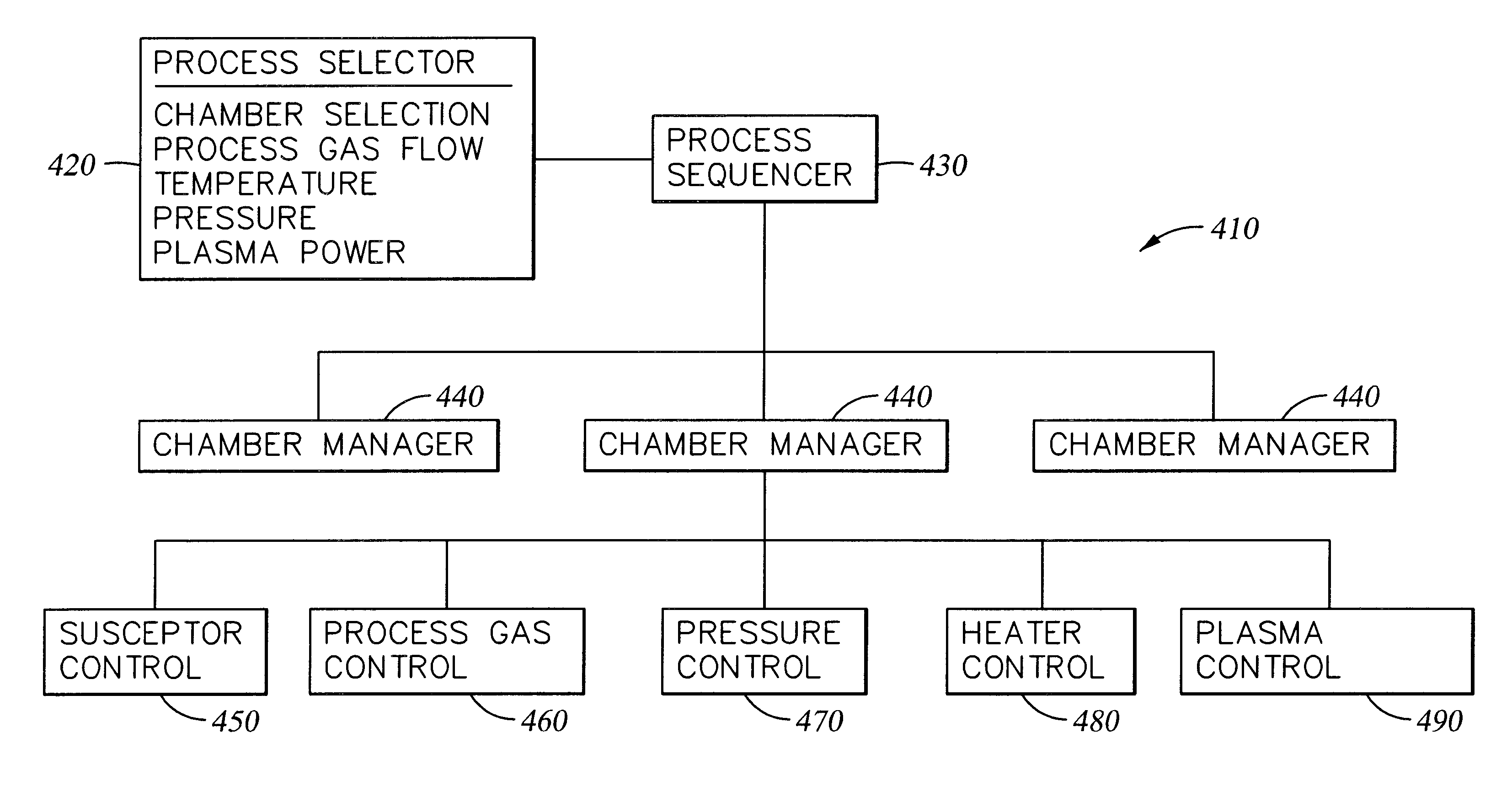

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

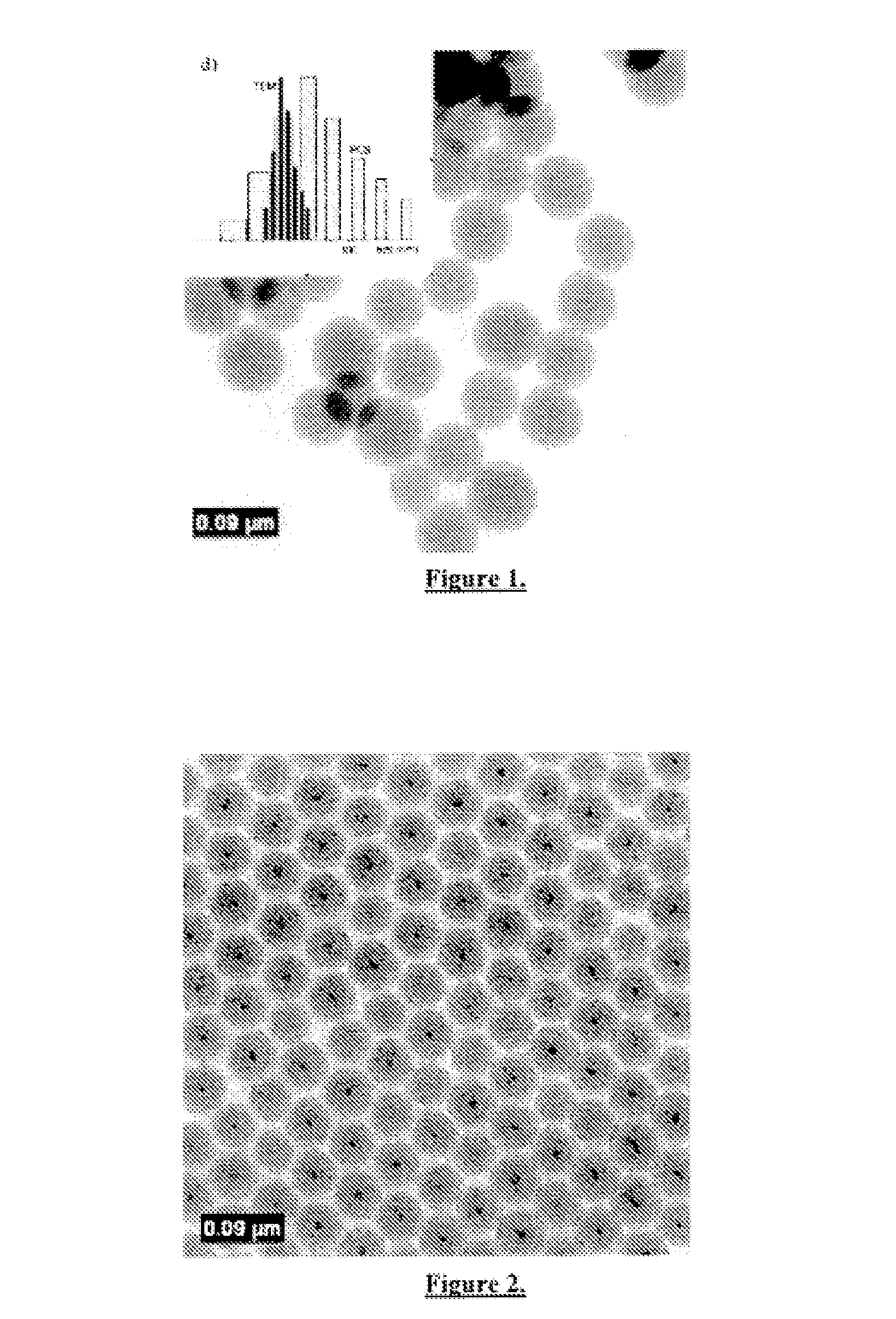

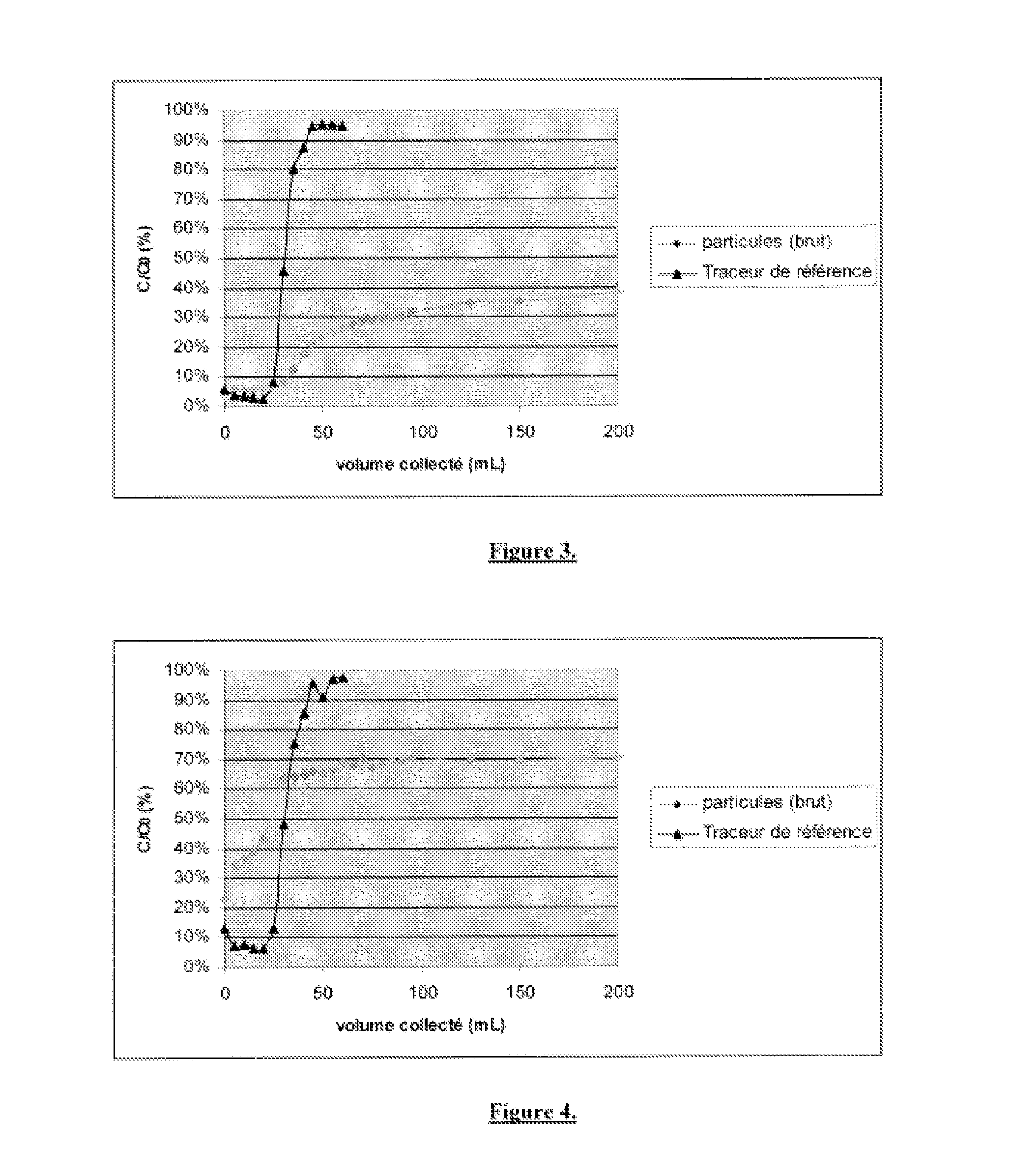

Use of nanoparticles for labelling oil field injection waters

InactiveUS20130084643A1Effective sizeEasy to implementOptical radiation measurementSurveyInjection wellOrganosilicon

The present invention relates to the development of tracer fluids, more generally, that of aqueous liquids, intended to be injected under pressure in an oil reservoir, for example from an injection well up to a production well.The object of the invention is to propose a new method of study of a solid medium, i.e. an oil reservoir, by diffusion of a liquid (i.e. injection waters) containing tracers, through said solid medium, which is simple to implement and economical and which remedies the drawbacks of the known tracers for injection waters of oil reservoirs.This method essentially consisting of injecting, in this solid medium, an injection liquid comprising a nanoparticle-based tracer having average dimensions comprised between 20 and 200 nm, detectable by means of one or several S signals at dilutions of less than or equal to 10−7, adapted to form a stable colloidal suspension in a saline medium, at least a portion of which is constituted of a core and a coating provided with an adjustable hydrophilic-lipophilic balance (HLB) and comprising at least one organic and / or organosilicon component; recovering the liquid having diffused; and analyzing this liquid having diffused to measure the quantity of tracer by detection of the signal or signals S.

Owner:TOTAL PUTEAUX FR

Two step post-deposition treatment of ILD layer for a lower dielectric constant and improved mechanical properties

InactiveUS20050064698A1Increase resistanceImprove the immunityDecorative surface effectsSemiconductor/solid-state device detailsMoistureMechanical property

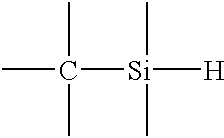

A method of lowering the dielectric constant of an organosilicon low k dielectric layer while improving the hardness and thermal stability is provided. A deposited layer of carbon doped oxide, HSQ, or MSQ is cured and treated with a He plasma which improves hardness for a subsequent CMP step and lowers the dielectric constant. There is no loss of H2O or CH4 during the He treatment. The low k dielectric layer is then treated with a H2 plasma which converts some of the Si—O and Si—CH3 bonds near the surface to Si—H bonds, thereby further lowering the dielectric constant and increasing thermal stability that improves breakdown resistance. Moisture uptake is also reduced. The method is especially useful for interconnect schemes with deep sub-micron ground rules. Surprisingly, the k value obtained from two different plasma treatments is lower than when two He treatments or two H2 treatment are performed.

Owner:TAIWAN SEMICON MASNUFACTURING

Methods for depositing dielectric material

Methods are provided for depositing a low dielectric constant material. In one aspects, a method is provided for depositing a low dielectric constant material including introducing a processing gas comprising hydrogen and an oxygen-containing organosilicon compound, an oxygen-free organosilicon compound, or combinations thereof, to a substrate surface in a processing chamber and reacting the processing gas at processing conditions to deposit the low dielectric constant material on the substrate surface, wherein the low k dielectric material comprises at least silicon and carbon. The processing gas may further include an inert gas, a meta-stable compound, or combinations thereof. The method may further include treating the low dielectric constant material with a hydrogen containing plasma, annealing the deposited low dielectric constant material, or combinations thereof.

Owner:APPLIED MATERIALS INC

Non-aqueous electrolyte secondary battery negative electrode material, making method, and lithium ion secondary battery

ActiveUS20040106040A1Large capacityImprove cycle performanceNon-aqueous electrolyte accumulatorsNegative electrodesConductive coatingMaterials science

A non-aqueous electrolyte secondary battery negative electrode material is provided wherein a negative electrode active material containing a lithium ion-occluding and releasing material which has been treated with an organosilicon base surface treating agent is surface coated with a conductive coating. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

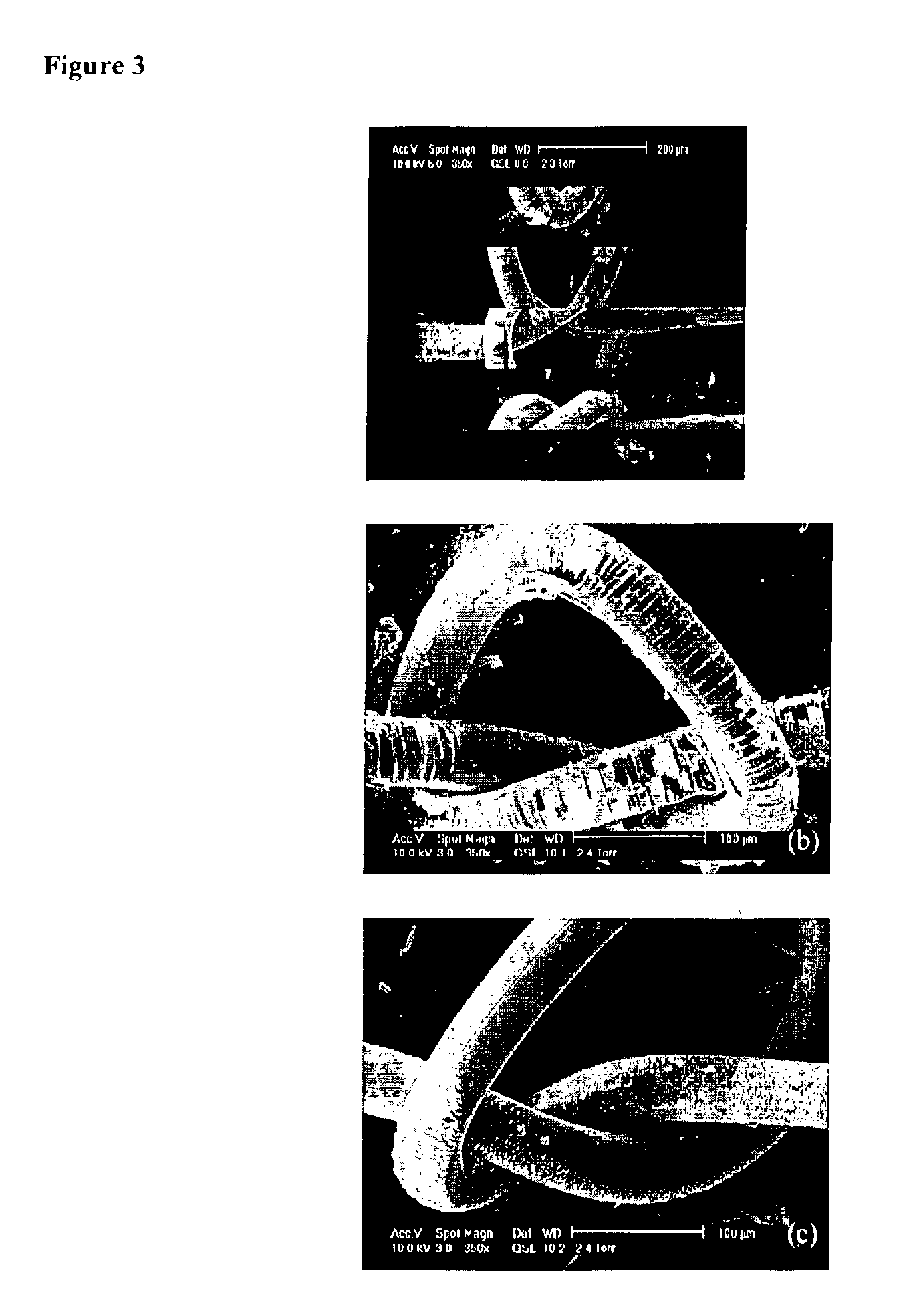

Fluorocarbon-organosilicon copolymers and coatings prepared by hot-filament chemical vapor deposition

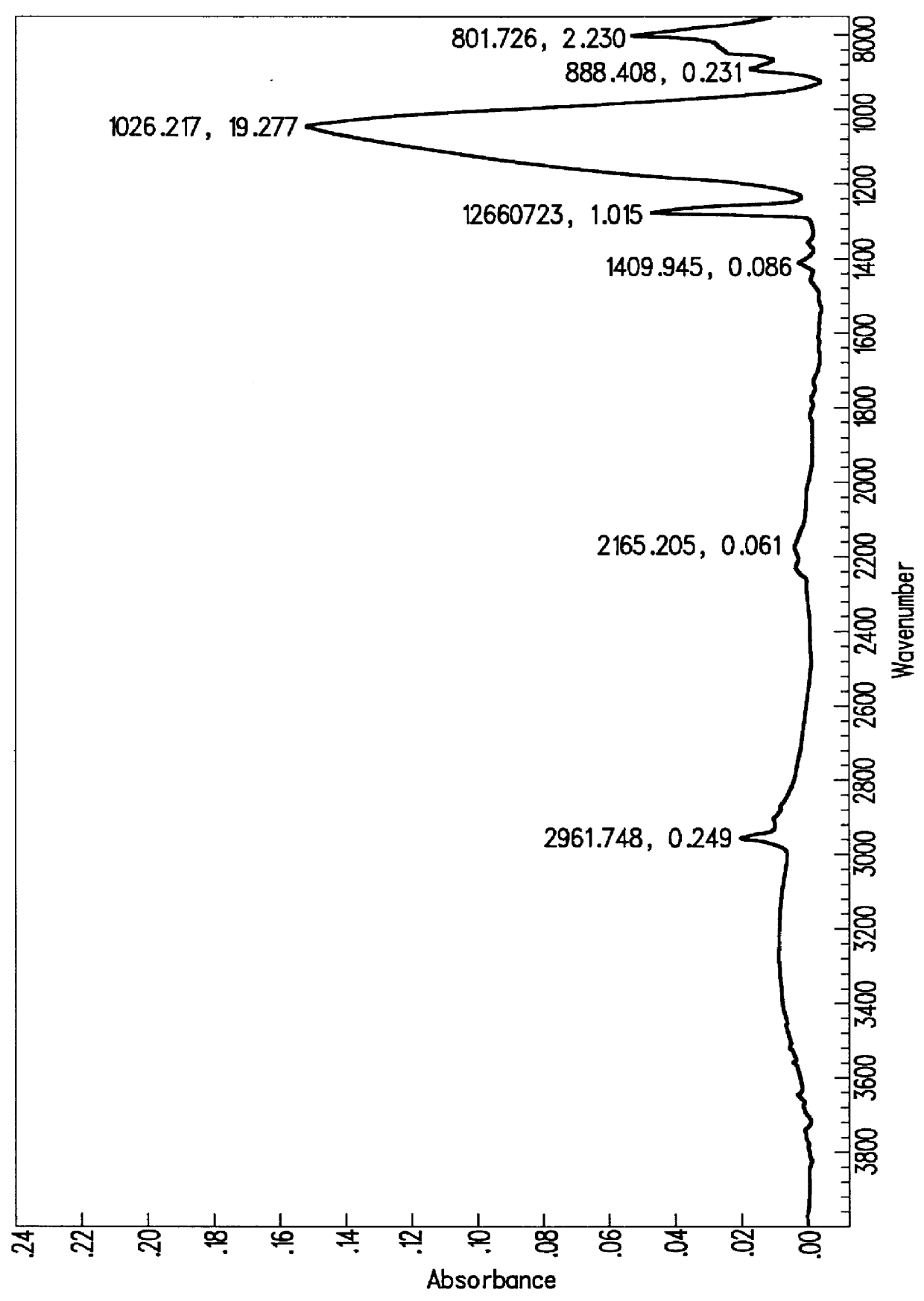

InactiveUS6887578B2Synthetic resin layered productsCellulosic plastic layered productsGas phaseX-ray

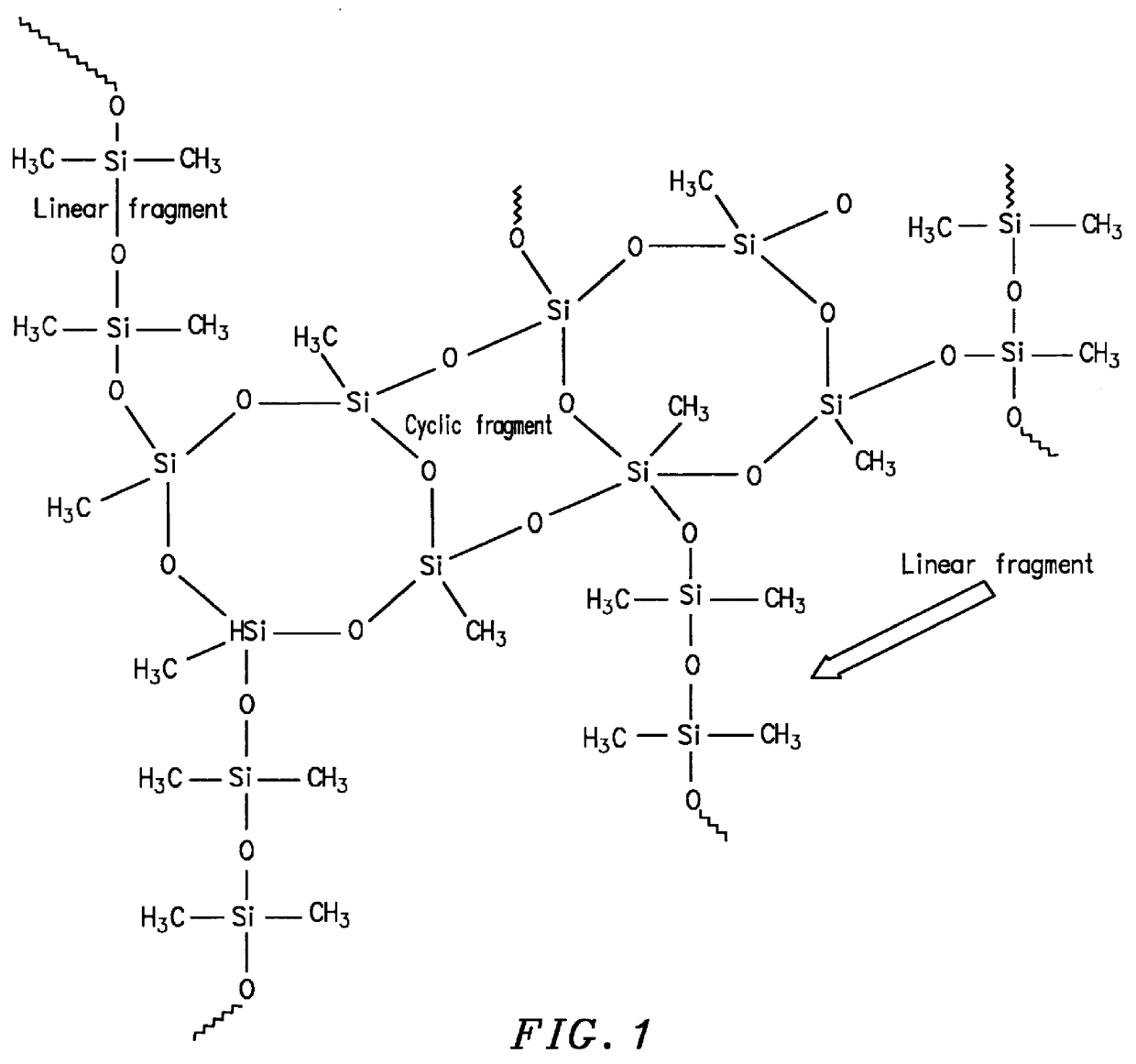

Hot-filament chemical vapor deposition has been used to deposit copolymer thin films consisting of fluorocarbon and siloxane groups. The presence of covalent bonds between the fluorocarbon and organosilicon moieties in the thin film has been confirmed by Infrared, X-ray Photoelectron (XPS) and solid-state 29Si, 19F, and 13C Nuclear Magnetic Resonance (NMR) spectroscopy. The film structure consists of chains with linear and cyclic siloxane groups and CF2 groups as repeat units.

Owner:MASSACHUSETTS INST OF TECH

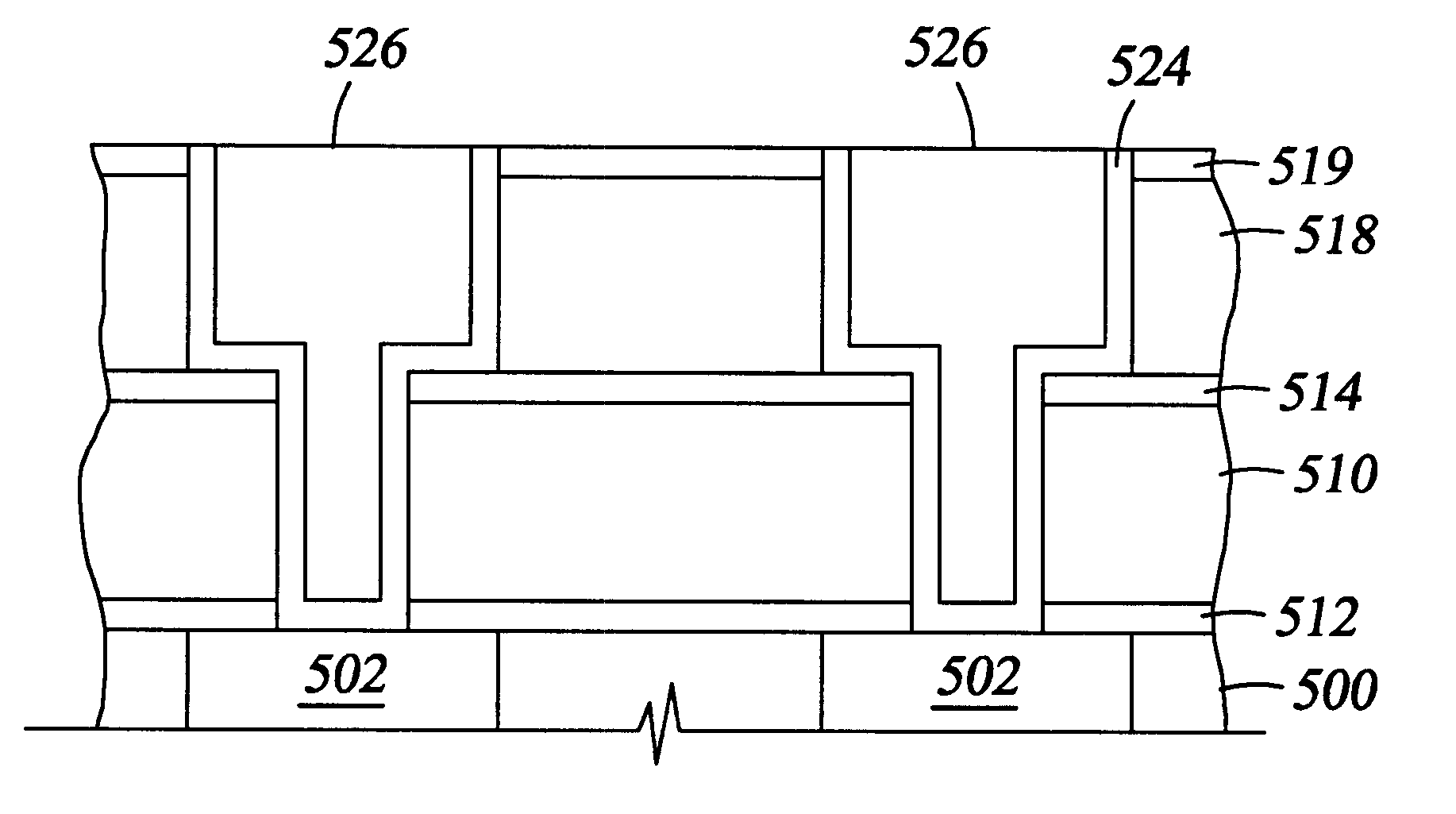

Method of depositing dielectric materials in damascene applications

InactiveUS6890850B2Semiconductor/solid-state device detailsSolid-state devicesMetallurgyOxygen content

Methods are provided for depositing an oxygen-doped dielectric layer. The oxygen-doped dielectric layer may be used for a barrier layer or a hardmask. In one aspect, a method is provided for processing a substrate including positioning the substrate in a processing chamber, introducing a processing gas comprising an oxygen-containing organosilicon compound, carbon dioxide, or combinations thereof, and an oxygen-free organosilicon compound to the processing chamber, and reacting the processing gas to deposit an oxygen-doped dielectric material on the substrate, wherein the dielectric material has an oxygen content of about 15 atomic percent or less. The oxygen-doped dielectric material may be used as a barrier layer in damascene or dual damascene applications.

Owner:APPLIED MATERIALS INC

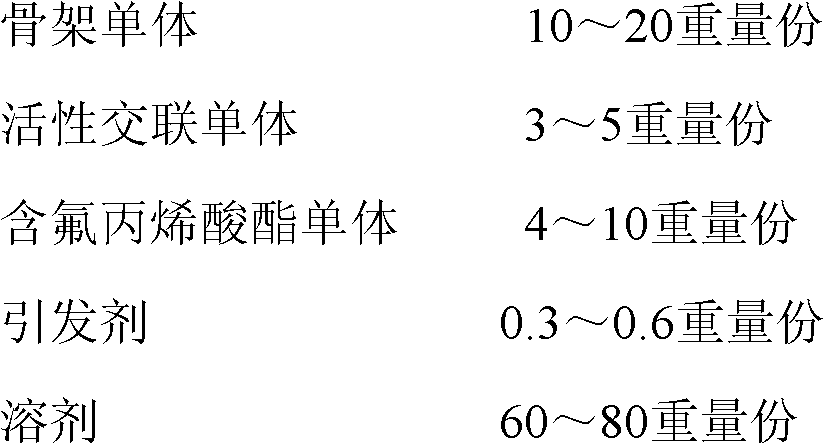

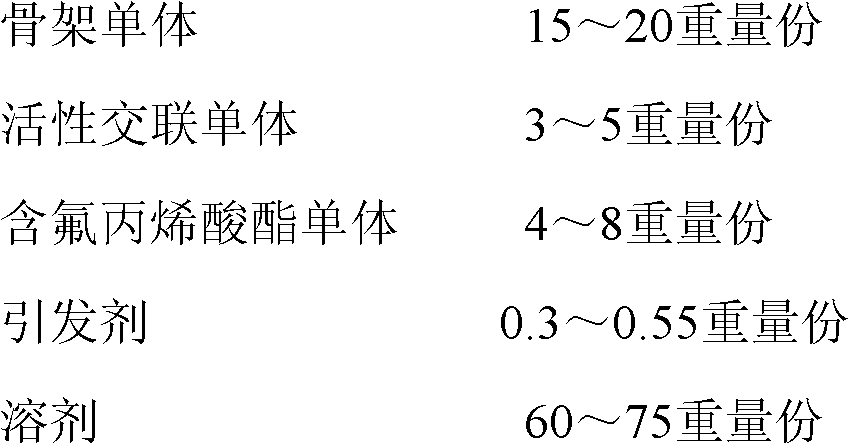

Fluorine-silicon acrylic resin nano composite anti-icing coating and preparation method thereof

InactiveCN102321415AReduce the amount of icingAchieve super-hydrophobic anti-icing effectCoatingsHysteresisAcrylic resin

The invention discloses a super hydrophobic anti-icing coating and a preparation method thereof, and is realized by preparing a fluorine contained acrylic resin and combining the fluorine contained acrylic resin with organosilicon resin and nano particles. In a scheme of the invention, the fluorine contained acrylic resin has small surface energy and strong hydrophobicity. The organosilicon resin utilizes effect of -CH3 on a surface thereof and small polarity to substantially reduce contact angle hysteresis. The fluorine contained acrylic resin can crosslink and solidify with the nano particles and active groups in the organosilicon resin to form a composite network. The invention can overcome defects of complex technology, high costs and unsuitability for large scale usage of an ordinary method for preparing a super hydrophobic coating; and the prepared coating can realize super hydrophobic anti-icing effect through a regular spraying method.

Owner:TIANJIN UNIV

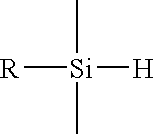

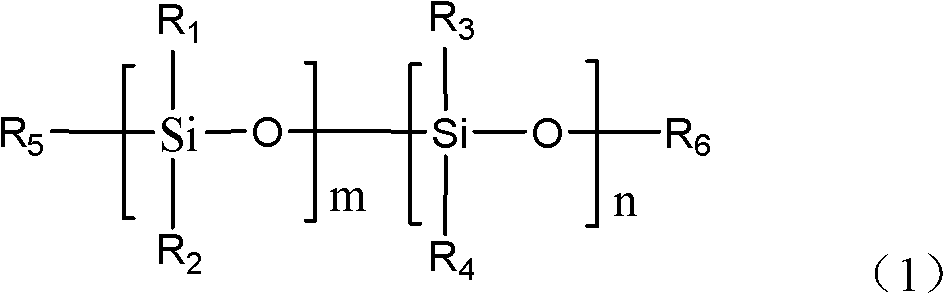

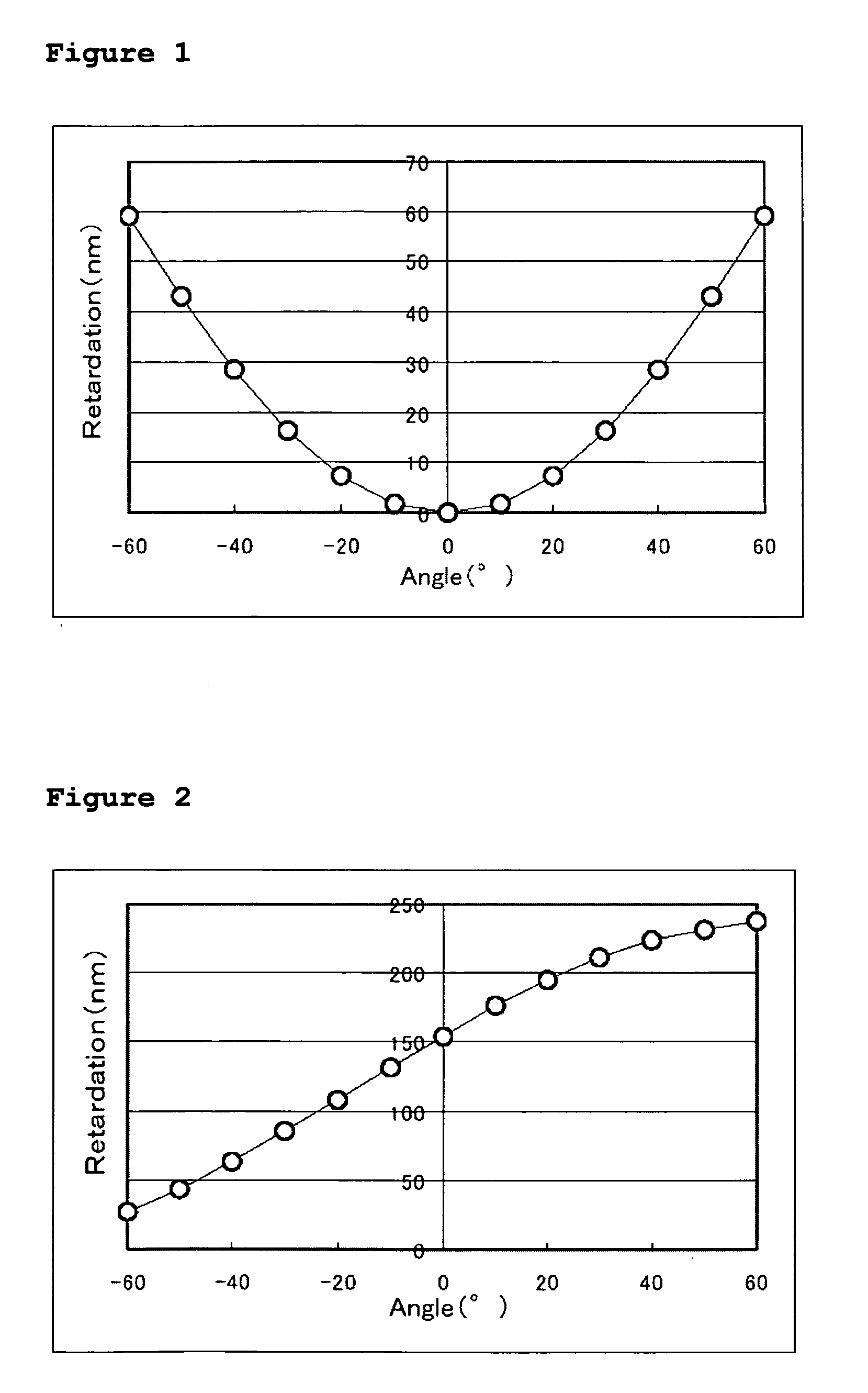

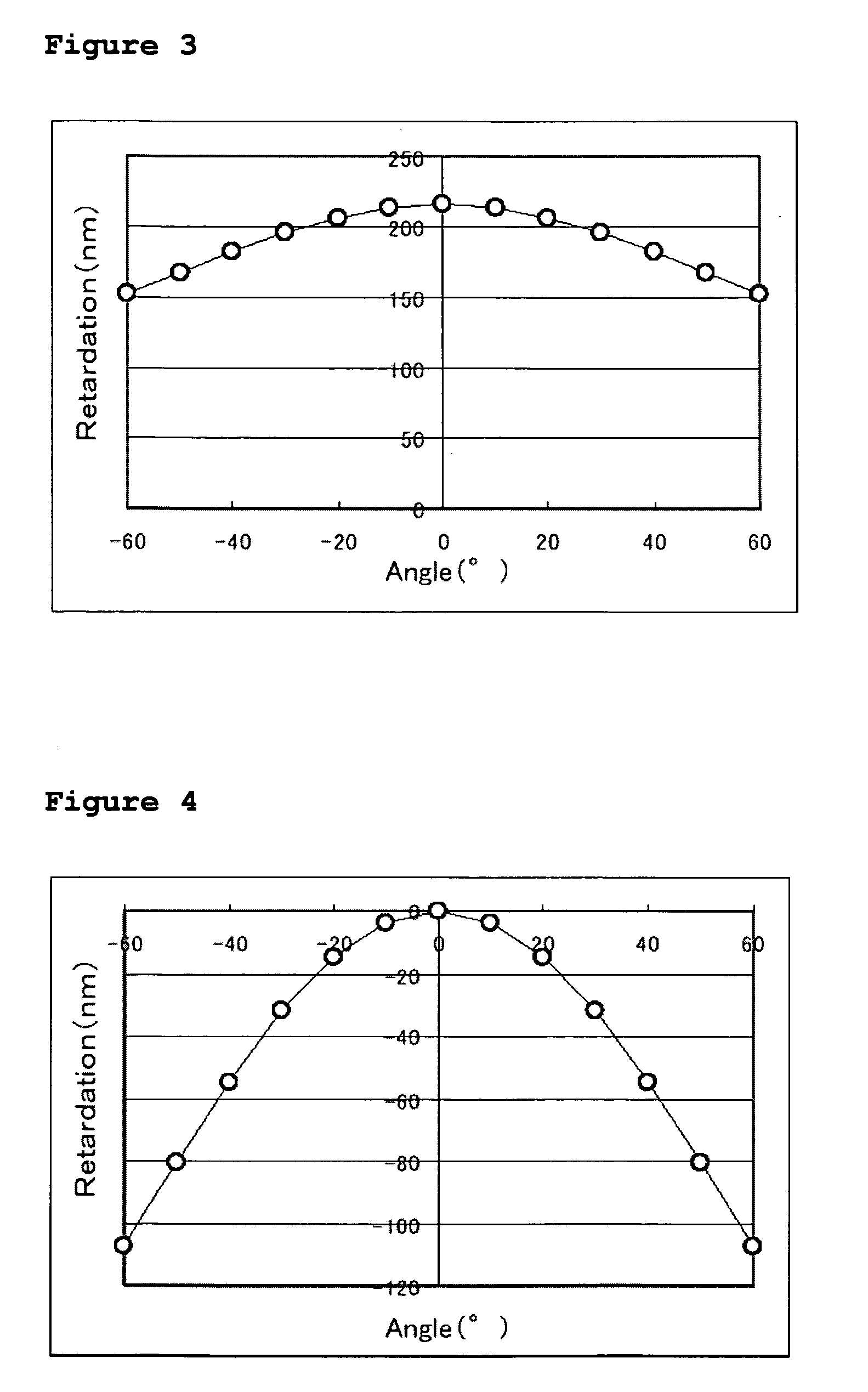

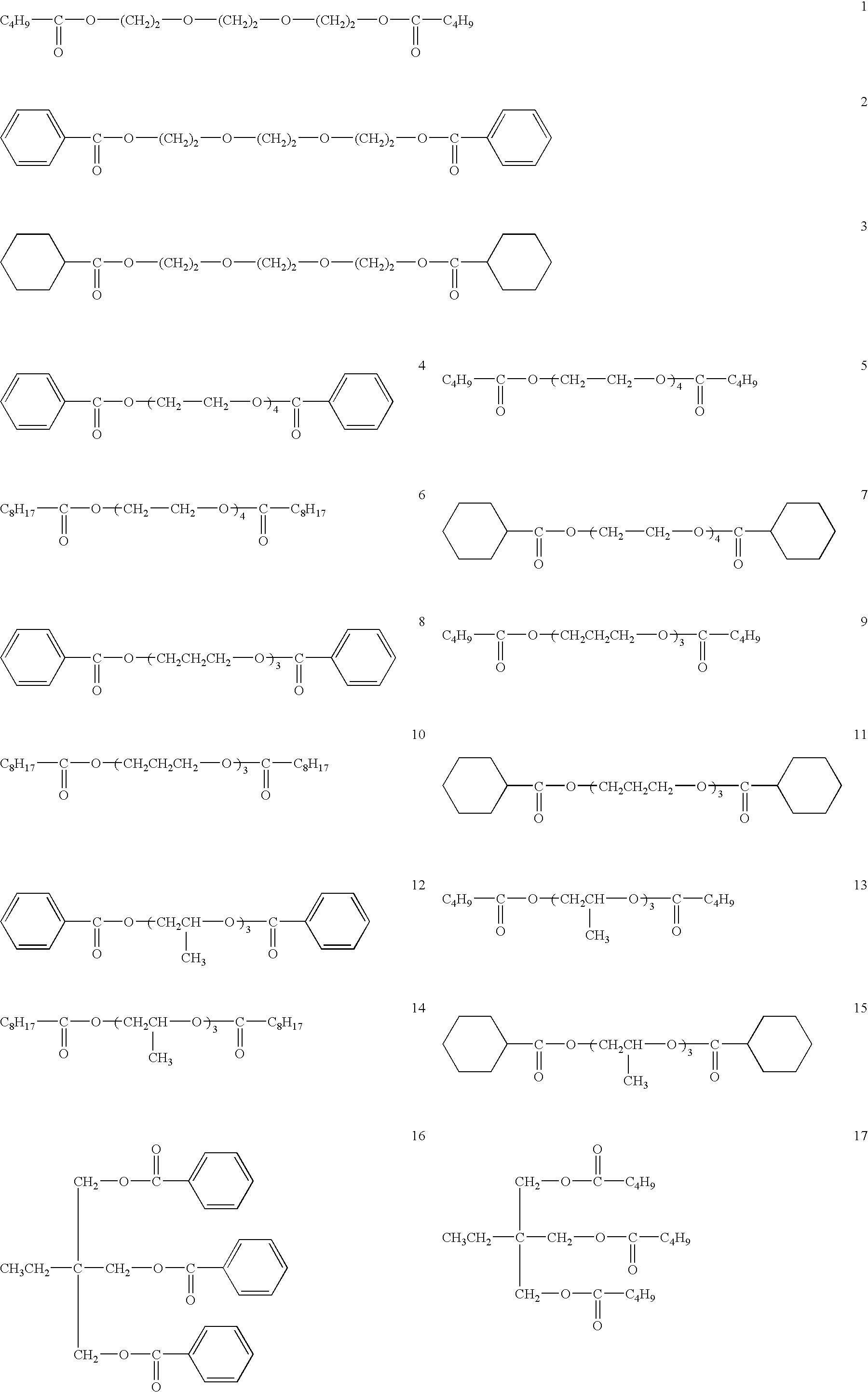

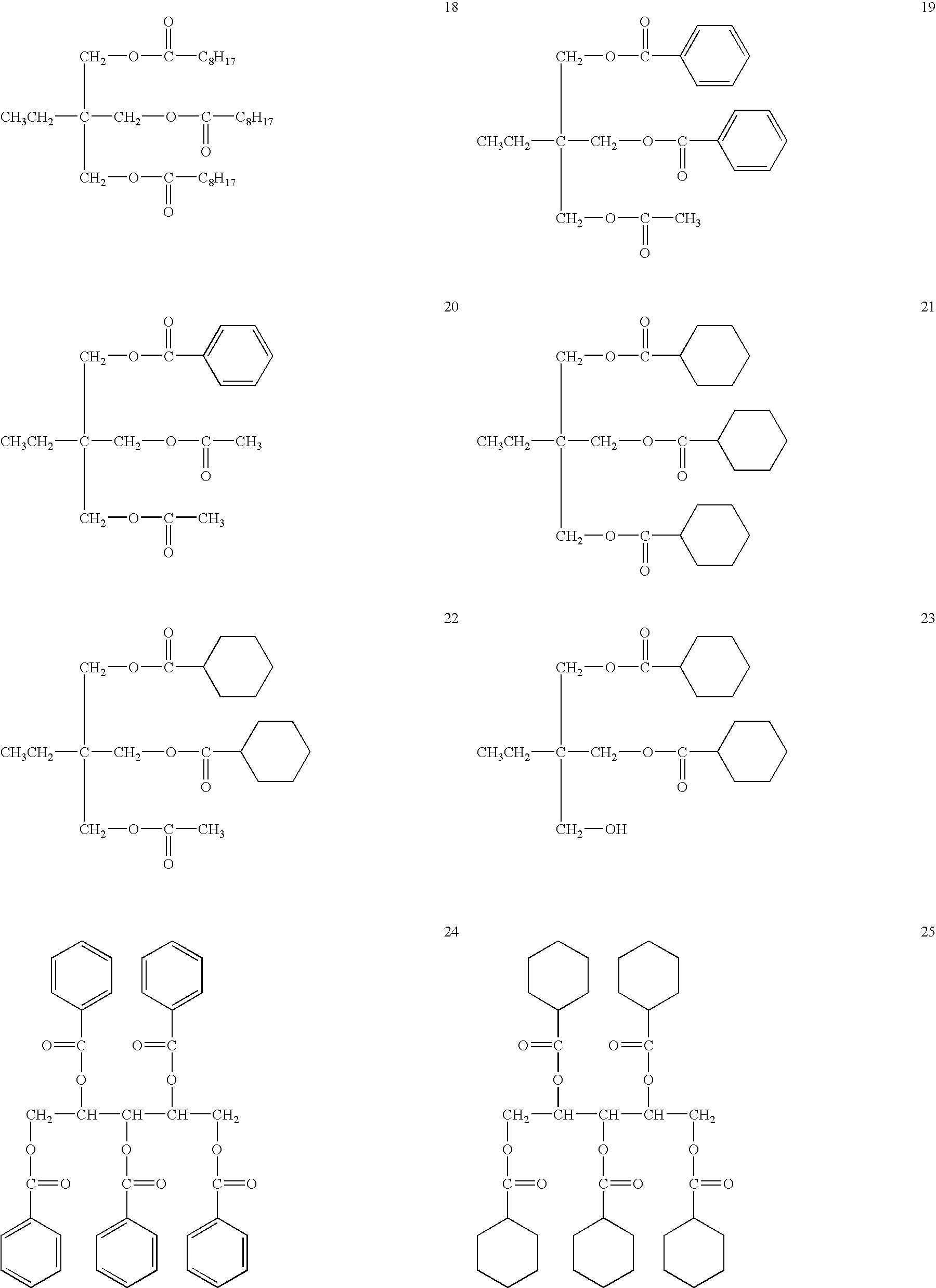

Organosilicon compound-containing polymerizable liquid-crystal composition

InactiveUS20050224754A1Improve adhesionUniform alignmentLiquid crystal compositionsThin material handlingHydrogenHalogen

An object of the invention is to provide a polymerizable liquid-crystal composition for obtaining a liquid-crystal film having good adhesiveness to supporting substrates. A polymerizable liquid-crystal layer of controlled alignment can be formed from the polymerizable liquid-crystal composition, and when the polymerizable liquid-crystal composition is polymerized, it gives a liquid-crystal film. The polymerizable liquid-crystal composition of the invention contains a polymerizable liquid-crystal compound represented by Formula (1) and a organosilicon compound having a primary amino group. wherein W is hydrogen, alkyl, alkenyl, halogen, —CN or -(G-Sp)r-P; P is a polymerizable group; Sp is alkylene; G is a bonding group; and MG is a mesogenic group represented by Formula (2): wherein T1 and T2 are ringed group; G1 is a bonding group; and f is an integer of 0 to 4. The symbols in these formulae are defined in detail in claim 2.

Owner:JNC PETROCHEM CORP +1

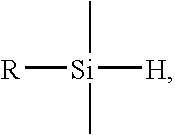

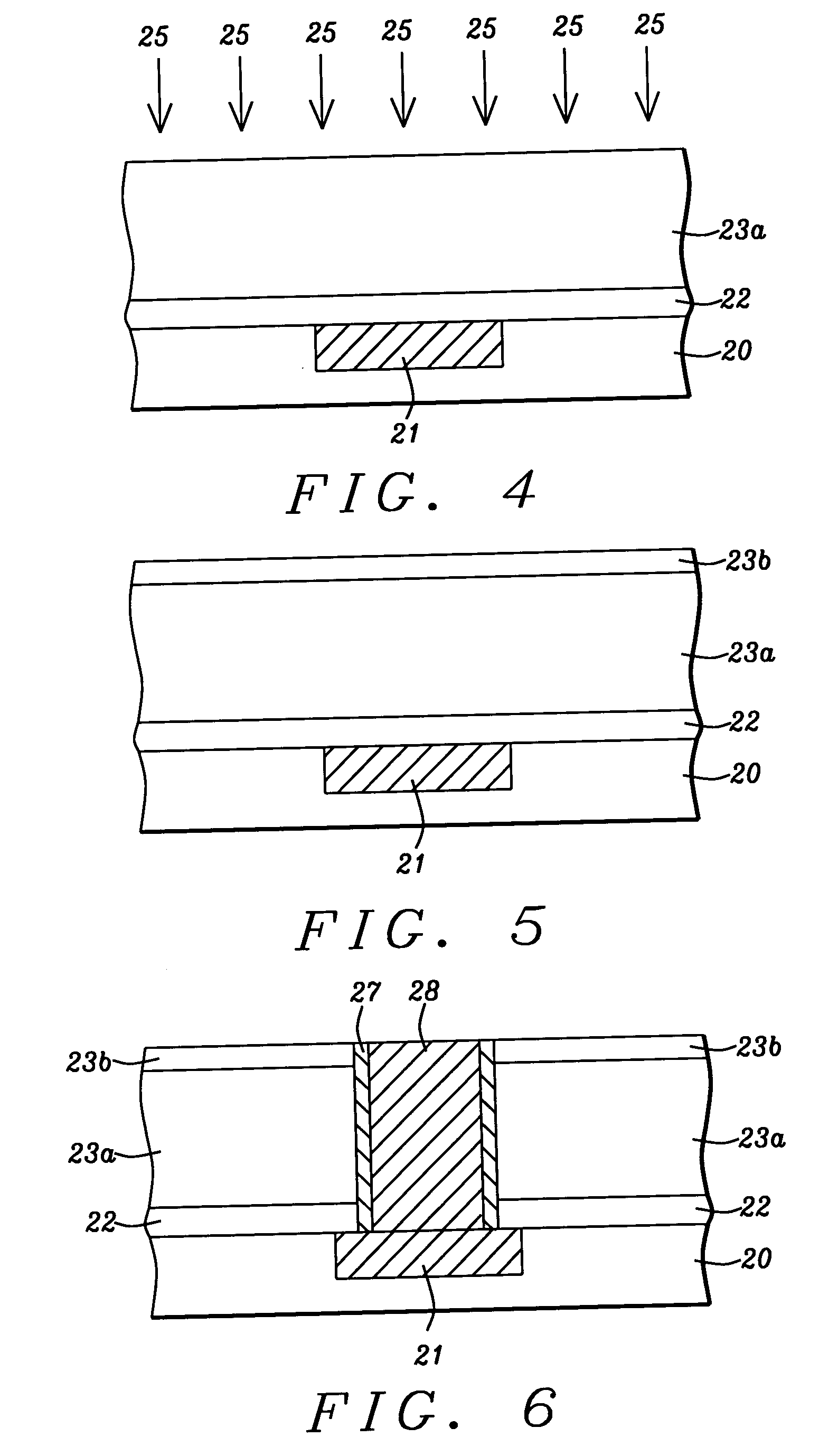

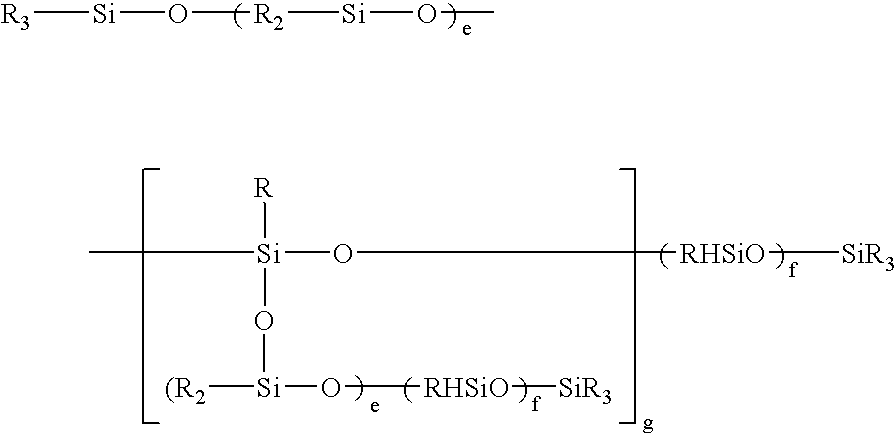

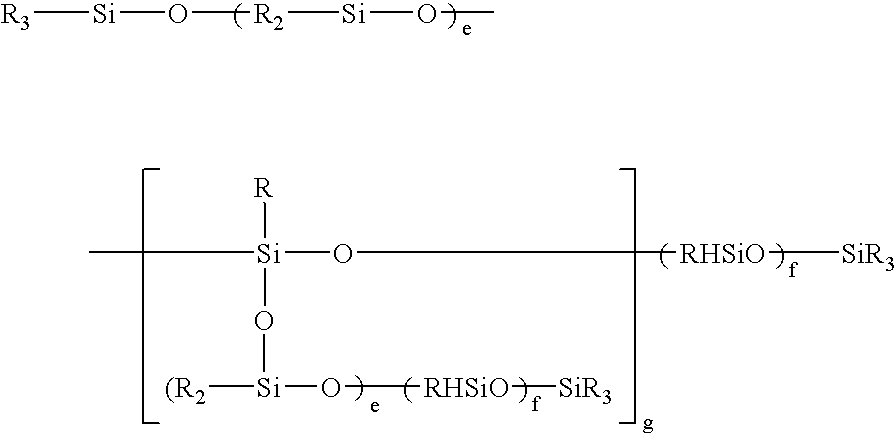

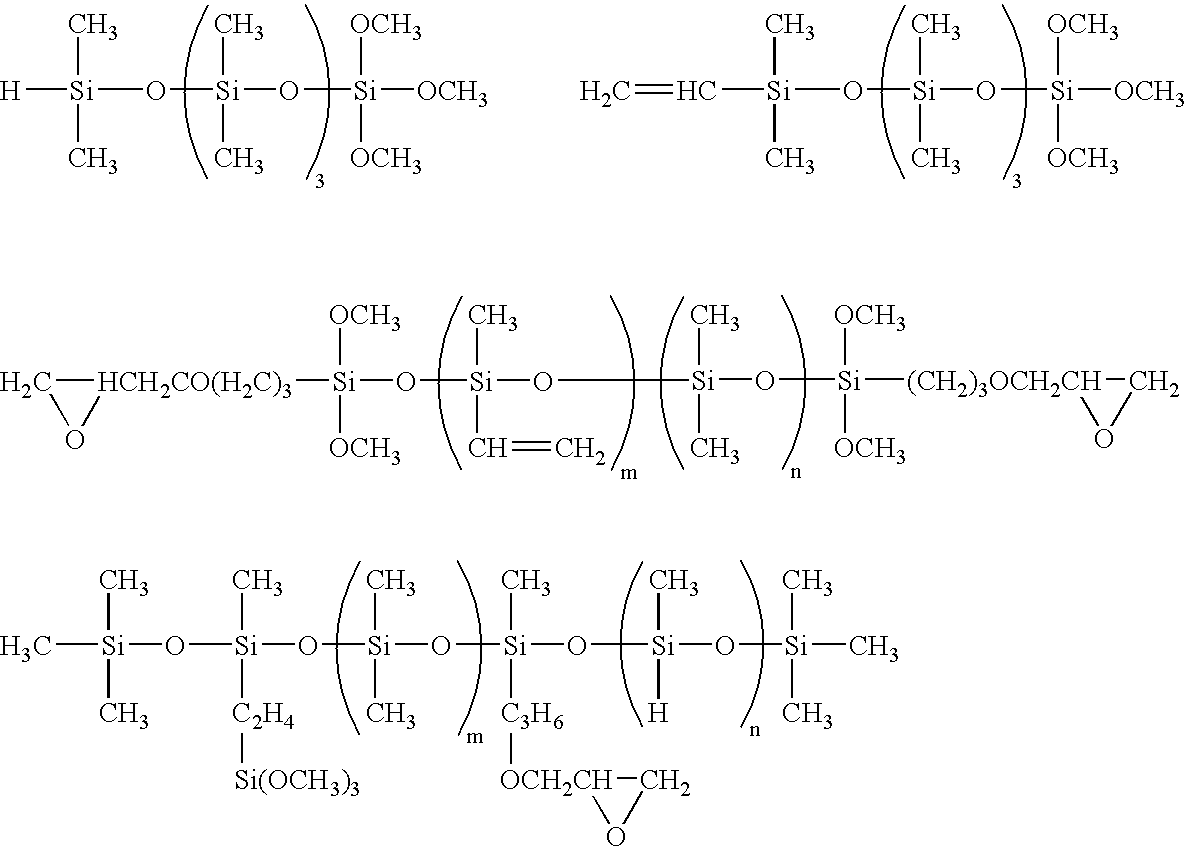

Process for an addition reaction of organic silicon compounds having SiH groups with compounds having olefinic double bonds

ActiveUS7157541B2Silicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilanesUnsaturated hydrocarbon

The invention relates to a process for the preparation of polyorganosiloxanes and polyorganosilanes of high purity by an addition reaction of siloxanes and / or silanes which contain at least one H—Si group with compounds having olefinic double bonds in the presence of a platinum catalyst and optionally further additional components, wherein the reaction is carried out in the presence of a platinum(0) complex catalyst which was dissolved in a solvent before addition to the reaction medium and to whose solution an effective amount of at least one unsaturated hydrocarbon having 2 to 6 carbon atoms was added.

Owner:EVONIK DEGUSSA GMBH

Plasma processes for depositing low dielectric constant films

InactiveUS20010005546A1Semiconductor/solid-state device detailsSolid-state devicesDisiloxaneMicrowave

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

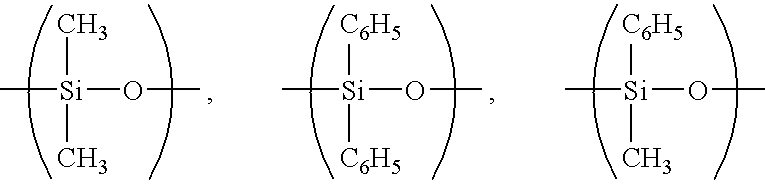

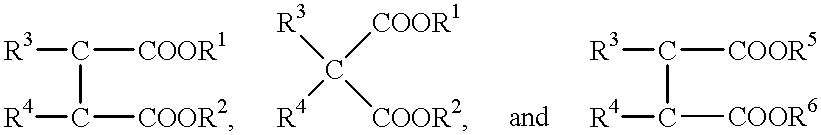

Light-emitting semiconductor potting composition and light-emitting semiconductor device

ActiveUS20040178509A1Semiconductor/solid-state device detailsSolid-state devicesMetal catalystAlkoxy group

A potting composition comprising (A) an organopolysiloxane having a vinyl group at an end of its molecular chain, (B) an organohydrogenpolysiloxane, (C) a platinum group metal catalyst, and optionally, (D) an organosilicon compound having a silicon atom-bonded alkoxy group. The cured product of the composition has a refractive index of 1.41-1.56 at 25° C. and 589 nm (sodium D line). The composition is suited for the embedment and protection of light-emitting semiconductor members. A package in which a light-emitting semiconductor member is embedded and protected with the potting composition undergoes little discoloration and maintains a high emission efficiency in heating tests, thus offering a light-emitting semiconductor device featuring a long life and energy saving.

Owner:SHIN ETSU CHEM IND CO LTD

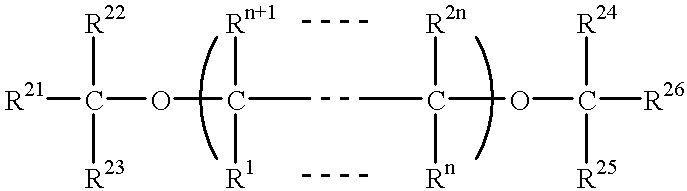

Olefin polymerization catalyst and process for preparing polypropylene and propylene block copolymer

InactiveUS6214939B1Component with highHigh molecular weightBulk chemical productionPolymer scienceAlpha-olefin

The present invention provides olefin polymerization catalysts and processes for preparing a polypropylene and a propylene block copolymer using the olefin polymerization catalysts. The olefin polymerization catalyst (1) of the invention is formed from: (I-1) a contact product obtained by contacting: (A) a solid titanium catalyst component, (B) an organometallic compound catalyst component, and (C) a specific organosilicon compound; (II-1) (D) a specific polyether compound; and optionally, (III) an organometallic compound catalyst component. The olefin polymerization catalyst (2) of the invention is formed from: (I-2) a contact product obtained by contacting: (A) a solid titanium catalyst component, (B) an organometallic compound catalyst component, and (D) a specific polyether compound; (II-2) (C) a specific organosilicon compound; and optionally, (III) an organometallic compound catalyst component. The propylene is polymerized in the presence of the above-mentioned olefin polymerization catalysts to prepare highly isotactic polypropylene. The propylene block copolymer is prepared by the steps of polymerizing propylene to form a polypropylene component and copolymerizing ethylene and an alpha-olefin of 3 to 20 carbon atoms to form an ethylene / alpha-olefin copolymer component in the presence of the polymerization catalysts.

Owner:MITSUI CHEM INC

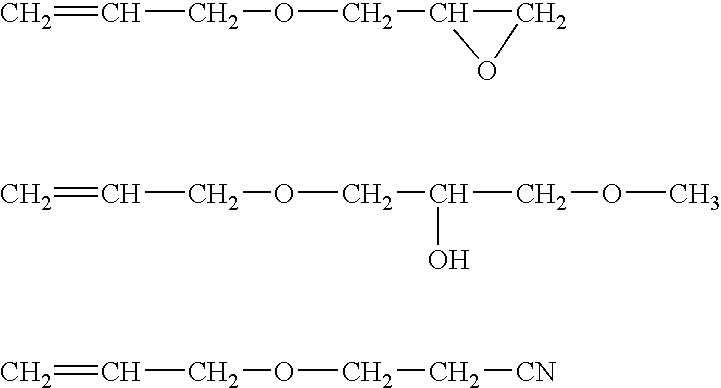

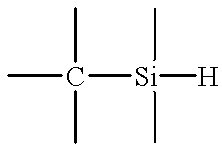

Ultra low k plasma enhanced chemical vapor deposition processes using a single bifunctional precursor containing both a SiCOH matrix functionality and organic porogen functionality

InactiveUS20060079099A1Easy to controlImprove film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDisiloxaneEpoxy

A method for fabricating a SiCOH dielectric material comprising Si, C, O and H atoms from a single organosilicon precursor with a built-in organic porogen is provided. The single organosilicon precursor with a built-in organic porogen is selected from silane (SiH4) derivatives having the molecular formula SiRR1R2R3, disiloxane derivatives having the molecular formula R4R5R6—Si—O—Si—R7R8R9, and trisiloxane derivatives having the molecular formula R10R11R12—Si—O—Si—R13R14—O—Si—R15R16R17 where R and R1-17 may or may not be identical and are selected from H, alkyl, alkoxy, epoxy, phenyl, vinyl, allyl, alkenyl or alkynyl groups that may be linear, branched, cyclic, polycyclic and may be functionalized with oxygen, nitrogen or fluorine containing substituents. In addition to the method, the present application also provides SiCOH dielectrics made from the inventive method as well as electronic structures that contain the same.

Owner:GLOBALFOUNDRIES INC

CVD plasma assisted lower dielectric constant sicoh film

InactiveUS6486082B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenHydrogen atom

A low dielectric constant film having silicon-carbon bonds and dielectric constant of about 3.0 or less, preferably about 2.5 or less, is provided. The low dielectric constant film is deposited by reacting a cyclic organosilicon compound and an aliphatic organosilicon compound with an oxidizing gas while applying RF power. The carbon content of the deposited film is between about 10 and about 30 atomic percent excluding hydrogen atoms, and is preferably between about 10 and about 20 atomic percent excluding hydrogen atoms.

Owner:APPLIED MATERIALS INC

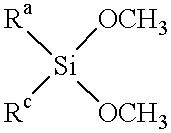

Antireflection film, production method of the same, polarizing plate and display

InactiveUS20060181774A1Improve visibilityImproved scratch resistance and pencil hardness and crack resistanceWash-standsHolders and dispensersRefractive indexDisplay device

An antireflection film comprising a transparent substrate film having thereon a hard coat, a high refractive index layer and a low refractive index layer, wherein: (i) the high refractive index layer is formed by applying a coating solution containing the following (a) to (c); (ii) the low refractive index layer is formed by applying a coating solution containing the following (d) and (e); (iii) the antireflection film is heat treated, wherein (a) metal oxide particles having an average primary particle diameter of 10 to 200 nm; (b) a metal compound; (c) an ionizing radiation curable resin; (d) an organosilicon compound having a prescribed structure, a hydrolyzed compound of the organosilicon compound, a decomposed compound of the organosilicon compound or a polycondensed compound of the organosilicon compound; and (e) hollow silica particles each having an outer shell, and a void or a porous portion in the inside.

Owner:KONICA MINOLTA OPTO

Antimicrobial substrate, a method and a composition for producing it

InactiveUS20070042198A1Improve adhesionIncrease surface charge densityBiocideBiochemical fibre treatmentHydrophilic polymersPolyethylenimine

Owner:APPEARTEX AB CHALMERS INNOVATION

Organic silicon modified aqueous polyurethane

InactiveCN1854165AImprove water resistanceFeel goodFibre treatmentPolyureas/polyurethane adhesivesWater basedCross-link

An organic silicon modified water-based polyurethane and its production are disclosed.The polyurethane consists of low-polymer polybasic alcohol, vulcabond and chain extender. The production is carried out by dispersing pre-polymer in water, adding ammonia silane coupling agent into system, synthesizing pre-polymer, reacting amine base with residual vulcabond base, chain extending for pre-polymer while hydrolytic condensation polymerizing, cross-linked reacting and obtaining final product. It has better water resistance and handle, less surface performance and wider temperature range. It can be used for pigment, leather finishing agent and adhesive.

Owner:广州宏昌胶粘带厂

Method for polymerization of an alpha -olefin

InactiveUS6066702AHigh reactivityEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorAlpha-olefin

A method for polymerization or copolymerization of alpha -olefin, characterized in that the polymerization is performed using a solid complex titanium catalyst comprising magnesium, a halogen-containing titanium compound, and internal electron donors; organometallic compounds of metals belonging to Groups I and III on the periodic table of elements; and, as external electron donors, a mixture of three or more kinds of organic silicon compounds, from which homopolyolefins having MFR less than 5, MFR in the range from 5 to 20, and MFR greater than 20 are polymerized under the same polymerization conditions. By use of the present invention it is possible to produce an olefin polymer with high stereoregularity, broad molecular weight distribution, and good fluidity, at high rates of yield.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com