Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

311results about How to "Improve film thickness uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas supply nozzle, substrate processing apparatus, and non-transitory computer-readable recording medium

ActiveUS20170051408A1Improve film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSpray nozzleEngineering

Provided is a technology including a nozzle base end portion which is provided in a processing chamber processing a substrate to extend in a vertical direction and into which a processing gas processing the substrate is introduced, a nozzle distal end portion which is configured in a U shape and in which a gas supply hole supplying the processing gas is provided to a side surface of the substrate, and a gas residence suppressing hole which is provided in a downstream end of the nozzle distal end portion and has a diameter larger than that of the gas supply hole.

Owner:KOKUSA ELECTRIC CO LTD

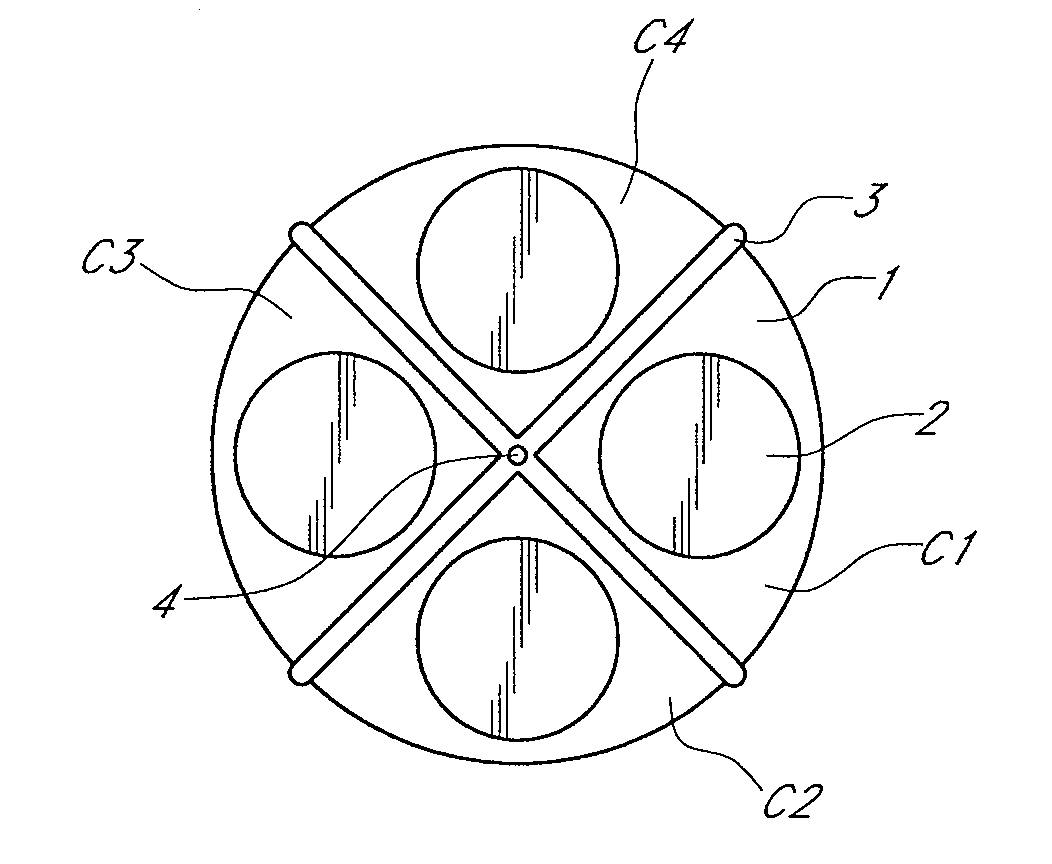

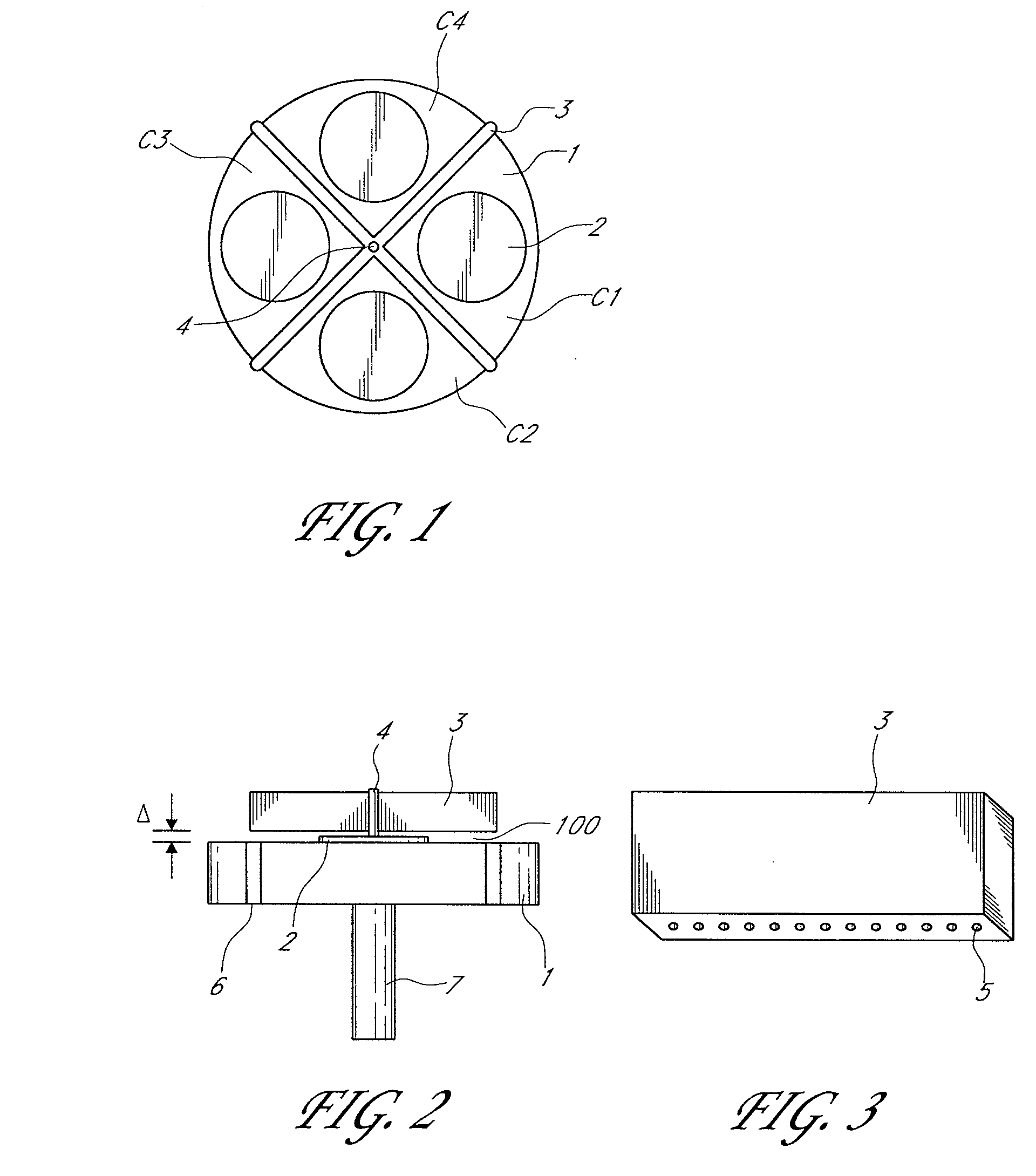

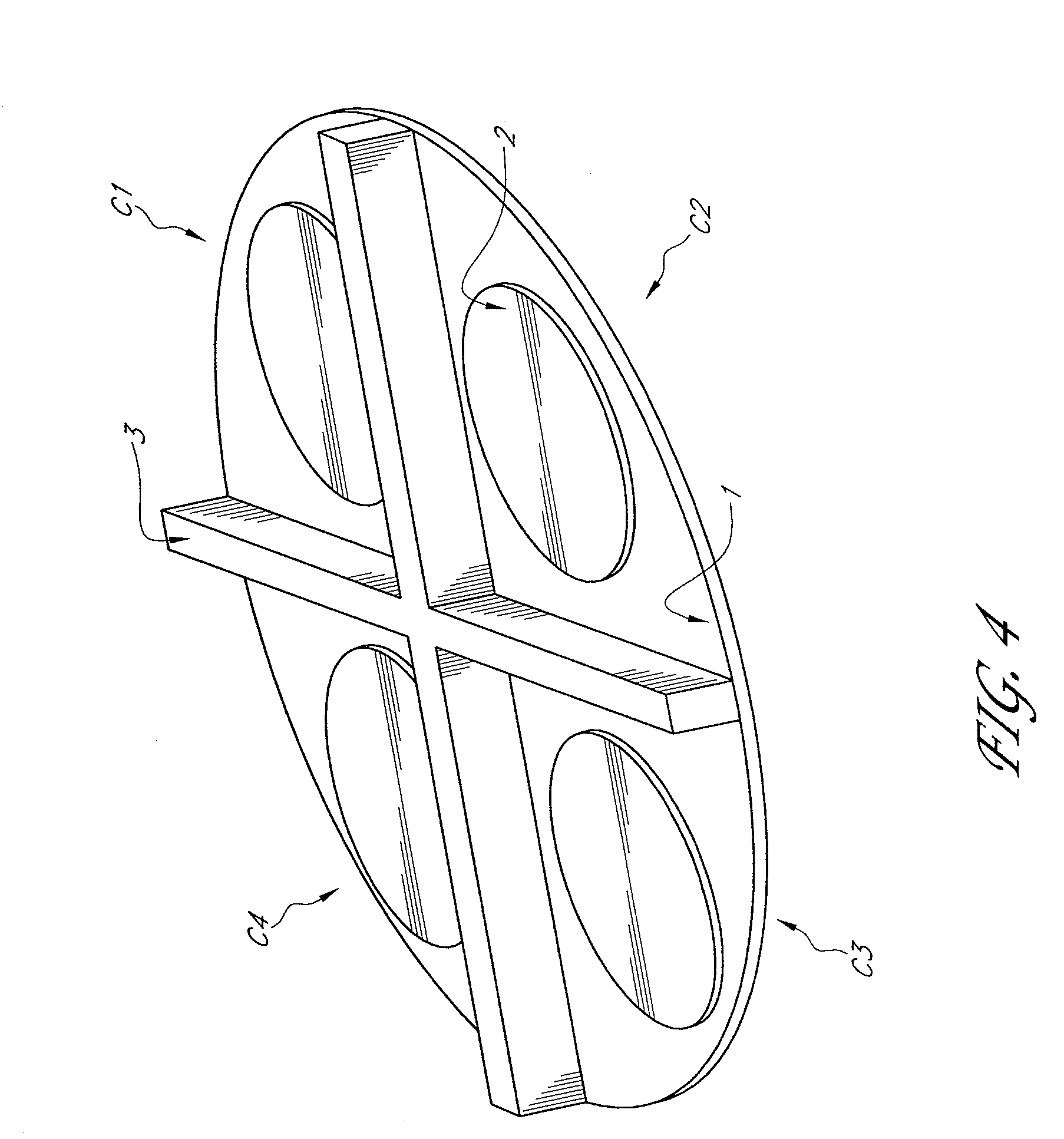

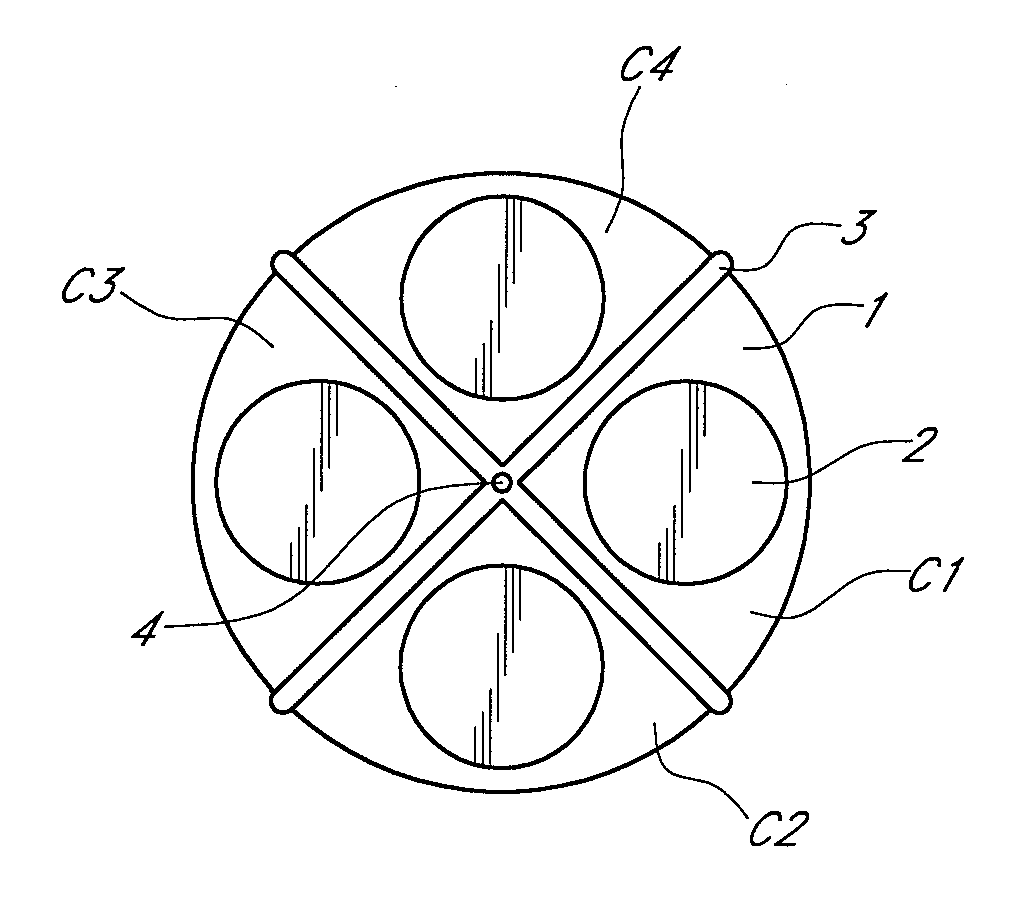

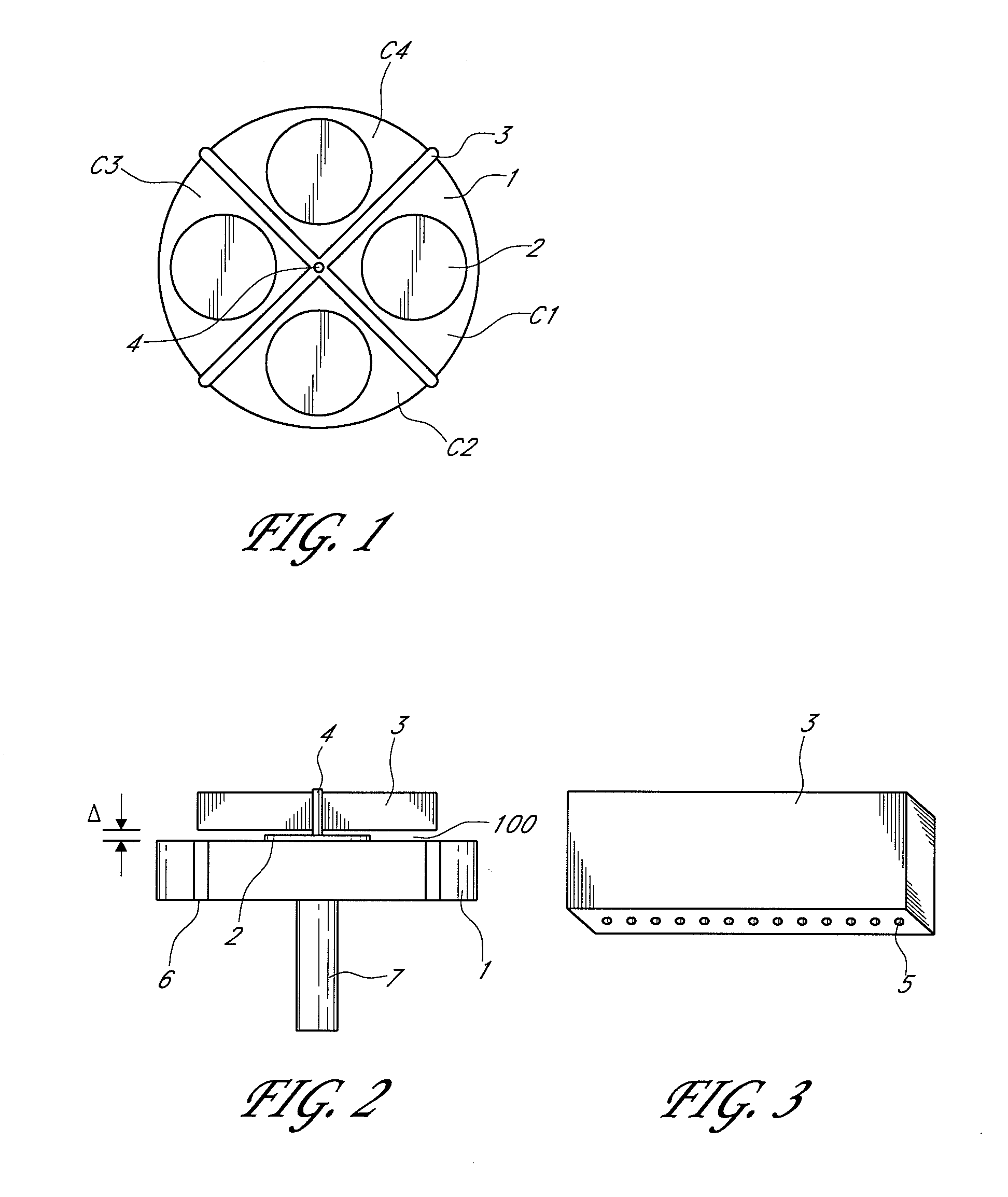

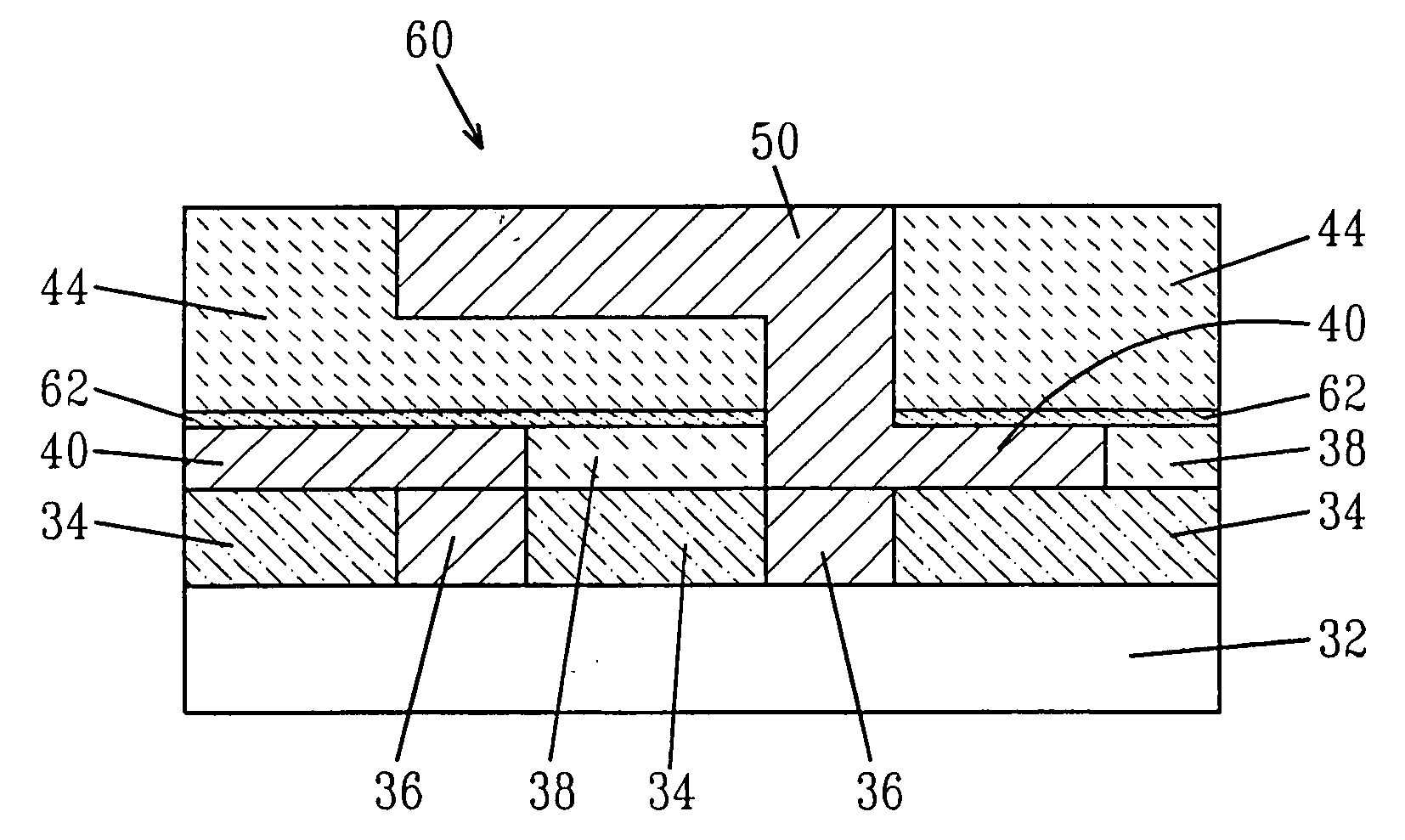

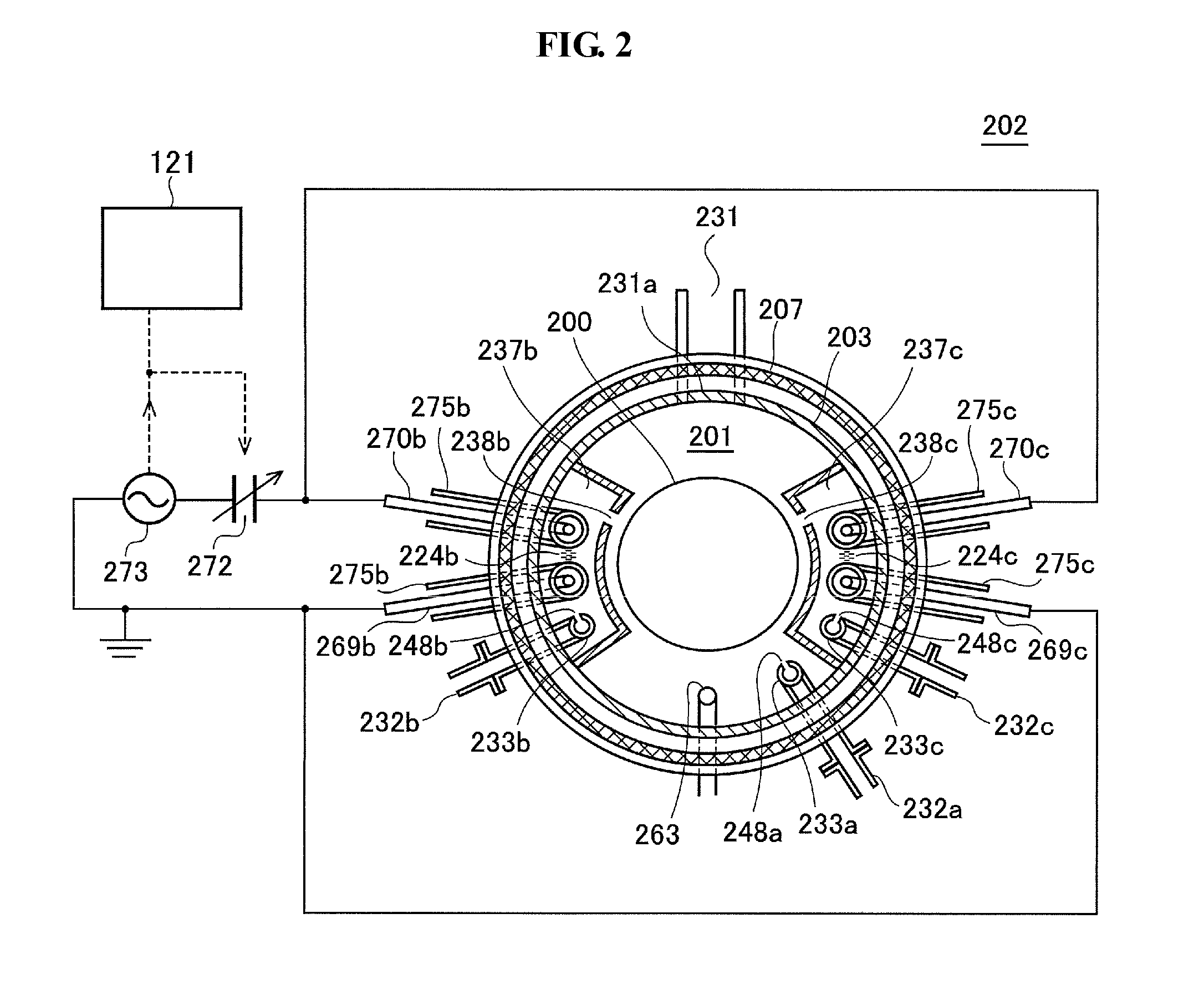

Semiconductor-processing apparatus with rotating susceptor

InactiveUS20070218702A1Establishing separateStable controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

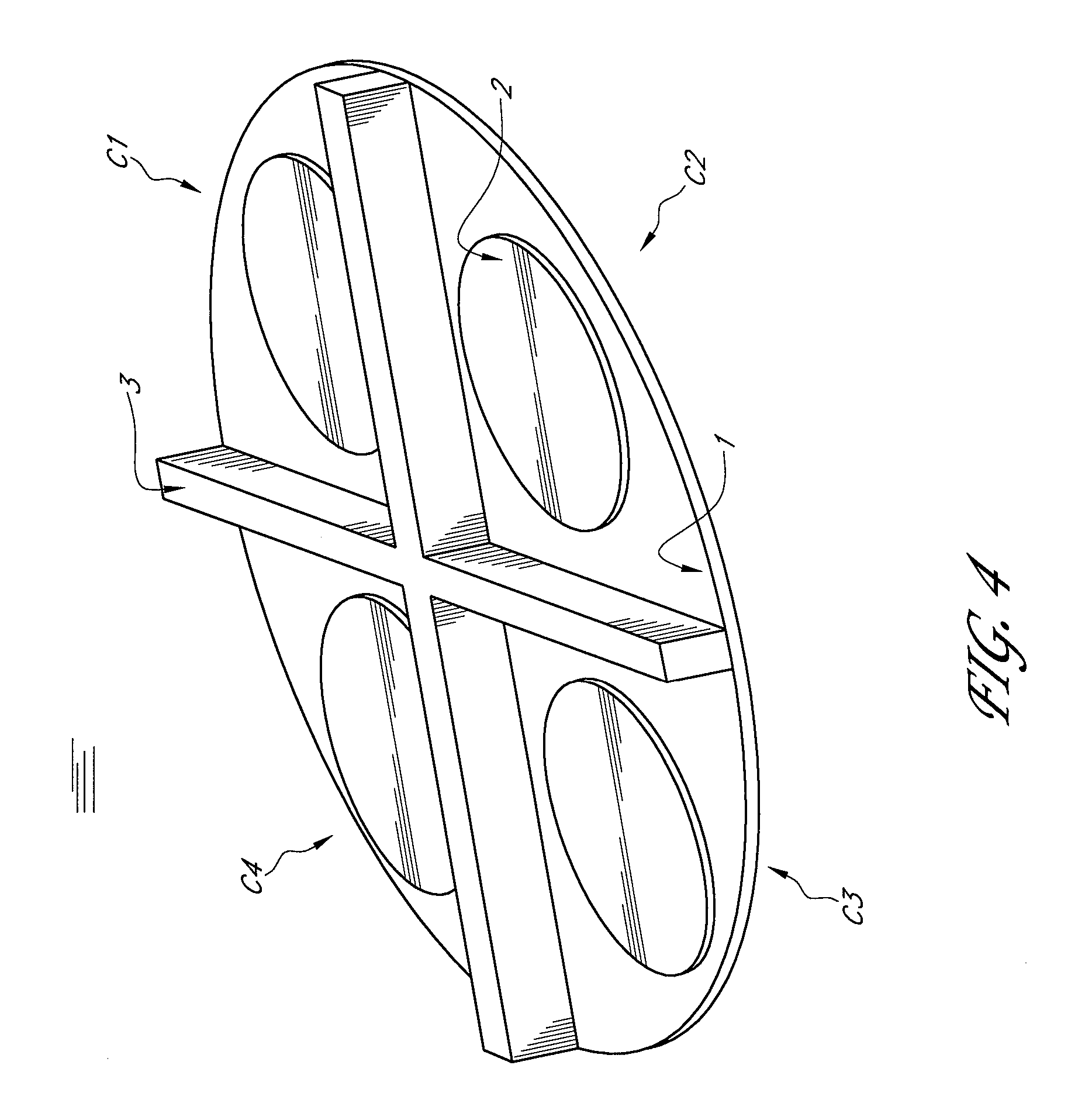

An apparatus for depositing thin film on a processing target includes: a reaction space; a susceptor movable up and down and rotatable around its center axis; and isolation walls that divide the reaction space into multiple compartments including source gas compartments and purge gas compartments, wherein when the susceptor is raised for film deposition, a small gap is created between the susceptor and the isolation walls, thereby establishing gaseous separation between the respective compartments, wherein each source gas compartment and each purge gas compartment are provided alternately in a susceptor-rotating direction of the susceptor.

Owner:ASM JAPAN

Semiconductor-processing apparatus with rotating susceptor

InactiveUS20070218701A1Stable controlUnnecessary film deposition is preventedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

An apparatus for depositing thin film on a processing target includes: a reaction space; a susceptor movable up and down and rotatable around its center axis; and isolation walls that divide the reaction space into multiple compartments including source gas compartments and purge gas compartments, wherein when the susceptor is raised for film deposition, a small gap is created between the susceptor and the isolation walls, thereby establishing gaseous separation between the respective compartments, wherein each source gas compartment and each purge gas compartment are provided alternately in a susceptor-rotating direction of the susceptor.

Owner:ASM JAPAN

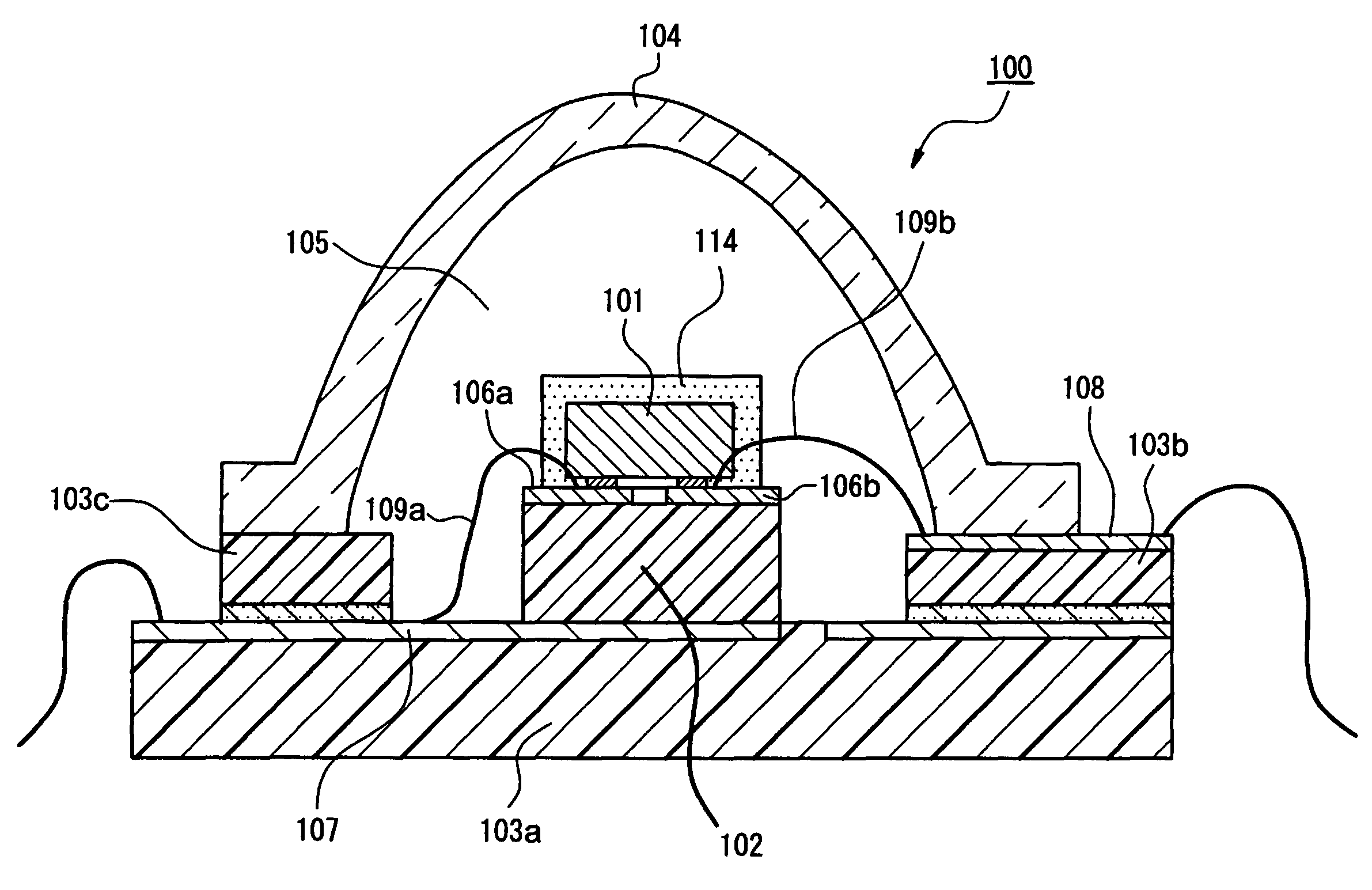

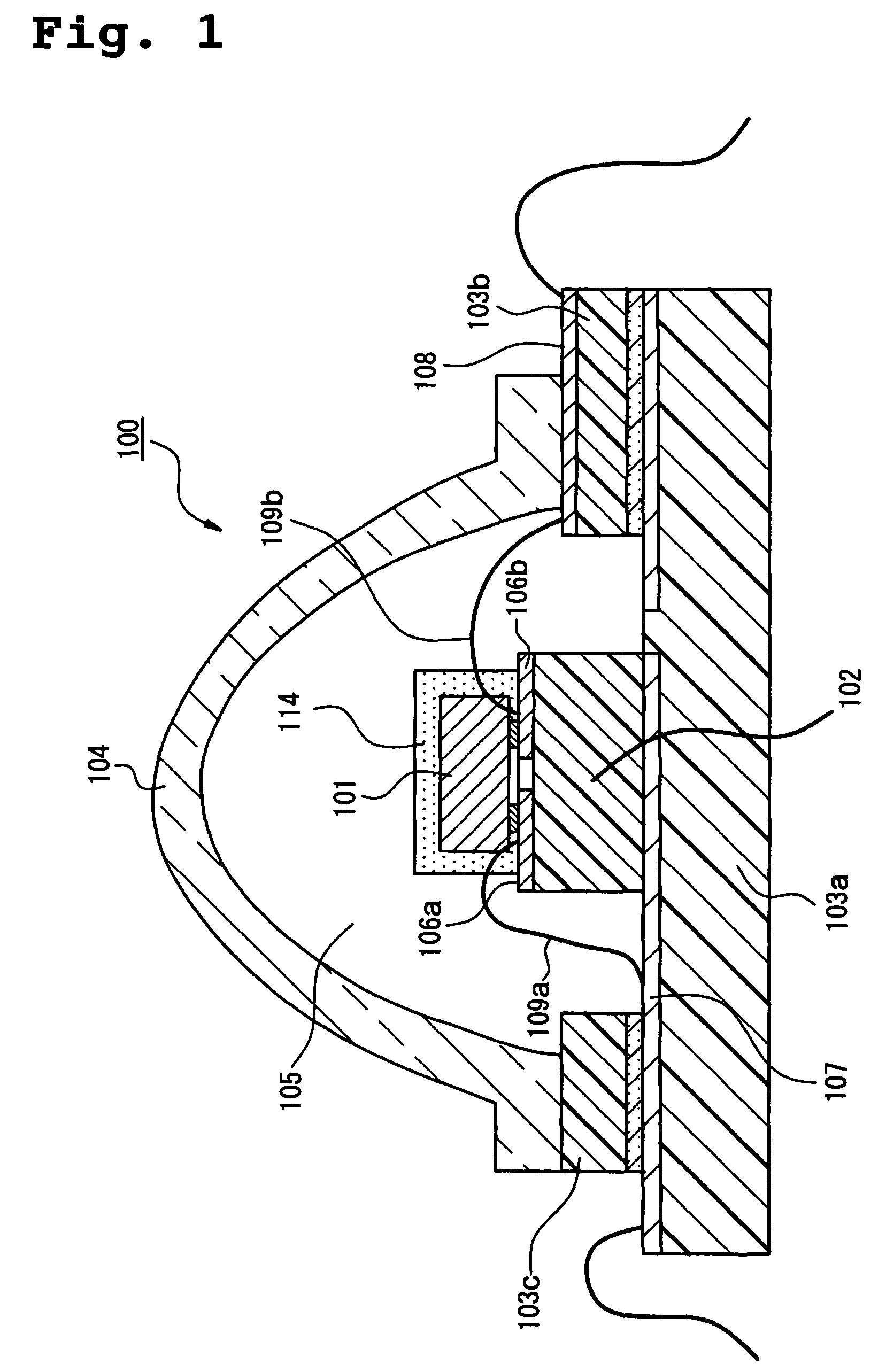

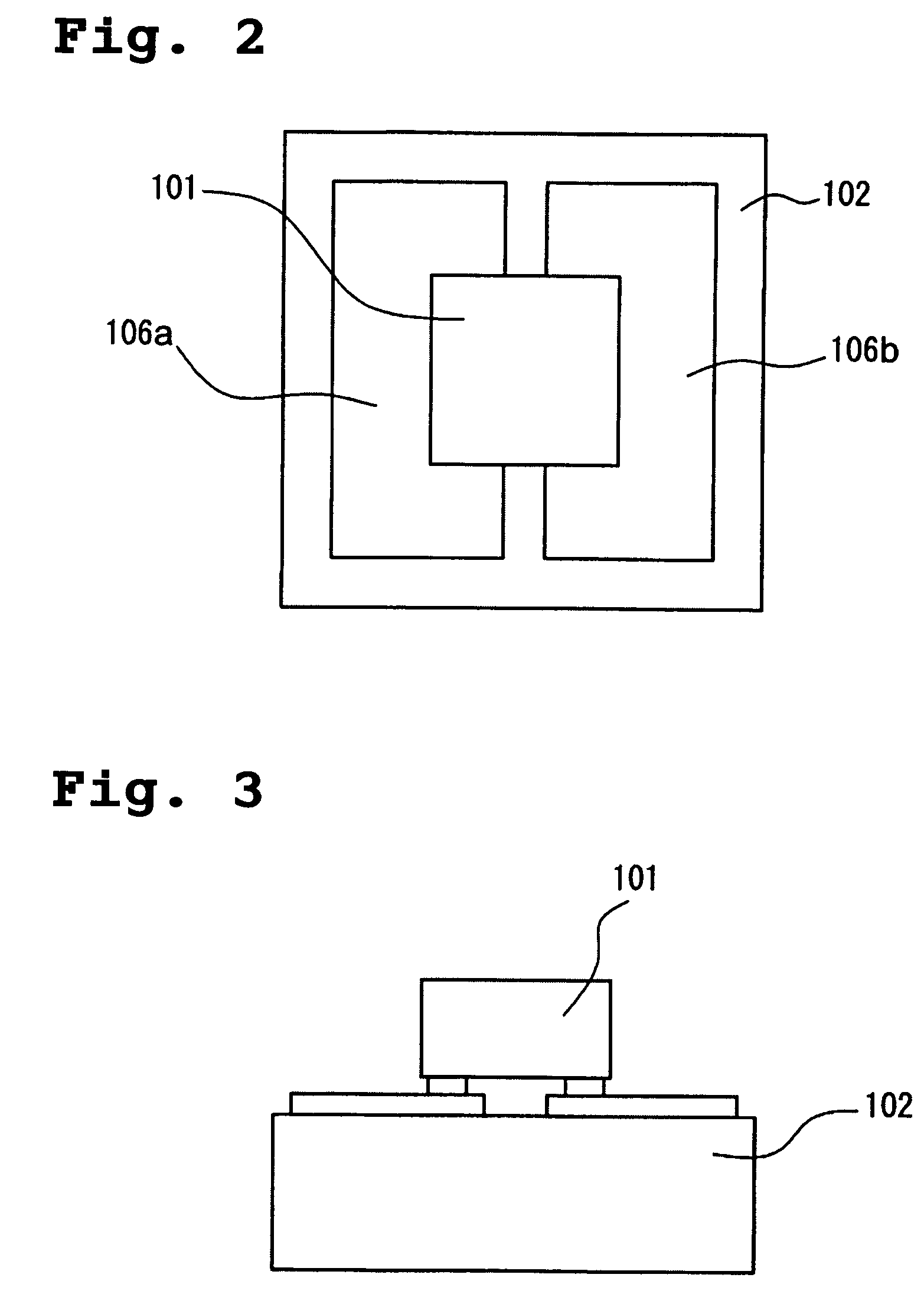

Light emitting device with silicone resin layer formed by screen printing

ActiveUS7745818B2Improve heat resistanceConvenient lightingDischarge tube luminescnet screensLamp detailsScreen printingPolystyrene

Owner:NICHIA CORP

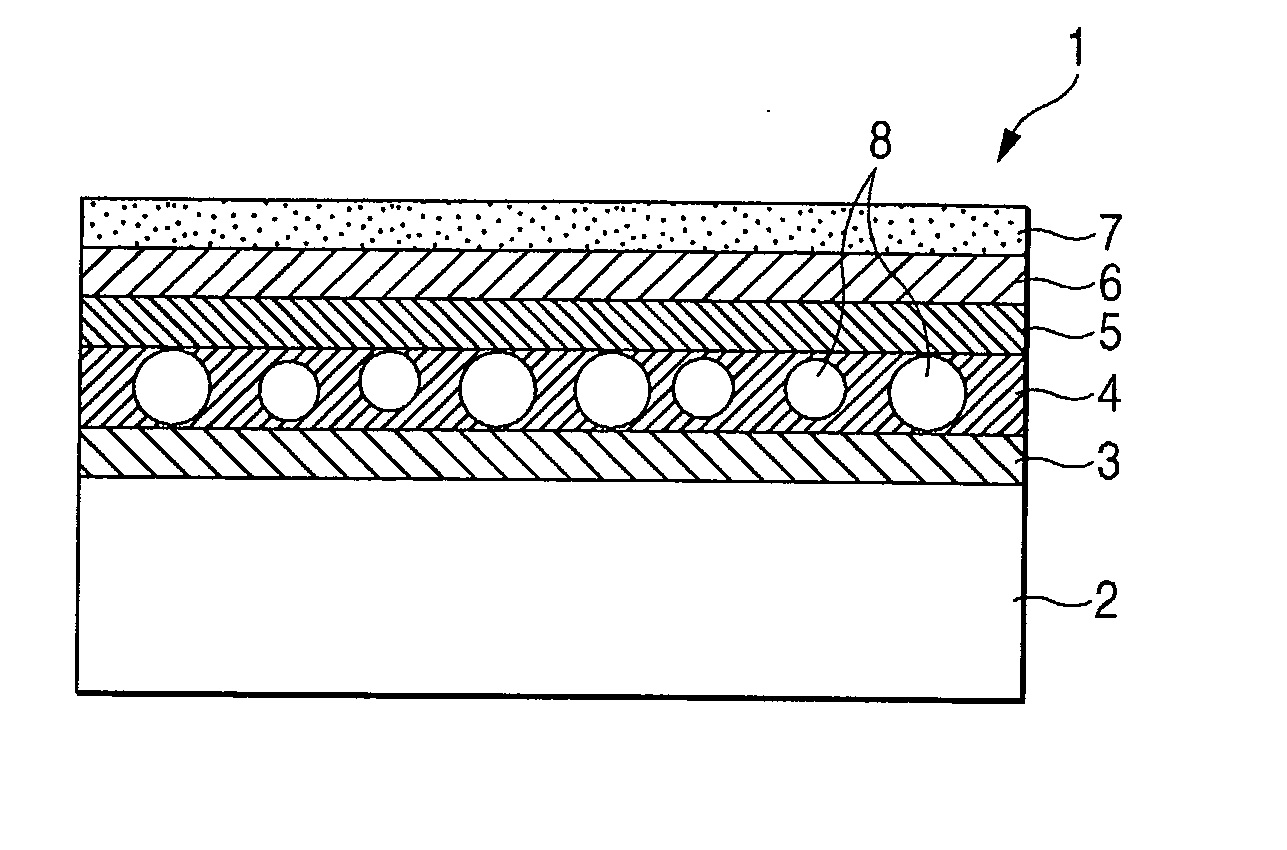

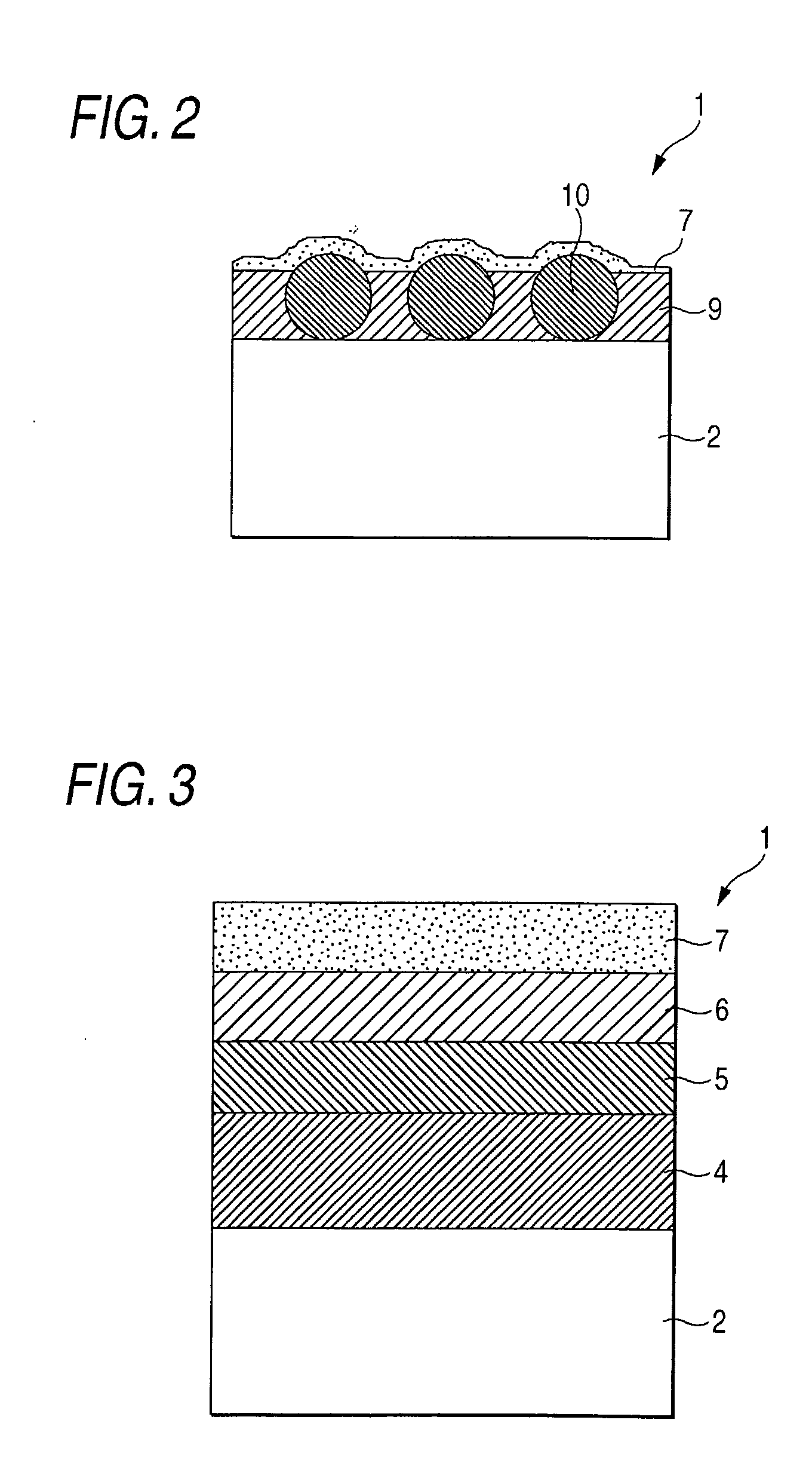

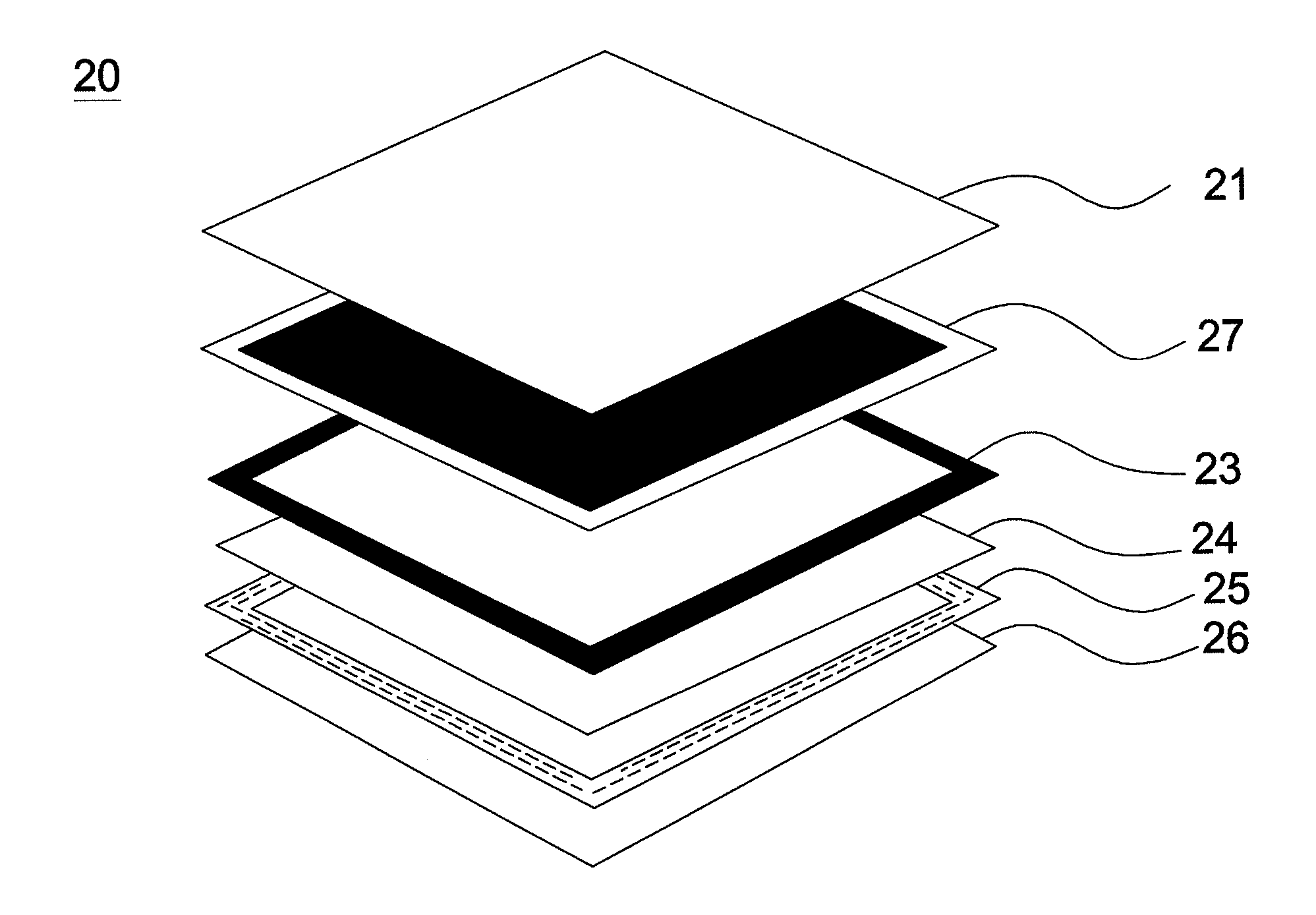

Antireflection film, polarizing plate, method for producing them, liquid cryatal display element, liquid crystal display device, and image display device

ActiveUS20070146887A1Reduce weightLow costLiquid crystal compositionsSynthetic resin layered productsSilica particleLiquid-crystal display

To provide an antireflection film which is easily and inexpensively producible and which has an antireflection property, a scratch resistance and a stain resistance in a sufficient level, and a polarizing plate and a liquid crystal display device utilizing the antireflection film of such excellent ability, the antireflection film includs a transparent support and a low-refractive index layer having a lower refractive index than the transparent support, wherein the low-refractive index layer is an outermost layer, and the low-refractive index layer contains a hollow silica particle and a compound that reduces a surface free energy of the outermost layer.

Owner:FUJIFILM CORP

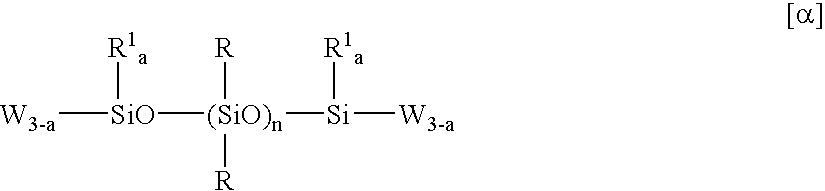

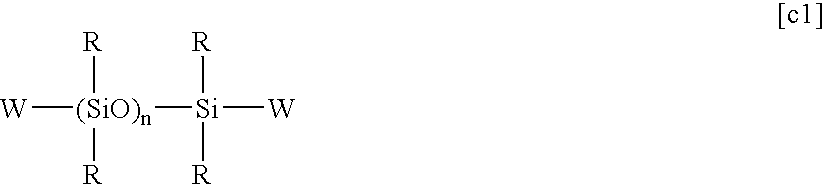

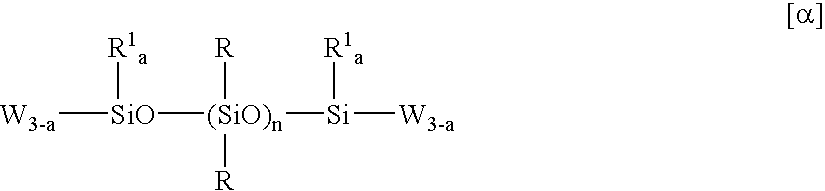

Ultra low k plasma enhanced chemical vapor deposition processes using a single bifunctional precursor containing both a SiCOH matrix functionality and organic porogen functionality

InactiveUS20060079099A1Easy to controlImprove film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDisiloxaneEpoxy

A method for fabricating a SiCOH dielectric material comprising Si, C, O and H atoms from a single organosilicon precursor with a built-in organic porogen is provided. The single organosilicon precursor with a built-in organic porogen is selected from silane (SiH4) derivatives having the molecular formula SiRR1R2R3, disiloxane derivatives having the molecular formula R4R5R6—Si—O—Si—R7R8R9, and trisiloxane derivatives having the molecular formula R10R11R12—Si—O—Si—R13R14—O—Si—R15R16R17 where R and R1-17 may or may not be identical and are selected from H, alkyl, alkoxy, epoxy, phenyl, vinyl, allyl, alkenyl or alkynyl groups that may be linear, branched, cyclic, polycyclic and may be functionalized with oxygen, nitrogen or fluorine containing substituents. In addition to the method, the present application also provides SiCOH dielectrics made from the inventive method as well as electronic structures that contain the same.

Owner:GLOBALFOUNDRIES INC

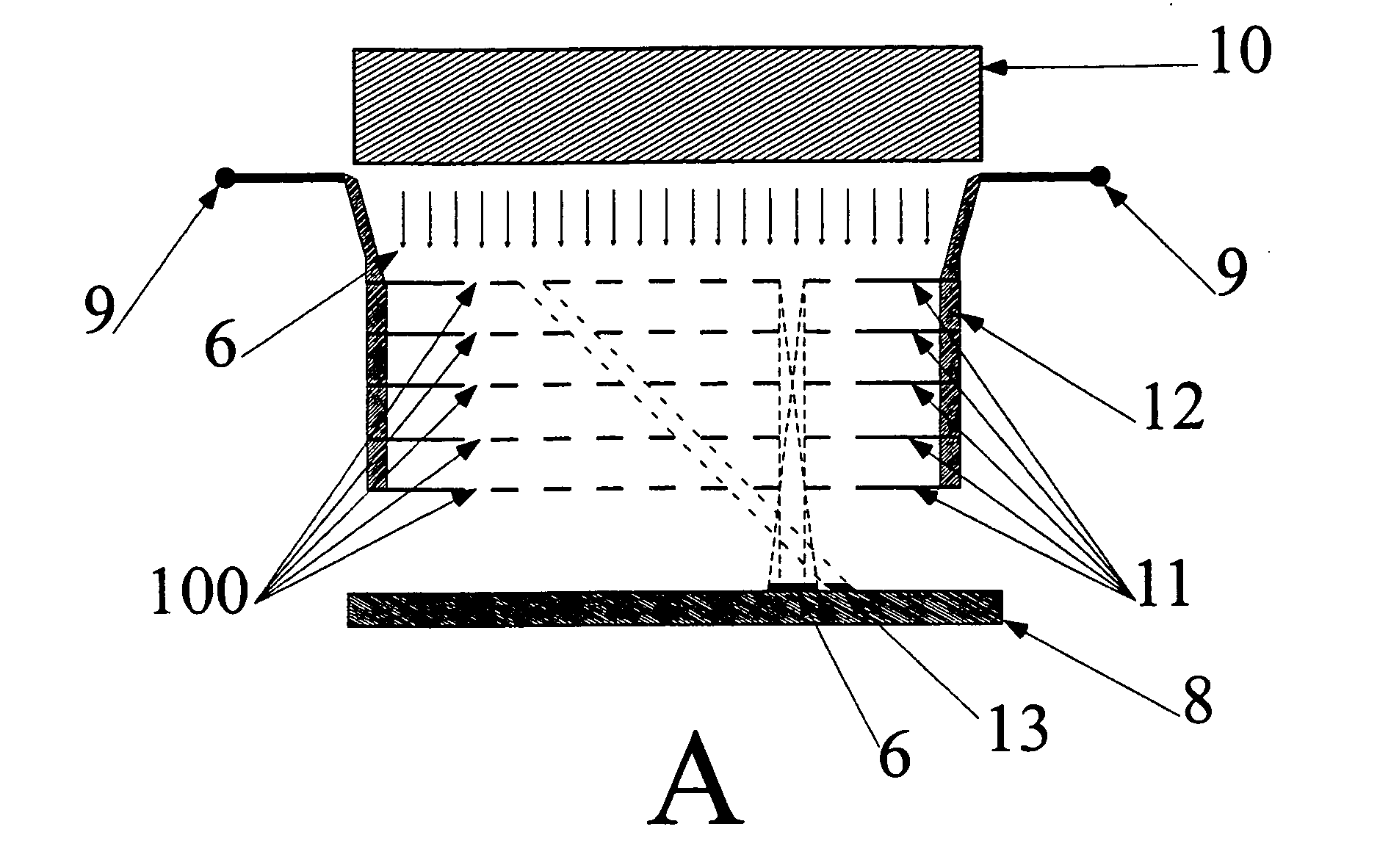

Patterned thin-film deposition using collimating heated masked assembly

InactiveUS20050183670A1Accurate timingUndesired heatingVacuum evaporation coatingSolid-state devicesEvaporationElectrical and Electronics engineering

Scanning localized evaporation and deposition of an evaporant on a substrate utilizes a mask assembly comprised of a series of mask elements with openings thereon and spaced apart in a stack. The openings are aligned so as to direct the evaporant therethrough onto the substrate. The mask elements are heated and the stack may include a movable shutter element to block openings in adjacent mask elements. The evaporant streams are usually vertical but some may be oblique to the substrate, and they may be of different materials.

Owner:OPTOELECTRONICS SYST

Method of controlling the uniformity of PECVD-deposited thin films

InactiveUS20050233092A1Improve performanceIncrease widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas compositionProduct gas

We have discovered that controlling a combination of PECVD deposition process parameters during deposition of silicon-containing thin film provides improved control over surface standing wave effects. By minimizing surface standing wave effects, the uniformity of film properties (particularly film thickness) across a substrate surface onto which the films have been deposited is improved. The process parameters which have the greatest effect on surface standing wave effects include: the spacing between the upper and lower electrodes in the plasma reactor; the RF frequency of the plasma source; the amount RF power to the plasma source; the process chamber pressure; the relative concentrations of the various components in the precursor gas composition; and the precursor gas overall flow rate relative to the substrate processing volume.

Owner:APPLIED MATERIALS INC

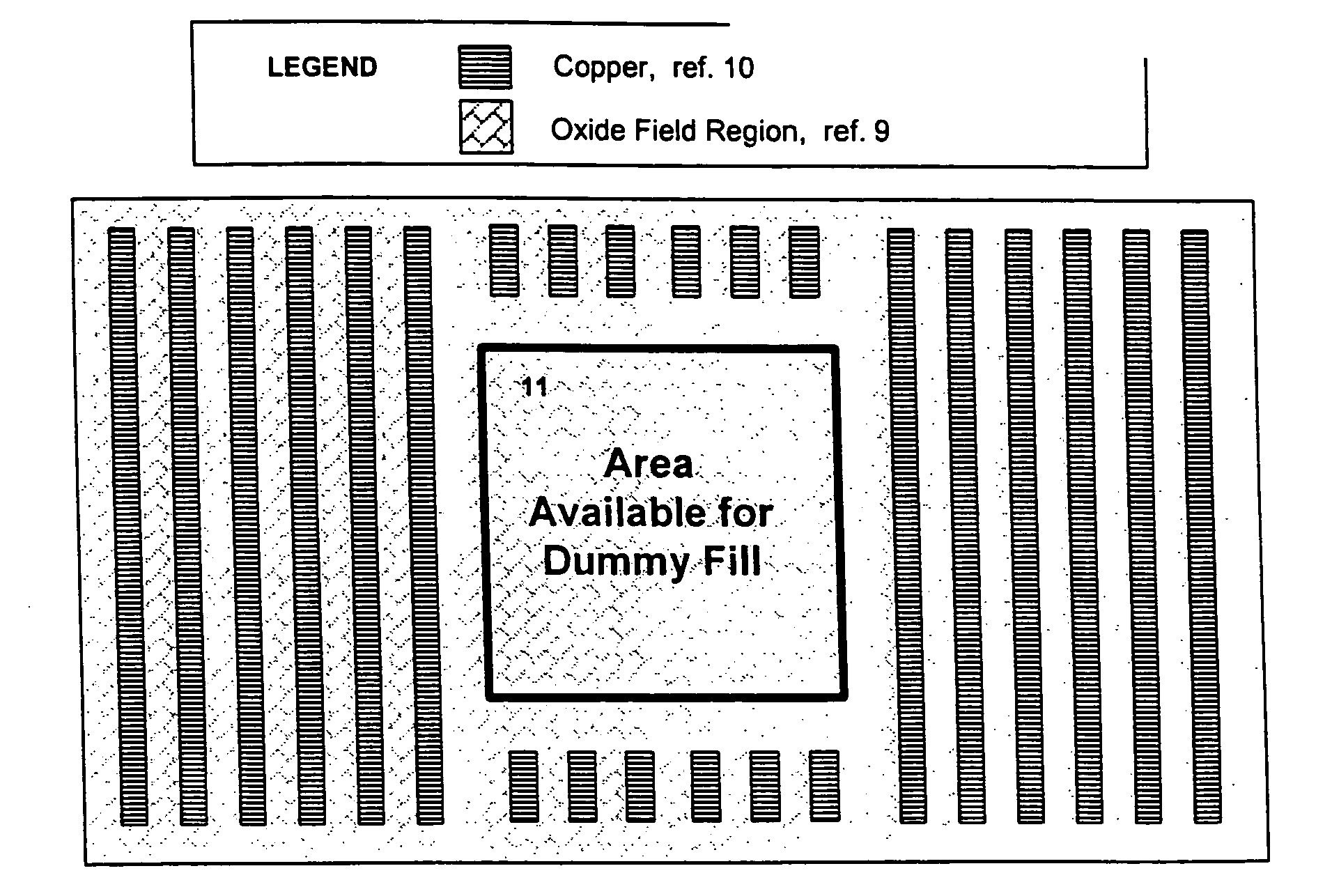

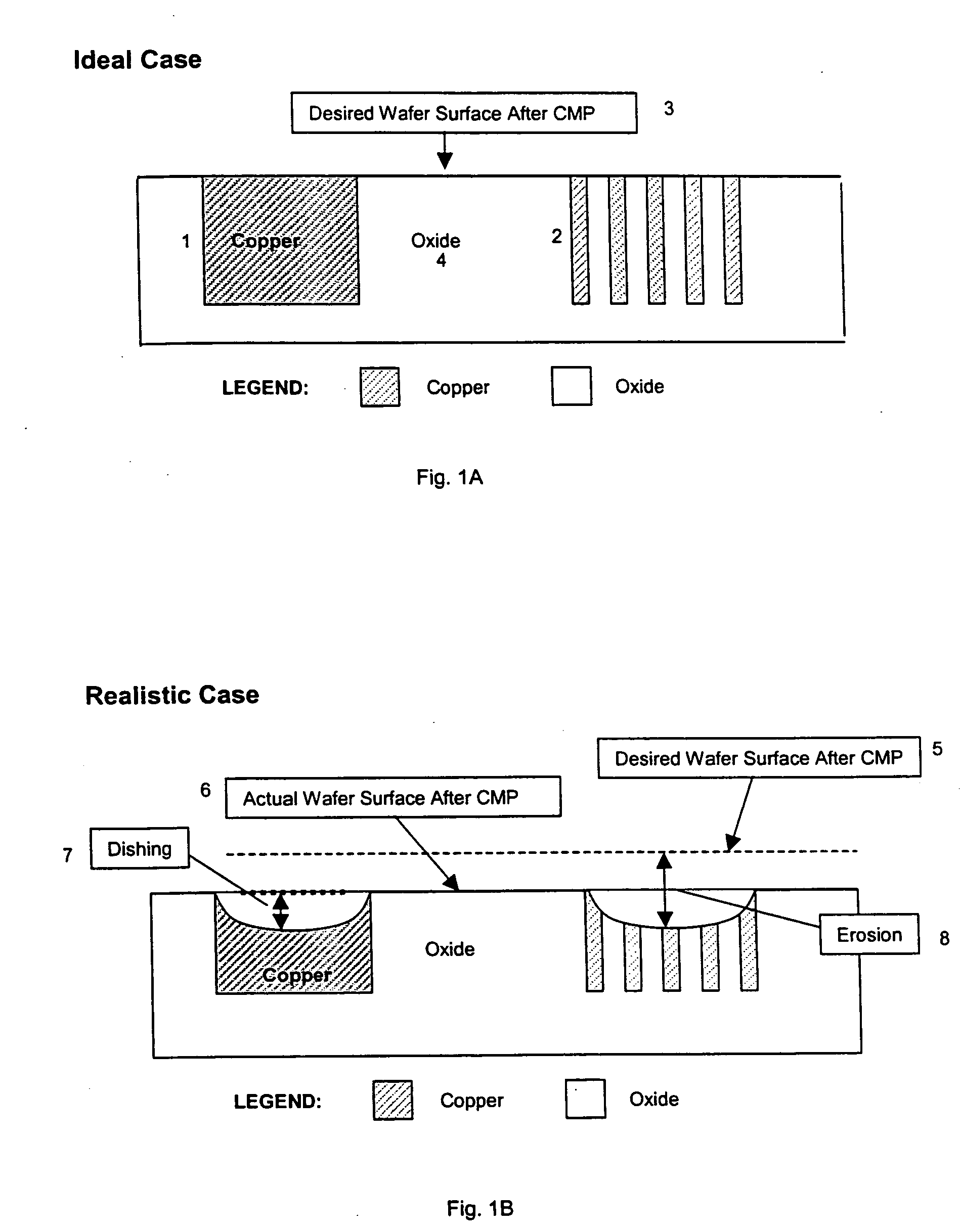

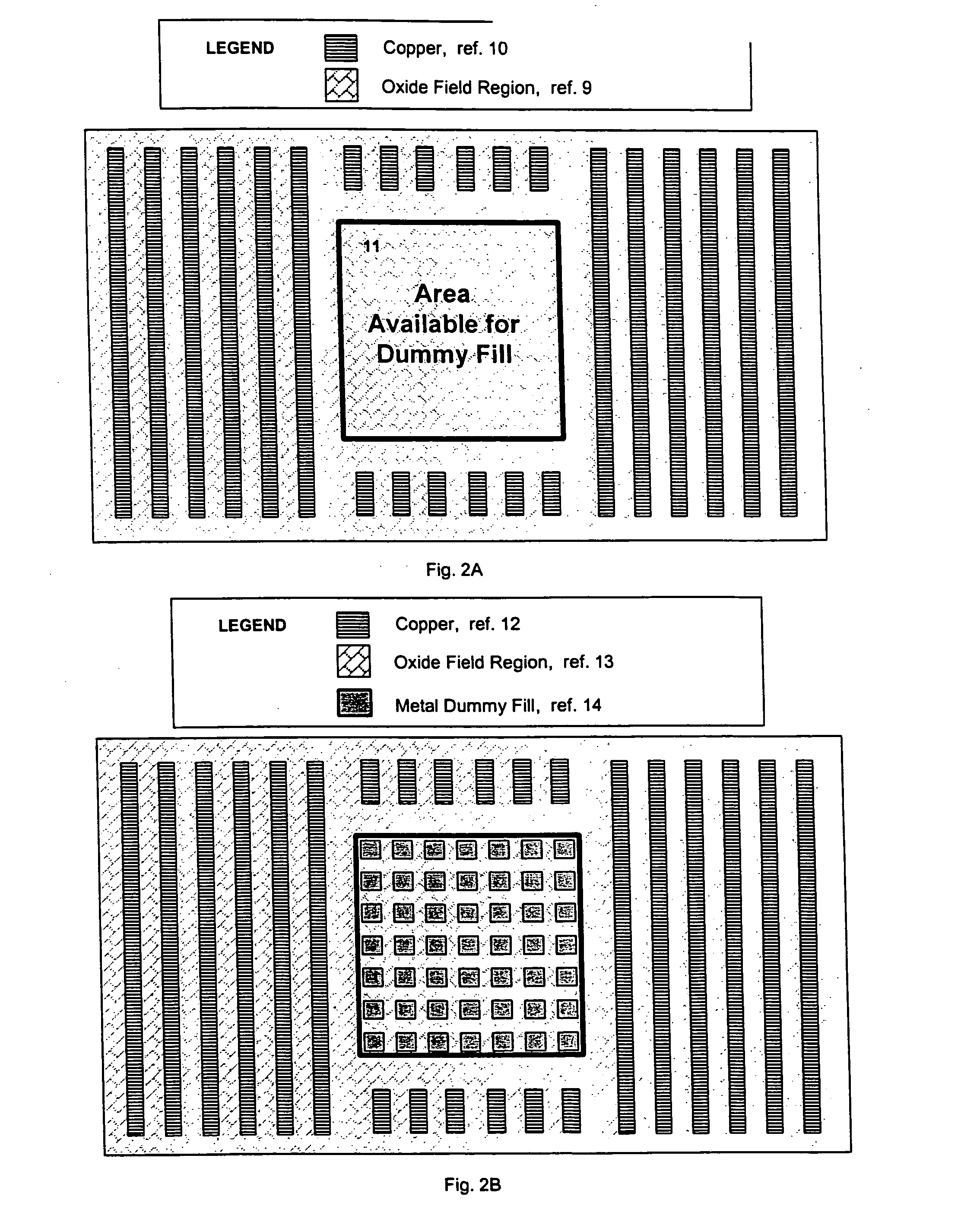

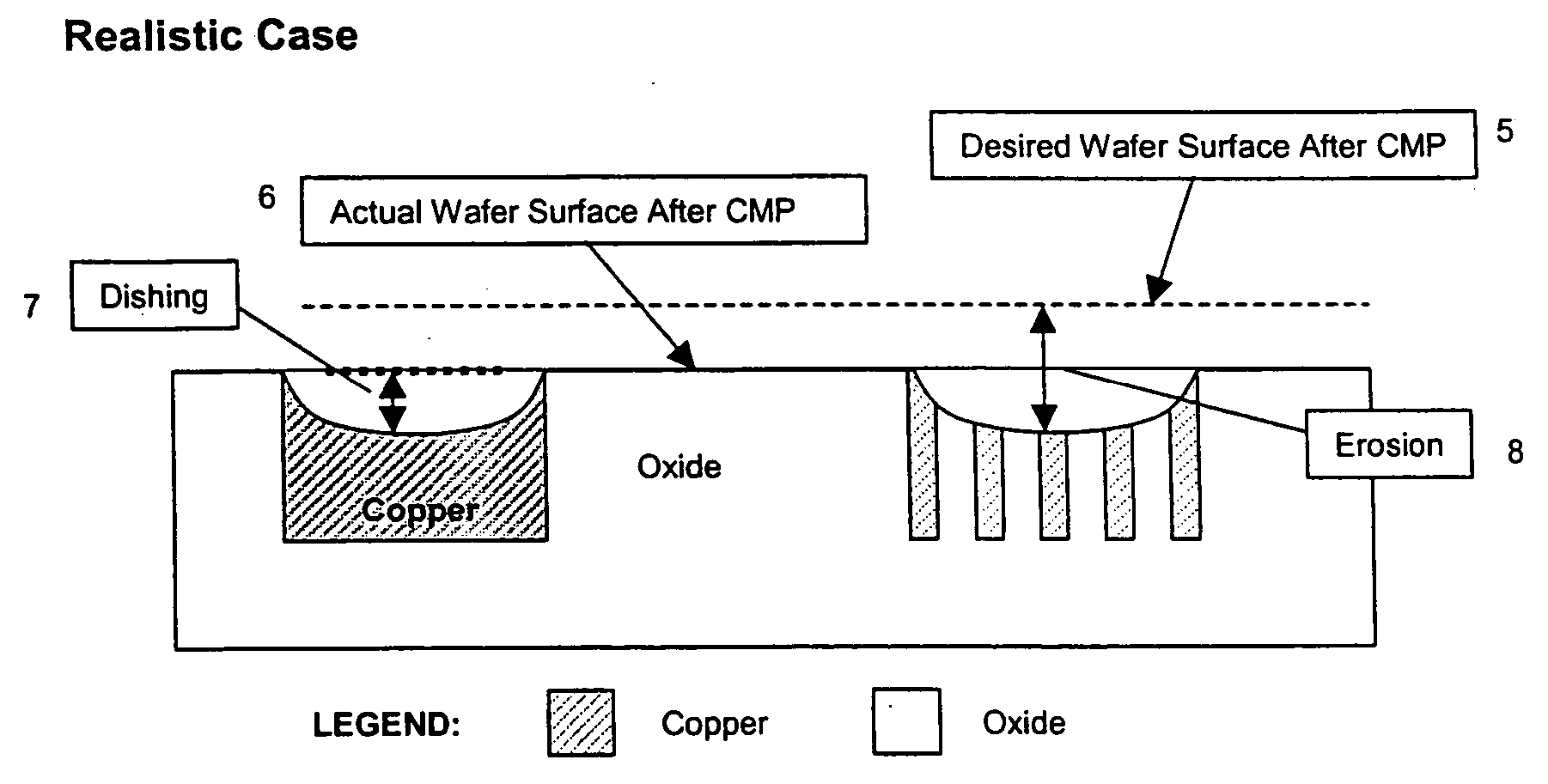

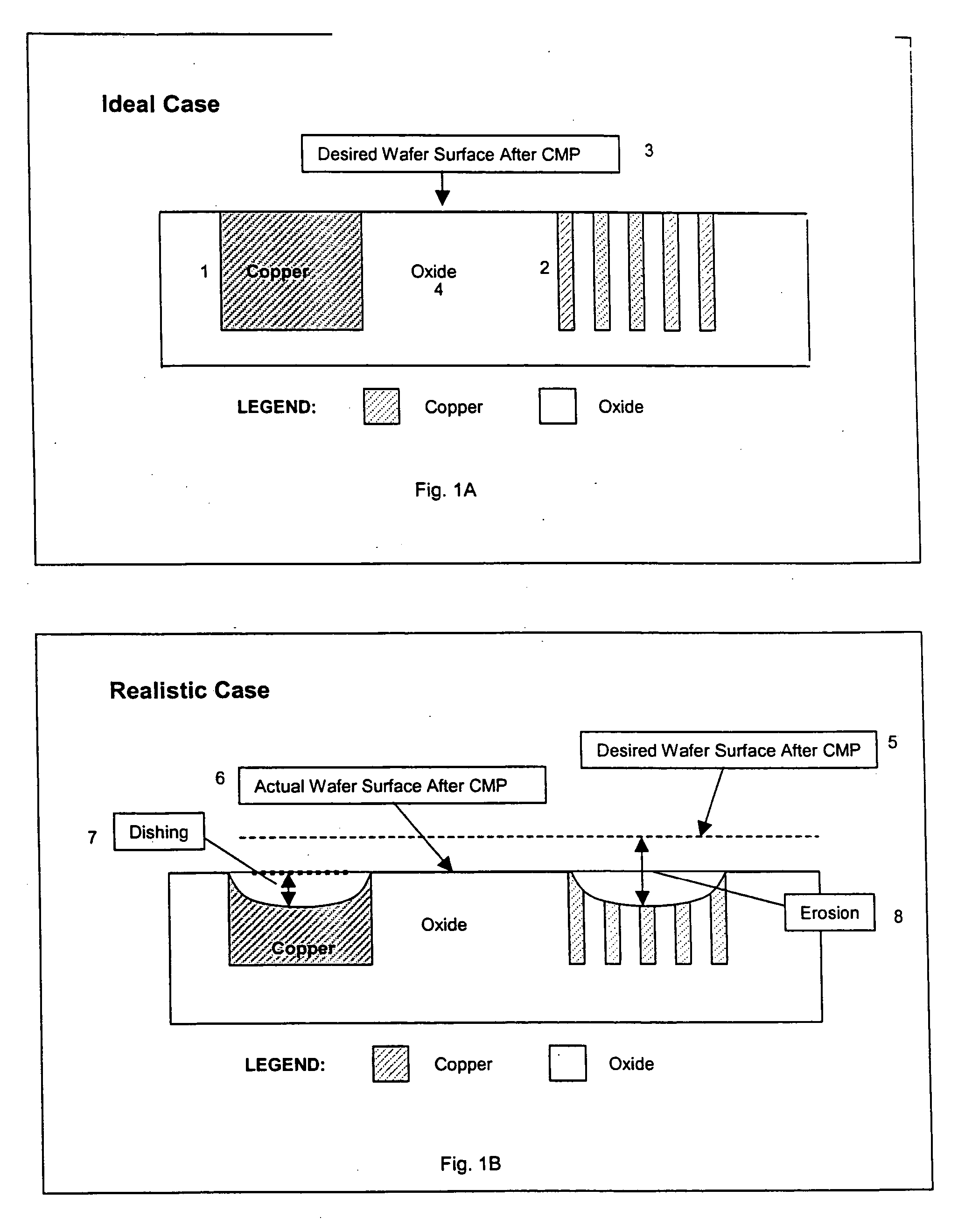

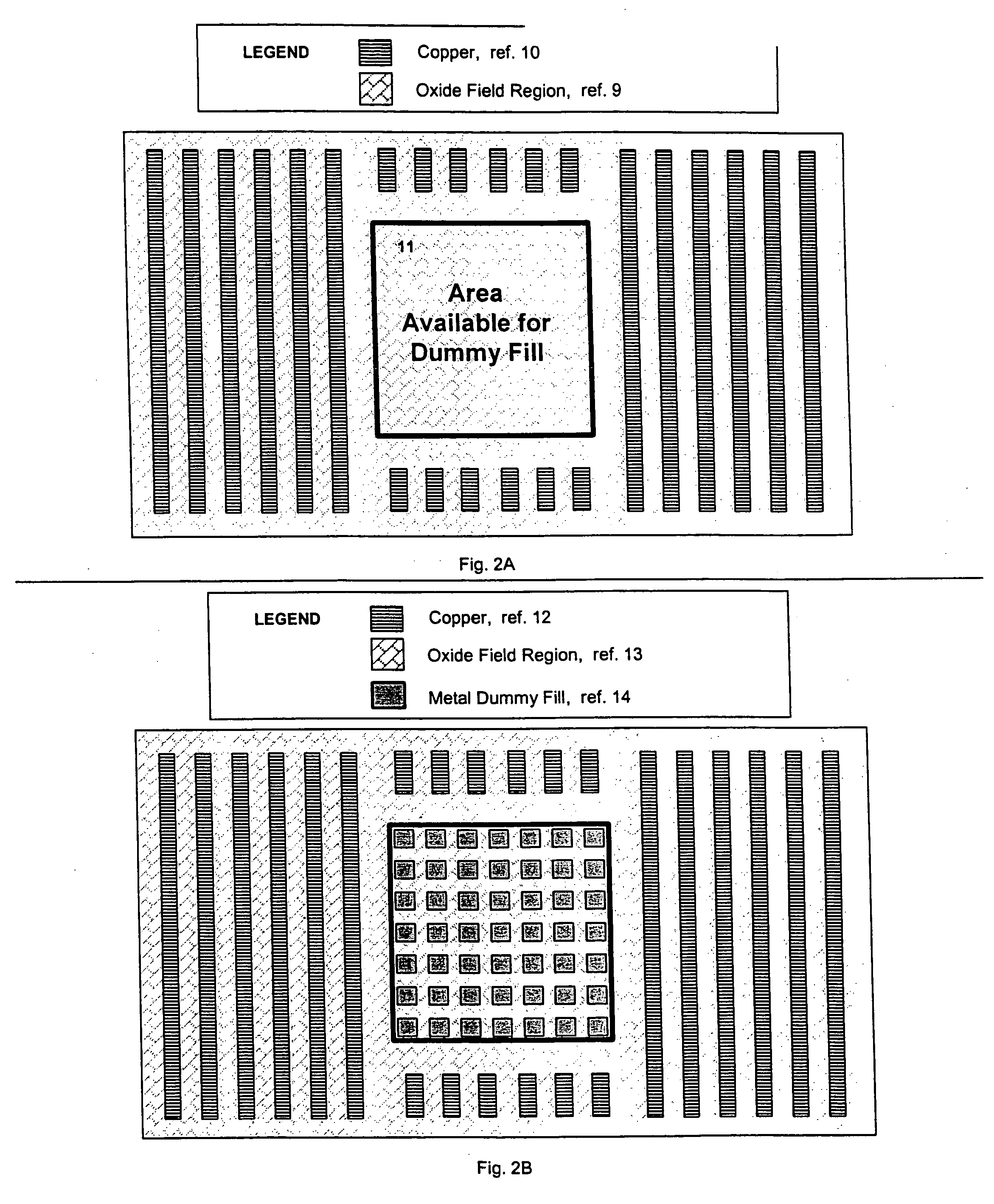

Dummy fill for integrated circuits

InactiveUS20050037522A1Minimize full-chip film thickness variationImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit manufacturingIntegrated circuit layout

A method and system are described to reduce process variation as a result of the electrochemical deposition (ECD), also referred to as electrochemical plating (ECP), and chemical mechanical polishing (CMP) processing of films in integrated circuit manufacturing processes. The described methods use process variation and electrical impact to direct the insertion of dummy fill into an integrated circuit.

Owner:CADENCE DESIGN SYST INC

Dummy fill for integrated circuits

InactiveUS20050051809A1Speed up the processHigh densitySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit manufacturingIntegrated circuit layout

A method and system are described to reduce process variation as a result of the electrochemical deposition (ECD), also referred to as electrochemical plating (ECP), and chemical mechanical polishing (CMP) processing of films in integrated circuit manufacturing processes. The described methods use process variation and electrical impact to direct the insertion of dummy fill into an integrated circuit.

Owner:CADENCE DESIGN SYST INC

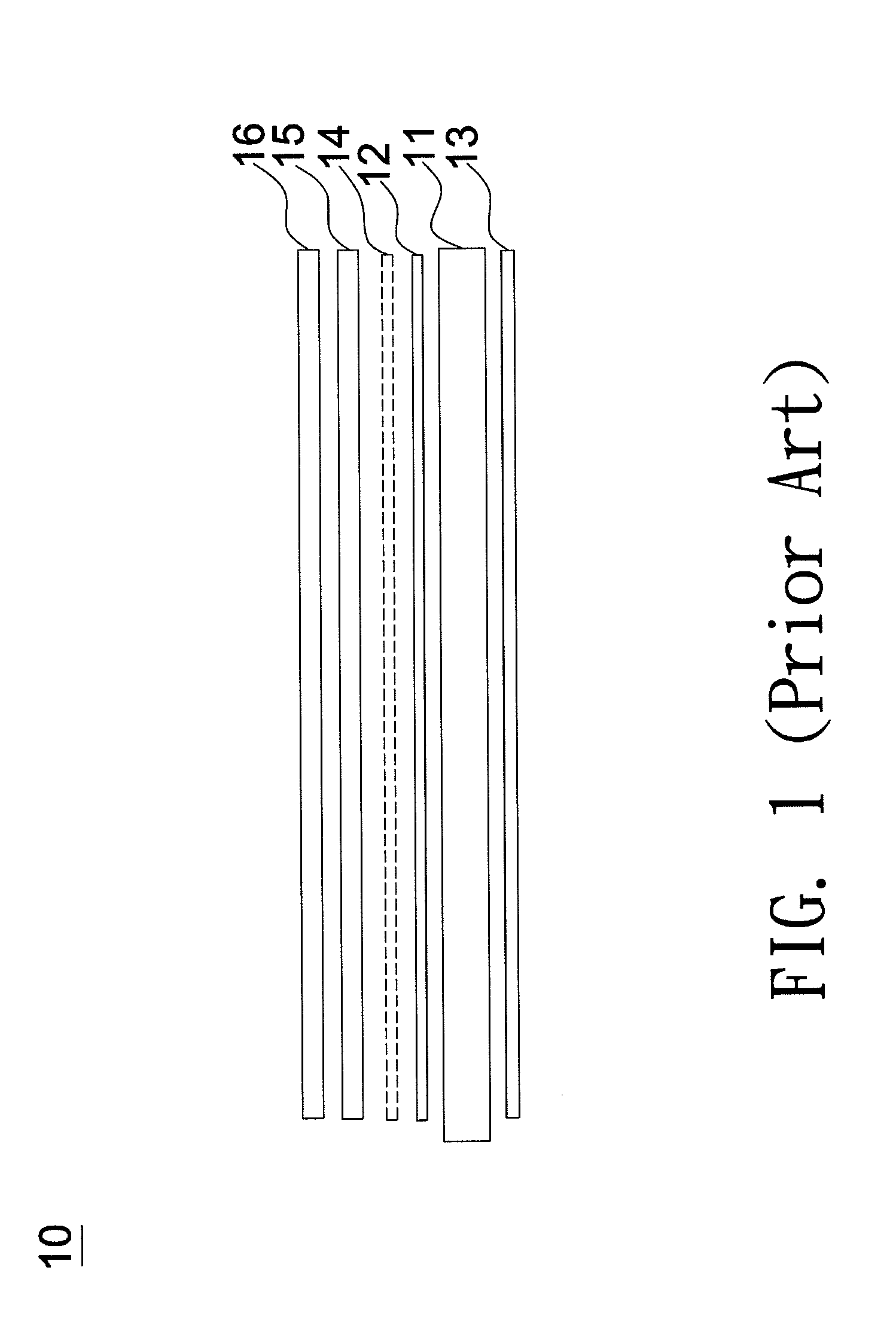

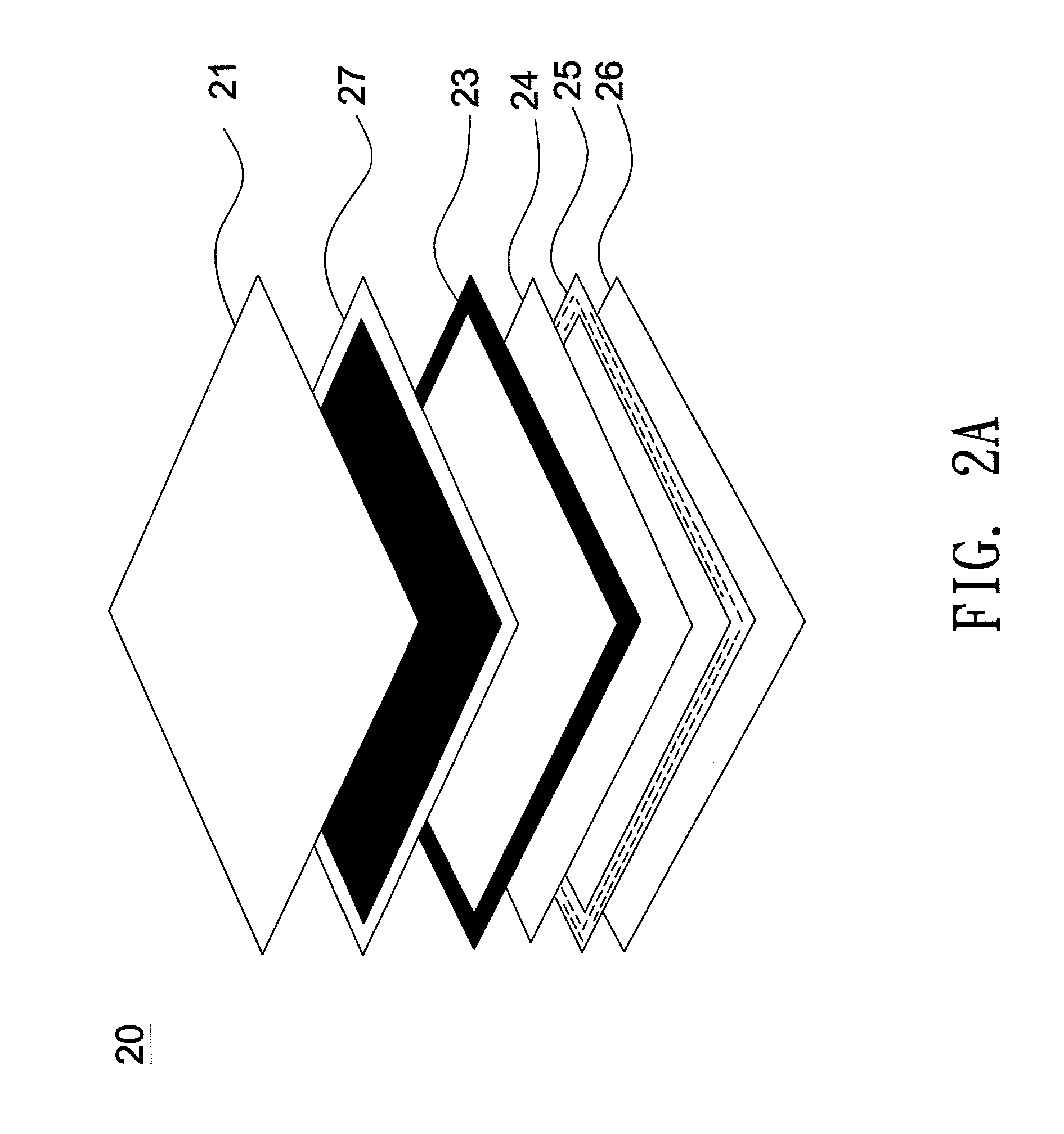

Surface capacitive touch panel and its fabrication method

InactiveUS20110199330A1Reduce film thicknessImprove film thickness uniformityTransmission systemsPrinted circuit manufactureCapacitive sensingTouch panel

A surface capacitive touch panel includes a transparent substrate, a decorative layer, a metal trace pattern layer, and a passivation layer. The decorative layer and the capacitive sensing electrode layer are formed on the transparent substrate. The metal trace pattern layer is formed on the capacitive sensing electrode layer. The decorative layer is disposed at a position substantially overlapping the metal trace pattern layer.

Owner:WINTEK CHINA TECH LTD +1

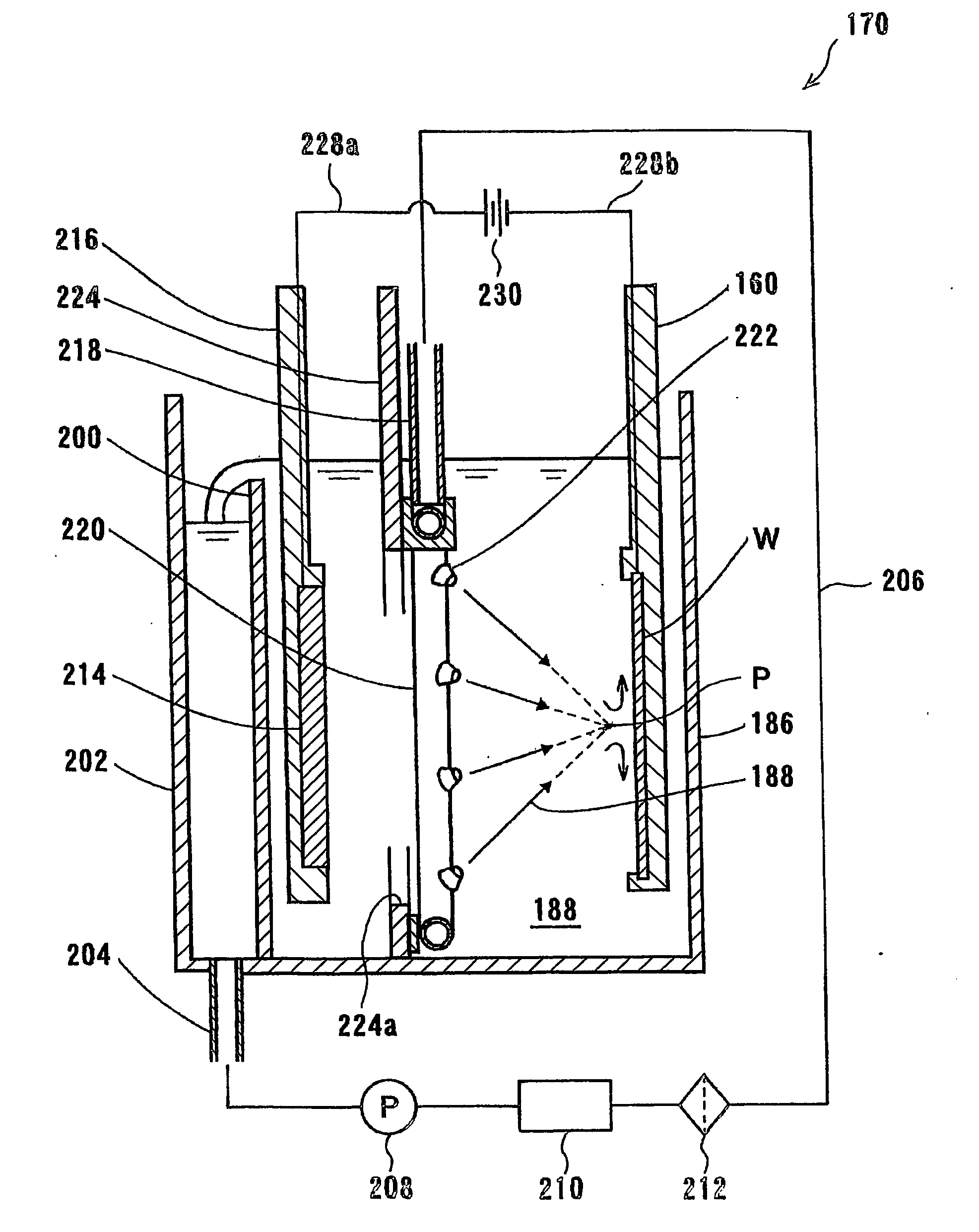

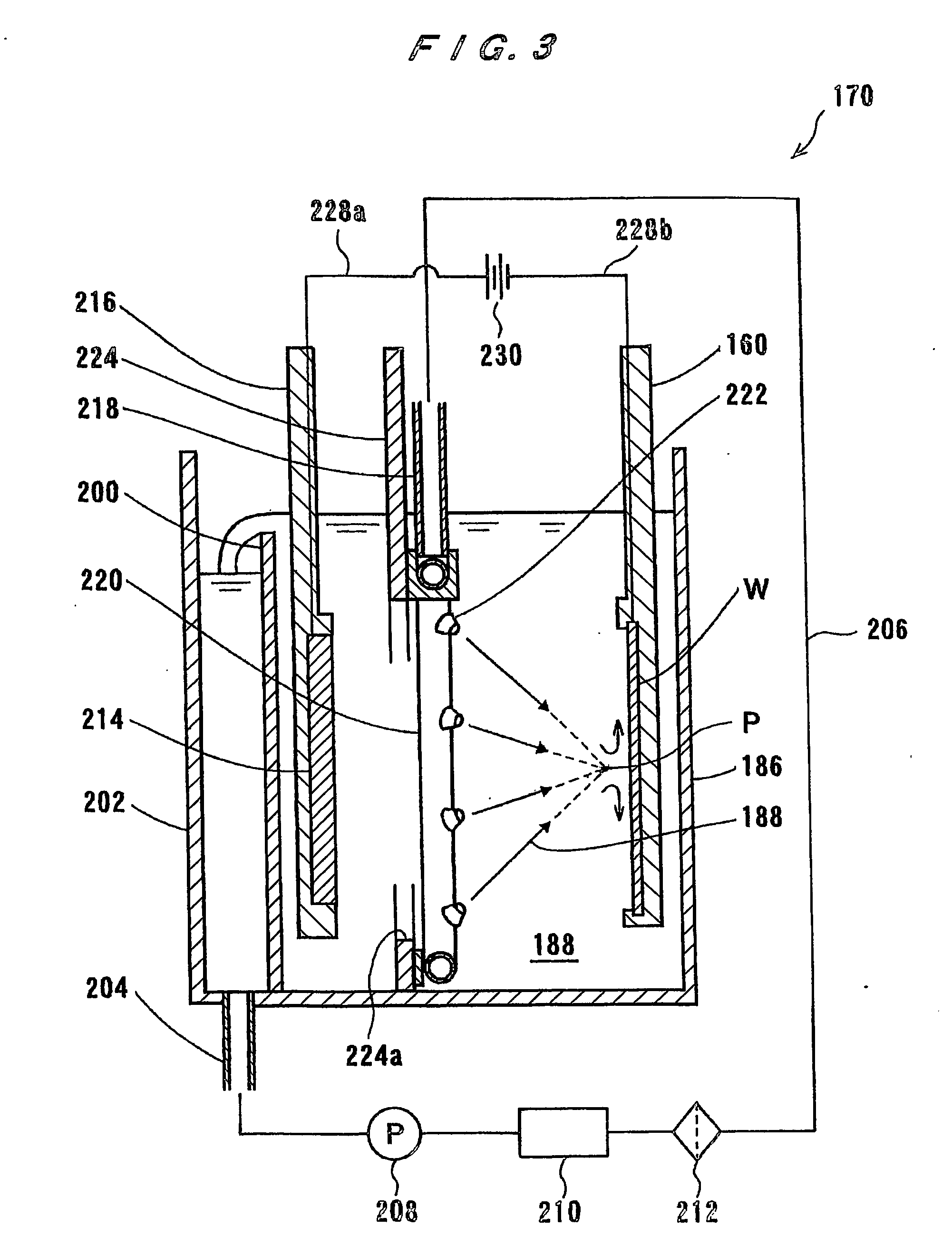

Plating apparatus

InactiveUS20060113185A1Fast plating speedHigh within-wafer uniformity of film thicknessCellsSolid-state devicesResistEngineering

The present invention is concerned with a plating apparatus for use in forming a plated film in trenches, via holes, or resist openings that are defined in a surface of a semiconductor wafer, and forming bumps to be electrically connected to electrodes of a package, on a surface of a semiconductor wafer. The plating apparatus (170) has a plating tank (186) for holding a plating solution (188), a holder (160) for holding a workpiece (W) and bringing a surface to be plated of the workpiece into contact with the plating solution (188) in the plating tank (186), and a ring-shaped nozzle pipe (220) disposed in the plating tank (186) and having a plurality of plating solution injection nozzles (222) for injecting the plating solution (188) to the surface to be plated of the workpiece held by the holder (160) to supply the plating solution (188) into the plating tank (186).

Owner:EBARA CORP

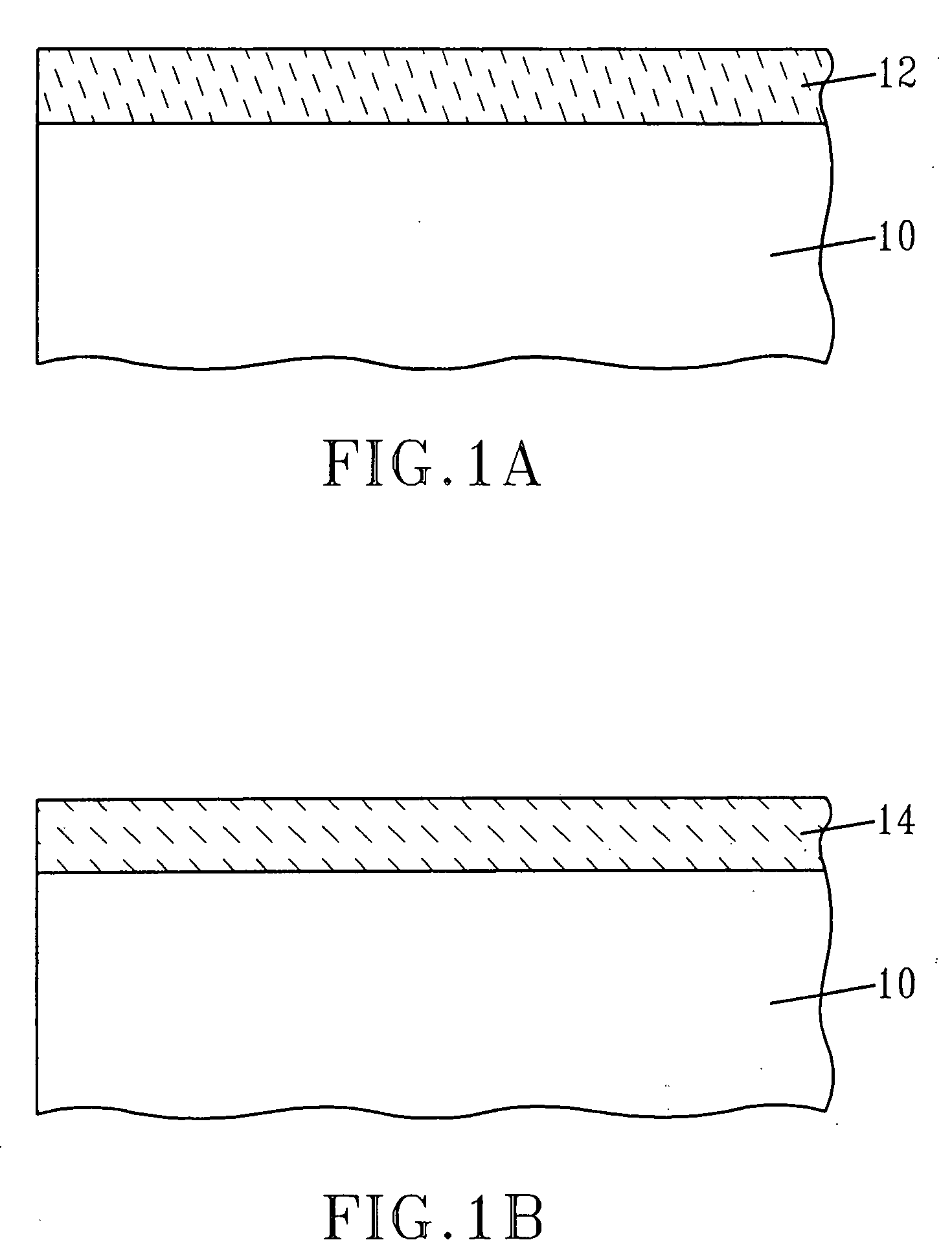

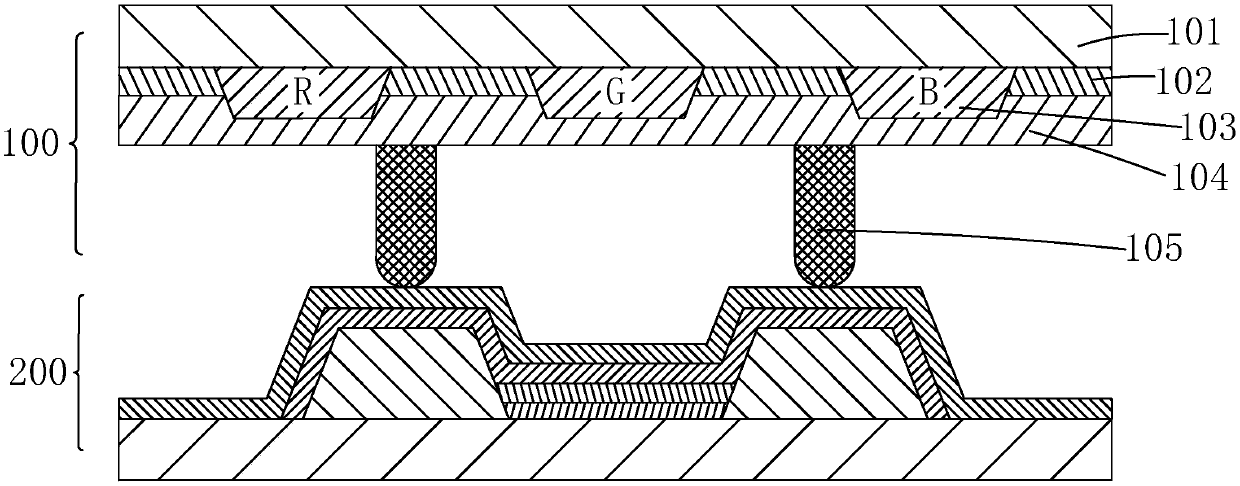

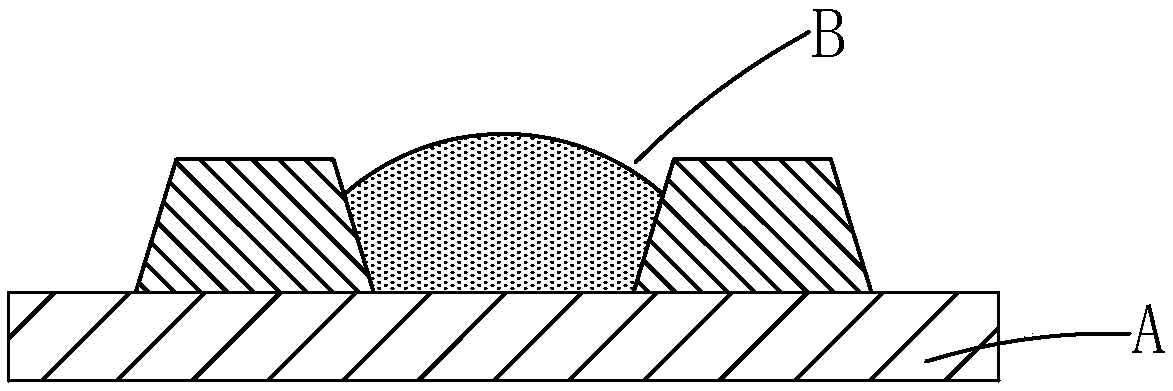

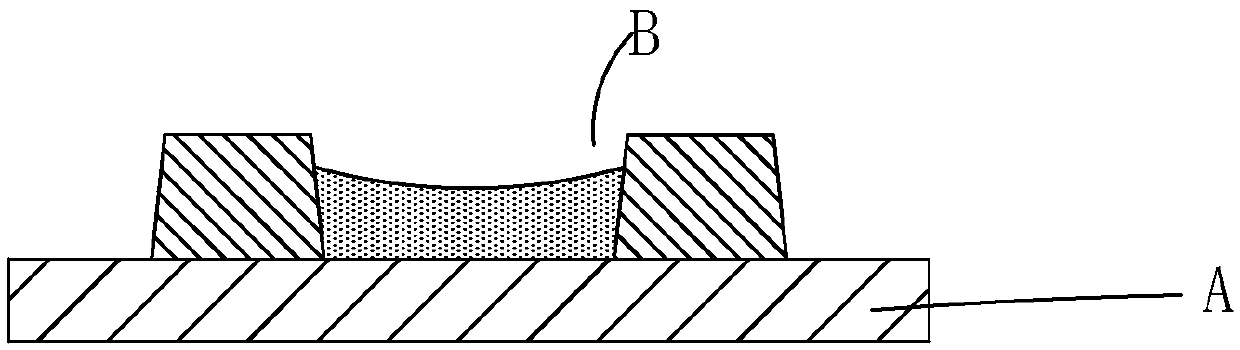

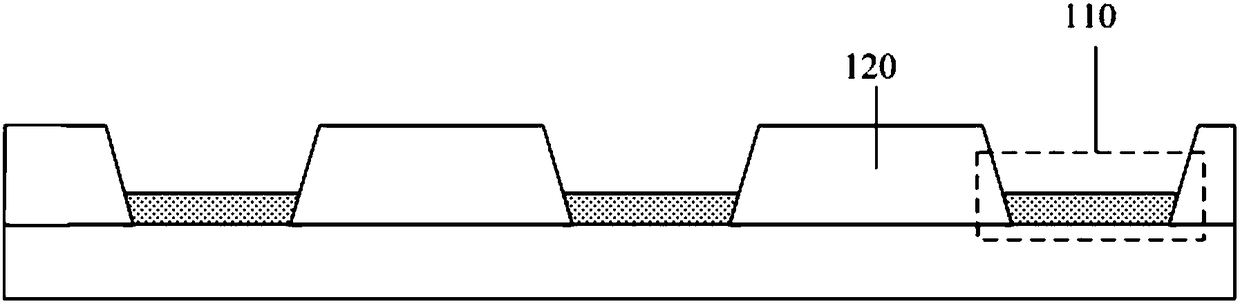

Color film substrate, manufacturing method thereof, and OLED display device

ActiveCN107731873AImprove flatnessImprove film thickness uniformitySolid-state devicesSemiconductor devicesResistColor film

The present invention provides a color film substrate, a manufacturing method thereof, and an OLED display device. The color film substrate is provided with a first black matrix (12) and a second black matrix (14) to block light together, and the risk of color mixing of display can be reduced. A first groove (121) of the first black matrix (12) and a second groove (131) of a dam layer (13) are setto contain and limit printing ink needed for the manufacture of a color-resist layer (15) together, the surface of the first groove (121) is hydrophilic, the surface of the second groove (131) is hydrophobic, the flatness and thickness uniformity of the color-resist layer 15 can be improved, the color film substrate is applied to the OLED display device, and the display quality can be improved. The dam layer (13) and the second black matrix (14) are set to substitute support posts in the prior art, and the process can be simplified.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

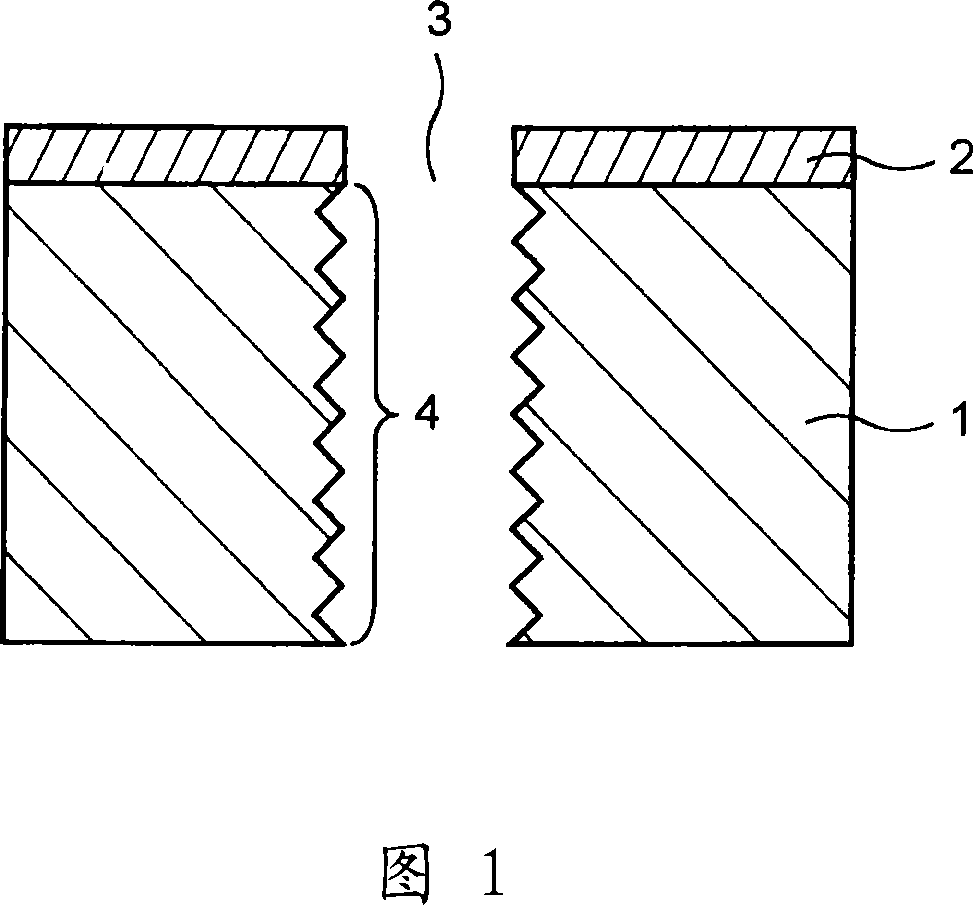

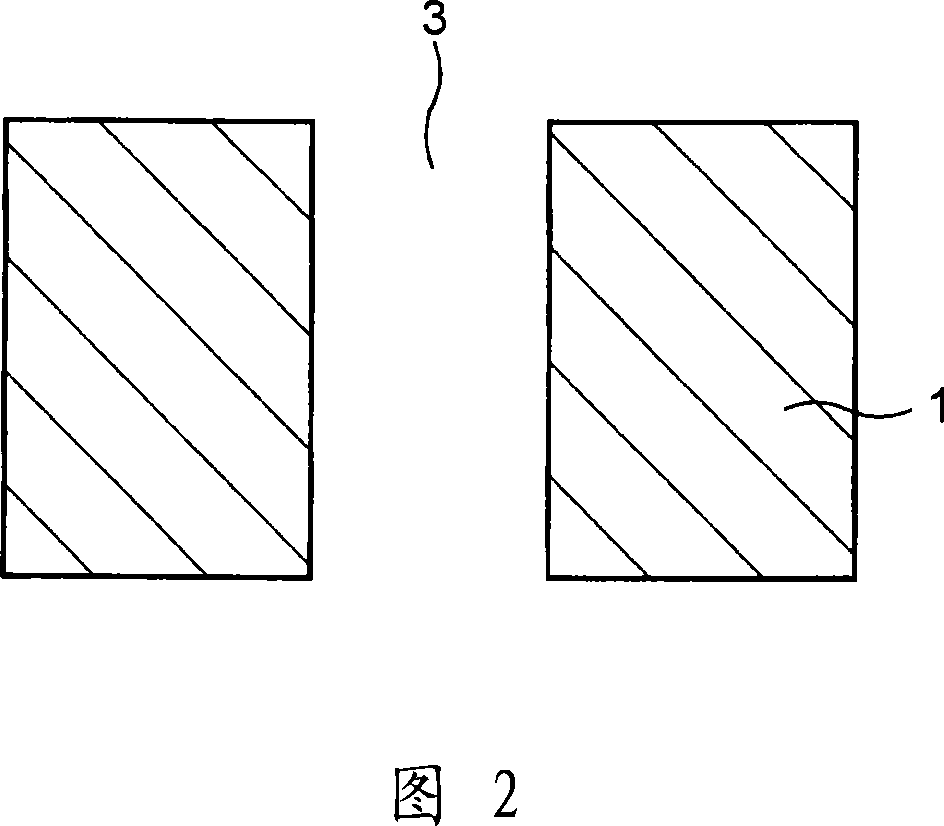

Tei Coat for Organopolysiloxane Antifouling Coat, Composite Coats, and Ships and Underwater Structures Covered with the Composite Coats

InactiveUS20090042042A1Big burden to solveWell formedAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond properties

Disclosed is a tie coat which is formed on a surface of a base or an undercoating film prior to formation of an organopolysiloxane-based antifouling coating film and is formed from a moisture-curing organopolysiloxane-based composition comprising (b1) organopolysiloxane having condensing functional groups at both ends of a molecule and / or (b2) a curing composition formed by subjecting the component (b1) and an extender pigment selected from the group consisting of silica, calcium carbonate, talc, mica, clay, kaolin and barium sulfate to contact treatment with heating or without heating. Also disclosed is a composite coating film wherein on a surface of the above tie coat is formed a finish coat formed from a three-pack type organopolysiloxane-based curing composition comprising (c1) a main agent comprising the component (b1), (c2) a curing agent component comprising tetraalkoxysilicate or its condensate and (c3) a curing accelerator component comprising a metallic compound. Further disclosed is a composite coating film wherein an epoxy-based sealer coat, the tie coat and the finish coat are formed in this order on a surface of an old antifouling coating film (G). There is provided by the invention a tie coat capable of forming a composite coating film having excellent interlaminar bond property. The composite coating film is favorably formed on a surface of a base, an undercoating film, an old antifouling coating film or the like, has excellent interlaminar bond strength and antifouling property and is preferably used for coating outer surfaces of ships, submerged parts of marine structures, water supply / drainage channels of atomic power plant, etc.

Owner:CHUGOKU MARINE PAINTS

Manufacturing method of semiconductor device

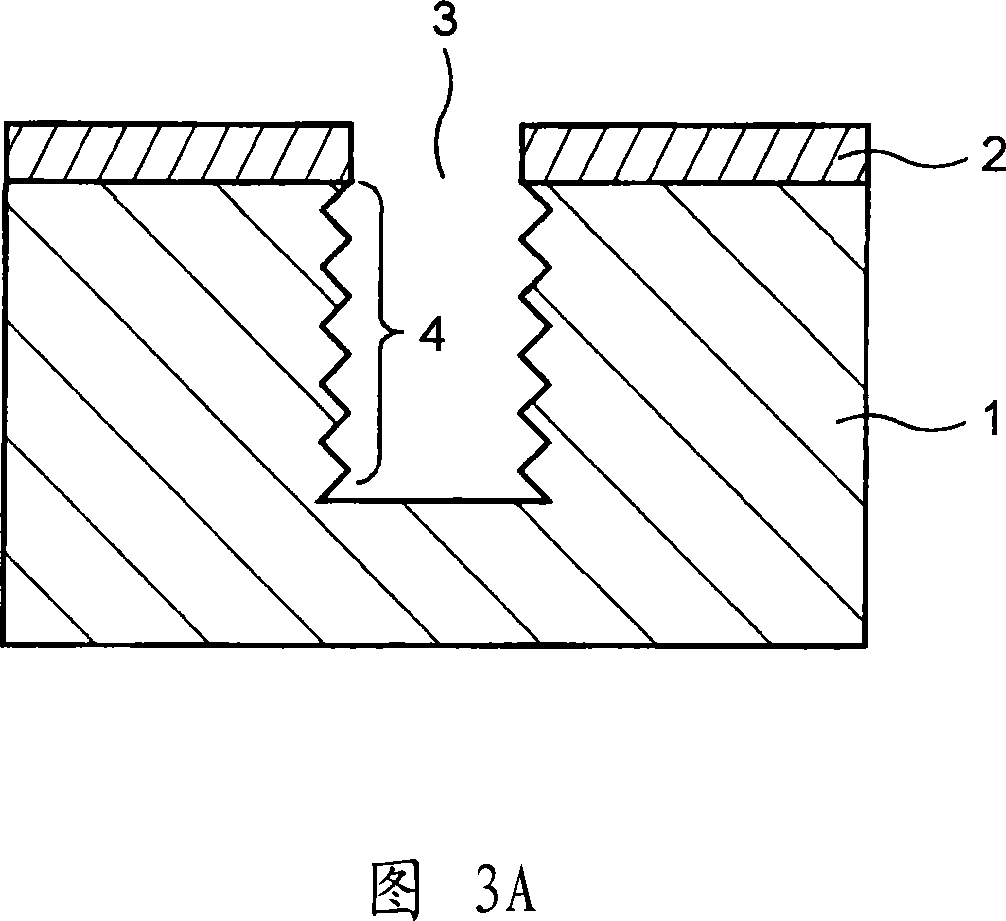

InactiveCN101075554AImprove rough shapeImprove film thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorDry etching

This invention is directed to form a homogeneous film (12) in a via hole formed in a semiconductor device using Bosch process. The via hole (12) that penetrates through a predetermined region in a semiconductor substrate (5) is formed by etching the semiconductor substrate (5) from one of its surface to the other by the Bosch process using a mask layer (11) as a mask. Next, the mask layer (11) is removed. Then, scallops (13) are removed by dry etching to flatten a sidewall of the via hole (12). Following the above, an insulation film, a barrier layer and the like are formed homogeneously in the via hole (12).

Owner:SANYO ELECTRIC CO LTD

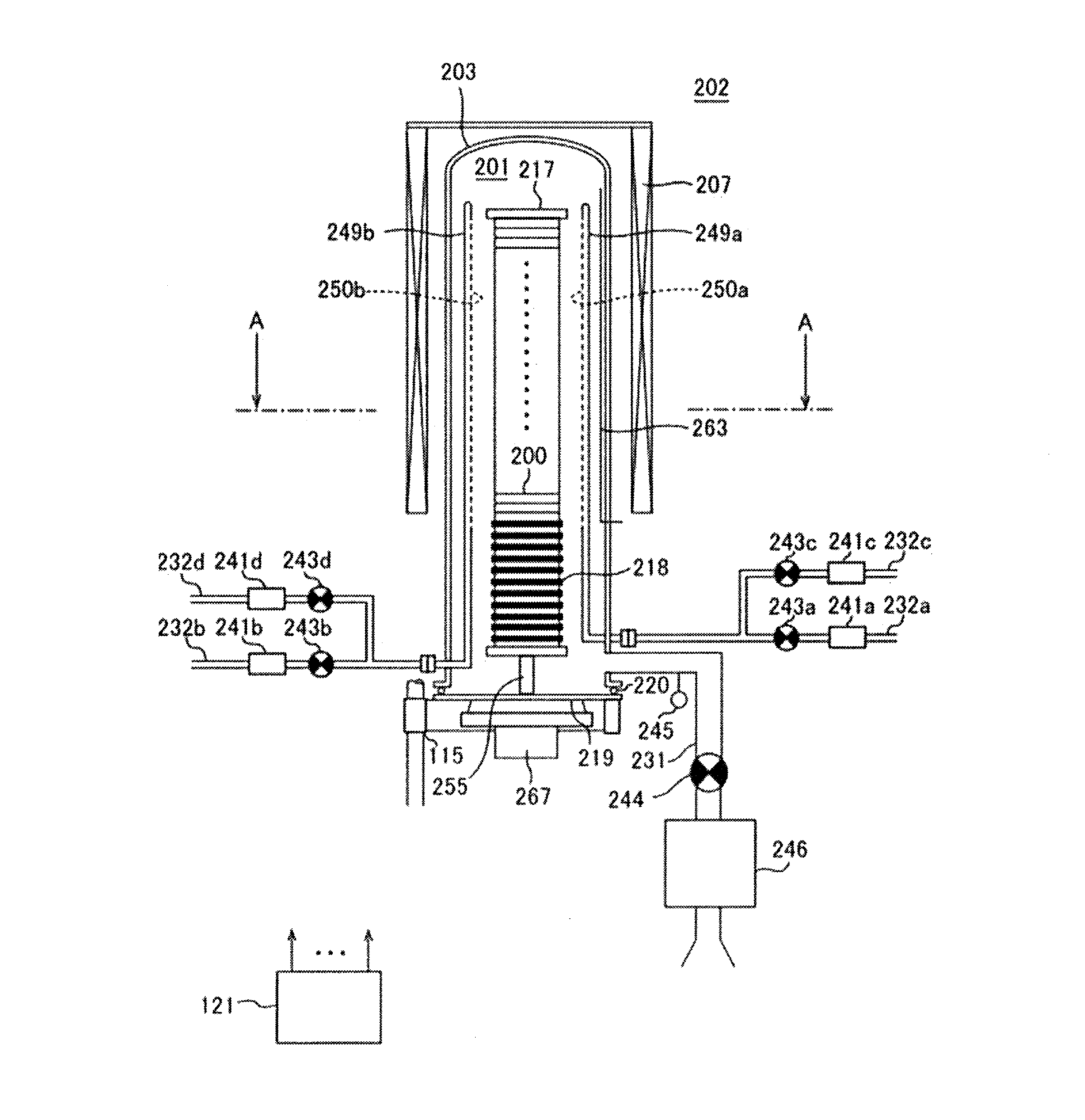

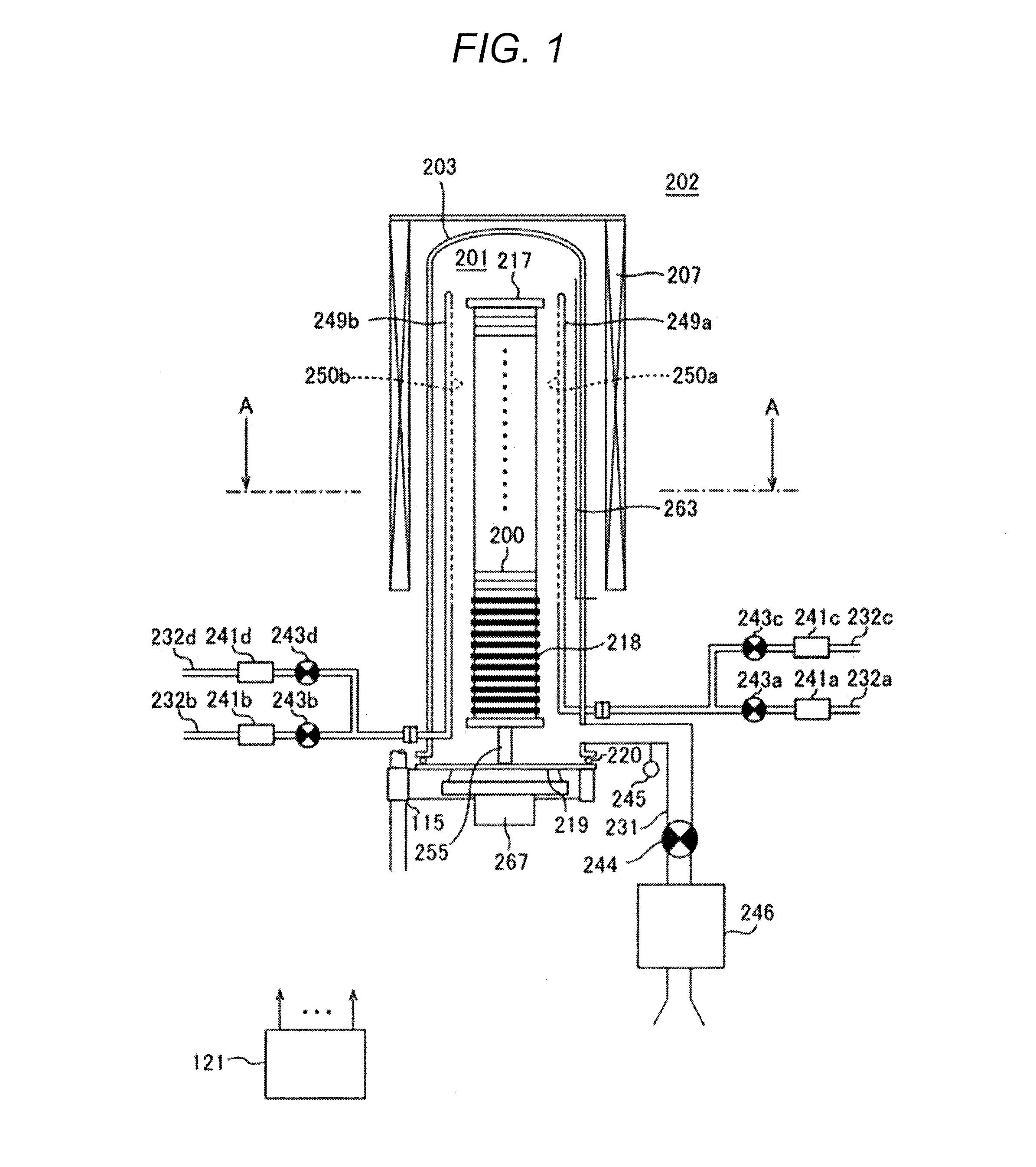

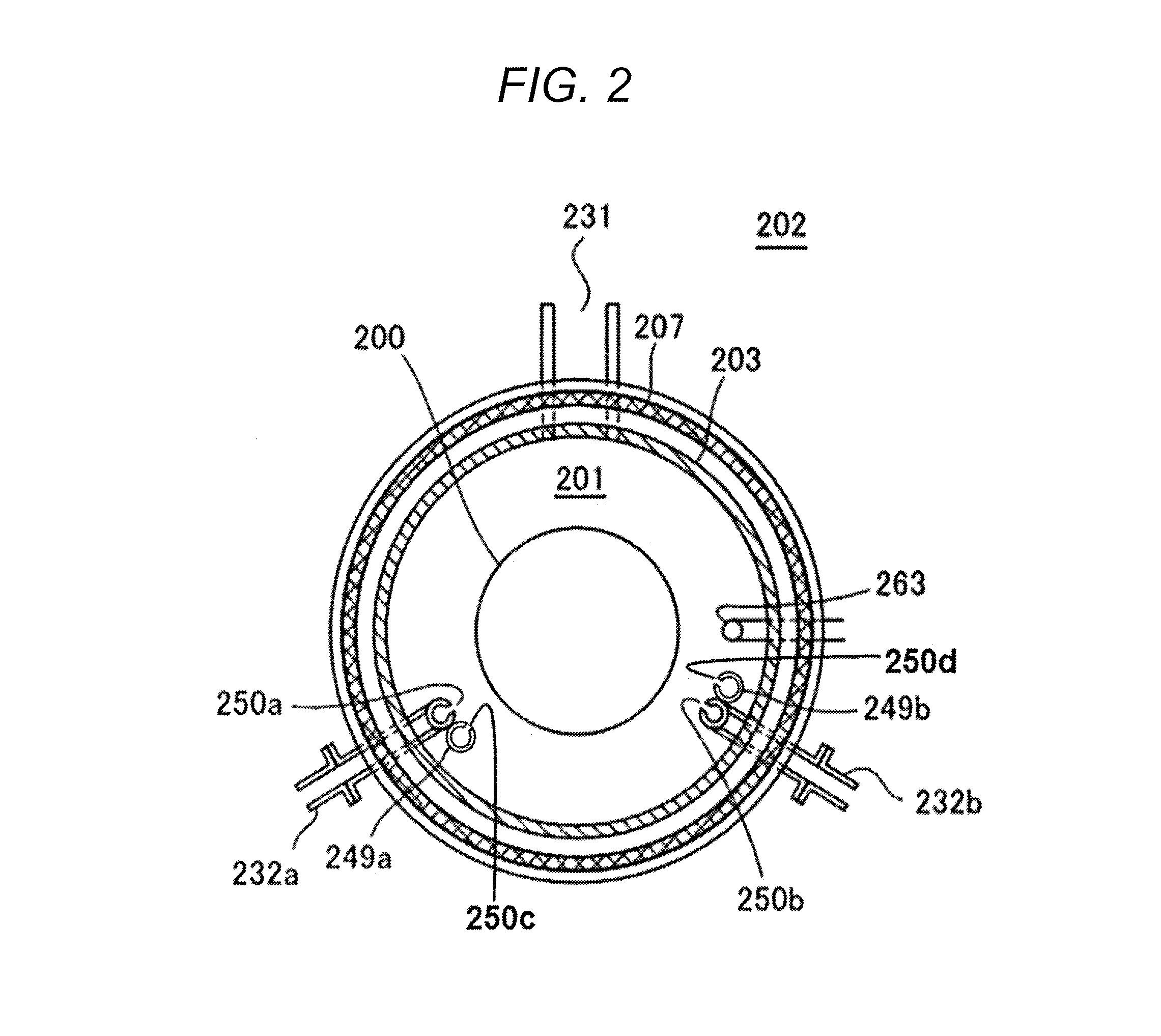

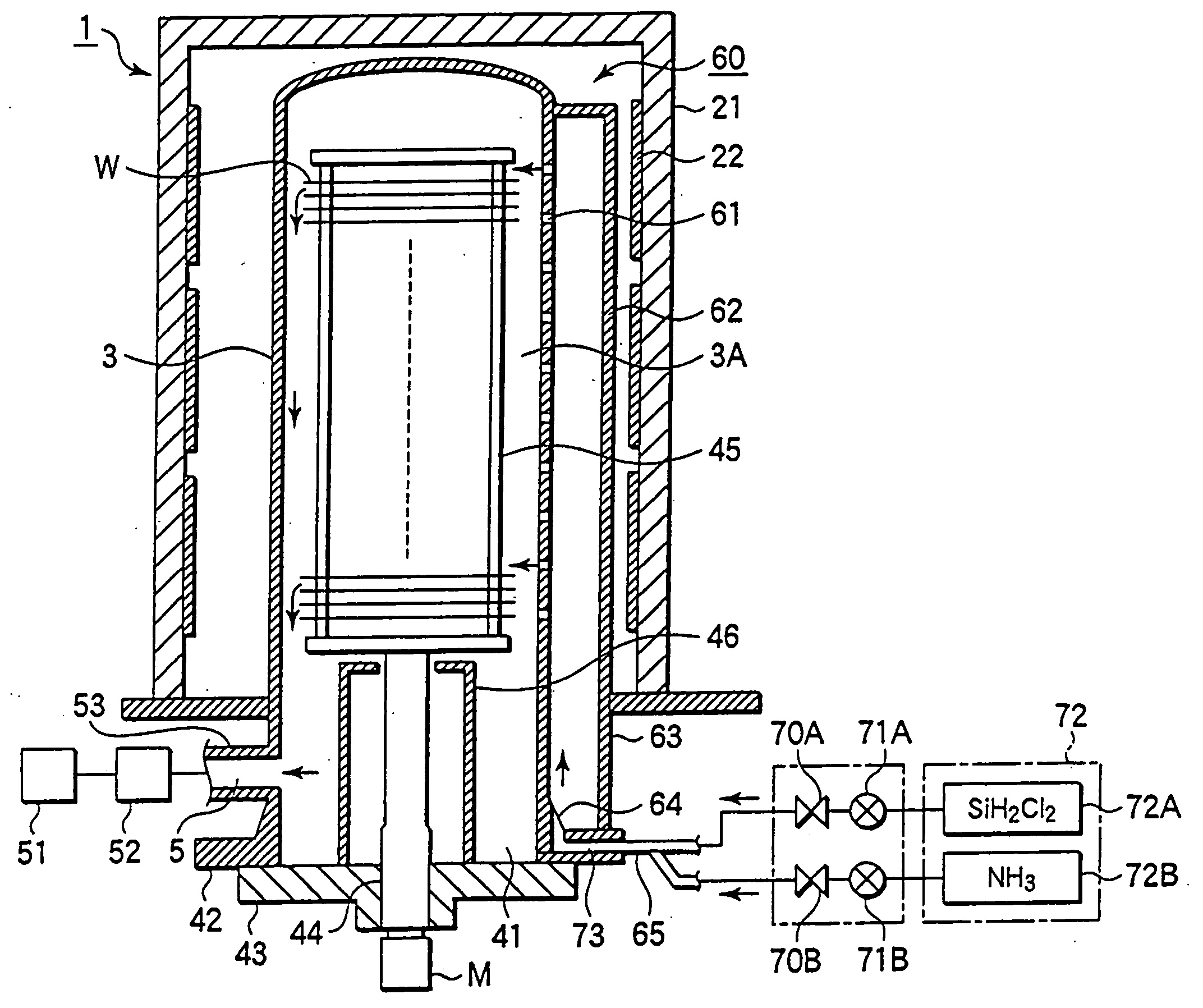

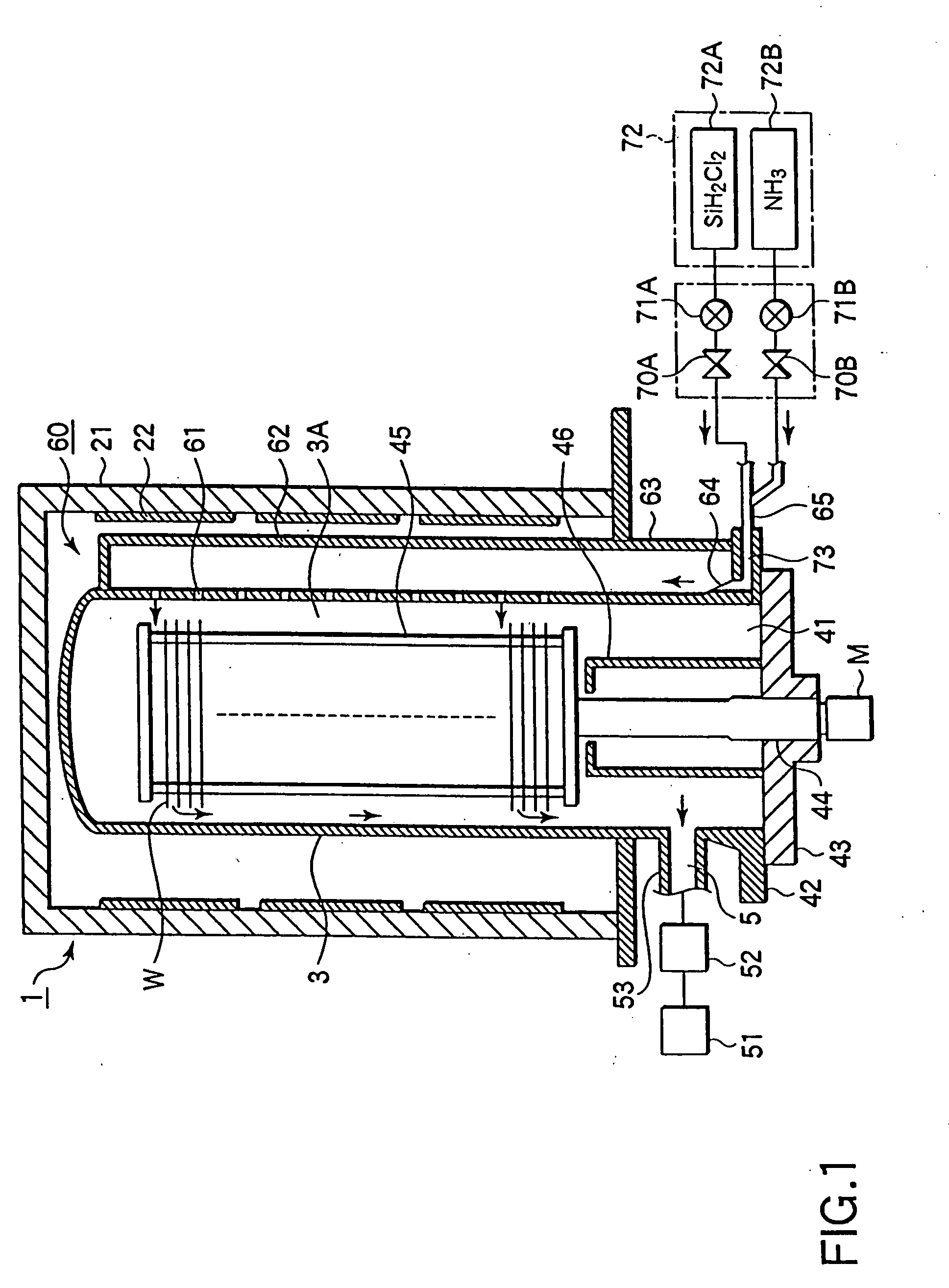

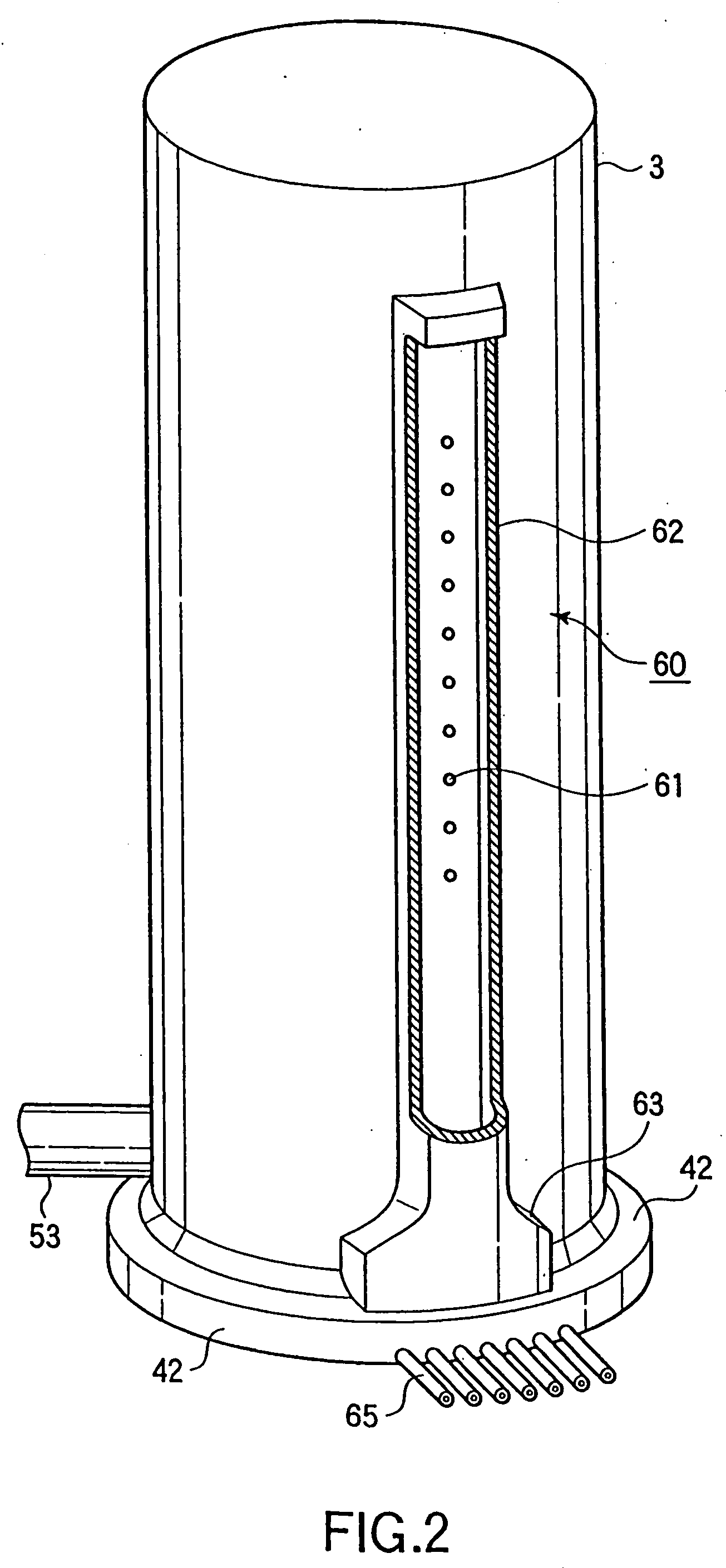

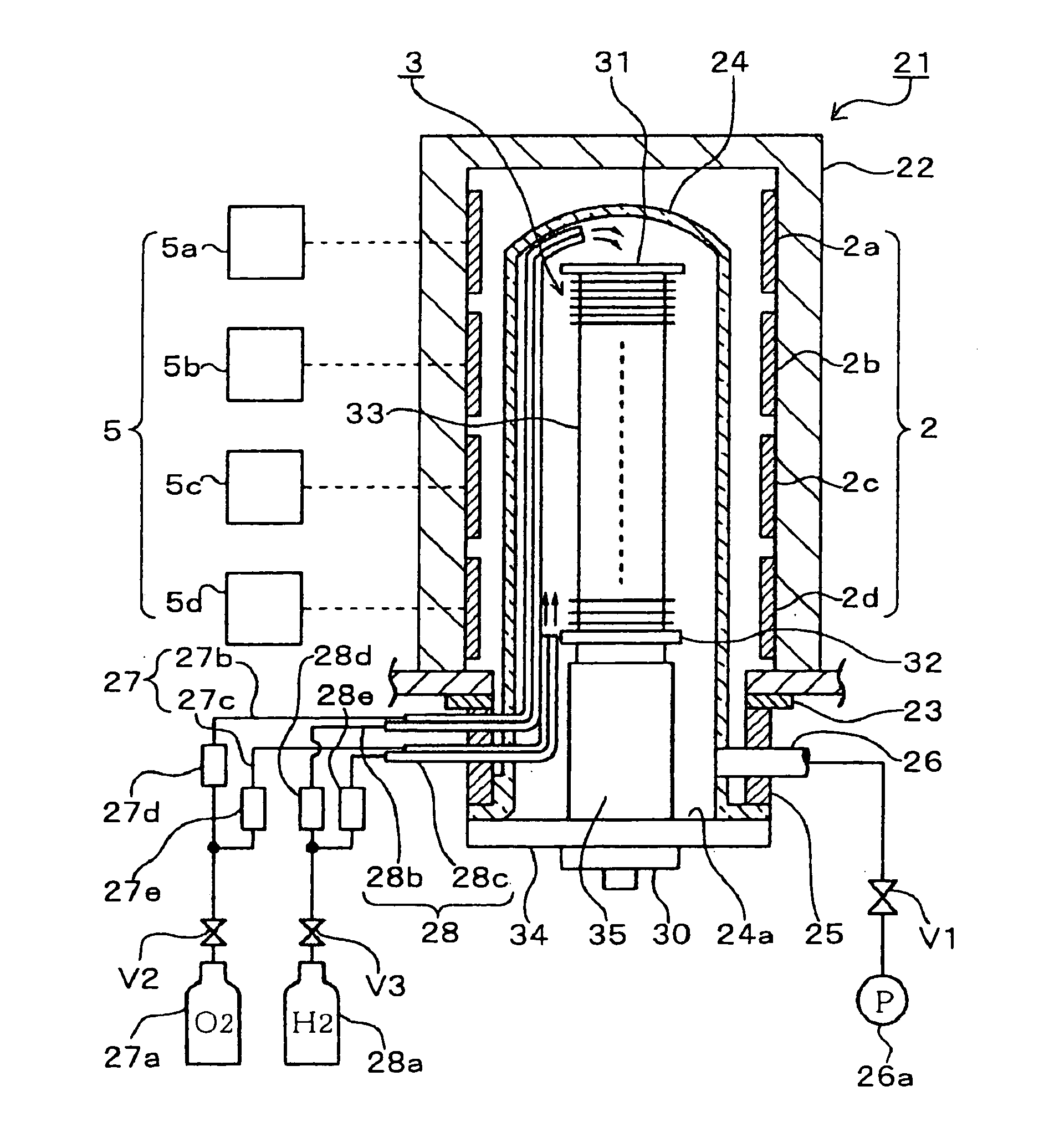

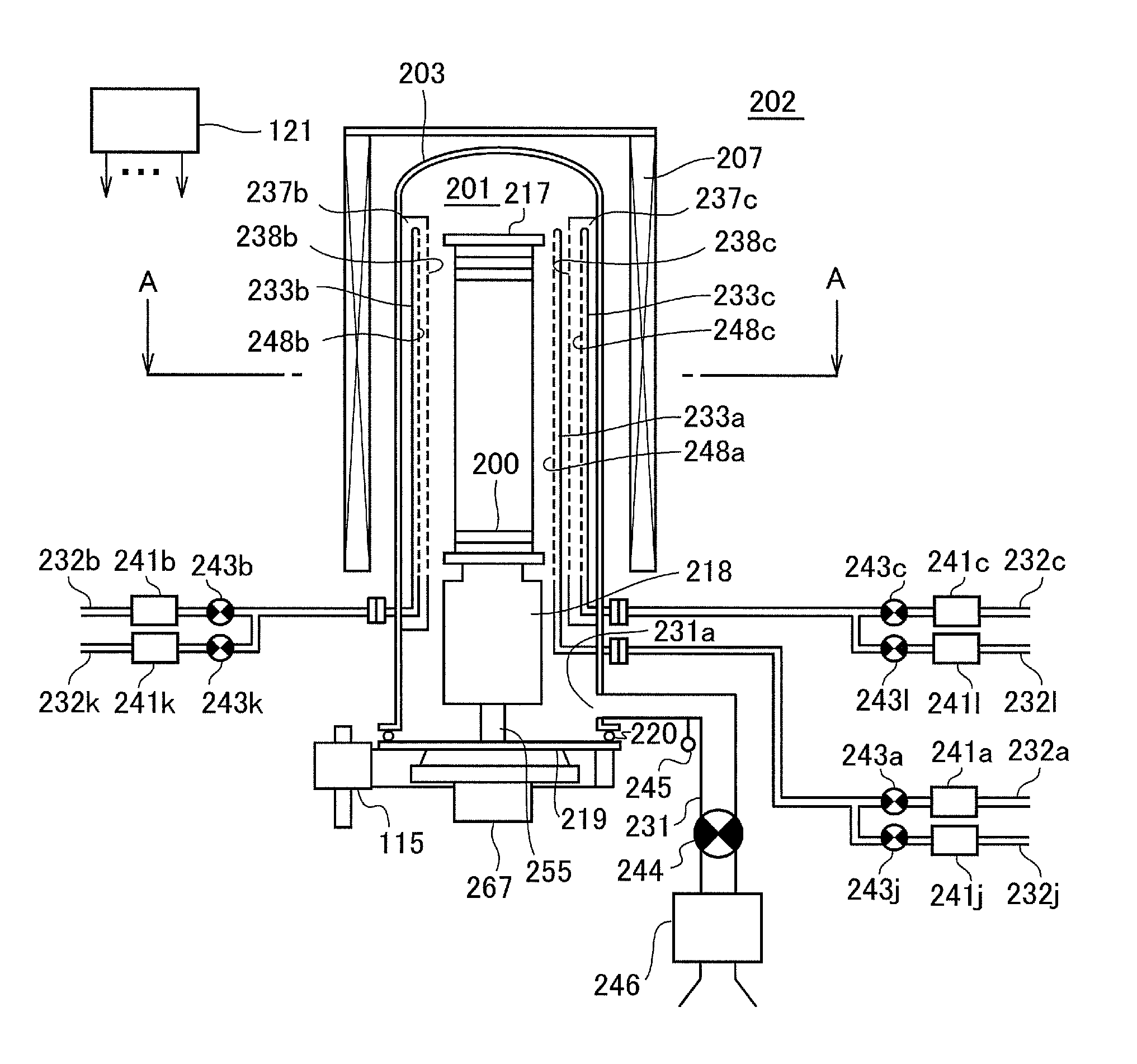

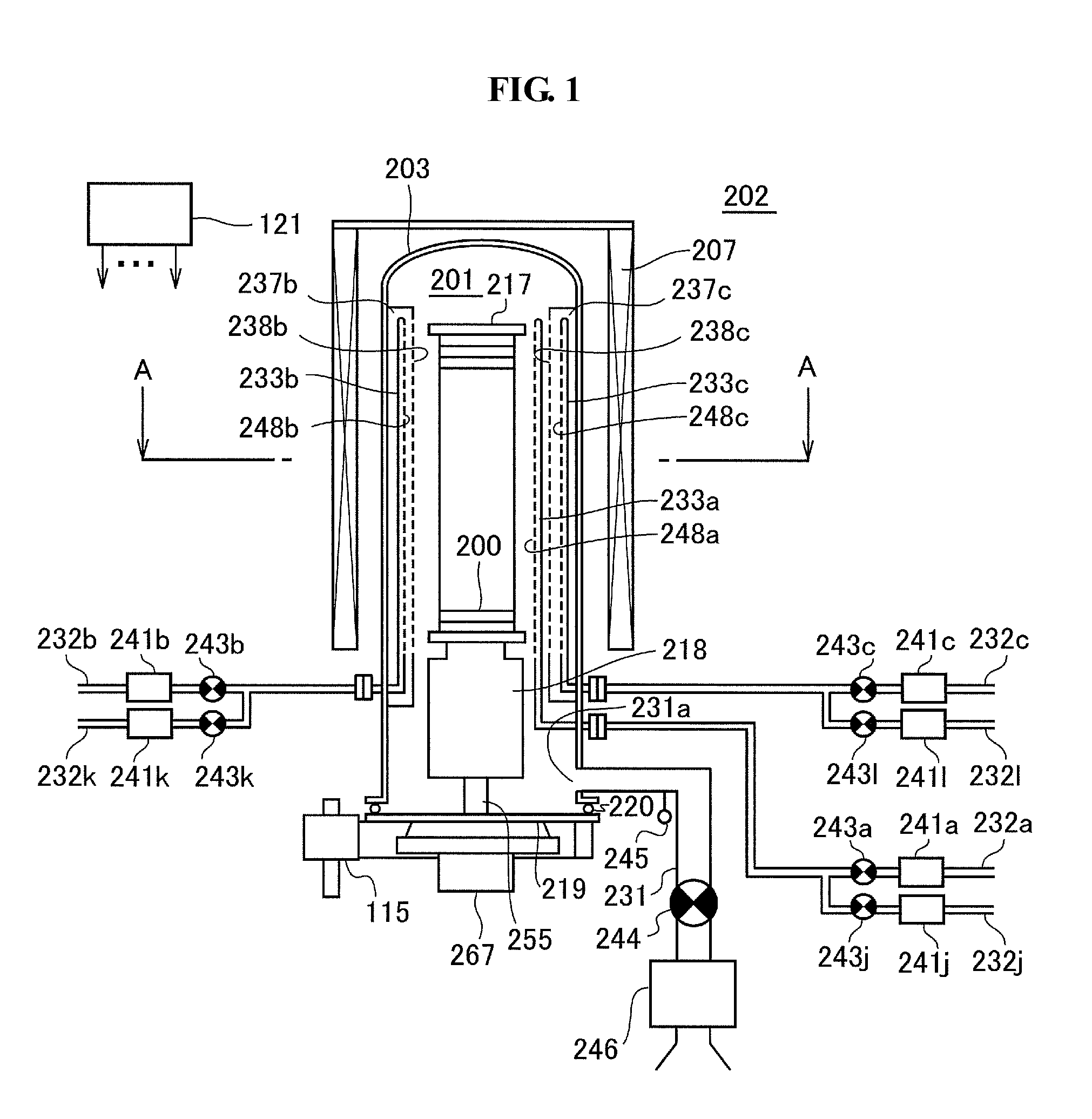

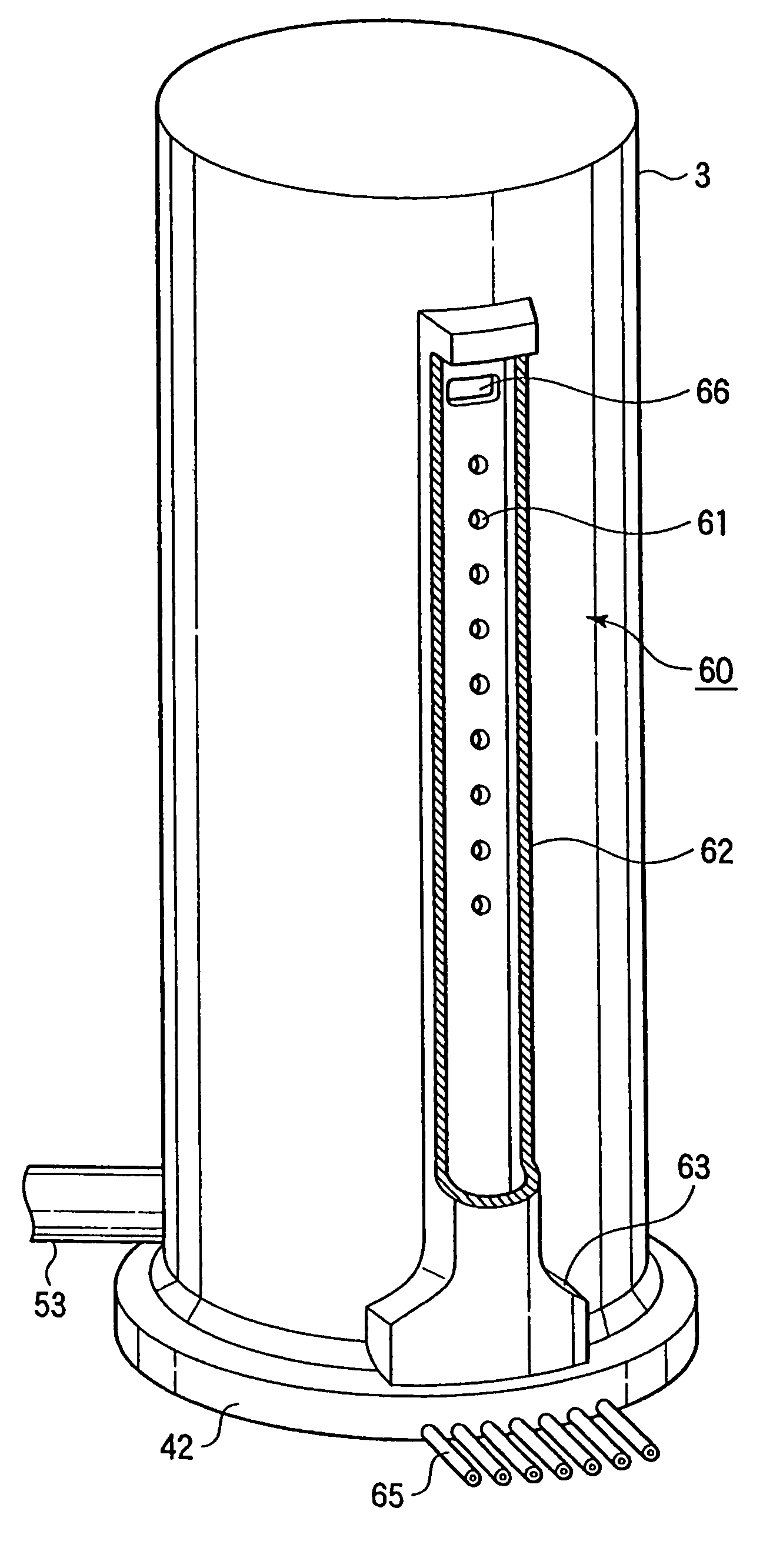

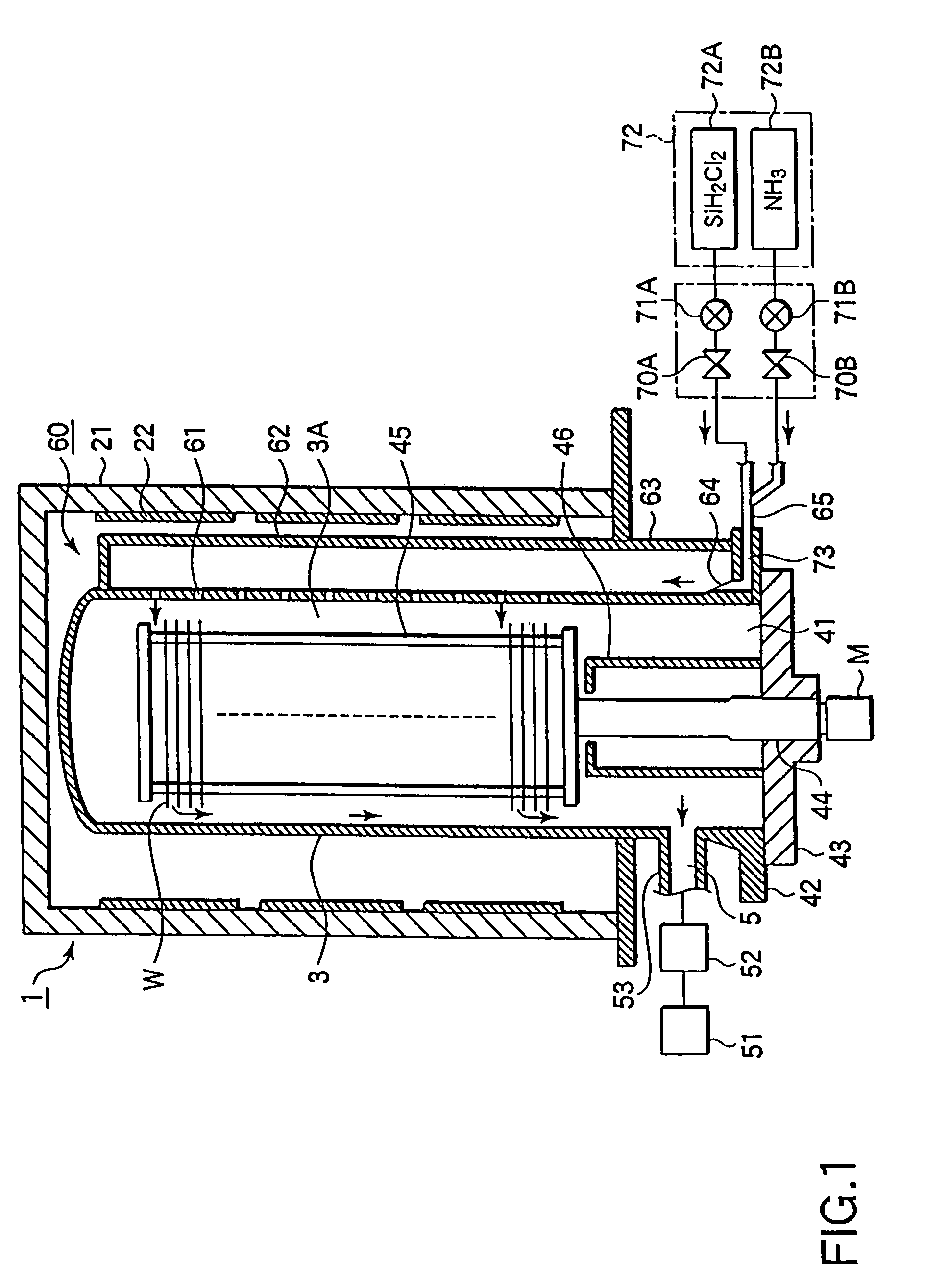

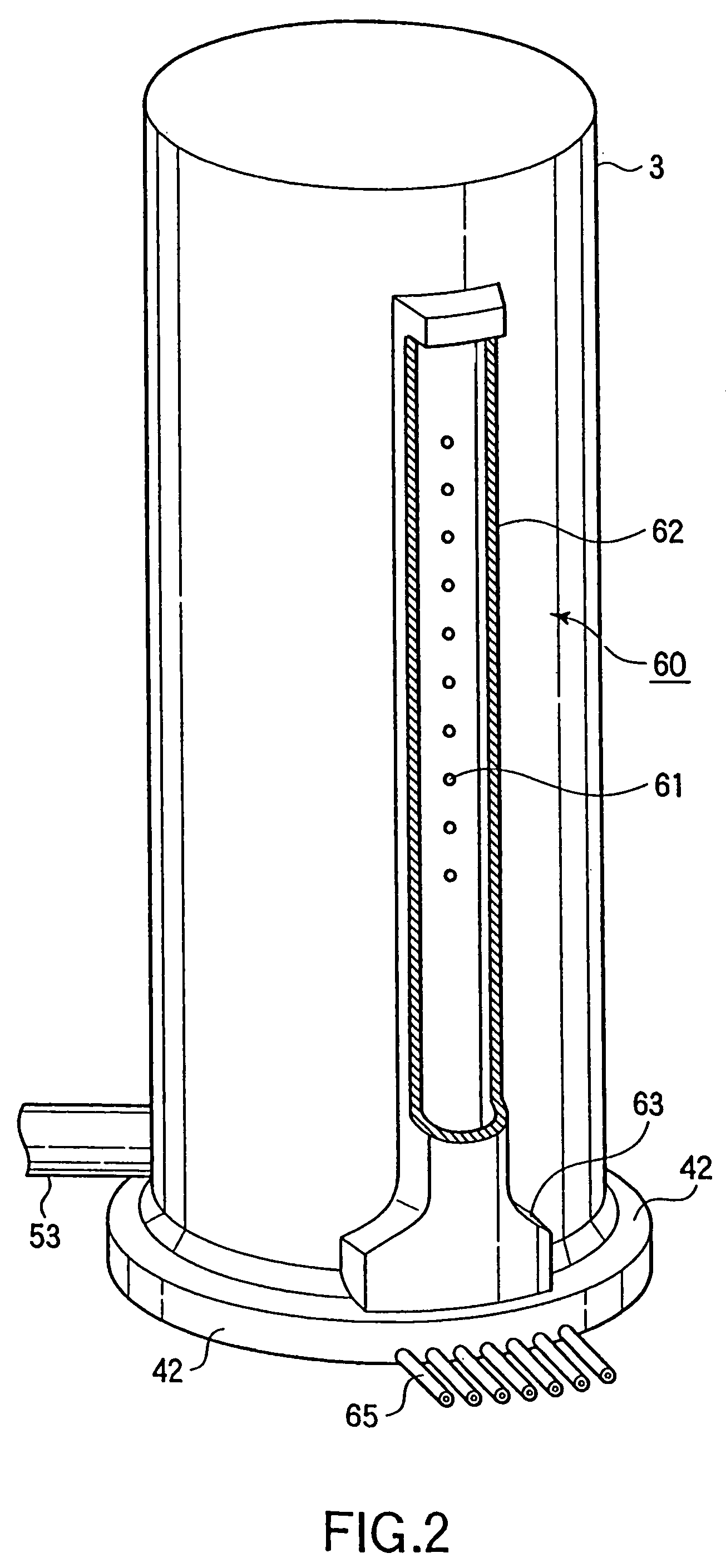

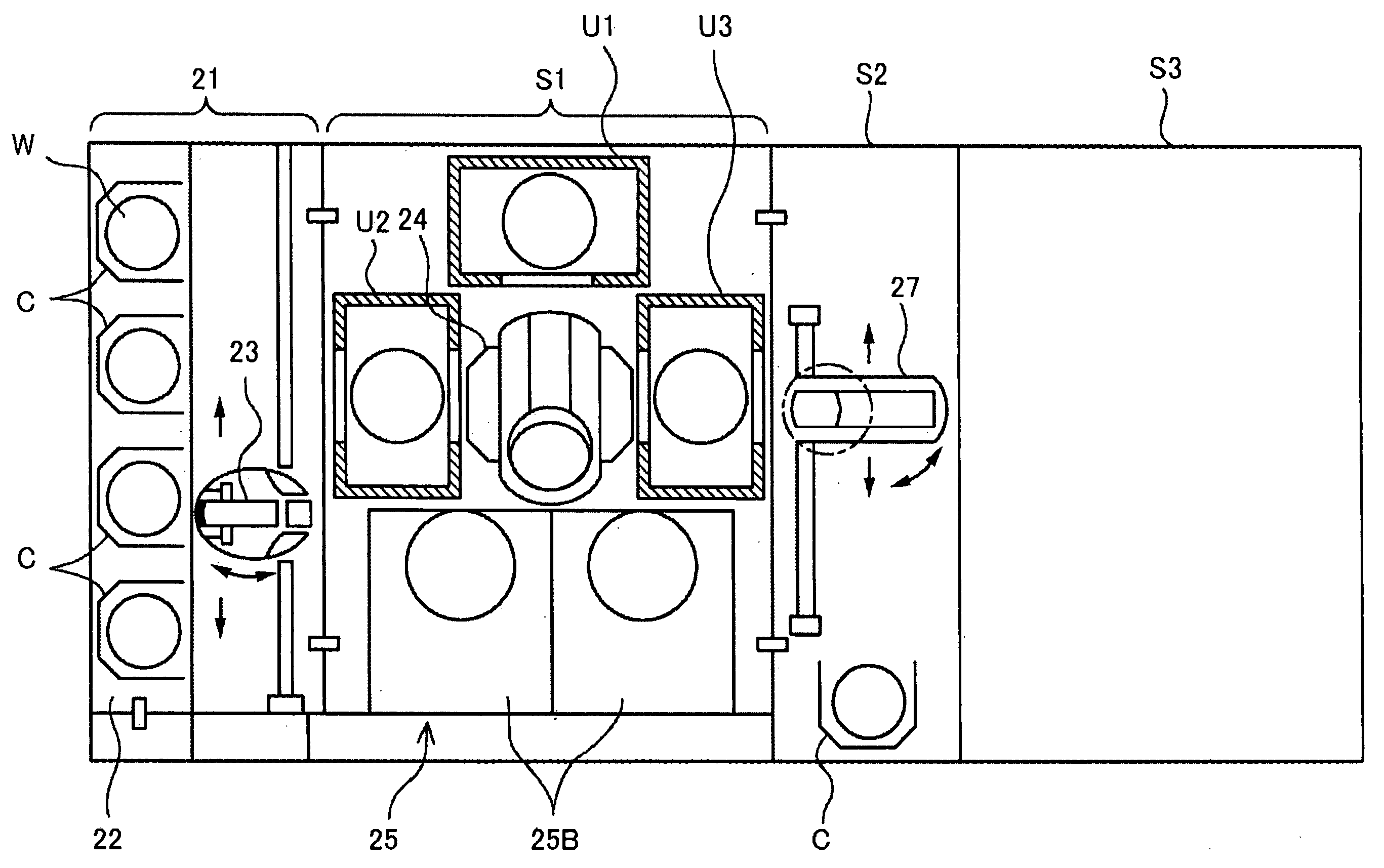

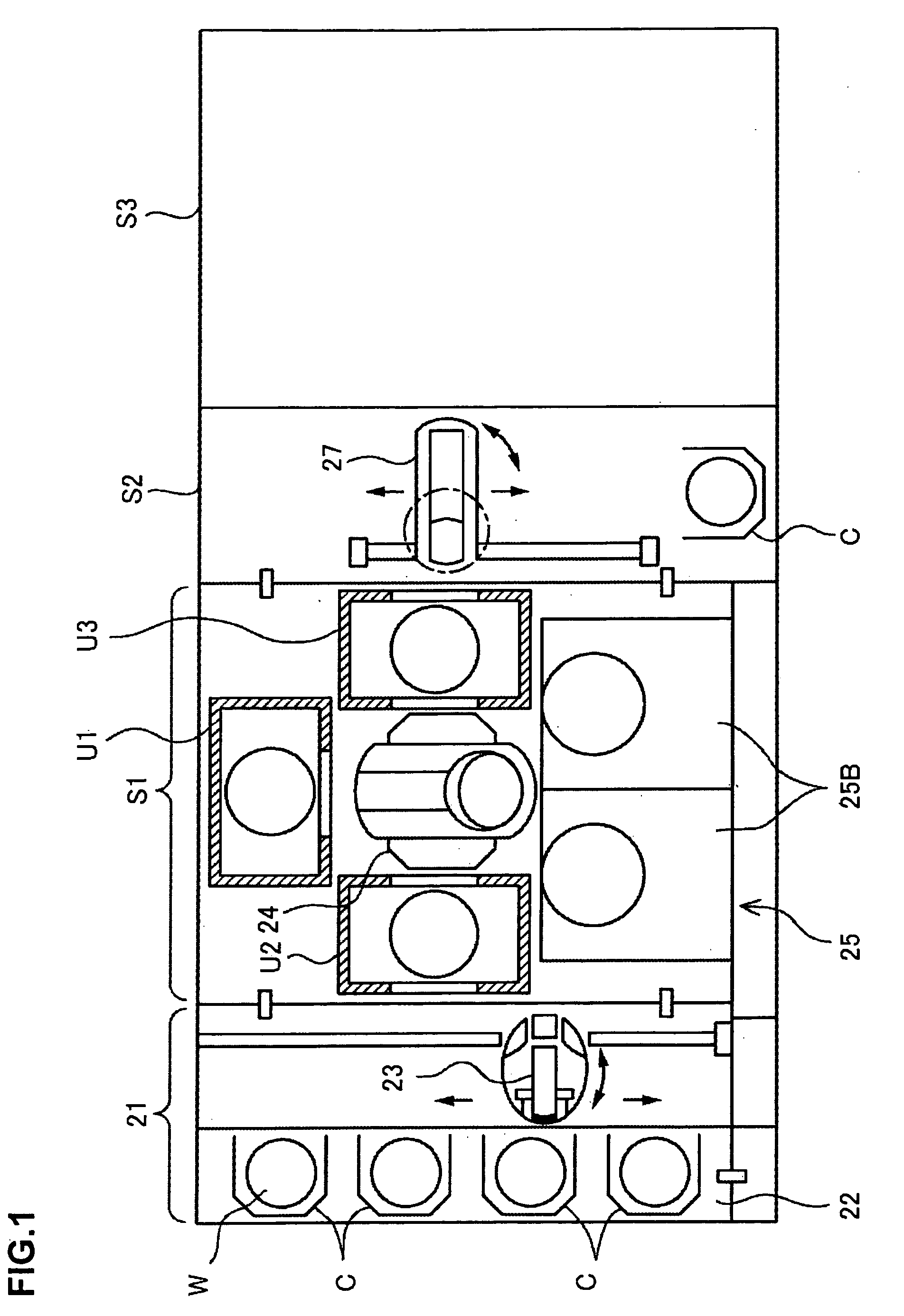

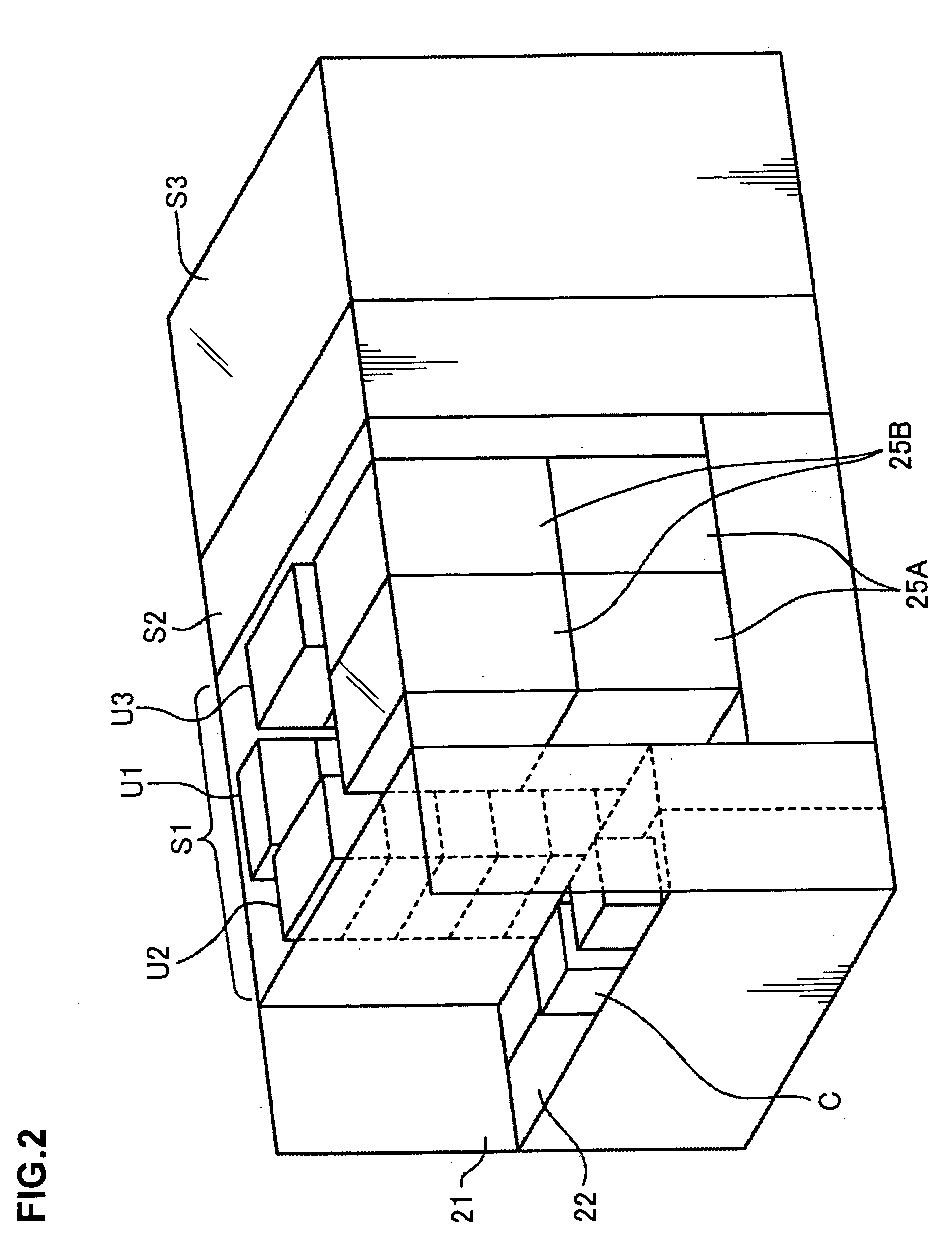

Heat processing apparatus for semiconductor process

ActiveUS20080083372A1Improve film thickness uniformityReduce gapChemical vapor deposition coatingProcess engineeringGas supply

A heat processing apparatus for a semiconductor process includes a reaction tube including a process field configured to store a plurality of target substrates stacked at intervals. A gas supply duct is integrally provided outside the wall of the reaction tube to extend vertically in a range that covers the process field. A plurality of gas delivery holes are formed in the side portion of the wall of the reaction tube, to be vertically arrayed in a range that covers the process field and communicate with the gas supply duct. A gas supply system is connected to a bottom portion of the gas supply duct to supply a process gas to the process field through the gas supply duct and the plurality of gas delivery holes.

Owner:TOKYO ELECTRON LTD

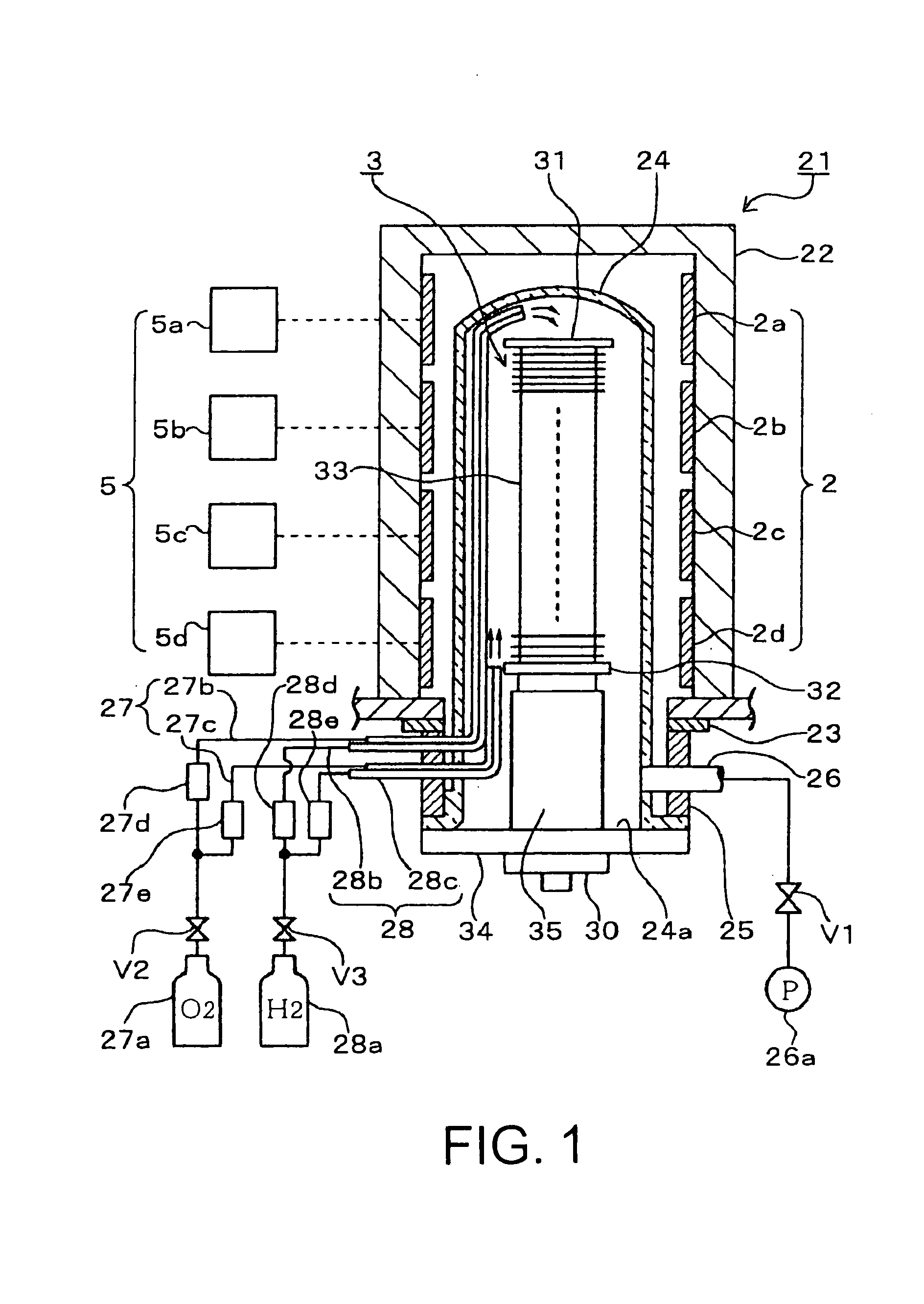

Heat treatment method and heat treament apparatus

ActiveUS20050201894A1Improve film thickness uniformityReduce the burden onAnalysis using chemical indicatorsSamplingValue setProcess engineering

The present invention relates to a thermal processing method including thermal processing steps having: a step of holding a plurality of substrates by means of a substrate holder, a step of conveying the substrate holder into a reaction container, a step of heating a plurality of zones of thermal process atmosphere in the reaction container by means of a plurality of heating units, respectively, and a step of forming thin films on surfaces of the plurality of substrates by introducing a process gas into the reaction container. The thermal processing method includes: a first thermal processing step of carrying out the thermal processing steps by using a plurality of first substrates as the plurality of substrates, wherein thin films are formed on surfaces of the plurality of first substrates by means of less consumption of the process gas than on surfaces of production substrates; a first measuring step of measuring a thickness of the thin films formed on the surfaces of the plurality of first substrates for each of the plurality of zones of the thermal process atmosphere in the reaction container; and a first setting step of setting respective temperature set values of the plurality of heating units in such a manner that the thickness measured for each of the plurality of zones substantially coincides with a target thickness of thin films to be formed on the surfaces of production substrates, based on measurement result of the first measuring step. Then, a second thermal processing step of carrying out the thermal processing steps by using a plurality of second substrates as the plurality of substrates, wherein thin films are formed on surfaces of the plurality of second substrates by means of more consumption of the process gas than on the surfaces of the plurality of first substrates, and wherein the plurality of heating units are respectively adjusted to the respective temperature set values set by the first setting step; a second measuring step of measuring a thickness of the thin films formed on the surfaces of the plurality of second substrates for each of the plurality of zones of the thermal process atmosphere in the reaction container; and a second correcting step of correcting the respective temperature set values of the plurality of heating units in such a manner that the thickness measured for each of the plurality of zones substantially coincides with the target thickness of thin films to be formed on the surfaces of production substrates, based on measurement result of the second measuring step; are carried out. Then, a third thermal processing step of carrying out the thermal processing steps by using at least a plurality of production substrates as the plurality of substrates, wherein the plurality of heating units are respectively adjusted to the respective temperature set values corrected by the second correcting step, is carried out.

Owner:TOKYO ELECTRON LTD

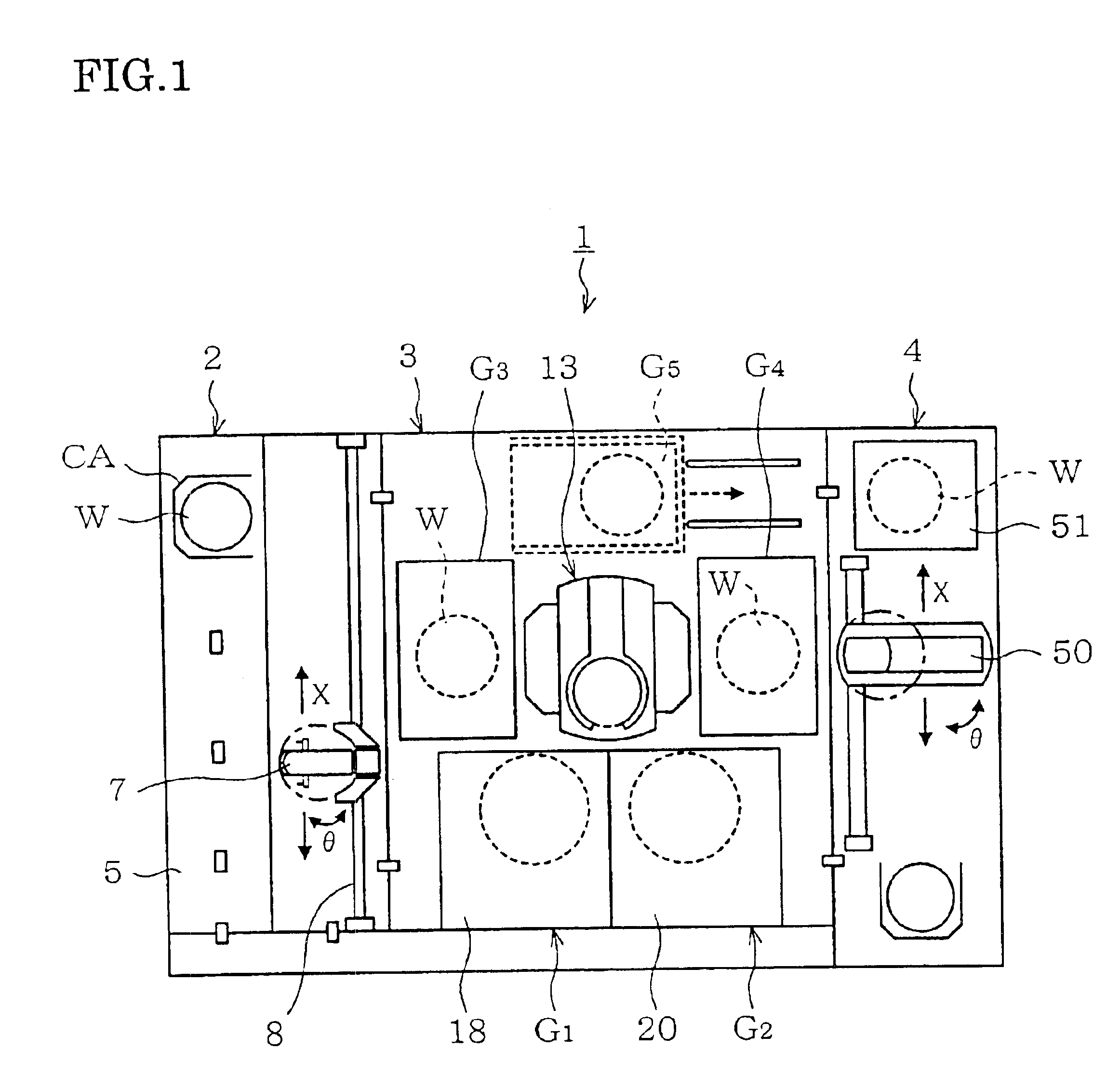

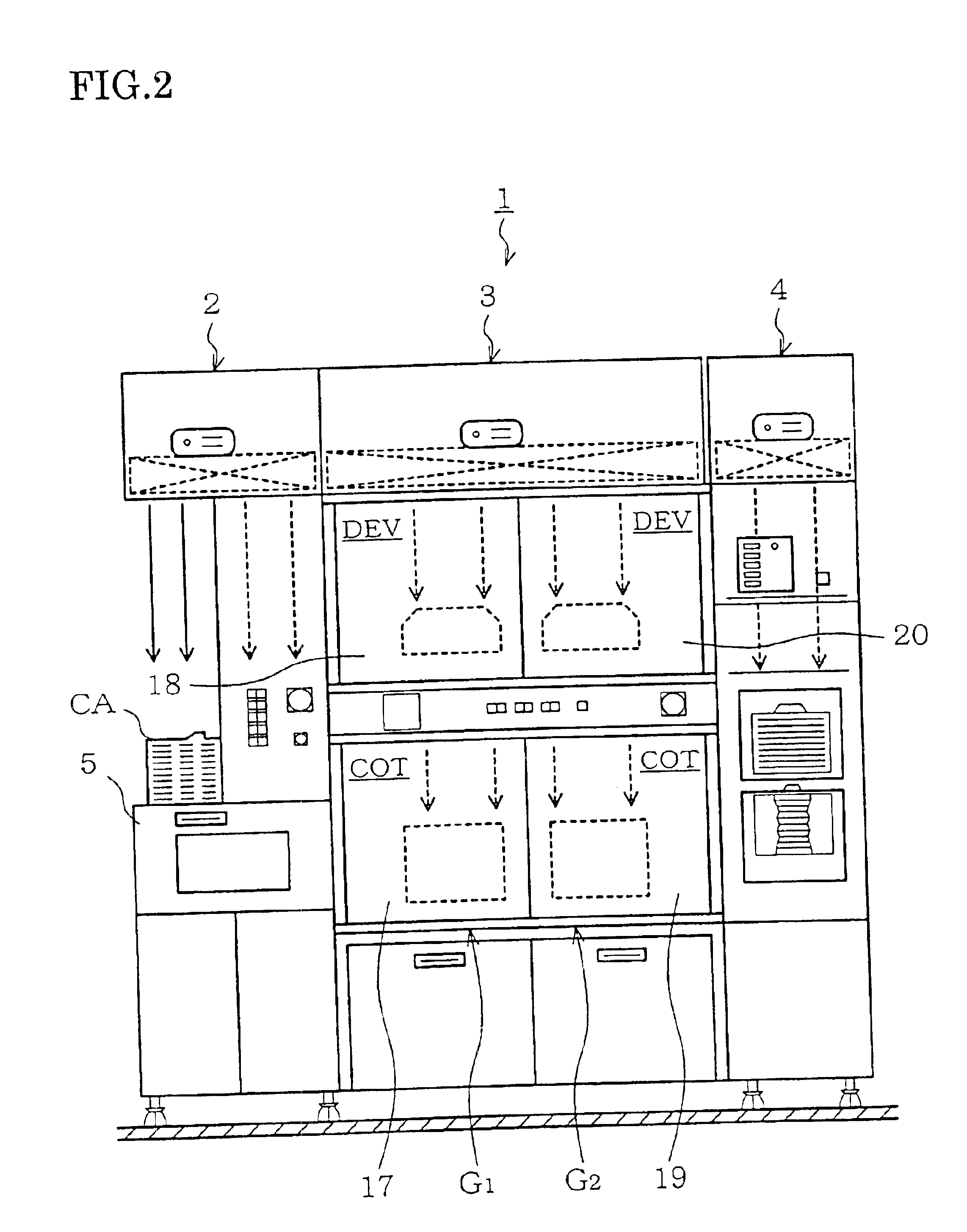

Film forming unit

InactiveUS6872256B2Quickly cleanImprove film thickness uniformityLiquid surface applicatorsMovable spraying apparatusSpray nozzleDischarge pressure

The present invention is a film forming unit for discharging a coating solution from a coating solution discharge nozzle toward a substrate to form a layer on a surface of the substrate, which has a supply flow path for supplying a cleaning fluid to a discharge flow path continuing to a discharging port of the coating solution discharge nozzle. When the cleaning fluid is positively supplied directly to the discharge flow path of the coating solution discharge nozzle, the supply pressure of the cleaning fluid as well as the capability of cleaning is added. Therefore, further effective cleaning is attained in compare with the conventional case where a coating solution discharge nozzle is simply dipped into a cleaning fluid. In consequence, even when the discharging port of the nozzle is minute, it is possible to perfectly remove the contamination. This allows the discharge pressure to remain constant so as to form a uniform coating layer on the substrate.

Owner:TOKYO ELECTRON LTD

Method of manufacturing semiconductor device, substrate processing apparatus, and non-transitory computer-readable recording medium

ActiveUS20140170858A1Improve film thickness uniformityMaintain good propertiesLiquid surface applicatorsSemiconductor/solid-state device manufacturingReactive gasNitrogen

Provided is a method including forming a film including a predetermined element, oxygen and at least one element selected from a group consisting of nitrogen, carbon and boron on a substrate by performing a cycle a predetermined number of times, the cycle including supplying a source gas to the substrate wherein the source gas contains the predetermined element, chlorine and oxygen with a chemical bond of the predetermined element and oxygen, and supplying a reactive gas to the substrate wherein the reactive gas contains the at least one element selected from the group consisting of nitrogen, carbon and boron.

Owner:KOKUSA ELECTRIC CO LTD

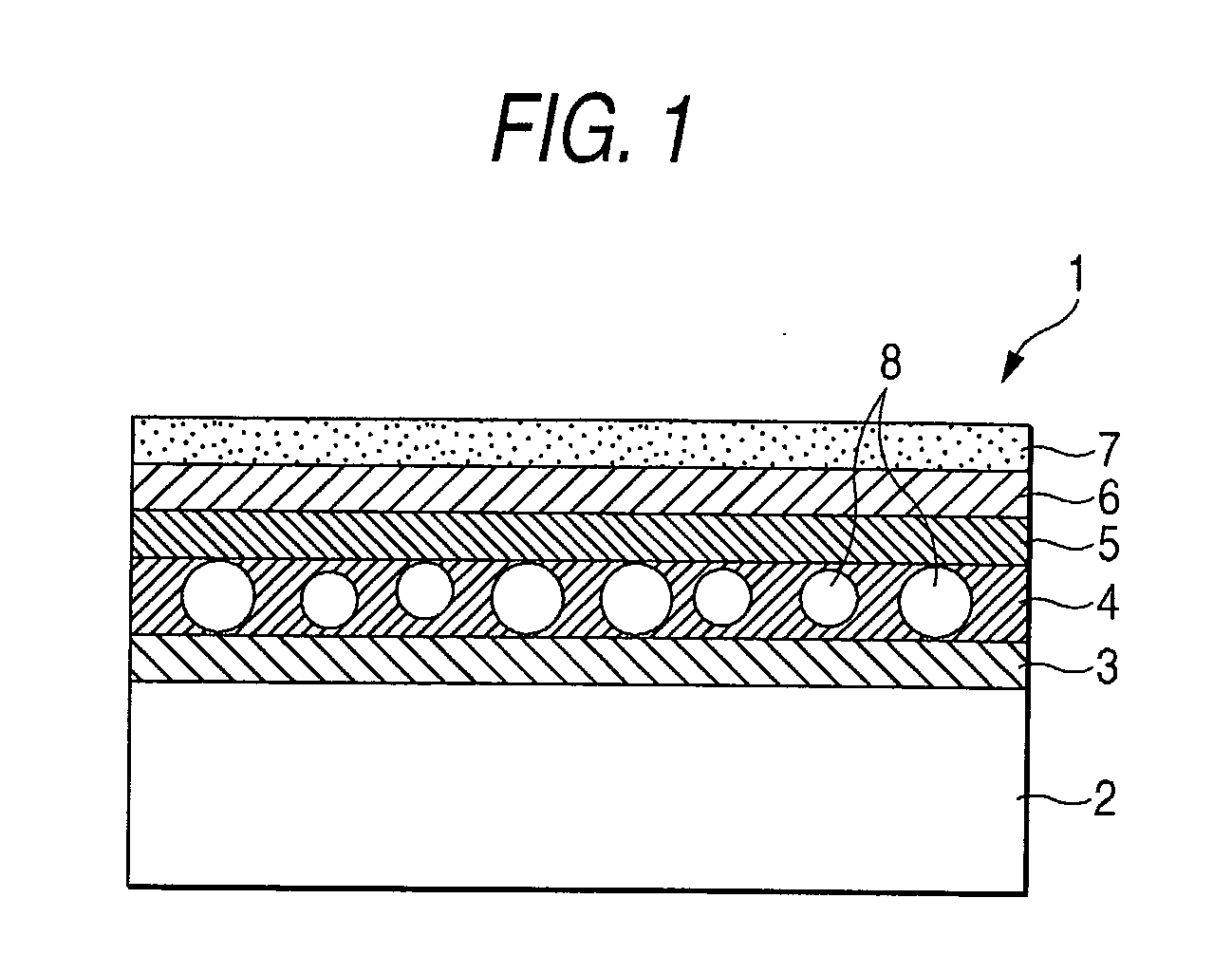

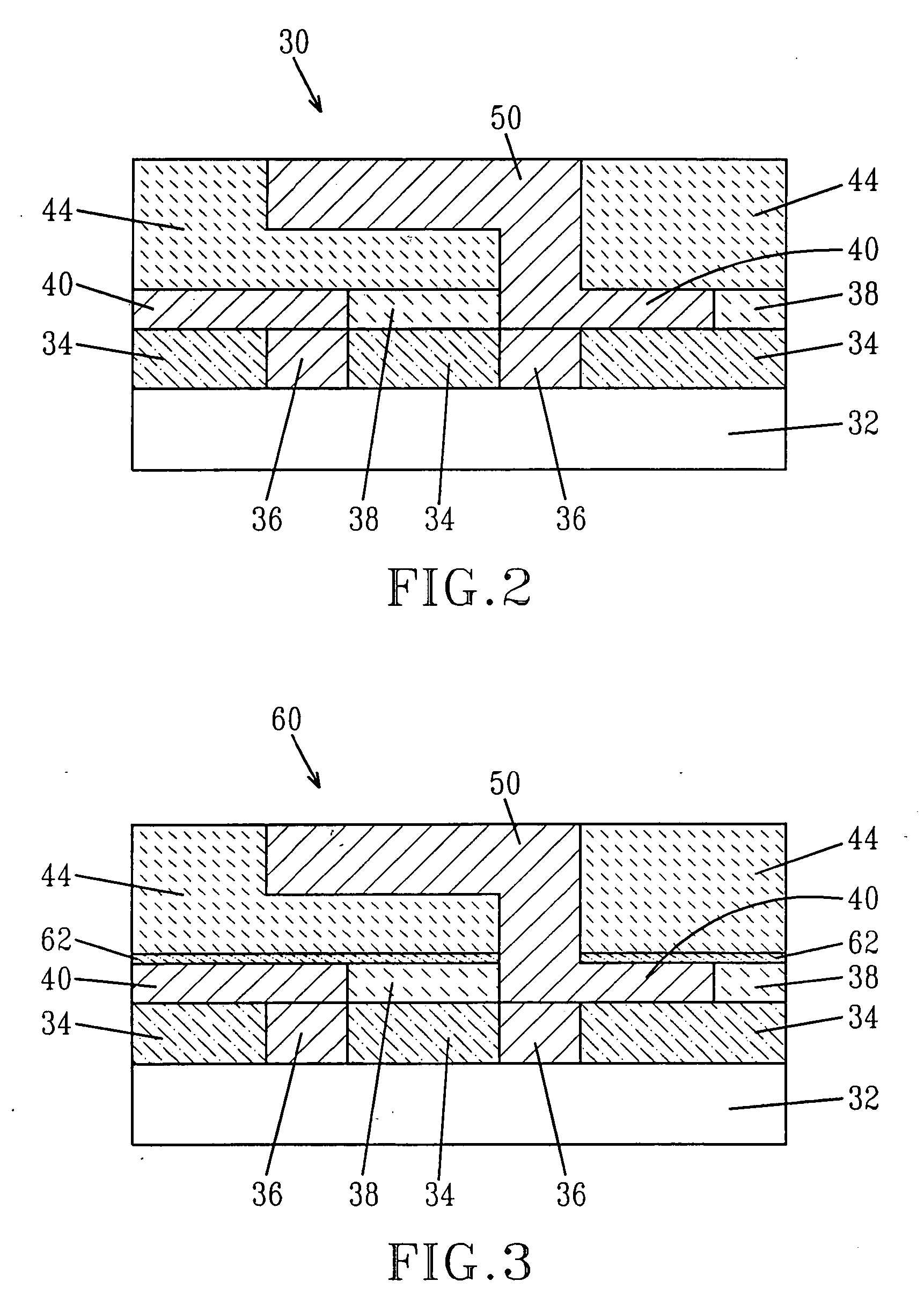

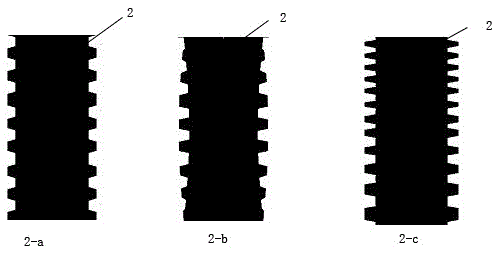

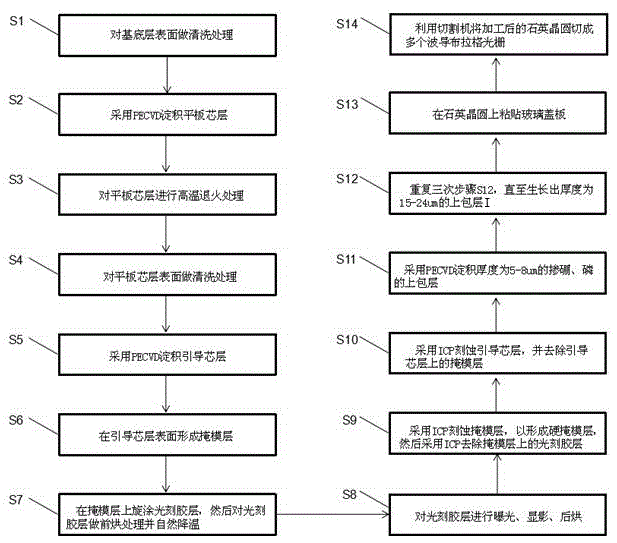

Waveguide Bragg grating based on SiO2 strip-loaded waveguide and manufacturing method thereof

ActiveCN105607186AHigh transparencyGood optical consistencyOptical waveguide light guideGratingRidge waveguides

The invention discloses a waveguide Bragg grating based on a SiO2 strip-loaded waveguide and a manufacturing method thereof. The waveguide Bragg grating comprises a substrate layer, a flat core layer, a guide core layer and an upper coating, wherein the flat core layer covers the front side of the substrate layer, the guide core layer is positioned on the front side of the flat core layer, and the upper coating covers the front side of the flat core layer and wraps the guide core layer. The waveguide Bragg grating has the advantages of simplicity in process, low cost, good consistency, large-scale production and the like; and compared with a manufacturing process of an outer ridge modulation type waveguide Bragg grating based on a ridge waveguide, the manufacturing method has the advantages that the process is simple, the cost is low, the size is small and the like.

Owner:HENAN SHIJIA PHOTONS TECH

Heat processing apparatus for semiconductor process

ActiveUS8002895B2Improve film thickness uniformityReduce gapSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductor packageProcess engineering

A heat processing apparatus for a semiconductor process includes a reaction tube including a process field configured to store a plurality of target substrates stacked at intervals. A gas supply duct is integrally provided outside the wall of the reaction tube to extend vertically in a range that covers the process field. A plurality of gas delivery holes are formed in the side portion of the wall of the reaction tube, to be vertically arrayed in a range that covers the process field and communicate with the gas supply duct. A gas supply system is connected to a bottom portion of the gas supply duct to supply a process gas to the process field through the gas supply duct and the plurality of gas delivery holes.

Owner:TOKYO ELECTRON LTD

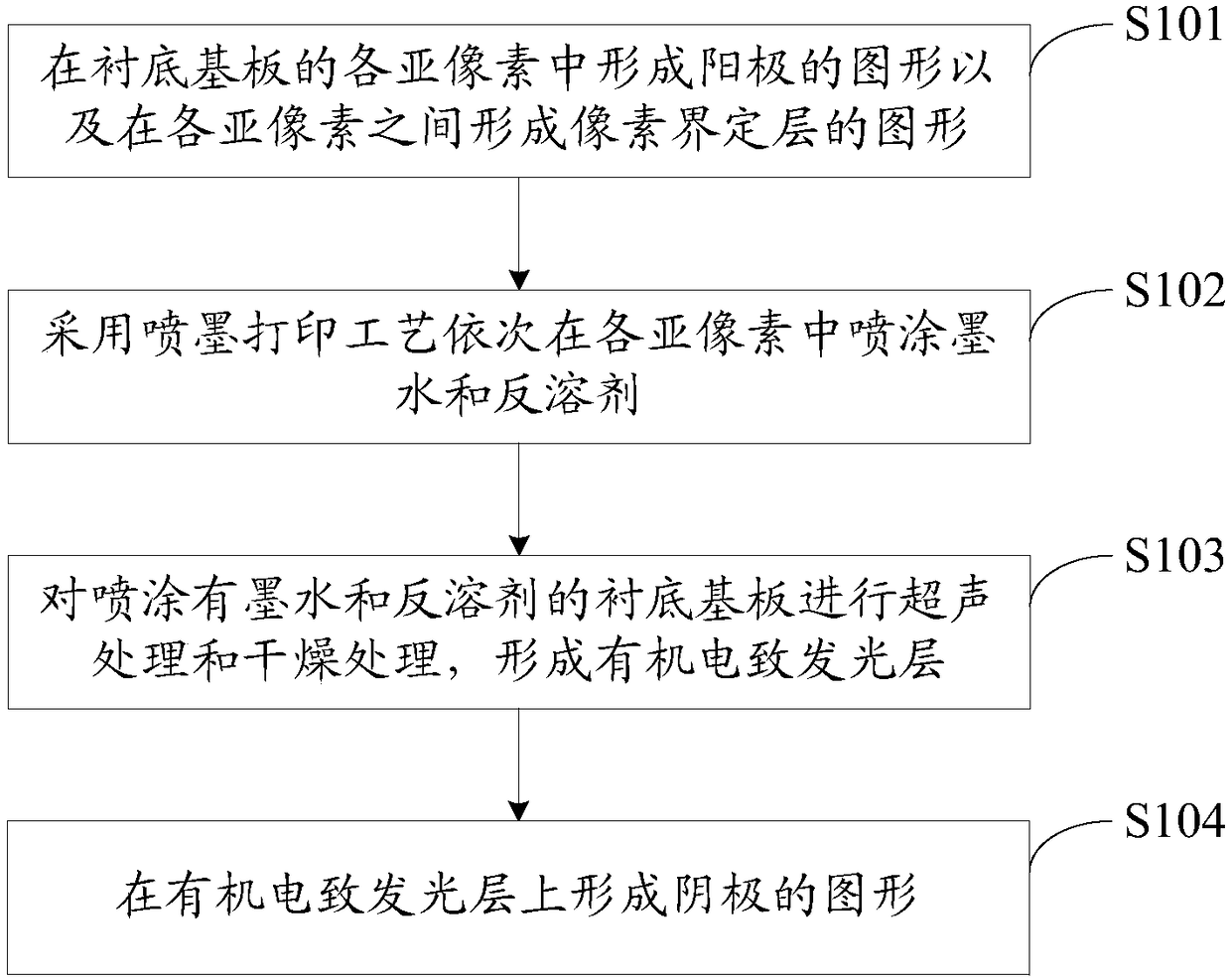

Electroluminescent display panel, preparation method thereof and display device

ActiveCN108389979AImprove the display effectIncrease film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingAnti solventCoffee ring effect

The invention discloses an electroluminescent display panel, a preparation method thereof and a display device. The preparation method comprises the steps of forming an anode in each sub-pixel of a substrate and a pixel defining layer between the sub-pixels; spraying ink and an anti-solvent on the anode of each sub-pixel by adopting an ink-jet printing process; performing ultrasonic treatment anddrying treatment on the substrate sprayed with the ink and anti-solvent to form an organic electroluminescent layer; and forming a cathode on the organic electroluminescent layer so as to form an electroluminescent display panel. The anode of each sub-pixel is sprayed with the ink and anti-solvent by adopting the ink-jet printing process, and a solute is separated out according to principles thatthe anti-solvent is mutually dissolved with a solvent and that the solute is not dissolved or slightly dissolved in the anti-solvent. The solute is enabled to be uniformly dispersed through the ultrasonic treatment, and then the solvent and the anti-solvent are removed through the drying treatment, so that the uniformity of the film thickness of the prepared organic electroluminescent layer is enabled to be improved, and a coffee-ring effect of the organic electroluminescent layer is avoided.

Owner:BOE TECH GRP CO LTD +1

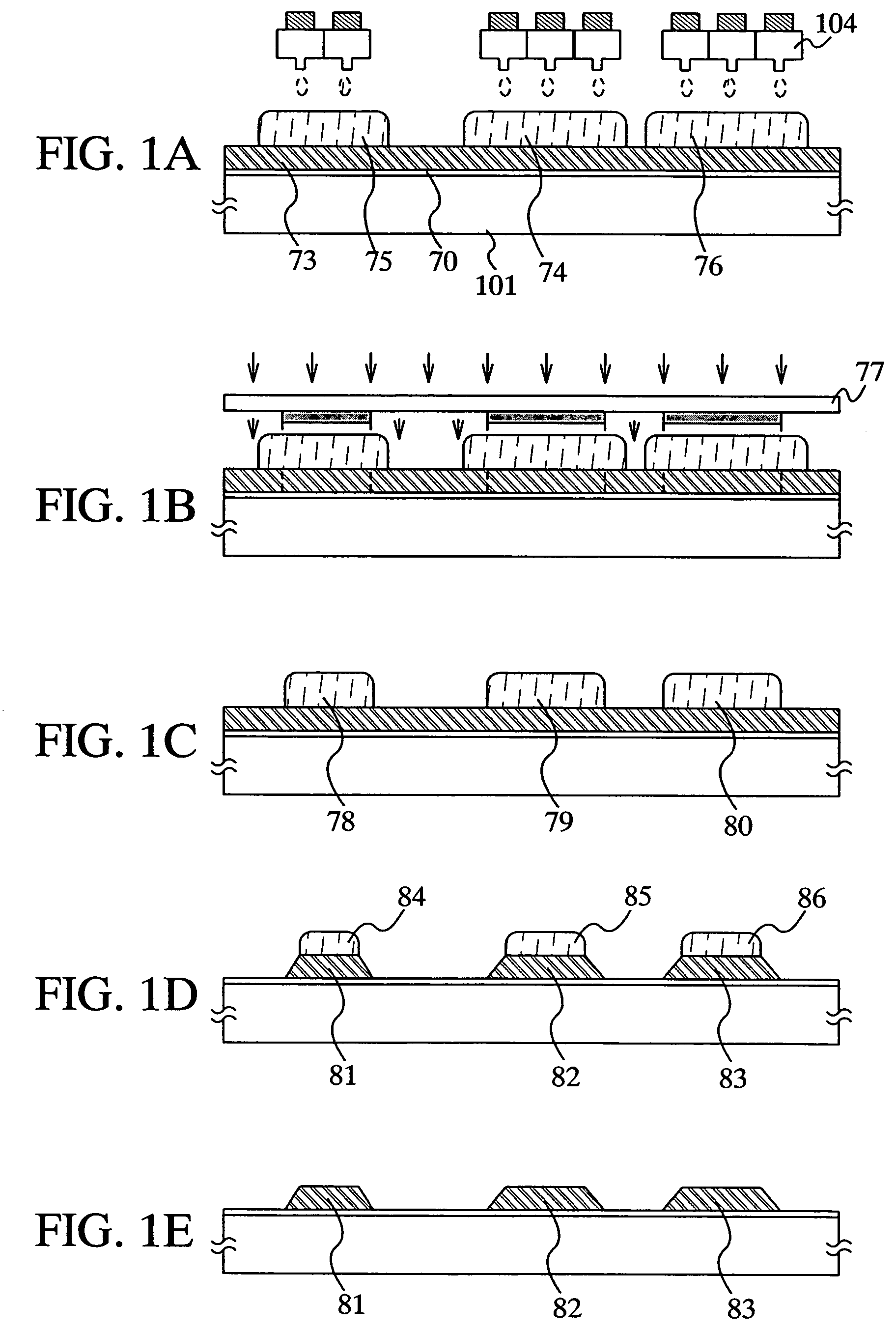

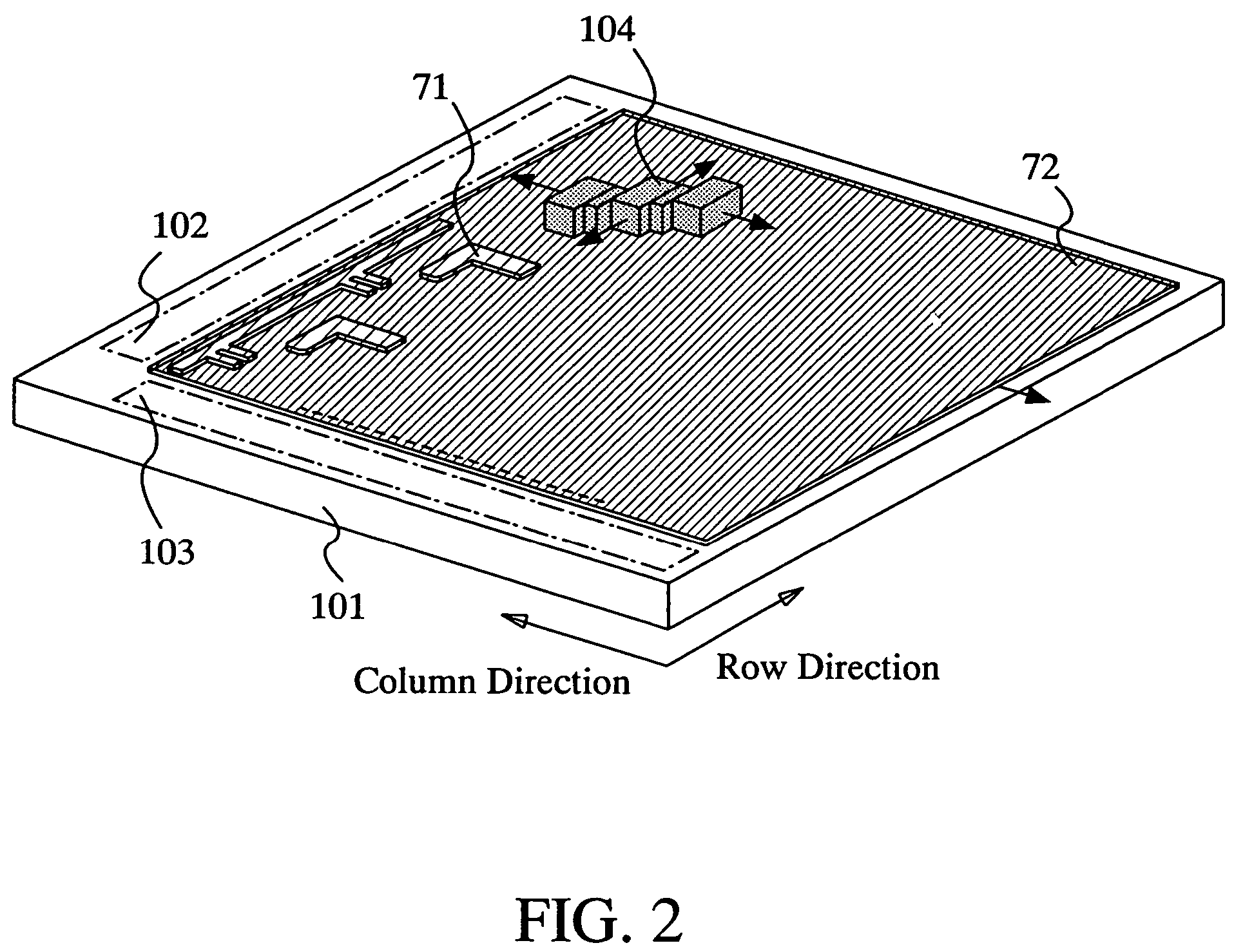

Method of manufacturing semiconductor device

InactiveUS7183146B2Improve efficiencyImprove throughputLight-sensitive devicesSolid-state devicesDisplay deviceConductive materials

To provide a method for manufacturing a wiring, a conductive layer, a display device, and a semiconductor device, each of which can meet a large sized substrate and which is manufactured with a higher throughput by using a material efficiently, the conductive layer is formed over the substrate having an insulating surface by discharging the conductive material, and heat treatment is performed by a lamp or a laser beam over the conductive layer. Furthermore, the conductive film is formed under reduced pressure according to the present invention.

Owner:SEMICON ENERGY LAB CO LTD

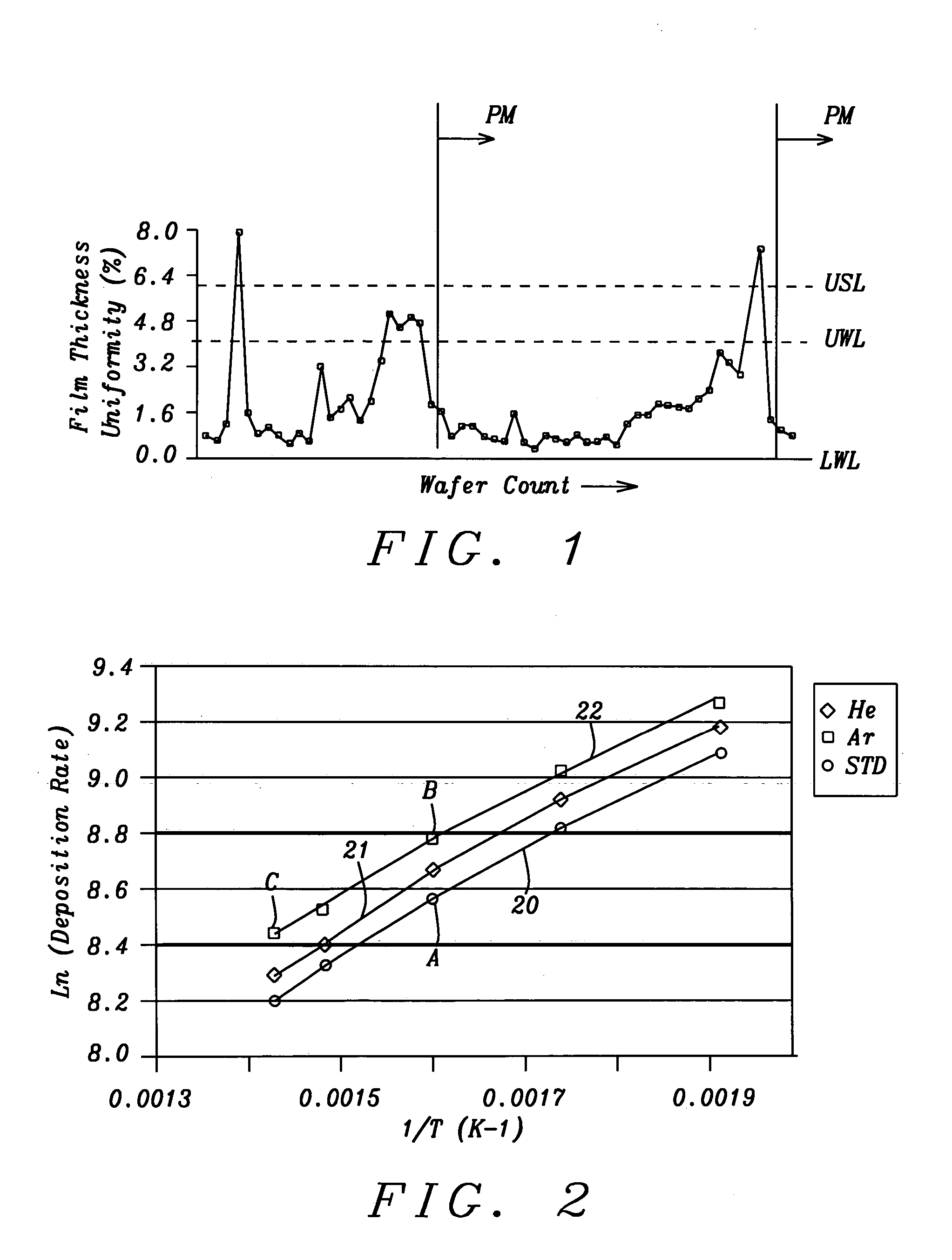

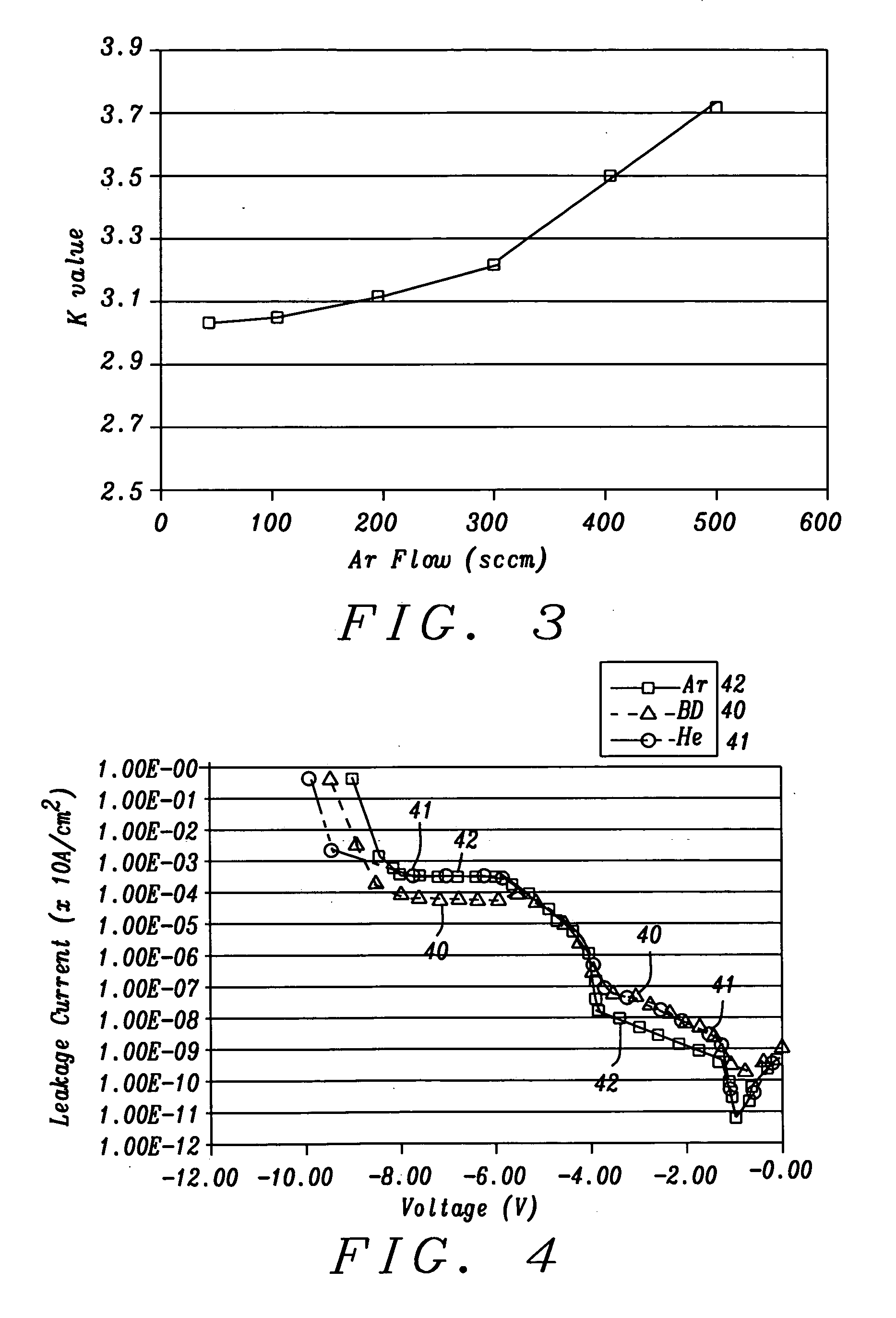

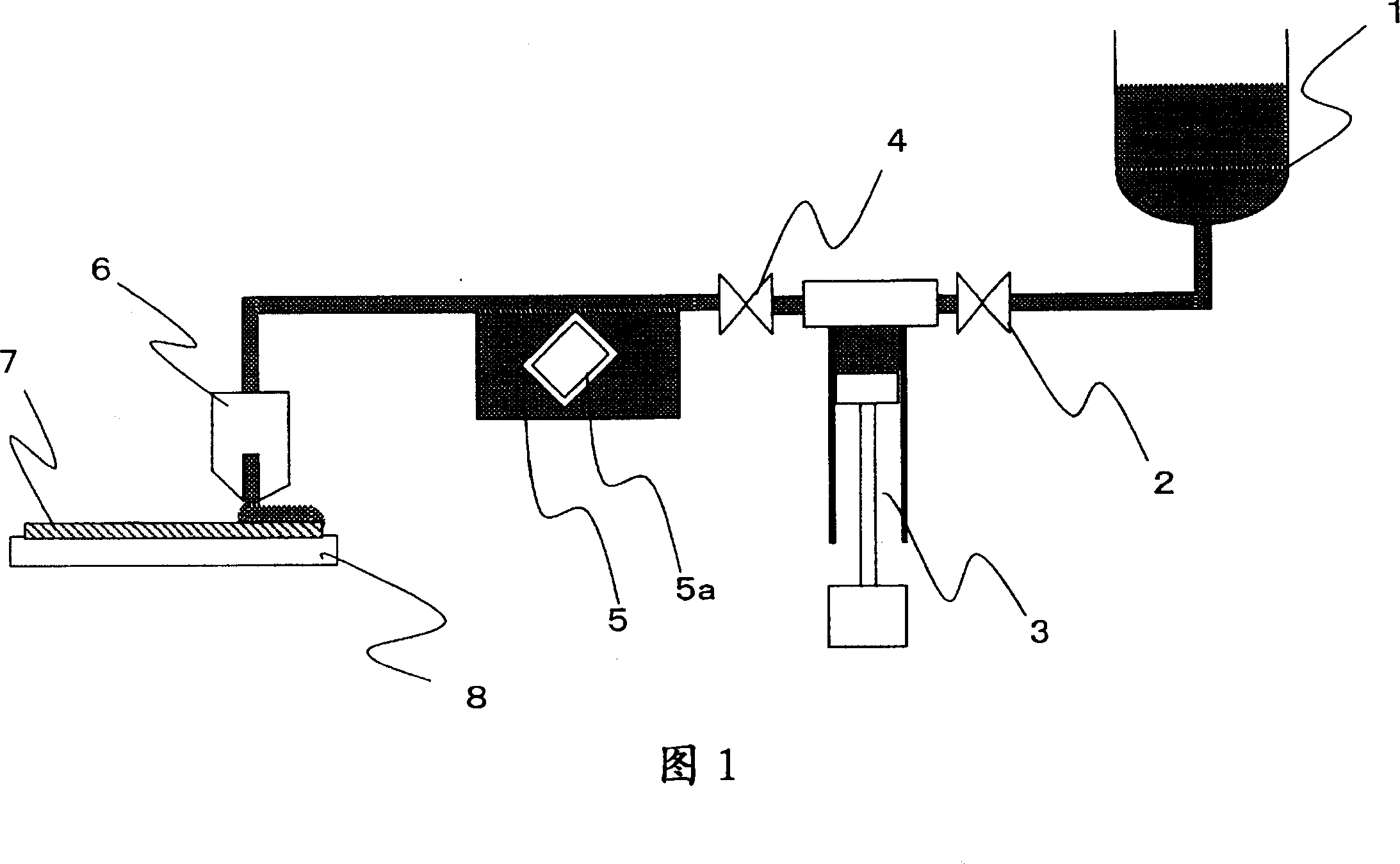

Novel method to deposit carbon doped SiO2 films with improved film quality

InactiveUS20050124151A1Increase deposition rateImprove film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal interconnectLow leakage

A method is disclosed for depositing a Black Diamond layer in a CVD chamber. Trimethylsilane, O2, and Ar are flowed into the chamber at 300° C. to 400° C. with an O2:Ar:trimethylsilane flow rate ratio that is preferably 1:1.5:6. The resulting low k dielectric layer is formed with a higher deposition rate than when Ar is omitted and has a k value of about 3 that increases only slightly in O2 plasma. A higher density, hardness, and tensile strength are achieved in the Black Diamond layer when Ar is included in the deposition process. The addition of Ar in the deposition maintains film thickness uniformity below 2% for a longer period so that PM cleaning operations are less frequent and affords a lower fluorocarbon plasma etch rate to enable improved trench depth control in a damascene scheme. A lower leakage current and higher breakdown voltage in achieved in the resulting metal interconnect.

Owner:TAIWAN SEMICON MFG CO LTD

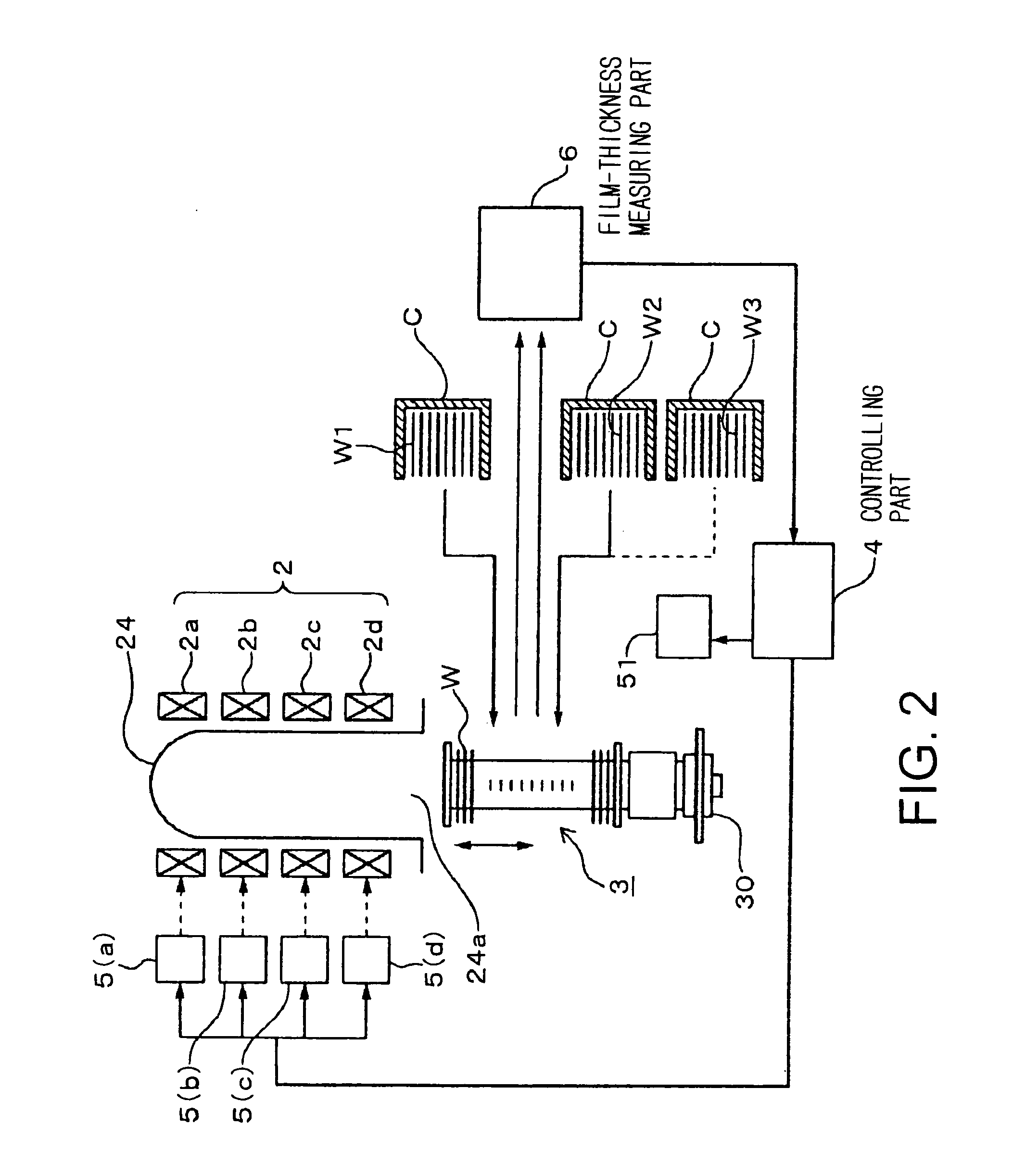

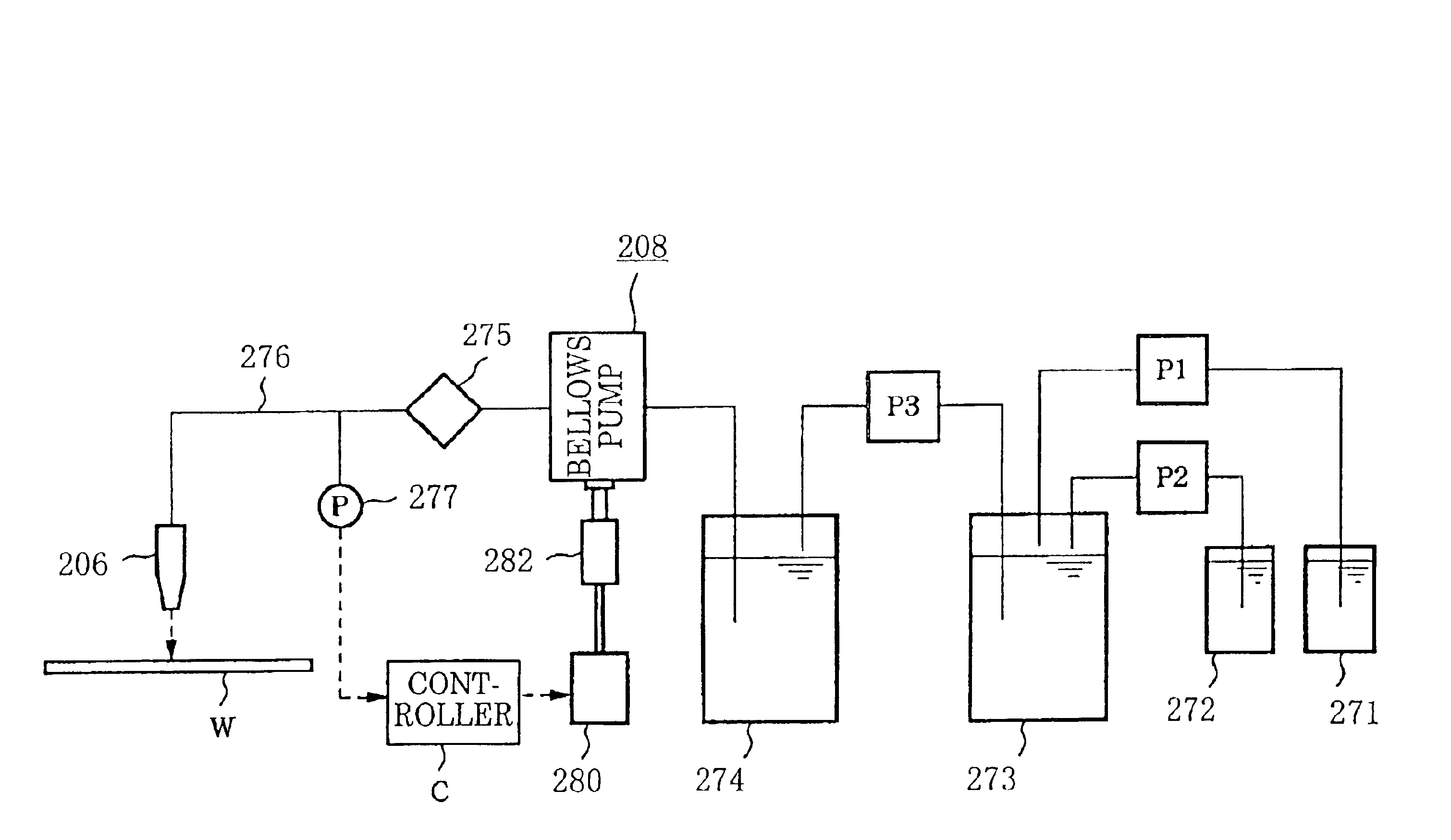

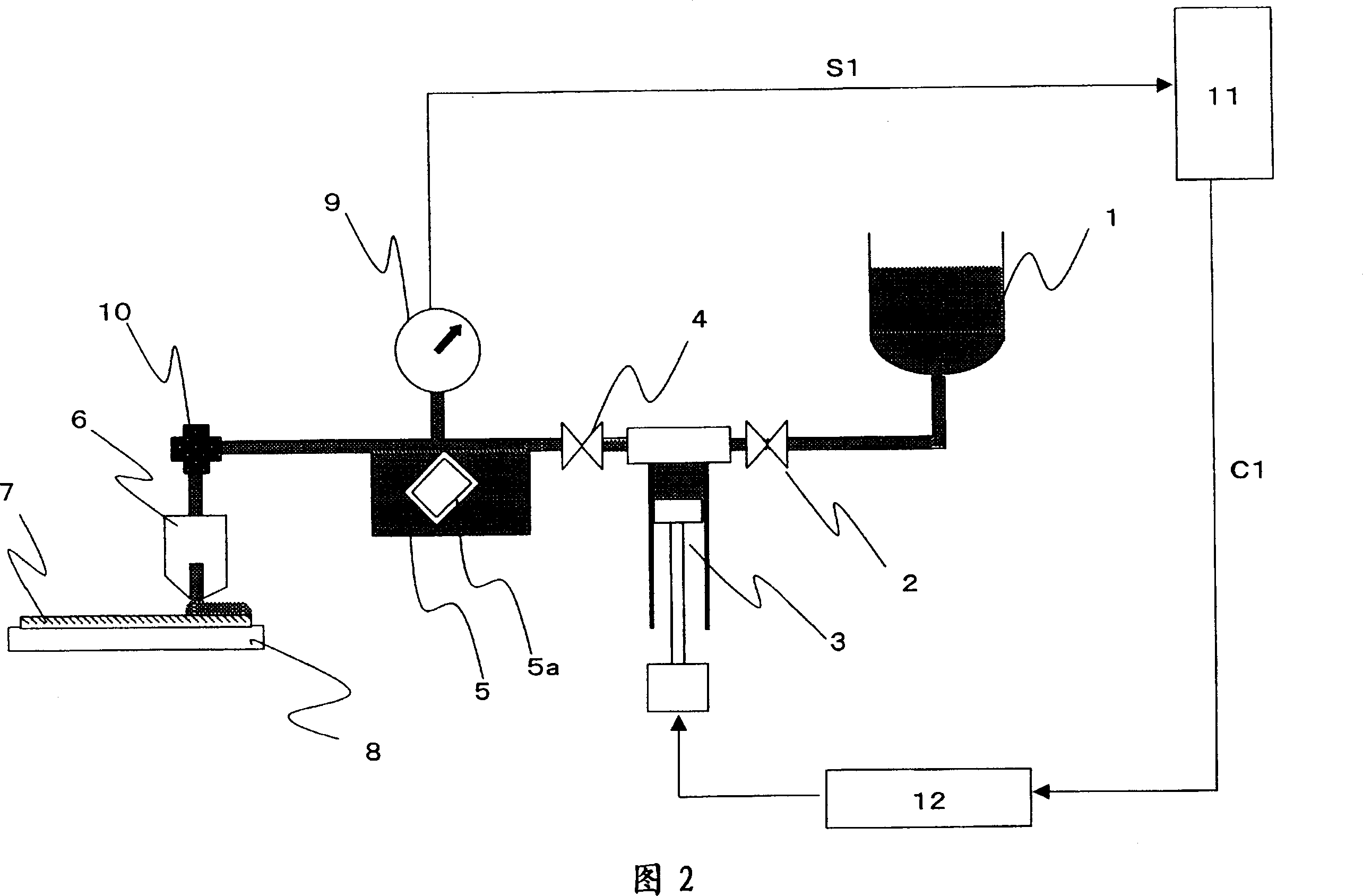

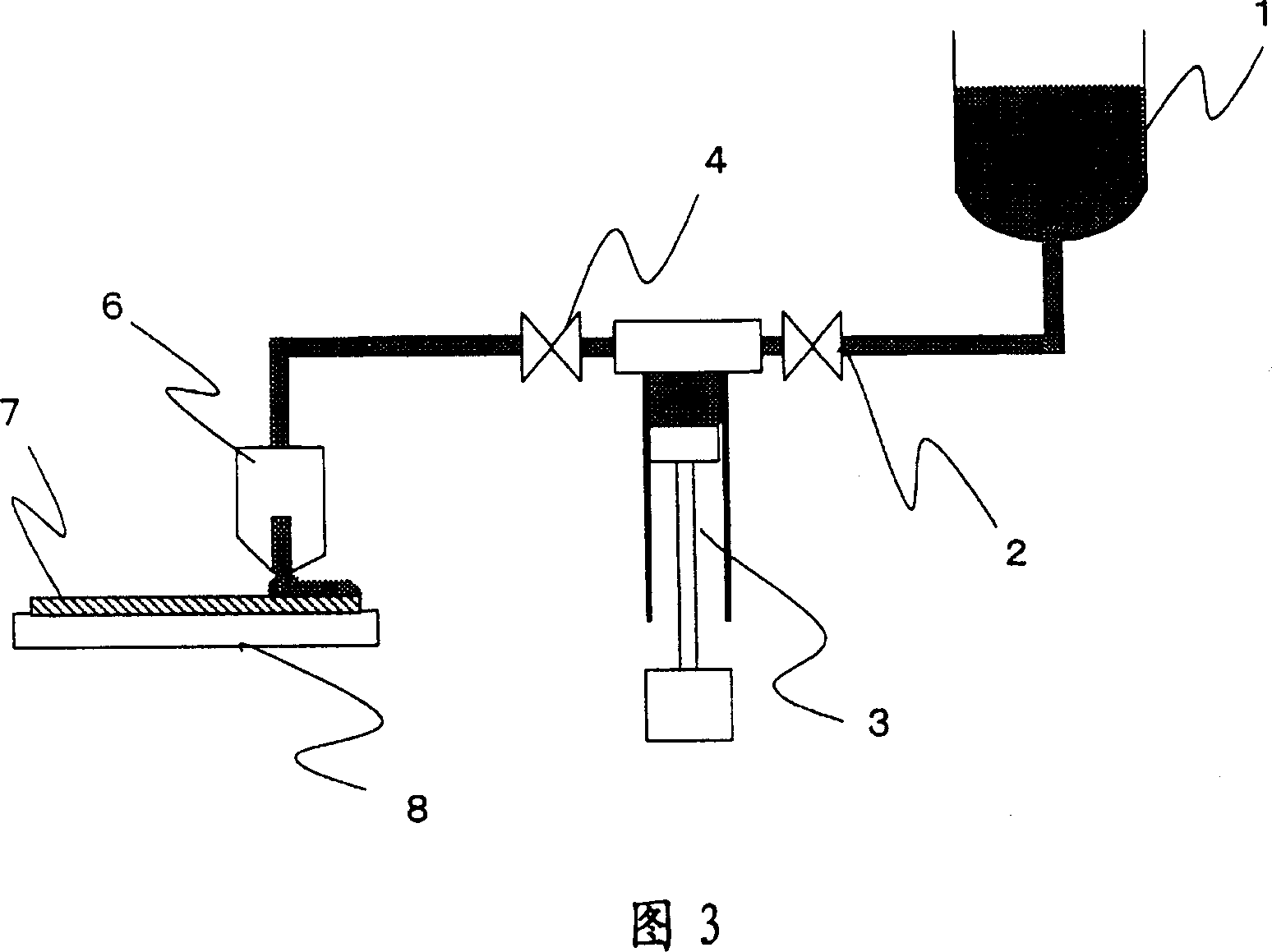

Painting device, painting method, and display member provided therefrom

InactiveCN1933920AImprove film thickness uniformityReduce the impact of spit fluctuationsPretreated surfacesCoatingsHydraulic pumpFilm-coated tablet

A painting device, a painting method, and a display member provided by the device and the method. In the painting device and the painting method capable of suppressing discharge pulsation, providing thin-film coating having excellent film thick uniformity, and having excellent discharge responsiveness, a member (portion 5) damping the discharge pulsation is installed between a paint liquid supply means (for example, syringe pump 3) and a painting means (for example, die ferrule 6). The discharge pulsation generated by the syringe pump is damped by the volumetric change of the member (5a) damping the pulsation which is disposed in the pulsation damping portion (5), and a constant volume of discharge with suppressed pulsation can be provided from the die ferrule.

Owner:TORAY IND INC

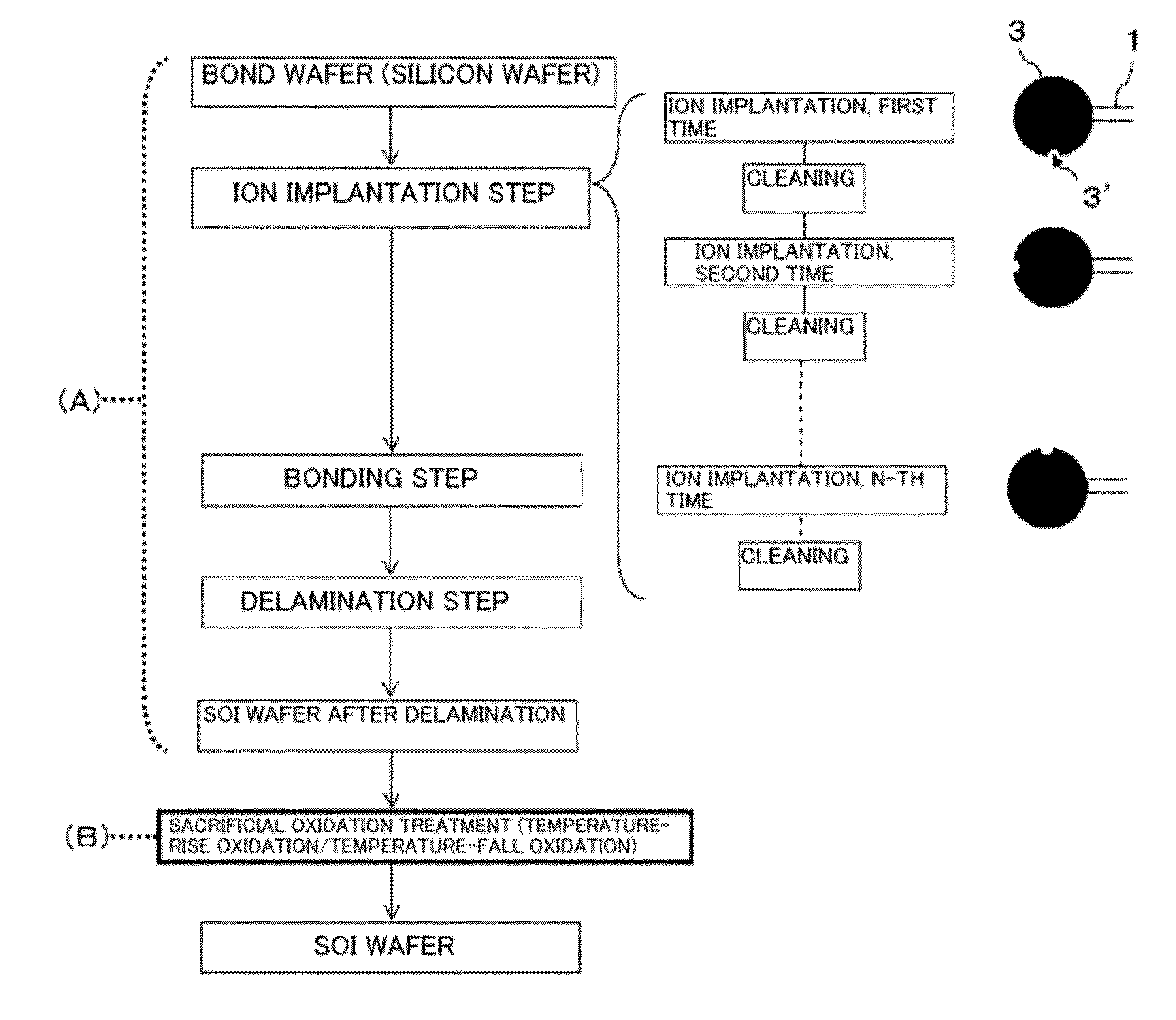

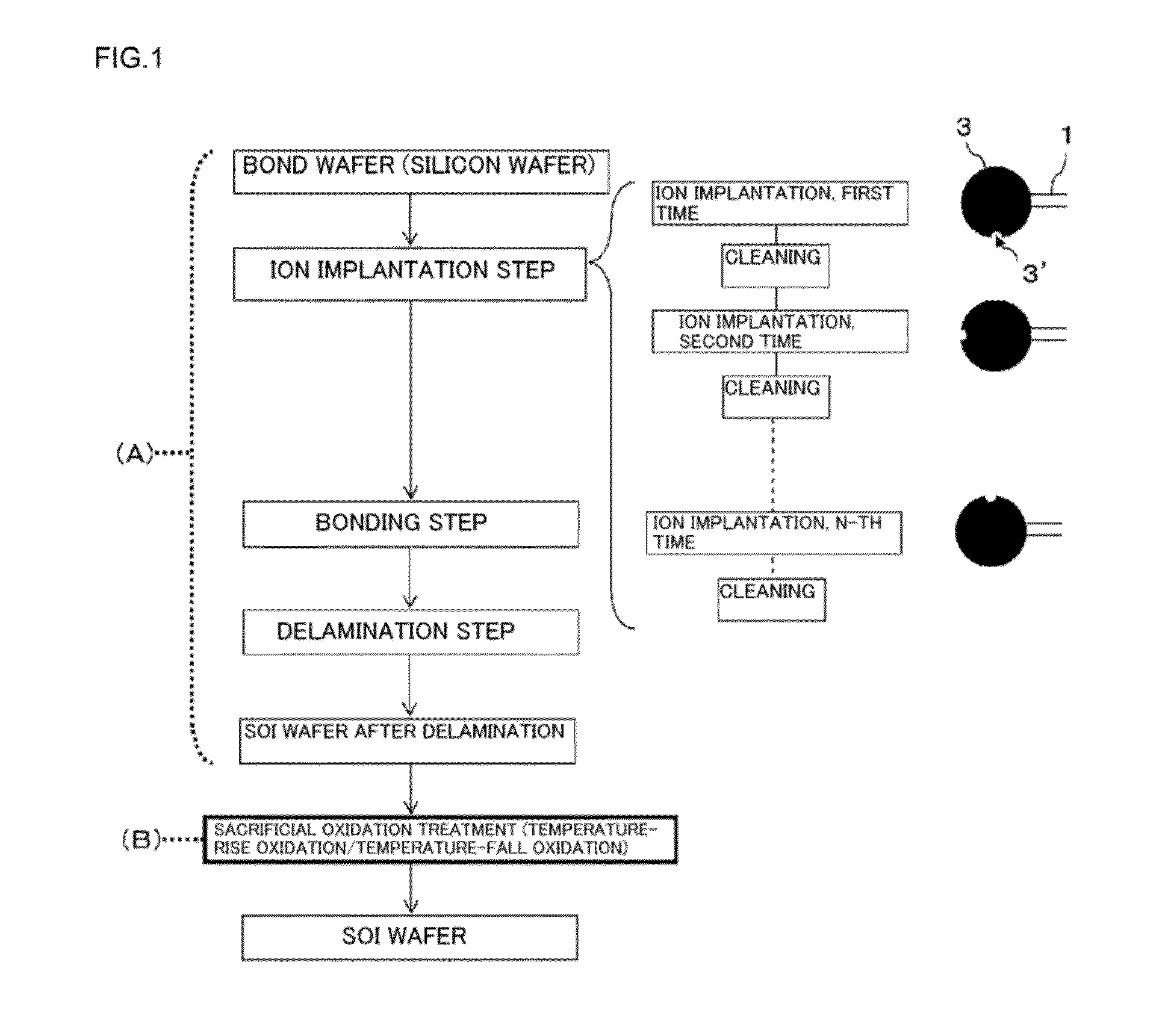

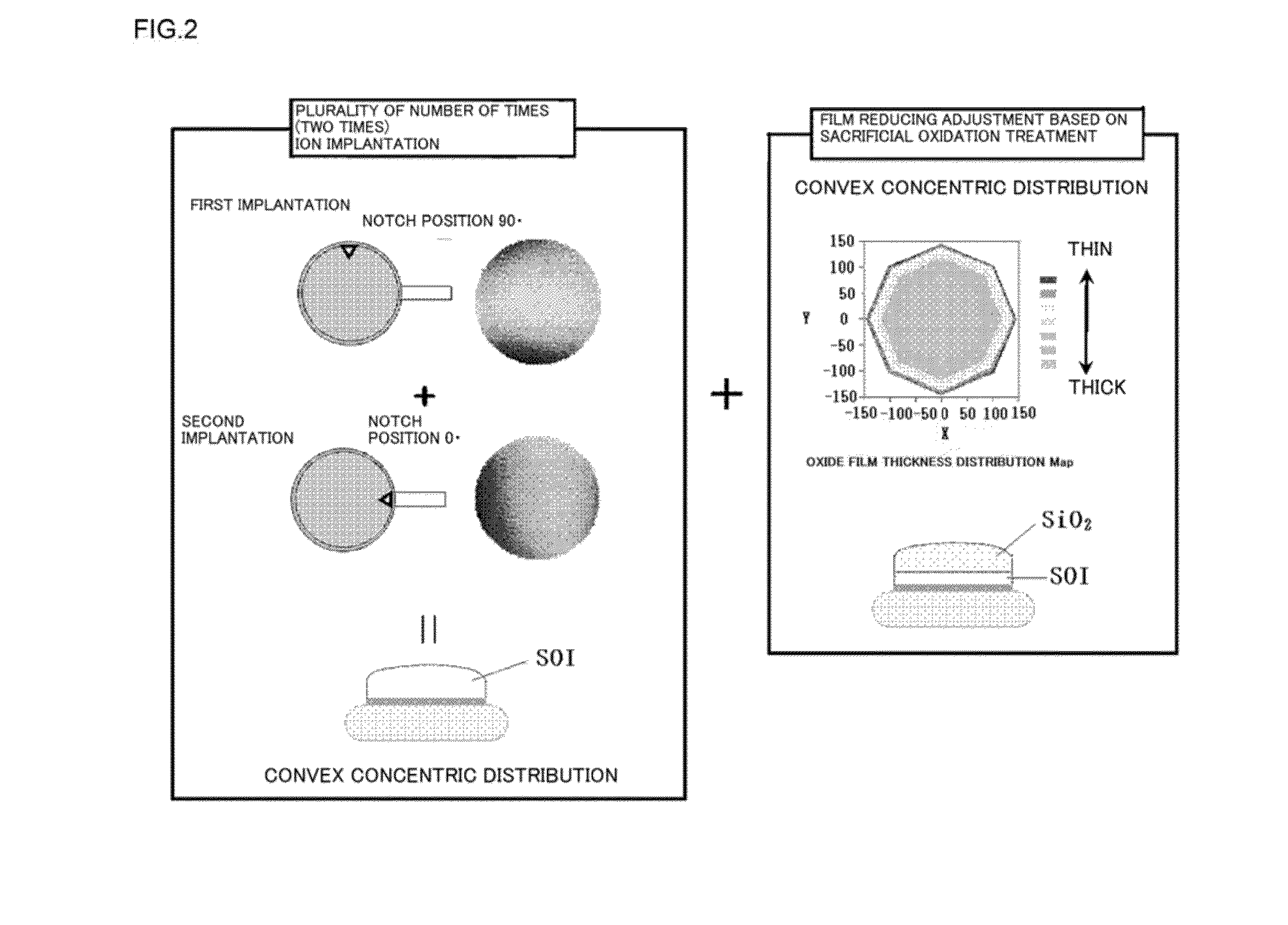

Method for manufacturing soi wafer

ActiveUS20140329372A1Improve film thickness uniformityImprove device yieldSemiconductor/solid-state device manufacturingProduction rateBatch processing

A method for manufacturing a SOI wafer, including a step of performing a thickness reducing adjustment to a SOI layer of the SOI wafer by carrying out a sacrificial oxidation to the SOI wafer for effecting thermal oxidation to a surface of the SOI layer and removing a formed thermal oxide film, wherein, when the thermal oxidation in the sacrificial oxidation treatment is carried out with the use of a batch processing heat treatment furnace during the rising of a temperature and / or the falling of a temperature, a substantially concentric oxide film thickness distribution is formed on the surface of the SOI layer. The result is a method for manufacturing a SOI wafer that enables manufacturing a SOI wafer that has improved radial film thickness distribution with good productivity by performing the sacrificial oxidation treatment for forming a substantially concentric oxide film and removing the formed thermal oxide film.

Owner:SHIN-ETSU HANDOTAI CO LTD

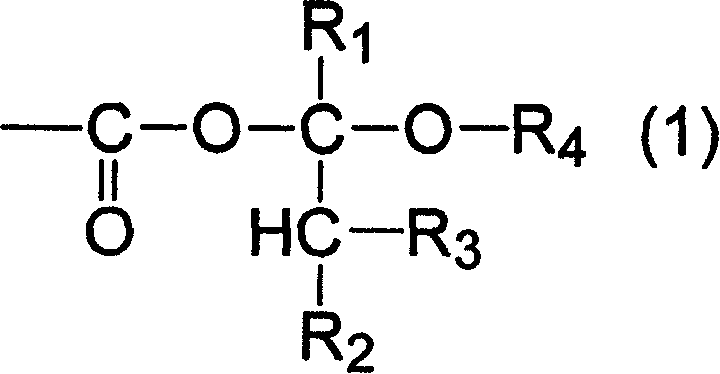

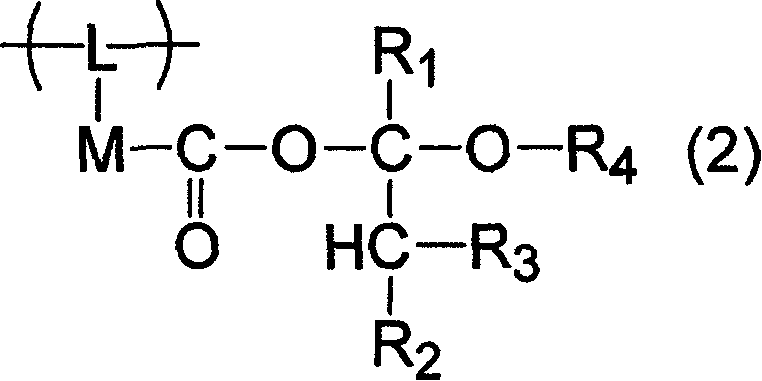

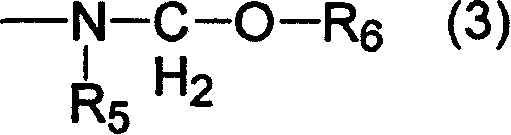

Composition for forming lower layer film for lithography comprising compound having protected carboxyl group

ActiveCN1830202AGood storage stabilityLess quantityPictoral communicationLithographic artistLithography process

There is provided an underlayer coating forming composition for lithography, and an underlayer coating having a high dry etching rate compared with photoresist, and causing no intermixing with the photoresist, which are used in lithography process of manufacture of semiconductor device. Concretely, it is an underlayer coating forming composition comprising a compound having a protected carboxyl group, a compound having a group capable of reacting with a carboxyl group and a solvent, and an underlayer coating forming composition comprising a compound having a group capable of reacting with a carboxyl group and a protected carboxyl group and a solvent.

Owner:NISSAN CHEM IND LTD

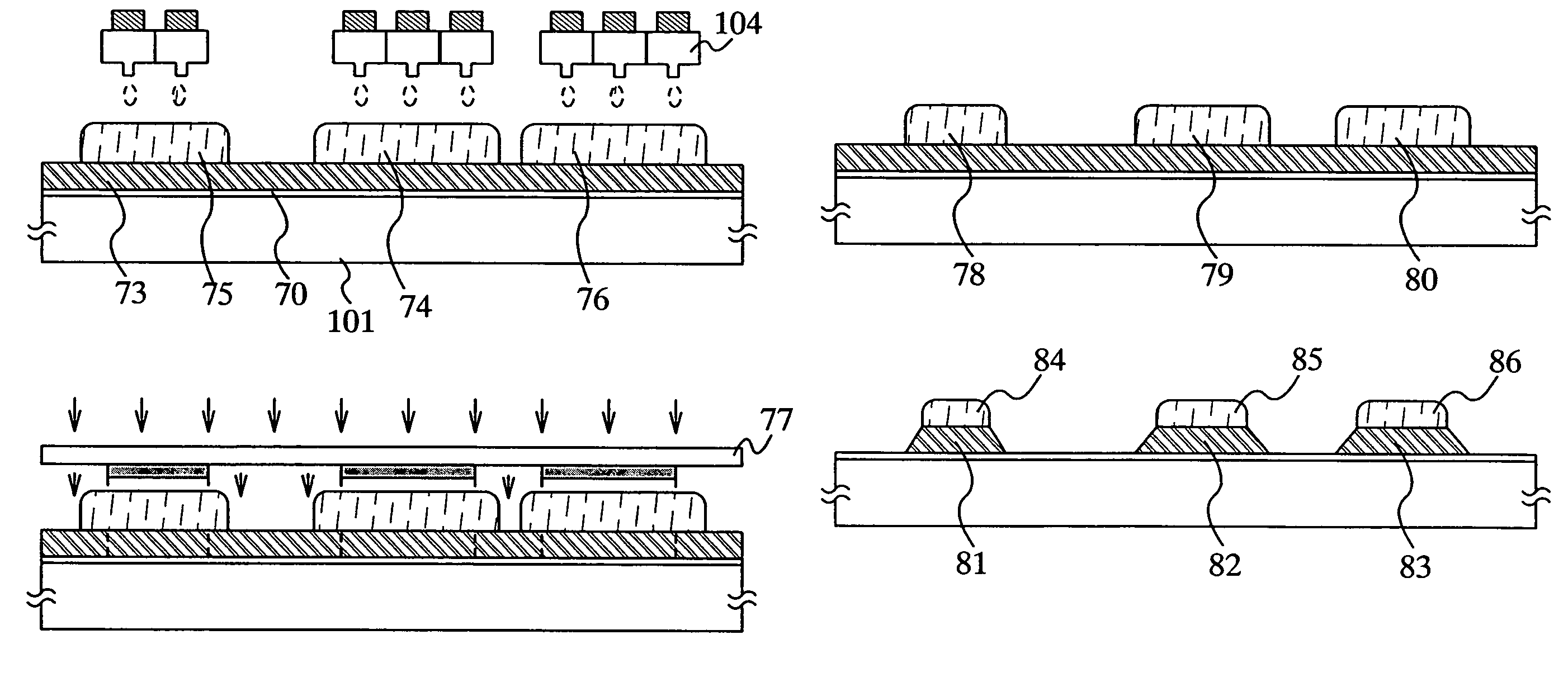

Method for manufacturing resist pattern and method for manufacturing semiconductor device

InactiveUS7405033B2Improve film thickness uniformityWell formedSolid-state devicesSemiconductor/solid-state device manufacturingResistManufacturing cost reduction

To provide a method for manufacturing a resist pattern designed to reduce a manufacturing cost by improving efficiency in the use of a resist material, a method for removing a resist pattern, and a method for manufacturing a semiconductor device.The present invention includes a step of forming a resist pattern by discharging a composition containing photosensitizer on a object to be processed under reduced pressure. The present invention includes a step of etching the object to be processed using the resist pattern as a mask, a step of irradiating the resist pattern through a photomask with light within a photosensitive wavelength region of a photosensitizer, and a step of removing the resist pattern on the object to be processed.

Owner:SEMICON ENERGY LAB CO LTD

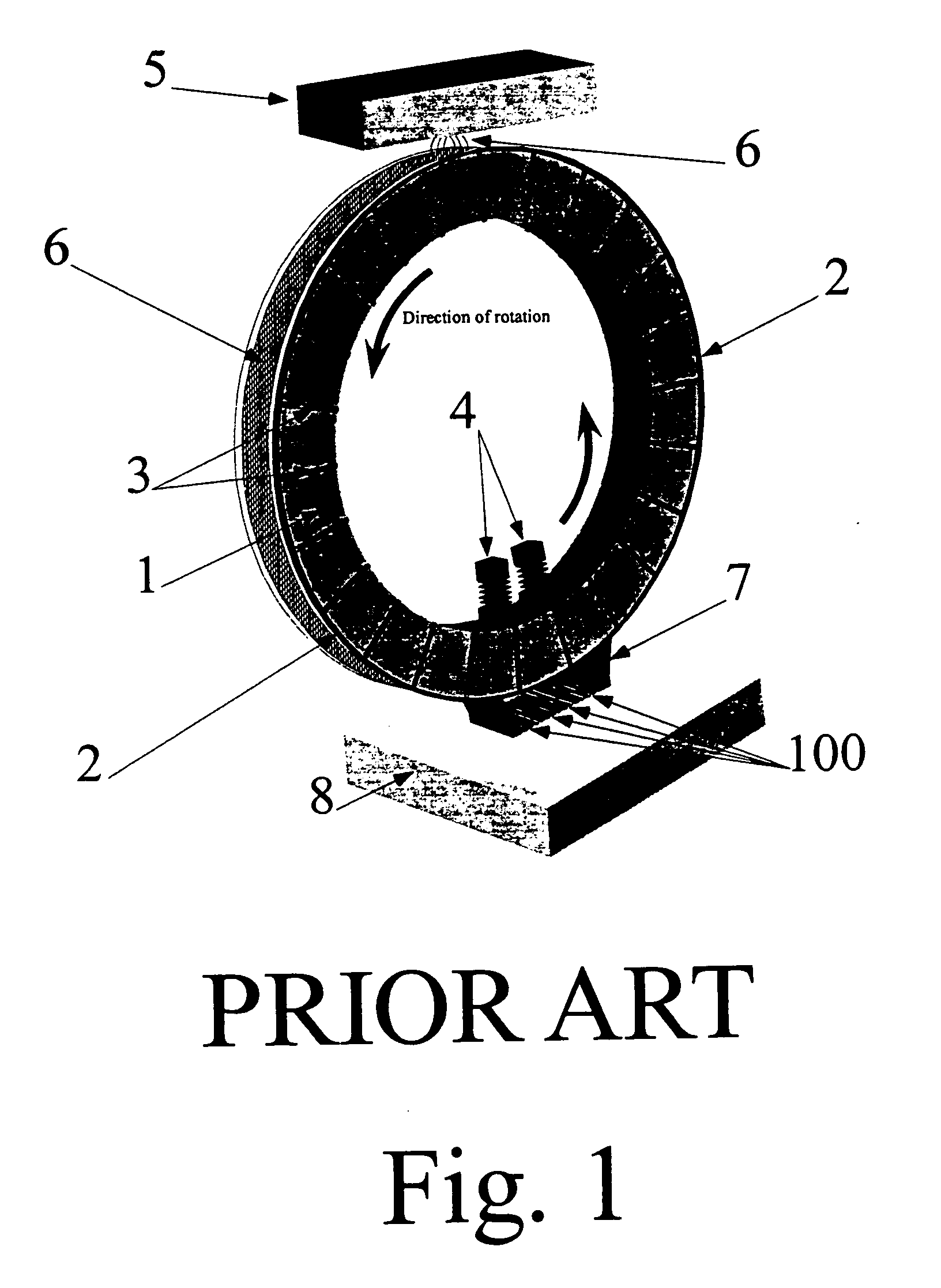

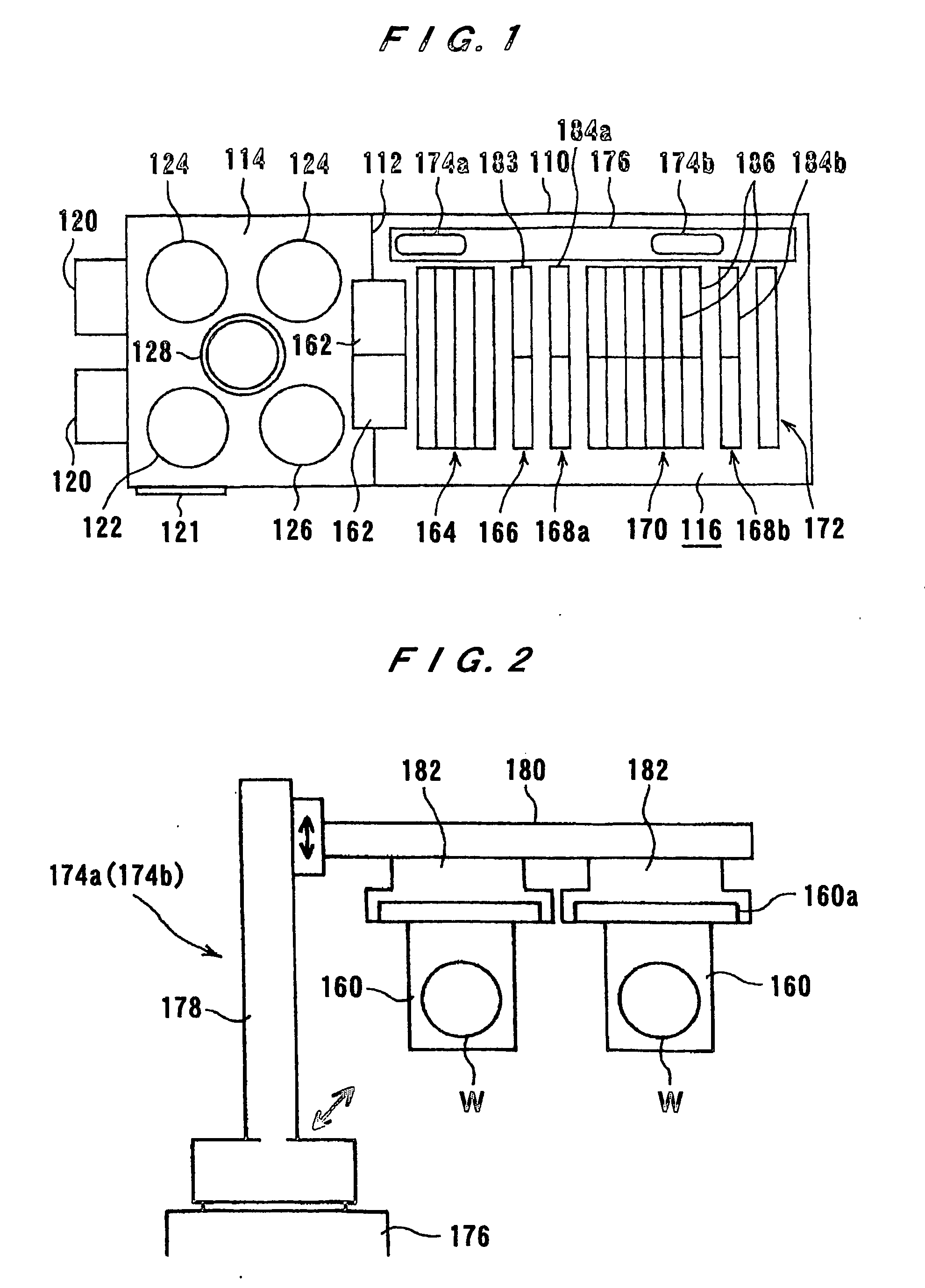

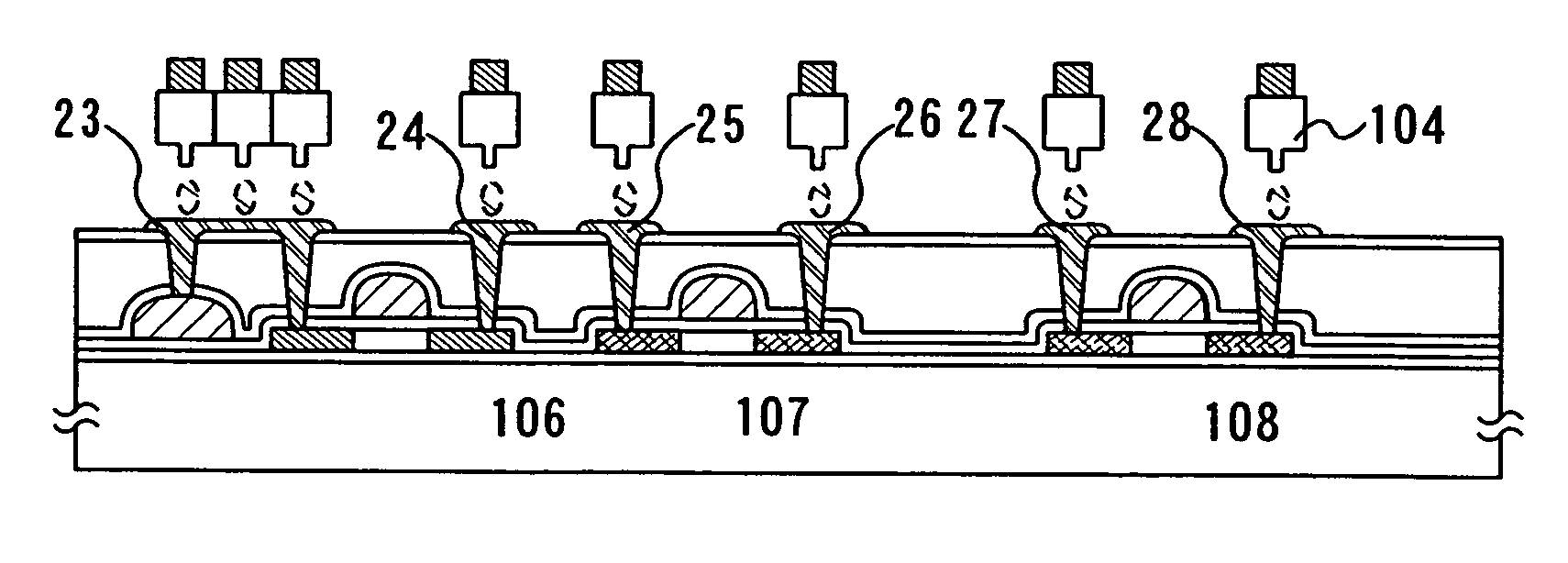

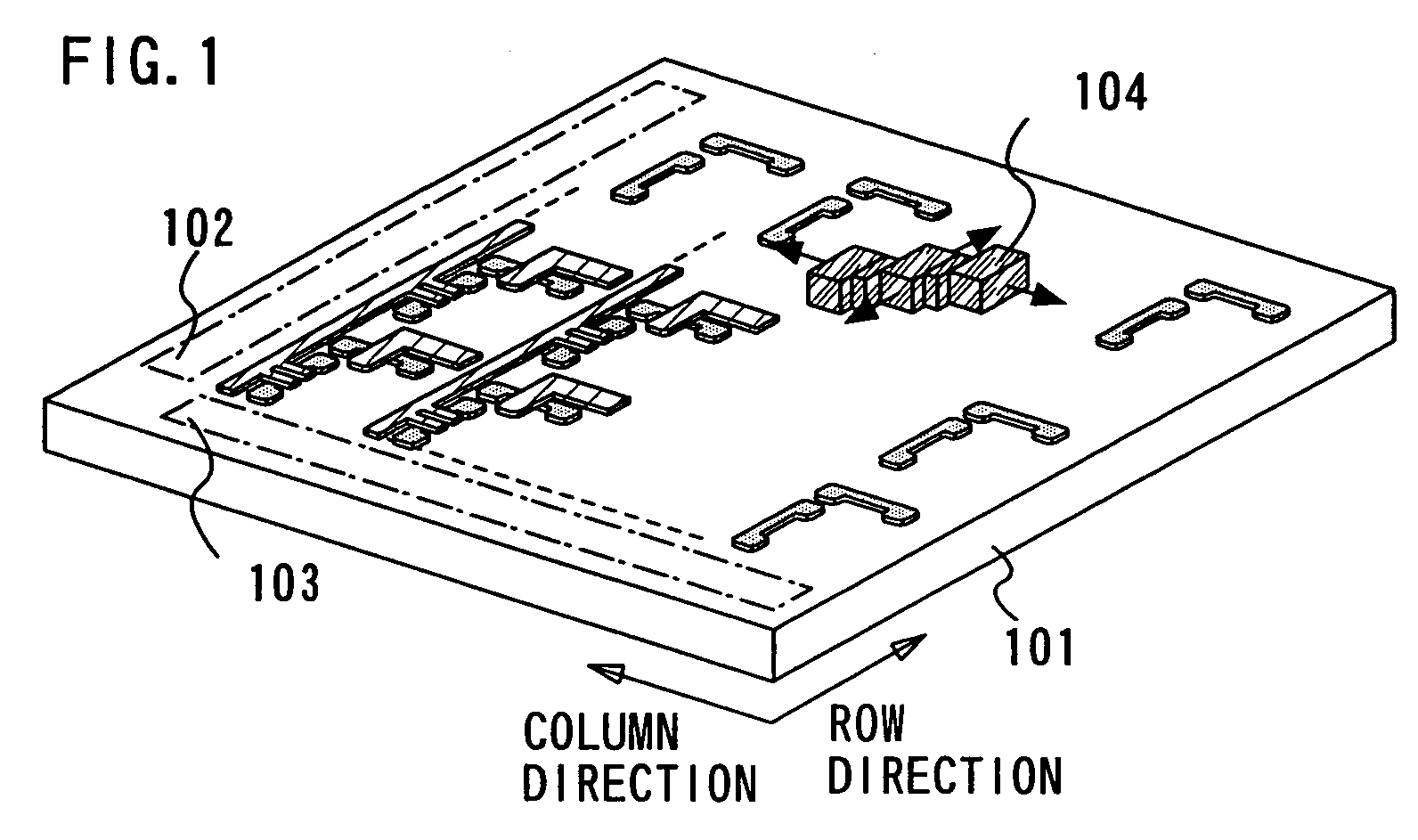

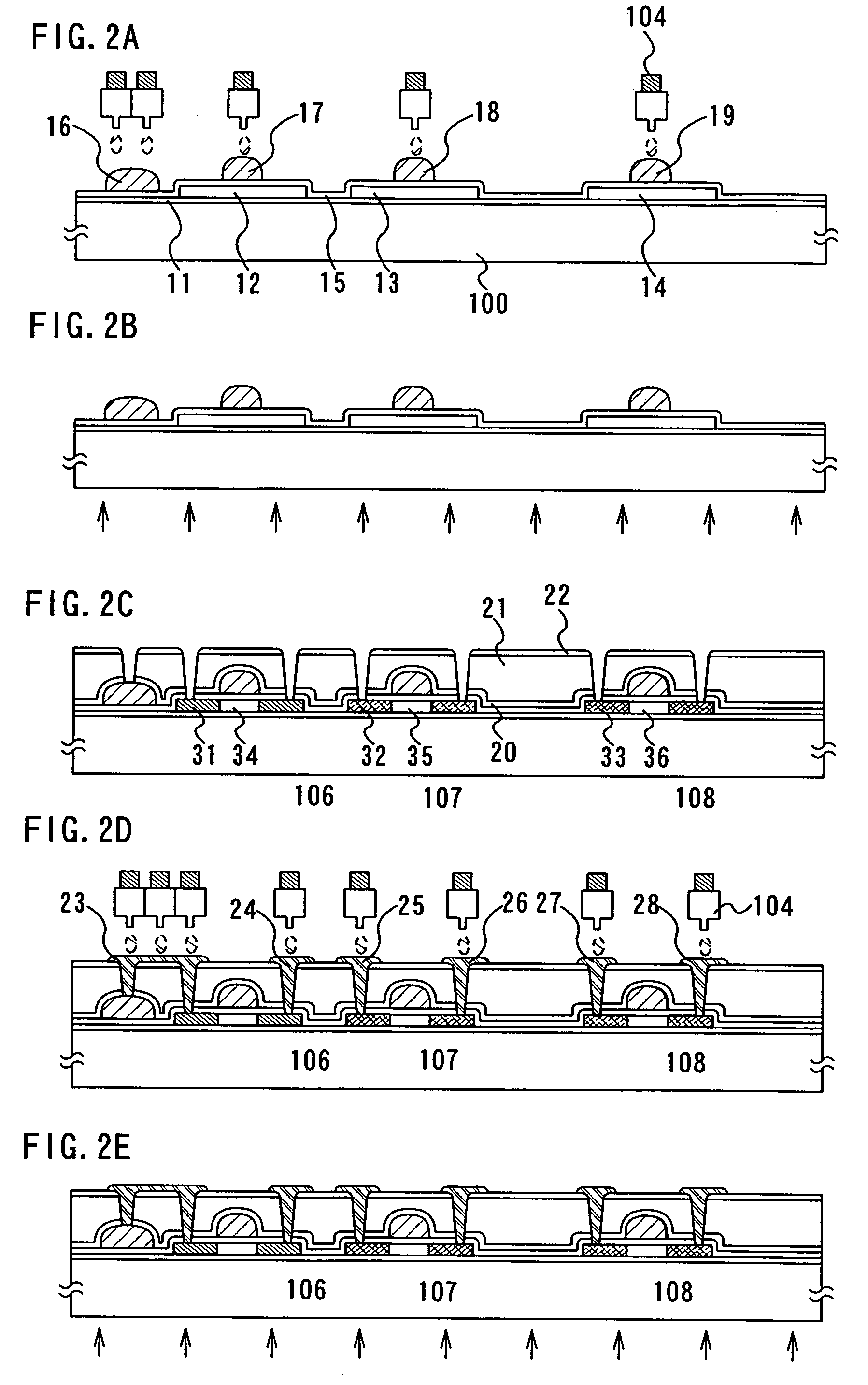

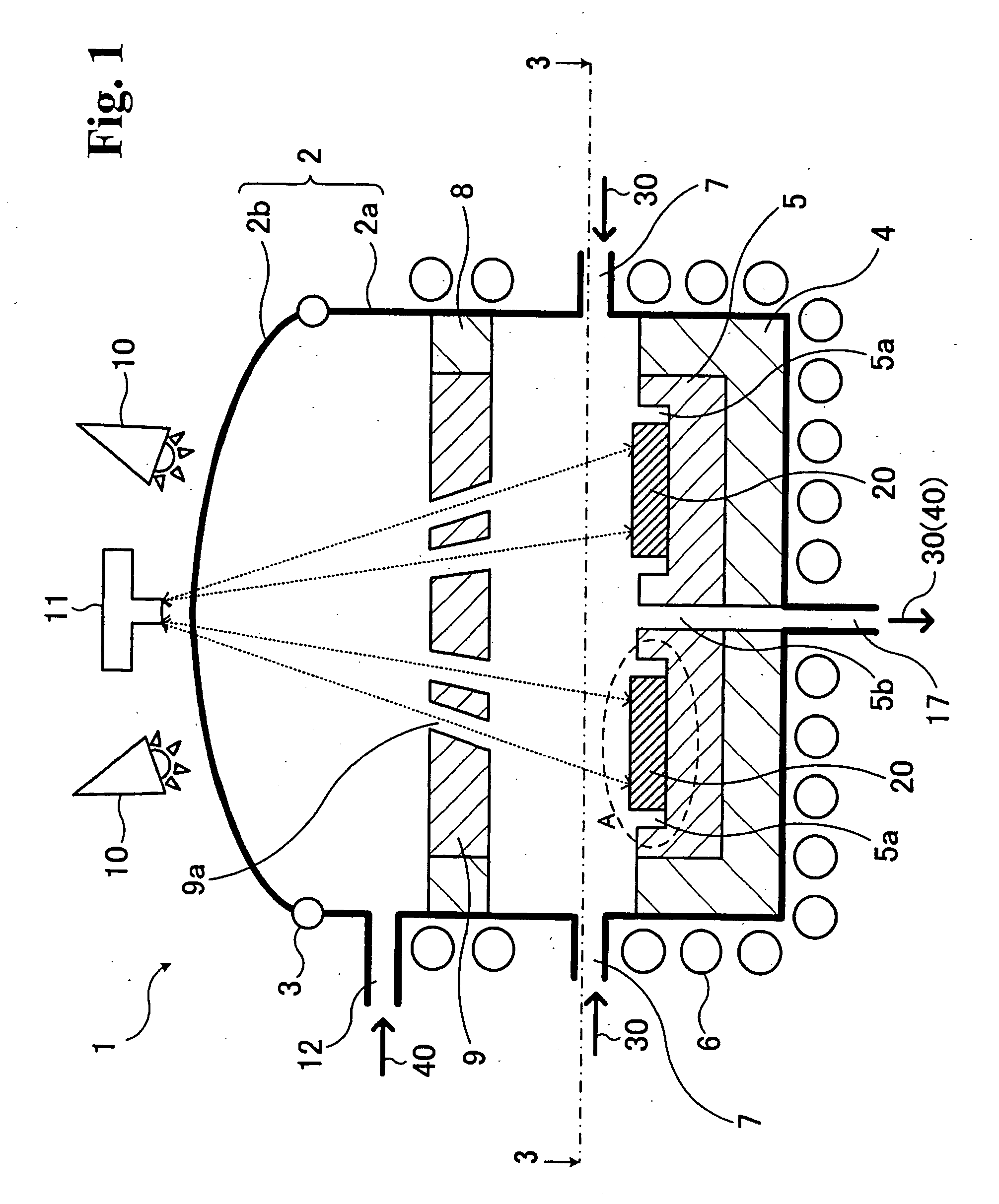

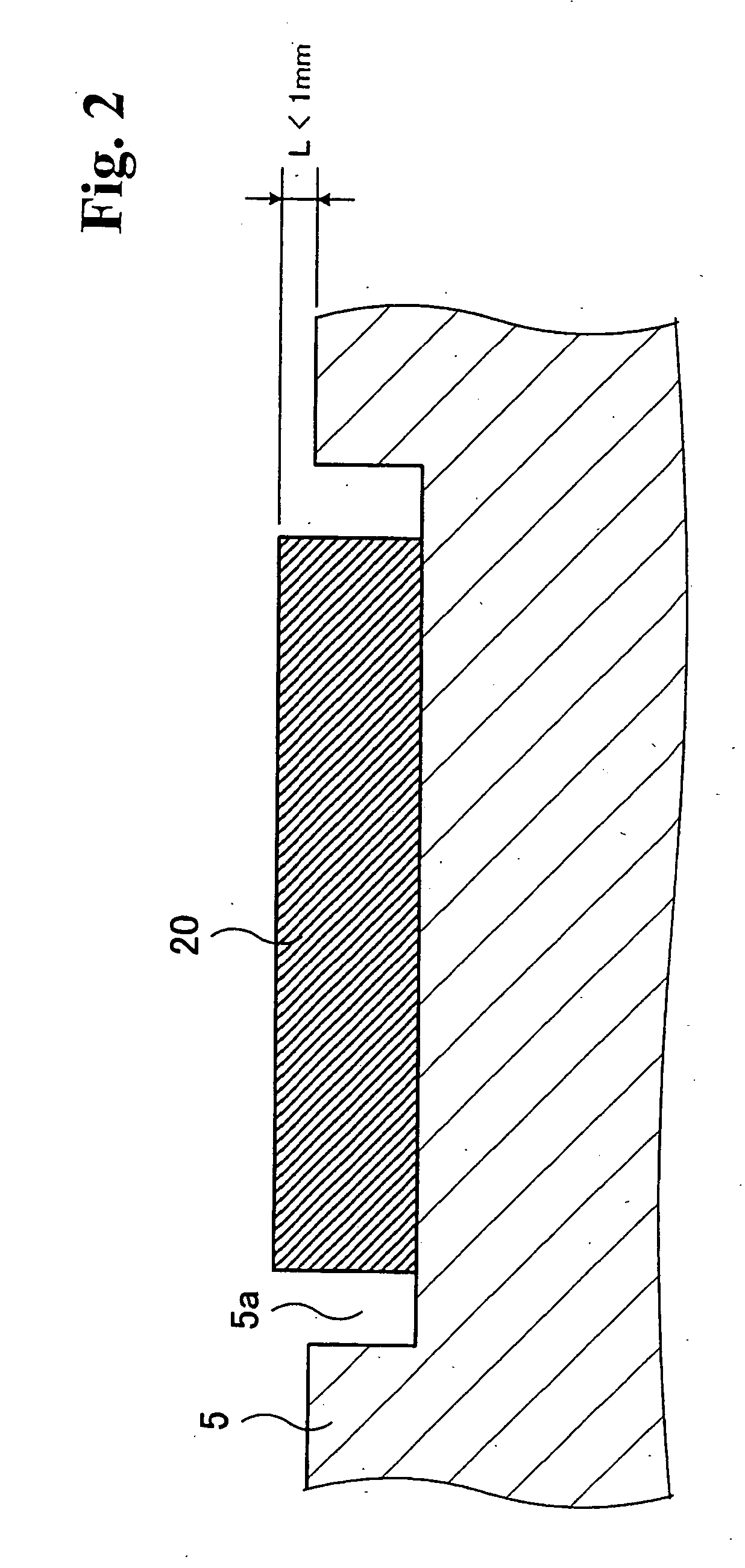

Epitaxial film deposition system and epitaxial film formation method

InactiveUS20060252243A1Improve film thickness uniformityImprove quality uniformitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesPyrometerEngineering

An epitaxial film deposition system includes a reactor, a susceptor, a wafer heating unit, a reactant gas supply orifice, and an aperture for venting the reactant gas. The reactant gas is supplied to a reactor region between the susceptor and a graphite plate so as to circulate in layered flow in a direction along the reactor inner wall in the planar direction of a mounted SiC wafer. The temperature of the wafer is controlled by a high frequency coil and halogen lamps based on temperatures detected by a pyrometer. By circulating the reactant gas over the surface of the stationary wafer, it is possible to form, under various process conditions, an SiC epitaxial film having good film quality and good uniformity of film thickness, without providing any wafer rotation mechanism.

Owner:FUJI ELECTRIC HLDG CO LTD

Reduced-pressure drying unit and coating film forming method

InactiveUS20050087129A1Improve film thickness uniformityLimited film thicknessVacuum evaporation coatingPretreated surfacesFree spaceElectrical and Electronics engineering

The invention includes a hermetic container provided with a substrate mount; a vacuum exhauster connected to the hermetic container; a current member; and a current member raising and lowering mechanism. When the current member is raised and lowered as a function of the pressure inside the hermetic container, a liquid flow of the coating solution on the substrate is controlled, thereby controlling the uniformity of the film thickness of the coating solution.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com