Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8931 results about "Lithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithography (from Ancient Greek λίθος, lithos, meaning 'stone', and γράφειν, graphein, meaning 'to write') is a method of printing originally based on the immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by German author and actor Alois Senefelder as a cheap method of publishing theatrical works. Lithography can be used to print text or artwork onto paper or other suitable material.

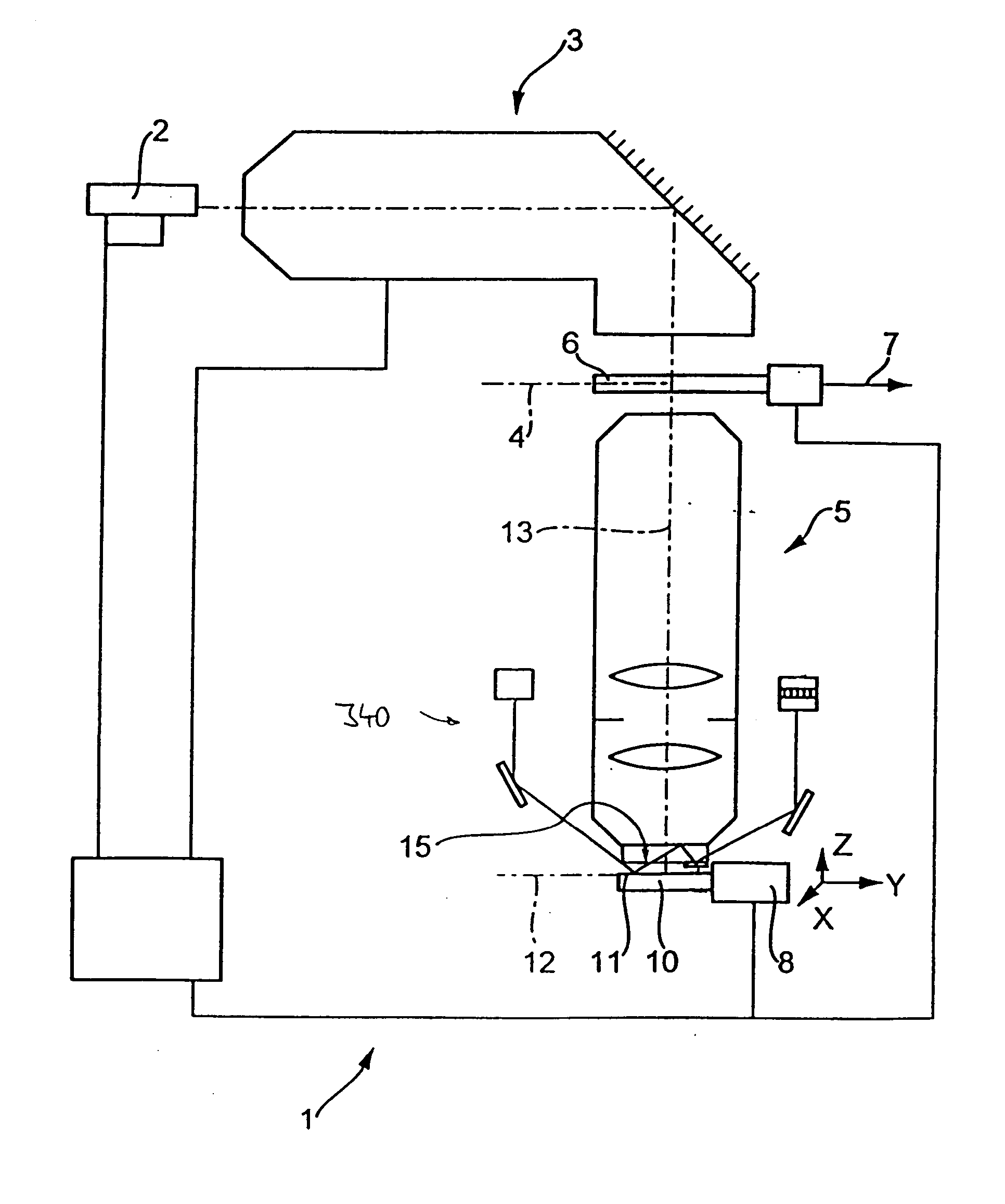

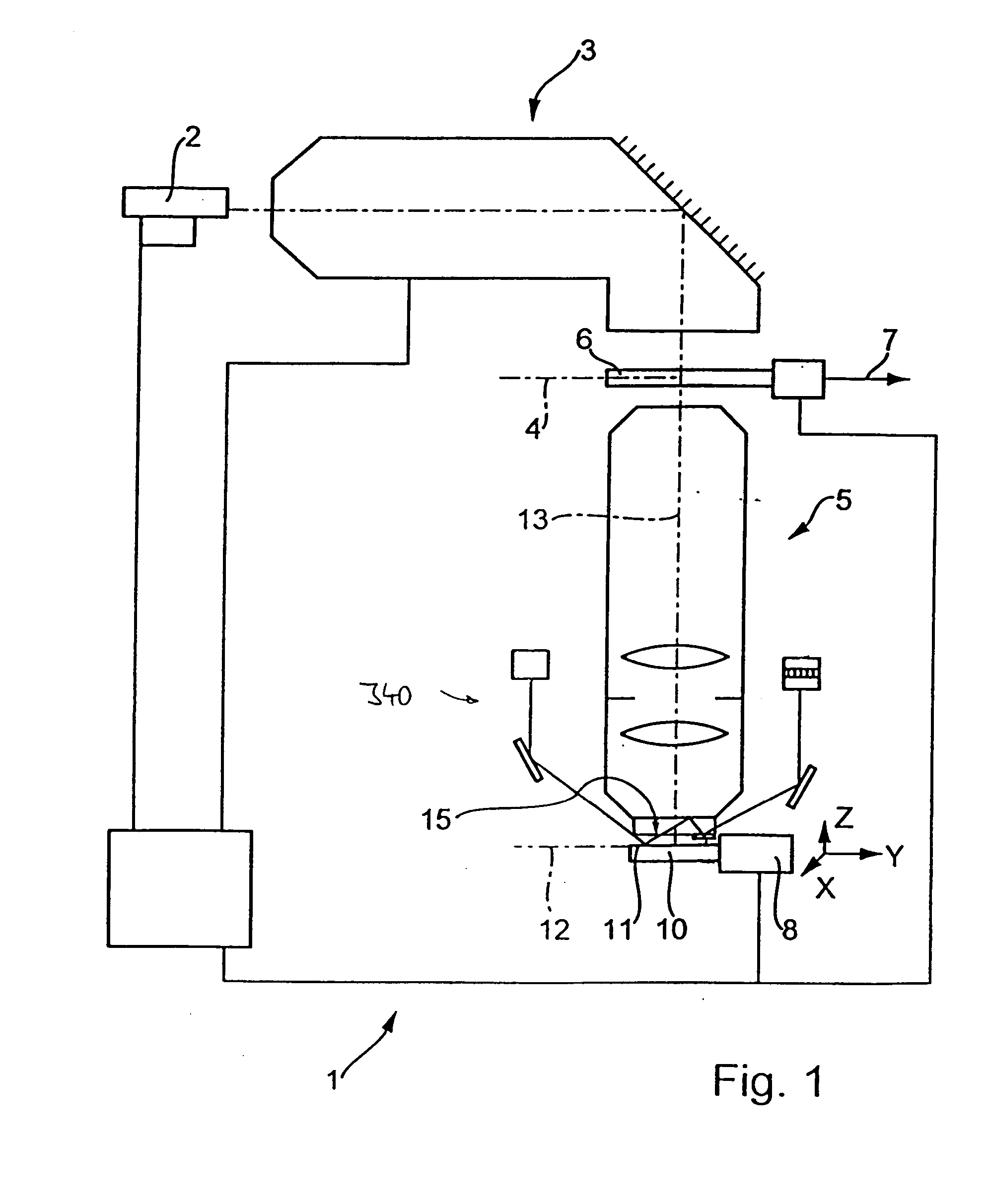

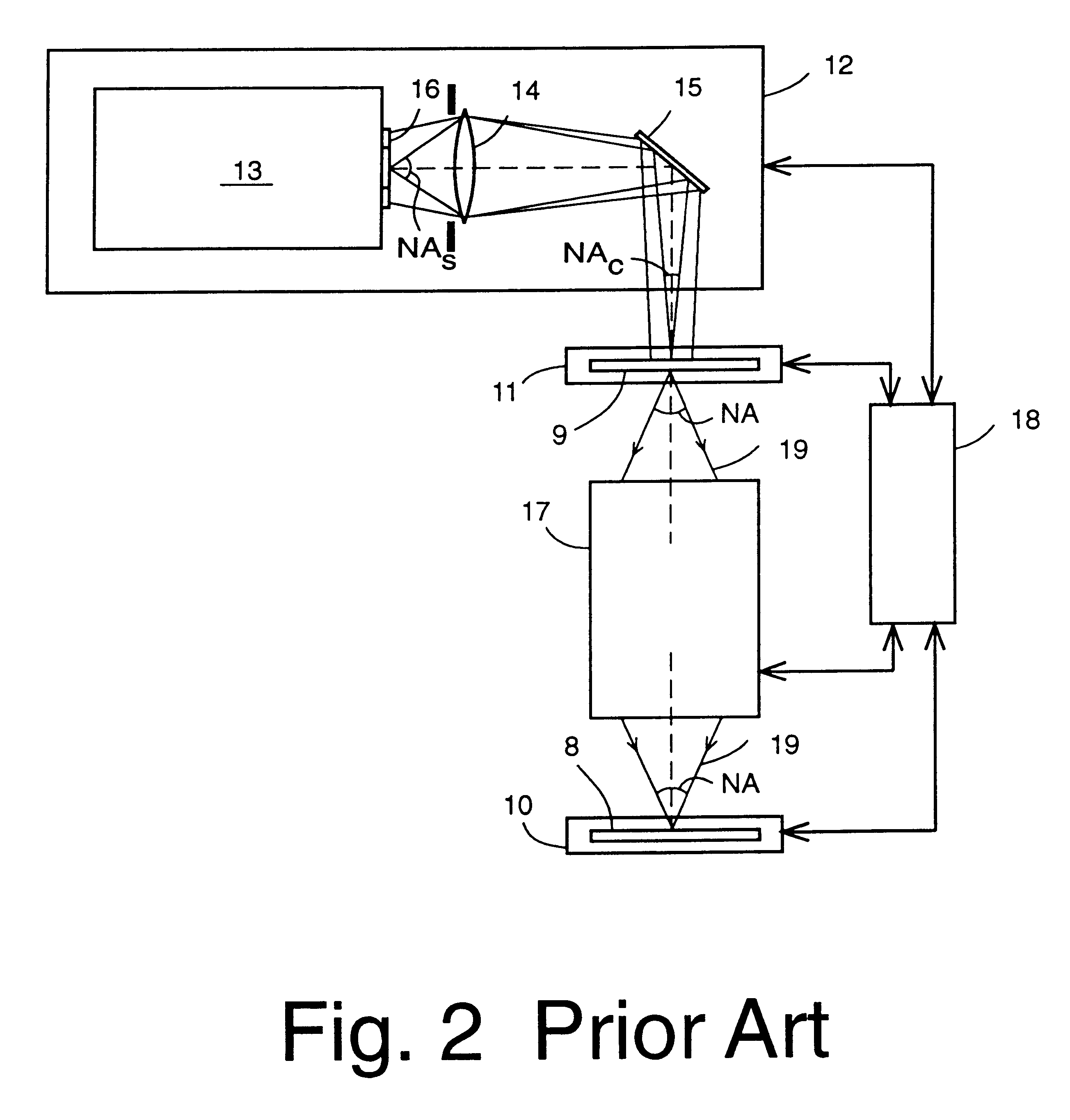

Projection exposure method and projection exposure system

InactiveUS20050030506A1Avoid defocusing errorProvides adequateNanoinformaticsMaterial analysis by optical meansLithographic artistHigh numerical aperture

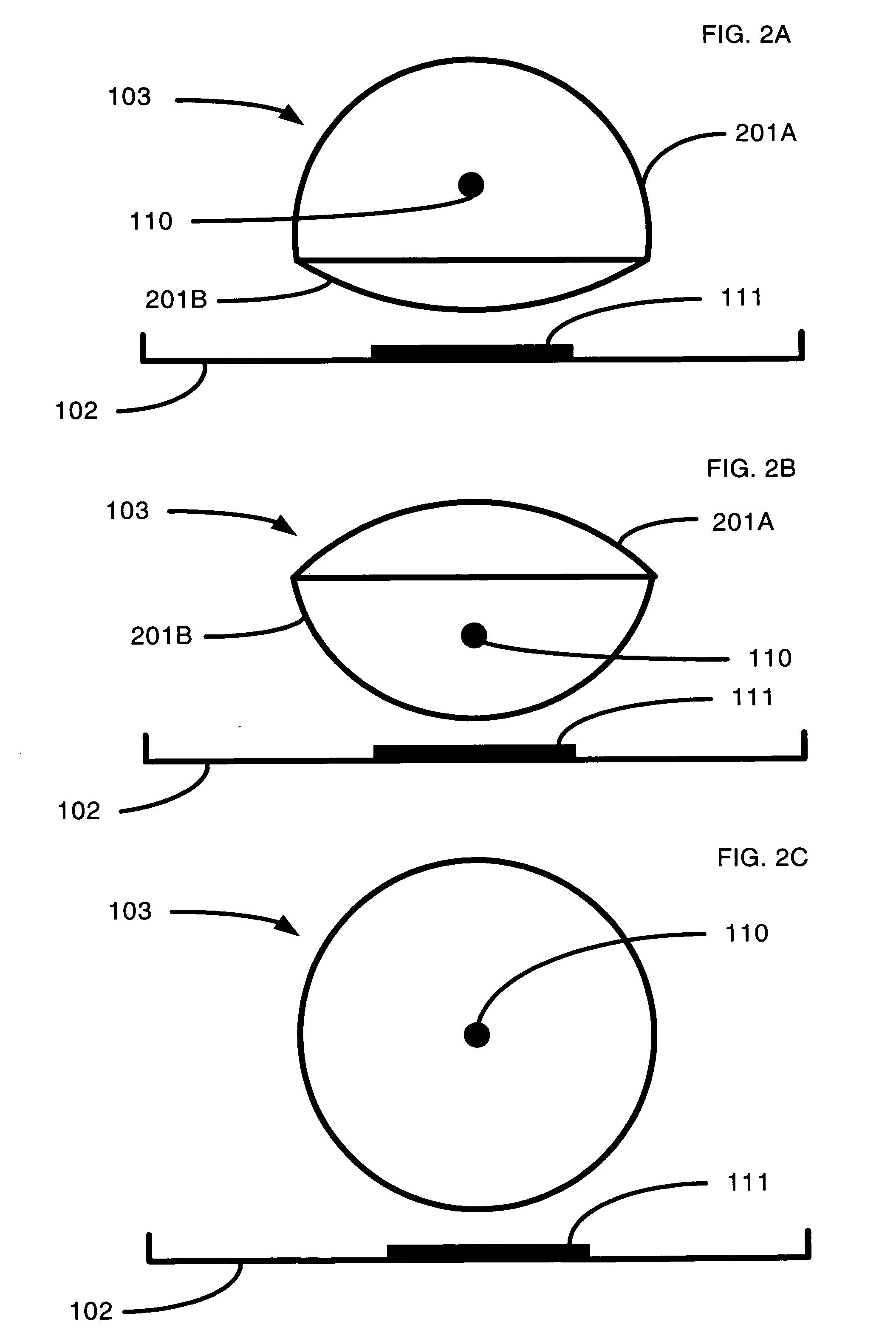

In a method for manufacturing semiconductor devices and other finely structured parts, a projection objective (5) is used in order to project the image of a pattern arranged in the object plane of the projection objective onto a photosensitive substrate which is arranged in the region of the image plane (12) of the projection objective. In this case, there is set between an exit surface (15), assigned to the projection objective, for exposing light and an incoupling surface (11), assigned to the substrate, for exposing light a small finite working distance (16) which is at least temporarily smaller in size and exposure time interval than a maximum extent of an optical near field of the light emerging from the exit surface. As a result, projection objectives with very high numerical apertures in the region of NA>0.8 or more can be rendered useful for contactless projection lithography.

Owner:CARL ZEISS SMT GMBH

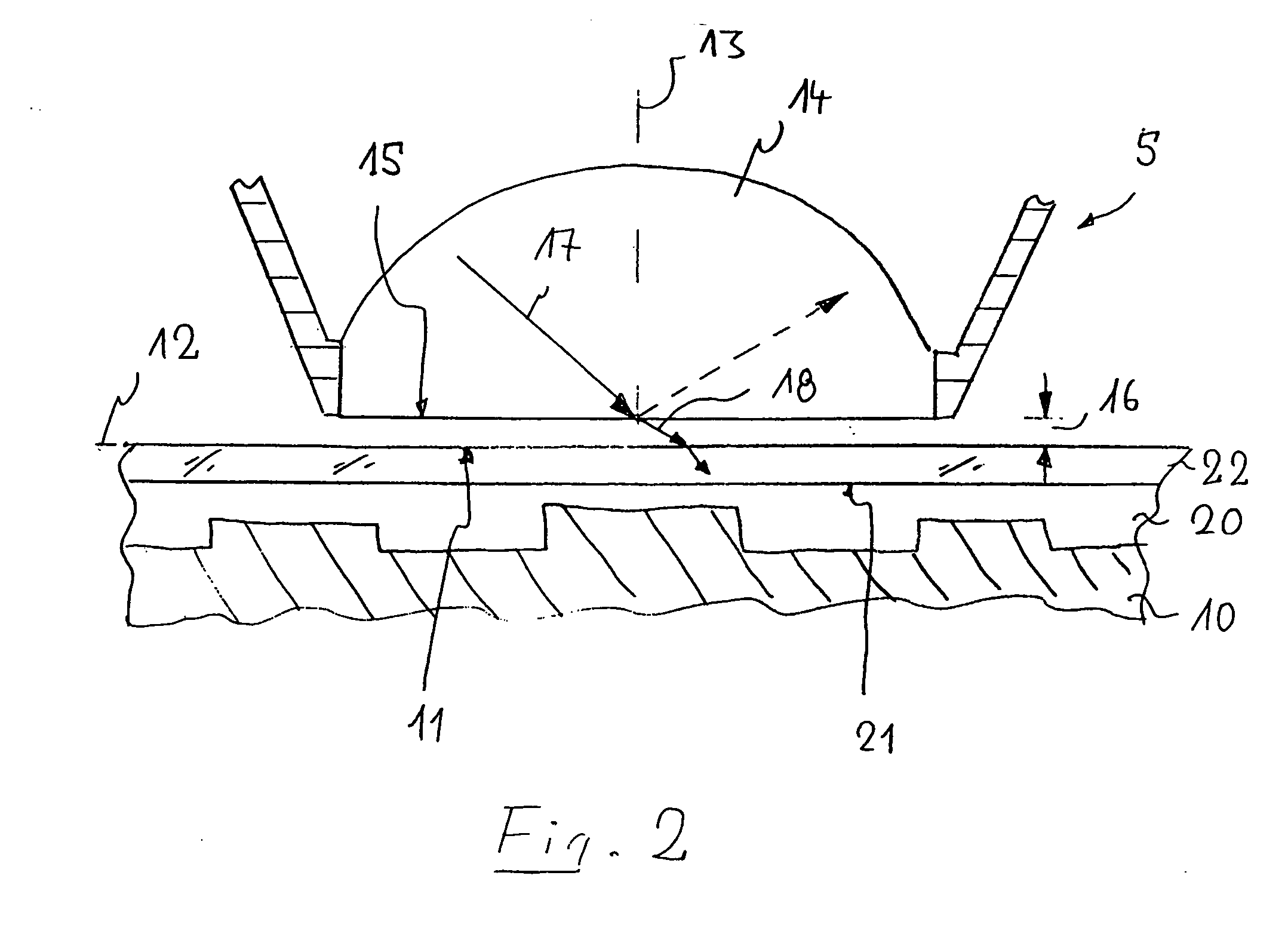

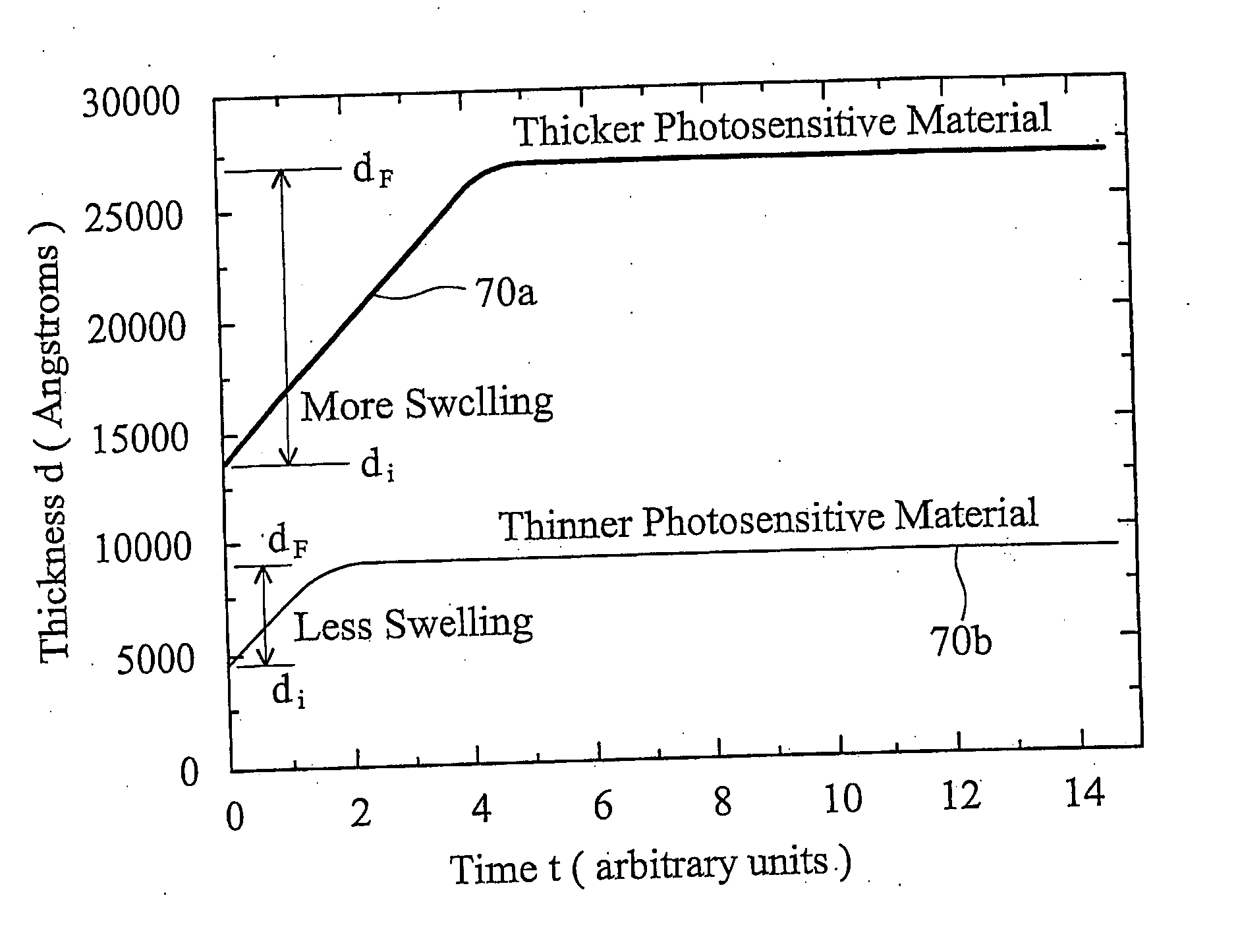

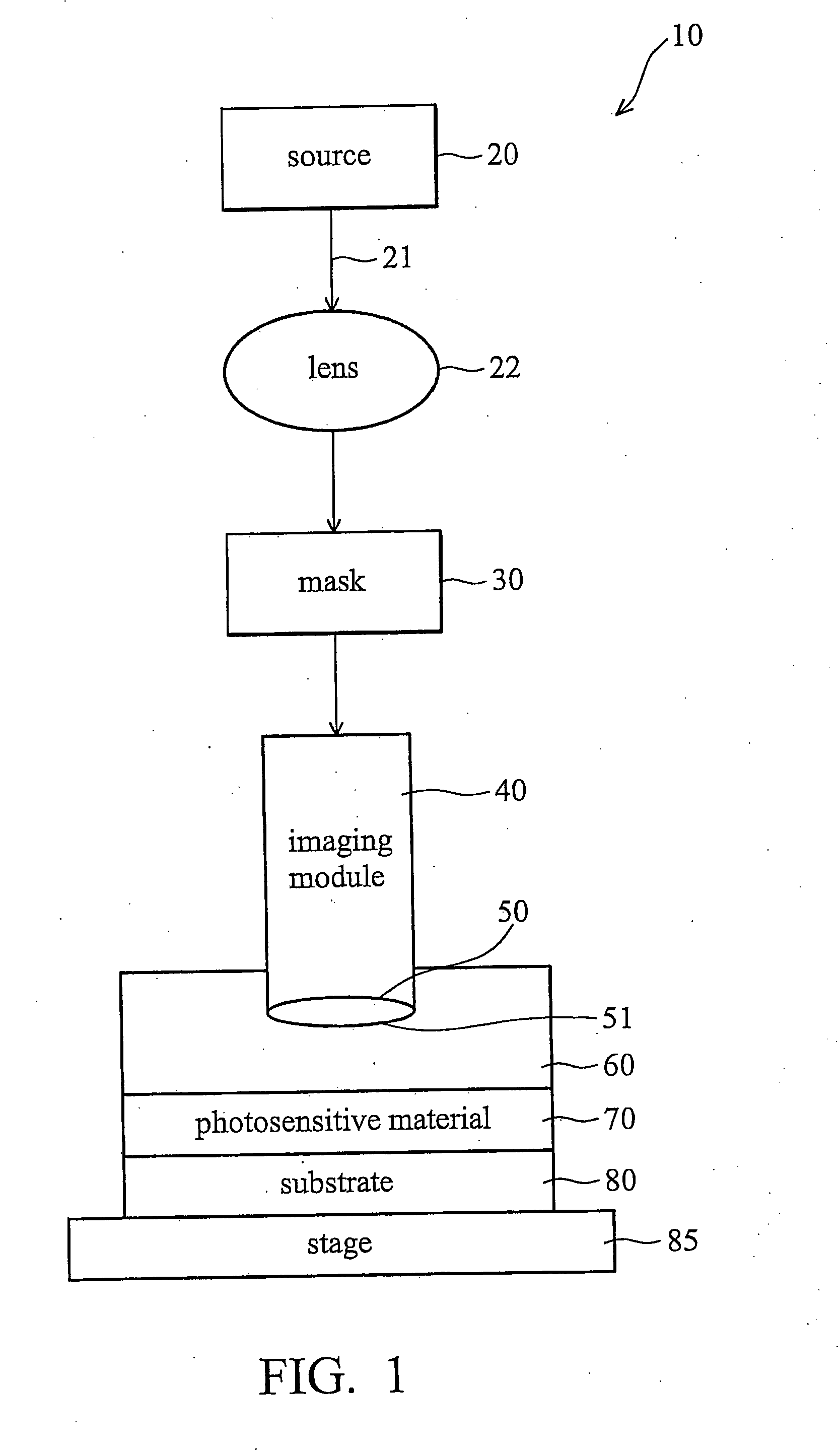

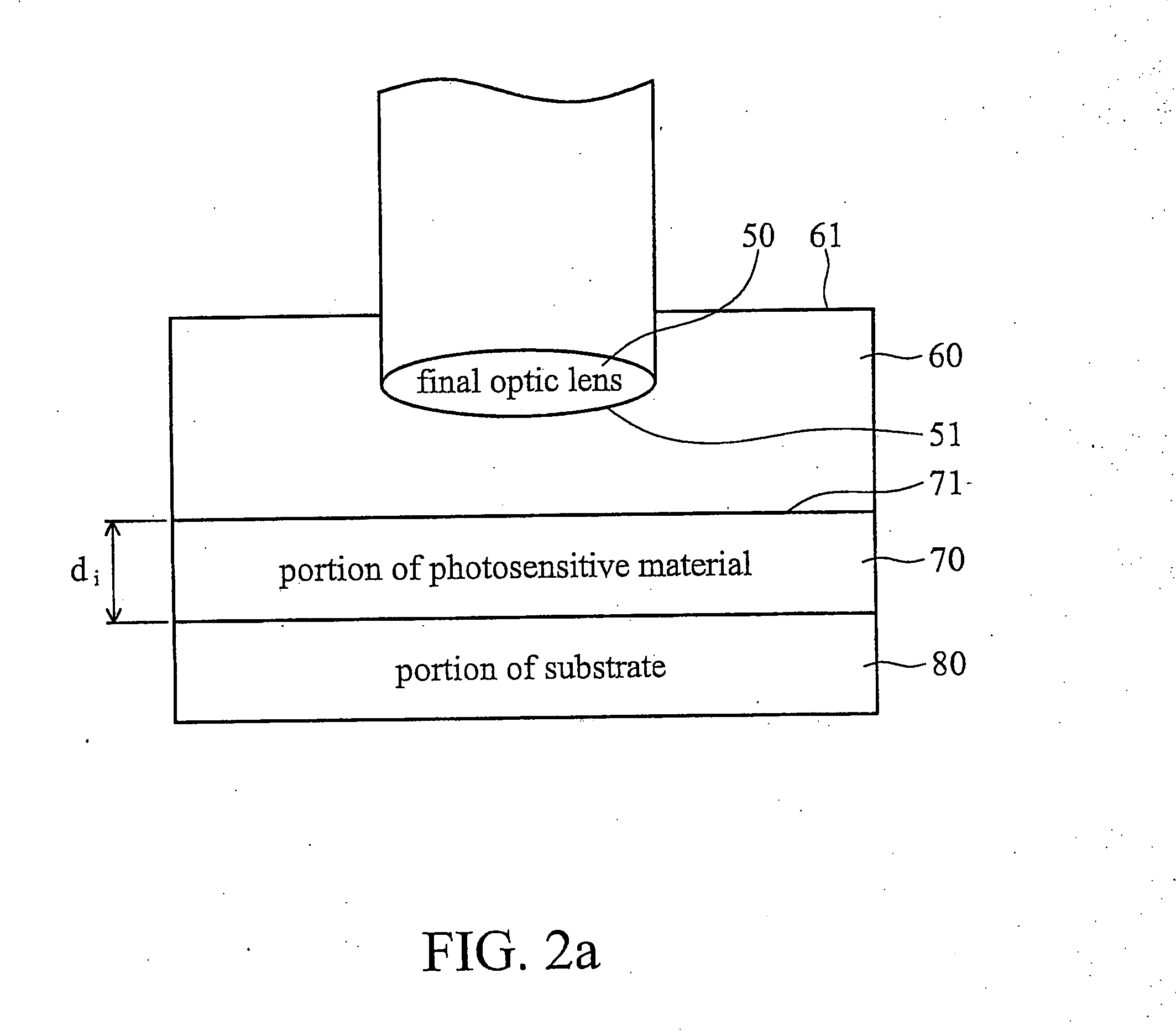

Lithography apparatus for manufacture of integrated circuits

ActiveUS20050036184A1Limit amount of swellingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLithographic artistSemiconductor structure

An immersion lithographic system 10 comprises an optical surface 51, an immersion fluid 60 contacting at least a portion of the optical surface, and a semiconductor structure 80 having a topmost photoresist layer 70 having a thickness of less than about 5000 angstroms, wherein a portion of the photoresist is in contact with the immersion fluid. Further, a method for illuminating a semiconductor structure 80 having a topmost photoresist layer 70 with a thickness of less than about 5000 angstroms, comprising introducing an immersion fluid 60 into a space between an optical surface 51 and the photoresist layer, and directing light preferably with a wavelength of less than about 450 nm through the immersion fluid and onto the photoresist.

Owner:TAIWAN SEMICON MFG CO LTD

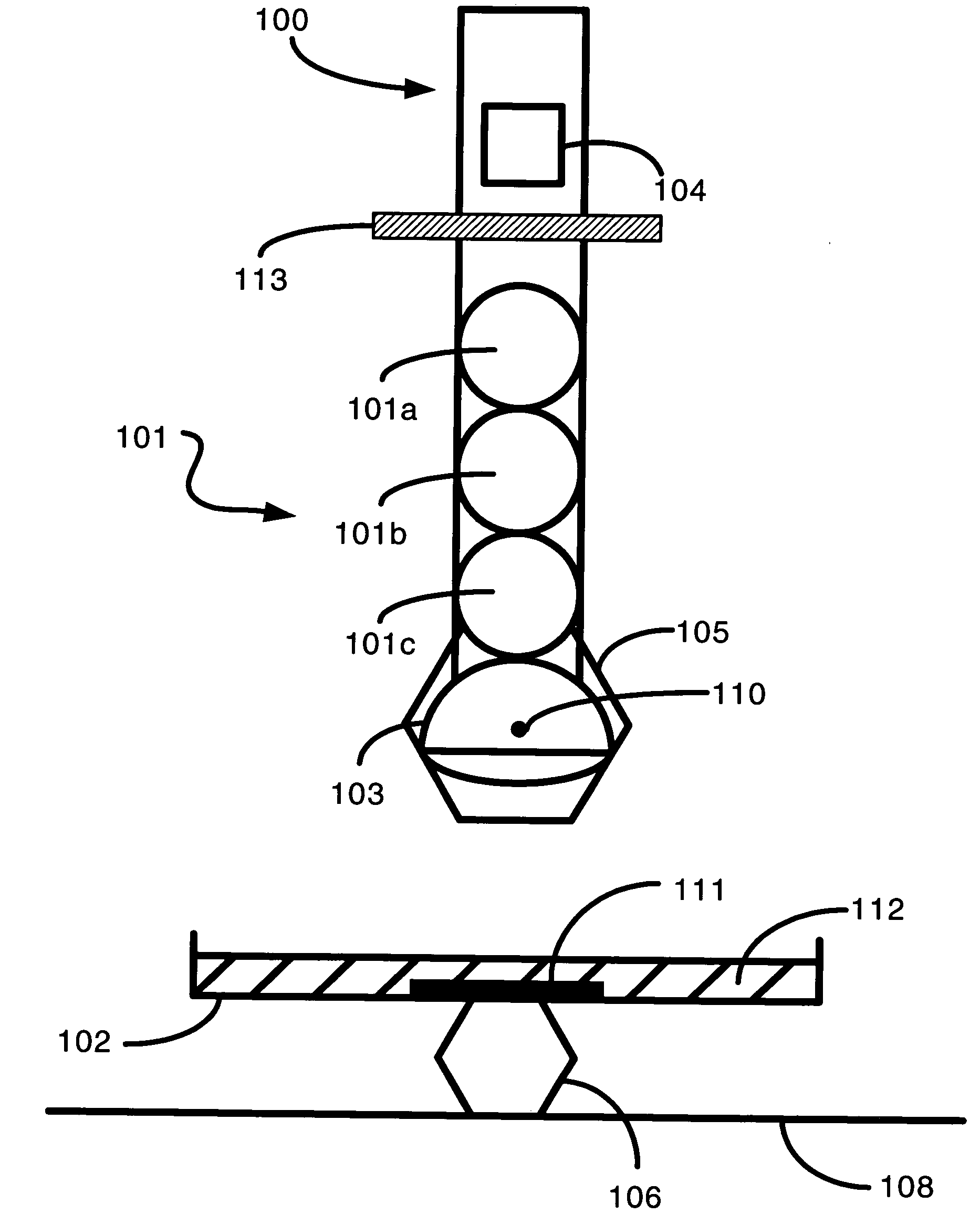

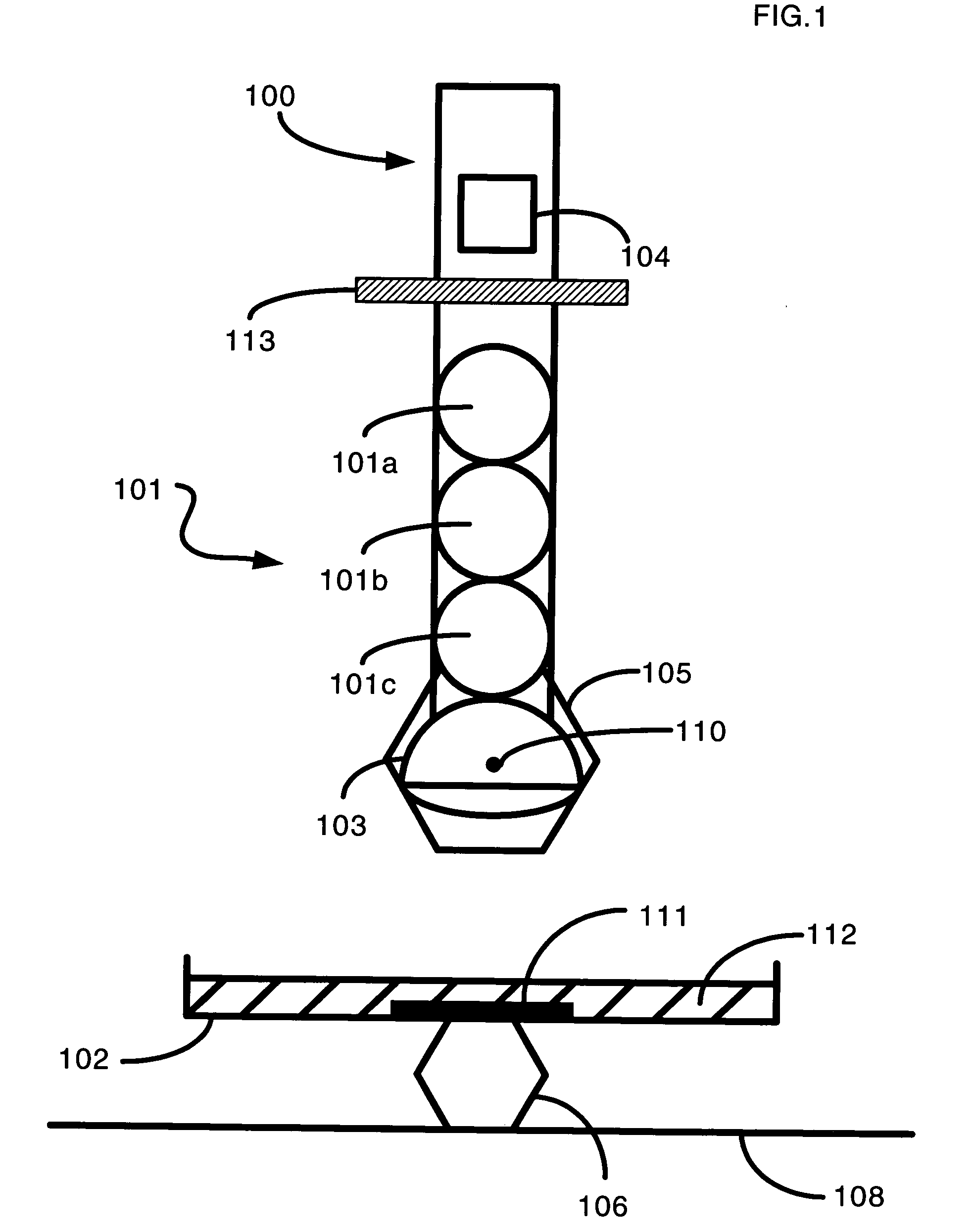

Moving lens for immersion optical lithography

InactiveUS20050145803A1Reduce turbulenceReduces air bubbleMaterial analysis using wave/particle radiationPhotometryLithographic artistImage resolution

An apparatus for immersion optical lithography having a lens capable of relative movement in synchrony with a horizontal motion of a semiconductor wafer in a liquid environment where the synchronous motion of the lens apparatus and semiconductor wafer advantageously reduces the turbulence and air bubbles associated with a liquid environment. The relative motions of the lens and semiconductor wafer are substantially the same as the scanning process occurs resulting in optimal image resolution with minimal air bubbles, turbulence, and disruption of the liquid environment.

Owner:IBM CORP

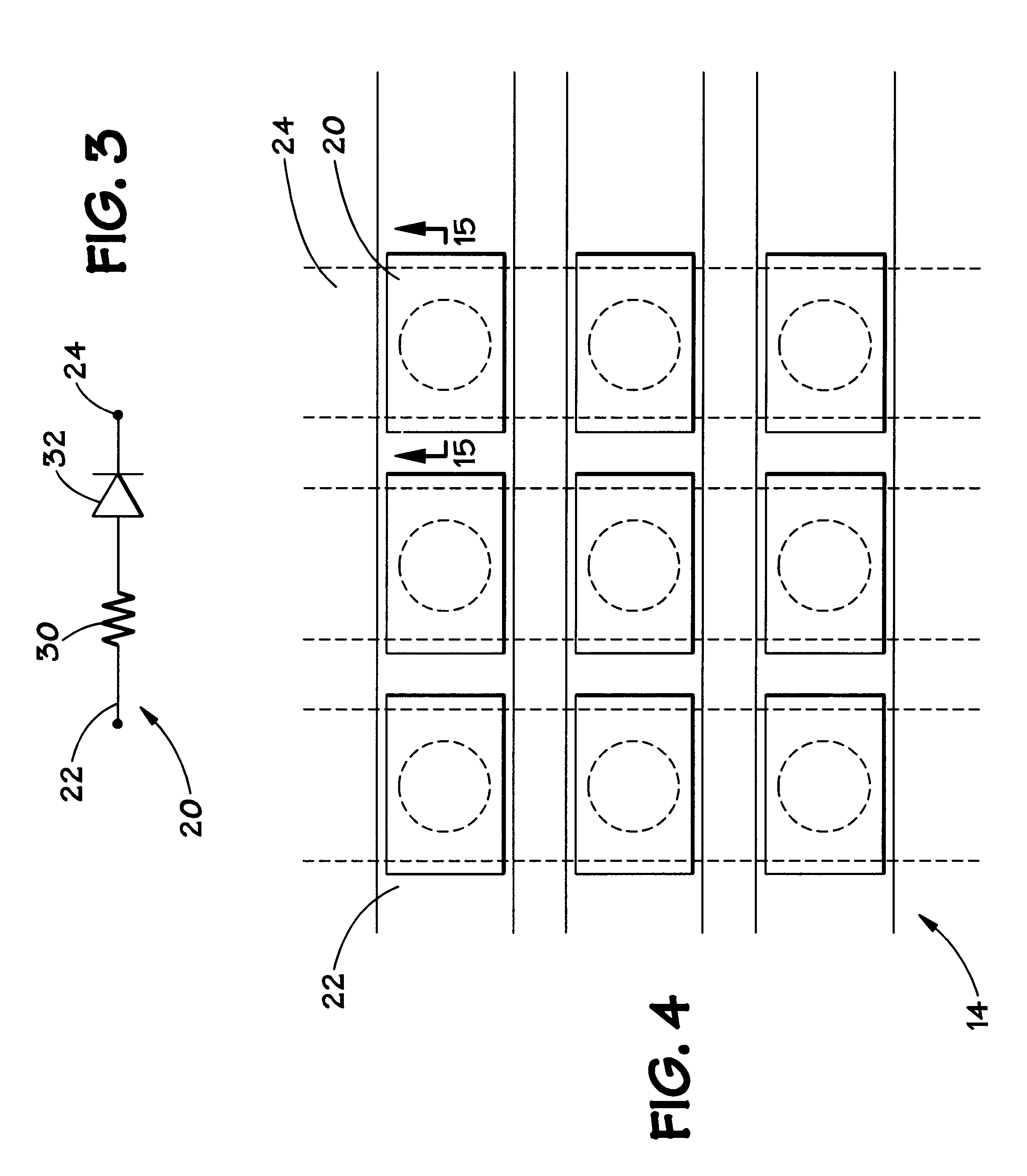

Design rule checking system and method

InactiveUS6470489B1Create efficientlyImprove system efficiencyOriginals for photomechanical treatmentComputer aided designDesign rule checkerLithography

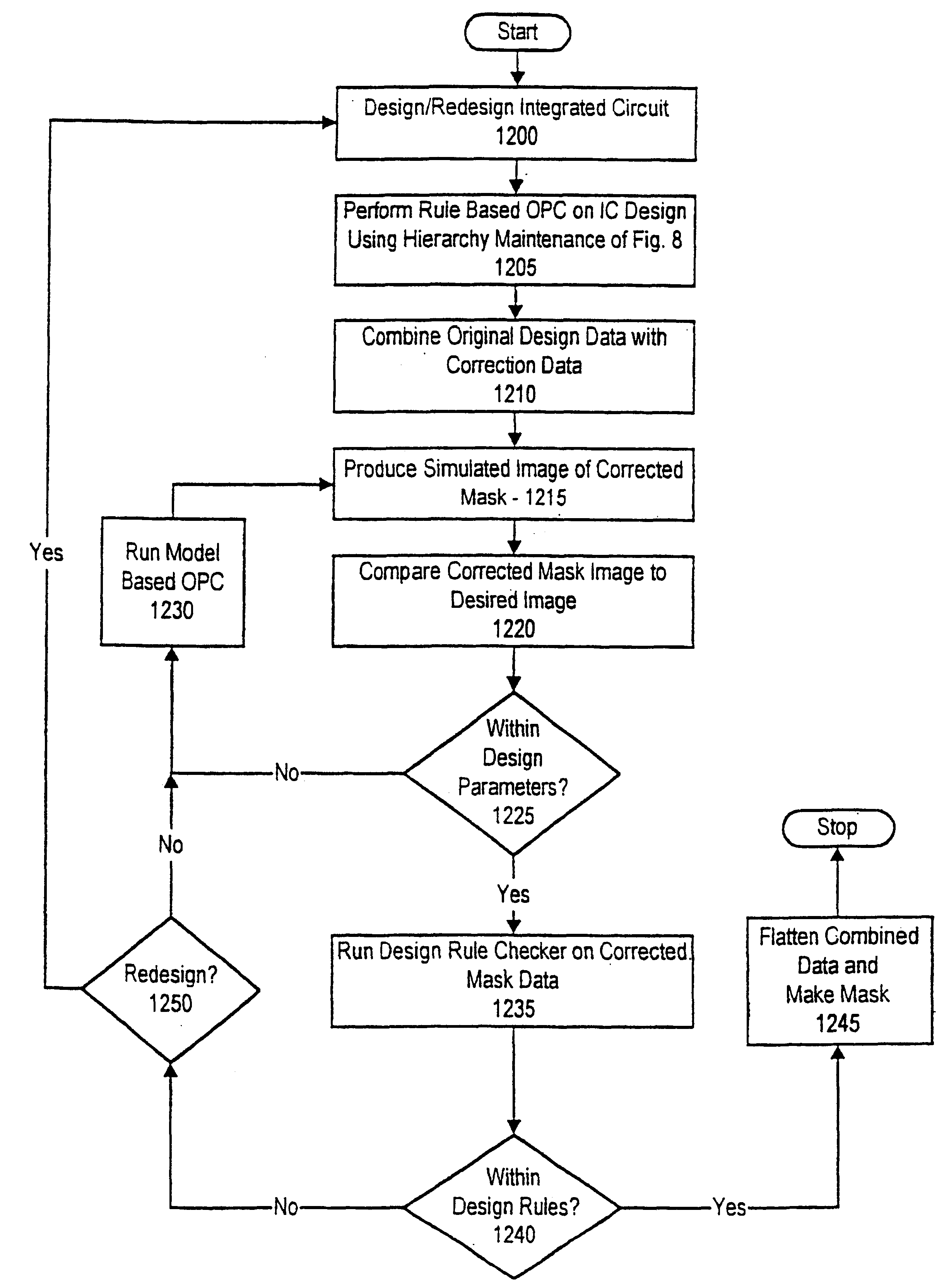

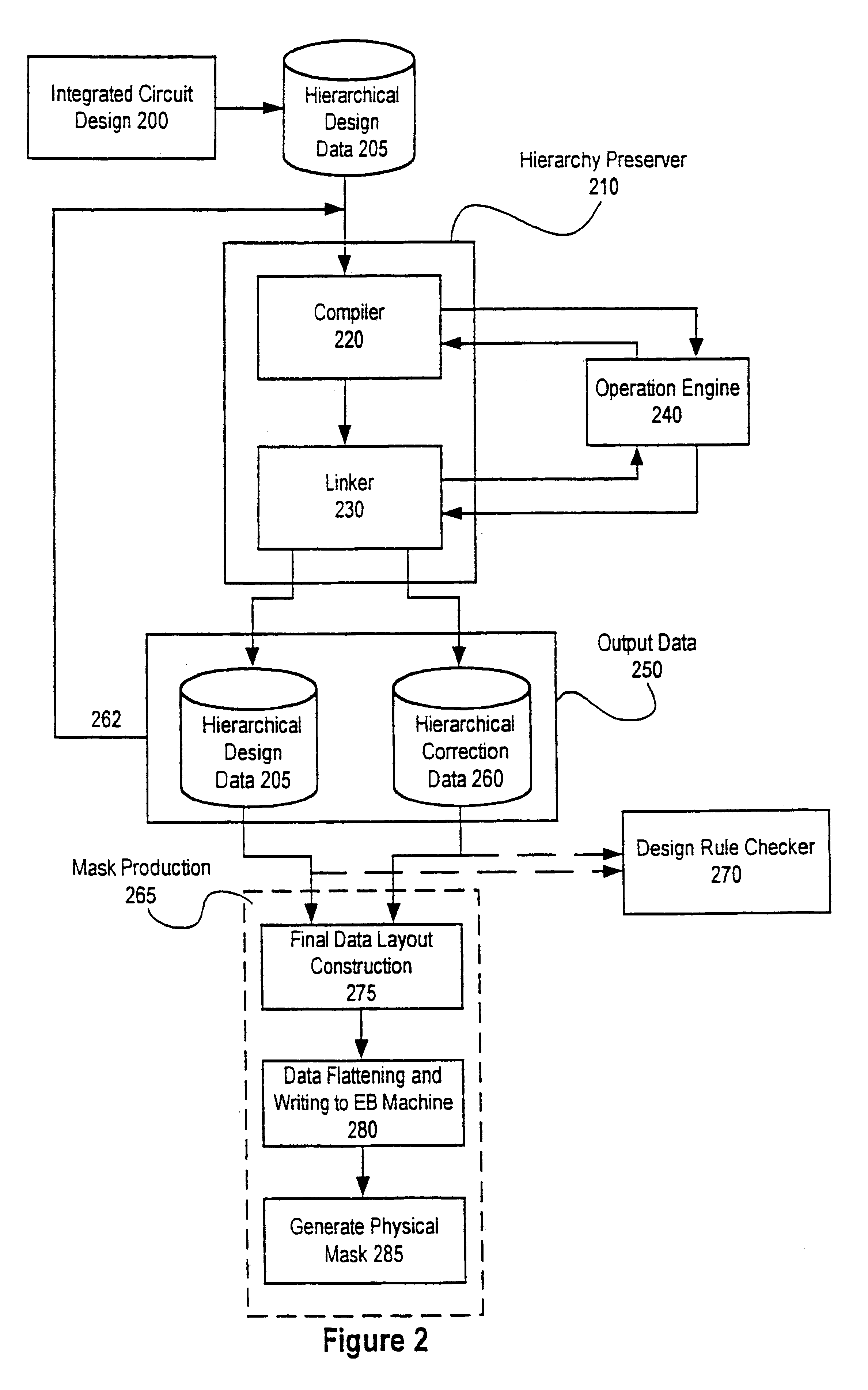

A method for performing design rule checking on OPC corrected or otherwise corrected designs is described. This method comprises accessing a corrected design and generating a simulated image. The simulated image corresponds to a simulation of an image which would be printed on a wafer if the wafer were exposed to an illumination source directed through the corrected design. The characteristics of the illumination source are determined by a set of lithography parameters. In creating the image, additional characteristics can be used to simulate portions of the fabrication process. However, what is important is that a resulting simulated image is created. The simulated image can then be used by the design rule checker. Importantly, the simulated image can be processed to reduce the number of vertices in the simulated image, relative to the number of vertices in the OPC corrected design layout. Also, the simulated image can be compared with an idea layout image, the results of which can then be used to reduce the amount of information that is needed to perform the design rule checking.

Owner:SYNOPSYS INC

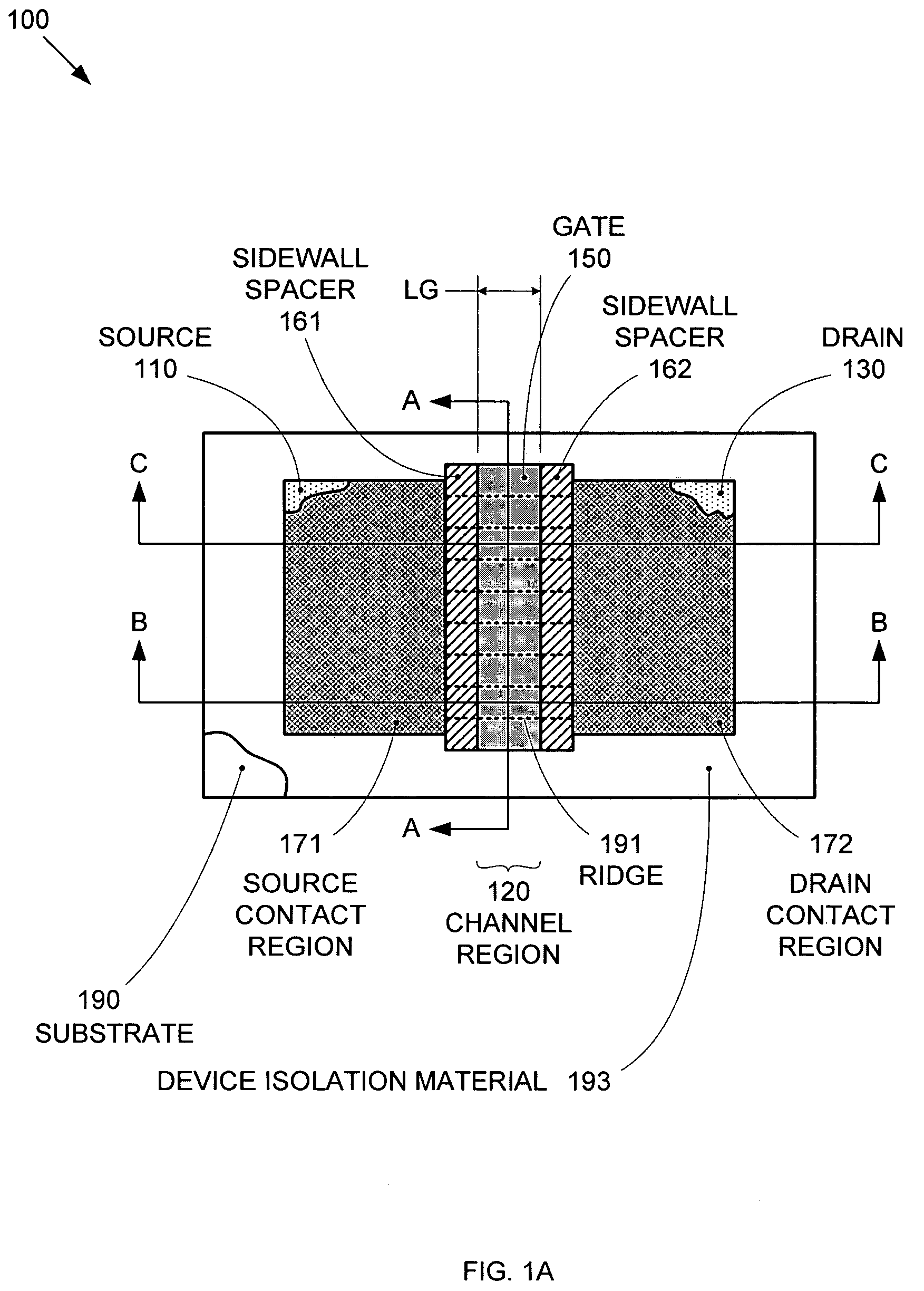

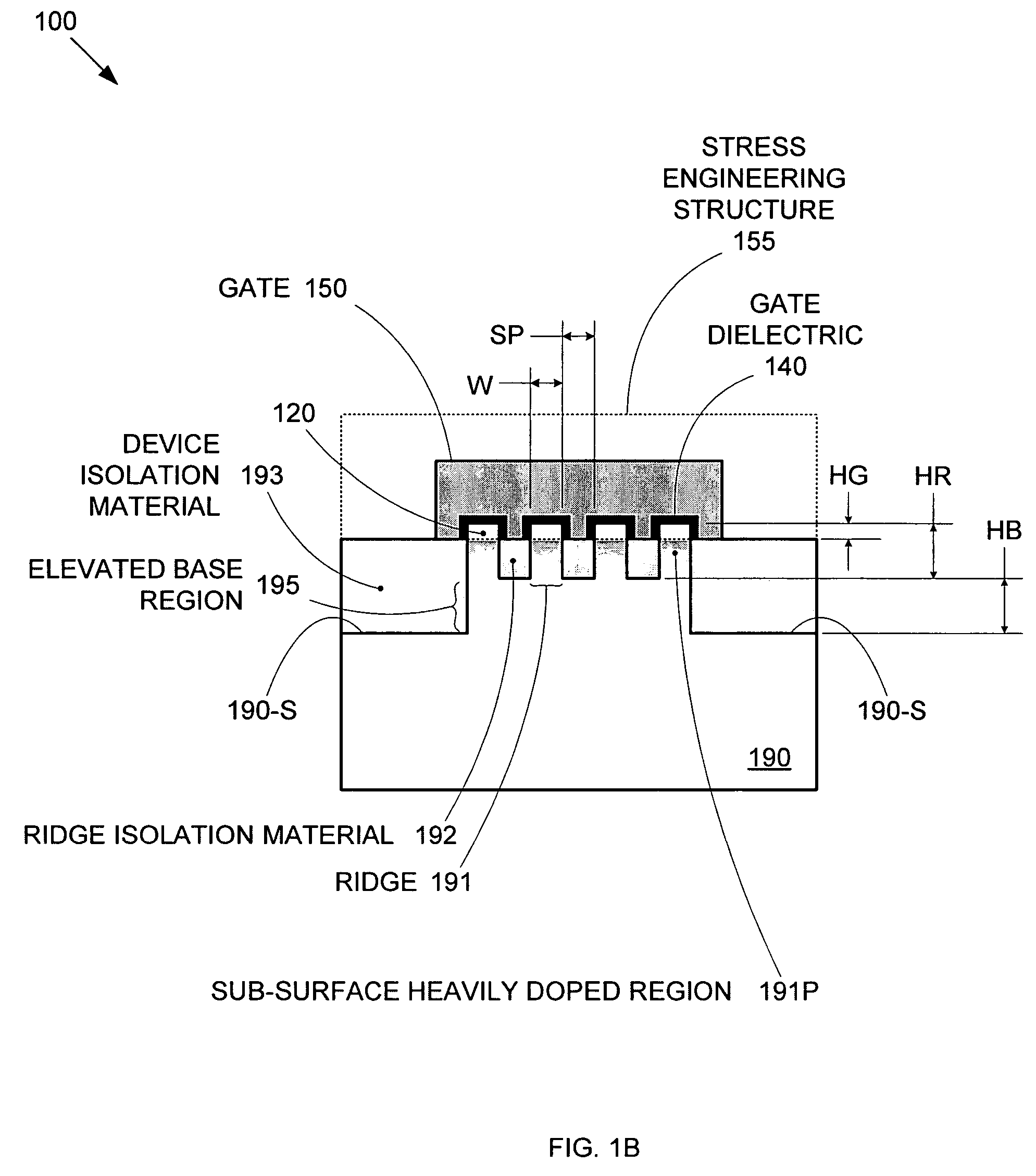

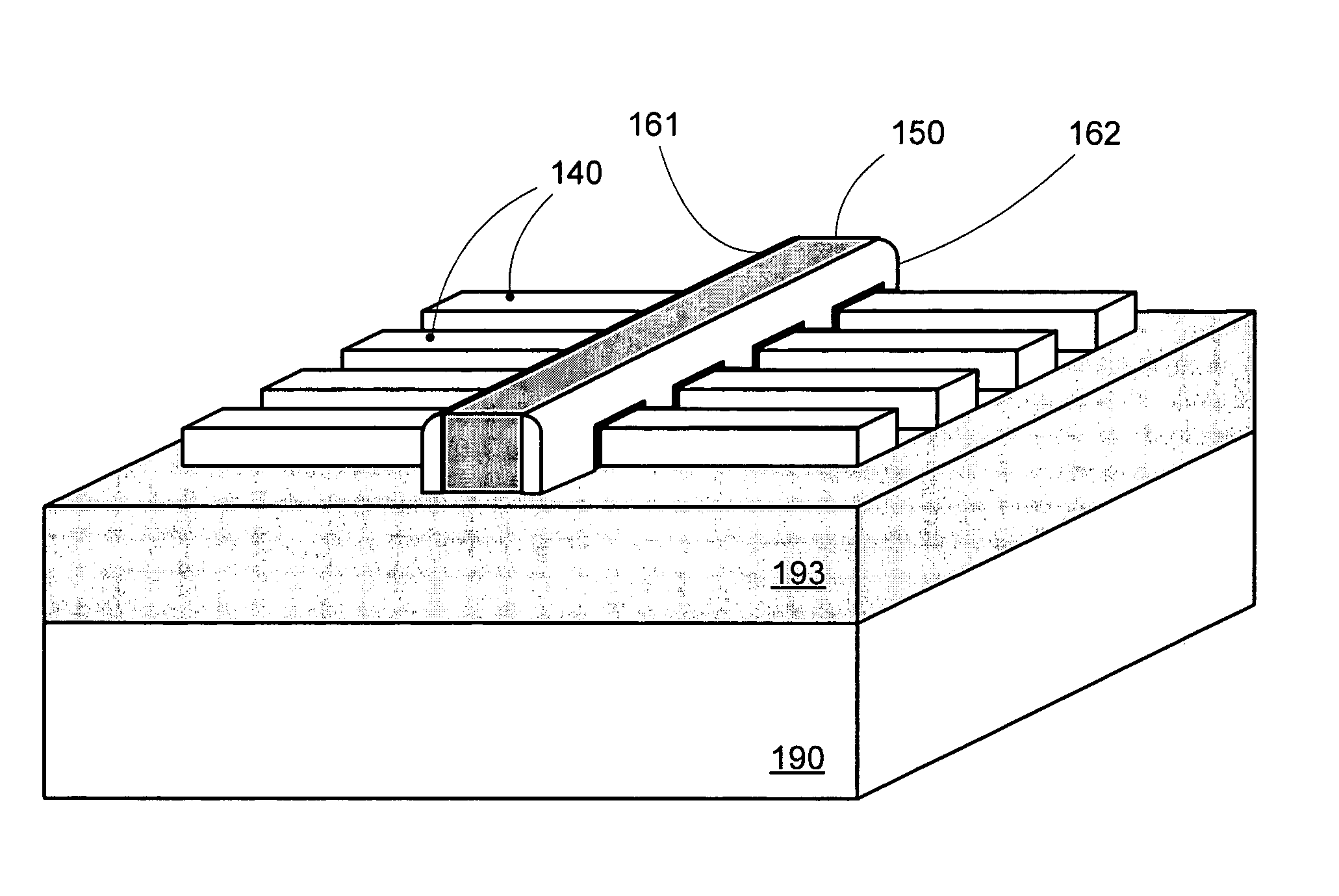

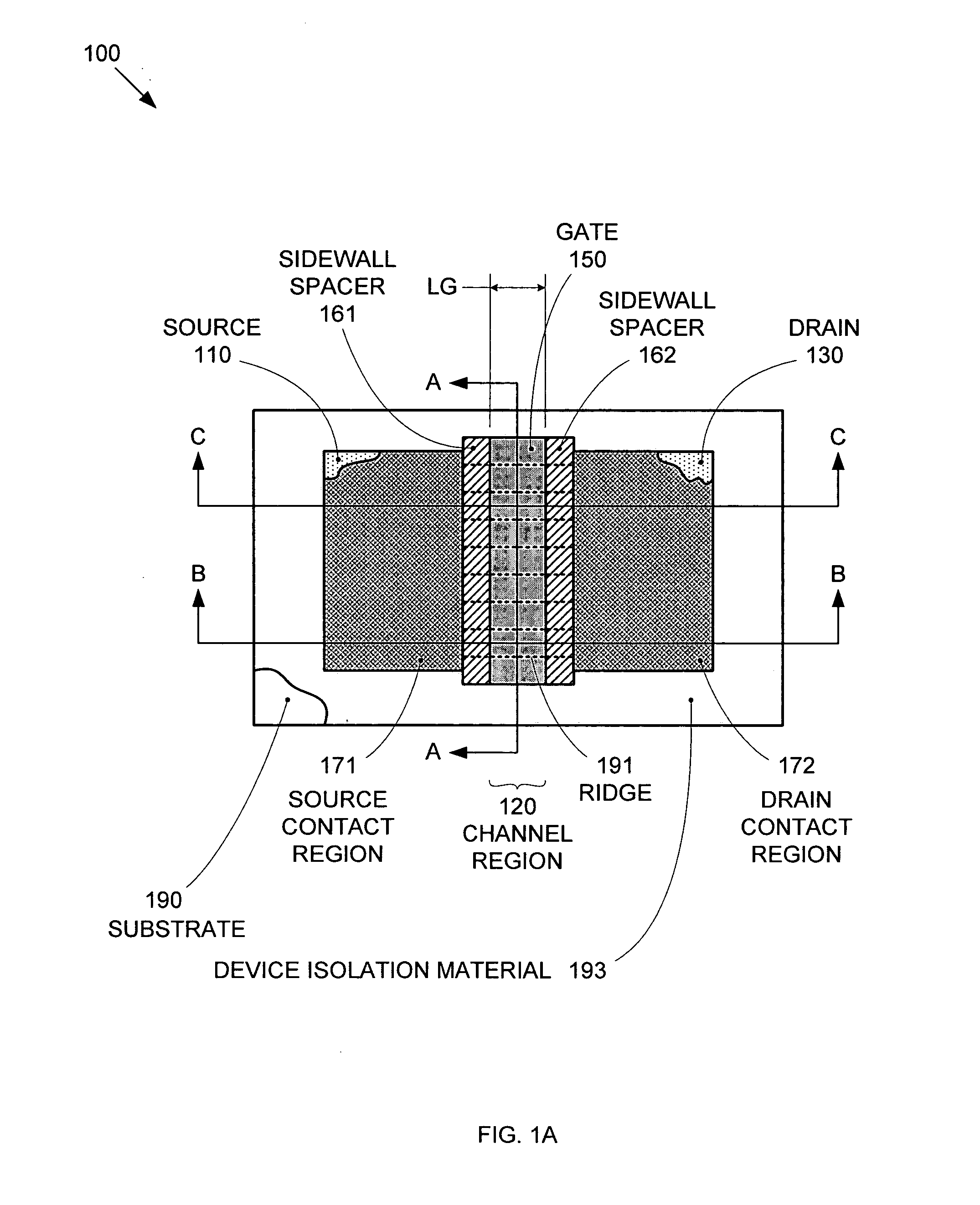

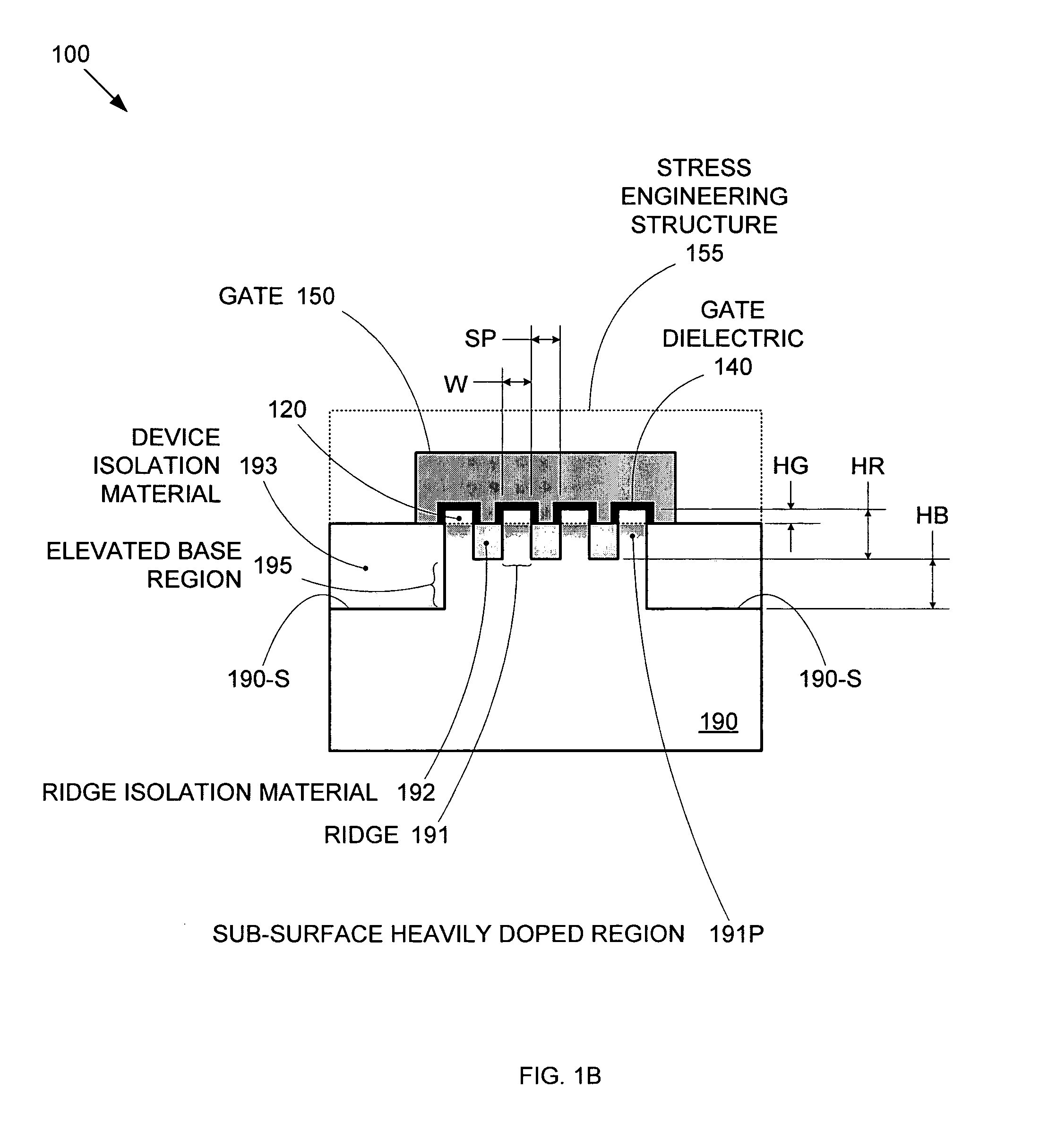

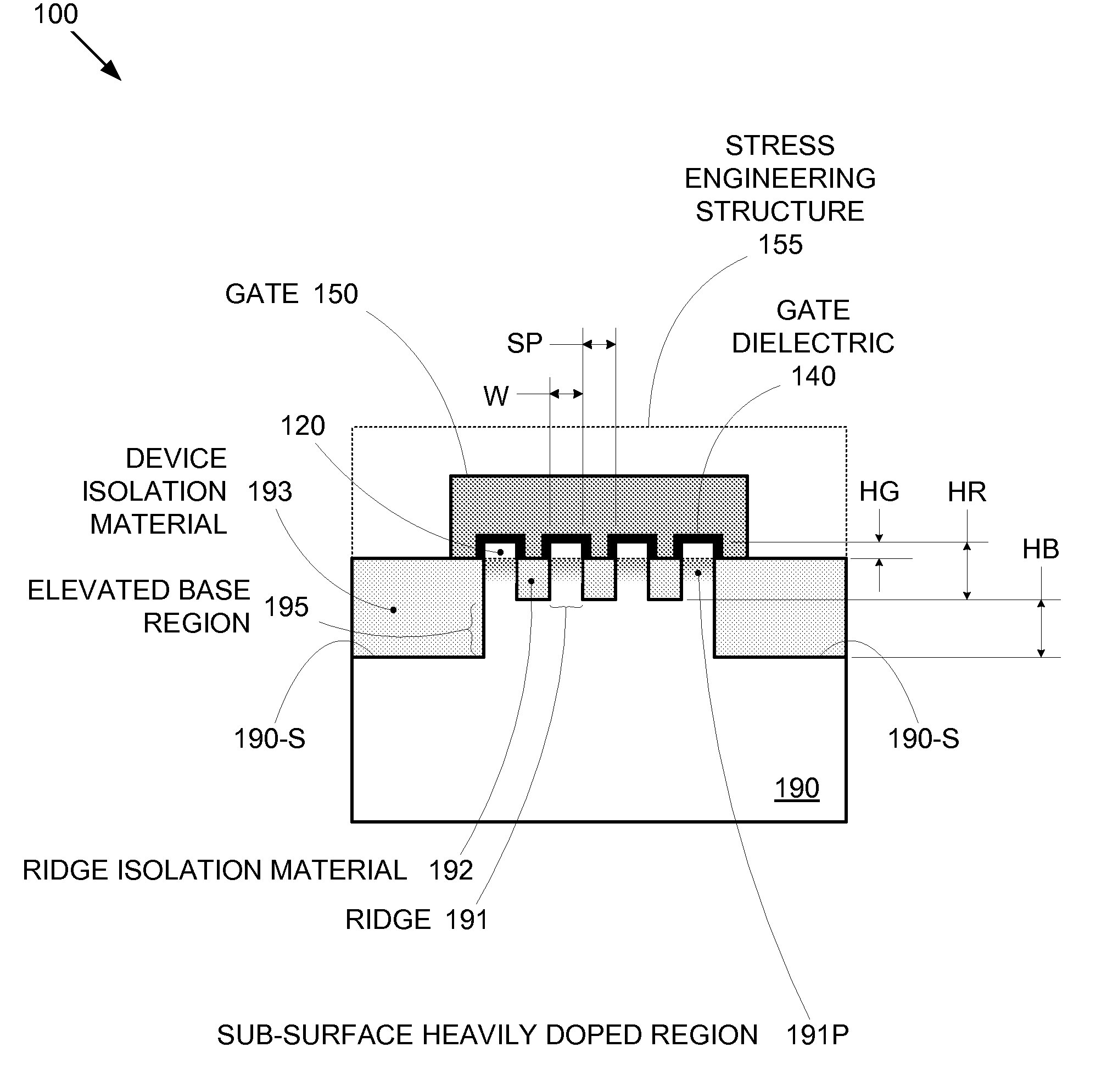

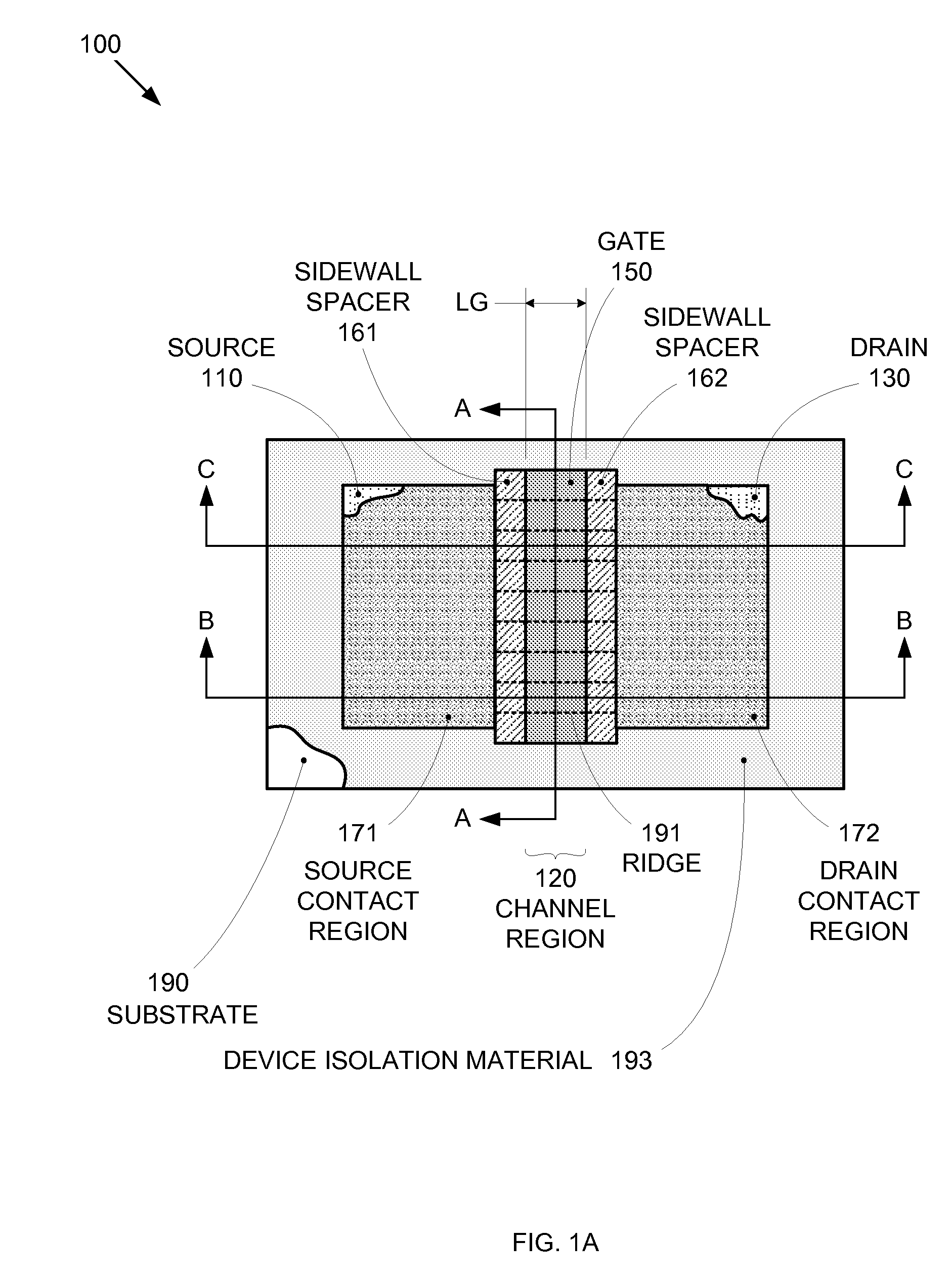

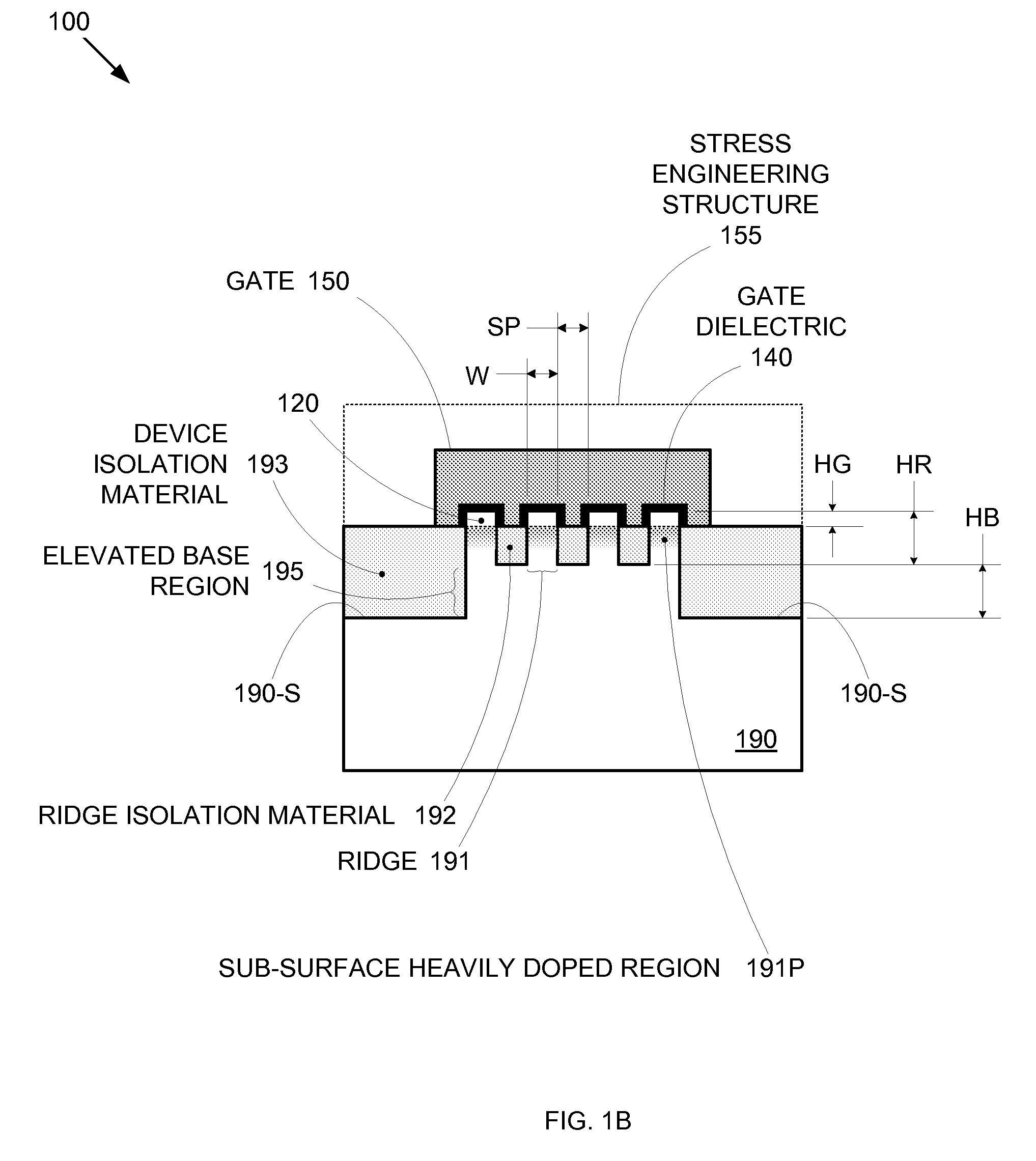

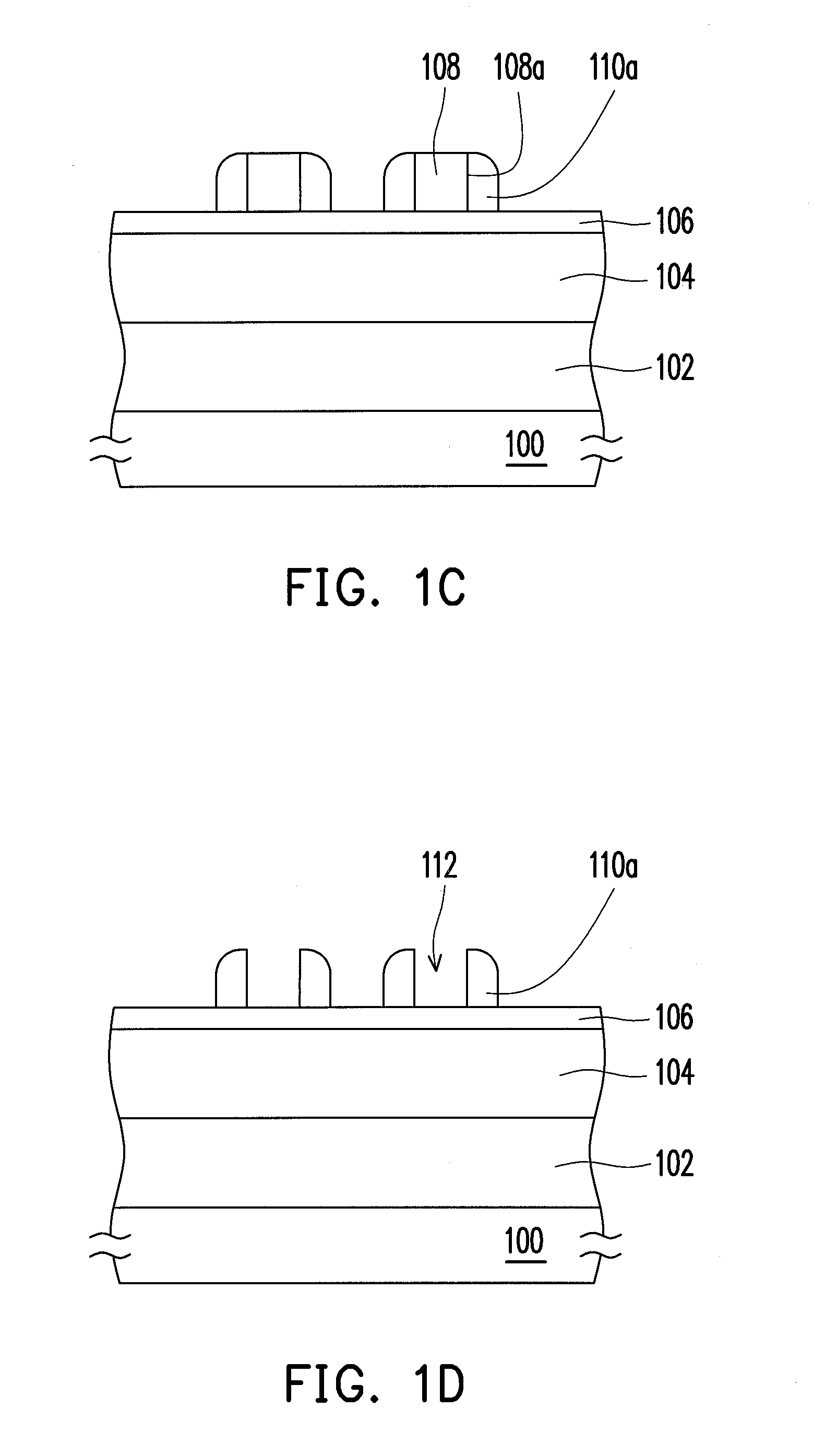

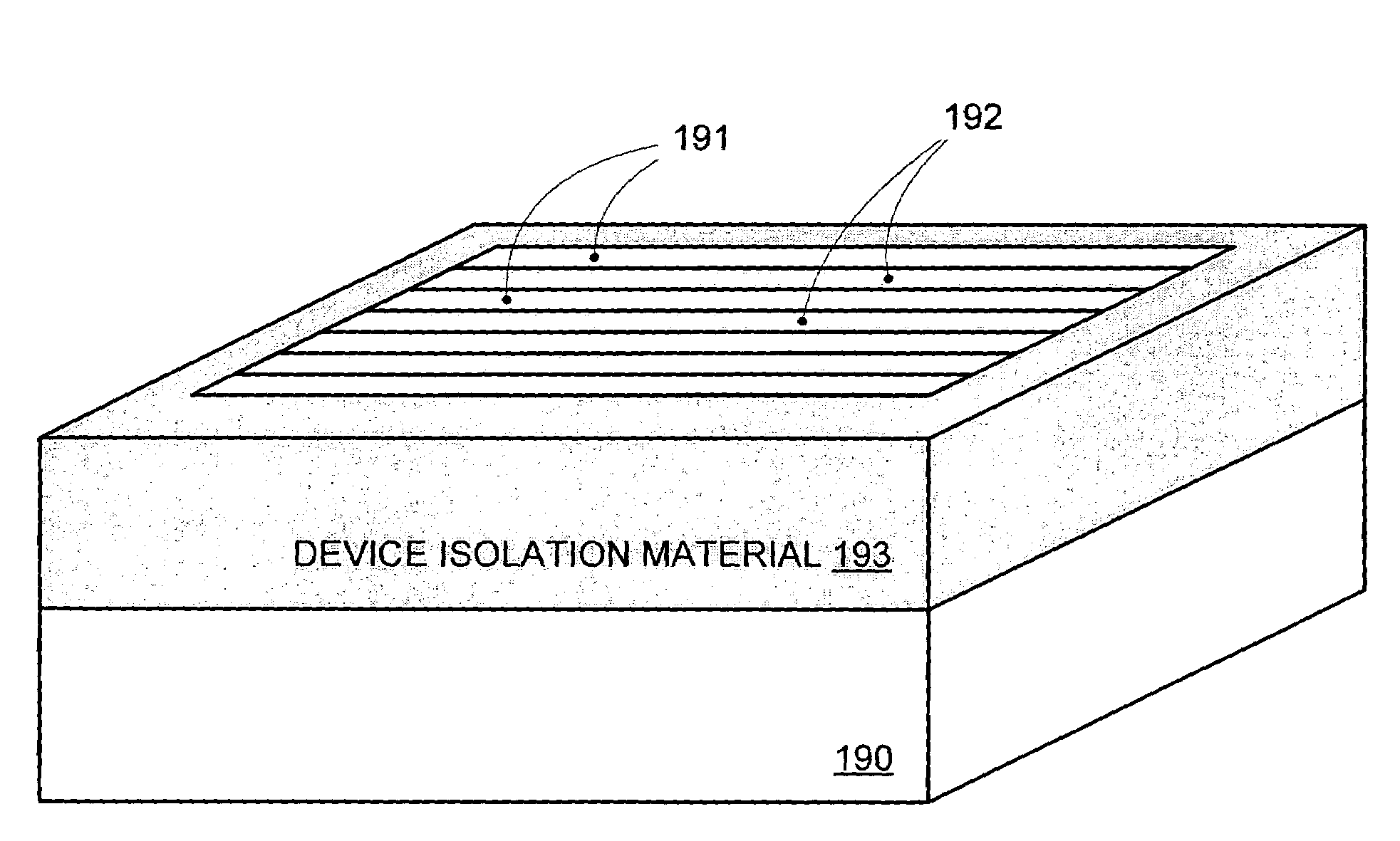

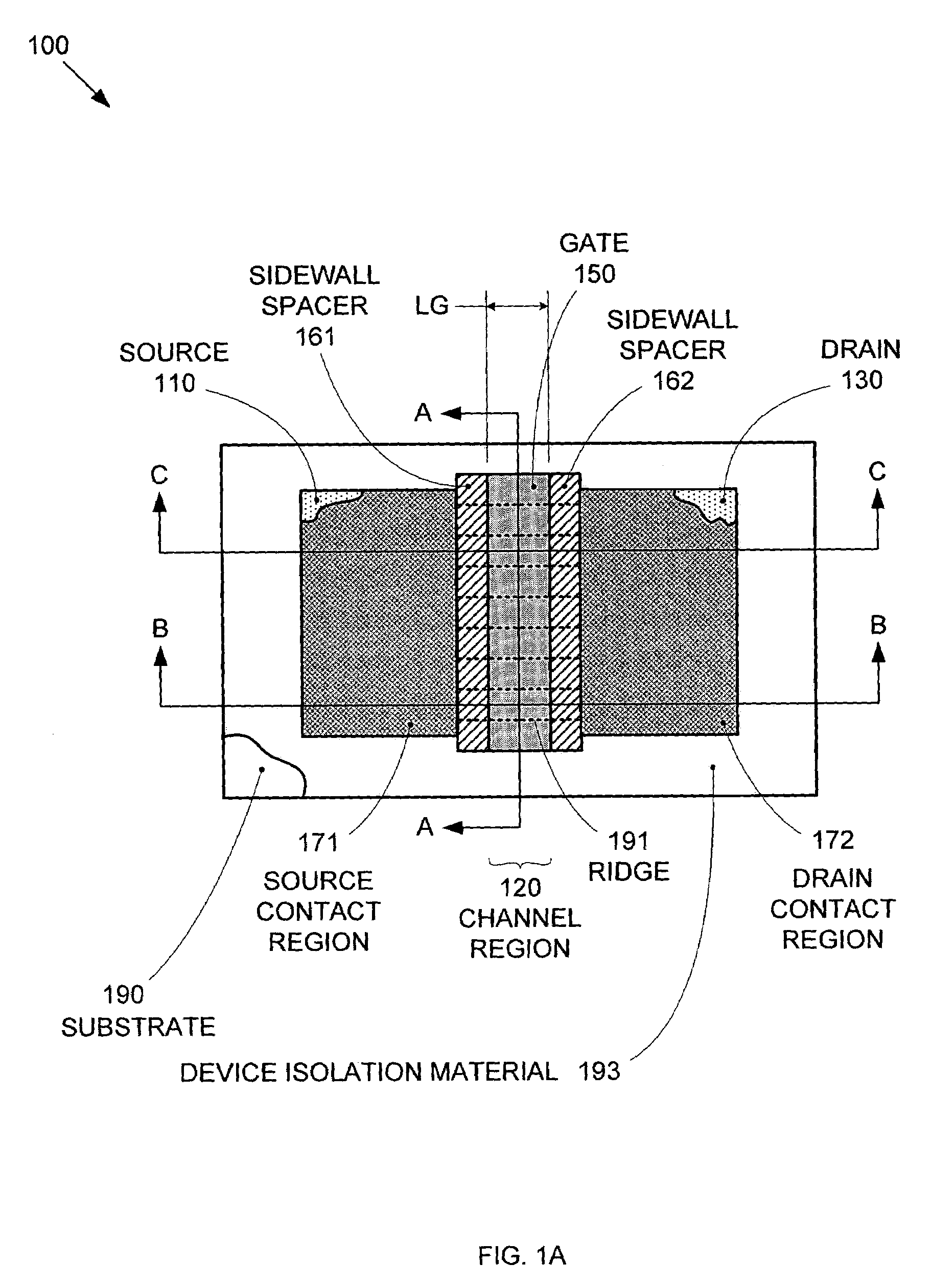

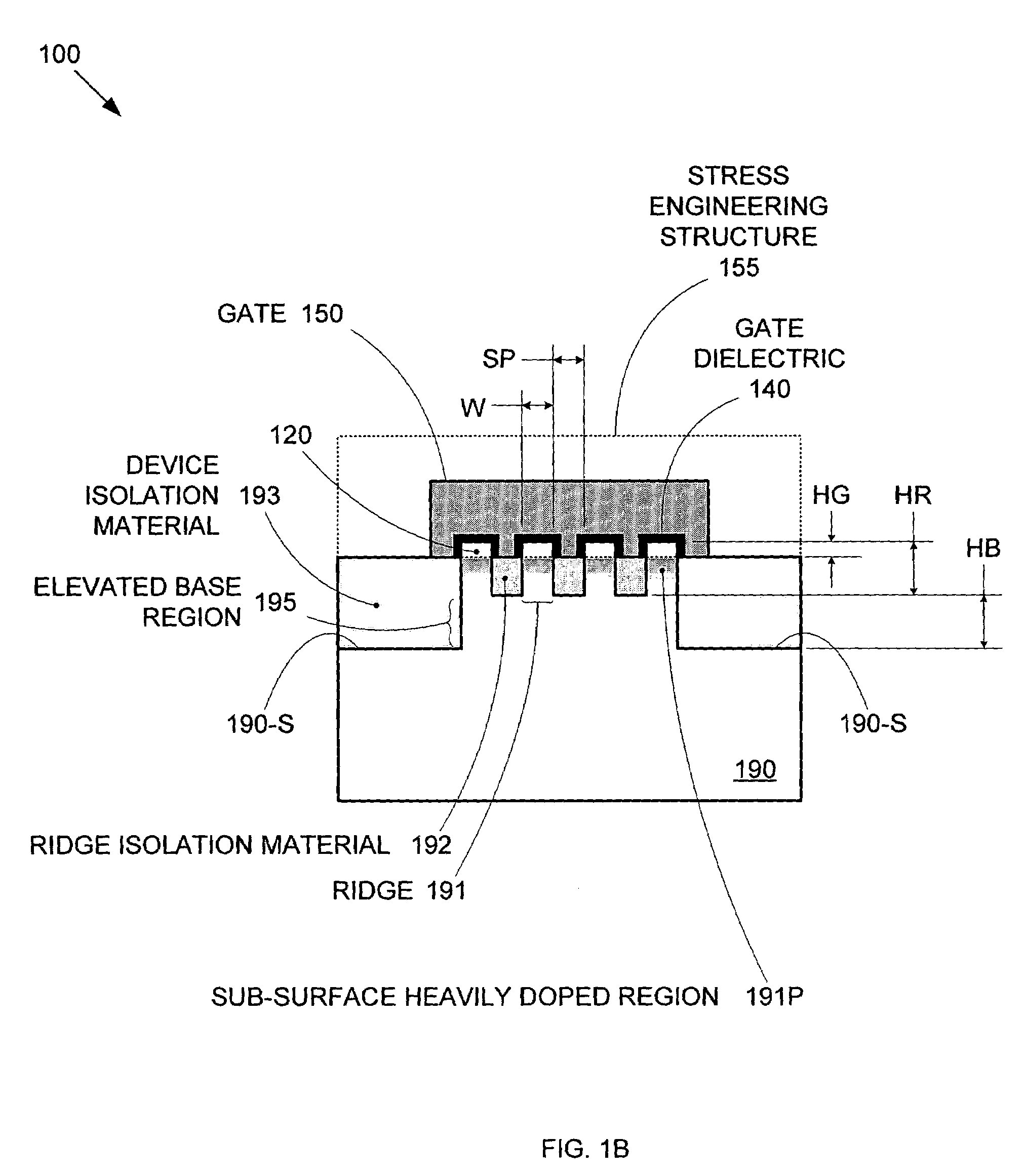

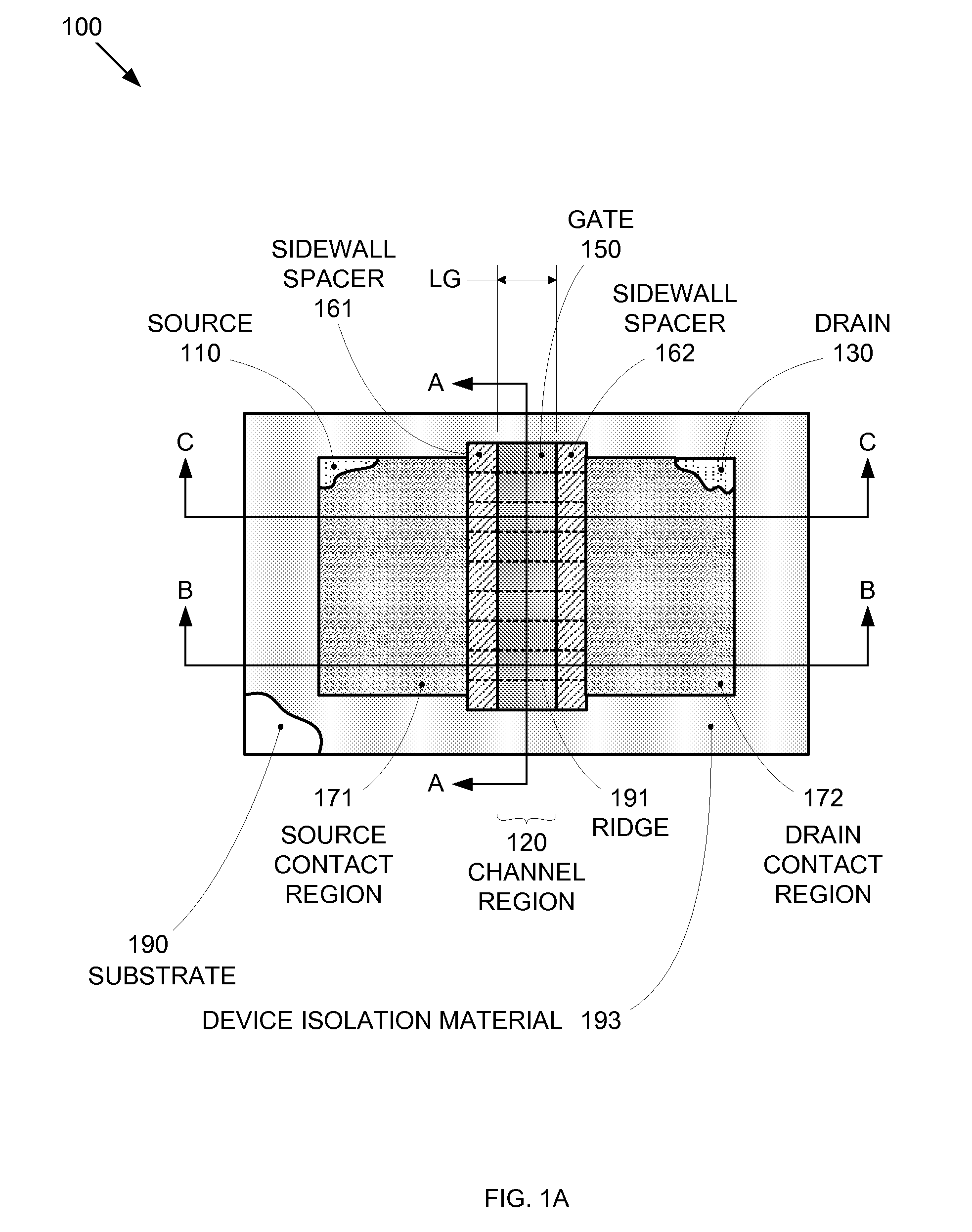

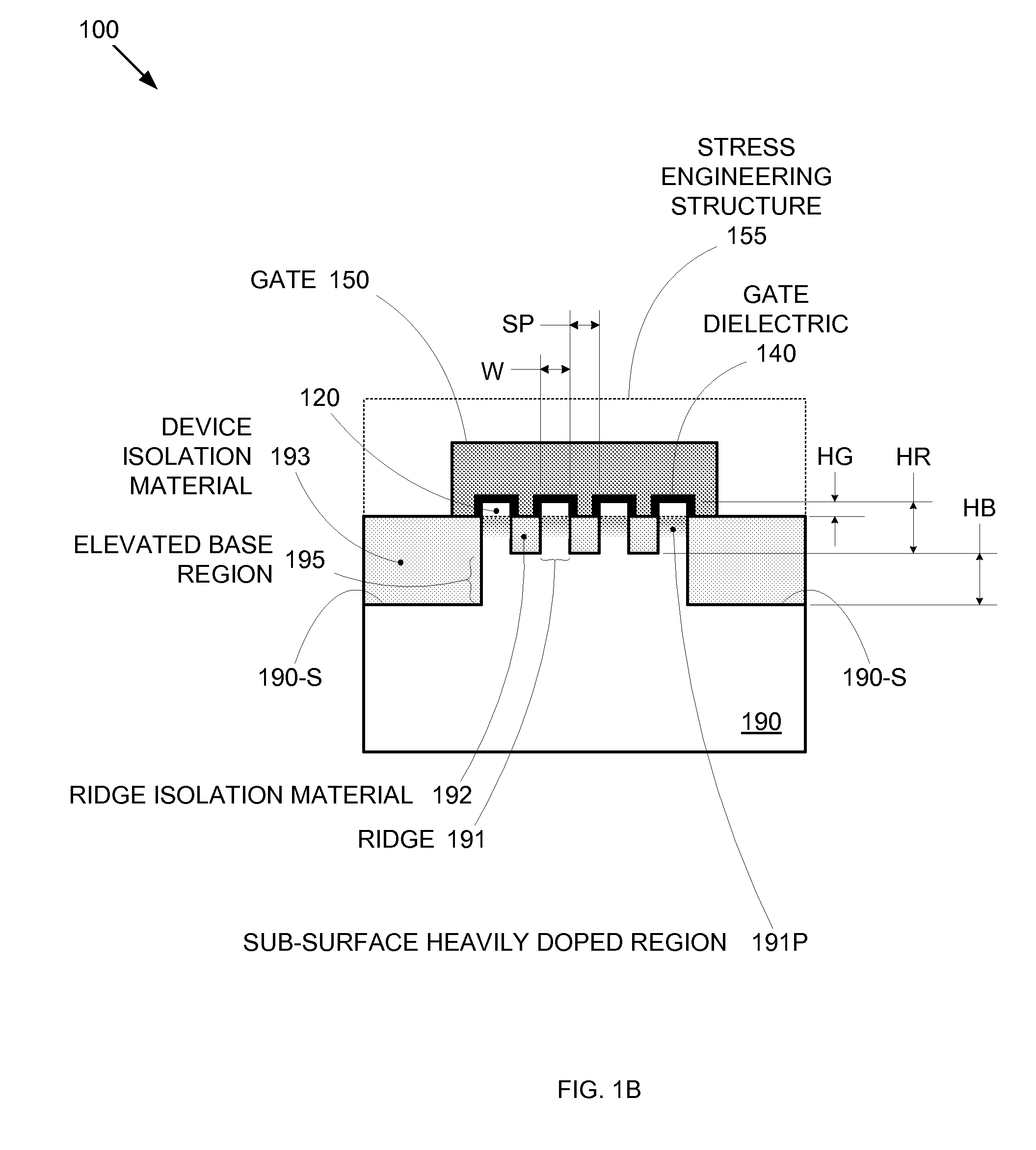

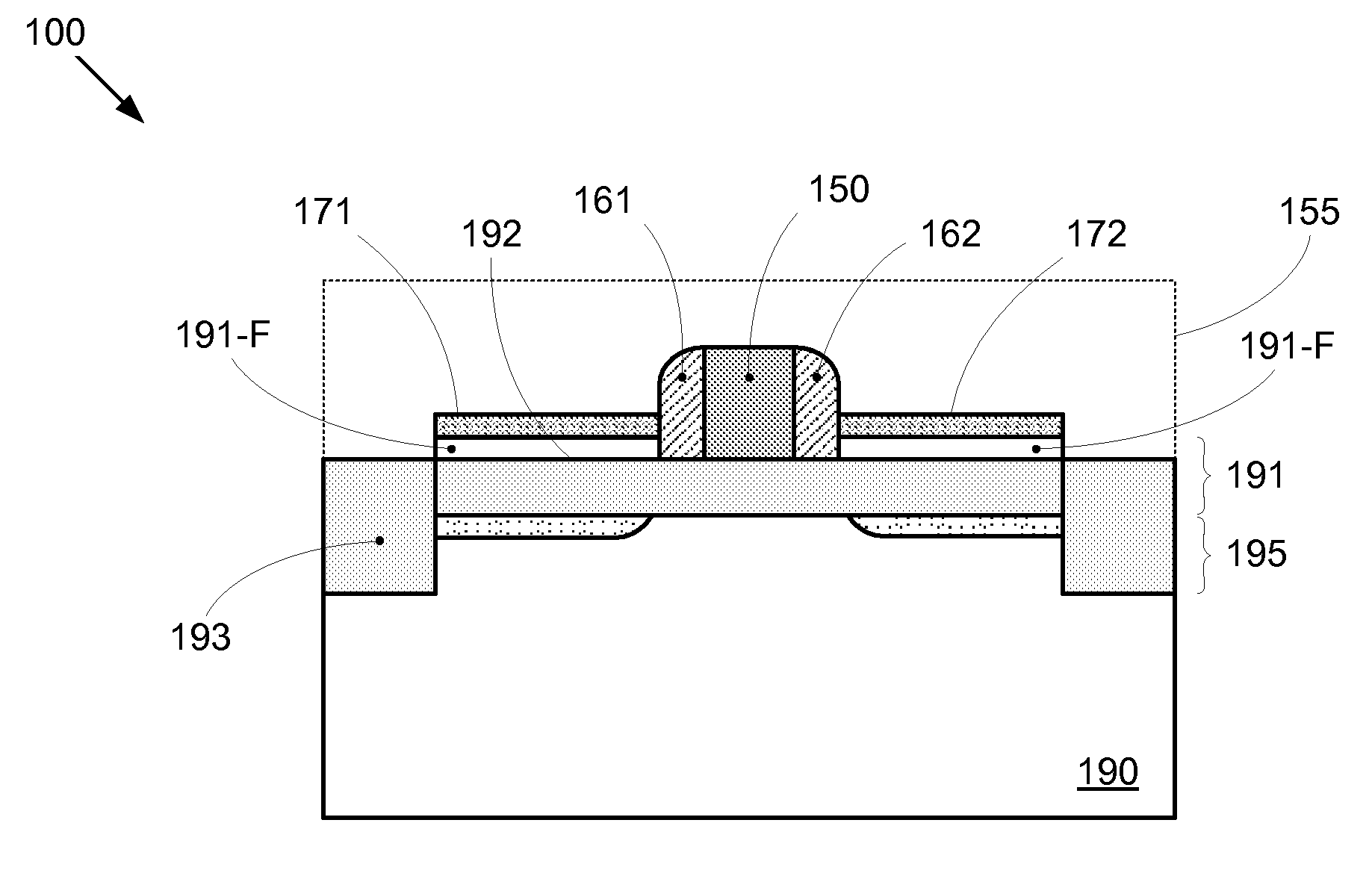

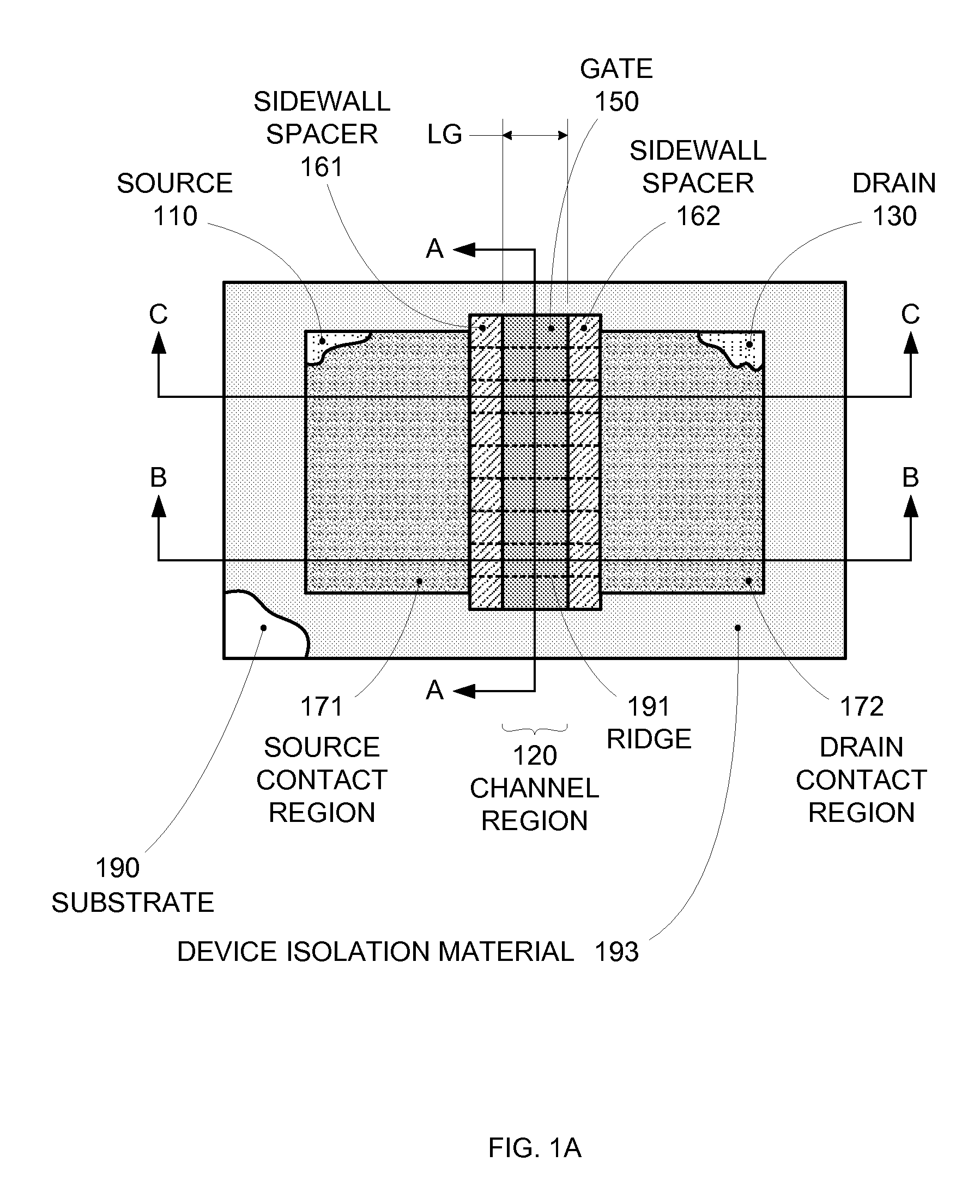

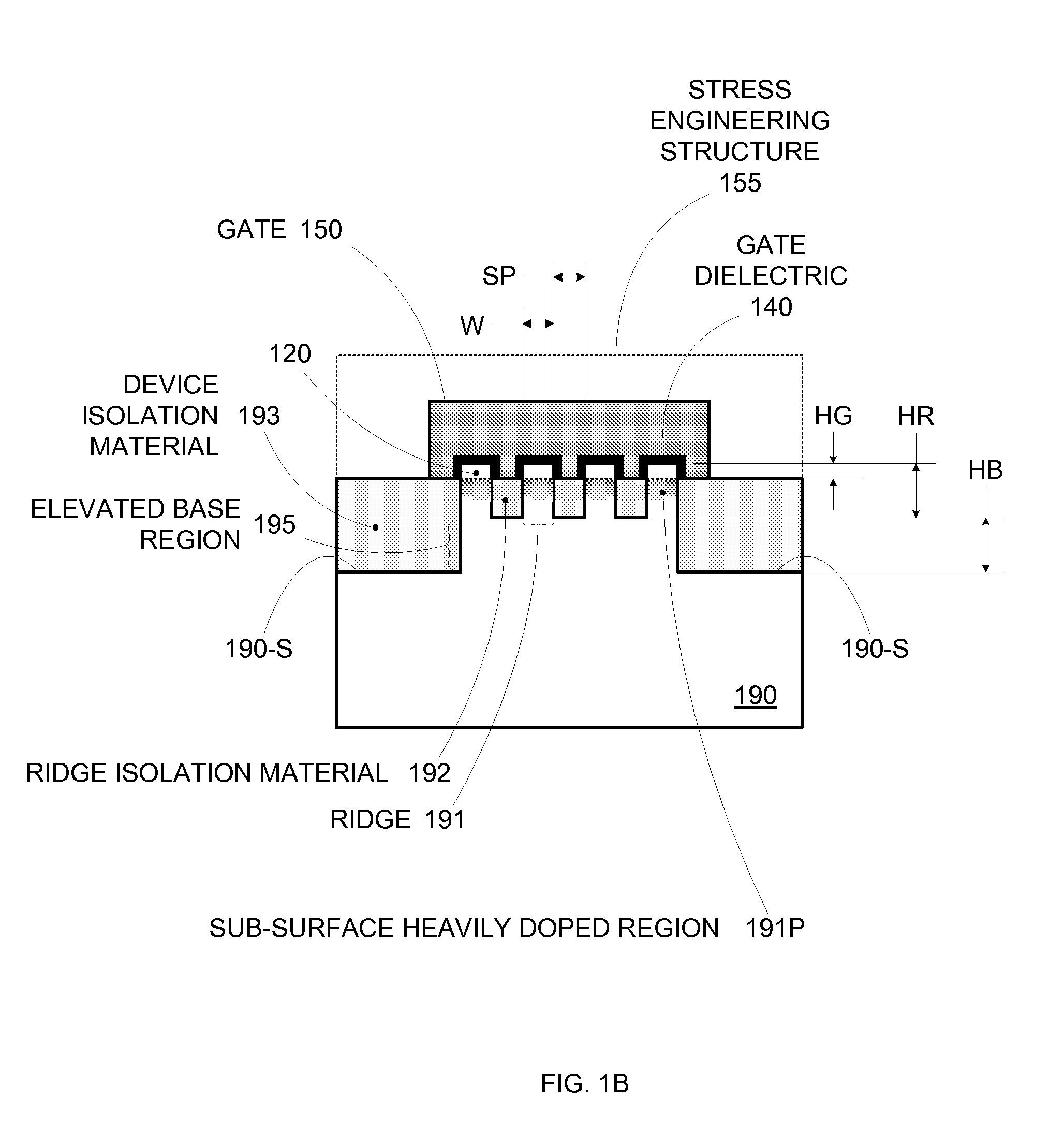

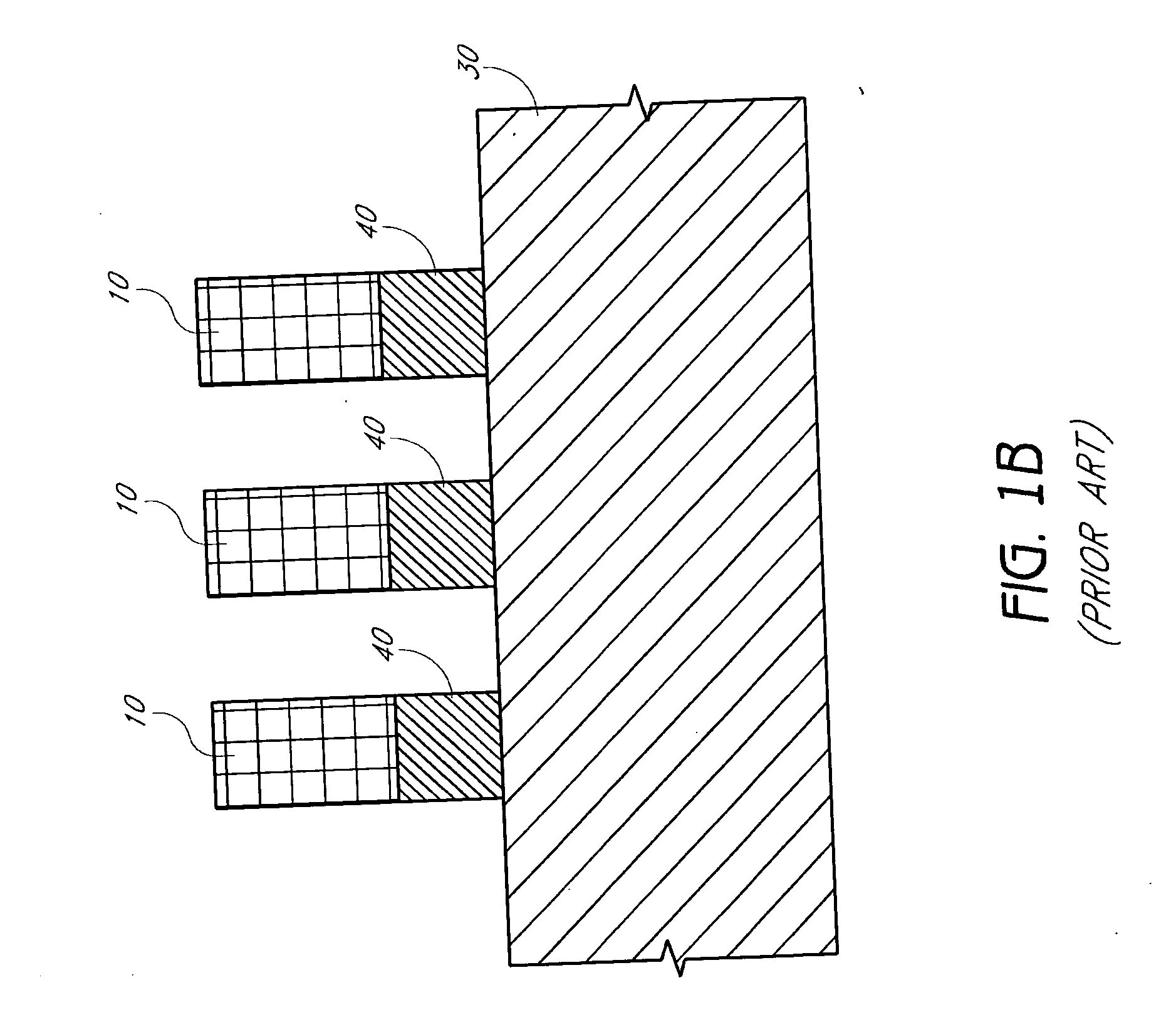

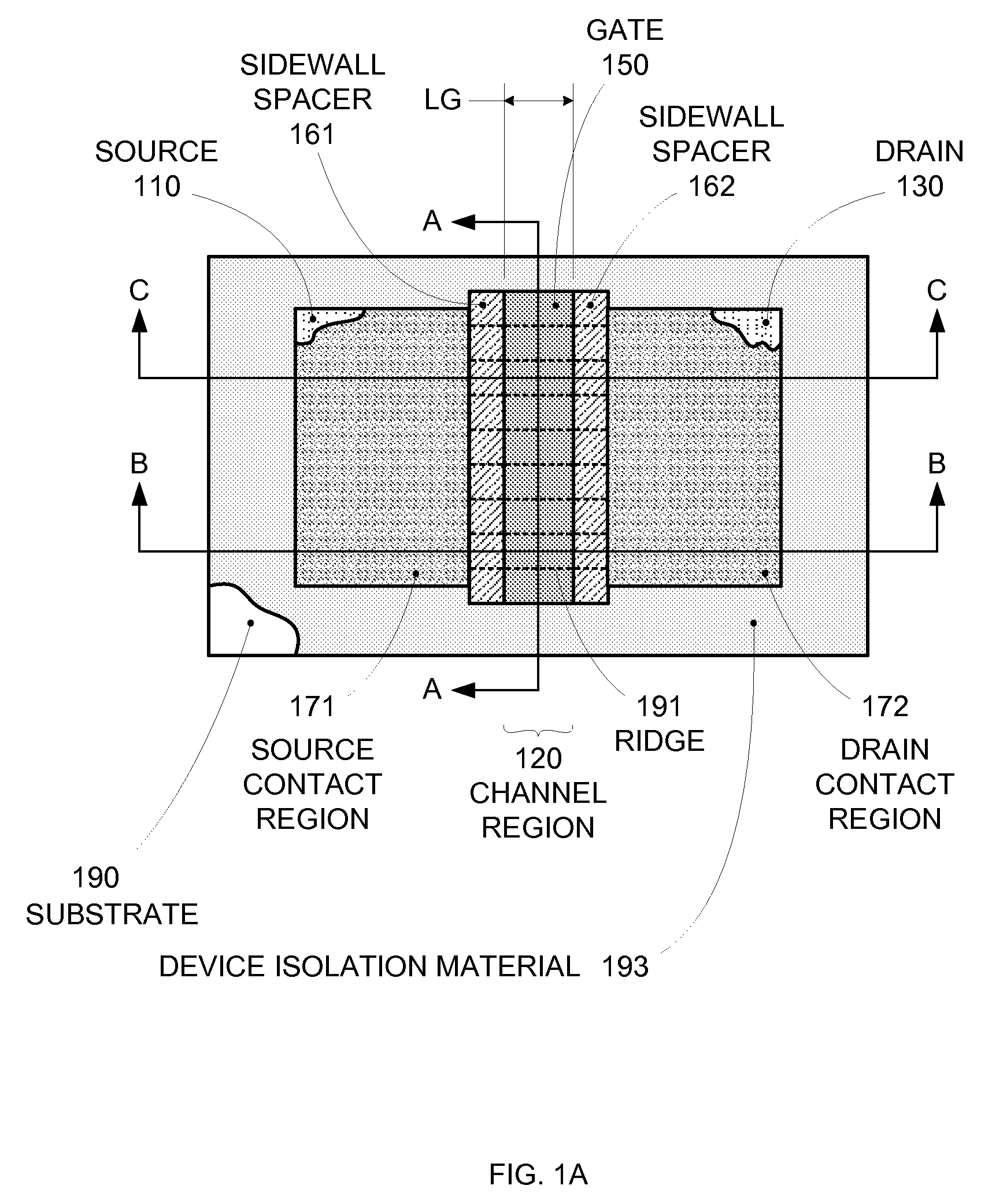

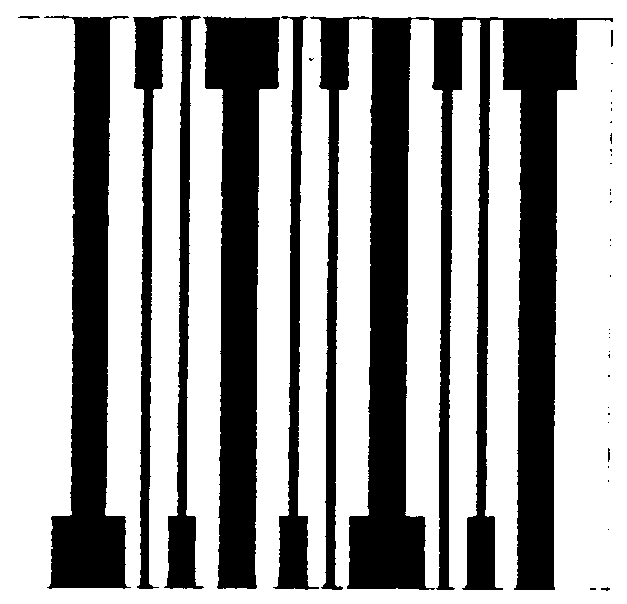

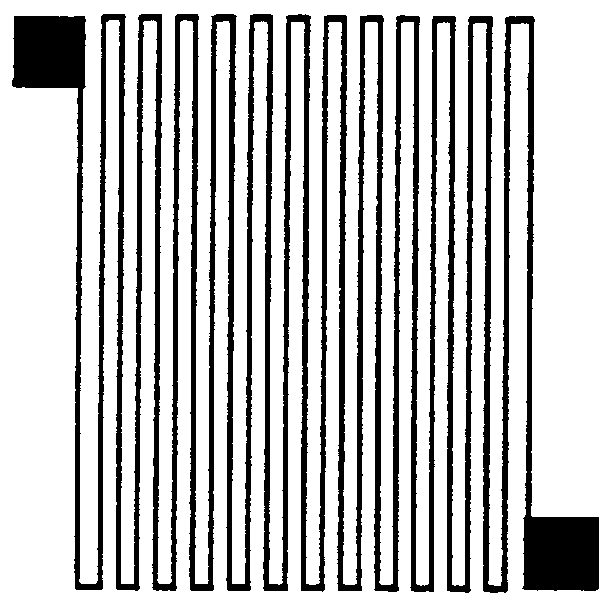

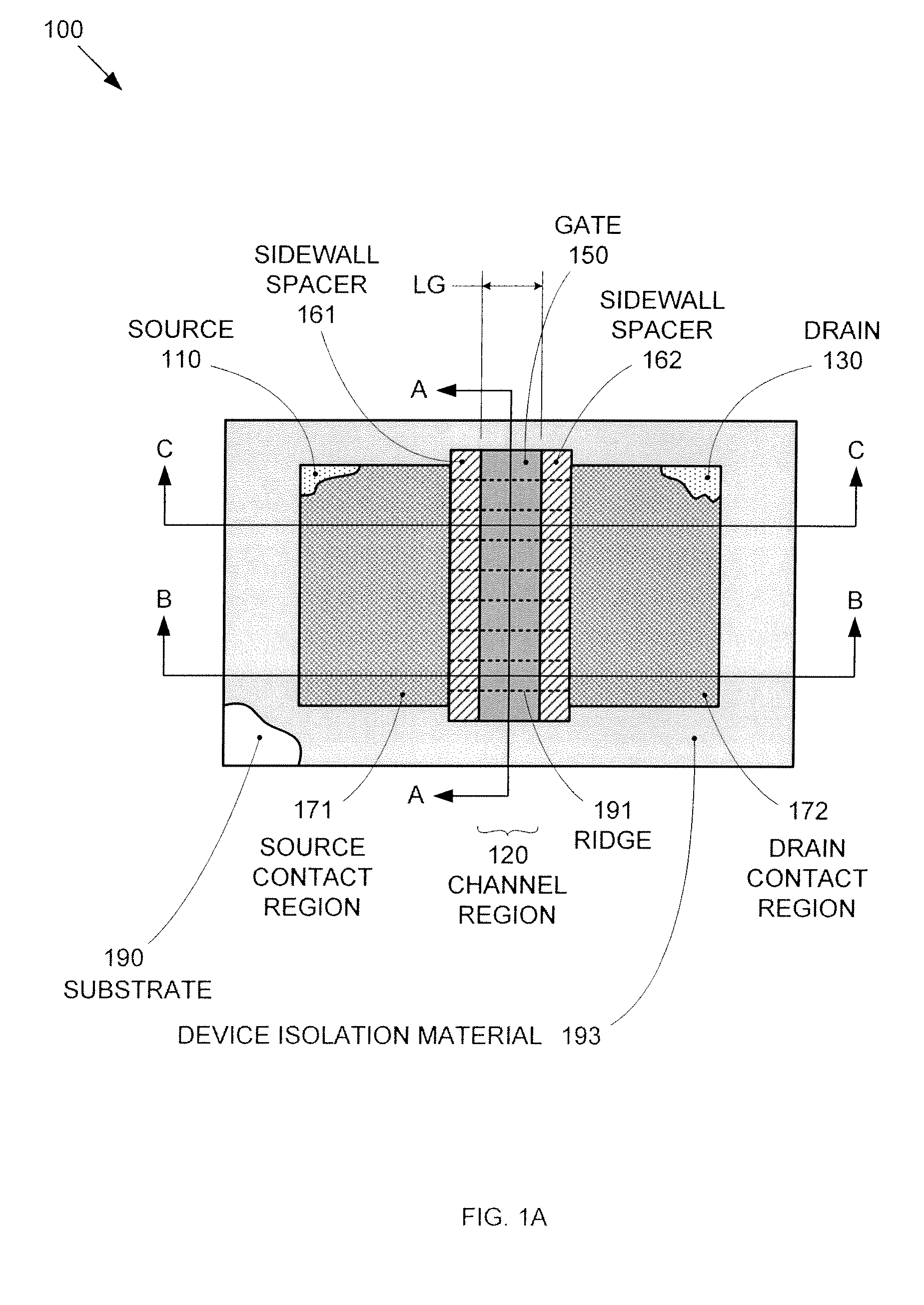

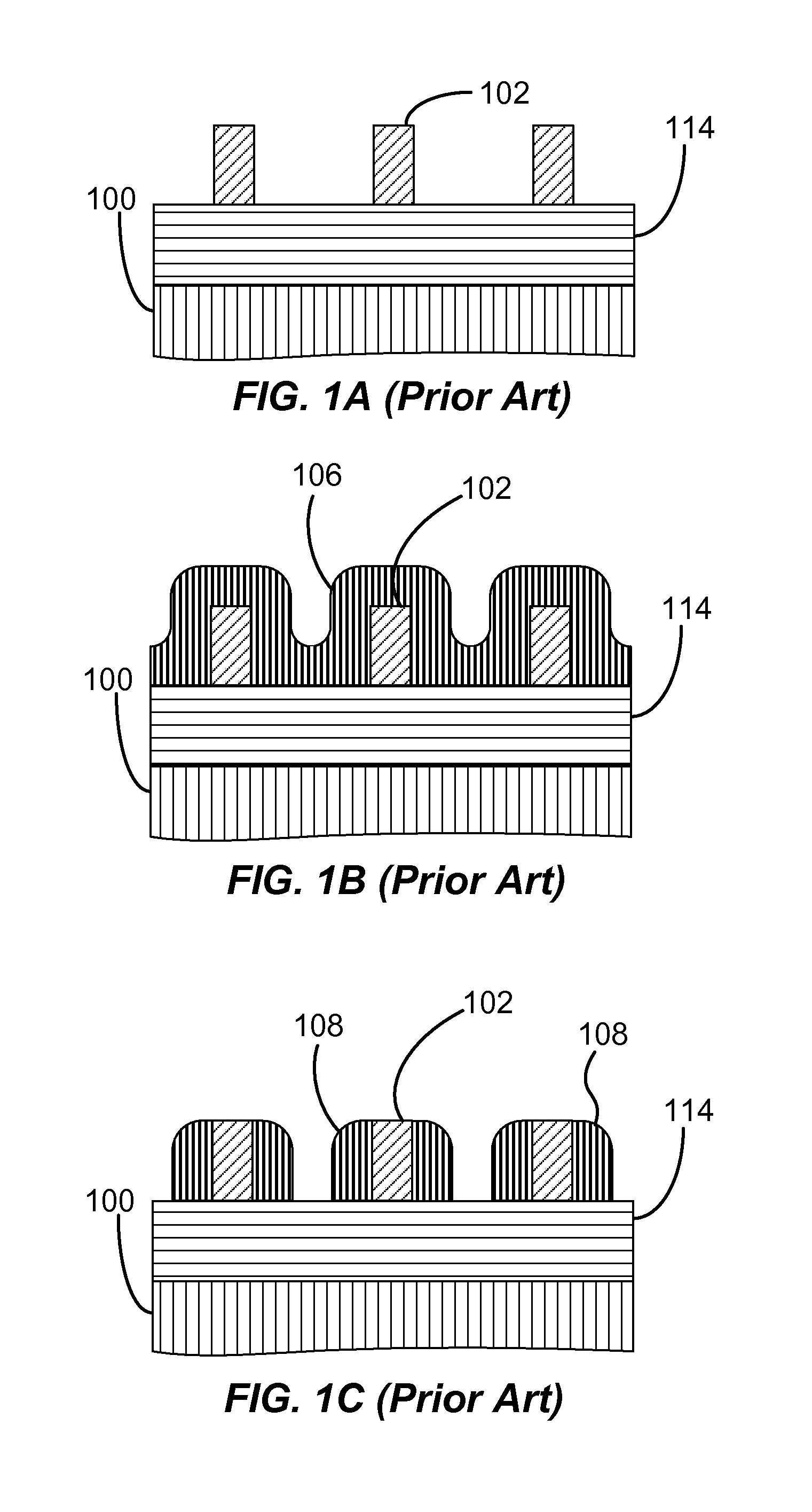

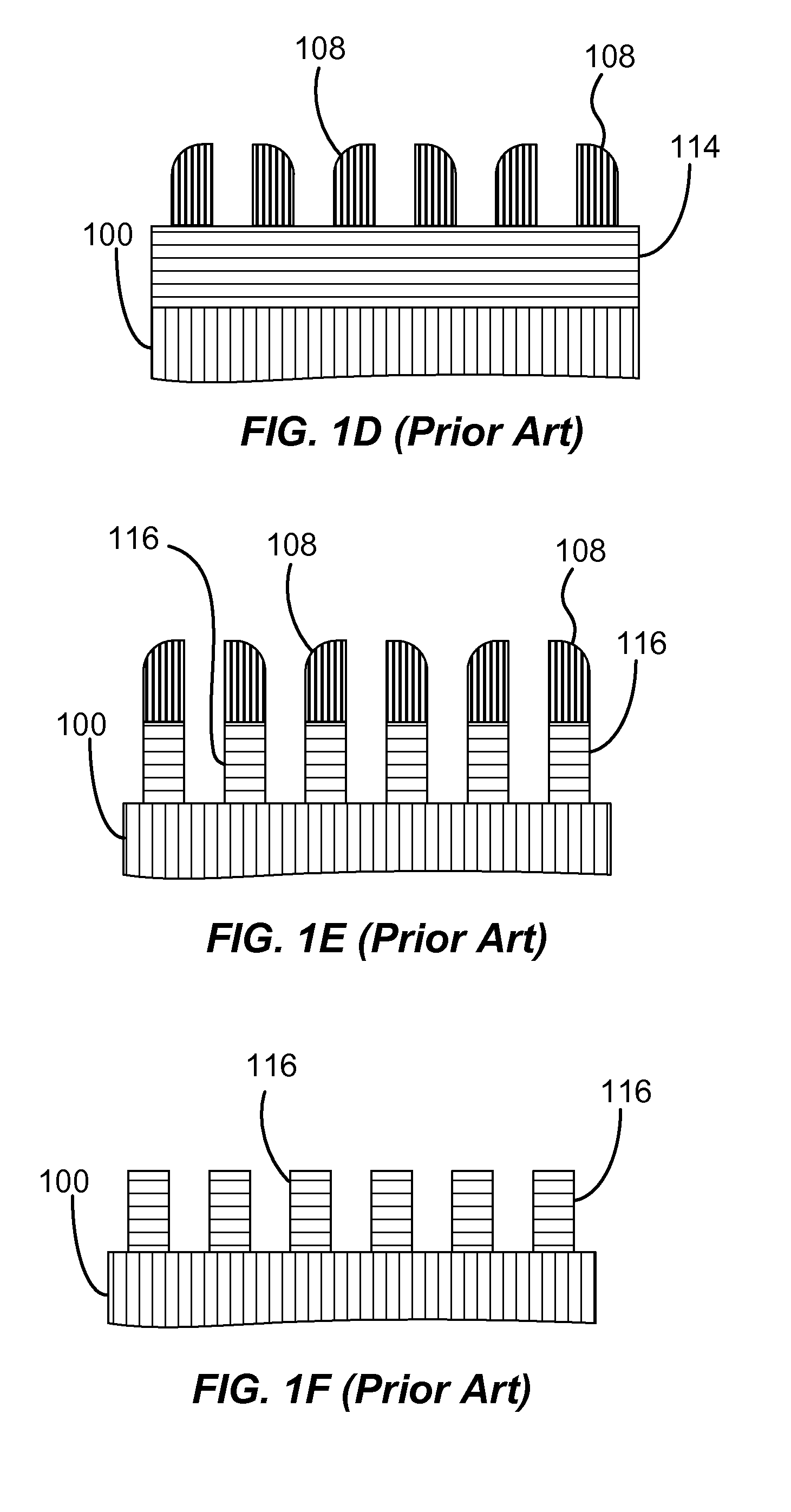

Segmented channel MOS transistor

ActiveUS7247887B2Improve performance consistencyImprove performanceTransistorSolid-state devicesMOSFETLithographic artist

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

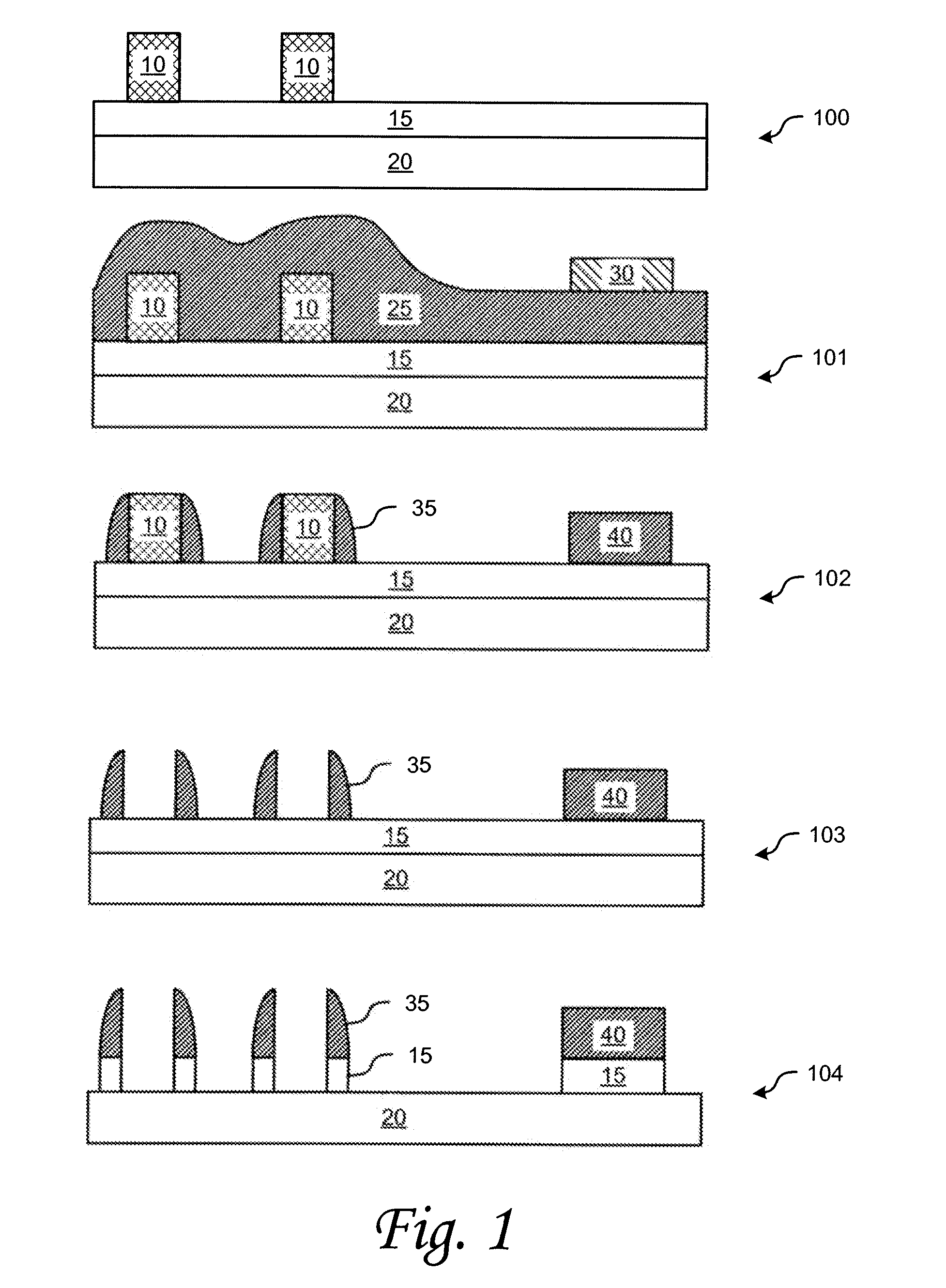

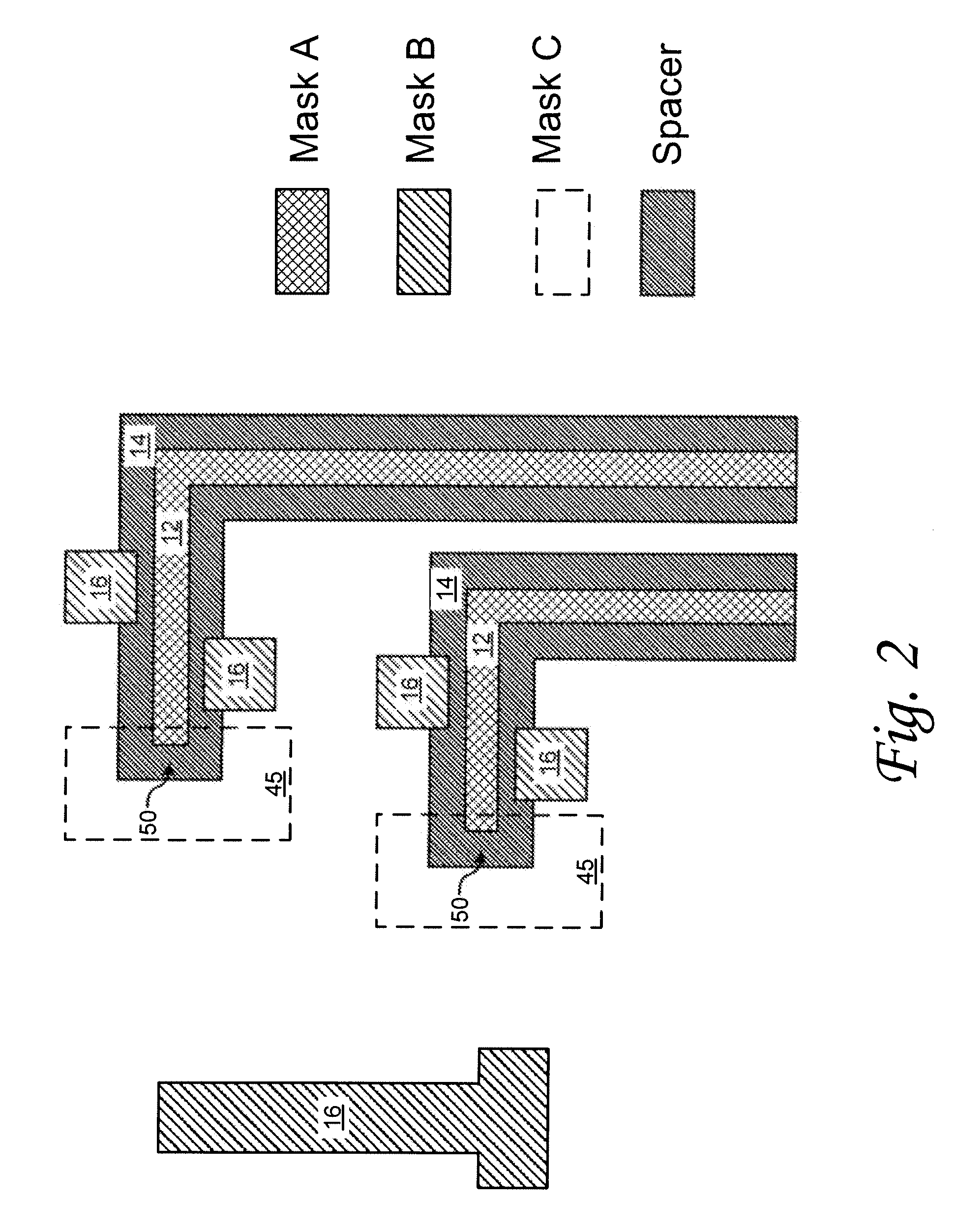

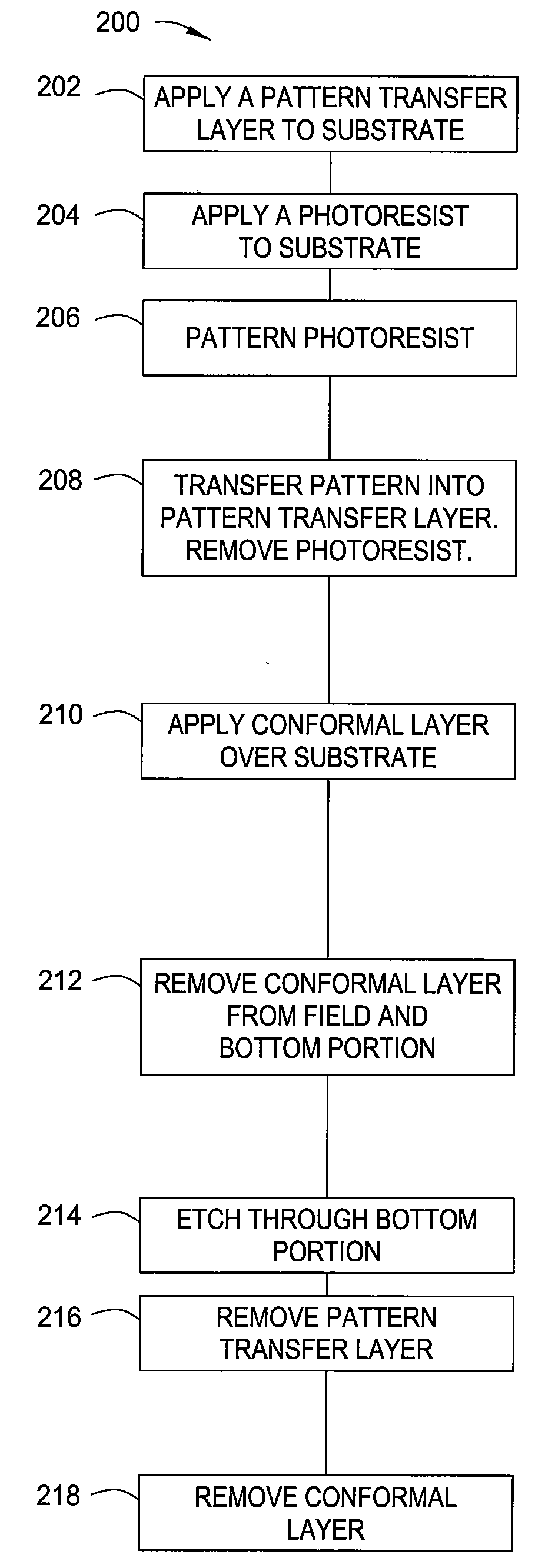

Method of eliminating a lithography operation

ActiveUS20090146322A1Semiconductor/solid-state device detailsSolid-state devicesLithographic artistEngineering

Methods of semiconductor device fabrication are disclosed. An exemplary method includes processes of depositing a first pattern on a semiconductor substrate, wherein the first pattern defines wide and narrow spaces; depositing spacer material over the first pattern on the substrate; etching the spacer material such that the spacer material is removed from horizontal surfaces of the substrate and the first pattern but remains adjacent to vertical surfaces of a wide space defined by the first pattern and remains within narrow a space defined by the first pattern; and removing the first pattern from the substrate. In one embodiment, the first pattern can comprise sacrificial material, which can include, for example, polysilicon material. The deposition can comprise physical vapor deposition, chemical vapor deposition, electrochemical deposition, molecular beam epitaxy, atomic layer deposition or other deposition techniques. According to another embodiment, features for lines and logic device components having a width greater than that of the lines are formed in the spacer material in the same mask layer.

Owner:CADENCE DESIGN SYST INC

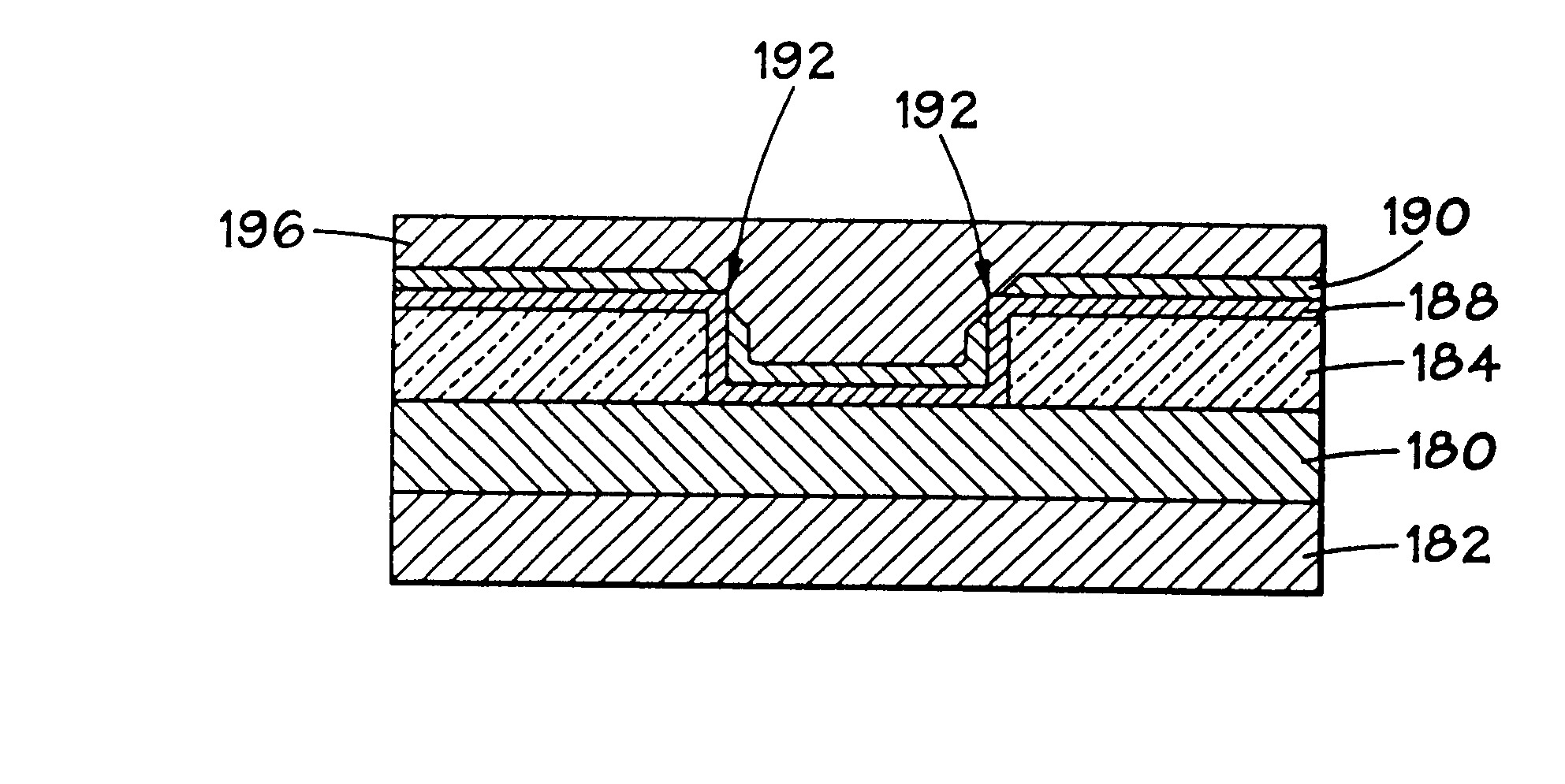

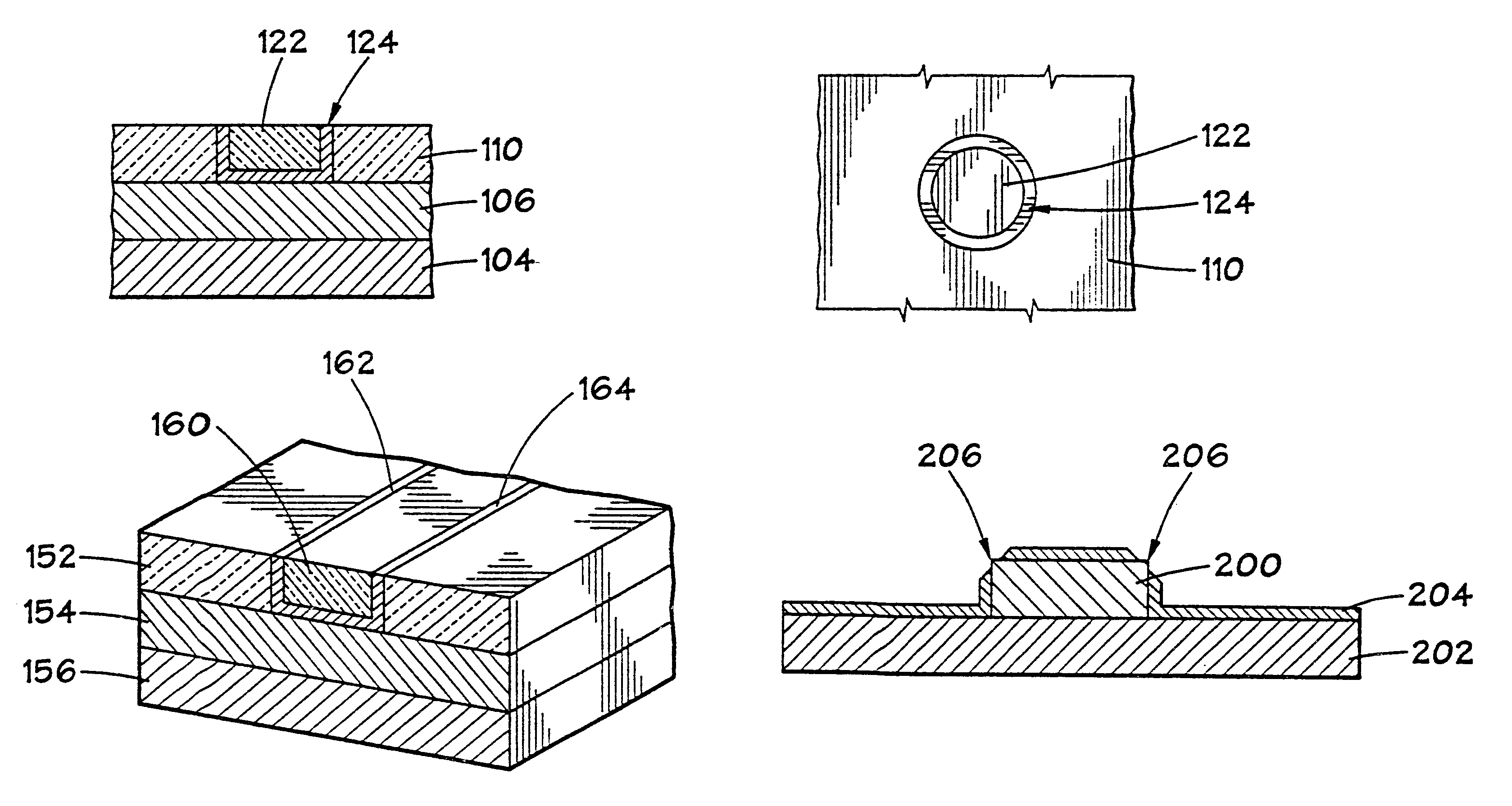

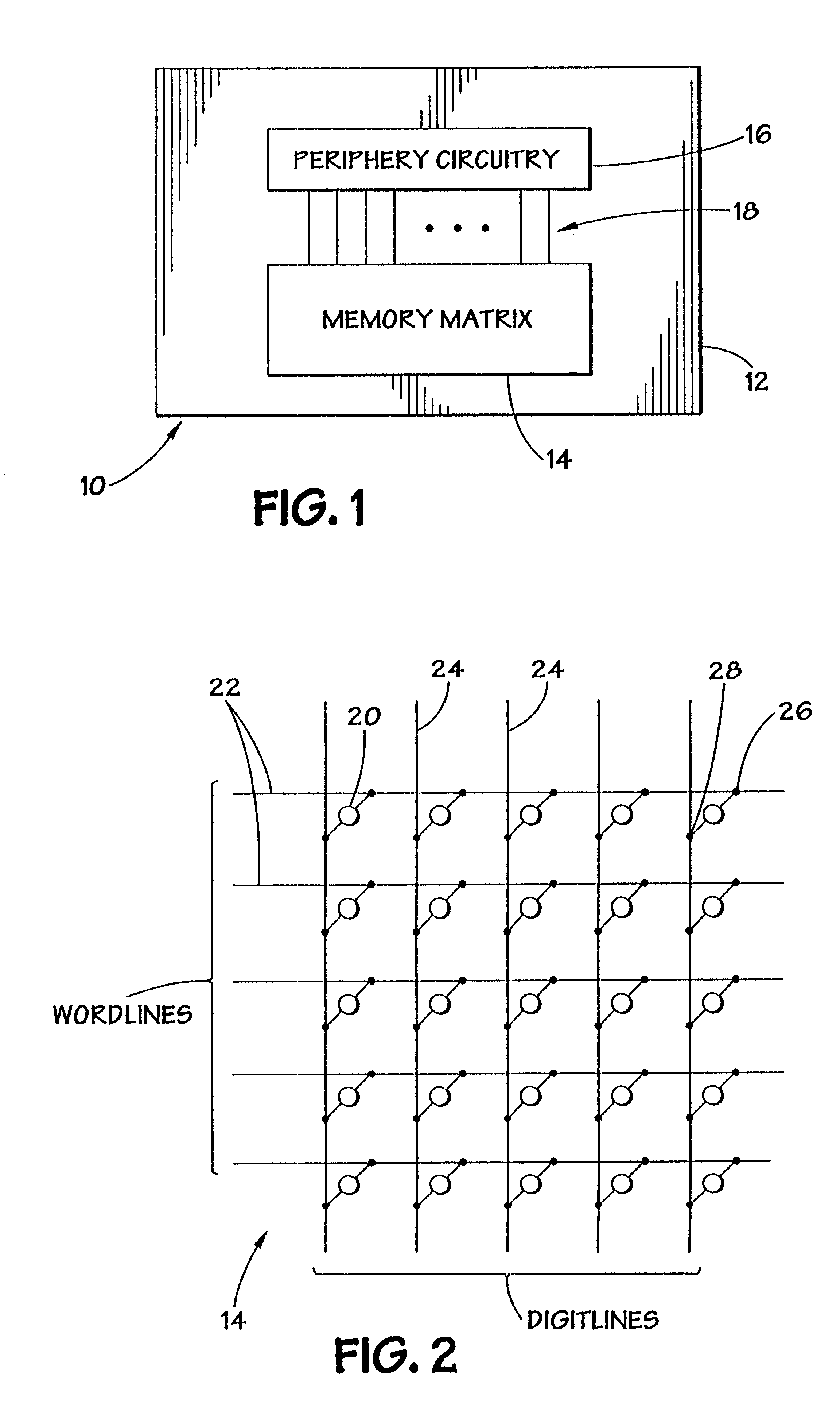

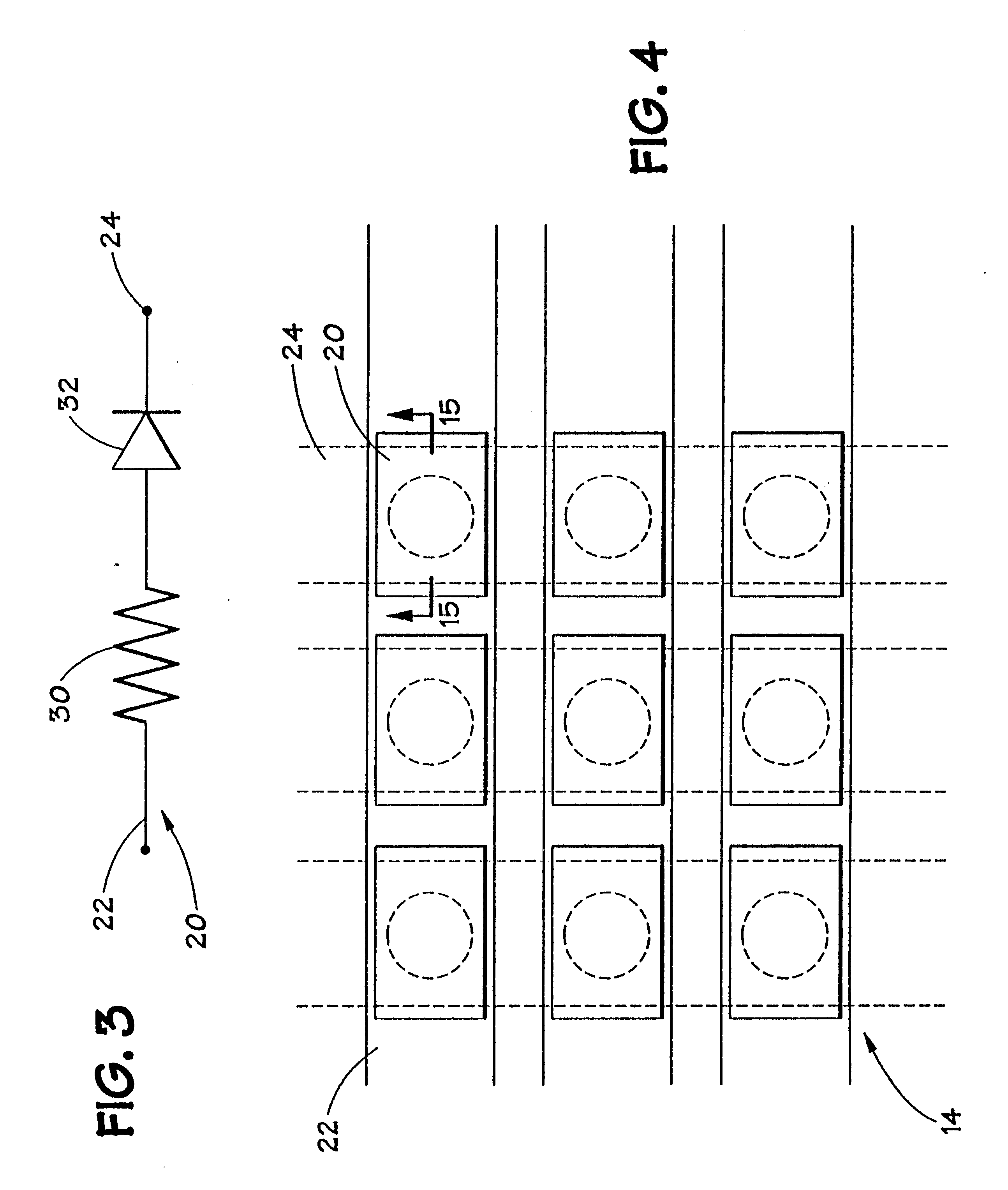

Small electrode for a chalcogenide switching device and method for fabricating same

InactiveUS6189582B1Solid-state devicesSemiconductor/solid-state device manufacturingDielectric layerElectrode material

A memory cell and a method of fabricating the memory cell having a small active area. By forming a spacer in a window that is sized at the photolithographic limit, a pore may be formed in dielectric layer which is smaller than the photolithographic limit. Electrode material is deposited into the pore, and a layer of structure changing material, such as chalcogenide, is deposited onto the lower electrode, thus creating a memory element having an extremely small and reproducible active area.

Owner:ROUND ROCK RES LLC

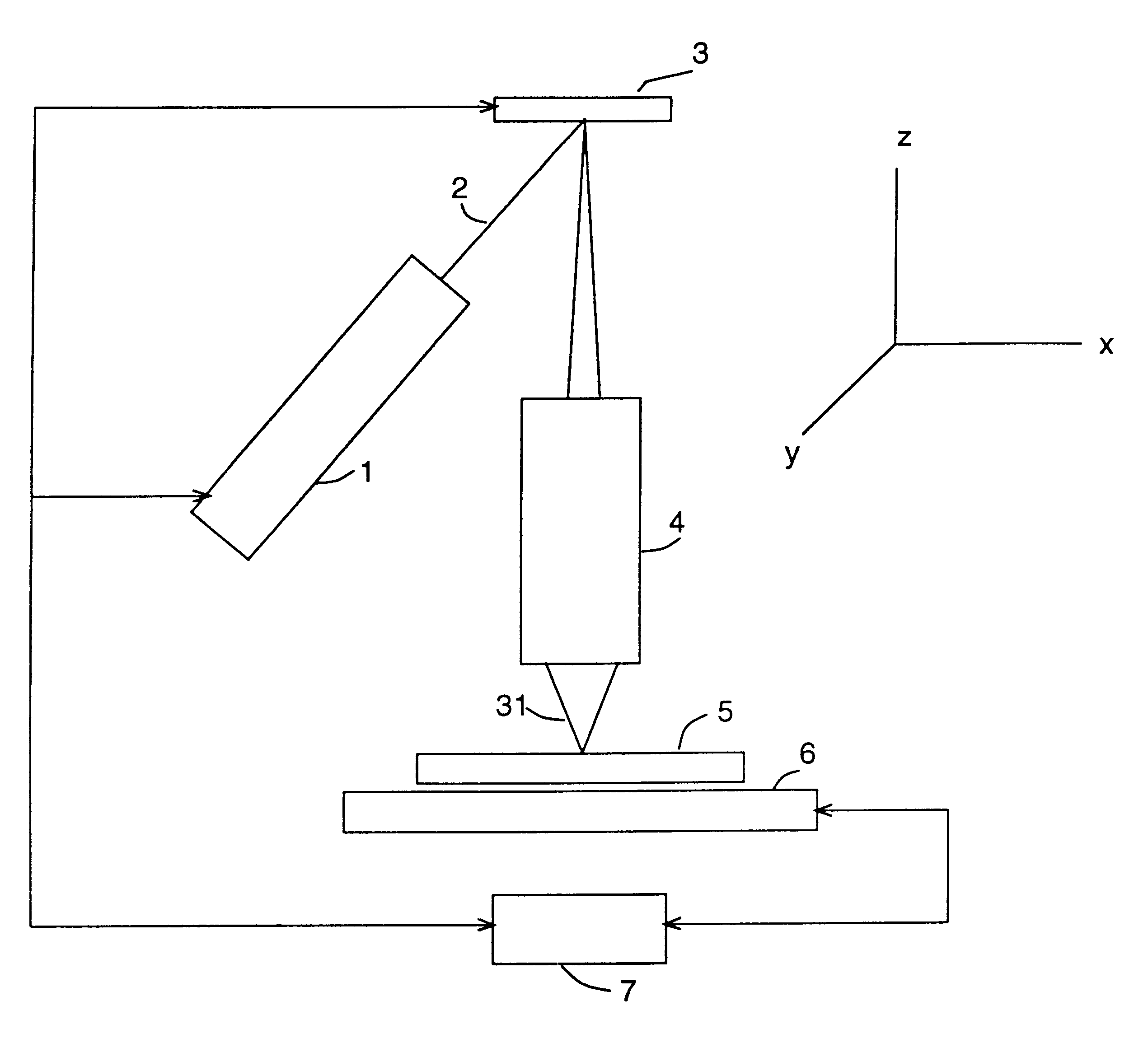

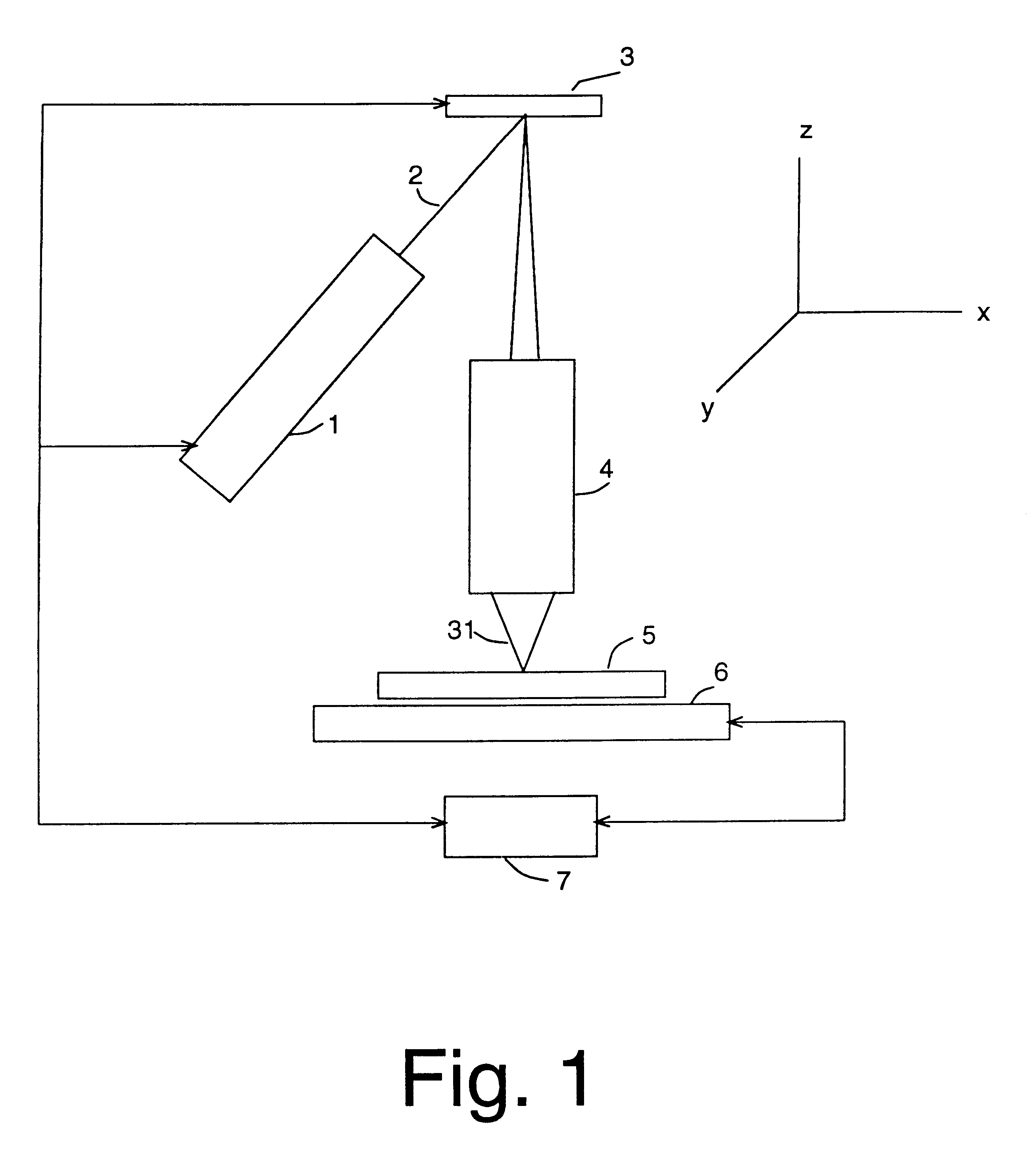

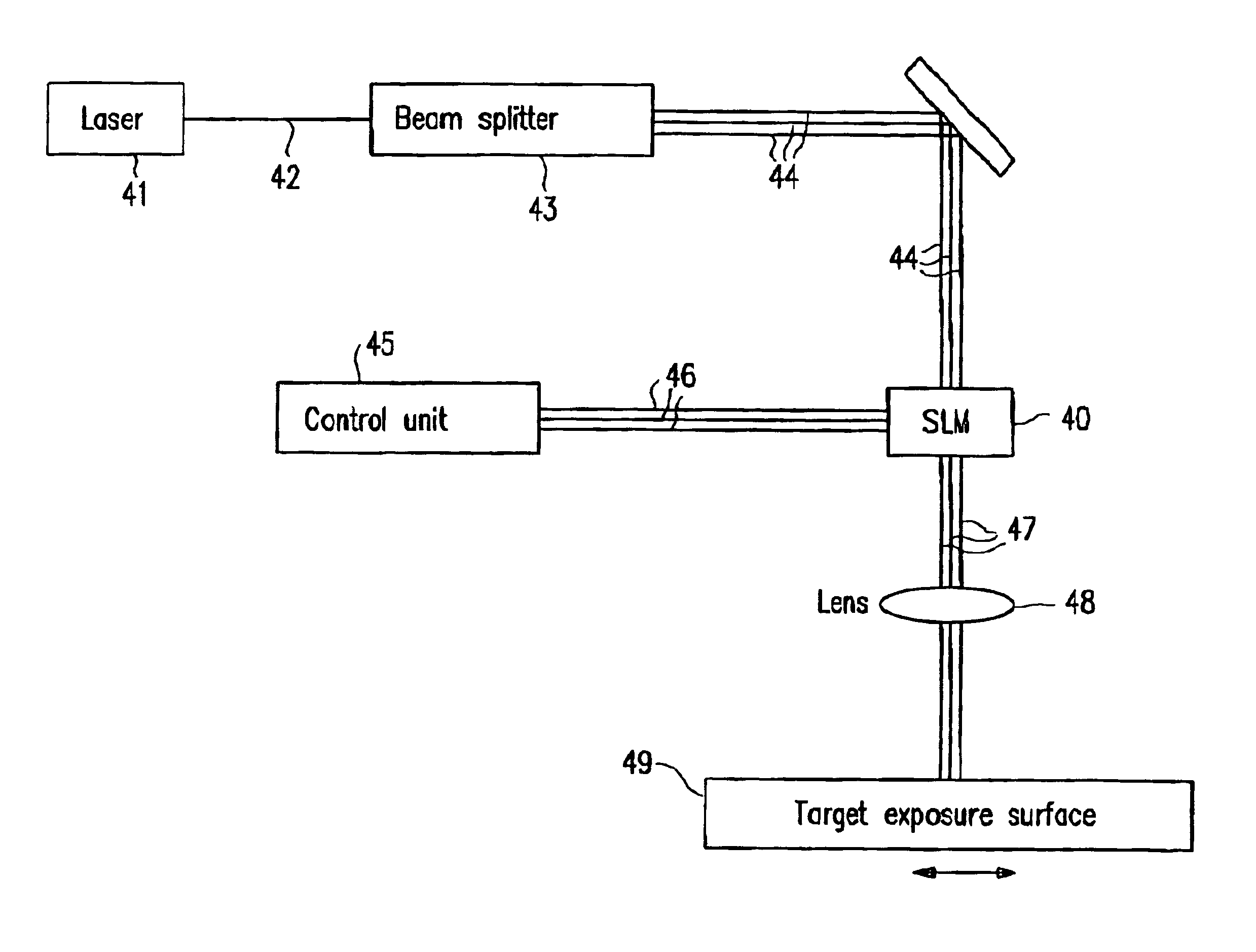

Seamless, maskless lithography system using spatial light modulator

InactiveUS6312134B1Eliminate needImprove processing throughputMirrorsPhotomechanical exposure apparatusRadiation DosagesSpatial light modulator

The invention is a seamless projection lithography system that eliminates the need for masks through the use of a programmable Spatial Light Modulator (SLM) with high parallel processing power. Illuminating the SLM with a radiation source (1), which while preferably a pulsed laser may be a shuttered lamp or multiple lasers with alternating synchronization, provides a patterning image of many pixels via a projection system (4) onto a substrate (5). The preferred SLM is a Deformable Micromirror Device (3) for reflective pixel selection using a synchronized pulse laser. An alternative SLM is a Liquid Crystal Light Valve (LCLV) (45) for pass-through pixel selection. Electronic programming enables pixel selection control for error correction of faulty pixel elements. Pixel selection control also provides for negative and positive imaging and for complementary overlapping polygon development for seamless uniform dosage. The invention provides seamless scanning by complementary overlapping scans to equalize radiation dosage, to expose a pattern on a large area substrate (5). The invention is suitable for rapid prototyping, flexible manufacturing, and even mask making.

Owner:ANVIK CORP

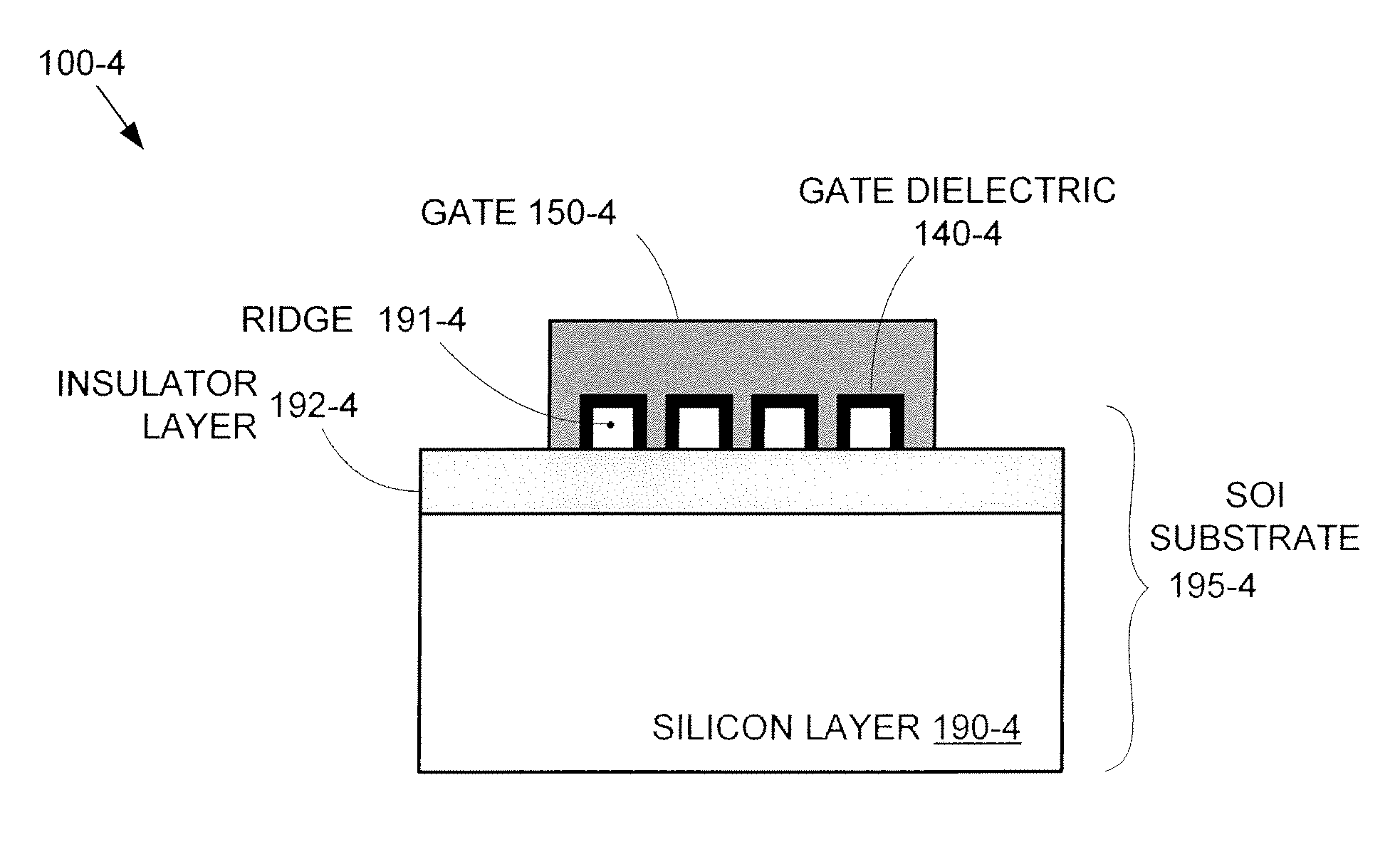

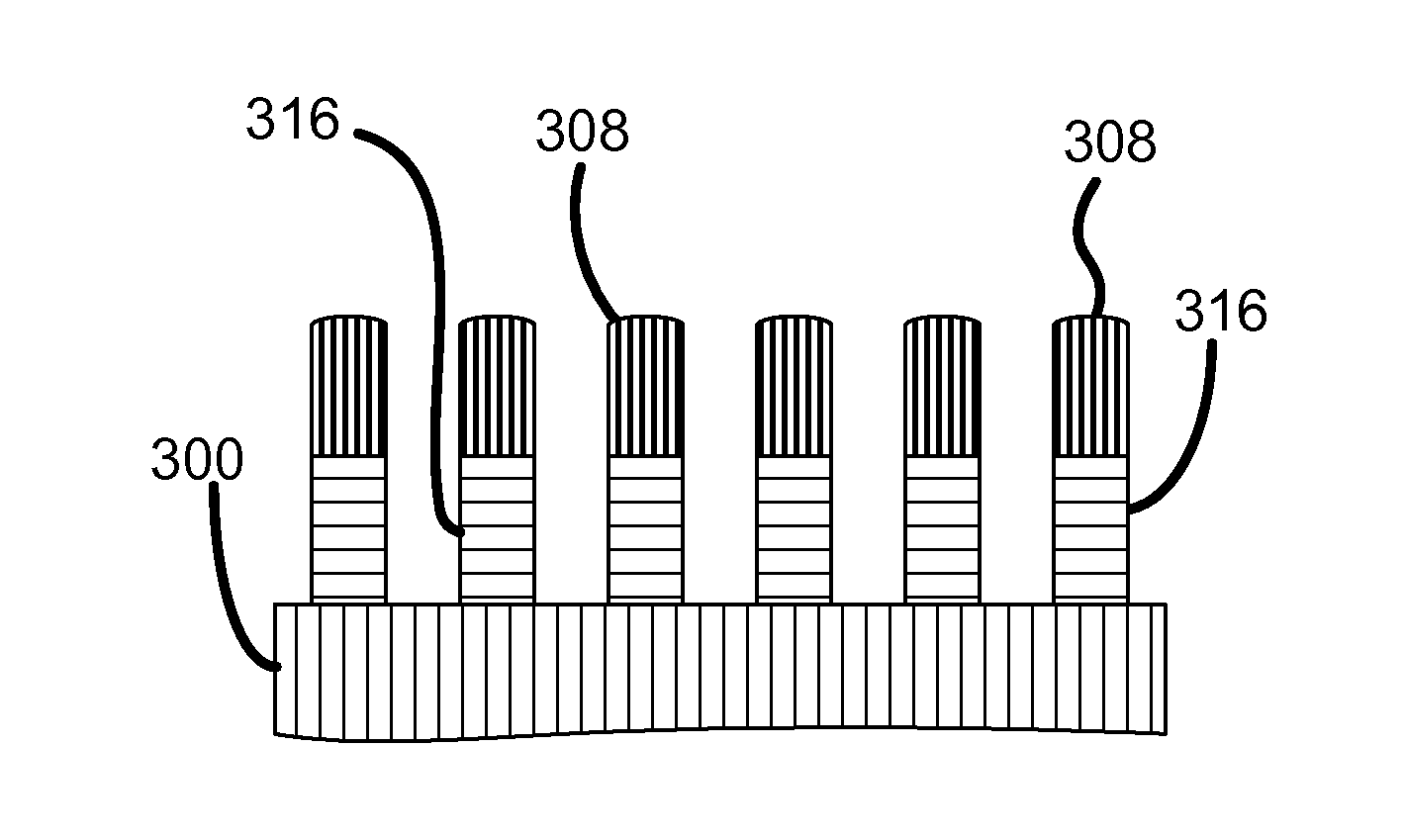

Integrated circuit on corrugated substrate

ActiveUS7190050B2Improve performance consistencyImprove performanceTransistorSemiconductor/solid-state device detailsMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

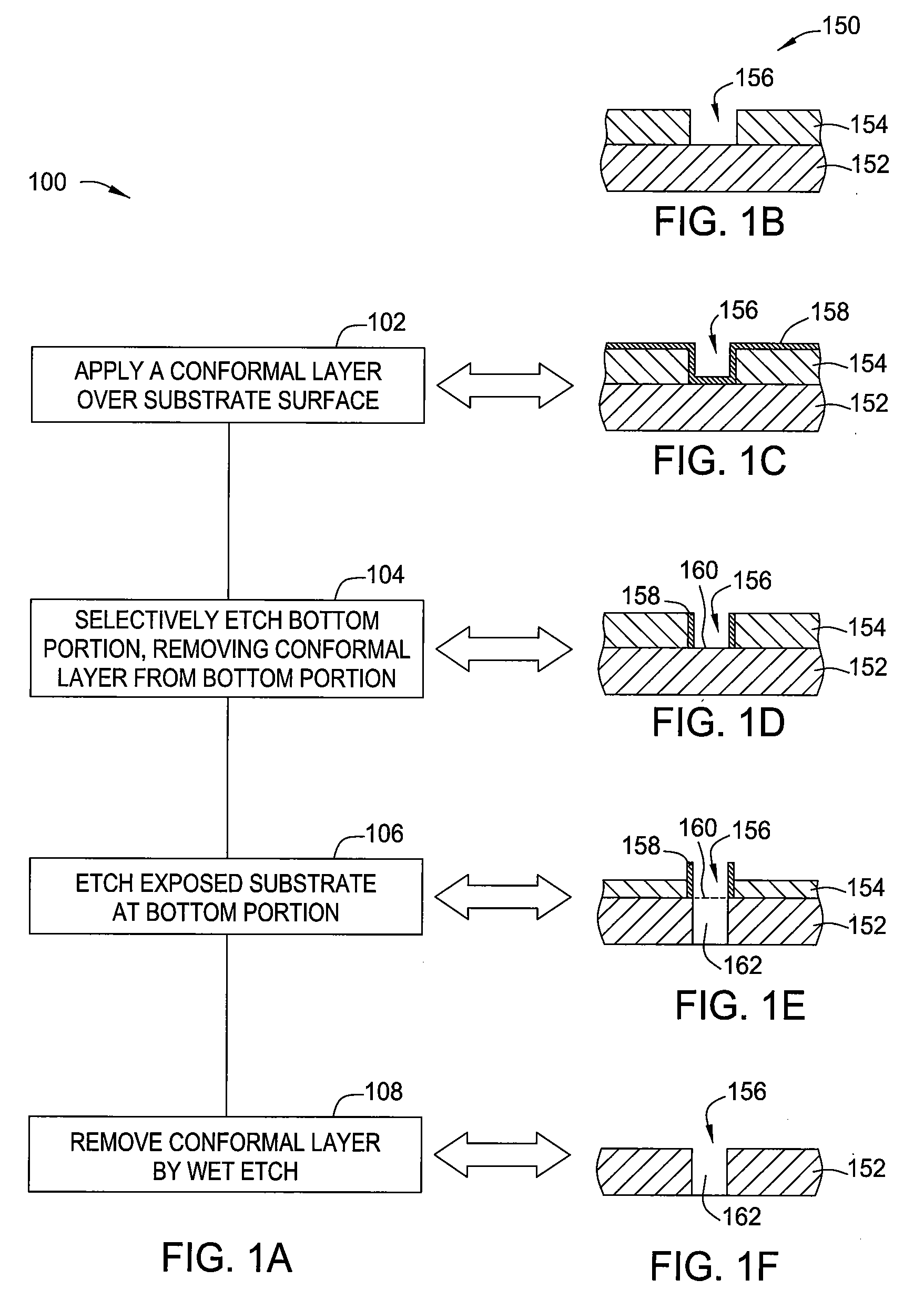

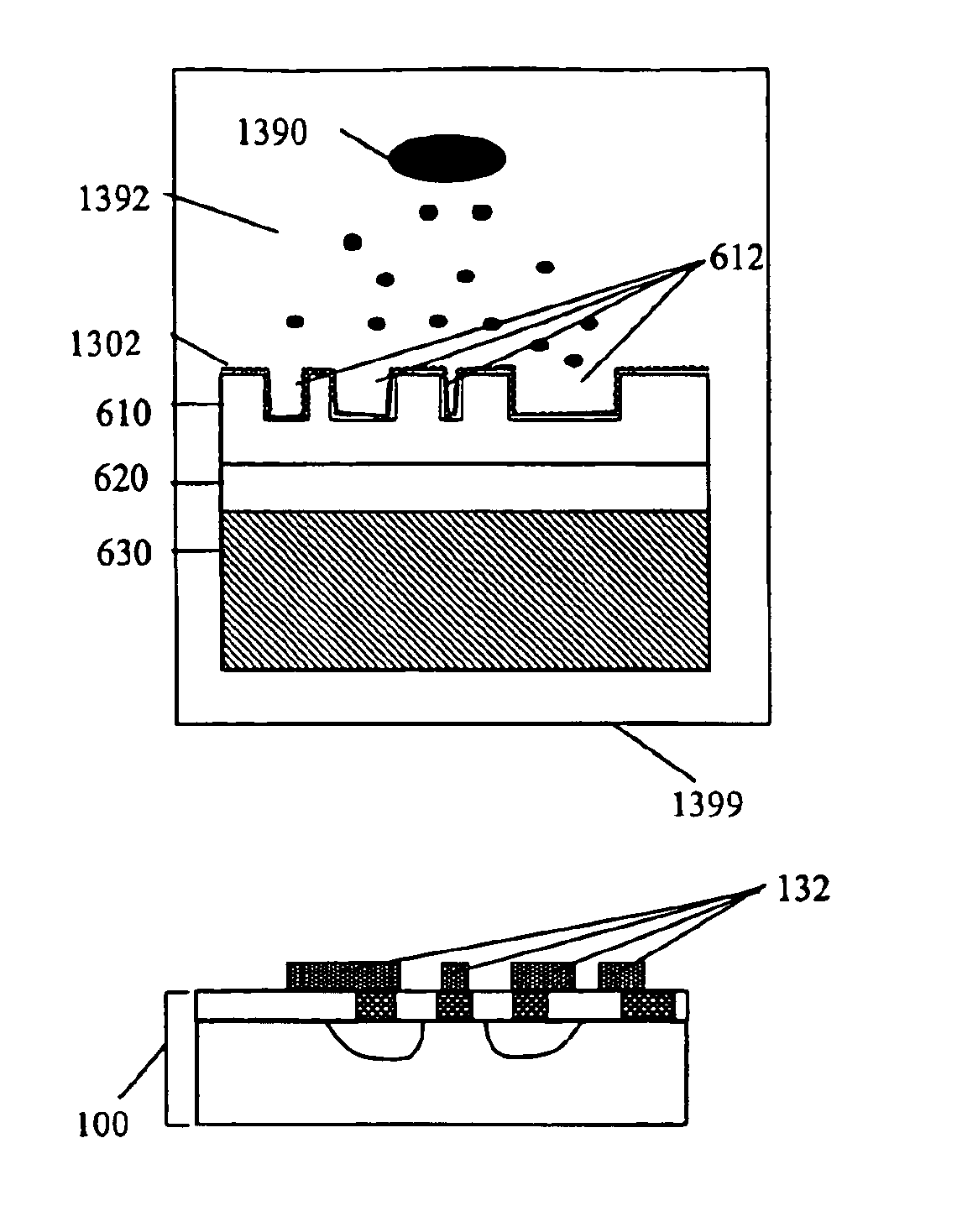

Method for critical dimension shrink using conformal pecvd films

InactiveUS20090286402A1Critical dimension reductionGood step coverageSemiconductor/solid-state device manufacturingLithographic artistAnisotropic etching

A method and apparatus for forming narrow vias in a substrate is provided. A pattern recess is etched into a substrate by conventional lithography. A thin conformal layer is formed over the surface of the substrate, including the sidewalls and bottom of the pattern recess. The thickness of the conformal layer reduces the effective width of the pattern recess. The conformal layer is removed from the bottom of the pattern recess by anisotropic etching to expose the substrate beneath. The substrate is then etched using the conformal layer covering the sidewalls of the pattern recess as a mask. The conformal layer is then removed using a wet etchant.

Owner:APPLIED MATERIALS INC

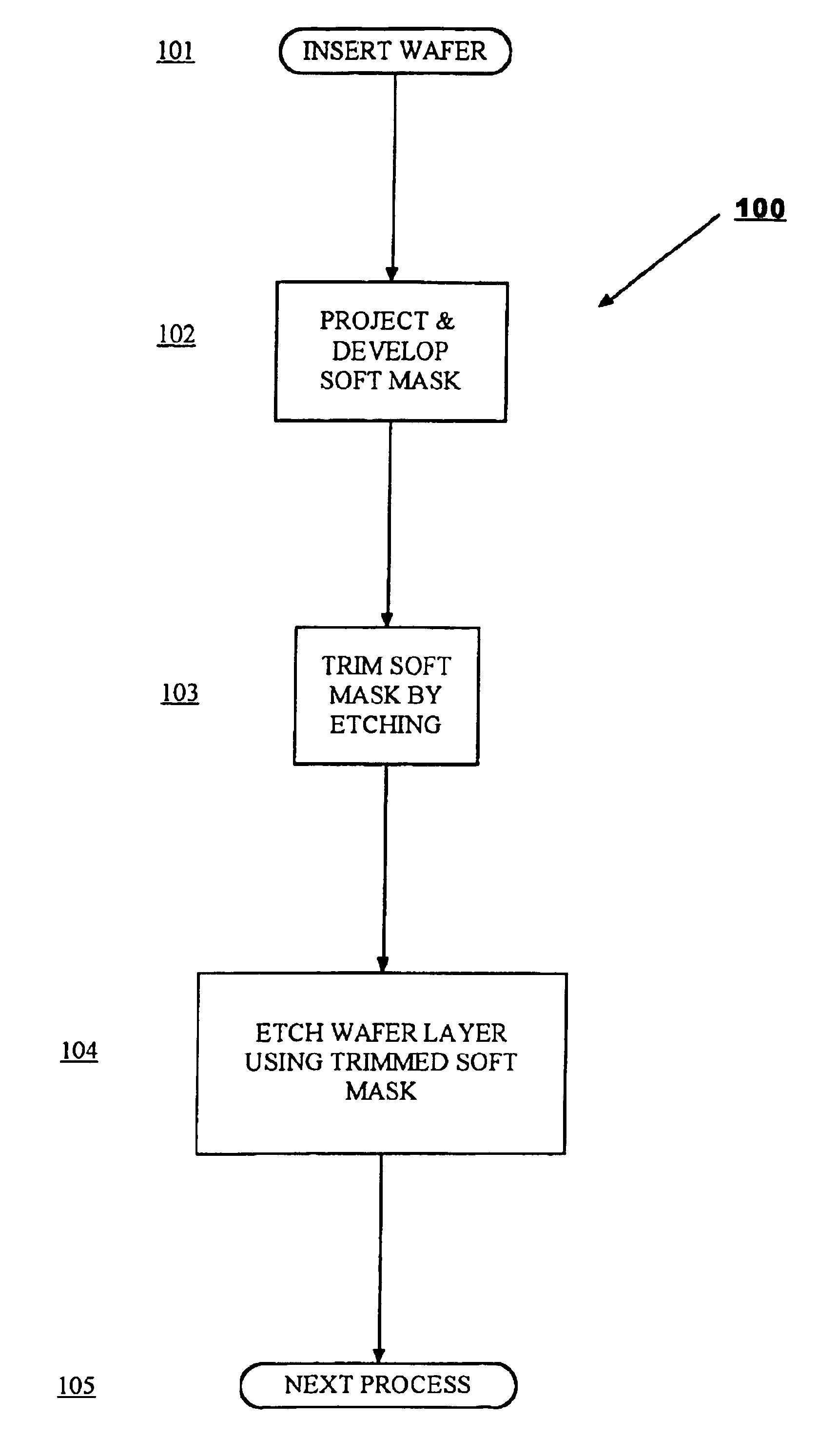

Gate linewidth tailoring and critical dimension control for sub-100 nm devices using plasma etching

InactiveUS6864041B2Tight tolerance variationMinimal variationVacuum gauge using ionisation effectsDecorative surface effectsImage resolutionLine width

A method of fabricating an electronic chip on a wafer in which a first mask at a predetermined lower resolution is developed on the wafer and then etched under a first set of conditions for a predetermined period to achieve a mask that is below the resolution limit of current lithography. The etched mask is then used as a hard mask for etching material on a lower layer.

Owner:INT BUSINESS MASCH CORP

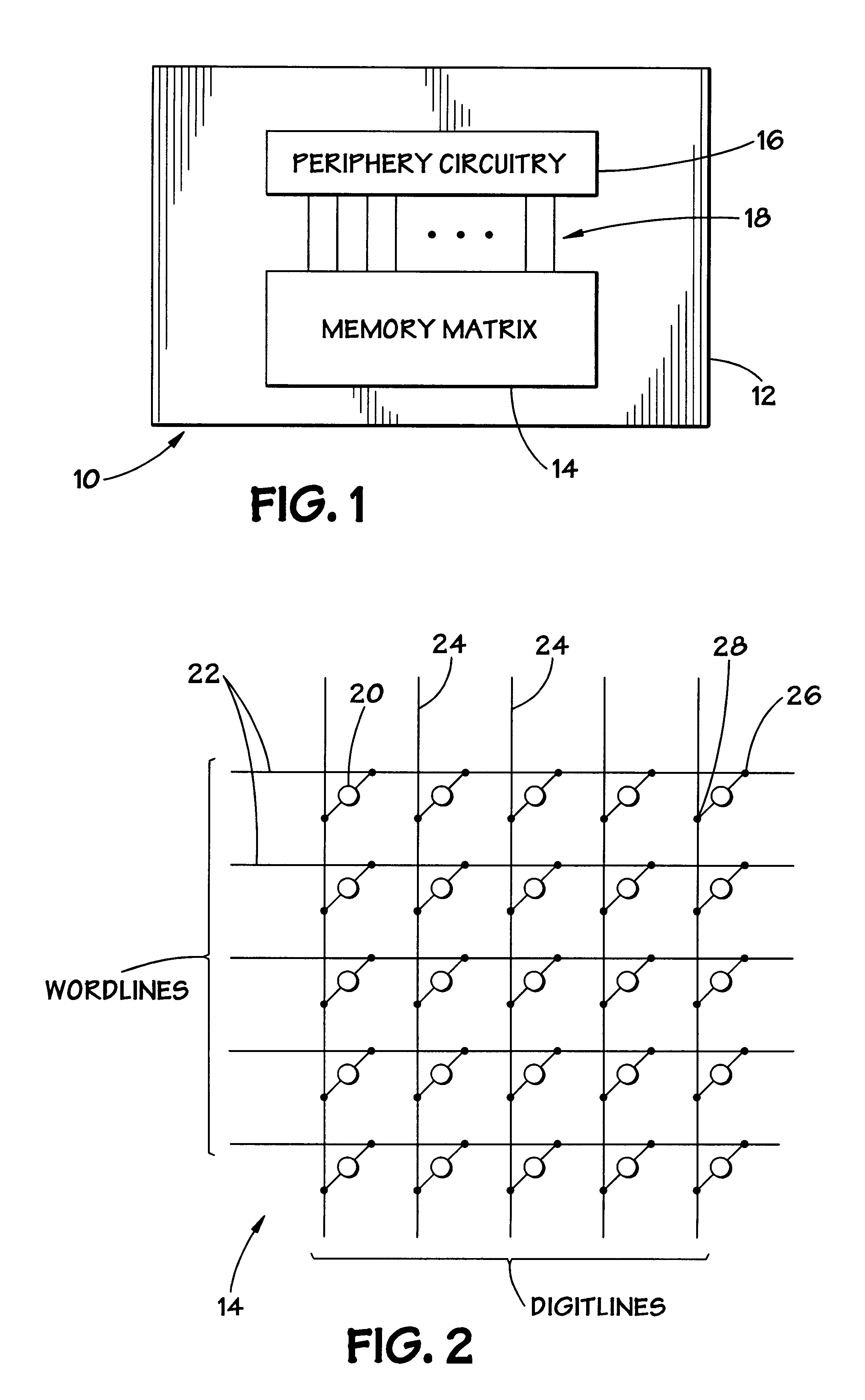

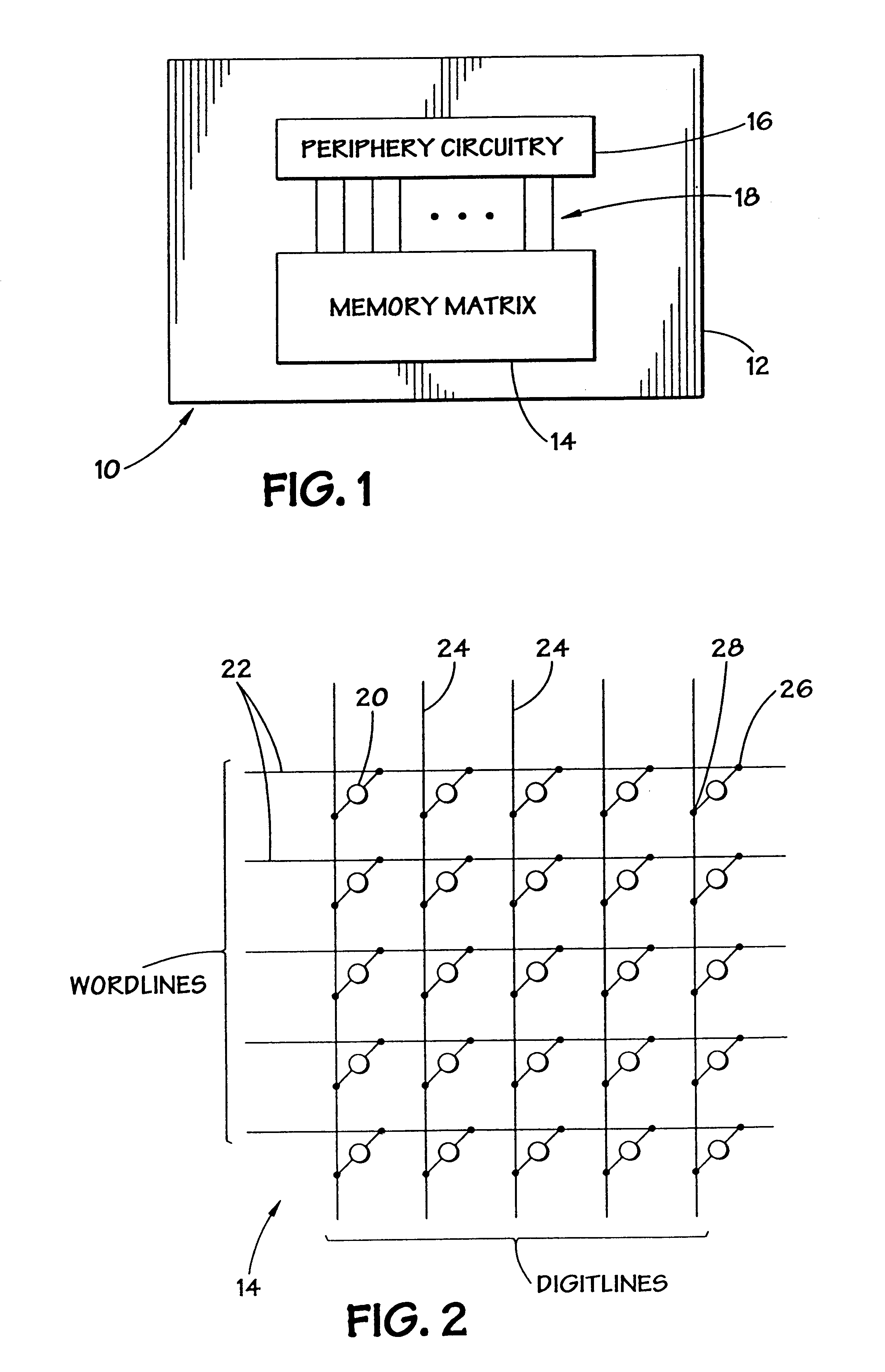

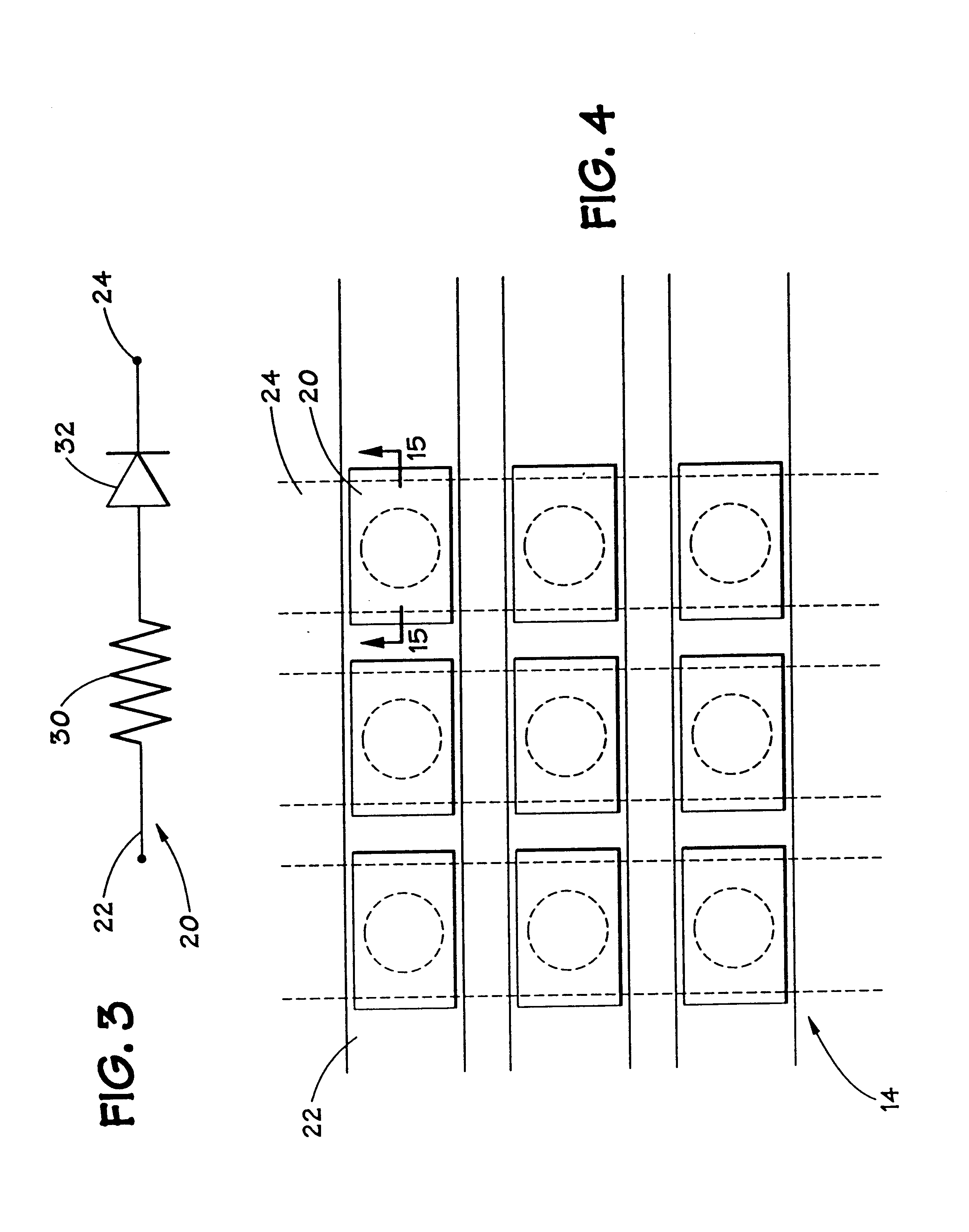

Memory elements and methods for making same

Annular, linear, and point contact structures are described which exhibit a greatly reduced susceptibility to process deviations caused by lithographic and deposition variations than does a conventional circular contact plug. In one embodiment, a standard conductive material such as carbon or titanium nitride is used to form the contact. In an alternative embodiment, a memory material itself is used to form the contact. These contact structures may be made by various processes, including chemical mechanical planarization and facet etching.

Owner:ROUND ROCK RES LLC

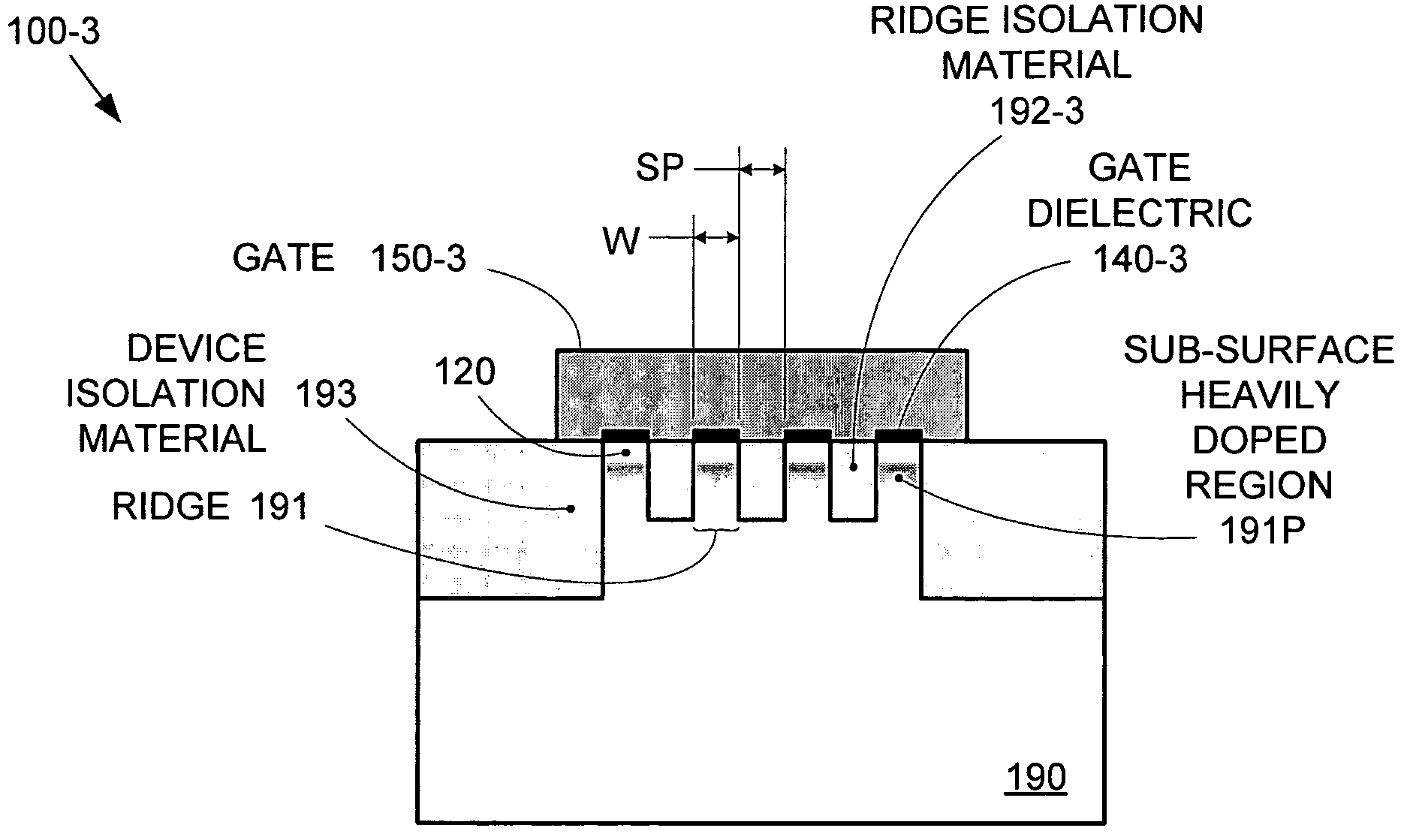

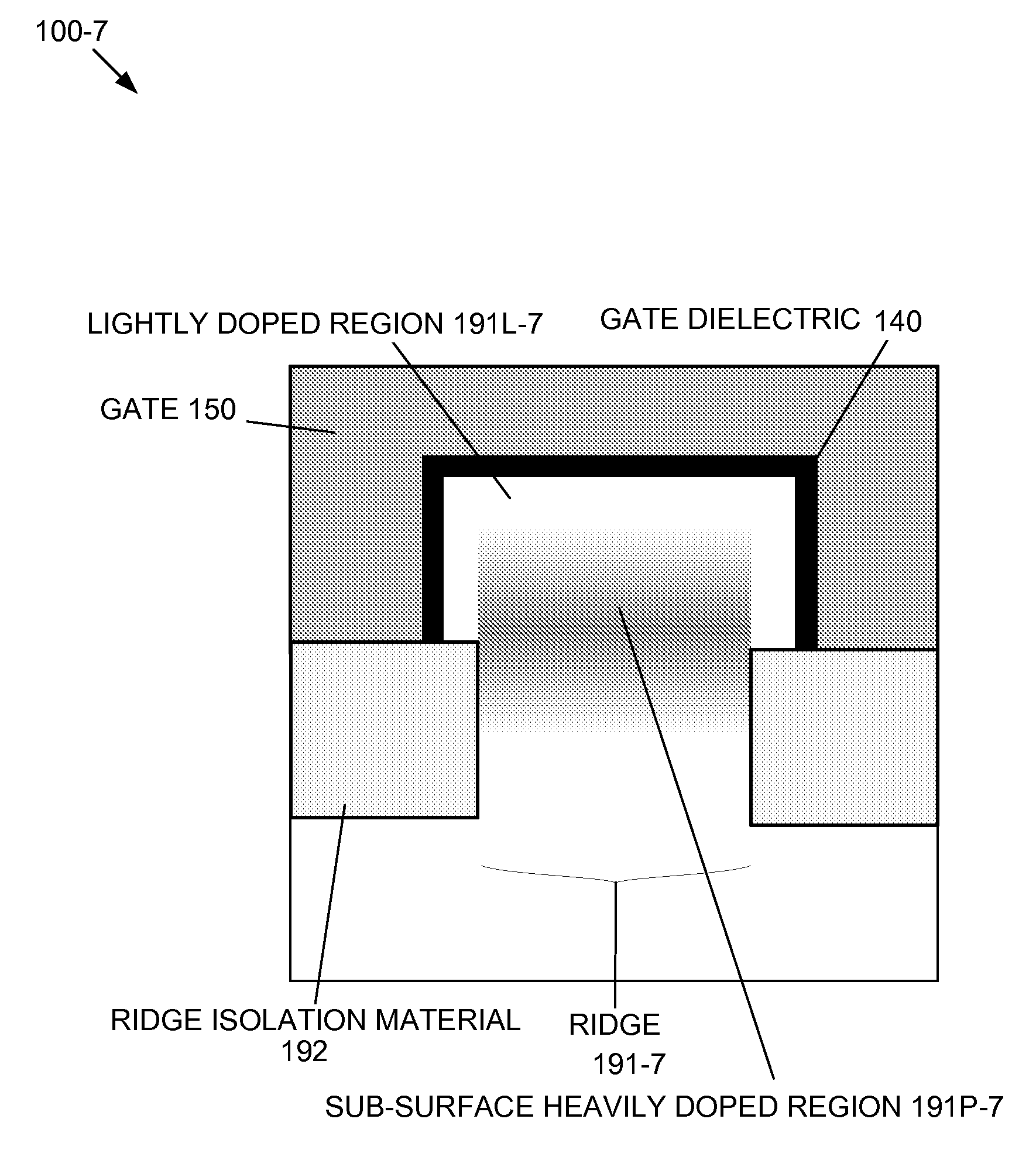

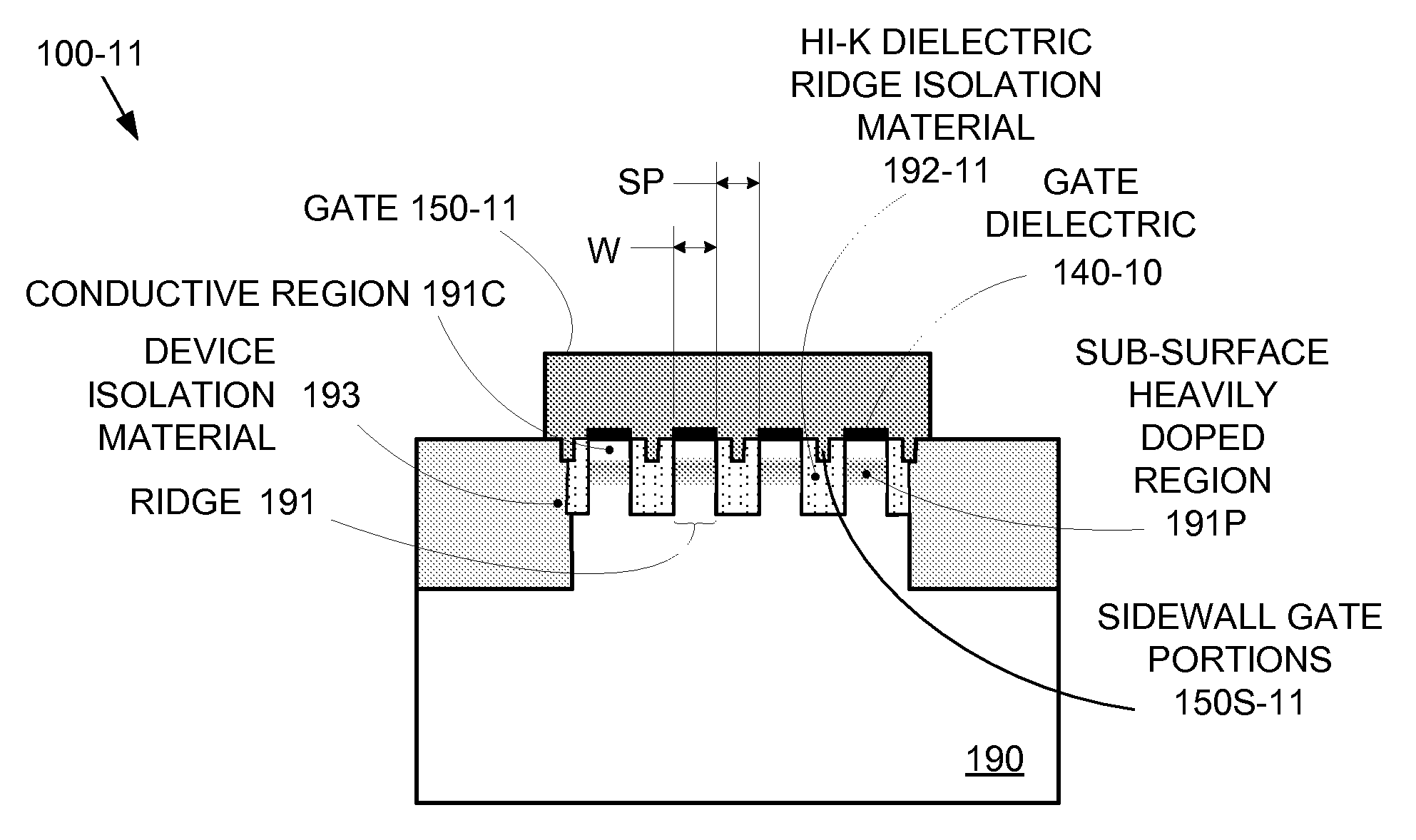

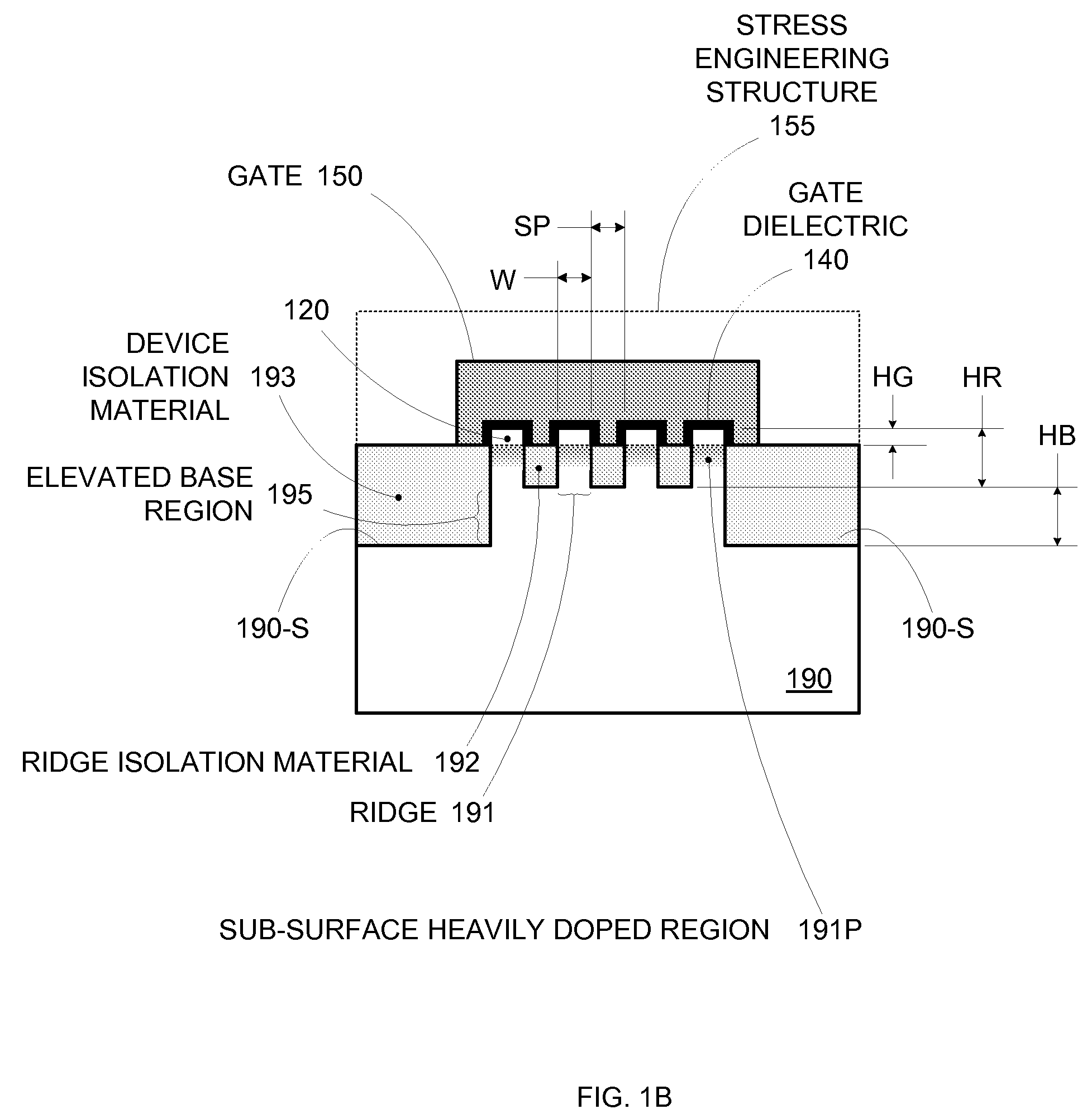

Enhanced Segmented Channel MOS Transistor with Multi Layer Regions

ActiveUS20070120156A1Increase costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

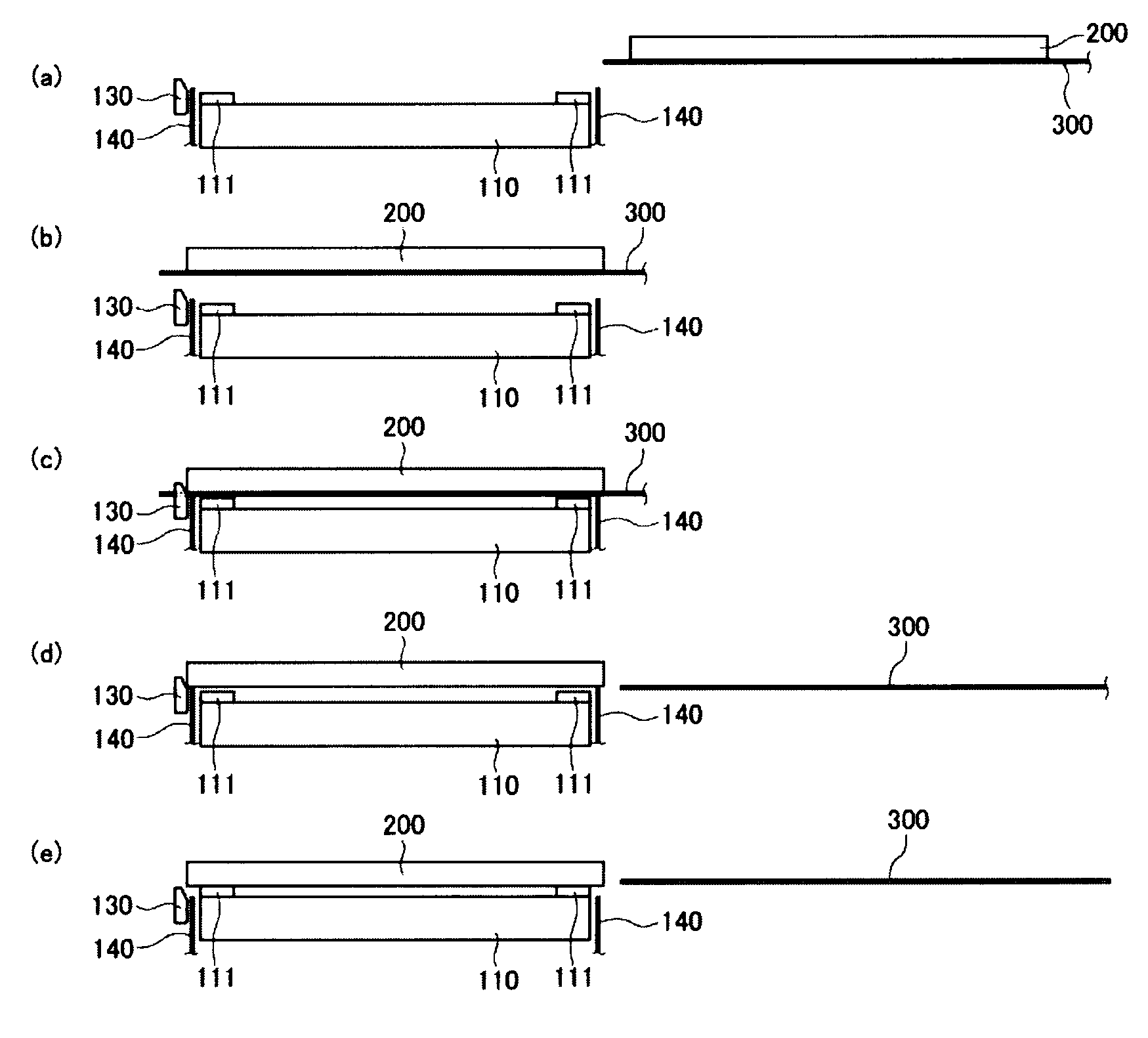

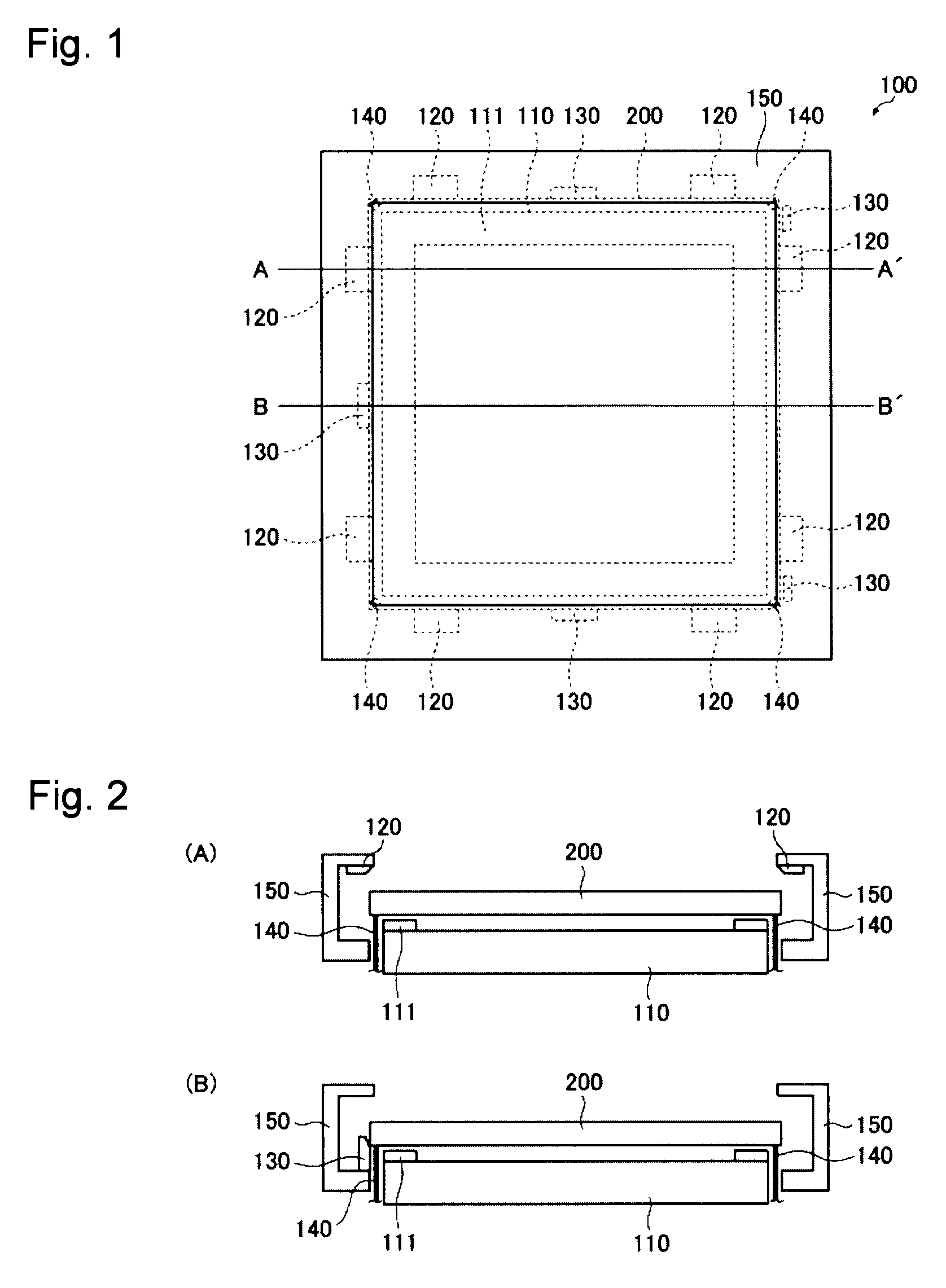

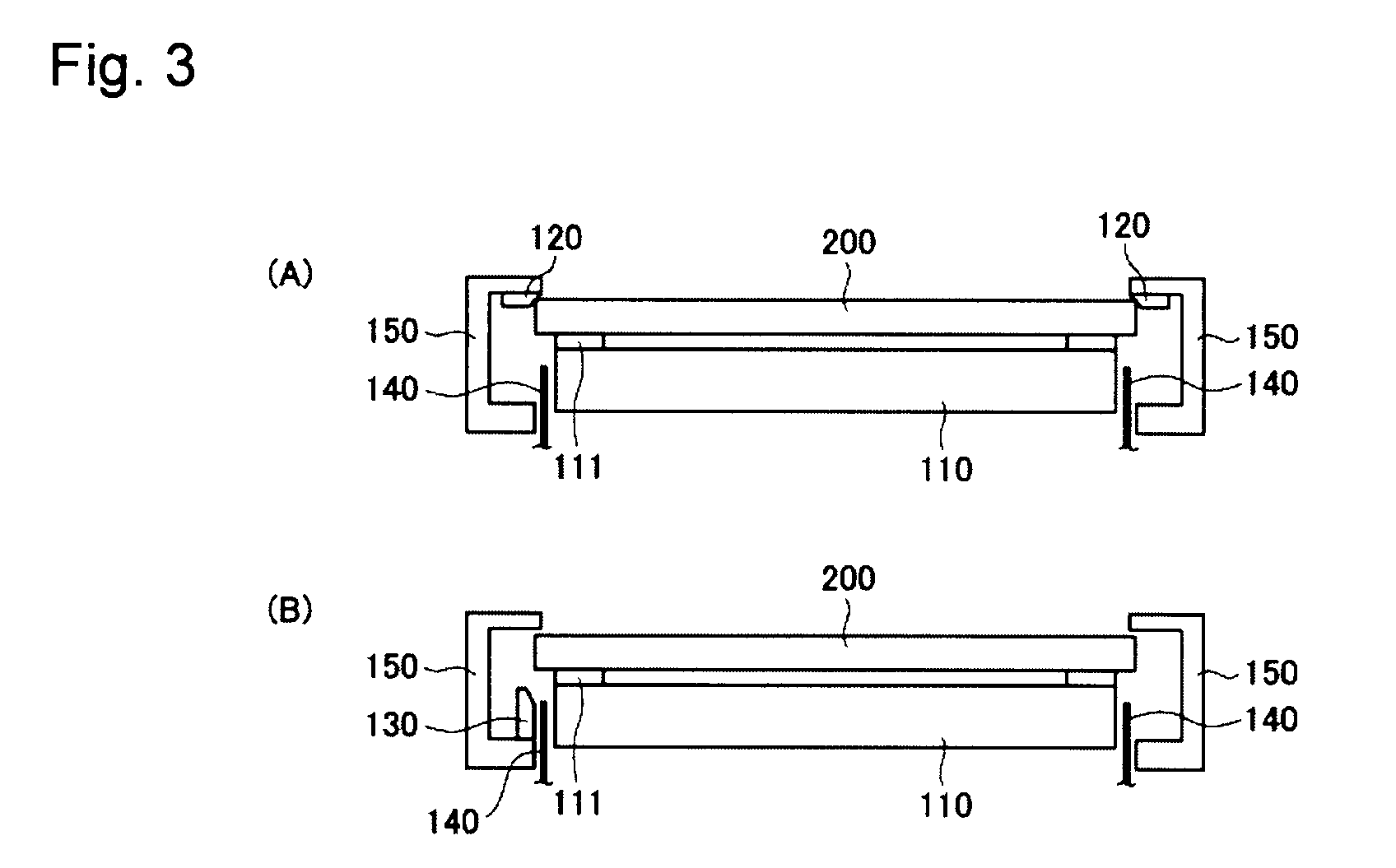

Glass substrate-holding tool and method for producing an EUV mask blank by employing the same

InactiveUS8967608B2InhibitionAccurate placementWorkpiece holdersVacuum evaporation coatingLithographic artistMaterials science

A glass substrate-holding tool employed during the production of a reflective mask blank for EUV lithography includes an electrostatic chuck and a mechanical chuck. A caught and held portion of a glass substrate caught and held by the electrostatic chuck, and pressed portions of the glass substrate pressed by the mechanical chuck are located outside a quality-guaranteed region on each of a film deposition surface and a rear surface of the glass substrate. The sum of a catching and holding force applied to the glass substrate by the electrostatic chuck and a holding force applied to the glass substrate by the mechanical chuck is at least 200 kgf. A pressing force per unit area applied to the glass substrate by the mechanical chuck is at most 25 kgf / mm2.

Owner:ASAHI GLASS CO LTD

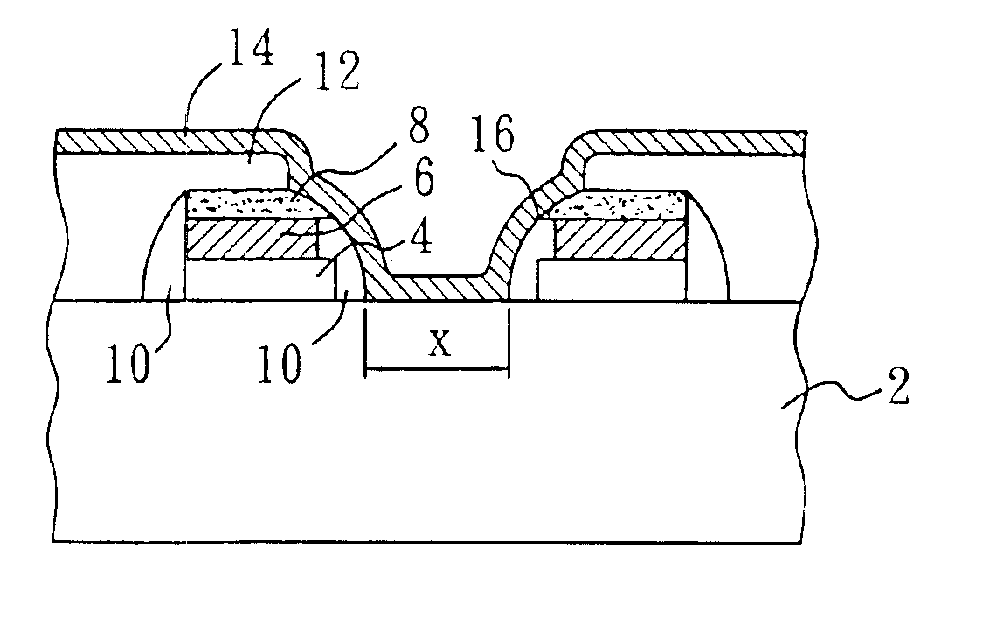

Method of forming self-aligned contact structure with locally etched gate conductive layer

InactiveUS6855610B2Reduce resistanceLarge processing windowSemiconductor/solid-state device detailsSolid-state devicesBit lineDielectric layer

A method of forming a self-aligned contact structure with a locally etched conductive layer comprises the steps of: preparing a substrate formed with gate structures comprising a first conductive layer, a second conductive layer, and an insulating layer; depositing a photoresist material layer on the substrate; performing a lithographic step with a bit-line contact node photomask or a bit-line contact photomask to expose a portion of the surface of the substrate; etching the exposed second conductive layer with an etchant; removing the remaining photoresist material layer; forming a sidewall spacer on the sidewalls of each gate structure; forming a dielectric layer to cover the substrate; and performing lithographic and etching steps to remove the dielectric layer and to form self-aligned contact structure.

Owner:PROMOS TECH INC

Polymer sacrificial light absorbing structure and method

InactiveUS6876017B2From solid stateSemiconductor/solid-state device detailsSolubilityLithographic artist

Method and structure for optimizing dual damascene patterning with polymeric dielectric materials are disclosed. Certain embodiments of the invention comprise polymeric sacrificial light absorbing materials (“polymer SLAM”) functionalized to have a controllable solubility switch wherein such polymeric materials have substantially the same etch rate as conventionally utilized polymeric dielectric materials, and subsequent to chemical modification of solubility-modifying protecting groups comprising the SLAM materials by thermal treatment or in-situ generation of an acid, such SLAM materials become soluble in weak bases, such as those conventionally utilized to remove materials in lithography treatments.

Owner:INTEL CORP

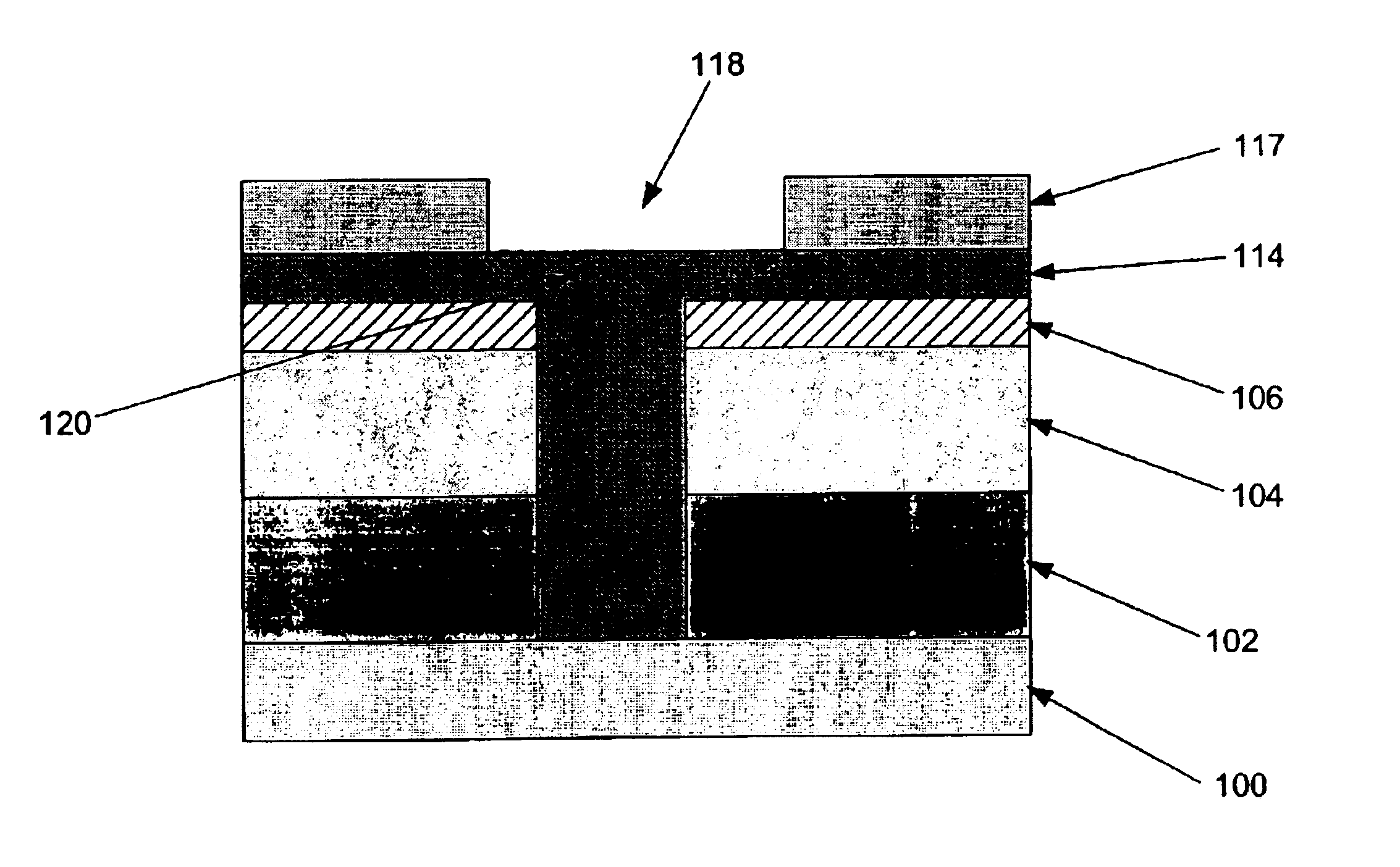

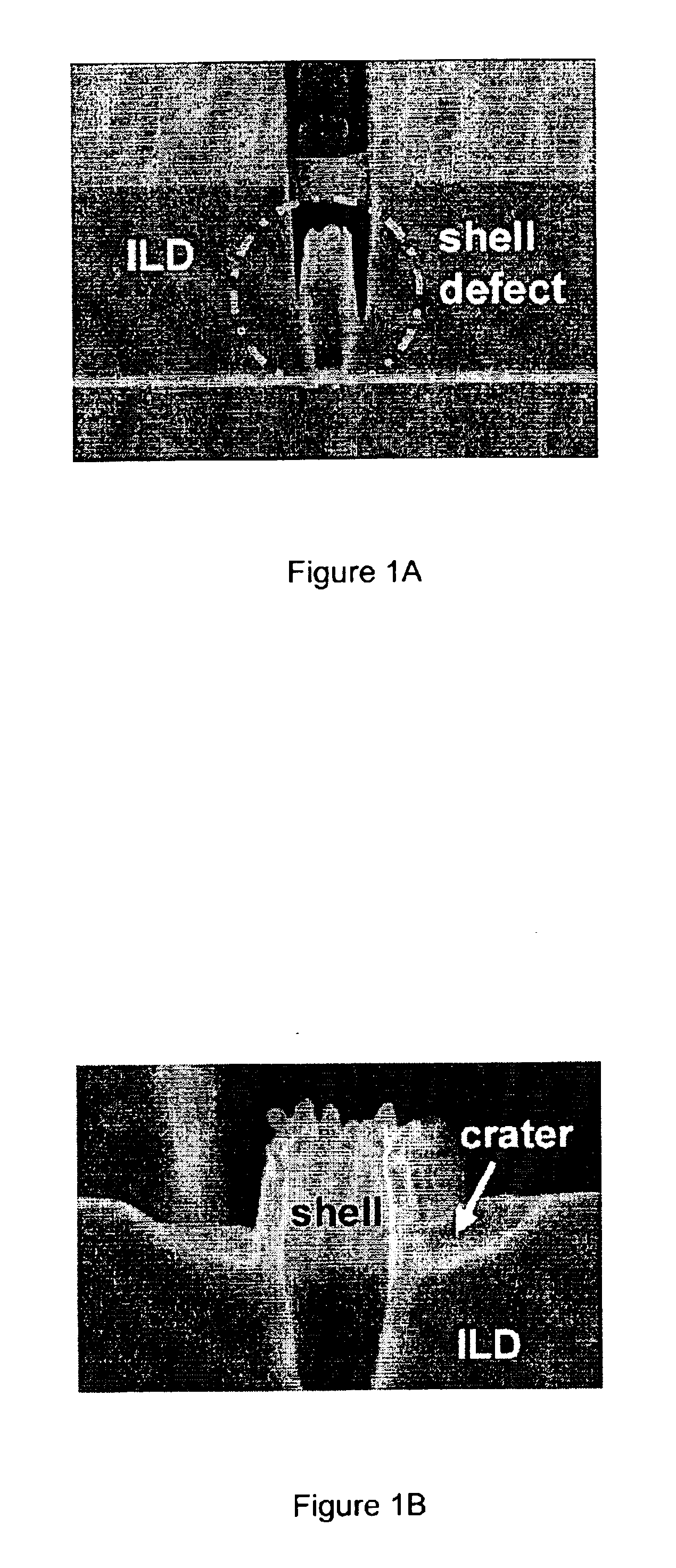

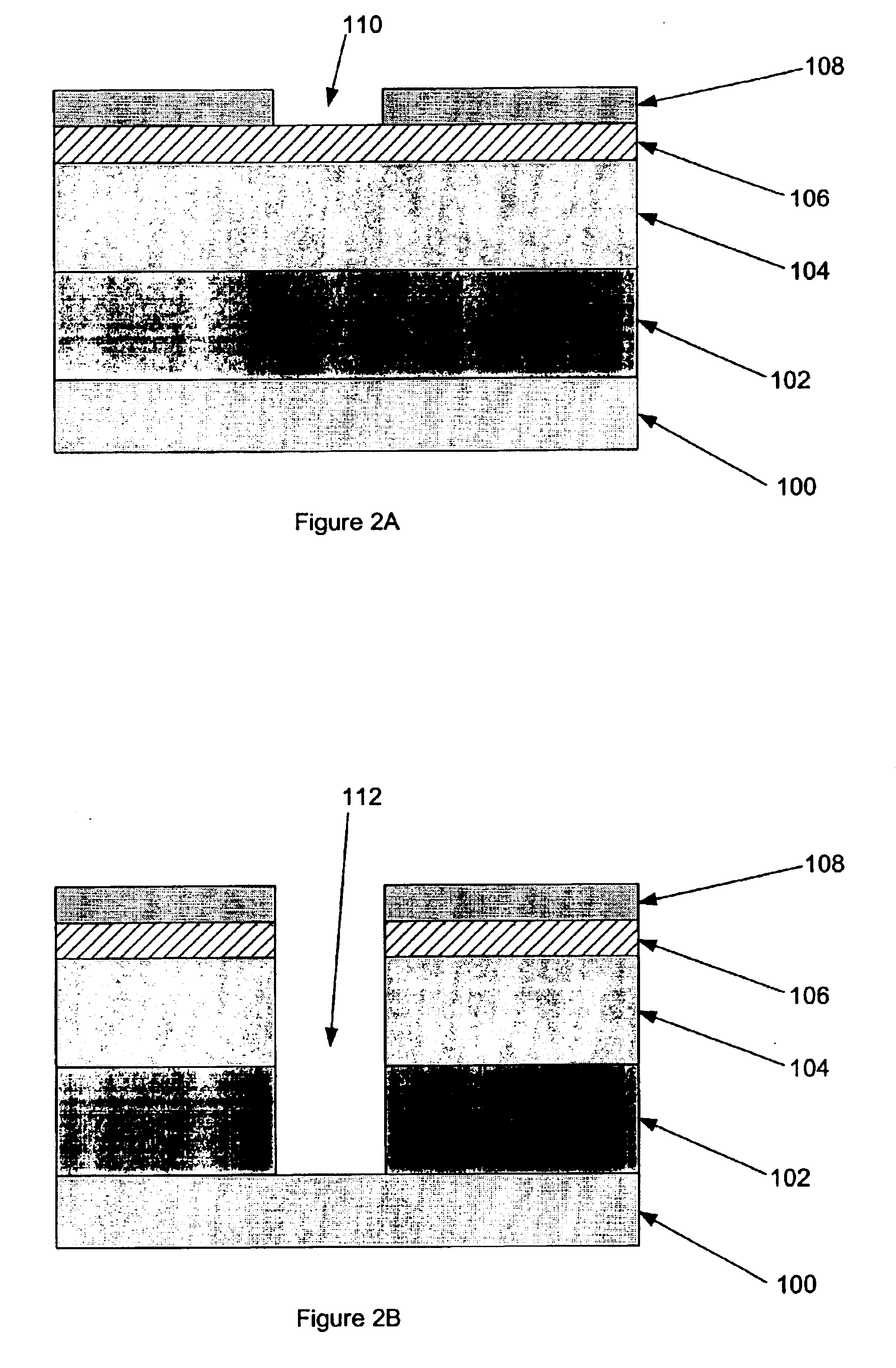

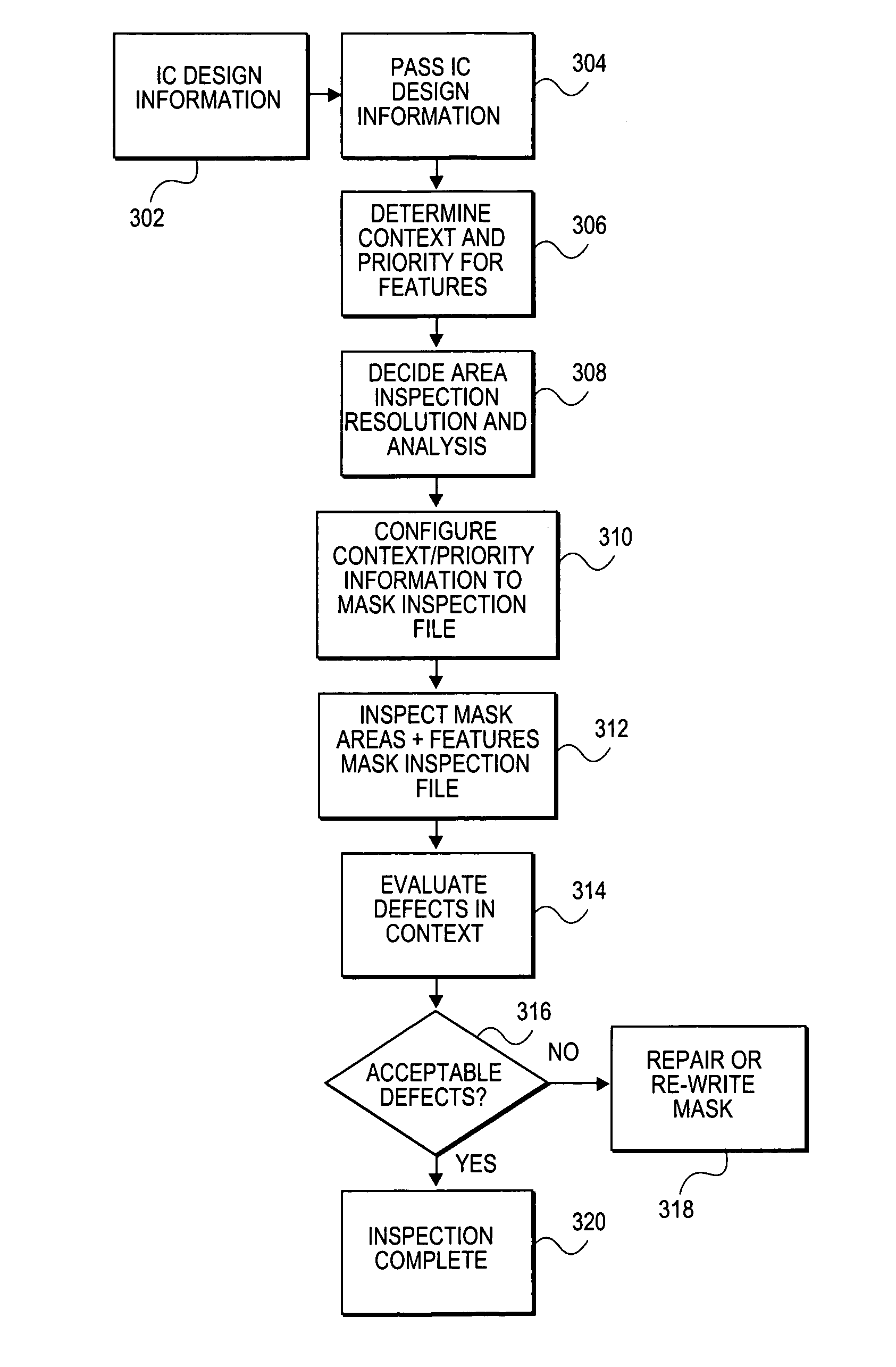

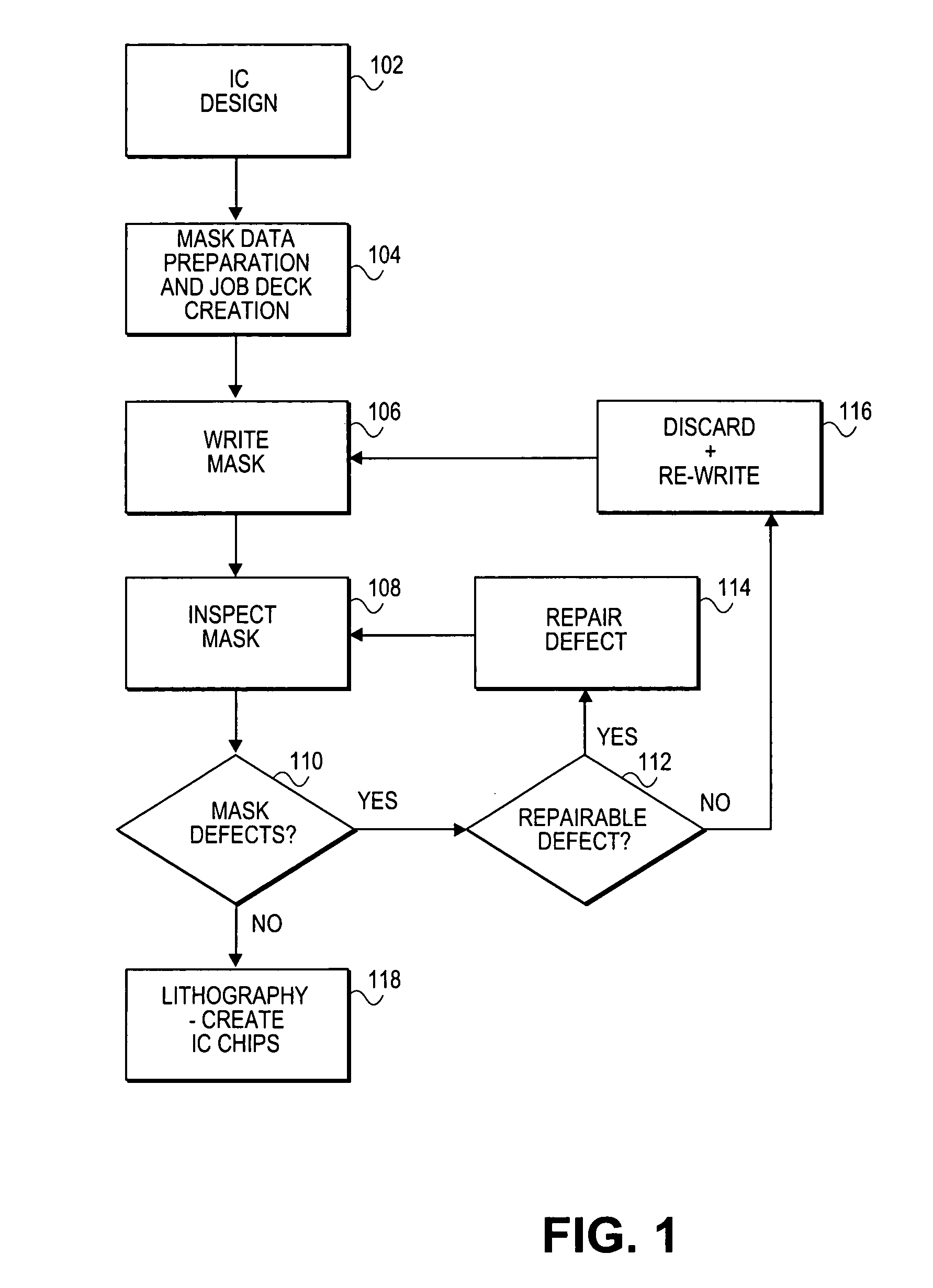

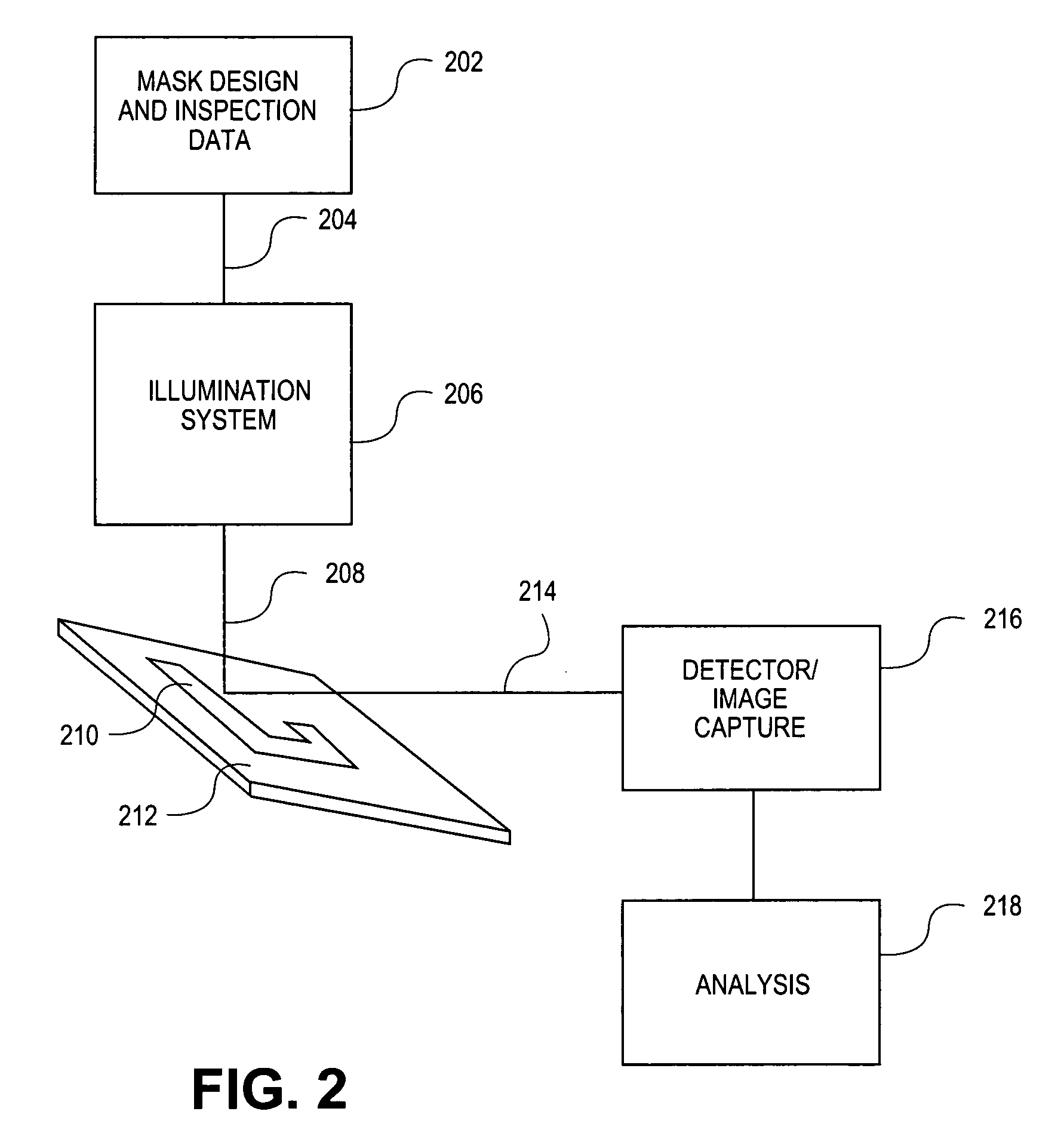

Method and system for context-specific mask inspection

InactiveUS7231628B2Electrical testingCharacter and pattern recognitionMask inspectionContext specific

A method for inspecting lithography masks includes generating integrated circuit design data and using context information from the integrated circuit design data to inspect a mask.

Owner:CADENCE DESIGN SYST INC

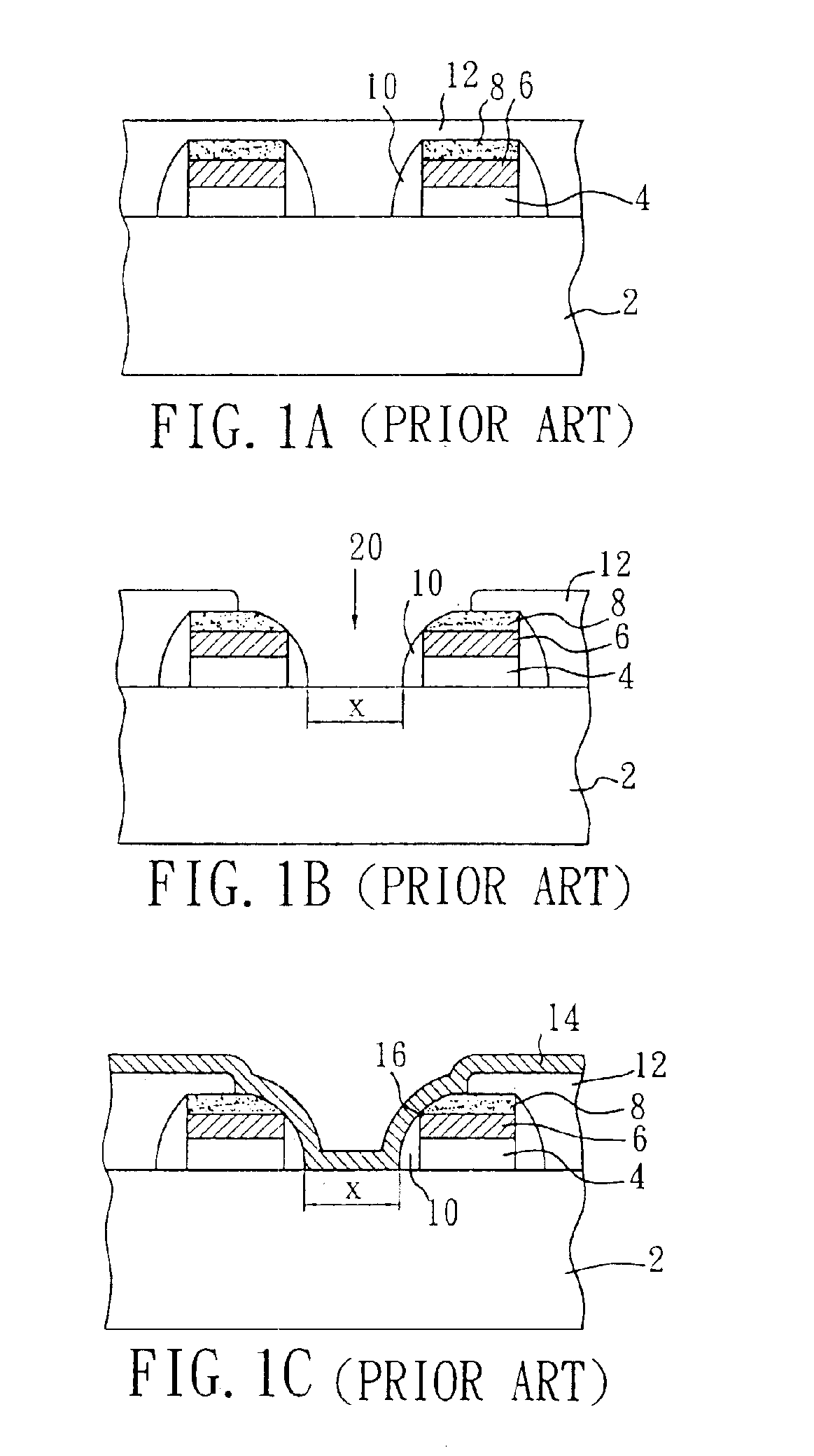

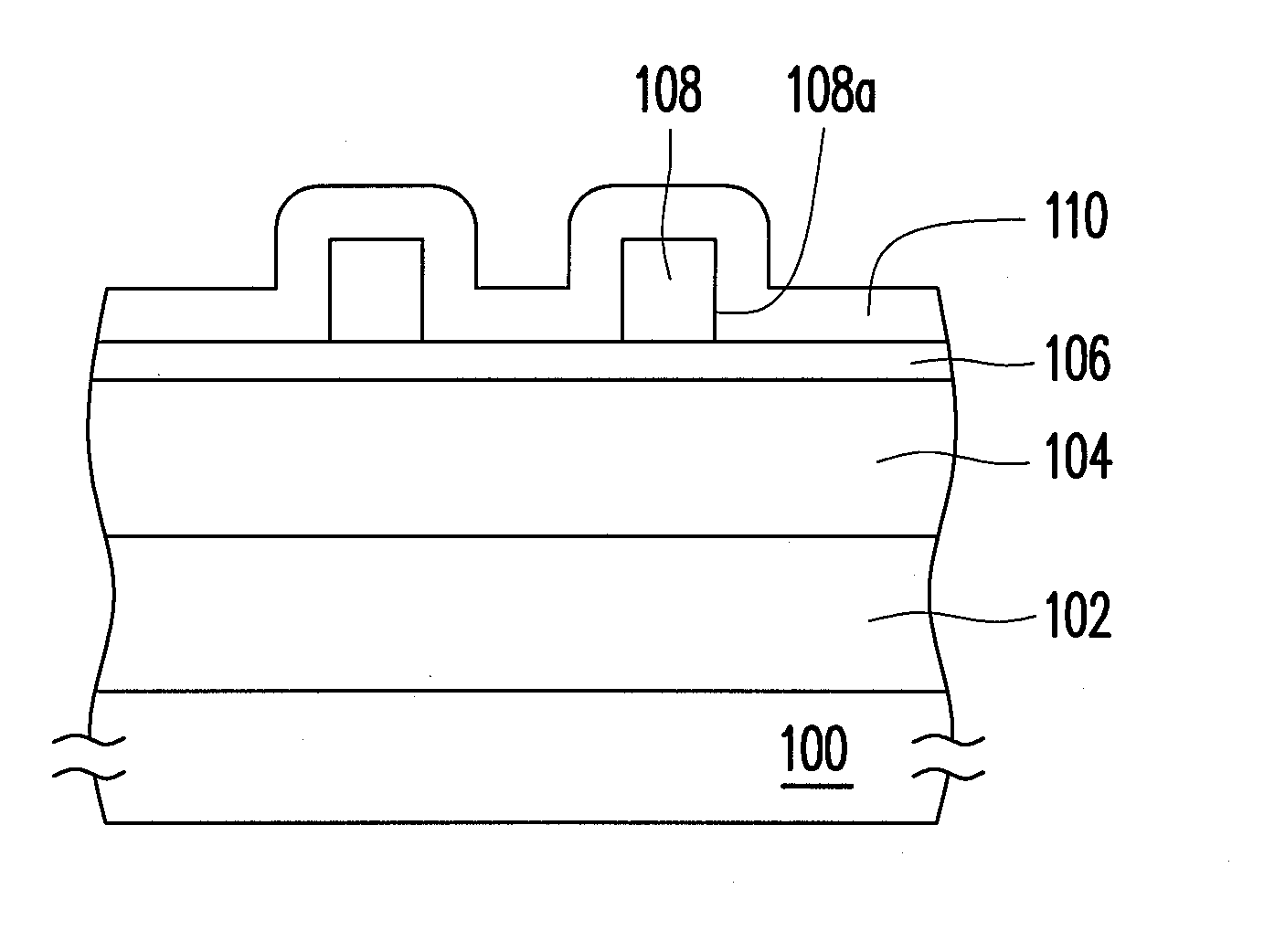

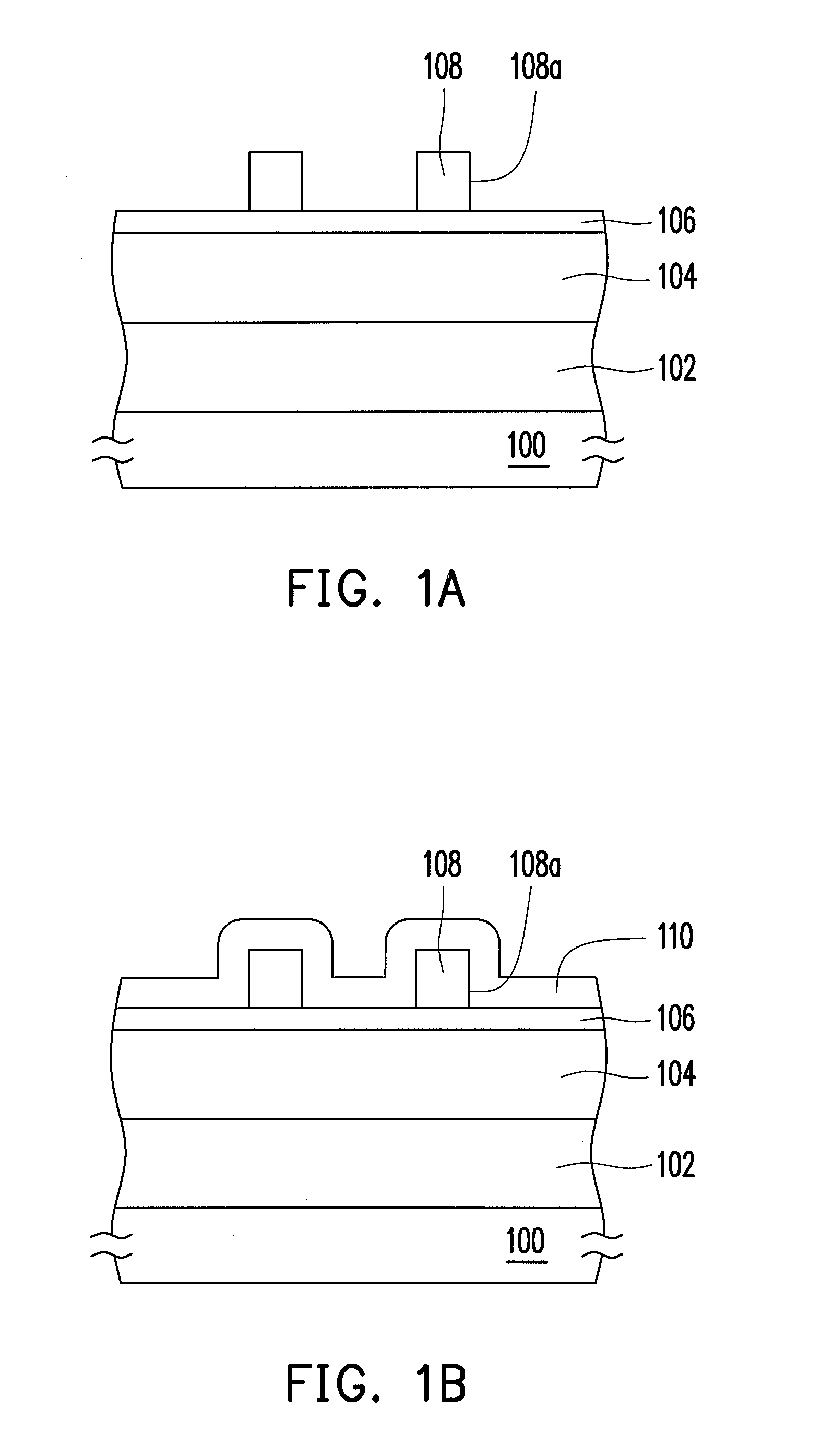

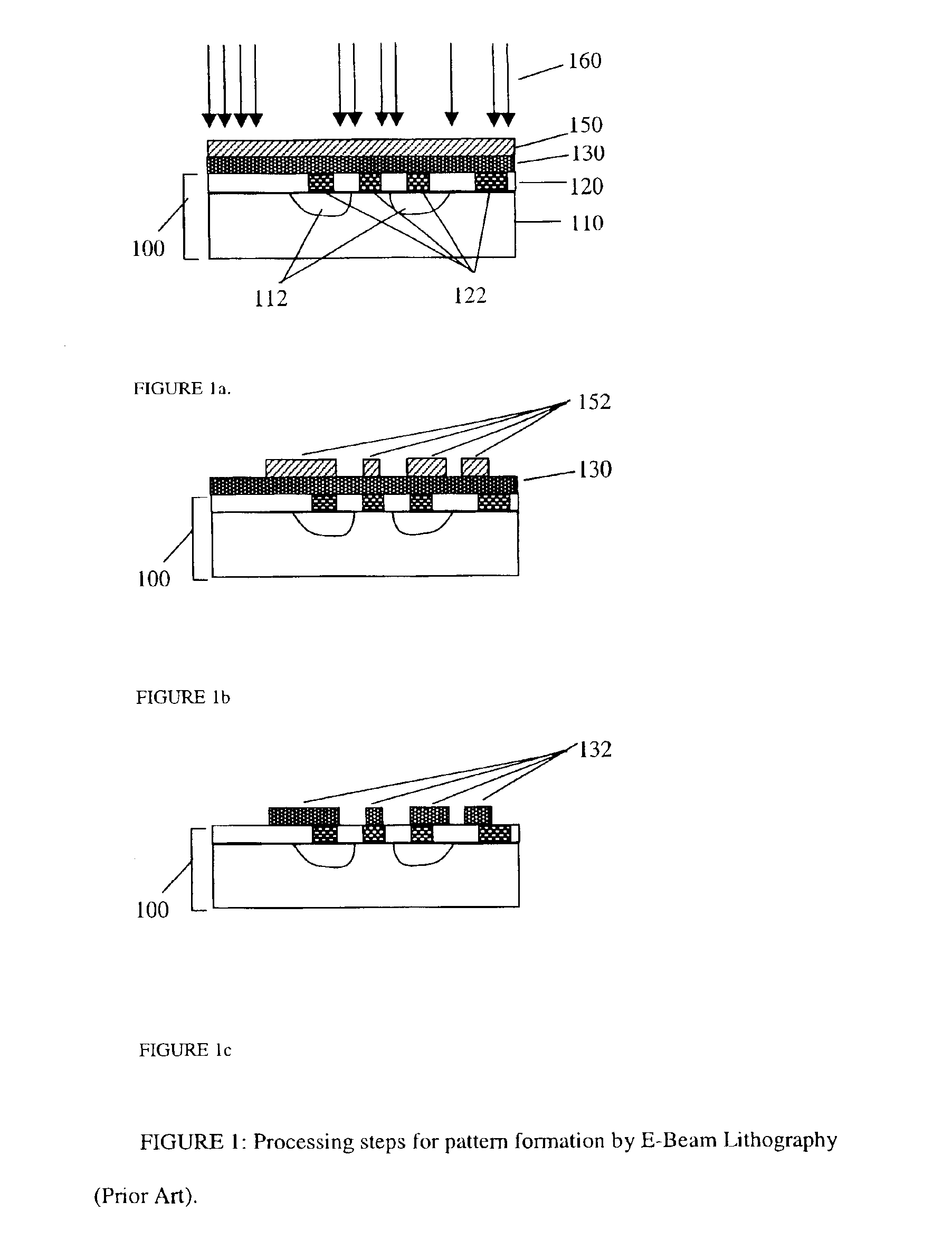

Patterning method

InactiveUS20110294075A1Reduce line widthLow costSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhotoresistMask layer

A patterning method of the present invention is described as follows. A mask layer and a patterned photoresist layer are formed on a target layer in sequence, wherein an etching rate of the mask layer is different from an etching rate of the target layer. A plurality of spacers is formed on sidewalls of the patterned photoresist layer respectively, wherein an etching rate of the spacers is different from the etching rate of the mask layer. The patterned photoresist layer is removed to form an opening between any two adjacent spacers. A portion of the mask layer is removed by using the spacers as a mask so as to form a patterned mask layer. A portion of the target layer is removed by using the patterned mask layer as a mask.

Owner:UNITED MICROELECTRONICS CORP

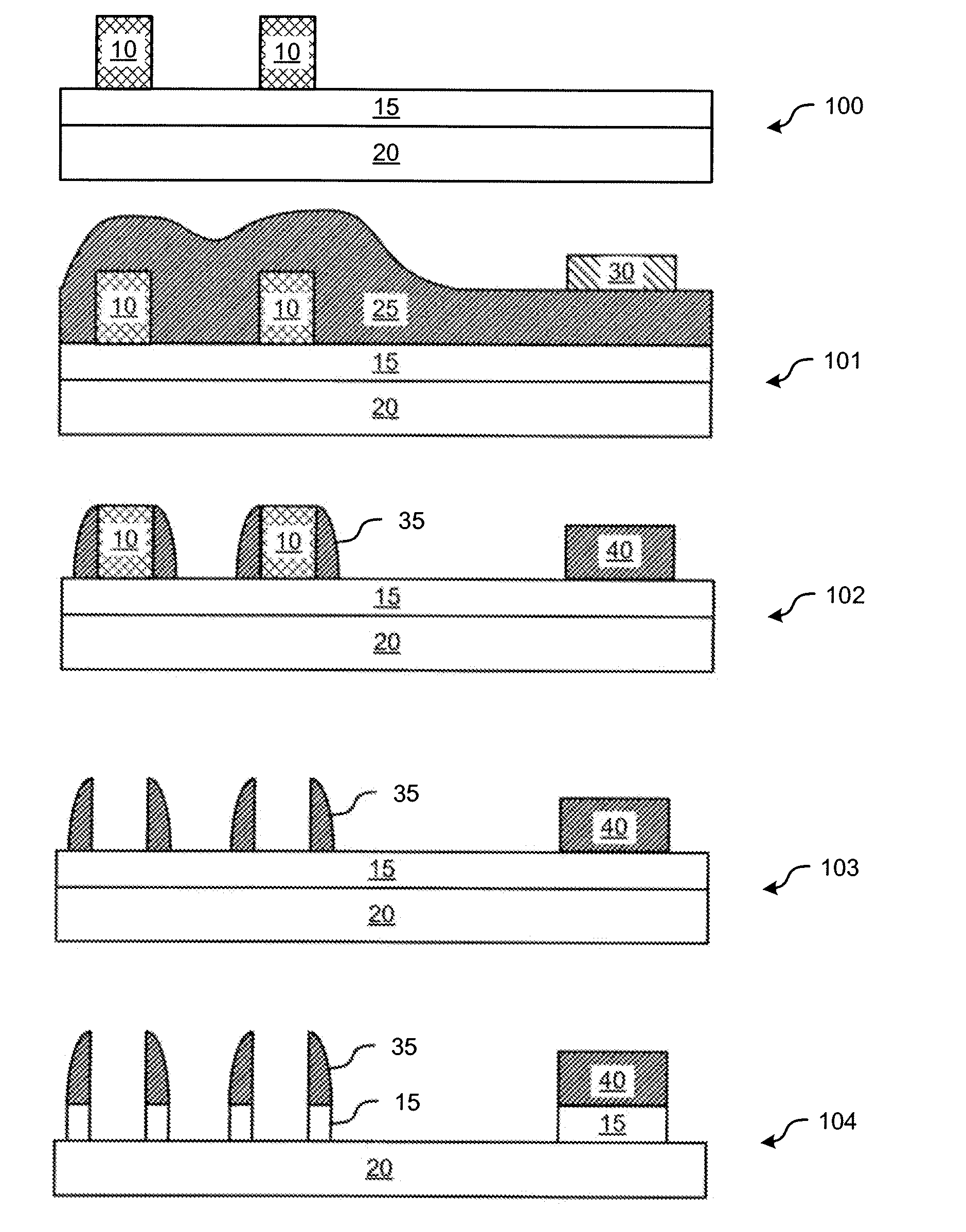

Method of IC production using corrugated substrate

ActiveUS7265008B2Improve performance consistencyImprove performanceLaser detailsSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Enhanced segmented channel MOS transistor with narrowed base regions

ActiveUS7508031B2Improve performance consistencyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably produced. Ridges on the corrugated substrate can be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials, high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Enhanced Segmented Channel MOS Transistor with High-Permittivity Dielectric Isolation Material

ActiveUS20070122953A1Increase costImprove performanceTransistorSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

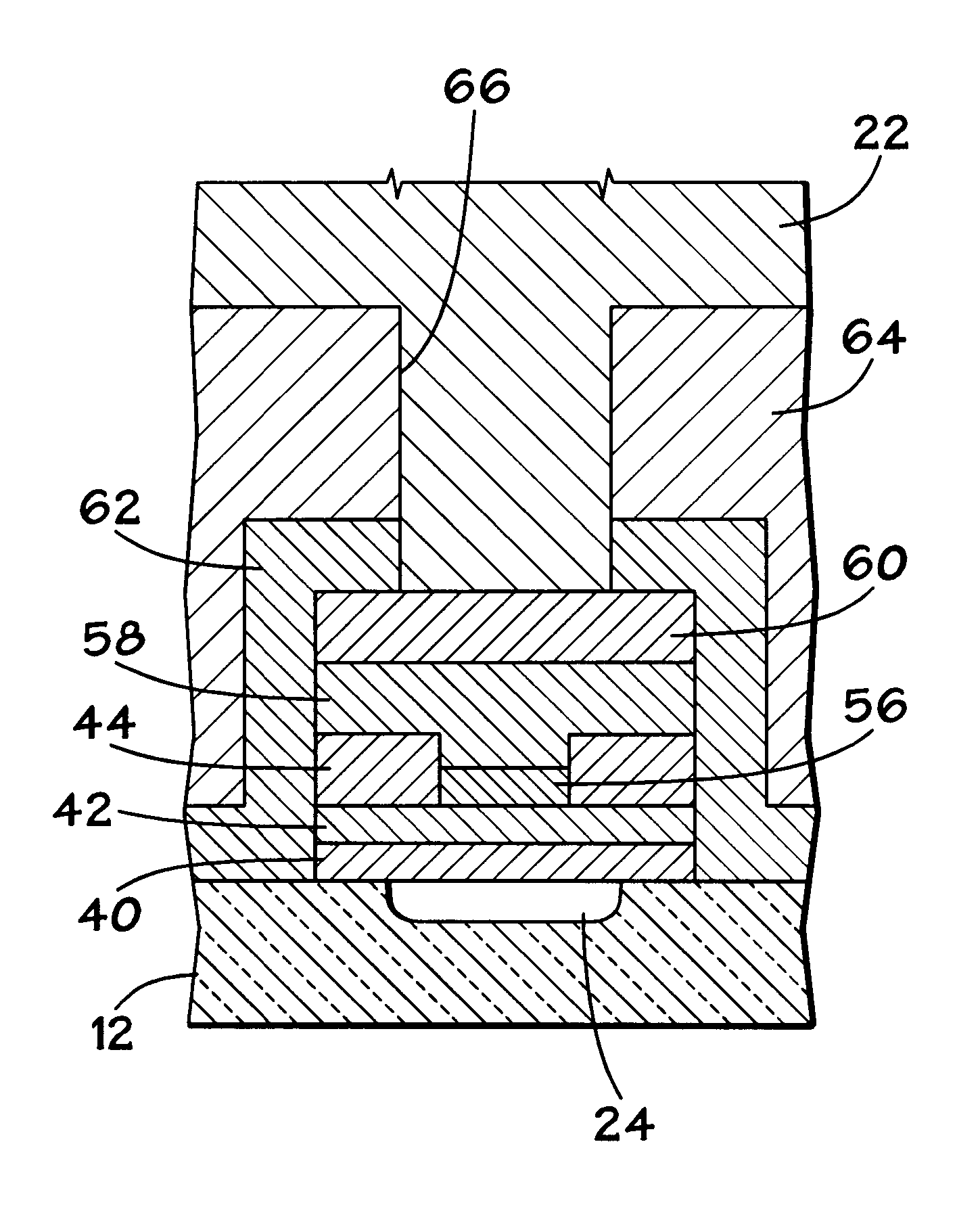

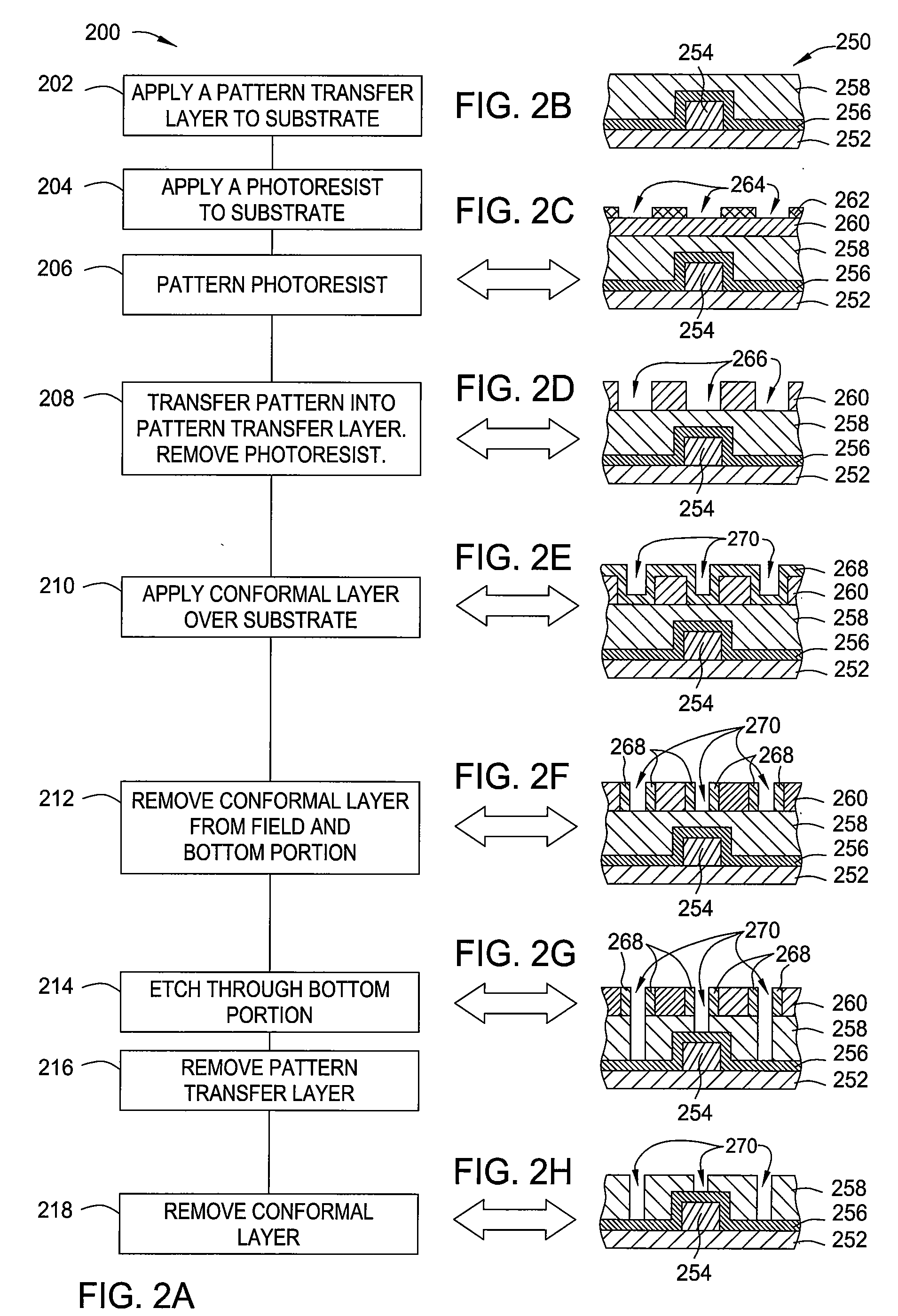

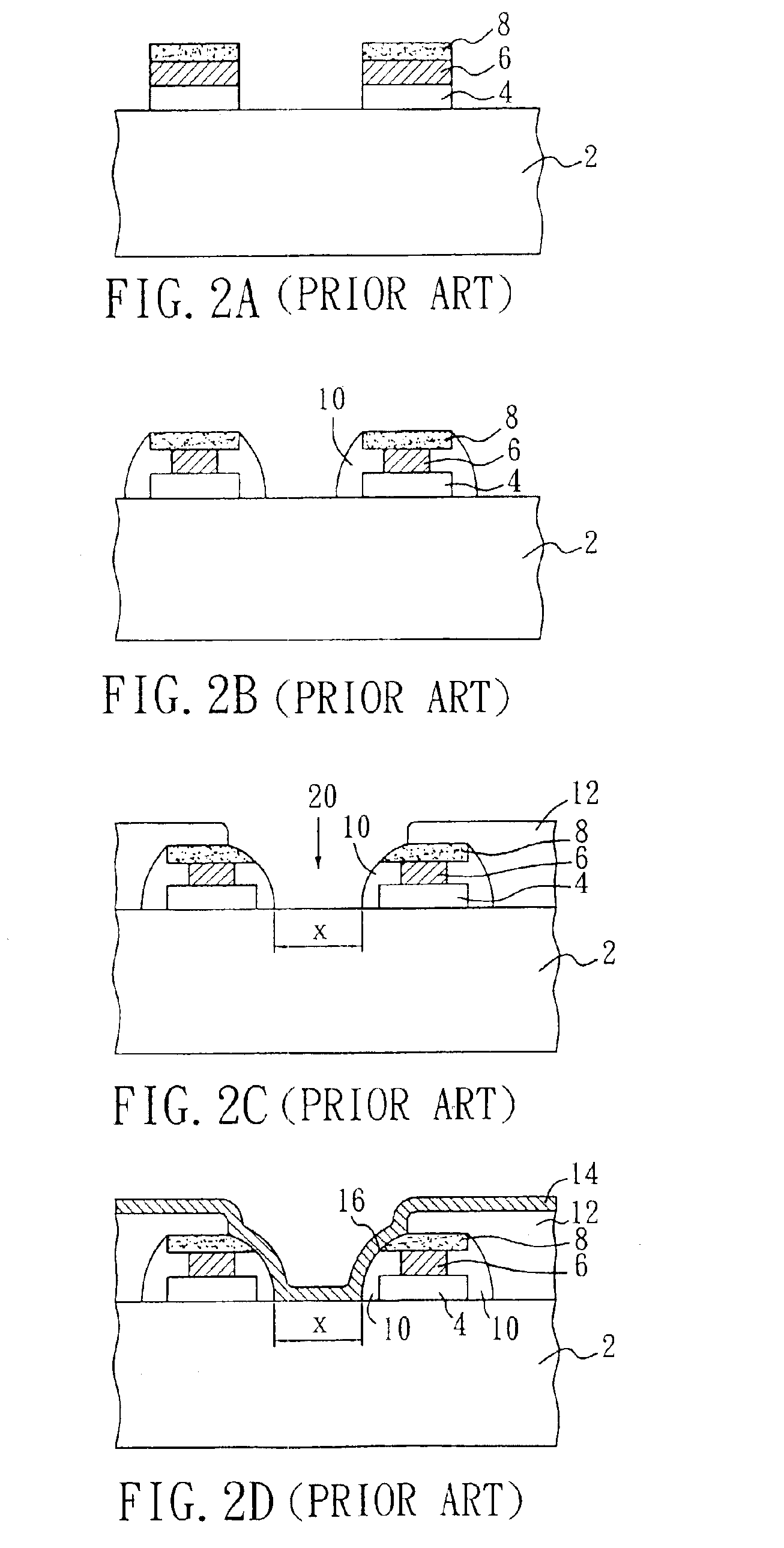

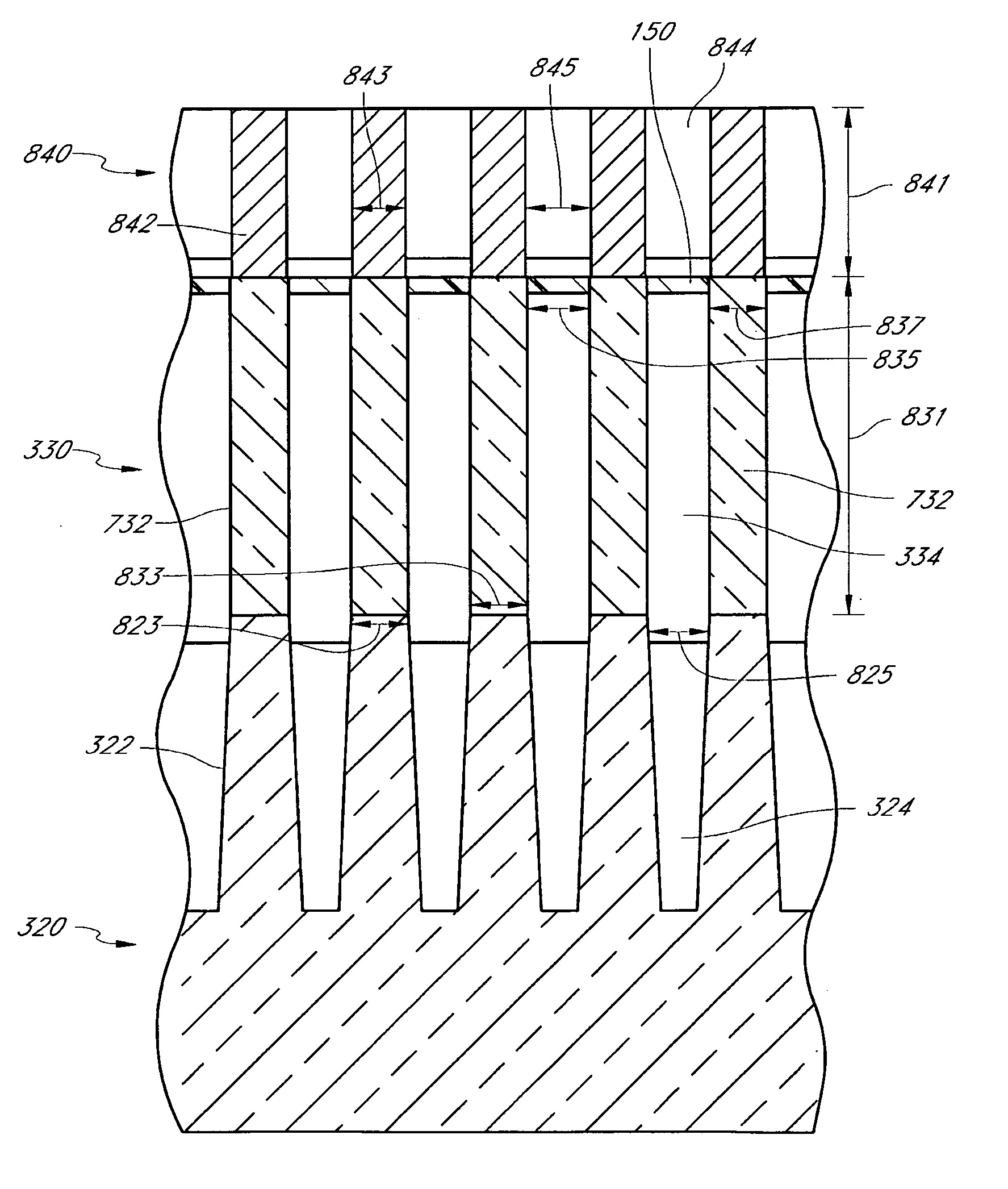

Method of forming pitch multipled contacts

ActiveUS20070049035A1Solid-state devicesSemiconductor/solid-state device manufacturingBit lineLithographic artist

Methods of forming electrically conductive and / or semiconductive features for use in integrated circuits are disclosed. Various pattern transfer and etching steps can be used, in combination with pitch-reduction techniques, to create densely-packed features. The features can have a reduced pitch in one direction and a wider pitch in another direction. Conventional photo-lithography steps can be used in combination with pitch-reduction techniques to form elongate, pitch-reduced features such as bit-line contacts, for example.

Owner:MICRON TECH INC

Enhanced segmented channel MOS transistor with high-permittivity dielectric isolation material

ActiveUS7605449B2Improve performance consistencyImprove performanceTransistorSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Electrical conductors formed from mixtures of metal powders and metallo-organic decomposition compounds

The present invention relates to a thick film formed of a mixture of metal powders and metallo-organic decomposition (MOD) compounds in an organic liquid vehicle and a process for advantageously applying them to a substrate by silk screening or other printing technology. The mixtures preferably contain metal flake with a ratio of the maximum dimension to the minimum dimension of between 5 and 50. The vehicle may include a colloidal metal powder with a diameter of about 10 to about 40 nanometers. The concentration of the colloidal metal in the suspension can range from about 10 to about 50% by weight. The MOD compound begins to decompose at a temperature of approximately about 200 DEG C. to promote consolidation of the metal constituents and bonding to the substrate which is complete at temperatures less than 450 DEG C. in a time less than six minutes. The mixtures can be applied by silk screening, stencilling, gravure or lithography to a polymer-based circuit board substrate for producing rigid and flexible printed wiring boards in a single operation with negligible generation of hazardous wastes. The same mixtures can be used in place of solder to assemble circuits by bonding electrical components to conductors as well as to make the conductors themselves.

Owner:PARELEC

Integrated Circuit On Corrugated Substrate

ActiveUS20070132053A1Improve performance consistencyImprove performanceTransistorSemiconductor/solid-state device detailsMOSFETSemiconductor materials

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

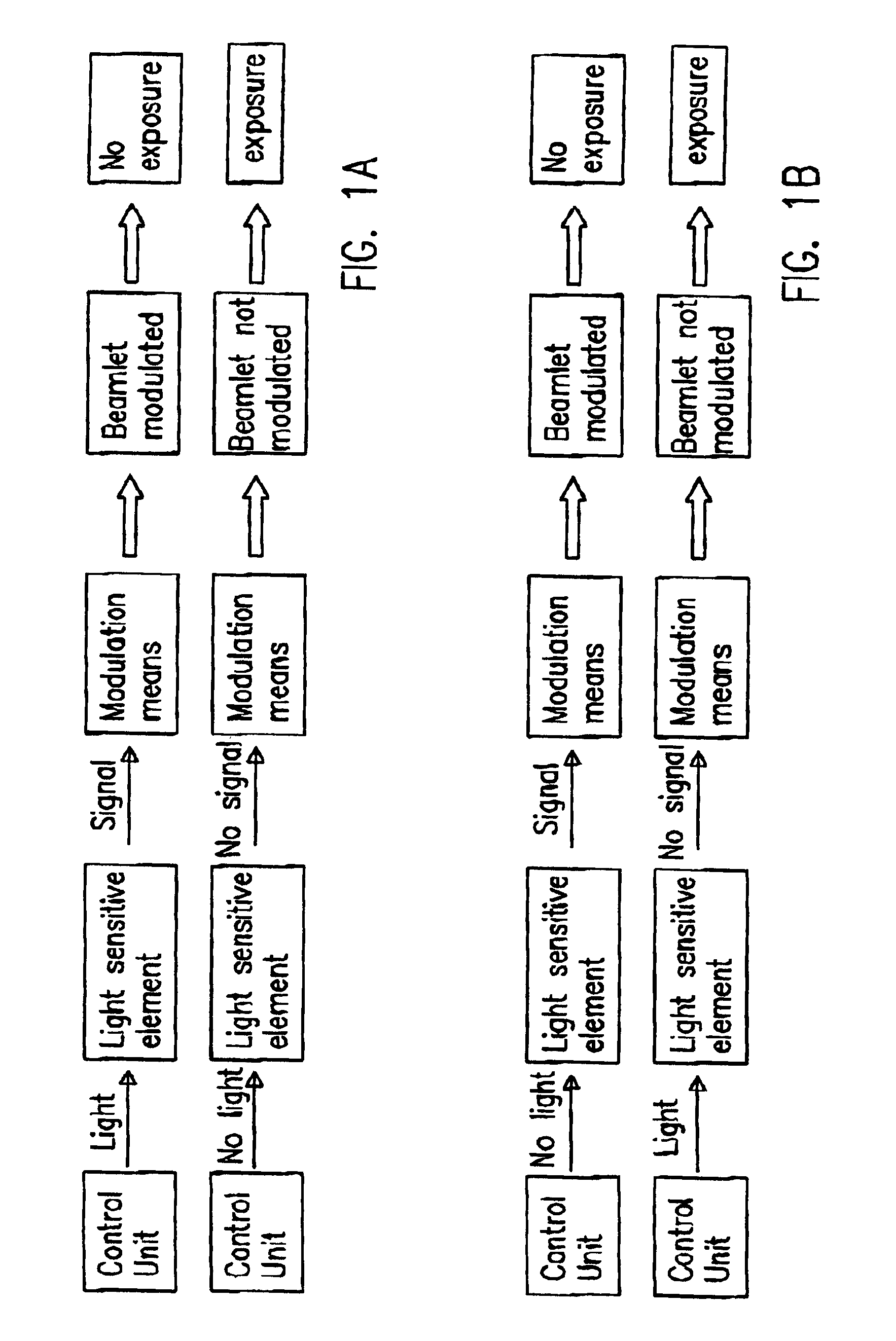

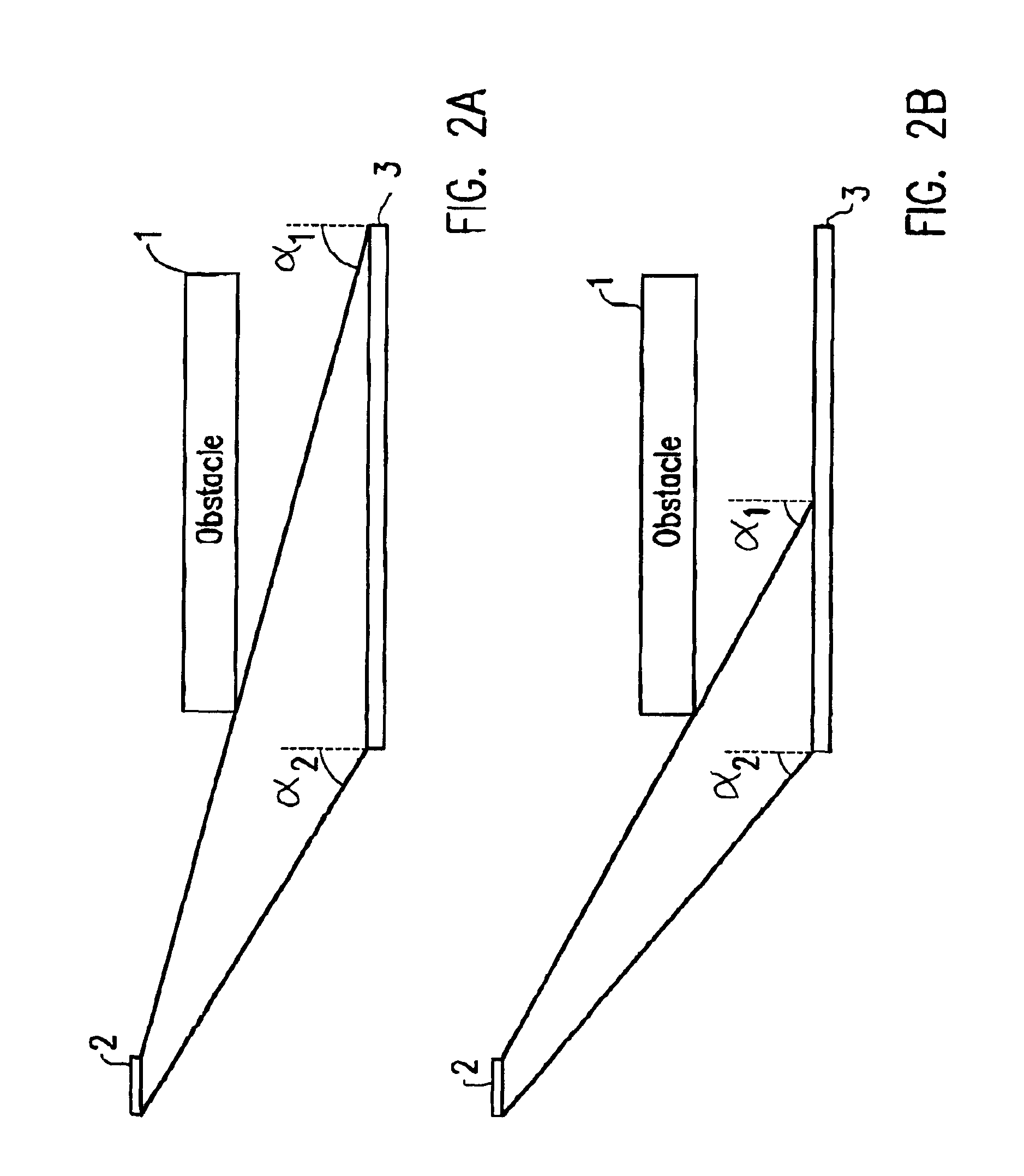

Lithography system

ActiveUS6958804B2Location somewhat remoteReduce transmission lossMirrorsElectric discharge tubesLithographic artistLight beam

A maskless lithography system for transferring a pattern onto the surface of a target. At least one beam generator for generating a plurality of beamlets. A plurality of modulators modulate the magnitude of a beamlet, and a control unit controls of the modulators. The control unit generates and delivers pattern data to the modulators for controlling the magnitude of each individual beamlet. The control unit includes at least one data storage for storing the pattern data, at least one readout unit for reading out the data from the data storage, at least one data converter for converting the data that is read out from the data storage into at least one modulated light beam, and at least one optical transmitter for transmitting the at least one modulated light beam to the modulation modulators.

Owner:ASML NETHERLANDS BV

Method of forming a contact structure in a semiconductor device

InactiveUS6440837B1Solid-state devicesSemiconductor/solid-state device manufacturingProcess deviationsEtching

Annular and linear contact structures are described which exhibit a greatly reduced susceptibility to process deviations caused by lithographic and deposition variations than does a conventional circular contact plug. In one embodiment, a standard conductive material such as carbon or titanium nitride is used to form the contact. In an alternative embodiment, a memory material itself is used to form the contact. These contact structures may be made by various processes, including chemical mechanical planarization and facet etching.

Owner:ROUND ROCK RES LLC

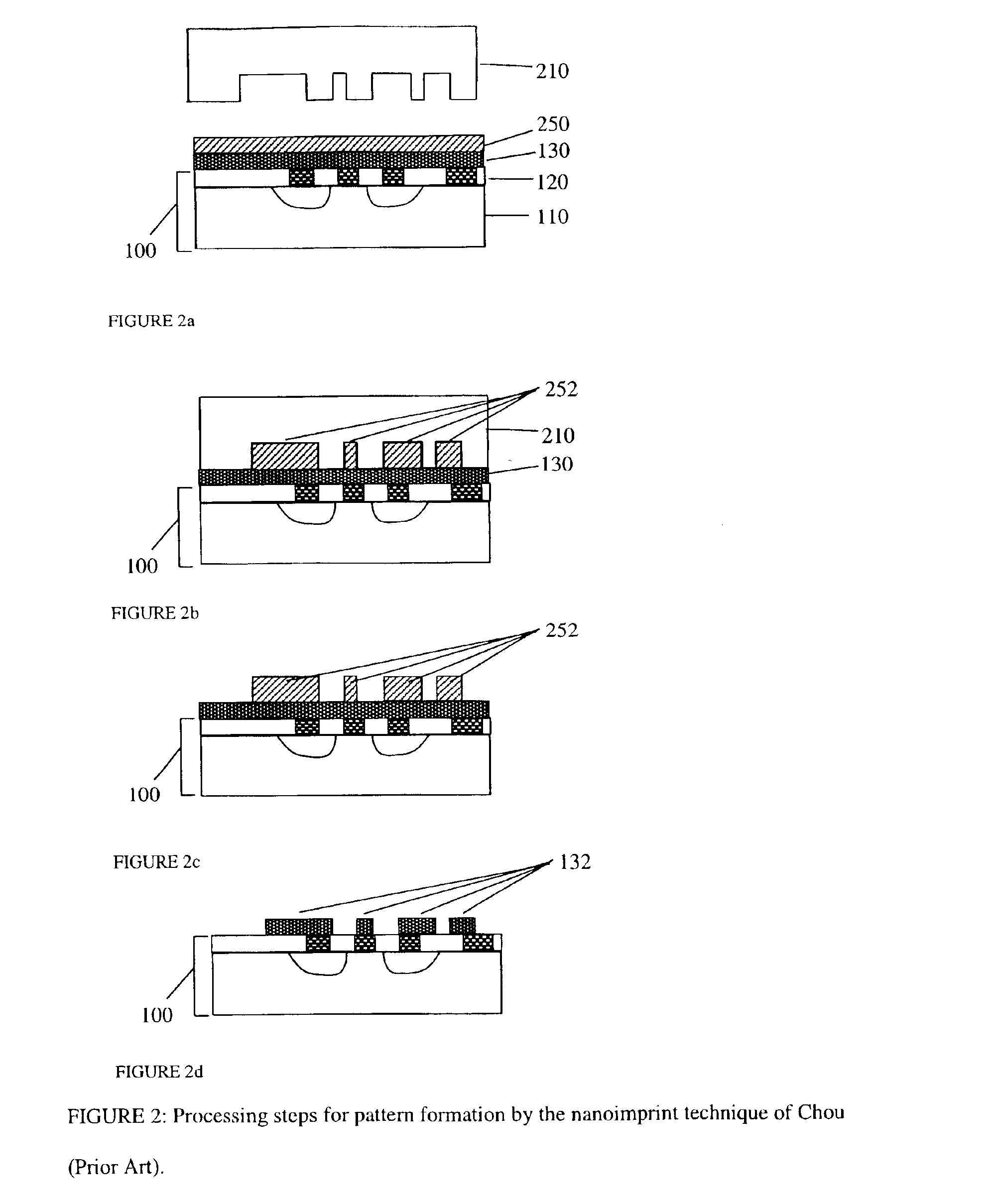

Replication and transfer of microstructures and nanostructures

InactiveUS6849558B2Facilitates pattern transferCheap to makeNanostructure manufactureDecorative surface effectsEngineeringMicroscopic scale

A method for the duplication of microscopic patterns from a master to a substrate is disclosed, in which a replica of a topographic structure on a master is formed and transferred when needed onto a receiving substrate using one of a variety of printing or imprint techniques, and then dissolved. Additional processing steps can also be carried out using the replica before transfer, including the formation of nanostructures, microdevices, or portions thereof. These structures are then also transferred onto the substrate when the replica is transferred, and remain on the substrate when the replica is dissolved. This is a technique that can be applied as a complementary process or a replacement for various lithographic processing steps in the fabrication of integrated circuits and other microdevices.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

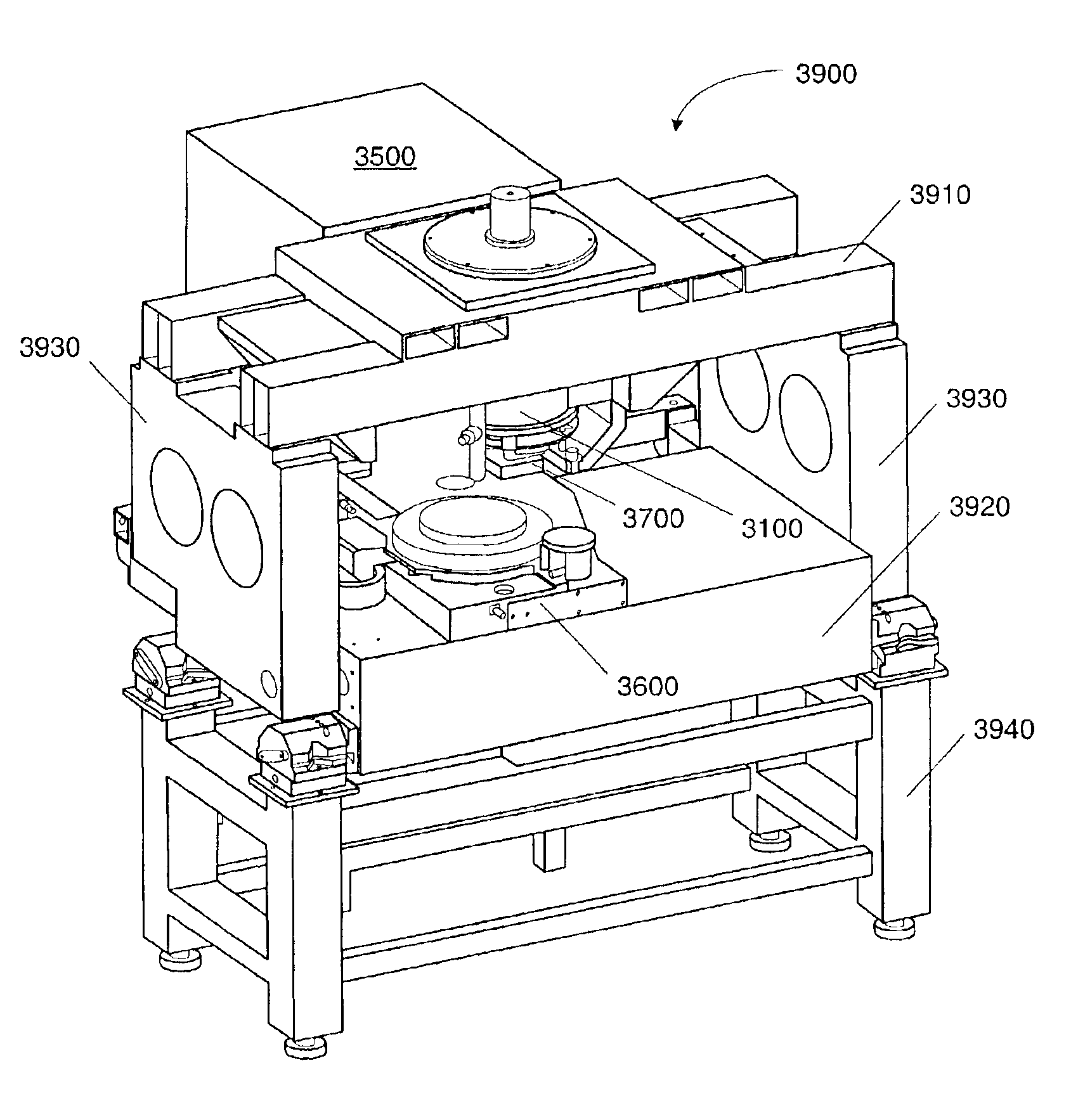

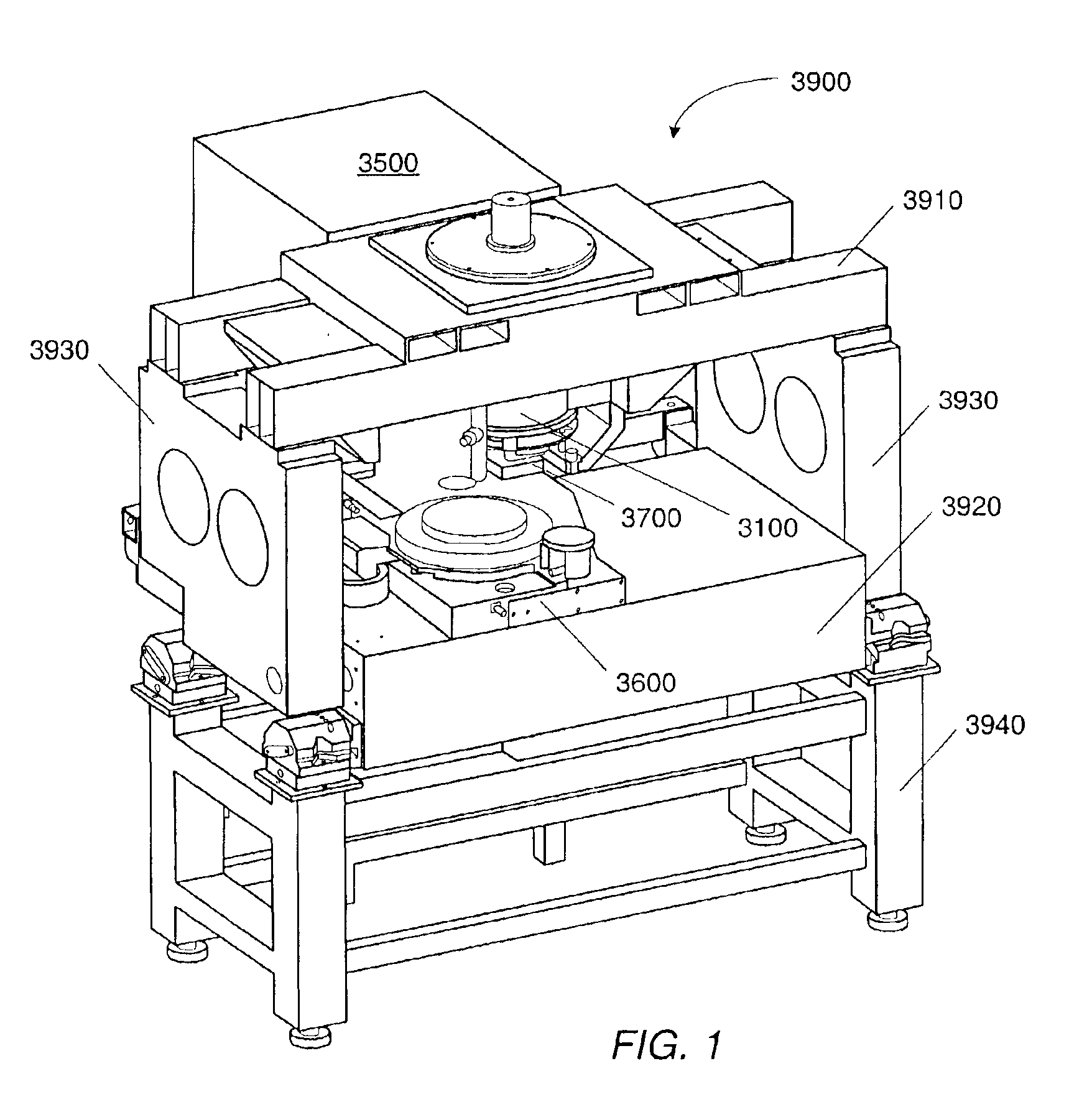

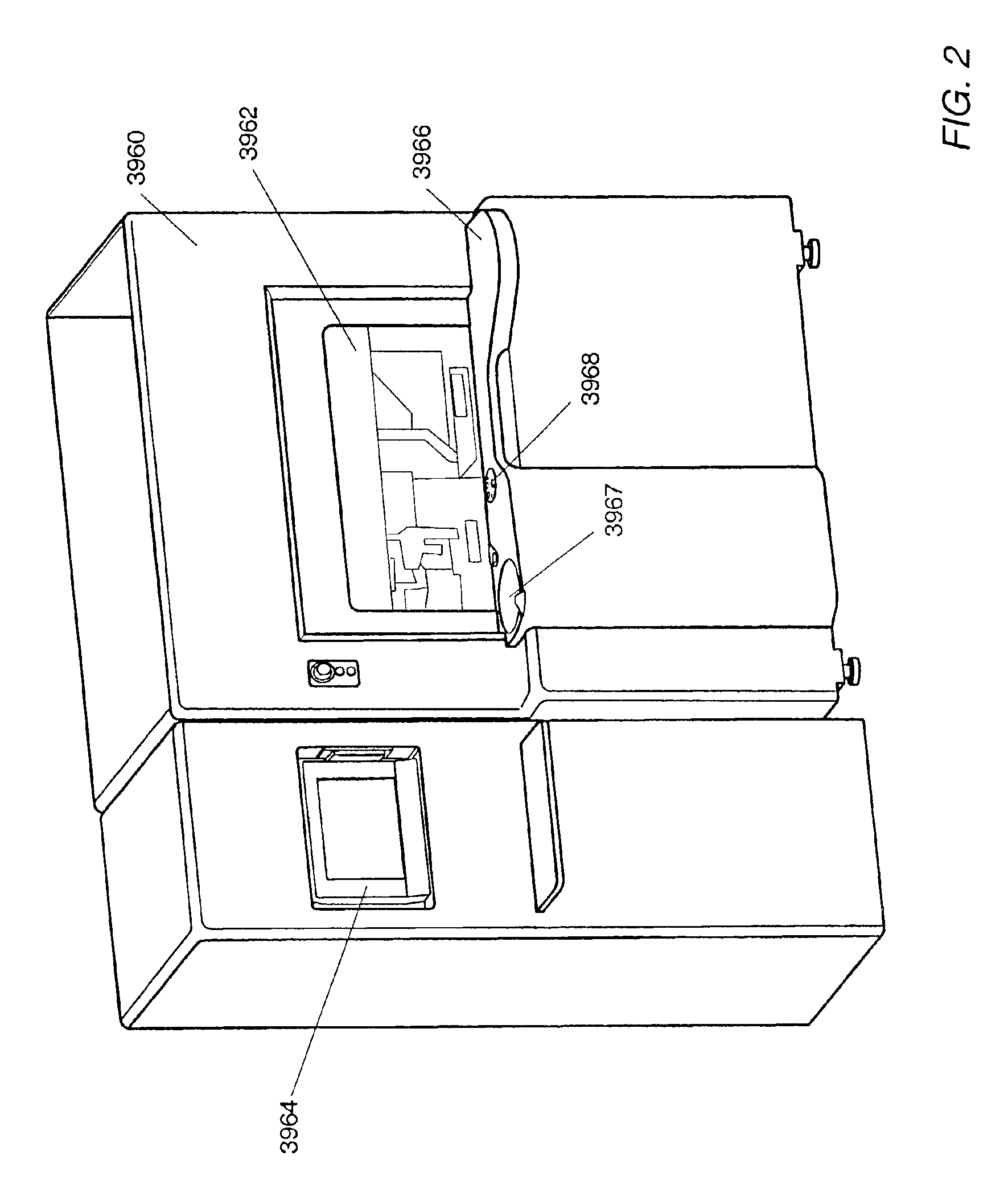

Step and repeat imprint lithography systems

Described are systems for patterning a substrate by imprint lithography. Imprint lithography systems include an imprint head configured to hold a template in a spaced relation to a substrate. The imprint lithography system is configured to dispense an activating light curable liquid onto a substrate or template. The system includes a light source that applies activating light to cure the activating light curable liquid.

Owner:CANON KK

Spacer formation

ActiveUS20150287612A1Semiconductor/solid-state device manufacturingImage resolutionOptical resolution

Embodiments of the present invention pertain to methods of forming more symmetric spacers which may be used for self-aligned multi-patterning processes. A conformal spacer layer of spacer material is formed over mandrels patterned near the optical resolution of a photolithography system using a high-resolution photomask. A carbon-containing layer is further formed over the conformal spacer layer. The carbon-containing layer is anisotropically etched to expose the high points of the conformal spacer layer while retaining carbon side panels. The conformal spacer layer may then be etched to form spacers without the traditional skewing of the profile towards one side or the other.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com