Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2572 results about "Point contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

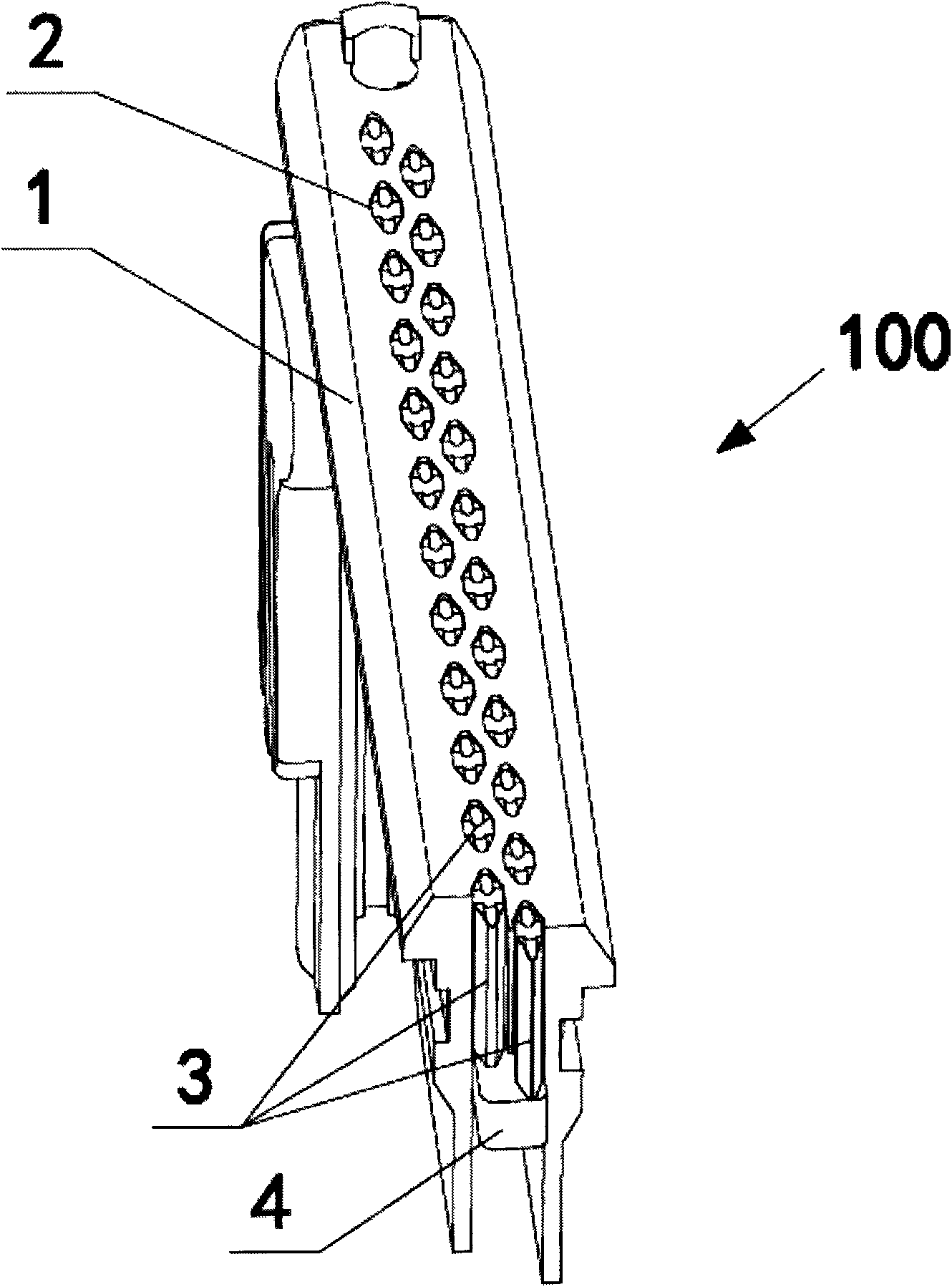

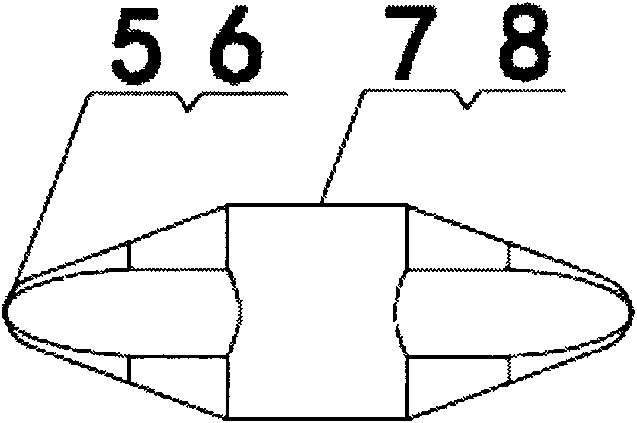

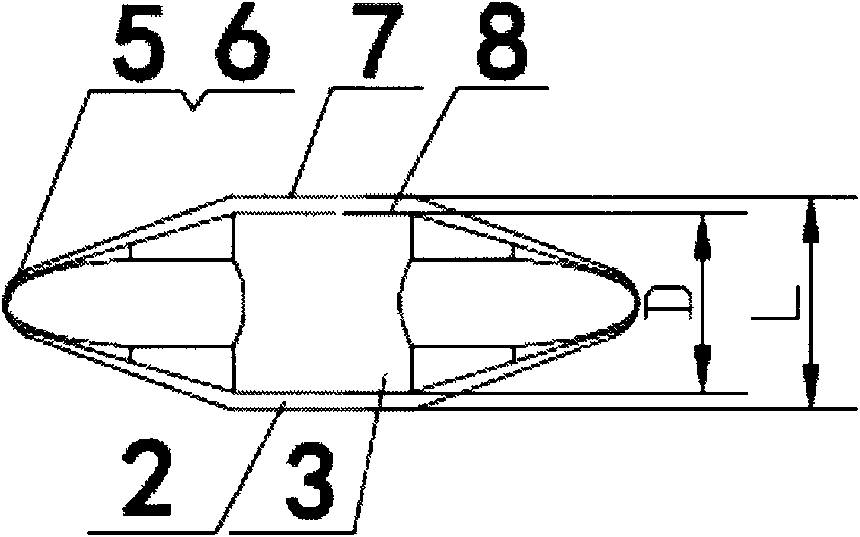

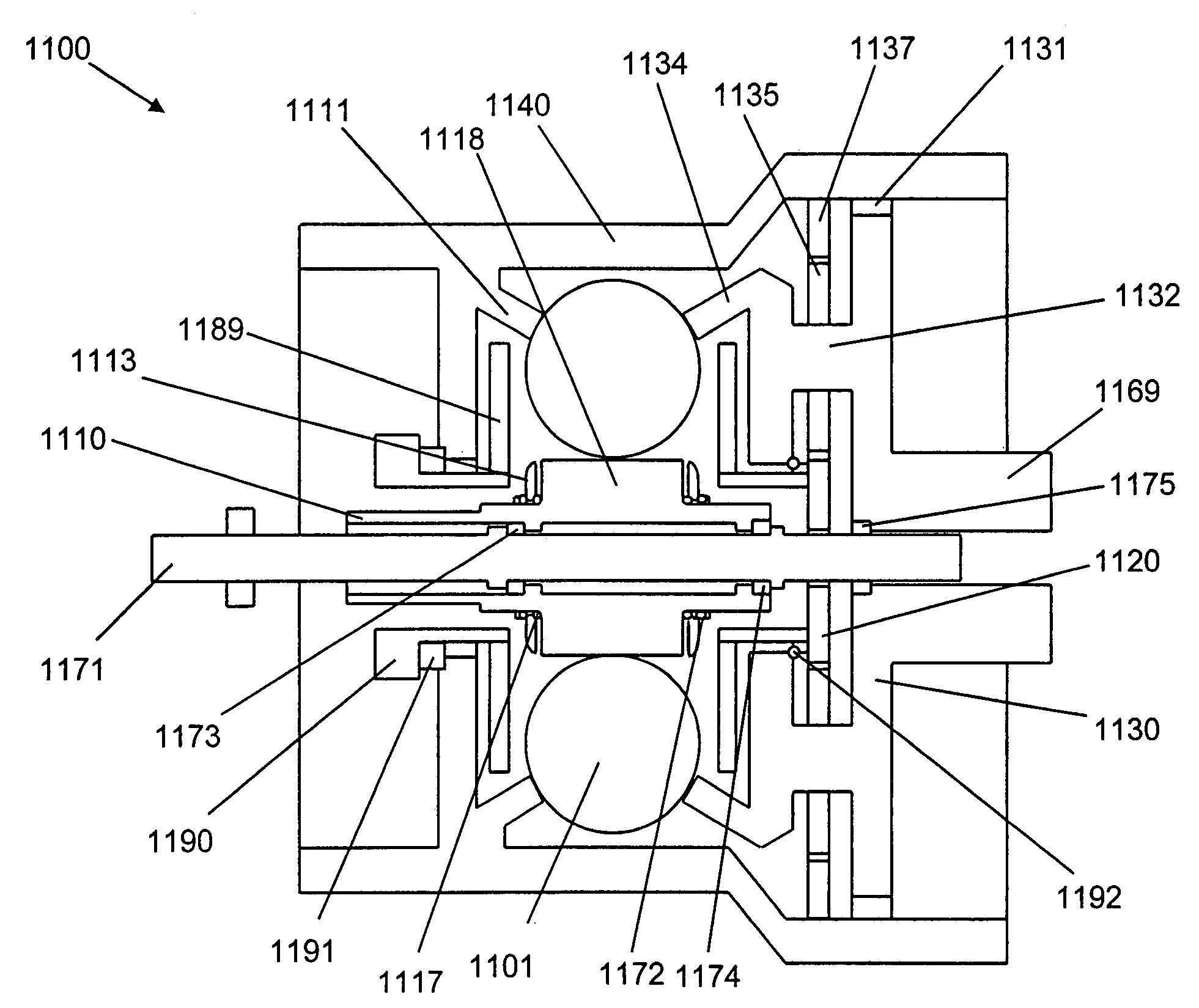

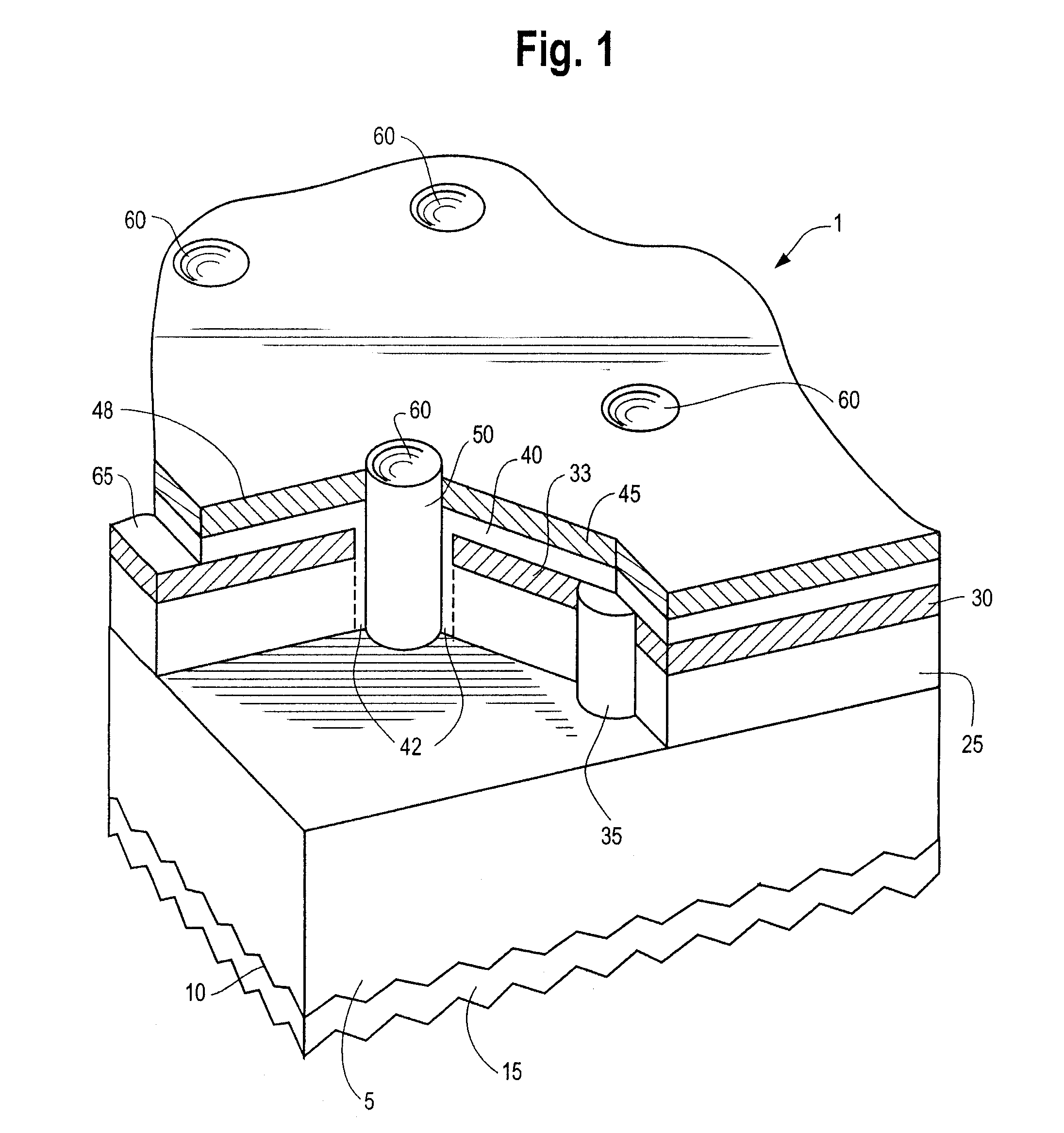

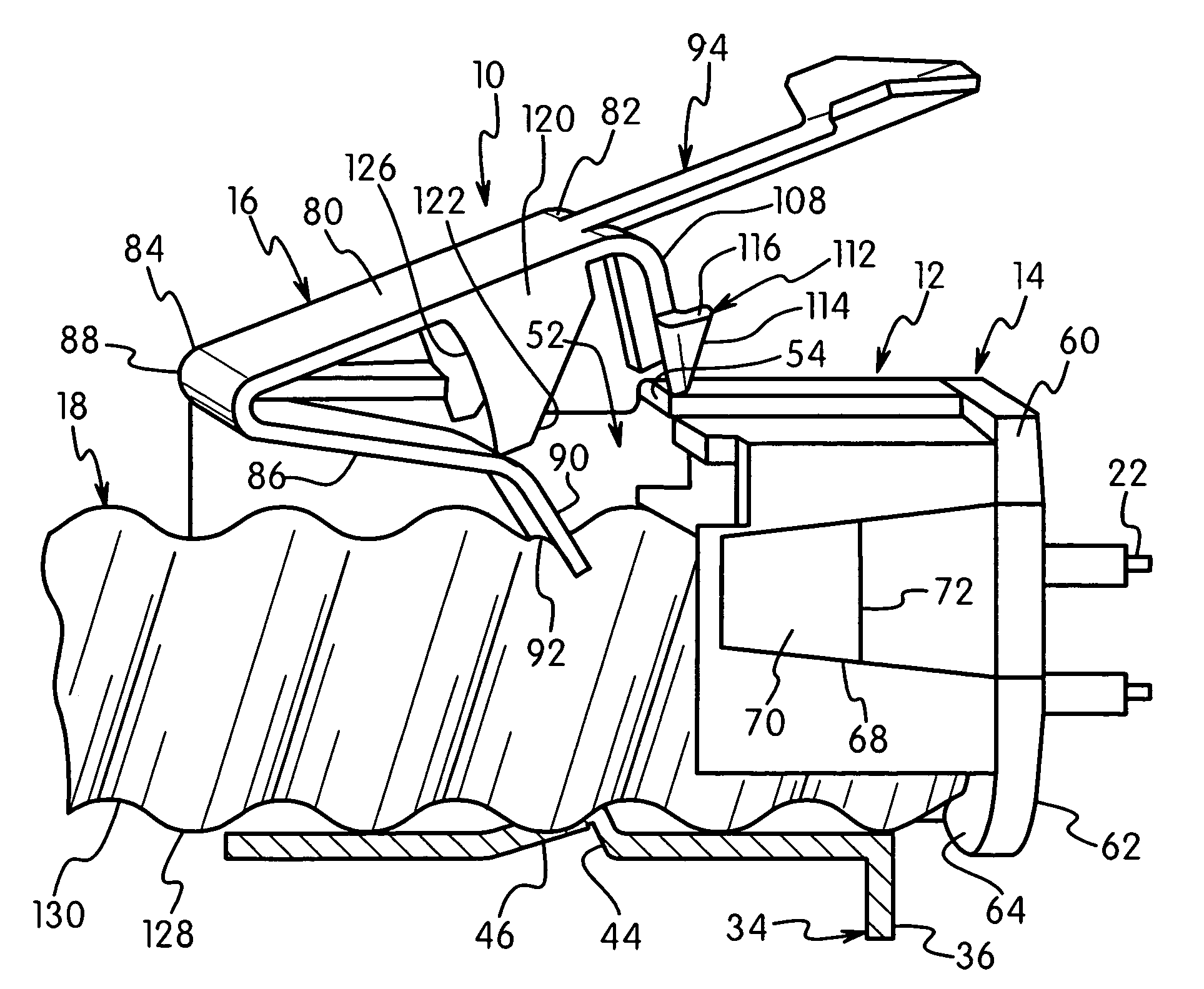

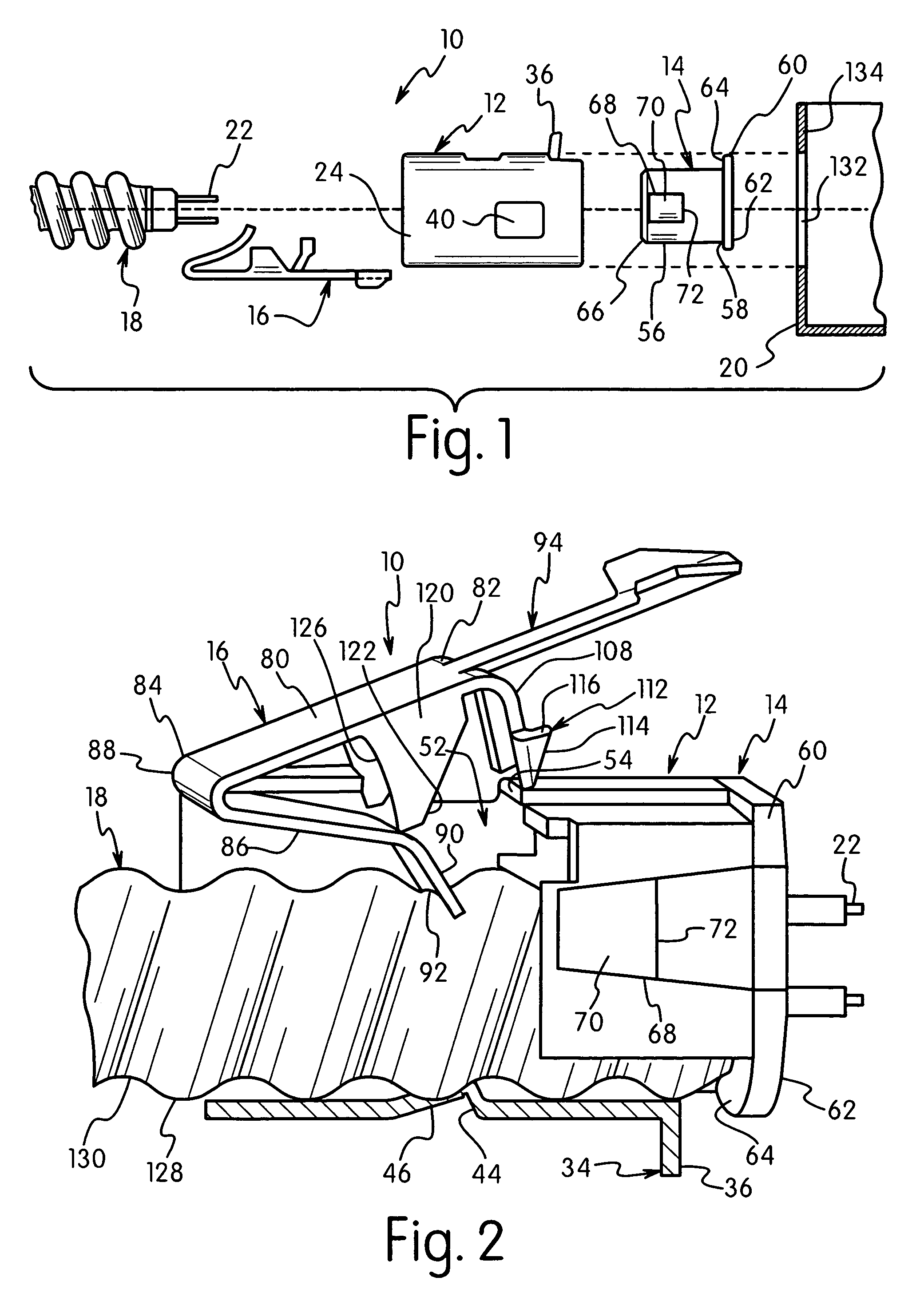

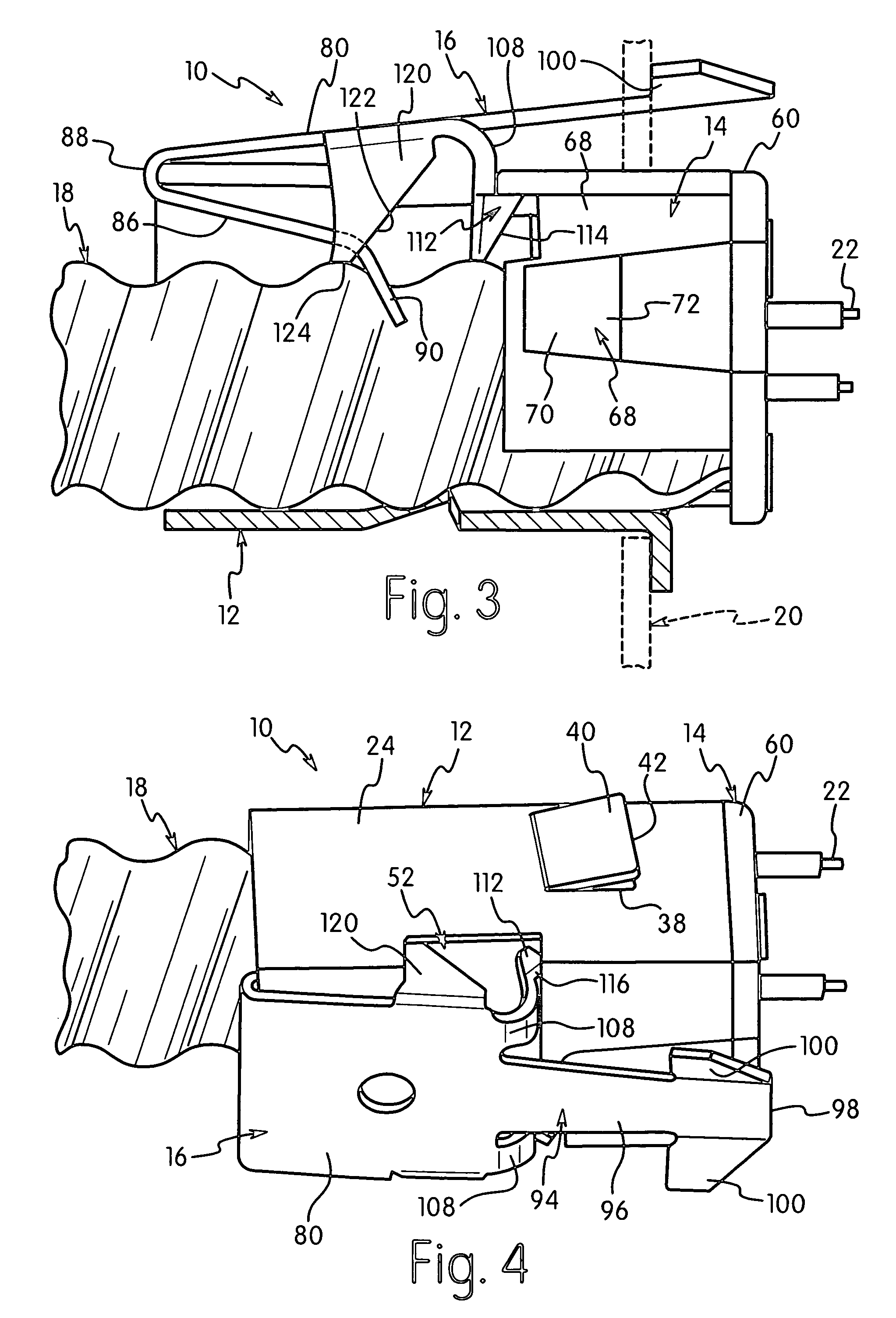

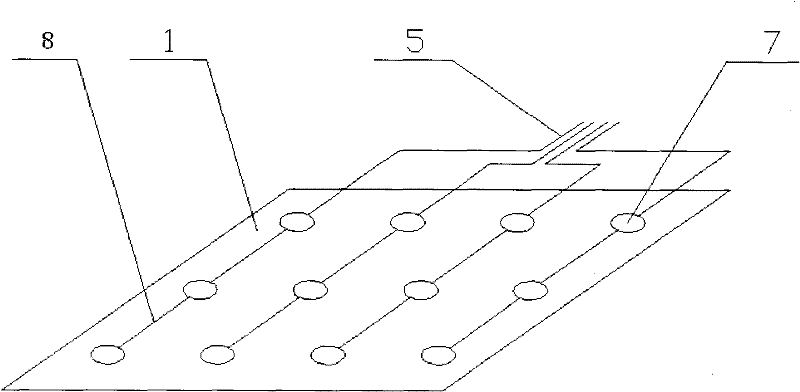

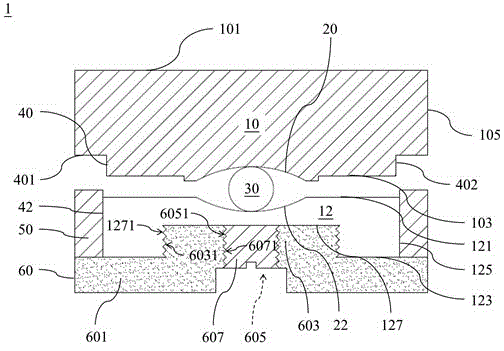

Nail bin assembly

InactiveCN102038532AReduce firing forceReduce frictionSurgical staplesBiomedical engineeringPoint contact

The invention discloses a nail bin assembly which comprises a nail bin, a nail bin hole and a nail-pushing slice, wherein the nail bin hole is thoroughly arranged on the surface of the nail bin, the nail-pushing slice is arranged in the nail bin hole and can slide relative to the nail bin hole, the transversal surfaces of the nail bin hole and the nail-pushing slice are respectively provided with a pair of long edges, and the distance between the long edges of the nail bin hole is greater than that between the long edges of the nail-pushing slice. The invention has the main beneficial effects that because the nail bin hole and the nail-pushing slice are in point contact, the friction between the nail bin hole and the nail-pushing slice is small, so that the percussive force of the whole nail bin assembly is relatively small.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

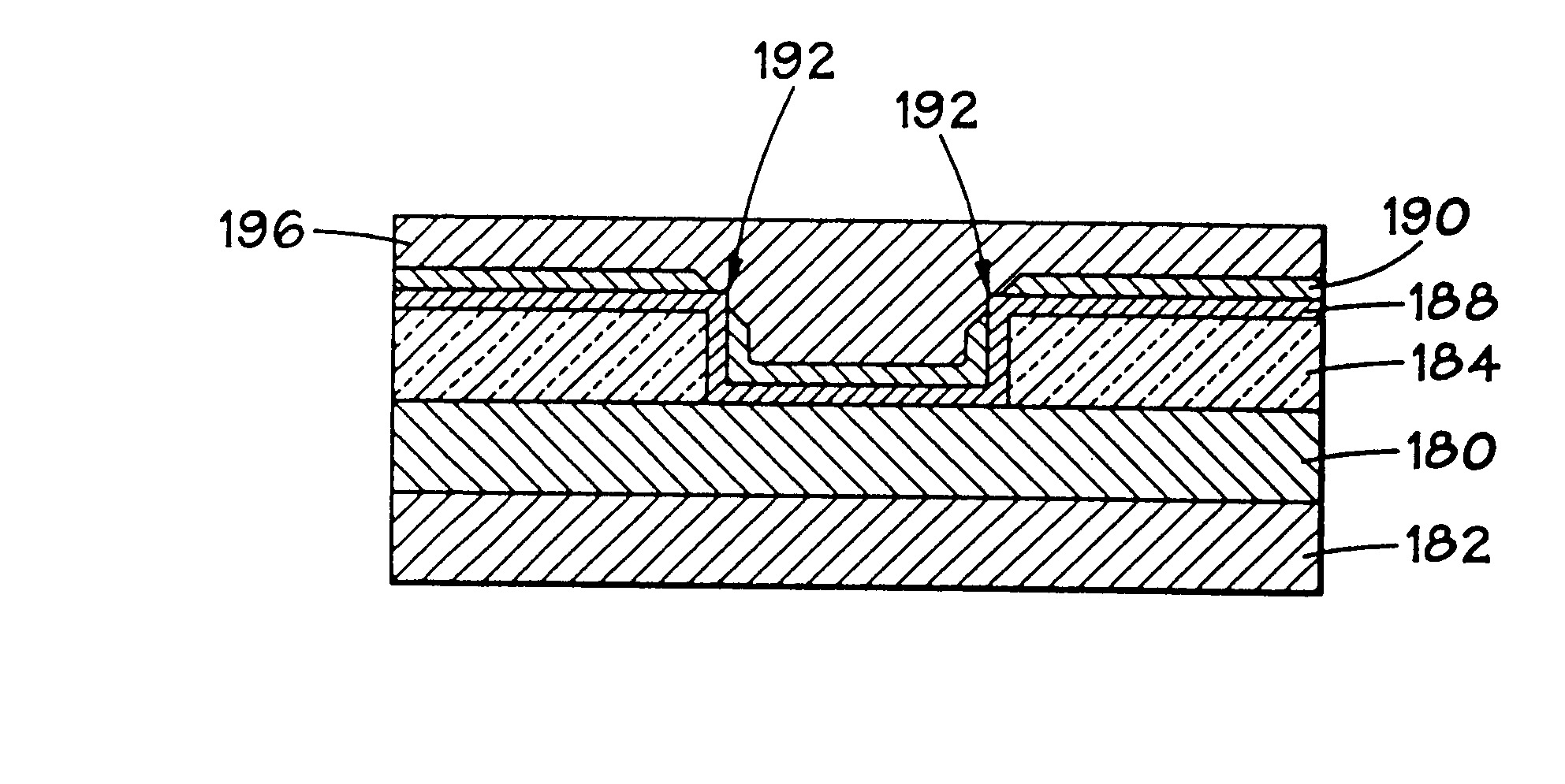

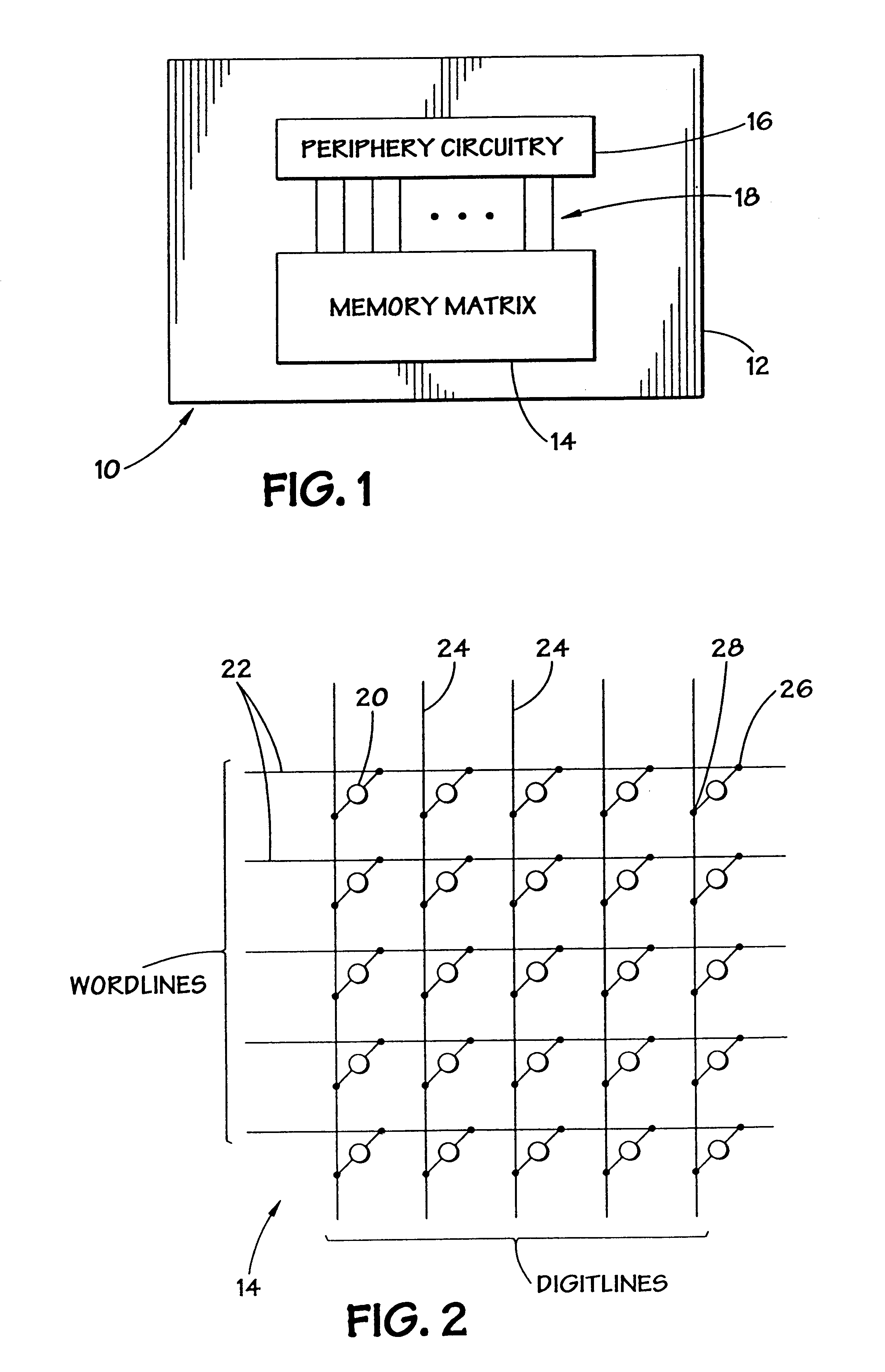

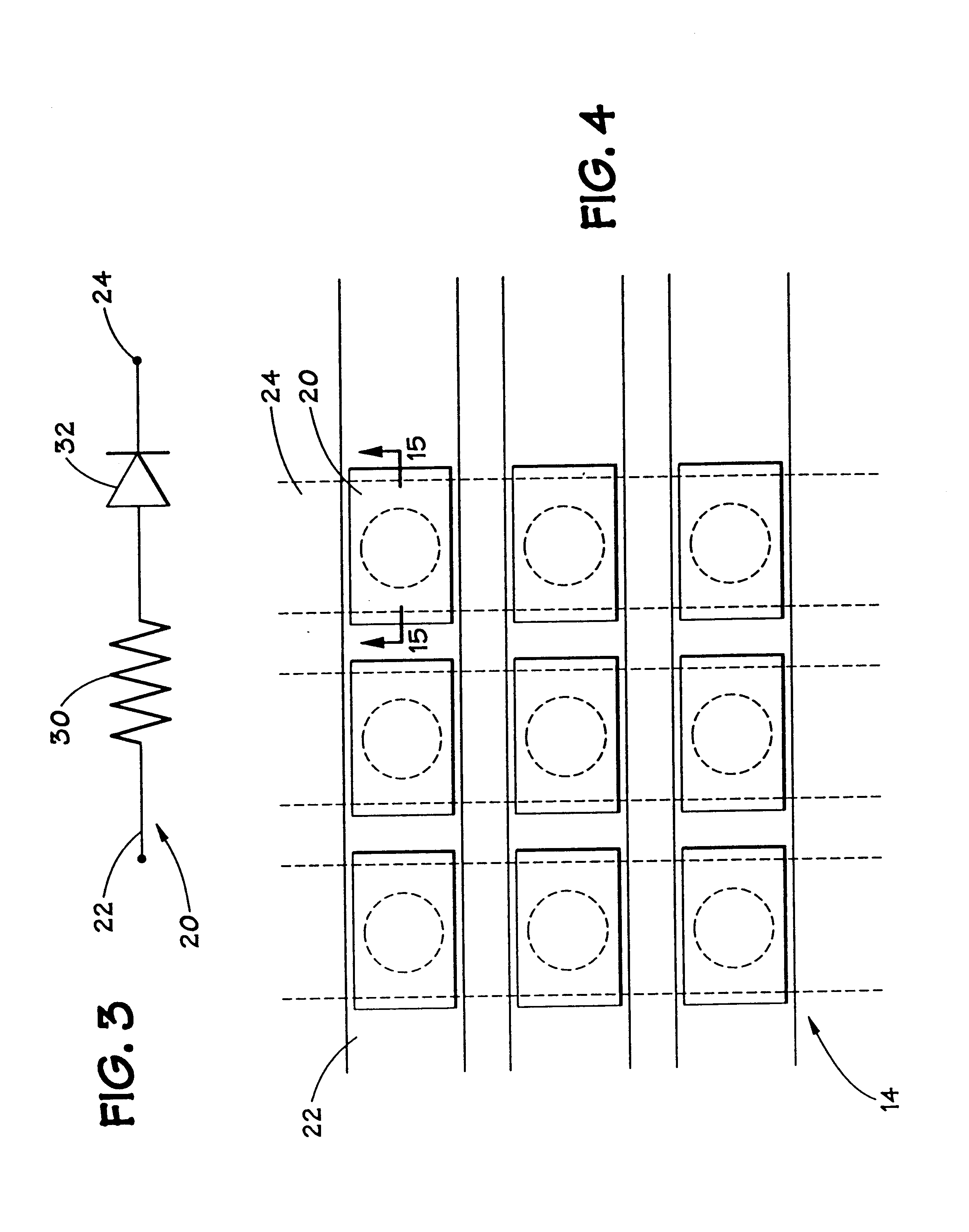

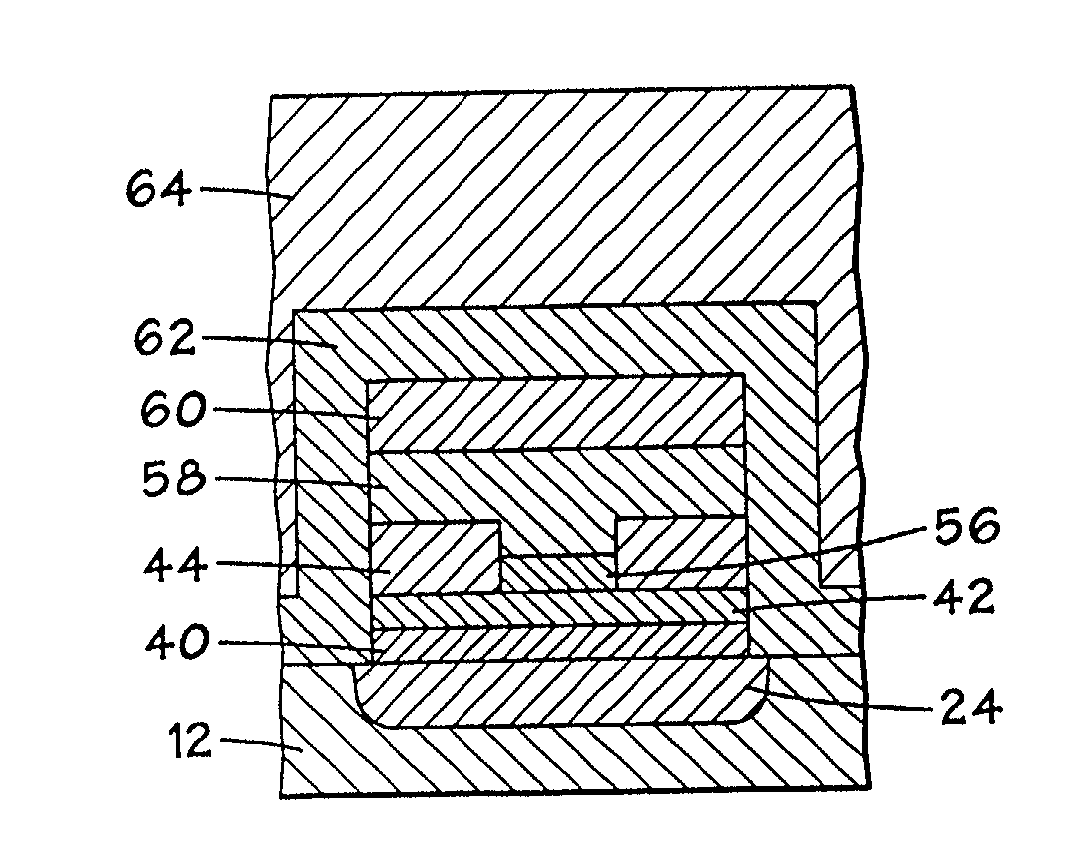

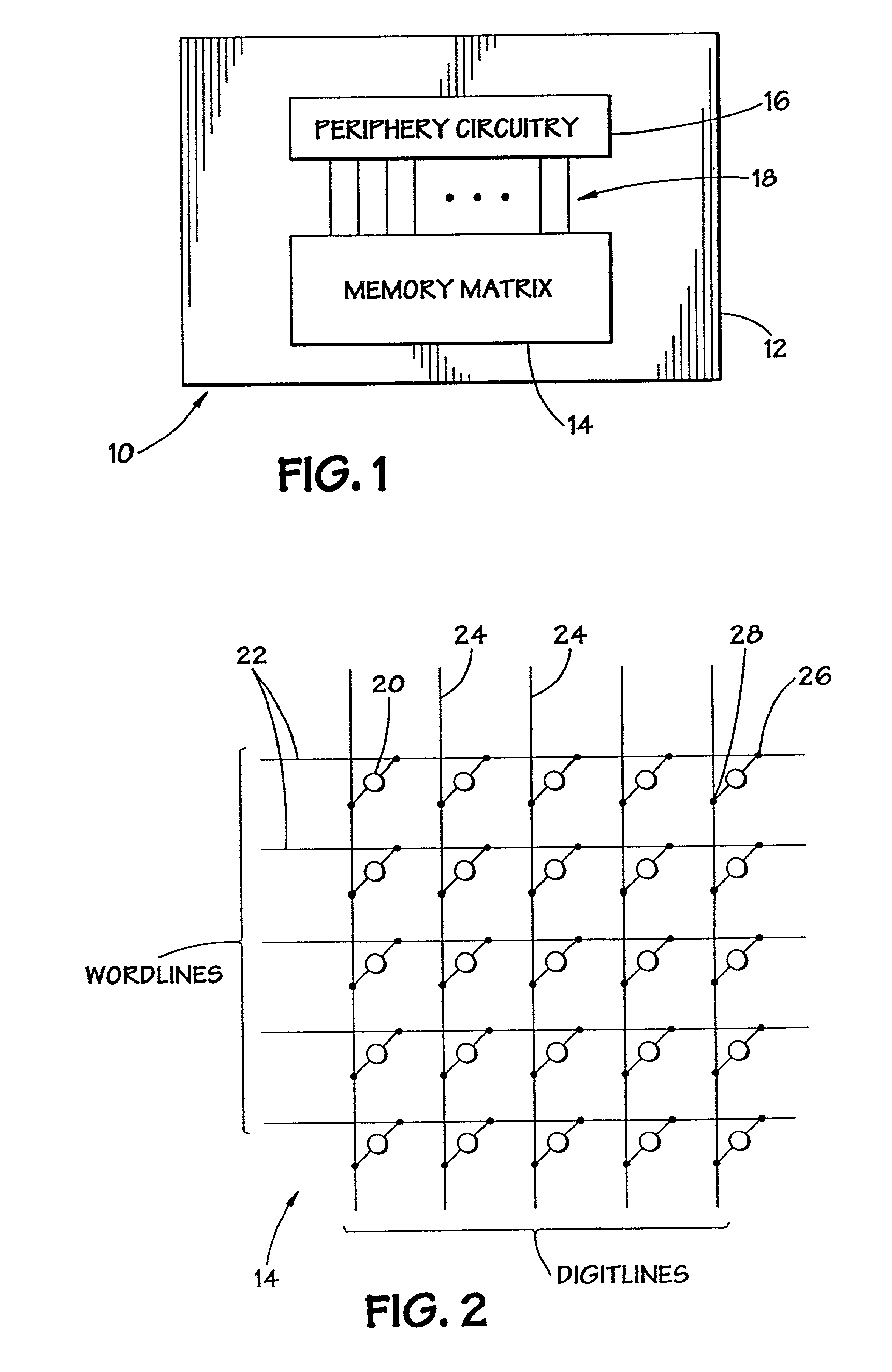

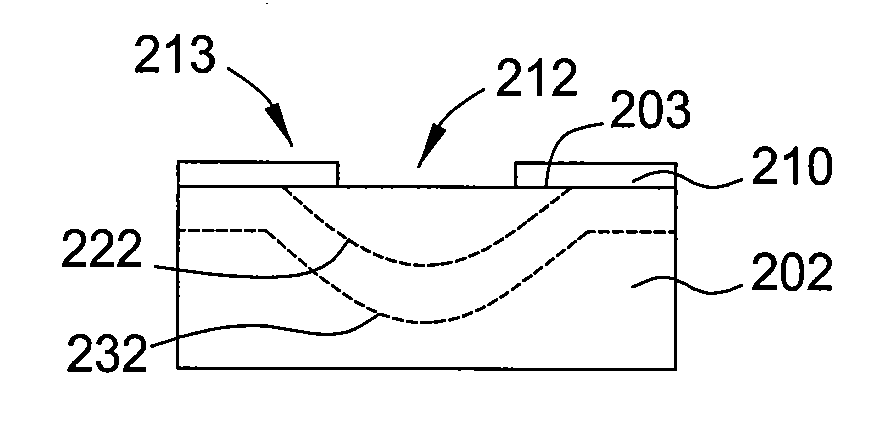

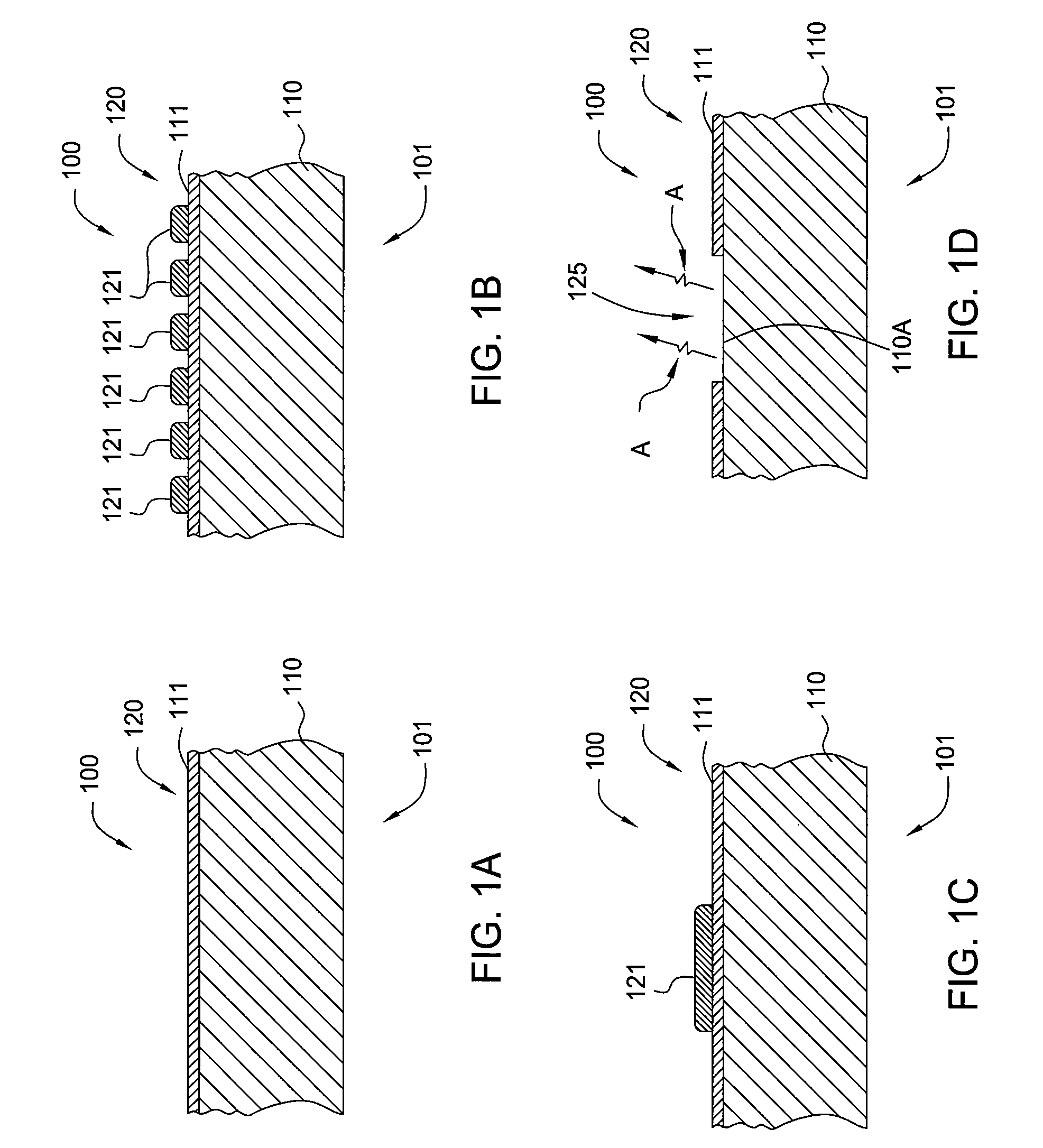

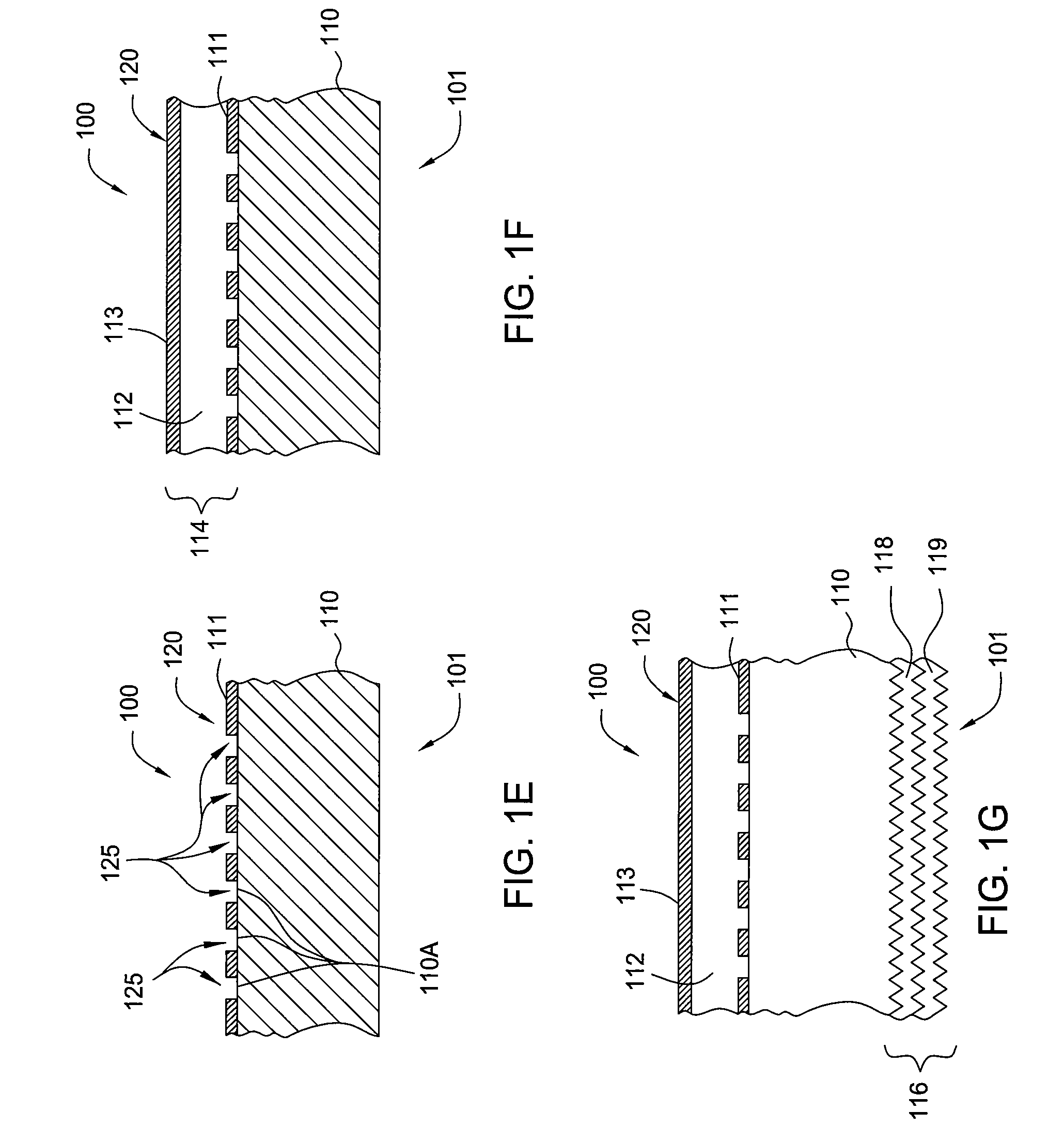

Memory elements and methods for making same

Annular, linear, and point contact structures are described which exhibit a greatly reduced susceptibility to process deviations caused by lithographic and deposition variations than does a conventional circular contact plug. In one embodiment, a standard conductive material such as carbon or titanium nitride is used to form the contact. In an alternative embodiment, a memory material itself is used to form the contact. These contact structures may be made by various processes, including chemical mechanical planarization and facet etching.

Owner:ROUND ROCK RES LLC

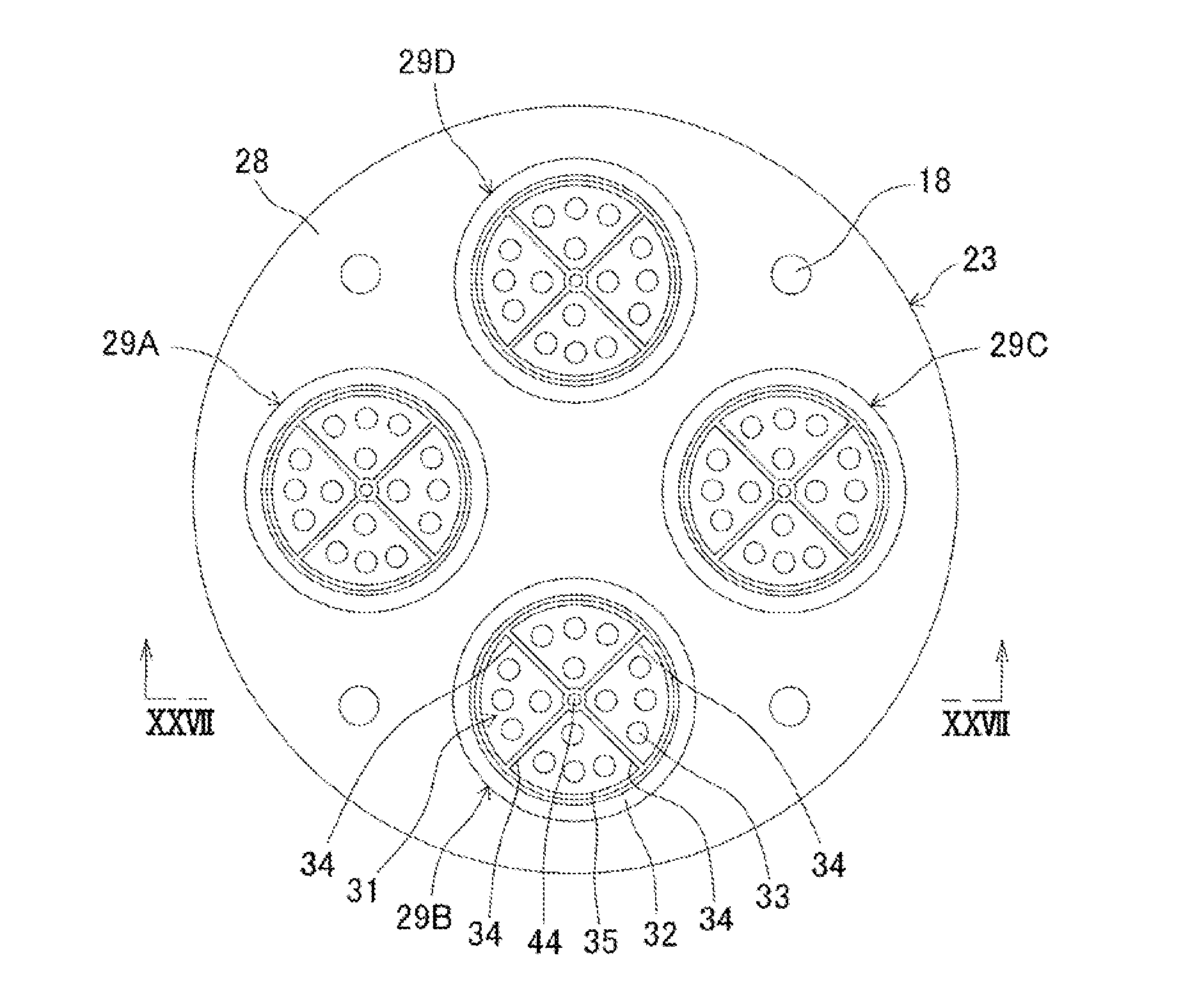

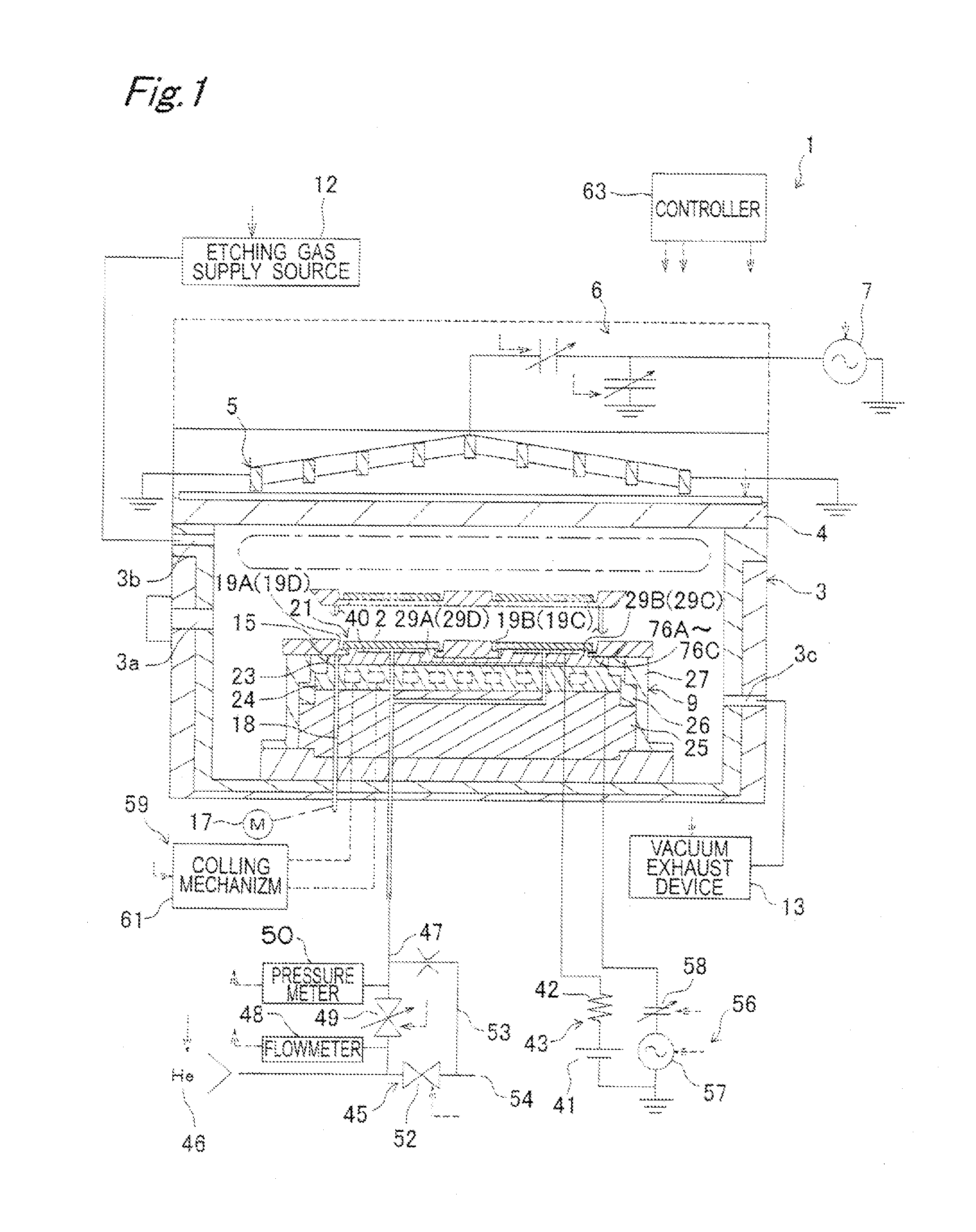

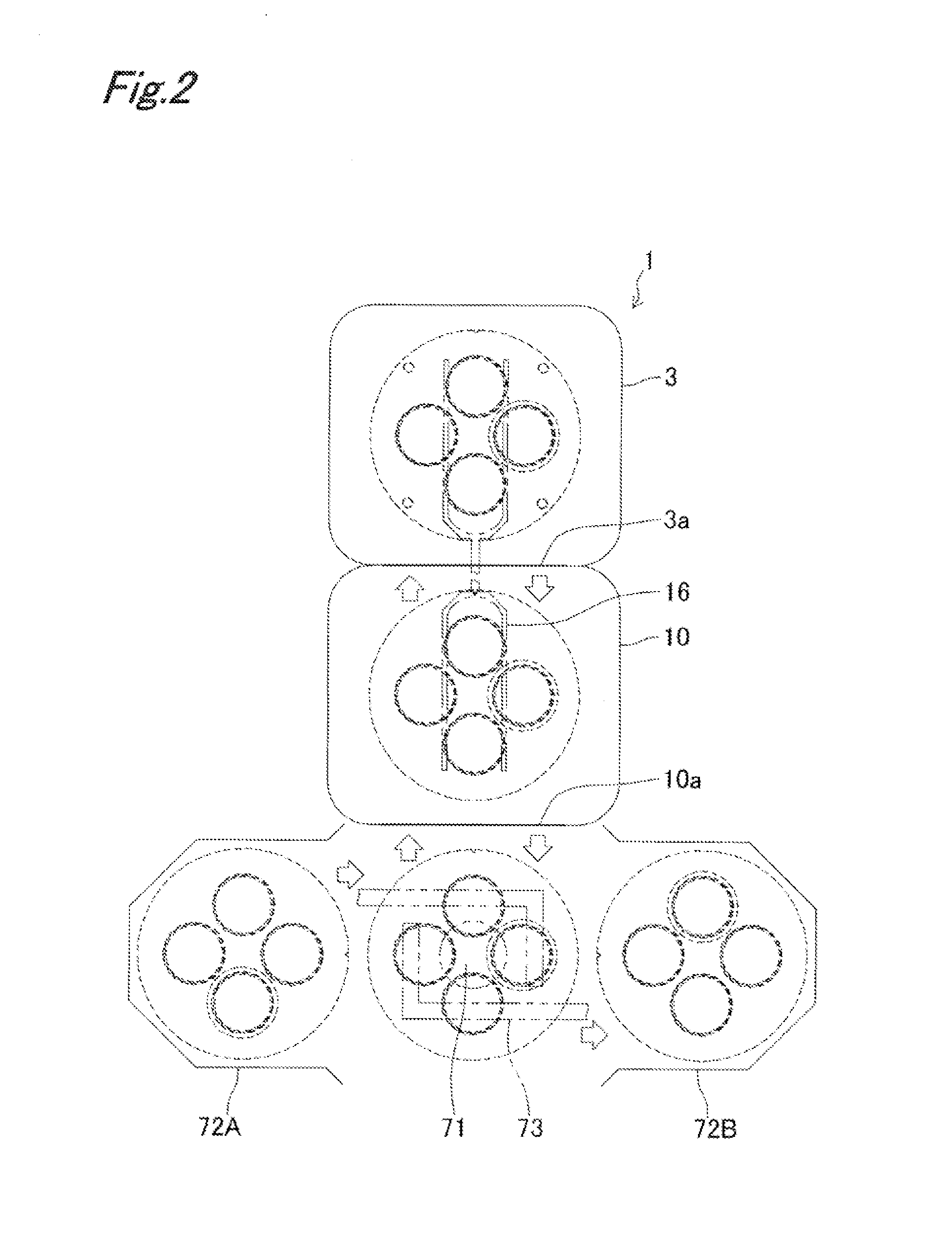

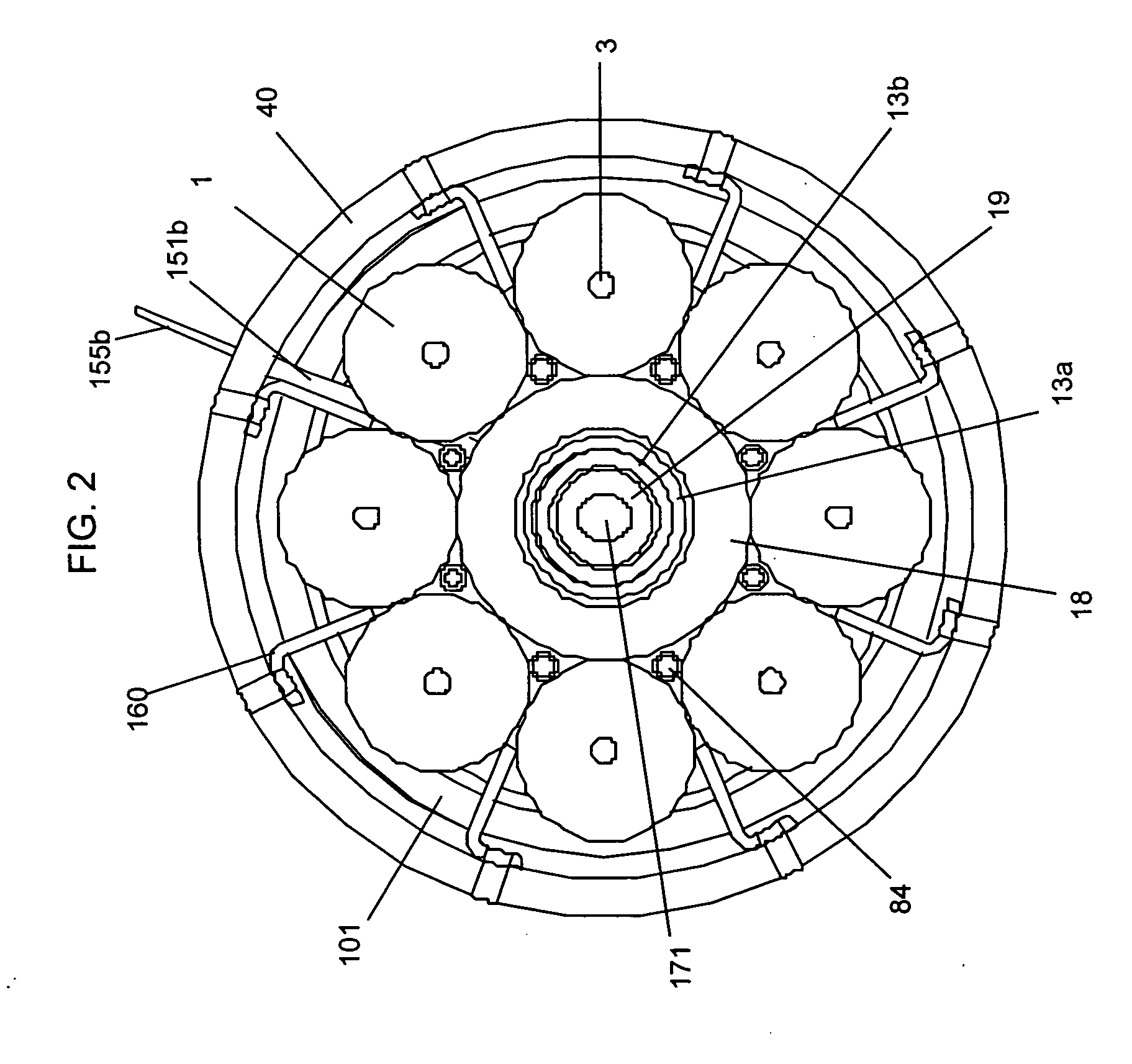

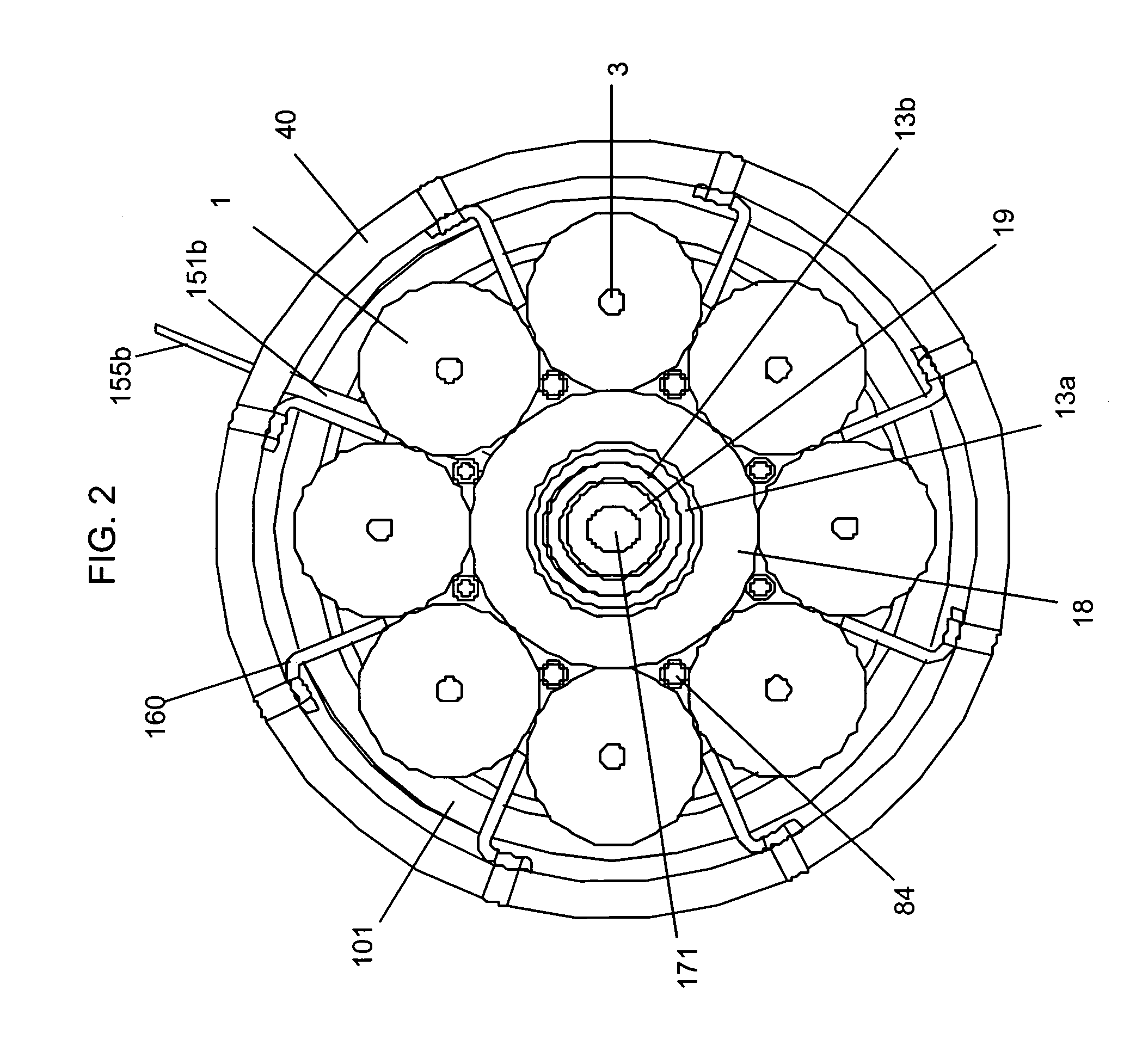

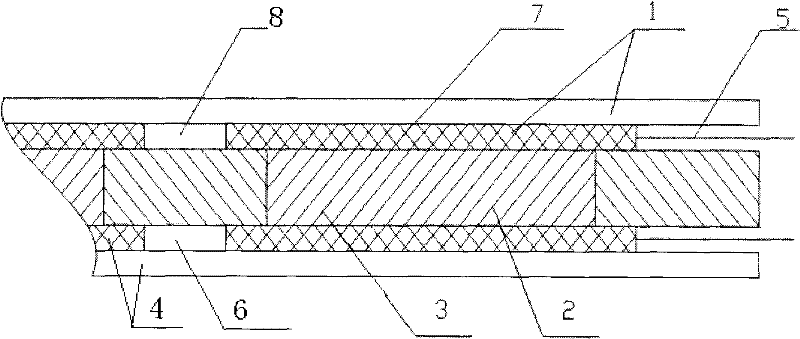

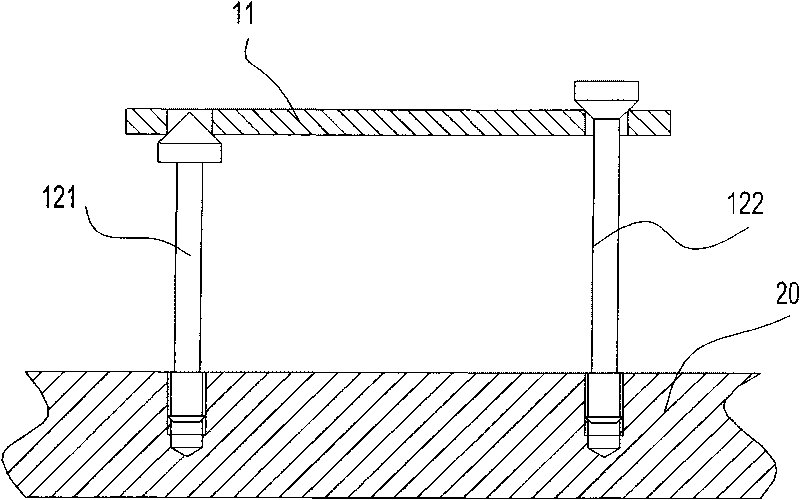

Plasma processing apparatus and plasma processing method

InactiveUS20120006489A1Heat suppressionIncrease of the substrate (Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric plateEngineering

Substrates are contained in substrate containing holes which penetrate a tray in the thickness direction. A dielectric plate in a chamber is provided with a tray supporting surface which supports the lower surface of the tray and substrate placing sections which protrude upward, and has an electrostatic chuck electrode therein. The substrate supporting section which supports the substrate contained in the substrate containing holes is provided with a plurality of protruding sections formed at intervals in the circumferential direction of the substrate containing holes. The substrates are supported in point-contact mode by means of the protruding sections.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

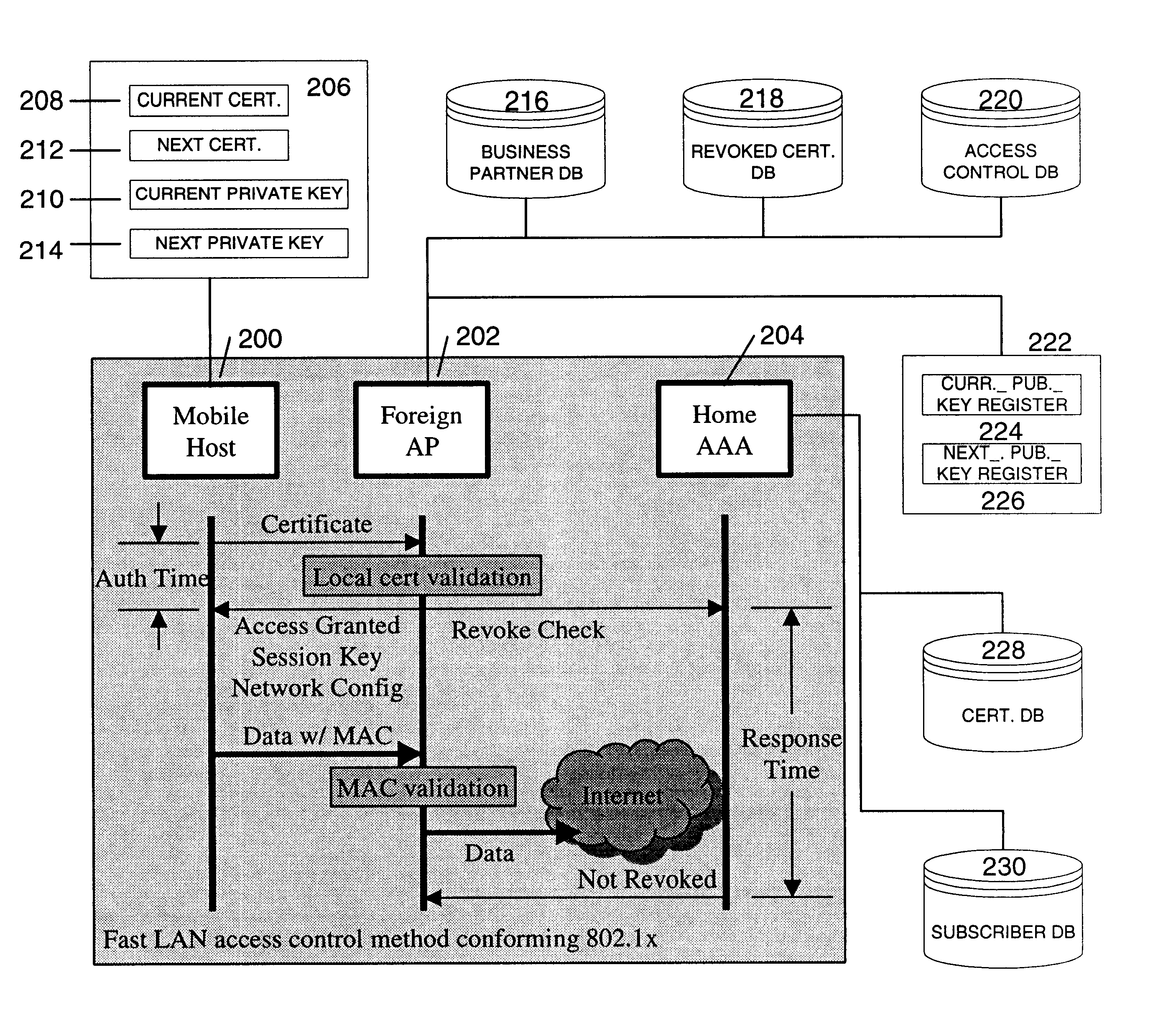

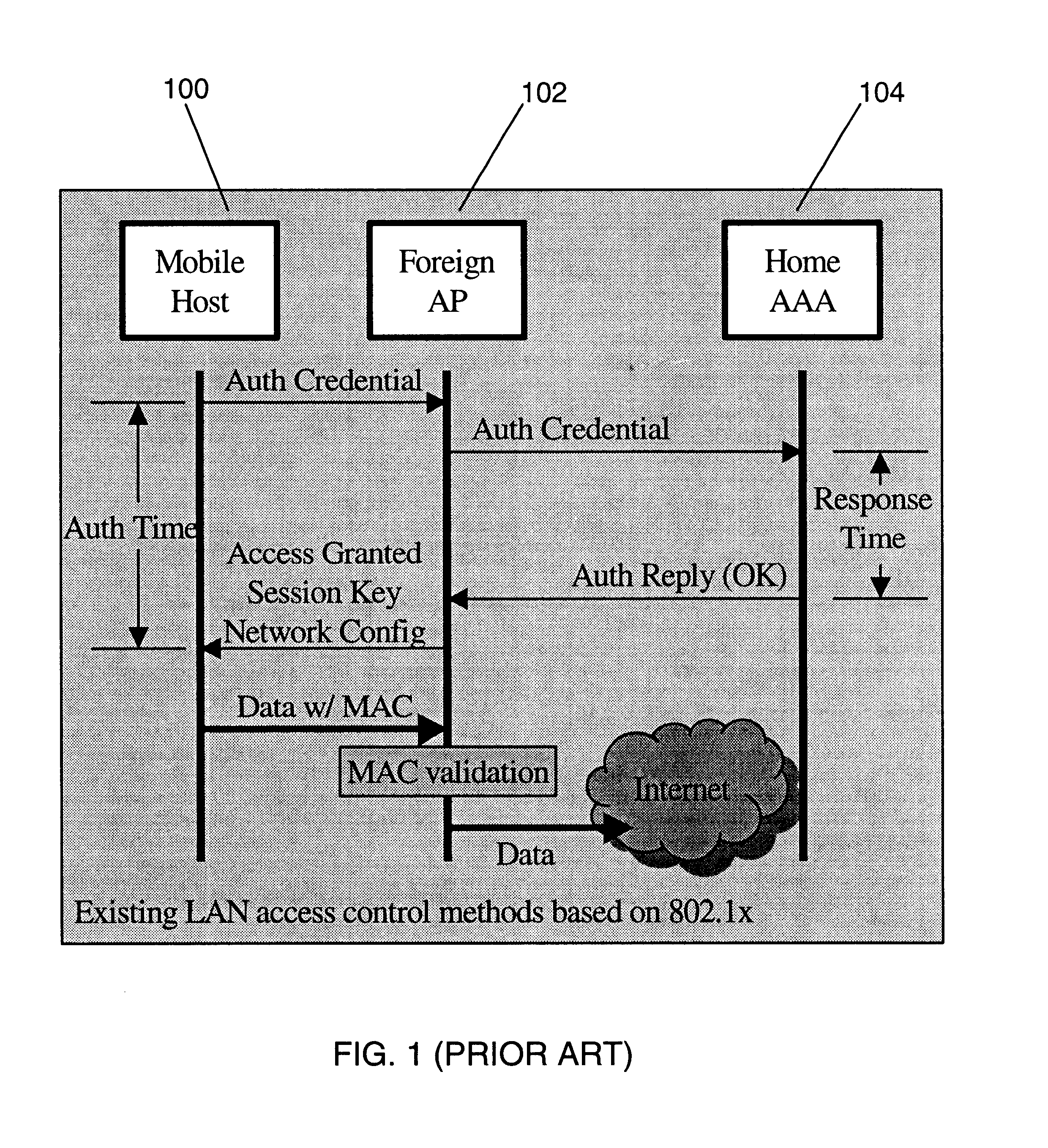

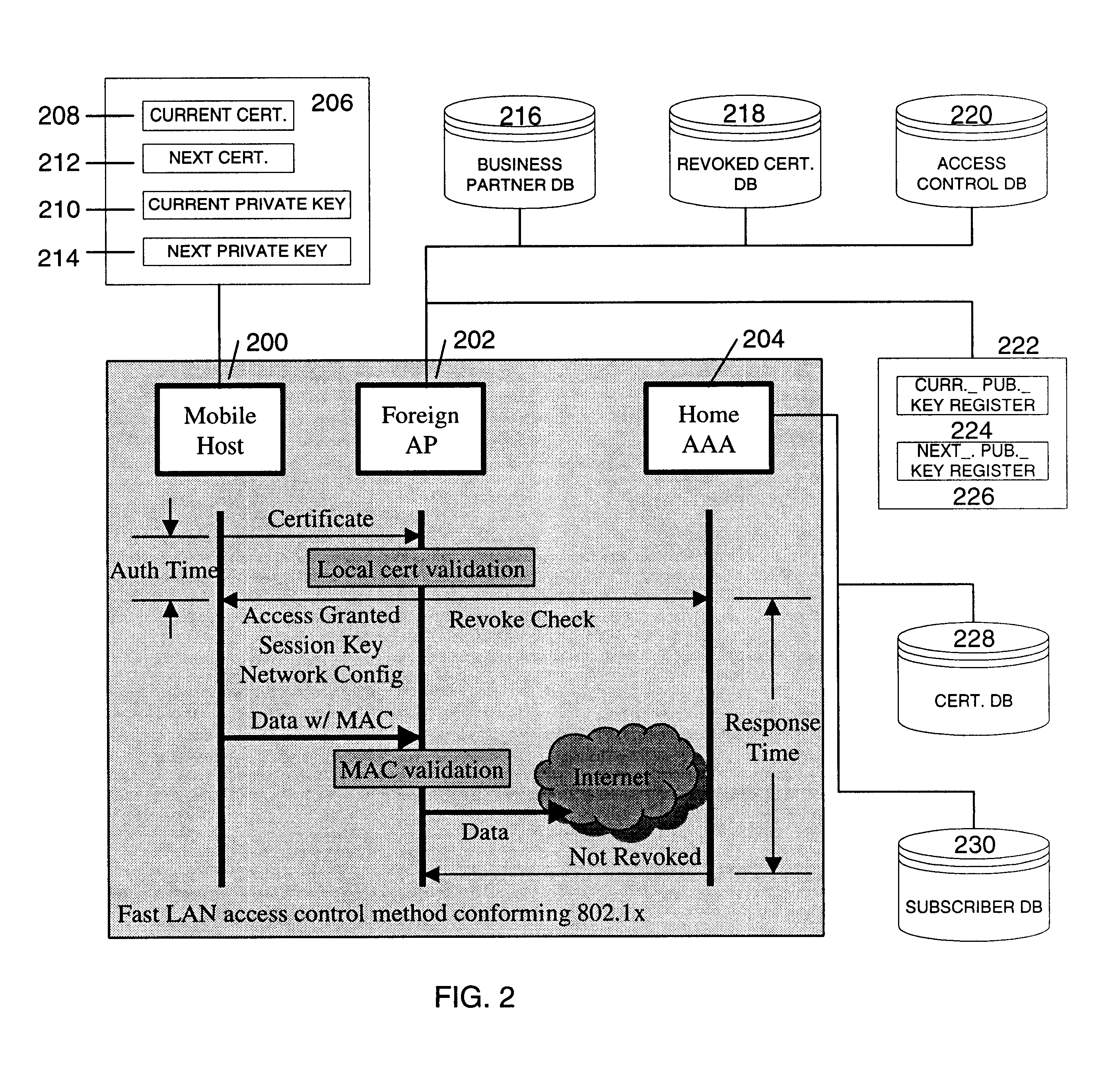

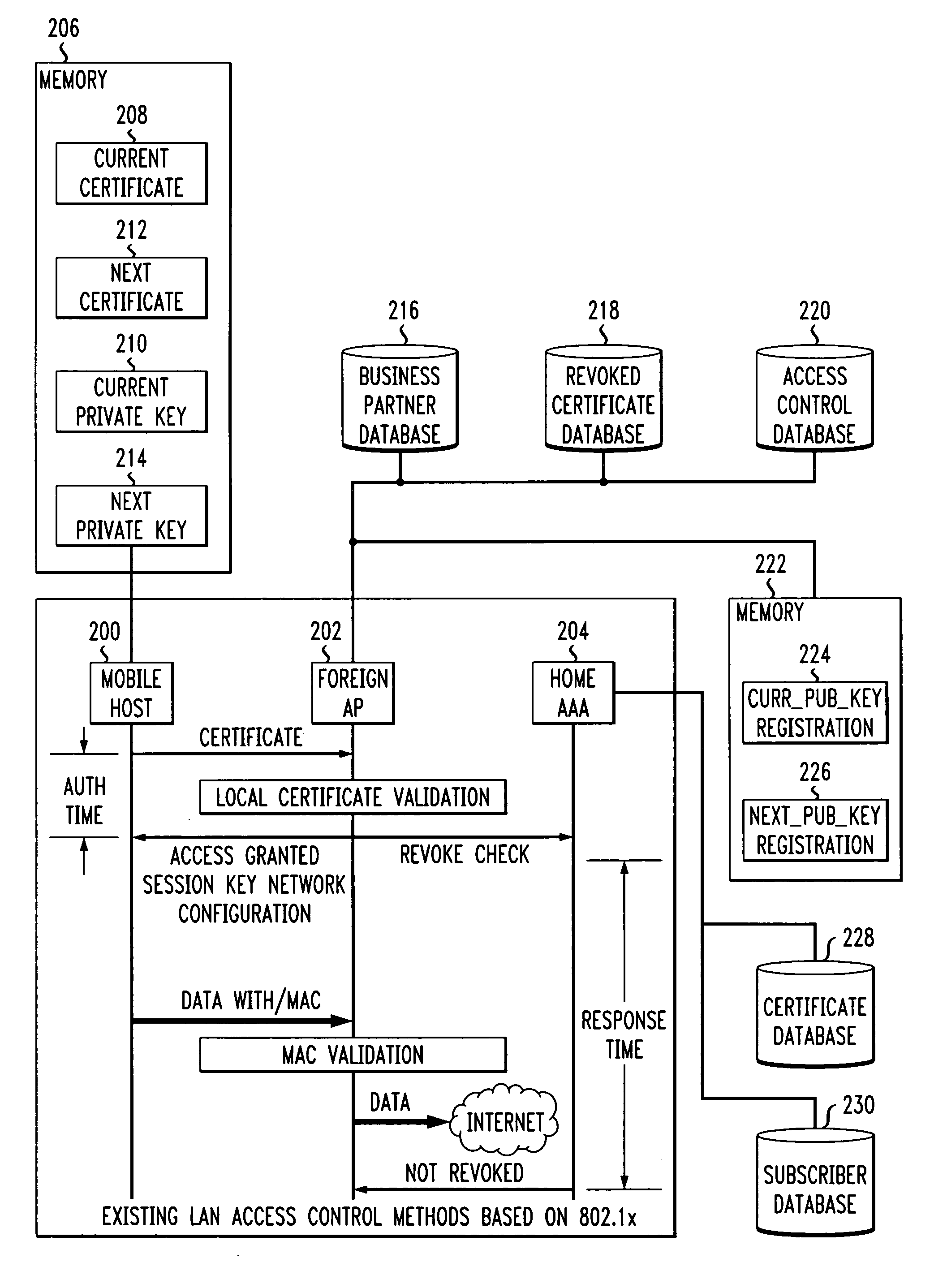

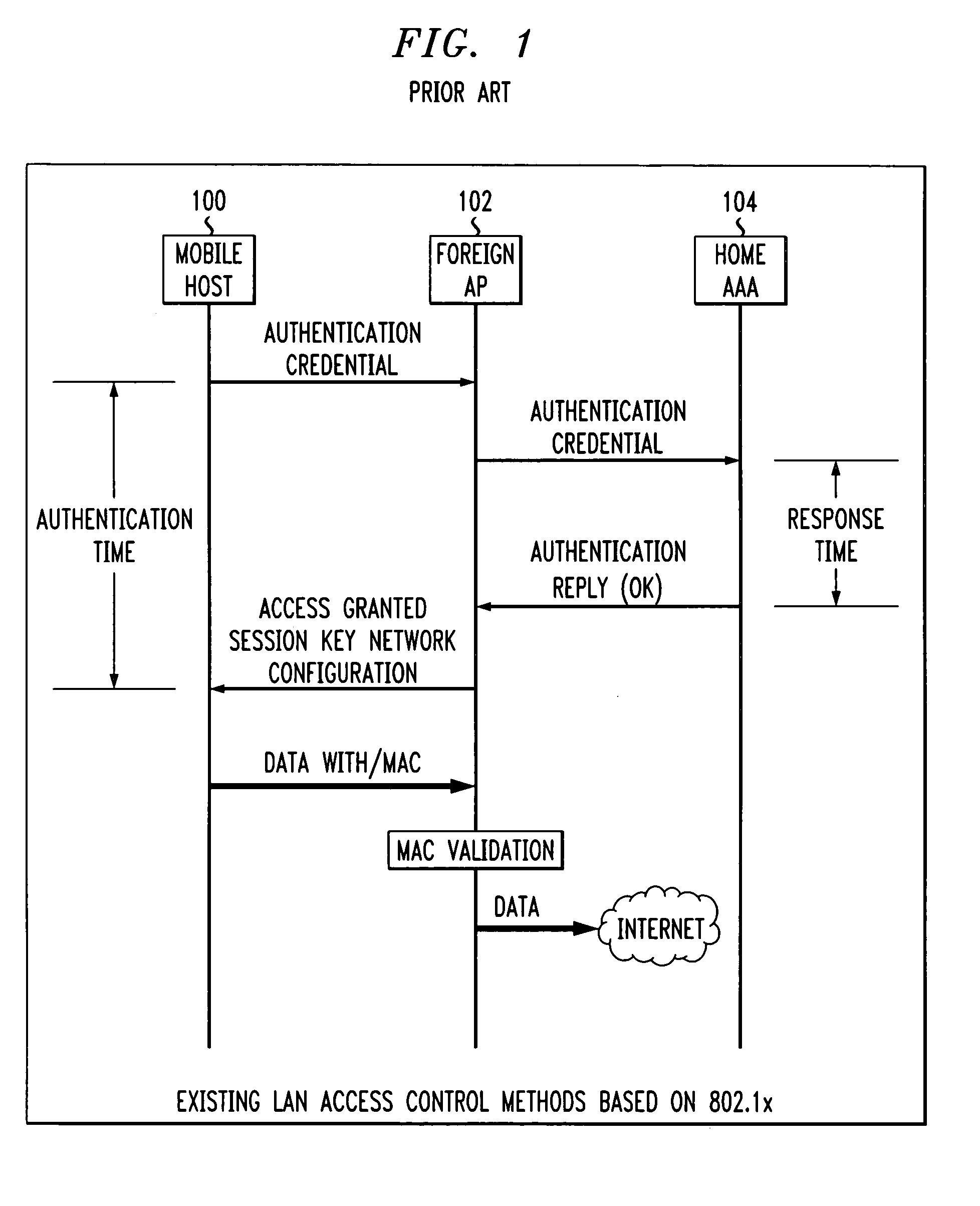

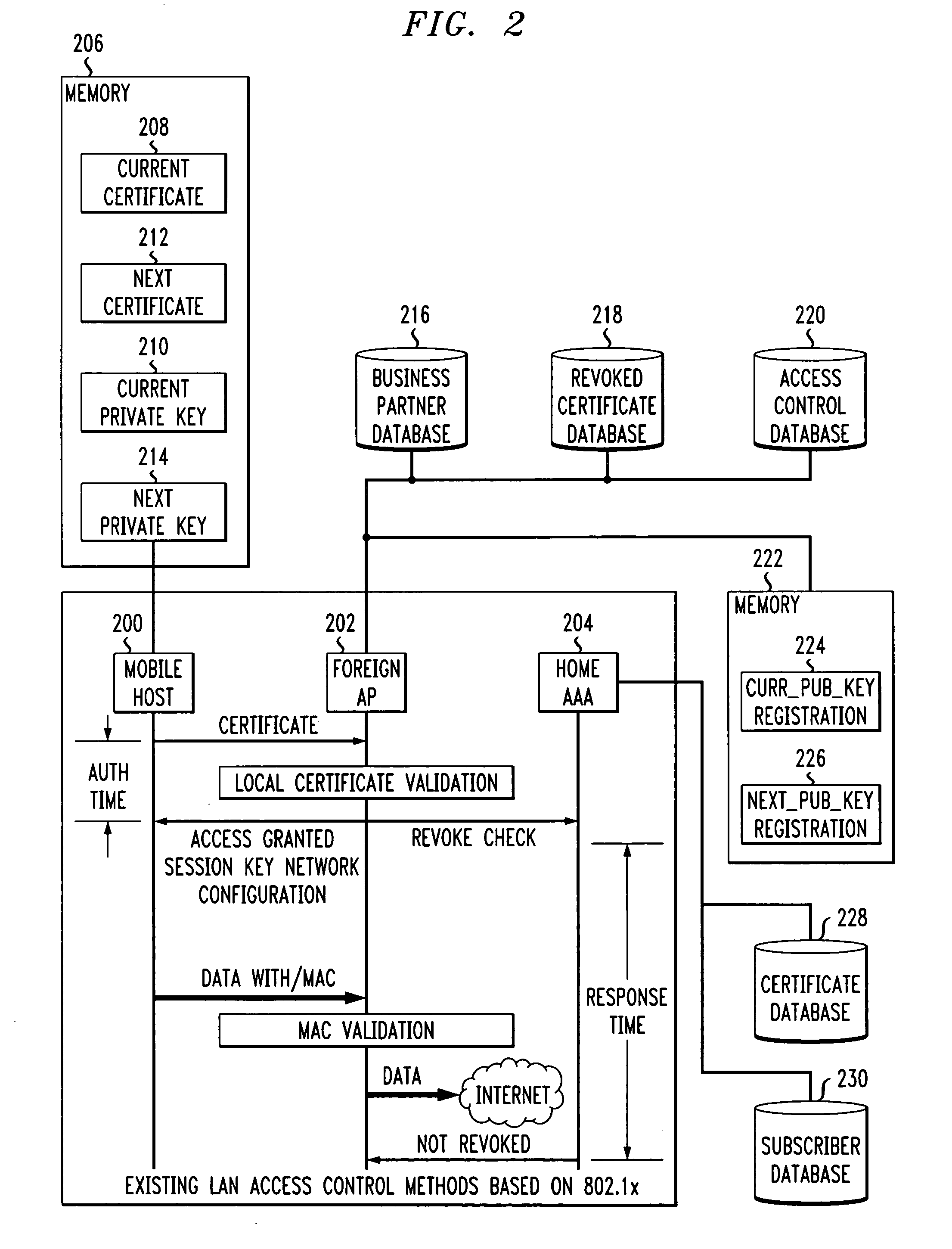

Fast authentication and access control system for mobile networking

InactiveUS6856800B1Easy to switchReduce certification timeUnauthorised/fraudulent call preventionEavesdropping prevention circuitsExpiration TimeWeb authentication

A fast authentication and access control method of authenticating a network access device to a communications network having an access point communicating with a remote authentication (home AAA) server for the network access device. The method includes the step of receiving an access request having an authentication credential from the network access device at the access point. The authentication credential includes a security certificate having a public key for the network access device and an expiration time. The security certificate is signed with a private key for the remote authentication server. The access point locally validates the authentication credential by accessing the public key of the remote authentication server from a local database, and checking the signature and expiration time of the security certificate. If the authentication credential is validated at the access point, the access point grants the network access device conditional access to the network by sending an access granted message to the network access device. The access granted message includes a session key encrypted with a public key for the network access device. The session key is stored in a database associated with the access point. The access point contacts the remote authentication server to check a revocation status of the security certificate for the network access device. If the access point receives a message from the remote authentication server that the authentication credential for the network access device has been revoked, it suspends network access for the network access device.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

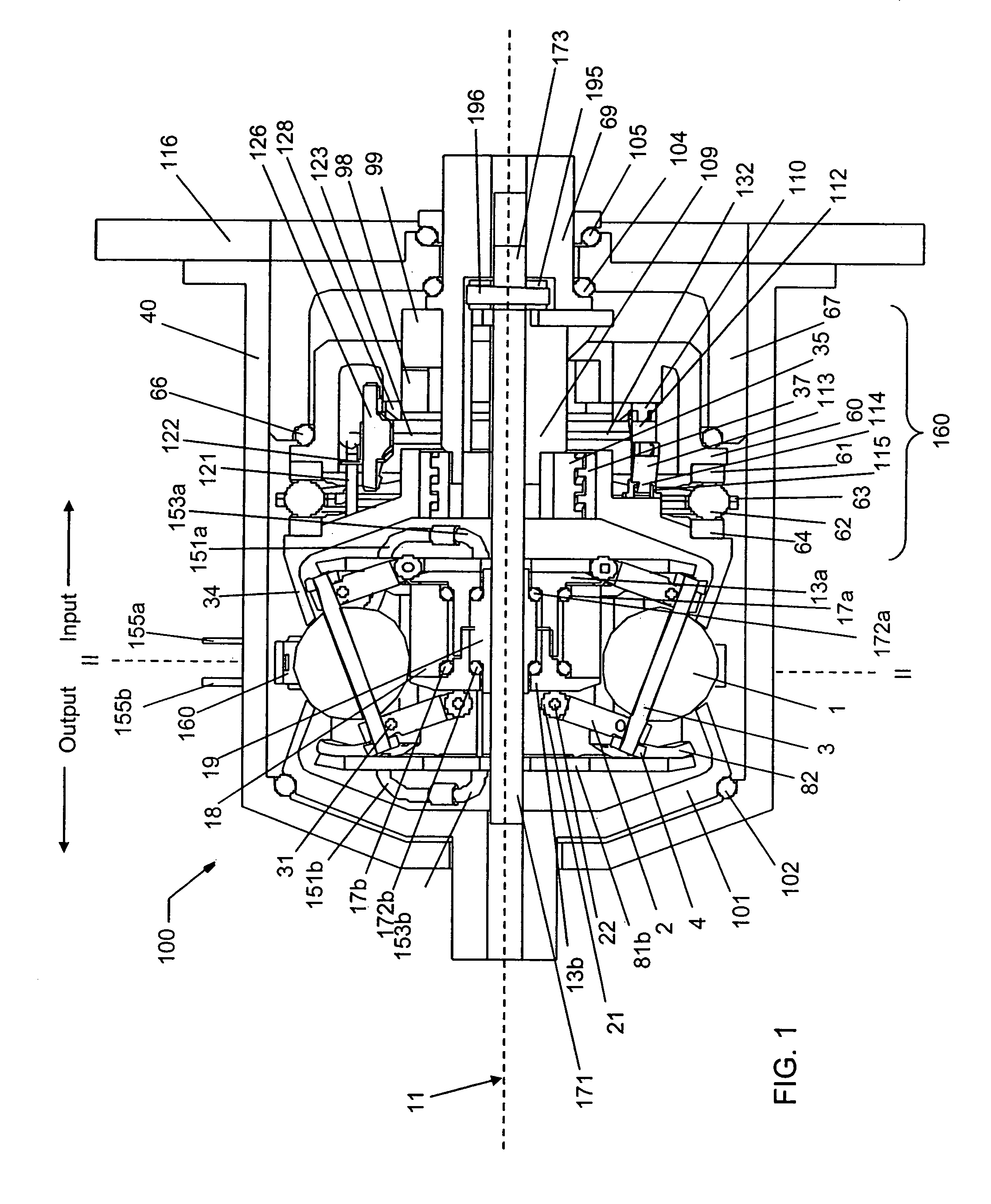

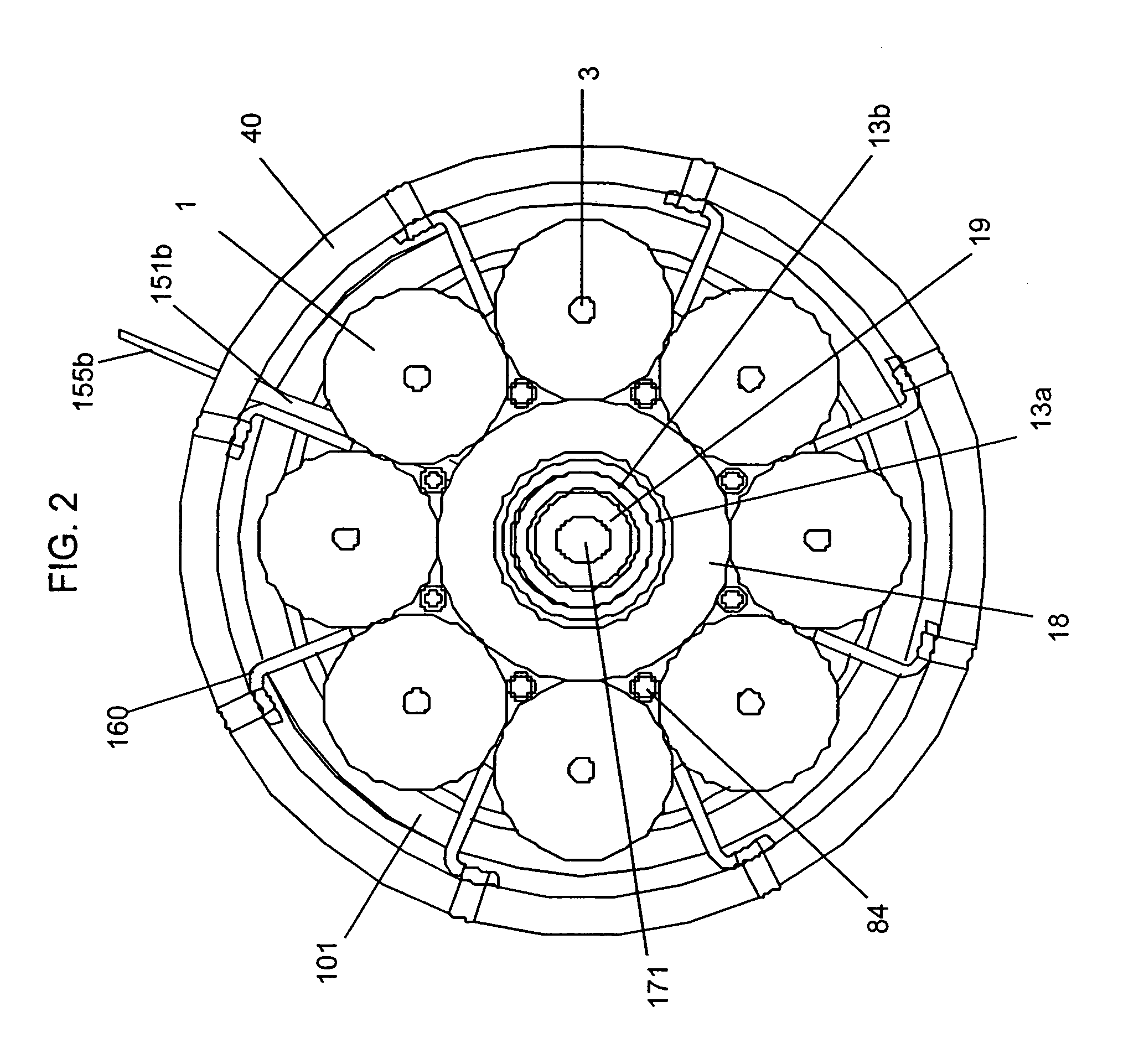

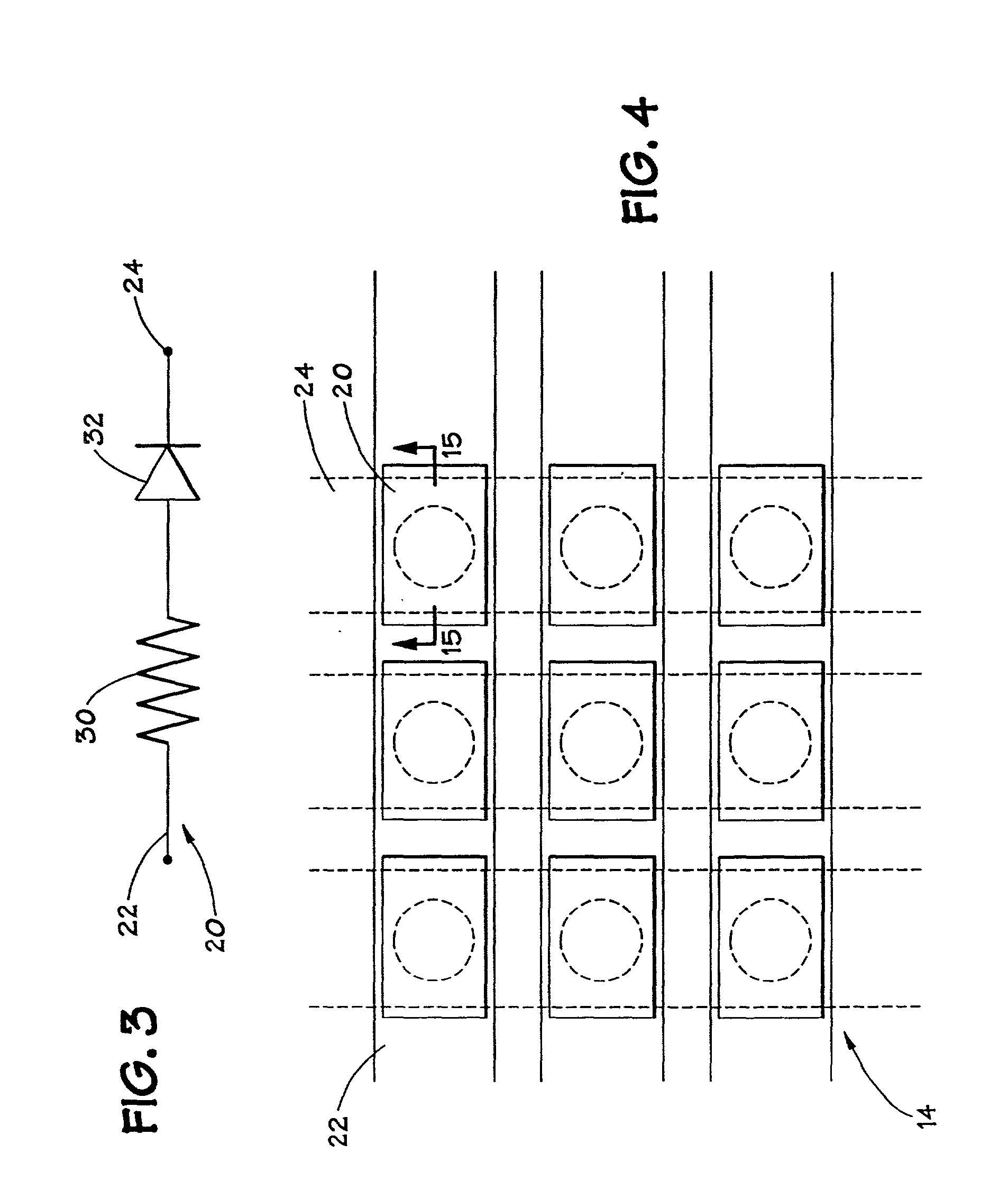

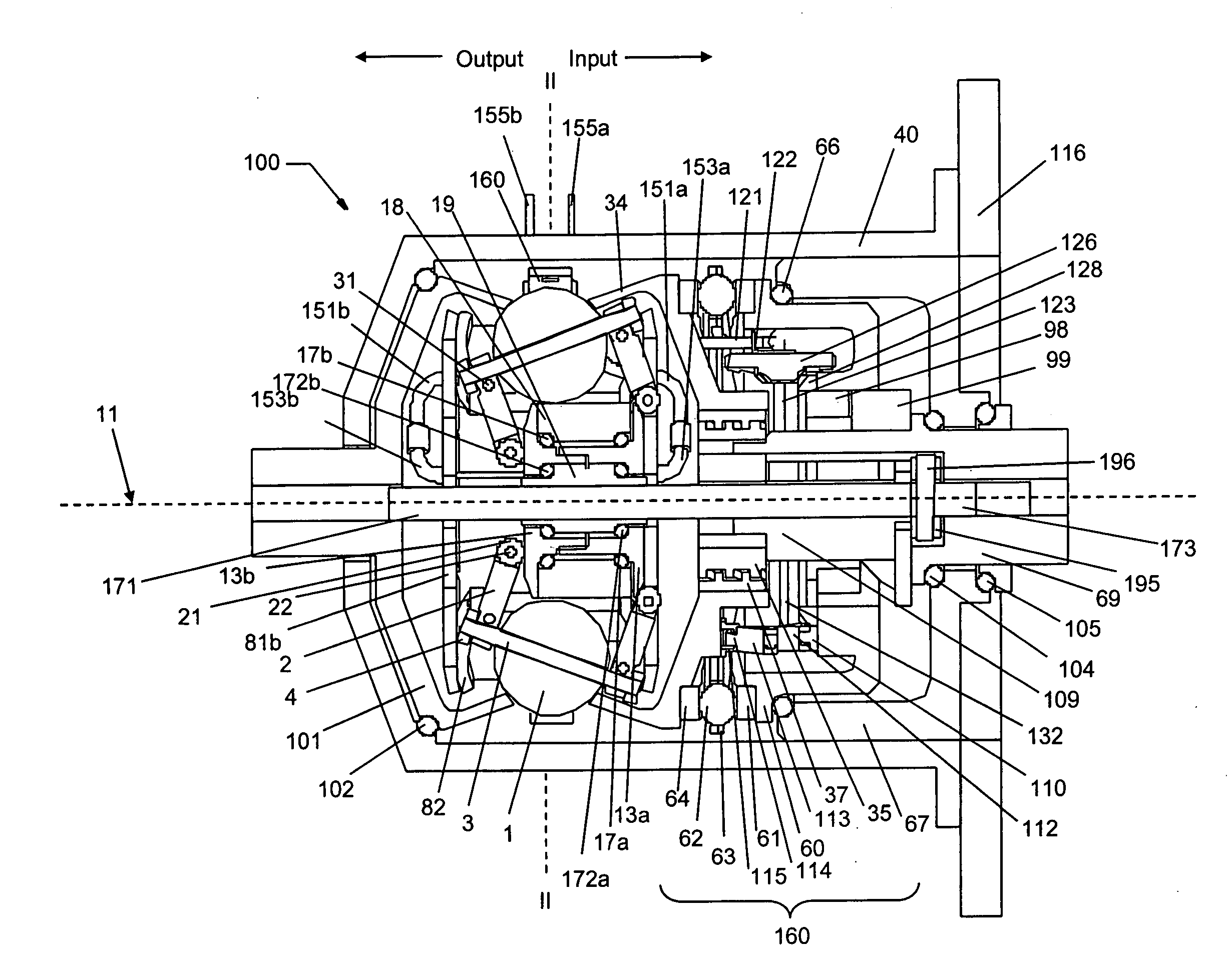

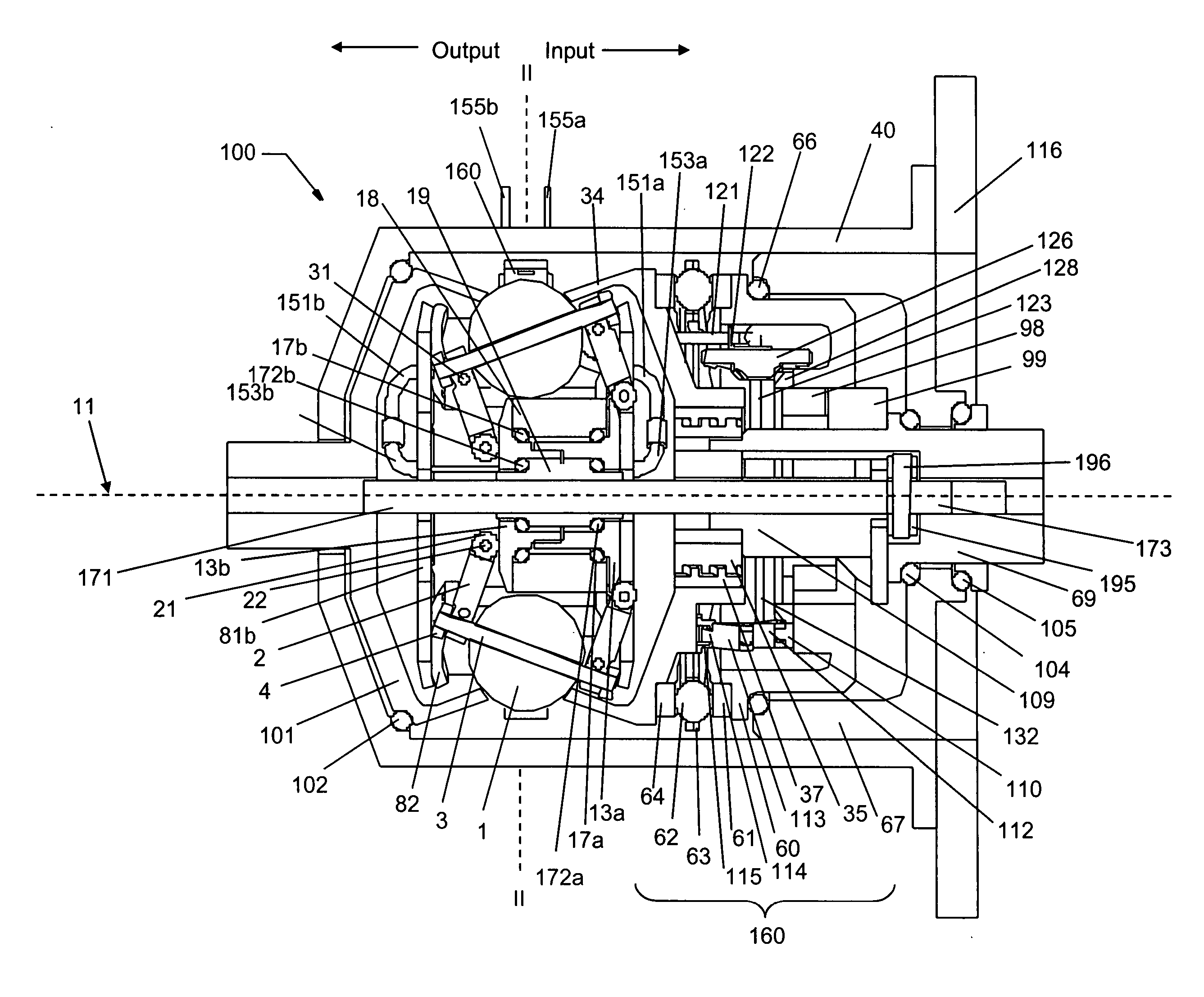

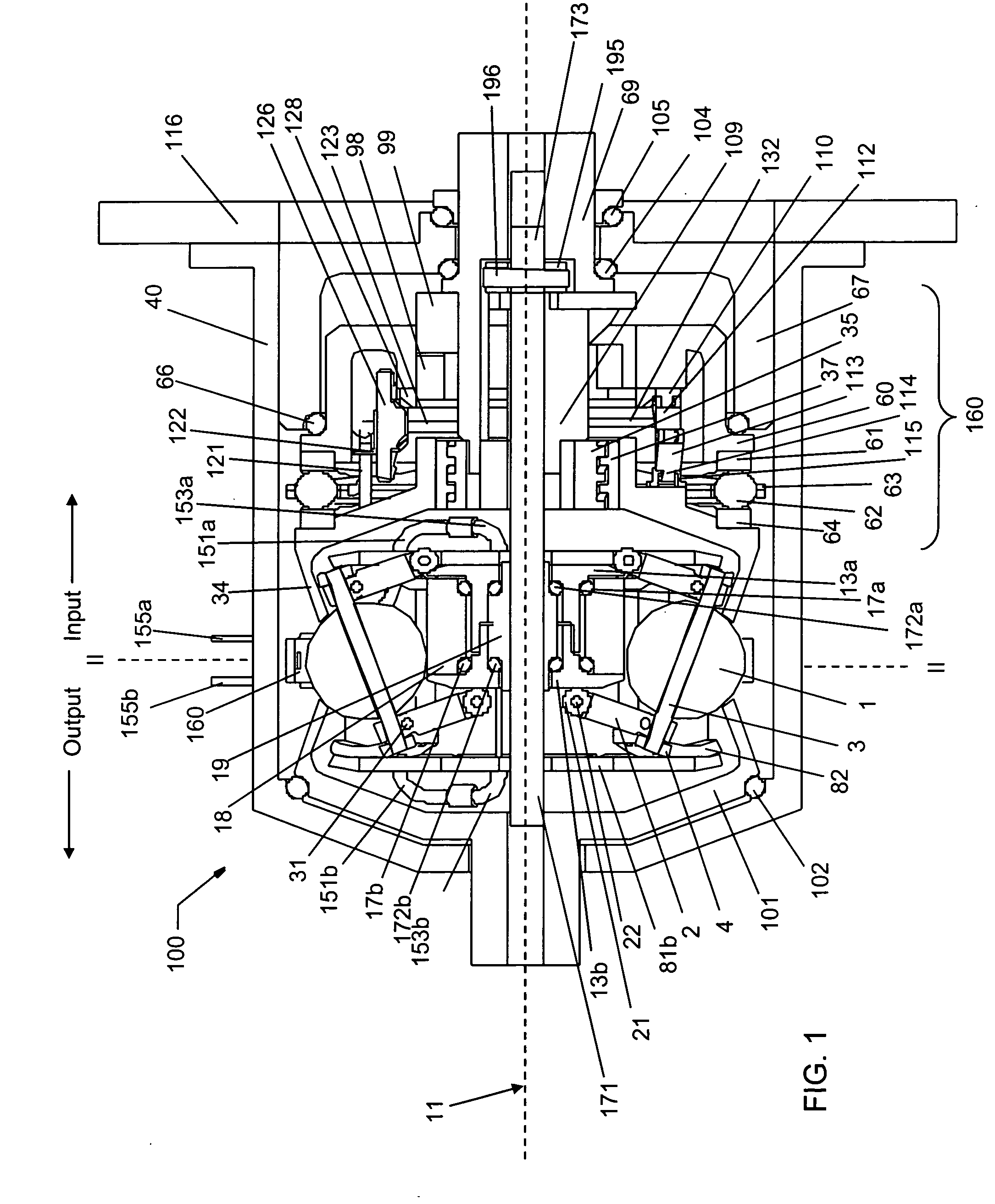

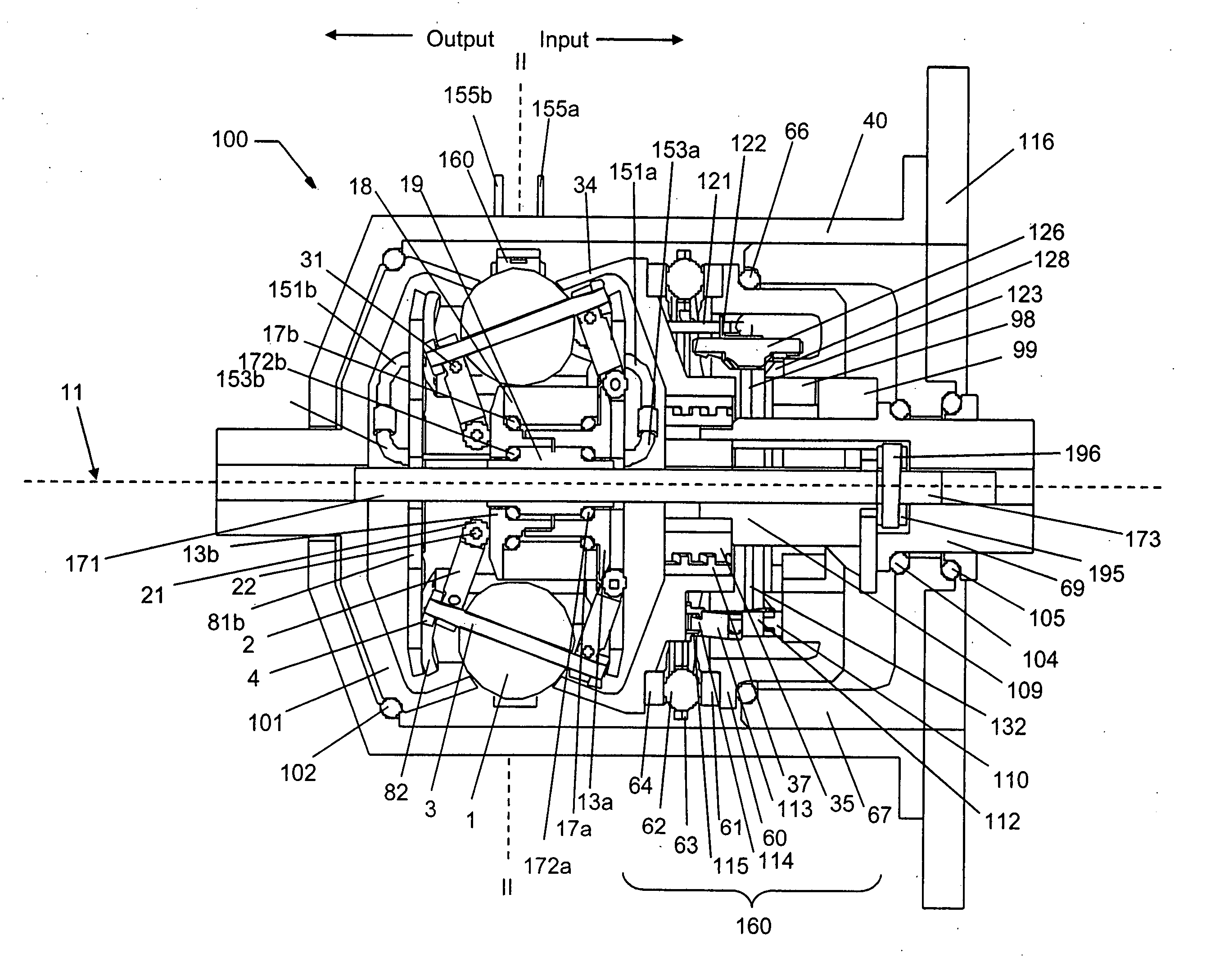

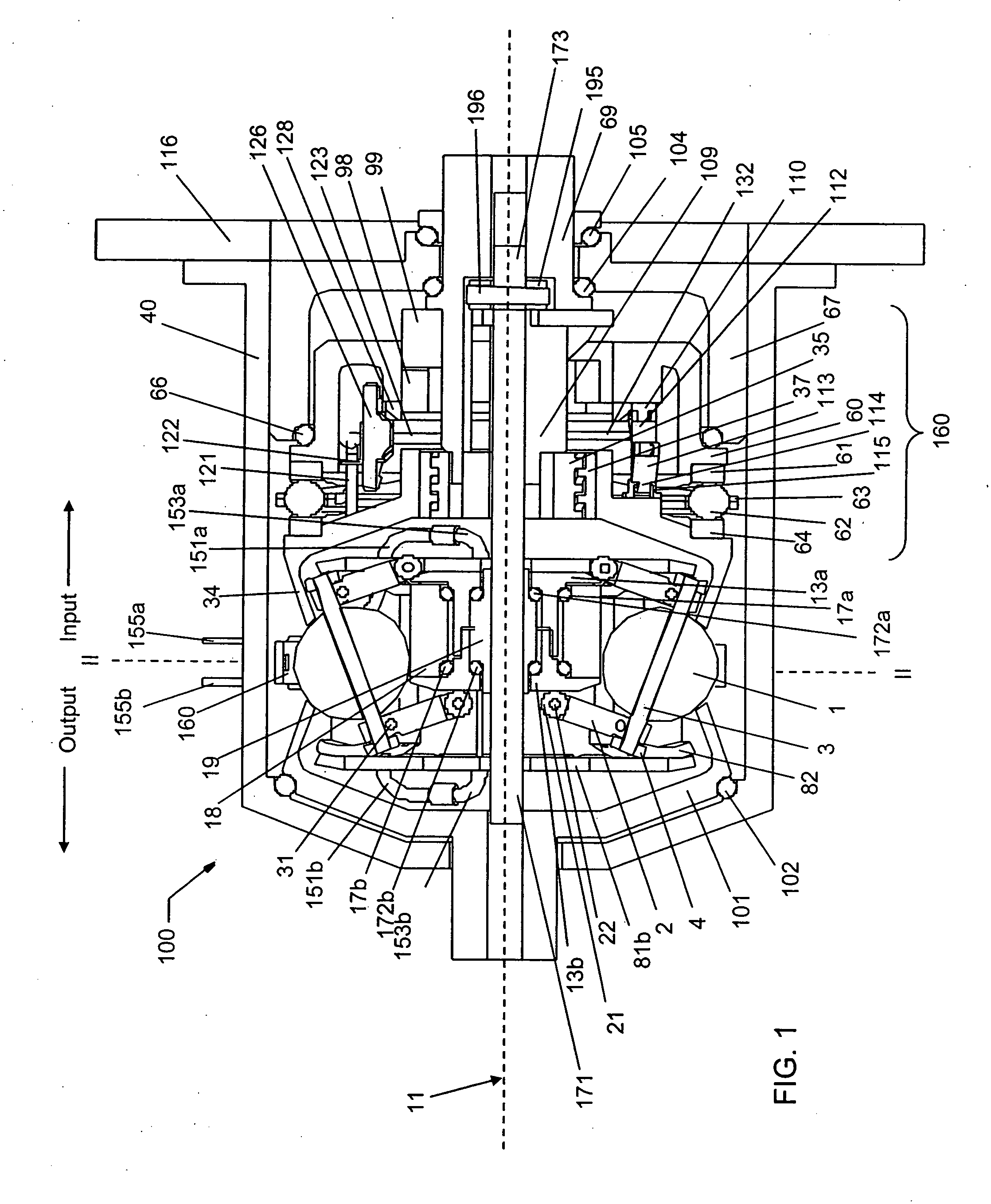

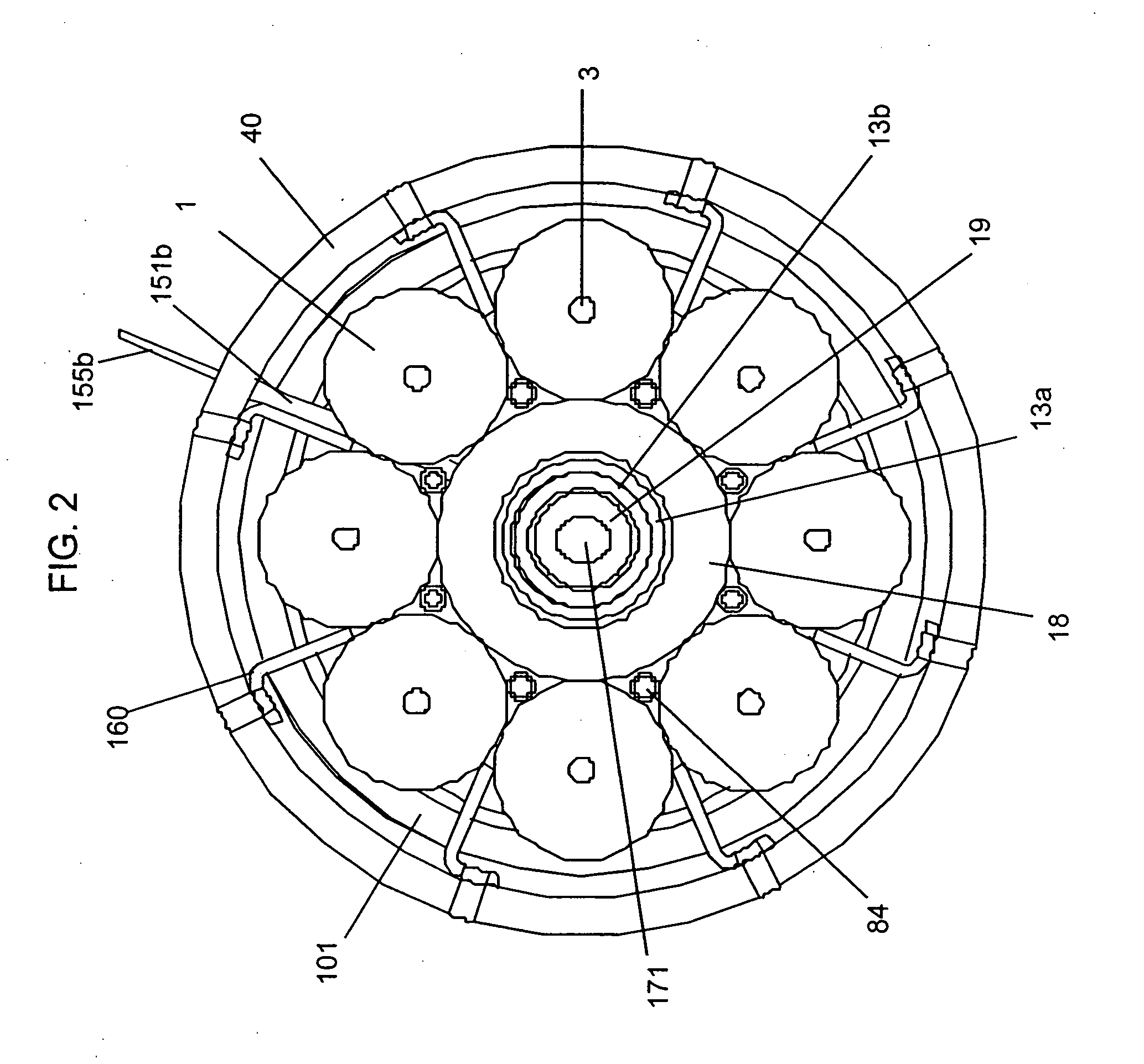

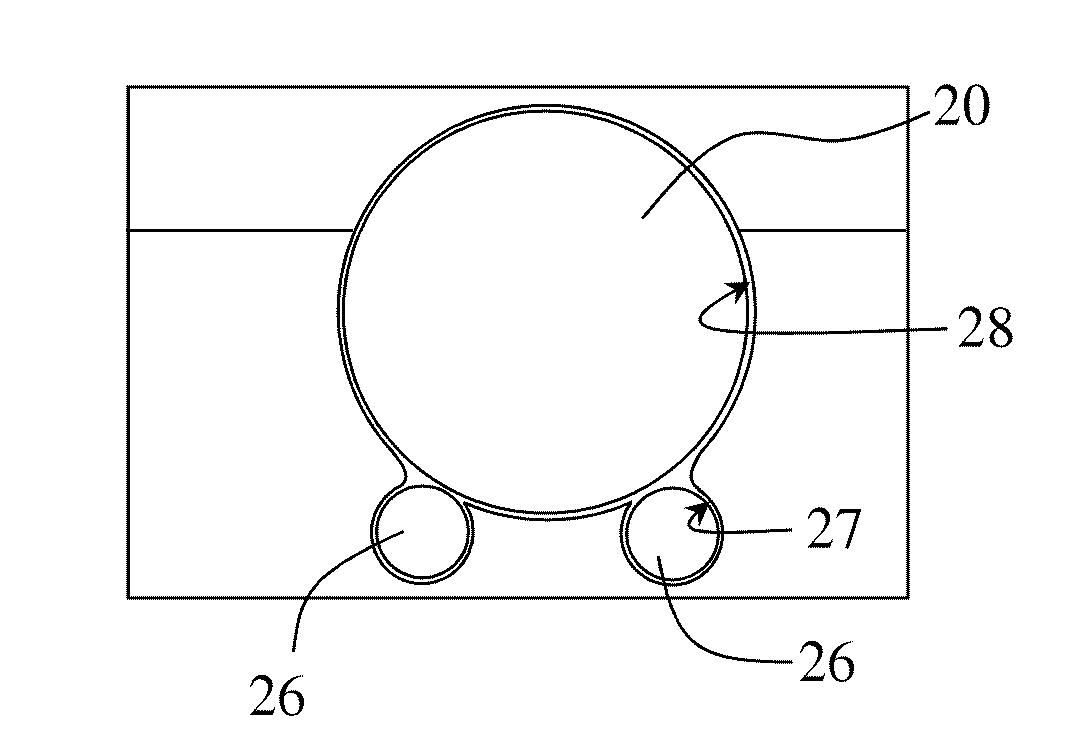

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

Memory elements and methods for making same

InactiveUS20020160551A1Solid-state devicesSemiconductor/solid-state device manufacturingProcess deviationsEtching

Annular, linear, and point contact structures are described which exhibit a greatly reduced susceptibility to process deviations caused by lithographic and deposition variations than does a conventional circular contact plug. In one embodiment, a standard conductive material such as carbon or titanium nitride is used to form the contact. In an alternative embodiment, a memory material itself is used to form the contact. These contact structures may be made by various processes, including chemical mechanical planarization and facet etching.

Owner:ROUND ROCK RES LLC

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

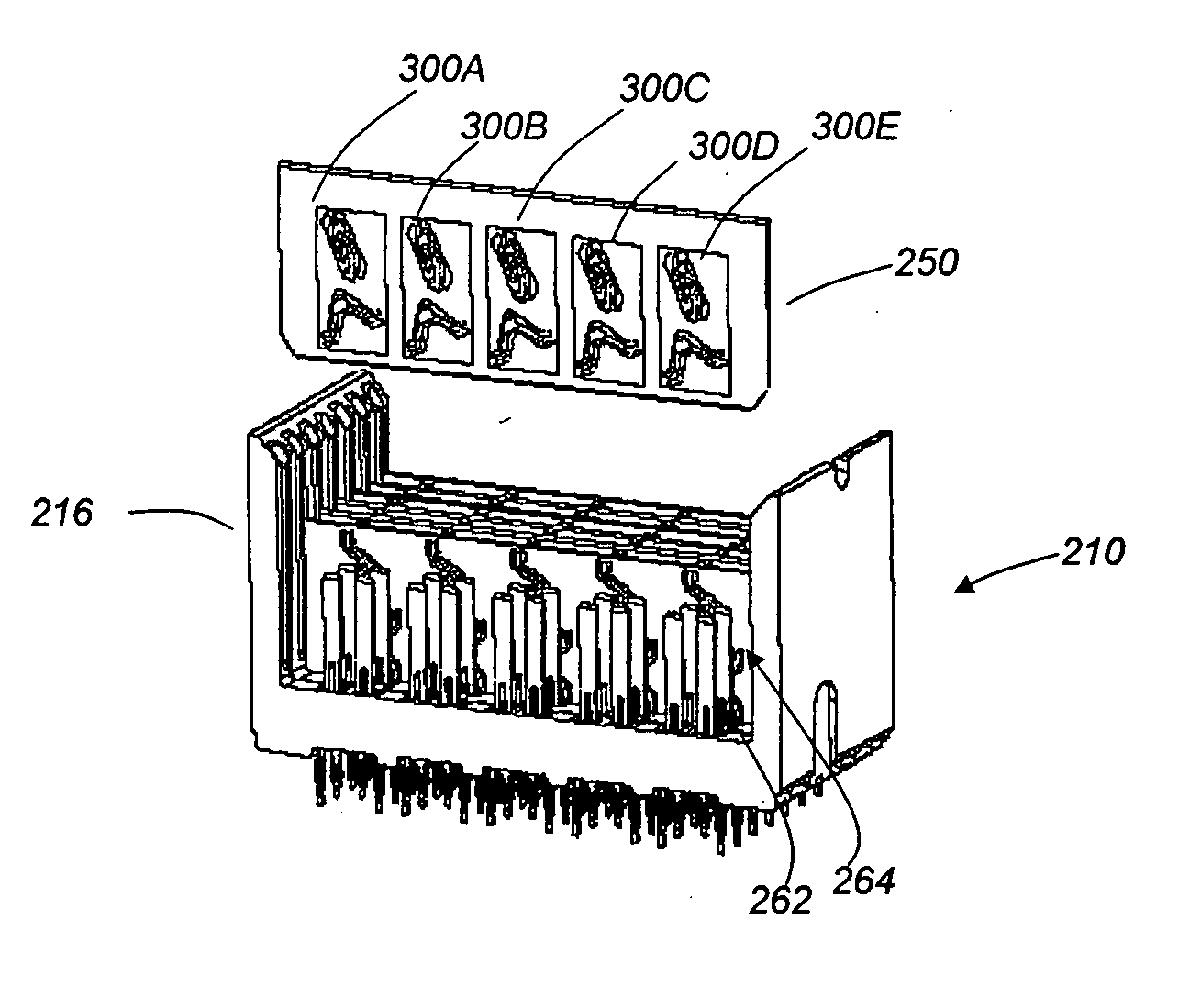

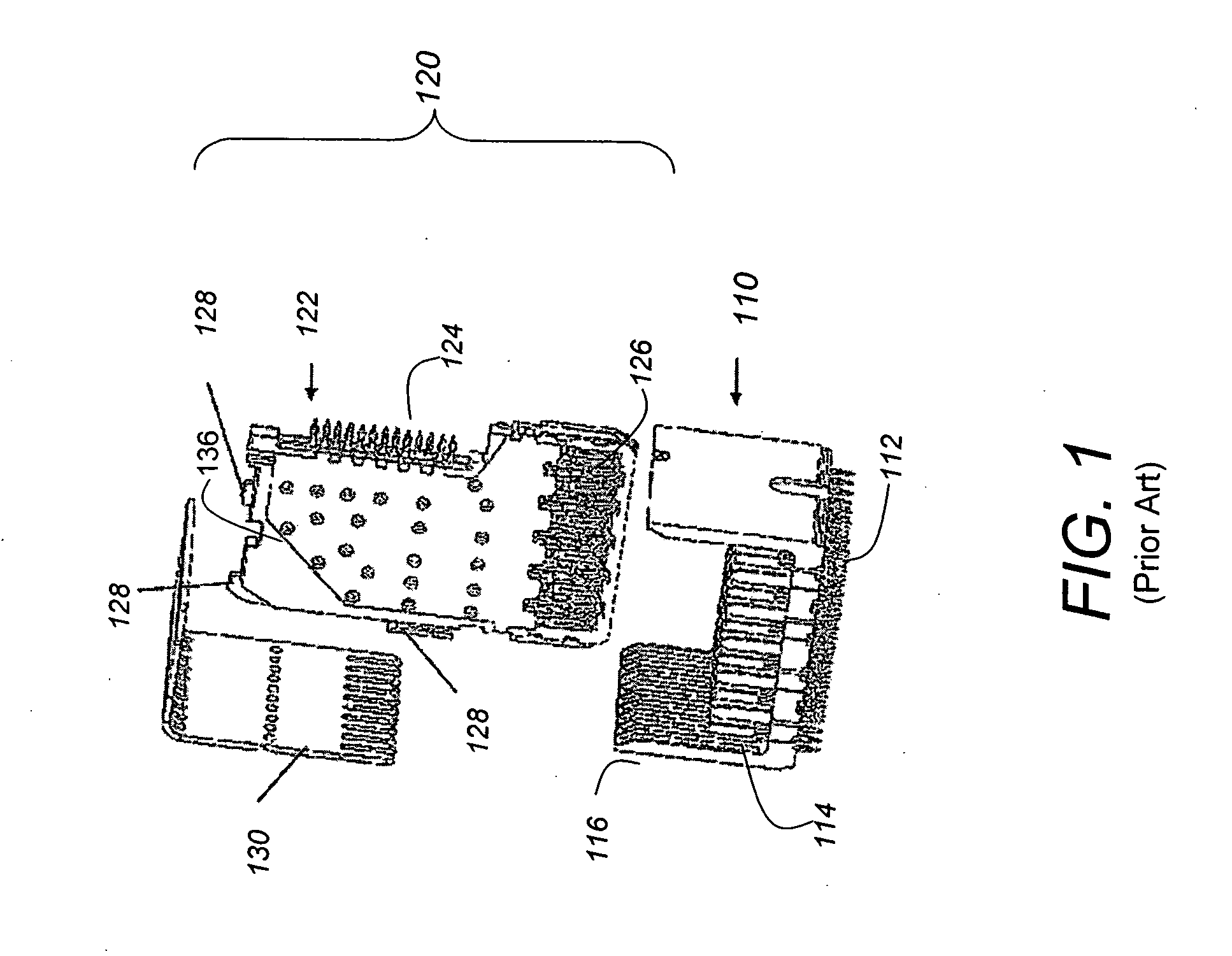

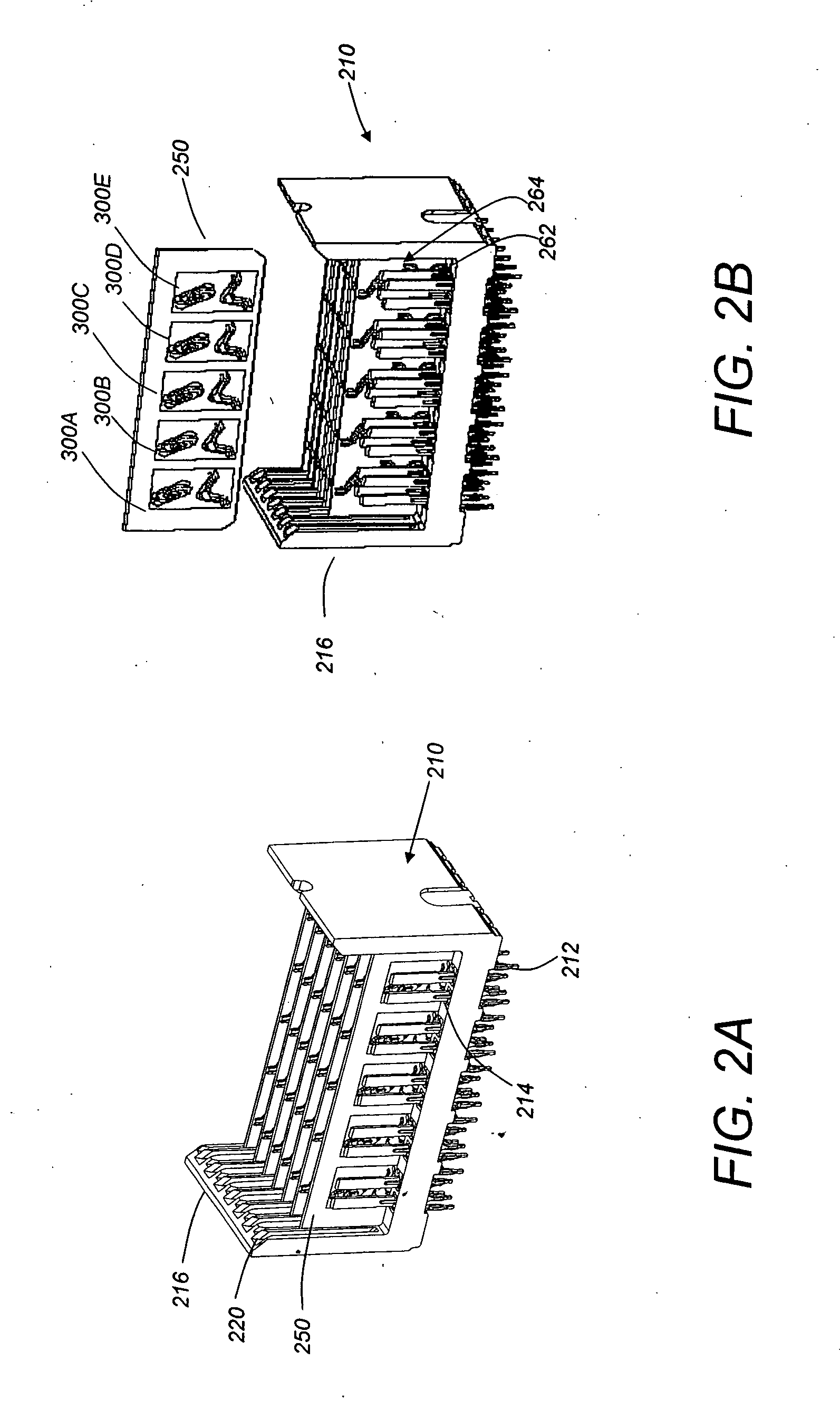

Connector with reference conductor contact

ActiveUS20070054554A1Two-part coupling devicesCoupling protective earth/shielding arrangementsMating connectionElectrical conductor

An electrical connector with a reference contact for improved shielding. The contact provides multiple points of contact between members in the ground structure of two mating connectors. The points of contact are arranged to provide desirable current flow in the signal paths and ground structures of the connectors. The contact is stamped from a shield plate and has multiple elongated members that provide spring force for adequate electrical connection. The elongated members are curved to position the points of contact with the desired orientation. Such a contact structure may be used alone or in combination with other compliant structures providing further points of contact.

Owner:AMPHENOL CORP

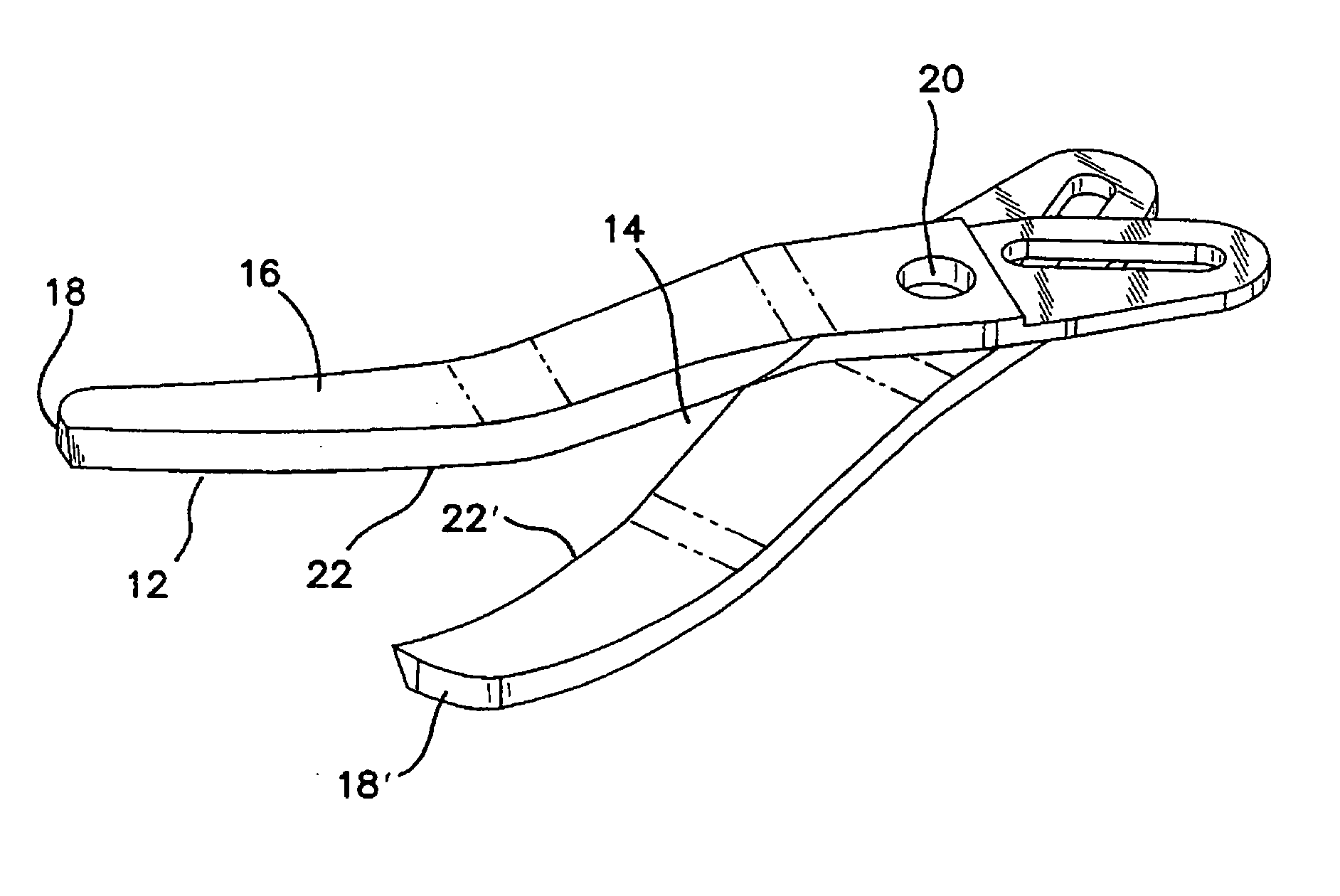

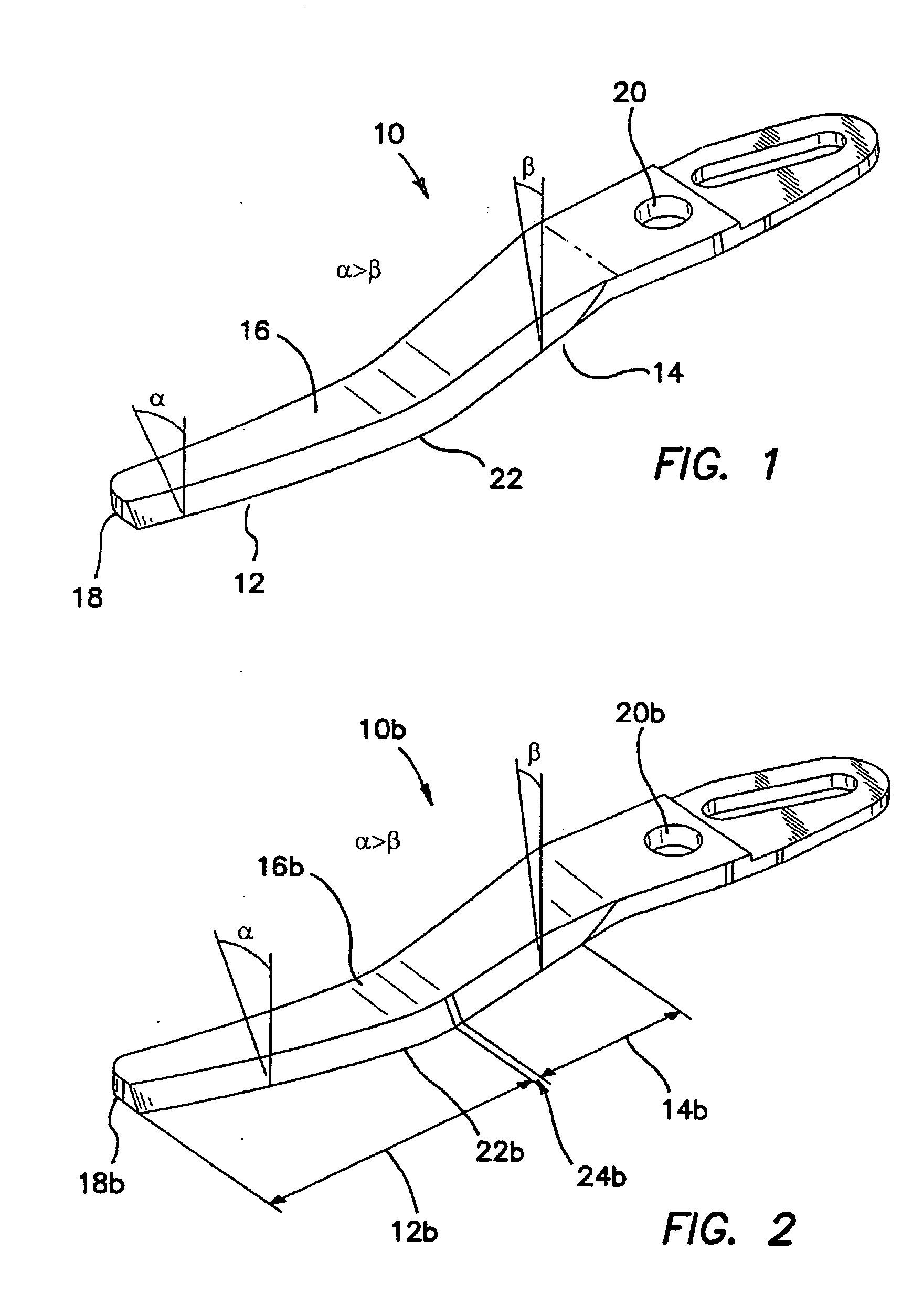

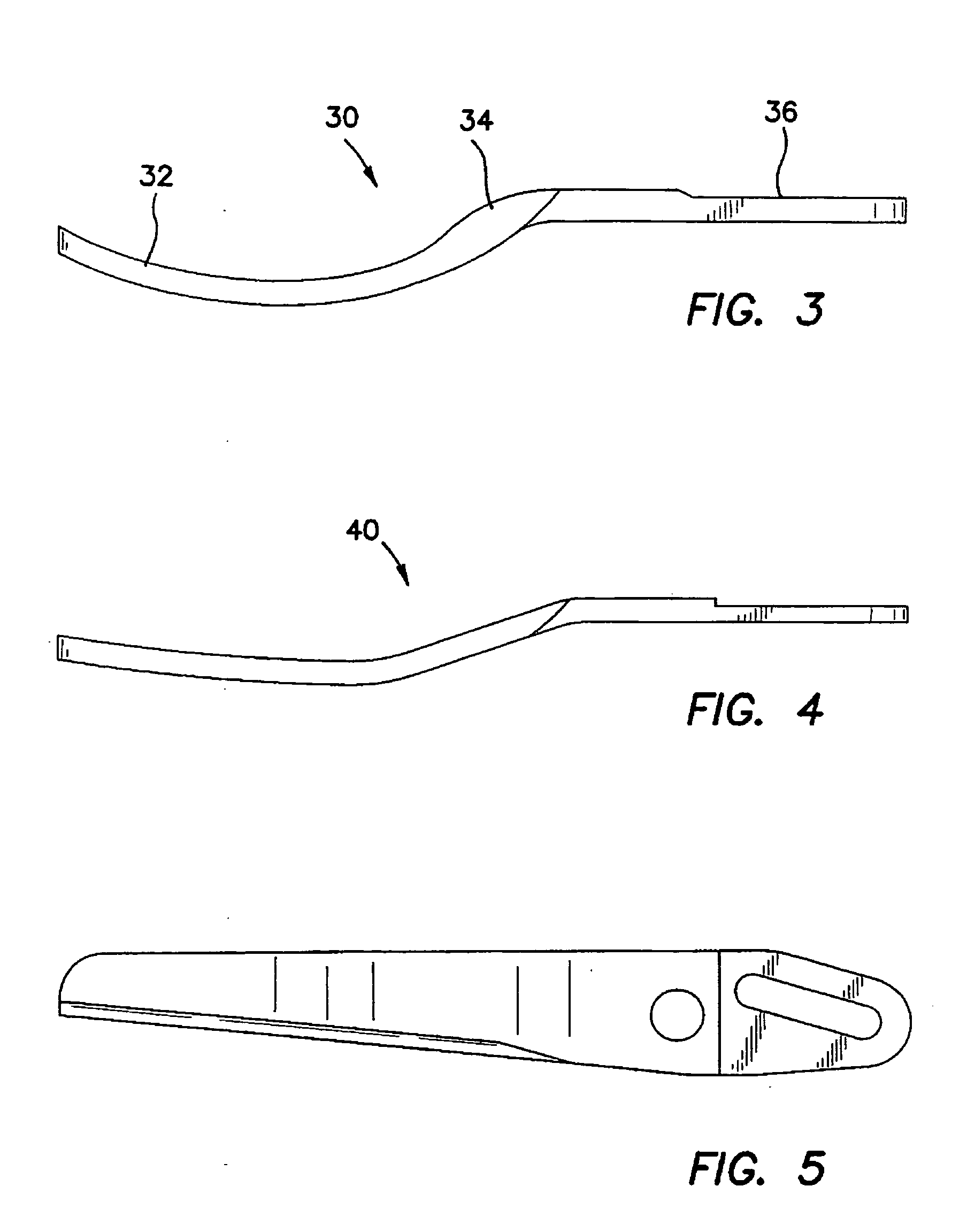

Multiple-angle scissor blade

InactiveUS20050149087A1More strengthReduce tensionSurgical scissorsOther manufacturing equipments/toolsManufacturing technologyLaser cutting

The invention is directed to a pair of laparoscopic scissors, comprising a pair of blades connected at a pivot, each of the blades having a length, a tip portion, a body portion, an outer surface, an inner surface and a cutting edge, the cutting edge forming an angle with the outer surface along the length of the blade such that tension during a cutting operation at the tip portion is about the same as tension at the body portion during the cutting operation. The angle formed may be greater at the tip portion which continuously decreases over the length of the blade. The tip portion may have a first body thickness and the body portion may have a second body thickness different from the first body thickness. During the cutting operation, the blades progressively move over each other to provide a point contact along the cutting edges. The blades may be thickened in a number of locations and combinations including: (1) one blade could be thicker than the other to force the opposing blade to flex; (2) both blades could be thicker at the body portions to give more strength when cutting staples; (3) each blade could be thickened on one side or the other to stiffen certain locations; and (4) the tips of each blade could be thicker than the body portions to provide increased tension at the tips. In another aspect of the invention, a process of manufacturing the pair of scissors of the invention is disclosed, comprising the steps of form grinding the blades into a desired shape from a pre-hardened block of material, and sharpening the cutting edges of the blades. The blades may also be formed through other processes including wire EDM, laser cutting, waterjet cutting, machining, cast or metal injection molding, and other independent profile manufacturing processes. The manufacturing process of the invention is beneficial in that each profile can be accurately controlled, and the parts will be exact every time.

Owner:APPL MEDICAL RESOURCES CORP

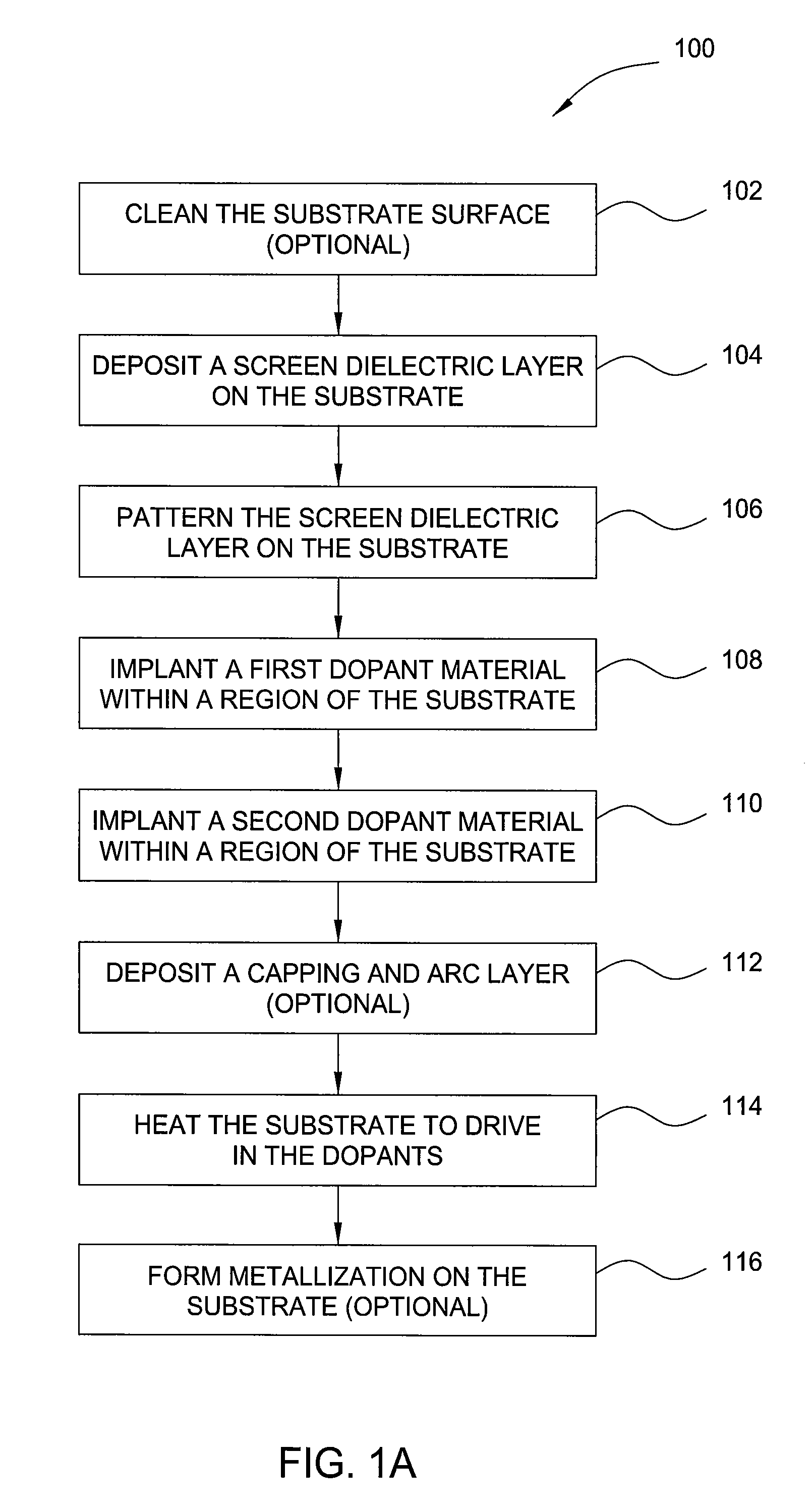

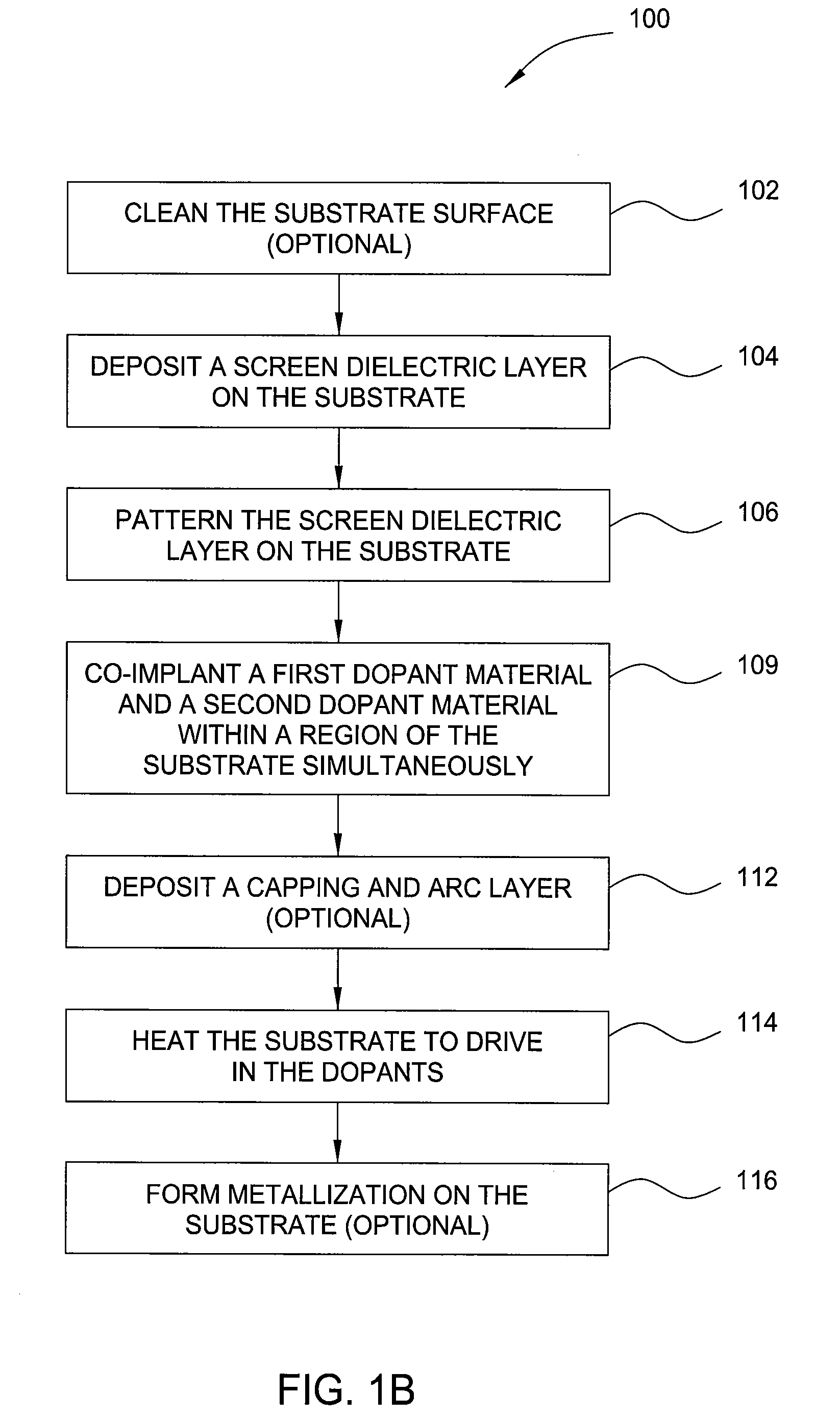

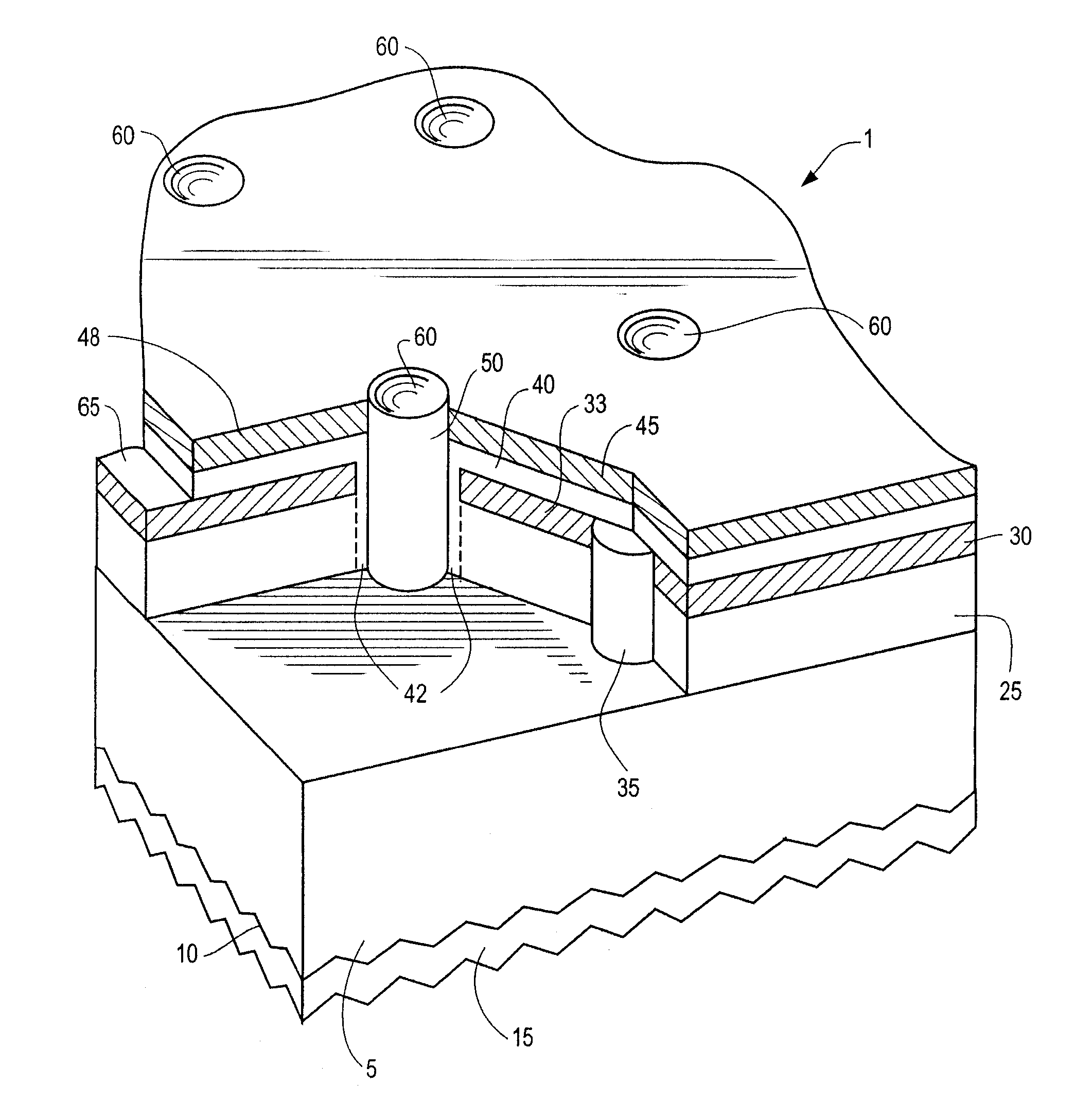

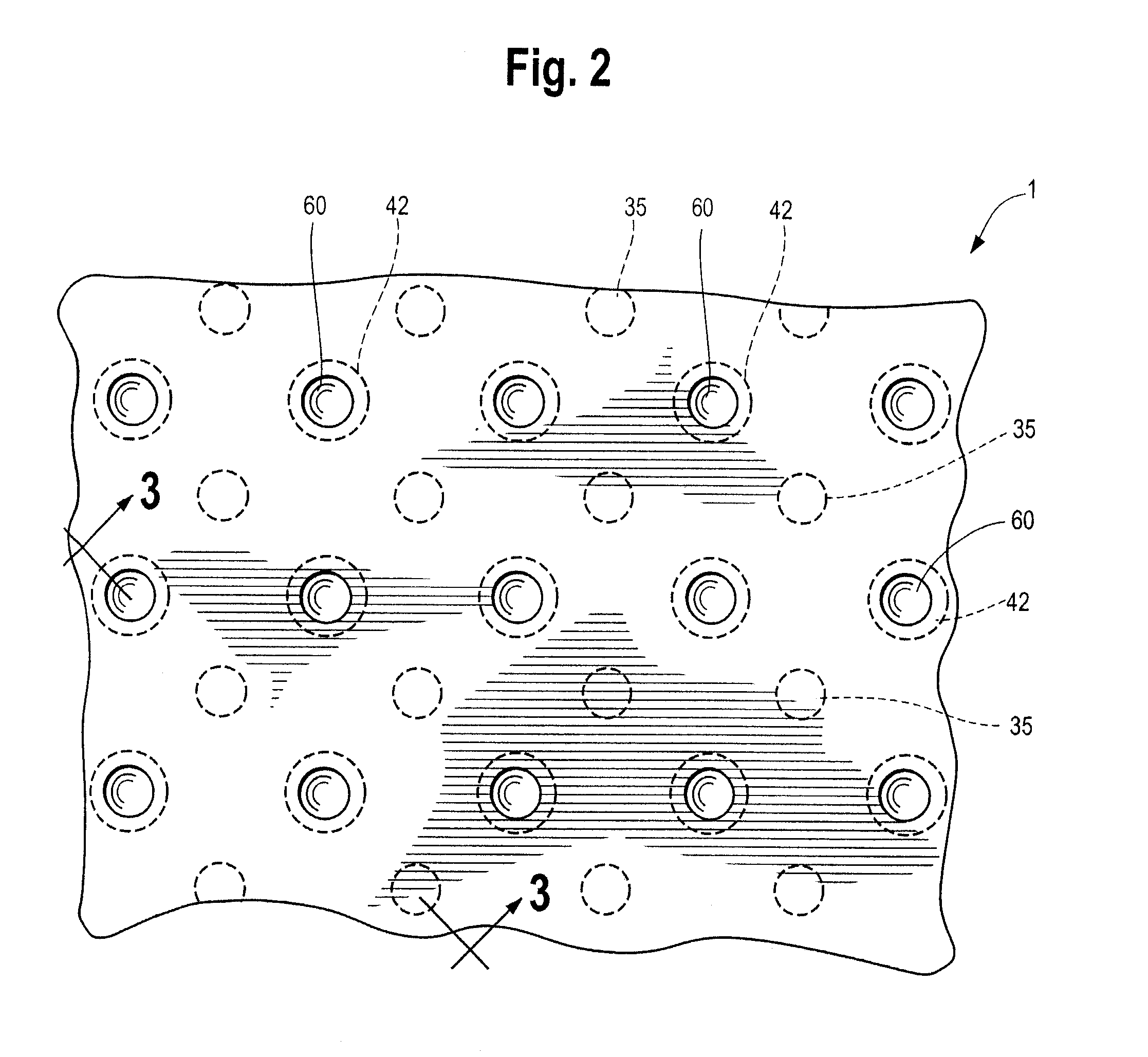

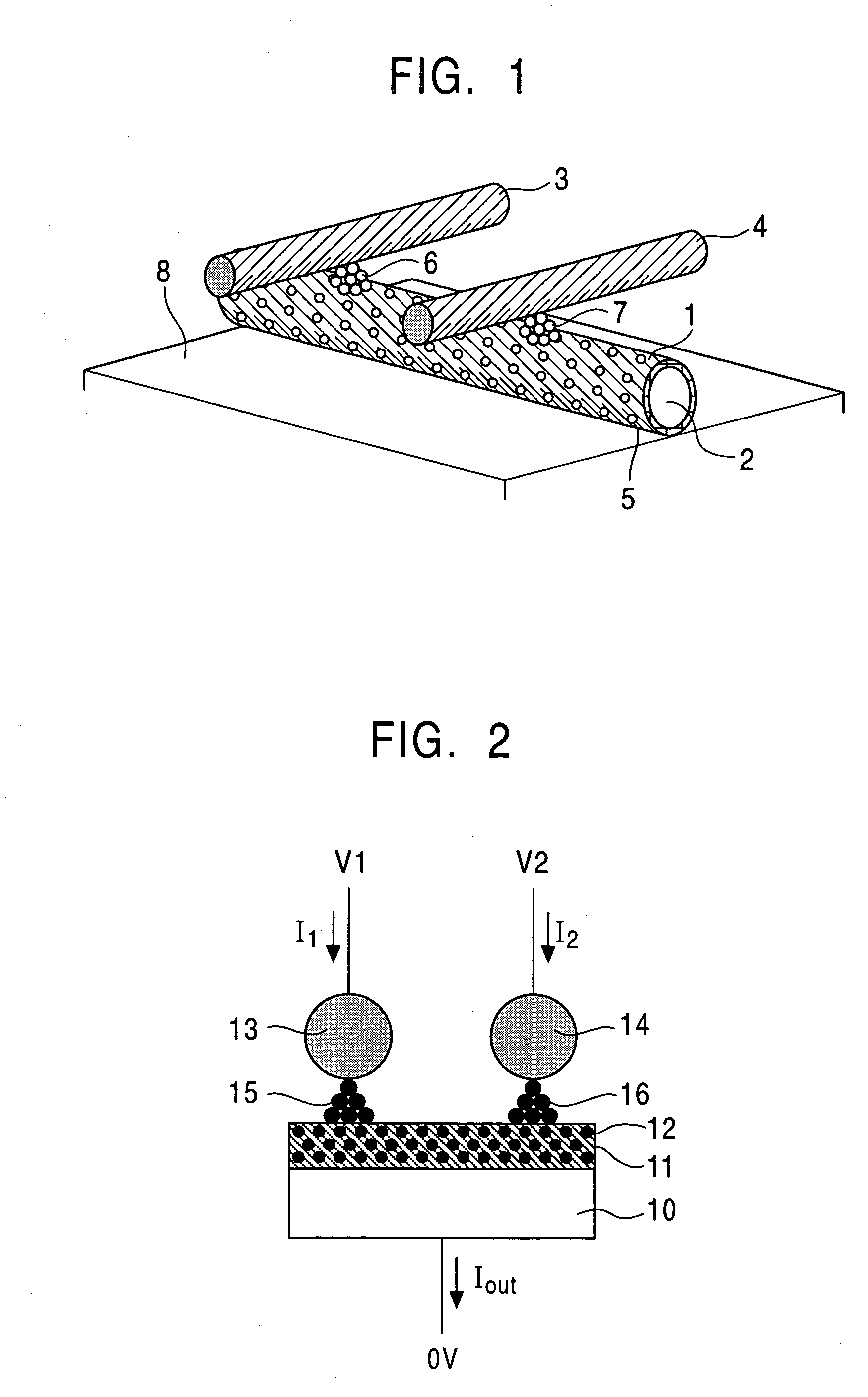

Methods of emitter formation in solar cells

InactiveUS20090068783A1Final product manufactureSemiconductor/solid-state device manufacturingDopantElectrical resistance and conductance

Embodiments of the invention contemplate high efficiency emitters in solar cells and novel methods for forming the same. One embodiment of the improved emitter structure, called a high-low type emitter, optimizes the solar cell performance by equally providing low contact resistance to minimize ohmic losses and isolation of the high surface recombination metal-semiconductor interface from the junction to maximize cell voltage. Another embodiment, called an alternating doping type emitter, provides regions of alternating doping type for use with point contacts in the back-contact solar cells. One embodiment of the methods includes depositing and patterning a doped or undoped dielectric layer on a surface of a substrate, implanting a fast-diffusing dopant and / or a slow-diffusing dopant into the substrate either simultaneously or sequentially, and annealing the substrate to drive in the dopants. Another embodiment of the methods includes using a physical mask to form a patterned dopant distribution in a substrate.

Owner:APPLIED MATERIALS INC

Continuously variable planetary gear set

ActiveUS20040224808A1Reduce amountEasy to removeHybrid vehiclesChain/belt transmissionRadial positionEngineering

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

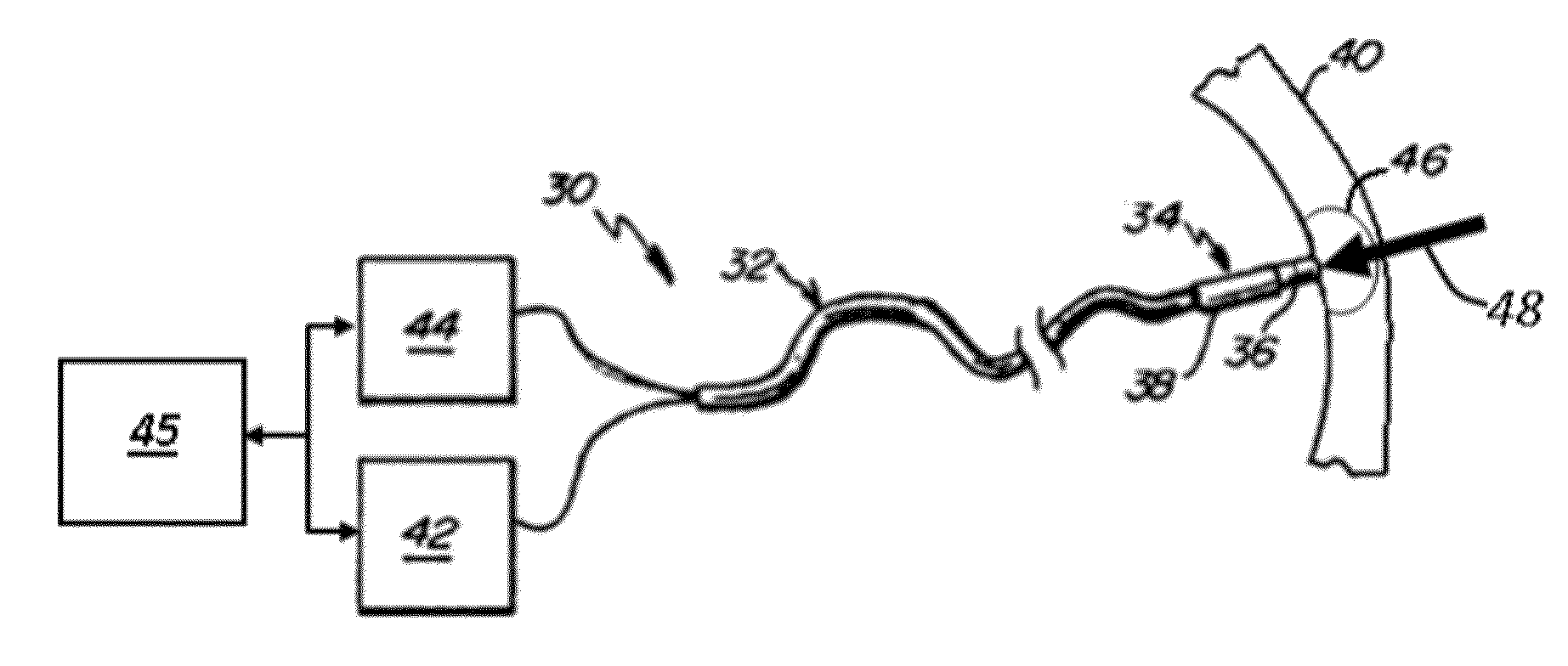

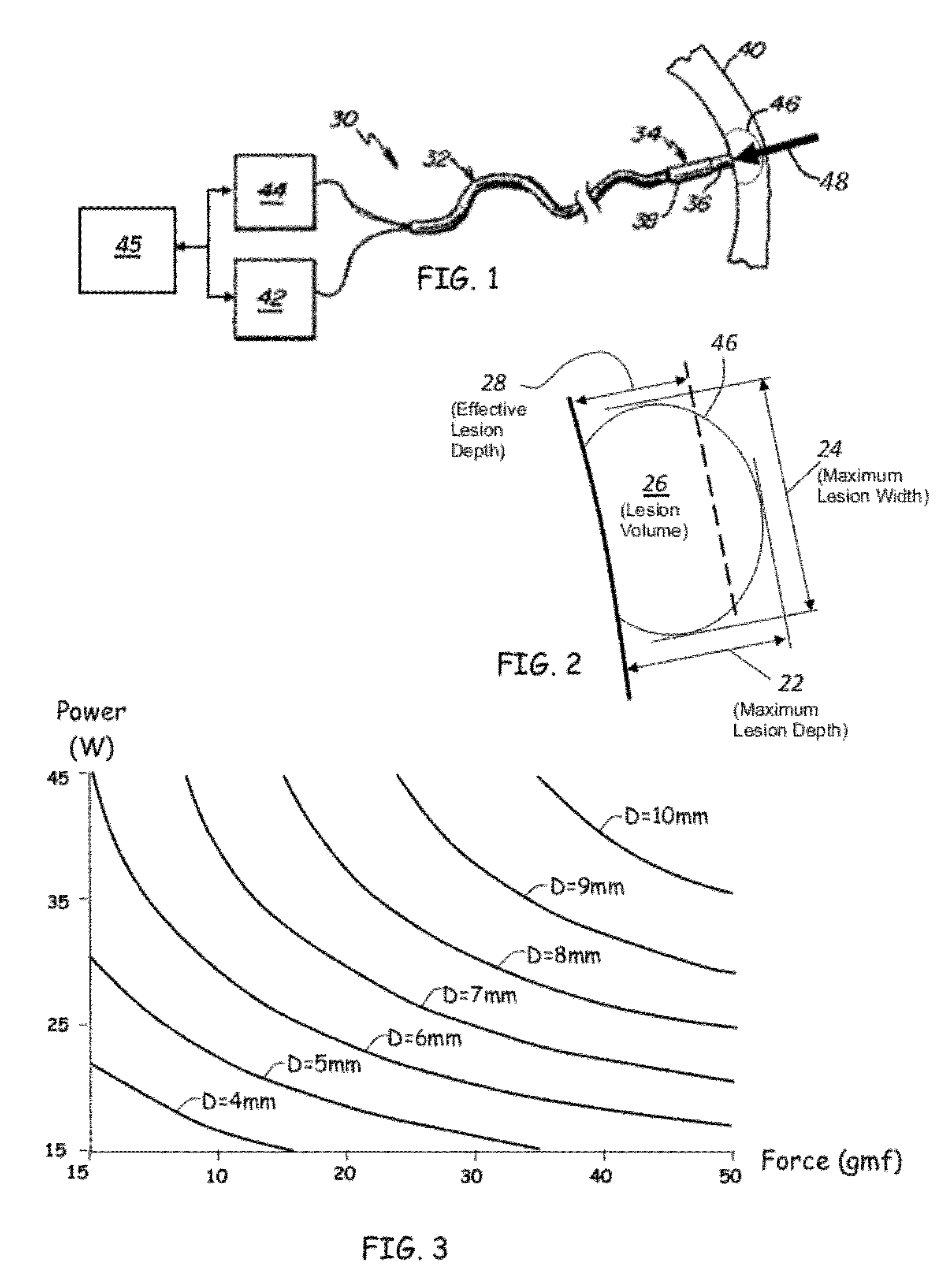

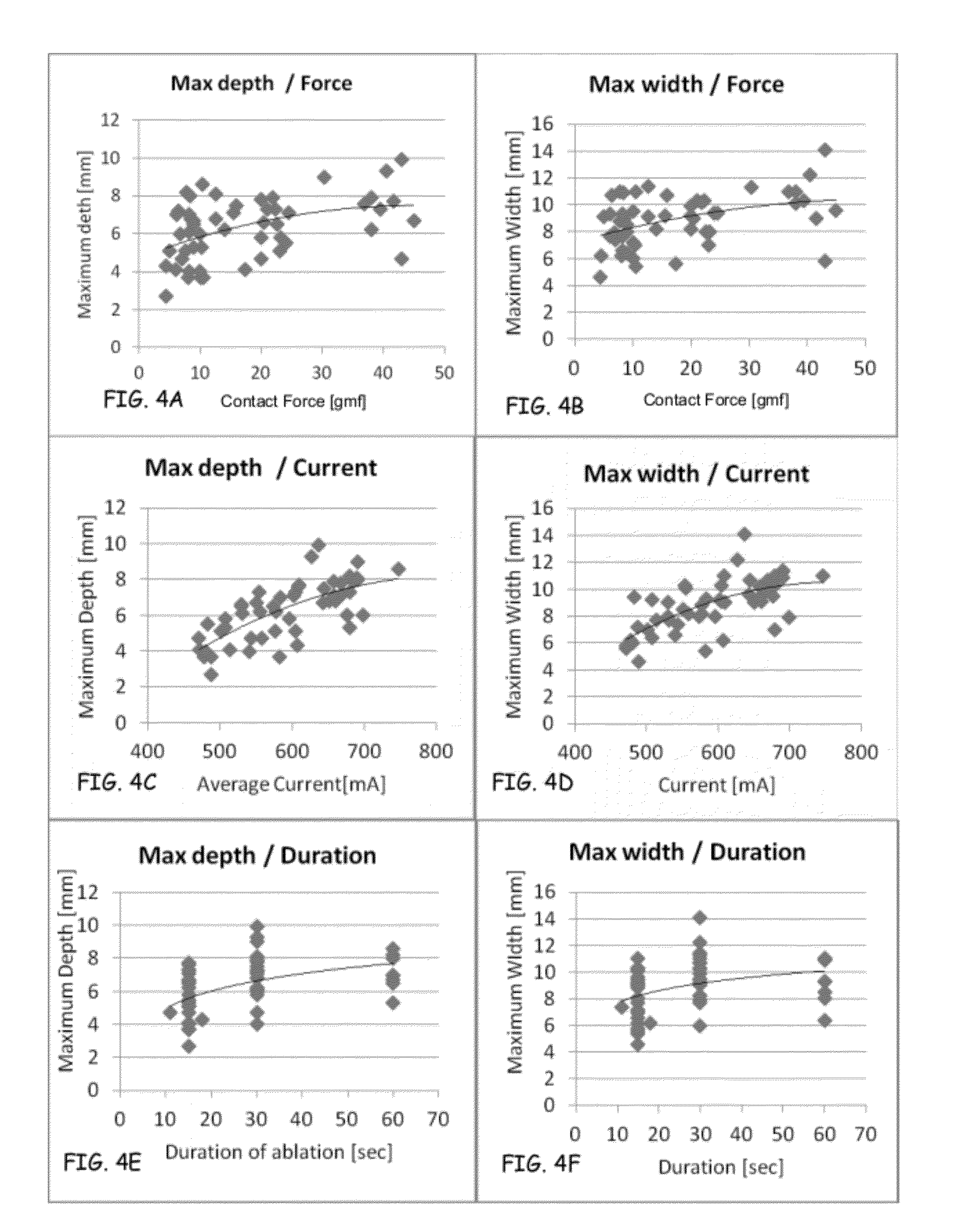

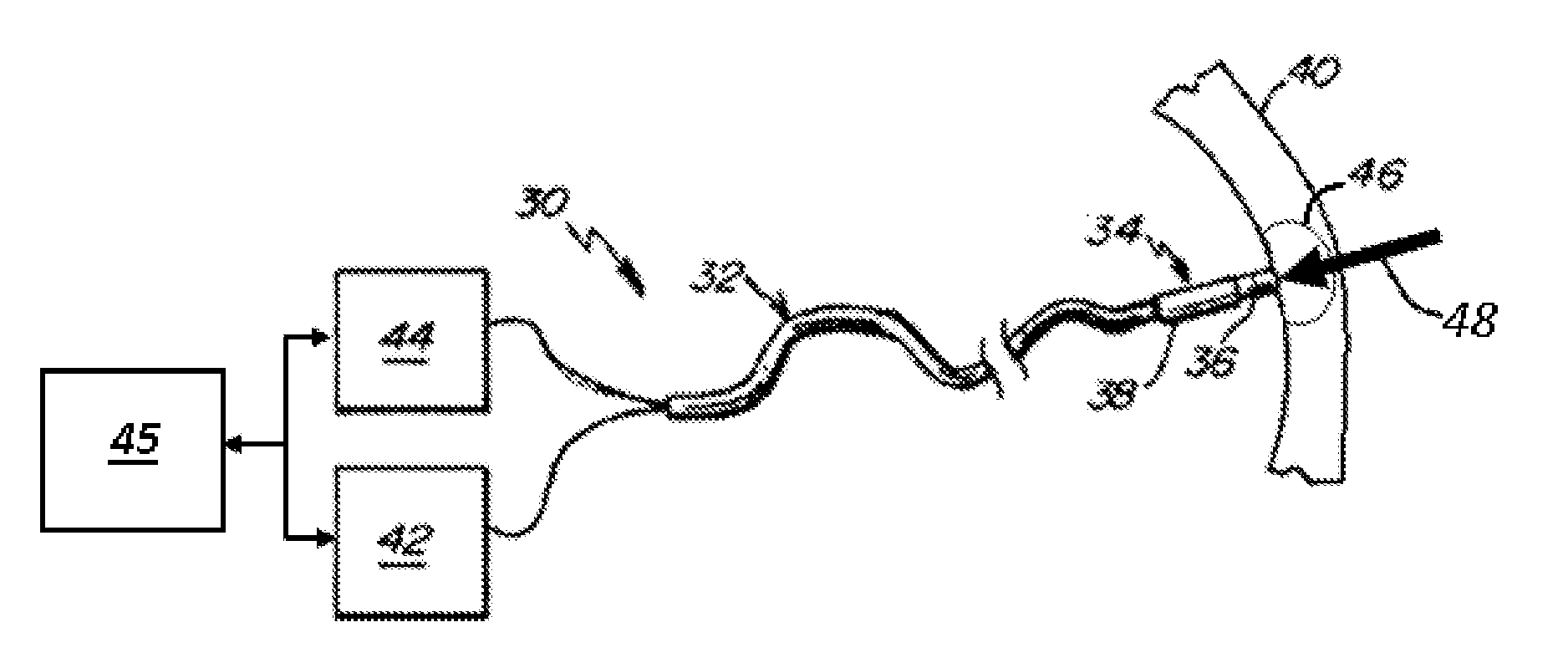

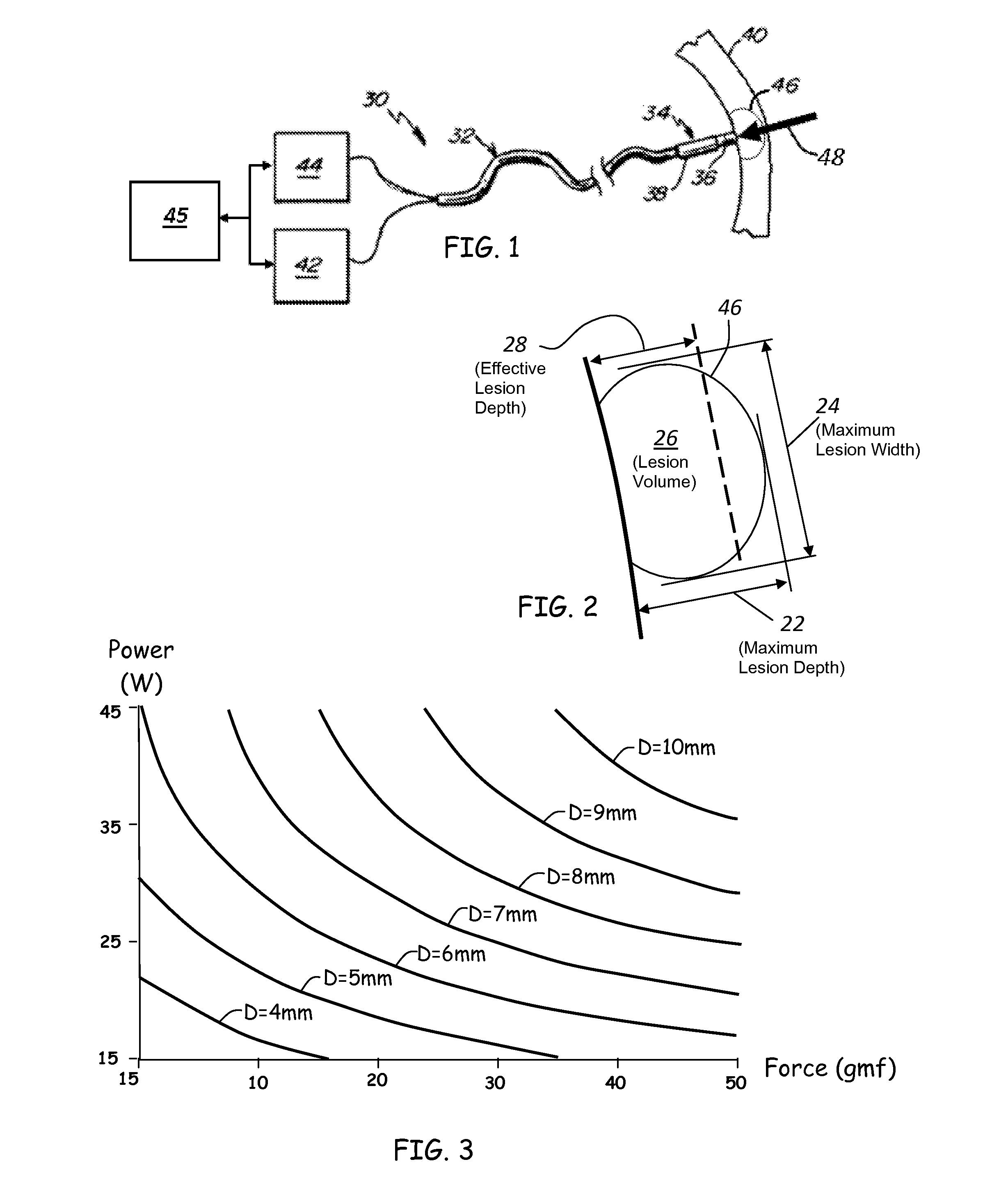

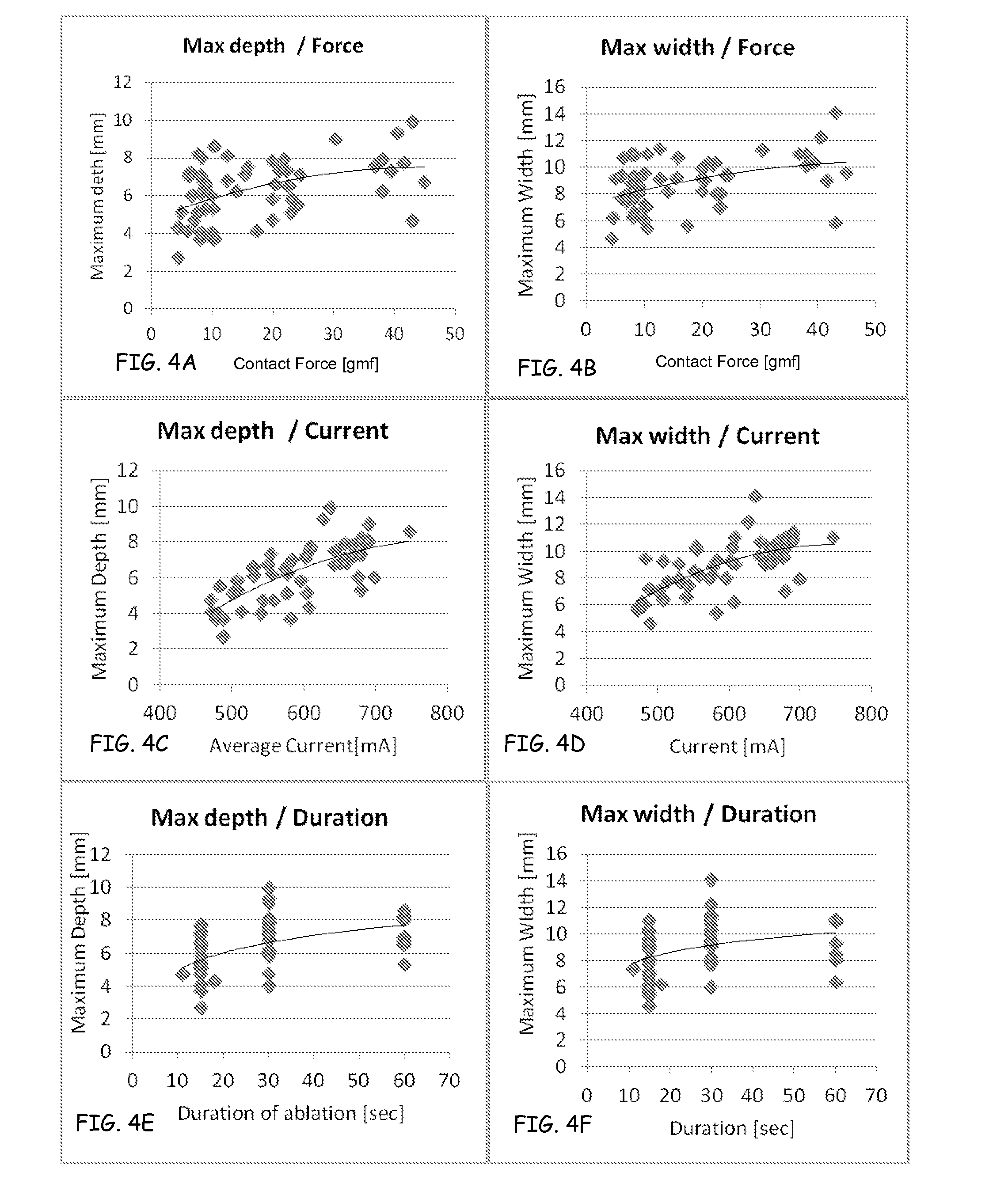

Prediction of atrial wall electrical reconnection based on contact force measured during RF ablation

ActiveUS20120209260A1Easy to predictEffective isolation lineDiagnosticsSurgical instruments for heatingRf ablationAtrial wall

A method and device for determining the transmuriality and / or continuity of an isolation line formed by a plurality of point contact ablations. In one embodiment, a method for determining the size of a lesion (width, depth and / or volume) is disclosed, based on contact force of the ablation head with the target tissue, and an energization parameter that quantifies the energy delivered to the target tissue during the duration time of the lesion formation. In another embodiment, the sequential nature (sequence in time and space) of the ablation line formation is tracked and quantified in a quantity herein referred to as the “jump index,” and used in conjunction with the lesion size information to determine the probability of a gap later forming in the isolation line.

Owner:ST JUDE MEDICAL INT HLDG SARL

Fast authentication and access control method for mobile networking

InactiveUS7174456B1Easy to switchReduce certification timeDigital data processing detailsUser identity/authority verificationExpiration TimeWeb authentication

A fast authentication and access control method of authenticating a network access device to a communications network having an access point communicating with a remote authentication (home AAA) server for the network access device. The method includes the step of receiving an access request having an authentication credential from the network access device at the access point. The authentication credential includes a security certificate having a public key for the network access device and an expiration time. The security certificate is signed with a private key for the remote authentication server. The access point locally validates the authentication credential by accessing the public key of the remote authentication server from a local database, and checking the signature and expiration time of the security certificate. If the authentication credential is validated at the access point, the access point grants the network access device conditional access to the network by sending an access granted message to the network access device. The access granted message includes a session key encrypted with a public key for the network access device. The session key is stored in a database associated with the access point. The access point contacts the remote authentication server to check a revocation status of the security certificate for the network access device. If the access point receives a message from the remote authentication server that the authentication credential for the network access device has been revoked, it suspends network access for the network access device.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

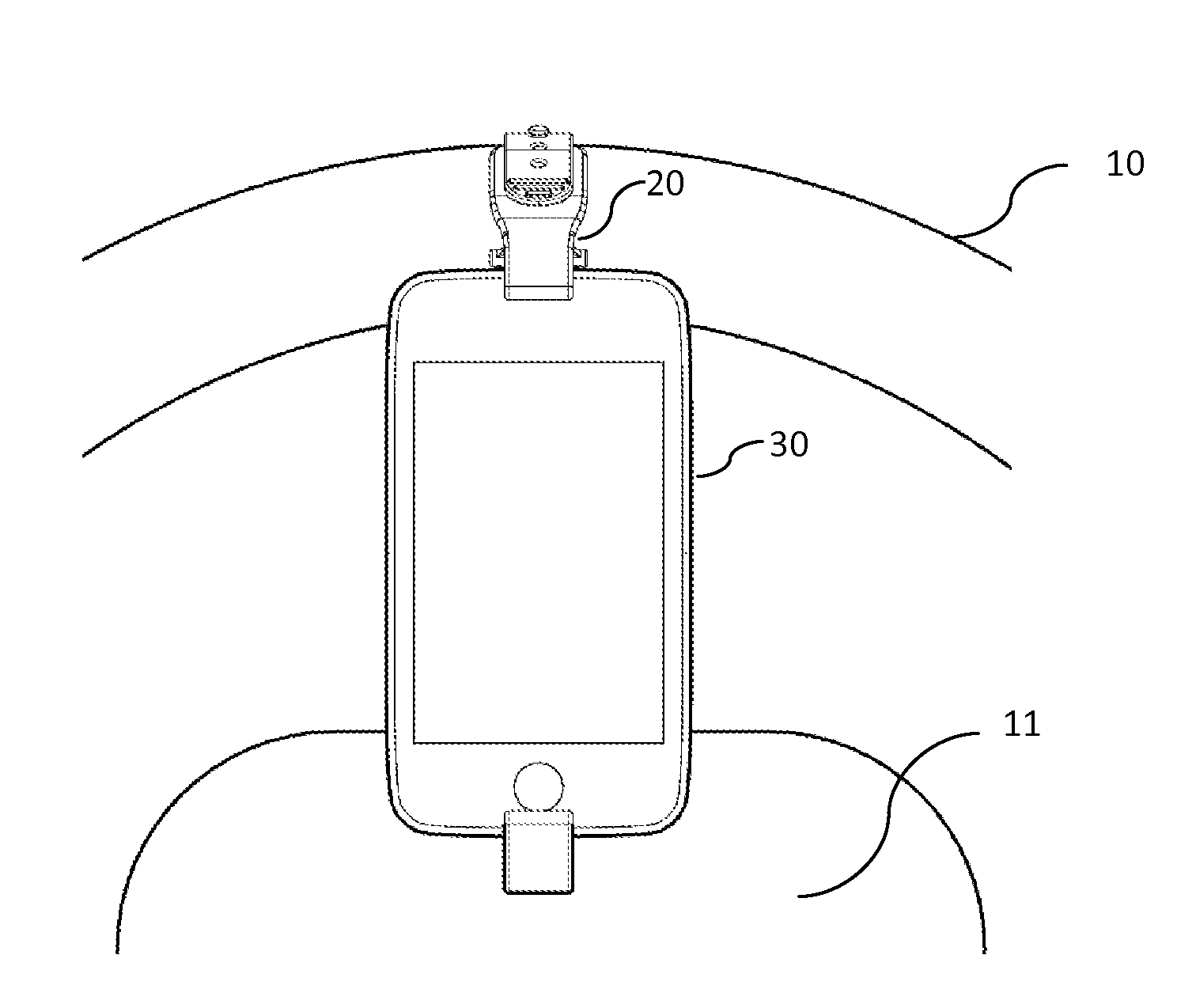

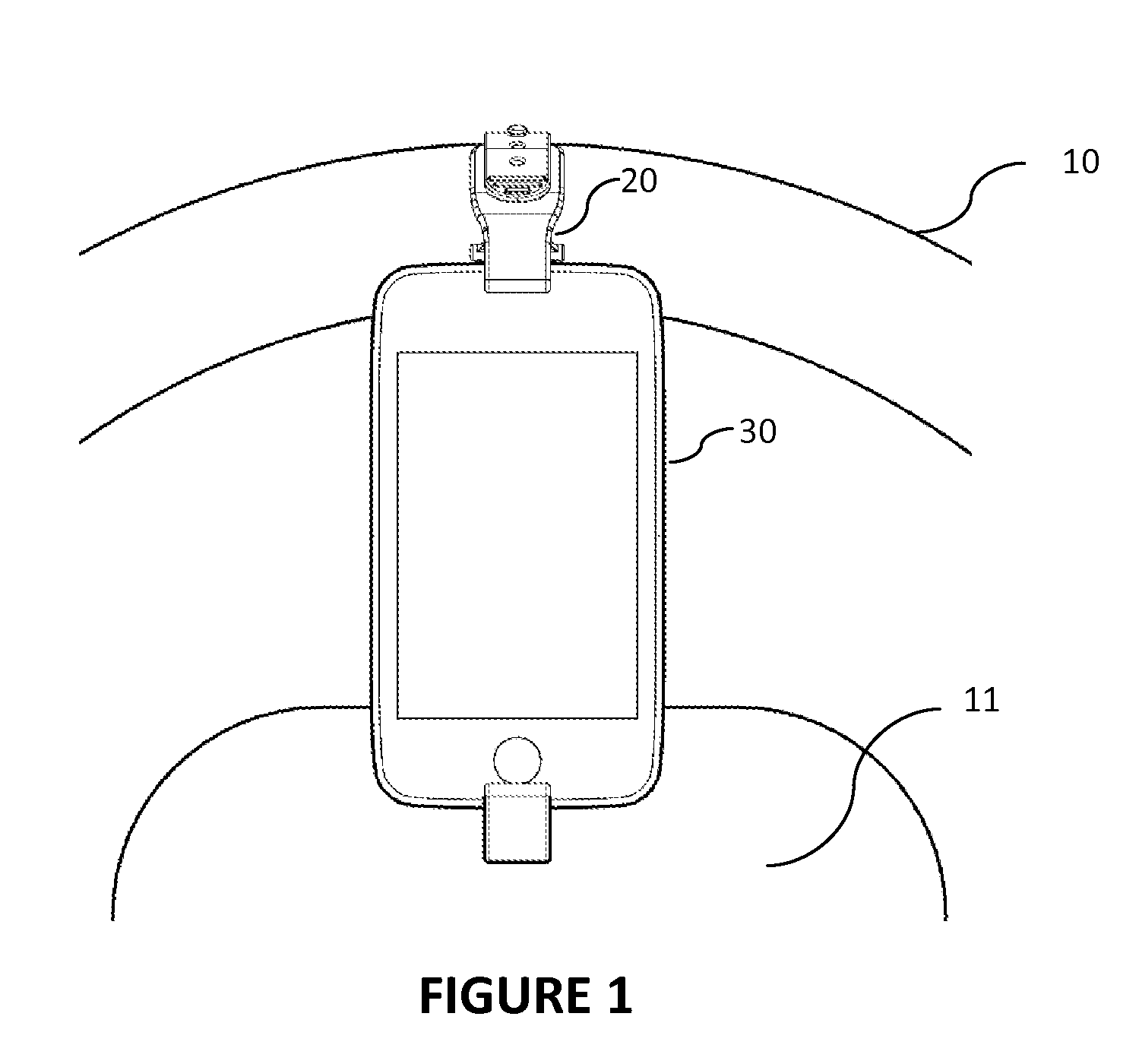

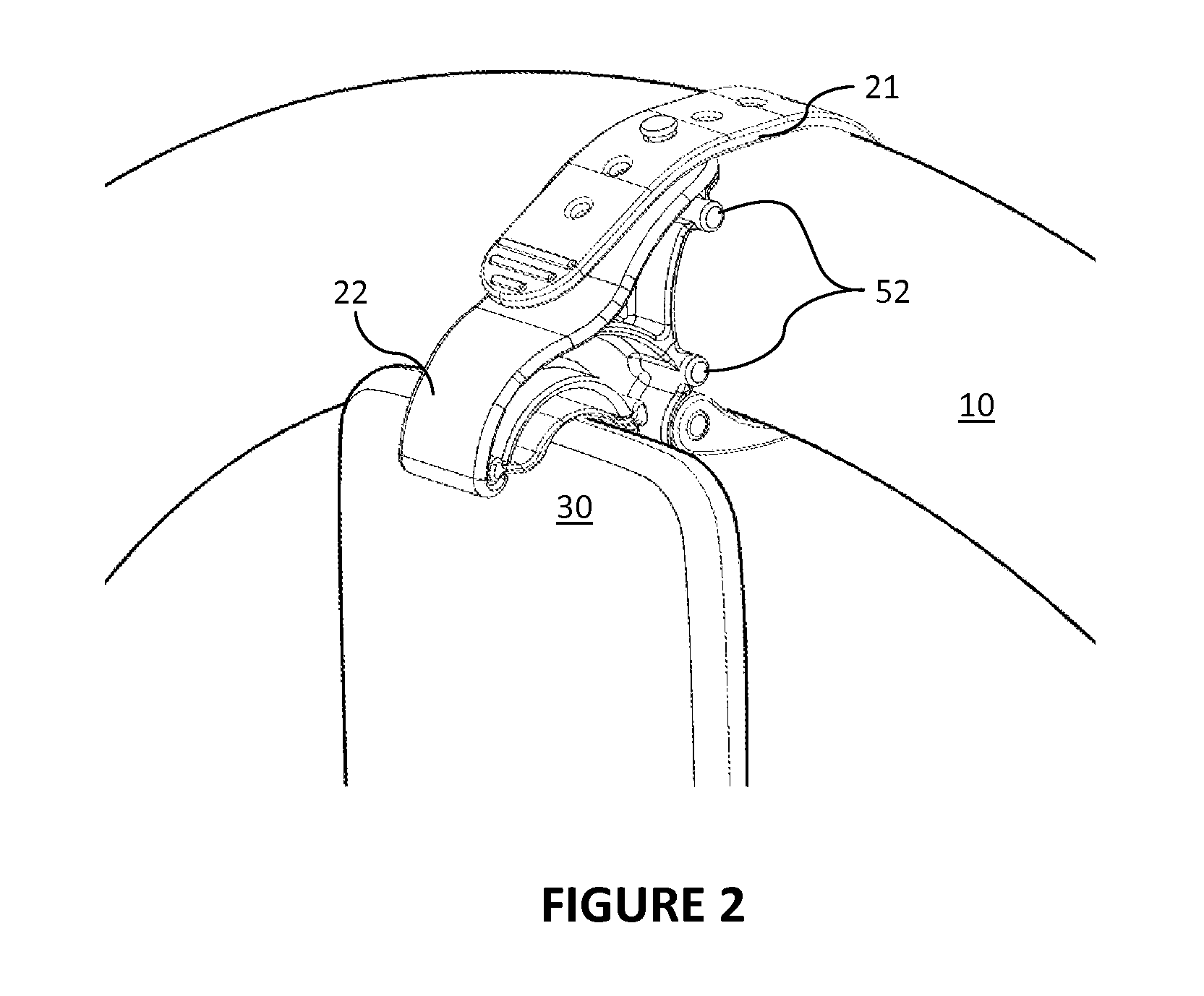

Removable steering wheel holder for an electronic device

InactiveUS20120080465A1Quick installation and removalSmall sizeSupplementary fittingsArticle supporting devicesVisibilitySteering wheel

A removable holder for a smart phone is provided to support the smart phone in front of a driver on a steering wheel. Close proximity of the smart phone allows easy access and good visibility of its display which helps in using the GPS navigation or other features of a smart phone while the vehicle is in motion. Retention of the smart phone assures its steady position when the steering wheel is turned but at the same time allows for its deflection out of the way in case of an airbag deployment. The attachment element of the holder includes two raised bars and an elastic band to form a 3-point contact area with the steering wheel. The smart phone retainer is length-adjustable to accommodate a variety of smart phones. The holder can be easily mounted and removed from the steering wheel without using hand tools.

Owner:GO SMART

Solar Cell Contact Formation Process Using A Patterned Etchant Material

InactiveUS20090142880A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationContact formationEtching

Embodiments of the invention contemplate the formation of a high efficiency solar cell using novel methods to form the active region(s) and the metal contact structure of a solar cell device. In one embodiment, the methods include the use of various etching and patterning processes that are used to define point contacts through a blanket dielectric layer covering a surface of a solar cell substrate. The method generally includes depositing an etchant material that enables formation of a desired pattern in a dielectric layer through which electrical contacts to the solar cell device can be formed.

Owner:APPLIED MATERIALS INC

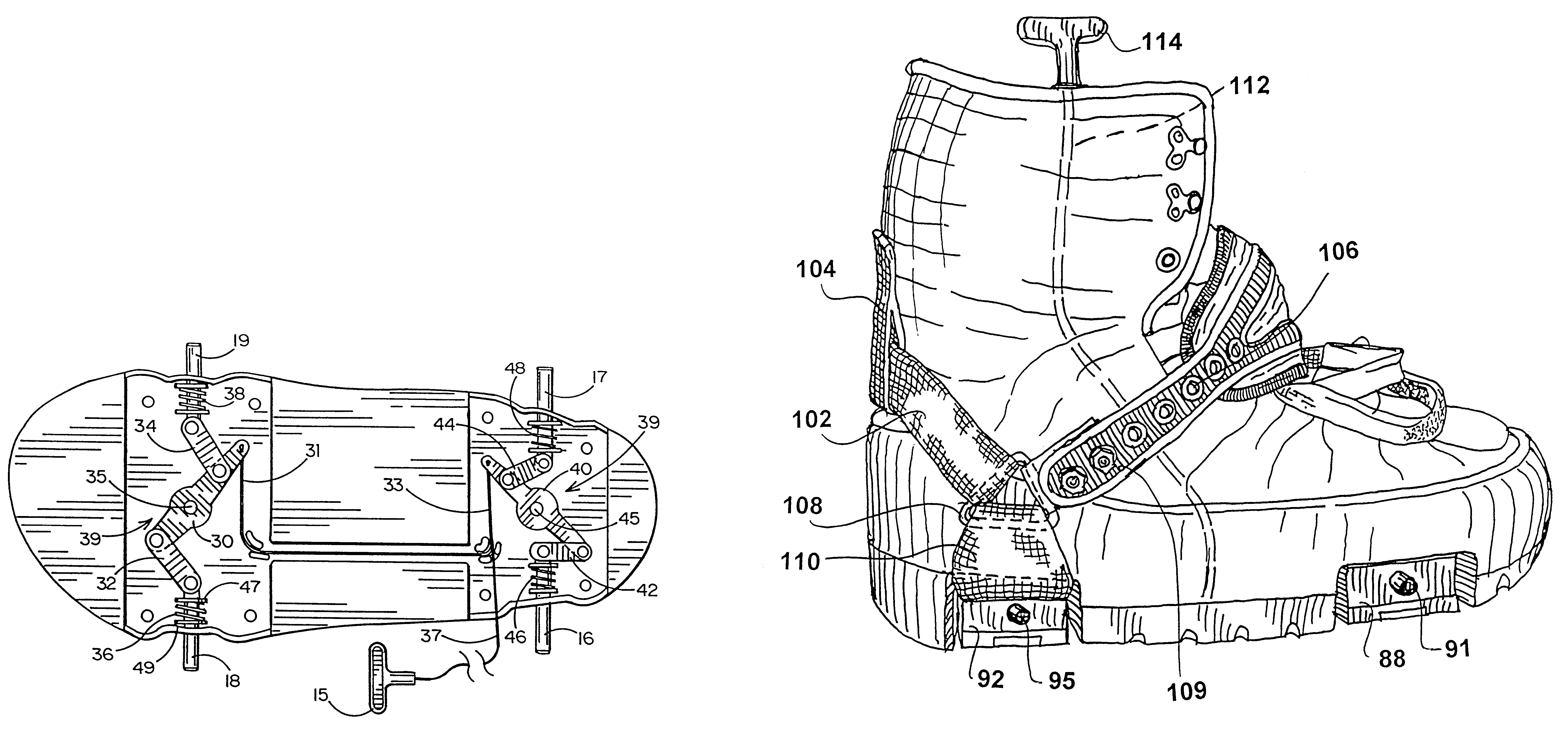

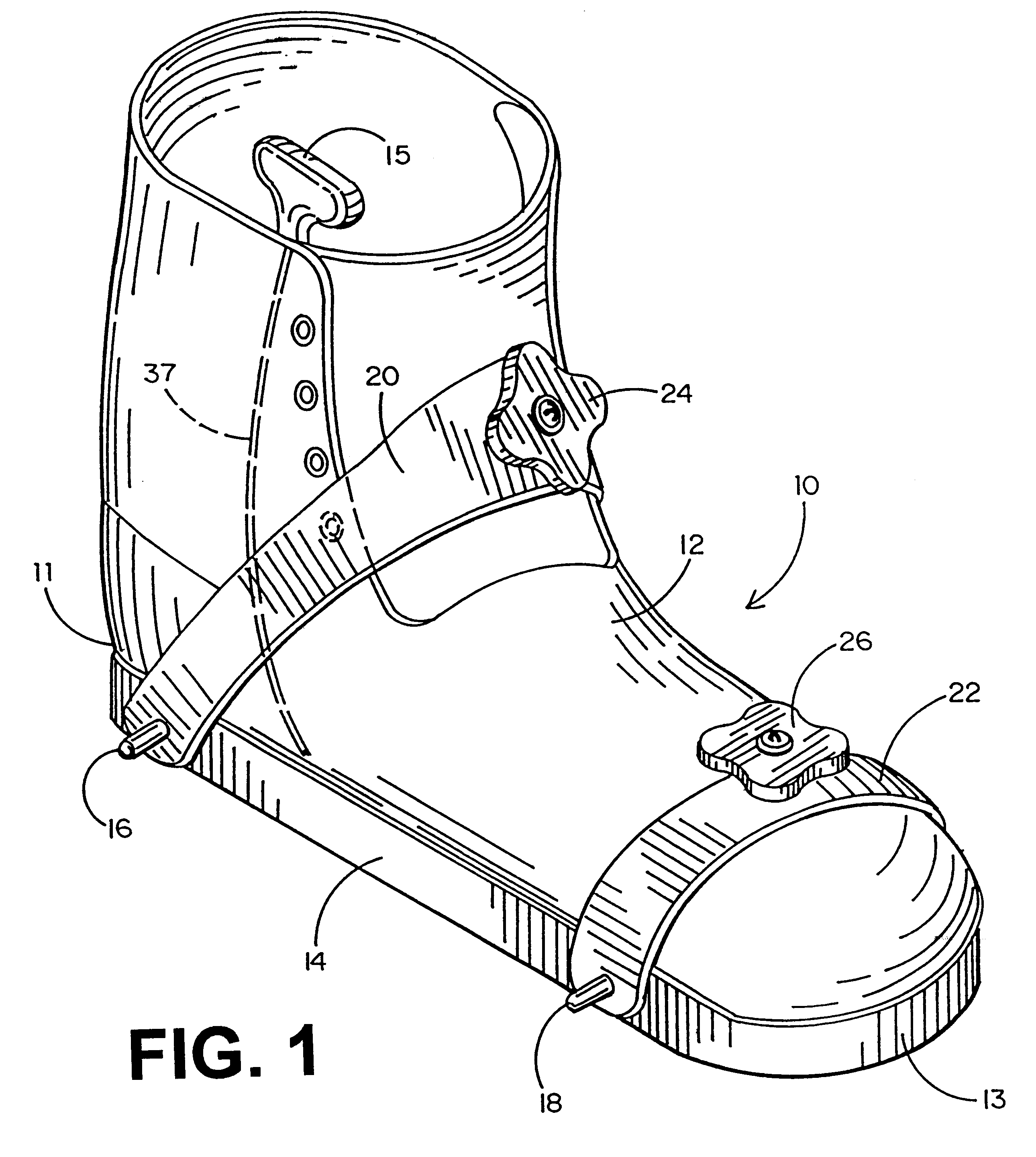

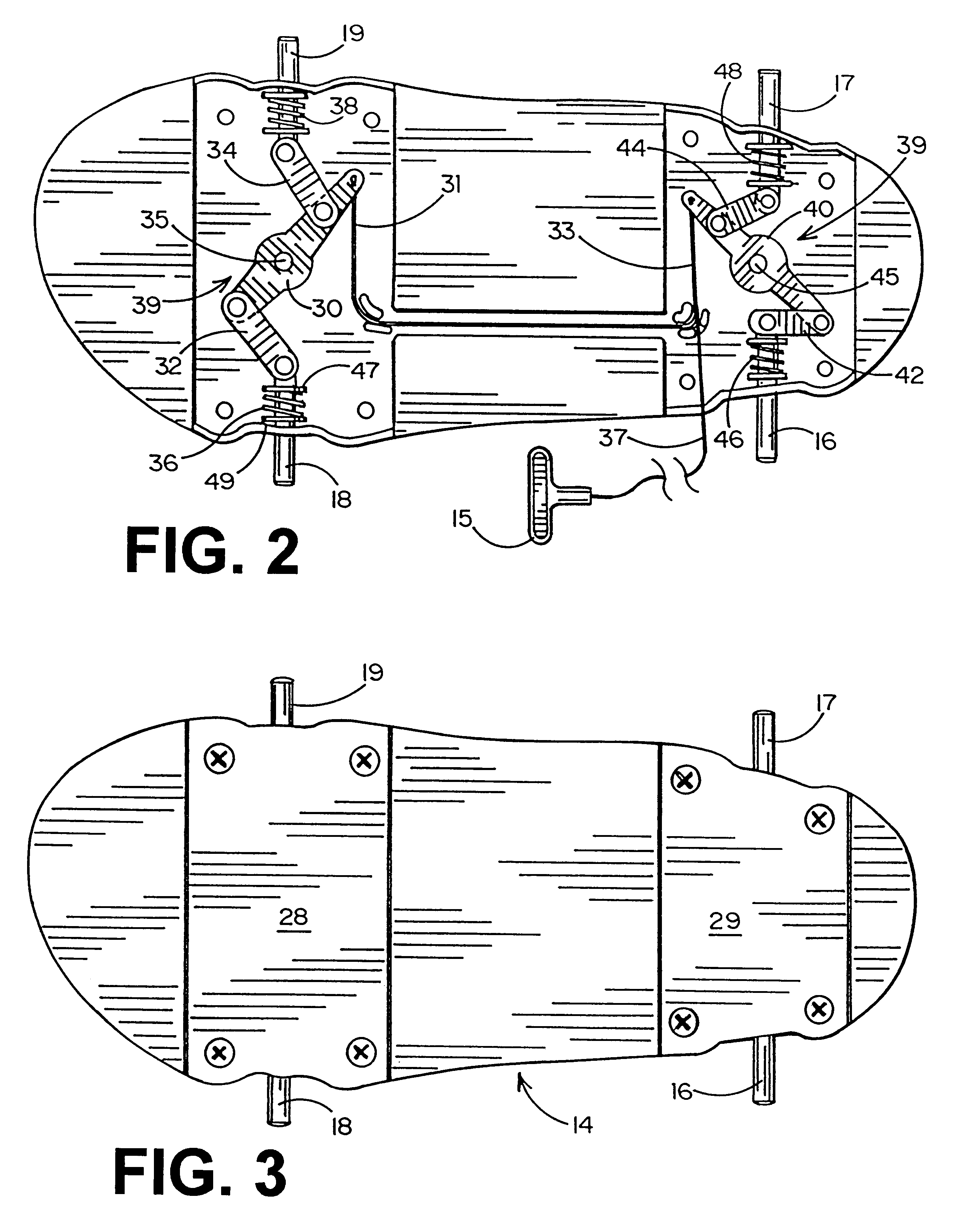

Snowboard boot and binding assembly

InactiveUS6276708B1Improve securityEasy to controlCarriage/perambulator accessoriesSki bindingsHeel-and-toeEngineering

A contact configuration between boot and binding for snowboarding. Contact pins are provided on opposing sides of the boot at both the heel area and the toe area. This 4-point contact configuration assures heel and toe stability and reliable side boot restraint. Concave mating receptacles at matching locations on the binding assure easy and simple interconnection which is also secure and reliable. A release mechanism is provided to selectively retract the pins using a simple pull cord arrangement. Strap linkages permit more convenient tightening and loosening of the boot straps. A strap / yoke configuration provides improved interconnection between the boot and the user's foot. The pull cord is routed within the sole of the boot and upward along the ankle area of the boot for more convenient access. The pull cord is connected to retract linkages at both heel and toe areas, both of those linkages being spring loaded to provide normally extended pins. A variety of pin receptacle configurations are shown for facilitating boot-to-binding step-in connection.

Owner:HOGSTEDT ROY L

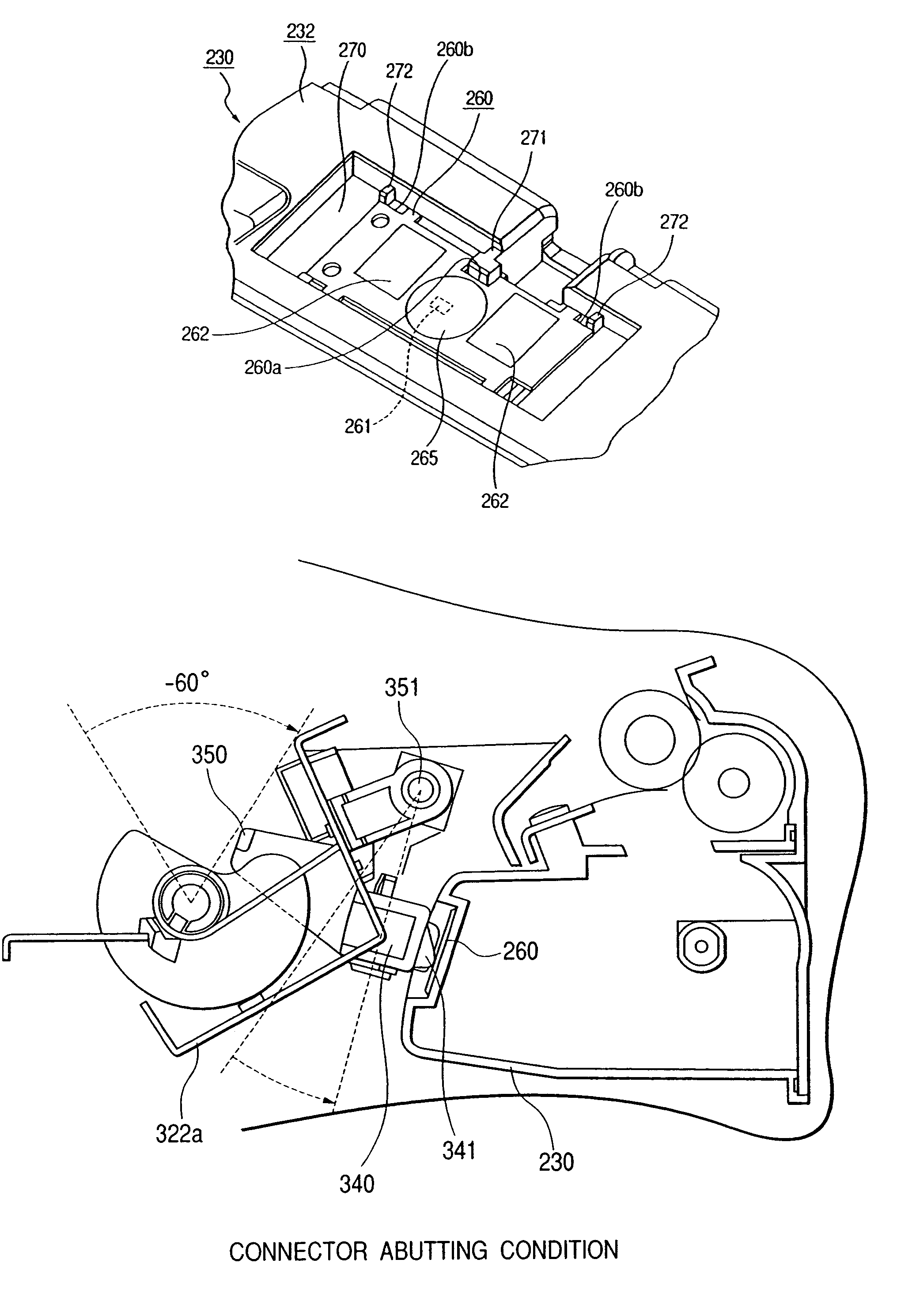

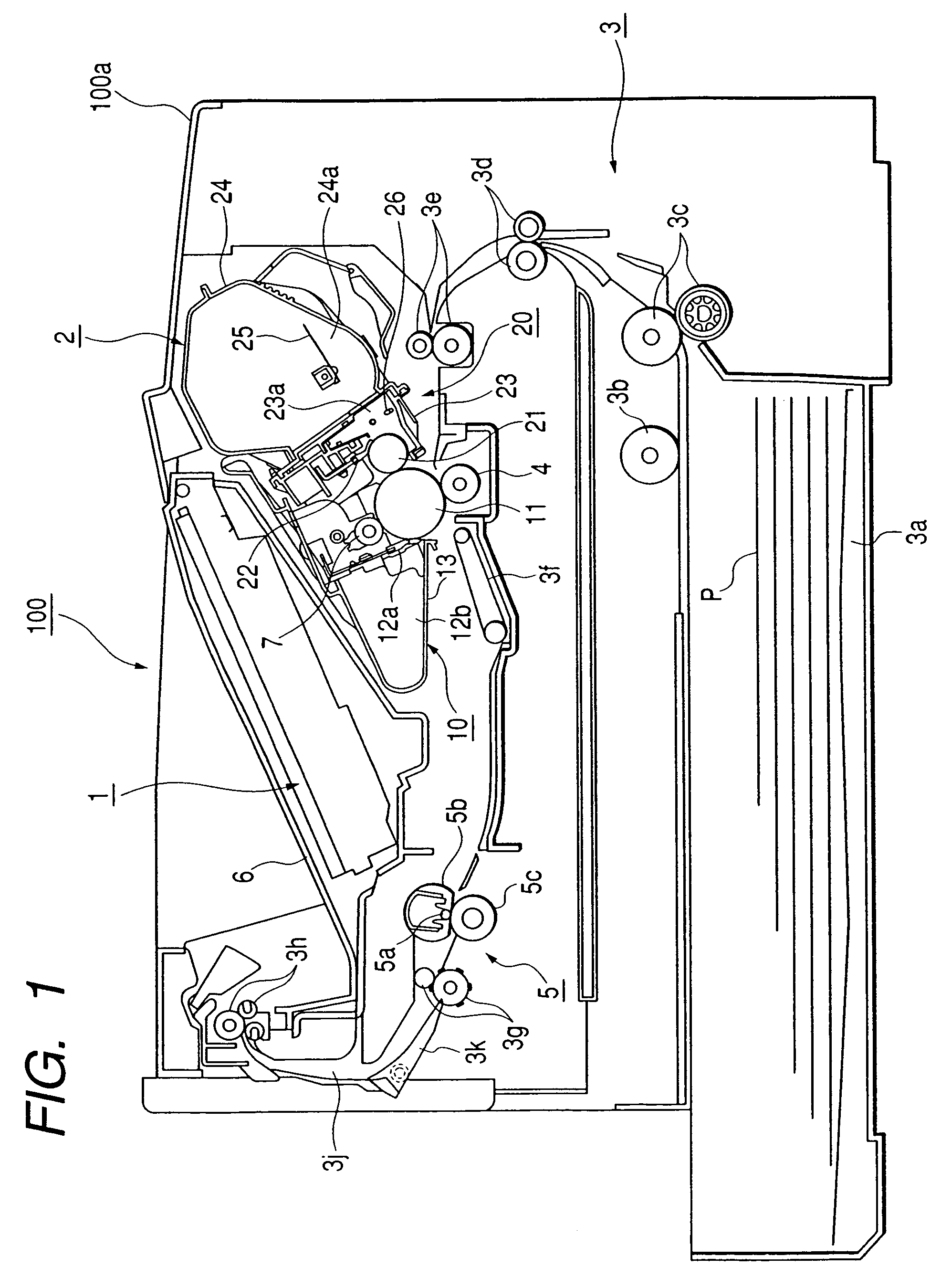

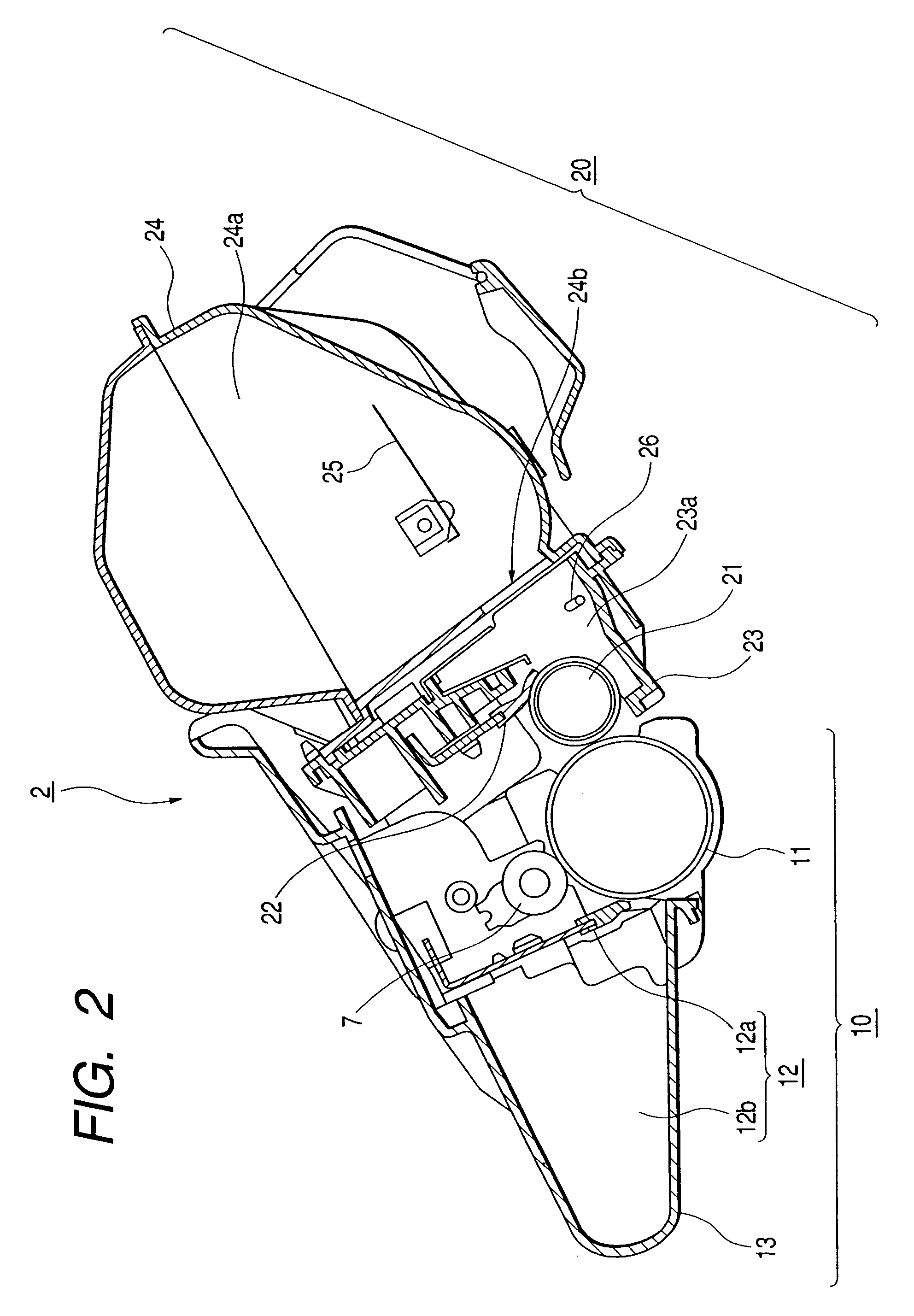

Information storing medium, unit, process cartridge, developing cartridge, and electrophotographic image forming apparatus

InactiveUS7082276B2Save spaceSmall sizeElectrographic process apparatusClamped/spring connectionsElectricityBiomedical engineering

The information storing medium has a substrate, a storing element, provided on the substrate, for storing information, a protecting portion, covering the storing element, for protecting the storing element, an electrical contact point that is provided beside the protecting portion on a side of the substrate, on which the storing element is provided, and is electrically connected to the storing element, and a sliding region that is provided on the electrical contact point. In the information storing medium, when the storing medium is mounted on the apparatus main body, the electrical contact point contacts a main body electrical contact point provided on the apparatus main body. Also, when the electrical contact point and the main body electrical contact point contact each other, the main body electrical contact point slides on the electrical contact point in the sliding region.

Owner:CANON KK

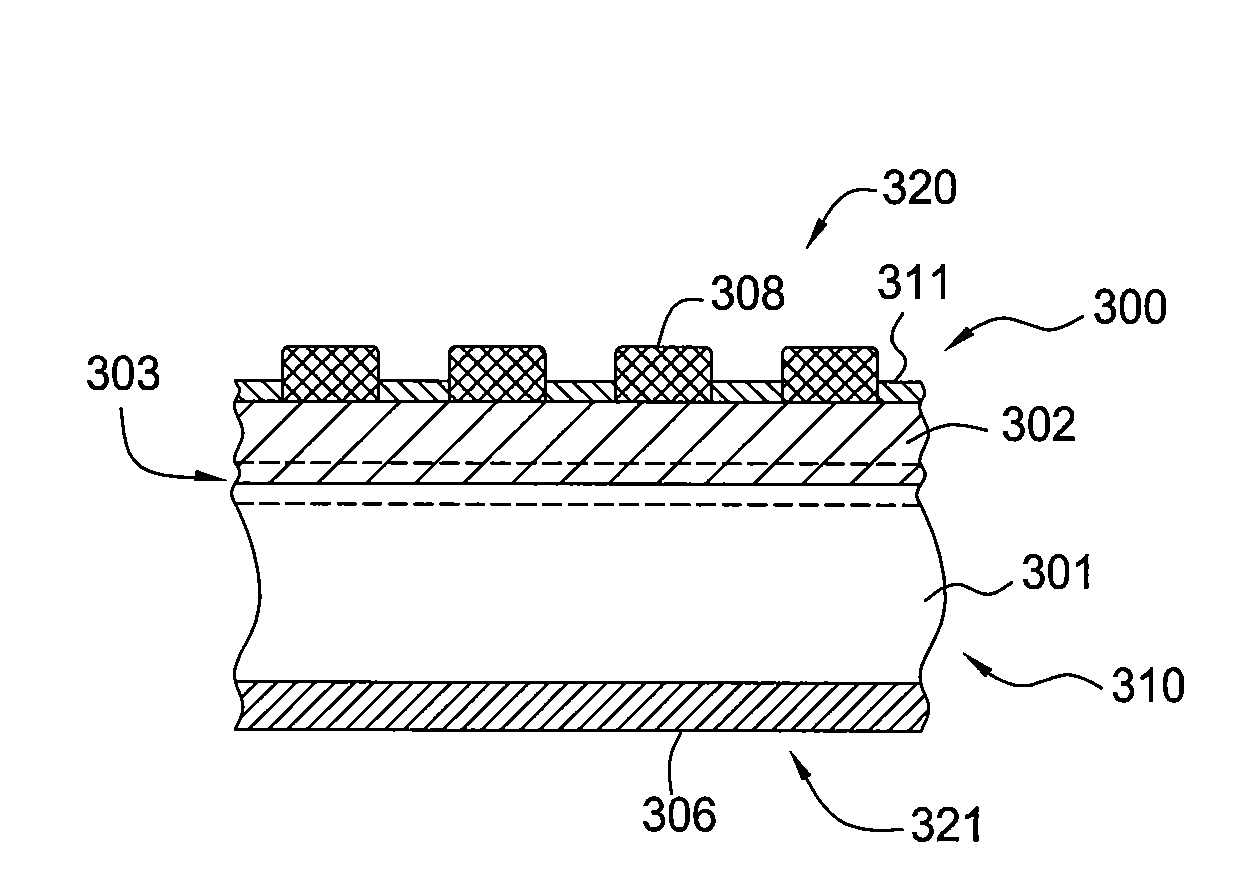

Back-Contact Photovoltaic Cells

A photovoltaic cell comprising a wafer comprising a semiconductor material of a first conductivity type, the wafer comprising a first light receiving surface and a second surface opposite the first surface; a first passivation layer positioned over the first surface of the wafer; a first electrical contact comprising point contacts positioned over the second surface of the wafer and having a conductivity type opposite to that of the wafer; and a second electrical contact comprising point contacts and positioned over the second surface of the wafer and separated electrically from the first electrical contact and having a conductivity type the same as that of the wafer.

Owner:BP CORP NORTH AMERICA INC

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

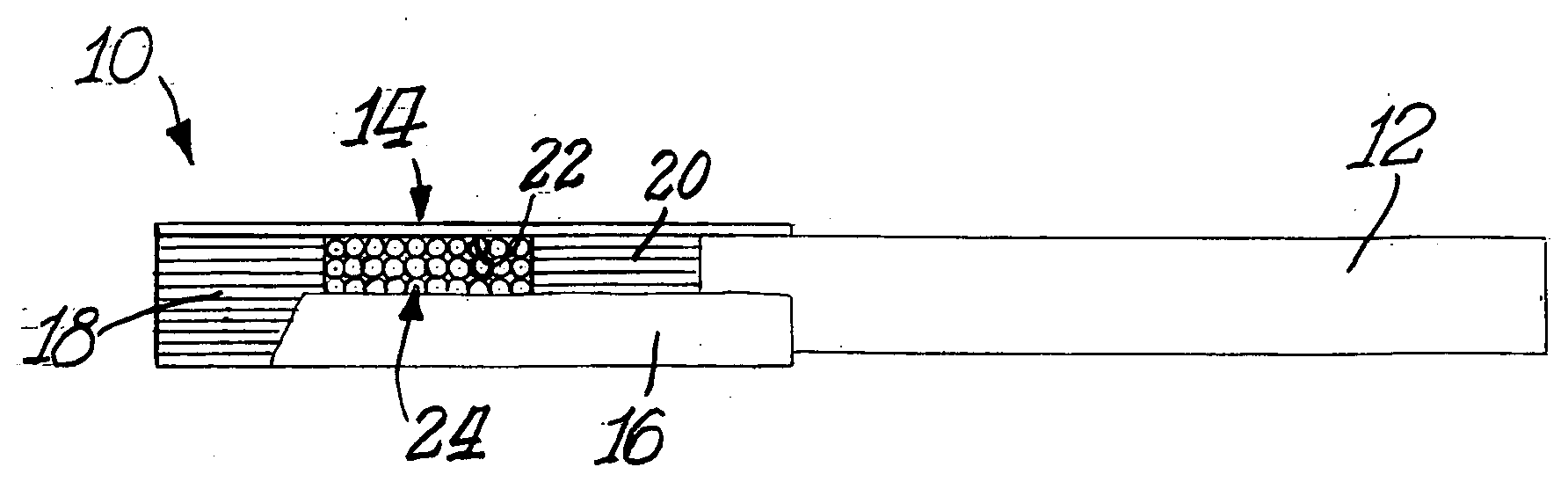

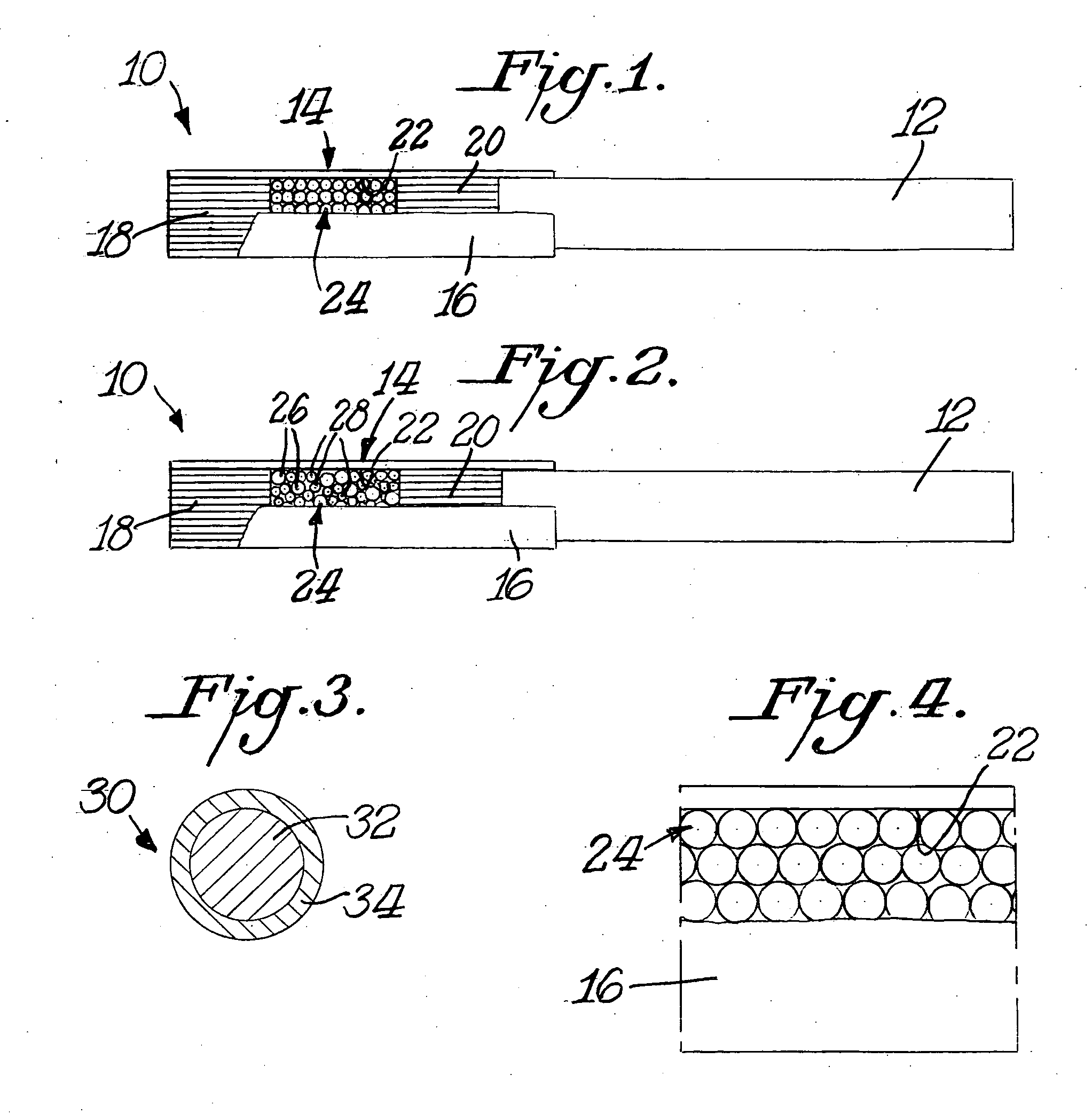

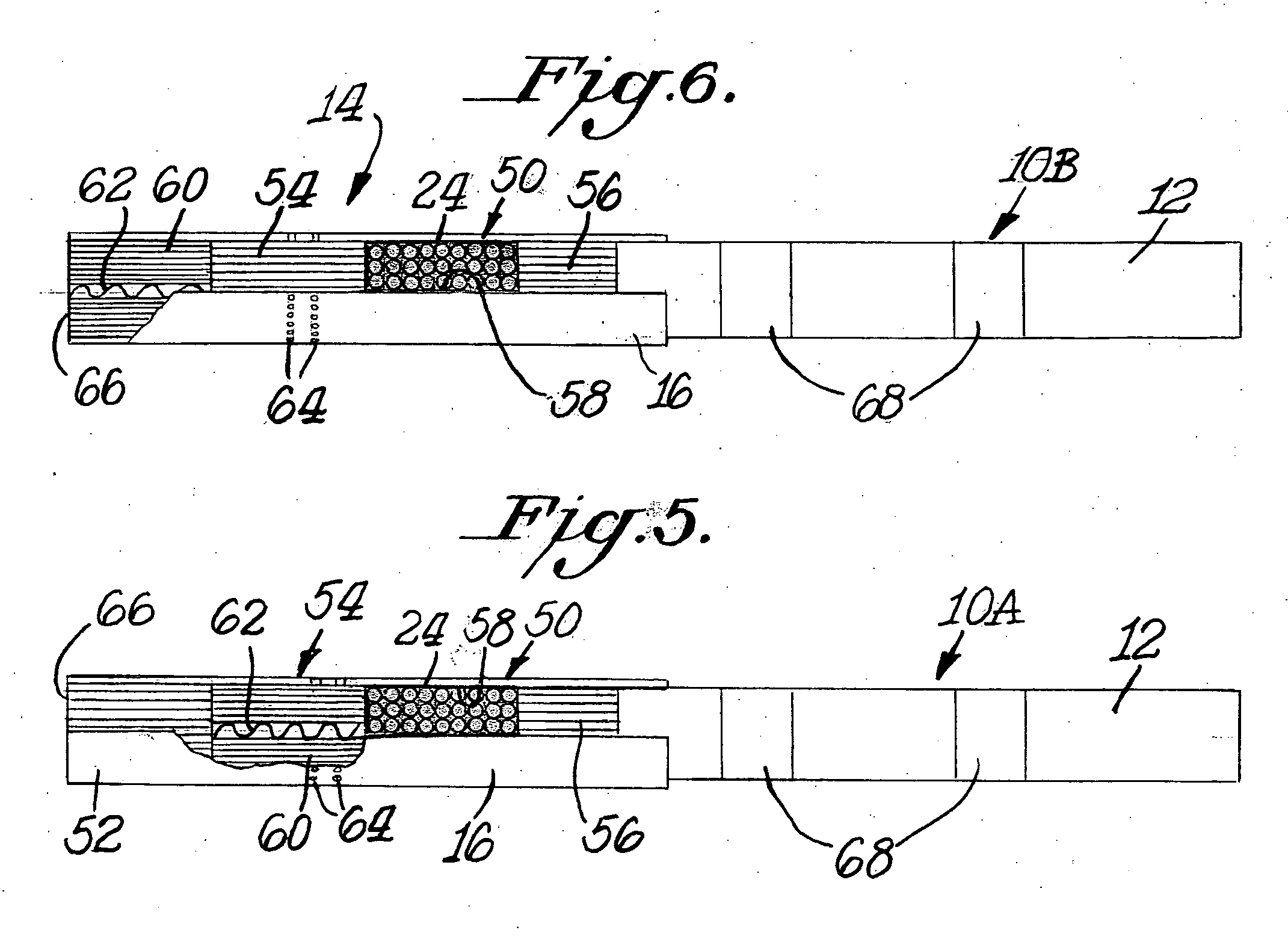

Cigarette filter with beaded carbon

ActiveUS20060180164A1Efficiently and effectively adsorbingAvoid excessive impactTobacco treatmentCigar manufactureGas phaseEngineering

A smoking article such as a cigarette comprises a tobacco rod and a filter component having a cavity filled with spherical beaded carbon. As mainstream tobacco smoke is drawn through the filter component, targeted gas phase smoke constituents are removed as the smoke passes through the carbon. During the filter manufacturing process the spherical beaded carbon flows like a liquid and substantially completely fills the cavity. Point-to-point contact between the spherical beads together with substantially complete filling of the cavity produces minimal channeling of ambulatory gas phase as well as maximum contact between the gas phase and the carbon surface of the spherical beads during smoking.

Owner:PHILIP MORRIS USA INC

Conduit connector assembly

ActiveUS7390979B1Easy to processEasy to assembleBranching pipesMulti-purpose toolsEdge surfaceEngineering

A conduit connector assembly which receives an end of a conduit carrying electrical wires includes a body, a grommet and a spring clip. The grommet and the spring clip are each mounted to the body. The spring clip is disposed within an interior bore of the fitting body and has a resiliently flexible body and a leg having a gripping end portion. The grip end has a substantially scalloped configuration for gripping and fitting partially about the conduit so as to center the grip end of the spring clip body on the conduit. The spring clip also includes a latching member to couple with the body to hold the spring clip in position and apply a biasing tension of the gripping end of the leg against the conduit. The grip end having the scalloped configuration is in the form of an arcuate concave-shaped edge surface on the gripping end portion of the body. The grip end of the spring clip body makes line contact with an inner convolution on an exterior of the conduit and makes at least a single point contact with an outer convolution on the exterior of the conduit. The grip end may be disposed at a predetermined angle for matching a predetermined pitch angle of the convolutions on the exterior of the conduit and thereby make line contact with the inner convolution on the exterior of the conduit and make a pair of point contacts with the outer convolution on the exterior of the conduit.

Owner:HUBBELL INC

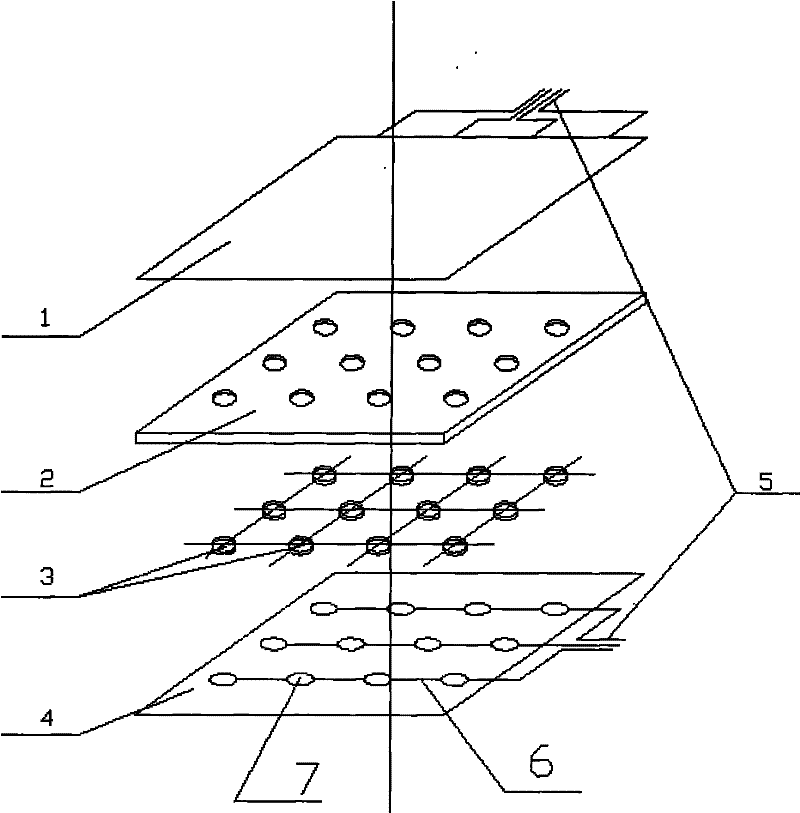

Conductive-rubber-based flexible array clip pressure sensor and manufacturing method

InactiveCN102207415AReduce weightLow costForce measurement using piezo-resistive materialsOther printing apparatusElectrical resistance and conductanceScreen printing

The invention relates to a conductive-rubber-based flexible array clip pressure sensor and a manufacturing method. In the conductive-rubber-based flexible array clip pressure sensor, upper and lower electrode wires and electrode rings are printed on an upper electrode layer and an electrode layer; the electrode ring is provided with a rubber voltage-sensitive unit; a silicon rubber liner is arranged at the position where sensitive elements do not exist; the rubber voltage-sensitive unit is nested into the silicon rubber liner; the upper and lower electrode wires are led and connected to an electrode lead-out head; the upper and lower electrode layers are sealed by high viscose; and when force acts on the rubber voltage-sensitive unit, the rubber voltage-sensitive unit is compressed and deformed due to stress, so a resistance value of the rubber voltage-sensitive unit is changed, and pressure or concentrated loads at the point contact position can be reflected according to the variablequantity of the resistance value on the rubber voltage-sensitive unit relative to an initial resistance value. By a manufacturing method based on a silk-screen printing process, the flexible array clip sensor has the characteristics of light weight, low cost, simple manufacturing and mass production, and is long in service life and convenient to operate.

Owner:XI AN JIAOTONG UNIV

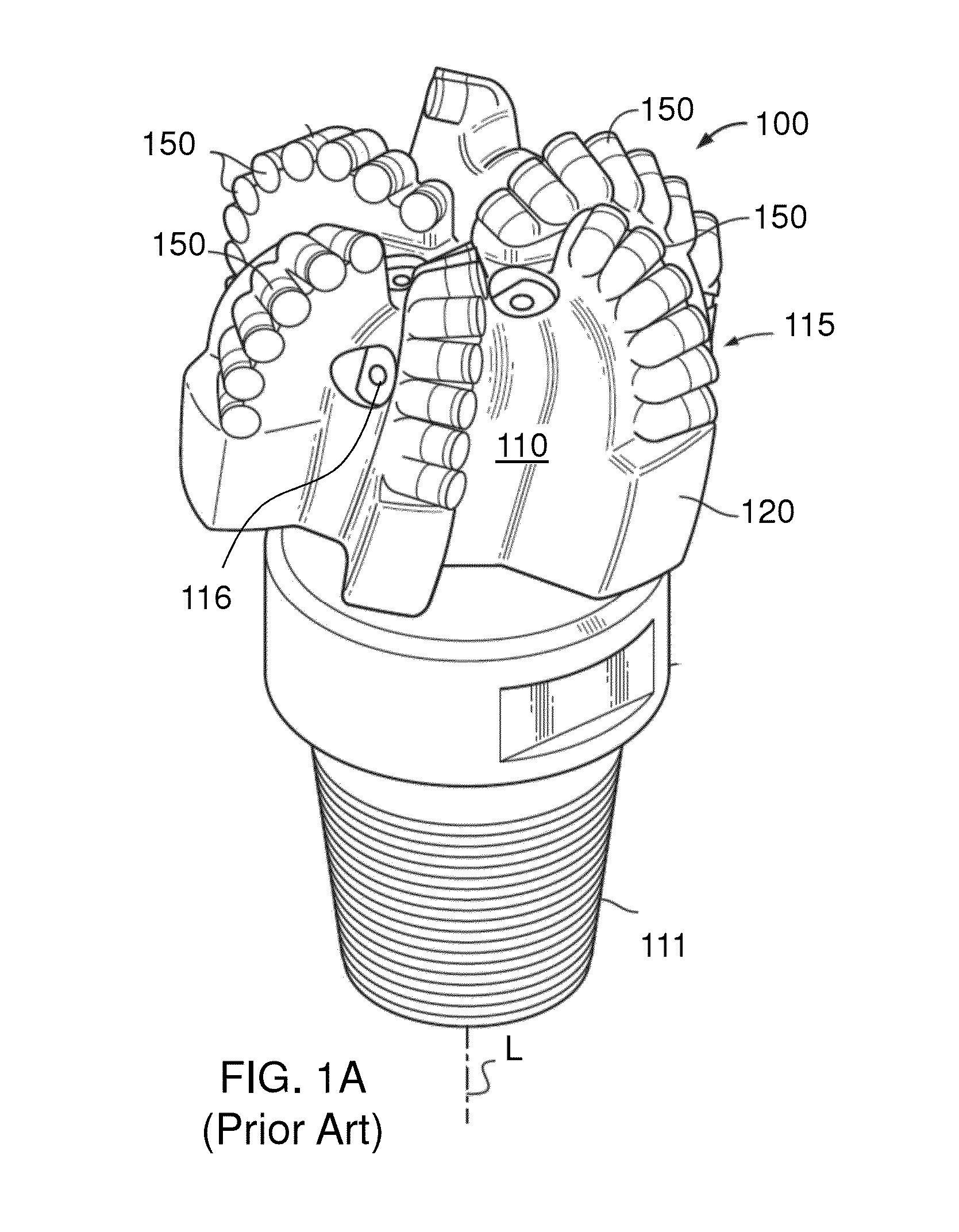

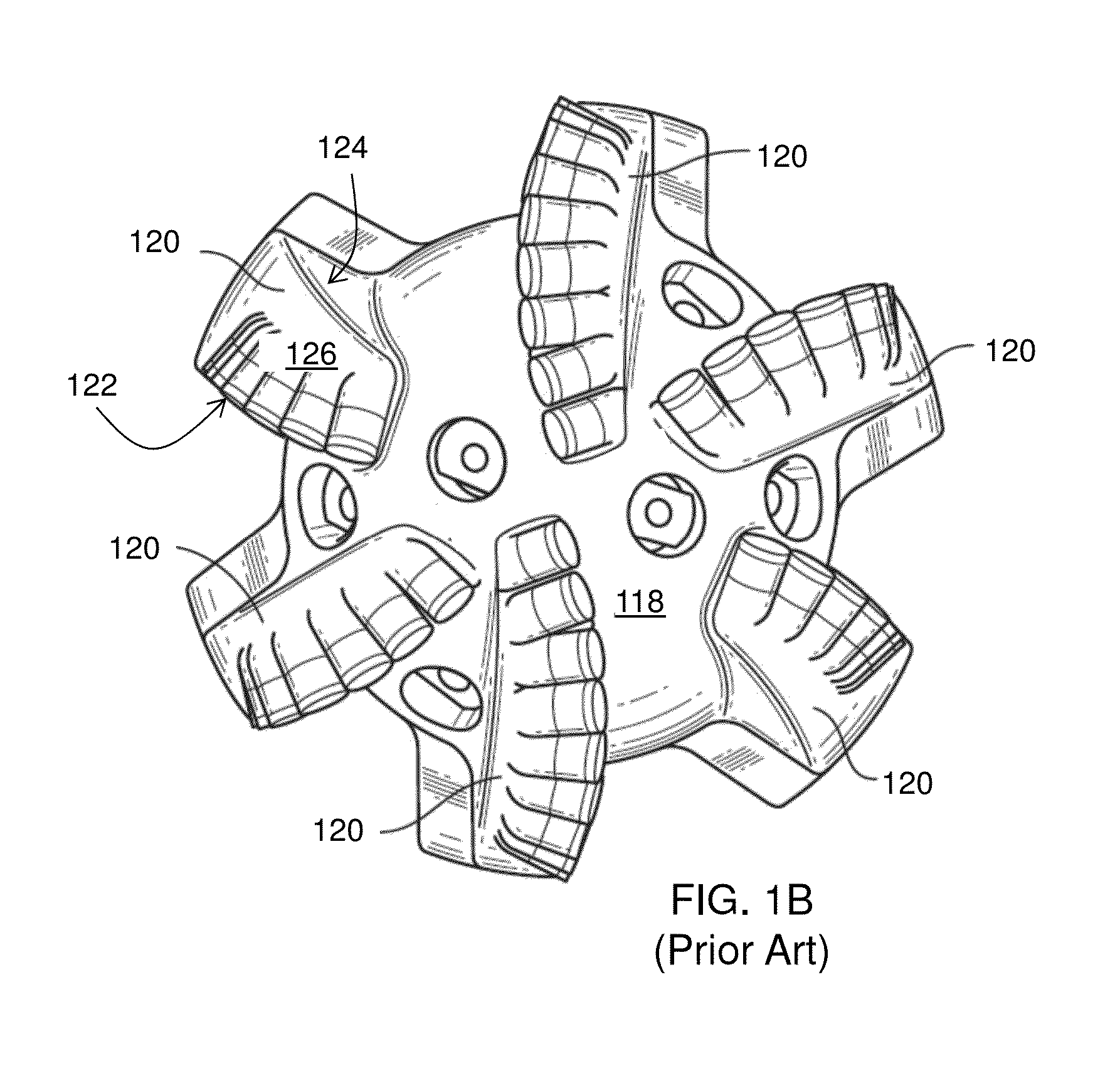

Rolling cutter with improved rolling efficiency

A cutting structure may include an outer support element; and an inner rotatable cutting element comprising a cutting surface at its upper end; wherein the inner rotatable cutting element comprises at least one line contact along a circumferential side surface thereof and / or at least one point contact at a bottom face thereof.

Owner:SMITH INT INC

Prediction of atrial wall electrical reconnection based on contact force measured during RF ablation

InactiveUS20160095653A1Easy to predictEffective isolation lineDiagnosticsCatheterRf ablationAtrial wall

A method and device for determining the transmurality and / or continuity of an isolation line formed by a plurality of point contact ablations. In one embodiment, a method for determining the size of a lesion (width, depth and / or volume) is disclosed, based on contact force of the ablation head with the target tissue, and an energization parameter that quantifies the energy delivered to the target tissue during the duration time of the lesion formation. In another embodiment, the sequential nature (sequence in time and space) of the ablation line formation is tracked and quantified in a quantity herein referred to as the “jump index,” and used in conjunction with the lesion size information to determine the probability of a gap later forming in the isolation line.

Owner:ST JUDE MEDICAL INT HLDG SARL

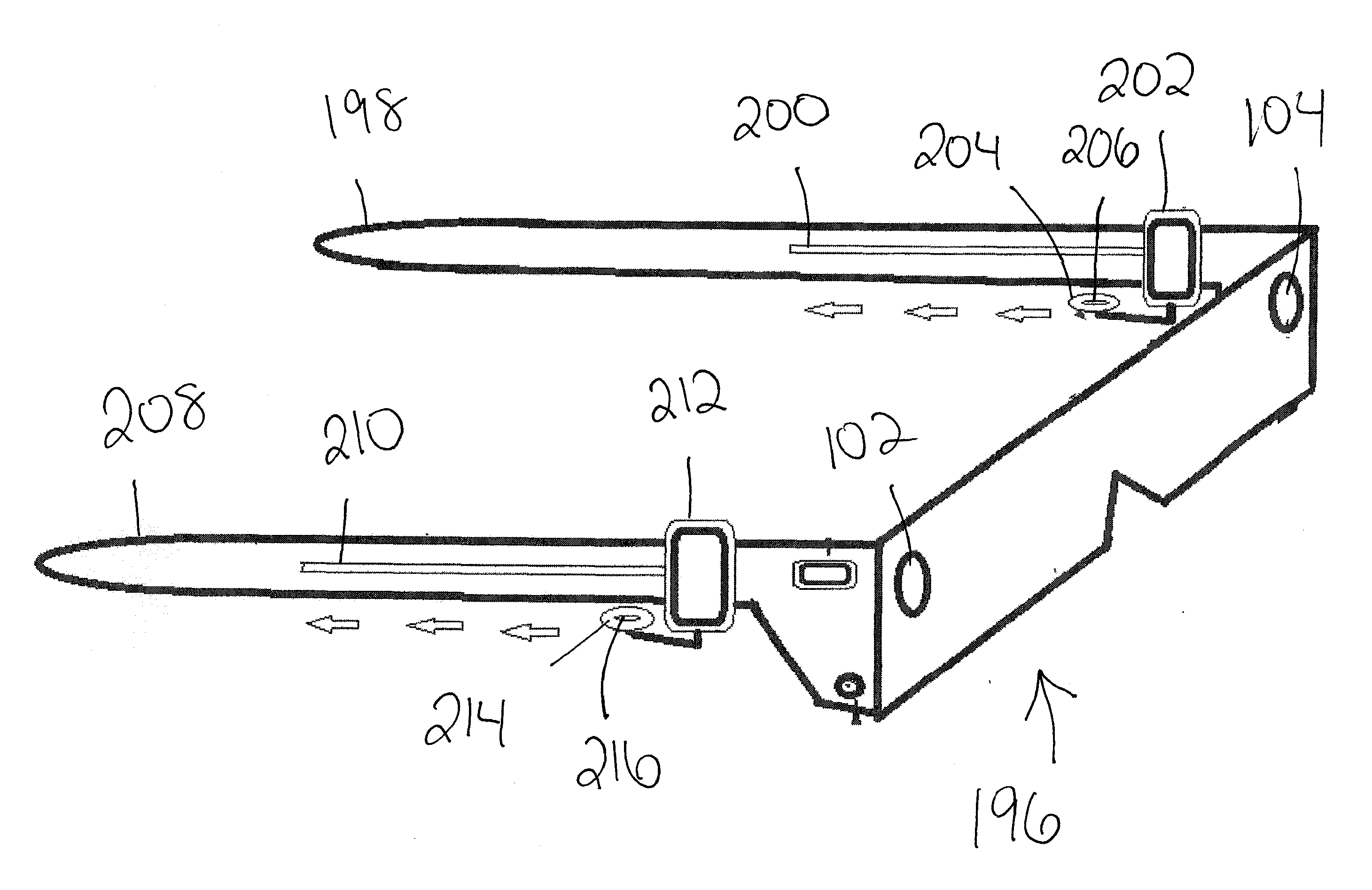

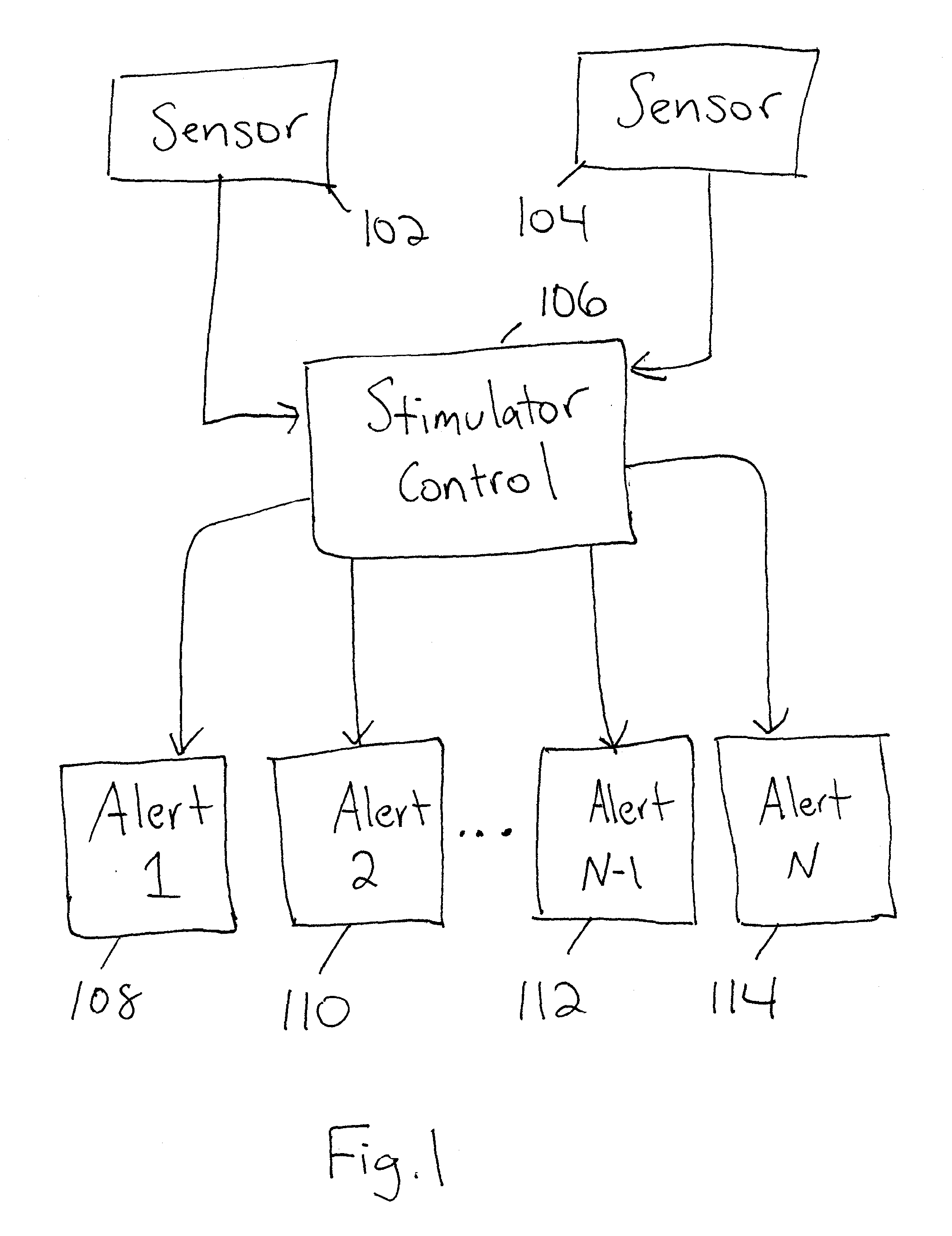

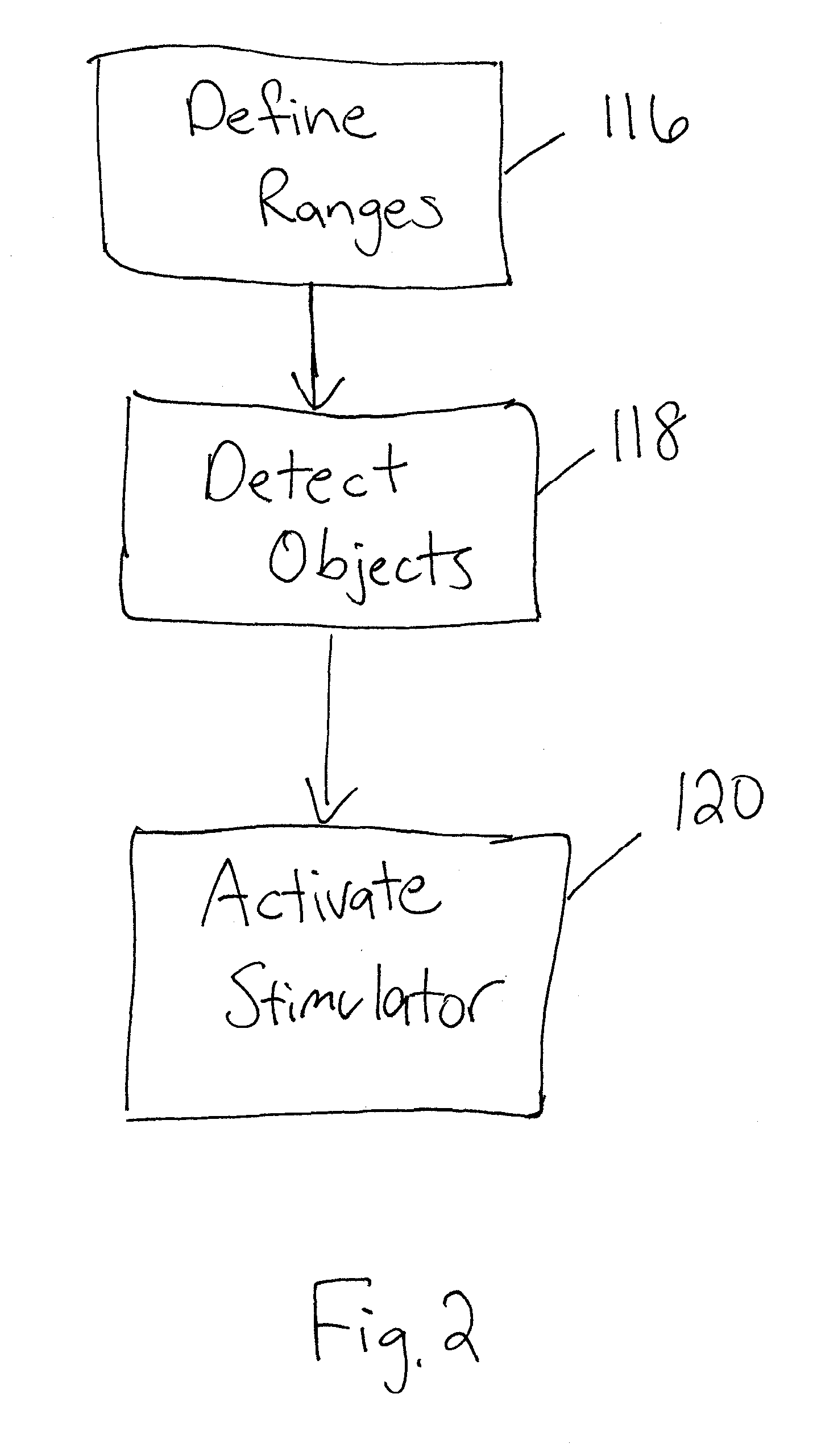

Object detection device

ActiveUS20130044005A1More experienceMore protective effectSignalling system detailsVisible signalling systemsProximity sensorHuman–computer interaction

When the sight impaired become mobile, they often bump their heads on unseen objects and / or hazards that could result in injury. The object detection device uses signal emitting proximity sensors that alert the user to unseen objects. The object detection device notifies the user of detected objects. Stimulators contact the user to warn the user that an object has been detected and the distance between the object and the user. Each stimulator contacts the user at a specific contact point. The stimulator finger contacting the user at a specific contact point informs the user of the distance between the user and the detected object.

Owner:FOSHEE GEORGE BRANDON +1

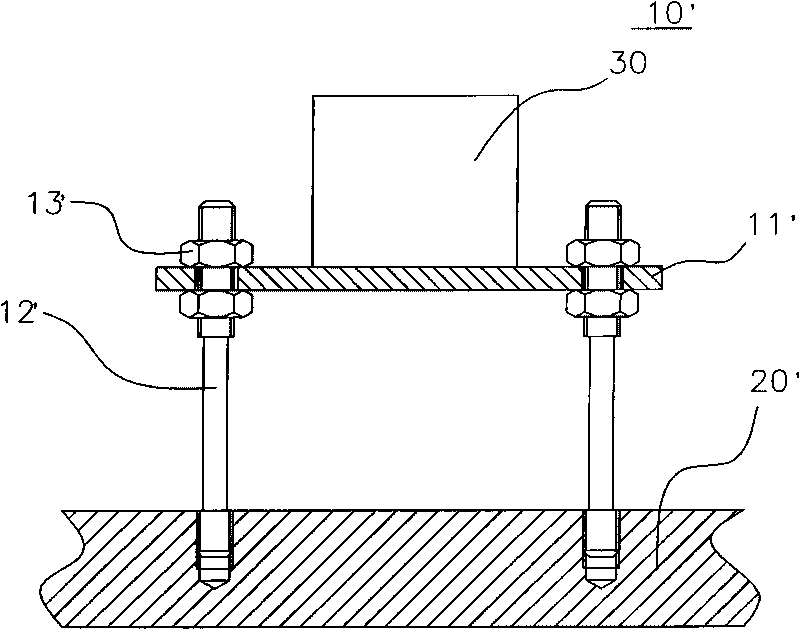

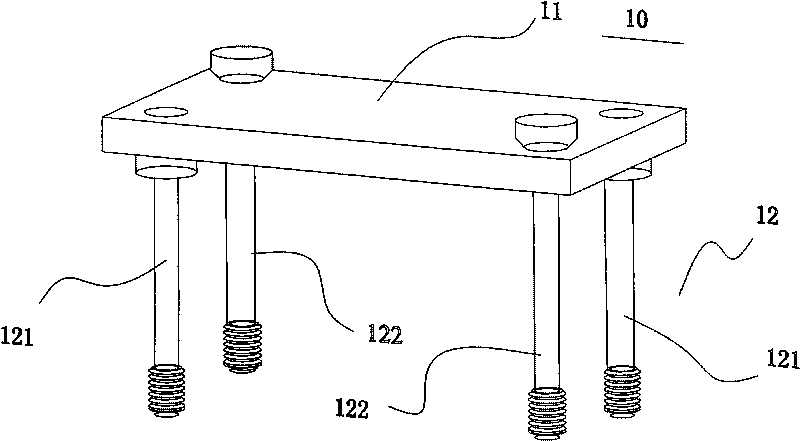

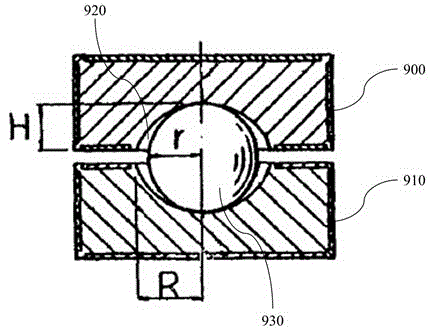

Adiabatic supporting device

ActiveCN101738127AGuaranteed stabilityReduce thermal contact areaHeat exchanger casingsEngineeringVacuum chamber

An adiabatic supporting device is used for supporting low temperature devices in a low temperature vacuum system. The supporting device comprises a cold platform with a plurality of mounting holes and support bars used for supporting the cold platform. The bottoms of the support bars are fixedly connected with a vacuum chamber. The support bars comprise upward ejecting support bars and downward pressing support bars. The upper parts of the upward ejecting support bars are matched with the mounting holes by way of point contact or line contact and the upward ejecting support bars provide upward ejecting force to the cold platform. After the downward pressing support bars pass through the mounting holes, the tops of the downward pressing support bars are matched with the mounting holes by way of point contact or line contact and the downward pressing support bars provide downward pressing force to the cold platform. The upward ejecting force reaches equilibrium with the downward pressing force. The supporting device furthest reduces the heat contact area under the premise of ensuring the stability of the mechanical structure and changes from the original nut surface contact to the current line contact or point contact, thus reducing heat leakage from the vacuum chamber to the cold platform and greatly reducing heat load.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Point contact array, not circuit, and electronic circuit comprising the same

A NOT circuit realized using an atomic switch serving as a two terminal device and including a first electrode made of a compound conductive material having ionic conductivity and electronic conductivity and a second electrode made of a conductive substance. Ag2S, Ag2Se, Cu2S, or Cu2Se is preferably used as the compound conductive material.

Owner:JAPAN SCI & TECH CORP

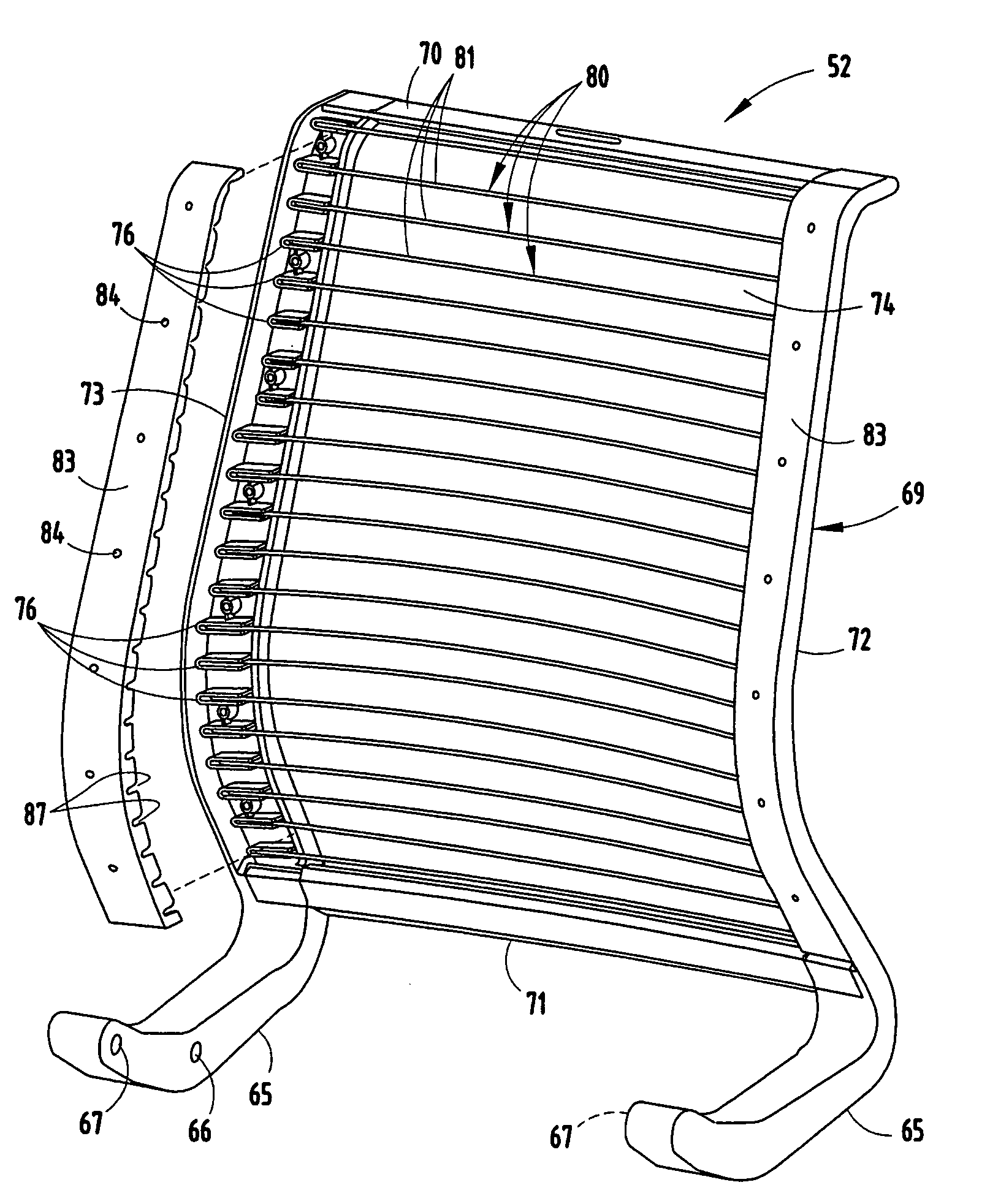

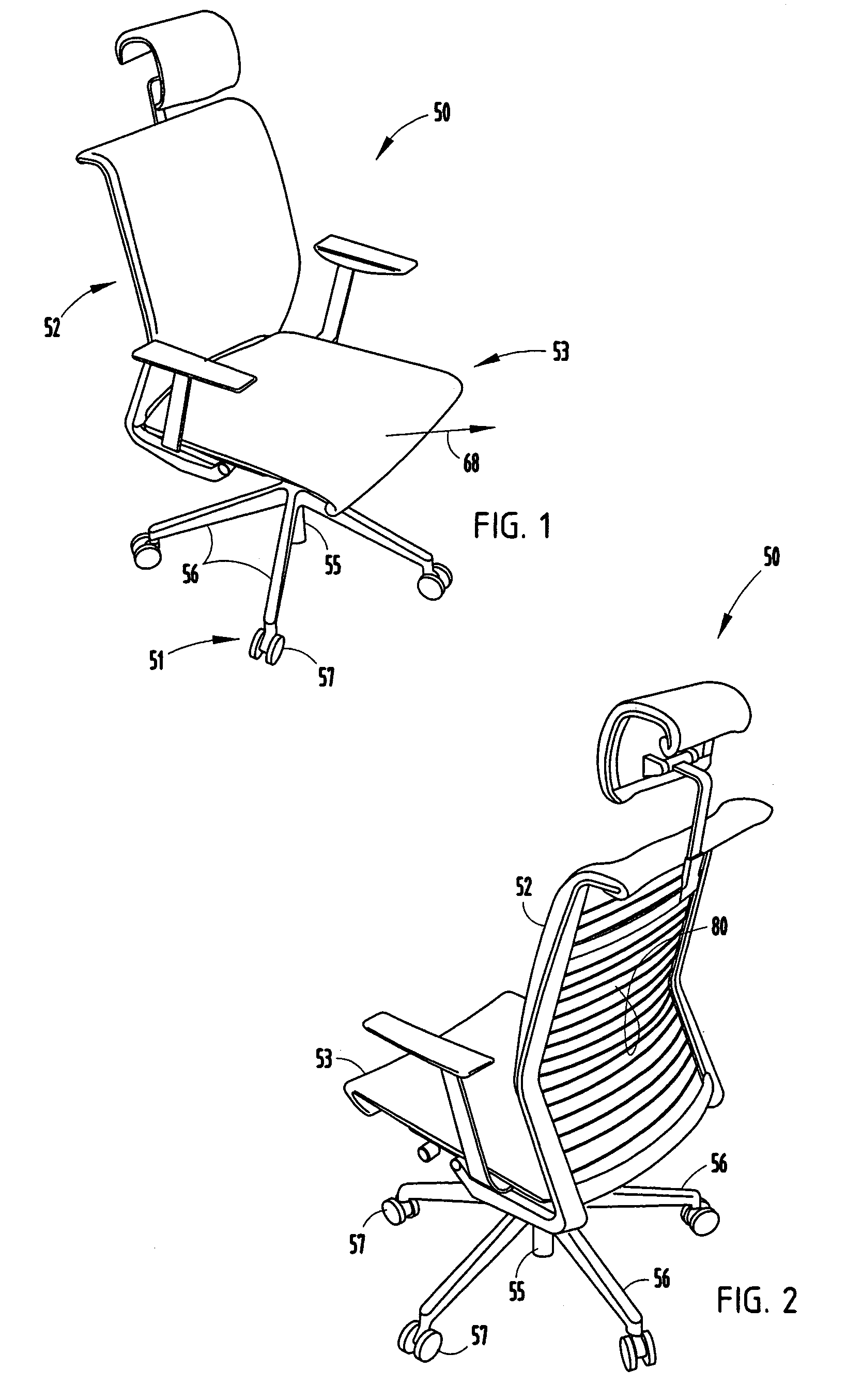

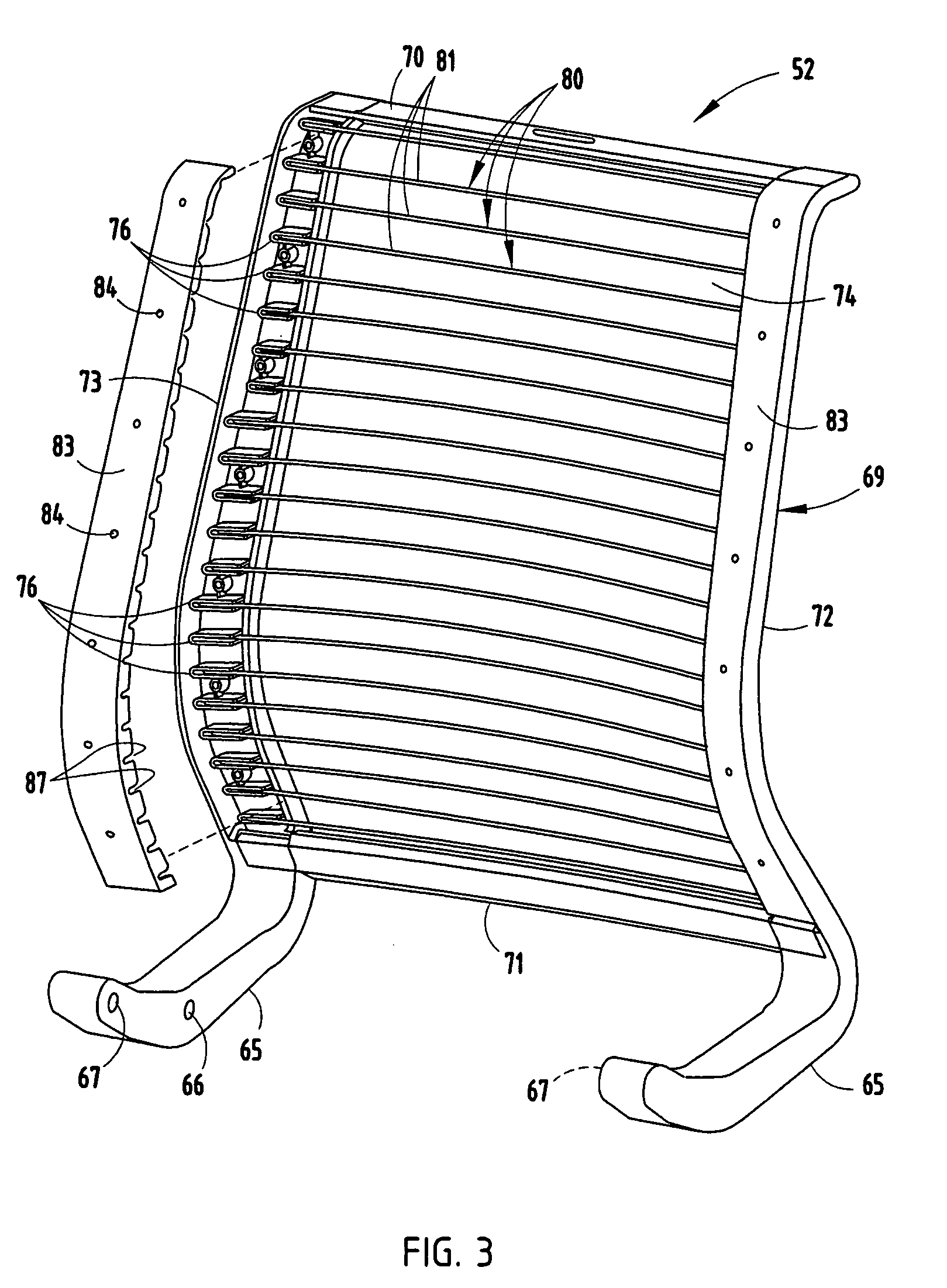

Comfort surface for seating

ActiveUS7334845B2Reduce localized deflection of seating surfaceReduce point contact pressureStoolsRocking chairsWire rodEngineering

A seating unit includes a perimeter frame, a flexible seating surface supported by the frame, and parallel elongated resilient force-distributing members coupled to the seating surface to control a contour of the seating surface when supporting a seated user. The resilient force-distributing members are bendable along their length and are sufficient in number and distribution to substantially reduce localized deflection of the seating surface and thereby reduce pressure point contact felt by the seated user. The resilient force-distributing members can be wire rods, long strips, or other resilient material with memory. The resilient force-distributing members can be supported on opposing sides of the perimeter frame in various ways to reduce inward pressure on the opposing sides during flexure of the resilient force-distributing members, such as by providing on ends of the resilient force-distributing members one or more rotatable pivots, sliding support at ends of the resilient force-distributing members, stretchable rubber supports, and / or elastic fabric.

Owner:STEELCASE INC

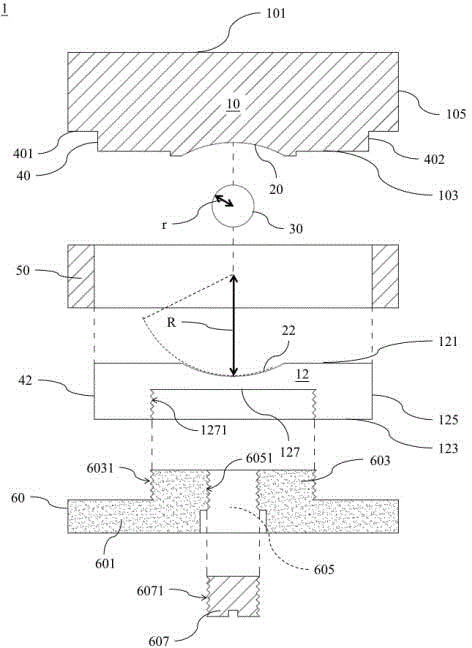

Vibration prevention footstand with alignment structure

InactiveCN105318150AEasy to installGood shockproofMachine framesNon-rotating vibration suppressionStructural engineeringPoint contact

A vibration prevention footstand with an alignment structure comprises an upper base, a lower base, a sphere and a sliding sleeve. The sphere is arranged in an arc groove formed between the upper base and the lower base and makes point contact with the arc groove to achieve the vibration prevention effect. In addition, due to an inclined plane configured on the upper base and the sliding sleeve, the upper base and the lower base can be easily aligned and centered, and unnecessary correcting time waste is avoided.

Owner:GAINIA SHANGHAI PATENT TECH LTD

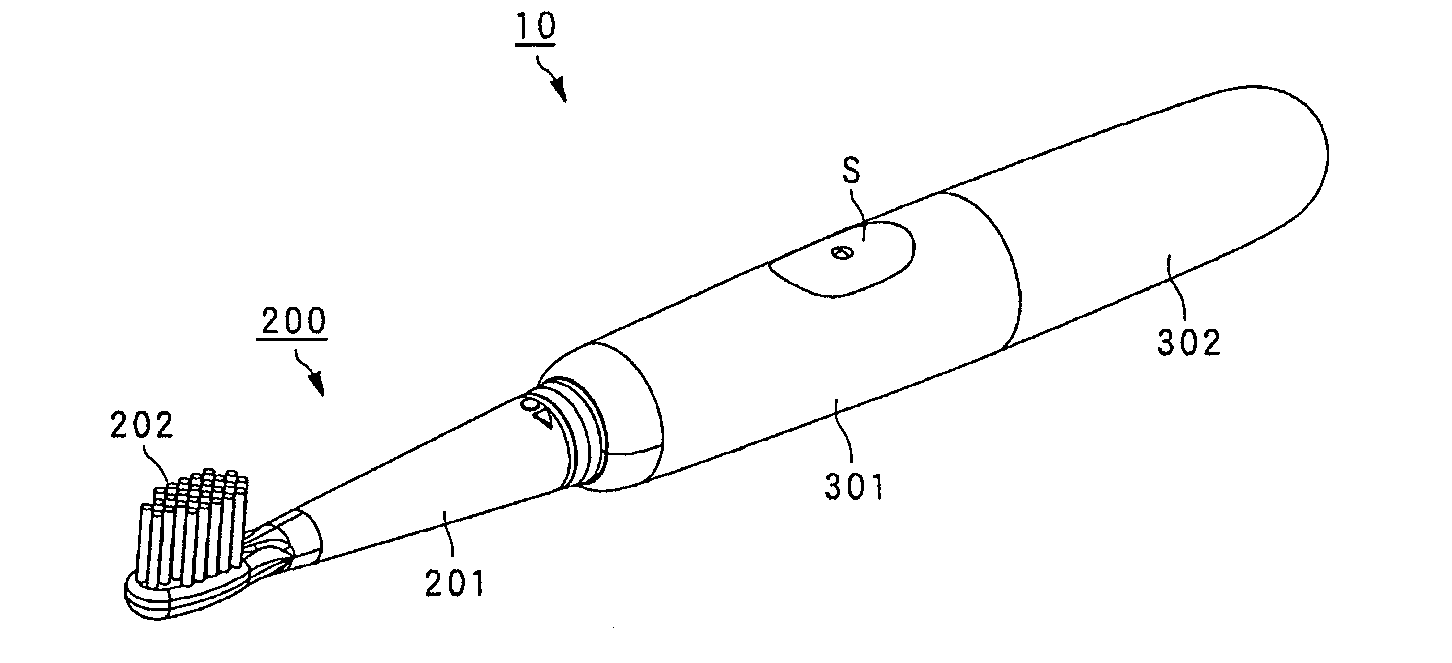

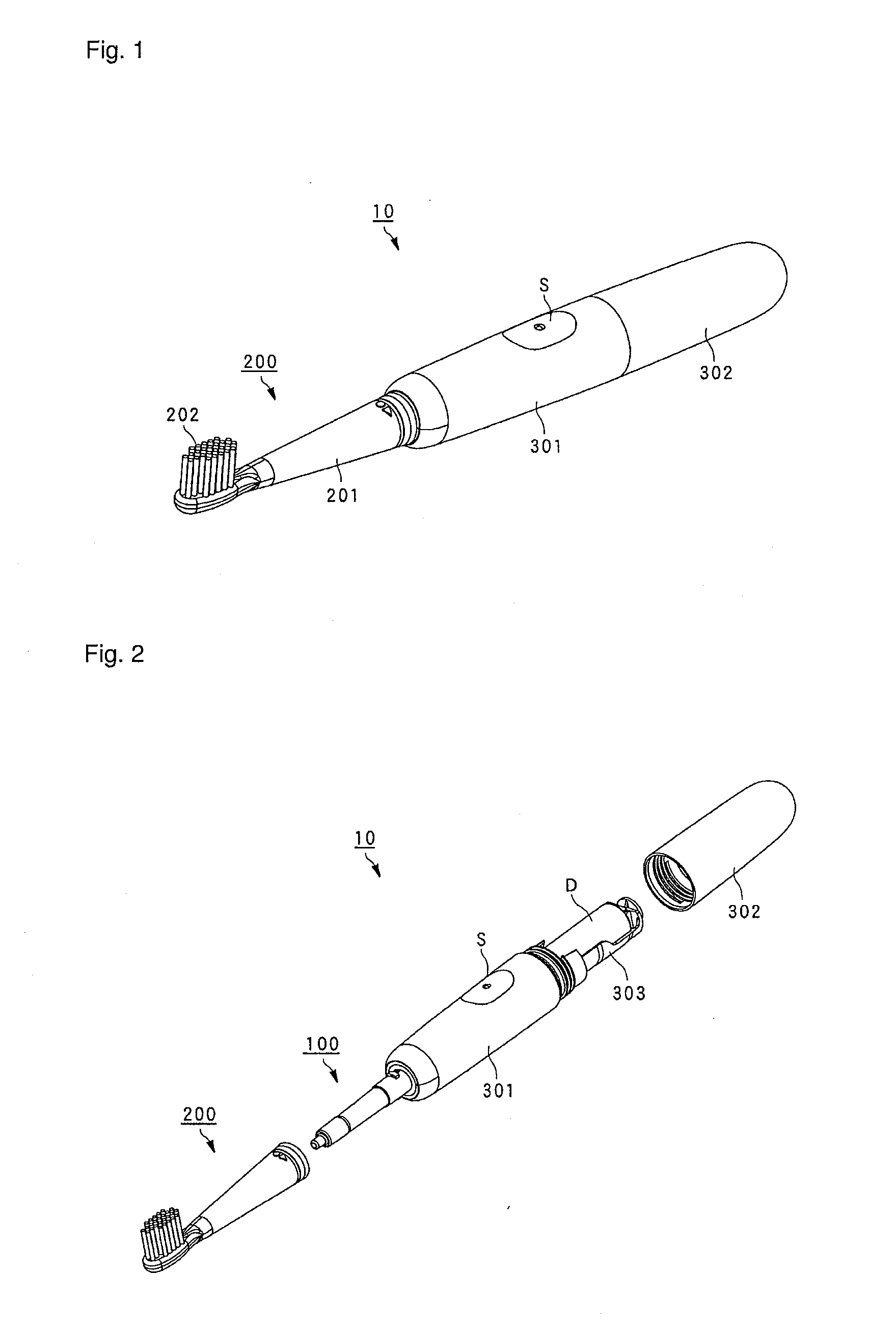

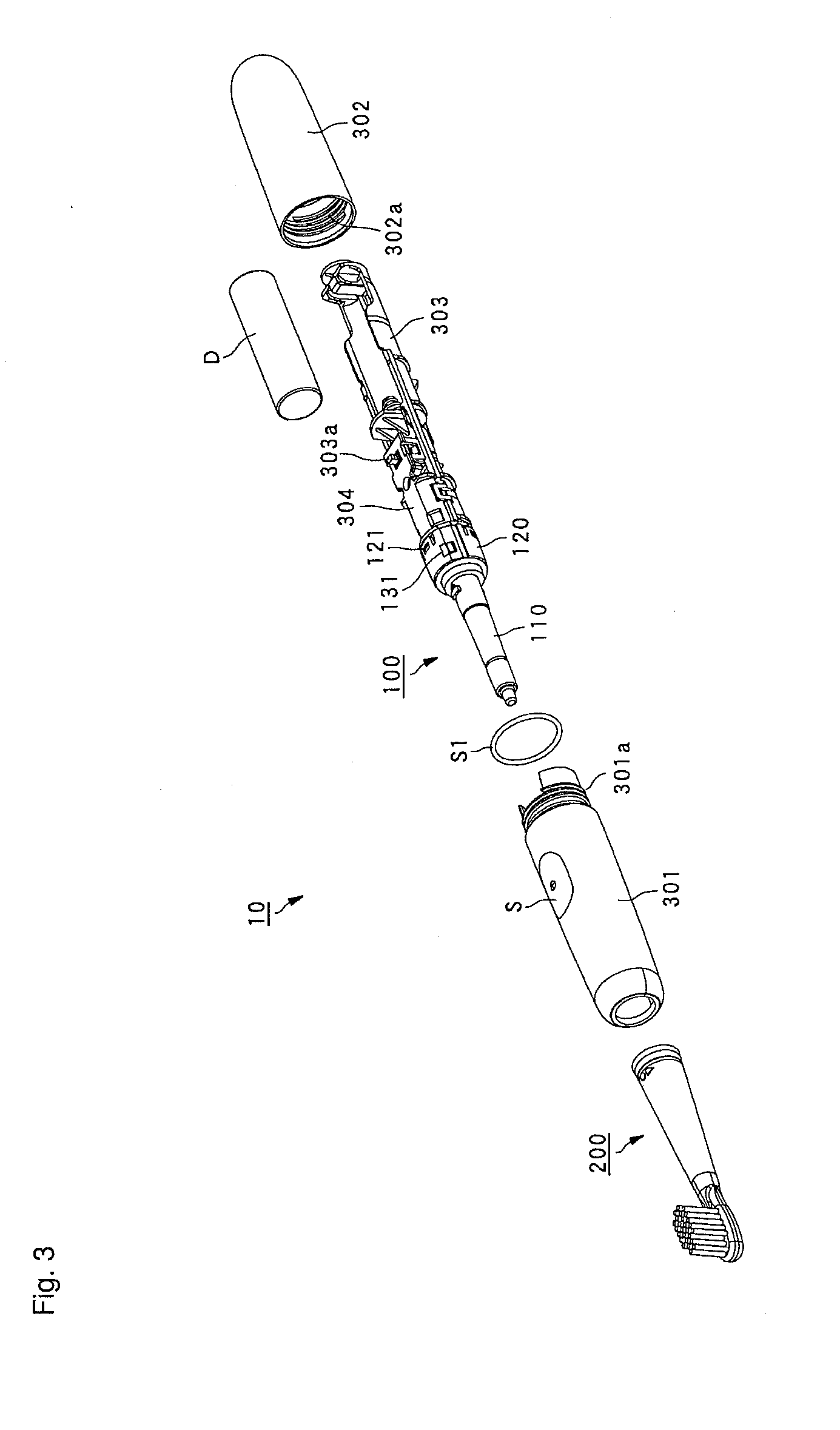

Electric toothbrush

ActiveUS20100269275A1Suppression in loss of vibration energyReduce vibrationCarpet cleanersBrush bodiesBrush toothEngineering

An electric toothbrush capable of suppressing loss of vibration energy while suppressing the vibration of the portion a user grips with hand is provided. In an electric toothbrush including an inner case, made up of an inner case main body and a motor holder, mounted with various components including a motor; an outer case which interiorly accommodates the inner case and which acts as a portion the user grips with hand when brushing teeth; an eccentric shaft, configured by a shaft main body and an eccentric member, which center of gravity is arranged at a position shifted from a shaft center and which rotates by a drive force of the motor; and a vibration transmitting component for transmitting the vibration generated with the rotation of the eccentric shaft to a brush portion; where the vibration transmitting component is positioned with respect to the outer case by point contacting the inner wall surface of the outer case at a plurality of locations.

Owner:OMRON HEALTHCARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com