Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1943results about "Force measurement using piezo-resistive materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

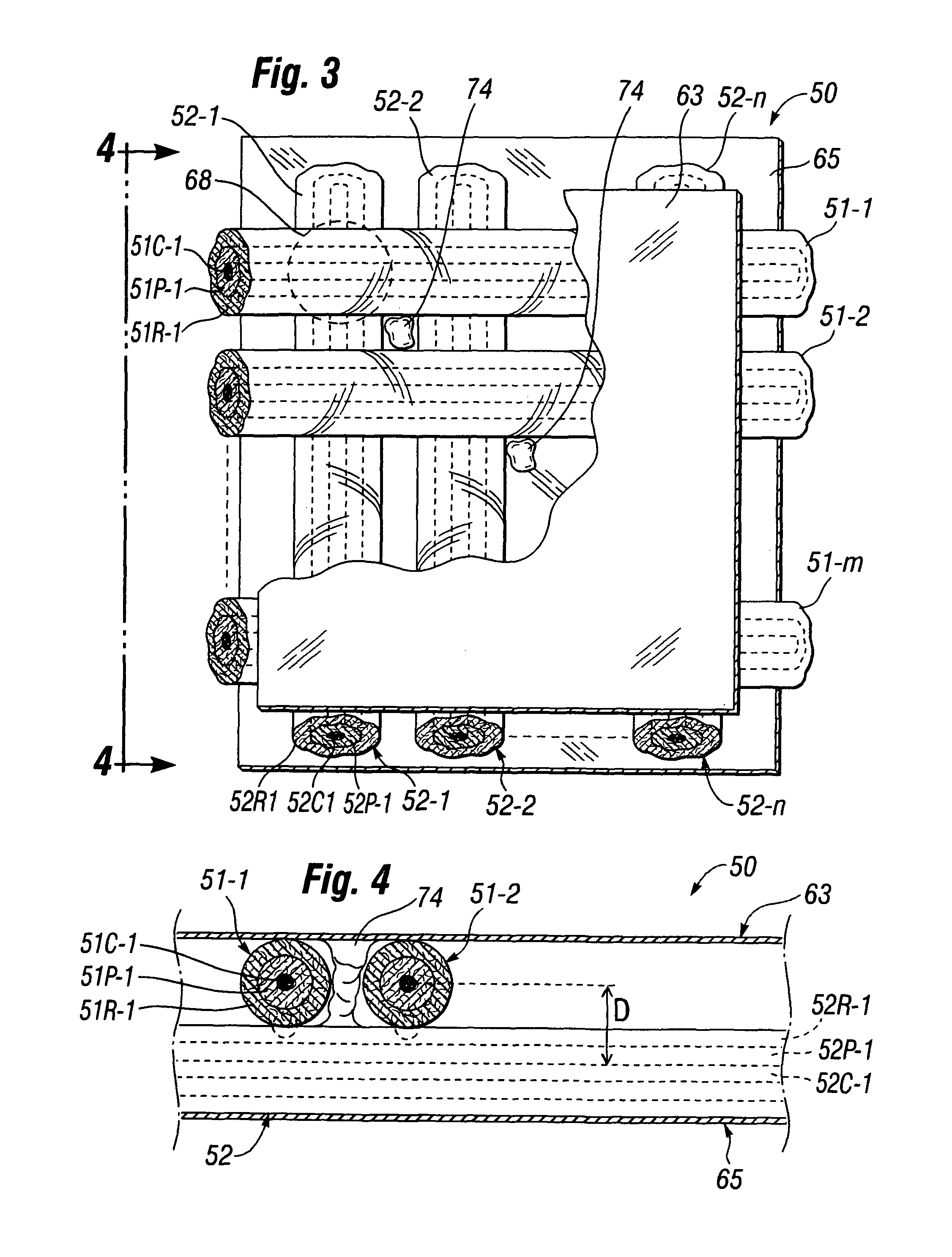

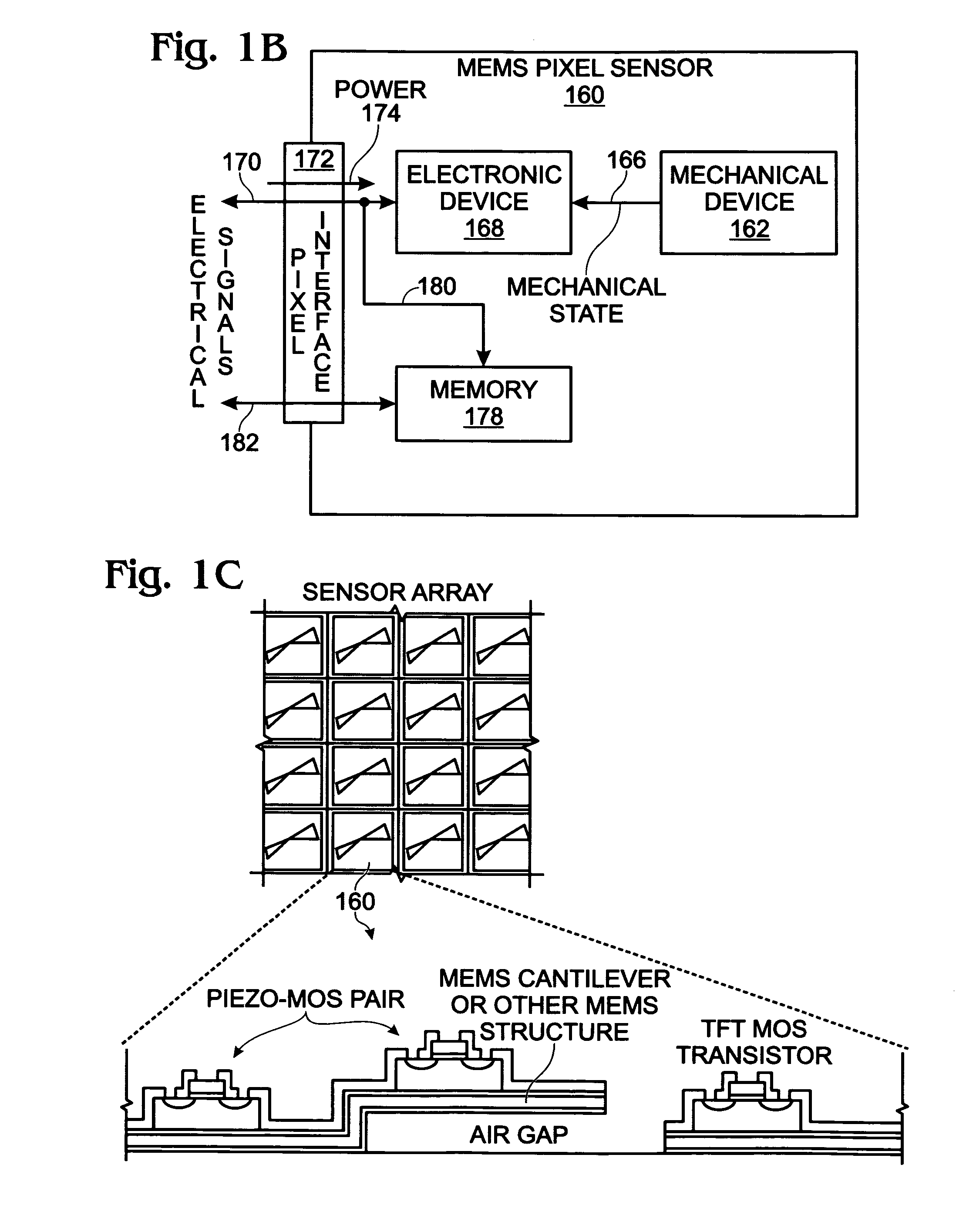

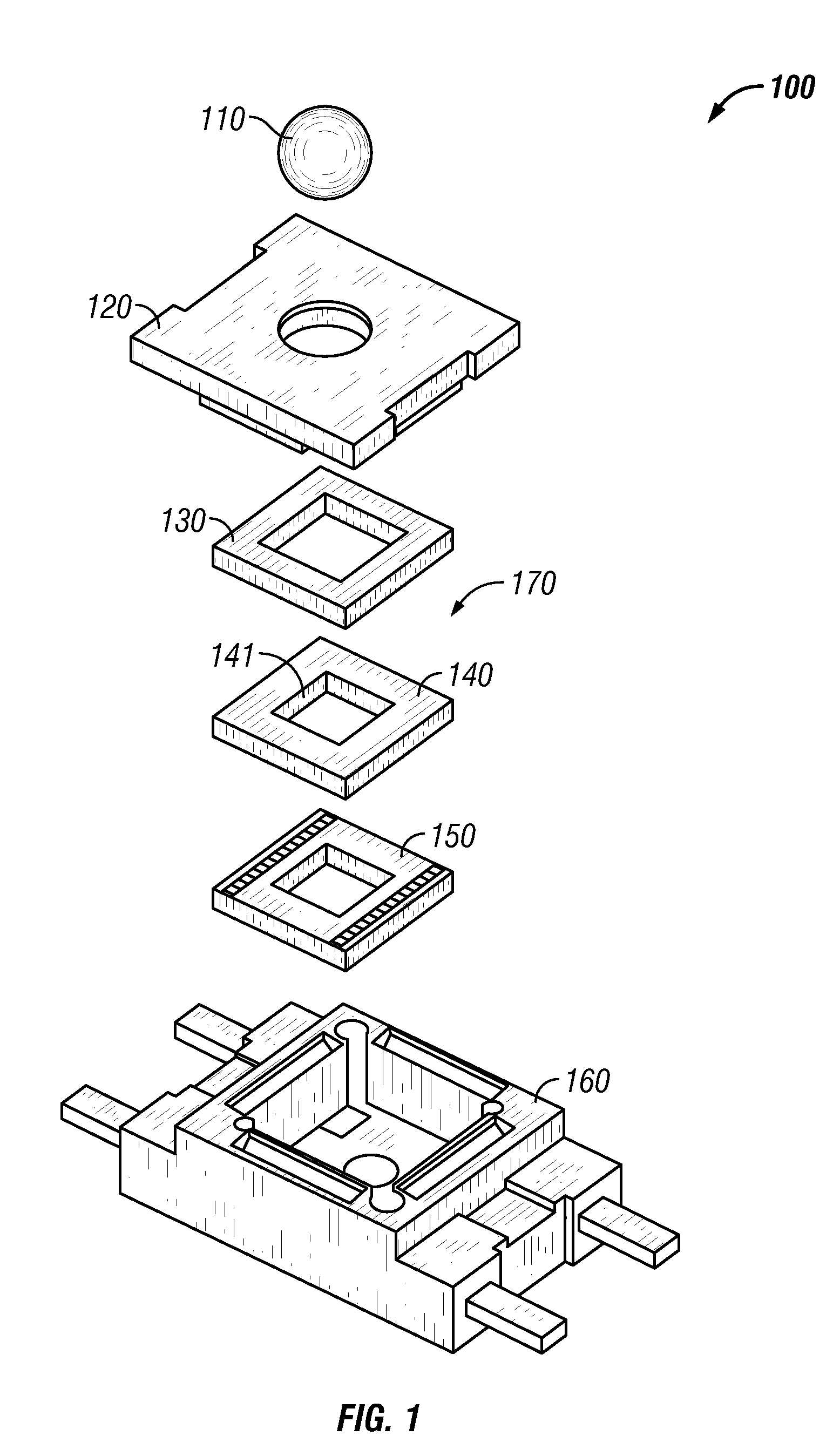

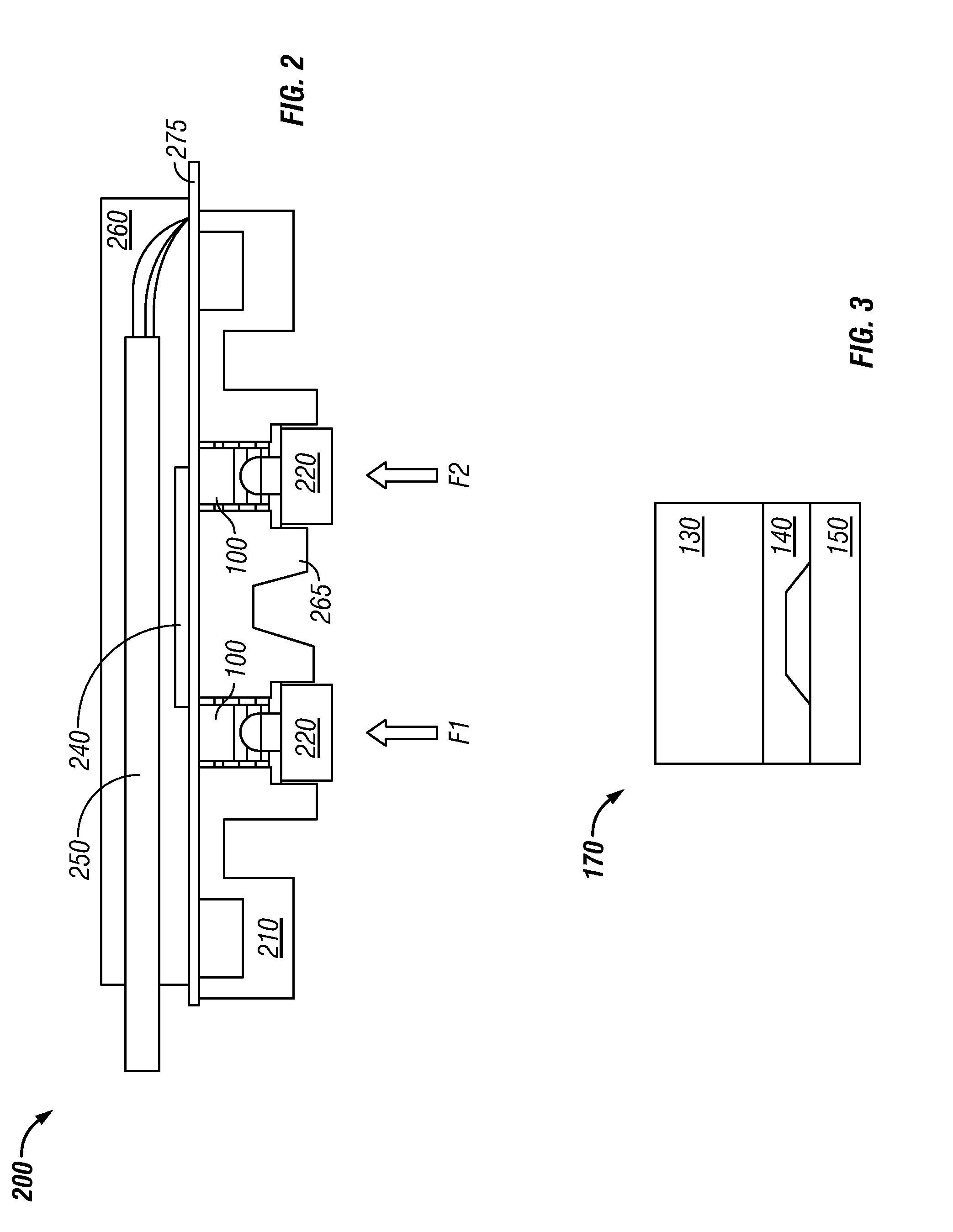

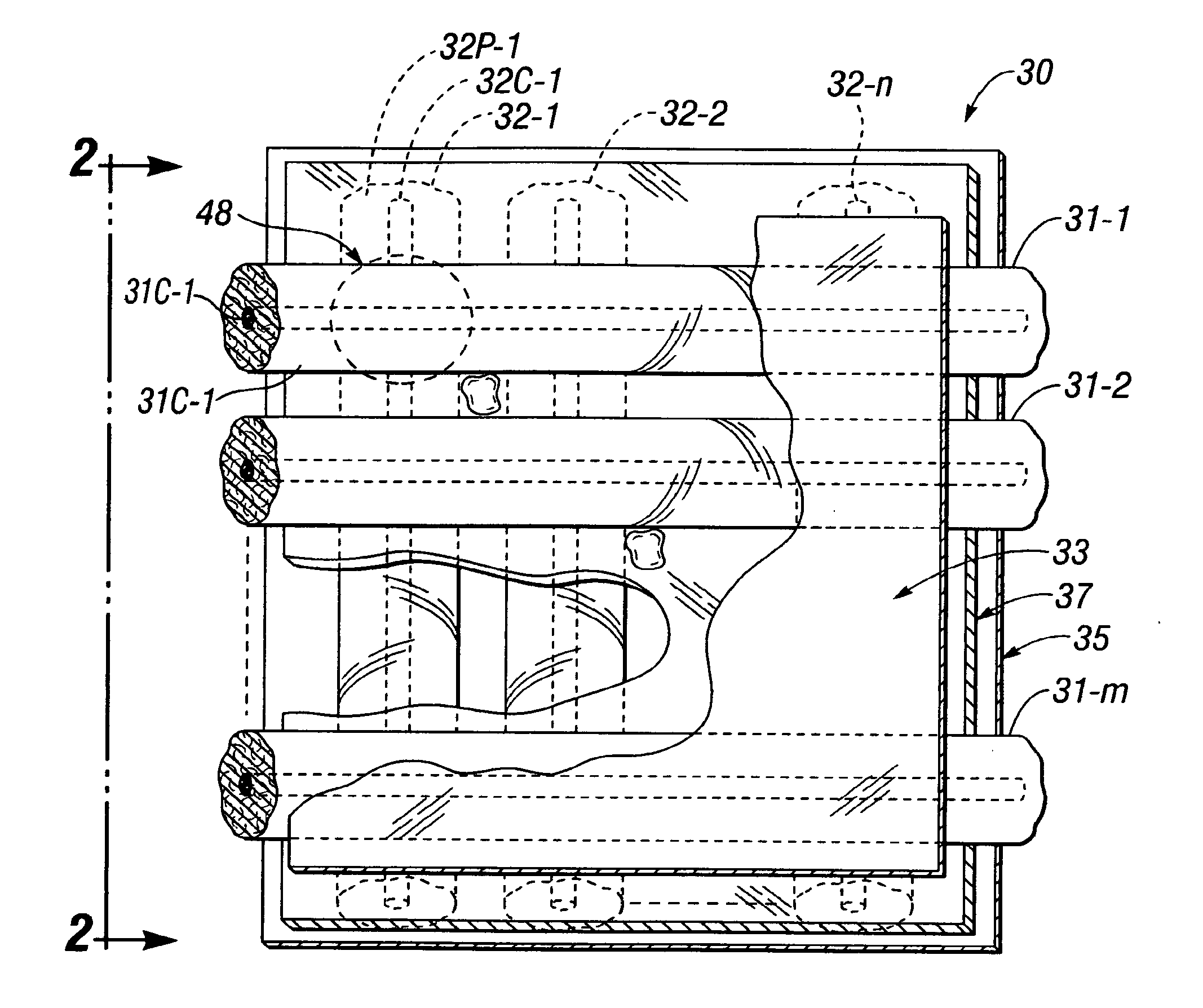

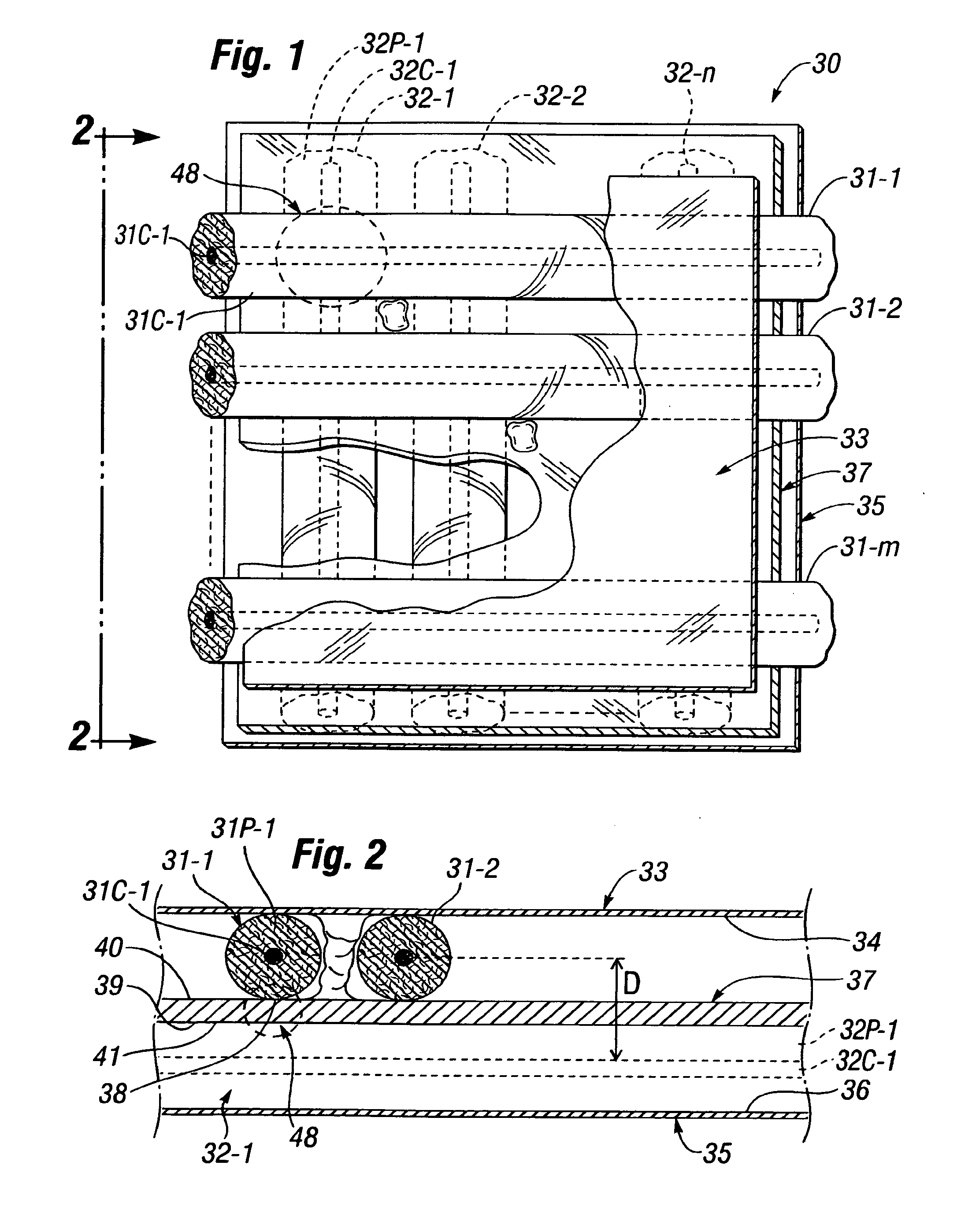

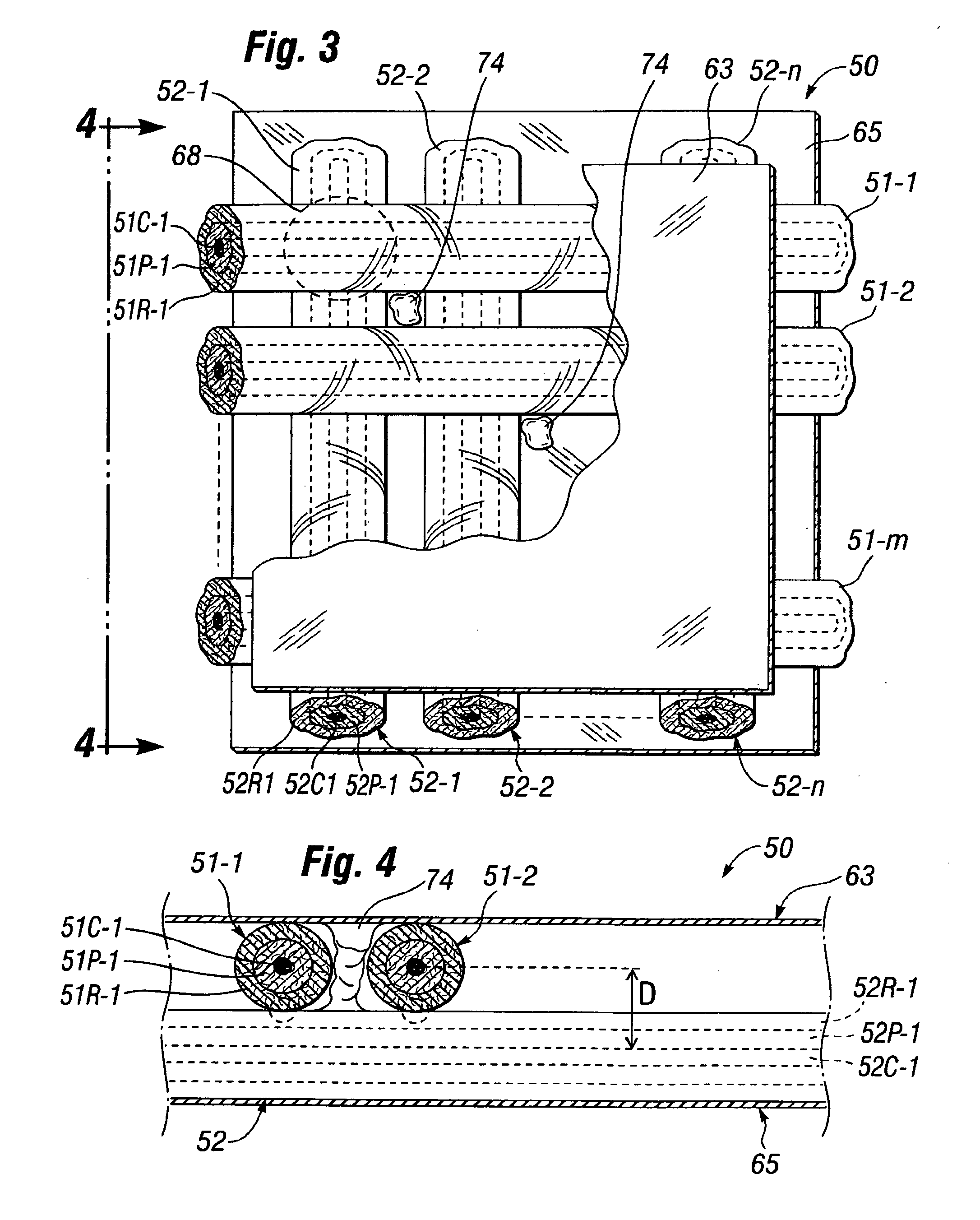

MEMS pixel sensor

InactiveUS20070023851A1Piezoelectric/electrostrictive microphonesSolid-state devicesBroadbandElectron

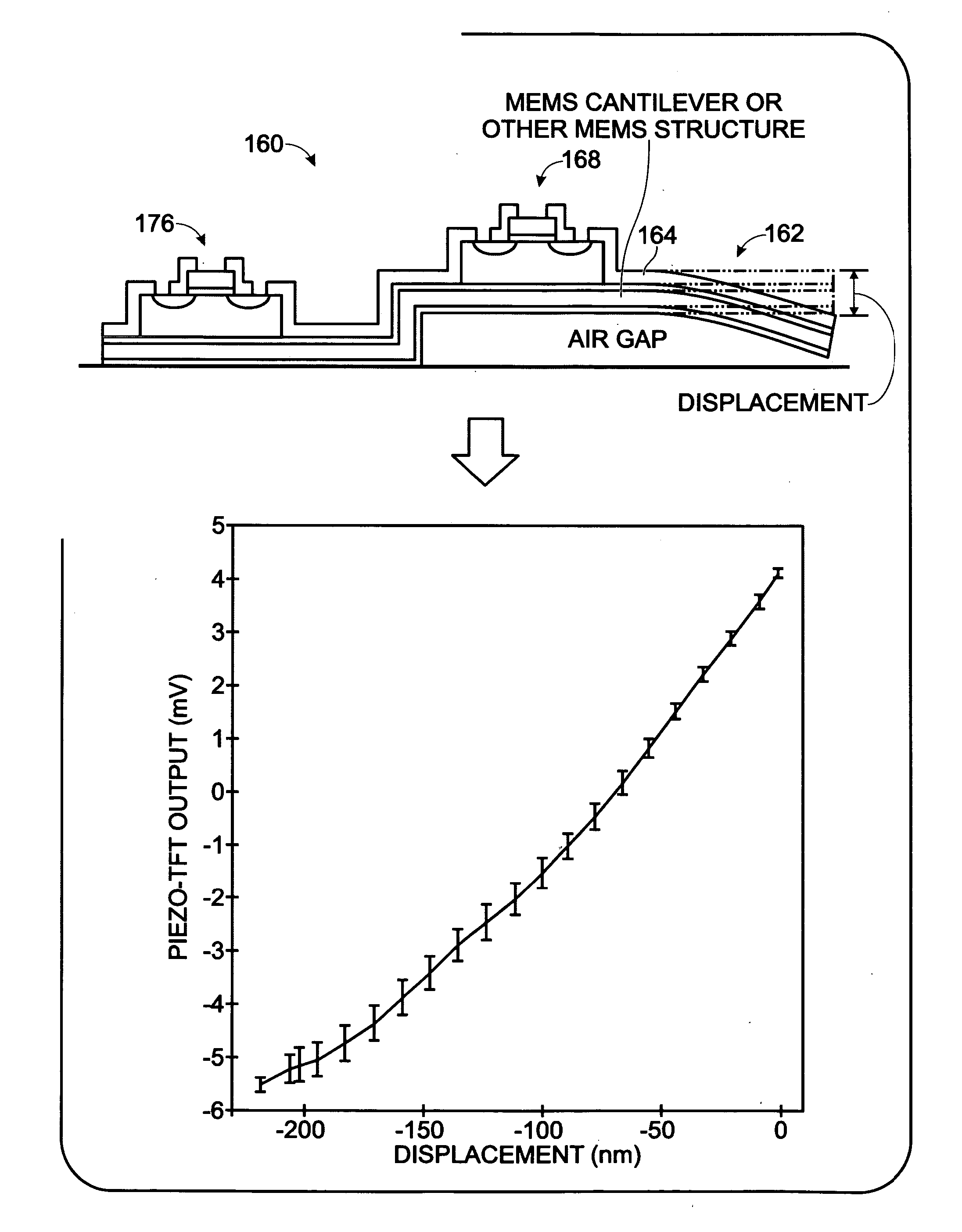

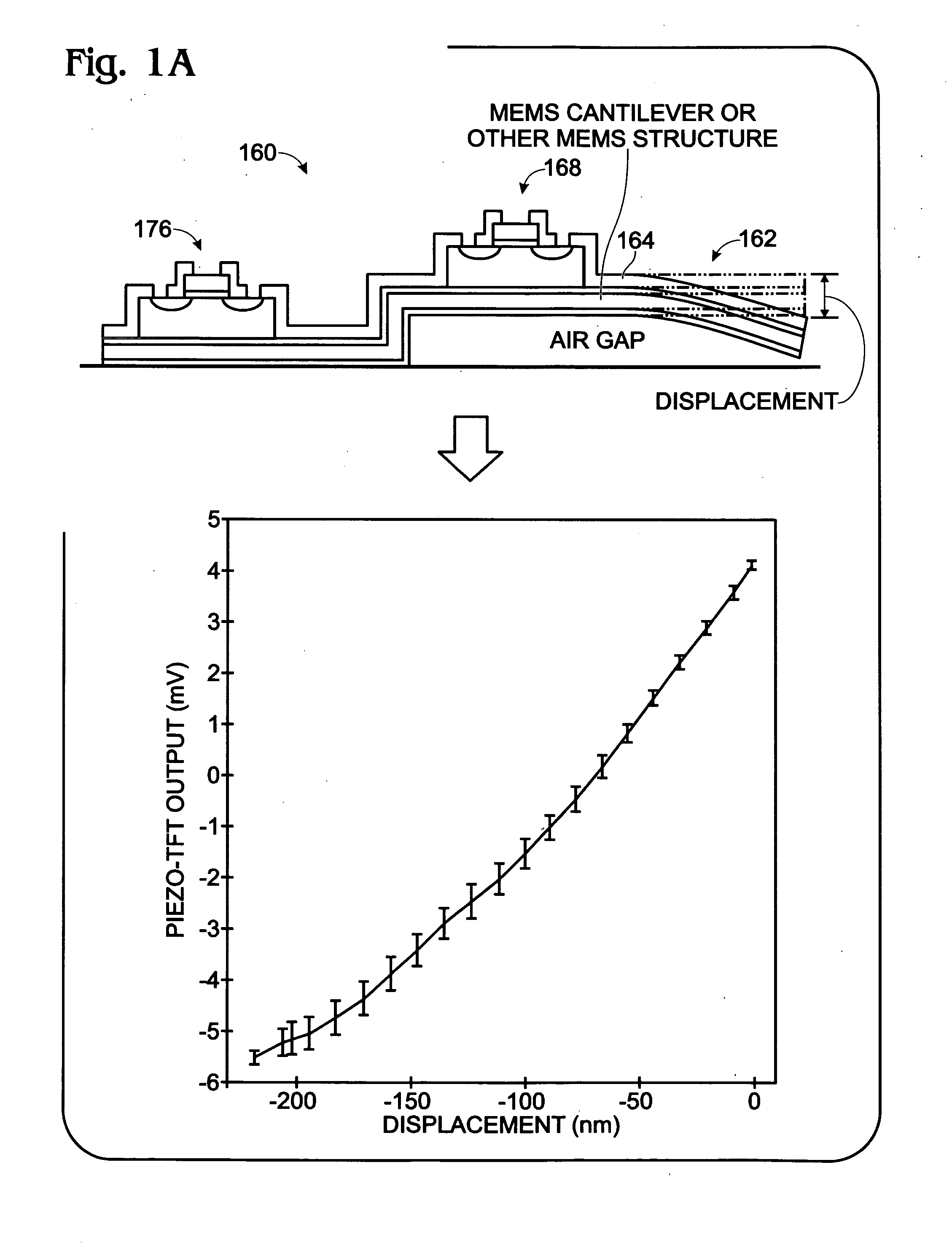

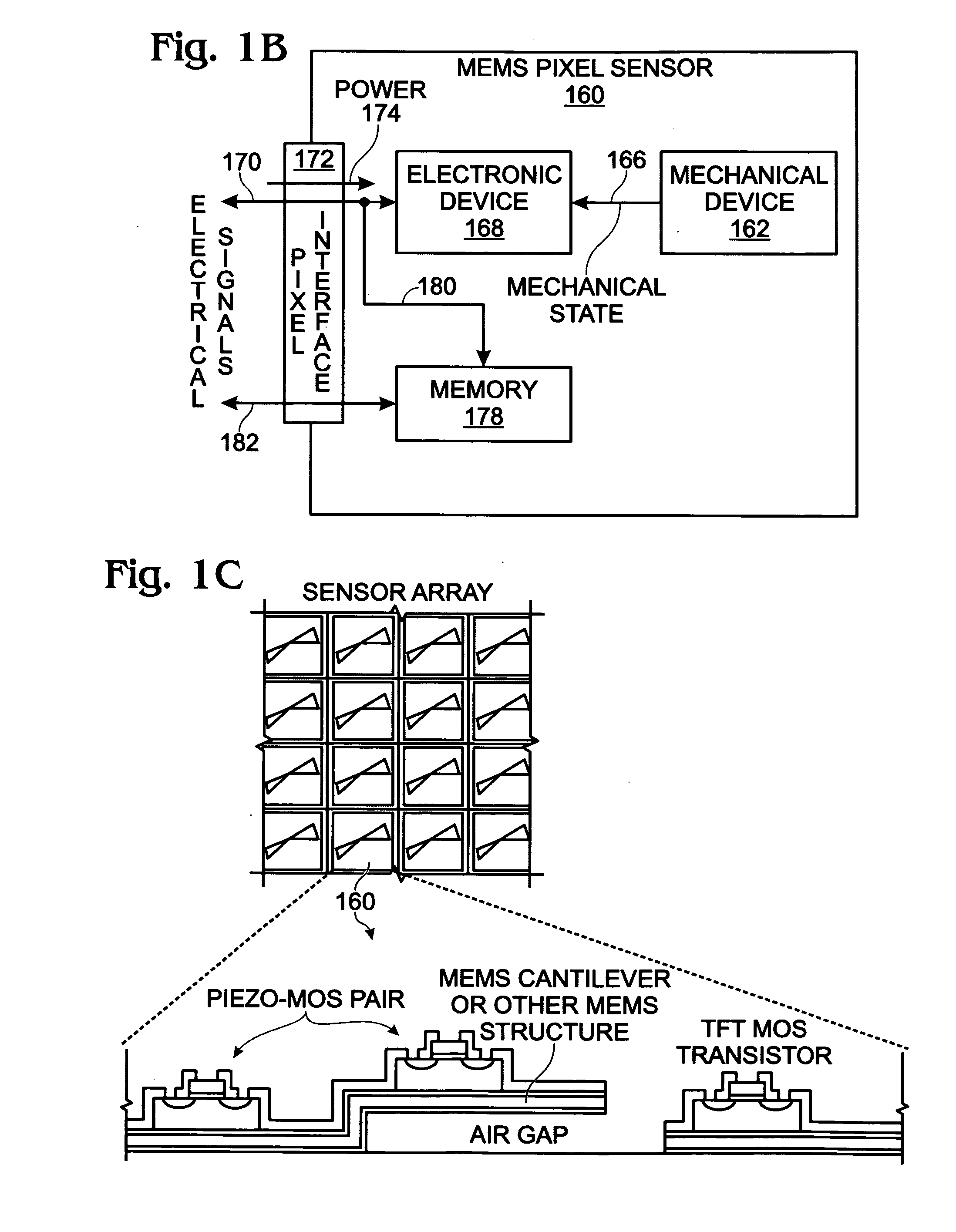

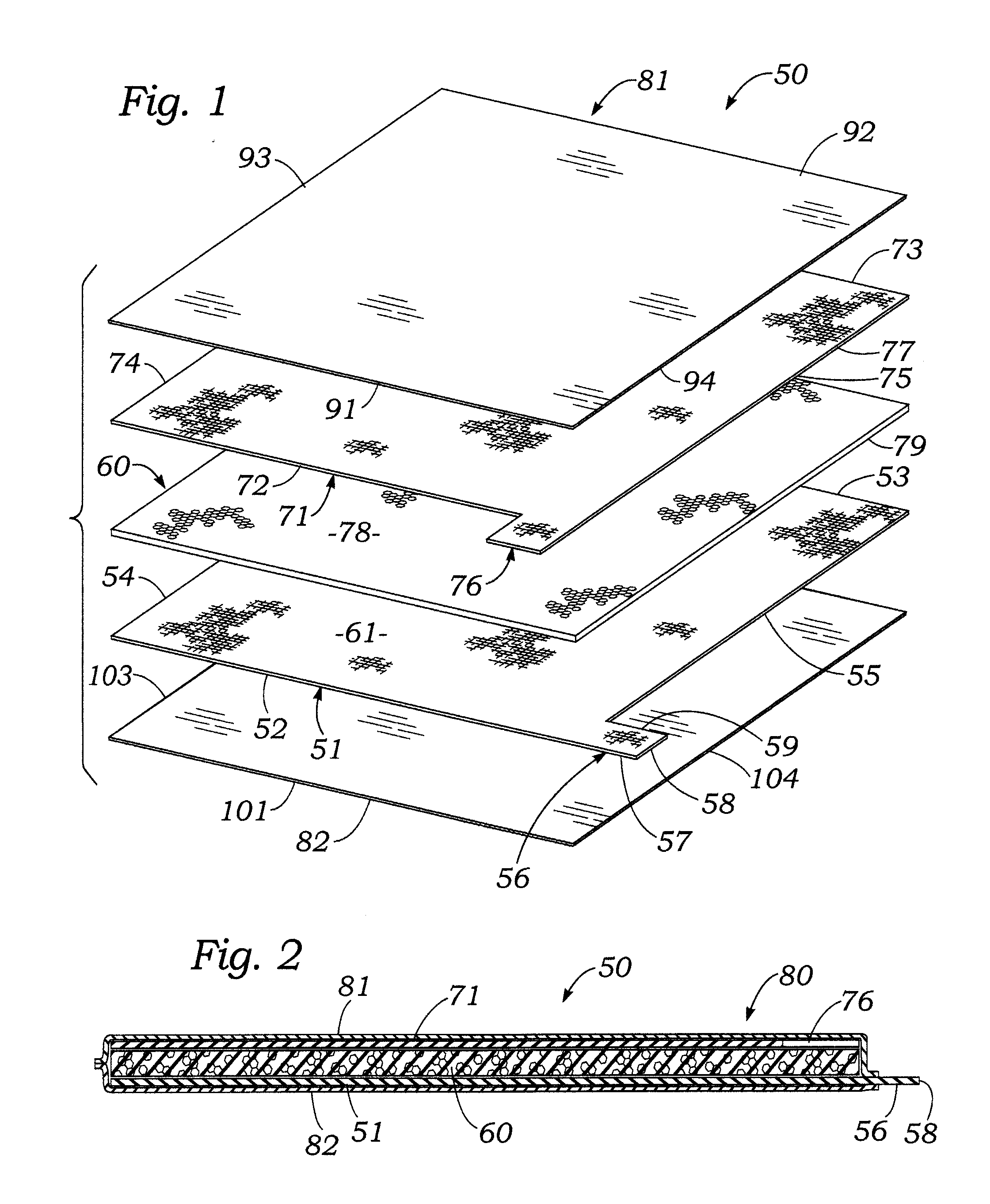

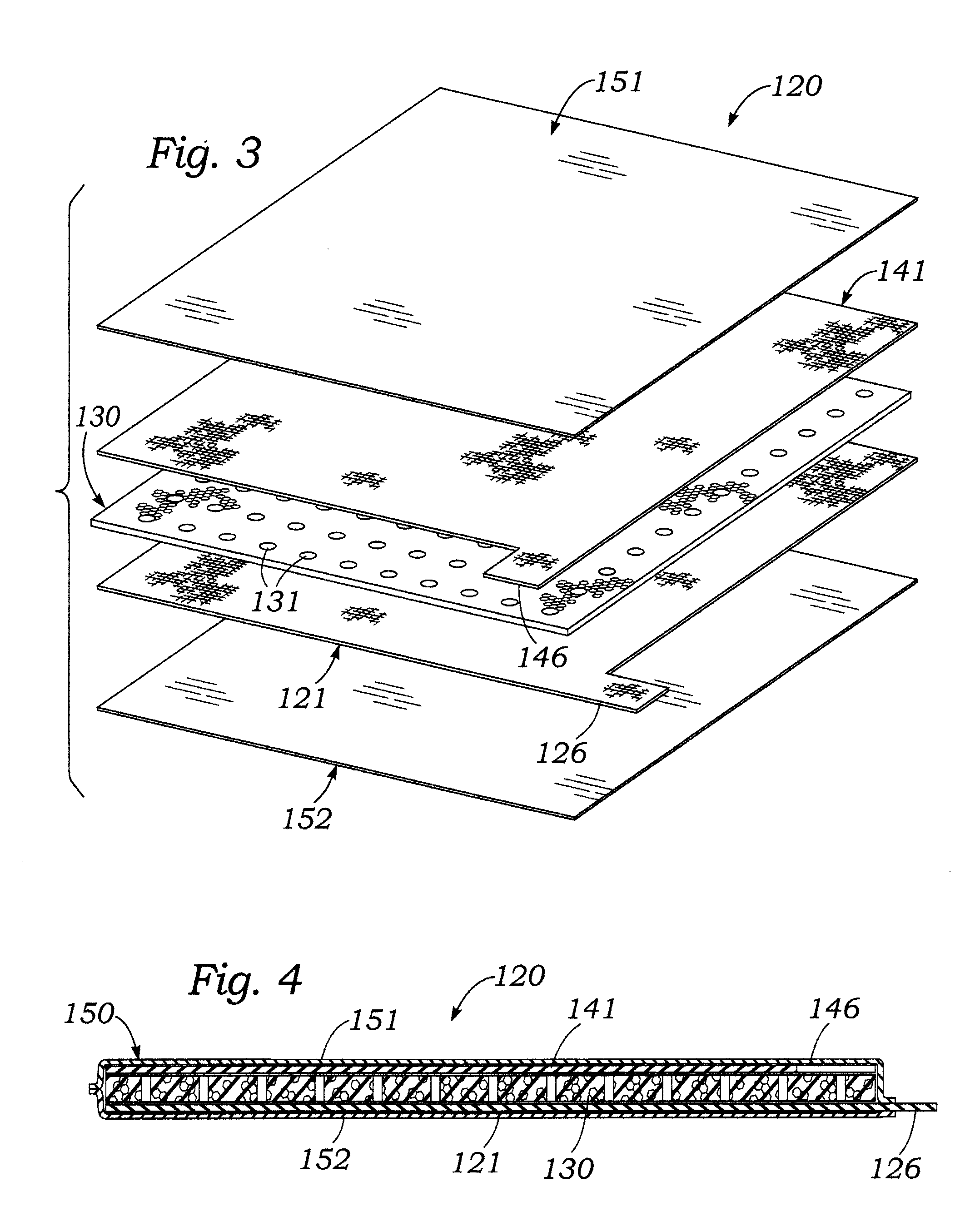

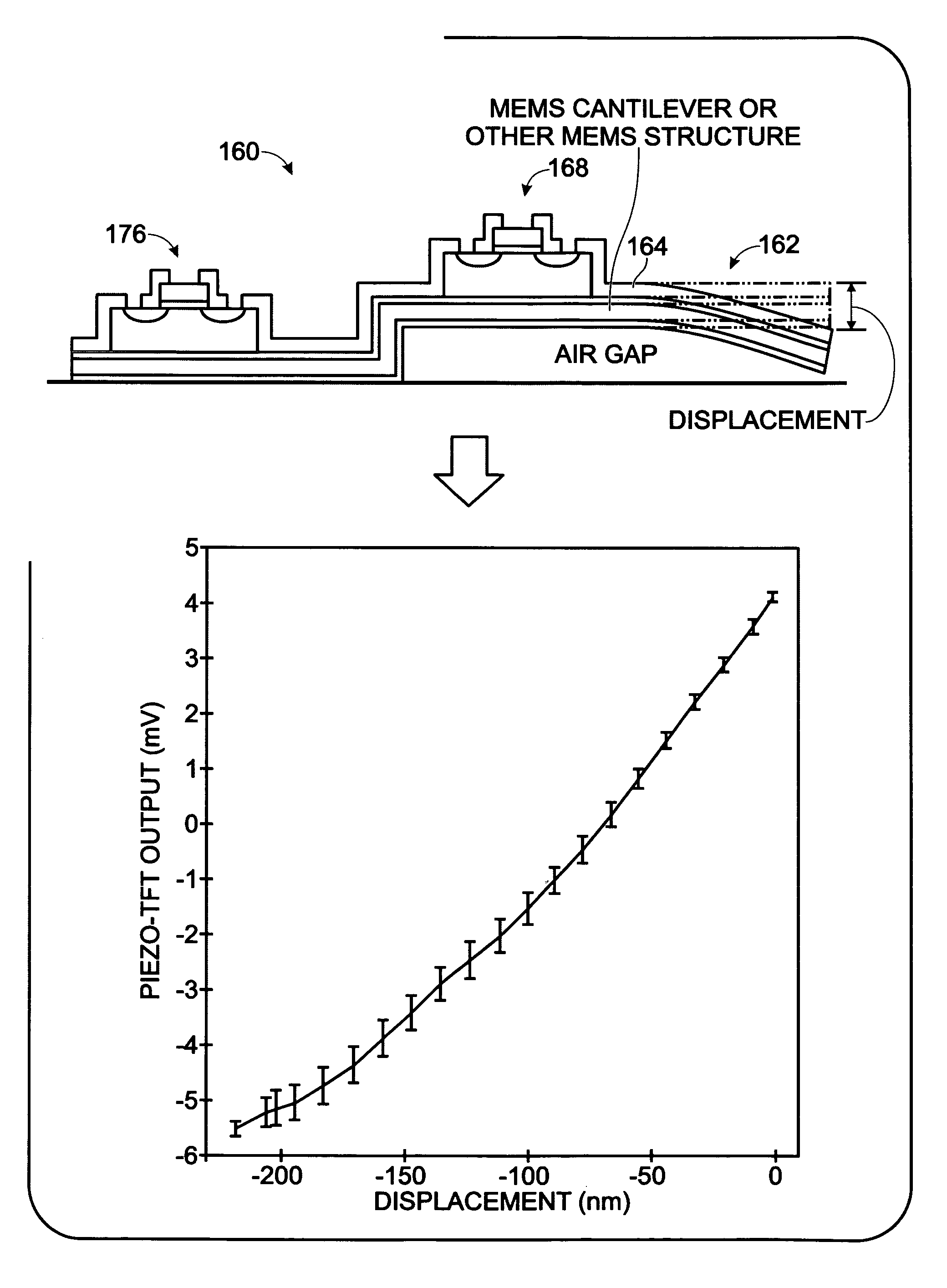

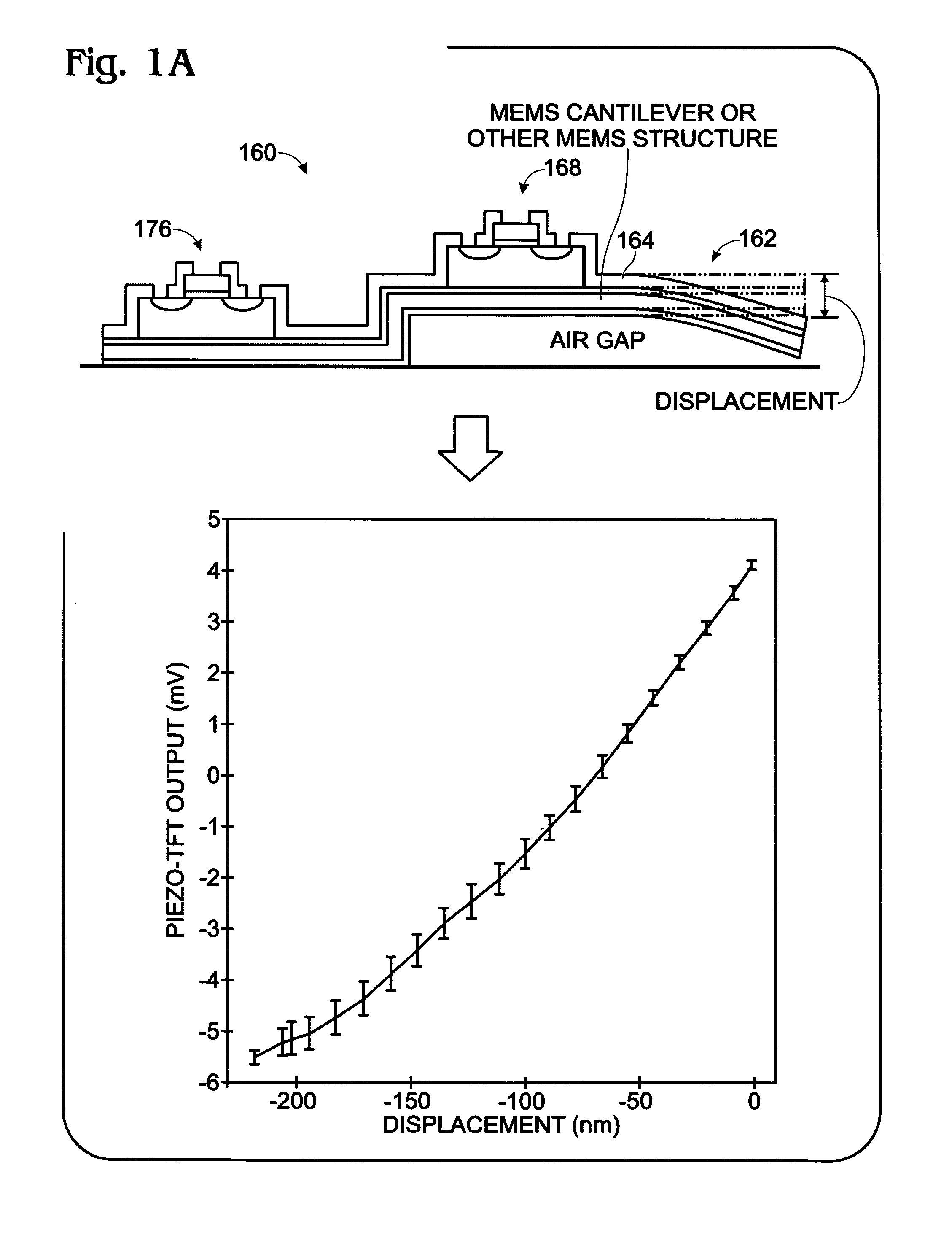

A MEMS pixel sensor is provided with a thin-film mechanical device having a mechanical body, with a mechanical state responsive to a proximate environment. A thin-film electronic device converts the mechanical state into electrical signals. A pixel interface supplies power to the electronic device and transceives electrical signals. The sensor is able to operate dynamically, in real-time. For example, if the mechanical device undergoes a sequence of mechanical states at a corresponding plurality of times, the electronic device is able to supply a sequence of electrical signals to the pixel interface that are responsive to the sequence of mechanical states, at the plurality of times. Each MEMS pixel sensor may include a number of mechanical devices, and corresponding electronic devices, to provide redundancy or to measure a broadband response range.

Owner:SHARP KK

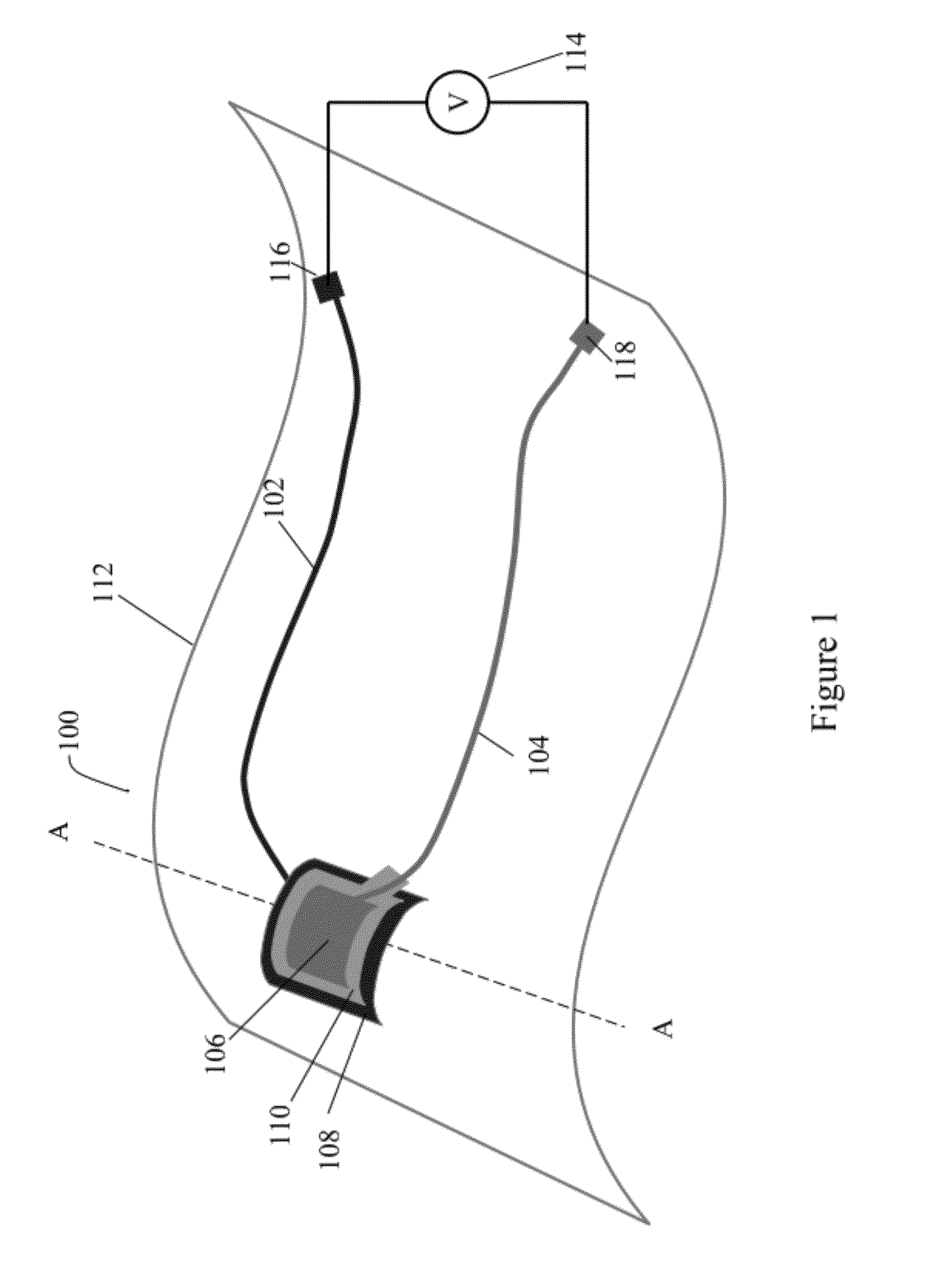

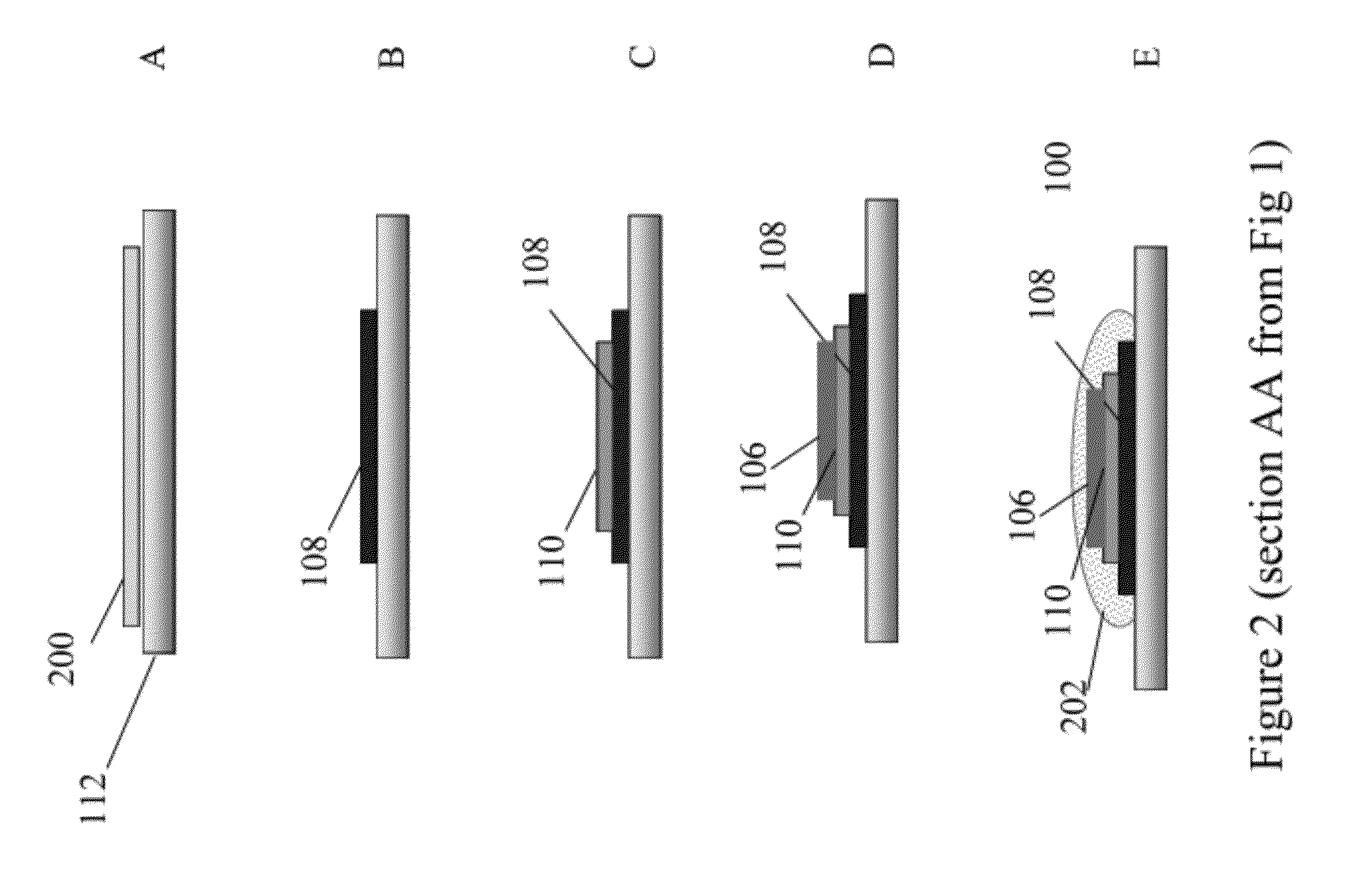

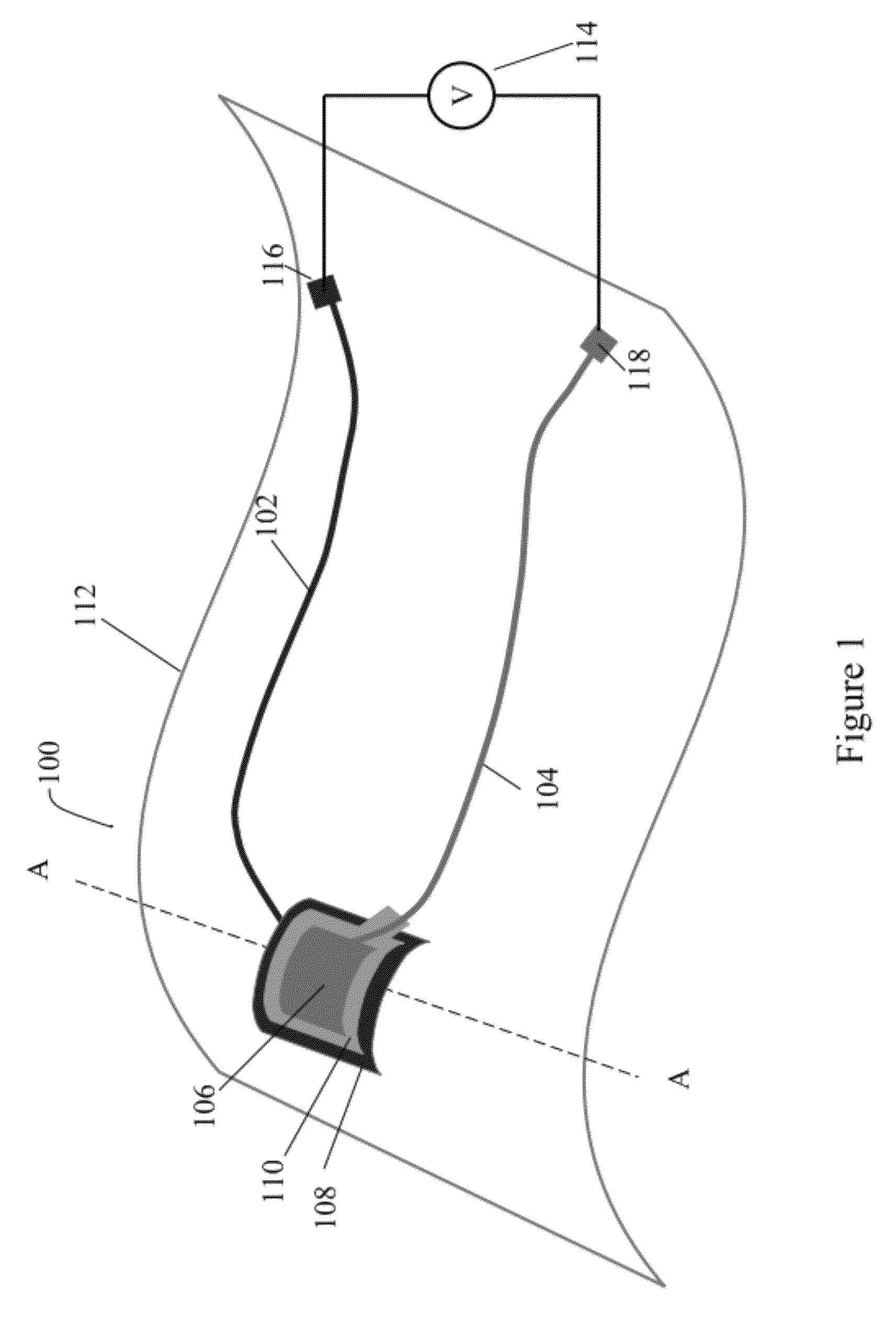

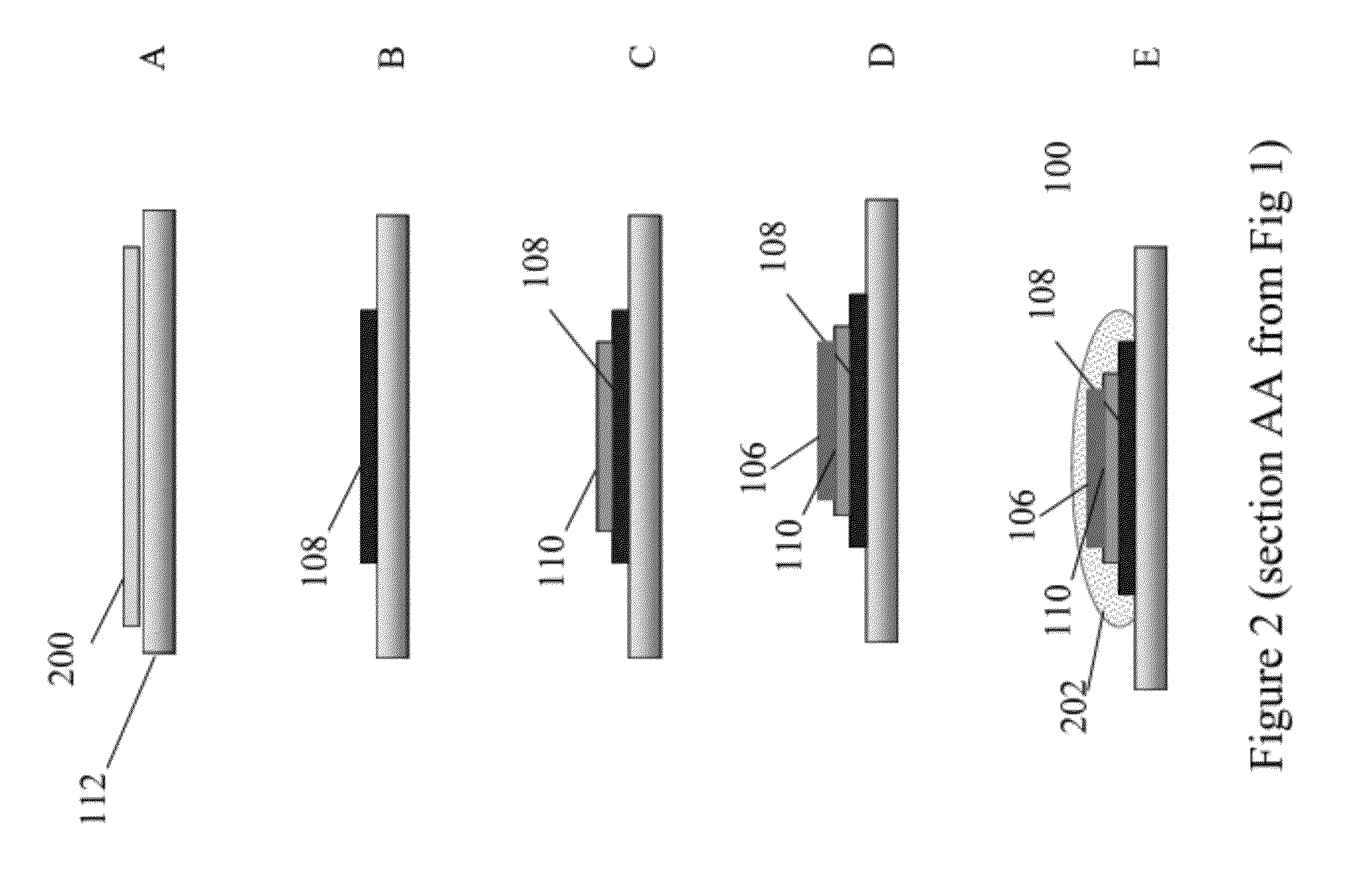

Pressure sensing or force generating device

ActiveUS20120055257A1Few contactsShorten the counting processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCapacitive effect

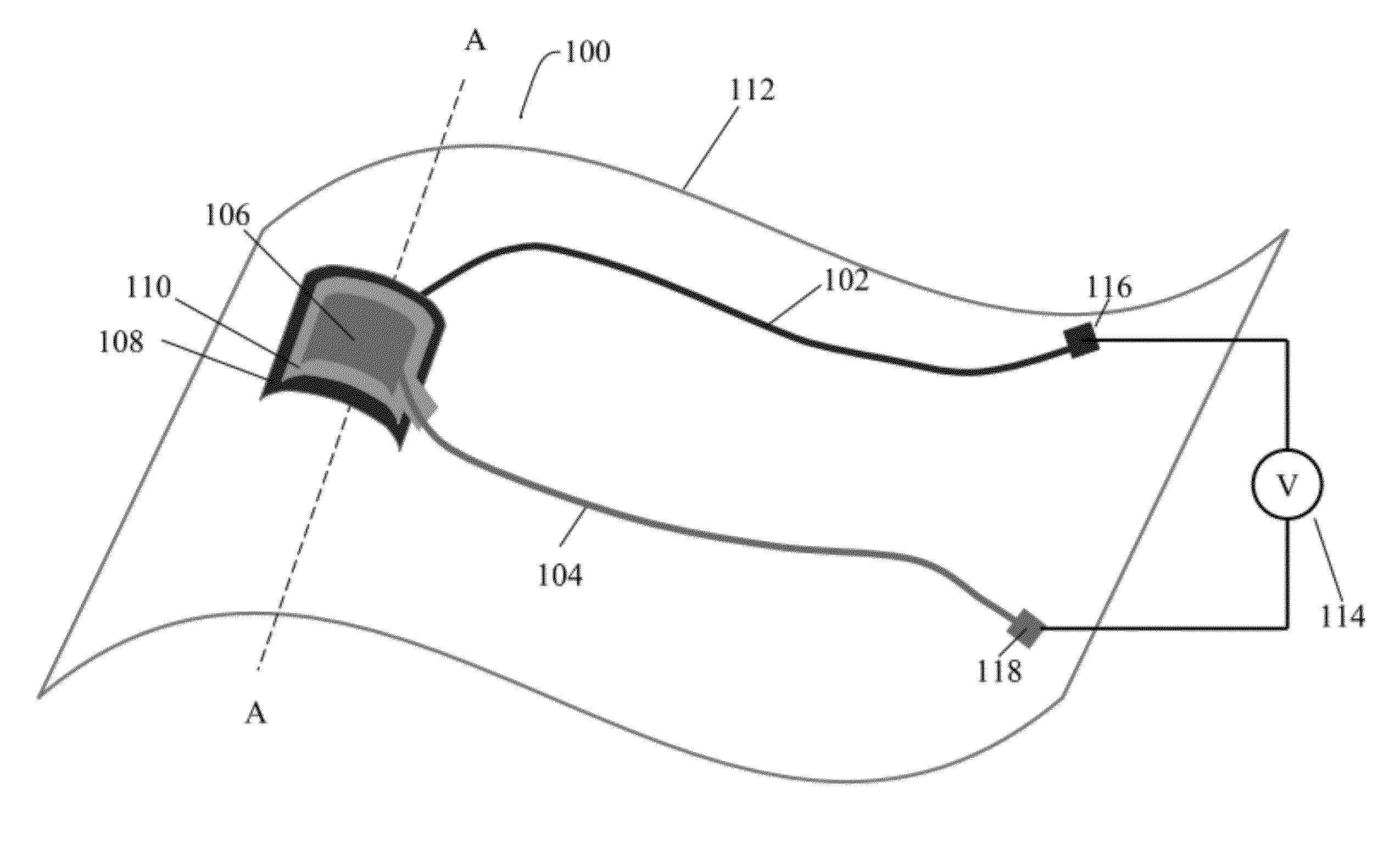

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

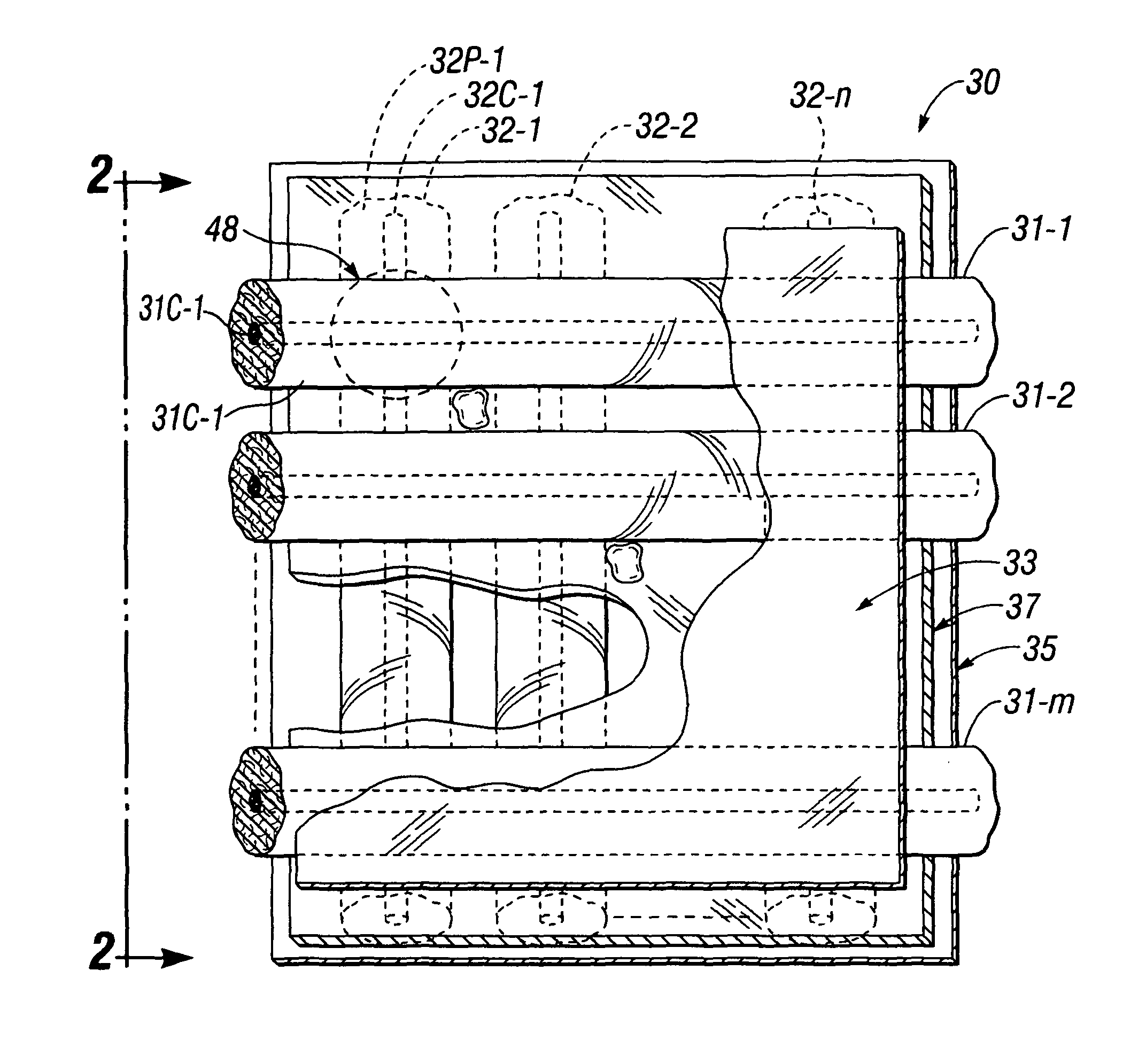

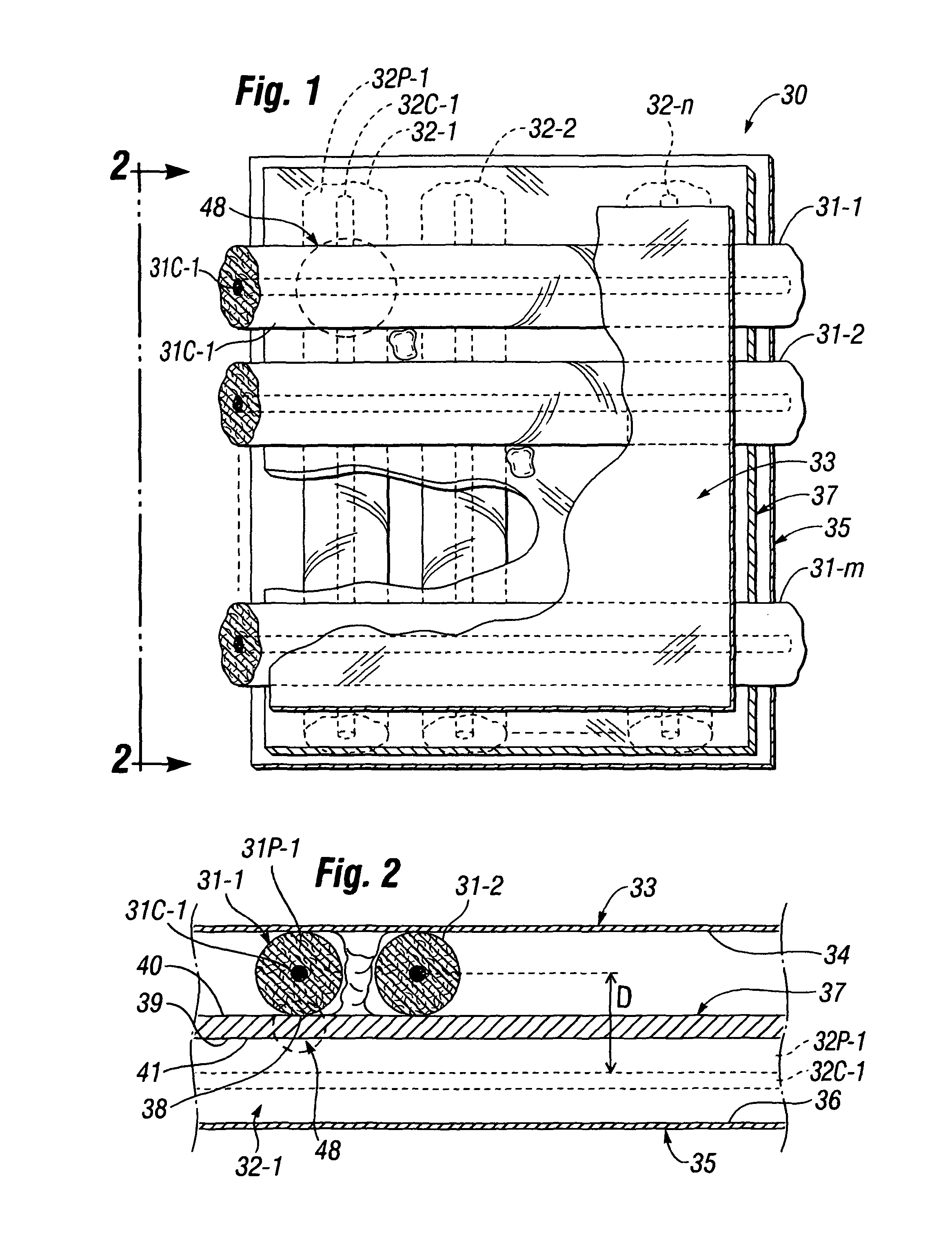

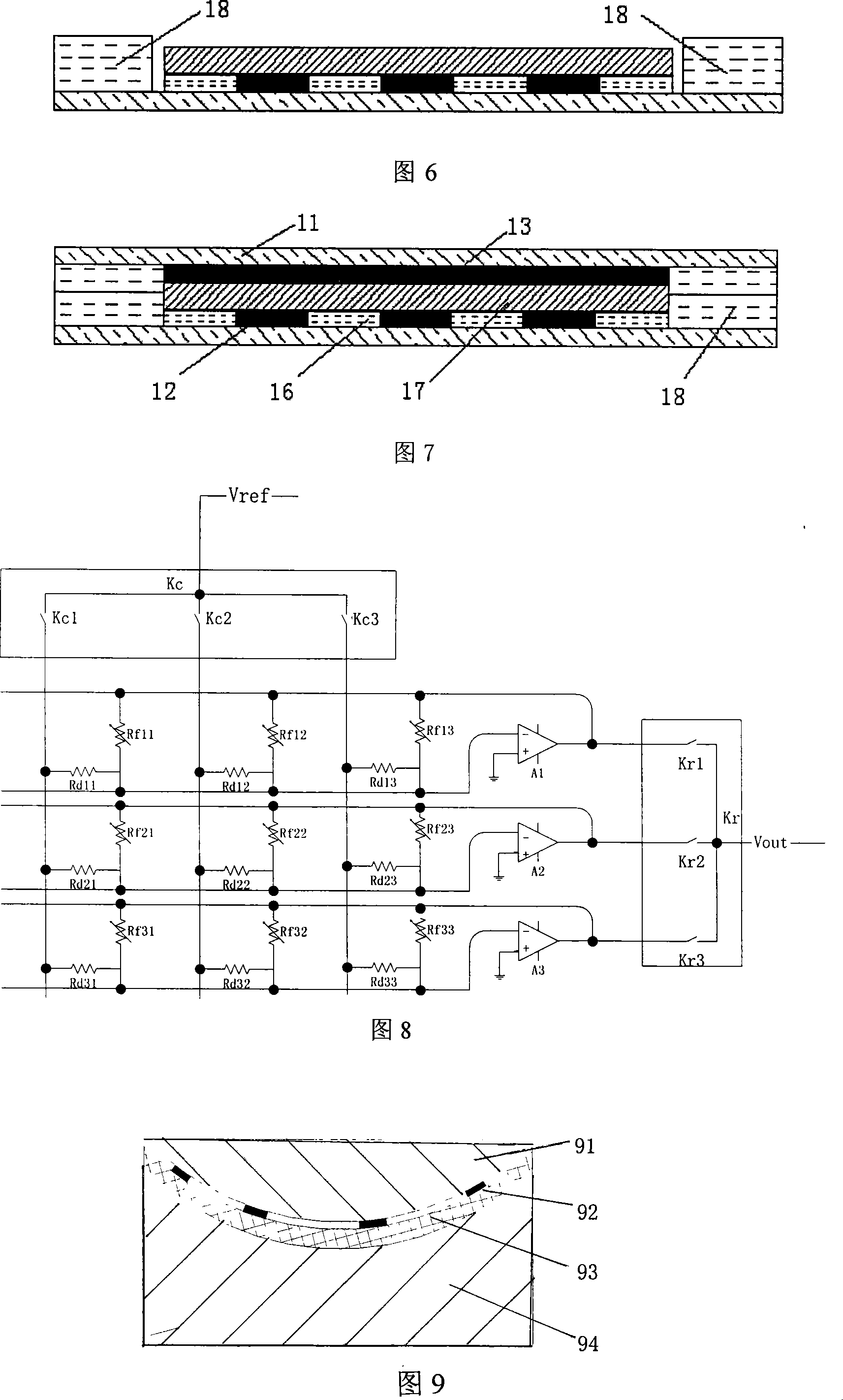

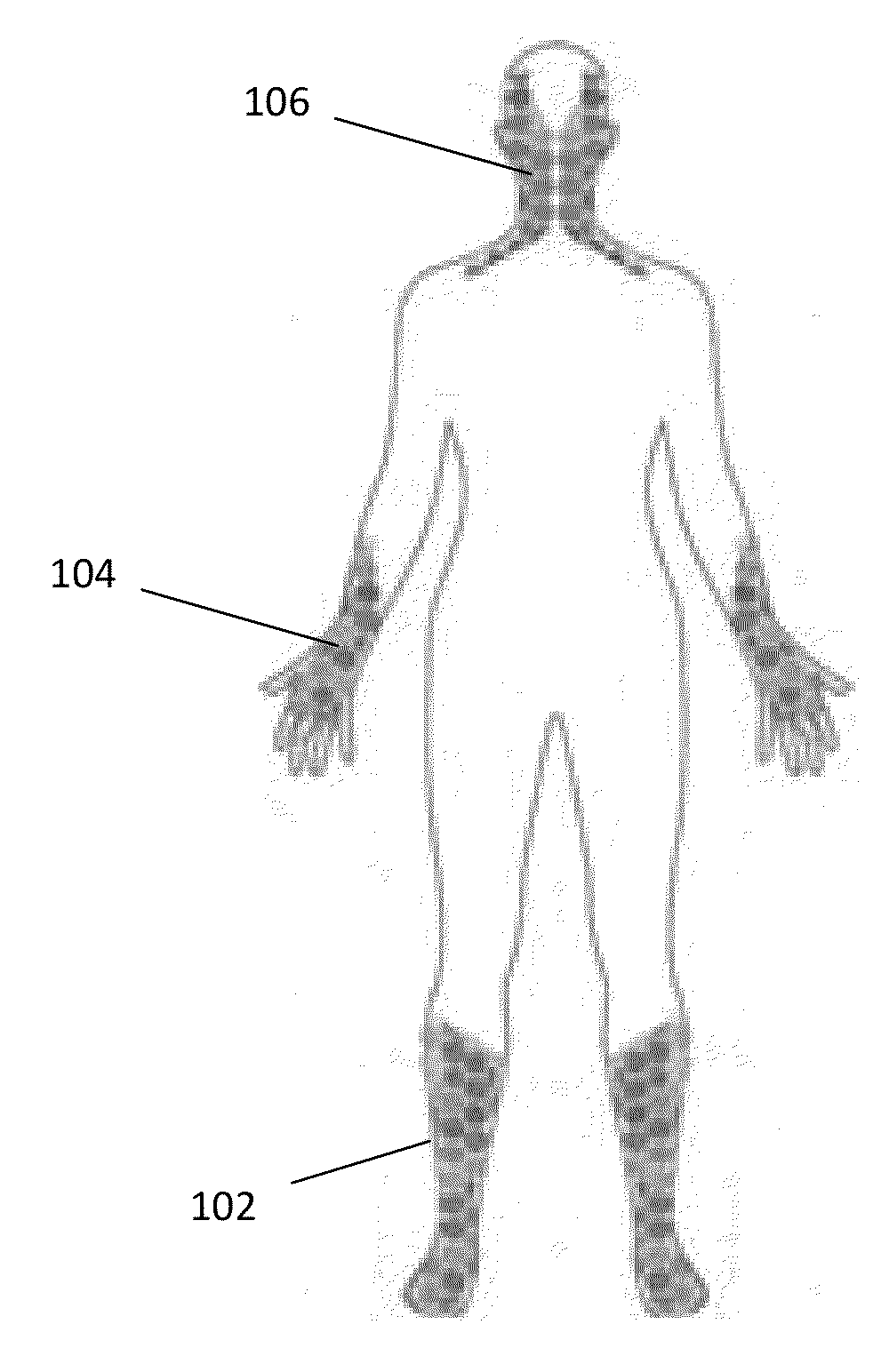

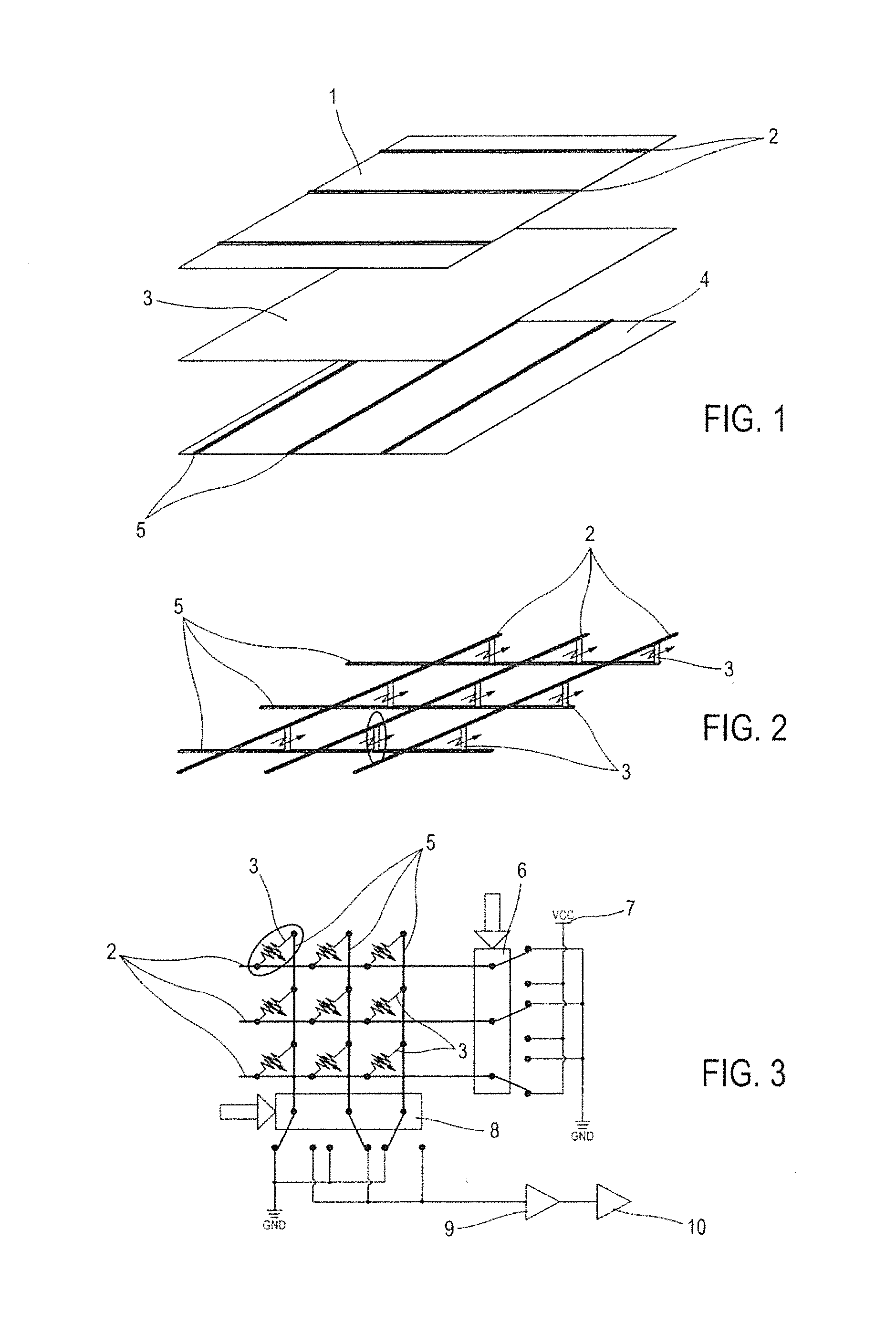

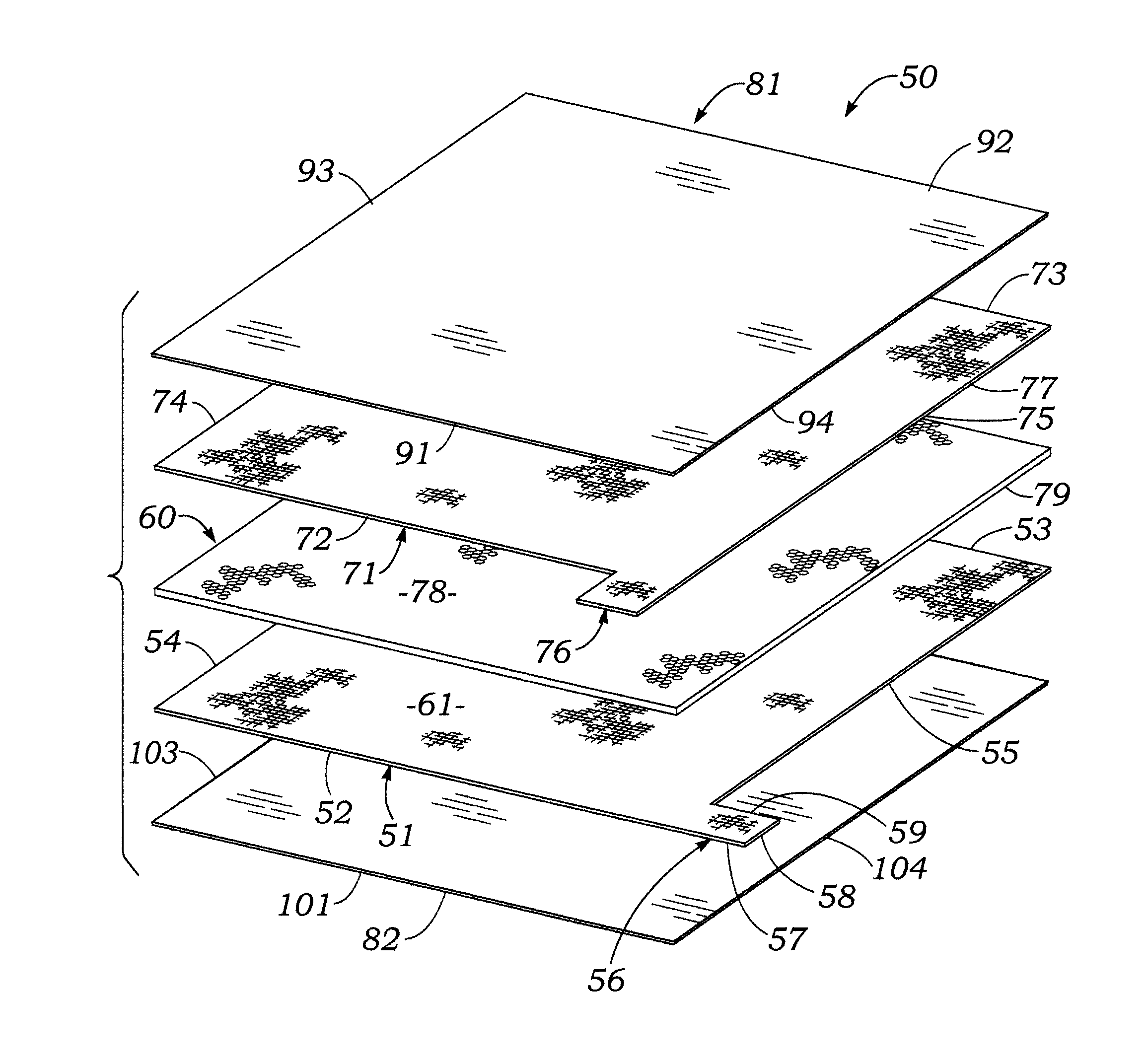

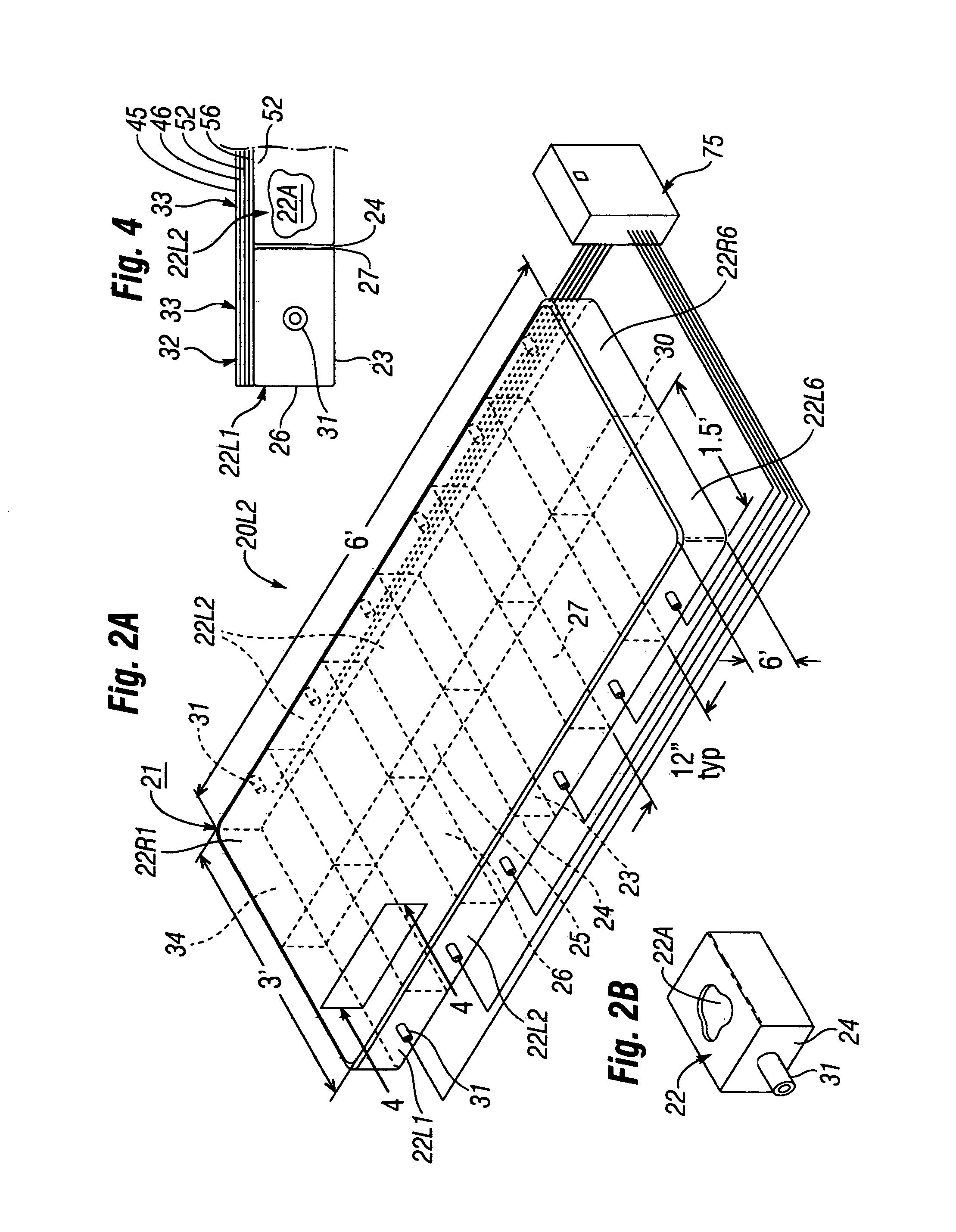

Elastically stretchable fabric force sensor arrays and methods of making

ActiveUS8161826B1Facilitate measuring and mapping forcesWork measurementMaterial strength using tensile/compressive forcesSensor arrayConductive polymer

Force or pressure transducer arrays have elastically stretchable electrically conductive polymer threads disposed in parallel rows and columns that contact at intersections thereof a piezoresistive material which has an electrical resistivity which varies inversely with pressure or force exerted thereon to form a matrix array of force or pressure sensor elements. The threads are fixed to a single one or pair of flexible elastically stretchable substrate sheets made of thin sheets of an insulating polymer such as PVC, or for greater elasticity and conformability to irregularly-shaped objects such as human body parts, an elastically stretchable fabric such as LYCRA or SPANDEX. Elastic stretchability of the sensor arrays is optionally enhanced by disposing either or both row and column conductive threads in sinuously curved, serpentine paths rather than straight lines.

Owner:PATIENTECH LLC

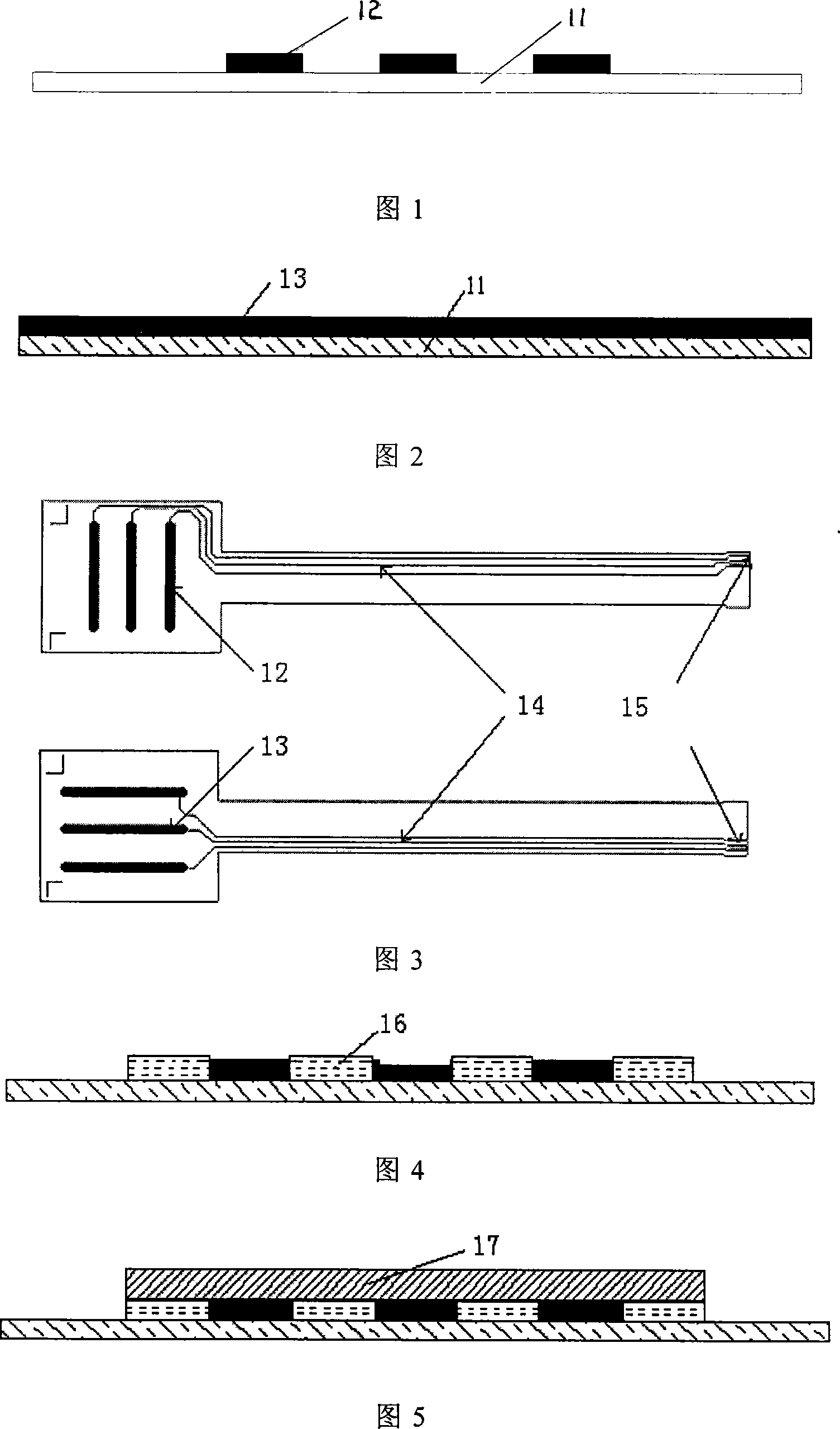

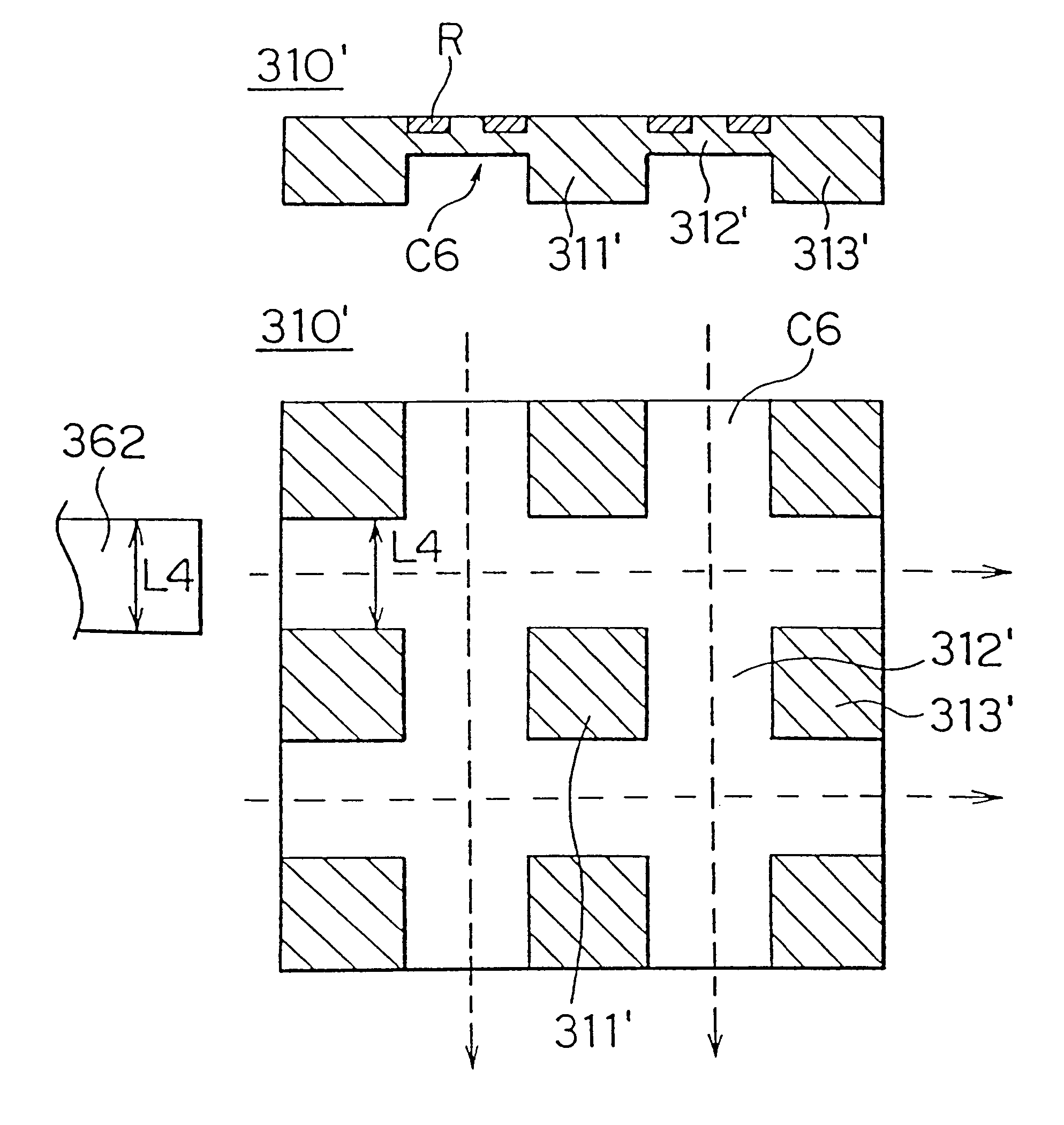

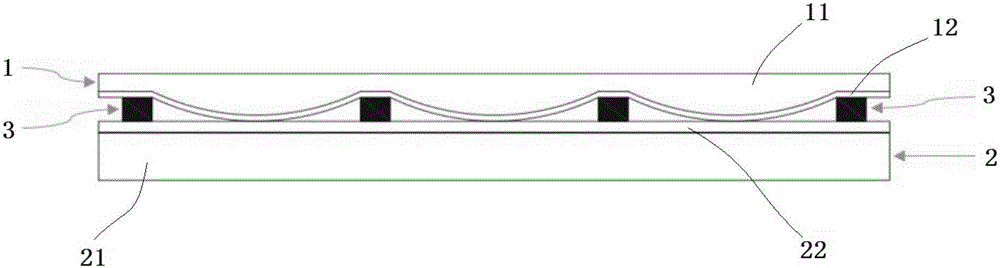

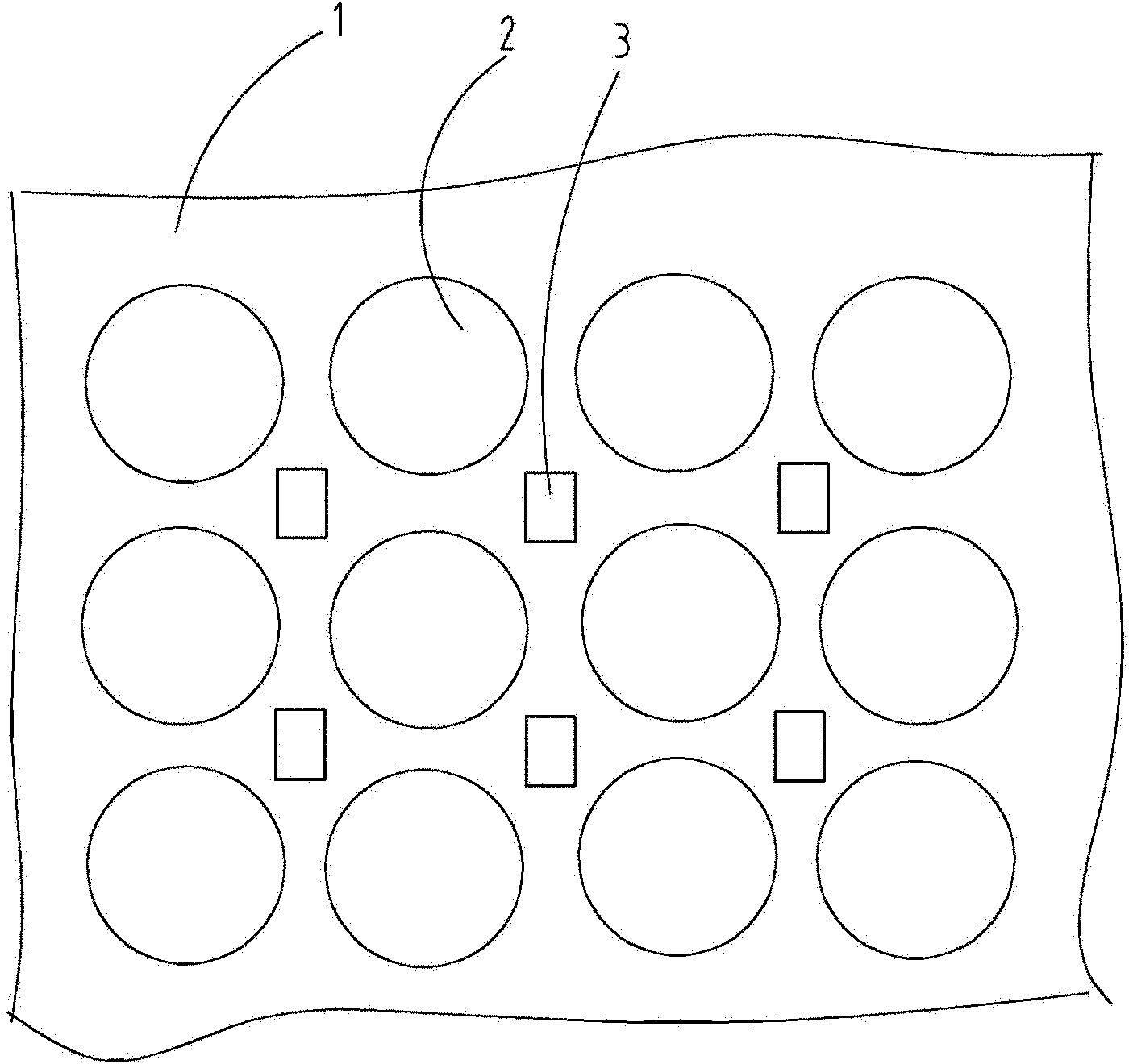

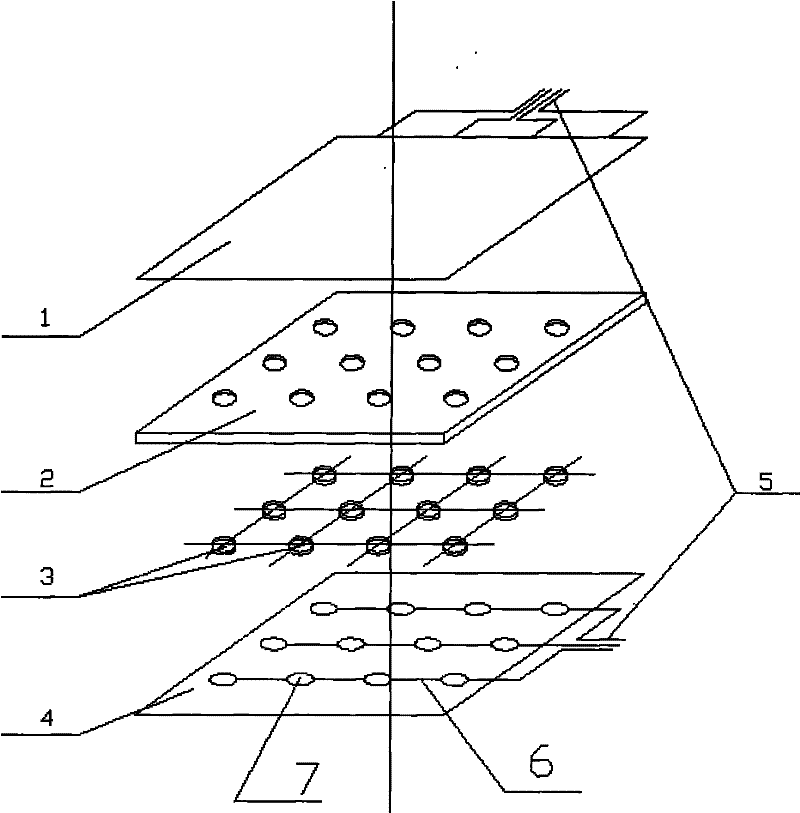

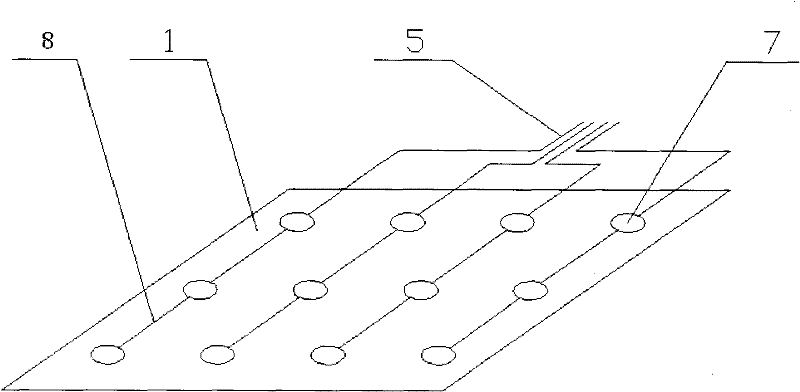

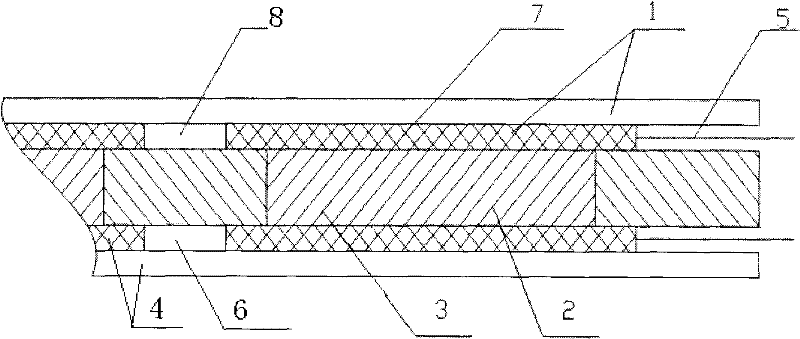

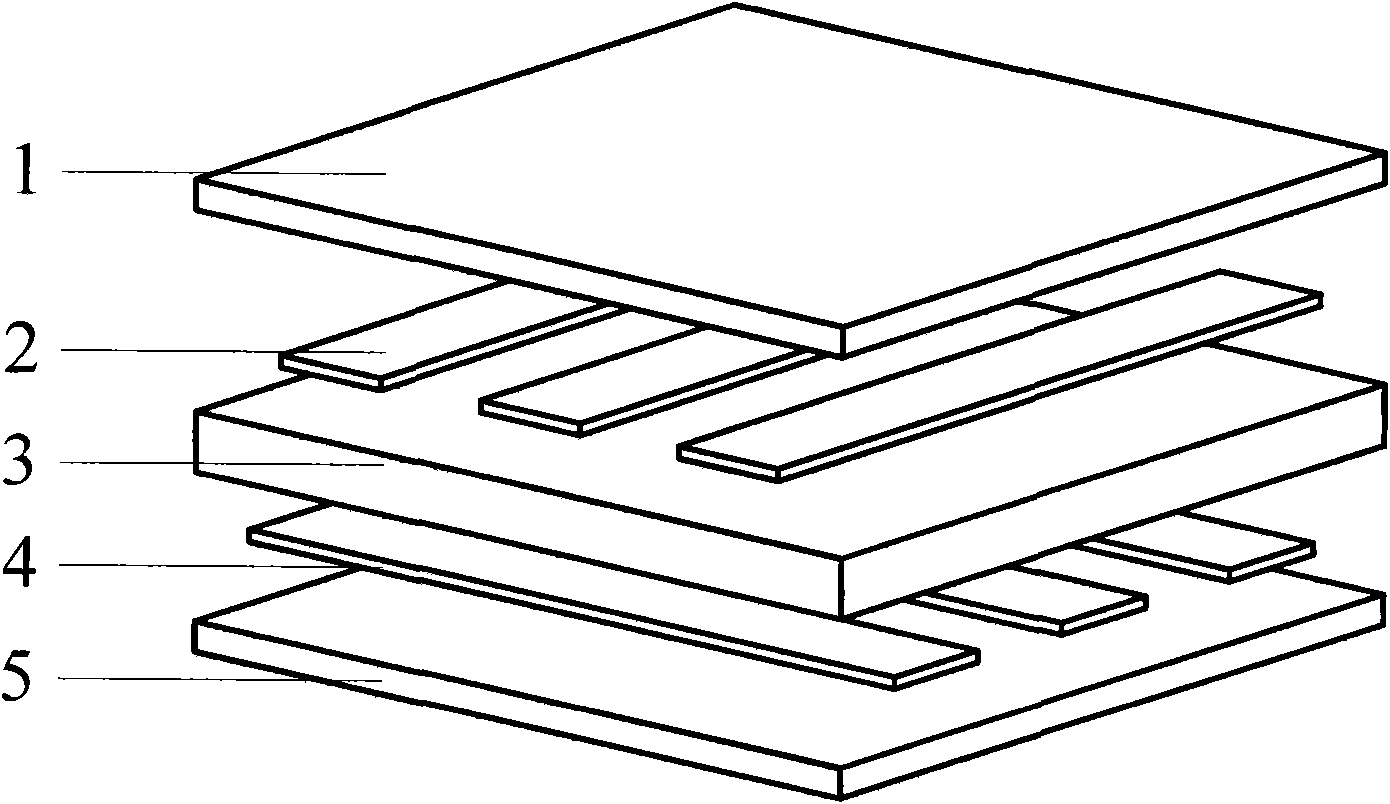

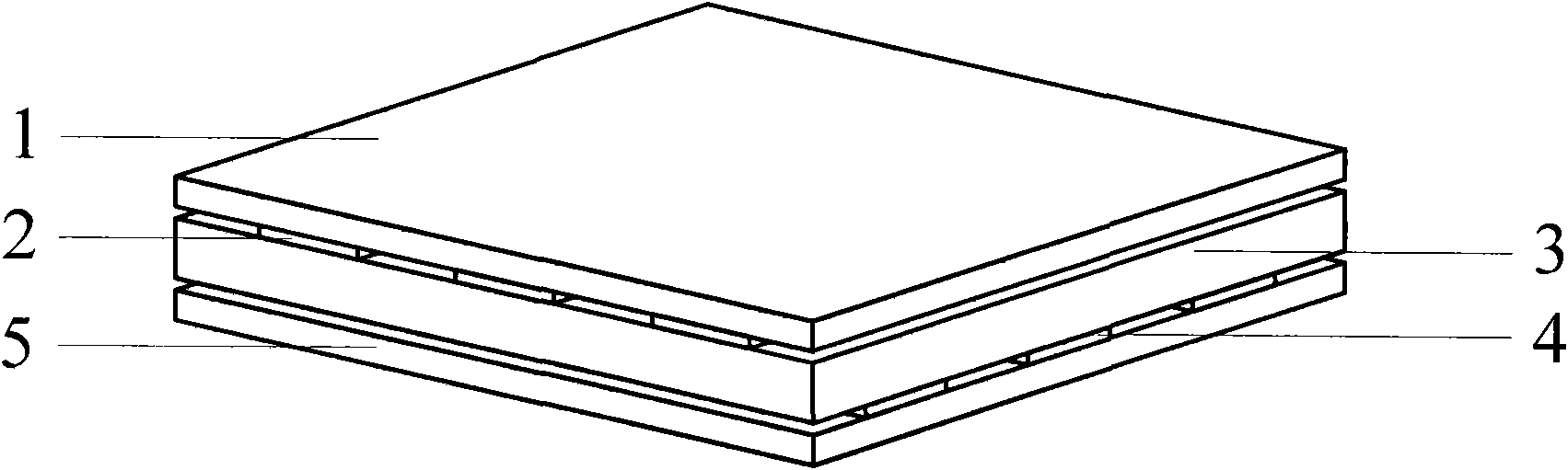

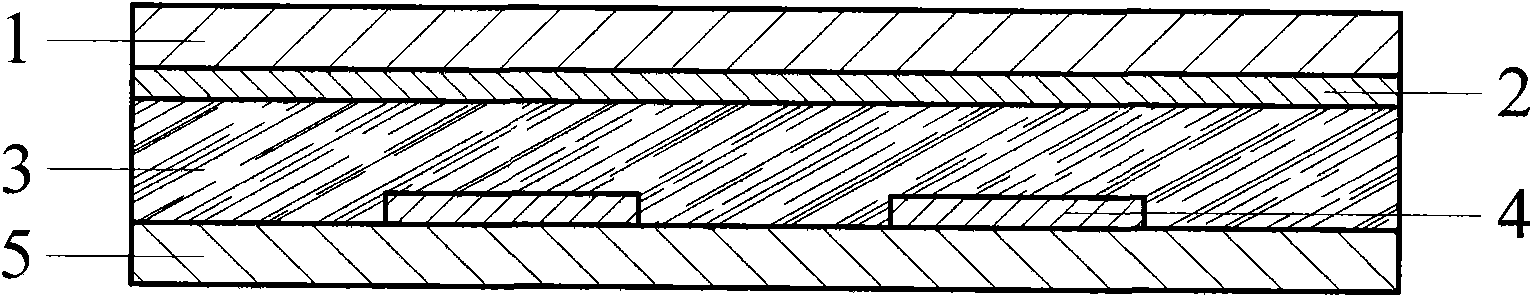

Array type ultra-thin submissive force sensor and preparation method thereof

InactiveCN101201277ALarge rangeHigh precisionForce measurement using piezo-resistive materialsImage resolutionCarbon black

The invention relates to an array-type compliant force sensor and a method of preparation thereof, and belongs to the technical field of a force sensor. The sensor comprises upper and lower poles which are enclosed into one piece, and a conduction macromolecule sensitive film compressed between the poles, and a front end circuit connected with the upper and lower poles through signal lines. The conduction macromolecule sensitive film primarily adopts the conduction macromolecule sensitive film having the compressive resistance effect consisting of graphitized carbon black as the conduction phase, single-component silastic as the insulation phase, and nanometer SiO2 dispersant. The upper and lower poles are a plurality of poles made on the substrate of the film by making use of flexible printed circuit board process and signal lines connected with each strip-shaped pole. The upper and lower strip-shaped poles are crossed and constitute an N*N sensitive cell array with the conduction macromolecule sensitive film. The signal lines are gathered to form led-out closely spaced cables. The invention has the characteristics of fine and thin structure, good flexibility, large range, high precision and high resolution.

Owner:TSINGHUA UNIV

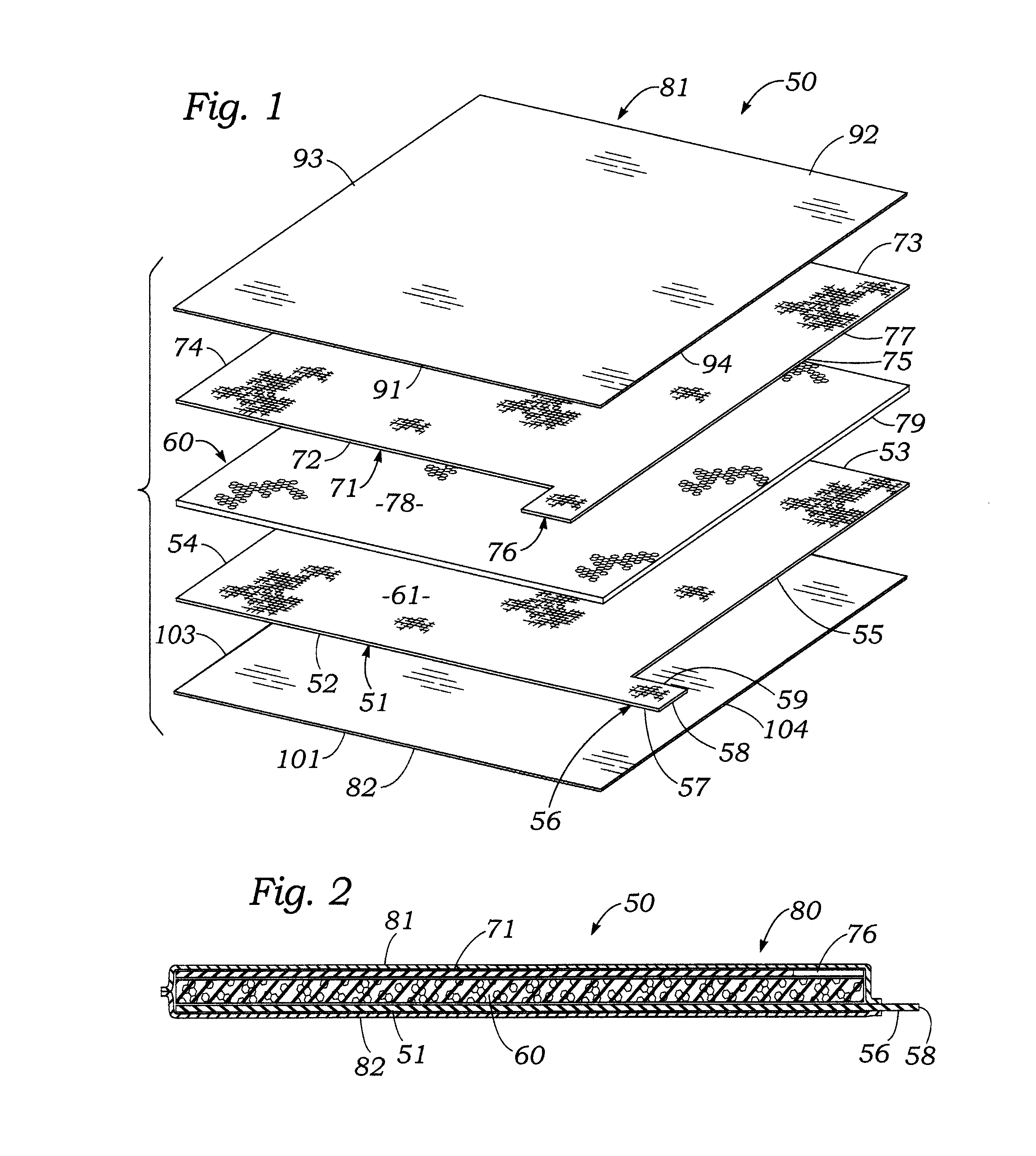

Flexible Piezocapacitive And Piezoresistive Force And Pressure Sensors

InactiveUS20140090488A1Facilitate measuring and mapping forcesForce measurement by measuring frquency variationsForce measurement using piezo-resistive materialsCapacitanceElectricity

Flexible force / pressure sensors for producing electrical output signals proportional to forces or pressures exerted on the sensor include a thin, elastically deformable foam pad laminated between a pair of electrically conducive fabric sheets. A piezocapacitive embodiment of the sensor utilizes an elastically deformable perforated open-cell polyurethane foam pad preferably saturated with glycerin to increase the capacitance of the sensor. The piezocapacitive sensor section is preferably stacked onto a piezoresistive section having a second open-cell foam pad containing piezoresistive carbon particles to form a hybrid piezocapacitive / piezoresistive sensor. A third, “leaky dielectric” embodiment of a sensor includes a single open-cell foam pad which contains both a dielectric liquid and conductive particles. A low frequency such as d.c. to a few hertz is applied to a sensor to determine piezoresistive response of the sensor to forces or pressures and a higher frequency such as 30 KHz is applied to determine piezocapactive response.

Owner:PATIENTECH LLC

MEMS pixel sensor

InactiveUS7425749B2Piezoelectric/electrostrictive microphonesAcceleration measurement using interia forcesBroadbandEngineering

A MEMS pixel sensor is provided with a thin-film mechanical device having a mechanical body, with a mechanical state responsive to a proximate environment. A thin-film electronic device converts the mechanical state into electrical signals. A pixel interface supplies power to the electronic device and transceives electrical signals. The sensor is able to operate dynamically, in real-time. For example, if the mechanical device undergoes a sequence of mechanical states at a corresponding plurality of times, the electronic device is able to supply a sequence of electrical signals to the pixel interface that are responsive to the sequence of mechanical states, at the plurality of times. Each MEMS pixel sensor may include a number of mechanical devices, and corresponding electronic devices, to provide redundancy or to measure a broadband response range.

Owner:SHARP KK

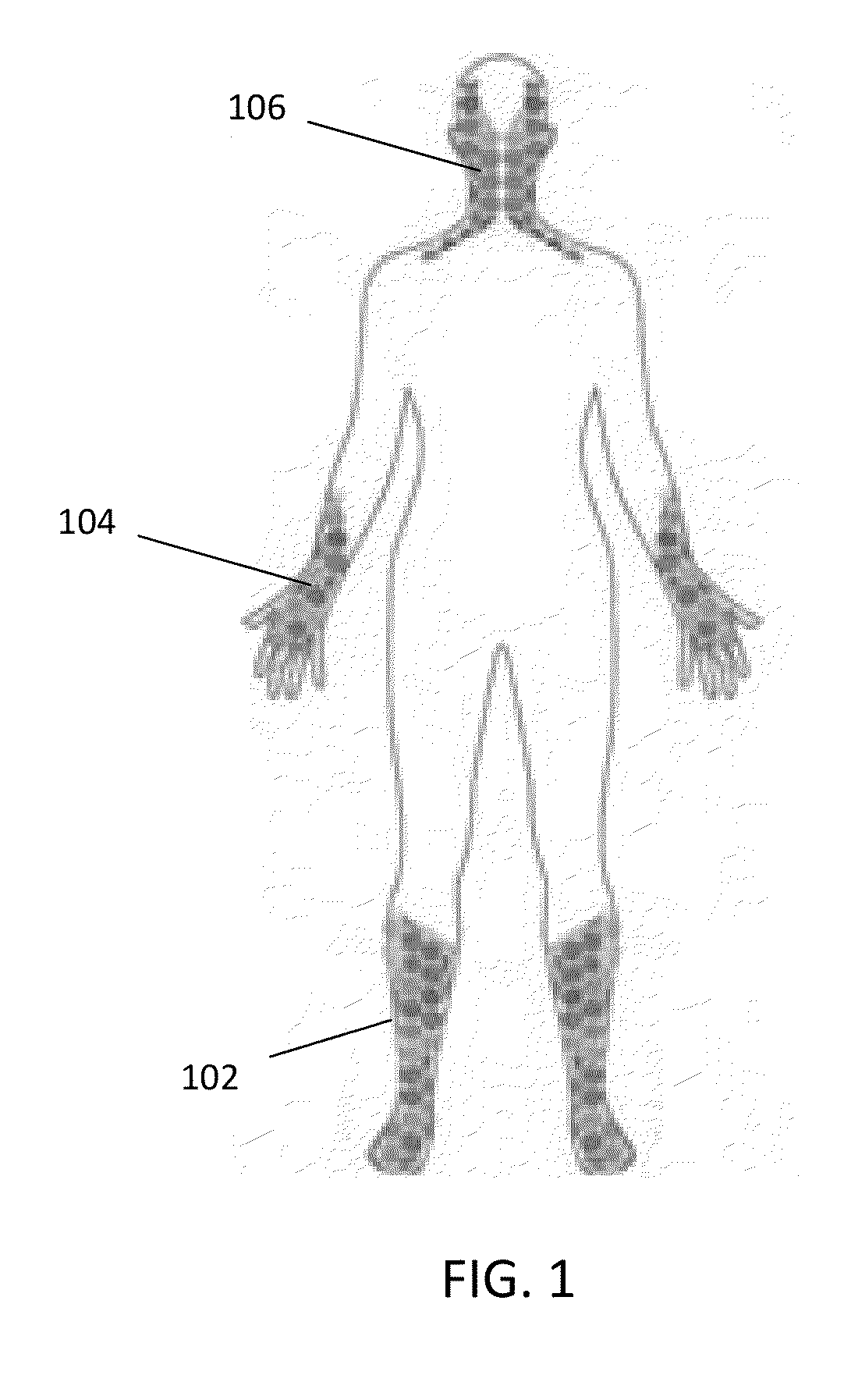

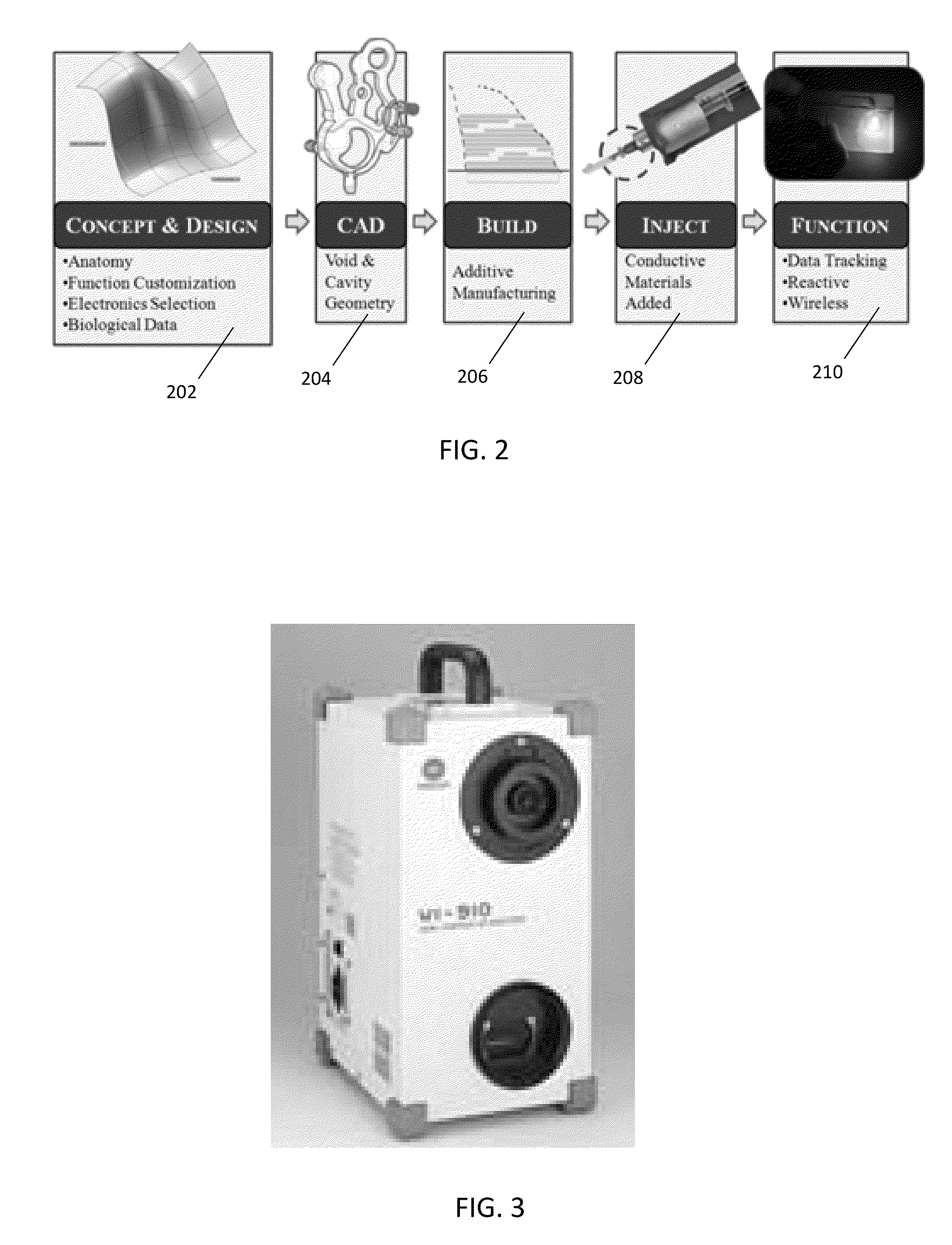

Customizable Embedded Sensors

InactiveUS20130079693A1Force measurement by permanent gauge deformationMeasurement apparatus componentsEngineeringEngineering physics

Owner:NORTHEASTERN UNIV

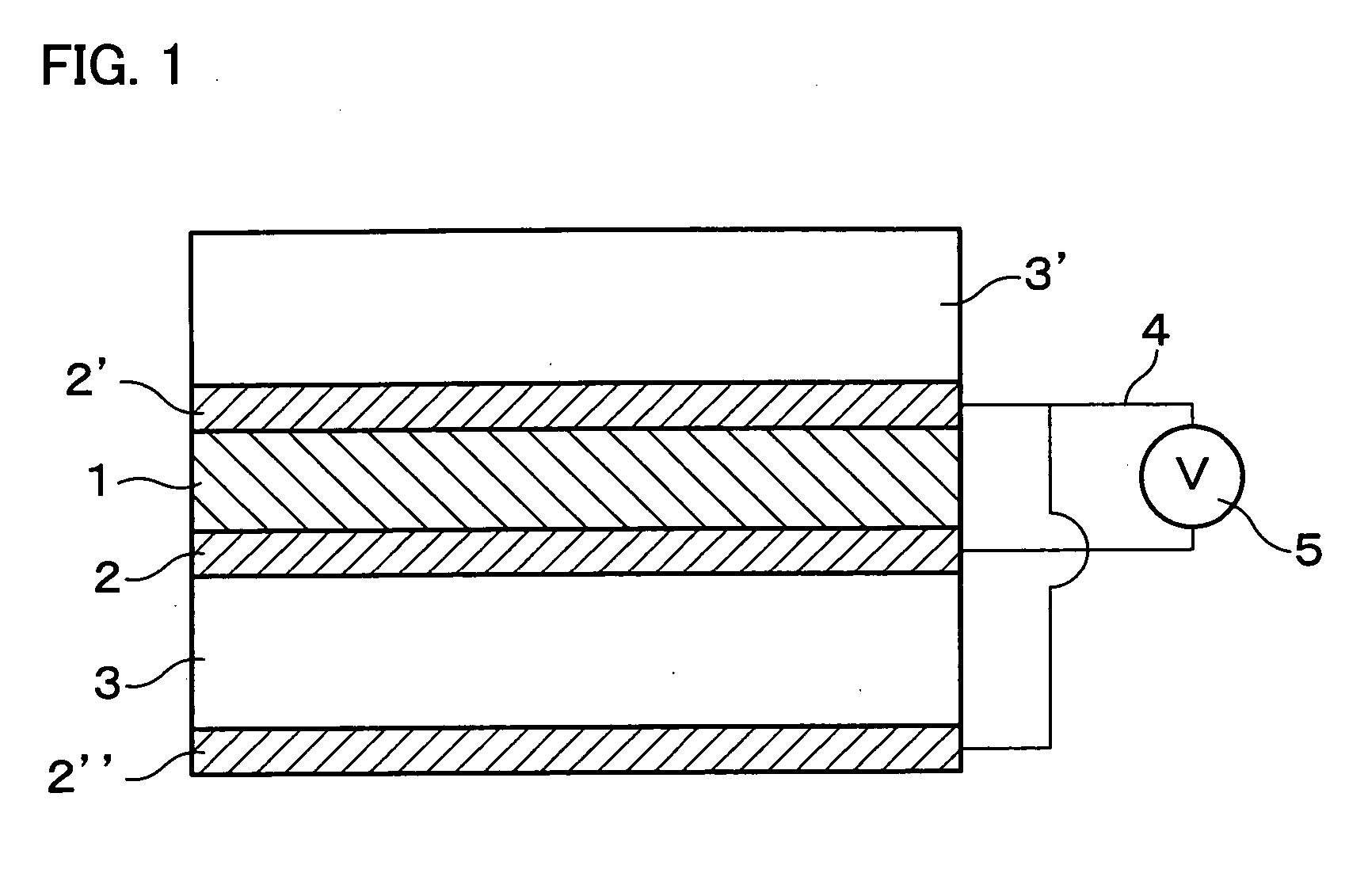

Piezoelectric sensor and input device comprising same

InactiveUS20060144154A1Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

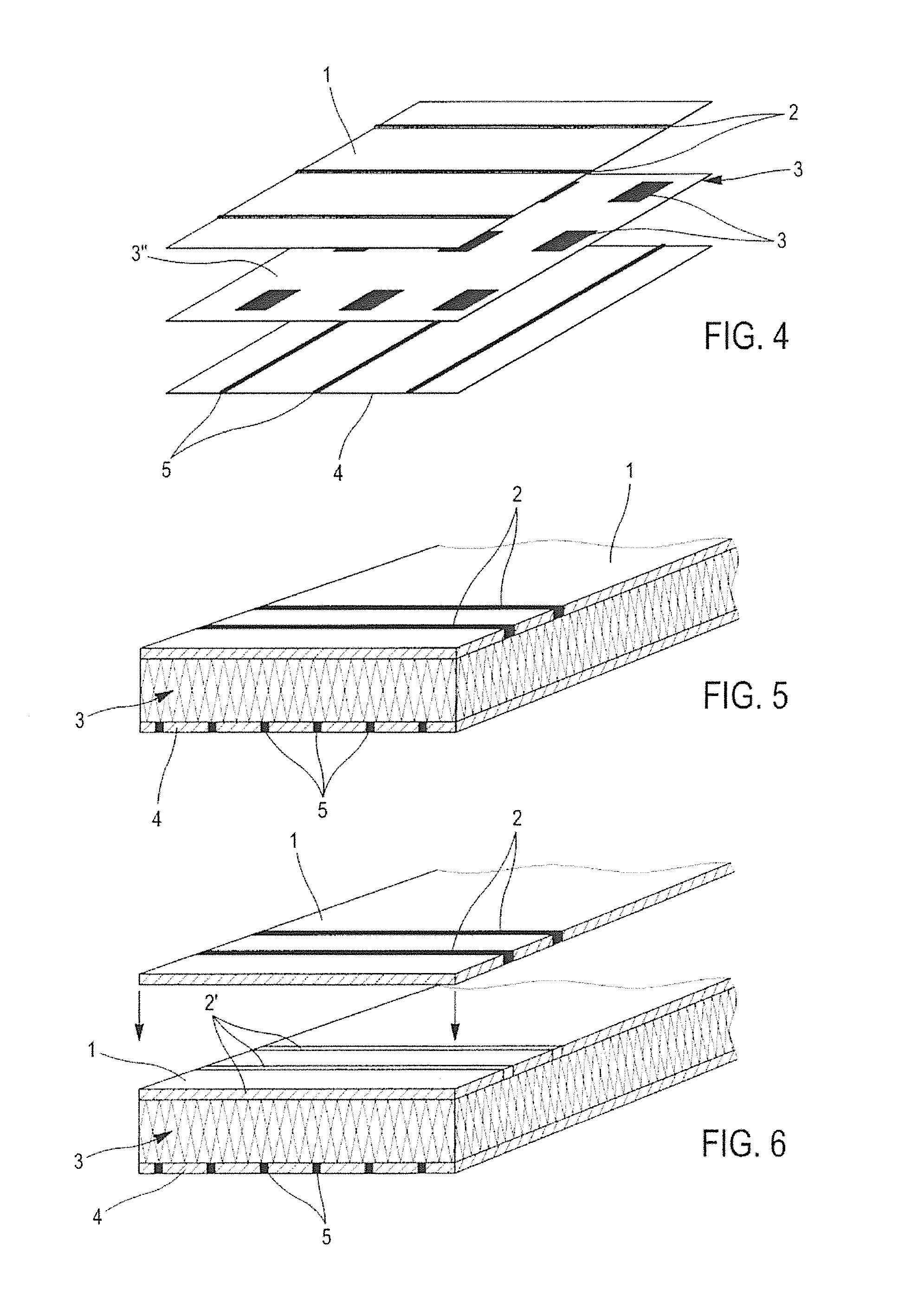

Device for Measuring Pressure from a Flexible, Pliable, and/or Extensible Object Made from a Textile Material Comprising a Measurement Device

ActiveUS20140150573A1Simple designLow costForce measurement using piezo-resistive materialsMulti-ply fabricsFiberElectrical resistance and conductance

A device and method for measuring the pressure exerted at different points of a flexible, pliable and / or extensible fabric capable of being worn as a garment, lapel, or the like, which provides three stacked layers including a first insulating layer comprising an arrangement of insulating fibers and at least one row of at least one conductive yarn in contact with a first surface of a piezoresistive layer of fibers of a piezoresistive material, and a second insulating layer comprising an arrangement of insulating fibers, including at least one row of at least one conductive yarn, in contact with a second surface of the piezoresistive layer, and an electronic circuit capable of measuring the electric resistance variation when a pressure is exerted on the fabric, the pressure being a function of the resistance variation.

Owner:TEXISENSE

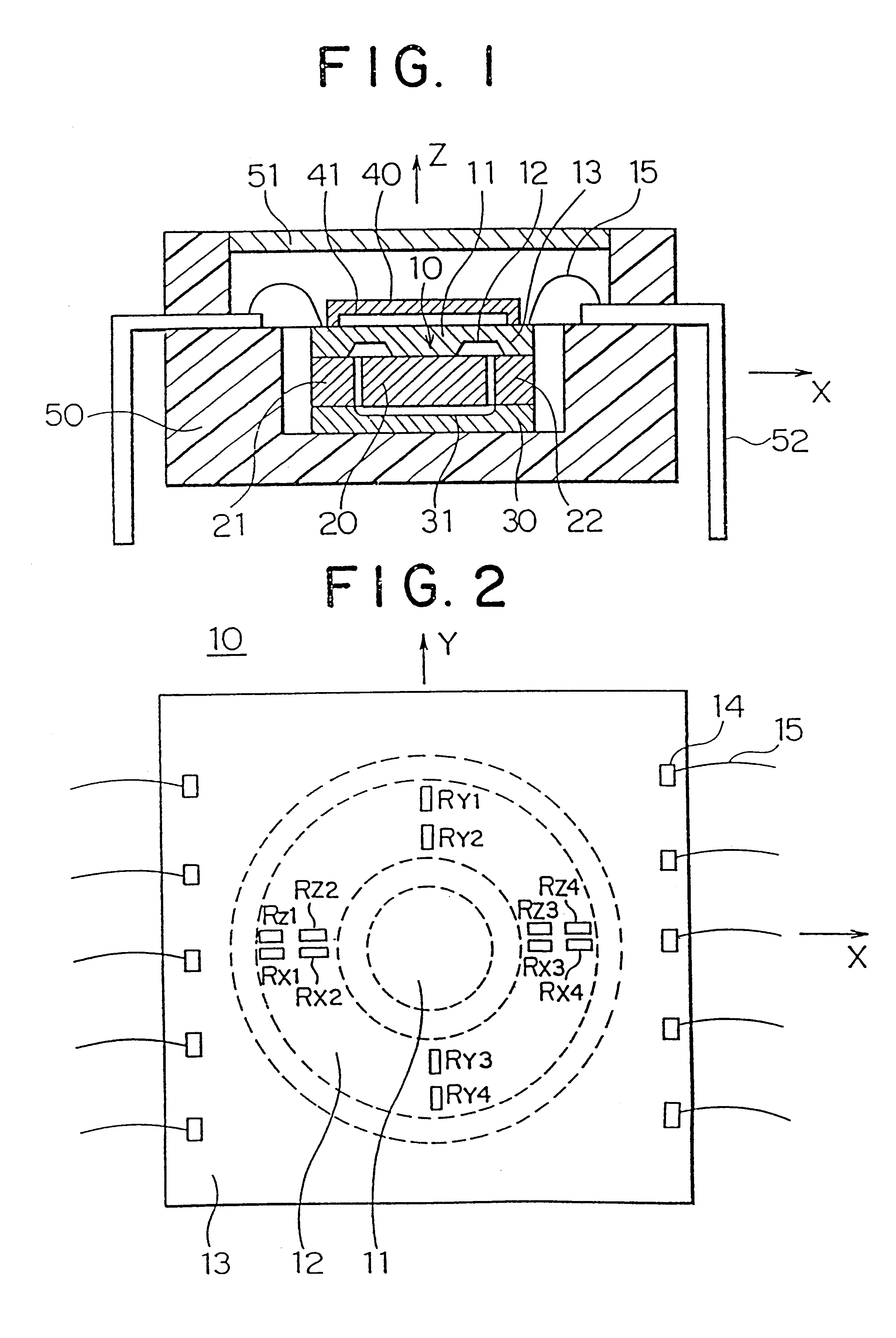

Method of manufacturing a sensor detecting a physical action as an applied force

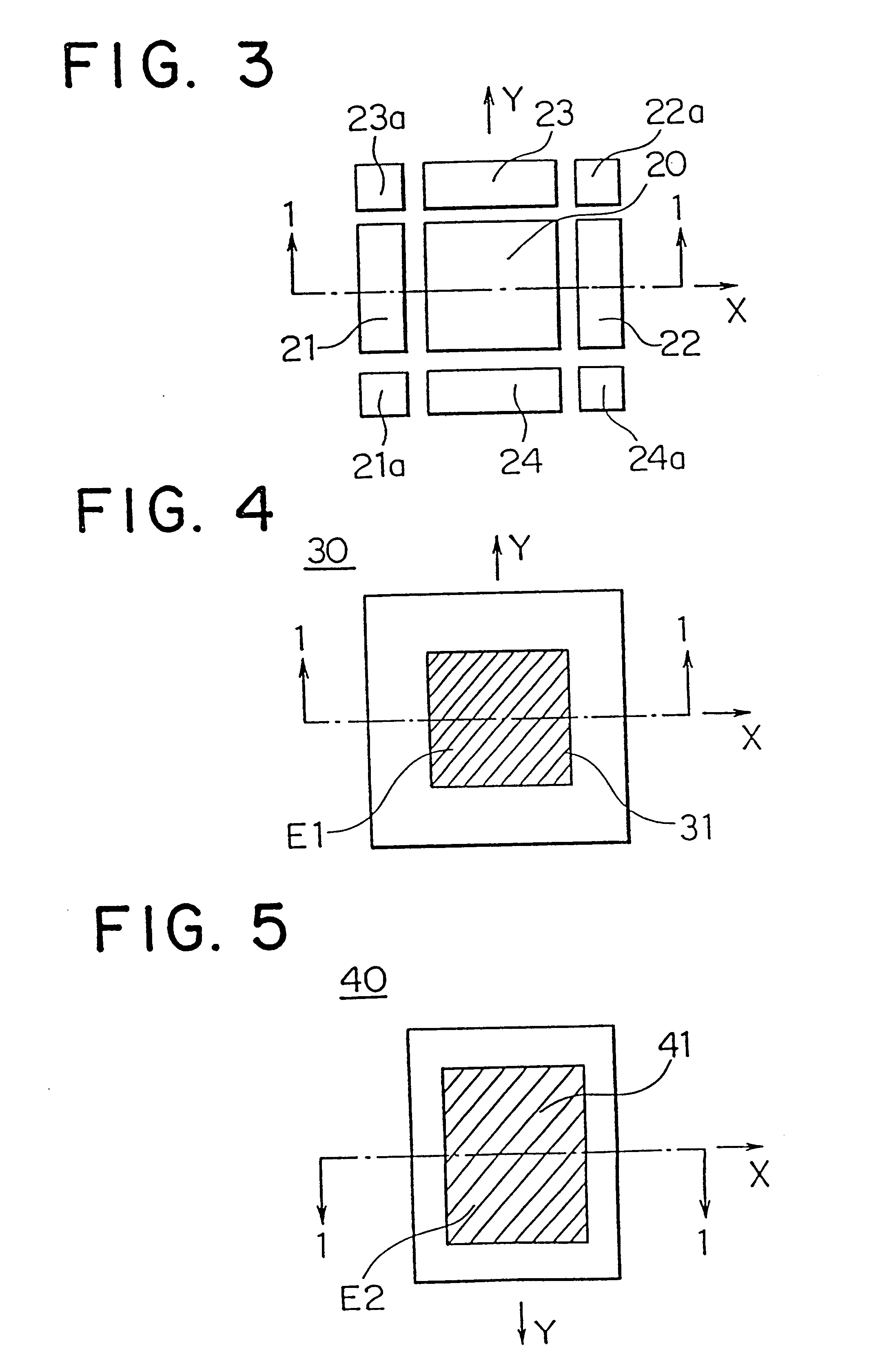

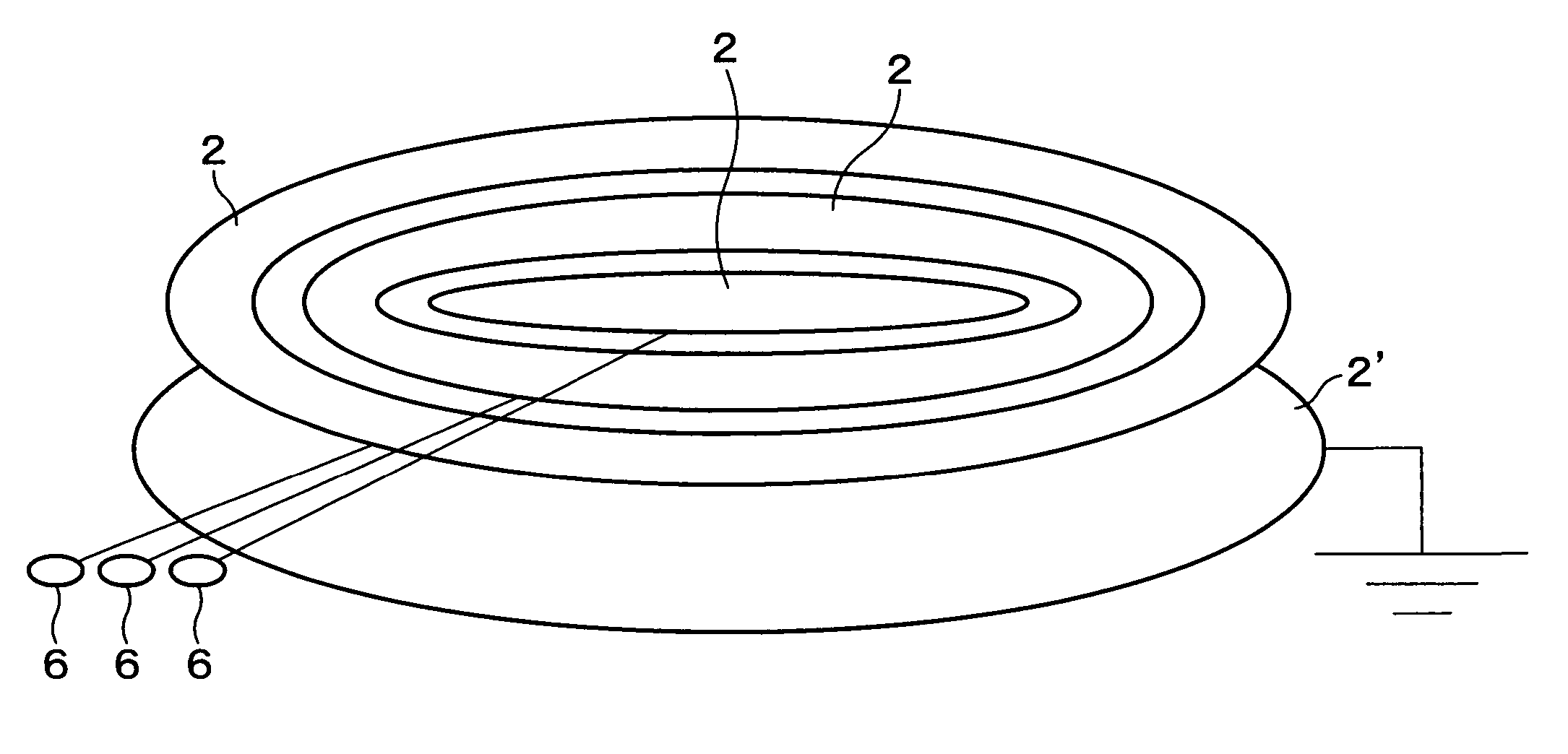

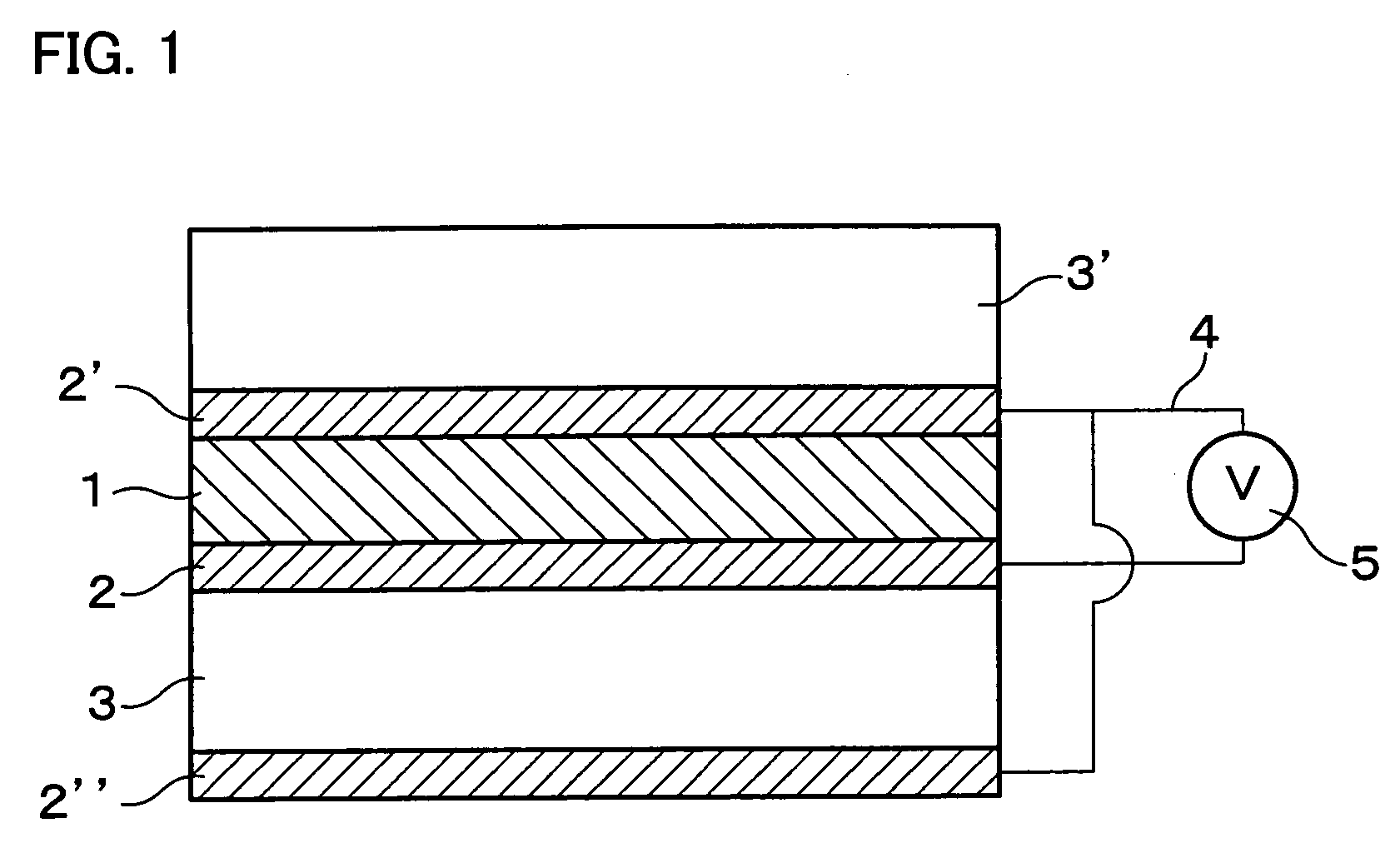

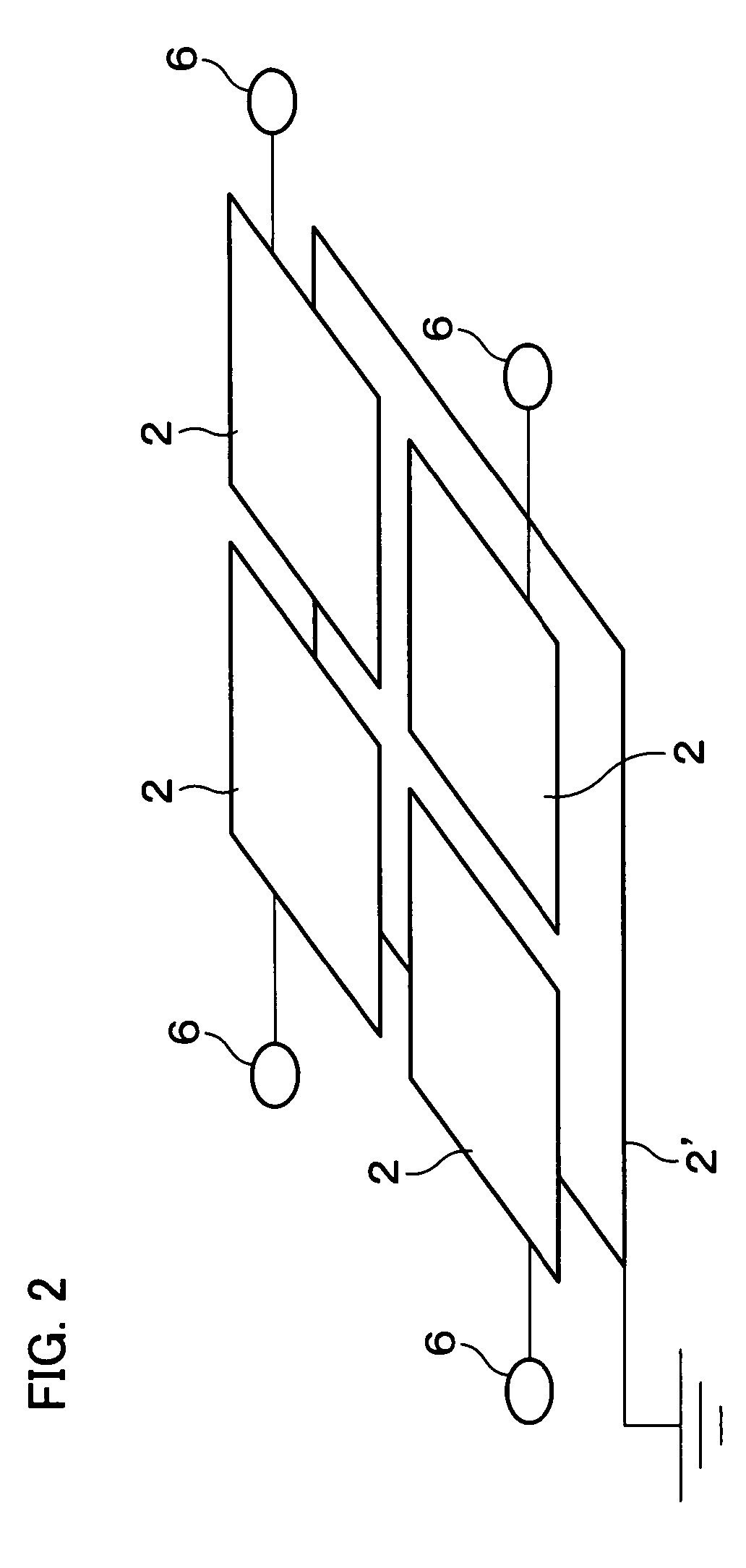

InactiveUS6185814B1Low costSimple circuit configurationAcceleration measurement using interia forcesForce measurement using piezo-resistive materialsSignal processing circuitsSemiconductor chip

A sensor comprises a semiconductor pellet (10) including a working portion (11) adapted to undergo action of a force, a fixed portion (13) fixed on the sensor body, and a flexible portion (13) having flexibility formed therebetween, a working body (20) for transmitting an exterted force to the working portion, and detector means (60-63) for transforming a mechanical deformation produced in the semiconductor pellet to an electric signal to thereby detect a force exerted on the working body as an electric signal. A signal processing circuit is applied to the sensor. This circuit uses analog multipliers (101-109) and analog adders / subtracters (111-113), and has a function to cancel interference produced in different directions. Within the sensor, two portions (E3, E4-E8) located at positions opposite to each other and producing a displacement therebetween by action of a force are determined. By exerting a coulomb force between both the portions, the test of the sensor is carried out. Further, a pedestal (21, 22) is provided around the working body (20). The working body and the pedestal are located with a predetermined gap or spacing therebetween. A displacement of the working body is caused to limitatively fall within a predetermined range corresponding to the spacing. The working body and the pedestal are provided by cutting a same common substrate (350, 350')

Owner:OKADA KAZUHIRO

Piezoelectric sensor and input device including same

InactiveUS7152482B2Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

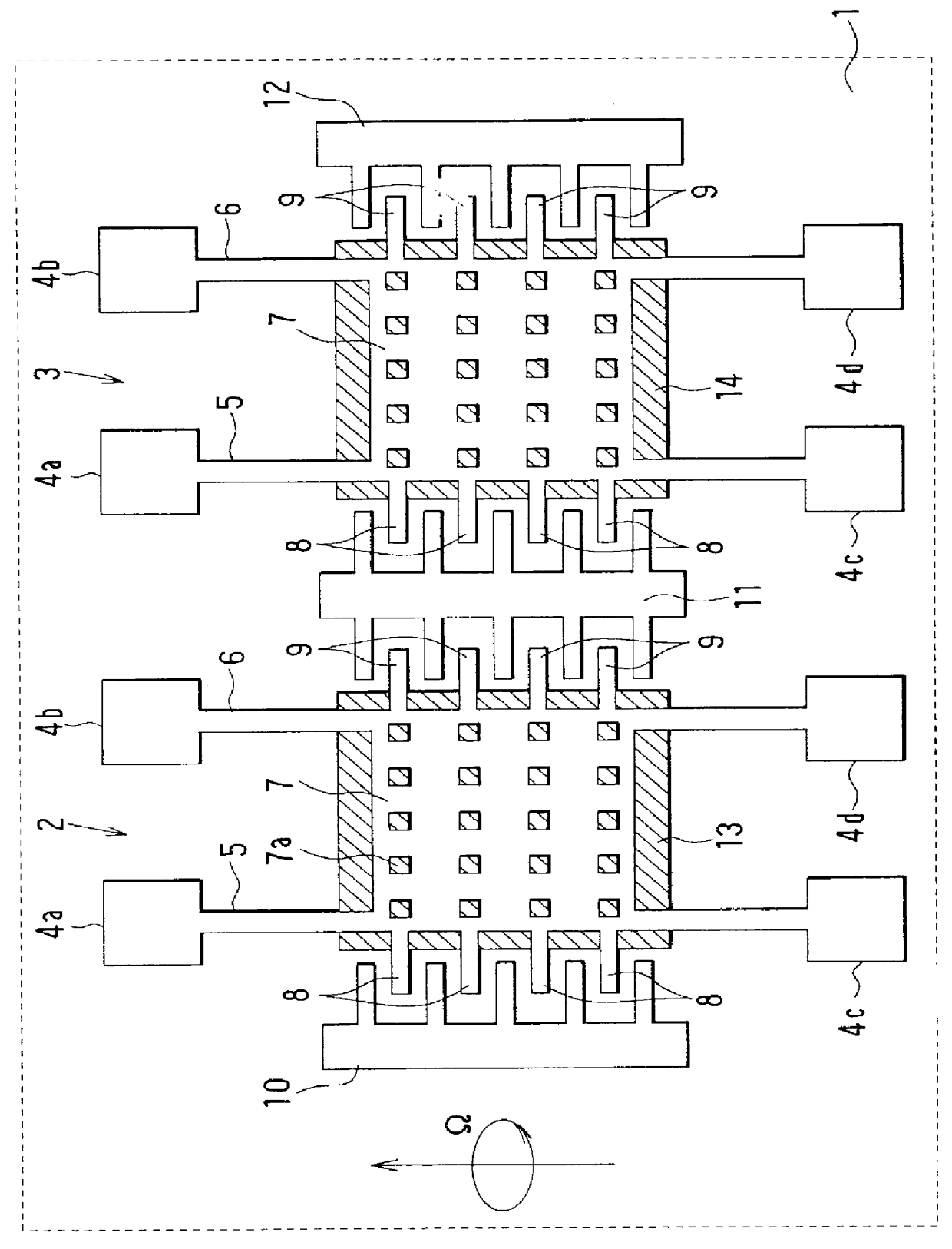

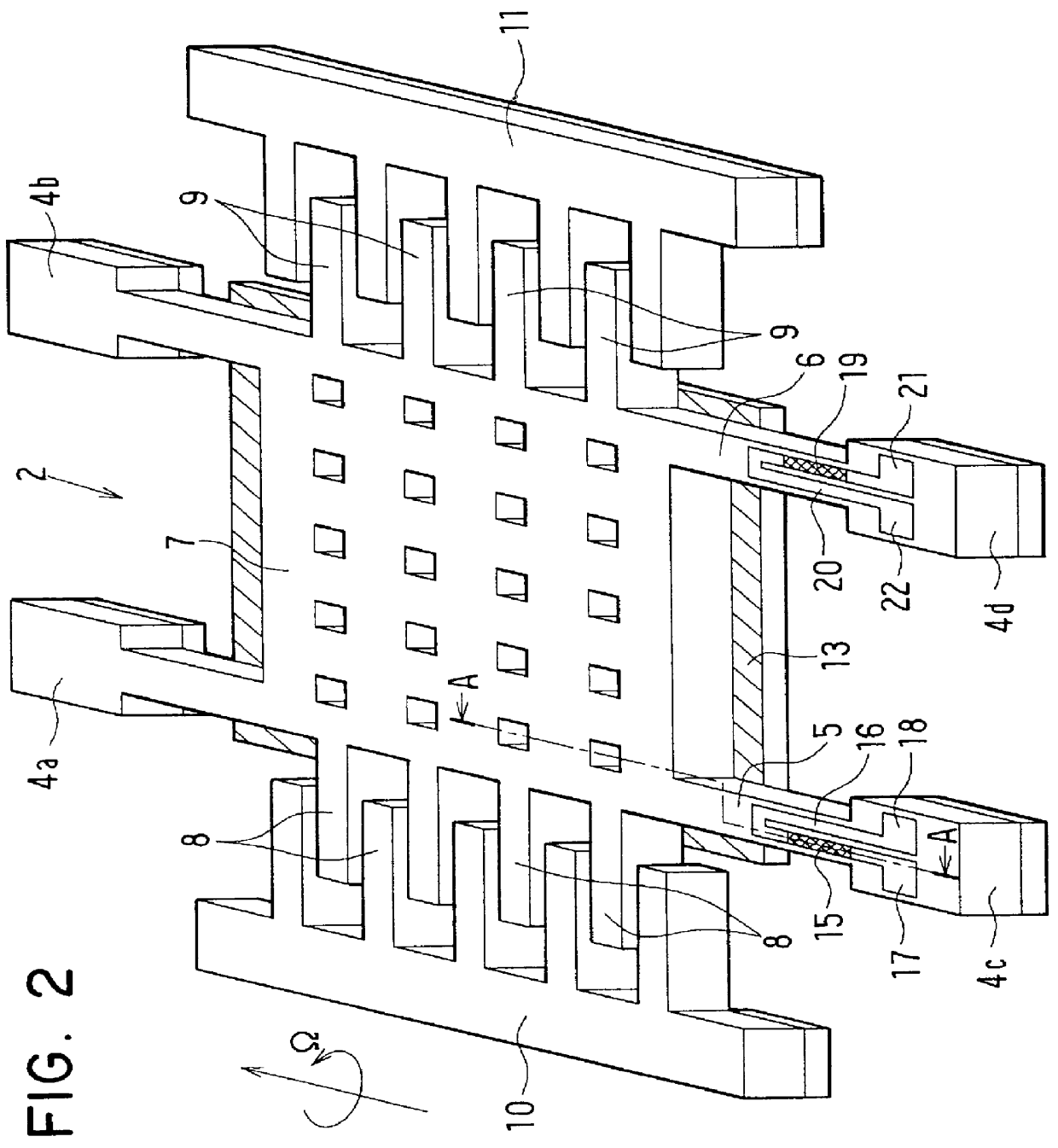

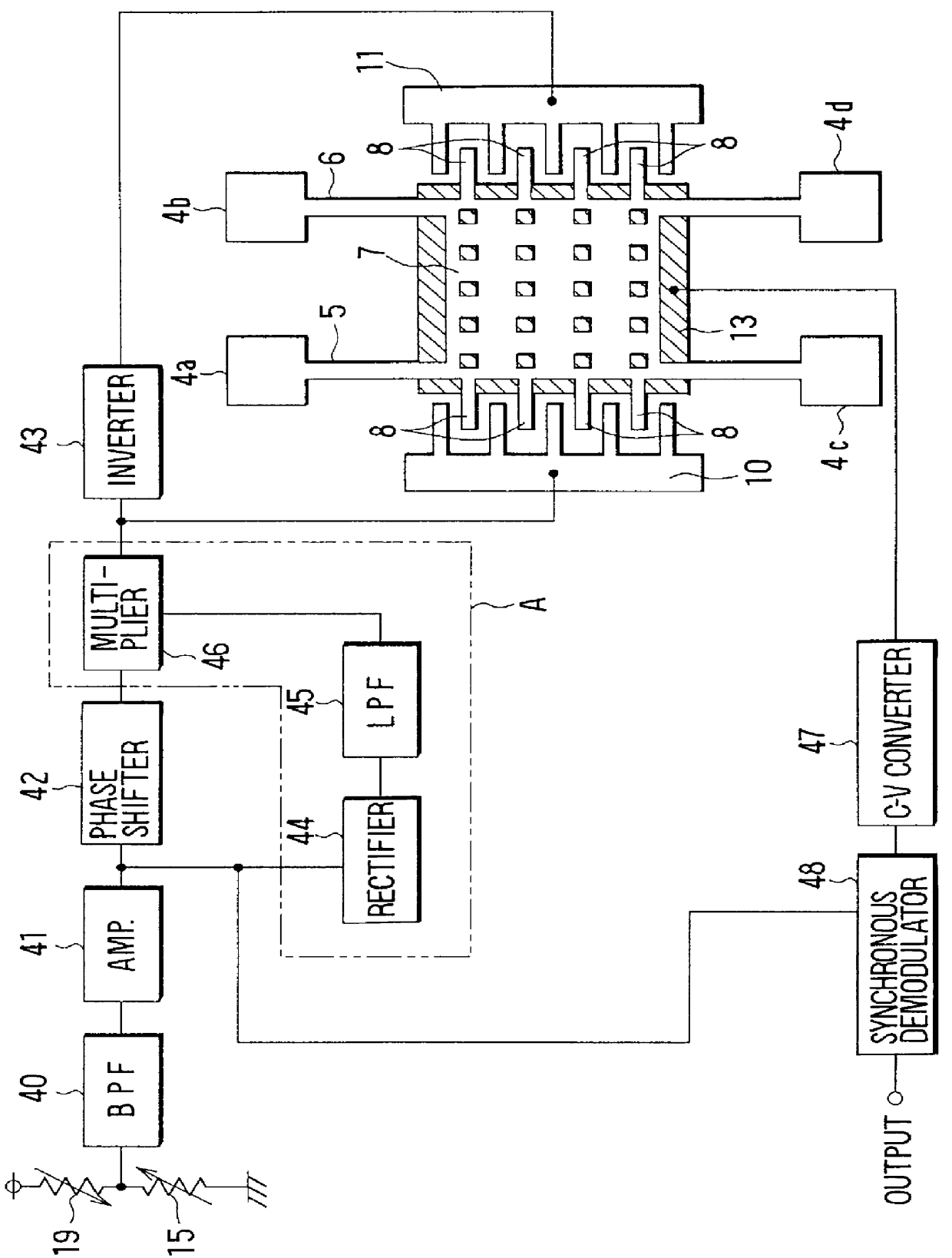

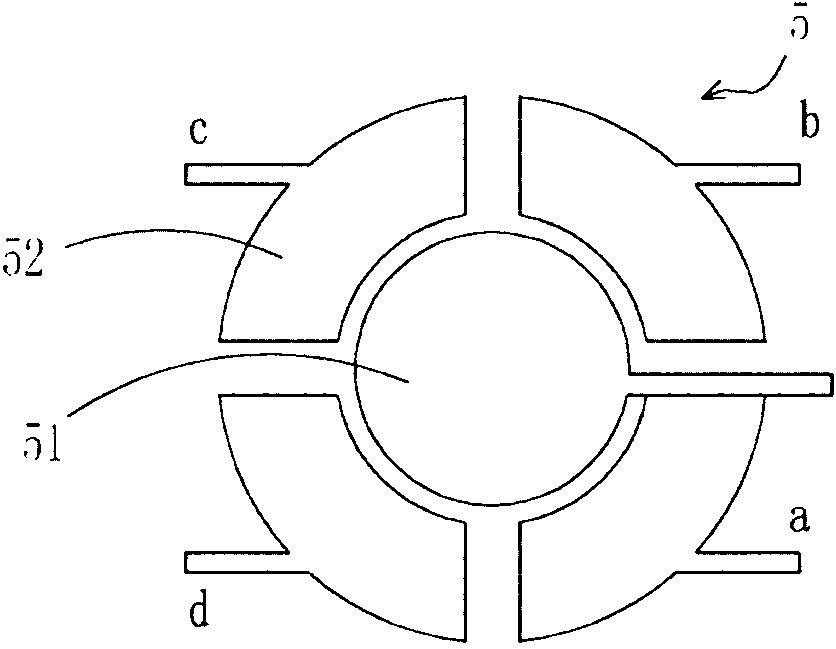

Semiconductor type yaw rate sensor

InactiveUS6028332AEasy to carryAccurate monitoringAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSemiconductor materialsEngineering

A semiconductor type yaw rate sensor has a substrate, a beam structure formed from a semiconductor material and having at least one anchor portion disposed on the substrate, a weighted portion located above the substrate a predetermined gap therefrom, and a beam portion which extends from the anchor portion and supports the weighted portion. A movable electrode is formed onto the weighted portion, and a fixed electrode is formed on the substrate in such a manner that the fixed electrode faces the movable electrode. When a drive voltage is applied between the movable electrode and the fixed electrode, the beam structure is forcibly caused to vibrate in a direction that is horizontal relative to a substrate surface plane. In this yaw rate sensor, a strain gauge to monitor forced vibration of the beam structure is formed in the beam portion. As a result, the forced vibration of the beam structure can be monitored with a simple structure.

Owner:DENSO CORP

Flexible pressure sensor and preparation method thereof

ActiveCN106197772AHigh sensitivityImprove reliabilityForce measurement using piezo-resistive materialsElectrical resistance and conductanceIsolation layer

The invention discloses a flexible pressure sensor which comprises an induction layer, a substrate layer, an isolation layer and electrodes. The isolation layer is positioned between the induction layer and the substrate layer and bonded to the induction layer and the substrate layer, and enables electric contact between the induction layer and the substrate layer to be isolated discontinuously; the surface of the induction layer is provided with a first conductive layer, the surface of the substrate layer is provided with a second conductive layer, and the first and second conductive layers are bonded to the isolation layer in opposite directions; and the electrodes are led out of the first or second conductive layer and connected with an external circuit. The flexible pressure sensor is used to detect the size and fluctuation of pressure, a flexible conductive material on the specific substrate is bonded to other conductive substrate, the electrodes are led out, change of resistance between the electrodes is measured, and the size and fluctuation of the pressure is detected in directly. The pressure sensor of high flexibility and high reliability can be applied to a flexible bearing body, technology is simple, and the sensor can be compatible with a present processing technology of a resistant screen to realize scaled production and application.

Owner:常州第六元素半导体有限公司

Flexible piezocapacitive and piezoresistive force and pressure sensors

InactiveUS8904876B2Facilitate measuring and mapping forcesFluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsCapacitanceDielectric

Owner:PATIENTECH LLC

Multifunctional flexible touch sensor

InactiveCN102175362ARealize multiple functionsRealize sensingThermometers using electric/magnetic elementsUsing electrical meansEngineeringTactile sensor

The invention discloses a multifunctional flexible touch sensor. The flexible touch sensor is characterized in that a flexible polyimide circuit board is used as a substrate; a three-dimensional force sensing unit array and a temperature sensing unit array are respectively arranged on the substrate; three-dimensional force sensing units in the three-dimensional force sensing unit array and temperature sensing units in the temperature sensing unit array are arranged at intervals; and the surface height of each temperature sensing unit is lower than the surface height of each three-dimensional force sensing unit, thereby forming the integral concave-convex distribution form. The full-flexibility multifunctional touch sensor disclosed by the invention has the advantages of excellent surface adaptability, high three-dimensional force measurement reliability, small cross interference of mechanics and temperature information.

Owner:HEFEI UNIV OF TECH

Pressure sensing or force generating device

ActiveUS8479585B2Few contactsDensely packedForce measurement using piezo-electric devicesUsing electrical meansCapacitive effectPressure sense

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

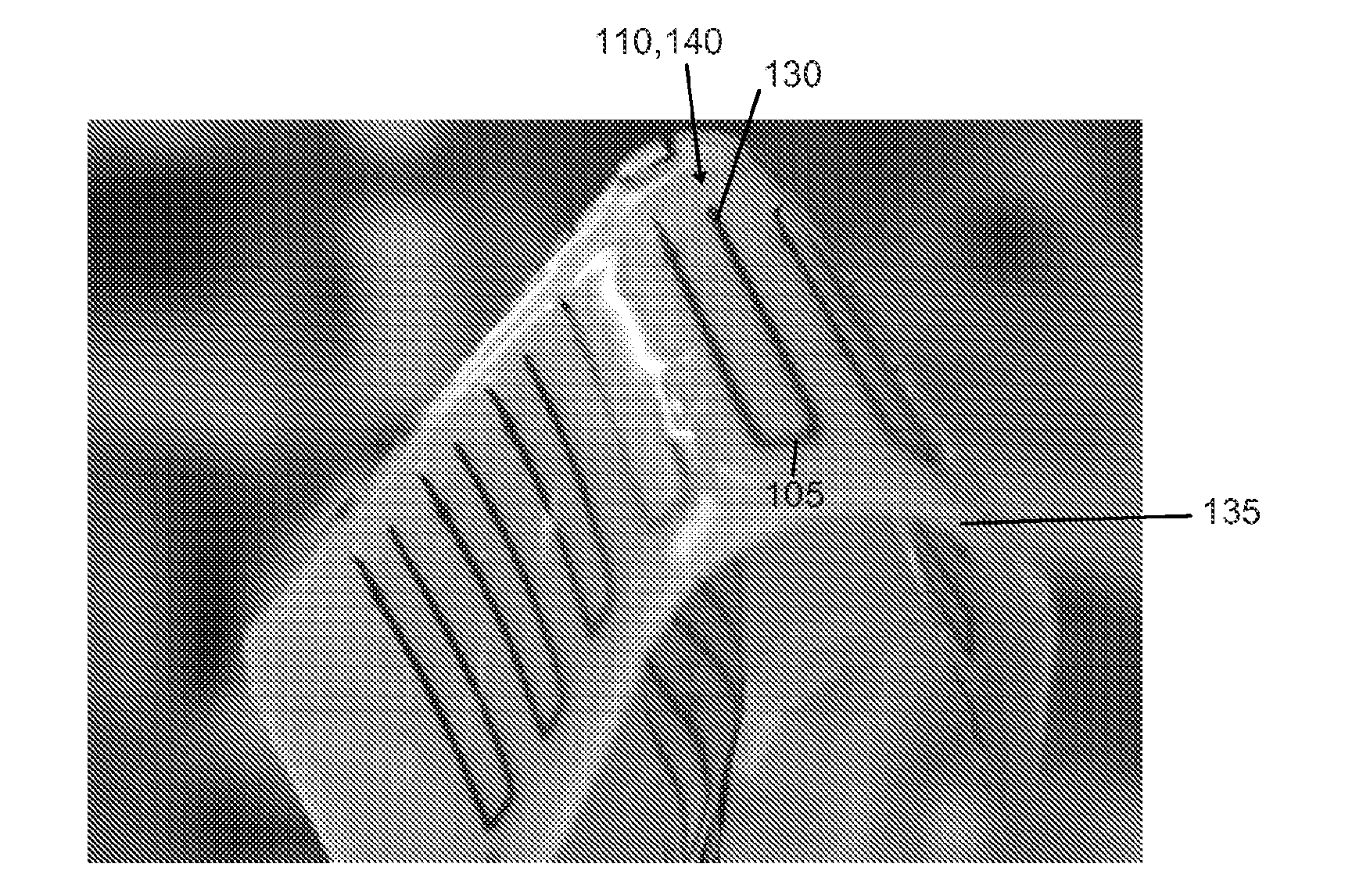

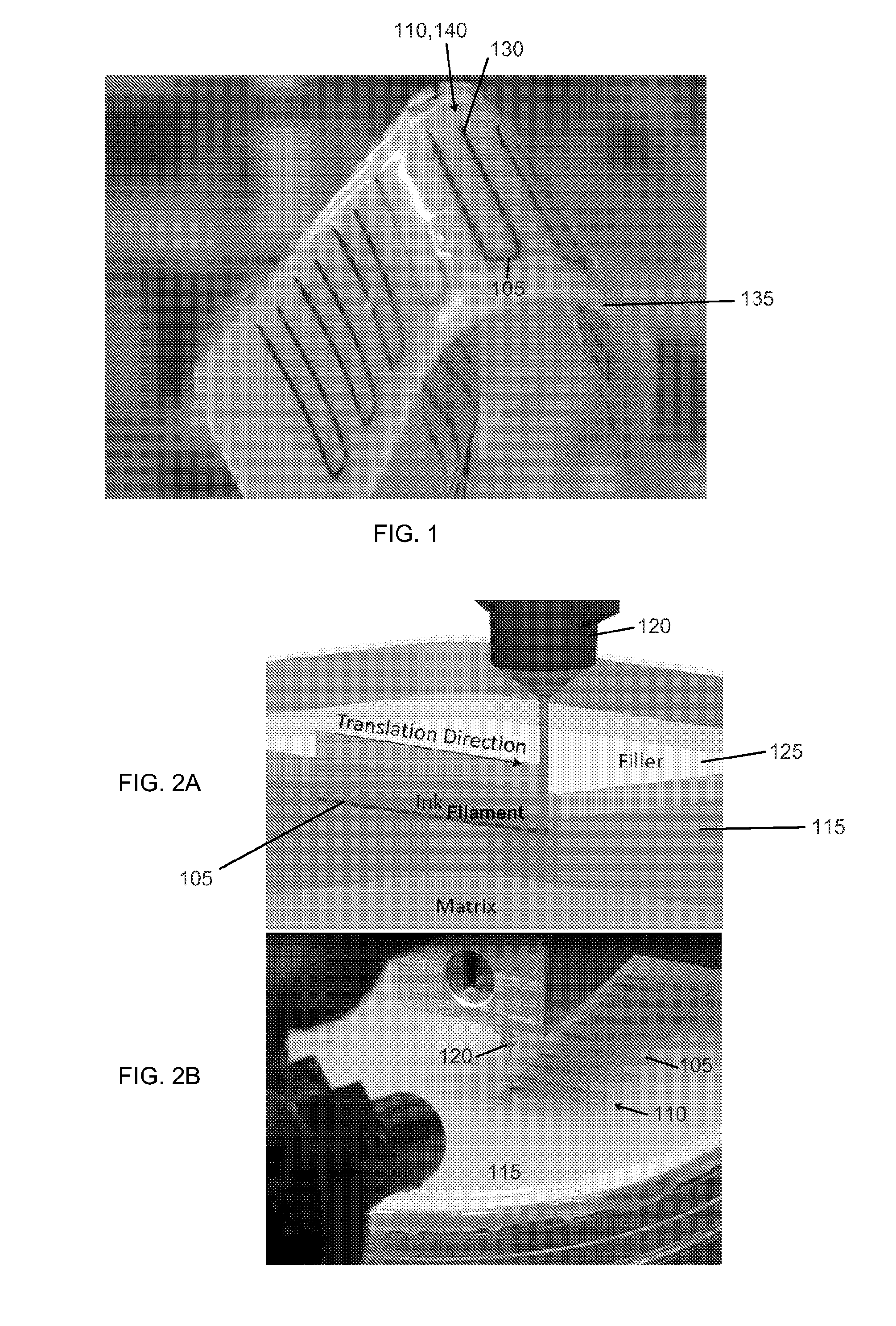

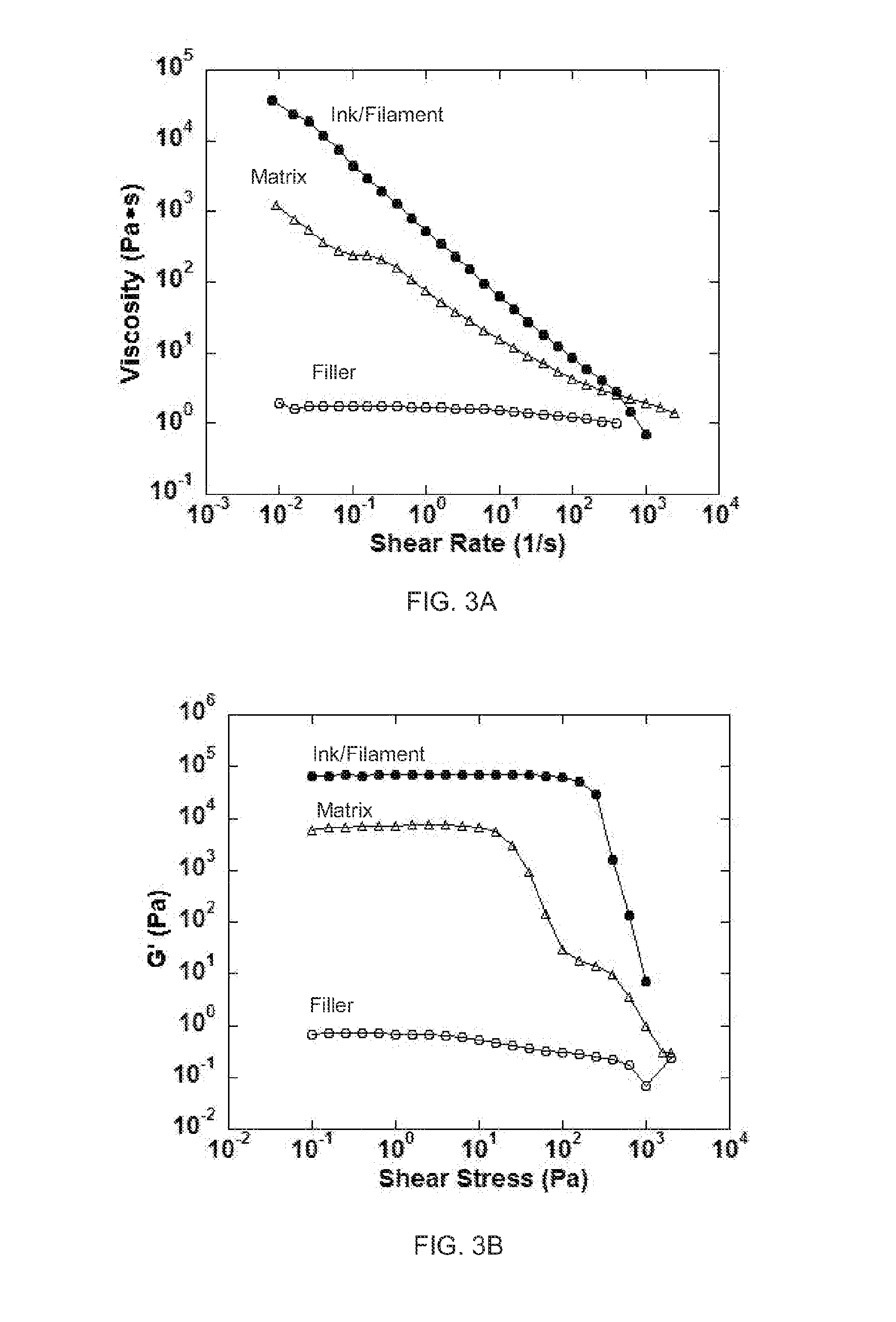

Printed stretchable strain sensor

ActiveUS20160290880A1Force measurement using piezo-resistive materialsInput/output processes for data processingSupport matrixEngineering

A printed stretchable strain sensor comprises a seamless elastomeric body and a strain-sensitive conductive structure embedded in the seamless elastomeric body. The strain-sensitive conductive structure comprises one or more conductive filaments arranged in a continuous pattern. A method of printing a stretchable strain sensor comprises depositing one or more conductive filaments in a predetermined continuous pattern into or onto a support matrix. After the depositing, the support matrix is cured to embed a strain-sensitive conductive structure in a seamless elastomeric body.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

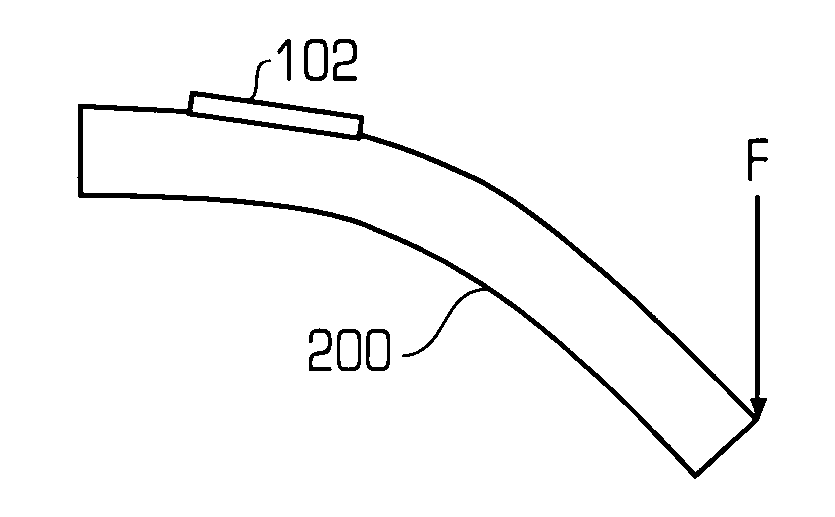

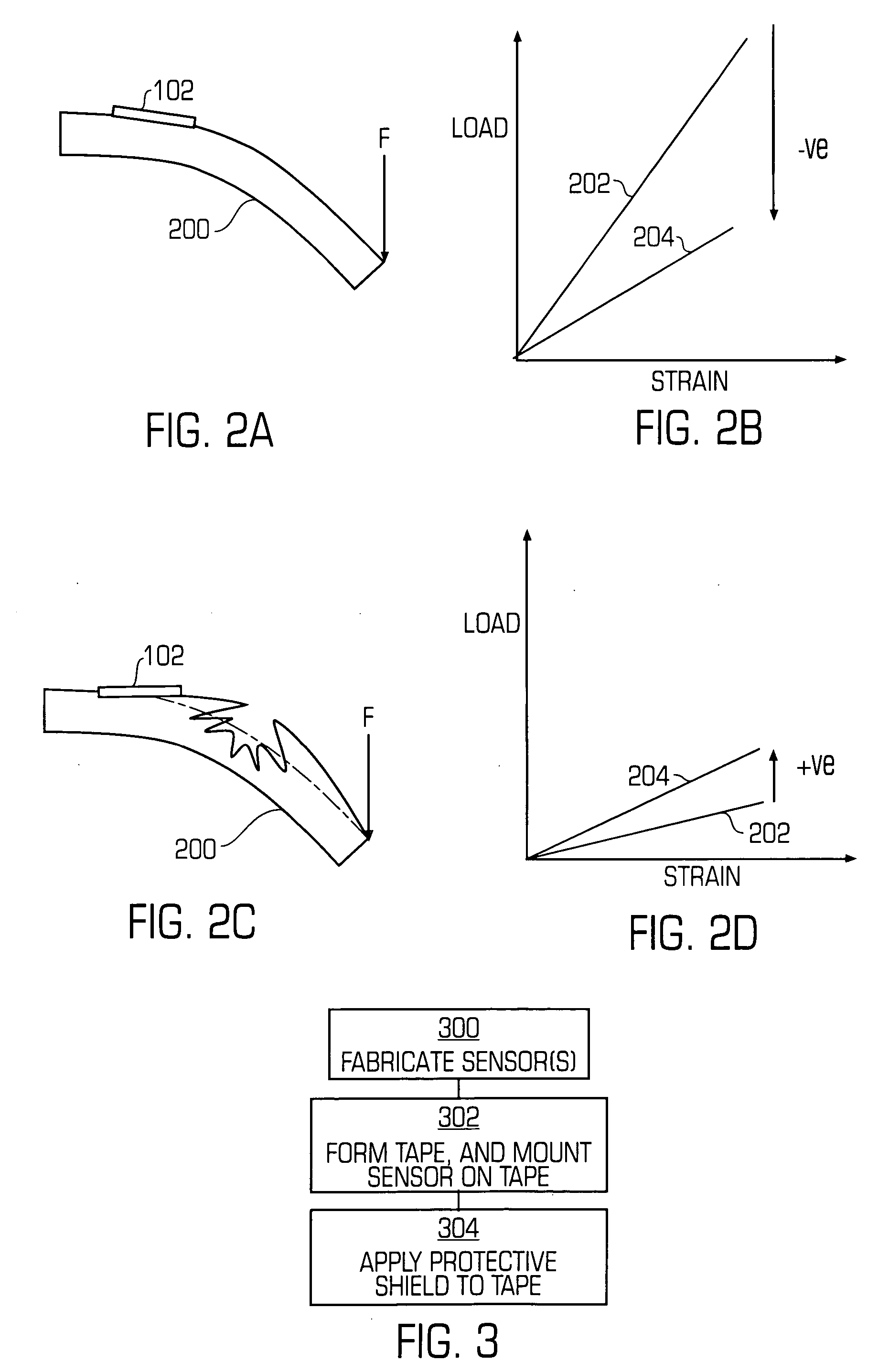

Miniature sensor

A strain sensing apparatus including a deformable substrate is presented. The deformable substrate is configured to detect a strain of the body that can be coupled to the deformable substrate. Sometimes, the deformable substrate is a flexible substrate having an upper surface and an opposite lower surface. The lower can be coupled to the body. There are sensing elements fabricated within the flexible substrate and proximate to the upper surface to detect properties of the body. The strain sensing apparatus is able to detect different strain modes, such as whether the strain is the result of bending of a body or a uniaxial elongation. Furthermore, the apparatus is small and less fragile than most conventional sensors, making it easy to use.

Owner:ANALATOM

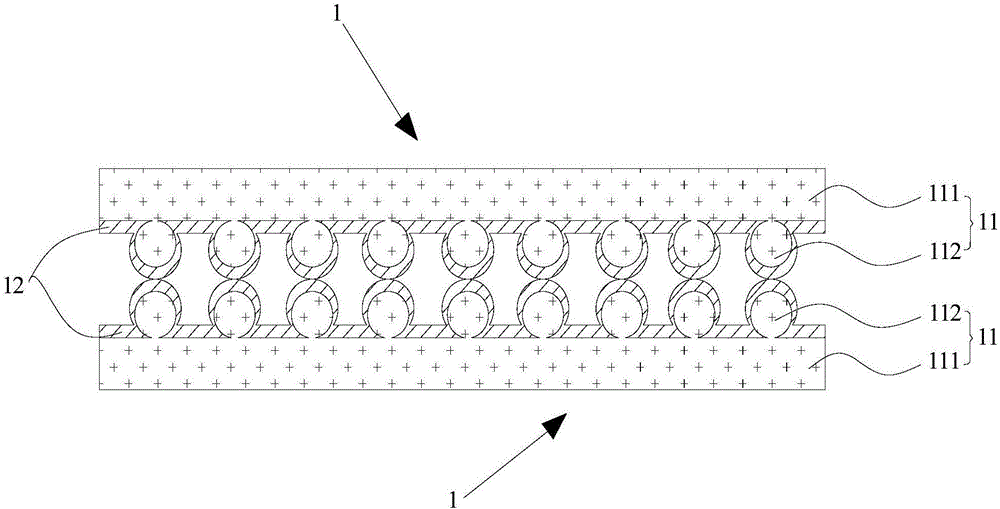

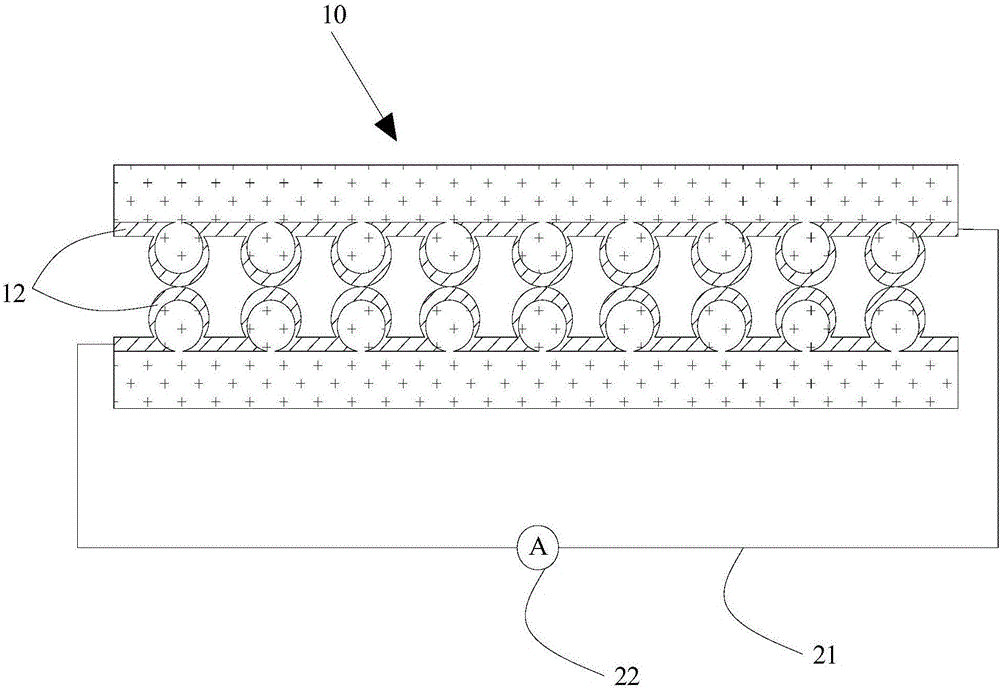

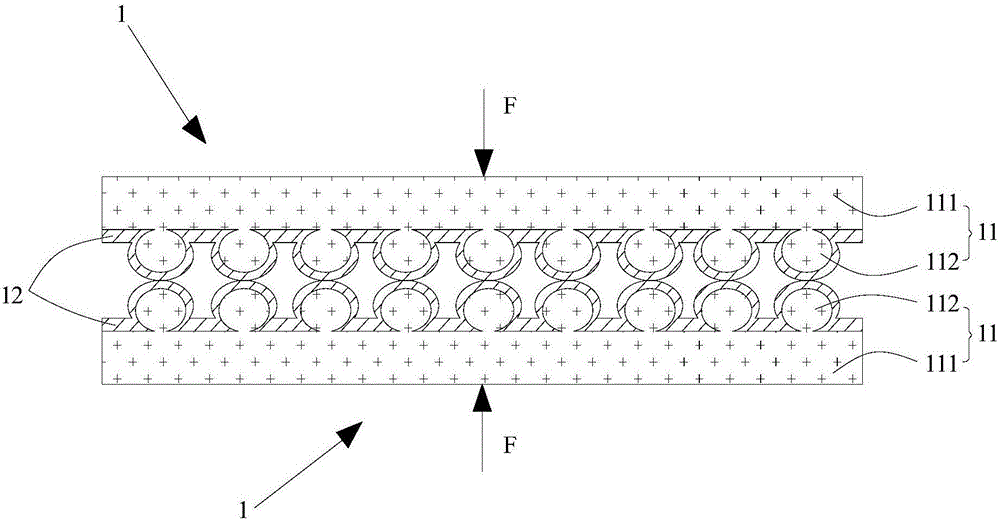

Conductive-rubber-based flexible array clip pressure sensor and manufacturing method

InactiveCN102207415AReduce weightLow costForce measurement using piezo-resistive materialsOther printing apparatusElectrical resistance and conductanceScreen printing

The invention relates to a conductive-rubber-based flexible array clip pressure sensor and a manufacturing method. In the conductive-rubber-based flexible array clip pressure sensor, upper and lower electrode wires and electrode rings are printed on an upper electrode layer and an electrode layer; the electrode ring is provided with a rubber voltage-sensitive unit; a silicon rubber liner is arranged at the position where sensitive elements do not exist; the rubber voltage-sensitive unit is nested into the silicon rubber liner; the upper and lower electrode wires are led and connected to an electrode lead-out head; the upper and lower electrode layers are sealed by high viscose; and when force acts on the rubber voltage-sensitive unit, the rubber voltage-sensitive unit is compressed and deformed due to stress, so a resistance value of the rubber voltage-sensitive unit is changed, and pressure or concentrated loads at the point contact position can be reflected according to the variablequantity of the resistance value on the rubber voltage-sensitive unit relative to an initial resistance value. By a manufacturing method based on a silk-screen printing process, the flexible array clip sensor has the characteristics of light weight, low cost, simple manufacturing and mass production, and is long in service life and convenient to operate.

Owner:XI AN JIAOTONG UNIV

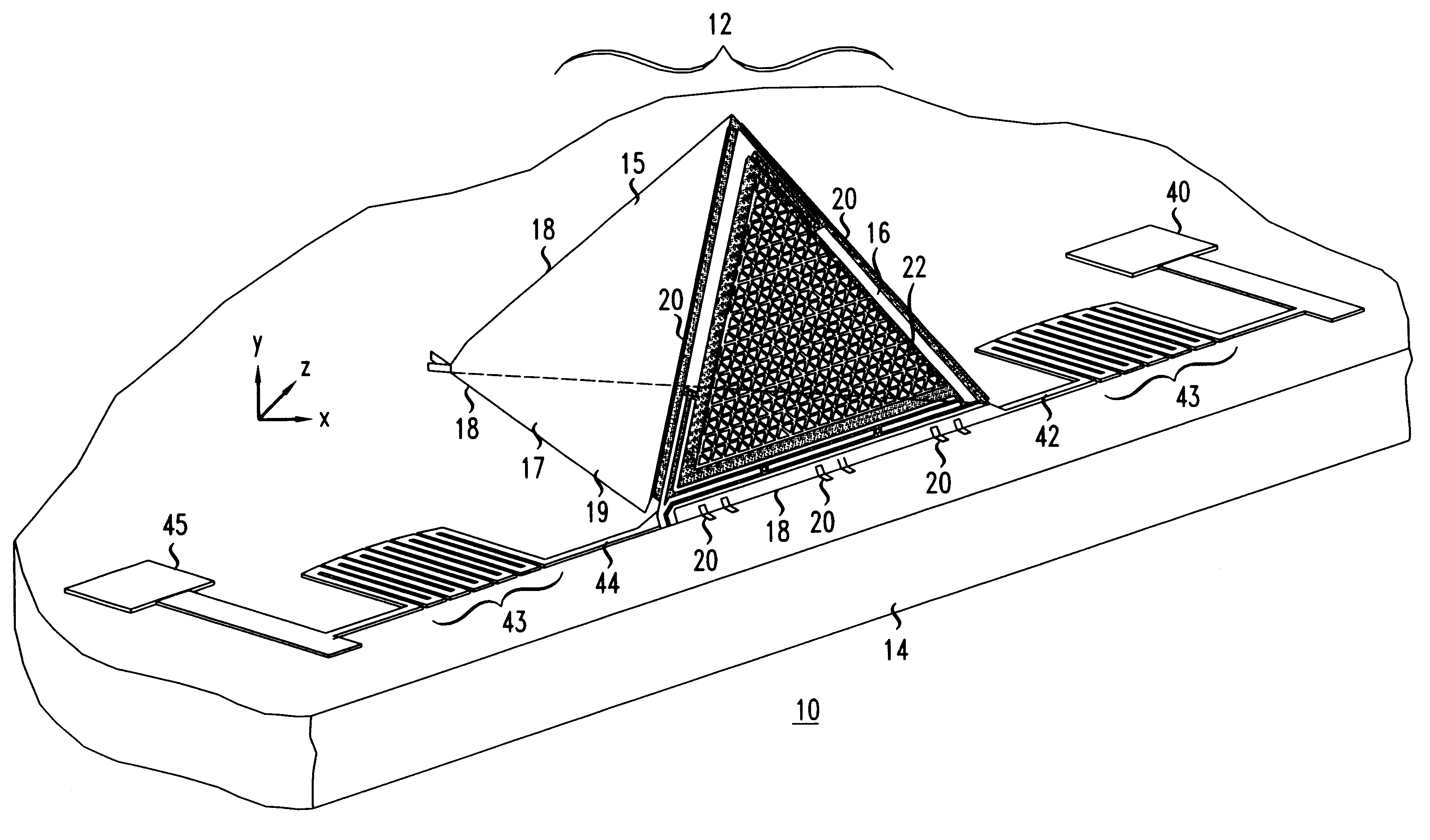

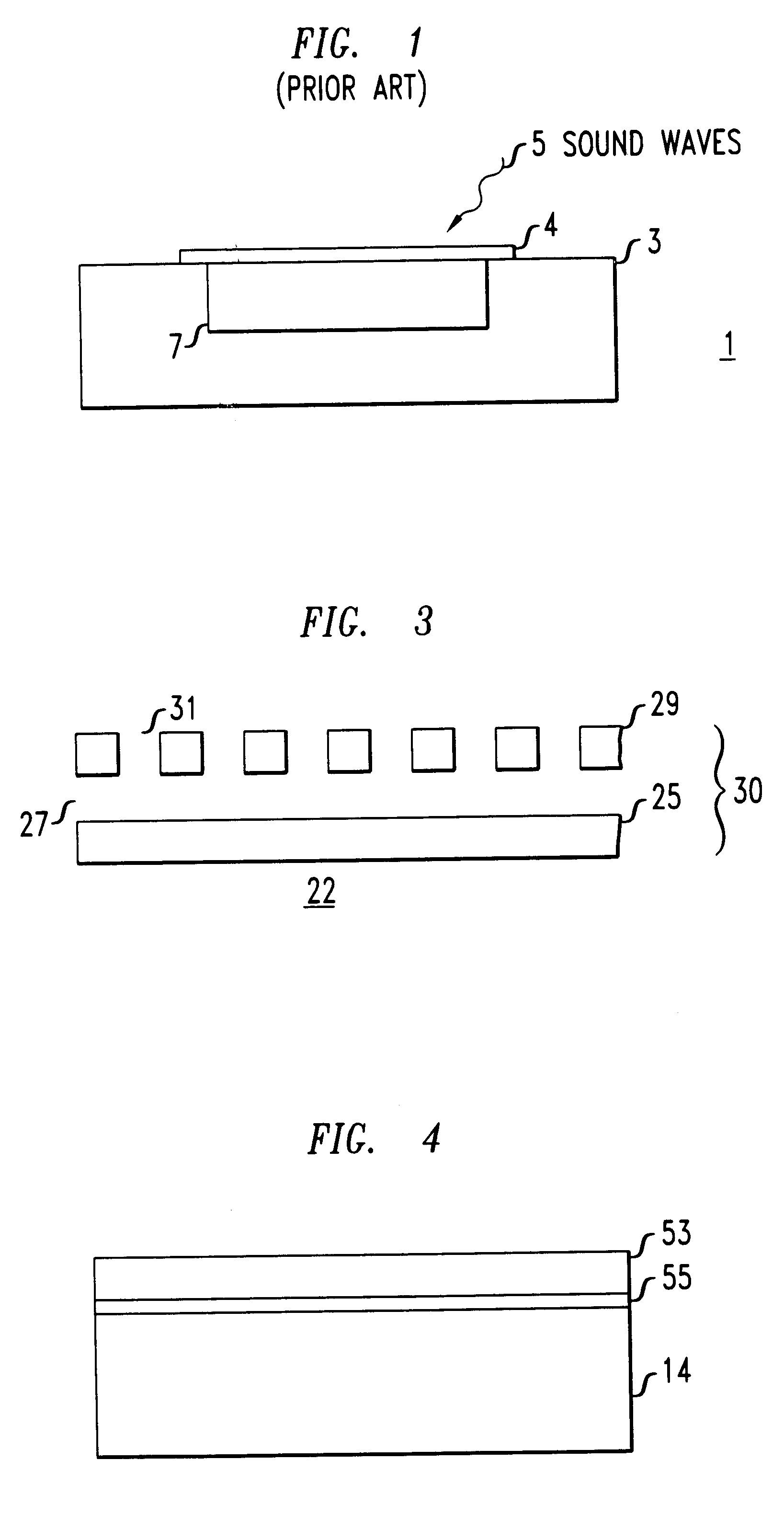

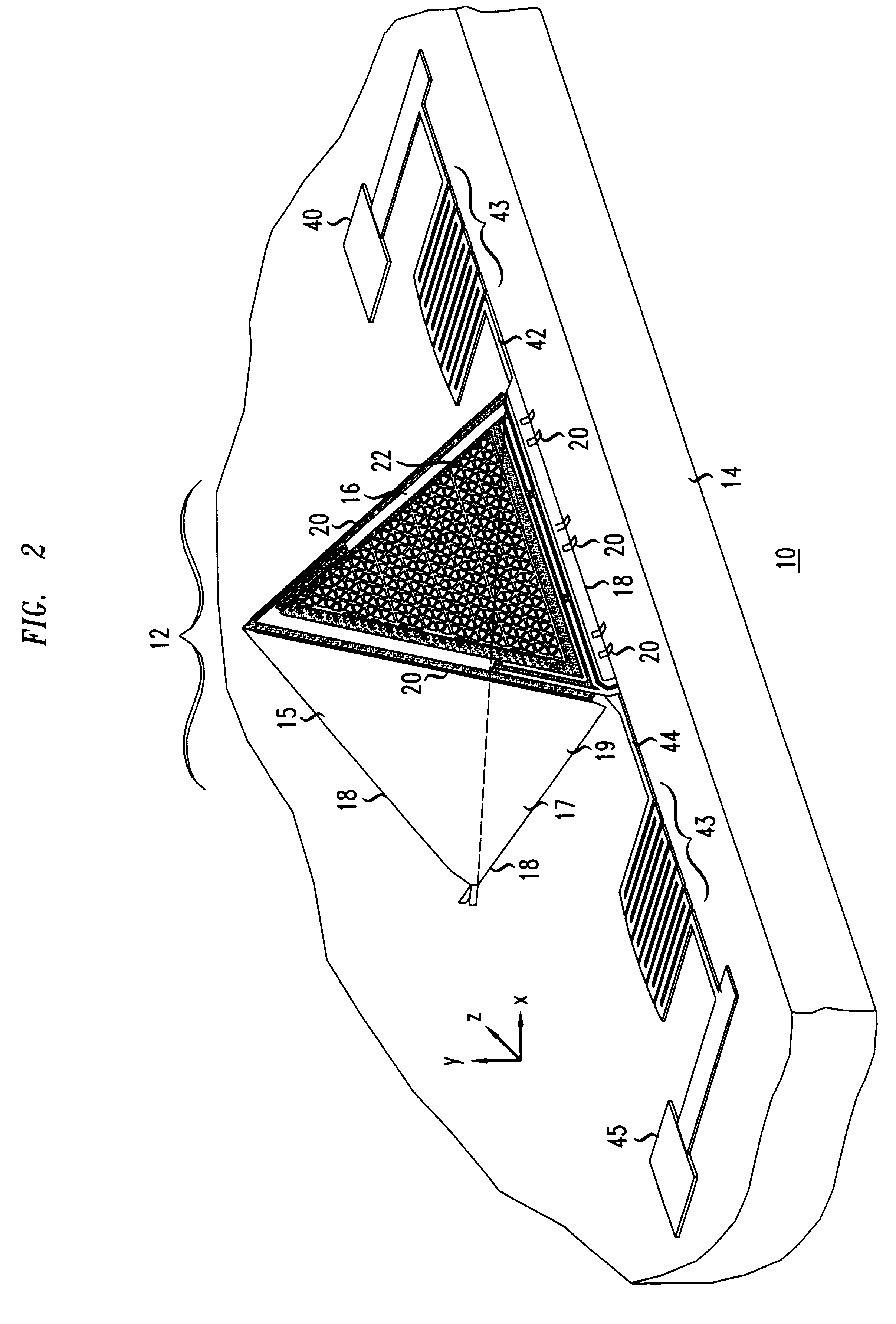

Surface micro-machined acoustic transducers

InactiveUS6249075B1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTransducerAcoustic cavity

A micro-machined transducer having a structure in which an acoustic enclosure is formed on a substrate above the plane of the substrate surface is disclosed. Forming the acoustic enclosure on the substrate above the plane of the substrate surface, rather than an acoustic cavity in a surface of the substrate, provides an acoustic cavity whose size is not limited by the thickness of the substrate.

Owner:LUCENT TECH INC +1

Flexible piezoresistive touch sensor array and preparation method thereof

ActiveCN106197774AIncreased pressure sensitivityImprove electrical isolationForce measurement using piezo-resistive materialsSensor arrayLow voltage

The invention provides a flexible piezoresistive touch sensor array and a preparation method thereof. The sensor array comprises N*N separated piezoresistive layers and a coplanar electrode layer. The piezoresistive layers are arranged on the coplanar electrode layer. Each piezoresistive layer comprises an upper finger pressing layer, a middle sensitive layer and a bottom sensitive layer, wherein the three layers are each provided with a micro pyramid; the coplanar electrode layer comprises a polymer electrode substrate and N*N gold electrode pairs located on the polymer electrode substrate. The piezoresistive layers adopt polymer films with the micro pyramid, and due to the three-layer structure, the sensitivity of the sensor at the low-voltage region can be greatly improved. In addition, in order to overcome the defect that a traditional touch sensor is large in crosstalk due to a sandwiched structure, the coplanar electrode layer is adopted, all electrodes are located on the same plane, each piezoresistive layer is attached to the corresponding electrode pair, the piezoresistive units are completely separated, and the sensitivity and anti-interference capacity of the sensor are effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

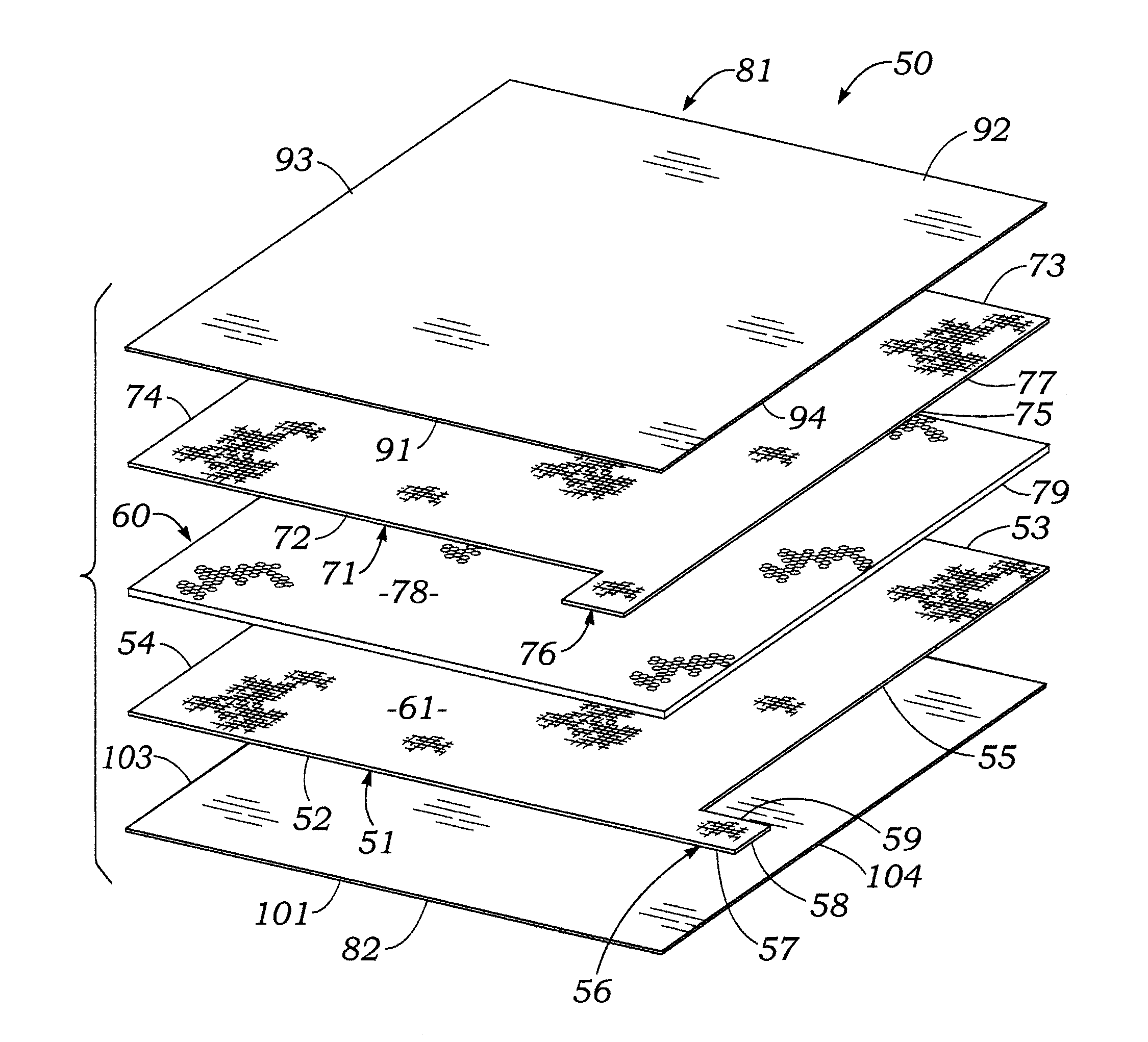

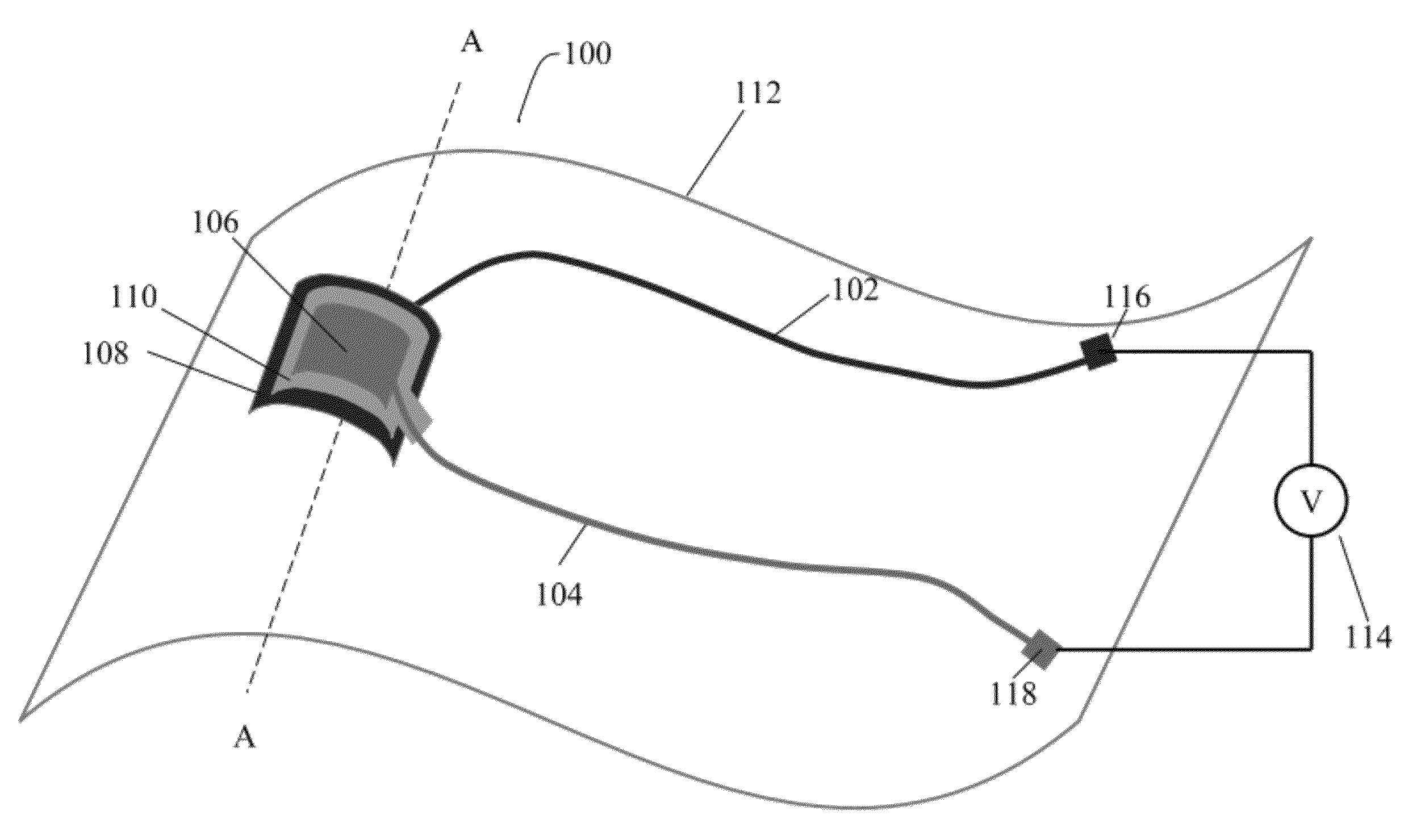

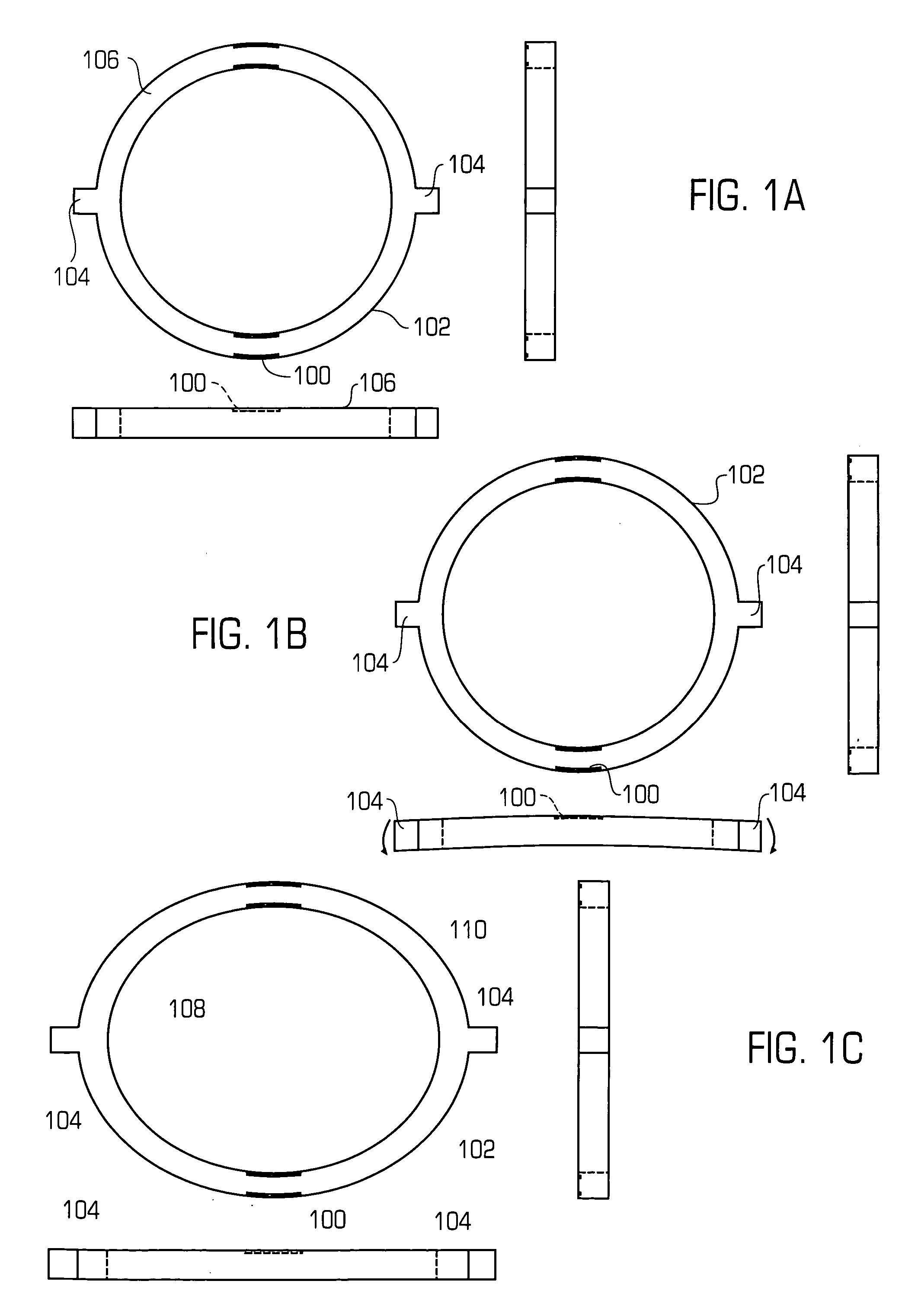

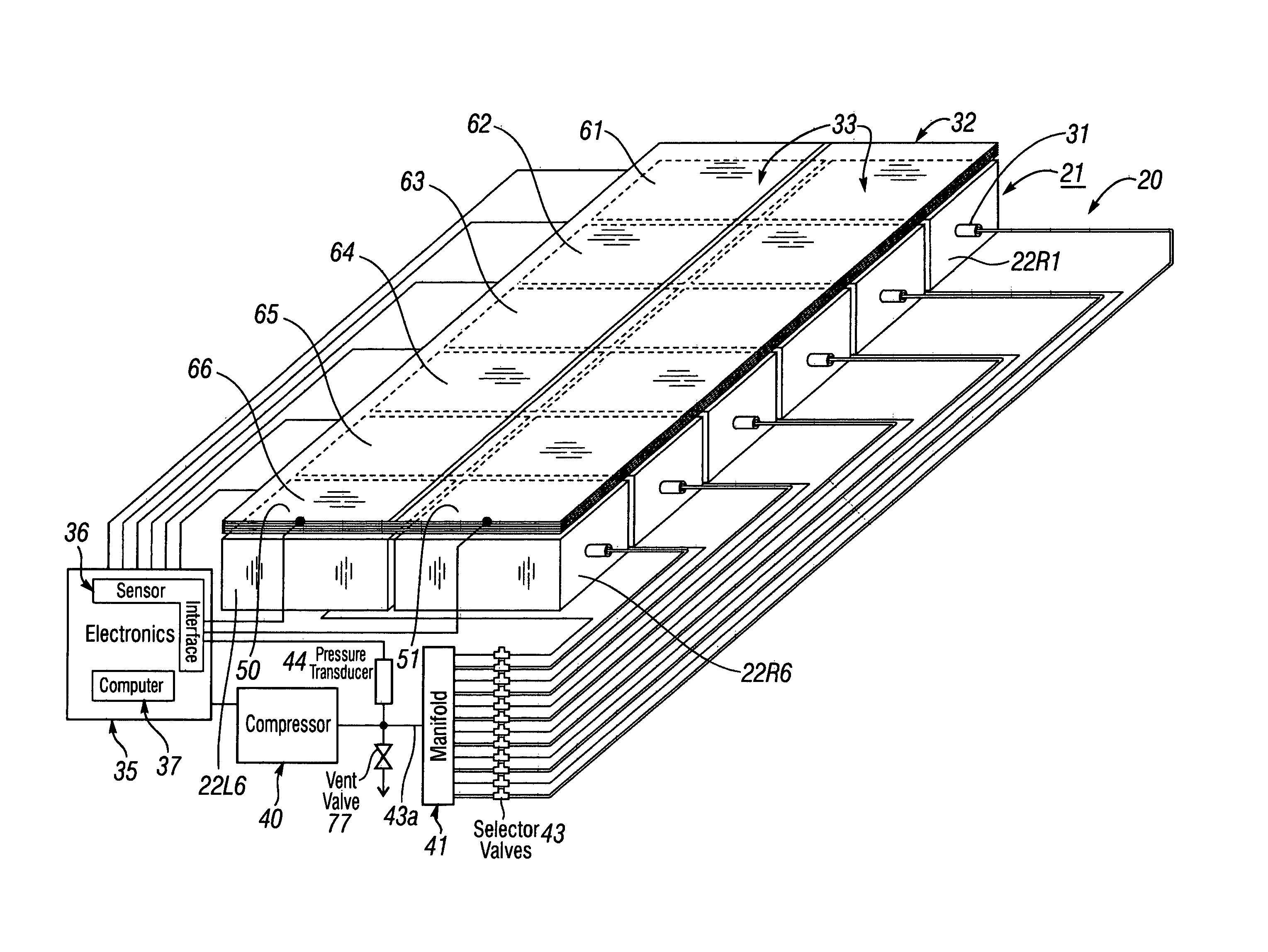

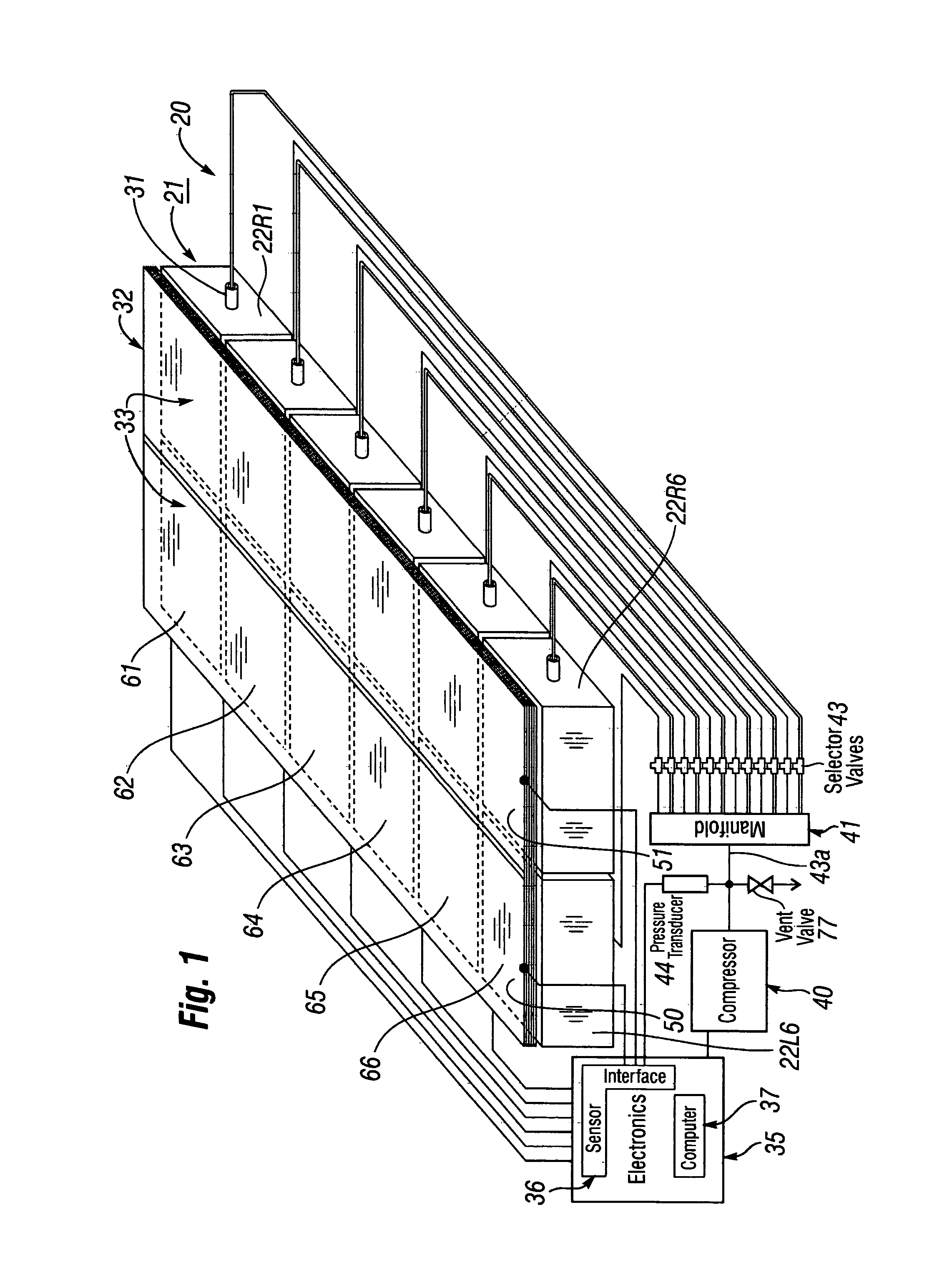

Adaptive cushion method and apparatus for minimizing force concentrations on a human body

ActiveUS8533879B1Minimizing reaction forceMinimize ambiguityStuffed mattressesSpring mattressesControl systemTransducer

An adaptive cushion apparatus for minimizing force concentrations on body parts of a person seated or lying on a chair or bed includes an overlay cushion having a plurality of individual air bladder cells, each having thereon a stretchable piezoresistive force sensor of novel design and construction. The apparatus includes an electro-pneumatic control system for inflating and deflating individual air bladder cells to pressures measured by a pressure transducer which tend to minimize force concentrations sensed by the force sensors. A force minimization method according to the invention includes varying the inflation pressure in a first air bladder cell while measuring the sum of the forces exerted on all air bladder cells, repressurizing the first cell to that pressure for which a minimum total force was obtained, repeating the cyclical variation in pressure and re-inflation to a minimum force-obtaining pressure for each of the remaining air bladder cells, and repeating the sequence for all air bladder cells until the force variations are minimized below a predetermined threshold value.

Owner:PATIENTECH LLC

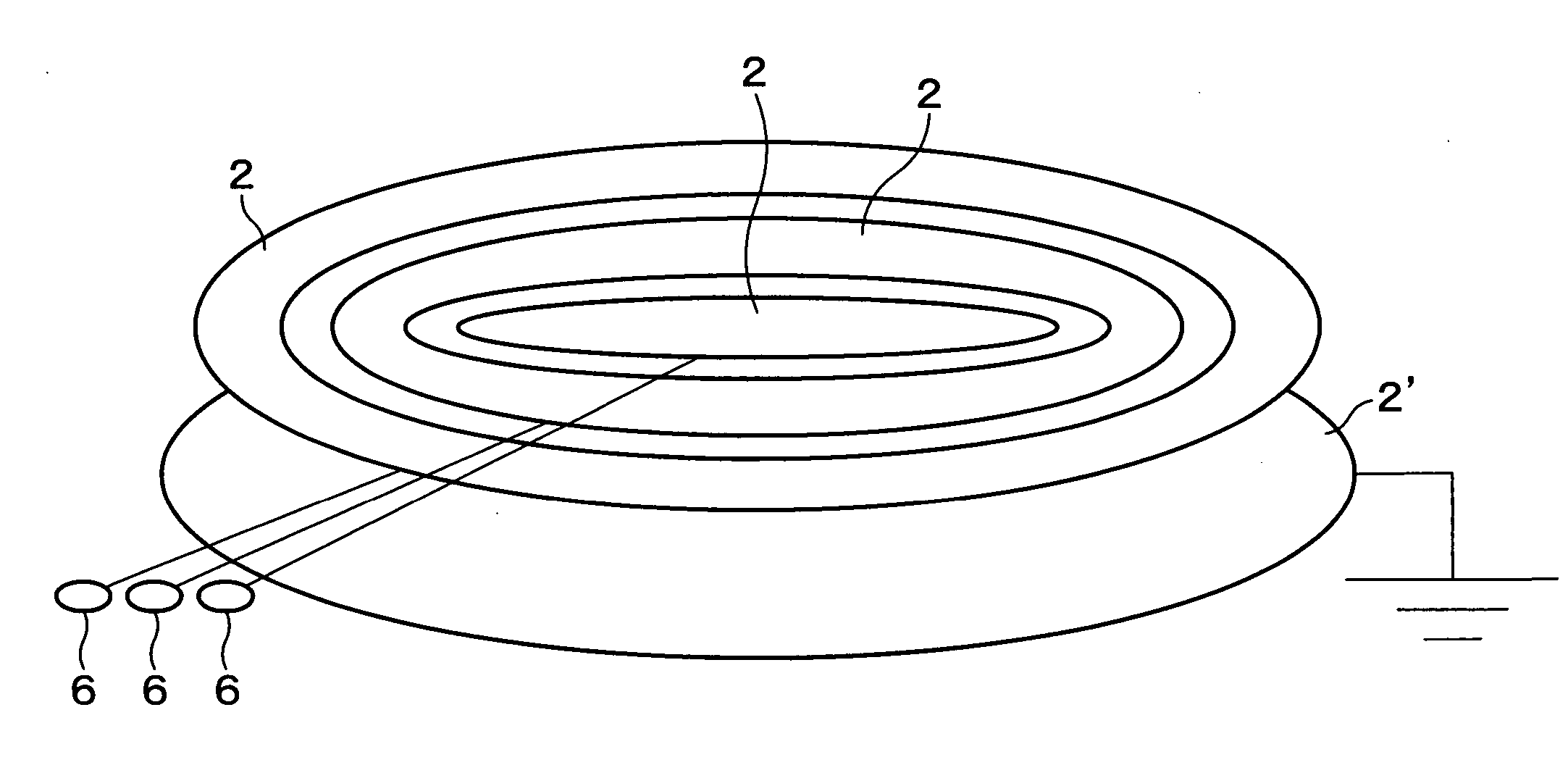

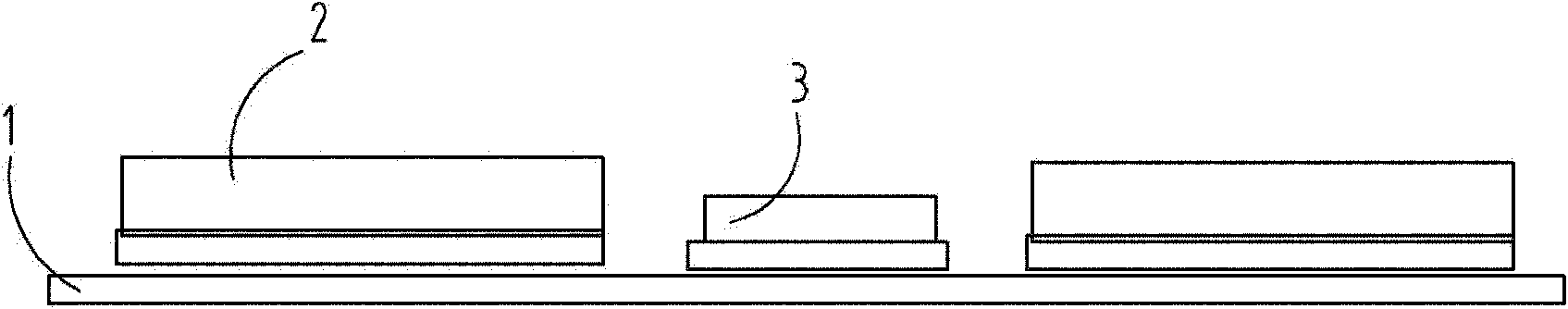

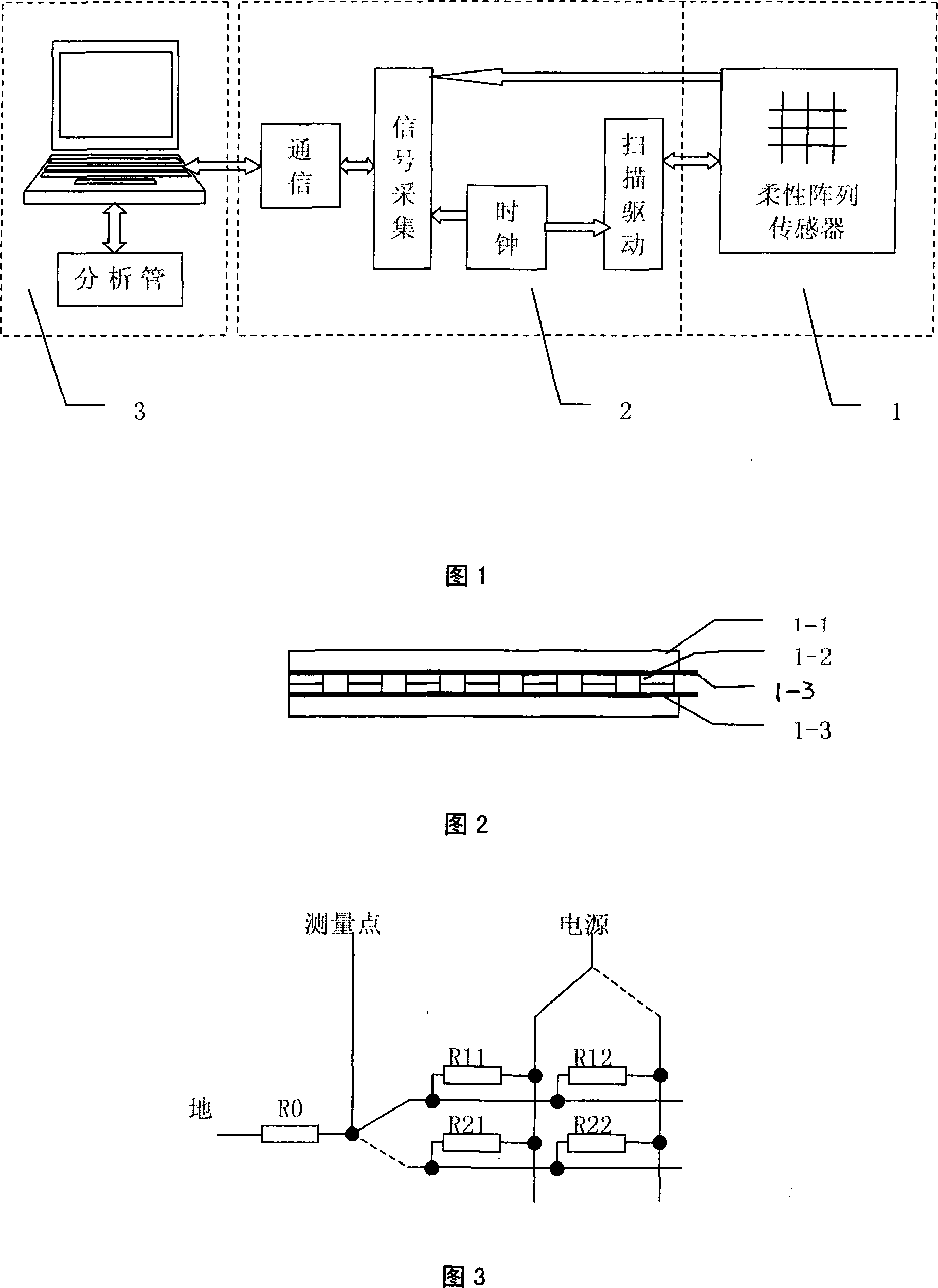

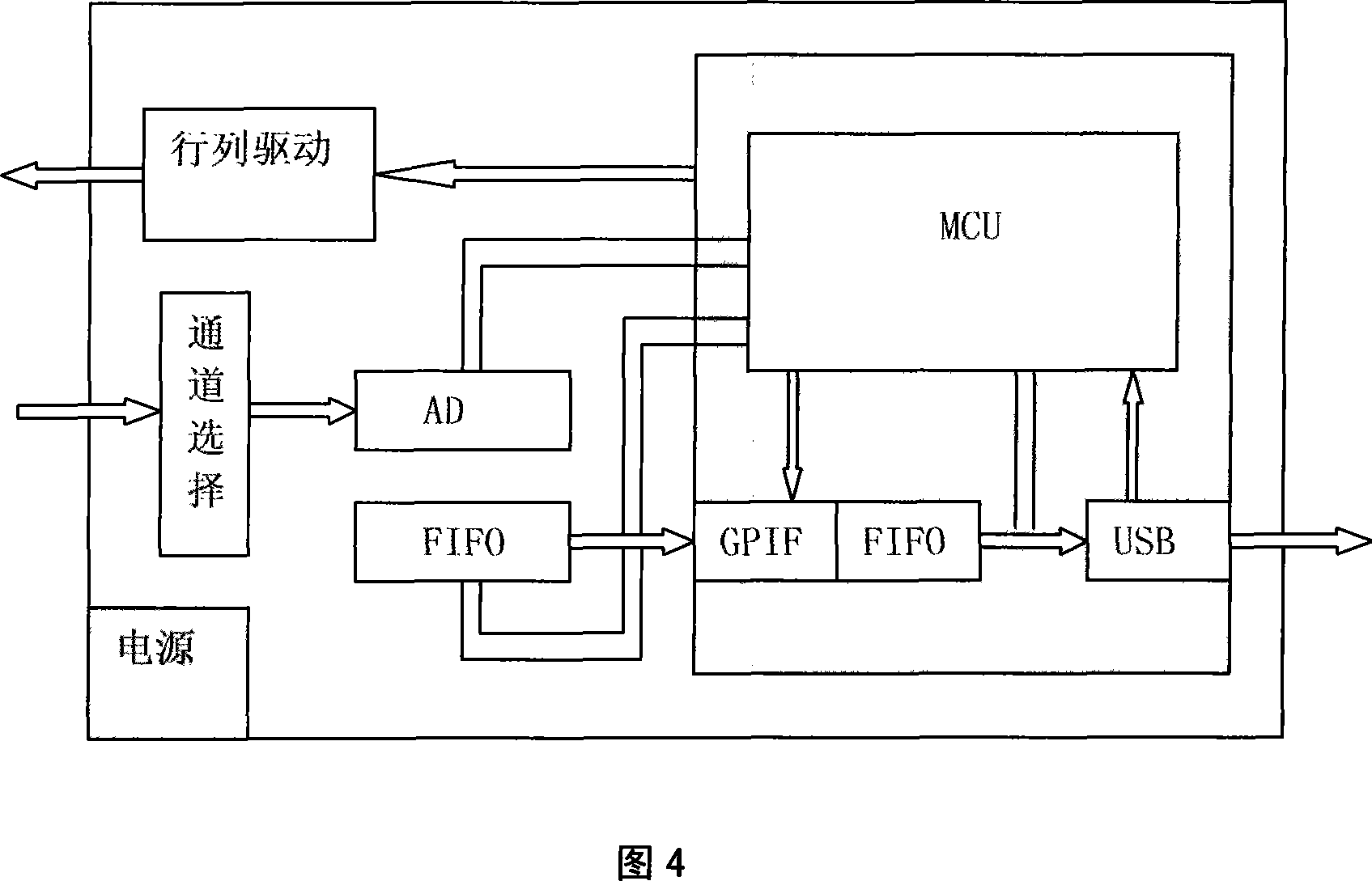

Apparatus for measuring pressure distribution and method for measuring thereof

ActiveCN101201279AElectric signal transmission systemsForce measurement using piezo-resistive materialsAthletic trainingData access

The invention provides a pressure distribution measuring device and a measuring method thereof. The pressure distribution measuring device consists of a flexible array sensor (1), an embedded signal drive collection unit (2) and computer analysis processing software (3). The embedded signal drive collection unit (2) has the function of scanning drive of array lines and rows, and the function of collection of pressure signals of array points. The embedded signal drive collection unit (2) is connected with a computer through a USB 2.0 interface. The computer analysis and processing software comprises a communication interface module, a data access module, a data analysis module, a records management module and a print driver module. The computer gets the information of the acting force, the distribution information of the acting force, the center of pressure, the information about the power spectrum and so on through collecting the information of the acting force output by the force sensor and the analysis software. The invention provides scientific basis for athletic research, instruction of athletic training, scientific research of medical treatment, disabled body recovery training instruction and so on.

Owner:ANHUI BIOFORCEN INTELLIGENT TECH

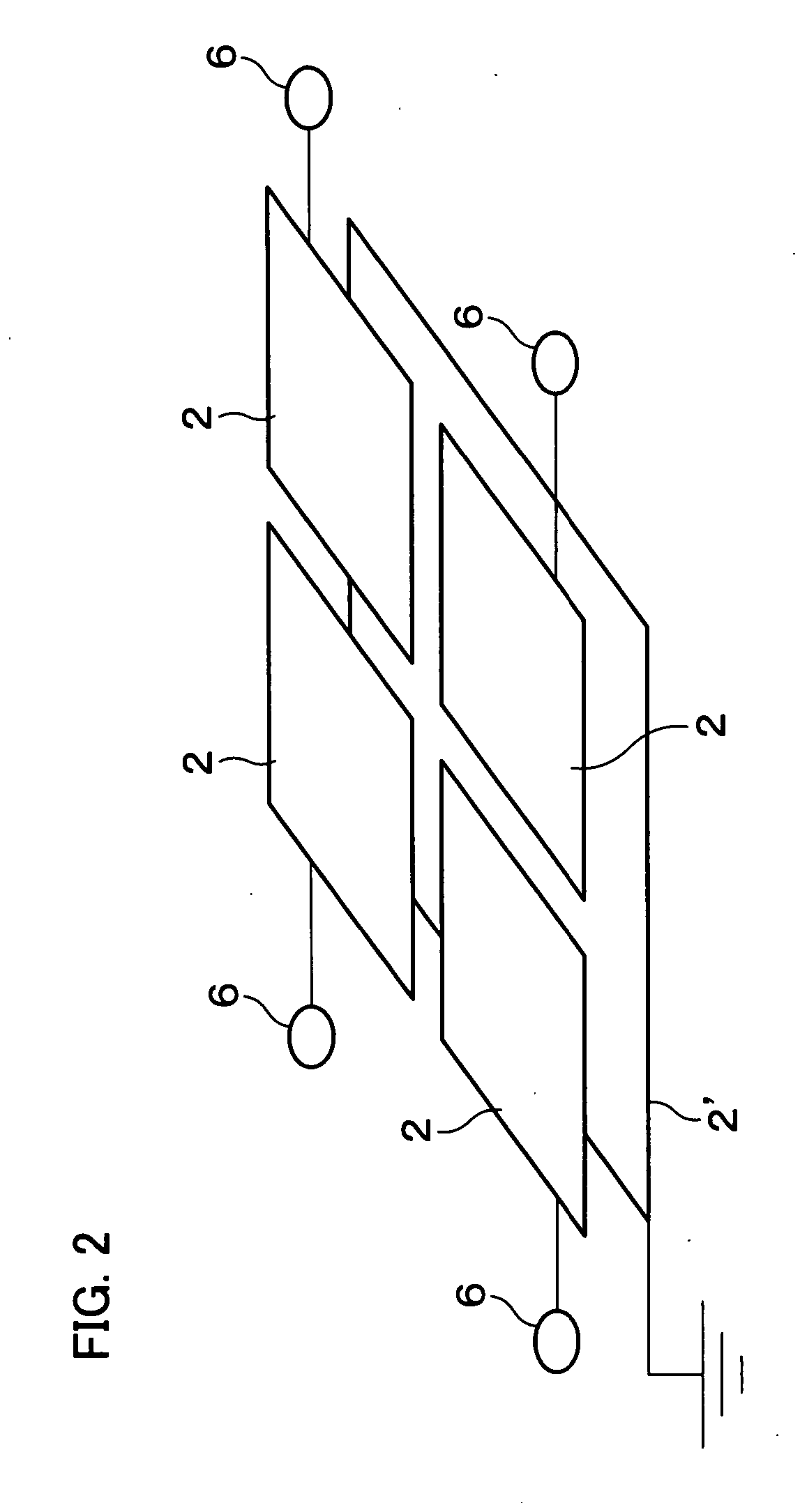

Carbon nanotube / polymer composite membrane array type flexible force sensor and manufacturing method thereof

InactiveCN102374910AReduce contentGood flexibilityDecorative surface effectsForce measurement using piezo-resistive materialsMembrane arrayCarbon nanotube

The invention relates to a carbon nanotube / polymer composite membrane array type flexible force sensor and a manufacturing method thereof. The carbon nanotube / polymer composite membrane array type flexible force sensor comprises a parallel metal row electrode and a parallel metal column electrode which are respectively and graphically arranged on the upper and lower surfaces of a carbon nanotube / polymer composite membrane, an upper insulation protecting layer adhered onto the row electrode, and a lower insulation protecting layer adhered onto the column electrode, wherein the row electrode and the column electrode are distributed in a spatial intersection way, and a spatial intersection part and the carbon nanotube / polymer composite membrane contained in the spatial intersection part form a force sensing unit of the array type flexible force sensor; and the carbon nanotube / polymer composite membrane is made by a composite material that carbon nanotubes are uniformly dispersed in a polymer matrix material, and the mass ratio of the carbon nanotubes to the polymer matrix material is (0.1-15): 100. The carbon nanotube / polymer composite membrane in the array type flexible force sensor has the characteristics of excellent flexibility, good repeatability, stable performances, good consistency and the like.

Owner:TSINGHUA UNIV

Flexible pressure sensor and manufacturing method thereof

ActiveCN106370327AEasy to transformHigh sensitivityForce measurement using piezo-resistive materialsConvex structureElectrical resistance and conductance

The invention discloses a flexible pressure sensor, which comprises two oppositely-arranged electrode structures, wherein each electrode structure comprises a flexible substrate and a conductive layer arranged on the flexible substrate; the conductive layers of the two electrode structures are connected in a mutually-facing abut joint mode; the flexible substrate comprises a substrate body and multiple convex structures arranged on the substrate body; and the conductive layer covers the surface, with the multiple convex structures, of the flexible substrate. According to the flexible pressure sensor disclosed by the invention, by using the characteristic that the inner multiple convex structures formed by a flexible material are likely to deform under a pressure effect, resistance changes, adjustment and control caused by contact area changes when the two conductive layers in the opposite electrode structures make contact can be realized, and thus, pressure sensing is realized. The invention also discloses a method of manufacturing the above flexible pressure sensor. Compared with an MEMS processing process generally adopted by the flexible pressure sensor in the prior art, the manufacturing method of the invention is simple and convenient, and the cost is lower.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

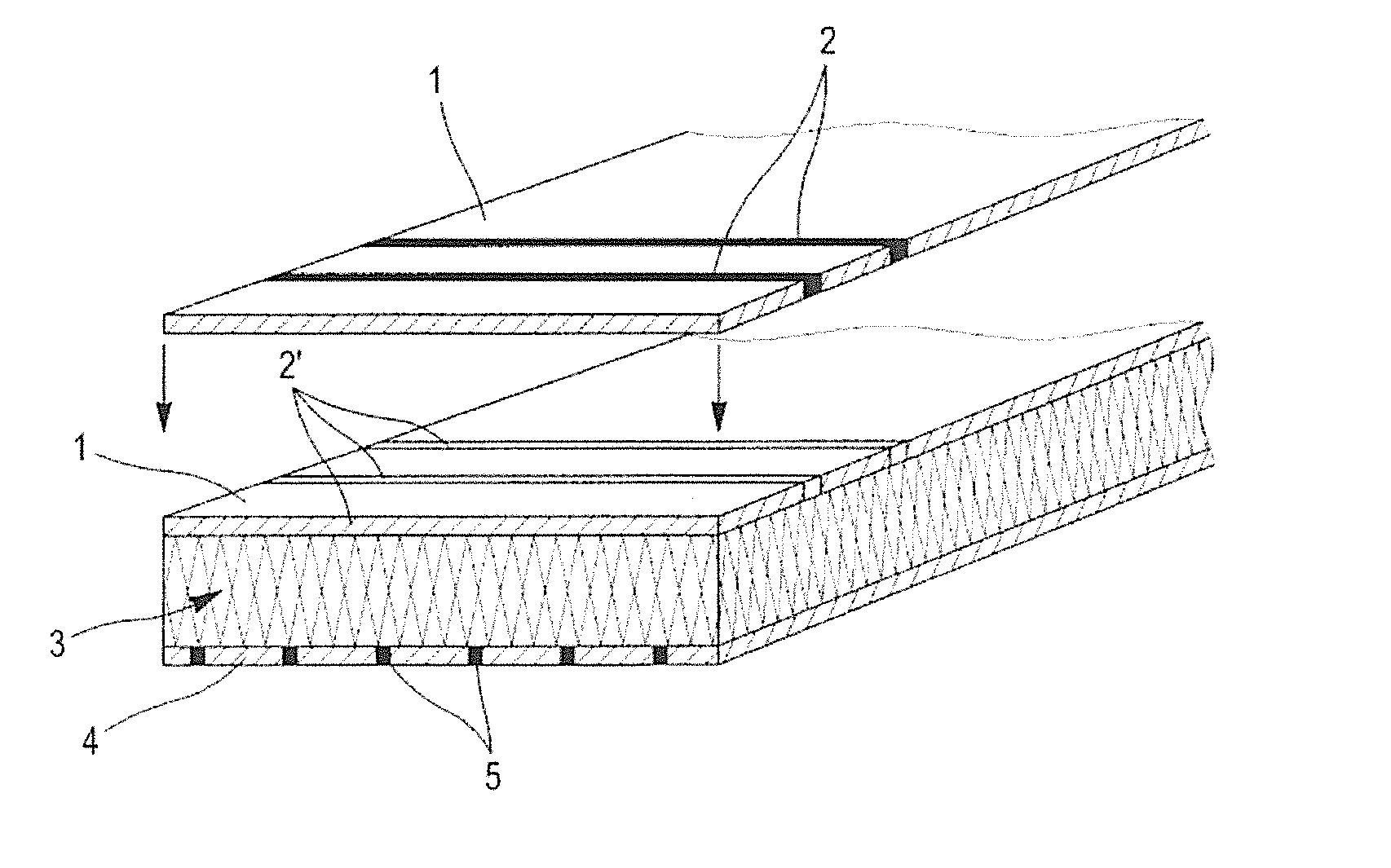

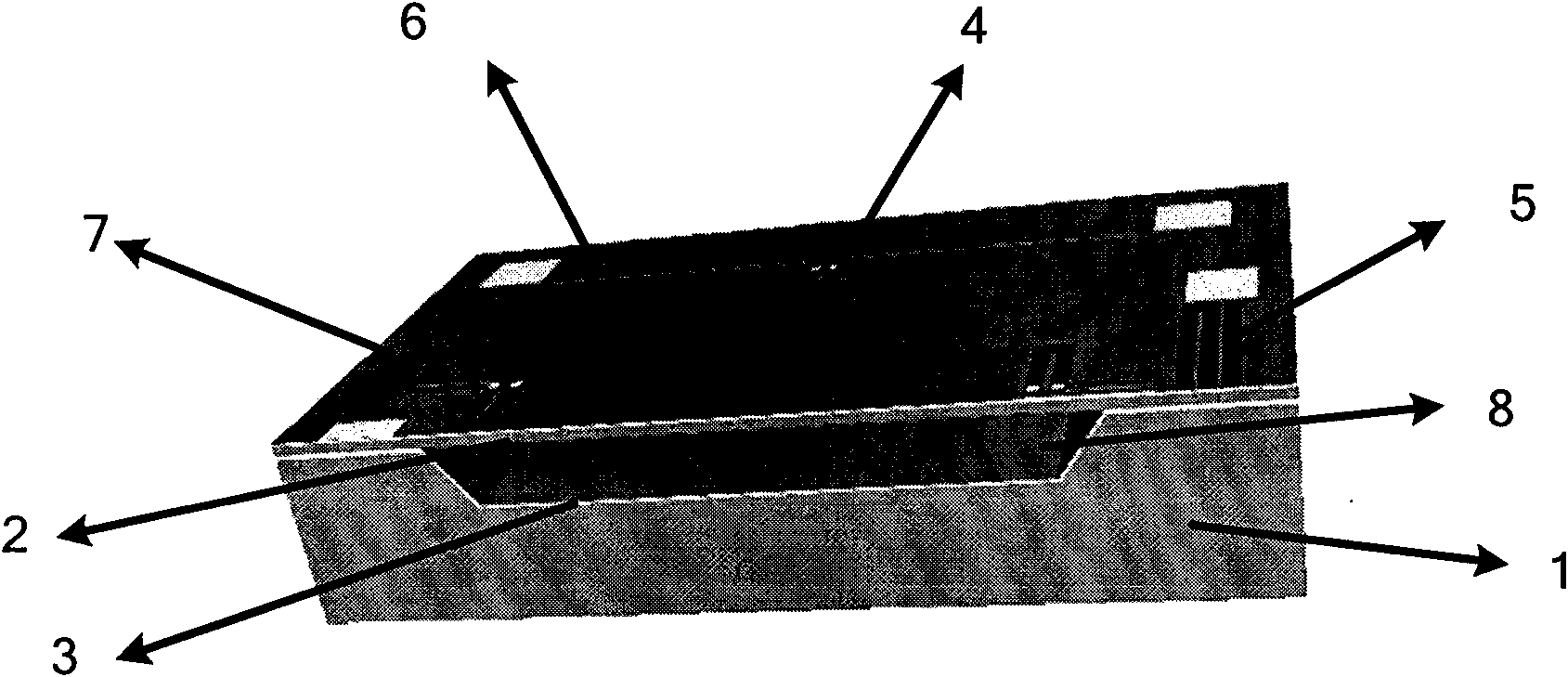

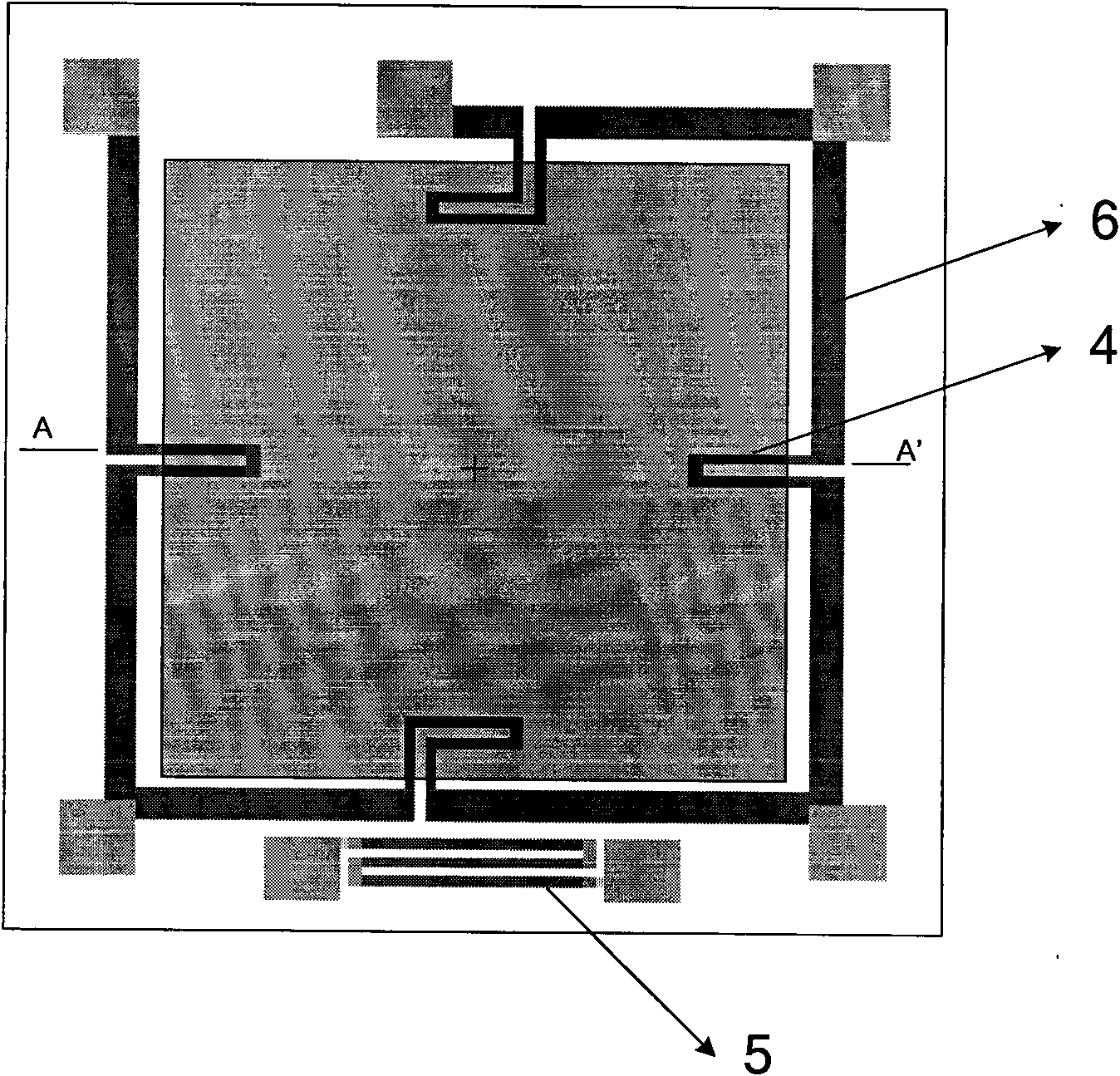

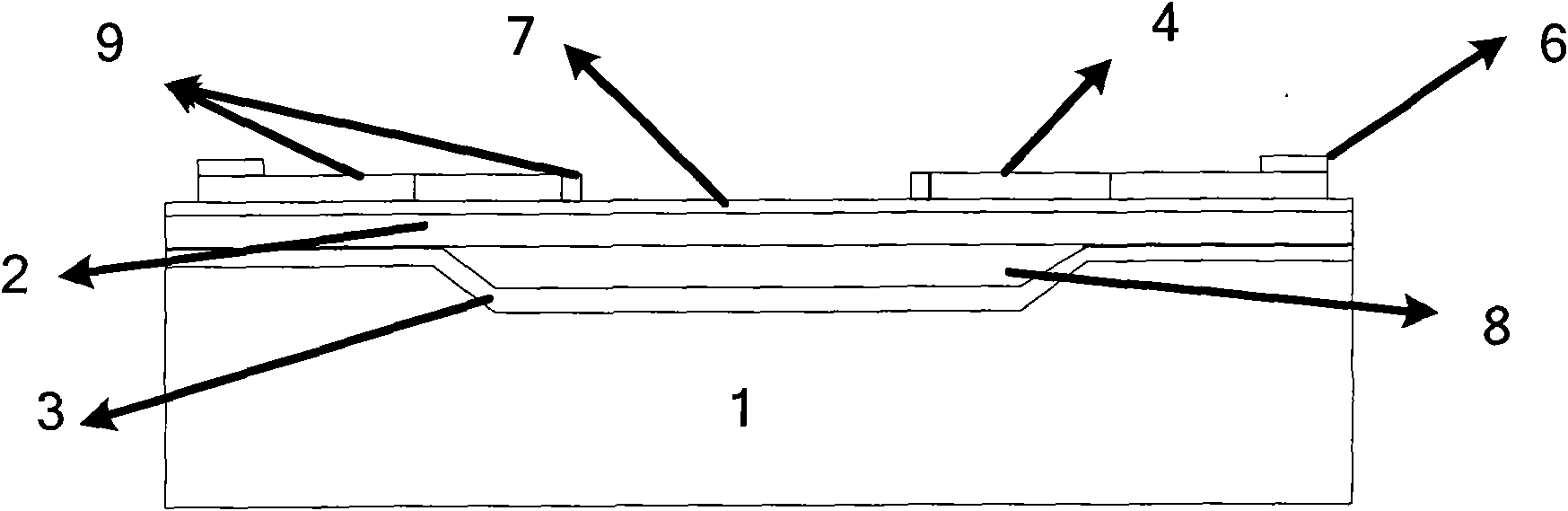

Pressure sensor based on Si-Si direct bonding and manufacturing method thereof

InactiveCN101551284APrecise size controlOvercome performance degradation flawsTelevision system detailsSemi-permeable membranesWorking temperatureBoron

The invention discloses a pressure sensor based on Si-Si direct bonding, comprising a silicon substrate (1) with a shallow groove (8); the silicon substrate (1) is provided with a single crystal silicon stress membrane (2); a silicon dioxide layer (3) is arranged between the silicon substrate (1) and the stress membrane (2); four P-type single crystal silicon piezoresistors (4) are arranged on the stress membrane (2); an insulating medium silicon dioxide layer (7) is arranged among the stress membrane (2) and the piezoresistors (4); and a Wheatstone bridge is formed among the piezoresistors (4) by utilizing concentrated boron doped silicon (9) and a golden lead (6). The pressure sensor adopts Si-Si direct bonding technology to form the stress membrane and the sealing cavity; the piezoresistors thereof adopt silicon dioxide as an insulating layer and the working temperature can be up to 300 DEG C; and the pressure sensor has firm structure and excellent performance and can meet the requirements on high-temperature pressure sensors in the fields of automobile, aerospace and the like. The invention also relates to a manufacturing method of the pressure sensor.

Owner:江苏英特神斯科技有限公司

Graphene-based array type flexible pressure distribution sensor and preparation method thereof

ActiveCN102564657AImprove detection accuracyExtended service lifeForce measurement using piezo-resistive materialsElectricityGraphene

The invention relates to a graphene-based array type flexible pressure distribution sensor. The sensor comprises a flexible substrate; a graphene film array is arranged on the flexible substrate; the graphene film array comprises at least one graphene conductor; and the graphene conductor is electrically connected with a row electrode and a column electrode on the flexible substrate. The graphene film array is arranged on the flexible substrate, the graphene conductor in the graphene film array is electrically connected with the row electrode and the column electrode, and corresponding detection information such as change of the voltage can be output through the row electrode or the column electrode when the graphene conductor is deformed by pressure, so the sensor has high detection precision; the sensor has long service life; the made sensor is light and thin; the sensor is applied in the field of pressure distribution measurement of tooth engaging pressure distribution, sole pressure distribution, tyre pressure distribution and the like; and the using range of the sensor is enlarged, and the sensor is safe and reliable.

Owner:中科芯未来微电子科技成都有限公司

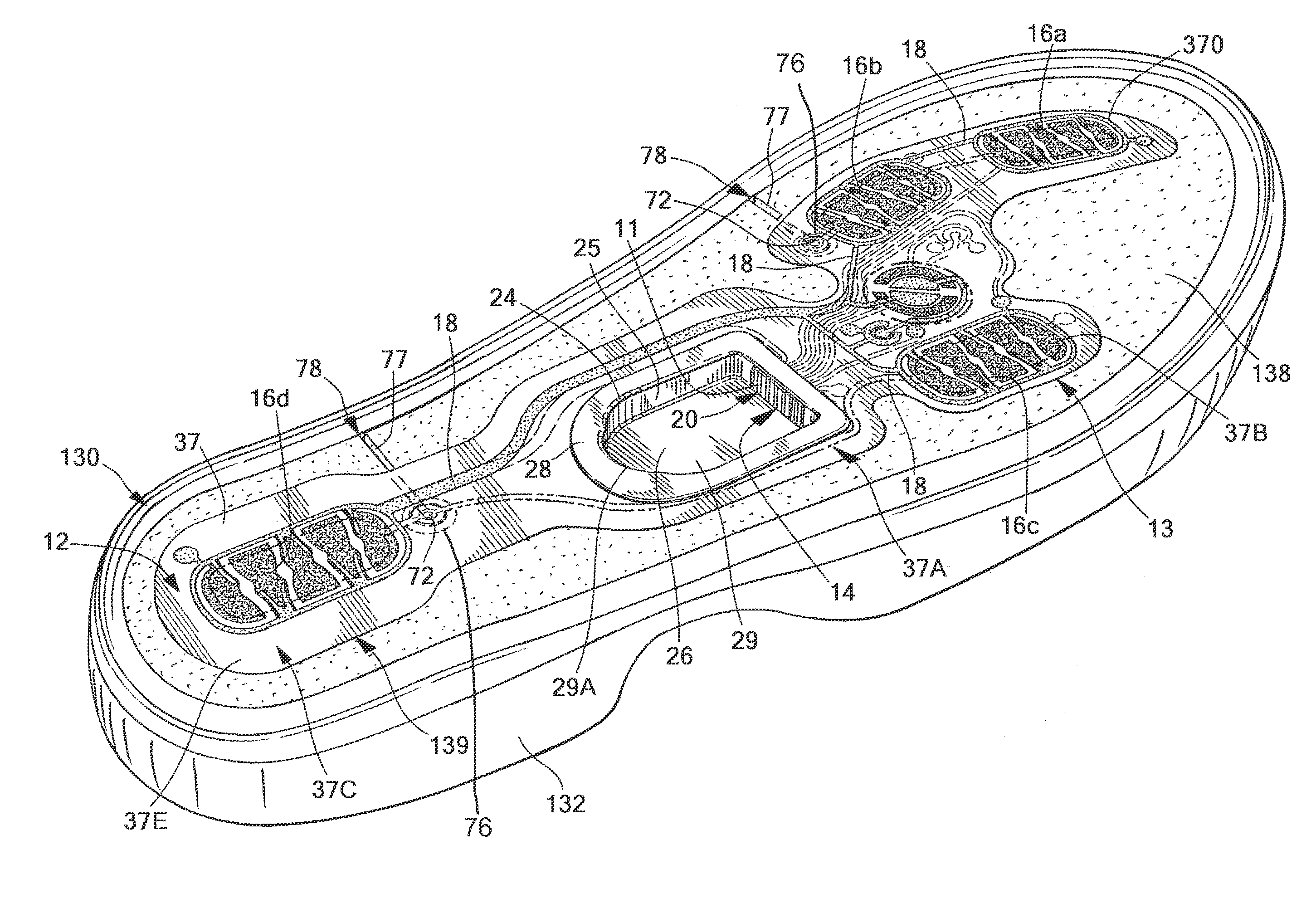

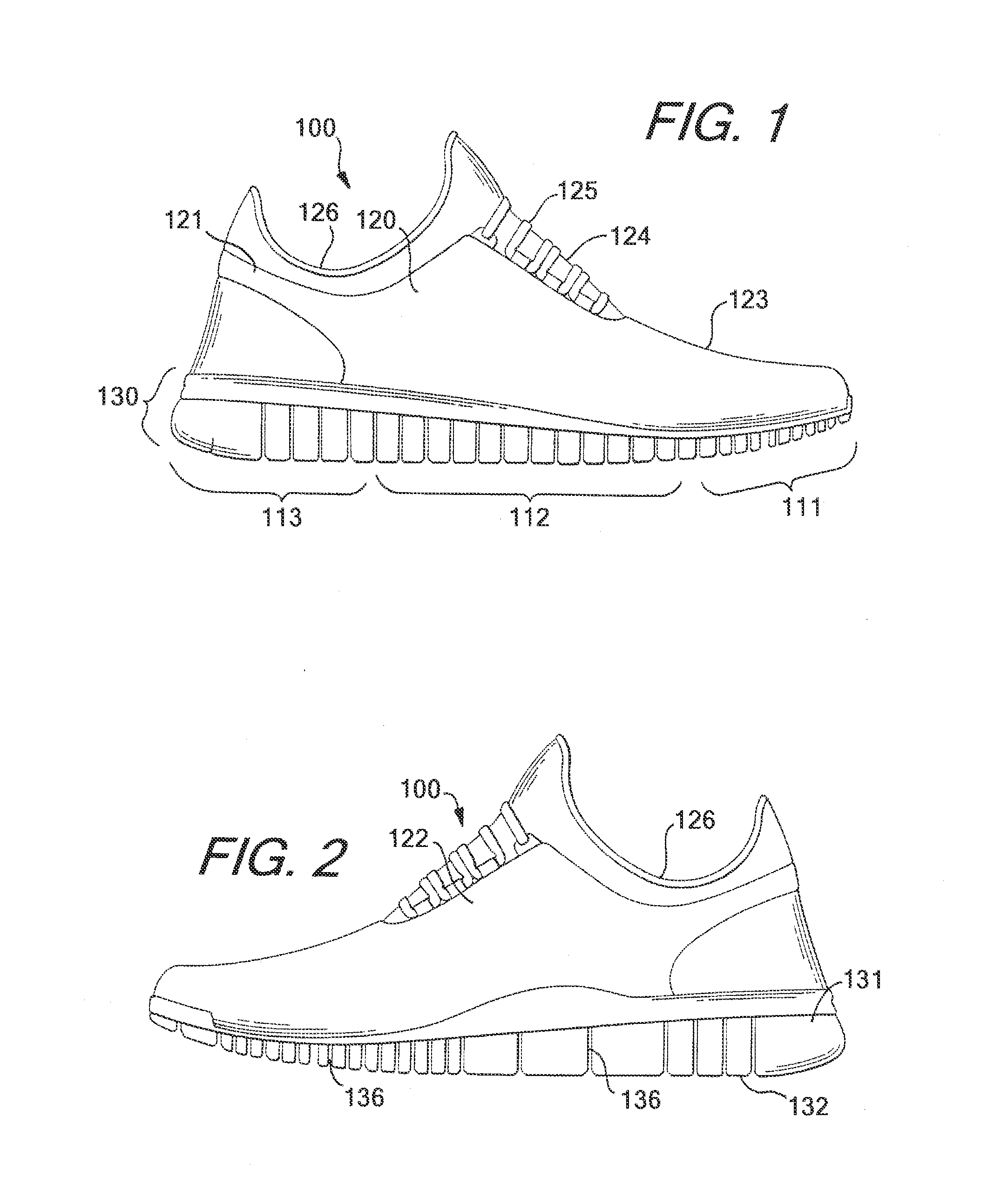

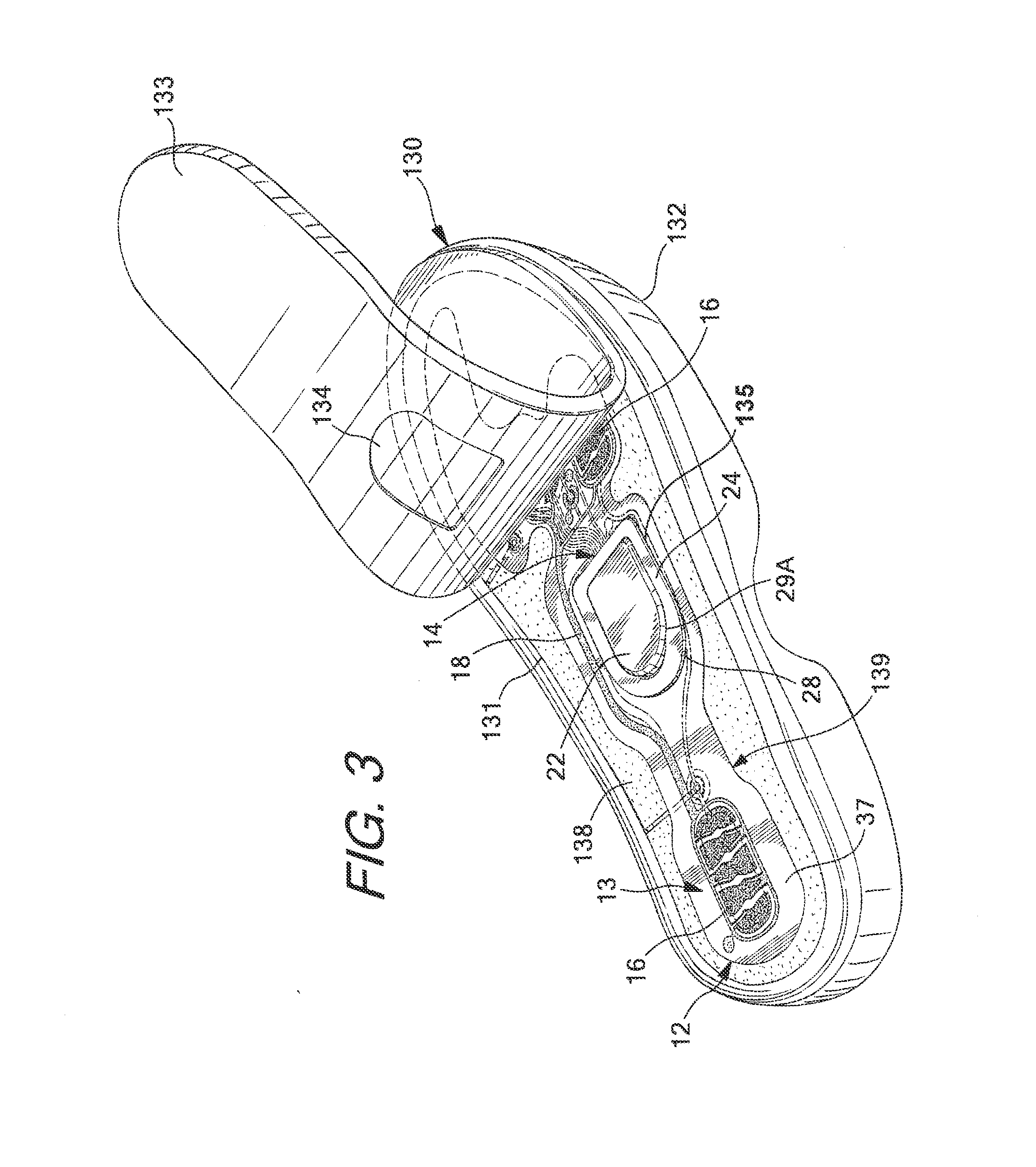

System and method for analyzing athletic activity

Various sensor systems are described herein, including inserts having sensors thereon, which are configured to be received in an article of footwear. The inserts may be connected to a sole member of the footwear, or may function as a sole member. The sensors may be bonded to an outer surface of the insert, or positioned within the insert, in some configurations. The system may also include an electronic module that is overmolded into the sole structure and includes a connector for external access.

Owner:NIKE INC

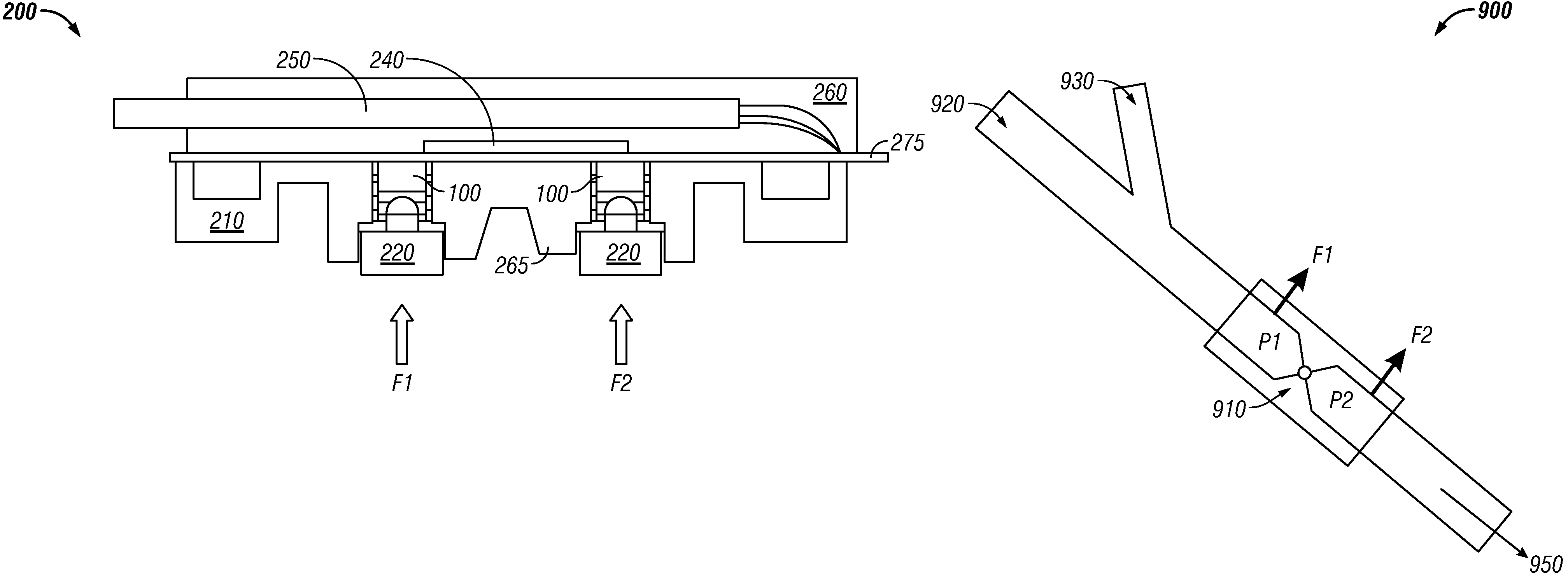

Fluid flow monitor

ActiveUS7775126B2Fluid pressure measurement by electric/magnetic elementsMedical devicesMicrocontrollerEngineering

A differential force sensor method and apparatus for automatically monitoring manual injections through an intravenous line. The differential force sensor includes two piezoresistive sense die that are packaged in close proximity utilizing a number of packaging processes. The two piezoresistive sense die can be utilized to measure forces exerted on a diaphragm on either side of an orifice. The piezoresistive sense die can be packaged in close proximity to make intimate contact with the diaphragms on either side of the orifice. The differential force sensor further includes two plungers that make intimate contact with the diaphragm and transfer the force into the piezo-resistive sense dies. Additionally, one or more ASICs and microcontrollers can be utilized to provide thermal calibration and differential calculation.

Owner:HONEYWELL INT INC

Elastically stretchable fabric force sensor arrays and methods of making

ActiveUS20120234105A1Facilitate measuring and mapping forcesWork measurementMaterial strength using tensile/compressive forcesSensor arrayConductive polymer

Force or pressure transducer arrays have elastically stretchable electrically conductive polymer threads disposed in parallel rows and columns that contact at intersections thereof a piezoresistive material which has an electrical resistivity which varies inversely with pressure or force exerted thereon to form a matrix array of force or pressure sensor elements. The threads are fixed to a single one or pair of flexible elastically stretchable substrate sheets made of thin sheets of an insulating polymer such as PVC, or for greater elasticity and conformability to irregularly-shaped objects such as human body parts, an elastically stretchable fabric such as LYCRA or SPANDEX. Elastic stretchability of the sensor arrays is optionally enhanced by disposing either or both row and column conductive threads in sinuously curved, serpentine paths rather than straight lines.

Owner:PATIENTECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com