Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

903results about How to "Precise size control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

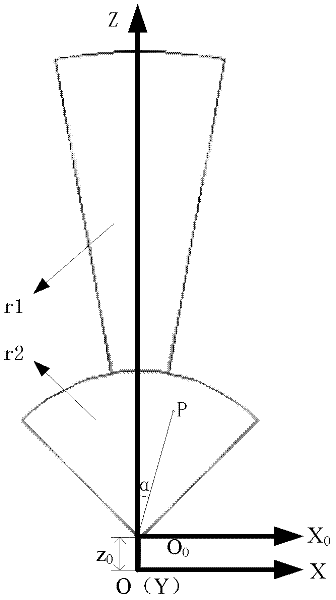

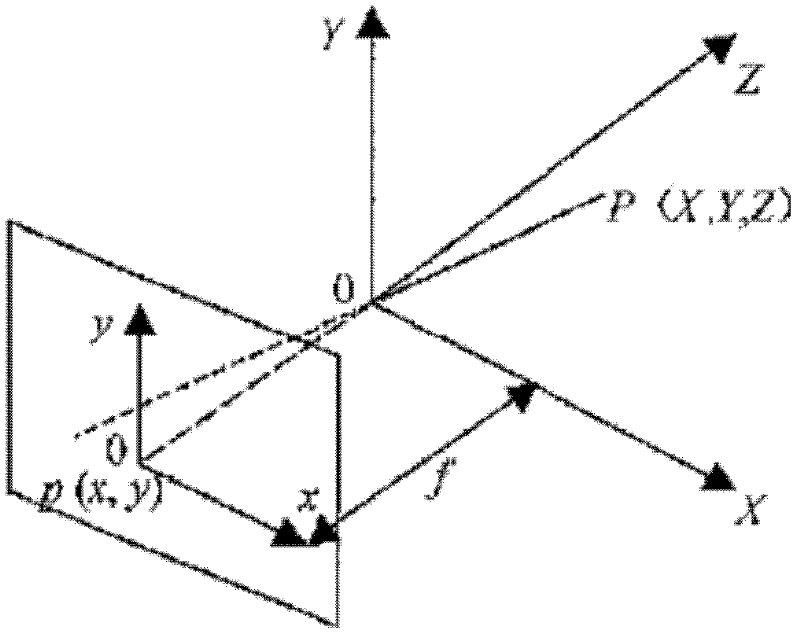

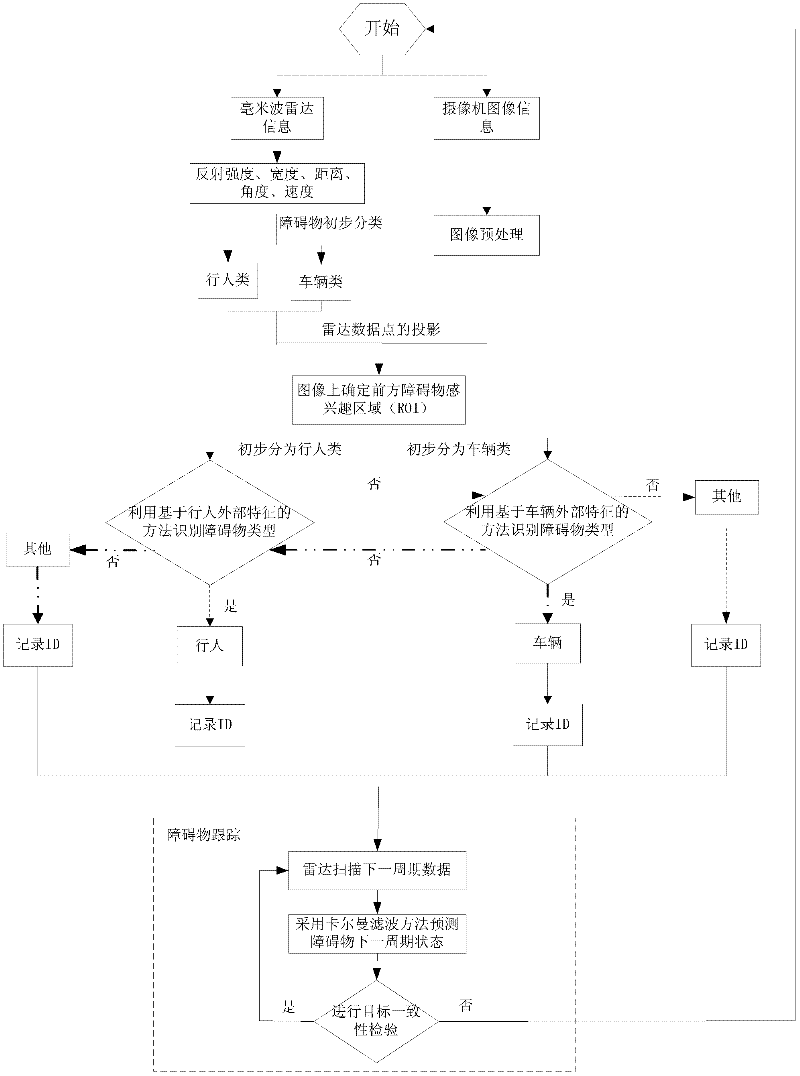

Method for detecting and tracking obstacles in front of vehicle

InactiveCN102508246ASolve problems that are difficult to classify and identify at the same timeSolve elusive problemsPhotogrammetry/videogrammetryCharacter and pattern recognitionCamera imageImaging processing

The invention discloses a method for detecting and tracking obstacles in front of a vehicle, aiming to overcome the defect and shortage in detection and tracking of obstacles in front of the vehicle by using a single-type sensor. The method comprises the following steps of: 1. establishing a relation for realizing data conversion between a millimeter wave radar coordinate system and a camera coordinate system; 2. receiving, resolving and processing the millimeter wave radar data, and carrying out preliminary classification on the obstacles; 3. synchronously collecting a camera image and receiving millimeter wave radar data; 4. classifying the obstacles in front of the vehicle: 1) projecting scanning points of the millimeter wave radar data on a camera coordinate system by combining the methods of millimeter wave radar and monocular vision, and establishing a region of interest (ROI) of the obstacles on the image; 2) carrying out preliminary classification on different obstacles in theROI established on the image, and confirming the types of the obstacles by using different image processing algorithms; and 5. tracking the obstacles in front of the vehicle.

Owner:JILIN UNIV

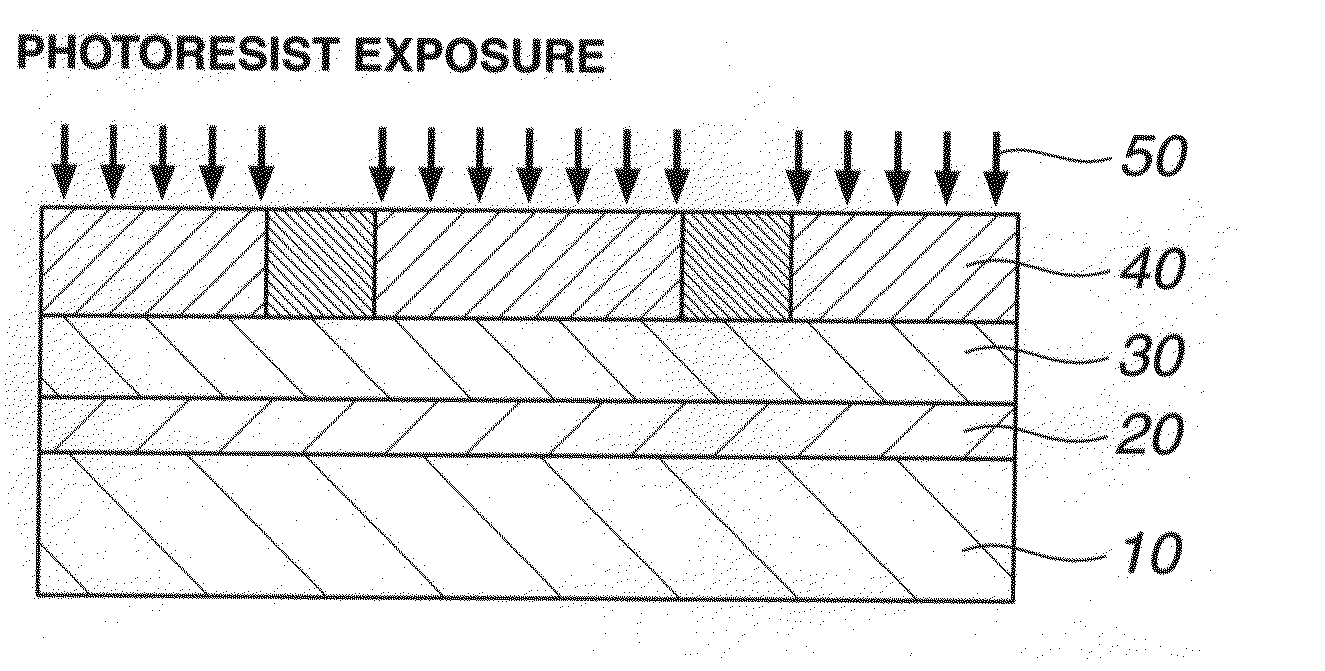

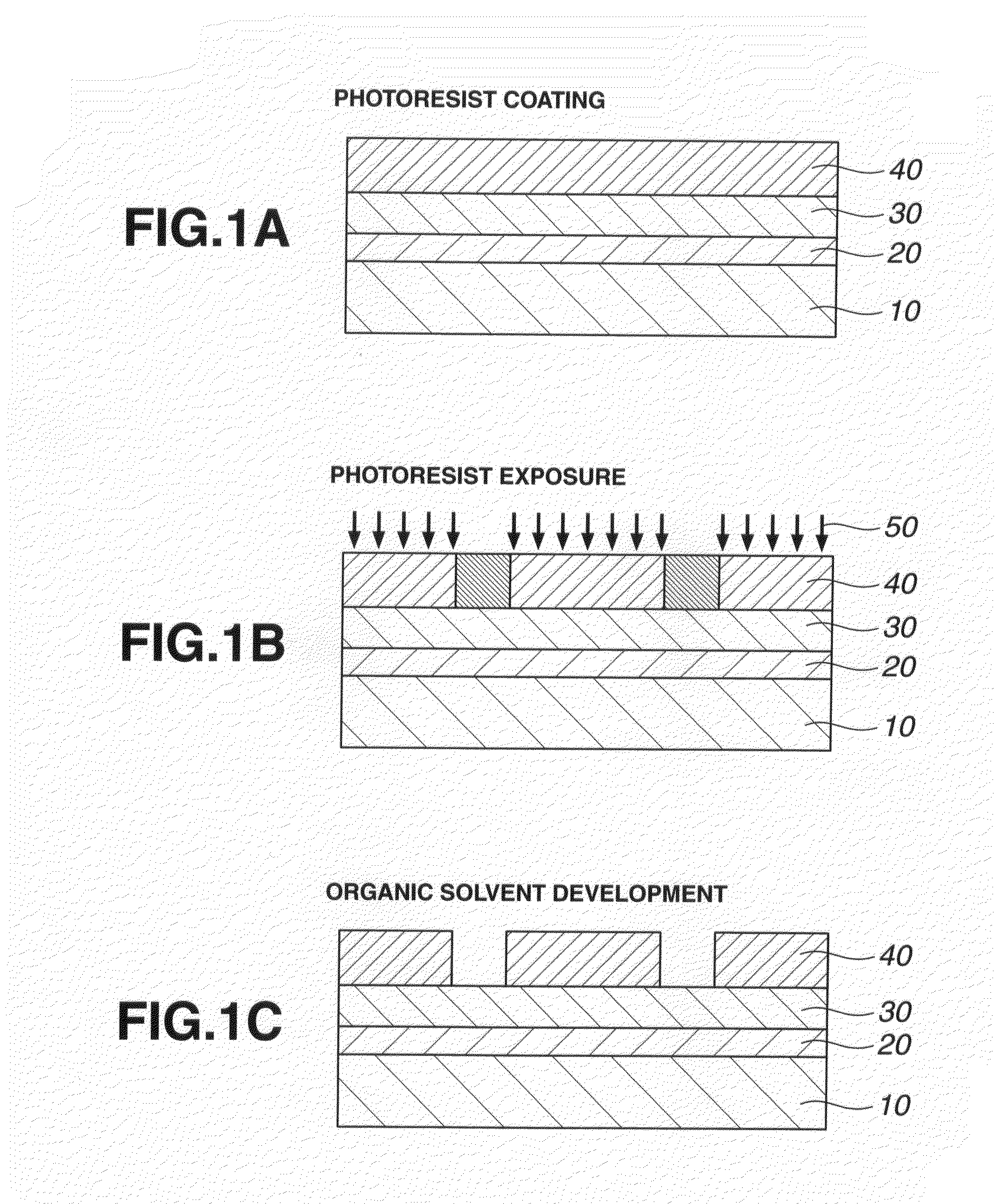

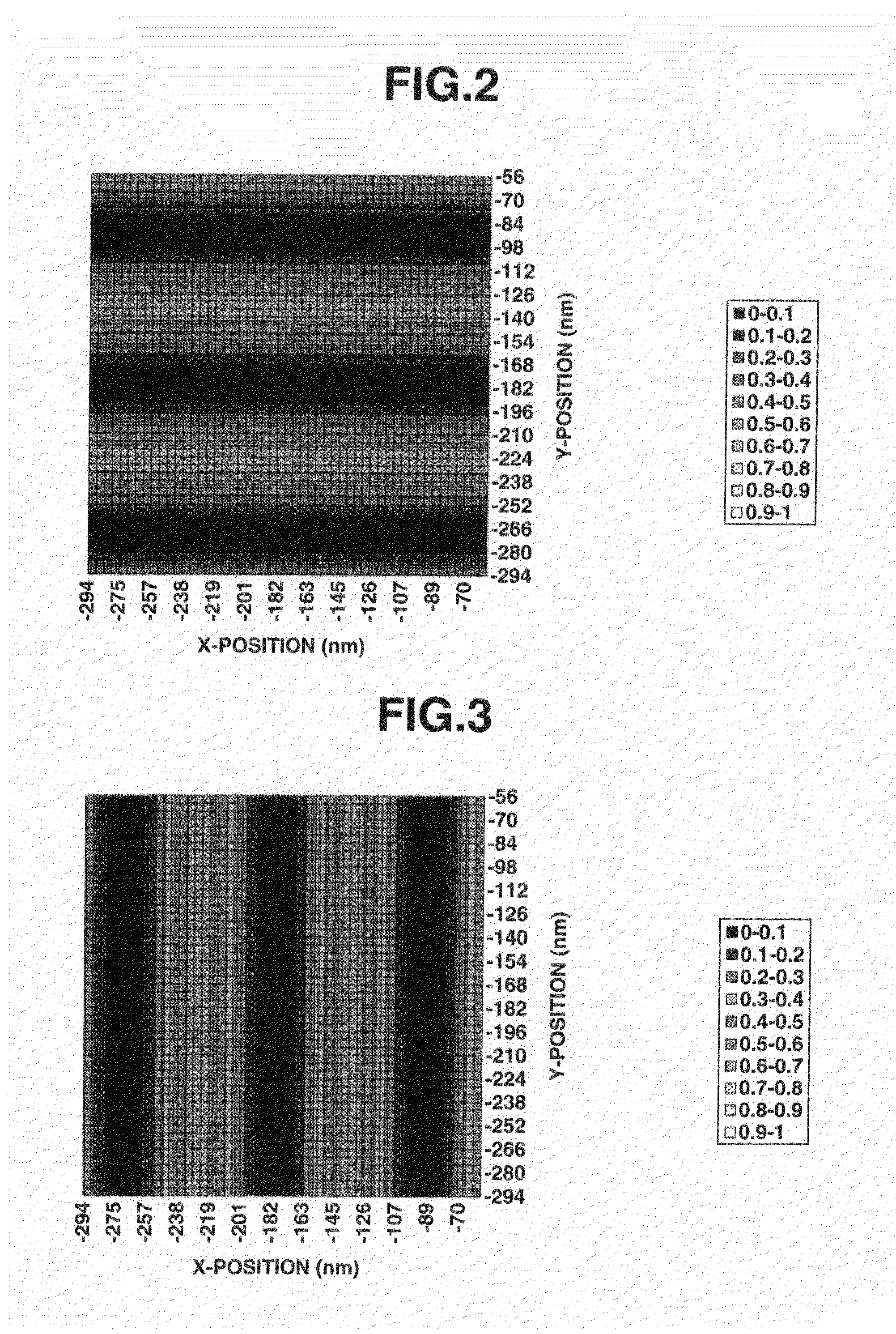

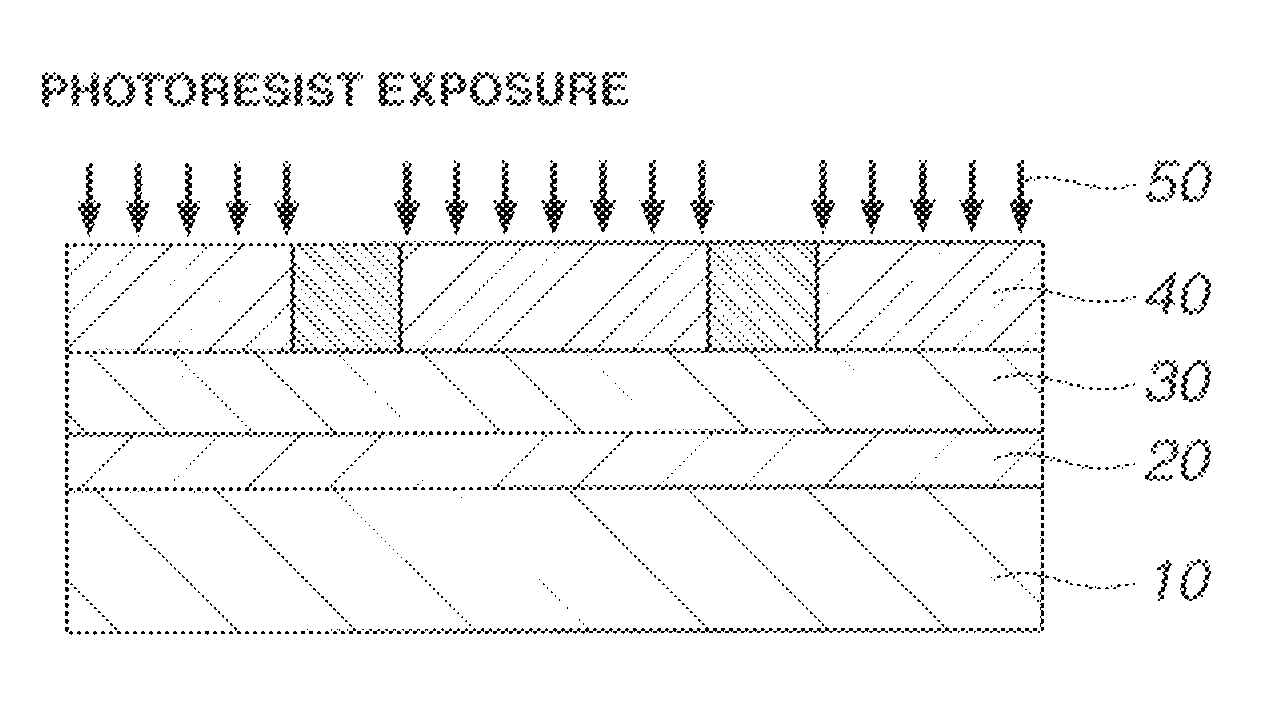

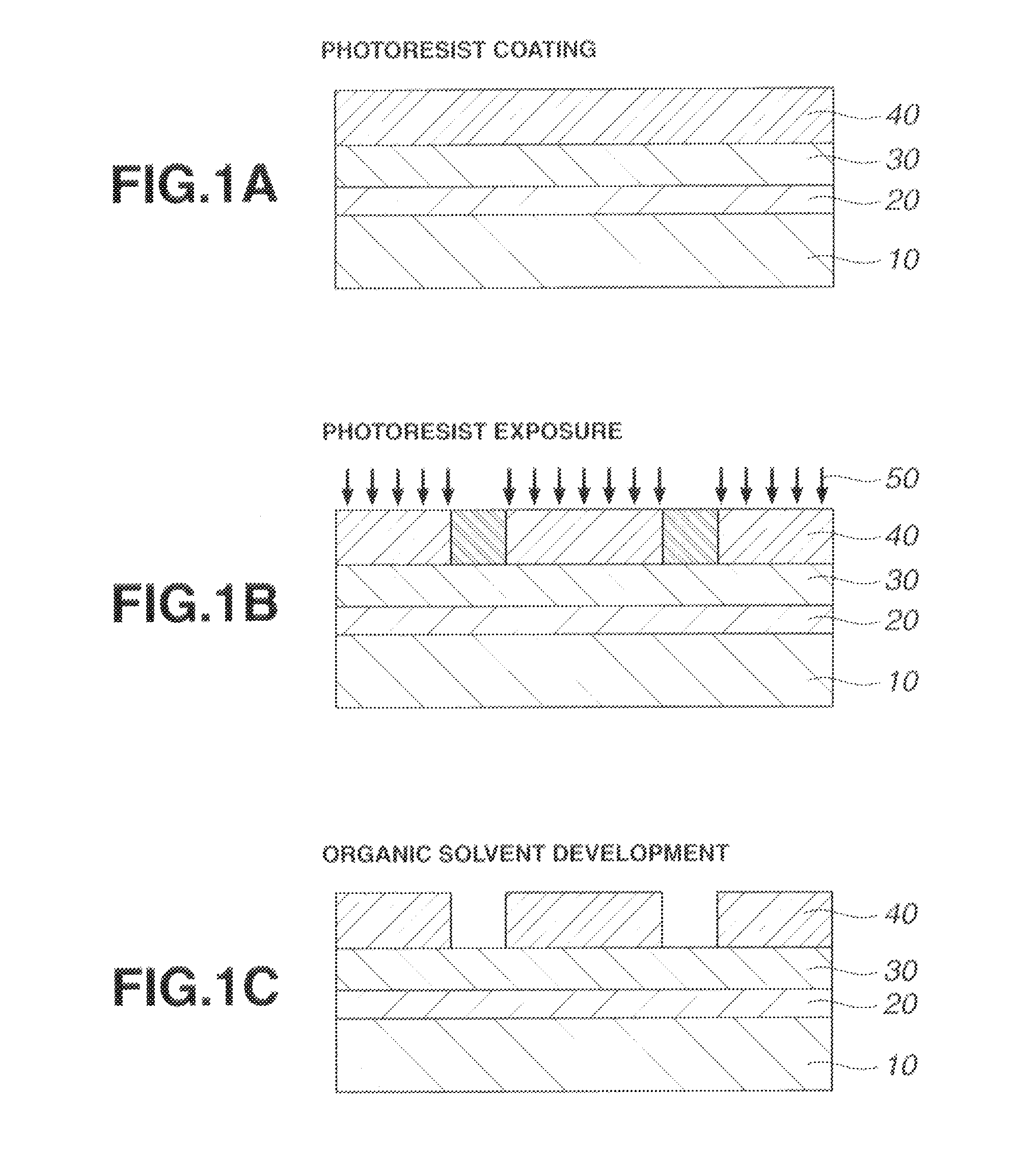

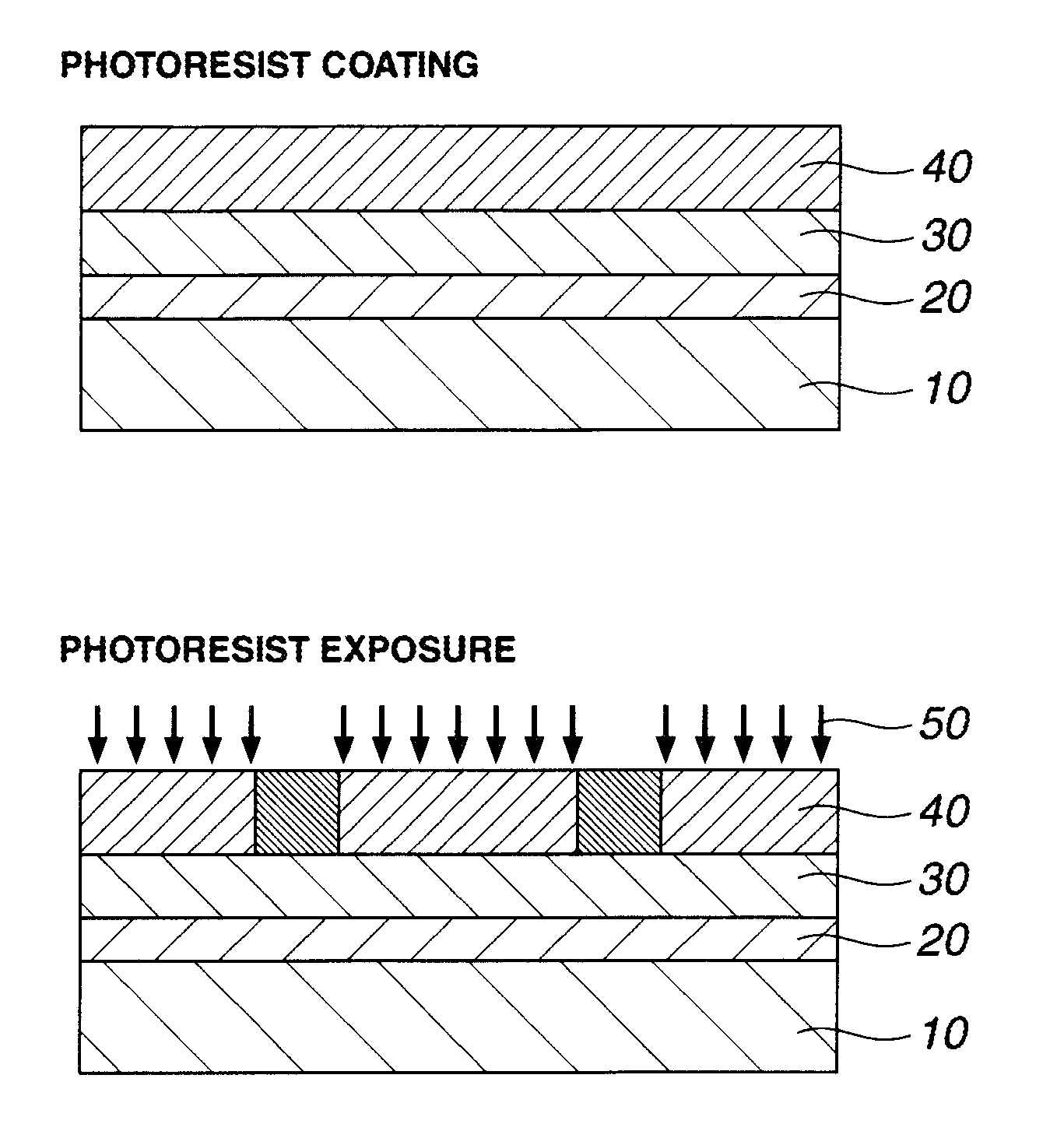

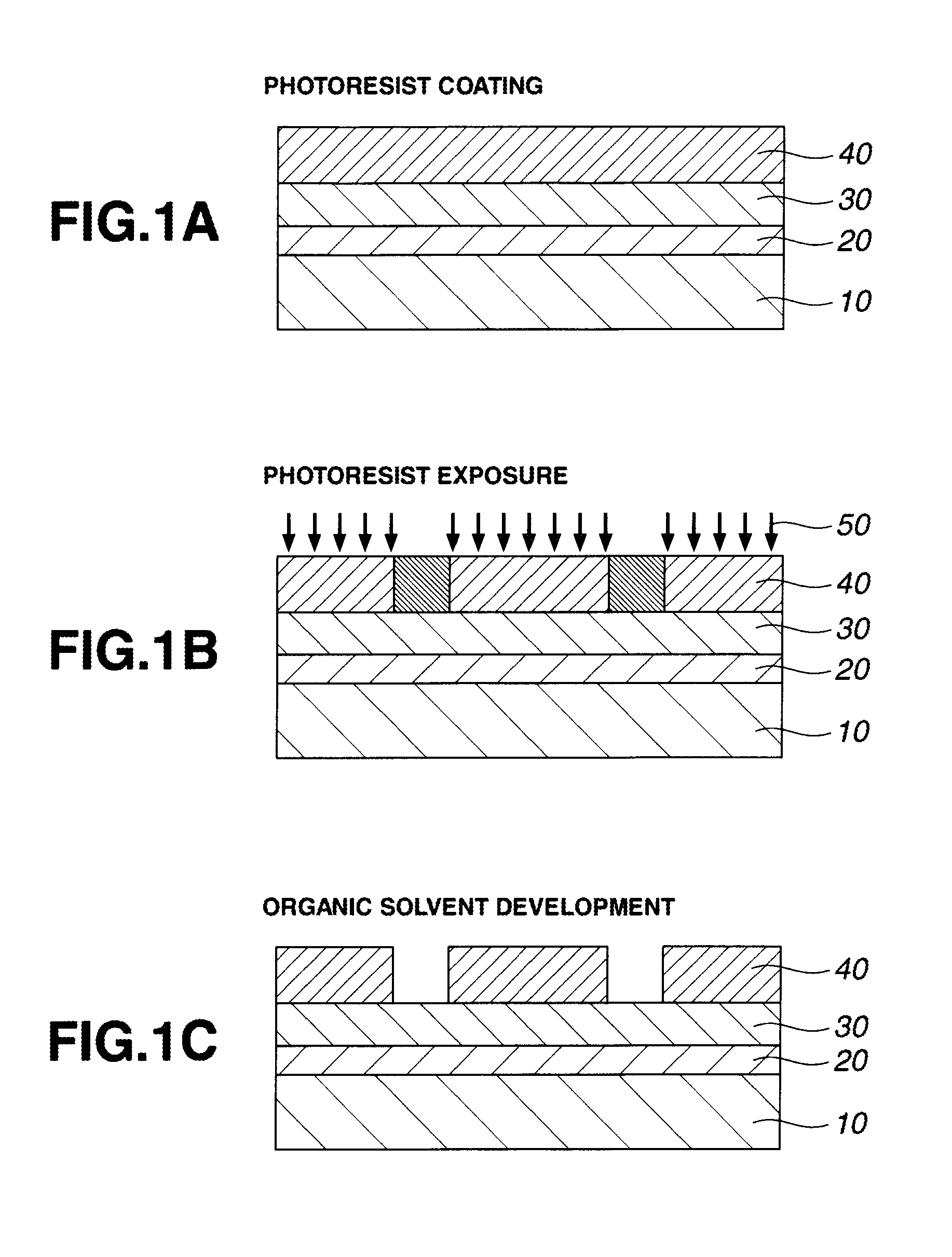

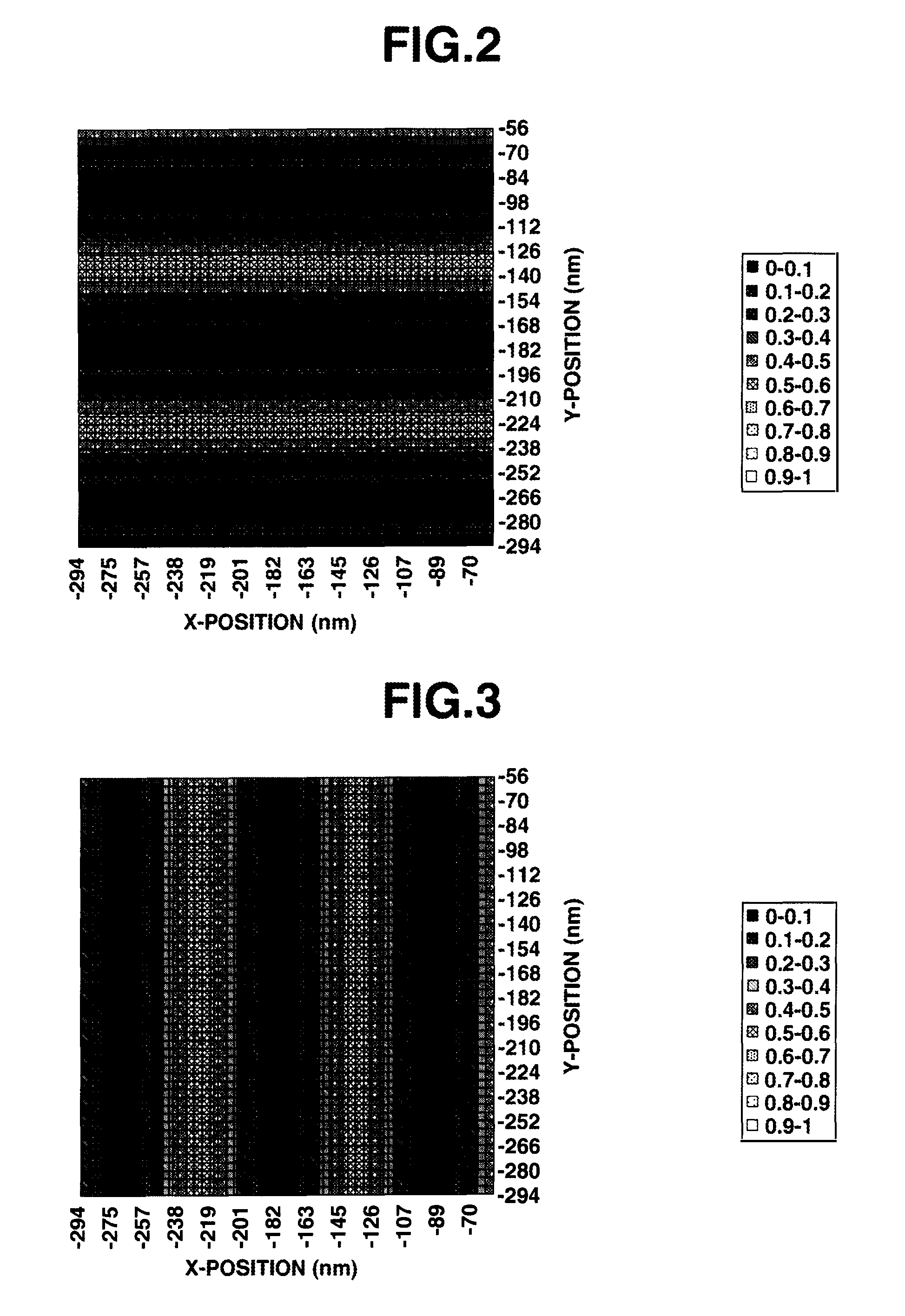

Patterning process

ActiveUS20110177462A1High dissolution contrastHigh dimensional control accuracyPhotosensitive materialsPhotomechanical exposure apparatusOrganic solventHigh energy

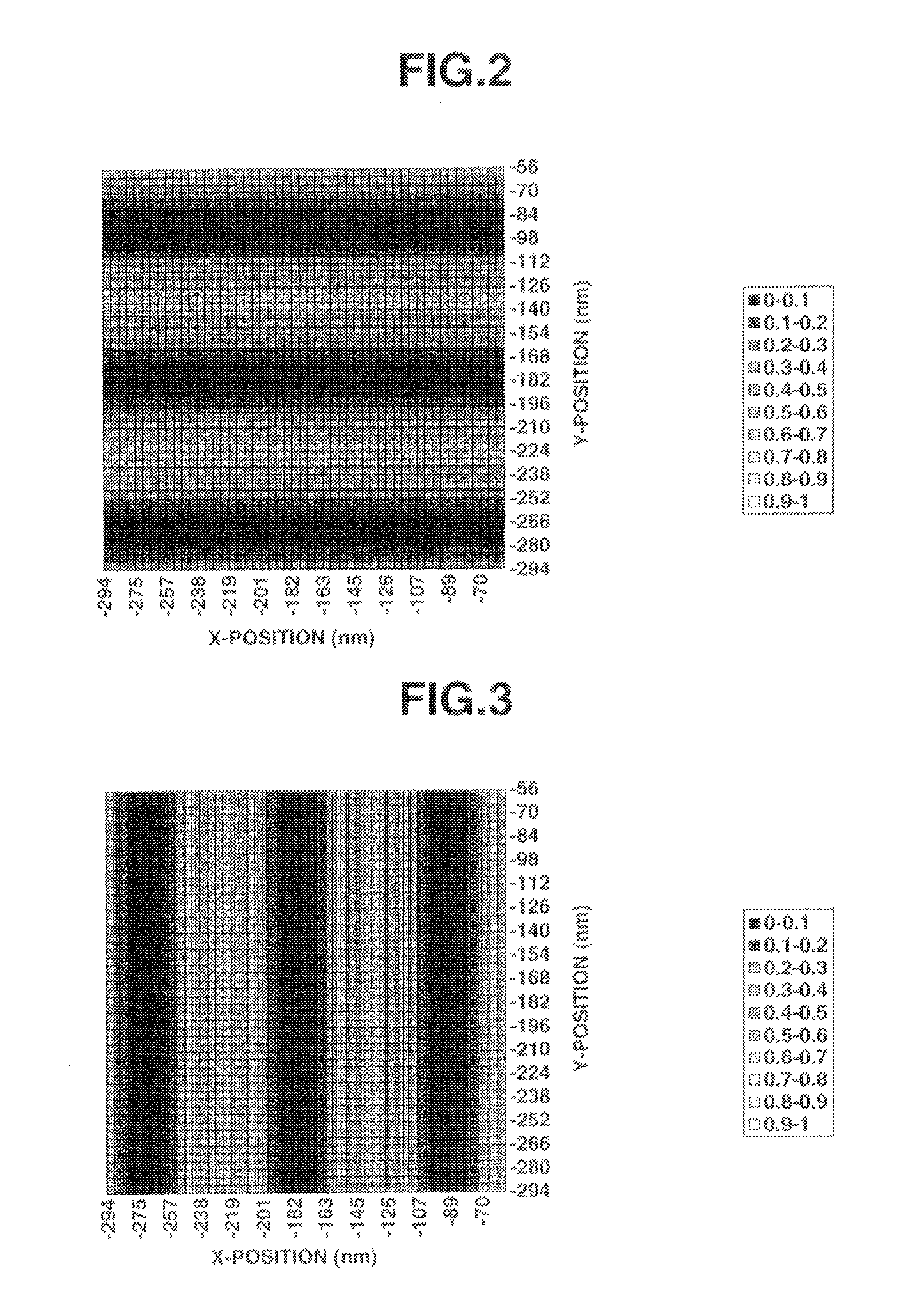

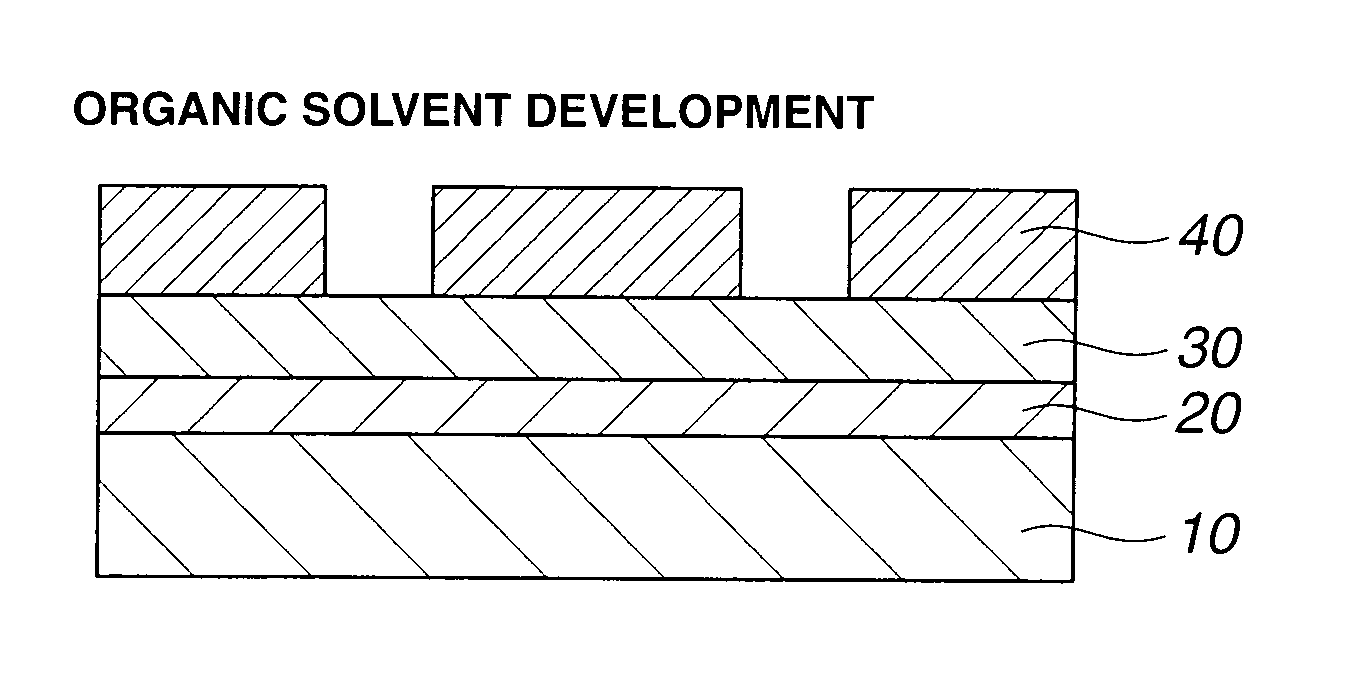

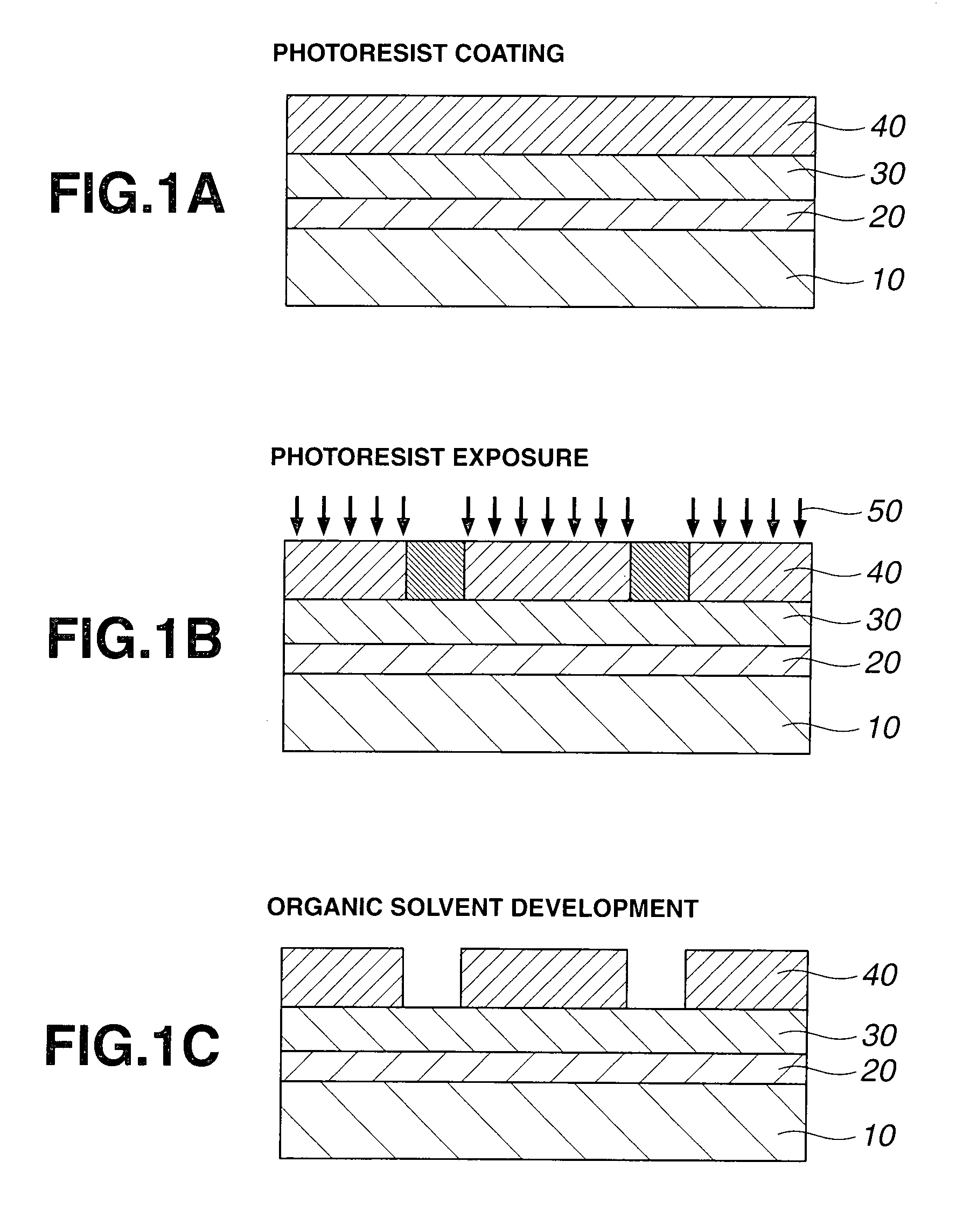

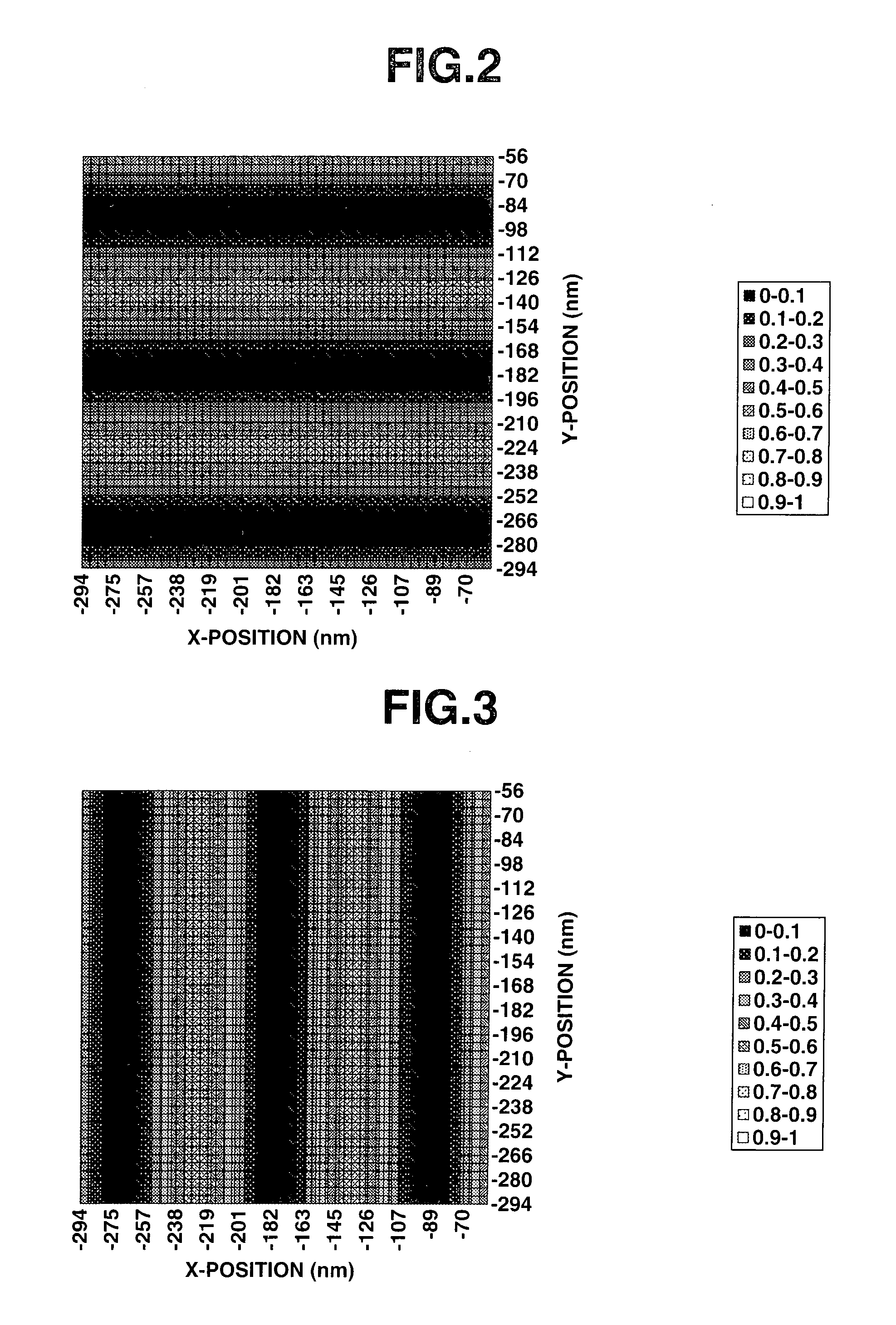

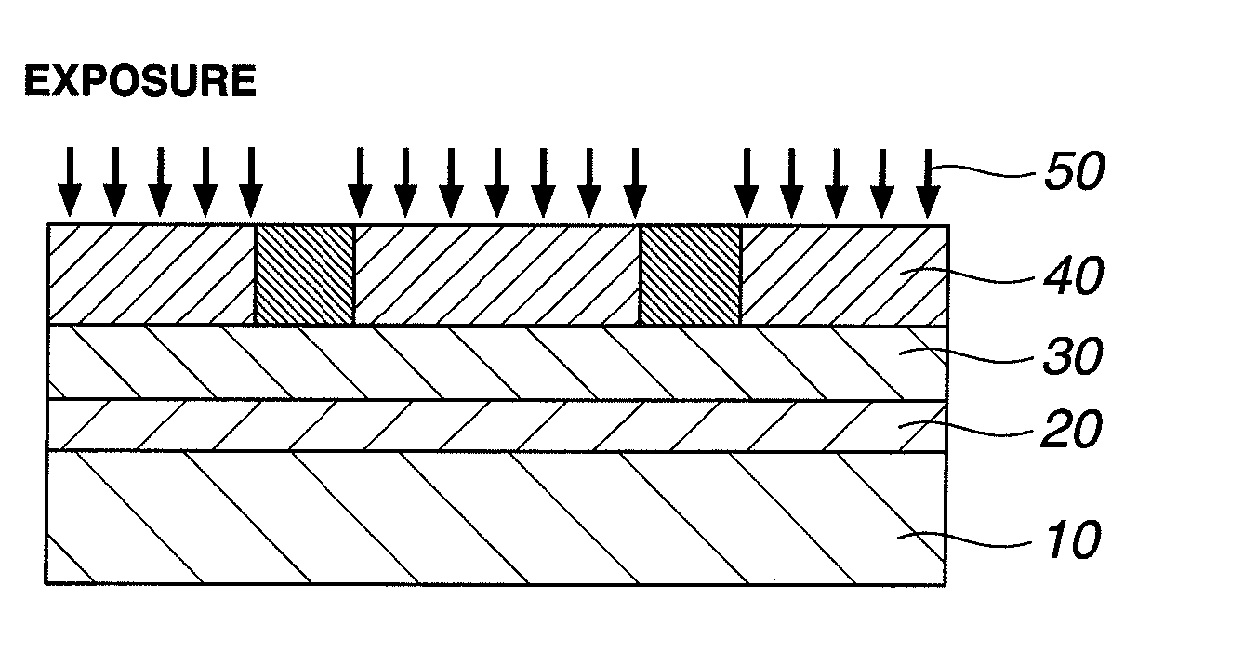

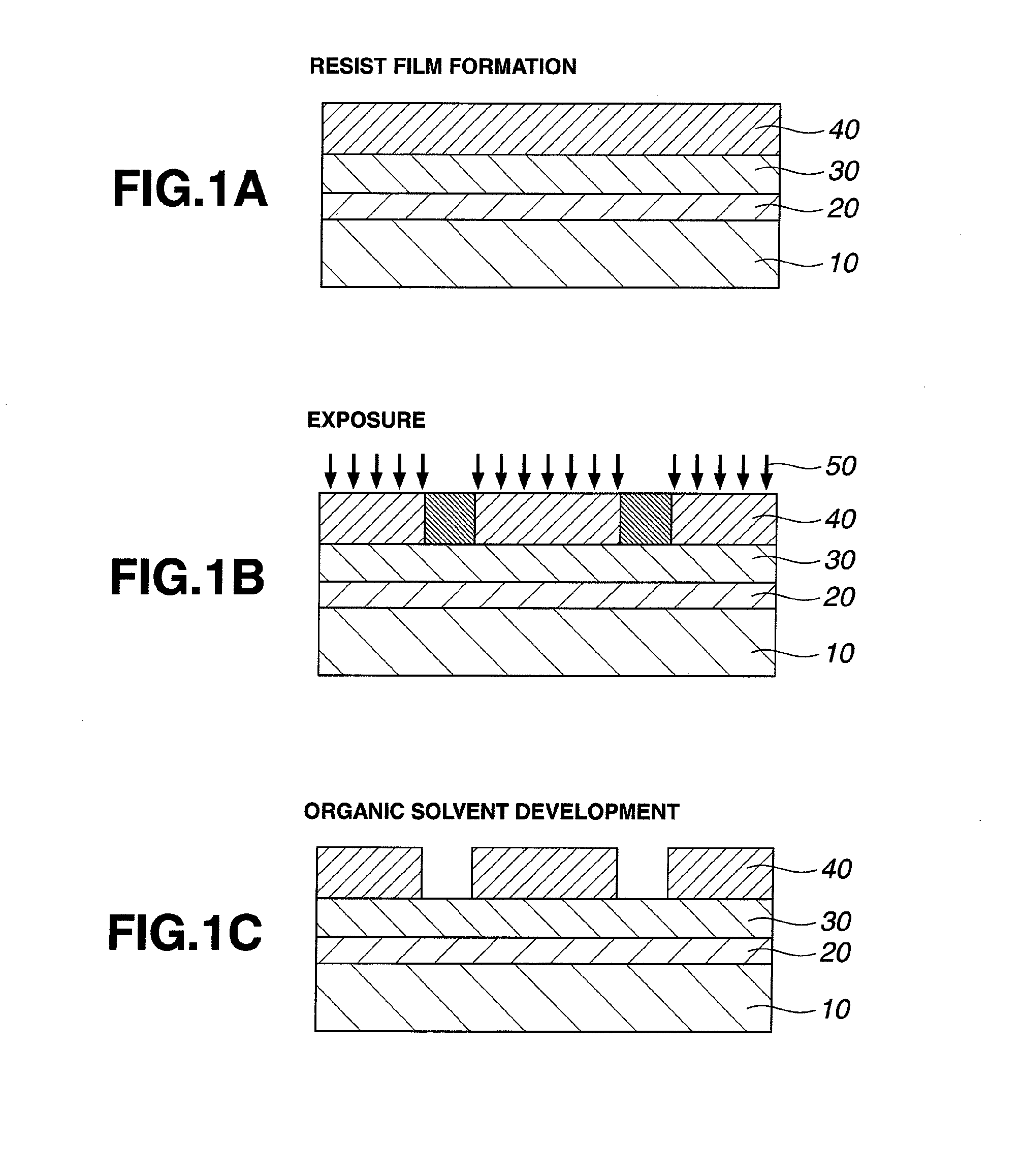

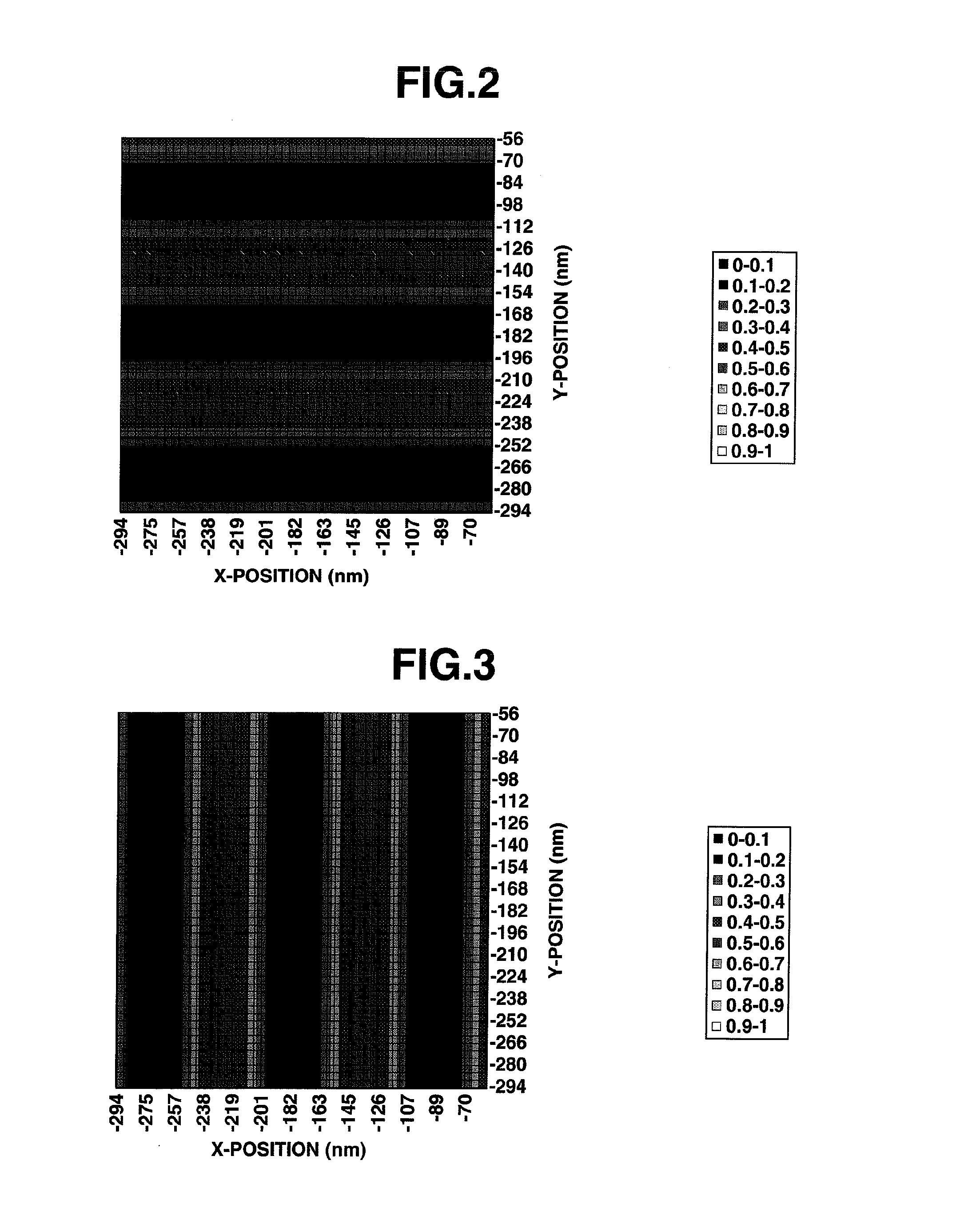

A pattern is formed by coating a resist composition comprising a polymer comprising recurring units having an optionally acid labile group-substituted naphthol group, an acid generator, and an organic solvent onto a substrate, baking to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with an organic solvent developer to form a negative pattern wherein the unexposed region of film is dissolved and the exposed region of film is not dissolved. In the process of image formation via positive / negative reversal by organic solvent development, the resist film has a high dissolution contrast and controlled acid diffusion. By subjecting the resist film to exposure through a mask having a lattice-like pattern and organic solvent development, a fine hole pattern can be formed at a high precision of dimensional control.

Owner:SHIN ETSU CHEM IND CO LTD

Patterning process, resist composition, and acetal compound

InactiveUS20110236826A1High dissolution contrastHigh sensitivityOrganic chemistryOrganic compound preparationHigh energyRadiation

A pattern is formed by applying a resist composition comprising a polymer comprising recurring units having an acid labile group-substituted hydroxyl group, an acid generator, and an organic solvent onto a substrate, prebaking the composition to form a resist film, exposing the resist film to high-energy radiation to define exposed and unexposed regions, baking, and developing the exposed film with an organic solvent developer to form a negative pattern wherein the unexposed region of film is dissolved and the exposed region of film is not dissolved.

Owner:SHIN ETSU CHEM CO LTD

Acetal compound, polymer, resist composition, and patterning process

ActiveUS20110236831A1High resolutionEfficient use ofOrganic chemistryOrganic compound preparationPolymer scienceOrganosolv

The invention provides an acetal compound containing an adamantane ring having an alcoholic hydroxyl group which is protected with an acetal group having a carbonyl moiety of branched structure. A photoresist film comprising a polymer comprising recurring units derived from the acetal compound and an acid generator is characterized by a high dissolution contrast when it is subjected to exposure and organic solvent development to form an image via positive / negative reversal.

Owner:SHIN ETSU CHEM IND CO LTD

Resist composition and patterning process

InactiveUS20120288796A1High sensitivityHigh precisionPhotosensitive materialsPhotomechanical exposure apparatusChemistryResist

A resist composition is provided comprising a polymer comprising recurring units having a hydroxyl group substituted with an acid labile group, an onium salt PAG capable of generating a sulfonic acid, imide acid or methide acid, and an onium salt PAG capable of generating a carboxylic acid. A resist film of the composition is improved in dissolution contrast during organic solvent development, and from which a hole pattern having minimized nano-edge roughness can be formed via positive / negative reversal.

Owner:SHIN ETSU CHEM IND CO LTD

Method of manufacturing semiconductor devices

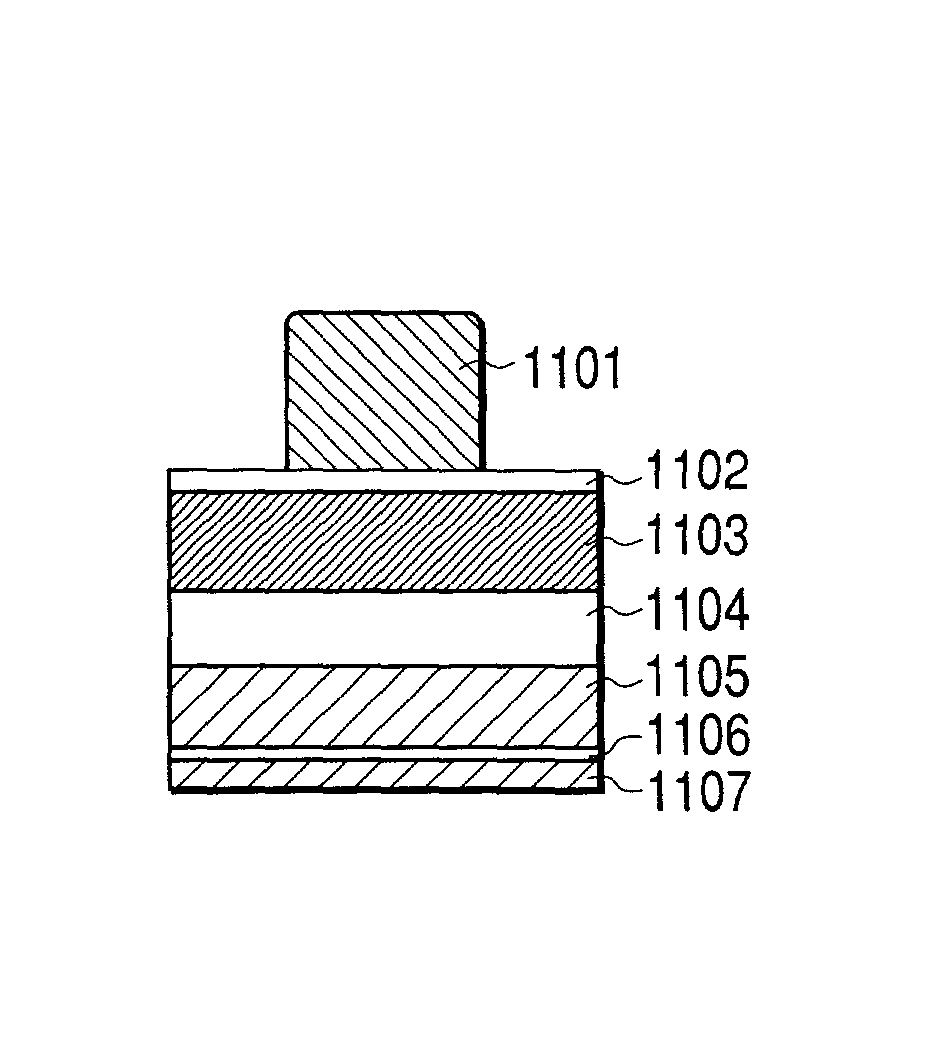

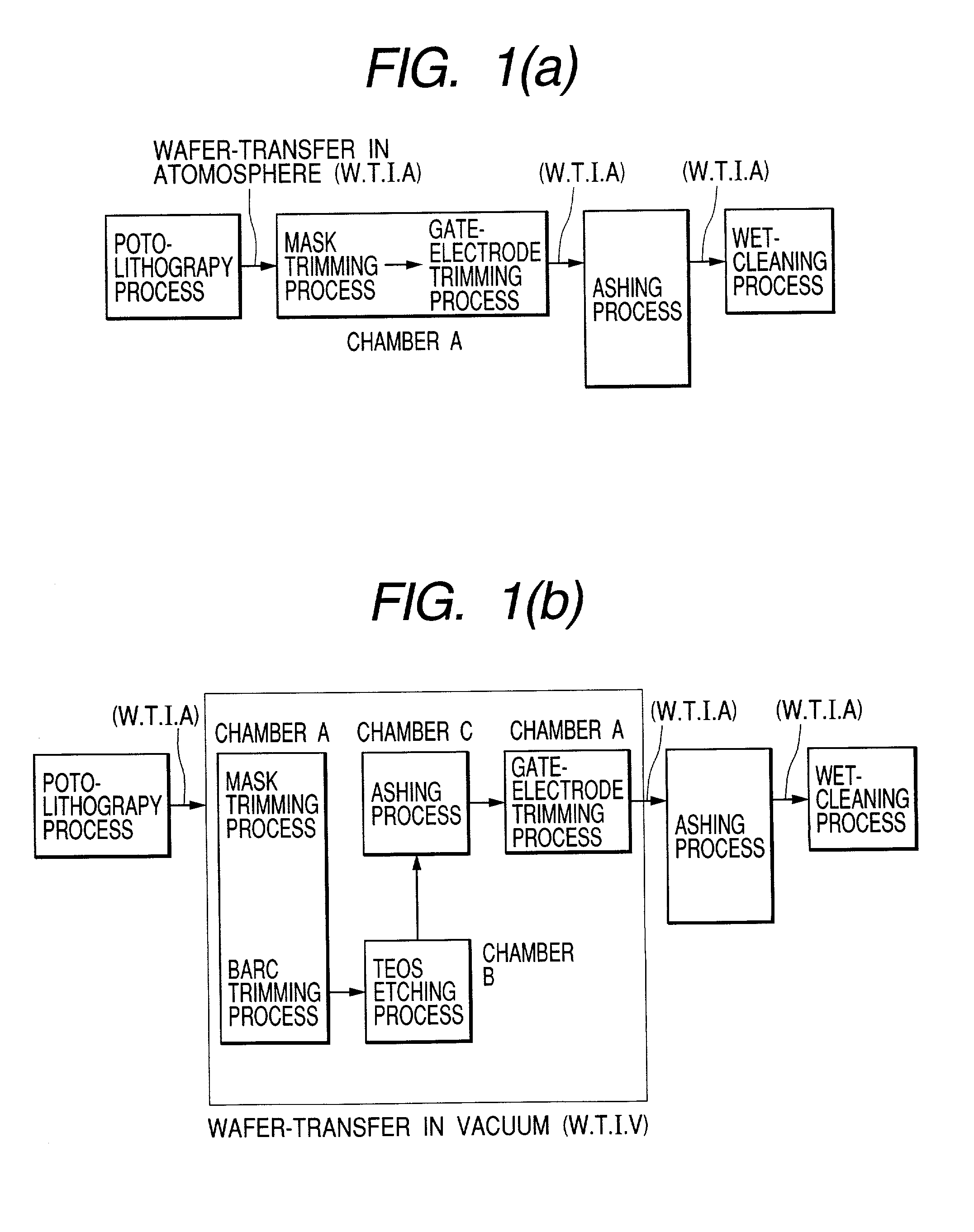

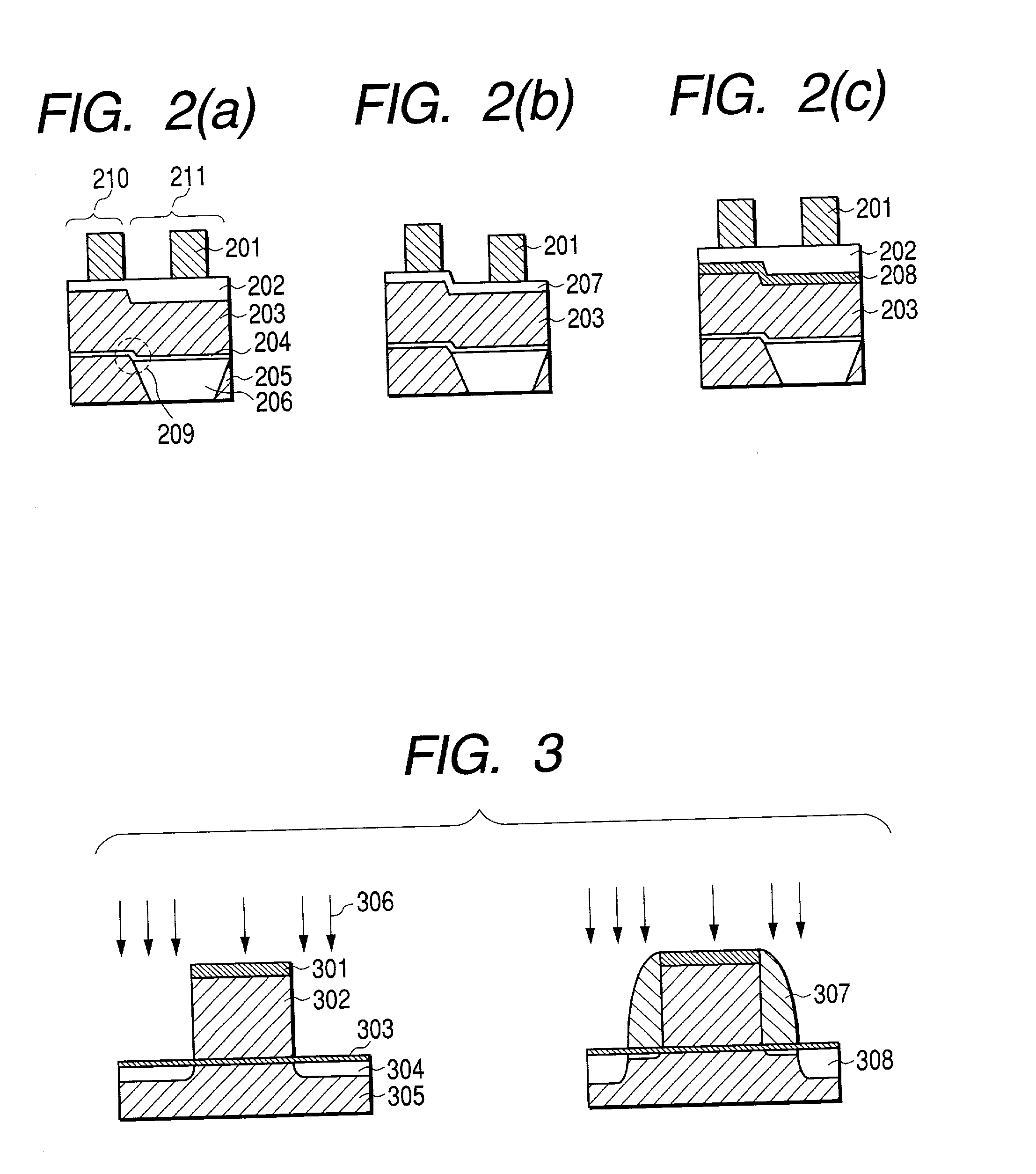

InactiveUS20030049876A1Reduce variationHigh precision machiningSemiconductor/solid-state device manufacturingSemiconductor devicesResistEngineering

A process for economical and efficient fabrication of gate electrodes no larger than 50 nm, which is beyond the limit of exposure, is characterized by gate-electrode trimming and mask trimming with high resist selectivity which are performed in combination. The process is also preferably characterized by performing trimming and drying cleaning in a vacuum environment and may also include steps of inspecting dimensions and contamination in a vacuum environment. The process can be implemented to provide the effects of forming a gate no longer than 50 nm (beyond the limit of exposure) without restrictions on the resist thickness; reducing contamination resulting from transfer of wafers from one step to next, thereby improving yields; preventing resist from hydrolysis by ArF laser, thereby reducing roughening which adversely affects the gate width; and ensuring stable yields despite variation in dimensions and contamination owing to the additional dry cleaning step and feed-forward control based on CD inspection and contamination inspection.

Owner:HITACHI LTD

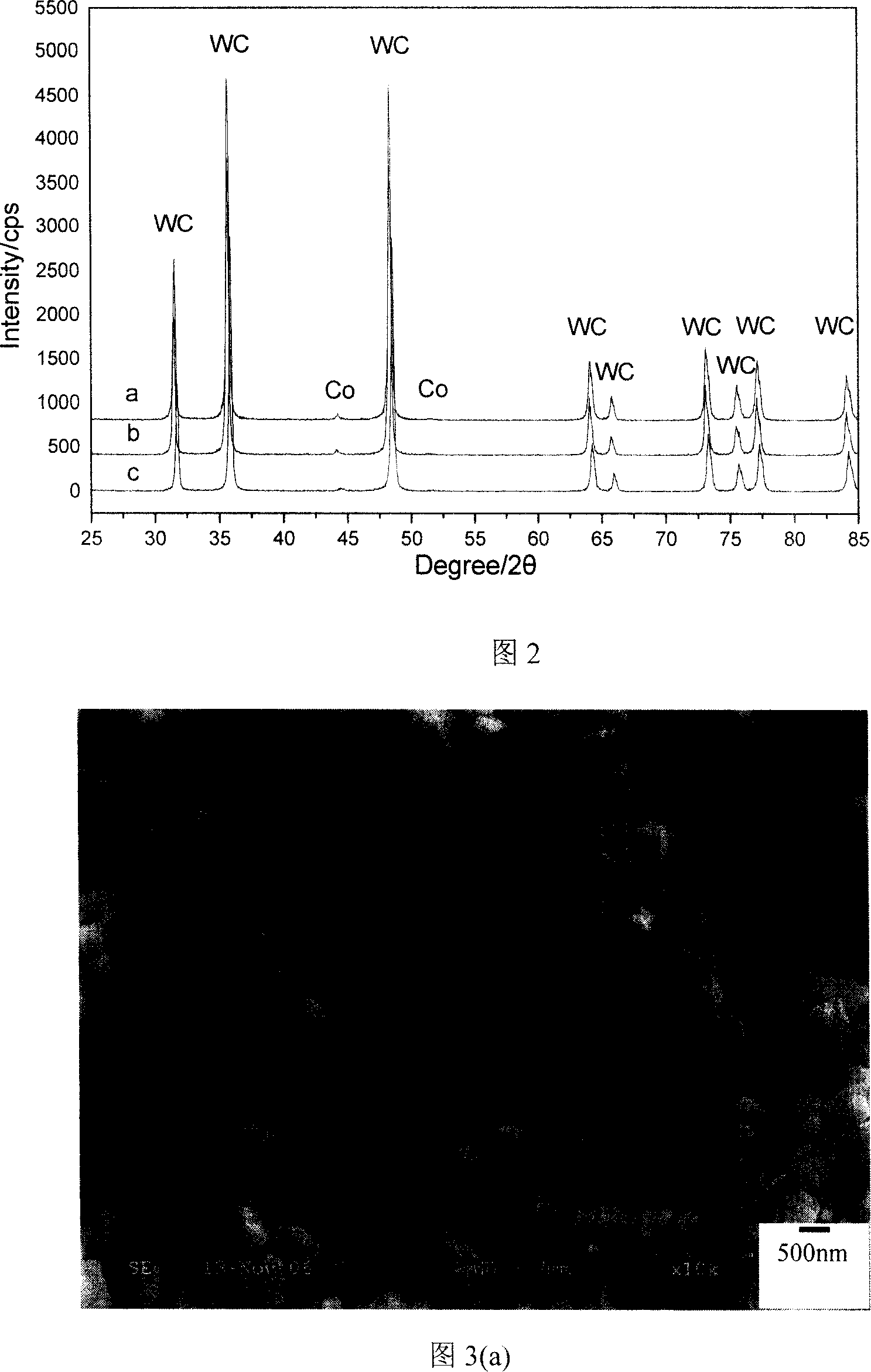

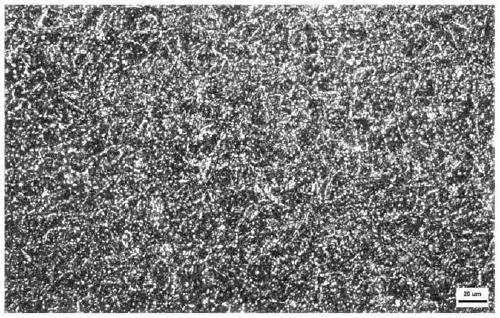

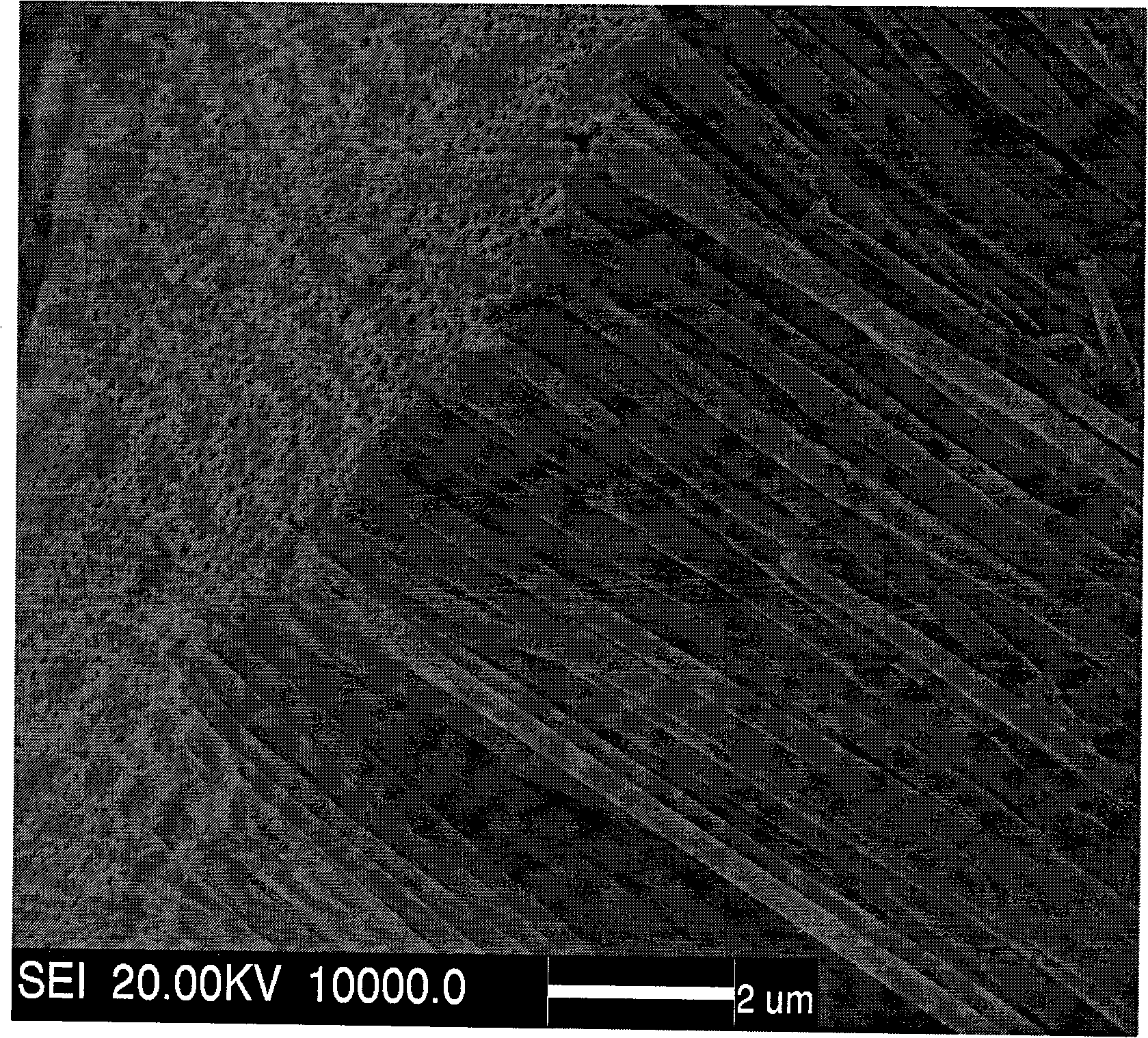

Simple fast preparing process of superfine WC-Co composite powder

The simple fast preparation process of superfine WC-Co composite powder belongs to the field of nanometer powder preparing technology. The preparation process includes the following steps: mixing WO2.9, Co3O4 and carbon black material in the required Co content; ball milling the mixture in a ball milling into superfine powder and cold pressing; heating in a vacuum furnace at vacuum condition to produce redox and carbonizing reaction at heating rate of 15-30 deg.c / min, reaction temperature 1050-1150 deg.c for 3-4 hr. The present invention has simple preparation path and short technological process, and obtains WC-Co composite powder of average particle size smaller than 400 nm.

Owner:BEIJING UNIV OF TECH

Transversal epitaxial growth method for nano area of semiconductor film

InactiveCN101510504AUniform crystal qualityImprove crystal qualityNanostructure manufactureSemiconductor/solid-state device manufacturingDiffusionEtching

The invention discloses a cross epitaxial growth method of a semiconductor film, which comprises the following steps: (1) a nucleated metallic catalyst film is evaporated on a substrate material and island-shaped metallic catalyst particles which are evenly distributed on the substrate are obtained after the film is annealed; (2) in external equipment, a crystal nucleus is formed on the bottom of island-shaped metallic particles; and then nano-column arrays grow longitudinally; (3) a wet etching method is used for eliminating the metallic catalyst on a nano-column to obtain semiconductor nano-column array structures with the same orientation and height; (4) the etched nano-column is put into the external equipment and a lateral epitaxy technology is used for integrating the nano-column arrays into a flat surface; and then a semiconductor epitaxial film with the required thickness grows on the flat surface. As cross epitaxy occurs in nano area, defects and diffusion of residual stress can be effectively restrained and the quality of film crystals is more uniform than that of film crystals prepared by the traditional method, thus improving the crystal quality of two-dimensional semiconductor films; furthermore, the invention has simple method and wide applicability.

Owner:SUZHOU NANOJOIN PHOTONICS

Patterning process and resist composition

ActiveUS20120183903A1High dissolution contrastEffective controlPhotosensitive materialsPhotomechanical exposure apparatusPolymer scienceOrganic solvent

A pattern is formed by applying a resist composition comprising a polymer comprising recurring units having a nitrogen atom bonded to an acid labile group, an acid generator, and an organic solvent onto a substrate, prebaking to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with an organic solvent developer to form a negative pattern wherein the unexposed region of film is dissolved and the exposed region of film is not dissolved.

Owner:SHIN ETSU CHEM IND CO LTD

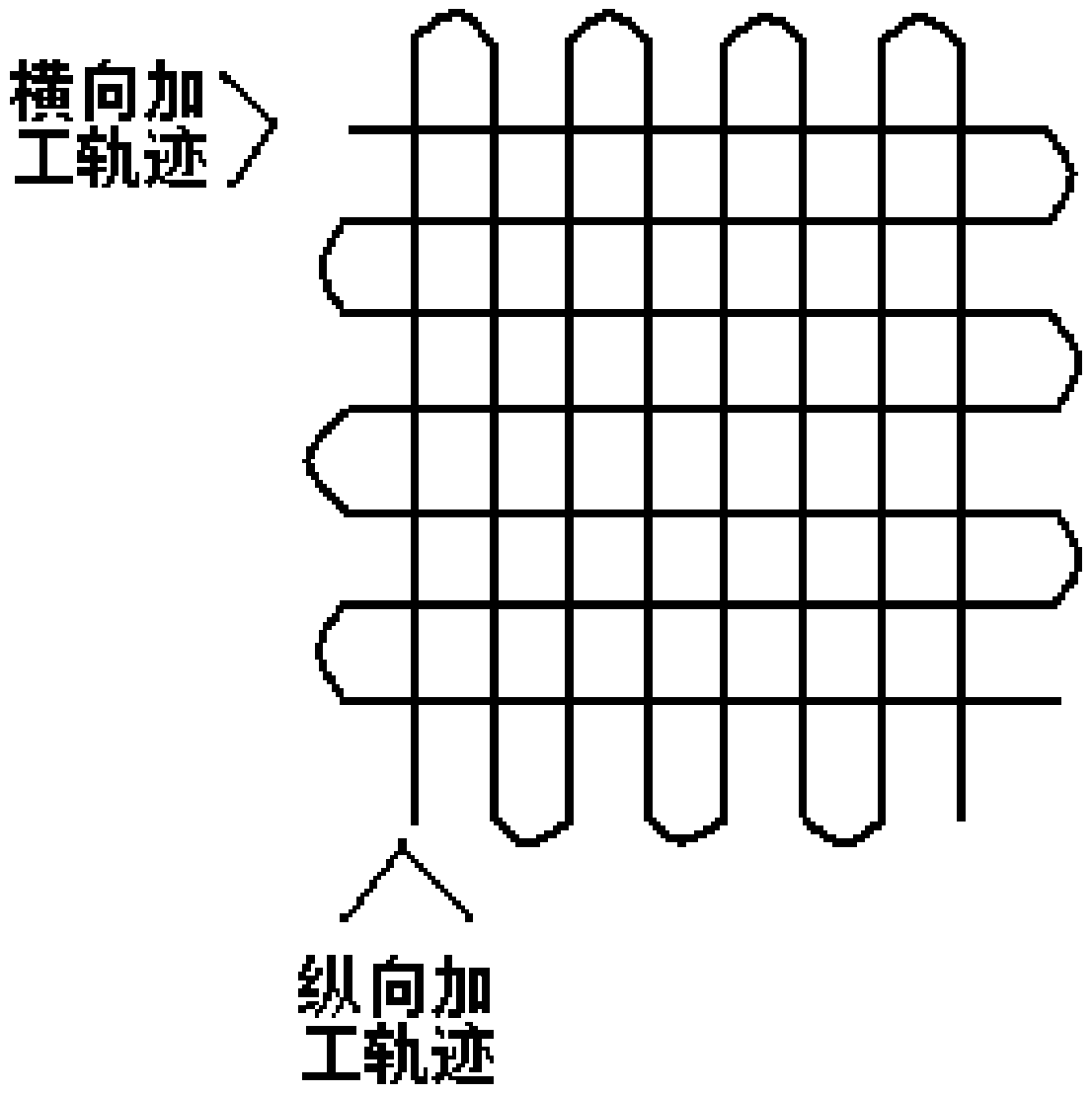

Resin matrix composite with super-hydrophobic bionic surface and preparation method of resin matrix composite

ActiveCN105504324AImprove environmental adaptabilityAvoid heat damageCoatingsMicrostructureResin matrix

The invention provides a resin matrix composite with a super-hydrophobic bionic surface and a preparation method of the resin matrix composite. The method comprises steps as follows: the surface of a matrix of the resin matrix composite is polished until the surface turns white; the matrix of the resin matrix composite is processed through ultrafast laser, and a microstructure is formed on the surface; a first coating is sprayed on the microstructure surface of the matrix of the resin matrix composite through a pneumatic type paint spray gun to form a bonding layer, a second coating containing nanosilicon dioxide particles is sprayed to form a surface hydrophobic function layer, and the resin matrix composite with the super-hydrophobic bionic surface is obtained. The preparation method is simple to operate and facilitates production, the prepared resin matrix composite with the super-hydrophobic bionic surface can allow water drops to freely slip off, and the real self-cleaning super-hydrophobic function is realized.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

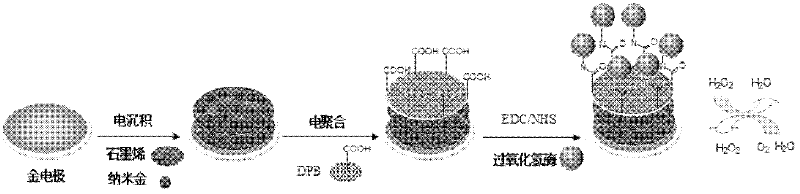

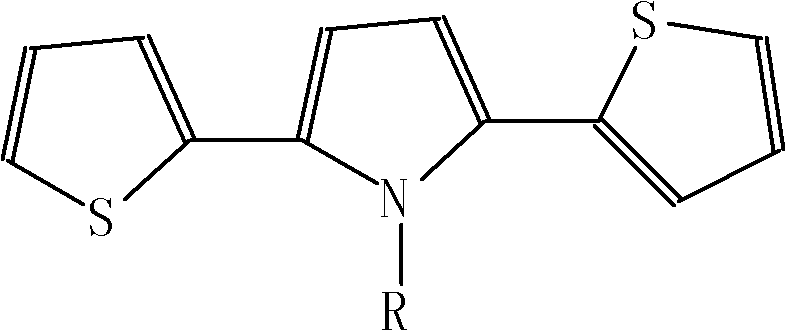

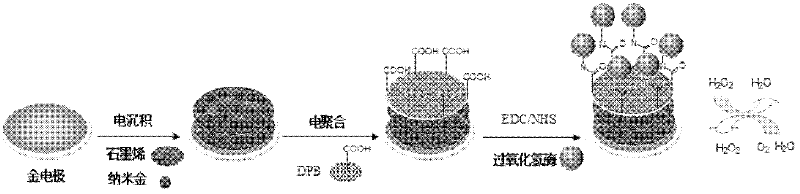

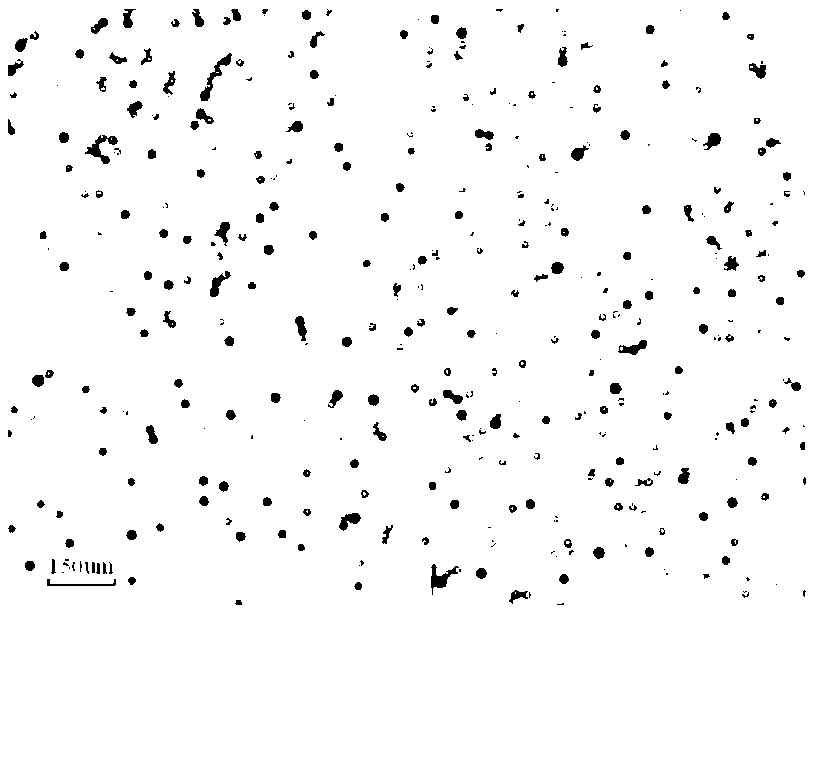

Method for preparing graphene biosensor

ActiveCN102520038ASensitive electrochemical responsePrecise size controlMaterial analysis by electric/magnetic meansSupporting electrolyteConductive polymer

The invention relates to a method for preparing a graphene biosensor, belonging to the technical field of electrochemistry. The method comprises the following steps of: immersing a processed gold electrode into graphene oxide and a sodium sulphate solution, electrically depositing the electrode through a control electric potential, taking out the electrode, washing the electrode by using water, after drying the electrode at room temperature, putting the electrode in a chloroauric acid solution, electrically depositing the electrode through the control electric potential, taking out the electrode, washing the electrode by using water, and drying the electrode at room temperature; putting a modified electrode in a conductive polymer monomer and a supporting electrolyte solution, polymerizing the electrode through the control electric potential by adopting a cyclic voltammetry, taking out the electrode, washing the electrode by using water, and drying the electrode at room temperature; and activating the modified electrode in an EDC / NHS (Dichloroethane / N-Hydroxysuccinimide) solution, and immersing the modified electrode in a vomiting toxin antibody. The method disclosed by the invention is used for fixing graphene, gold nanoparticles and conducting polymers through electro-deposition; therefore, the method is very green and environment-friendly; furthermore, the thickness of a coating and sizes and distribution densities of the gold nanoparticles can be precisely controlled, thus, the batch production repeatability of the modified electrode is good.

Owner:盐城福万家保温板有限公司

Preparation method of metal nanostructure

InactiveCN103668130AAvoid influencePrecise shape controlLiquid/solution decomposition chemical coatingUltraviolet lightsNanostructure

The invention discloses a preparation method of a metal nanostructure. The preparation method comprises the steps of (1) manufacturing a mask plate; (2) providing a clean and dry base plate, uniformly coating a positive ultraviolet photoresist on the base plate, and pre-baking to ensure that the positive ultraviolet photoresist is solidified to form a photoresist base plate; (3) overlapping the mask plate on the photoresist base plate, and performing exposure, development, residual adhesive removal and hardening under ultraviolet light to obtain a forming mold with shape grooves of a nanostructure graph; (4) depositing a metal in the forming mold by adopting a chemical synthetic method; (5) soaking the forming mold deposited with the metal in an acetone solution, and performing ultrasonic adhesive removal to obtain the metal nanostructure of the nanostructure graph. The preparation method disclosed by the invention is simple in process and high in efficiency; the shape, size and position of the prepared metal nanostructure can be accurately controlled, and the light extraction efficiency and light absorption efficiency of a metal nanostructure material are effectively improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

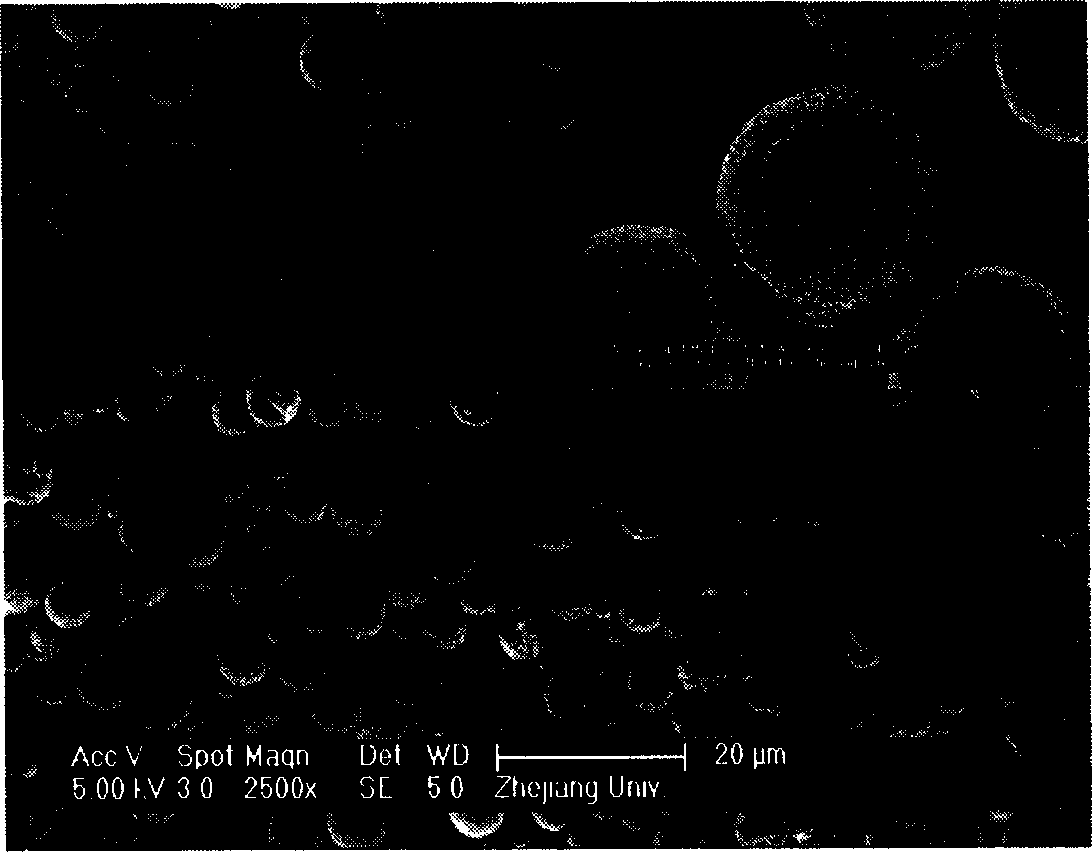

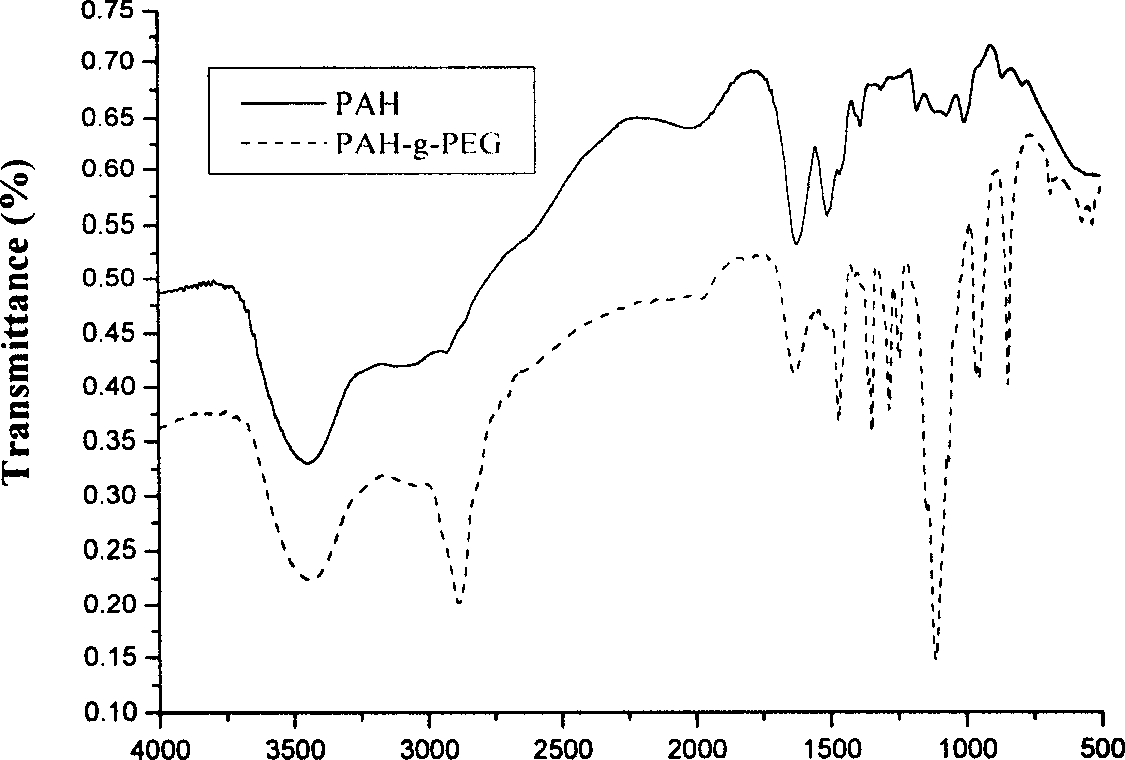

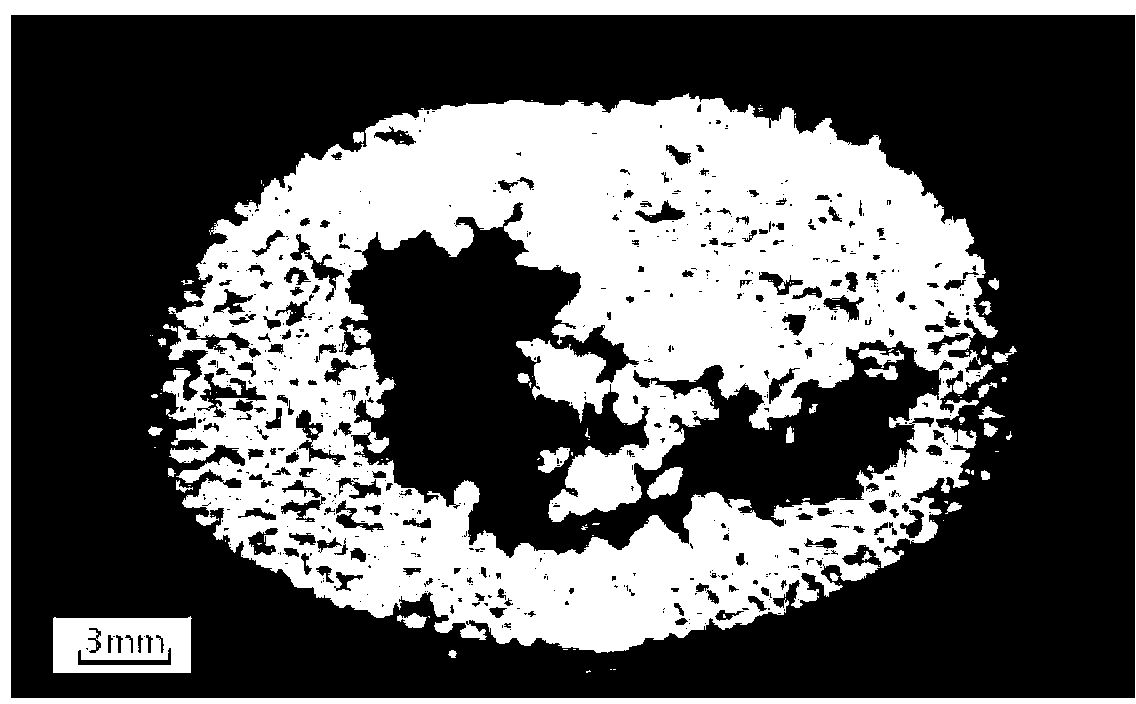

Prepn process of microcapsule with included anticancer medicine

InactiveCN1771917AGood biocompatibilityGood tissue compatibilityOrganic active ingredientsUnknown materialsNanometer sizeWater soluble

The present invention discloses the preparation process of microcapsule with included anticancer medicine. The process adopts colloid particle containing polyelectrolyte as template, assembles polyelectrolytes with dislike charges via layer-by-layer self-assembling to the surface of colloid particle, and dissolves or decomposes the colloid particle to obtain hollow polymer microcapsule containing polyelectrolyte. The microcapsule has wall micro structure and thickness capable of being regulated precisely in nanometer size, and the contained polyelectrolyte can interact with the medicine so as to include the medicine into the microcapsule. The included medicine has controllable release speed. Introducing polyelectrolyte with grafted polyglycol to the surface of the microcapsule can raise the biocompatibility of the microcapsule. The process of the present invention is simple, feasible and repeatable, and suitable for inclusion and controllable release of various kinds of water soluble anticancer medicine.

Owner:ZHEJIANG UNIV

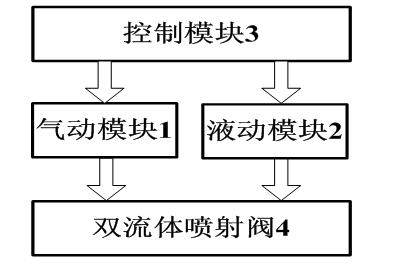

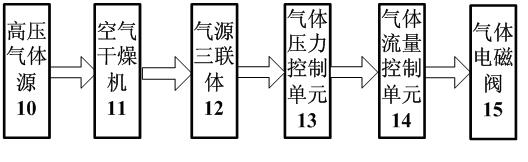

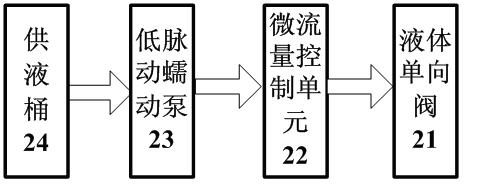

Two-fluid jet system

InactiveCN102527541AExtended service lifeSimplified implementation pathLiquid spraying apparatusPhysicsPowder metallurgy

The invention relates to a two-fluid jet system, which comprises a pneumatic module, a hydraulic module, a control module and a two-fluid jet valve, wherein the control module is respectively connected with a gas pipe and a liquid pipe of the two-fluid jet valve through the pneumatic module and the hydraulic module. The two-fluid jet system is based on the microchannel gas-liquid flow movement principle, namely the control module is used for controlling gas-liquid flow velocity ratio or flow ratio of the pneumatic module and the hydraulic module, so that liquid jet of slug flow is realized in a microchannel. The two-fluid jet system is applicable to fluid jet in the fields of semiconductor film preparation, composite preparation, electronic package, MEMS (micro-electromechanical systems), spraying, ink jet, powder metallurgy, biomedicine, food processing, welding, combustion, chemical engineering and the like.

Owner:SHANGHAI UNIV

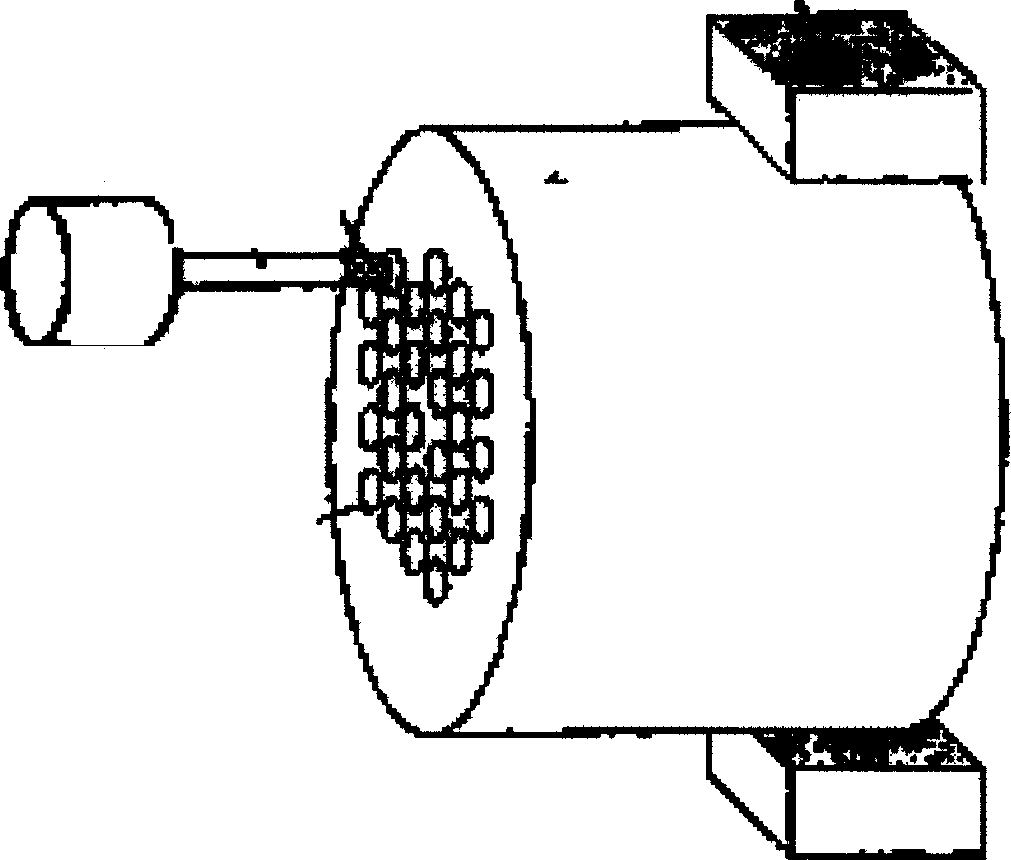

Method for preparing photon crystal optical fibre and apparatus therefor

ActiveCN1583617ASimple preparation procedureReduce lossGlass making apparatusGlass productionAtmospheric pressureMaterials science

The method is: Put many glass pipe in order to form a specific structure (photon crystal optical fibre prefab stick) in the glass cannula. The thin glass pipe is longer then the others. The equipment controls the pressure of photon-crystal optical fibre prefab stick. In another word is to vacuum the glass cannula, to input the thin glass pipe of 10 -1 mbar air.

Owner:FENGHUO COMM SCI & TECH CO LTD

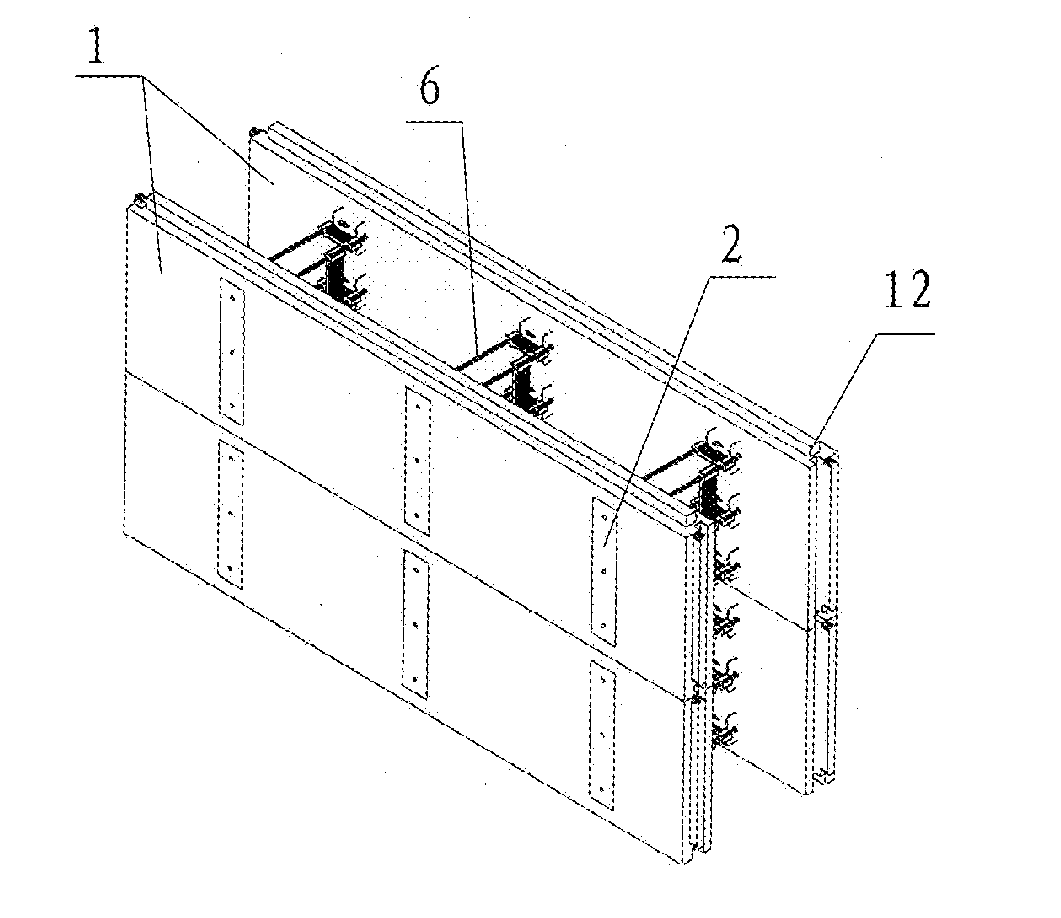

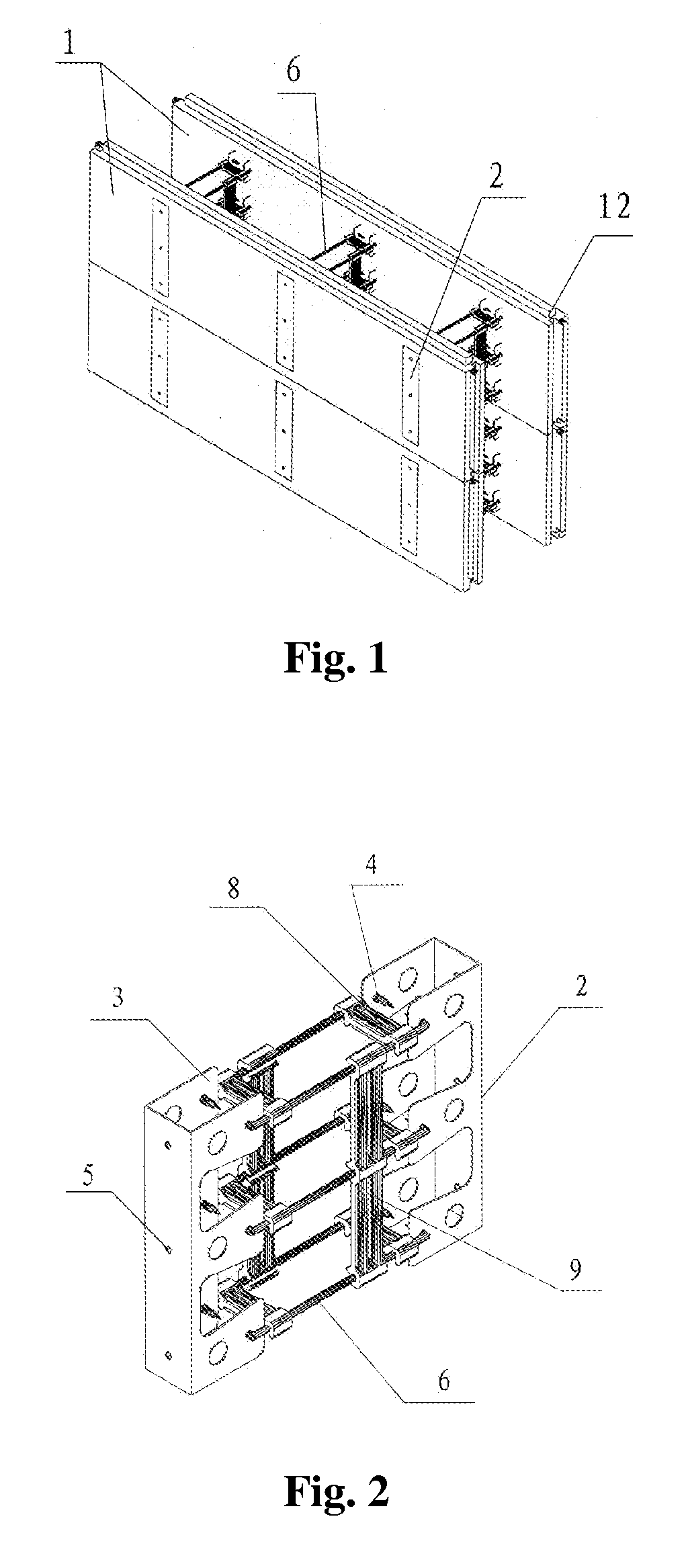

Assemblage concrete forms and method for manufacturing thereof

InactiveUS20070094973A1Avoid separationReduce construction costsWallsBuilding repairsPolystyreneStructural engineering

Taught herein is inter alia a concrete wall modulus comprising a concrete-steel wall having one or more steel mesh plates; at least two form panels being physically connected to the concrete-steel wall; a plurality of steel plates; and a plurality of jointing pieces; wherein the form panels are made in part of polystyrene foam; at least two form panels are arranged in parallel to one another; and at least two the form panels are interconnected by a plurality of the jointing pieces by means of the steel plates.

Owner:ZHU QINJIANG

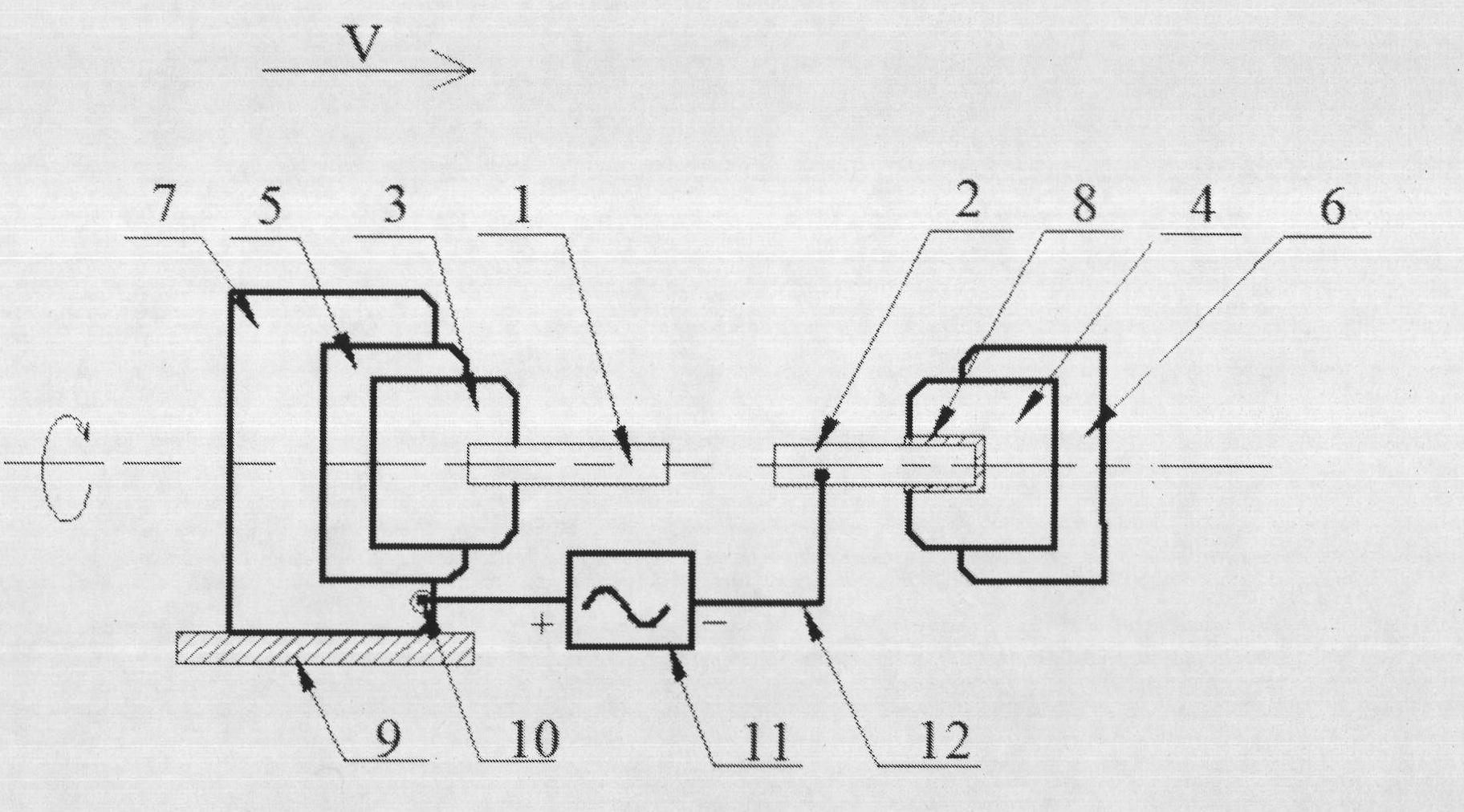

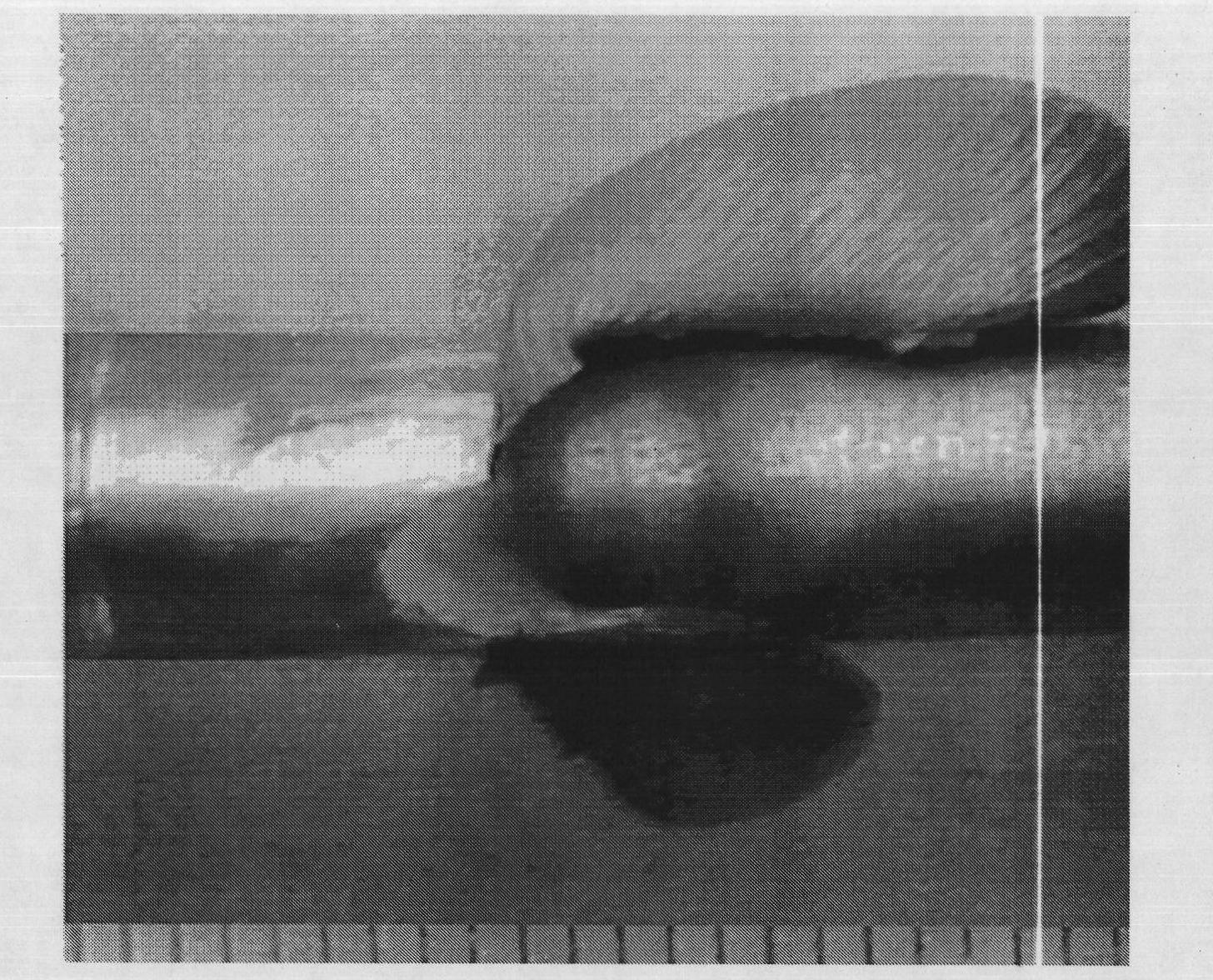

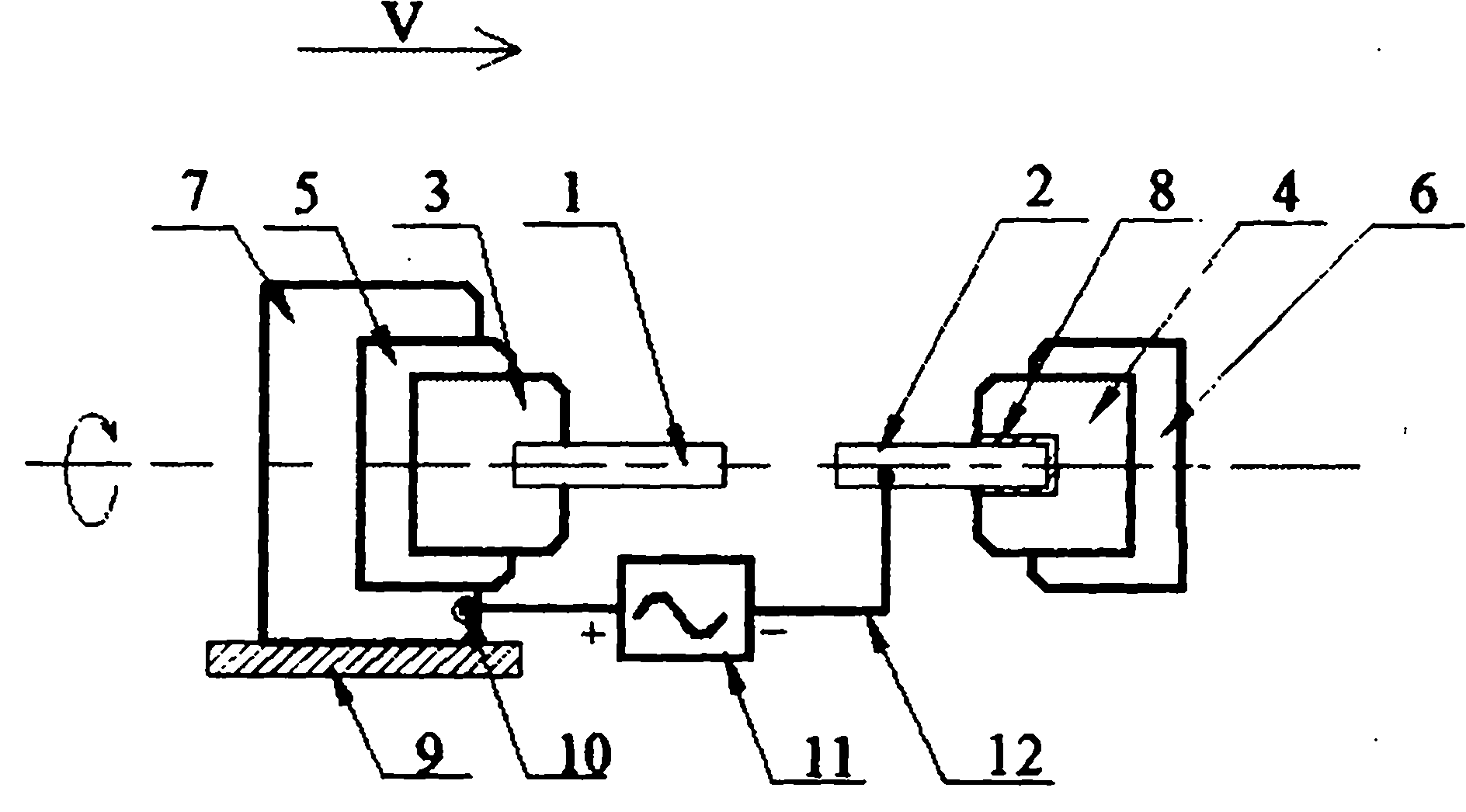

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

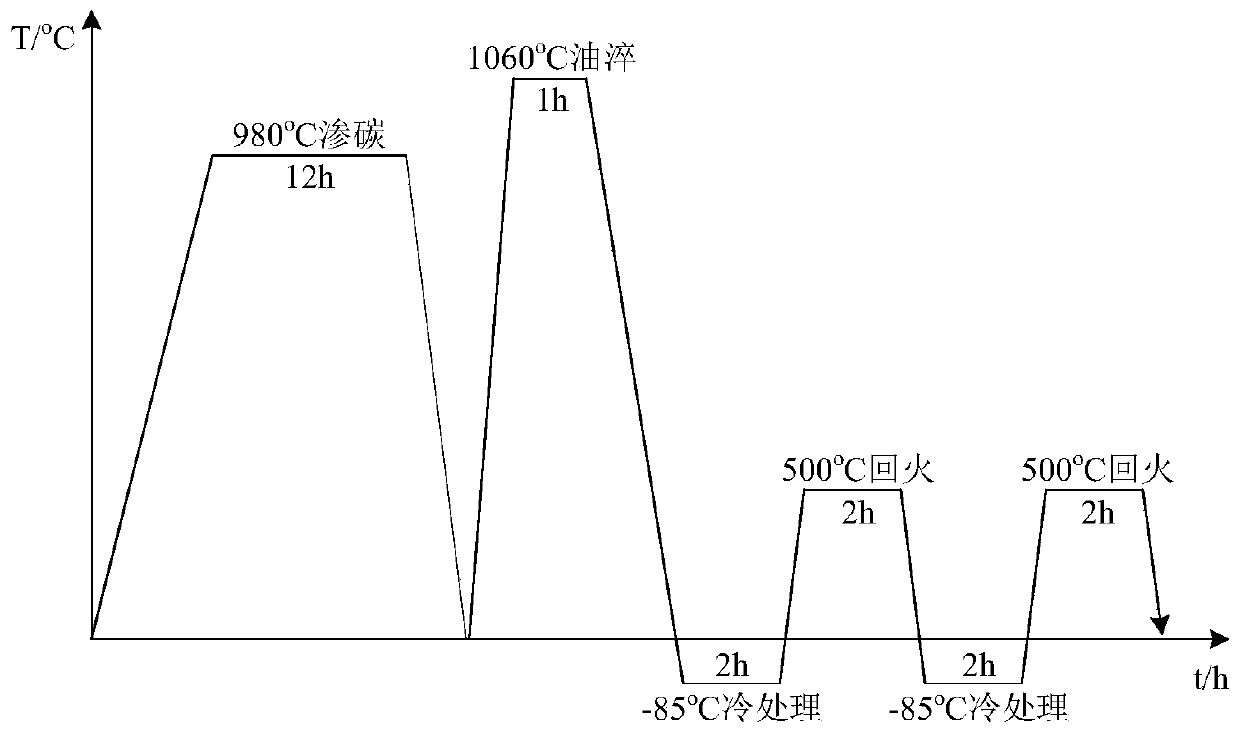

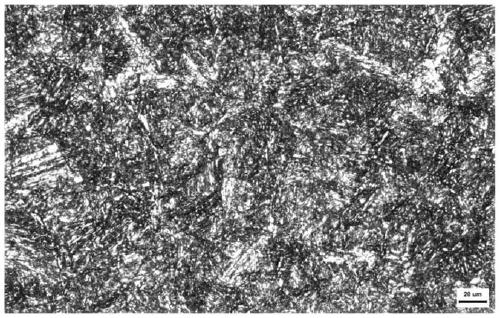

Low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel

ActiveCN109735794ASolve pollutionHigh fatigueSolid state diffusion coatingQuenchingPrepared Material

The invention relates to a low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel. The method comprises the treatment steps of low-pressure vacuum carbonizing, quenching, deep cooling and high-temperature tempering; and the steps can be repeatedly performed. The low-pressure vacuum carbonizing process uses a saturated value adjusting method for multi-section pulse carbonizing; a carbonizing agent adopts acetylene gas; the carbonizing temperature is 850-1050 DEG C; the carbonizing pressure is 100-2000 Pa; and the powerful seepage and dispersion circulating period is 20-70 times. The treatment method is safe, energy-saved and environment-friendly, can eliminate intergranular oxidation, realizes precise control of the seepage layer depth, and canguarantee excellent service performances of prepared materials above 400 DEG C.

Owner:NORTHEASTERN UNIV

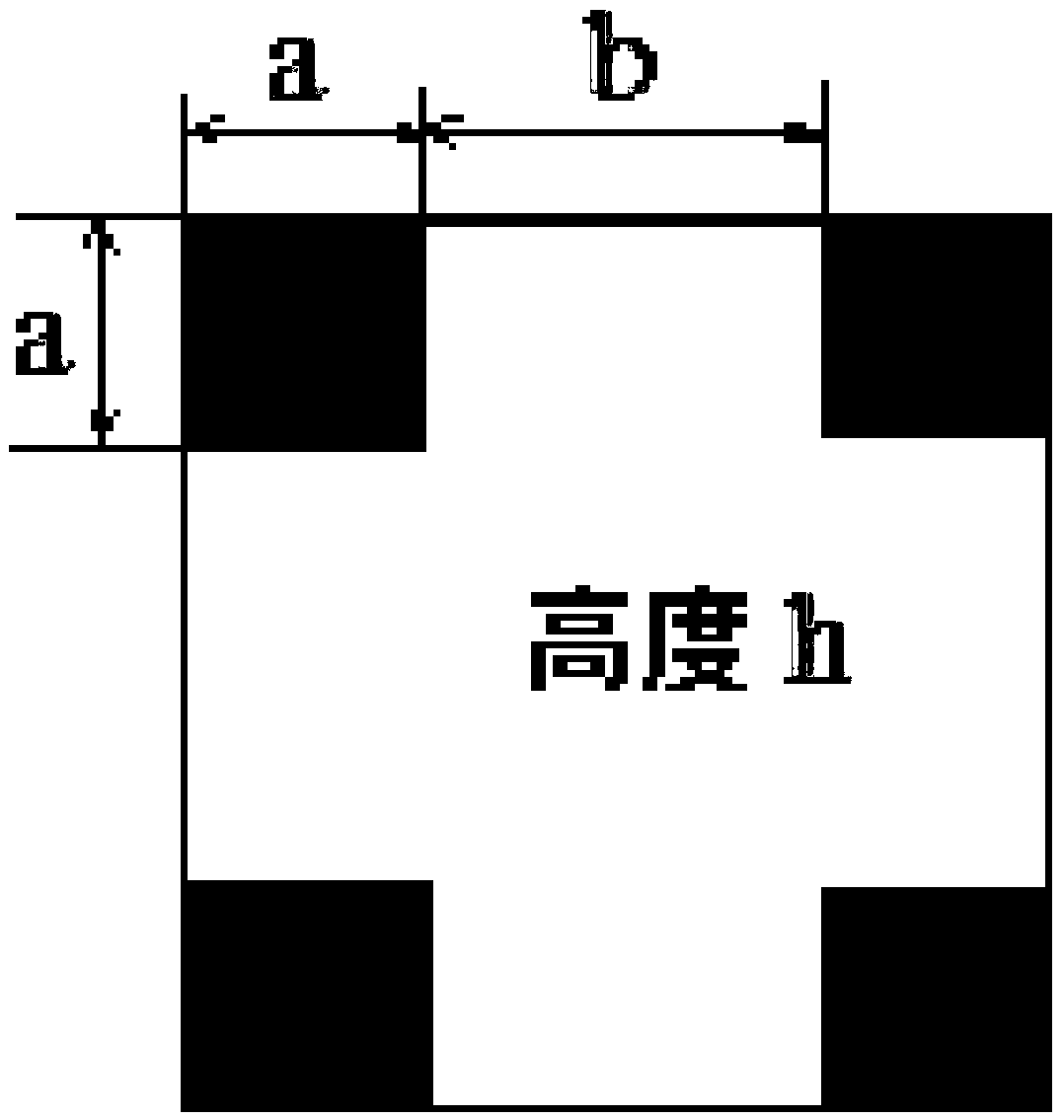

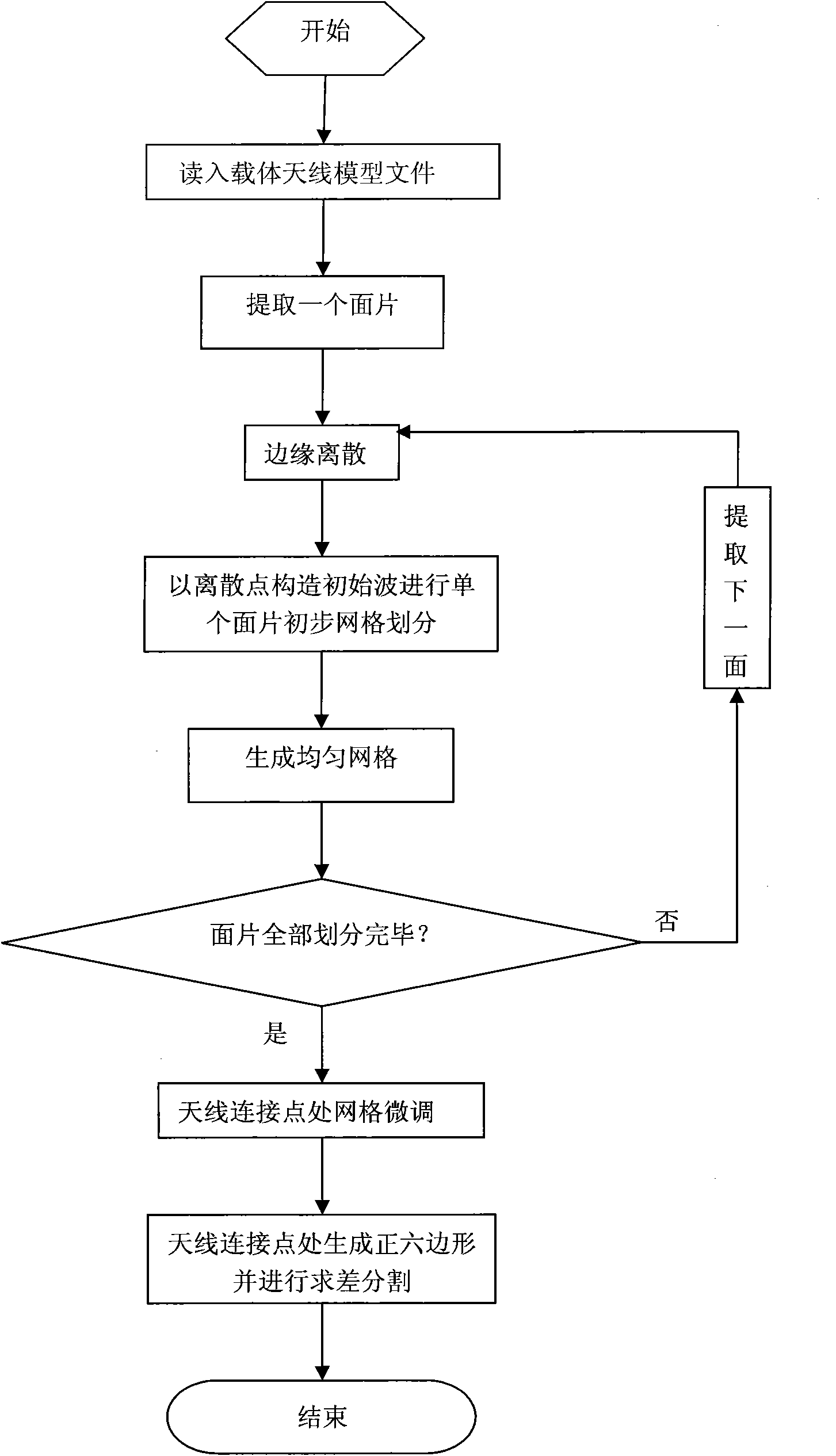

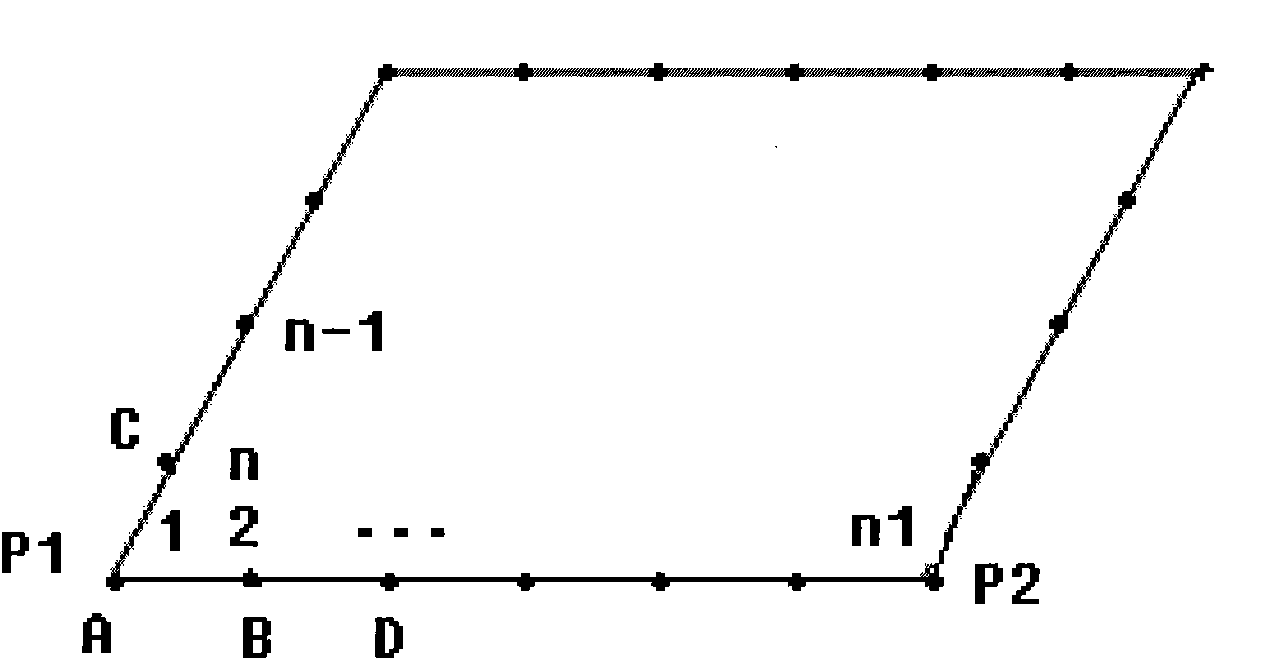

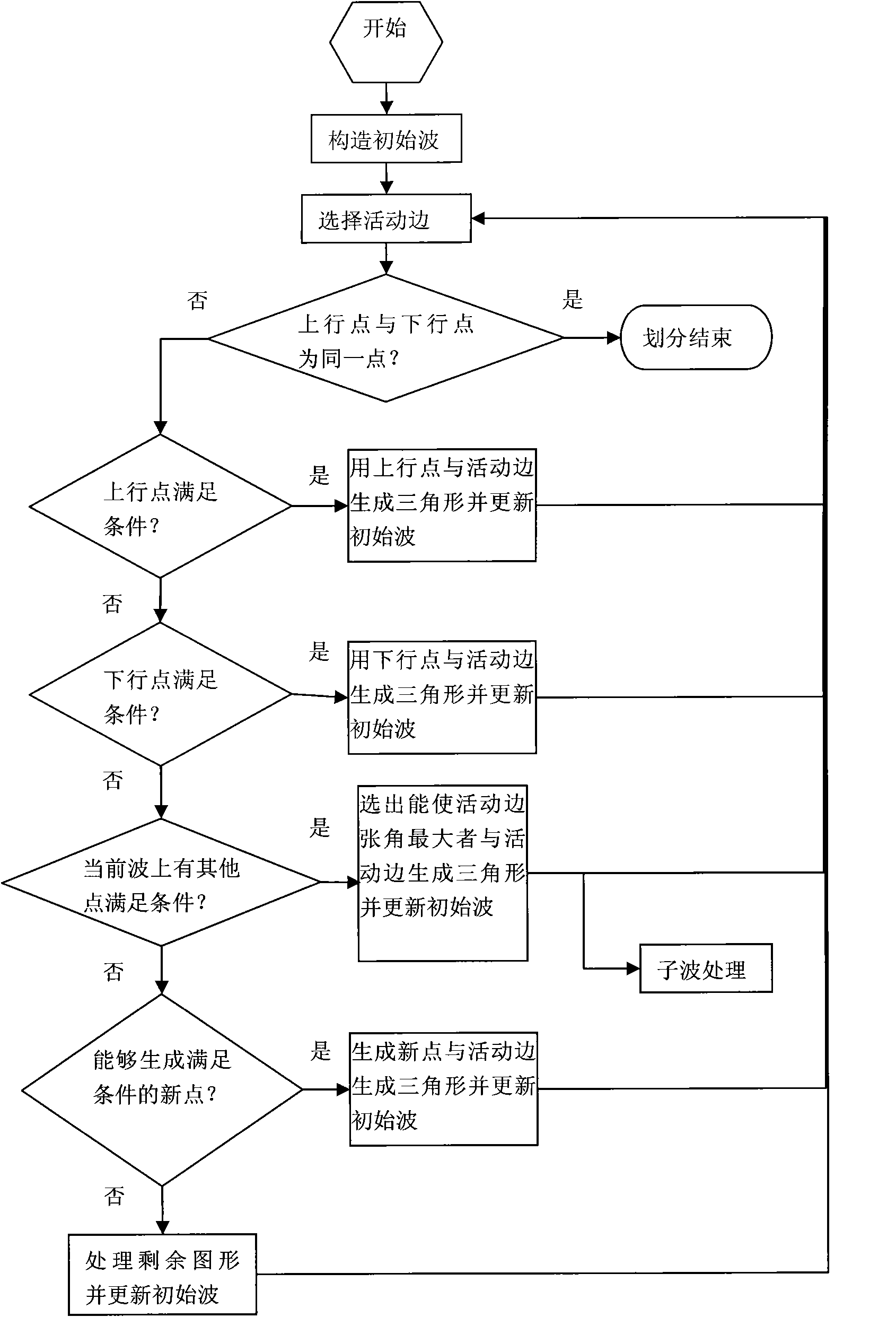

Carrier antenna structure meshing method based on method of moment (MOM) for triangular vector basis function

InactiveCN101877022AImprove calculation accuracySmall amount of calculationSpecial data processing applicationsAlgorithmEngineering

The invention discloses a carrier antenna structure meshing method based on a method of moment (MOM) for a triangular vector basis function, which mainly the problems that the traditional meshing method does not meet the requirements of the MOM for a triangular vector basis function, can not accurately control the mesh size, can not evenly divide parts, the curvature of which is discontinuous, and needs repeated iterations to generate uniform meshes. The meshing method comprises the following steps of: firstly, dispersing edges of each patch of a carrier antenna model; secondly, preliminarily meshing each patch and generating uniform meshes under the condition of not considering the antenna; then, carrying out fine adjustment on the meshes at the connection points of the antenna and constructing one regular hexagon by using each connection point of the antenna as the center; and finally, carrying out differential division on the regular hexagon and all triangles which use the connection points of the antenna as common vertexes to obtain triangularized meshes meeting the requirements of MOM for a triangular vector basis function. The method has the advantages of reliability, high computing speed, uniform generated meshes and good quality of unit shape, and can be used for the electromagnetic calculation of the carrier antenna structure.

Owner:XIDIAN UNIV

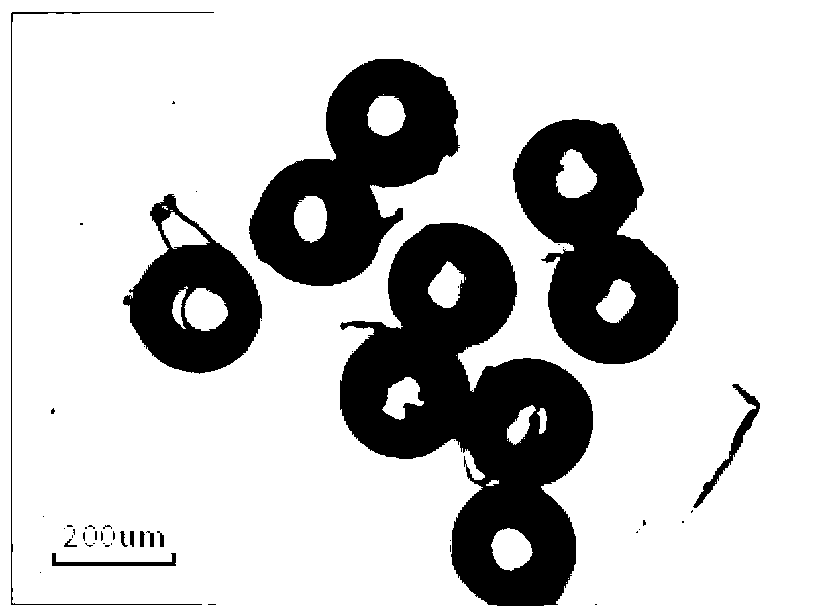

Particle size controllable mono-disperse polyacrylamide gel microspheres and preparation method as well as used device thereof

InactiveCN102898579ALarge particle sizePrecise size controlChemical/physical/physico-chemical processesMicroballoon preparationMicrosphereViscosity

The invention provides a preparation method of particle size controllable mono-disperse polyacrylamide gel microspheres. The preparation method comprises the following steps of: preparing disperse phase solution and continuous phase solution; controlling flow velocities and viscosities of the disperse phase and the continuous phase; and converging the disperse phase and the continuous phase to obtain polyacrylamide solution droplets with different particle sizes and uniform diameter size, wherein the droplets are subjected to polymerization reaction to obtain the particle size controllable mono-disperse polyacrylamide gel microspheres. The invention also relates to a preparation device of the particle size controllable mono-disperse polyacrylamide gel microspheres and the mono-disperse polyacrylamide gel microspheres obtained thereby. By adjusting the flow velocities and the viscosities of the disperse phase and the continuous phase or the size of capillary tubes, accurate control over the particle size of the microspheres can be realized; and the particle size of the prepared microspheres is within a range of 10-1,000 mum.

Owner:UNIV OF SCI & TECH OF CHINA

Heat resistance stainless steel and smelting method thereof

Heat resisting stainless steel and its smelting process are both disclosed herewith. It comprises (wt%): C 0.05-0.10, Si 1.40-2.00, Ce 0.03-0.08, Cr 20.0-22.0, Ni10.0-12.0, N 0.14-0.20, and Mn 0.4-0.80, with impurities of P not more than 0.040 and S 0.030. It is produced by: (1) pouring mother liquid of stainless steel with C (1.2-2.5) into AOD furnace, (2) decarbonizing to C (0.05-0.10), (3) reducing steel liquid and desulfurizing, (4) floss removing and regulating components of steel liquid, (5) pouring out and adding B-iron and Al cakes, (6) feeding Ce wires, (7) regulating temperature and controlling impurities, and (8) continuously casting. It costs low and has good performance at high temperature.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

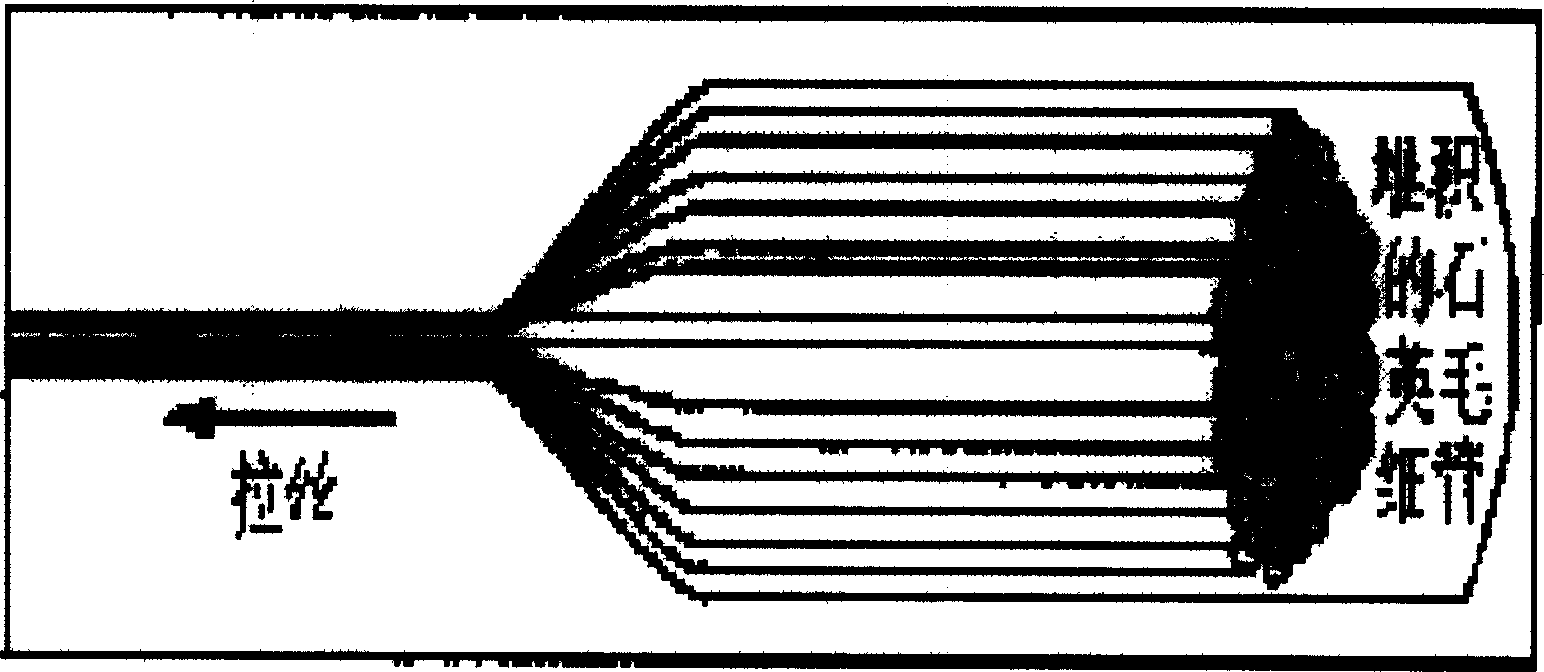

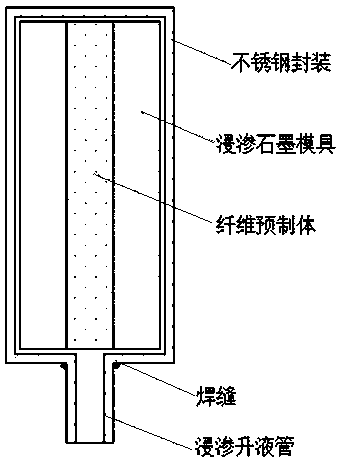

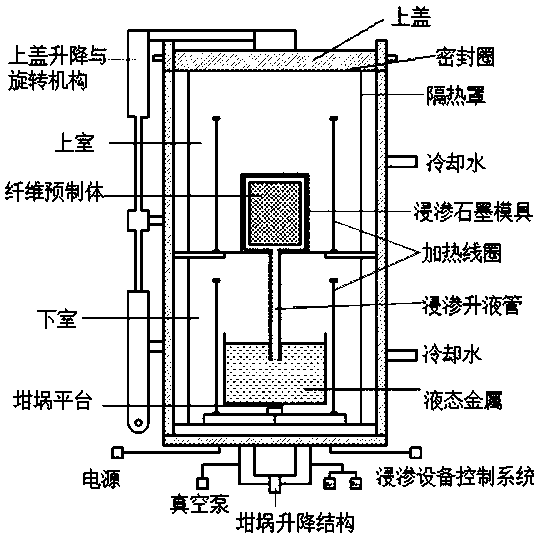

Near-net forming method of 3D braided fiber reinforced metal-based composite material

The invention discloses a near-net forming method of the 3D braided fiber reinforced metal-based composite material, and belongs to the technical field of advanced composite materials. The method is characterized in that a vacuum air pressure infiltration preparation technology based on a liquid binder is adopted to assist in accurately controlling the shape and the size of a 3D braided fiber preform structure; in the 3D weaving process of the fiber preform, a liquid binder is adopted to accurately fix and shape the 3D braided fiber preform, then the size precision of the 3D braided fiber reinforced metal-based composite material is accurately controlled through the impregnated graphite mold of the embedded fiber preform, and deformation and local fiber polarization of the 3D braided fiberpreform in the infiltration process are prevented. The prepared 3D braided fiber reinforced metal-based composite material has high dimensional accuracy and excellent mechanical properties, the near-net forming of the 3D braided fiber reinforced metal-based composite material is realized, batch industrial production can be realized, the near-net forming method has a wide application prospect in the fields of aerospace, national defense, military and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

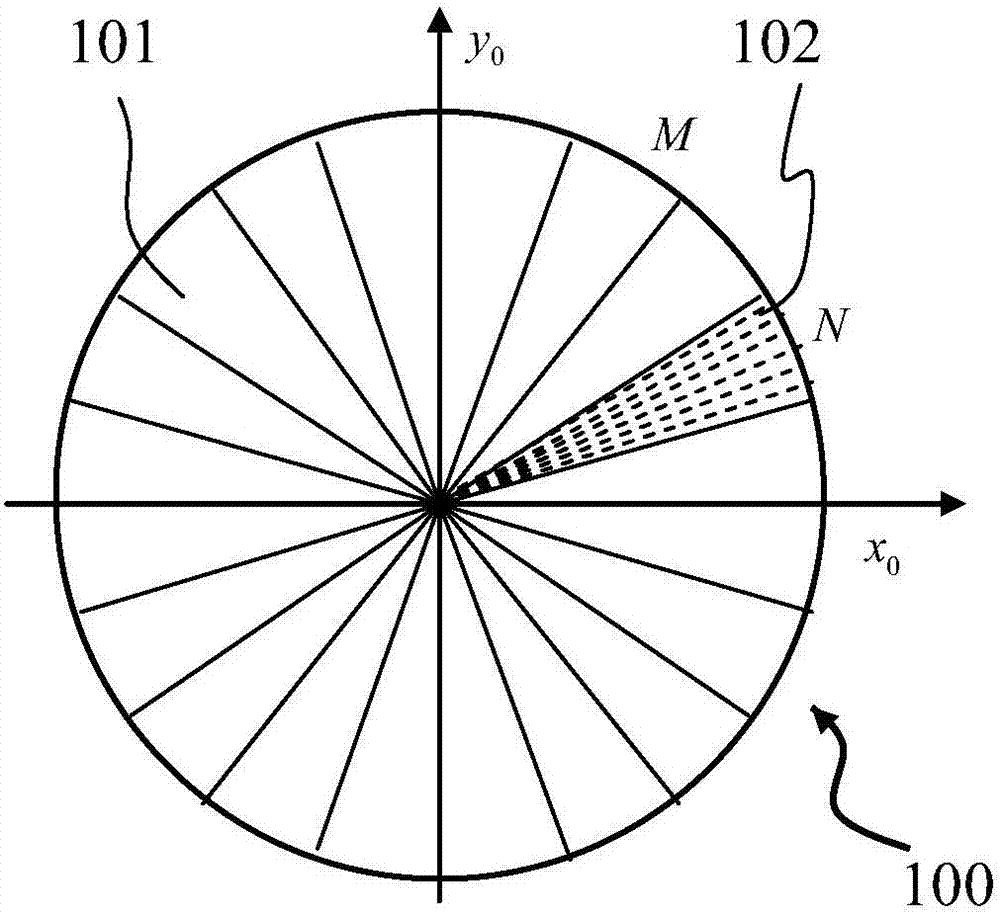

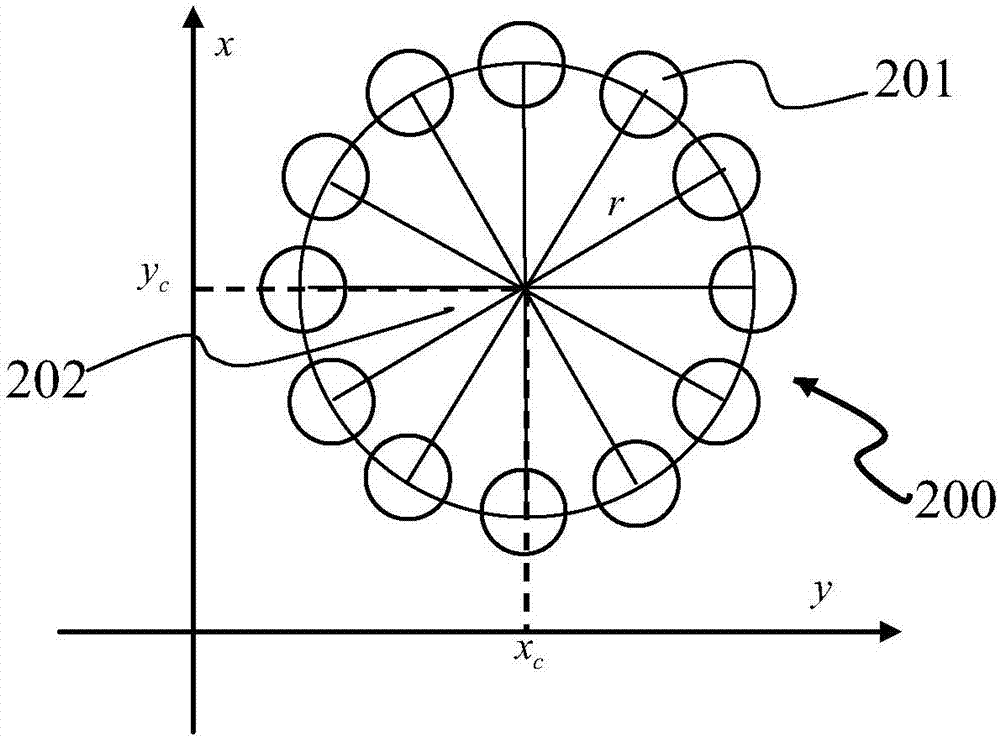

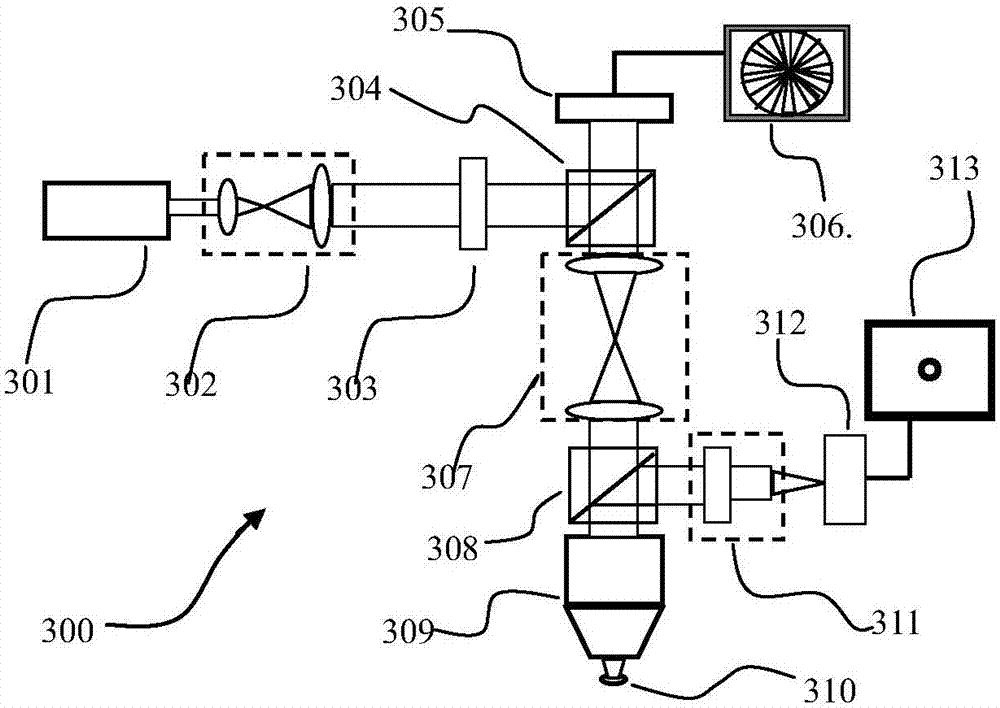

Annular focusing light spot realization method and realization device thereof

ActiveCN106950705APrecise position controlPrecise size controlOptical elementsSpatial light modulatorLight spot

The invention discloses an annular focusing light spot realization method. The method includes that a laser beam is expanded and collimated and then the expanded and collimated laser beam is converted into a linearly polarized laser beam; the laser beam phase modulation is carried out on the linearly polarized laser beam after the collimation and expansion by means of a reflective pure phase spatial light modulator; the linearly polarized light is imaged after the phase modulation to the rear aperture plane of a focusing object lens via a 4F imaging system; the object lens is used to focus the phase-modulated incident linearly polarized laser beam, a plurality of focal points are generated on the circumference in the focal plane area, and the azimuthal spacing between the focal points equal is equal; an annular light spot is generated when the circumference radius is reduced to a wavelength lambda, and the size of the annular light spot is continuously decreased when the circumference radius r changes until a solid light spot is formed; and when a plurality of phase modulation graphs are calculated, the change in the corresponding position movement of each graph is small, and the phase map of the spatial light modulator is updated so that the annular light spot moves continuously. The annular focusing light spot realization method realizes the non-vortex plane linearly polarized light focusing to generate the dynamic annular light spot which is accurate in position and size control.

Owner:唐山斯腾光电科技有限公司

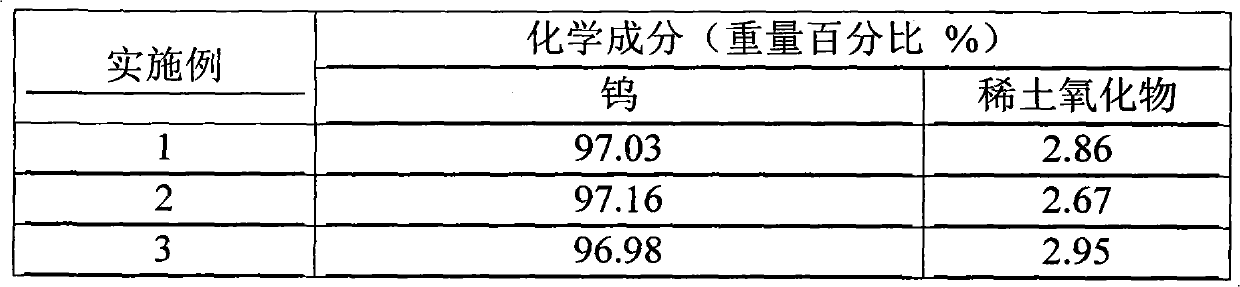

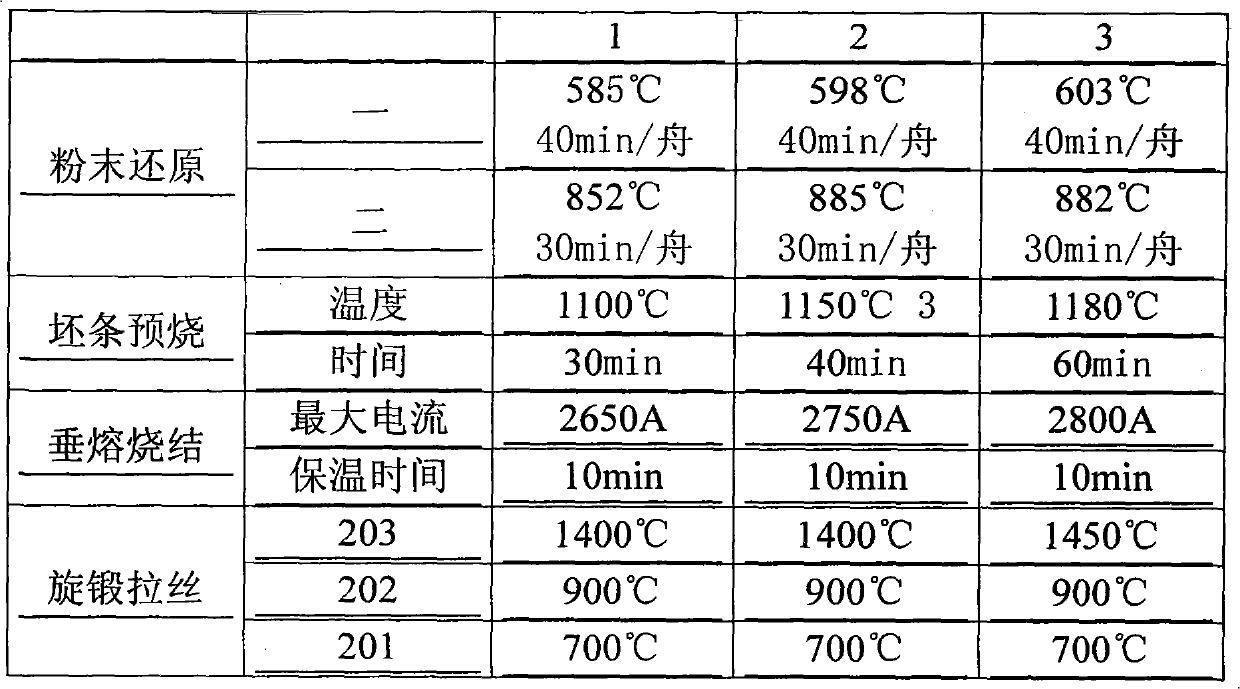

Multi-element composite rare earth tungsten electrode material and preparation method thereof

InactiveCN102000923AGood welding performanceGood thermionic emission performanceWelding/cutting media/materialsSoldering mediaRheniumRare earth

The invention relates to a multi-element composite rare earth tungsten electrode material, which is prepared by adding rare earth oxides in a tungsten metal substrate, wherein the weight percentage of the tungsten metal substrate is 95 to 98%; and the weight percentage of the rare earth oxides is 2.0 to 5.0%. The preparation method comprises: the tungsten substrate powder is weighed according to the proportioning weight and is poured into a mixing pot, and deionized water is added to the mixture to be stirred so as to prepare a uniform suspension; lanthanum nitrate, cerous nitrate, rhenium nitrate and erbium nitrate are weighed according to the required proportioning weight and are prepared into a solution; the solution is added to the suspension to be stirred uniformly, and the mixing solution is heated and dried to prepare the mixing alloy powder; the mixing alloy powder is prepared into the rare earth tungsten composite powder through the twice hydrogen reduction; and the argon arc welding electrodes with various specifications are prepared through tamping, presintering, vertically sintering and rotary swaging. The rare earth tungsten electrode material has the advantages of good welding property, green environment protection type electrode material, good arc strike and retention of electrodes, and rapid heating and cooling properties, and the heat input on welding pieces and the dimension of a melting pool can be accurately controlled.

Owner:天津市春风钨业有限公司 +1

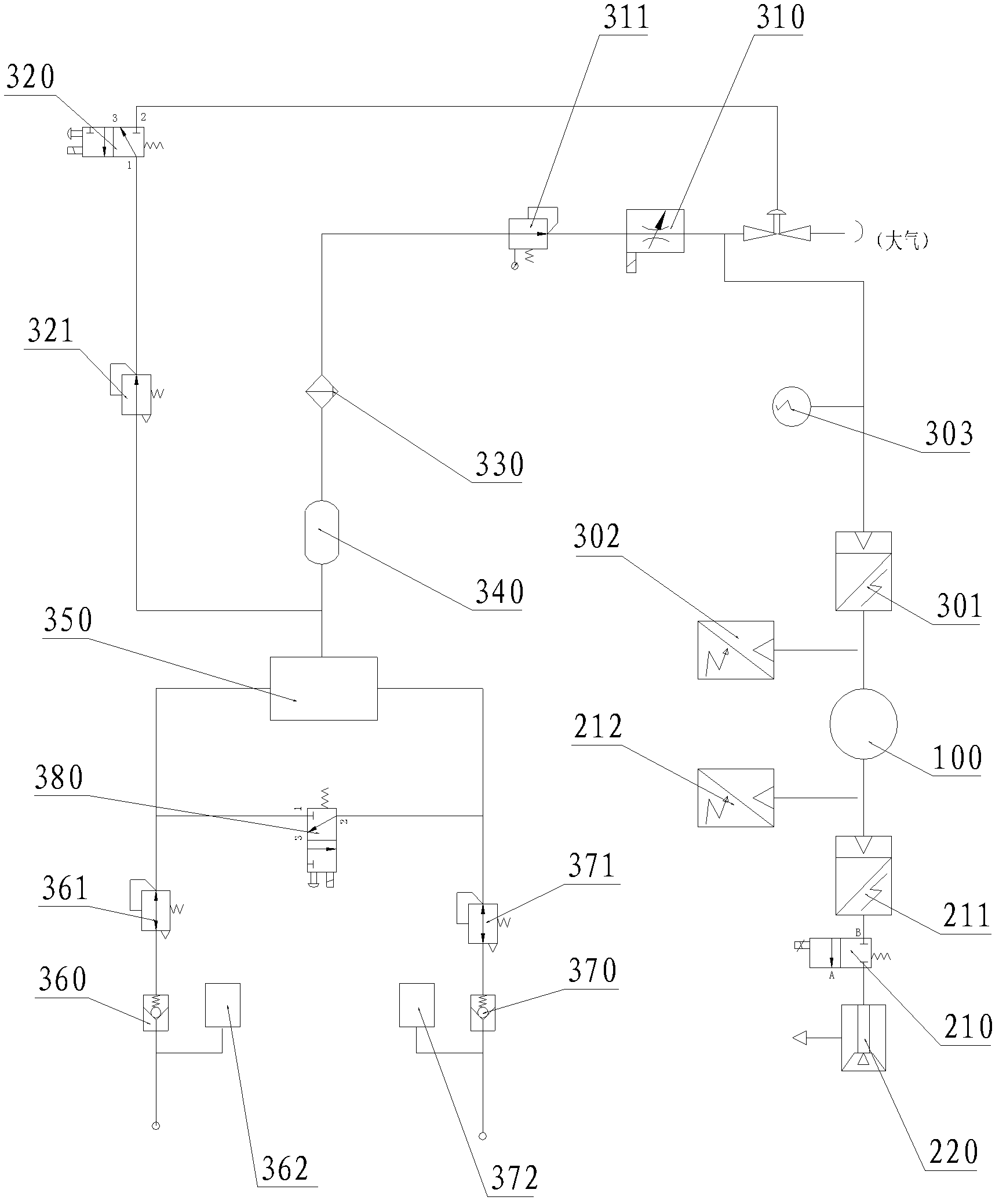

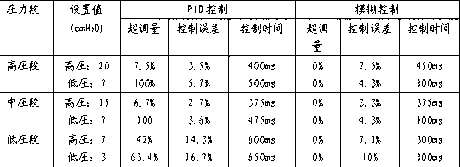

Breathing pressure fuzzy control type respirator and breathing pressure fuzzy control method

ActiveCN103028170AReduce air pressurePrecise size controlRespiratorsMedical devicesControl signalControl theory

The invention relates to a respirator, and discloses a breathing pressure fuzzy control type respirator and a breathing pressure fuzzy control method. The breathing pressure fuzzy control type respirator controls action of each part by means of actual control output of fuzzy piping and instruments diagram (PID) controller in a template embodiment, and each sensor collects signal variable of each part and transfers to the fuzzy PID controller to do fuzzy control operation. An air suction electromagnetic proportional valve is capable of controlling opening of a valve hole to continuously vary in a certain range according to corresponding control signal (voltage or current signal). The fuzzy PID controller is capable of controlling flow which enters back stage gas channel to continuously vary in a certain range through controlling opening of each valve and further controlling airway pressure. Breath becomes more comfortable and safer after patients using the respirator.

Owner:南京普澳医疗设备有限公司

Lithium battery and electrode for same, and preparation method of solid electrolyte film

ActiveCN103268930ASimple equipmentReduce manufacturing costFinal product manufactureCell electrodesLaser printingCurrent collector

The invention relates to a lithium battery and an electrode for the same, and a preparation method of a solid electrolyte film, and belongs to the technical field of materials, and solves the problems of the film electrode prepared by the traditional method that the requirement on equipment is high, the process is complicated, the energy consumption is high and the pollution of organic solvent exists. A computer laser printing technology is used for preparing the electrode, the solid electrolyte film, the lithium battery and a full-solid lithium battery on a printing substrate or a current collector through electrode active substances and solid electrolyte materials. The method not only can conveniently and precisely control the shape, the size and the thickness of the electrode and the battery and can be environment-friendly and simple in equipment, but also can realize the mass production, can greatly reduce the production cost of the battery and can reduce the environmental pollution of the organic solvent.

Owner:HARBIN INST OF TECH

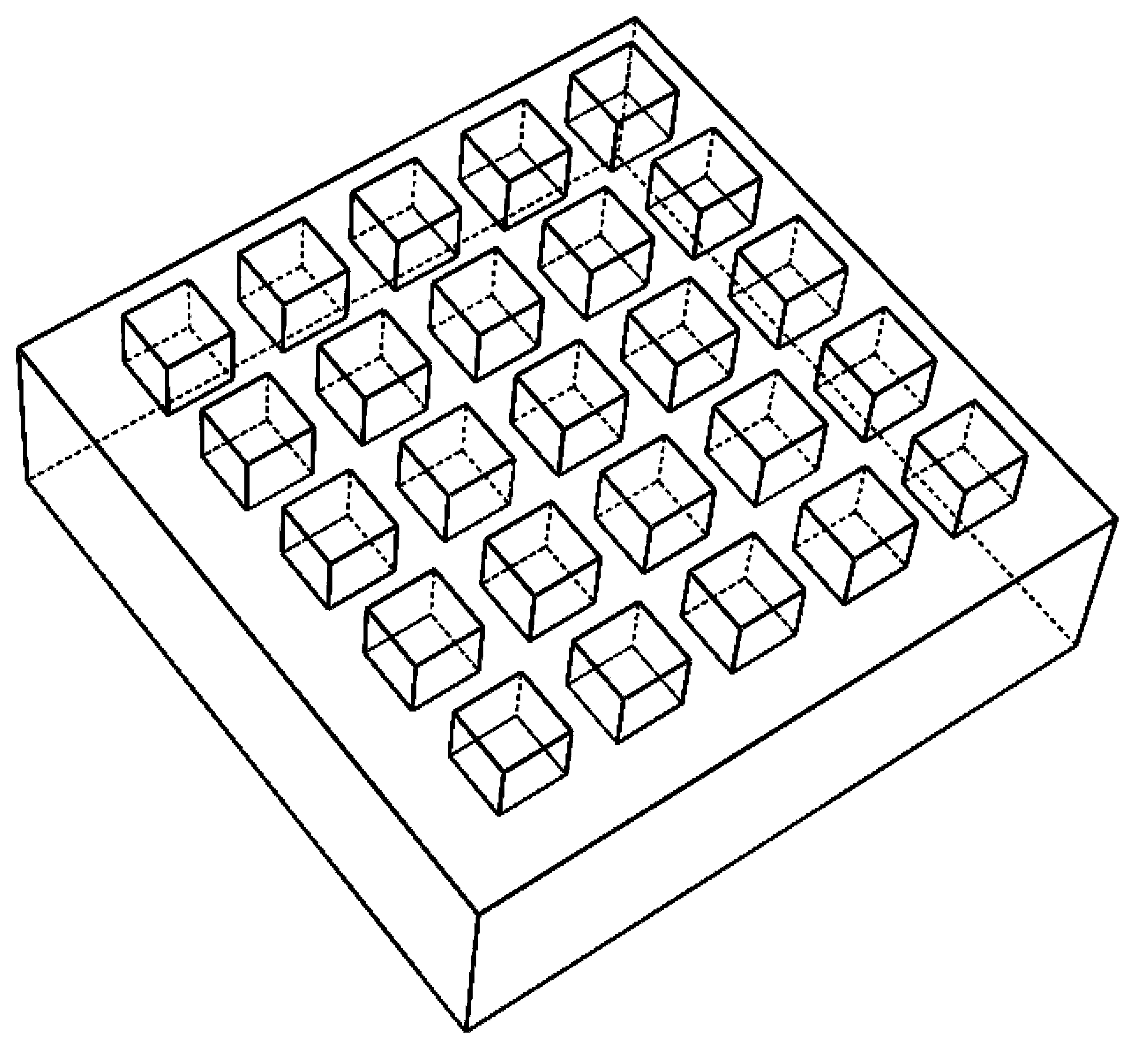

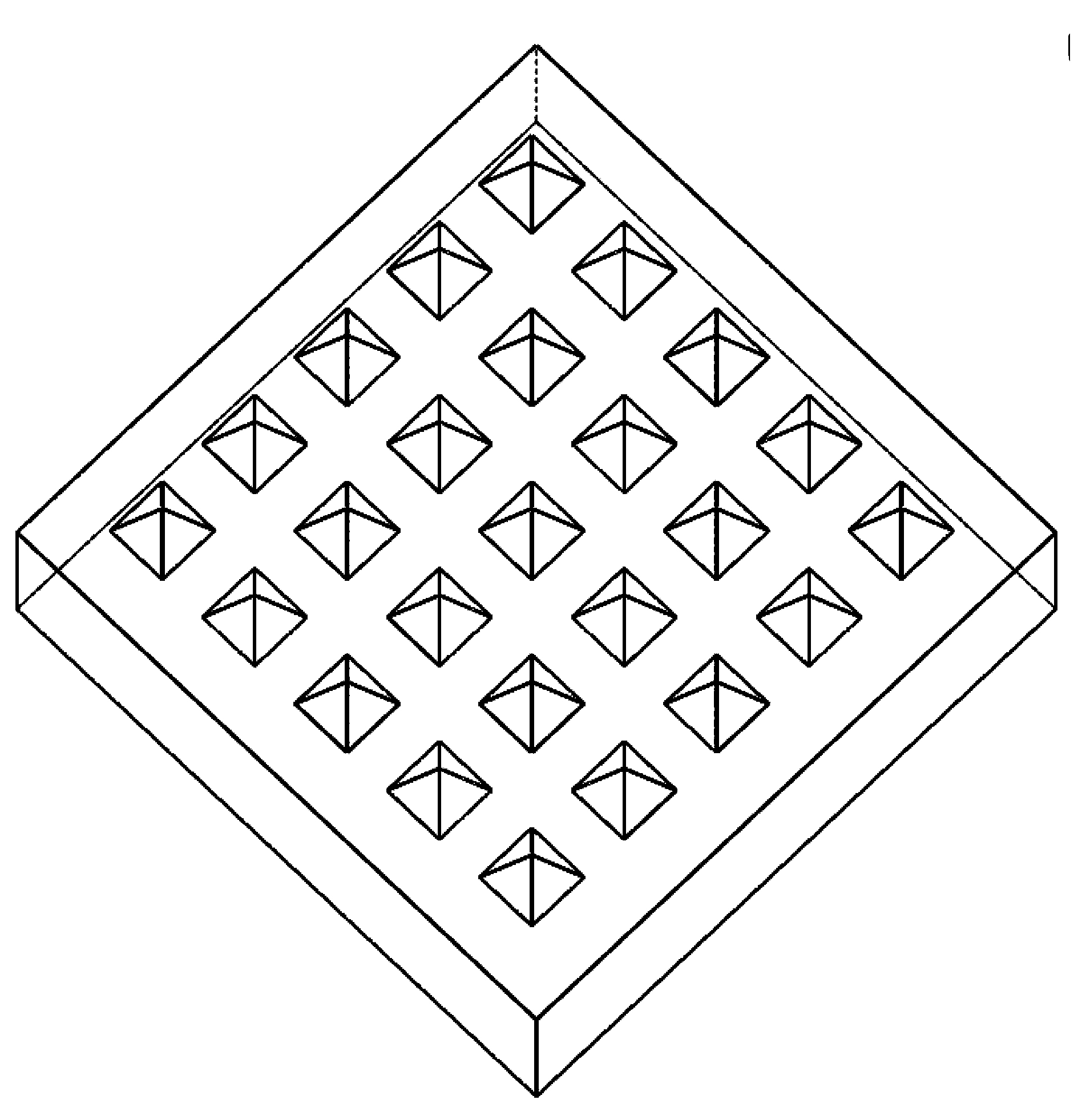

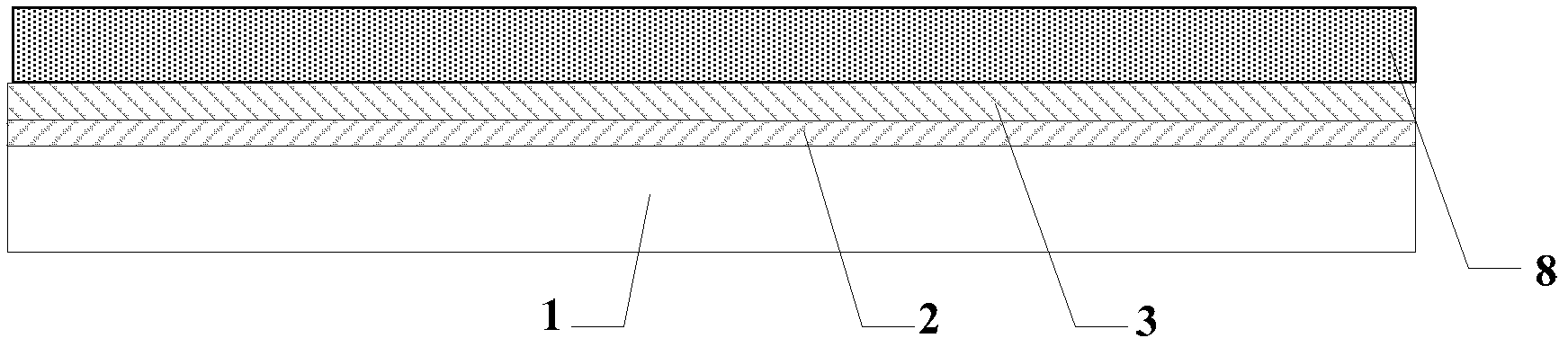

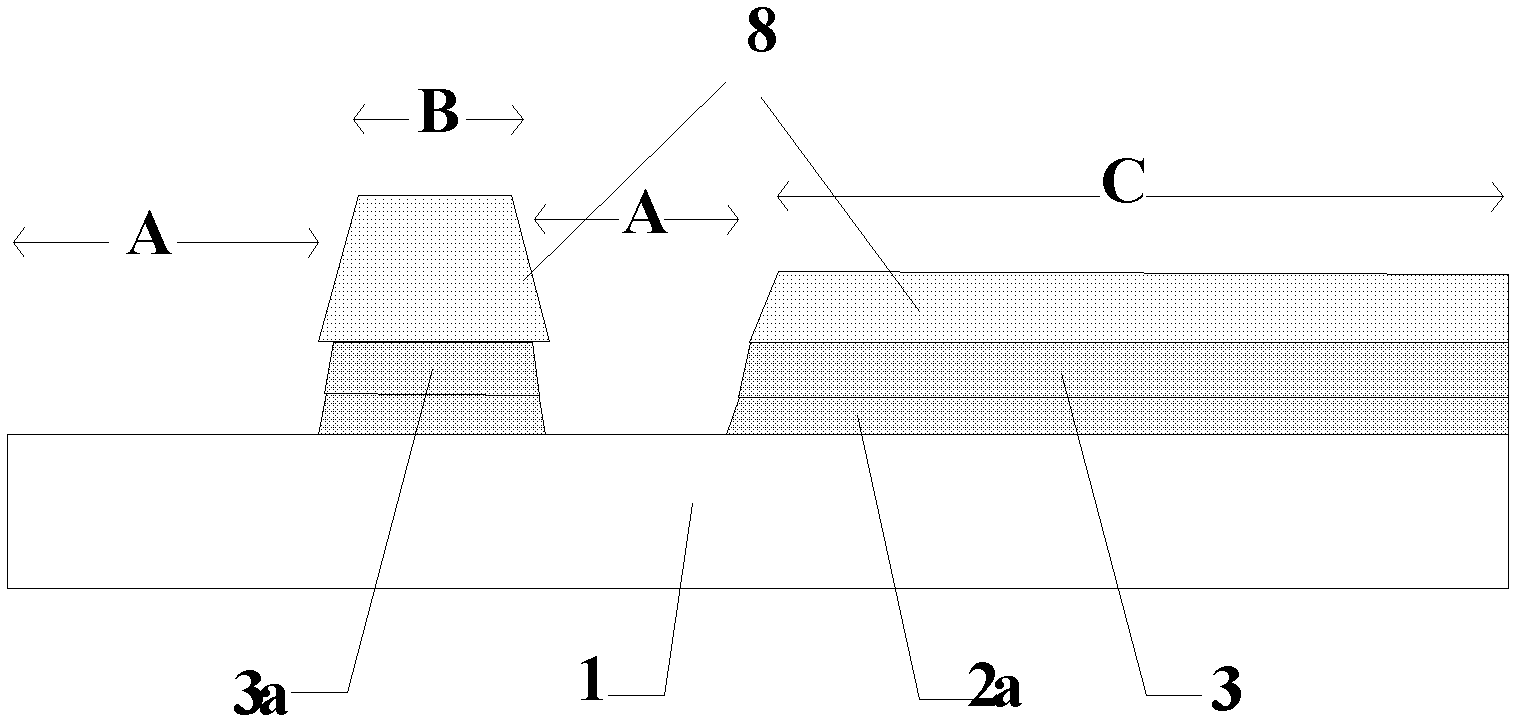

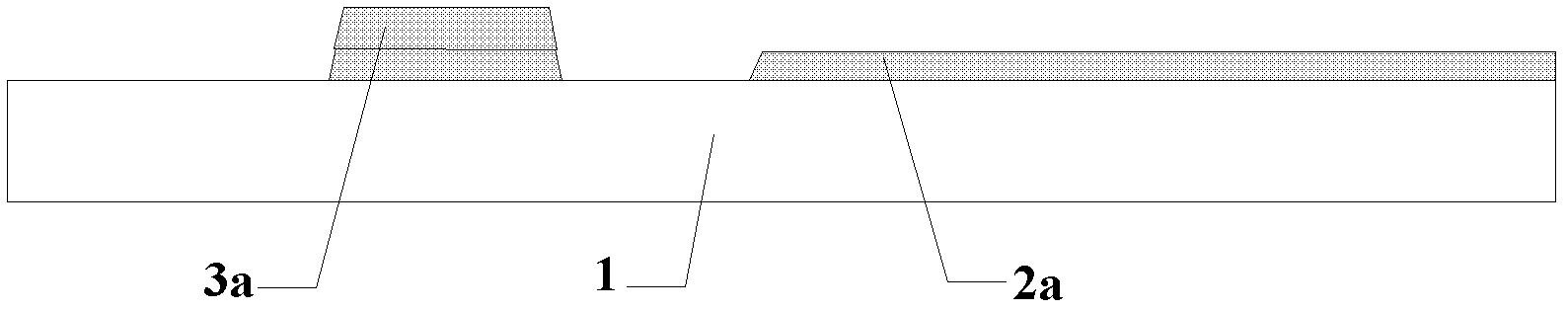

Array substrate and manufacturing method thereof, and display apparatus

ActiveCN102629664AAvoid flowPrecise size controlTransistorSolid-state devicesInsulation layerLiquid-crystal display

The invention discloses an array substrate and a manufacturing method thereof, and a display apparatus and relates to the display technology field. The invention aims at accurately control shapes of a source electrode and a drain electrode of a TFT (thin film transistor). The array substrate comprises a pixel structure formed on the substrate. The pixel structure comprises a grid line, a data line, the TFT and a pixel electrode. The TFT comprise a grid, a gate insulation layer, an active layer, the source electrode and the drain electrode, wherein the grid is electrically connected with the grid line, the source electrode is electrically connected with the data line, and the drain electrode is electrically connected with the pixel electrode. The pixel structure also comprises an organic insulating layer which is located above the gate insulation layer and is an E-shape structure at the position of the TFT. The source electrode and the drain electrode of the TFT are located on two valleys of the E-shape structure respectively. The scheme of the invention is suitable for production manufacturing of a liquid crystal display panel and a liquid crystal display.

Owner:BOE TECH GRP CO LTD

Preparation of lanthanide series rare-earth doped bismuth titanate nano-tube

InactiveCN101279767APrecise size controlThe higher the yieldNanostructure manufactureTitanium compoundsRare earthLanthanide

Disclosed is a method for the production of a lanthanide rare-earth doping bismuth titanate nano-tube, which relates to a method for the production of a bismuth titanate nano-tube. The method solves the problems of complex technique and equipment, long preparation cycle, high cost, low yield and being unable to control the size of the nanostructure material accurately when preparing the lanthanide rare-earth doping bismuth titanate nanostructure material by the prior art. The method of preparation has steps of: firstly, weighting nitrate and tetrabutyl titanate in bismuth salt and lanthanide rare-earth; secondly, preparing a lanthanide rare-earth doping bismuth titanate sol, thirdly, dripping the lanthanide rare-earth doping bismuth titanate sol on the surface of an aluminum oxide template and drying the template after being soaked; fourthly, repeating the third step and preserving the heat of the dried template at a certain temperature; and fifthly, repeating the third and the fourth steps and taking out the template at a certain temperature and then placing the template in a KOH or NaOH solution, thereby obtaining the lanthanide rare-earth doping bismuth titanate nano-tube. The method of preparation has advantages of simple process and equipment, short preparation cycle, low cost, high yield and being able to control the size of the nano-tube accurately.

Owner:HARBIN INST OF TECH

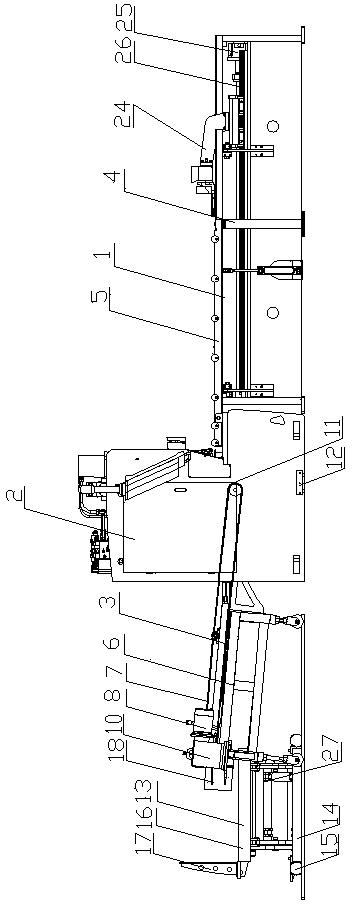

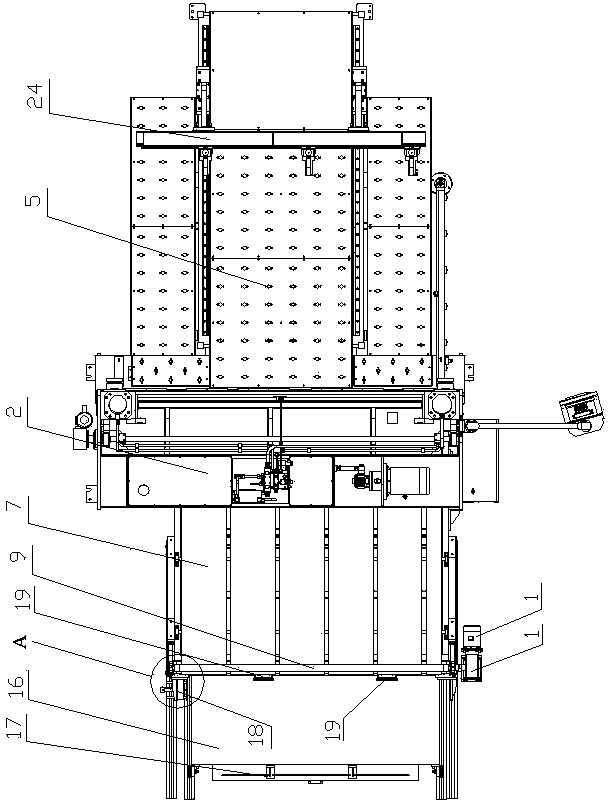

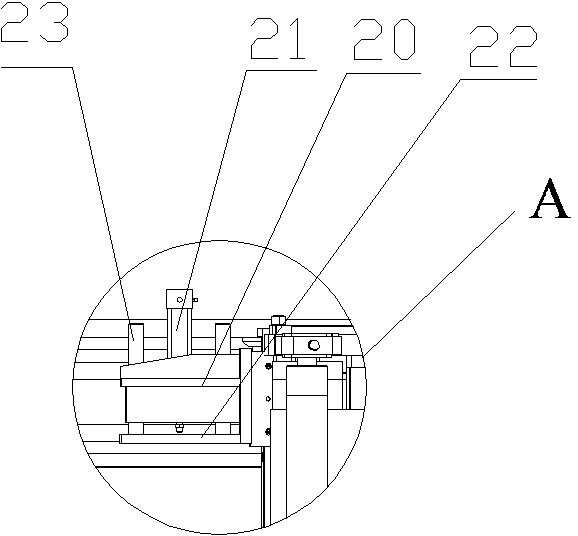

Numerical control plate shearing and stacking production line

ActiveCN103586526AHigh degree of automationPrecise size controlShearing machinesStacking articlesEngineeringAutomation

The invention provides a numerical control plate shearing and stacking production line, and belongs to the field of machinery. The numerical control plate shearing and stacking production line comprises a front feed mechanism, a main machine of a plate shearing machine and a rear discharge mechanism, wherein the front feed mechanism and the rear discharge mechanism are matched with and connected to the front end of the main machine of the plate shearing machine and the rear end of the main machine of the plate shearing machine respectively. The front feed mechanism comprises a bottom support, wherein a conveying platform is arranged on the bottom support, and a feeding clamp is matched above the conveying platform. The rear discharge mechanism comprises a bottom support, wherein a conveying belt is arranged on the bottom support, a discharge motor and a feed roller are arranged at the rear end of the bottom support, the discharge motor is in drive connection with the feed roller through a speed reducer, the feed roller is in matched transmission with the conveying belt, the discharge motor rotates forward and backward to drive the feed roller to conduct bidirectional rotation, and a material falling interval is arranged between the rear discharge mechanism and the main machine of the plate shearing machine. According to the numerical control plate shearing and stacking production line, disqualified materials do not need to be separated through manual work, and therefore the automation degree of equipment is greatly improved, the shearing accuracy is high, and the product percent of pass is high.

Owner:江苏麦斯铁机械有限公司

High-precision valve resistant to abrasion and corrosion and manufacturing method thereof

A high-precision valve resistant to abrasion and corrosion comprises a high-strength valve body resistant to abrasion and corrosion and 3D printed high-precision valve internal parts. The high-strength valve body resistant to abrasion and corrosion is made of raw materials in a cast mode, wherein special element matching is adopted for the raw materials. A 3D printing technology is adopted for manufacturing and assembling all the valve internal parts at the same time; finally, the high-strength valve body resistant to abrasion and corrosion and the 3D printed high-precision valve internal parts are assembled. The high-precision valve has the advantages that valve body is excellent in resistance to abrasion and corrosion; the production efficiency and precision of the valve internal parts are high, and the high-precision valve is convenient to assemble and stable in working.

Owner:ANHUI JINDA INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com