Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10904results about "Chemical/physical/physico-chemical processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

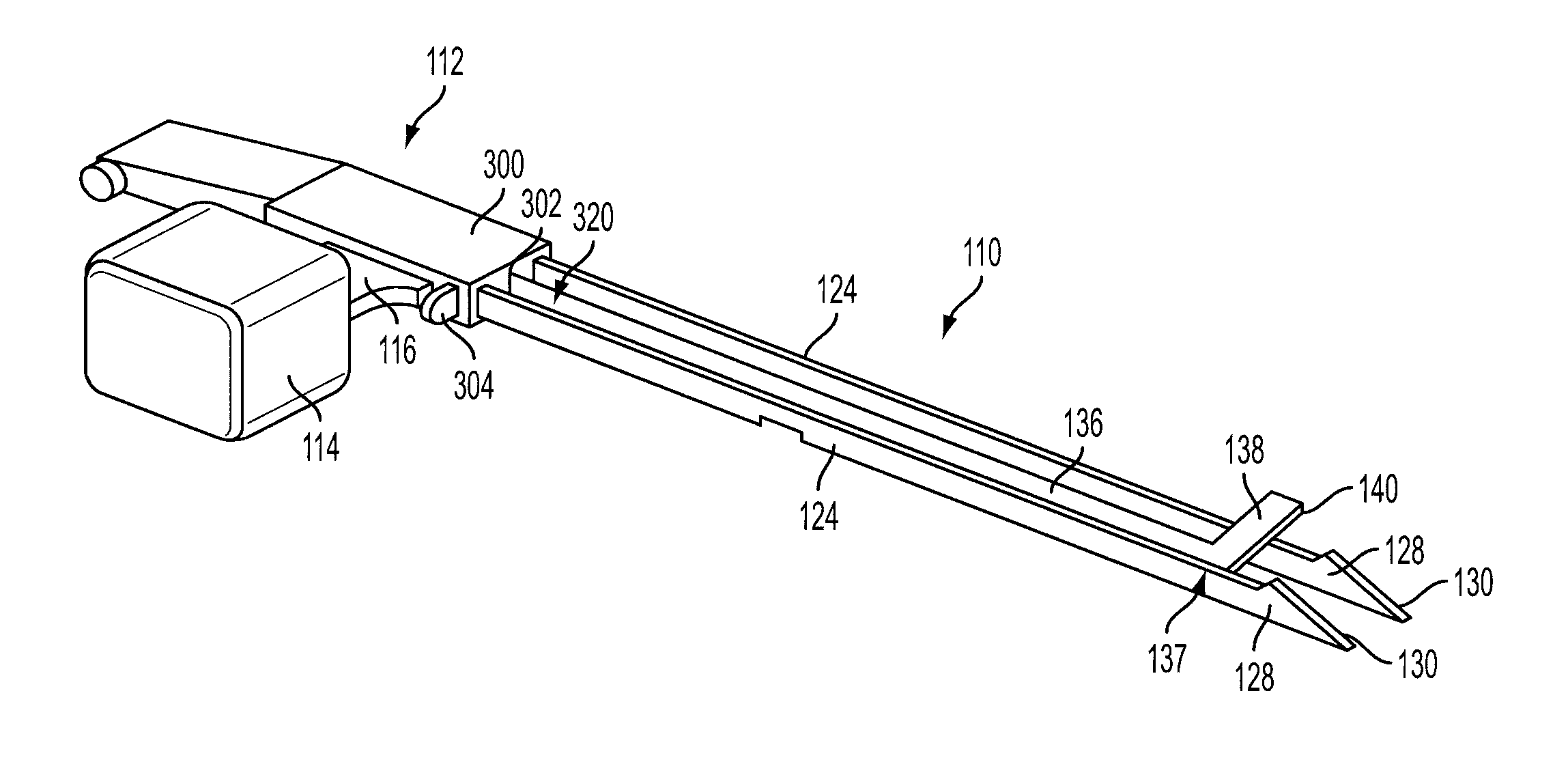

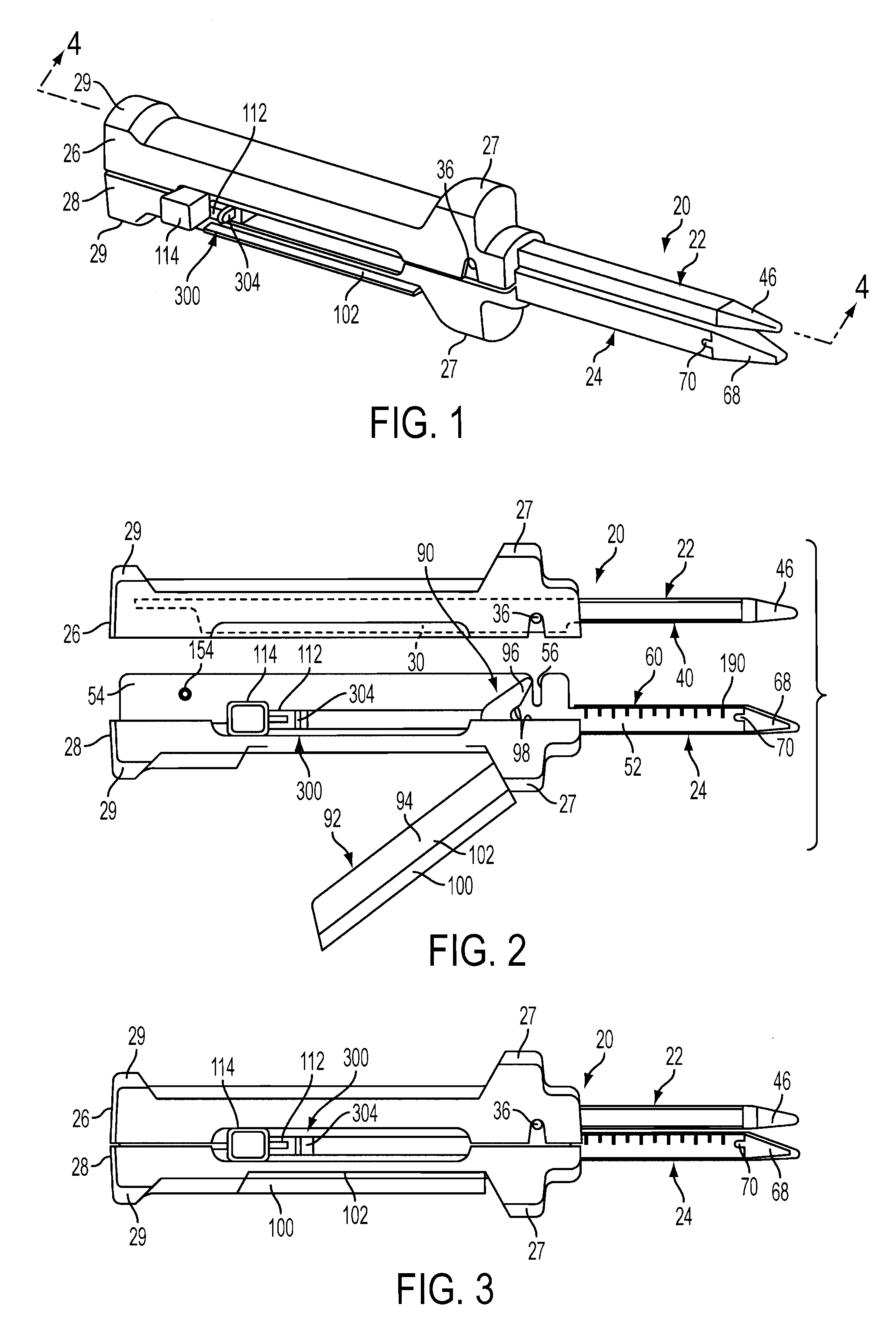

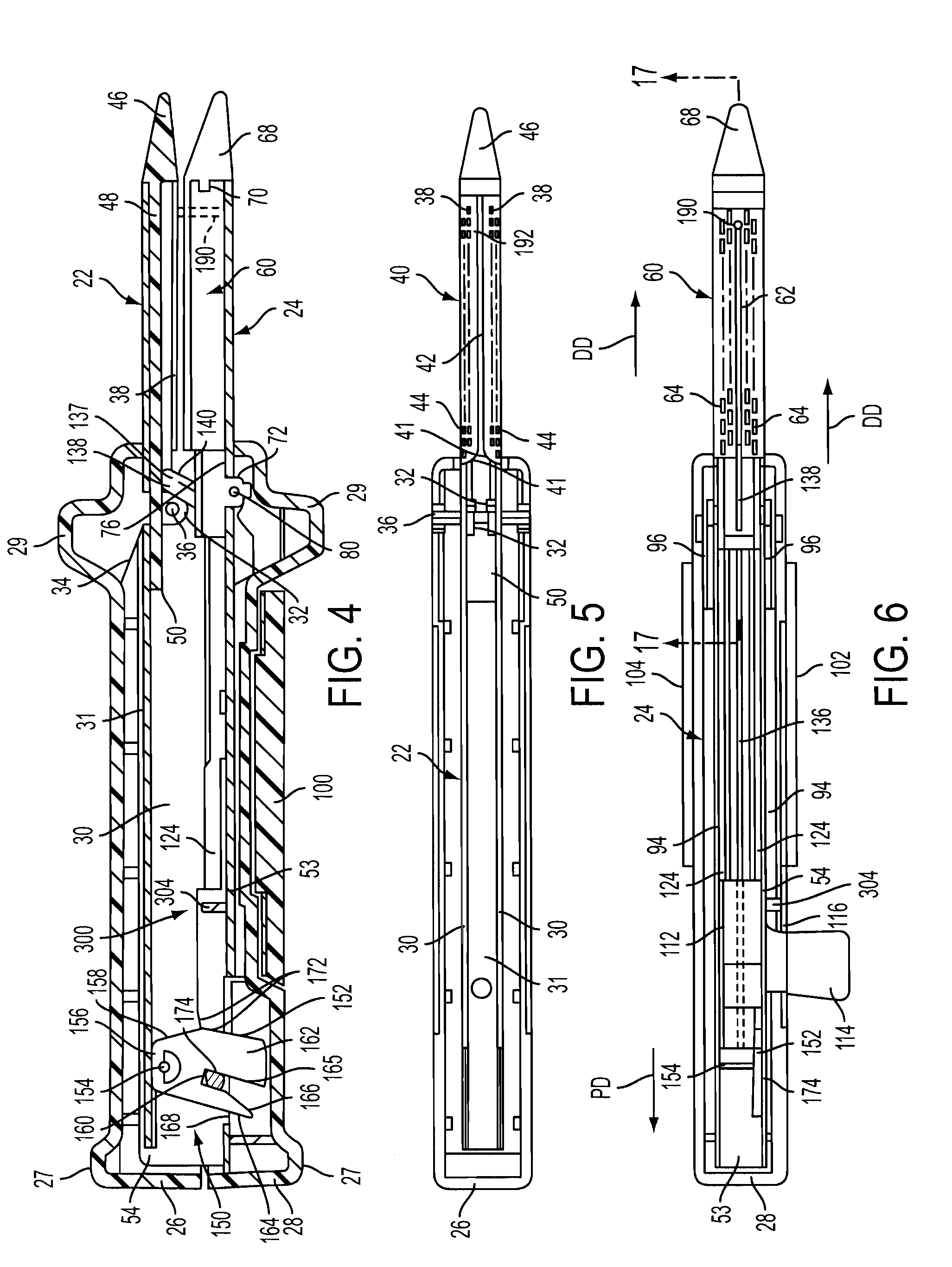

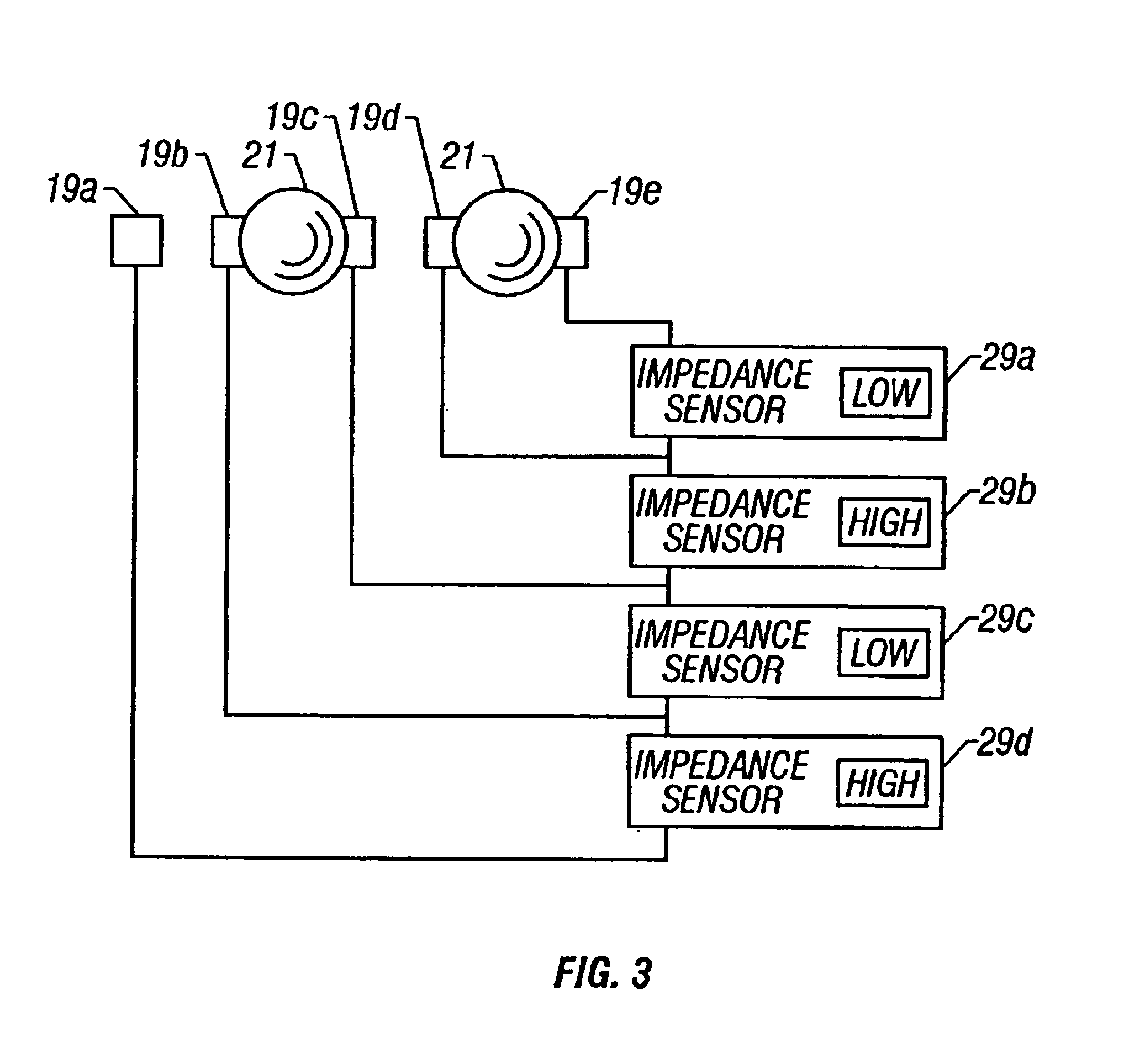

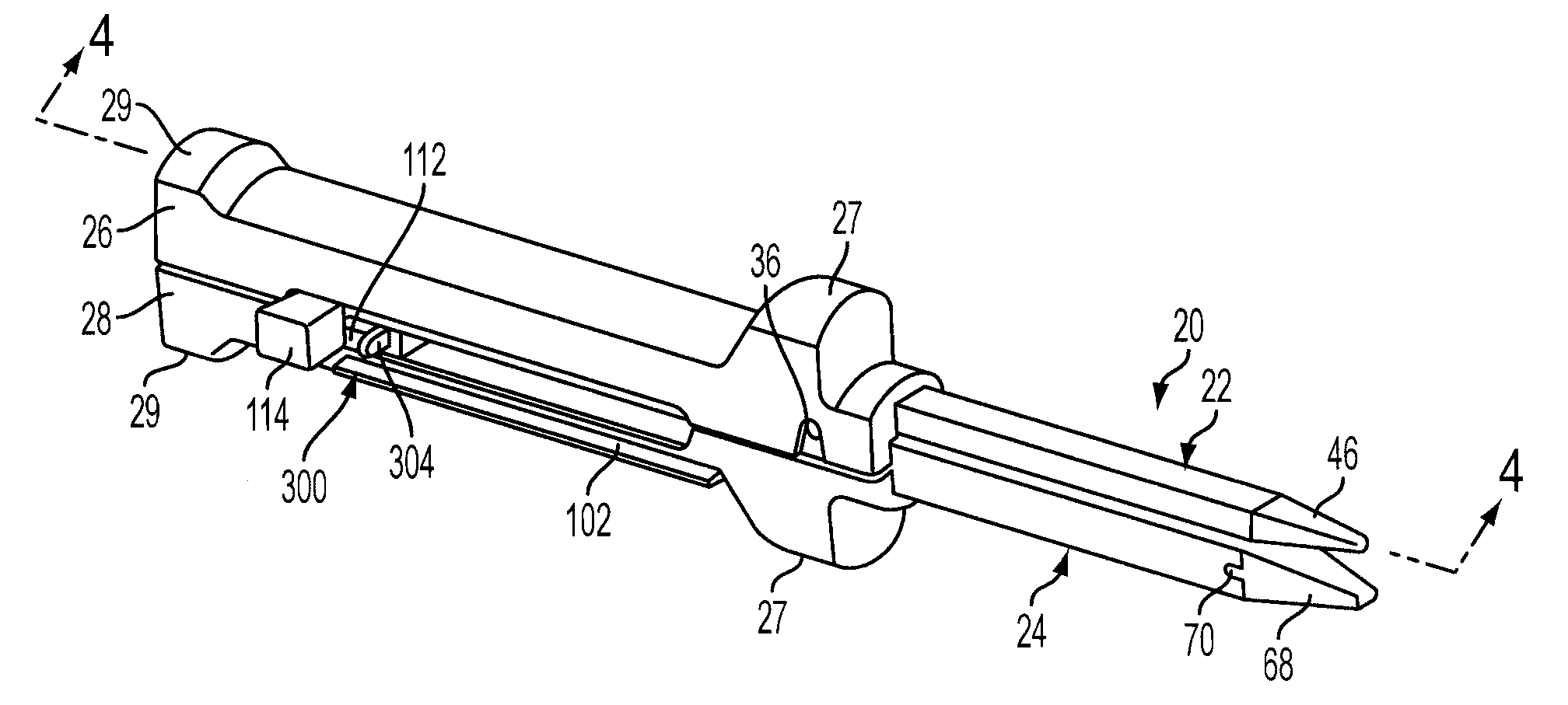

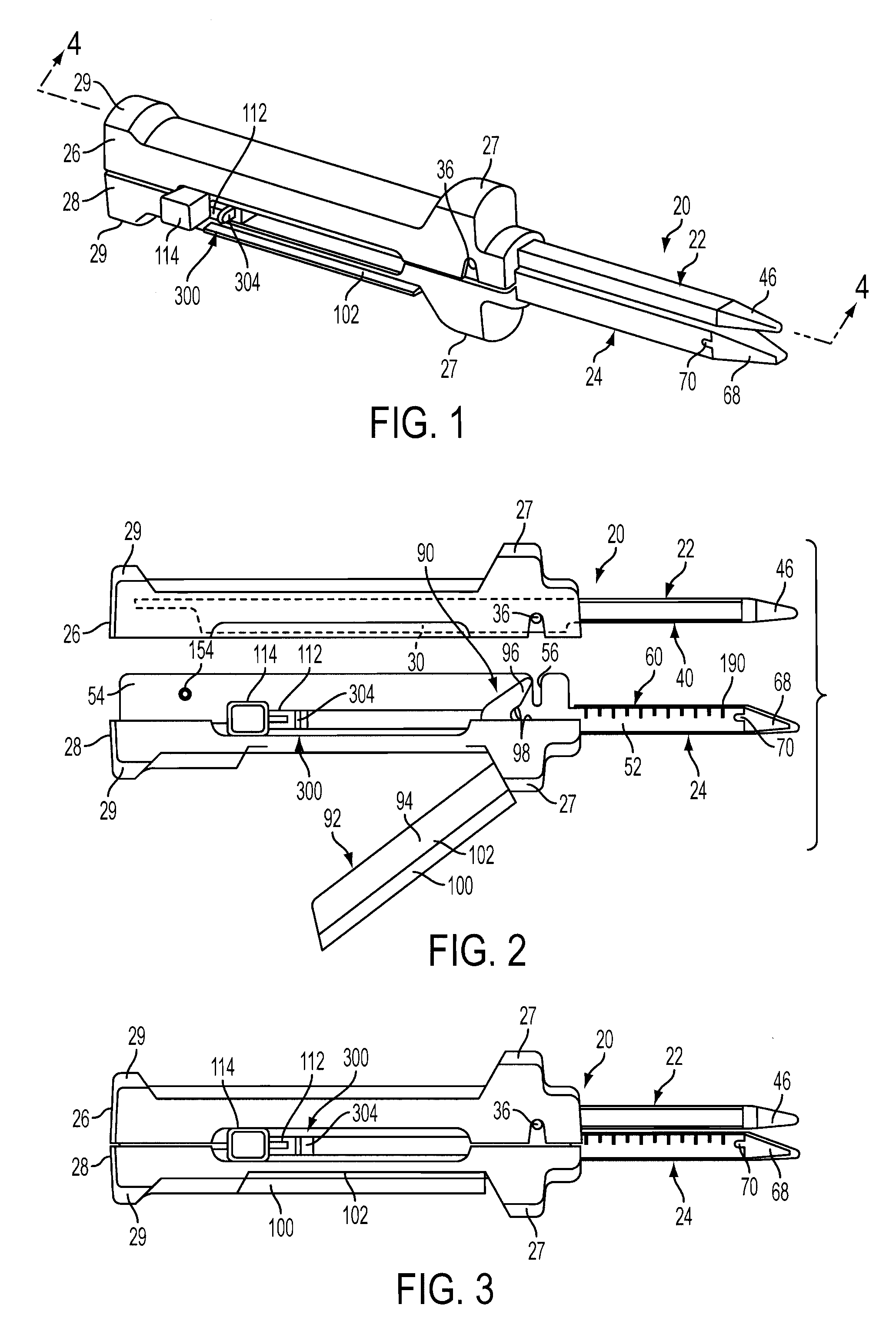

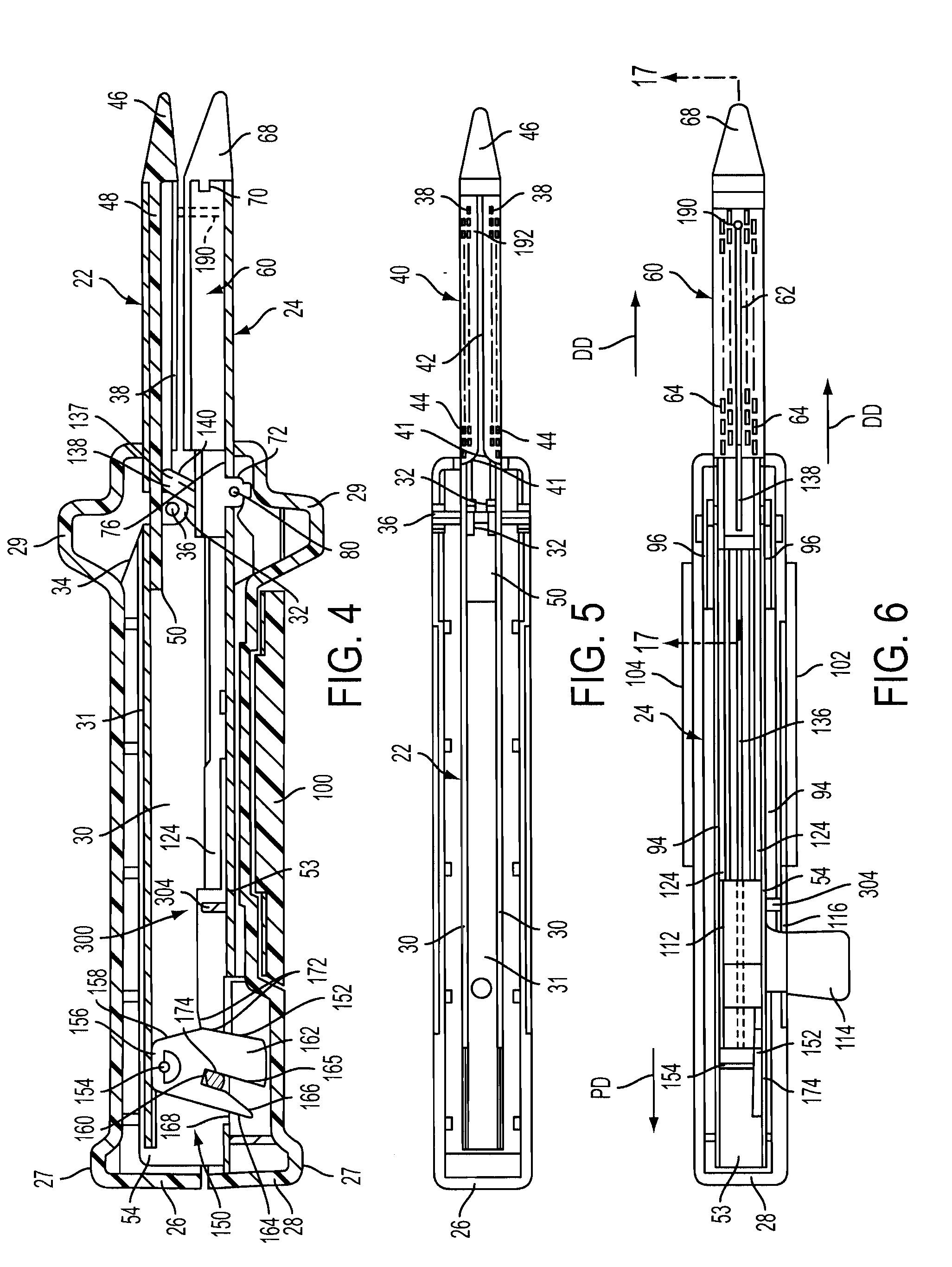

Linear cutting and stapling device with selectively disengageable cutting member

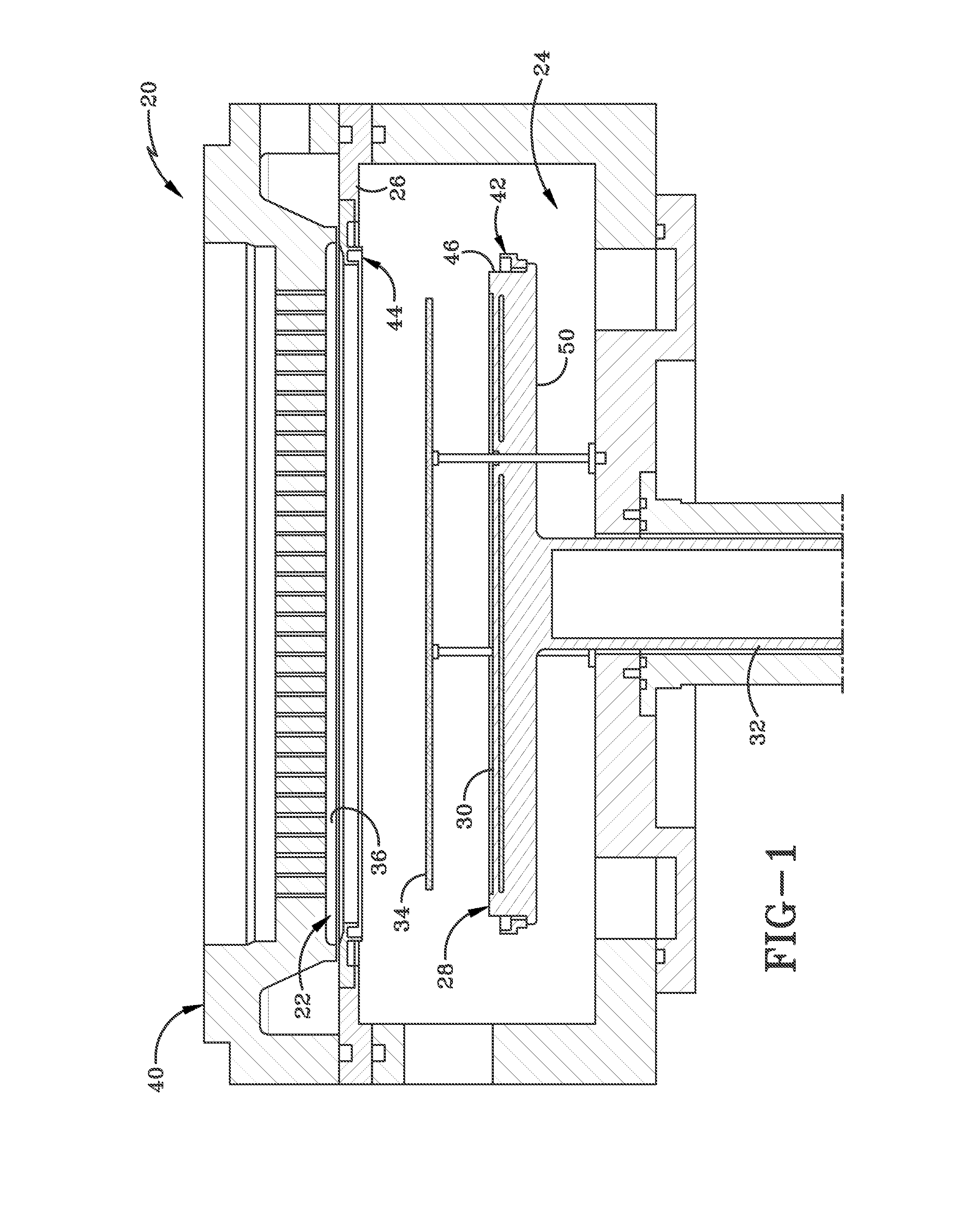

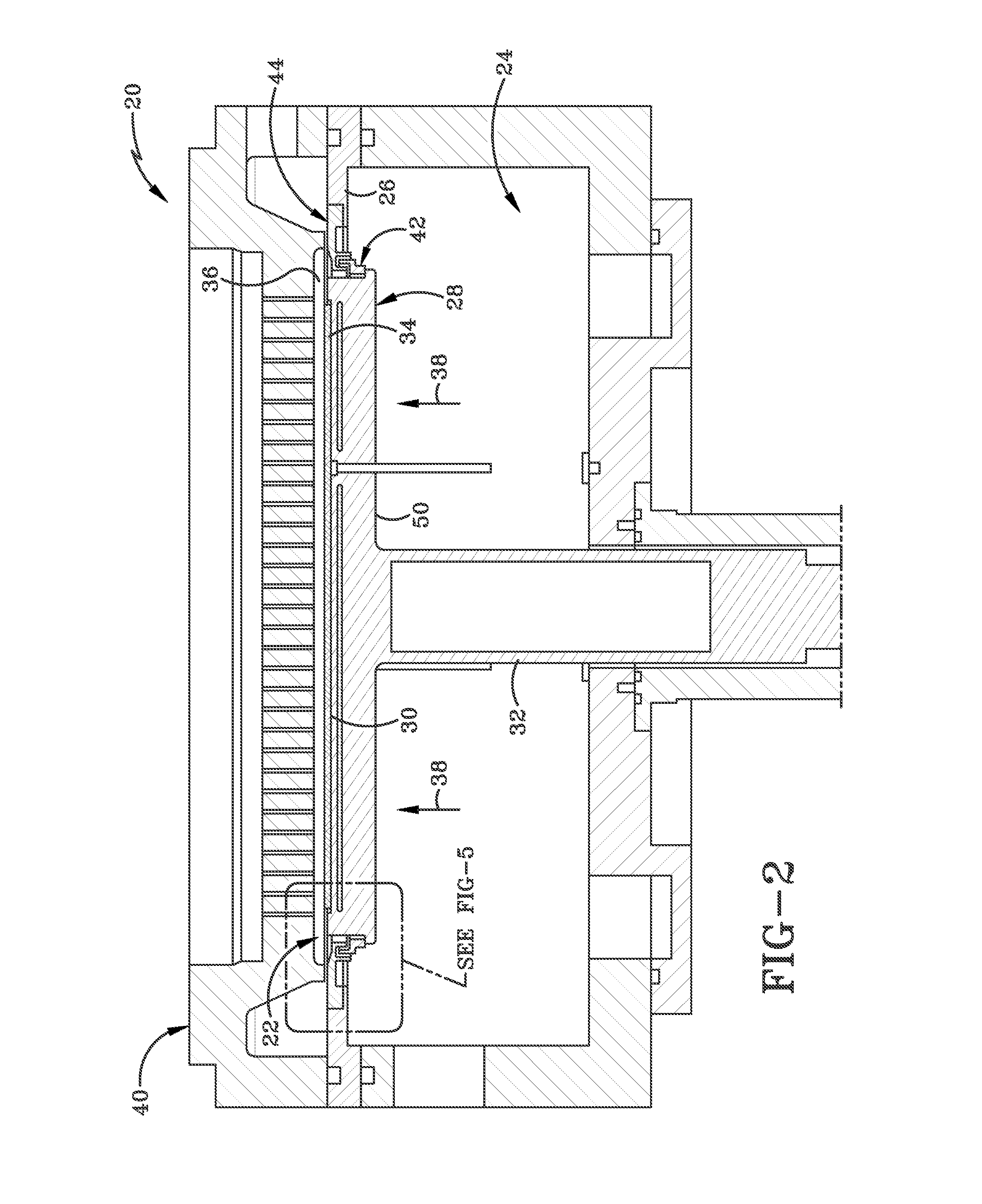

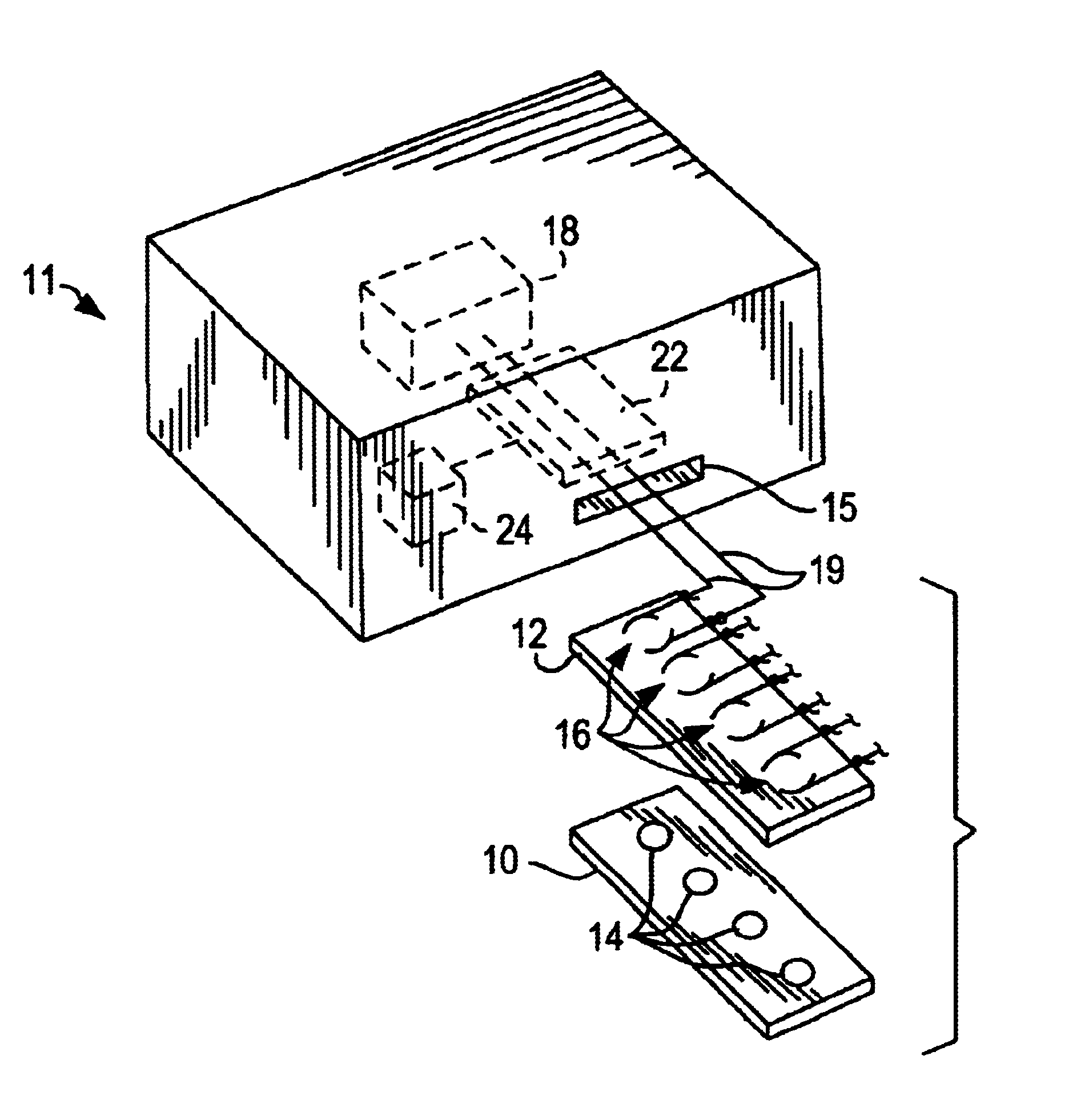

A surgical stapling instrument including a selectively actuatable cutting member. The stapling instrument may be used as a surgical stapler without cutting tissue or, if desired, the surgeon may selectively actuate the cutting member to cut tissue as the staples are being deployed and formed. A stapling instrument can include an actuator knob that has at least one pusher bar attached thereto. Advancement of the actuator knob in a distal direction causes the pusher bars to apply a firing motion to the staples contained within a staple cartridge supported within the stapling instrument. A knife bar may be selectively coupleable to the actuator knob by a selector switch that is movable from an actuated position wherein movement of the actuator knob in the distal direction advances the knife bar which has a cutting blade portion to advance between rows of staples in the staple cartridge to an unactuated position wherein movement of the actuator knob advances the pusher bars without advancing the knife bar.

Owner:ETHICON ENDO SURGERY INC

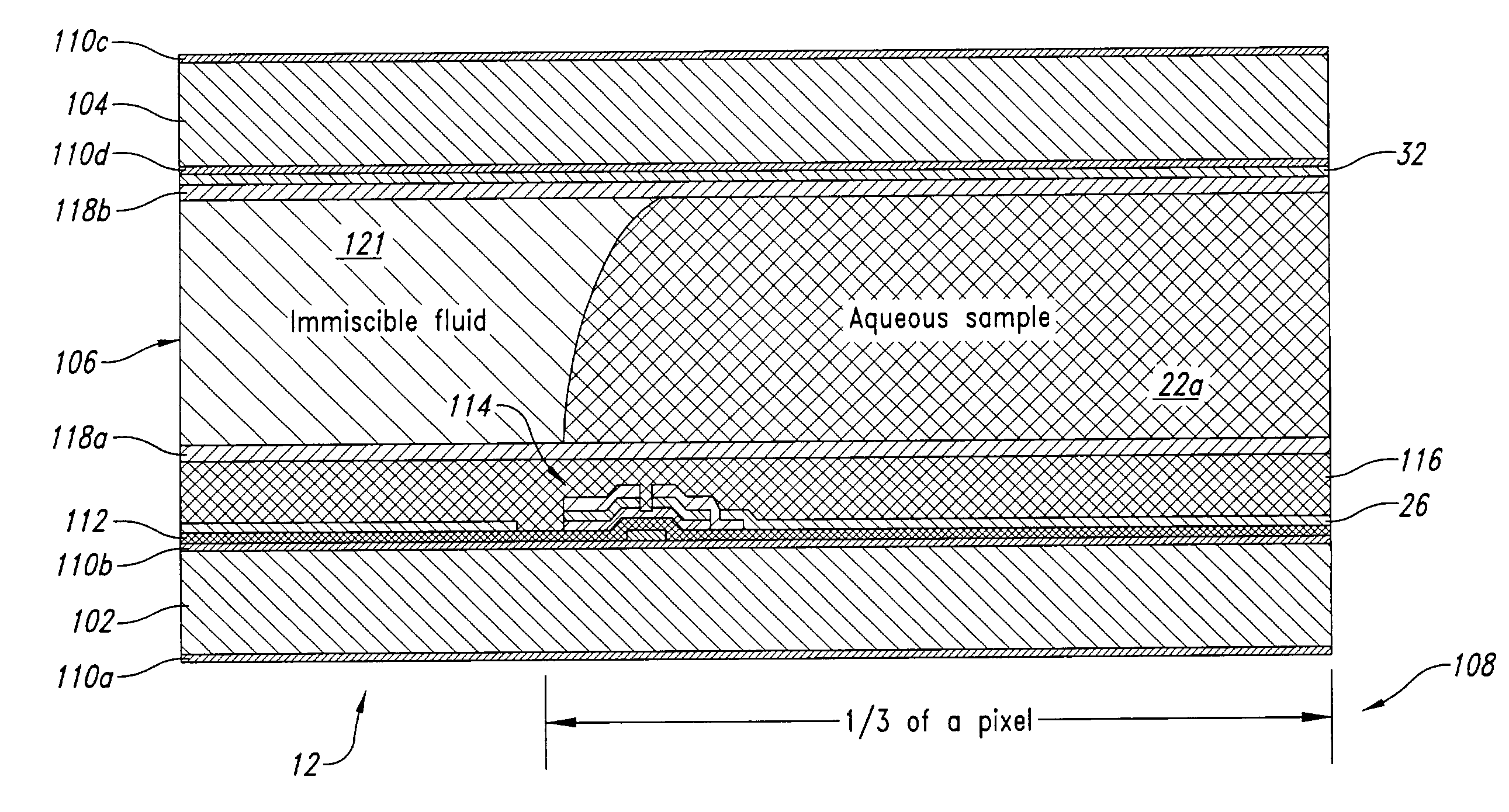

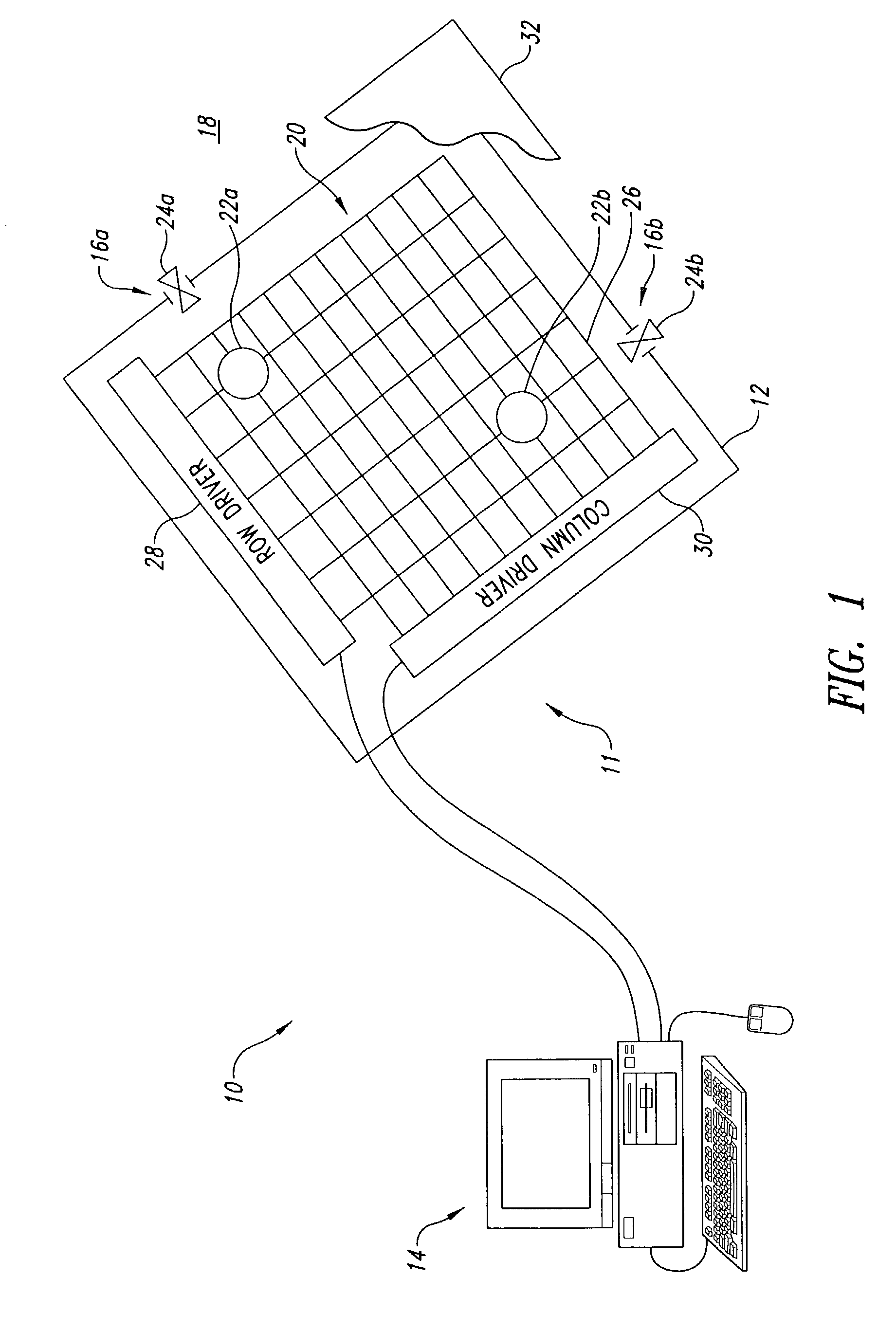

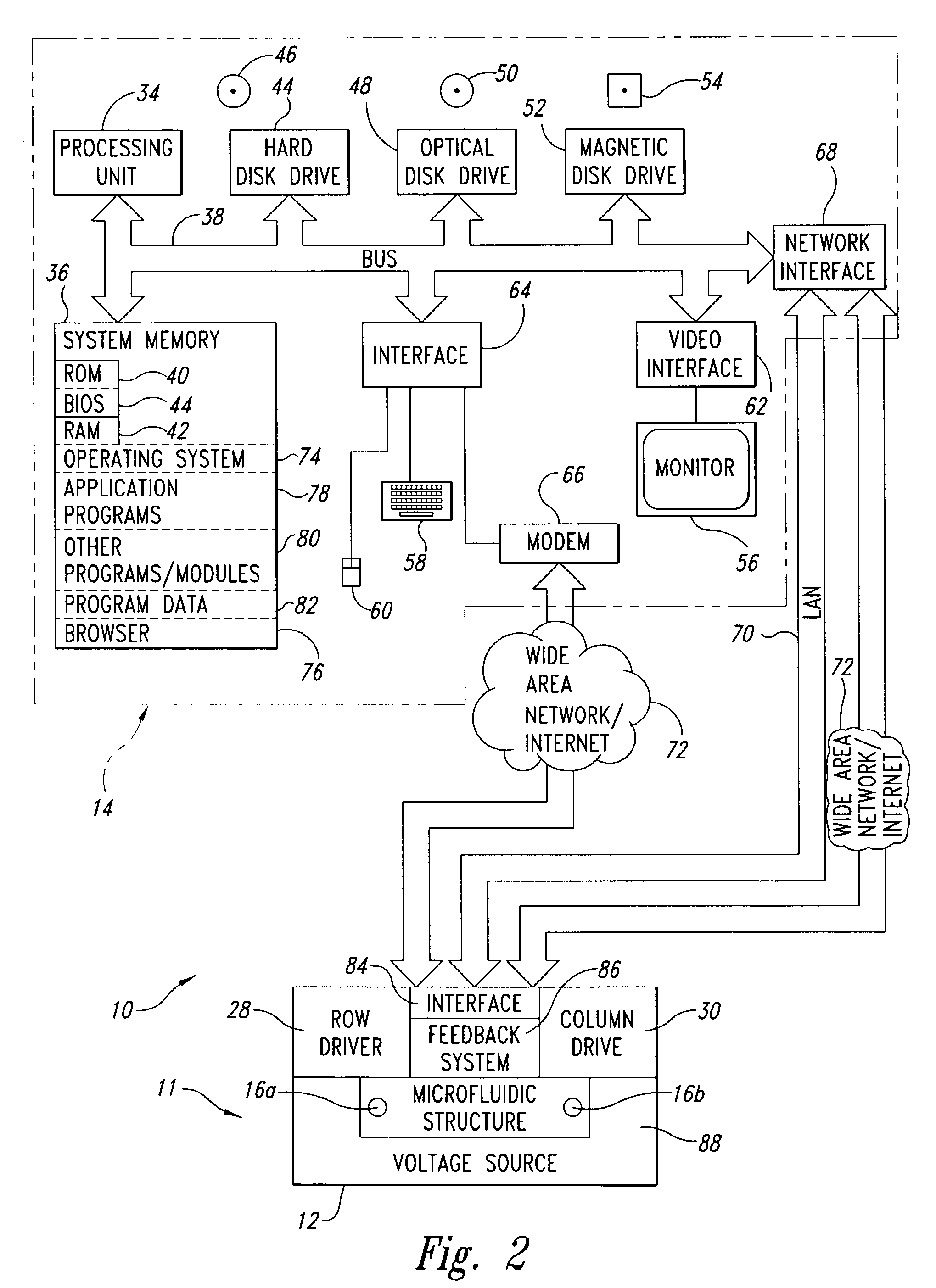

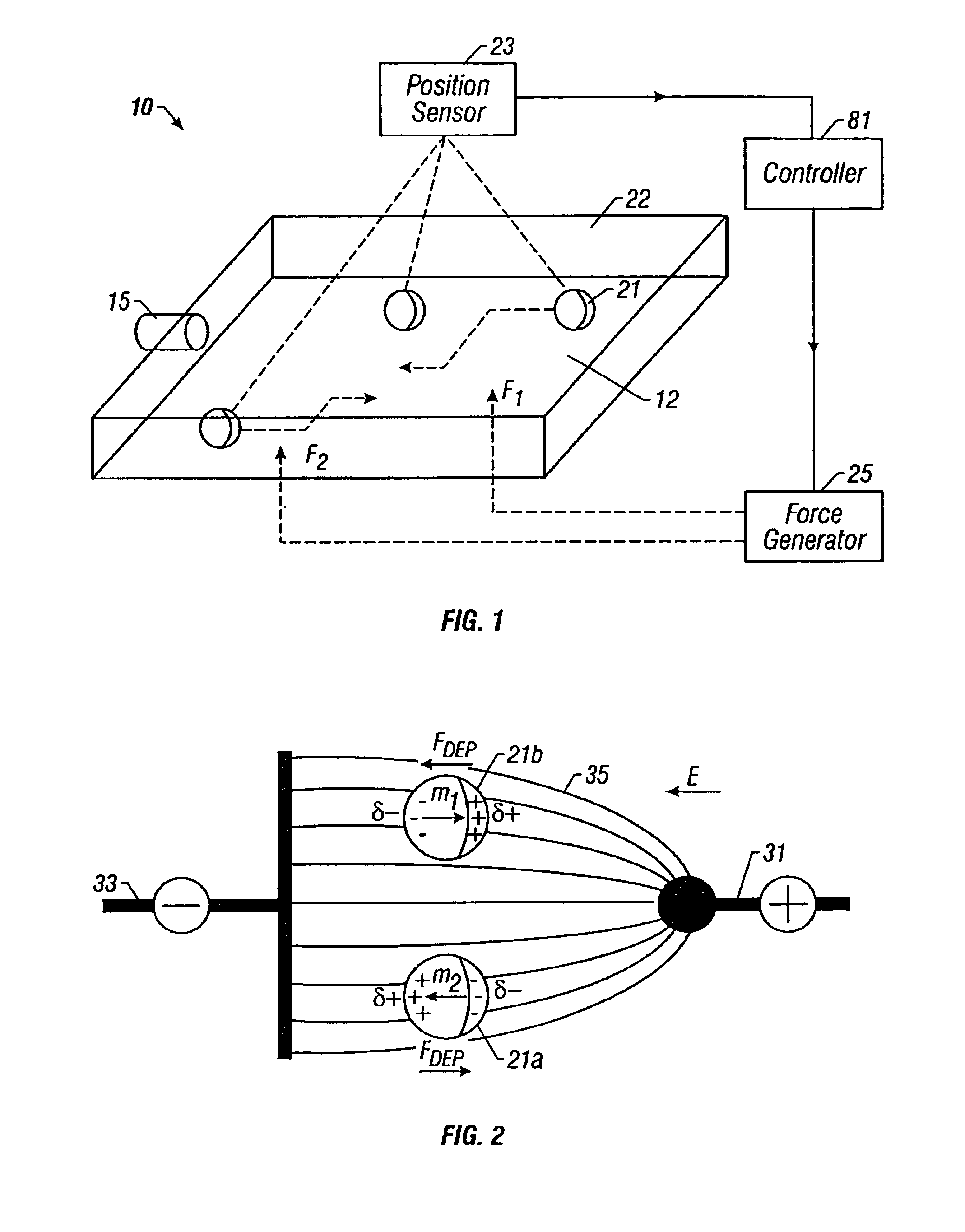

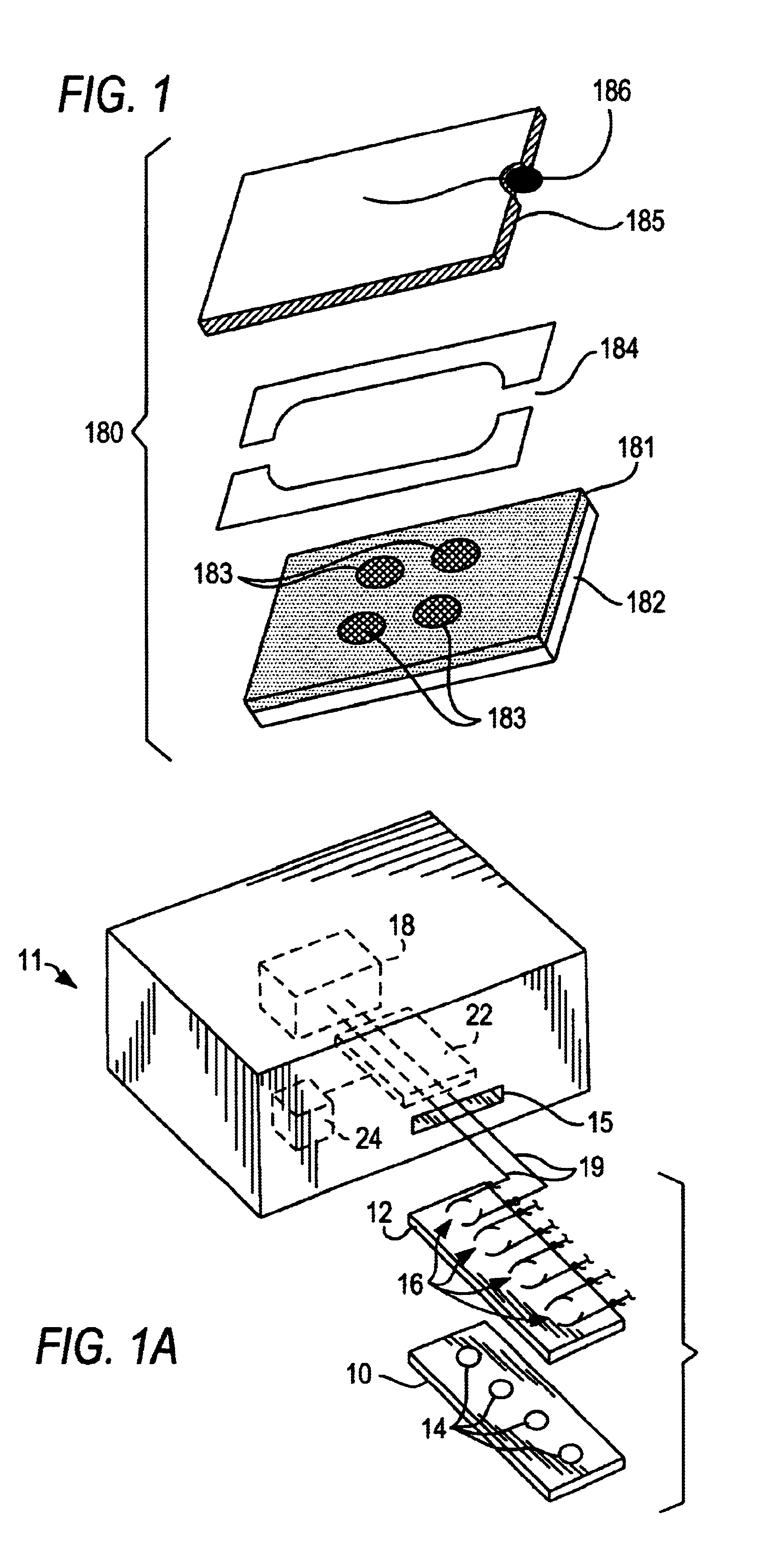

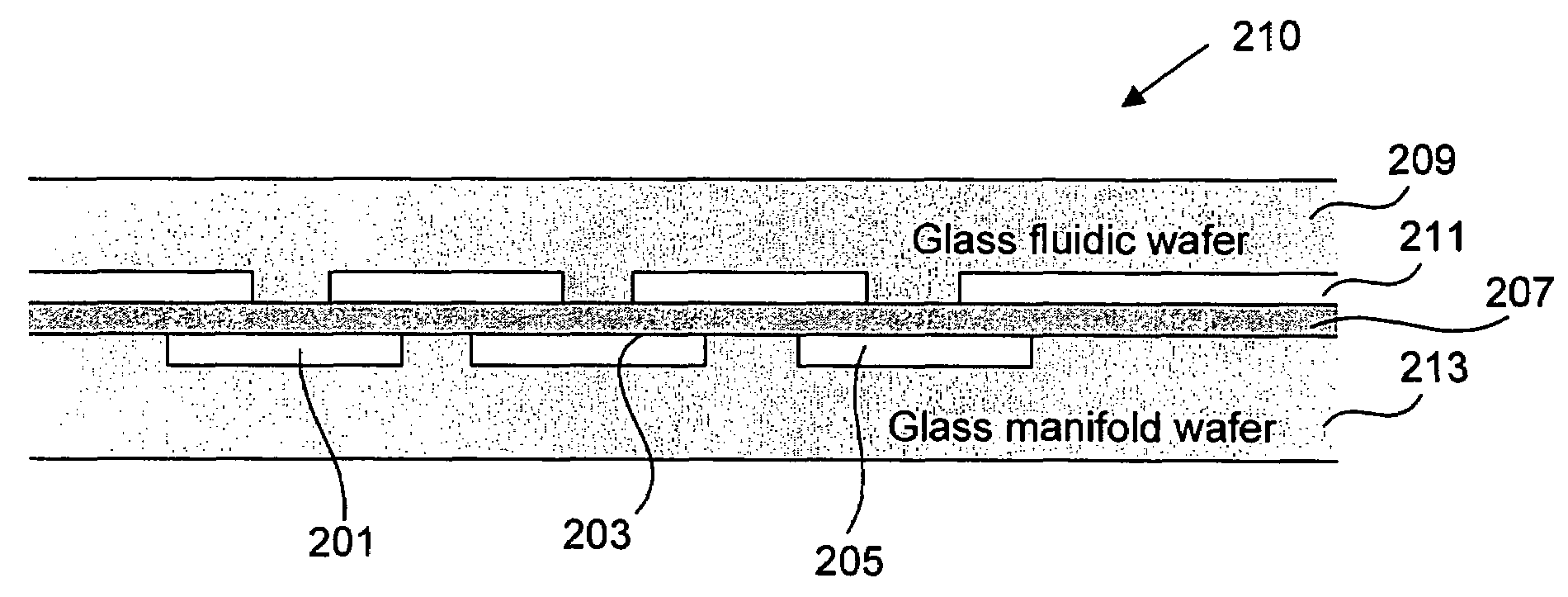

Method, apparatus and article for microfluidic control via electrowetting, for chemical, biochemical and biological assays and the like

InactiveUS7163612B2Low costElectrostatic separatorsSludge treatmentOff the shelfLiquid-crystal display

An active matrix microfluidic platform employs thin film transistor active (“TFT”) matrix liquid crystal display technology to manipulate small samples of fluid for chemical, biochemical, or biological assays without moving parts, for example, using a two-dimensional matrix array of drive electrodes. The active matrix microfluidic platform may employ existing active matrix addressing schemes and / or commercial “off-the-shelf” animation software to program assay protocols. A feedback subsystem may determine an actual location of a fluid in the microfluidic structure, and provides location information to for display, for example, on an active matrix display, and / or to control movement of one or more fluid bodies in the microfluidic structure.

Owner:KECK GRADUATE INST OF APPLIED LIFE SCI

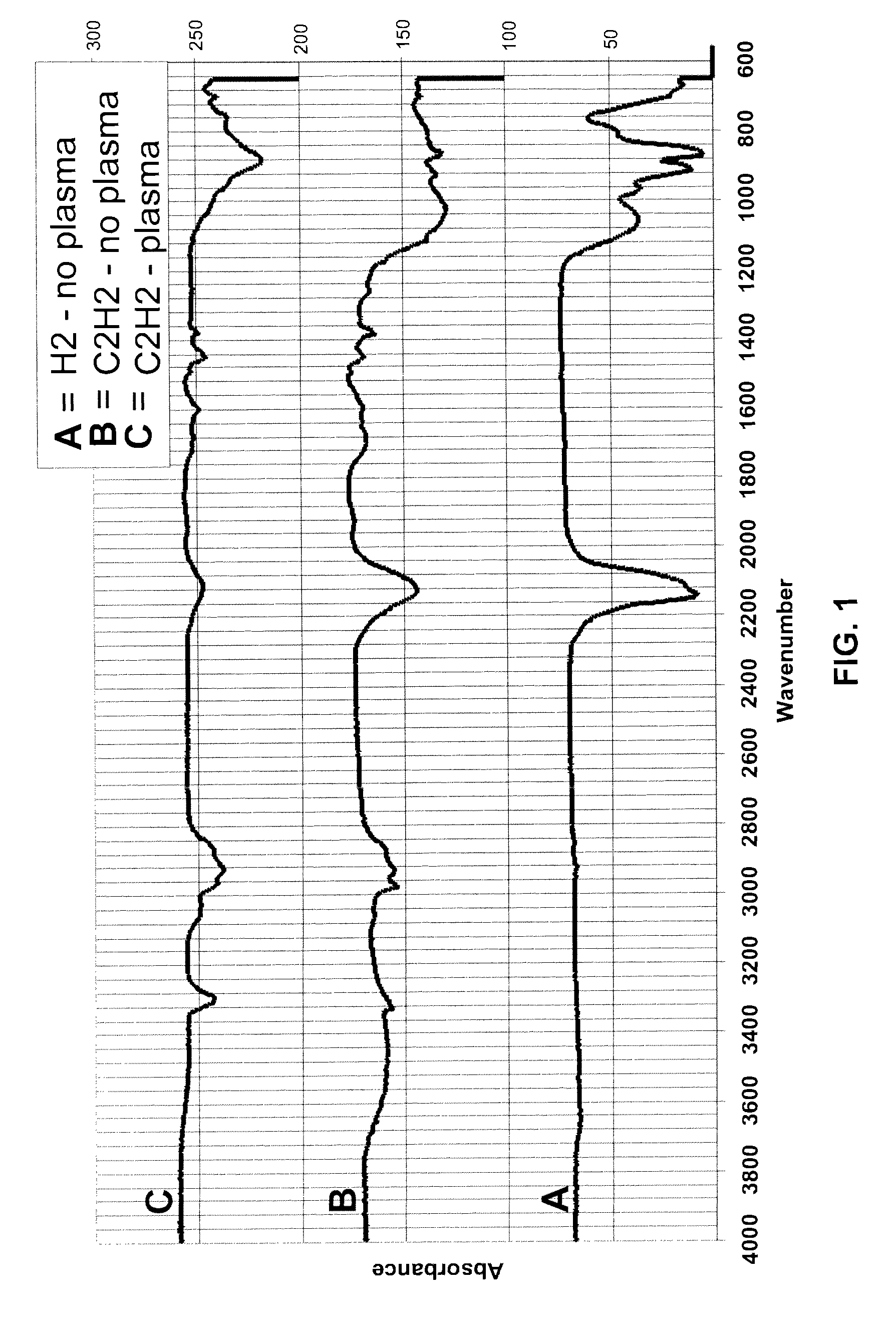

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

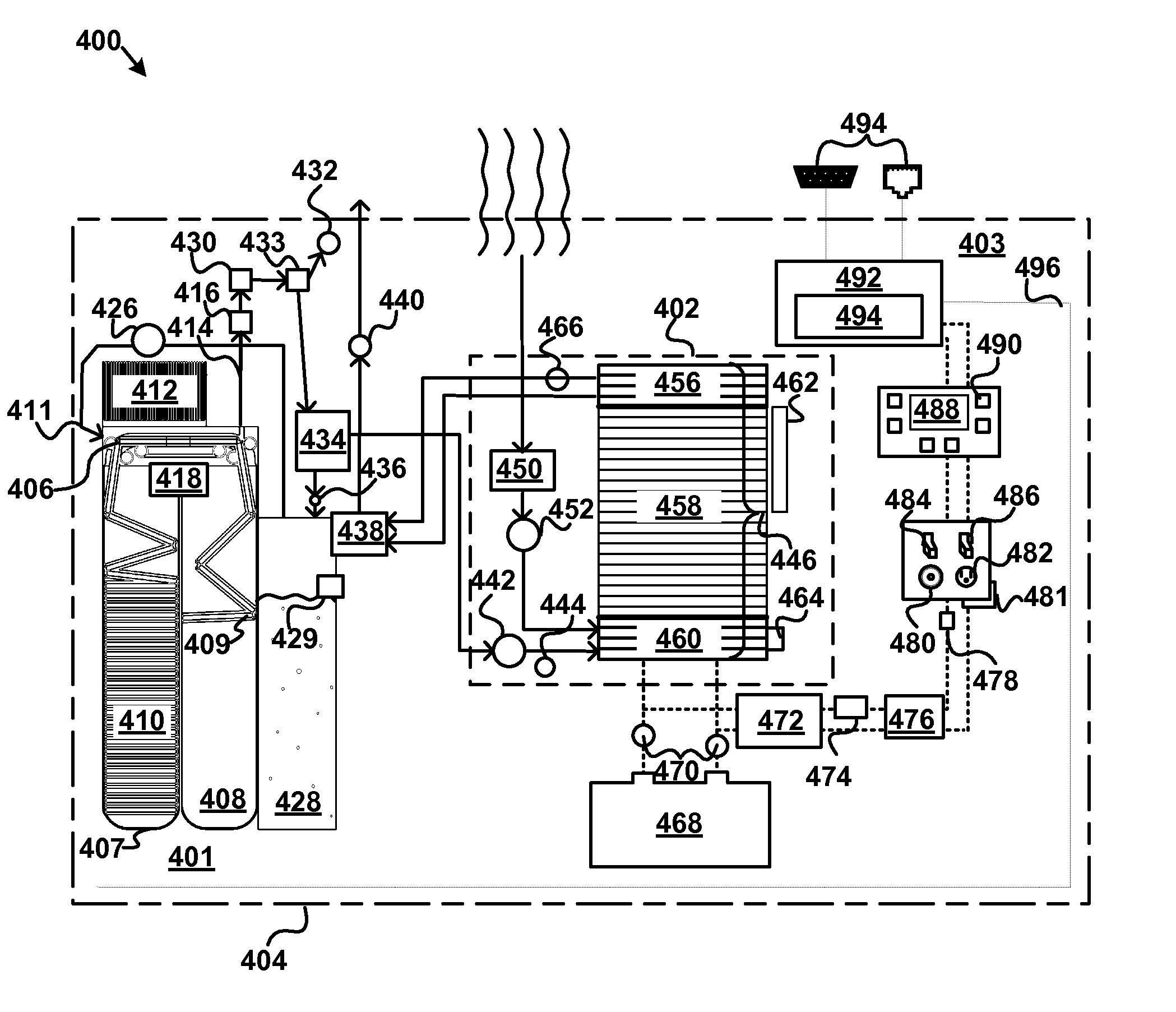

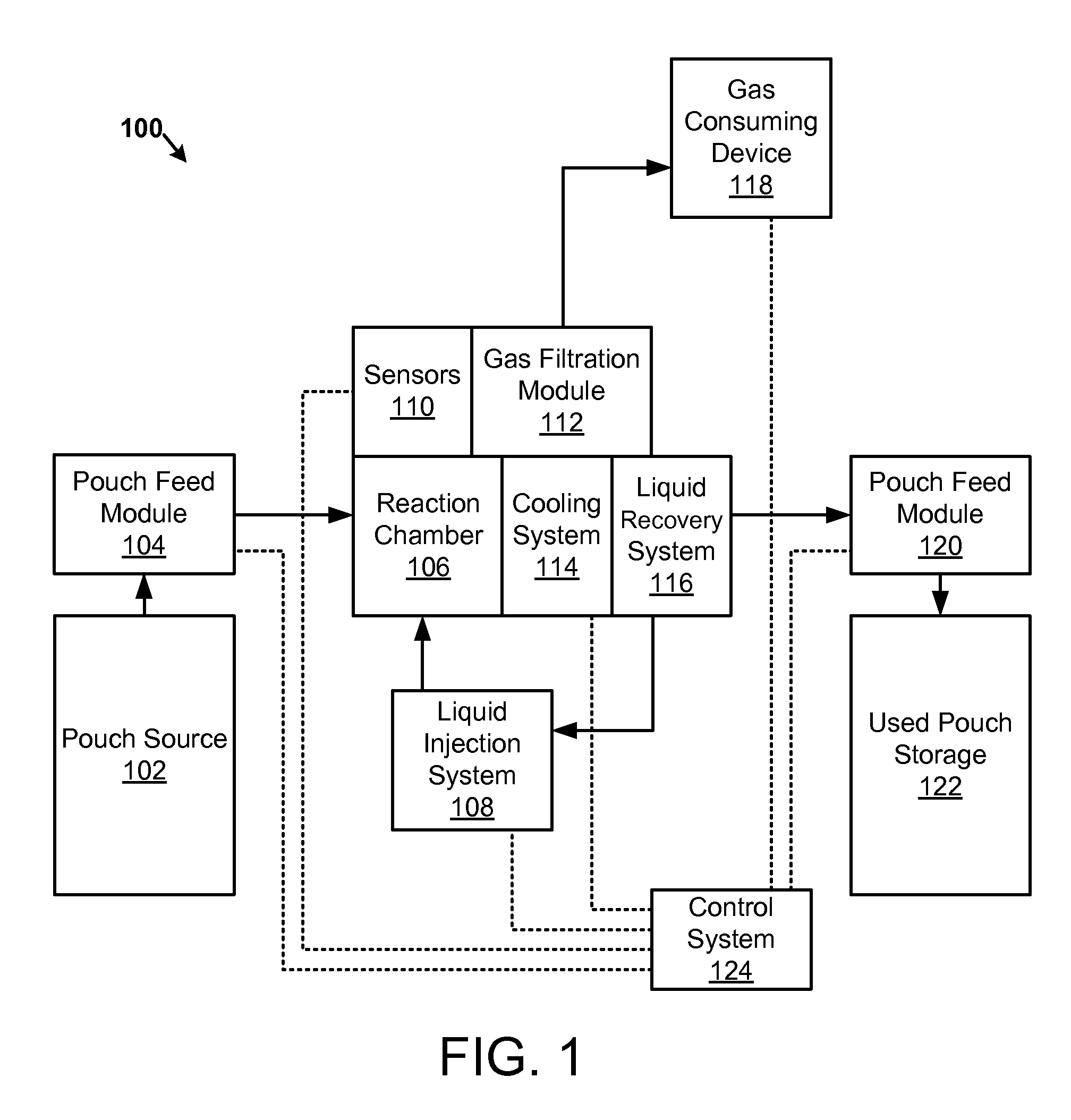

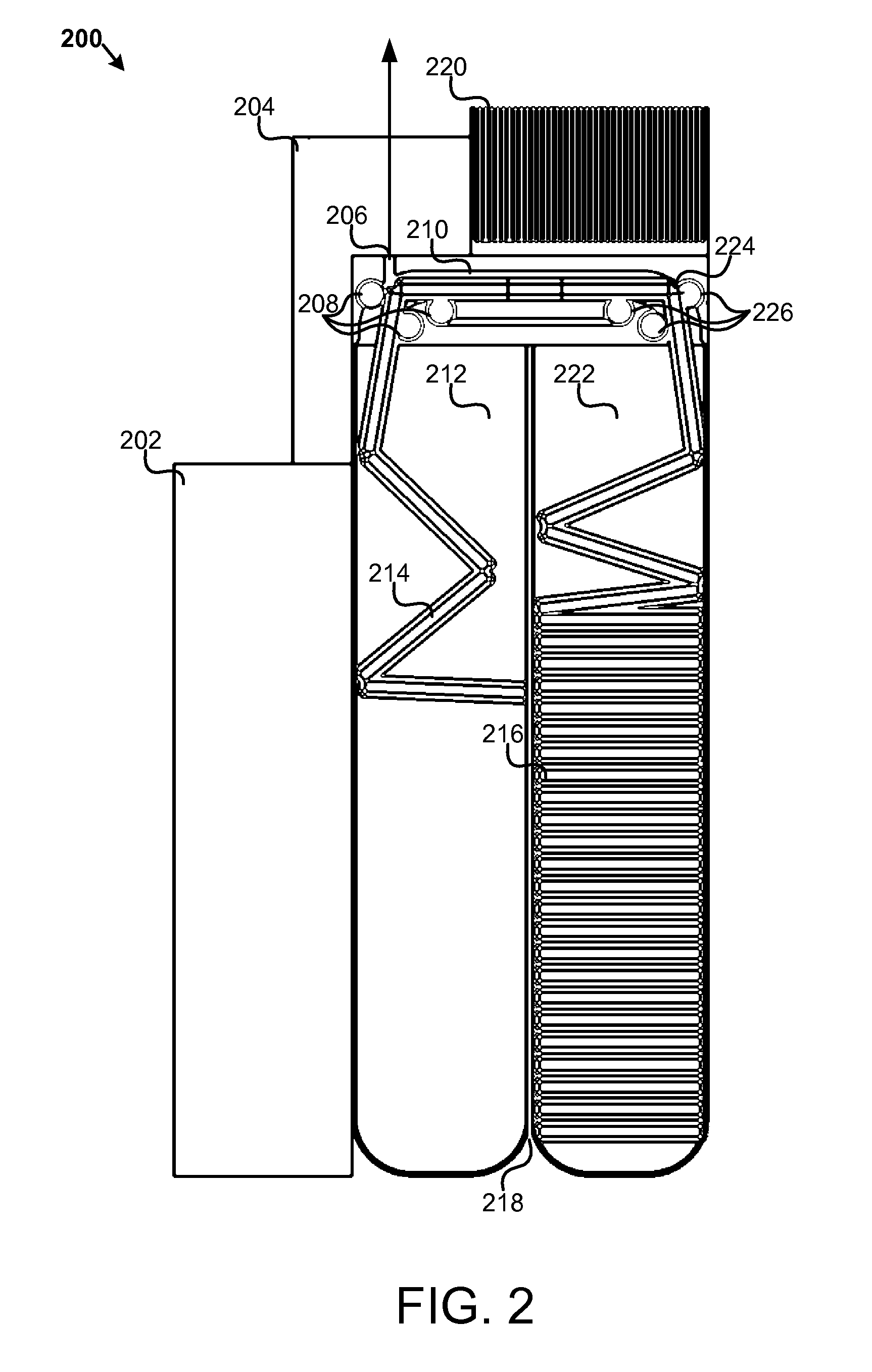

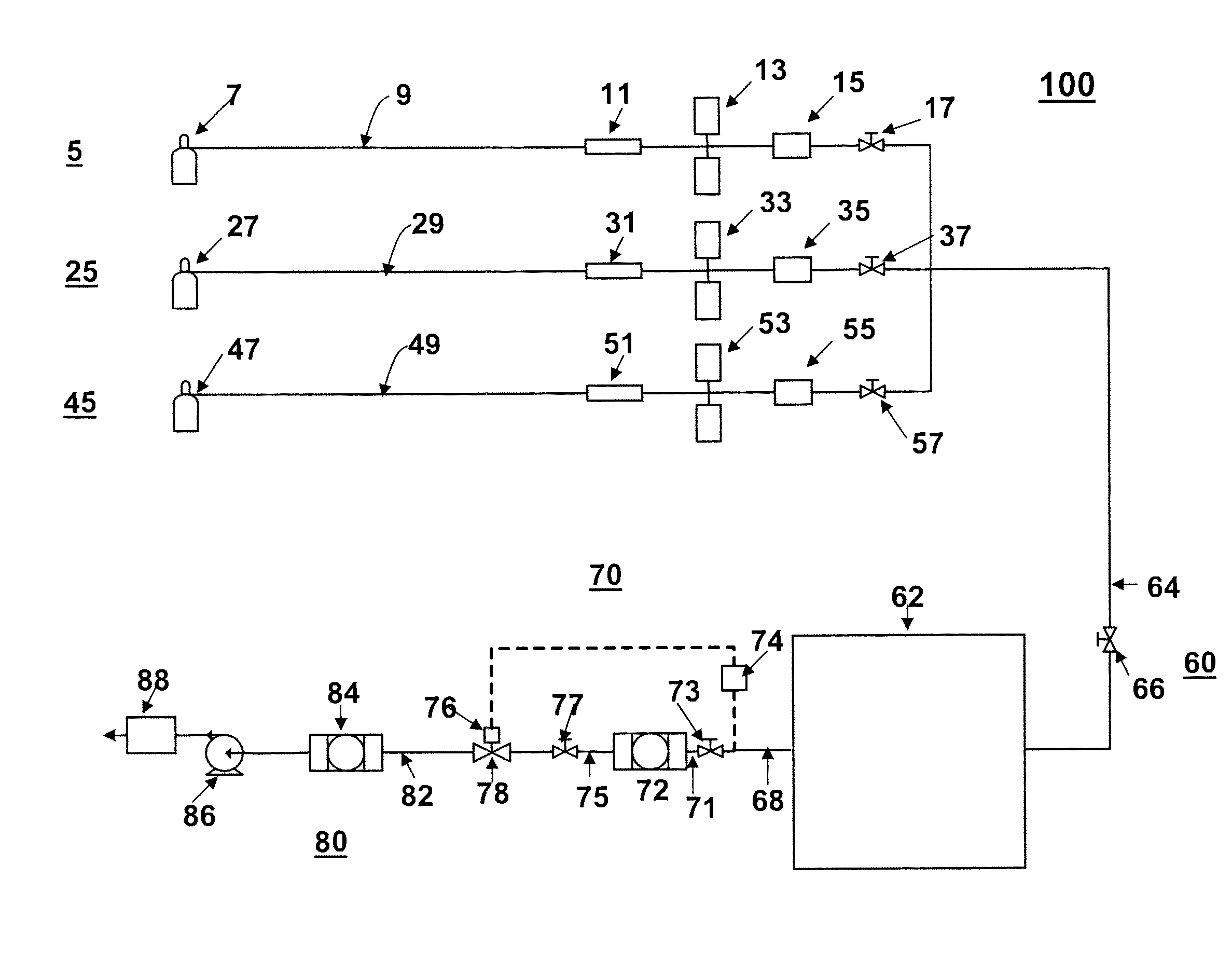

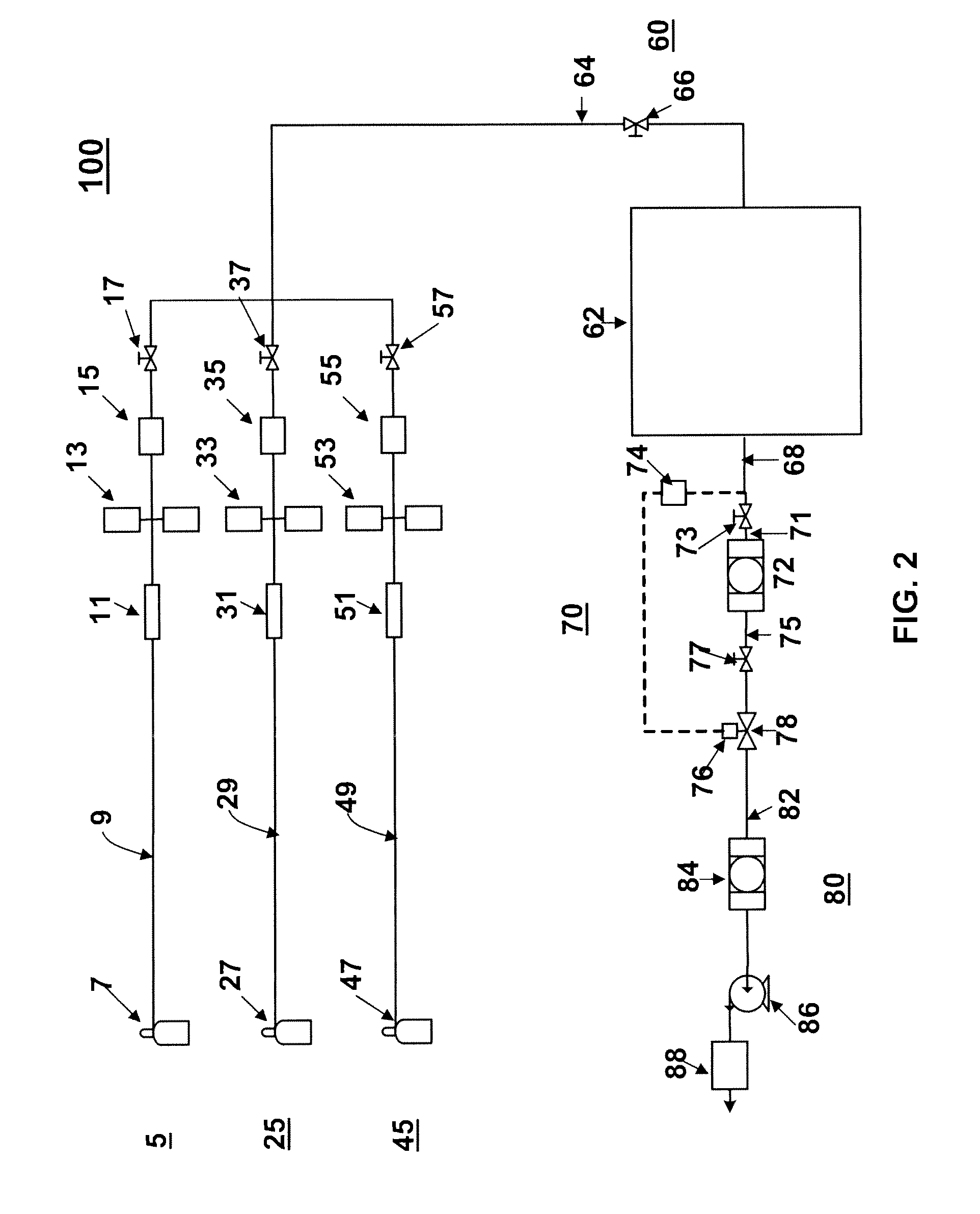

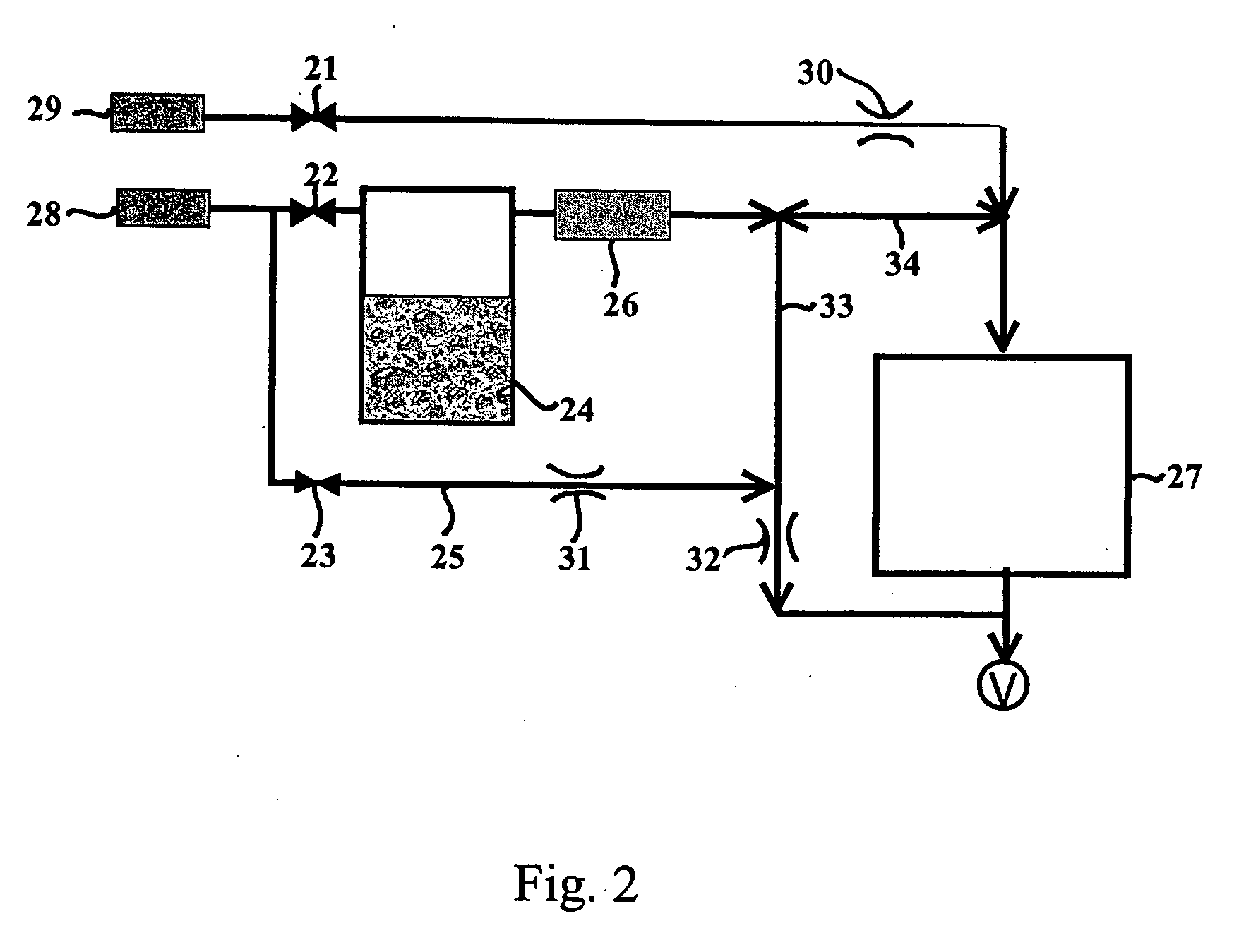

Apparatus, system, and method for generating a gas from solid reactant pouches

An apparatus, system, and method are disclosed for generating a gas. One or more liquid permeable pouches each define a cavity that contains a solid anhydrous reactant, such as a chemical hydride. A reaction chamber made of a heat, chemical and / or pressure resistant material receives the one or more pouches from a pouch feeder that transfers the one or more pouches into the reaction chamber successively at a feed rate. One or more liquid sources inject a liquid reactant into the reaction chamber so that the liquid reactant contacts a portion of the one or more pouches. The one or more liquid sources inject the liquid reactant at an injection rate that corresponds to the feed rate. A gas outlet releases a gas, such as hydrogen, oxygen, ammonia, borazine, nitrogen, or a hydrocarbon, that is produced by a reaction between the solid reactant and the liquid reactant.

Owner:TRULITE INC

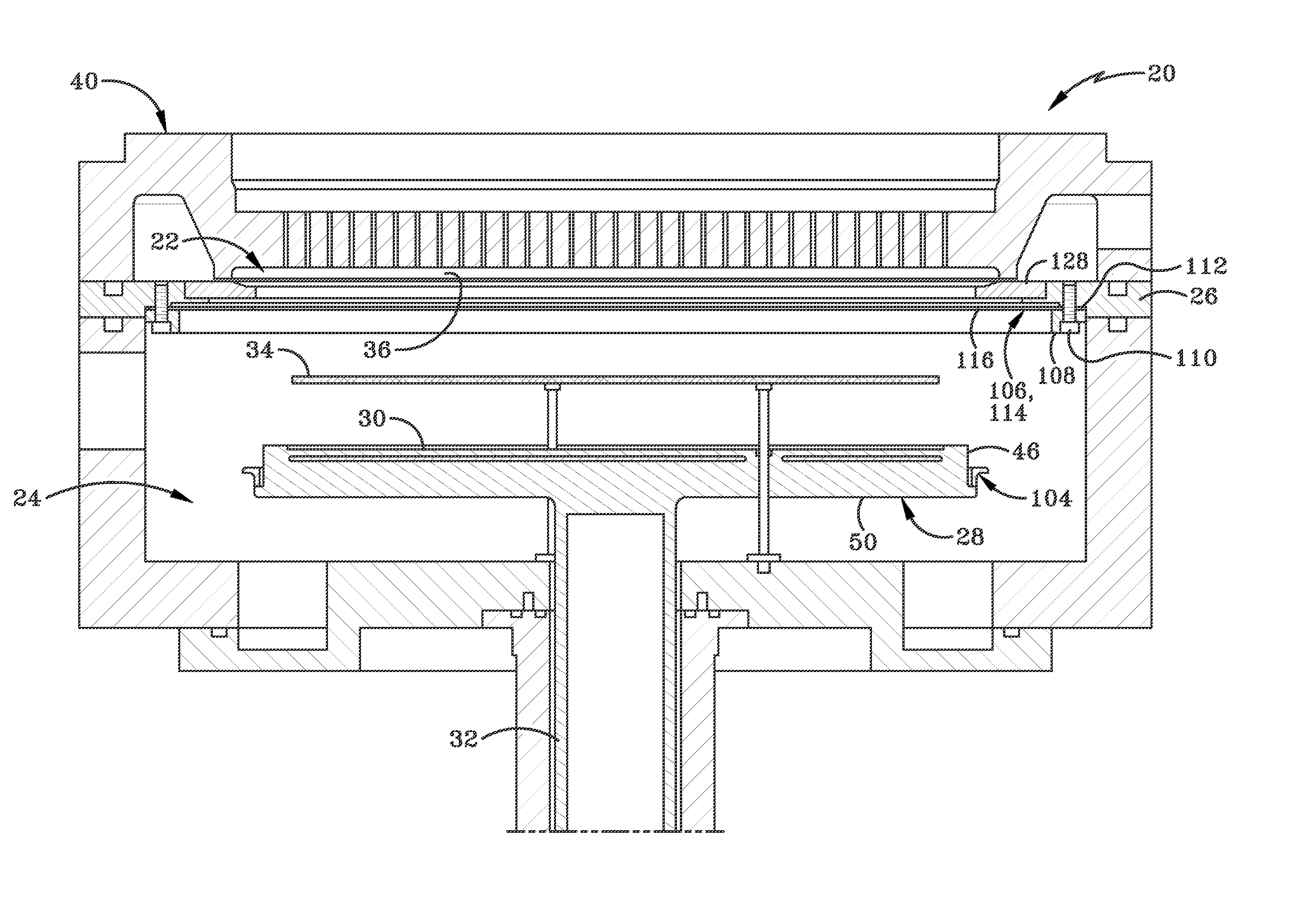

Chamber sealing member

ActiveUS20130129577A1Semiconductor/solid-state device manufacturingChemical/physical/physico-chemical processesSusceptorMechanical engineering

A reaction chamber including an upper region for processing a substrate, a lower region for loading a substrate, a susceptor movable within the reaction chamber, a first sealing member positioned on a perimeter of the susceptor, a second sealing member positioned between the upper region and the lower region, wherein the first and second sealing members are selectively engaged with one another to limit communication between the upper region and the lower region.

Owner:ASM IP HLDG BV

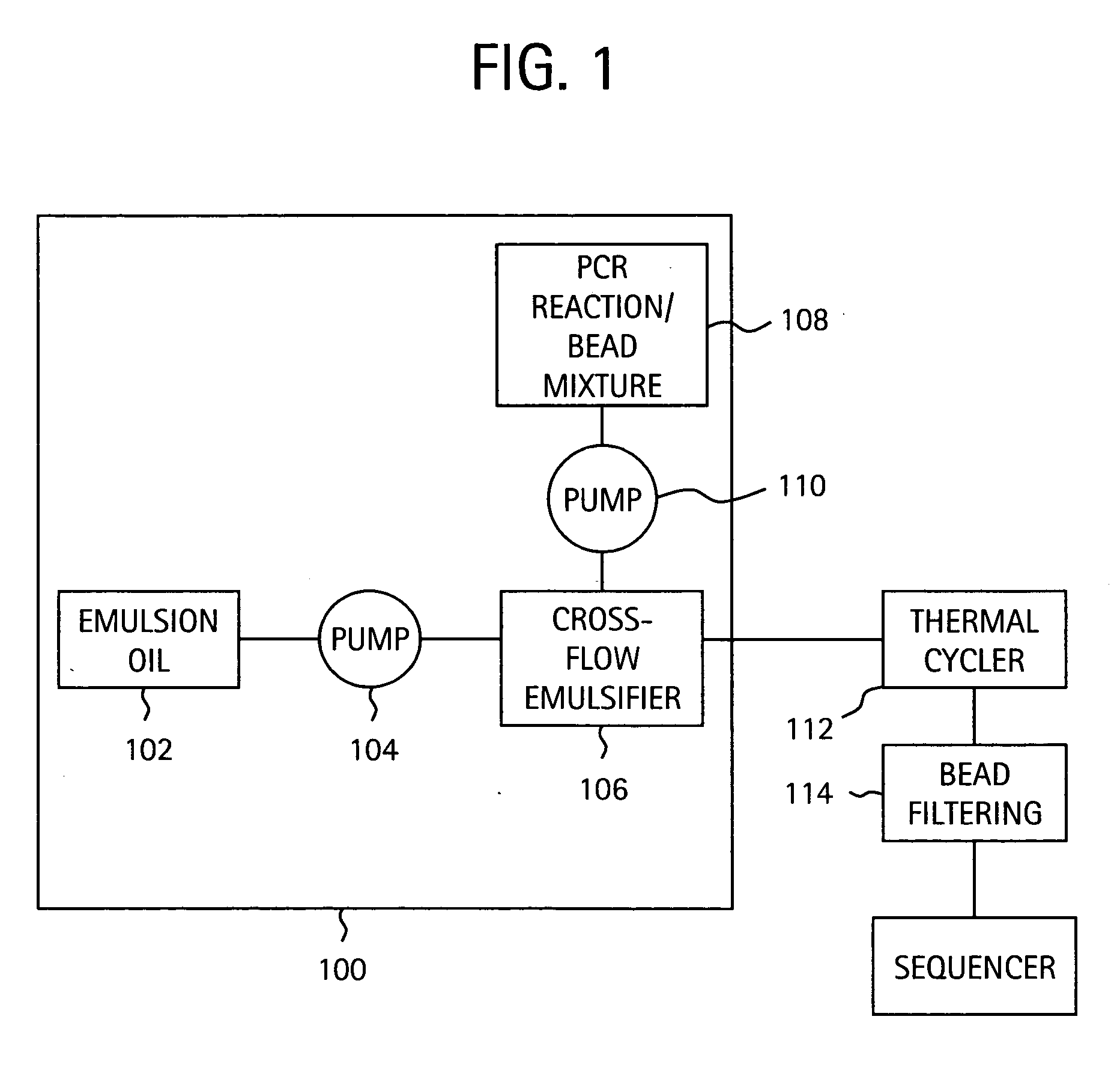

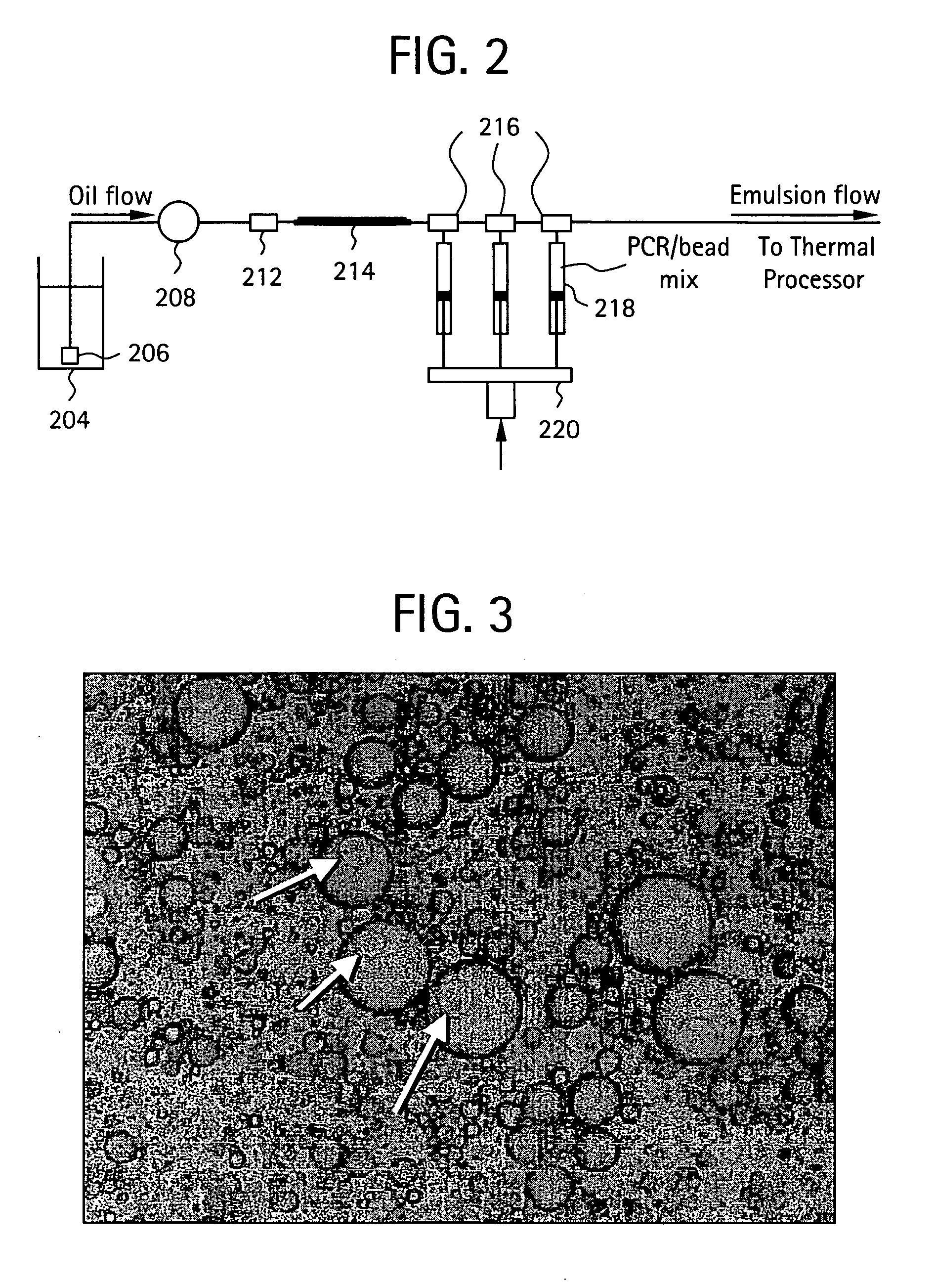

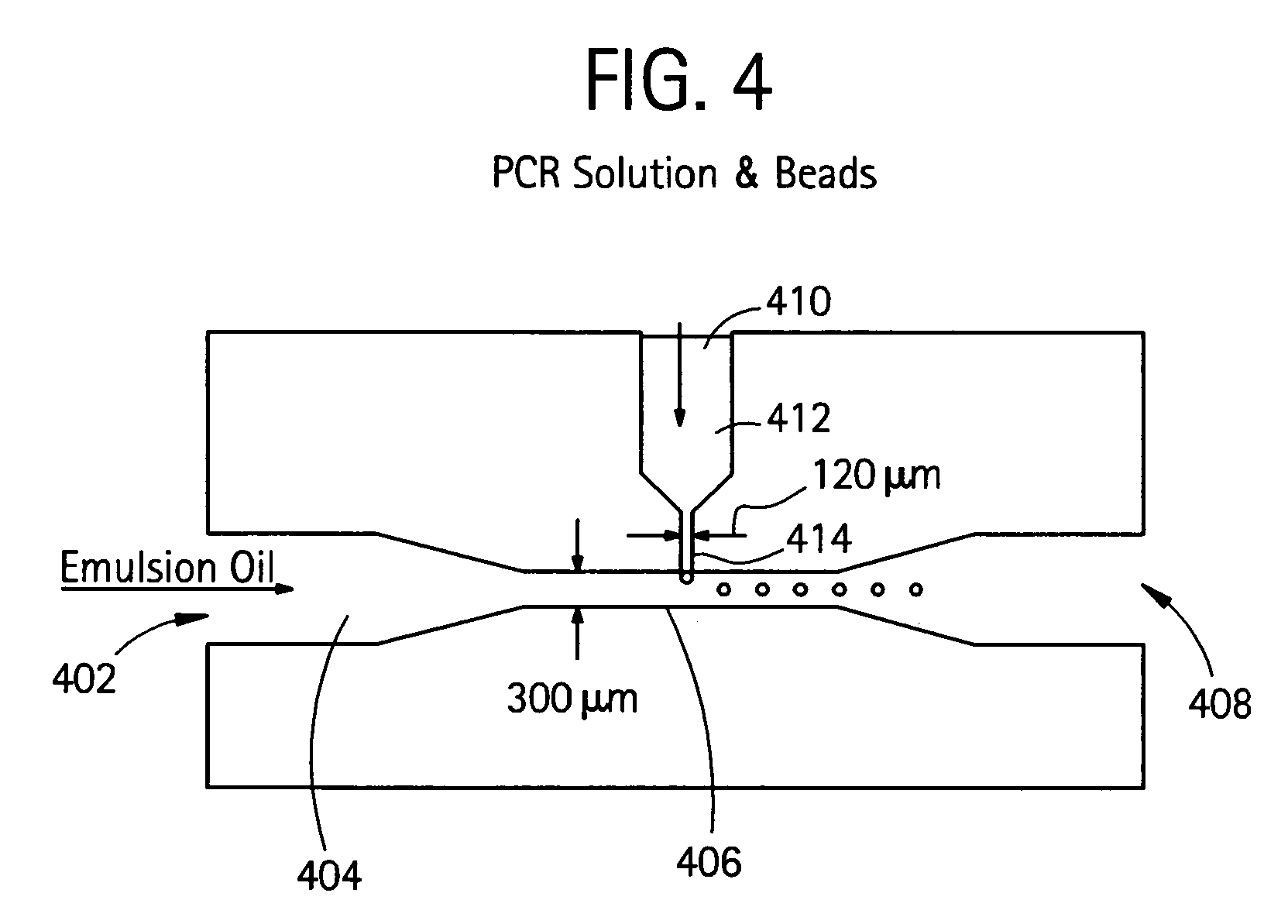

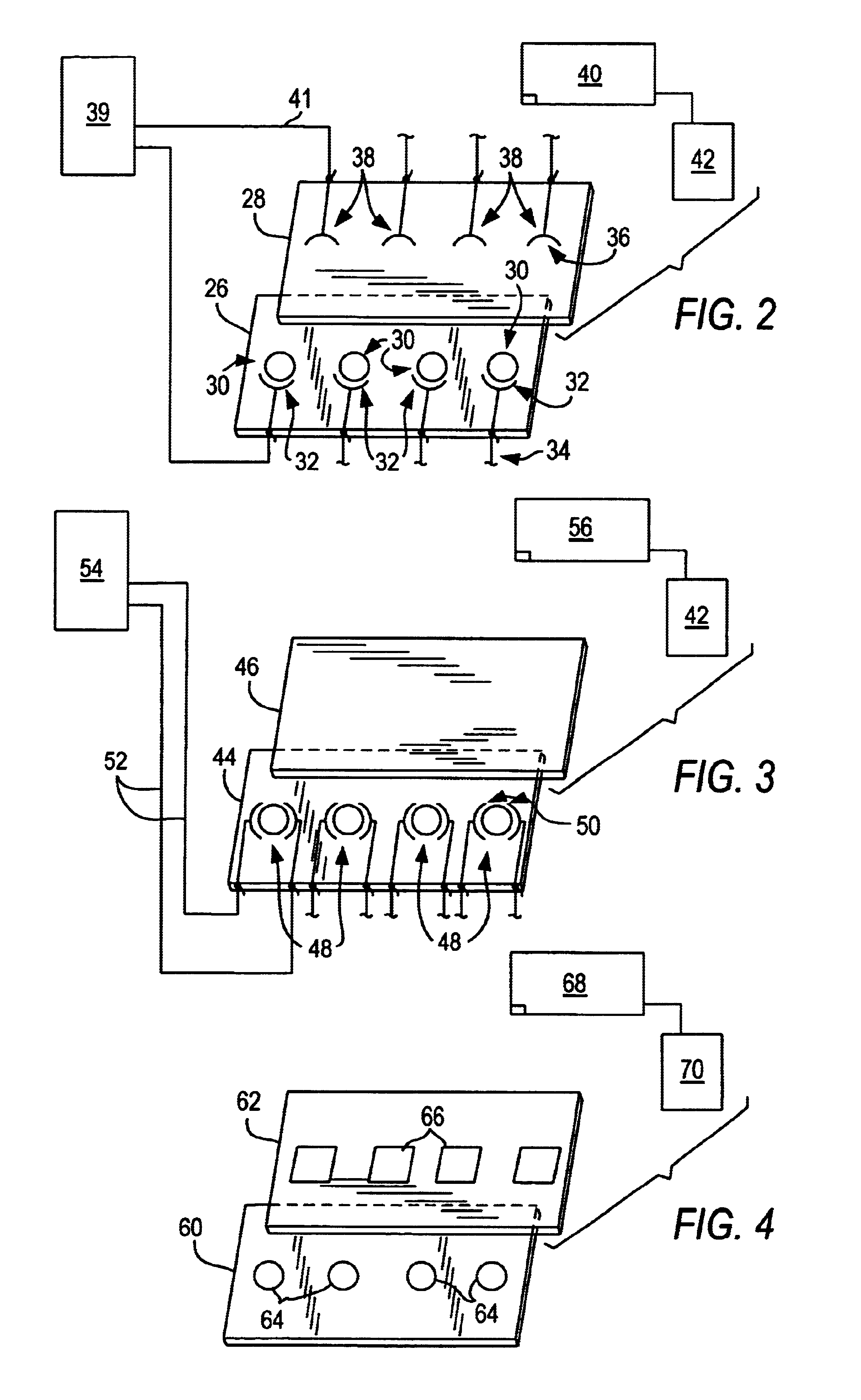

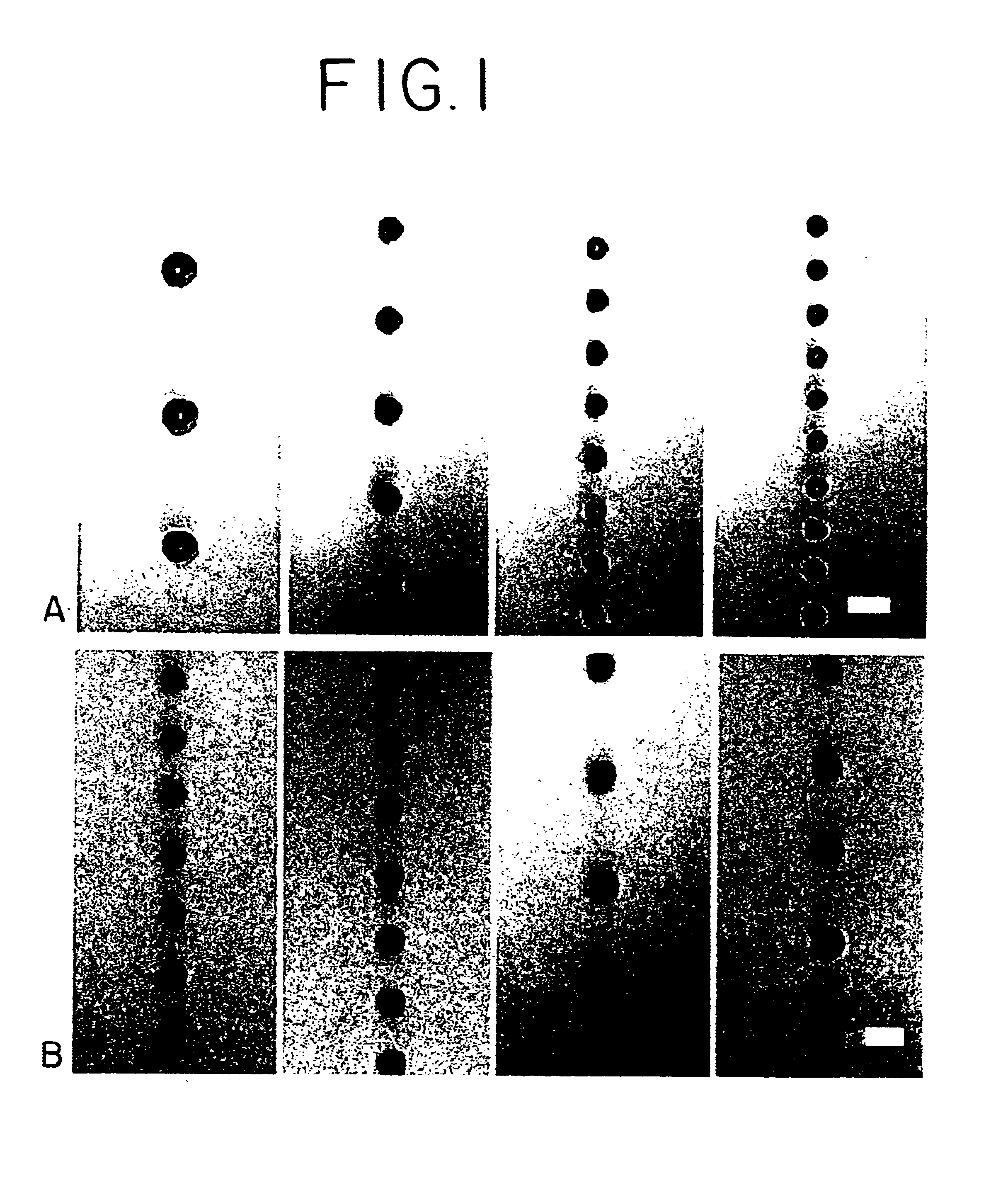

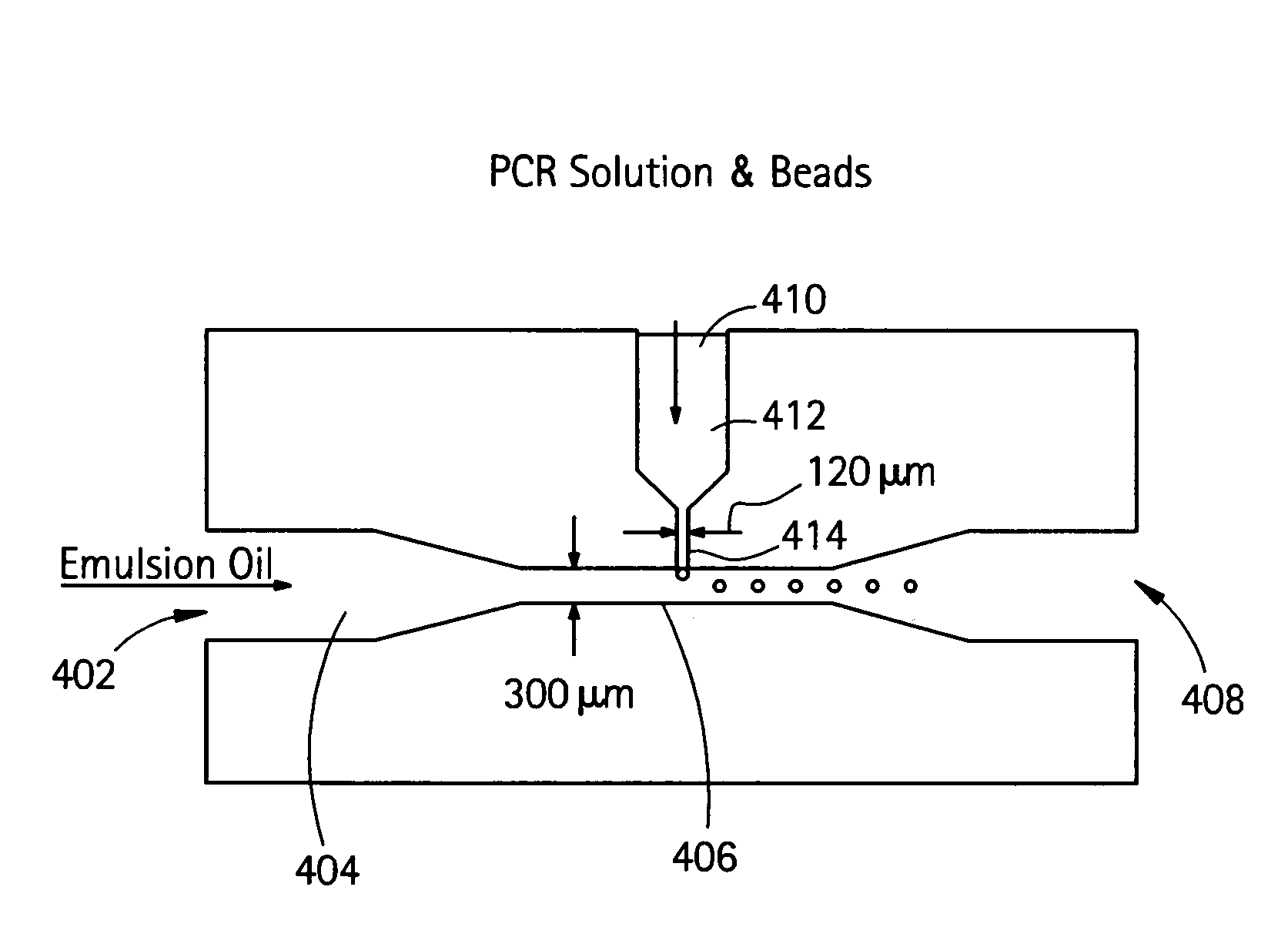

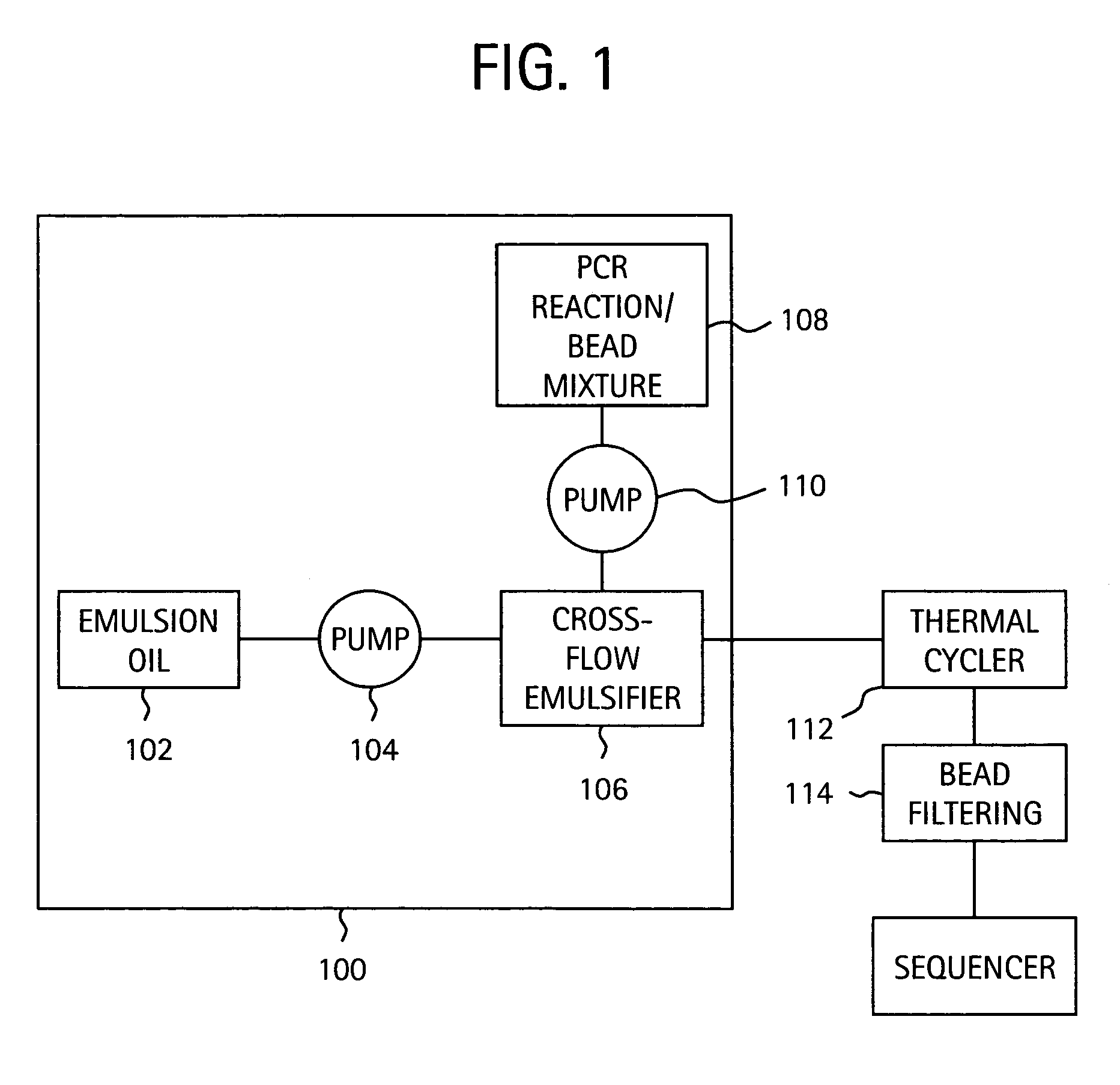

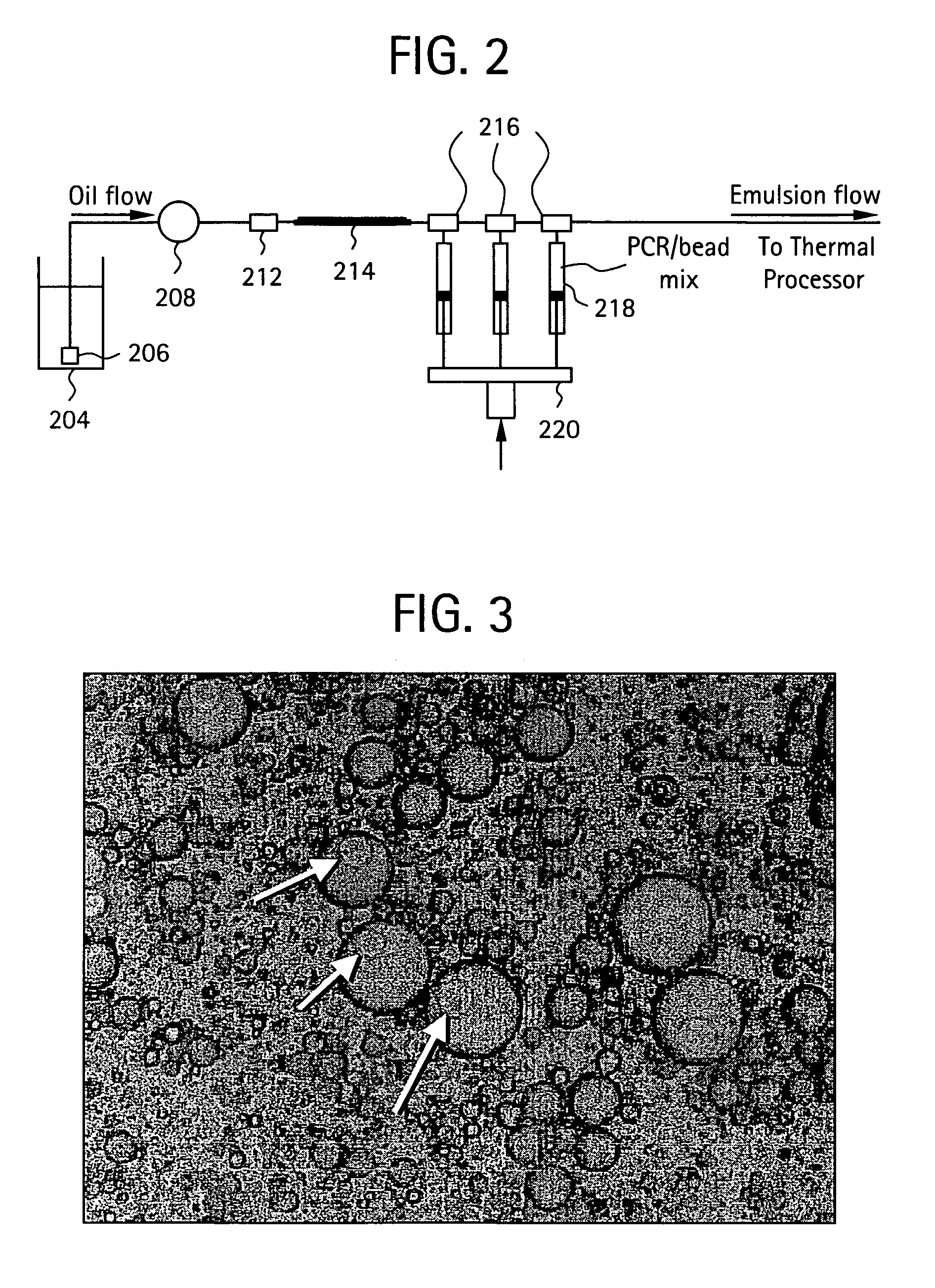

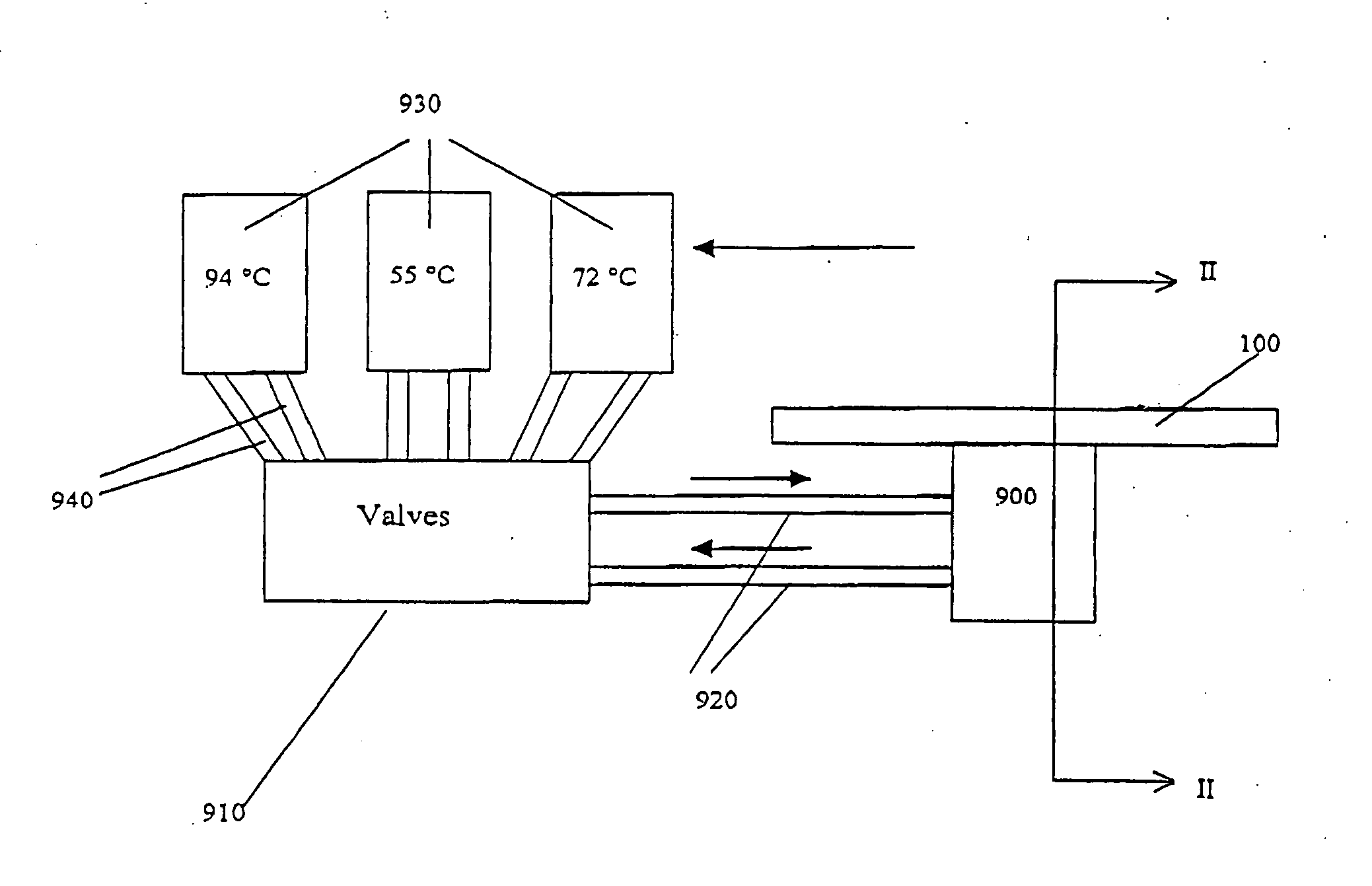

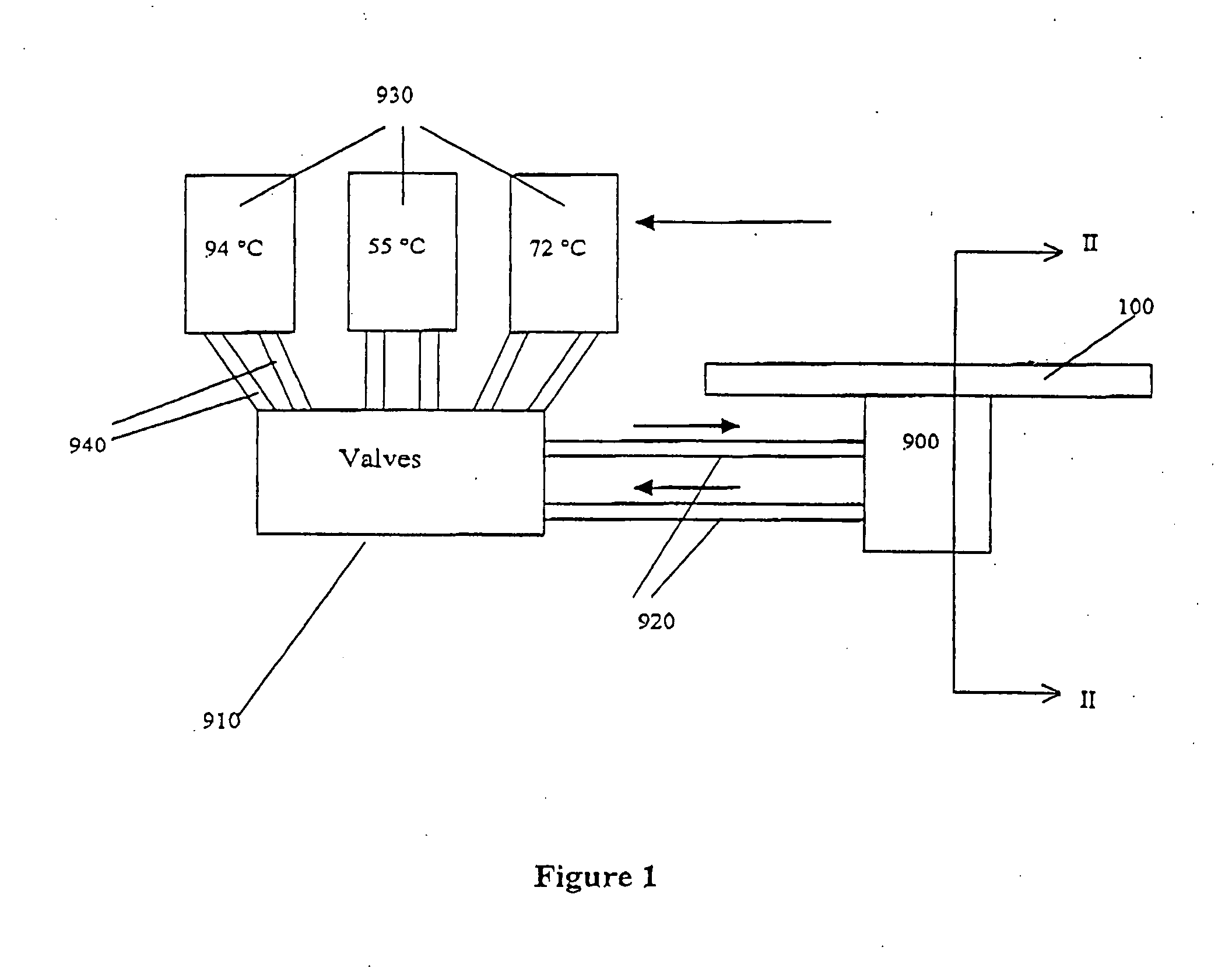

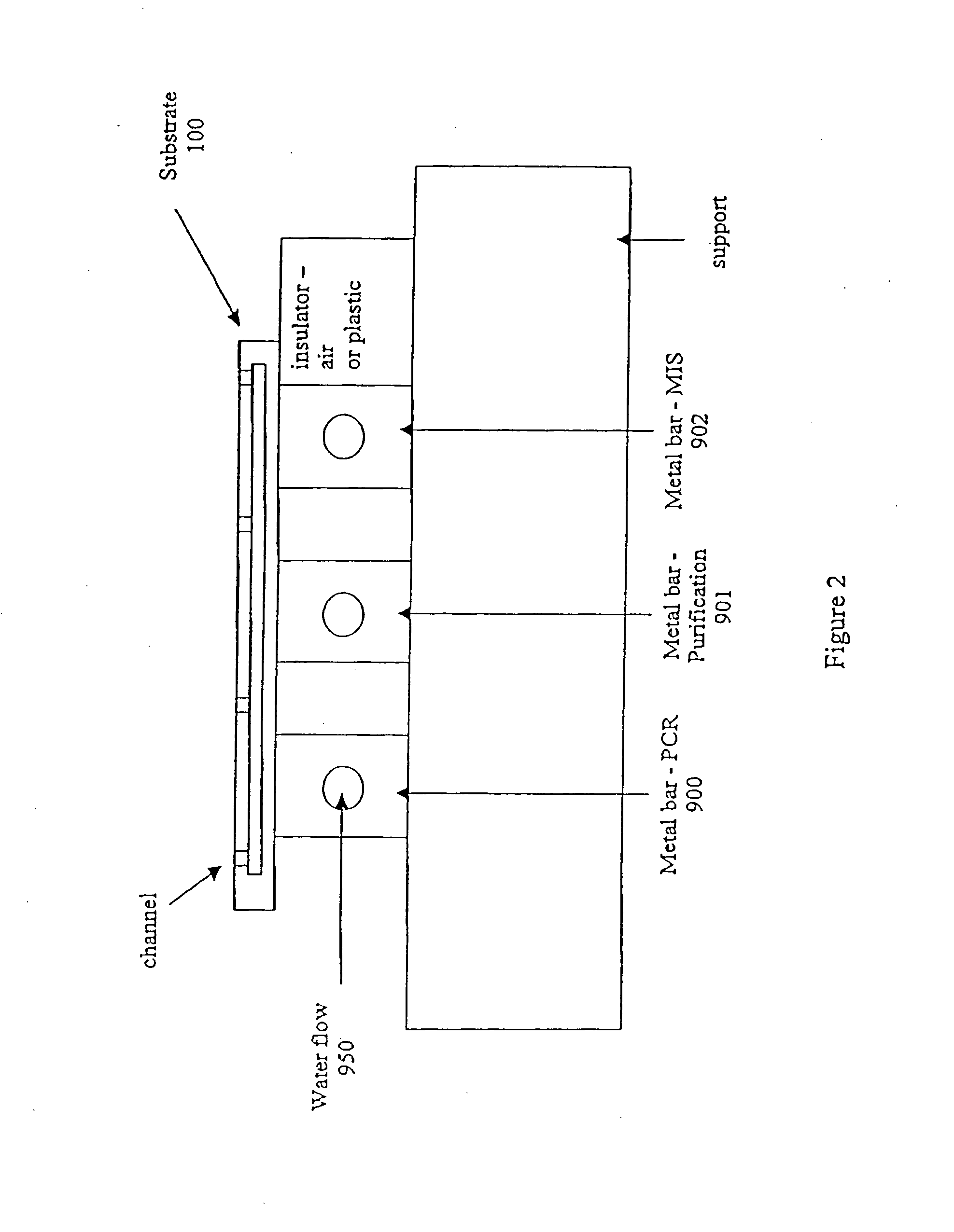

Nucleic acid amplification with continuous flow emulsion

InactiveUS20050227264A1Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

In situ modification of group iv nanoparticles using gas phase nanoparticle reactors

A method for creating an organically capped Group IV semiconductor nanoparticle is disclosed. The method includes flowing a Group IV semiconductor precursor gas into a chamber. The method also includes generating a set of Group IV semiconductor precursor radical species from the Group IV semiconductor precursor gas with a laser pyrolysis apparatus, wherein the set of the Group IV semiconductor precursor radical species nucleate to form the Group IV semiconductor nanoparticle; and flowing an organic capping agent precursor gas into the chamber. The method further includes generating a set of organic capping agent radical species from the organic capping agent precursor gas, wherein the set of organic capping agent radical species reacts with a surface of the Group IV semiconductor nanoparticle and forms the organically capped Group IV semiconductor nanoparticle.

Owner:LI XUEGENG +3

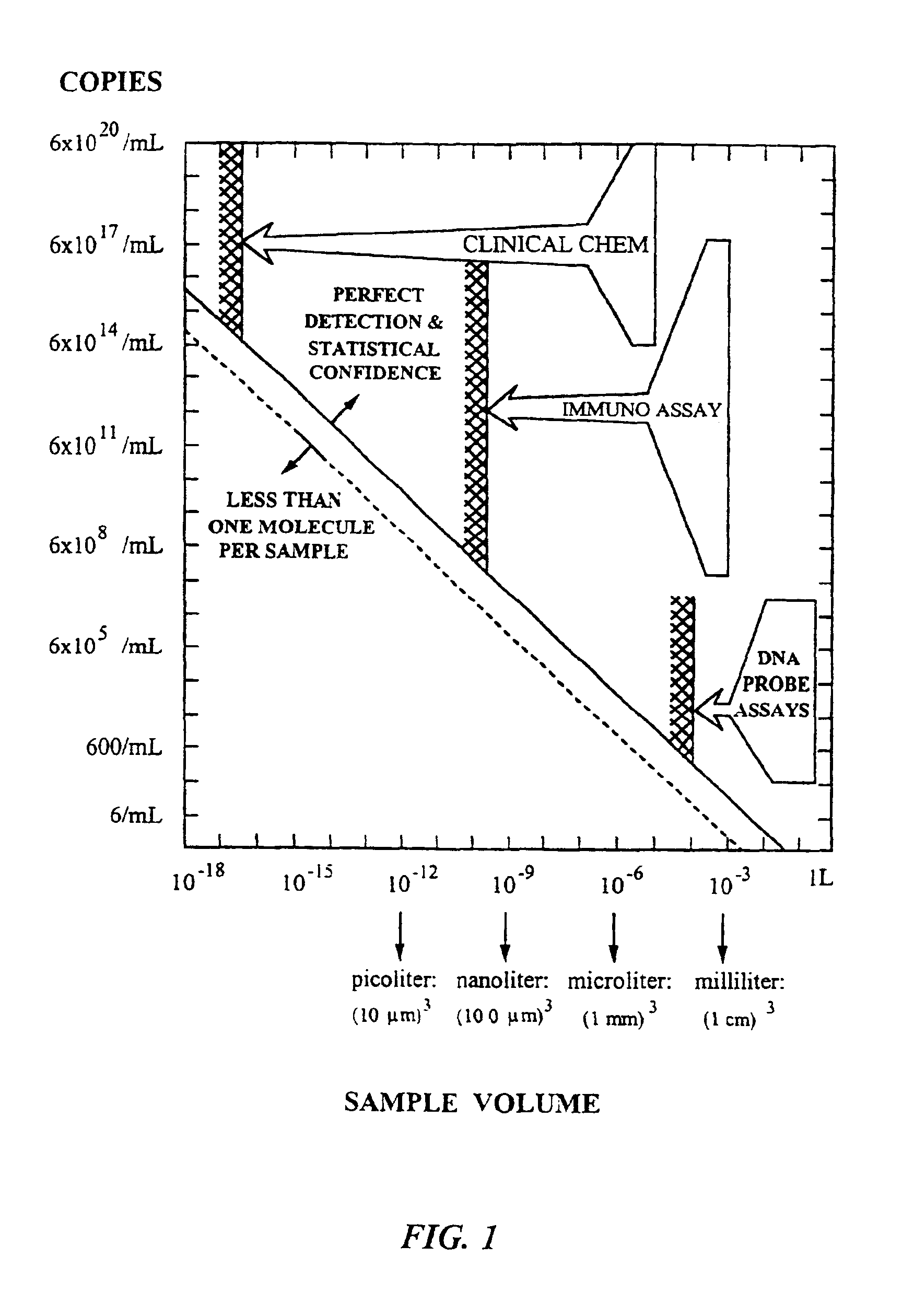

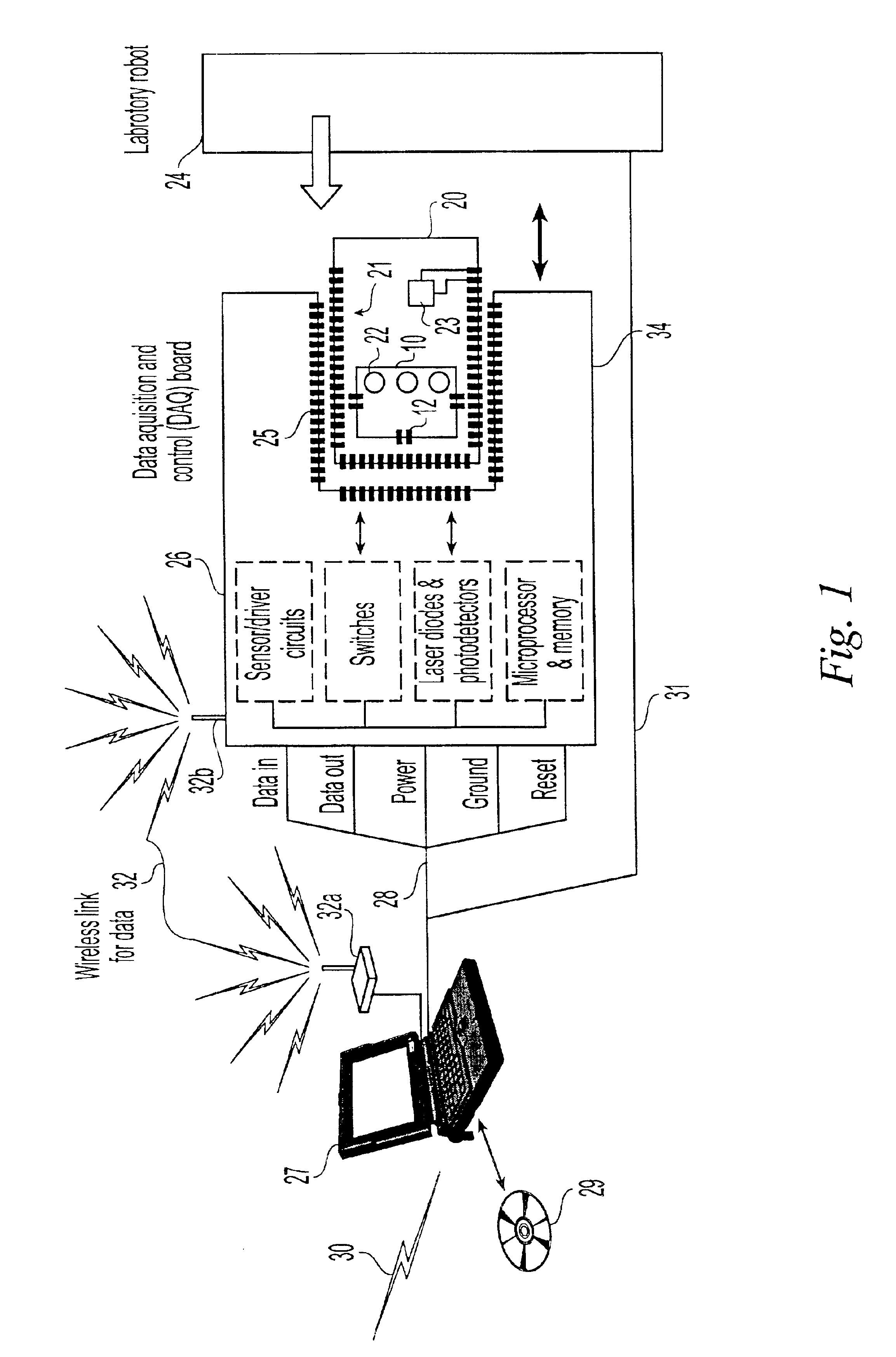

Method for separating analyte from a sample

InactiveUS6893879B2Improve elution efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsSporeChemical reaction

An analyte is separated from a fluid sample by introducing the sample into a cartridge having an extraction chamber containing capture material for capturing the analyte. The sample is forced to flow through the extraction chamber to capture the analyte with the capture material in the extraction chamber. The captured analyte is then eluted from the extraction chamber by forcing an elution fluid to flow through the extraction chamber. The cartridge may optionally include a lysing region for lysing sample components (e.g., cells spores, or microorganisms), a waste chamber for storing waste fluid, and reaction or detection chambers for chemically reacting or detecting the eluted analyte.

Owner:CEPHEID INC

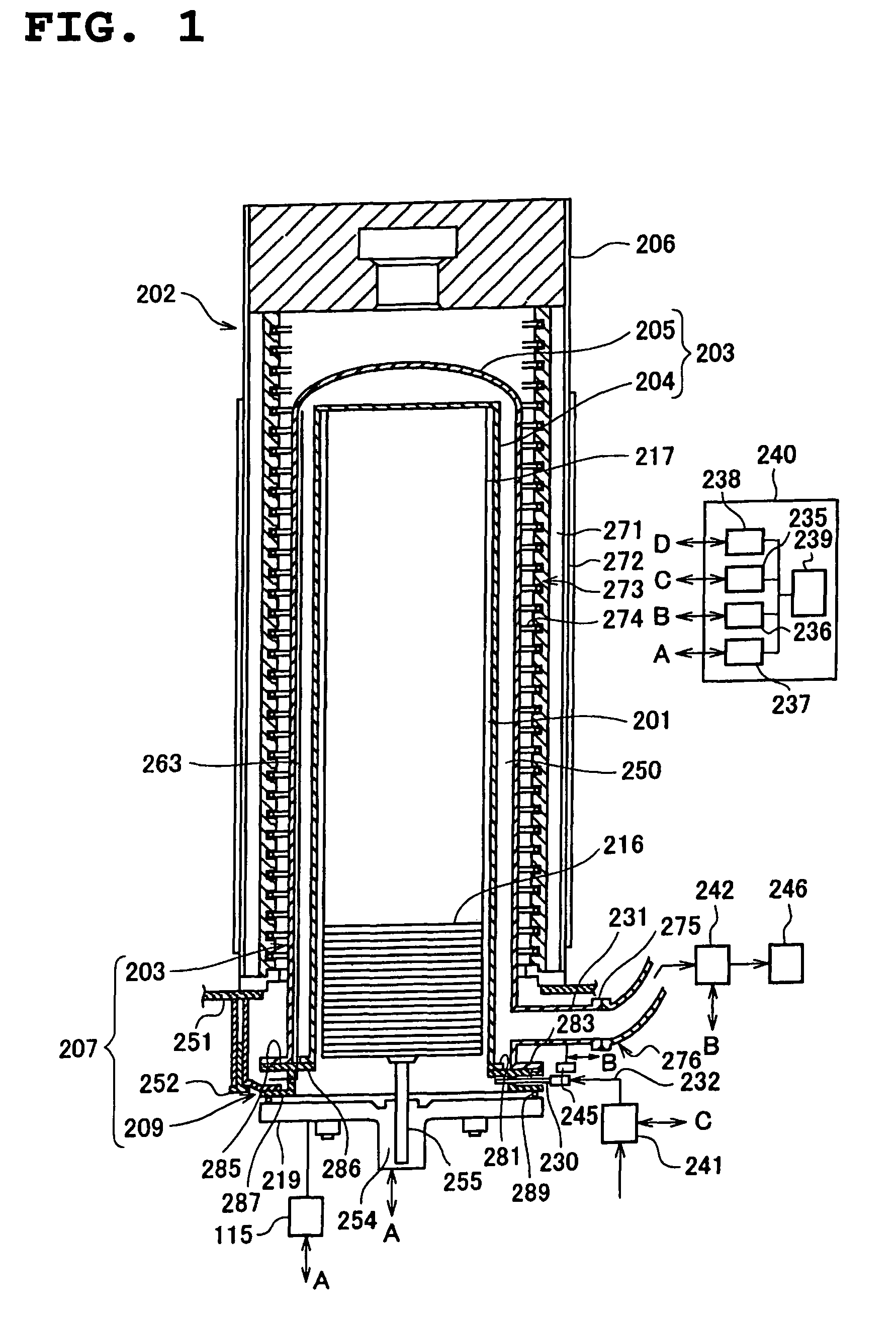

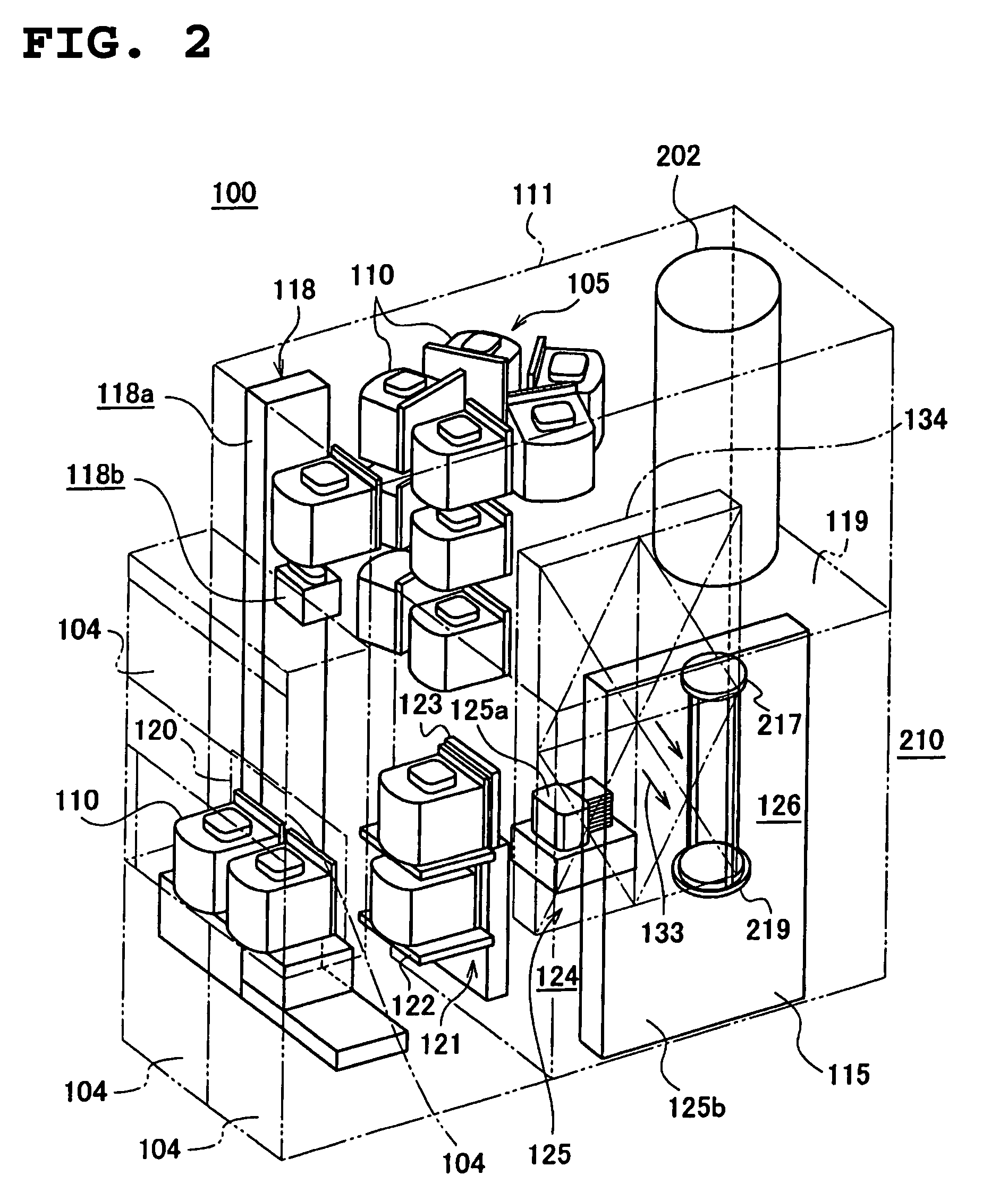

Substrate processing apparatus and attaching/detaching method of reaction vessel

ActiveUS8172947B2Linings repairSemiconductor/solid-state device manufacturingEngineeringMental detachment

Owner:KOKUSA ELECTRIC CO LTD

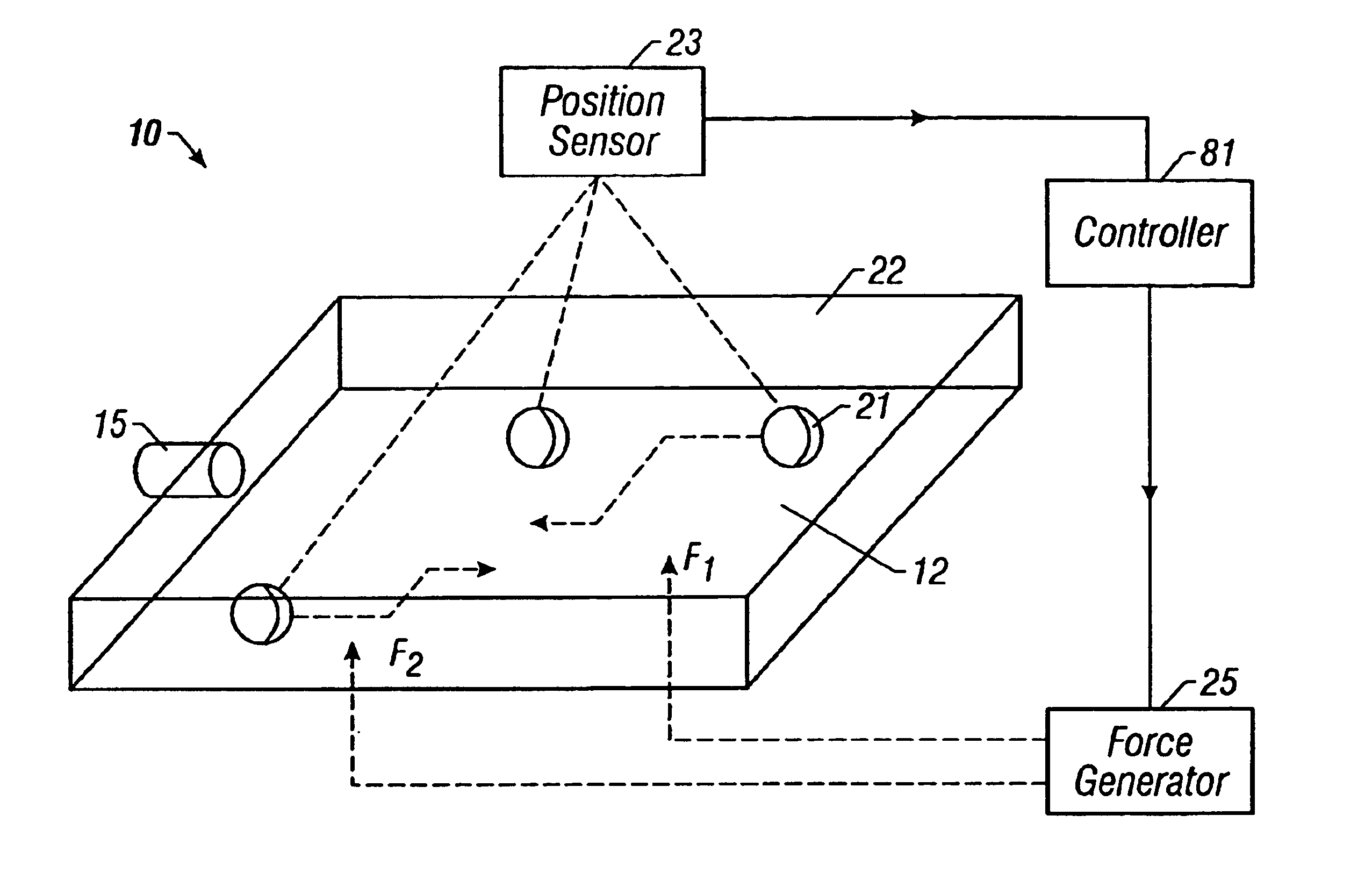

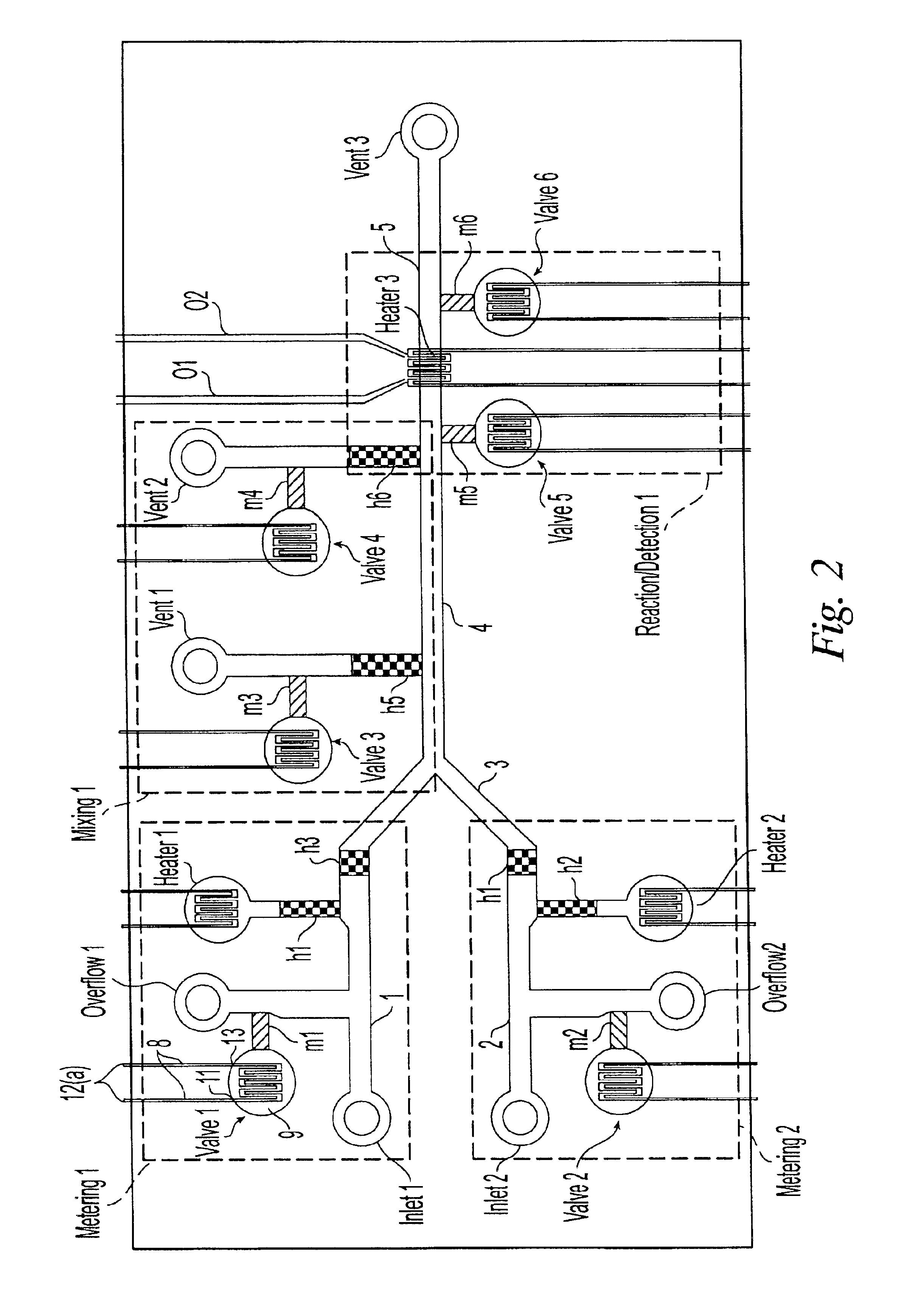

Method and apparatus for programmable fluidic processing

A method and apparatus for microfluidic processing by programmably manipulating a packet. A material is introduced onto a reaction surface and compartmentalized to form a packet. A position of the packet is sensed with a position sensor. A programmable manipulation force is applied to the packet at the position. The programmable manipulation force is adjustable according to packet position by a controller. The packet is programmably moved according to the programmable manipulation force along arbitrarily chosen paths.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

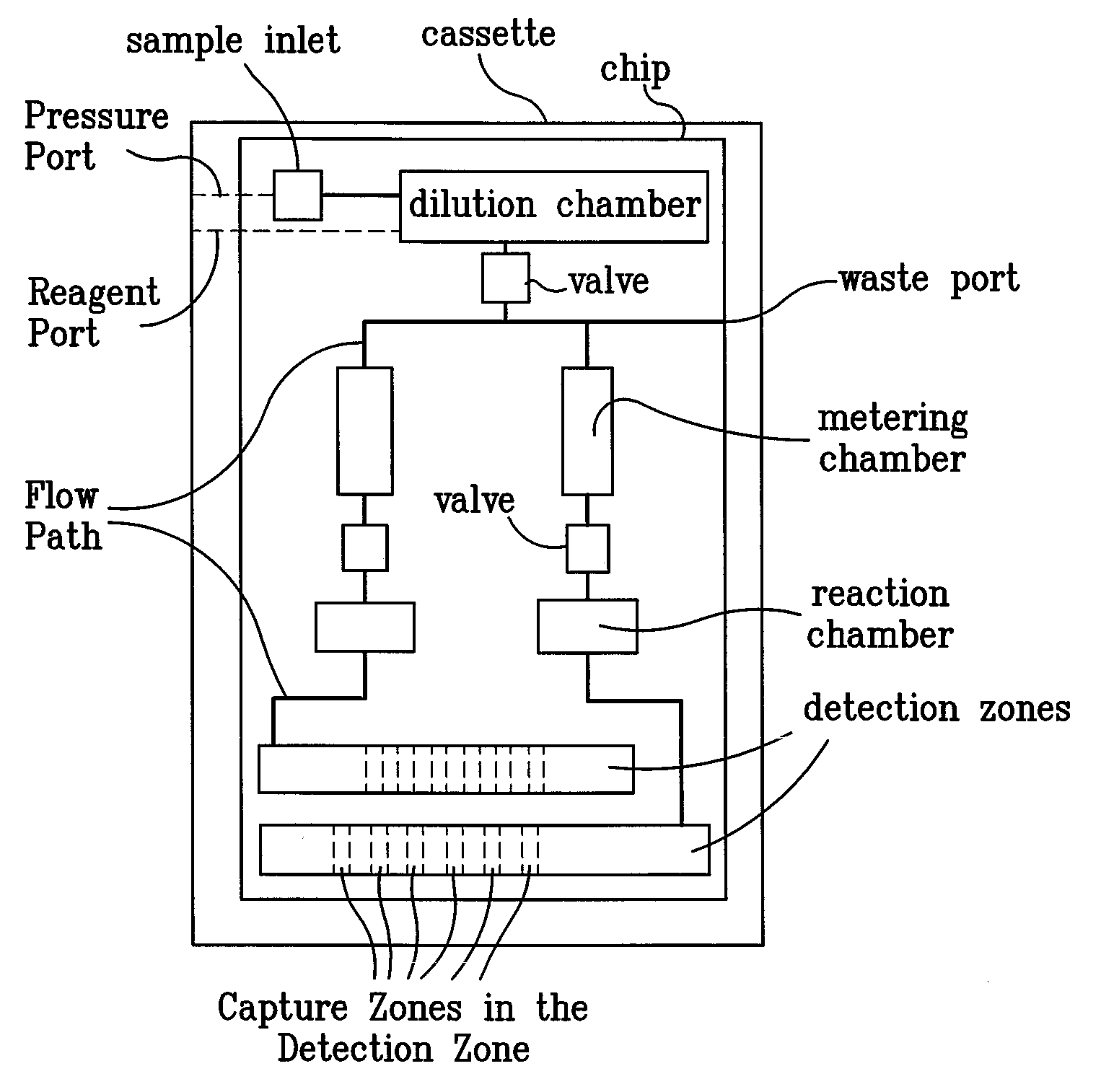

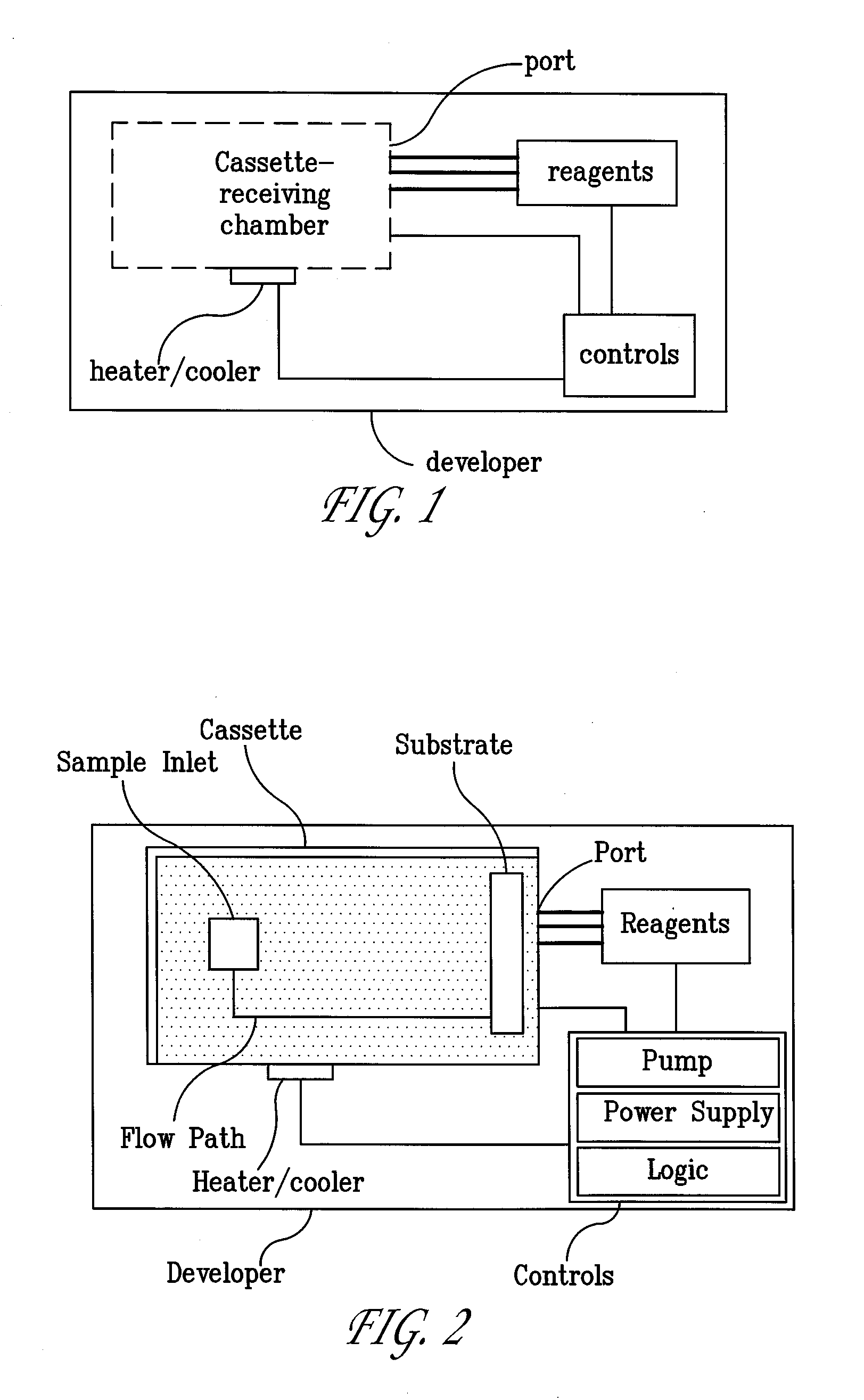

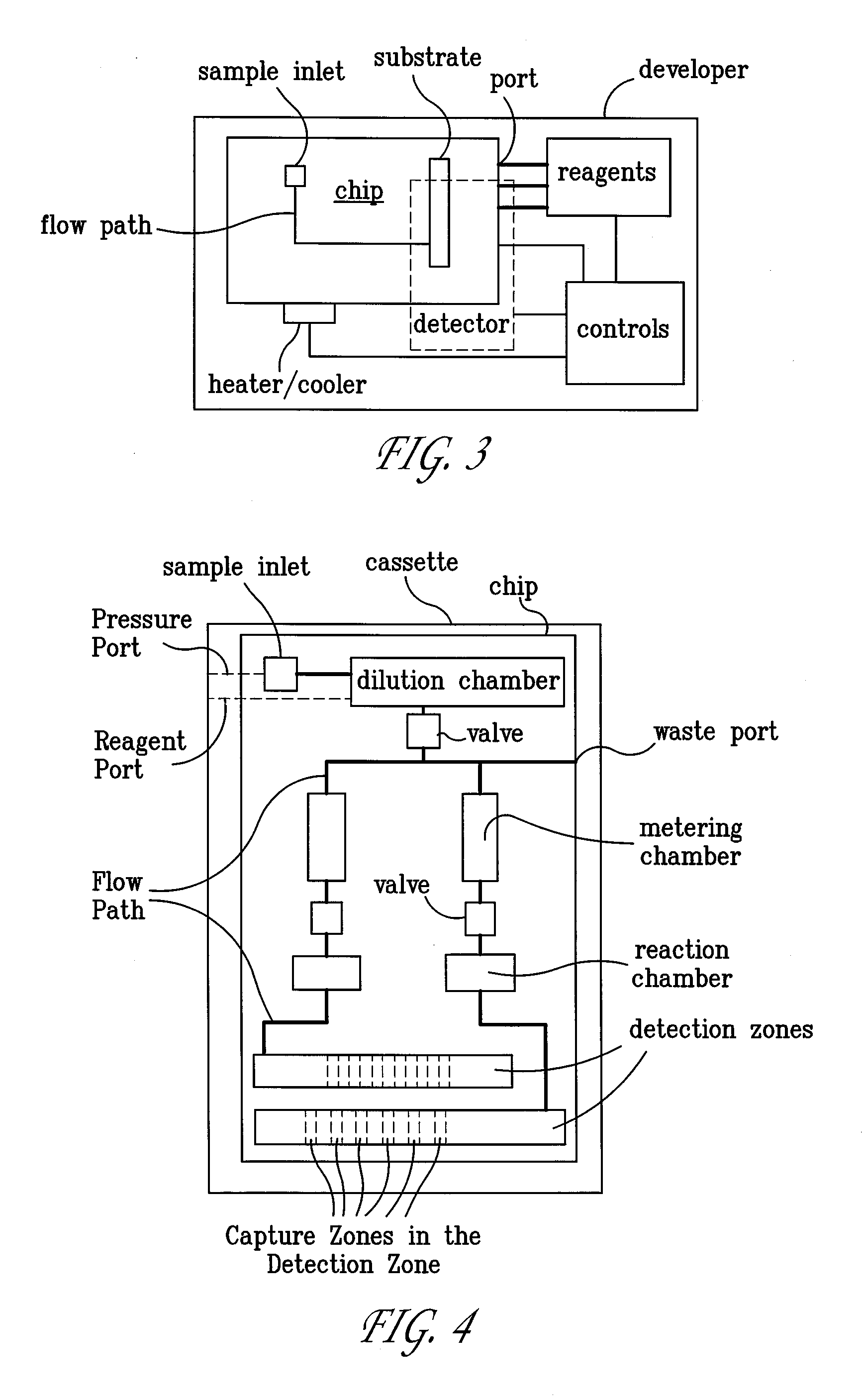

Systems and Methods For Testing using Microfluidic Chips

InactiveUS20080280285A1Easy to controlReduce materialBioreactor/fermenter combinationsHeating or cooling apparatusAntigenRNA Sequence

Disclosed are methods, devices and systems for biological and chemical sample processing using microfluidic chips. The disclosed microfluidic chips contain at least two detection zones for interacting with pre-selected RNA sequences, DNA sequences, antibodies, or antigens to determine their presence in the sample. Systems are also described comprising a cassette having at least one port and a sample inlet in fluid communication with a detection zone for interacting with pre-selected RNA sequences, DNA sequences, antibodies, or antigens, or mixtures thereof, if present, in a sample. Methods for concurrent testing of at least two of RNA, DNA, antibody, and antigen in a sample are also described, as are methods for testing for pre-selected pathogens and microfluidic methods.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

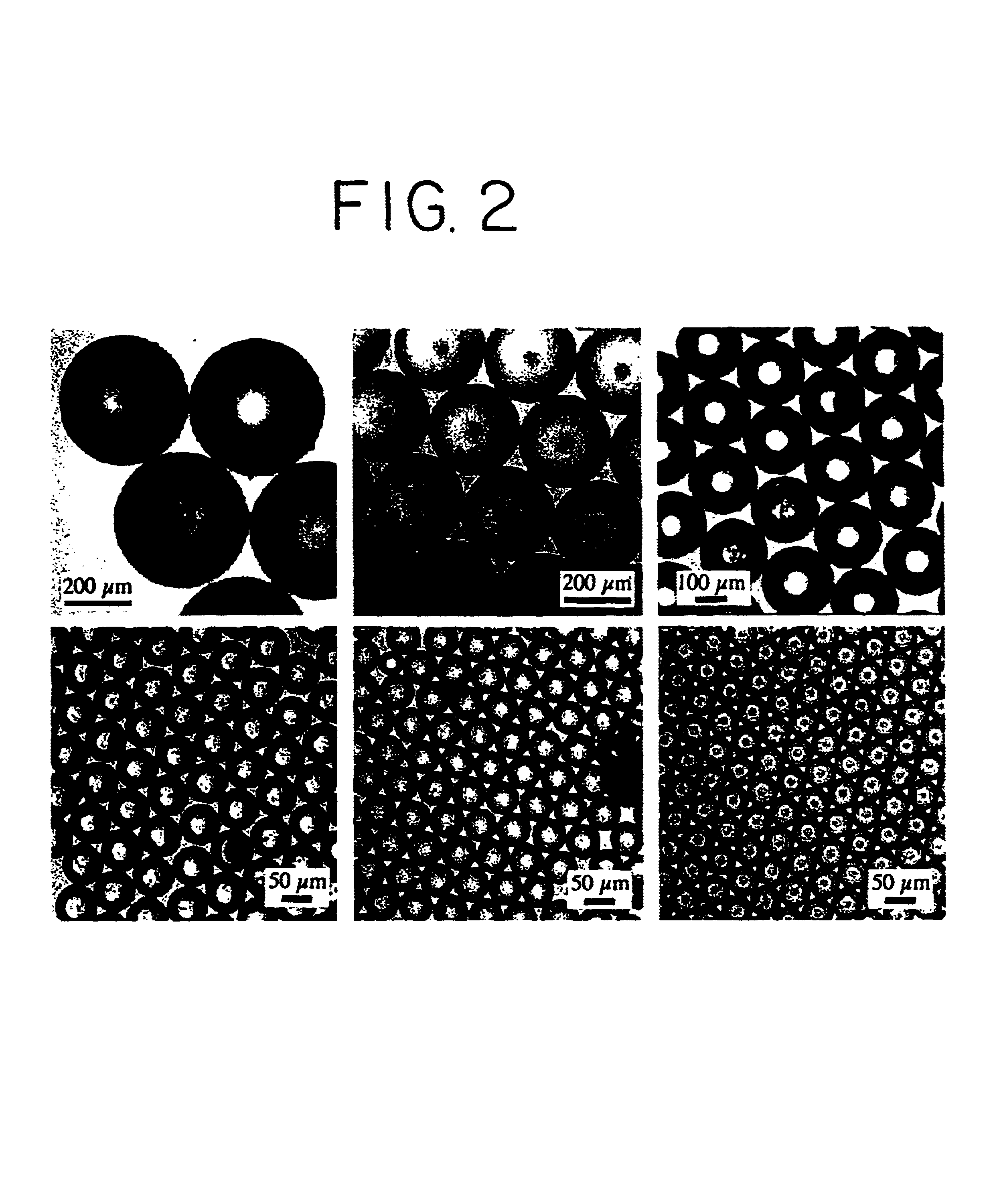

Multi-array multi-specific electrochemiluminescence testing

InactiveUS6673533B1Bioreactor/fermenter combinationsMaterial nanotechnologyAnalyteElectrochemiluminescence

Materials and methods are provided for producing patterned multi-array, multi-specific surfaces for use in diagnostics. The invention provides for electrochemiluminescence methods for detecting or measuring an analyte of interest. It also provides for novel electrodes for ECL assays. Materials and methods are provided for the chemical and / or physical control of conducting domains and reagent deposition for use multiply specific testing procedures.

Owner:MESO SCALE TECH LLC

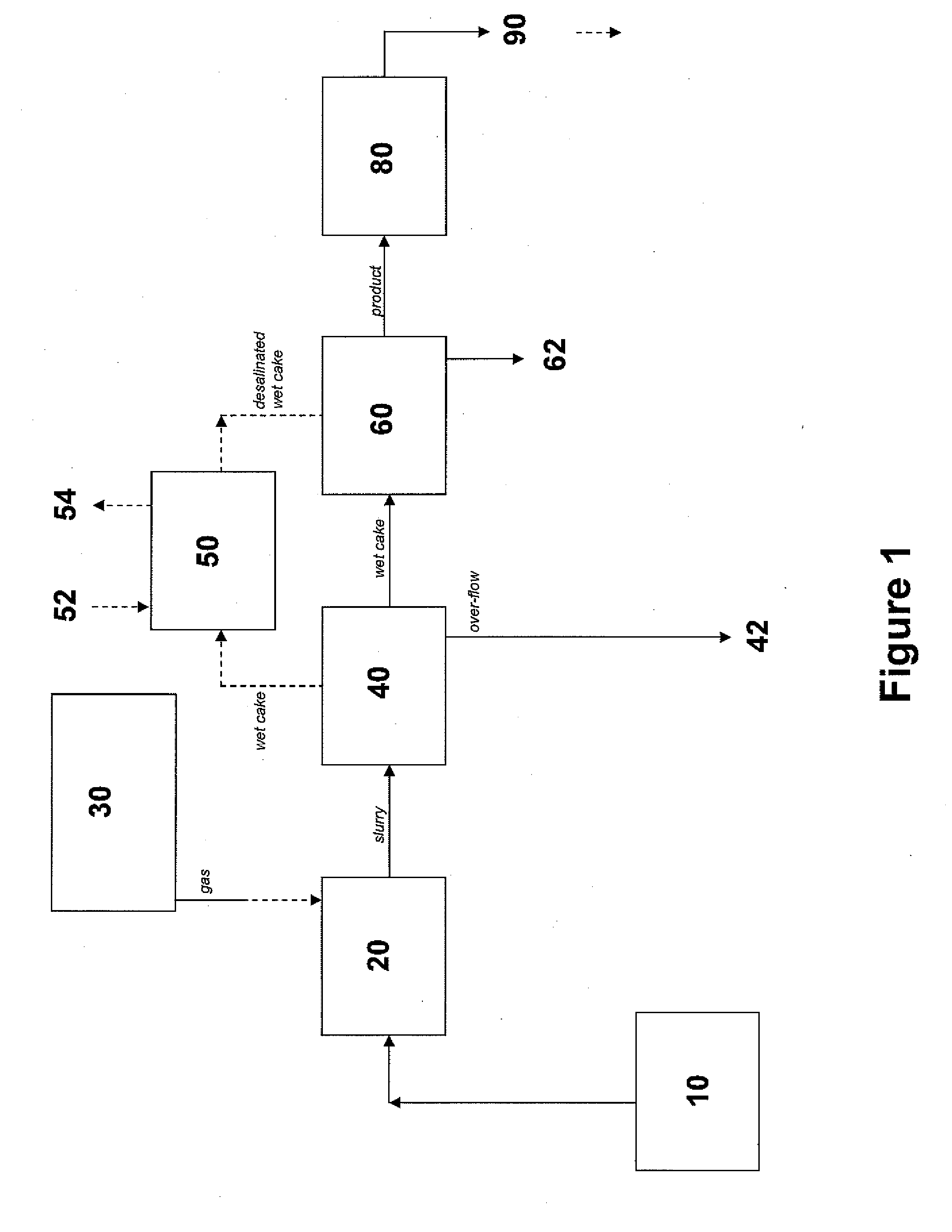

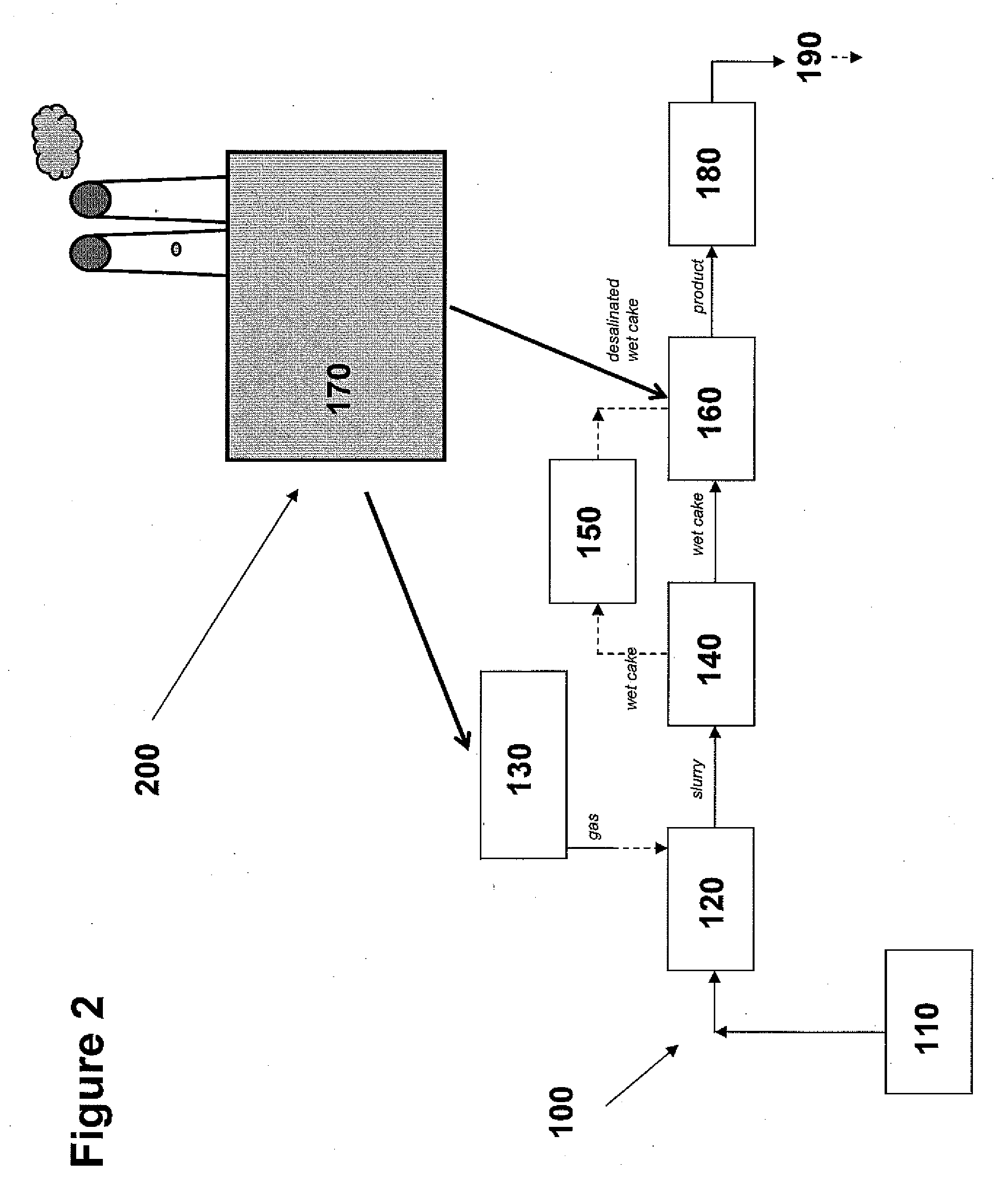

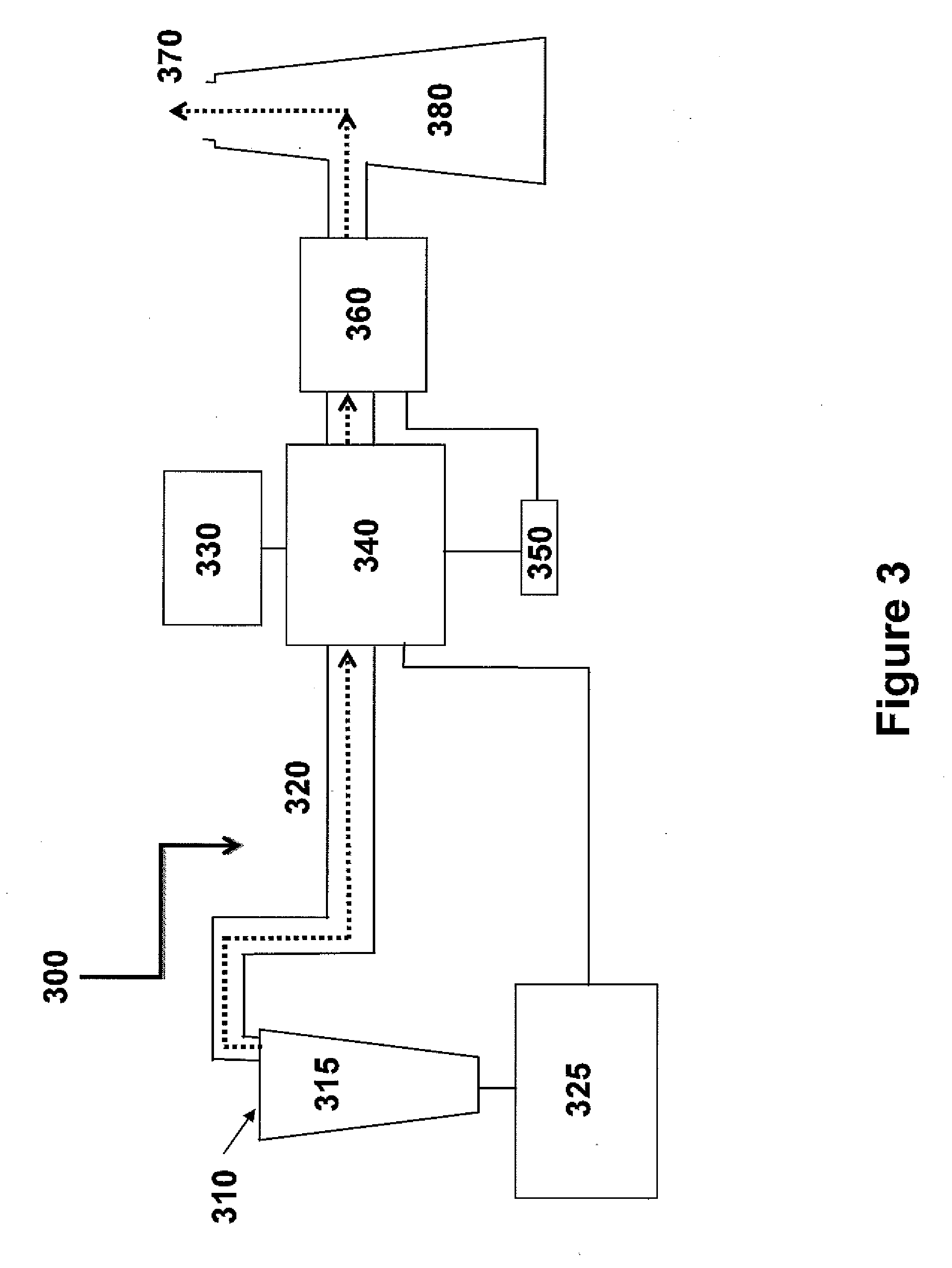

Methods of sequestering co2

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:ARELAC INC

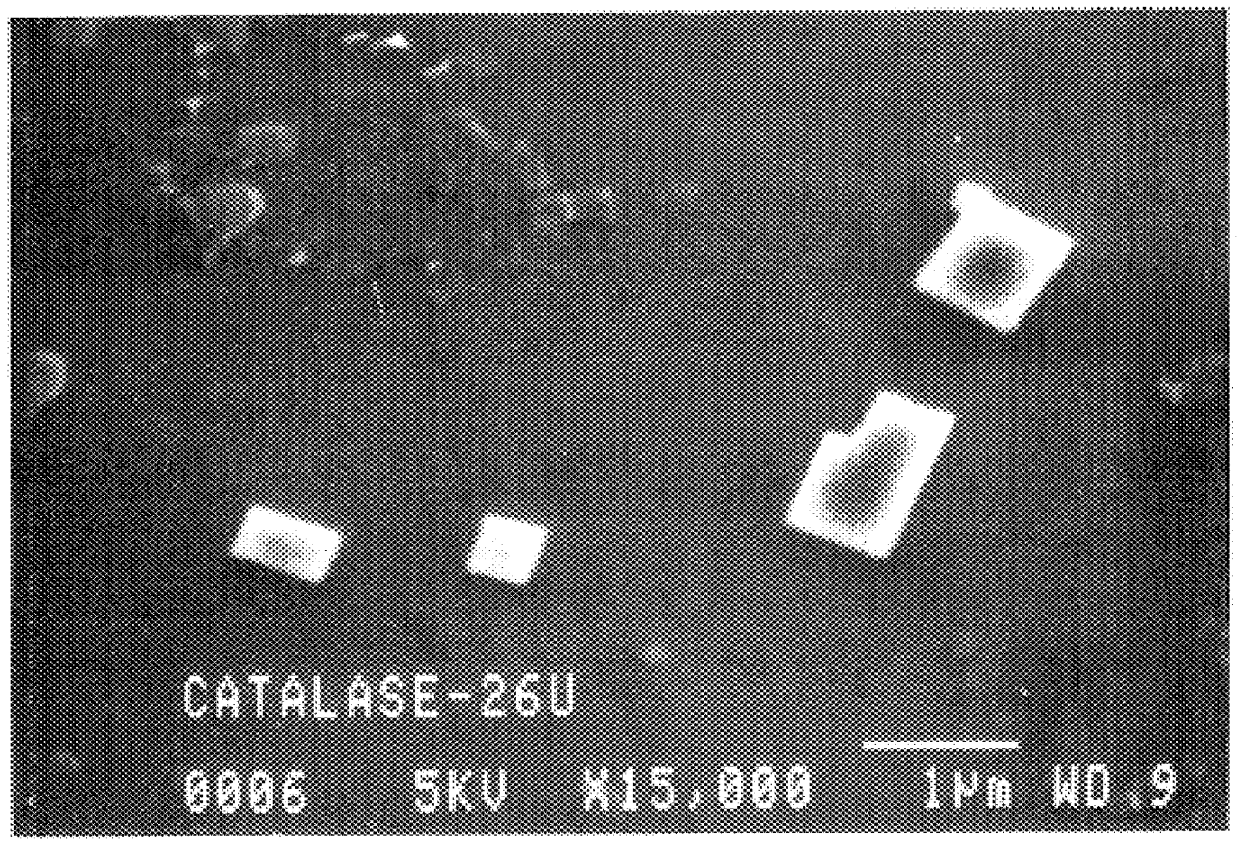

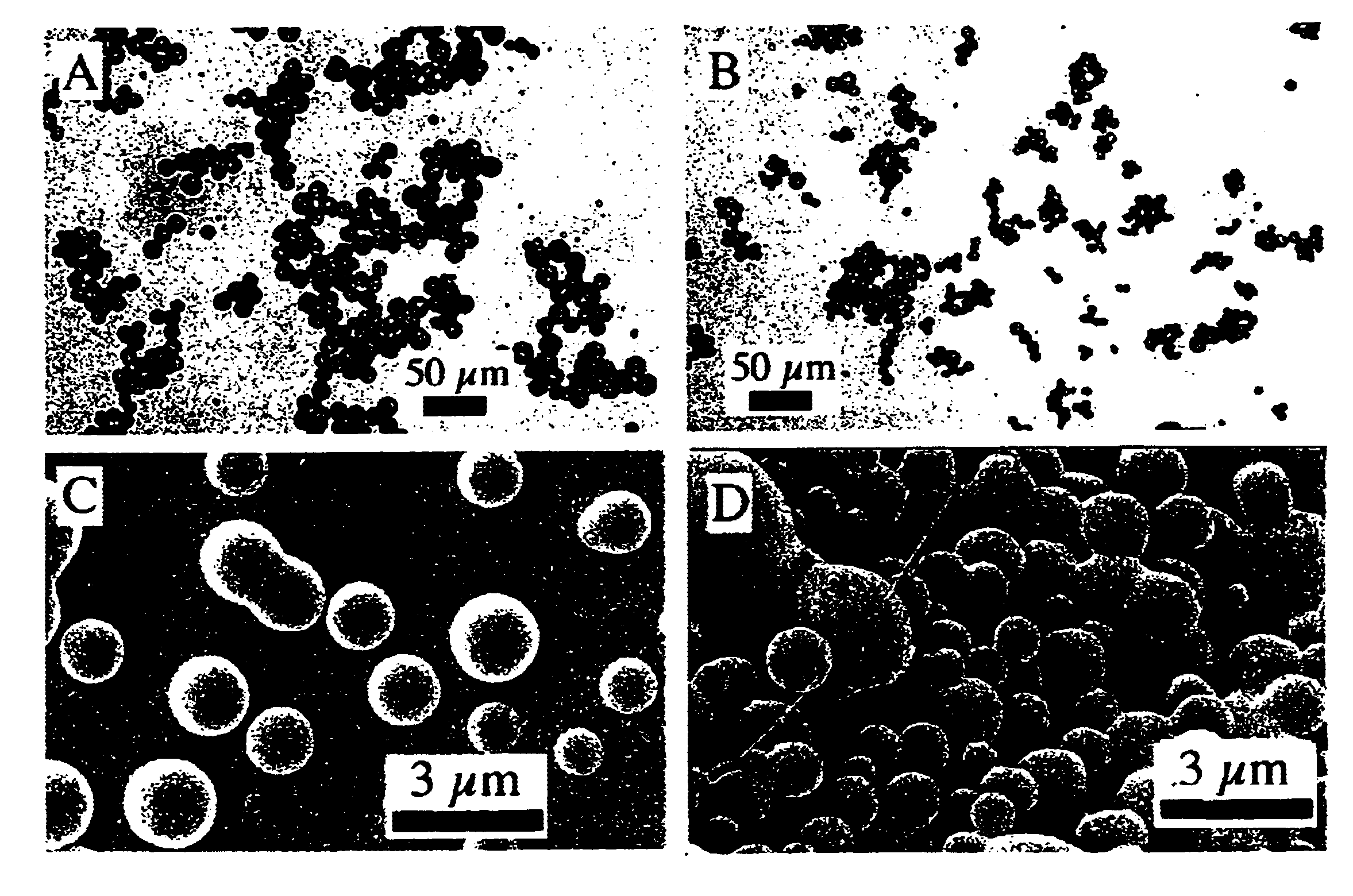

Preparation of protein microparticles by supercritical fluid precipitation

InactiveUS6063910AUniform and fine particle sizePowder deliveryPeptide/protein ingredientsMicroparticleSolvent

The present invention comprises passing a solution of a soluble material, preferably a protein, in a solvent through a continuum of supercritical antisolvent fluid and precipitating the soluble material. This can be conducted by passing the solution through the continuum of supercrital fluid in the form of droplets, which can be sprayed through the supercritical fluid. The plurality of droplets can be passed cocurrently or countercurrently with respect to a stream of antisolvent fluid. Alternatively, the solution can be passed through the continuum of supercritical antisolvent fluid in the form of a thin film or a plurality of fine streams.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Methods and devices for microfluidic point-of-care immunoassays

ActiveUS20090181411A1Endpoint detectionReduce incubation timeBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careSystems design

Microfluidic methods and devices for heterogeneous binding and agglutination assays are disclosed, with improvements relating to mixing and to reagent and sample manipulation in systems designed for safe handling of clinical test samples.

Owner:PERKINELMER HEALTH SCIENCES INC

Temperature-controlled flange and reactor system including same

ActiveUS20200002811A1Reduce sealReduce condensationElectric discharge tubesVacuum evaporation coatingReactor systemMechanical engineering

A flange, flange assembly, and reactor system including the flange and flange assembly are disclosed. An exemplary flange assembly includes heated and cooled sections to independently control temperatures of sections of the flange. Methods of using the flange, flange assembly and reactor system are also disclosed.

Owner:ASM IP HLDG BV

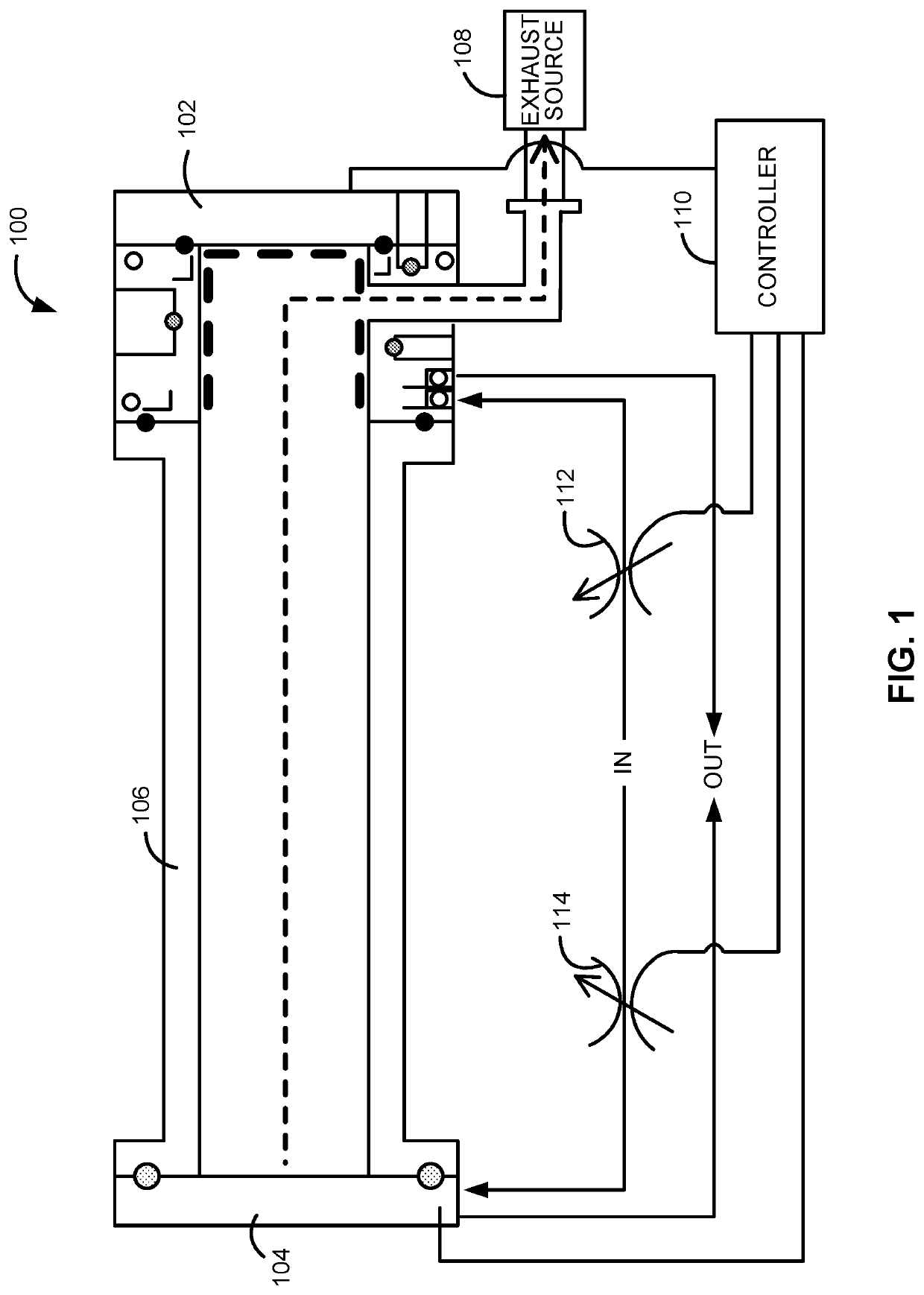

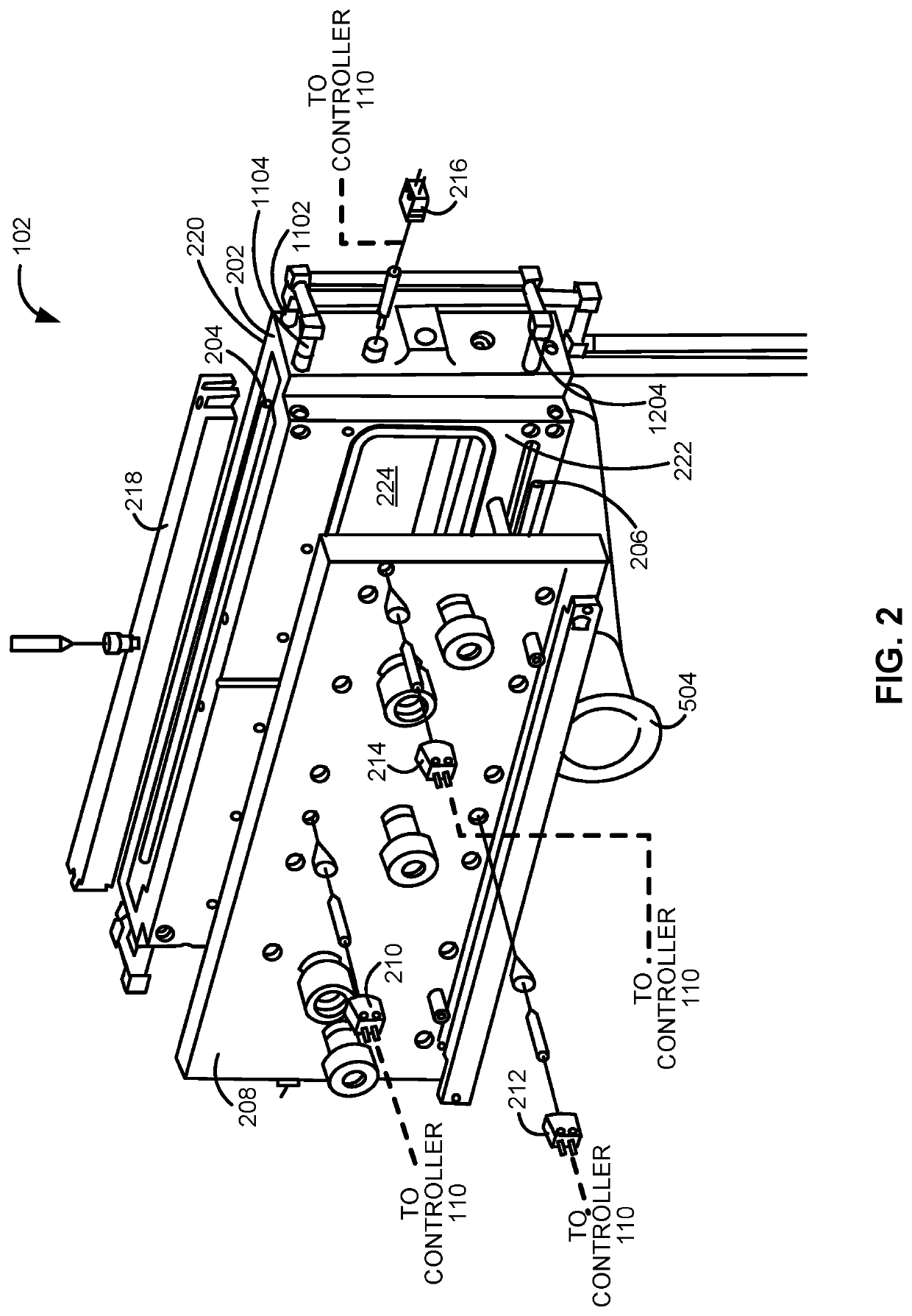

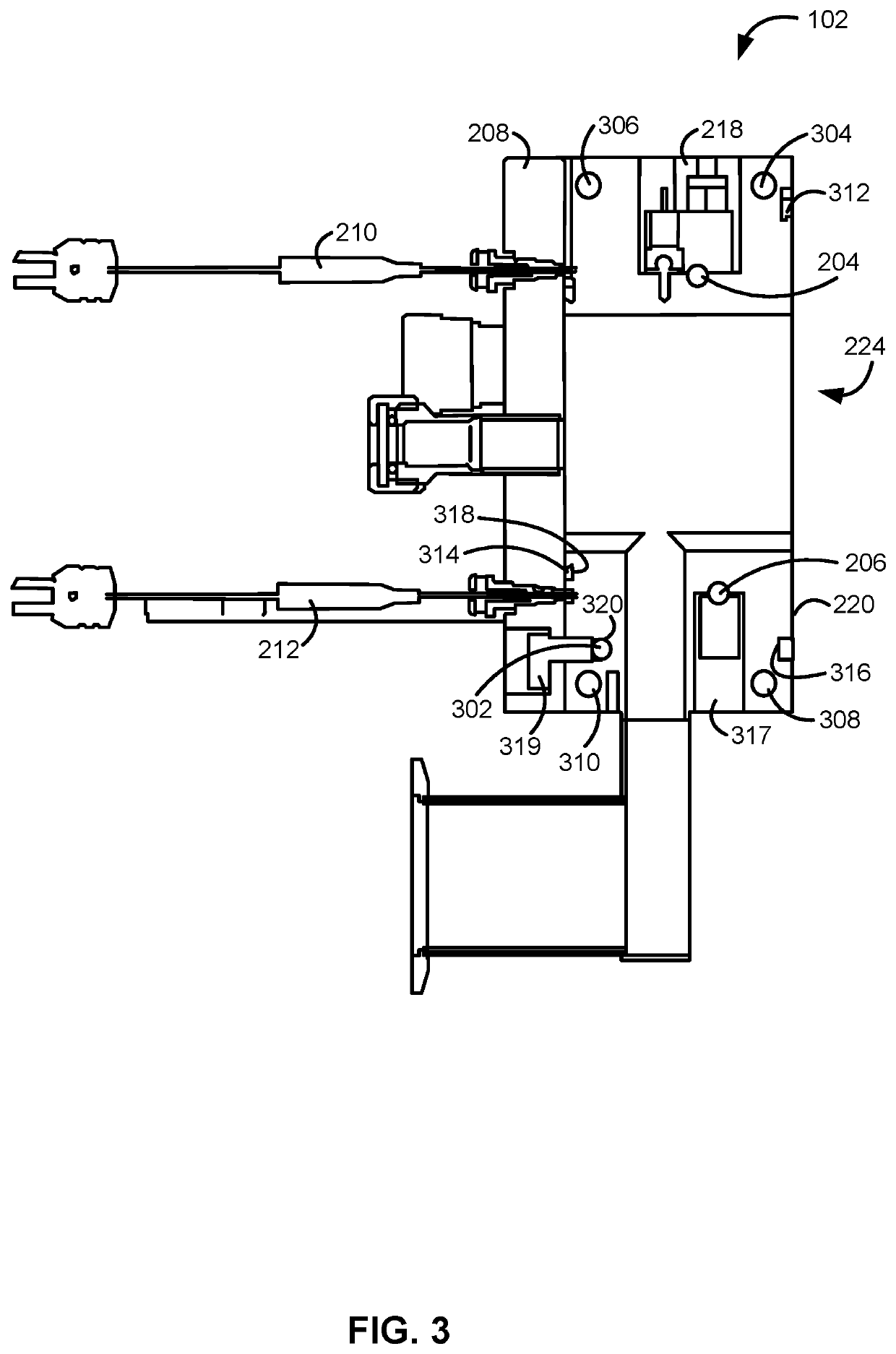

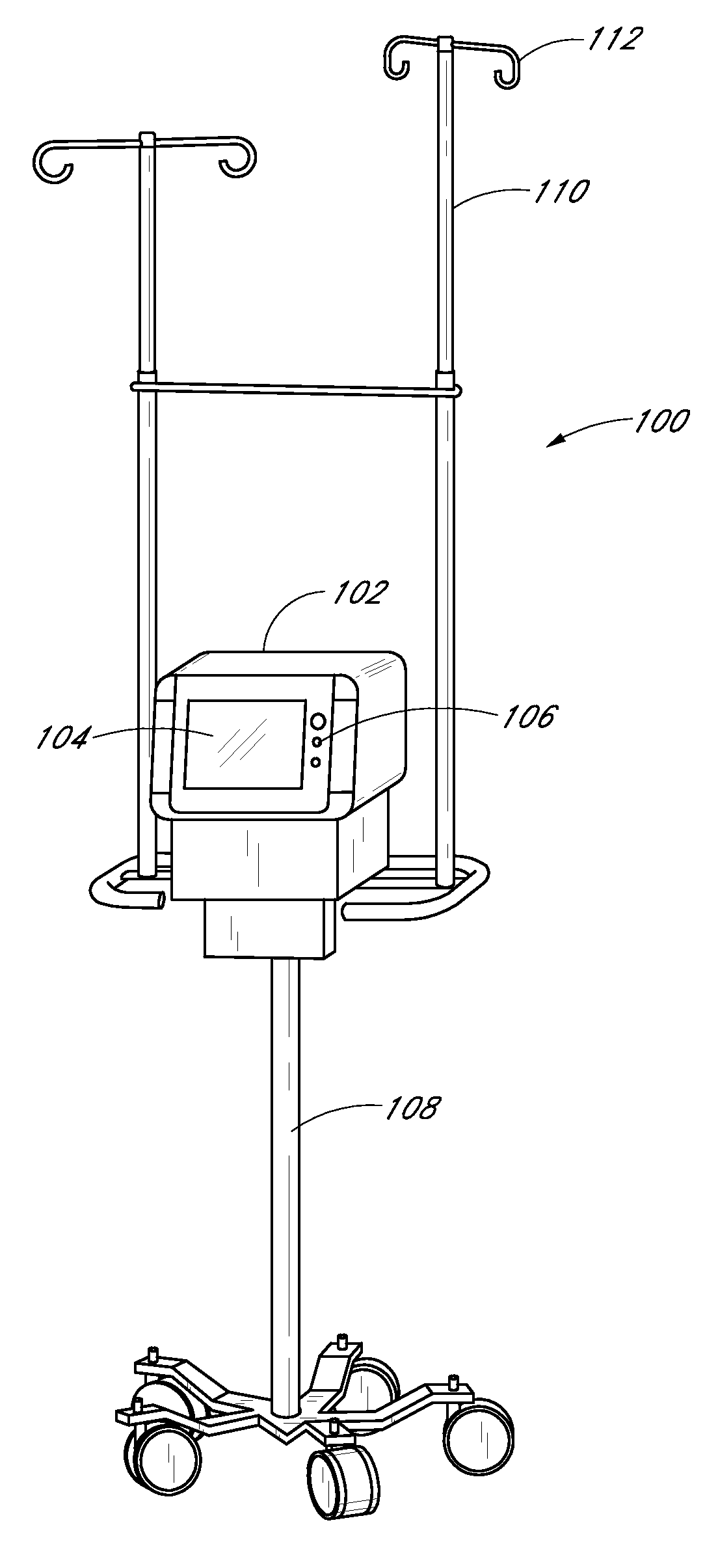

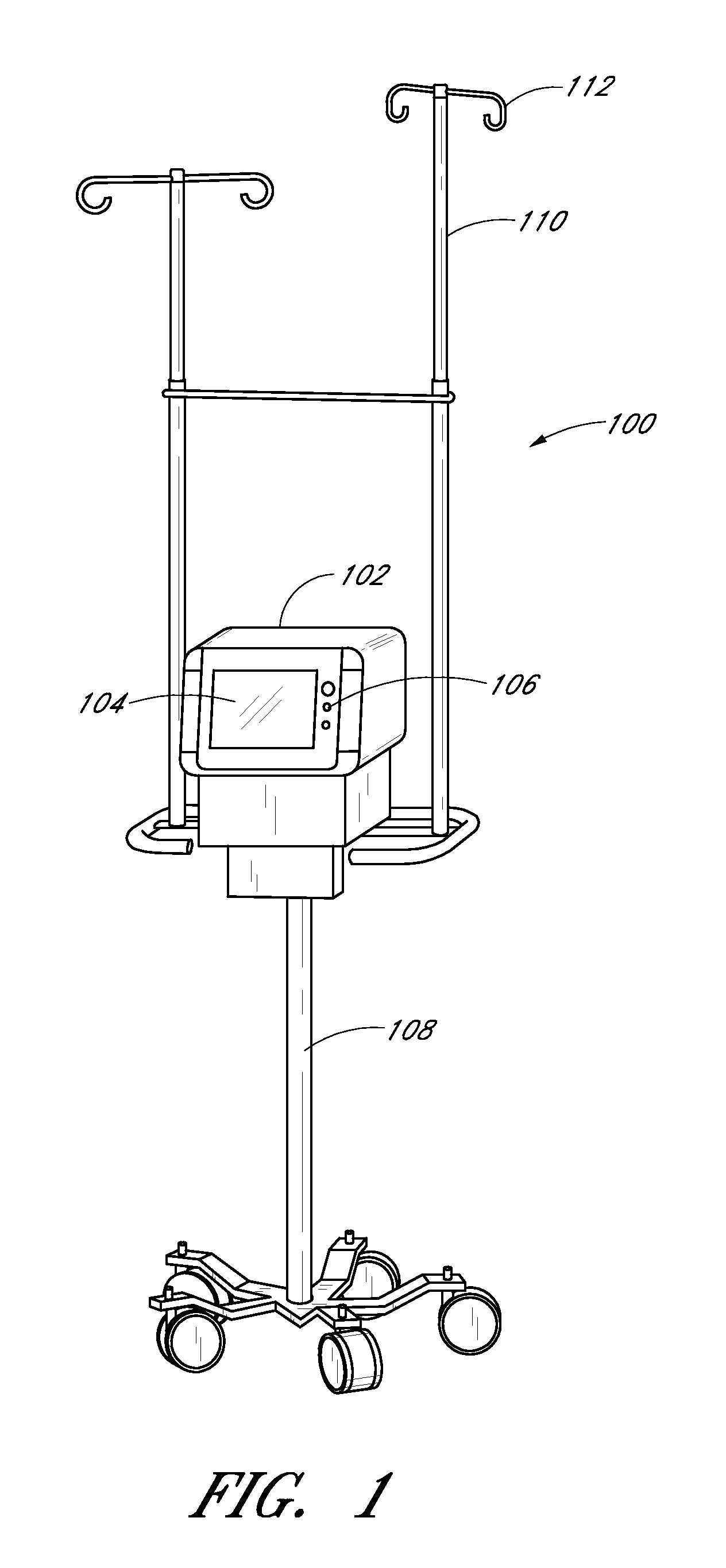

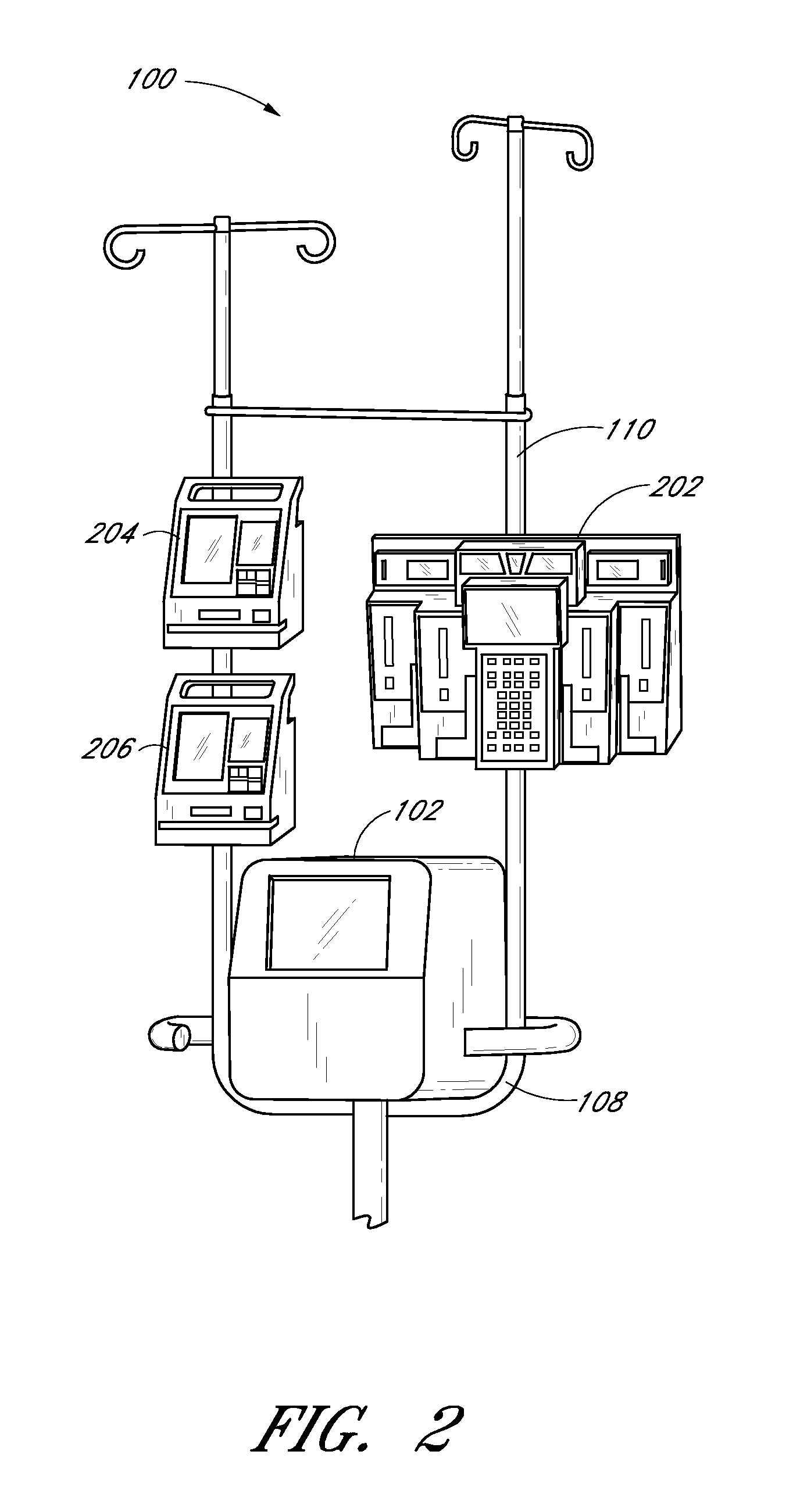

Accurate and timely body fluid analysis

InactiveUS20080072663A1Specific gravity using centrifugal effectsMedical devicesPoint of careAnalyte

A method of extracting and analyzing bodily fluids from a patient at the point of care for the patient is provided. The method comprises establishing fluid communication between an analyte detection system and a bodily fluid in the patient. A portion of the bodily fluid is drawn from the patient. A first component of the bodily fluid is separated from the drawn portion, while the analyte detection system remains in fluid communication with the patient. The analyte detection system analyzes the first component to measure a concentration of an analyte in an accurate and timely manner.

Owner:OPTISCAN BIOMEDICAL

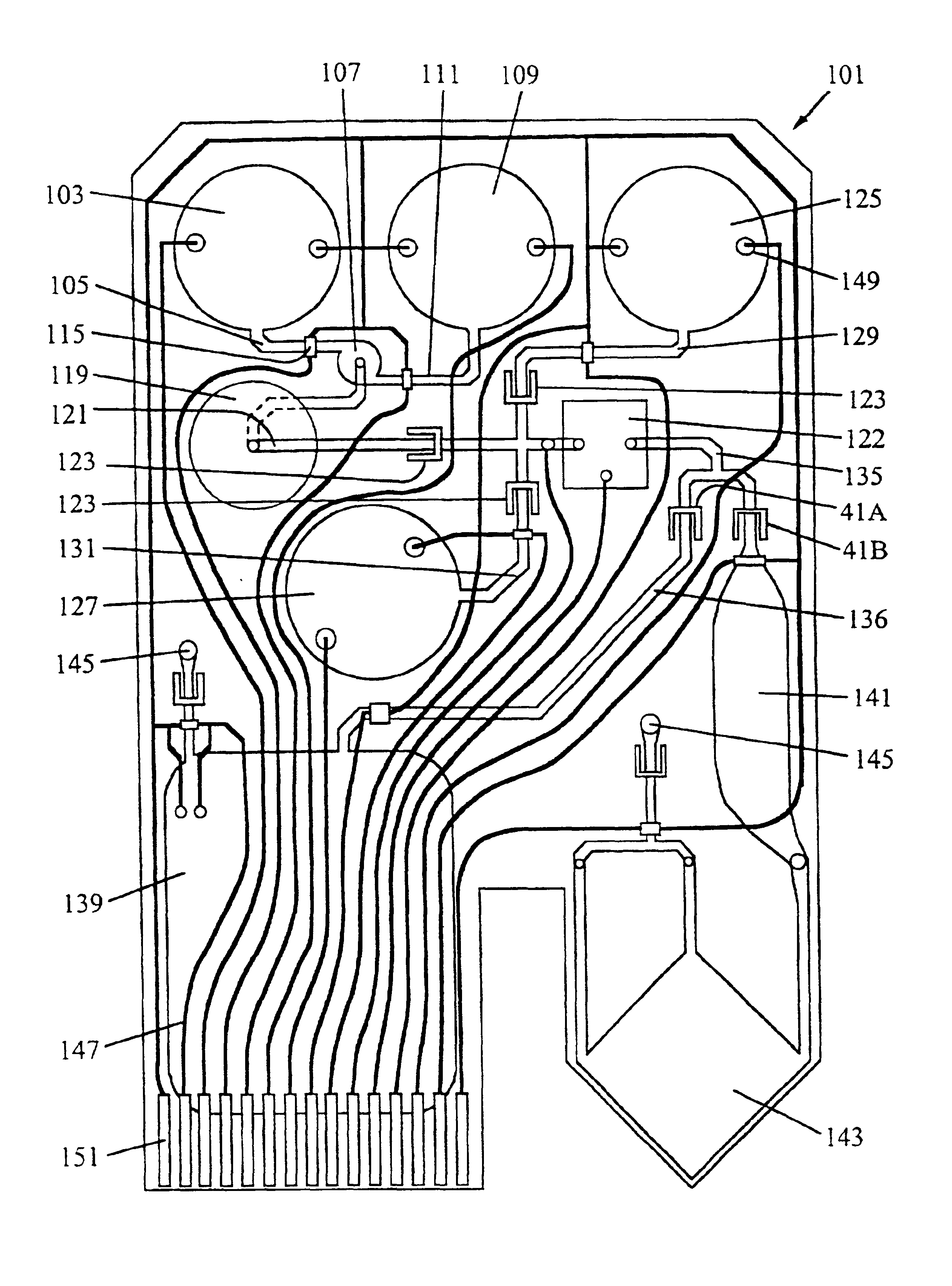

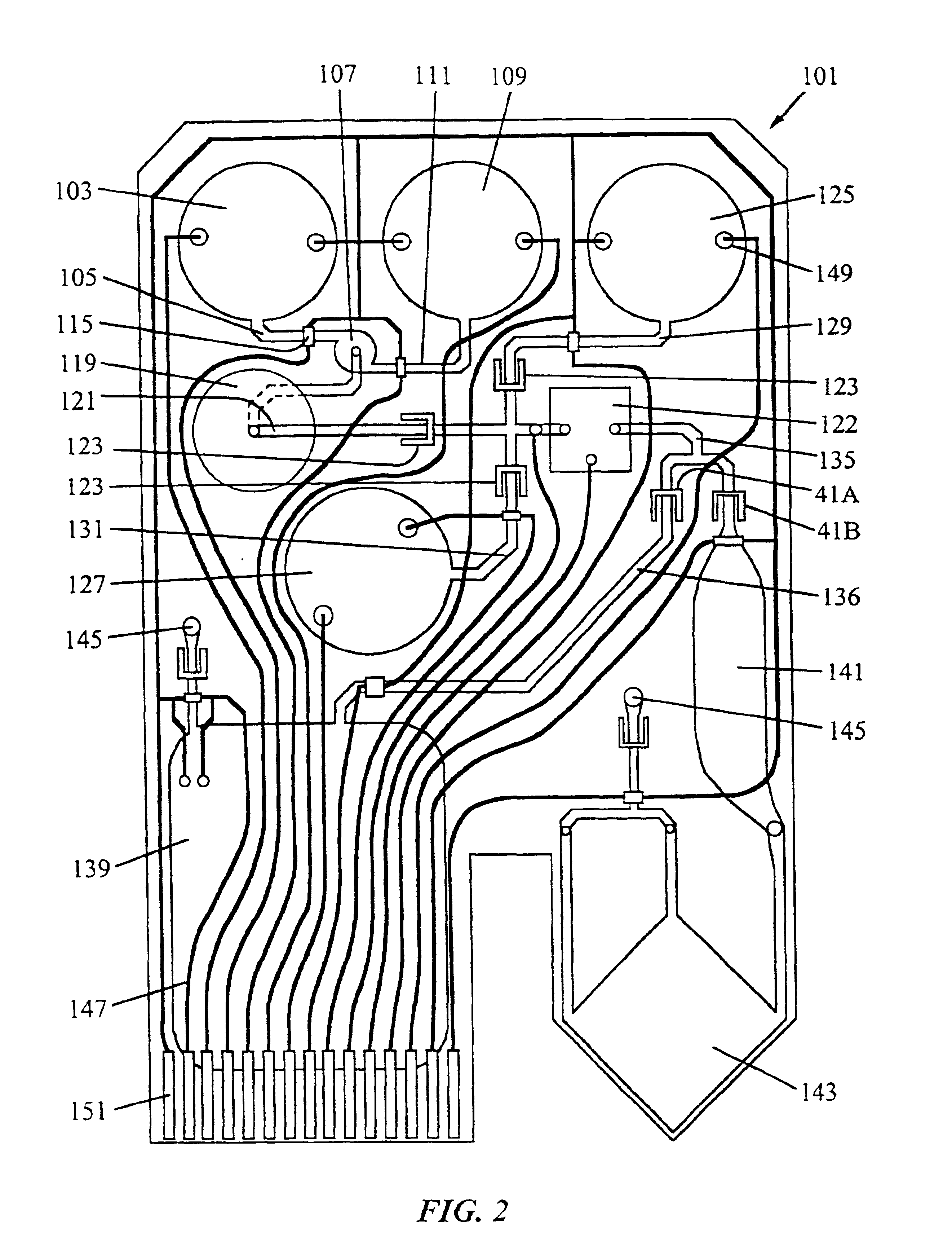

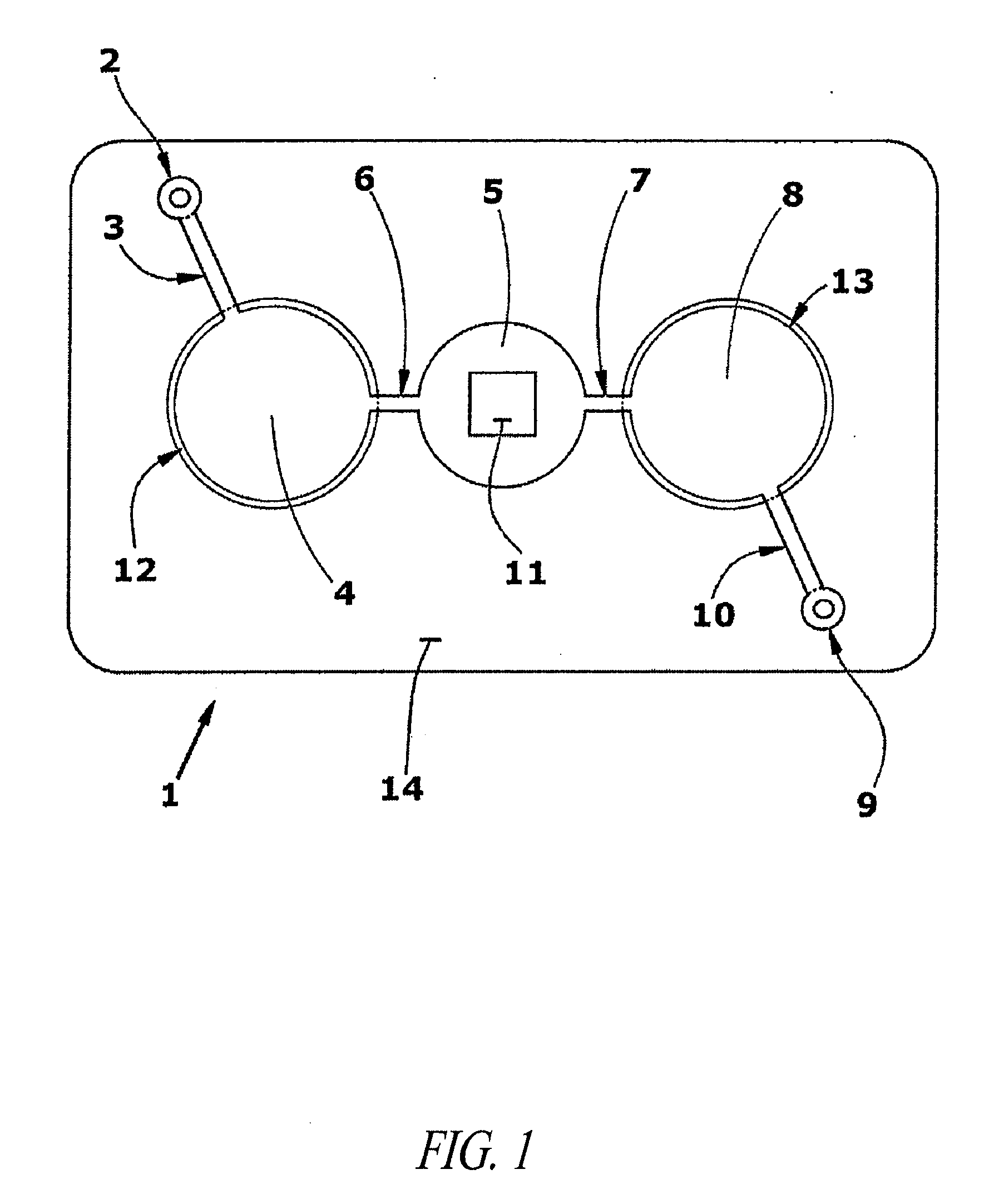

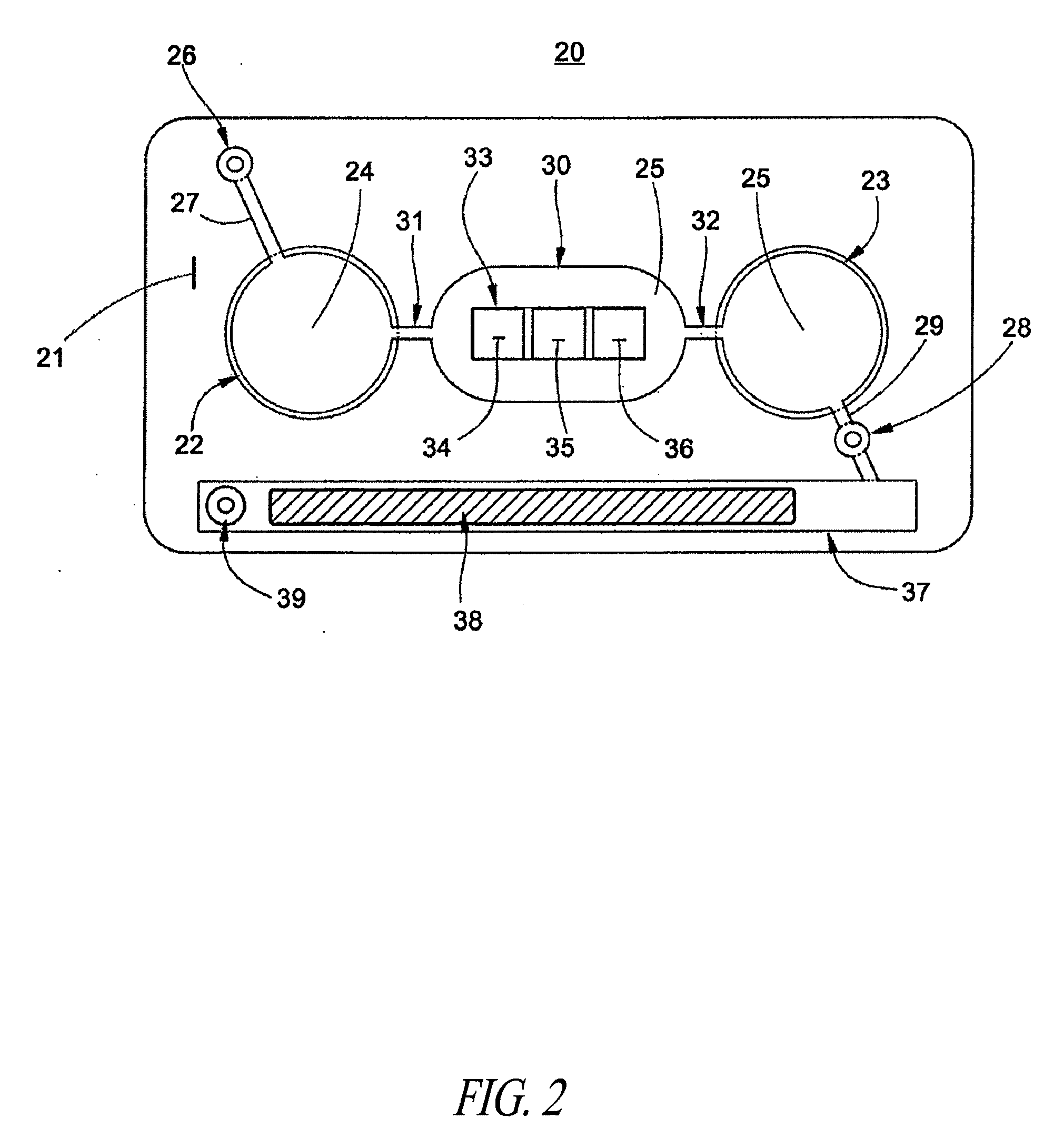

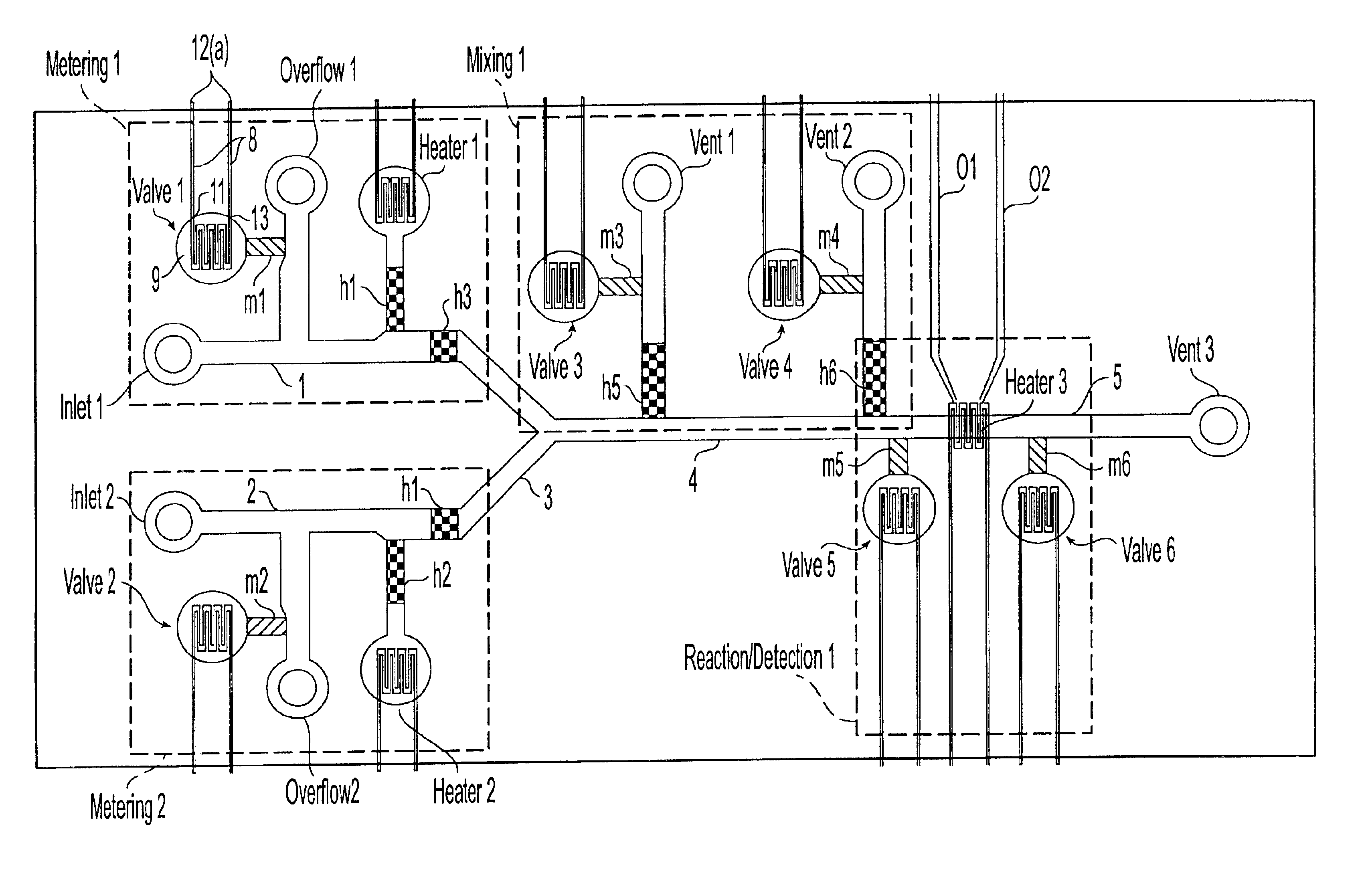

Microfluidic devices having a reduced number of input and output connections

InactiveUS6852287B2Reduce in quantityHeating or cooling apparatusFixed microstructural devicesElectrical resistance and conductanceControl signal

A system and method for reducing the number of input / output connections required to connect a microfluidic substrate to an external controller for controlling the substrate. In one example, a microfluidic processing device is fabricated on a substrate having a plurality of N independently controllable components, (e.g., a resistive heating elements) each having at least two terminals. The substrate includes a plurality of input / output contacts for connecting the substrate to an external controller, and a plurality of leads for connecting the contacts to the terminals of the components. The leads are arranged to allow the external controller to supply control signals to the terminals of the components via the contacts using substantially fewer contacts than the total number of component terminals. For example, in one embodiment, each lead connects a corresponding contact to a plurality of terminals to allow the controller to supply to signals to the terminals without requiring a separate contact for each terminal. However, to assure that the components can each be controlled independently of the others, the leads are also arranged so that each component's terminals are connected to a unique combination of contacts. Thus, the external controller can activate a selected component by supplying control signals to the combination of contacts uniquely associated with that component.

Owner:HANDYLAB

Microparticles

InactiveUS6669961B2Minimal deformationHardening of the spheresPowder deliveryNanostructure manufactureMicroparticleNanometre

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

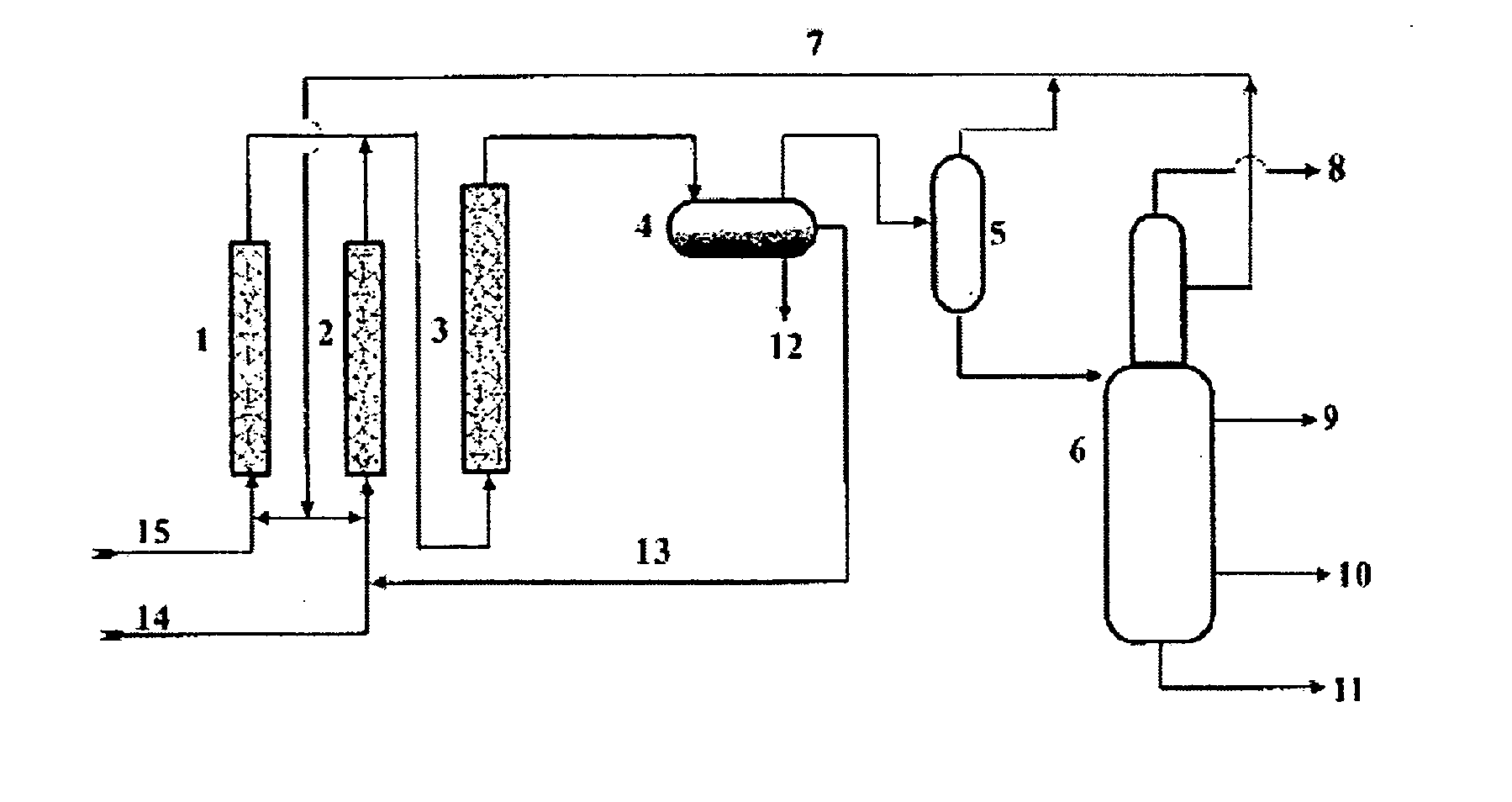

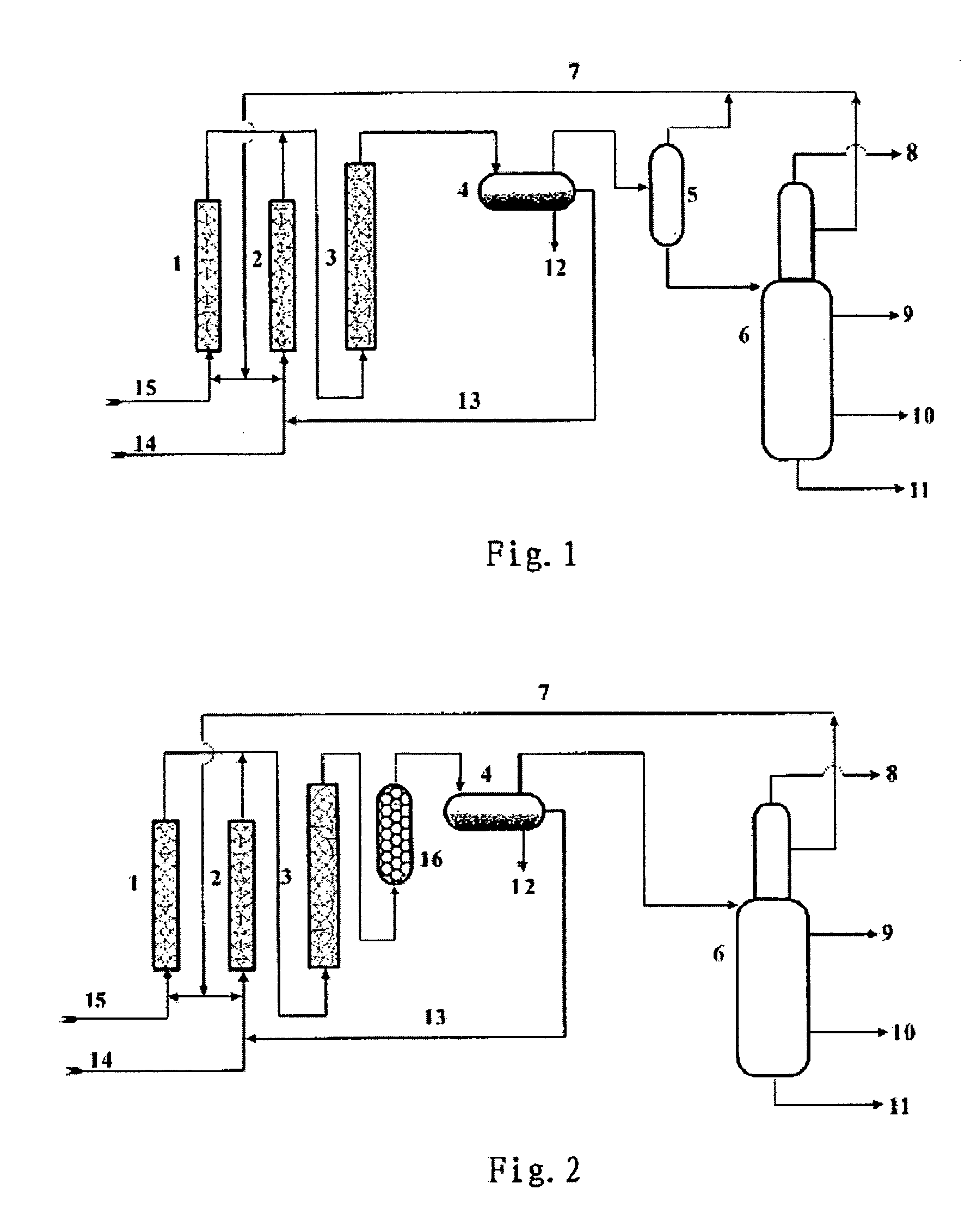

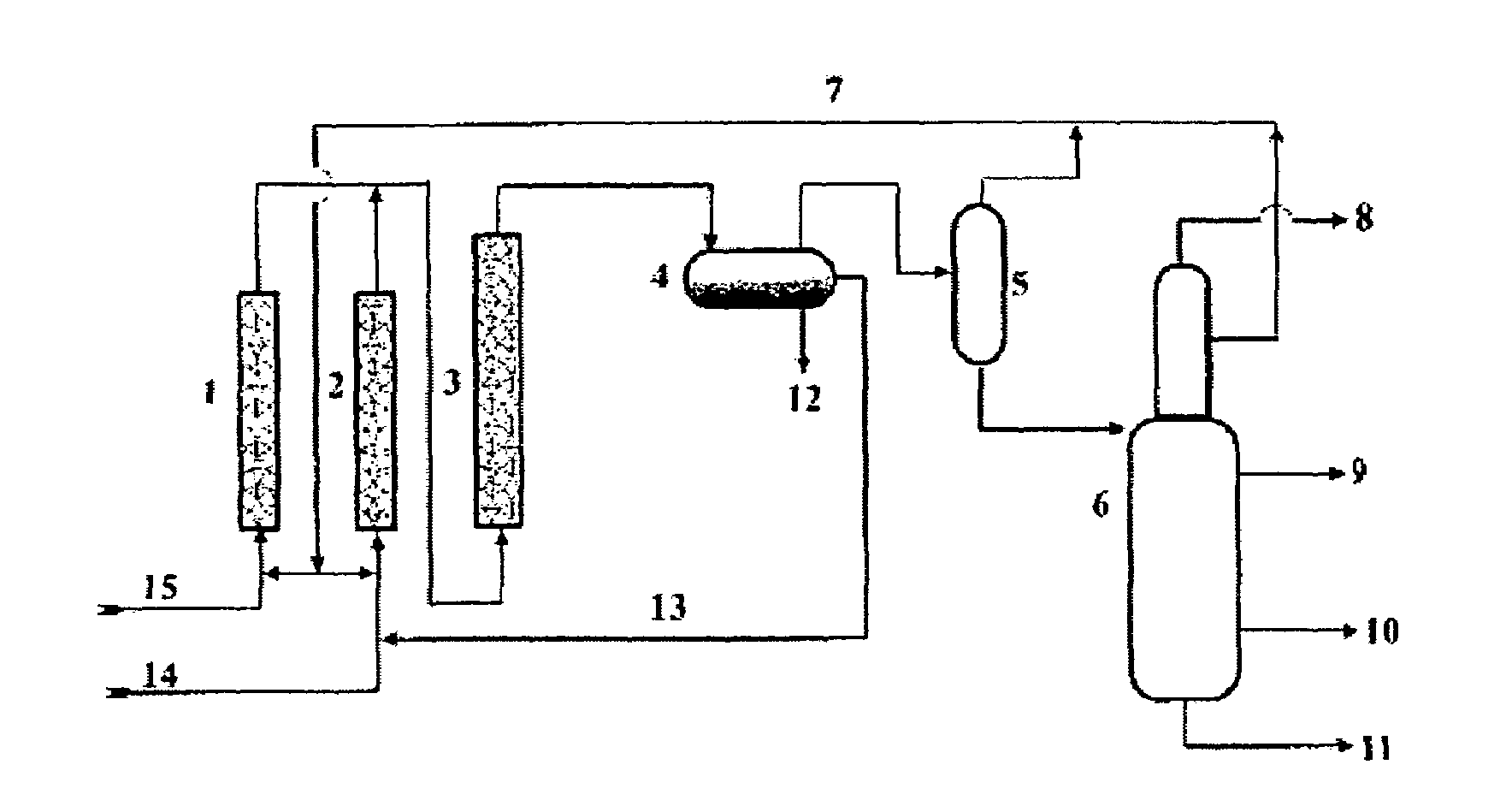

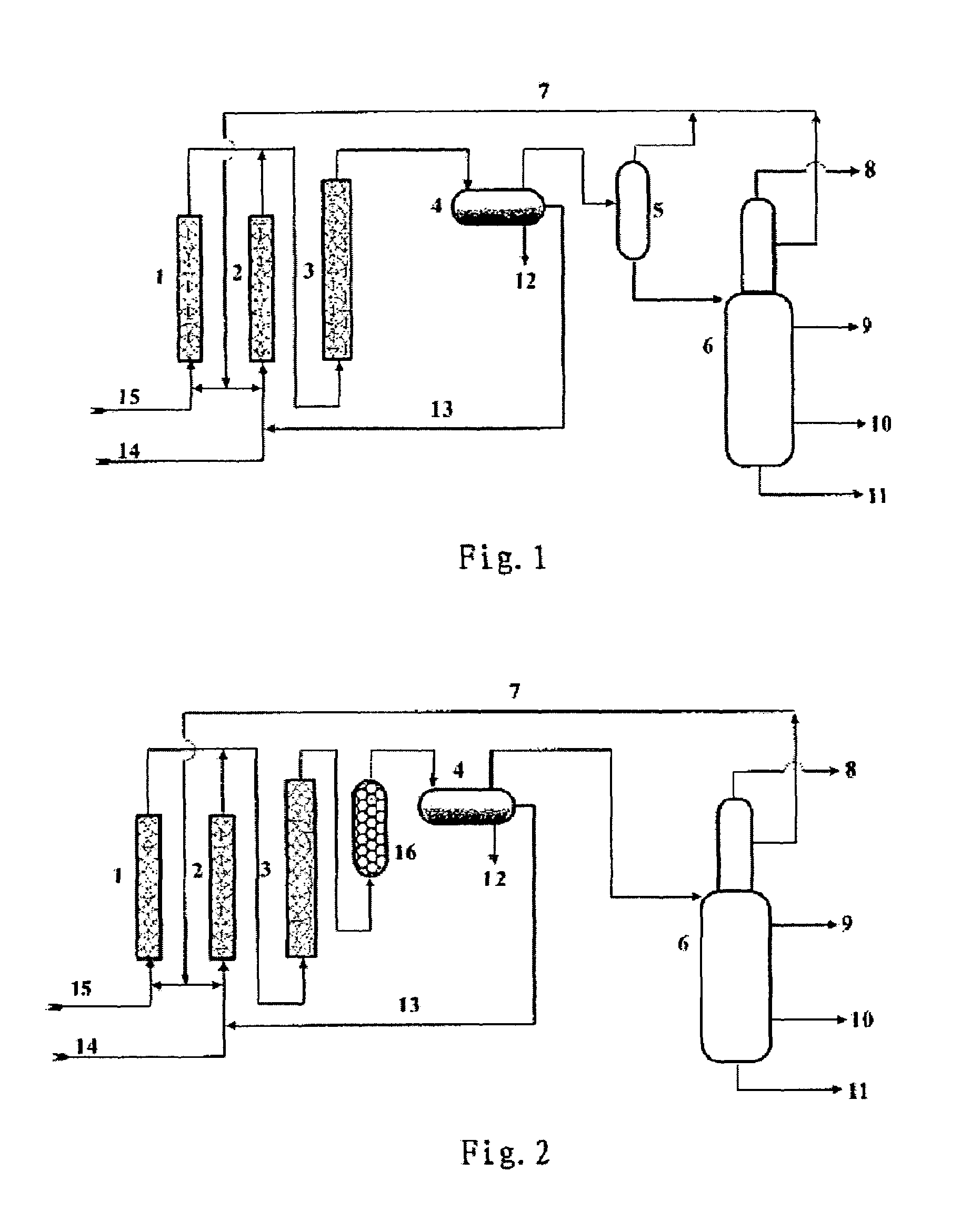

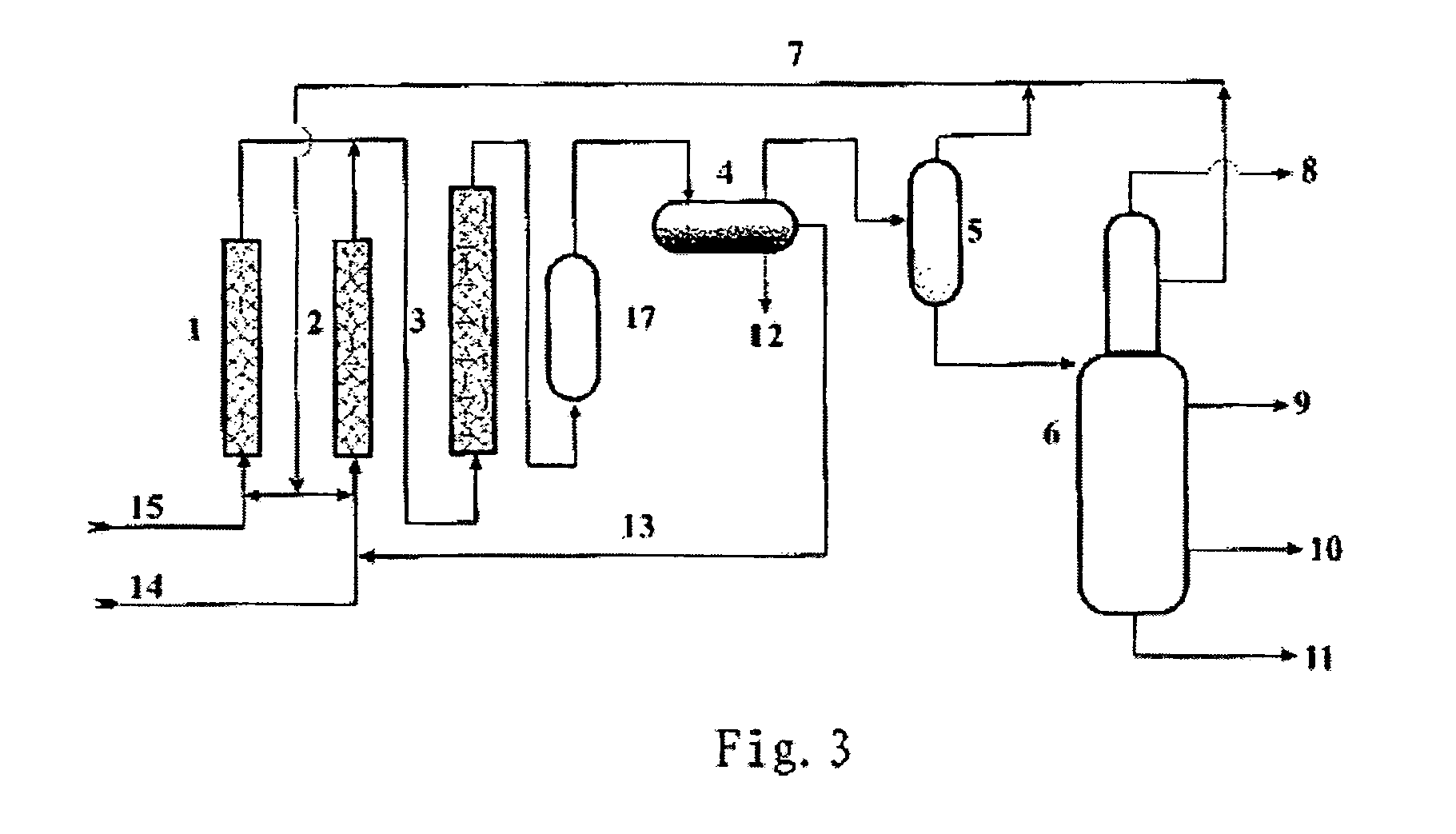

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

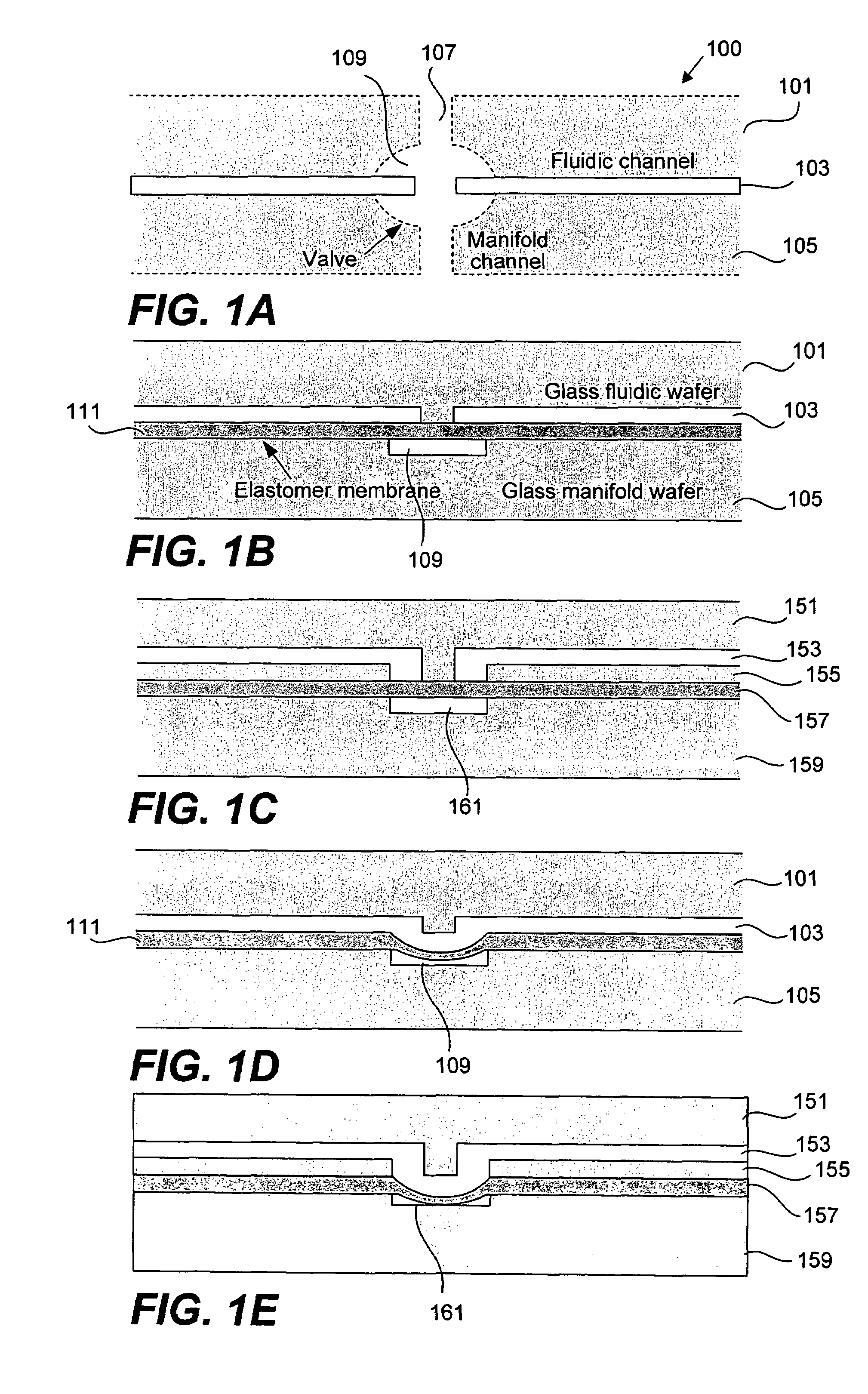

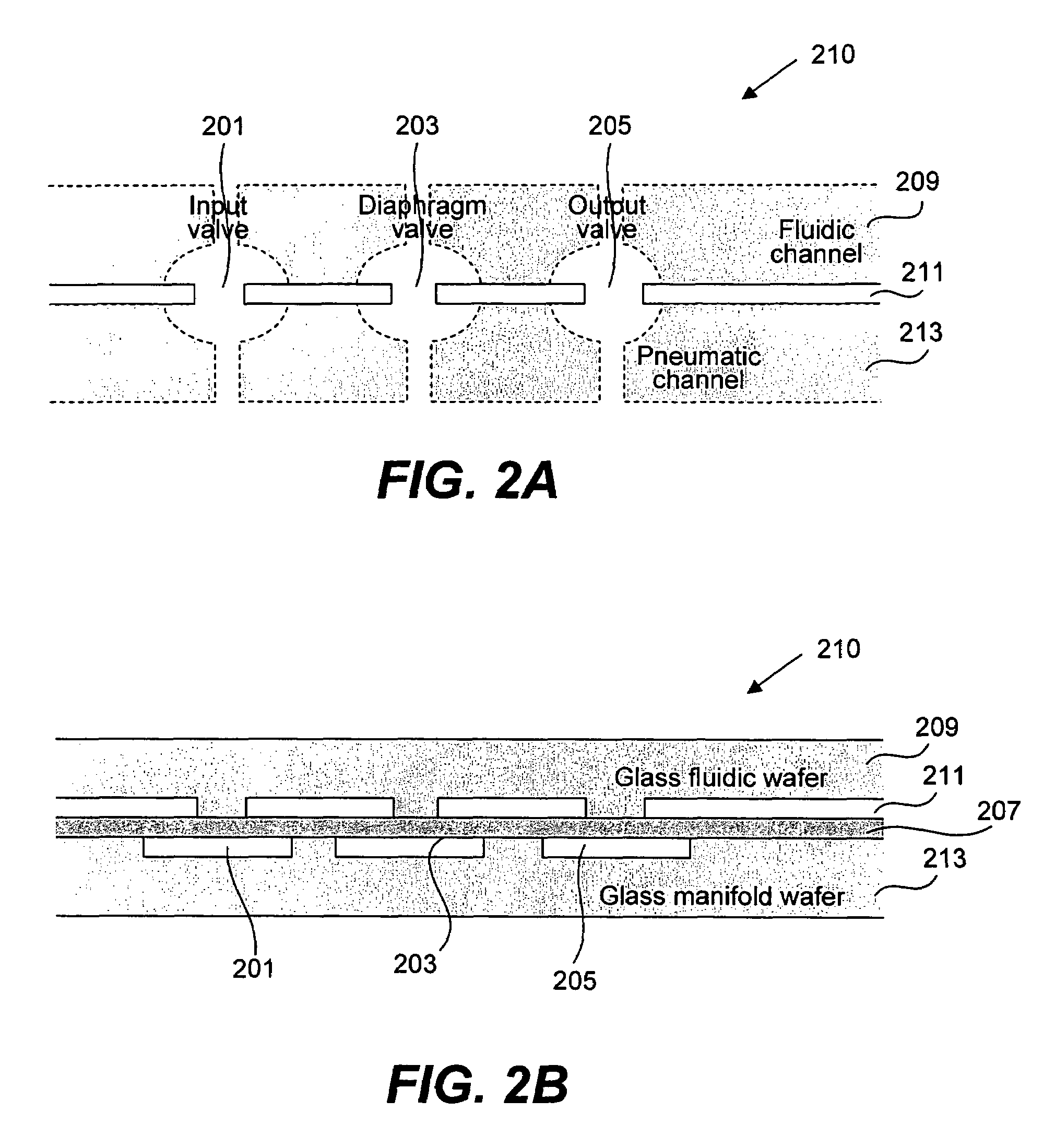

Fluid control structures in microfluidic devices

ActiveUS7445926B2Bioreactor/fermenter combinationsBiological substance pretreatmentsElastomerFluid control

Methods and apparatus for implementing microfluidic analysis devices are provided. A monolithic elastomer membrane associated with an integrated pneumatic manifold allows the placement and actuation of a variety of fluid control structures, such as structures for pumping, isolating, mixing, routing, merging, splitting, preparing, and storing volumes of fluid. The fluid control structures can be used to implement a variety of sample introduction, preparation, processing, and storage techniques.

Owner:RGT UNIV OF CALIFORNIA

Nucleic acid amplification with continuous flow emulsion

InactiveUS7927797B2Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

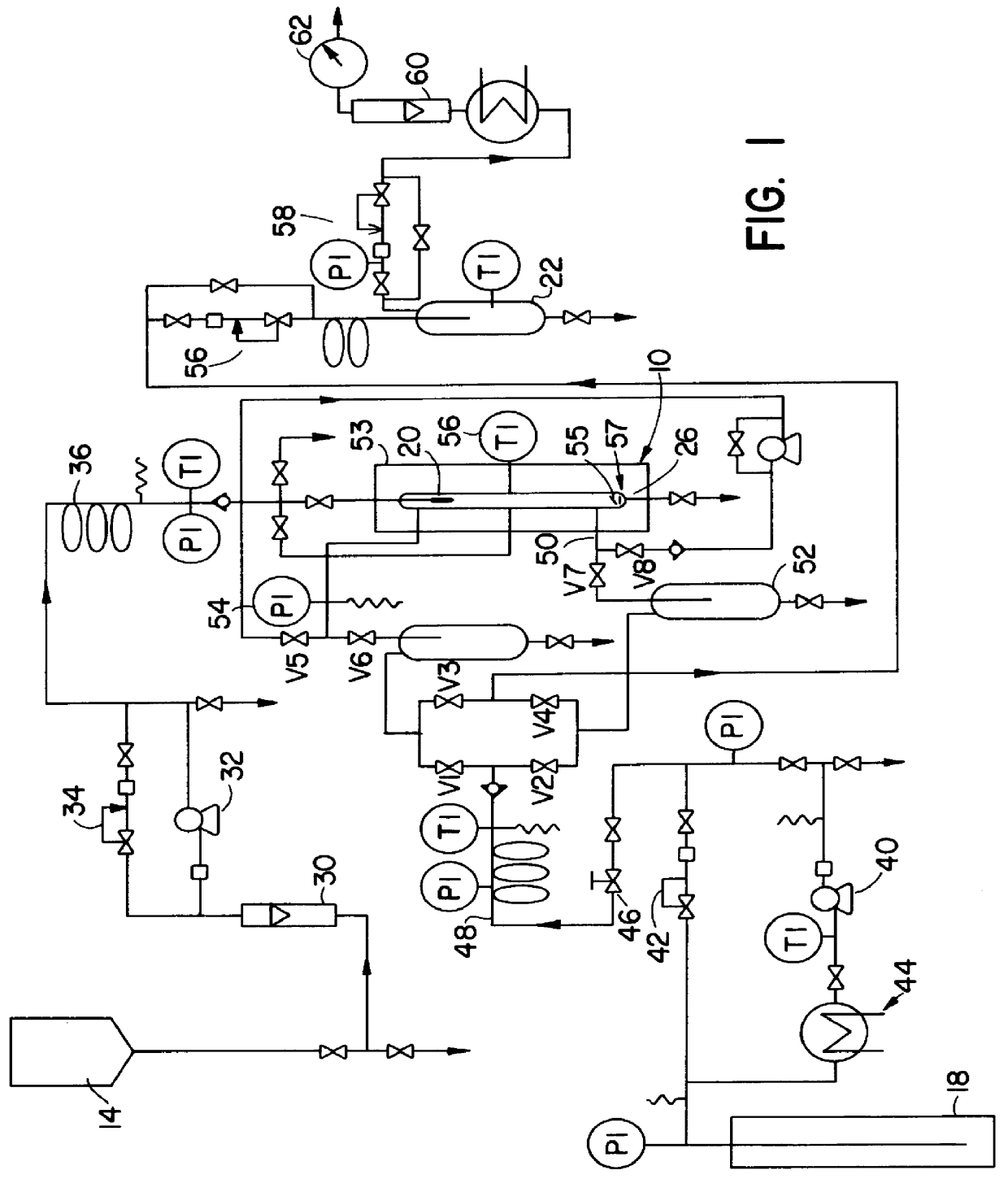

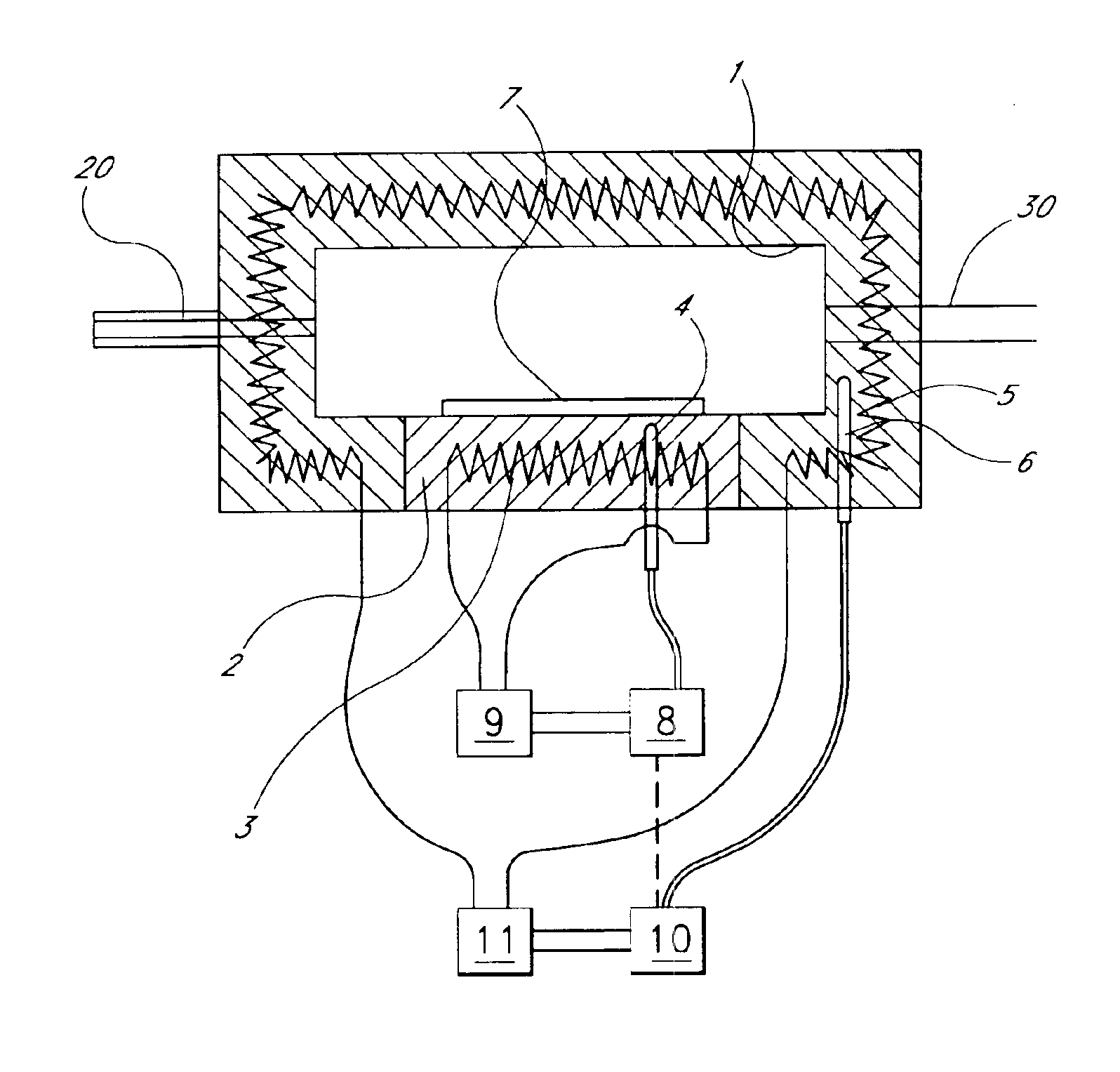

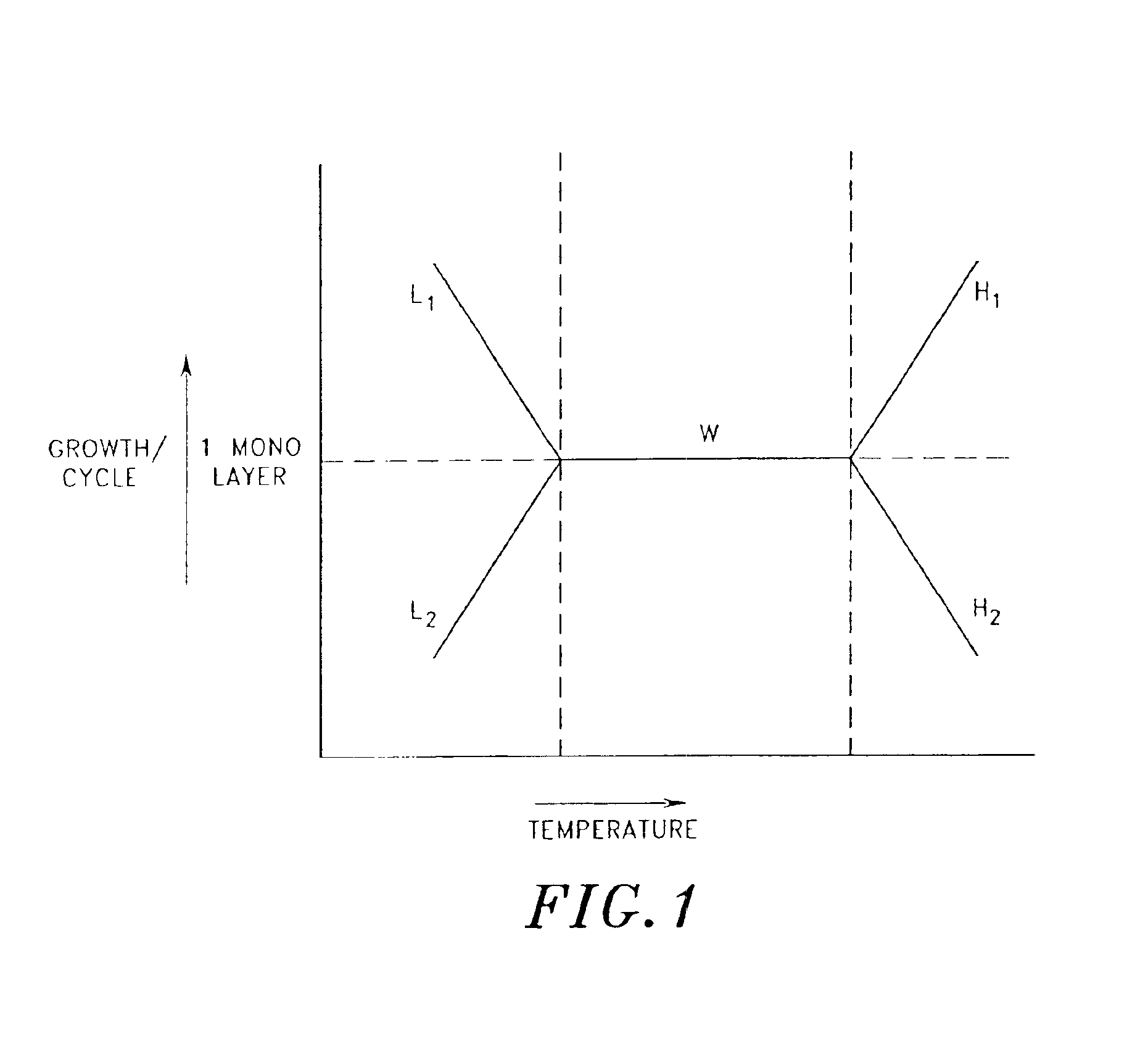

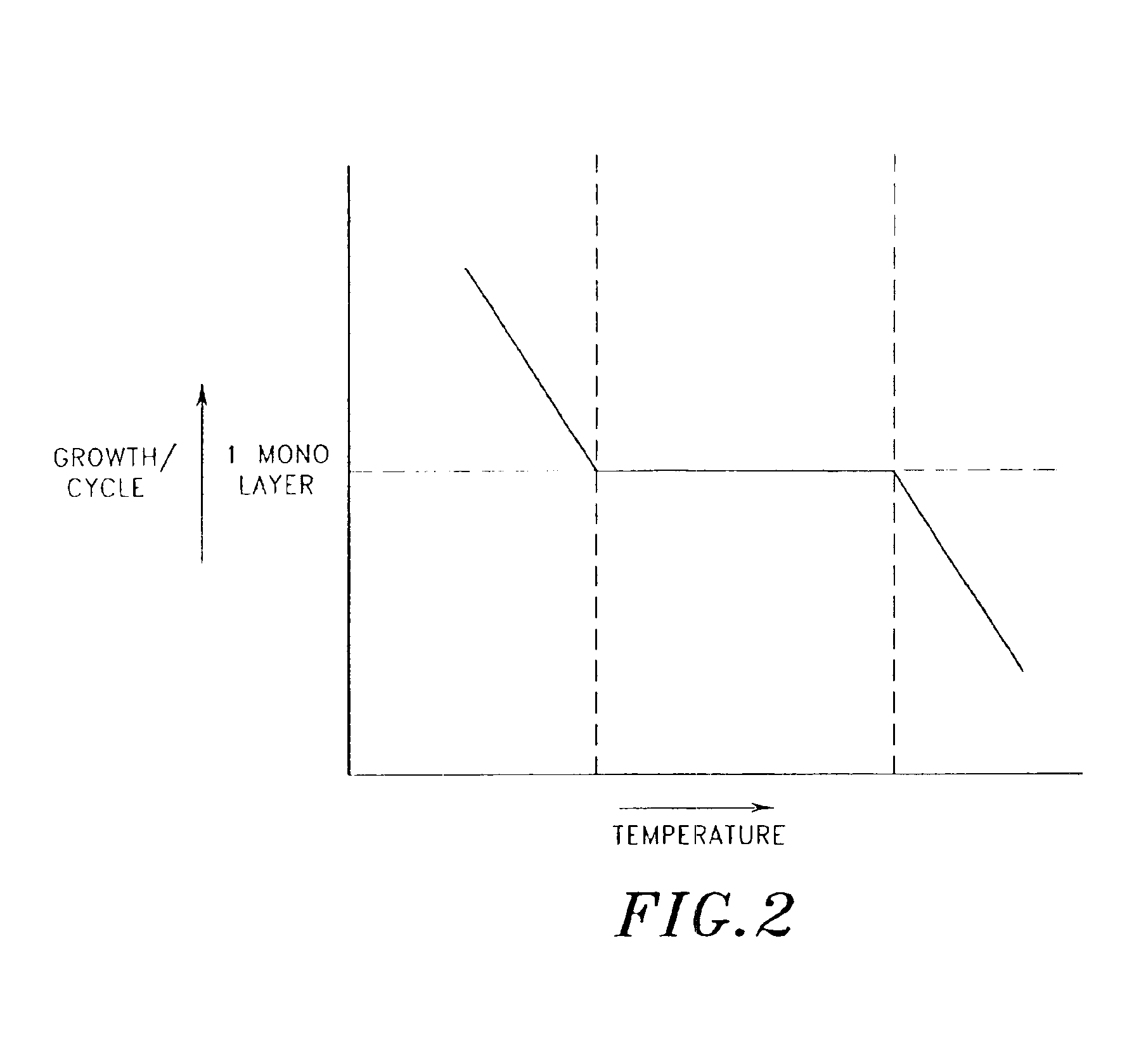

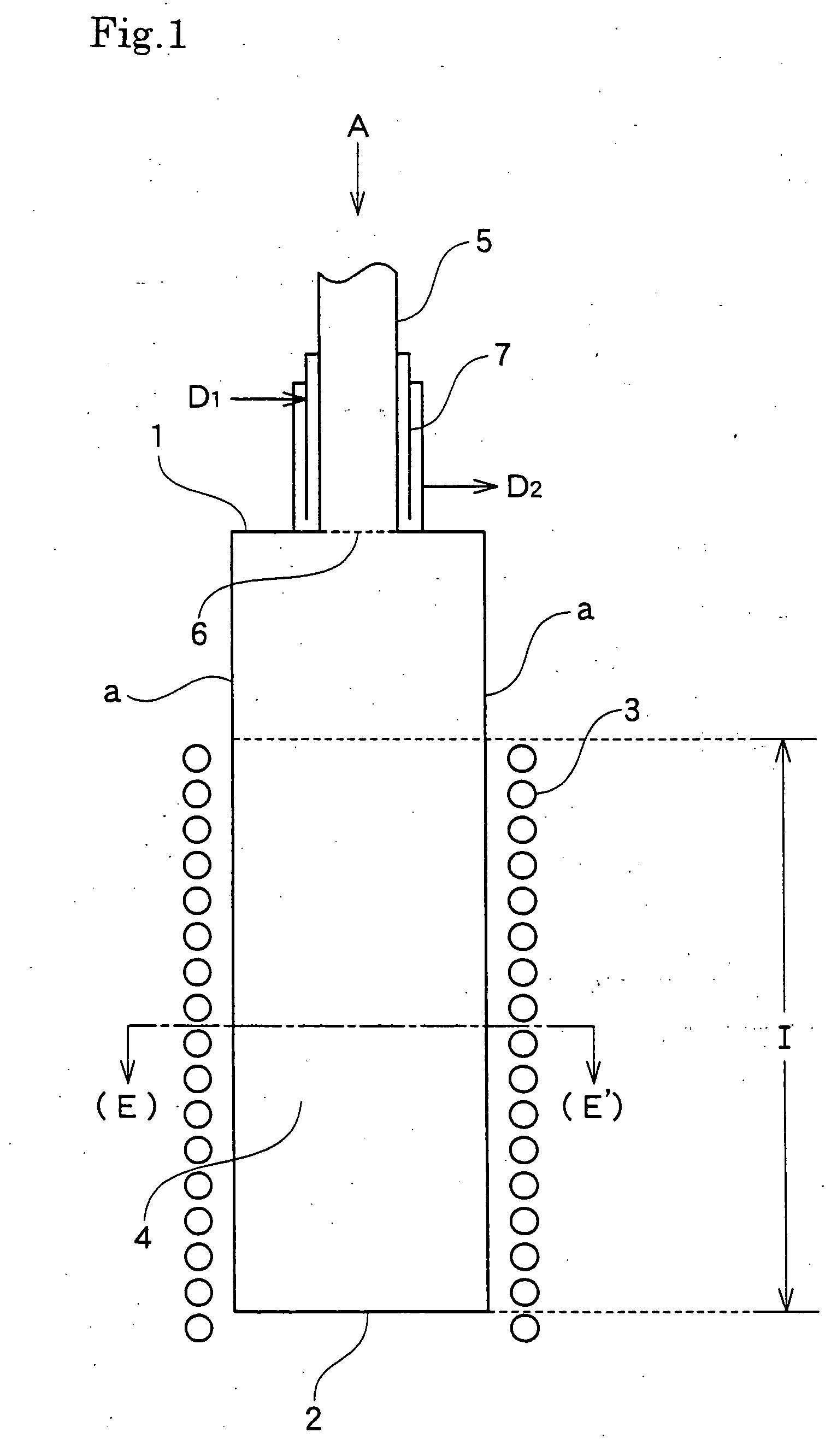

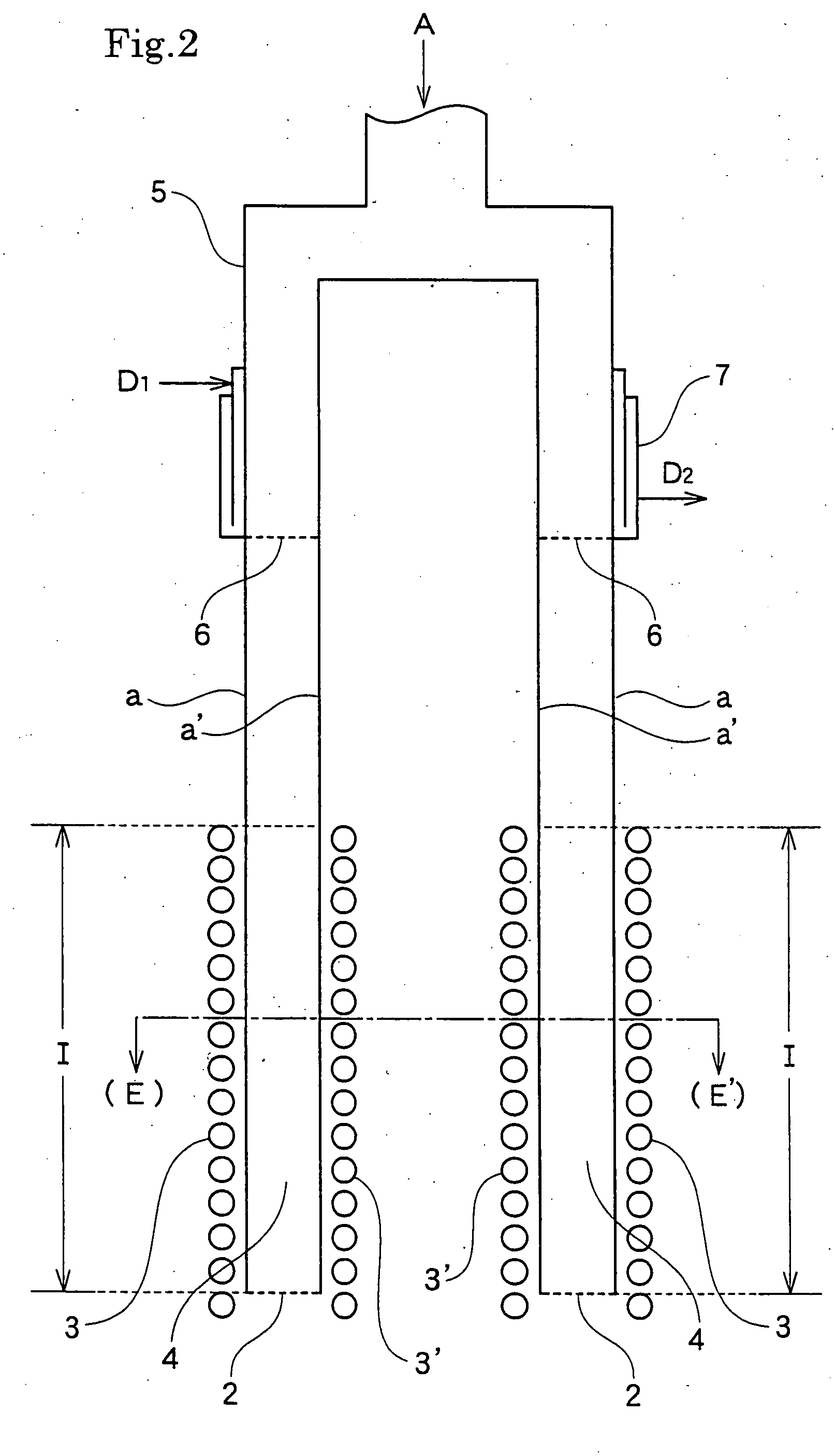

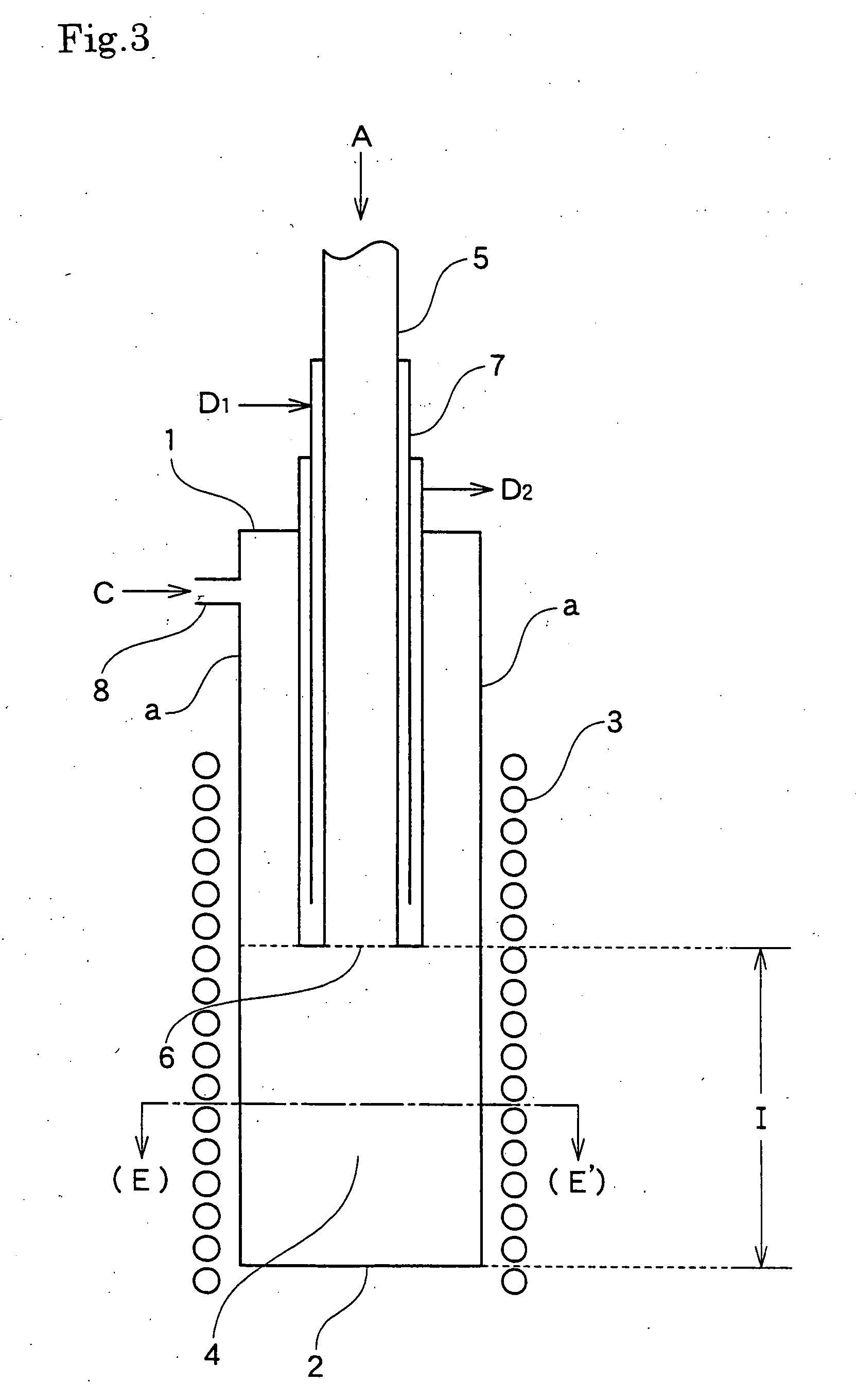

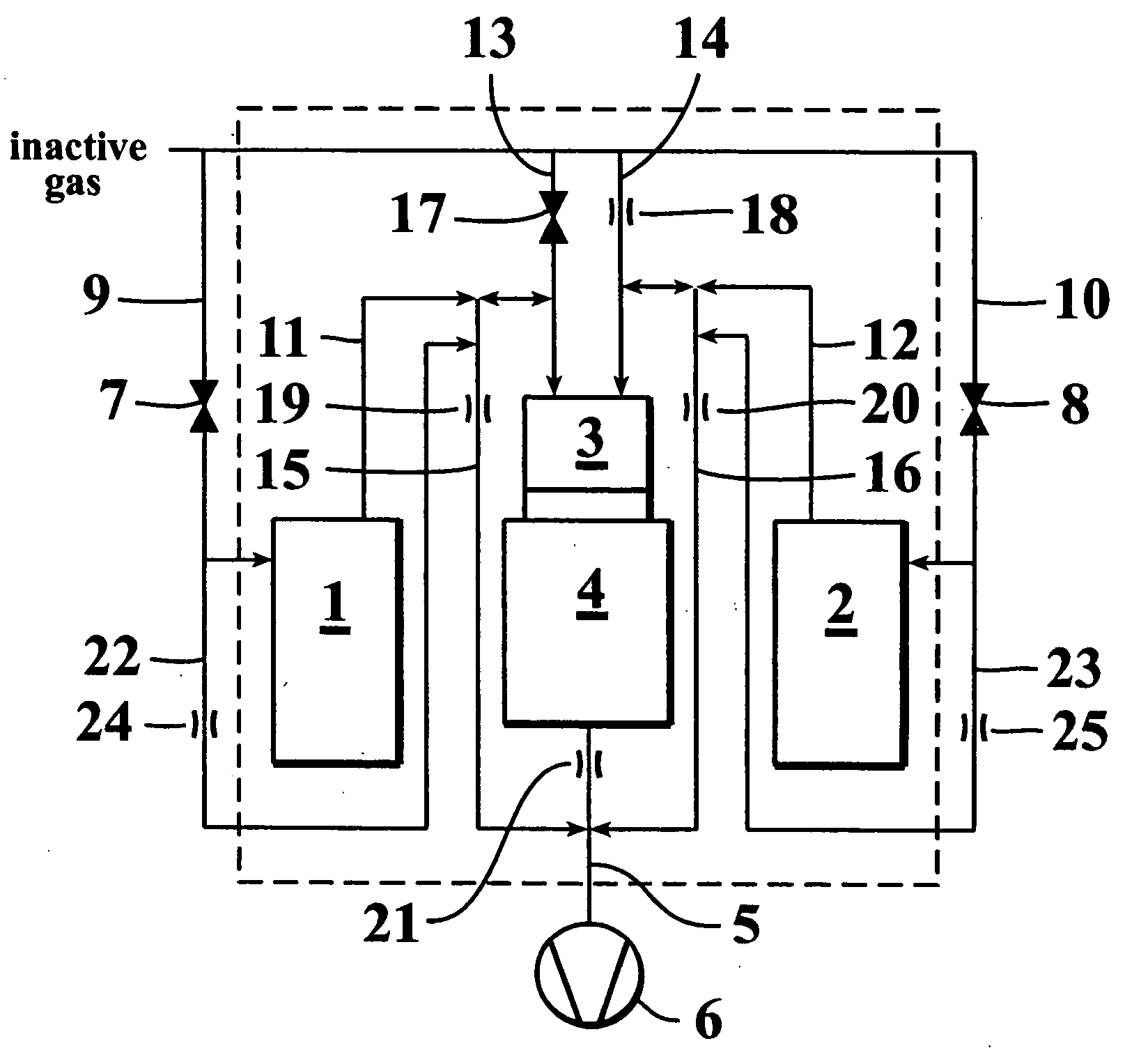

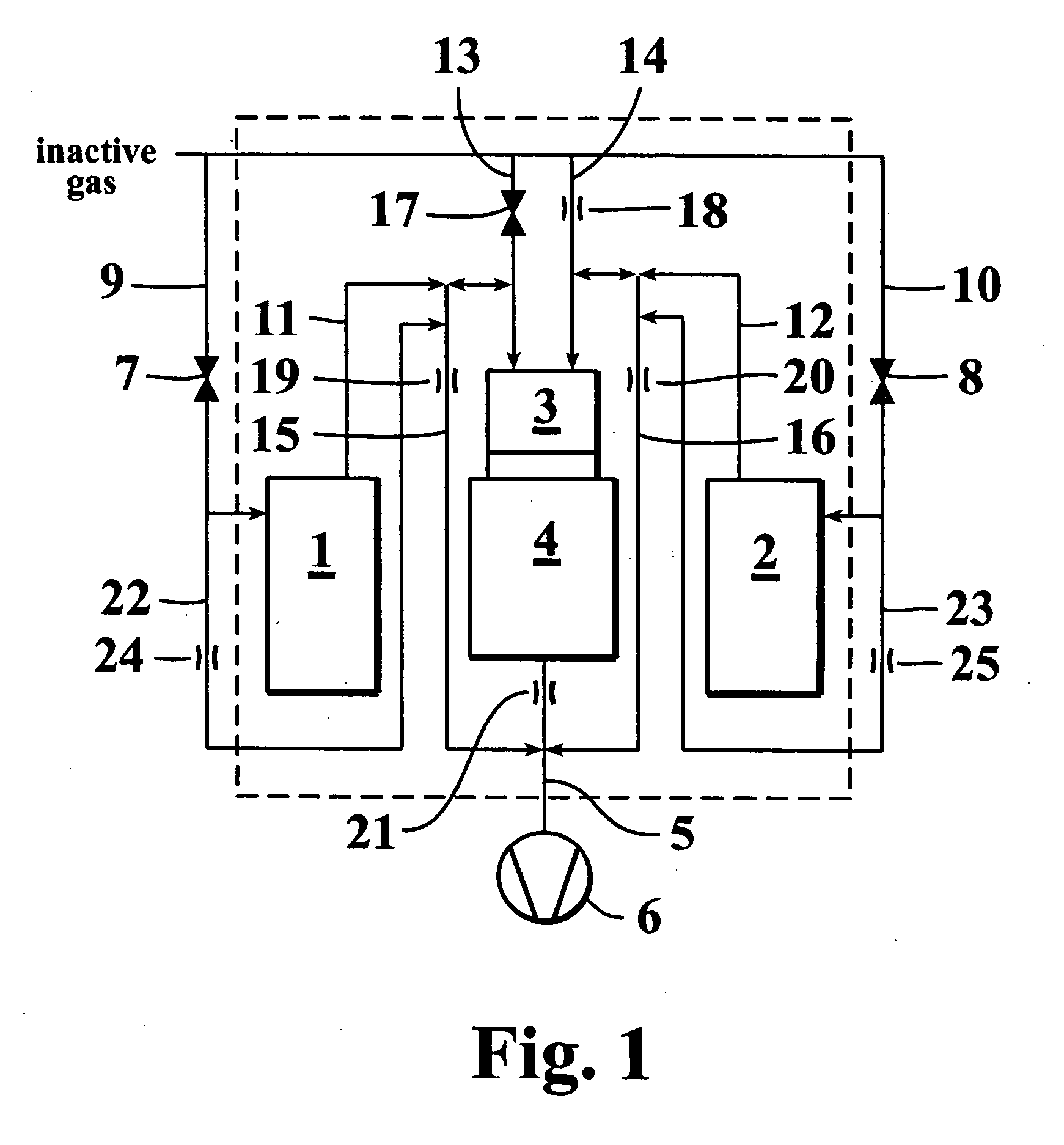

ALD reactor and method with controlled wall temperature

InactiveUS6939579B2Impair reactionReduce the probability of depositionFurnaces without endless corePolycrystalline material growthDisplay devicePhysisorption

The present invention relates to improved methods and apparatus for atomic layer deposition (ALD) of thin films on substrates such as wafers and flat panel displays. The invention provides an ALD reactor comprising a first temperature regulating system to control the temperature of the substrate and a second temperature regulating system to independently control the temperature of the reaction chamber walls. The invention also provides a method for ALD of a film onto a substrate in a reaction chamber, in which the temperature of the substrate is maintained to maximize ALD on the substrate while the temperature of the reaction chamber walls is set to minimize film growth thereon, whether by ALD, condensation, physisorption or thermal decomposition. The temperature of the walls may be maintained at the same temperature as the substrate, or higher or lower than the substrate temperature, depending upon the particular reaction being used.

Owner:ASM INTERNATIONAL

Reaction apparatus for producing silicon

ActiveUS20050201908A1Reduce spacingReduce distanceAfter-treatment apparatusSiliconProcess engineeringSilicon

A silicon production reactor comprising a reaction vessel and heating means, said reaction vessel comprising a vertically extending wall and a space surrounded by the wall, said heating means being capable of heating at least a part, including lower end portion, of the wall's surface facing the space to a temperature of not lower than the melting point of silicon, said silicon production reactor being adapted to flow raw gas for silicon deposition from an upper part of the space of the reaction vessel toward a lower part thereof, characterized in that the space of the reaction vessel is of slit form in cross-sectional view. This silicon production reactor is capable of attaining improvement with respect to problems encountered at apparatus scaleup, such as decrease of reactivity of raw gas and generation of by-products, thereby accomplishing a striking enhancement of production efficiency.

Owner:TOKUYAMA CORP

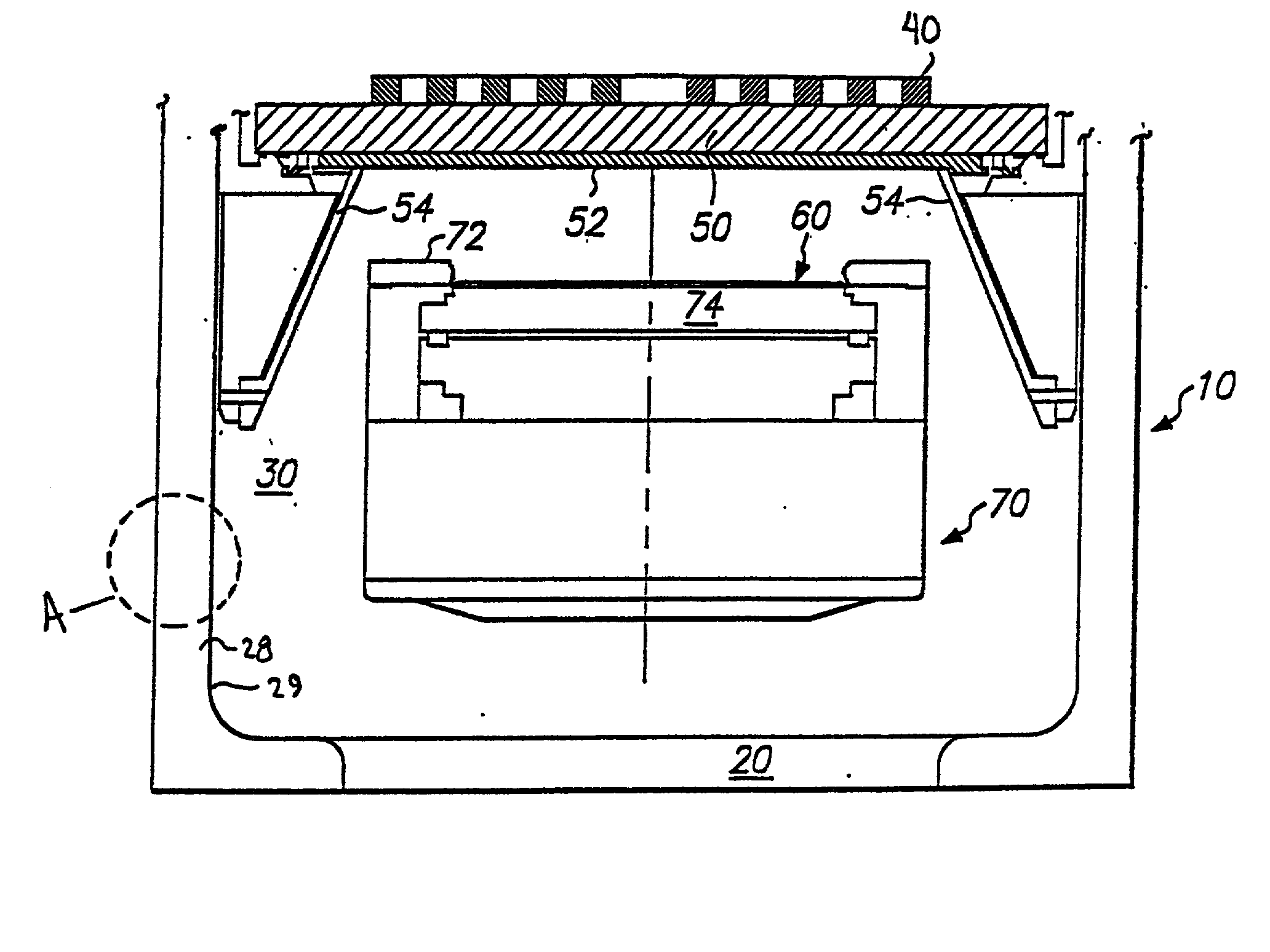

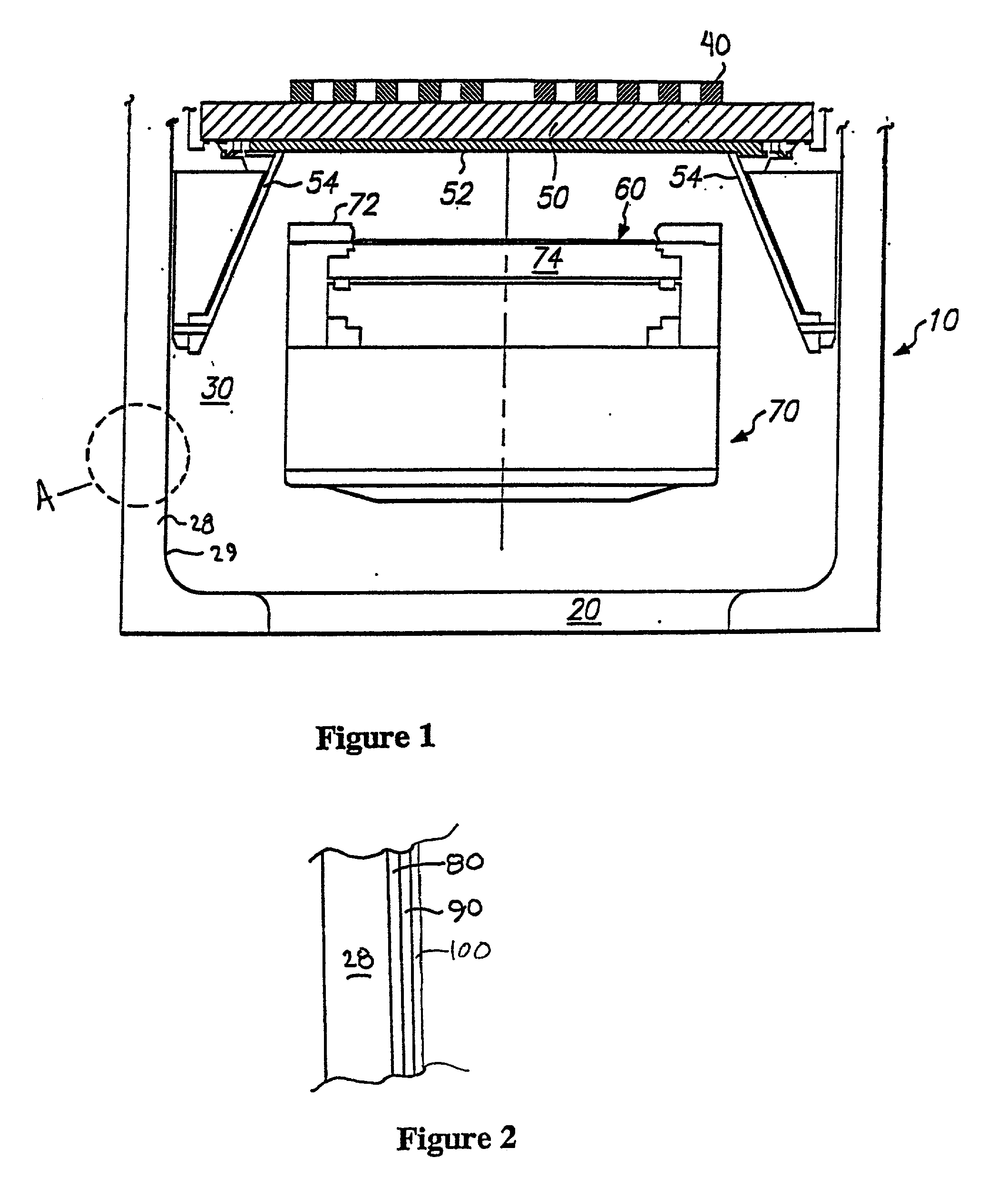

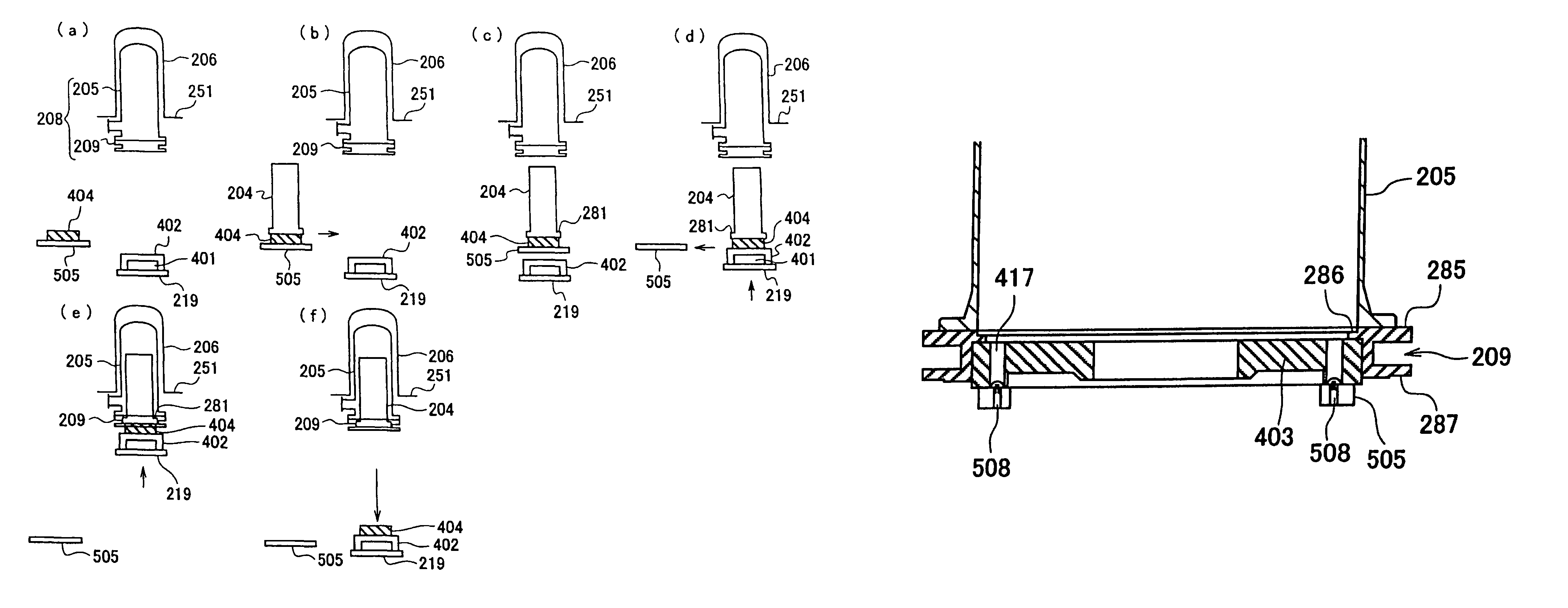

Linear cutting and stapling device with selectively disengageable cutting member

A surgical stapling instrument including a selectively actuatable cutting member. The stapling instrument may be used as a surgical stapler without cutting tissue or, if desired, the surgeon may selectively actuate the cutting member to cut tissue as the staples are being deployed and formed. A stapling instrument can include an actuator knob that has at least one pusher bar attached thereto. Advancement of the actuator knob in a distal direction causes the pusher bars to apply a firing motion to the staples contained within a staple cartridge supported within the stapling instrument. A knife bar may be selectively coupleable to the actuator knob by a selector switch that is movable from an actuated position wherein movement of the actuator knob in the distal direction advances the knife bar which has a cutting blade portion to advance between rows of staples in the staple cartridge to an unactuated position wherein movement of the actuator knob advances the pusher bars without advancing the knife bar.

Owner:ETHICON ENDO SURGERY INC

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for carrying out a biochemical protocol in continuous flow in a microreactor

InactiveUS20050282224A1Reduce in quantityImprove throughputBioreactor/fermenter combinationsFixed microstructural devicesMicroreactorTwo temperature

Devices and methods for carrying out a chemical or biochemical protocol are disclosed. In one embodiment, the chemical or biochemical protocol is performed by cycling at least one thermal transfer member between at least two temperatures while liquid samples on which the chemical or biochemical protocol is to be performed are continuously moving through at least one temperature regulated zone upon which the at least one thermal transfer member acts. In some embodiments, the device comprises a sample transport member that comprises liquid samples in sample receiving regions. The sample transport member moves the samples continuously through a temperature regulated zone which cycles between at least two temperatures while the liquid samples are moving through a temperature regulated zone on which at least one thermal transfer member acts. In some embodiments, the sample receiving regions comprise wells, hydrophillic films or hydrophillic filaments.

Owner:SERONO GENETICS INST SA +1

Method of growing a thin film onto a substrate

InactiveUS20040261706A1Uniform smoothnessAvoid it happening againPolycrystalline material growthPressurized chemical processSurface reactionGas phase

A method of growing a thin film onto a substrate placed in a reaction chamber according to the ALD method by subjecting the substrate to alternate and successive surface reactions. The method includes providing a first reactant source and providing an inactive gas source. A first reactant is fed from the first reactant source in the form of repeated alternating pulses to a reaction chamber via a first conduit. The first reactant is allowed to react with the surface of the substrate in the reaction chamber. Inactive gas is fed from the inactive gas source into the first conduit via a second conduit that is connected to the first conduit at a first connection point so as to create a gas phase barrier between the repeated alternating pulses of the first reactant entering the reaction chamber. The inactive gas is withdrawn from said first conduit via a third conduit connected to the first conduit at a second connection point.

Owner:ASM IP HLDG BV

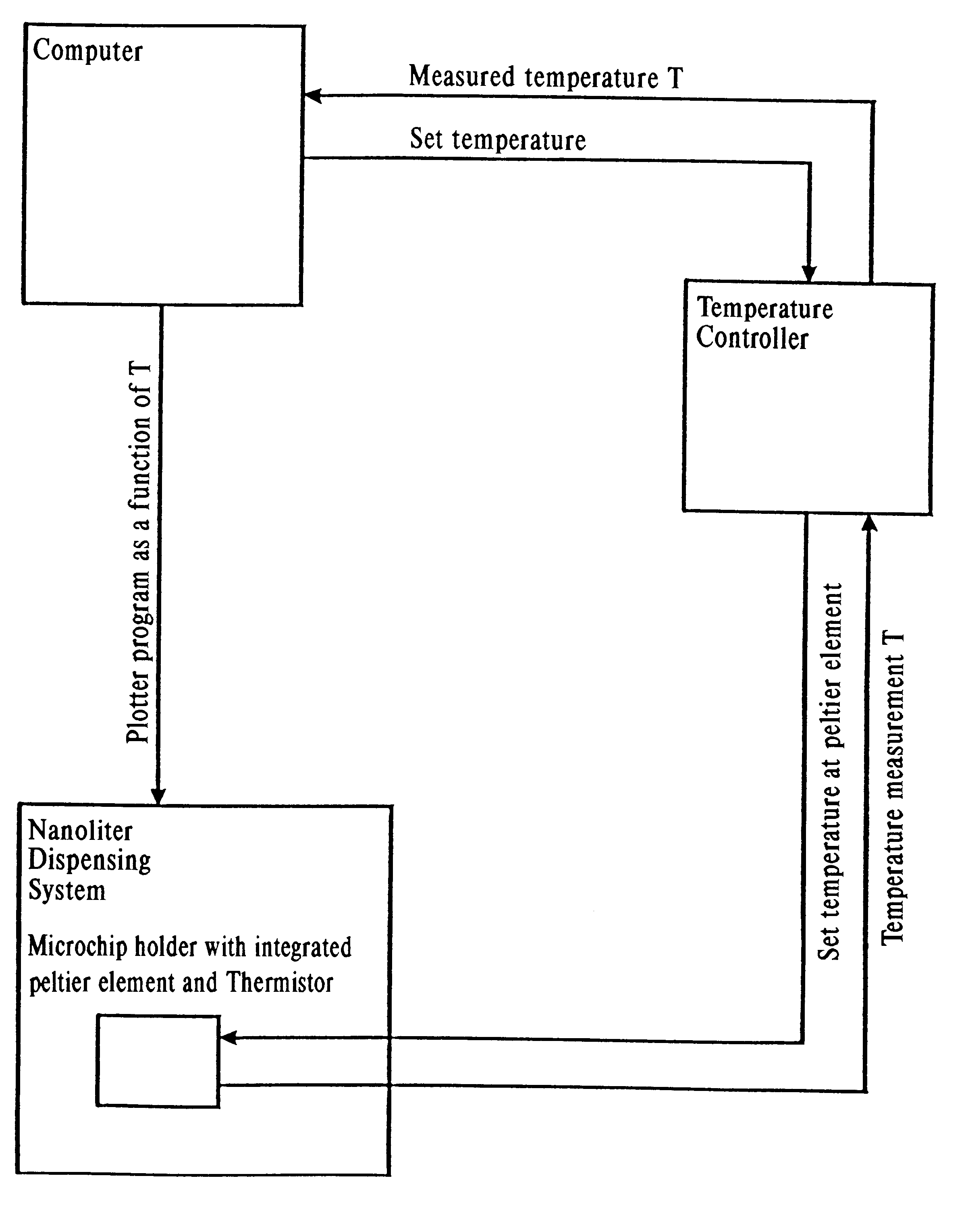

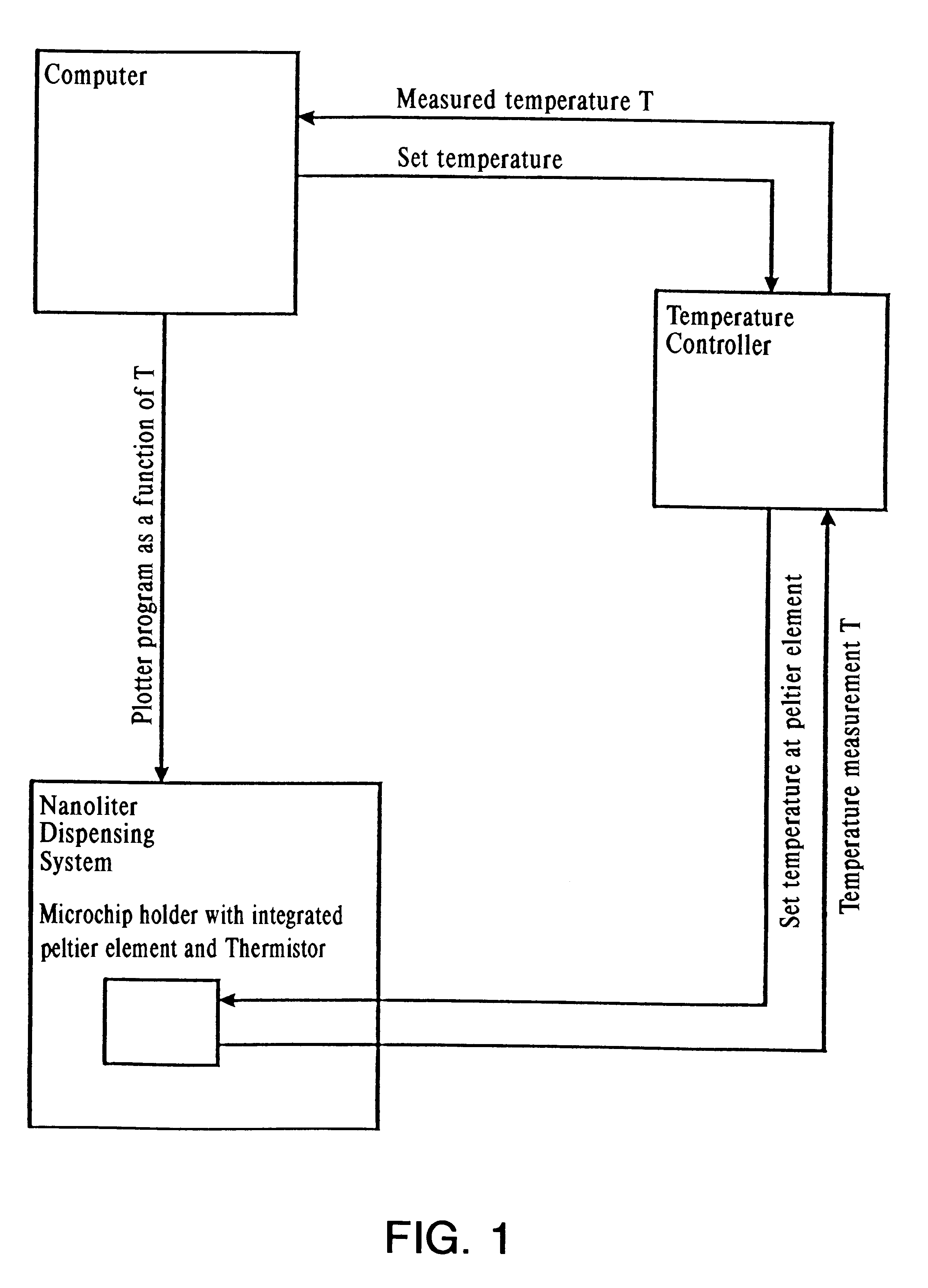

Systems and methods for performing reactions in an unsealed environment

InactiveUS6485913B1Drying using combination processesMicrobiological testing/measurementTemperature controlBiomedical engineering

Open systems for performing submicroliter reactions are provided. The systems can include a support for performing the reaction; a liquid dispensing system for dispensing a submicroliter amount of a liquid to a site on or in the support; a temperature controlling device for regulating the temperature of the support; and an interface for controlling the amount of liquid dispensed from the liquid dispensing system are provided. Methods using the systems are also provided.

Owner:AGENA BIOSCI

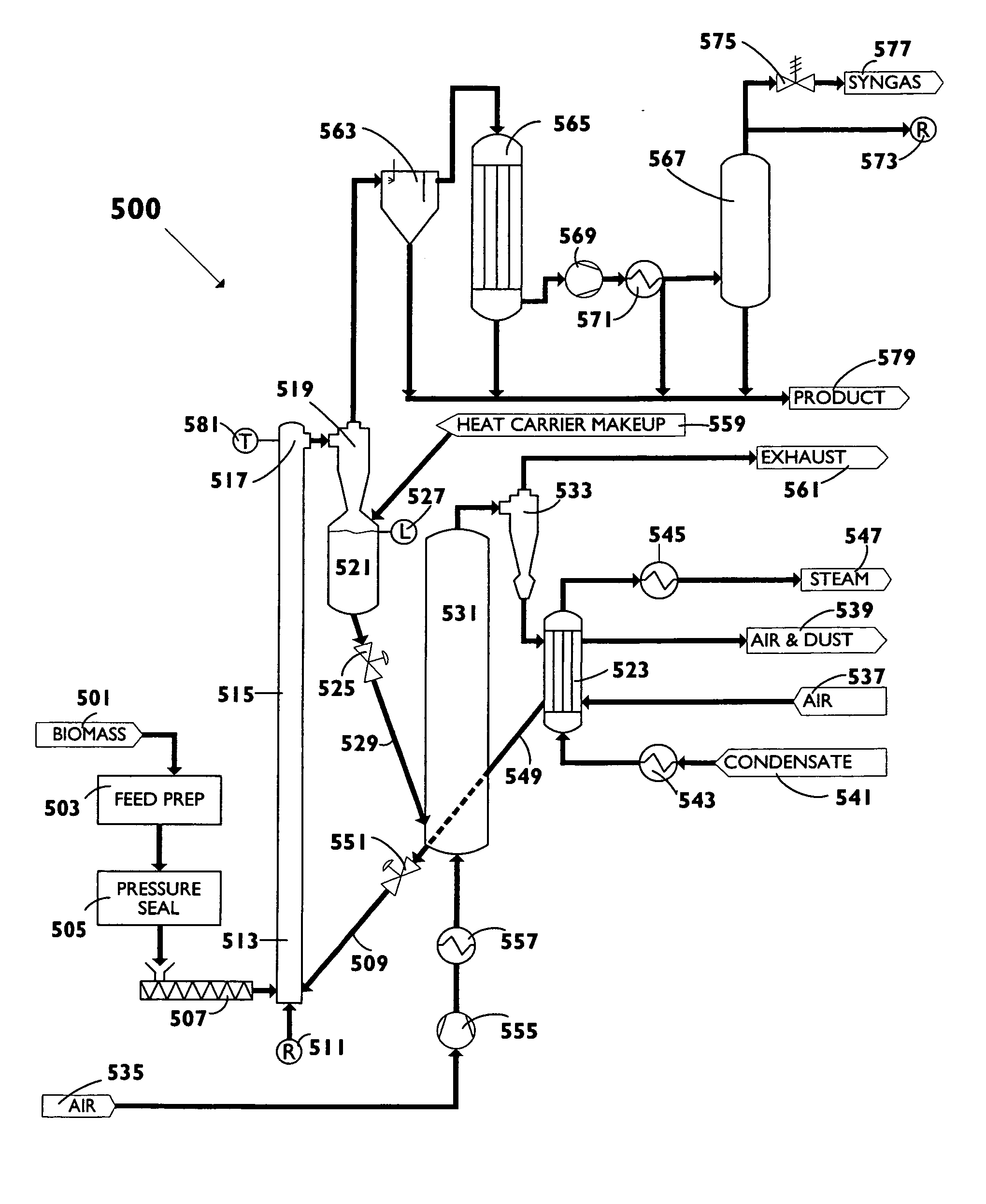

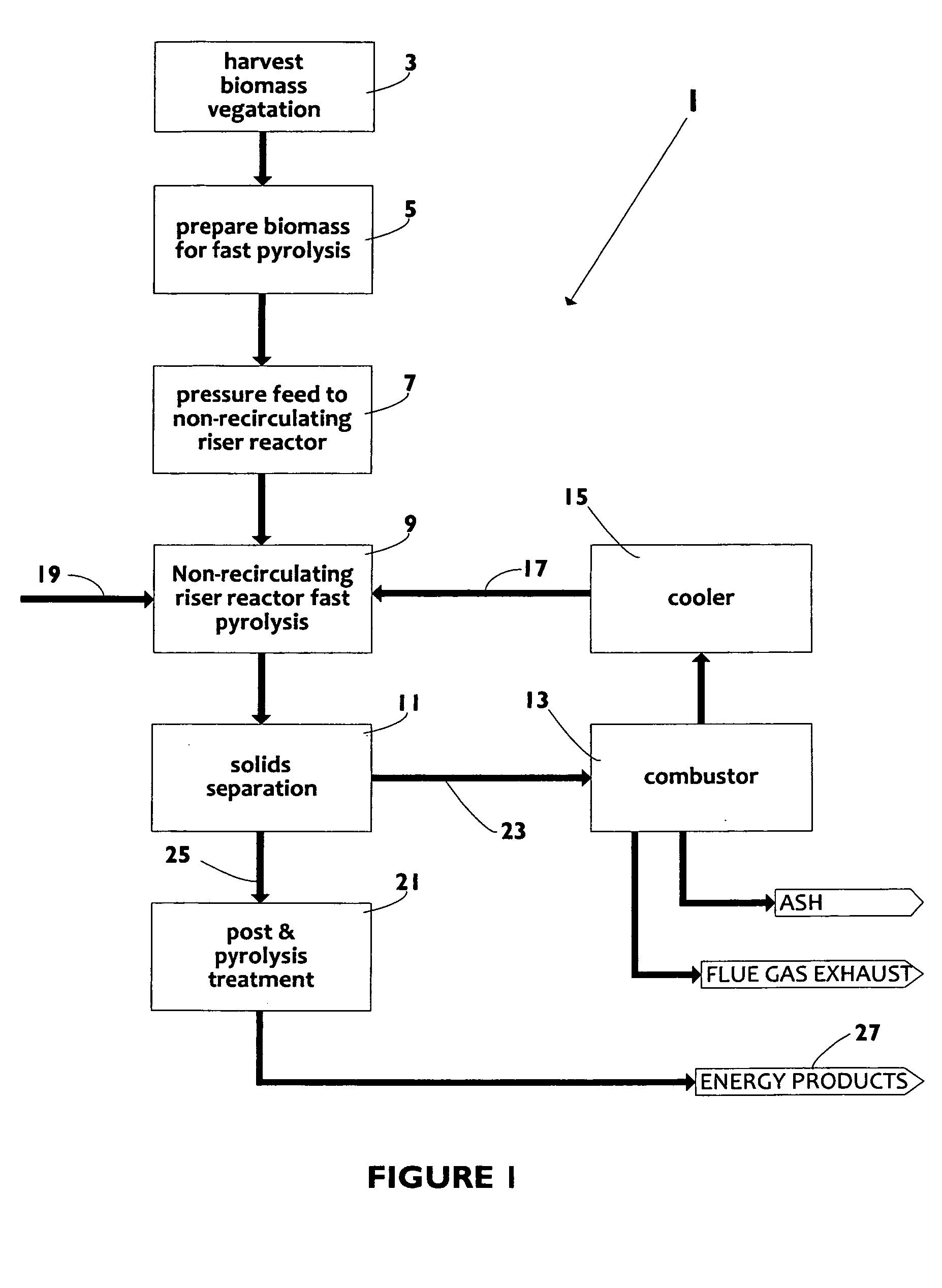

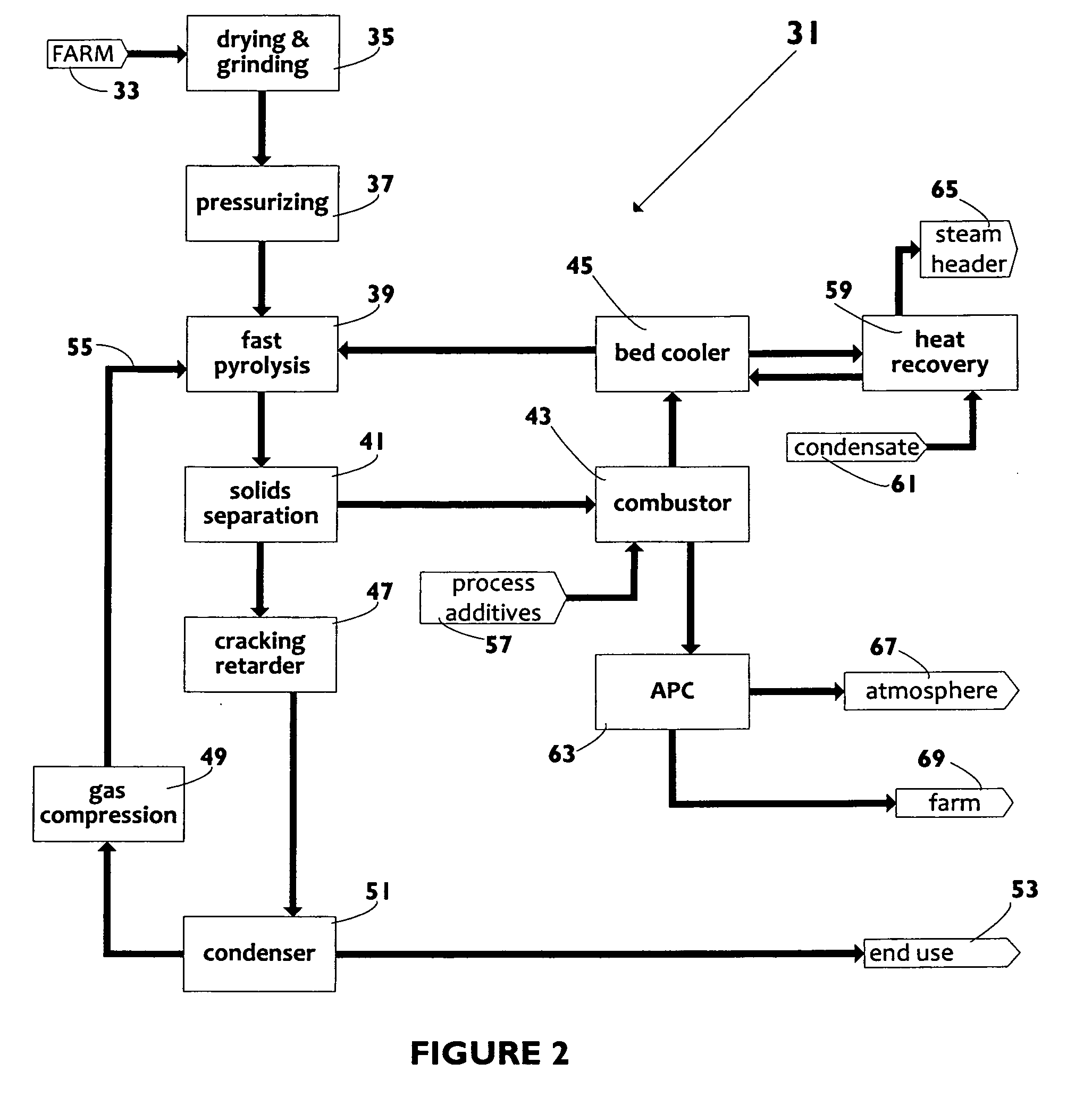

Biomass fast pyrolysis system utilizing non-circulating riser reactor

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com