Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1660 results about "Heat carrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

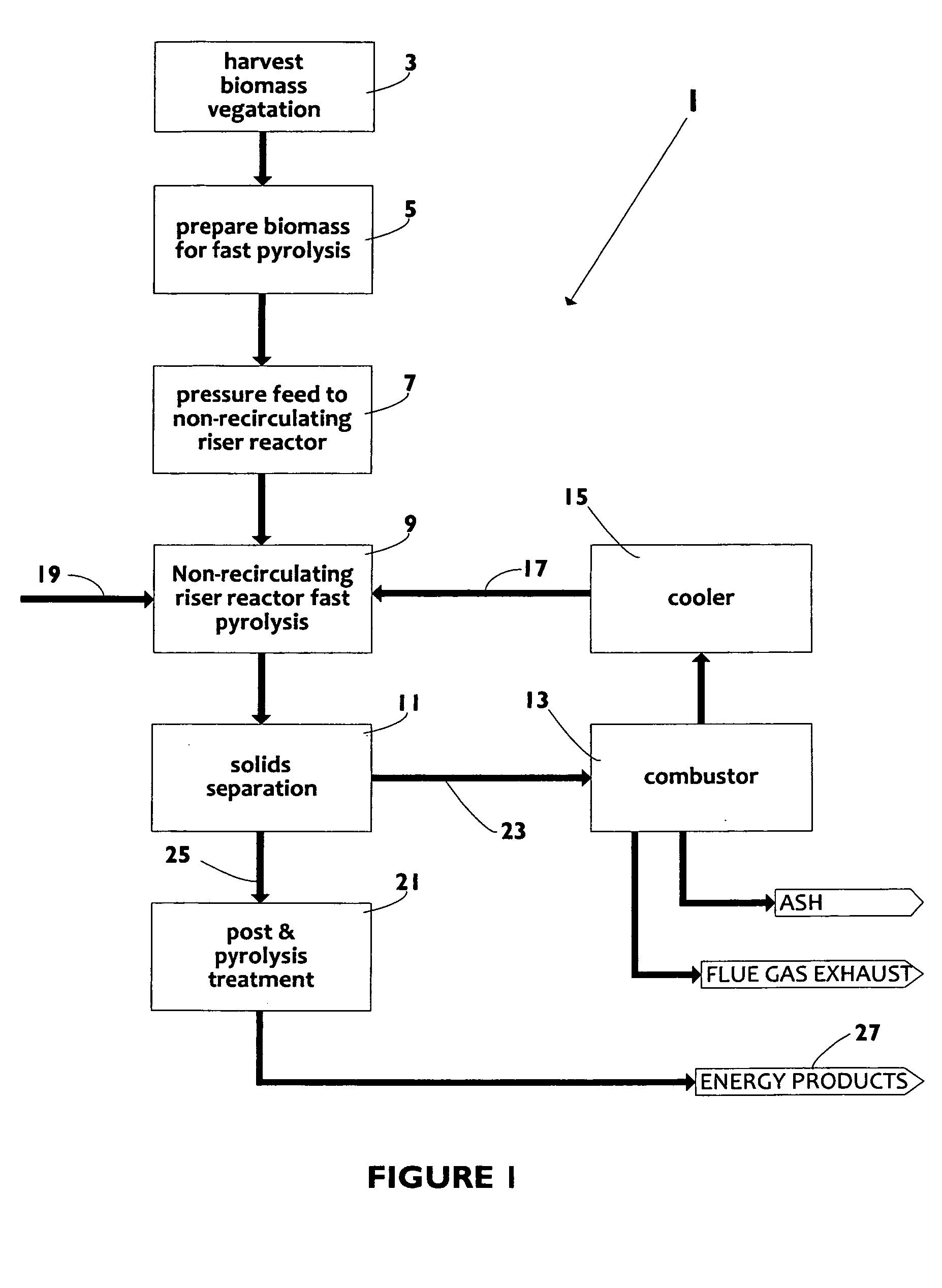

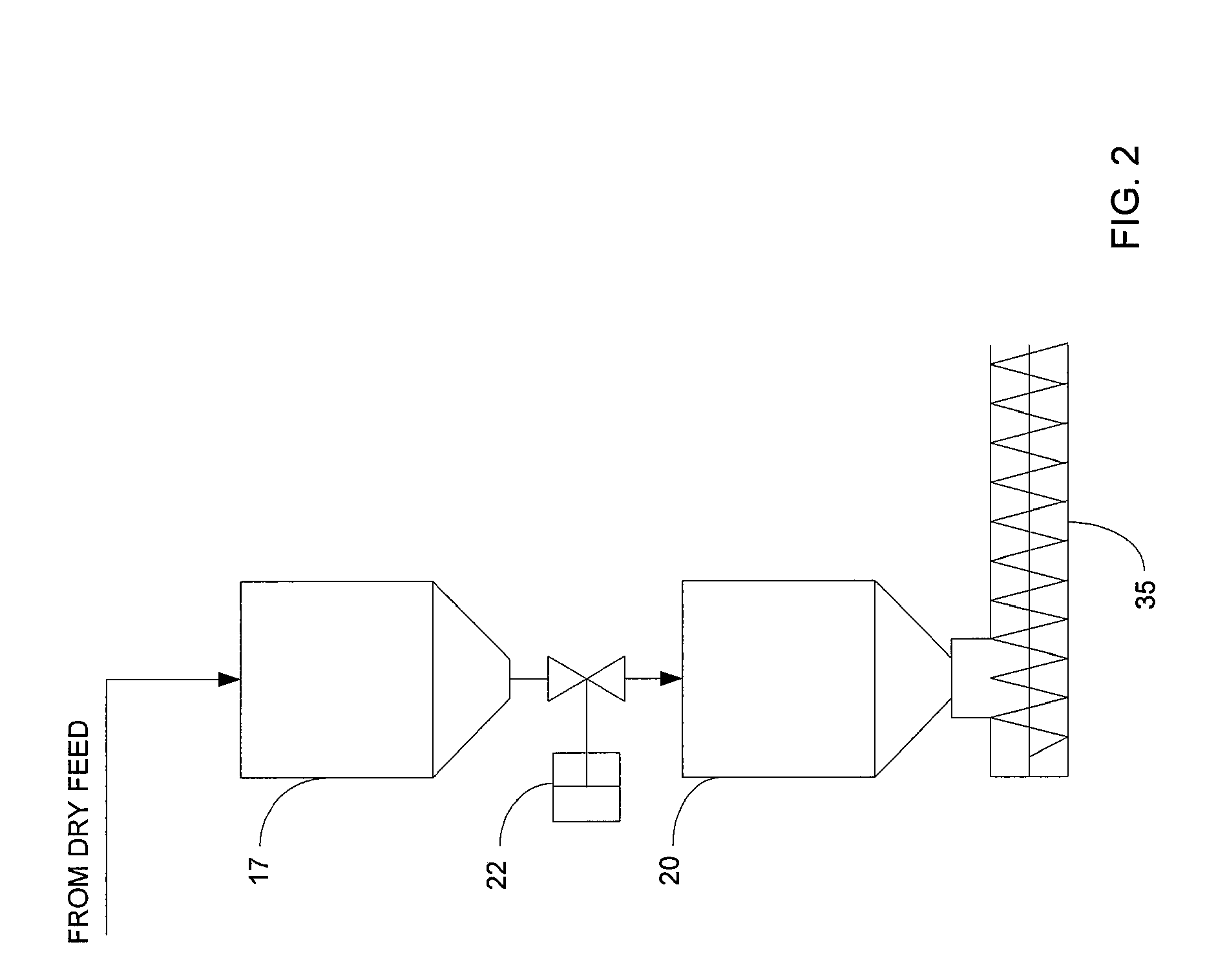

Biomass fast pyrolysis system utilizing non-circulating riser reactor

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

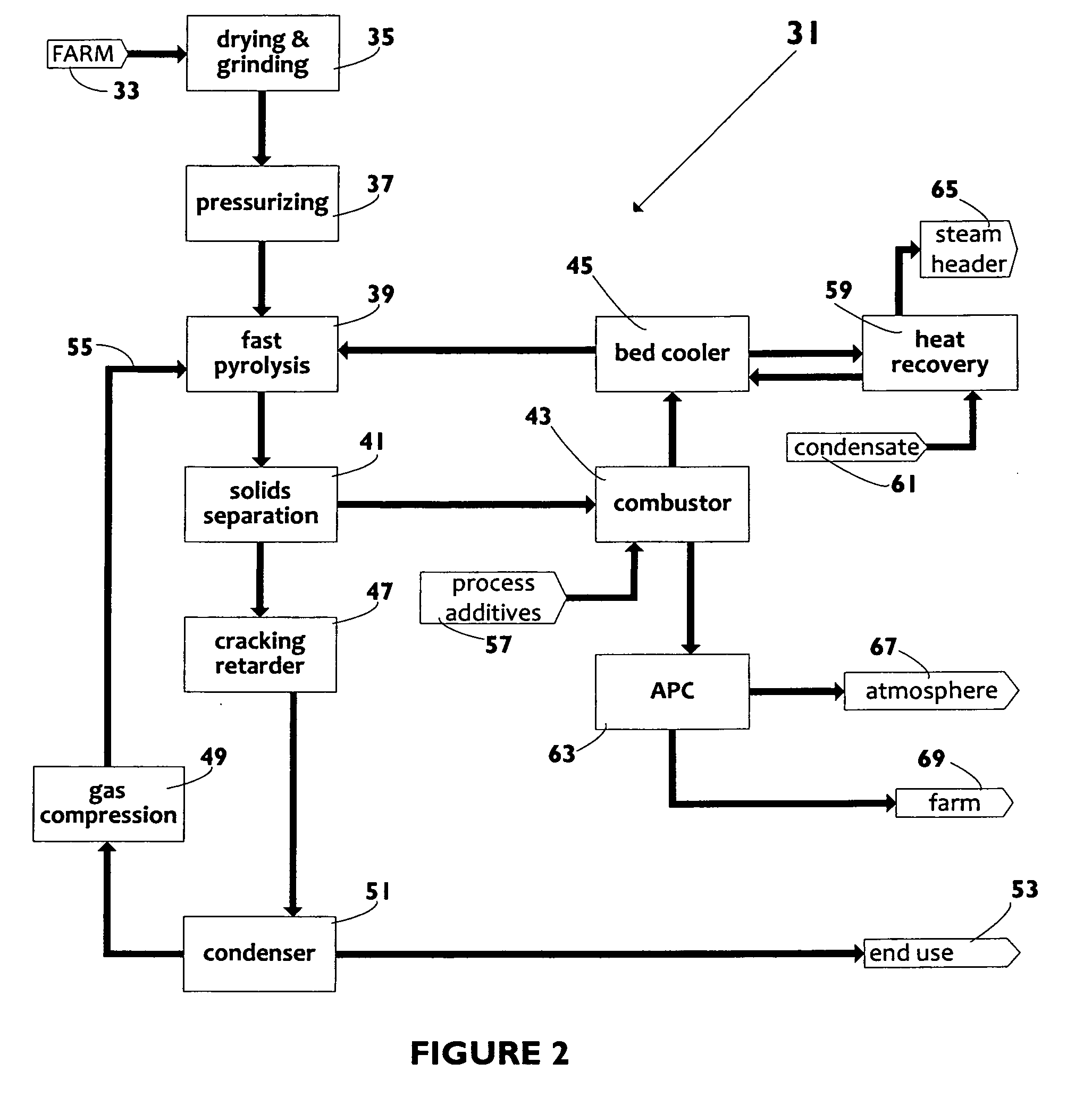

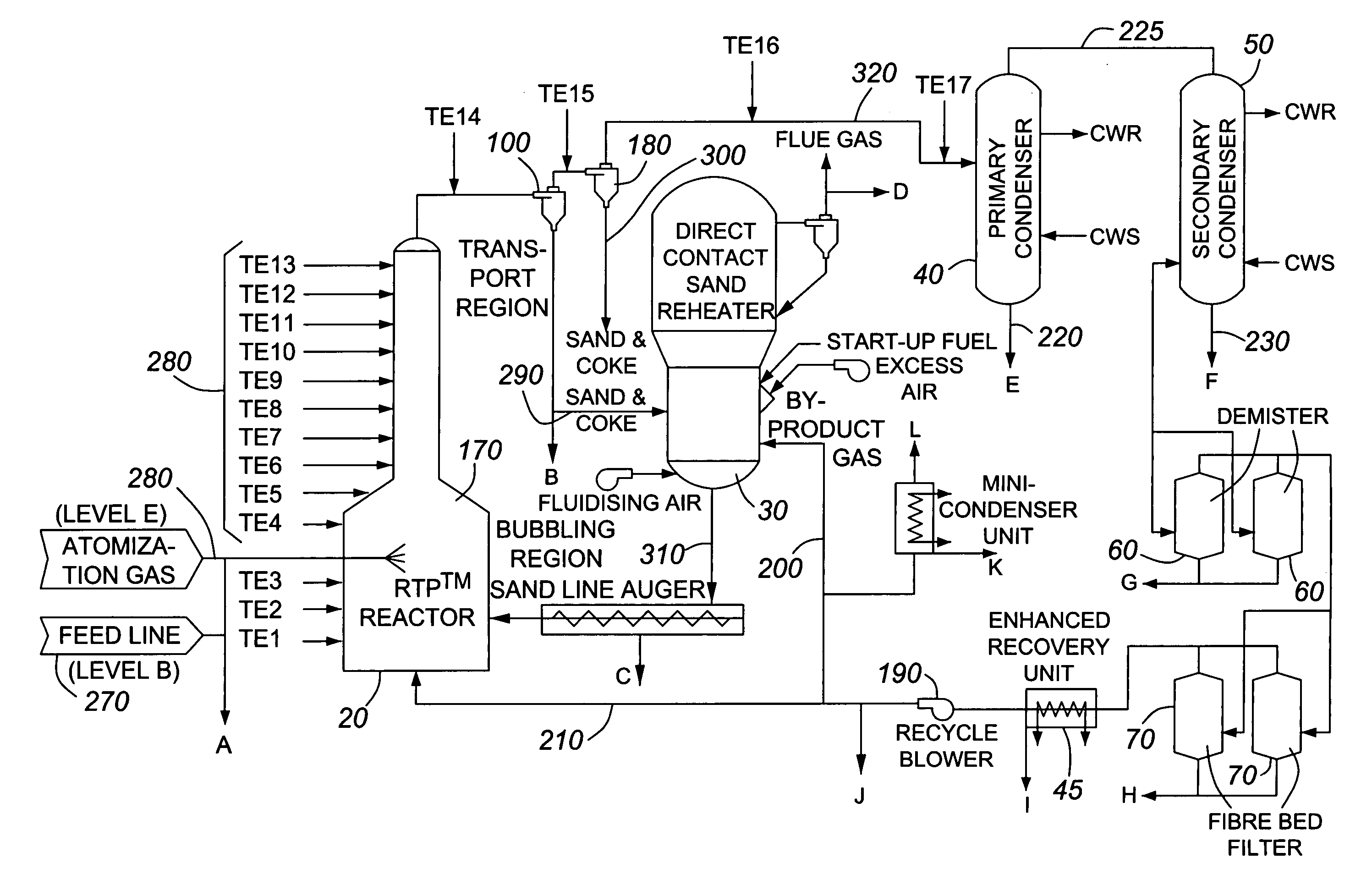

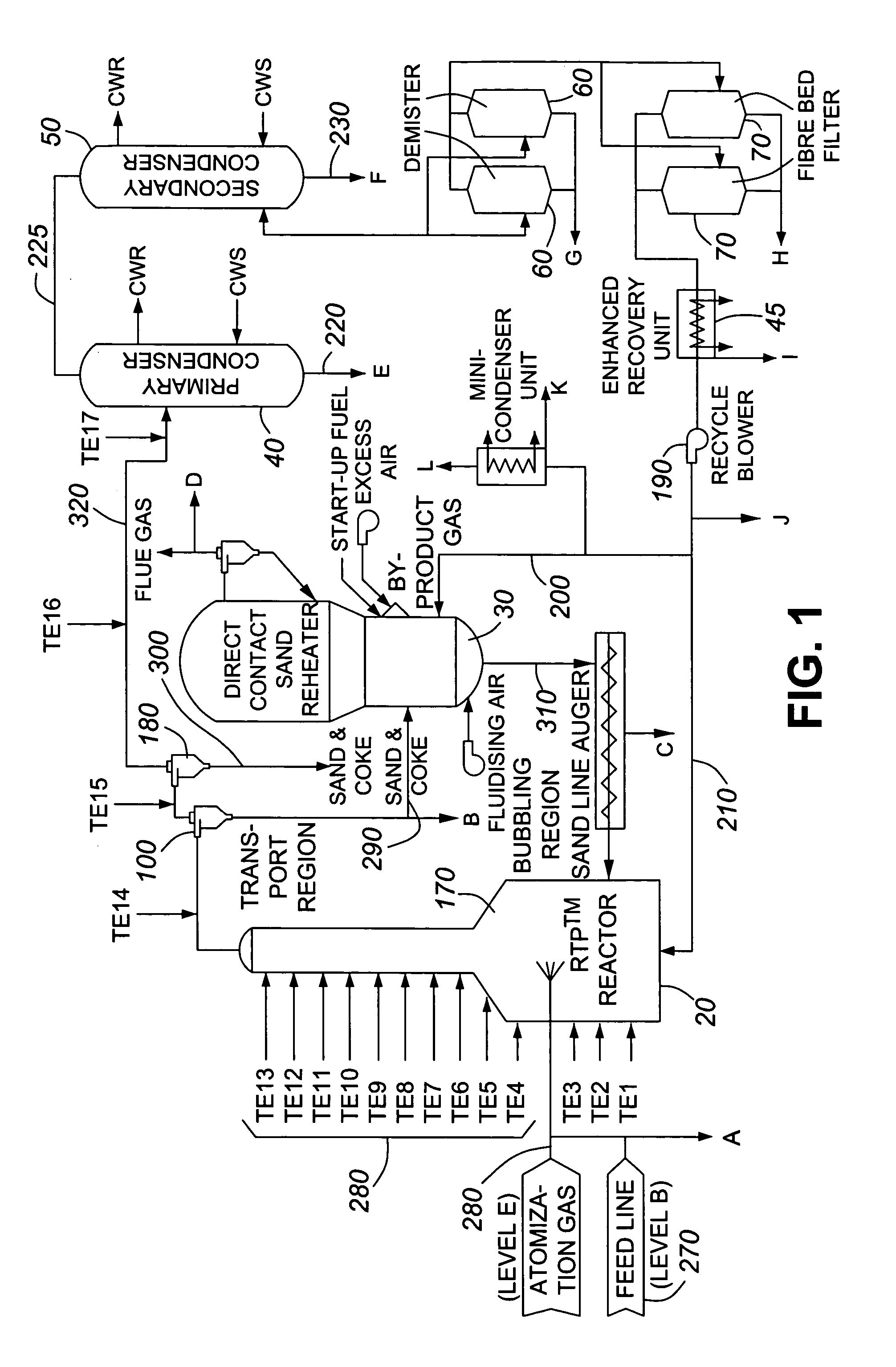

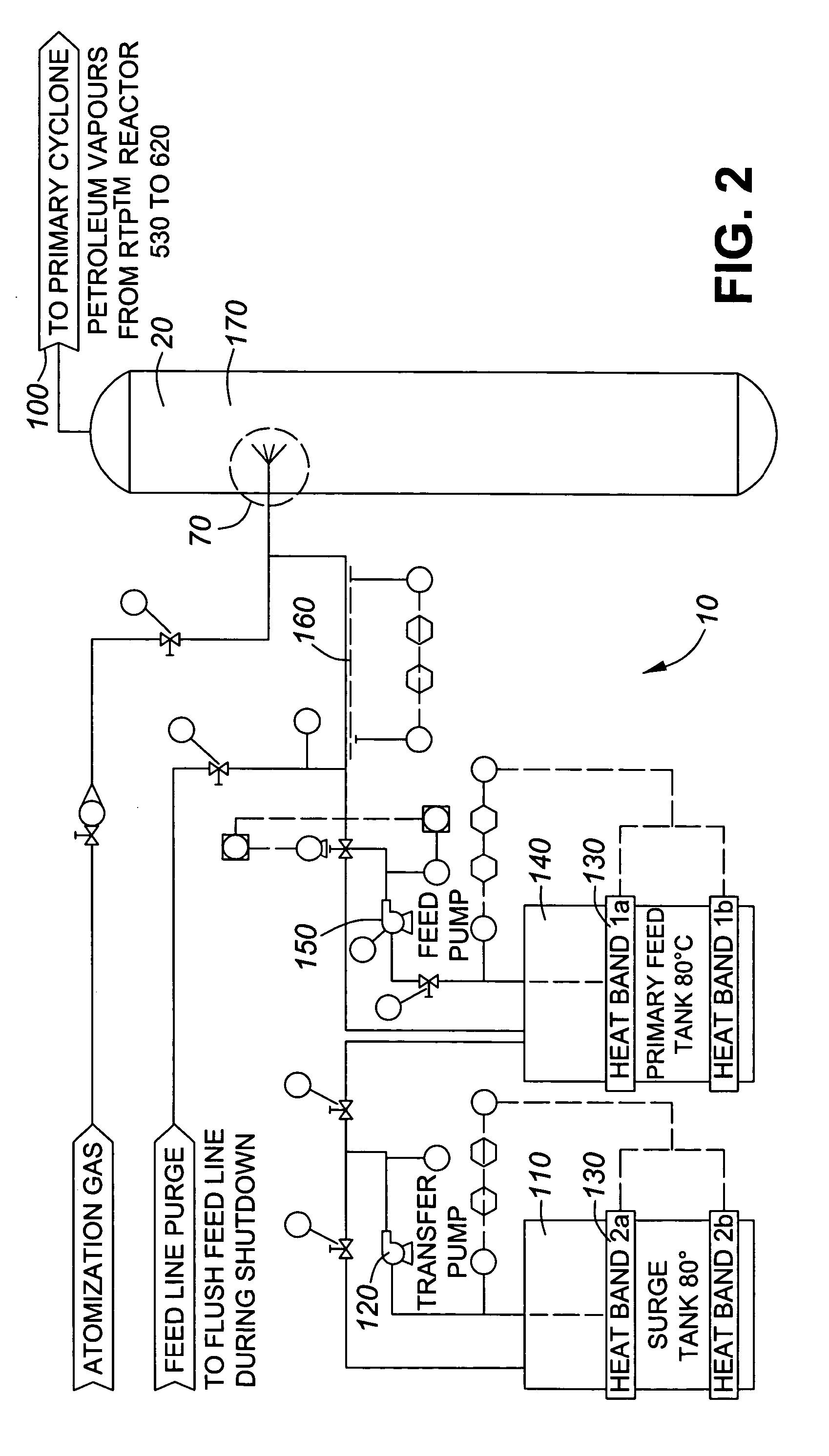

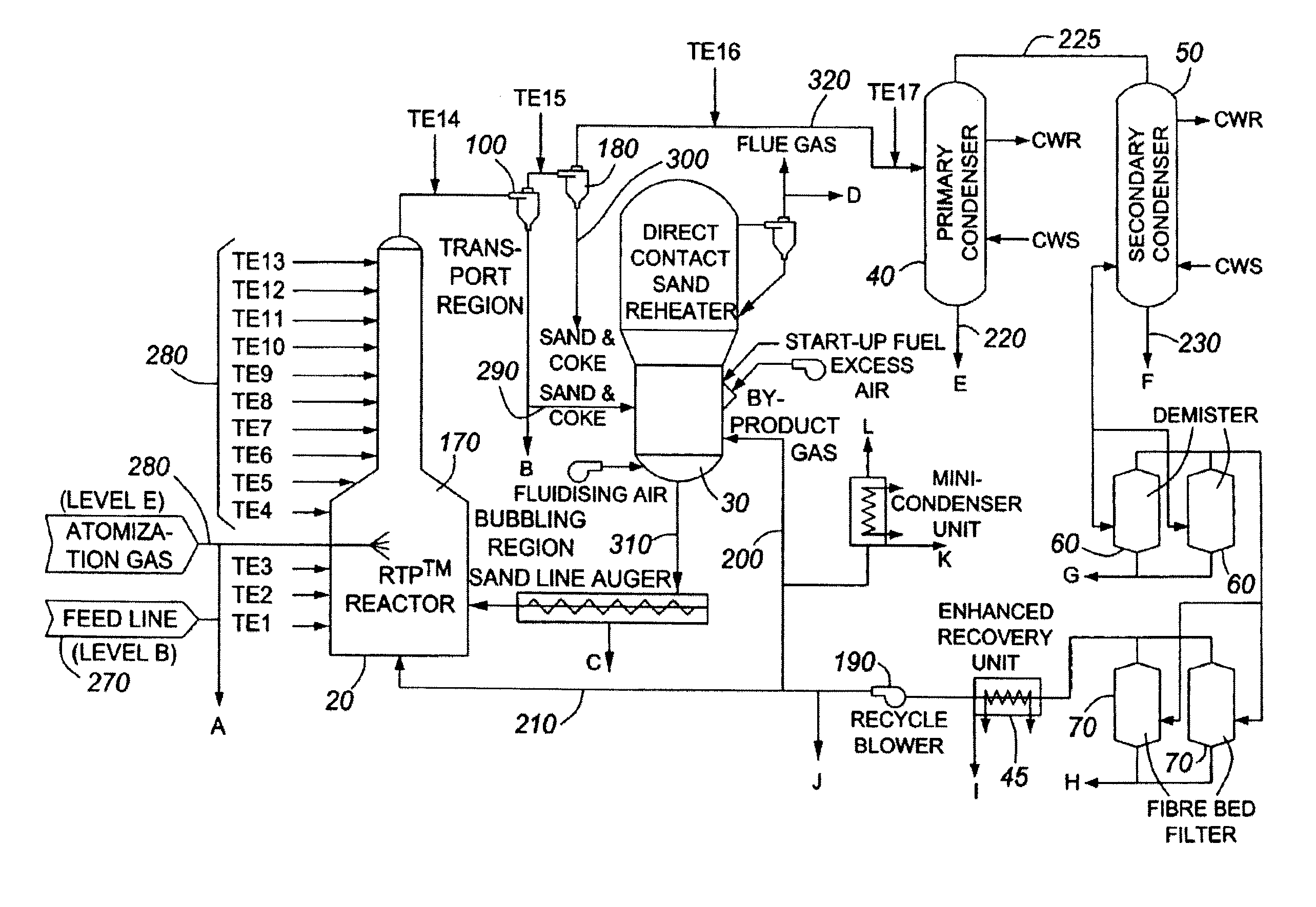

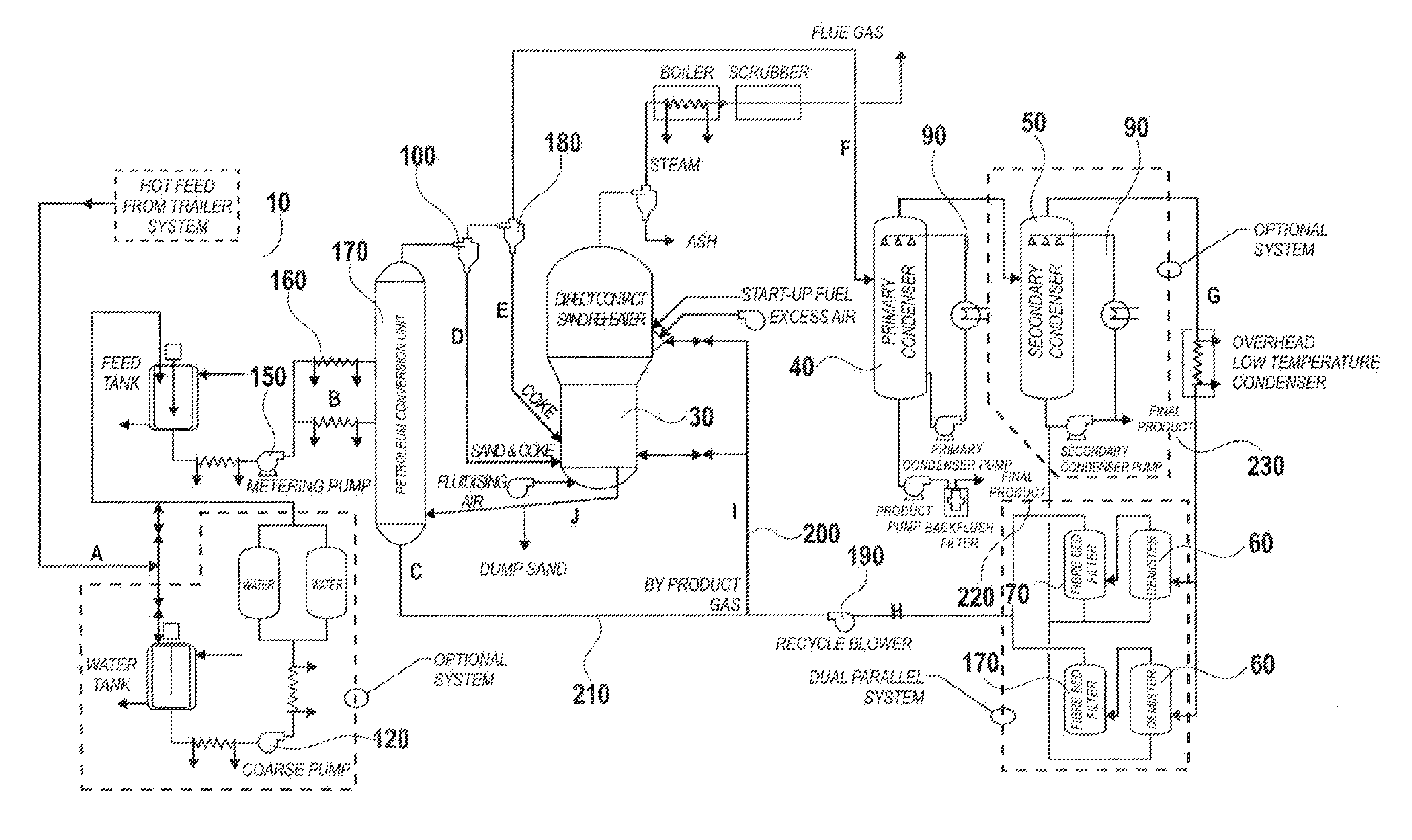

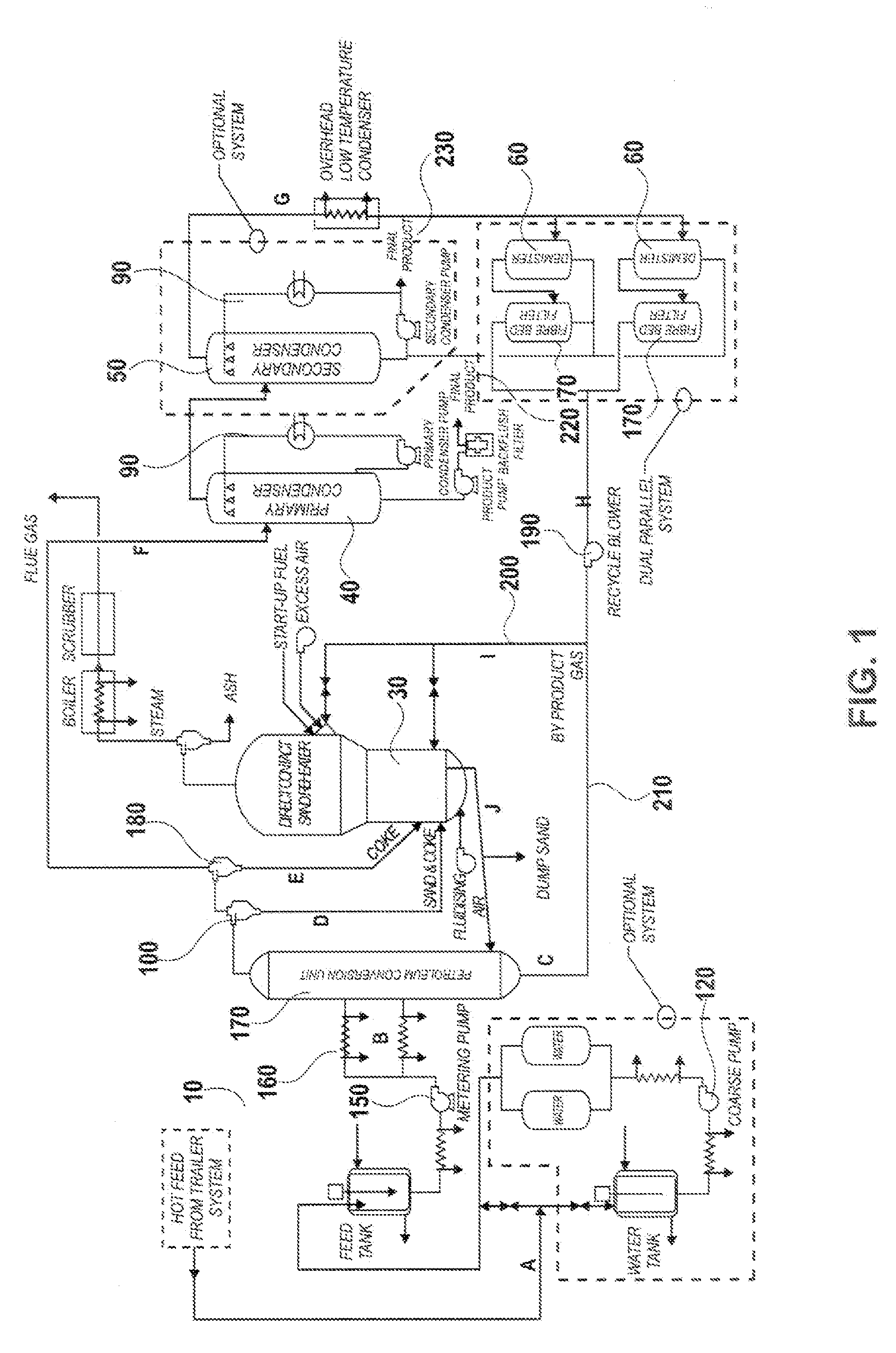

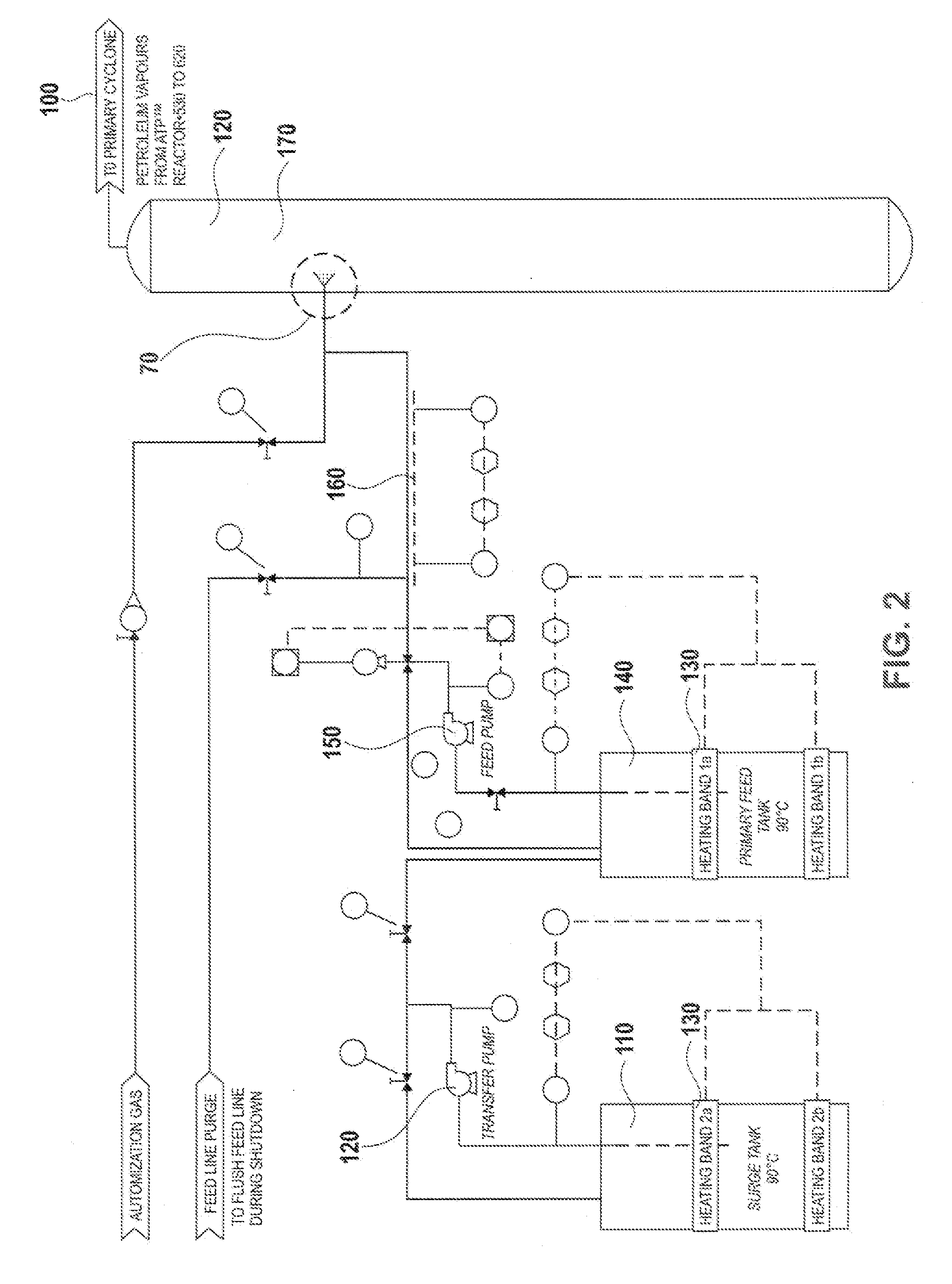

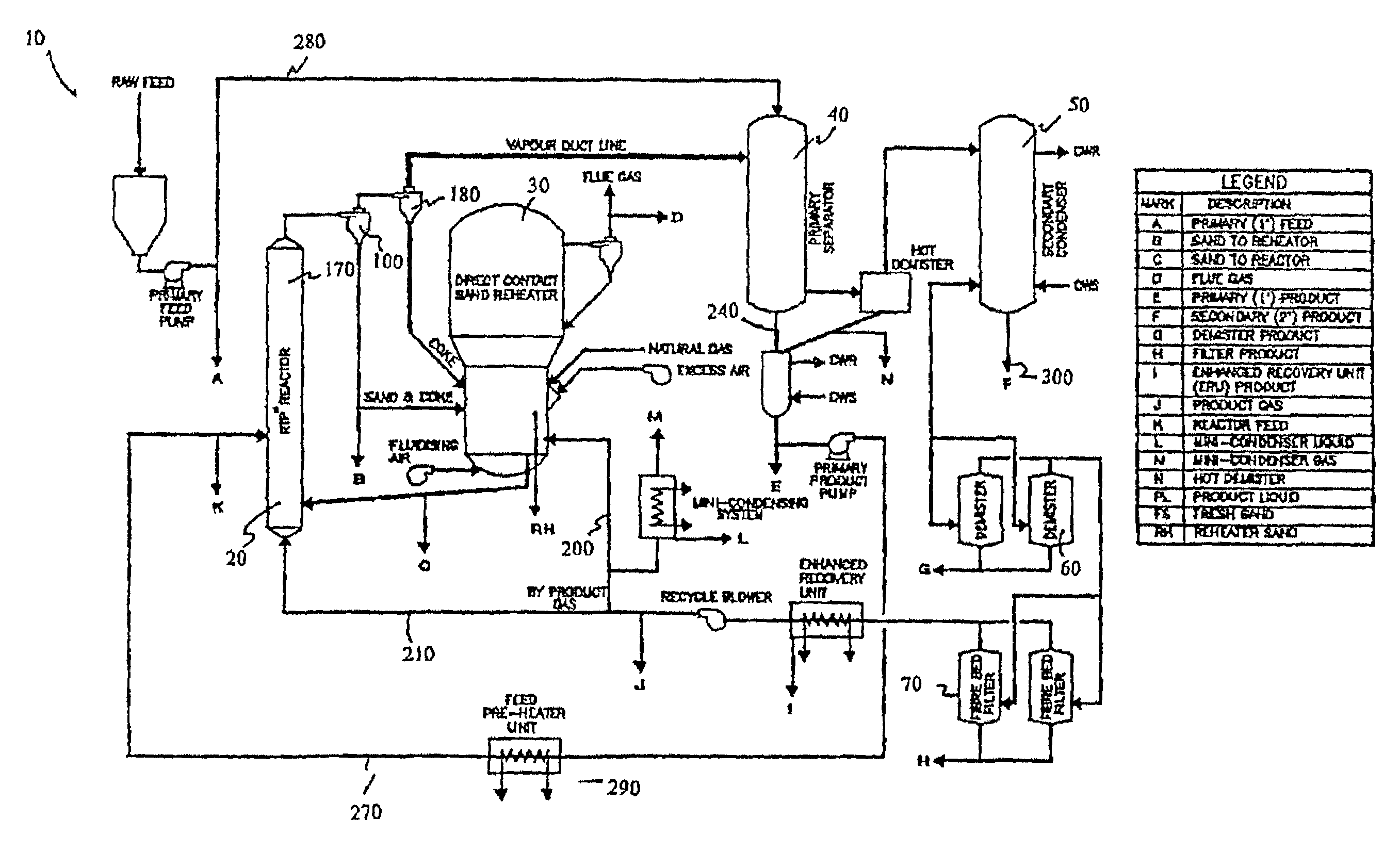

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

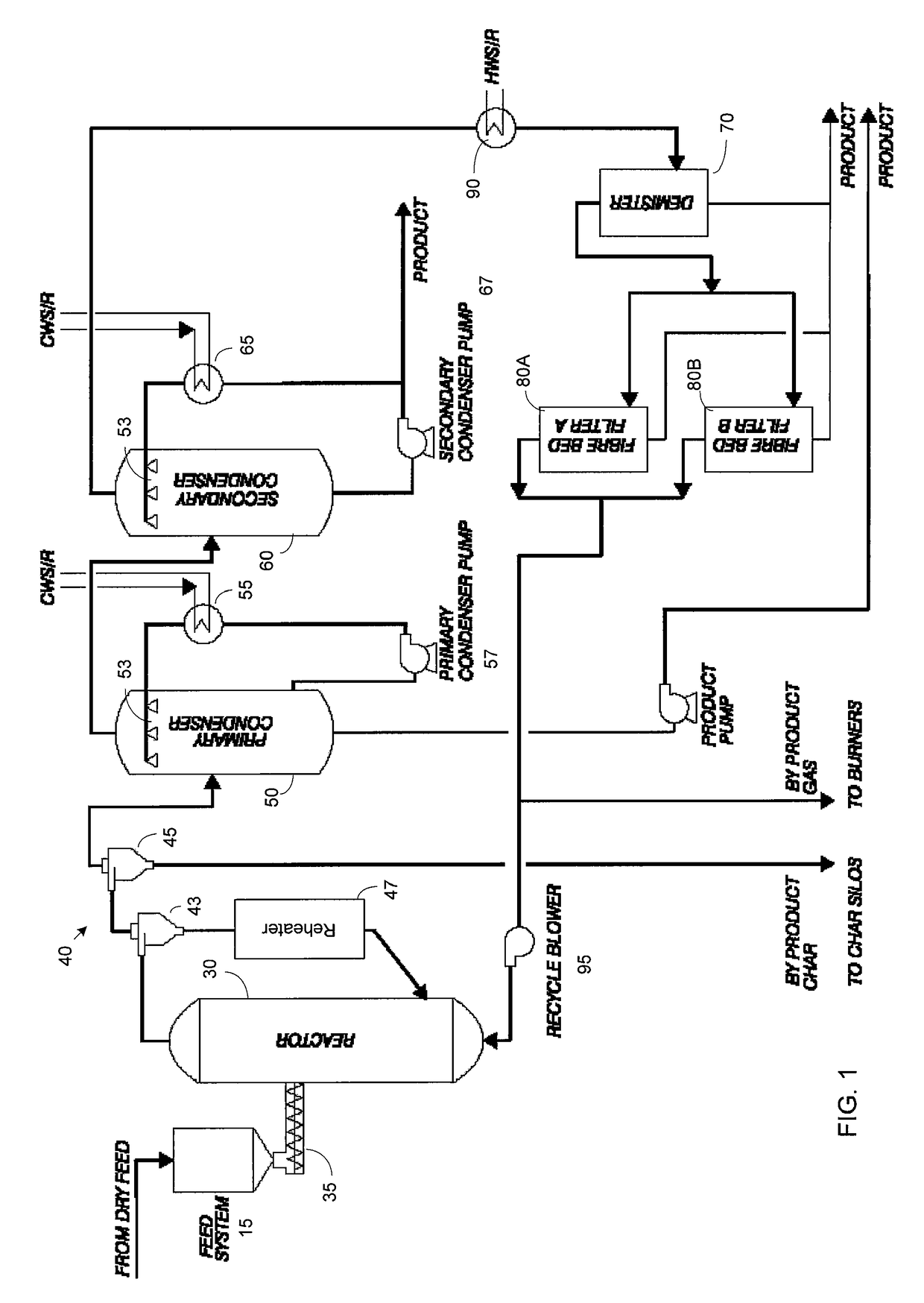

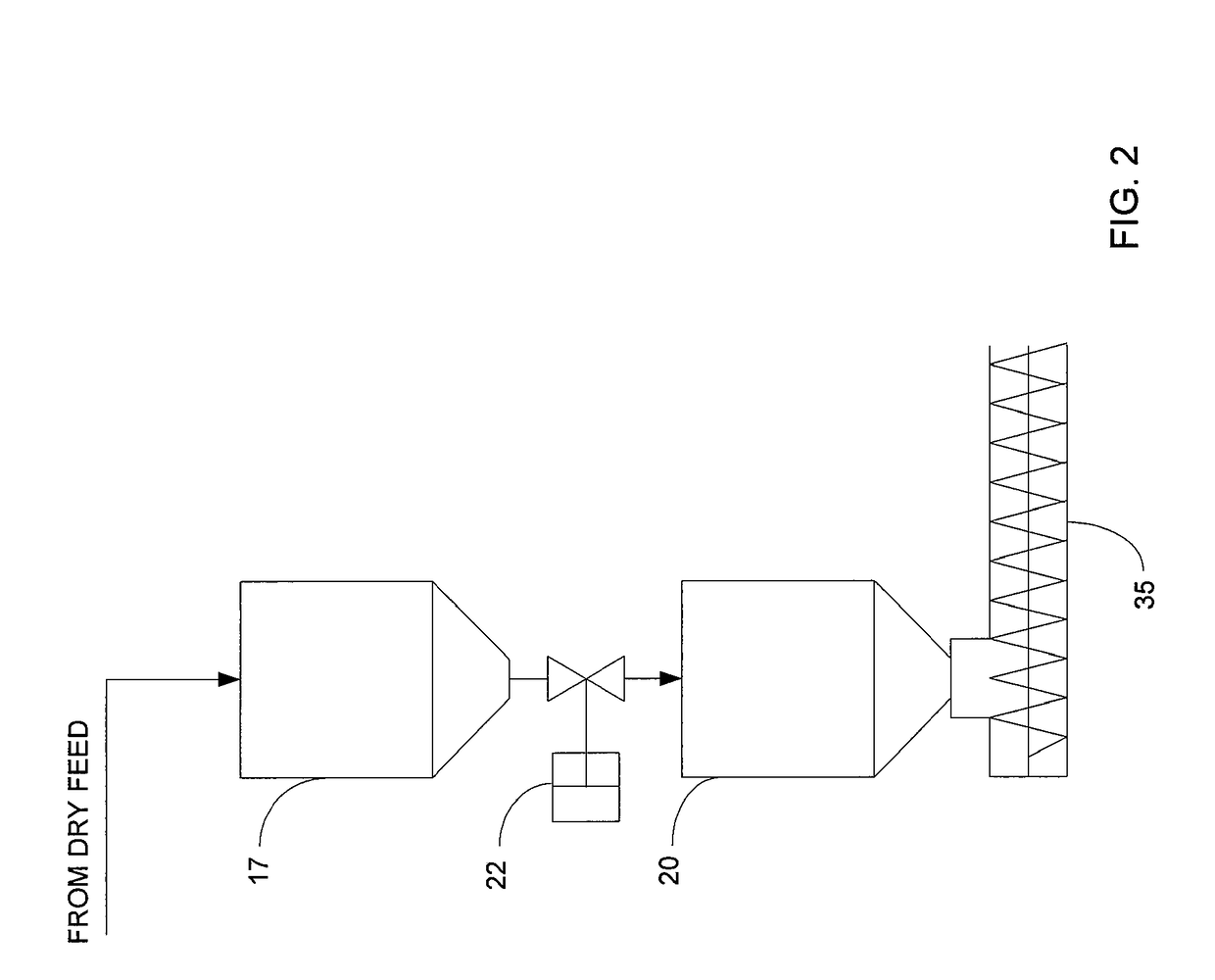

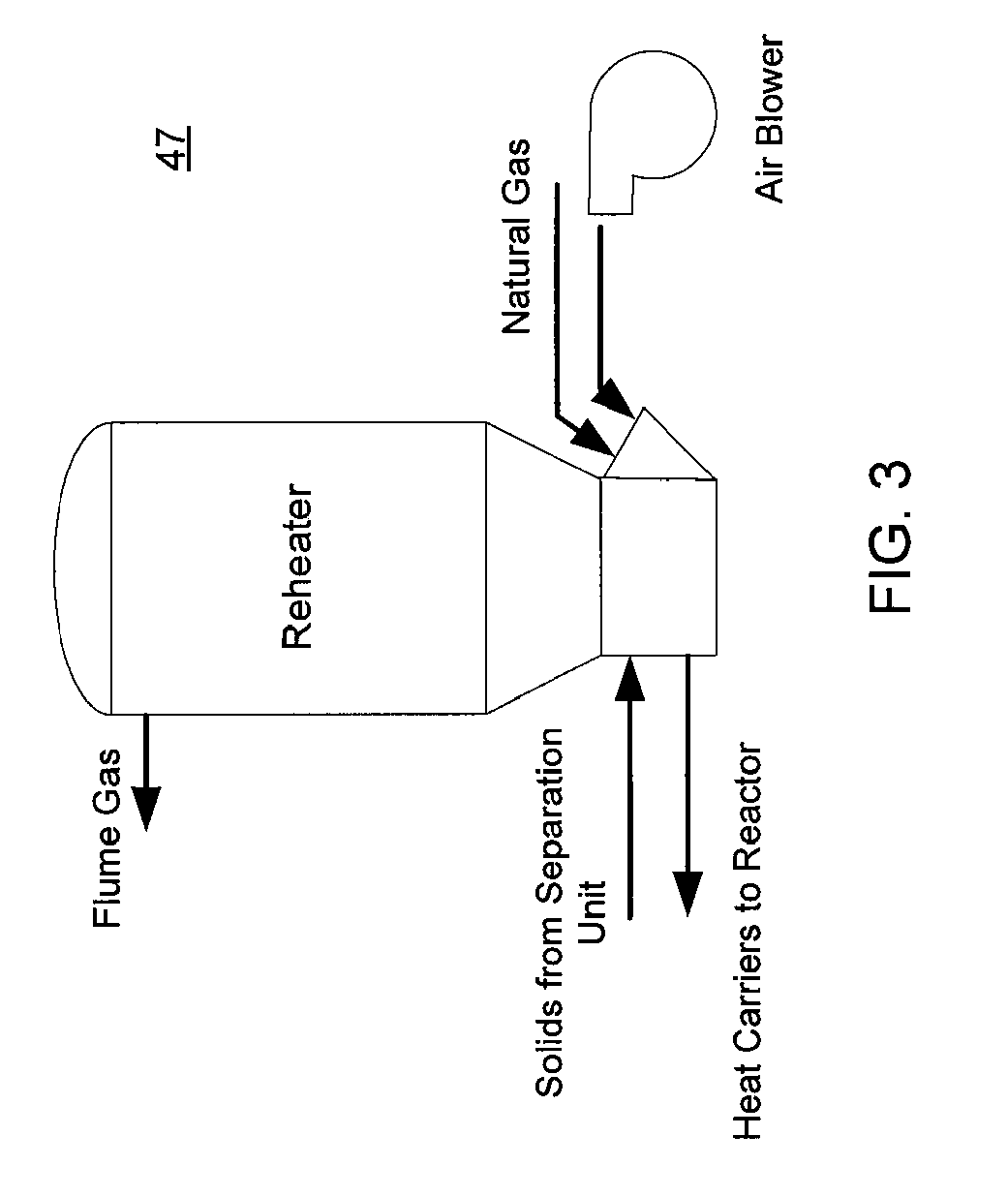

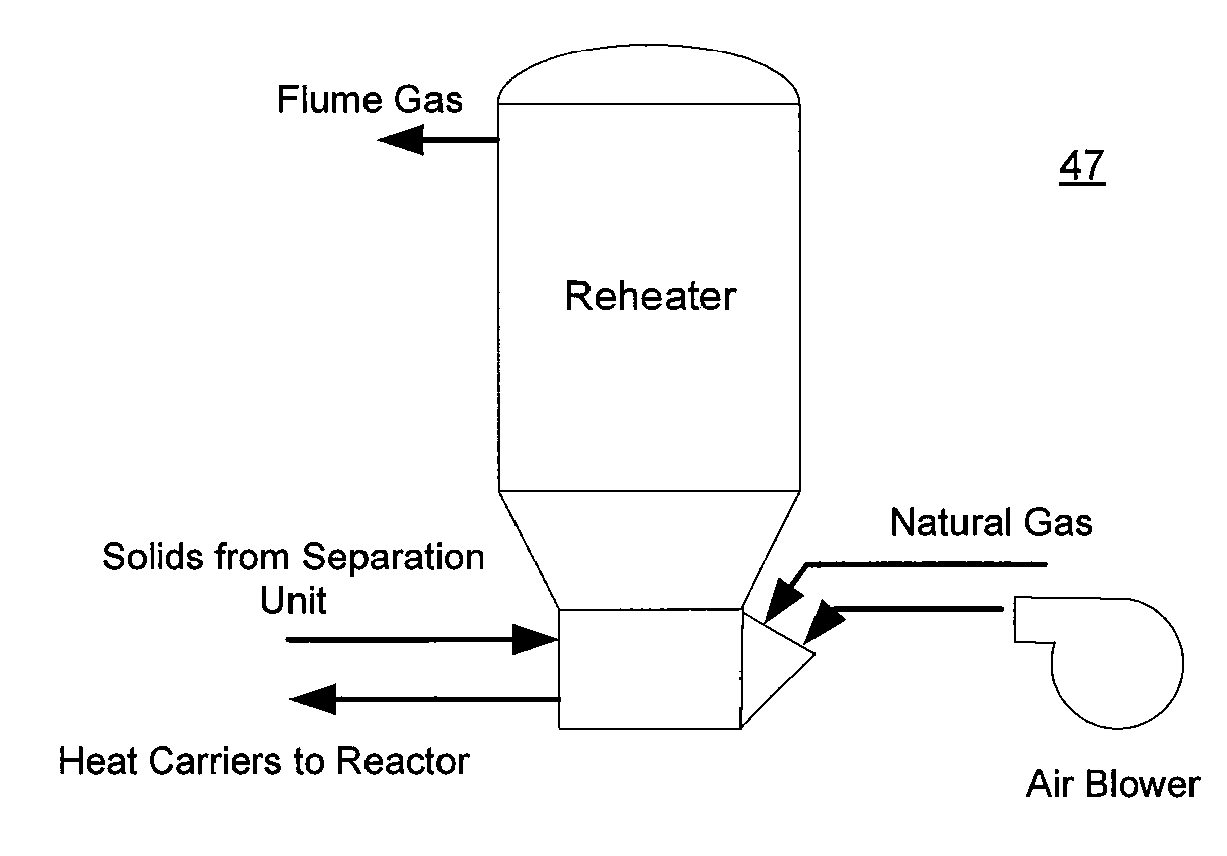

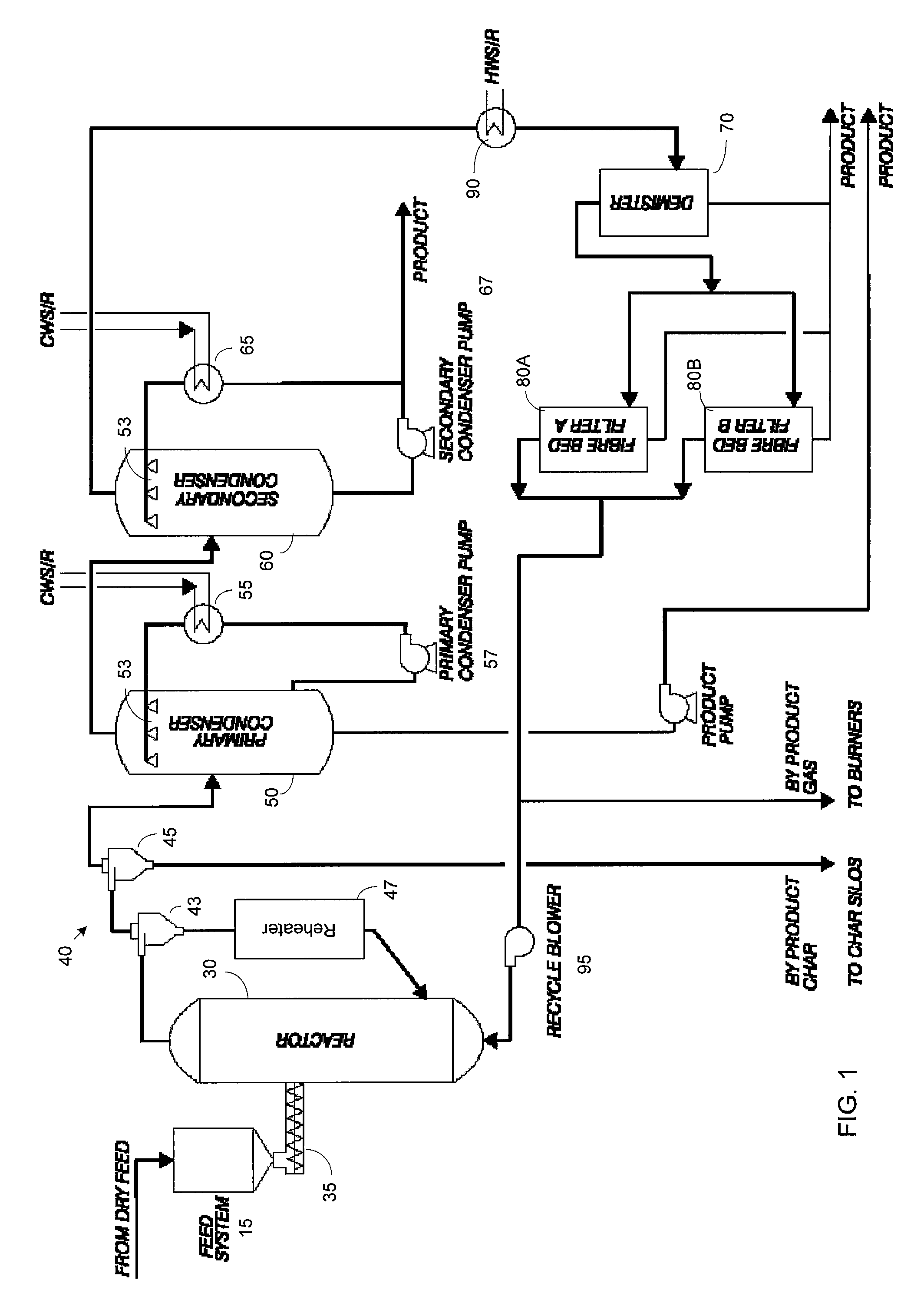

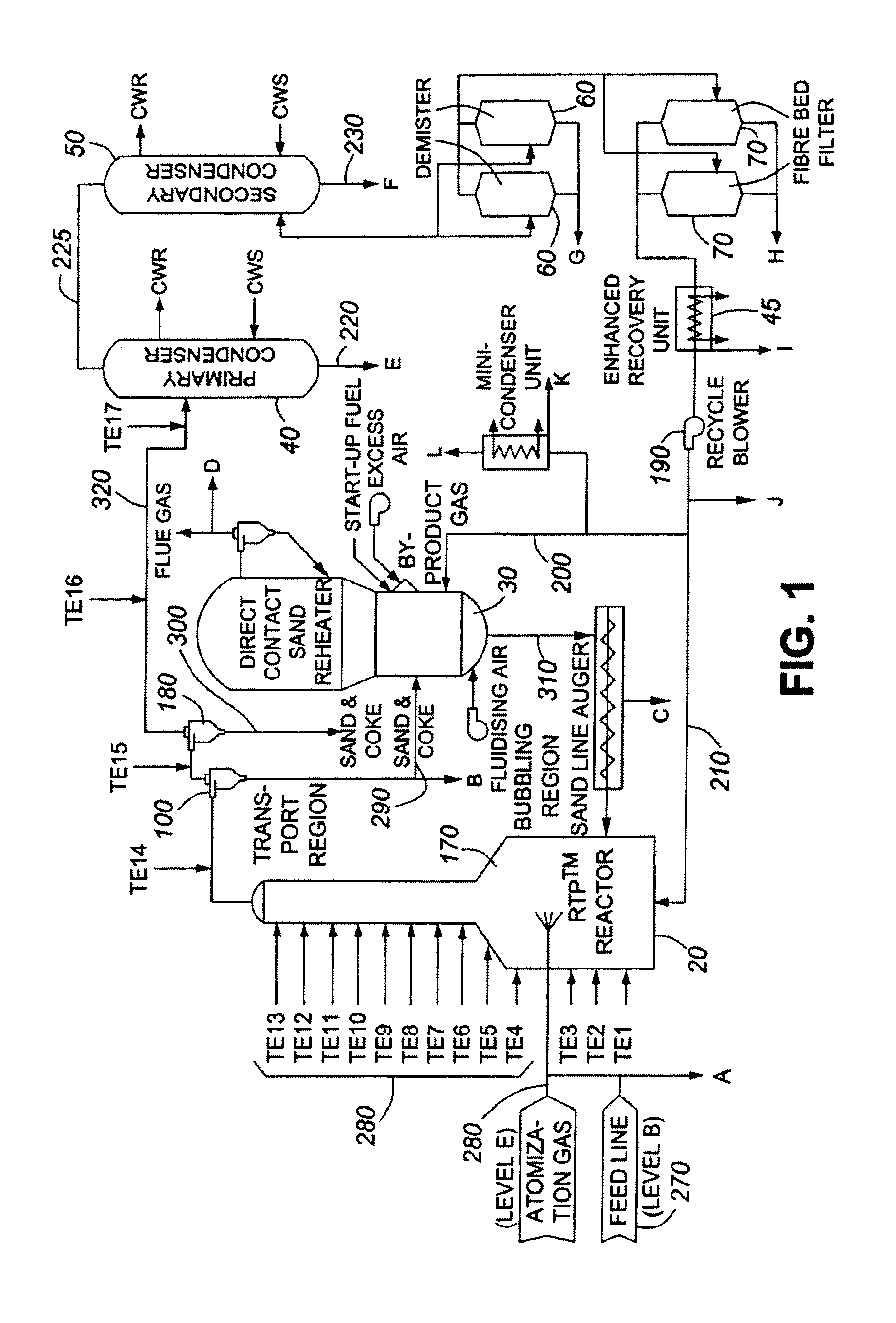

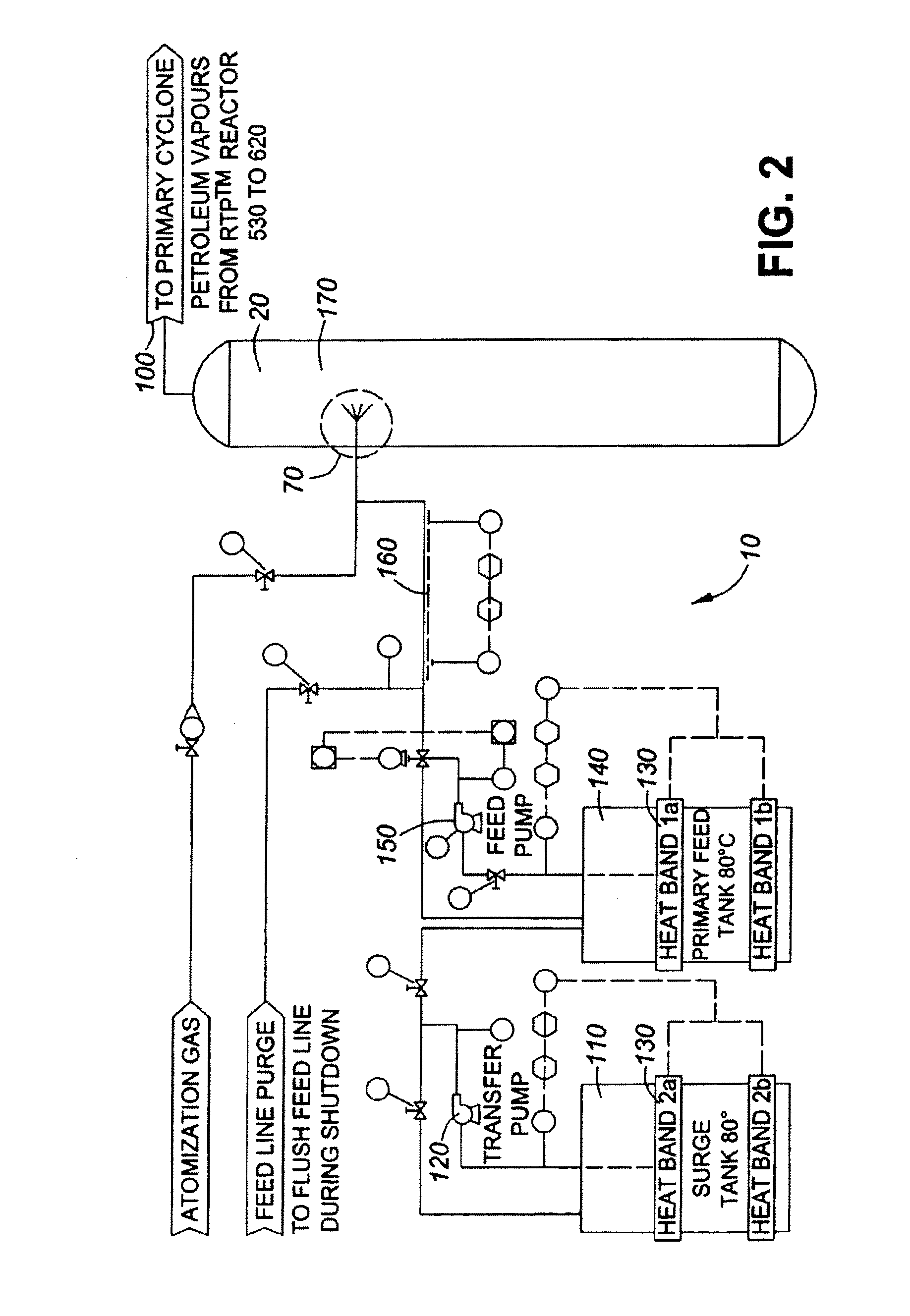

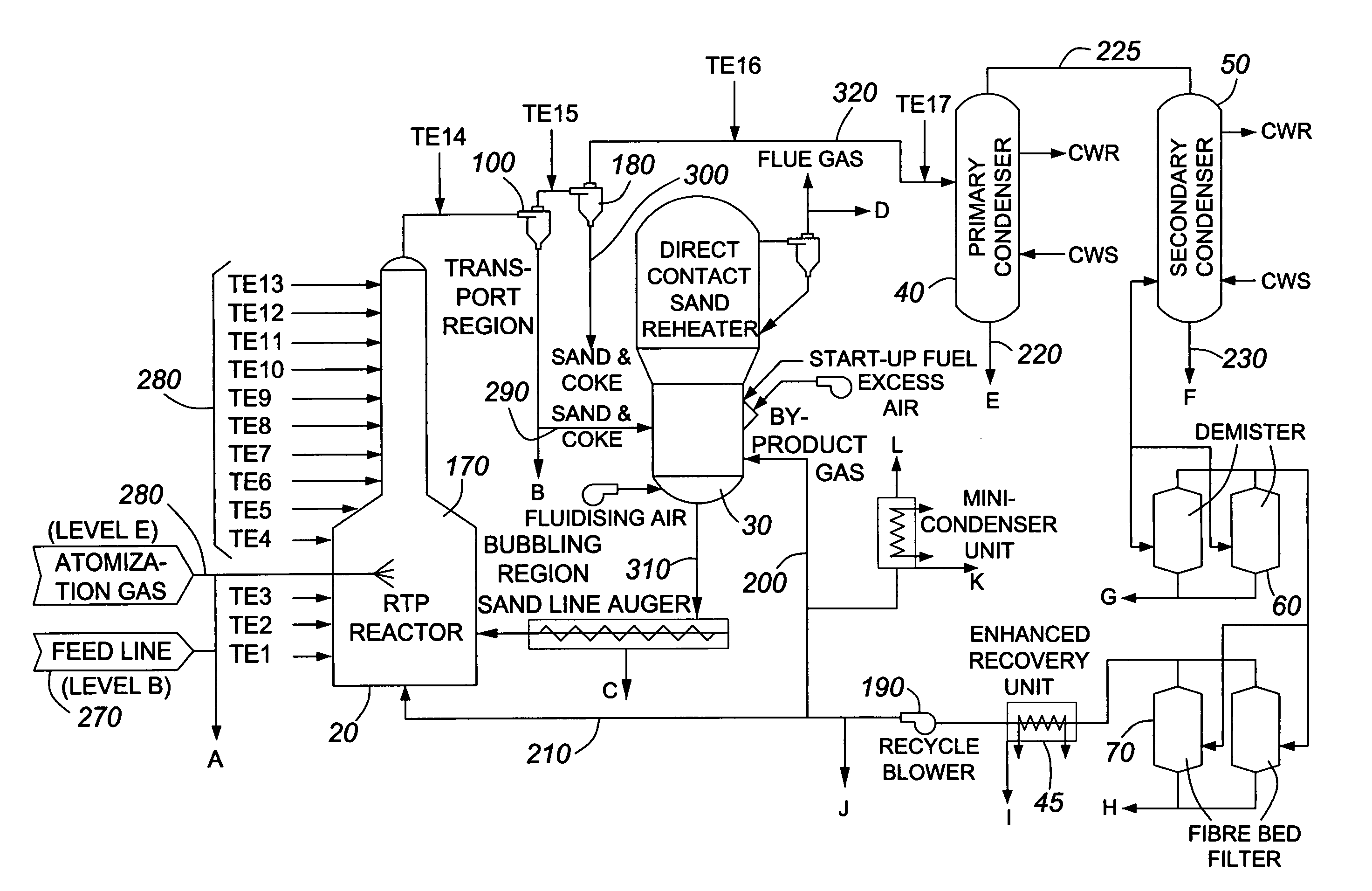

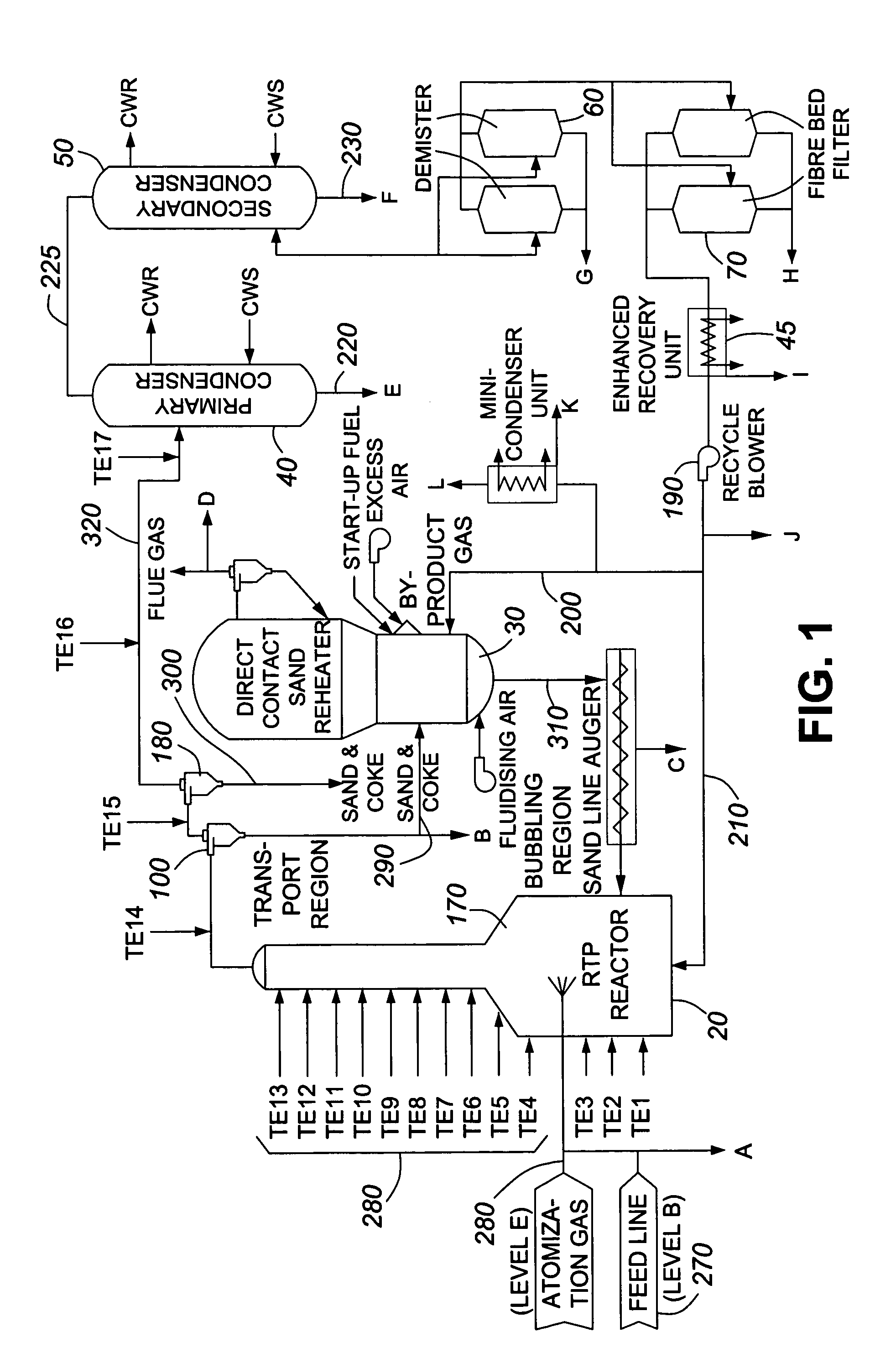

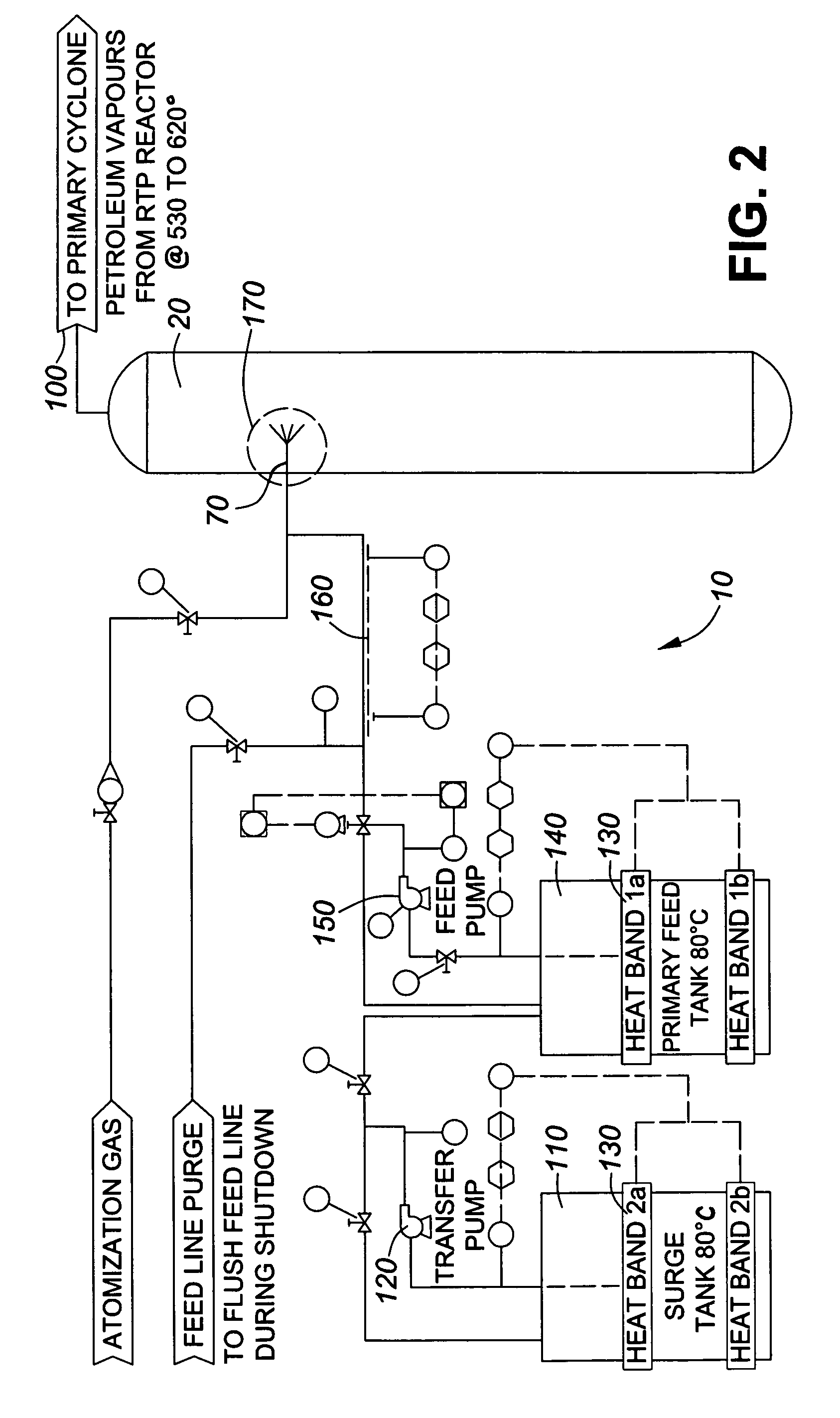

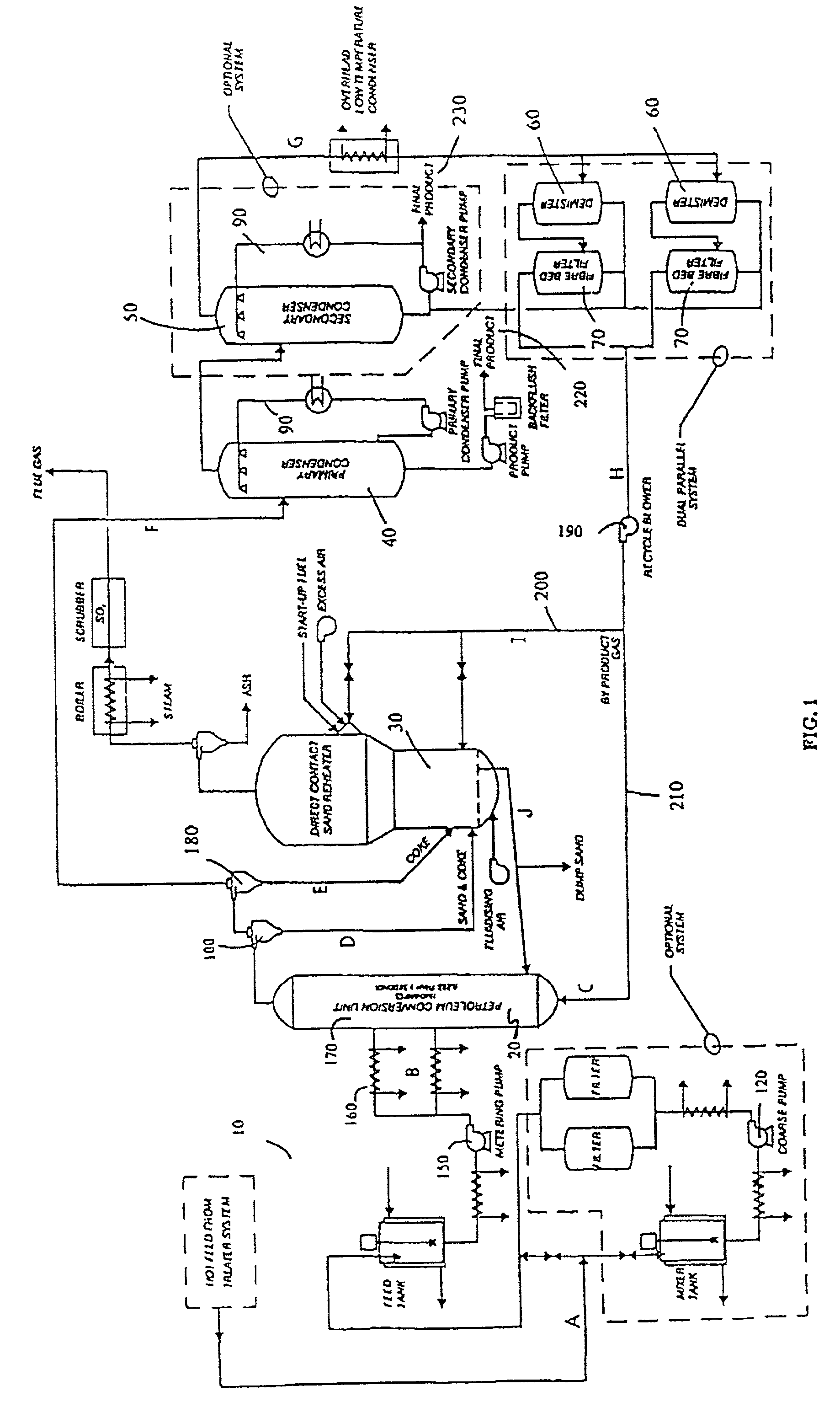

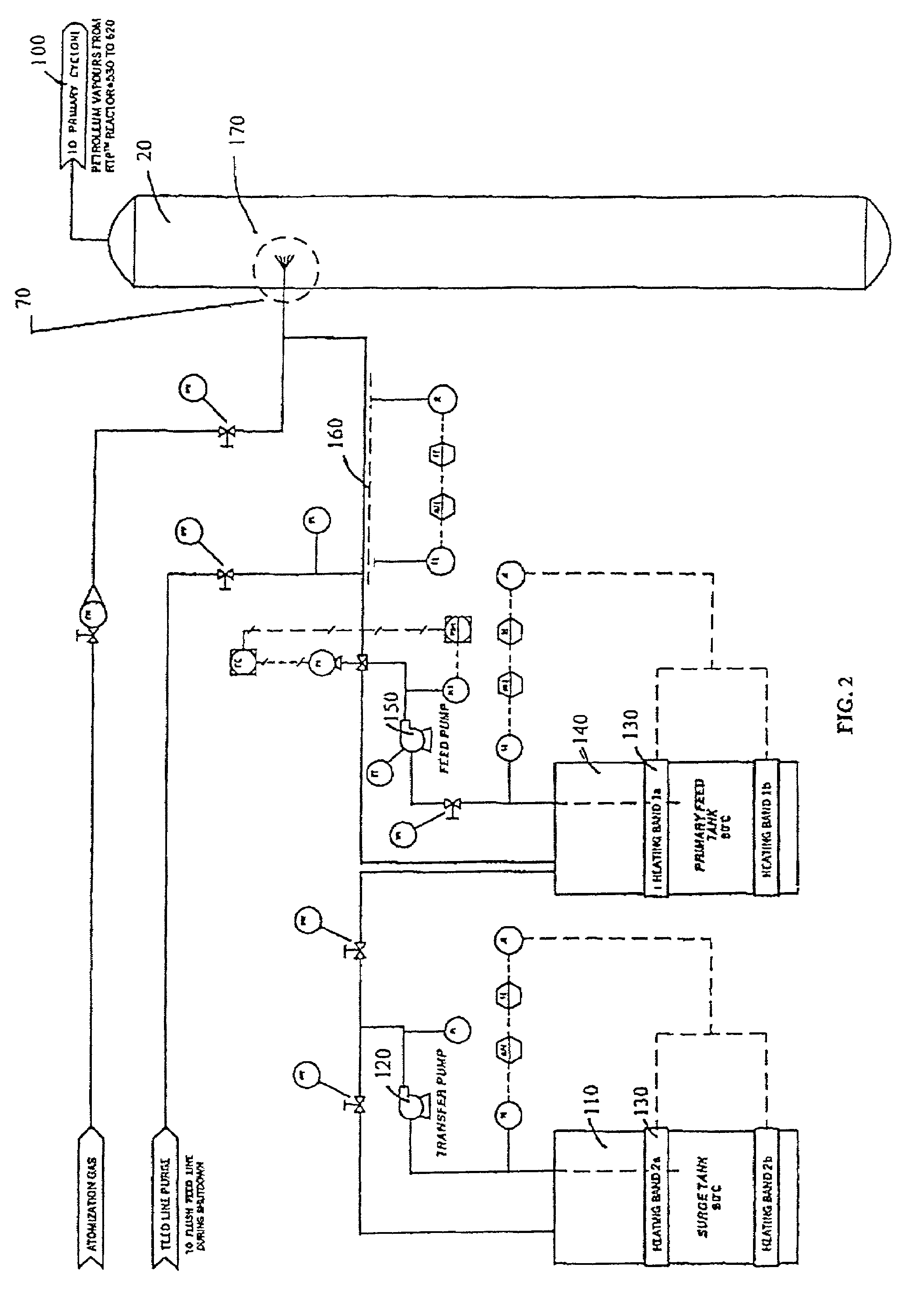

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

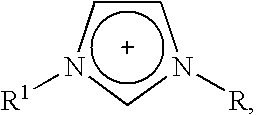

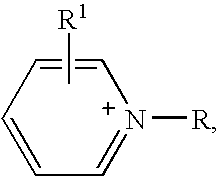

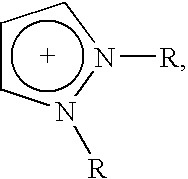

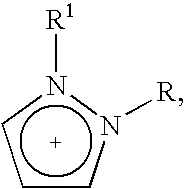

Ionic liquids

InactiveUS7252791B2Stable to hydrolysisImprove the level ofPreparation by carbon monoxide reactionDissolvingHeat carrierChemical reaction

Low melting ionic compounds of the general formula (cation) (R′SO4) in which R′ is a branched or linear, saturated or unsaturated, aliphatic or alicyclic functionalized or non-functionalized hydrocarbon chain with 3-36 carbon atoms are provided. These compounds can serve as ionic liquids, e.g. as solvents or solvent additives in chemical reactions, as extraction agents or as heat carriers. The compounds comprise a cation and anionic sulfate ester.

Owner:MERCK PATENT GMBH

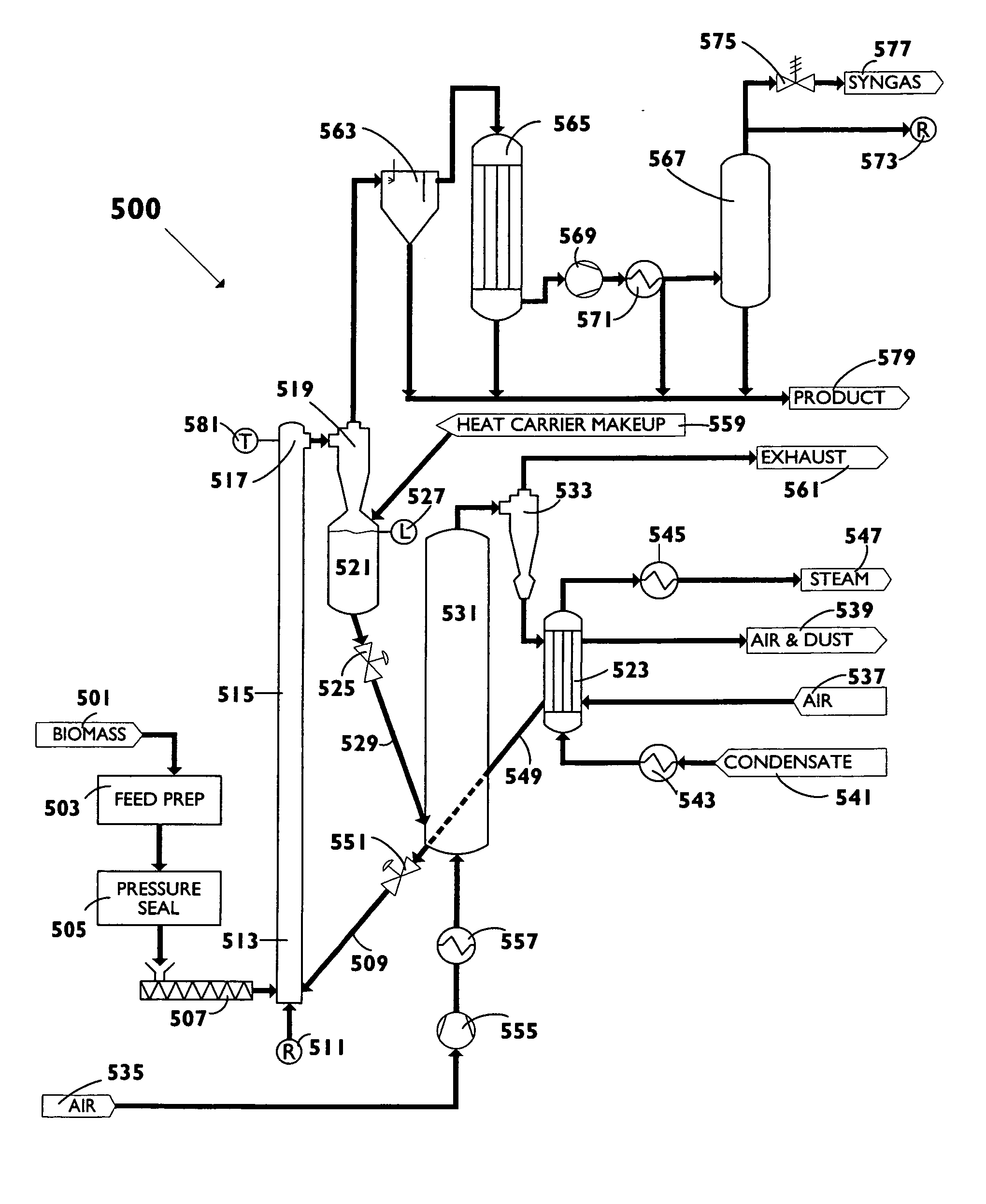

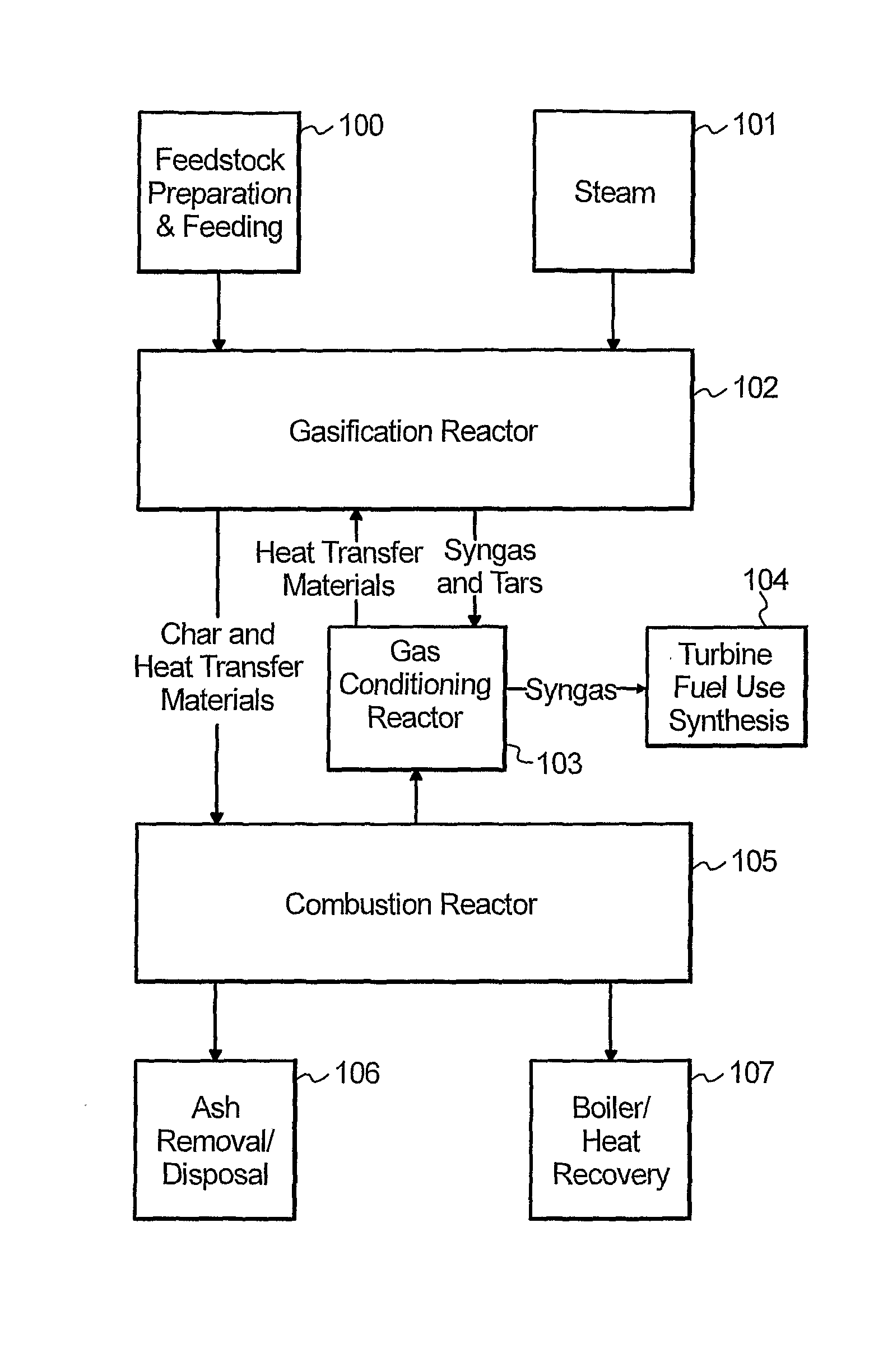

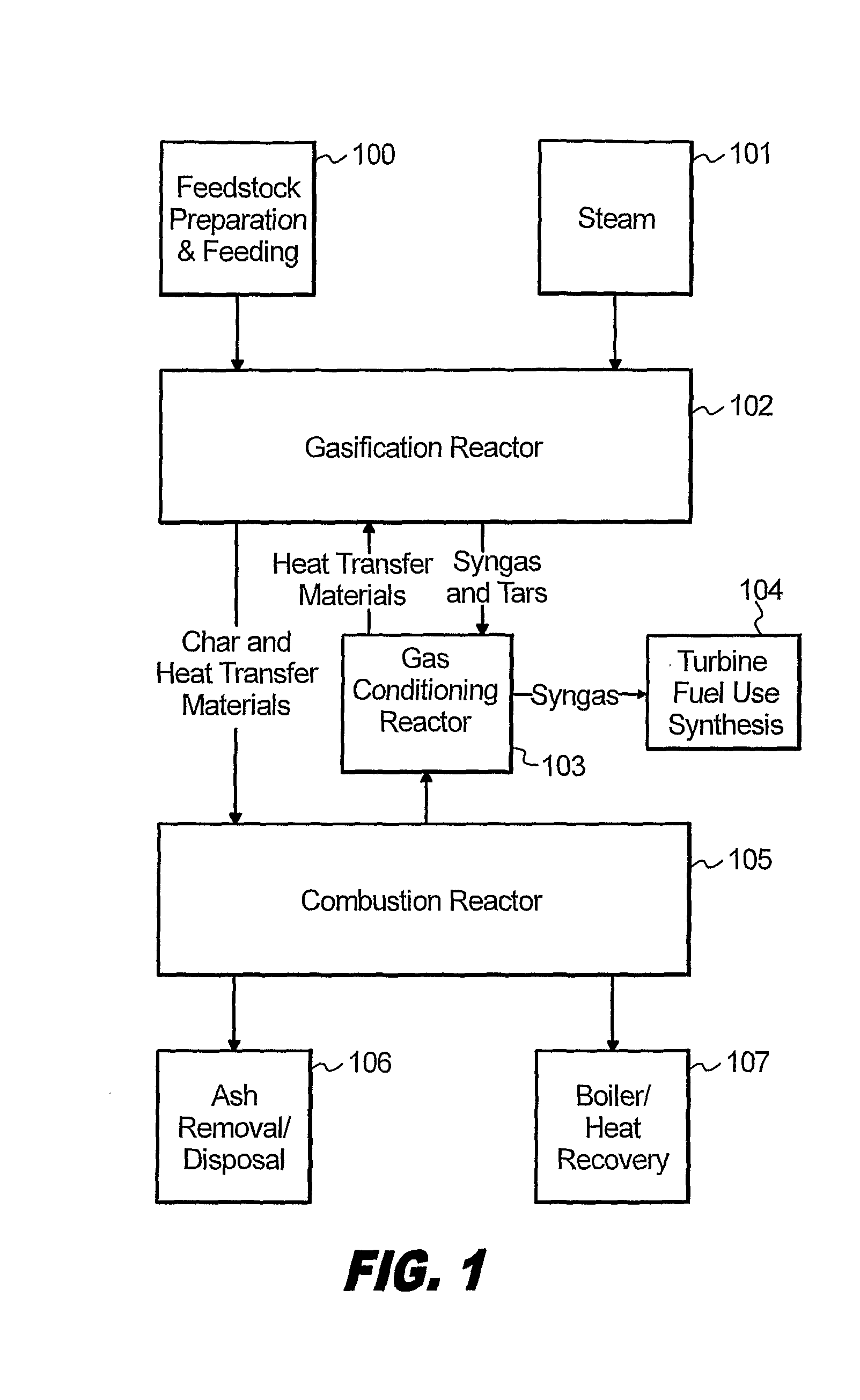

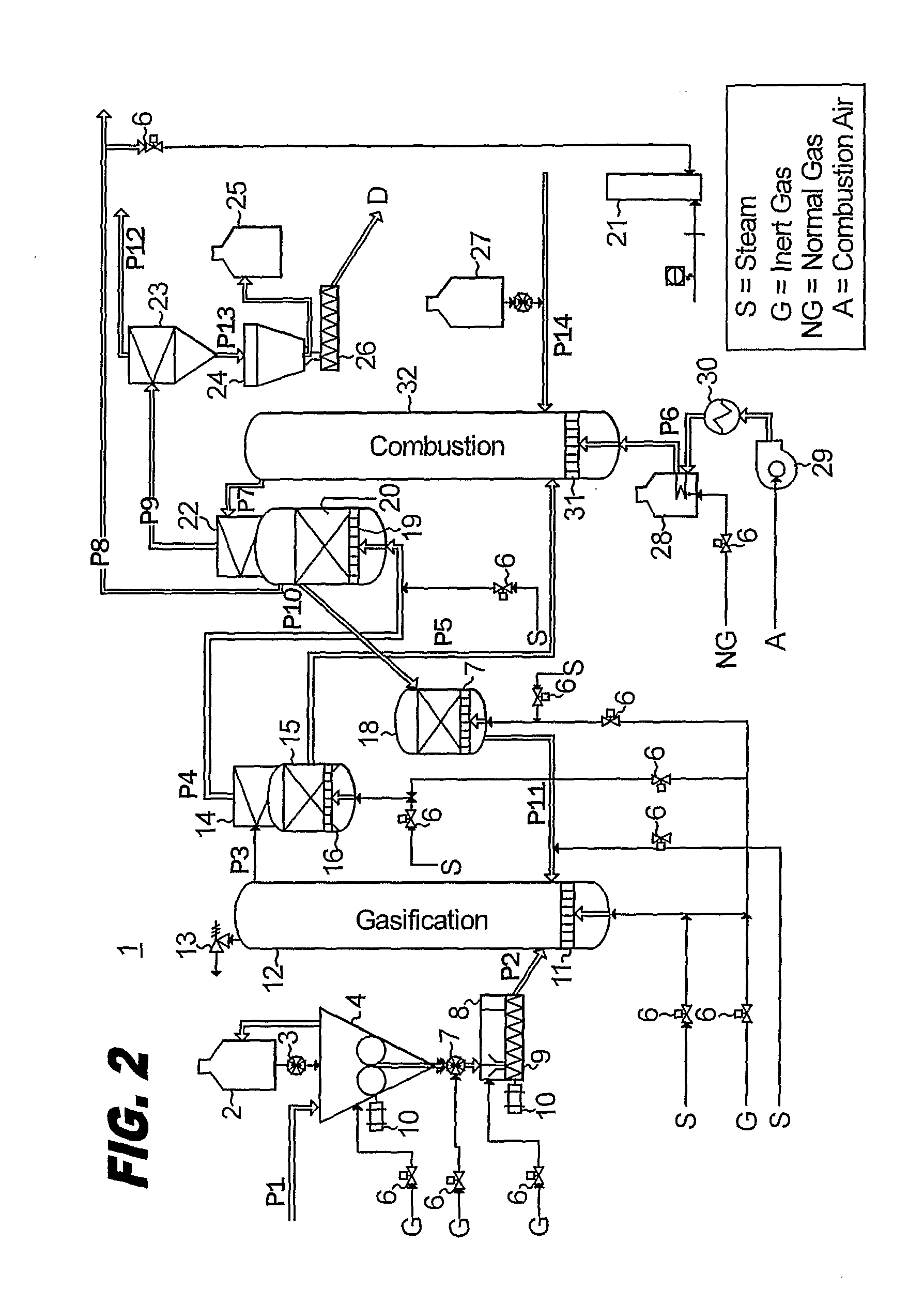

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

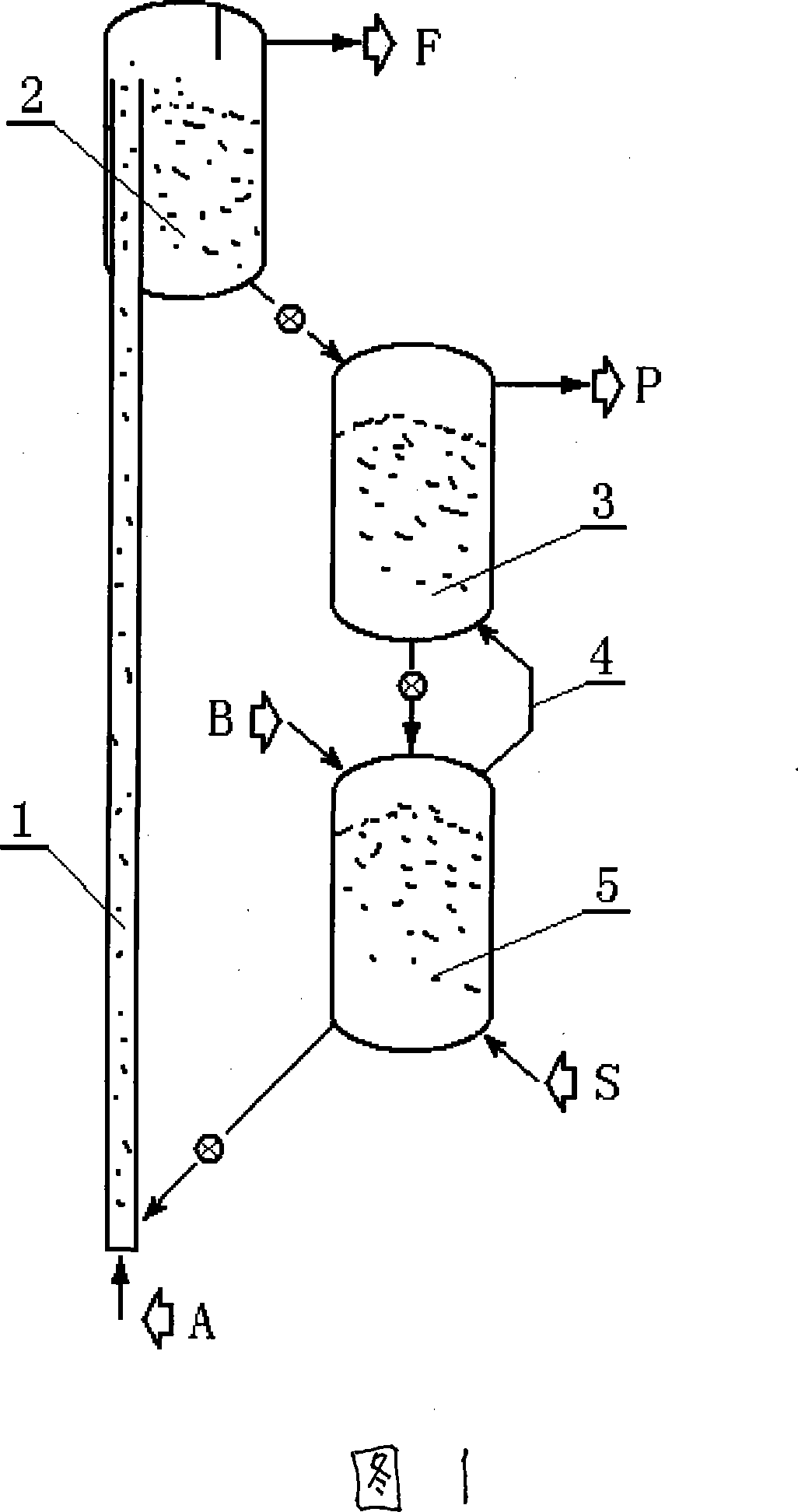

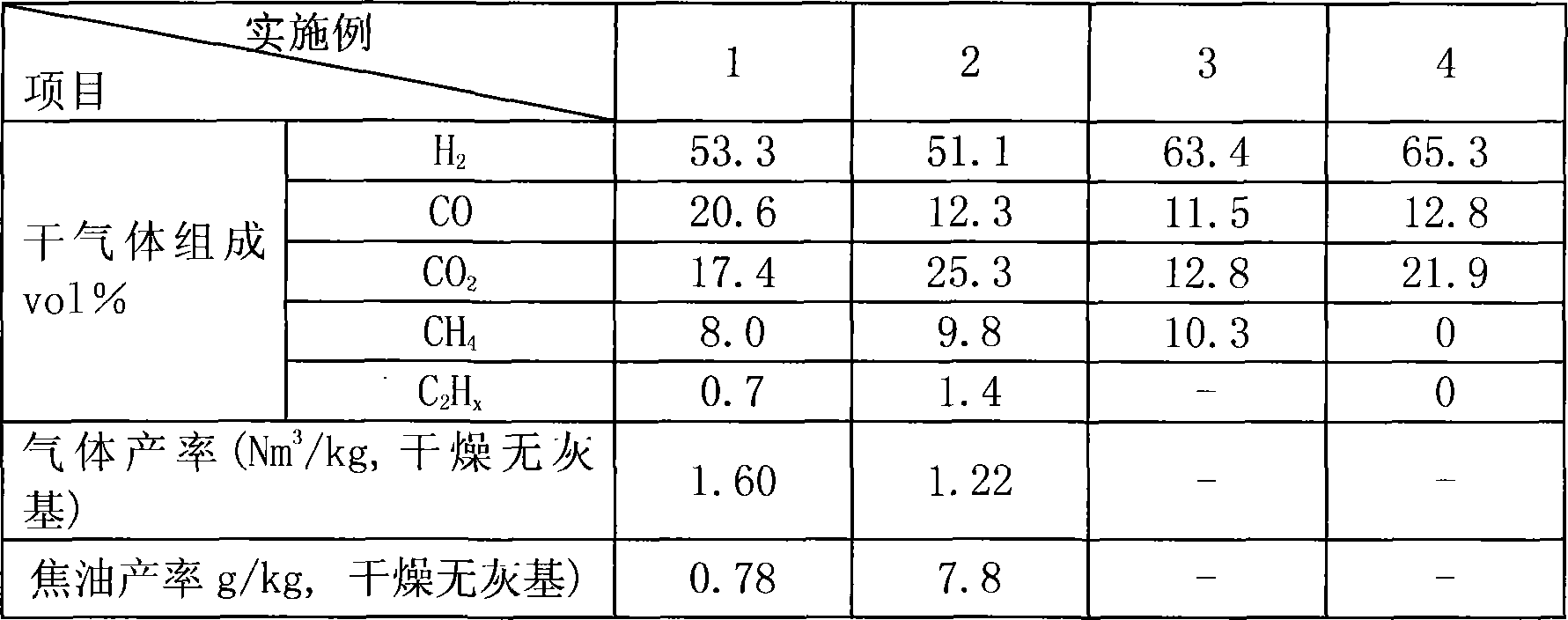

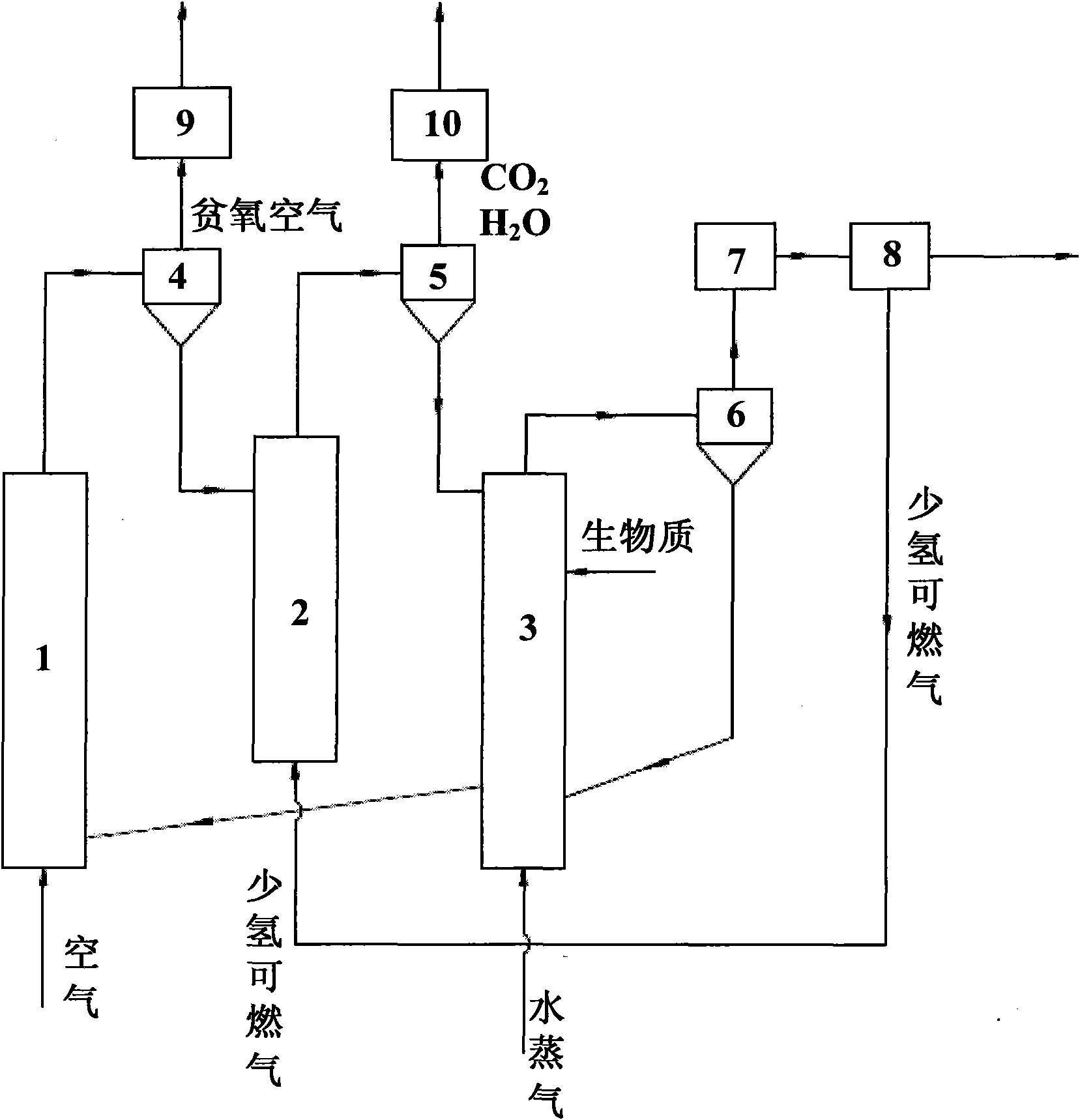

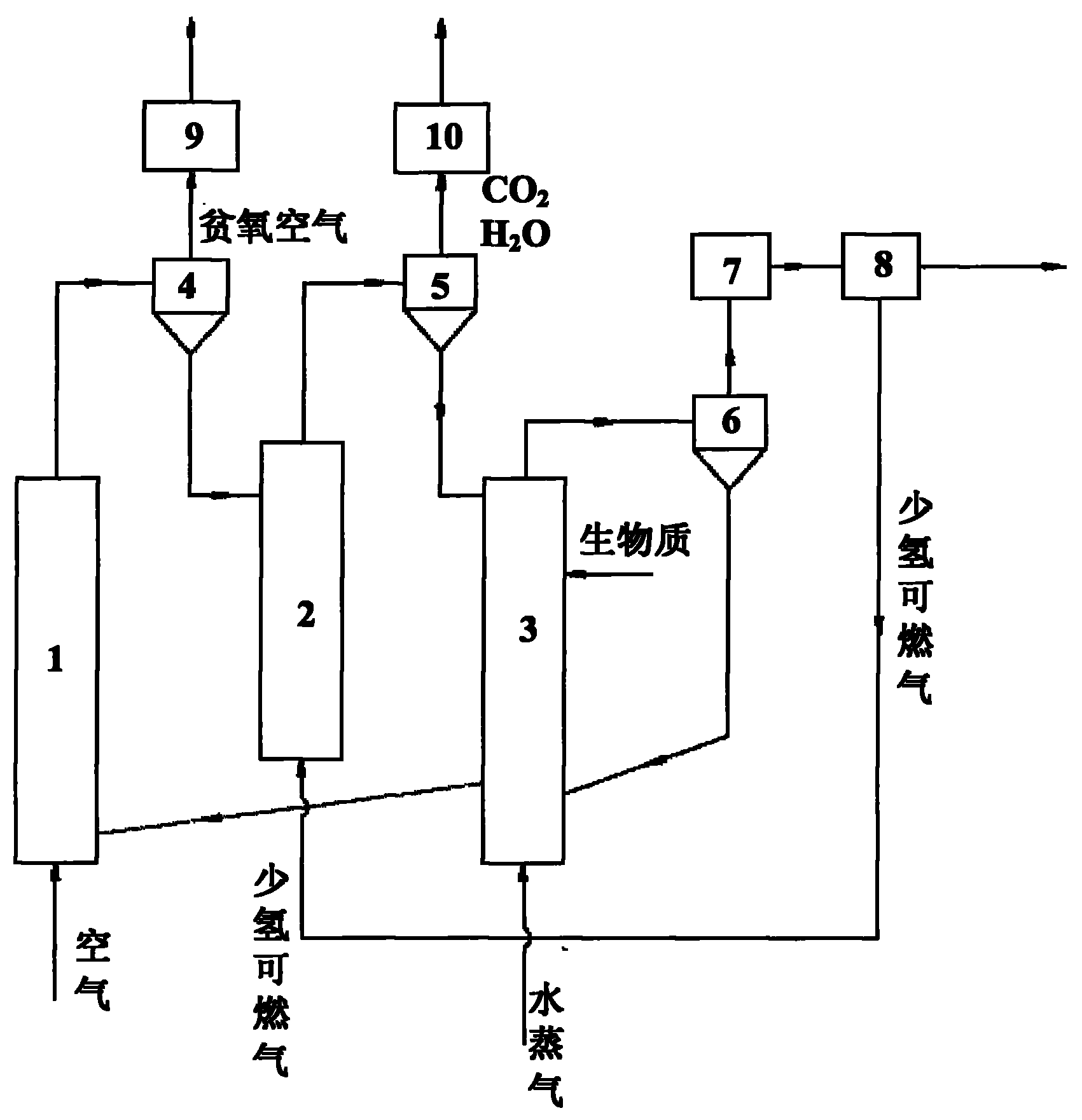

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524AReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingHeat carrier

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction. Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

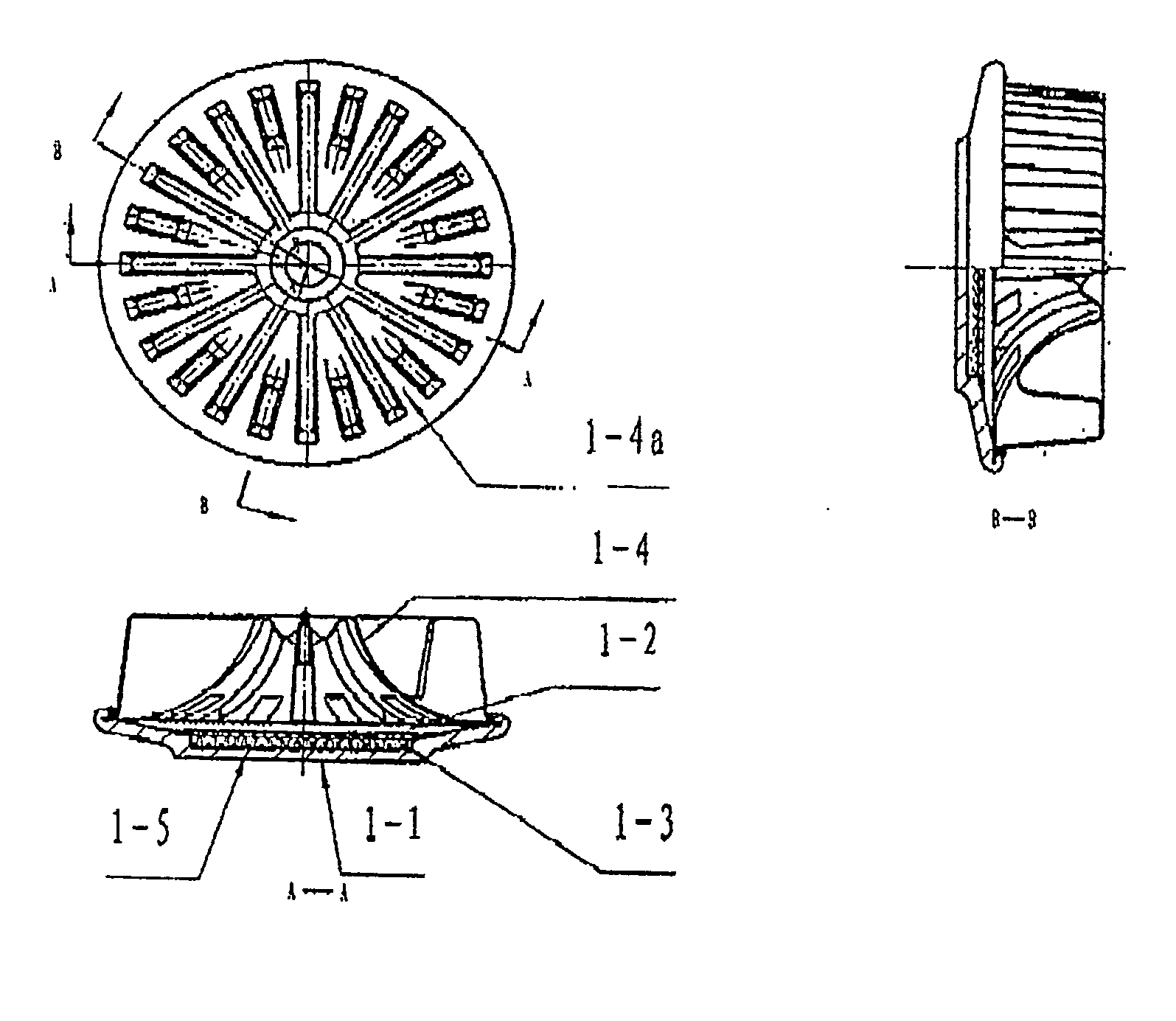

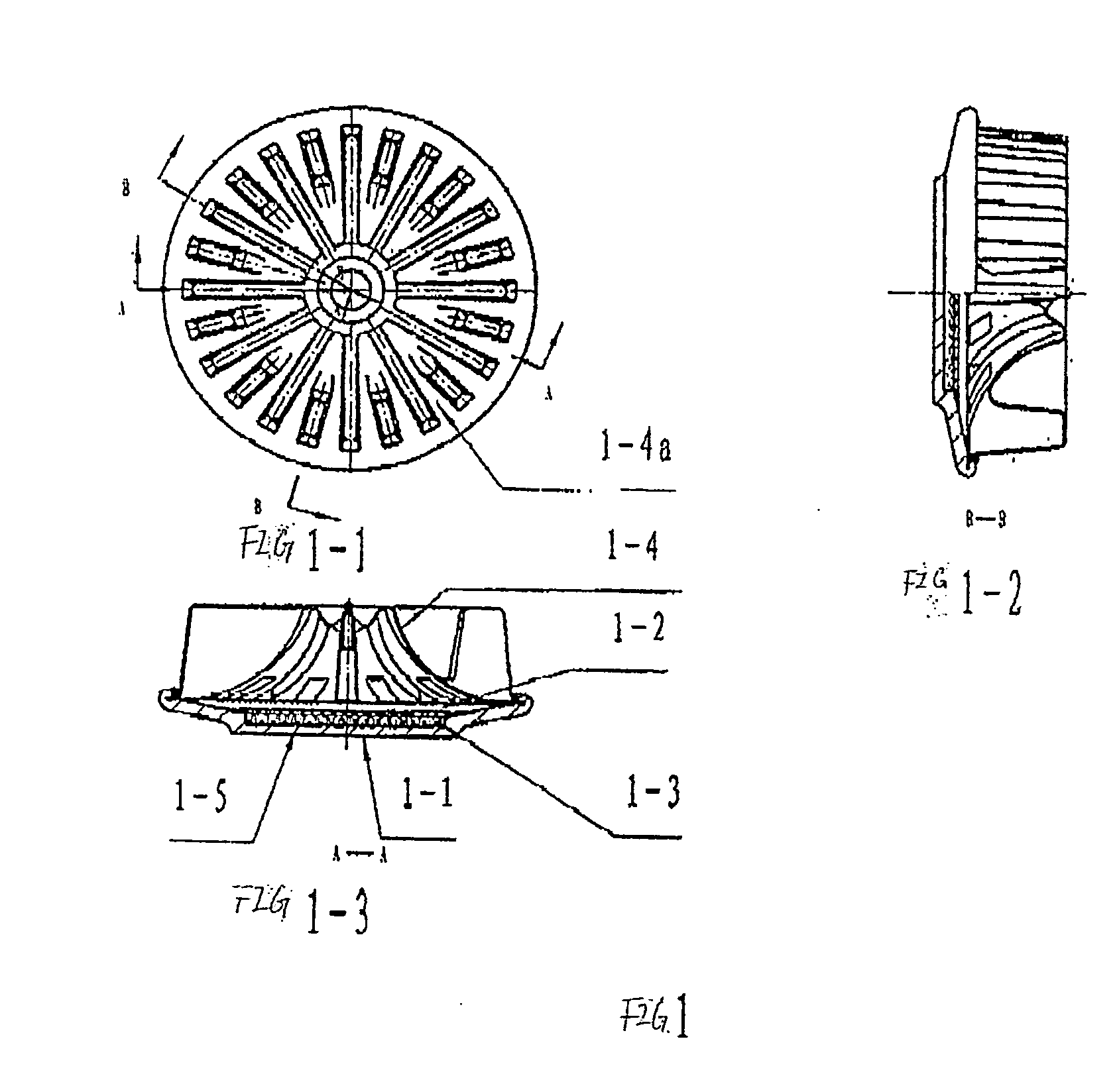

Integrated heat pipe and its method of heat exchange

InactiveUS20050061486A1Improve heat transfer efficiencyRemove heatStationary conduit assembliesHeat carrierEngineering

The present invention relates to a kind of integrated heat pipe and a method of heat exchange. The heat pipe includes a tank (1-2) as a heating potion and a lot of heat carriers (1-4) as a radiating portion. The tank (1-2) and the heat carriers (1-4) have same cavity in which a coolant (1-3) is partially filled. The tank (1-2) is held in close contact with a heat source (such as electronic elements). The heat carriers (1-4) are arranged at an interval so that the radiating channels (1-4a) are formed between them. The coolant (1-3) in the tank (1-2) is heated by the heat sources, vaporized coolant moves to the heat carriers (1-4) and condenses in there. According to the invention, the heat pipe can be increased its radiating surface significantly with the varied arrangement of the heat carriers (1-4).

Owner:YANG HONGWU

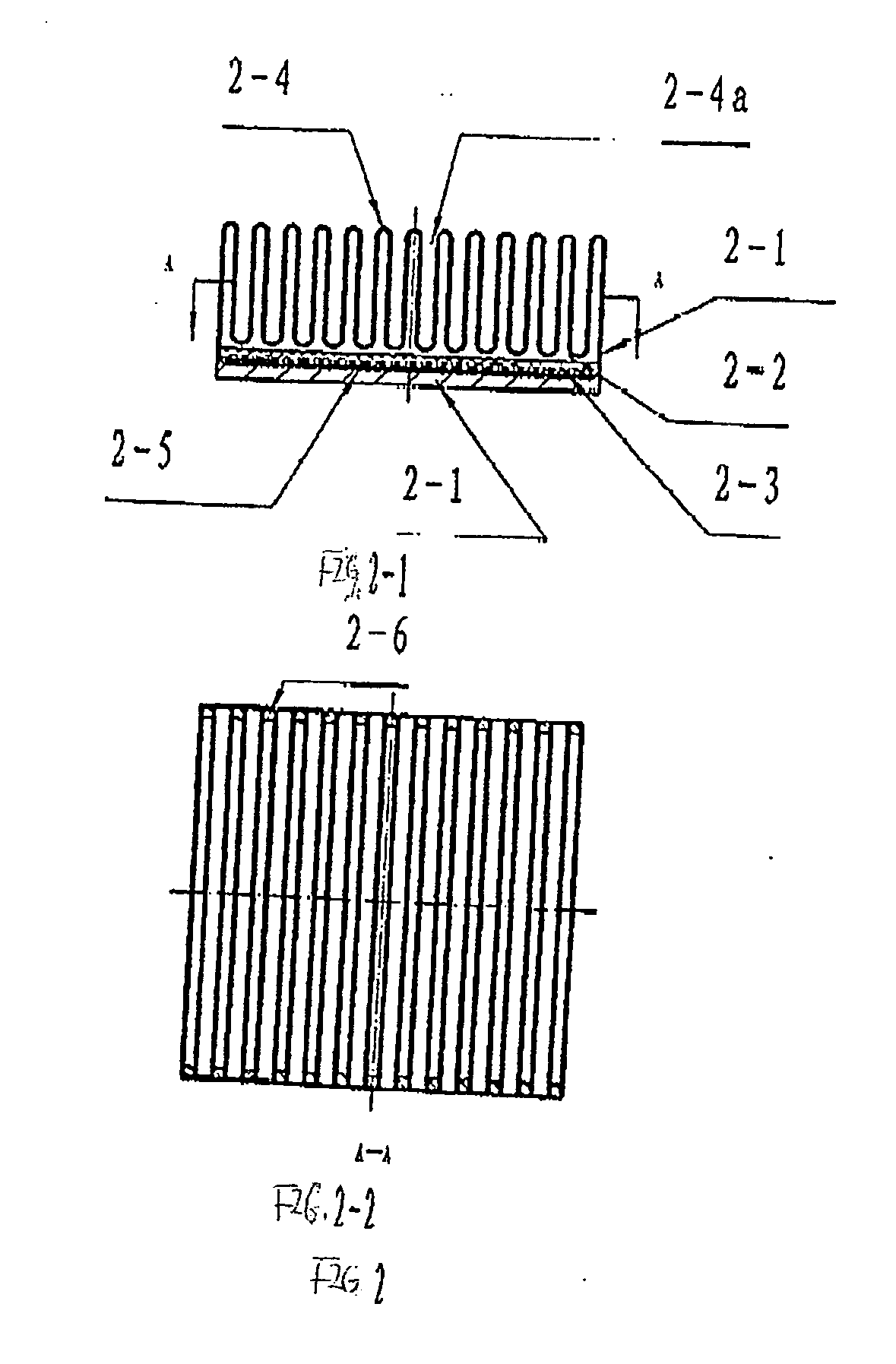

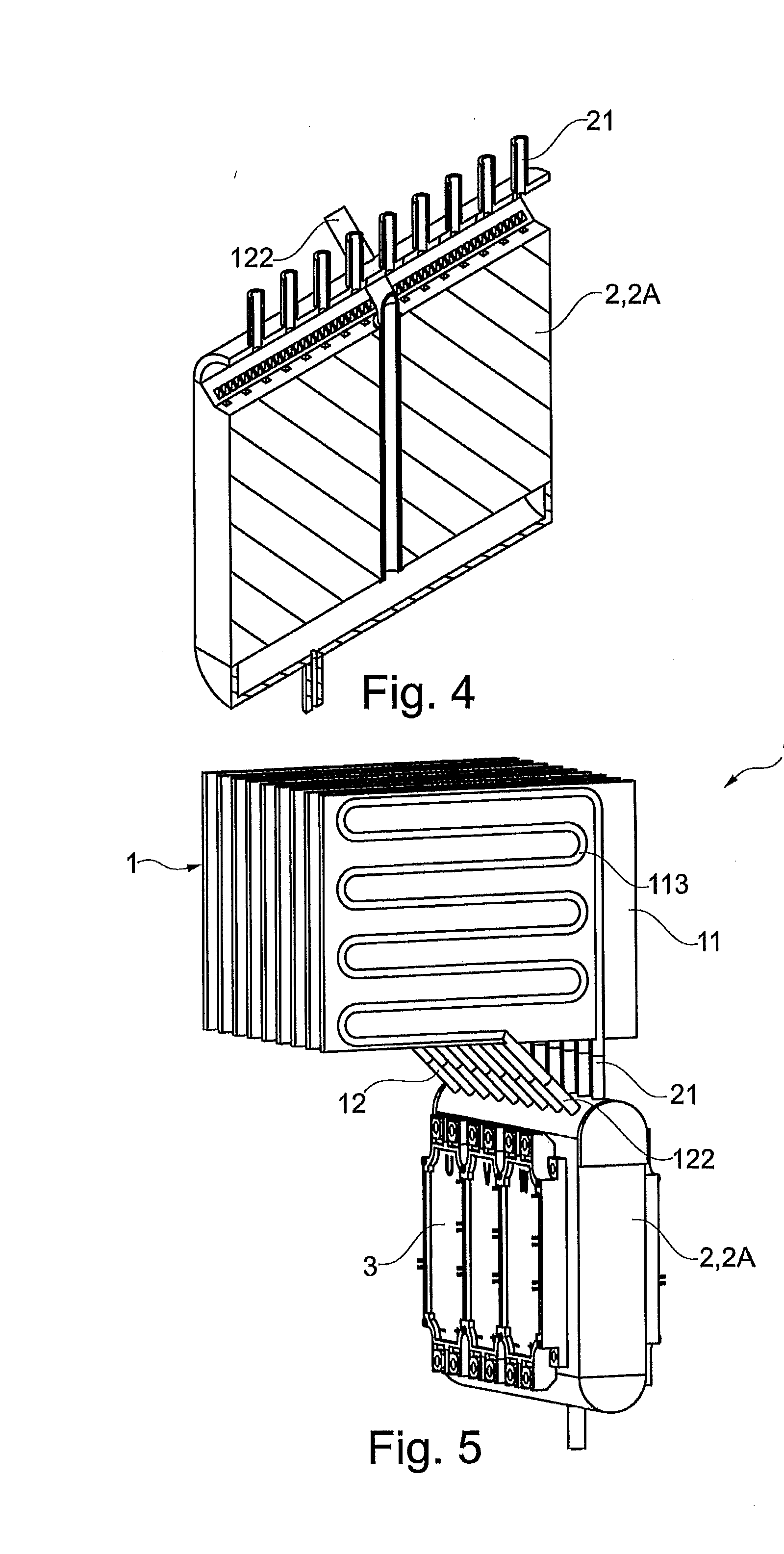

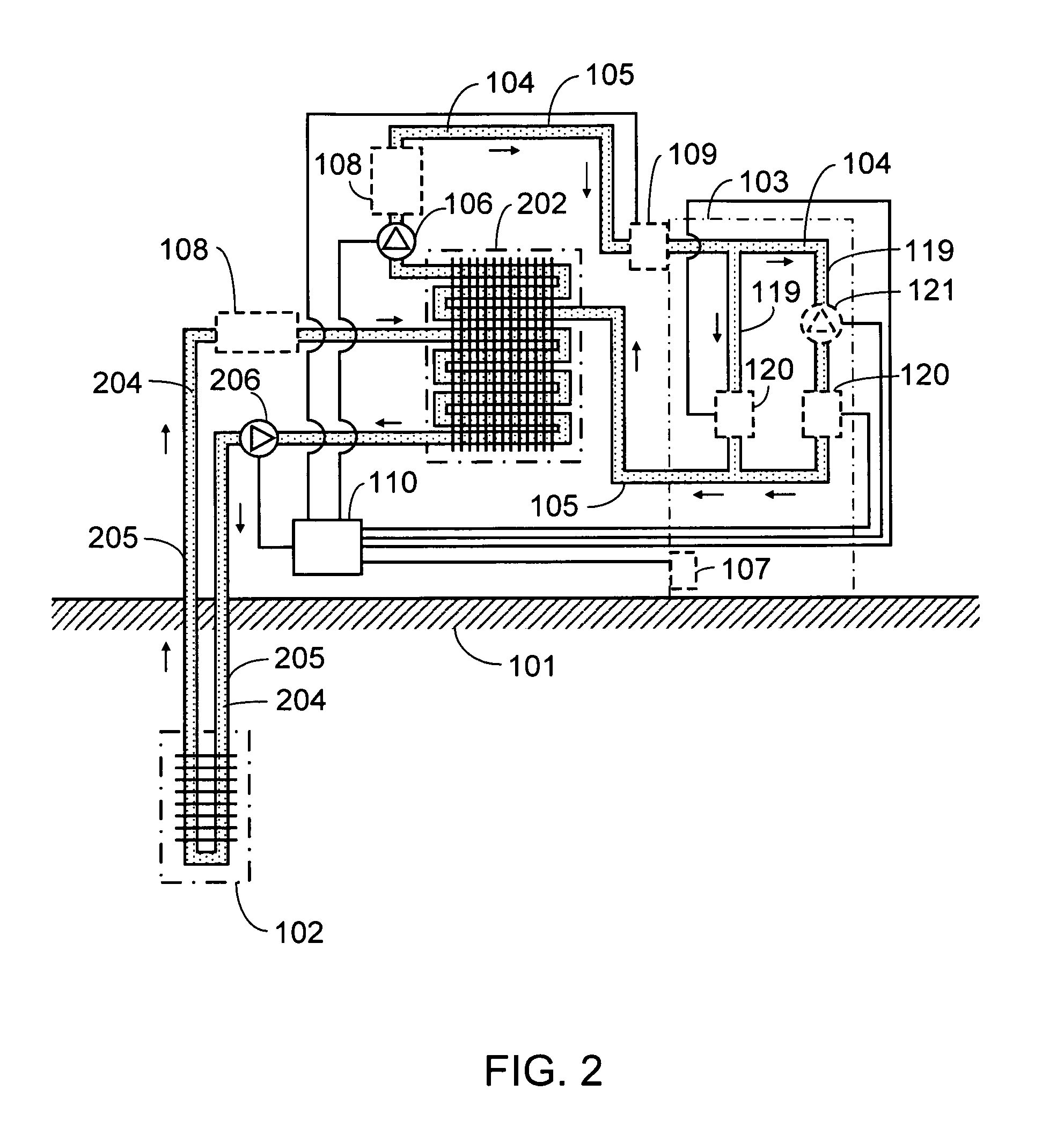

Cooling module for cooling electronic components

InactiveUS20130077245A1Semiconductor/solid-state device detailsSolid-state devicesEvaporationComputer module

A cooling module including a condenser, a power module including the cooling module and a method for cooling electric and / or electronic components are provided. The condenser of the cooling module includes at least one panel for cooling electric and / or electronic components. Two sheets of the panel are attached to one another by a process involving roll-bonding such that a conduit is formed between the two sheets. The conduit extends in a direction of a plane formed by the sheets. Cooling may be provided by evaporating coolant in the conduit at an evaporation section of the panel and by condensing the coolant at a condensing section of the panel. A heat load may be transferred from a heat source to a heat receiving unit. The heat receiving unit is adapted to transfer the heat load to the panel which transfers the heat load to an ambient environment by a thermal carrier.

Owner:ABB RES LTD

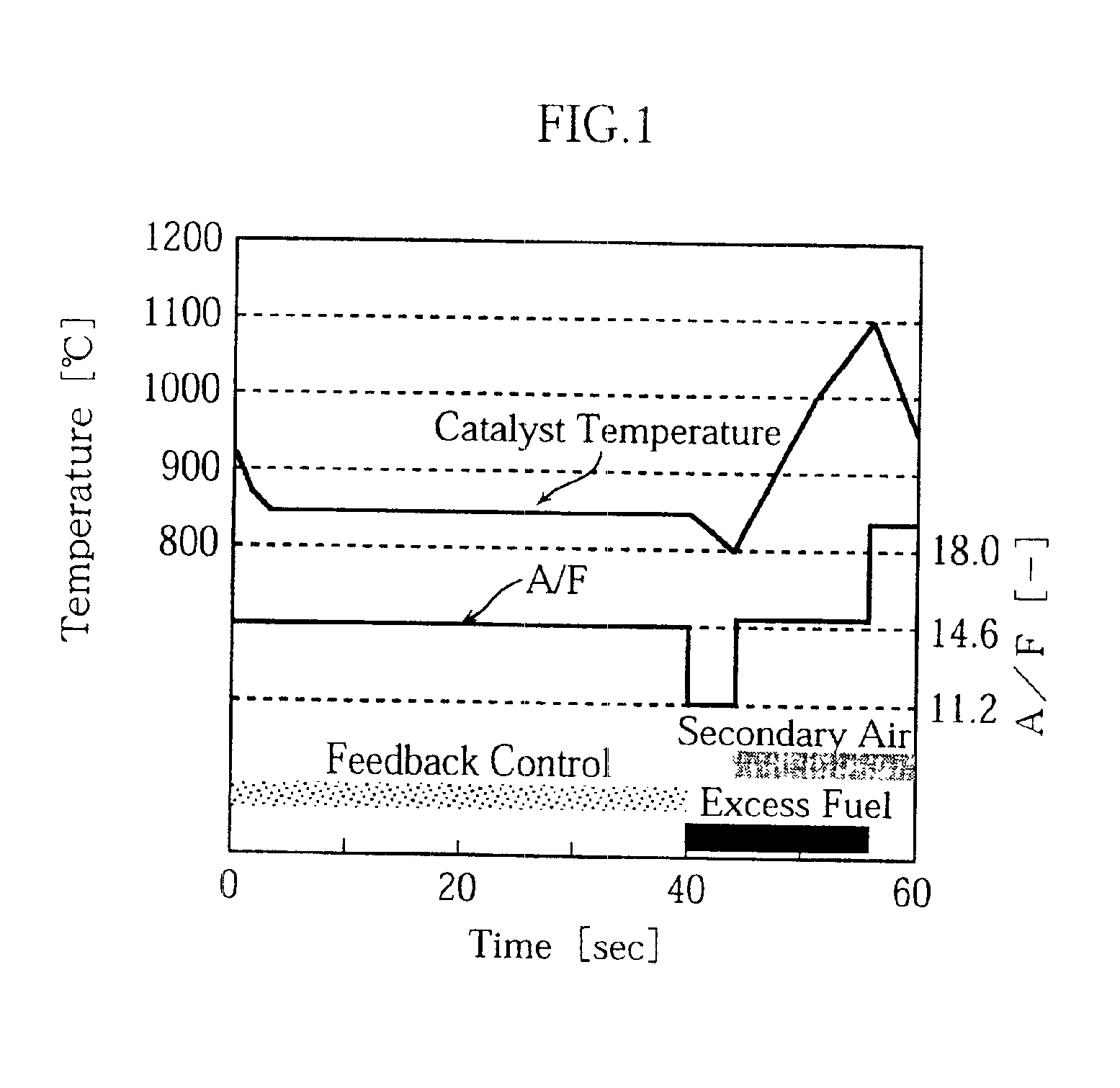

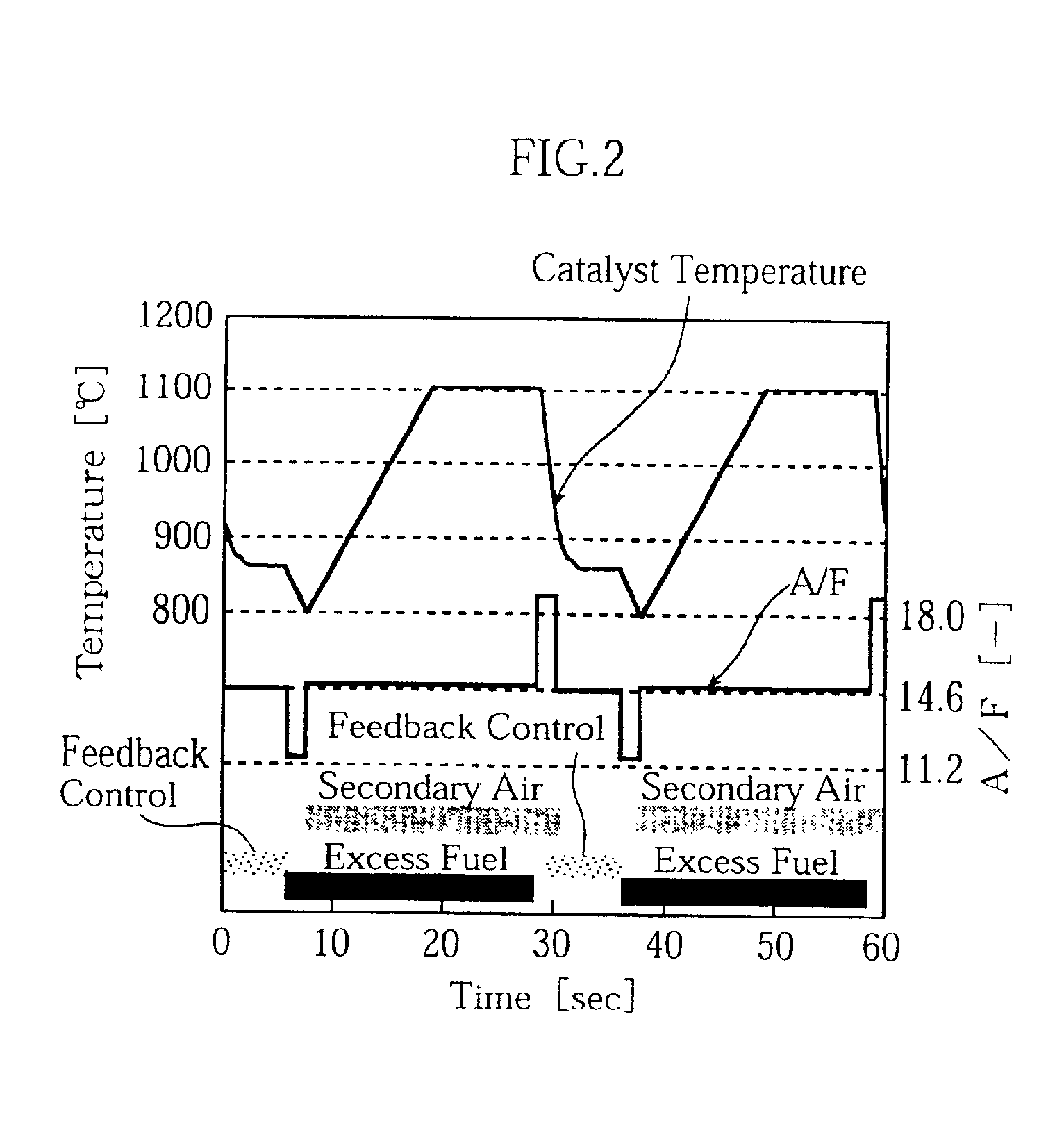

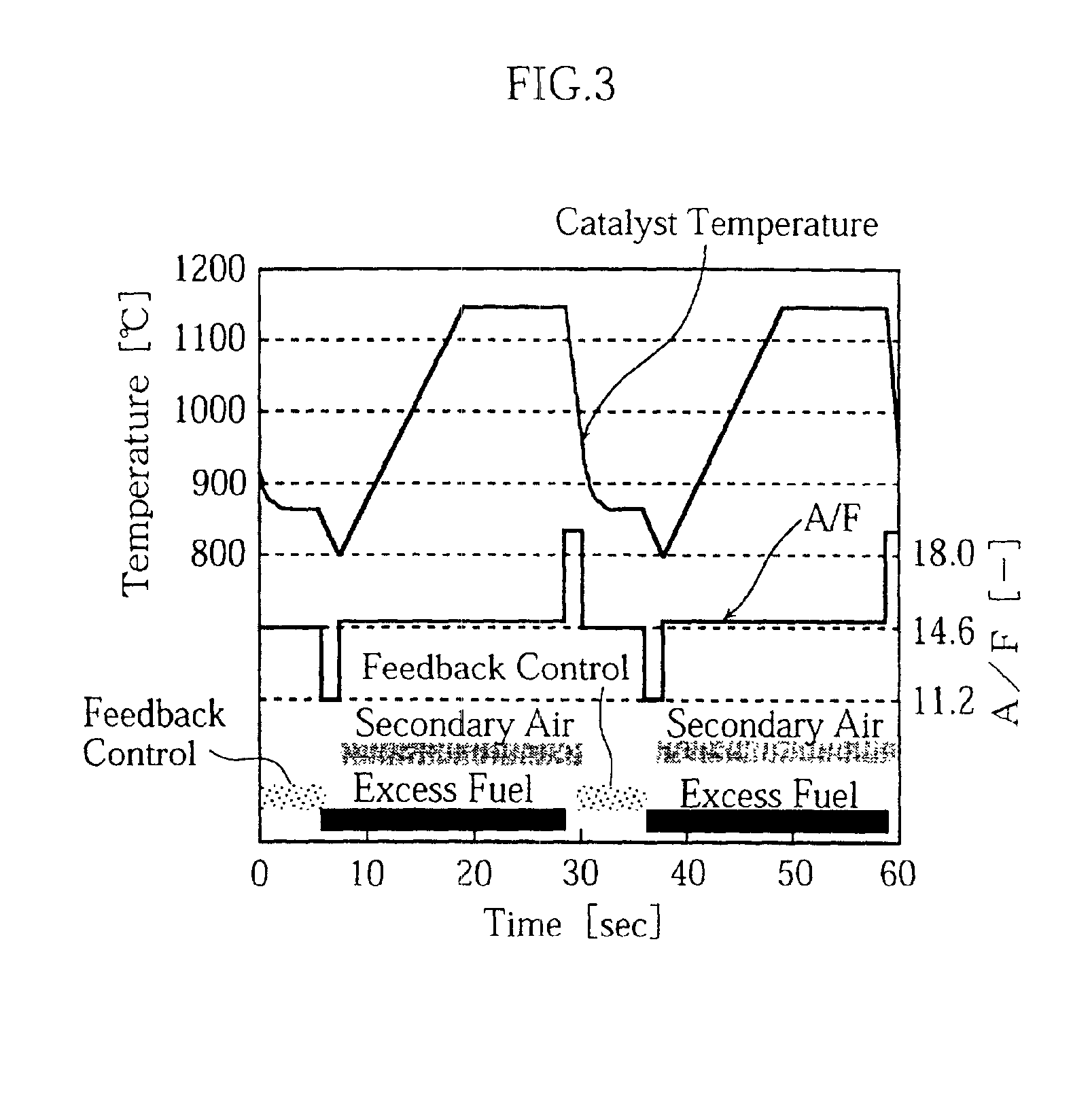

Catalytic converter for cleaning exhaust gas

InactiveUS6881384B1High catalytic activityEffectively its catalytic activityCombination devicesInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains zirconium complex oxide on which Pt and Rh are coexistently carried, and cerium complex oxide on which Pt and Rh are coexistently carried. The Pt- and Rh-carrying zirconium complex oxide and the Pt- and Rh-carrying cerium complex oxide are contained in a same layer of the catalytic coating.

Owner:DAIHATSU MOTOR CO LTD

Methods and Systems for Producing Reduced Resid and Bottomless Products from Heavy Hydrocarbon Feedstocks

InactiveUS20080230440A1Cost controlReduce operating costsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesLiquid product

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, collecting a gaseous and liquid product mixture comprising a mixture of a light fraction and a heavy fraction from the product stream, and using a vacuum tower to separate the light fraction as a substantially bottomless product and the heavy fraction from the product mixture.

Owner:IVANHOE HTL GASOLINEEUM

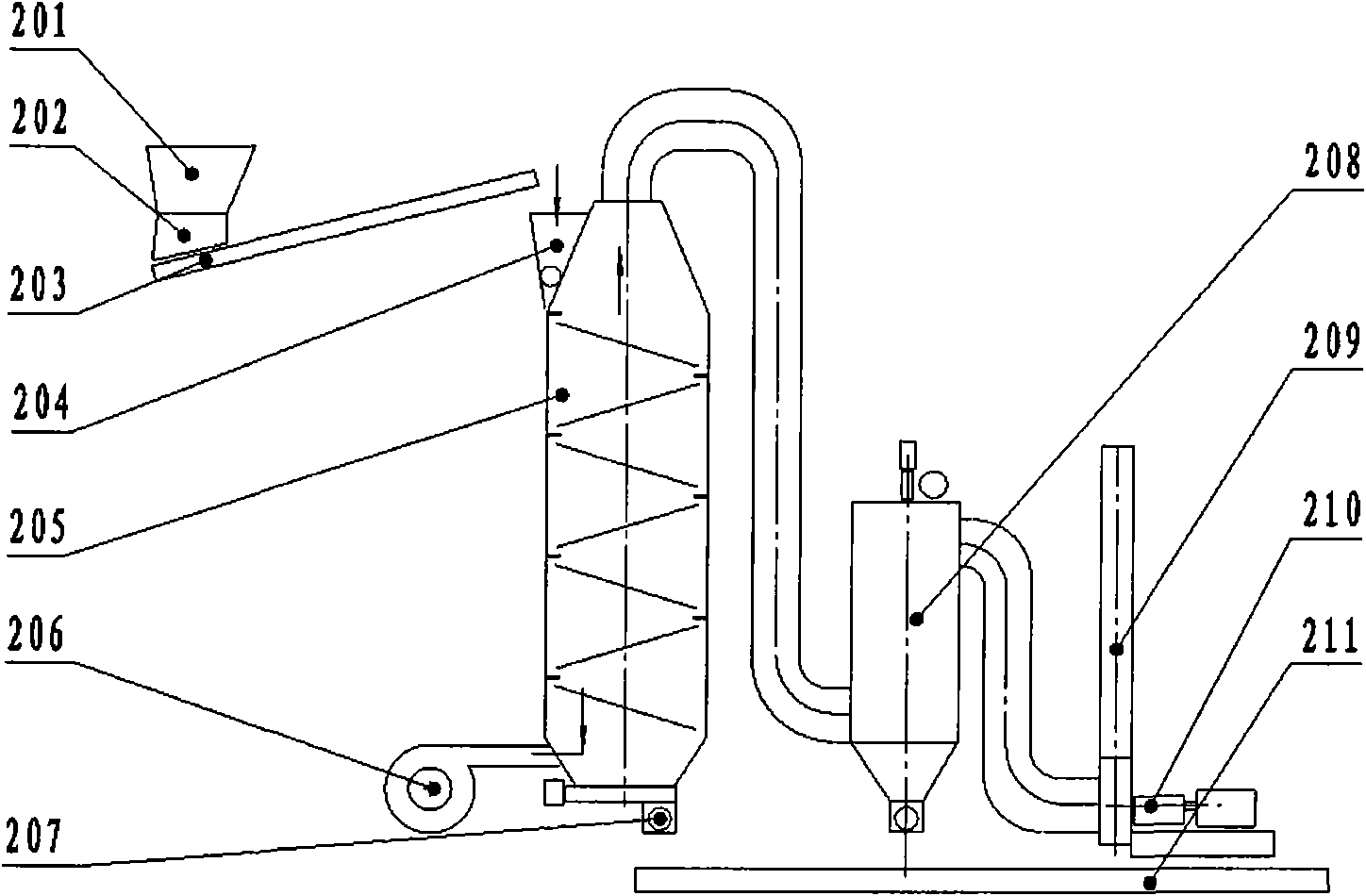

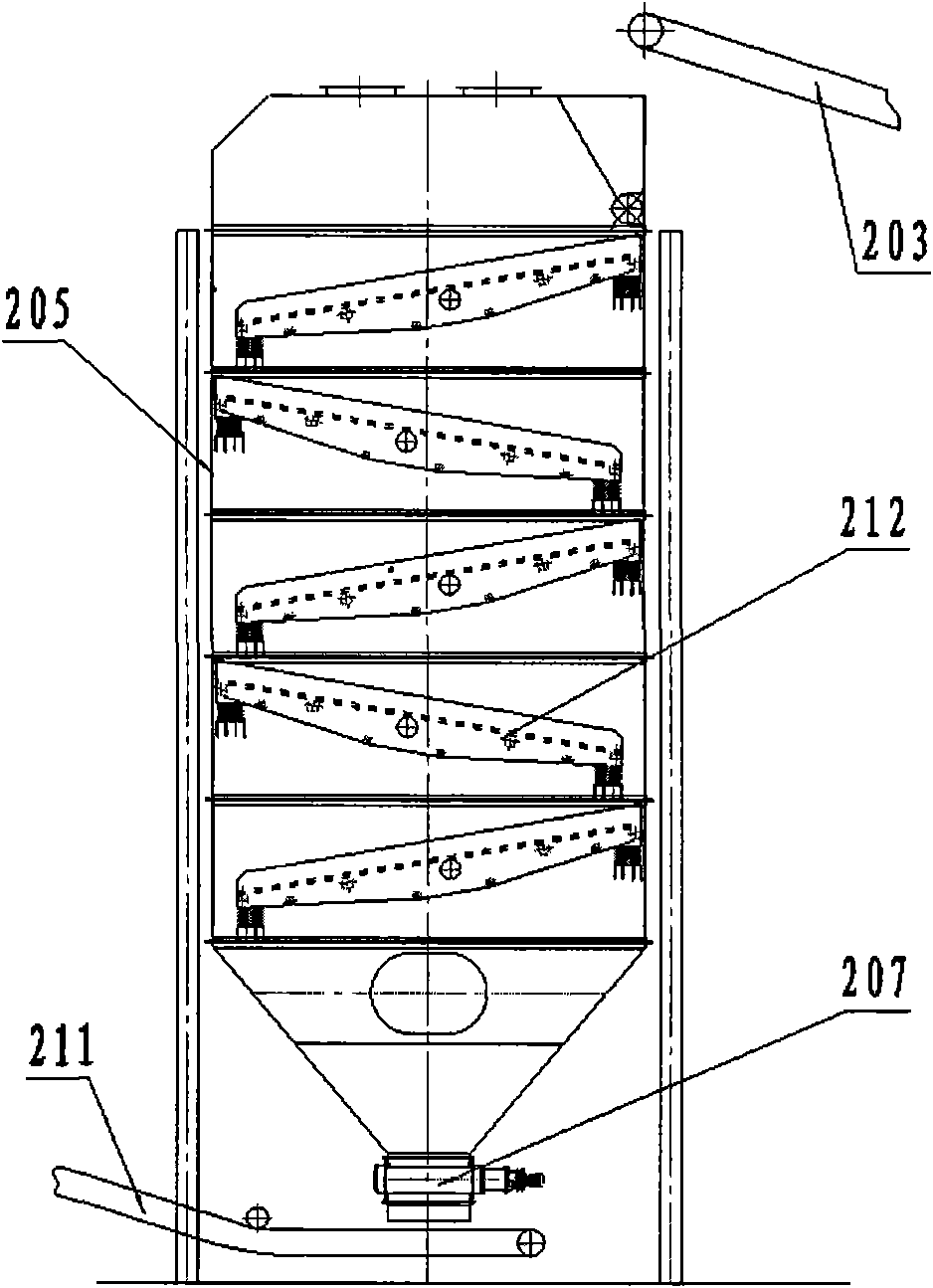

Method and device for preparing biological oil by biomass cracking

InactiveCN101544901ALow costReduce heatingLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The invention provides a method and a device for preparing biological oil by biomass cracking. Biomass material is prepared into the biological oil after being smashed, dried, thermally cracked, secondarily condensed and separated. The device mainly comprises a feeding system, a fluidized bed reactor, a heat carrier separator, a gas-solid separator, a heat carrier heating device, a condenser, and the like, wherein the heat carrier heating device is divided into two layers which are partitioned by a heat insulated board and evenly distributed with a plurality of ceramic heat pipes used as a heating carrier of a heat transfer element. The invention not only utilizes subsidiary product of thermal cracking, namely carbon and non-condensable gas as energy sources for thermal cracking liquification, but also effectively utilizes the smoke discharged by the heat carrier heating device as fluidizing gas, thereby having various advantages of reasonable process, no secondary pollution, energy saving, low cost, and the like. Compared with the prior art, the invention is easier to popularize and apply.

Owner:JIANGSU UNIV

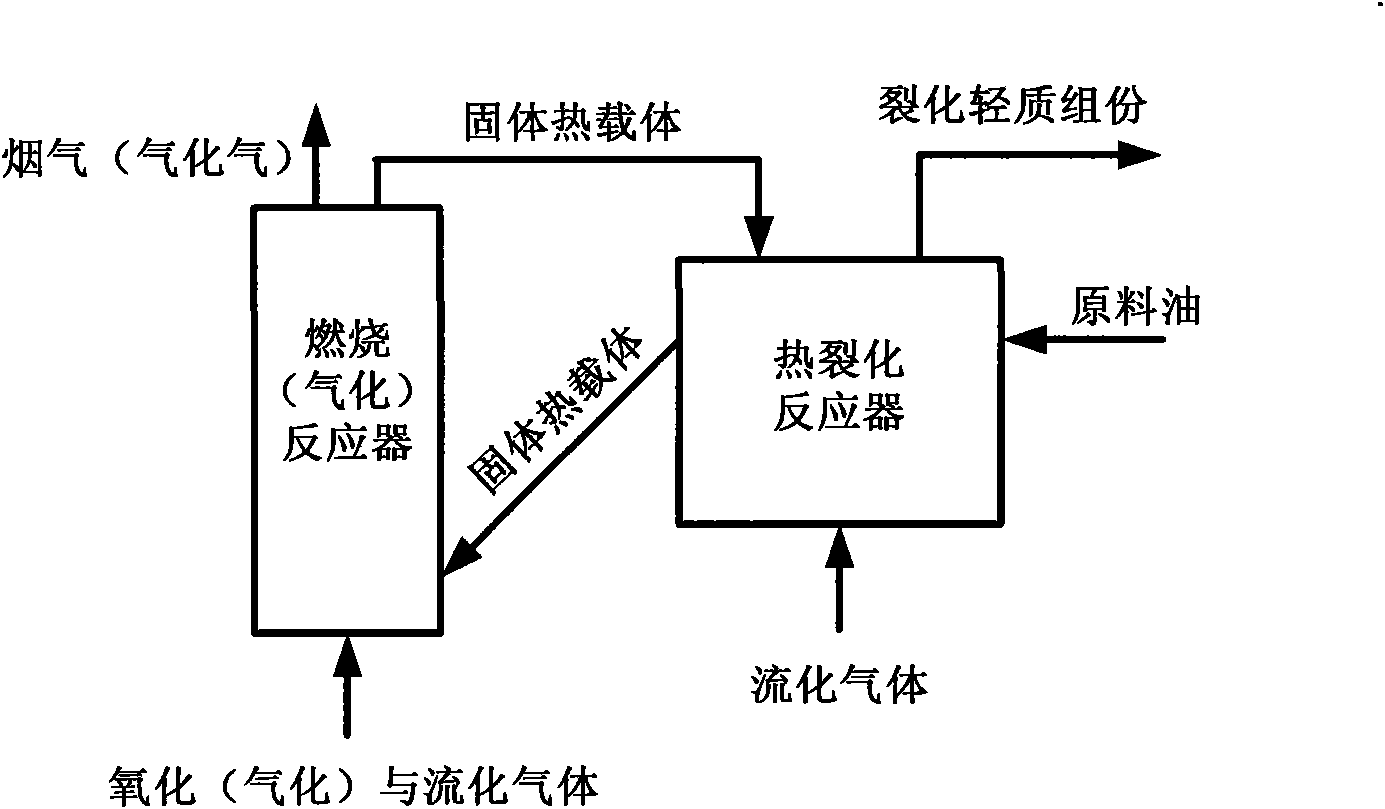

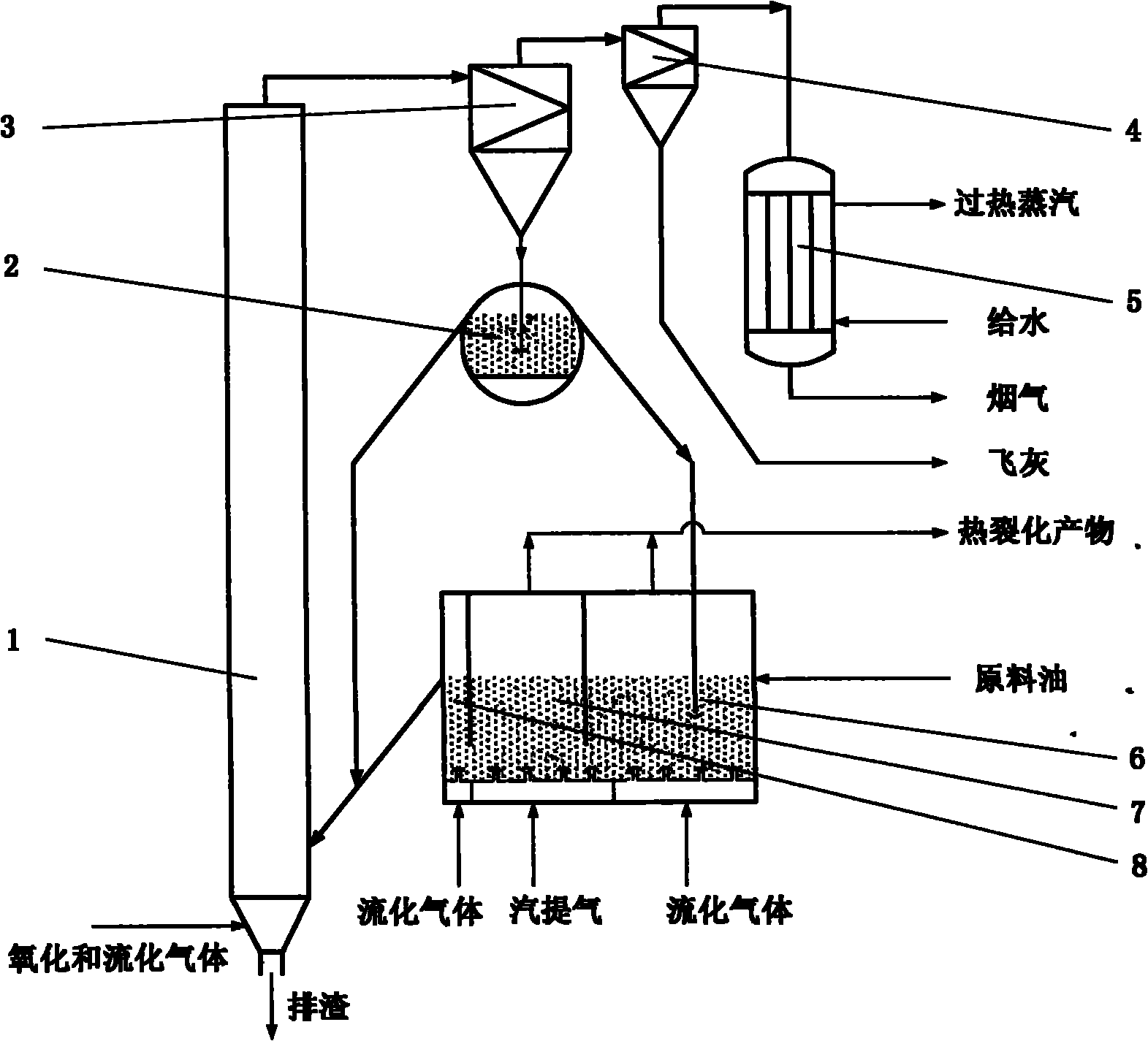

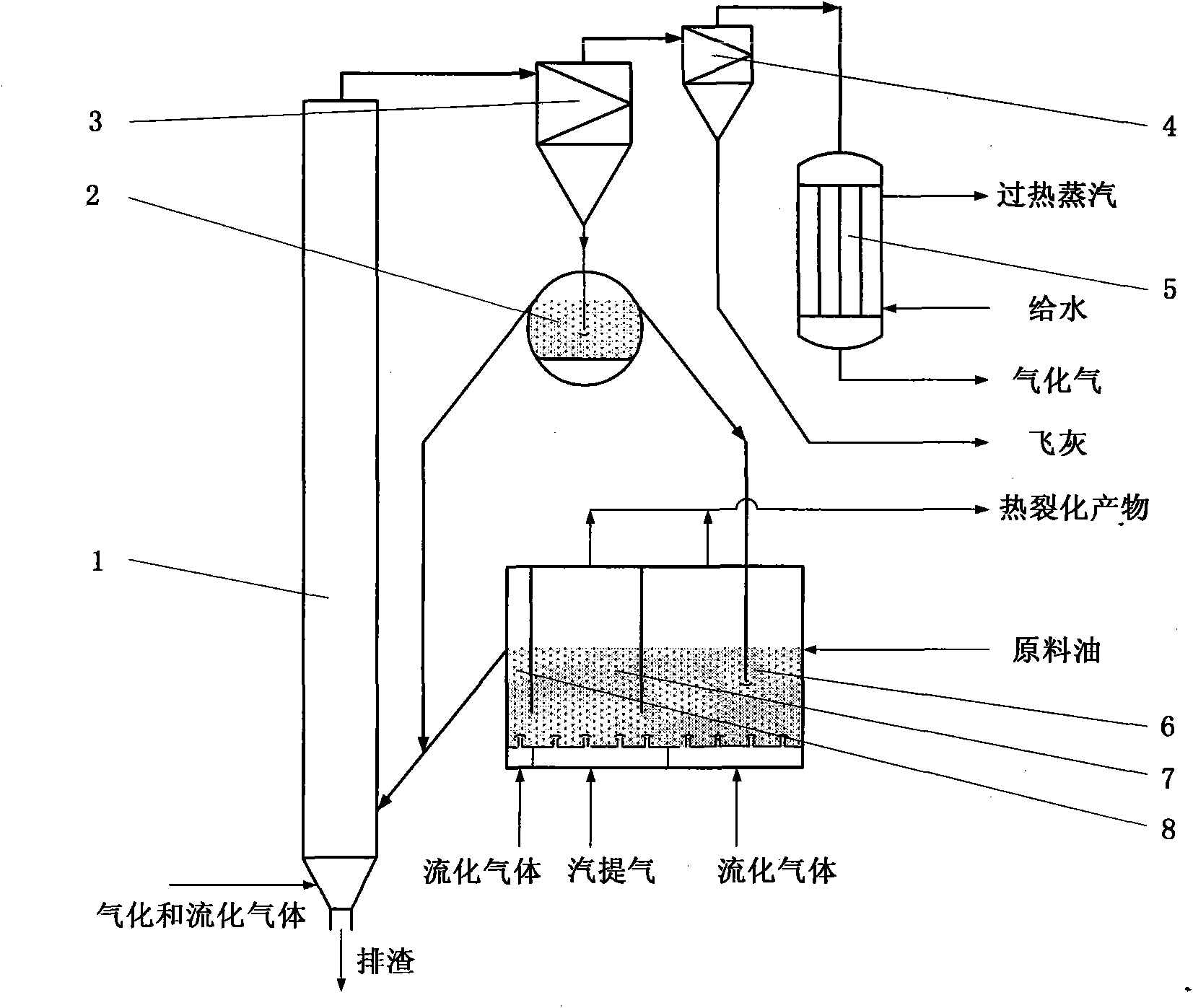

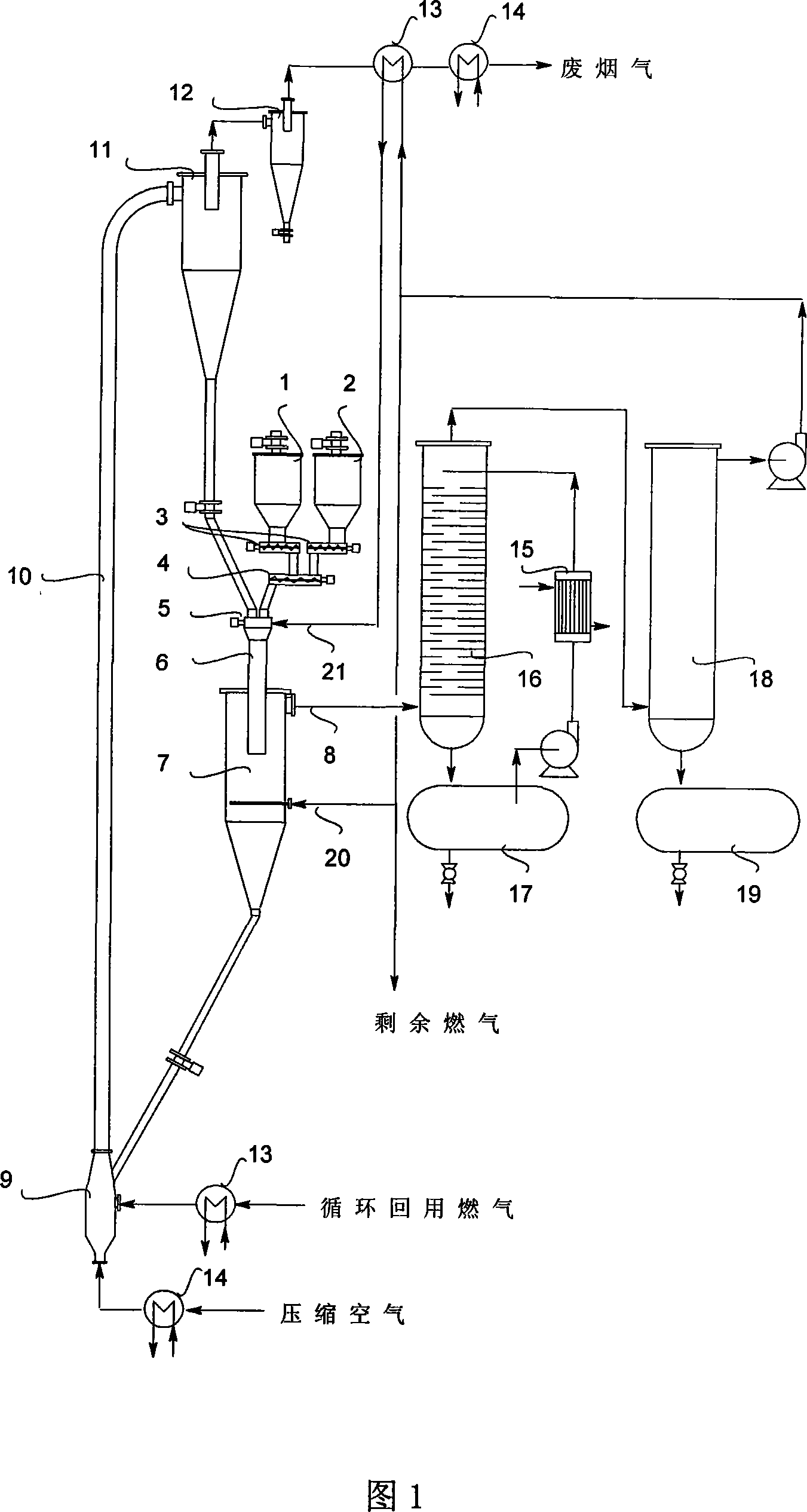

Heavy oil lightening method and device

InactiveCN102115675AAchieve conversionEfficient conversionThermal non-catalytic crackingEnergy inputHeat carrierCombustion

The invention relates to a heavy oil lightening method and technique. The method comprises steps as follows: raw oil is introduced into a thermal cracking reactor through a feed system, and mixed with a high-temperature solid heat carrier from a combustion (gasifying) reactor, so that the raw oil is subjected to fluidizing heat exchange with the solid heat carrier and carries out thermal cracking reaction on the surface of the solid heat carrier; the cracking gas generated by the thermal cracking reaction and a light component product are subjected to steam stripping by fluidizing medium gas and enter a subsequent absorption and stabilization system and a purification and separation system, heavy coke (petroleum coke) is attached to the surface of the solid heat carrier and enters the combustion (gasifying) reactor via a material returning valve, and an oxidizing (gasifying) and fluidizing gas is introduced to realize combustion (gasifying) reaction in the fluidization elevation process of the petroleum coke; and after the reaction product (fume or gasified gas) and the solid heat carrier are separated by a gas-solid separator, the fume (gasified gas) is led into a waste heat recovery system and a gas purification system, the high-temperature solid heat carrier is distributed by a distribution valve and respectively enters the thermal cracking reactor and the combustion (gasifying) reactor for cyclic use, and the collected fly ash can be used after further processing, thereby complete high-value conversion and use of the heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

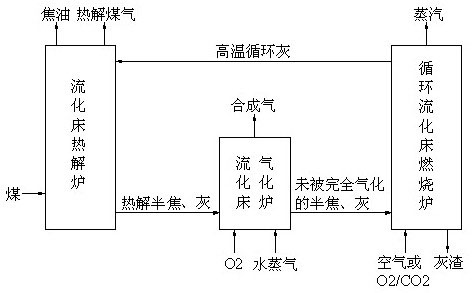

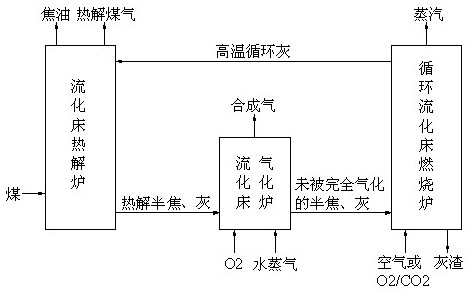

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

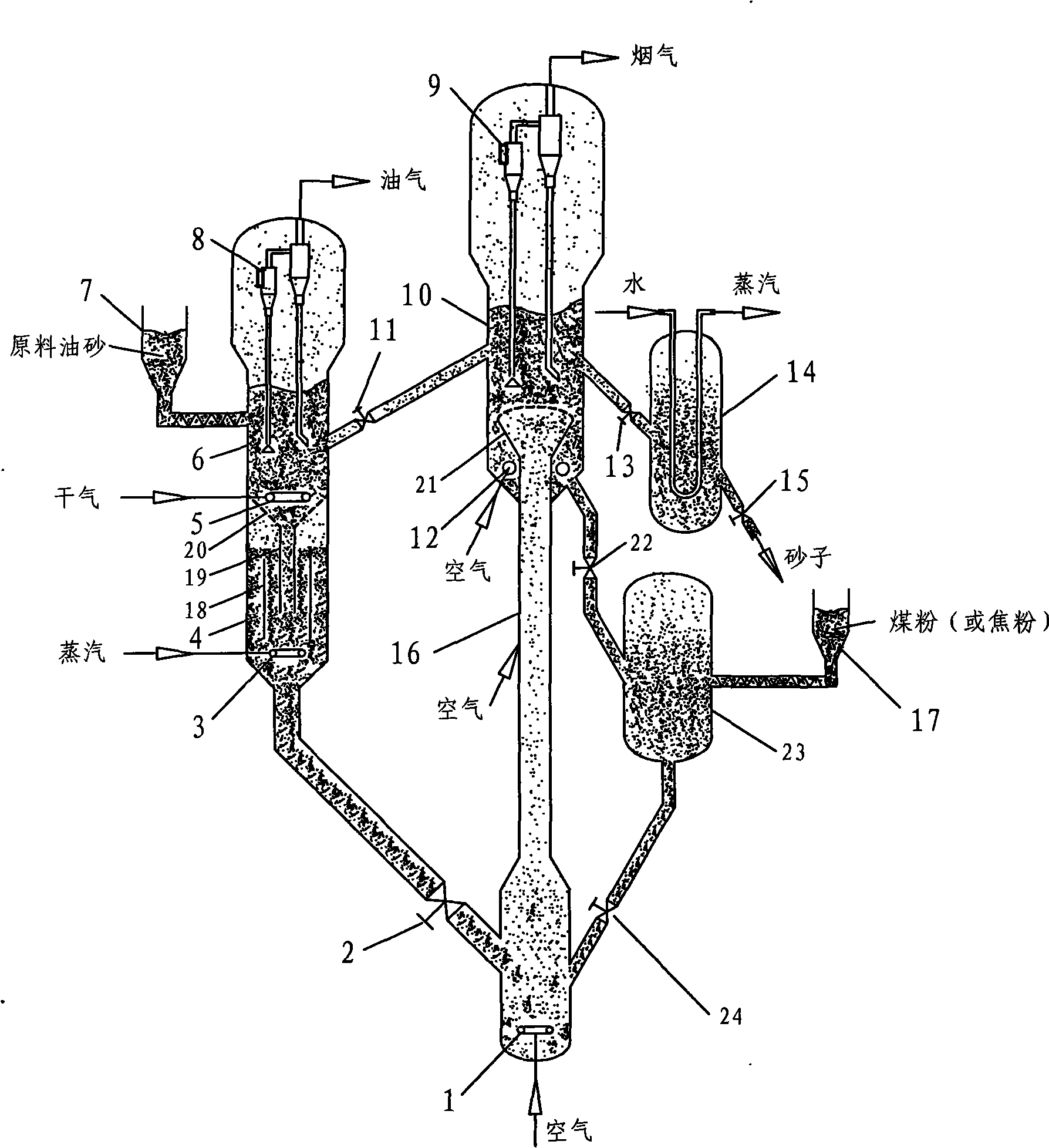

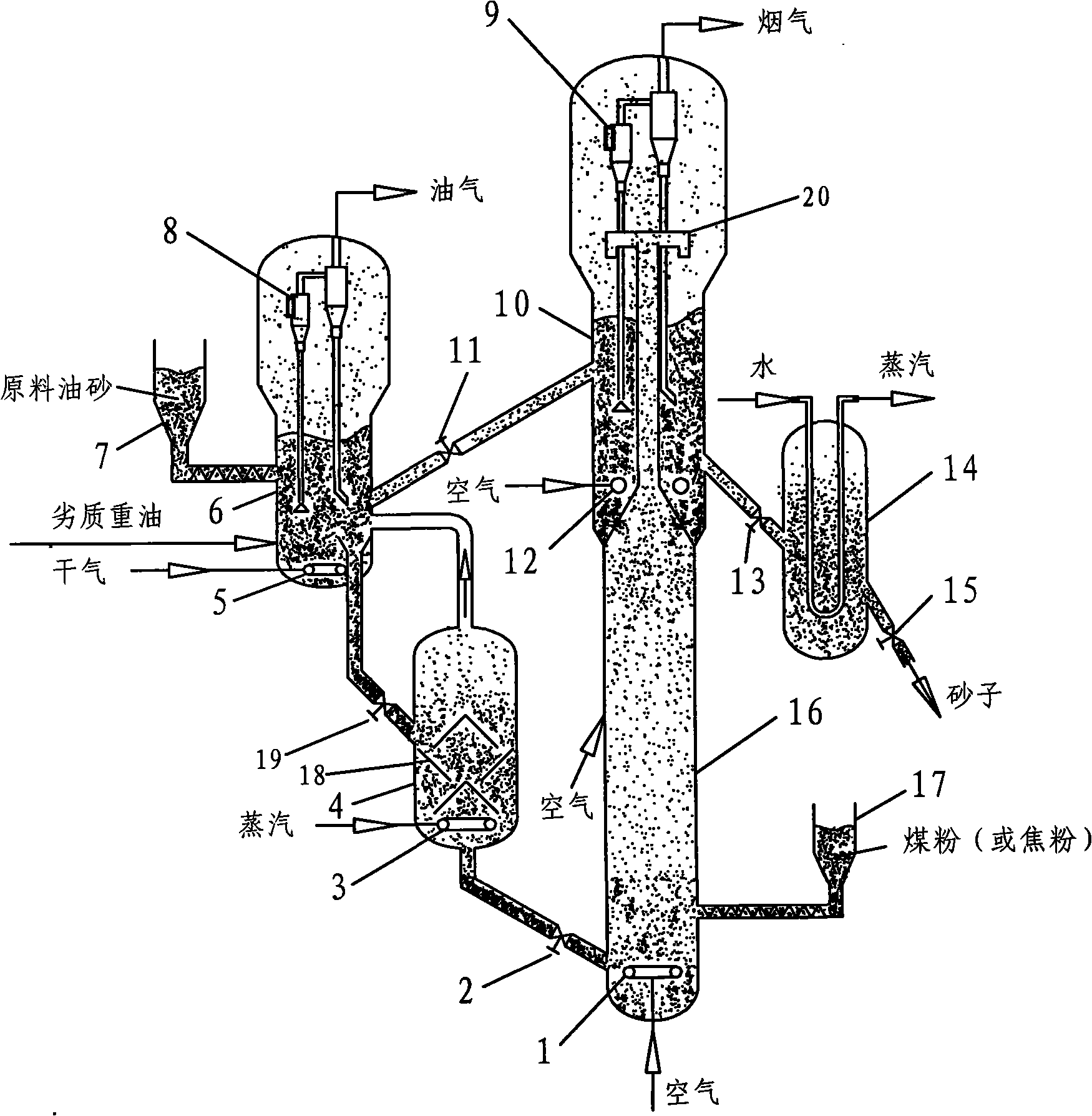

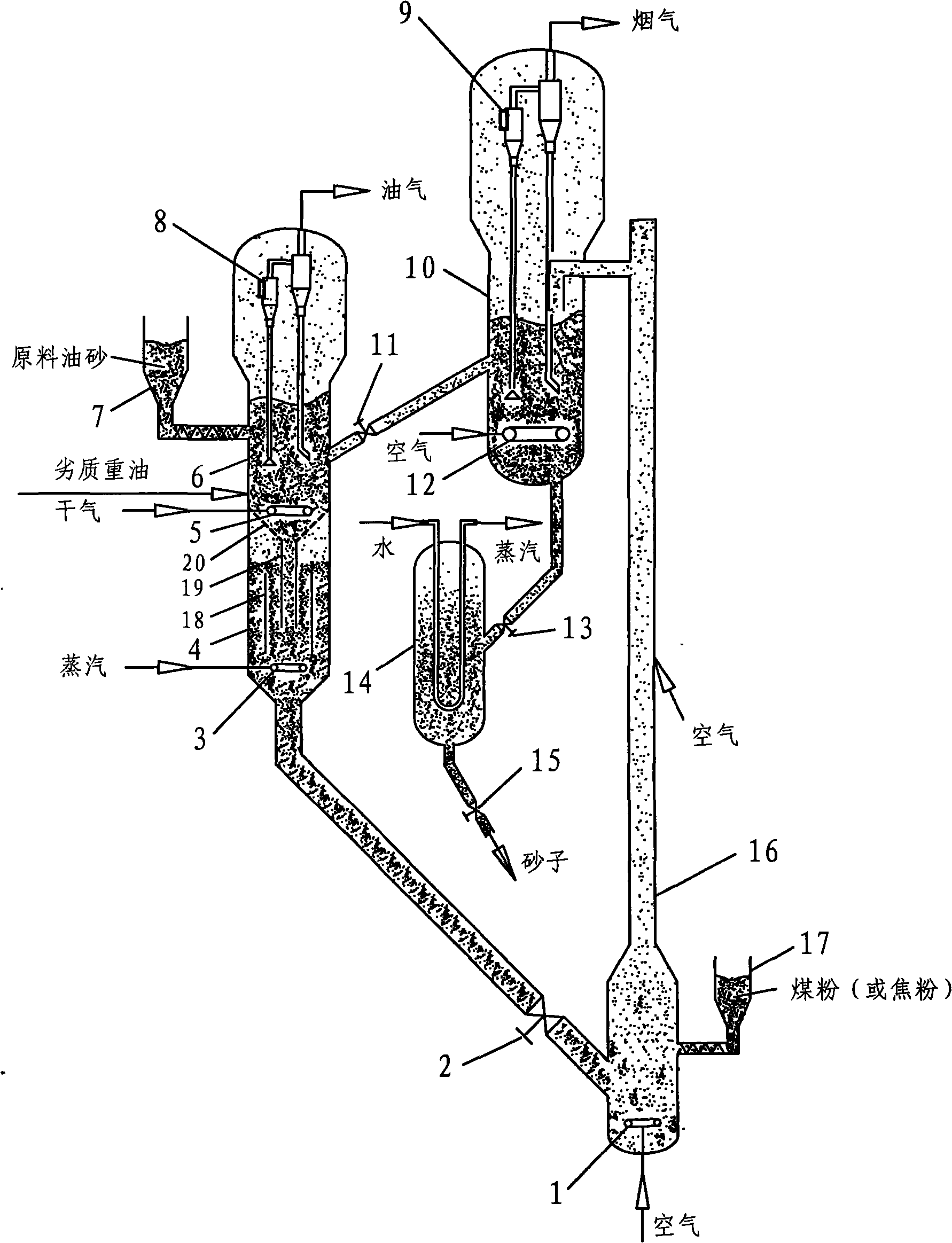

Method for directly fluid coking oil sand and apparatus

ActiveCN101358136ANo pollution in the processContinuous processingLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The present invention provides a method and a device which are used for the direct coking of oil sand on a fluidized bed. The method is as follows: after being mixed with and exchanging heat with the high-temperature sand from a dense-phase coking-burning reactor, the oil sand material in a coking reactor undergoes coking reaction; the dedusted oil gas enters into a fractionation and absorption stabilization system; after being stripped by a stripper, tar sand is led into a dilute-phase coking-burning riser to be burnt in the dilute-phase coking-burning riser and the dense-phase coking-burning reactor above the dilute-phase coking-burning riser; and one flow of the burnt hot sand serving as a heat carrier is led into the coking reactor, and the other flow is led into an external heat collector for heat exchange. If the coke yield is low and the coke-burning heat is insufficient, burning oil, coal dust or coke powder can be added into the coking-burning riser in order to maintain the heat balance of the system. The device at least comprises a material feeder, the coking reactor, the stripper, the dilute-phase coking-burning riser, the dense-phase coking-burning reactor, the external heat collector and a cyclone separator. The device, which is characterized by strong continuous operability and high flexibility, can directly process unconventional petroleum resources such as oil sand and oil shales and does not pollute the environment, and the comprehensive energy utilization rate of the system is high.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

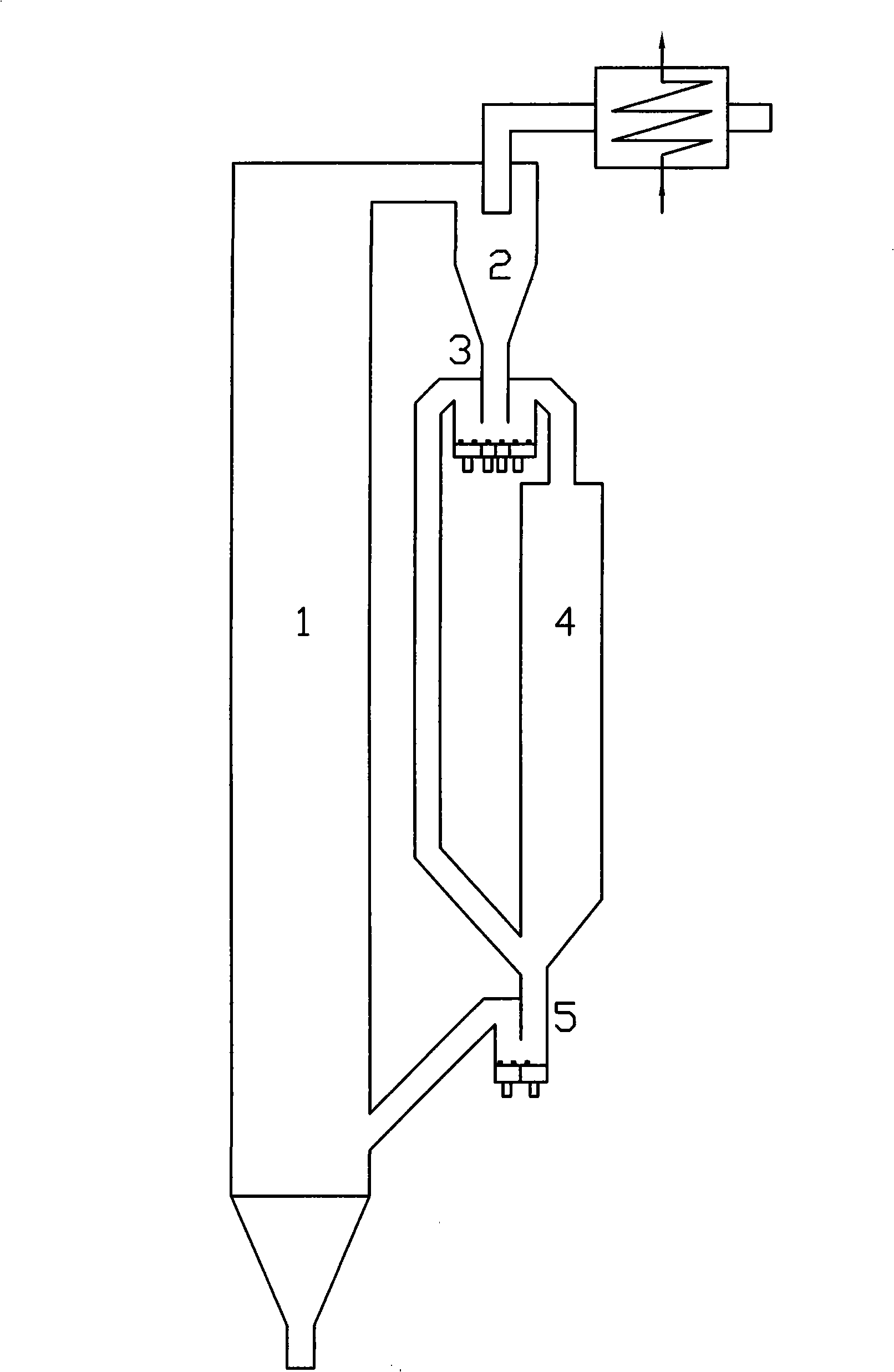

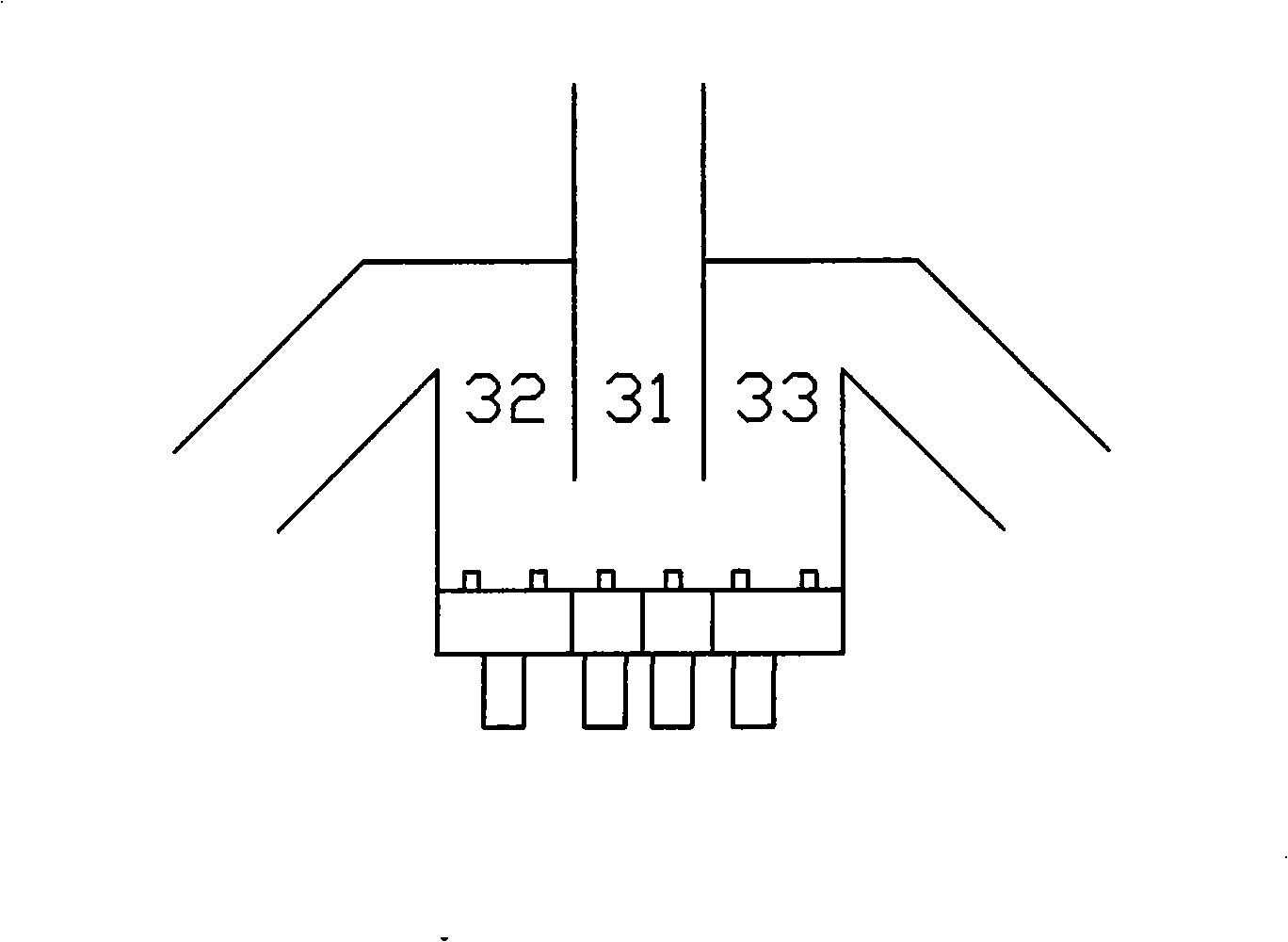

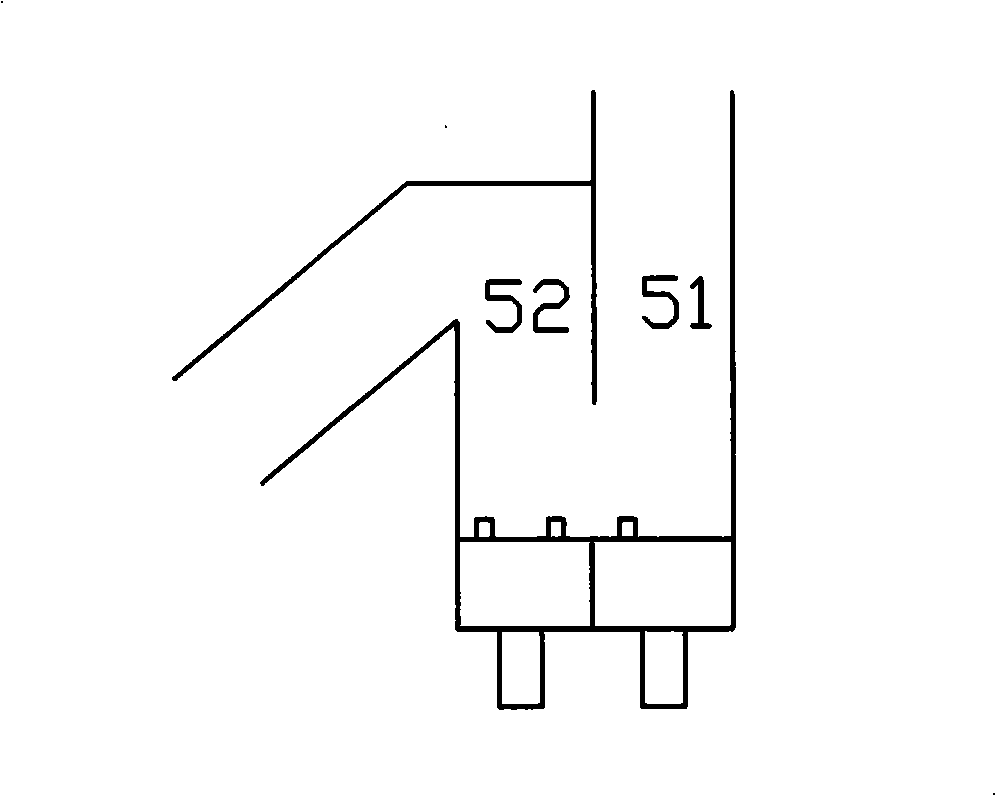

Solid heat carrier rapid pyrolysis method and apparatus

ActiveCN101353582AStable and reliable distributionEasy to control temperatureDirect heating destructive distillationHeat carrierCombustion chamber

The invention relates to a method and a device for the quick pyrolysis of solid heat carriers; the device comprises a circulating fluidized bed combustor, a cyclone separator, an aerodynamic hot ash distributor, a pyrolysis chamber and a differential bed material return device; fuel is burnt in the circulating fluidized bed combustor, the high-temperature circulation ash of flue gas collected by the cyclone separator is divided into two parts by the hot ash distributor aerodynamically controlled, one part enters the pyrolysis chamber of a moving bed as the solid heat carrier to supply heat for flue pyrolysis, the other part does not enter the pyrolysis chamber but returns to the combustor, together with the semicoke and circulation ash discharged from the bottom of the pyrolysis chamber through the differential bed material return device. The method and the device for the quick pyrolysis of solid heat carrier provided by the invention can distribute the high-temperature circulation ash between combustion and pyrolysis loops stably and reliably, with controllable temperature of the pyrolysis chamber, strengthen the balance capacity between combustion and pyrolysis by virtue of a hot ash cooler, have good adaptability of the flue, and can be used for the pyrolysis of coal, biomass and other carbonaceous refuses.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572365B2Quick upgradeReduce sulfur emissionsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas) and to reducing the total acid number (TAN) of the liquid product. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

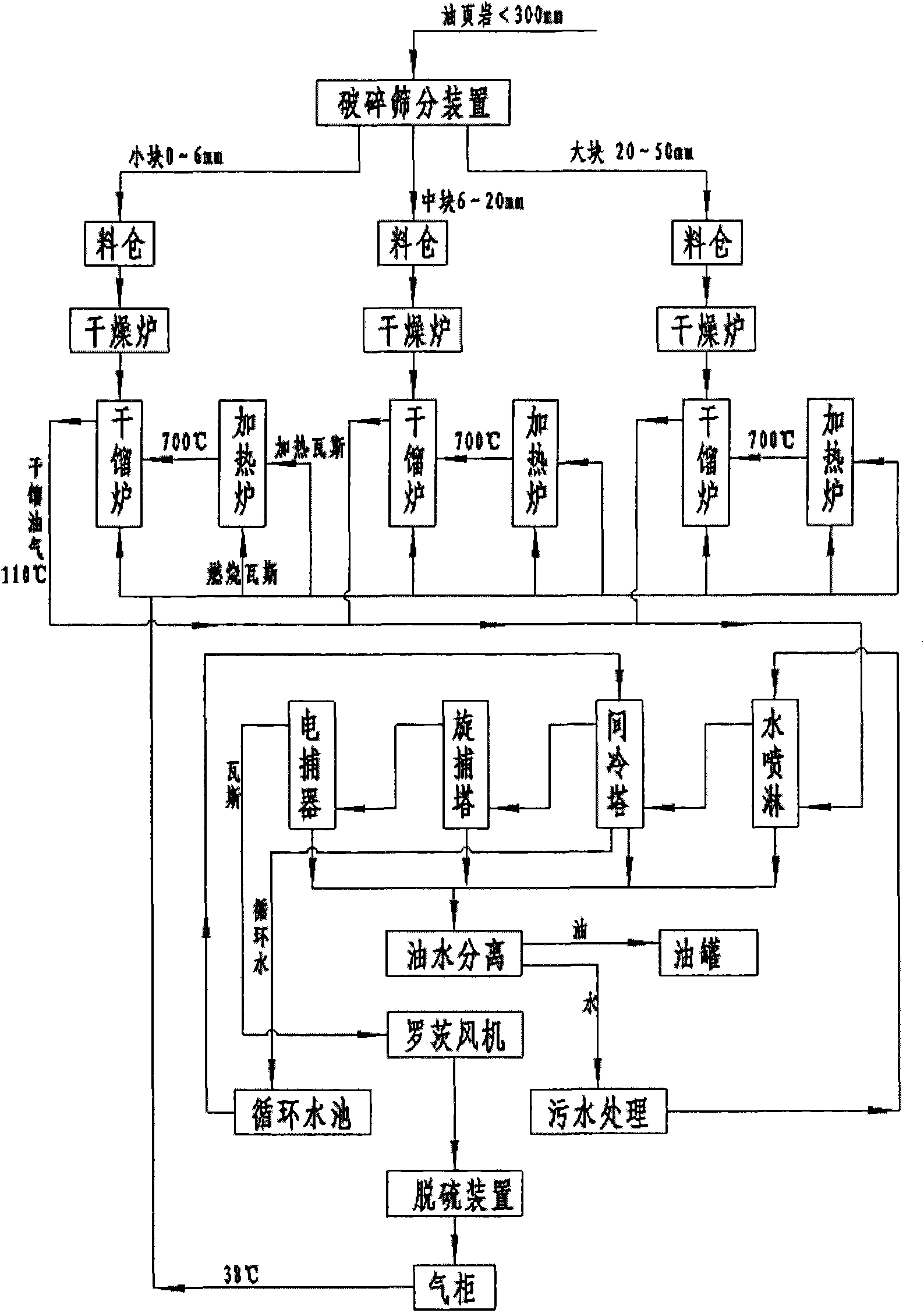

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

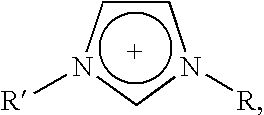

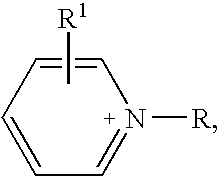

Halogen-free ionic liquids

InactiveUS20050070717A1Improve hydrolytic stabilityOrganic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsHeat carrierHalogen

An ionic liquid according to the invention is substantially halogen-free, has a low viscosity and is stable to hydrolytic degradation under test conditions. The ionic liquid is a compound of the formula (cation) (R′—O—SO3), (cation) (R′—SO3), or a mixture of the two compounds. It can be used in processes for the chemical conversion and separation of materials by employing the ionic liquid as a solvent, solvent additive, extraction agent or phase-transfer catalyst. It can also be used in a heat exchange device wherein the ionic liquid serves as a heat carrier or heat carrier additive.

Owner:MERCK PATENT GMBH

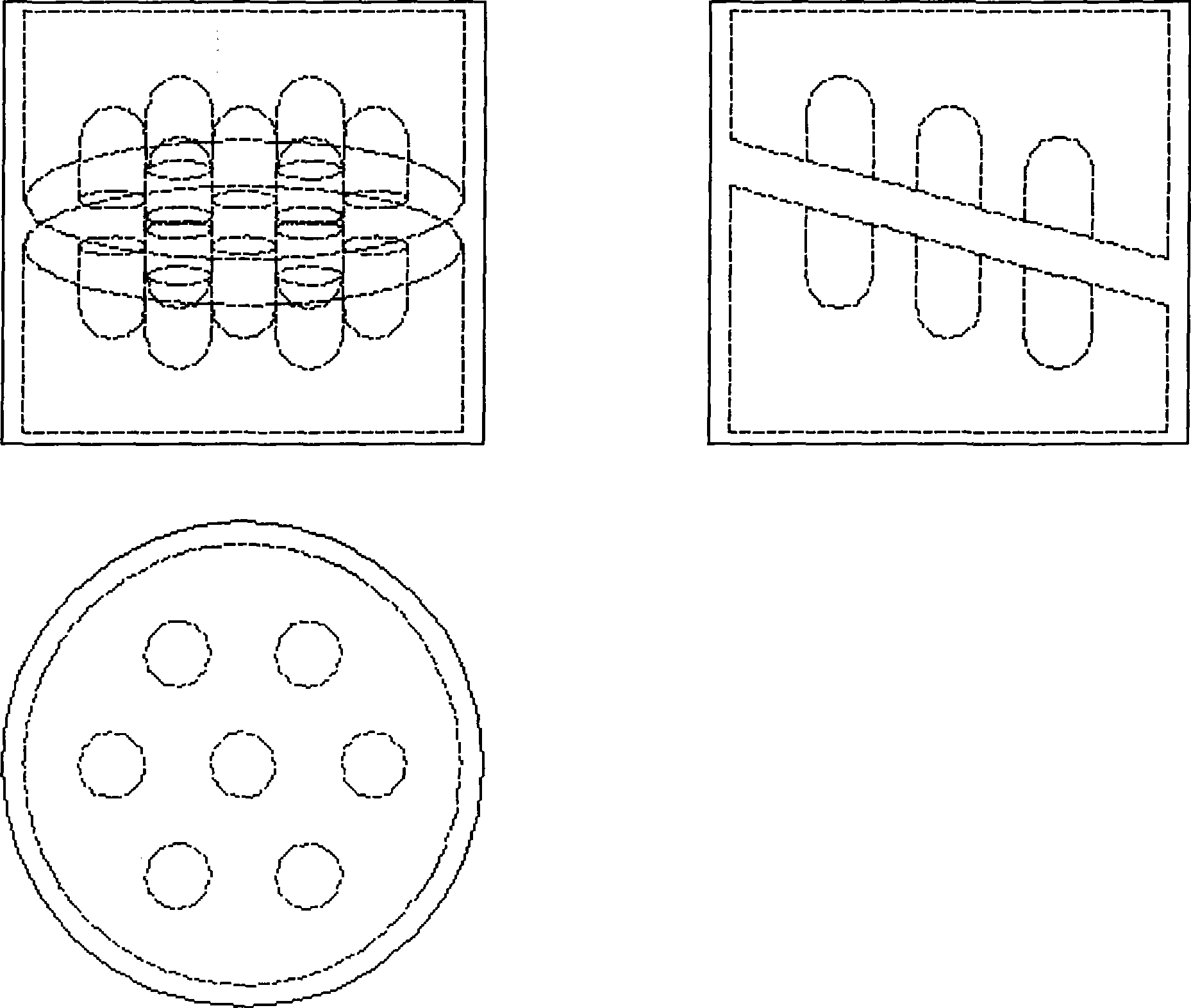

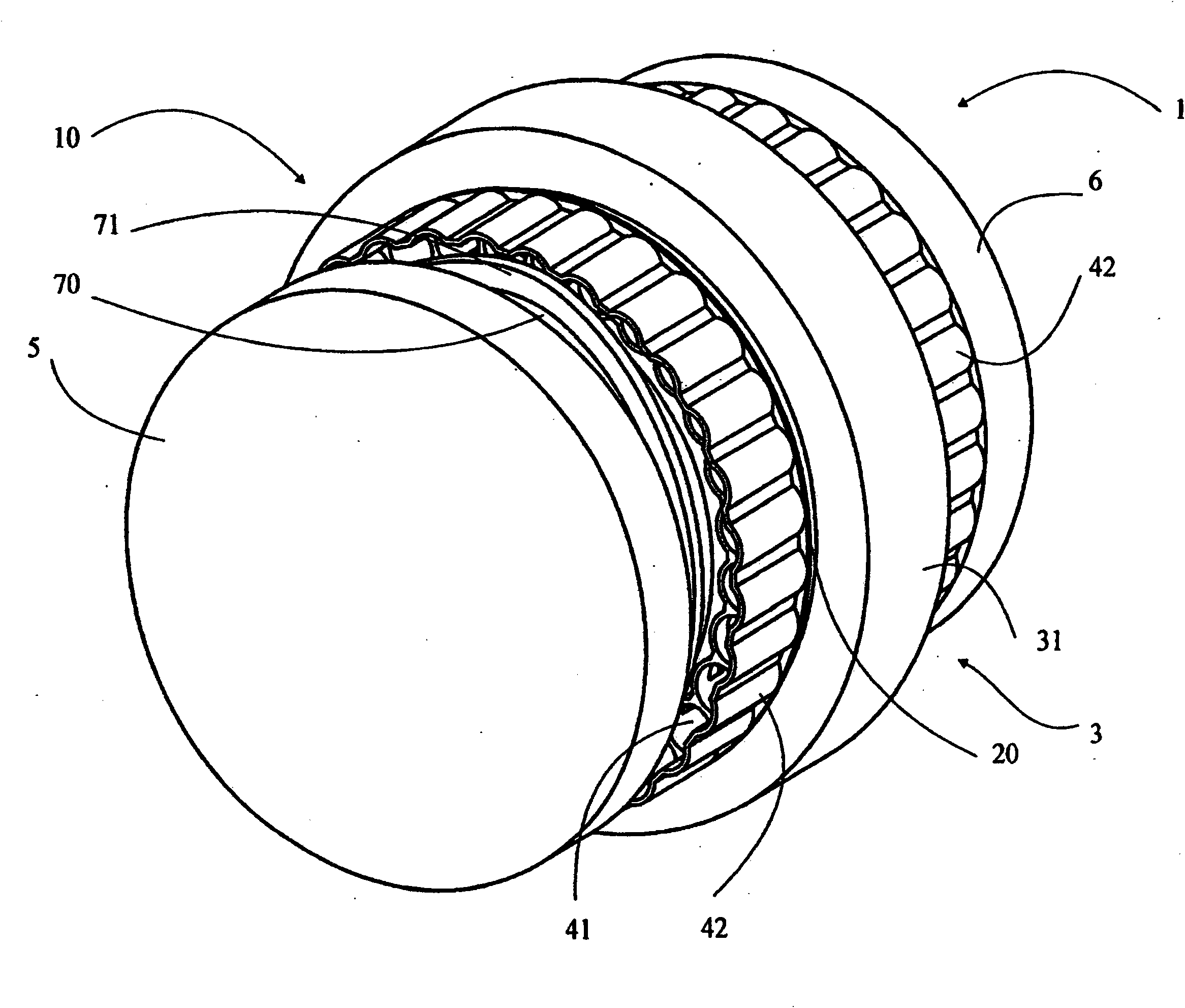

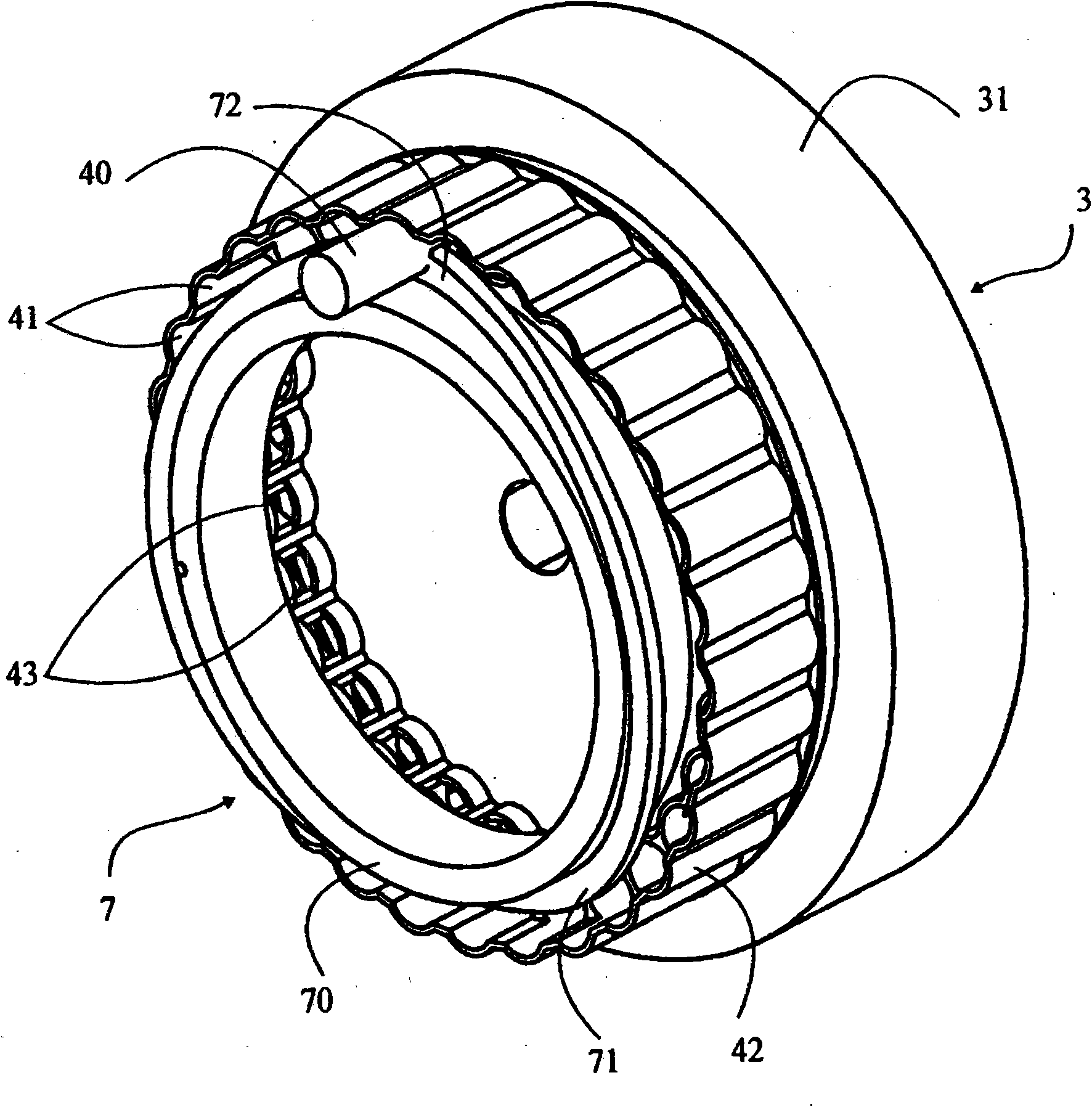

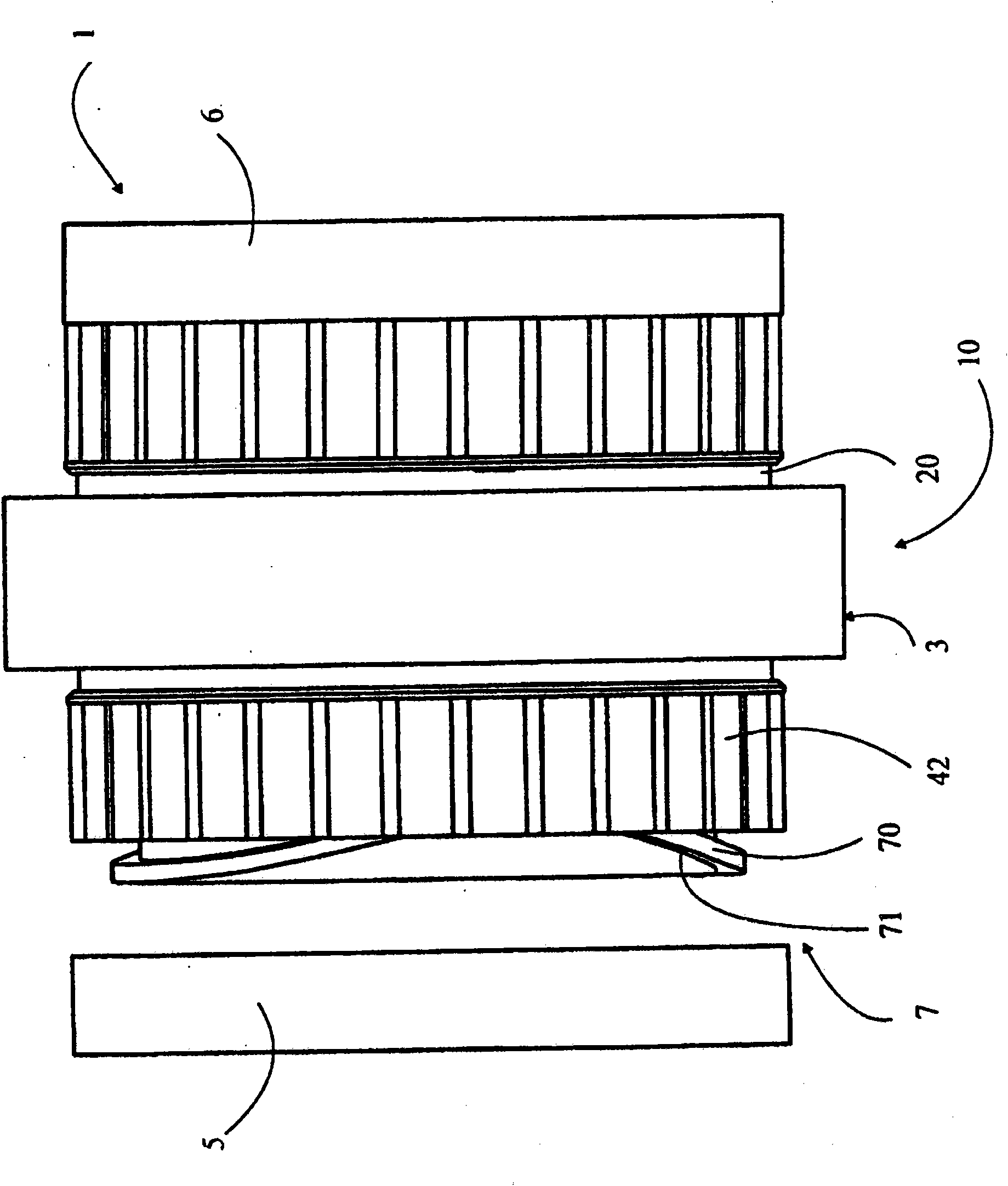

Thermal generator with magneto-caloric material

ActiveCN101842647AEnergy efficient heating/coolingMachines using electric/magnetic effectsHeat carrierReciprocating motion

The invention relates to a thermal generator (1) characterised in that it comprises at least one thermal module (10) including N adjacent magneto-caloric members (2) arranged in a circle about a central axis (A) and submitted to a magnetic field variation generated by a magnetic means (3) in order to vary their temperature. The magneto-caloric members (2) are associated with N pistons (40) driven according to a reciprocating translation movement by a control cam (70) in order to move the heat-carrier fluid contained in the thermal module (10) simultaneously in two opposite directions, so that a first fraction of the heat-carrier fluid flows towards a hot exchange chamber (5) through the magneto-caloric members (2) submitted to a heating cycle, and so that a second fraction of the heat-carrier fluid flows towards a cold exchange chamber (6) through the magneto-caloric members (2) submitted to a cooling cycle, and vice versa. The exchange chambers (5, 6) are coupled to outer calorie- and frigorie-consuming circuits, such as heating circuits, air conditioning circuits, tempering circuits, etc.

Owner:马格诺里克公司

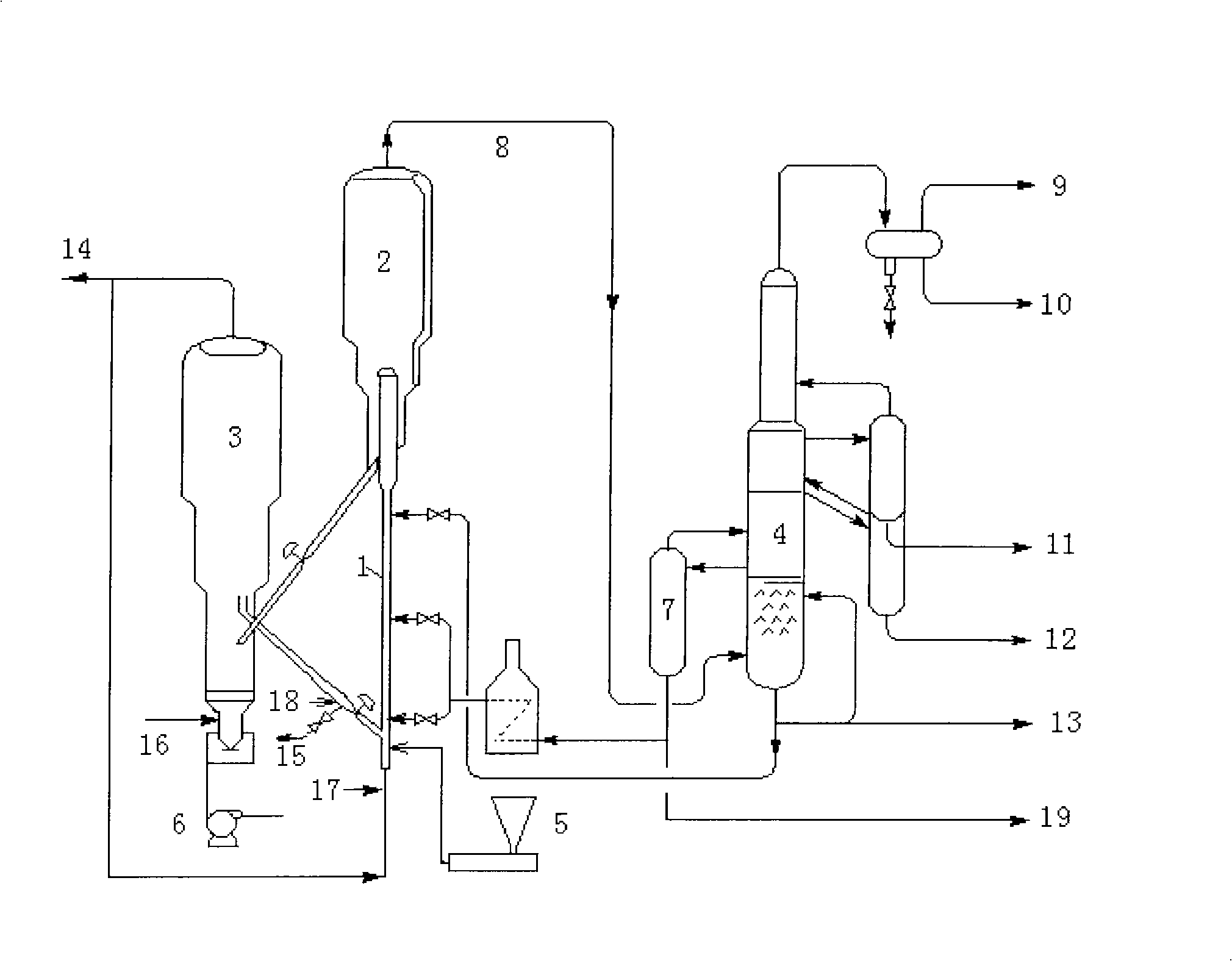

Method for manufacturing wet fuel by rapid common thermal decomposition of biomass and coal

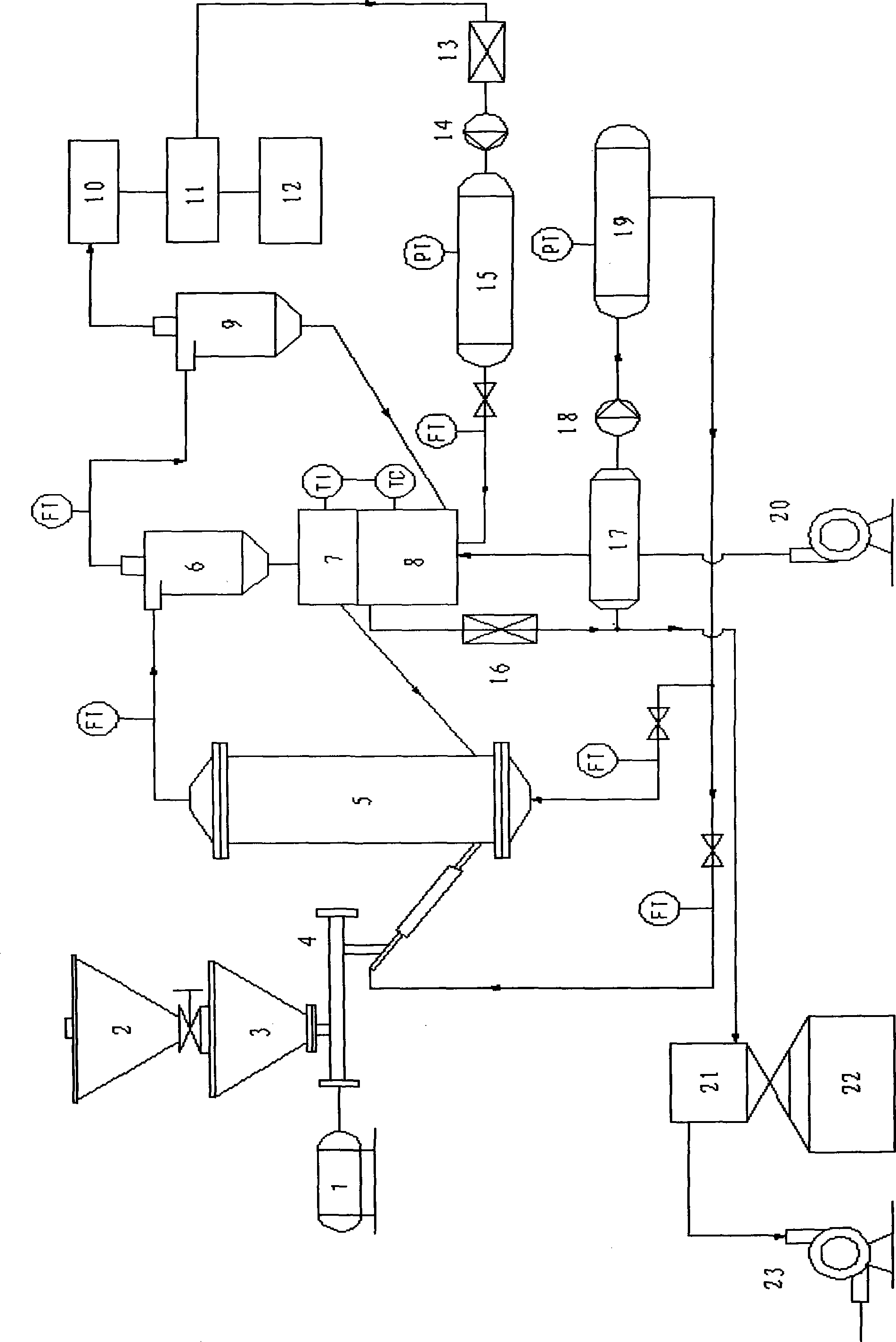

InactiveCN101108970AFast co-pyrolysisSimple processLiquid hydrocarbon mixture productionChemical industryHeat carrier

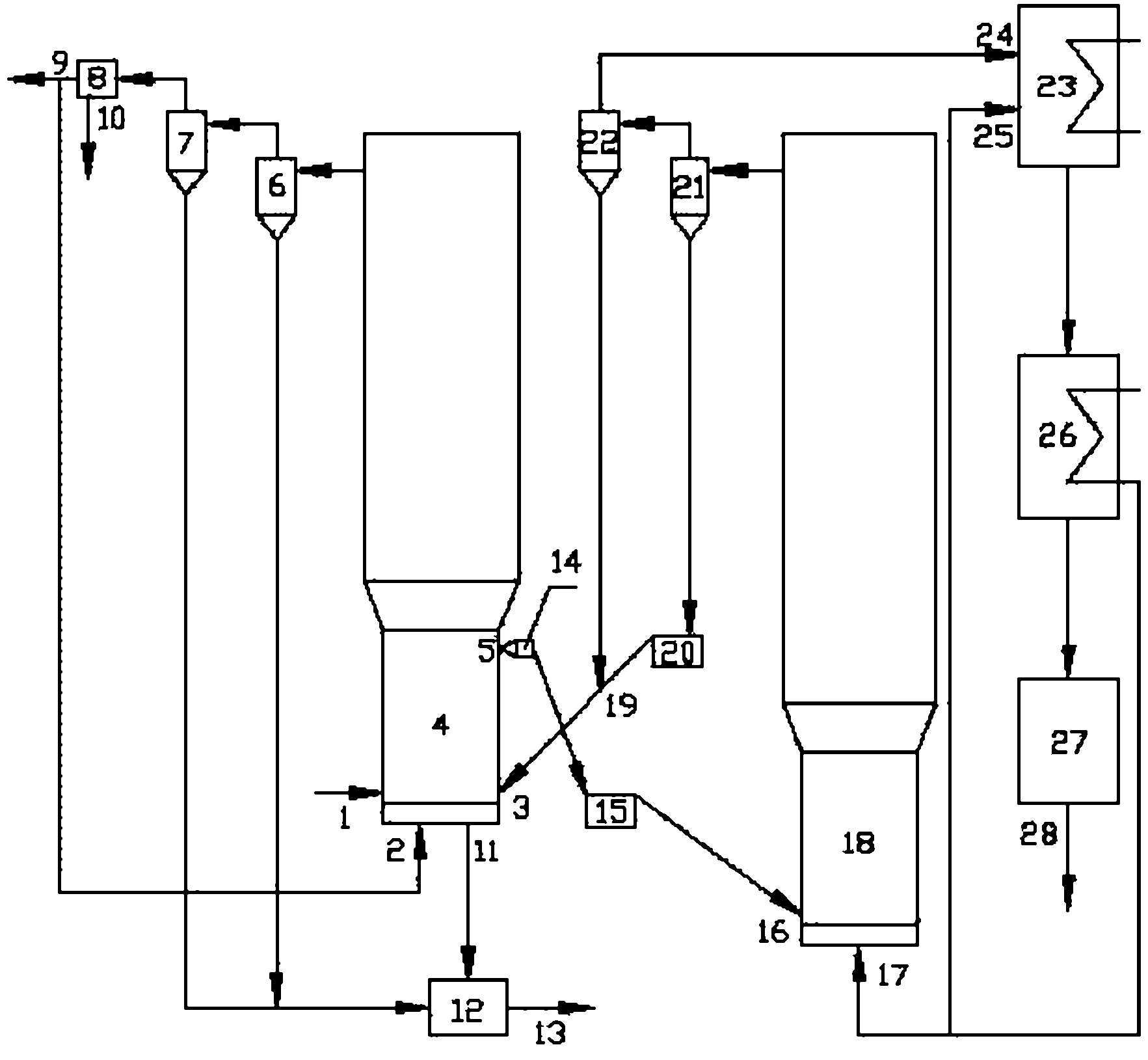

The invention provides a method that a biomass and coal are pyrolyzed rapidly to prepare liquid fuel, which belongs to the technology field of energy and chemical industry. The reaction system consists of a riser combustion reactor (10) and a biomass / coal rapid co-pyrolysis reactor. The two reactors are linked circularly through a solid heat carrier. A pyrolysis reactor consists of an upper pyrolysis reactor mixing section (5), a middle pyrolysis reactor cocurrent pyrolysis section (6) and a lower pyrolysis reactor gas-solid separation section (7); the quality ratio of the biomass and the coal is 95 / 5 to 50 / 50; the byproduct hydrogen rich gas led for circular reuse in the pyrolysis reactor is regarded as carrier gas and quenching gas; the co-pyrolysis char is completely burnt in the riser combustion reactor (10). The beneficial effects of the invention are capable of operating under normal temperature, simple in process, high in heat efficiency, high in liquid fuel yield, good in quality and suitable for the co-pyrolysis liquefaction of the solid biomass and low rank coal.

Owner:DALIAN UNIV OF TECH

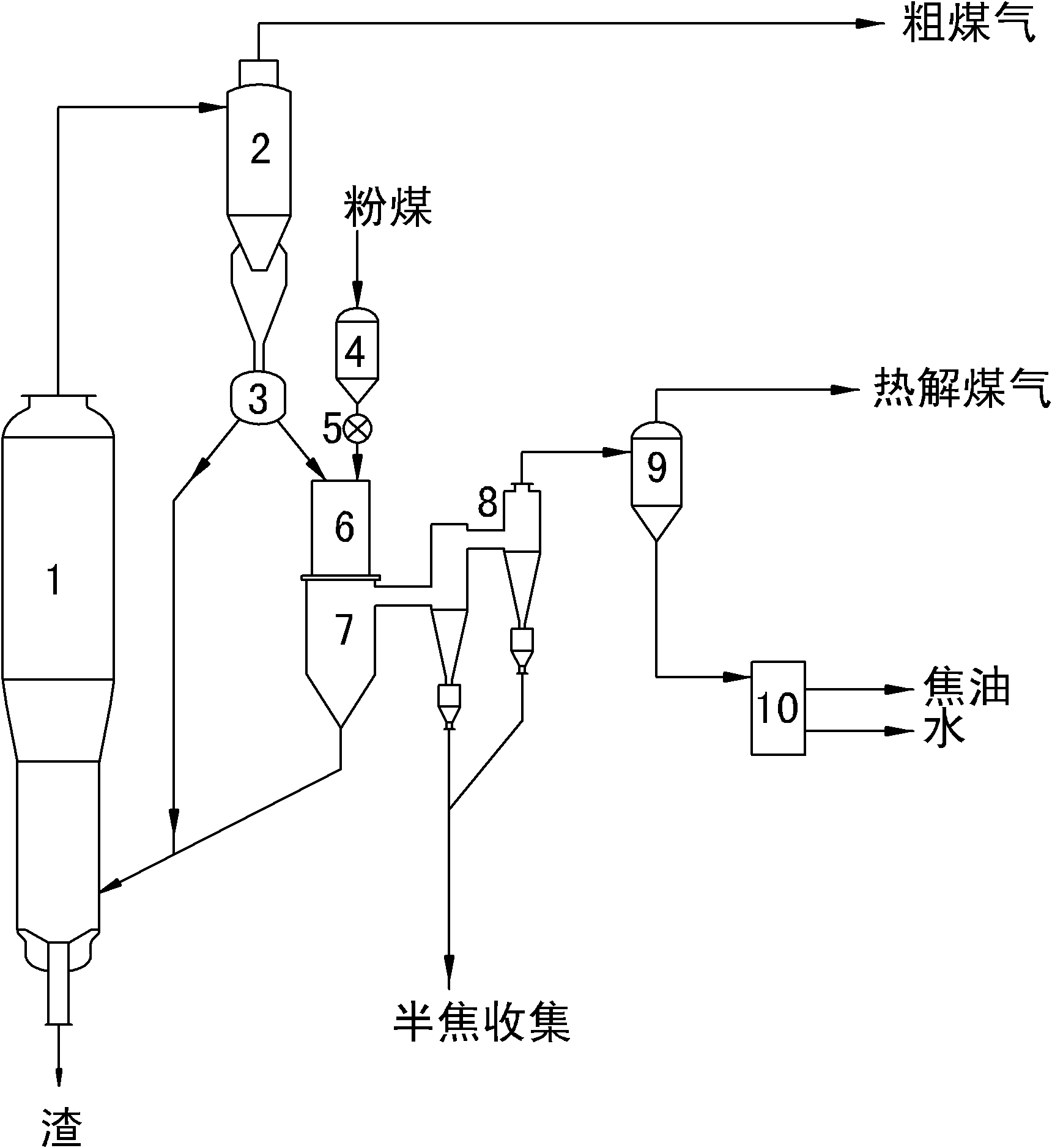

Air-oil co-production device and method adopting fluidized bed pulverized coal gasification and solid heat carrier pyrolysis coupling

ActiveCN101921627ASolve problems such as low thermal efficiency of the processDirect heating destructive distillationChemical industryHeat carrierLoop control

The invention relates to an air-oil co-production device and method adopting fluidized bed pulverized coal gasification and solid heat carrier pyrolysis coupling. The high-temperature circulating semicoke of a fluidized bed pulverized coal gasifier adopts two-loop control, one loop enters a pyrolysis reactor to be used as heat carrier for performing pyrolysis with coal and forming semicoke, the formed semicoke enters the fluidized bed pulverized coal gasifier; and the other loop directly returns to the return fluidized bed pulverized coal gasifier. The invention is based on the fluidized bed pulverized coal gasification technology, uses the high-temperature circulating semicoke as heat carrier to pyrolyze raw material and generate pyrolysis coal gas and tar before sending raw material to the coal furnace; and the semicoke generated through pyrolysis returns the fluidized bed pulverized coal gasifier for further burning and gasifying, thus raw gas can be produced and air-oil co-production can be realized. The problems such as low process heat efficiency of the traditional solid heat carrier can be overcome, thus the method of the invention is better than the traditional solid heat carrier technology.

Owner:陕西华祥能源科技集团有限公司

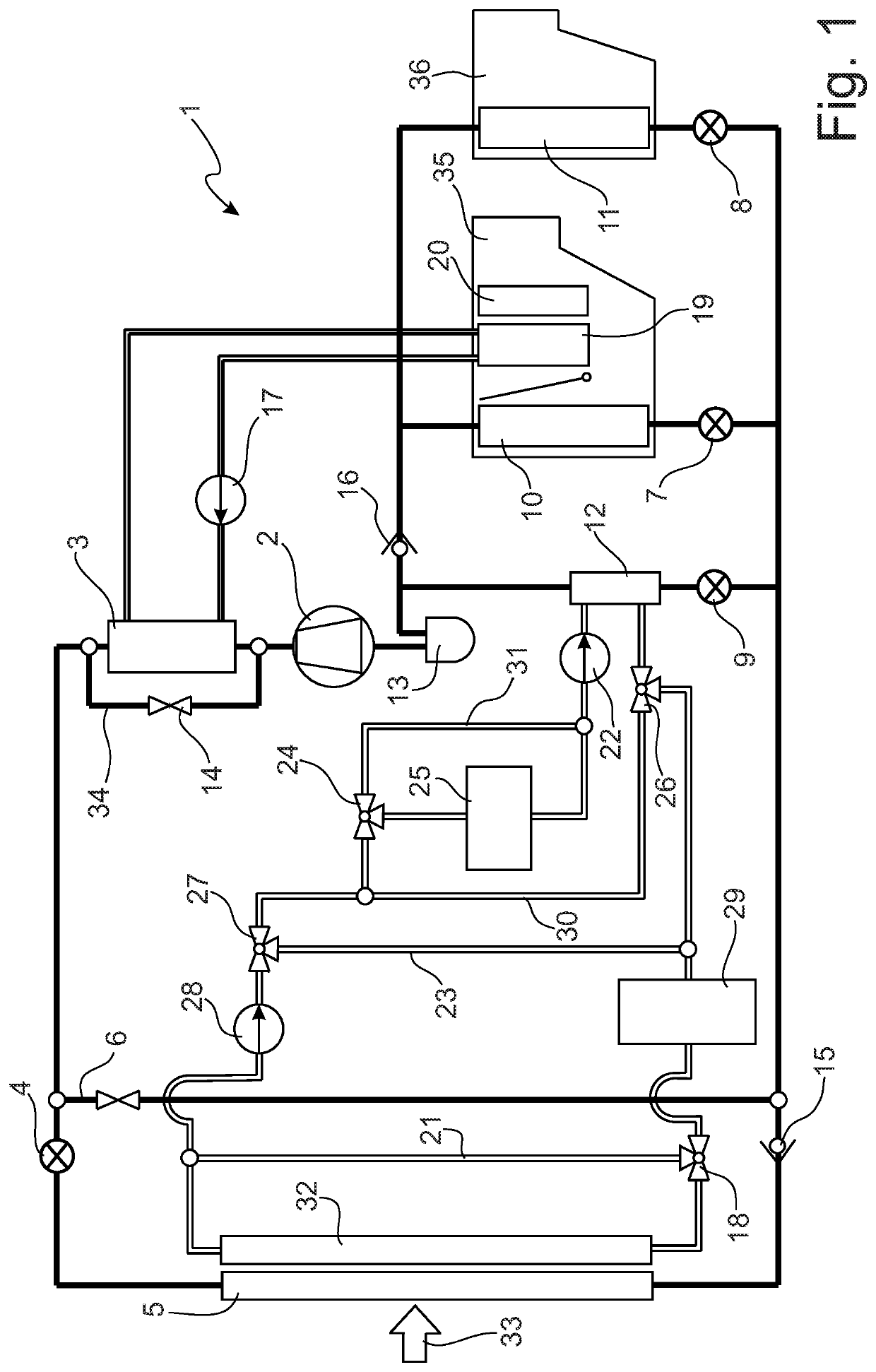

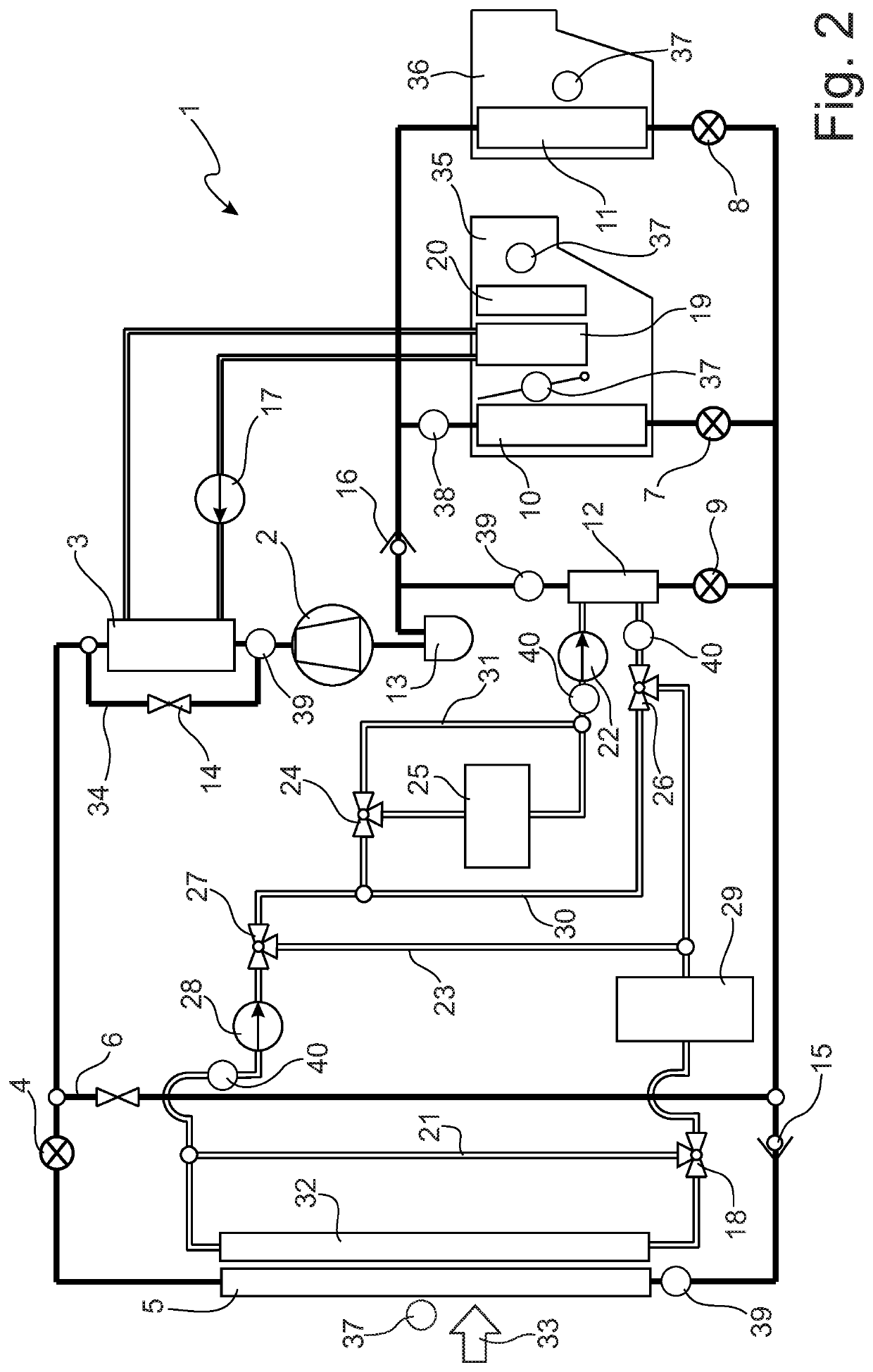

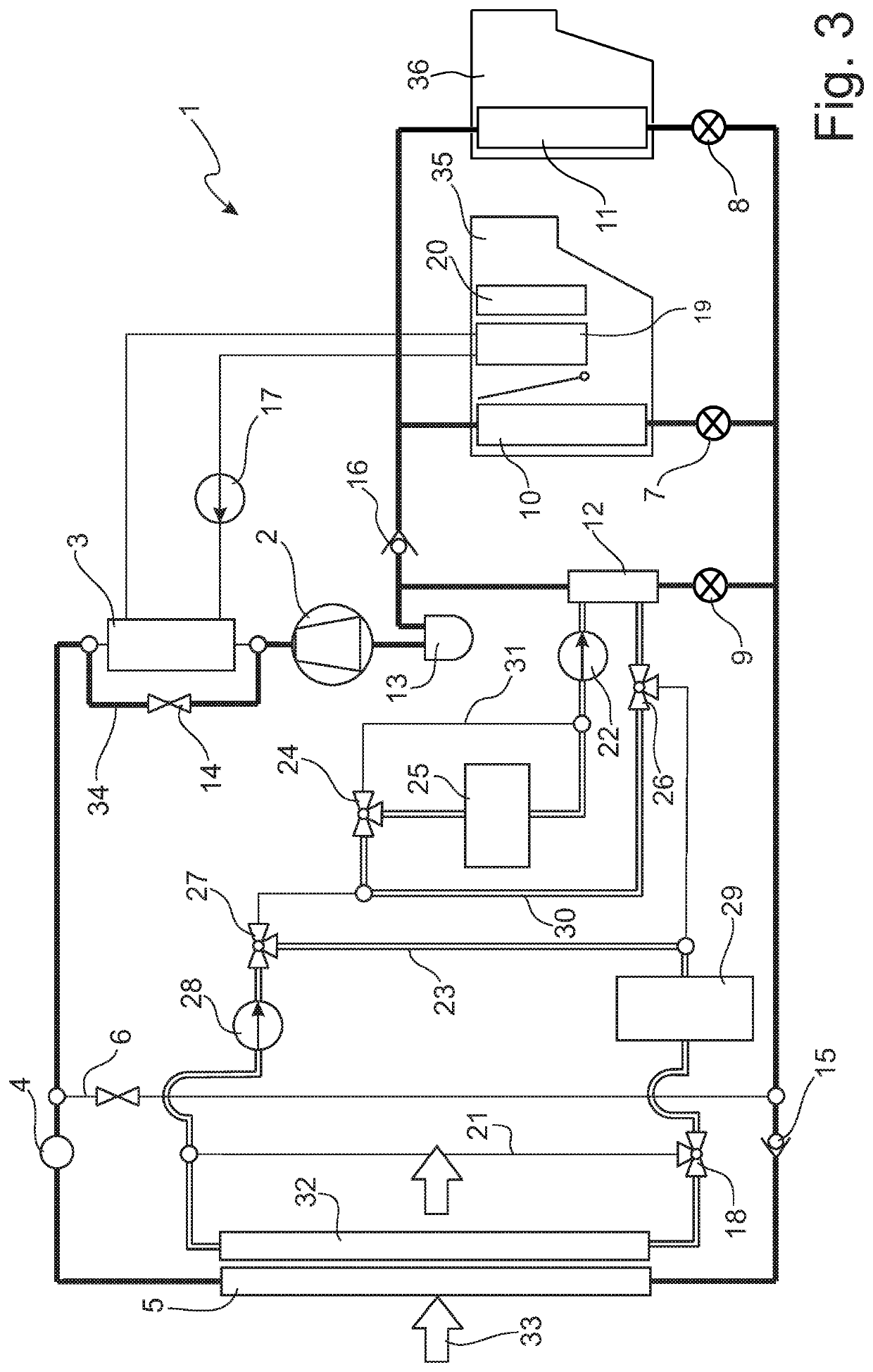

Rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS20120279825A1Upgrade and reduce viscosityRapid heat treatmentWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

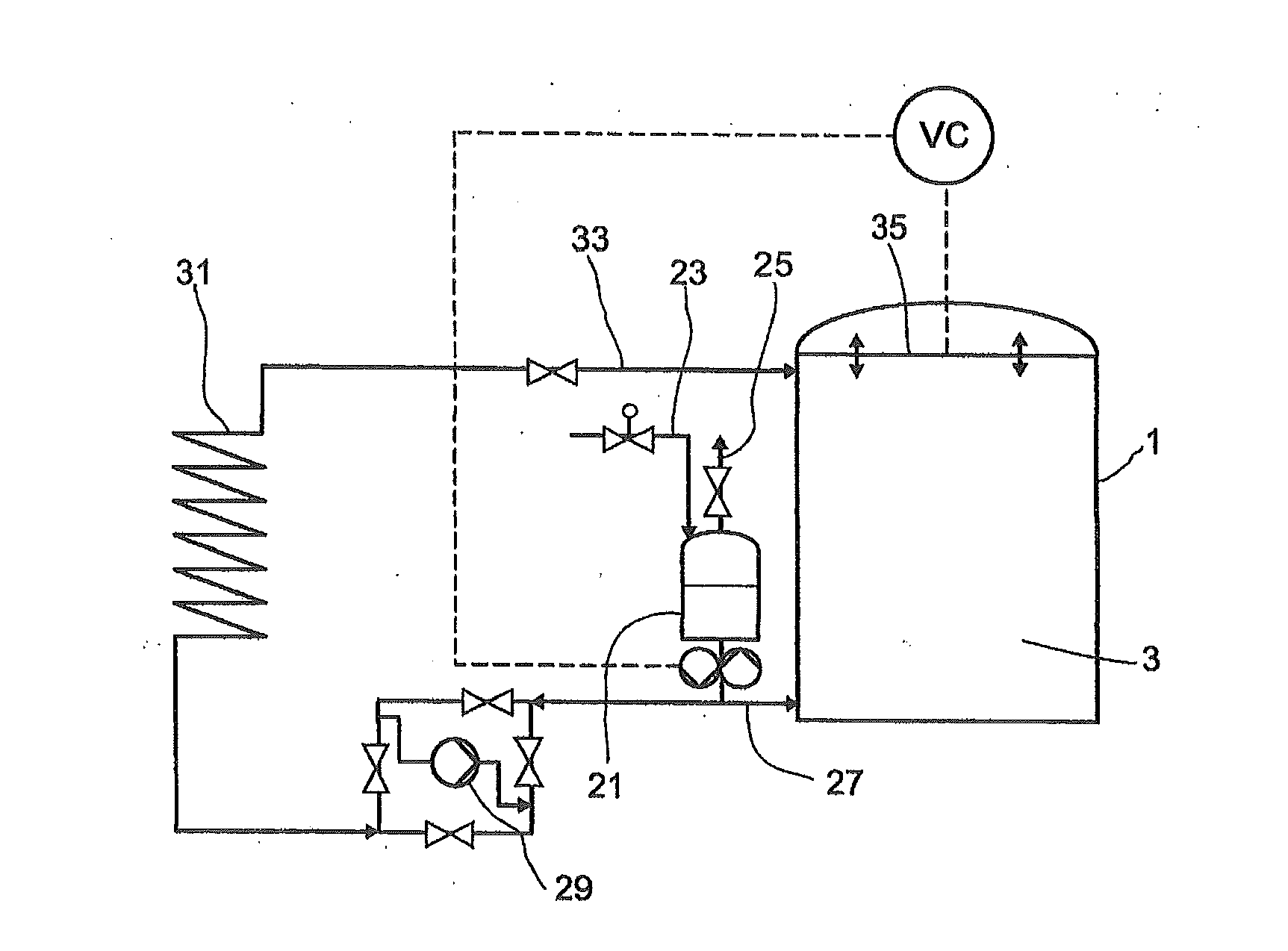

Heat flow management device and method for operating a heat flow management device

ActiveUS20190366800A1Simplified oil managementImprove cooling efficiencyAir-treating devicesVehicle heating/cooling devicesHeat carrierEngineering

Heat flow management device for motor vehicles has a refrigerant circulation, a power train coolant circulation and a heating line heat carrier circulation. The refrigerant circulation includes a compressor, an indirect condenser, an expansion element, an ambient heat exchanger, an evaporator and a chiller. The power train coolant circulation includes a coolant pump, the chiller, an electric motor heat exchanger and a power train coolant radiator, wherein the heating line heat carrier circulation comprises a coolant pump, the indirect condenser and a heating heat exchanger, wherein the refrigerant circulation and the power train coolant circulation are directly thermally coupled with one another across the chiller. Refrigerant circulation and heating line heat carrier circulation are directly thermally coupled with one another across the indirect condenser. Power train coolant circulation and the heating line heat carrier circulation are only indirectly thermally coupled with one another across the refrigerant circulation.

Owner:HANON SYST

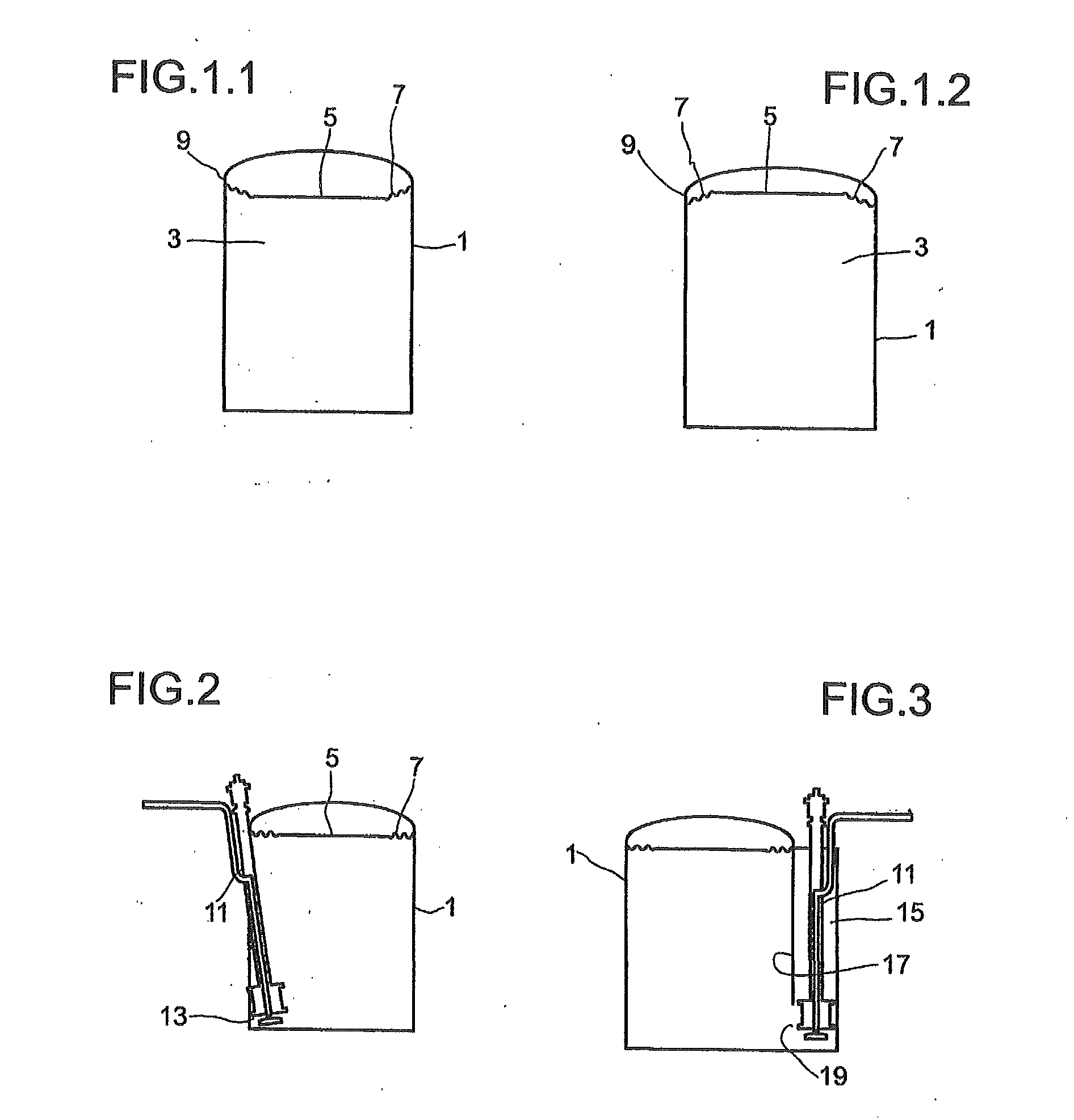

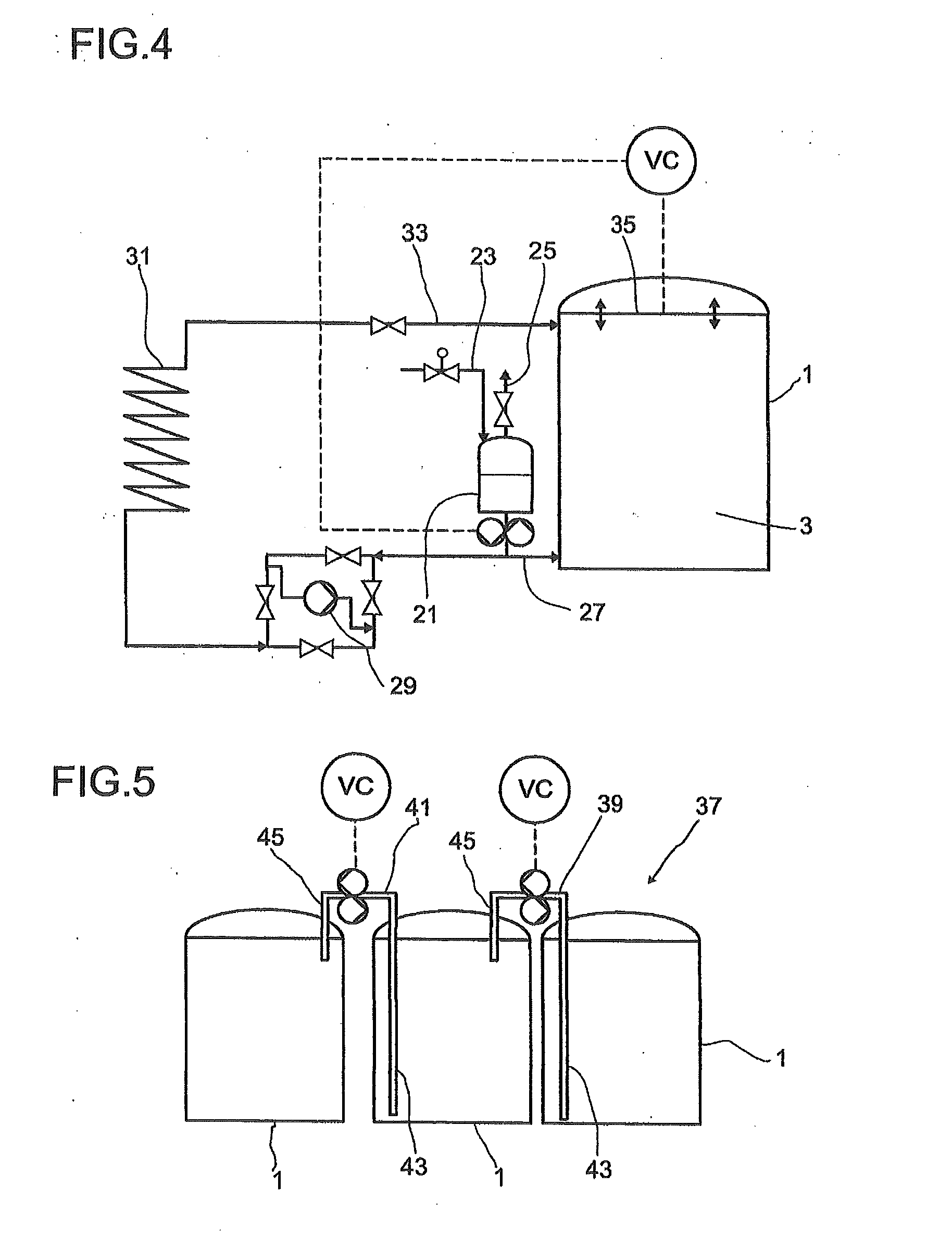

Device and method for storing heat

InactiveUS20110271953A1Guaranteed uptimeSolar heating energySolar heat devicesHeat carrierEngineering

The invention relates to a device for storing heat, comprising a heat storage medium which absorbs heat in order to store heat and releases heat in order to use the stored heat, and a container for holding the heat storage medium, the container being closed by a gastight cover, and the device comprising volume compensation means in order to compensate for a volume increase of the heat storage medium (3) due to a temperature rise and a volume decrease due to a temperature reduction. The invention furthermore relates to a method for storing heat, in which heat is transferred to a heat storage medium in order to store heat or heat is discharged from the heat storage medium to the heat carrier in order to use the heat, the heat storage medium being held in a container which is closed by a gastight cover, wherein a volume expansion of the heat storage medium (3) is compensated for by a volume increase of the container (1) or by heat storage medium (3) flowing out of the container (1) into a buffer container (21; 63, 65), and a volume decrease of the heat storage medium (3) is compensated for by a volume decrease of the container (1) or by heat storage medium (3) flowing out of the buffer container (21; 63, 65) into the container (1).

Owner:BASF AG

Products produced form rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS7270743B2Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

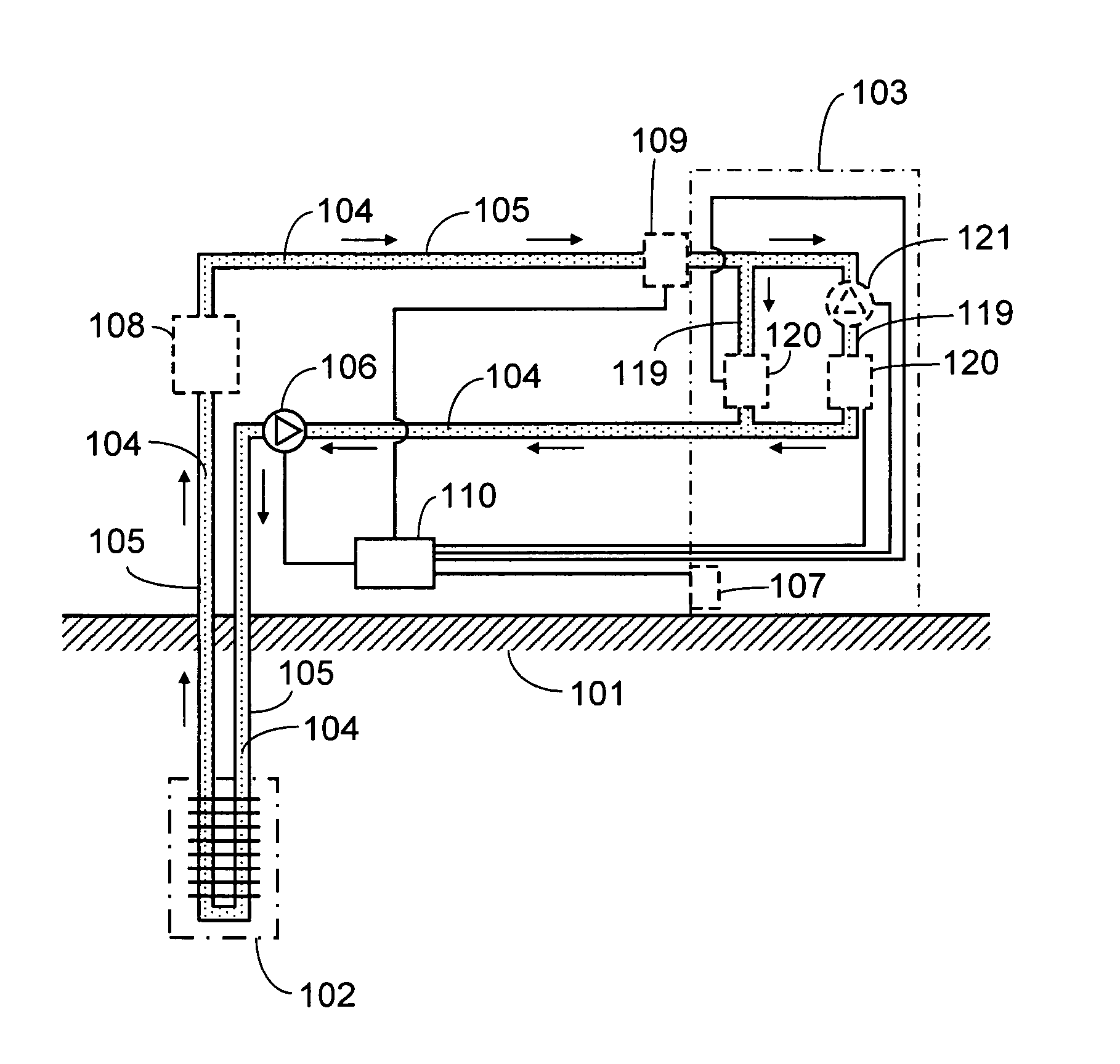

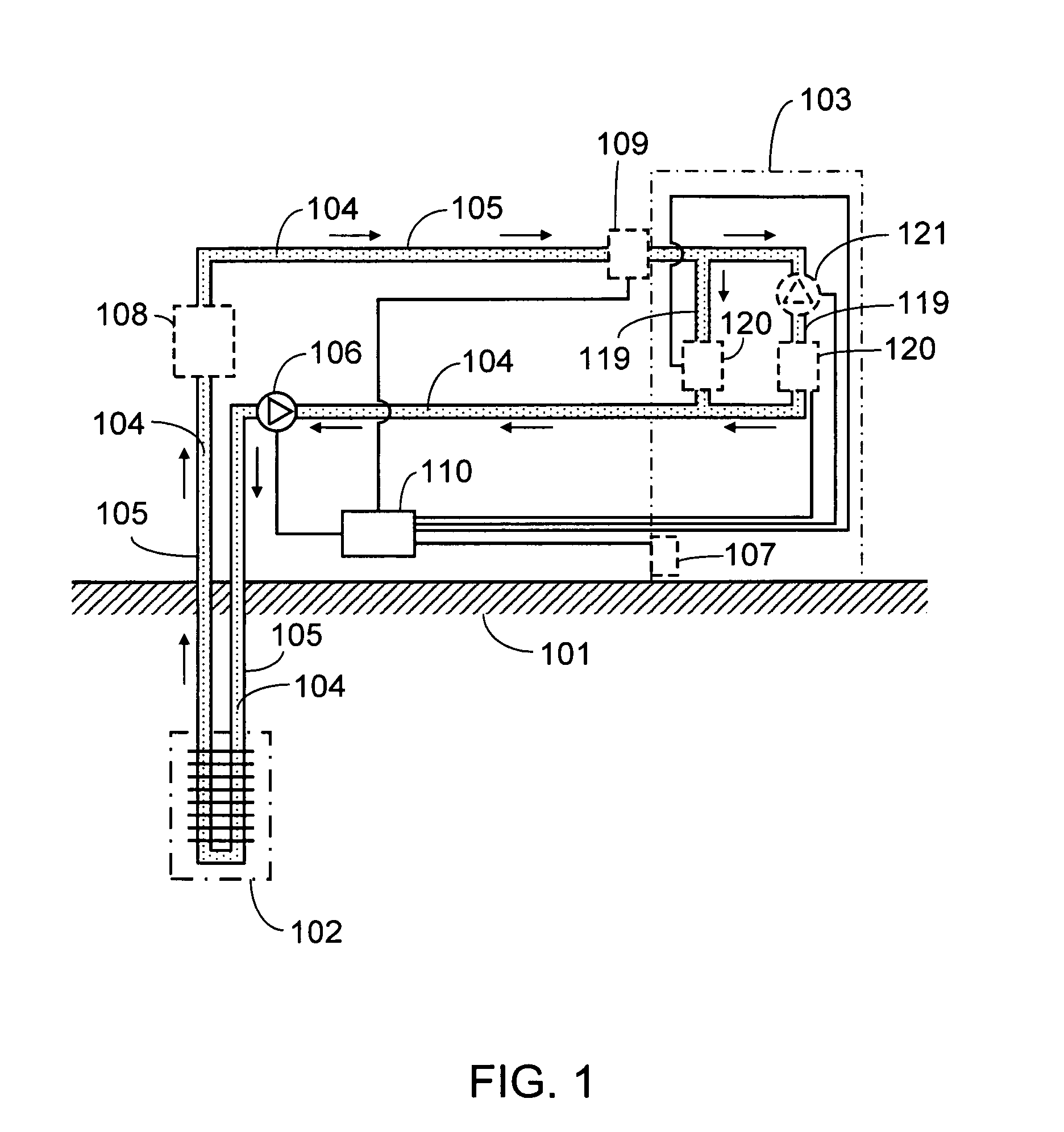

Semiconductor application installation adapted with a temperature equalization system

ActiveUS20100314070A1Large and reliable heat carrying capacityImprove thermal conductivityPhotovoltaic supportsSolar heating energyCarrying capacityHeat carrier

The primary purpose of the present invention is to provide an fluid circulating installation adapted with a temperature equalization system and fluid transmission duct disposed in a heat carrier existing in solid or liquid state in the nature where presents comparatively larger and more reliable heat carrying capacity. The fluid passes through the solid or gas state semiconductor application installation to regulate the semiconductor application installation for temperature equalization, and flows back to the heat equalization installation disposed in the natural heat carrier of heat for the heat equalization installation providing good heat conduction in the natural heat carrier to provide the operation of temperature equalization regulating function on the backflow of the fluid.

Owner:YANG TAI HER

Biomass gasification hydrogen-producing system and method

InactiveCN101774542AReduce utilizationTo achieve hierarchical utilizationHydrogen productionGas solidHeat carrier

The invention discloses a biomass gasification hydrogen-producing system and a method, which belongs to the technical field of hydrogen production. Biomass gasification hydrogen production and chemical-looping combustion are combined to realize low-cost separation of carbon dioxide; and the fractional utilization of matter and energy is realized via the circulation among three beds with metal oxide as a heat carrier and an oxygen carrier. The system mainly comprises an air reactor, a fuel reactor, a moving bed gasifier, a gas-solid separation device, a gas purification device, a hydrogen separation device and a follow-up hydrogen-producing device. The system not only can realize hydrogen production, but also can realize hydrogen production with near zero emission of CO2, thereby realizing efficient cleaning and utilization of biomass.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Piston type fluidized bed low temperature dry distillation technological process

InactiveCN101328415AReduce lossesIncrease profitSpecial form destructive distillationHeat carrierOxygen

The invention relates to a process method for low temperature carbonization on a fluidized bed. The process method uses the principle of a lift pipe fluid catalytic cracker, uses a lift pipe reactor of the lift pipe fluid catalytic cracker as a carbonization reactor, uses a catalyst regenerator of the lift pipe fluid catalytic cracker as a high-temperature water gas generator, and uses high-temperature water gas as a fluidizing medium and a heat carrier of a carbonization raw material. The carbonization method comprises the following steps that: a carbonizing raw material is conveyed to the lift pipe fluidized bed reactor for a carbonization reaction of the raw material; the reacted oil and gas are separated to produce a carbonized product; carbonized carbocoal enters the water gas regenerator; carbon in the carbonized carbocoal, oxygen and water vapour in air are subjected to oxidation reaction and water gas reaction; the water gas obtained in the reaction is used as the fluidizing medium and the heat carrier during the carbonization process; and solid clinkers produced after the carbonized carbocoal is subjected to the water gas reaction are discharged. Compared with the prior art, the method has the advantages of simple process, high production capacity, less equipment and so on, and can be used in oil shale, oil sand, coal and other substances to produce liquid petroleum products.

Owner:ZHUHAI TOP ENERGY TECH

Coal gas, tar, semi-coke and steam poly-generation method based on fluidized bed pyrolysis technology

ActiveCN102585913AImprove qualityEasy to controlEnergy inputSpecial form destructive distillationAir preheaterHeat carrier

The invention relates to a coal gas, tar, semi-coke and steam poly-generation method based on a fluidized bed pyrolysis technology. The method comprises the following steps of: mixing coal and high-temperature semi-coke serving as a heat carrier in a fluidized bed pyrolysis furnace, heating, precipitating volatiles, and cooling and separating the volatiles to obtain tar and pyrolysis coal gas; discharging one part of semi-coke to obtain a semi-coke product, feeding the other part of semi-coke into a fluidized bed semi-coke heating furnace, performing combustion reaction with a small amount of fed air, heating all the fed semi-coke by using heat released after a small amount of semi-coke is combusted, feeding the heated semi-coke into a cyclone separator along with flue gas, and feeding the separated high-temperature semi-coke serving as the heat carrier into the fluidized bed pyrolysis furnace; and feeding the flue gas subjected to gas-solid separation into a complementary combustion waste heat boiler, completely combusting a small number of combustible components in the flue gas, producing steam, feeding into an air preheater to heat air required by combustion, removing dust by using a dust remover, and emptying. The method has the advantages of realizing the fractional conversion of the coal and improving the utilization efficiency and benefit of the coal.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com