Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

689results about How to "Improve hydrolytic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

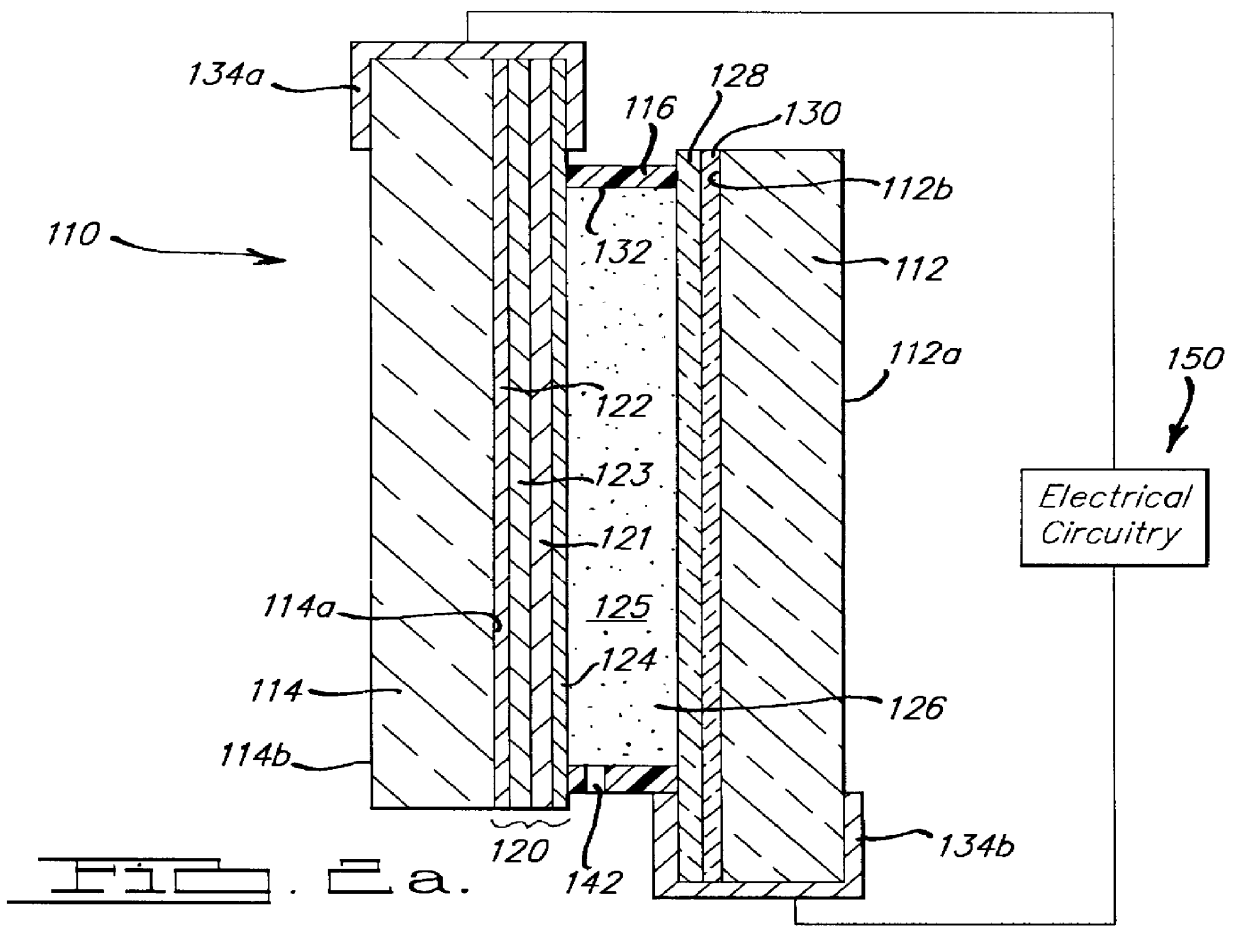

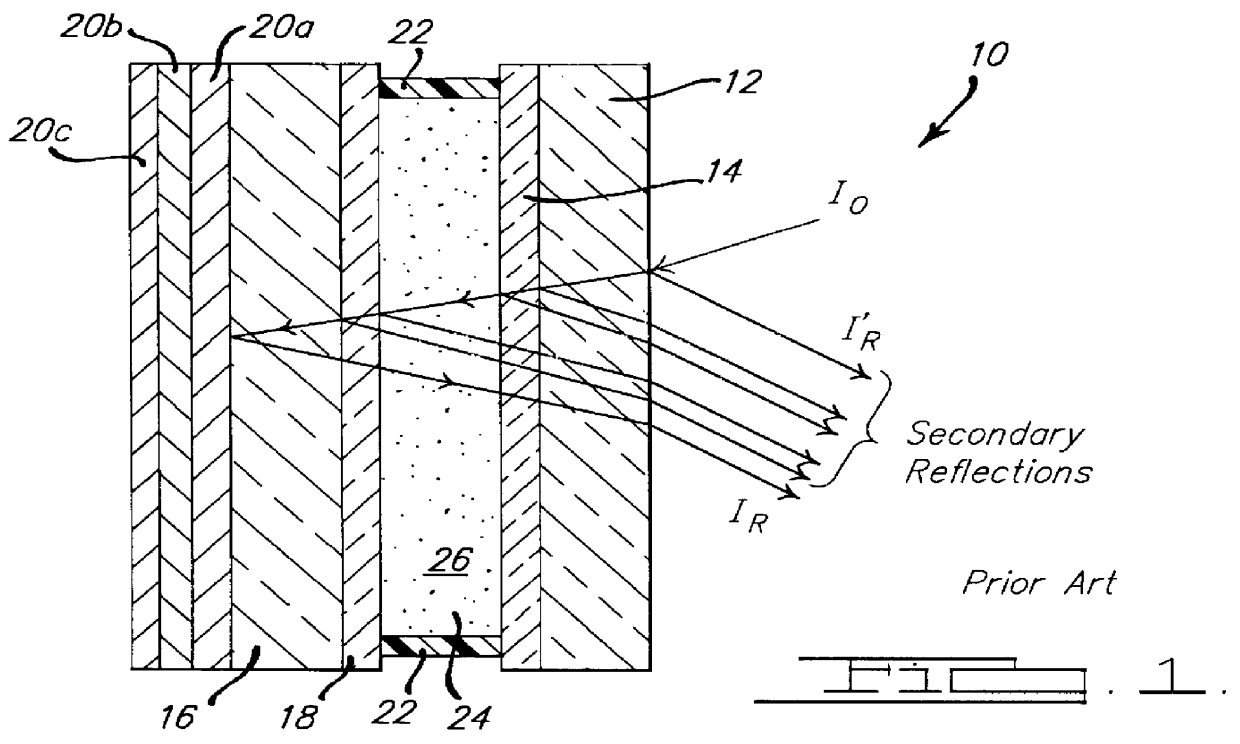

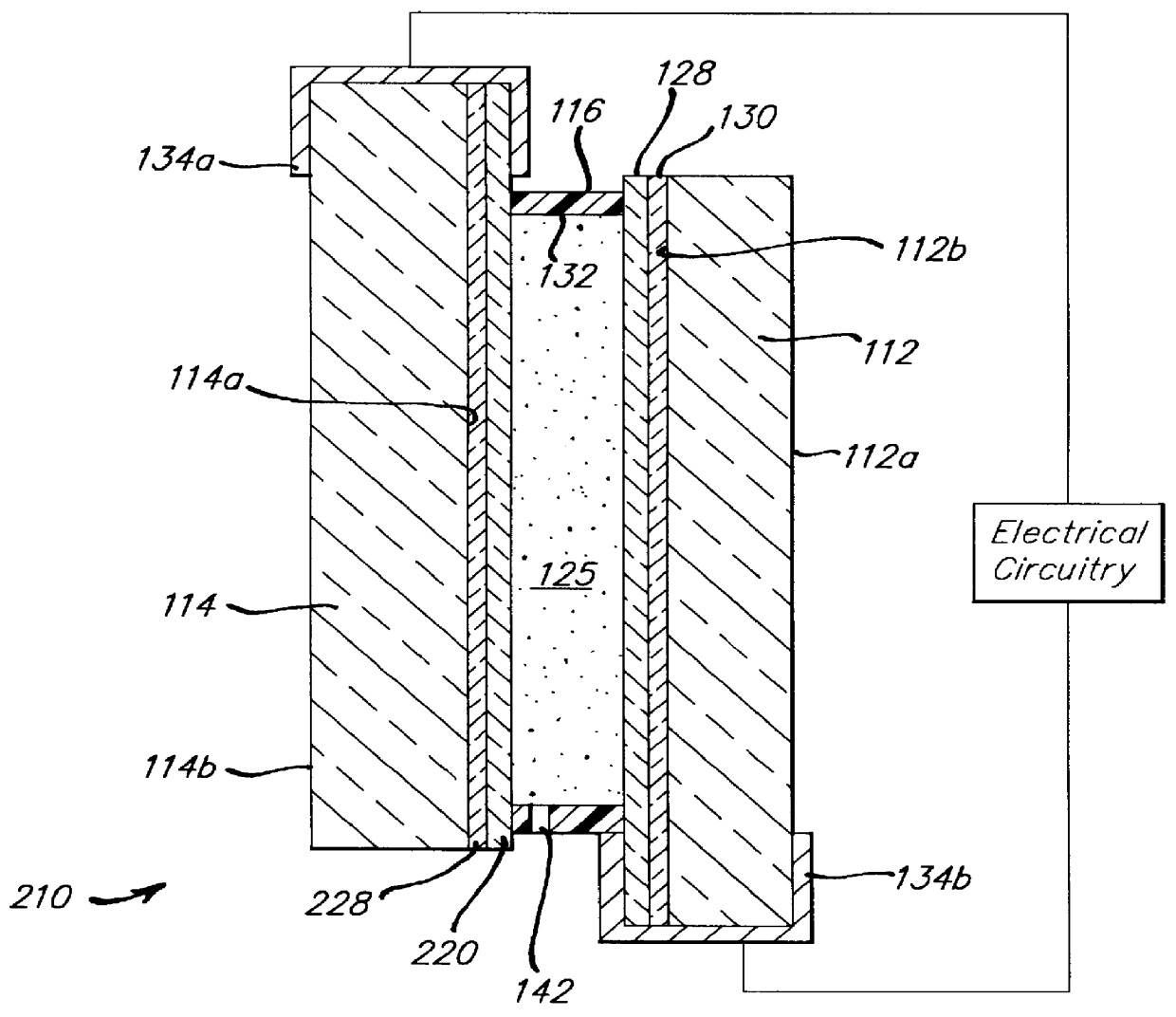

Seal for electrochromic devices

An improved seal member is provided as a part of an electrochromic device to bond two glass elements together in a spaced-apart relationship. In one embodiment the seal member provides improved adhesion to a reflector / electrode on the third surface of an electrochromic mirror, or to a layer of metal on the second or third surface for an electrochromic light filter. This seal member comprises a mixture of an organic resin sealing system and an adhesion promoter, where the adhesion promotor comprises a first and a second region, where the first region interacts with the reflector / electrode or the metal layer, and a second region that interacts with the organic resin sealing system, and may even chemically react with the organic resin sealing system. In another embodiment the seal member is provided with a coefficient of thermal expansion that is closer to glass than a standard epoxy sealing system.

Owner:GENTEX CORP

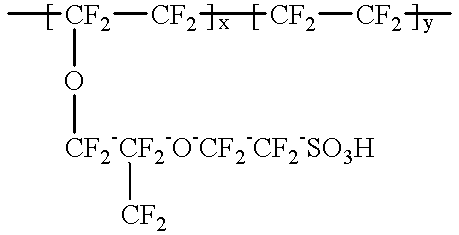

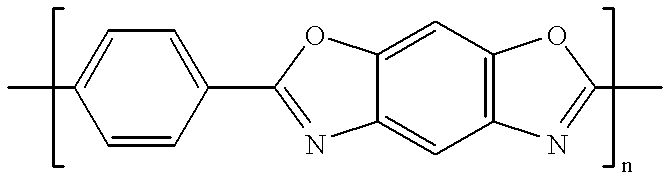

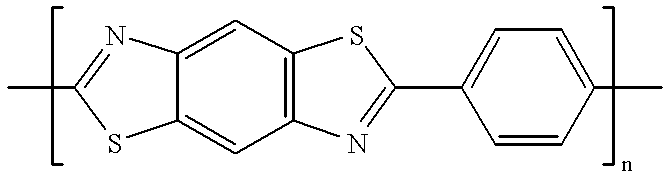

Composite solid polymer elecrolyte membranes

InactiveUS20020045085A1Optimize swellingOptimize fuel crossover resistanceElectrolyte holding meansFinal product manufacturePolymer electrolytesPolymer science

The present invention relates to composite solid polymer electrolyte membranes (SPEMs) which include a porous polymer substrate interpenetrated with an ion-conducting material. SPEMs of the present invention are useful in electrochemical applications, including fuel cells and electrodialysis.

Owner:FOSTER-MILLER

Method of Packaging a Lens

InactiveUS20070149428A1Avoid changeChange physical propertiesLavatory sanitoryOther accessoriesLens plateCopolymer

A contact lens package includes a sealed receptacle containing a contact lens immersed in a sterile solution. The contact lens is made of a silicone hydrogel copolymer, and the solution includes a stabilizing agent in an amount effective to inhibit changes in physical properties of the silicone hydrogel copolymer.

Owner:BAUSCH & LOMB INC

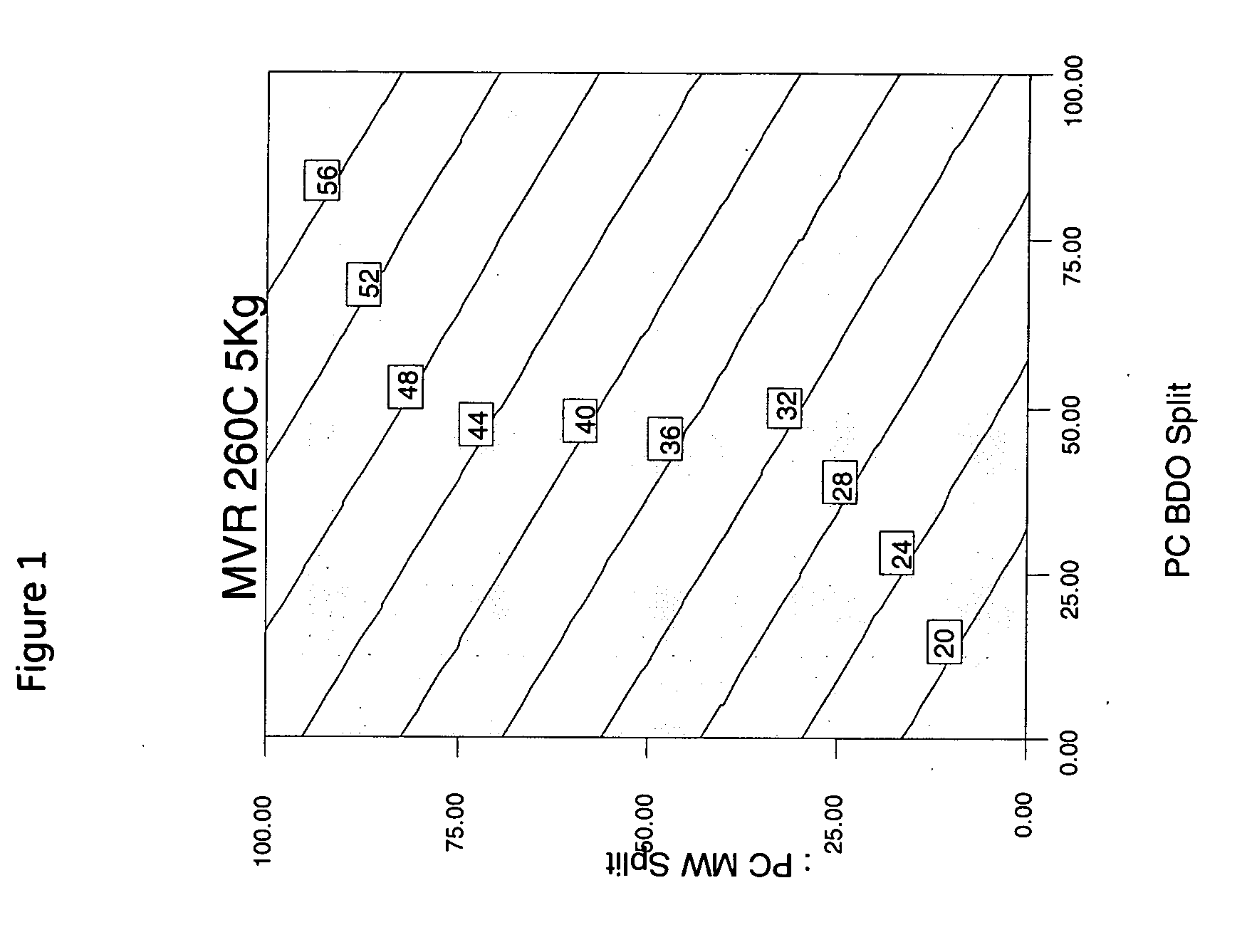

Thermoplastic polycarbonate compositions, method of manufacture, and method of use thereof

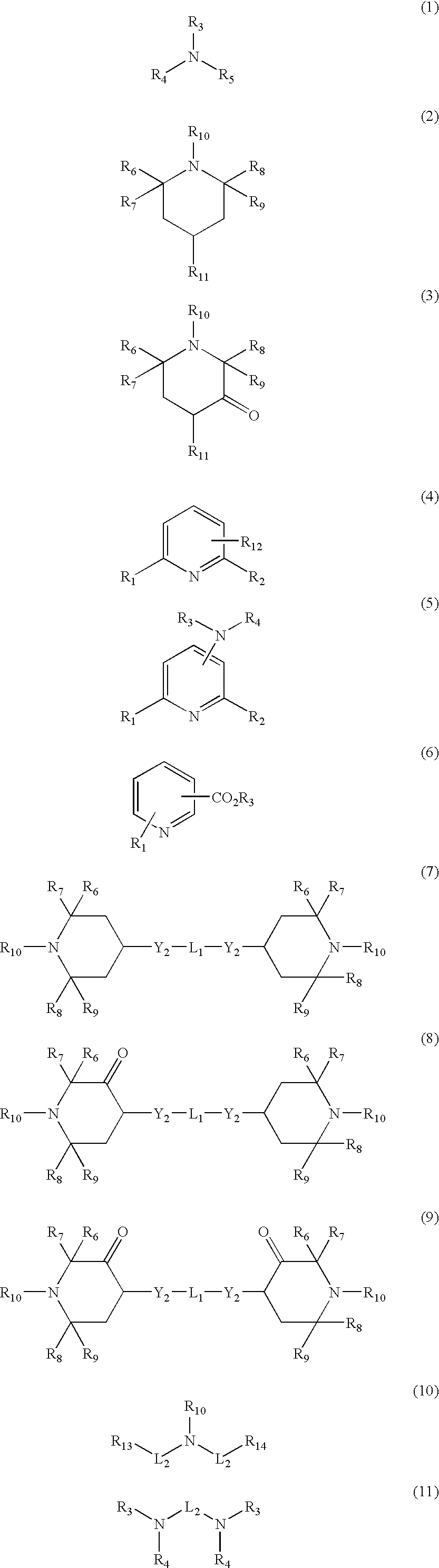

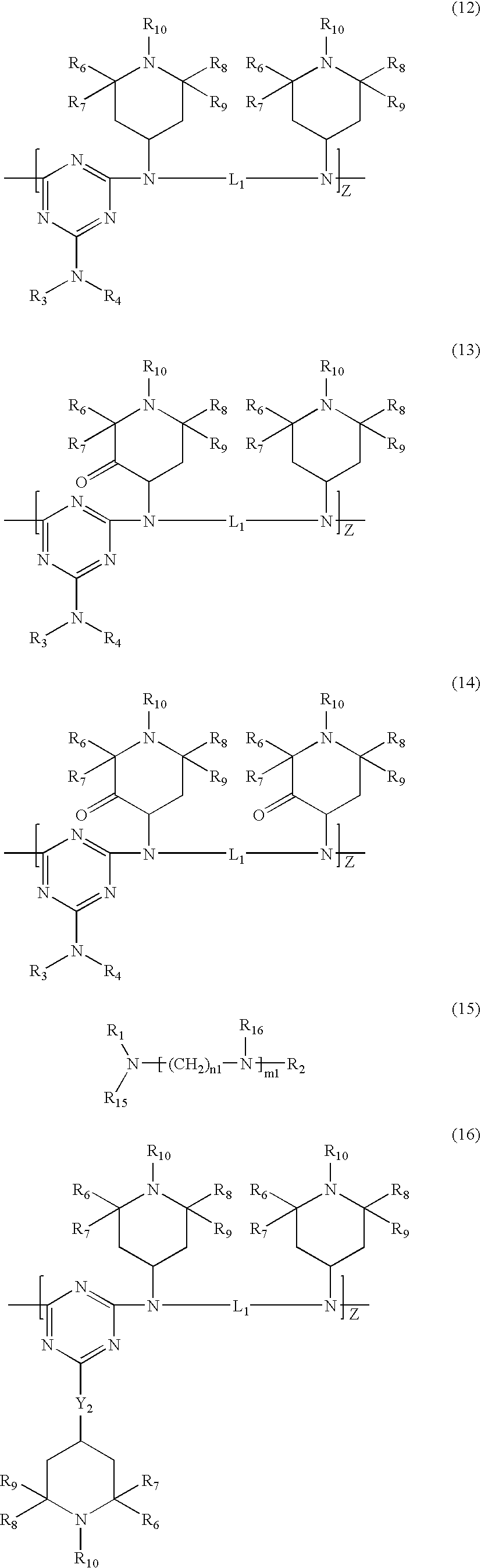

InactiveUS20070135569A1Improve hydrolytic stabilityImprove thermal stabilitySynthetic resin layered productsThermoplasticPolycarbonate

A thermoplastic composition comprising in combination an aliphatic / aromatic co-polycarbonate component; an impact modifier; and a rigid copolymer, and optionally a polycarbonate component and / or a polycarbonate-polysiloxane copolymer is disclosed. The co-polycarbonate comprises repeating carbonate units and repeating aliphatic units. The compositions have a significantly improved balance of properties, including melt flow and impact.

Owner:SABIC INNOVATIVE PLASTICS IP BV

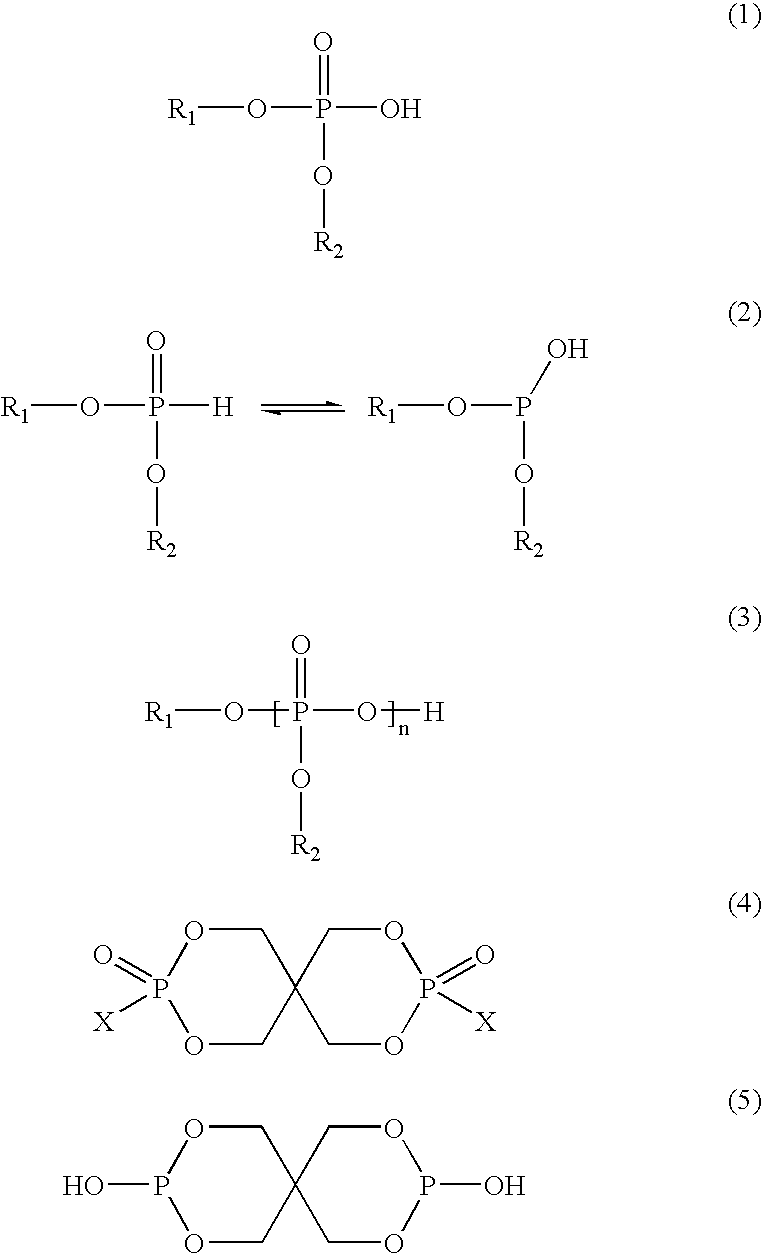

Polyester compositions

InactiveUS7468409B2Avoid harmful effectsImprove hydrolytic stabilityGroup 5/15 element organic compoundsPolyesterCarboxylic acid

Disclosed are polymer compositions comprising:(A) at least one polyester prepared by the reaction of at least one diol with at least one dicarboxylic acid or dialkyl ester thereof in the presence of a metallic catalyst; and(B) at least one salt prepared from the reaction of one or more acidic phosphorus-containing compounds and one or more basic organic compounds which contain nitrogen.The polyester compositions exhibit improved color, especially when used as a component of a polyester / polycarbonate blend. Also disclosed are polymer compositions comprising a polycarbonate in combination with components (A) and (B).

Owner:EASTMAN CHEM CO

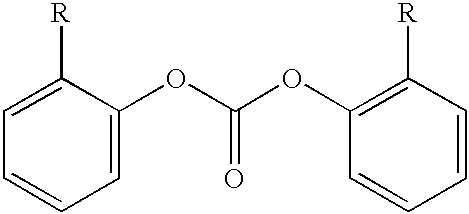

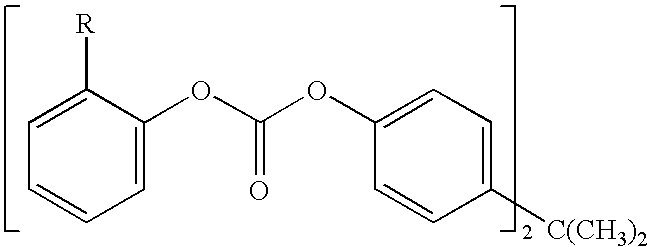

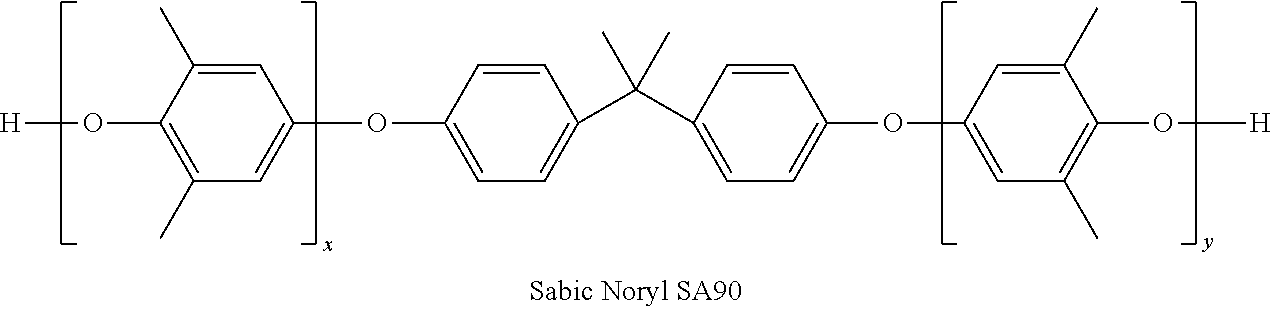

Method for end-capping polycarbonate resins and composition for use in same

A method for end-capping polycarbonate resins, comprising the step of processing a mixture comprising a polycarbonate having free hydroxyl-end groups and an end-capping reagent in a melt transesterification reaction to produce a polycarbonate resin, wherein the end-capping reagent comprises a mixture of: (a) at least one species of a symmetrical activated aromatic carbonate, and (b) at least one species of an optionally-substituted phenol, whereby said end-capping reagent reacts with at least some of the free hydroxyl end-groups of the polycarbonate to produce an end-capped polycarbonate resin.

Owner:SABIC GLOBAL TECH BV

Seal for electrochromic devices

An improved seal member is provided as a part of an electrochromic device to bond two glass elements together in a spaced-apart relationship. In one embodiment the seal member provides improved adhesion to a reflector / electrode on the third surface of an electrochromic mirror, or to a layer of metal on the second or third surface for an electrochromic light filter. This seal member comprises a mixture of an organic resin scaling system and an adhesion promoter, where the adhesion promotor comprises a first and a second region, where the first region interacts with the reflector / electrode or the metal layer, and a second region that interacts with the organic resin sealing system, and may even chemically react with the organic resin sealing system. In another embodiment the seal member is provided with a coefficient of thermal expansion that is closer to glass than a standard epoxy sealing system.

Owner:GENTEX CORP

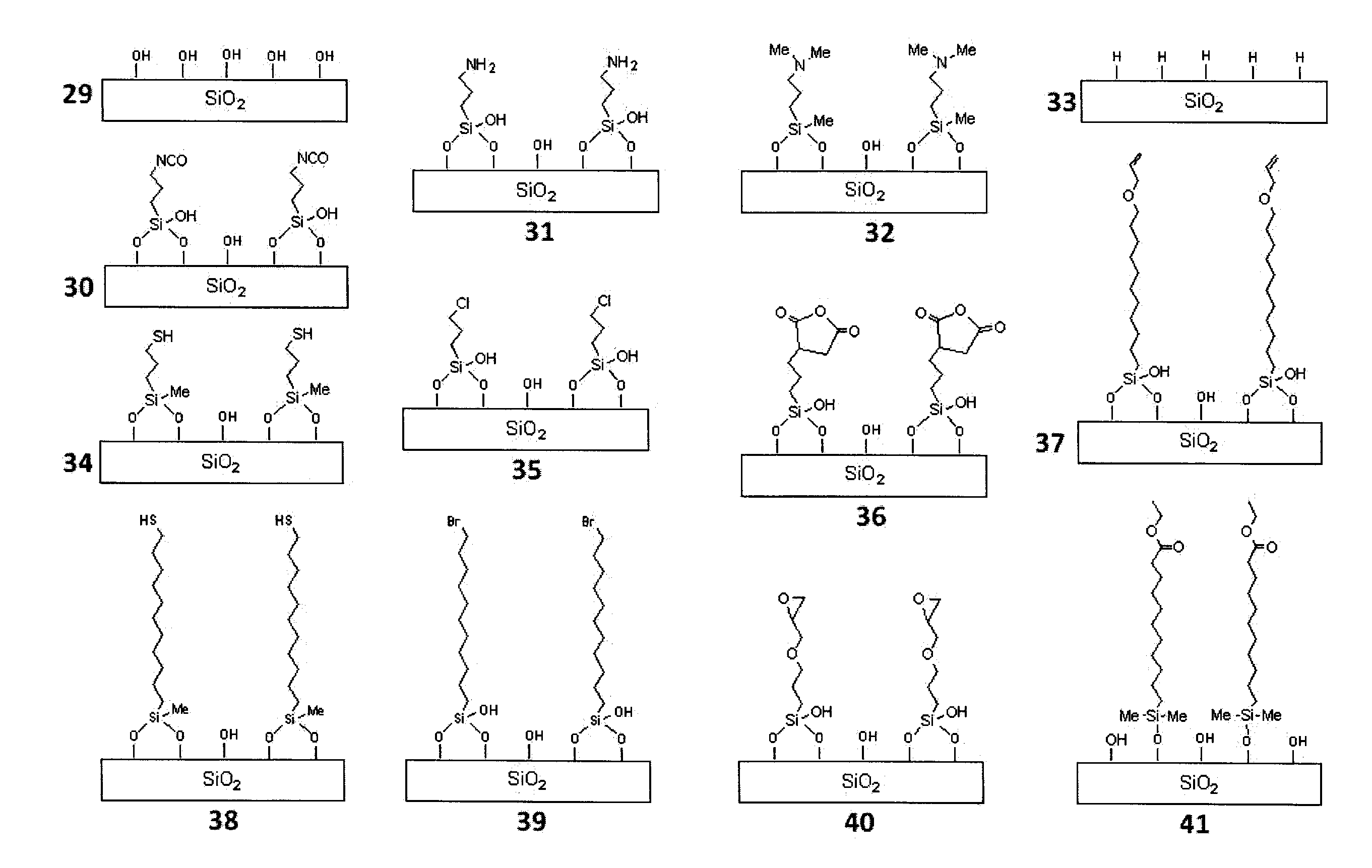

Nanometer size chemical modified materials and uses

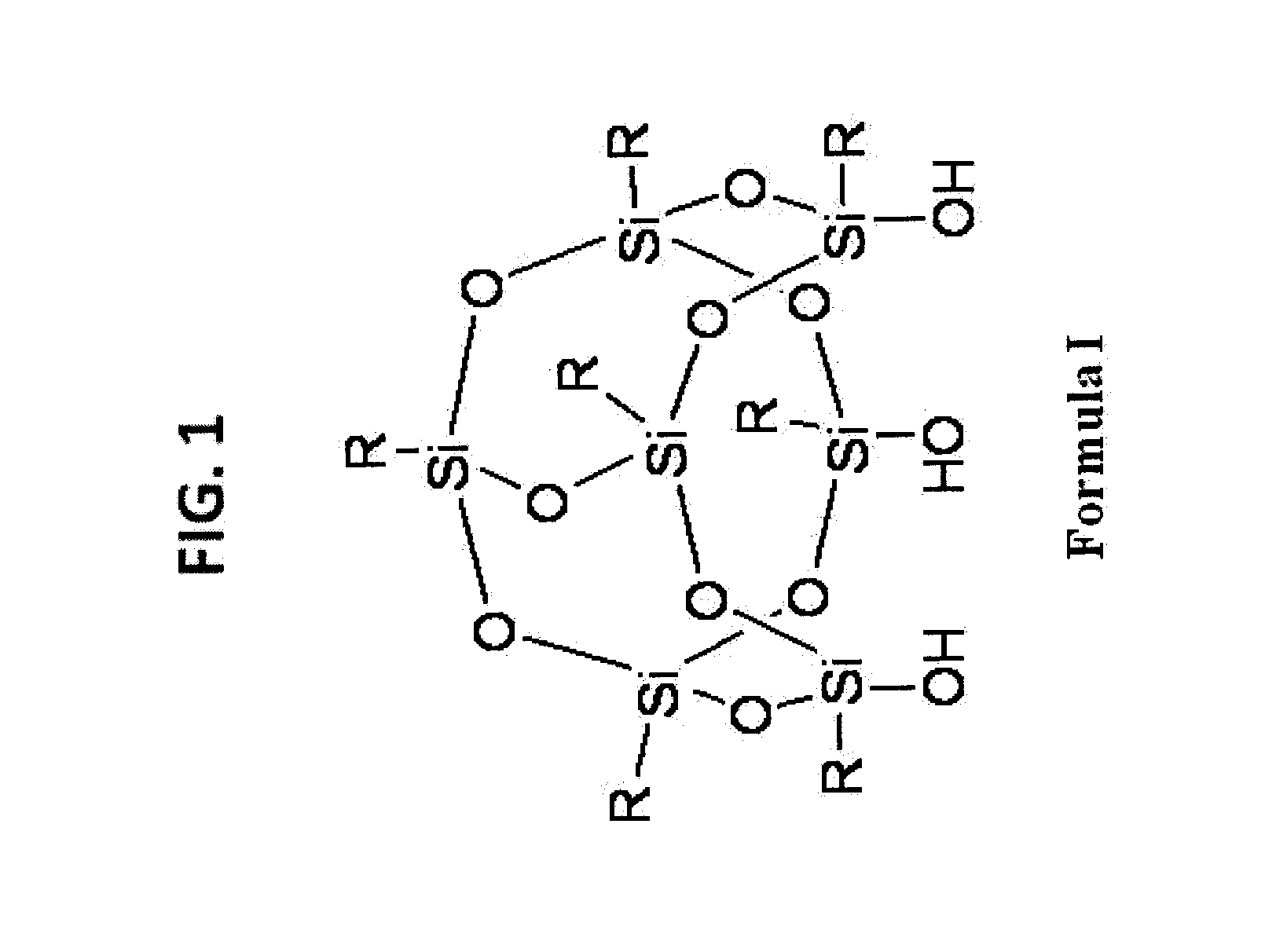

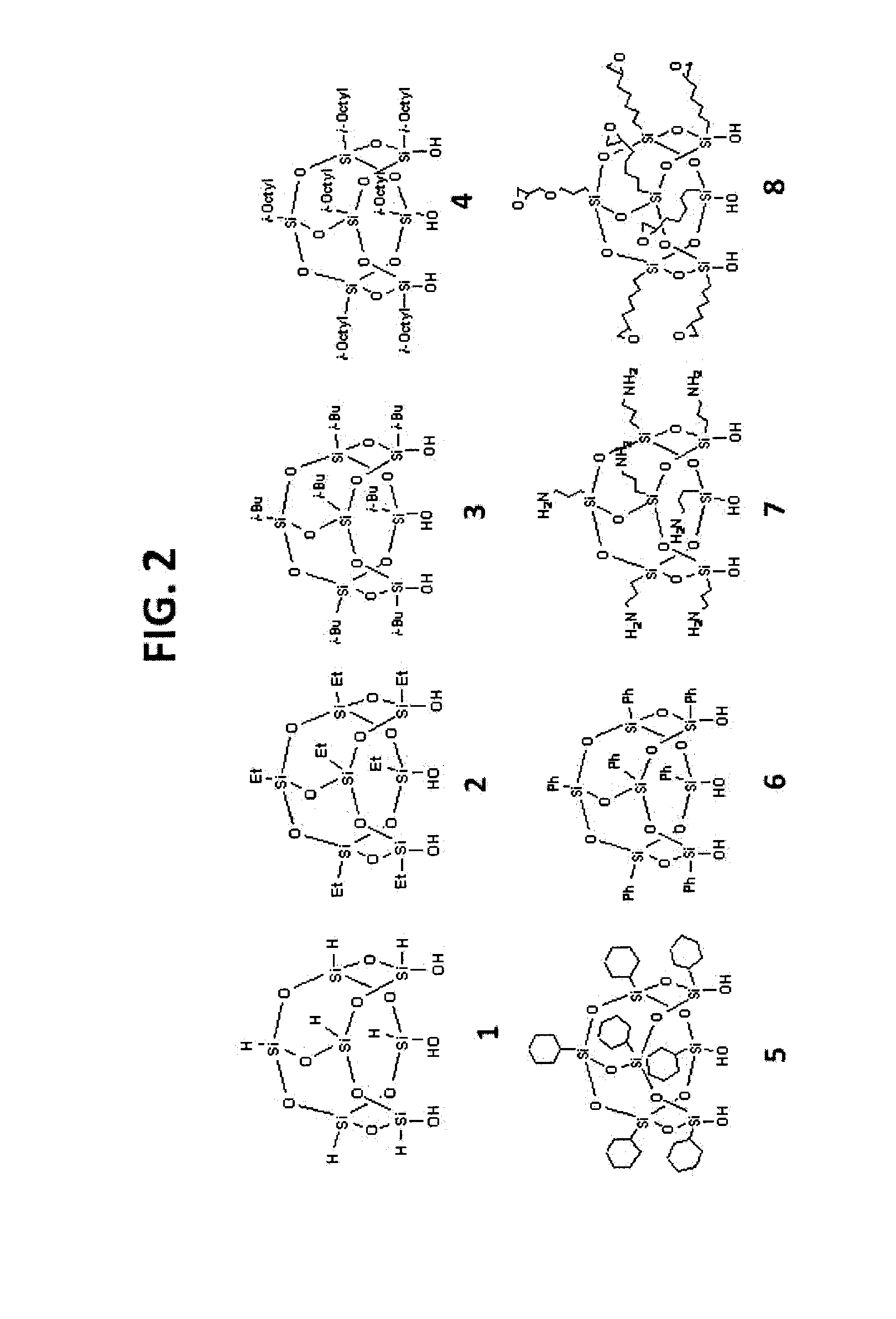

InactiveUS20120205315A1Improve hydrolytic stabilityImprove hydrophobicityIon-exchange process apparatusSilicon organic compoundsStationary phaseSilsesquioxane

There are provided ligand compositions and stationary phases comprising a polyhedral oligomeric silsequioxane moiety. Also provided are chromatographic devices comprising the stationary phases, and methods of making and using the ligands, stationary phases and chromatographic devices of the invention.

Owner:DIONEX CORP

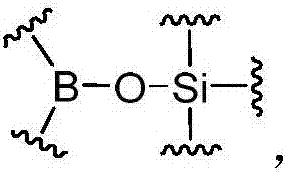

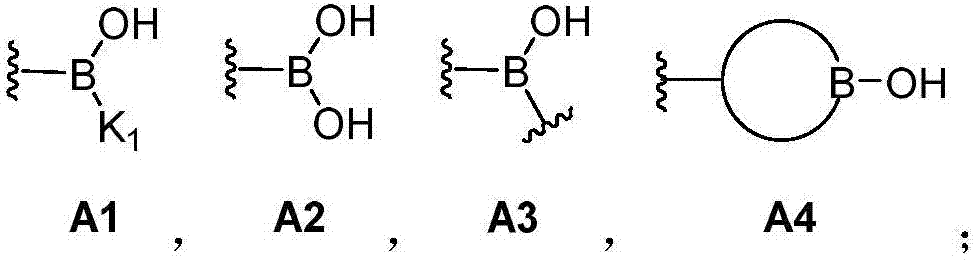

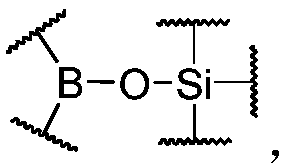

Dynamic polymer with dynamic cross-linked structure

The invention discloses a dynamic polymer with a dynamic cross-linked structure. Organic boric acid silicon ester bonds are contained on polymer chain skeletons of a cross-linked network and / or on cross-linked link skeletons between polymer chains, wherein the organic boric acid silicon ester bonds are necessary for forming / maintaining a dynamic polymer structure. The dynamic polymer is rich in structure and diverse in properties. By regulating and controlling the structure of a reactant, the dynamic polymers with different properties can be prepared. In addition, due to strong dynamic reversibility of the organic boric acid silicon ester bonds in the polymer, the polymer can exhibit functional characteristics of stimulus responsiveness, self-healing property, recoverability and the like; and besides, due to the presence of the organic boric acid silicon ester bonds, the polymer can also have the energy absorbing effects, and polymer materials can be toughened in a given structure. The dynamic polymer can be used for making shock-absorption cushioning materials, impact-resistance protection materials, self-healing materials, ductile materials and the like.

Owner:厦门天策材料科技有限公司

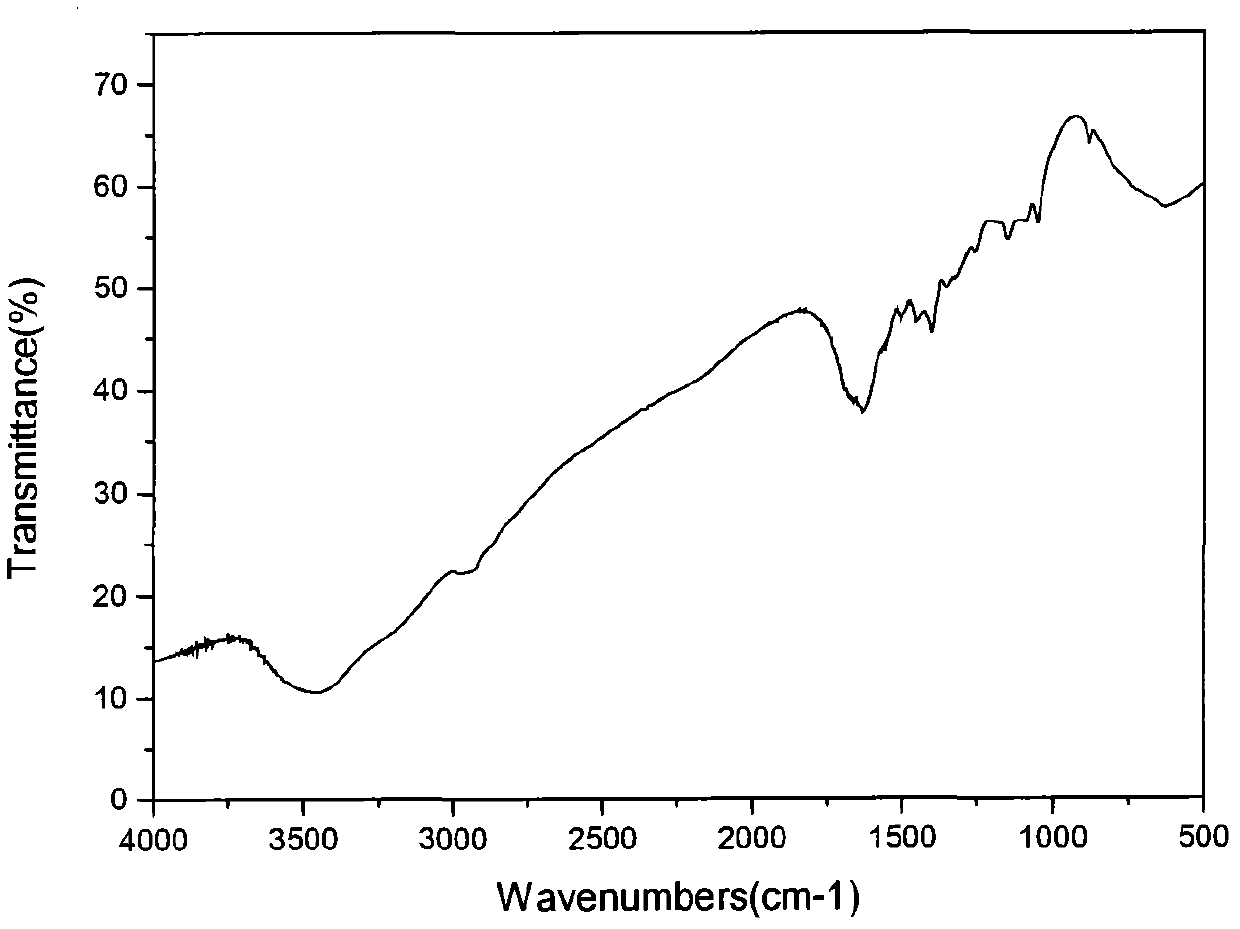

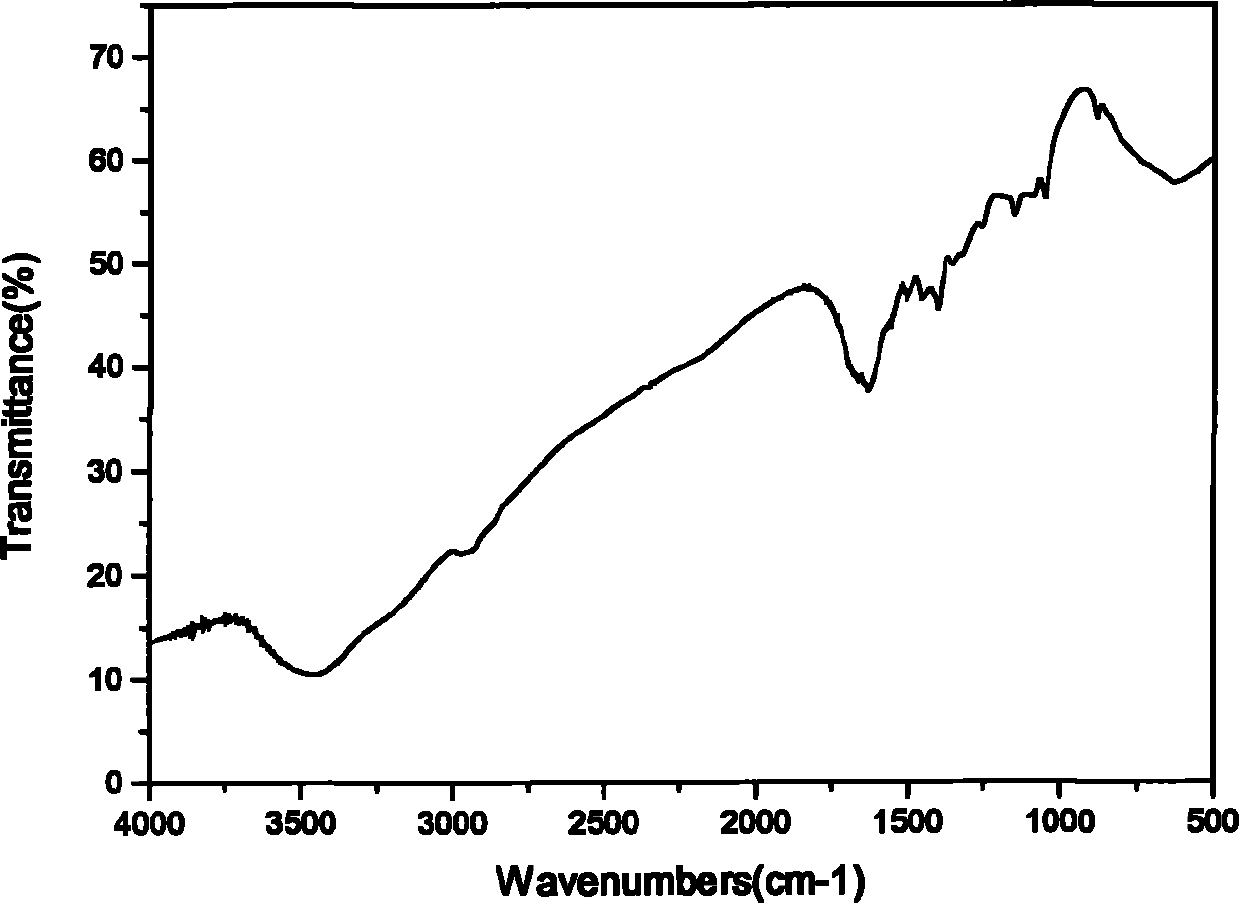

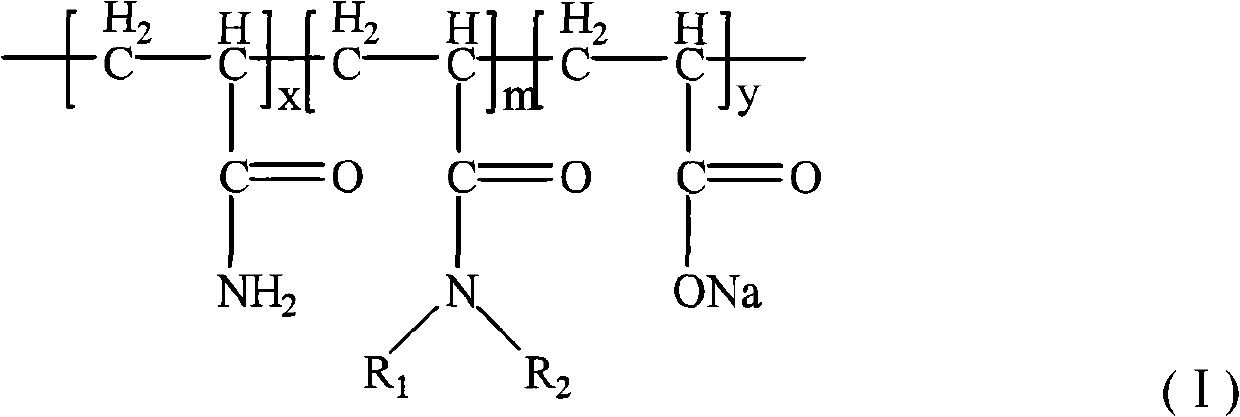

Temperature and salt resistant copolymer for oil field and preparation method thereof

ActiveCN102372818AAvoid hydrolysisImprove stabilityDrilling compositionSalt resistanceFracturing fluid

The invention relates to a temperature and salt resistant copolymer KWKY-PAD for oil field and a preparation method thereof, and mainly solves the problem that polyacrylamide is easy to hydrolyze at high temperature and high salinity in the prior art. The temperature and salt resistant copolymer KWKY-PAD as shown in formula (I) is obtained by the copolymerization of acrylamide and a N-alkyl substituted acrylamide derivative. The technical scheme provided by the invention greatly solves the problem. By the adoption of the preparation method, the hydrolytic stability of the copolymer is raised,and the copolymer has good viscosifying ability and hydrolytic stability at high temperature and high salinity as well as good temperature and salt resistance. The copolymer provided by the inventioncan be used in an oil displacement agent for oil extraction in oil field, and also can be used in oil field application fields of a thickening agent of fracturing fluids, a water plugging profile modification agent, a drilling fluid processing agent and the like. In addition, the preparation method requires less monomer, is simple and is suitable for industrialization.

Owner:CHINA PETROLEUM & CHEM CORP +1

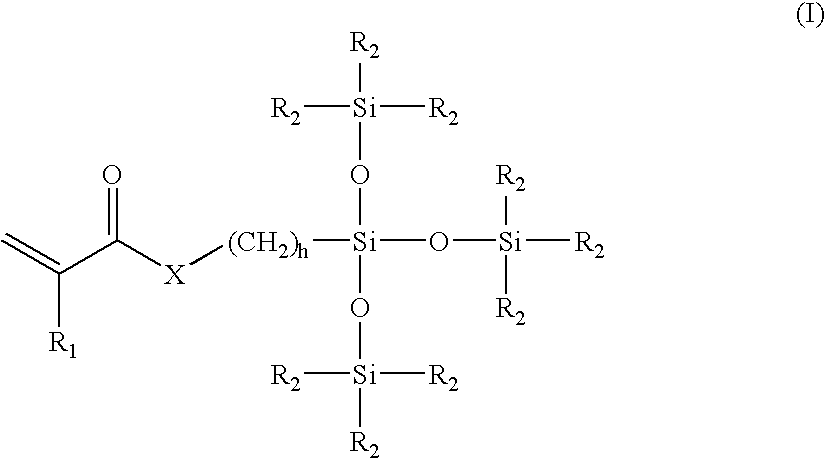

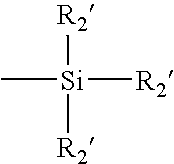

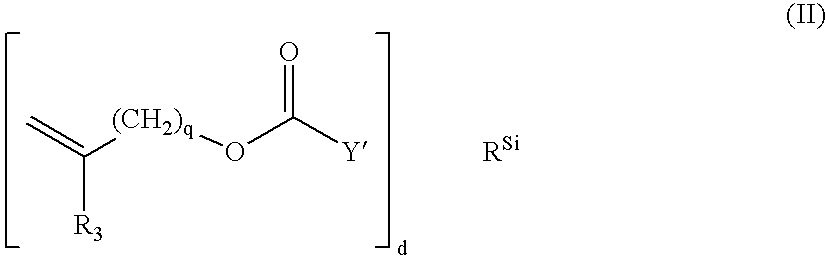

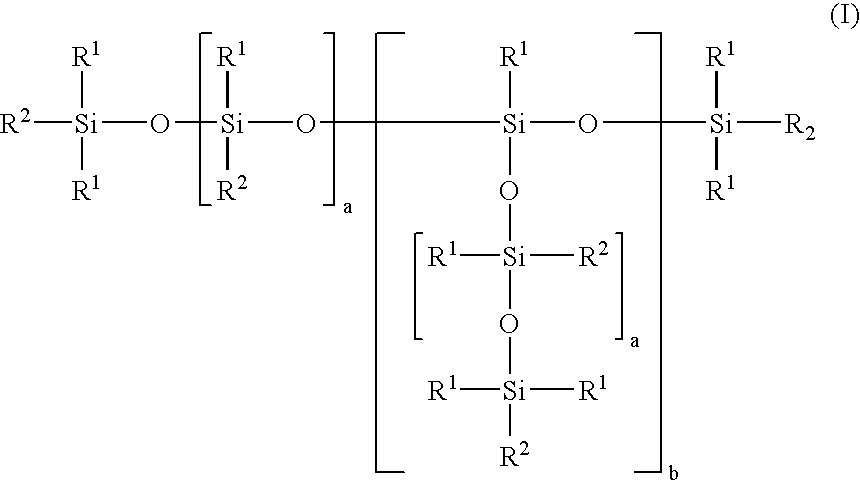

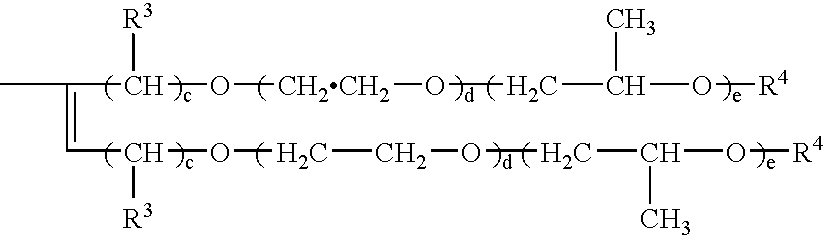

Agrochemical compositions comprising alkylenediol-modified polysiloxanes

InactiveUS20070213226A1Good curative effectImprove performanceBiocideAnimal repellantsCarboxyl radicalHydrogen

Described are agrochemical compositions which comprise of one or more one agrochemical active ingredient(s) and alkylenediol-modified polysiloxanes of the general formula (I): wherein R1 are alkyl radicals having 1 to 4 carbon atoms or aryl radicals, wherein at least 80% of the radicals R1 are methyl radicals , R2 in the molecule are identical or different and can have the following definitions: a) in which R3 is a hydrogen or alkyl radical, R4 is a hydrogen, alkyl or carboxyl radical, c is a number from 1 to 20, d is a number from 0 to 50, e is a number from 0 to 50 or b) correspond to R1, with the provisio that in the average molecule at least one radical R2 has the definition (a), a is a number from 1 to 200; b is a number from 0 to 10; and optionally one or more other agrochemically acceptable ingredients. The agrochemical compositions of the invention have enhanced efficacy, enhanced hydrolytic stability and / or decreased foaming properties.

Owner:EVONIK GOLDSCHMIDT GMBH

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

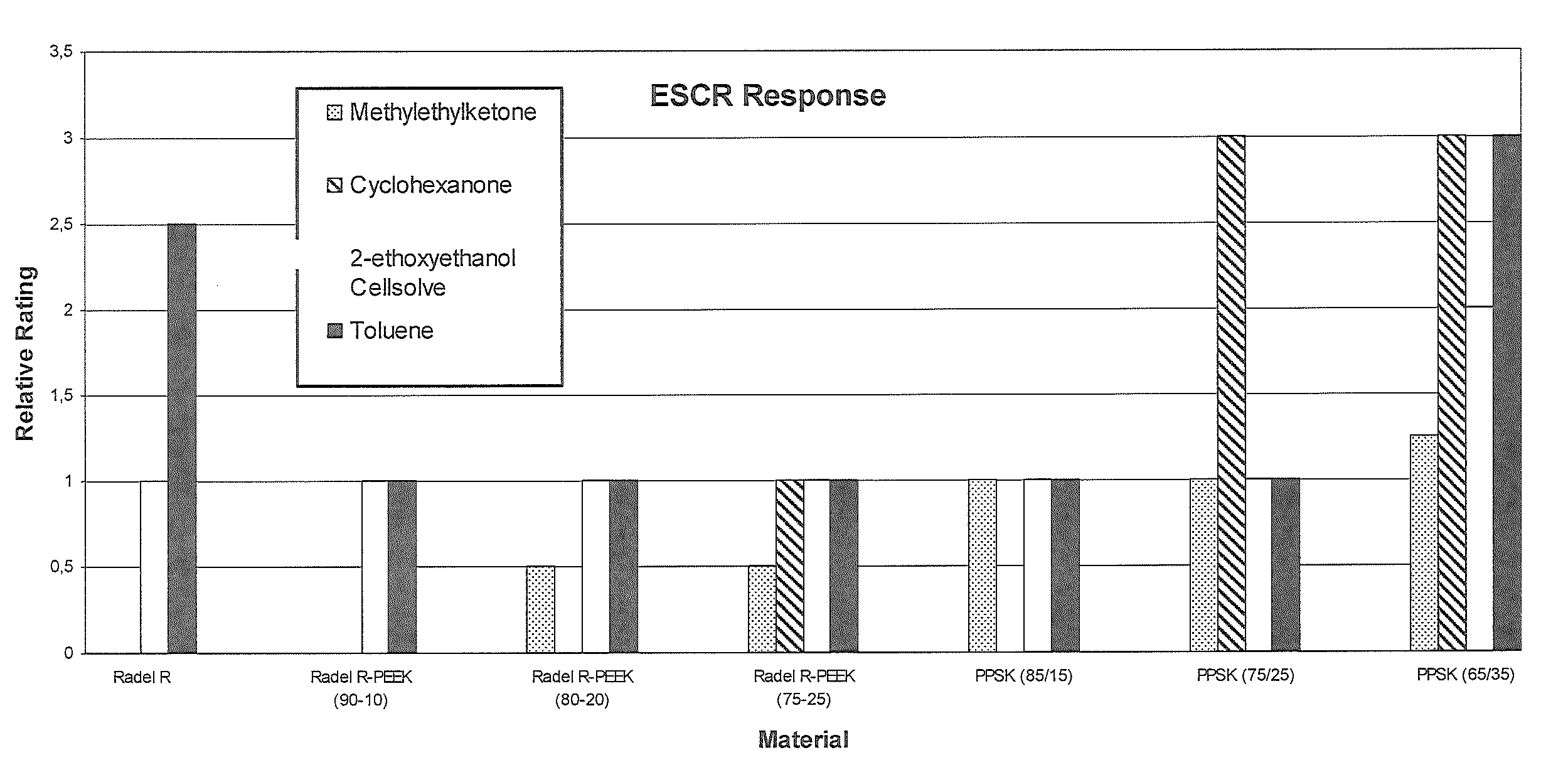

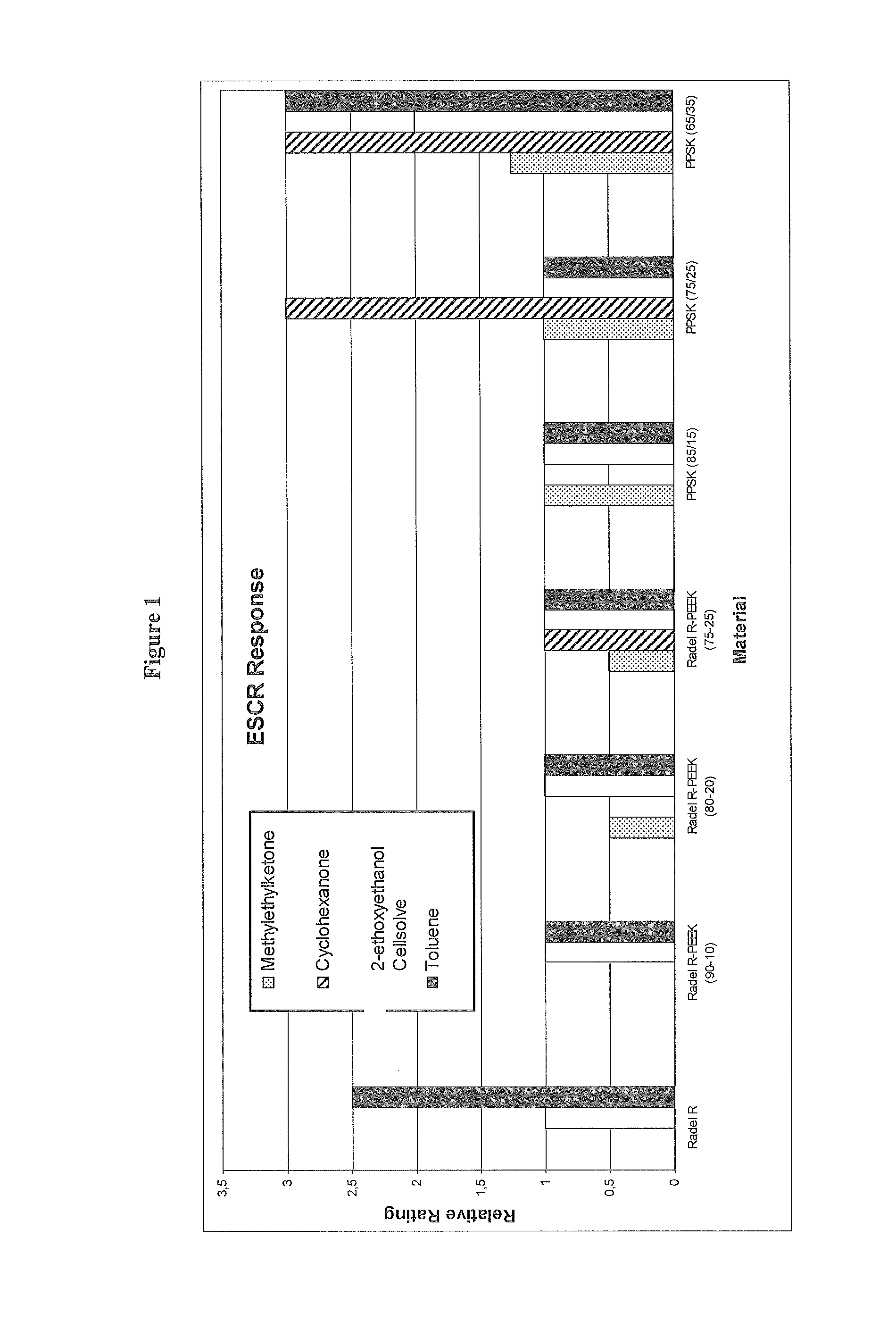

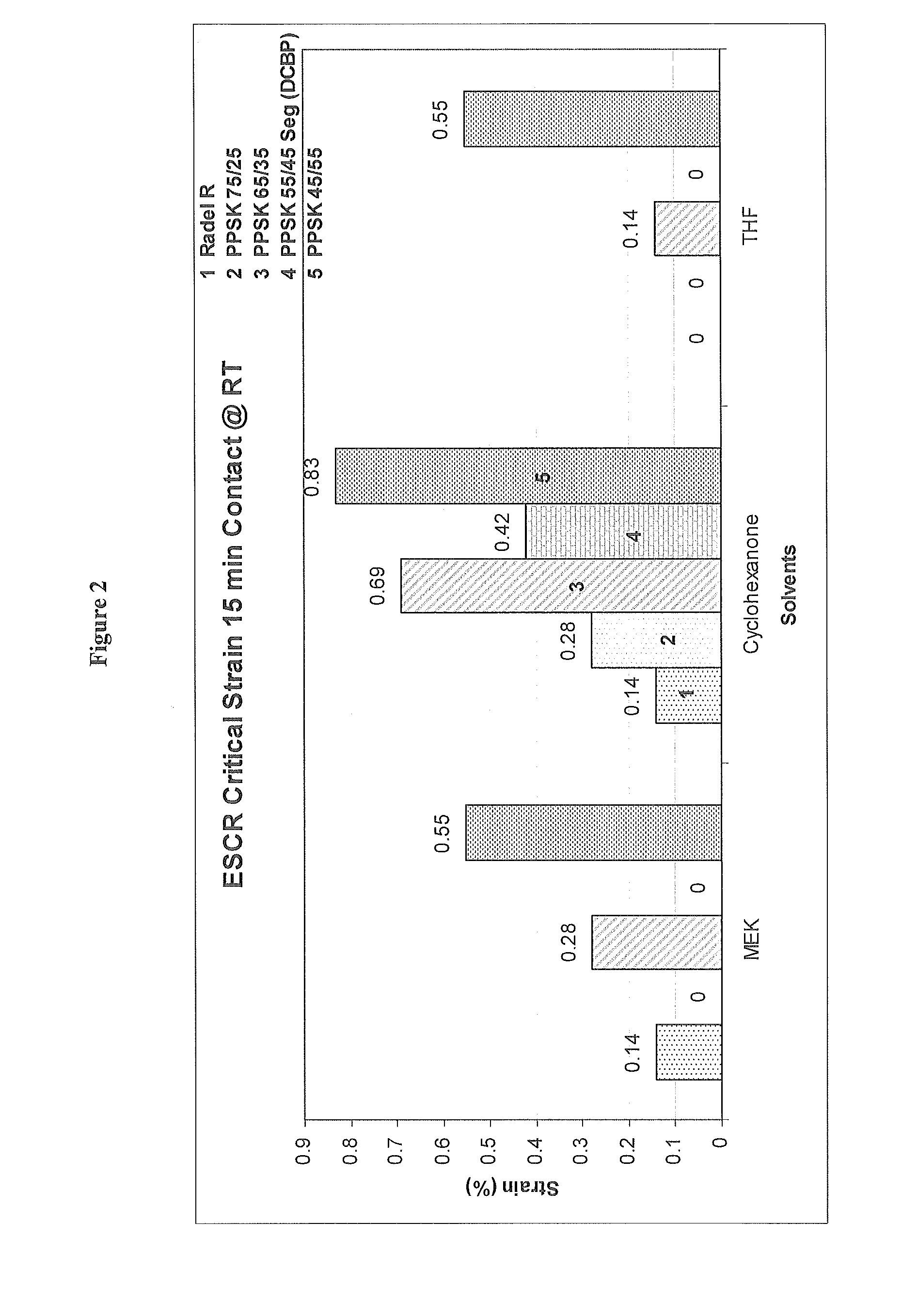

Polyphenyl sulfone ketone copolymers

InactiveUS20100310804A1Improve the immunityLow creepLayered productsThin material handlingPolymer scienceKetone

A polymer comprising sulfone groups, ketone groups and optionally substituted polyarylene groups, wherein the number of moles of sulfone groups over the number of moles of ketone groups ratio is greater than 1. A process for making such polymer, a composition comprising such polymer, and articles made therefrom.

Owner:SOLVAY ADVANCED POLYMERS LLC

Cation water polyurethane/acrylic ester composite emulsion and preparation method thereof

The invention relates to cationic water-based polyurethane / acrylic ester composite emulsion and the preparation process, belonging to the chemical product and preparation technology field. Raw materials comprise diisocyanate mixture, polyhydric alcohol, organotin catalyst, chain extender, thinner, neutralizing agent and initiating agent. The preparation process comprises adding polyhydric alcohol into a reactor to dehydrate in vacuum, adding into diisocyanate mixture and organotin catalyst, conducting prepolymerization reaction to synthesize prepolymer with isocyanate-termi-nated, coldly adding thinner to dilute and to condense and reflow, adding chain extender to obtain mixture through chain extending reaction, cooling down, adding neutralizing agent to finish salt-forming reaction, regulating pH value, adding deionized water to conduct dispersed emulsification to obtain cationic water-based polyurethane elusion, and heating up and adding initiating agent to initiate free radical polymerization reaction to prepare composite elusion. The cationic water-based polyurethane / acrylic ester composite emulsion is synthesized through adopting non solvent process with low pollution and environment-friendly, increases solvent resistance, water resistance and tensile strength of glue film through introducing micro-cross-linked structure, increases hydrolytic stability of the glue film through introducing carbodiimide structure, and increases elongation at break and elasticity property through of glue film through introducing 2, 4-MDI.

Owner:WANHUA CHEM GRP CO LTD

Dynamic polymer having non-covalent crosslinking structure and application thereof

ActiveCN107805309AFast self-healingAchieve synthesisPolyureas/polyurethane adhesivesFibre treatmentBoric acidBiomimetic materials

The invention discloses a dynamic polymer having a non-covalent crosslinking structure. The dynamic polymer contains organic boric acid silicon ester bonds on polymer chain backbone; wherein the organic boric acid silicon ester bonds are existed as polymeric chain contacts of the dynamic polymer, and are the necessary condition for forming or maintaining a dynamic polymer structure. The dynamic polymer has energy dissipation performance by means of the organic boric acid silicon ester bonds having strong dynamic reversibility, embodies functional characteristics of stimulation responsiveness and self-repairability, and has a wide application prospect in the fields of sport protection, a functional coating, and a bionic material.

Owner:厦门天策材料科技有限公司

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Biologically degradable polyester, materials made from the polyester and production process

PCT No. PCT / EP96 / 03879 Sec. 371 Date Aug. 14, 1998 Sec. 102(e) Date Aug. 14, 1998 PCT Filed Sep. 4, 1996 PCT Pub. No. WO97 / 09364 PCT Pub. Date Mar. 13, 1997The invention concerns biologically degradable polyesterS which are degraded under the action of micro-organisms in the natural environment. Said polyesters are high molecular weight satistical copolyesters which are made using an aliphatic polyalcohol, an aromatic polycarboxylic acid and also an aliphatic polycarboxylic acid as monomer components. They contain constitutional repeating or recurrent units comprising (i) a polyalcohol and an aromatic polycarboxylic acid and (ii) a polyalcohol and an aliphatic polycarboxylic acid, where over 90% of the units of type (i) are directly bonded with none or at most one other unit of type (i). The polyesters are produced by using a di-isocyanate as an additional monomer component, less isocyanate being used than any of the other monomer components. The present invention also concerns materials made from said biodegradable polyester and a process for producing said polyesters.

Owner:DEGUSSA HUELS DEGUSSA HUELS

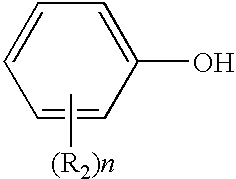

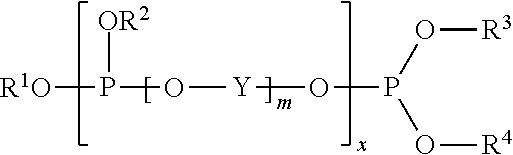

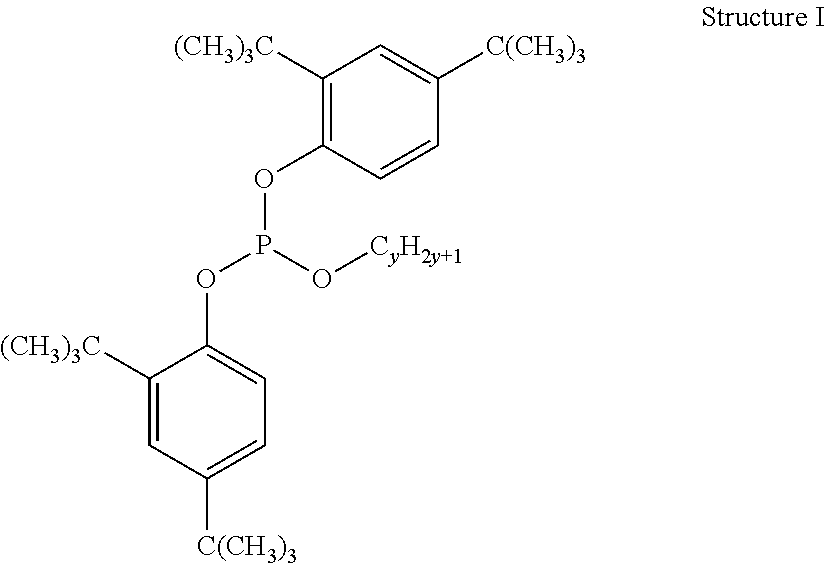

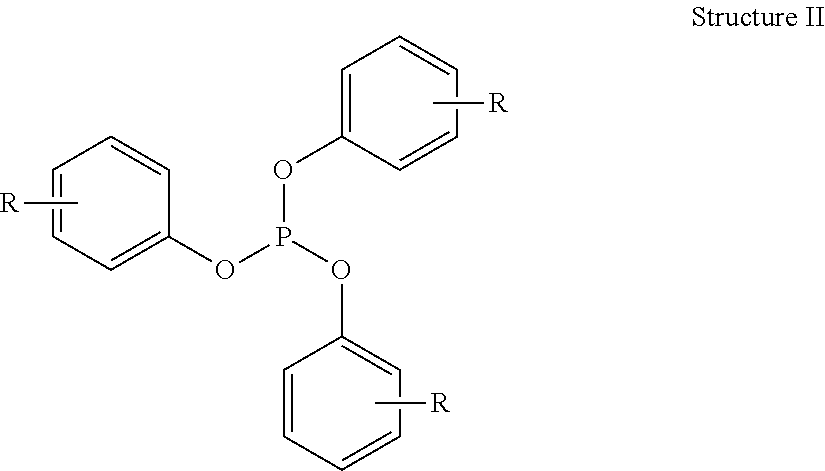

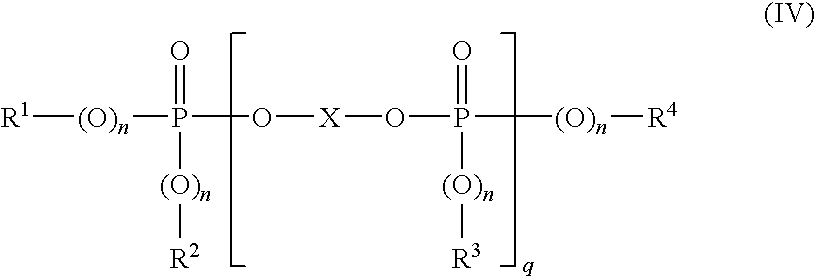

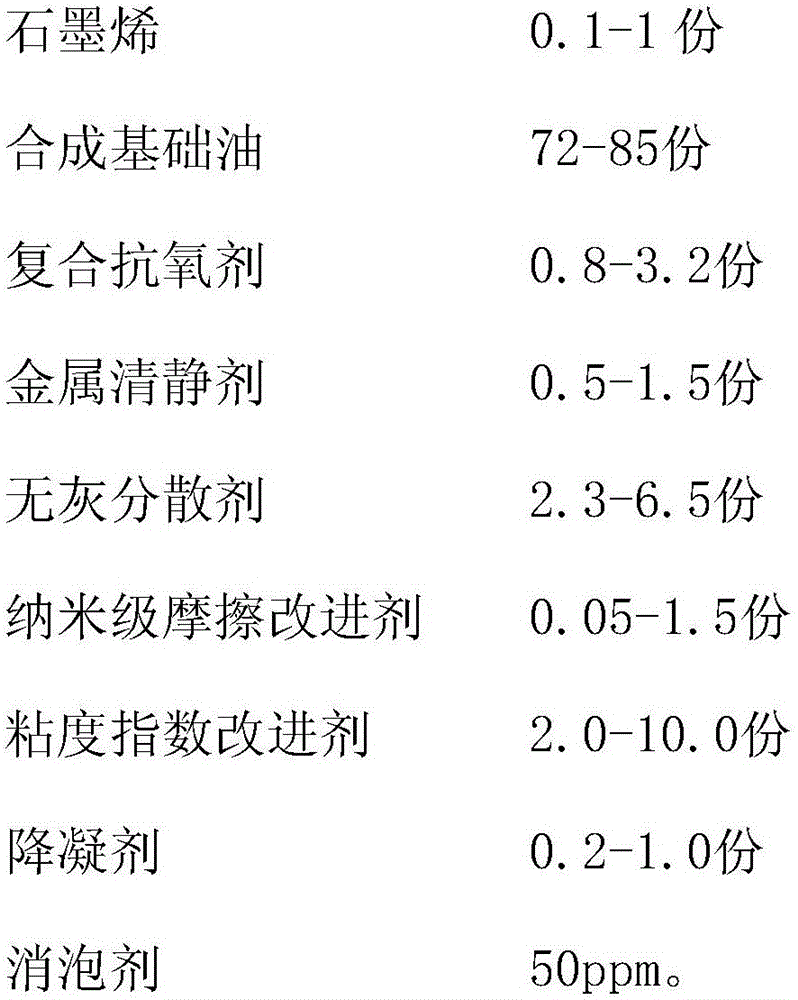

Alkylphenol free-liquid polymeric phosphite polymer stabilizers

ActiveUS8563637B2Difficult to extractImprove hydrolytic stabilityPhosphorus organic compoundsAlkylphenolGlycol ethers

Owner:DOVER CHEM CORP

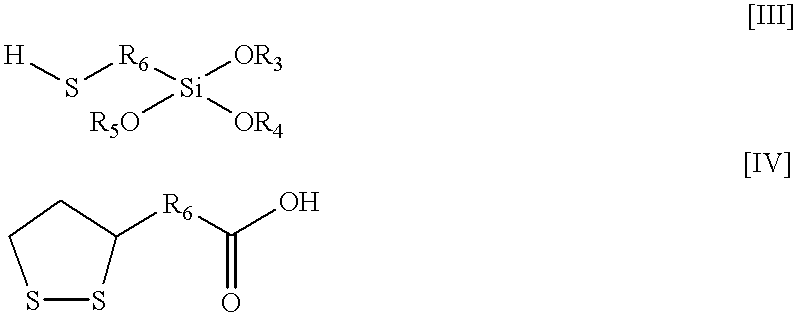

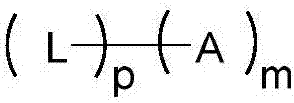

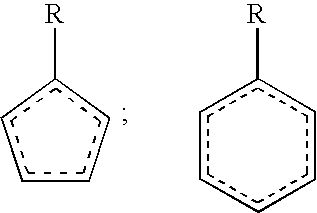

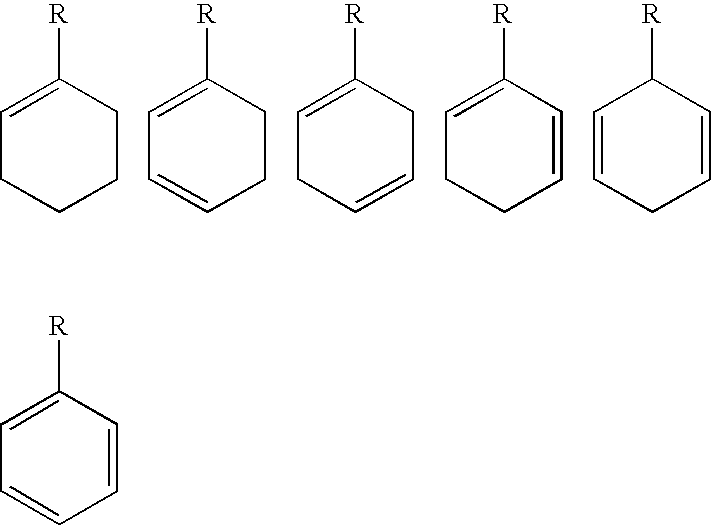

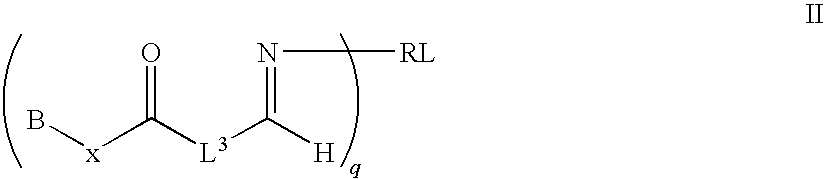

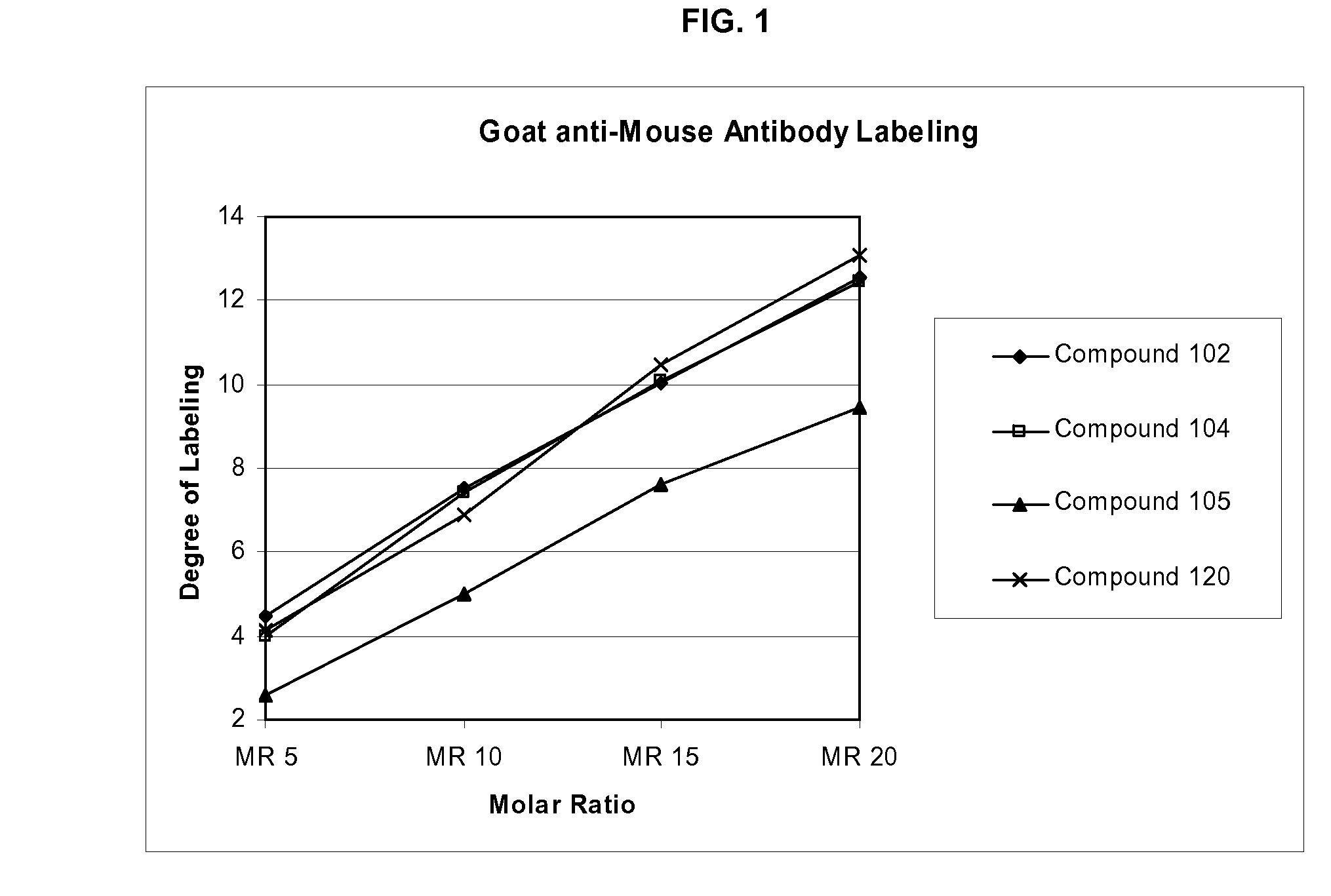

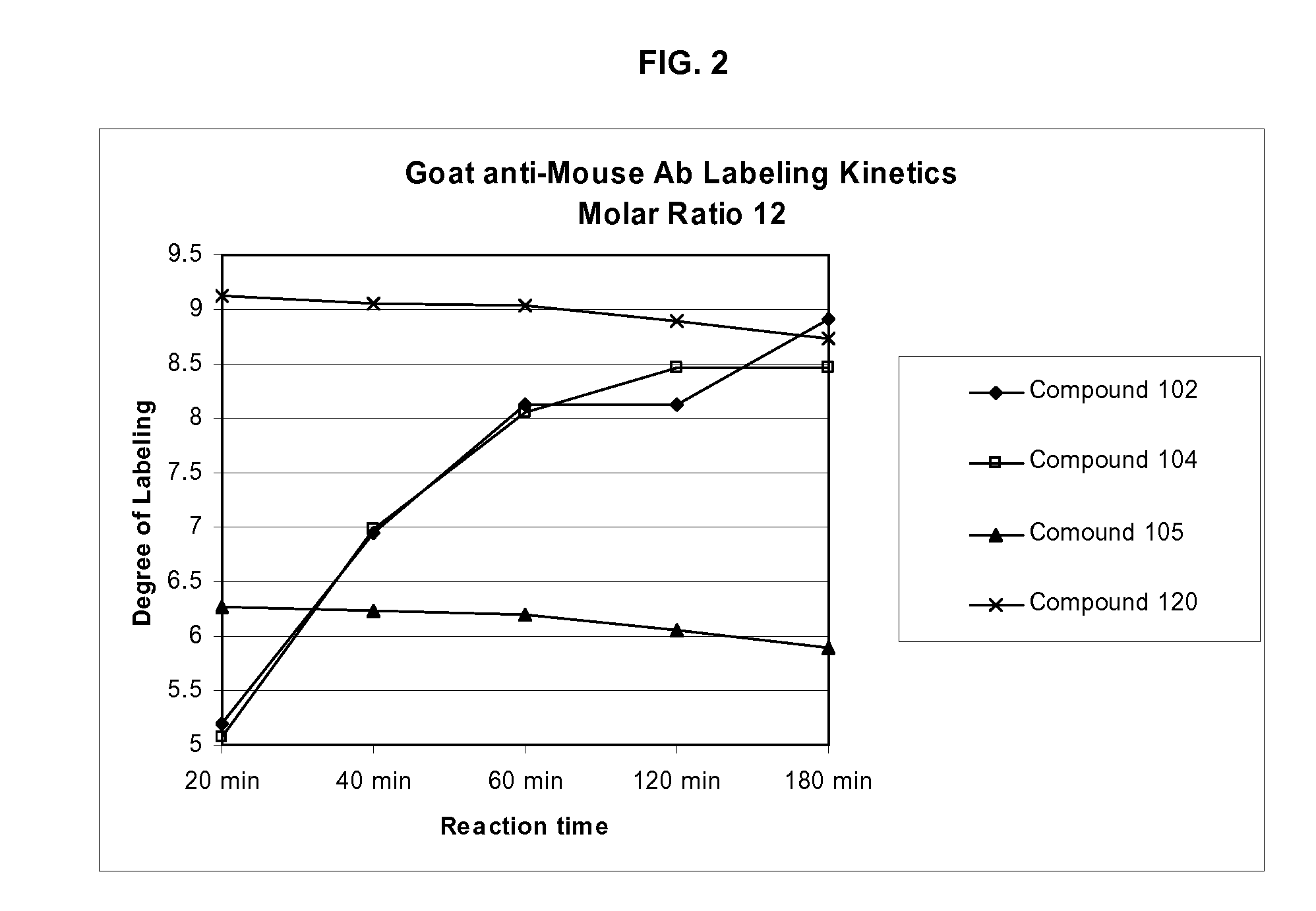

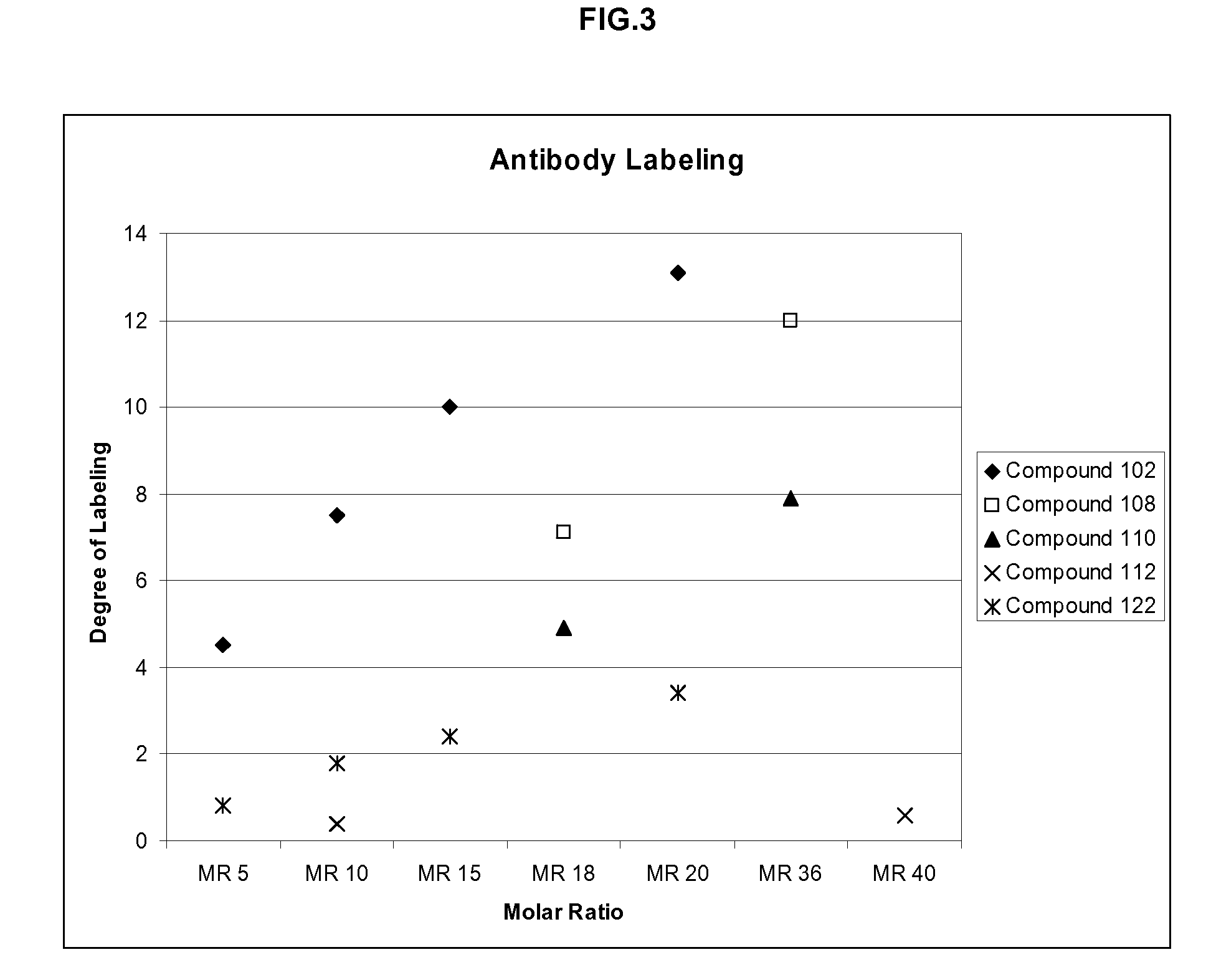

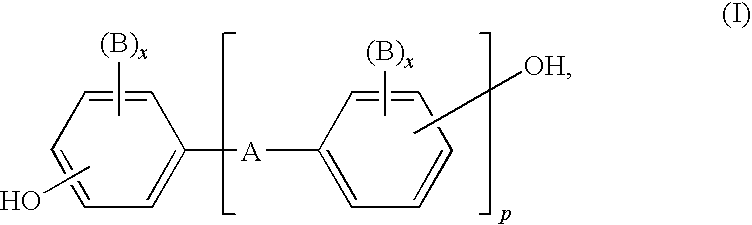

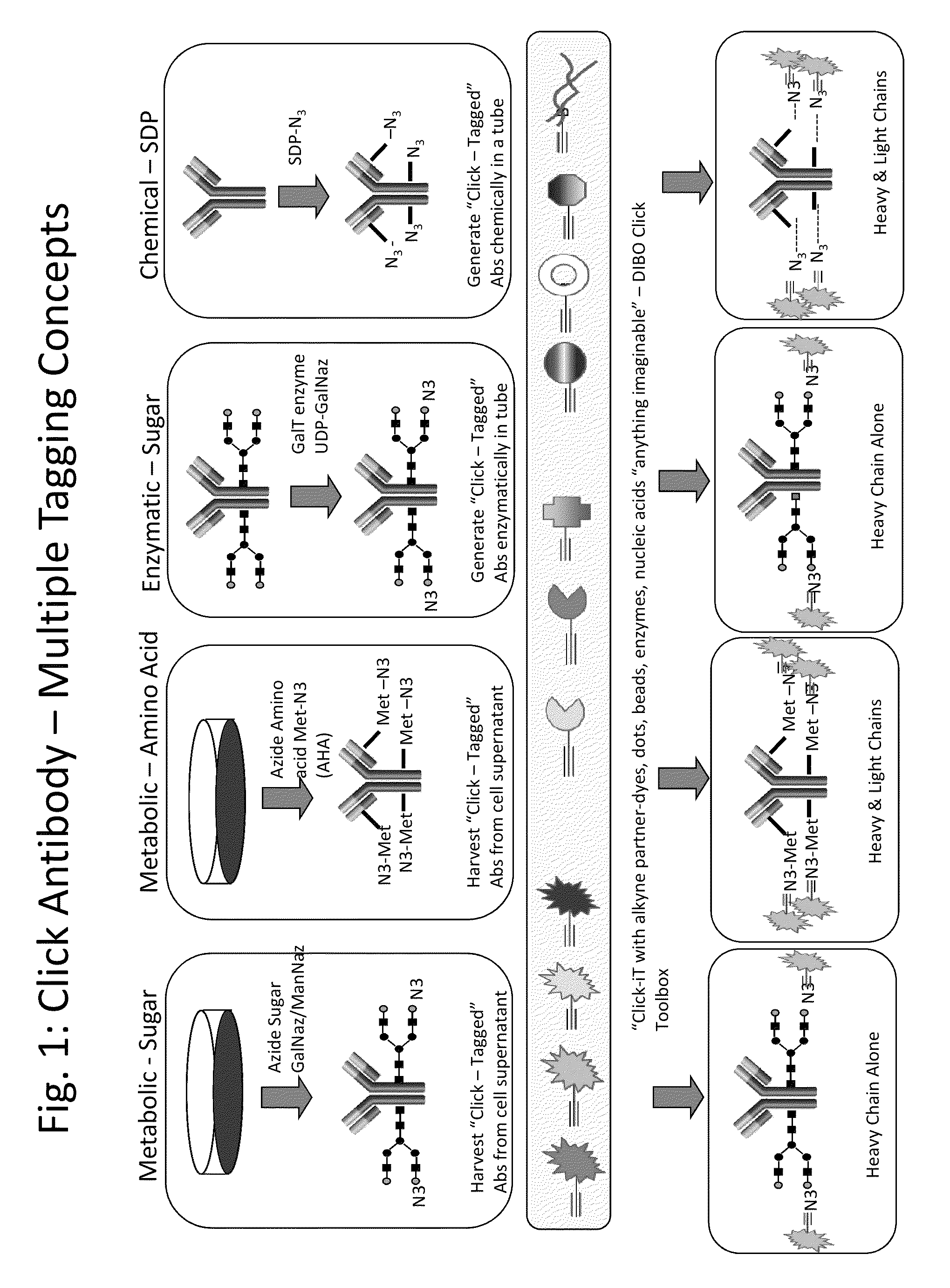

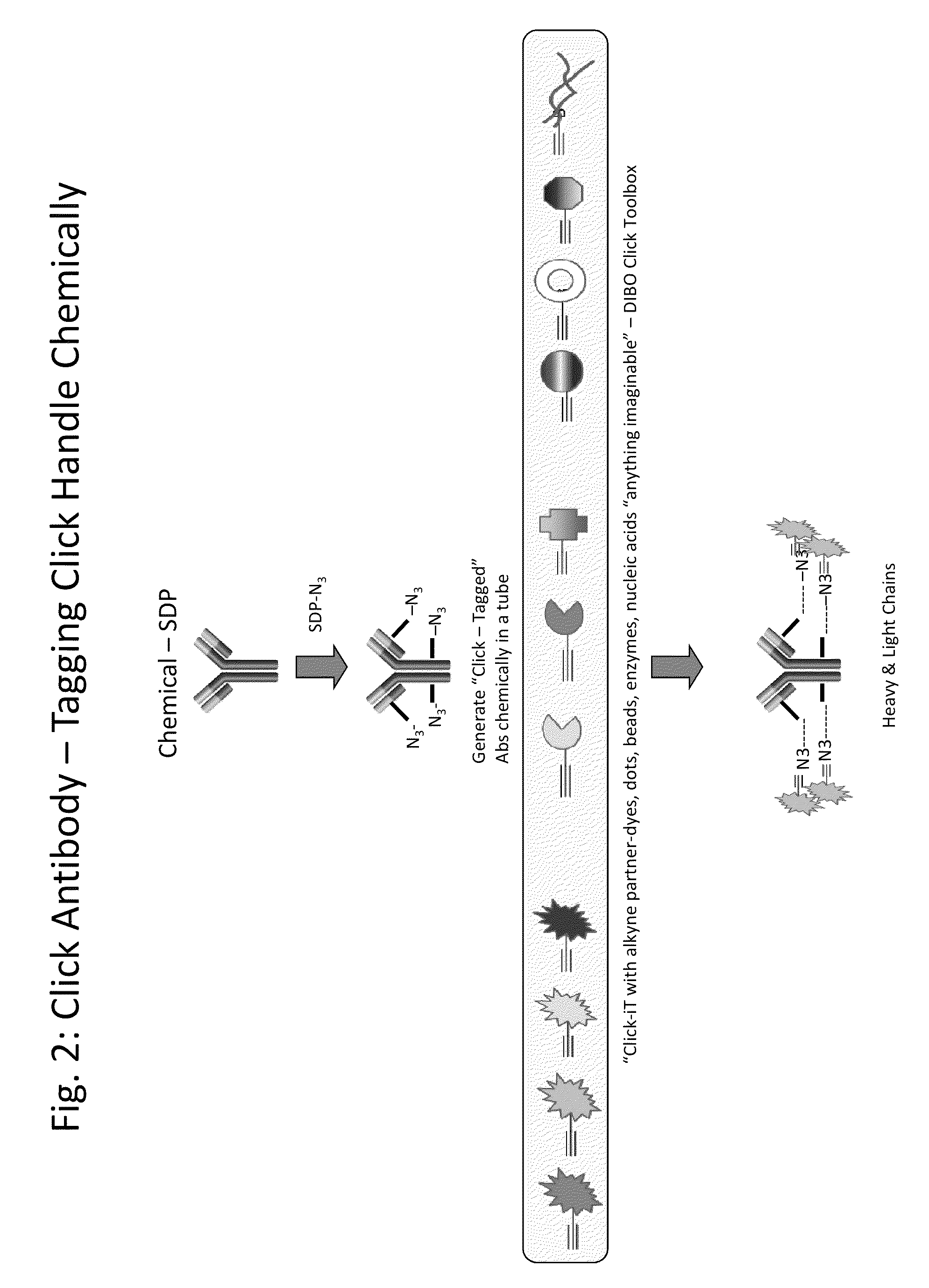

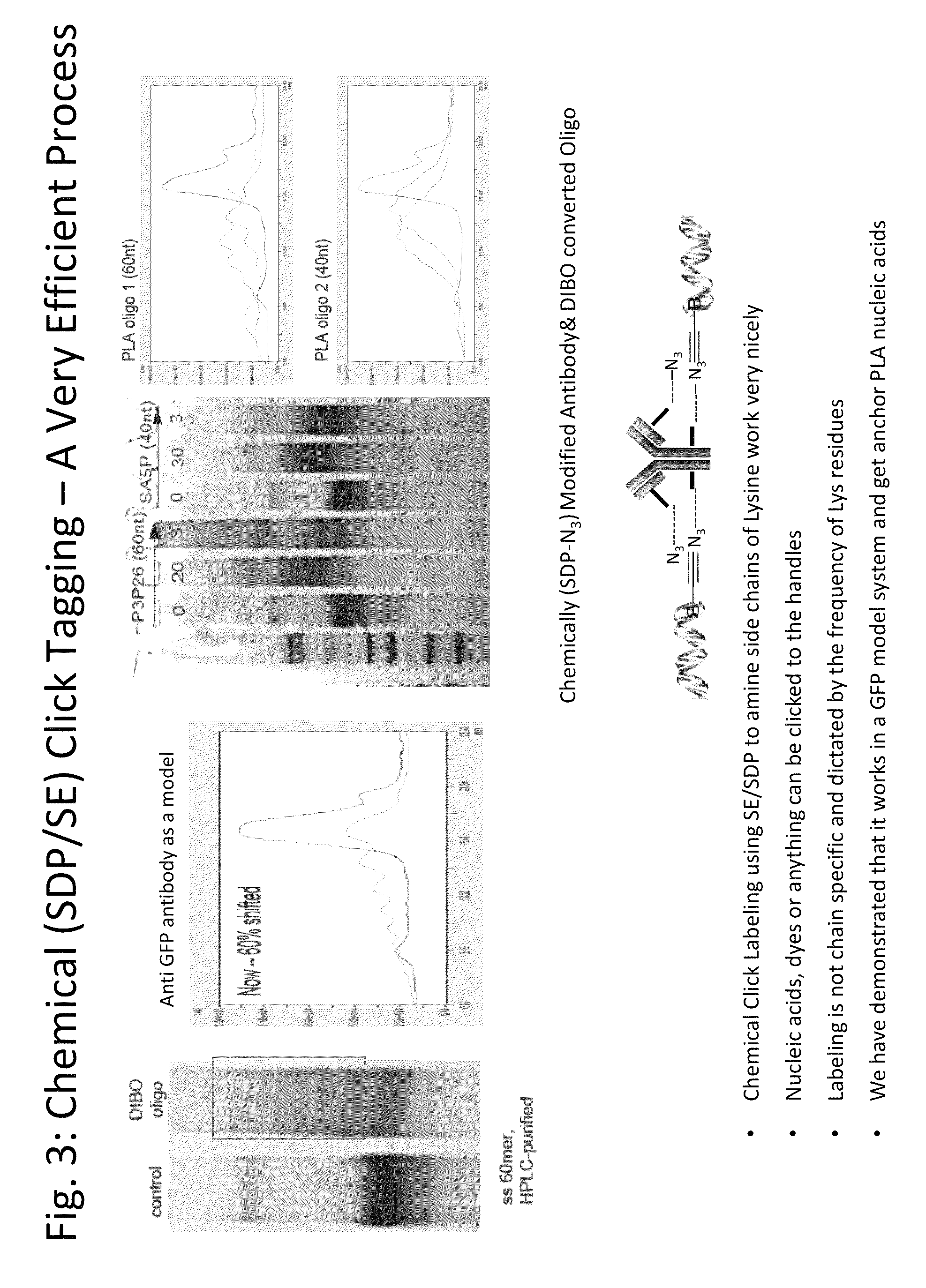

Molecular constructs suitable for targeted conjugates

InactiveUS20090246211A1Improve hydrolytic stabilityPeptide/protein ingredientsAntibody ingredientsSulfurBioactive molecules

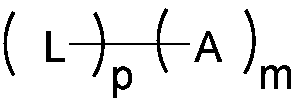

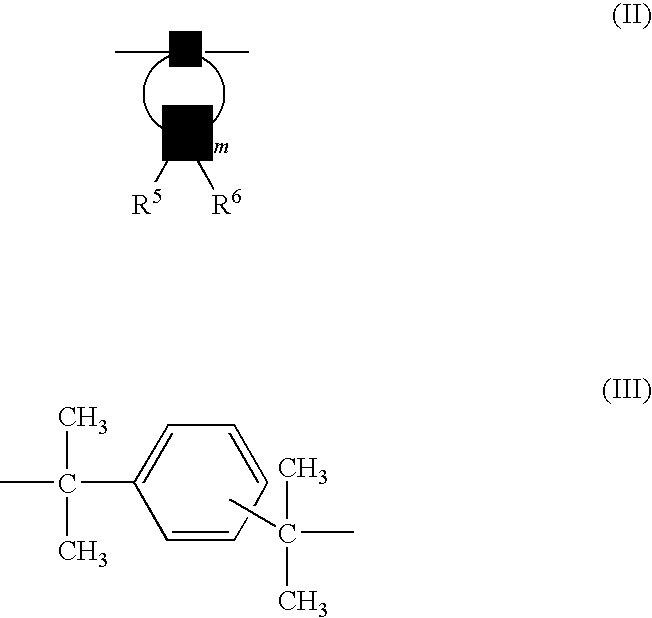

The present invention relates generally to effective drug-linker constructs suitable for conjugation with ligands. The present invention also discloses methods of conjugating these constructs with peptides to form the compound of formula I. These methods are readily extended to any hydroxyl, amine or sulfur bearing biologically active molecules.B—X—L1—(L2)m—(L3)n—Y—RL I

Owner:TAPESTRY PHARMACEUTICALS INC

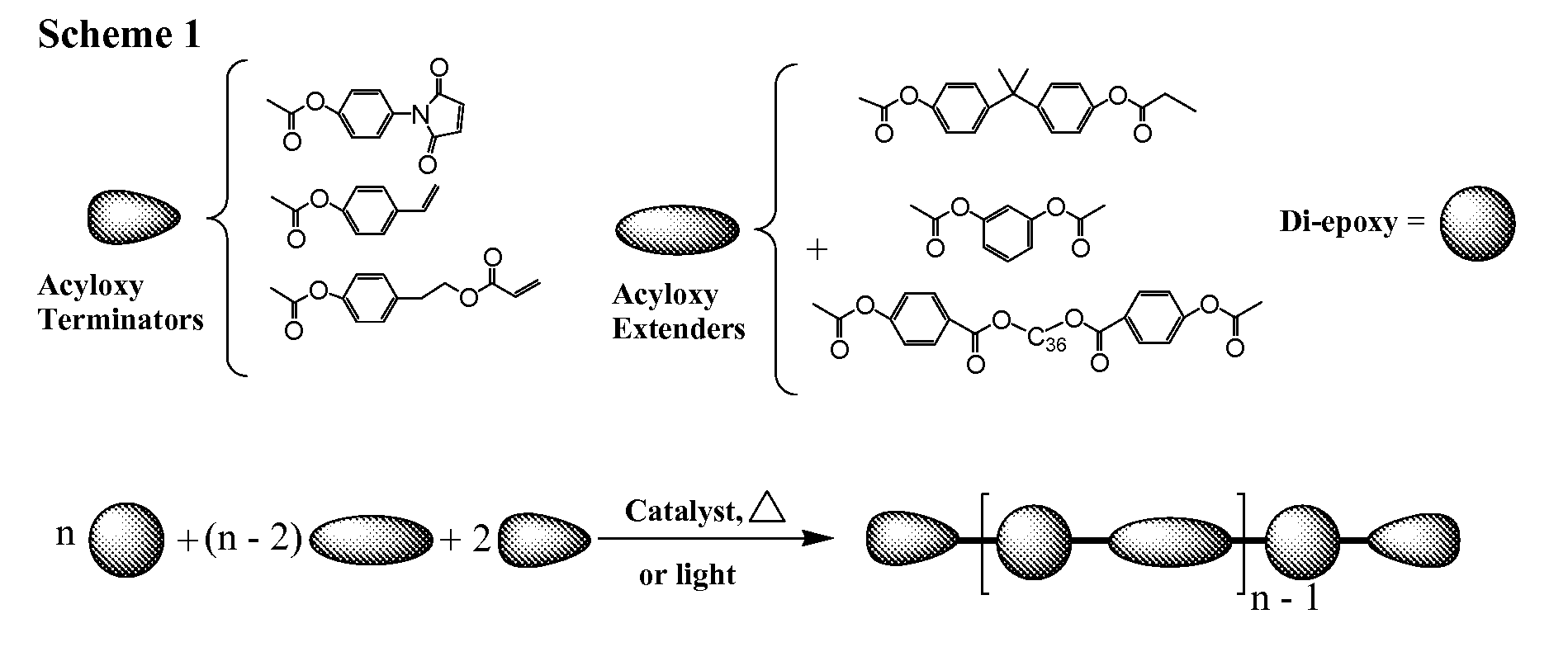

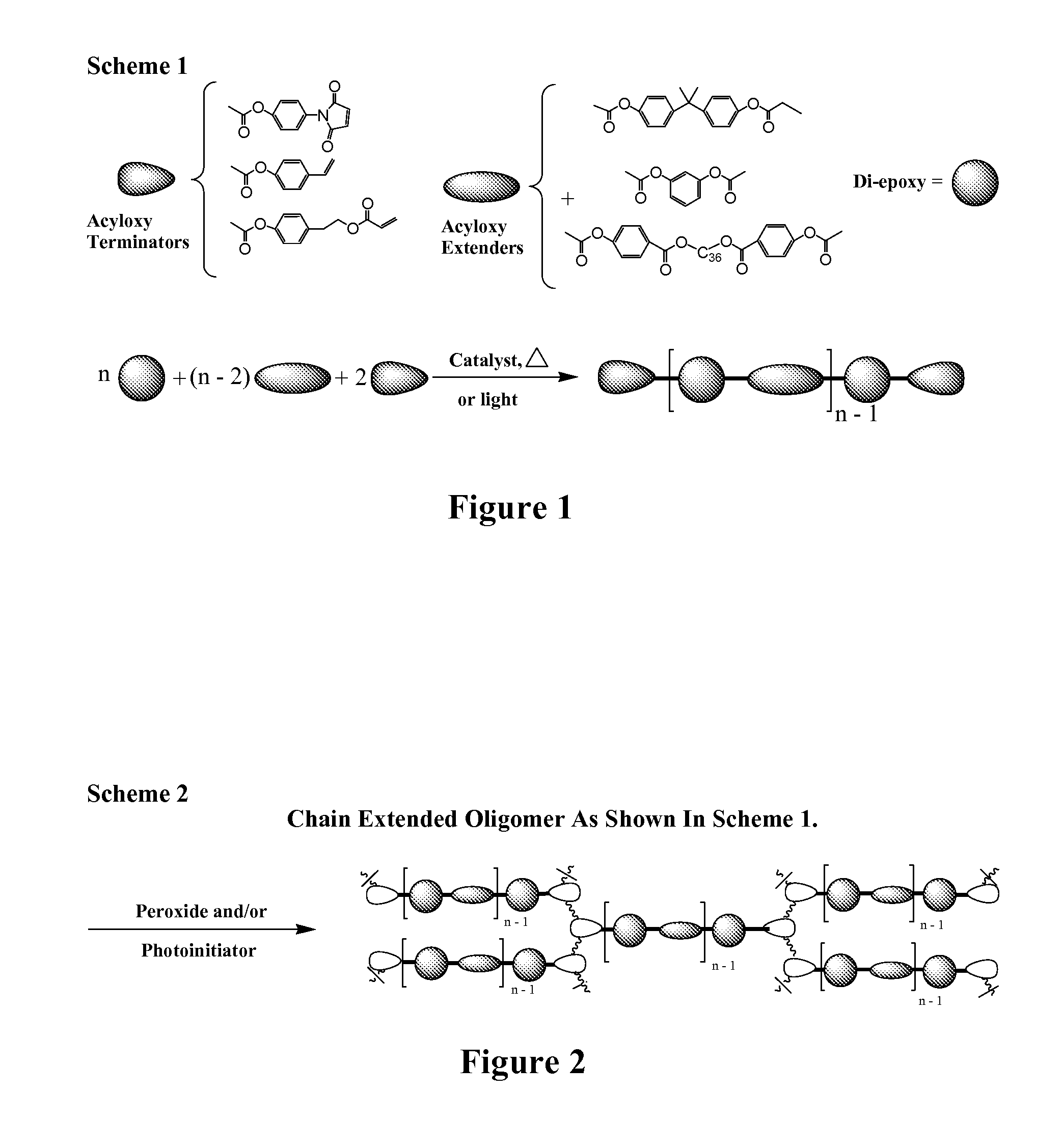

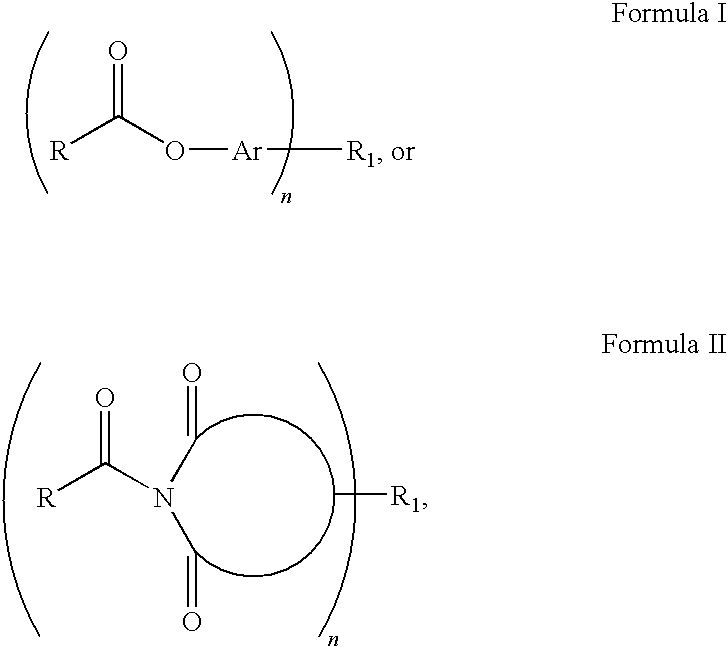

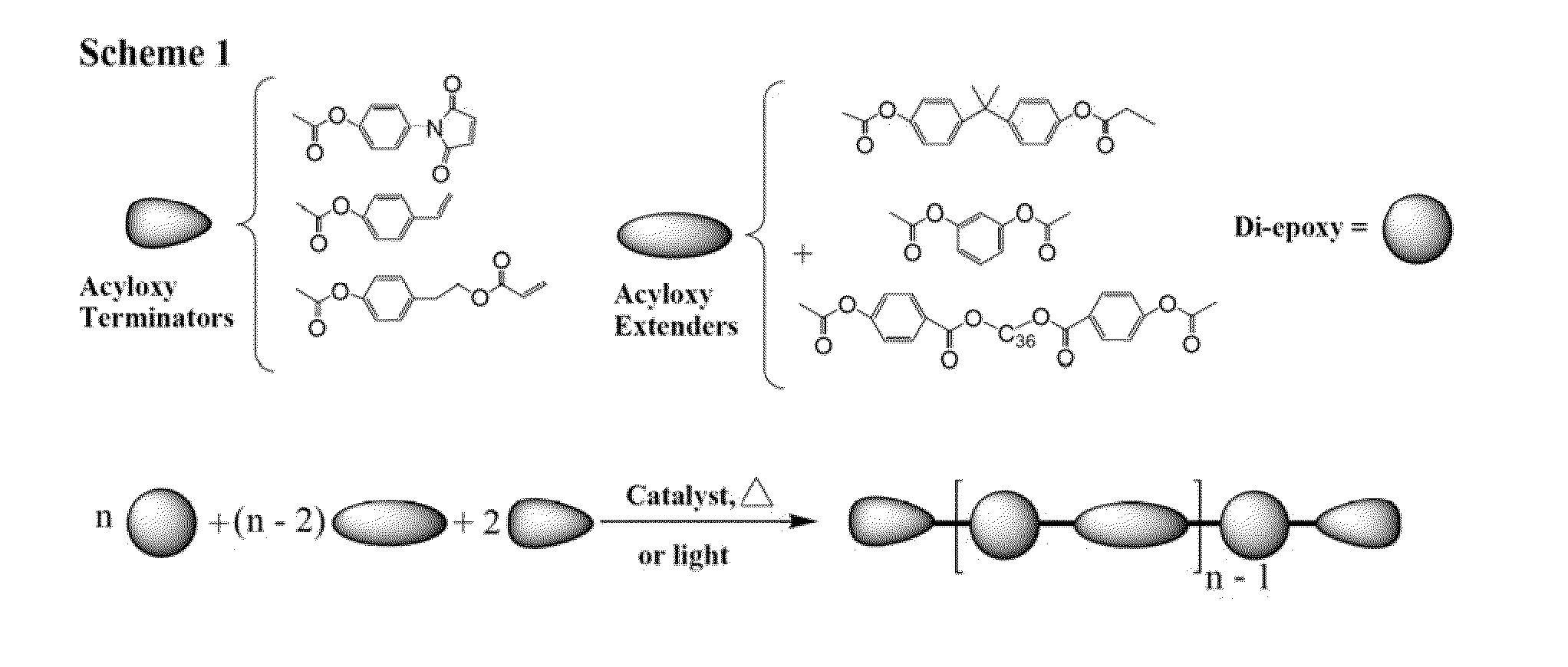

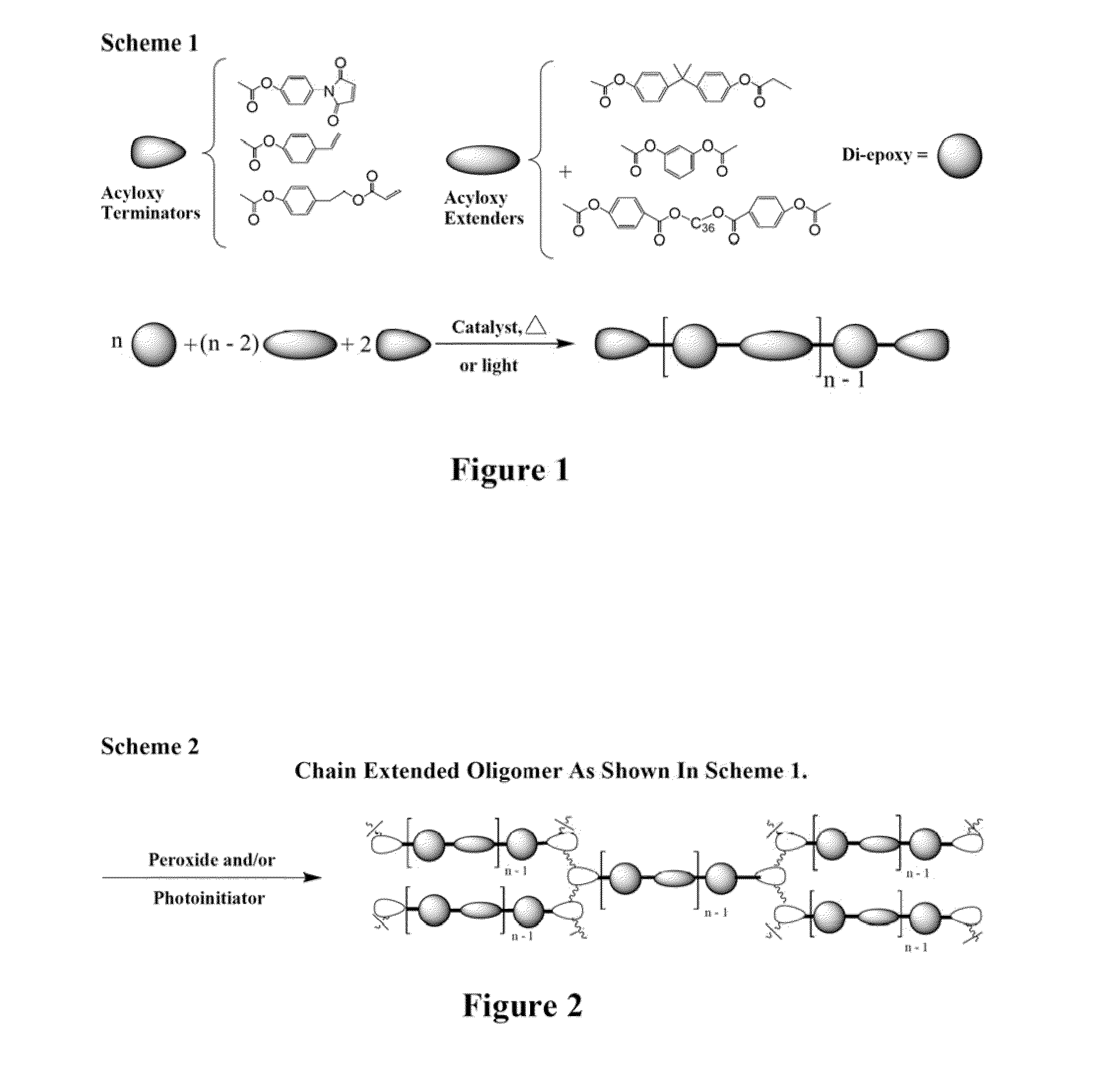

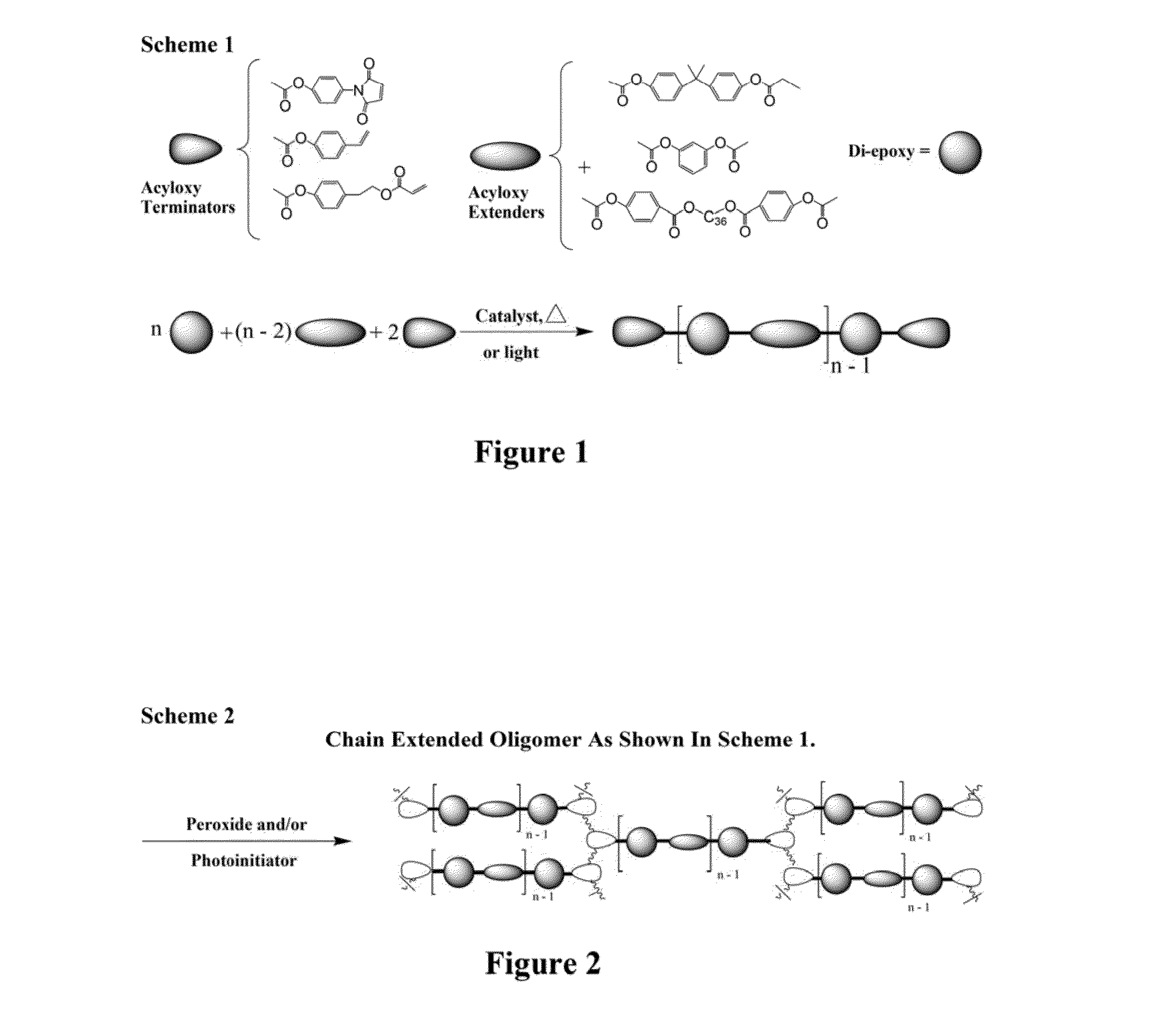

Curatives for epoxy adhesive compositions

InactiveUS20100113643A1Increase opportunitiesReduce hydrophilicitySilicon organic compoundsCosmetic preparationsFirming agentEpoxy adhesive

The invention provides epoxy and oxetane compositions including the novel acyloxy and N-acyl curing agents described herein. Use of invention curing agents result in cured adhesive compositions with remarkably increased adhesion and reduced hydrophilicity when compared to resins cured with other types of curing agents. Furthermore, the curatives of this invention do not interfere with free-radical cure and are thus suited for use in hybrid cure thermoset compositions.

Owner:DESIGNER MOLECULES

Curatives for epoxy compositions

ActiveUS20100249276A1Improve adhesionLow viscositySilicon organic compoundsOrganic compound preparationEpoxyChemistry

The invention provides epoxy and oxetane compositions including the novel acyloxy and N-acyl curing agents described herein. Use of invention curing agents result in cured adhesive compositions with remarkably increased adhesion and reduced hydrophilicity when compared to resins cured with other types of curing agents. Furthermore, the curatives of this invention do not interfere with free-radical cure and are thus suited for use in hybrid cure thermoset compositions.

Owner:DESIGNER MOLECULES

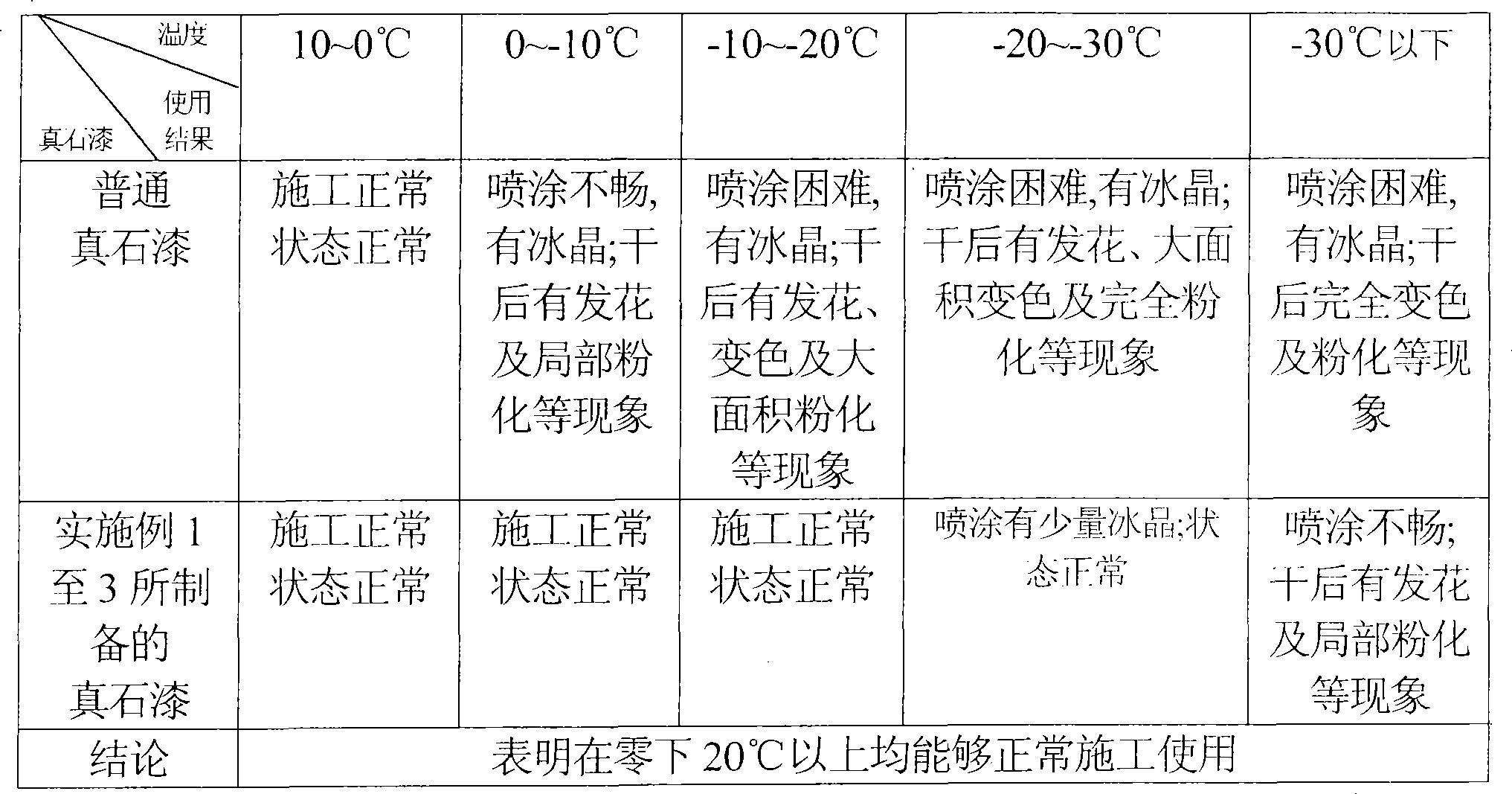

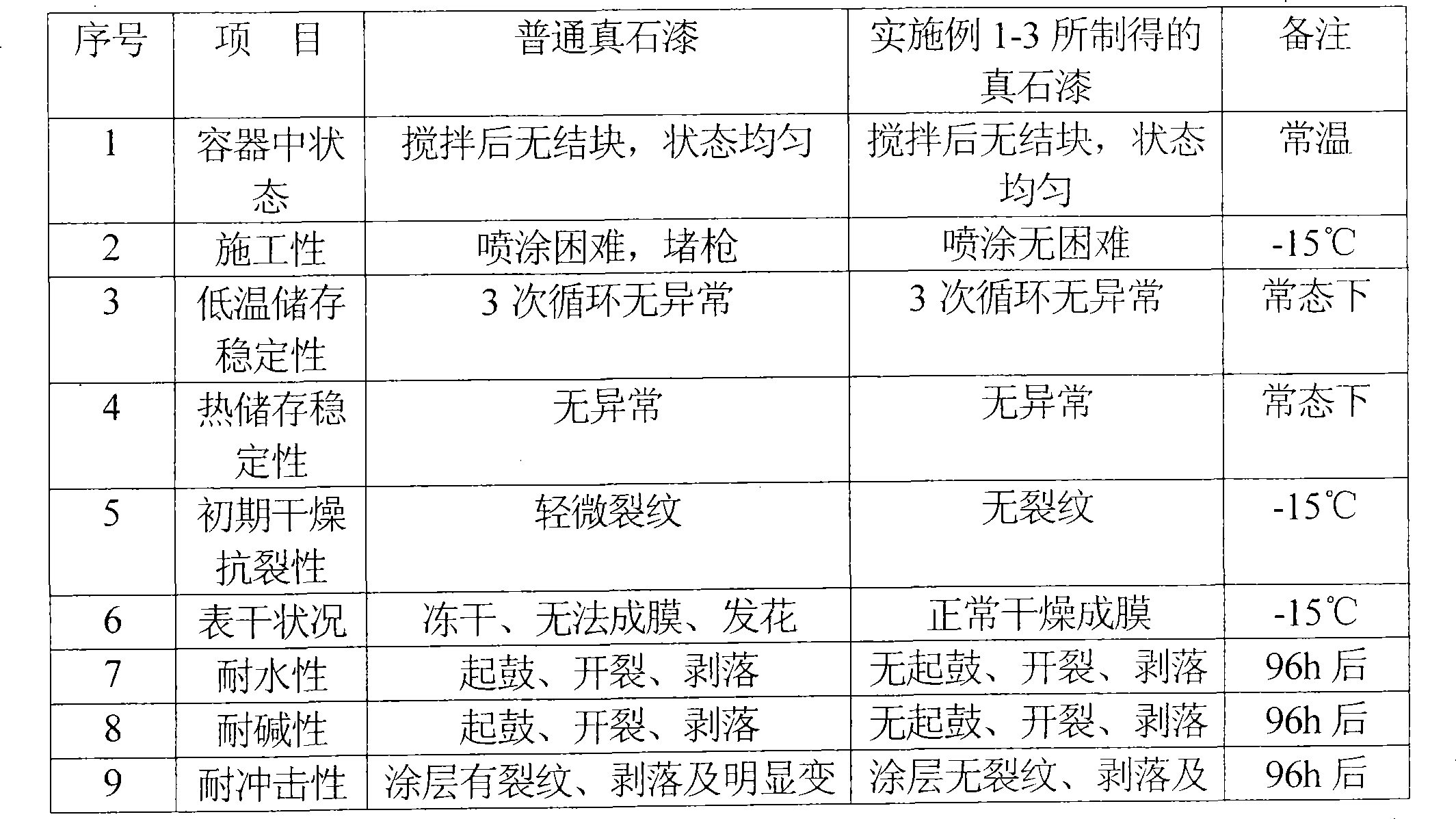

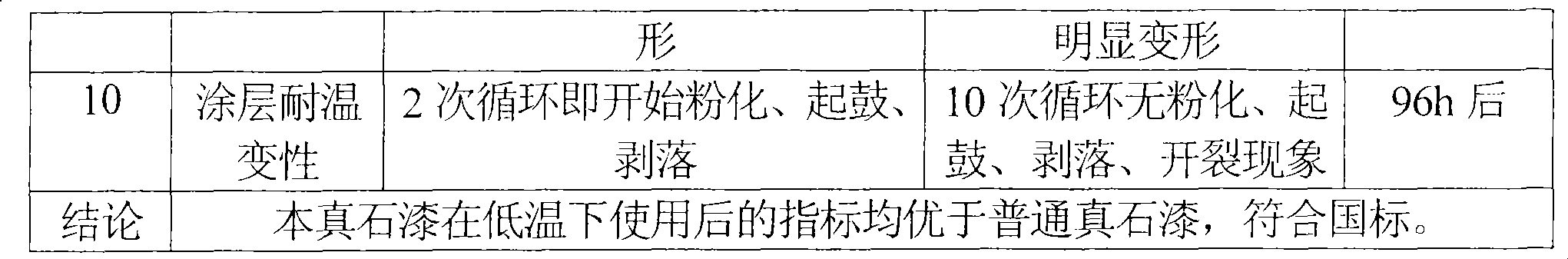

Environment friendly antifreezing stone-like paint and preparation thereof

The invention discloses an environment freeze protection stone paint, which comprises the following raw material components according to the parts by weight: 0.1-5 of fibrin aqueous solution of 1-4% concentration, 0.8-1.2 of glycol, 50-70 of colored sand of 41-80 mesh, 5-25 of colored sand of 81-120, 17-23 of KE025 acrylic emulsion, 0.6-0.9 of alcohol ester-12 addition agent, 0.02-0.06 of foam killer, 0.01-0.1 of thickness agent and 0.02-0.06 of neutralizing agent. Meanwhile, the invention also discloses a preparation method for the stone paint. The stone paint has the environment and freeze protection performance, provides powerful guarantee for being suitable for winter construction, in particular to various severe conditions of winter construction in the northern area of our country.

Owner:许军 +1

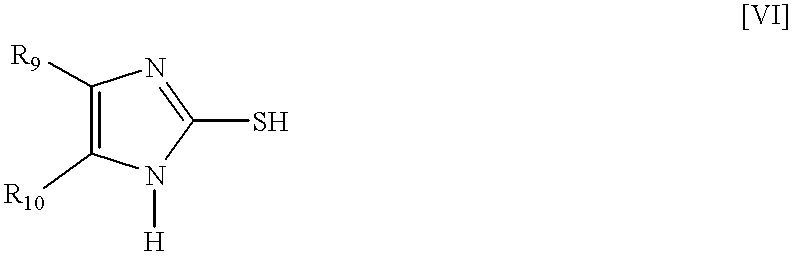

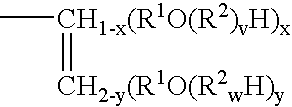

Labeling reagents and methods of their use

ActiveUS20090004753A1Improve hydrolytic stabilityImprove stabilitySilicon organic compoundsMethine/polymethine dyesCombinatorial chemistryReagent

The present disclosure is directed to a reactive ester agent capable of conjugating a reporter molecule to a carrier molecule or solid support. The reactive ester agent has the general formula:wherein the variables are described throughout the application.

Owner:LIFE TECH CORP

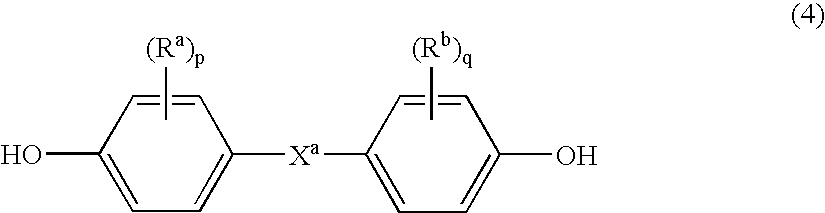

Impact-modified polycarbonate compositions having a good combination of natural color, hydrolytic stability and melt stability

The present invention relates to polycarbonate compositions comprisingA) from 10 to 99 parts by weight, in each ease based on the sum of components A+B+C, of aromatic polycarbonate and / or aromatic polyester carbonate,B) from 1 to 35 parts by weight, in each case based on the sum of components A+B+C, of rubber-modified graft polymer ofB.1 from 5 to 95 wt. % of at least one vinyl monomer onB.2 from 95 to 5 wt. % of one or more graft bases having a glass transition temperature <10° C.,C) from 0 to 40 parts by weight, in each case based on the sum of components A+B+C, of vinyl (co)polymer and / or polyalkylene terephthalate,D) from 0 to 50 parts by weight, in each case based on the sum of components A+B+C, of phosphorus-containing flameproofing agent,E) from 0 to 1.0 part by weight, in each case based on the sum of components A+B+C, of acidic additives, andF) from 0 to 50 parts by weight, in each case based on the sum of components A+B+C, of additives,wherein component B is obtainable by reacting component B.1 with the graft base B.2 by means of emulsion polymerization, with the proviso that in those compositions that are free of components D) and E), the graft polymer dispersion in the spray drying or in the precipitation has a pH value of less than 7,characterized in that there are used in the graft reaction from 0.1 to 5 parts by weight (based on the sum of the parts by weight of the monomers B.1 and of the graft base B.2 that are used=100 parts by weight) of at least one emulsifier selected from the group consisting of alkali, alkaline earth, ammonium and phosphonium salts of a saturated fatty acid having from 10 to 50 carbon atoms, wherein the emulsifier or emulsifiers remains or remain in component B,and also to a process for the preparation of these polycarbonate compositions and to the use of the polycarbonate compositions in the production of molded bodies, and to the molded bodies themselves.

Owner:BAYER MATERIALSCIENCE AG

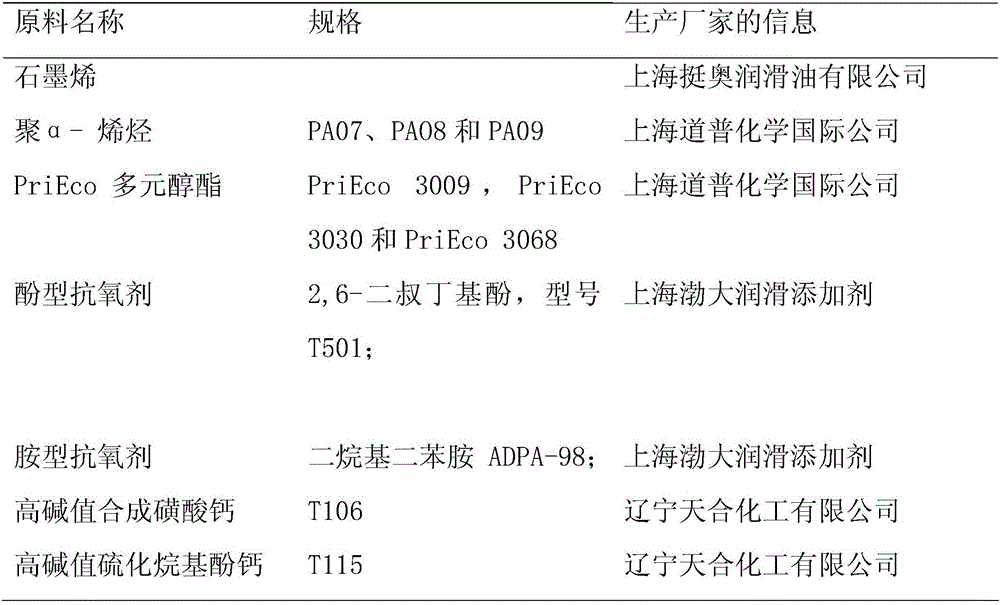

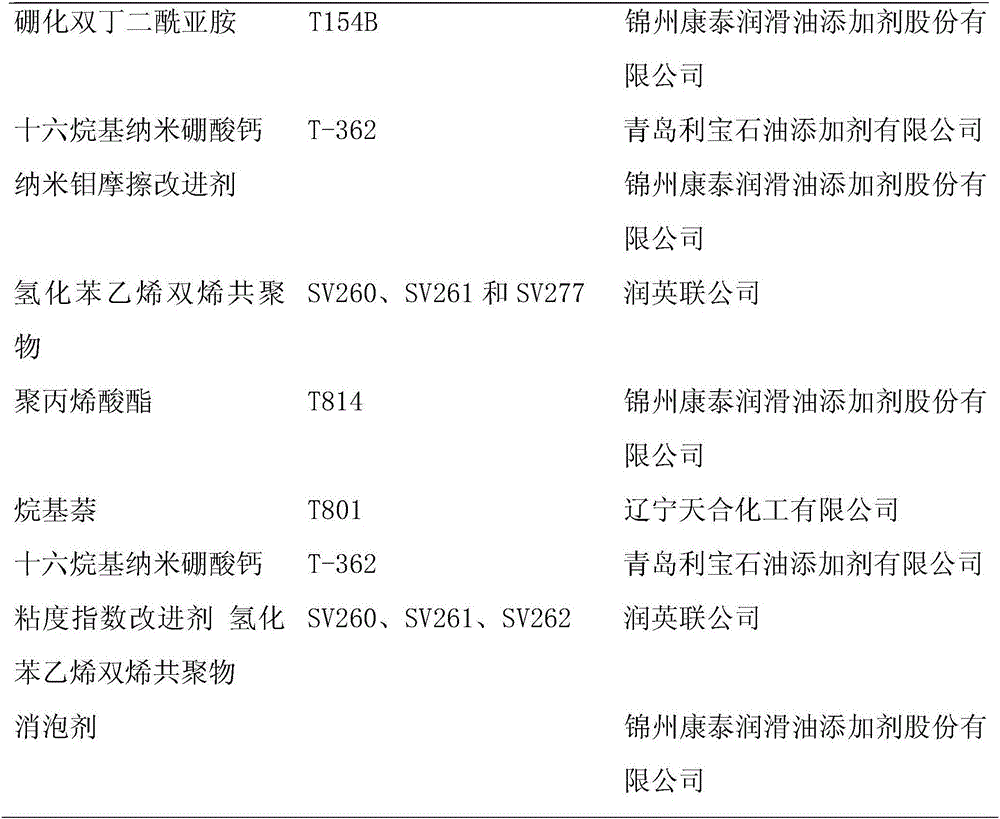

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

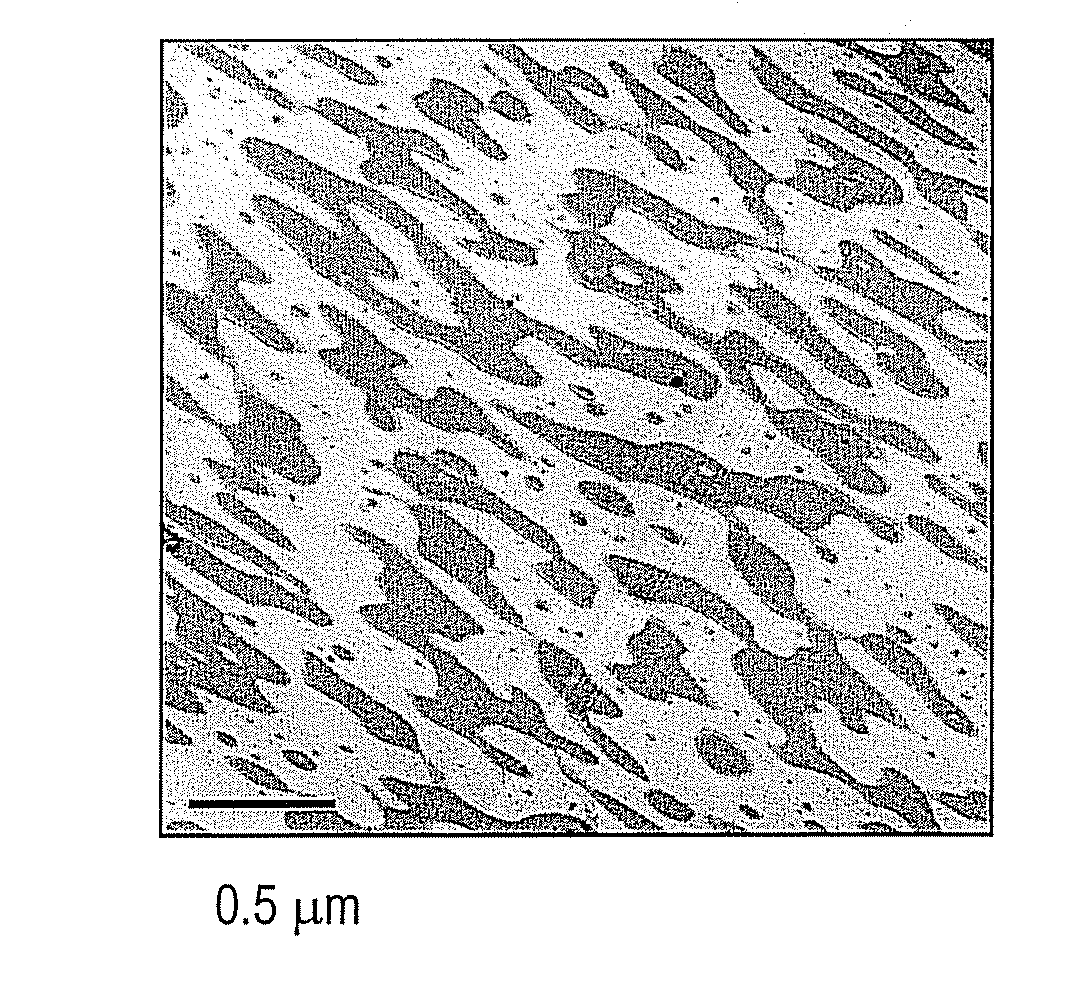

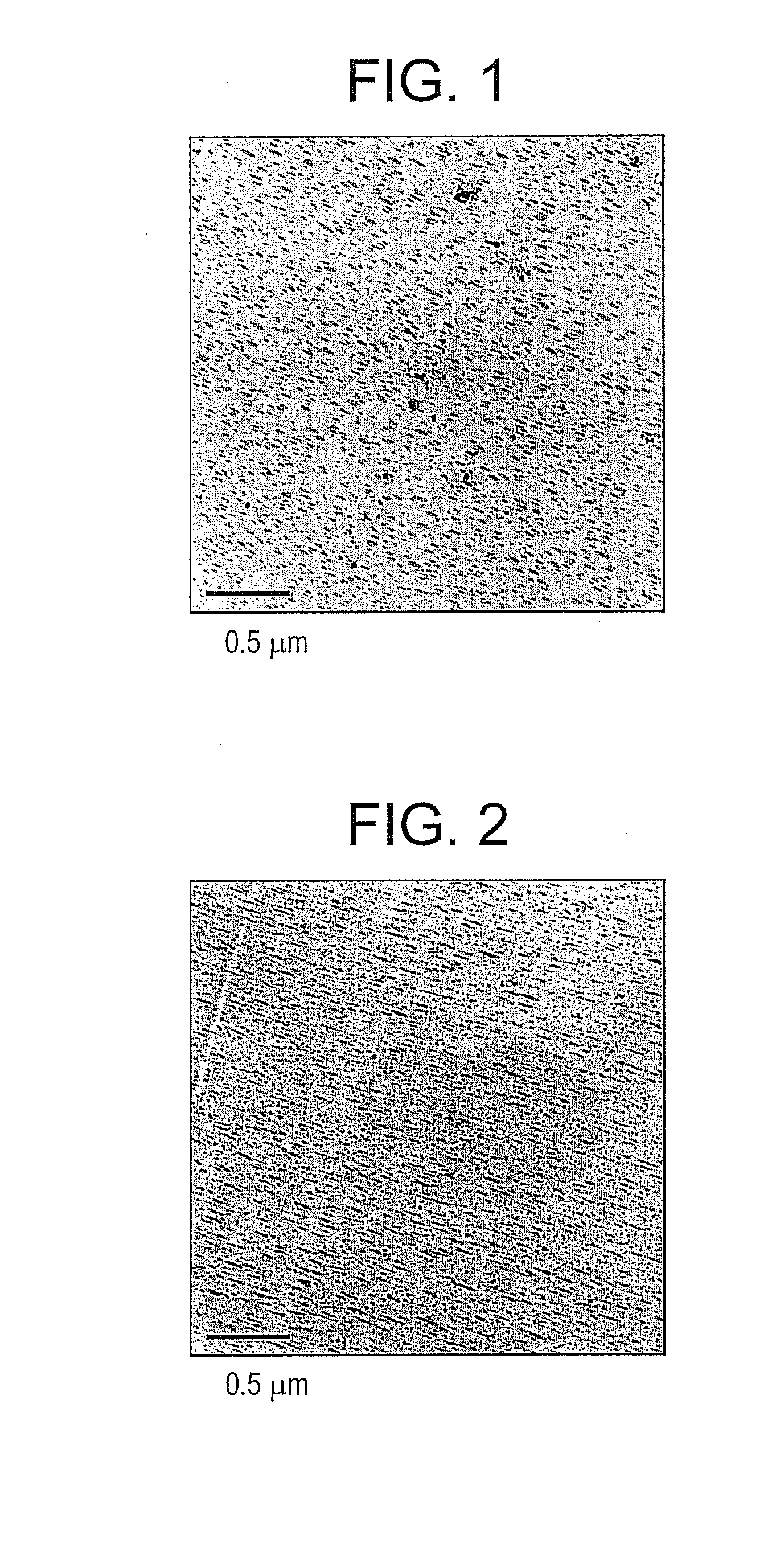

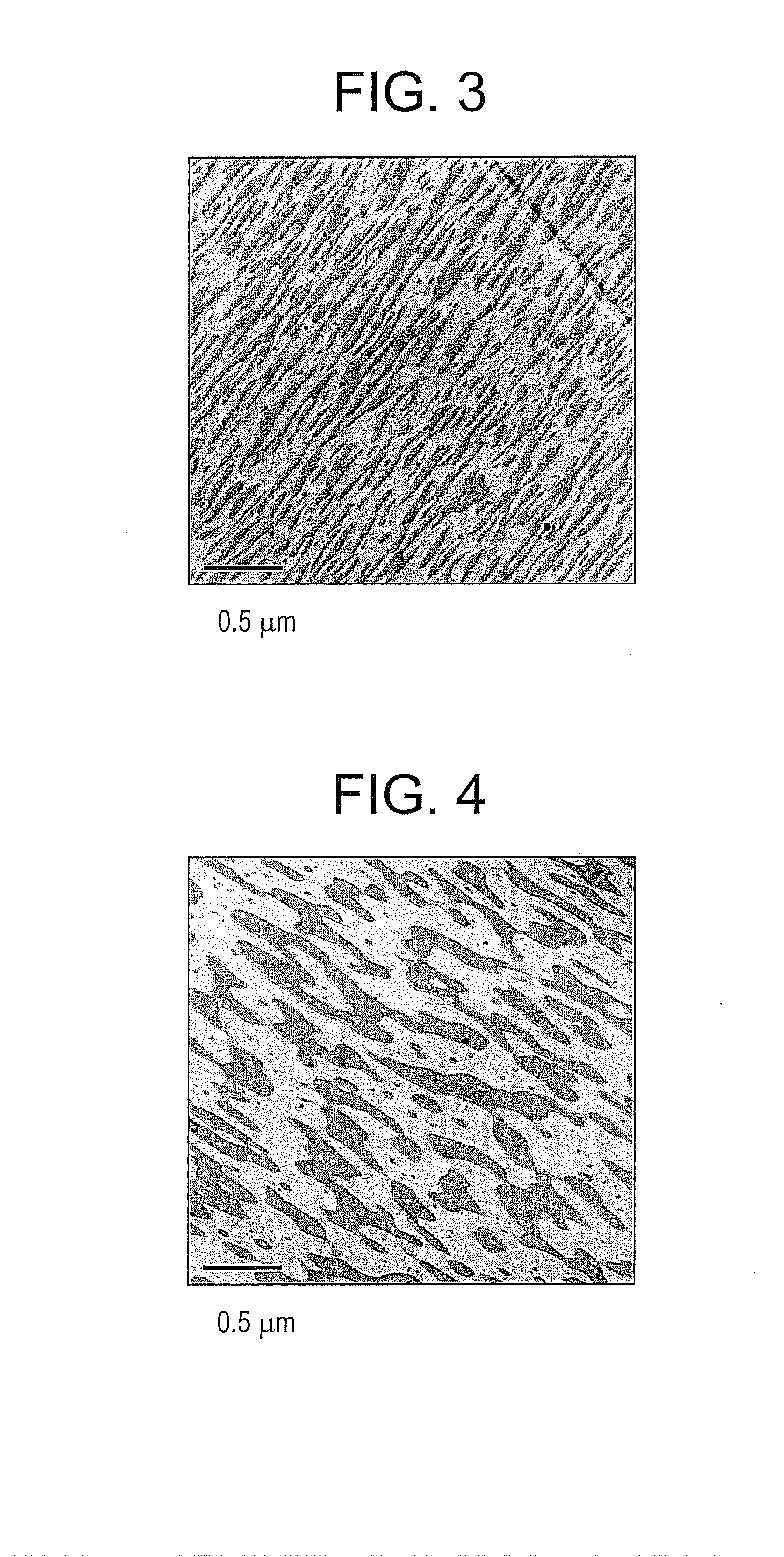

Polyetherimide/polyphenylene ether sulfone blends

Compositions comprise phase separated polyetherimide / polyphenylene ether sulfone blends. The dispersed phase has an average cross sectional size of 0.1 to 10 micrometers. The composition retains has good hydrolytic stability and is capable of withstanding steam autoclaving at temperatures of 130 to 138° C.

Owner:SHPP GLOBAL TECH BV

SDP-containing heterobifunctional agents

ActiveUS9145361B2Improve hydrolytic stabilityImprove water stabilityOrganic compound preparationImmunoglobulins against animals/humansHeterobifunctional reagentCombinatorial chemistry

Owner:LIFE TECH CORP

Curatives for epoxy compositions

InactiveUS20130199724A1Improve adhesionLow viscositySilicon organic compoundsEpoxy resin adhesivesEpoxyChemistry

The invention provides epoxy and oxetane compositions including the novel acyloxy and N-acyl curing agents described herein. Use of invention curing agents result in cured adhesive compositions with remarkably increased adhesion and reduced hydrophilicity when compared to resins cured with other types of curing agents. Furthermore, the curatives of this invention do not interfere with free-radical cure and are thus suited for use in hybrid cure thermoset compositions.

Owner:DESIGNER MOLECULES

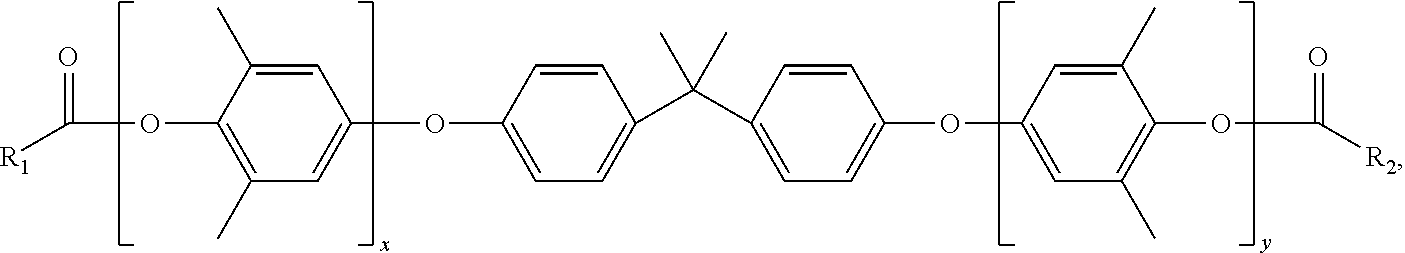

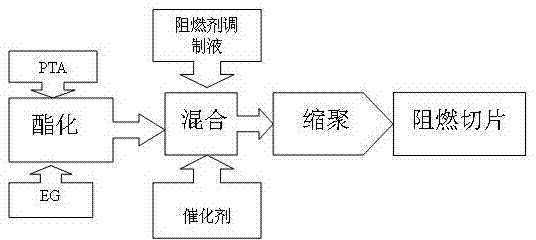

Method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns

ActiveCN102199807ADoes not affect the molecular skeleton structureImprove hydrolytic stabilityArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnHigh intensity

The invention discloses a method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns, which is characterized by comprising the following steps: pumping ethylene glycol (EG) and purified terephthalic acid (PTA) into a pulping kettle according to a molar ratio of 1.15 for pulping; after uniform pulping, transferring the uniform pulp into an esterification kettle for esterification; after the esterification is accomplished, adding blended liquid of a flame retardant, uniformly mixing, and adding the mixture into a polymerization kettle; after the polymerization is accomplished, discharging and cutting to obtain flame-retarding polyester chips with a viscosity of 0.61; feeding the prepared flame-retarding polyester chips into a solid-phase polymerization system, and improving the viscosity to 0.90 to 1.10; and melting at a high temperature into molten spinning solution in a screw extruder, spinning by a spinning component, drawing, and thermally setting to obtain phosphorus copolymerized flame-retarding terylene high-strength industrial yarns. In the invention, a copolymerized flame-retarding modification process is used for flame-retarding modification of the polyester, and the obtained terylene industrial yarns have high strength and a permanent flame-retarding property.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

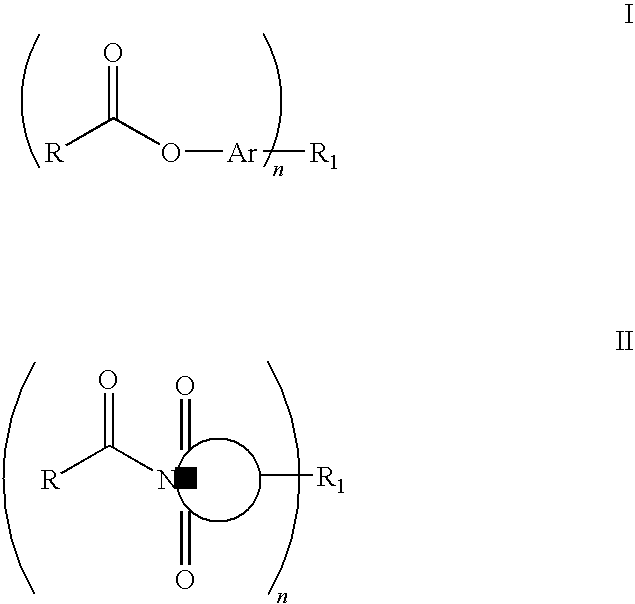

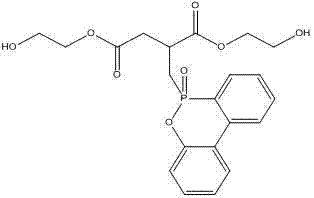

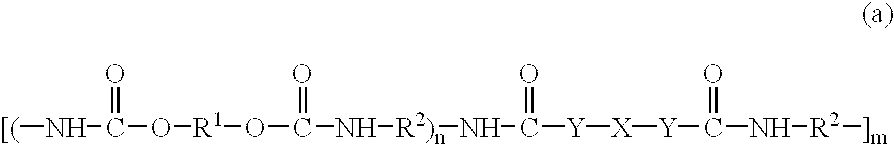

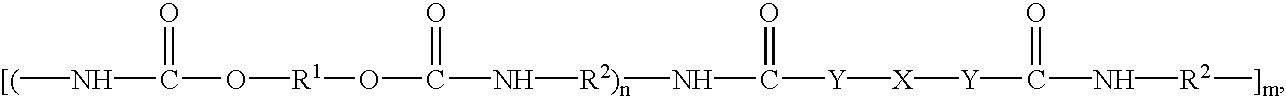

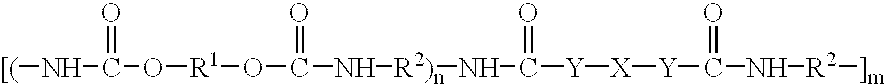

Polyurethane elastomers, method of producing them and their use

InactiveUS6458866B1Advantageous low-temperature behaviorImprove hydrolytic stabilityMonocomponent polyurethanes artificial filamentPhysical treatmentPolyurethane elastomerHeat deflection temperature

The invention concerns a polyurethane elastomer containing structural units of type (a), in which: the group -O-R1-O-is a macrodiol group with a molecular weight of approximately 500 to 10000, R2 is a bivalent aliphatic, cycloaliphatic and / or aliphatic-cycloaliphatic group; and X is a short-chain olefinically unsaturated group, Y is NH or O, n is an integer from 1 to 10 and m is an integer of at least 4. The invention also concerns a method of preparing this polyurethane elastomer which can be melt-spun to form fibres or melt-extruded to form foils. The fibres or foils can be exposed to energy-rich radiation such that crosslinking of the polyurethane occurs. Fibres according to the invention display superior properties in terms of textile-mechanical properties, in particular good tensile strength, elongation at tear, residual elongation and heat distortion temperature.

Owner:RHODIA SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com