Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216 results about "Ductile materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ductile materials are those which could show plastic deformation.Such materials can be actually drawn or bent or rolled before it reaches its fracture point. Brittle materials fracture before yield point but ductile materials go beyond yield point.examples are copper,aluminium etc.

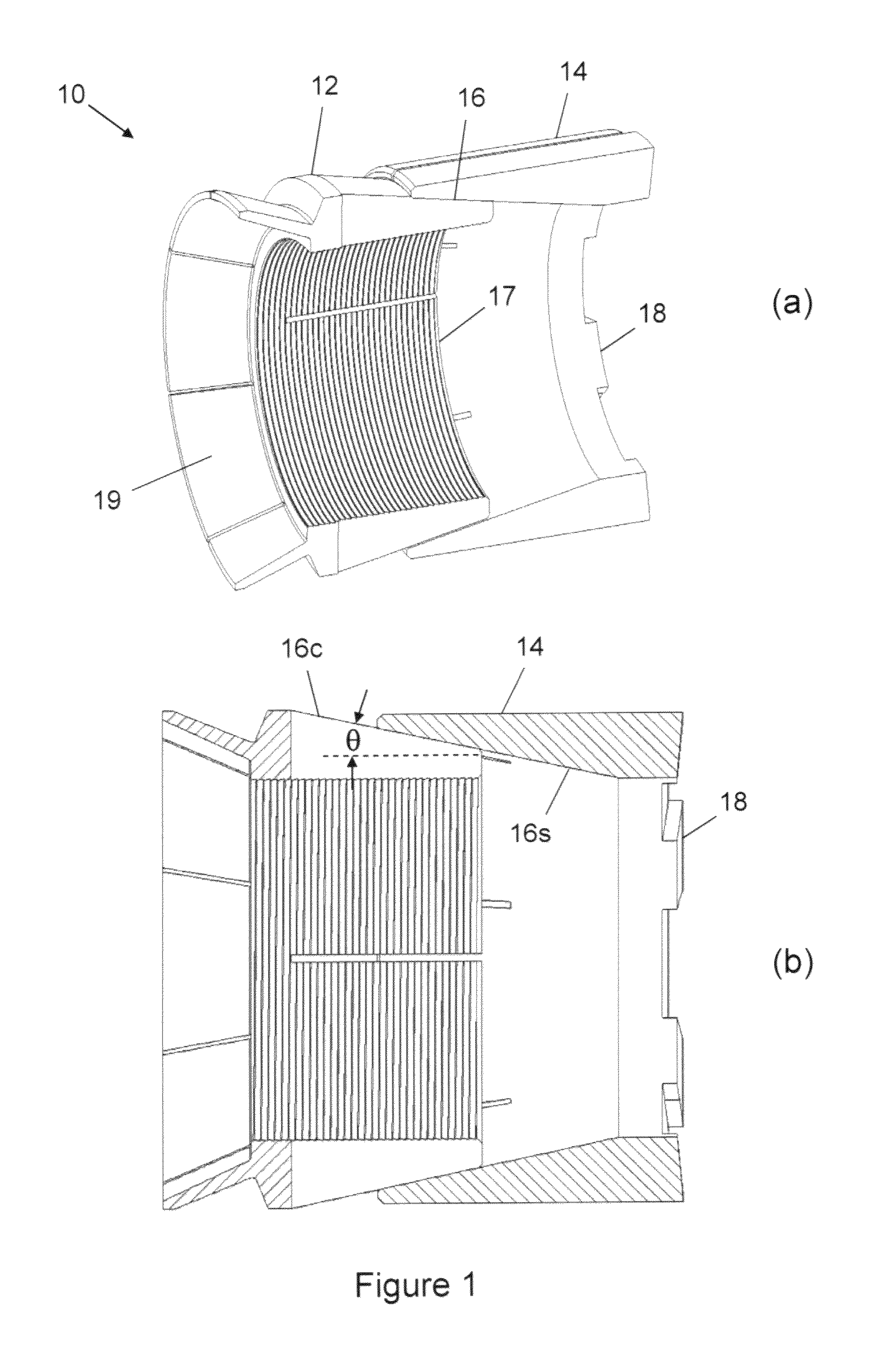

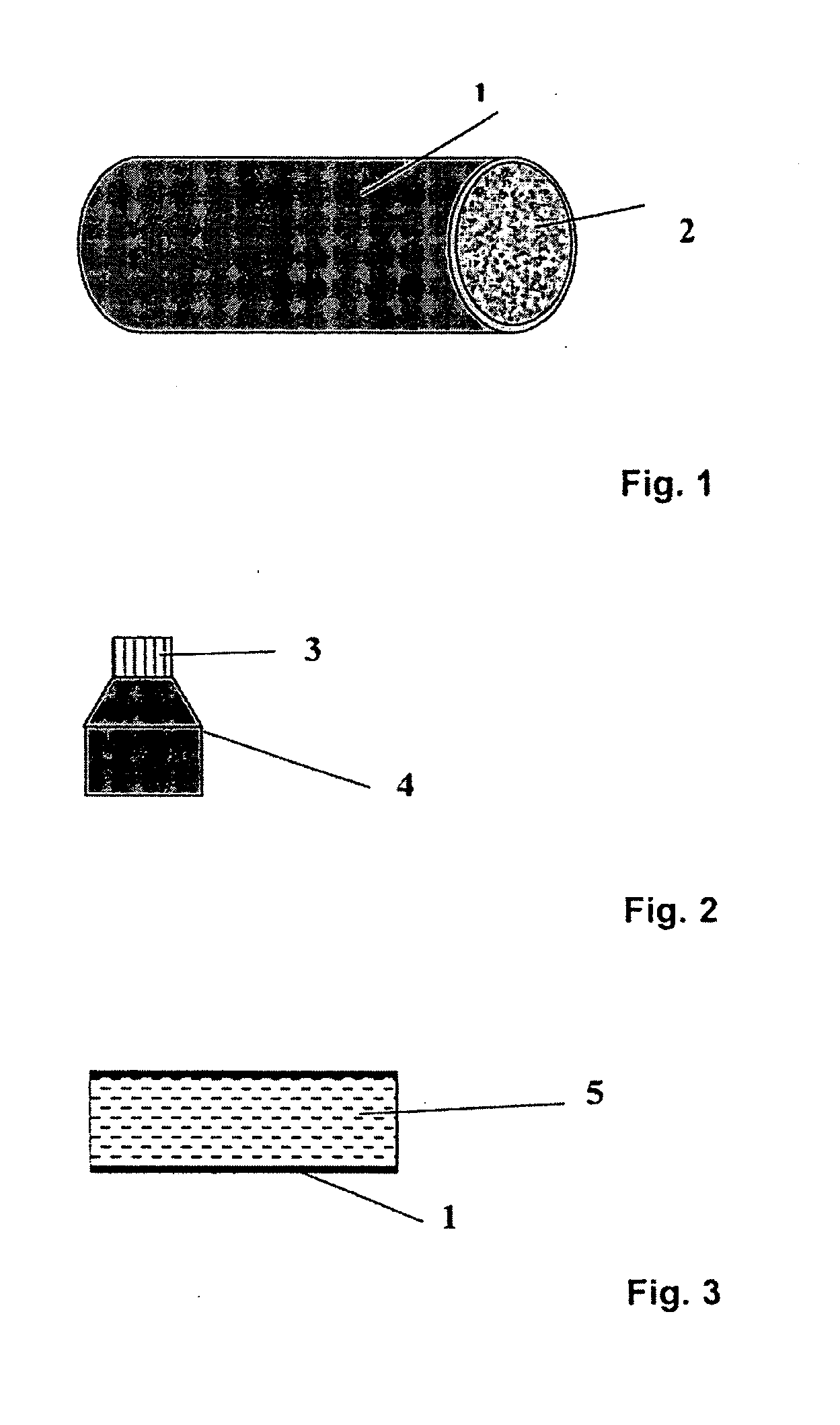

Clad composite stent

InactiveUS20050059889A1Reduce the cross-sectional areaEliminate strainStentsBlood vesselsPlatinumCobalt

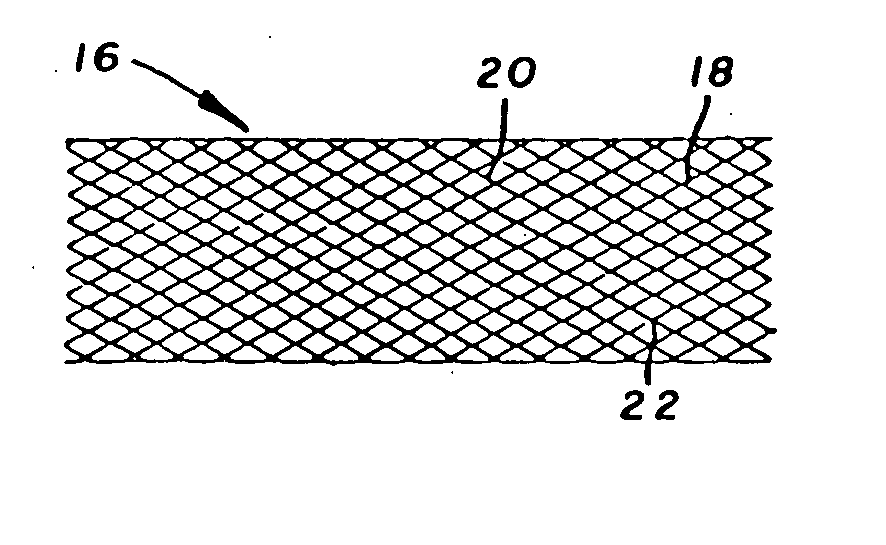

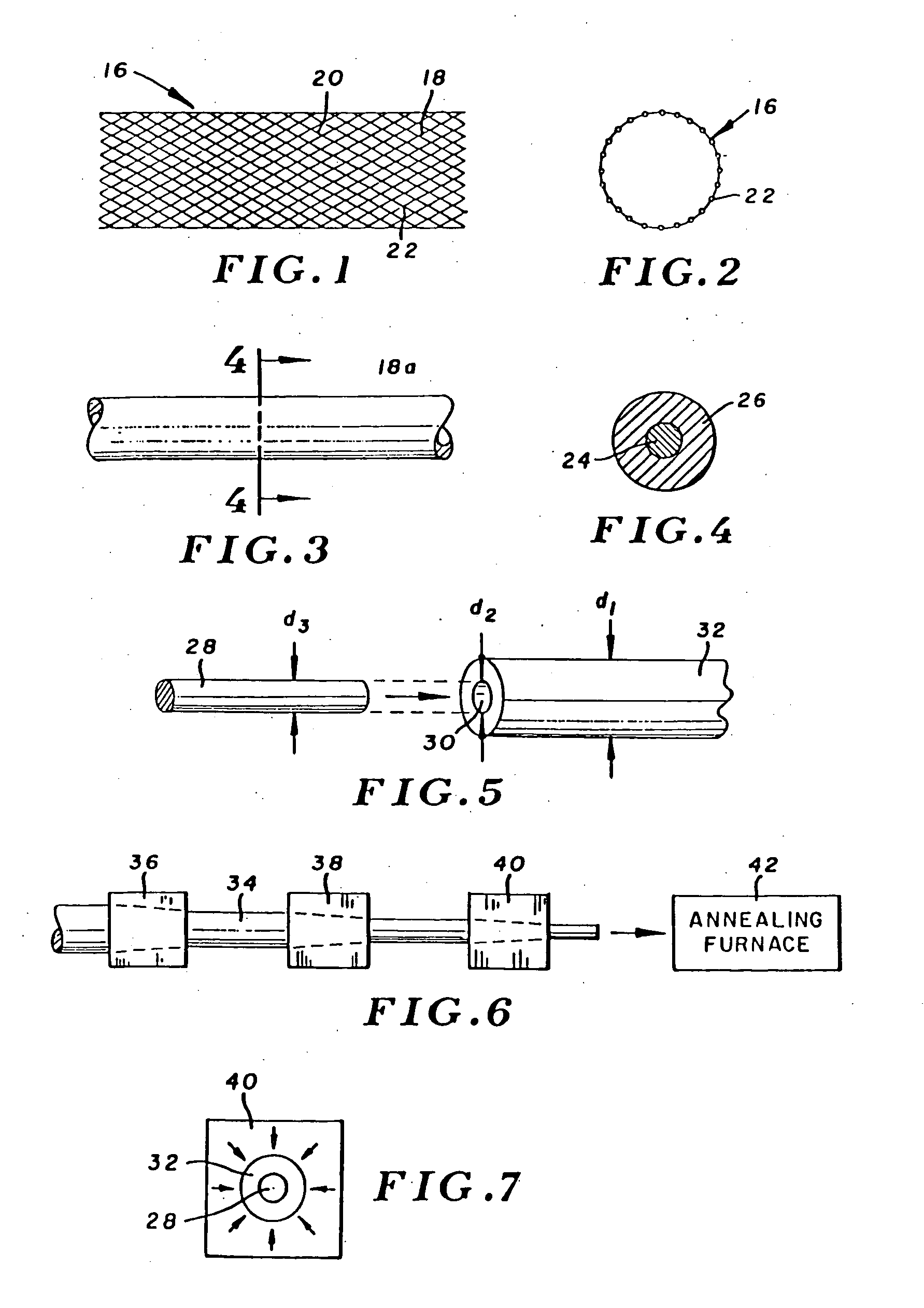

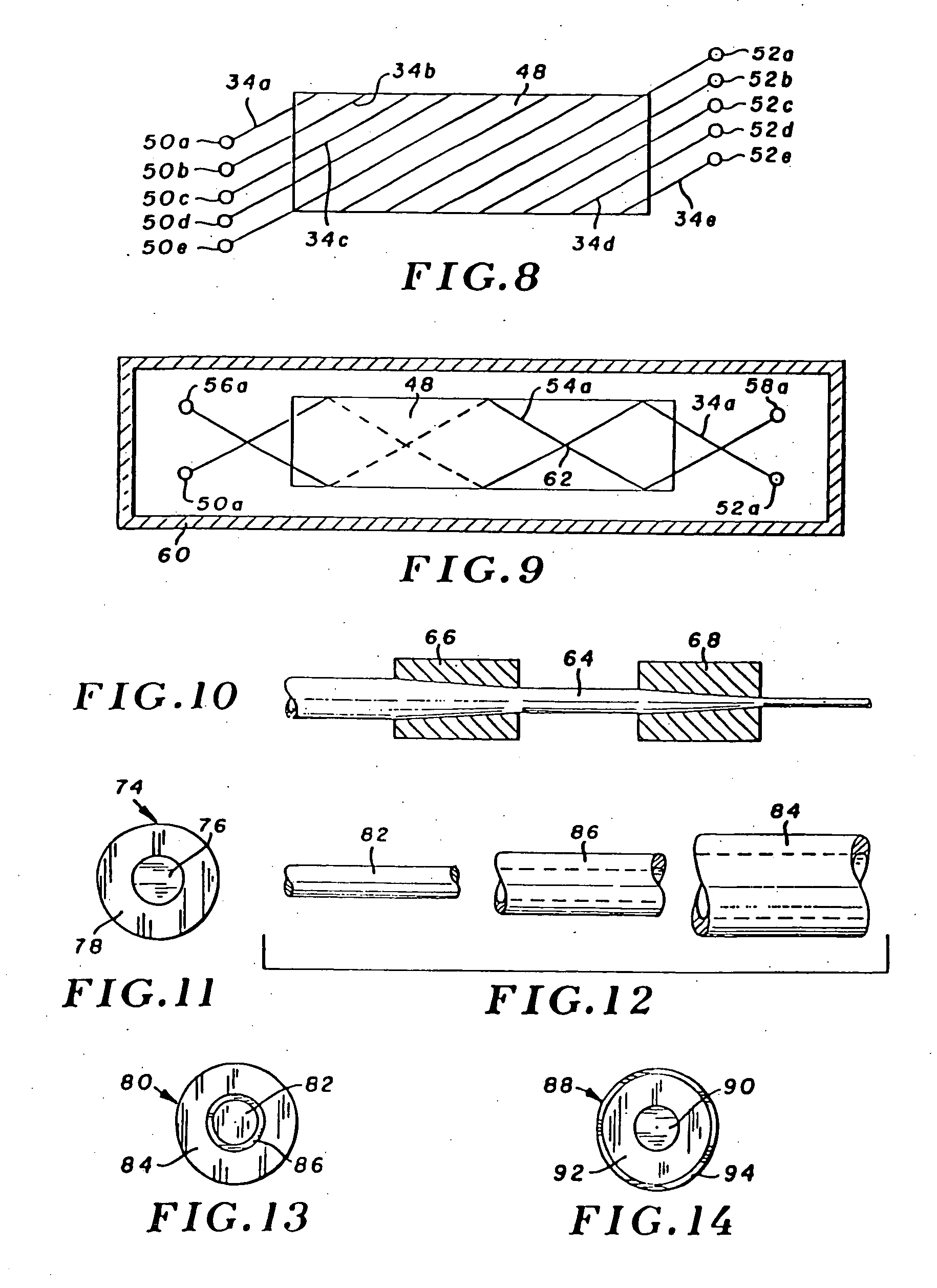

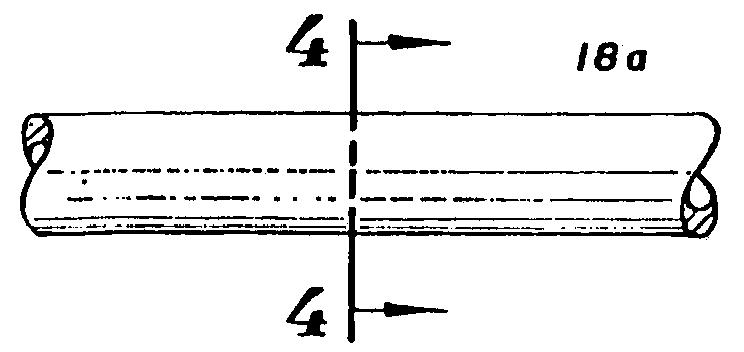

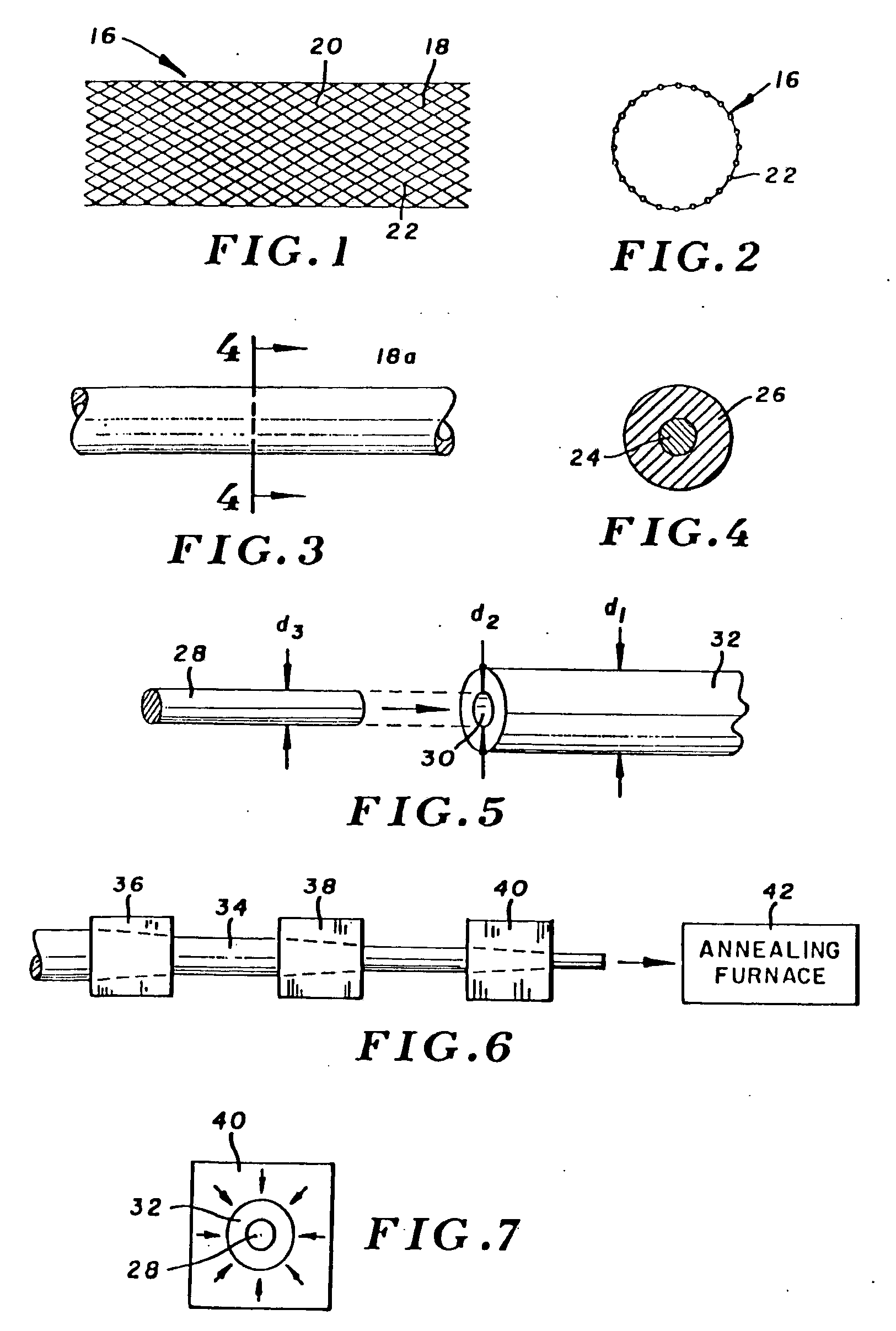

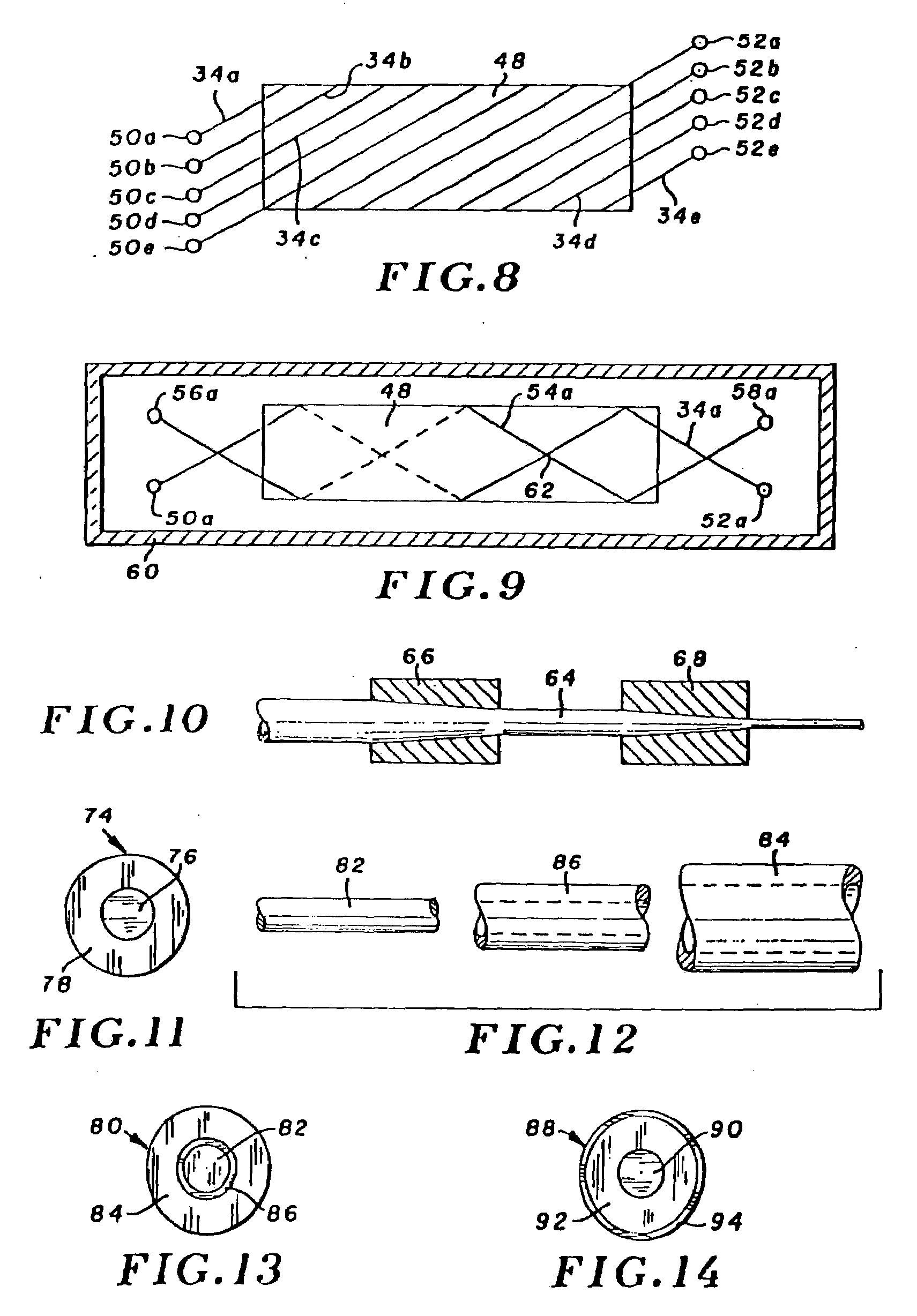

A body compatible stent is formed of multiple filaments arranged in at least two sets of oppositely directed helical windings interwoven with one another in a braided configuration. Each of the filaments is a composite including a central core and a case surrounding the core. In the more preferred version, the core is formed of a radiopaque and relatively ductile material, e.g. tantalum or platinum. The outer case is formed of a relatively resilient material, e.g. a cobalt / chromium based alloy. Favorable mechanical characteristics of the stent are determined by the case, while the core enables in vivo imaging of the stent. The composite filaments are formed by a drawn filled tubing process in which the core is inserted into a tubular case of a diameter substantially more than the intended final filament diameter. The composite filament is cold-worked in several steps to reduce its diameter, and annealed between successive cold working steps. After the final cold working step, the composite filament is formed into the desired shape and age hardened. Alternative composite filaments employ an intermediate barrier layer between the case and core, a biocompatible cover layer surrounding the case, and a radiopaque case surrounding a structural core.

Owner:BOSTON SCI SCIMED INC

Non-damaging slips and drillable bridge plug

ActiveUS8579024B2Easy to drillPrevent rotationFluid removalSealing/packingNon destructiveMechanical engineering

A non-damaging slip assembly includes slips having grit on a smooth surface, the slips preferably made from a ductile material, such that the slips do not cause damage to the wall of a tubular when the slips are set. The slips fail under tensile force during setting. The cone used to expand the slips may have slits that narrow during setting of the slips. The slip assembly may be used to anchor a variety or devices inside a tubular. A drillable, non-damaging bridge plug using the non-damaging slip assembly has a threaded mandrel holding the cone by threads inside the cone. When the slips are set, the slits in the cone narrow such that threads in the cone do not allow rotation of the slips as they are drilled. The bridge plug can be drilled by a PDC bit without damaging the tubular.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

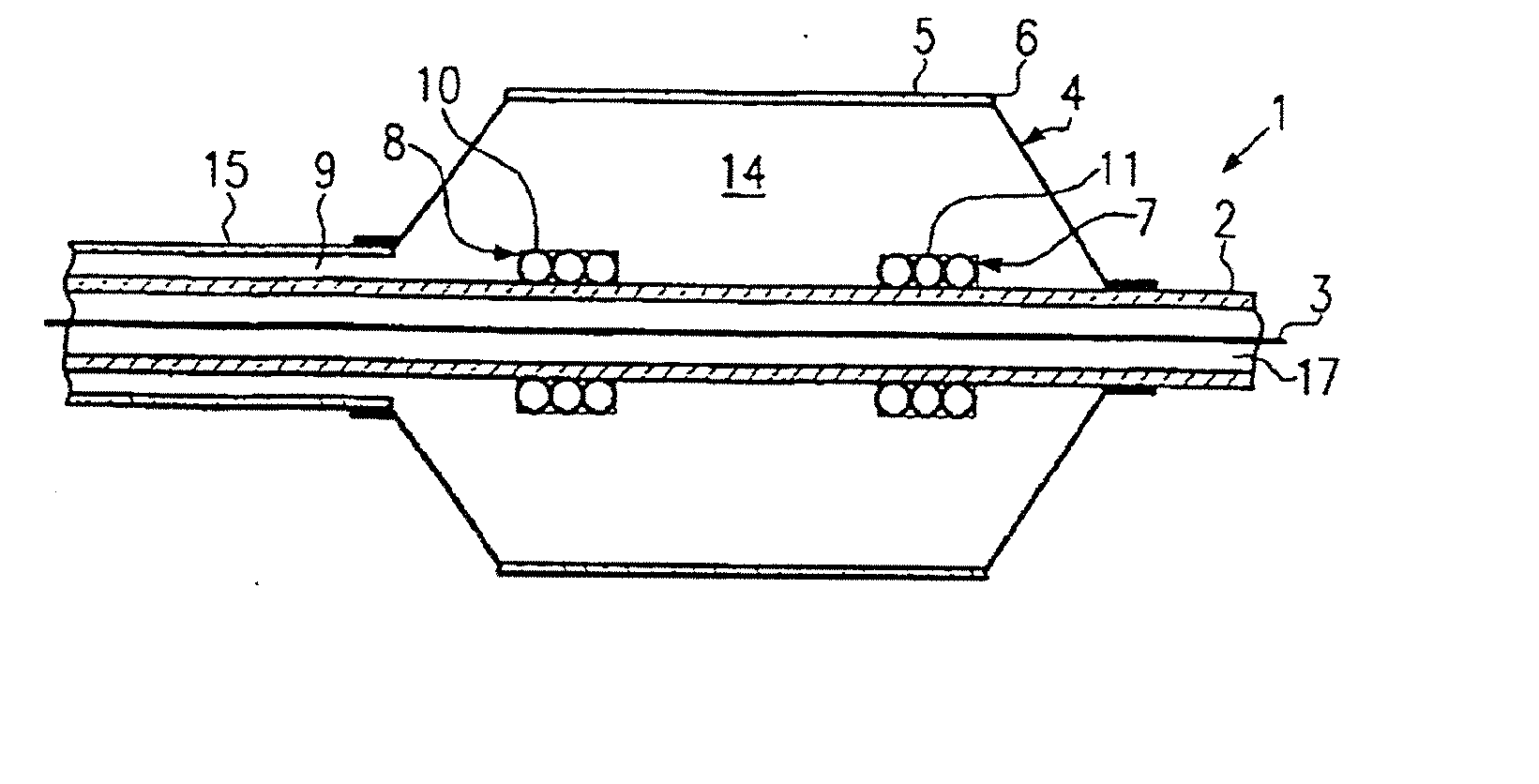

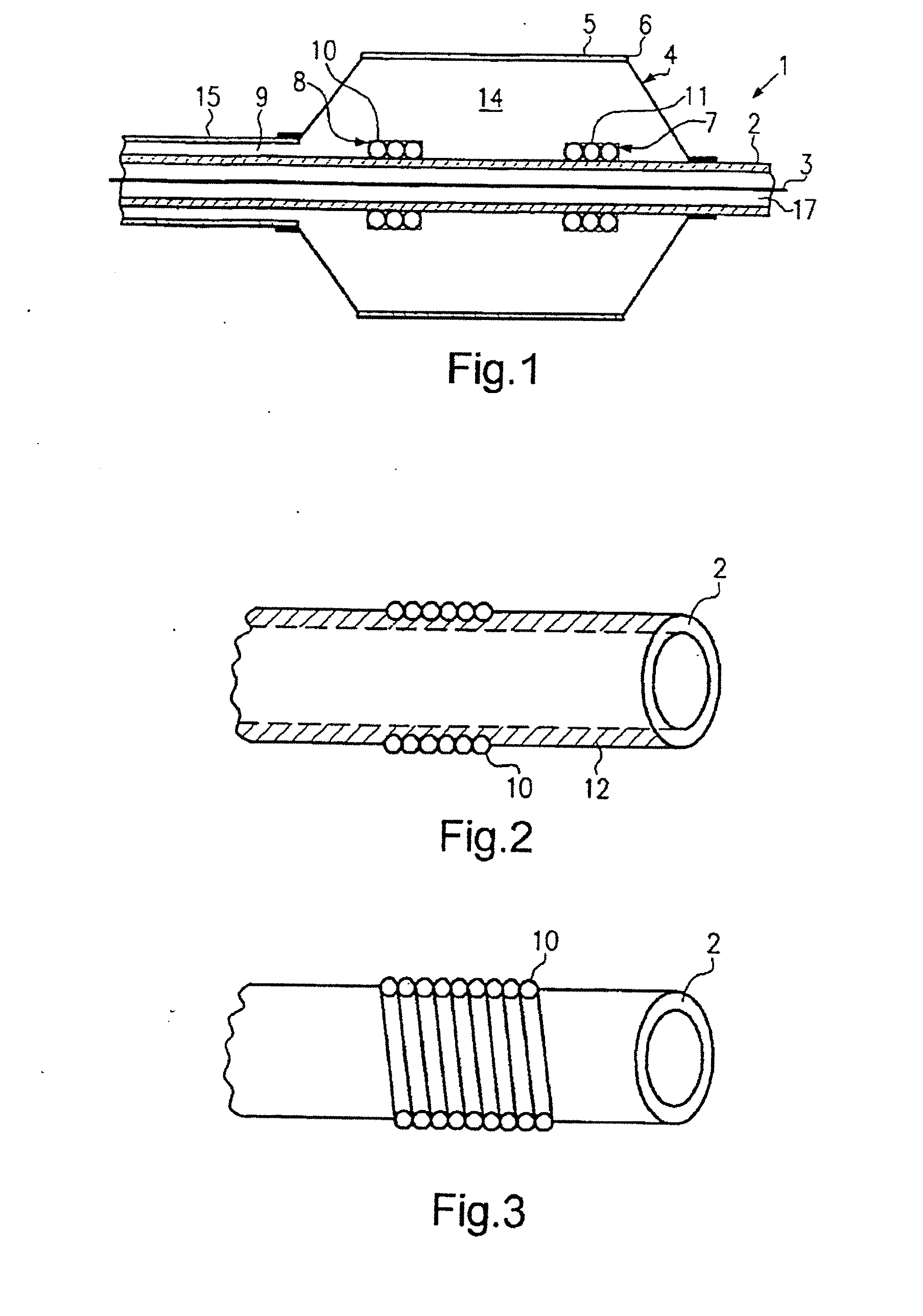

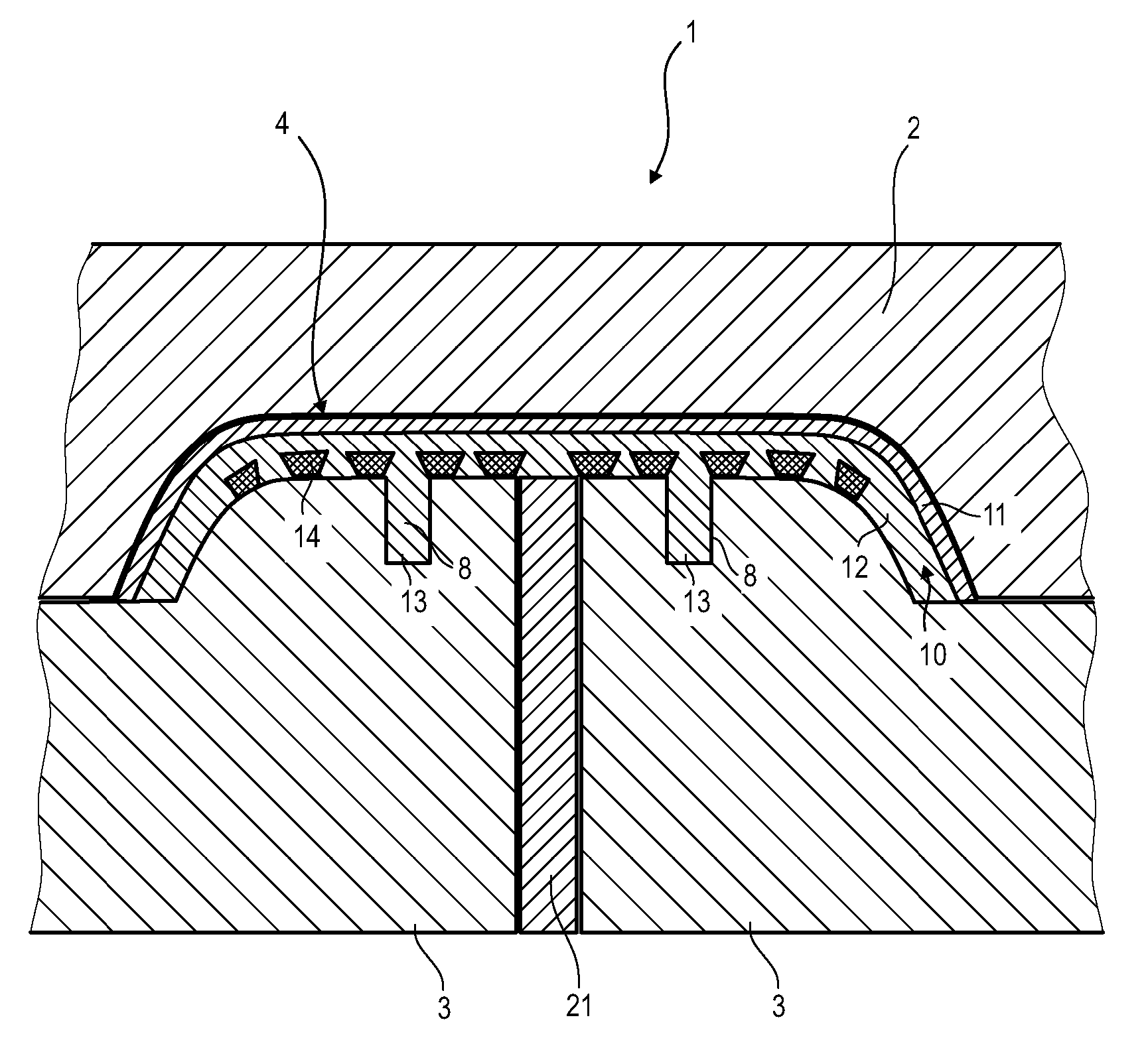

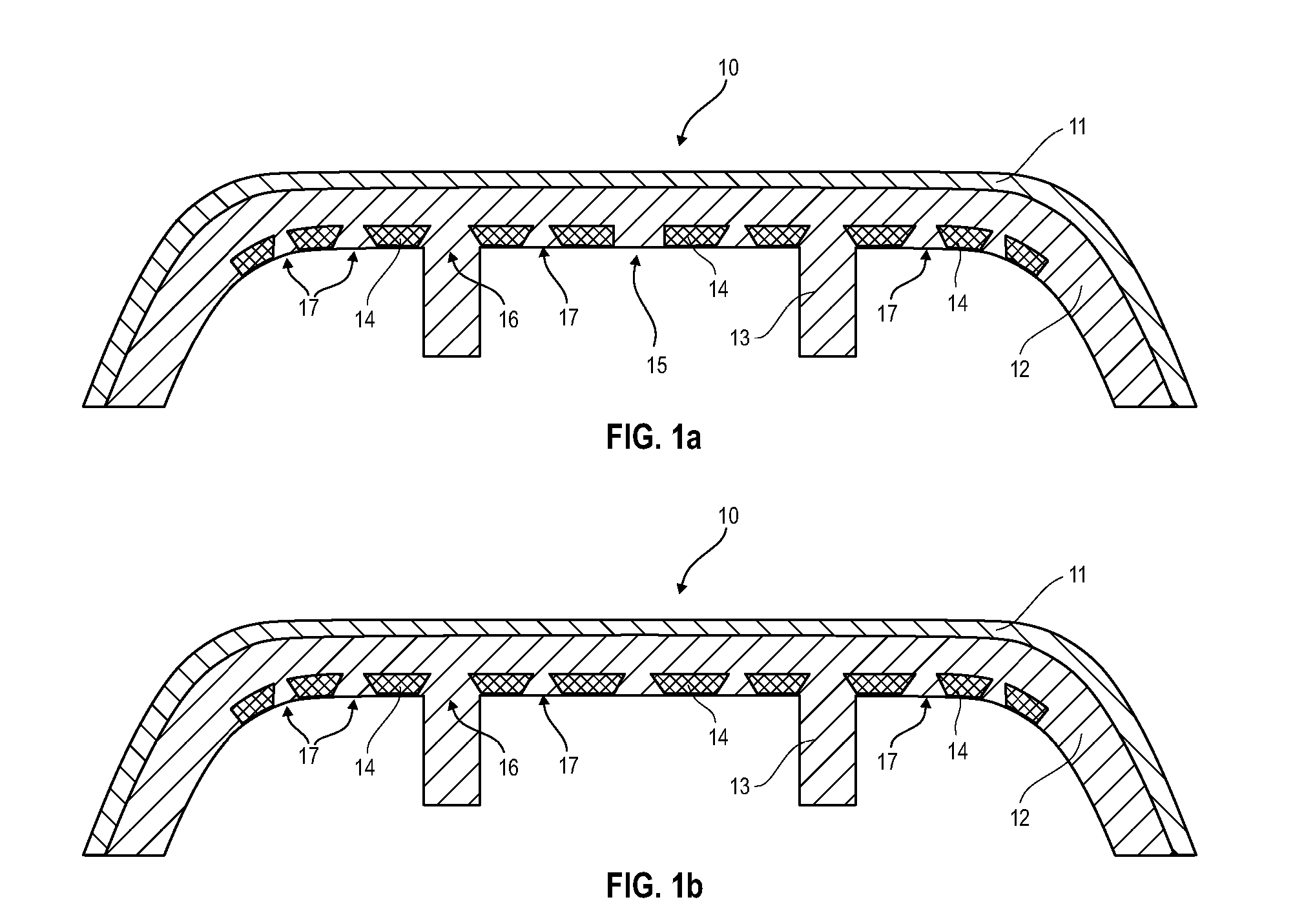

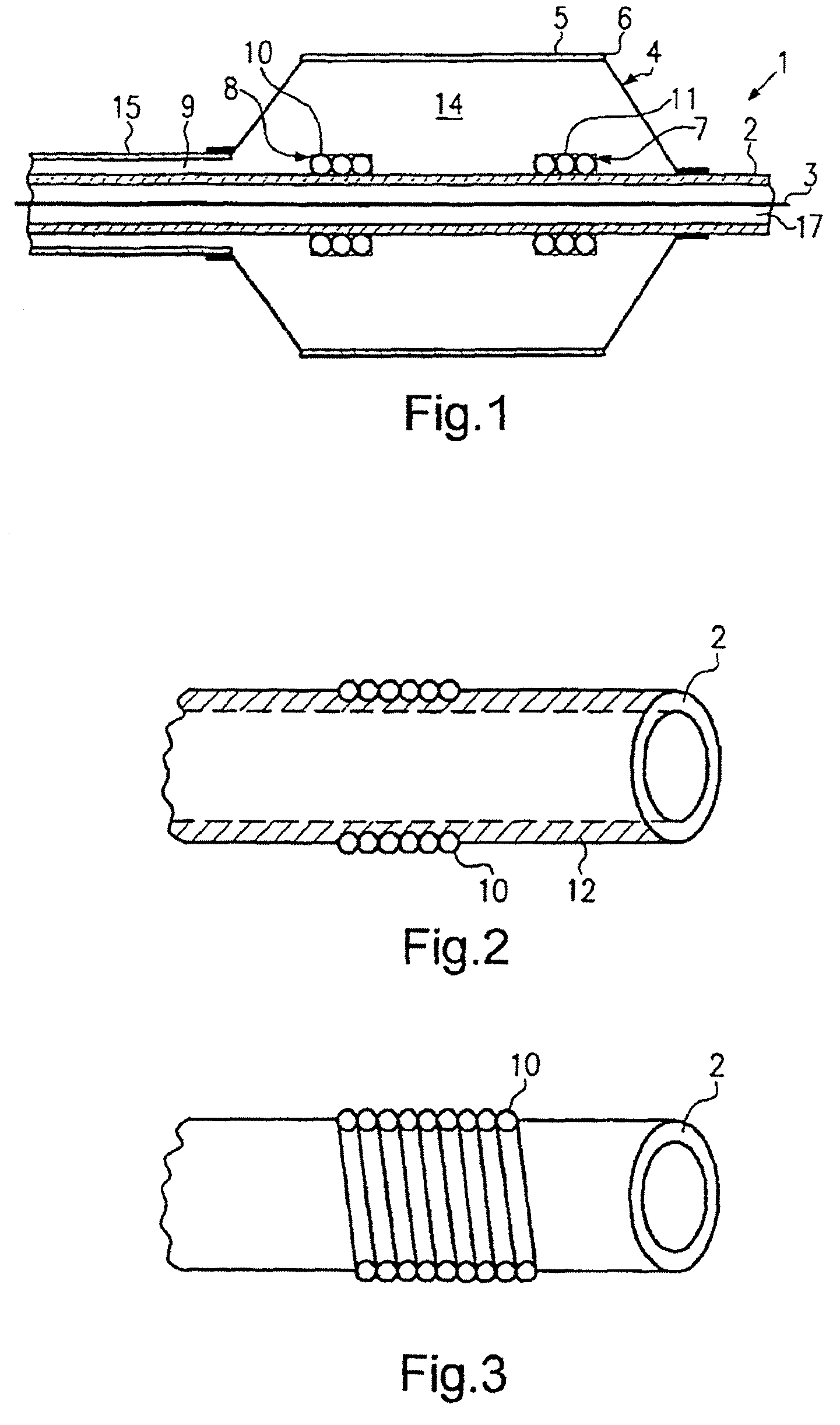

Balloon Catheter With Radiopaque Marker

InactiveUS20080015499A1Reduce rigid lengthIncrease flexibilityStentsBalloon catheterInsertion stentBalloon catheter

A catheter for delivering a stent includes an outer tube having a proximal end, a distal end and a wall defining a lumen; an inner tube disposed within the outer tube and defining a lumen for a guidewire, wherein a portion of a length of the inner tube is wrapped around with a spiral-shaped wire; a balloon sealingly connected to the inner tube and the outer tube adjacent the distal ends thereof, the balloon defining an interior volume and having an exterior surface; and a marker made from a wire of a highly radiopaque and ductile material, wherein the wire is wrapped in a plurality of at least partially overlapping layers such that the marker is flexible along the length of the catheter.

Owner:ABBOTT LAB INC

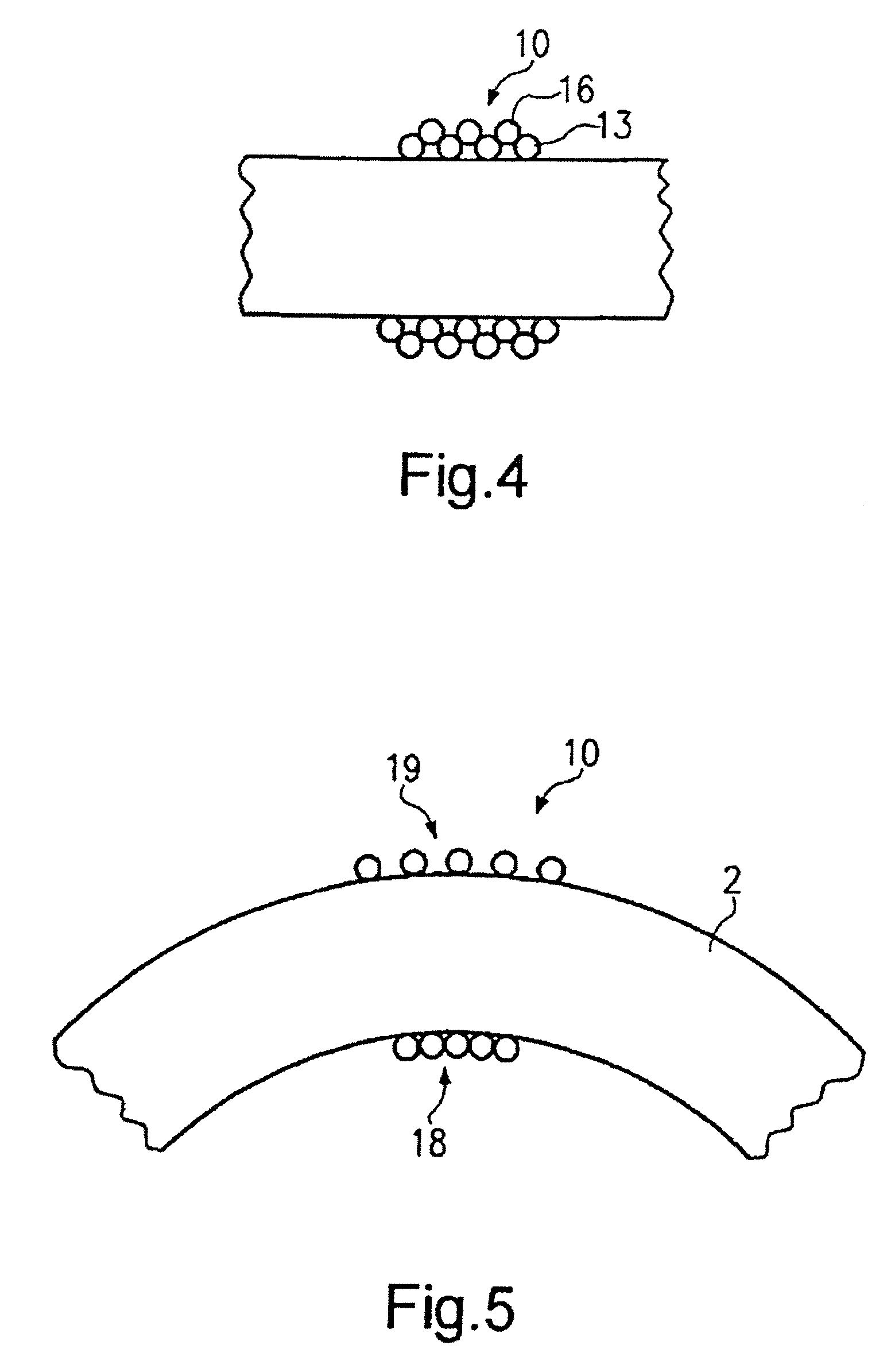

Molded part, in particular decorative part and/or trim part for the passenger compartment of a vehicle, and process for producing molded parts

ActiveUS20080292851A1Improved propertyImprove productivitySynthetic resin layered productsLaminationCompression moldingInjection molding process

Implementations of the present invention relate to a molded part, in particular a decorative part and / or a trim part for the passenger compartment of a vehicle, comprising a support of plastic, a decorative layer and a ductile insert of ductile material. According to implementations of the present invention, the ductile material for forming the ductile insert is or comprises a nonmetallic mat, in particular a textile mat or a prepreg mat. Implementations of the present invention also relate to an injection molding process and a compression molding process for producing molded parts, in particular decorative parts and / or trim parts for the passenger compartment of a vehicle, the molded parts comprising a support of plastic, a decorative layer and a ductile insert of ductile material.

Owner:NOVEM CAR INTERIOR DESIGN GMBH

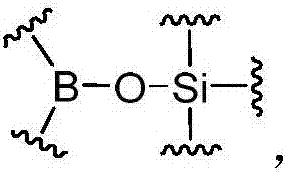

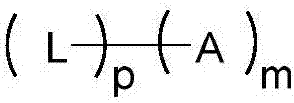

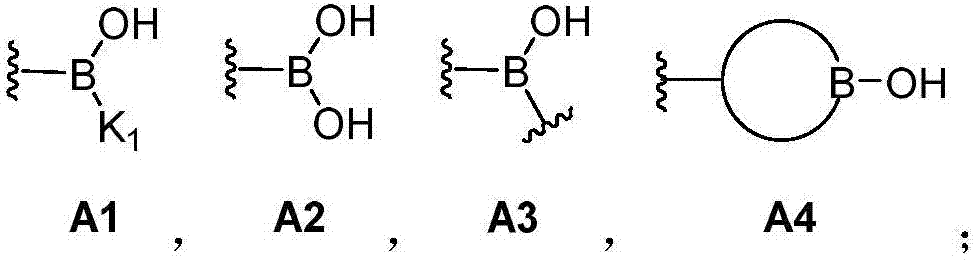

Dynamic polymer with dynamic cross-linked structure

The invention discloses a dynamic polymer with a dynamic cross-linked structure. Organic boric acid silicon ester bonds are contained on polymer chain skeletons of a cross-linked network and / or on cross-linked link skeletons between polymer chains, wherein the organic boric acid silicon ester bonds are necessary for forming / maintaining a dynamic polymer structure. The dynamic polymer is rich in structure and diverse in properties. By regulating and controlling the structure of a reactant, the dynamic polymers with different properties can be prepared. In addition, due to strong dynamic reversibility of the organic boric acid silicon ester bonds in the polymer, the polymer can exhibit functional characteristics of stimulus responsiveness, self-healing property, recoverability and the like; and besides, due to the presence of the organic boric acid silicon ester bonds, the polymer can also have the energy absorbing effects, and polymer materials can be toughened in a given structure. The dynamic polymer can be used for making shock-absorption cushioning materials, impact-resistance protection materials, self-healing materials, ductile materials and the like.

Owner:厦门天策材料科技有限公司

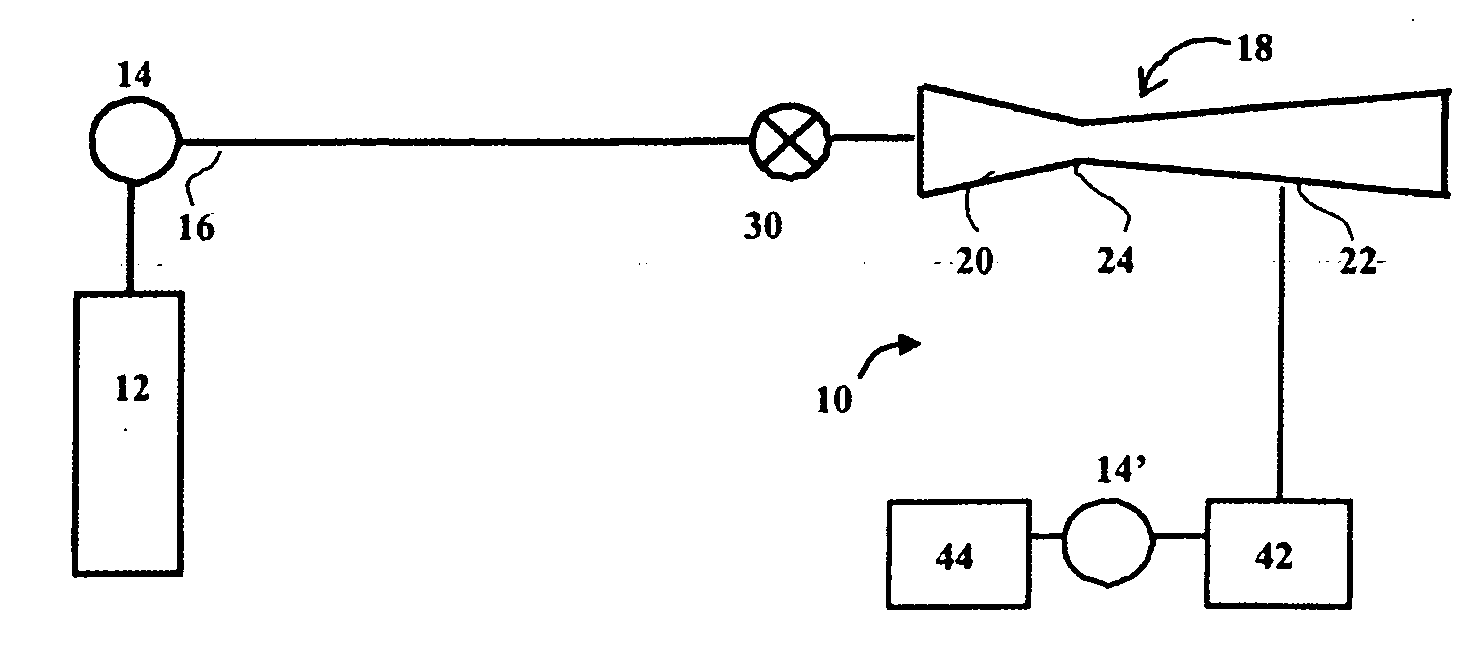

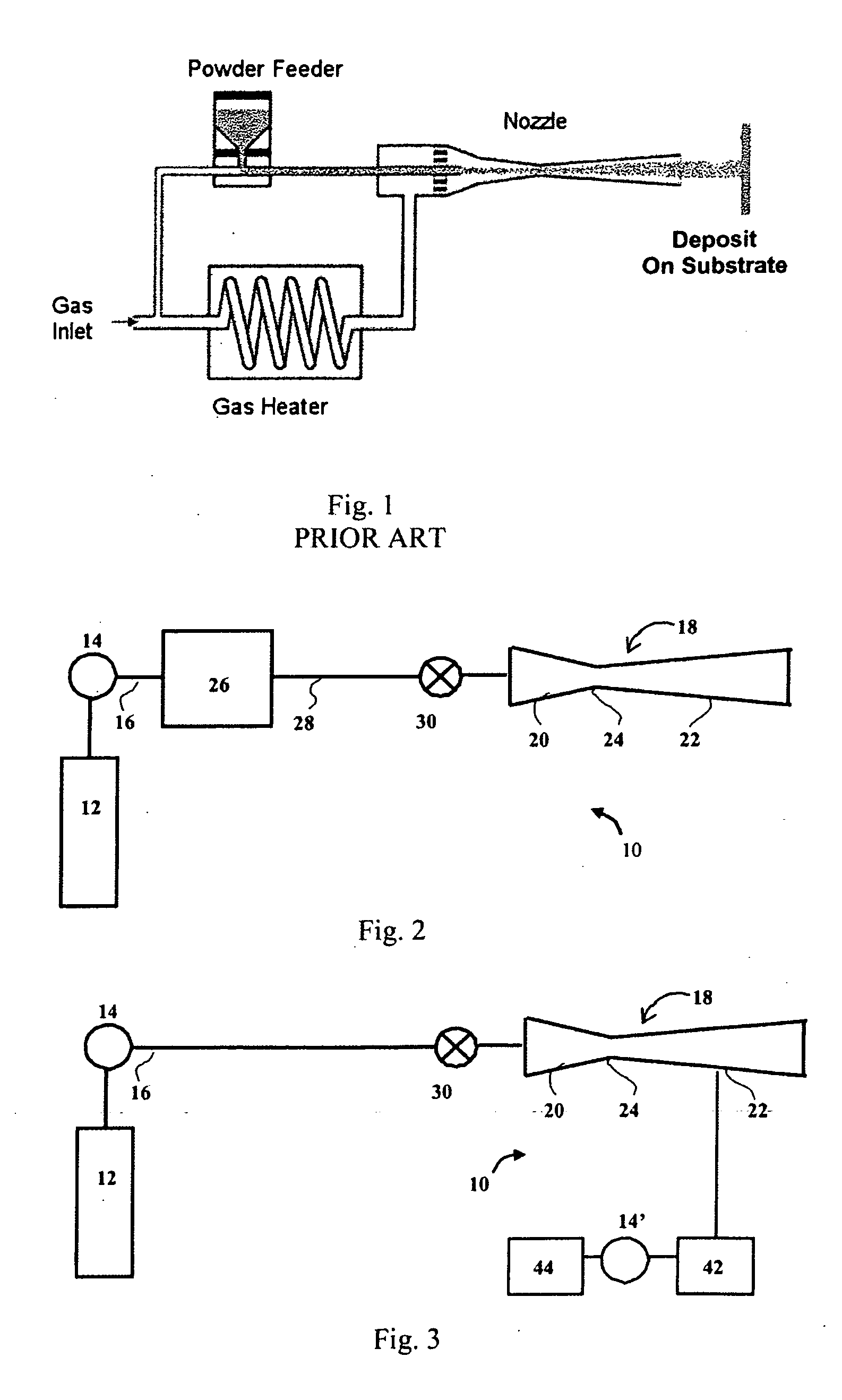

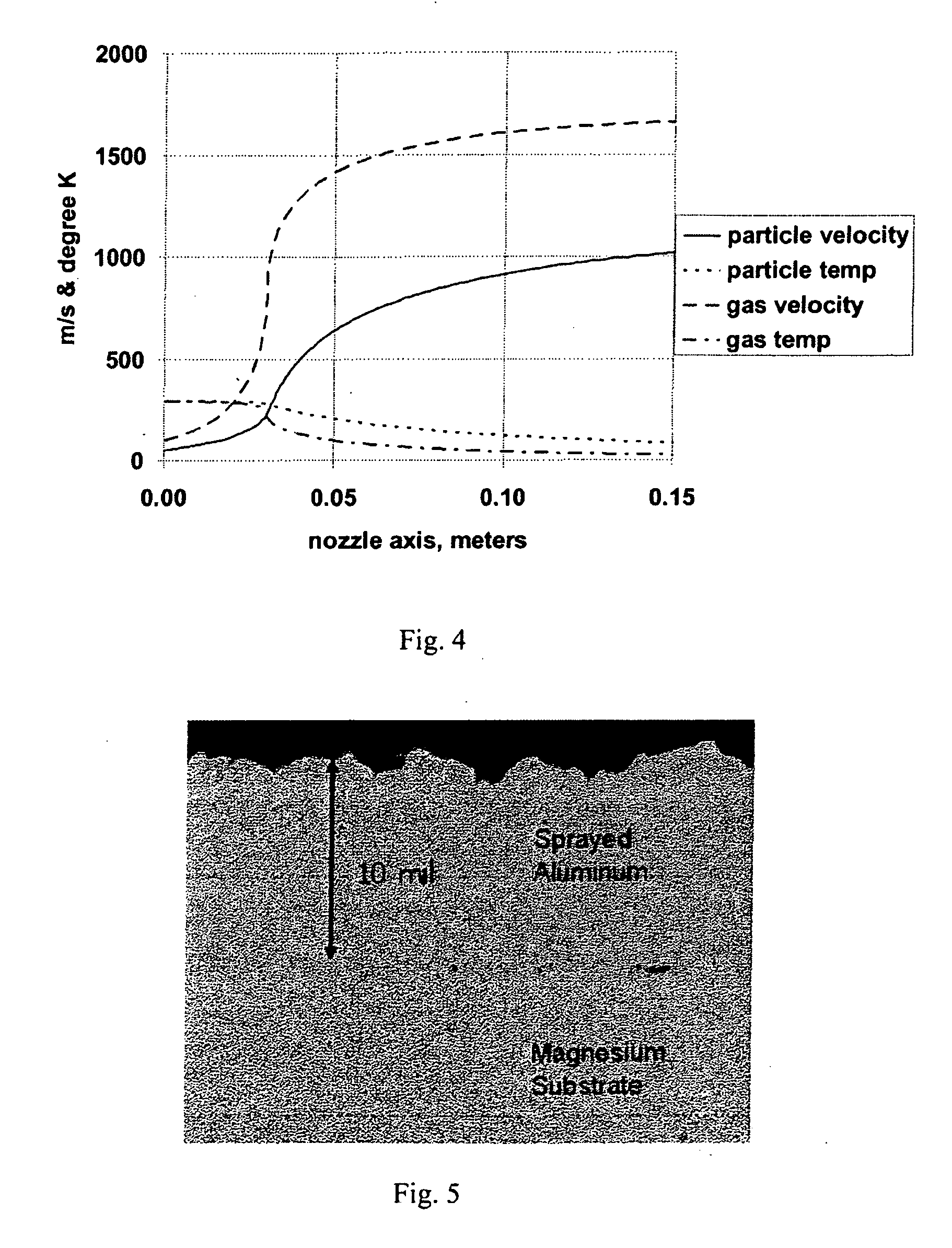

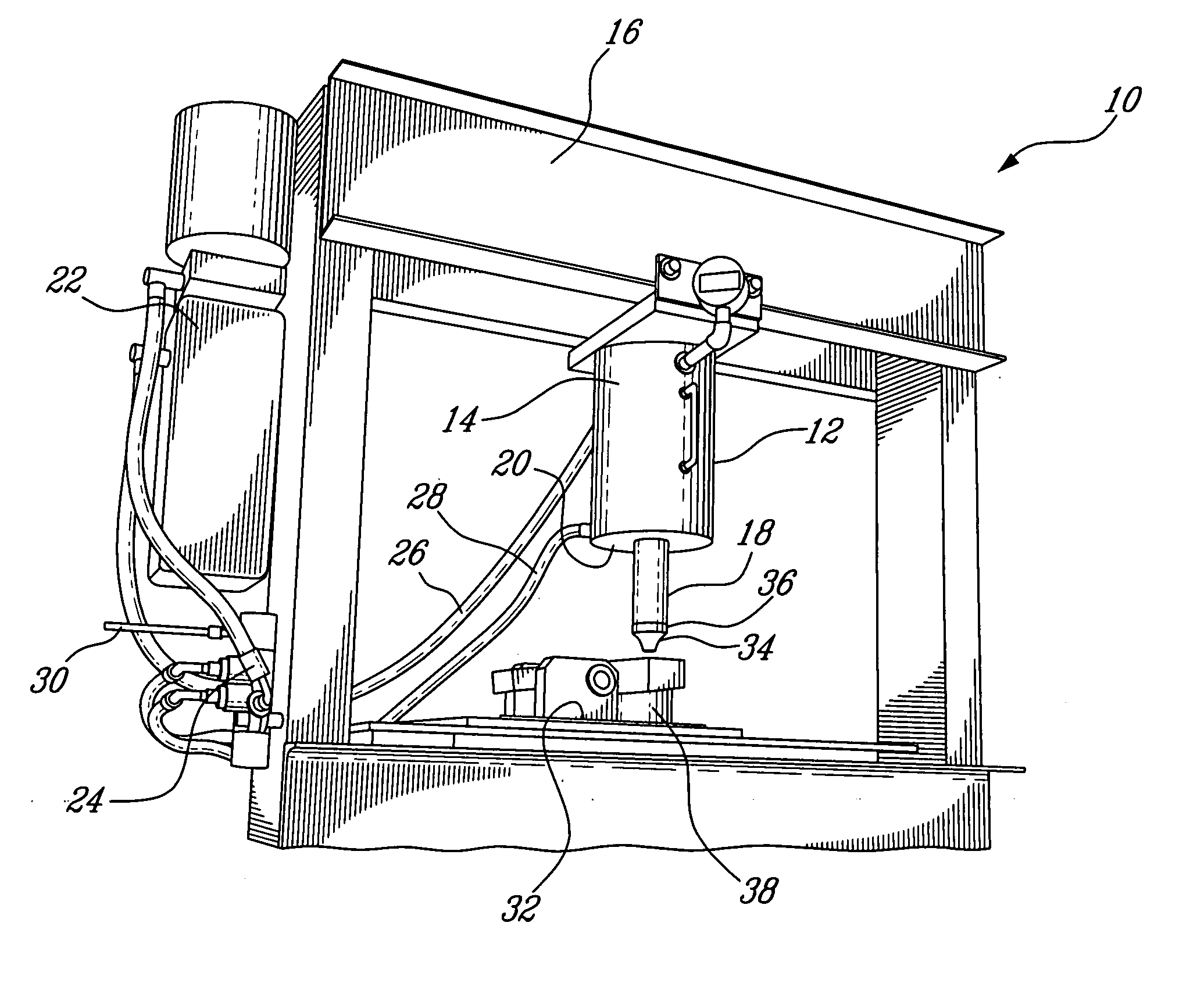

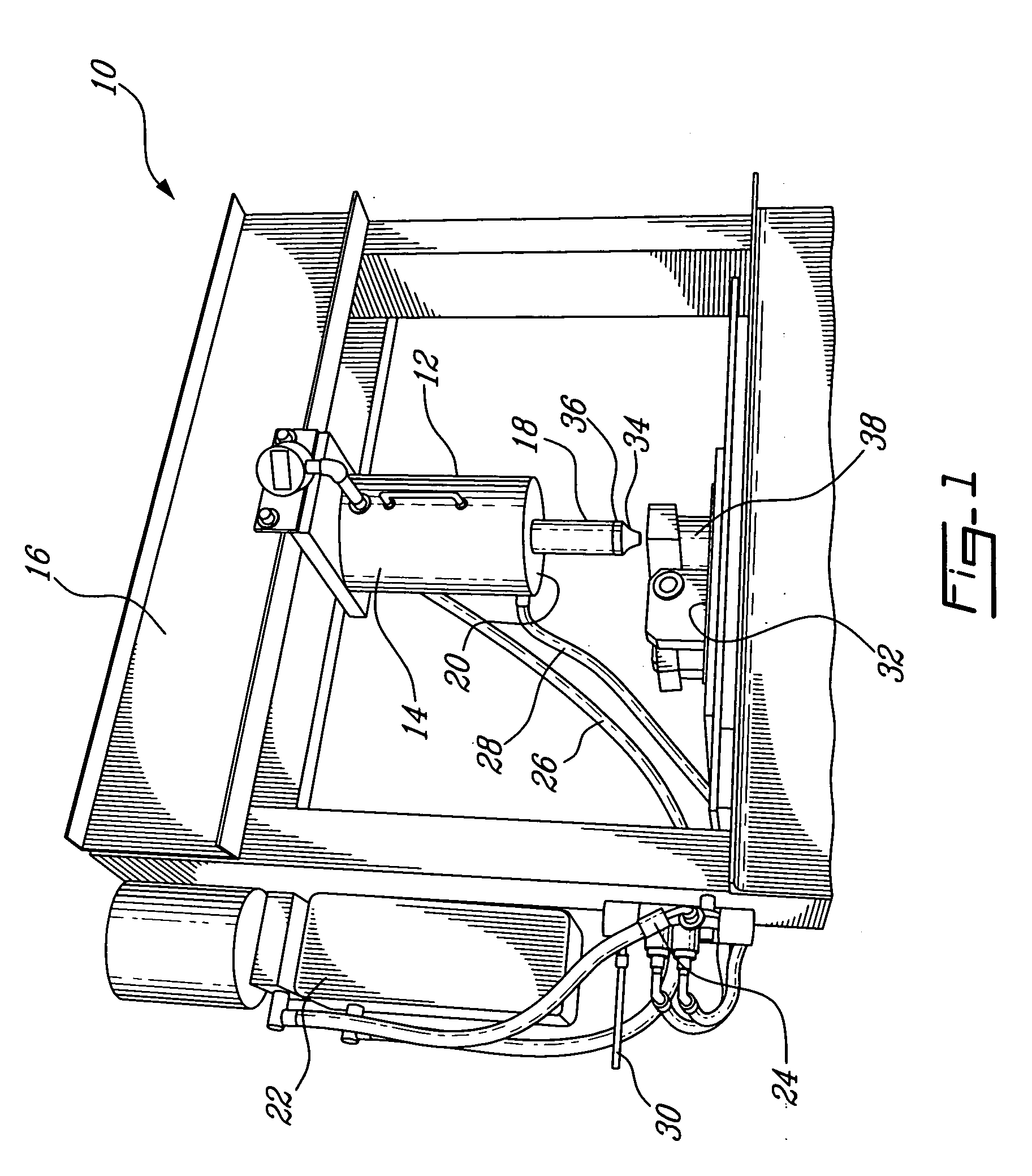

Cold spray impact deposition system and coating process

A cold spray apparatus is provided that includes a nozzle having a converging section and a diverging terminal section. A gas supply meters a majority by atomic percent helium gas to the nozzle at an incident gas temperature of less than 30° Celsius and at an incident velocity of between 2 and 6 MPa. A particulate feeder provides ductile material particulate having a mean x-y-z axially averaged linear dimension of between 0.9 and 95 microns to the nozzle. A composition is also provided that includes a substrate and a coating of ductile metal. The coating has a void density of less than 1% by volume, and an average domain size of between 0.9 and 95 microns. The coating has a compressive residual stress.

Owner:US SEC THE ARMY THE

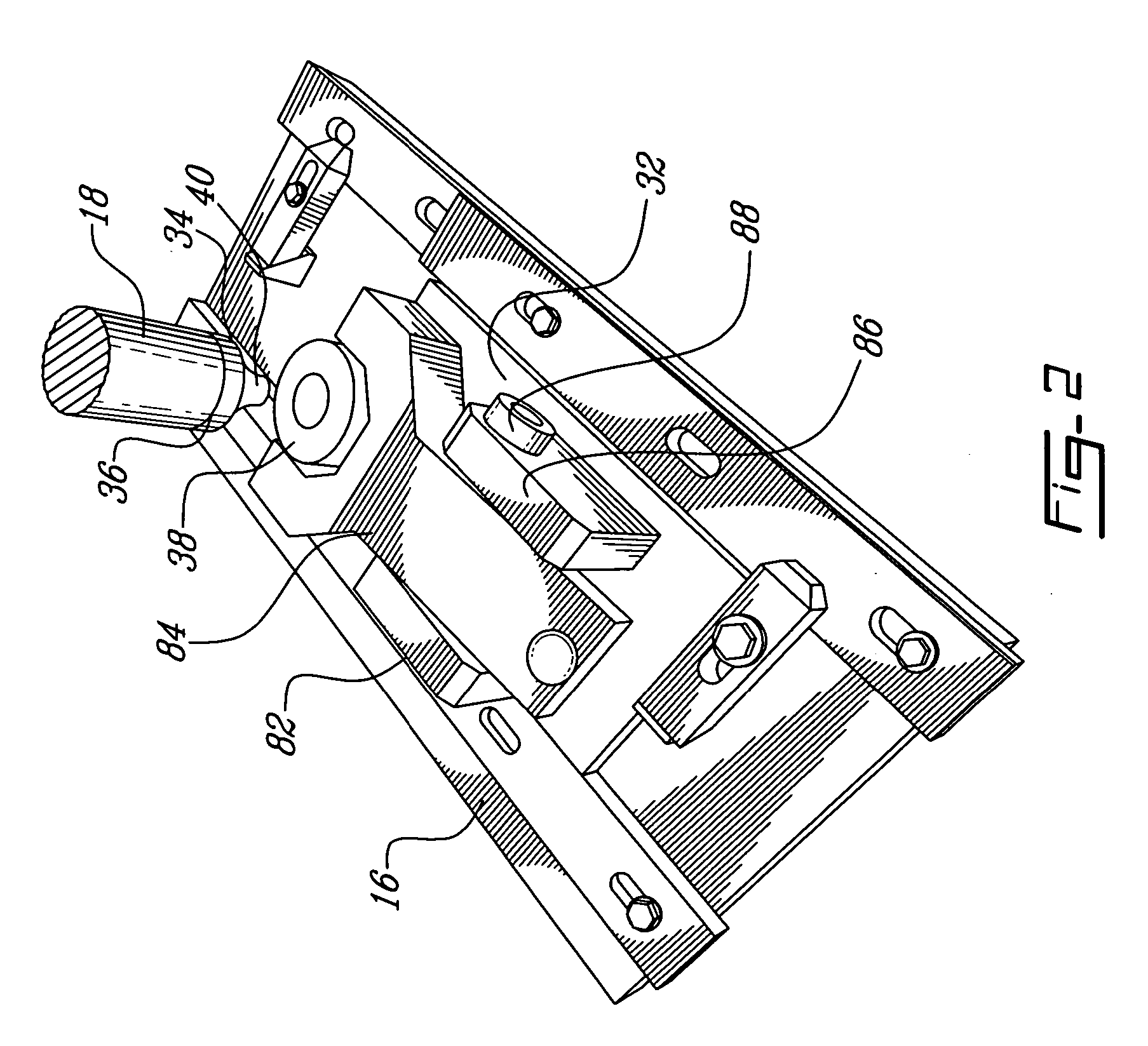

Clinching tool, die and method for use thereof

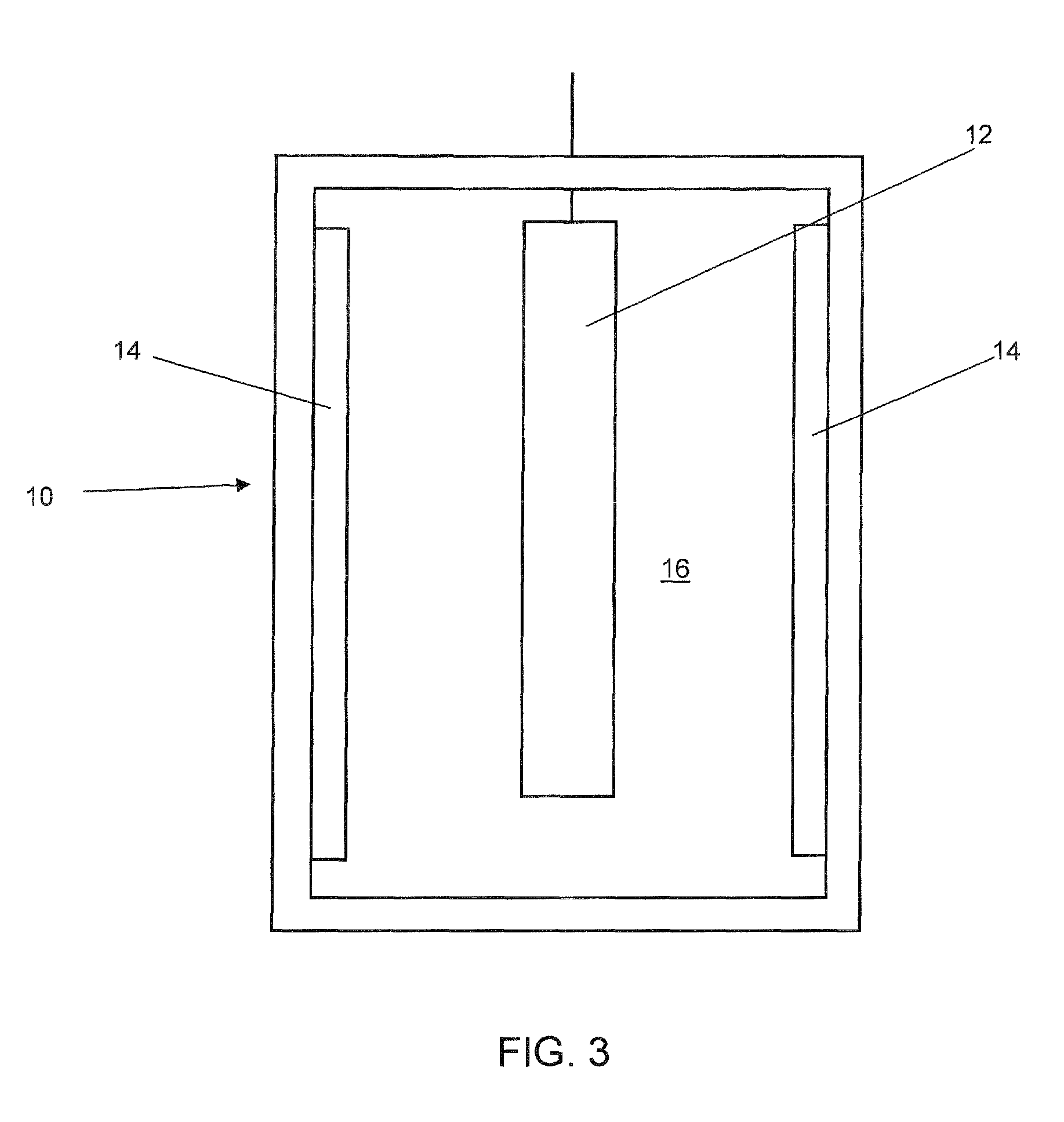

InactiveUS20060096075A1Large fixed membersMetal working apparatusMechanical engineeringDuctile materials

A clinching tool for mechanically interconnecting at least two stacked sheets manufactured of a ductile material comprises a punch and a die axially aligned thereto. The die cavity features a radiused surface profile at its closed end thus facilitating material flow therein during clinching action. This design, while minimizing tooling material stresses and reducing the likelihood of premature tooling failure, allows for clinch fastening of thicker sheets by forming a secure and distinguishable clinch.

Owner:FALCONBRIDGE LTD

Rotary contact structures and cutting elements

Owner:DVORACHEK HAROLD A

Superalloy Component Welding at Ambient Temperature

A method for welding superalloy components at ambient temperature conditions while reducing the propensity of the superalloy material to crack as a result of the weld. A root pass region of the weld is formed using a filler material that exhibits ductility that is higher than that of the base superalloy material. The ductile material mitigates stress in the root region, thereby preventing the formation of cracks. A remaining portion of the weld is formed using a filler material that essentially matches the base superalloy material. The method may utilize a pre-weld heat treatment to grow a gamma prime precipitate phase in the superalloy material, a chill fixture to remove heat during welding, a relief cut to reduce stress in the root region, and a conventional post-weld heat treatment.

Owner:SIEMENS ENERGY INC

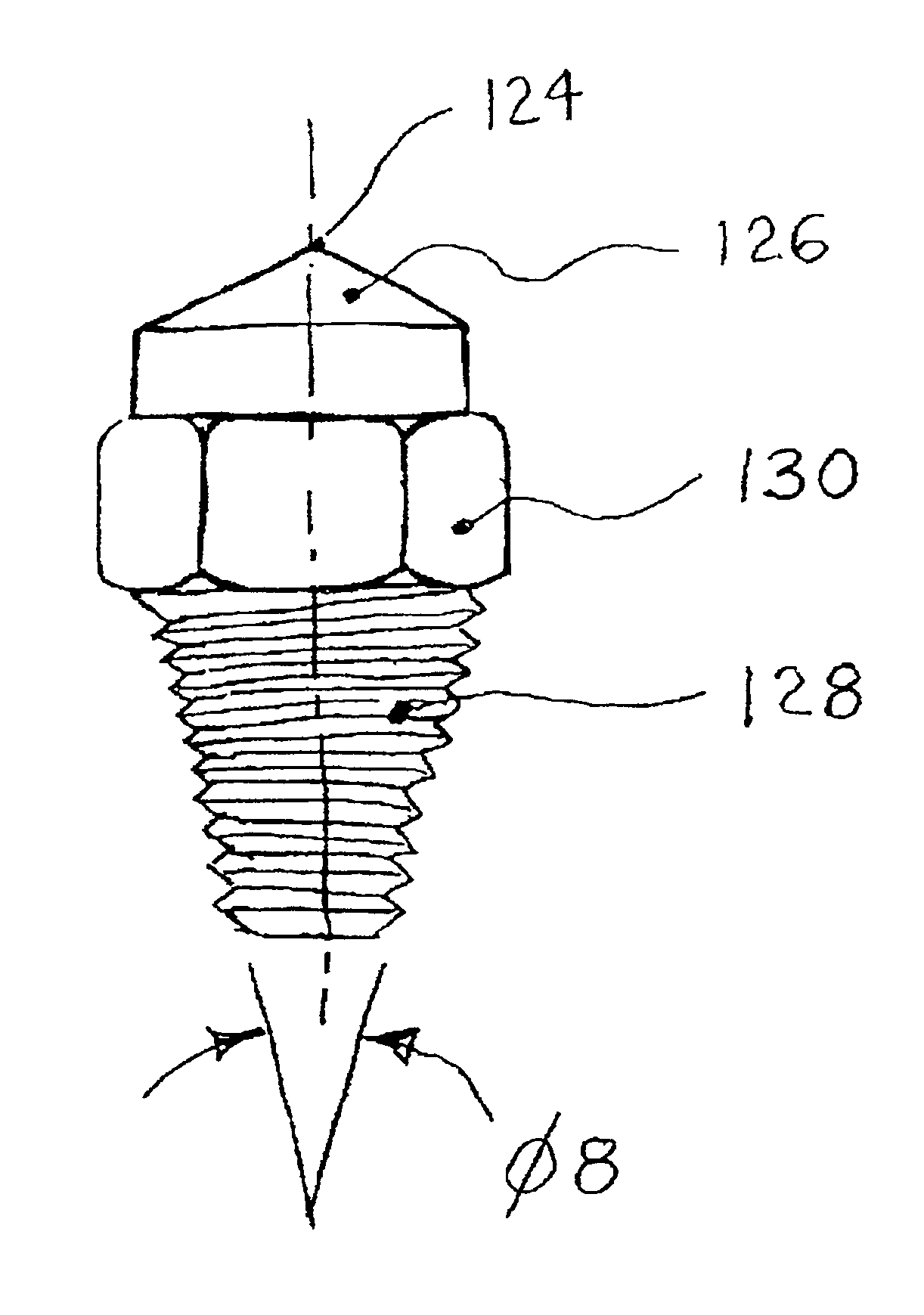

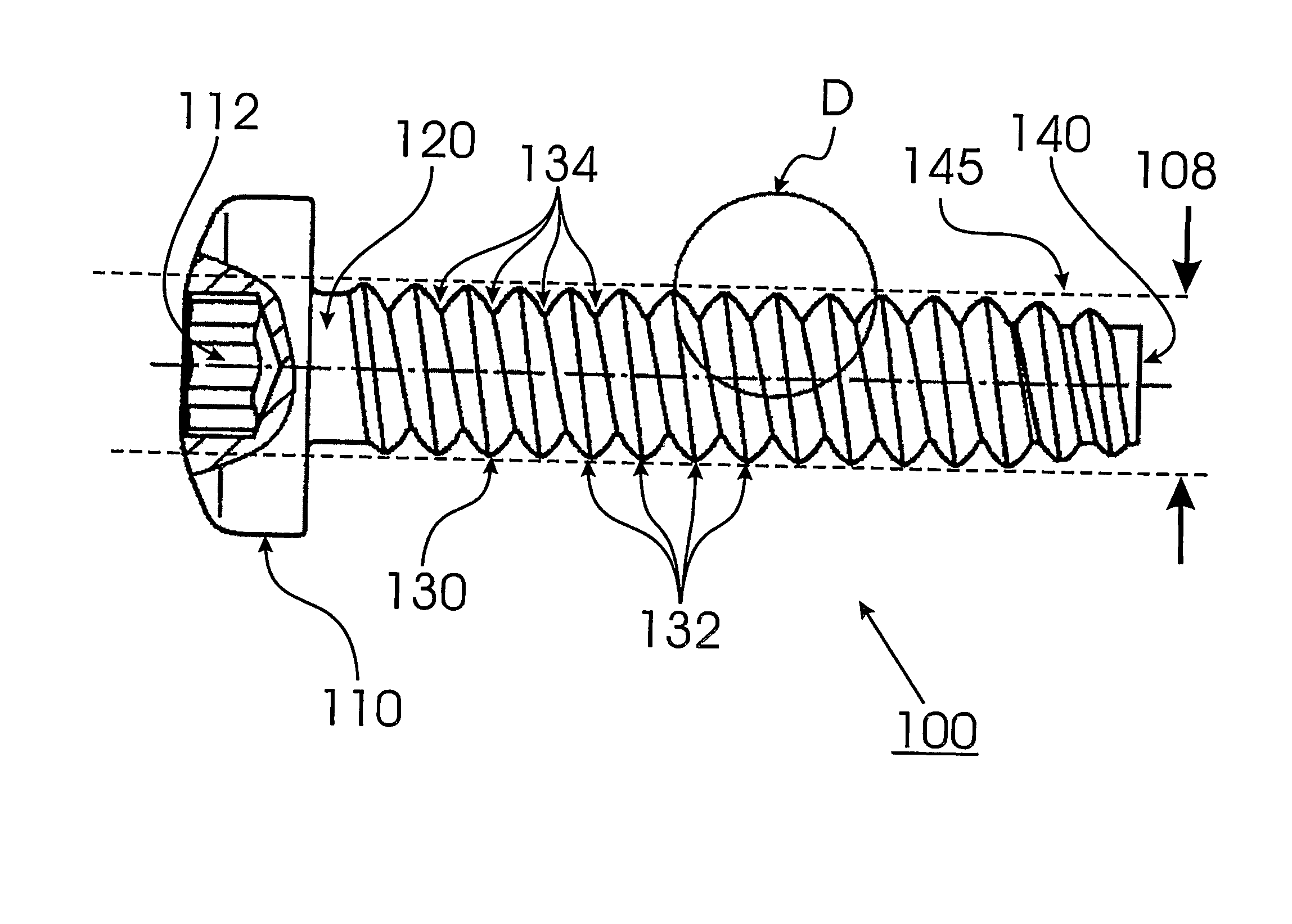

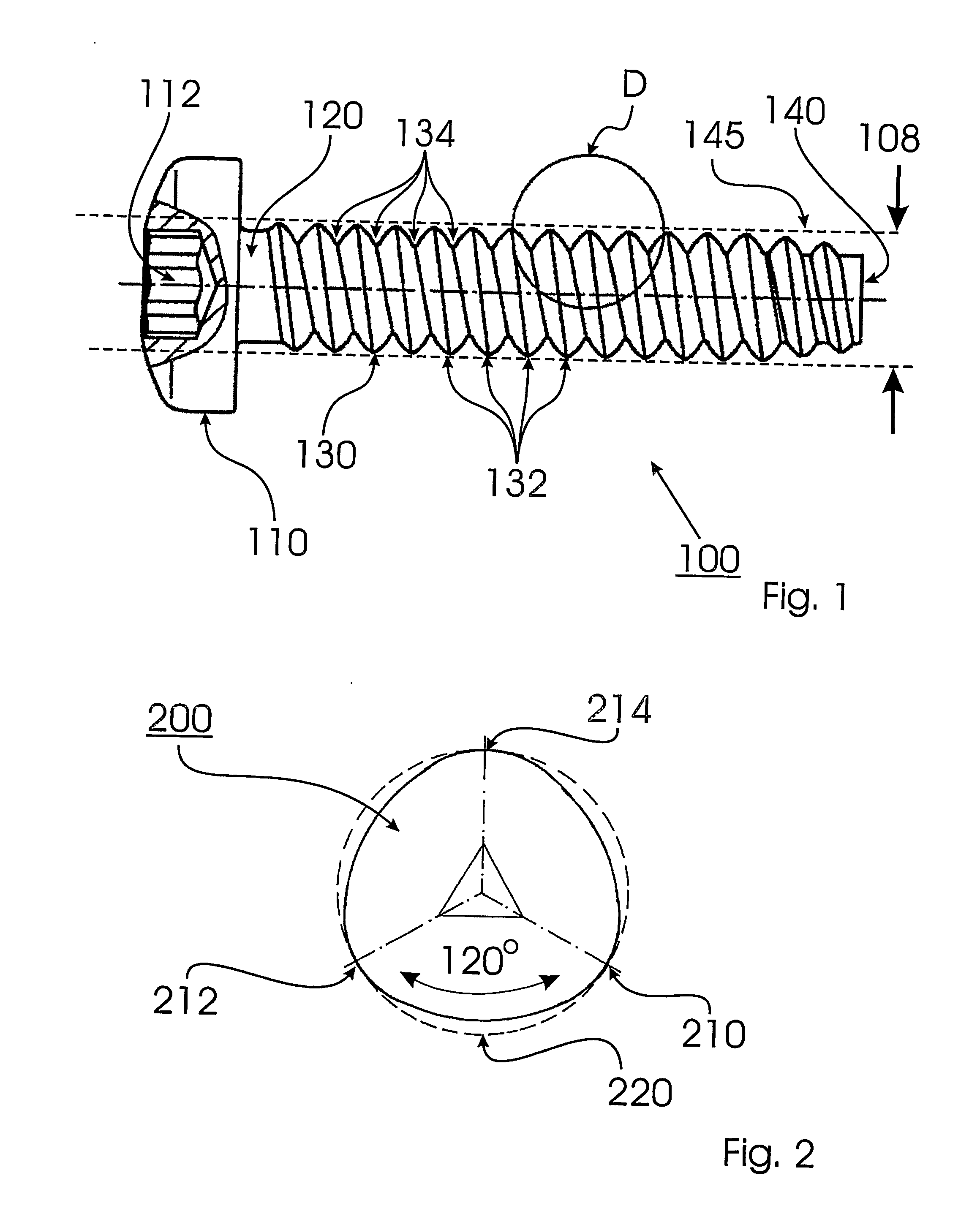

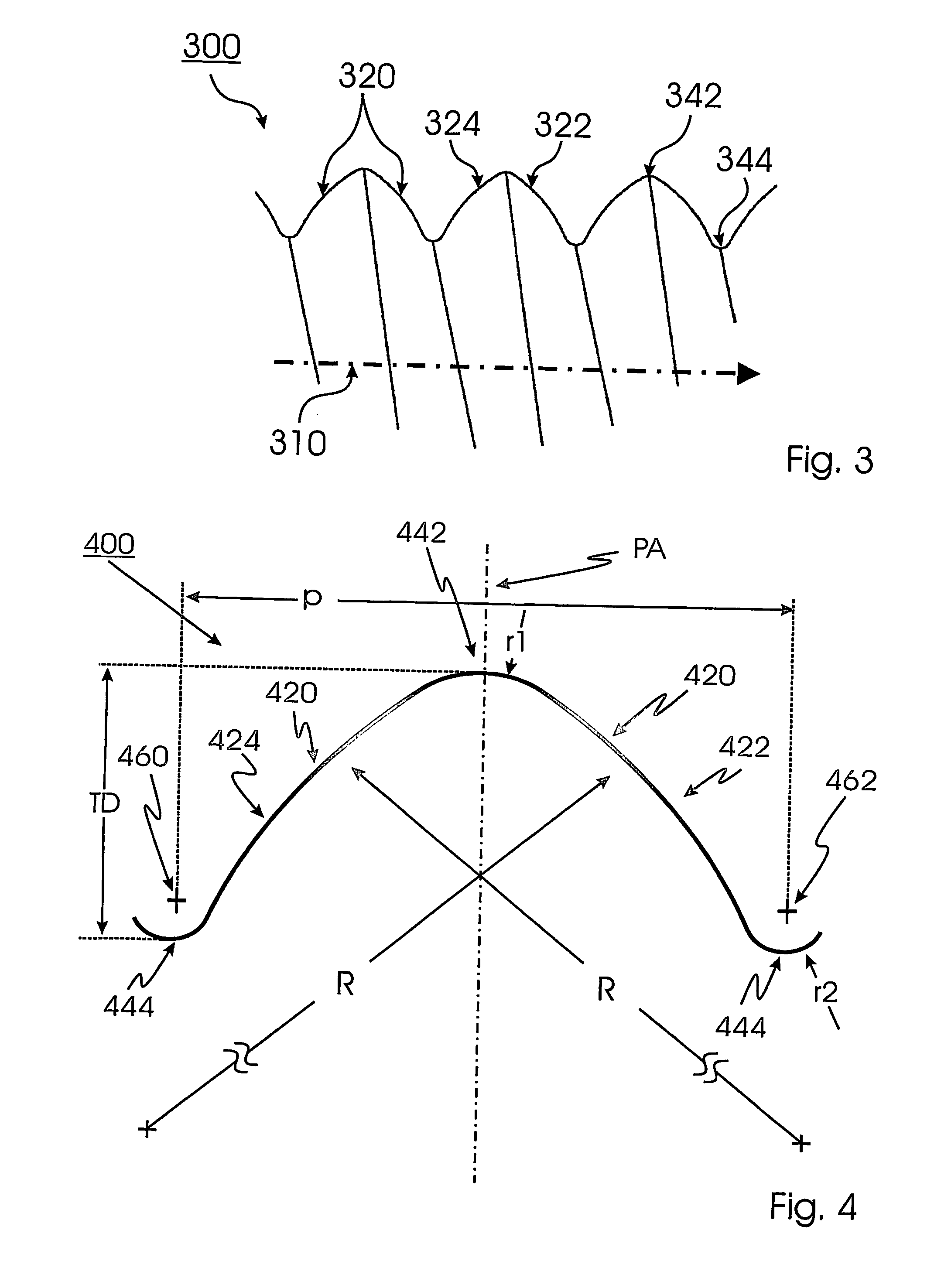

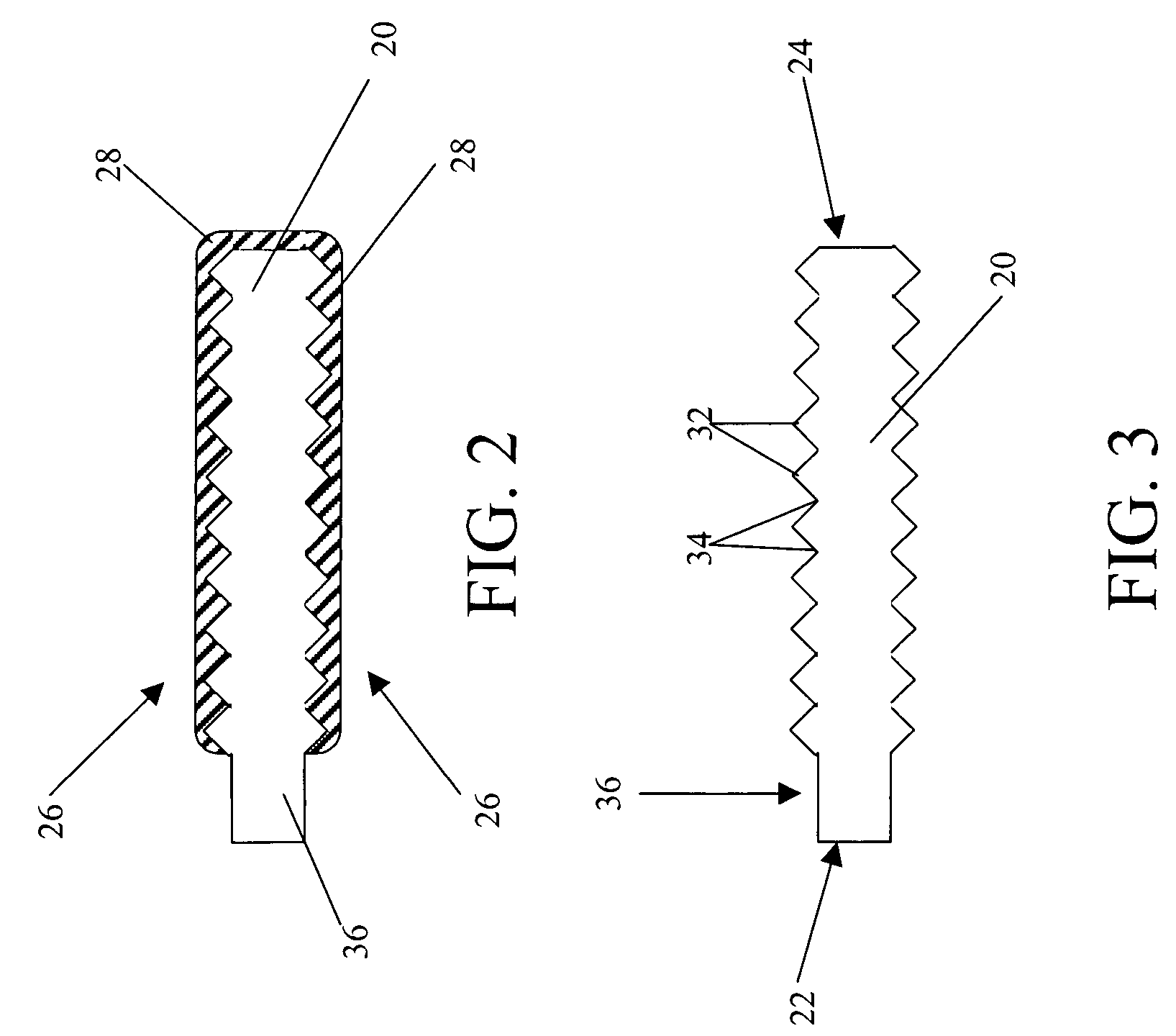

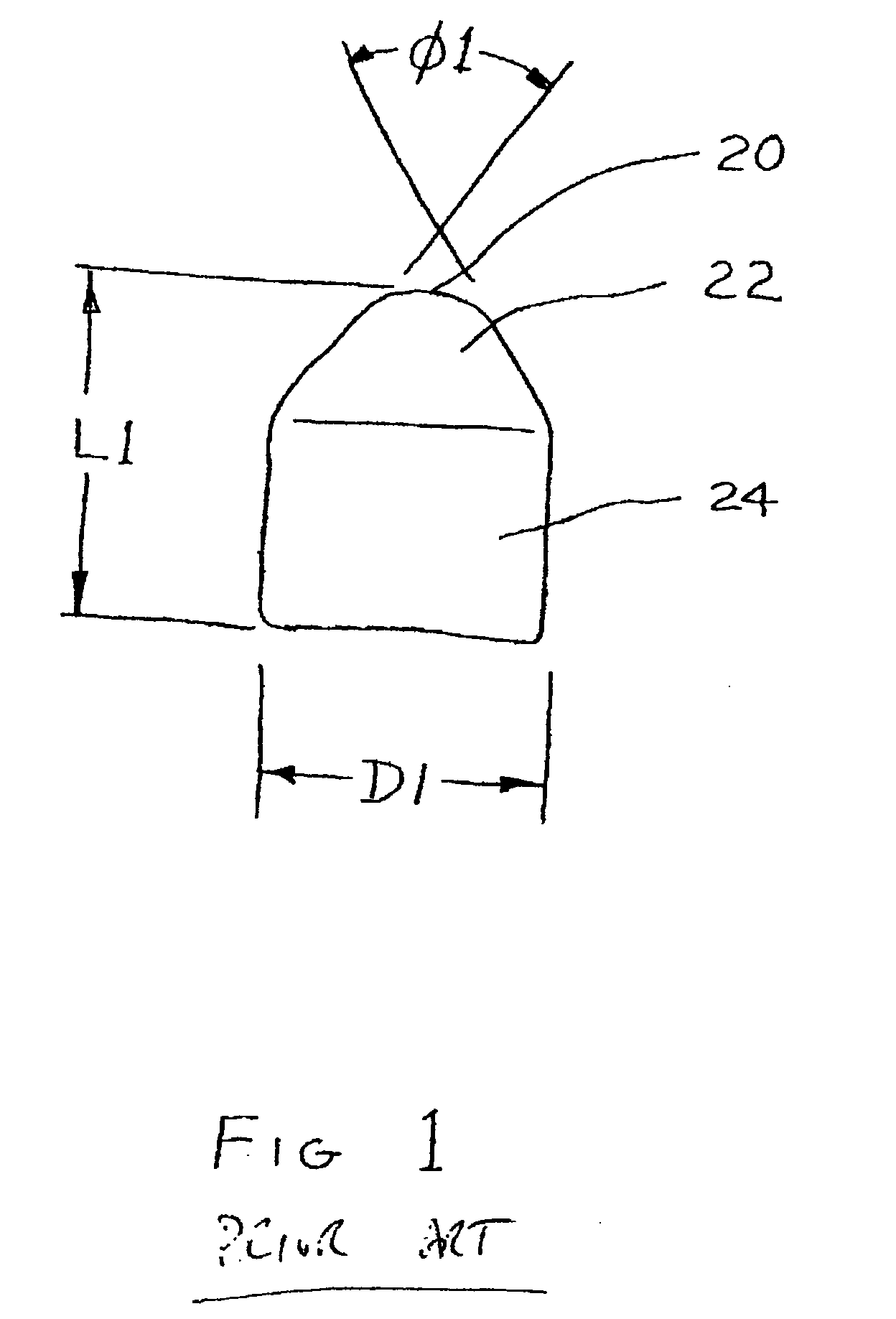

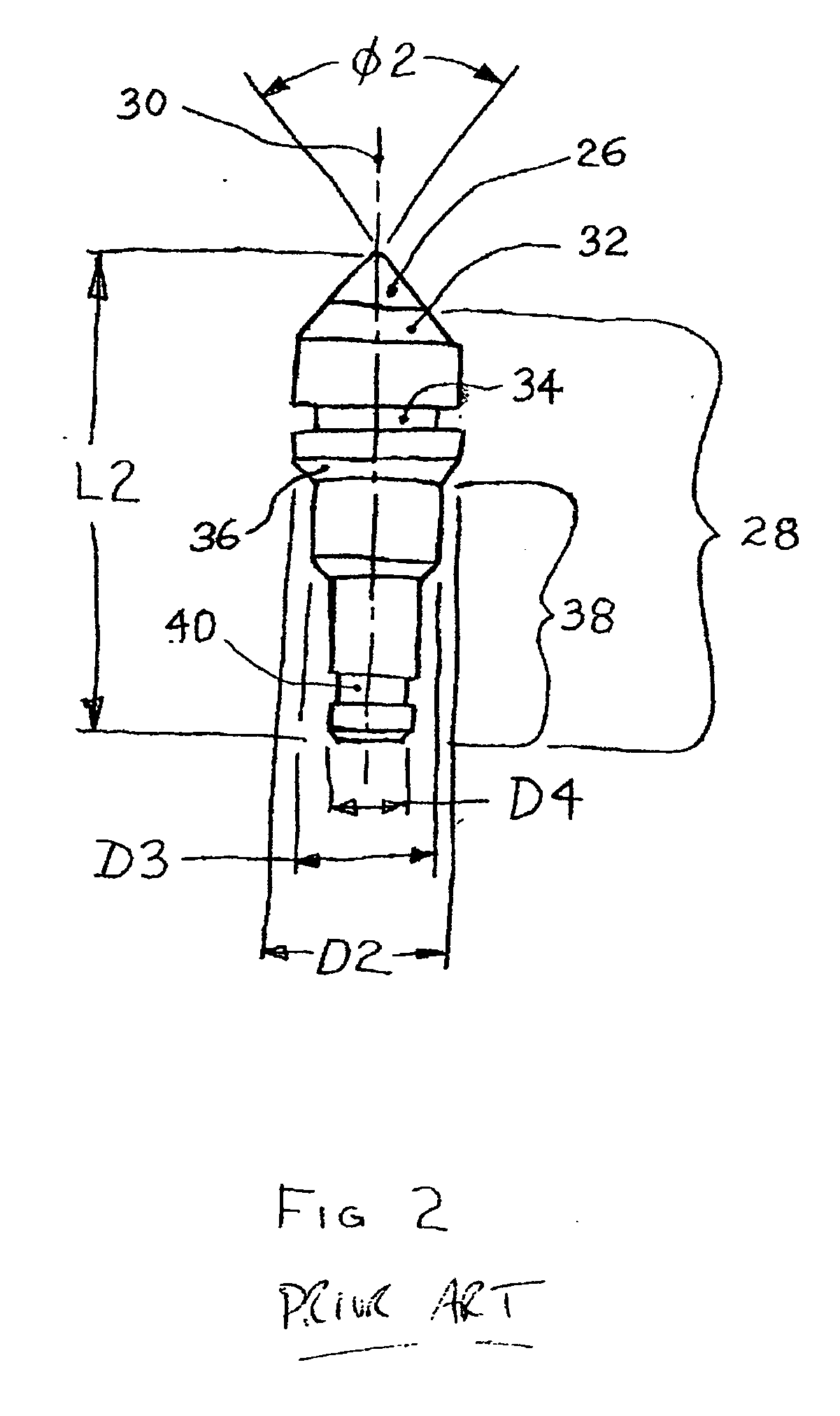

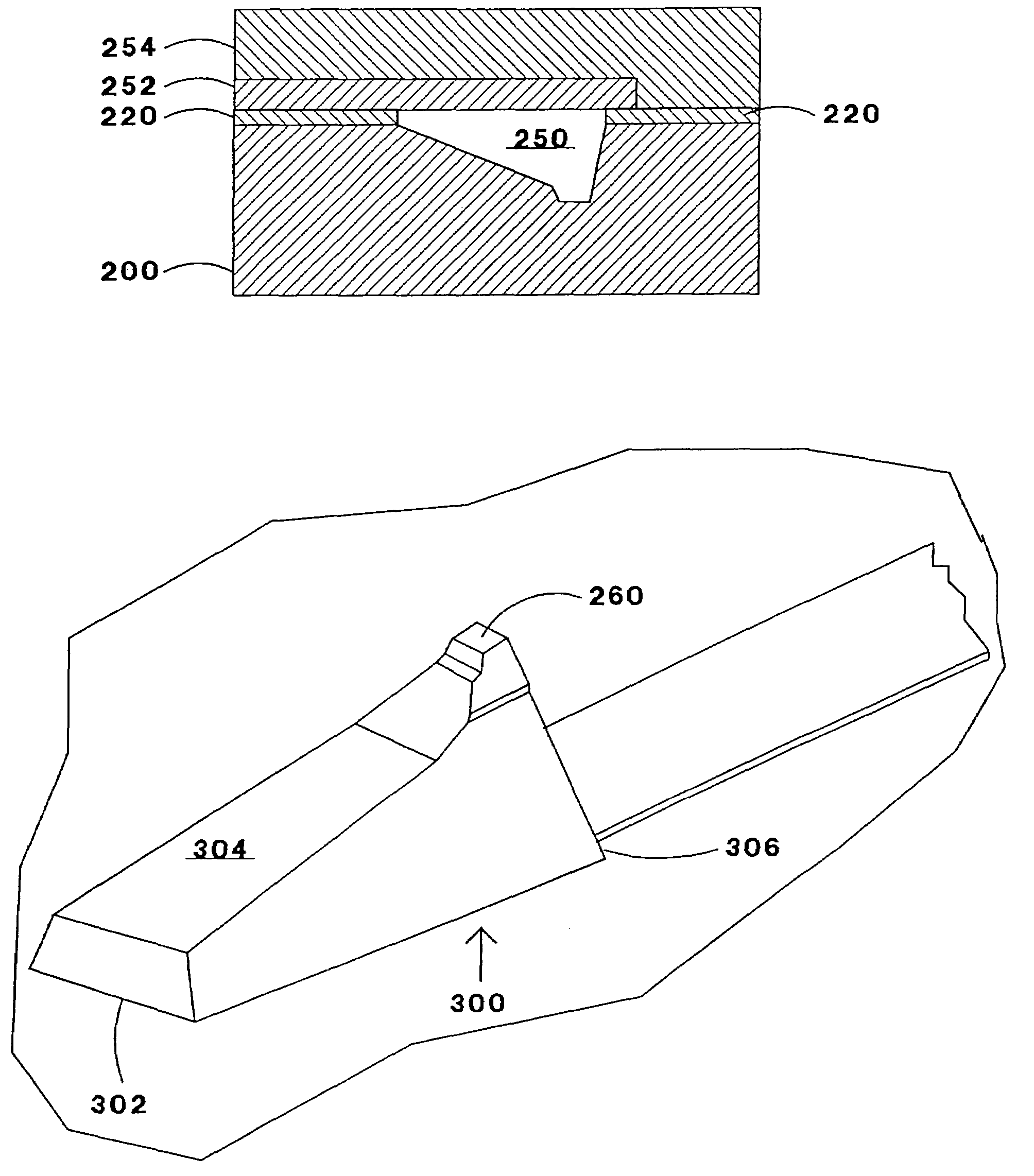

Self-tapping screw for use in low ductile materials

The present invention relates to a thread (400) in particular for a thread-rolling or self-tapping screw (100) or nut, respectively, having a non-triangular thread profile (300) with leading thread faces (422) and trailing thread faces (424) wherein at least one of said leading thread faces (422) and trailing thread faces (424) is provided with a convex curvature having a first radius (R). The tip (442) of said non-triangular thread profile (400) has also a convex curvature with a second radius (r1) wherein the value of the first radius (R) is different from the value of the second radius (r1).

Owner:CONTI FASTENERS

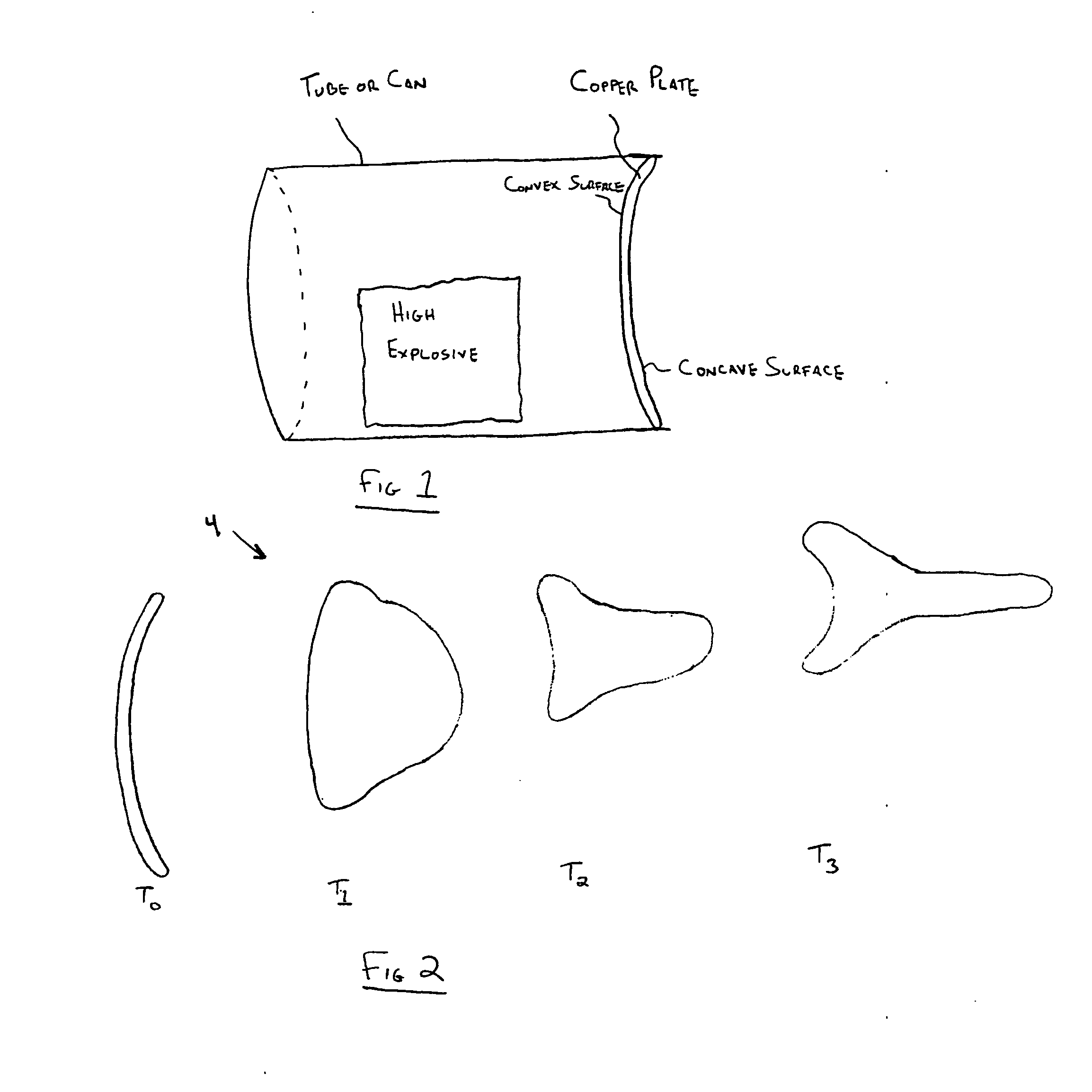

Armor protection against explosively-formed projectiles

A hybrid armor architecture is provided that is effective against explosively-formed and other high-energy ballistic projectiles. The architecture includes at least one laminate reactive armor panel including a layer of non-explosively reactive material sandwiched between outer layers of a ductile material, an armor plate disposed behind the laminate reactive armor panel, and a flyer plate disposed behind the armor plate. The flyer plate or a portion thereof is configured to move toward and impact a body panel that is being protected on impact of a high-energy ballistic projectile with the flyer plate or the portion thereof, to thereby increase the total area of impact with the body panel relative to the projectile alone.

Owner:INTPROP HLDG

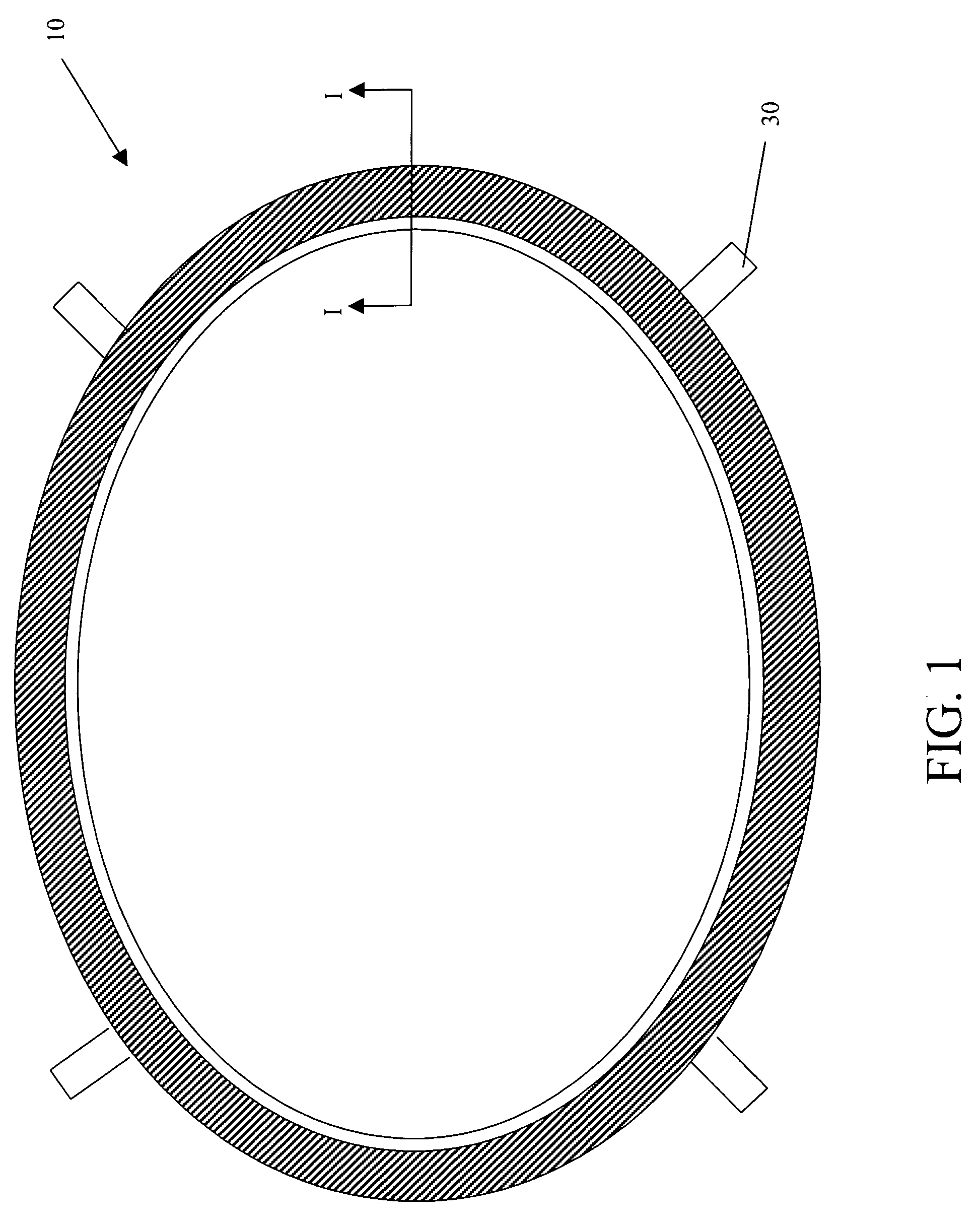

Gasket of non-rounded shape with installation aids

A gasket assembly is comprising a substantially flat annular stainless steel gasket core having two partially profiled faces and defining an aperture therethrough, said partially profiled faces comprising a radially spaced alternating peak and groove configuration defined by peak angles of approximately 90°, and four installation tabs secured to an outer periphery of said gasket core formed of a ductile material, wherein said gasket core comprises a gasketing material is disposed upon the profiled faces.

Owner:GARLOCK SEALING TECHNOLOGIES

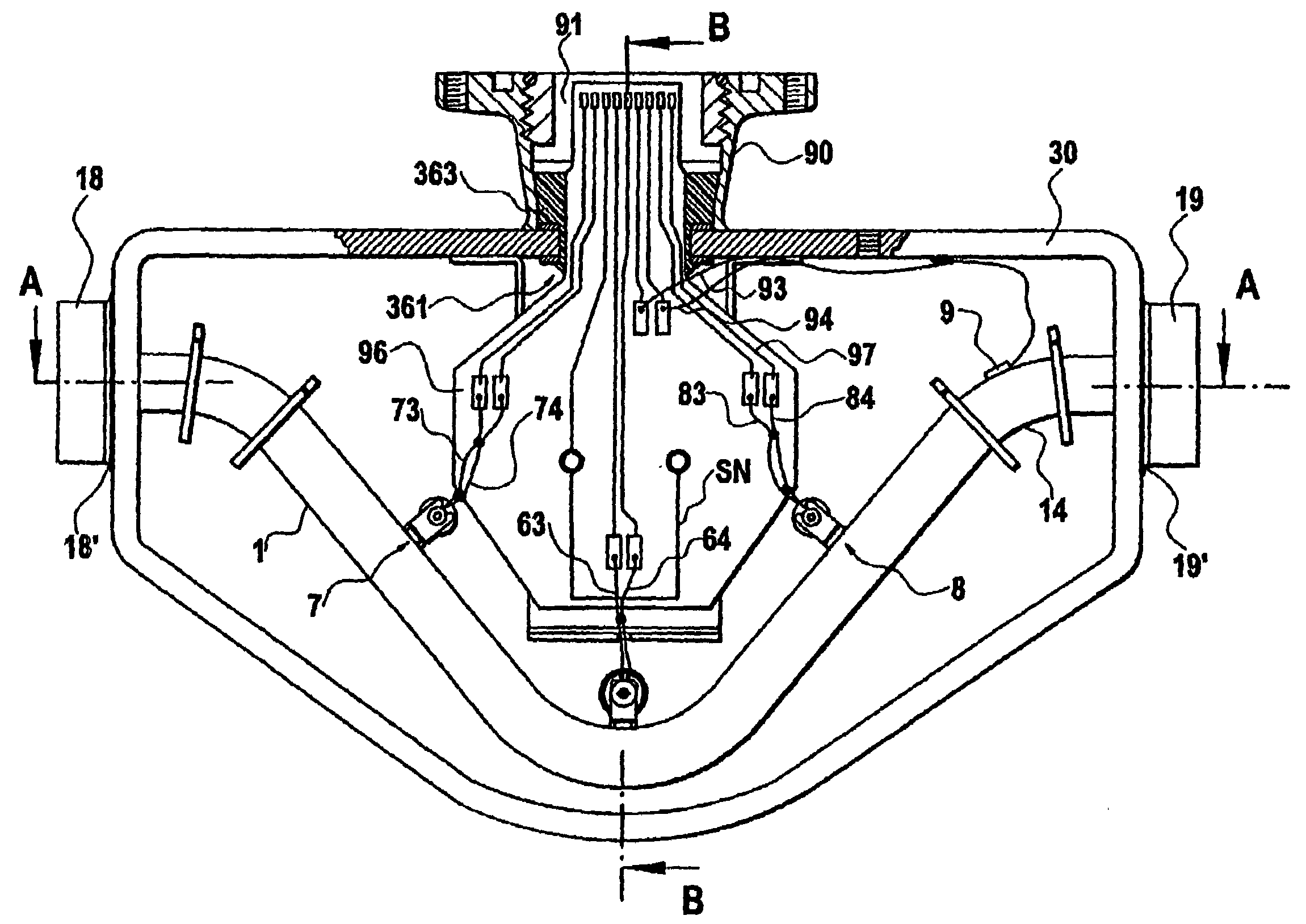

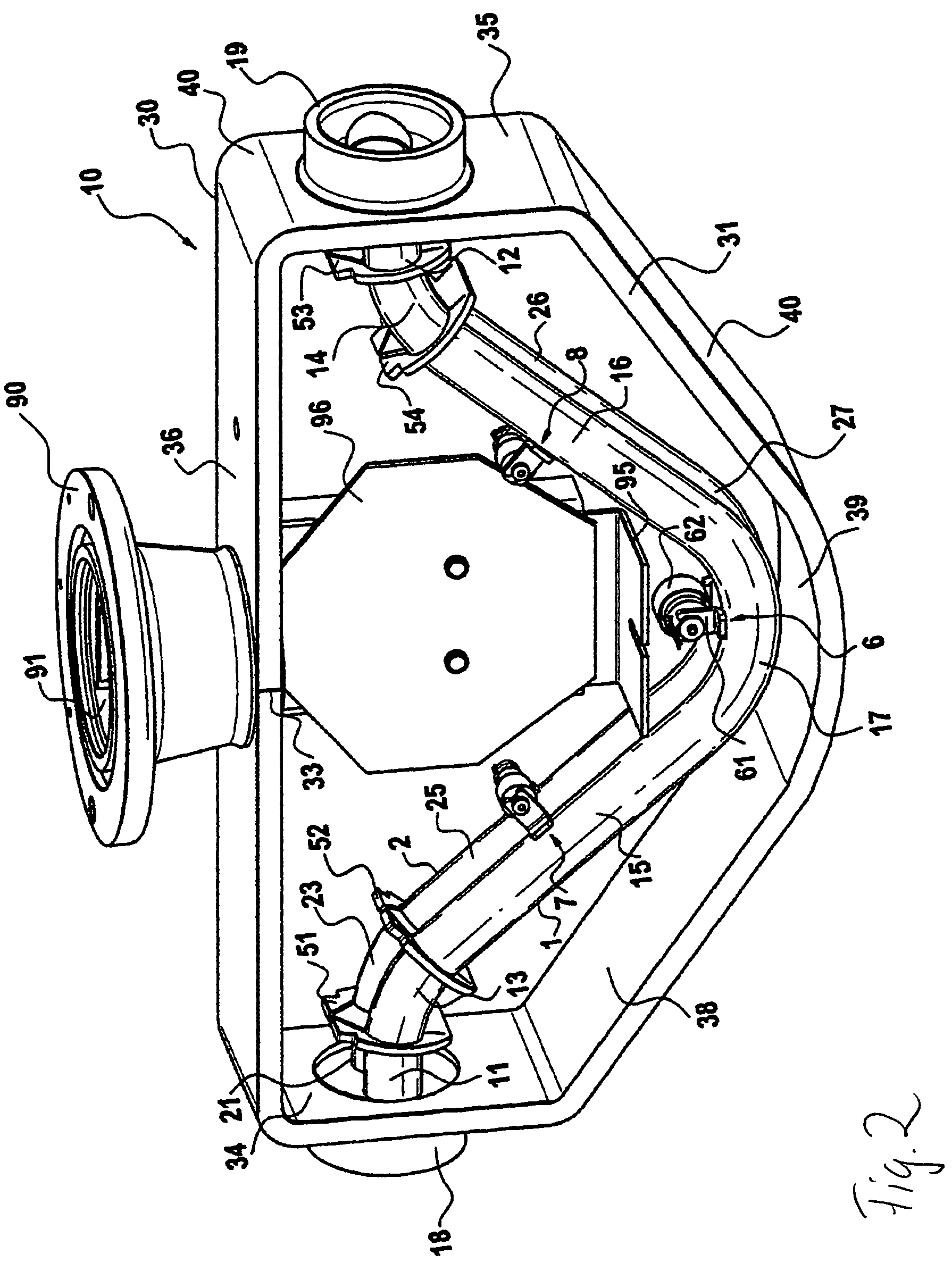

Method for adjusting a mechanical natural frequency

ActiveUS7610795B2Increase the differential pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesStatic/dynamic balance measurementInternal pressurePressure difference

A method serves to adjust a mechanical natural frequency of a hollow body which at least partly comprises a ductile material, in particular a pickup housing of a measurement pickup or a measurement pipe of a measurement pickup. A static external pressure of an atmosphere surrounding the hollow body and / or a static internal pressure prevailing in a lumen of the hollow body, the lumen being sealed off substantially in a pressuretight fashion, is varied in order to generate a pressure difference between the lumen and the atmosphere surrounding the hollow body. The pressure difference is adjusted to a value that causes the material of the hollow body to expand, and at least a proportion of the material of the hollow body is made to flow under the influence of the pressure difference for plastically deforming the material. The method can readily be integrated into already-established pressure tests for measurement pickups of the vibrational type.

Owner:ENDRESS HAUSER FLOWTEC AG

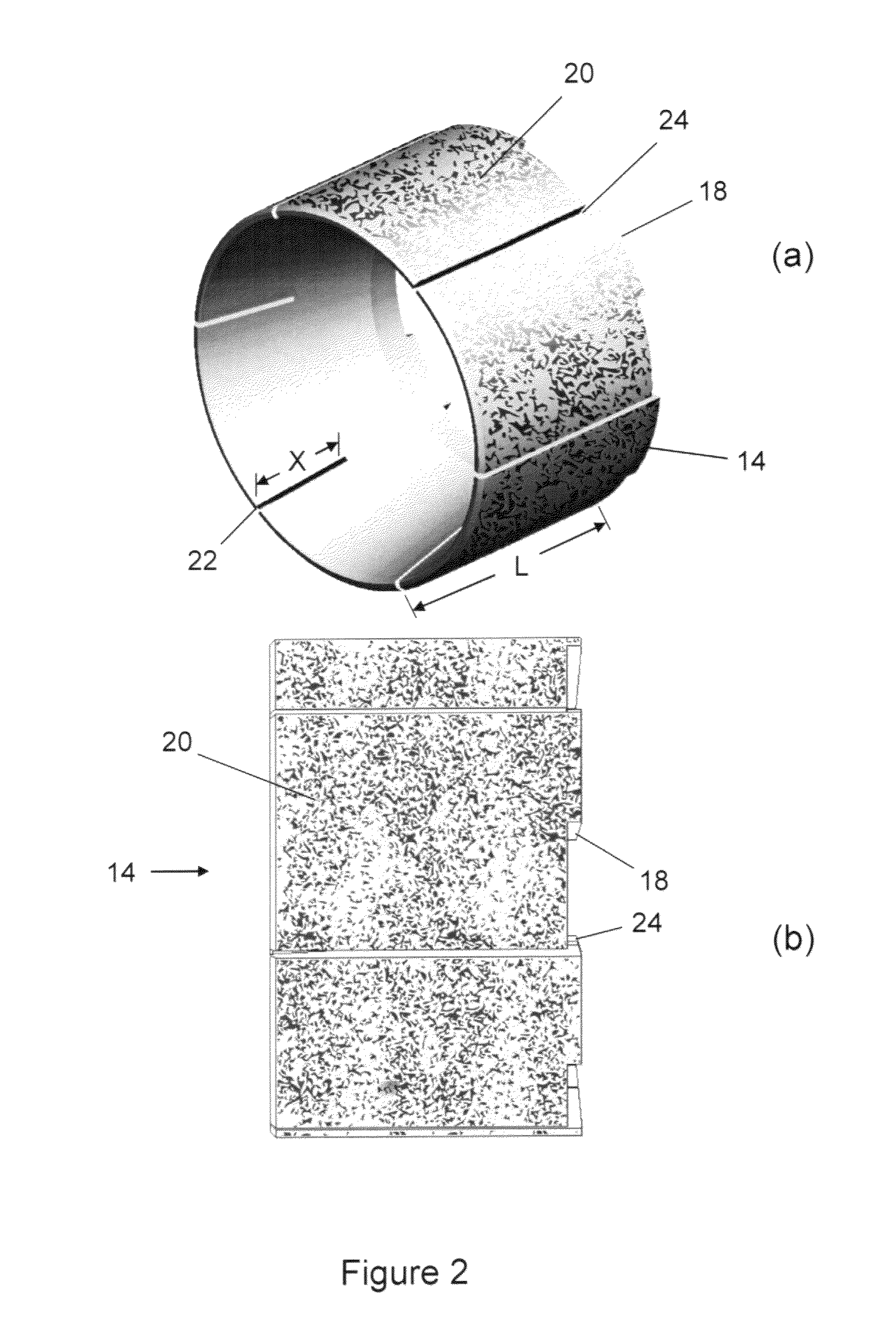

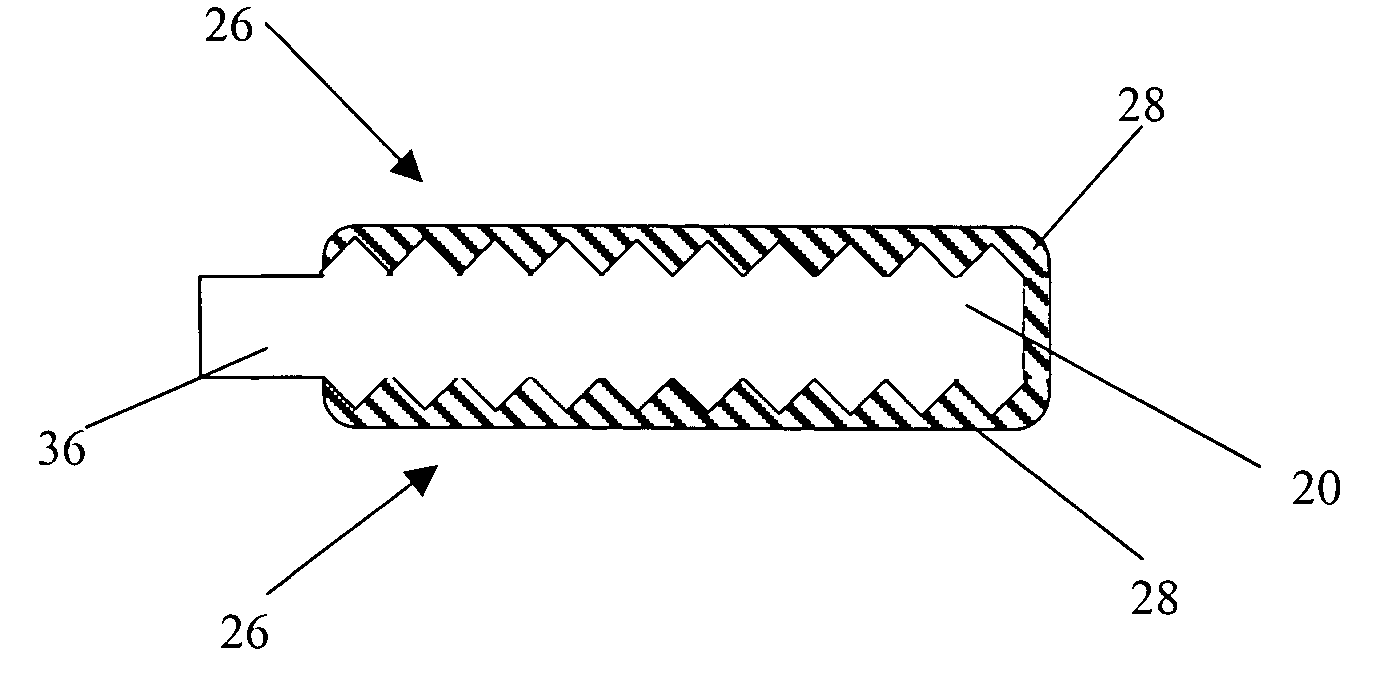

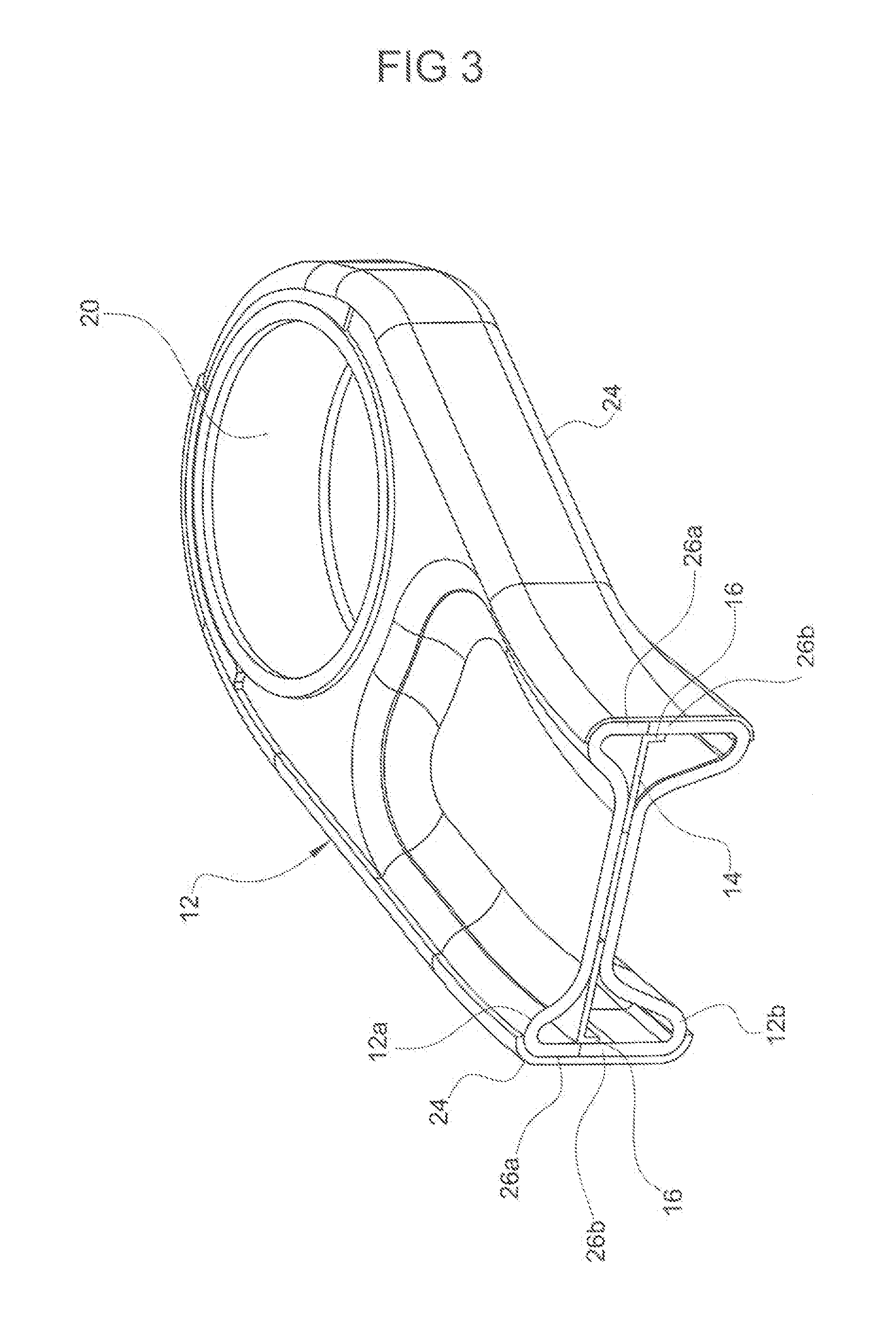

Clad Composite Stent

A body compatible stent is formed of multiple filaments arranged in at least two sets of oppositely directed helical windings interwoven with one another in a braided configuration. Each of the filaments is a composite including a central core and a case surrounding the core. In the more preferred version, the core is formed of a radiopaque and relatively ductile material, e.g. tantalum or platinum. The outer case is formed of a relatively resilient material, e.g. a cobalt / chromium based alloy. Favorable mechanical characteristics of the stent are determined by the case, while the core enables in vivo imaging of the stent. The composite filaments are formed by a drawn filled tubing process in which the core is inserted into a tubular case of a diameter substantially more than the intended final filament diameter. The composite filament is cold-worked in several steps to reduce its diameter, and annealed between successive cold working steps. After the final cold working step, the composite filament is formed into the desired shape and age hardened. Alternative composite filaments employ an intermediate barrier layer between the case and core, a biocompatible cover layer surrounding the case, and a radiopaque case surrounding a structural core.

Owner:BOSTON SCI SCIMED INC

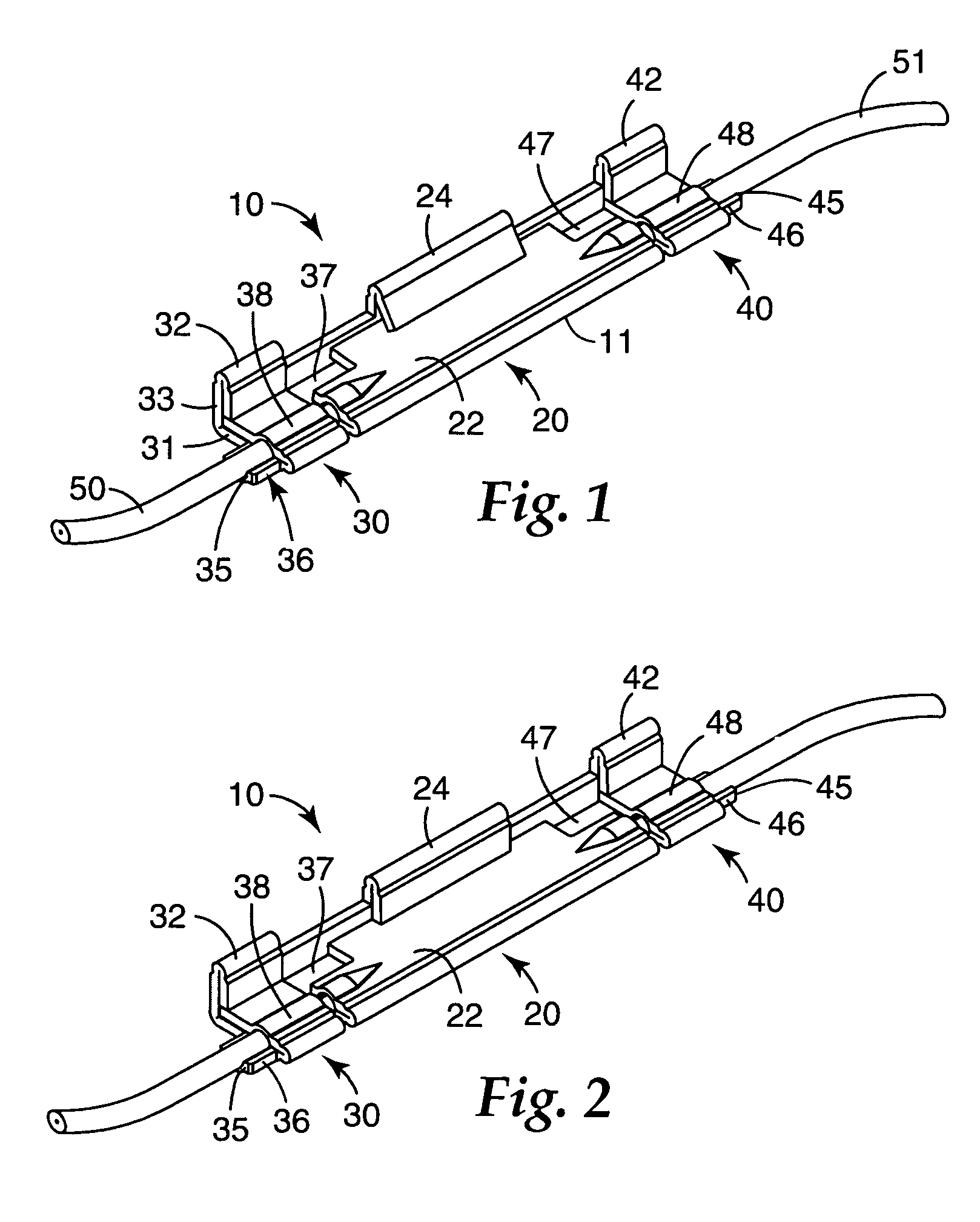

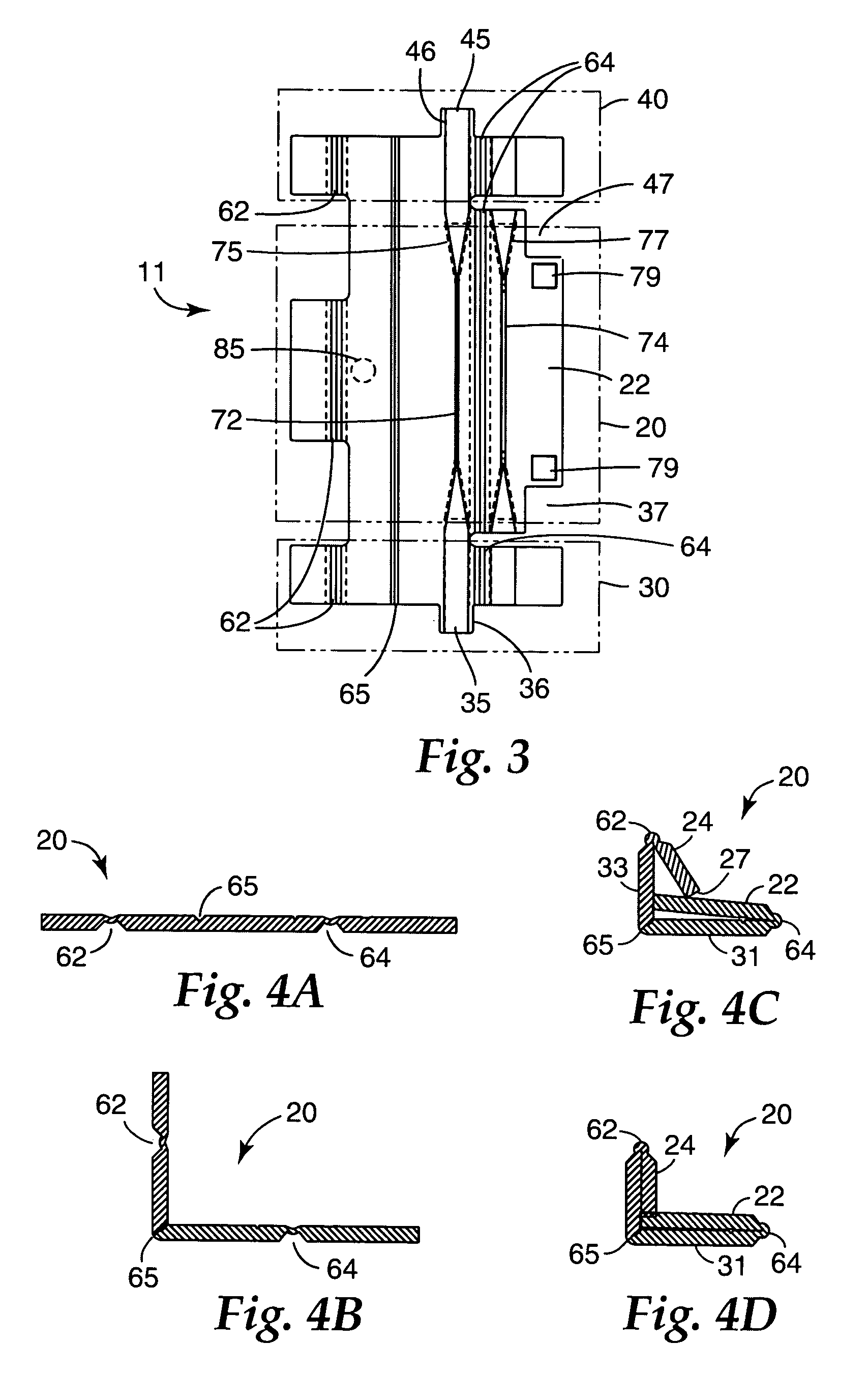

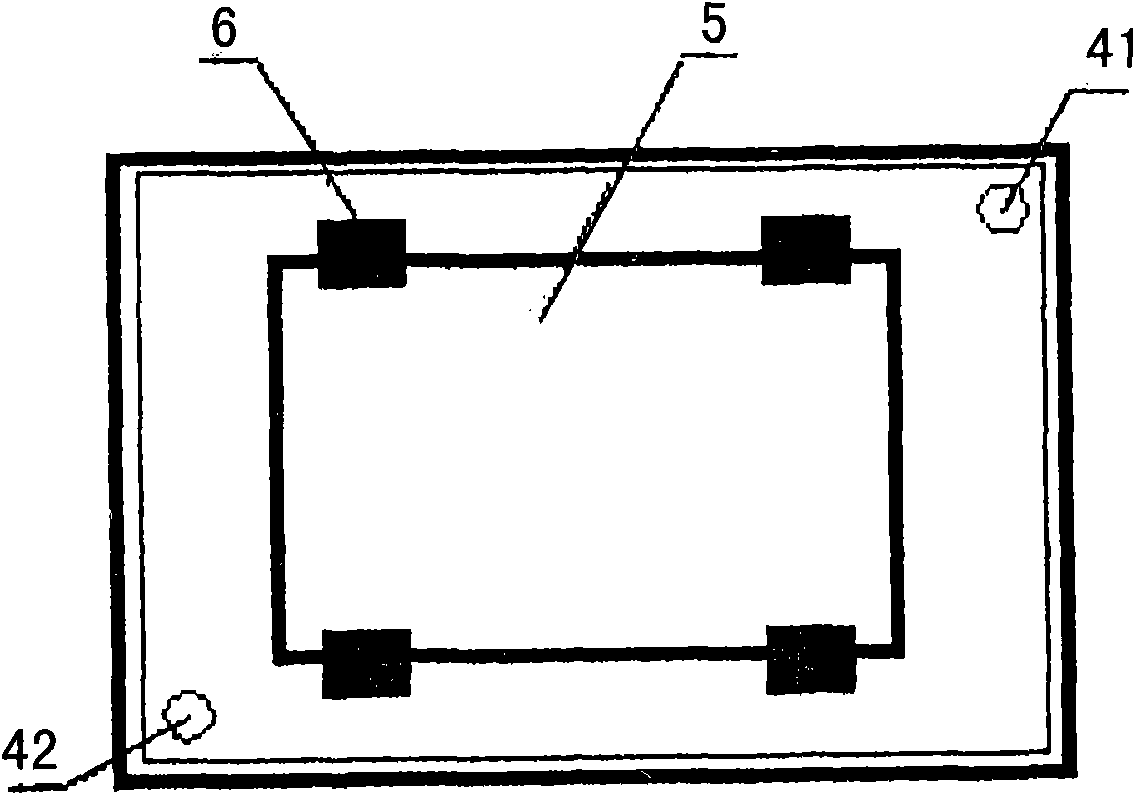

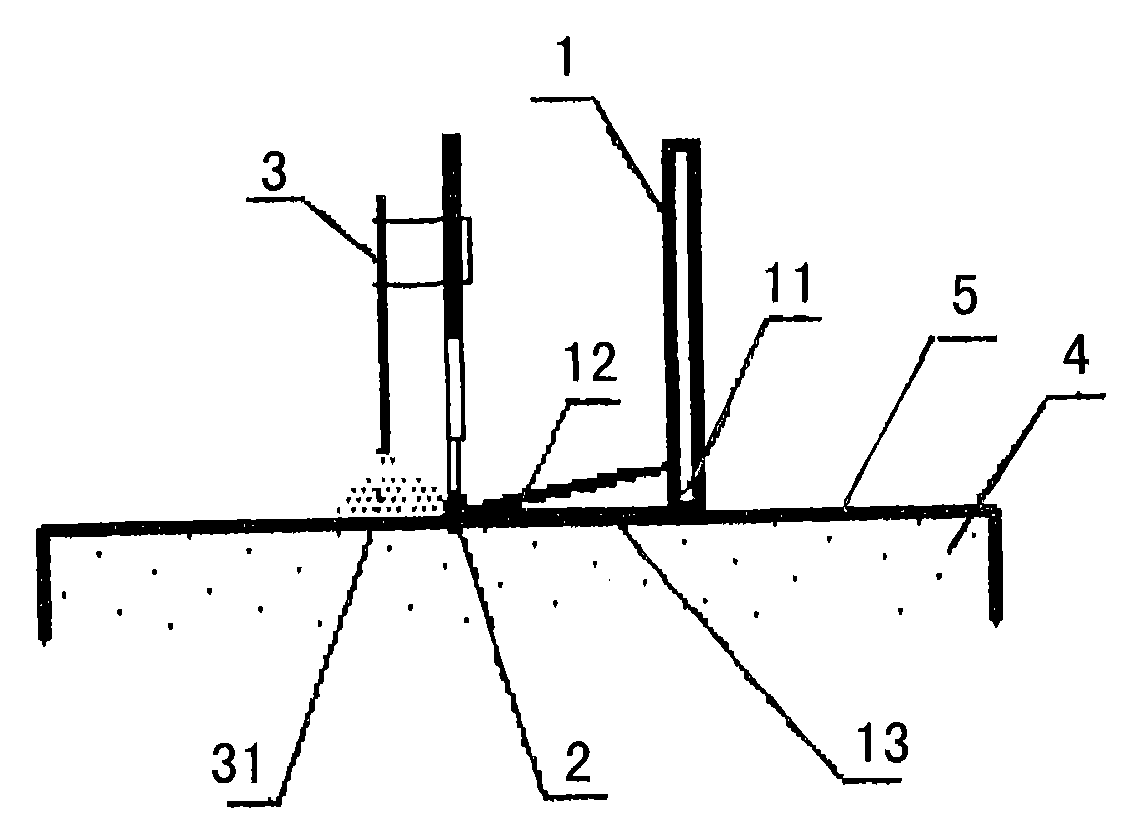

Fiber splice device

A fiber splice device includes a body comprising a ductile material. First and second end port sections located on opposite ends of the body are provided and are adapted to receive first and second optical fibers, respectively. The splice device further includes a fiber splicing section, adapted to house a fiber splice, located on the body between the end port sections. The fiber splicing section includes a fiber splice actuation section having a self-locking mechanism integral with the body. The splice device can be used in a variety of locations, such as in the access and metro areas of the fiber optic network, and it is not damaged easily.

Owner:3M INNOVATIVE PROPERTIES CO

Method for manufacturing high-chromium alloy overlaying composite abrasion resistant plate

The invention discloses a method for manufacturing a high-chromium alloy overlaying composite abrasion resistant plate and relates to an abrasion resistant plate technology. The front of a contact tube of a self-protecting flux-cored wire is provided with a powder feeding device; while swinging and overlaying, the self-protecting flux-cored wire, a spray cooling device and a scraping plate synchronously swing; when visible arc swing overlaying is carried out, the spray cooling device sprays cooling water, a powder feeding pipe conveys alloy powder out, and the alloy powder is uniformly distributed on the upper surface of the abrasion resistant base plate by the scraping plate; and the self-protecting flux-cored wire is mixed with the alloy powder, the ratio of the mass of the alloy powder to the mass of the welding wire is larger than 0.8, the mixture is distributed on the surface of the abrasion resistant base plate by visible arc overlaying to form an abrasion resistant layer, thus the composite abrasion resistant plate is obtained. The method of the invention has simplicity, easy operation, low cost, good water-cooling effect, guarantee of oriented growth of carbide and even as well as fine cracks, and the product has dual performances of a high-hardness material and a ductile material and long service life.

Owner:CHINA JINGYE ENG TECH CO LTD +1

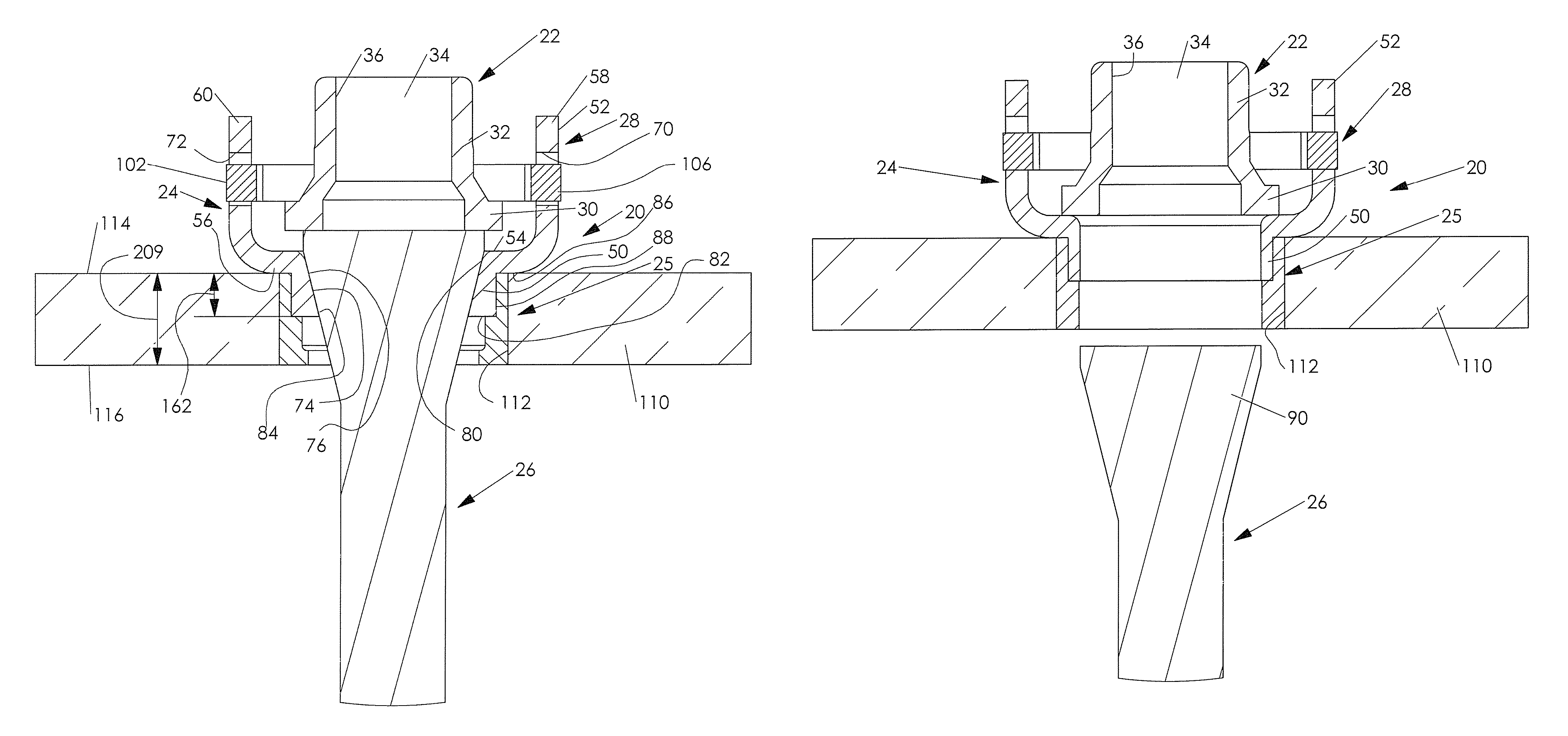

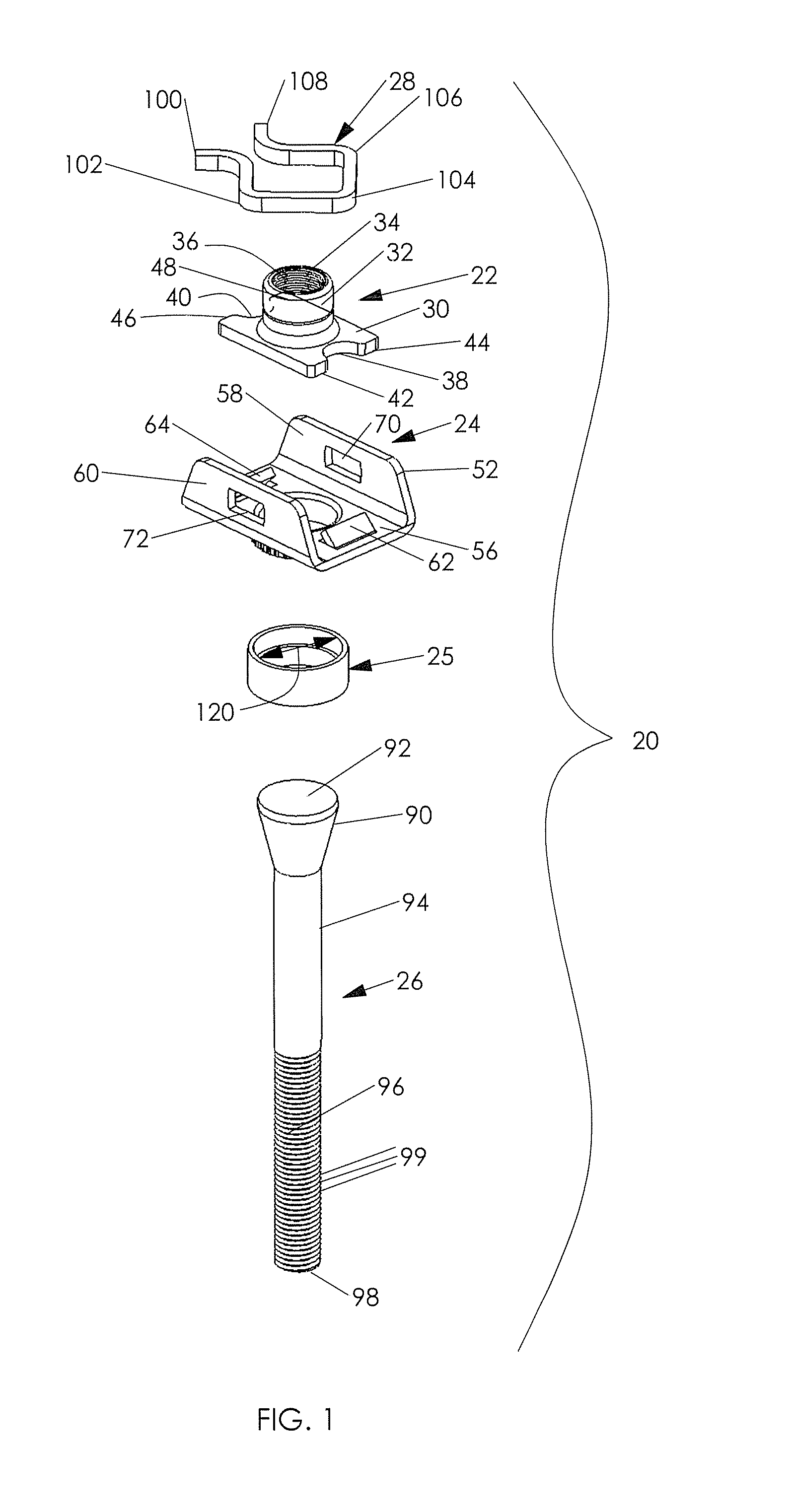

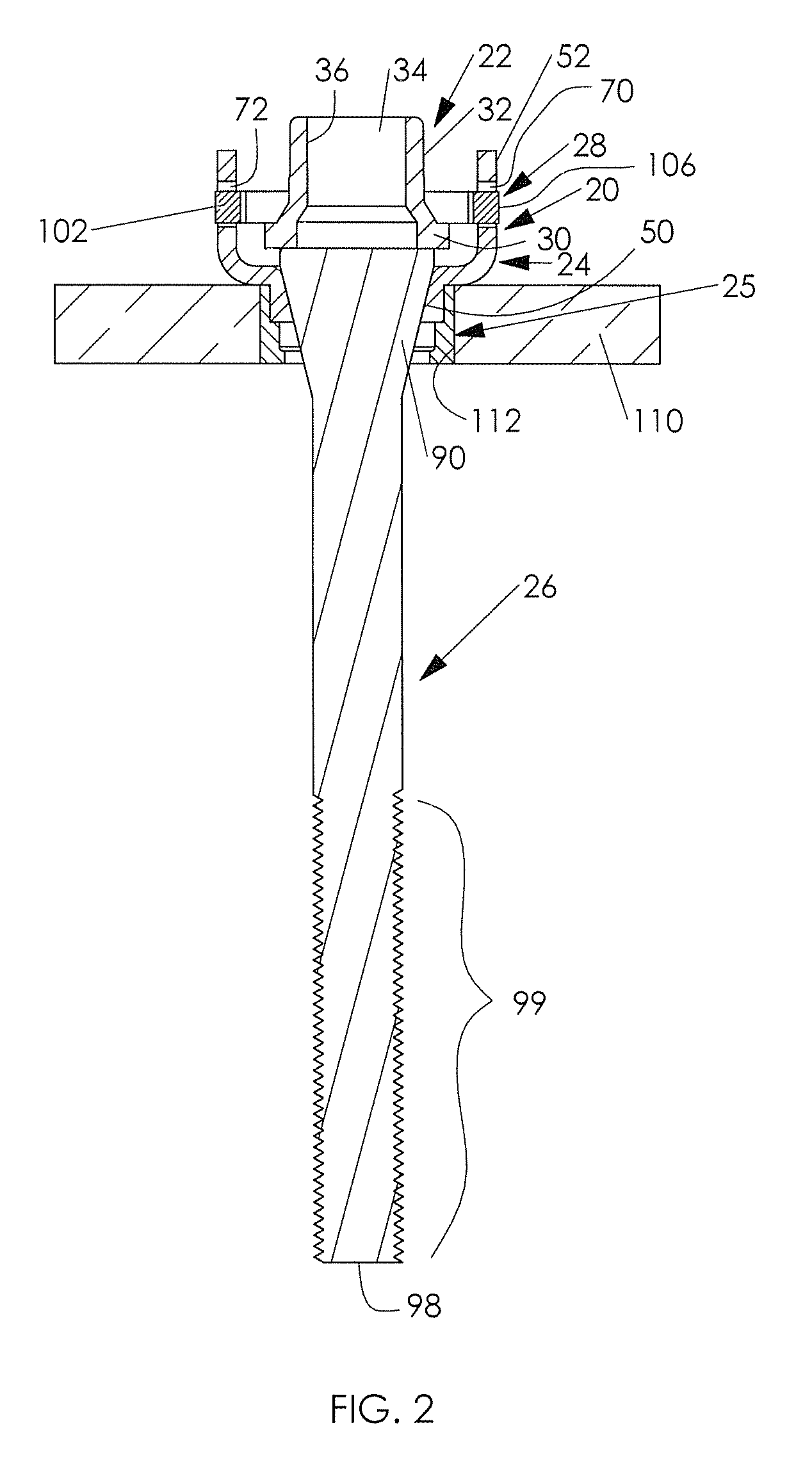

Nut plate fastener assembly for composite materials

InactiveUS7575404B2Without risking delaminationSo as not to damageRivetsNutsMetallic materialsEngineering

A rivetless nut plate assembly, which is fully preassembled, which can be installed into an aperture of a composite material workpiece, such as a carbon fiber structure, without risking delamination of the workpiece. The rivetless nut plate assembly includes a nut, a holding bracket, a retainer, and a sleeve member. Additionally, a stem is used to install the rivetless nut plate assembly. The sleeve member is configured such that the nut plate assembly can be installed in a composite material workpiece without risking delamination. The sleeve member may be formed of 45Cb-55Ti Titanium Columbium, as Titanium Columbium is a high strength and ductile material that resists corrosion in the presence of, for example, a carbon fiber composite structure. Monel, Titanium alloys, and other soft Nickel alloys are also good material selections for the sleeve, for similar reasons. Non-metallic materials with high tensile and shear strengths, such as Torlon or Parmax, would provide the desired corrosion protection and also offer a potential weight savings.

Owner:SPS TECH LLC

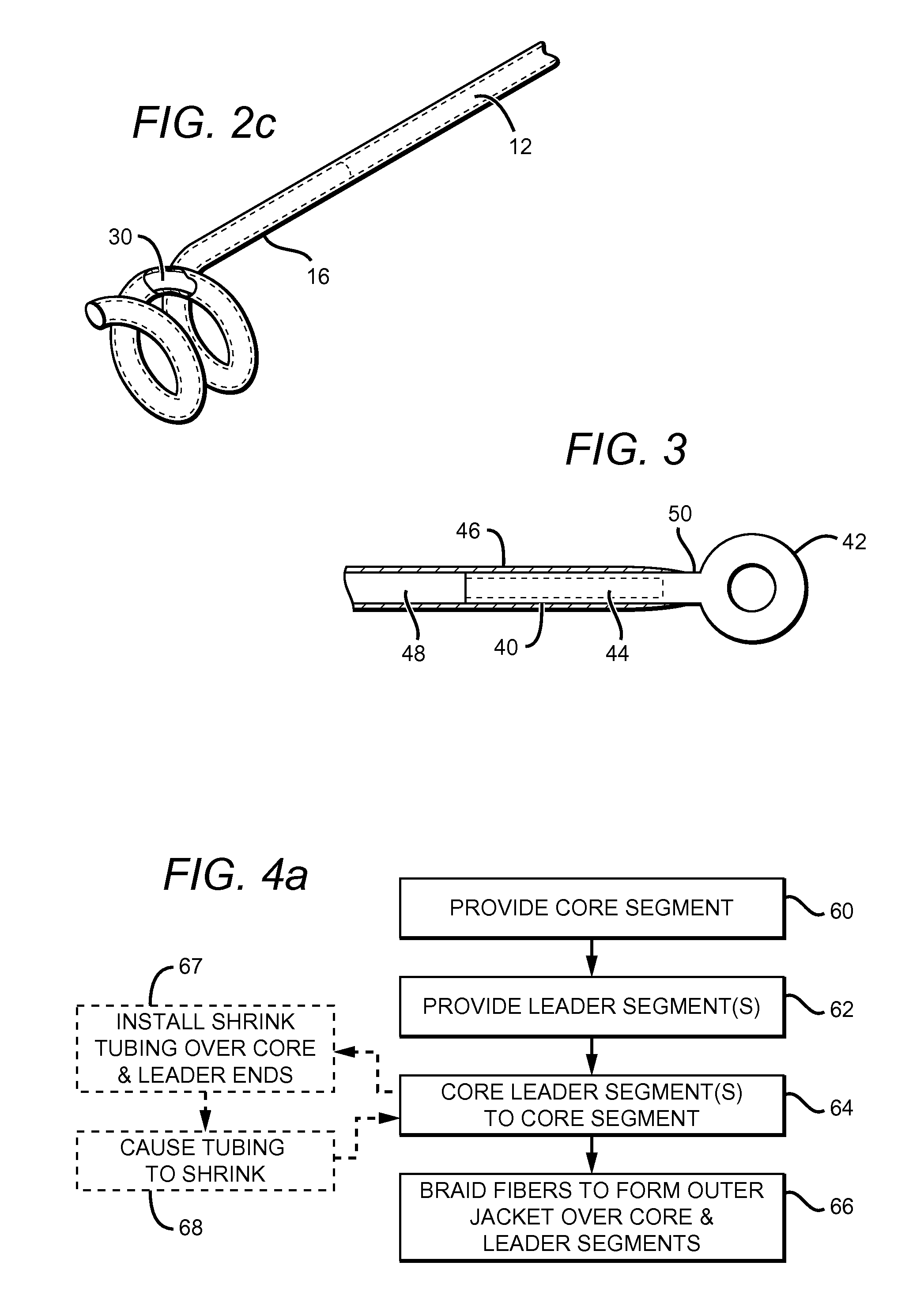

Surgical cable with malleable leader segment

InactiveUS20090204118A1Easy to operateInternal osteosythesisJoint implantsAnatomical structuresDuctile materials

A surgical cable comprises a core segment, at least one leader segment, and an outer jacket. The core segment is made from a material having a high tensile strength and which is capable of elongation. Each leader segment is arranged axially in tandem with the core segment and comprises a semi-rigid ductile material capable of being manipulated into a desired shape. A plurality of braided fibers form the outer jacket, which surrounds the core segment and at least a portion of the leader segment. The cable is manipulated by means of the leader segments, which are preferably capable of resisting bending in response to head-on compression, thereby enabling the cable to be more easily manipulated around and through anatomical structures.

Owner:KINAMED

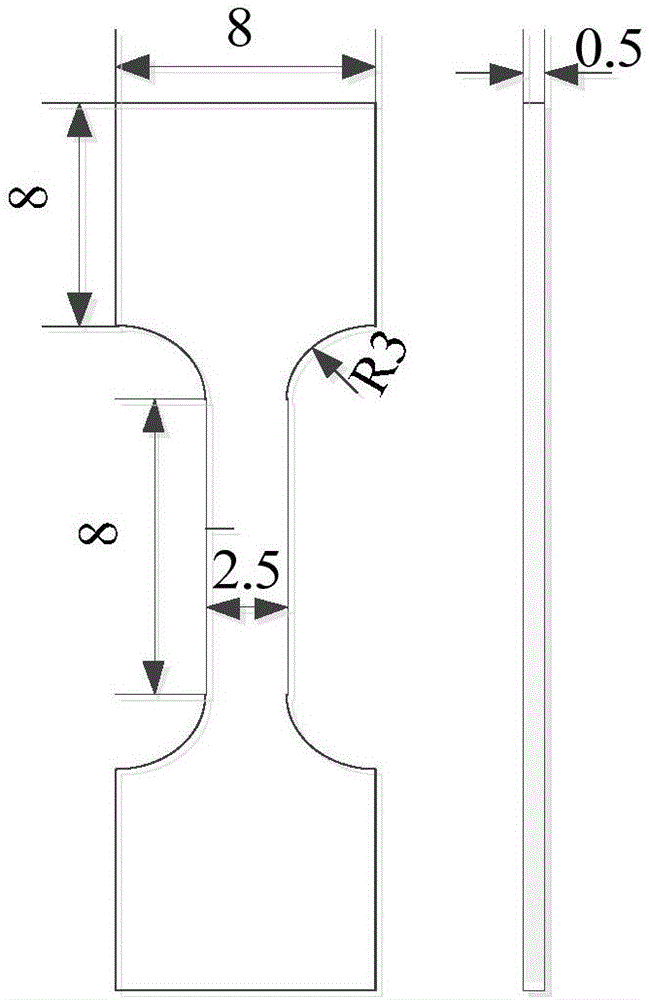

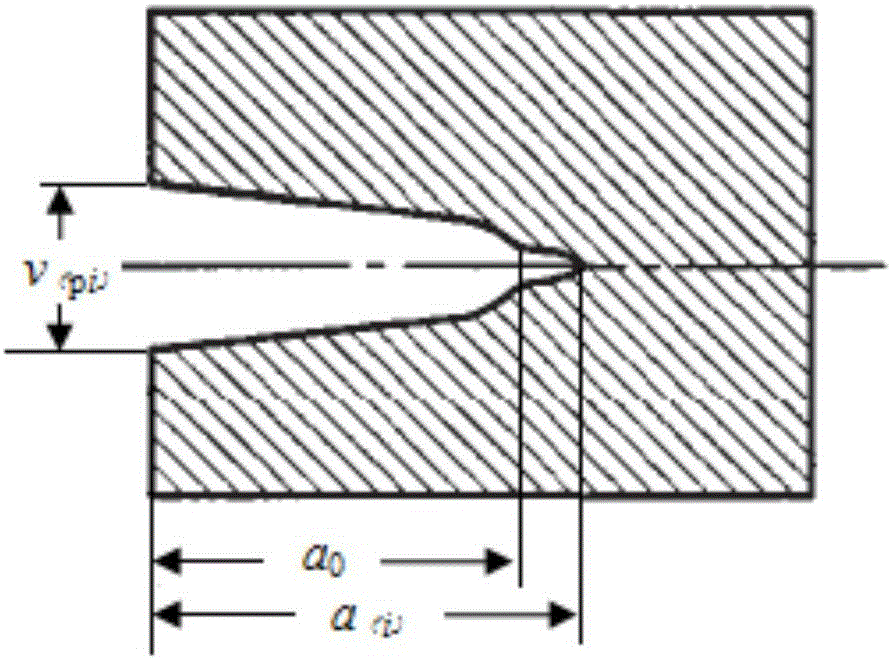

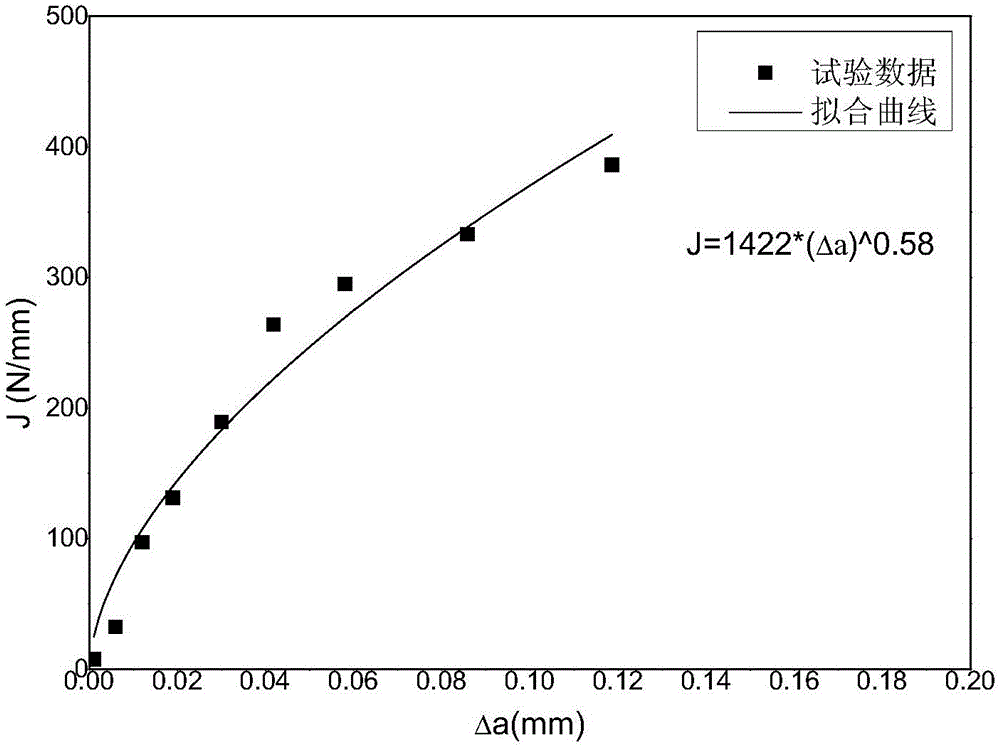

Method for testing microzone fracture toughness of material

ActiveCN106289975APrecise positioningAccurate tip positioningPreparing sample for investigationMaterial strength using tensile/compressive forcesLarge specimenStress intensity factor

The invention provides a method for testing the microzone fracture toughness of a material. The method comprises the following steps: preparing an ultrathin single-edge notched tensile (SENT) specimen; performing repeated loading and unloading operations on an in-situ tensile test machine; recording test load Fi, crack length ai and notch opening displacement Vi by virtue of a scanning electron microscope in-situ test machine; calculating a Ki value for a brittle material and calculating a Ji value for a ductile material; and drawing a K-a curve or J-R curve capable of characterizing crack propagation fracture resistance, thereby obtaining a stress intensity factor K or J integral capable of characterizing the fracture toughness of a miniature specimen. The ultrathin SENT specimen is adopted to measure the microzone fracture toughness of a metallic material, so that the problem that measurement on fracture toughness of ultrathin members and accurate microzones of a large specimen based on traditional standards cannot be realized is solved, and the method has the characteristics of accurate crack tip positioning and high dimension measurement accuracy.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

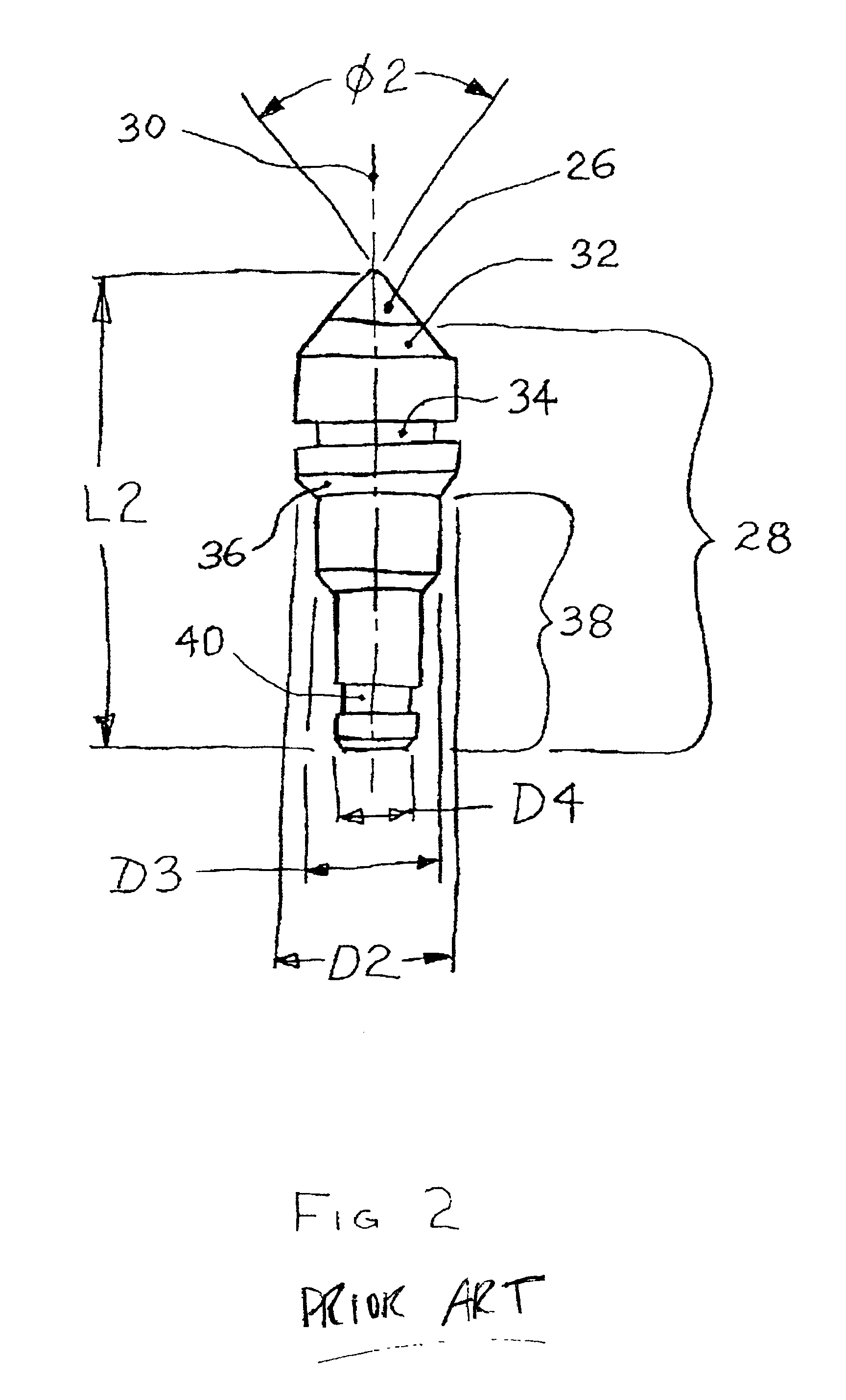

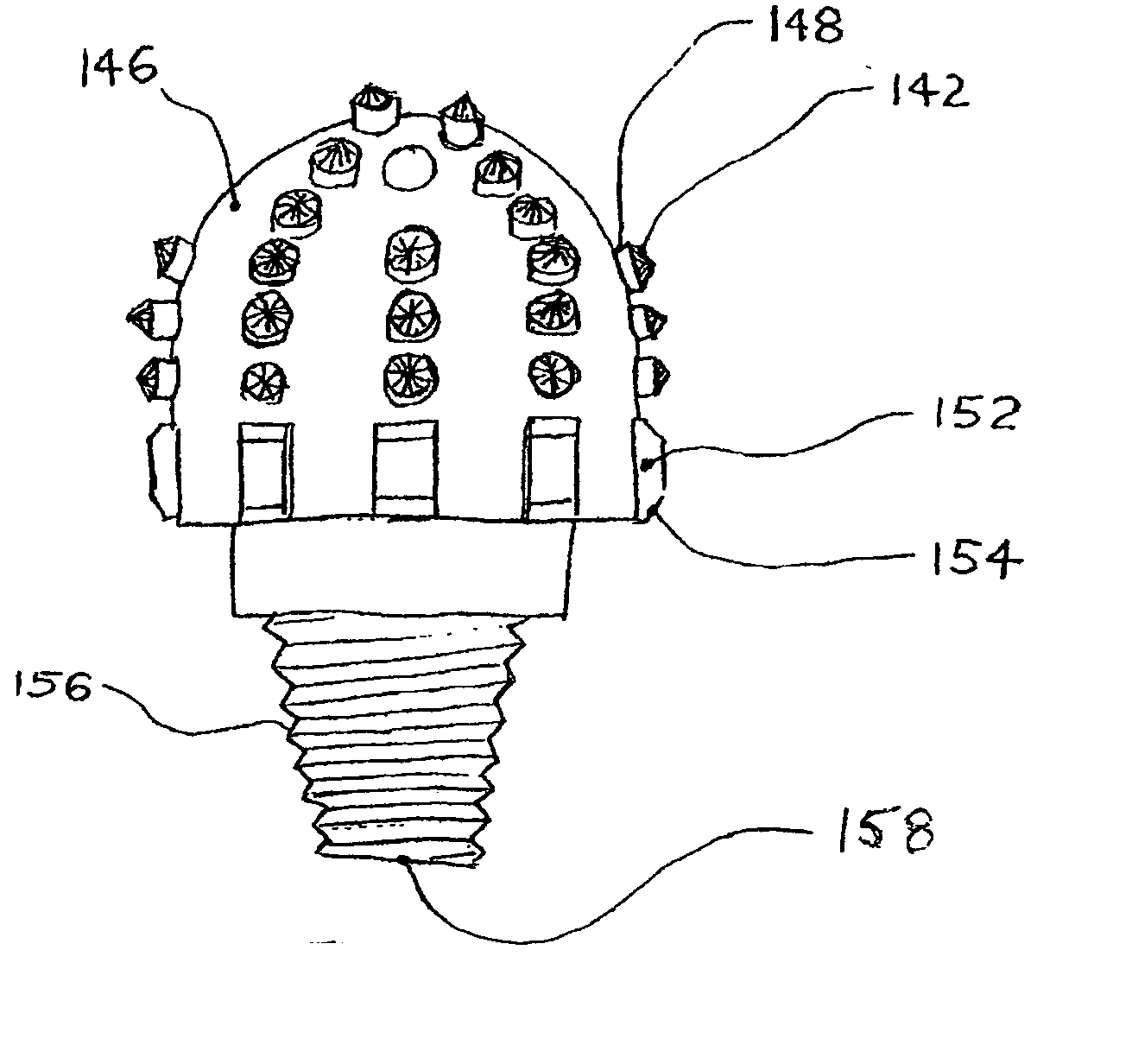

Rotary tools or bits

Rotary tools or bits carry cutter element including pointed contact structures and elements for chipping, cutting, and breaking non-ductile materials such as rock. The cutter elements directly contact and cut through rock and other materials and have tapered contact structure ends. Rotary tools or bits for carrying the cutter elements carry fixed cutter elements, or have sockets for removable threaded or rotatable cutter elements, arranged in straight or curved rows on the head opposite a drill-string-engaging base of the tool. The tools also have radially-extending buttresses which help to protect the cutter elements from damage as a drill string and bit are withdrawn from a bore.

Owner:DVORACHEK HAROLD A

Silver barrier layers to minimize whisker growth in tin electrodeposits

InactiveUS20060292847A1Reduce formationHeavy loadSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSurface layerCompound (substance)

The invention relates to a method of reducing tin whisker formation in a plated substrate that includes a surface layer comprising tin. The method includes providing on electroplatable portions of the substrate (a) an underlayer comprising silver or (b) a barrier layer that passes a mechanical load test when the surface layer, after 48 hours of contact with a 1 mm hemispherical tip that carries a load of between 500 to 2000 g, exhibits no whiskers having a length of greater than 5 microns. The underlayer or barrier layer, whichever is present, is provided in a thickness sufficient to prevent formation of intermetallic compounds between the substrate and surface layer so that the surface layer exhibits reduced whisker formation compared to the same surface layer deposited directly upon the substrate. Typically, the underlayer or barrier layer includes 50 to 100% by weight silver or similar ductile material.

Owner:TECHNIC INC

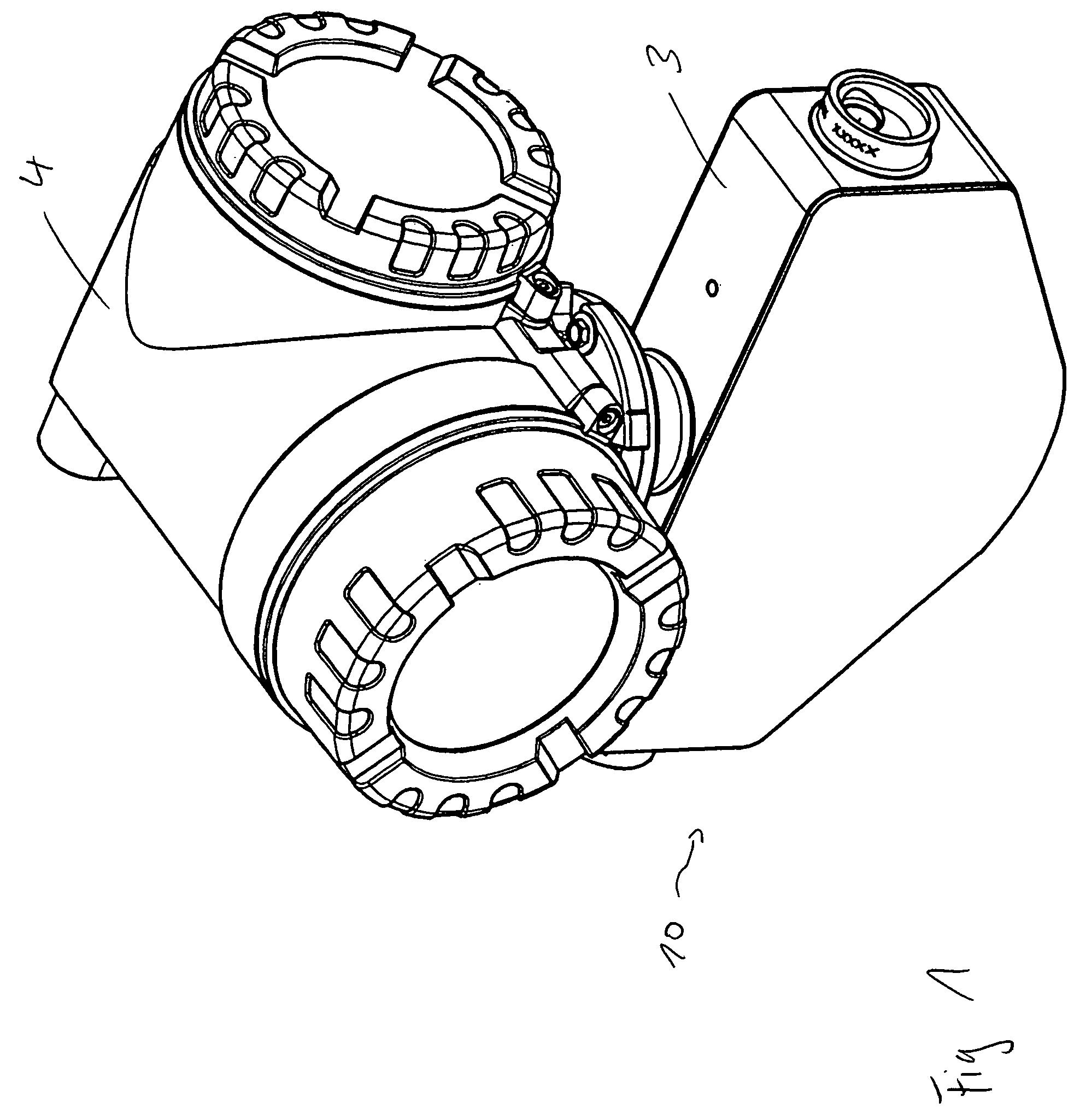

Composite produced from intermetallic phases and metal

InactiveUS20110198983A1Cheap productionIncrease flexibilityElectrode assembly support/mounting/spacing/insulationWelding/cutting media/materialsProduction lineMetal powder

A method is provided for producing a wire or tape, especially for use as an electrode or electrode tip in spark plugs. The method includes the following steps: (a) producing an intermetallic compound having a melting point above 1700° C.; (b) grinding the intermetallic compound; (c) mixing the intermetallic compound with metal powder; (d) introducing the mixture obtained in step (c) in a tube produced from ductile material; and (e) shaping the tube filled in step (d) to give a wire or tape. Also provided are a wrapped wire or wrapped tape, especially a semifinished product for producing electrodes or electrode tips of spark plugs.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

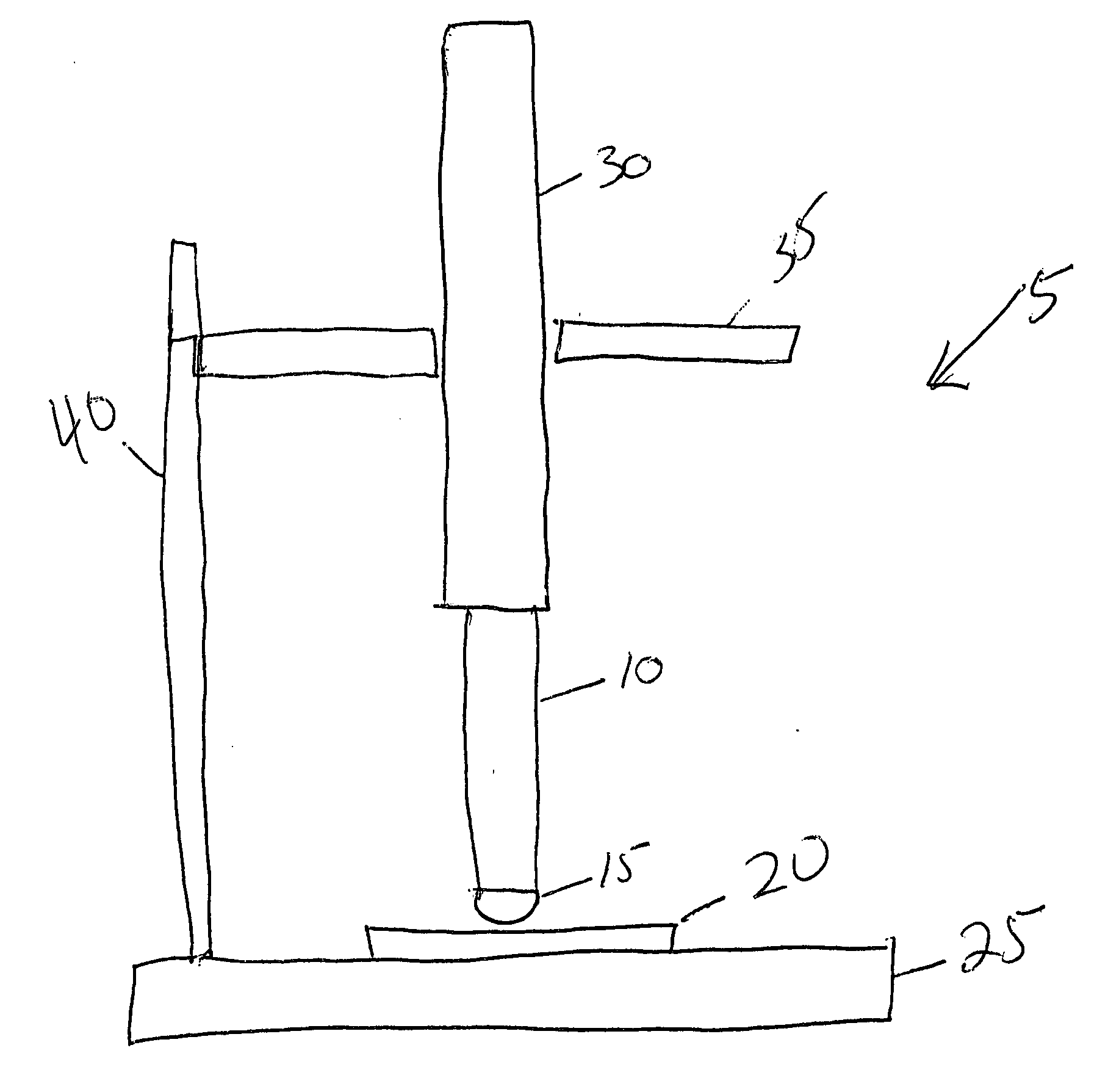

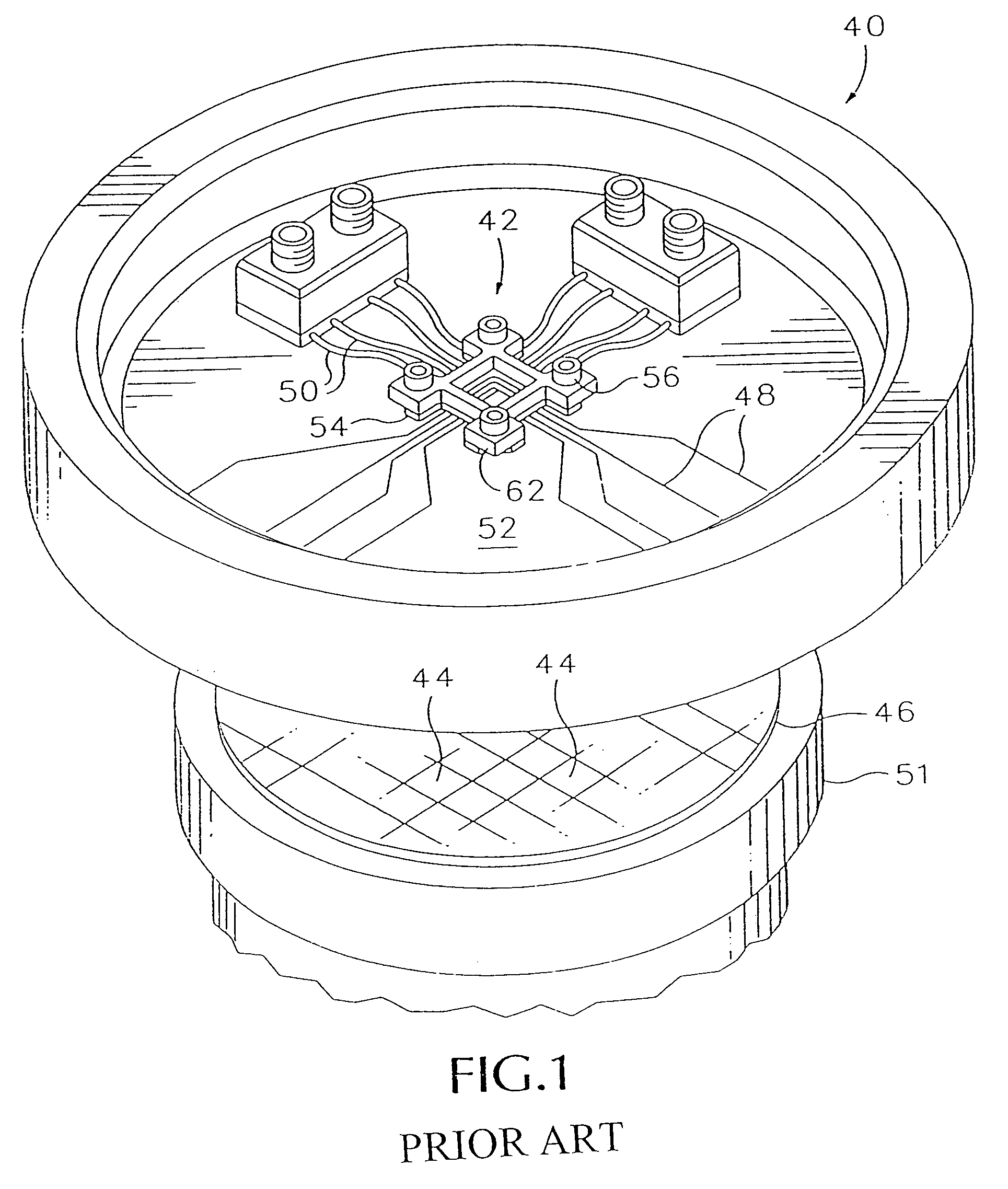

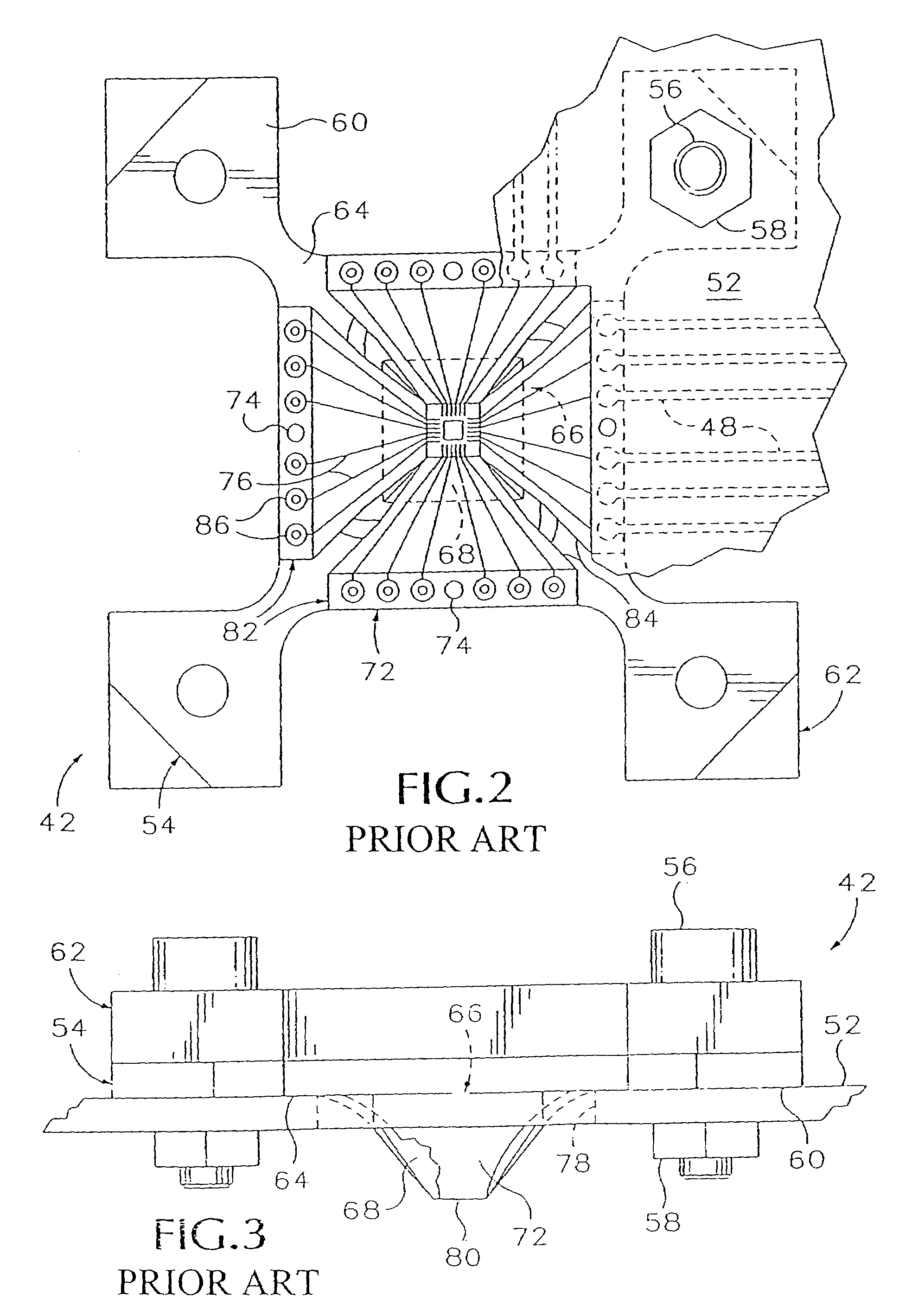

Membrane probing system

InactiveUS7266889B2Contact member manufacturingSemiconductor/solid-state device testing/measurementContact padEngineering

Owner:FORMFACTOR BEAVERTON INC

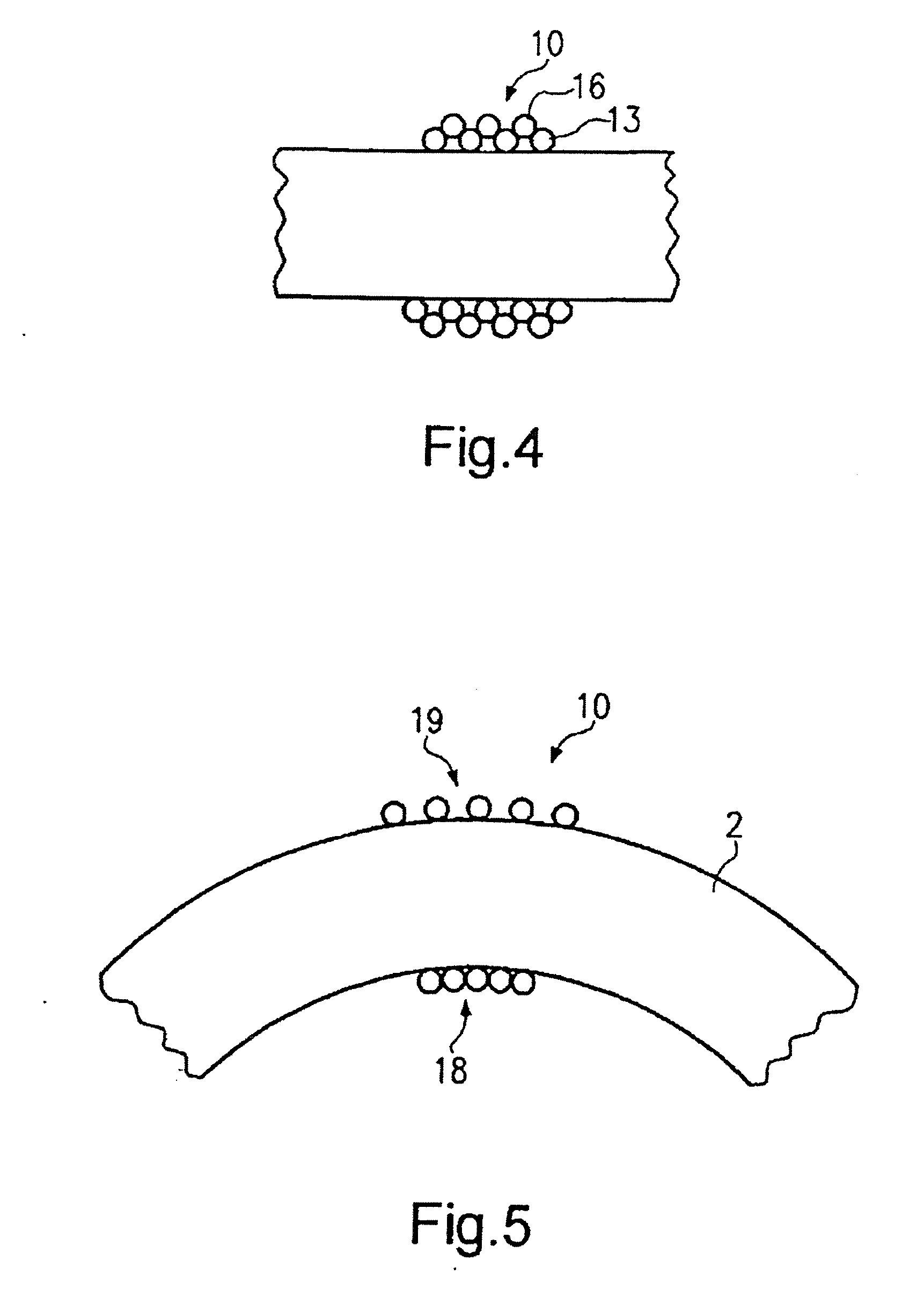

Joining Of Dissimilar Materials

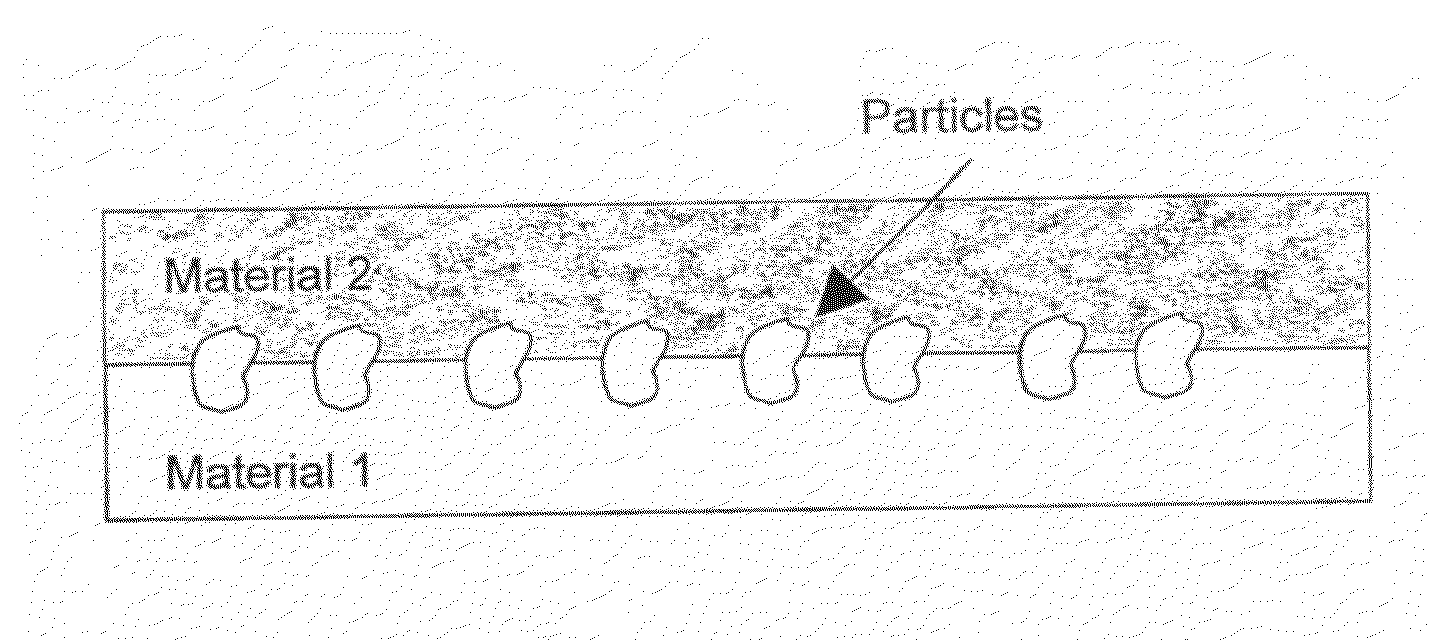

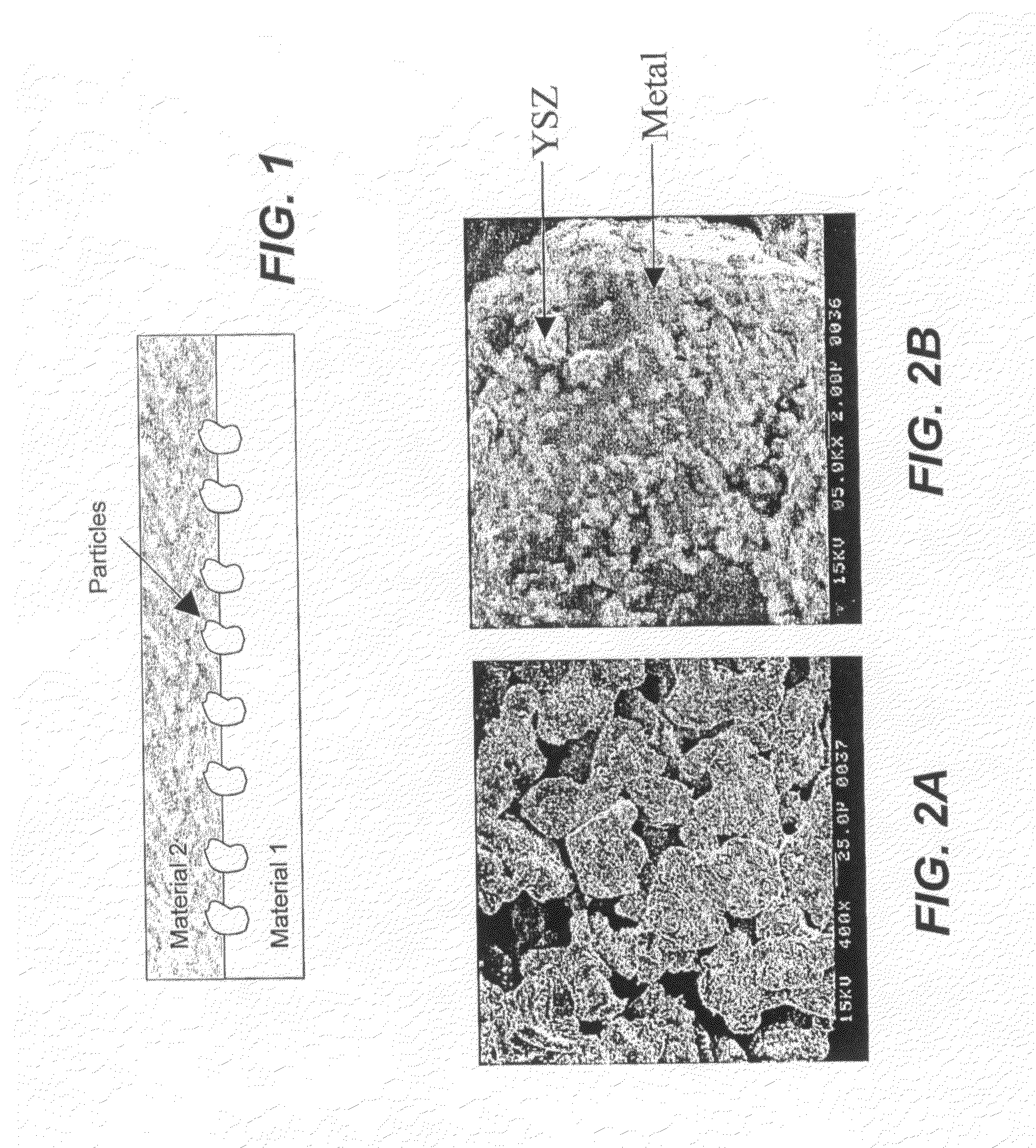

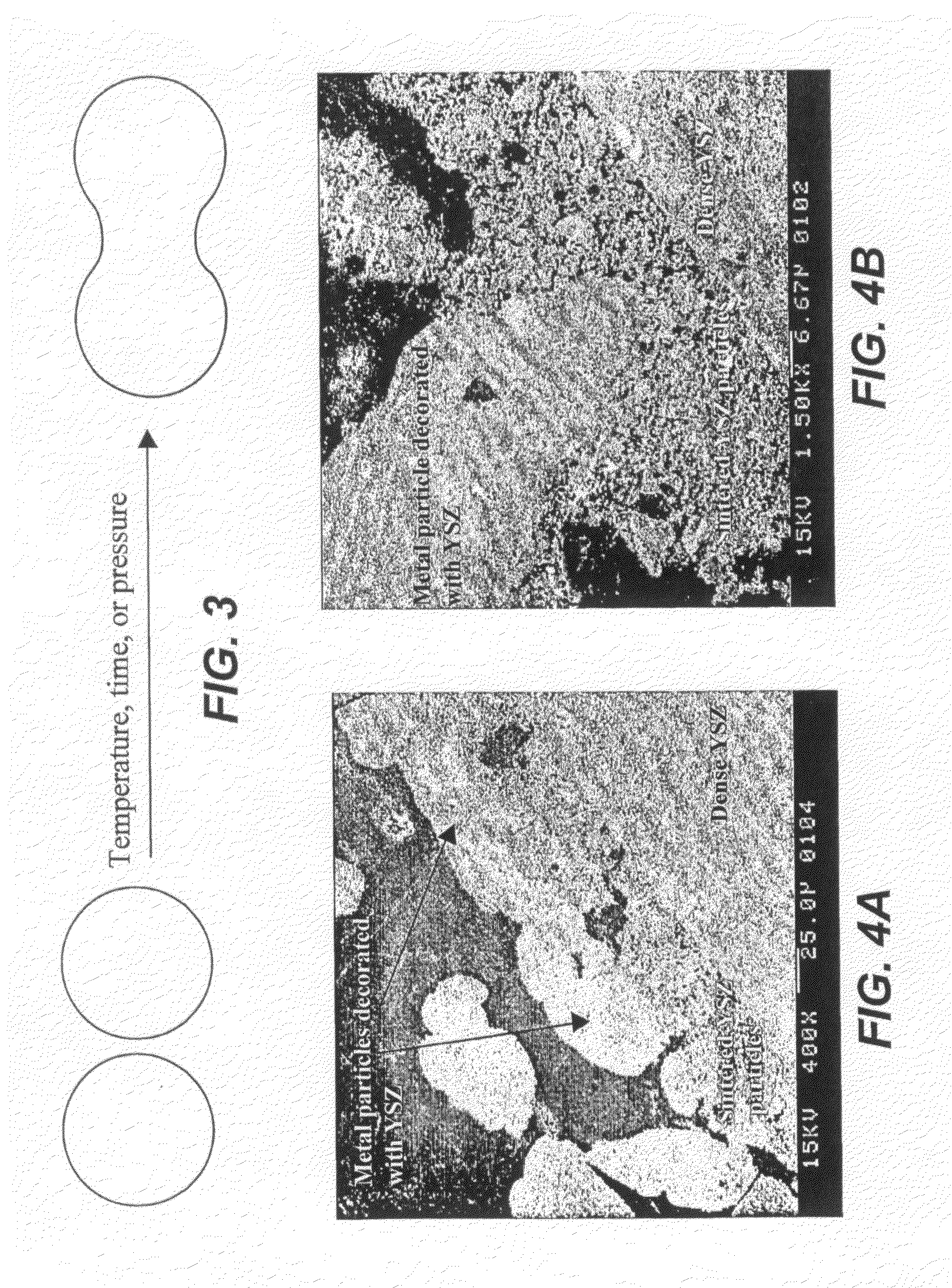

ActiveUS20080118804A1Different ductilityGood adhesionFinal product manufactureActive material electrodesSharp interfaceFiber

A method of joining dissimilar materials having different ductility, involves two principal steps: Decoration of the more ductile material's surface with particles of a less ductile material to produce a composite; and, sinter-bonding the composite produced to a joining member of a less ductile material. The joining method is suitable for joining dissimilar materials that are chemically inert towards each other (e.g., metal and ceramic), while resulting in a strong bond with a sharp interface between the two materials. The joining materials may differ greatly in form or particle size. The method is applicable to various types of materials including ceramic, metal, glass, glass-ceramic, polymer, cermet, semiconductor, etc., and the materials can be in various geometrical forms, such as powders, fibers, or bulk bodies (foil, wire, plate, etc.). Composites and devices with a decorated / sintered interface are also provided.

Owner:RGT UNIV OF CALIFORNIA

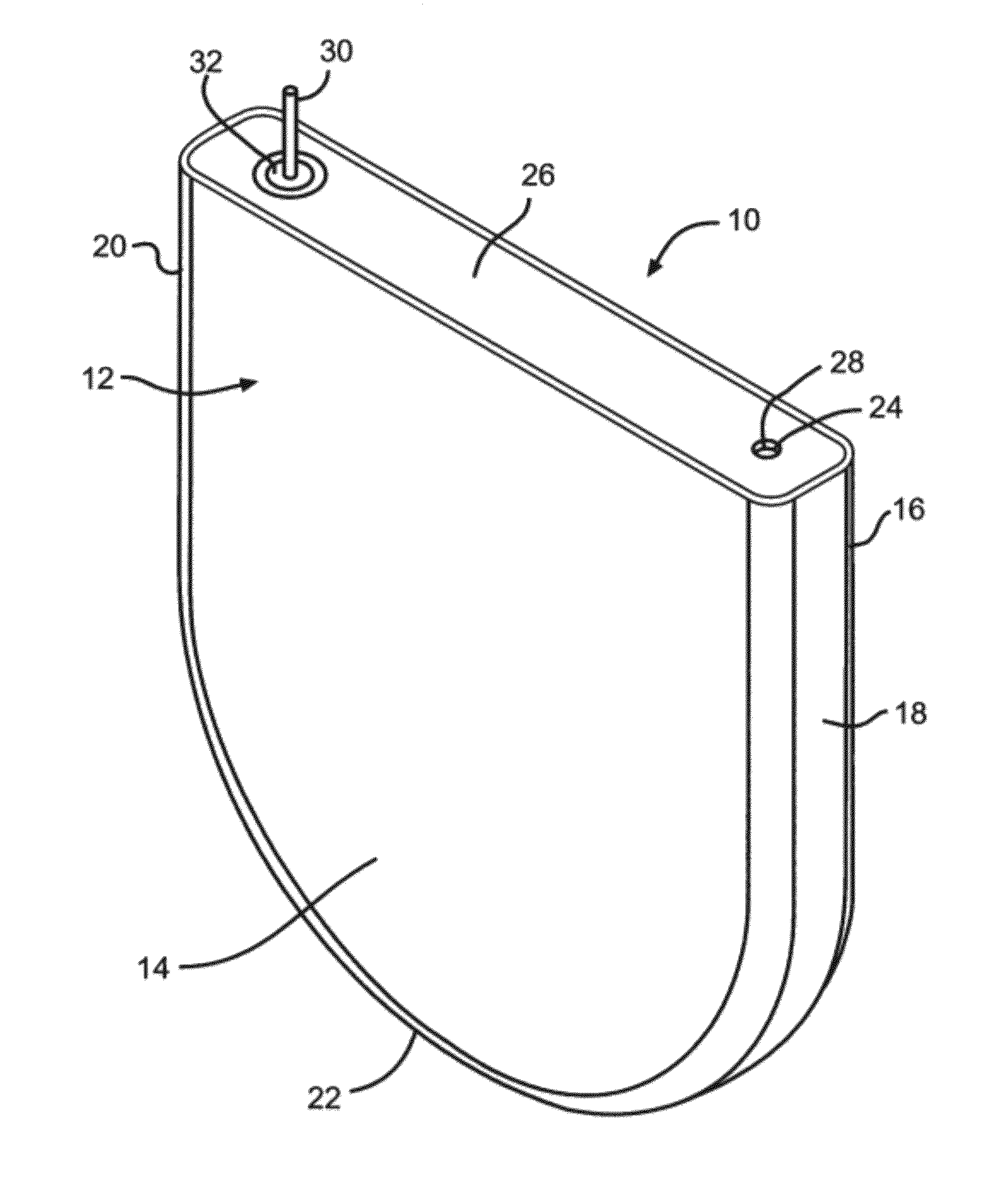

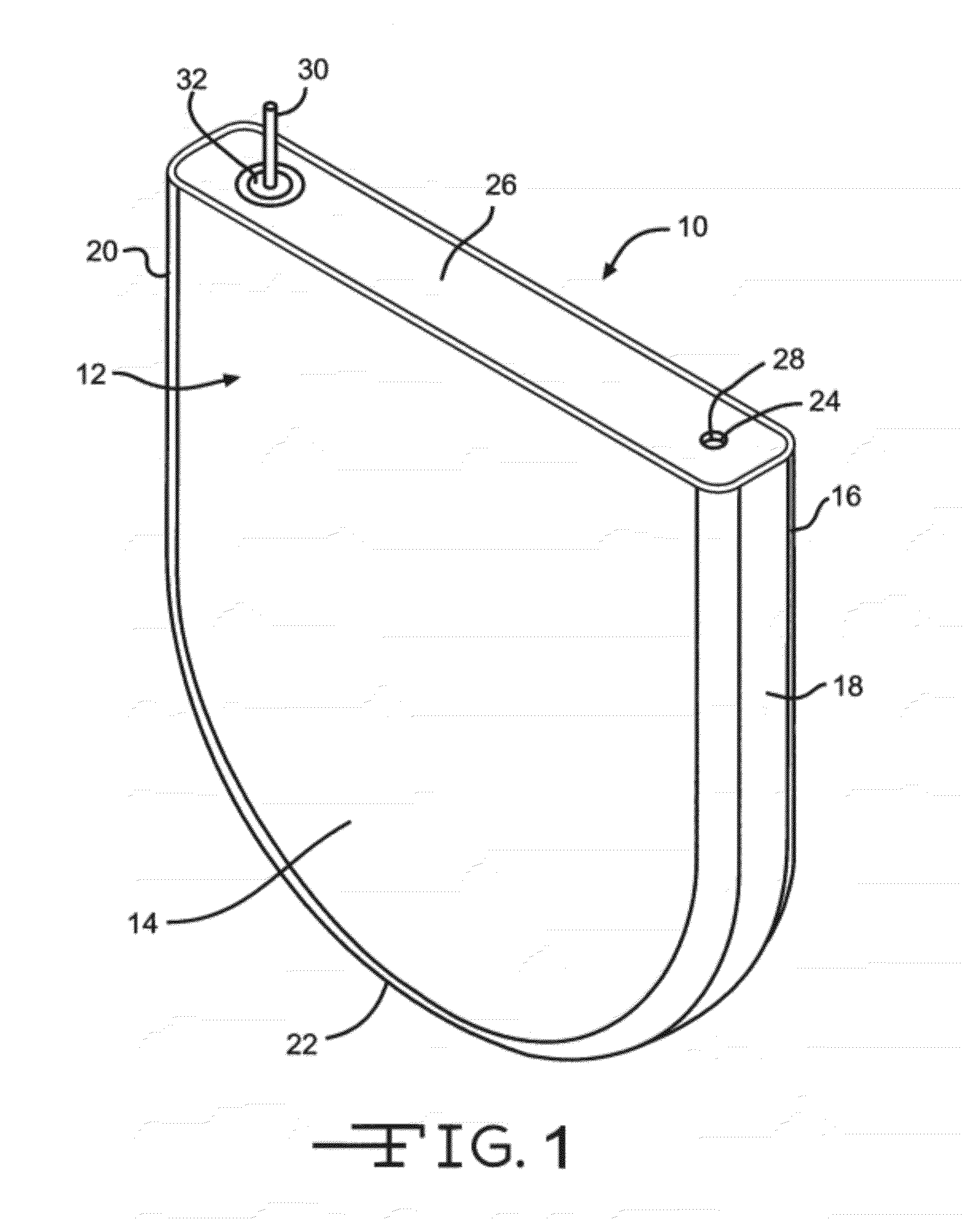

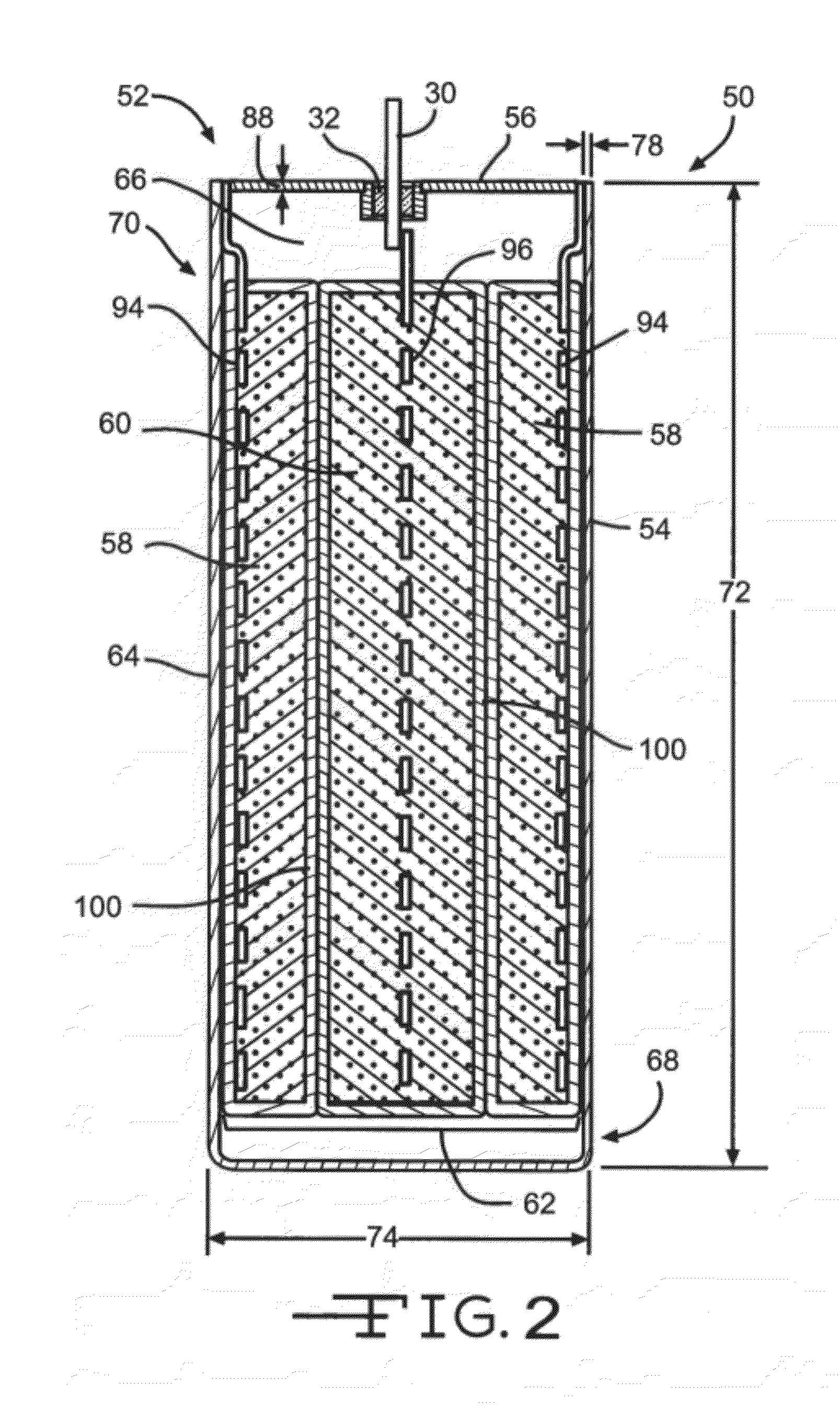

Dissimilar Material Battery Enclosure for Improved Weld Structure

InactiveUS20120282519A1Mechanically robustRobust cell designPrimary cellsElectrode carriers/collectorsEngineeringEddy current

An electrochemical cell having an enclosure comprised of an enclosure body portion composed of a relatively high electrical resistivity material and an enclosure lid portion composed of a ductile material is discussed. The body portion of the enclosure preferably comprises Grade 5 or 23 titanium and the lid portion preferably comprises Grade 1 or 2 titanium. The enclosure lid is joined to the body of the enclosure through a welding process such as laser welding. The combination of these differing materials provides an enclosure that effectively retards the occurrence of eddy current induced heating as well as provides an enclosure that is more mechanically robust.

Owner:WILSON GREATBATCH LTD

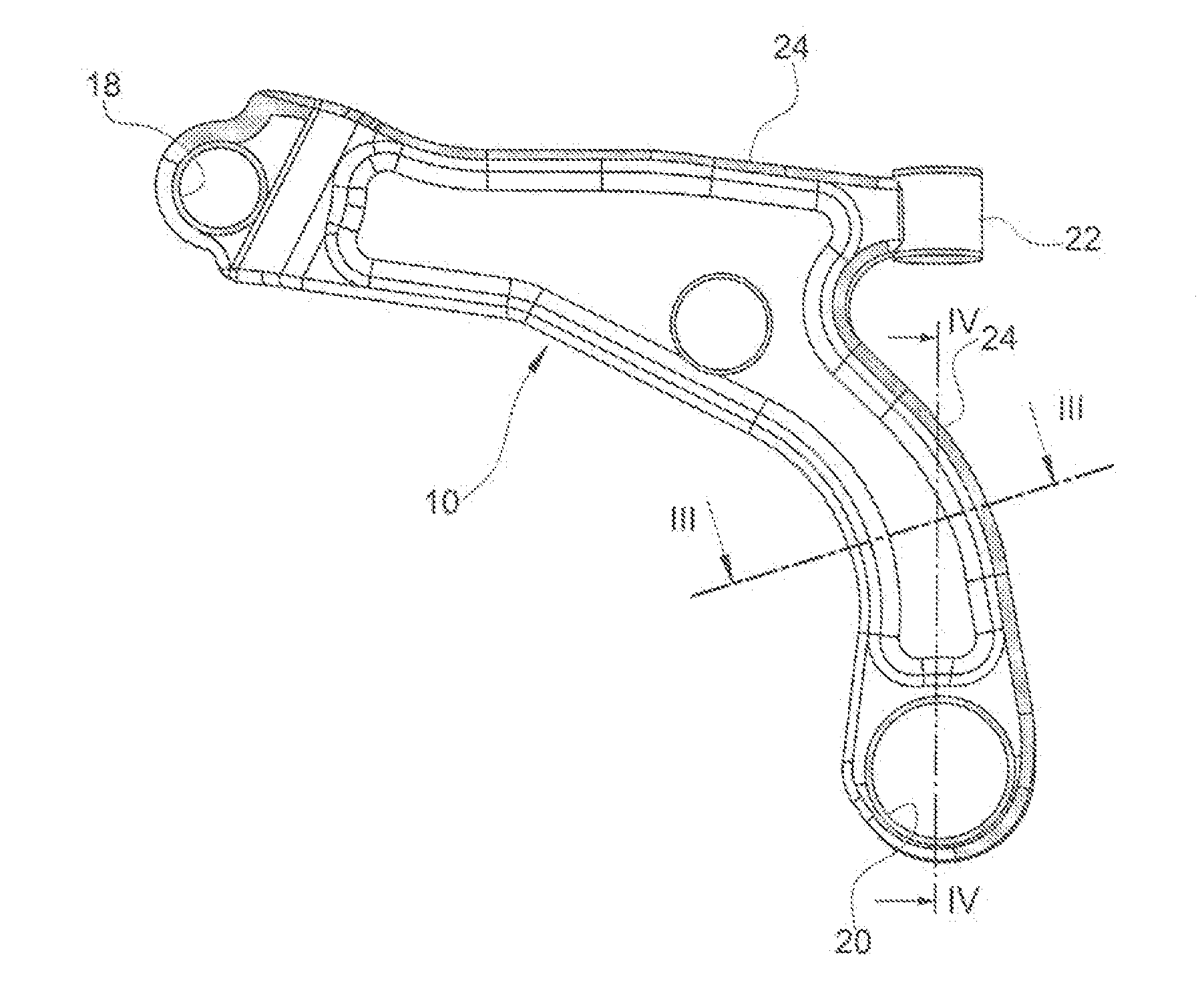

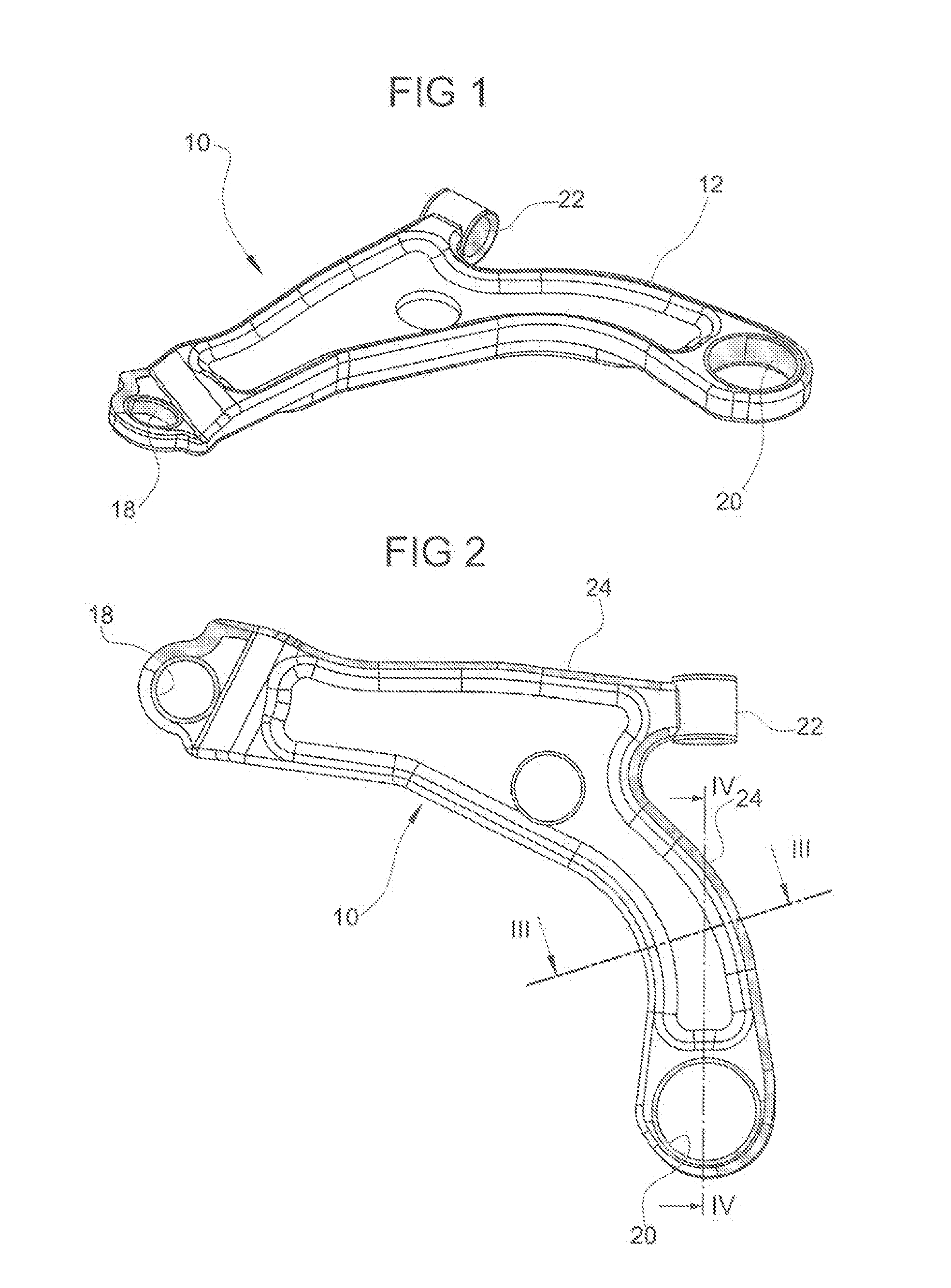

Composite structural element, particularly for a vehicle suspension, and method for manufacturing the same

ActiveUS20130205591A1Improve mechanical propertiesReduce weightMetal-working apparatusGirdersFiberComposite construction

A method for manufacturing a structural element comprises steps of providing separate first and second half-shells made of at least one layer of composite material including a fibre-reinforced polymeric matrix, providing a core made of ductile material Joking the core to the first half-shell such that at least one cavity is defined inside the structural element, and joining the second half-shell to the first half-shell.

Owner:SISTEMI SOSPENSIONI SPA

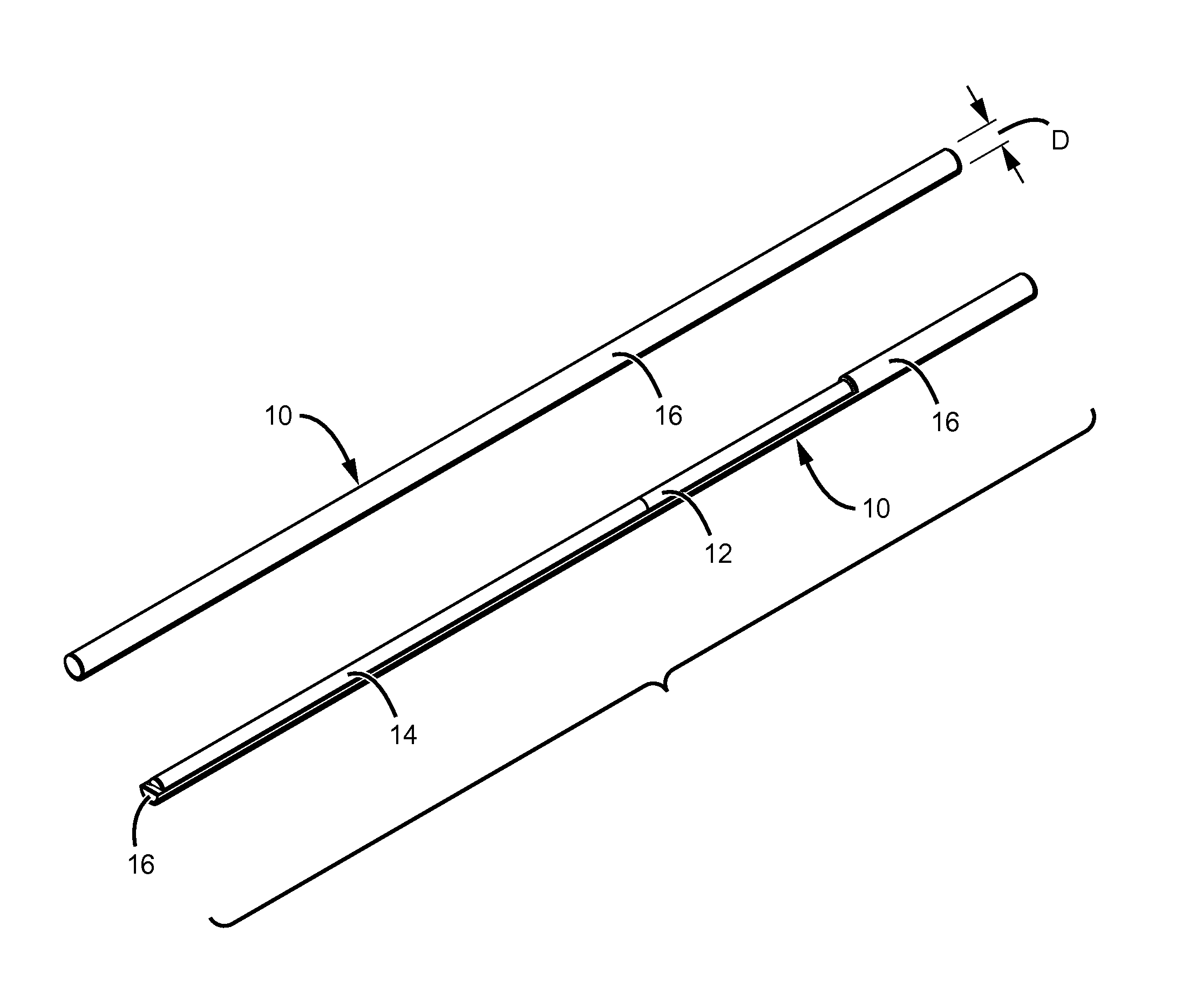

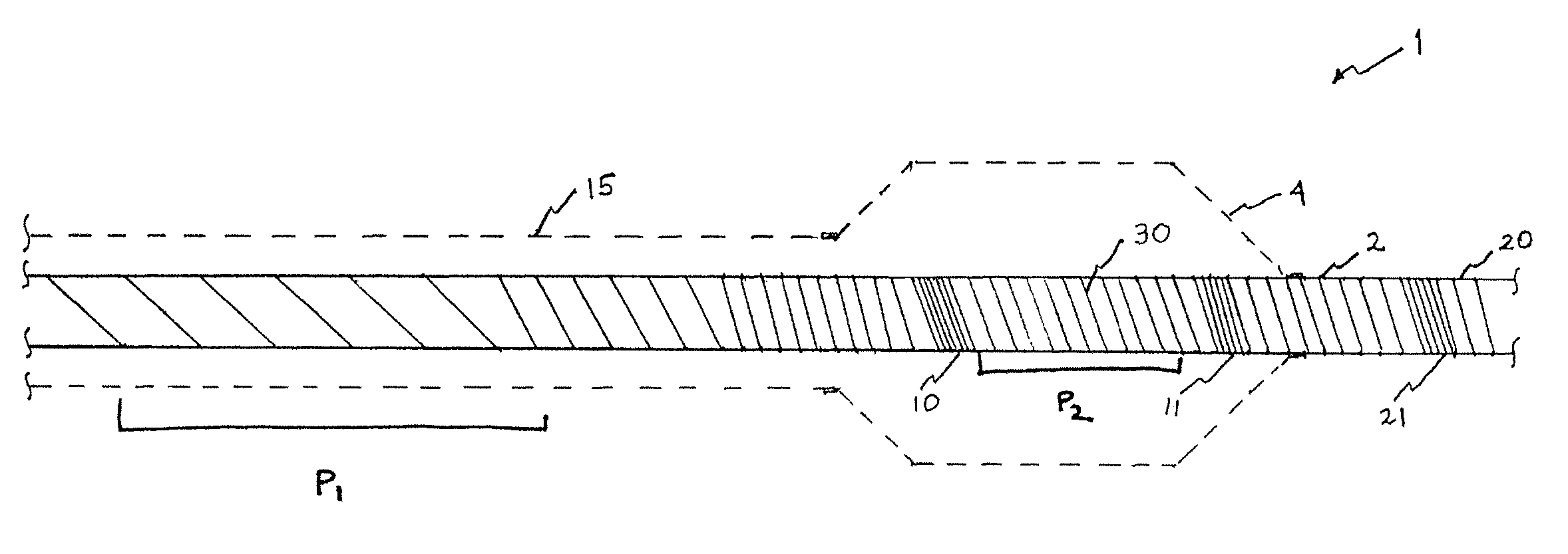

Balloon catheter with radiopaque marker

InactiveUS8251949B2Reduce rigid lengthIncrease flexibilityStentsBalloon catheterInsertion stentBalloon catheter

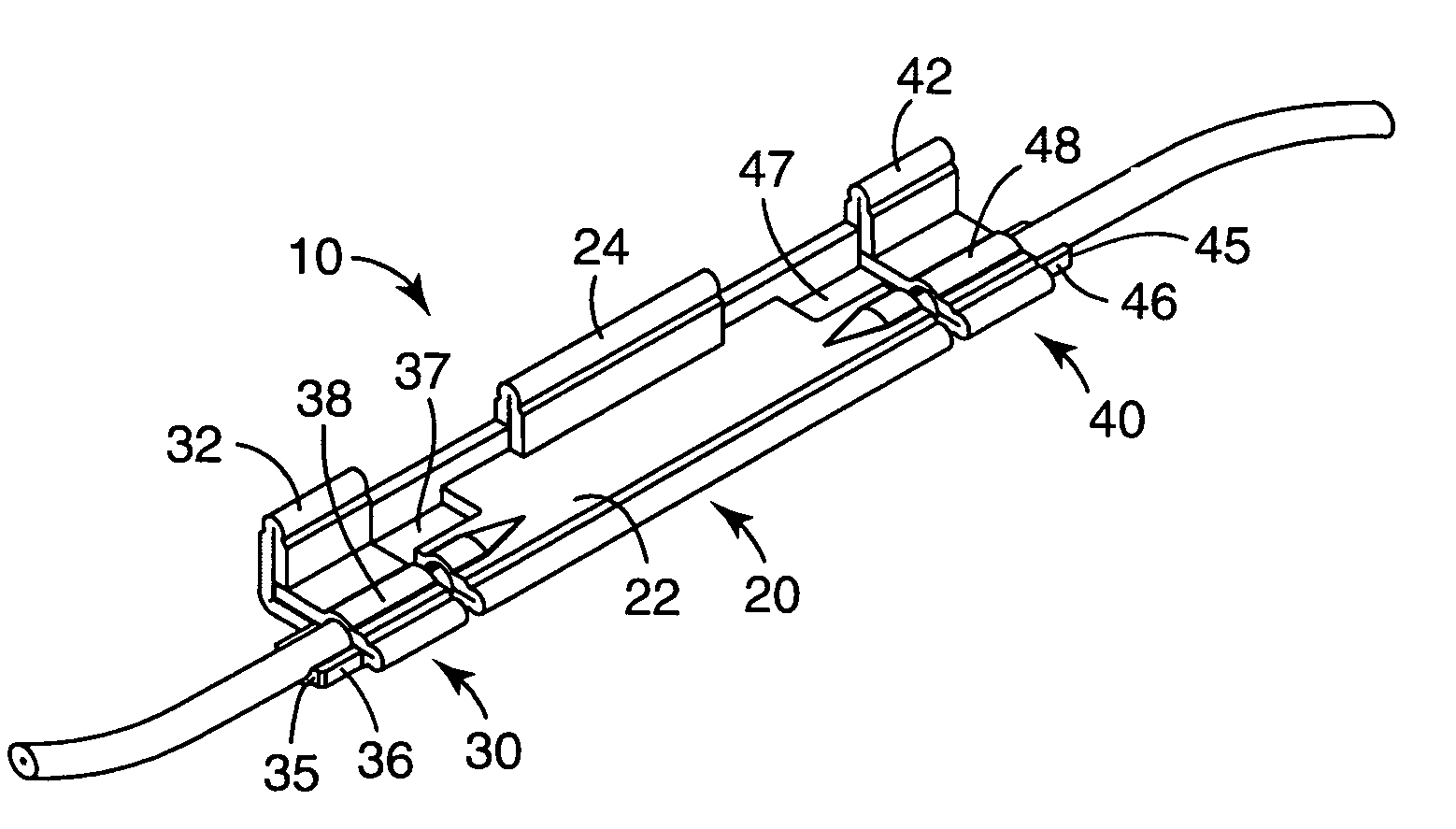

A catheter for delivering a stent includes an outer tube having a proximal end, a distal end and a wall defining a lumen; an inner tube disposed within the outer tube and defining a lumen for a guidewire, wherein a portion of a length of the inner tube is wrapped around with a spiral-shaped wire; a balloon sealingly connected to the inner tube and the outer tube adjacent the distal ends thereof, the balloon defining an interior volume and having an exterior surface; and a marker made from a wire of a highly radiopaque and ductile material, wherein the wire is wrapped in a plurality of at least partially overlapping layers such that the marker is flexible along the length of the catheter.

Owner:ABBOTT LAB INC

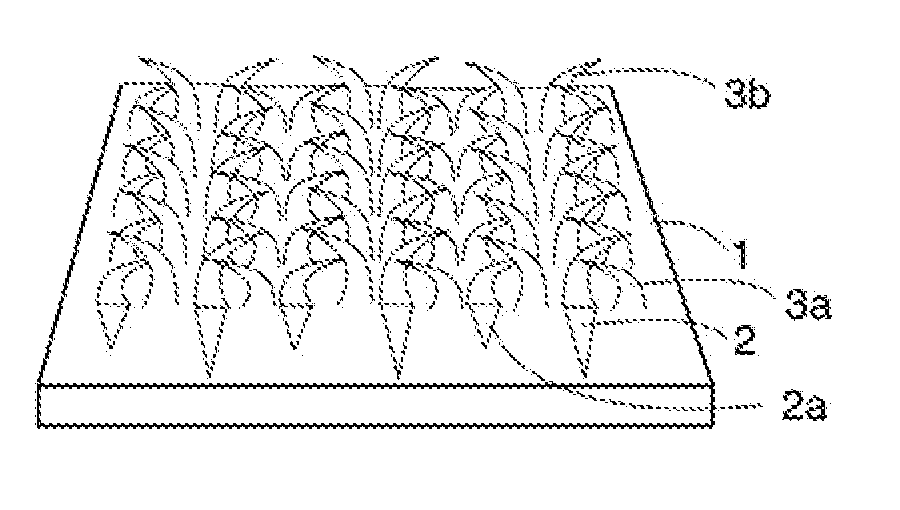

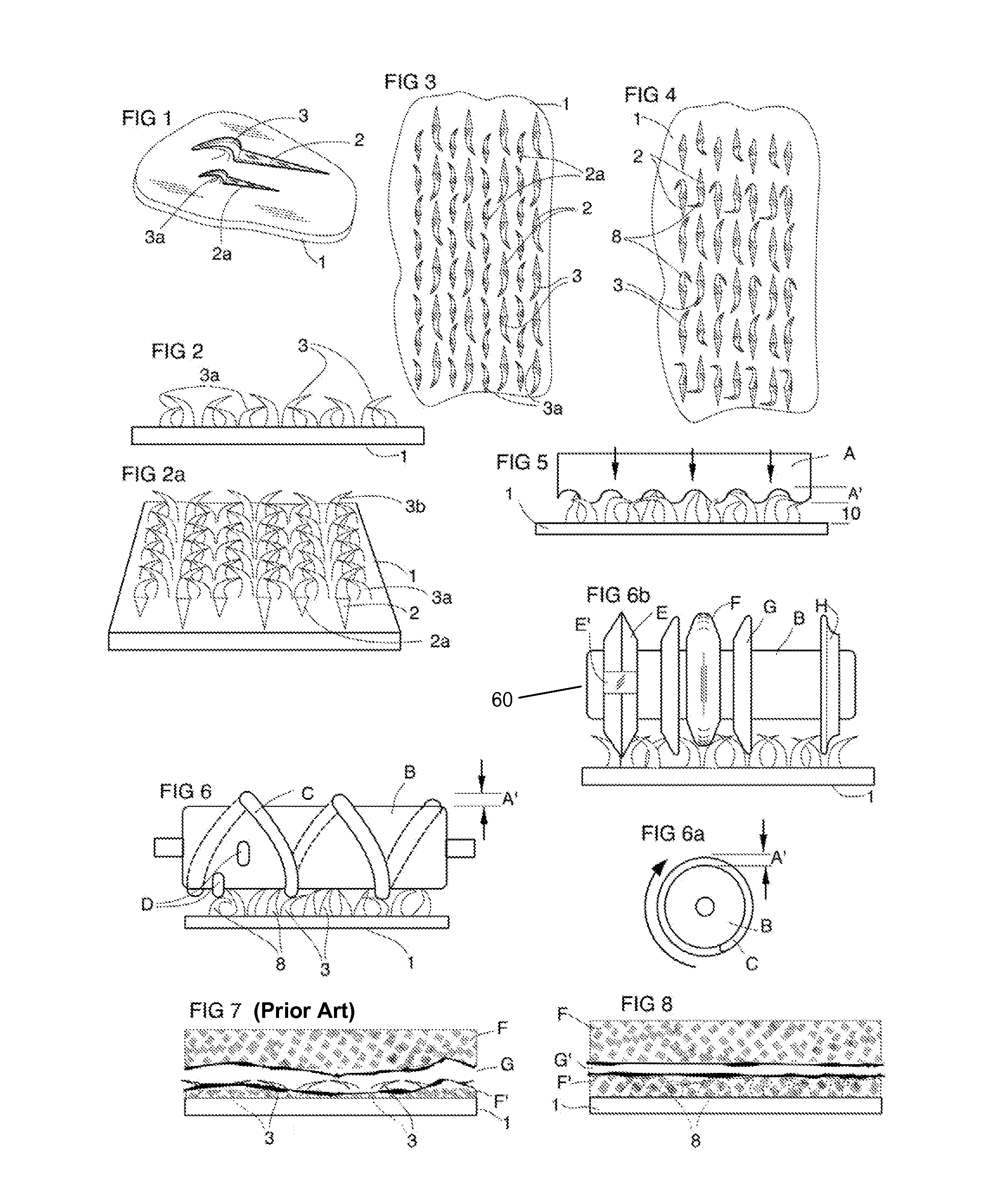

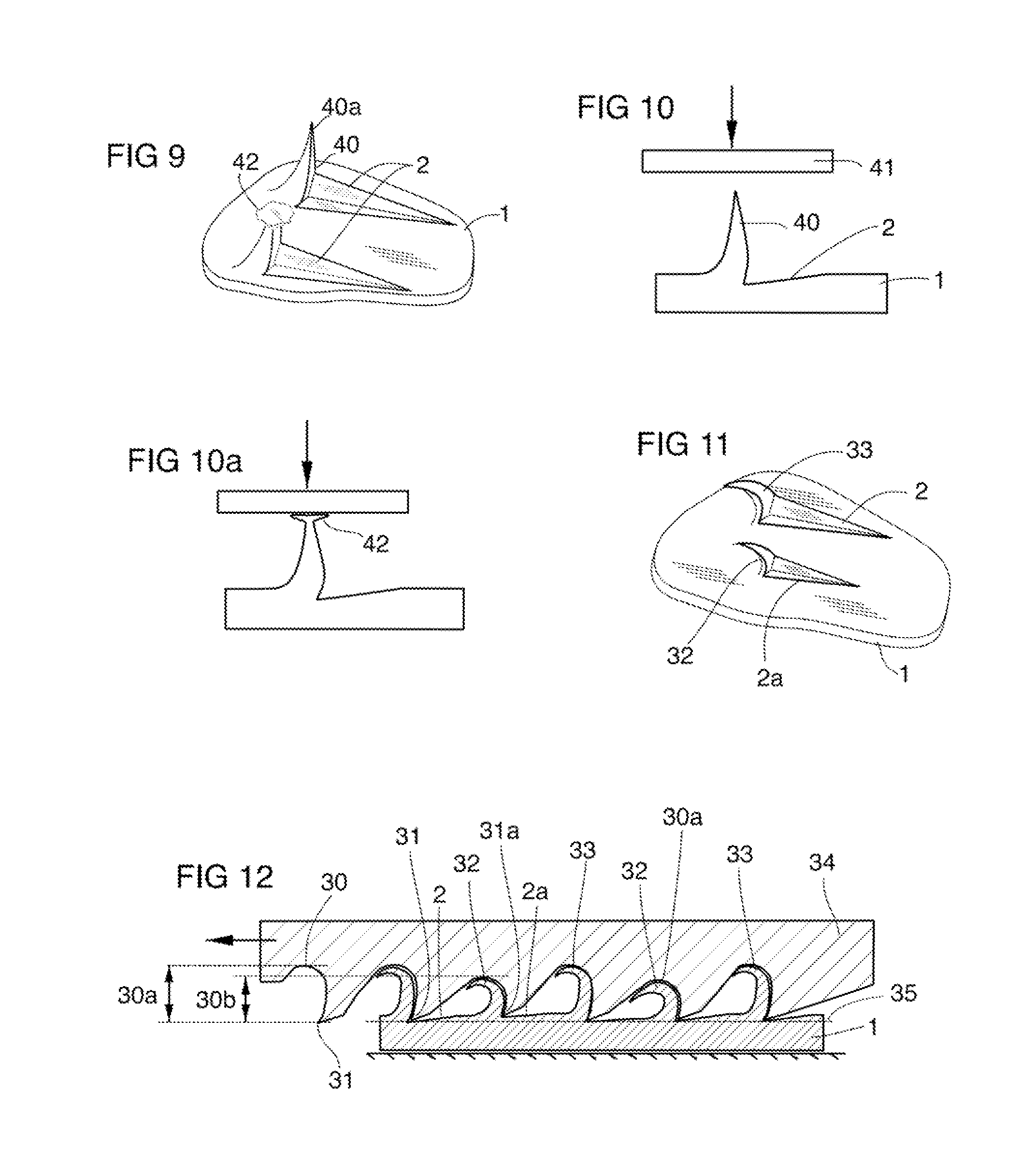

Material with variable height barbs

InactiveUS20160091041A1Reduce the overall heightLayered productsMetal-working apparatusMechanical engineeringDisc brake

The present invention is a differentially textured material made from a workpiece made of a ductile material with a substantially flat face on which are raised rows of integral and generally pointed barbs. Each barb has a height above the substantially flat face of the ductile material from which the barbs are gouged out. The heights of the barbs vary substantially. The material may be steel and in the form of a sheet. The differentially textured material is particularly well suited for manufacturing disc brake backing plates where the barbs are used to bond the backing plate to friction material. The present invention also includes methods for making such differentially textured material.

Owner:R A INVESTMENT MANAGEMENT S A R L

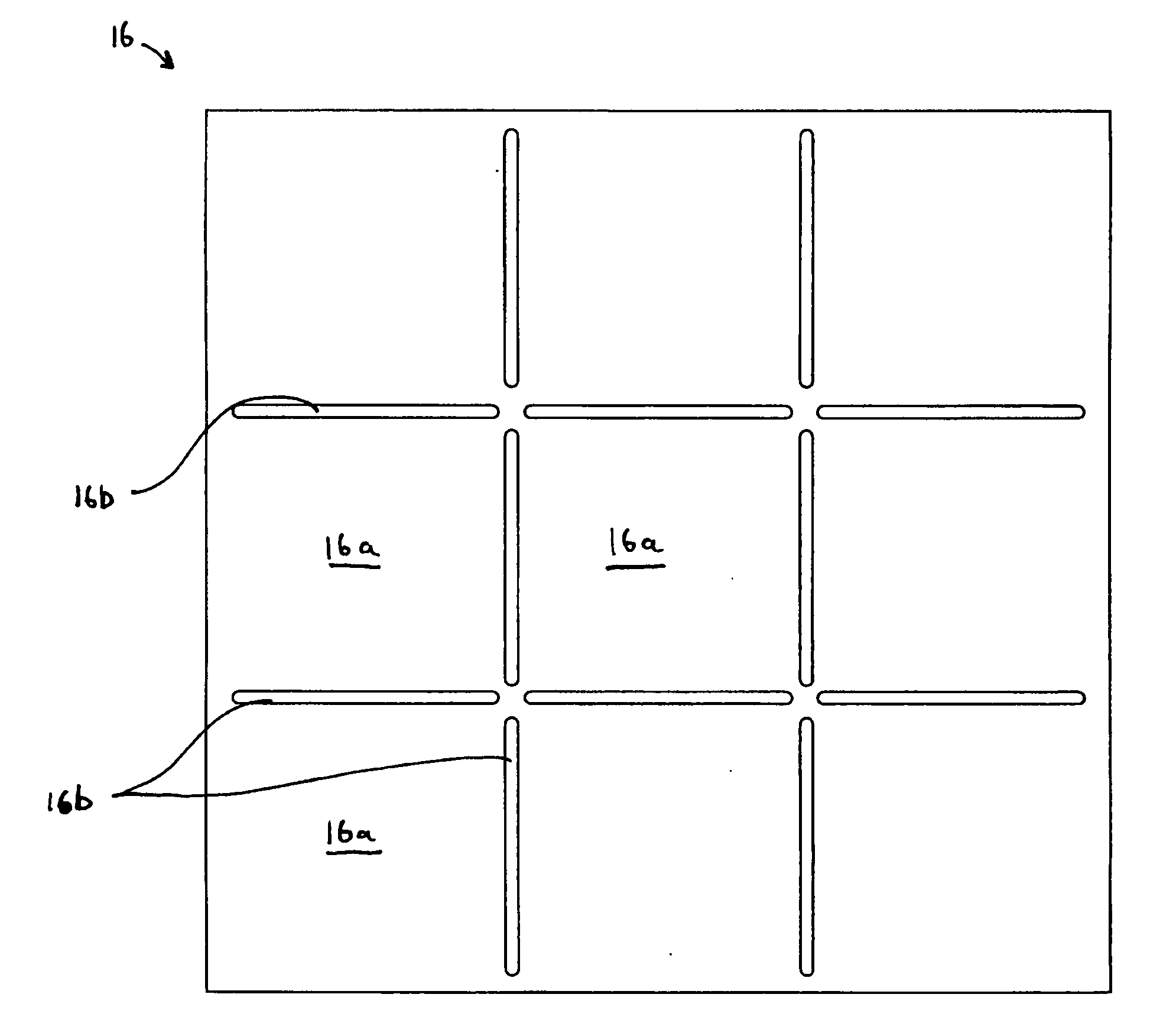

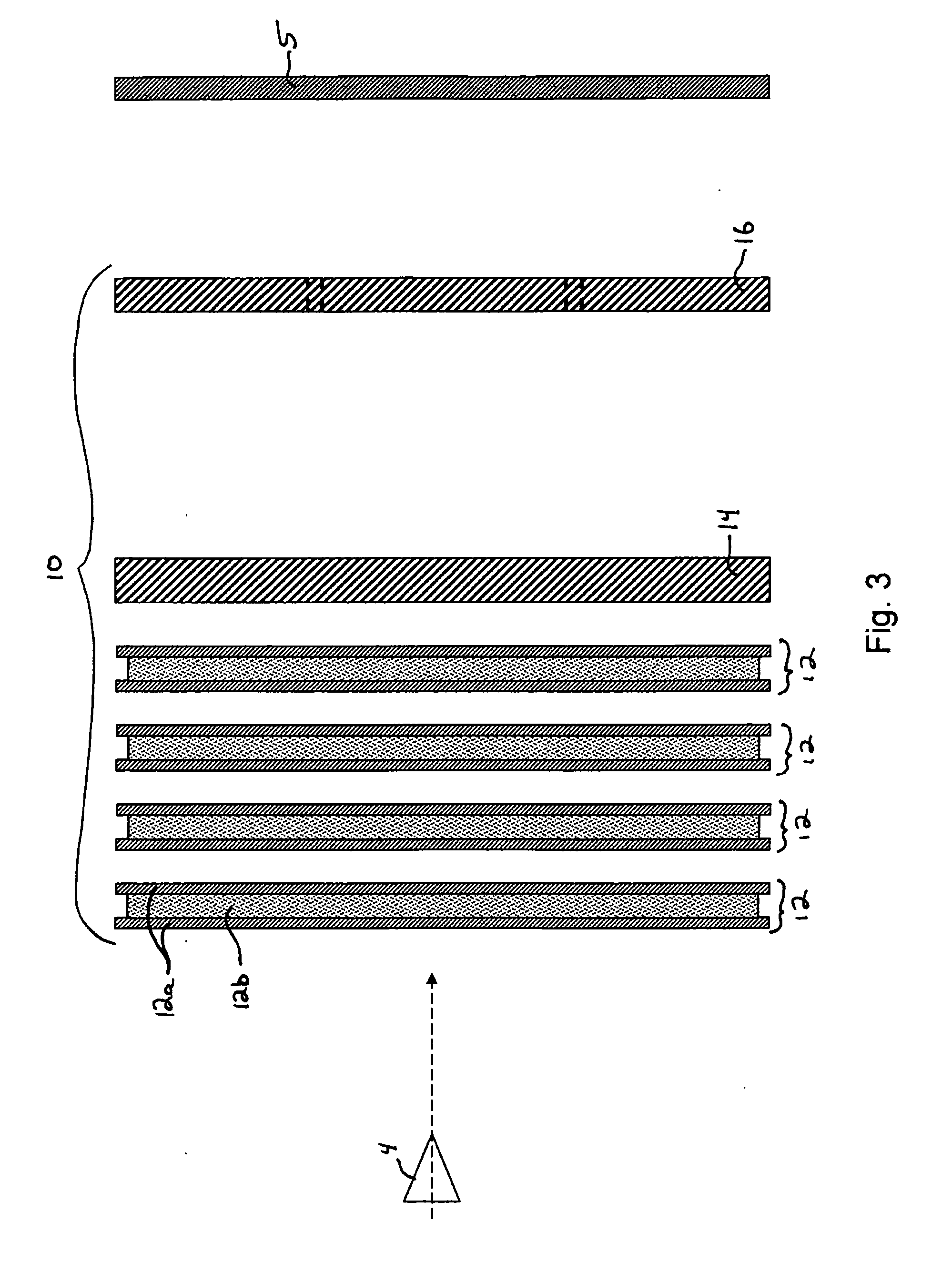

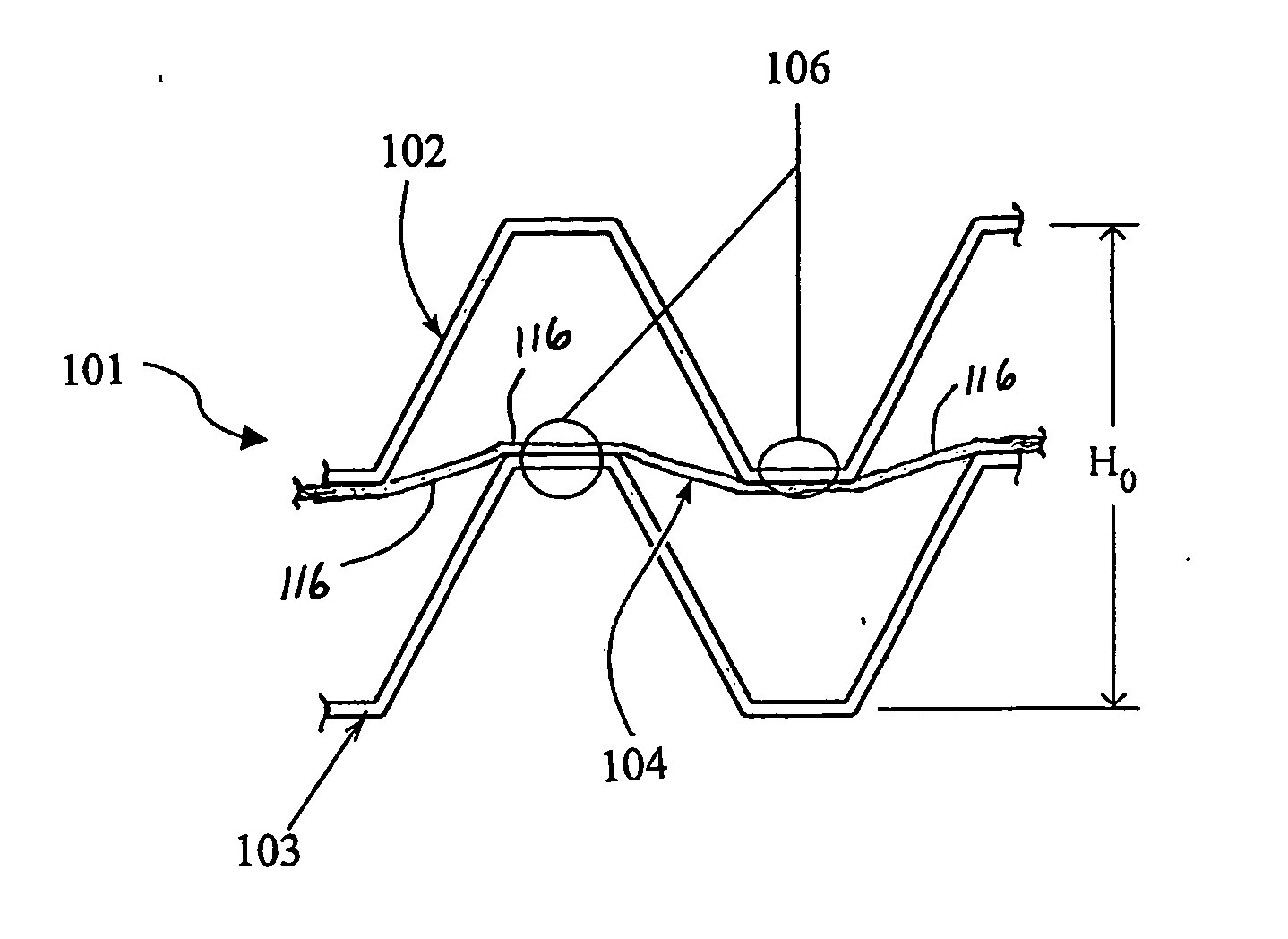

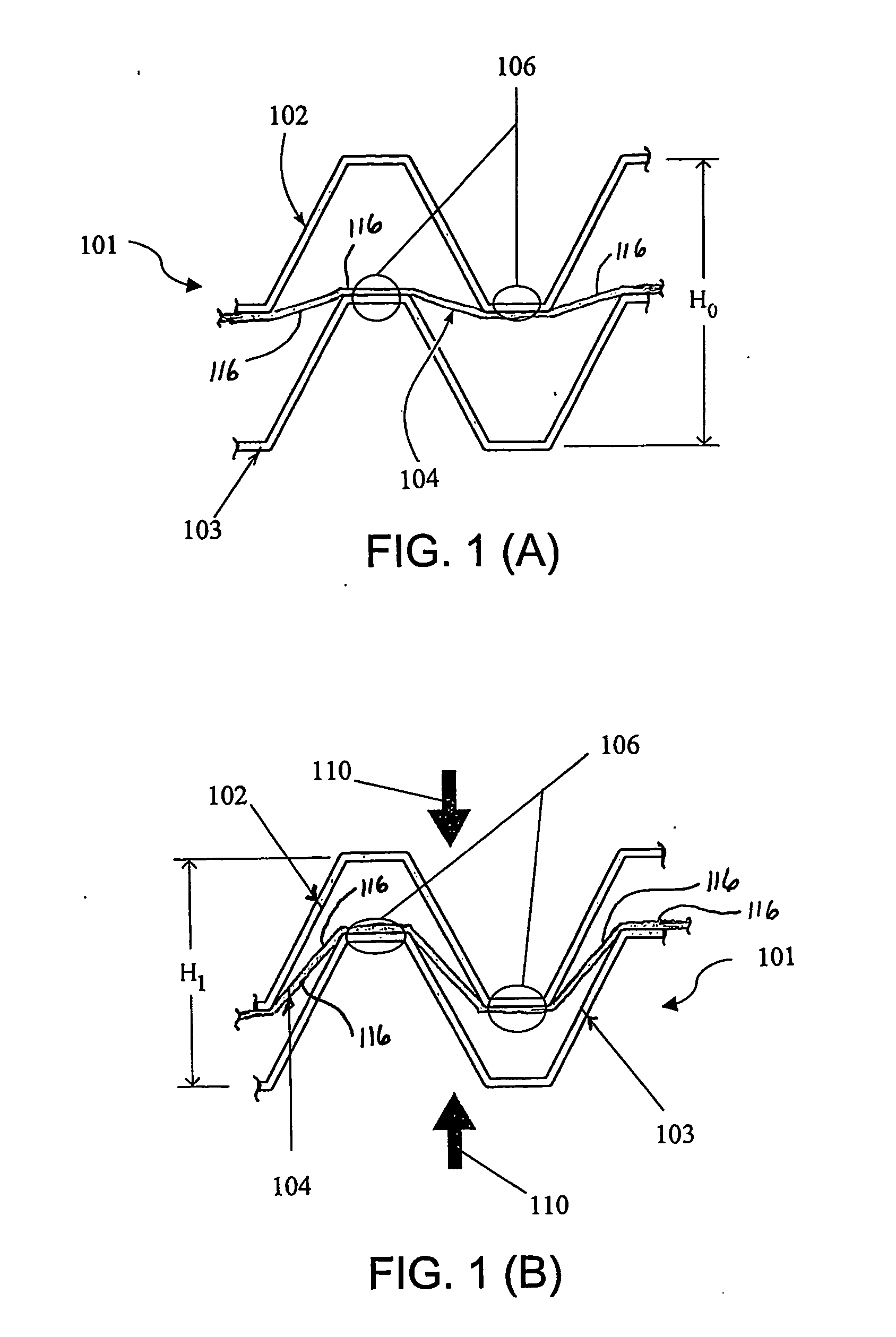

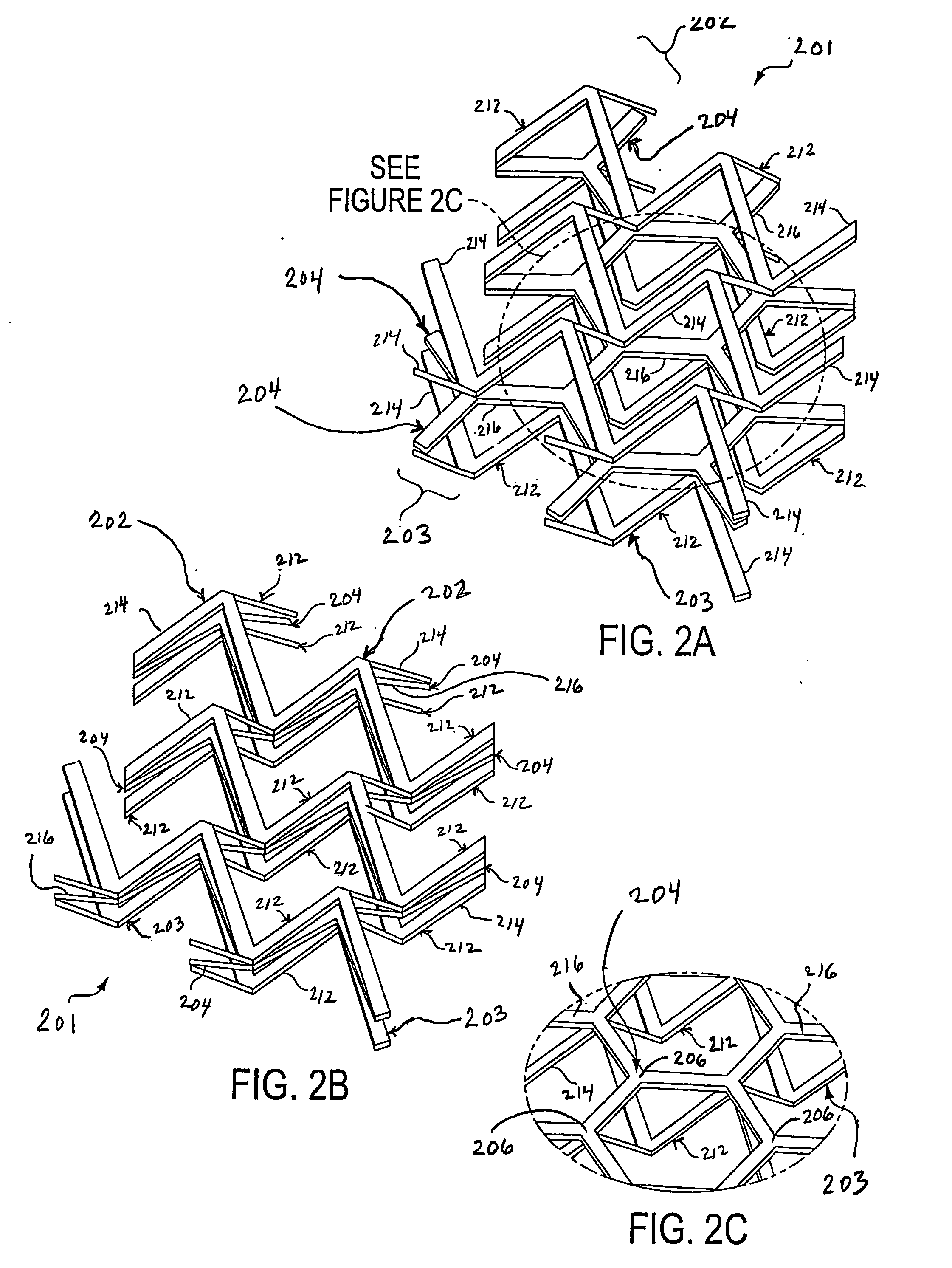

Re-entrant cellular multifunctional structure for energy absorption and method of manufacturing and using the same

InactiveUS20060286342A1Effective absorptionDeformation MinimizationLayered productsPedestrian/occupant safety arrangementCellular topologyEnergy absorption

A cellular composite laminate structure (101) adapted for efficient energy absorption is provided along with the related use and method of manufacture. The structure uses rigid cellular core layers (102, 103) designed to remain rigid during impact loading to channel an imposed compressive force into plastic deformation of deforming sacrificial layers (116). The rigid cellular core layers (102, 103) are arranged such that they will interpenetrate during impact loading while the deforming sacrificial layers (116) are arranged such that they will impede interpenetration of the rigid cellular core layers (102, 103) and be subjected to tensile deformation only. The rigid cellular core layers (102, 103) and deforming sacrificial layers (116) can be formed to create two-dimensional cellular sheet or three-dimensional cellular topology structures. The deforming sacrificial layers (116) can be connected at various points to the rigid cellular core layers (102, 103) or can be connected only at the periphery of the overall structure. Higher strength, rigid materials are contemplated for the rigid cellular core layers (102, 103) while ductile materials are contemplated for the deforming sacrificial layers (116).

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

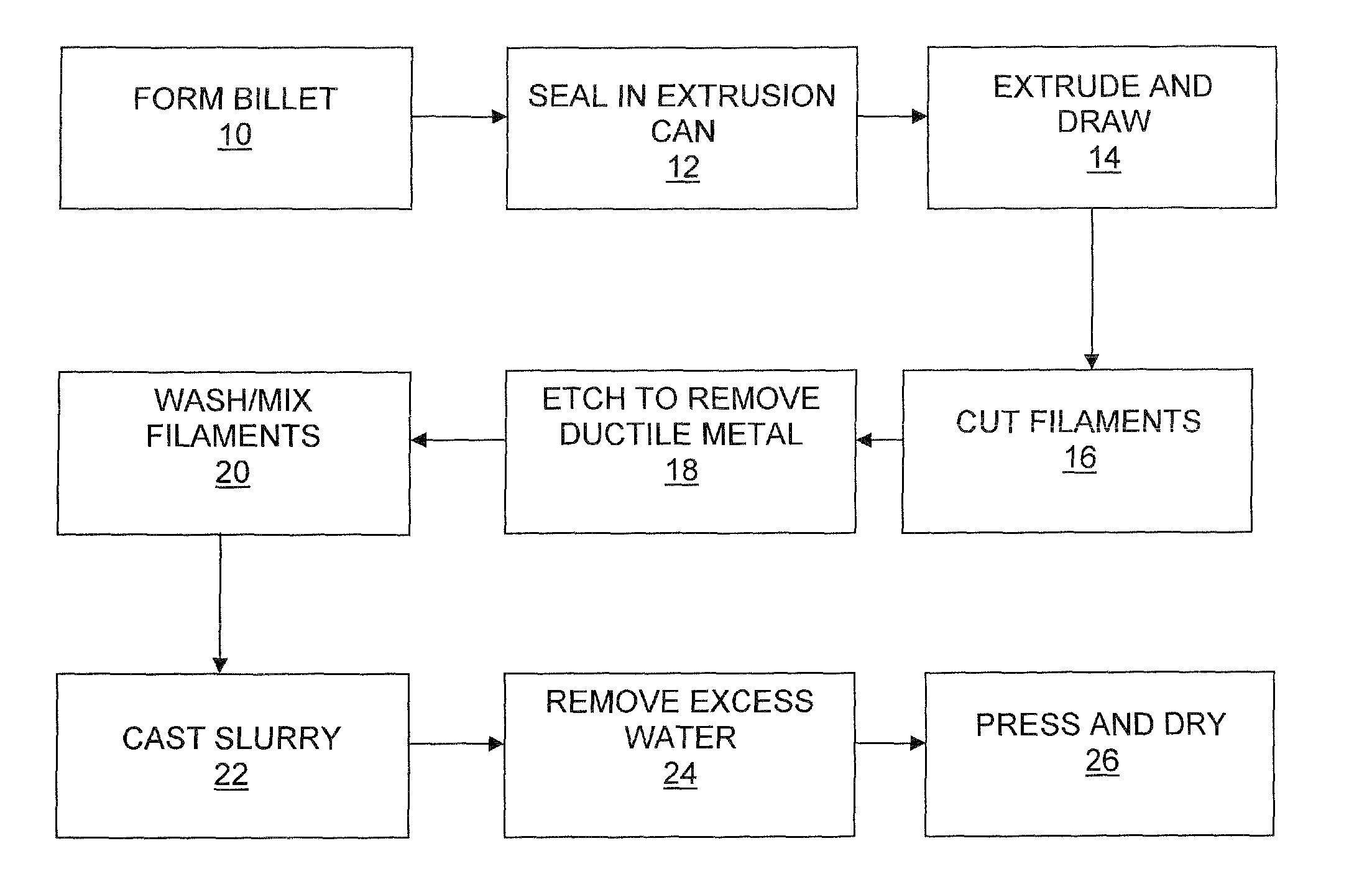

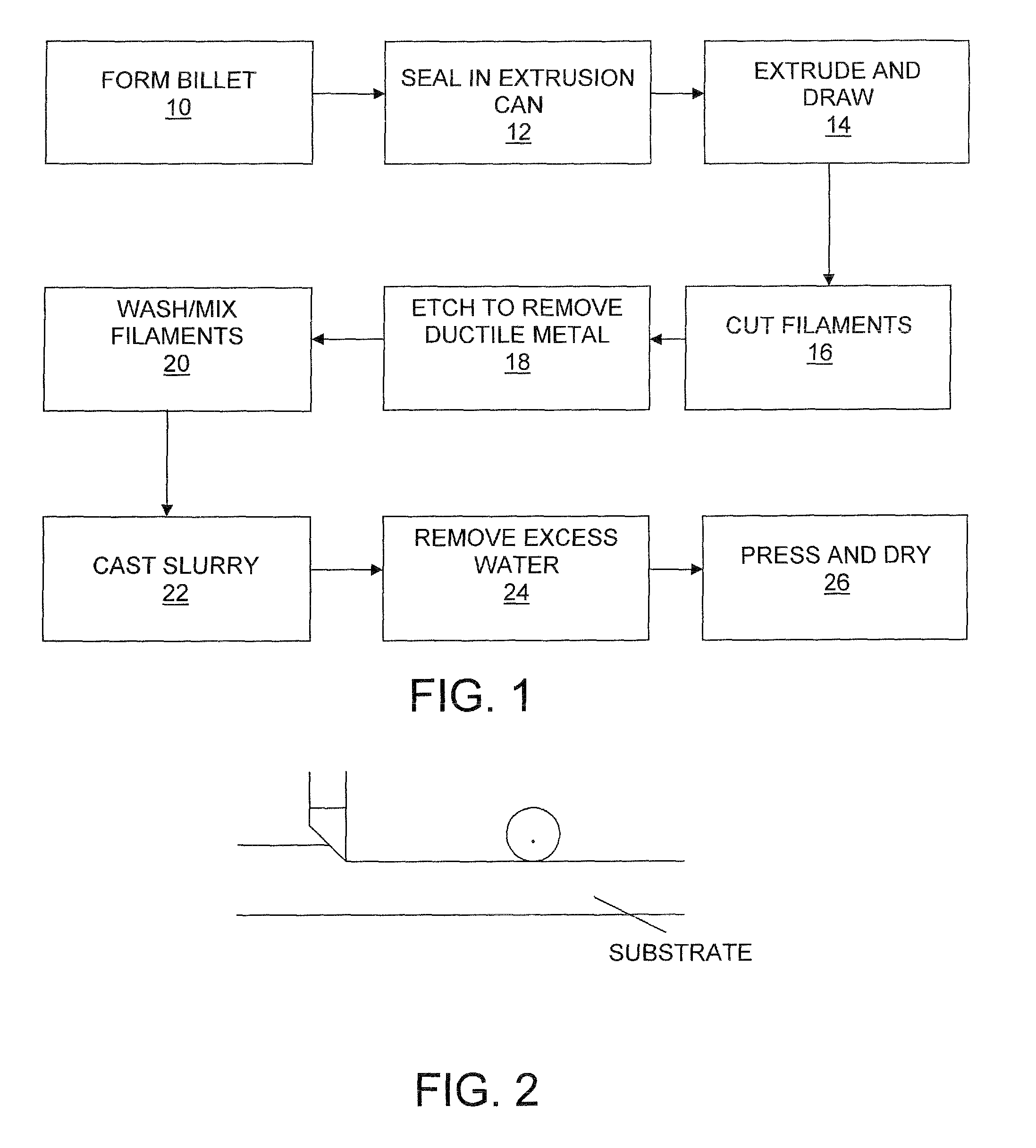

Wet electrolytic capacitor and method for fabricating of improved electrolytic capacitor cathode

A process for making a valve metal material useful for forming electrolytic devices comprising the steps of: establishing multiple tantalum or niobium components in a billet of a ductile material; working the billet to a series of reduction steps to form said tantalum or niobium components into elongated elements; cutting the resulting elongated elements and leaching the ductile metal from the elements; washing and mixing the cut elements; and forming the cut elements into a sheet. The resulting sheet may be formed into anodes and cathodes and assembled to form a wet electrolytic capacitor.

Owner:COMPOSITE MATERIALS TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com