Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3487 results about "Metal coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Capacity Anode Materials for Lithium Ion Batteries

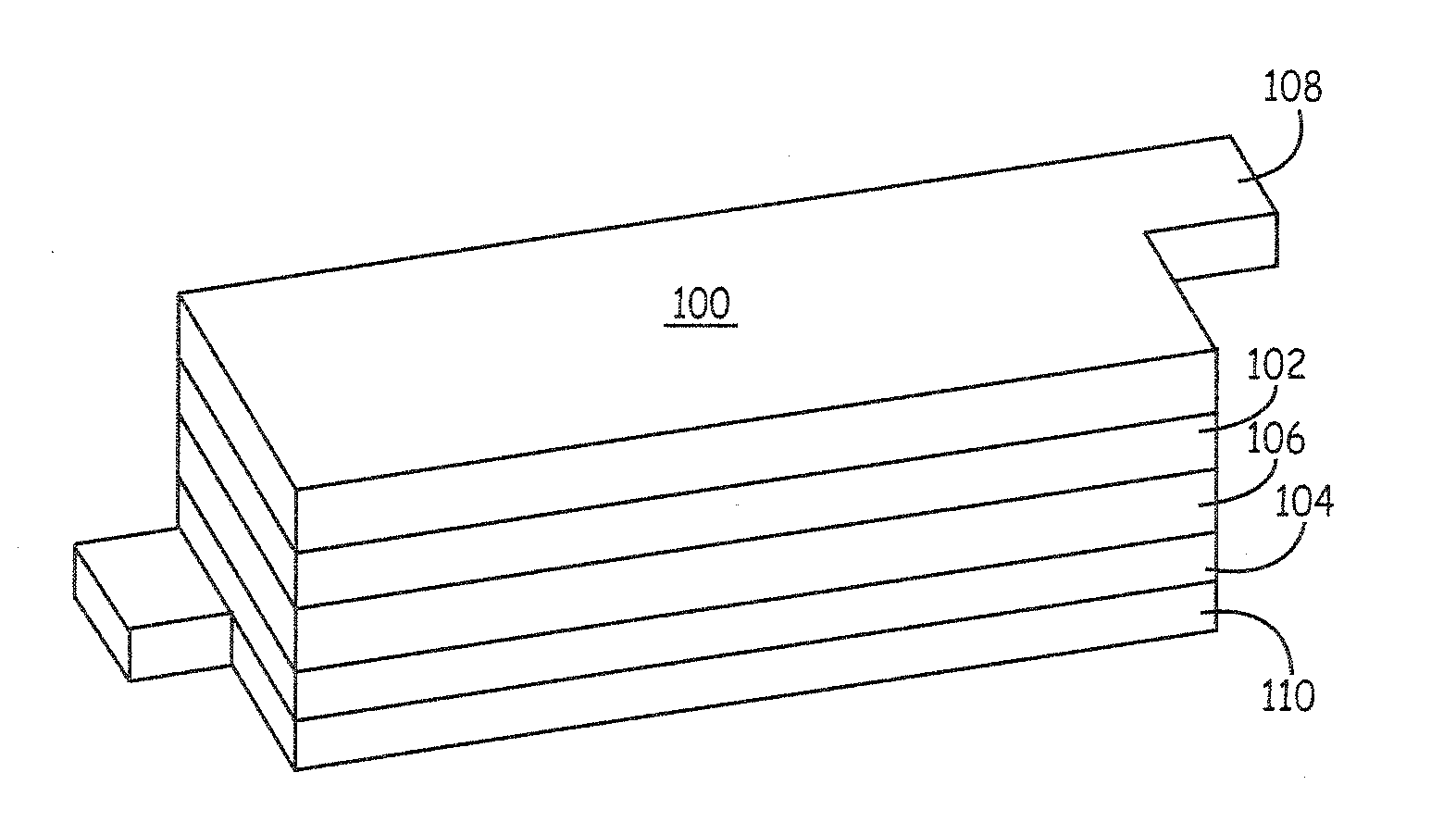

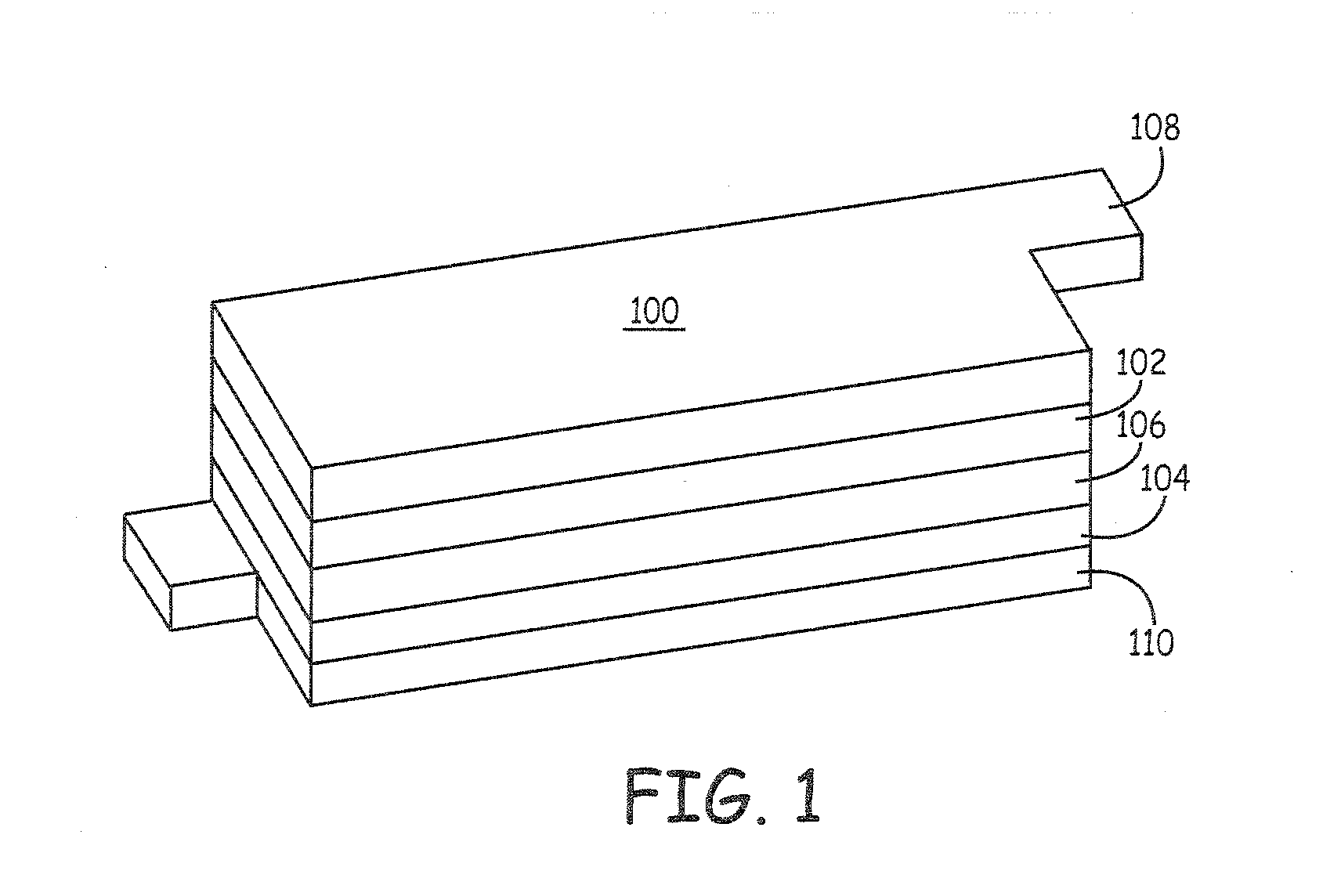

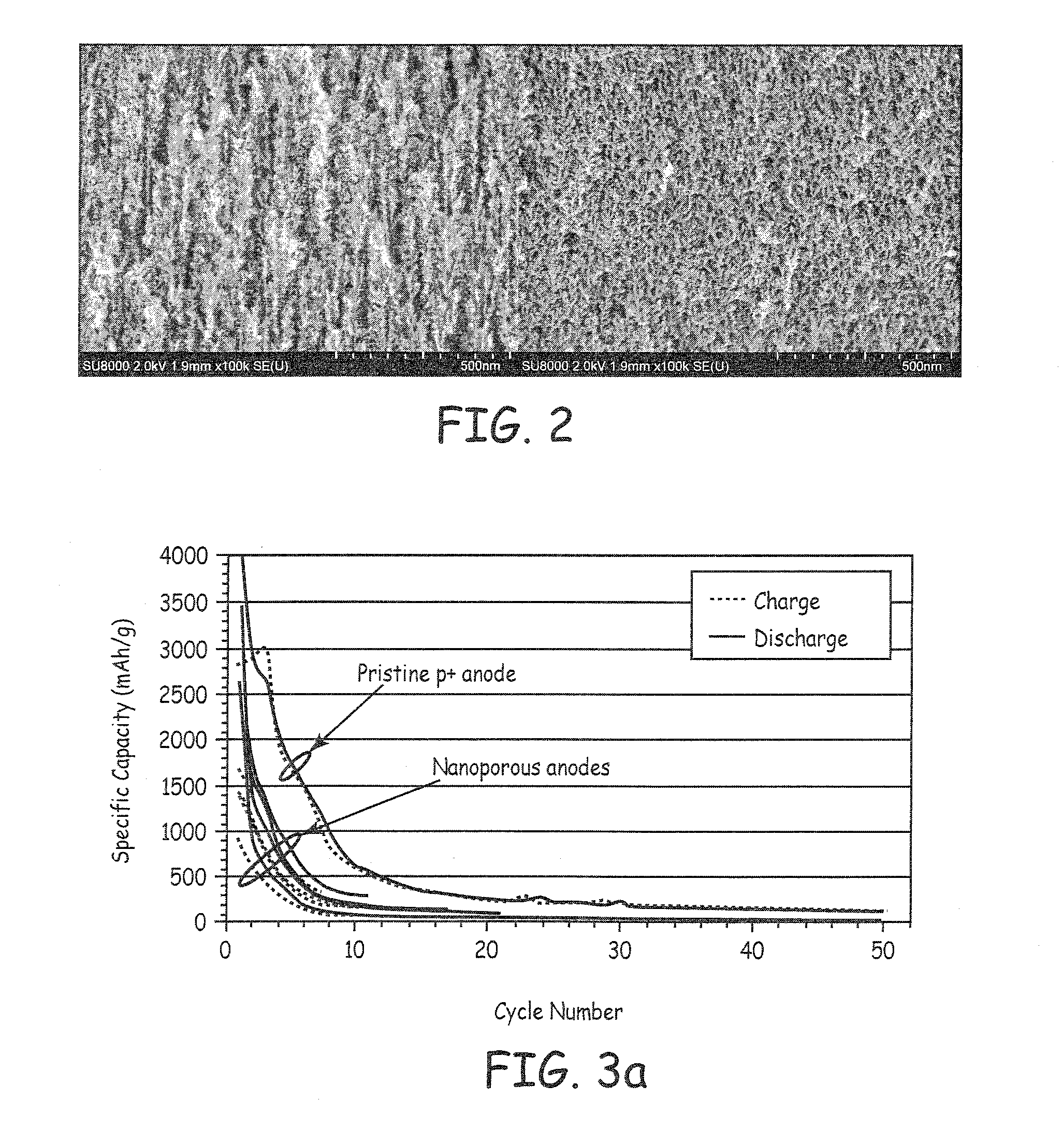

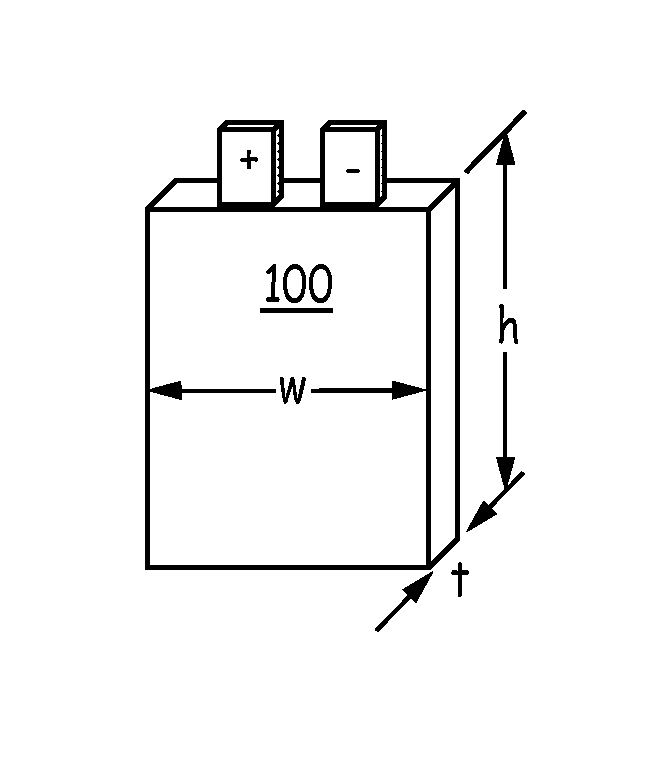

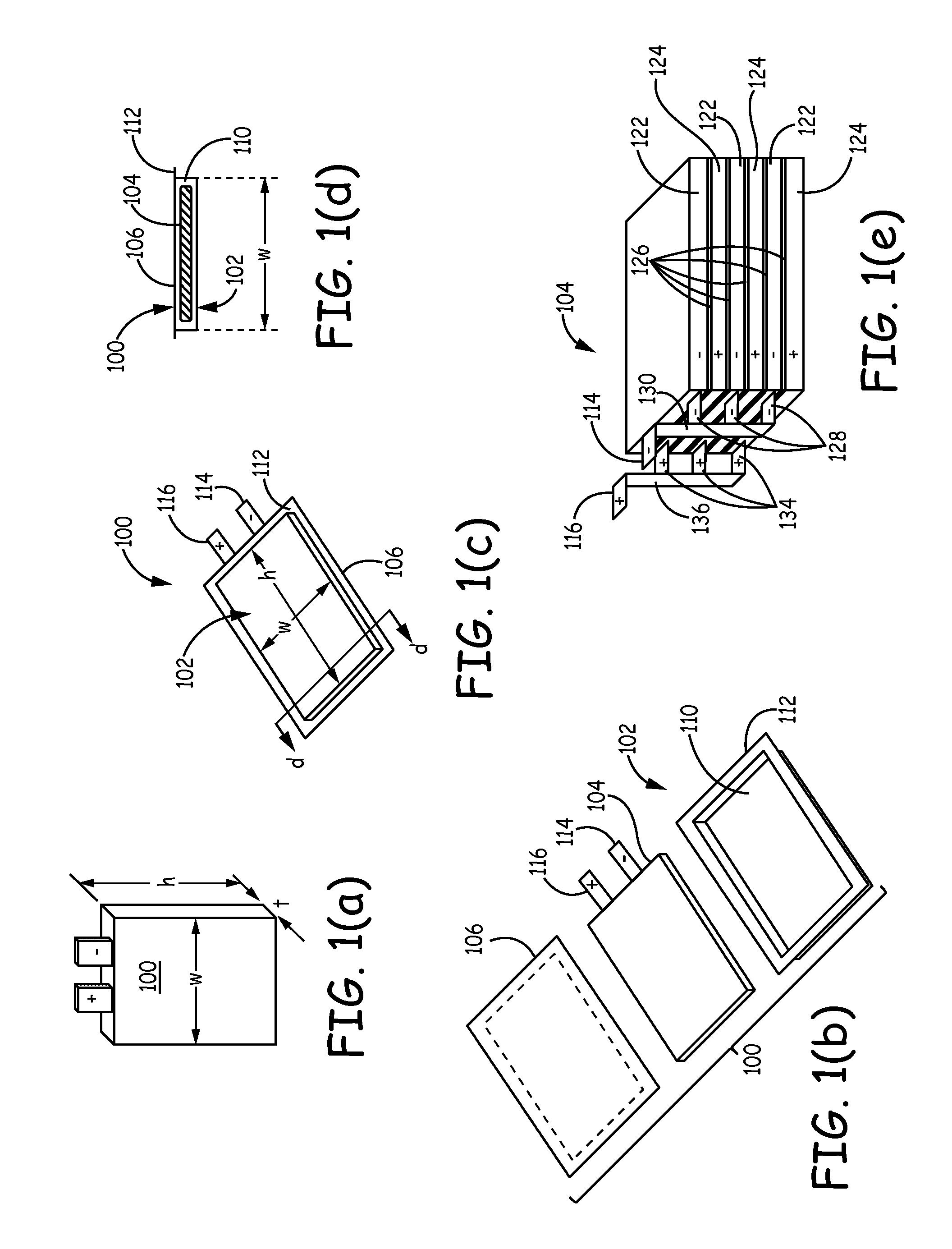

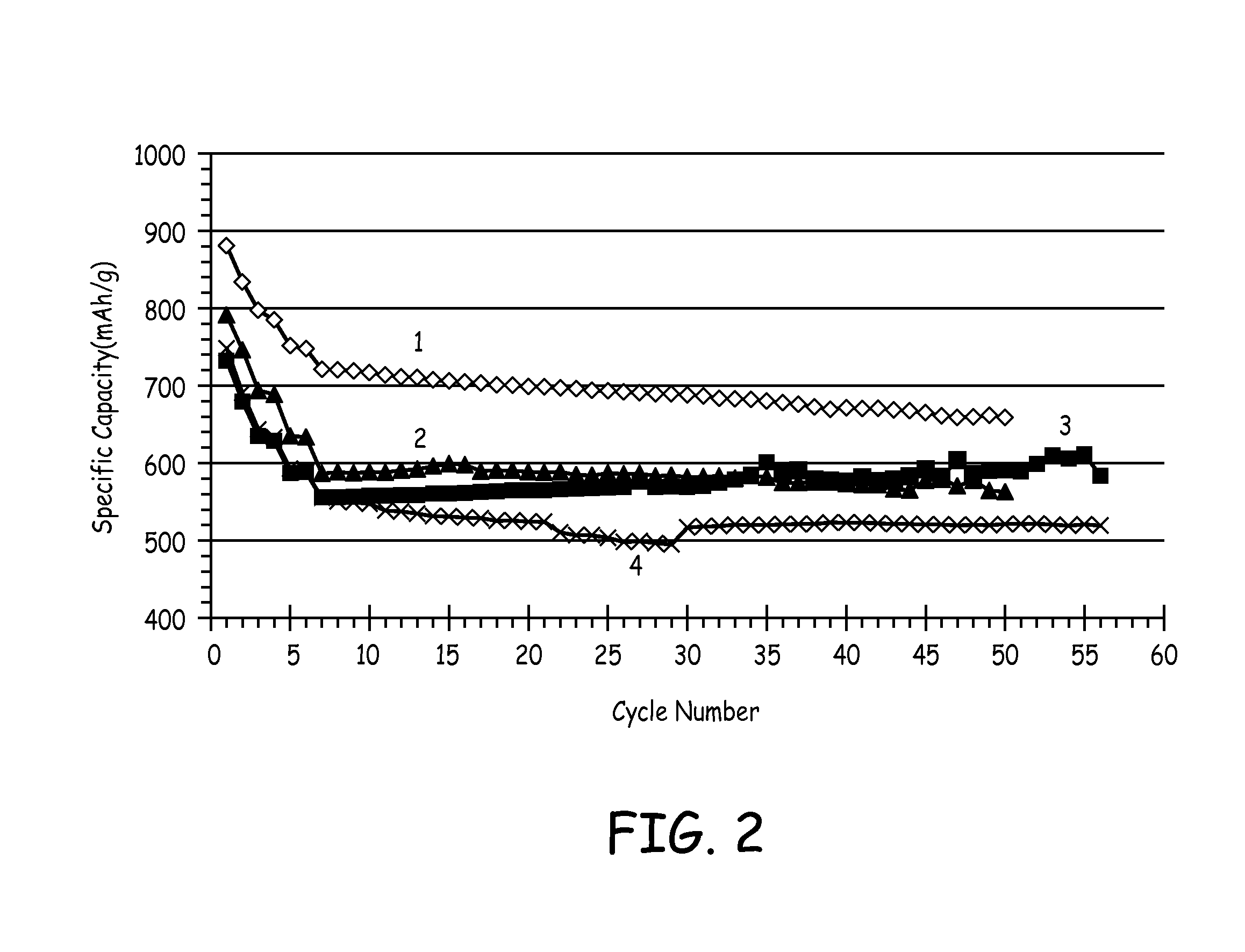

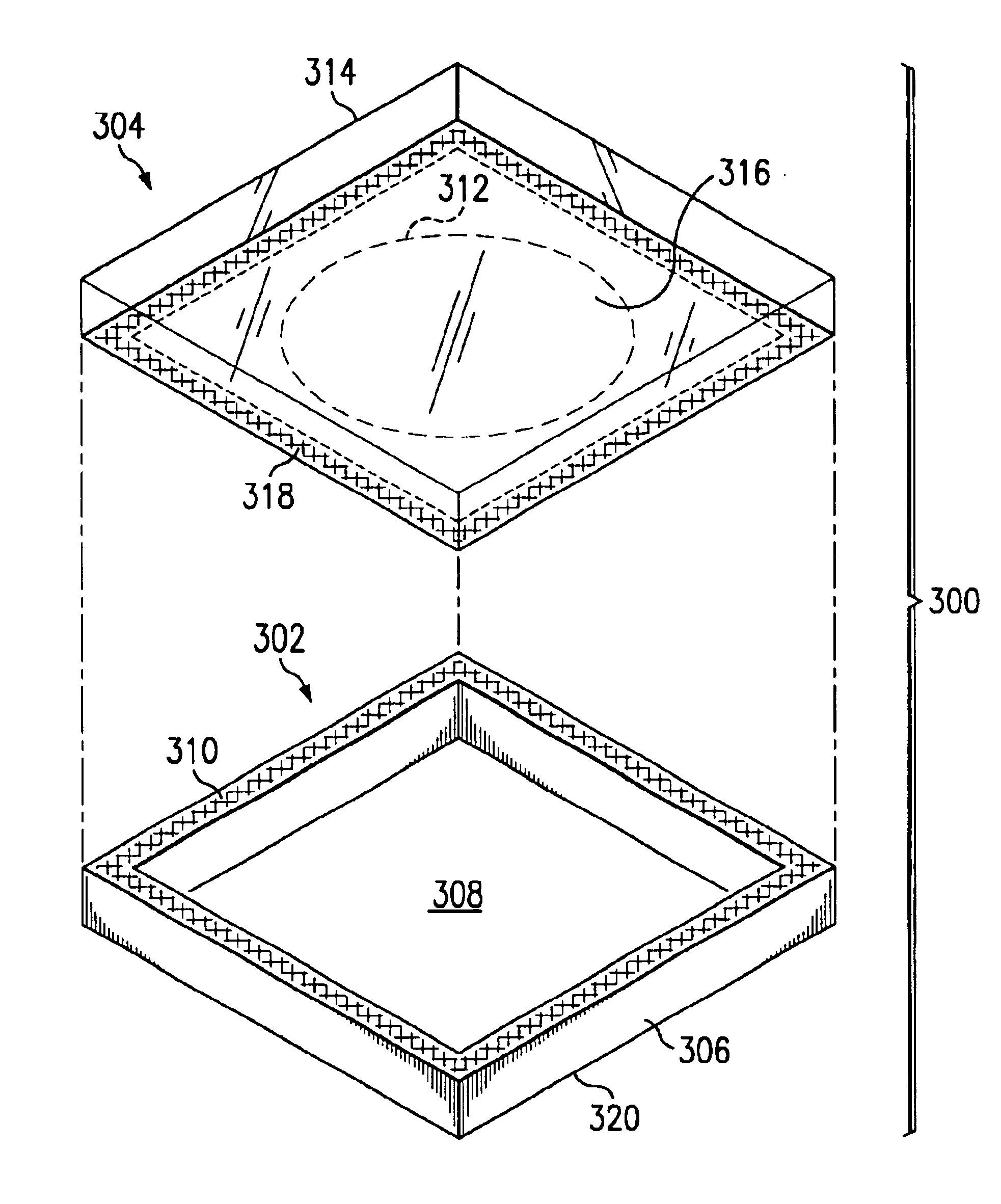

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

Process for the electrolytic deposition of metal layers

InactiveUS6099711AOptimize allocationImpairing propertyCellsElectrolysisHigh current densityMetal coating

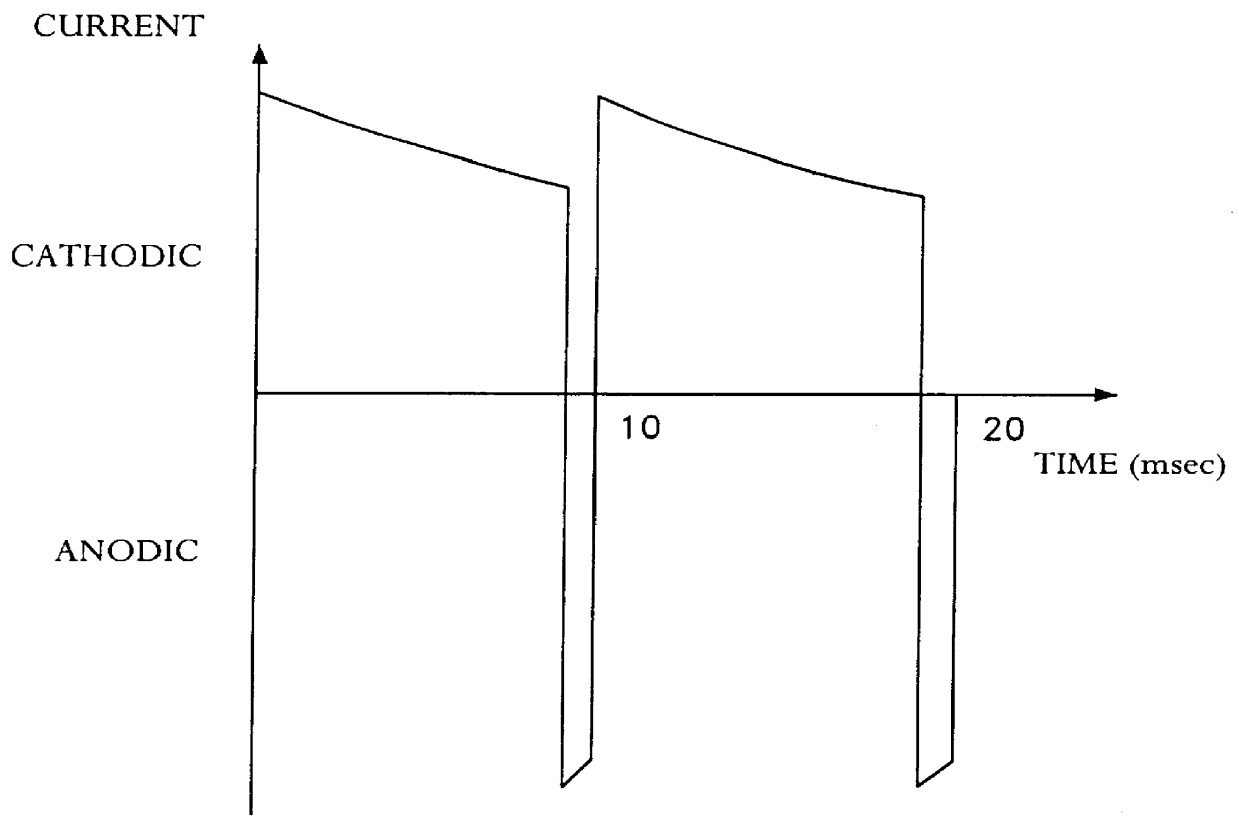

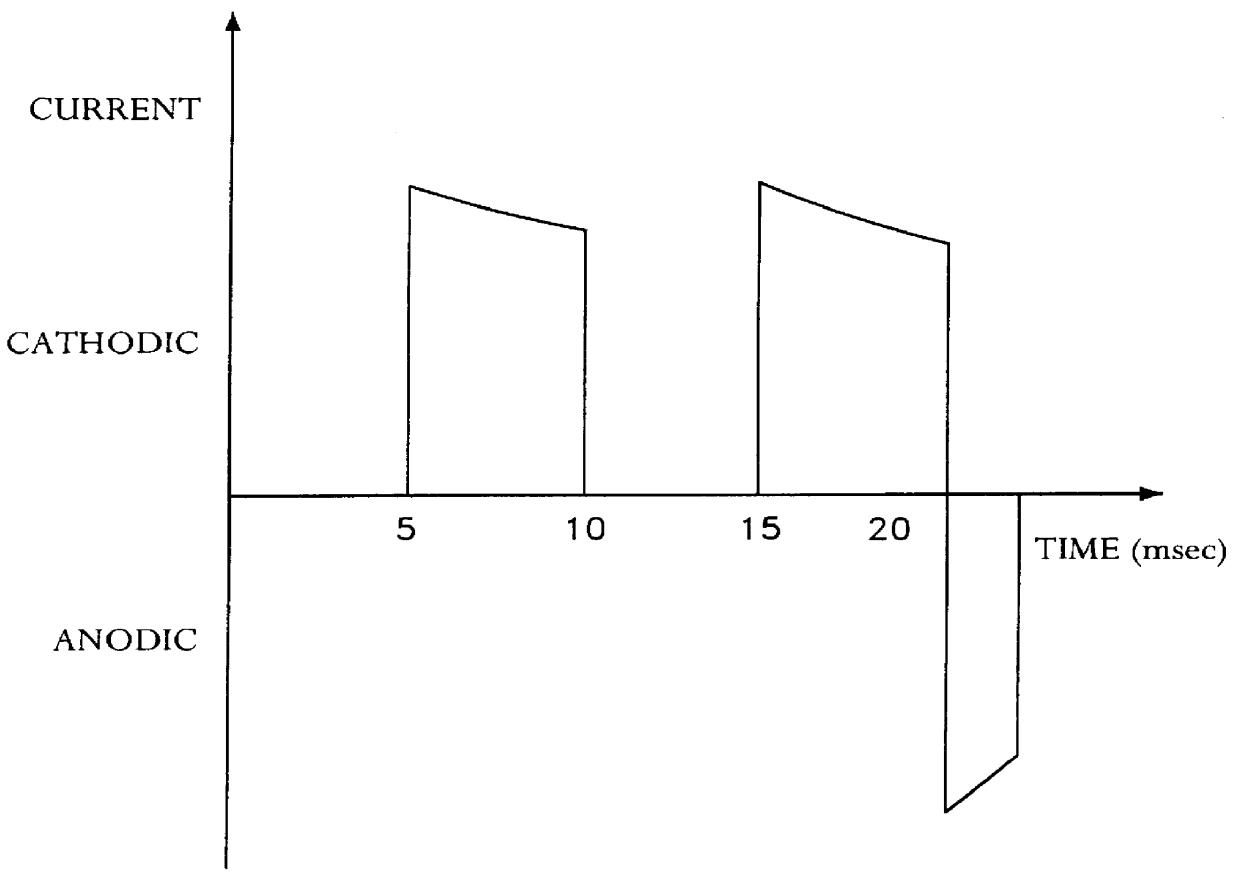

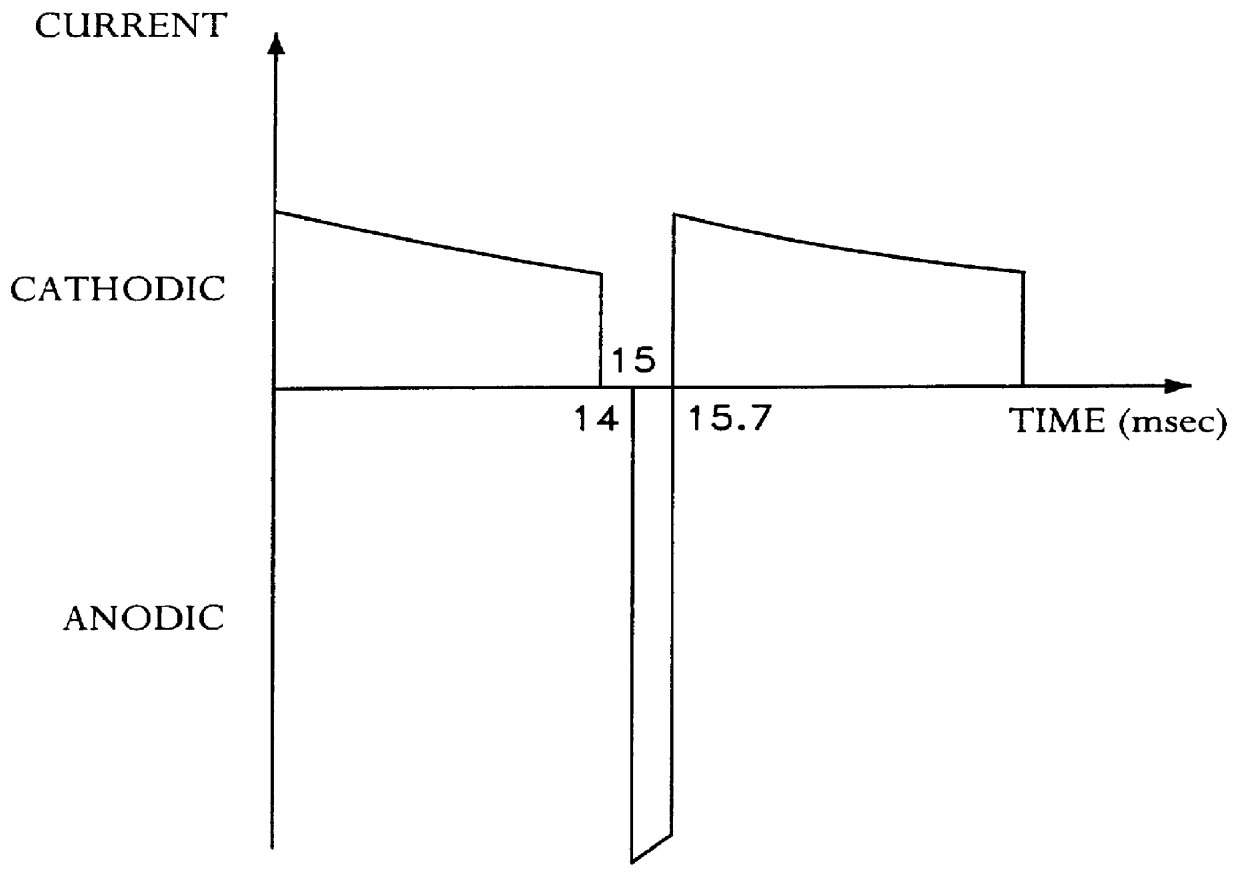

PCT No. PCT / EP96 / 05140 Sec. 371 Date Apr. 23, 1998 Sec. 102(e) Date Apr. 23, 1998 PCT Filed Nov. 21, 1996 PCT Pub. No. WO97 / 19206 PCT Pub. Date May 29, 1997The invention relates to a method for the electrolytic deposition of metal coatings, in particular of copper coatings with certain physical-mechanical and optical properties and uniform coating thickness. According to known methods using soluble anodes and applying direct current, only uneven metal distribution can be attained on complex shaped workpieces. By using a pulse current or pulse voltage method, the problem of the coatings being of varying thickness at various places on the workpiece surfaces can indeed be reduced. However, the further problem of the geometric ratios being changed continuously during the depositing process by dissolving of the anodes is not resolved thus. This can be avoided by using insoluble anodes. In order to guarantee sufficient stability of the anodes and a bright coating even at those points on the workpiece surfaces, onto which the metal is deposited with high current density, it is essential to add compounds of an electrochemically reversible redox system to the depositing solution.

Owner:ATOTECH DEUT GMBH

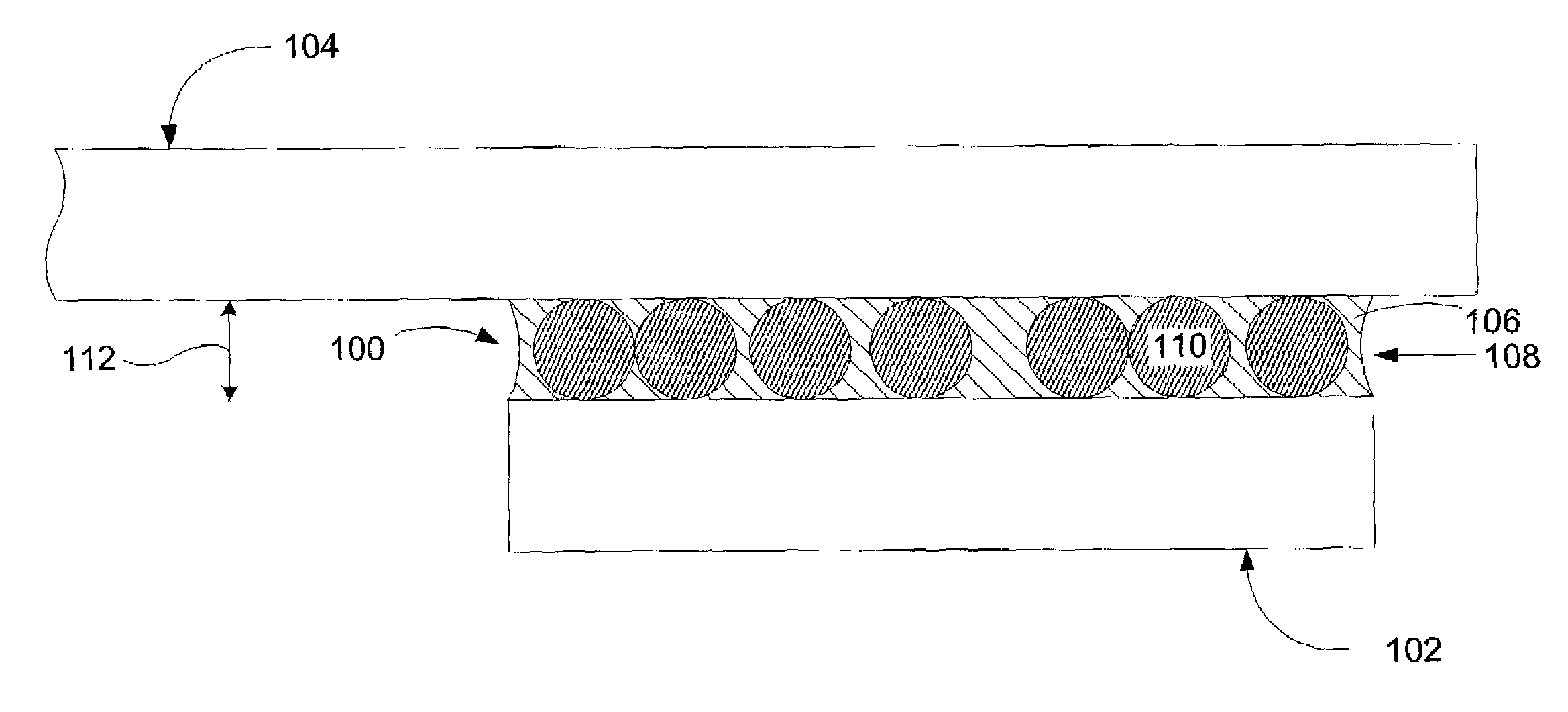

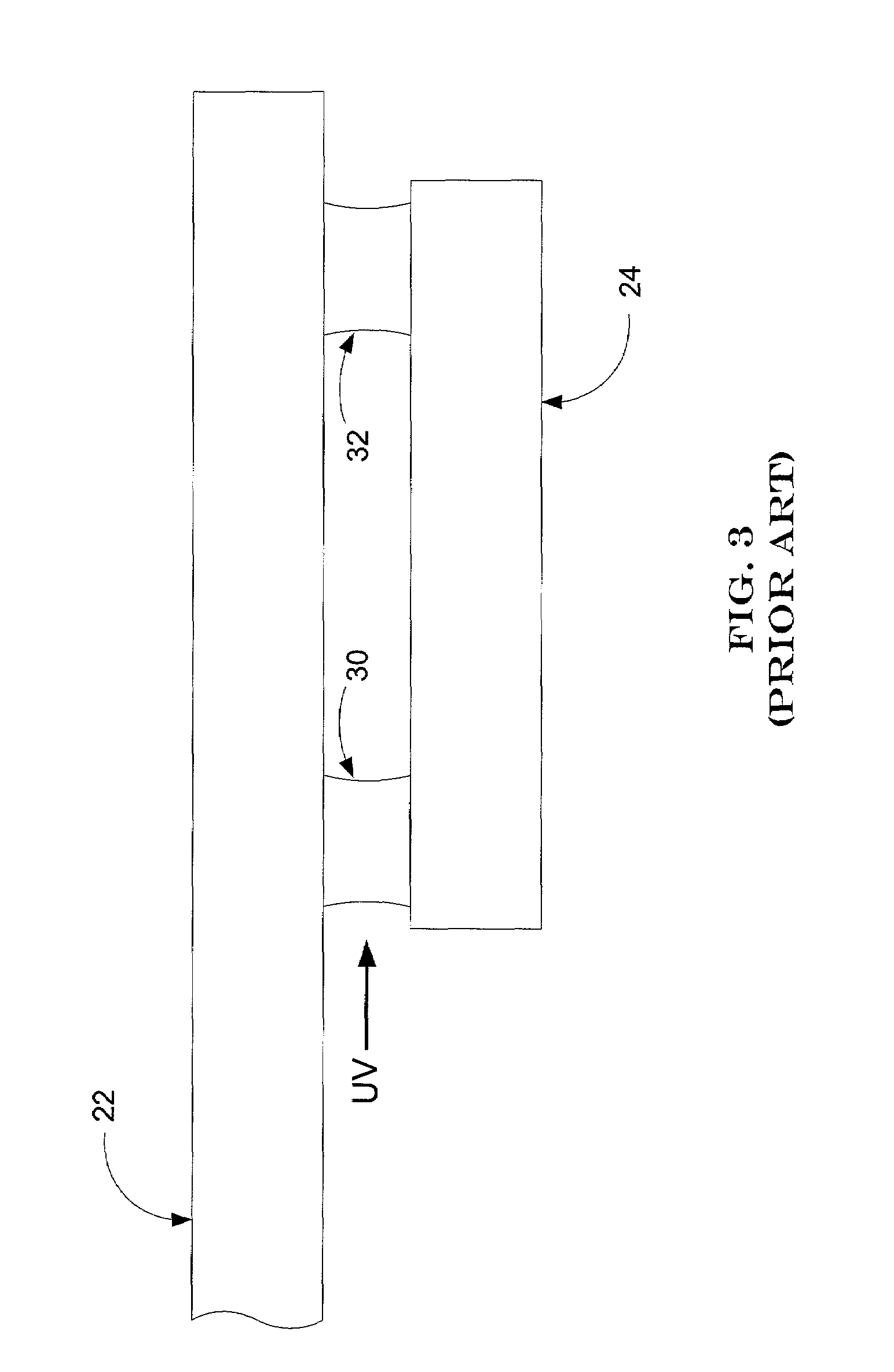

UV curable and electrically conductive adhesive for bonding magnetic disk drive components

An electrically conductive adhesive includes a resin component, a photoinitiator, and metal-coated polymer beads. The beads have an average diameter and a very narrow size distribution around the average diameter. The adhesive is applied between a read / write head and a suspension to attach the two, and the adhesive is cured by exposure to an illumination and / or heat. A pad spacer is included between the read / write head and the suspension to define a spacing and parallelism therebetween. The beads in the adhesive can form one or more layers between the read / write head and the suspension or can be disordered. The metal coating of the beads provide electrical conductivity between the read / write head and the suspension.

Owner:WESTERN DIGITAL TECH INC

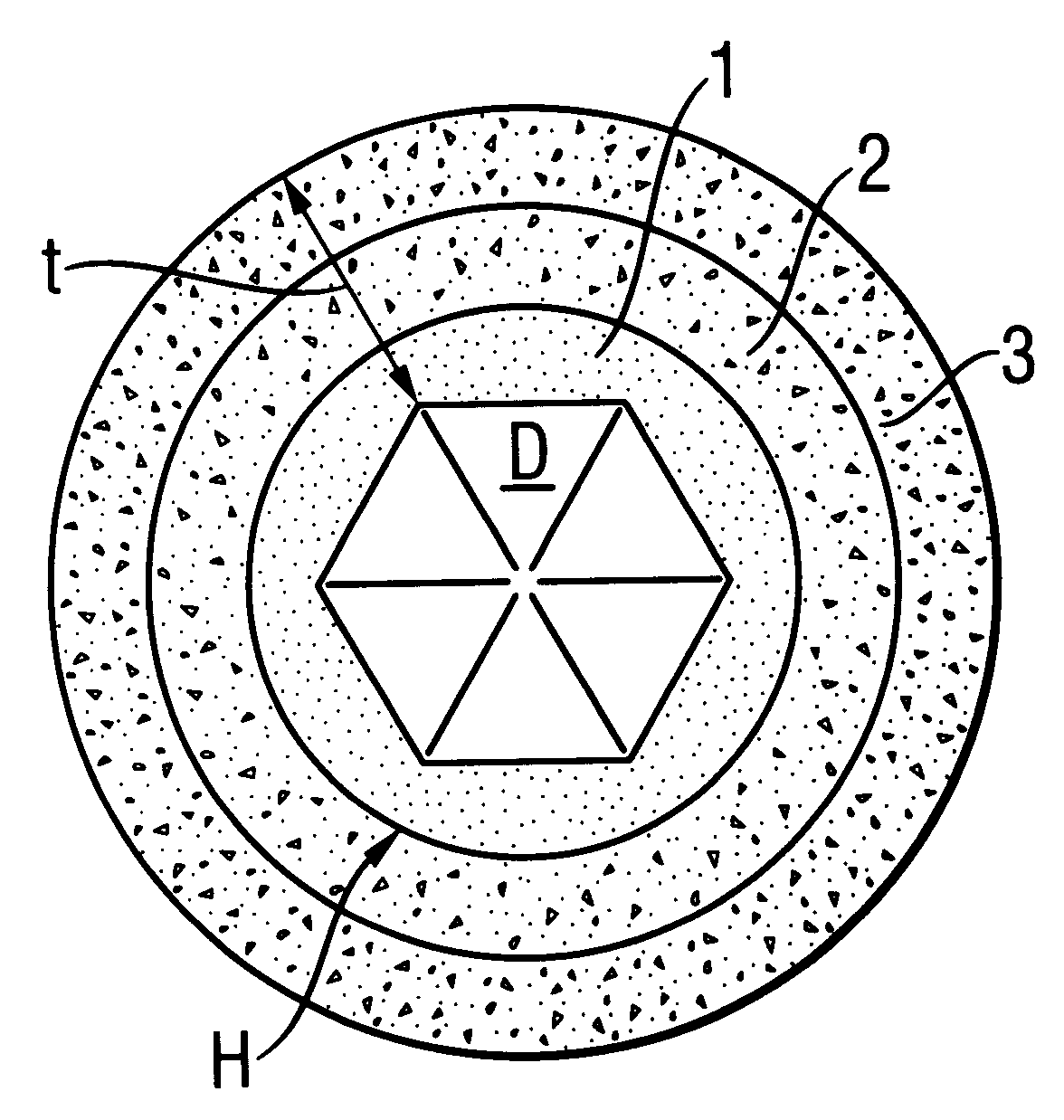

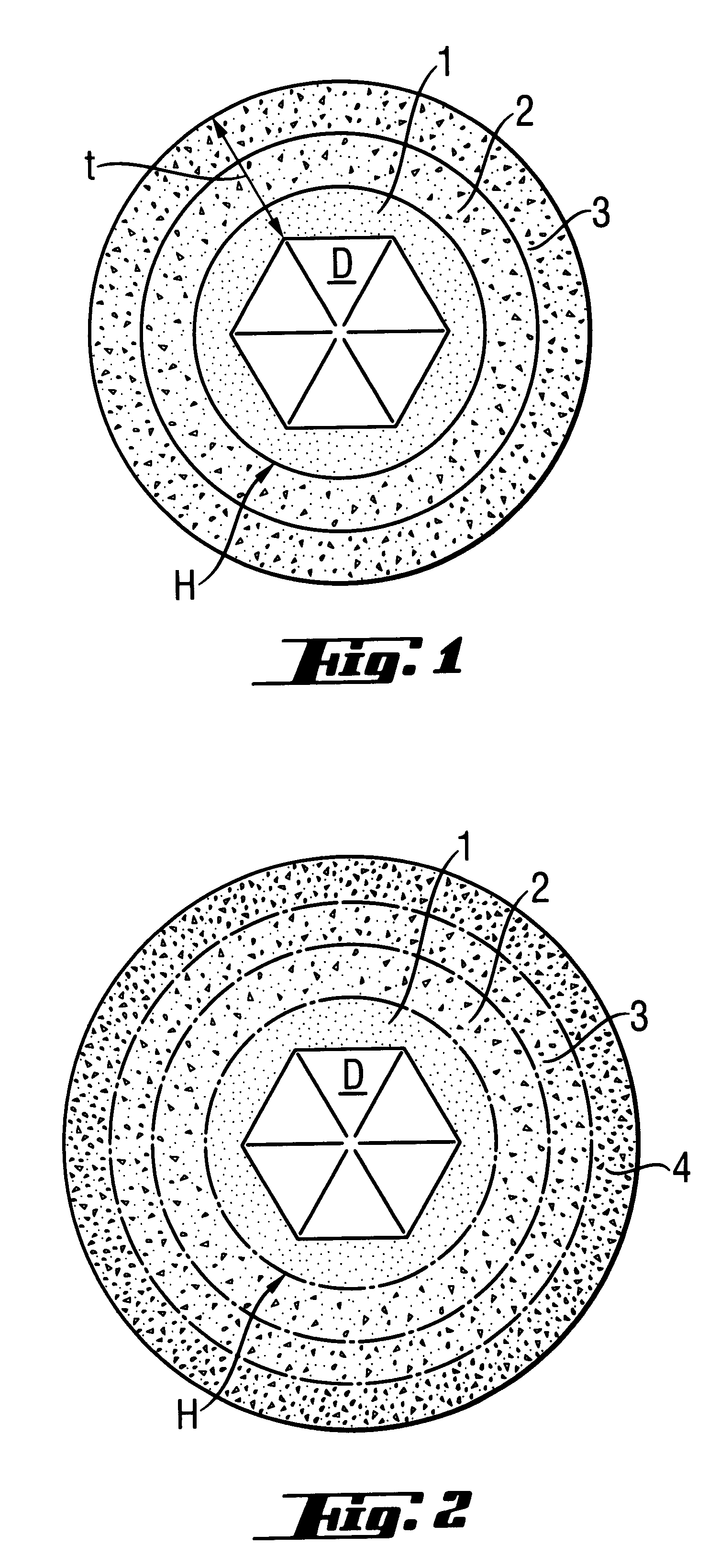

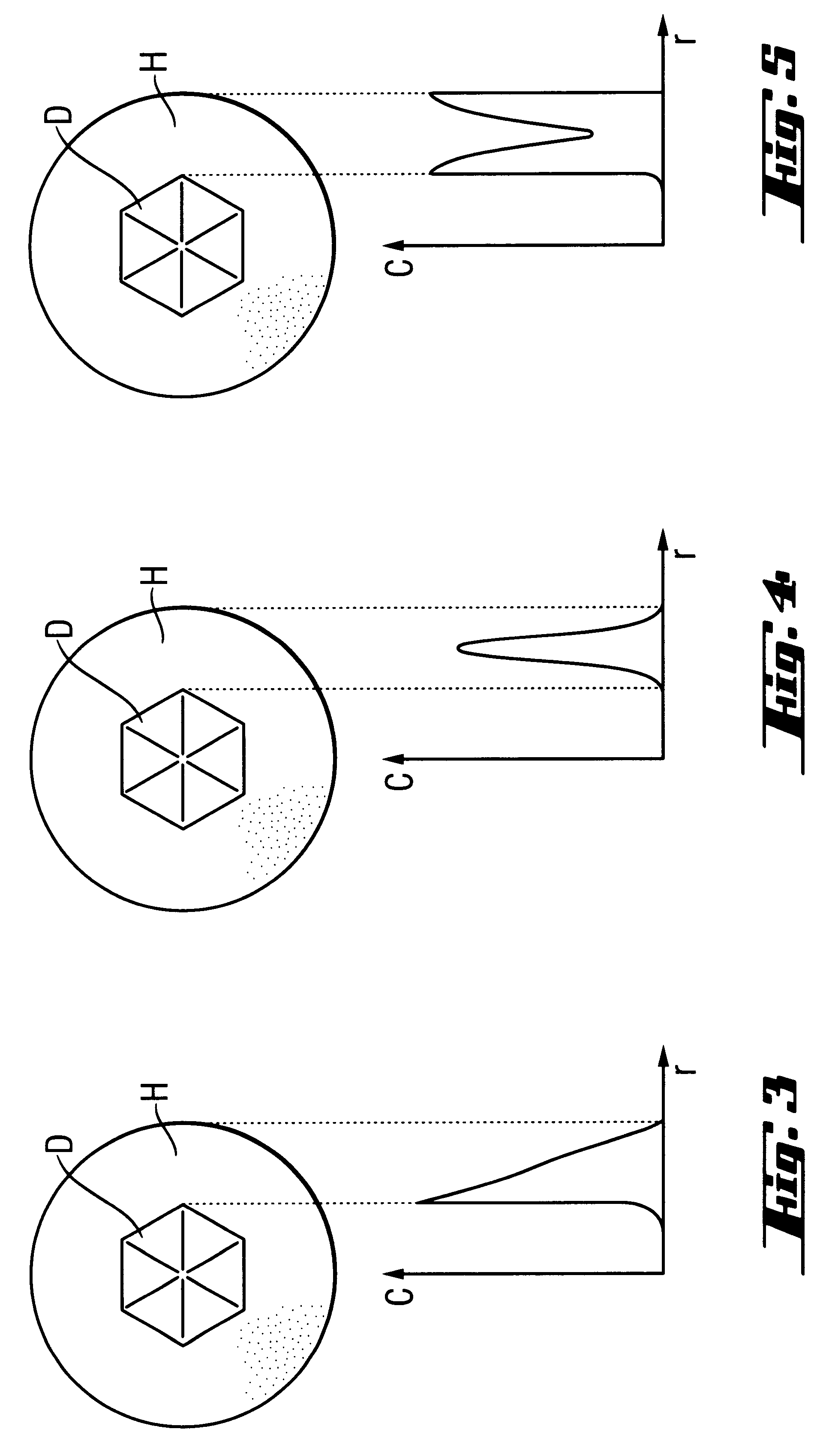

Abrasive cutter containing diamond particles and a method for producing the cutter

InactiveUS6238280B1Eliminate disadvantagesAvoid attenuationRevolution surface grinding machinesBonded abrasive wheelsMetal coatingDiamond crystal

An abrasive cutter formed of at least one diamond particle, preferably at least one mono-diamond crystal and metallic binder material distinguished by the fact that the diamond particle (D) has a size of about 50 mum to about 500 mum and each diamond particle (D) is enclosed by a coating (H) produced in a fluidized bed with the coating having a wall thickness of about 10 mum to about 200 mum. The volume of the coating (H) constitutes at least 30% of the volume of the diamond particles (D) in the fully consolidated state following individual sintering of the coated diamond particles (D, H). The abrasive cutters can be applied directly onto an abrasive tool. Further they can be processed to form composite cutters or cutting segments. In the method of forming the abrasive cutter, the diamond particle (D) is brought into a fluidized bed reactor and enclosed in a metallic coating (H). Coated diamond particle (D, H) can be processed into larger cutters or segments in each case individually sintered and fixed directly on an abrasive tool.

Owner:HILTI AG

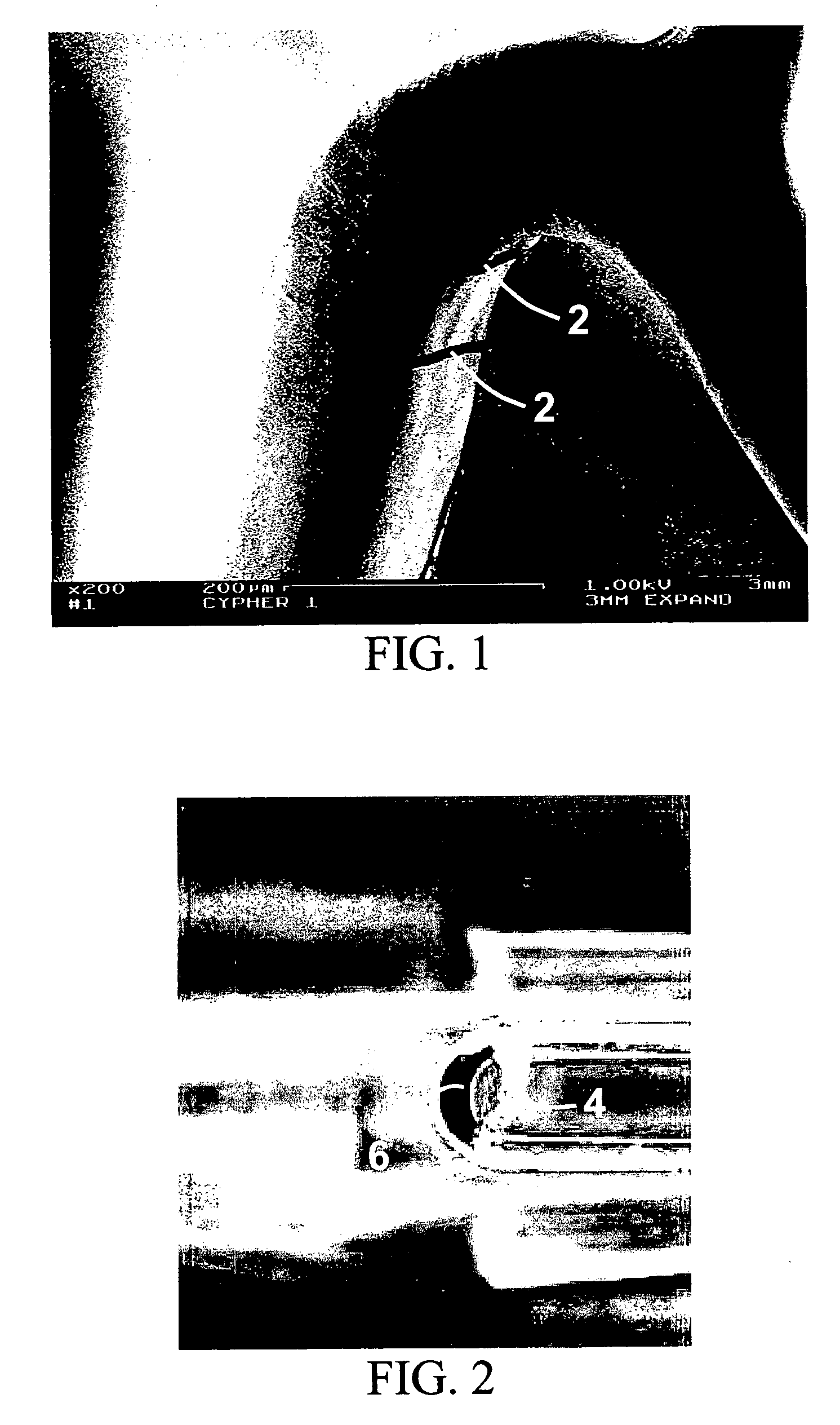

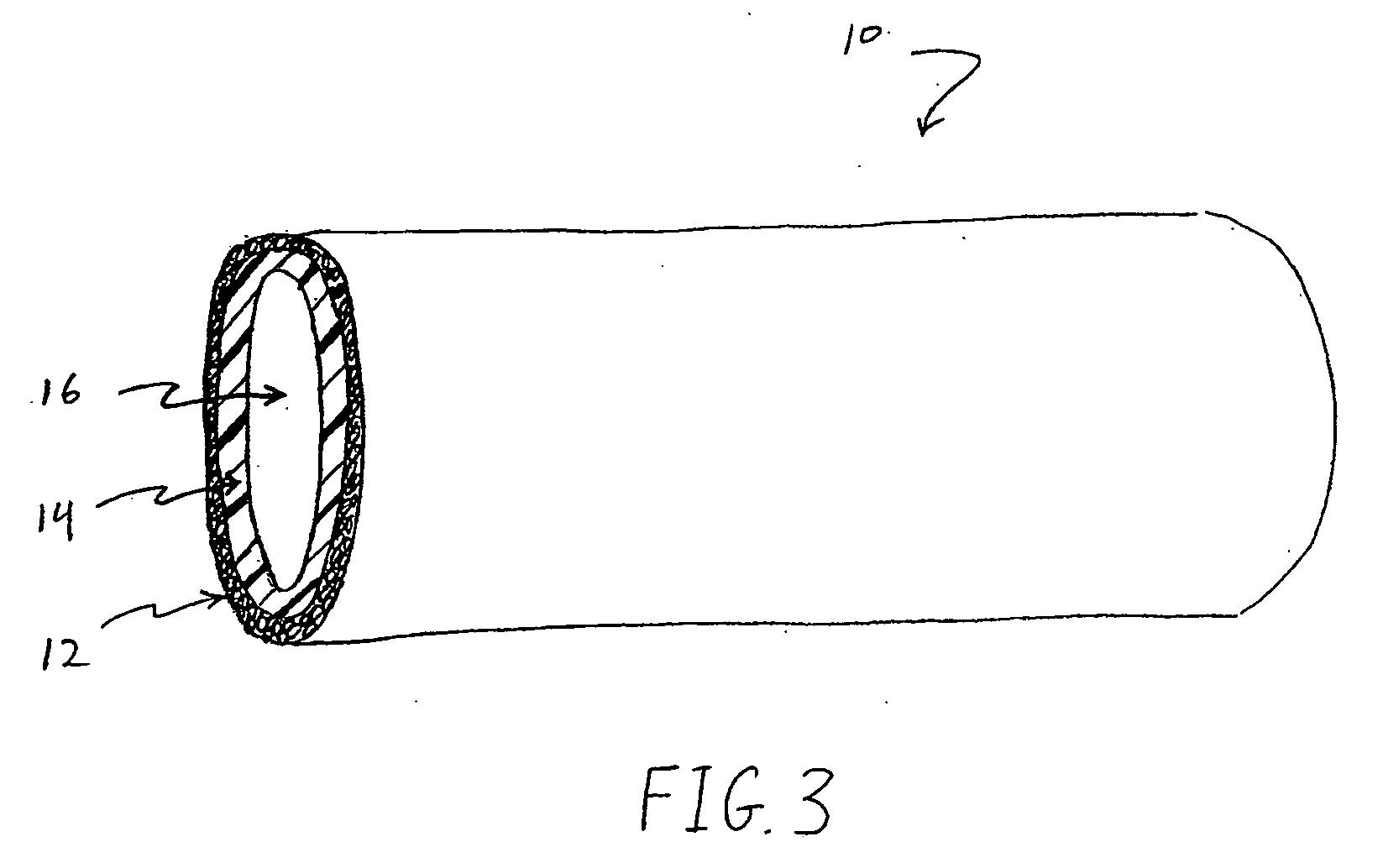

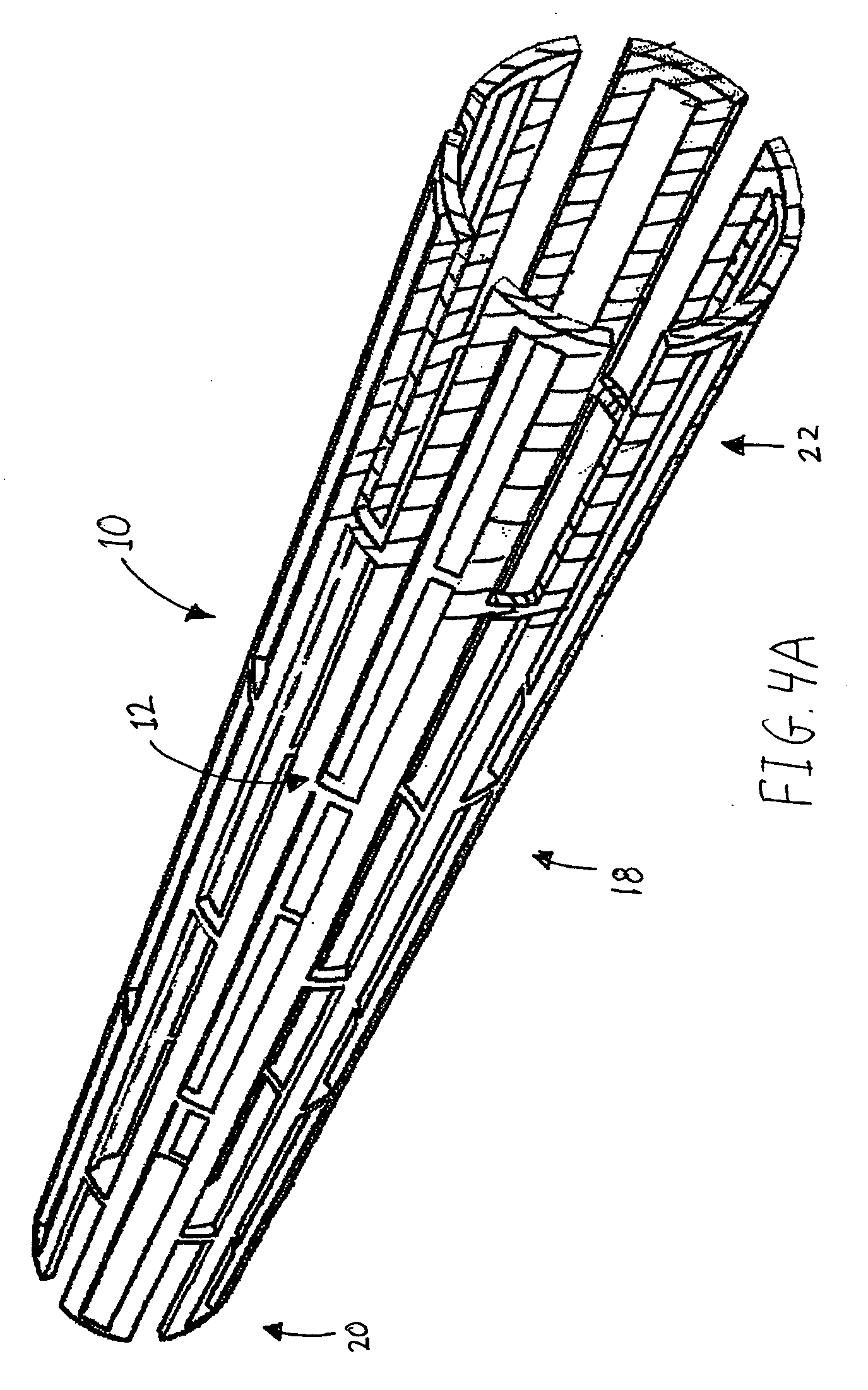

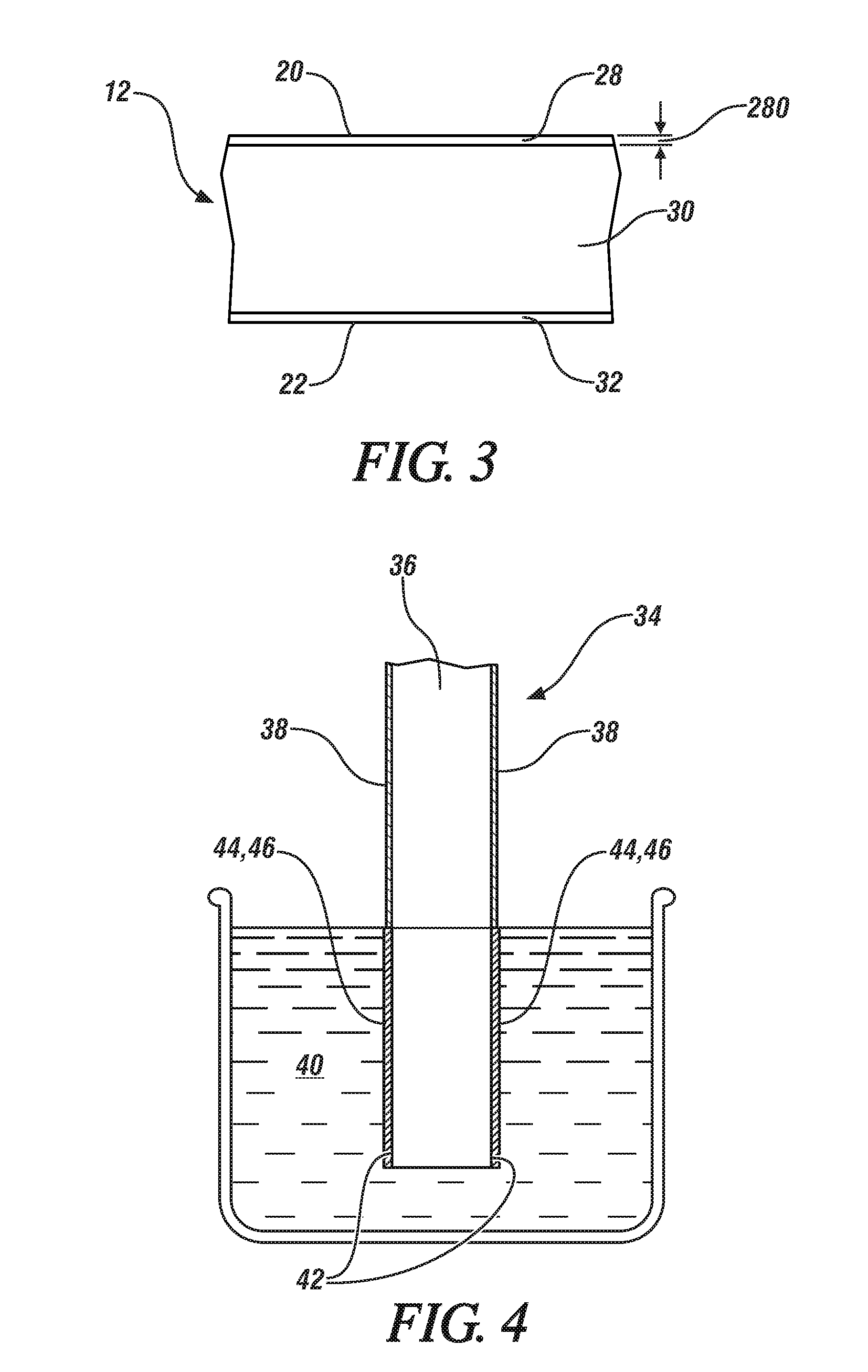

Method for loading nanoporous layers with therapeutic agent

The present invention relates generally to medical devices with therapy eluting components and methods for making same. More specifically, the invention relates to implantable medical devices having at least one porous layer, and methods for making such devices, and loading such devices with therapeutic agents. A mixture or alloy is placed on the surface of a medical device, then one component of the mixture or alloy is generally removed without generally removing the other components of the mixture or alloy. In some embodiments, a porous layer is adapted for bonding non-metallic coating, including drug eluting polymeric coatings. A porous layer may have a random pore structure or an oriented or directional grain porous structure. One embodiment of the invention relates to medical devices, including vascular stents, having at least one porous layer adapted to resist stenosis or cellular proliferation without requiring elution of therapeutic agents. The invention also includes methods, devices, and specifications for loading of drugs and other therapeutic agents into nanoporous coatings.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

Medical devices having antimicrobial coatings thereon

InactiveUS20050008676A1Improve antibacterial propertiesLow cytotoxicityAntibacterial agentsBiocideMetal coatingExtended wear contact lenses

The present invention provides a medical device, preferably a contact lens, which a core material and an antimicrobial metal-containing LbL coating that is not covalently attached to the medical device and can impart to the medical device an increased hydrophilicity. The antimicrobial metal-containing coating on a contact lens of the invention has a high antimicrobial efficacy against microorganisms including Gram-positive and Gram-negative bacterial and a low toxicity, while maintaining the desired bulk properties such as oxygen permeability and ion permeability of lens material. Such lenses are useful as extended-wear contact lenses. In addition, the invention provides a method for making a medical device, preferably a contact lens, having an antimicrobial metal-containing LbL coating thereon.

Owner:NOVARTIS AG

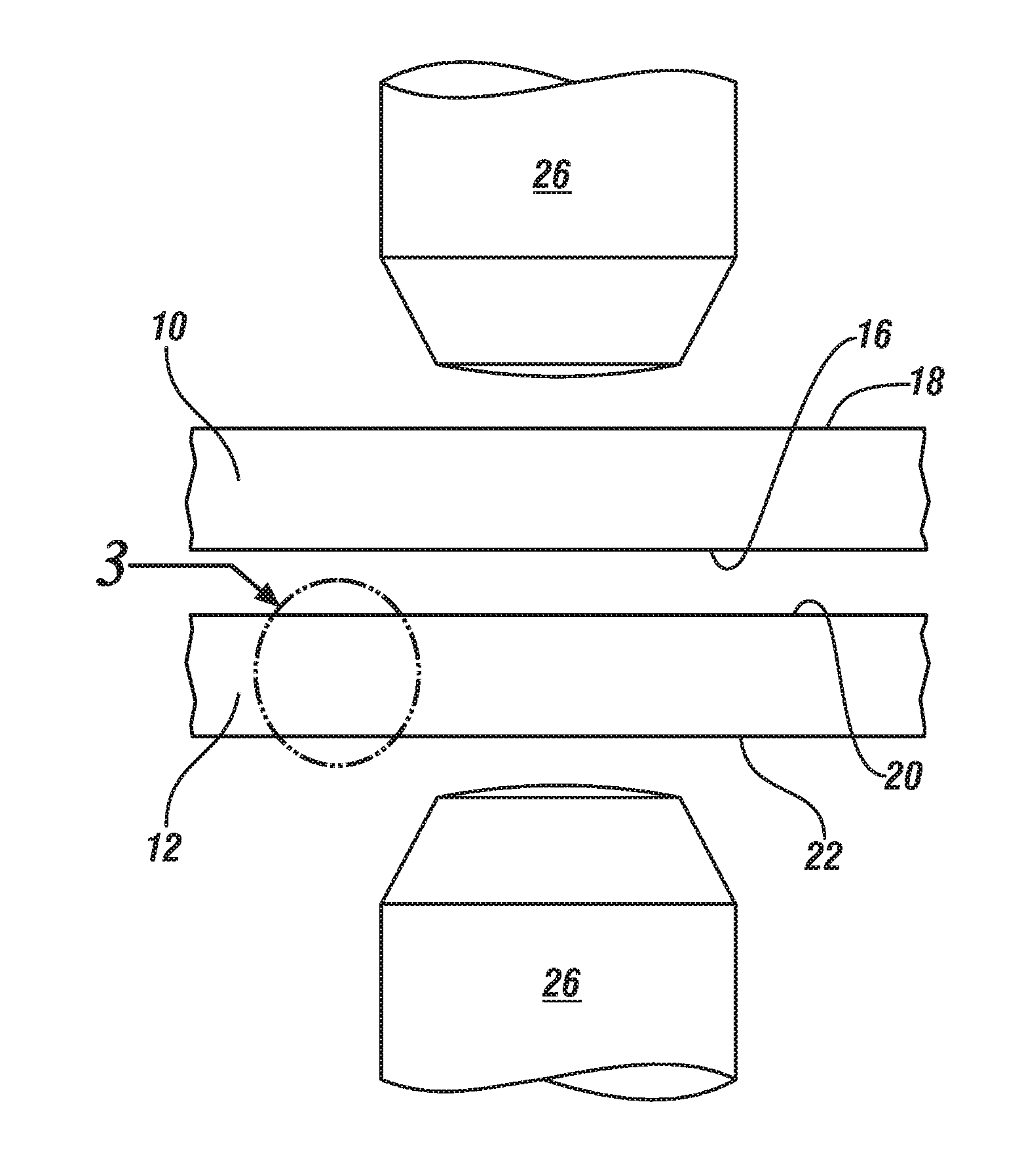

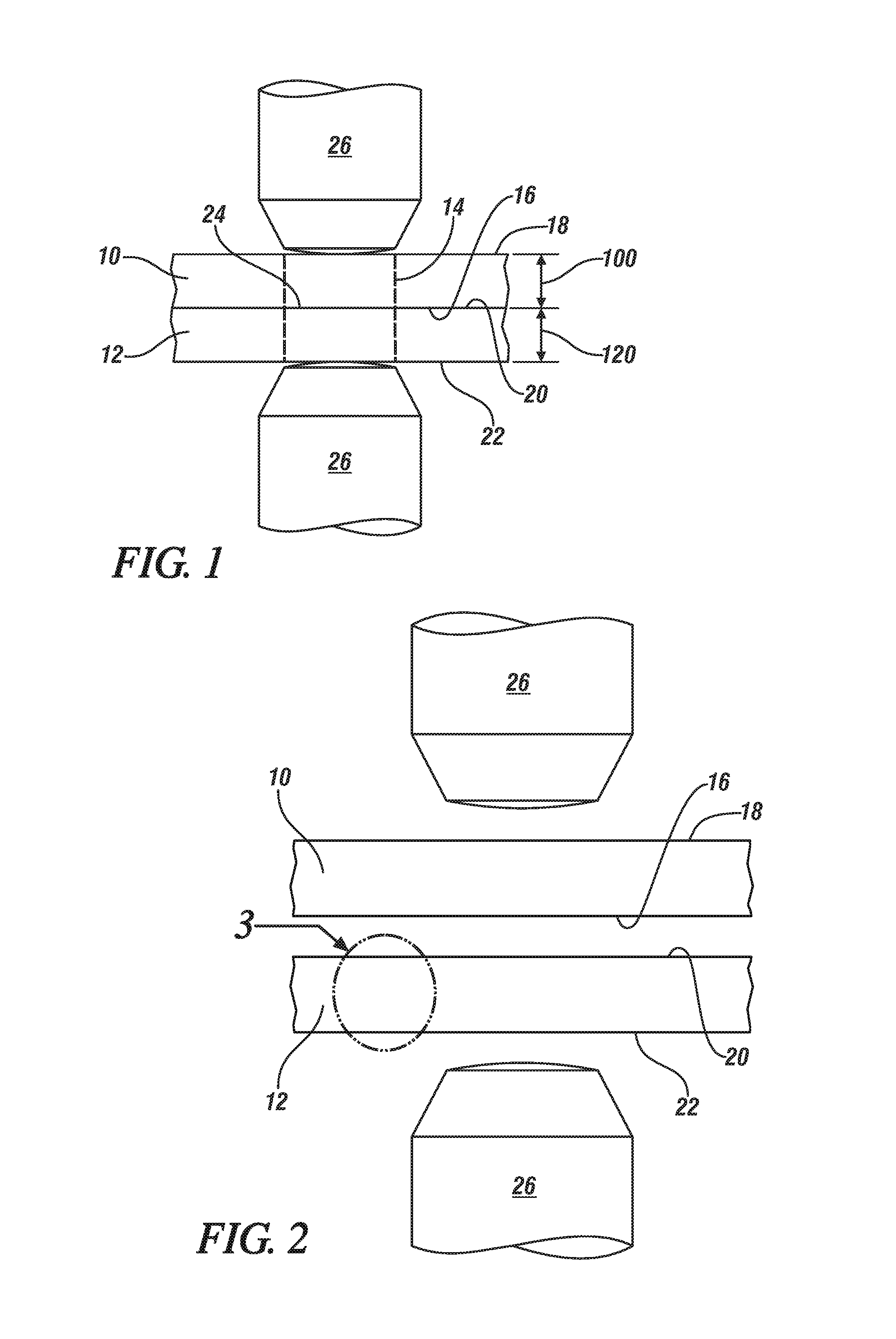

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

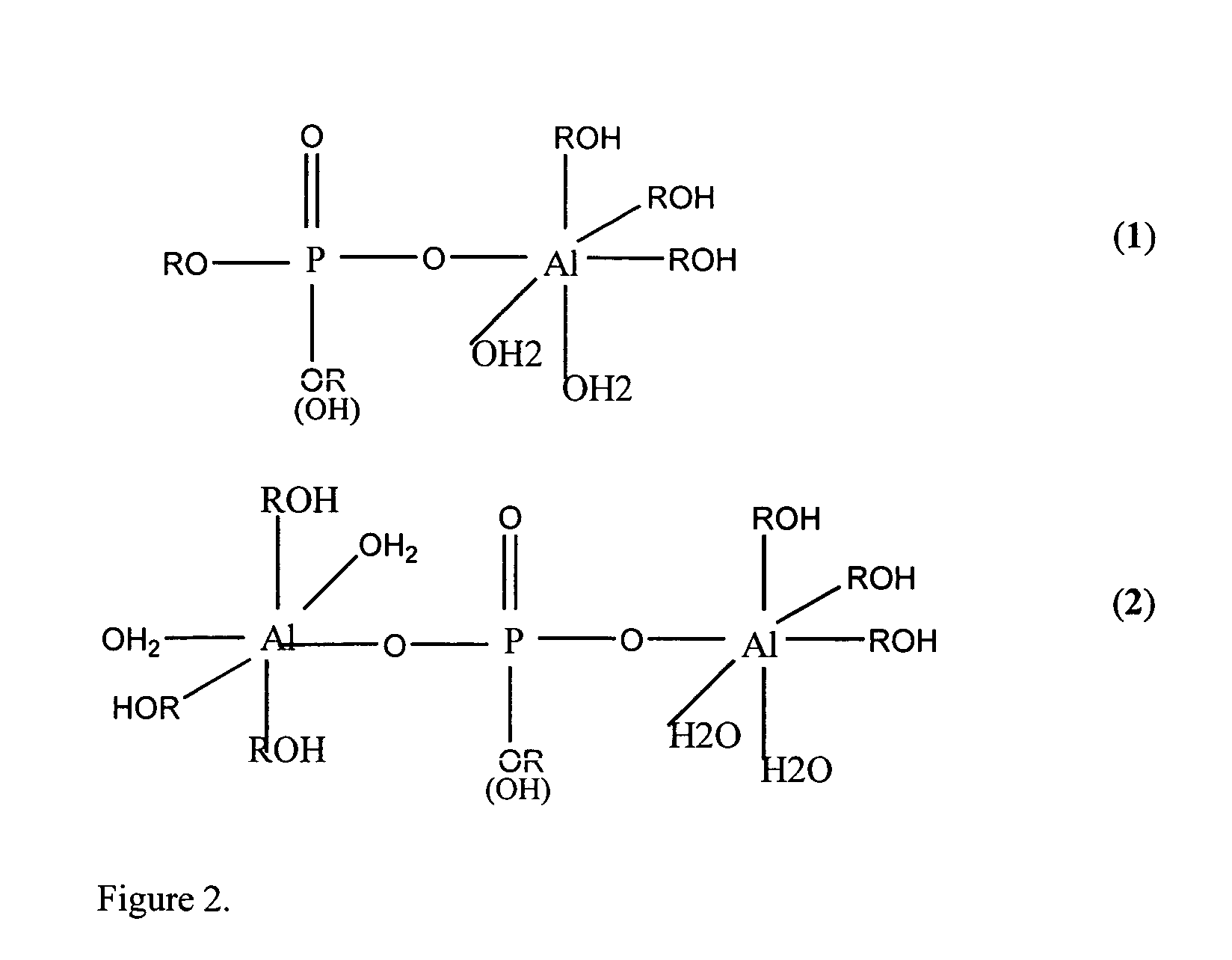

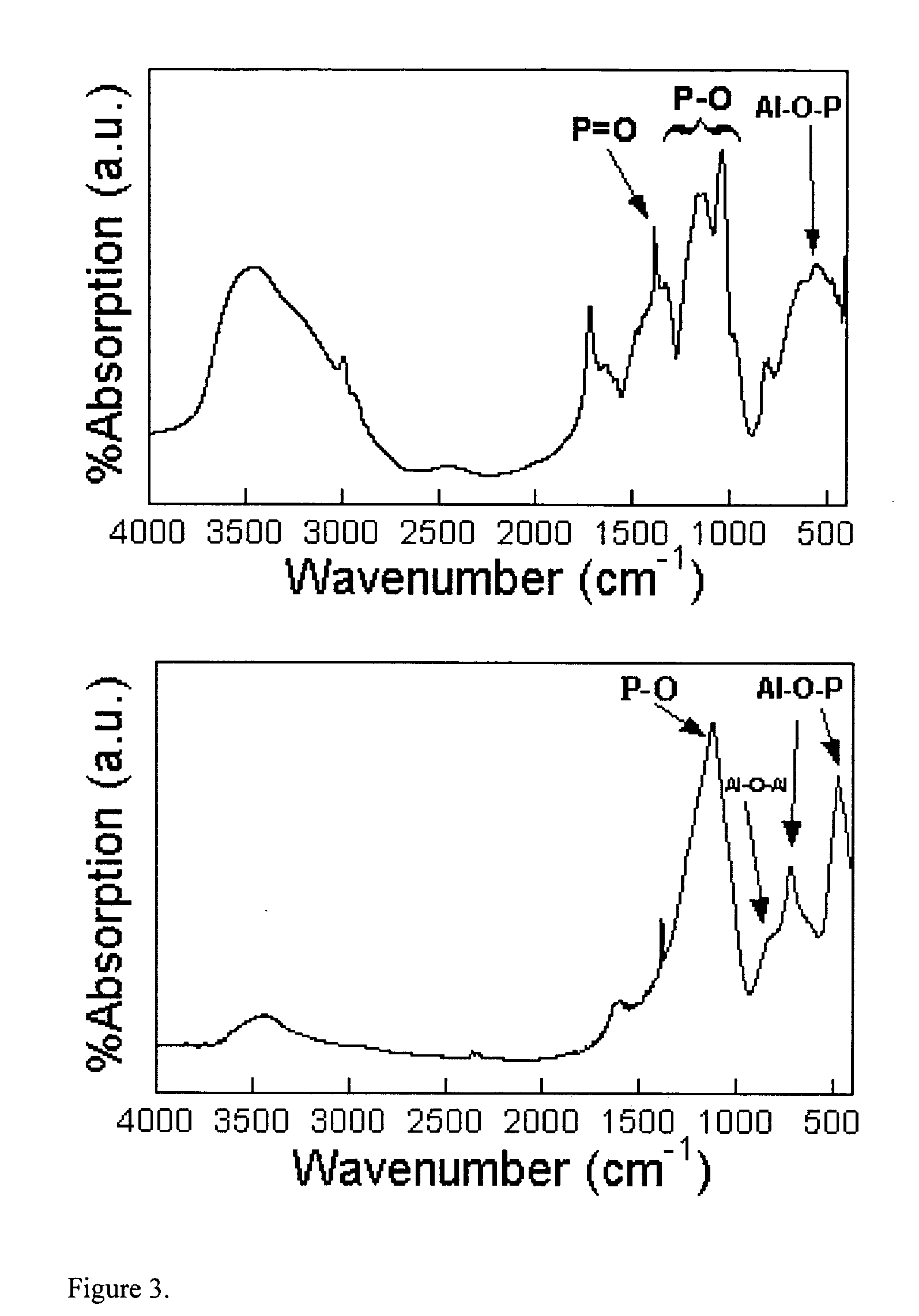

Aluminum phosphate compounds, compositions, materials and related metal coatings

ActiveUS20040138058A1Improve heat transfer efficiencyIncrease temperaturePhysical/chemical process catalystsMetallic material coating processesMetal coatingMetallurgy

Owner:APPL THIN FILMS INC

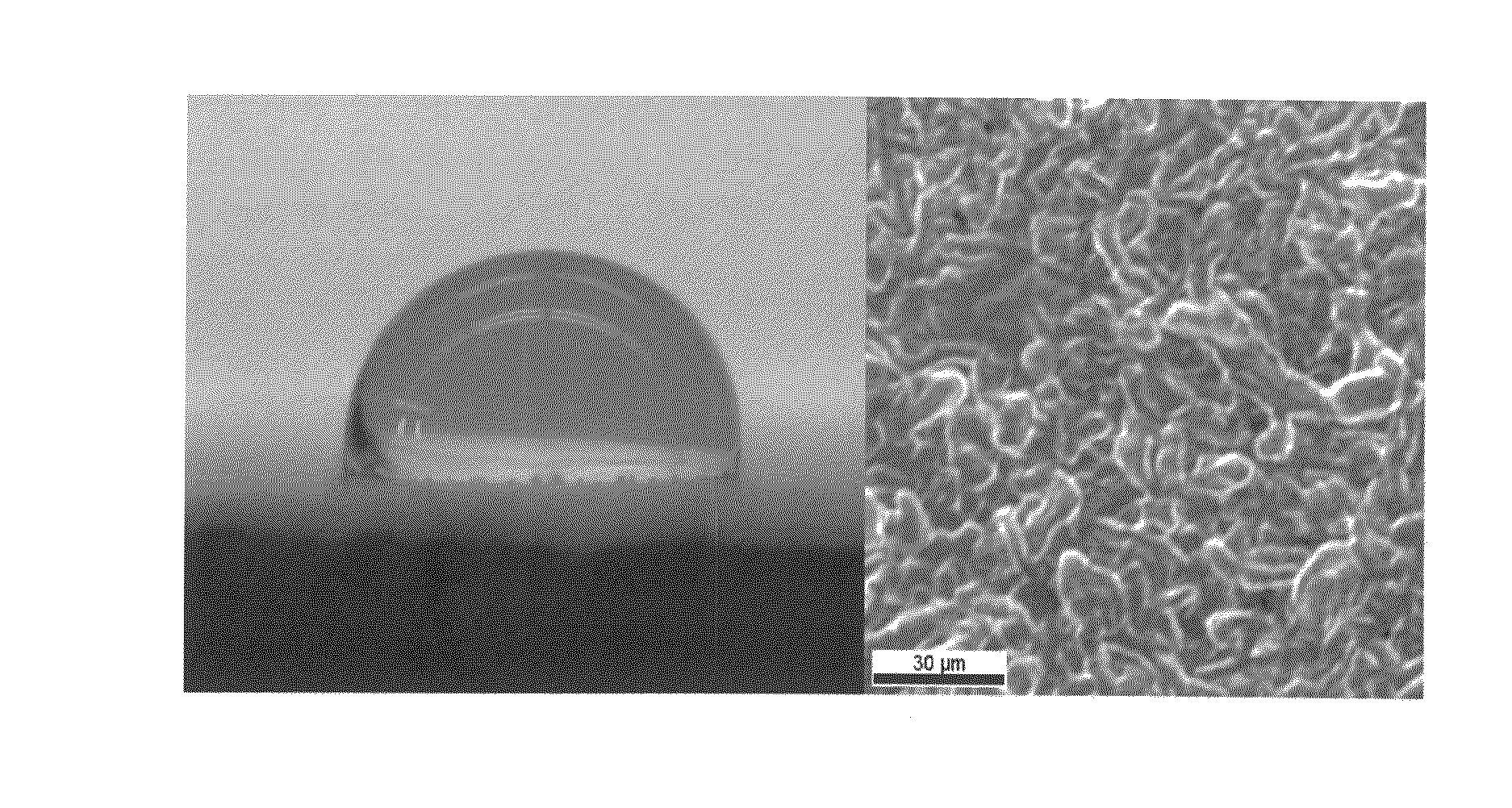

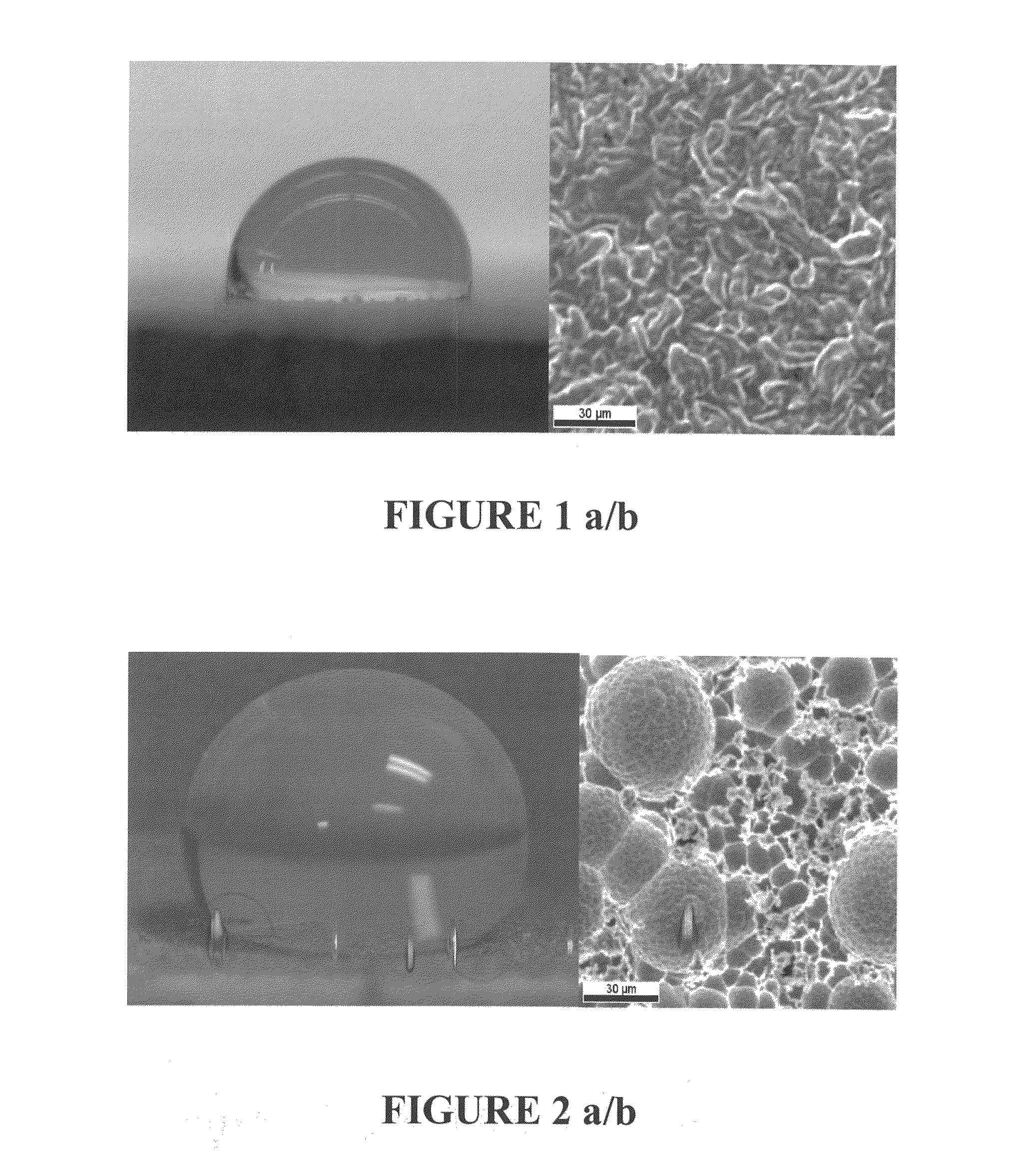

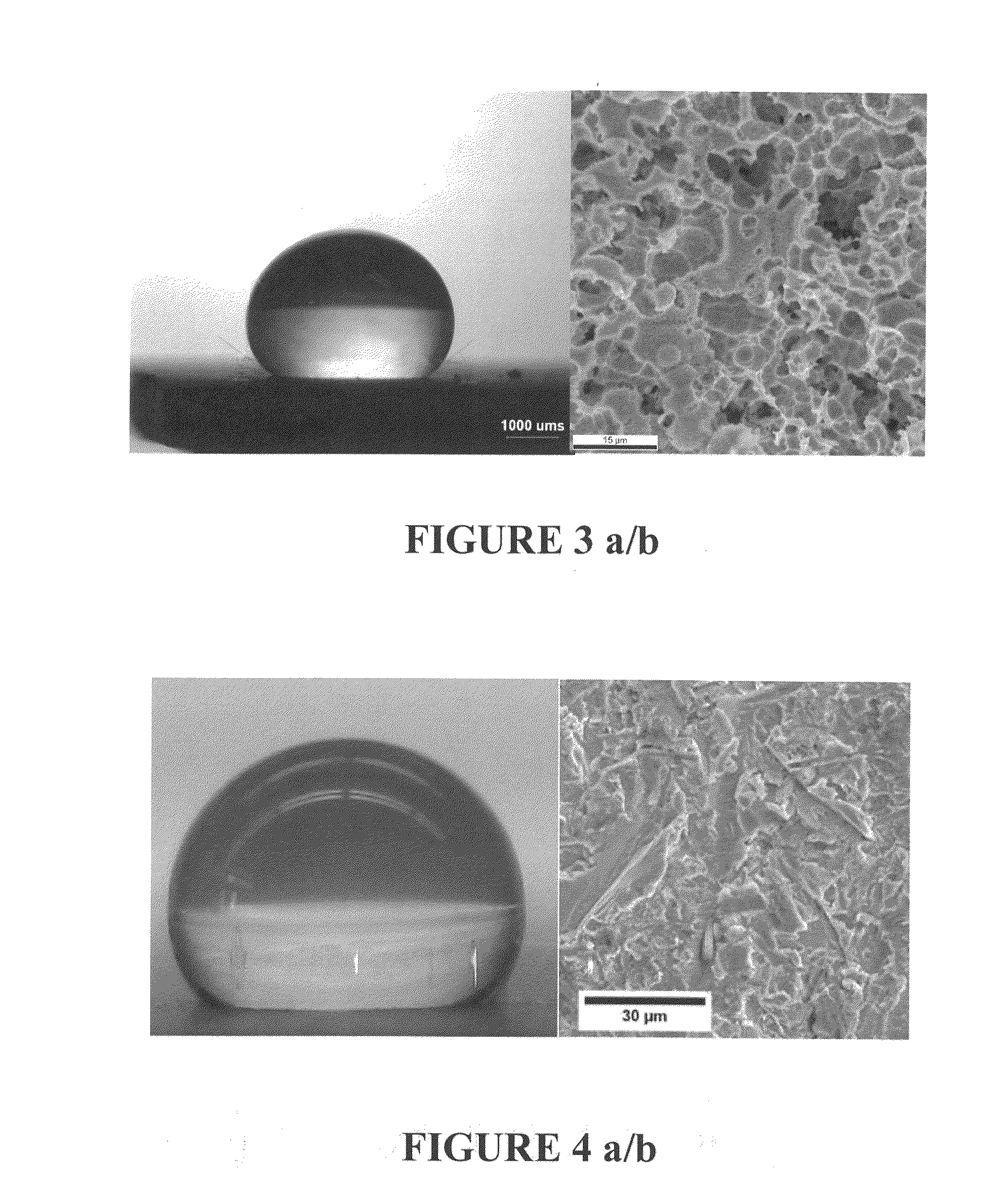

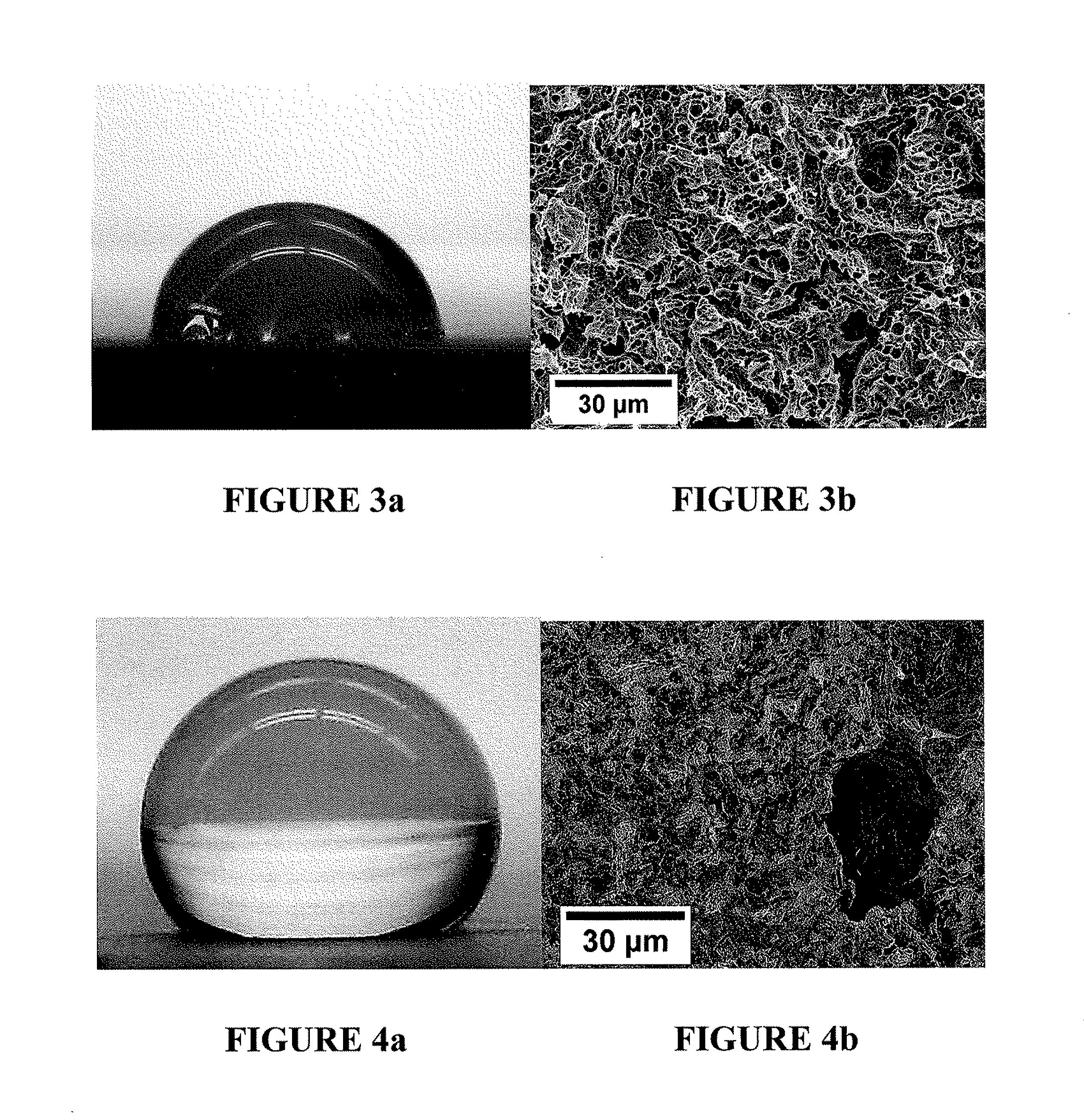

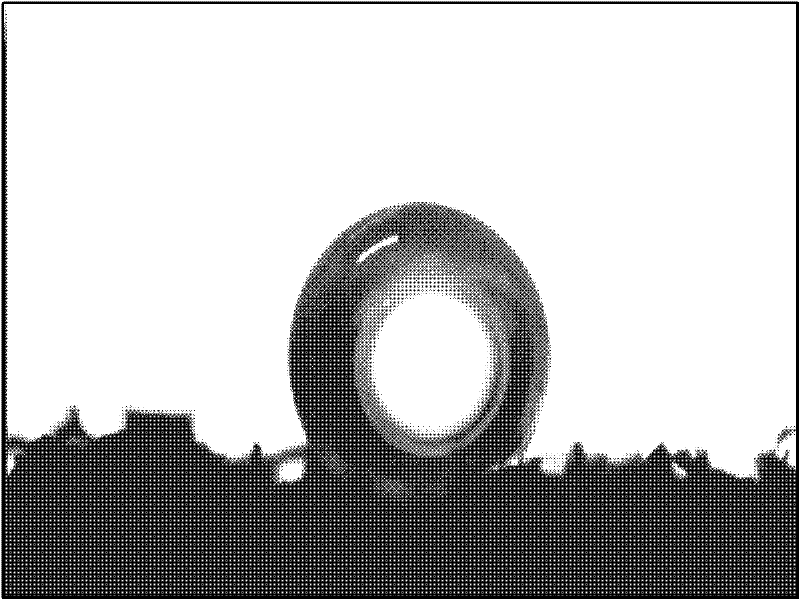

Metallic articles with hydrophobic surfaces

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

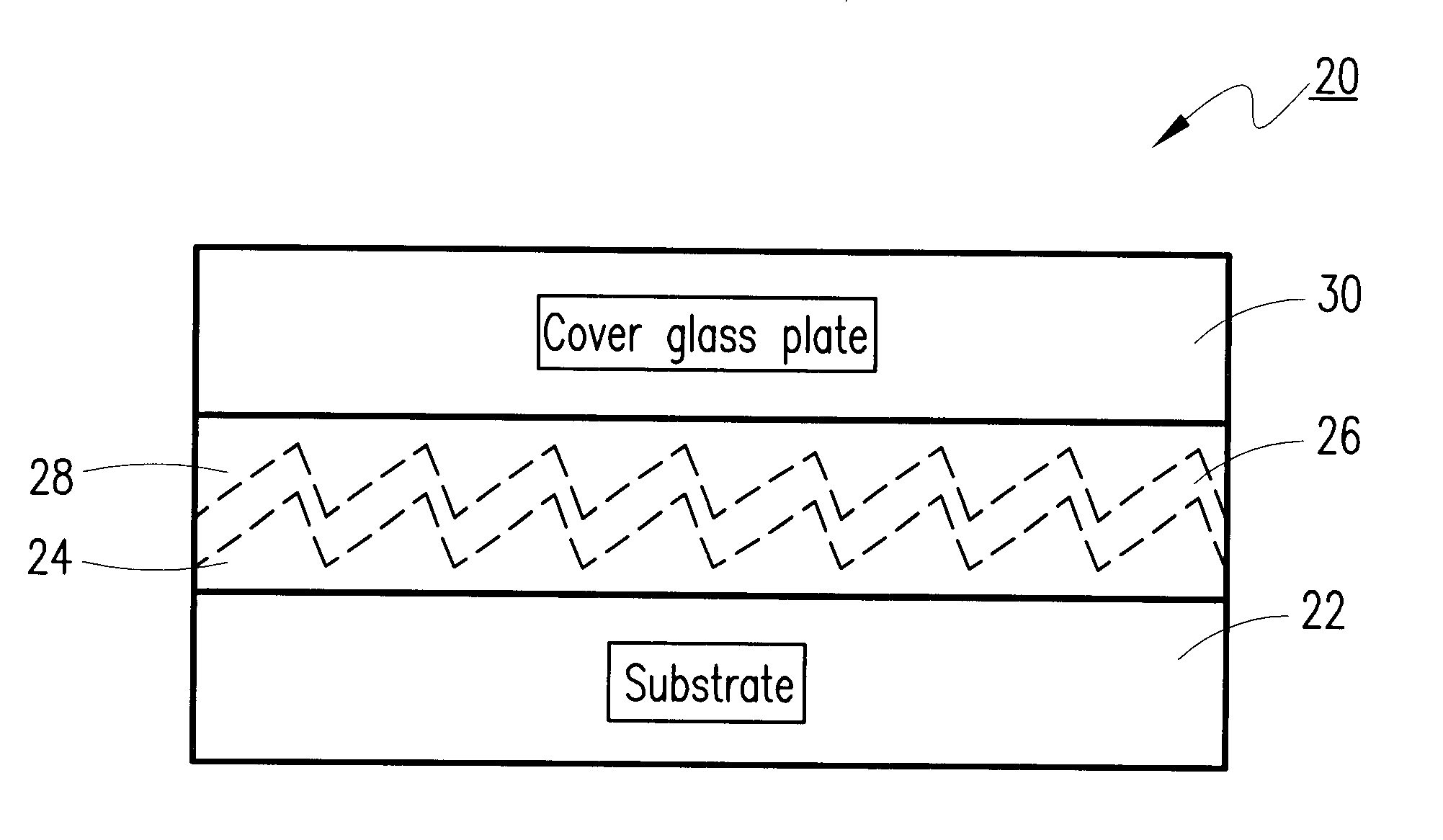

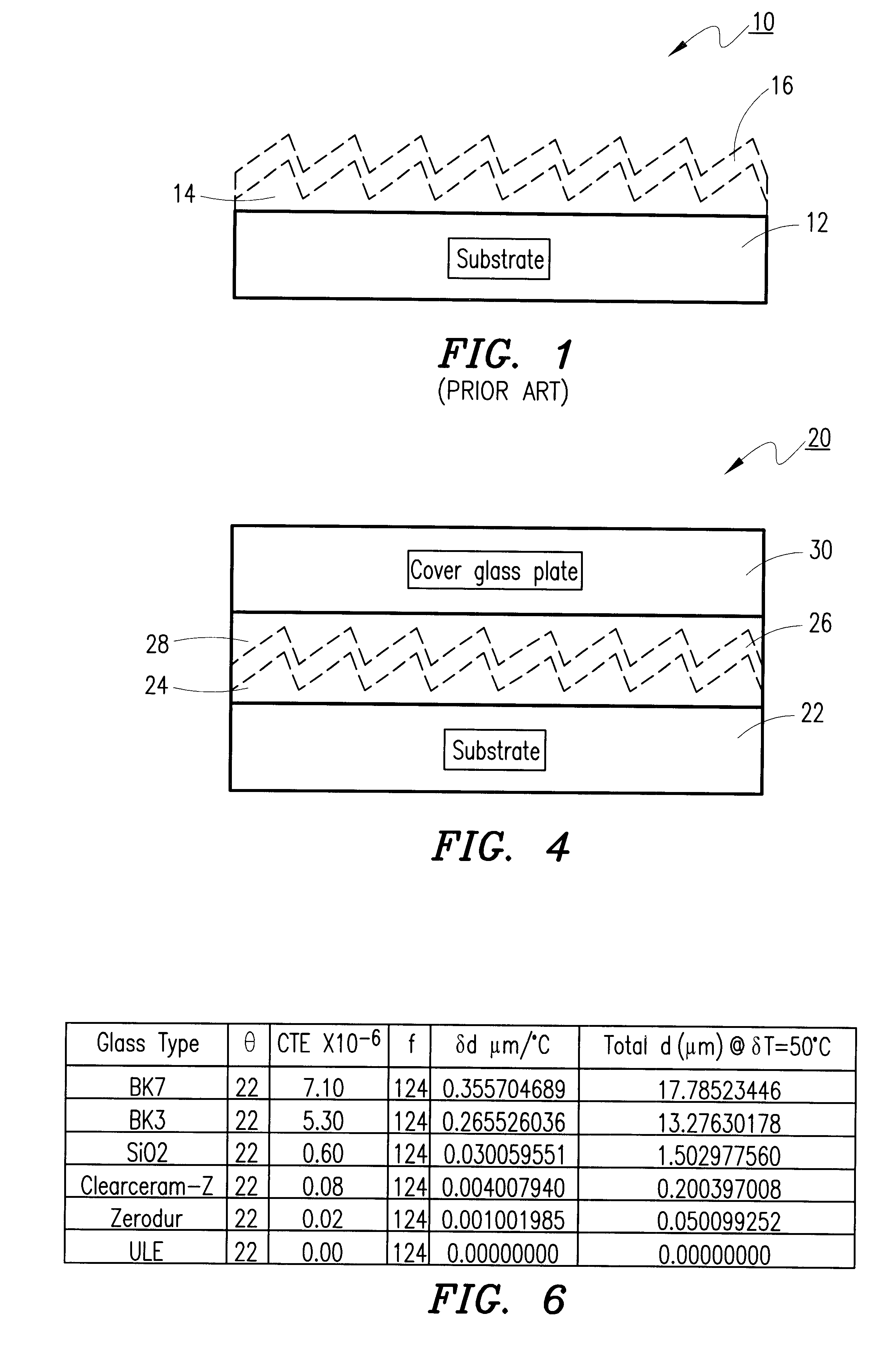

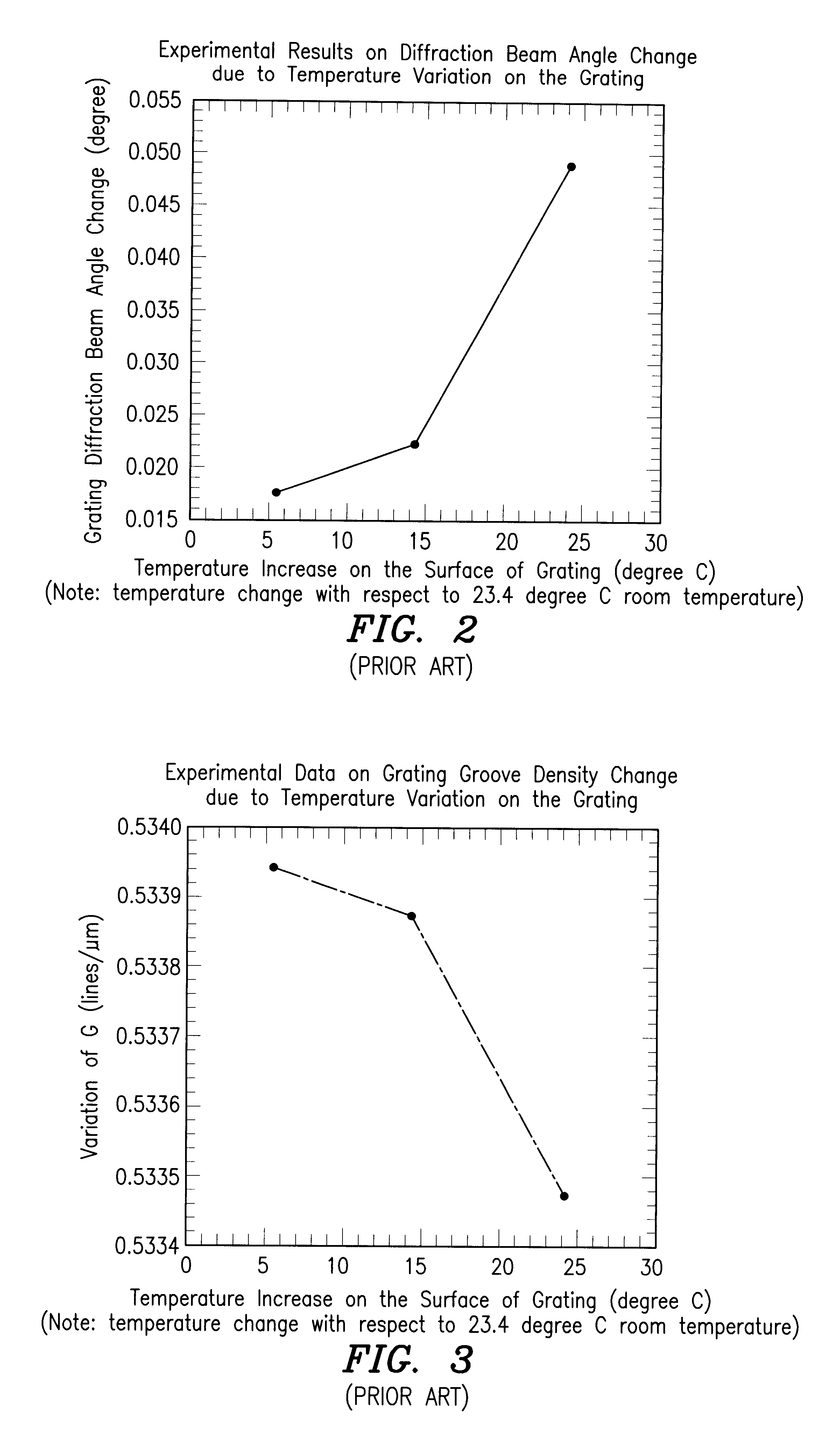

Diffraction grating for wavelength division multiplexing/demultiplexing devices

An improved diffraction grating for wavelength division multiplexing / demultiplexing devices is disclosed. The improved diffraction grating has a glass substrate, a polymer grating layer located adjacent to the glass substrate, and a metal coating layer located adjacent to the polymer grating layer. The improvement comprises a polymer coating layer located adjacent to the metal coating layer, and a glass cover located adjacent to the polymer coating layer, wherein the polymer coating layer and the glass cover compensate for thermal characteristics associated with the polymer grating layer and the glass substrate, respectively.

Owner:AUXORA

Silicon-based active materials for lithium ion batteries and synthesis with solution processing

Silicon based anode active materials are described for use in lithium ion batteries. The silicon based materials are generally composites of nanoscale elemental silicon with stabilizing components that can comprise, for example, silicon oxide-carbon matrix material, inert metal coatings or combinations thereof. High surface area morphology can further contribute to the material stability when cycled in a lithium based battery. In general, the material synthesis involves a significant solution based processing step that can be designed to yield desired material properties as well as providing convenient and scalable processing.

Owner:IONBLOX INC

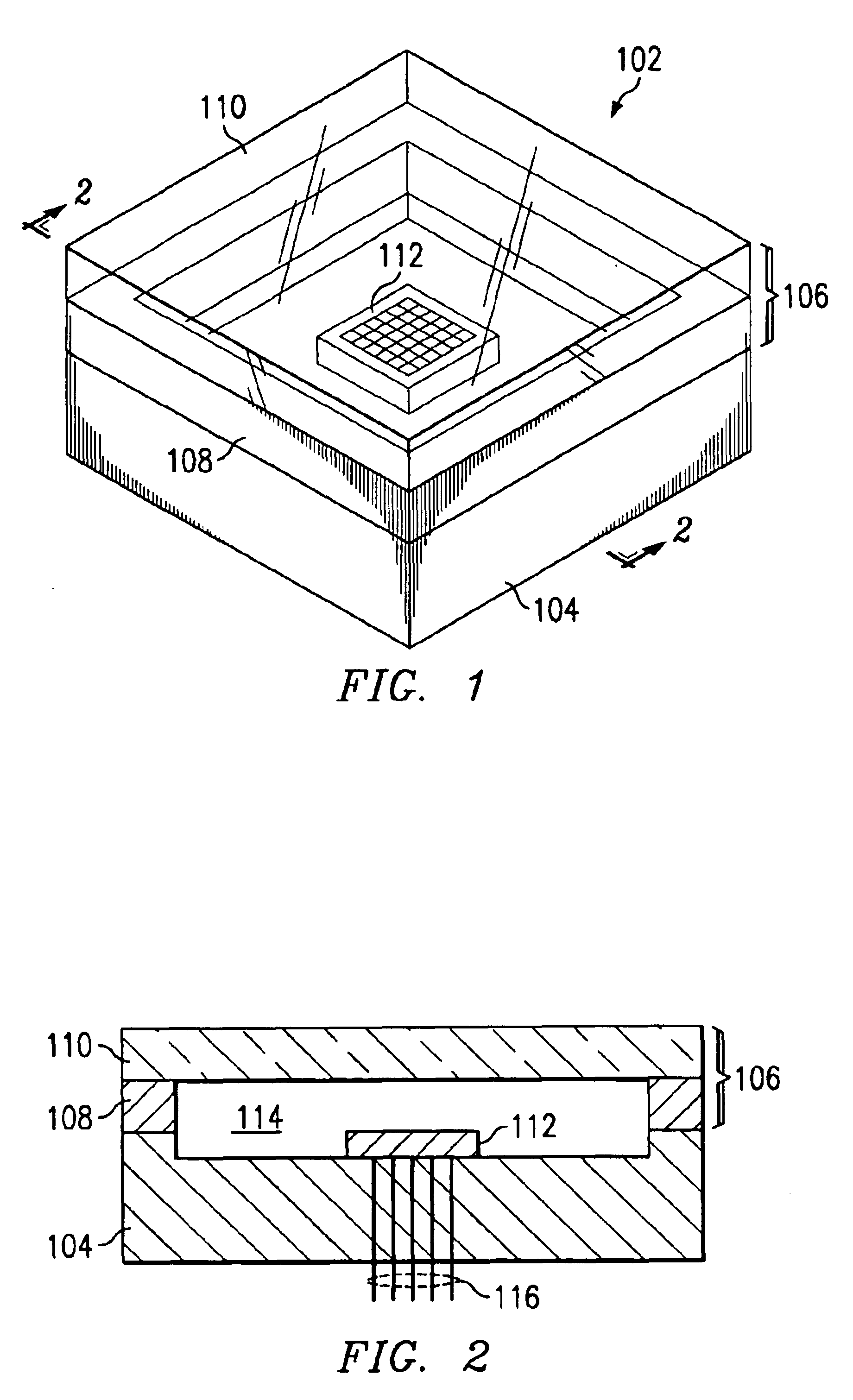

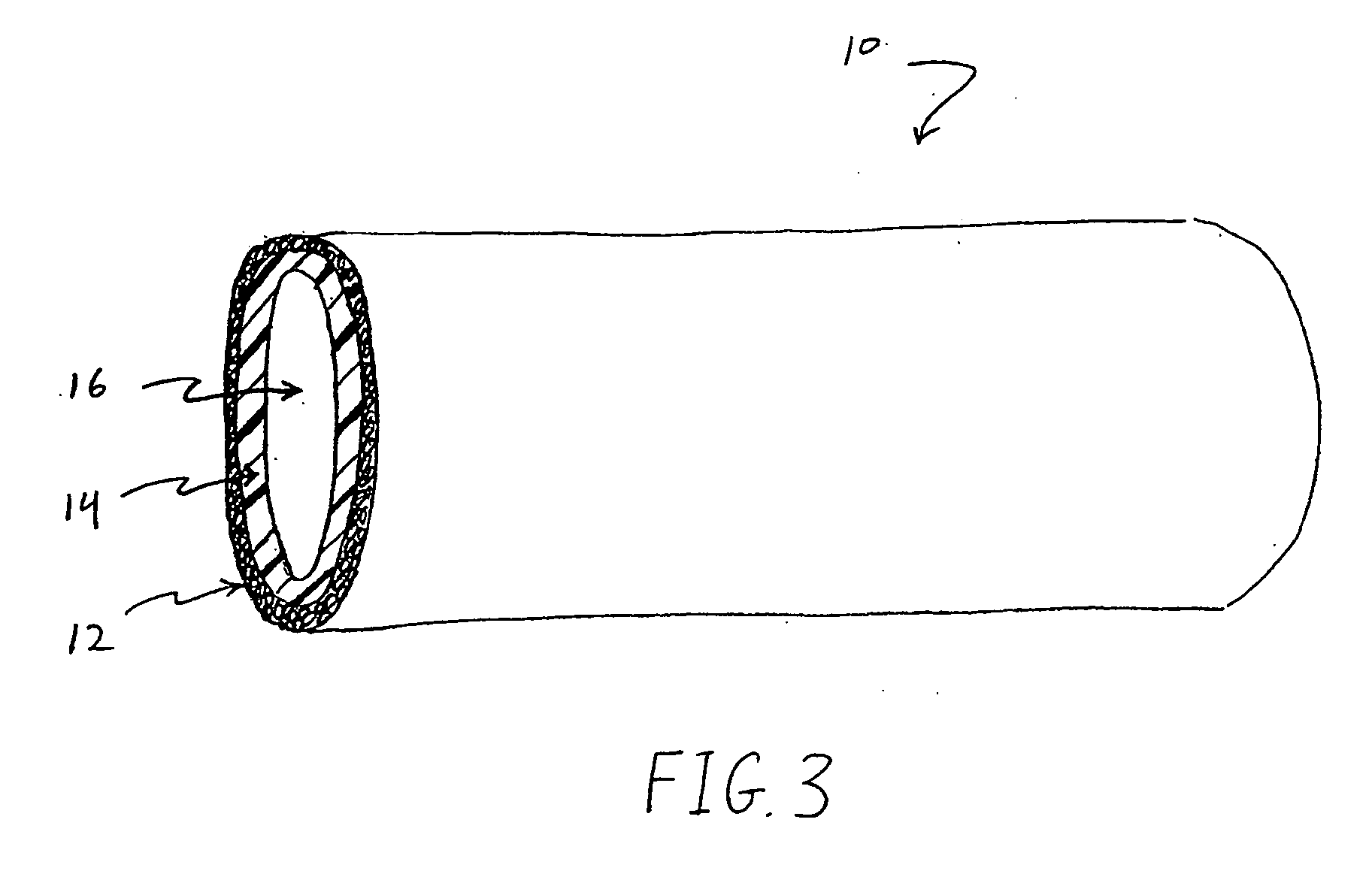

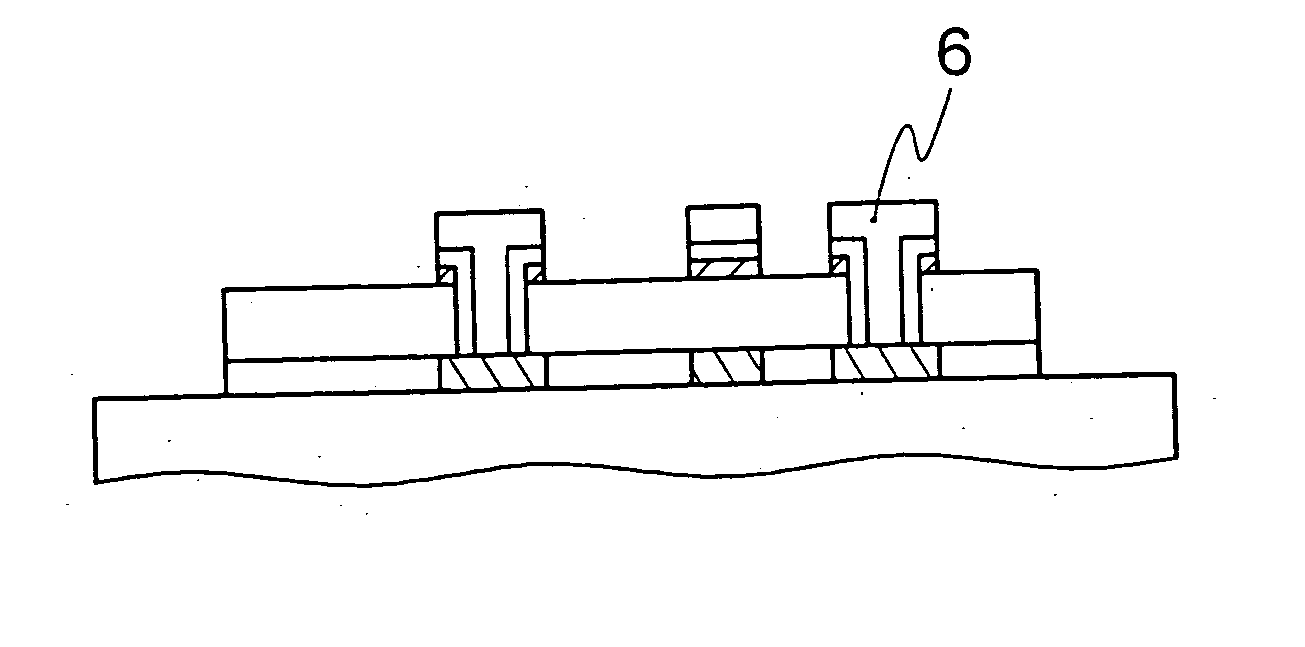

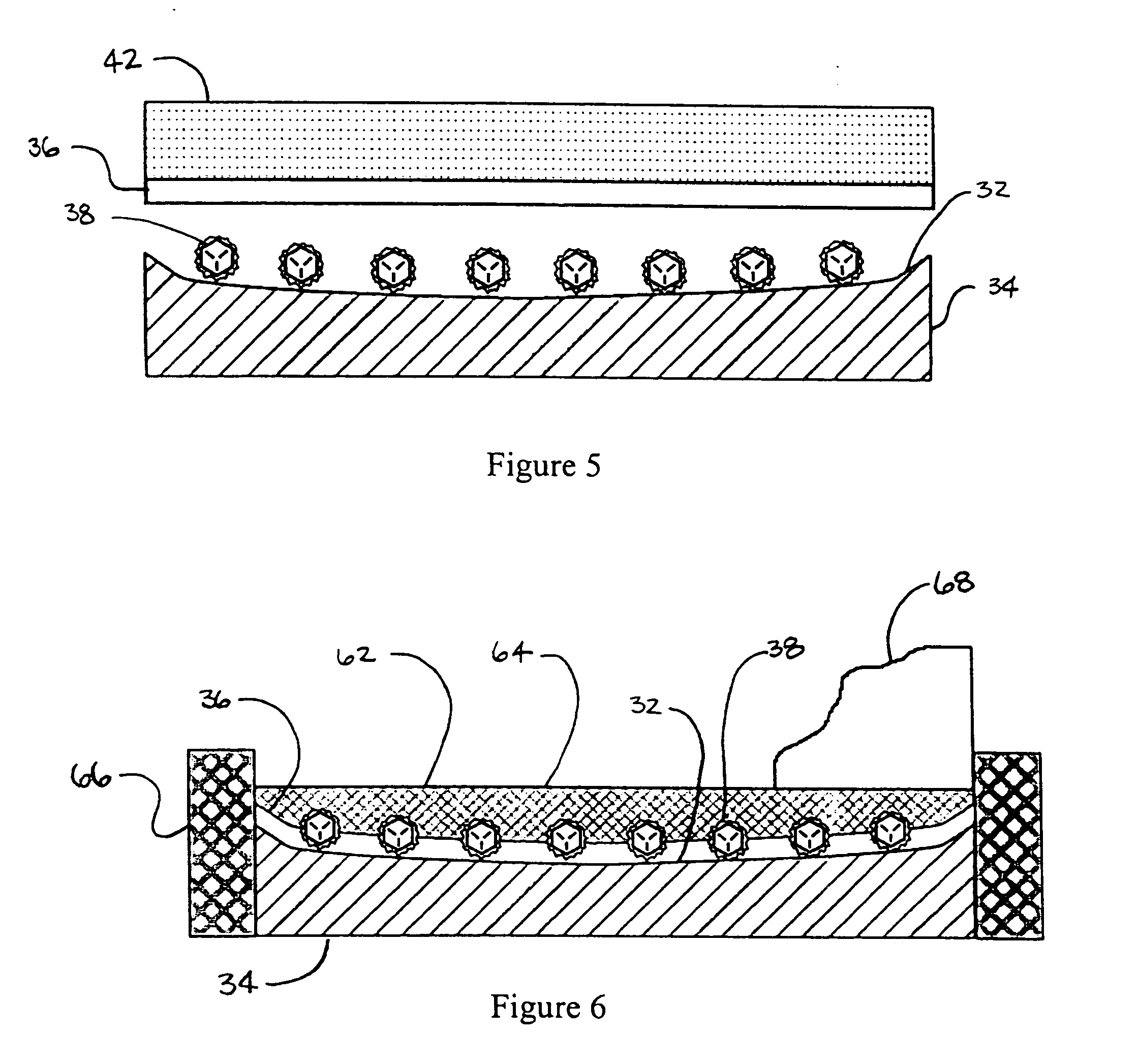

Hermetically sealed micro-device package using cold-gas dynamic spray material deposition

InactiveUS6924974B2Digital data processing detailsSemiconductor/solid-state device detailsMetal coatingMetal framework

A cover assembly for welding to a package base to form a hermetically sealed micro-device package. The cover assembly includes a sheet of a transparent material having a window portion. A built-up metallic frame adheres to the sheet and circumscribes the window portion, the frame having been deposited as follows: First, powdered metal particles are sprayed onto a prepared area of the sheet using a gas jet at a temperature below the fusing temperature of the particles, the jet having a velocity sufficient to cause the particles to merge with one another upon impact with the sheet and with one another to form an initial continuous metallic coating adhering to the prepared area of the sheet. Next, successive metal particles are applied over the initial coating using the jet to form the frame incorporating the initial continuous metallic coating as its base and having an predetermined overall thickness.

Owner:ASTRAVAC GLASS INC

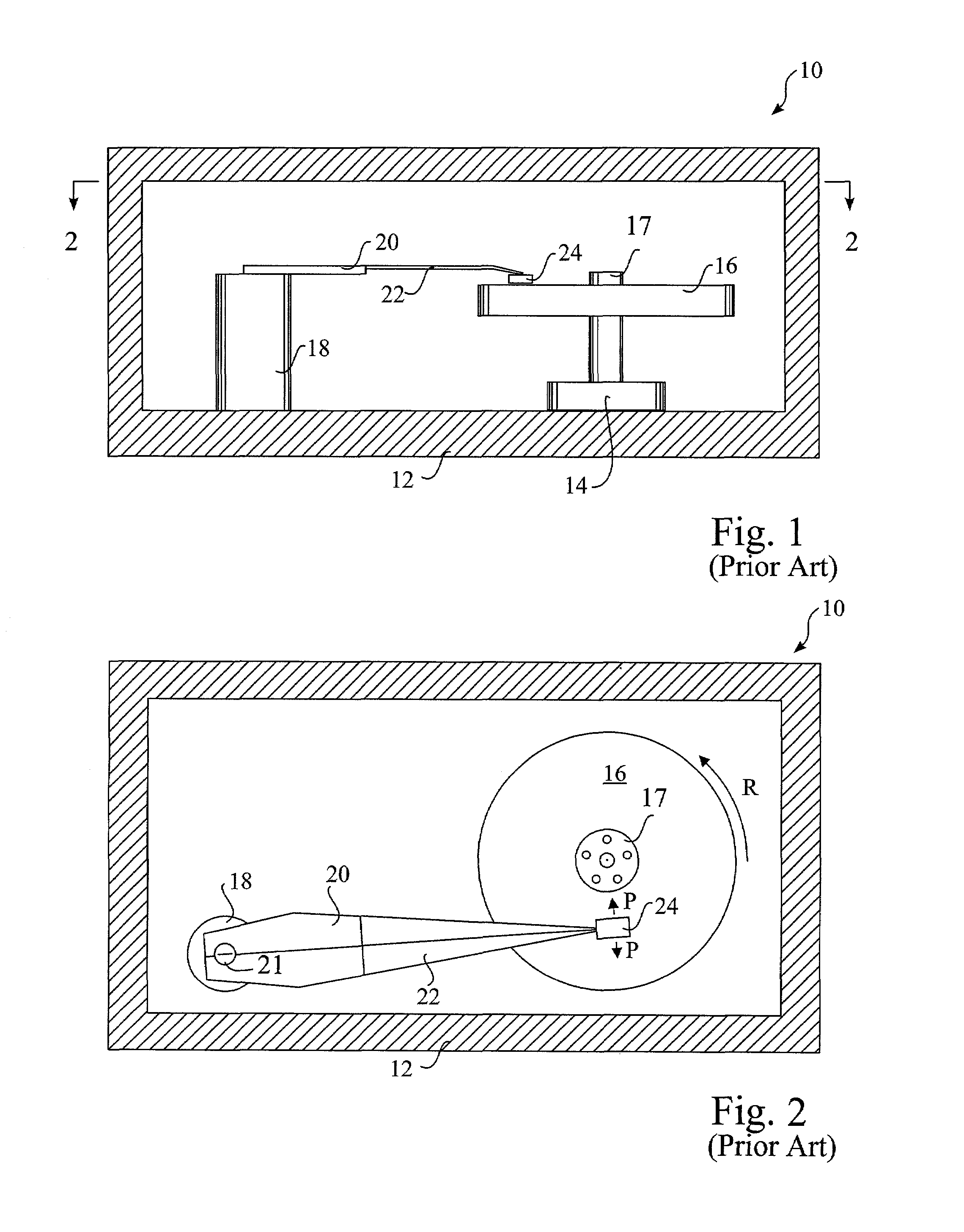

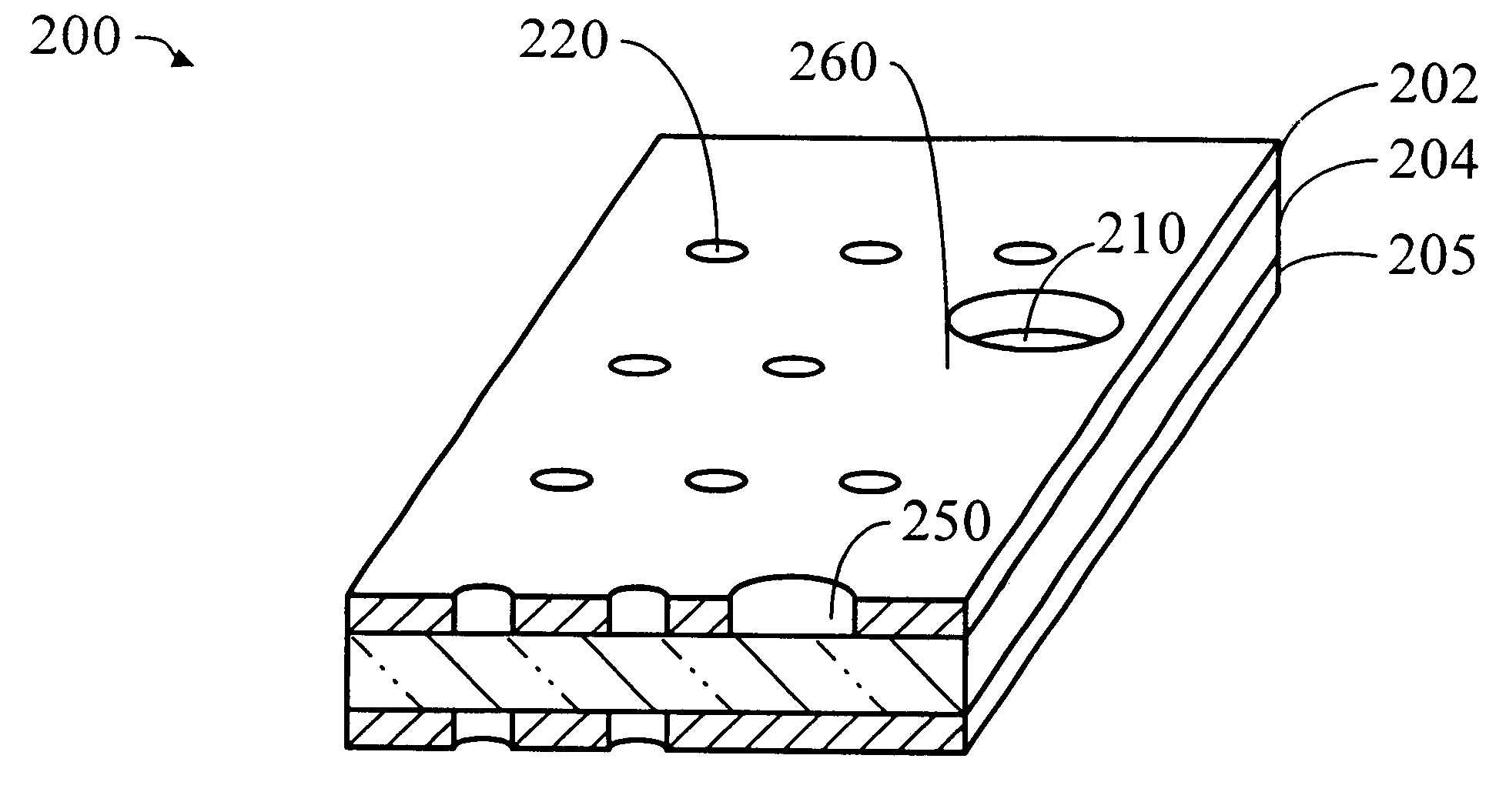

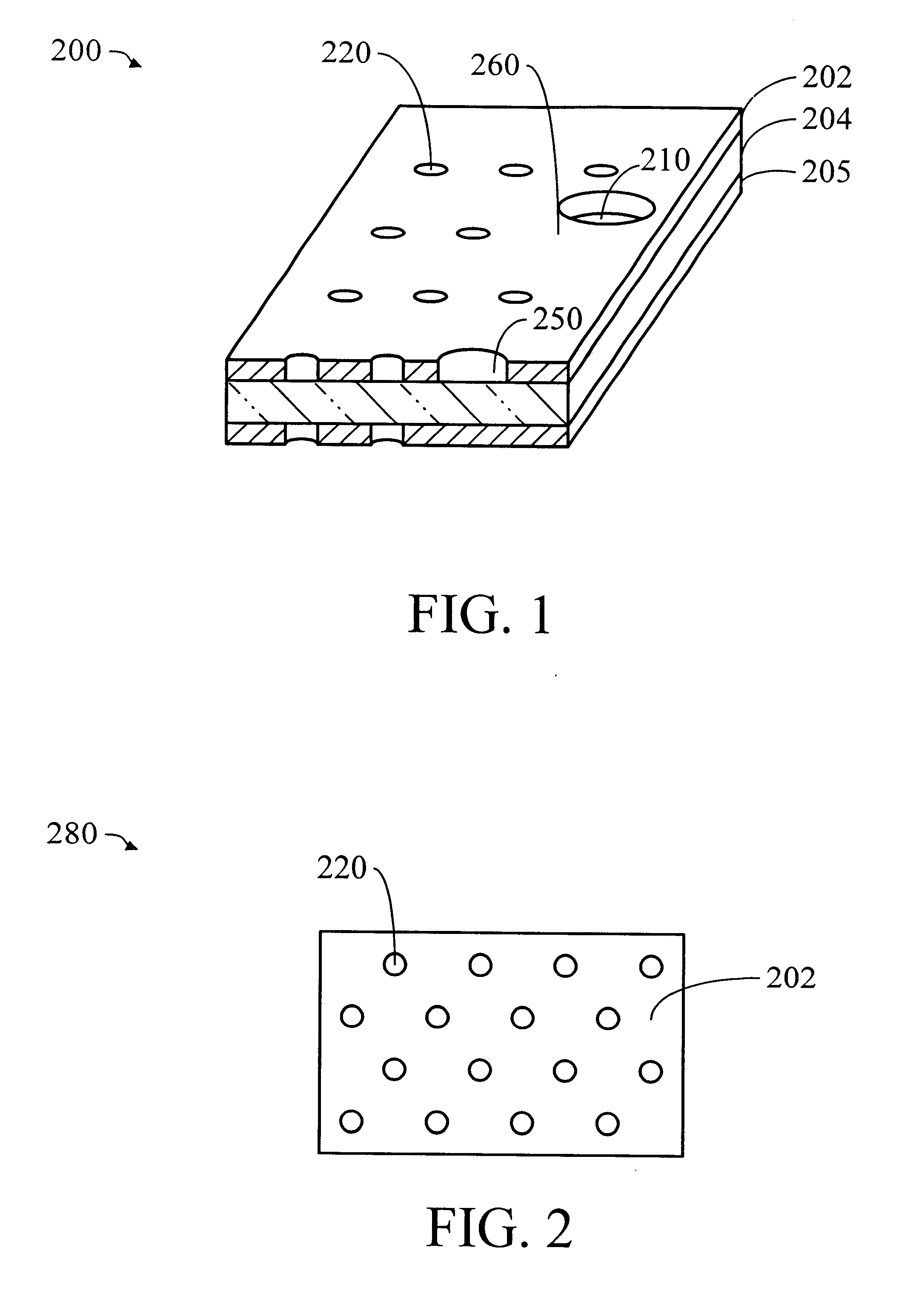

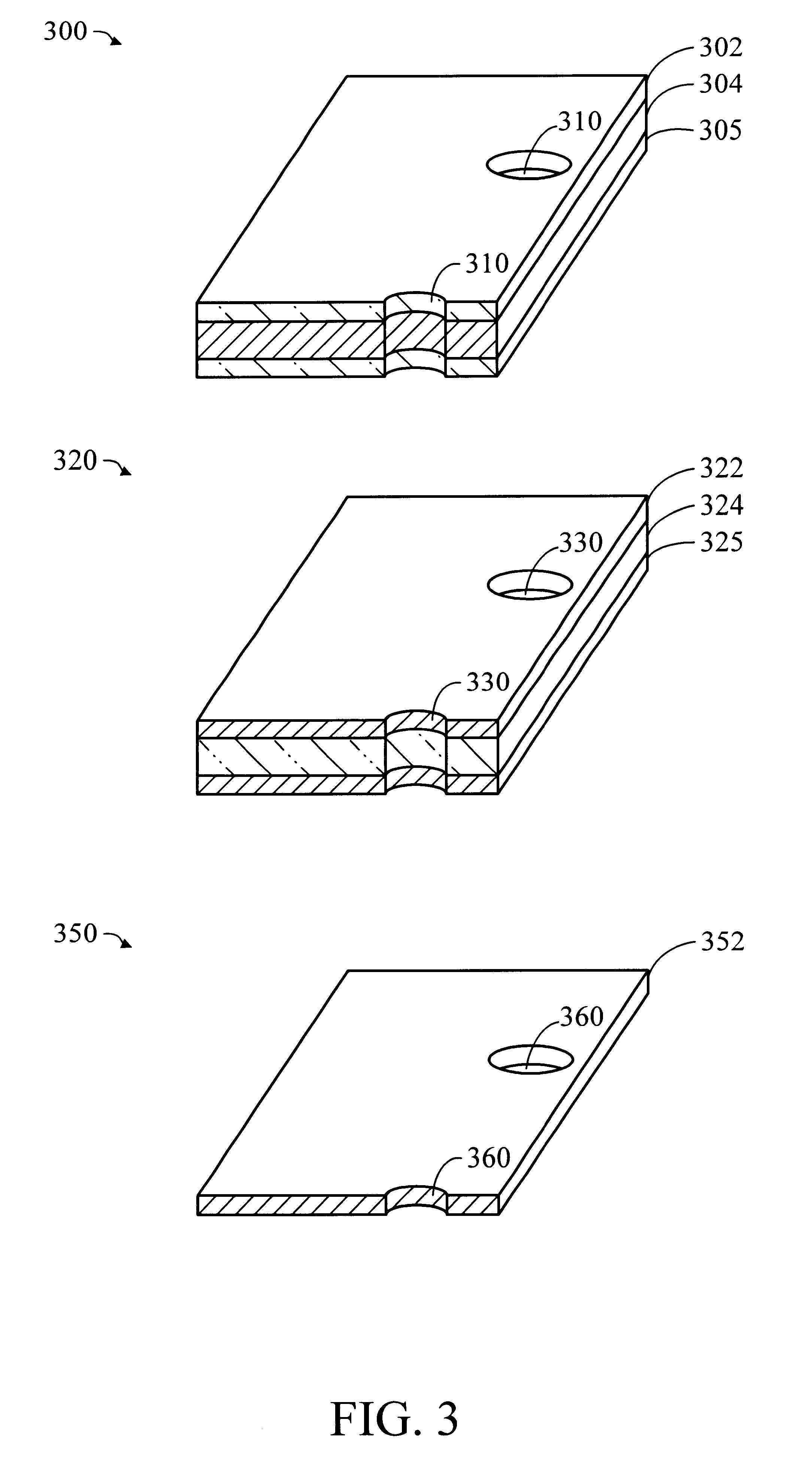

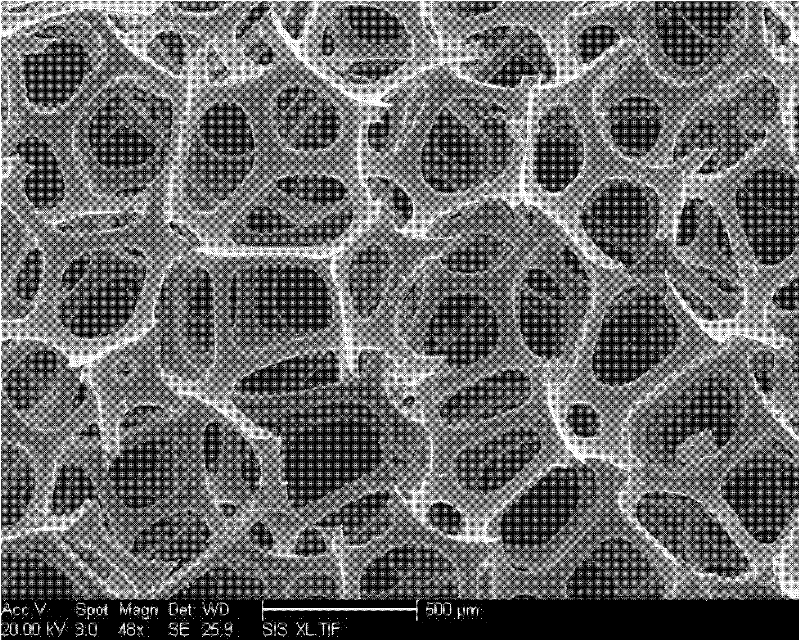

Porous power and ground planes for reduced PCB delamination and better reliability

InactiveUS6613413B1Decrease failureReduce failurePorous dielectricsPrinted circuit secondary treatmentSolventGround plane

Power and ground planes used in Printed Circuit Boards (PCBs) having porous, conductive materials allow liquids (e.g., water and / or other solvents) to pass through the power and ground planes, thus decreasing failures in PCBs (or PCBs used as laminate chip carriers) caused by cathodic / anodic filament growth and delamination of insulators. Porous conductive materials suitable for use in PCBs may be formed by using metal-coated organic cloths (such as polyester or liquid crystal polymers) or fabrics (such as those made from carbon / graphite or glass fibers), using metal wire mesh instead of metal sheets, using sintered metal, or making metal sheets porous by forming an array of holes in the metal sheets. Fabrics and mesh may be woven or random. If an array of holes is formed in a metal sheet, such an array may be formed with no additional processing steps than are performed using conventional PCB assembly methods.

Owner:GLOBALFOUNDRIES INC

Nanoporous layers using thermal dealloying

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

Barrier Packaging Webs Having Metallized Non-Oriented Film

ActiveUS20090110888A1Improve sealingImprove barrier propertiesFlexible coversWrappersThermoplasticFiber

Owner:BEMIS COMPANY INC

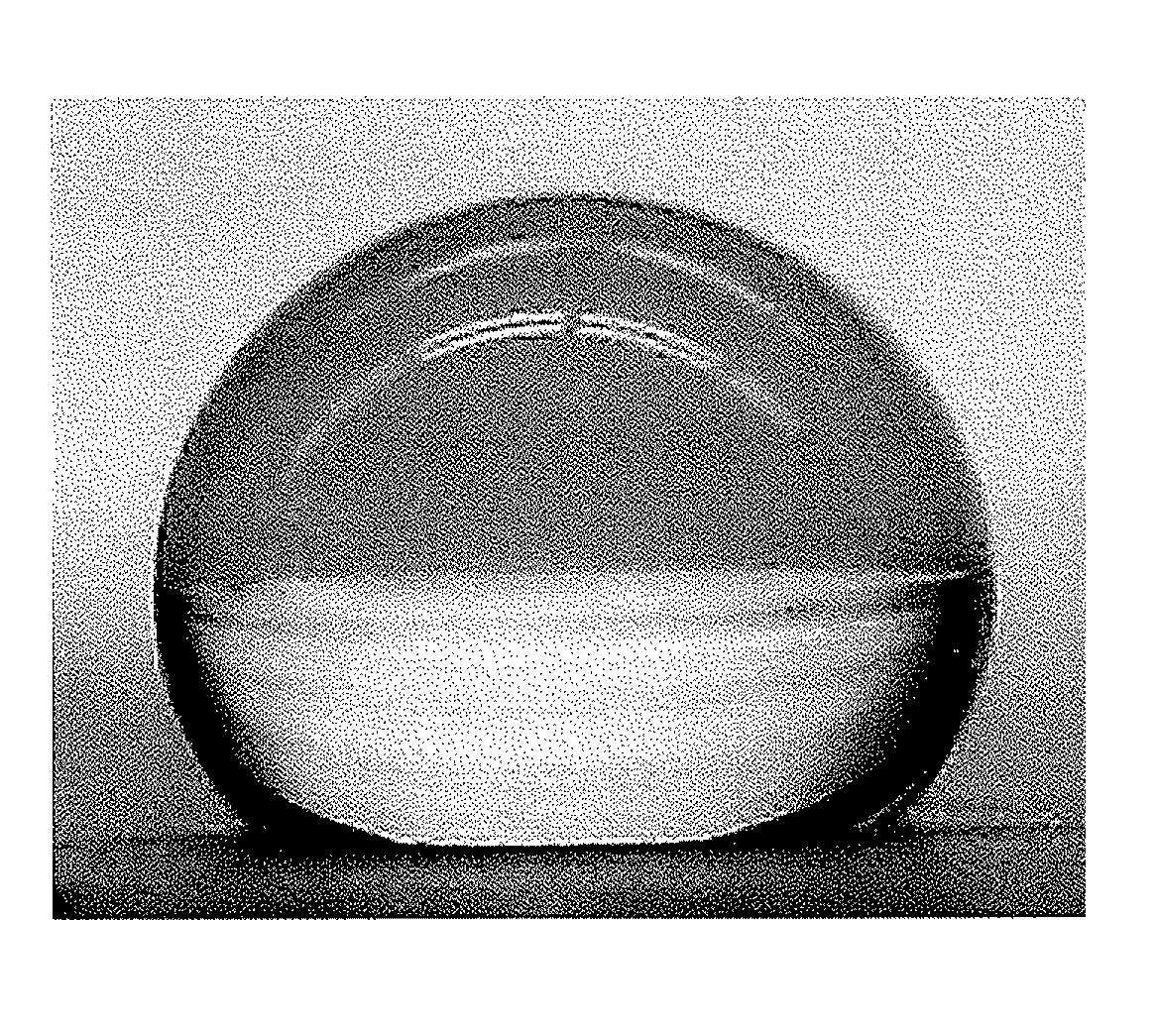

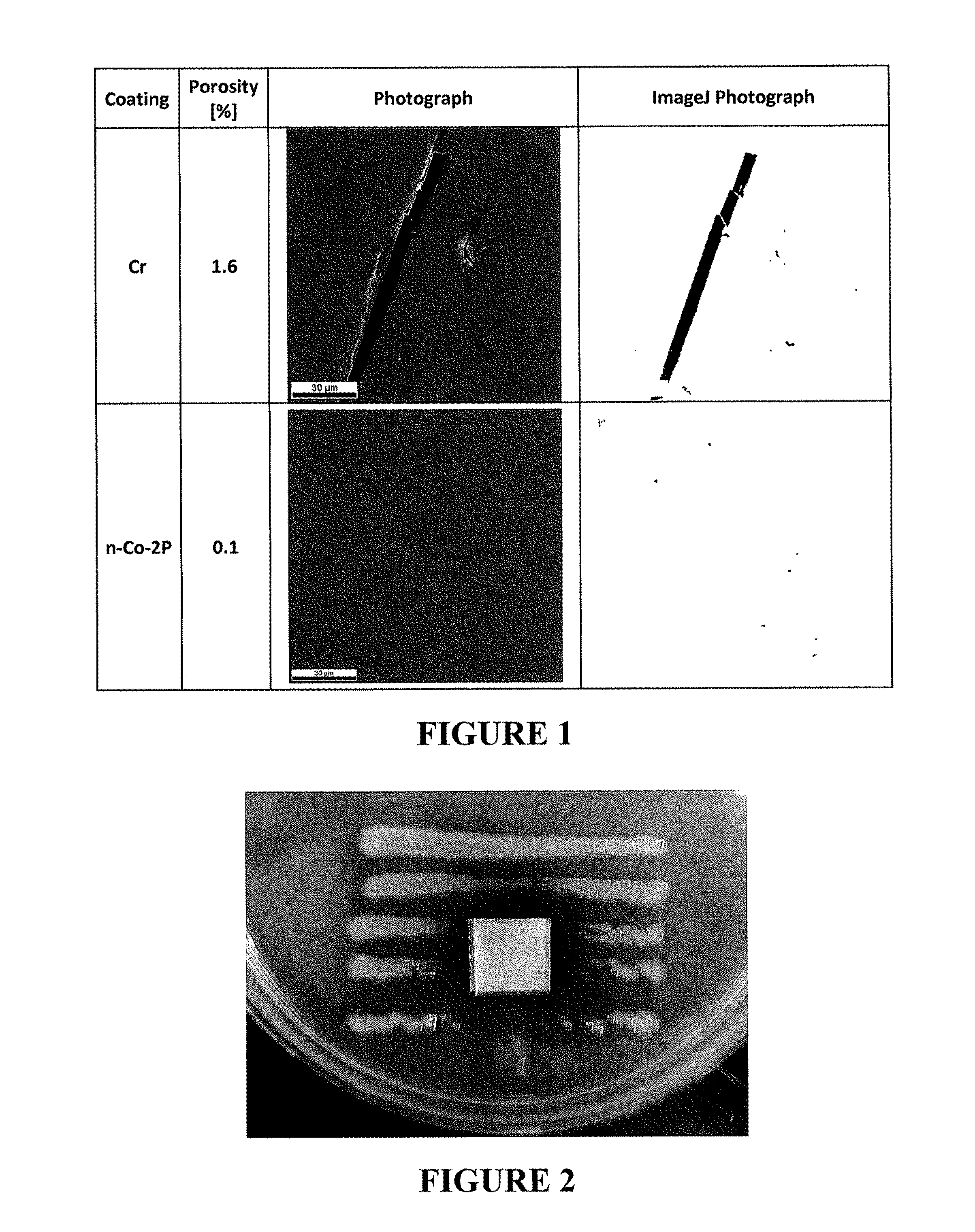

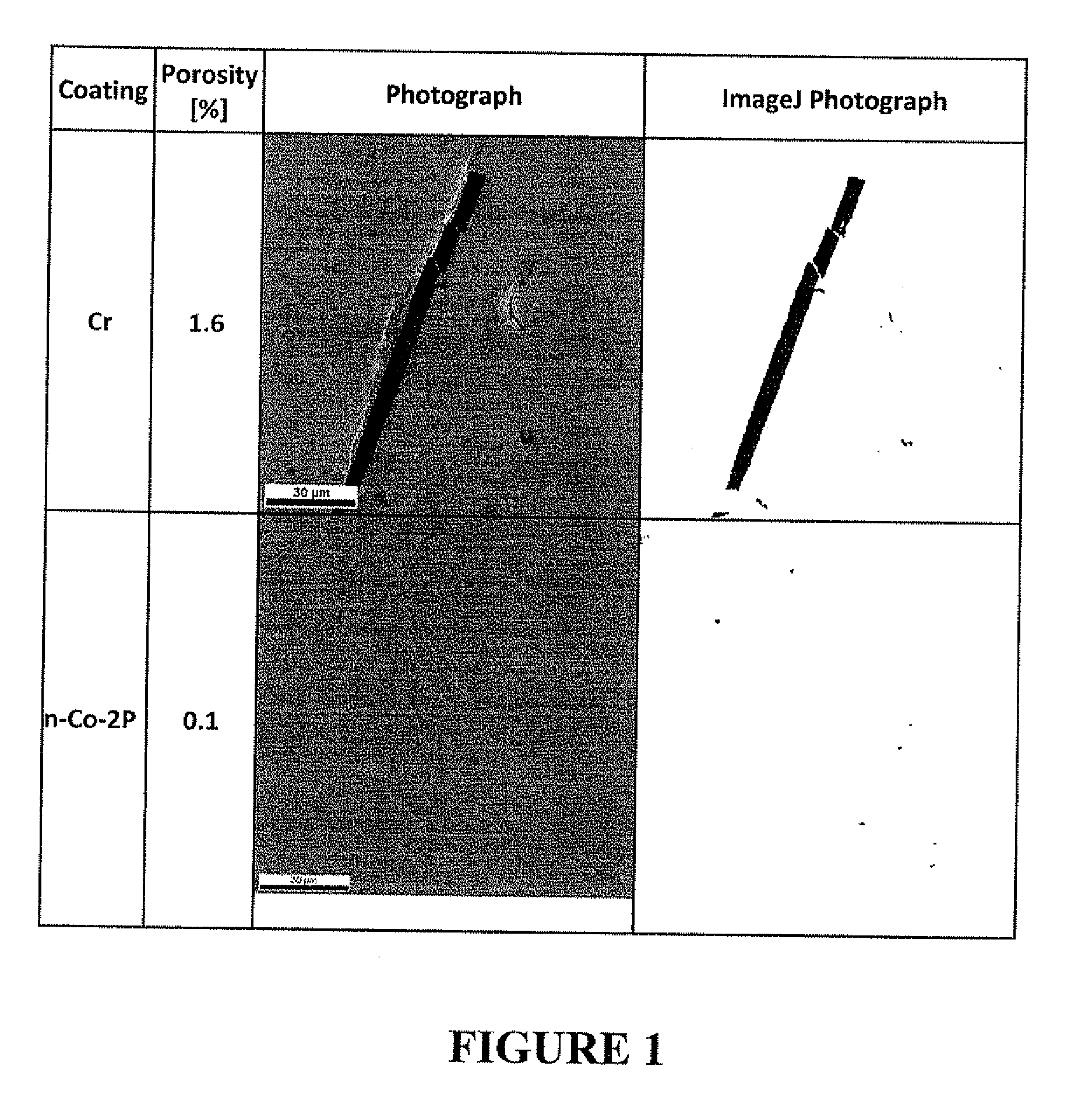

Electrodeposited metallic materials comprising cobalt

ActiveUS20100304179A1Reduce resistanceEliminate security concernsPig casting plantsElectrolytic coatingsMetal coatingMetallic materials

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness Cr coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial and hydrophobic properties.

Owner:INTEGRAN TECH

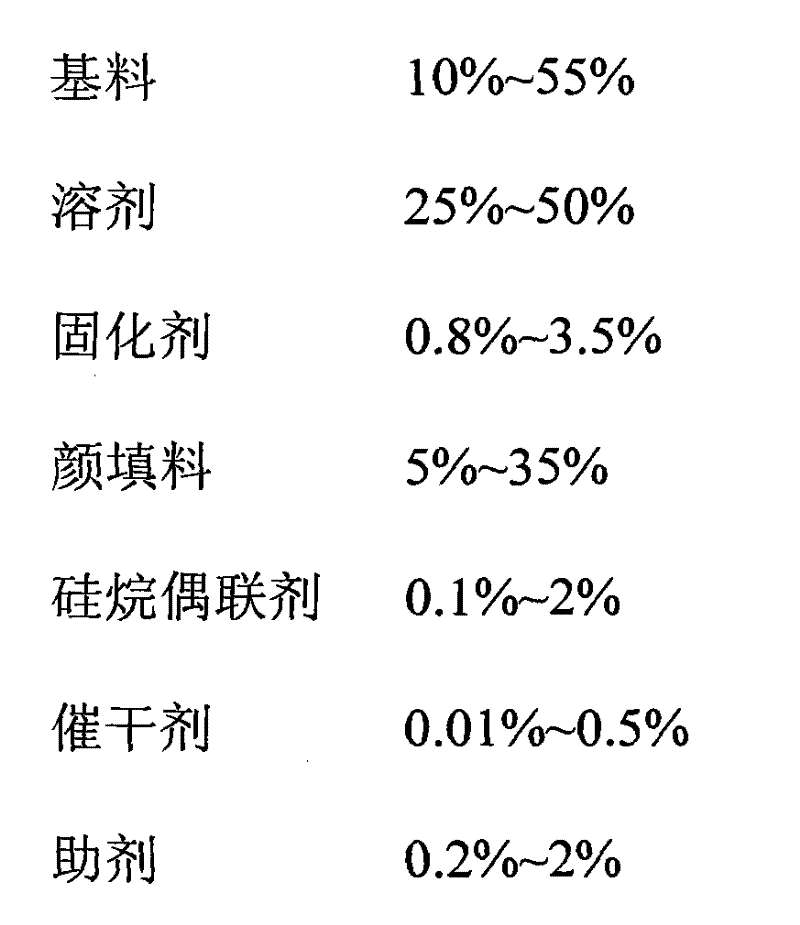

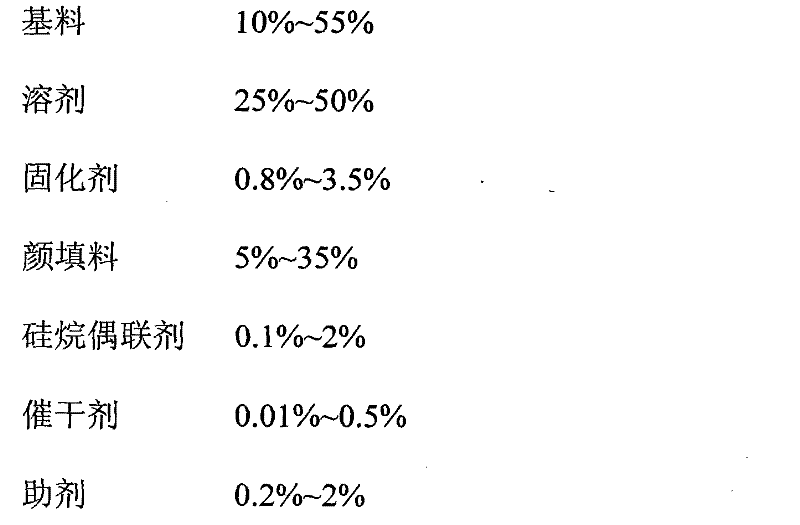

anti-corrosion coating

InactiveCN102260450AStrong adhesionEasy constructionAlkali metal silicate coatingsAnti-corrosive paintsMetal coatingSolvent

The invention belongs to the field of metal coatings, and in particular relates to a coating that can be used at high temperatures and is corrosion-resistant; the technical problem to be solved by the invention is to provide a coating that still has strong mechanical strength, strong adhesion, Corroded paint; in order to solve the above problems, the technical solution provided by the present invention is: a high-temperature anti-corrosion paint, including base material, solvent, curing agent, pigment and filler, silane coupling agent, drier, auxiliary agent; the present invention The beneficial effect is that: it has good adhesion, impact resistance and mechanical strength, the thickness of the coating film is 50 μm, the coating can withstand the temperature of 600 ° C, and has good corrosion resistance.

Owner:SNTO TECH GRP

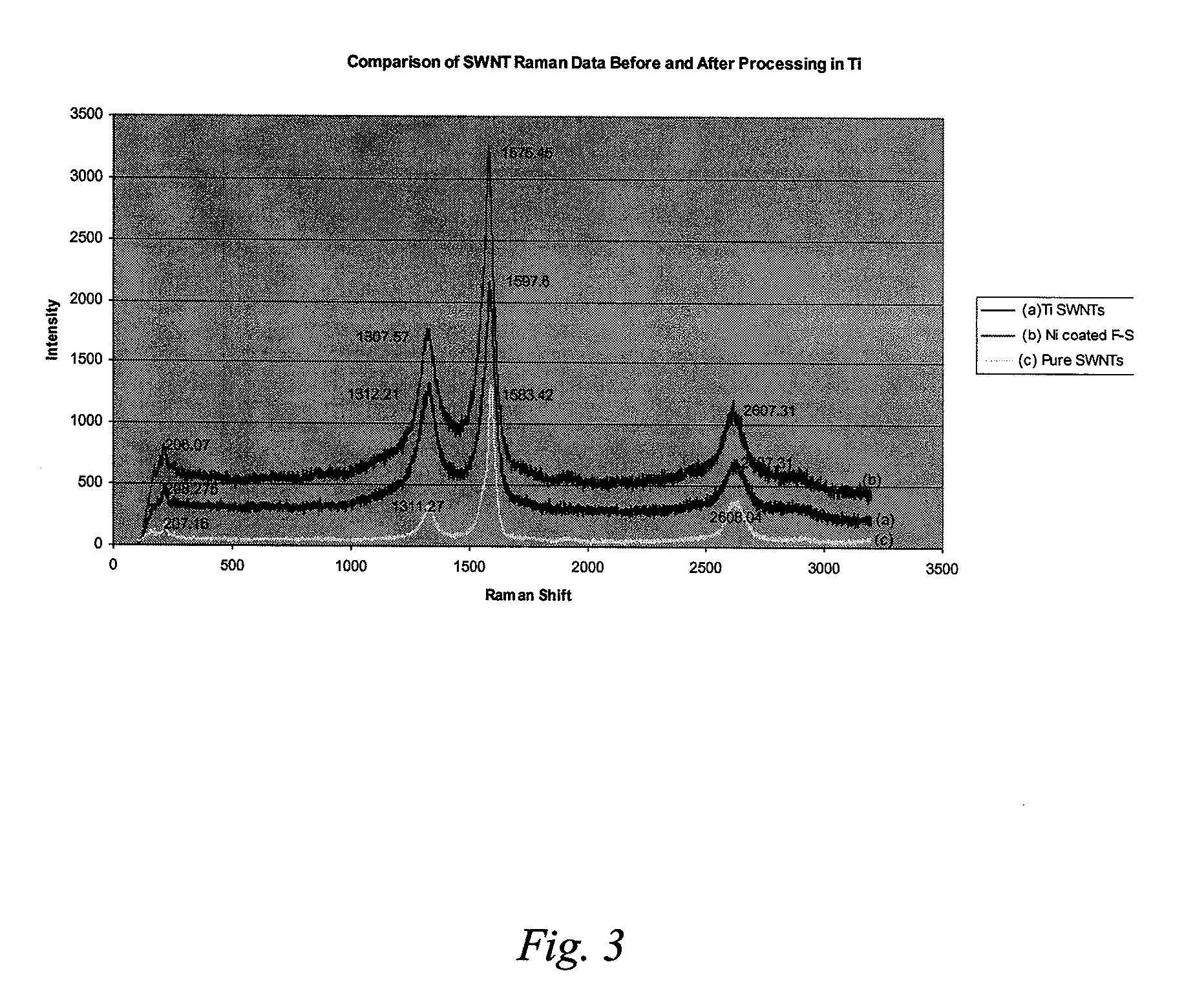

Processing of Single-Walled Carbon Nanotube Metal-Matrix Composites Manufactured by an Induction Heating Method

In some embodiments, the present invention is directed to a new composition of matter. Such a composition generally comprises a functionalized single-wall carbon nanotube (SWNT) which is coated with a metal that would not react with carbon at elevated temperatures. The metal-coated tube is incorporated into a metal matrix that could potentially form carbides. In some or other embodiments, the present invention is directed to methods of making such compositions.

Owner:RICE UNIV

Electrodeposited metallic-materials comprising cobalt

ActiveUS20100304182A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageParticulatesPorosity

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

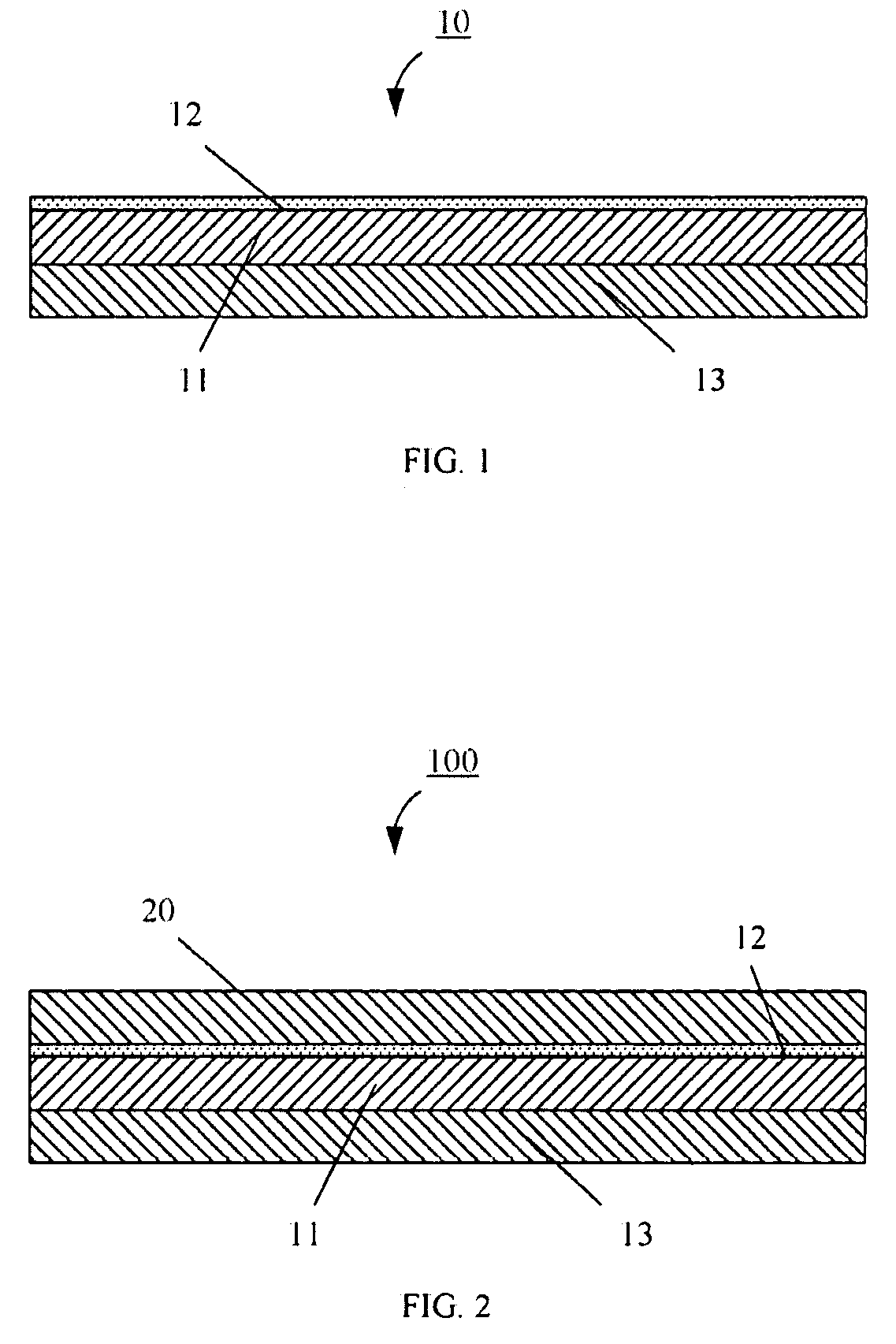

Laminate and its producing method

InactiveUS20040231141A1Improve surface smoothnessImprove adhesionPrinted circuit assemblingInsulating substrate metal adhesion improvementMetal coatingHigh density

A laminate is prepared by forming metal layer A on one face of a polymer film by dry plating method. When circuit is formed by using the laminate according to the semi-additive method, a high-density printed wiring board having excellent circuit shape, insulating property between the circuits and adhesion with the substrate can be obtained. By forming an adhesive layer on the other side of the polymer film of the laminate, an interlayer adhesive film is prepared. By thermally fusing or curing the adhesive layer after laminating the interlayer adhesive film on the inner layer circuit board, a multi-layer printed wiring board can be prepared. When preparing the circuit board by etching the first metal coating, an etchant which selectively etches the first metal coating is preferably used.

Owner:KANEKA CORP

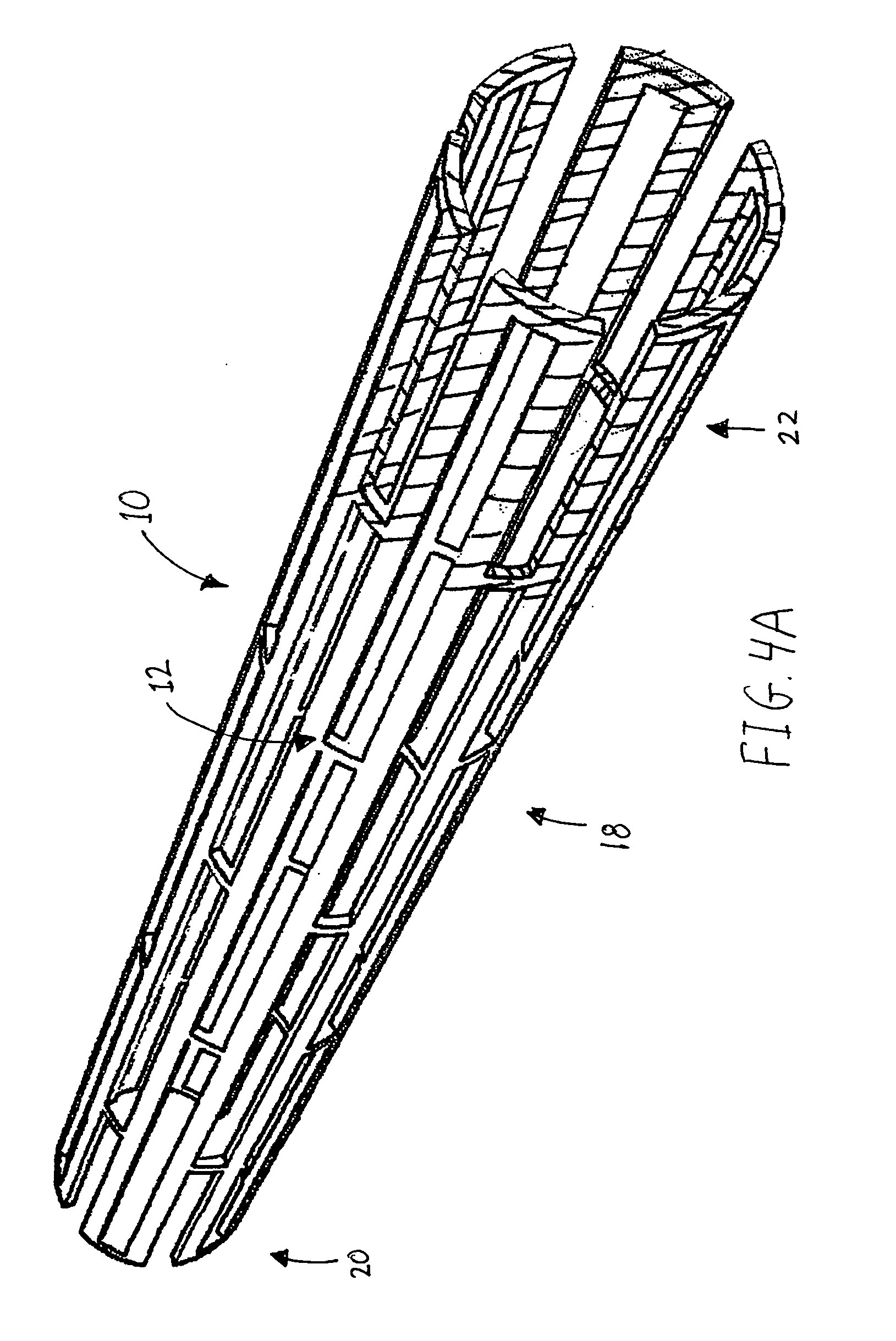

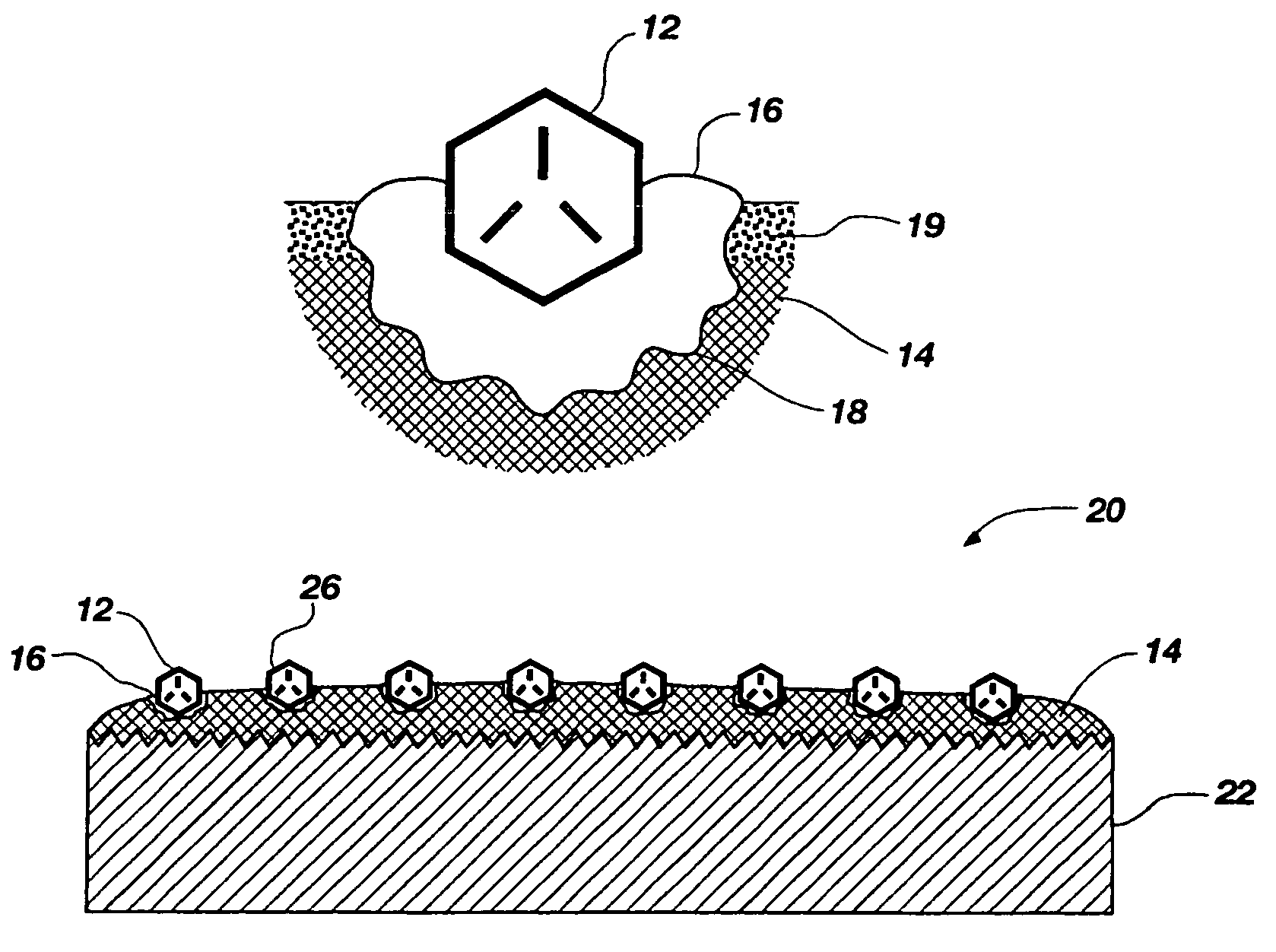

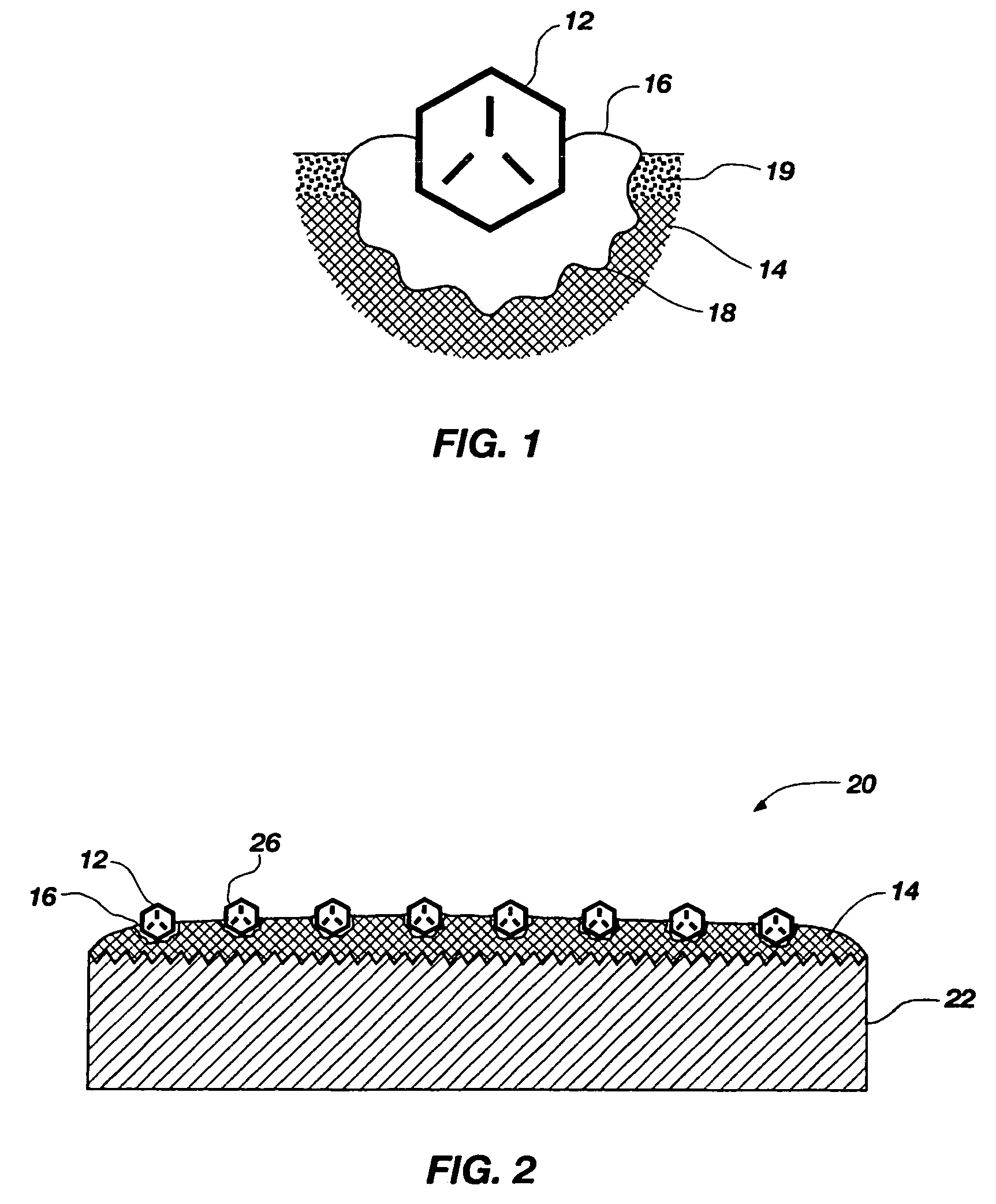

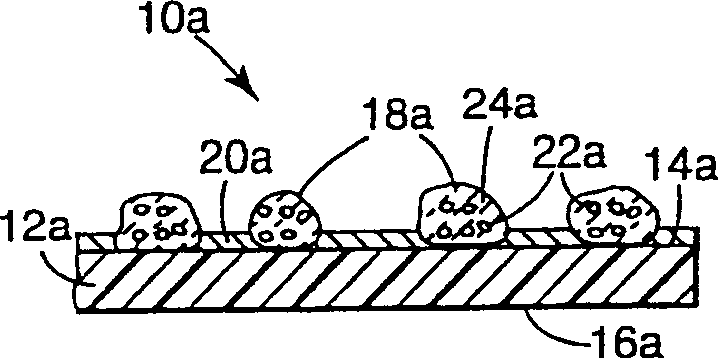

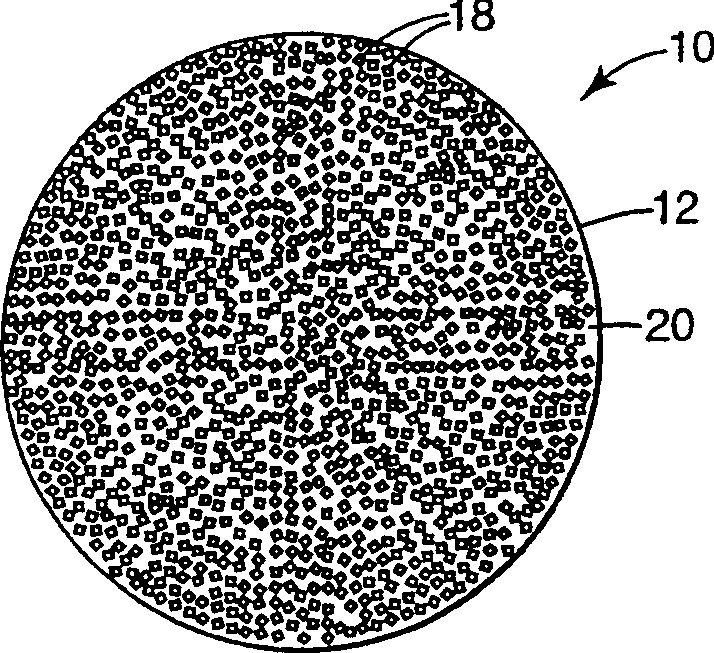

Chemical mechanical polishing pad dresser

ActiveUS7258708B2Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

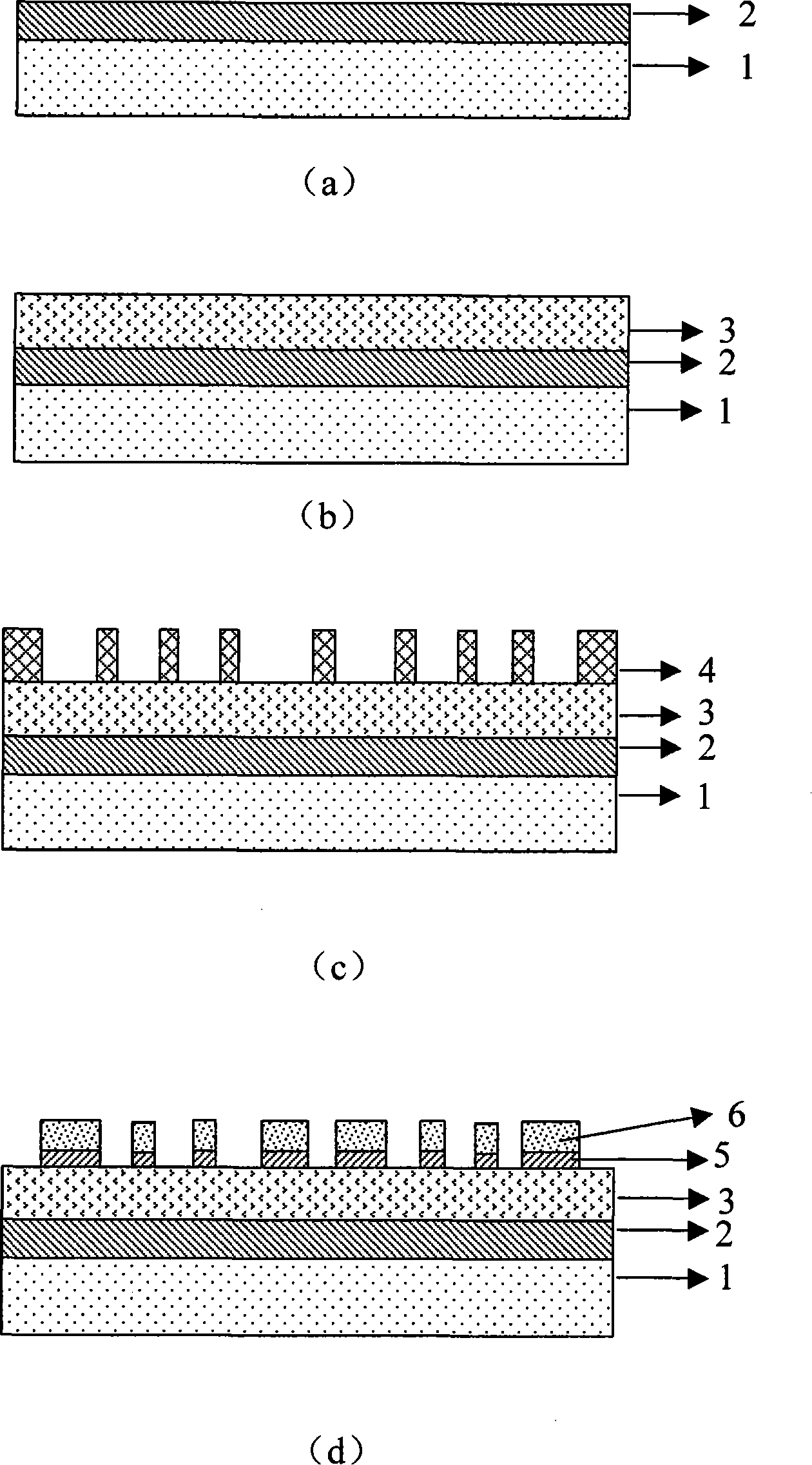

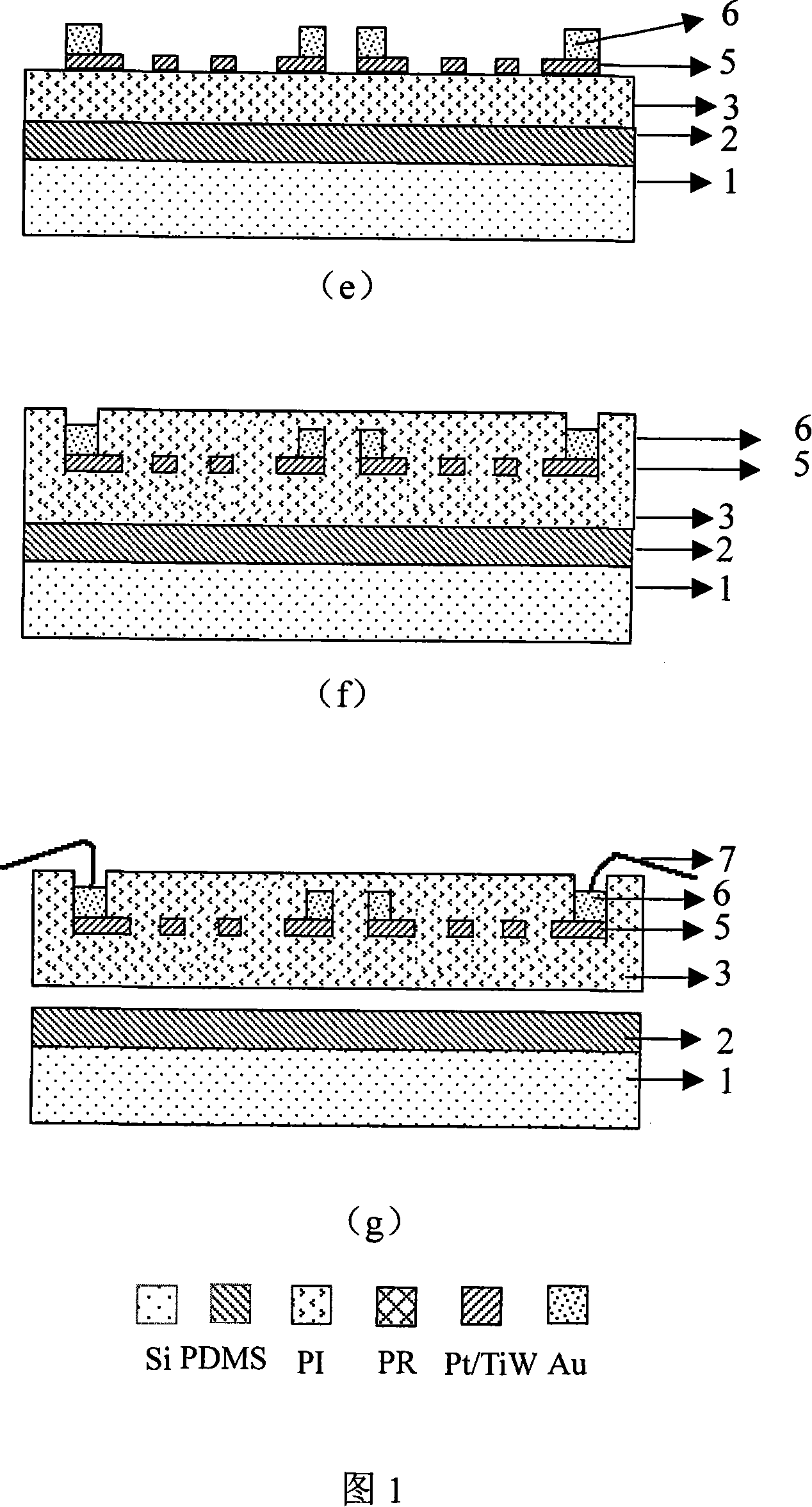

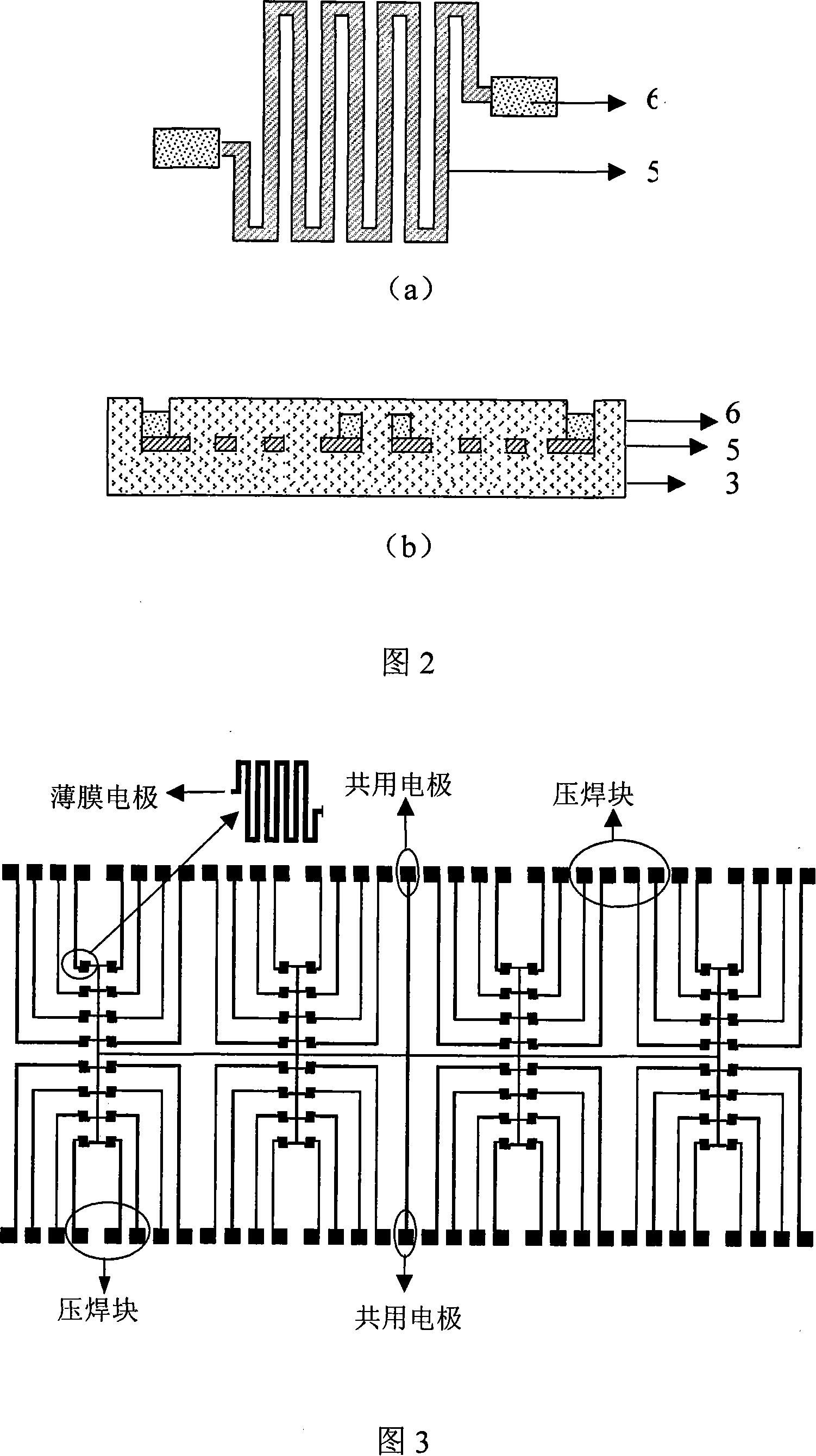

Method for making flexibility temperature sensor

InactiveCN101082523AAchieve integrationSimple preparation processThermometers using electric/magnetic elementsUsing electrical meansEngineeringDimethyl siloxane

This invention discloses a production method of flexibility humidity sensor. Its character is washing a dimethyl siloxane interlayer on silicon dice carrier firstly, after solidification in room-temperature, activing the surface with oxygen plasma, then washing high viscosity polyimide again and procuring with staged technology, then, overlapping and depositing all the metal coating and using stripping technology and wet-method corroding figure technology to firm mental humidity-dependent resistor and electric connector, after this, overlapping a light low viscosity PI protective layer, using wet method to corrode the outside metal press welding part; then putting the device on the heating plate and peeling the interlayer from the flexible carrier, after all, putting the flexible carrier peeled into the bake oven to solidify it to two PI membranous layers completely, so realizing the compatible craft. The method to make it is simple, the cost is low and the rate of finished products is high, and it is more near the achievement of mass production and the integration of the high density sensor.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Metal-clad polymer article

Metal-clad polymer articles containing structural fine-grained and / or amorphous metallic coatings / layers optionally containing solid particulates dispersed therein, are disclosed. The fine-grained and / or amorphous metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling although the coefficient of linear thermal expansion (CLTE) of the metallic layer and the substrate are mismatched. The interface between the metallic layer and the polymer is suitably pretreated to withstand thermal cycling without failure.

Owner:INTEGRAN TECH

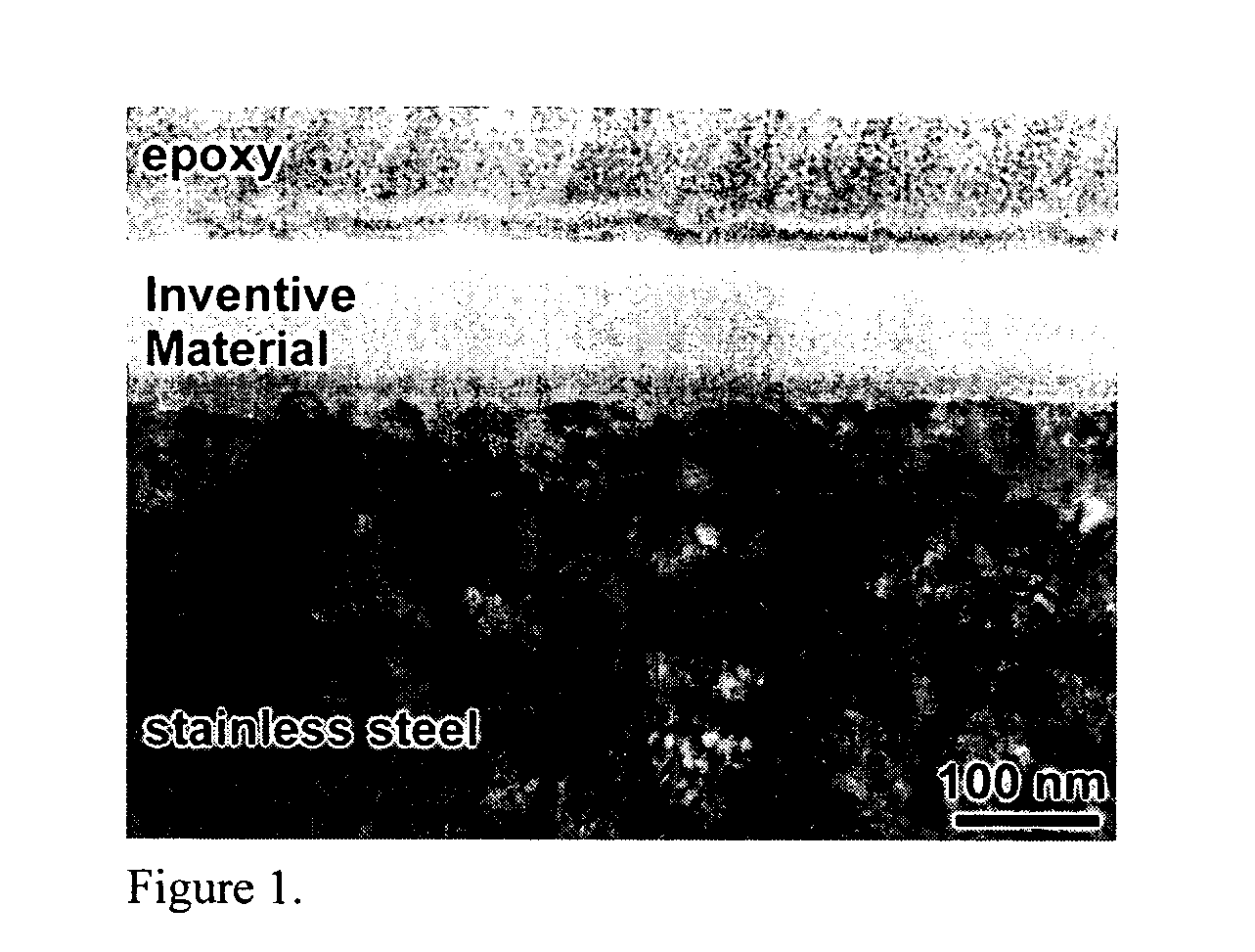

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS20070281176A1Cost-effective and convenient processIncrease stiffnessMaterial nanotechnologyRodsThermal dilatationMetal coating

Fine-grained (average grain size 1 nm to 1,000 nm) metallic coatings optionally containing solid particulates dispersed therein are disclosed. The fine-grained metallic materials are significantly harder and stronger than conventional coatings of the same chemical composition due to Hall-Petch strengthening and have low linear coefficients of thermal expansion (CTEs). The invention provides means for matching the CTE of the fine-grained metallic coating to the one of the substrate by adjusting the composition of the alloy and / or by varying the chemistry and volume fraction of particulates embedded in the coating. The fine-grained metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling. The low CTEs and the ability to match the CTEs of the fine-grained metallic coatings with the CTEs of the substrate minimize dimensional changes during thermal cycling and prevent premature failure.

Owner:INTEGRAN TECH

Chemical mechanical polishing pad dresser

ActiveUS20060143991A1Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

Metallized films

InactiveUS6033786AImprove propertiesImprove adhesionSynthetic resin layered productsGlass/slag layered productsButeneMetal coating

A biaxially oriented, heat-set, multilayer film includes a core layer, a bonding layer having a surface adhered to the core layer and a flame treated surface opposite the surface adhered to the core layer. A metal coating for providing oxygen and moisture barrier properties deposited on the flame treated surface and a protective plastic film adhered to said metal coating. The core layer and bonding layer either are free of void-creating additives or include only a quantity of such additives that does not create a matte surface adversely affecting the barrier properties of the metal coating. The bonding layer comprising a mixture including 40 to 100% by weight of propylene / butene-1 copolymer containing up to about 14% by weight of butene-1 (PBC), 0 to 60% of an isotactic polypropylene (PP) and 0 to 50% of a copolymer of ethylene and propylene wherein propylene is the predominant component by weight (EPC).

Owner:APPLIED EXTRUSION TECH

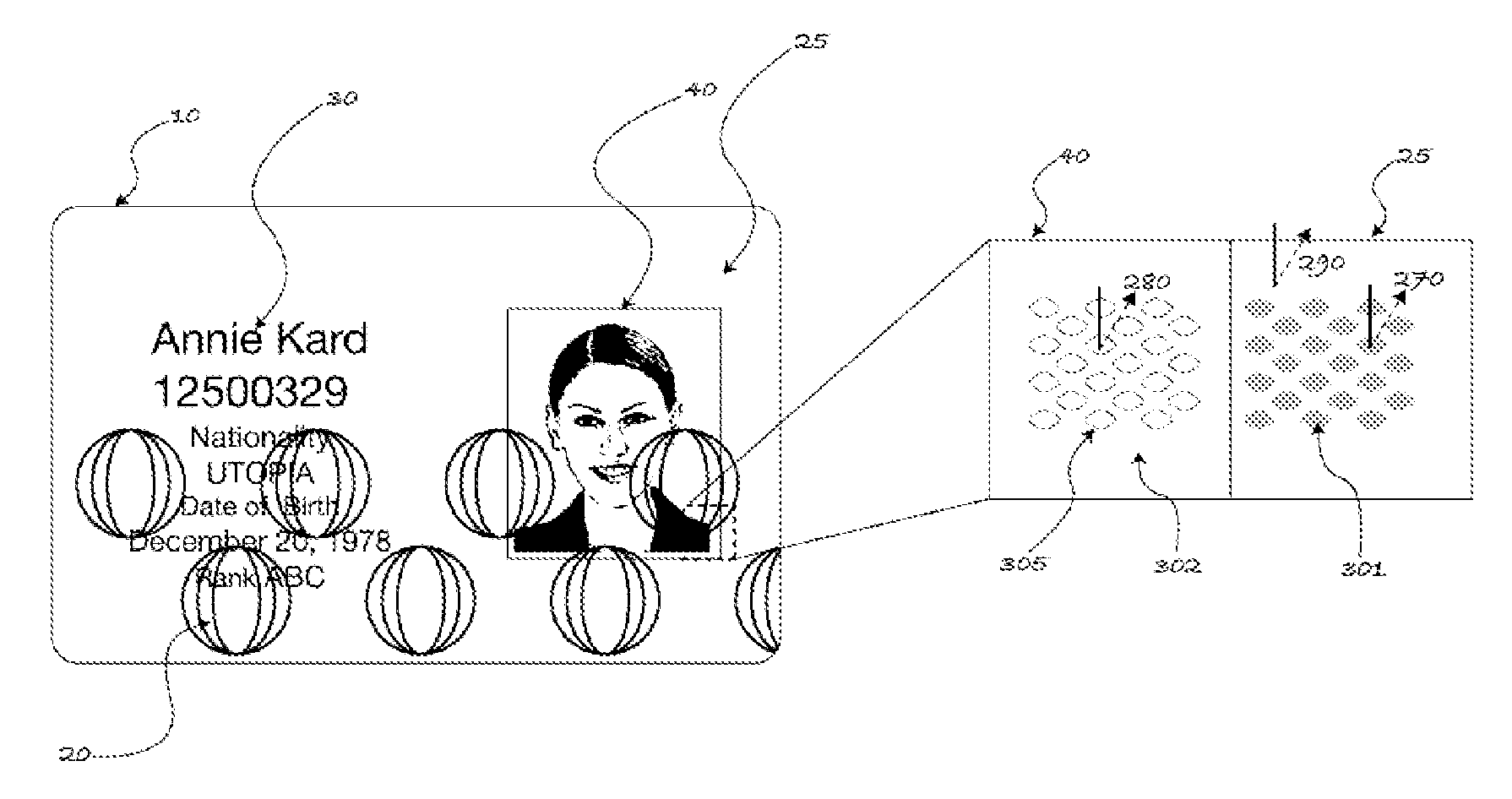

Ovd containing device

InactiveUS20090251749A1Good optical performanceOther printing matterSynthetic resin layered productsVisibilityMetal coating

A holographic overlay is provided, including: a polycarbonate substrate having a first side and a second side, a diffractive structure cast upon the first side of the polycarbonate substrate, and a reflection-enhancing coating on at least a part of the diffractive structure; wherein the second side of the polycarbonate substrate provides a substantially flat external surface of the overlay capable of fusing to a conforming surface in the presence of heat and pressure without an adhesive. Optionally, the overlay is laser-engraved so as to form ablated voids in the metal coating and carbonize the laser engravable polycarbonate under the ablated voids. According to another aspect of the invention, a metal coating on a hologram is made substantially transparent using a laser to form a transparent portion of a hologram. Optionally, it is done after applying the hologram to an object such as a card, a document, etc., in register with underlying information to ensure its visibility and continuity of the hologram.

Owner:OPSEC SECURITY GROUP

Quick high-flexibility manufacturing method for ceramic circuit board

ActiveCN103188877AImprove bindingImprove thermal conductivityPrinted circuit manufactureLaser beam welding apparatusChemical platingChemical reaction

A quick high-flexibility manufacturing method for a ceramic circuit board comprises the following steps: irradiating laser on the surface of a ceramic matrix, and controlling the energy density of the laser to reach above the fracture threshold of the chemical bond of the compound containing active ions, so that chemical reaction occurs on the surface of the ceramic matrix, an active substance is separated out to serve as a chemical plating catalytic source, and the active substrate generated by the reaction and the matrix form chemical metallurgical bonding, wherein different laser sources are selected aiming at different ceramic materials according to the chemical bond energy of the ceramic material components, and the laser energy is controlled to reach the ceramic modified threshold by controlling the average power of laser output, pulse repetition frequency, scanning speed, defocusing amount, space between scanning line and scanning times; and the ceramic matrix modified by the laser is placed into a chemical plating solution to perform plating to form a metal coating. The surface of the ceramic is modified by the laser, so that a metal conductive layer and the matrix form chemical metallurgical bonding, the bonding force of the circuit board is greatly increased, and the heat-conducting property and the electric property are improved.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

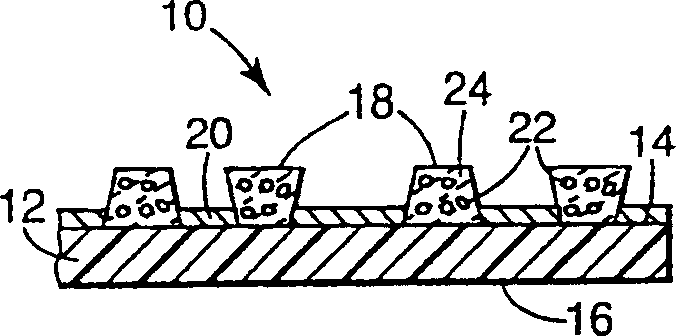

Metal bond abrasive article comprising porous ceramic abrasive composites and method of using same to abrade a workpiece

The present invention relates to an abrasive article comprising a rigid backing having a first major surface and a second major surface; a plurality of ceramic abrasive composites each comprising a plurality of abrasive particles distributed throughout a porous ceramic matrix; and at least one metal coating, optimally, a set of metal coatings, which affixes the ceramic abrasive composites to at least one major surface of the backing. The present invention also relates to a method for grinding workpiece using the abrasive article, which comprises the steps of bringing the surface of the workpiece into contact with the abrasive article, applying a liquid on the interface between the workpiece and the abrasive article, moving the workpiece and the abrasive article with respect to each other.

Owner:3M INNOVATIVE PROPERTIES CO

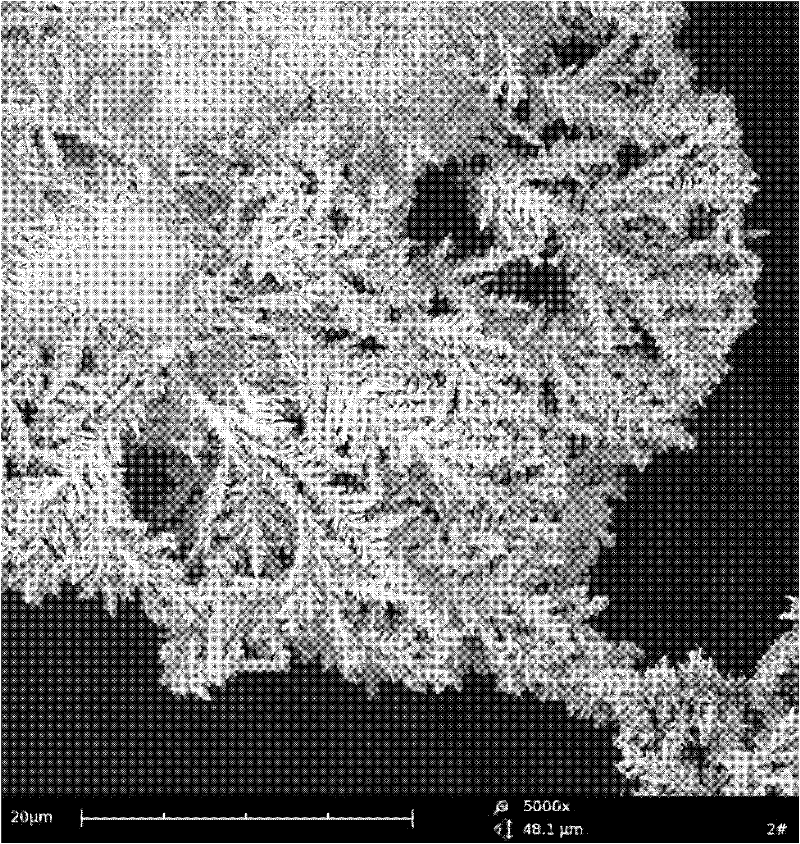

Preparation method and application of super-hydrophobic/super-lipophilic material in oil-water separation field

InactiveCN102228884APromote regenerationLight weightFatty/oily/floating substances removal devicesLiquid/solution decomposition chemical coatingCopper platingThiol

The invention provides a preparation method and application of a super-hydrophobic / super-lipophilic material in oil-water separation field, involving the preparation method and application of an oil / water separation material. In the invention, the technical problems that the existing oil-water separation materials have low organic matter adsorption efficiency and high cost can be solved. The preparation method comprises the following steps of: treating a substrate with a roughening liquid, sensitizing liquid and an activating liquid in a proper order, then plating copper or zinc on the surface of the substrate, then immersing the substrate with the metal coating in an etching liquid for treatment to obtain the substrate with the rough metal layer on the surface, finally soaking the substrate in an organic solution of a fatty acid or a thiol and drying to obtain the super-hydrophobic / super-lipophilic material. The obtained super-hydrophobic / super-lipophilic material can be applied in oil-water separation, can absorb 1-40 g of organic matters per gram of the material, can be recycled repeatedly and can be used to control and treat oil pollution.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com