Metal-clad polymer article

A metal cladding, polymer technology, applied in the direction of metal layered products, tubular articles, synthetic resin layered products, etc., can solve the problem of not providing information on thermal cycle performance or adhesion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

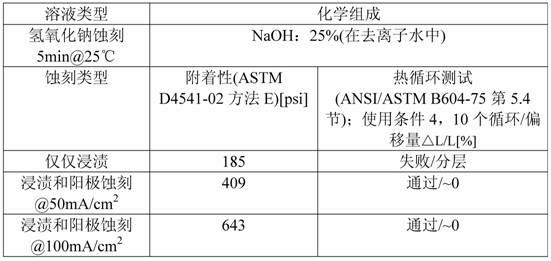

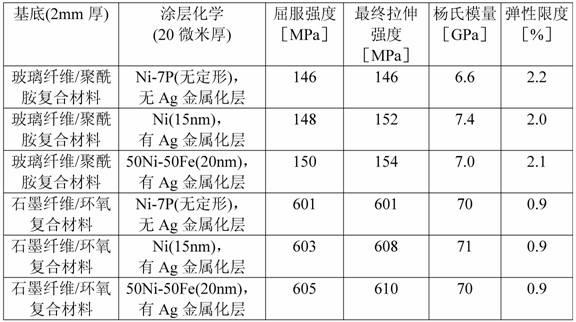

[0184] The present invention relates to a laminated article comprising a layer of structured metallic material on a polymeric substrate suitable for shaping to form a precursor to the metal-clad polymeric article. The metallic material / coating is fine-grained and / or amorphous and is produced by DC or pulse electrodeposition, electroless deposition, physical vapor deposition (PVD), chemical vapor deposition (CVD) and gas condensation, etc. of. Overcoming the debonding of the coating from the substrate due to the inherent mismatch in the coefficients of thermal expansion of the metal and polymer of the metal-clad polymer articles of the present invention and through appropriate surface activation and / or Surface roughness and / or metal-polymer interface surface design increases the detachment strength between the metal material and the polymer to achieve acceptable thermal cycling performance.

[0185] Those skilled in the art of electroplating will know how to electroplate or el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com