Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

407results about "Silver accumulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

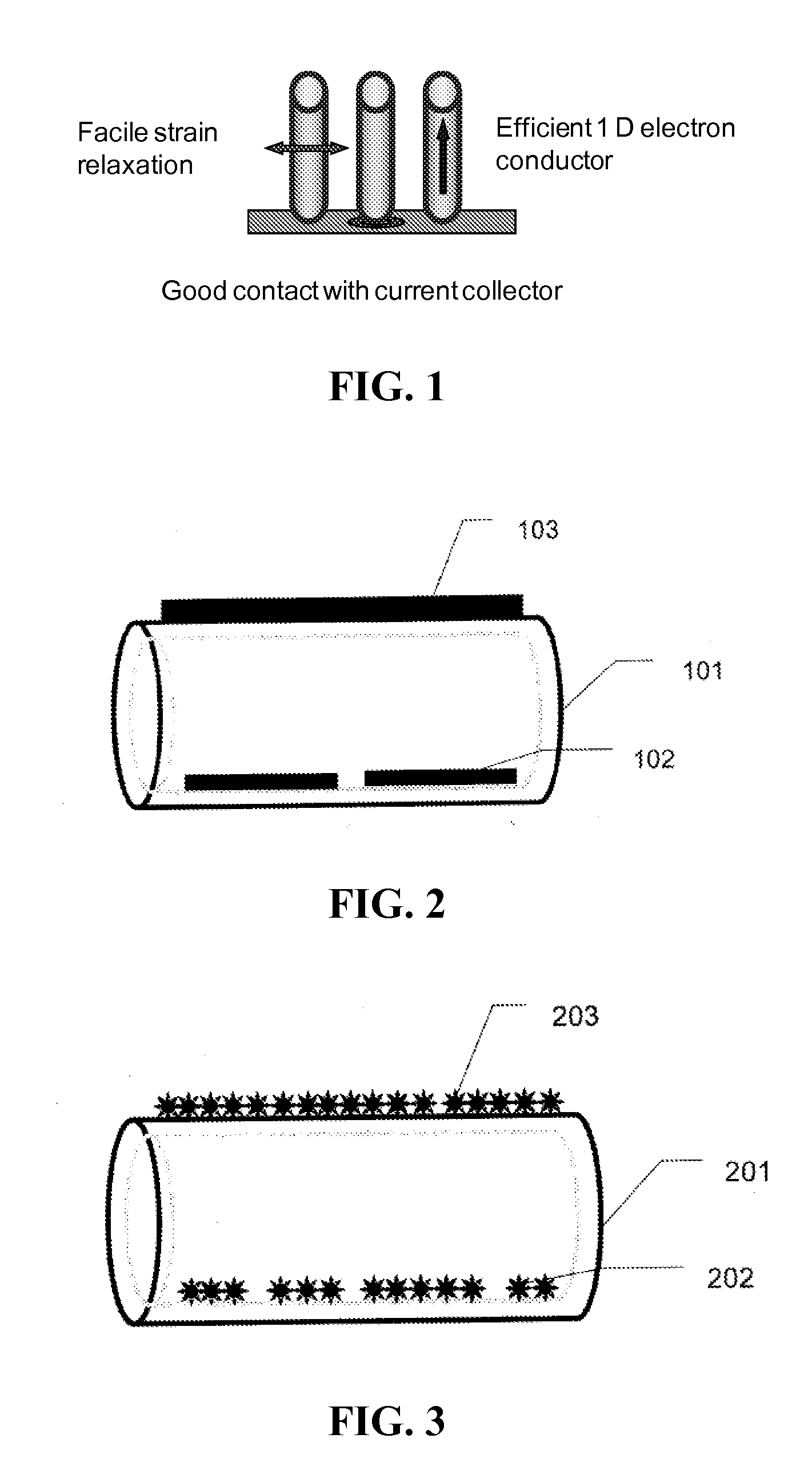

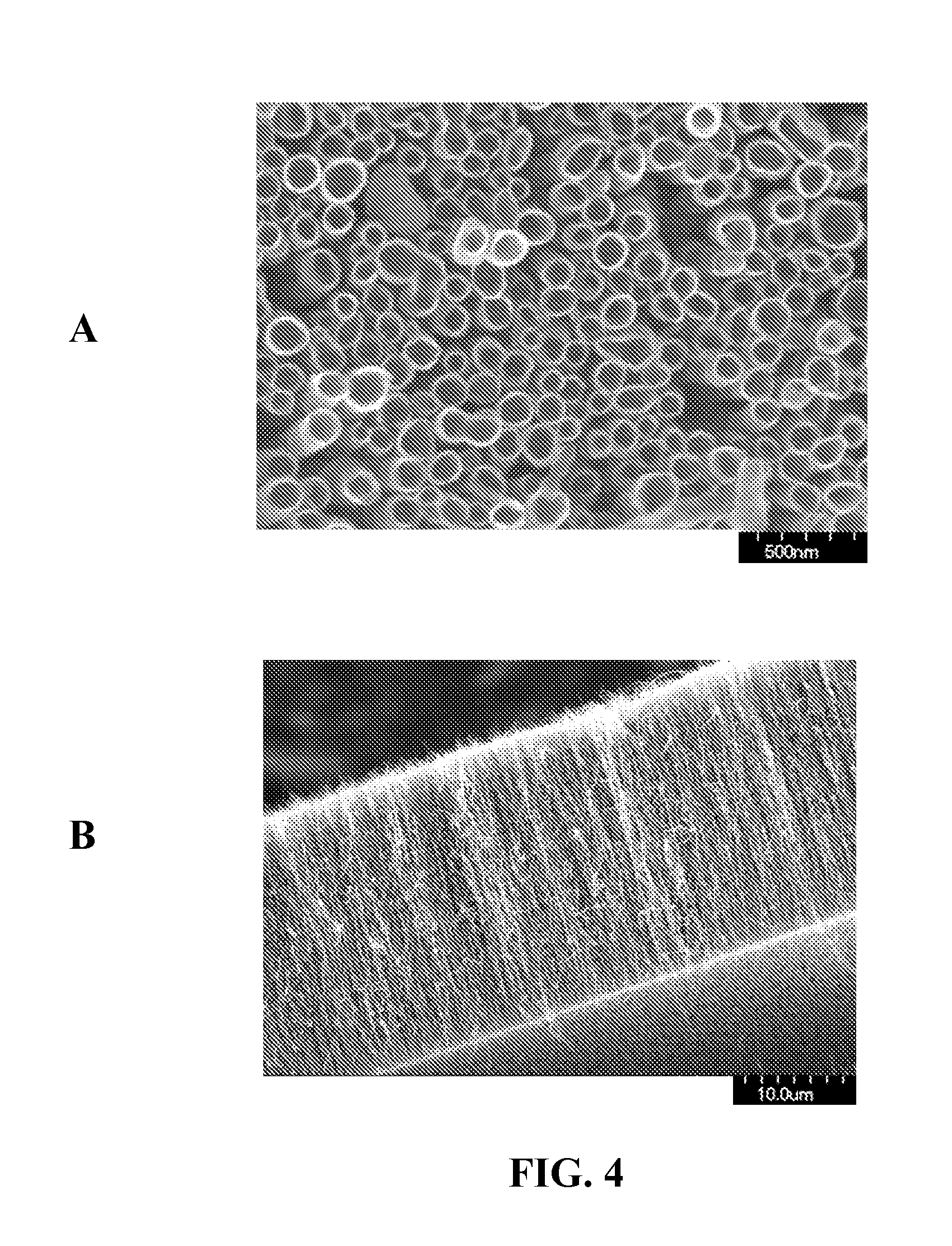

Porous silicon particulates for lithium batteries

An anode structure for lithium batteries includes nanofeatured silicon particulates dispersed in a conductive network. The particulates are preferably made from metallurgical grade silicon powder via HF / HNO3 acid treatment, yielding crystallite sizes from about 1 to 20 nm and pore sizes from about 1 to 100 nm. Surfaces of the particles may be terminated with selected chemical species to further modify the anode performance characteristics. The conductive network is preferably a carbonaceous material or composite, but it may alternatively contain conductive ceramics such as TiN or B4C. The anode structure may further contain a current collector of copper or nickel mesh or foil.

Owner:TIEGS TERRY N

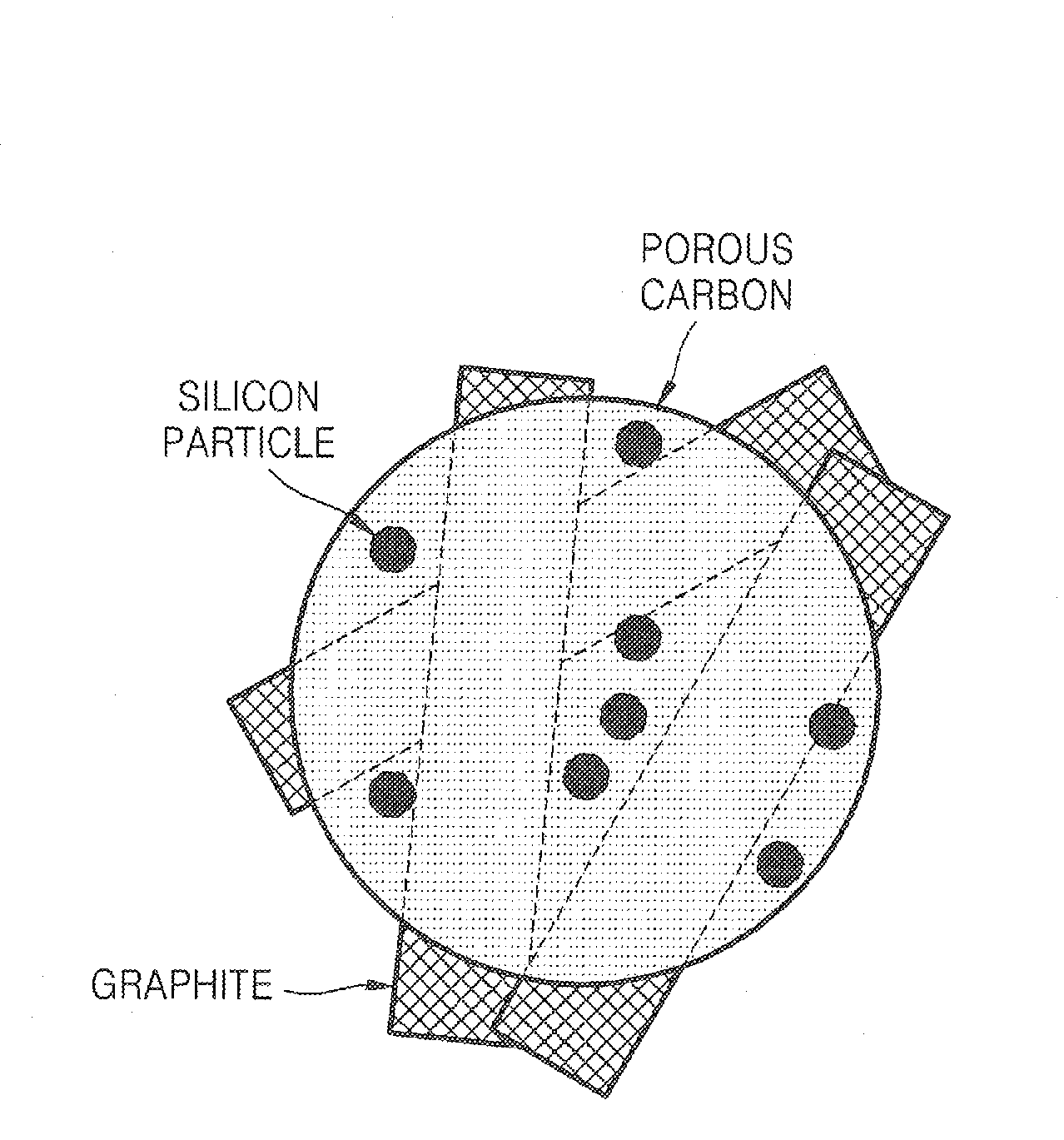

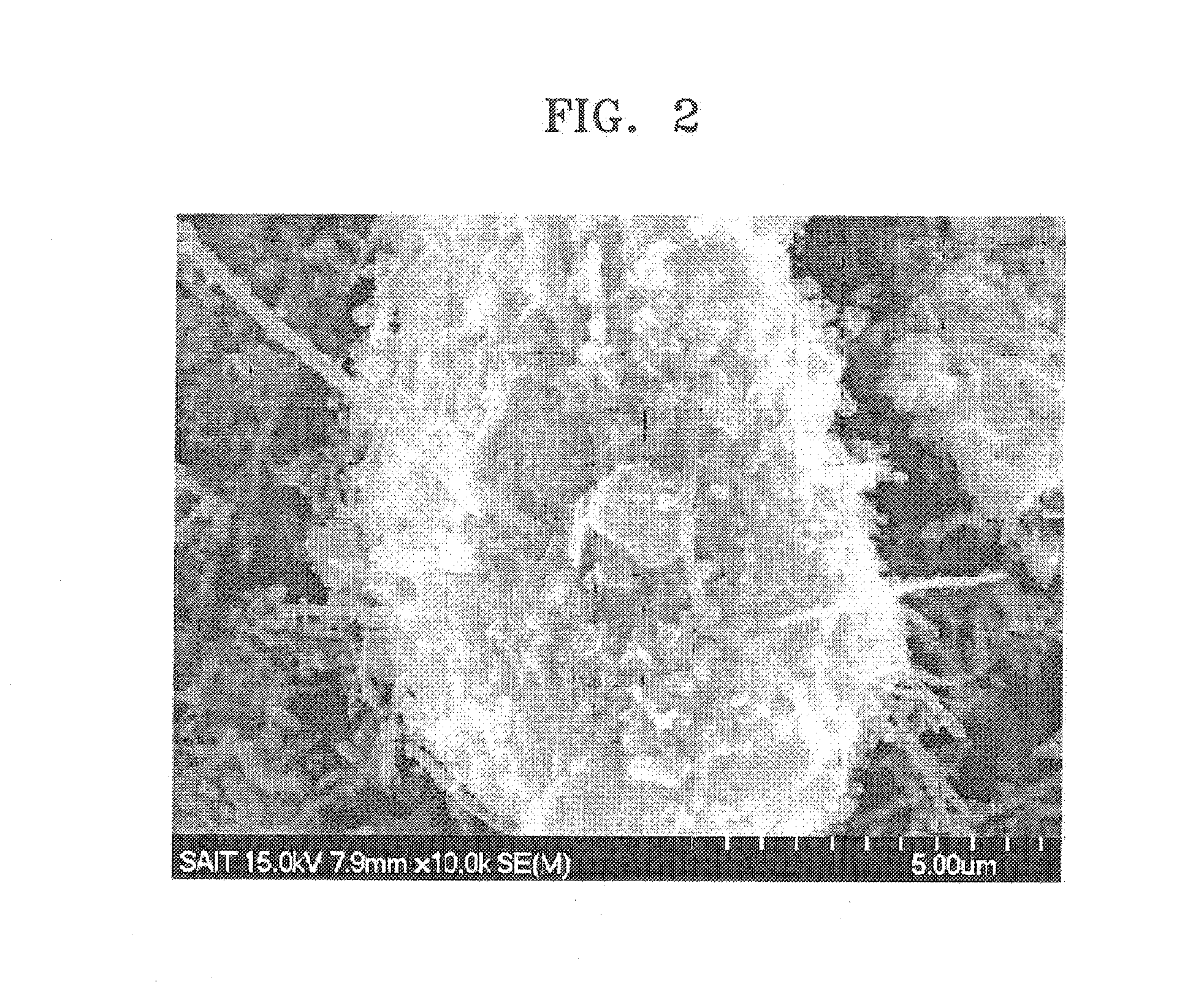

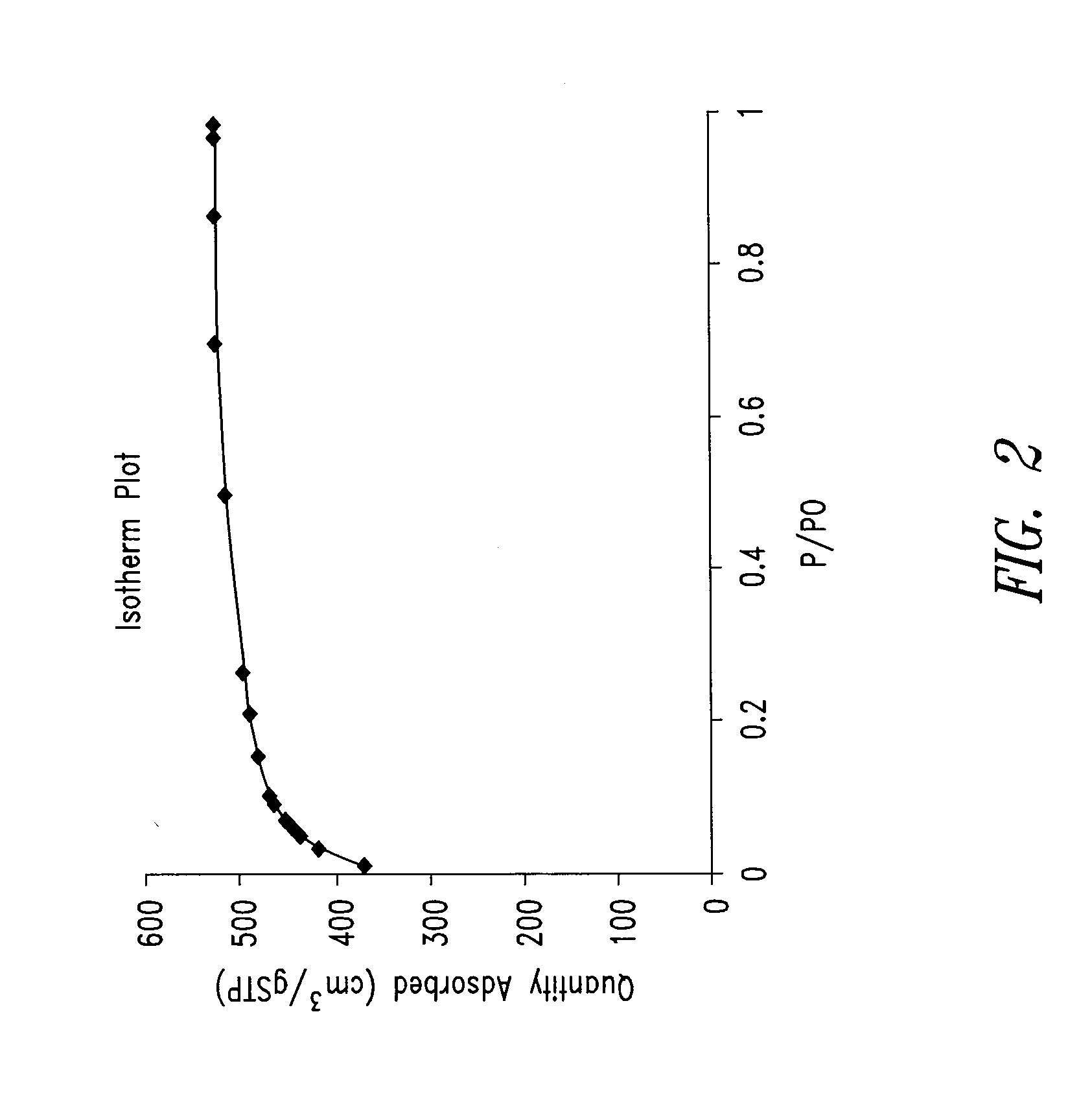

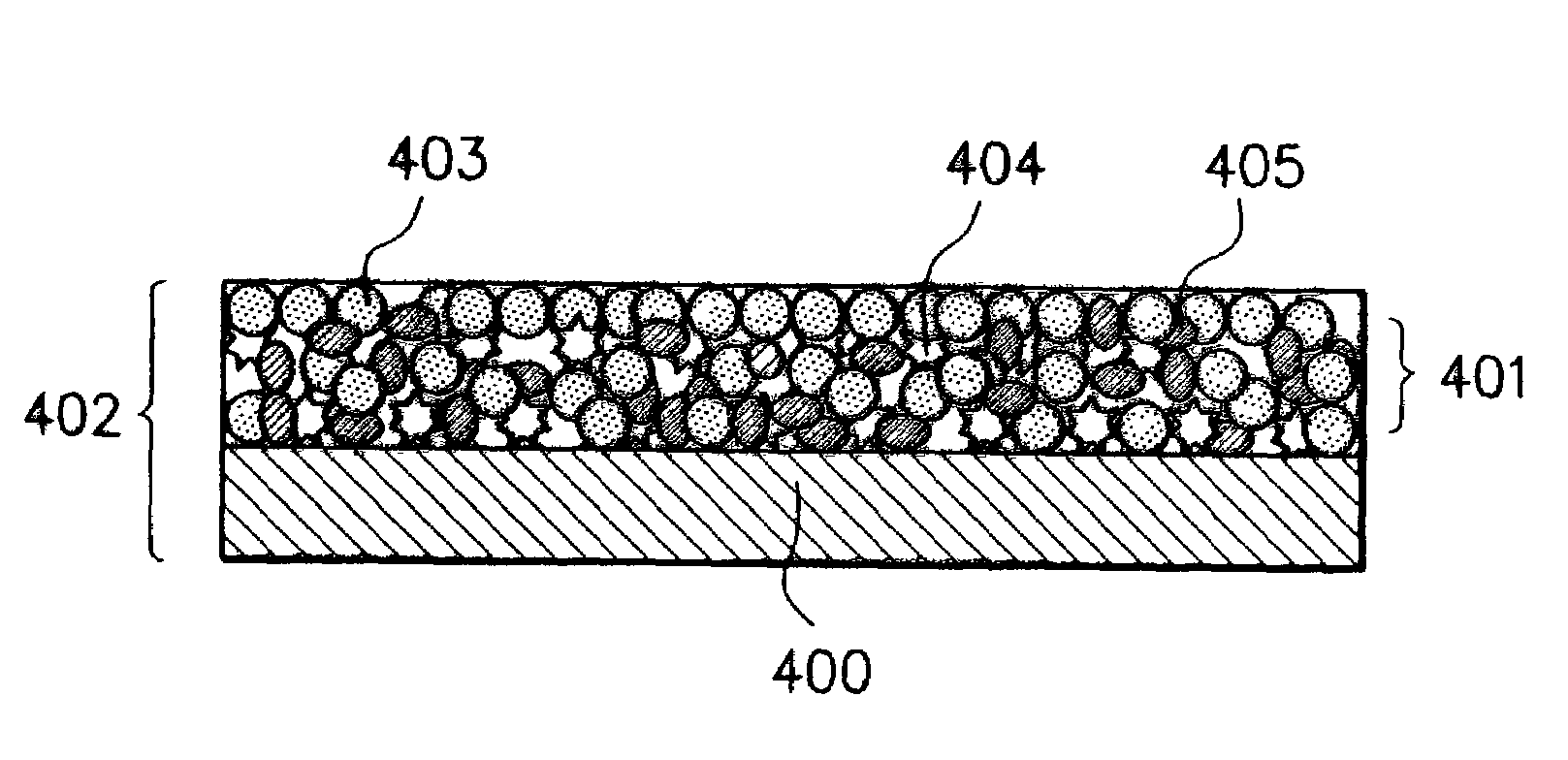

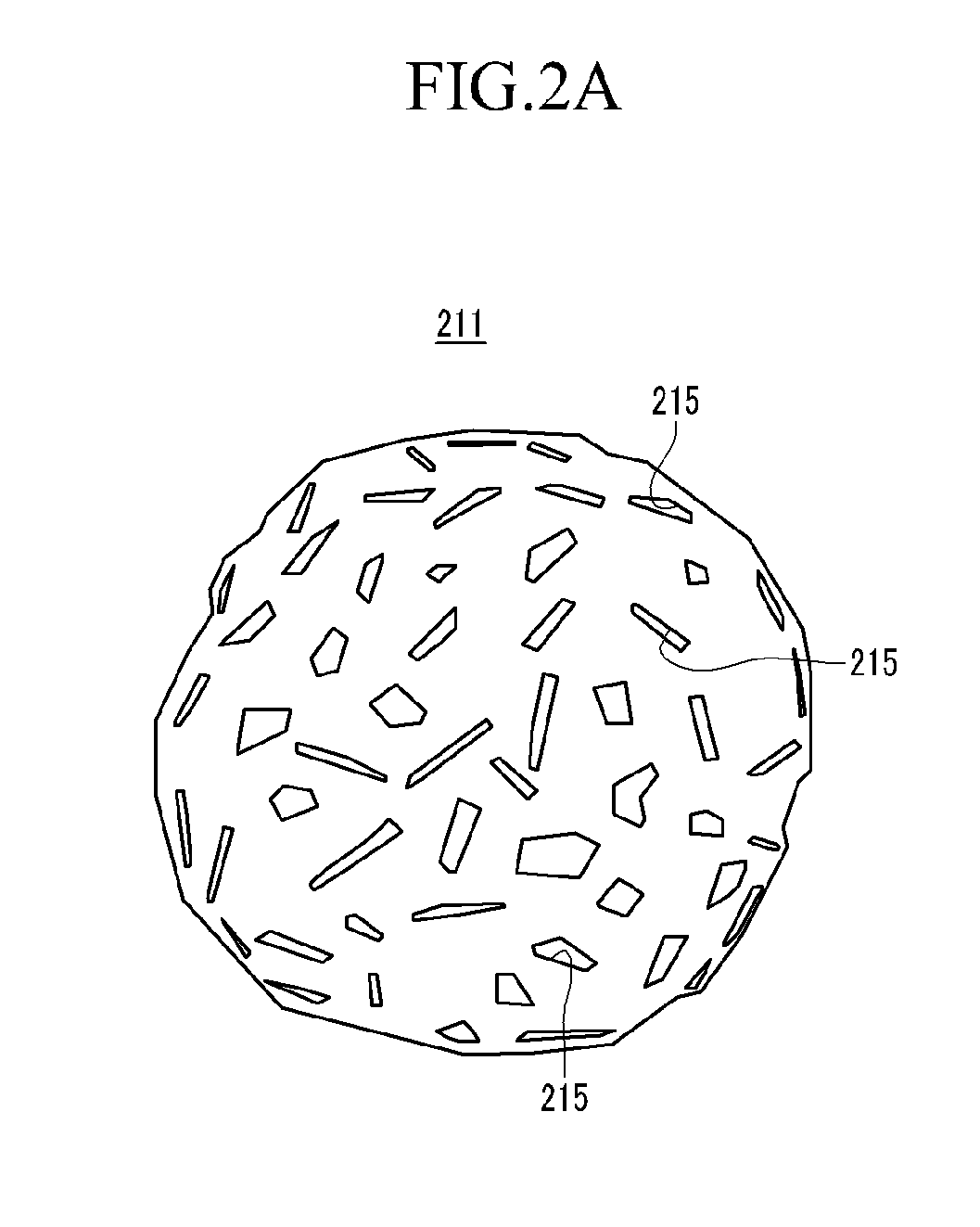

Porous anode active material, method of preparing the same, and anode and lithium battery employing the same

ActiveUS20080145757A1Efficiently remove stressExcellent charge and discharge characteristicsSilver accumulatorsMaterial nanotechnologyAlloyPore diameter

Provided are a porous anode active material, a method of preparing the same, and an anode and a lithium battery employing the same. The porous anode active material includes fine particles of metallic substance capable of forming a lithium alloy; a crystalline carboneous substance; and a porous carboneous material coating and attaching to the fine particles of metallic substance and the crystalline carboneous substance, the porous anode active material having pores exhibiting a bimodal size distribution with two pore diameter peaks as measured by a Barrett-Joyner-Halenda (BJH) pore size distribution from a nitrogen adsorption. The porous anode active material has the pores having a bimodal size distribution, and thus may efficiently remove a stress occurring due to a difference of expansion between a carboneous material and a metallic active material during charging and discharging. Further, the anode electrode and the lithium battery comprising the anode active material have excellent charge / discharge characteristics.

Owner:SAMSUNG SDI CO LTD

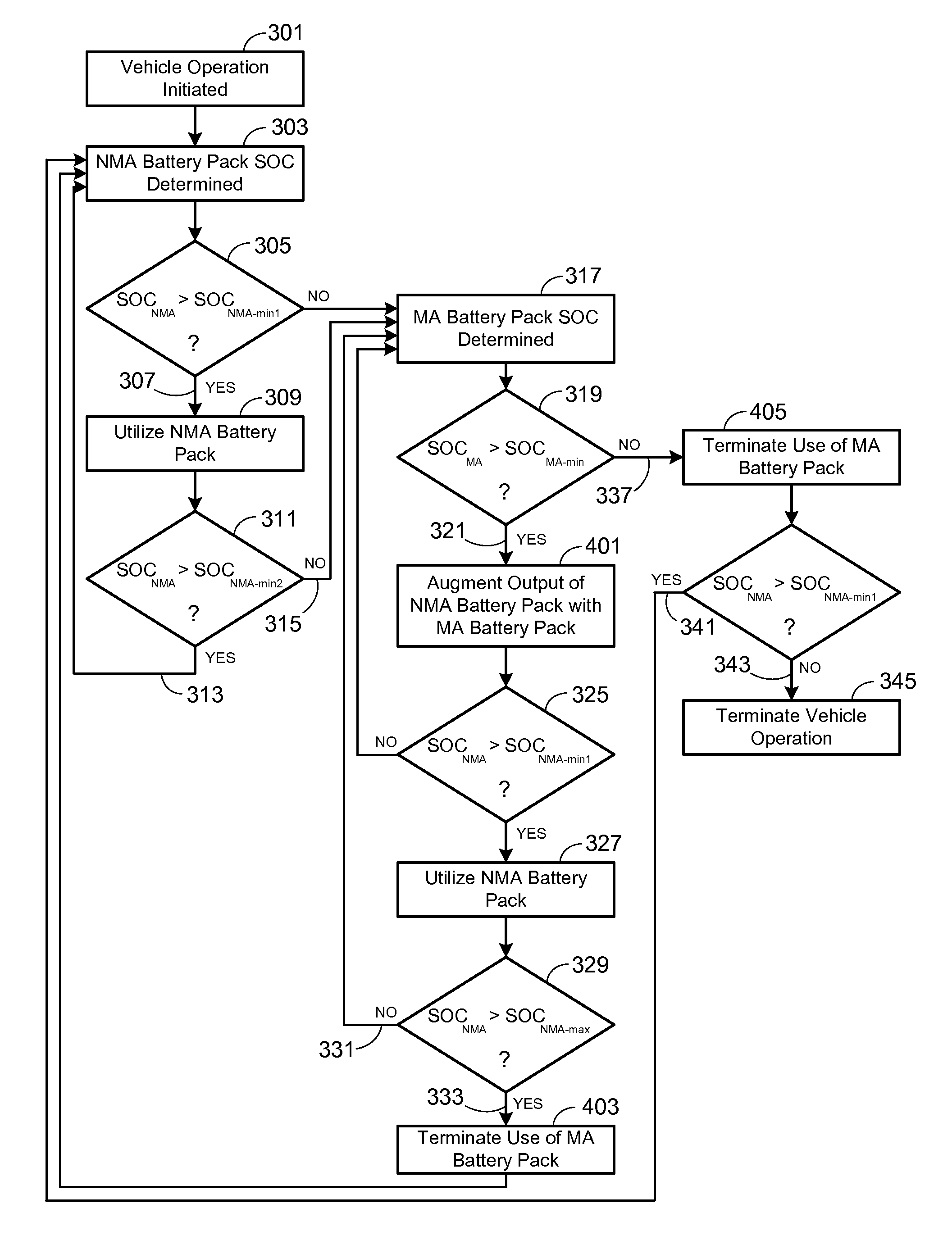

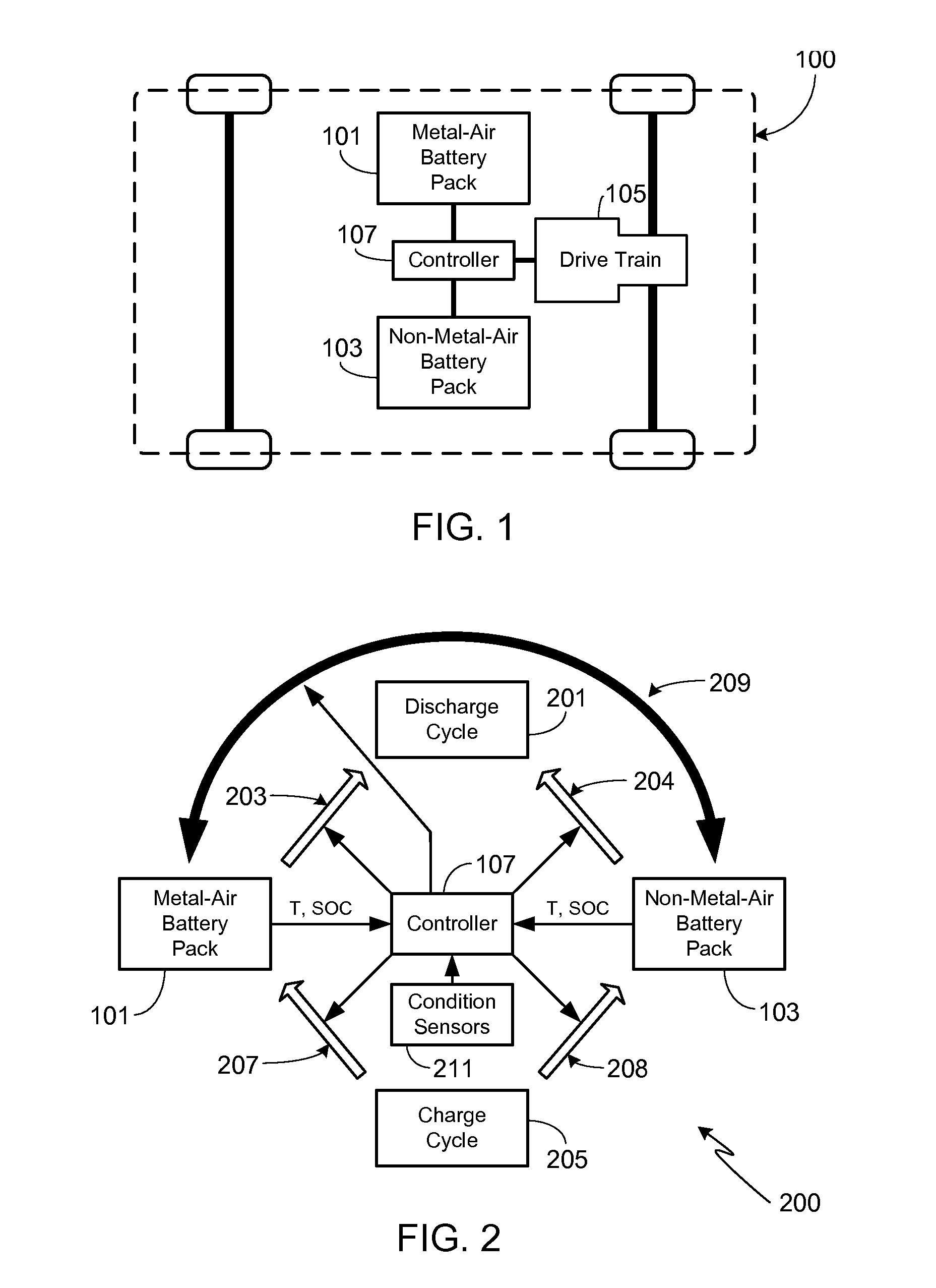

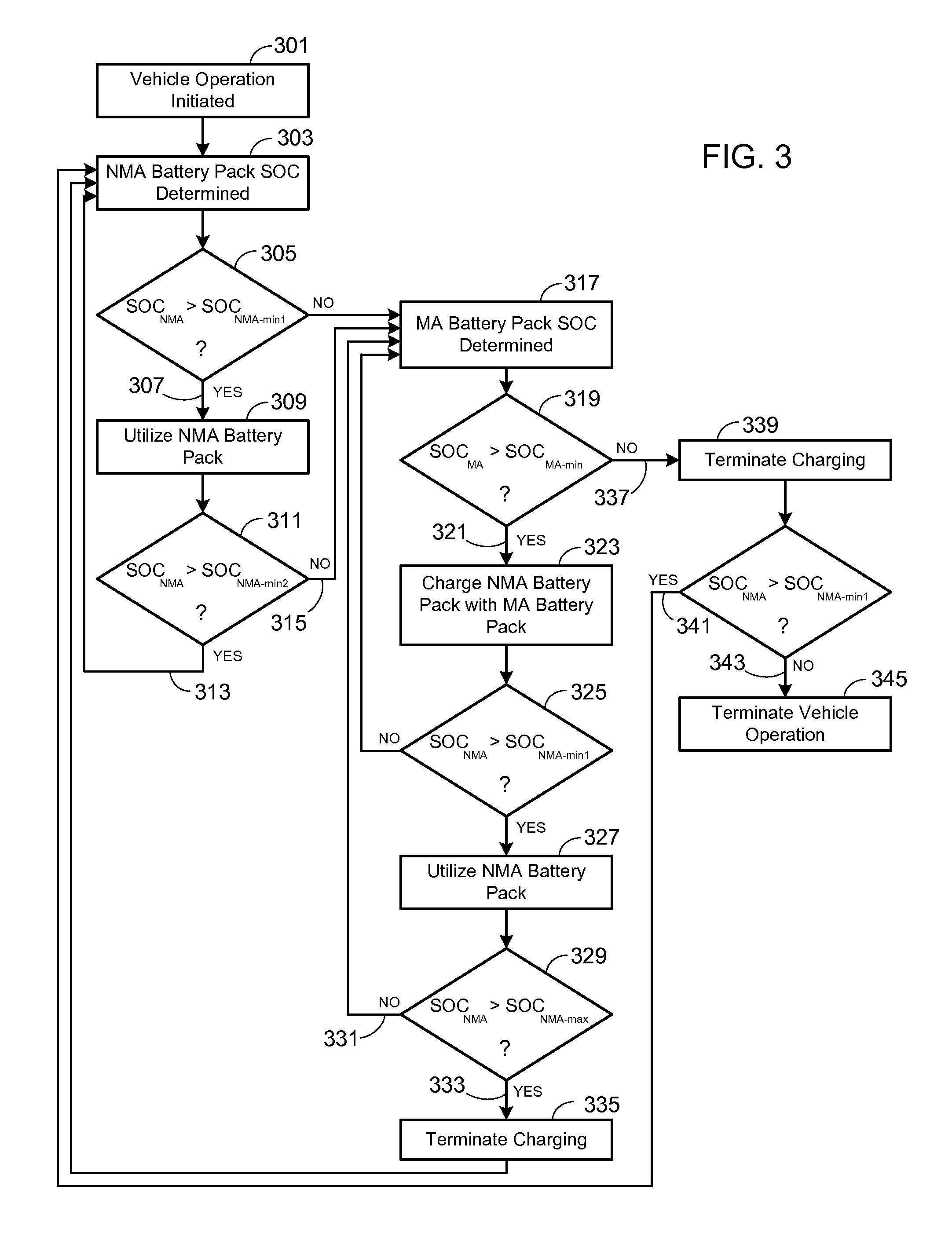

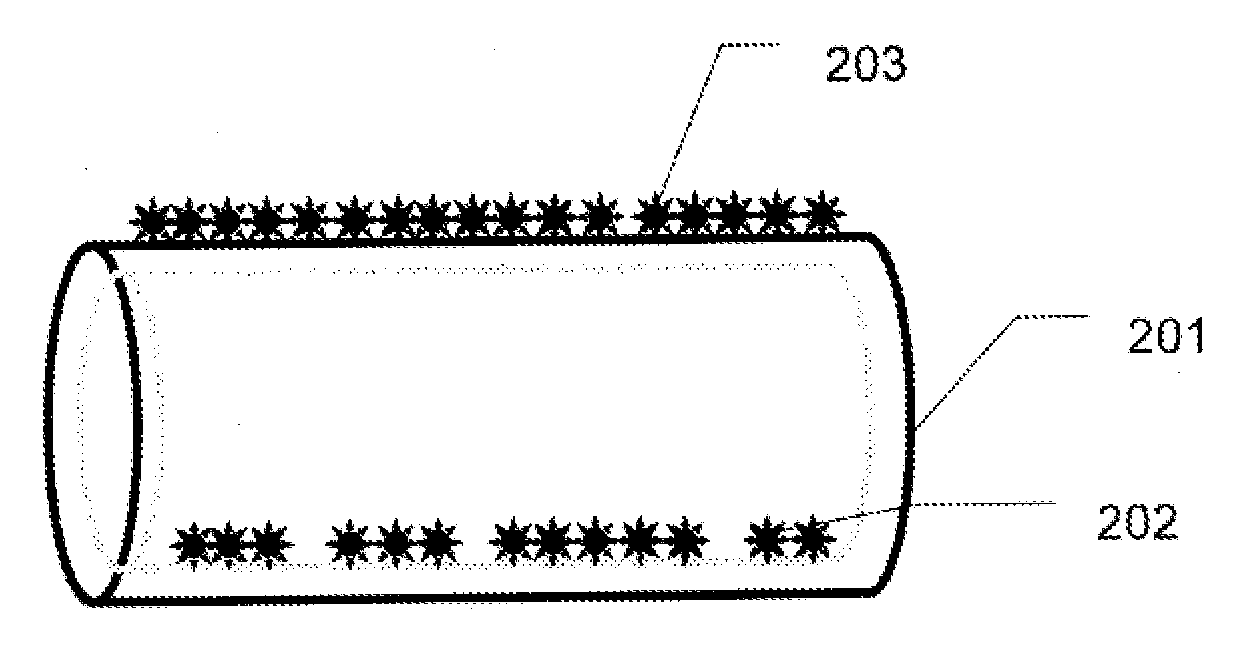

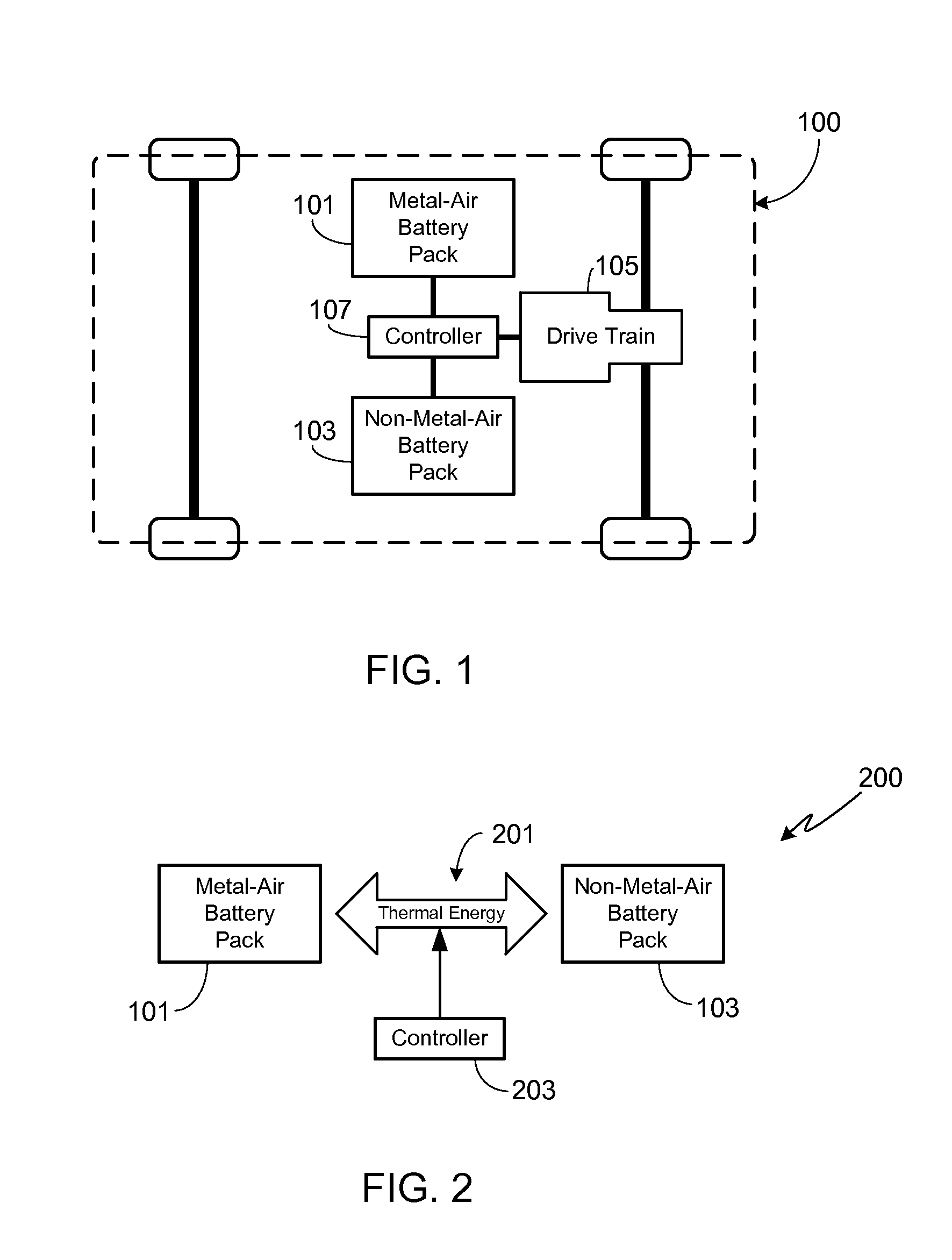

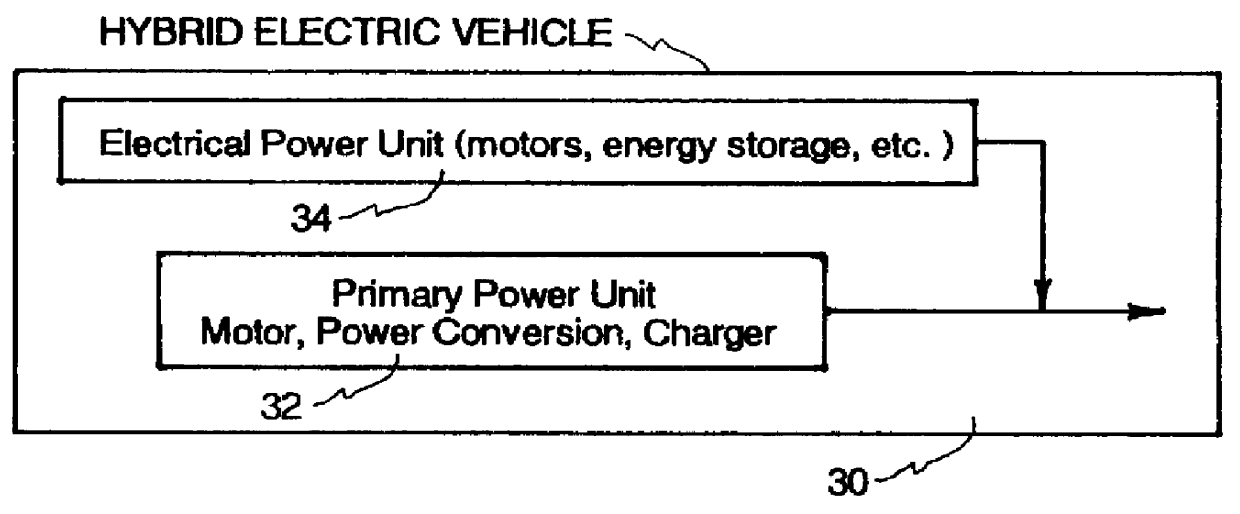

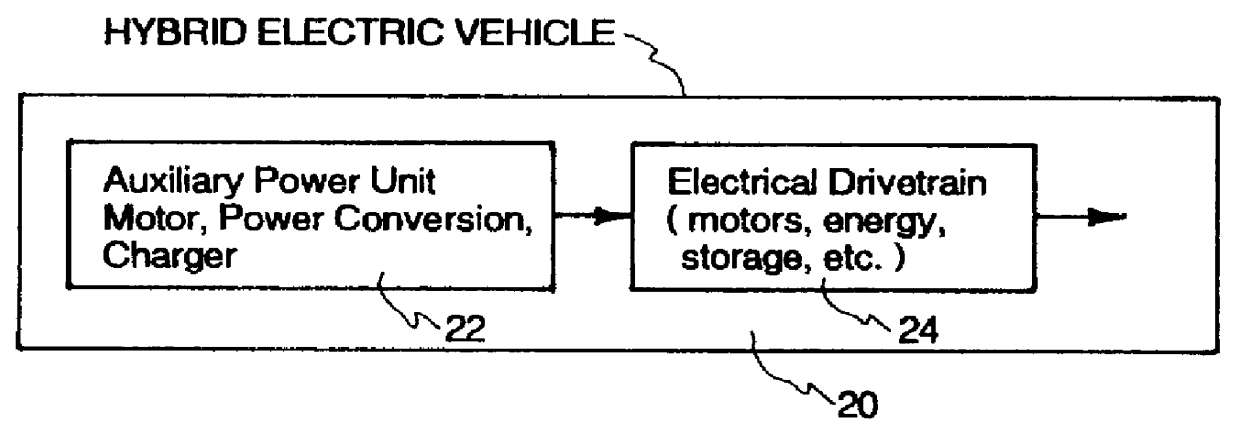

Electric Vehicle Extended Range Hybrid Battery Pack System

A power source comprised of a first battery pack (e.g., a non-metal-air battery pack) and a second battery pack (e.g., a metal-air battery pack) is provided, wherein the second battery pack is only used as required by the state-of-charge (SOC) of the first battery pack or as a result of the user selecting an extended range mode of operation. Minimizing use of the second battery pack prevents it from undergoing unnecessary, and potentially lifetime limiting, charge cycles. The second battery pack may be used to charge the first battery pack or used in combination with the first battery pack to supply operational power to the electric vehicle.

Owner:TESLA INC

Nanotube composite anode materials suitable for lithium ion battery applications

The present invention provides a composite material suitable for use in an anode for a lithium ion battery, the composite material comprising a layer of a lithium-alloying material on the walls of an aligned nanotubular base material. Preferably, the lithium-alloying material comprises a material selected from the group consisting of Si, Sn, Pb, Al, Au, Pt, Zn, Cd, Ag, Mg, and a combination of two or more of the foregoing.

Owner:UCHICAGO ARGONNE LLC

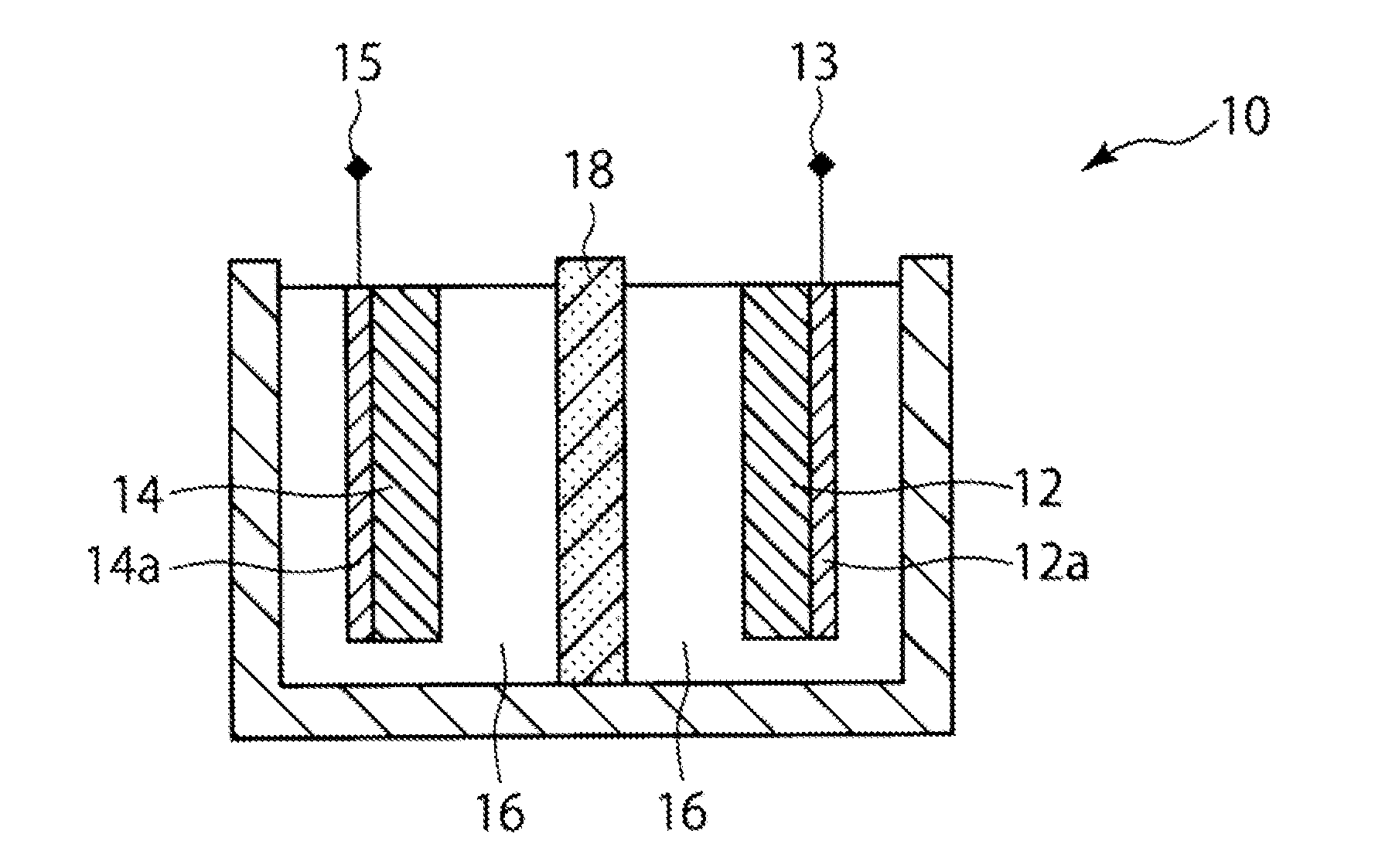

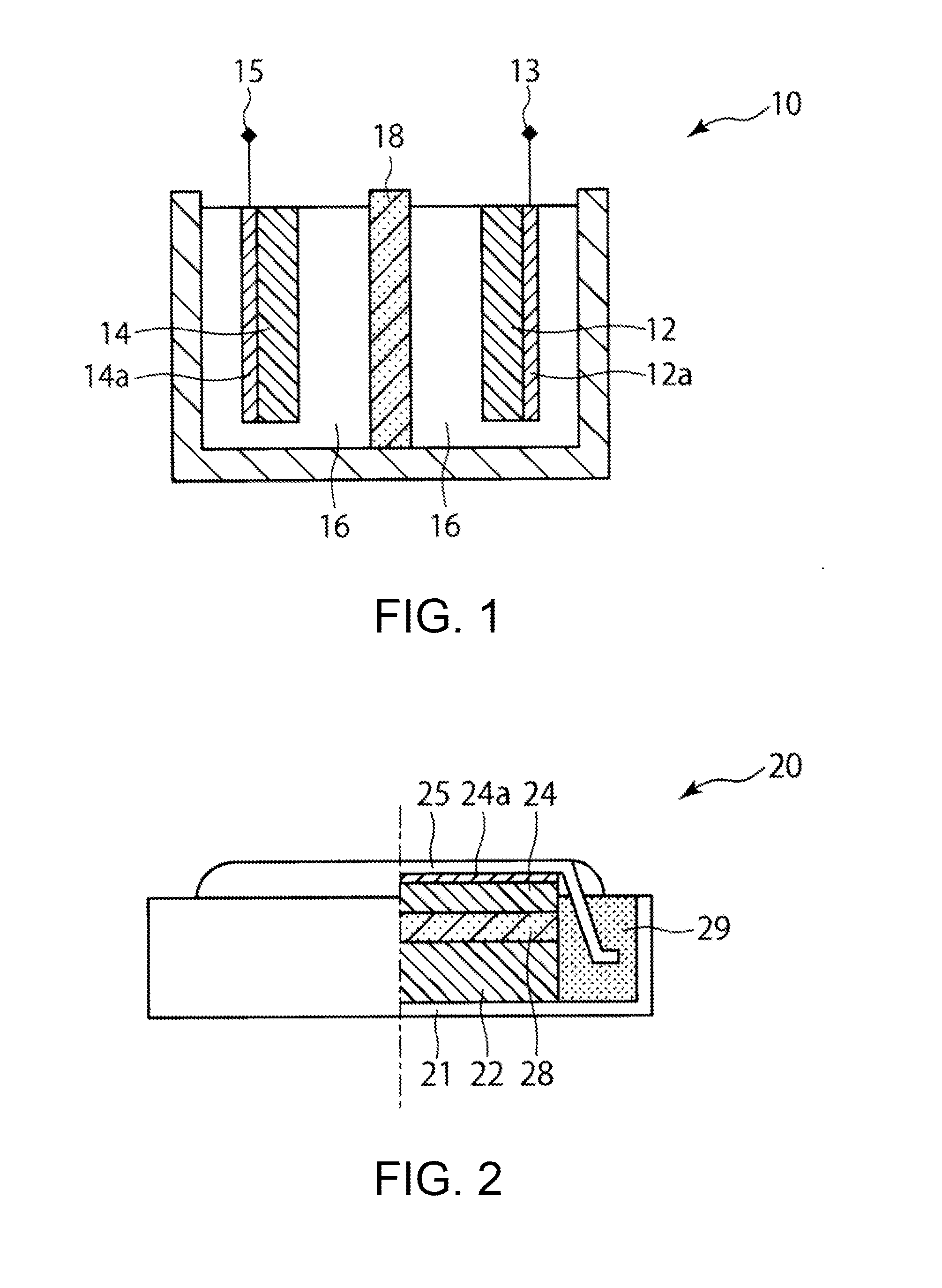

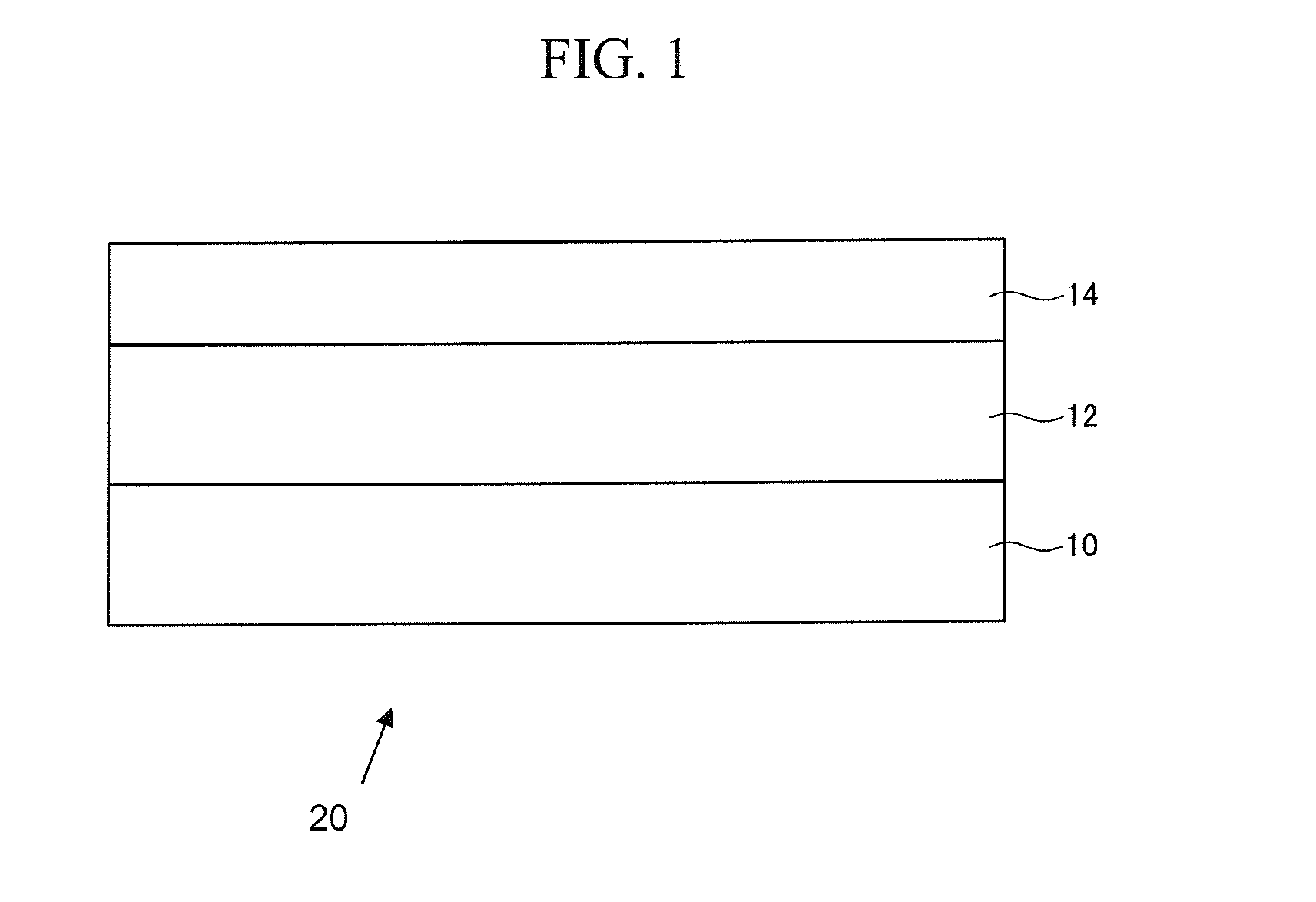

Electrochemical cell with a non-liquid electrolyte

InactiveUS20020122980A1High ambient temperature proton conductivityNon-corrosive materialSilver accumulatorsSolid electrolytesElectrochemical responseElectrochemical cell

A non-liquid electrolyte containing electrochemical cell which operates efficiently at room temperature. The cell includes: (a) a non-liquid electrolyte (14) in which protons are mobile; (b) an anode (10) including an active material based on the organic compound which is a source of protons during cell discharge; and (c) a solid cathode (12) including a compound which forms an electrochemical couple with the anode. The active materials can be chosen so that the cell has the feature that the electrochemical reactions at the anode and cathode are at least partially reversible. An important feature of the cell is that no thermal activation is required for its operation. Therefore, the cell efficiently operates under ambient temperatures.

Owner:FLEISCHER NILES A +4

Carbon materials comprising an electrochemical modifier

InactiveUS20110159375A1Prolong lifeImprove stabilitySilver accumulatorsConductive materialElectrical devicesMaterials science

The present application is directed to carbon materials comprising an electrochemical modifier. The carbon materials find utility in any number of electrical devices, for example, in lead acid batteries. Methods for making the disclosed carbon materials are also disclosed.

Owner:BASF AG

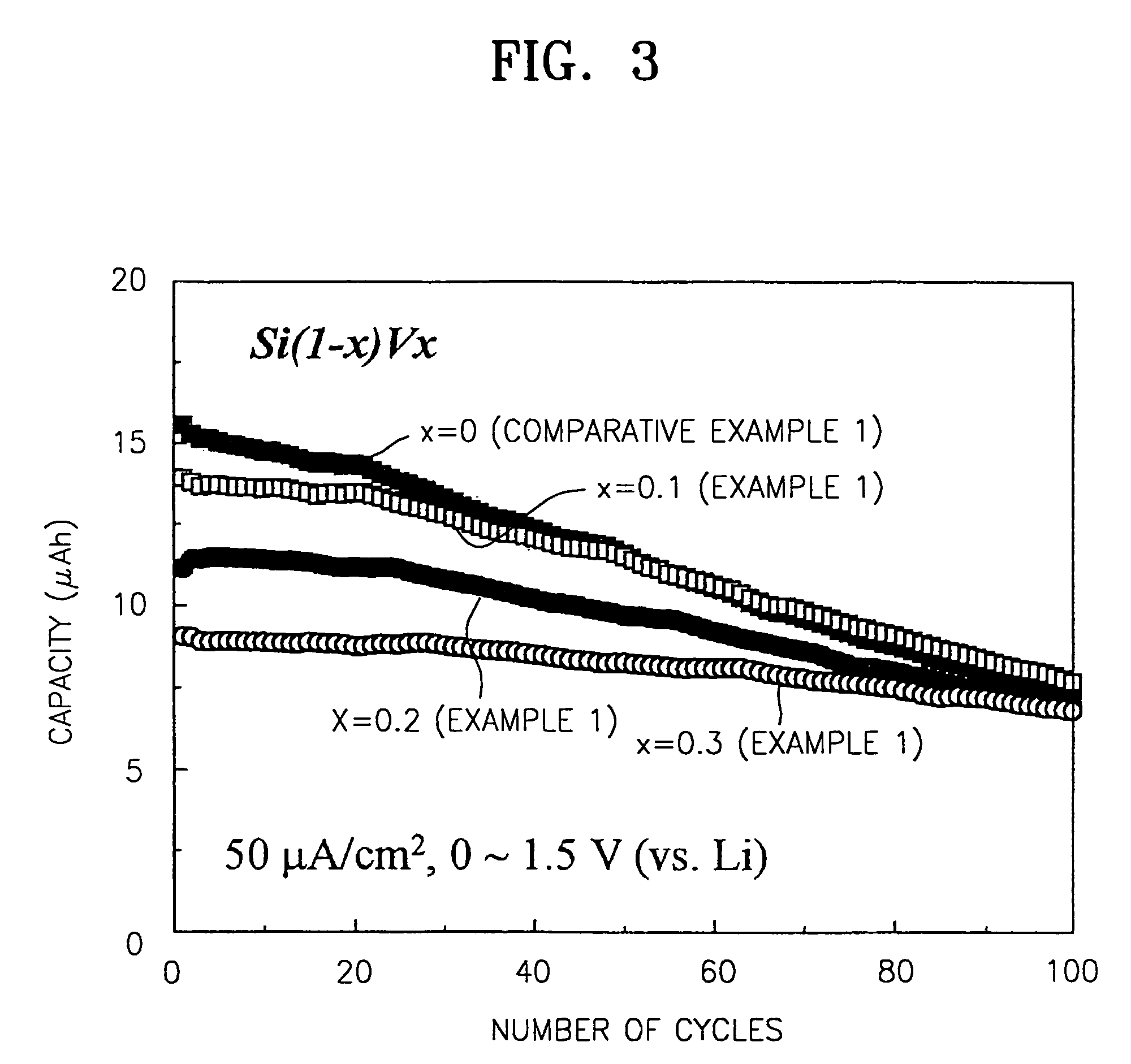

Electrode material for anode of rechargeable lithium battery, electrode structural body using said electrode material, rechargeable lithium battery using said electrode structural body, process for producing said electrode structural body, and process for producing said rechargeable lithium battery

InactiveUS6949312B1Improve featuresLarge capacitySilver accumulatorsFinal product manufactureElectrochemical responseElectrode material

An electrode material for an anode of a rechargeable lithium battery, containing a particulate comprising an amorphous Sn.A.X alloy with a substantially non-stoichiometric ratio composition. For said formula Sn.A.X, A indicates at least one kind of an element selected from a group consisting of transition metal elements, X indicates at least one kind of an element selected from a group consisting of O, F, N, Mg, Ba, Sr, Ca, La, Ce, Si, Ge, C, P, B, Pb, Bi, Sb, Al, Ga, In, Tl, Zn, Be, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, As, Se, Te, Li and S, where the element X is not always necessary to be contained. The content of the constituent element Sn of the amorphous Sn.A.X alloy is Sn / (Sn+A+X)=20 to 80 atomic %. An electrode structural body for a rechargeable lithium battery, comprising said electrode material for an anode and a collector comprising a material incapable of being alloyed with lithium in electrochemical reaction, and a rechargeable lithium battery having an anode comprising said electrode structural body.

Owner:CANON KK

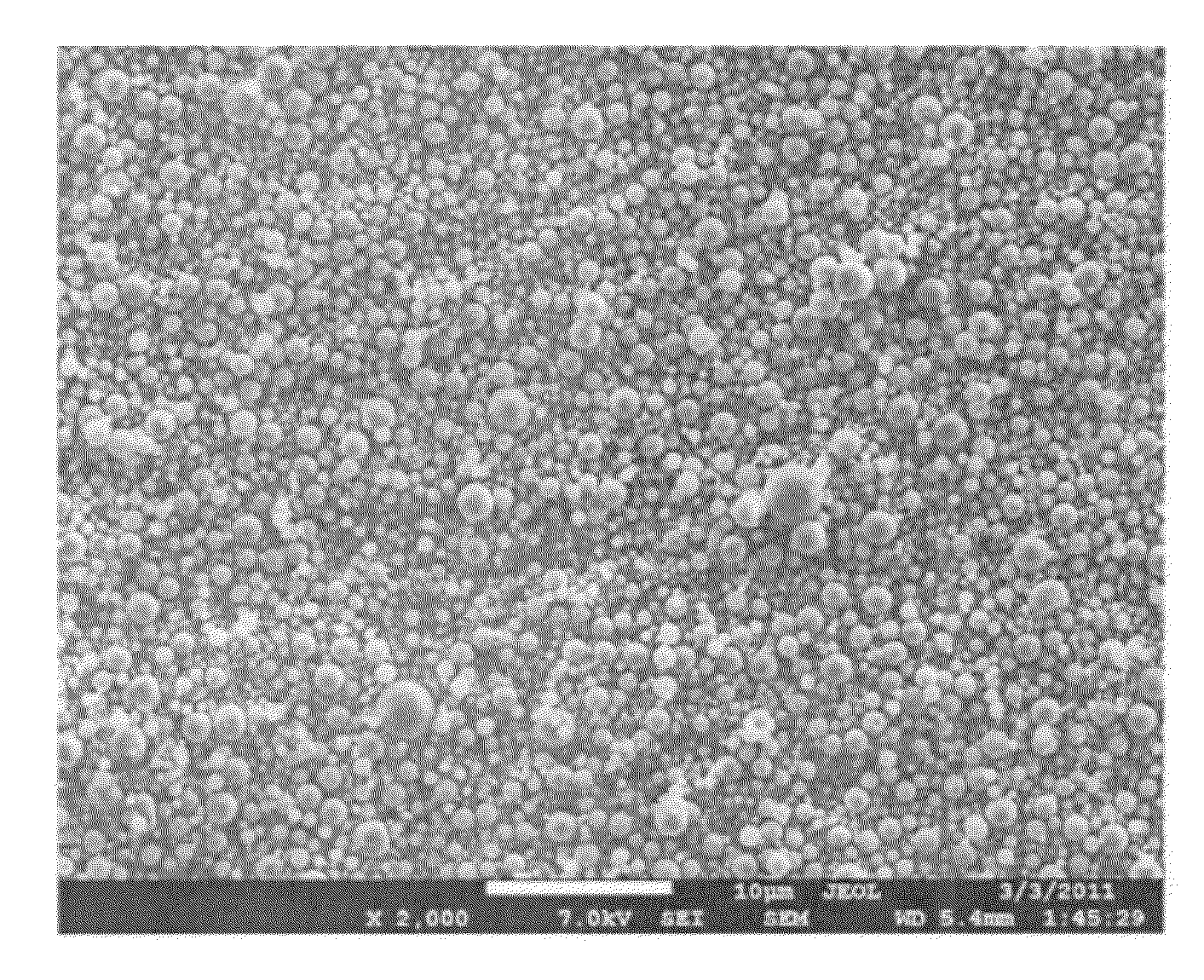

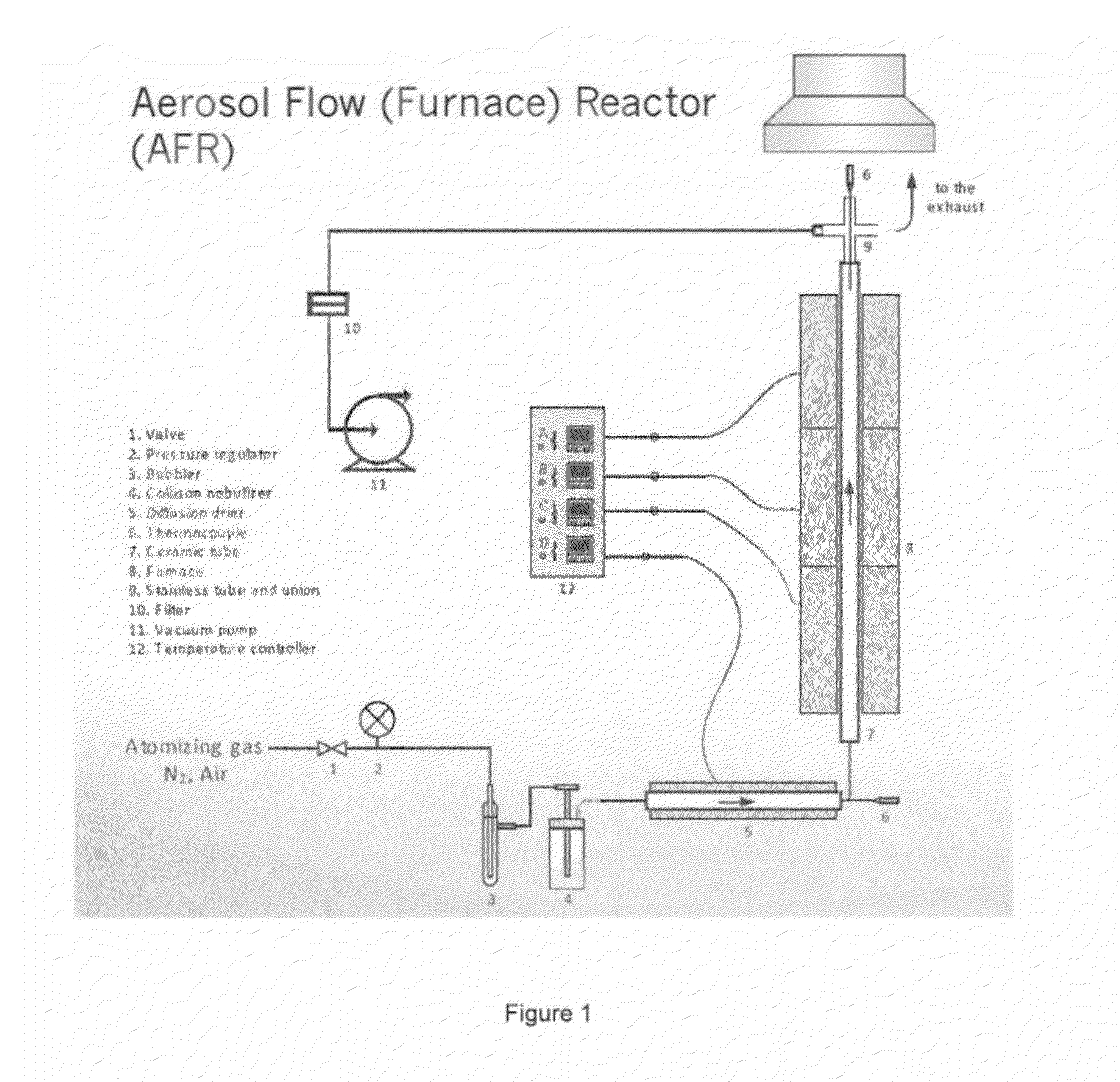

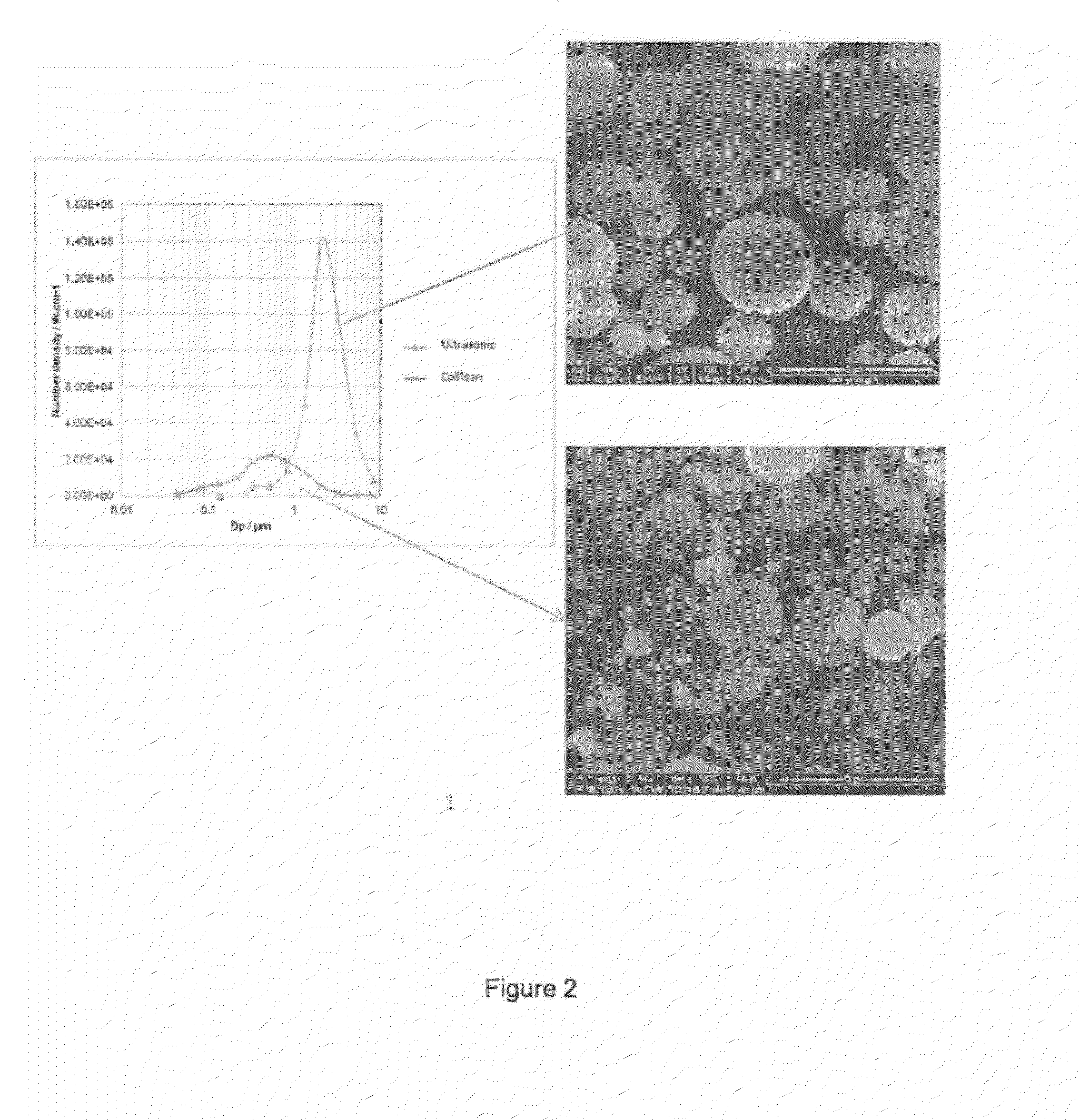

Spray Pyrolysis Synthesis of Mesoporous Positive Electrode Materials for High Energy Lithium-Ion Batteries

A lithium metal oxide positive electrode material useful in making lithium-ion batteries that is produced using spray pyrolysis. The material comprises a plurality of metal oxide secondary particles that comprise metal oxide primary particles, wherein the primary particles have a size that is in the range of about 1 nm to about 10 μm, and the secondary particles have a size that is in the range of about 10 nm to about 100 μm and are uniformly mesoporous.

Owner:WASHINGTON UNIV IN SAINT LOUIS

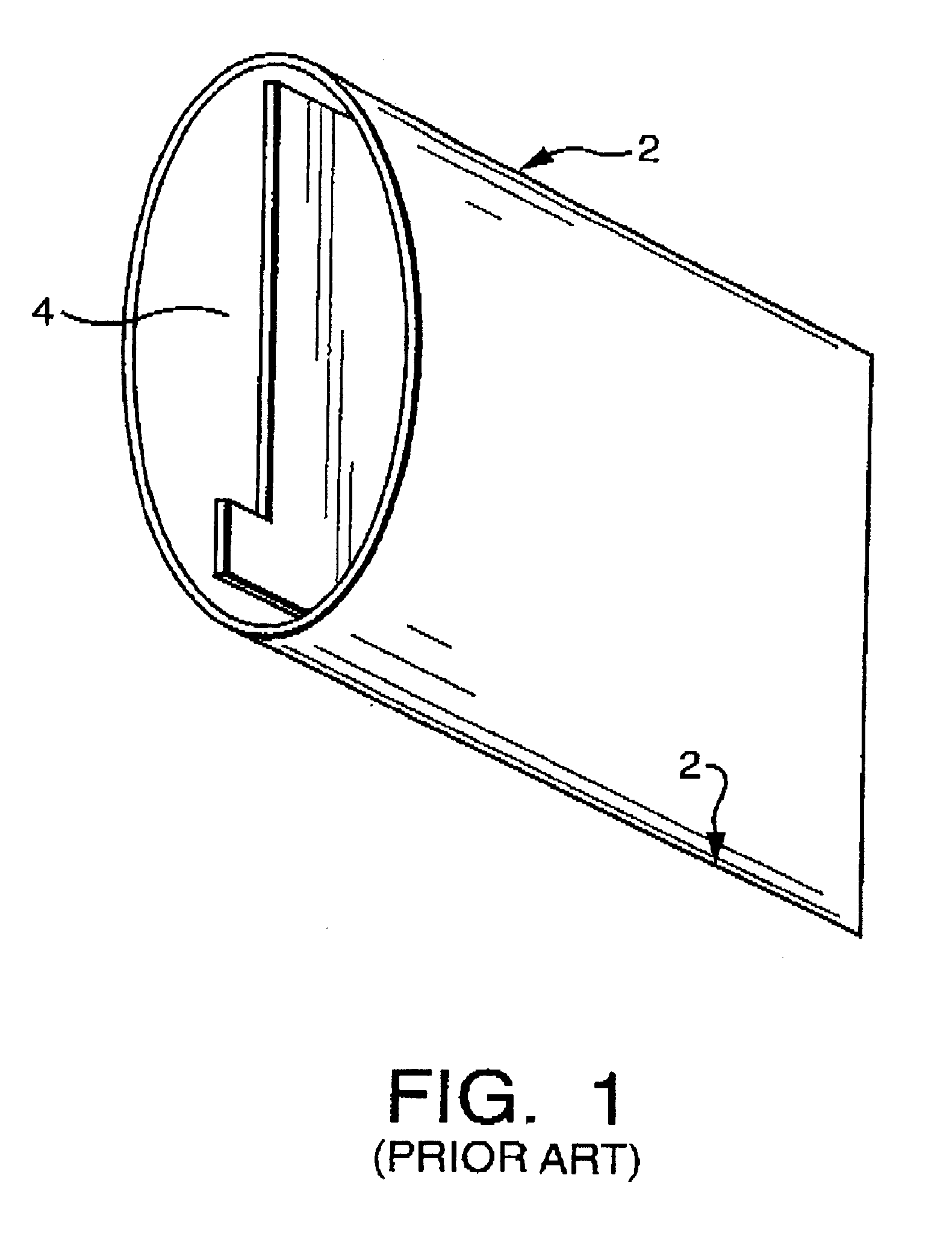

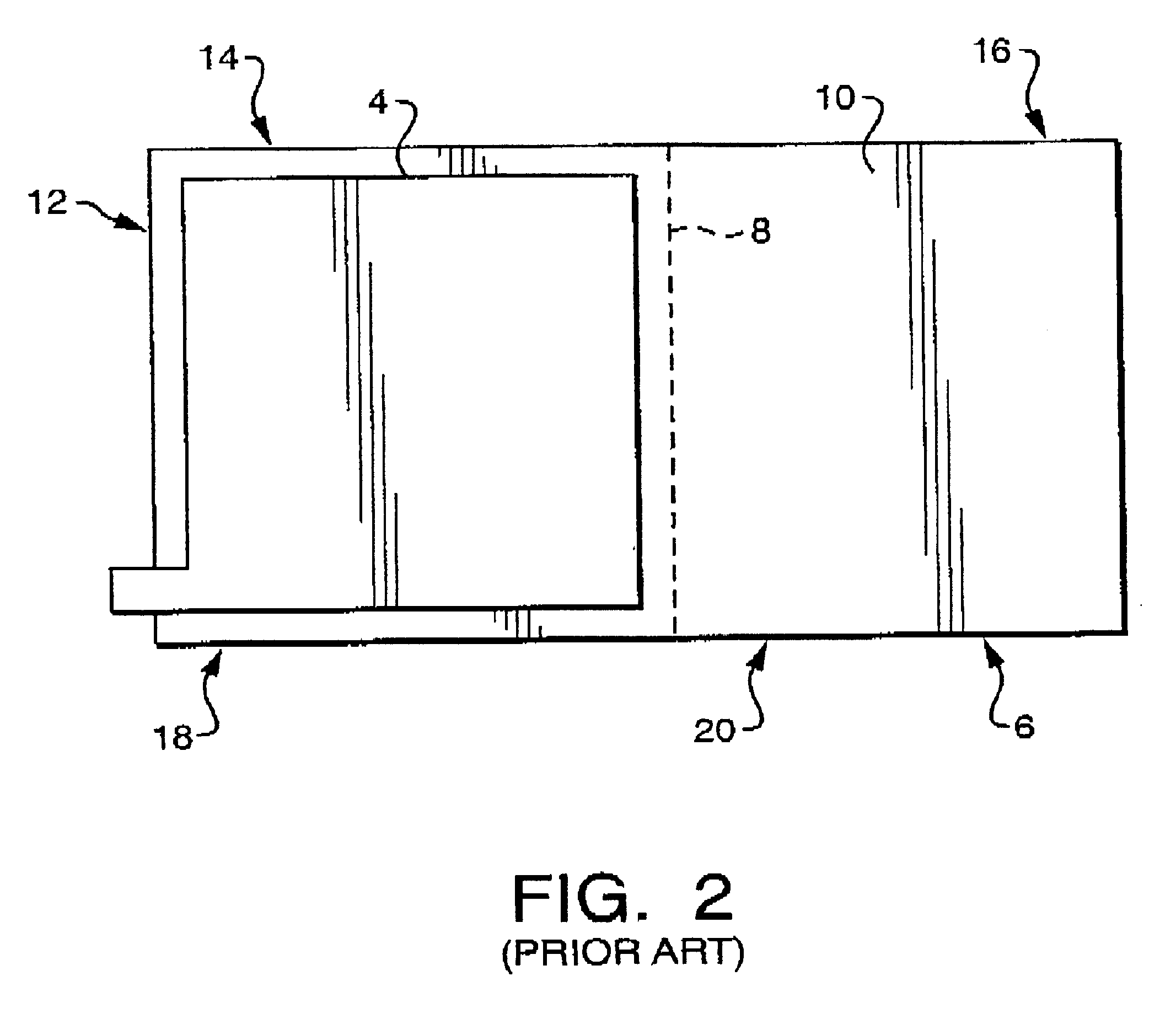

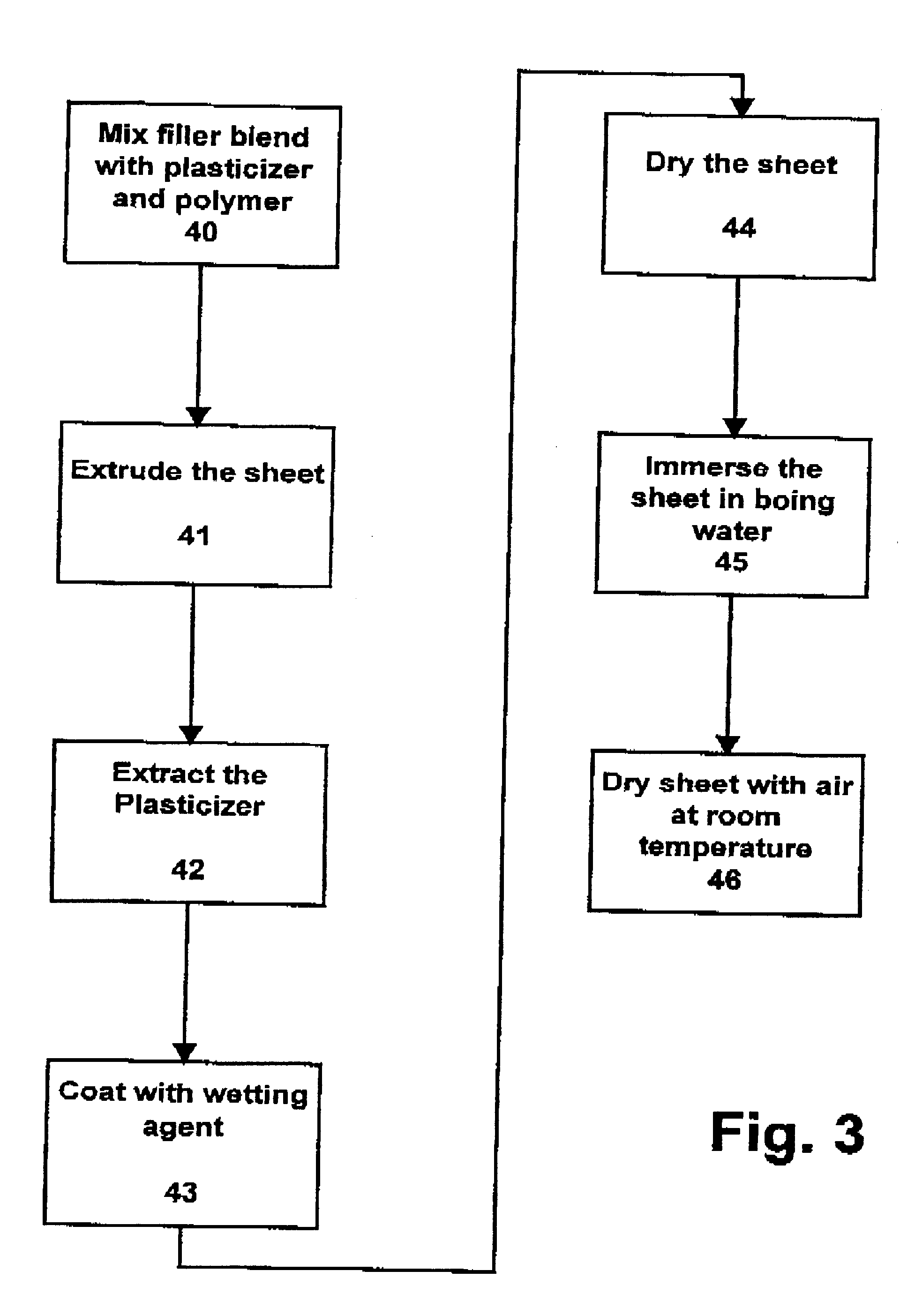

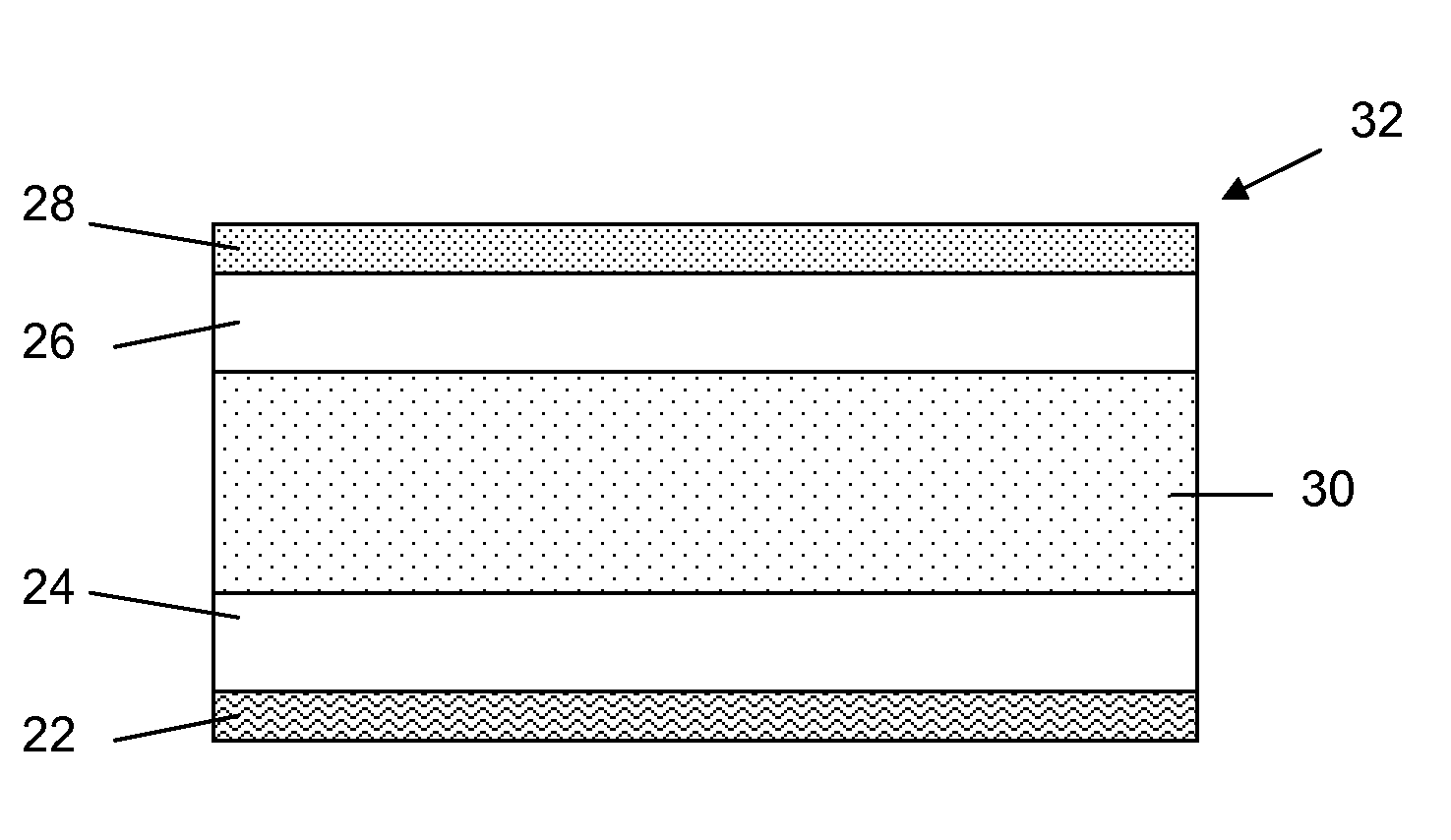

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

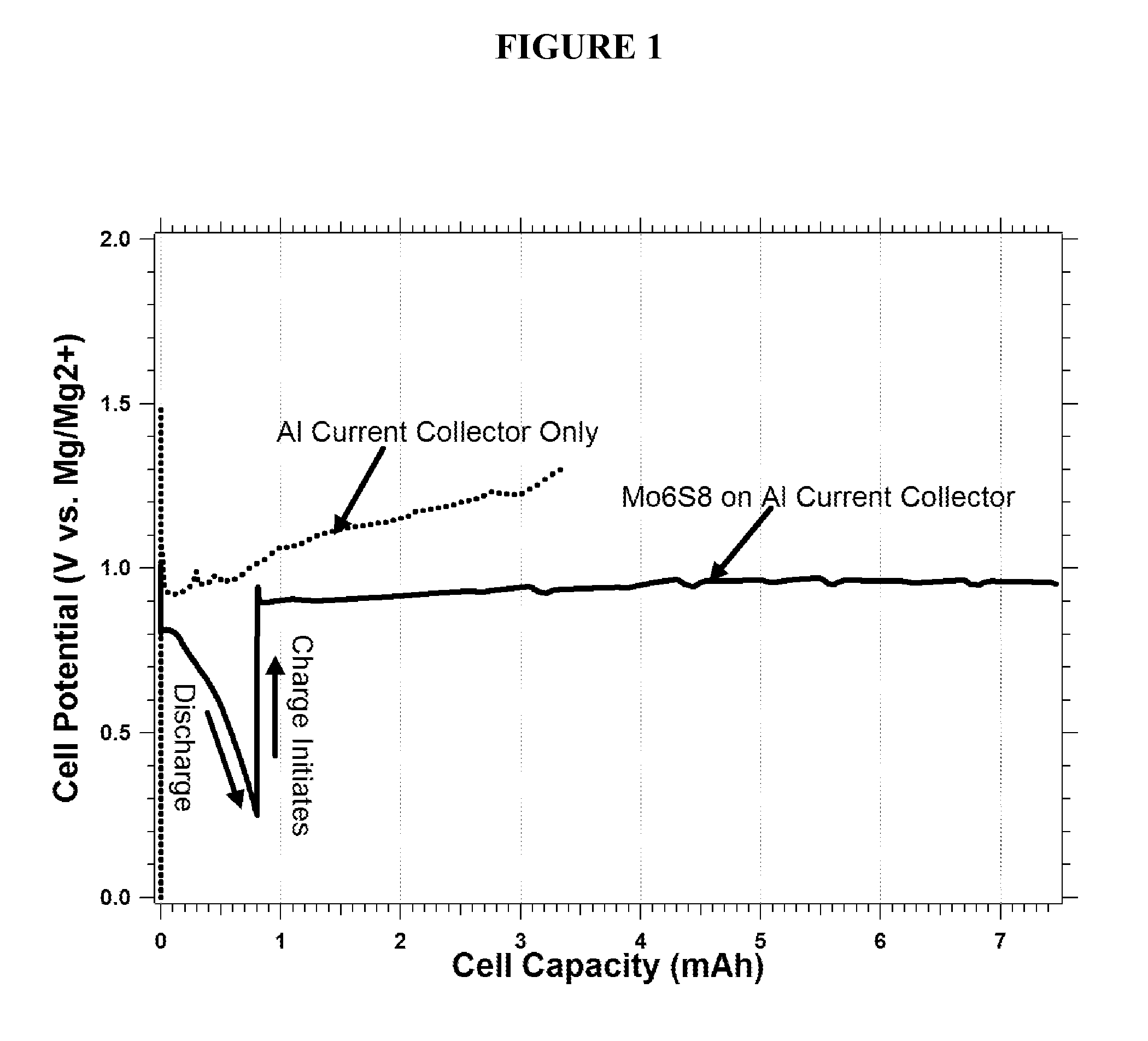

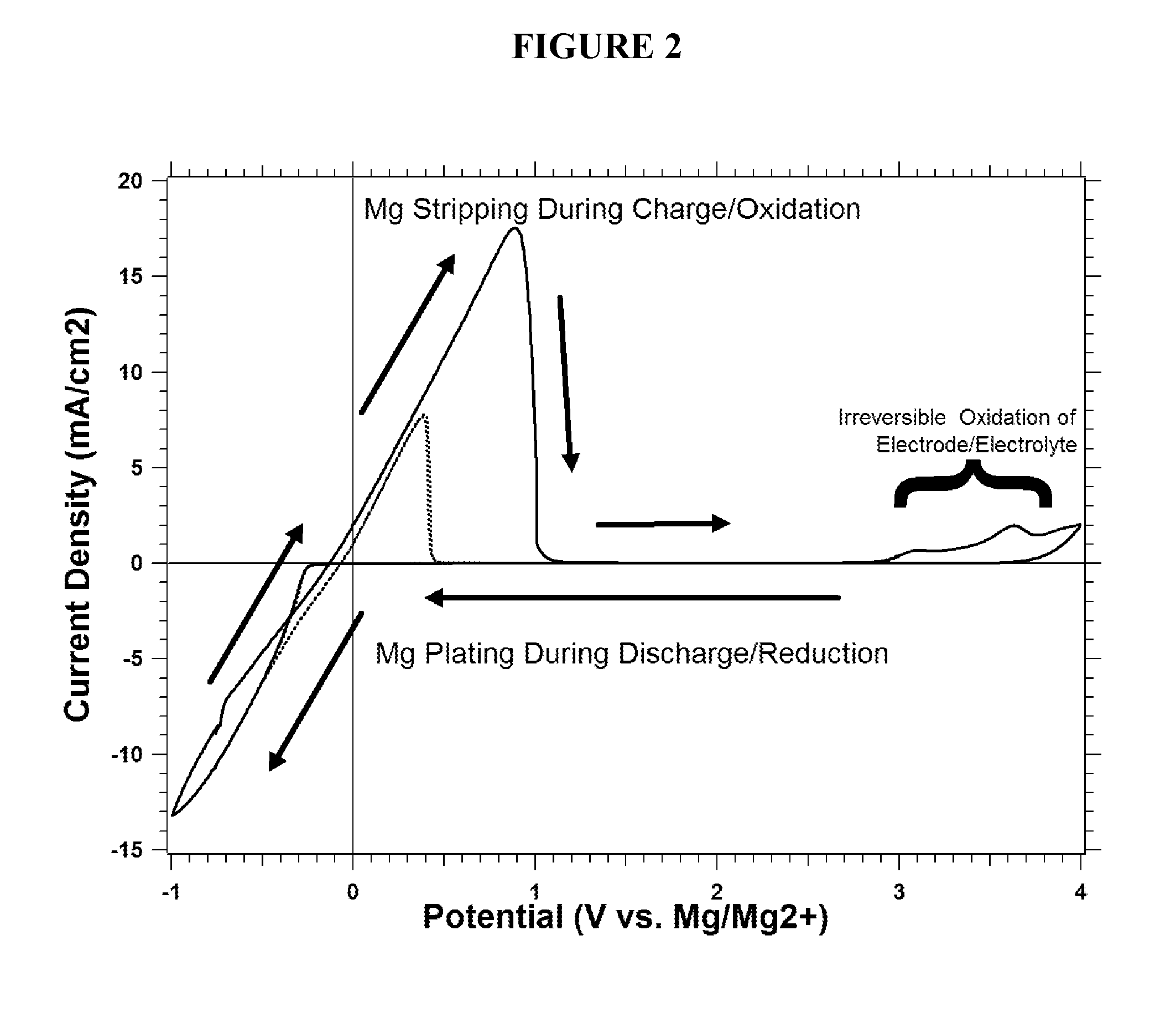

Rechargeable magnesium ion cell components and assembly

InactiveUS20110159381A1Cost-effective fabricationHigh voltageSilver accumulatorsElectrode carriers/collectorsEngineeringMagnesium ion

A magnesium battery electrode assembly is described, including a current collector comprising a carbonaceous material and an electrode layer comprising an electrode active material disposed on the current collector.

Owner:PELLION TECH

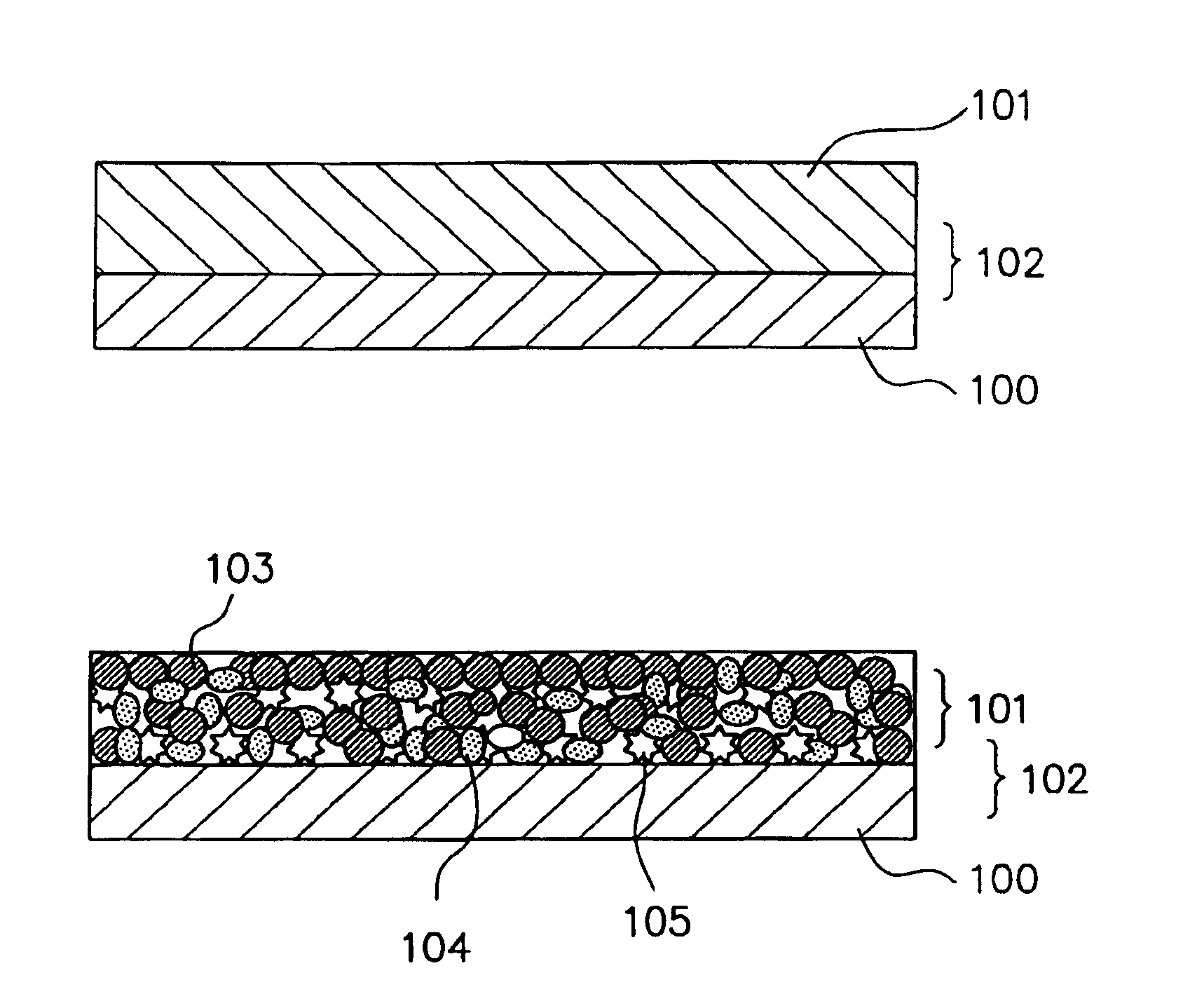

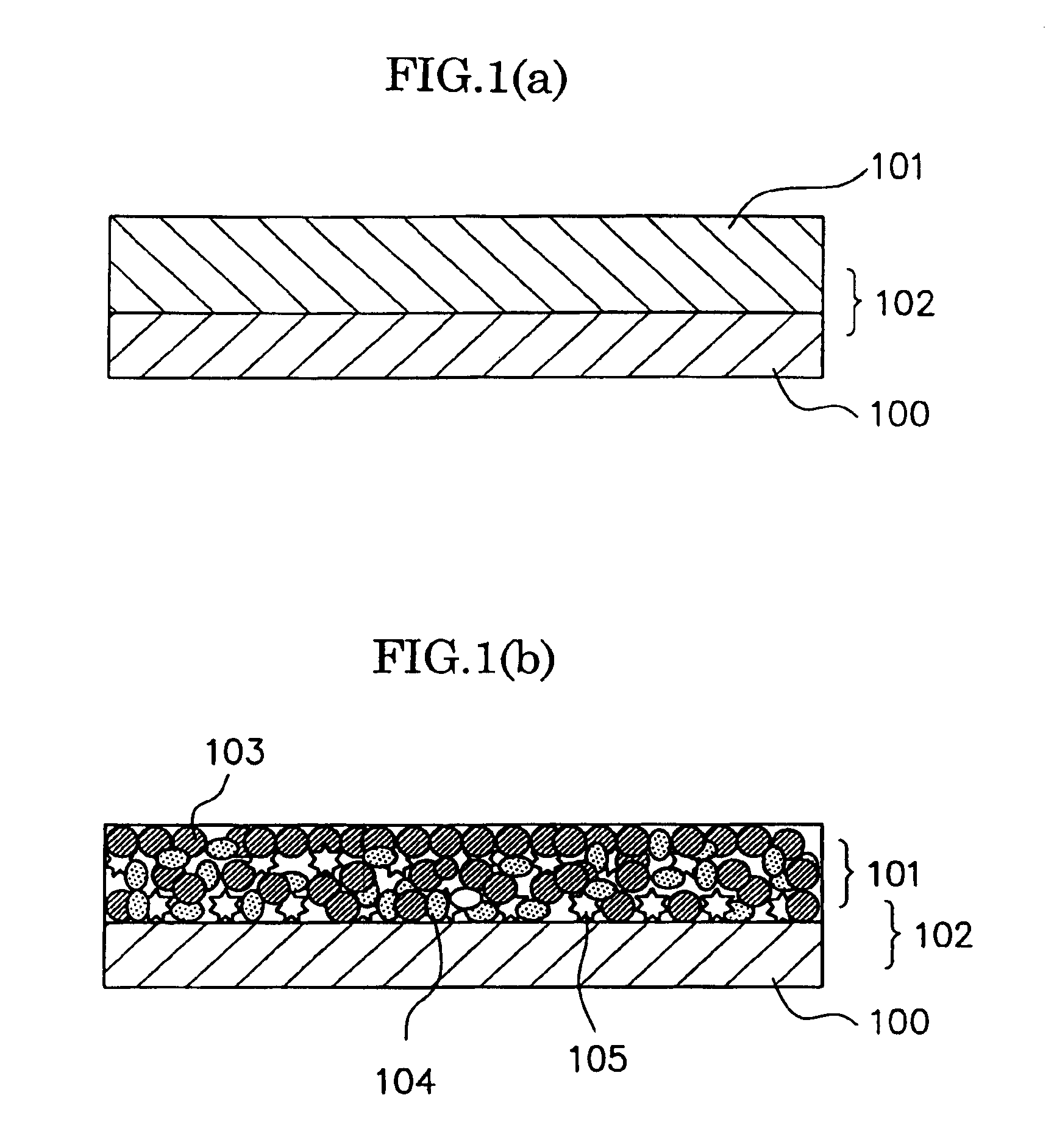

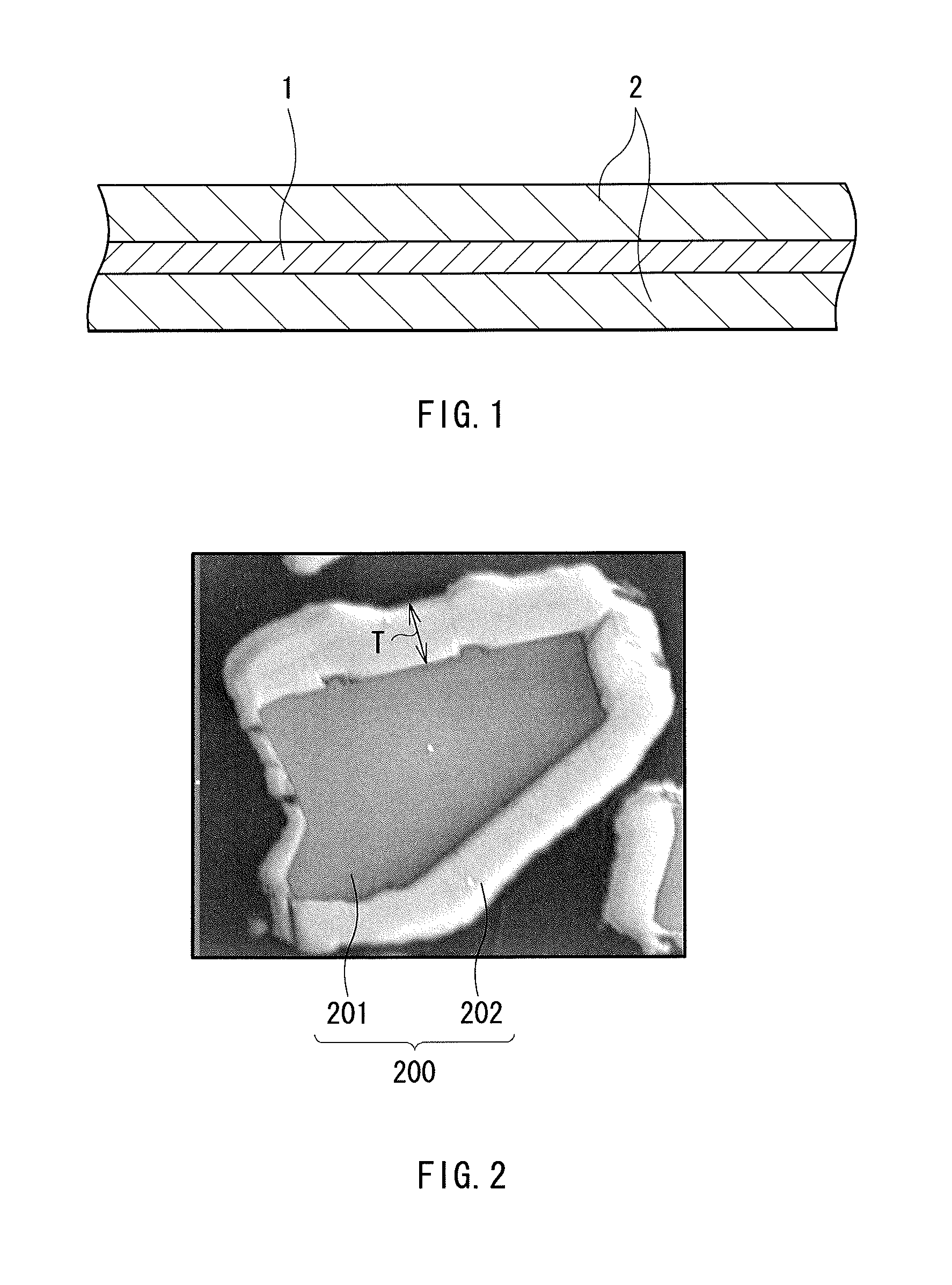

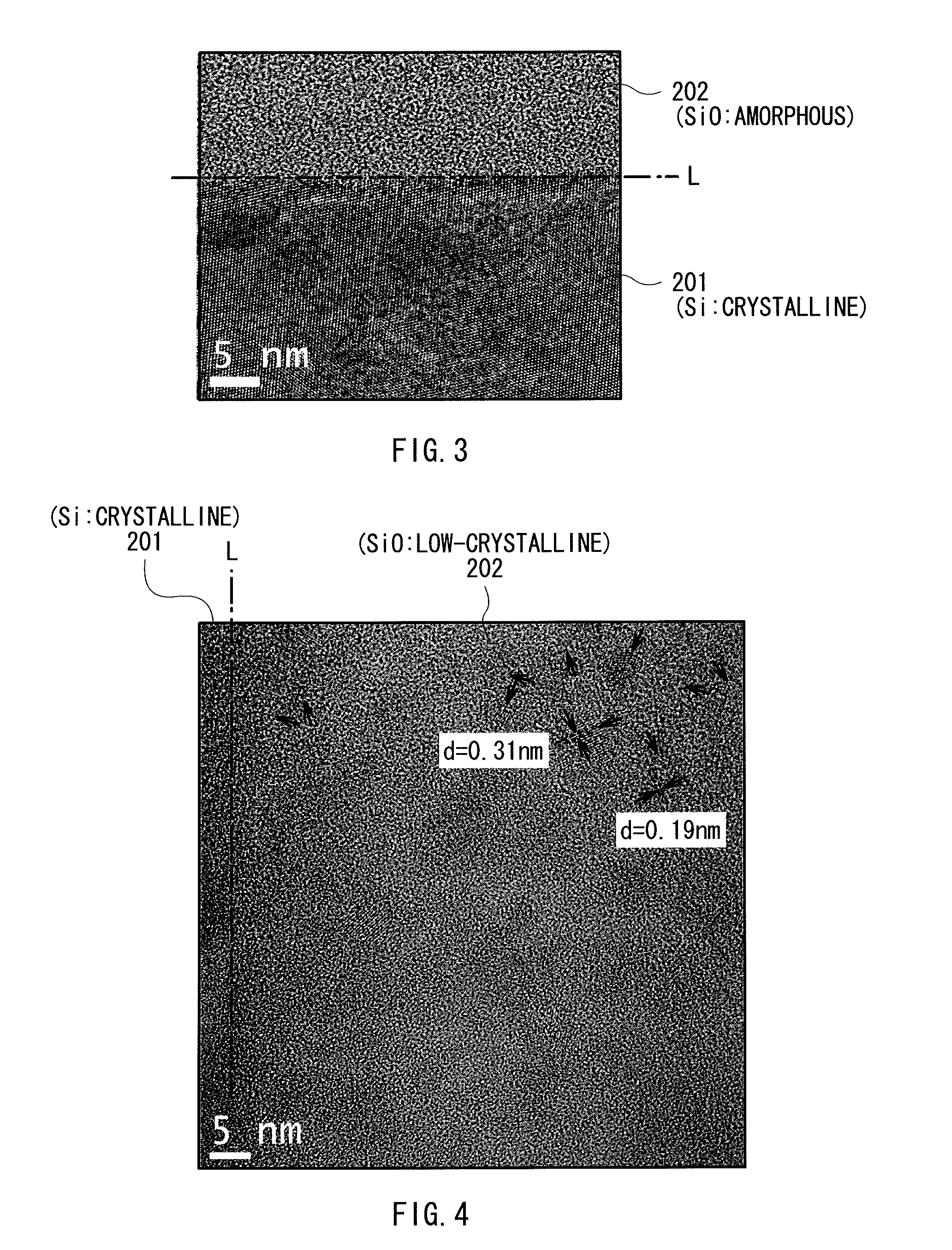

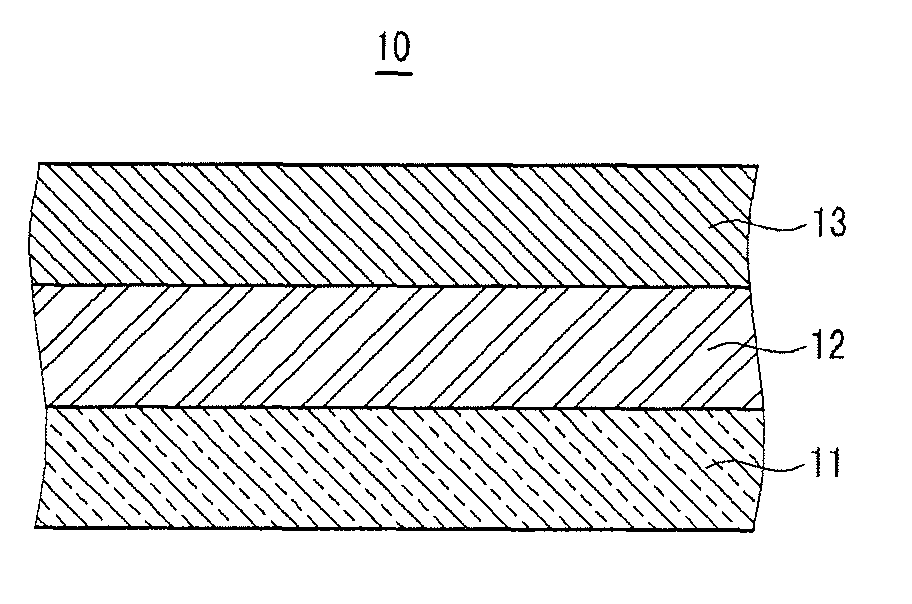

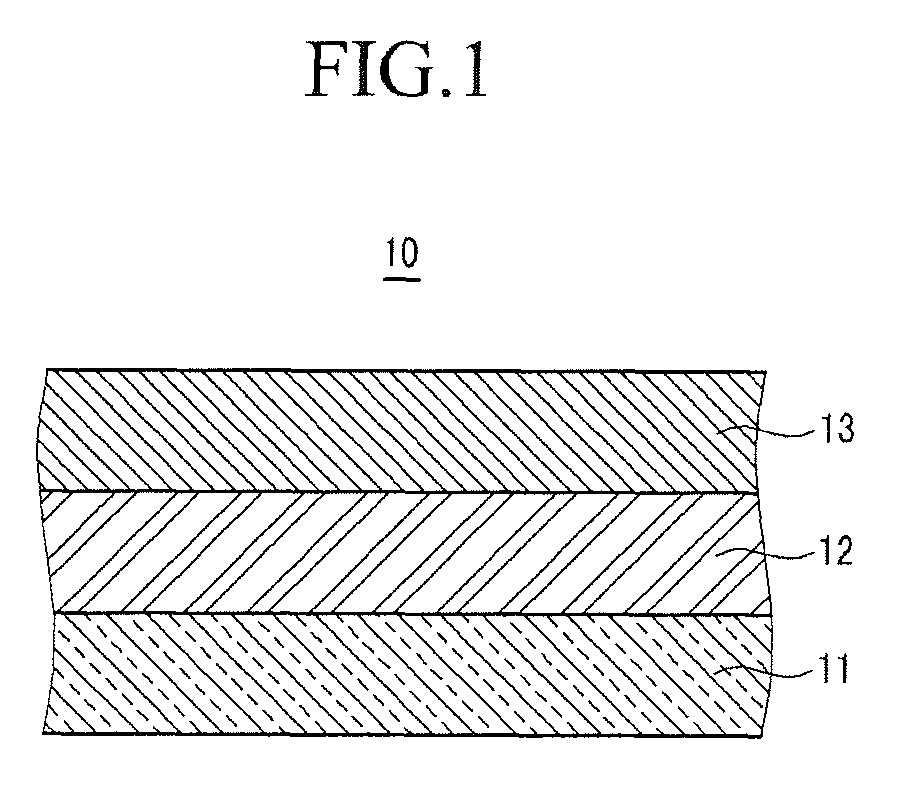

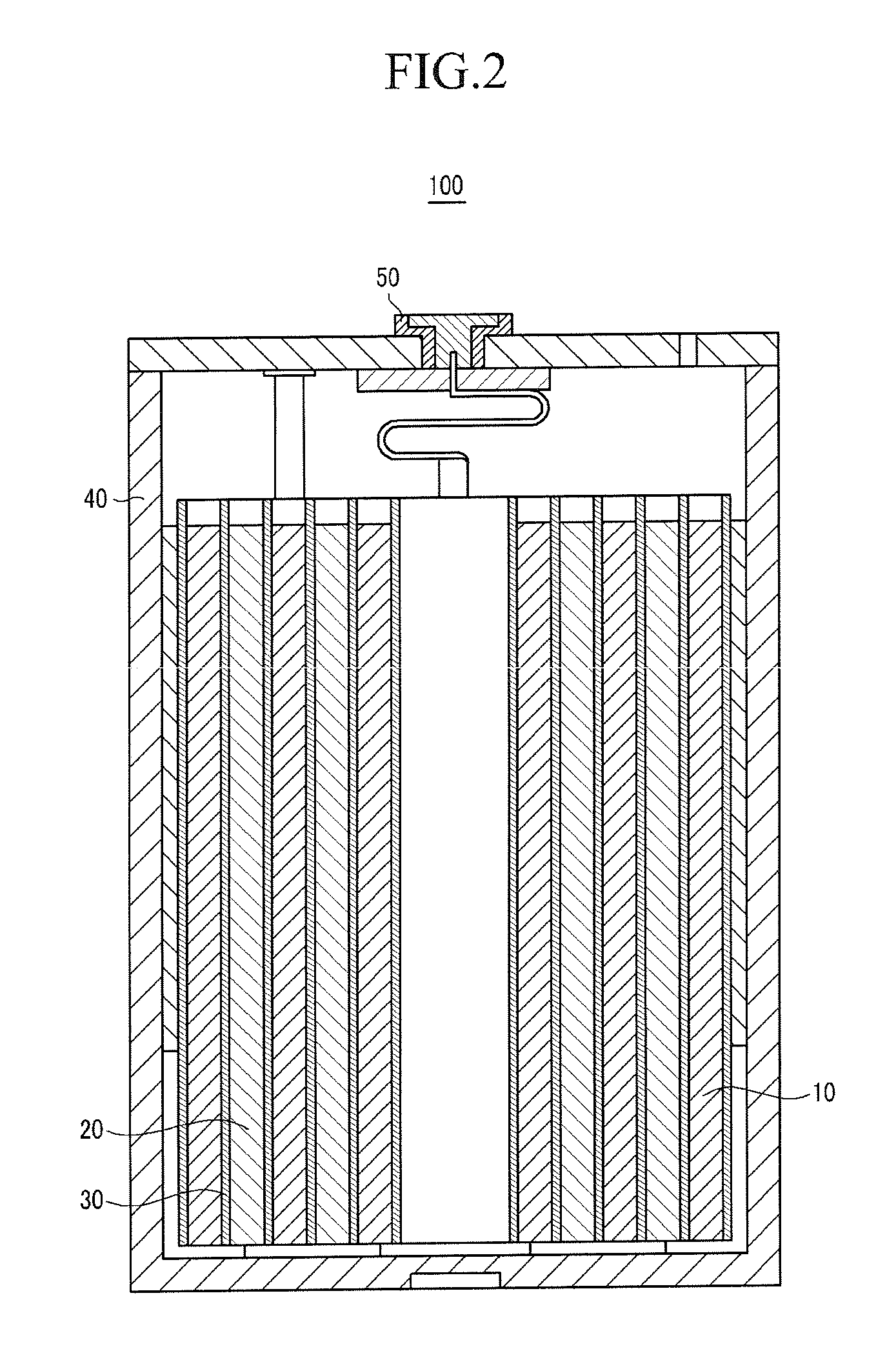

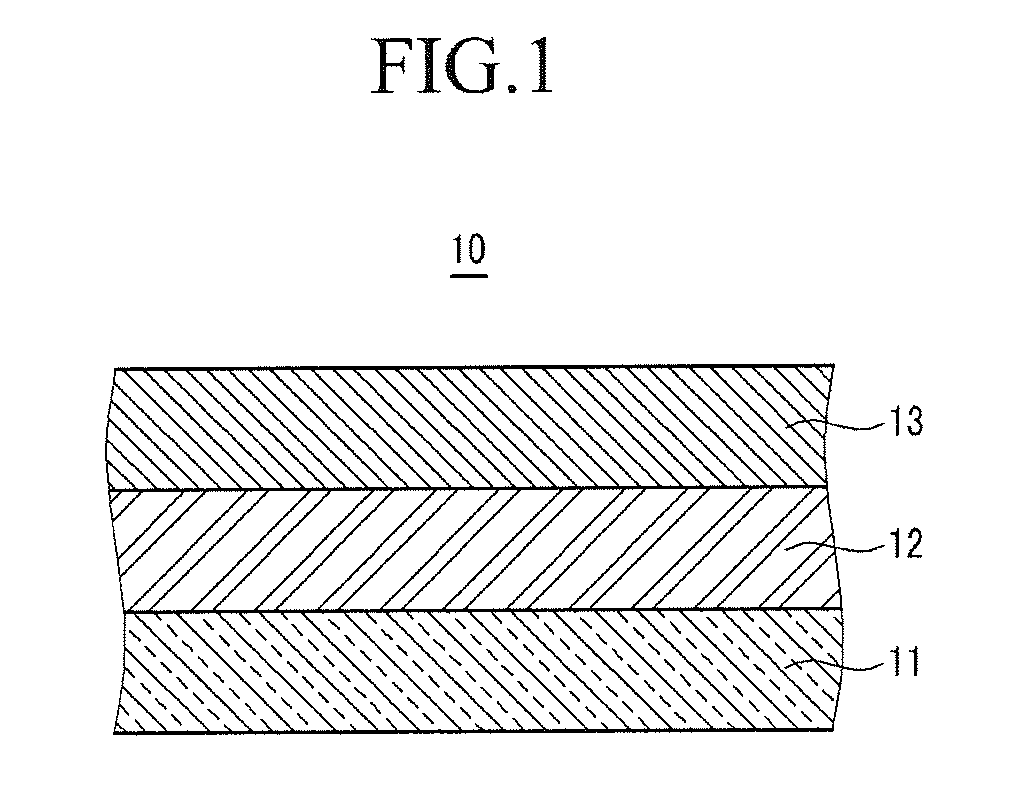

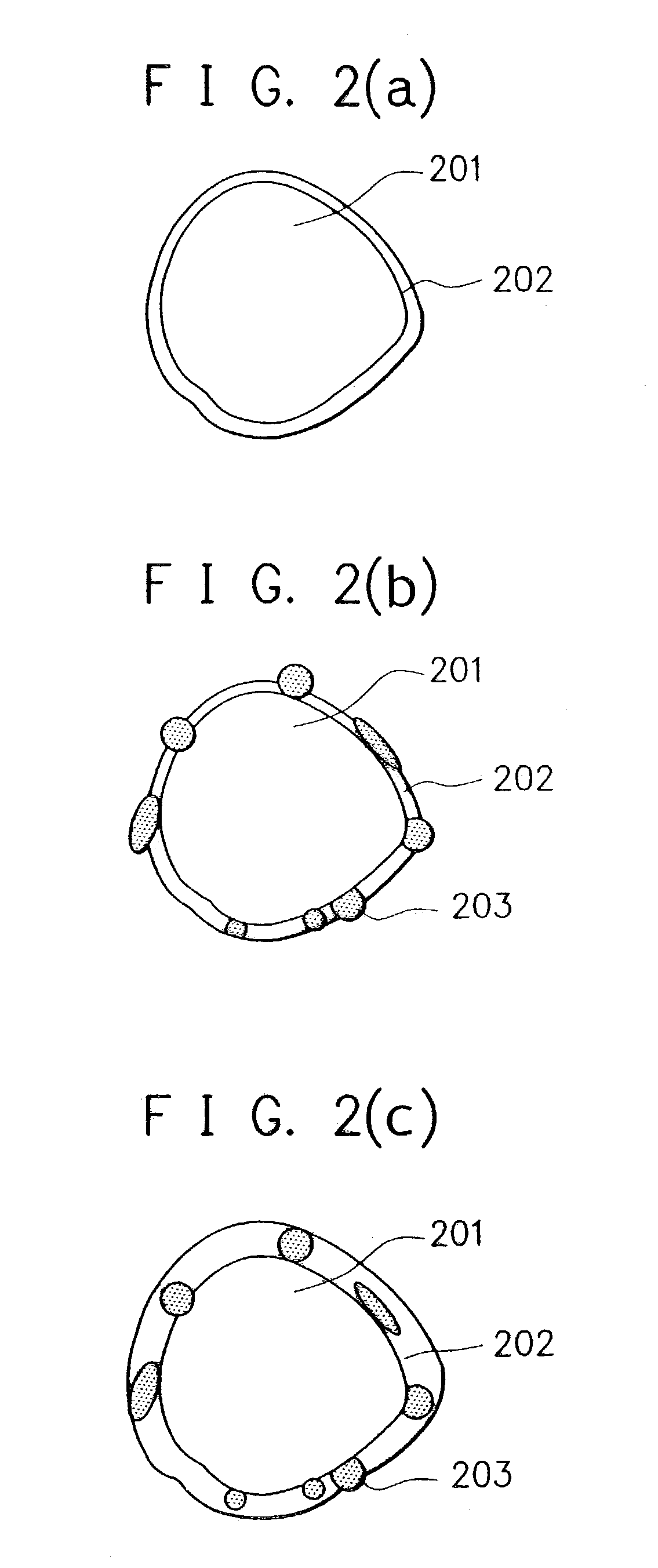

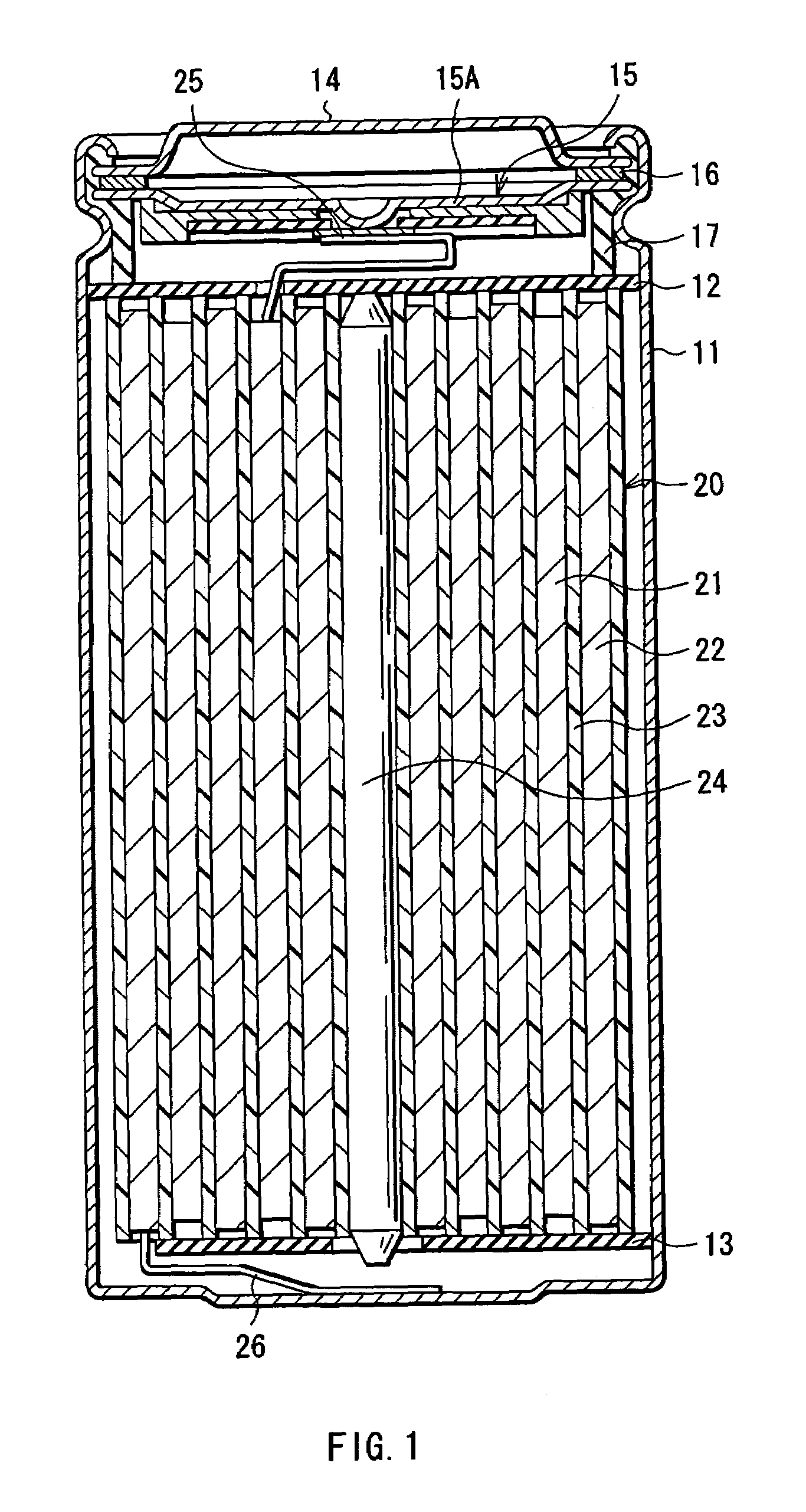

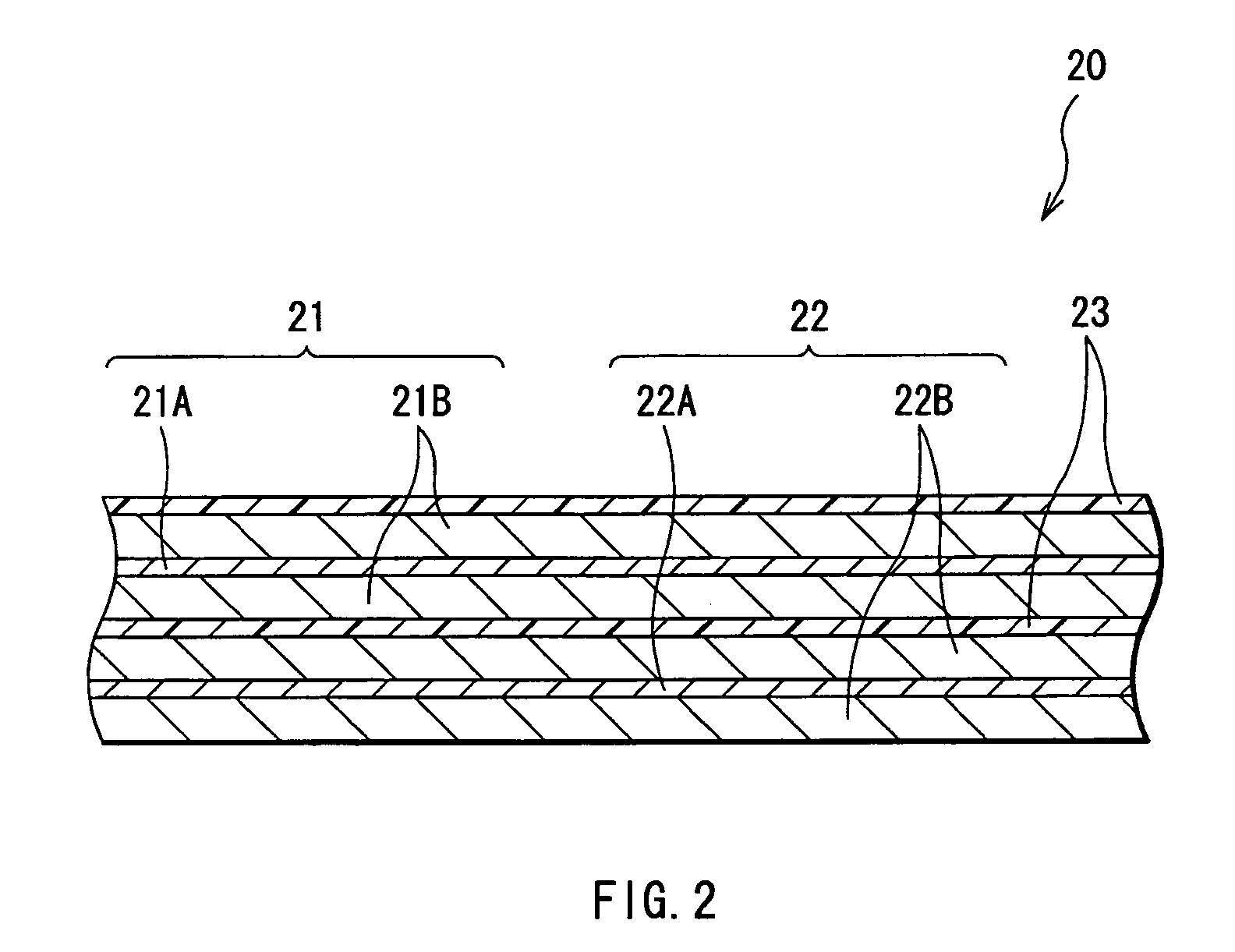

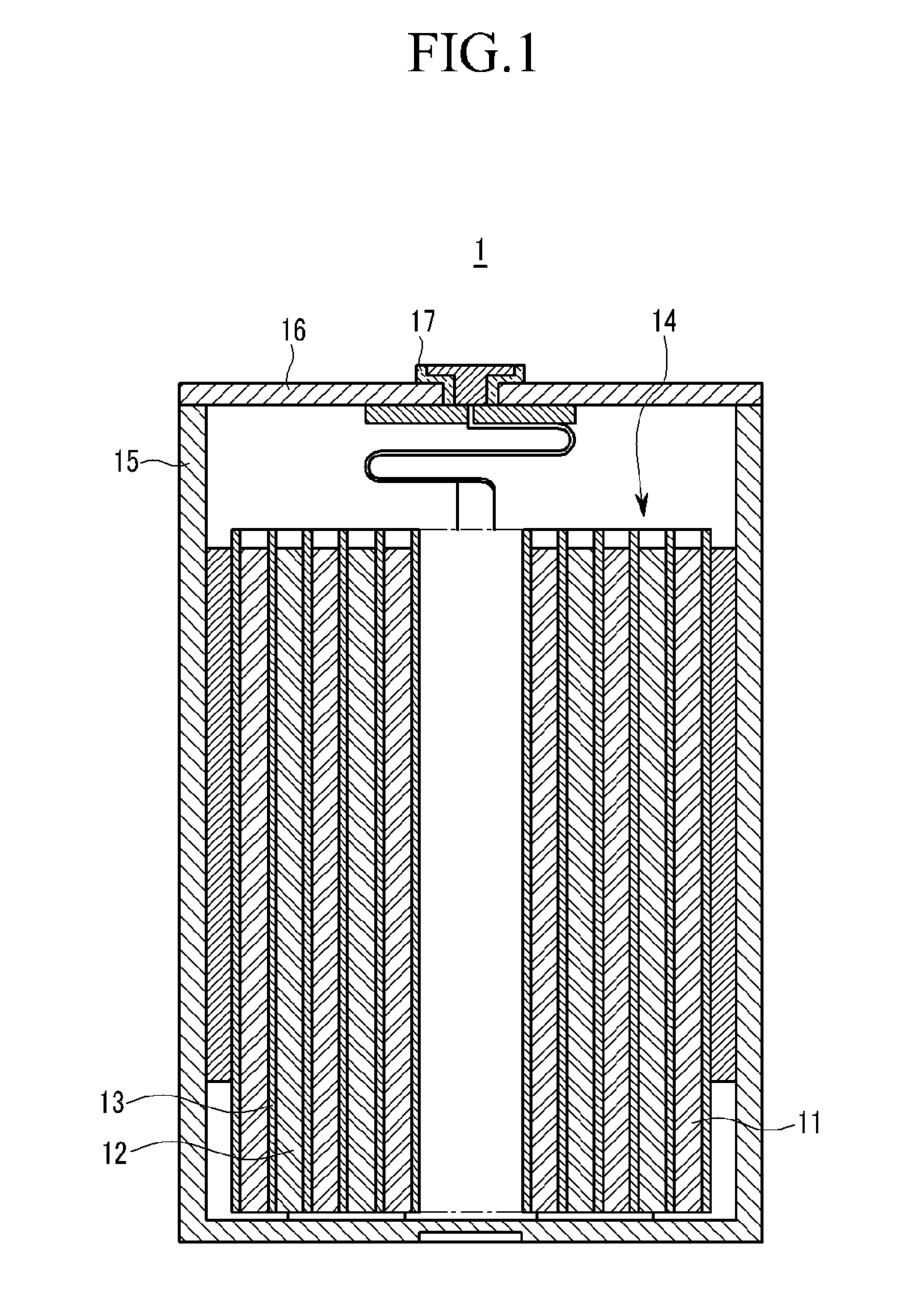

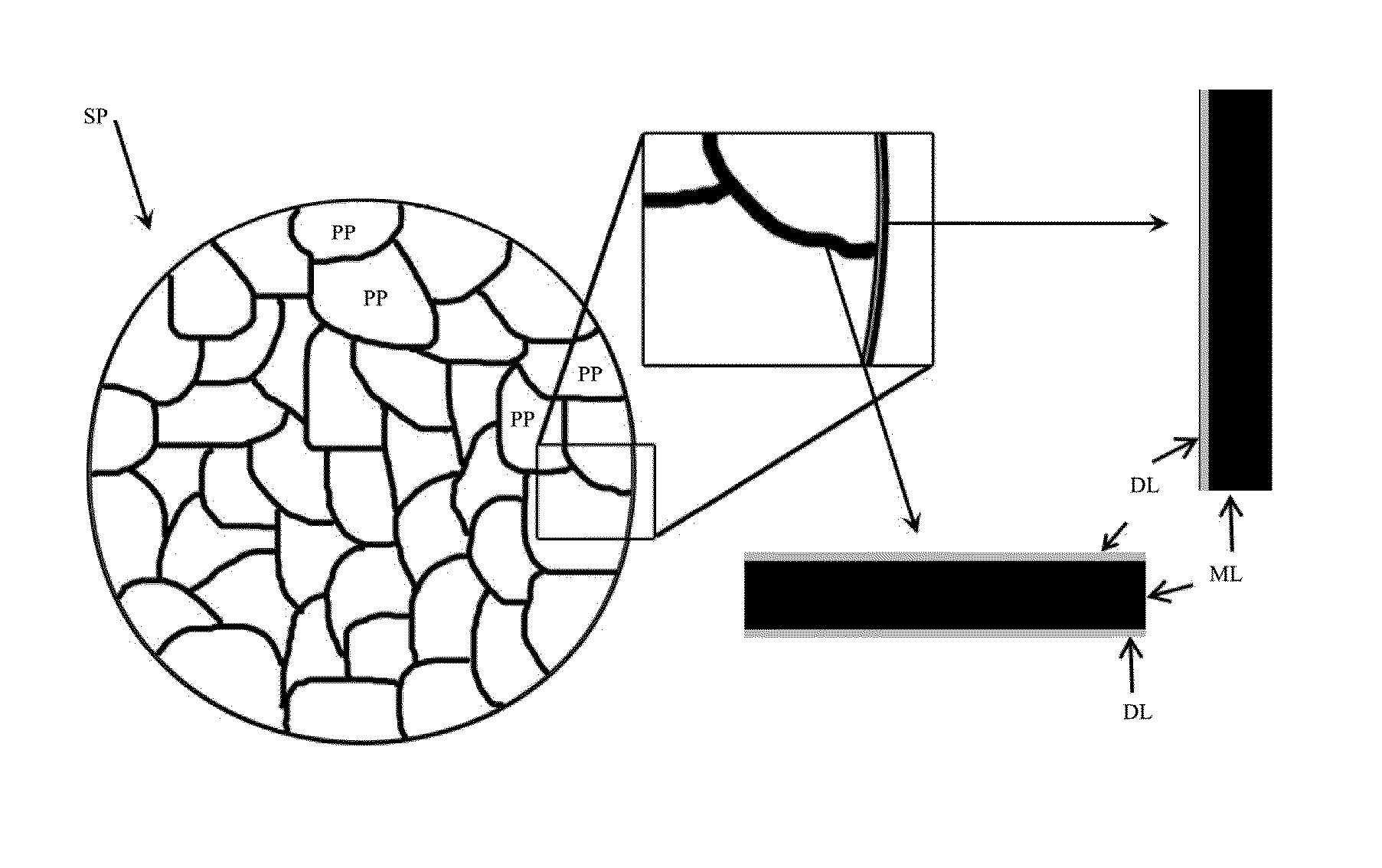

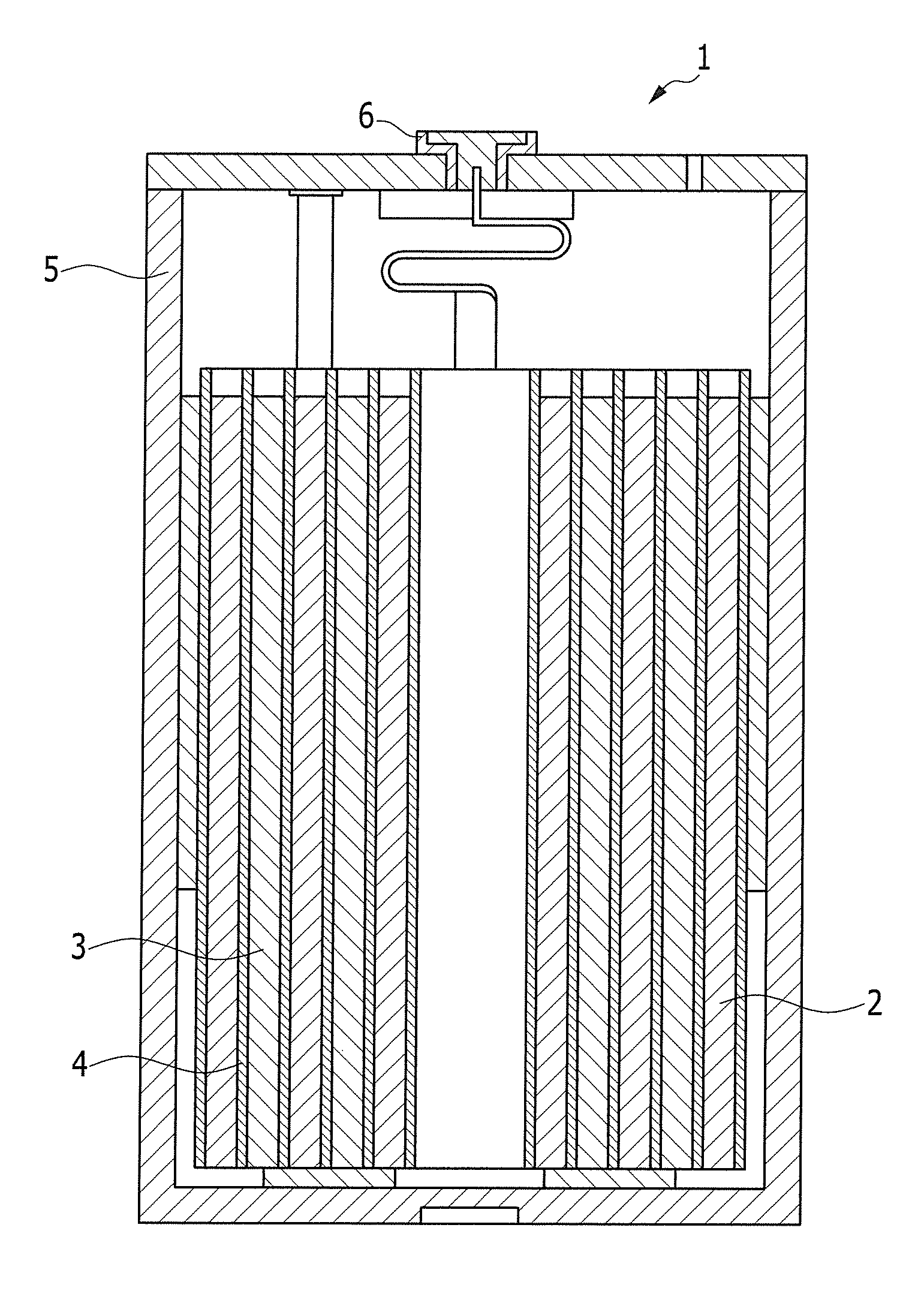

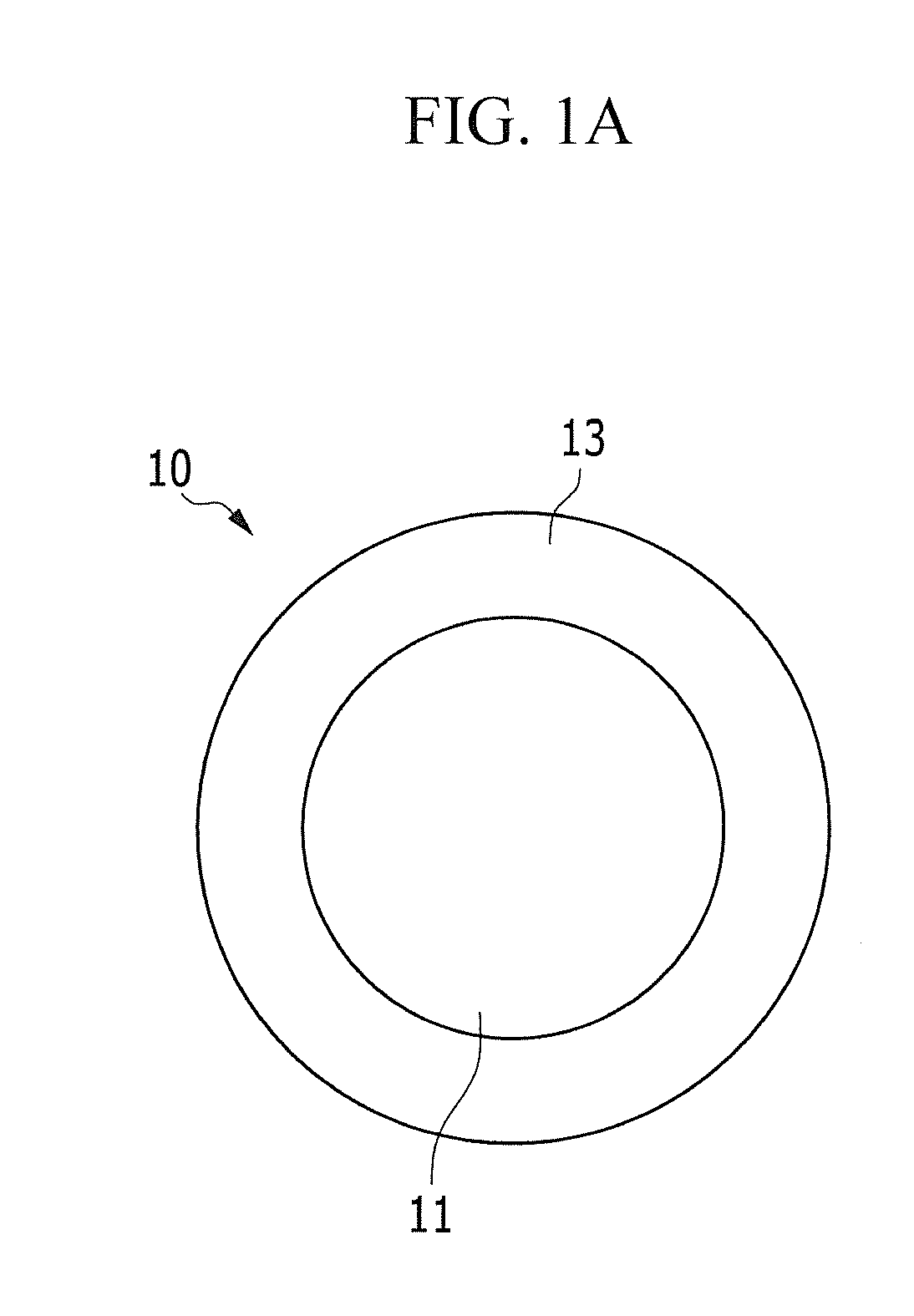

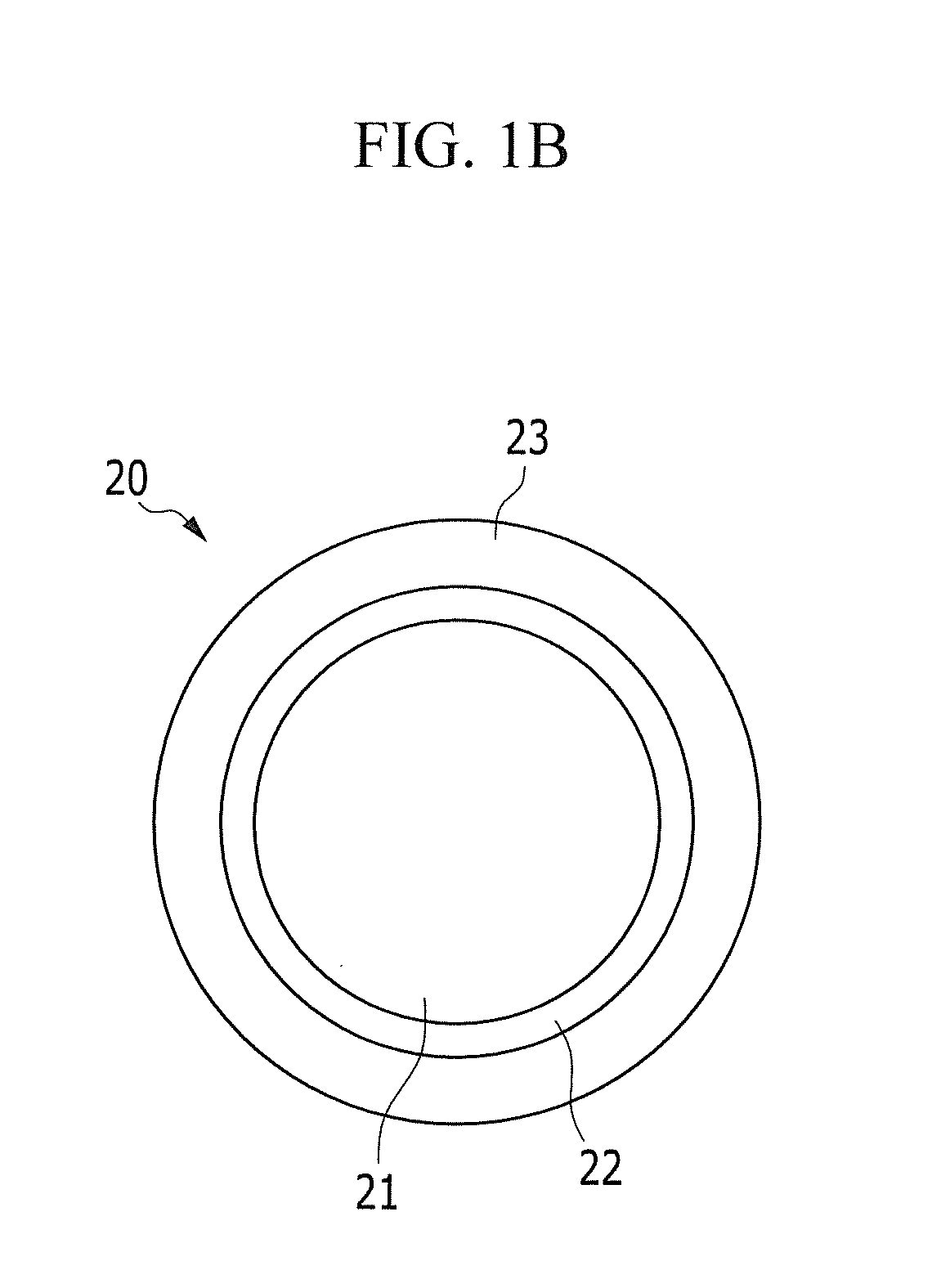

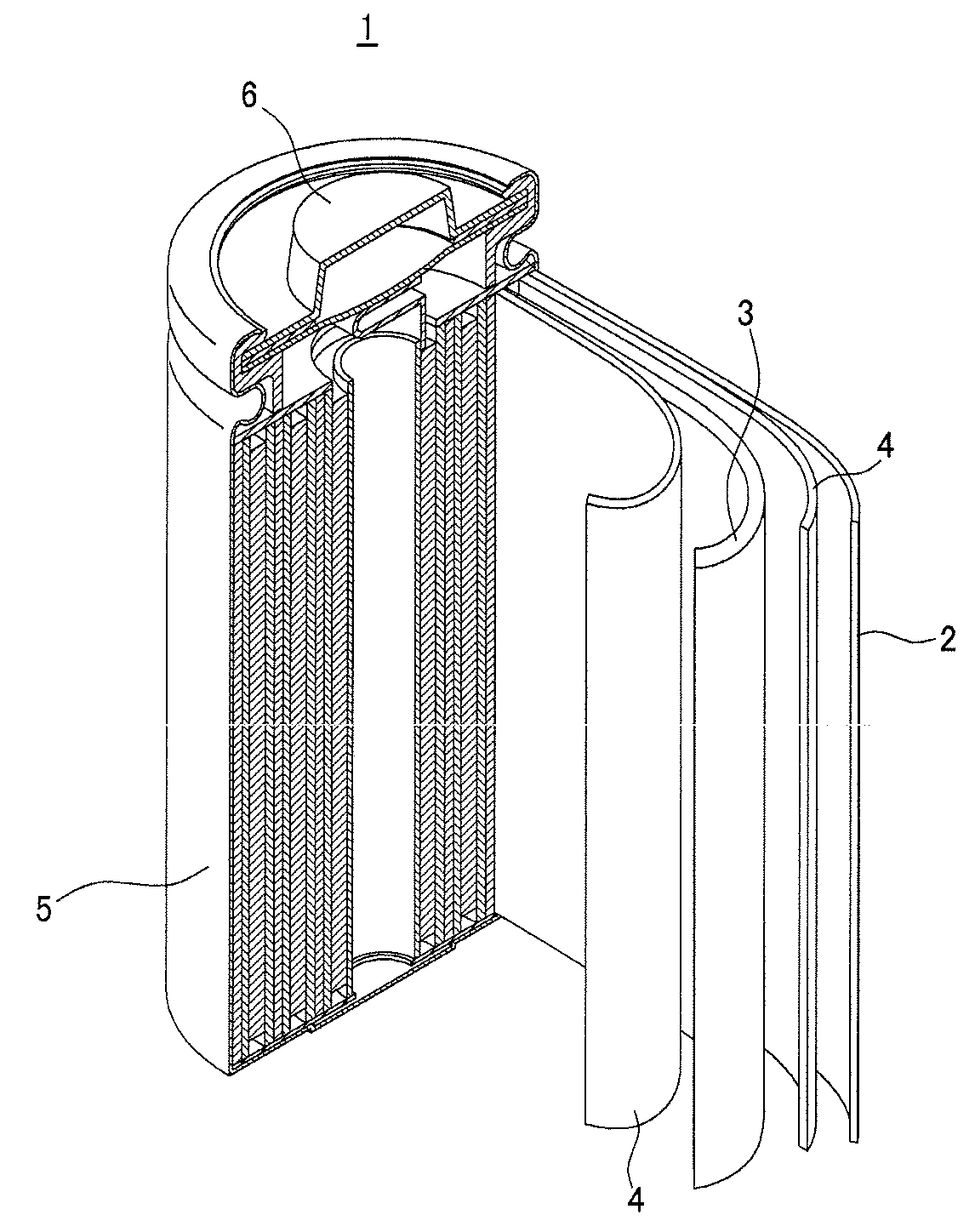

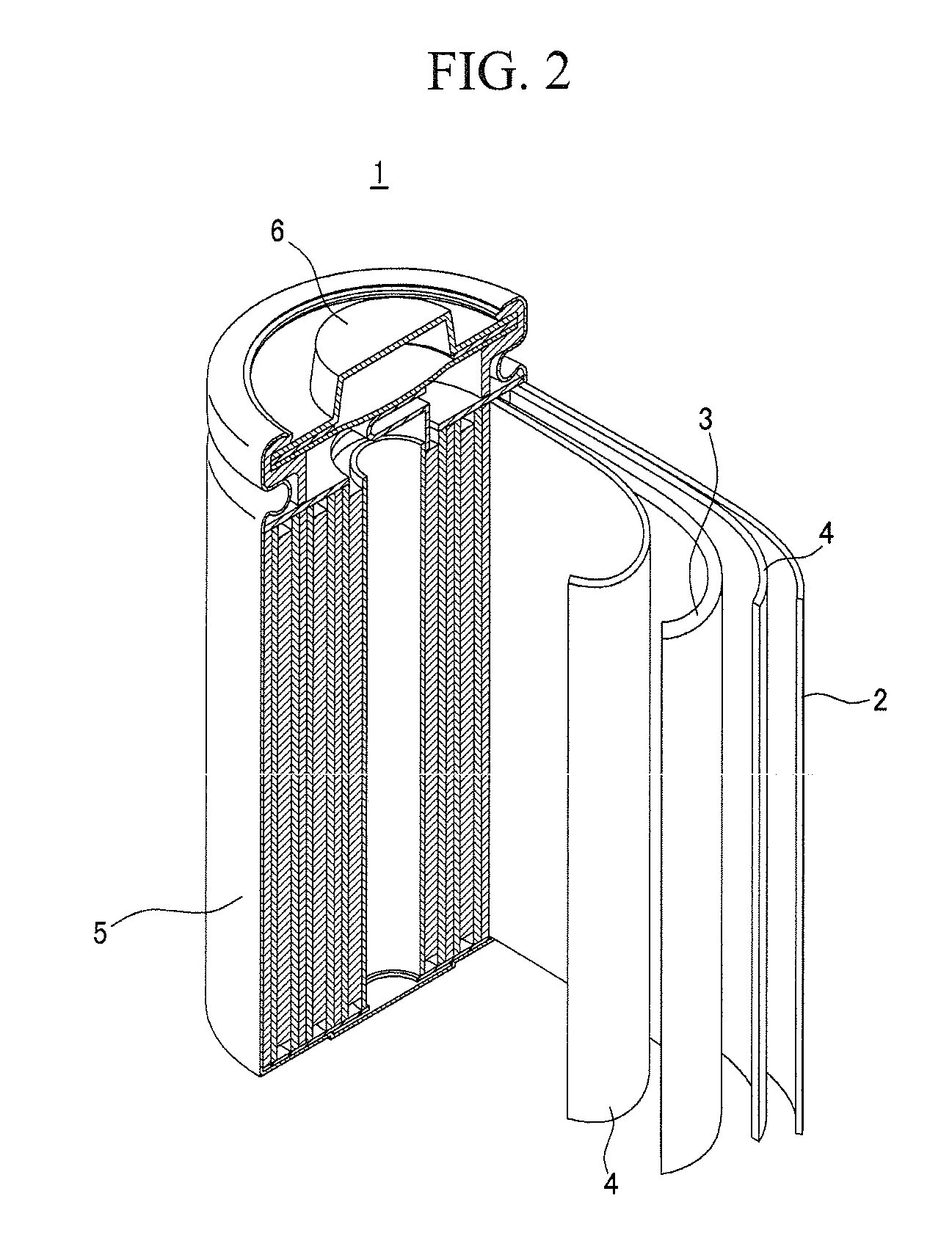

Lithium-ion secondary battery, anode for lithium-ion secondary battery, power tool, electric vehicle and energy storage system

ActiveUS20110159368A1Improve performanceMany functionsSilver accumulatorsAlkaline accumulator electrodesElectrical batteryEngineering

A lithium-ion secondary battery allowed to improve cycle characteristics and initial charge-discharge characteristics is provided. The lithium-ion secondary battery includes a cathode; an anode; and an electrolytic solution. The anode includes an anode active material layer including a plurality of anode active material particles. The anode active material particles each include a core section and a coating section applied to a part or a whole of a surface of the core section, and the core section includes a silicon-based material (SiOx: 0≦x<0.5) and the coating section includes an amorphous or low-crystalline silicon-based material (SiOy: 0.5≦y≦1.8).

Owner:MURATA MFG CO LTD

Positive electrode for rechargeable lithium battery and rechargeable lithium battery including same

ActiveUS7923149B2Inhibit side effectsImprove stability and reliabilitySilver accumulatorsElectrode carriers/collectorsHexafluoropropyleneCopolymer

A positive electrode including a current collector; a positive active material layer disposed on the current collector; and a coating layer disposed on the positive active material layer. The coating layer includes a binder and a inorganic additive. The binder is a poly(vinylidenefluoride-hexafluoropropylene) copolymer comprising 2 to 16 mole % of hexafluoropropylene. The positive electrode for a rechargeable lithium battery suppresses side-reactions between a positive electrode and an electrolyte, at a high voltage.

Owner:SAMSUNG SDI CO LTD

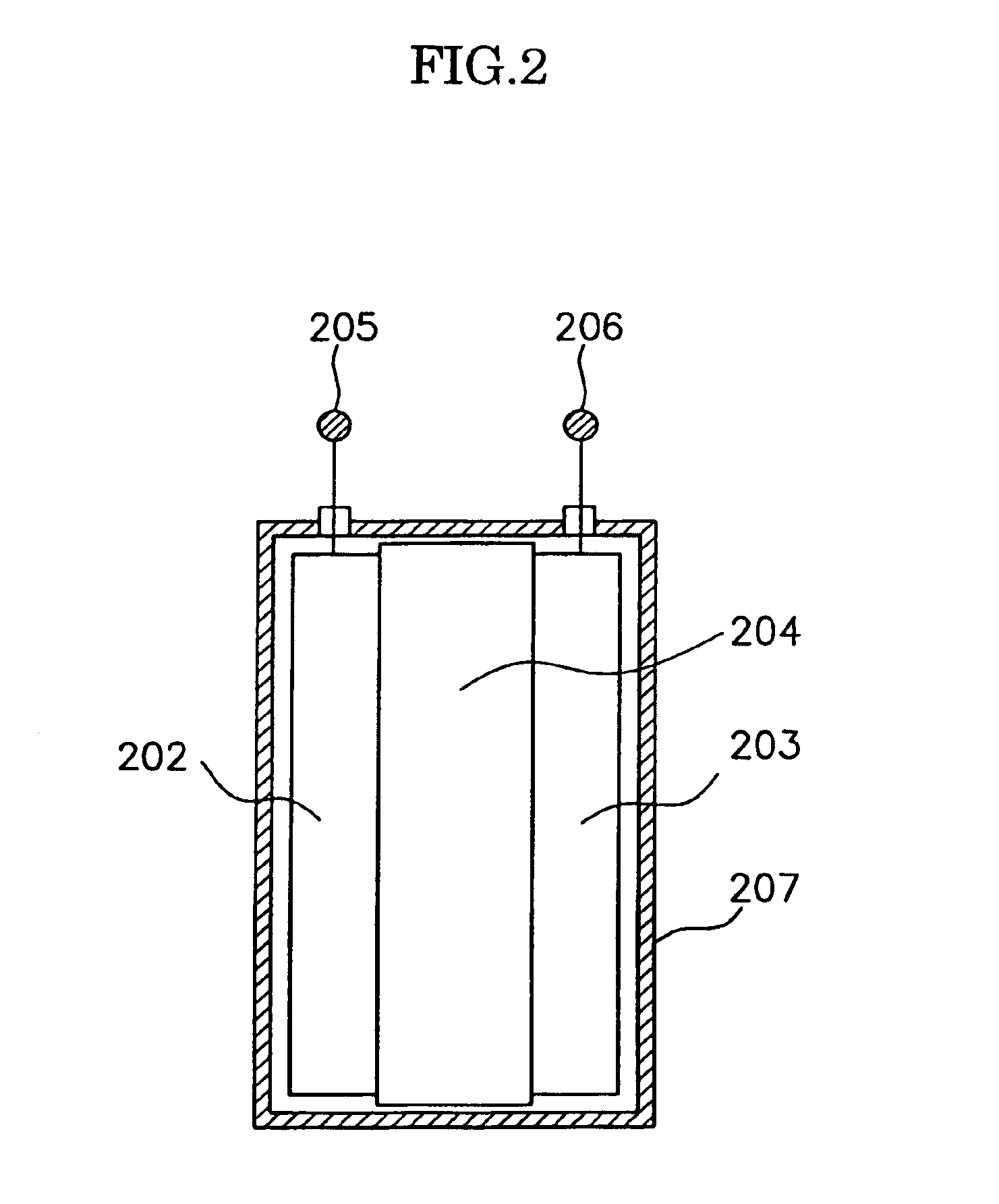

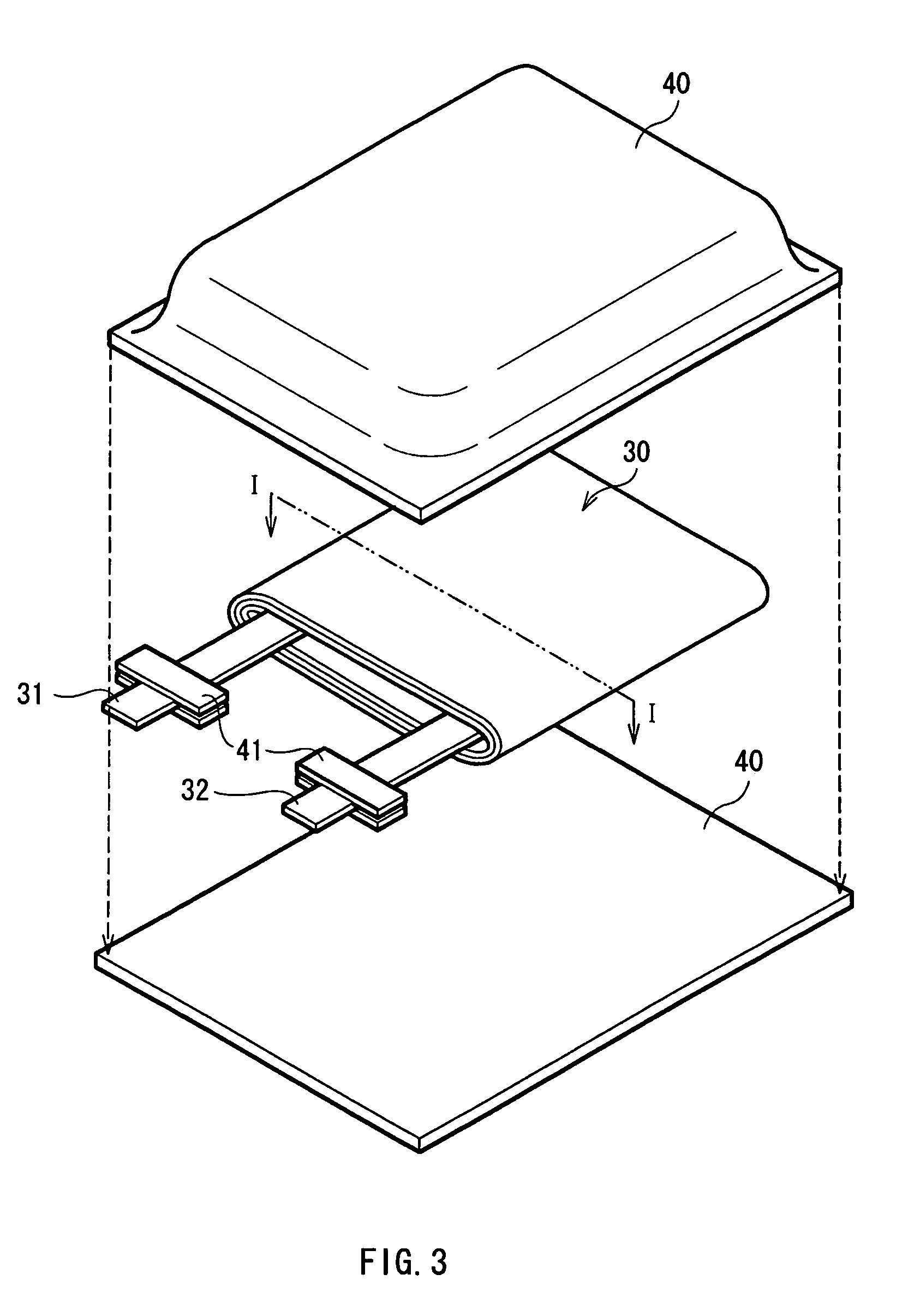

Electrochemical device

ActiveUS20090081553A1Maintain good propertiesIncrease resistanceSilver accumulatorsElectrode rolling/calenderingElectrochemistryOragene

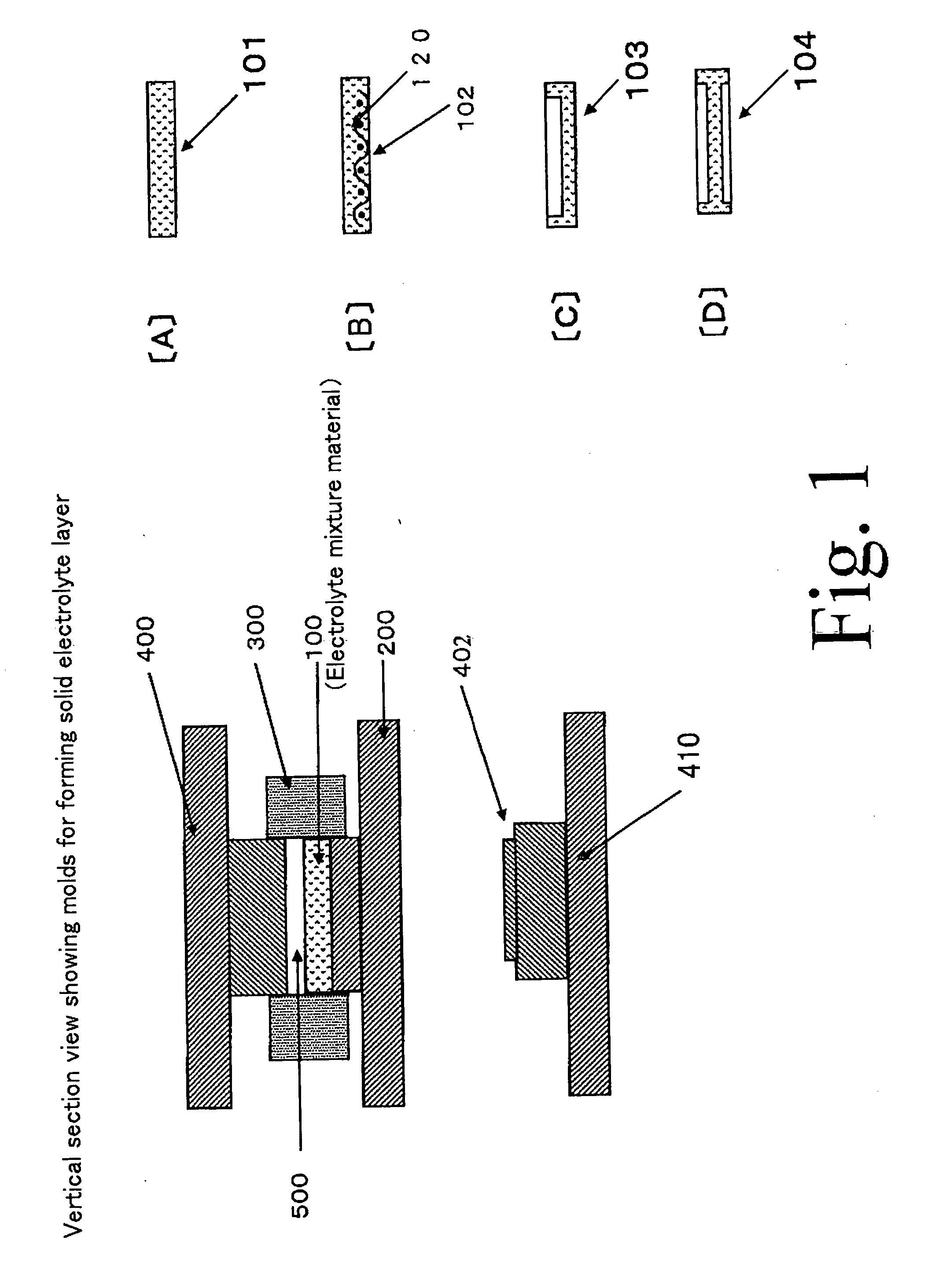

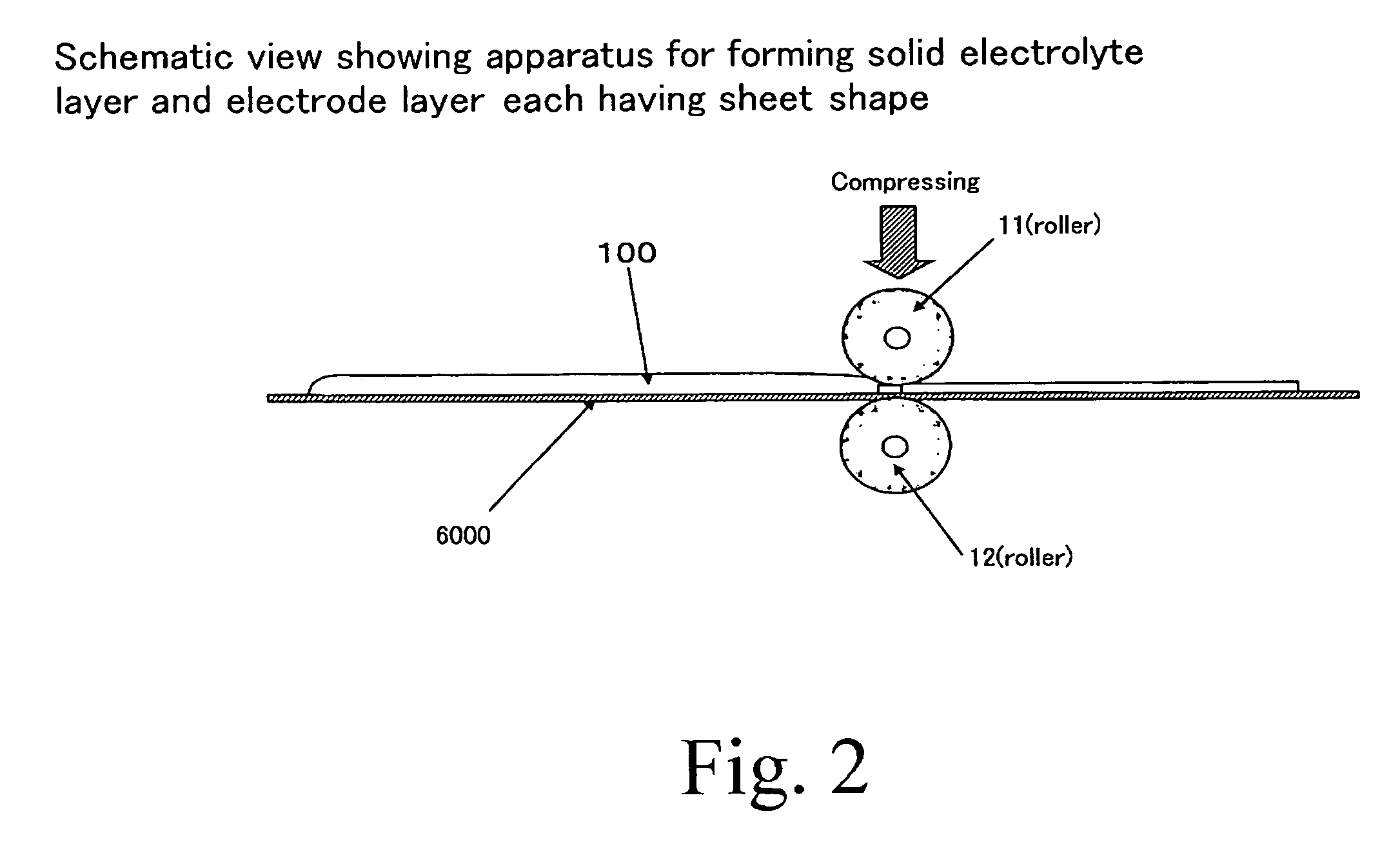

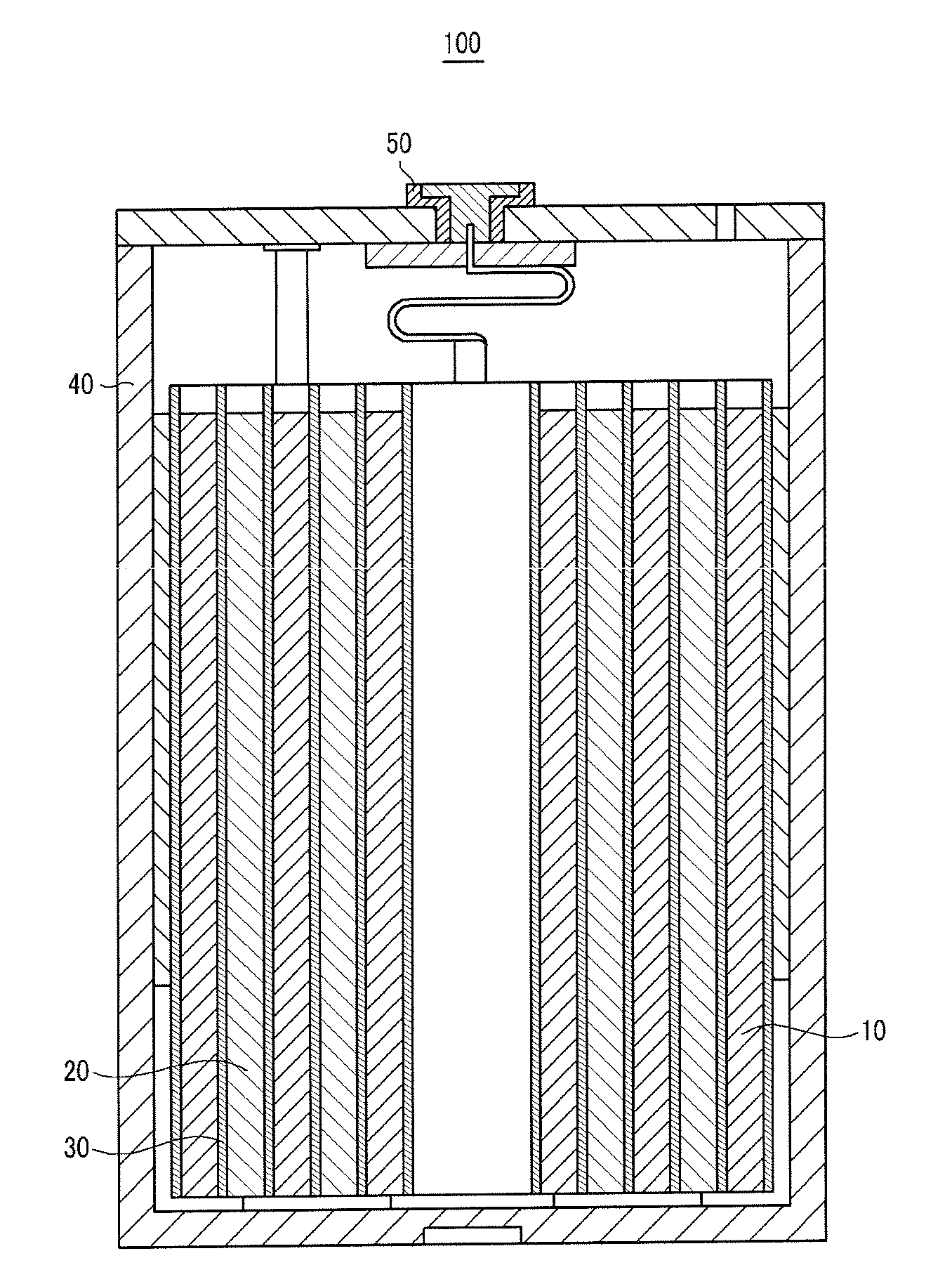

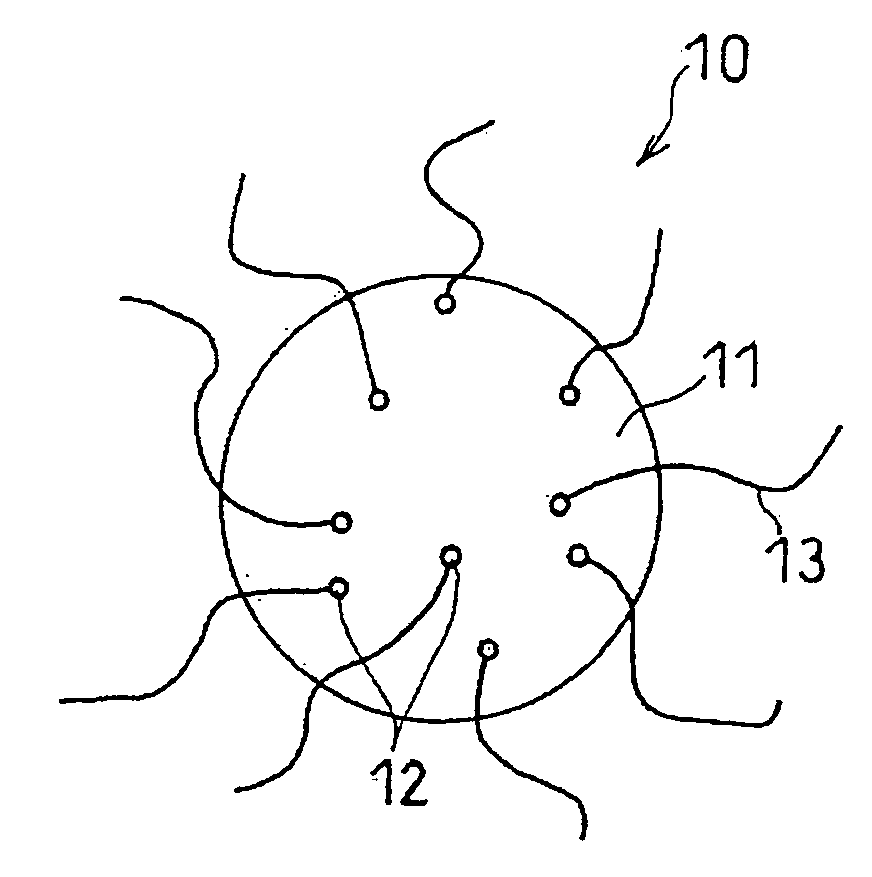

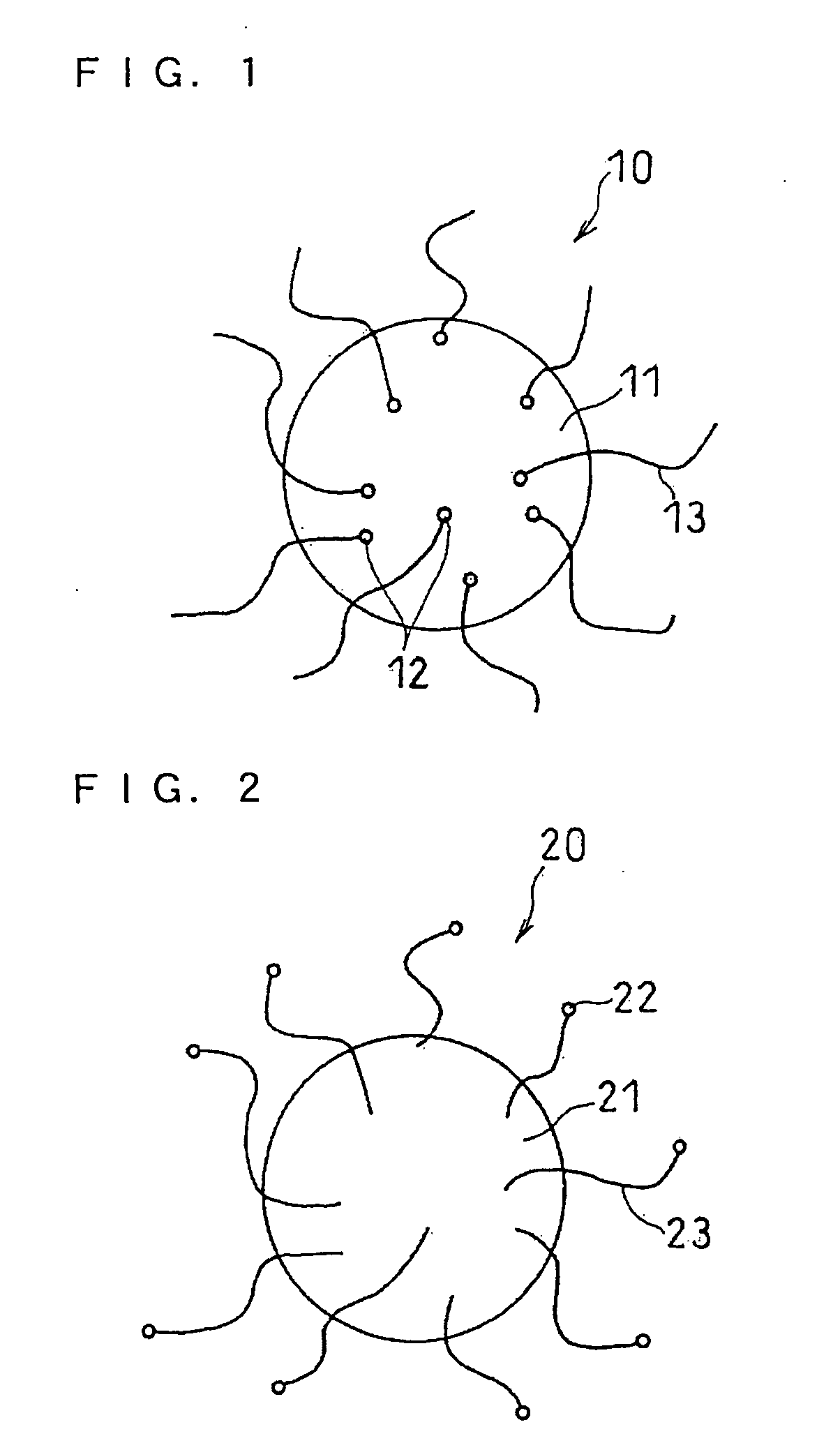

An electrochemical device manufactured using an electrode layer in which severe increase of electrode resistance is prevented and / or a solid electrolyte layer in which severe decrease of ion conductivity of a solid electrolyte is prevented is provided. The electrochemical device includes a pair of electrode layers, and a solid electrolyte layer provided between the pair of electrode layers, wherein at least one layer of the electrode layers and the solid electrolyte layer is composed of first particles each providing a function of the at least one layer, second particles and a binder which is composed of an organic polymer and binds the first and second particles, and wherein the at least one layer is formed from a mixture material containing the first particles and binder particles, each of the binder particles including the second particle and the binder carried on at least a part of a surface thereof.

Owner:SEIKO EPSON CORP

Postive electrode for rechargeable lithium battery and rechargeable lithium battery including same

ActiveUS20080118836A1Inhibit side effectsImprove reliabilitySilver accumulatorsElectrode carriers/collectorsHexafluoropropyleneCopolymer

A positive electrode including a current collector; a positive active material layer disposed on the current collector; and a coating layer disposed on the positive active material layer. The coating layer includes a binder and a inorganic additive. The binder is a poly(vinylidenefluoride-hexafluoropropylene) copolymer comprising 2 to 16 mole % of hexafluoropropylene. The positive electrode for a rechargeable lithium battery suppresses side-reactions between a positive electrode and an electrolyte, at a high voltage.

Owner:SAMSUNG SDI CO LTD

Anode for nonaqueous secondary electrochemical cells

InactiveUS6730437B2Improve performanceAvoid corrosionSilver accumulatorsElectrode carriers/collectorsGraphiteMetallic sulfide

The negative electrode or anode for a secondary electrochemical cell comprising a mixture of graphite or "hairy carbon" and a lithiated metal oxide, a lithiated mixed metal oxide or a lithiated metal sulfide, and preferably a lithiated metal vanadium oxide, is described. A most preferred formulation is graphite mixed with lithiated silver vanadium oxide or lithiated copper silver vanadium oxide.

Owner:WILSON GREATBATCH LTD

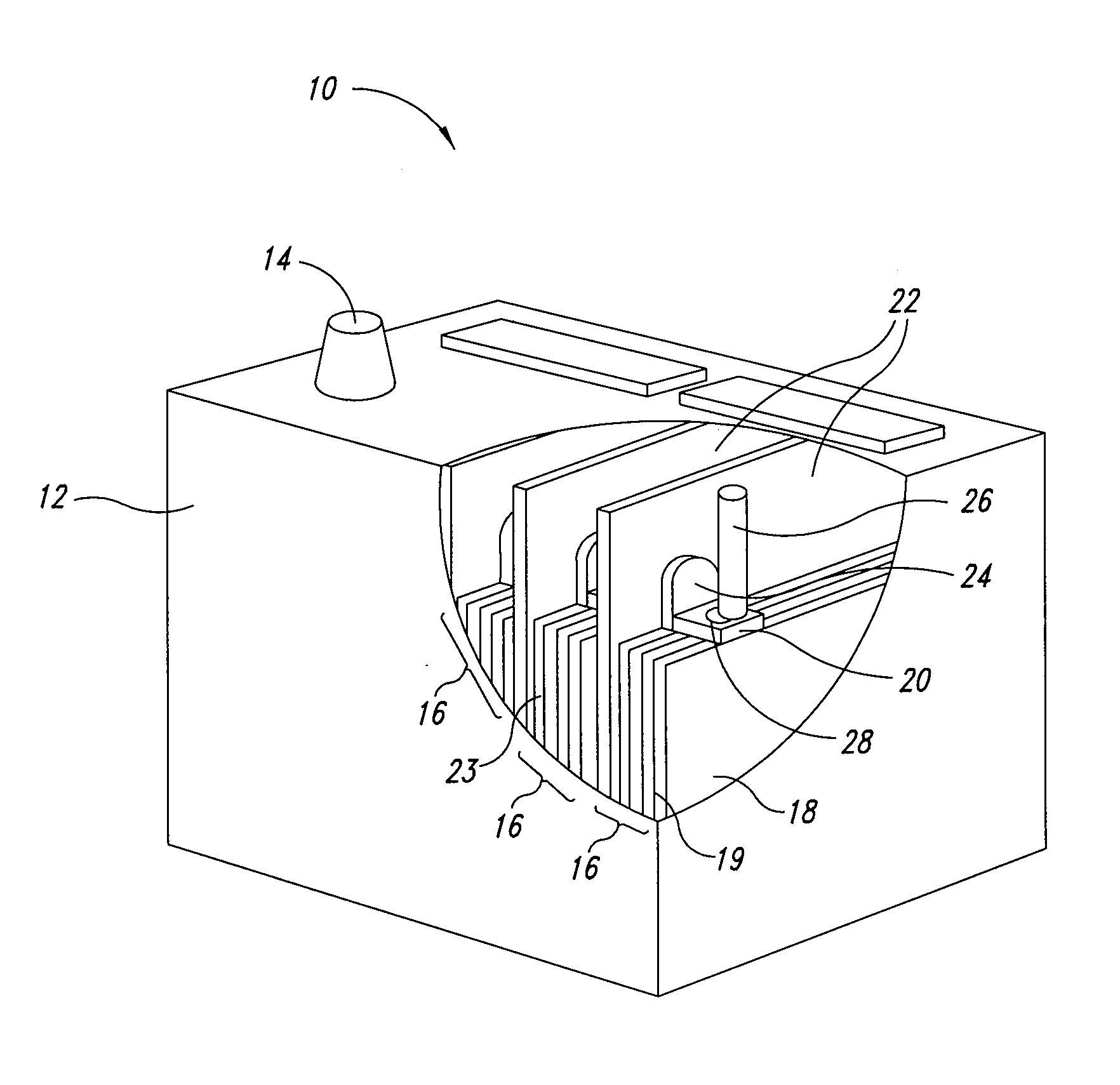

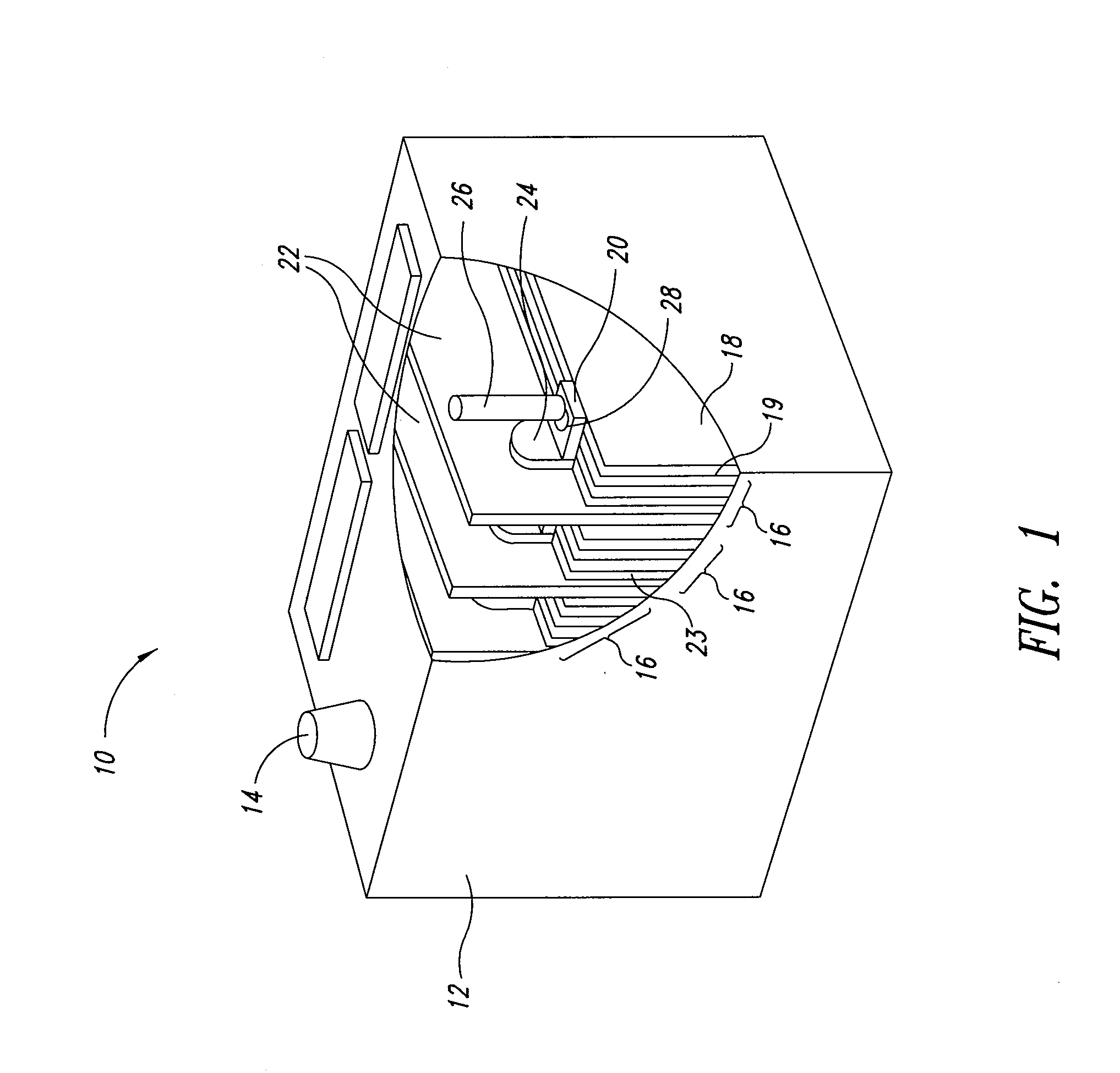

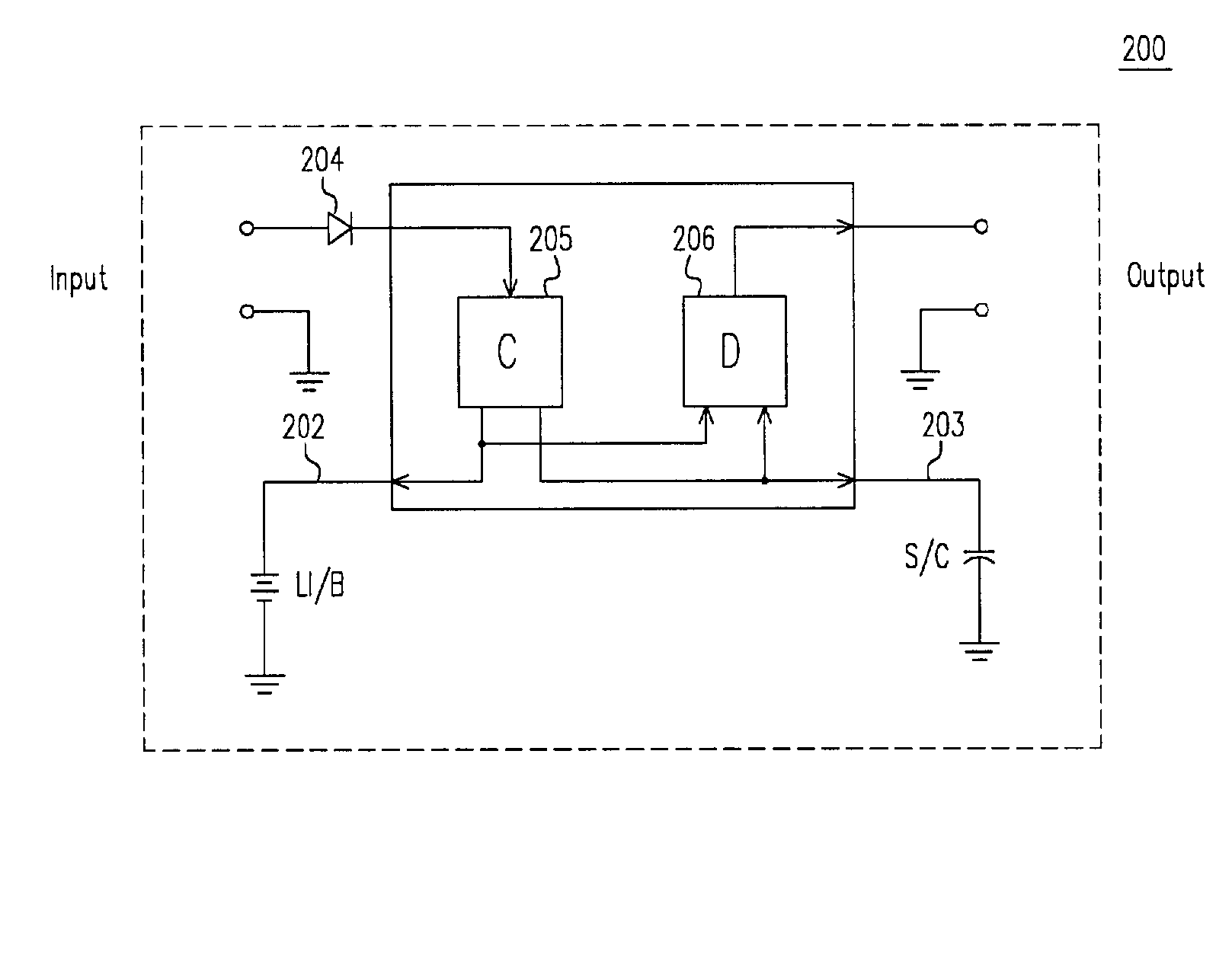

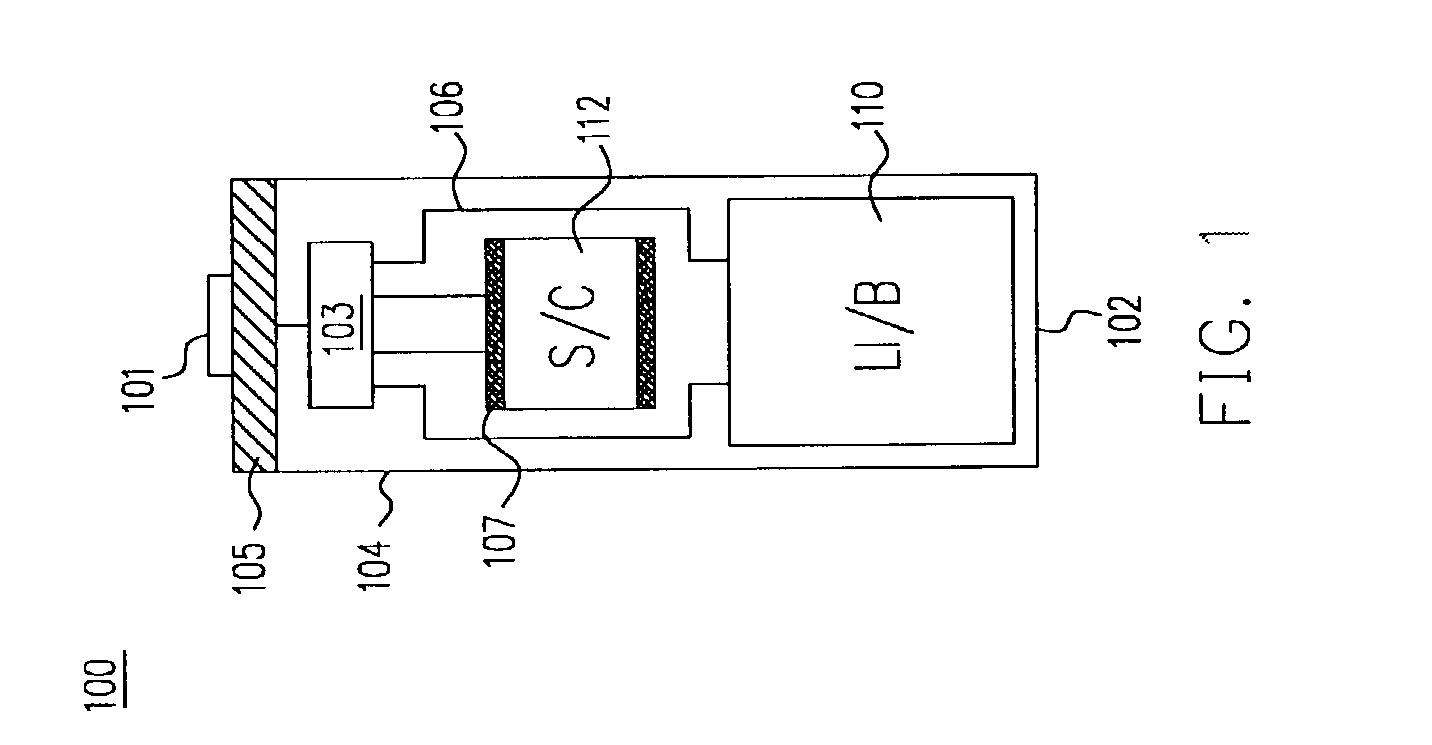

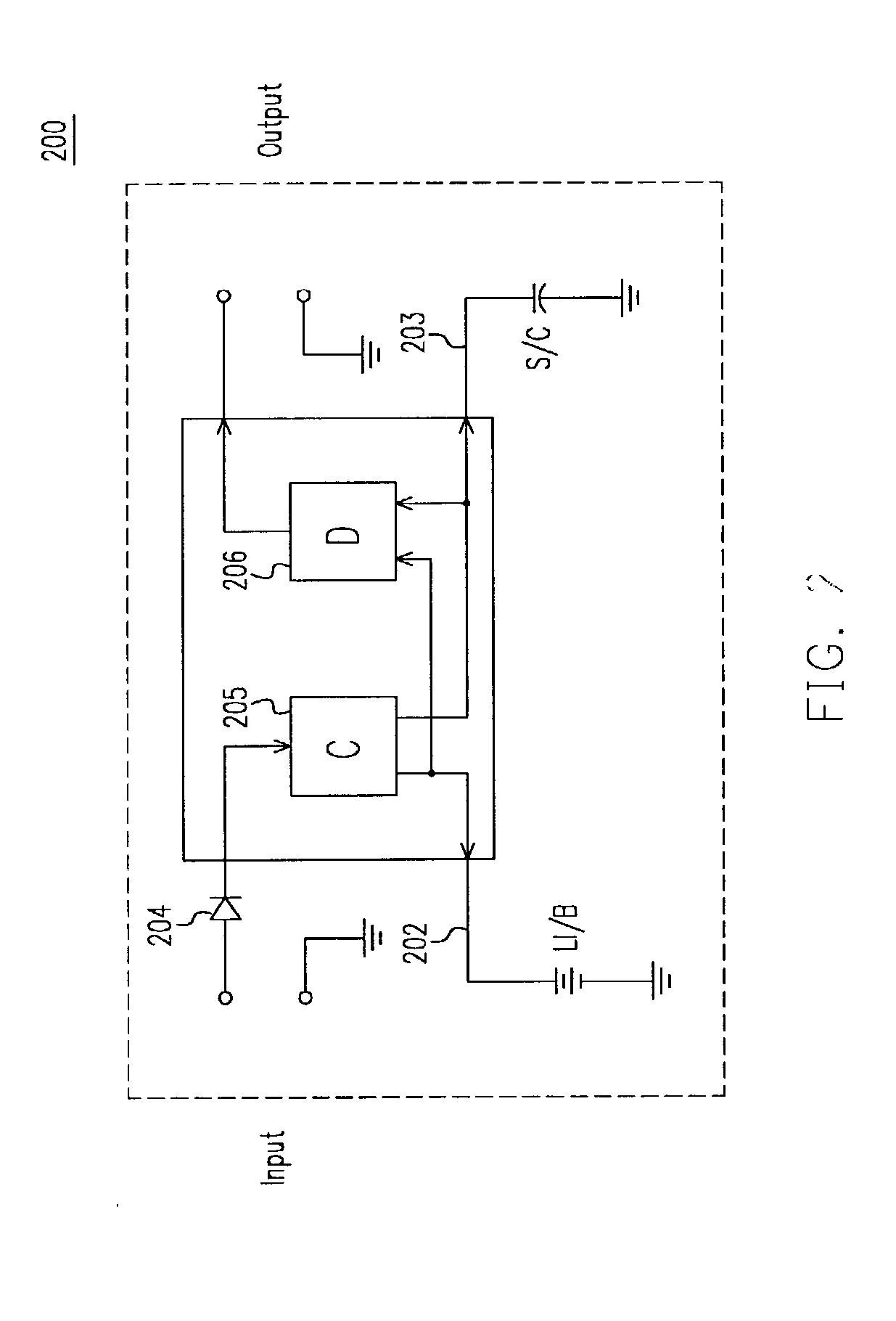

Battery with built-in load leveling

ActiveUS20040038087A1Fast energy storageEnergetic and reliableSilver accumulatorsFuel and primary cellsAir managementElectronic controller

An integrated battery by incorporating battery elements, supercapscitors elements, and miniaturized electronic controllers within a single housing is devised. The supercapacitors provide a load leveling for the battery elements at both charging and discharging. So long as the rated working voltage of supercapacitor is complied, the capacitor can be charged with charging currents of any magnitude. Then, the energy stored in the supercapacitors can be transferred from the capacitors to the batteries resulted in fast charging and energy conservation. With load leveling provided by the supercapacitors, the batteries are set to constantly discharge at 1C or lower rates and their residual energy near the end of discharge cycle can become useful as well. Therefore, the service run time, cycle life, and energy utilization of the batteries integrated are improved. In addition, the supercapacitor can be a built-in actuator to provide powers to in-cell air management systems for generating air draft inside metal-air batteries and fuel cells to increase their shelf life and power density.

Owner:GAINIA INTELLECTUAL ASSET SERVICES

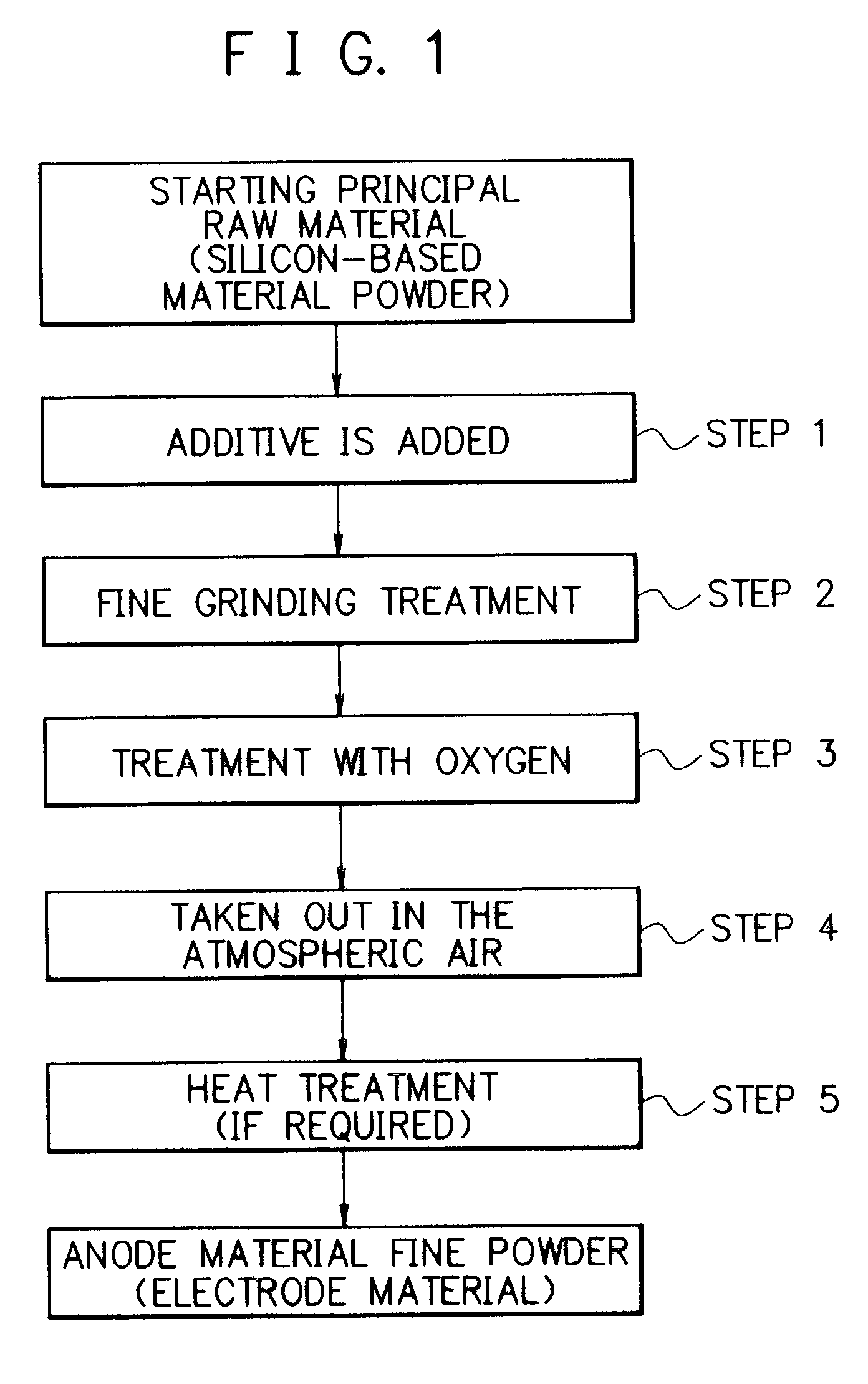

Electrode material for rechargeable lithium battery, electrode structural body comprising said electrode material, rechargeable lithium battery having said electrode structural body, process for the production of said electrode structural body, and process for the production of said rechargeable lithium battery

InactiveUS7141187B2Increase storage capacityImprove cycle lifeSilver accumulatorsElectrode thermal treatmentMaterials scienceFine powder

An electrode material for a rechargeable lithium battery, characterized in that said electrode material comprises a fine powder of a silicon-based material whose principal component is silicon element, said fine powder having an average particle size (R) in a range of 0.1 μm≦R<0.5 μm. An electrode structural body for a rechargeable lithium battery, having an electrode material layer comprising said silicon-based material fine powder. A rechargeable lithium battery whose anode comprising said electrode structural body.

Owner:CANON KK

Anode active material and battery using it

InactiveUS7229717B2Large capacityReduce crystallinitySilver accumulatorsCarbon compoundsIndiumNiobium

A battery with a high capacity and superior cycle characteristics, and an anode active material used for it are provided. An anode active material contains tin as a first element, a second element, and a third element. The second element is at least one from the group consisting of boron, carbon, aluminum, and phosphorus, andthe third element is at least one from the group consisting of silicon, magnesium, titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, gallium, zirconium, niobium, molybdenum, silver, indium, cerium, hafnium, tantalum, tungsten, and bismuth. The content of the second element in the anode active material is from 9.8 wt % to 49 wt %.

Owner:SONY CORP

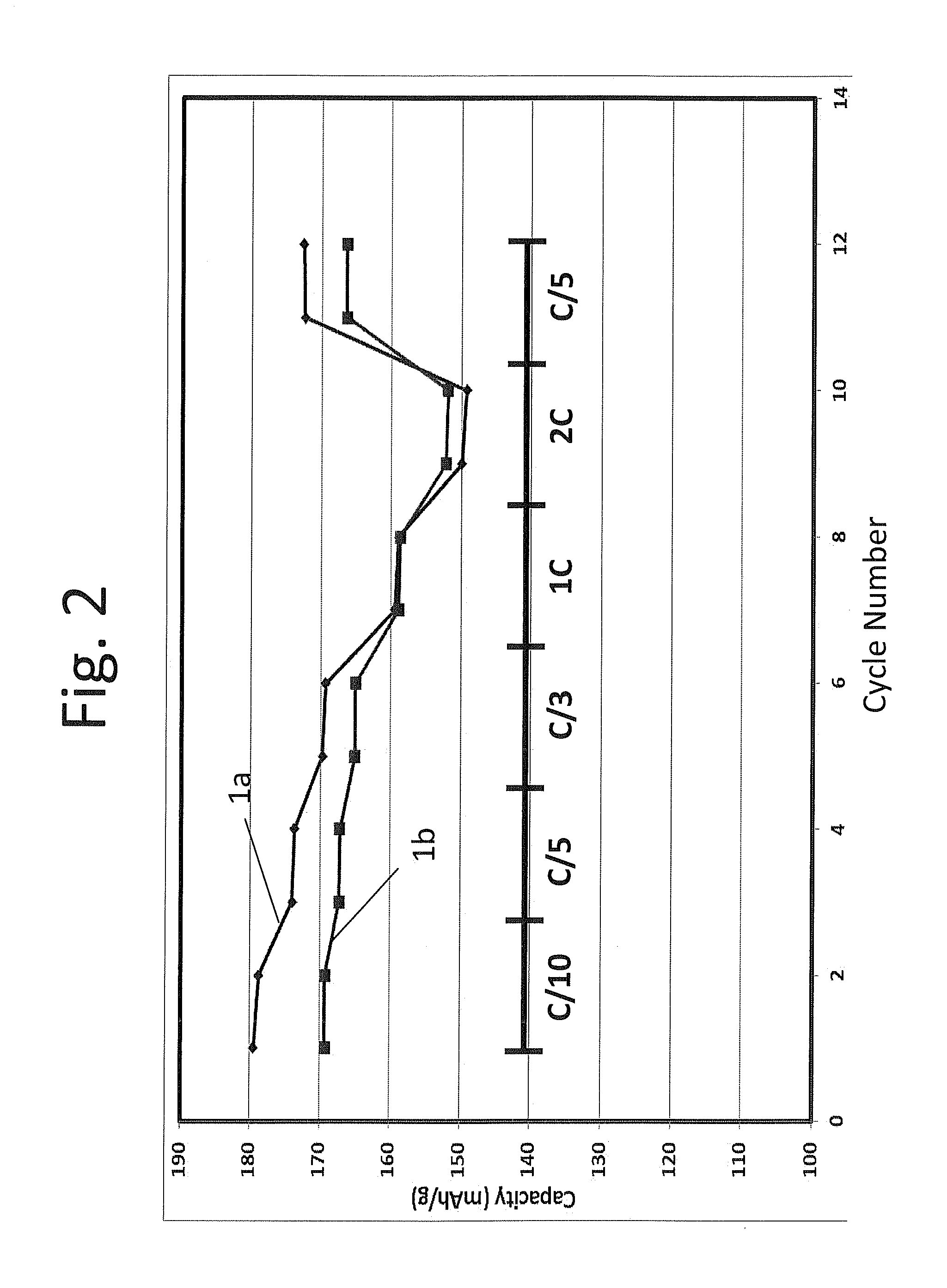

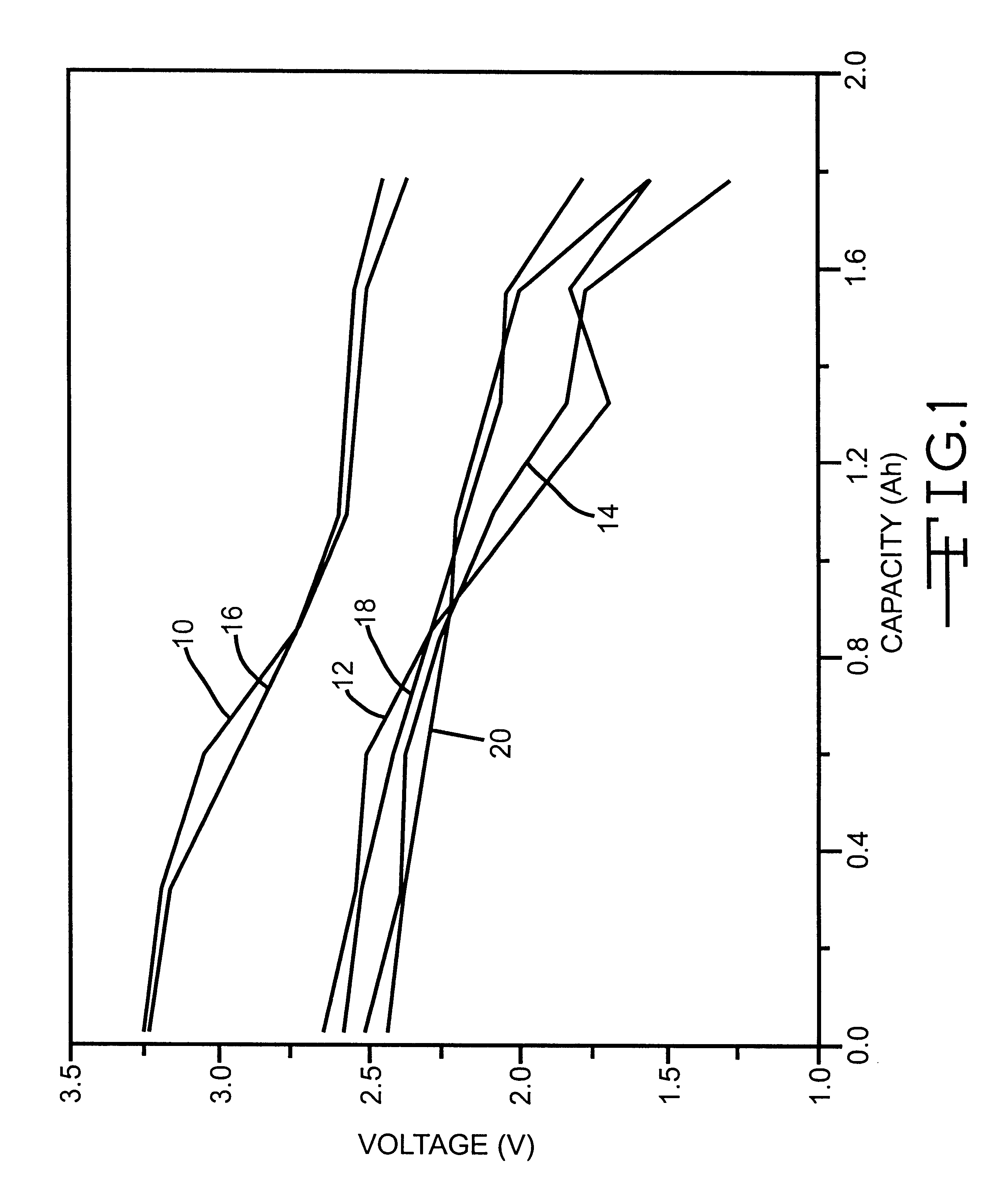

High capacity lithium ion battery formation protocol and corresponding batteries

Battery formation protocols are used to perform initial charging of batteries with lithium rich high capacity positive electrode to result a more stable battery structure. The formation protocol generally comprises three steps, an initial charge step, a rest period under an open circuit and a subsequent charge step to a selected partial activation voltage. The subsequent or second charge voltage is selected to provide for a desired degree of partial activation of the positive electrode active material to achieve a desired specific capacity while providing for excellent stability with cycling. The formation protocol is particularly effective to stabilize cycling for compositions with moderate lithium enrichment.

Owner:IONBLOX INC

Zinc secondary battery

ActiveUS20140315099A1Improve reliabilityPreventing a short circuitSilver accumulatorsSolid electrolytesElectrolyteIon

Provide is a zinc secondary battery capable of preventing a short circuit between the positive and negative electrodes caused by zinc dendrites. The zinc secondary battery of the present invention comprises a positive electrode; a negative electrode containing zinc; an electrolytic solution in which the positive electrode and the negative electrode are immersed or with which the positive electrode and the negative electrode are in contact, wherein the electrolytic solution is an aqueous solution containing an alkali metal hydroxide; and a separator being placed between the positive electrode and the negative electrode and separating the positive electrode and the negative electrode from each other, wherein the separator comprises an inorganic solid electrolyte body having hydroxide ion conductivity.

Owner:NGK INSULATORS LTD

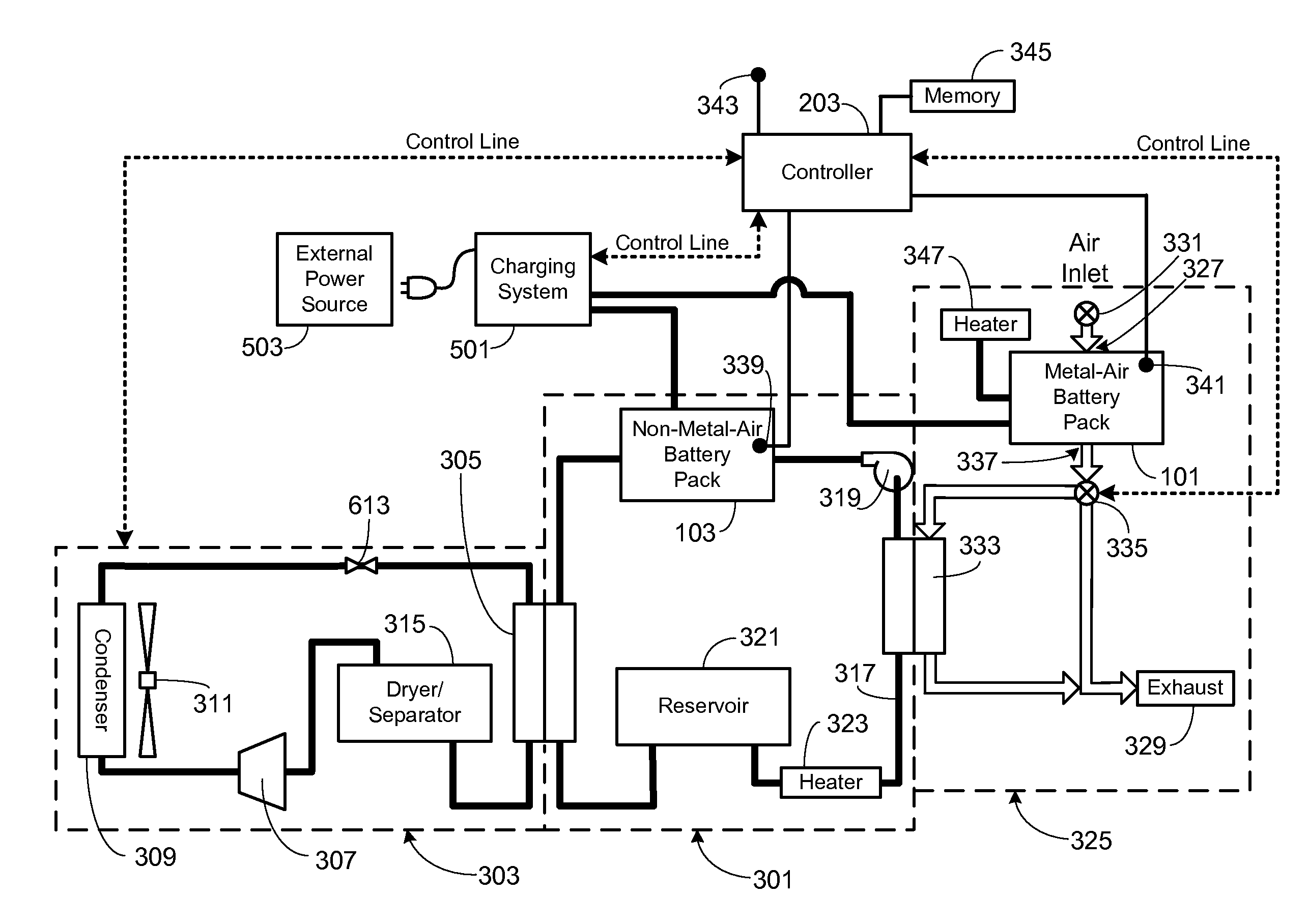

Thermal energy transfer system for a power source utilizing both metal-air and non-metal-air battery packs

A power source comprised of a metal-air battery pack and a non-metal-air battery pack is provided, wherein thermal energy from the metal-air battery pack is used to heat the non-metal-air battery pack. In one aspect, a thermal energy transfer system is provided that controls the flow of thermal energy from the metal-air battery pack to the non-metal-air battery pack. In another aspect, the flow of thermal energy from the metal-air battery pack to the non-metal-air battery pack is controlled and used to heat the non-metal-air battery pack prior to charging the non-metal-air battery pack.

Owner:TESLA INC

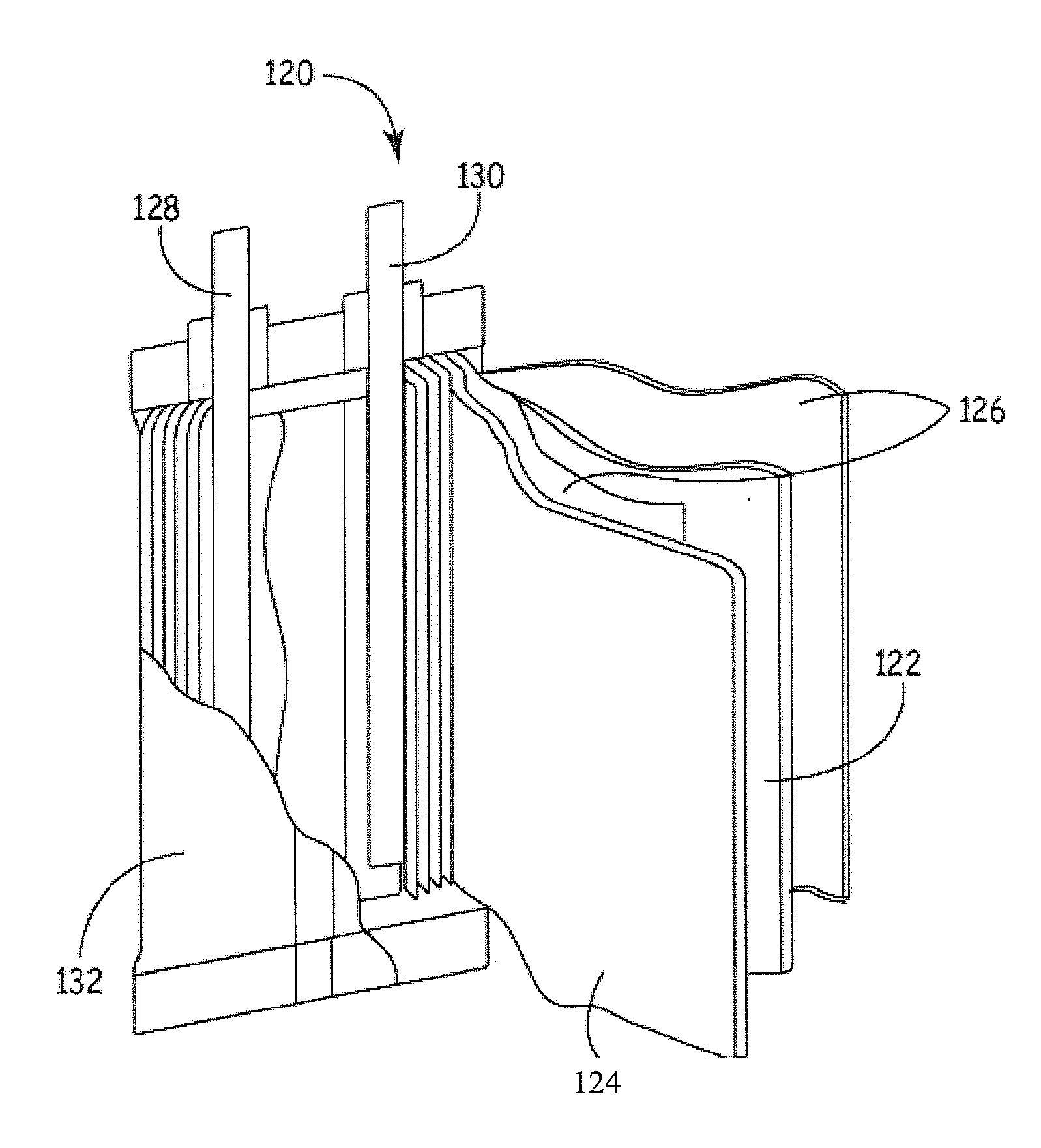

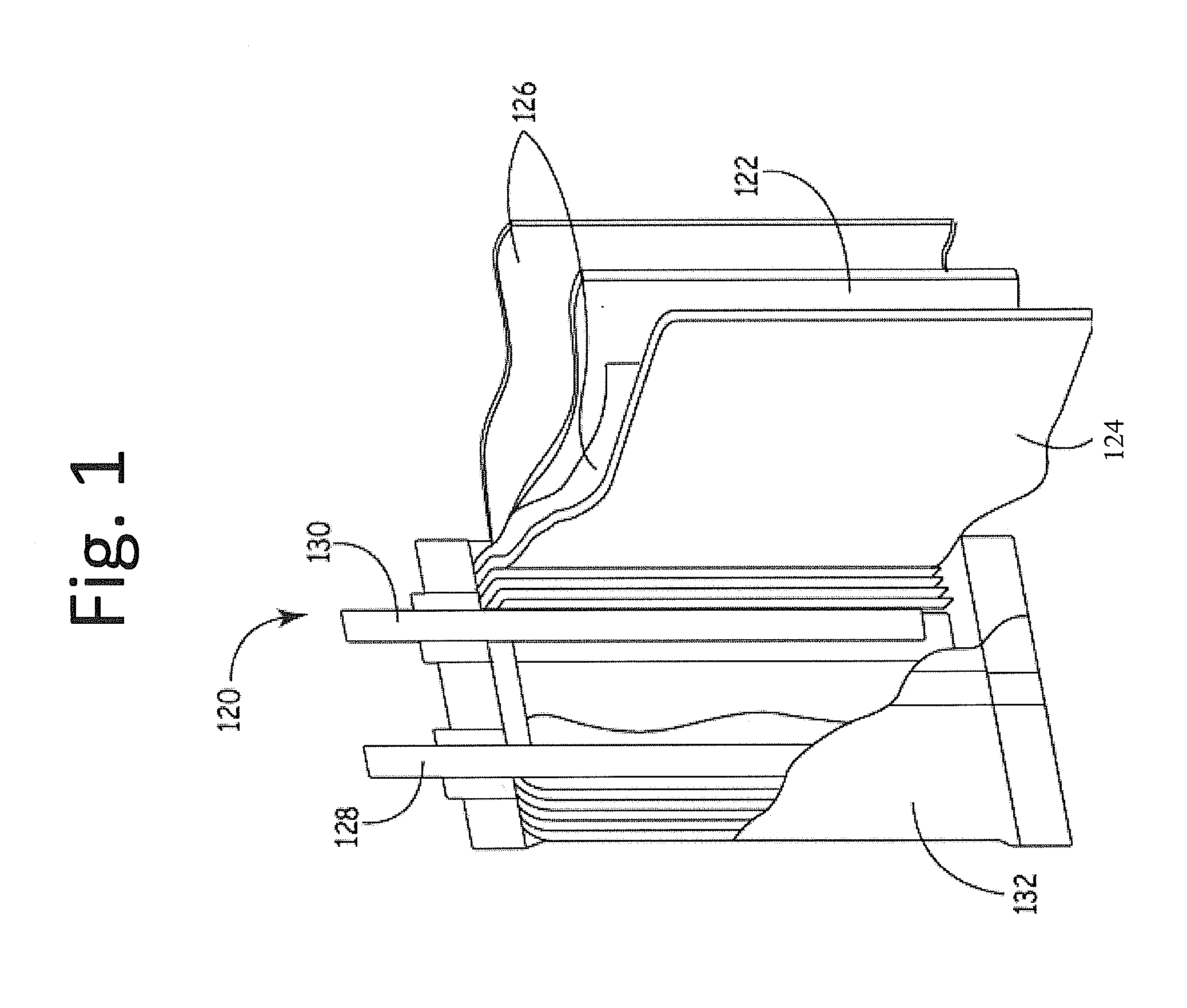

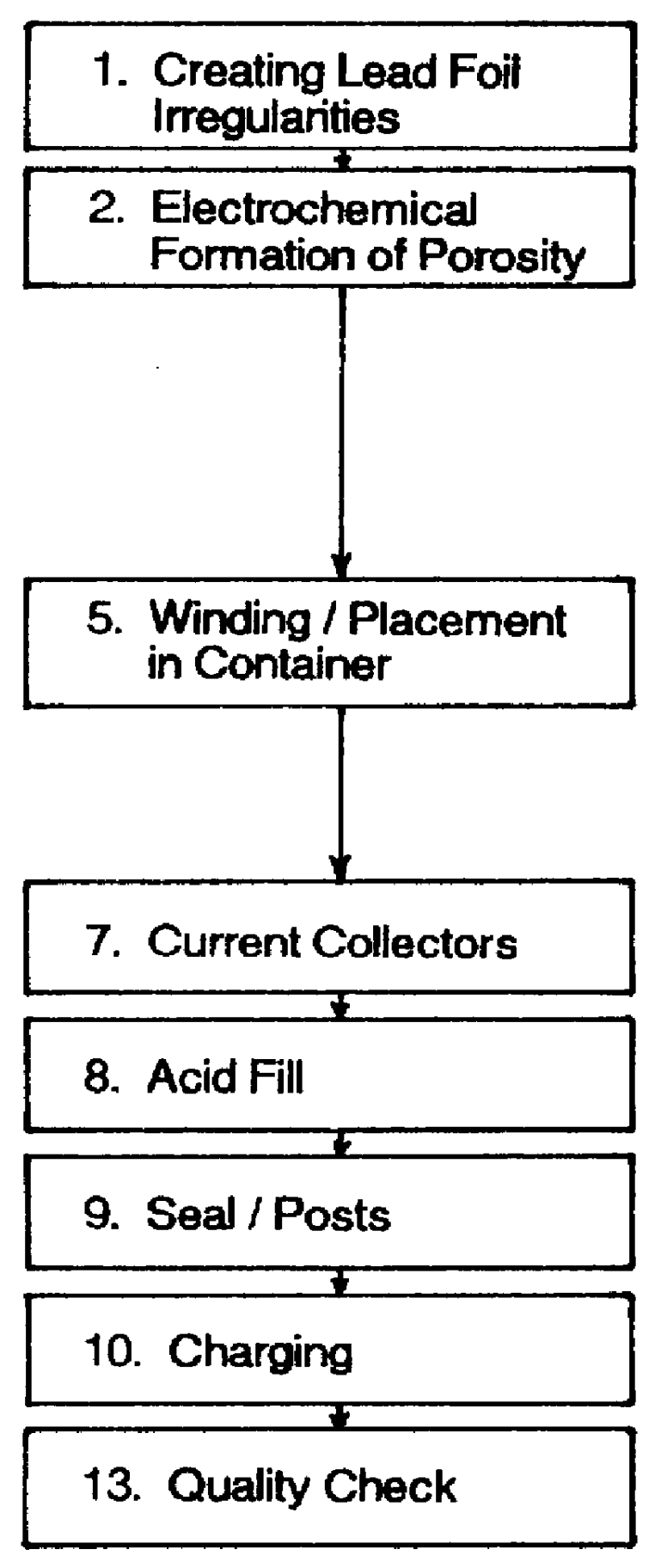

Source of electrical power for an electric vehicle and other purposes, and related methods

InactiveUS6063525AIncrease capacityIncrease powerSilver accumulatorsElectrode manufacturing processesCapacitancePorosity

Microthin sheet technology is disclosed by which superior batteries are constructed which, among other things, accommodate the requirements for high load rapid discharge and recharge, mandated by electric vehicle criteria. The microthin sheet technology has process and article overtones and can be used to form thin electrodes used in batteries of various kinds and types, such as spirally-wound batteries, bipolar batteries, lead acid batteries, silver / zinc batteries, and others. Superior high performance battery features include: (a) minimal ionic resistance; (b) minimal electronic resistance; (c) minimal polarization resistance to both charging and discharging; (d) improved current accessibility to active material of the electrodes; (e) a high surface area to volume ratio; (f) high electrode porosity (microporosity); (g) longer life cycle; (h) superior discharge / recharge characteristics; (j) higher capacities (Axhr); and k) high specific capacitance.

Owner:BIPOLAR TECH

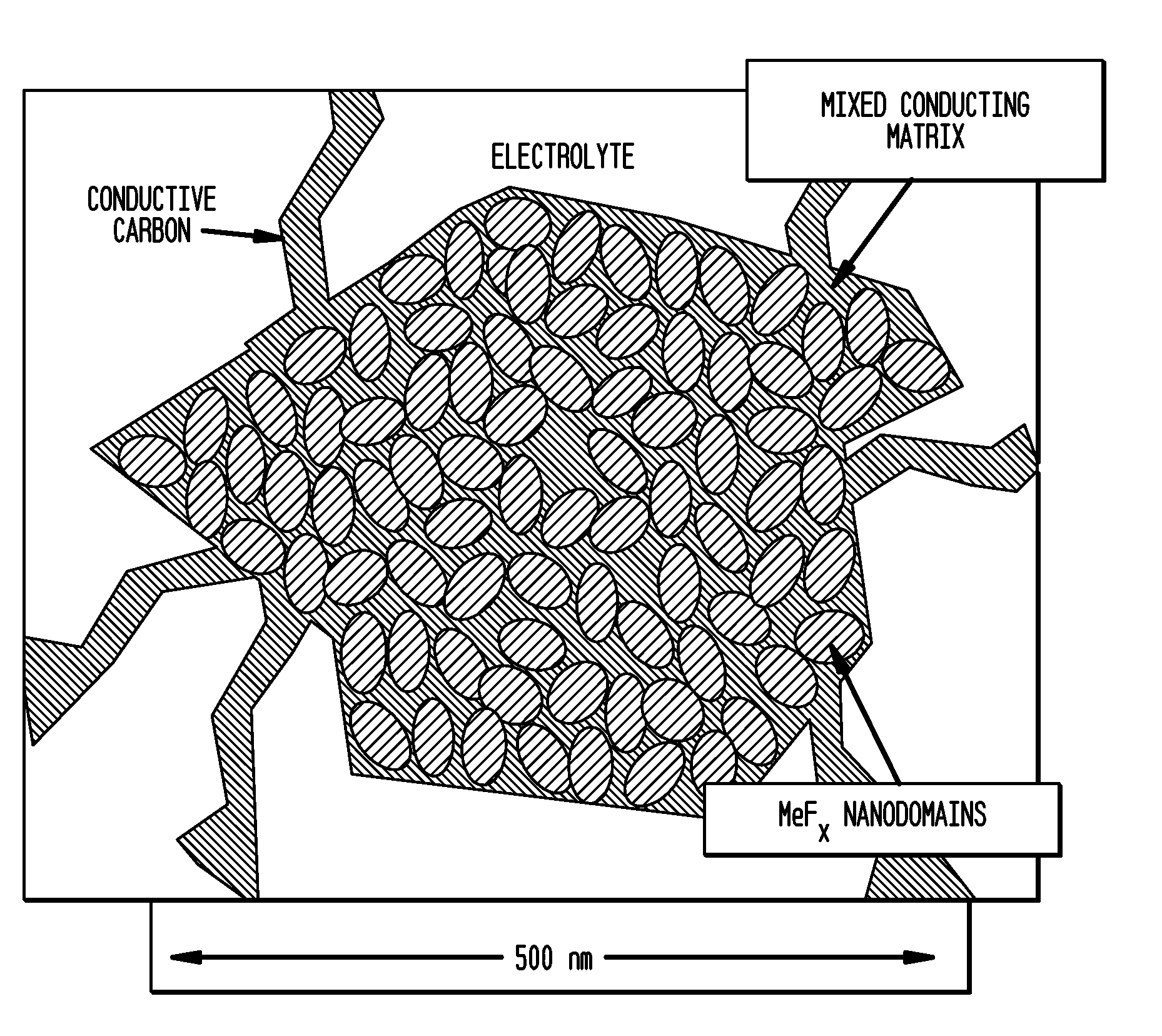

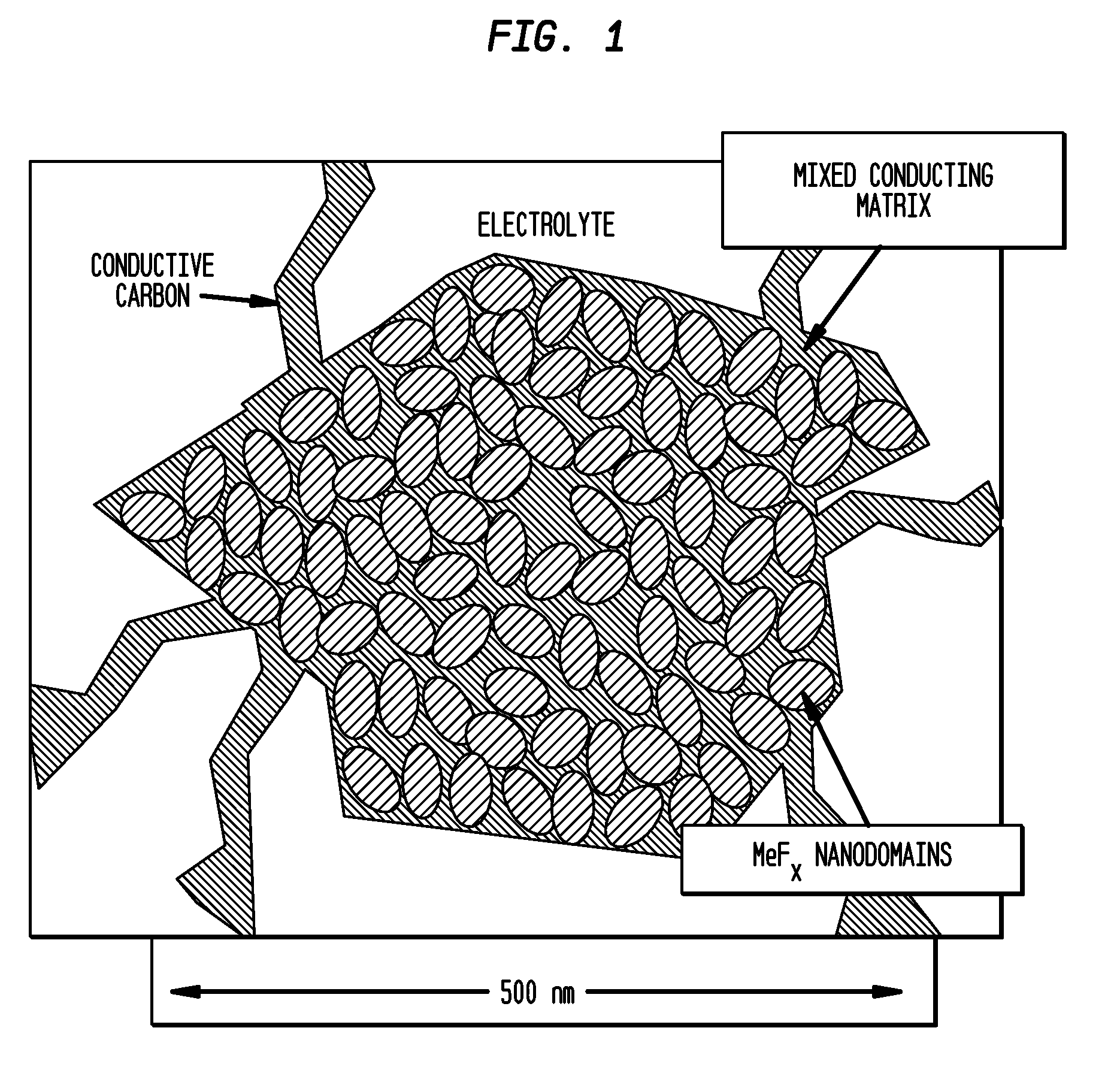

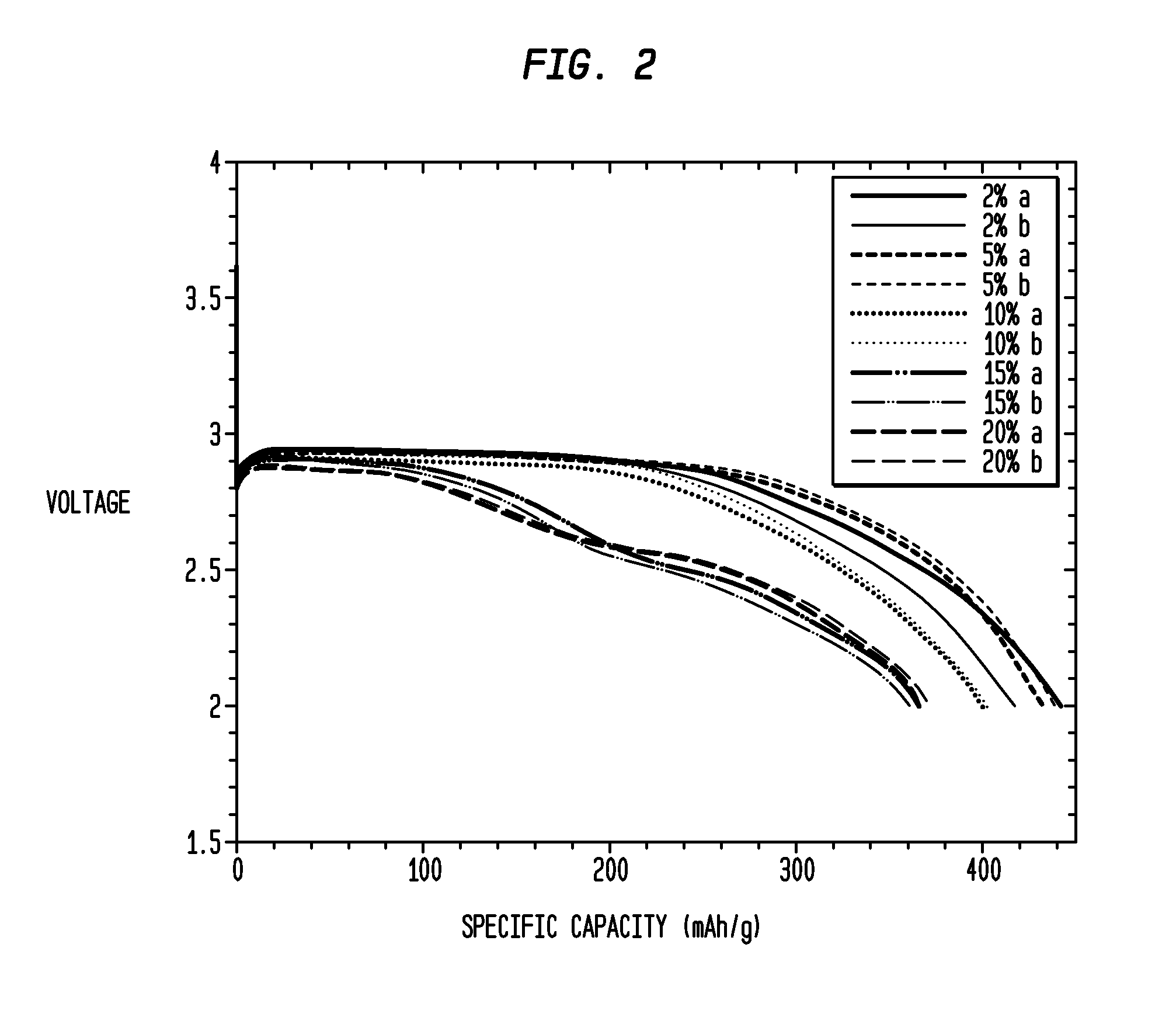

Metal Fluoride And Phosphate Nanocomposites As Electrode Materials

ActiveUS20080199772A1High specific capacityHigh discharge rateSilver accumulatorsElectrode manufacturing processesPhosphatePhysical chemistry

The present invention relates to primary and secondary electrochemical energy storage systems. More particularly, the present invention relates to such systems as battery cells, especially battery cells utilizing metal fluorides with the presence of phosphates or fluorophosphates, which use materials that take up and release ions as a means of storing and supplying electrical energy.

Owner:RUTGERS THE STATE UNIV

Rechargeable lithium battery and method for manufacturing the same

A rechargeable lithium battery according to the present invention includes a positive electrode including a positive active material being capable of intercalating and deintercalating lithium; a negative electrode including a negative active material being capable of intercalating and deintercalating lithium; and a non-aqueous electrolyte. The negative electrode includes a lithium-containing metal compound that is inactive for water, and can intercalate lithium during at least discharge. The rechargeable lithium battery has an irreversible capacity during a first charge and discharge, and has no problems such dendrite, electrolyte decomposition, or dissolution of a negative current collector.

Owner:SAMSUNG SDI CO LTD

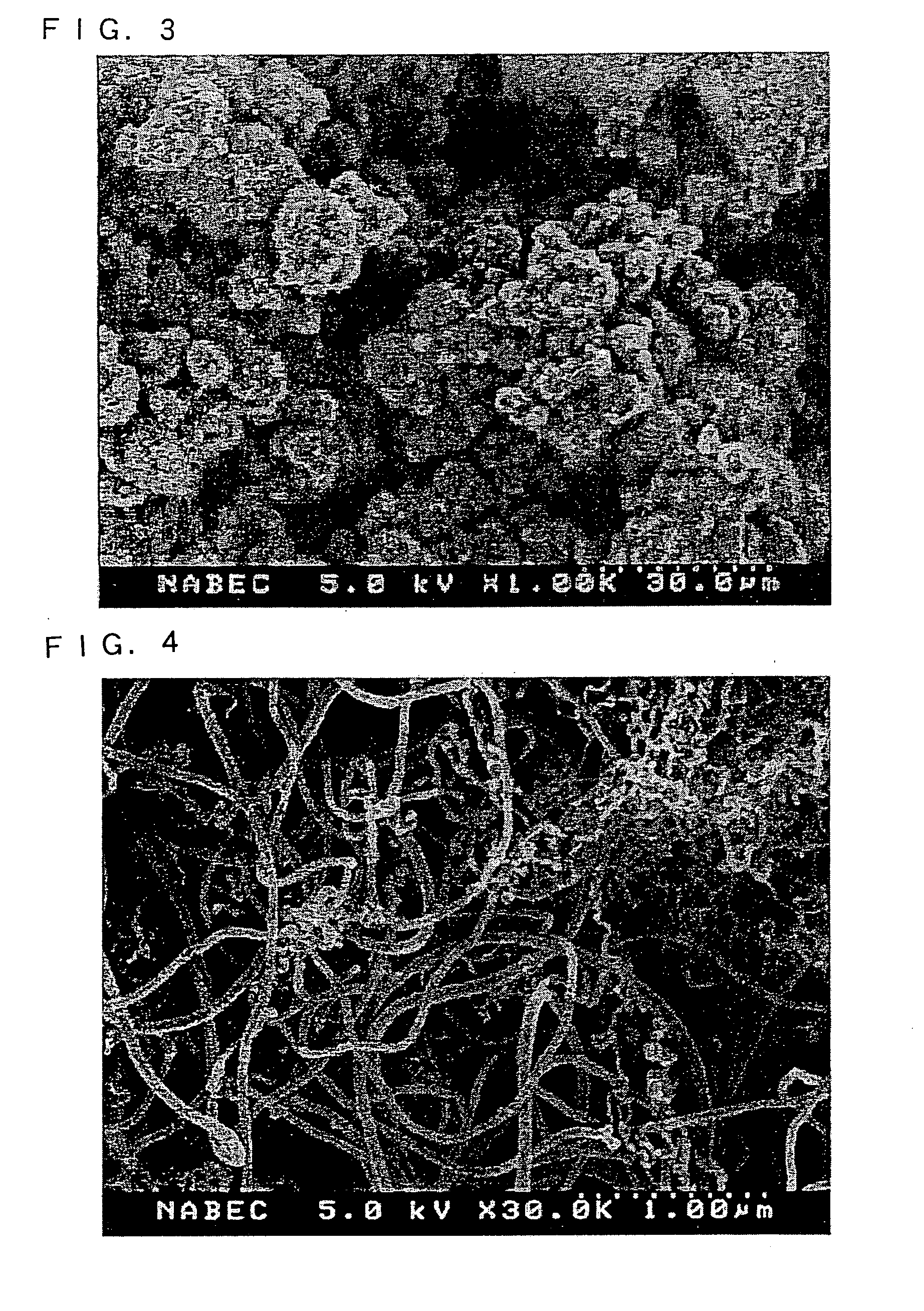

Composite Negative Electrode Active Material, Method For Producing The Same And Non-Aqueous Electrolyte Secondary Battery

InactiveUS20090004564A1Improve electronic conductivityExcellent initial charge/discharge characteristicSilver accumulatorsMaterial nanotechnologyFiberCarbon nanofiber

A composite negative electrode active material including silicon oxide particles represented by SiOx (0.05<x<1.95) capable of charging and discharging lithium, carbon nanofibers (CFN) bonded to the surface of the silicon oxide particles and a catalyst element for promoting the growth of carbon nanofiber. For example, Au, Ag, Pt, Ru, Ir, Cu, Fe, Co, Ni, Mo or Mn is preferred as the catalyst element.

Owner:PANASONIC CORP

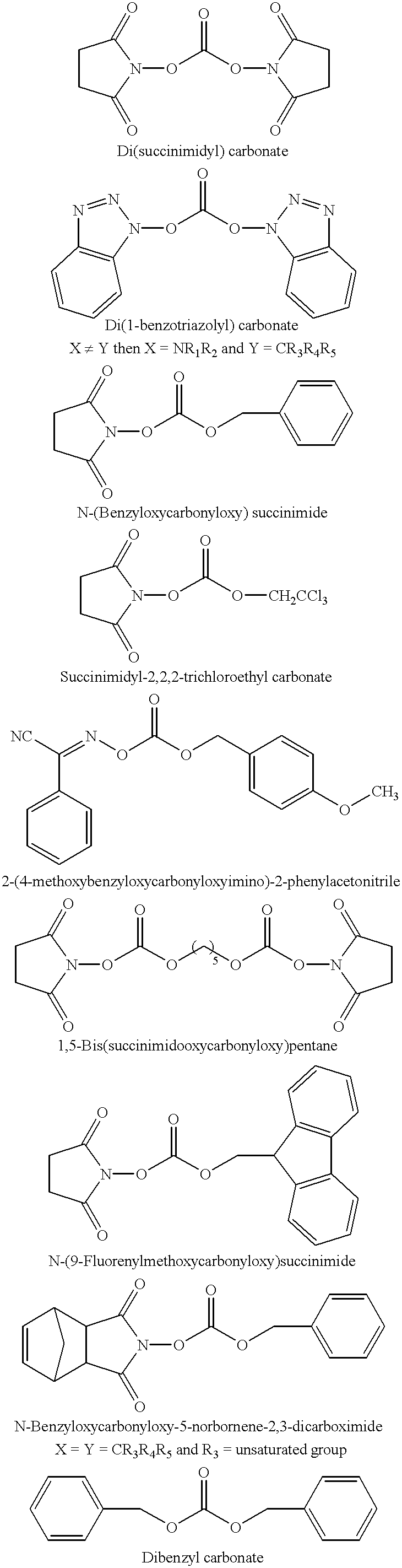

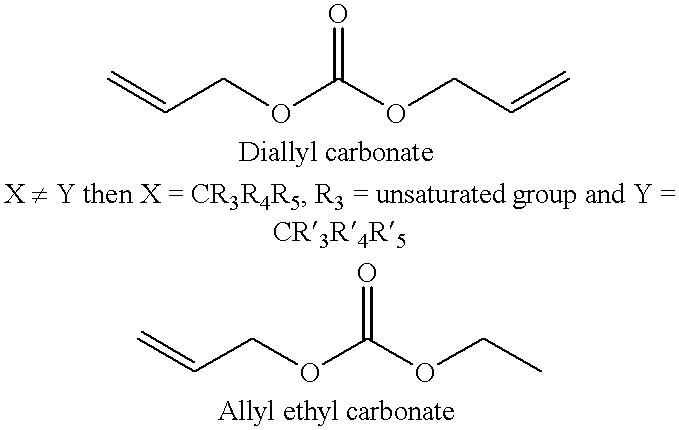

Alkali metal electrochemical cell having an improved cathode activated with a nonaqueous electrolyte having a carbonate additive

The present invention is directed to an unexpected benefit in a lithium cell derived from using a combination of silver vanadium oxide prepared in a temperature range of about 450° C. to about 500° C. activated with a nonaqueous electrolyte having a passivation inhibitor additive selected from a nitrite, a nitrate, a carbonate, a dicarbonate, a phosphonate, a phosphate, a sulfate and hydrogen fluoride, and mixtures thereof. The benefits include additional battery life resulting from a reduction in voltage delay and RDC build-up. A preferred electrolyte is 1M LiAsF6 in a 50:50 mixture, by volume, of PC and DME having dibenzyl carbonate added therein.

Owner:WILSON GREATBATCH LTD

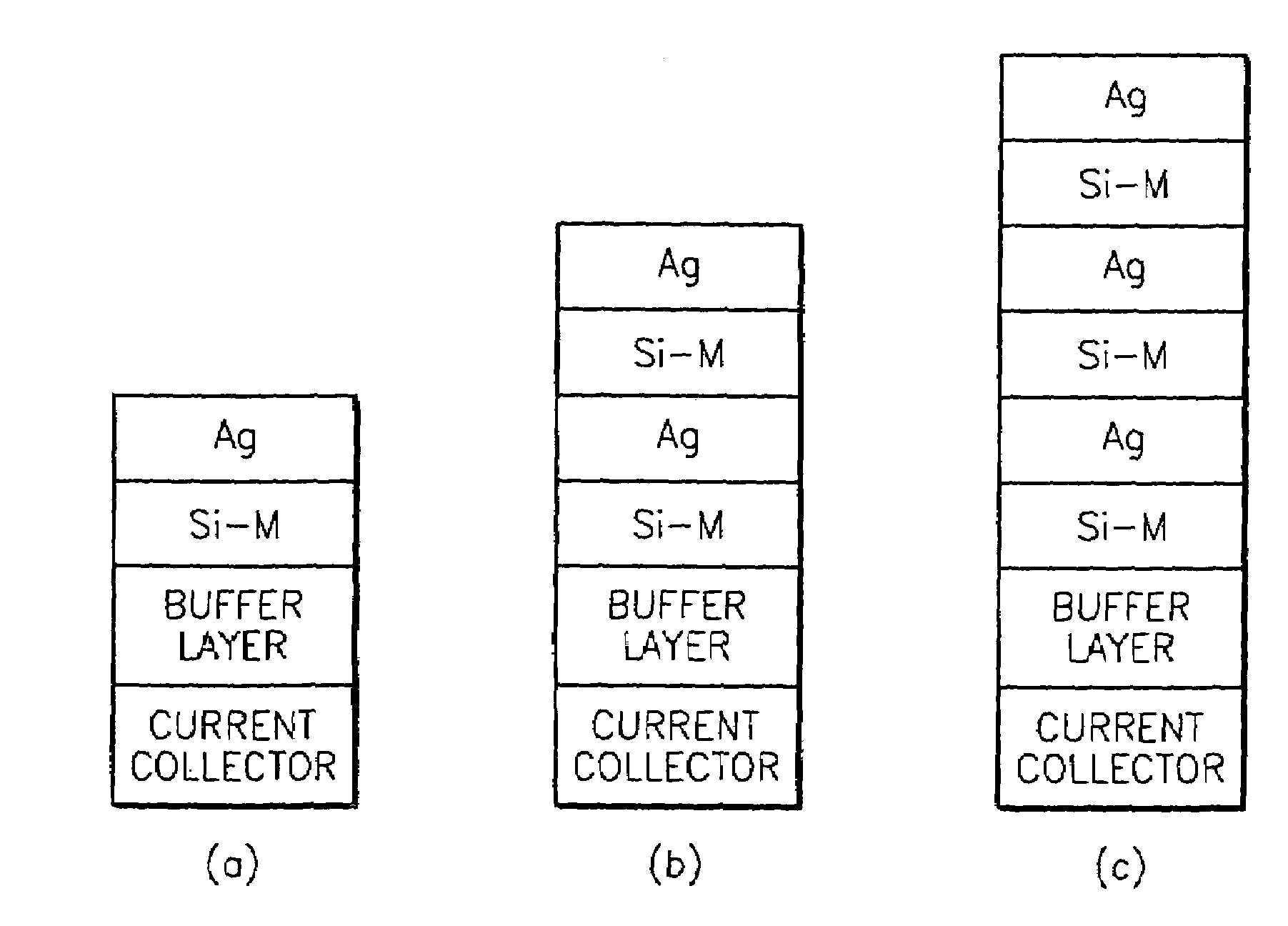

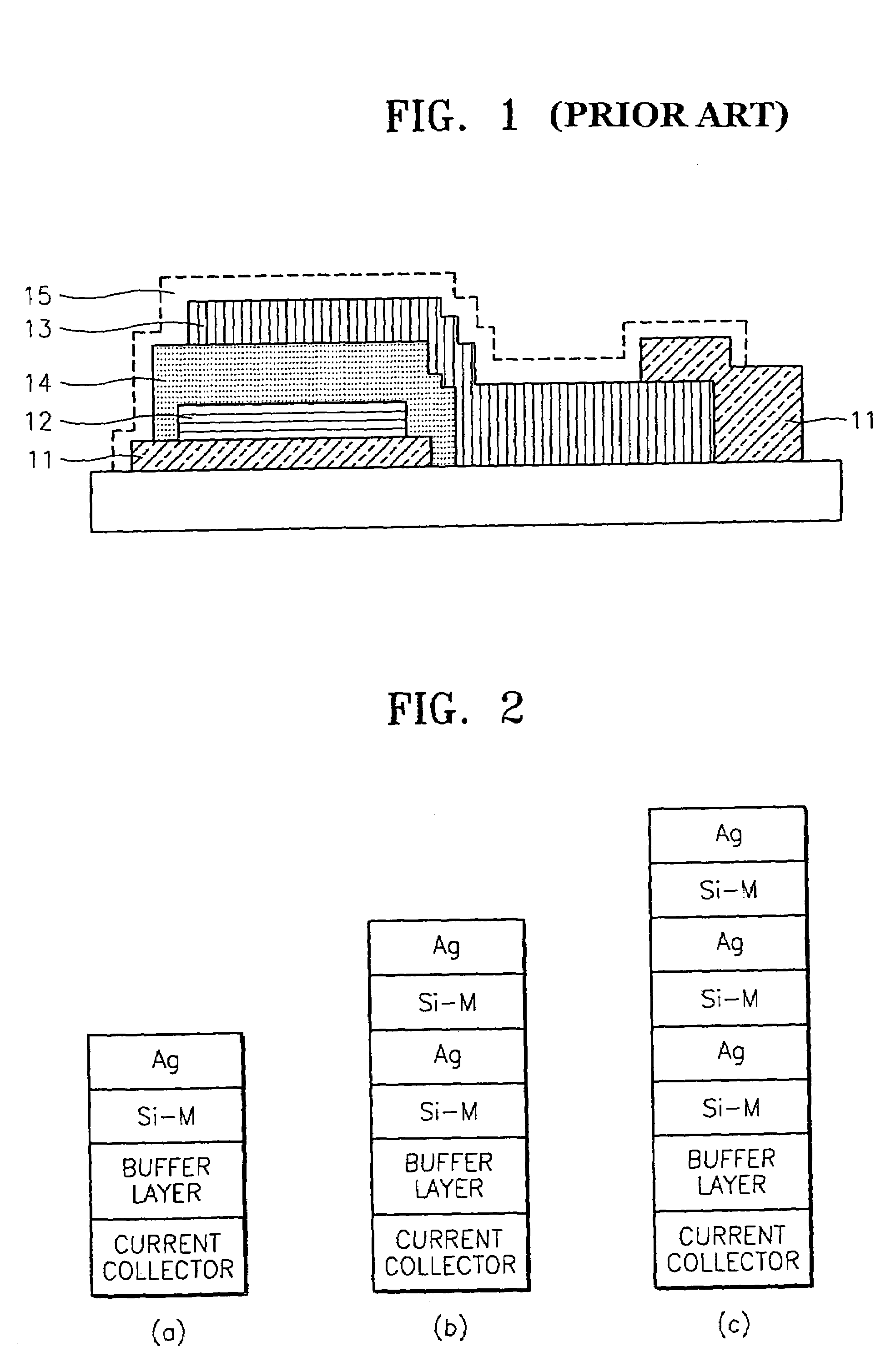

Method for manufacturing a multi-layered thin film for use as an anode in a lithium secondary battery

InactiveUS7316867B2Improve charge and discharge cycle characteristicsSilver accumulatorsFinal product manufactureMechanical stabilityLithium-ion battery

A thin film for an anode of a lithium secondary battery having a current collector and an anode active material layer formed thereon is provided. The anode active material layer is a multi-layered thin film formed by stacking a silver (Ag) layer and a silicon-metal (Si-M) layer having silicon dispersed in a base made from metal reacting with silicon while not reacting with lithium. The cycle characteristic of the thin film for an anode can be improved by suppressing the volumetric expansion and shrinkage of Si occurring during charging / discharging cycles. Thus, a lithium secondary battery with improved life characteristics by employing the thin film for an anode, which greatly improves the chemical, mechanical stability of the interface between an electrode and an electrolyte.

Owner:SAMSUNG SDI CO LTD

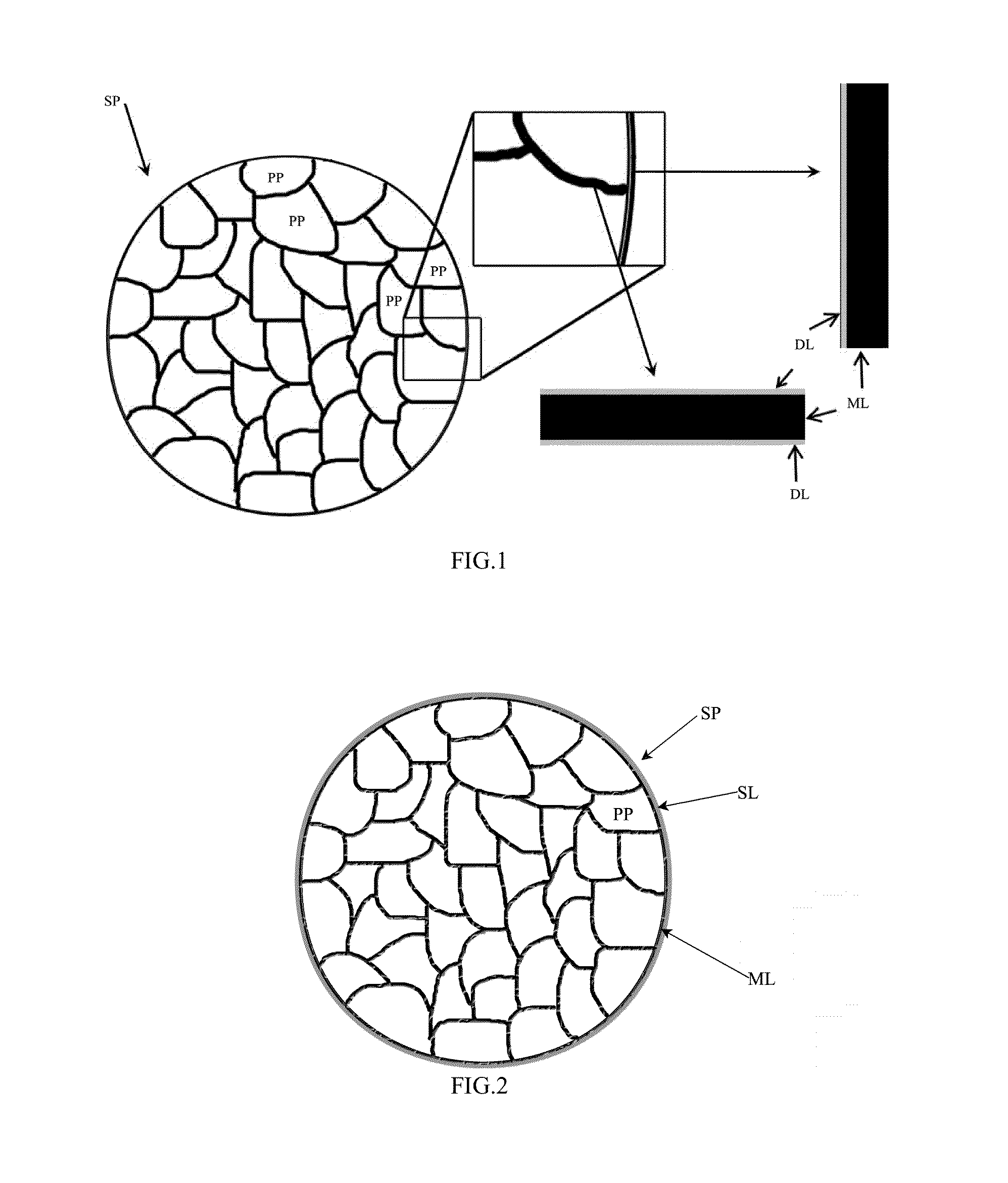

Lithium-ion battery positive electrode material and preparation method thereof

InactiveUS20150079471A1Good stretchabilityGood ductibilitySilver accumulatorsPositive electrodesLithium-ion batteryDiffusion layer

The present disclosure provides a lithium-ion battery positive electrode material and a preparation method thereof. In the lithium-ion battery positive electrode material, a secondary particle comprises lithium-containing multi-element transition metal oxide primary particles and a second phase material, a second phase material forms a second phase material layer distributed on a surface of the primary particle and forms a diffusion layer together with the lithium-containing multi-element transition metal oxide by means of atoms mutual diffusion to make the second phase material layer combined with the primary particle during formation of the secondary particle from the primary particles, thereby effectively suppressing chalking of the secondary particle along boundary among the primary particles, and effectively controlling size of the primary particles and the secondary particles, and improving specific capacity, cycling performance and safety performance of a lithium-ion battery to which the lithium-ion battery positive electrode material is applied.

Owner:NINGDE AMPEREX TECH +1

Positive active material for rechargeable lithium battery and rechargeable lithium battery including the same

InactiveUS20130183579A1Improve thermal stabilitySilver accumulatorsMaterial nanotechnologyLithium iron phosphateMetal

Owner:ROBERT BOSCH GMBH +1

Electrode for rechargeable lithium battery and rechargeable lithium battery including same

ActiveUS20080248396A1Improve securityImprove thermal stabilitySilver accumulatorsElectrode carriers/collectorsRare-earth elementAlkaline earth metal

An electrode, for a rechargeable lithium battery, including a current collector; an active material layer disposed on the current collector; and a coating layer disposed on the active material layer. The coating layer includes a lithium ion conductive polymer and an inorganic material represented by Formula 1: MwHxPyOz, wherein M is an element selected from the group consisting of an alkali metal, an alkaline-earth metal, a Group 13 element, a Group 14 element, a transition element, a rare earth element, and a combination thereof; and 1≦w≦4, 0≦x≦4, 1≦y≦7, and 2≦z≦30.

Owner:SAMSUNG SDI CO LTD

Popular searches

Individual molecule manipulation Non-aqueous electrolyte accumulator electrodes Non-metal conductors Non-conductive material with dispersed conductive material Primary cell electrodes Li-accumulators Fuel and secondary cells Power to auxillary motors Propulsion by batteries/cells Vehicular energy storage

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com