Patents

Literature

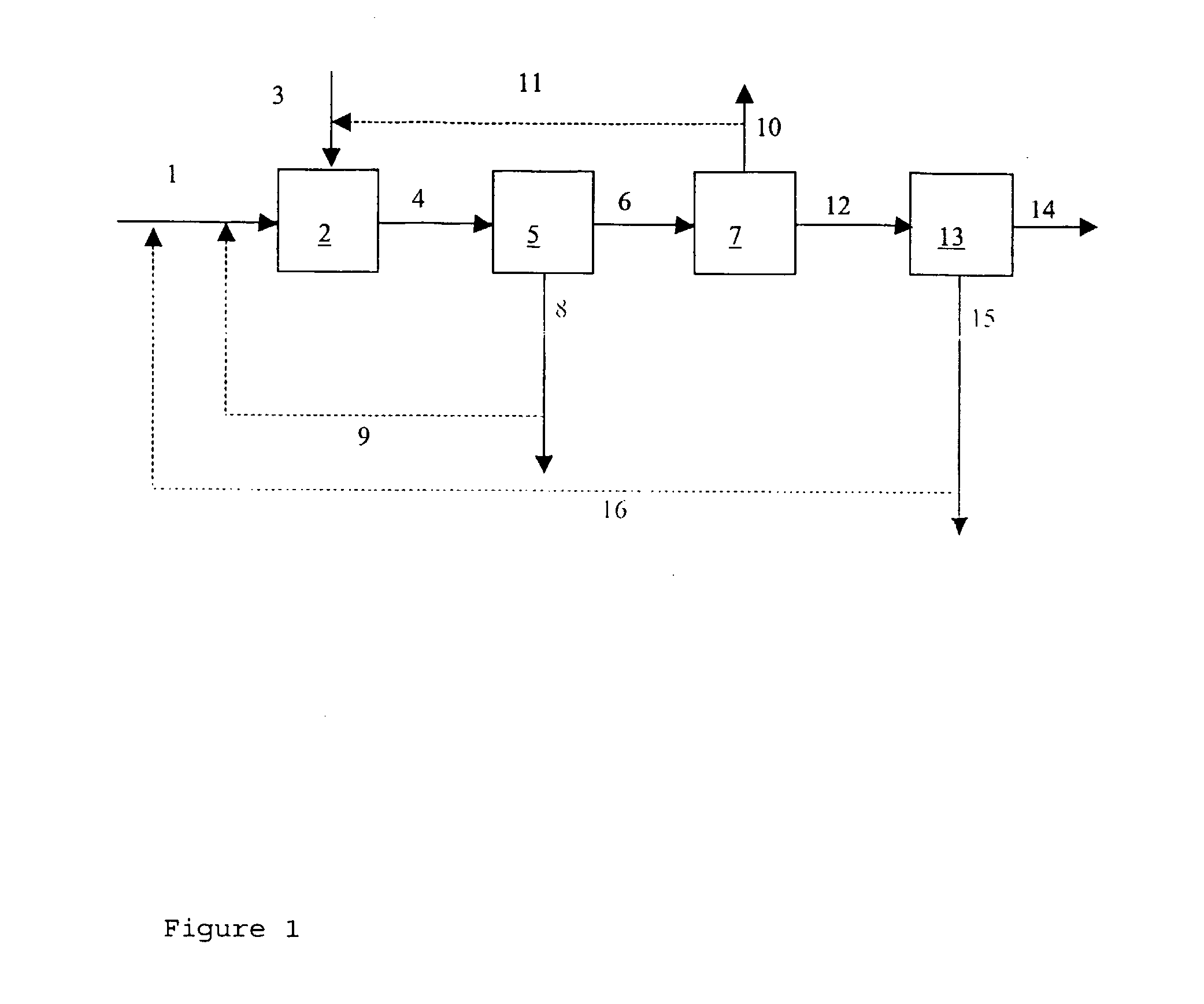

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1676 results about "Mixed metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

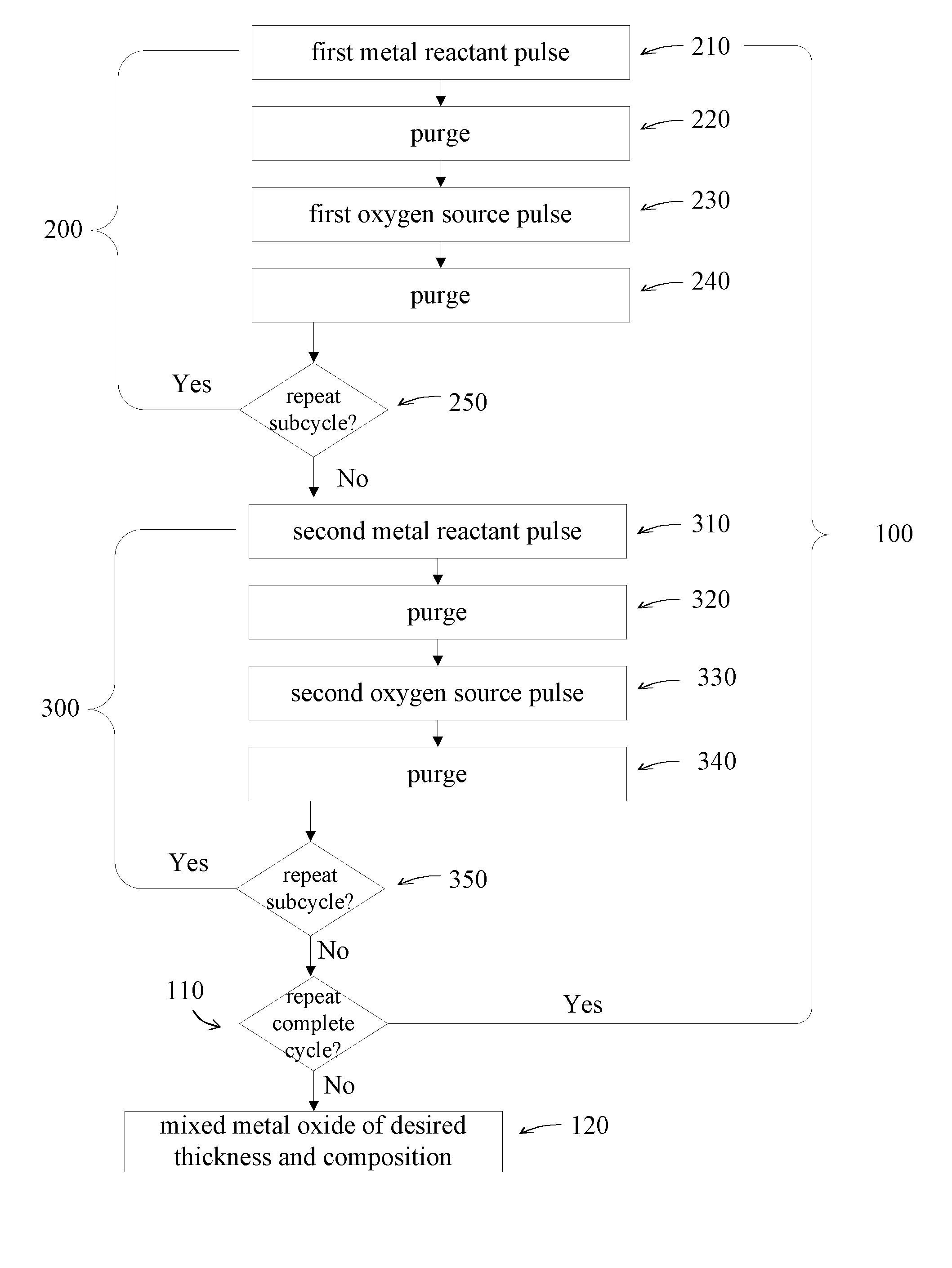

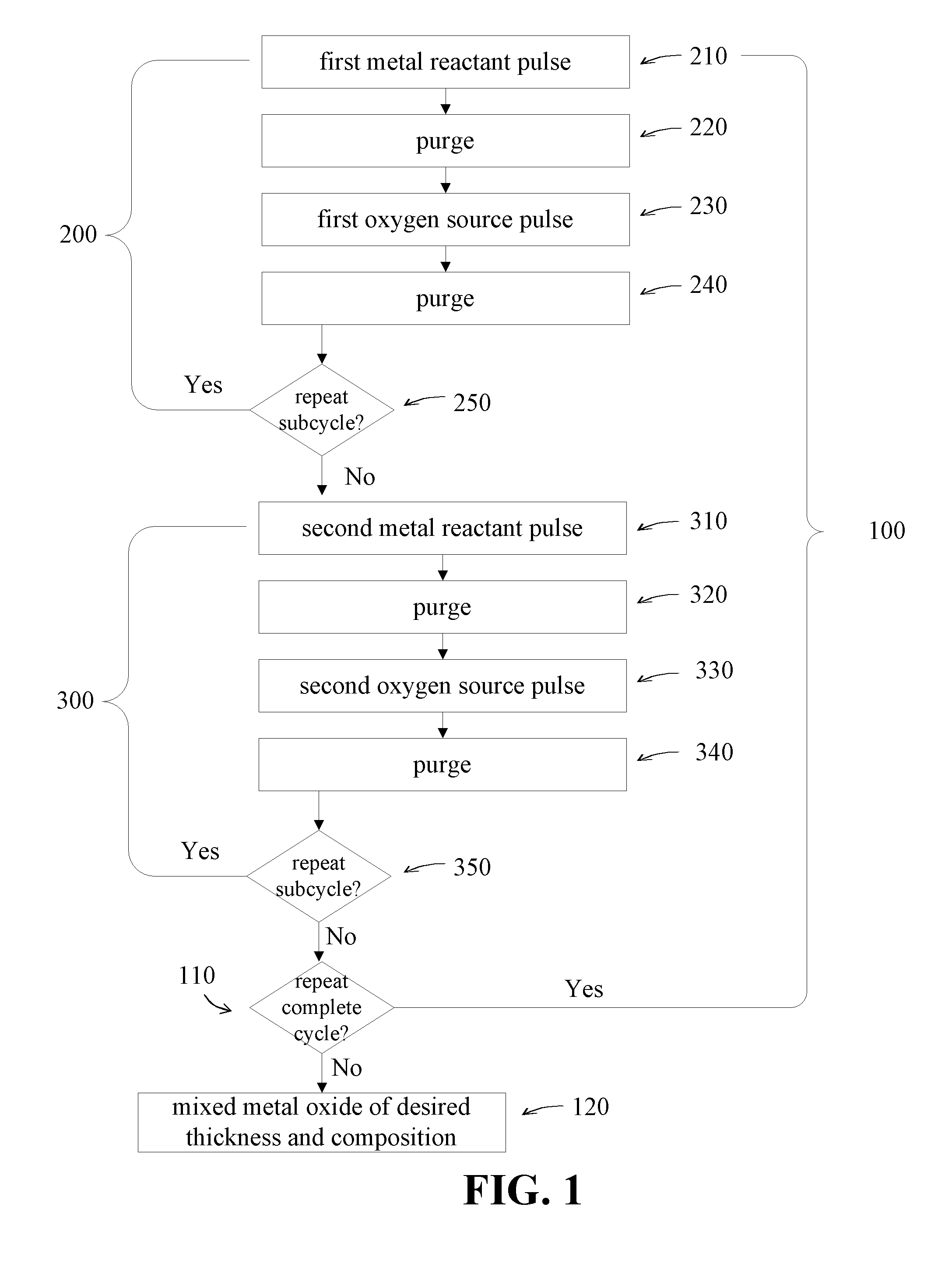

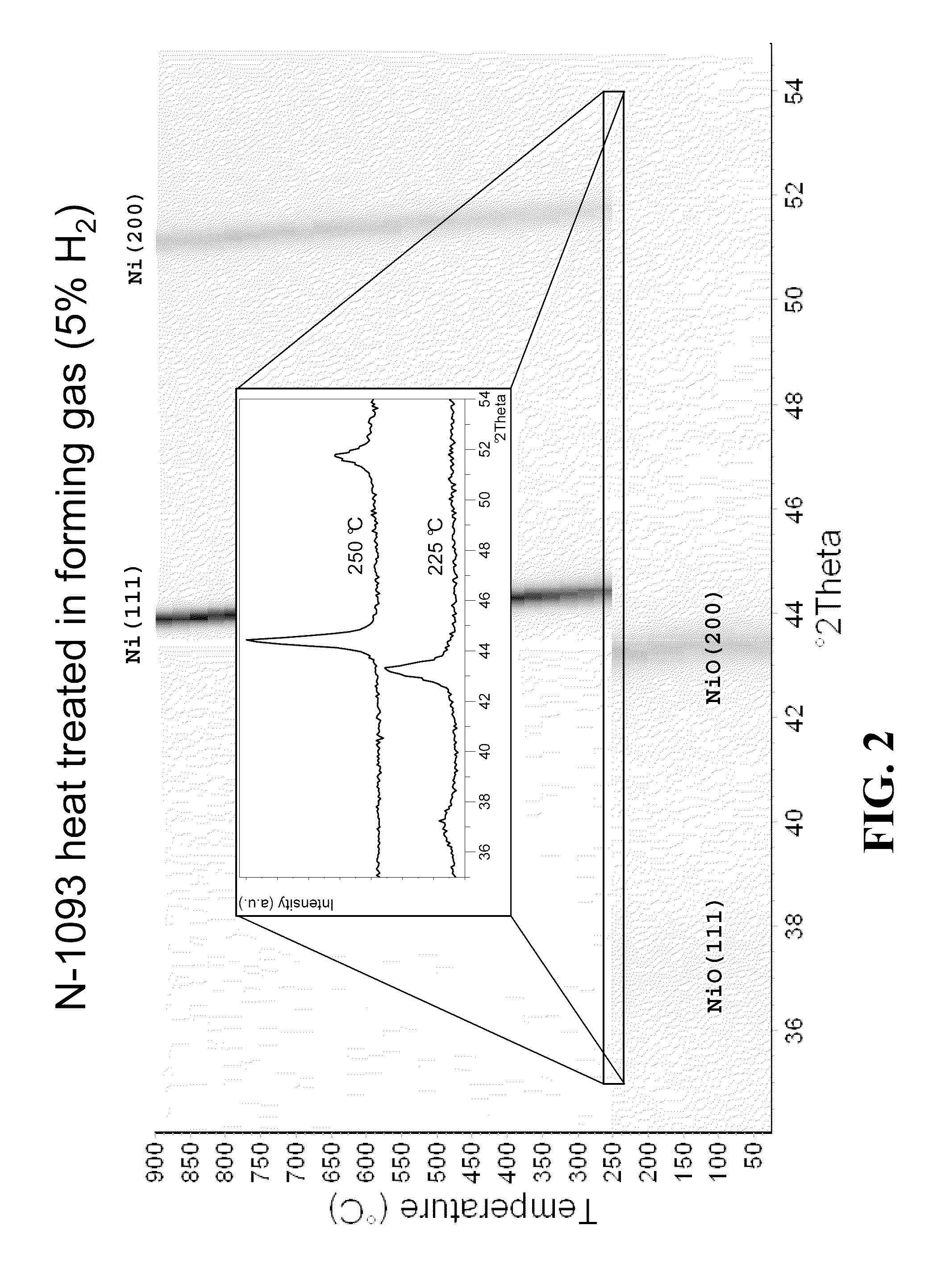

Deposition and reduction of mixed metal oxide thin films

ActiveUS20120302055A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogen atmospherePhysical chemistry

Owner:ASM IP HLDG BV

Flame made metal oxides

ActiveUS7211236B2Add featureWell mixedMaterial nanotechnologyZirconium oxidesSpray pyrolysisCarboxylic acid

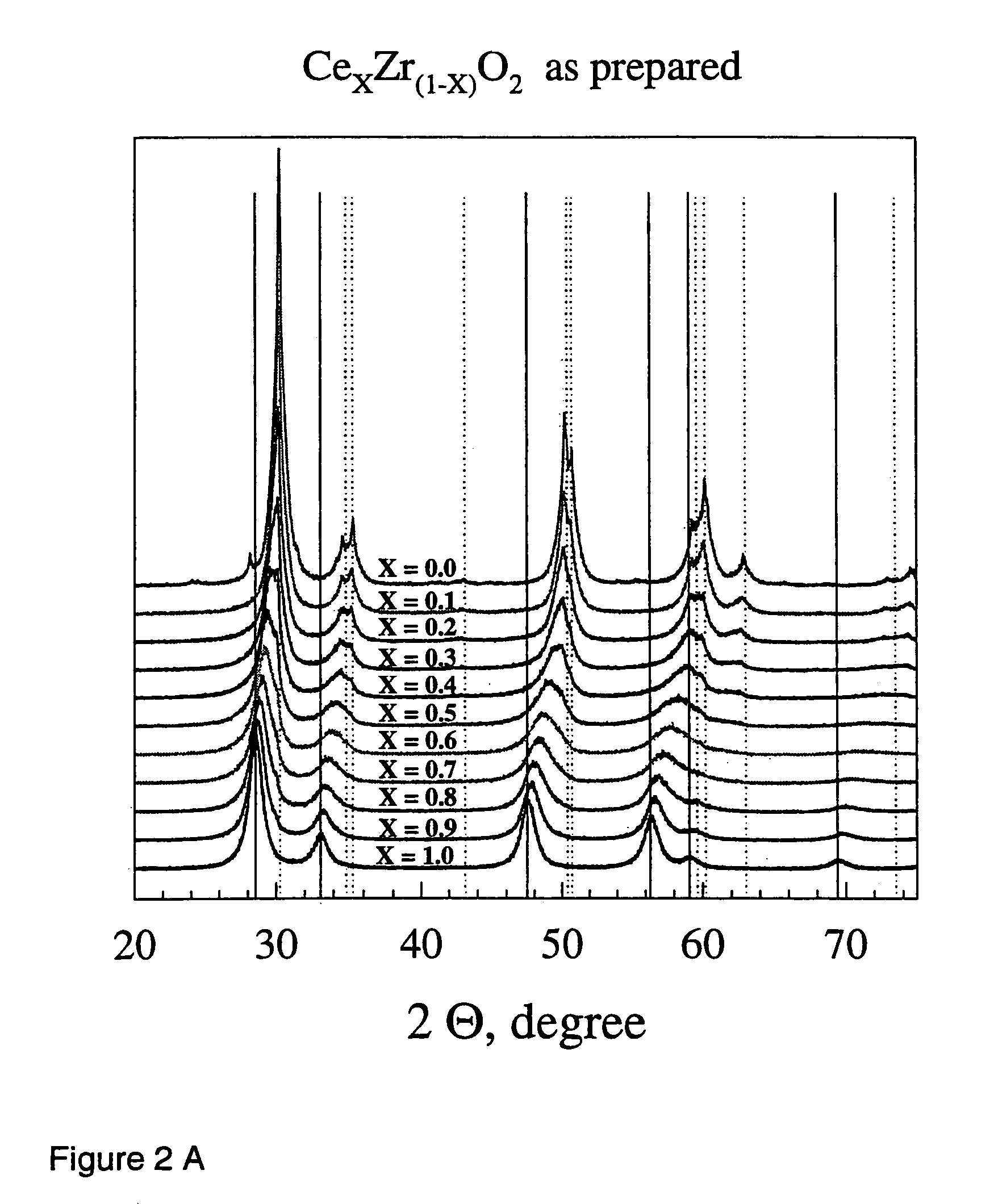

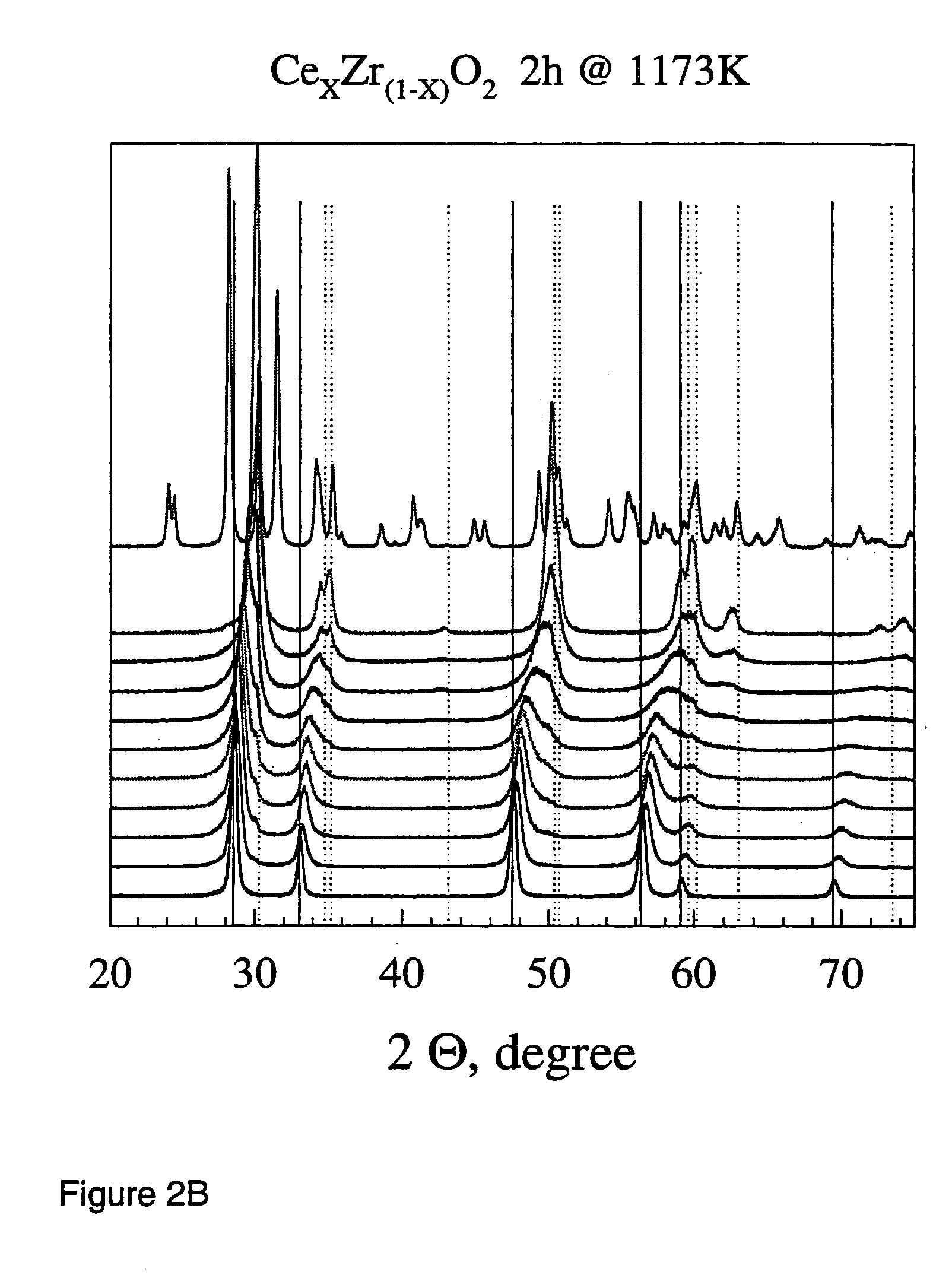

Described is a method for the production of metal oxides by flame spray pyrolysis, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

Zero platinum group metal catalysts

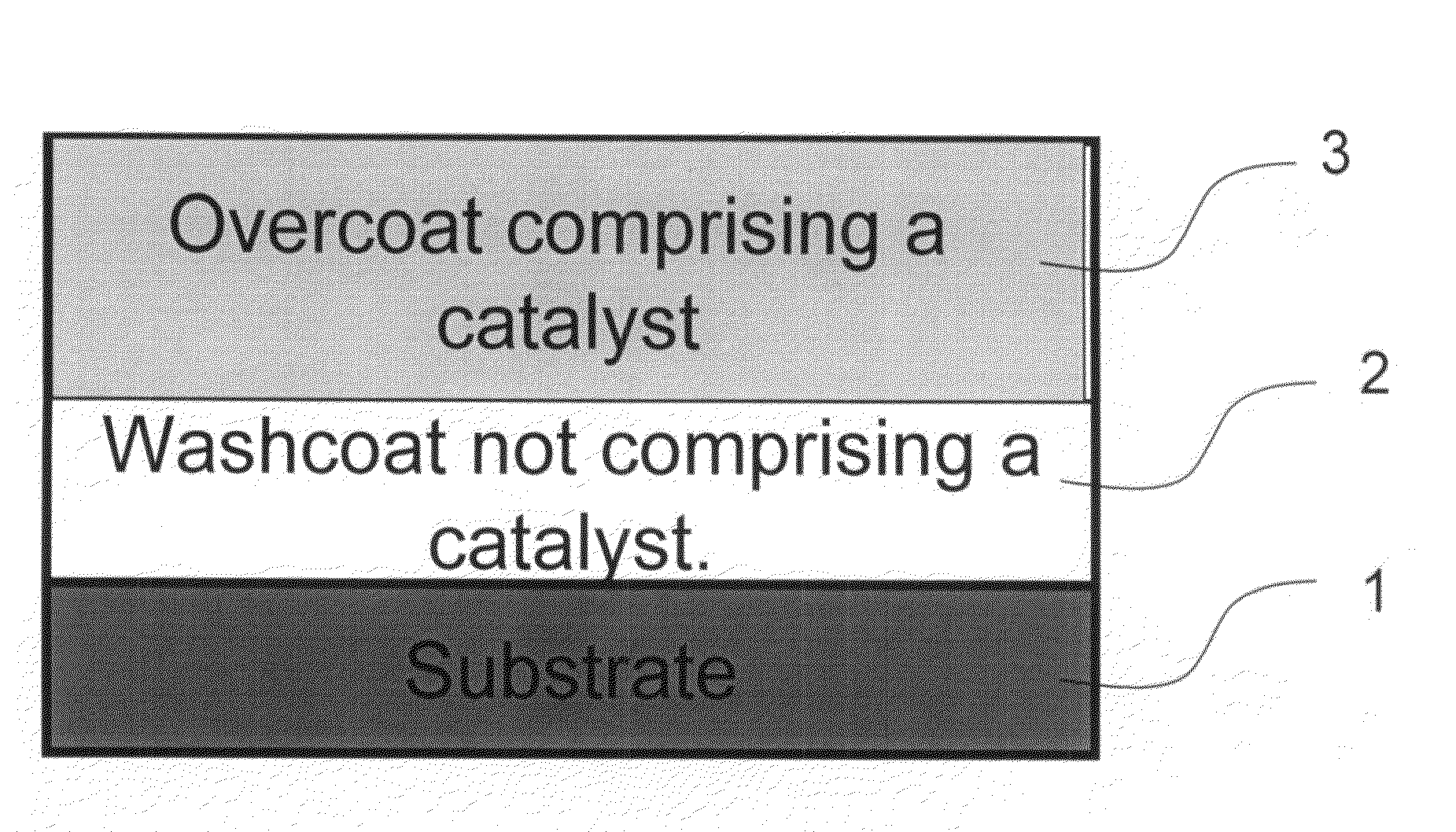

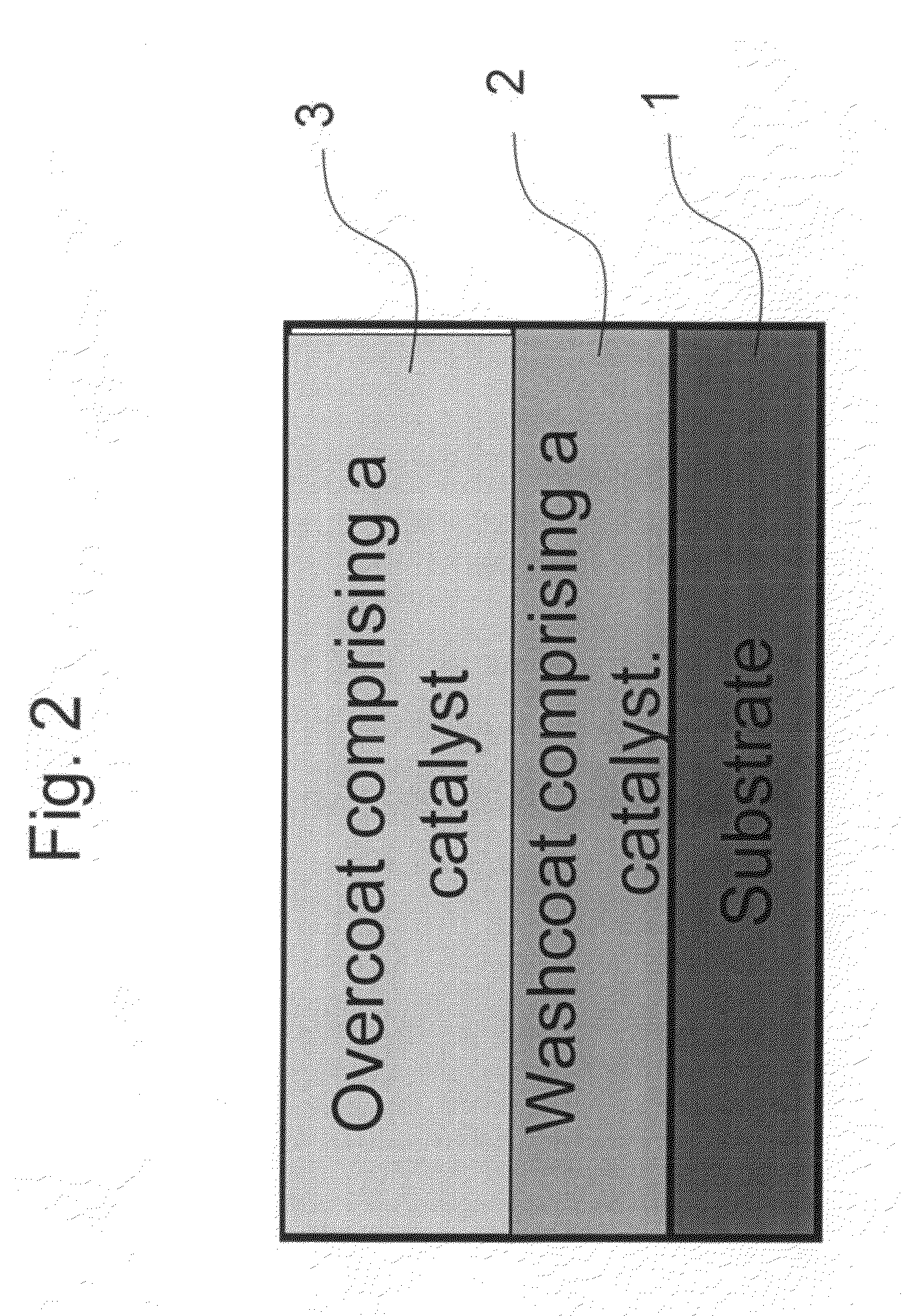

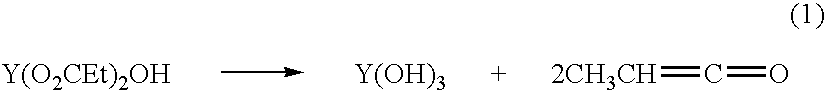

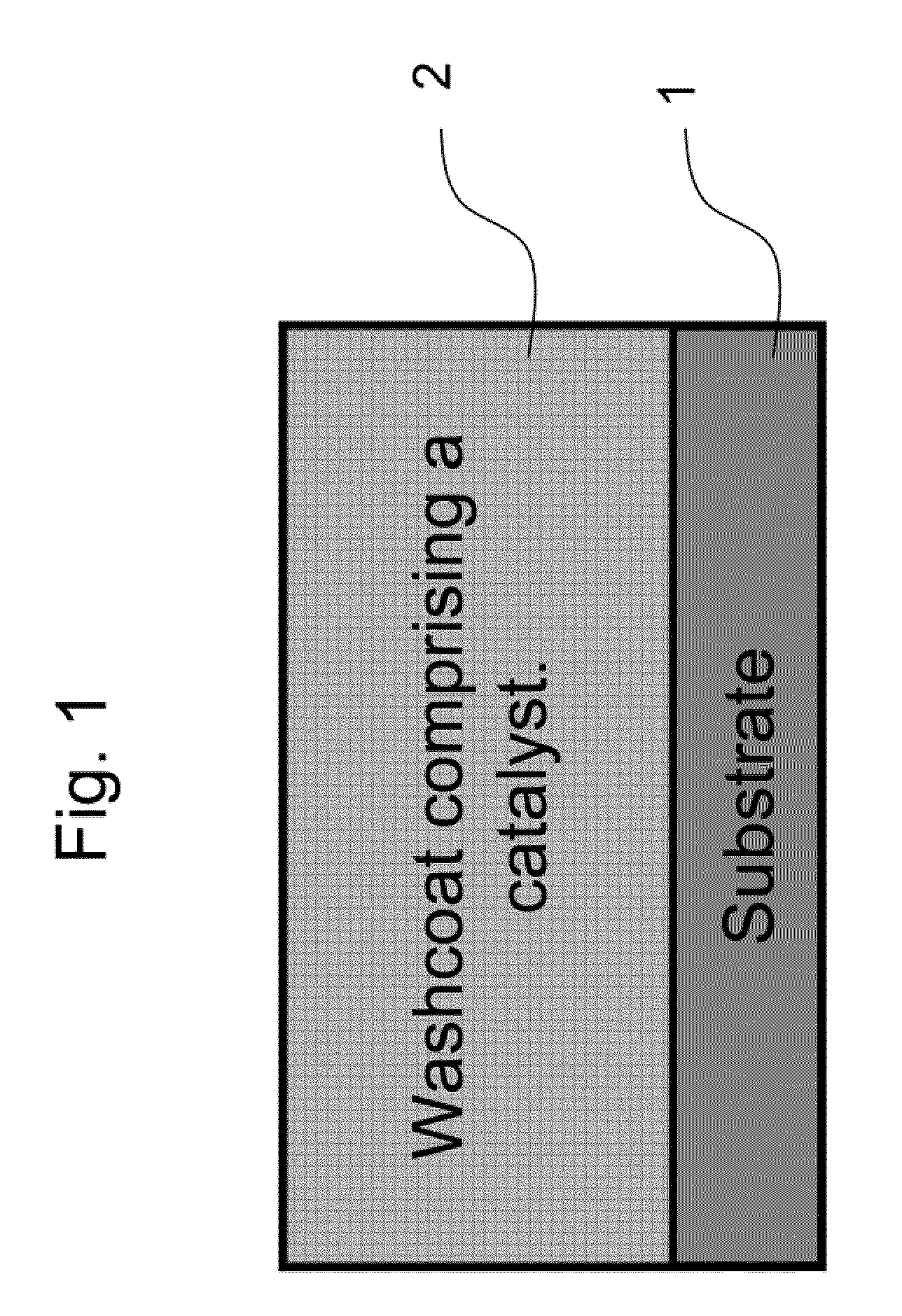

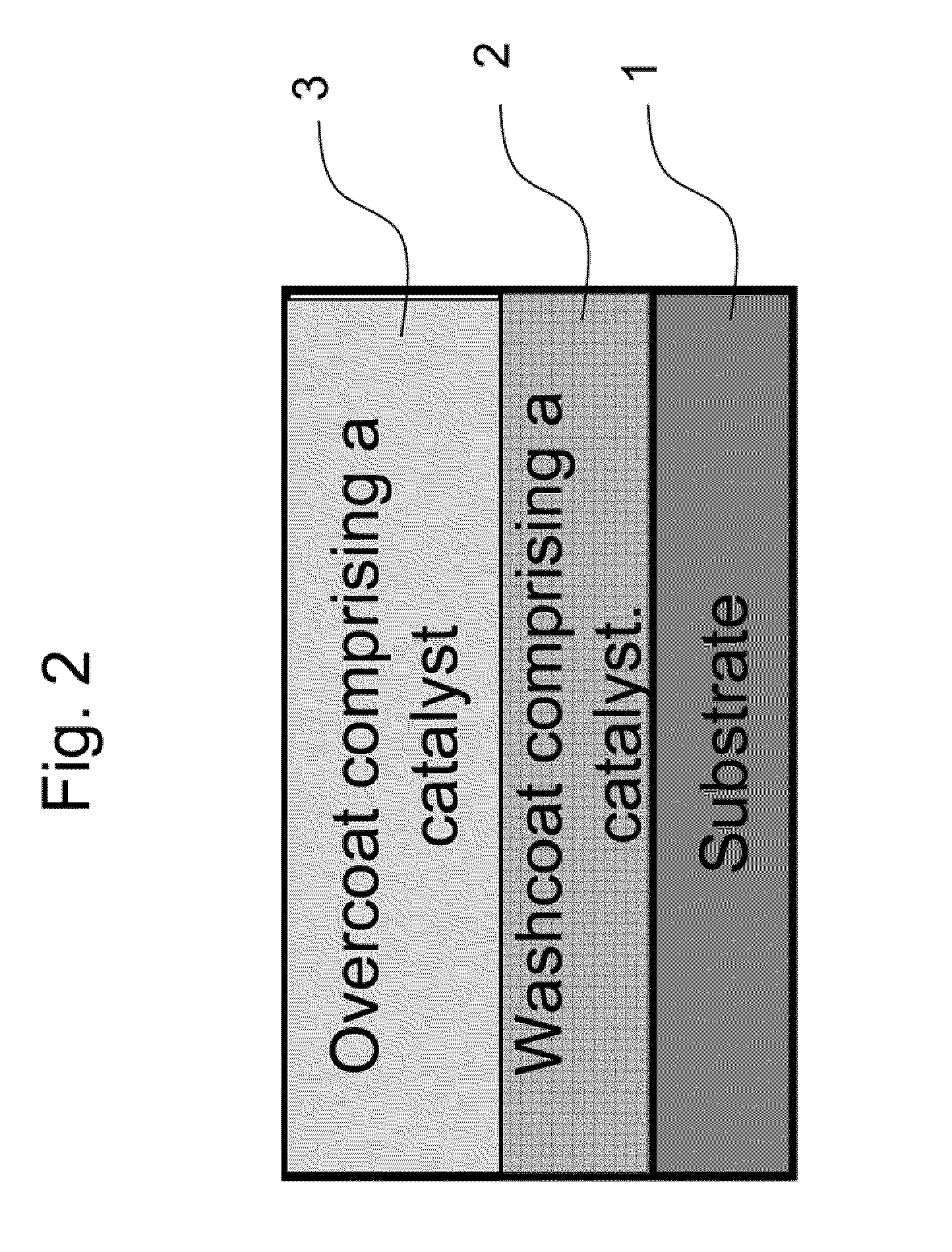

The present invention pertains to catalyst systems for nitrogen oxide, carbon monoxide, hydrocarbon, and sulfur reactions that are free or substantially free of platinum group metals. The catalyst system of the present invention comprise a substrate and a washcoat, wherein the washcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst system may optionally have an overcoat, wherein the overcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst comprises one or more selected from the group consisting of a ZPGM transition metal catalyst, a mixed metal oxide catalyst, a zeolite catalysts, or mixtures thereof.

Owner:CATALYTIC SOLUTIONS INC

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

Zero Platinum Group Metal Catalysts

Owner:ECS HLDG +1

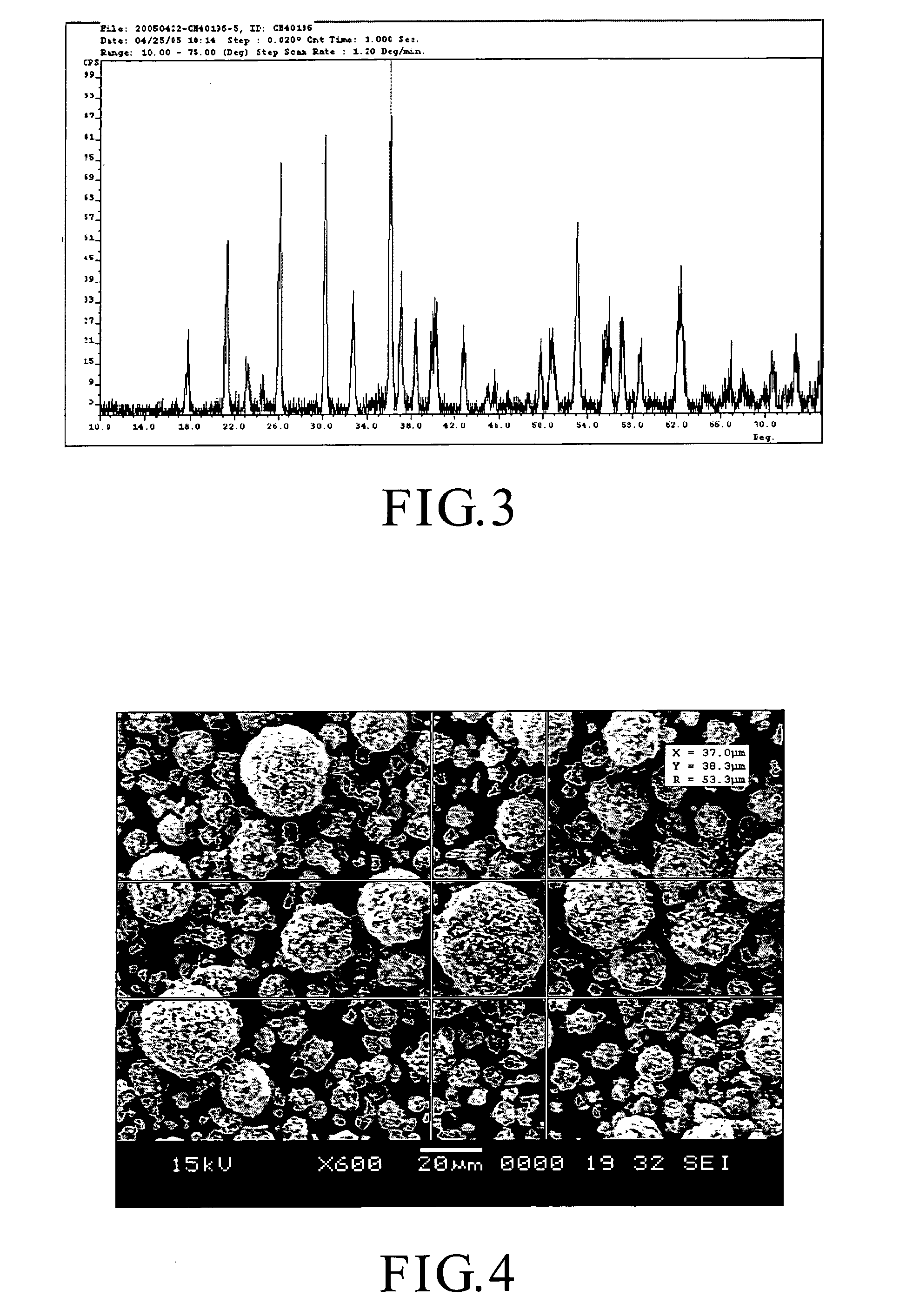

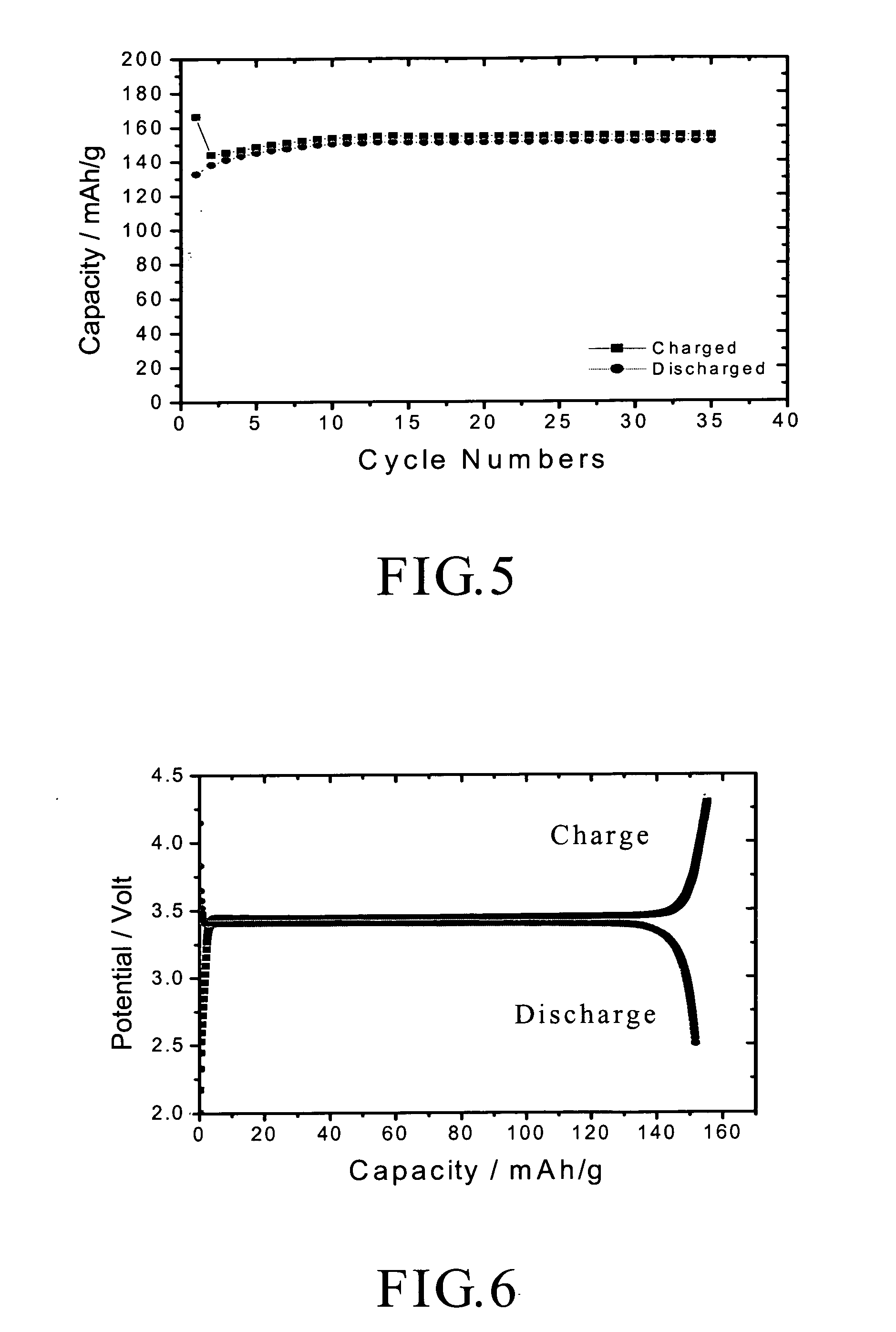

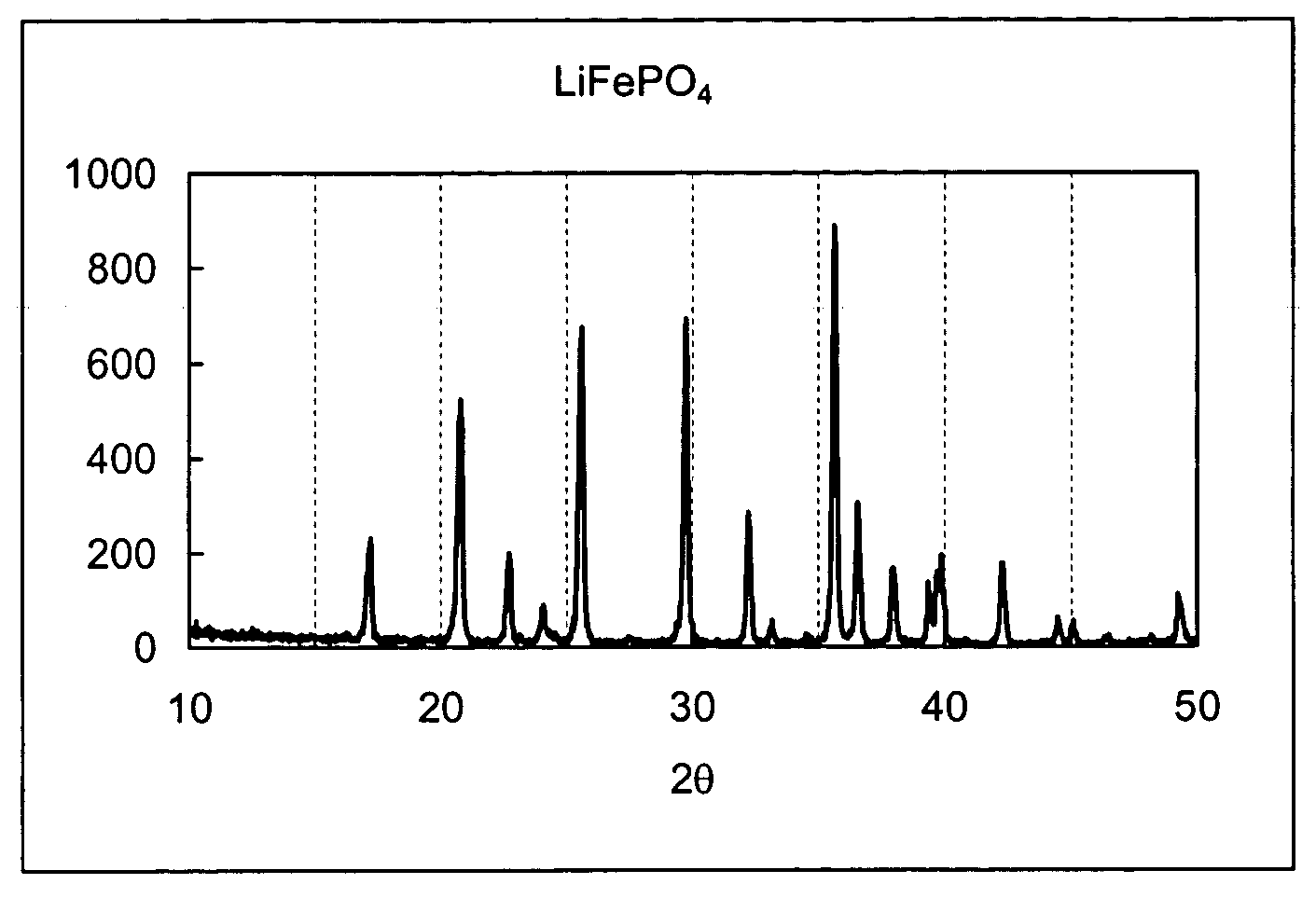

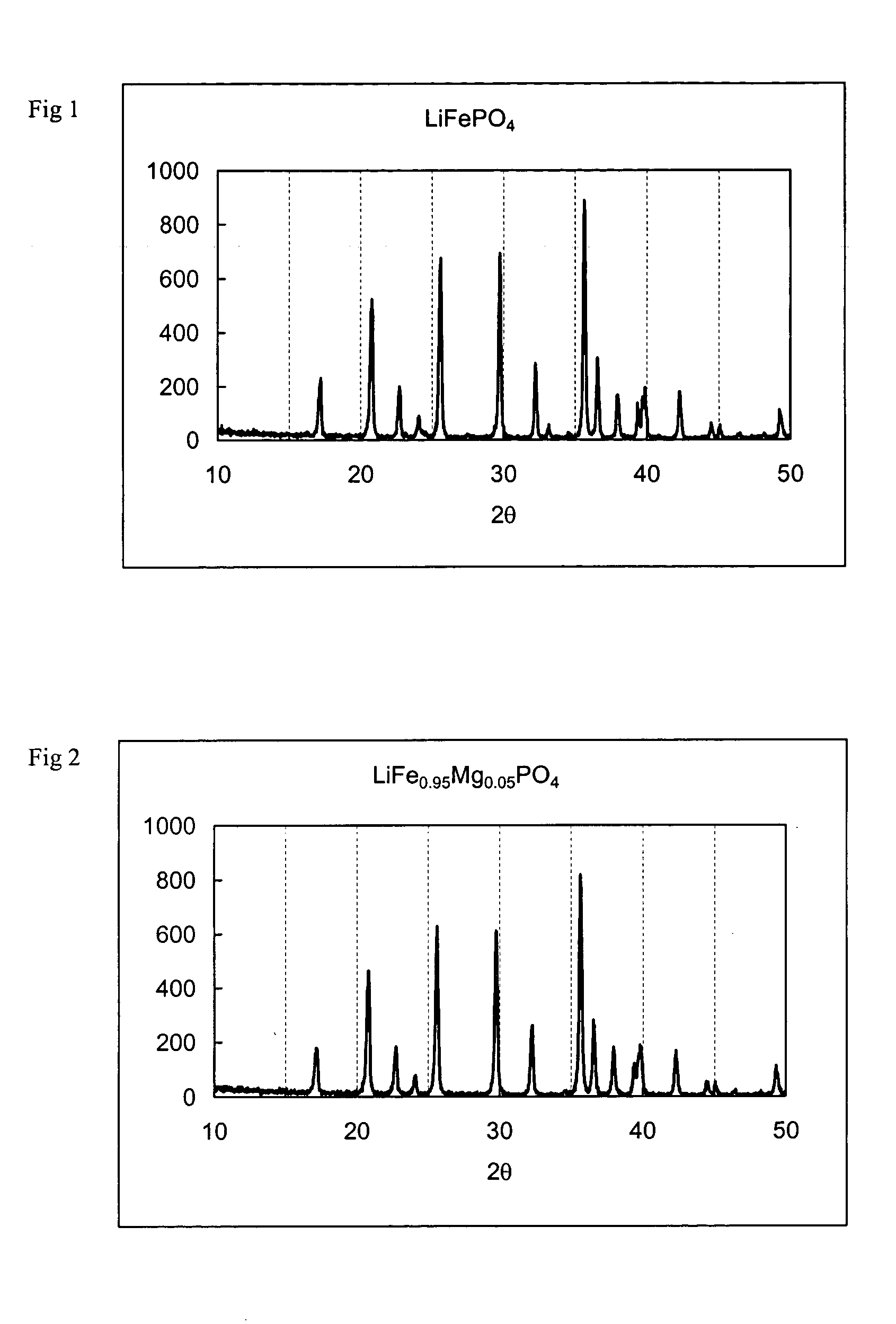

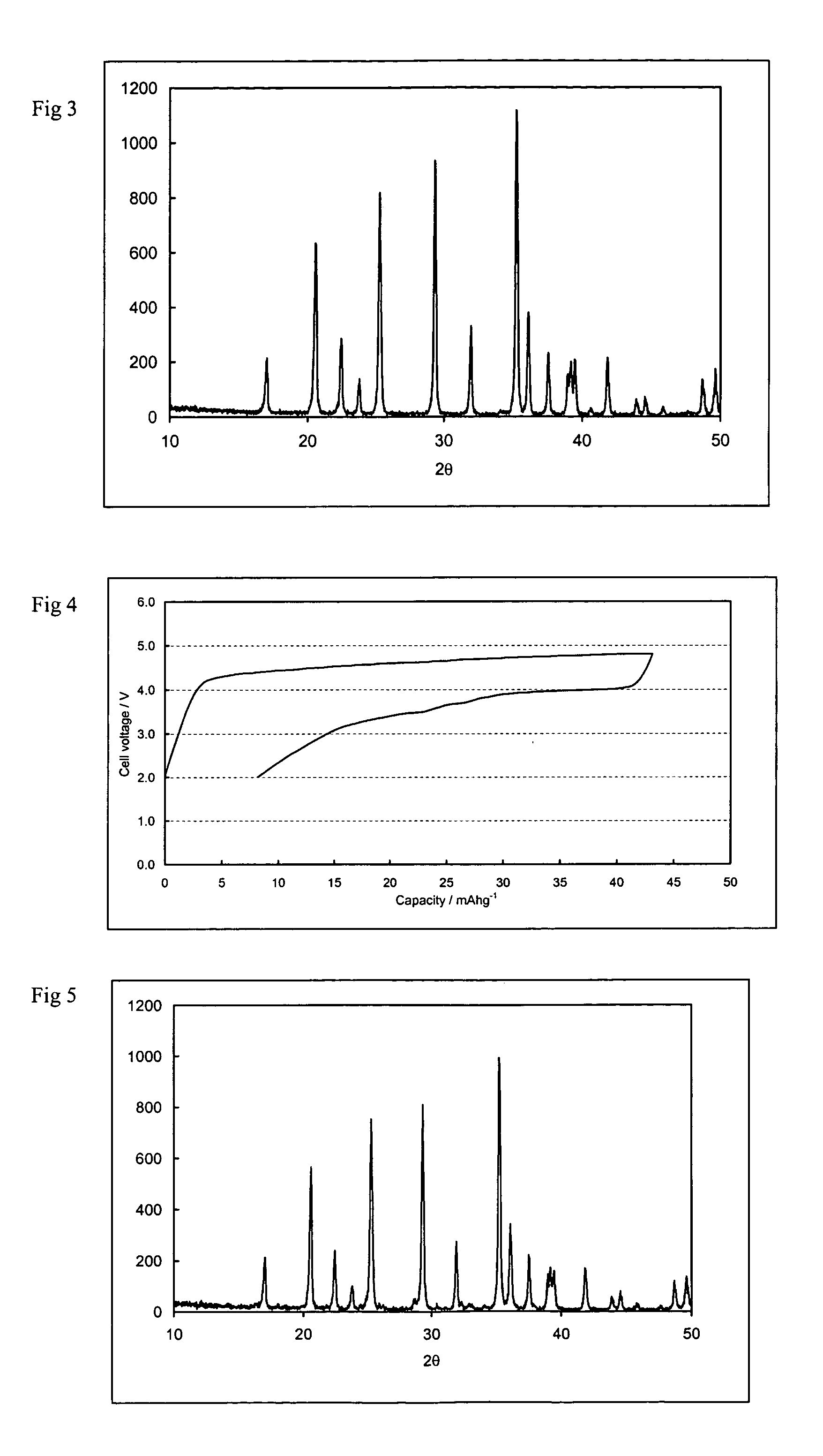

Method for making a lithium mixed metal compound having an olivine structure

ActiveUS20070207080A1Mitigate such drawbackNon-metal conductorsLiquid surface applicatorsLithiumCarbon layer

Owner:AQUIRE ENERGY CO LTD

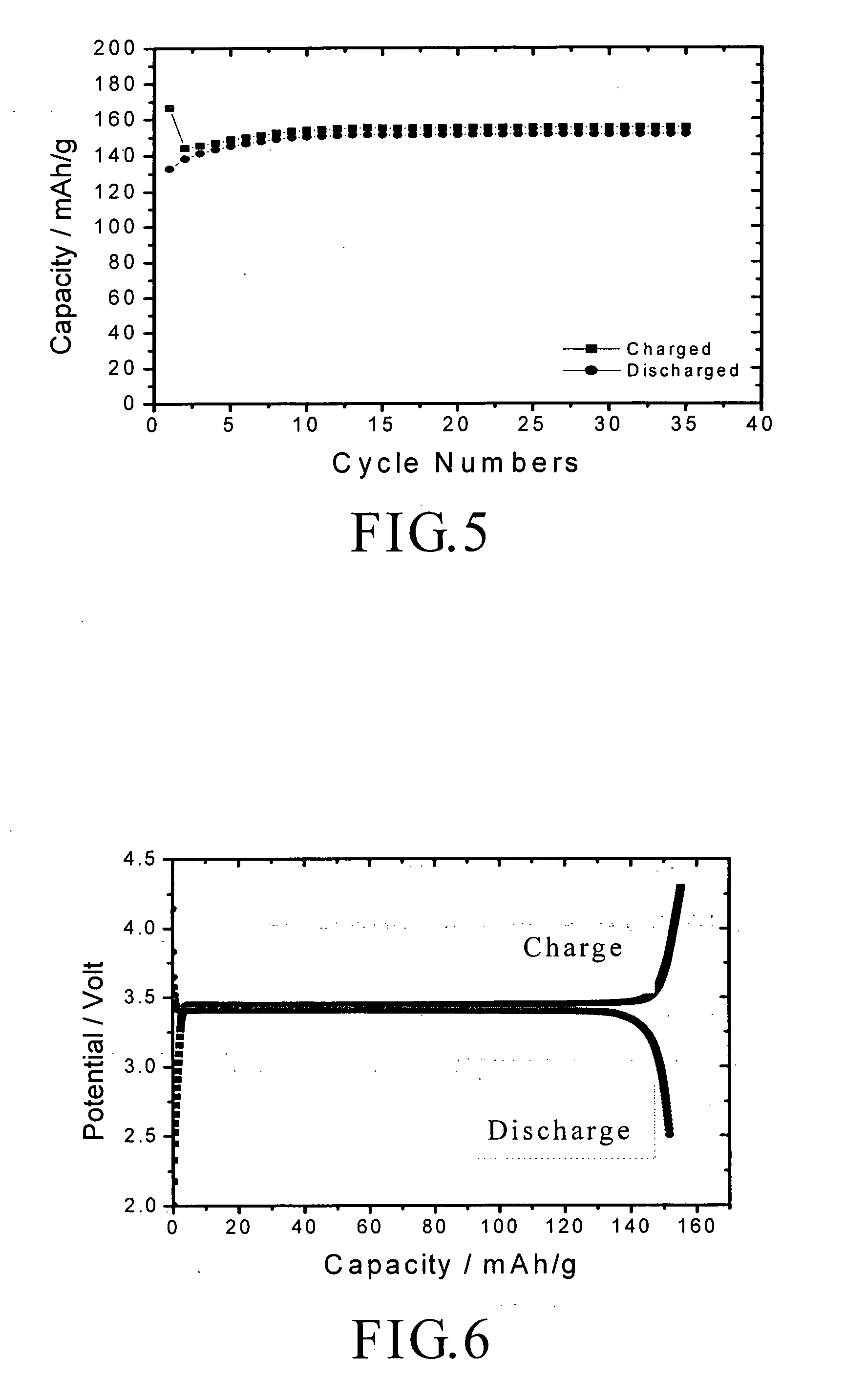

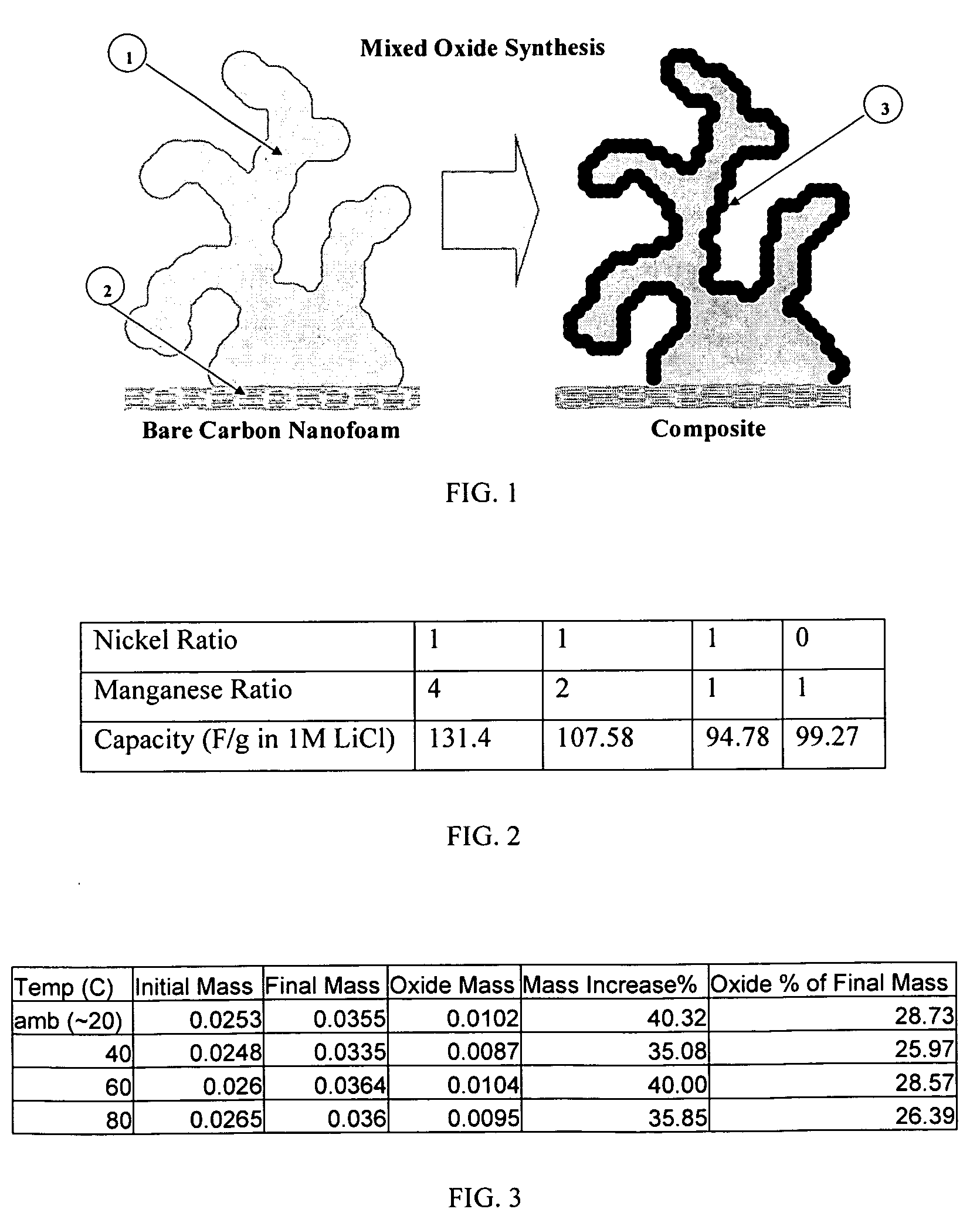

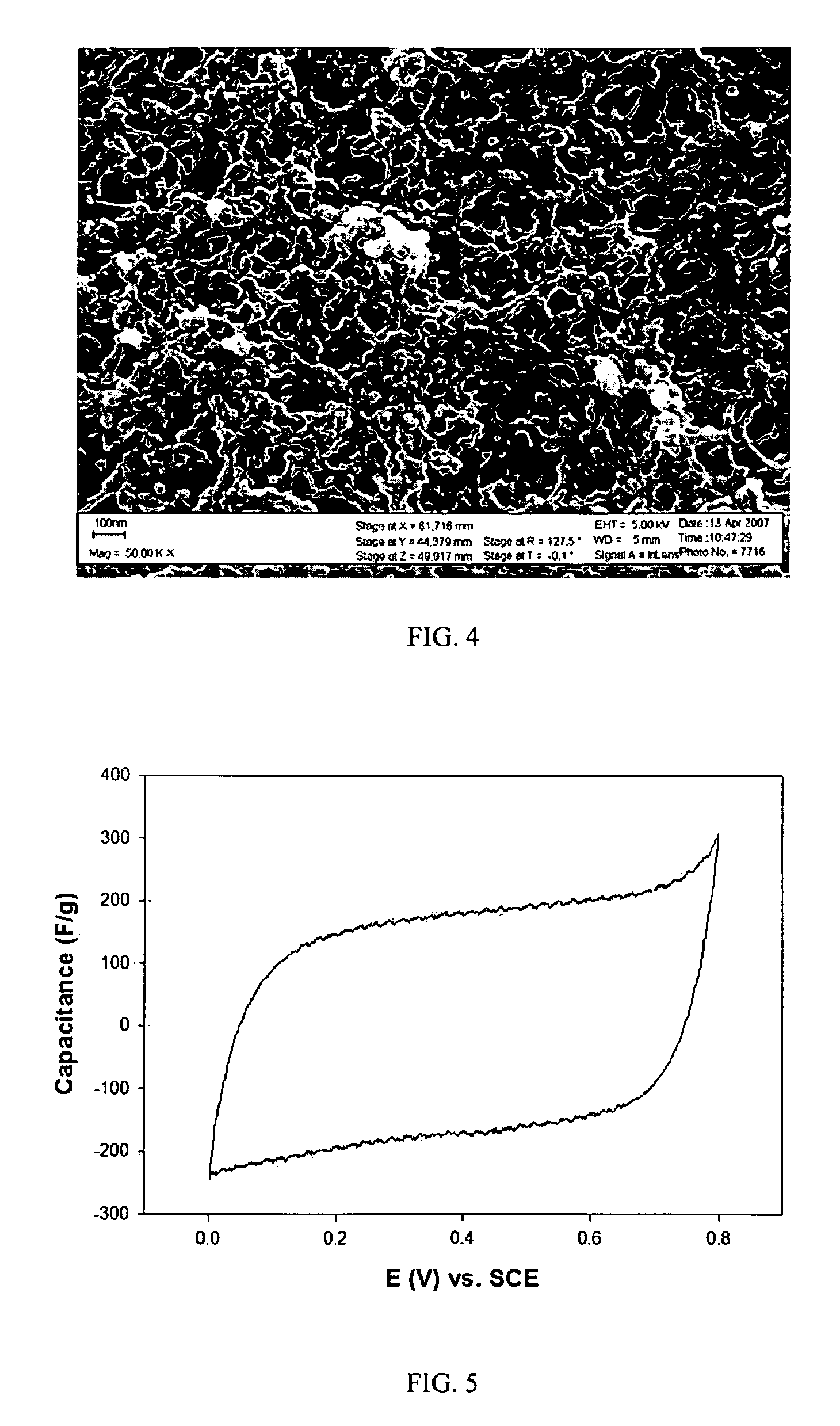

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

Electrophoretic particles, and processes for the production thereof

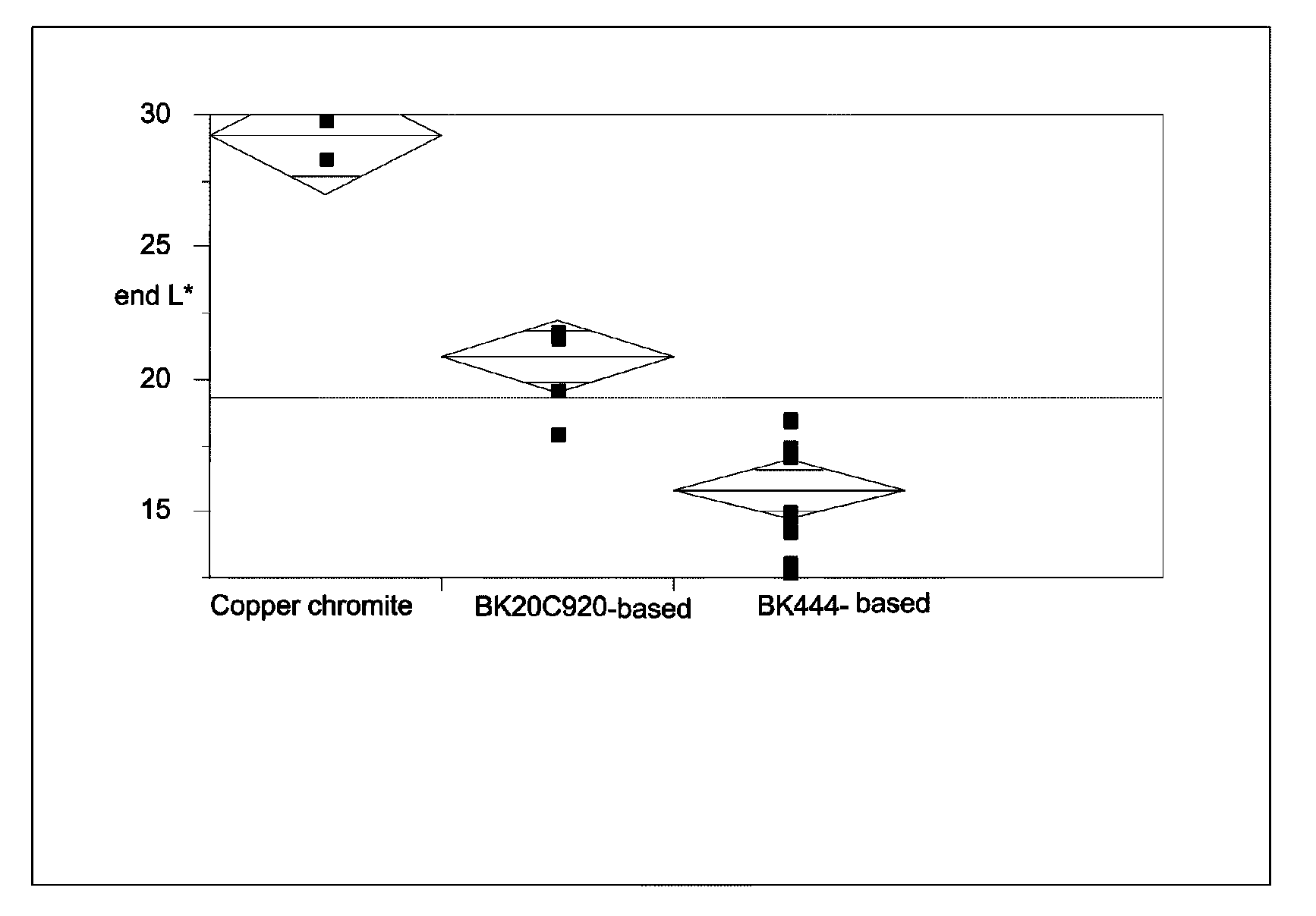

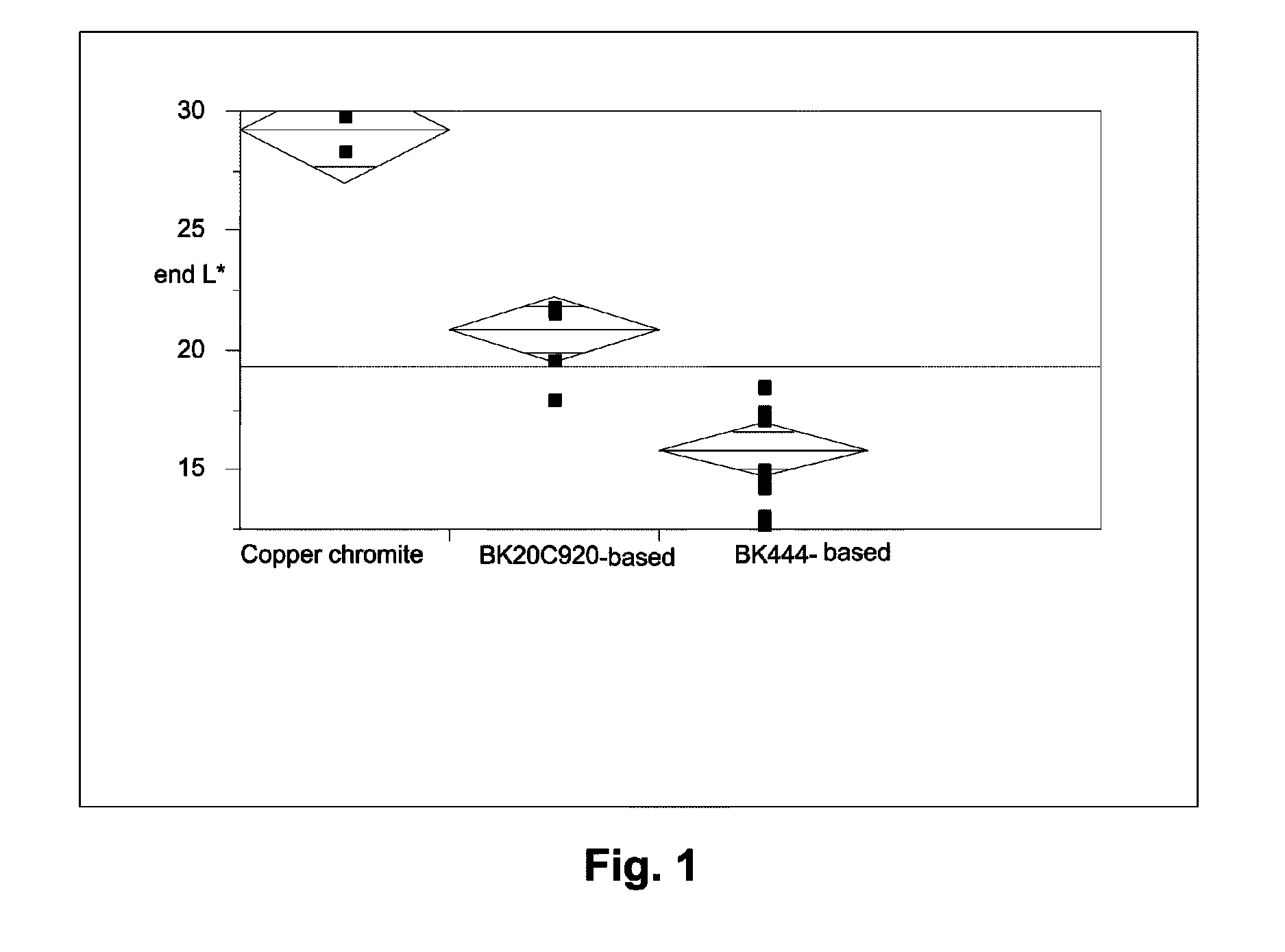

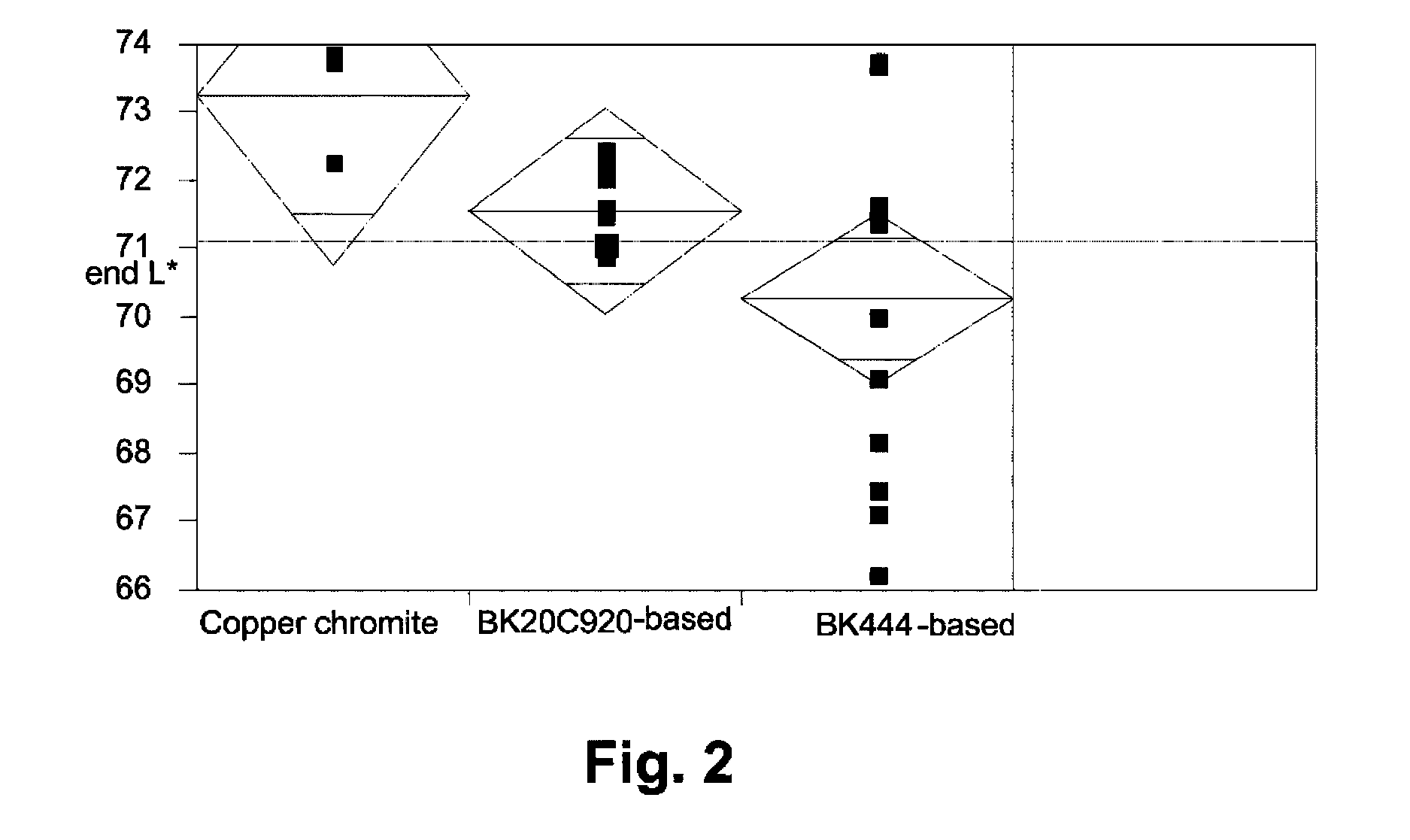

ActiveUS8270064B2Easy to useGood color saturationPigmenting treatmentStatic indicating devicesMagnetiteManganese oxide

An electrophoretic medium comprises at least one electrically charged particle dispersed posed in a fluid. The electrically charged particle comprises an inorganic black pigment having a surface area of at least about 7 m2 / g. Preferred pigments are magnetite and mixed metal oxides containing two or more of iron, chromium, nickel, manganese, copper and cobalt, for example copper iron manganese oxide spinel and copper chromium manganese oxide spinel. The inorganic black pigment may bear a polymer coating.

Owner:E INK CORPORATION +1

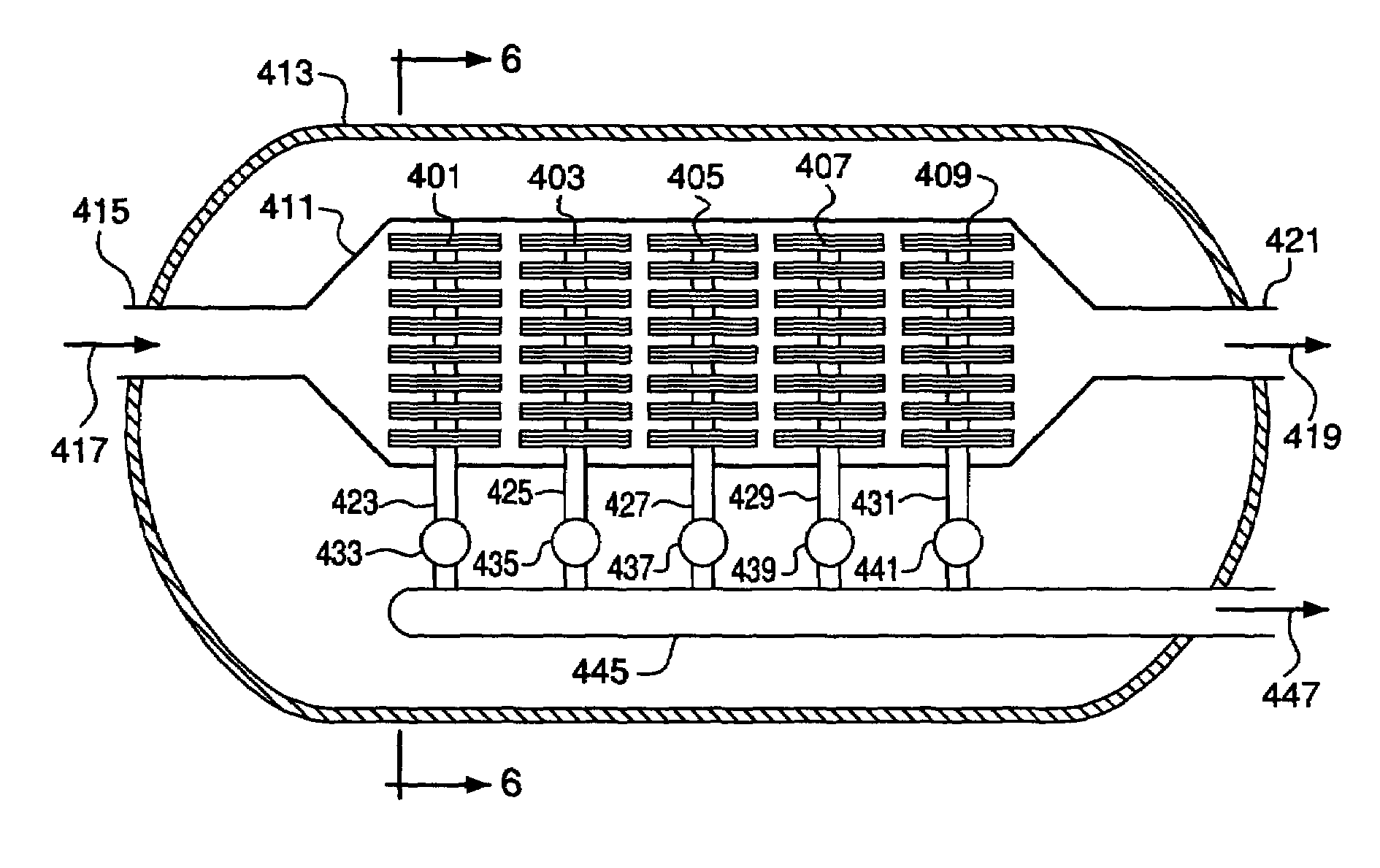

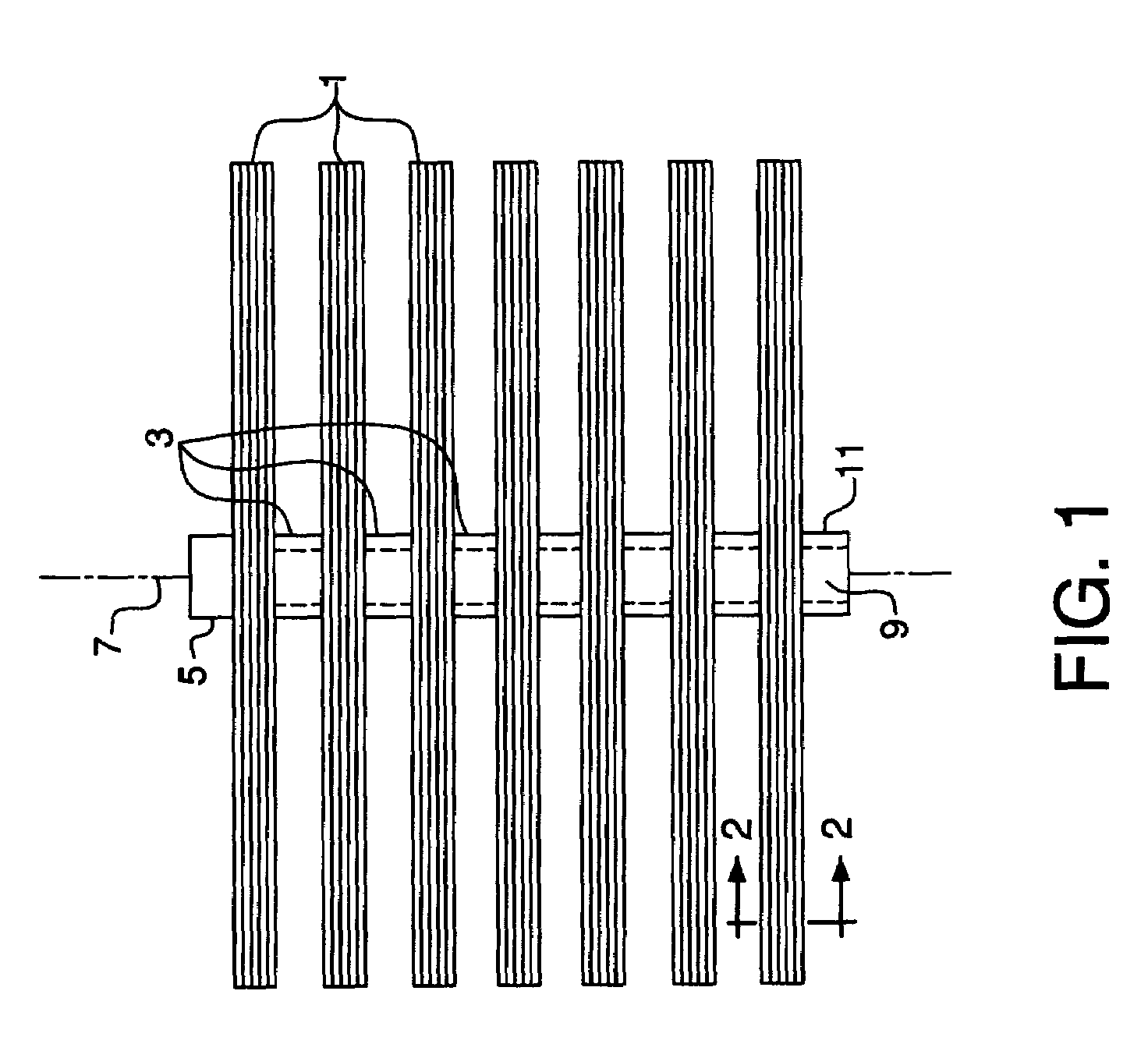

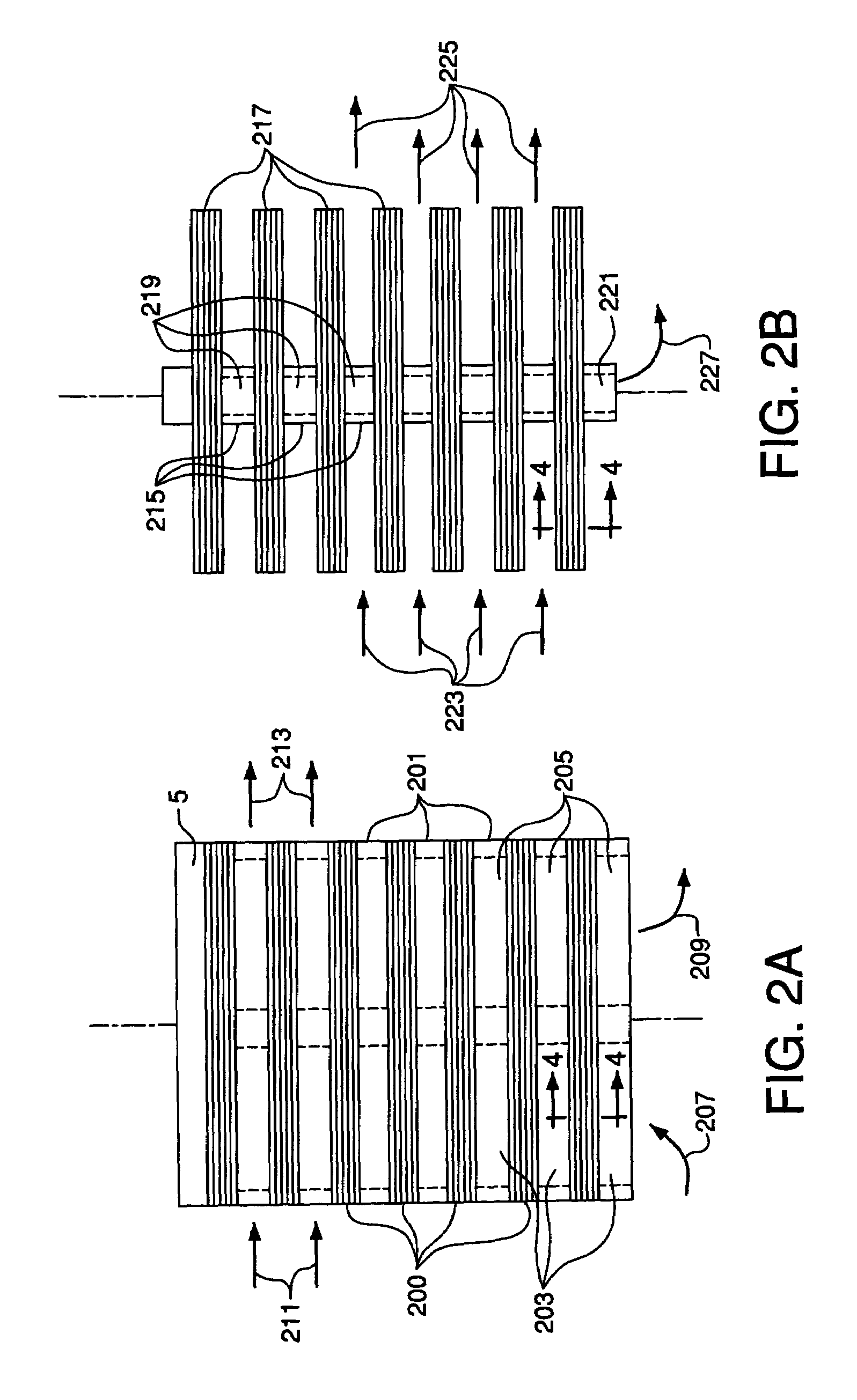

Ion transport membrane module and vessel system

An ion transport membrane system comprising (a) a pressure vessel having an interior, an exterior, an inlet, and an outlet; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region, wherein any inlet and any outlet of the pressure vessel are in flow communication with exterior regions of the membrane modules; and (c) one or more gas manifolds in flow communication with interior regions of the membrane modules and with the exterior of the pressure vessel.The ion transport membrane system may be utilized in a gas separation device to recover oxygen from an oxygen-containing gas or as an oxidation reactor to oxidize compounds in a feed gas stream by oxygen permeated through the mixed metal oxide ceramic material of the membrane modules.

Owner:AIR PROD & CHEM INC

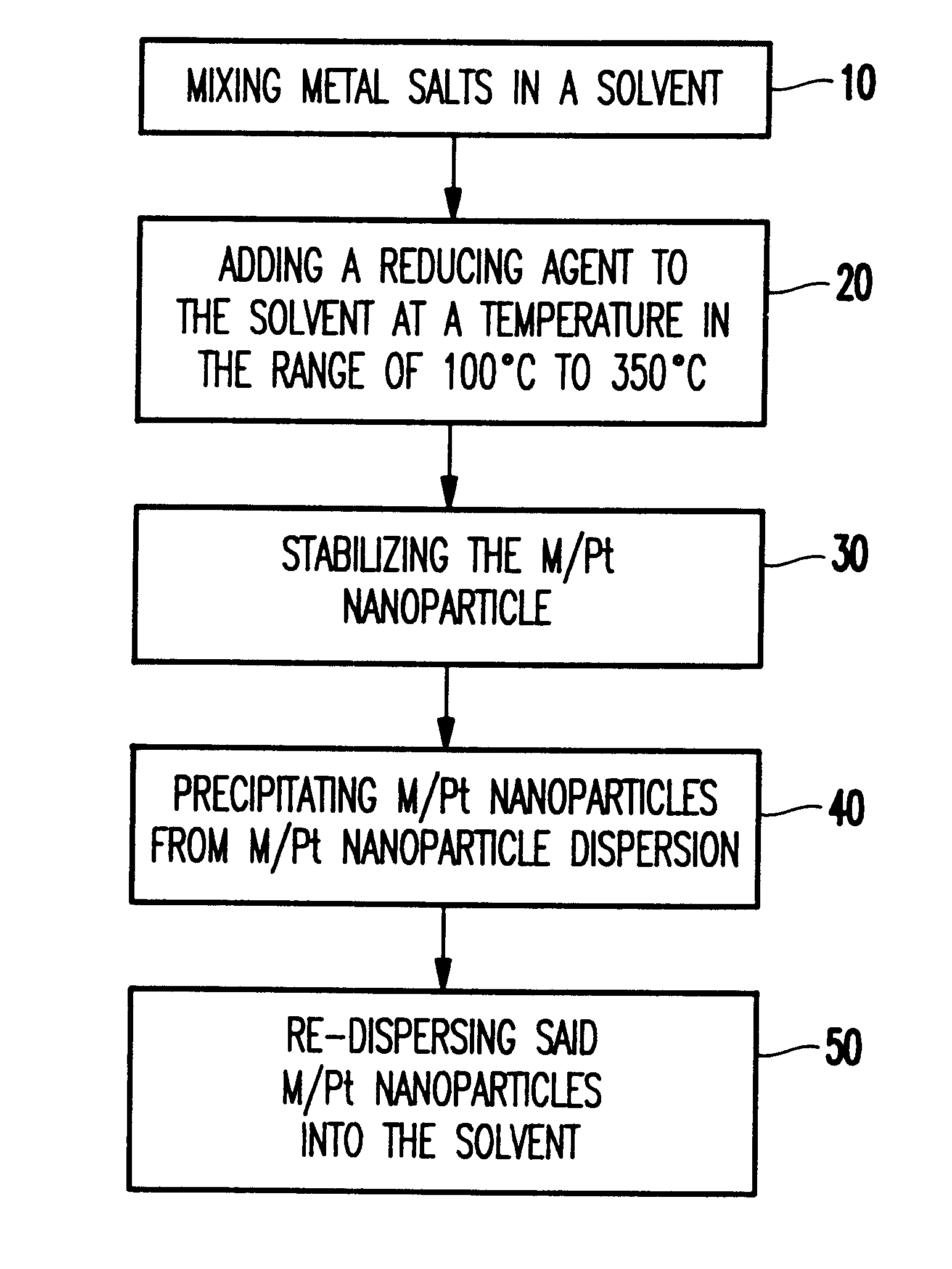

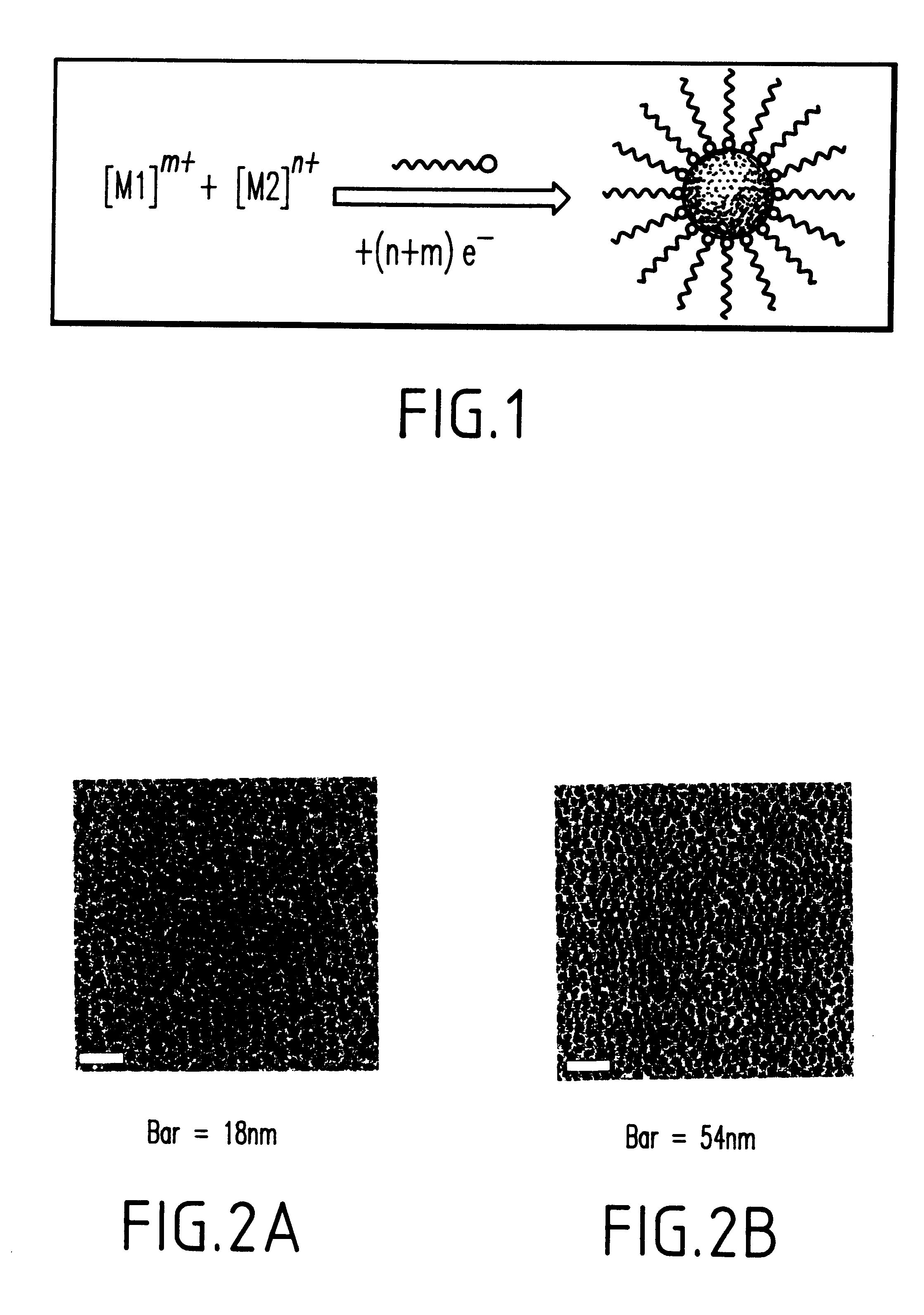

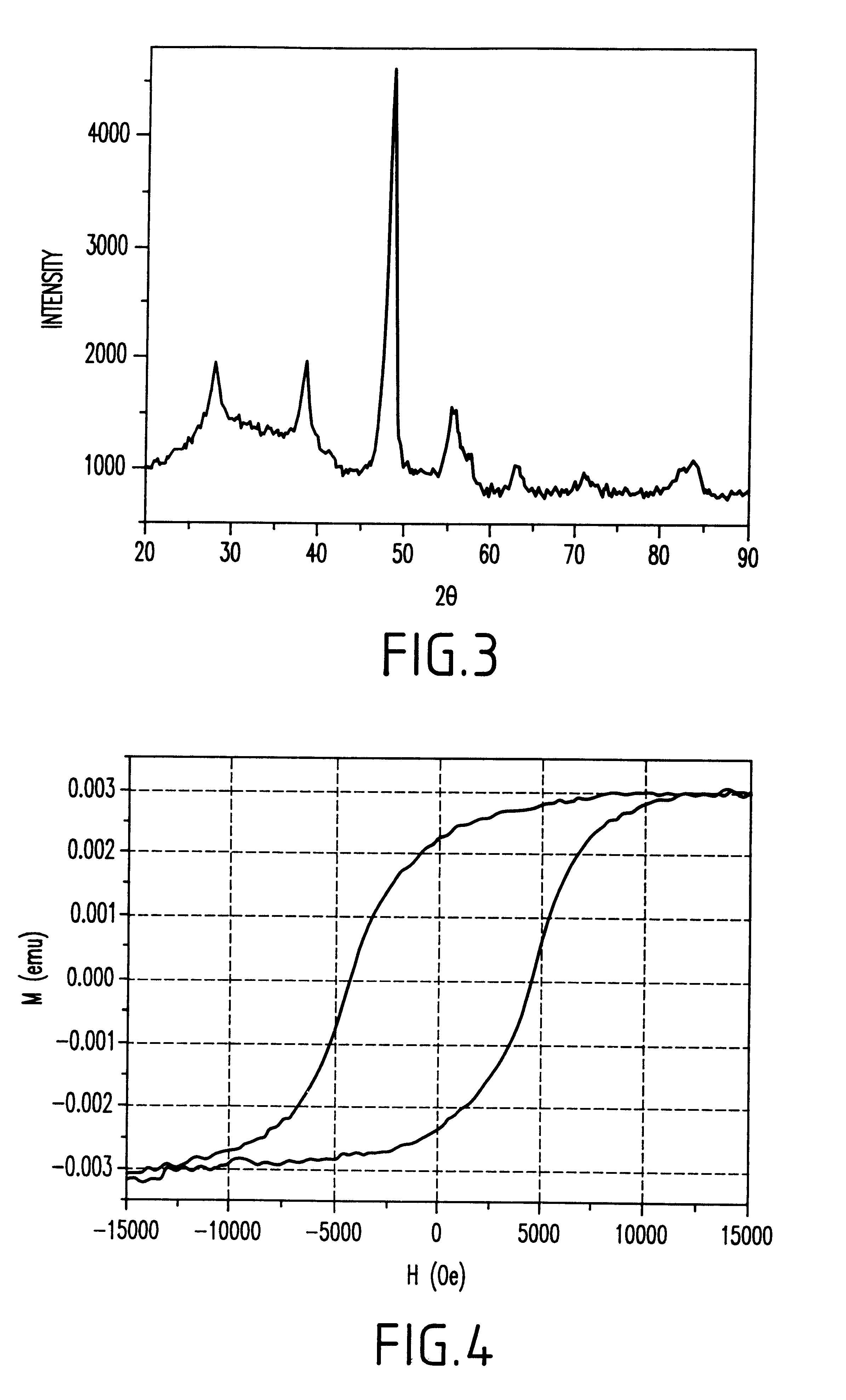

Metal salt reduction to form alloy nanoparticles

A method for making nanoparticles via metal salt reduction comprises, first, mixing metal salts in a solvent. Second, a reducing agent is added to the solvent at a temperature in the range of 100° C. to 350° C. Third, the nanoparticles dispersion is stabilized. Fourth, the nanoparticles are precipitated from the nanoparticle dispersion. Finally, the nanoparticles are re-dispersed into the solvent. The metal salt comprises a combination of FeCl2, FeCl3, Fe(OOCR)2, Fe(RCOCHCOR)3, CoCl2, Co(OOCR)2, Co(RCOCHCOR)2, and one of Pt(RCOCHCOR)2, PtCl2. The reducing agent comprises one of MBR3H, MH, M naphthalides, and polyalcohol; wherein R comprises one of H and an alkyl group, wherein M comprises one of Li, Na, and K. Long chain alkyl diols, and alkyl alcohol, can be used as a co-surfactant or a co-reducing agent to facilitate nanoparticle growth and separation.

Owner:GOOGLE LLC

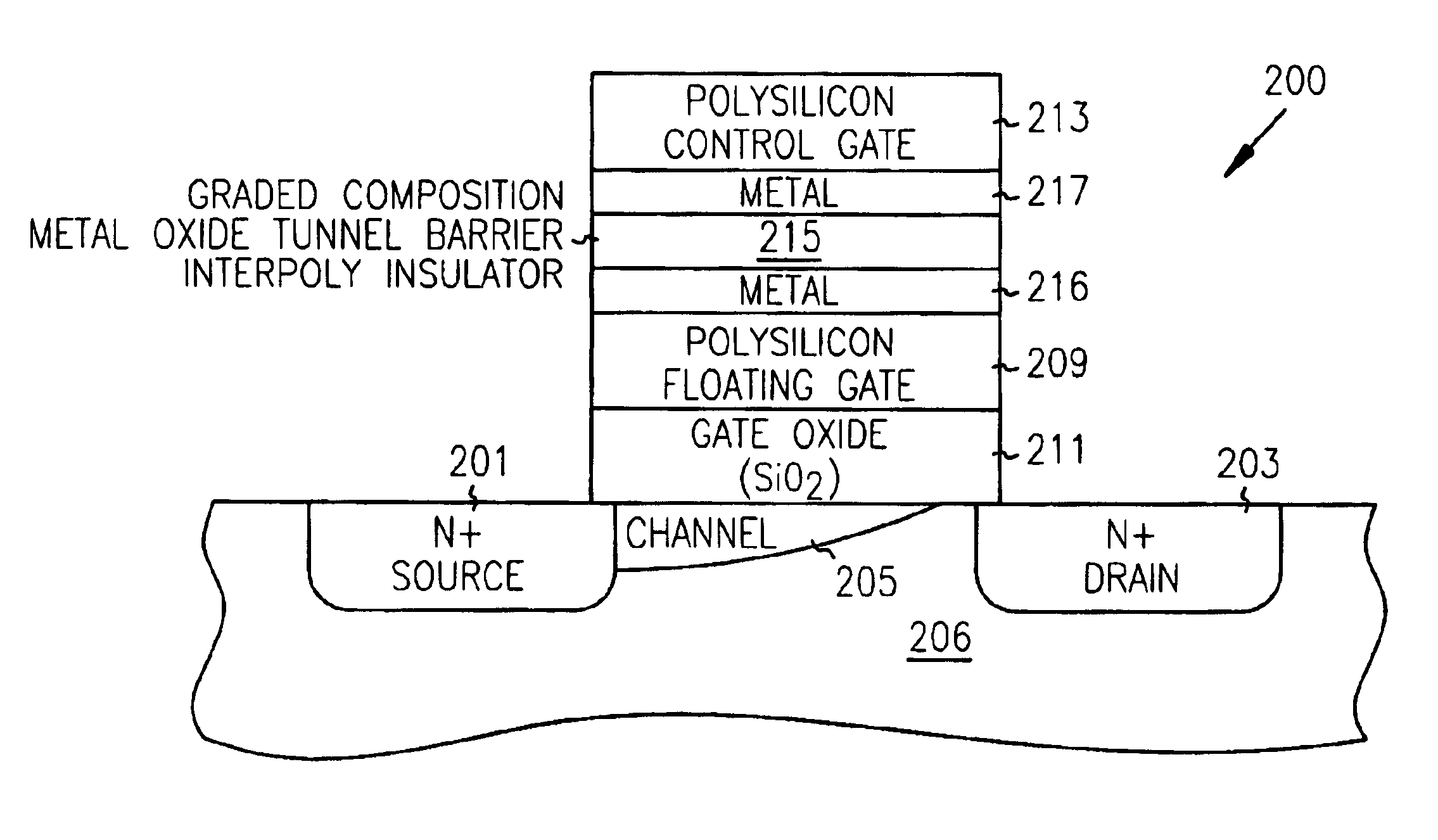

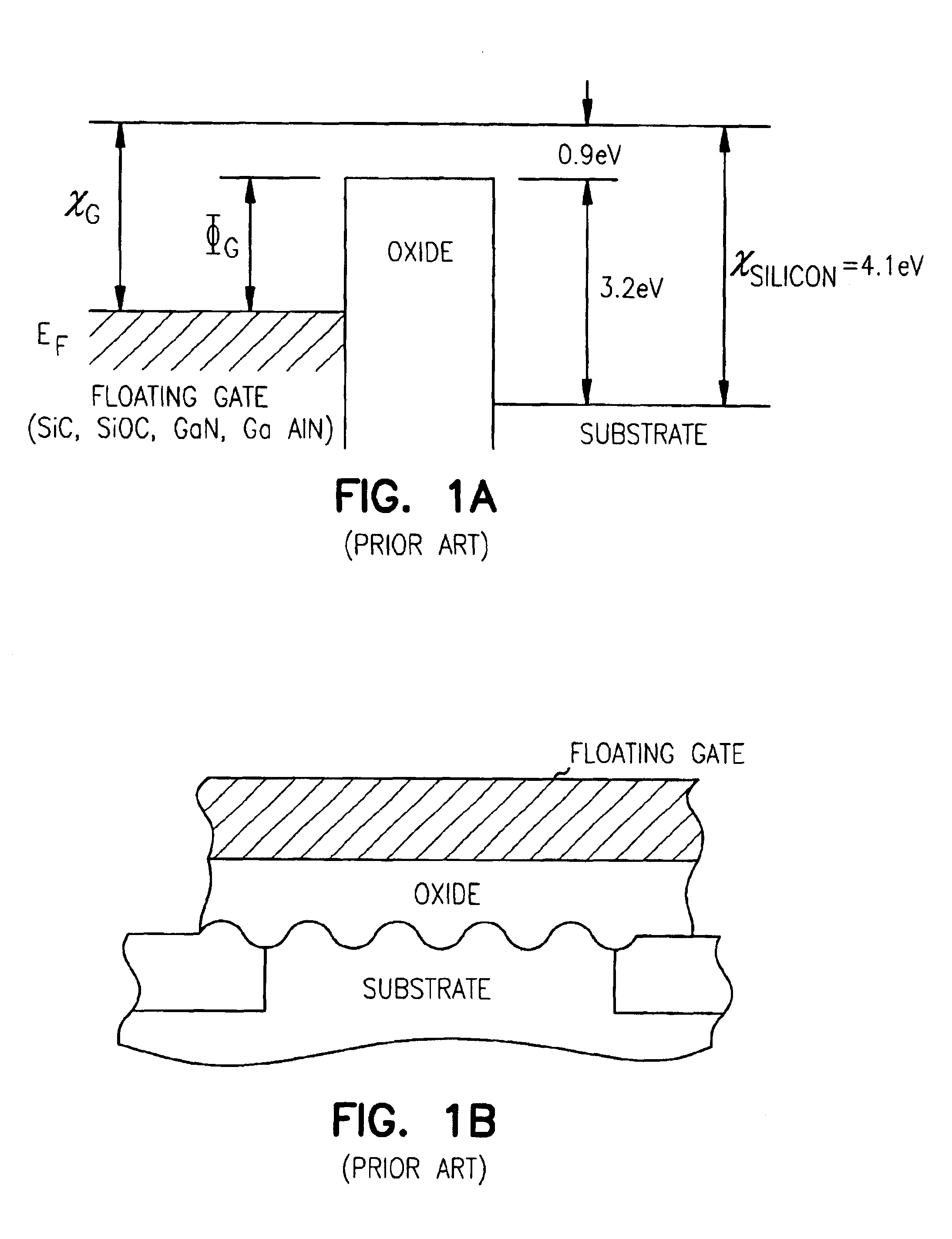

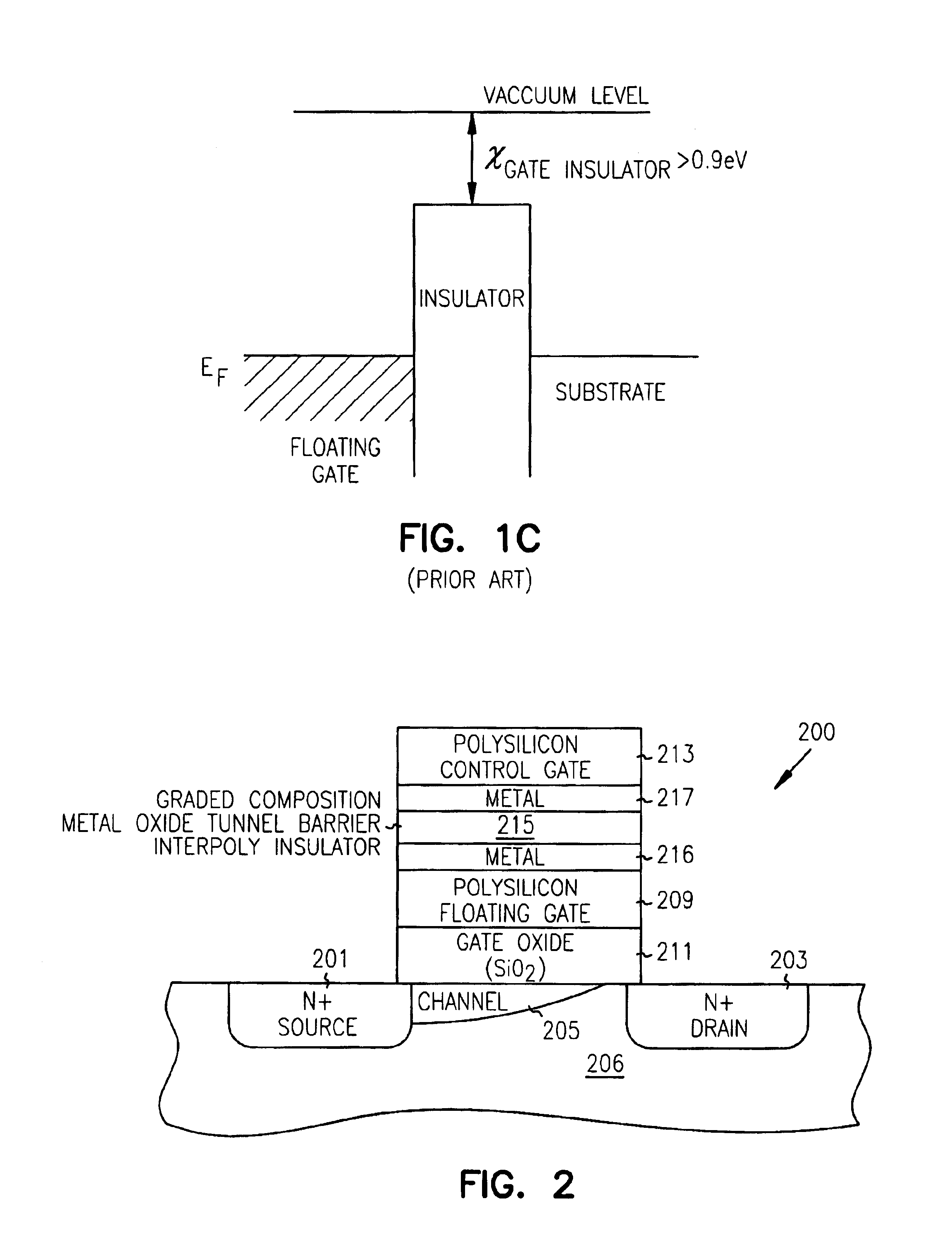

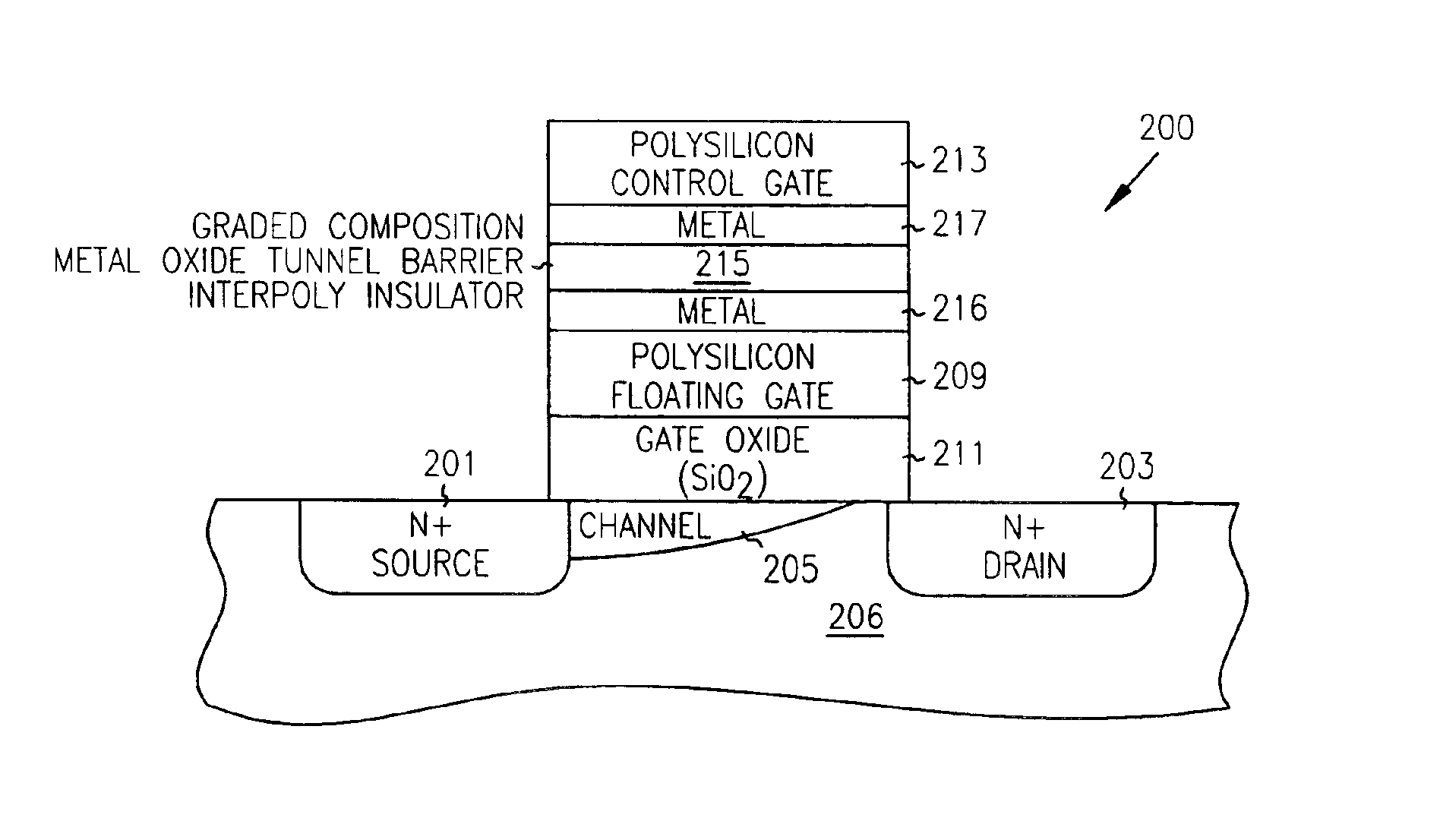

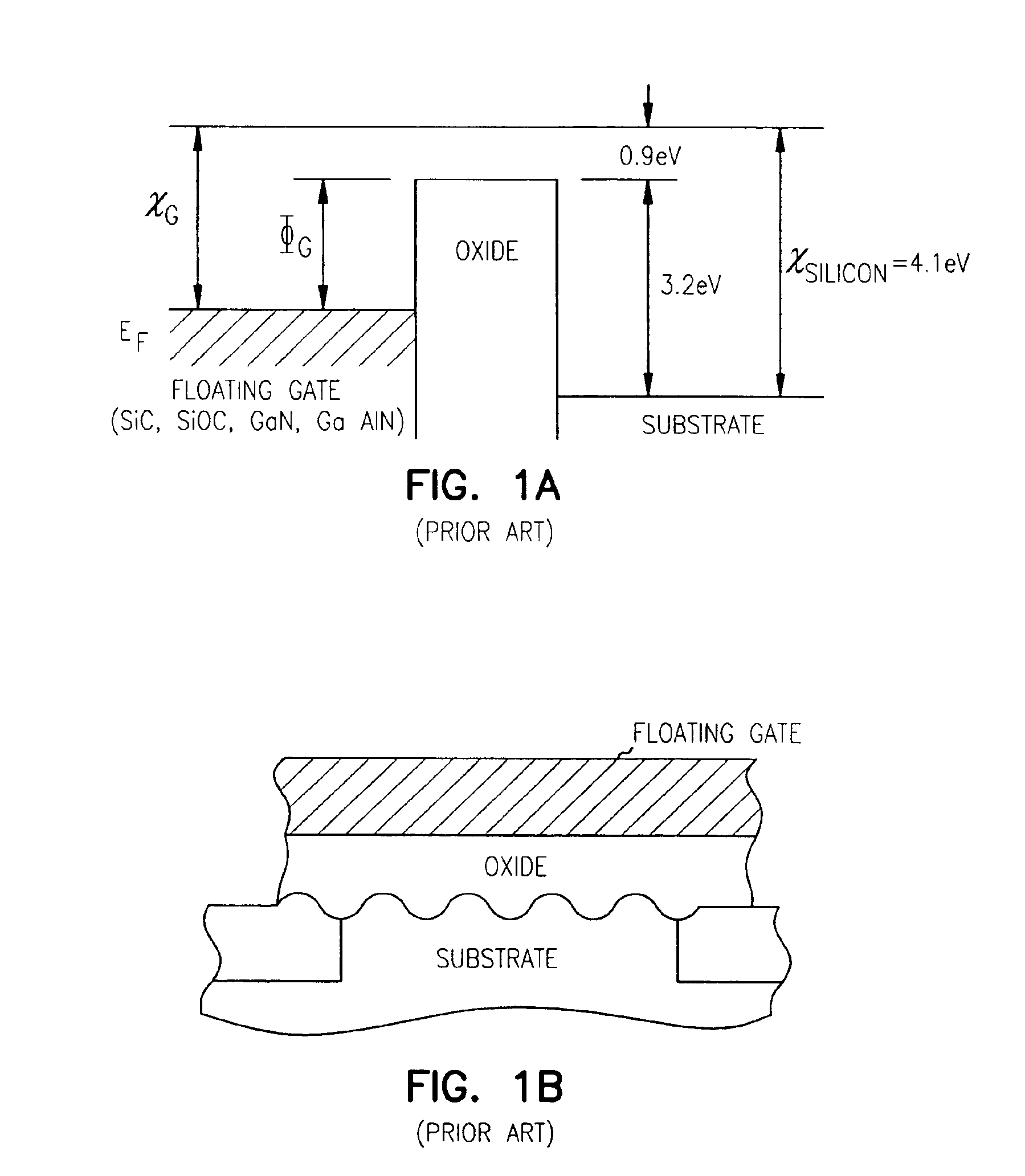

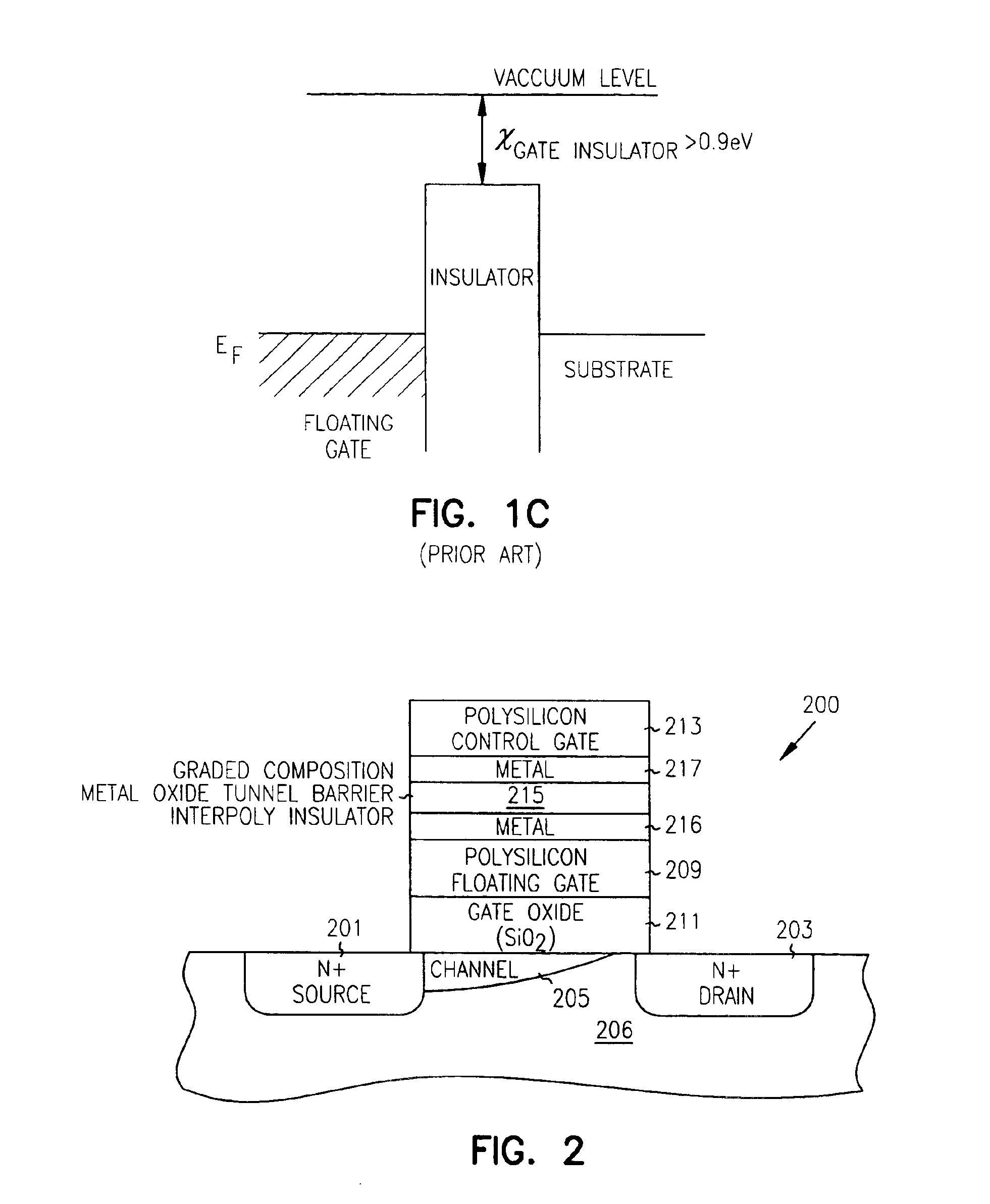

Graded composition metal oxide tunnel barrier interpoly insulators

Structures and methods for programmable array type logic and / or memory devices with graded composition metal oxide tunnel barrier intergate insulators are provided. The programmable array type logic and / or memory devices include a floating gate transistor. The floating gate has a first source / drain region and a second source / drain region separated by a channel region in a substrate. A floating gate opposes the channel region and is separated therefrom by a gate oxide. A control gate opposes the floating gate and is separated from the floating gate by a compositionally graded mixed metal oxide tunnel barrier intergate insulator.

Owner:MICRON TECH INC

Process for Producing Caco3 or Mgco3

InactiveUS20070202032A1Reduce the temperatureLow pressureCalcium/strontium/barium compoundsMagnesium carbonatesAqueous solutionMixed metal

The present invention relates to a process for producing CaCO3 or MgCO3 from a feedstock comprising a Ca- or Mg-comprising mixed metal oxide, wherein: (a) an aqueous slurry of the feedstock is contacted with a C02 containing gas to form an aqueous solution of Ca(HCO3)2 or Mg(HCO3)2 and a solid Ca- or Mg-depleted feedstock; (b) part or all of the aqueous solution of Ca(HCO3)2 or Mg(HCO3)2 is separated from the solid Ca- or Mg-depleted feedstock; (c) CaCO3 or MgCO3 is precipitated from the separated aqueous solution of Ca(HCO3)2 or Mg(HCO3)2; and (d) the precipitated CaCO3 or MgCO3 is recovered as product. The invention further relates to a process for the production of an aqueous solution of Ca(HCO3)2 or Mg(HCO3)2.

Owner:SHELL OIL CO

Graded composition metal oxide tunnel barrier interpoly insulators

InactiveUS7112841B2Increase the number ofReduce the numberTransistorSolid-state devicesEngineeringGate oxide

Structures and methods for programmable array type logic and / or memory devices with graded composition metal oxide tunnel barrier intergate insulators are provided. The programmable array type logic and / or memory devices include a floating gate transistor. The floating gate has a first source / drain region and a second source / drain region separated by a channel region in a substrate. A floating gate opposes the channel region and is separated therefrom by a gate oxide. A control gate opposes the floating gate and is separated from the floating gate by a compositionally graded mixed metal oxide tunnel barrier intergate insulator.

Owner:MICRON TECH INC

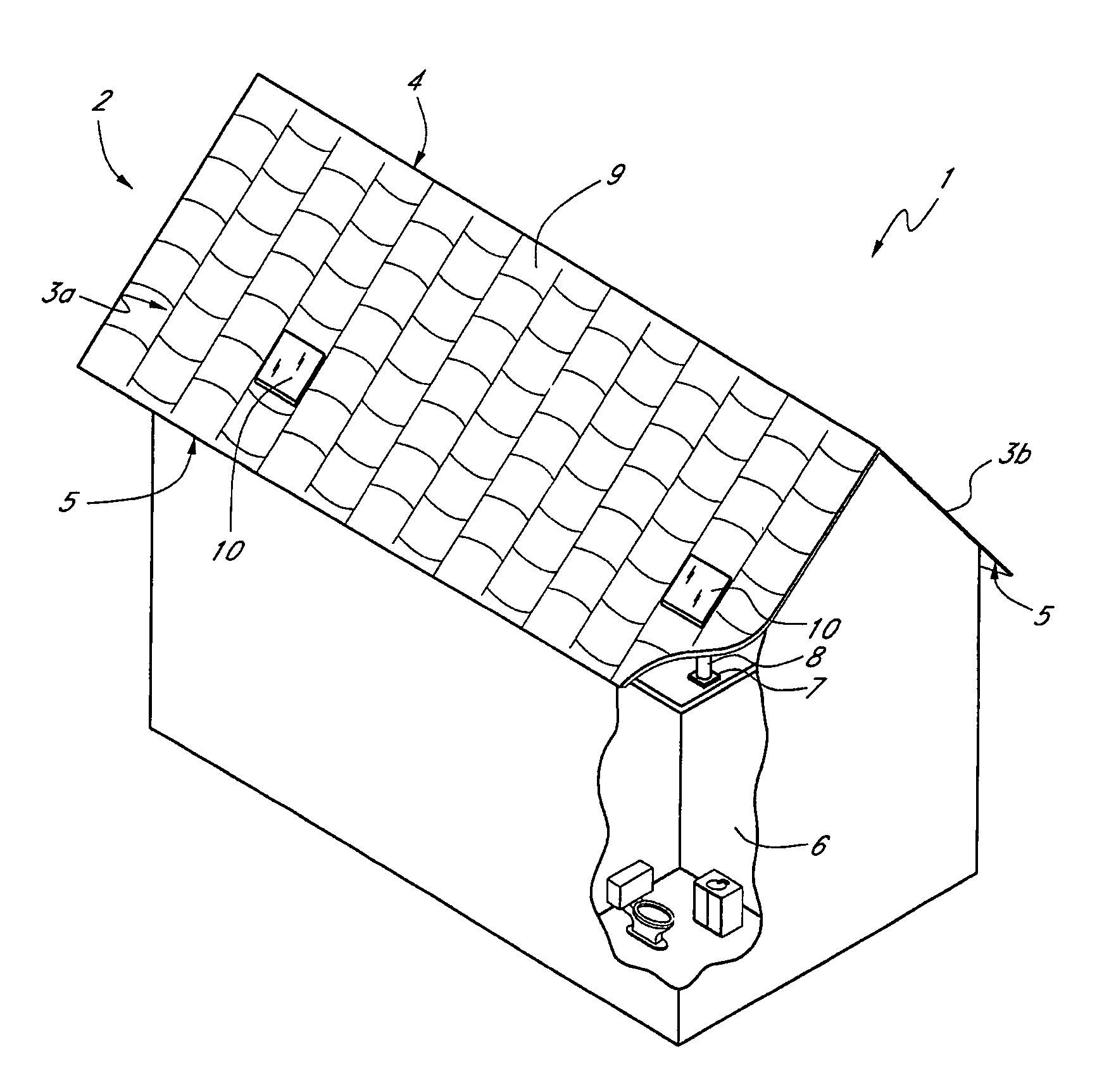

Hybrid metal-plastic roof vent

ActiveUS7901278B2Facilitate selective attachment and detachmentPrevent rainBuilding roofsRoof covering using tiles/slatesPlastic materialsMixed metal

A vent for a tile roof is disclosed. The vent includes a first member preferably substantially formed of a metal, a second member preferably substantially formed of a plastic material, and a connector attached to the underside of the second member. The second member is positioned below and spaced apart from the first member. The first and second members together define a ventilation gap therebetween. The first member and second member are preferably releasably connected to each other. The connector is configured to connect with an air conduit. The connector is further configured to be compatible with a plurality of sizes and types of air conduits. The ventilating access and the connector are together configured to permit airflow between above the roof and the air conduit.

Owner:OHAGIN CAROLINA STOLLENWERK

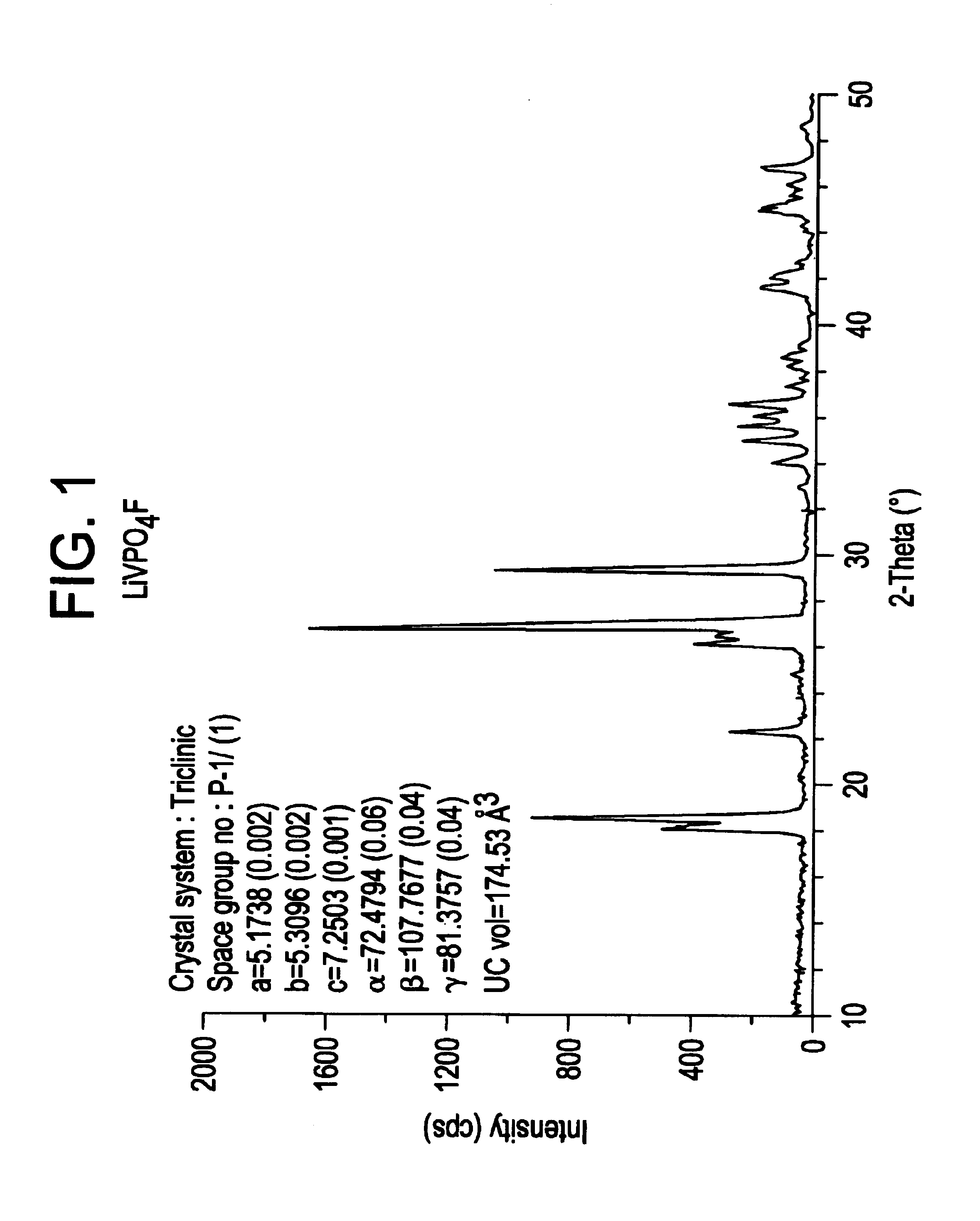

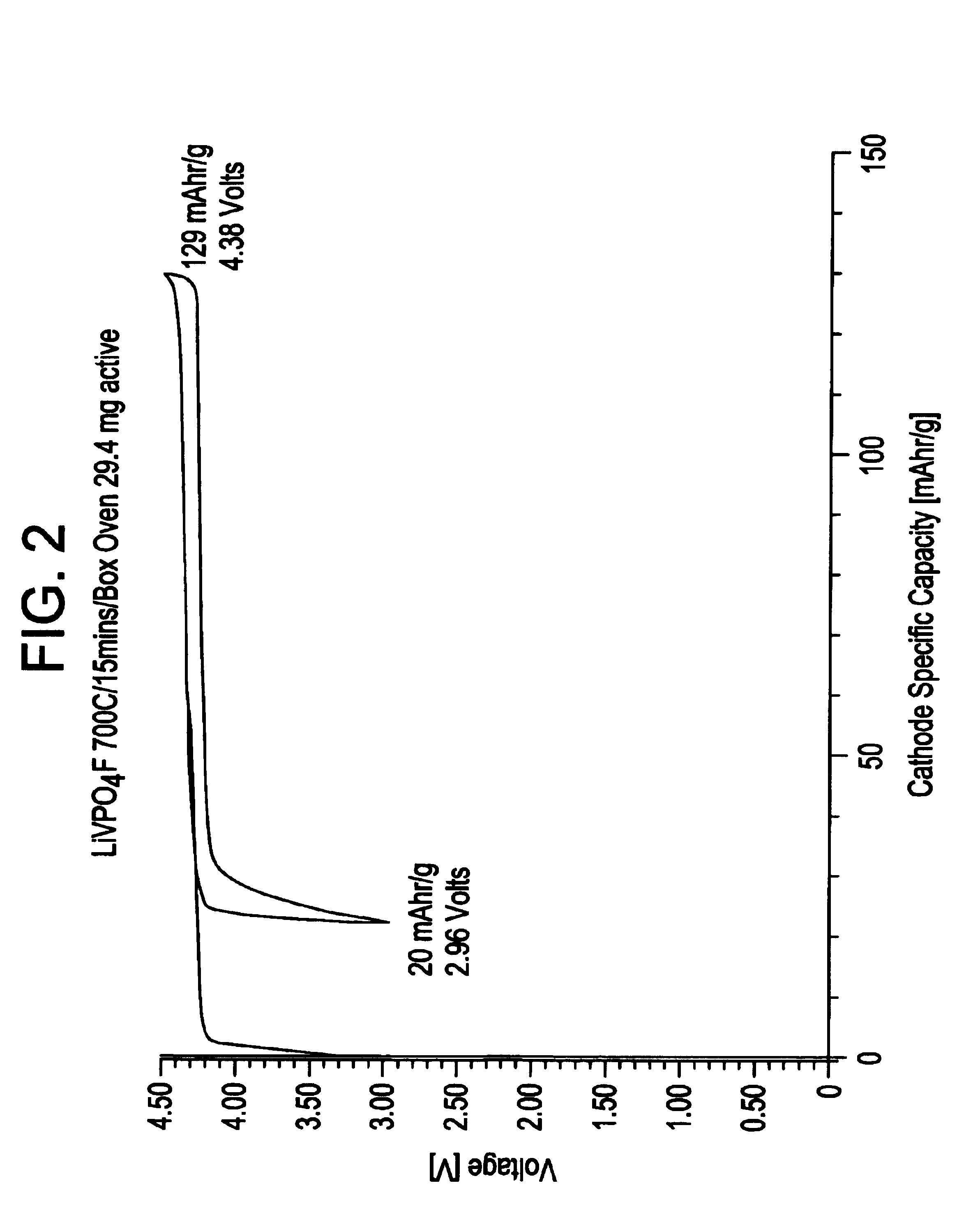

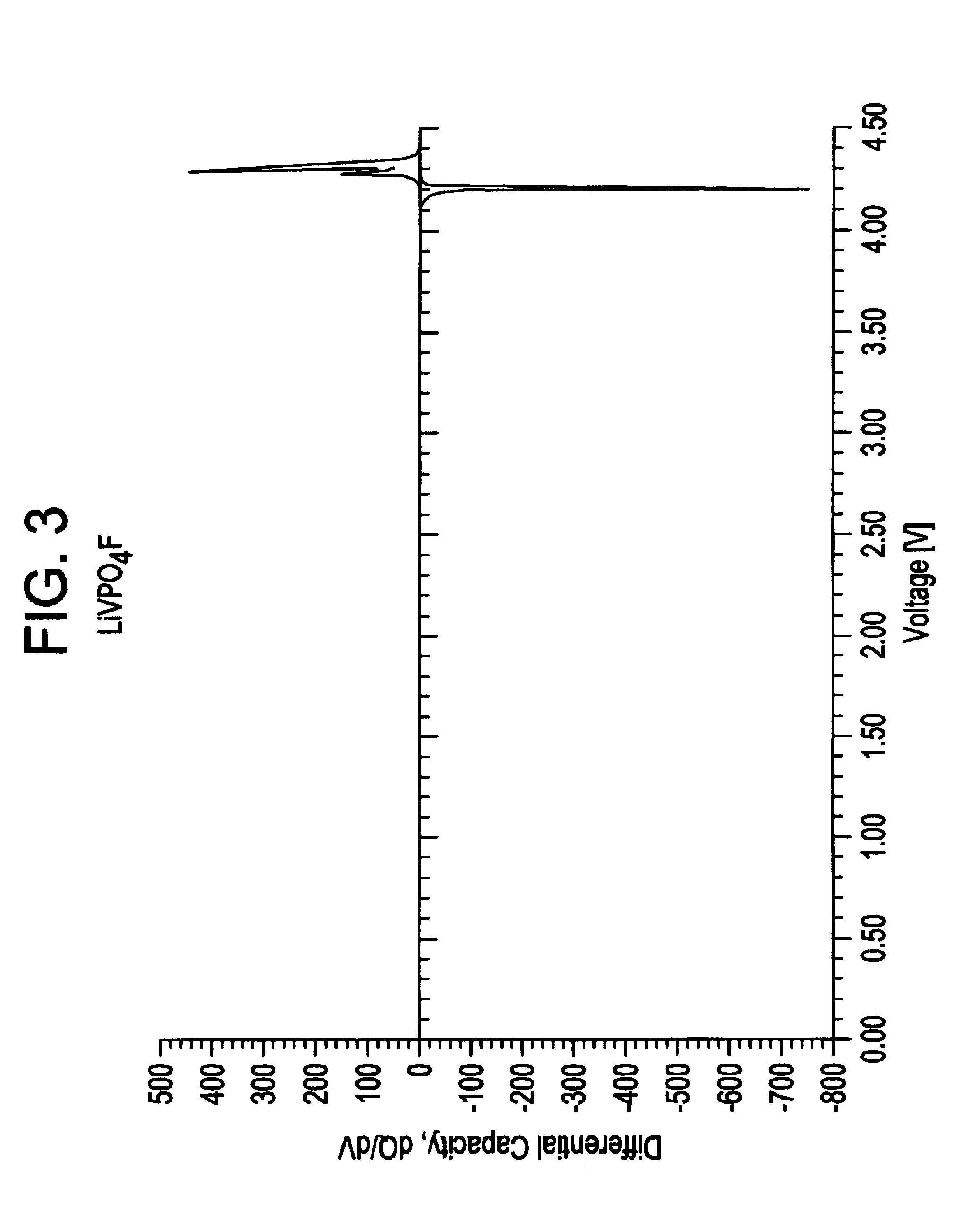

Methods of making lithium metal cathode active materials

The invention provides a novel method for making lithium mixed metal materials in electrochemical cells. The lithium mixed metal materials comprise lithium and at least one other metal besides lithium. The invention involves the reaction of a metal compound, a phosphate compound, with a reducing agent to reduce the metal and form a metal phosphate. The invention also includes methods of making lithium metal oxides involving reaction of a lithium compound, a metal oxide with a reducing agent.

Owner:LITHIUM WERKS TECH BV

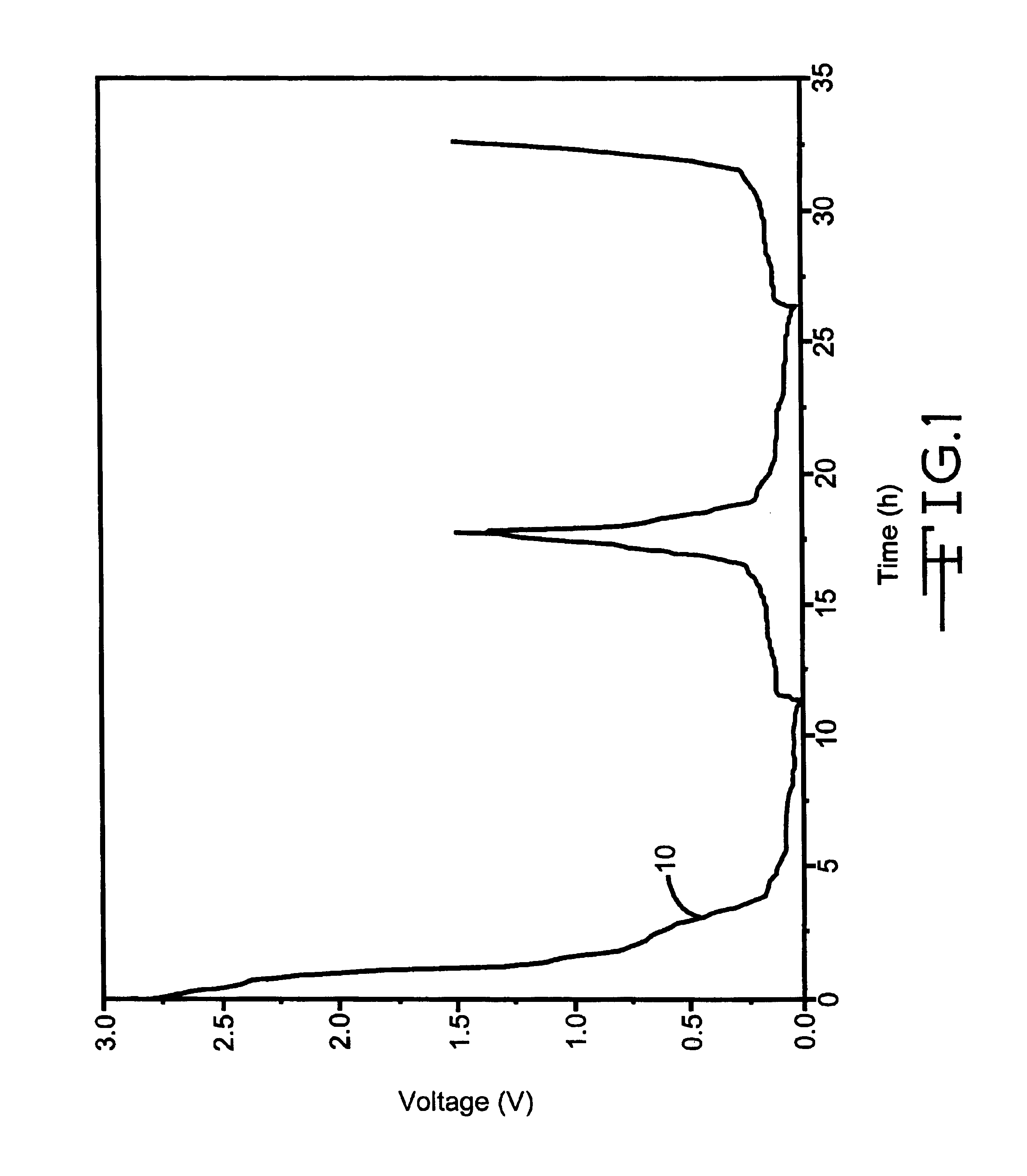

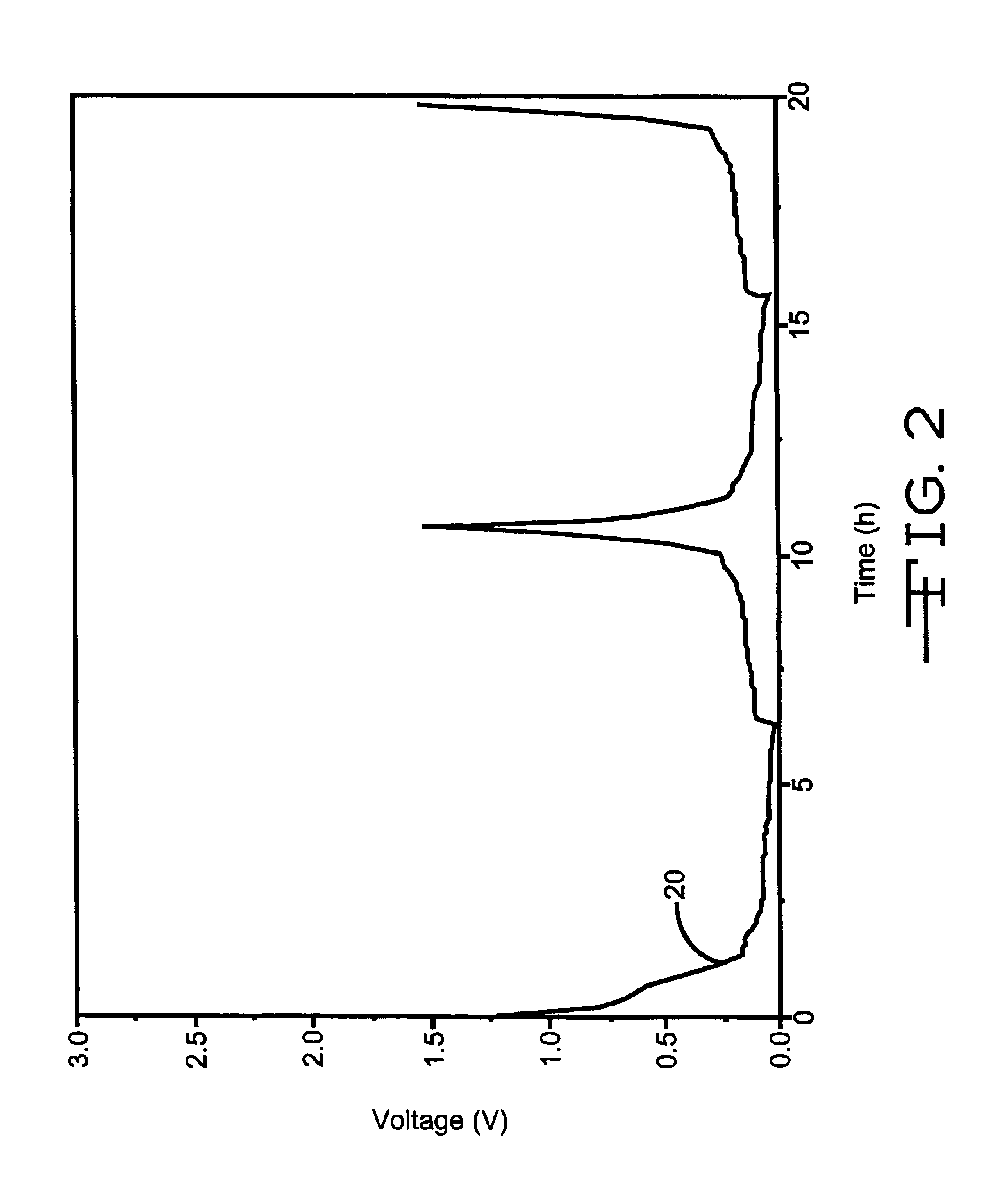

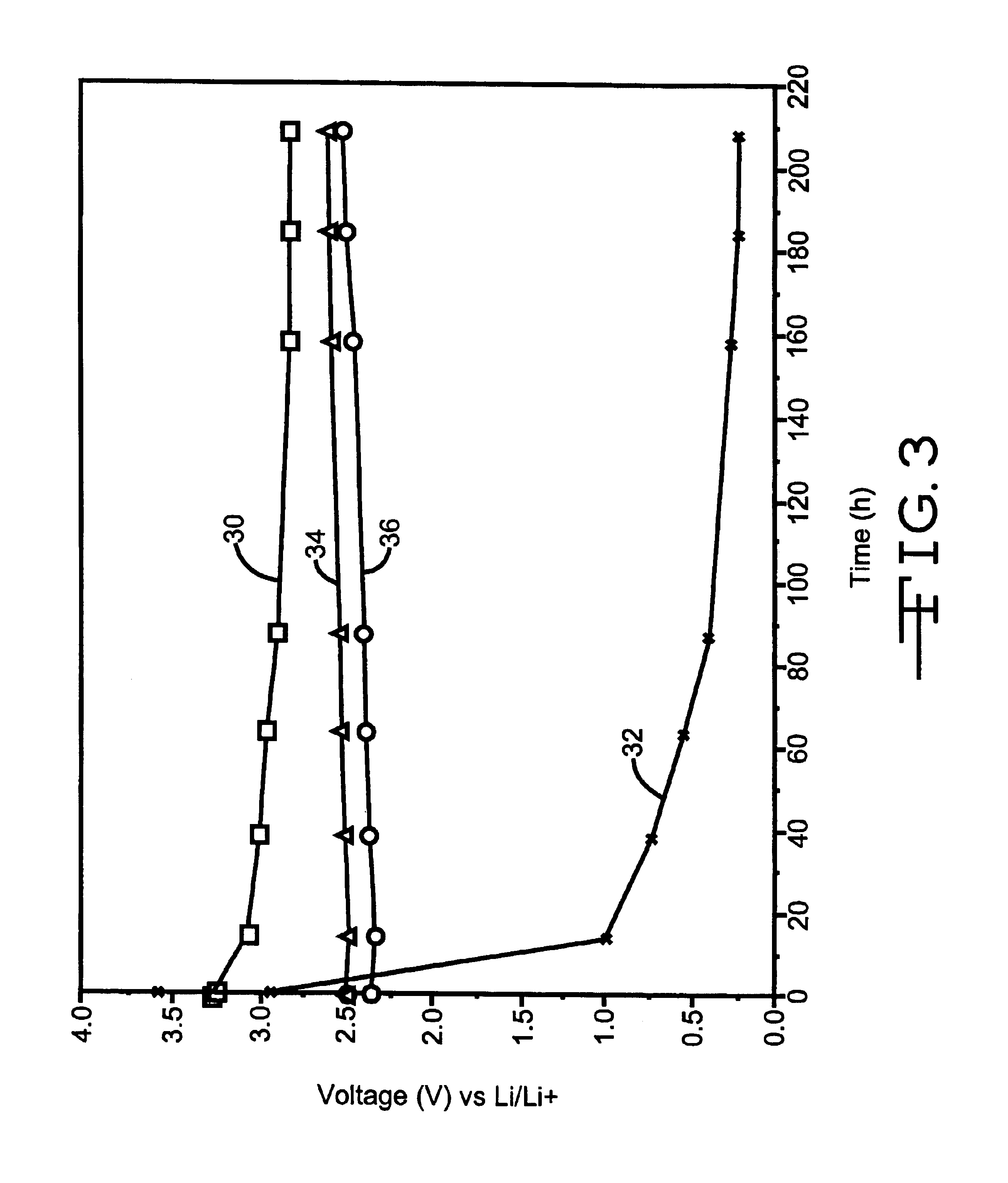

Anode for nonaqueous secondary electrochemical cells

InactiveUS6730437B2Improve performanceAvoid corrosionSilver accumulatorsElectrode carriers/collectorsGraphiteMetallic sulfide

The negative electrode or anode for a secondary electrochemical cell comprising a mixture of graphite or "hairy carbon" and a lithiated metal oxide, a lithiated mixed metal oxide or a lithiated metal sulfide, and preferably a lithiated metal vanadium oxide, is described. A most preferred formulation is graphite mixed with lithiated silver vanadium oxide or lithiated copper silver vanadium oxide.

Owner:WILSON GREATBATCH LTD

Method for making a lithium mixed metal compound

A method for making a lithium mixed metal compound includes: preparing a reactant mixture that contains a metal compound, a lithium compound, and optionally, a phosphate-containing compound; and exposing the reactant mixture to an atmosphere in the presence of suspended carbon particles, and conducting a reduction to reduce oxidation state of at least one metal ion of the reactant mixture at a temperature sufficient to form a reaction product containing lithium and the reduced metal ion.

Owner:AQUIRE ENERGY CO LTD

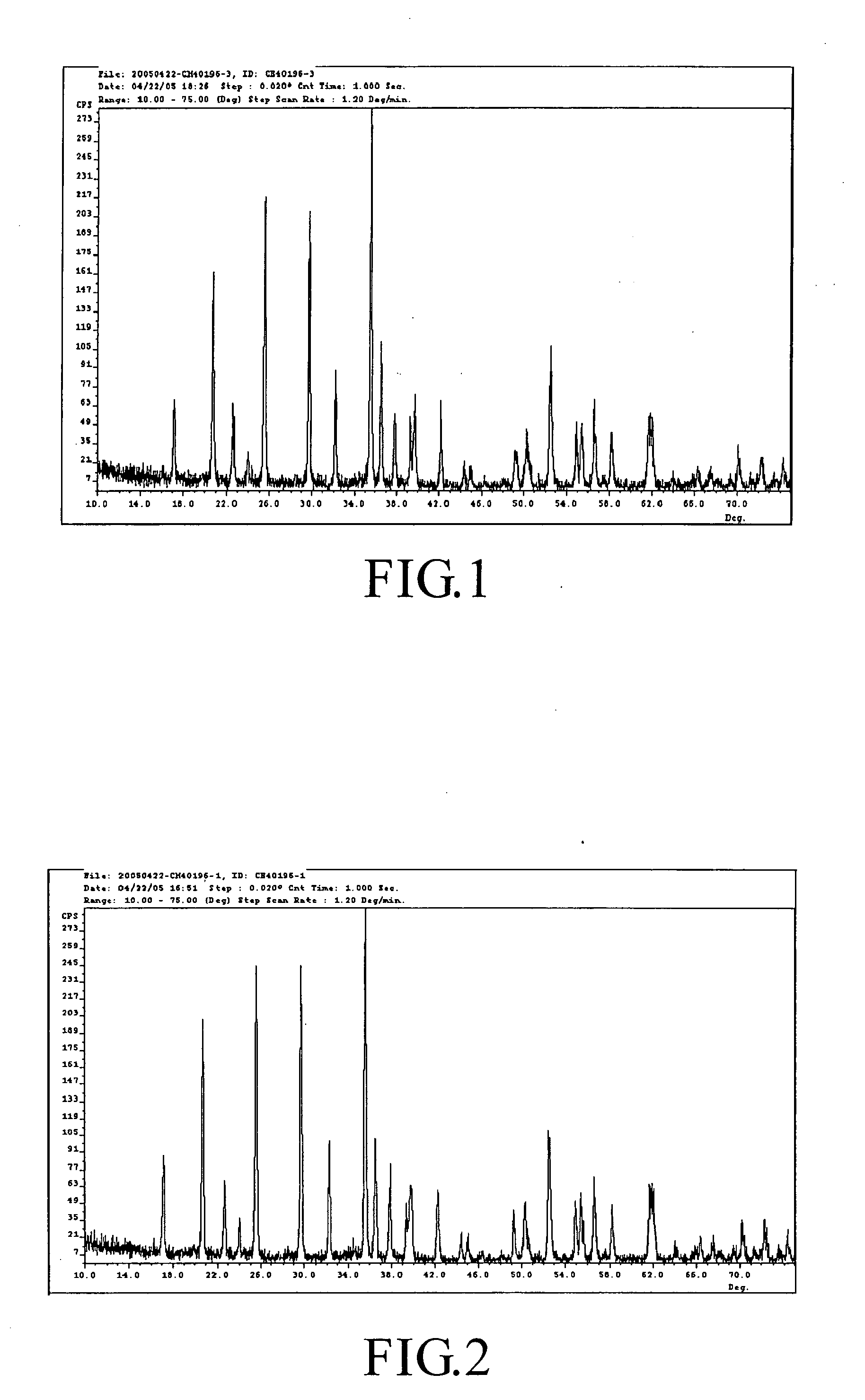

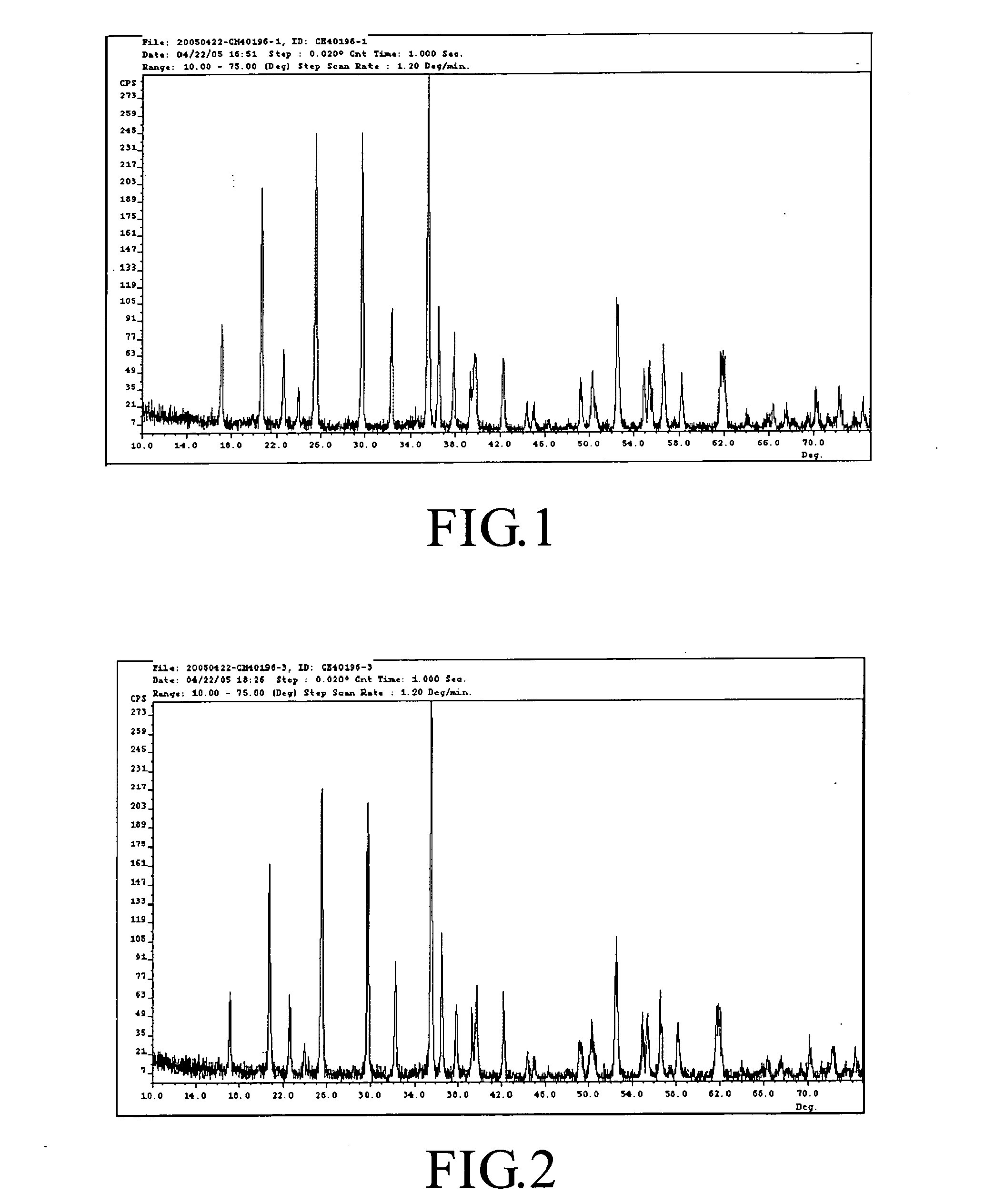

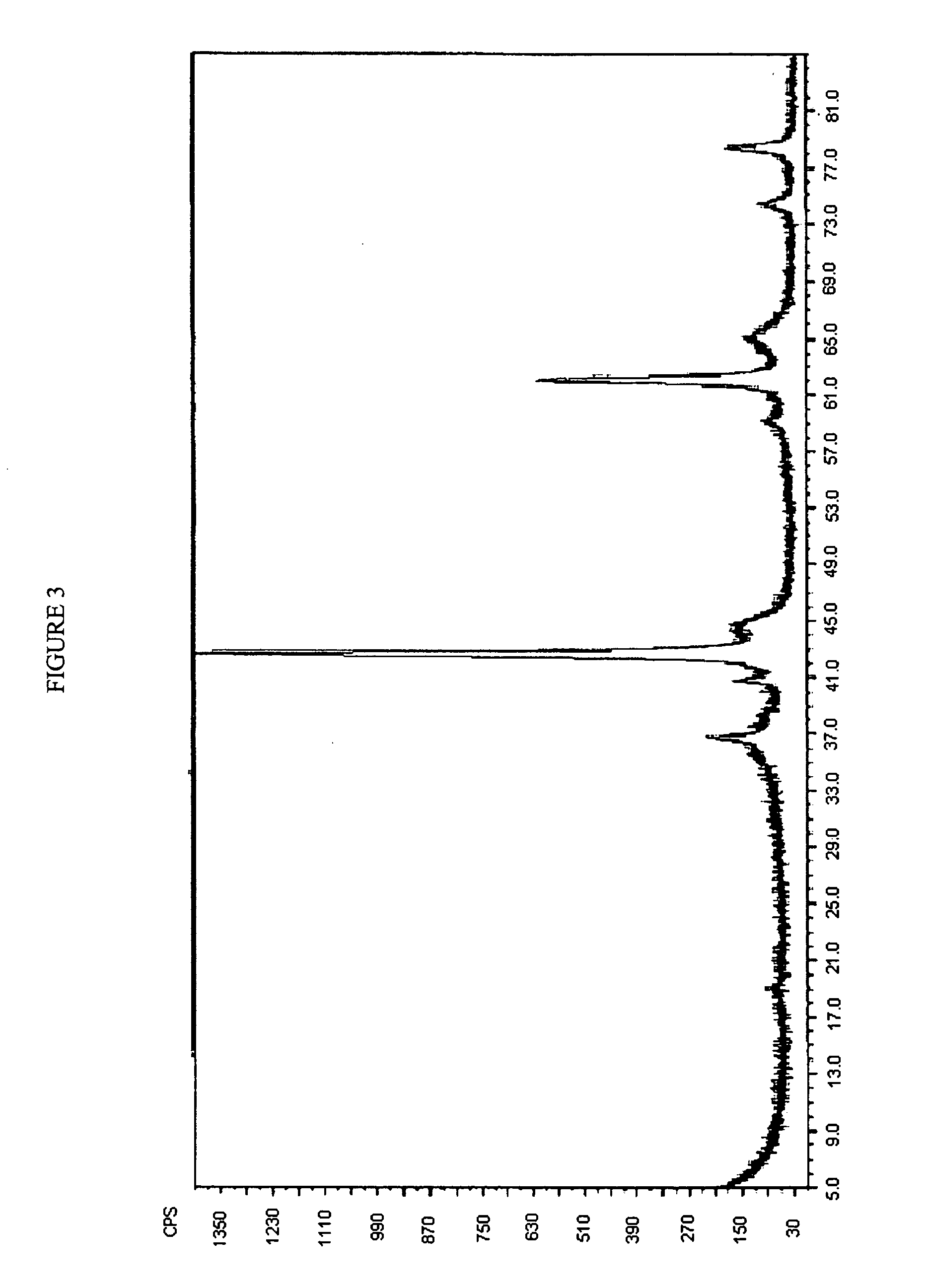

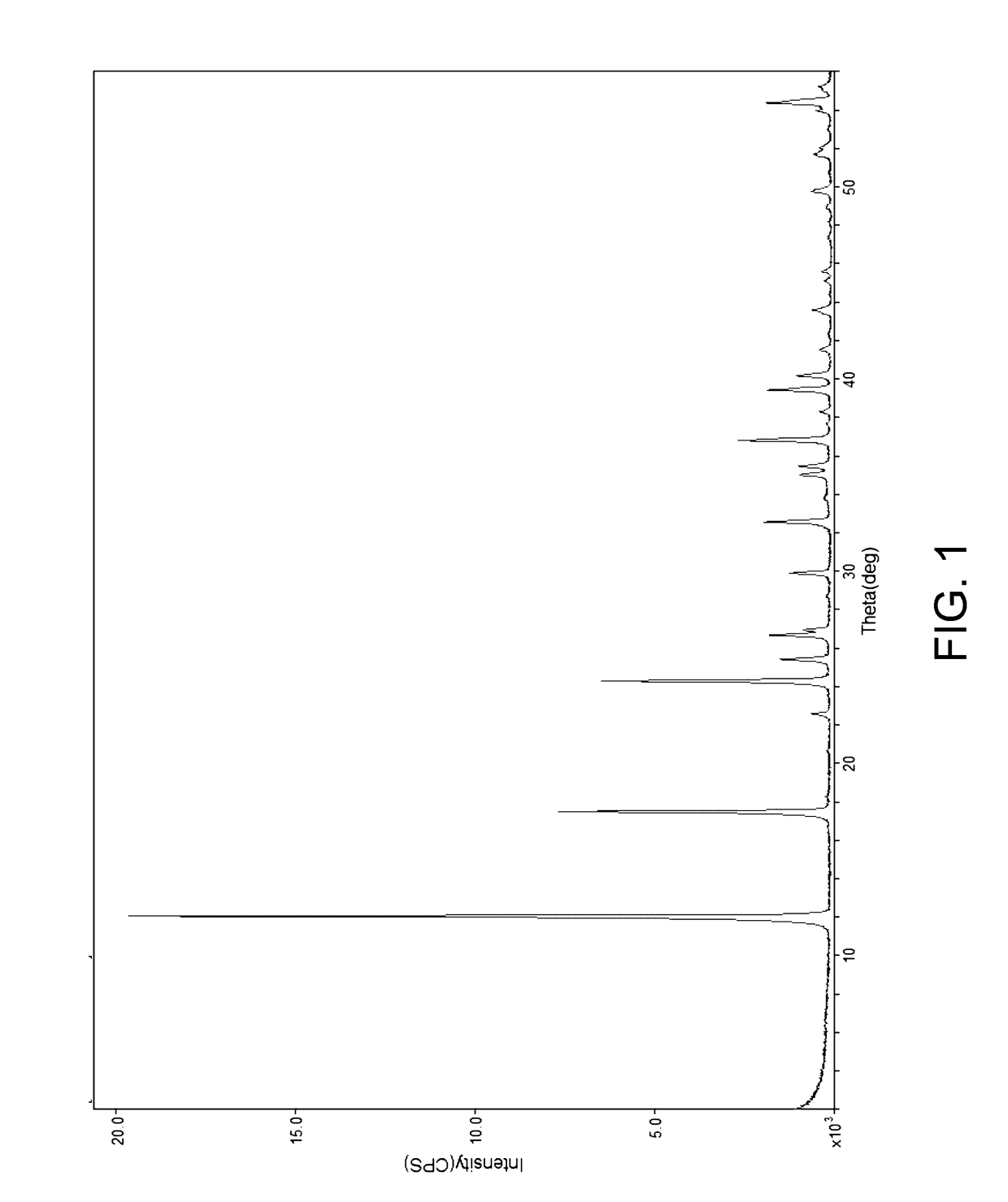

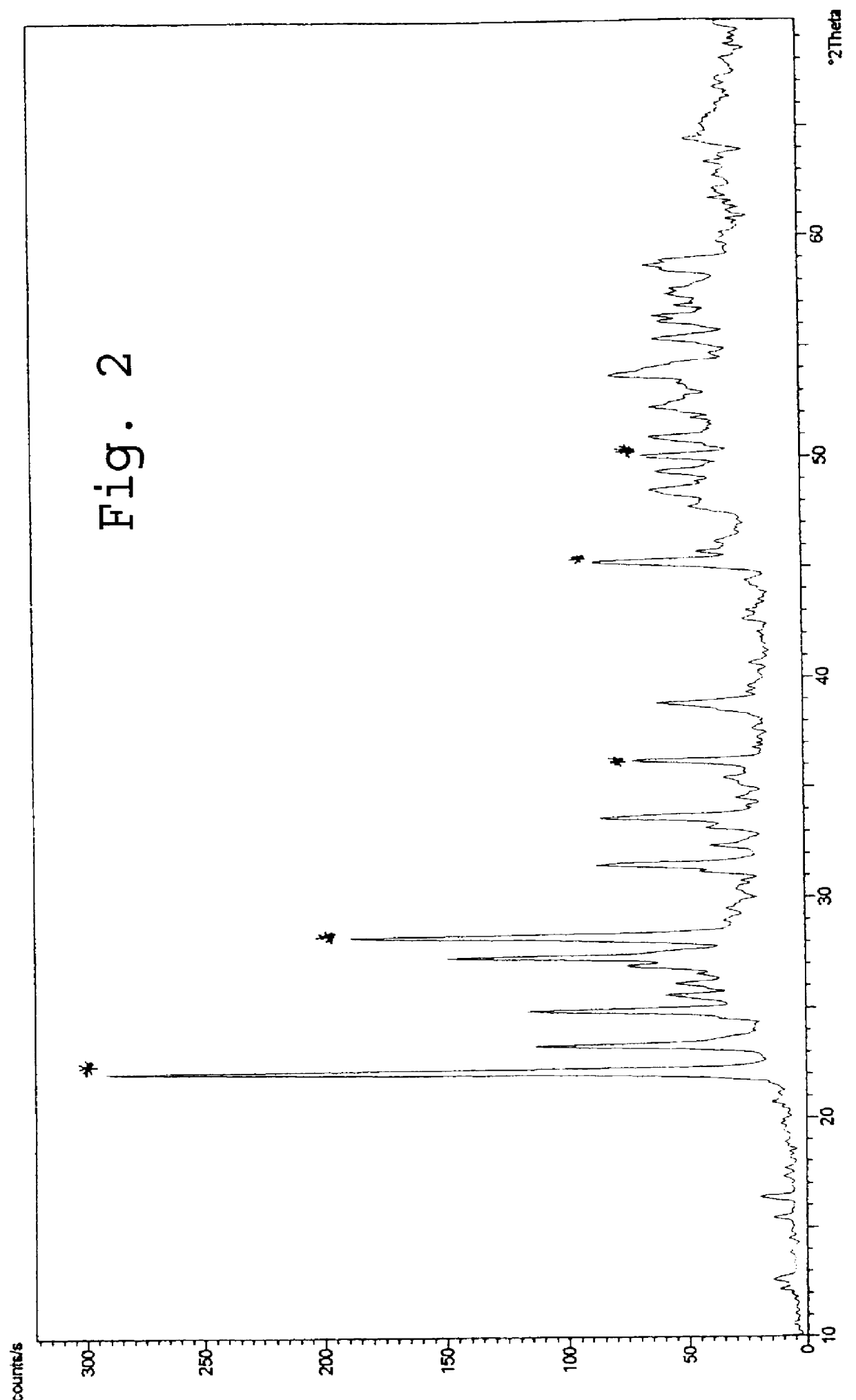

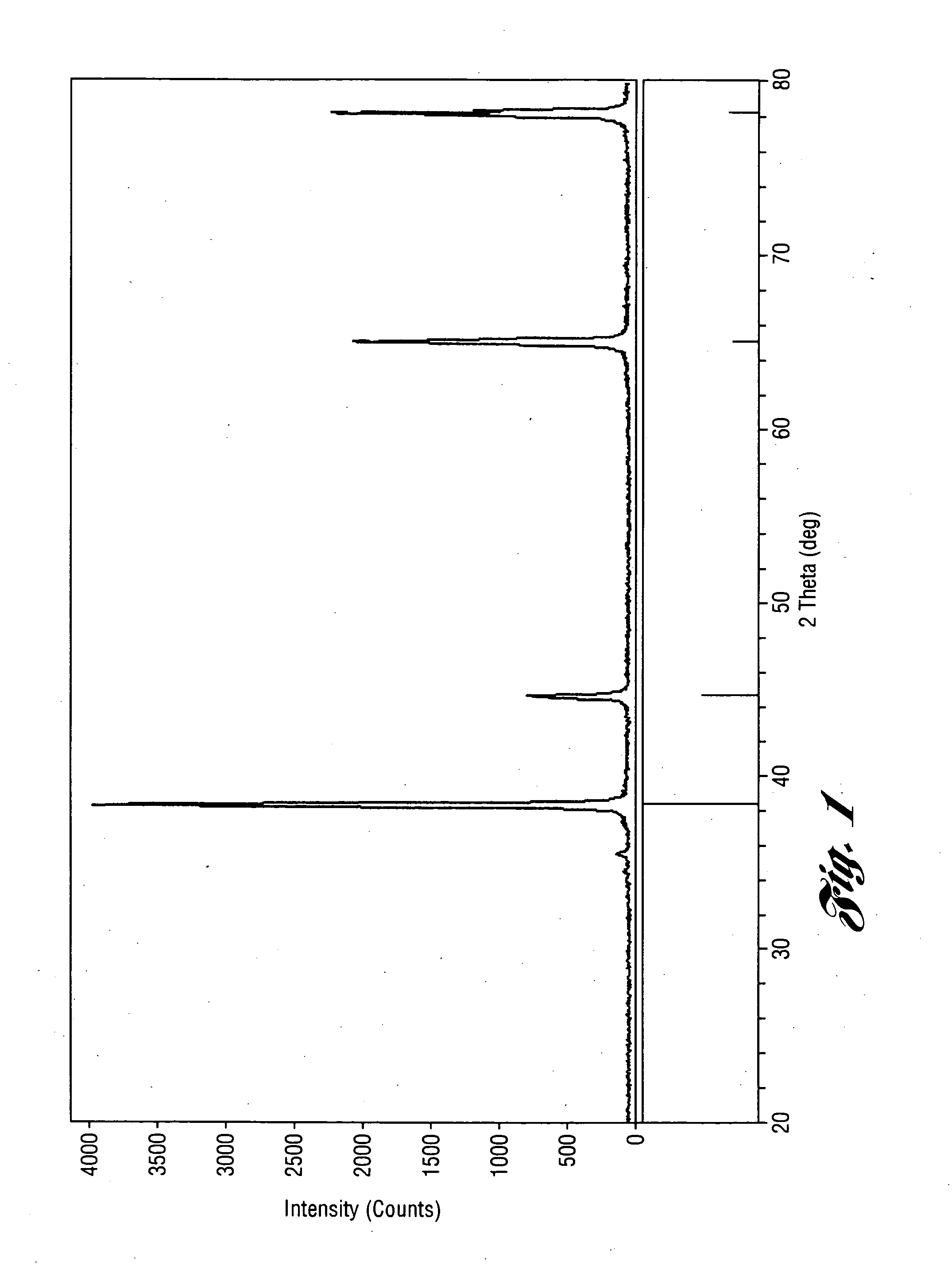

Mixed metal oxide sorbents

The present invention is directed to methods for reducing SOx, NOx, and CO emissions from a fluid stream comprising contacting said fluid stream with a compound comprising magnesium and aluminum and having an X-ray diffraction pattern displaying at least a reflection at a two theta peak position at about 43 degrees and about 62 degrees, wherein the ratio of magnesium to aluminum in the compound is from about 1:1 to about 10:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1:1 to about 6:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 10:1. In another embodiment, the invention is directed to methods wherein the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 6:1.

Owner:JOHNSON MATTHEY PROCESS TECH

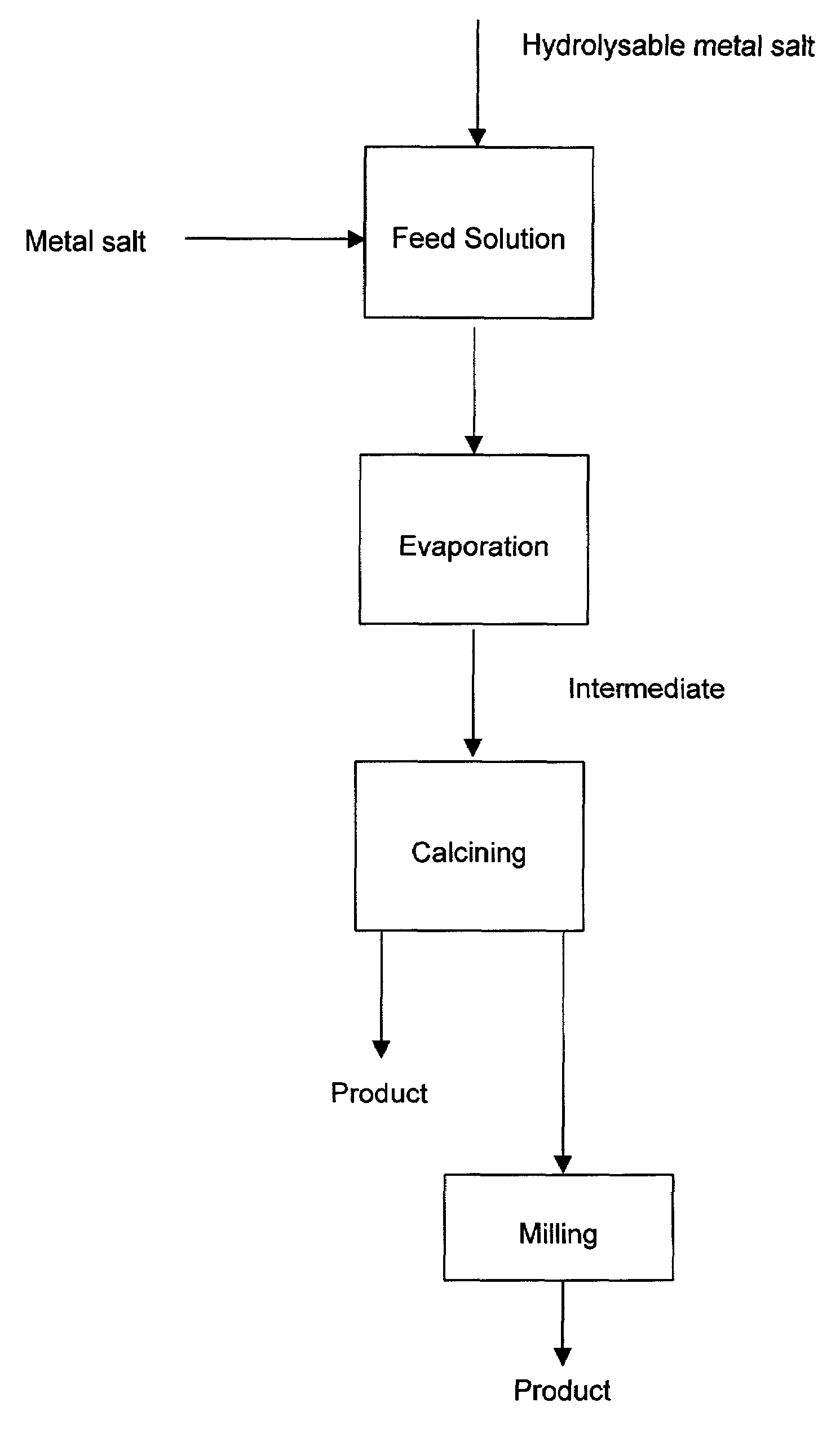

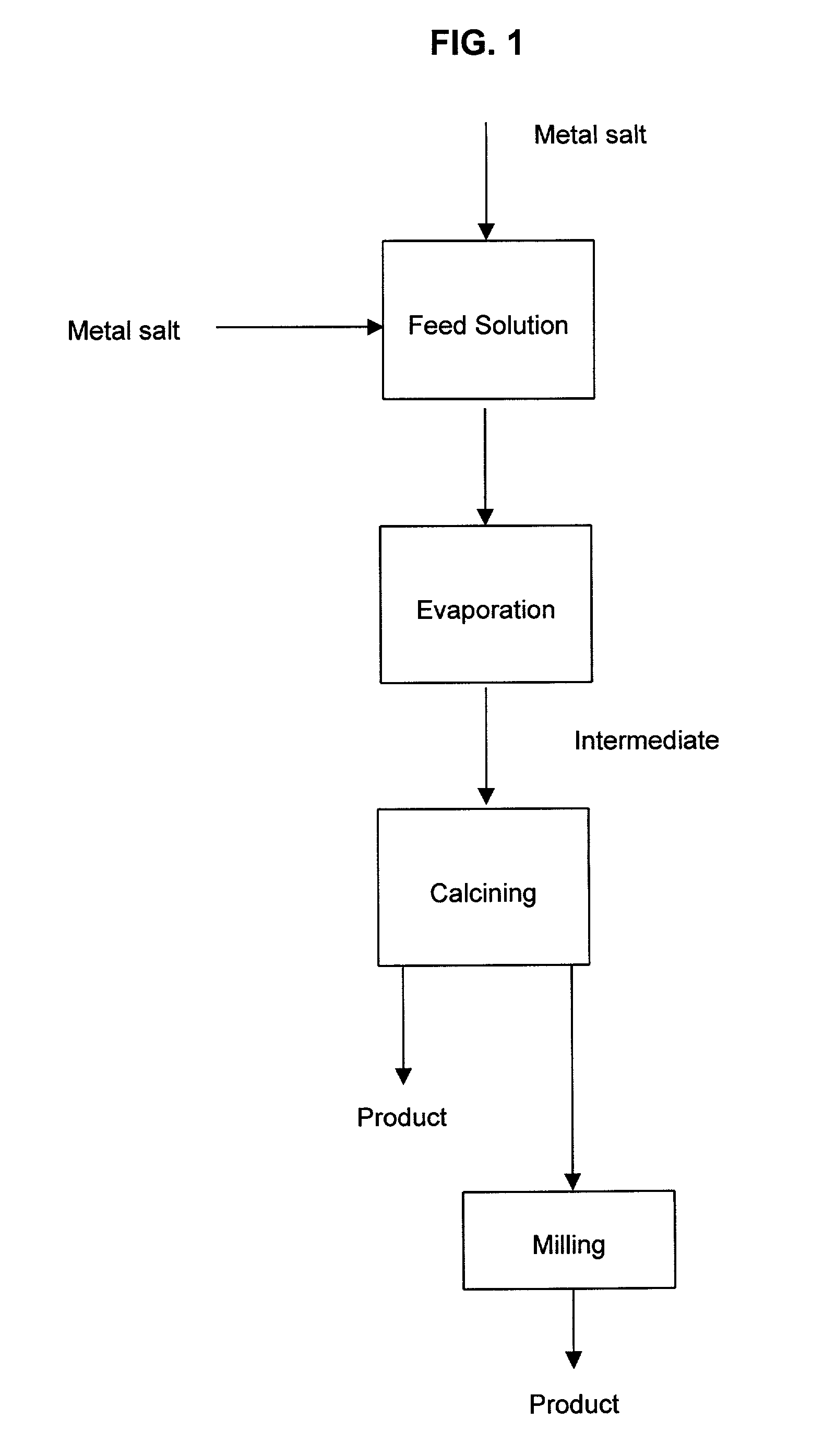

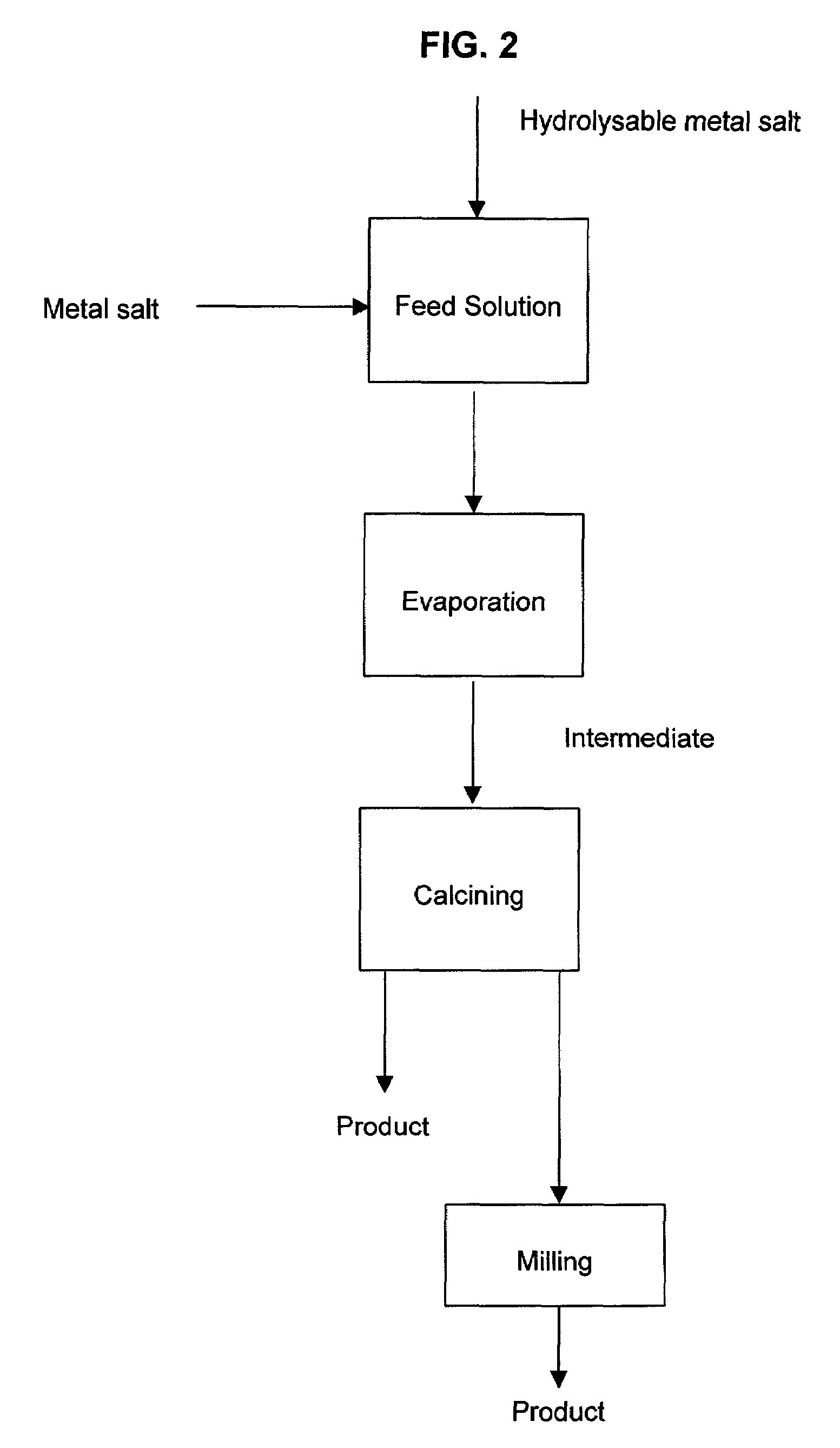

Method for producing mixed metal oxides and metal oxide compounds

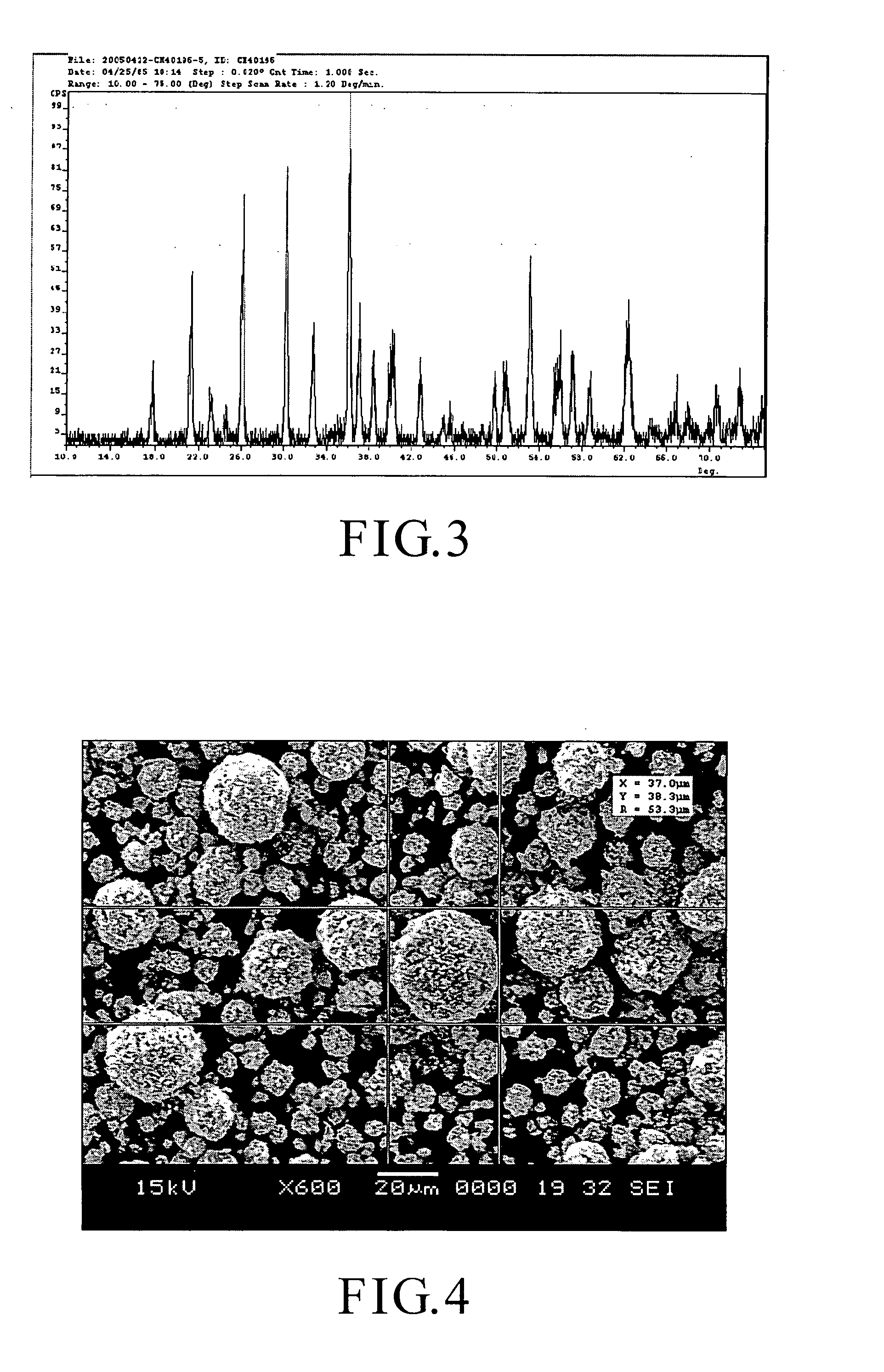

A process to produce mixed metal oxides and metal oxide compounds. The process includes evaporating a feed solution that contains at least two metal salts to form an intermediate. The evaporation is conducted at a temperature above the boiling point of the feed solution but below the temperature where there is significant crystal growth or below the calcination temperature of the intermediate. The intermediate is calcined, optionally in the presence of an oxidizing agent, to form the desired oxides. The calcined material can be milled and dispersed to yield individual particles of controllable size and narrow size distribution.

Owner:ALTAIR NANOMATERIALS INC

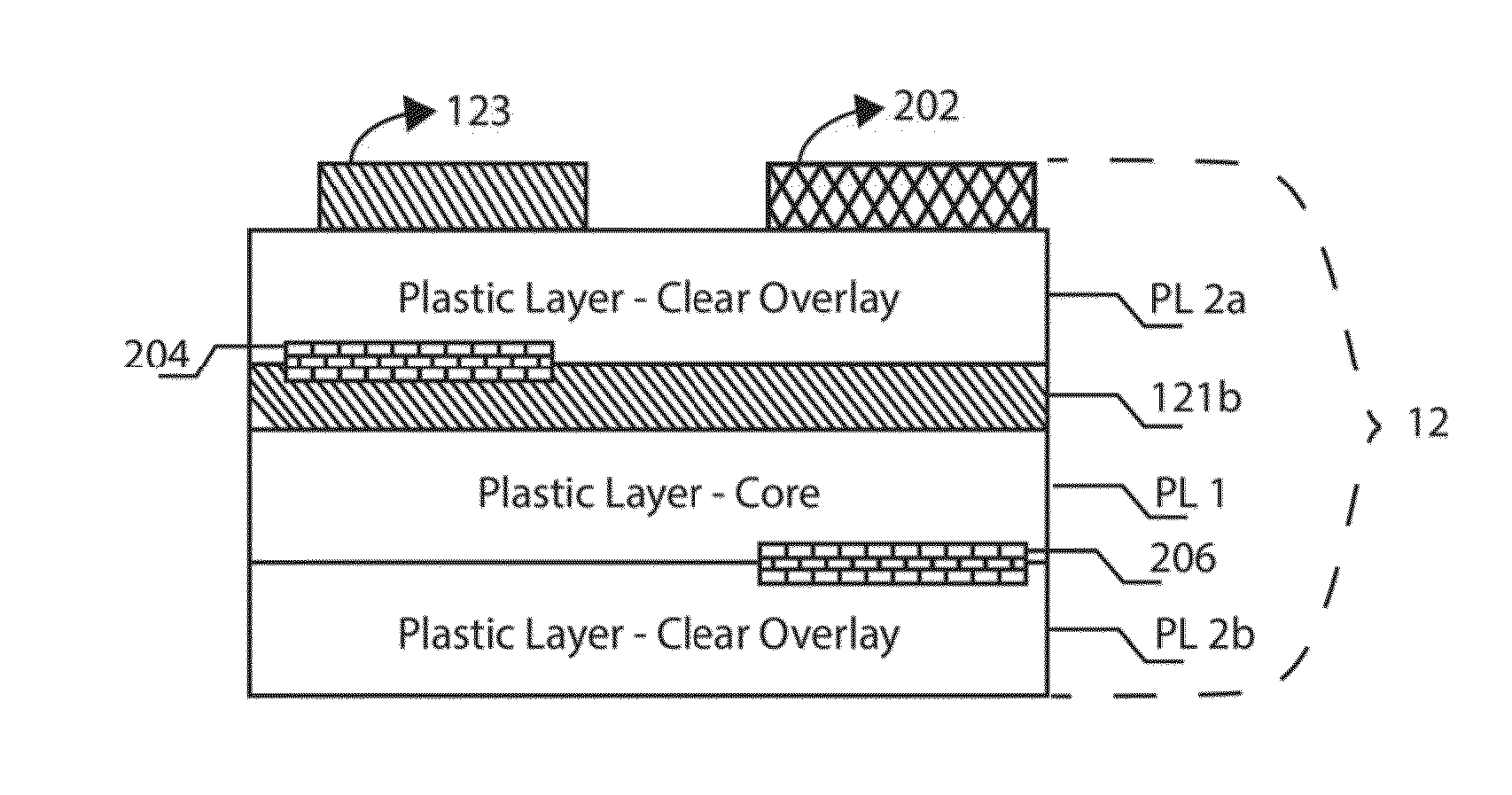

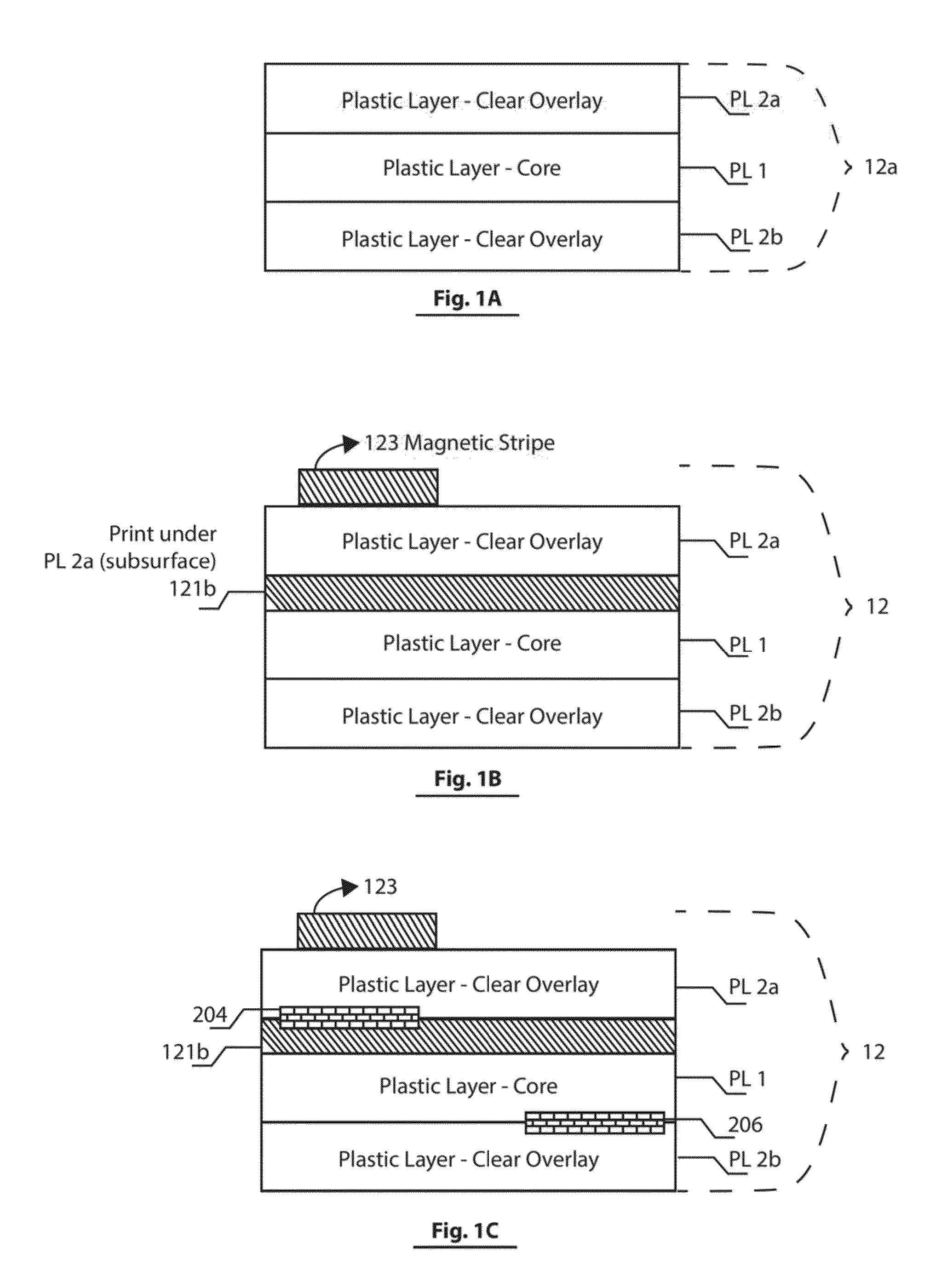

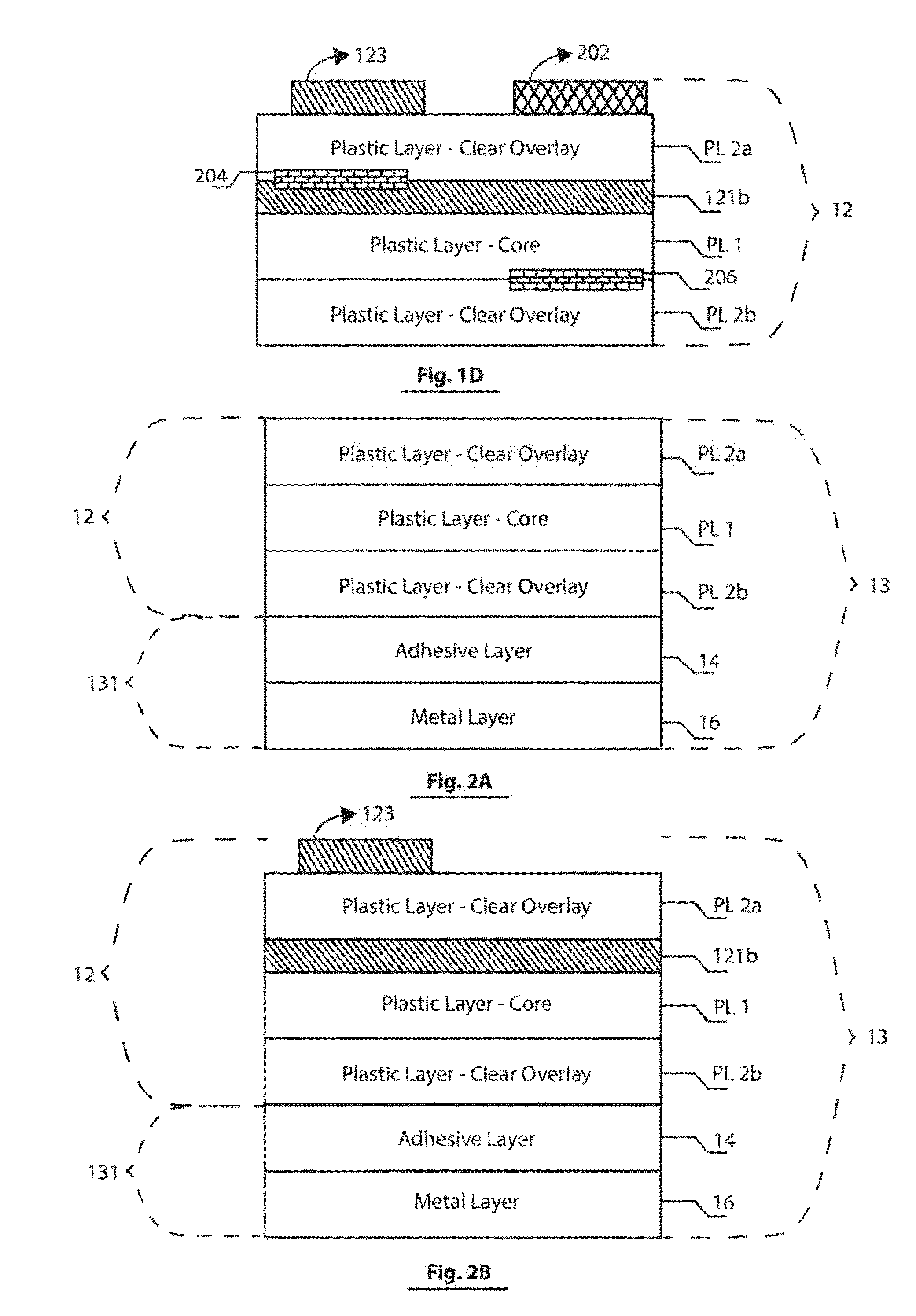

Card with metal layer and electrostatic protection

ActiveUS20150180229A1Minimize the possibilityReduce the possibilityLamination ancillary operationsSynthetic resin layered productsDual stageAcrylic resin

A metal card or a hybrid metal-plastic includes an acrylic resin protective clear coat layer and / or a “hard” nano-particle top-coat layer overlying any exposed metal surface in order to insulate the metal and reduce the likelihood of an electrostatic discharge (ESD) or a short circuit condition. In a particular embodiment the “hard” nano-particle top-coat layer overlies the clear coat layer. The dual stage protective layers which include a clear-coat layer and a top-coat ensure that the problem associated with an ESD and / or a short circuit condition is minimized. In addition, the dual stage protection imparted to a card by forming a clear-coat layer and a top-coat layer ensures that any card surface treatment or card decoration is protected over time from excessive wear or scratching due to use in conjunction with a POS device and / or handling.

Owner:COMPOSECURE LLC

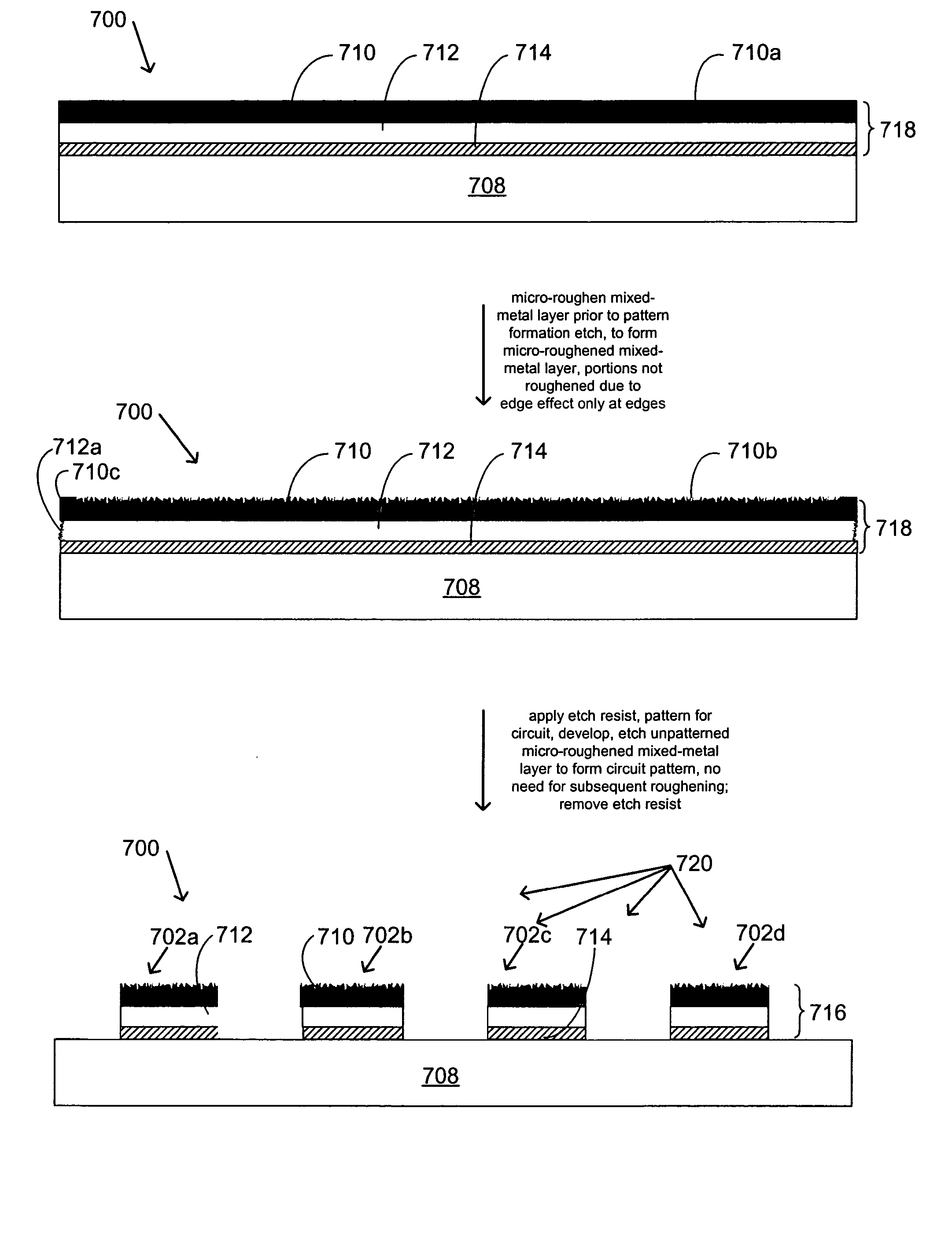

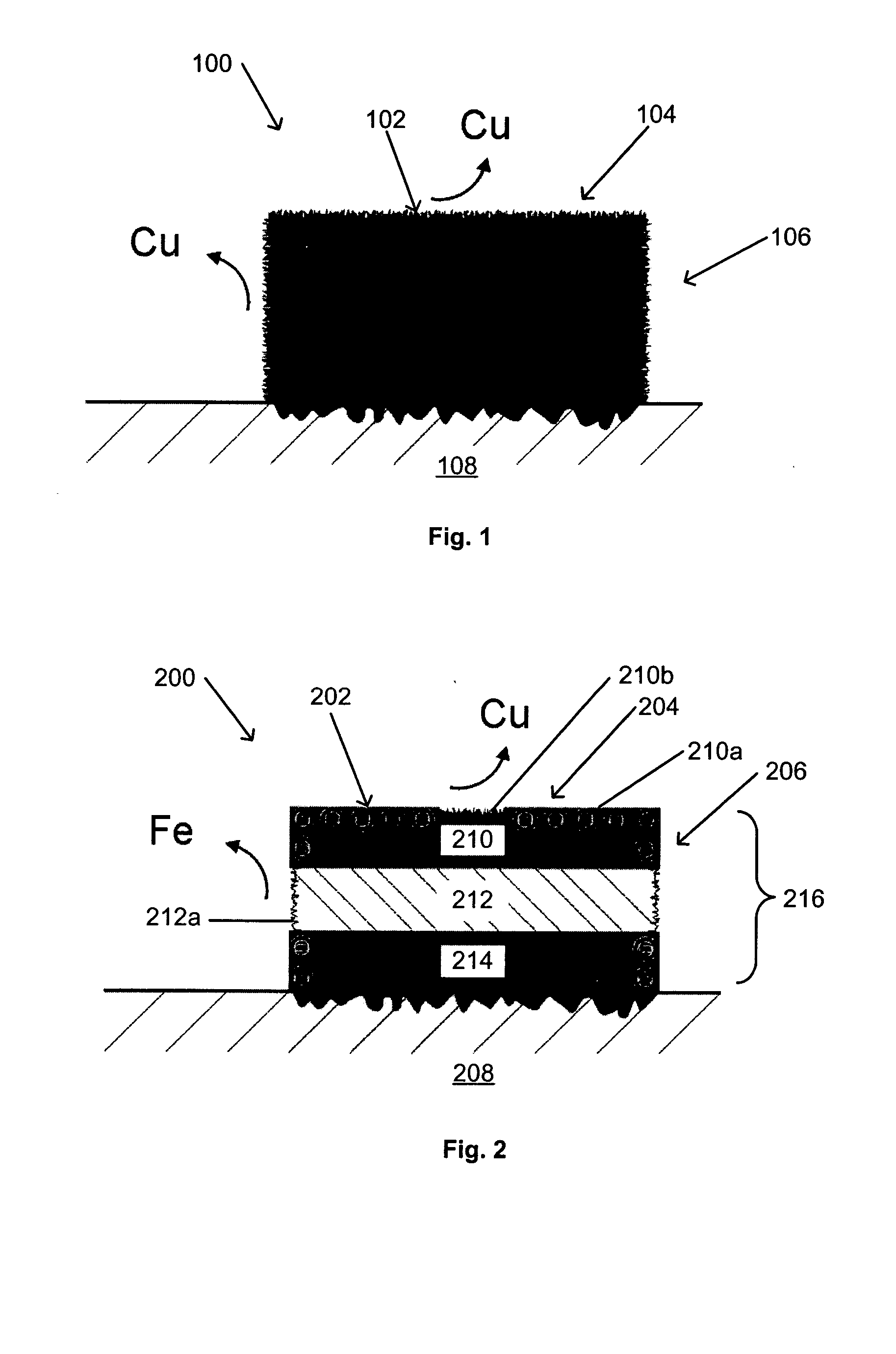

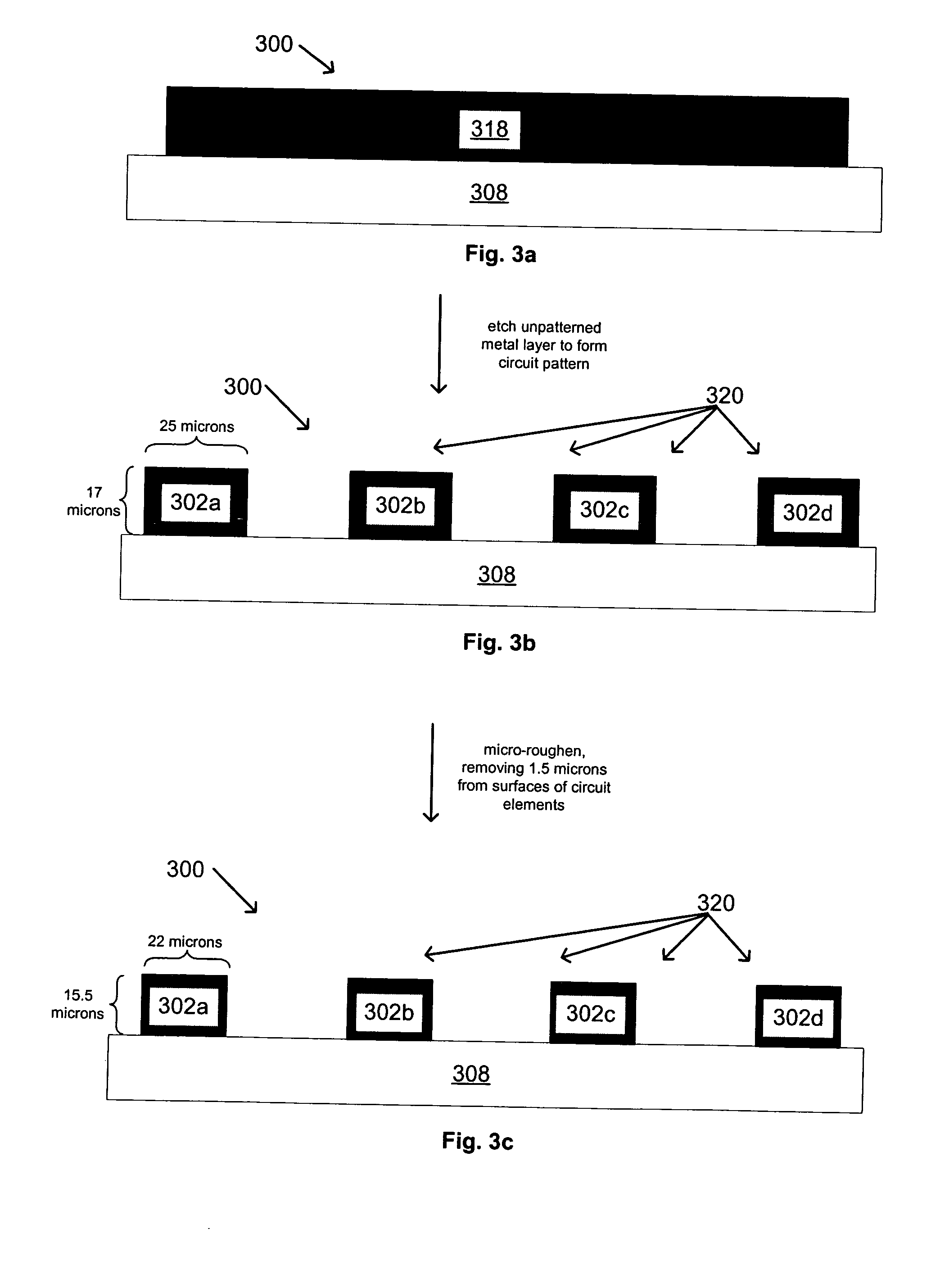

Method for micro-roughening treatment of copper and mixed-metal circuitry

InactiveUS20050067378A1Improve uniformityImprove adhesionInsulating substrate metal adhesion improvementDecorative surface effectsEtchingCopper

Process to improve adhesion of dielectric materials to a metal layer, including providing an unpatterned metal layer having a first major surface; micro-roughening the first major surface to form a micro-roughened surface; and etching the metal layer to form a circuit pattern in the metal layer, in which the micro-roughening is carried out prior to the etching.

Owner:ATOTECH DEUT GMBH

Novel mixed metal oxides

ActiveUS20170165645A1Catalyst activation/preparationHydrocarbon oil crackingHydrodesulfurizationMaterials science

A unique mixed metal molybdotungstate material has been developed. The material may be used as a hydroprocessing catalyst. The hydroprocessing may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodearomatization, hydrodesilication, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

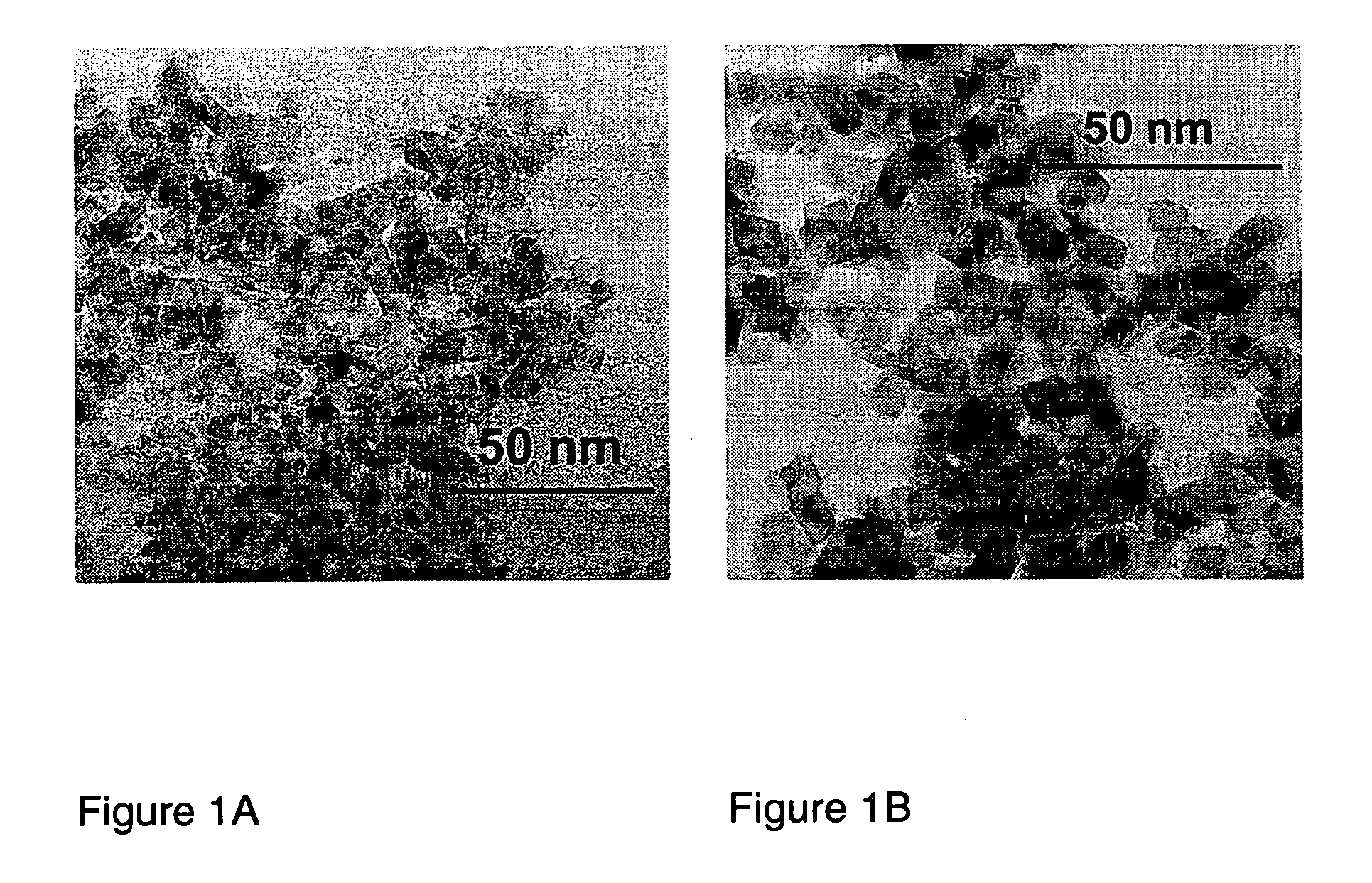

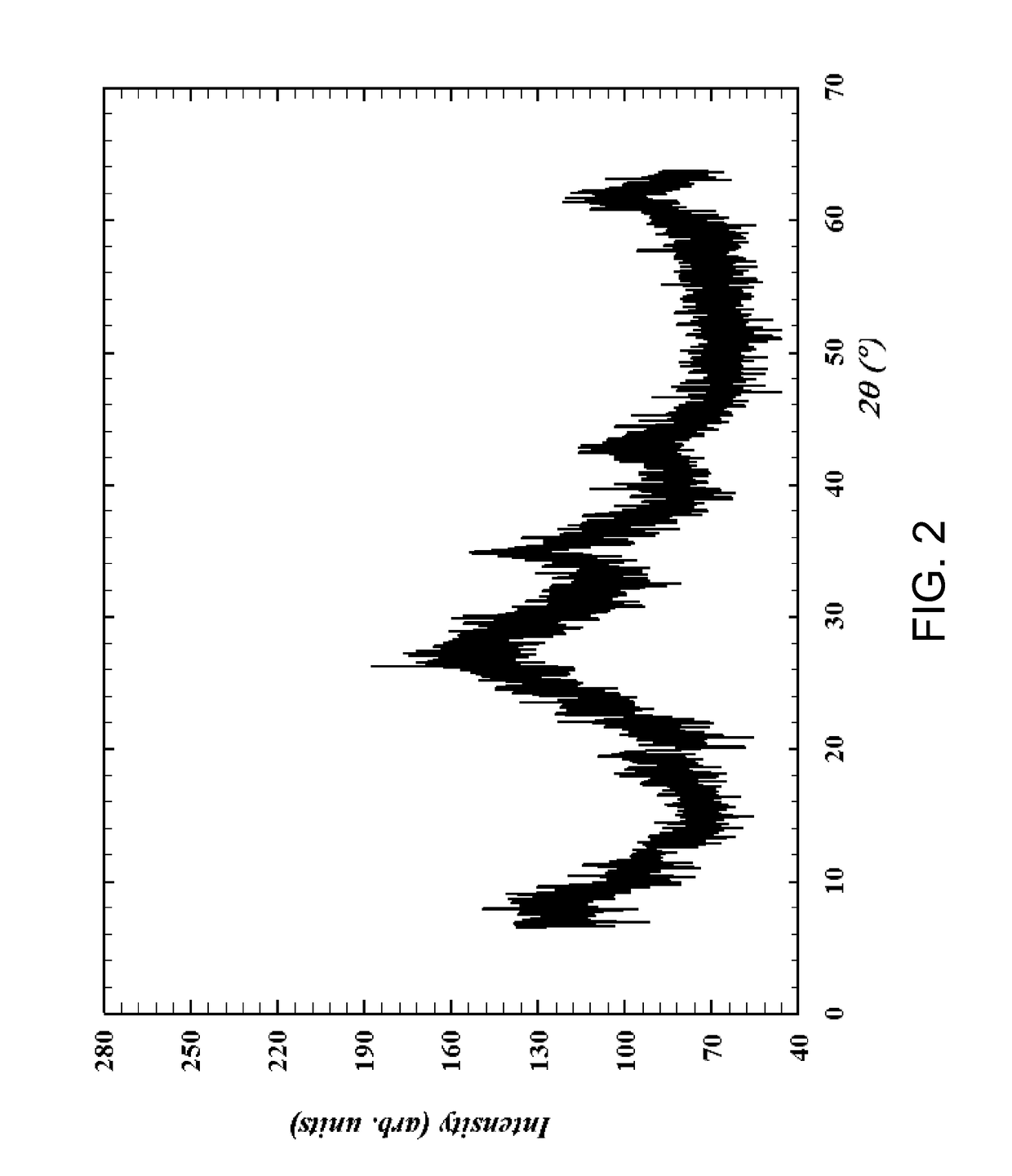

Ceria-based mixed-metal oxide structure, including method of making and use

InactiveUS20030186805A1Increase surface areaSimple structureRare earth metal oxides/hydroxidesMaterial nanotechnologyPtru catalystCerium(IV) oxide

A homogeneous ceria-based mixed-metal oxide, useful as a catalyst support, a co-catalyst and / or a getter, is described. The mixed-metal oxide has a relatively large surface area per weight, typically exceeding 150 m<2> / g, a structure of nanocrystallites having diameters of less than 4 nm, and including pores larger than the nanocrystallites and having diameters in the range of 4 to about 9 nm. The ratio of the pore volumes, VP, to skeletal structure volumes, VS, is typically less than about 2.5, and the surface area per unit volume of the oxide material is greater than 320 m<2> / cm<3>, such that the structural morphology supports both a relatively low internal mass transfer resistance and large effective surface area for reaction activity of interest. The mixed metal oxide is made by co-precipitating a dilute metal salt solution containing the respective metals, which may include Zr, Hf, and / or other metal constituents in addition to Ce, replacing water in the co-precipitate with a water-miscible low surface-tension solvent, and relatively quickly drying and calcining the co-precipitate at moderate temperatures. A highly dispersive catalyst metal, such as Pt, may be loaded on the mixed metal oxide support from a catalyst-containing solution following a selected acid surface treatment of the oxide support. The mixed metal oxide, as catalyst support, co-catalyst or getter, is applied in various reactions, and particularly water gas shift and / or preferential oxidation reactions as associated with fuel processing systems, as for fuel cells and the like.

Owner:INT FUEL CELLS

Synthesis of metal phosphates

InactiveUS7060238B2PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesLithiumSufficient time

The present invention relates to a method for preparing a metal phosphate which comprises milling in a carbonaceous vessel a lithium source, a phosphate source, such as LiH2PO4, and a metal oxide containing a metal ion wherein the metal ion is capable of being reduced, to produced a milled mixture and heating the milled mixture in an inert atmosphere at a temperature and for a time sufficient to form a metal phosphate wherein the metal ion of the metal oxide is reduced in oxidation state without the direct addition of a reducing agent to the starting materials. In another embodiment the present invention relates to a method for preparing a mixed metal phosphate which comprises milling a lithium source and a phosphate source, such as LiH2PO4, a metal oxide and another metal compound wherein at least one of the metal compounds contains a metal ion capable of being reduced to produce a milled mixture and heating the resulting milled mixture in an inert atmosphere at a temperature and for a time sufficient to form a mixed metal phosphate, wherein the oxidation state of at least one of the metal ions is reduced in oxidation state without the direct addition of a reducing agent to the reactants. It is another object of the invention to provide electrochemically active materials produced by said methods.

Owner:VALENCE TECH INC

Catalysts for catalytic oxidation of propane to acrylic acid, methods of making and using the same

InactiveUS6114278AIncrease productivityHigh yieldOrganic compound preparationOrganic chemistry methodsPartial oxidationCatalytic oxidation

A mixed metal oxide Mo-V-Ga-Pd-Nb-X (where X=La, Te, Ge, Zn, Si, In or W) catalytic system providing a higher selectivity to acrylic acid in the low temperature partial oxidation of propane with a molecular oxygen-containing gas.

Owner:SAUDI BASIC IND CORP SA

WET CHEMICAL METHOD OF FORMING STABLE PiPd DIESEL OXIDATION

InactiveUS20120214666A1Minimizing and eliminating mobilityMinimizing and eliminating and agglomerationMaterial nanotechnologyCatalyst activation/preparationNanoparticleCopper

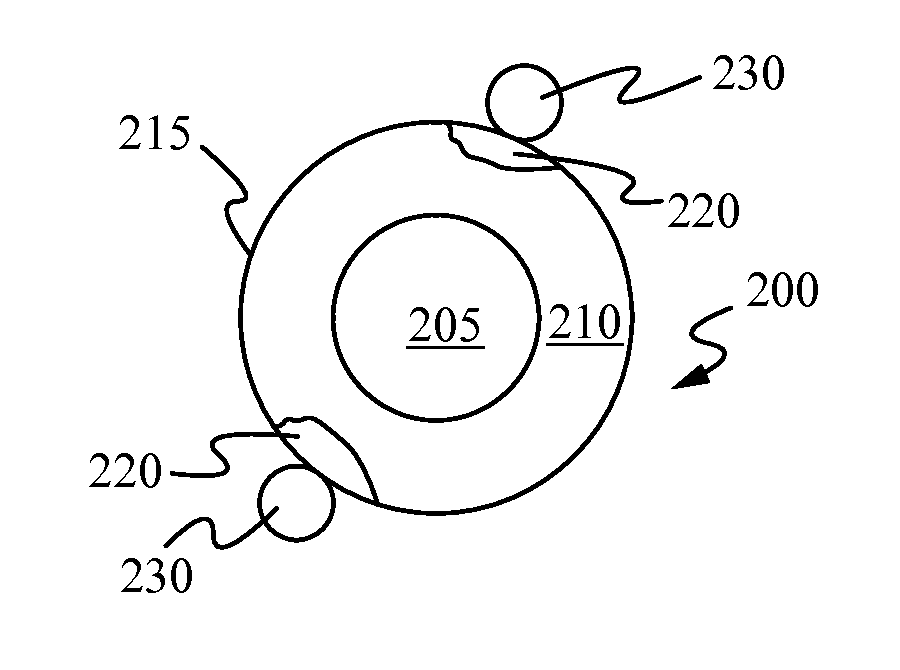

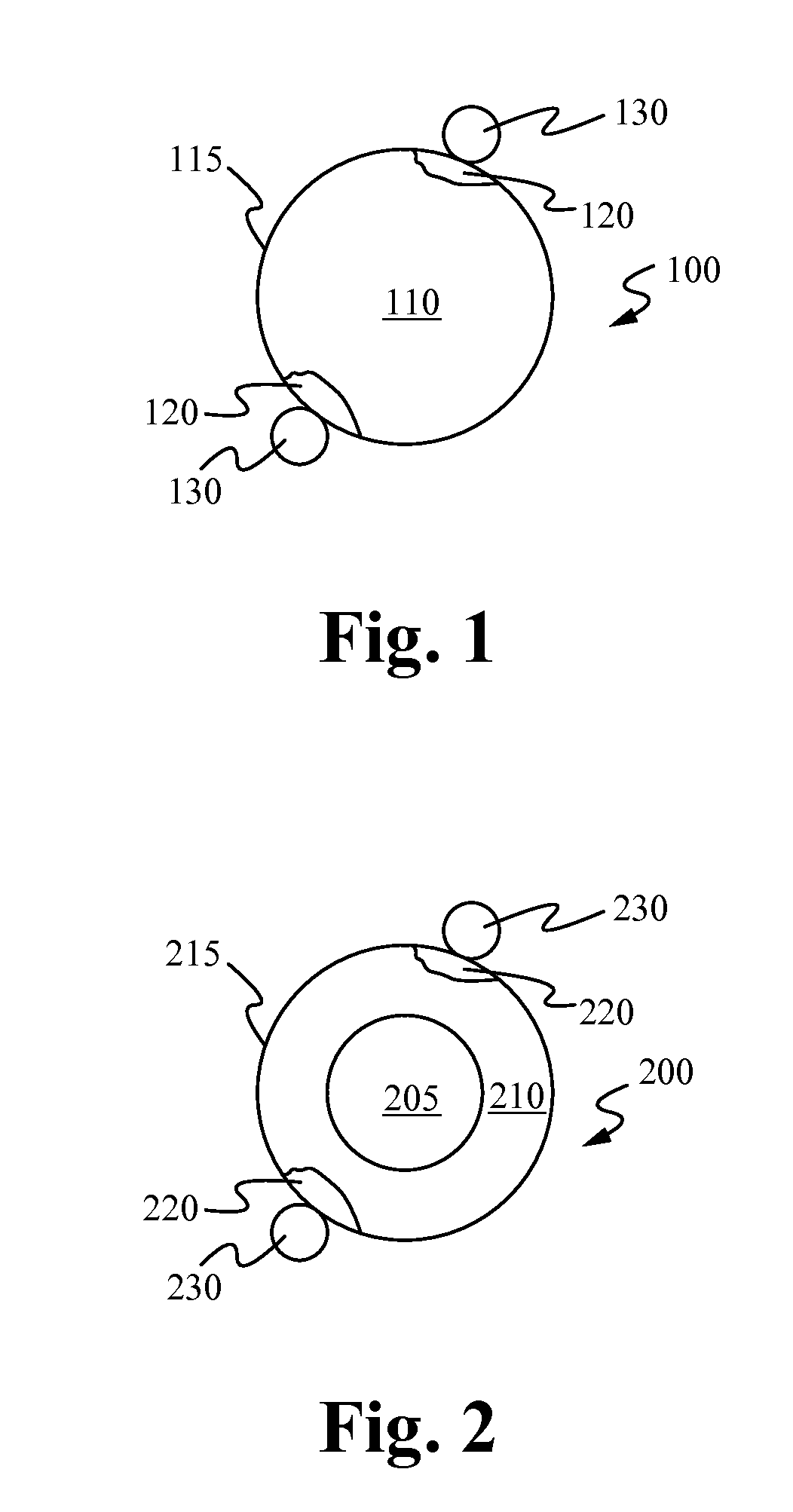

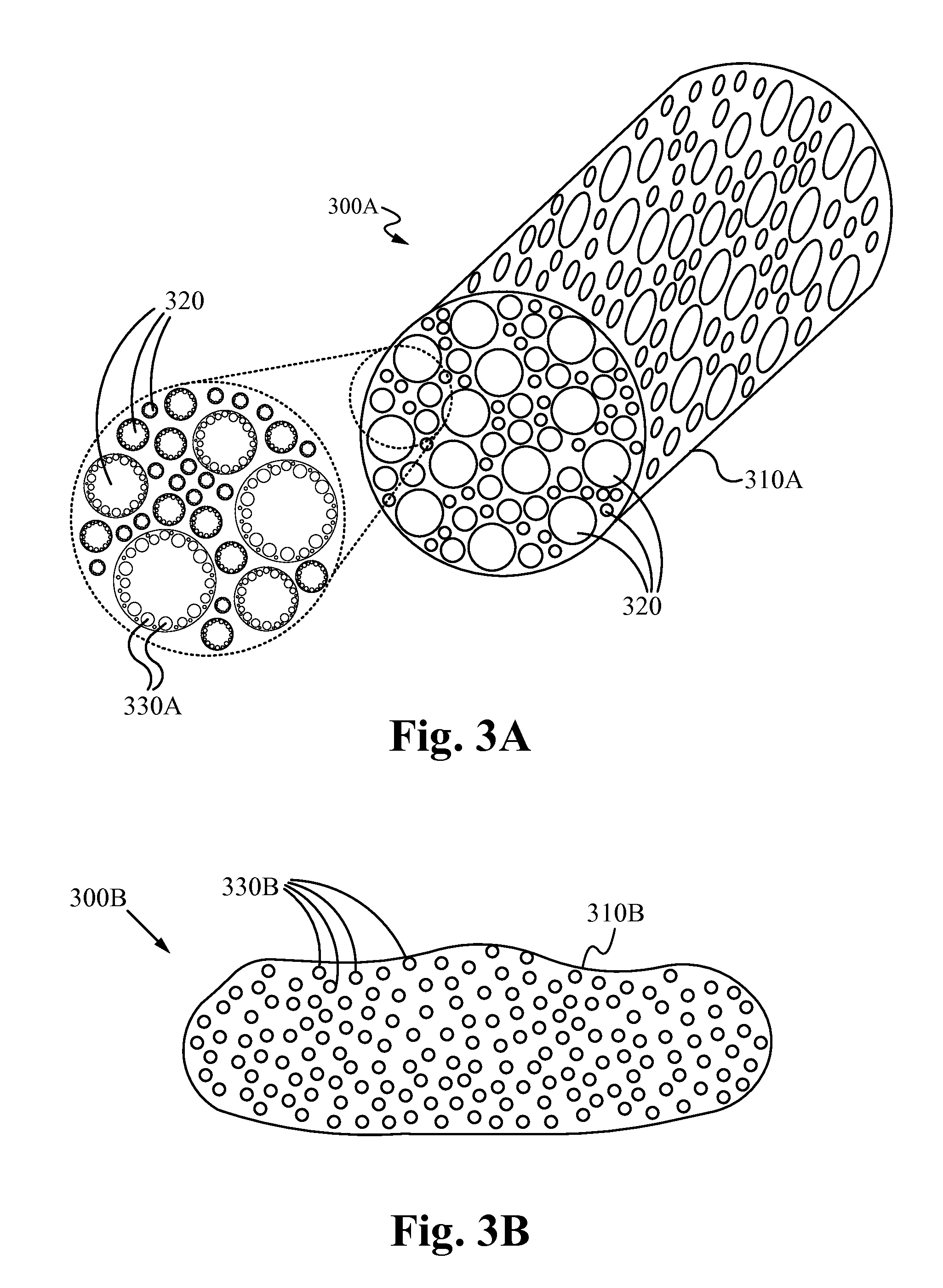

A nano-particle comprising: an interior region comprising a mixed-metal oxide; and an exterior surface comprising a pure metal. In some embodiments, the mixed-metal oxide comprises aluminum oxide and a metallic pinning agent, such as palladium, copper, molybdenum, or cobalt. In some embodiments, the pure metal at the exterior surface is the same as the metallic pinning agent in the mixed-metal oxide in the interior region. In some embodiments, a catalytic nano-particle is bonded to the pure metal at the exterior surface. In some embodiments, the interior region and the exterior surface are formed using a plasma gun. In some embodiments, the interior region and the exterior surface are formed using a wet chemistry process. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a plasma gun. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a wet chemistry process.

Owner:UMICORE AG & CO KG +1

Hybrid beam and stanchion incorporating hybrid beam

A hybrid metal / composite material beam is suitable for withstanding bending stresses. The hybrid beam is a combination of dissimilar materials that are geometrically optimized in a structure to provide benefits beyond the characteristics of the materials separately. Also a stanchion assembly incorporates the hybrid beam.

Owner:KAZAK COMPOSITES

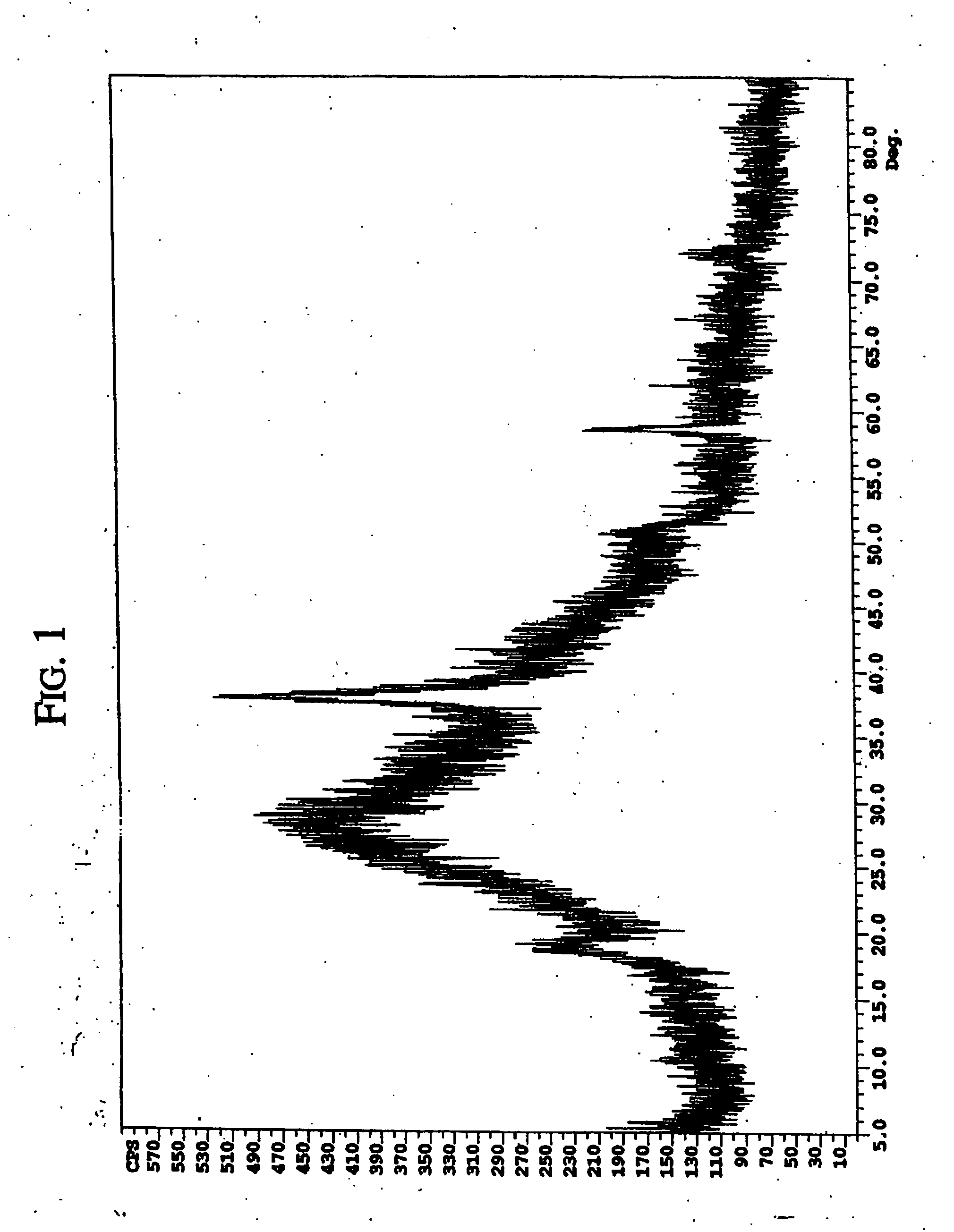

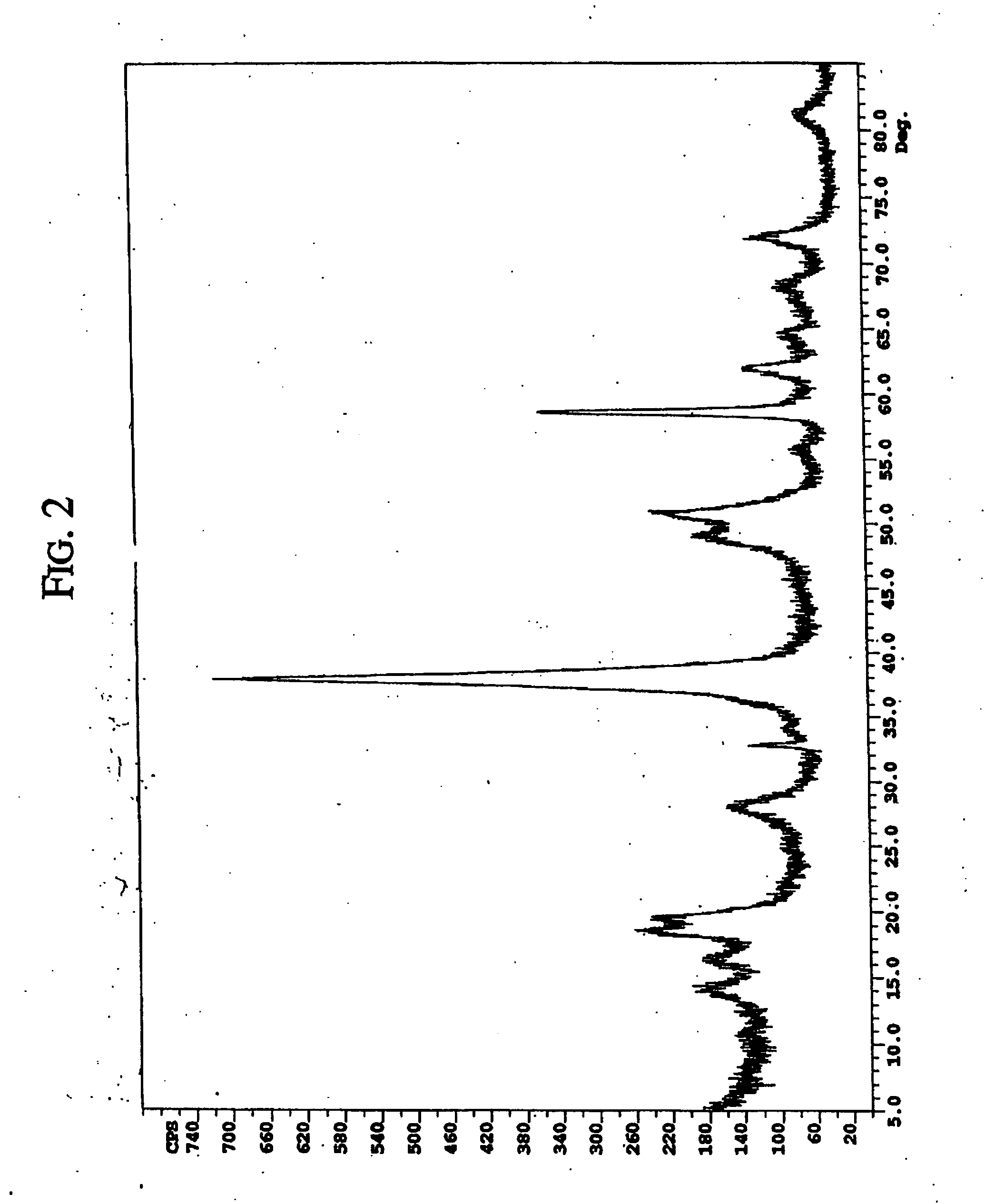

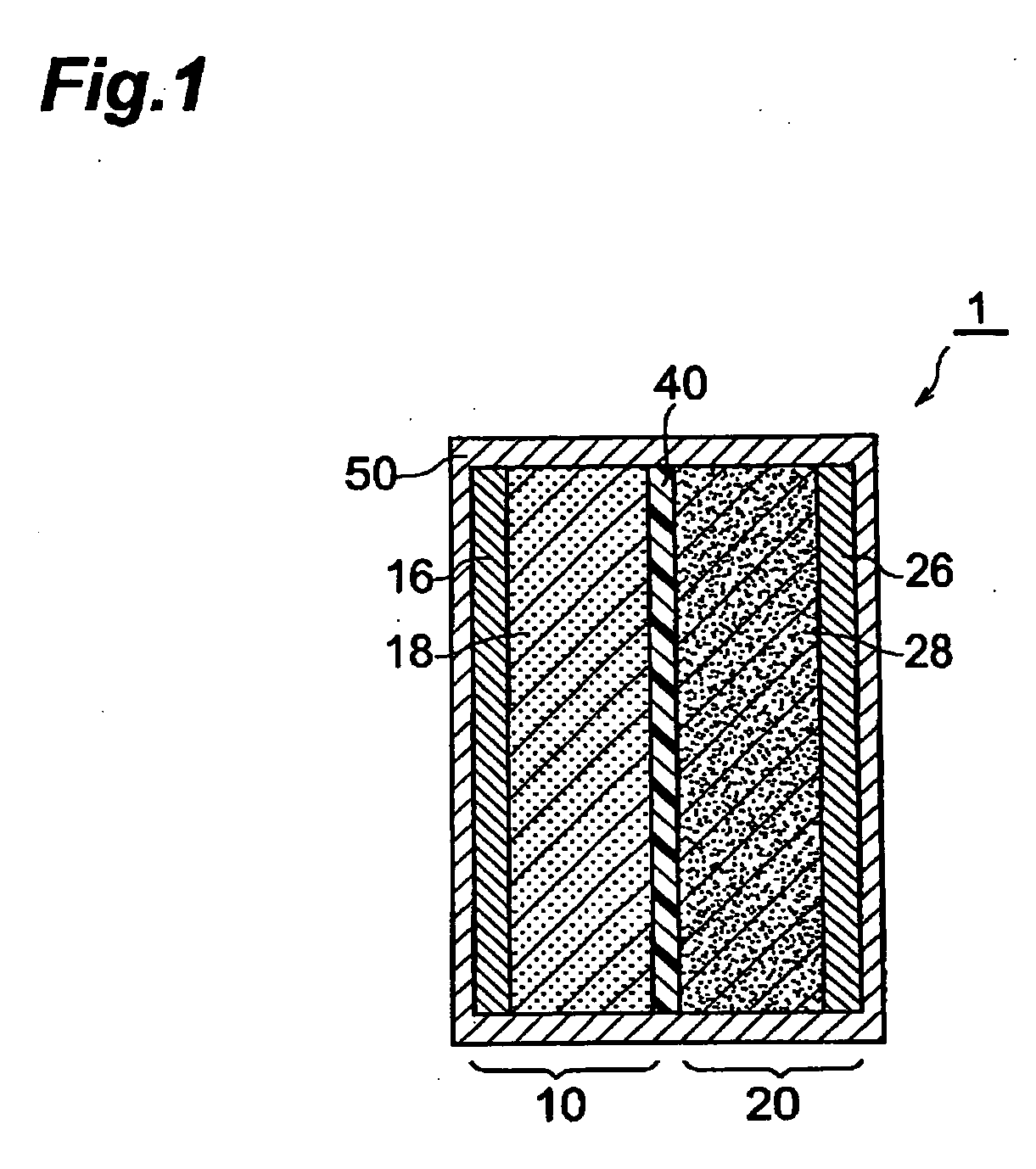

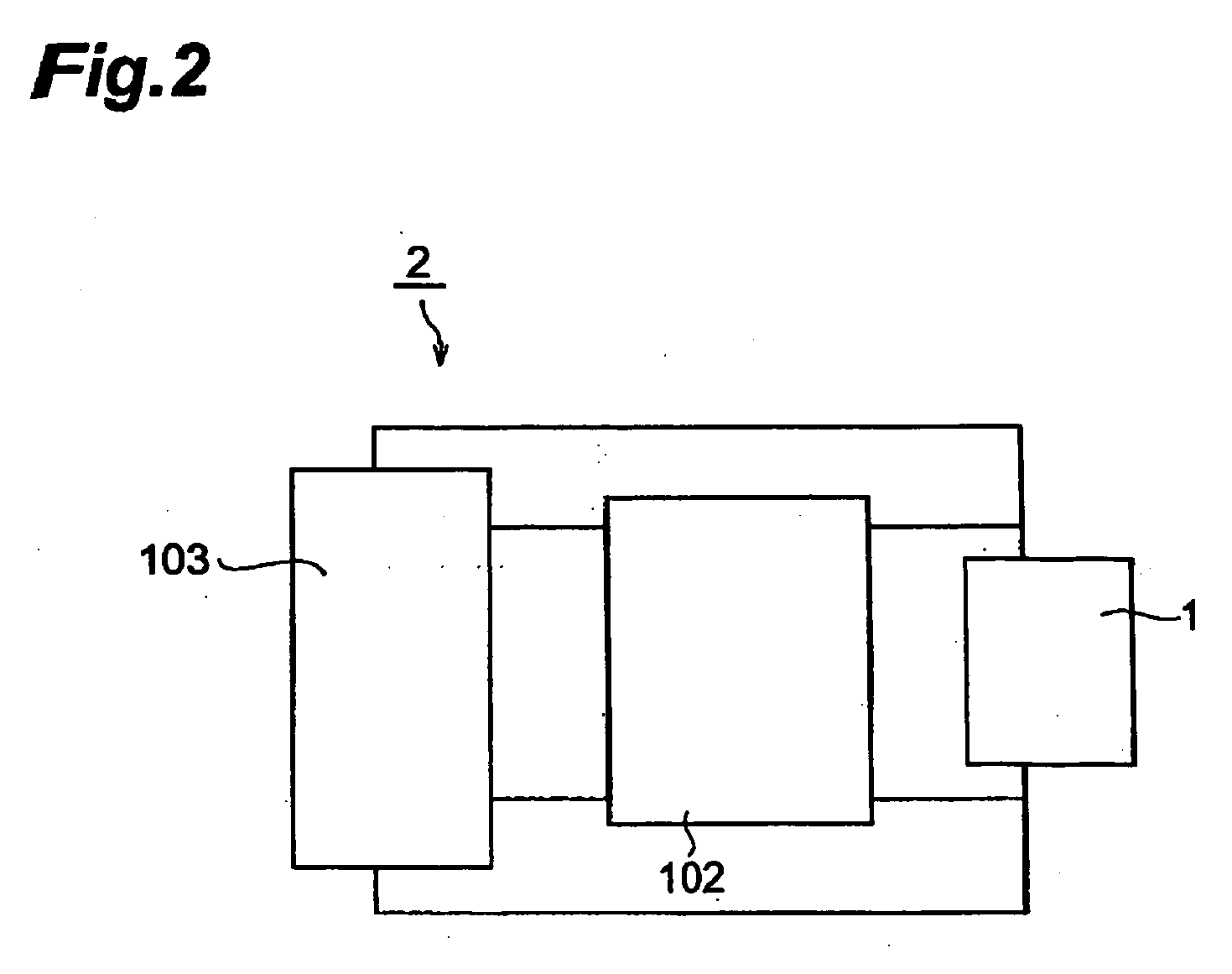

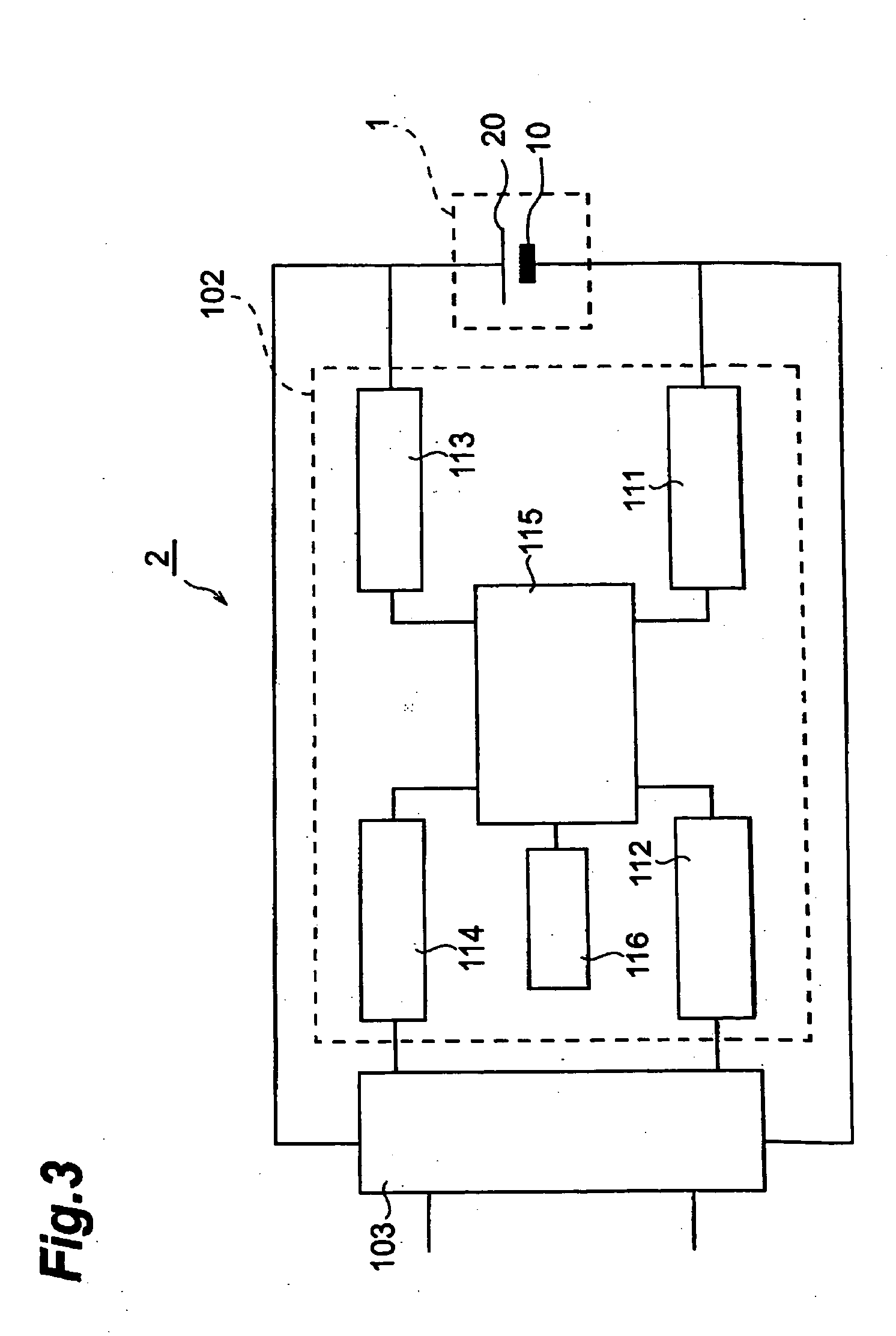

Method of charging lithium ion secondary battery, charging apparatus, and power supply apparatus

ActiveUS20050194934A1Short timeReduced characteristicsBatteries circuit arrangementsNon-aqueous electrolyte accumulatorsLithiumCapacity value

The method of charging a lithium ion secondary battery uses a lithium ion secondary battery comprising a positive electrode including a mixed metal oxide containing at least Li, Mn, and Ni as metal components as a positive electrode active material, a negative electrode, and a nonaqueous electrolytic solution containing a lithium salt; and includes a constant current charging step of carrying out constant current charging with a set charging current value I1 corresponding to a set value nC satisfying the condition represented by the expression of 2C≦nC≦60C, where C is a rated capacity value of the lithium ion secondary battery, and n is a number of 2 to 60.

Owner:TDK CORPARATION

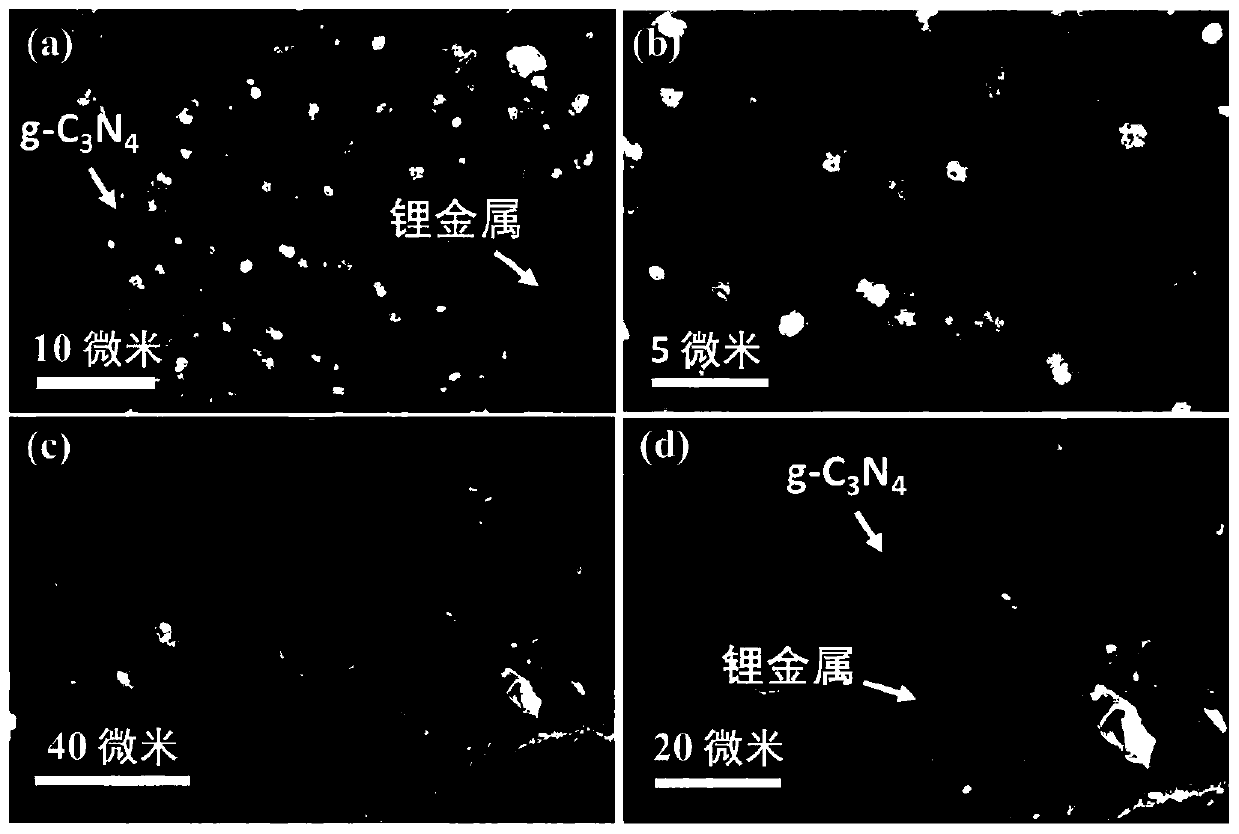

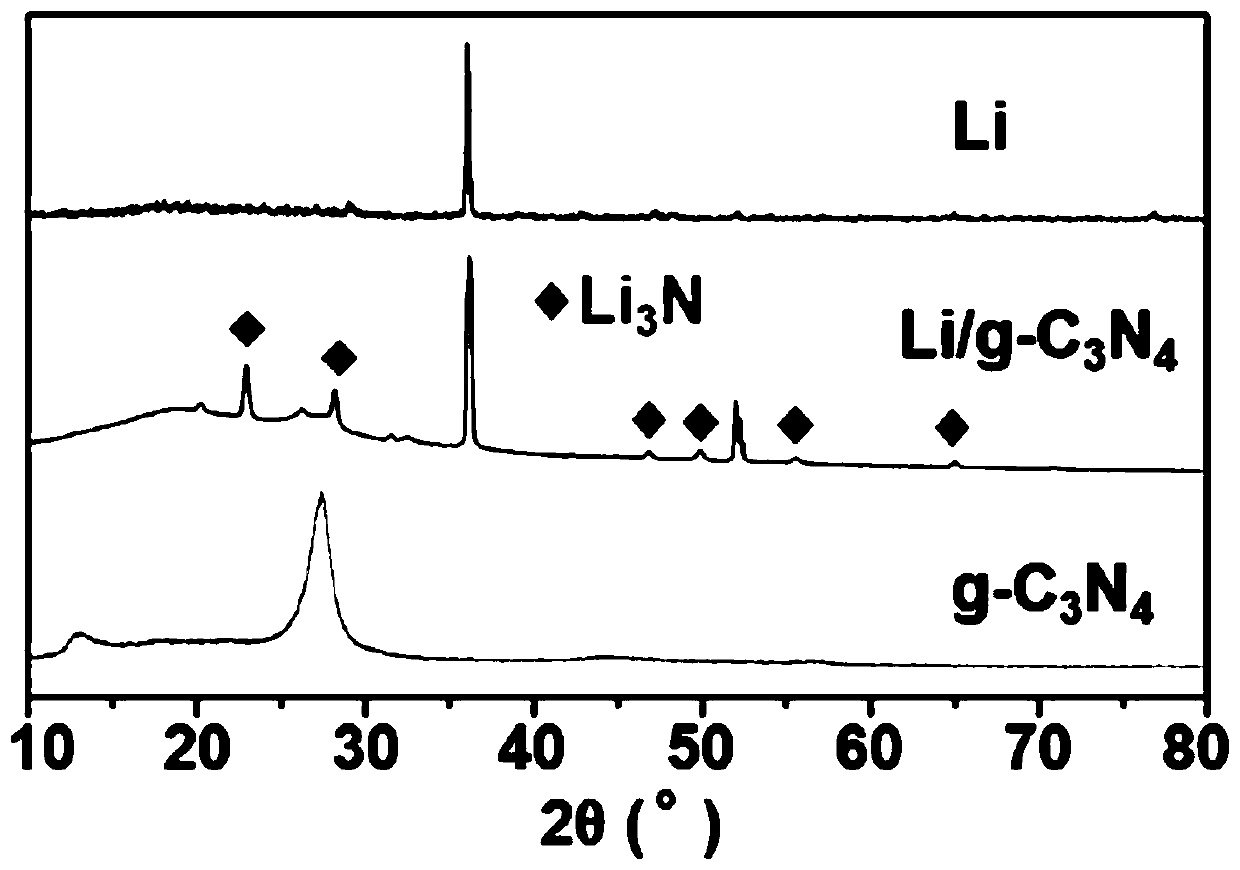

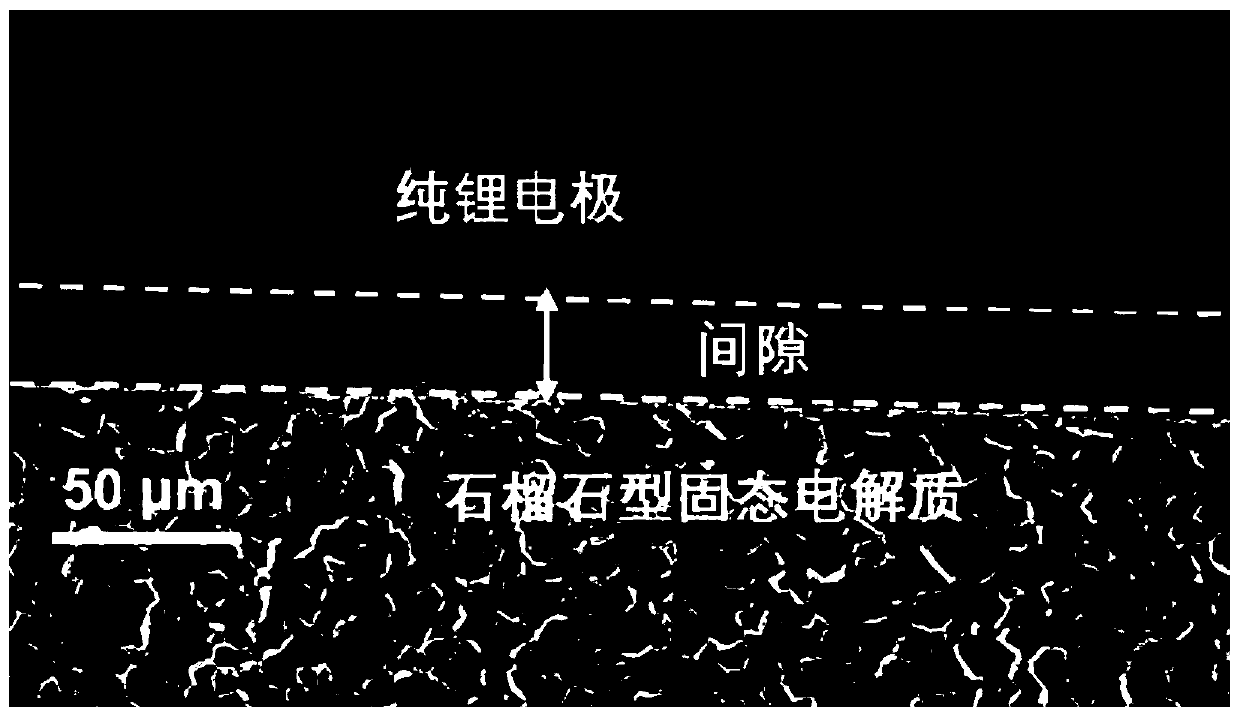

Modified lithium-based composite negative material for solid state battery and preparation and application of material

InactiveCN109841817AOptimize interface compositionImprove cyclic charge and discharge capacityElectrode manufacturing processesSecondary cellsSolid state electrolyteInterfacial resistance

The invention relates to a modified lithium-based composite negative material for a solid state battery and preparation and application of the material. The modified lithium-based composite negative material comprises 50-95 parts of lithium and 5-50 parts of a modified additive by weight; and the modified additive comprises one or multiple nitride or fluoride. The preparation method comprises thatthe lithium and modified additive are mixed, heated to 180-400 DEG C, stirred uniformly, and cooled to the room temperature; and the modified composite negative material is used to the solid state battery, and combined with a solid electrolyte. Compared with the prior art, the lithium metal is mixed with the modified additive by mixing in a heating fusing way, the surface energy of the lithium metal can be reduced effectively, elements including nitrogen and fluorine are introduced in a controllable way, the interfacial resistance between the solid electrolyte and lithium cathode is reduced effectively, the limit current that can be born by the solid electrolyte is increased, the recyclable charge and discharge capacity is improved, and the solid electrolyte and cathode interface is stable for a longer time in the long circulation process.

Owner:TONGJI UNIV

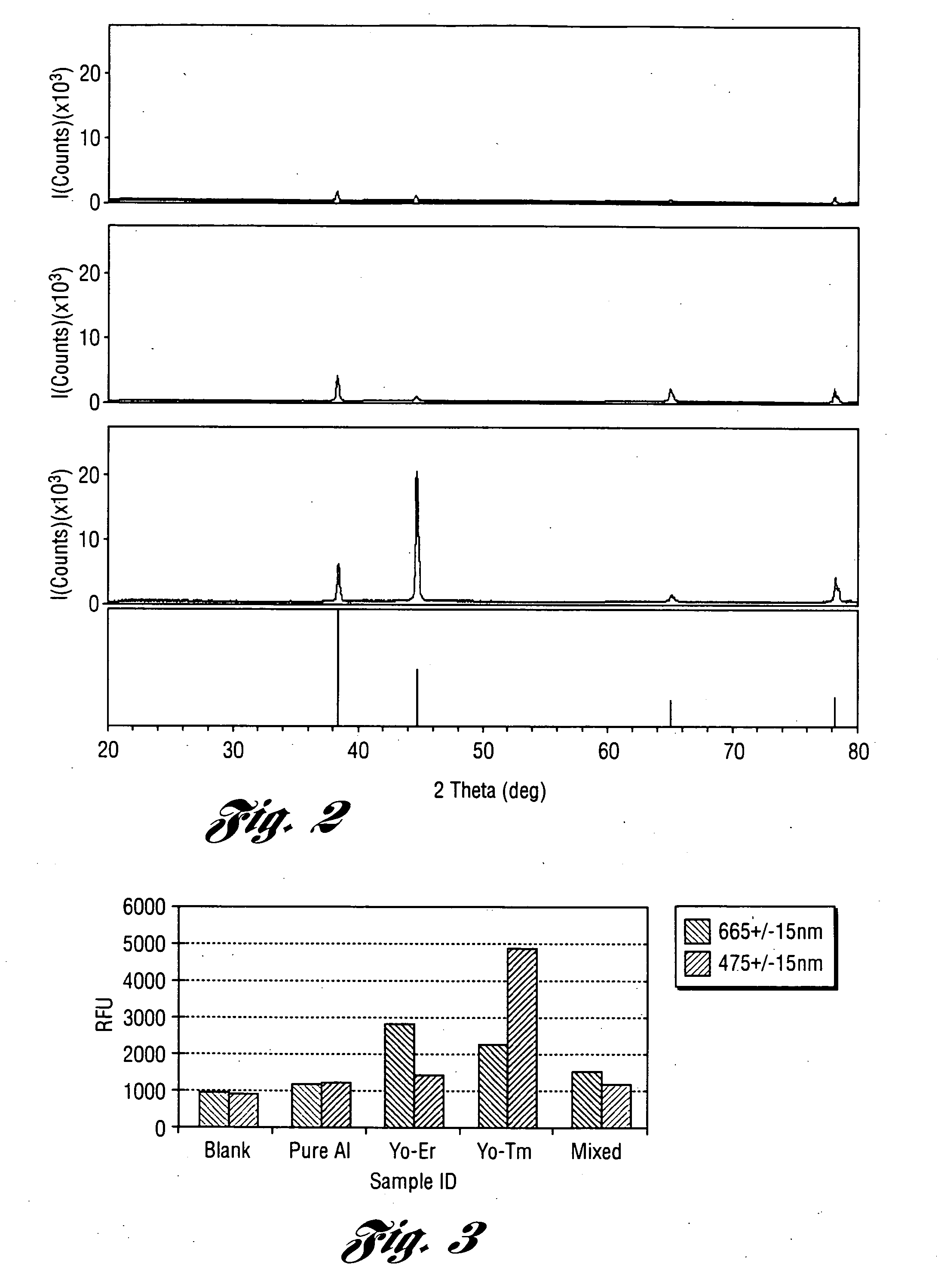

Process for tagging of manufactured articles with up-and down-converting metal oxide nanophosphors and articles produced thereby

Manufactured articles are rendered identifiable as to their source or genuineness by incorporating one or more populations of up- and / or down-converting metal oxide or mixed metal oxides during or post manufacture. The nanoparticles exhibit emission of light upon irradiation by energy sources which allows comparison between the emission spectrum of an article with the emission expected of a genuine article or a material from a given manufacturing process, i.e. a batch of material.

Owner:NANOMARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com