Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6185results about "Roof covering using tiles/slates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

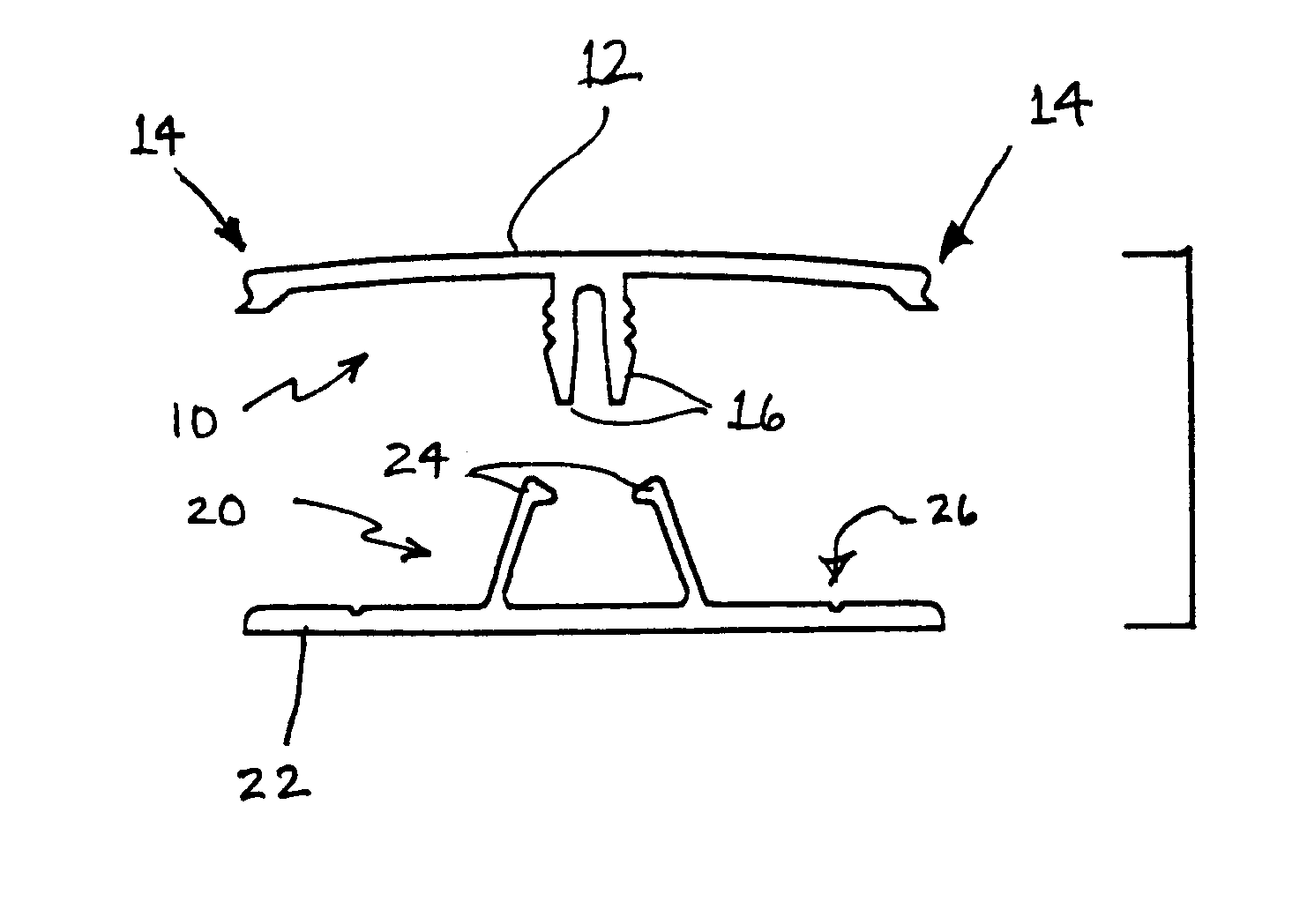

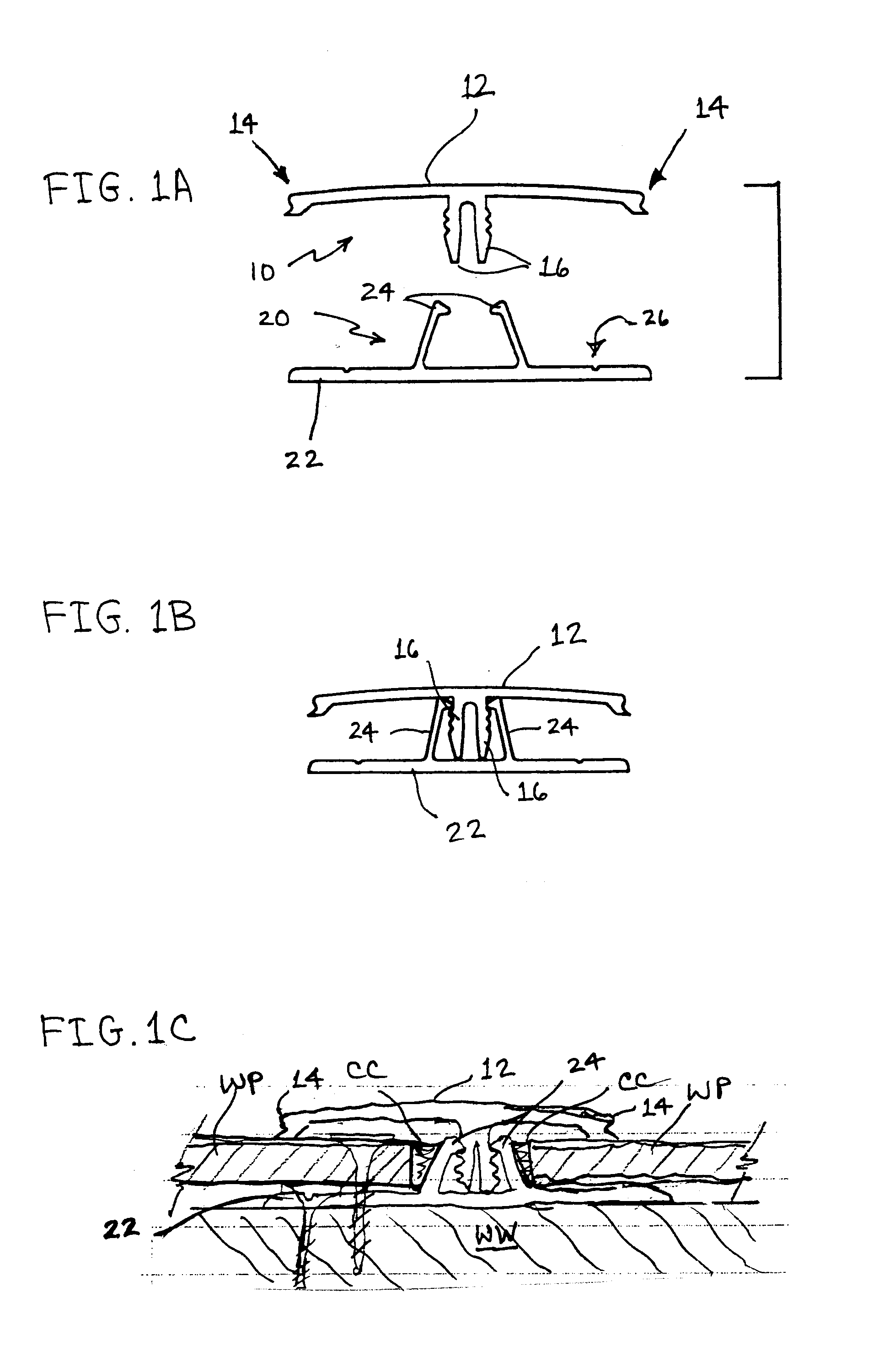

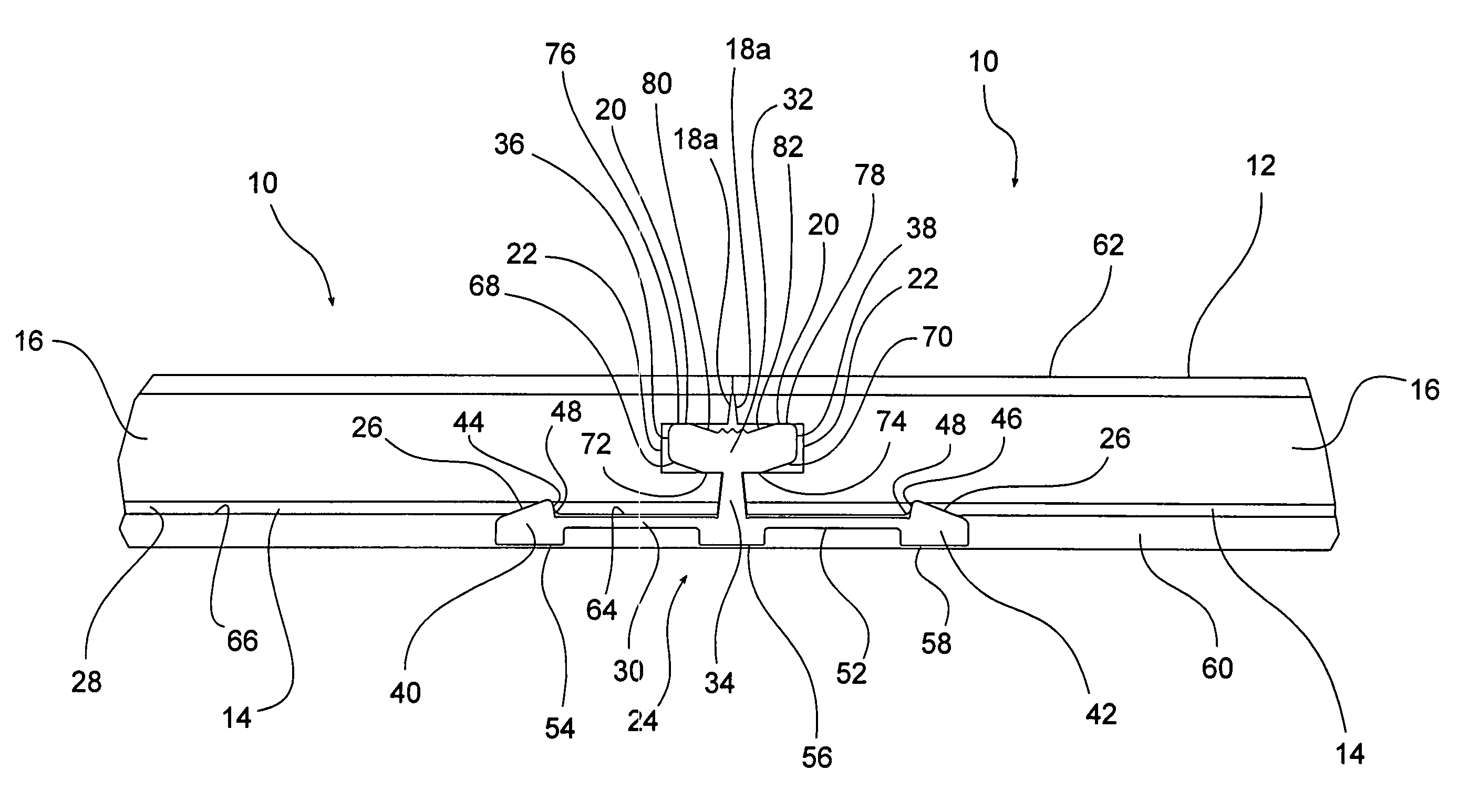

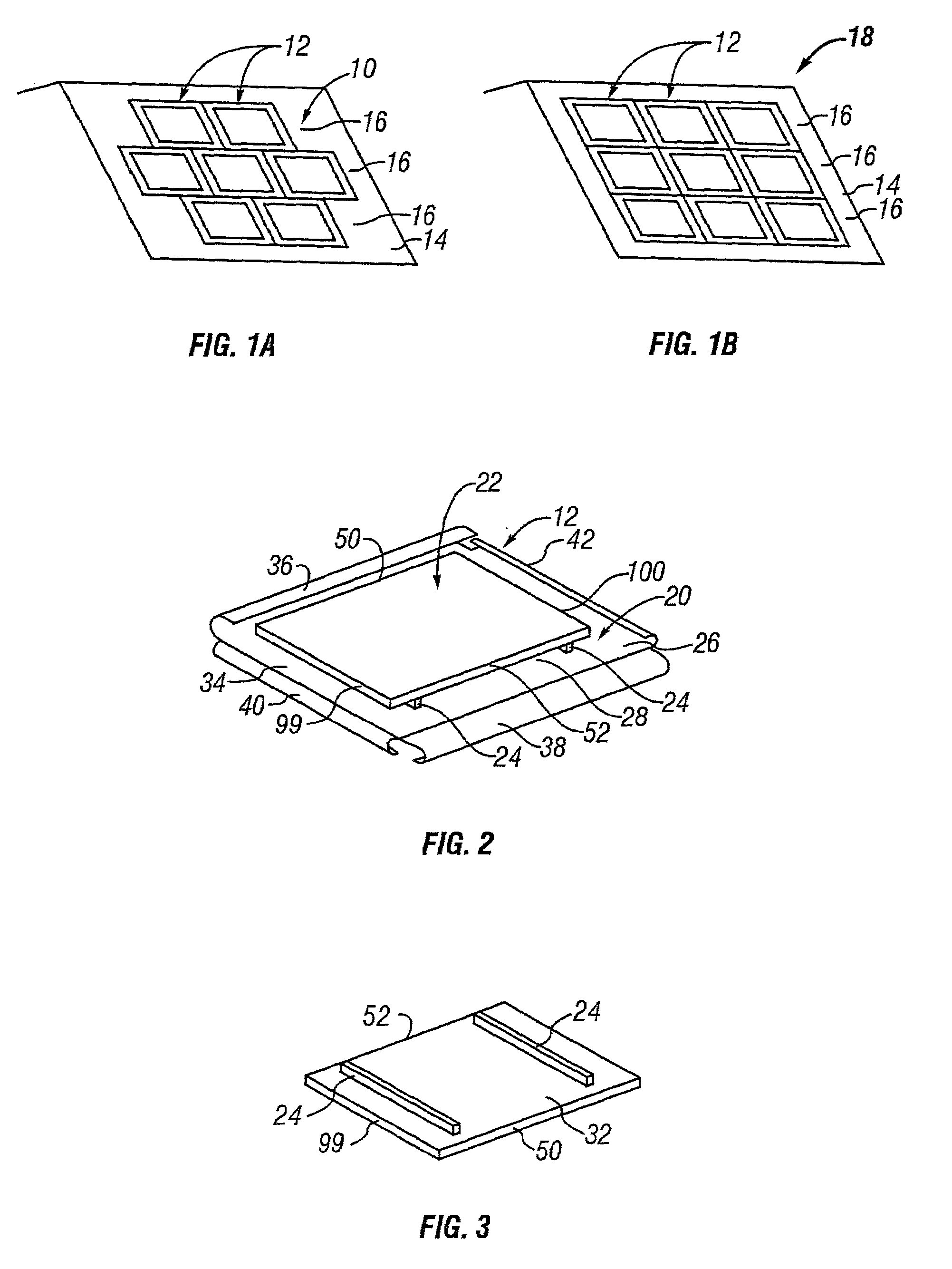

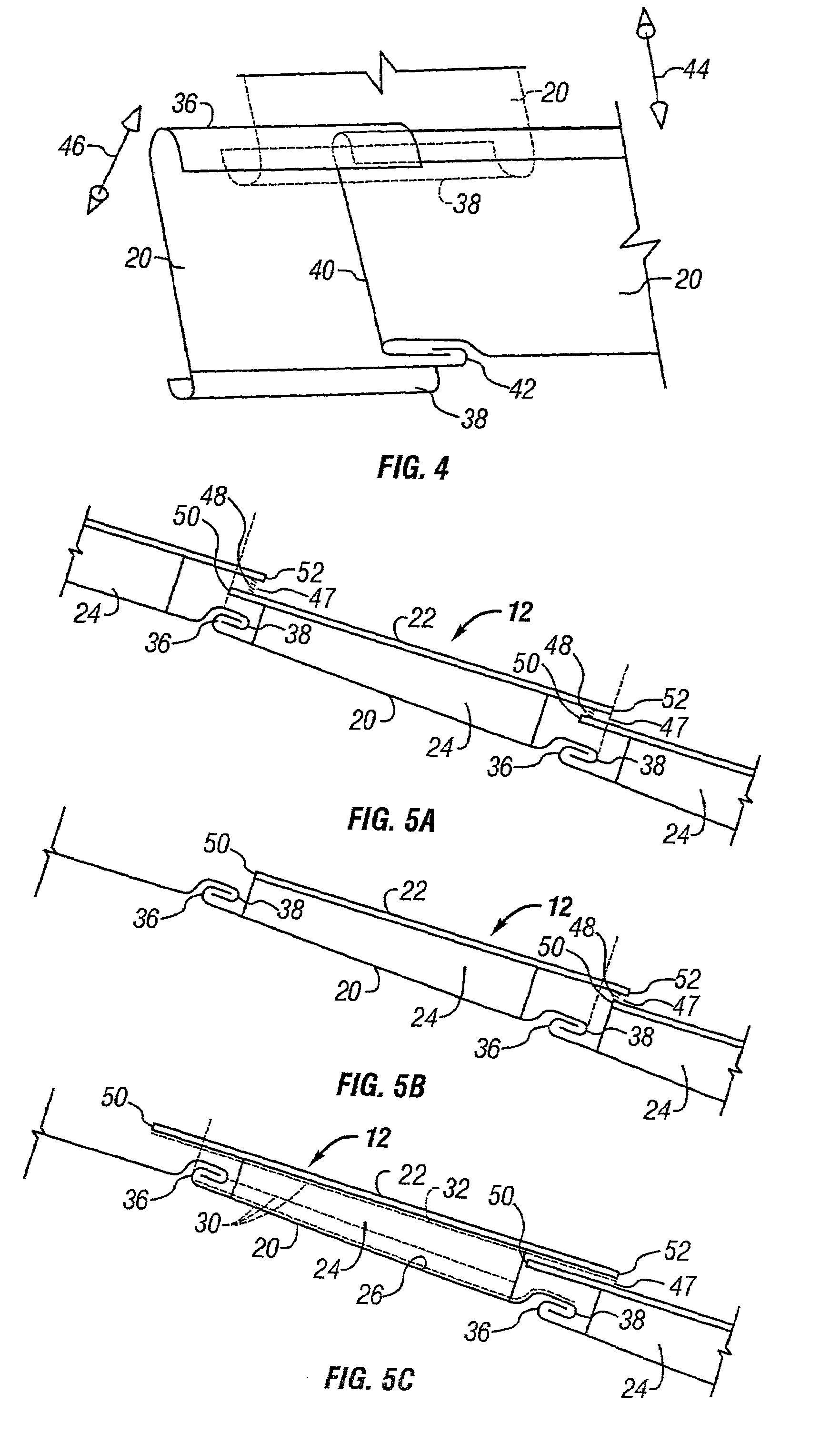

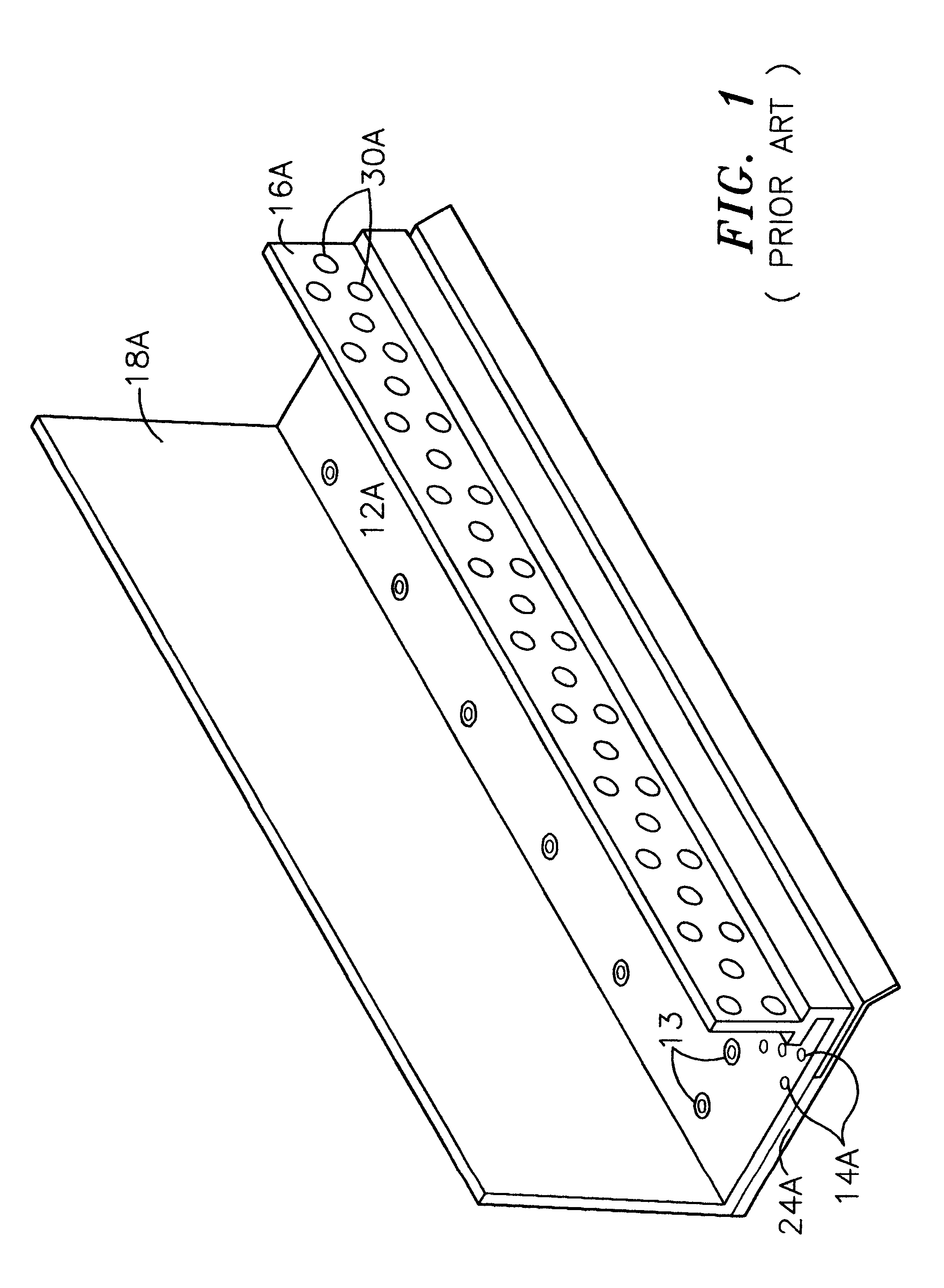

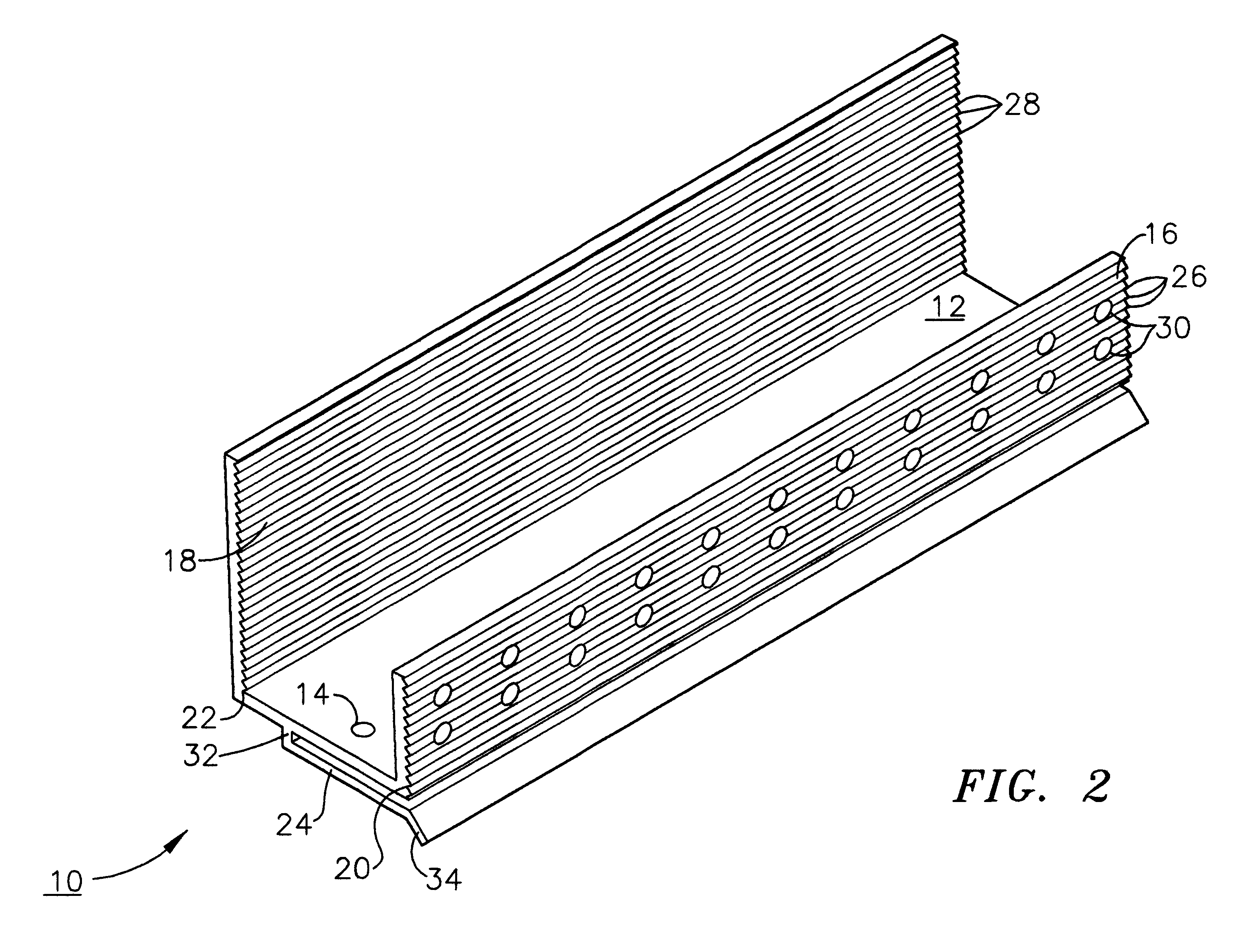

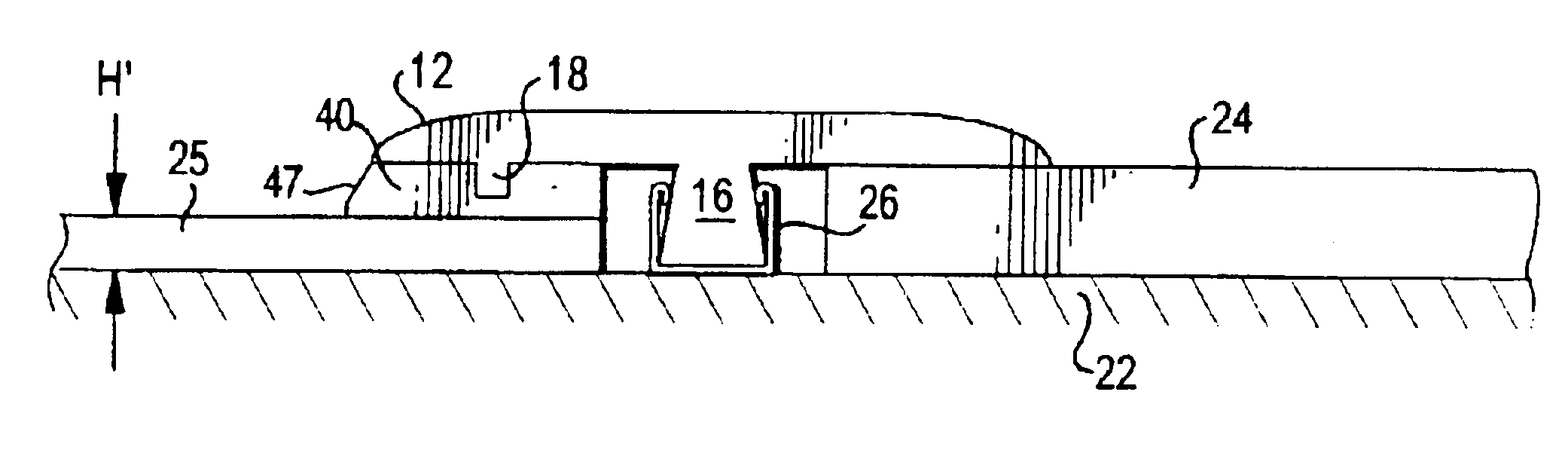

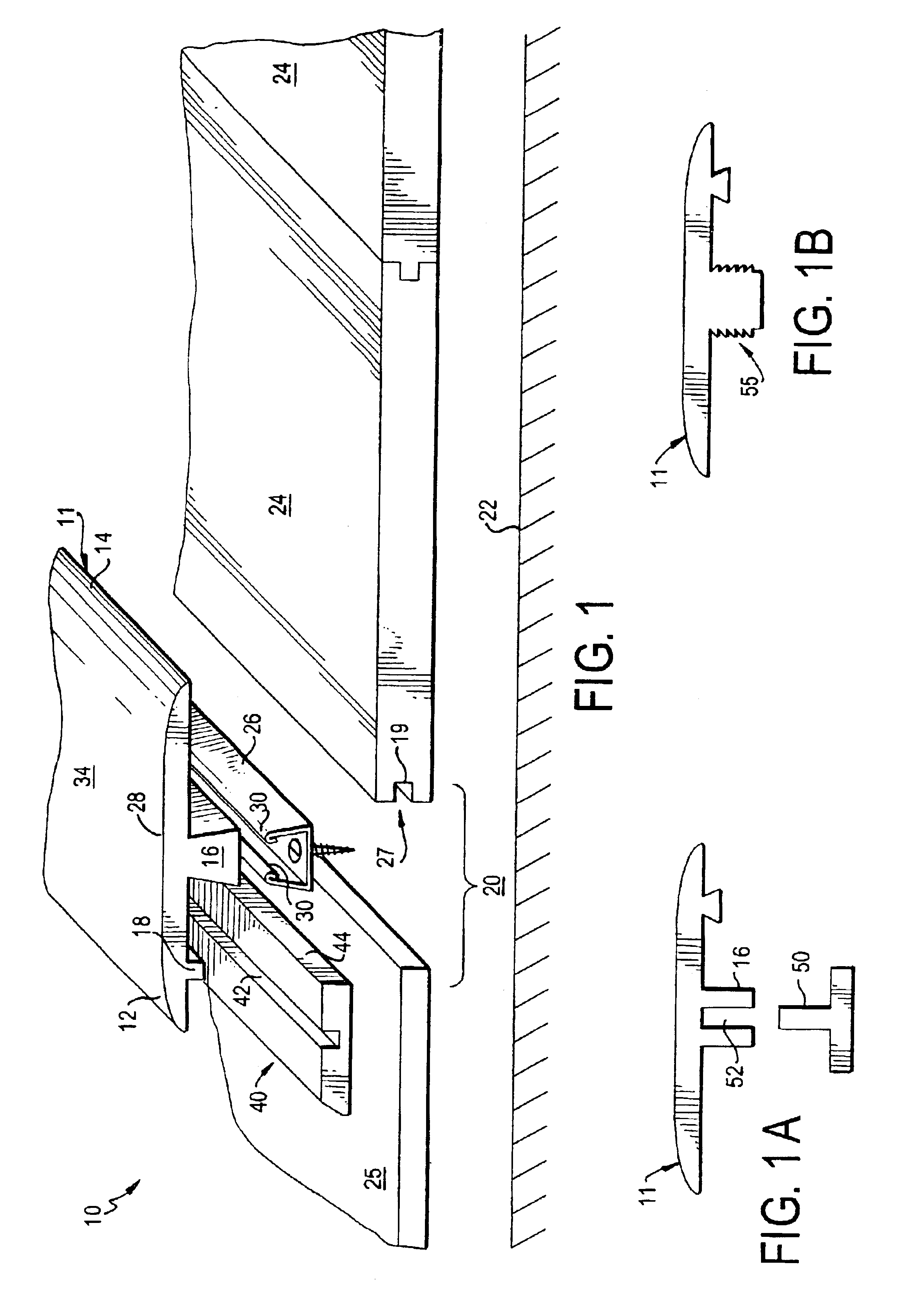

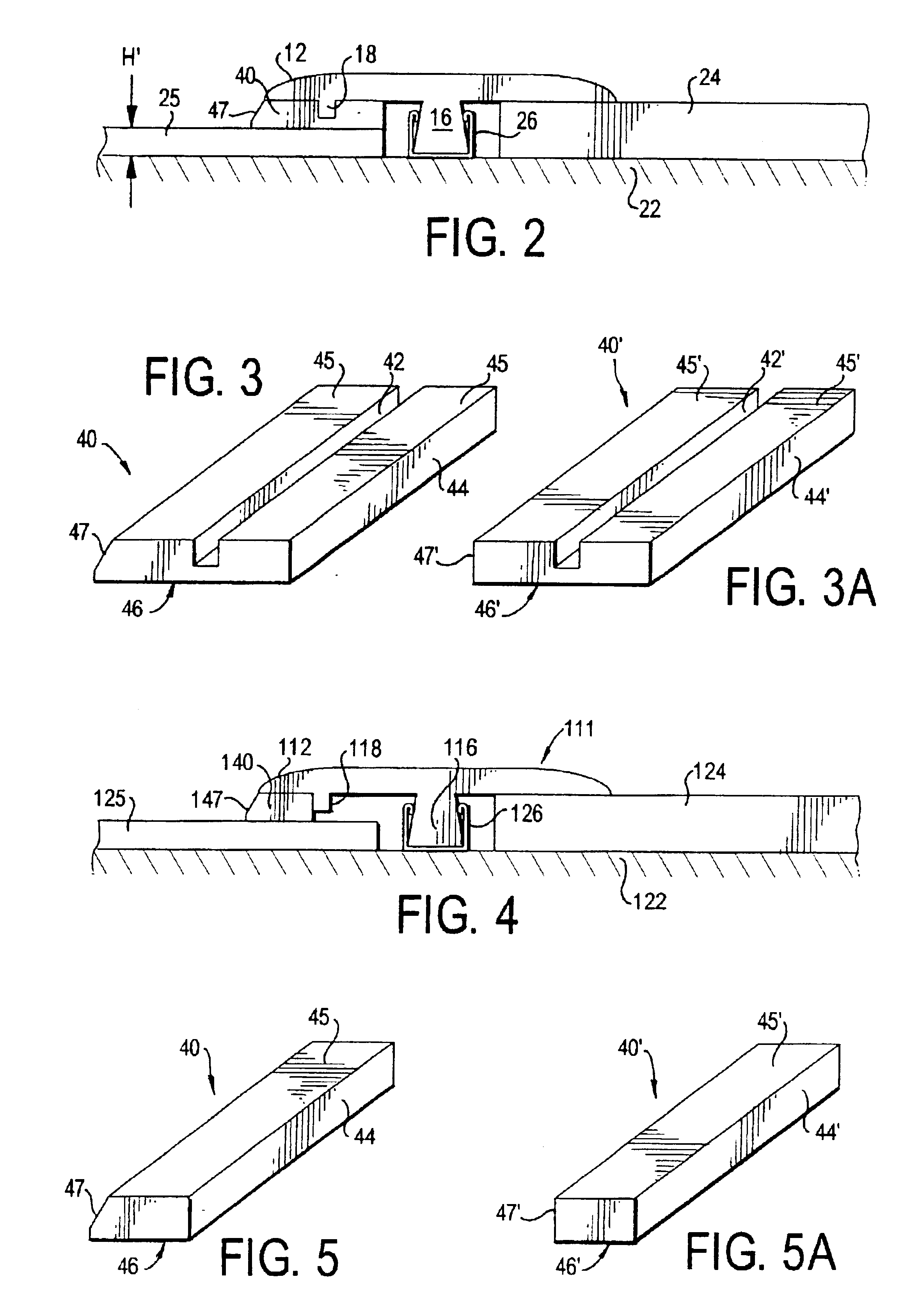

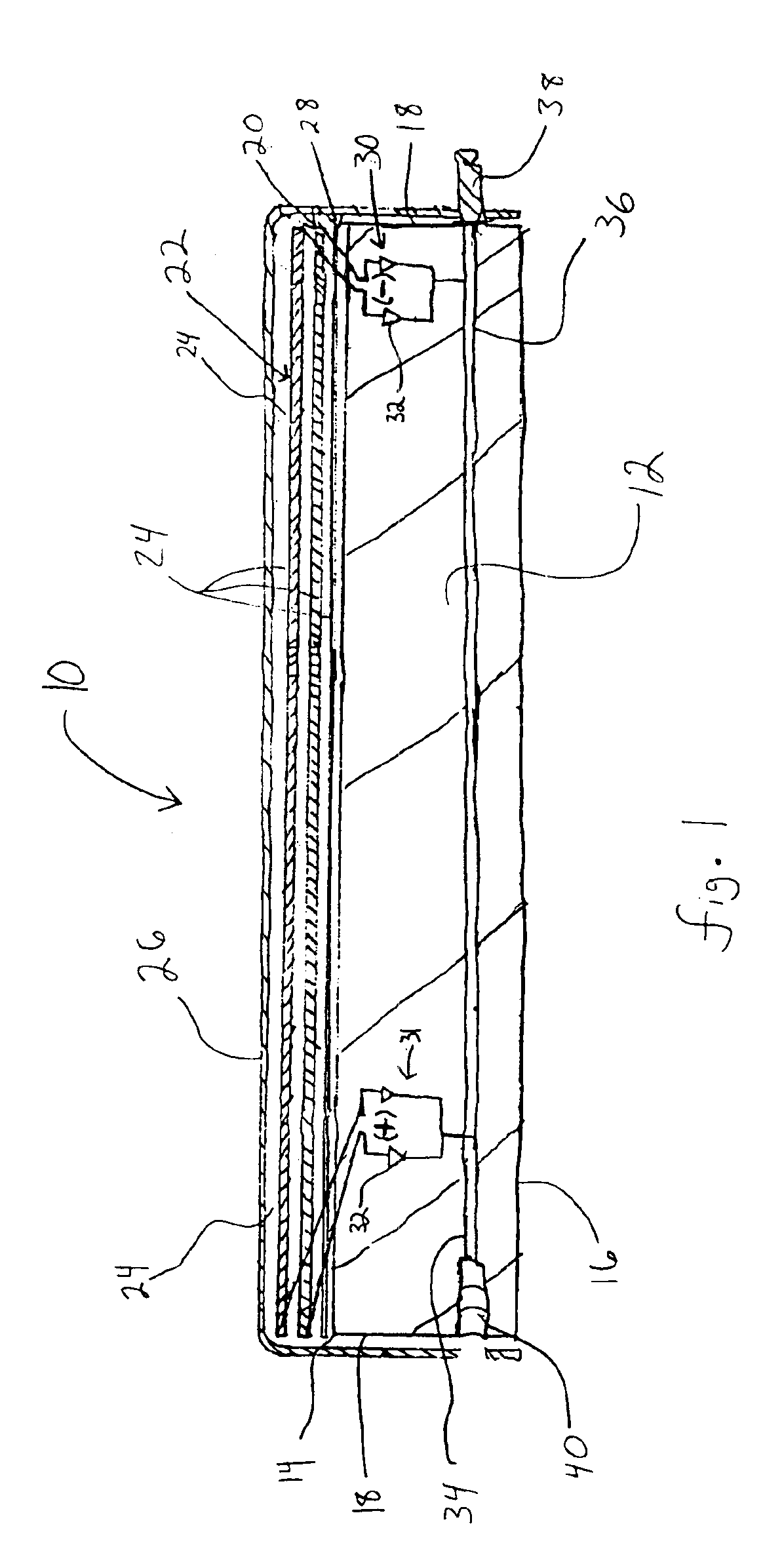

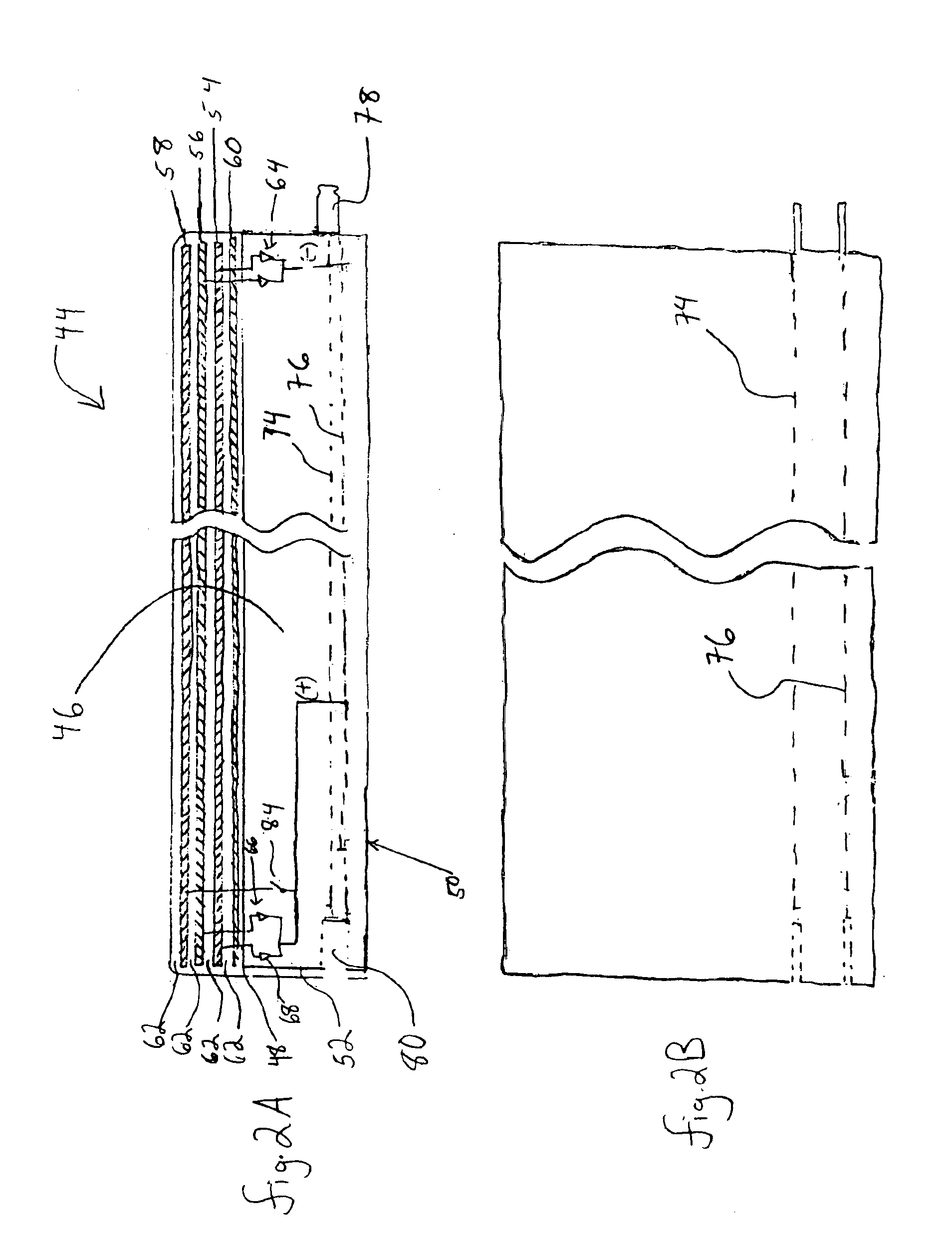

Extrusion devices for mounting wall panels

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

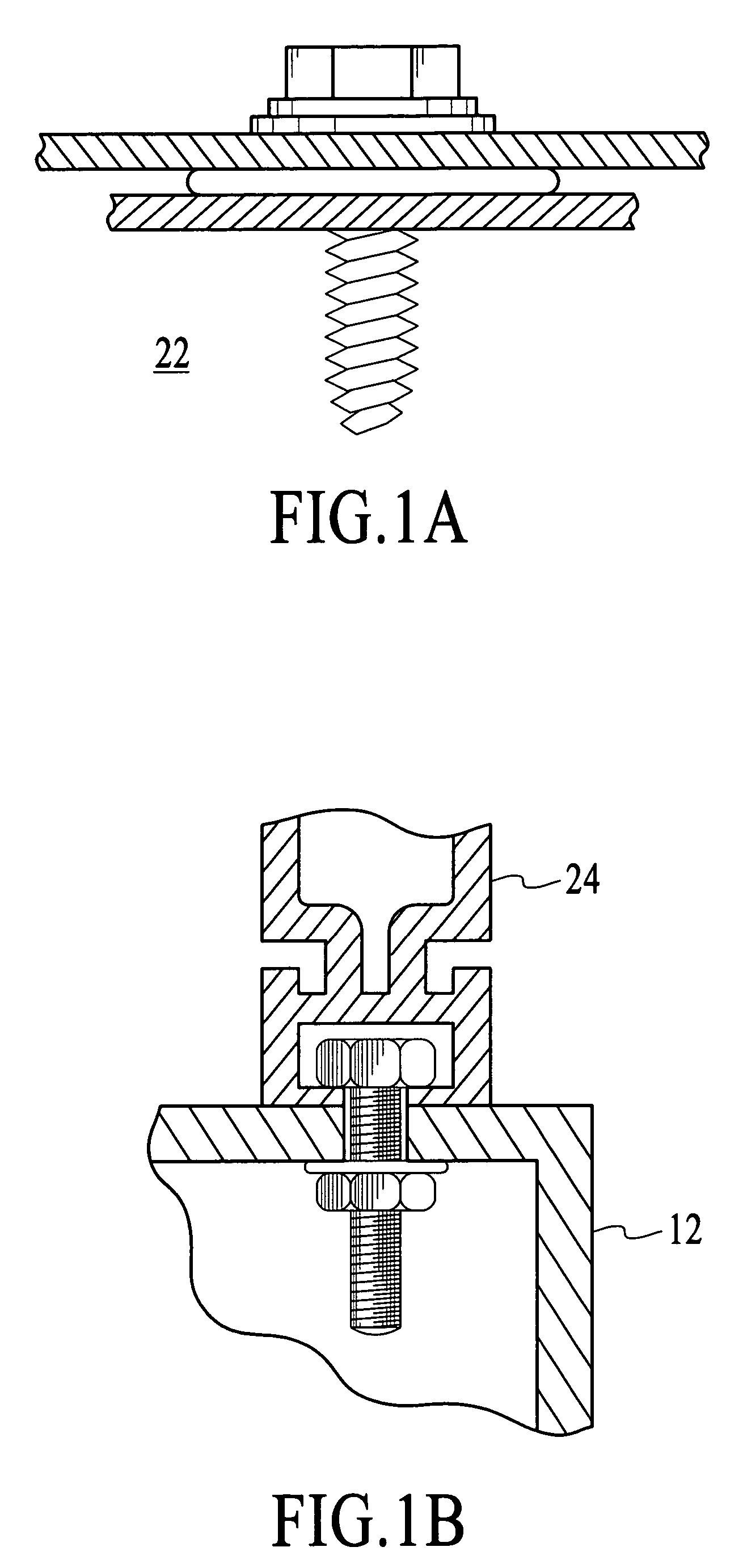

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

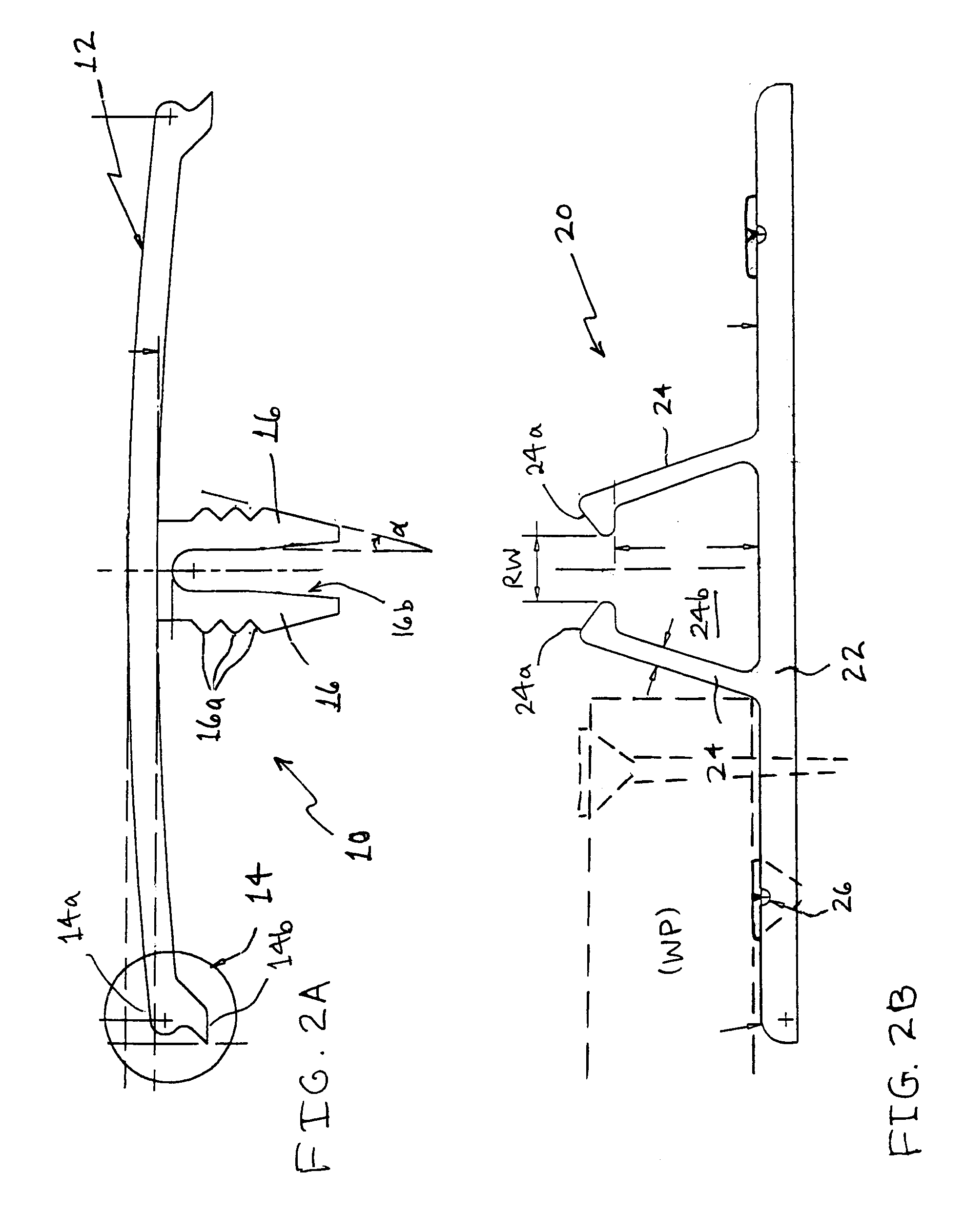

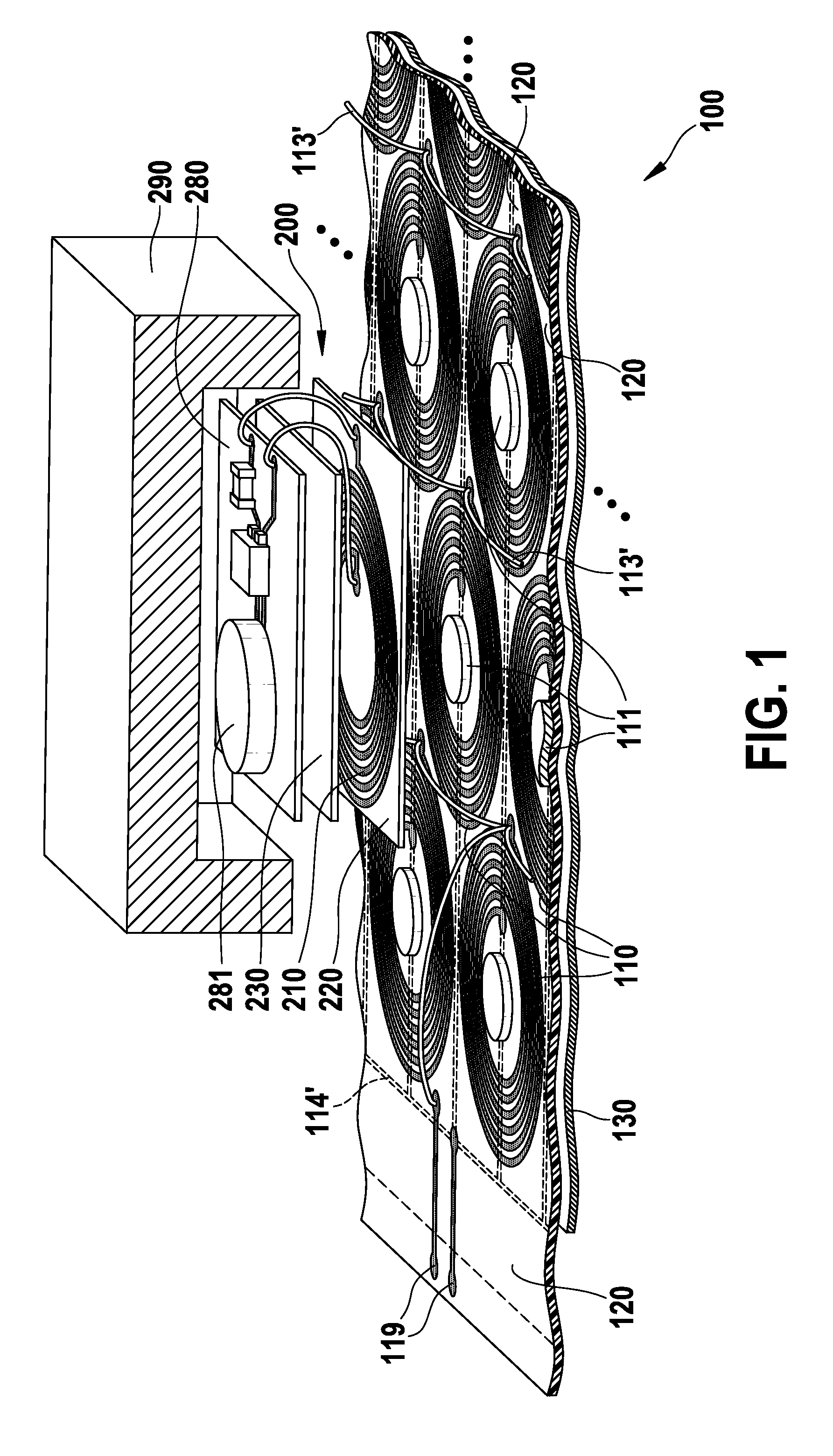

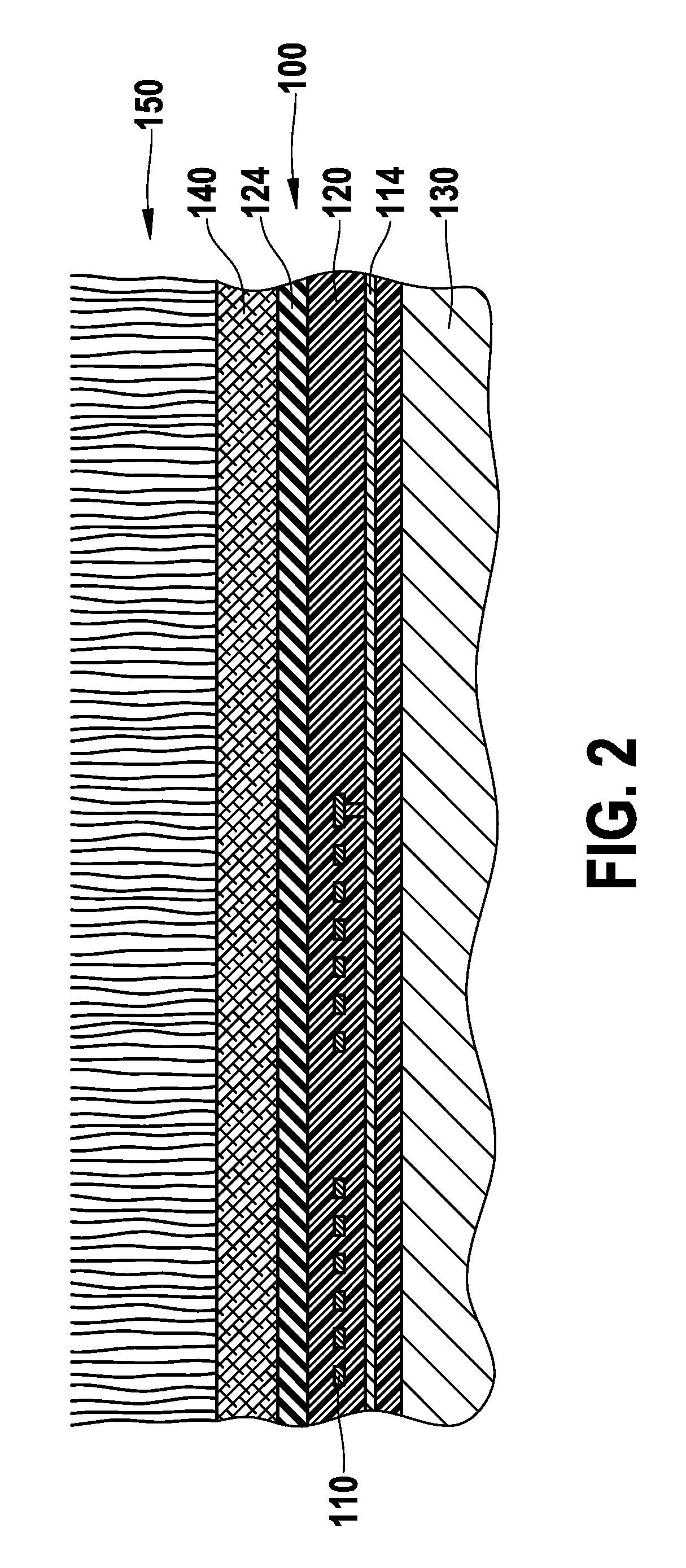

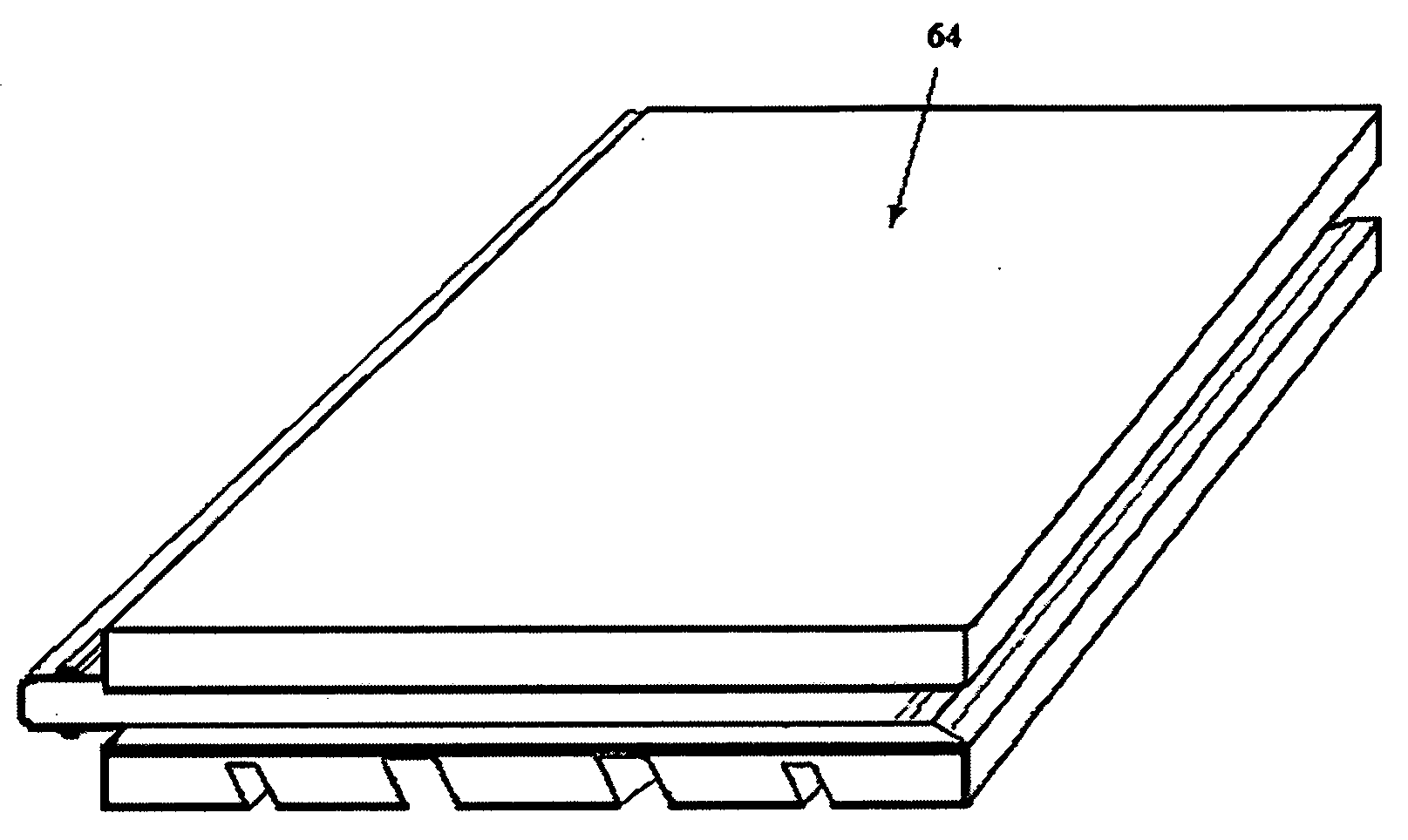

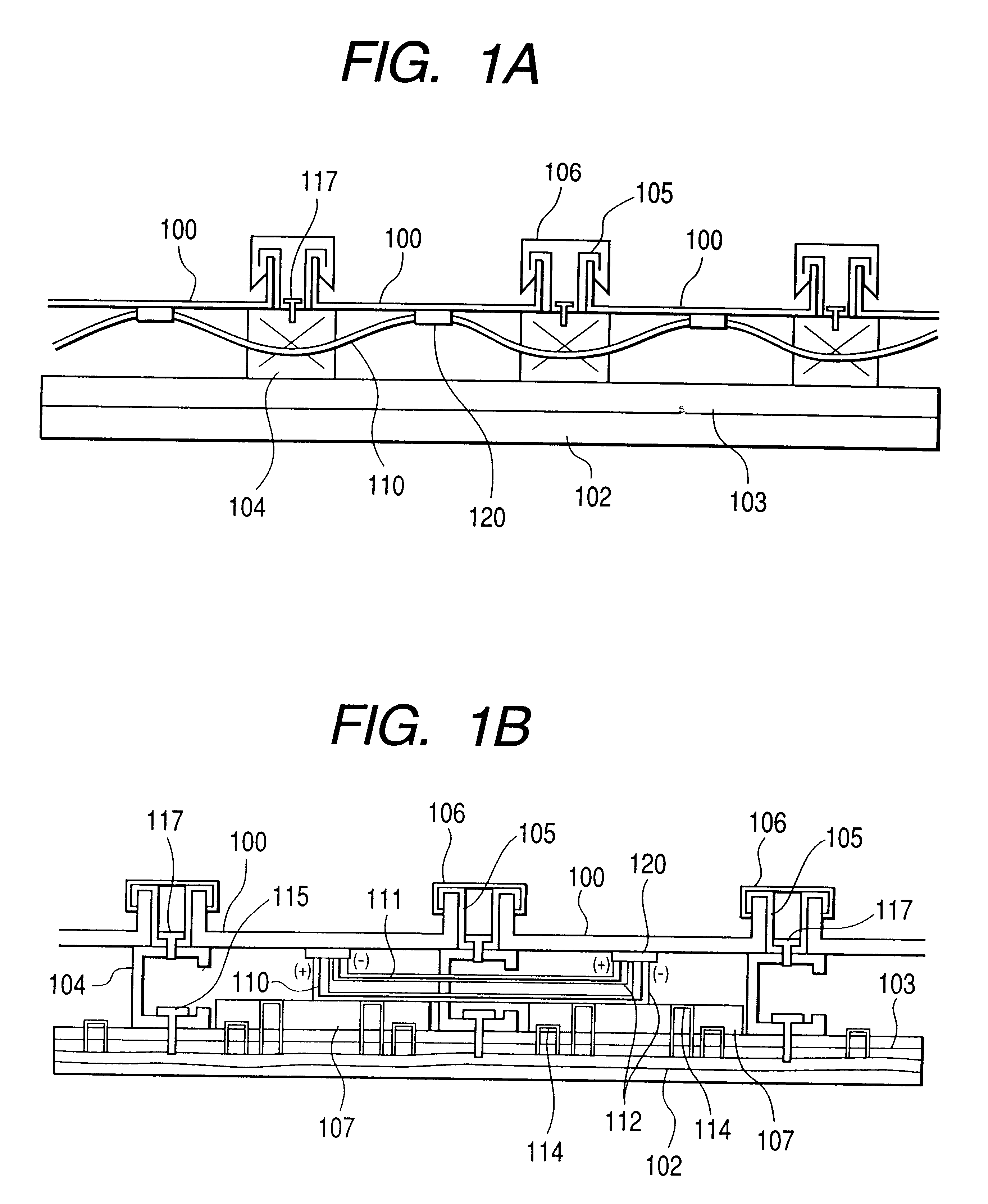

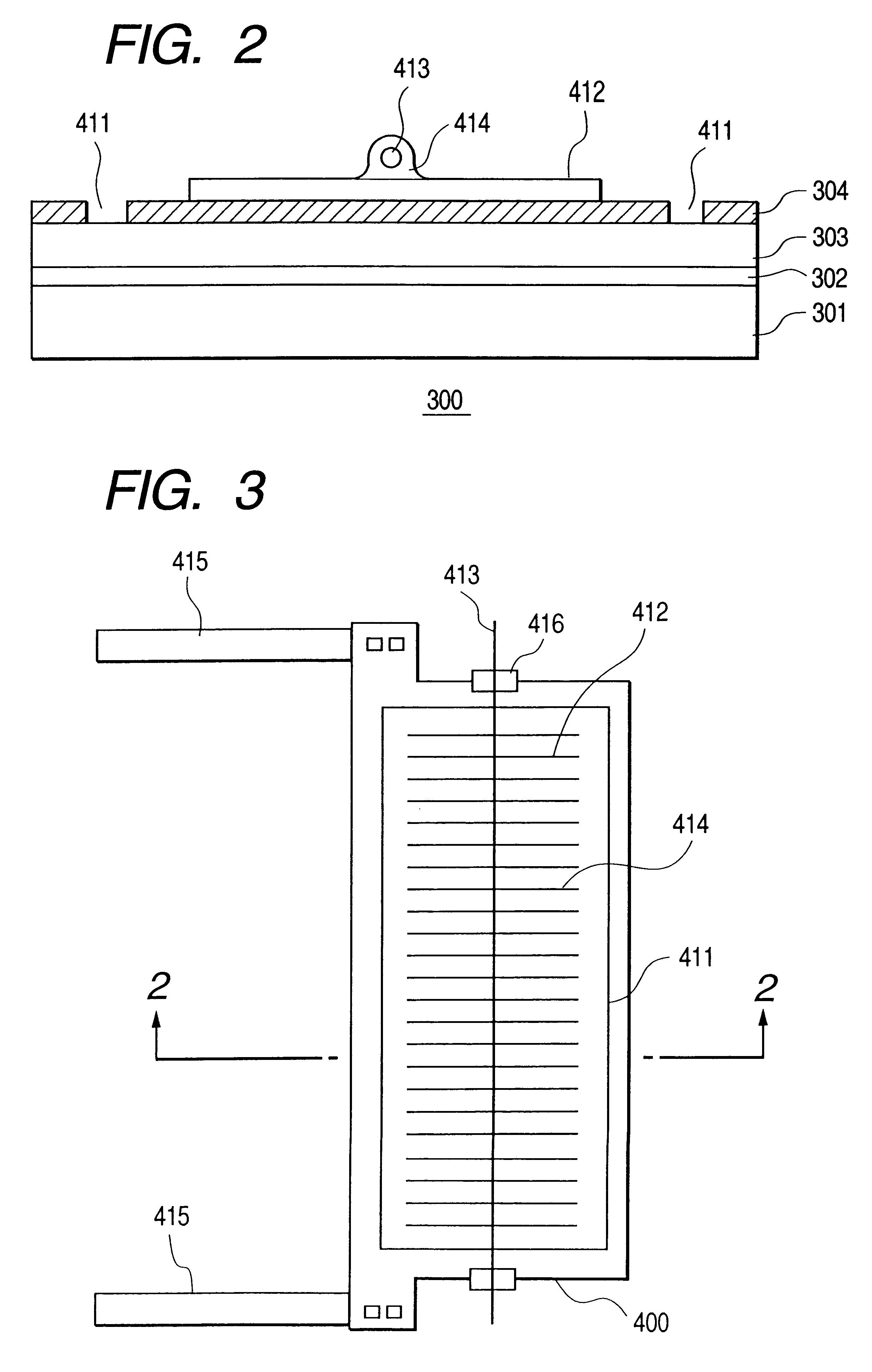

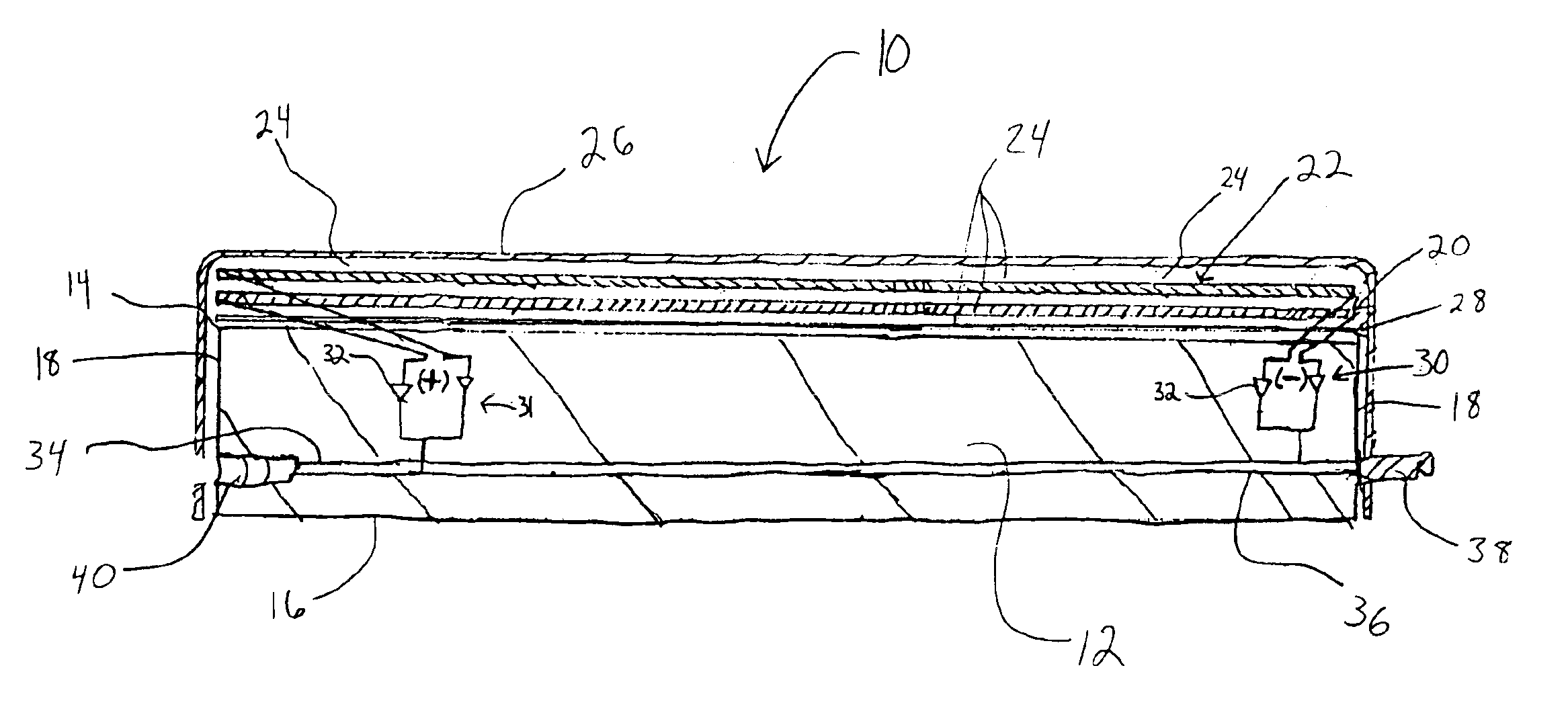

Floor covering and inductive power system

InactiveUS20100314946A1Improving magnetic couplingPrevent short-circuitingRoof covering using slabs/sheetsBatteries circuit arrangementsCharge currentEngineering

The invention relates to a floor covering (100) comprising: a plurality of coils (110), each coil (110) being operable to supply inductive energy to a power receiver circuit (200); wherein the plurality of coils comprises a transmitter area occupying the largest area of the floor covering (100); and a charging current through the coils is operable to generate said inductive energy.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

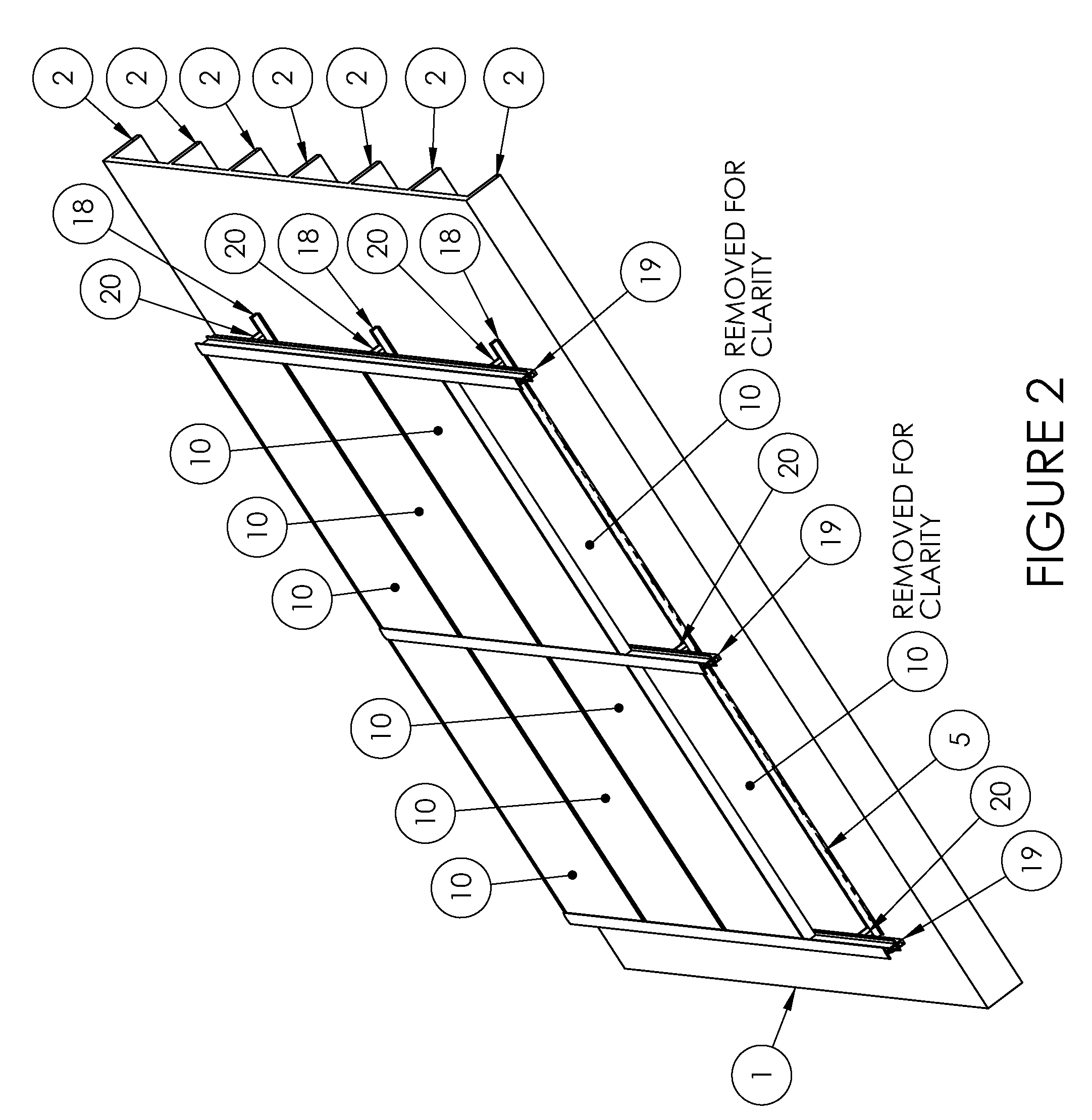

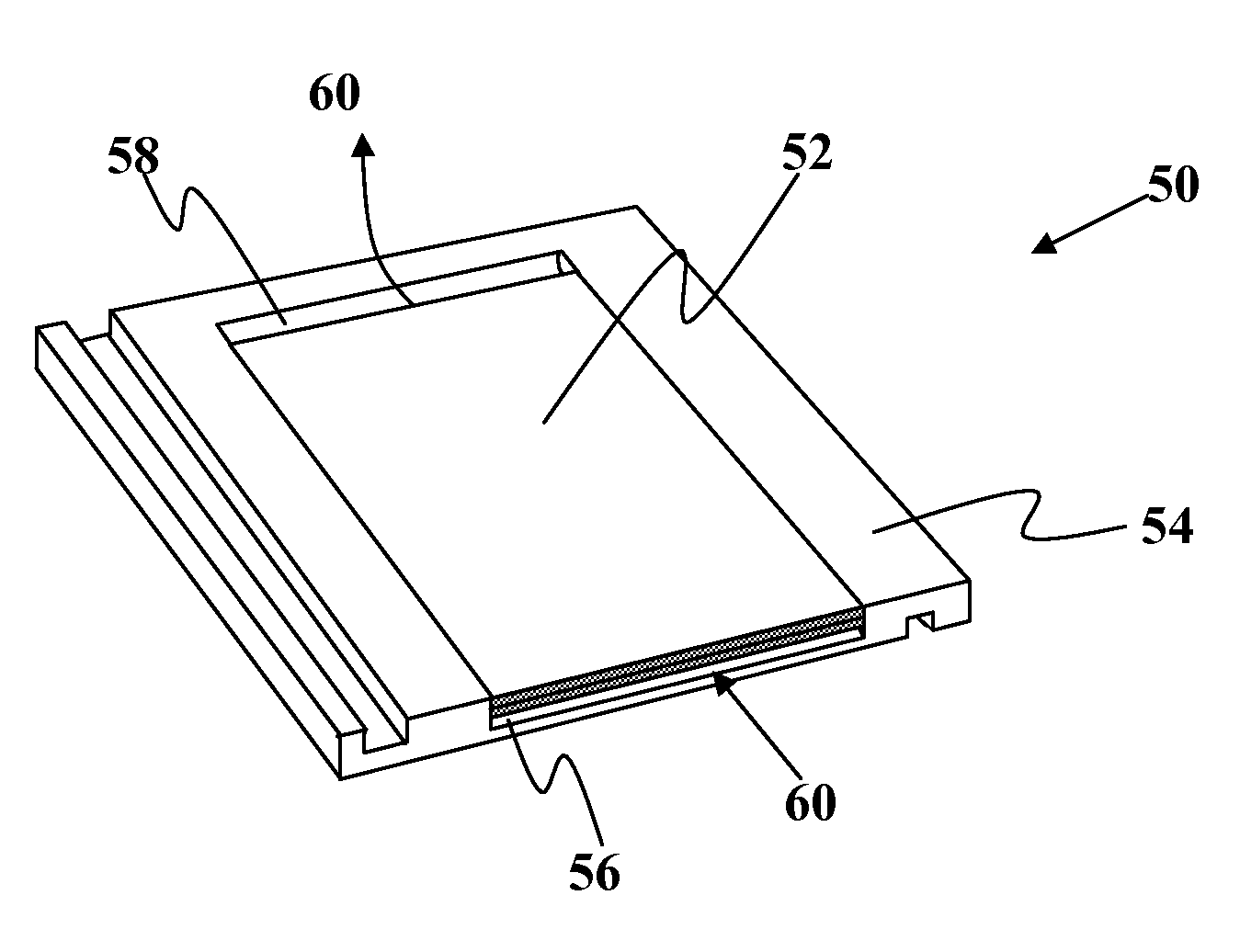

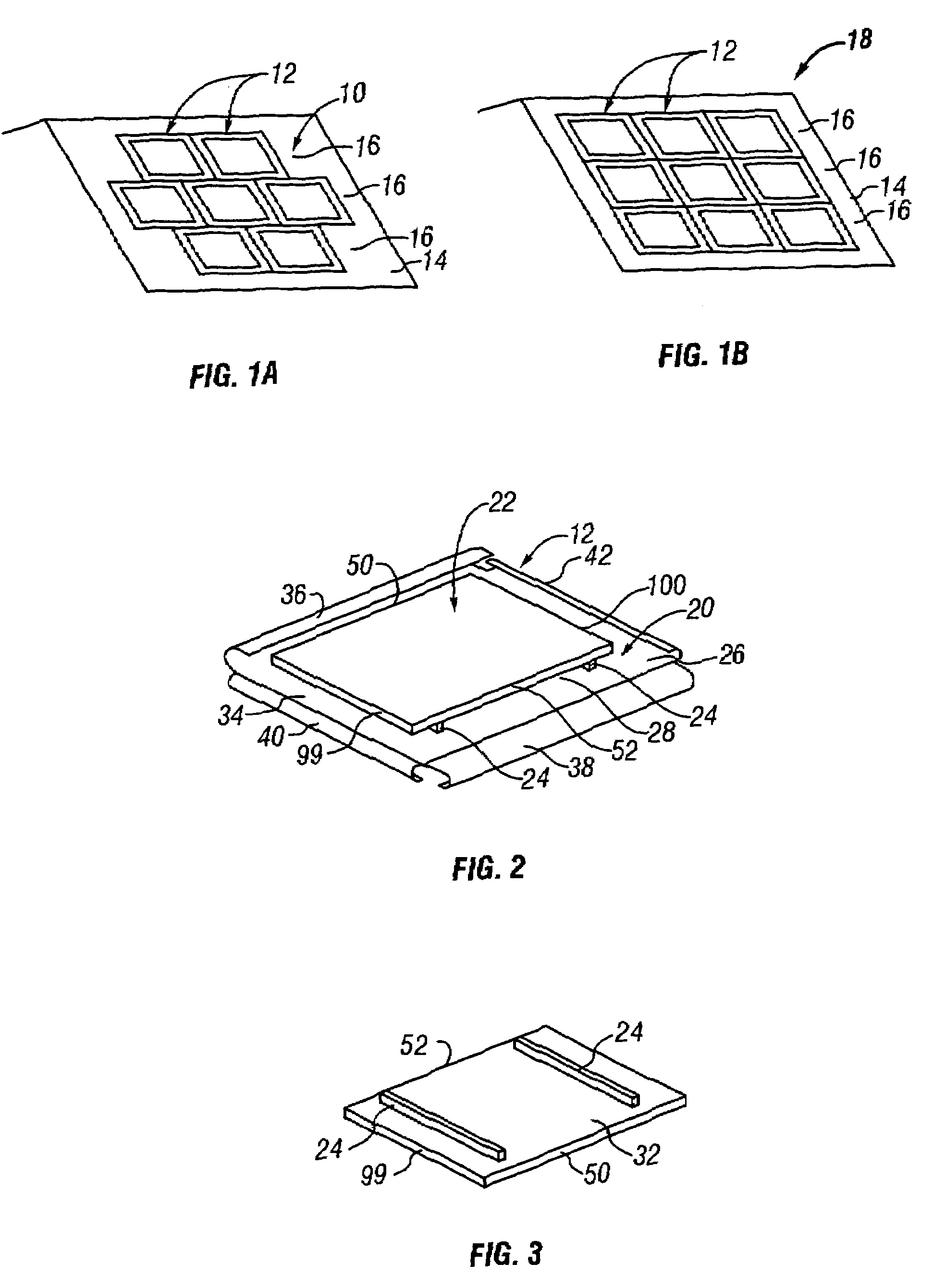

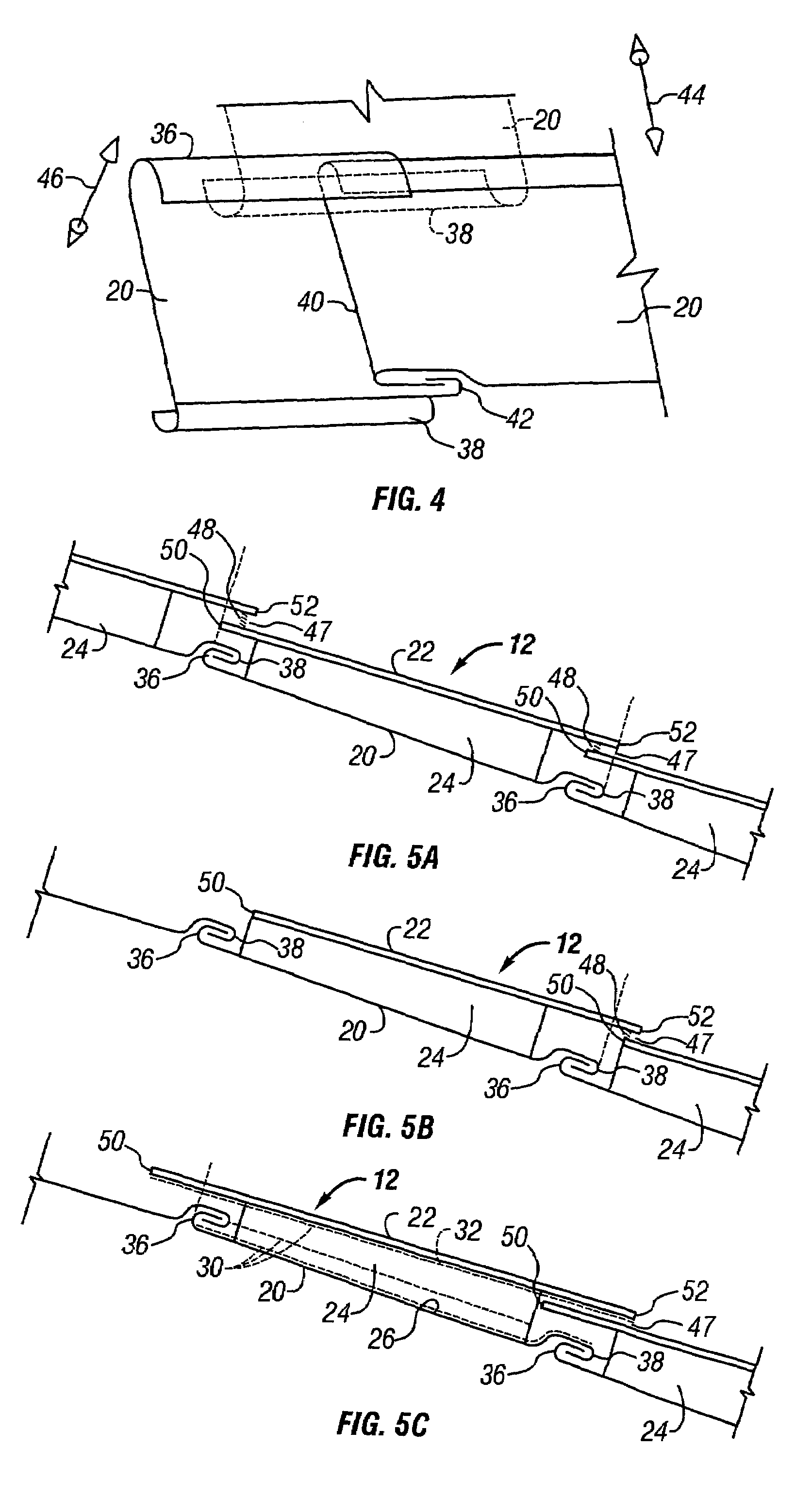

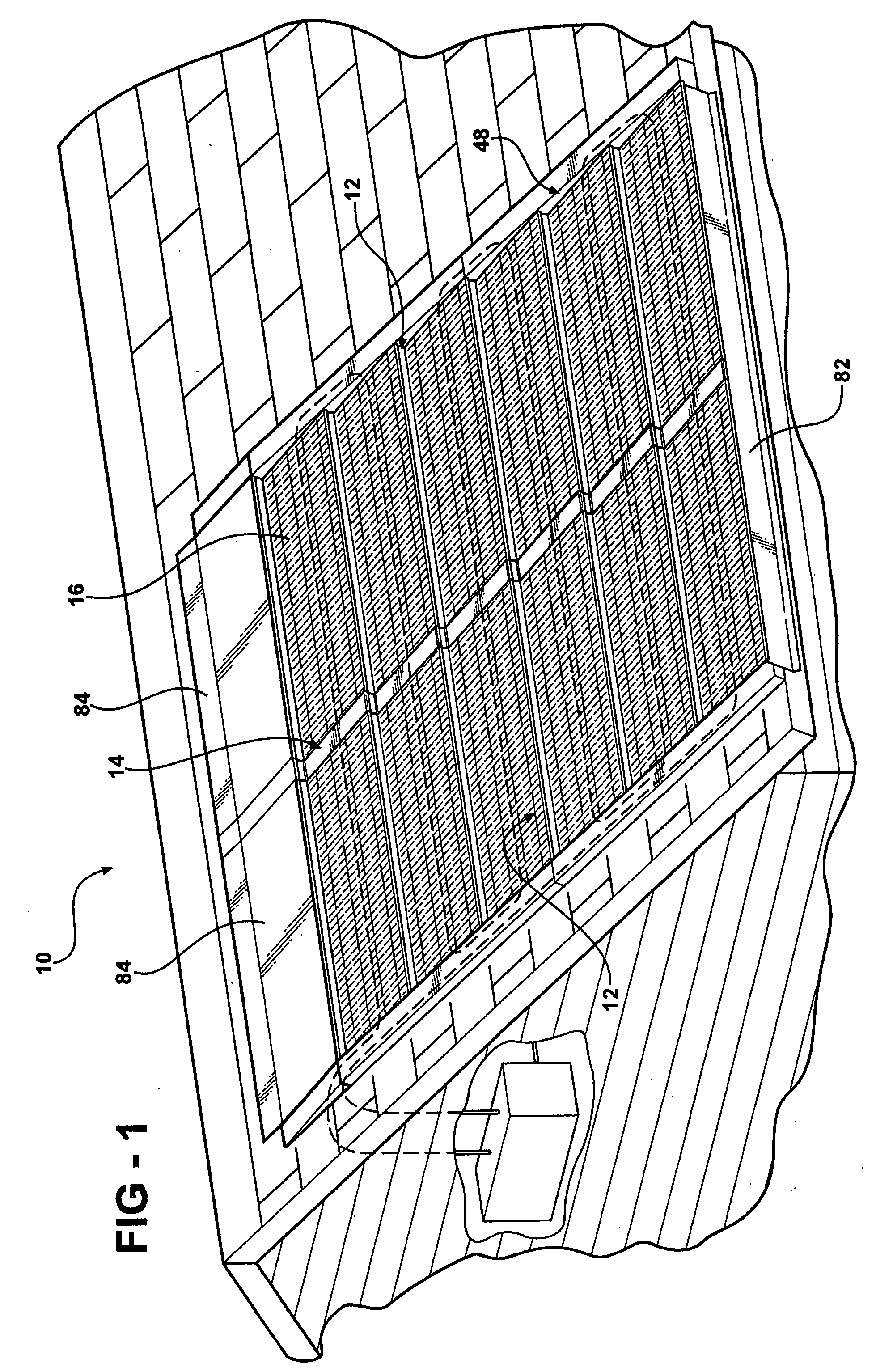

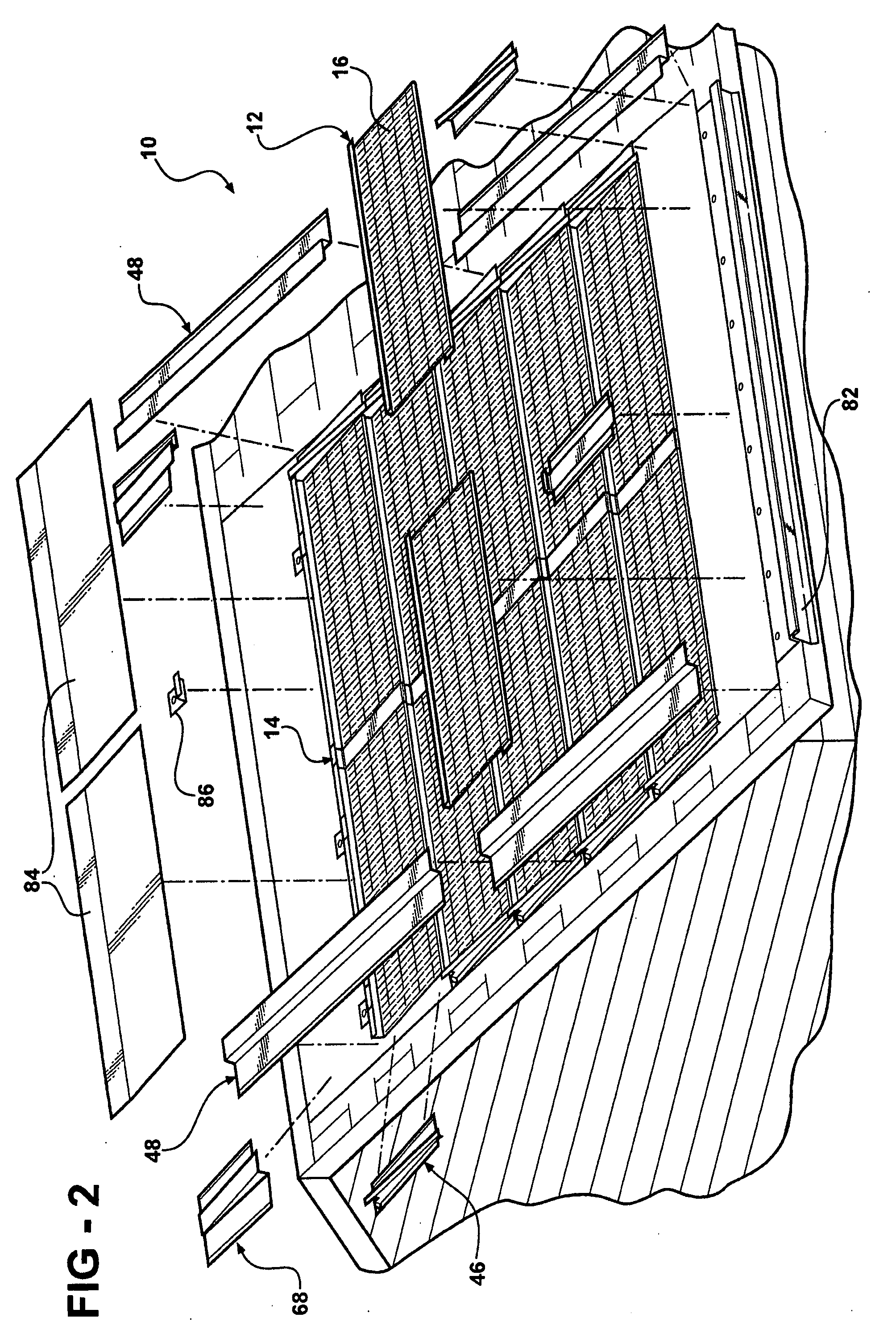

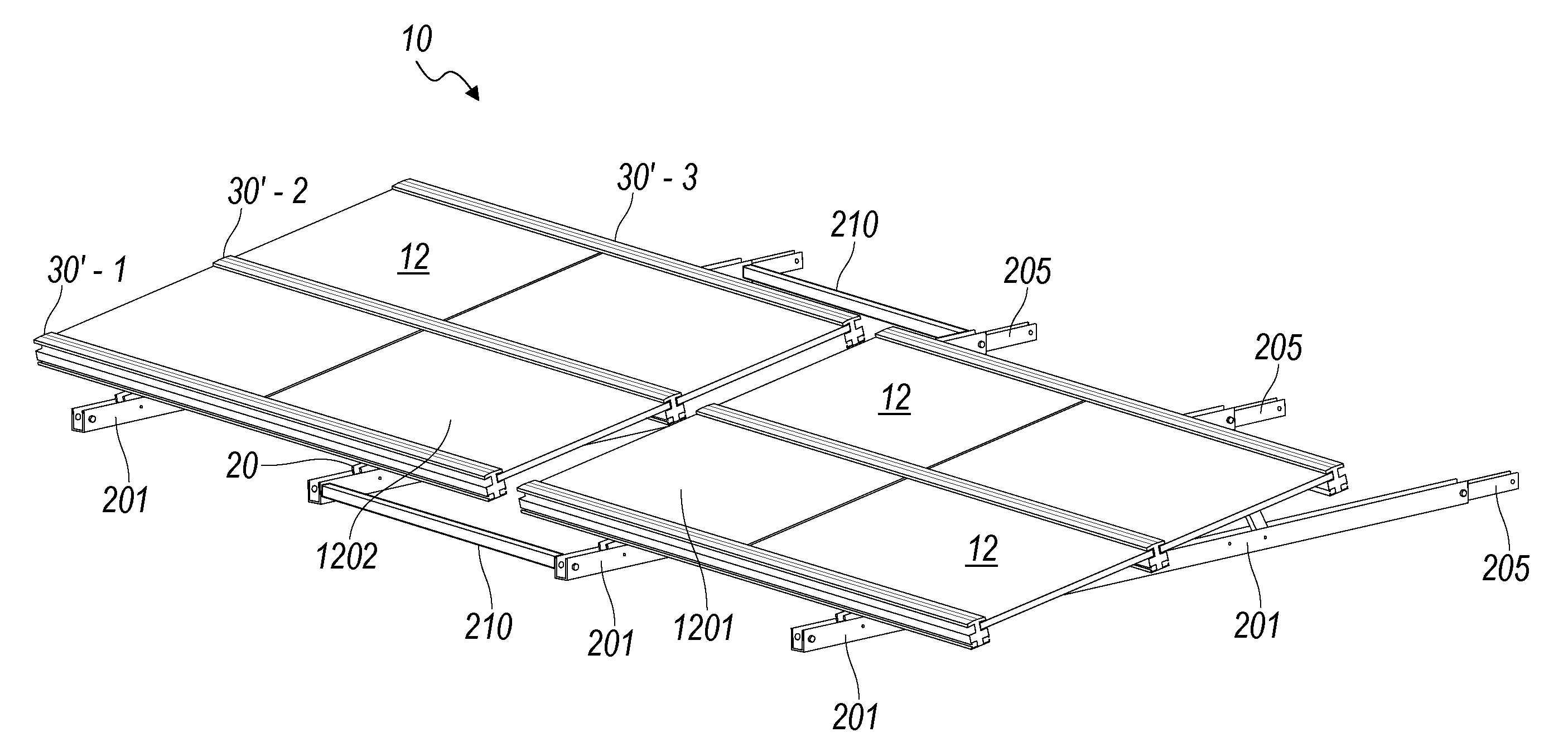

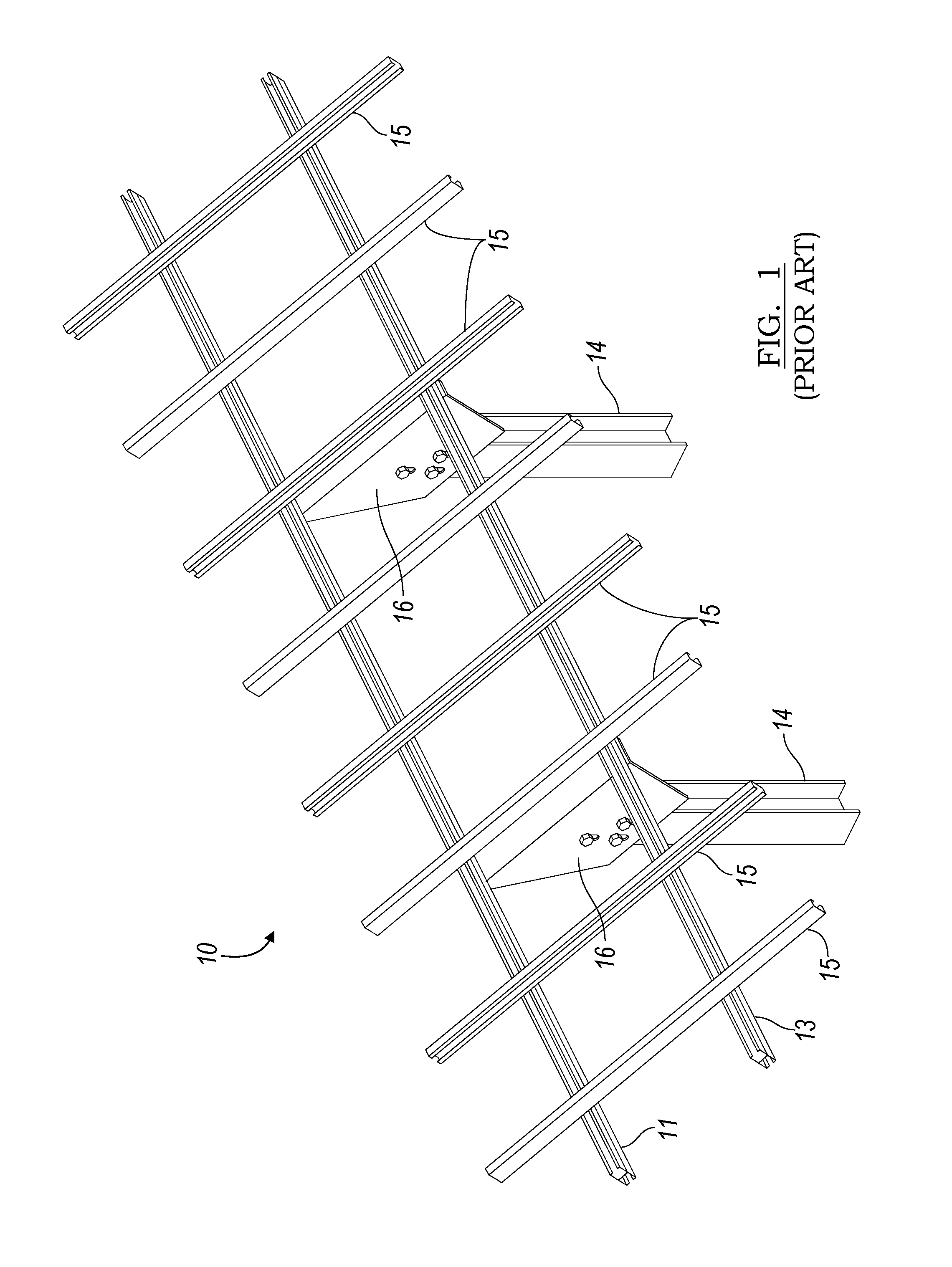

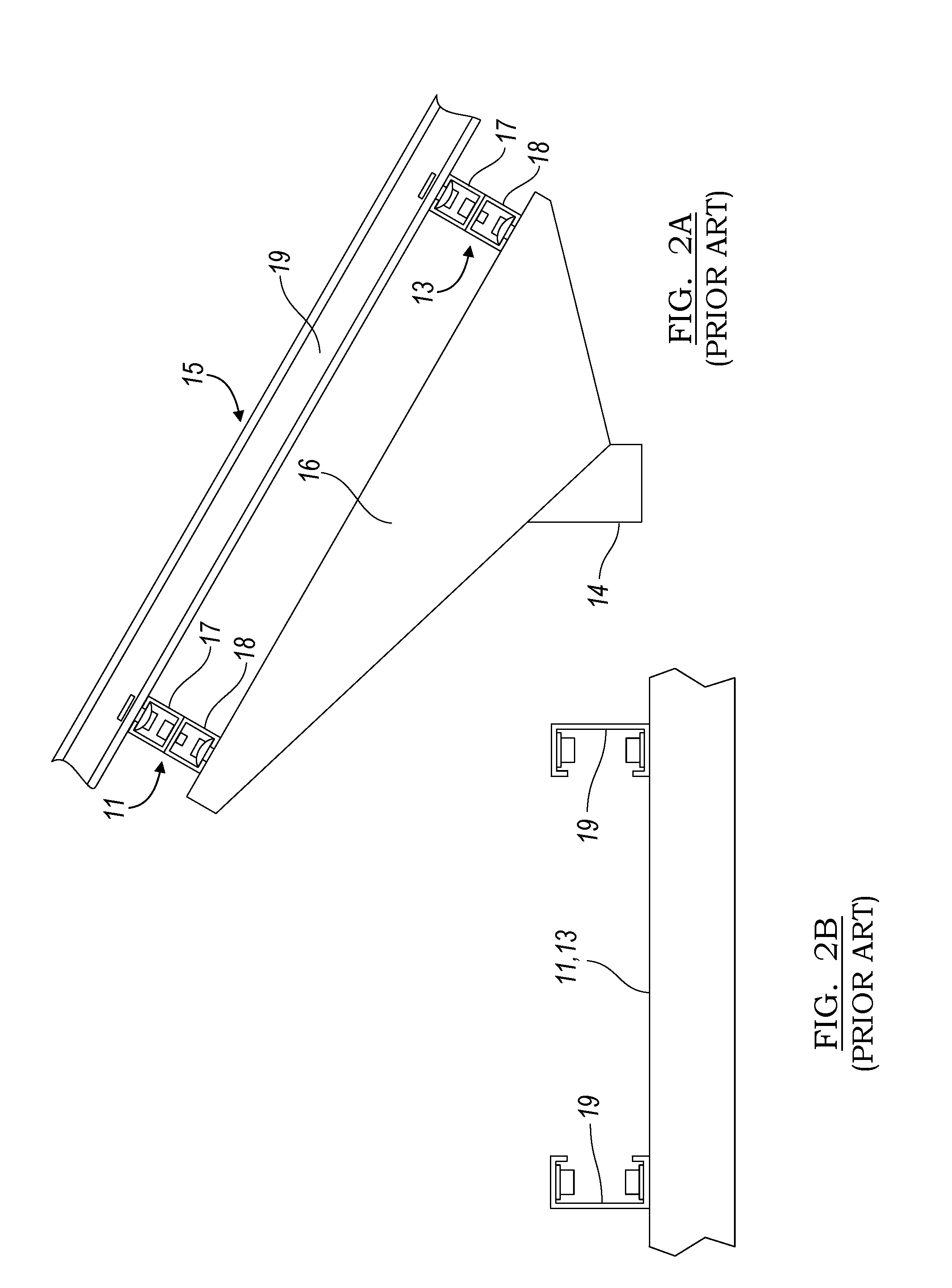

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS20090282755A1Cost-effectiveTurn easilyPhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

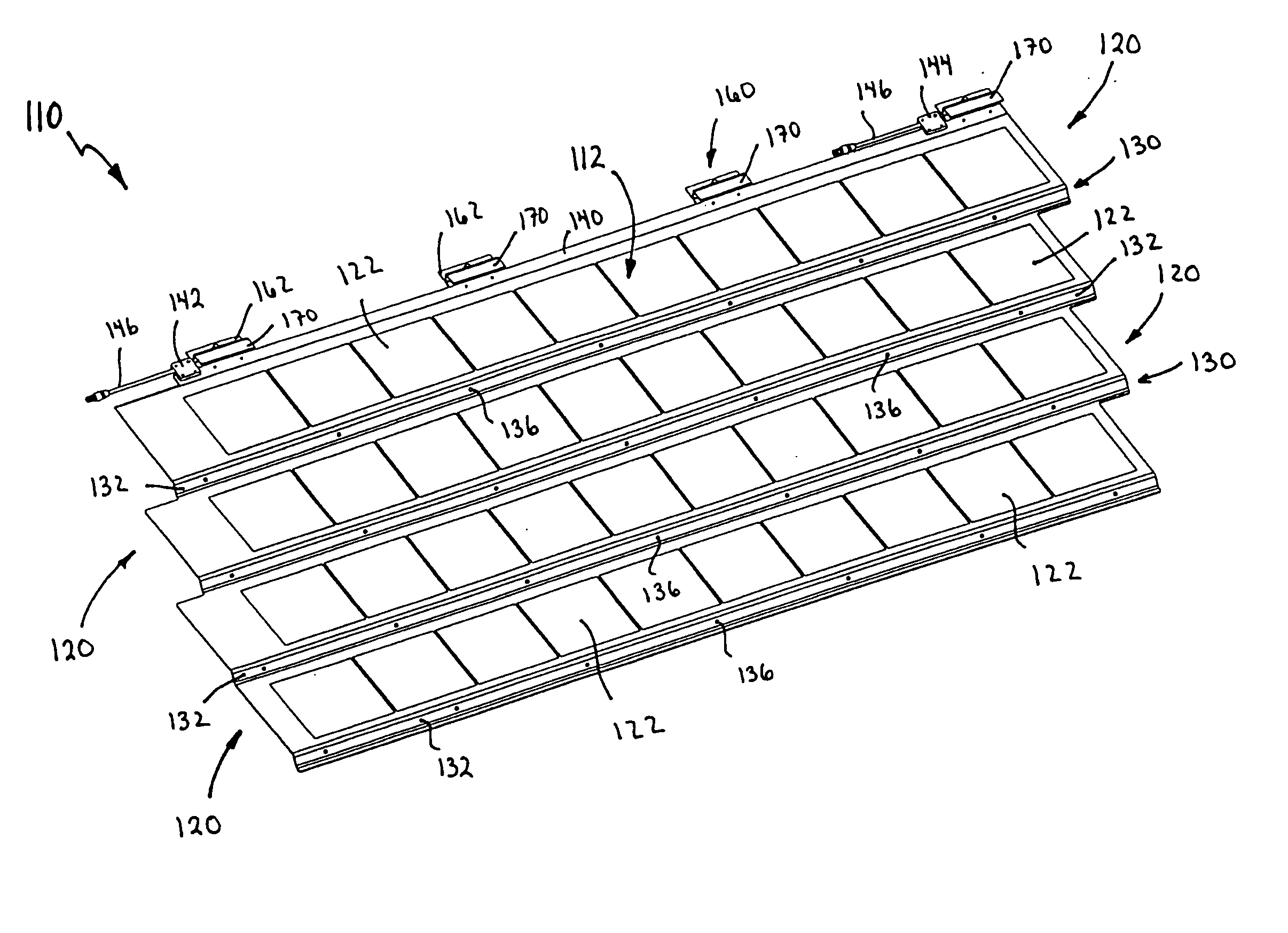

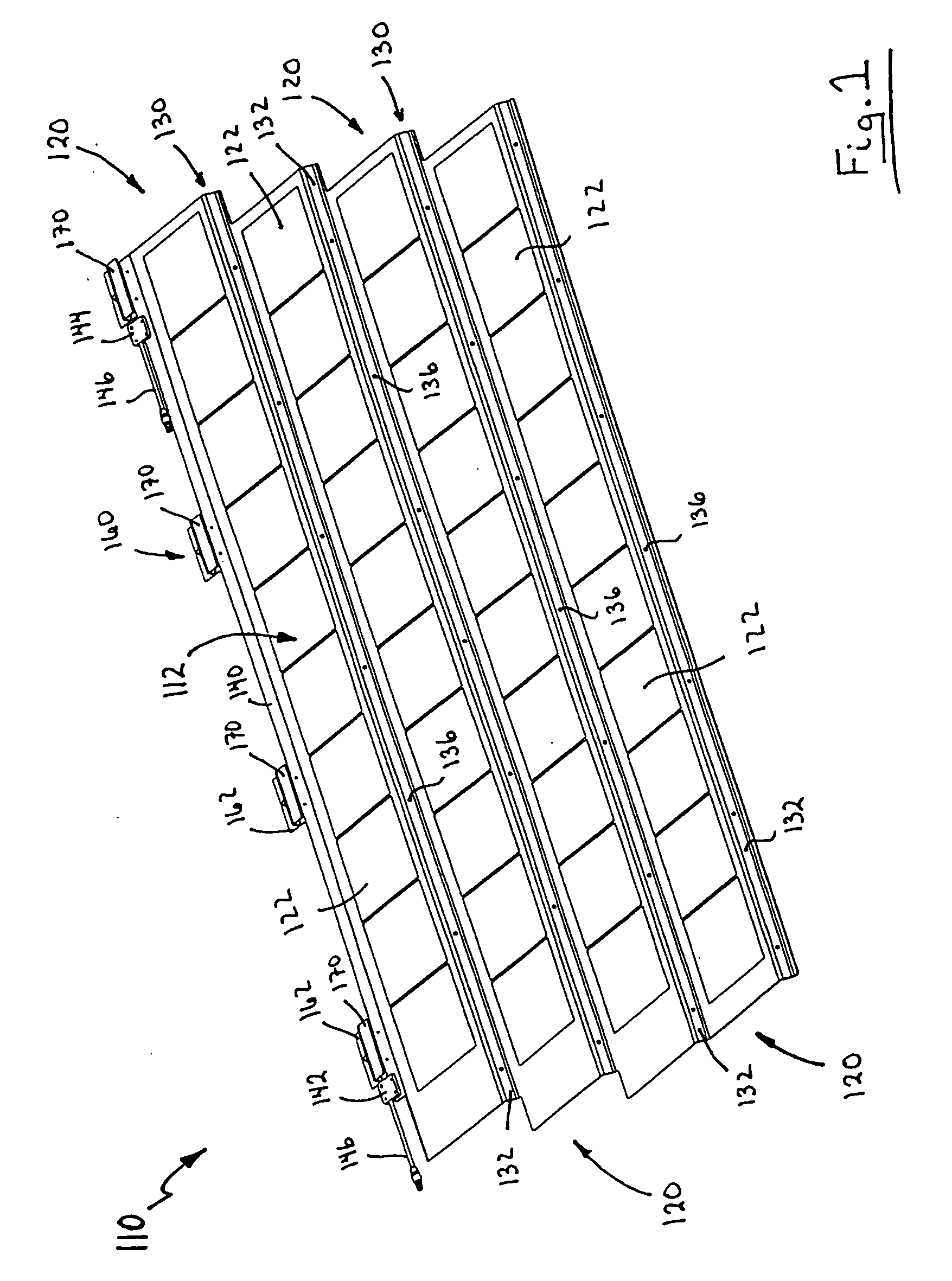

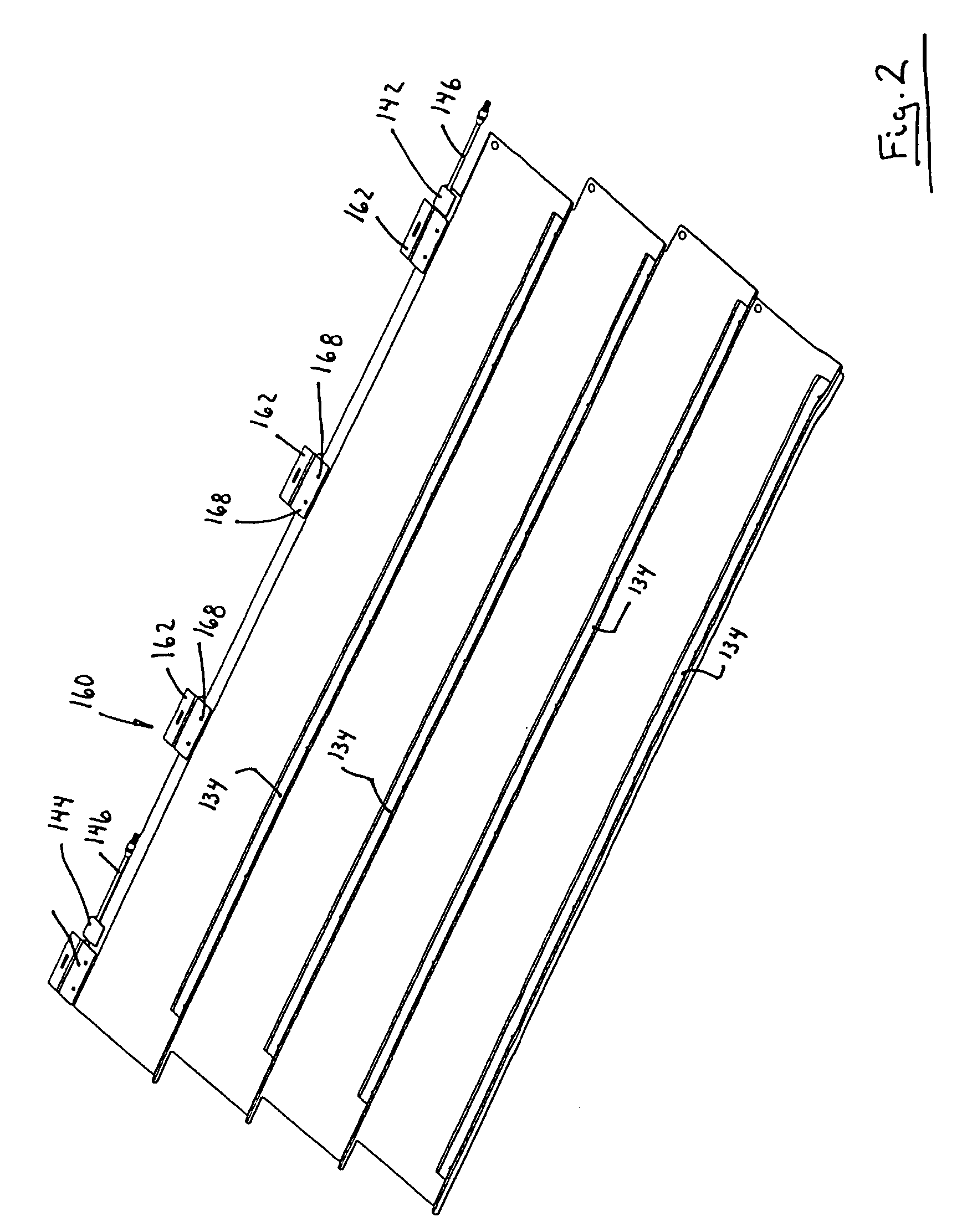

A cam-actuated connection device joins rail mounting members of a photovoltaic panel array. The connection device slides within channels of mounting members until the members are in a properly positioned grid. When in position, the connection device is rotated to lock the mounting members in a rigid grid network. The connecting device can be subsequently loosened, repositioned and locked into position. The rail-mounting members create a grid for installation of multiple PV panels. The mounting rail allows the unit to remain relatively compact in nature but still covers a wide range of PV panel thicknesses. The rail system has a hinged connection with the mounting rail that allows an installer to assemble the module in a near perpendicular fashion to the mounting rail, make the required electrical connections and then lower the PV module into its working position. The unit is then locked into its working position.

Owner:POWERMOUNT SYST +1

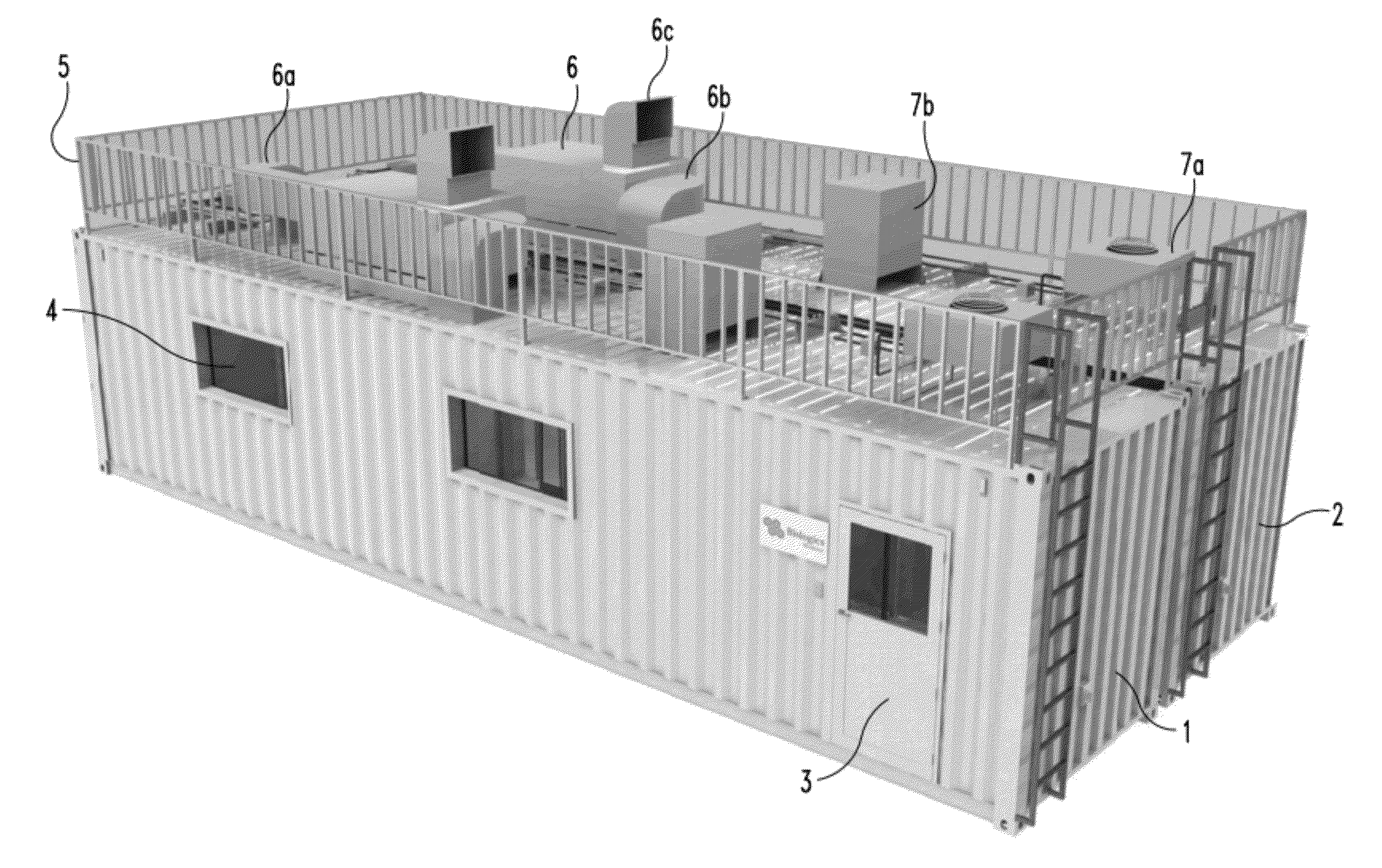

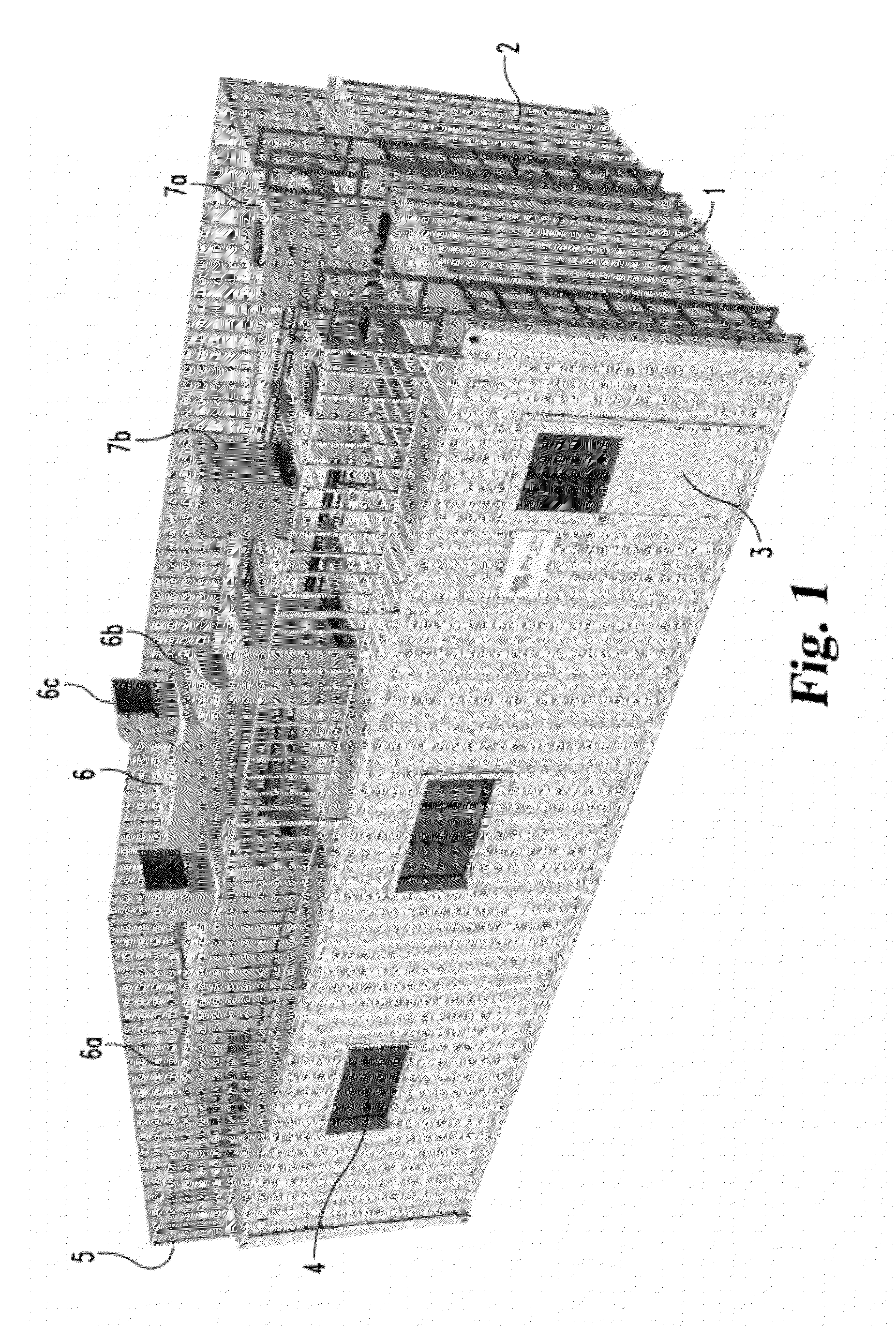

Mobile, modular cleanroom facility

ActiveUS20120077429A1Mechanical apparatusLighting and heating apparatusAir filtrationComputer module

A mobile, modular, cleanroom facility is made from one or more pre-assembled modules, transportable in their pre-assembled form. Each pre-assembled module includes an air filtration system including a ceiling plenum for providing clean air to the interior of the module. The air filtration system provides air cleaned to at least an ISO 8 classification. When the mobile, modular cleanroom facility is made of two or more modules, each of the modules is pre-assembled, and is transportable in its pre-assembled form. Each of the modules also includes an air filtrations system having a ceiling plenum for providing clean air to the interior of the module. Most preferably, the modules are connected by a connection assembly effective for providing a seamless transition from one module to the other while maintaining the appropriate clean air classification in the transition space.

Owner:BIOLOGICS MODULAR

Structures for Low Cost, Reliable Solar Roofing

InactiveUS20080302030A1Simple configurationReduce material costsPhotovoltaic supportsRoof covering using slabs/sheetsRoof tileEngineering

Owner:AERIS CAPITAL SUSTAINABLE IP

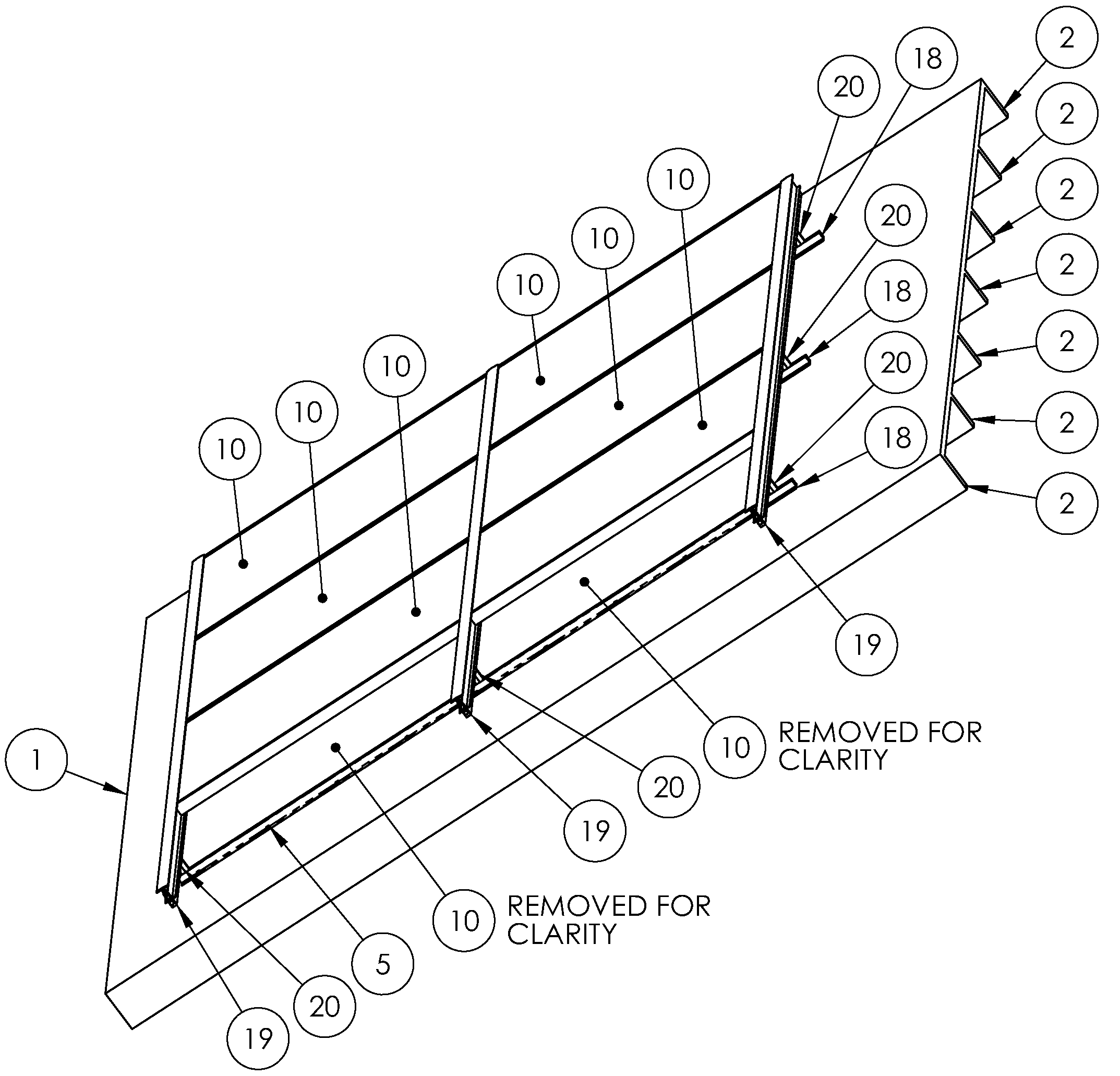

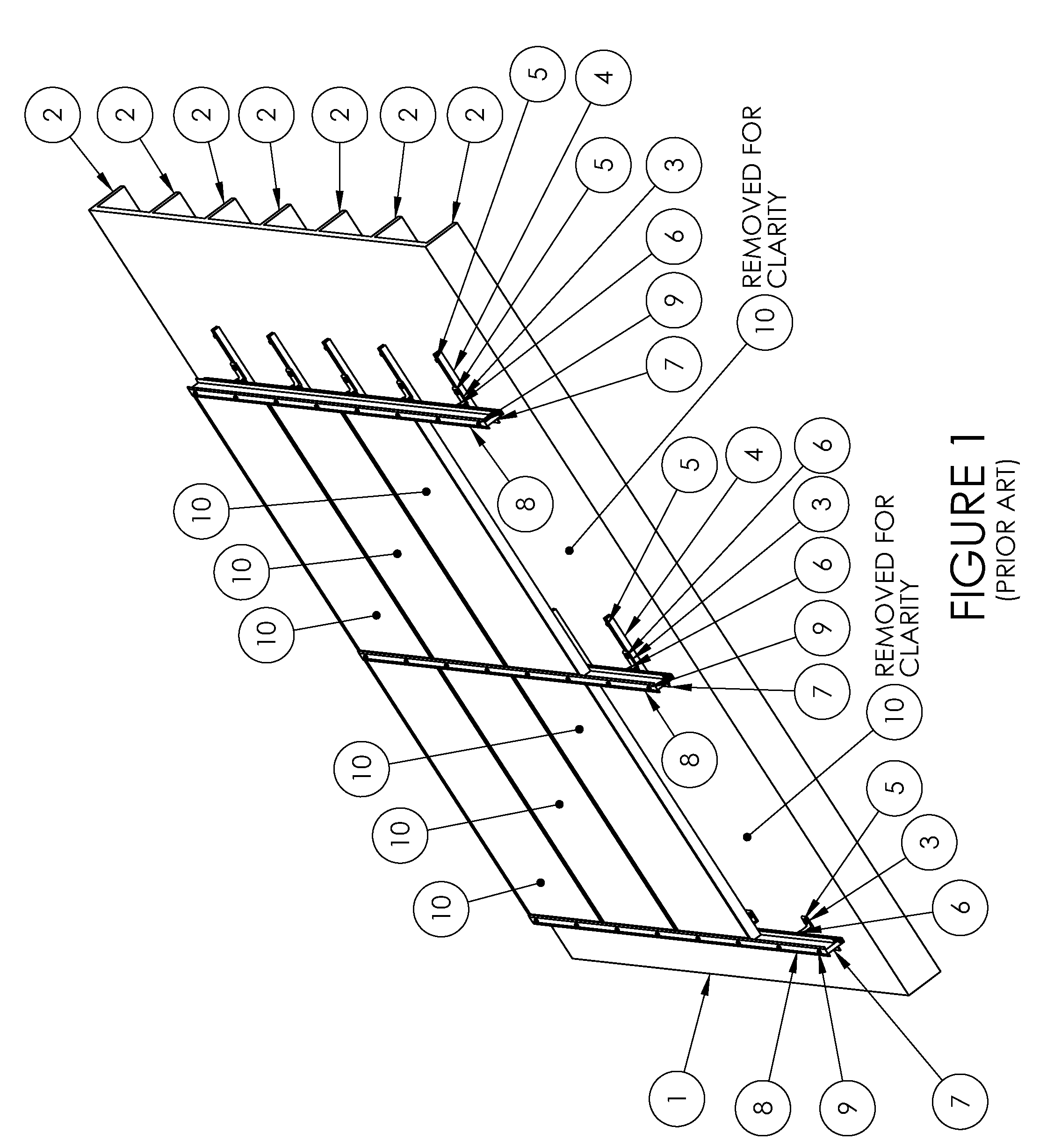

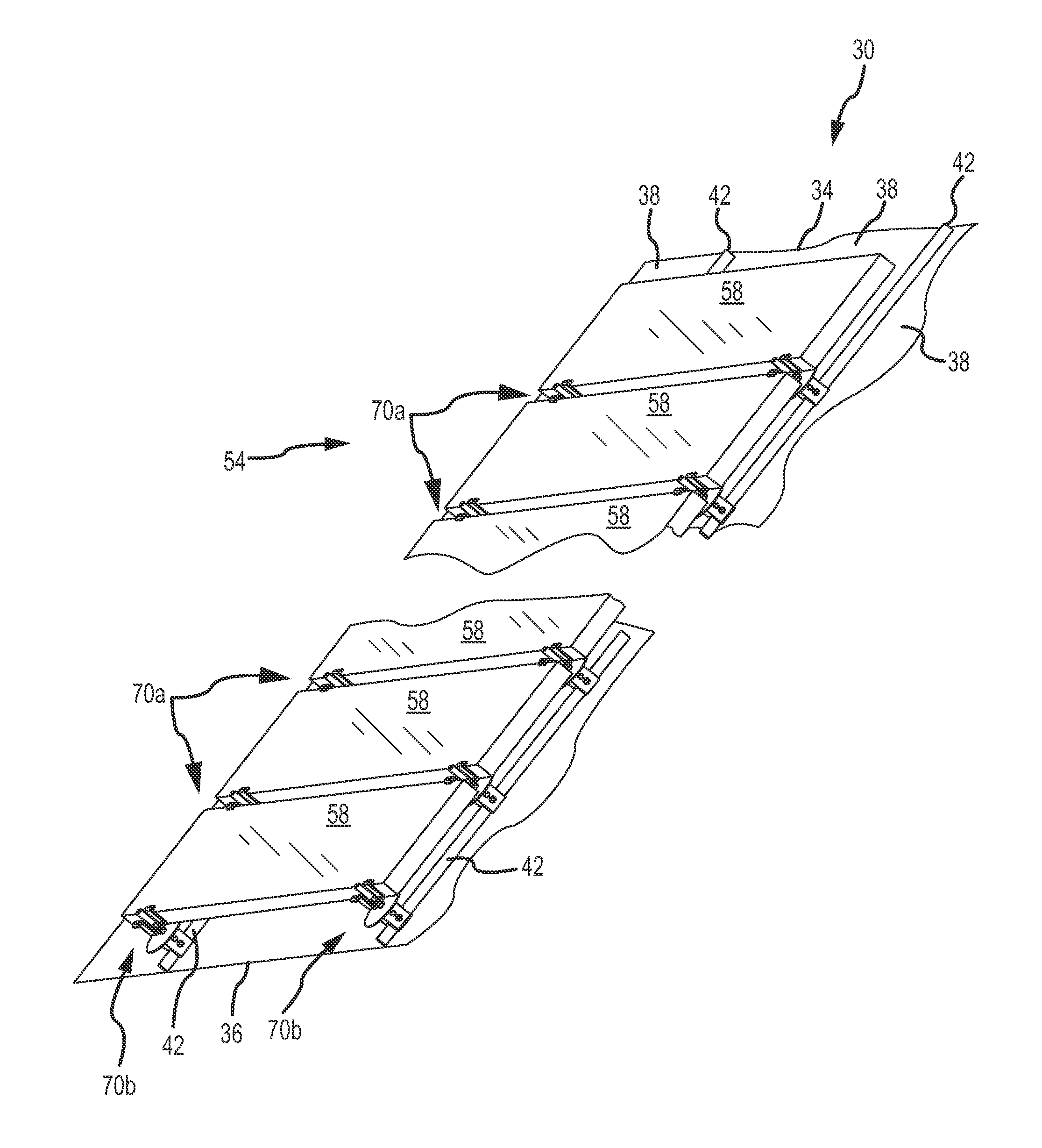

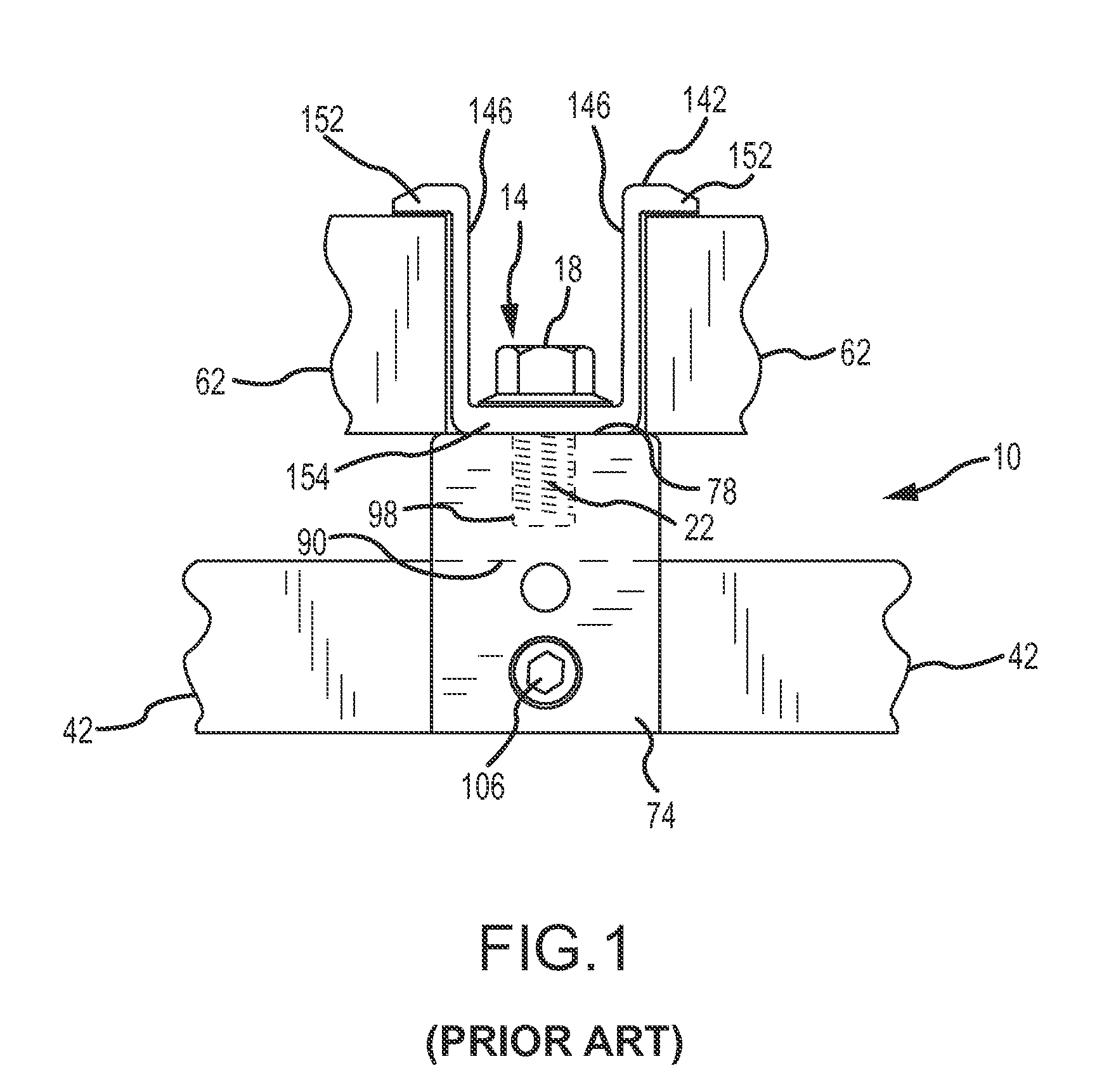

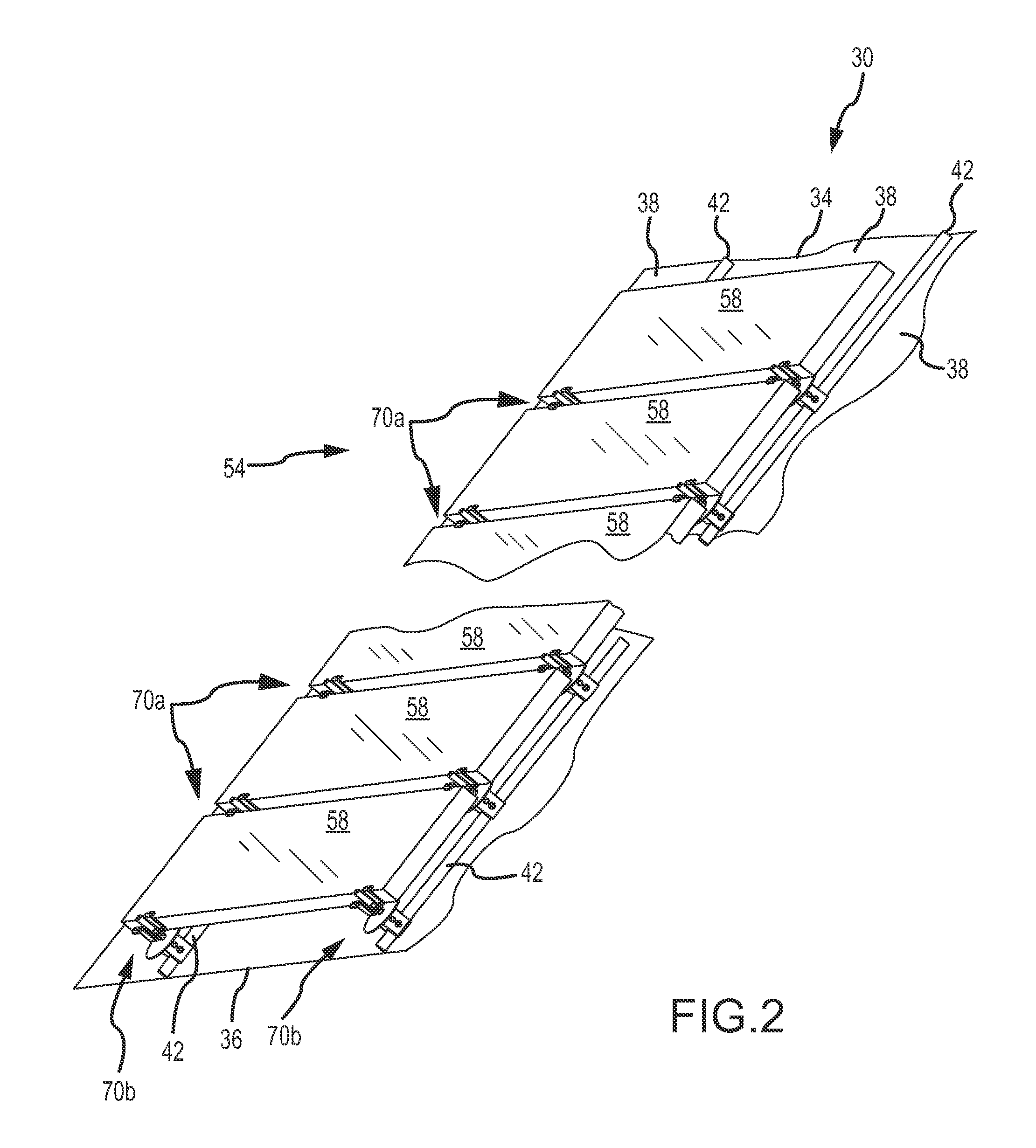

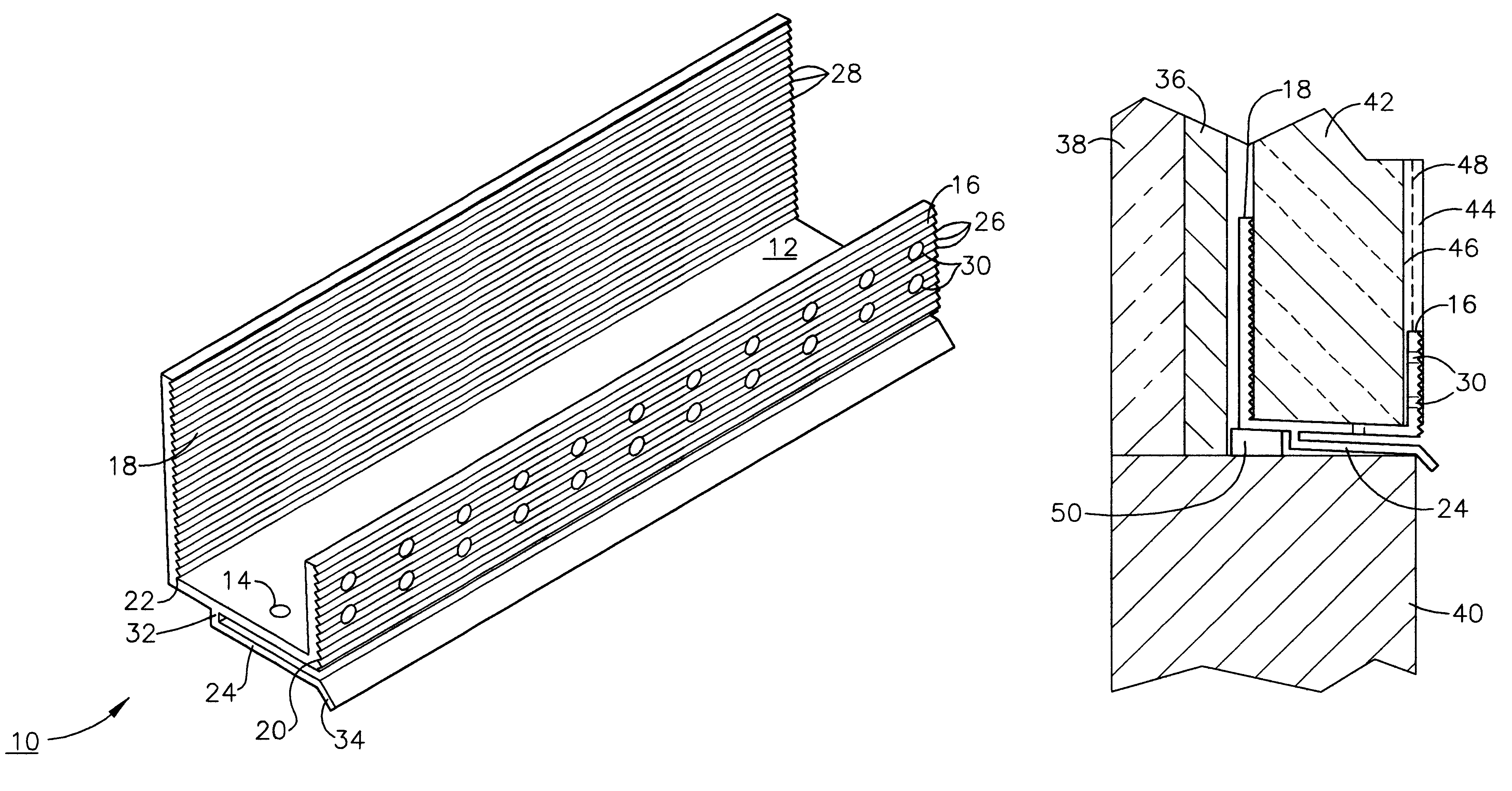

Adjustable mounting assembly for standing seam panels

ActiveUS20100269430A1Not to damagePhotovoltaic supportsSolar heating energySolar cellMechanical engineering

An adjustable mounting assembly (70a / 70b) for installing solar cell modules (58) on a building surface (34) is disclosed. The mounting assembly (70a / 70b) includes a mounting device (74), a stud (114) that may be threaded to the mounting device (74), a clamping member (142) that may be positioned on the stud (114), and a nut (128) that may be threaded onto the stud (114) to secure the clamping member (142) to the mounting device (74). A nut (126) is fixed to the stud (114) at an intermediate location along its length. This fixed nut (126) may be used to tighten the stud (114) to a mounting device (74), and furthermore may be positioned such that the stud (114) does not extend into a slot (90) of the mounting device (74).

Owner:RMH TECH LLC

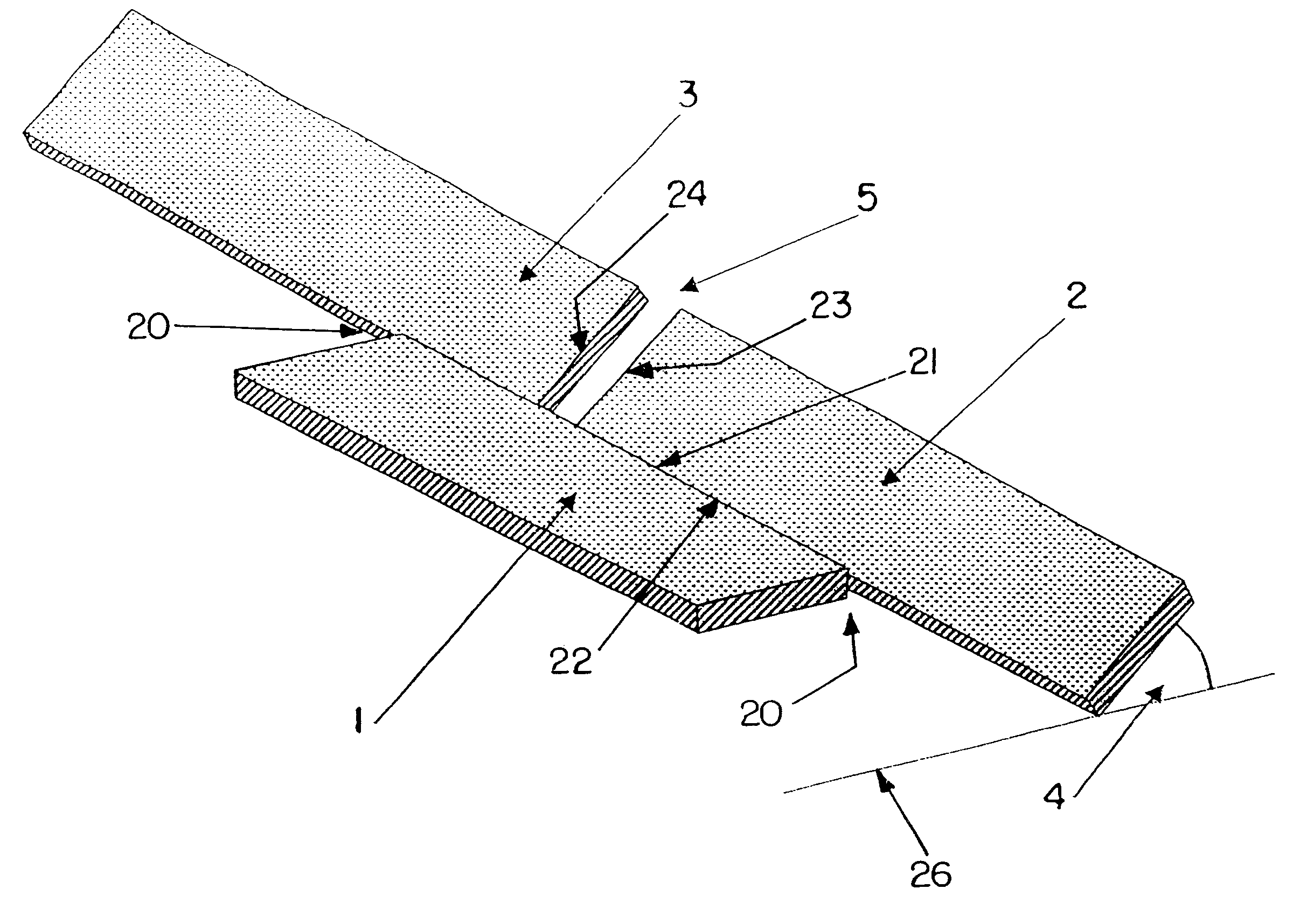

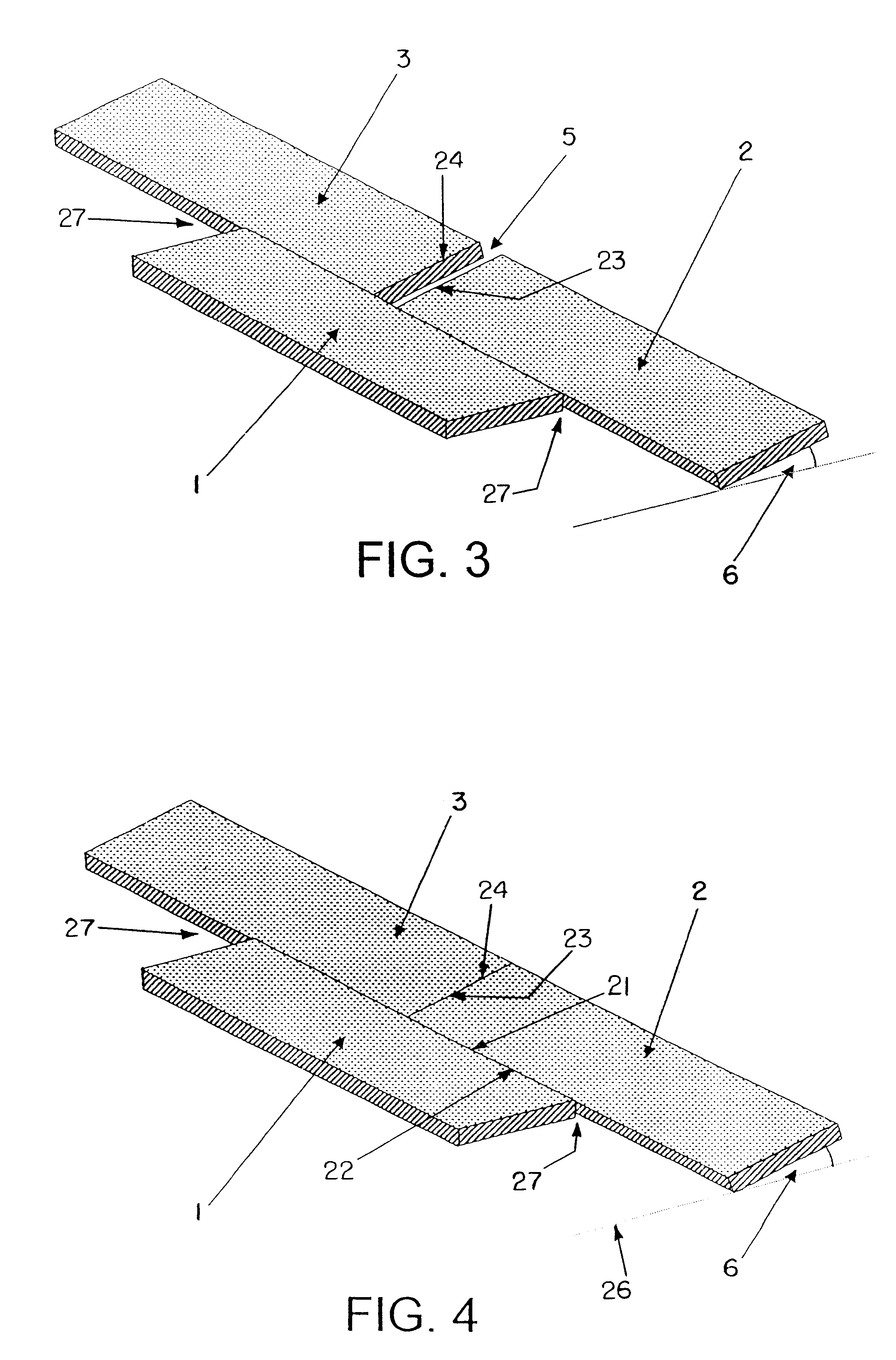

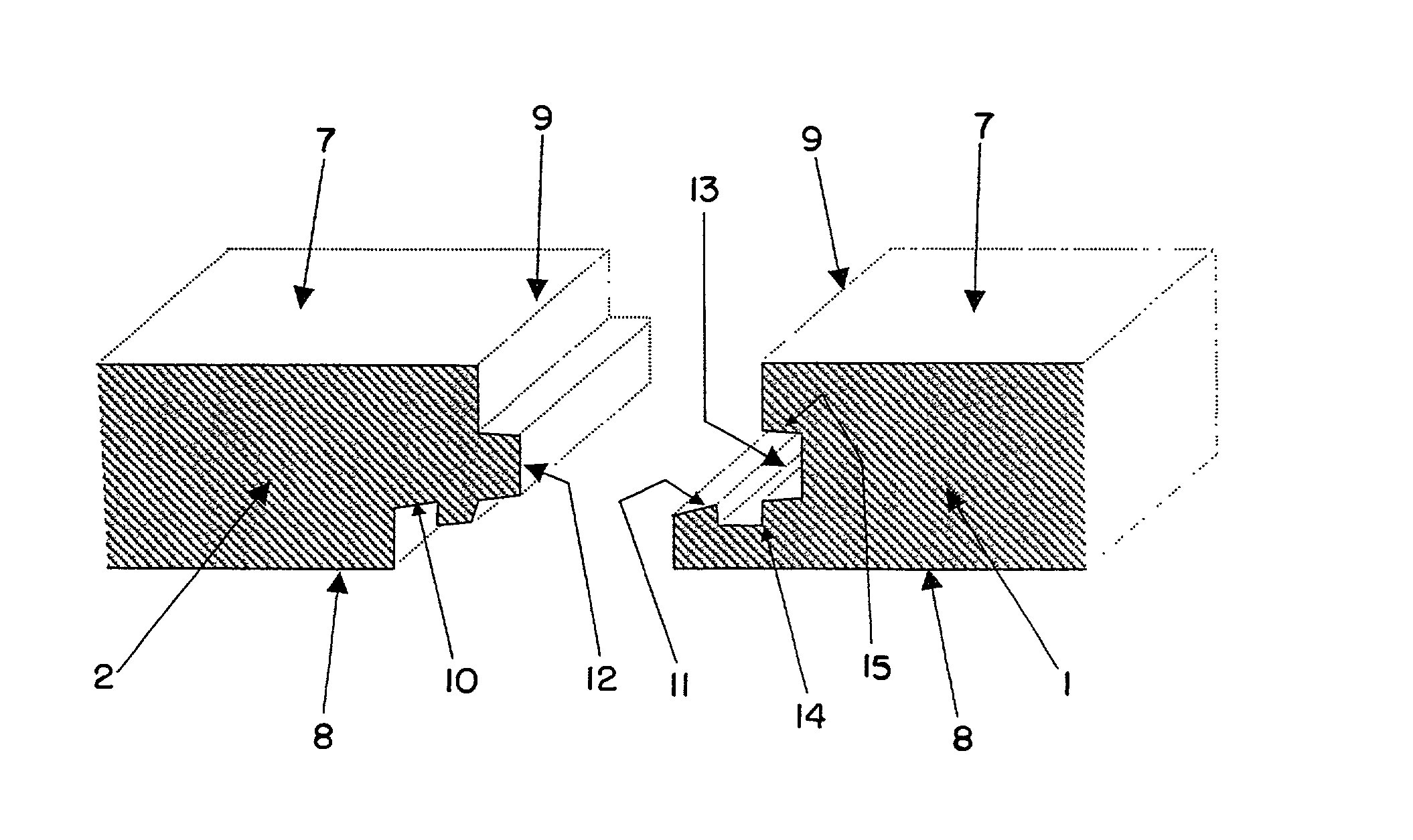

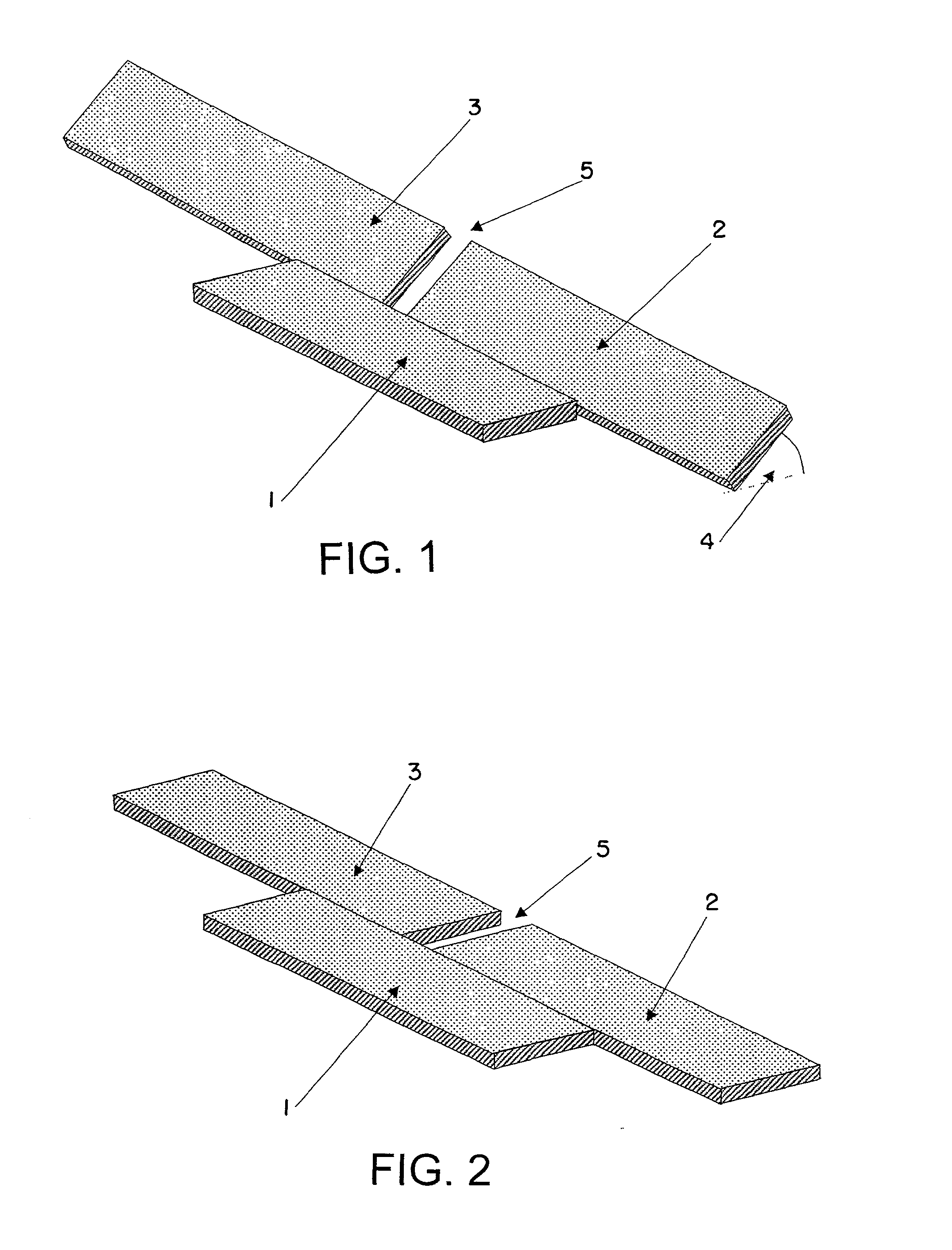

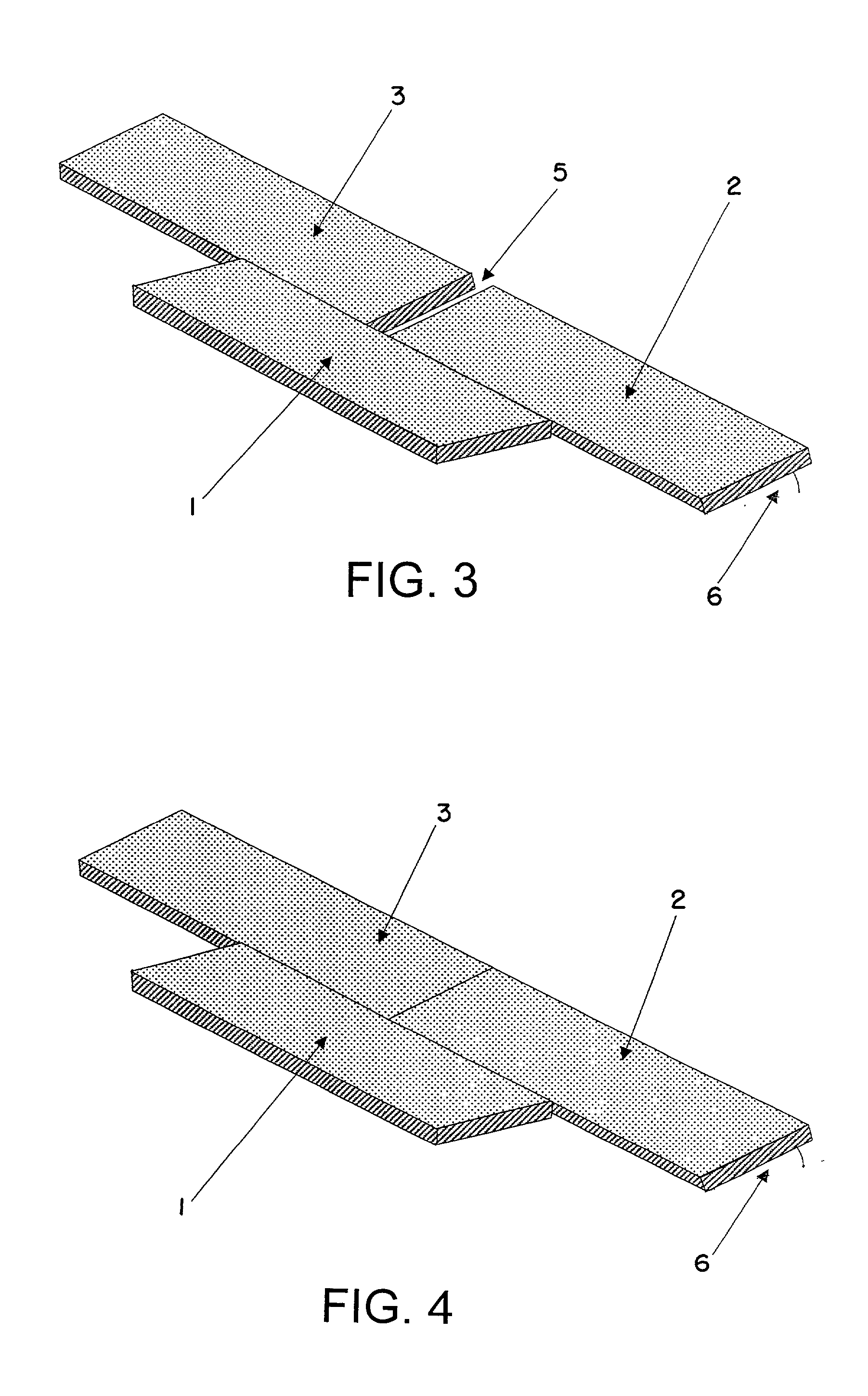

Method of laying panels

InactiveUS6546691B2Increase displacementAvoid the needRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

Laminate flooring

InactiveUS7614197B2Improve the immunityCeilingsRoof covering using tiles/slatesEngineeringSurface plate

A disengageable connector for interconnecting panels includes a longitudinally extending connector body. The connector body including a base and a projection extending from the base. The base includes a top surface and a bottom surface, and at least one footing member extending downwardly from the bottom surface of the base. The footing member is shaped and dimensioned to compress the upper surface of a resilient pad positioned beneath the connector and the panels. The connector is used in conjunction with an interlocking flooring system. The interlocking flooring system includes a plurality of flooring panels, each flooring panel including a plurality of edges. A first connecting member is provided for connecting adjacent flooring panels and a second connecting member is provided for connecting adjacent flooring panels. The first connecting member is the same as the connector described above and is different from the second connecting member. The first connecting member provides greater resistance to disengagement of adjacent flooring panels when compared to the second connecting member.

Owner:WILSONART

Tracking solar shelter

InactiveUS7531741B1Space minimizationQuantity maximizationPhotovoltaic supportsSolar heating energyEngineeringSolar power

The present invention comprises a tracking solar power array that provides shelter to items disposed beneath the solar power array, particularly to vehicles.

Owner:SACRED POWER CORP

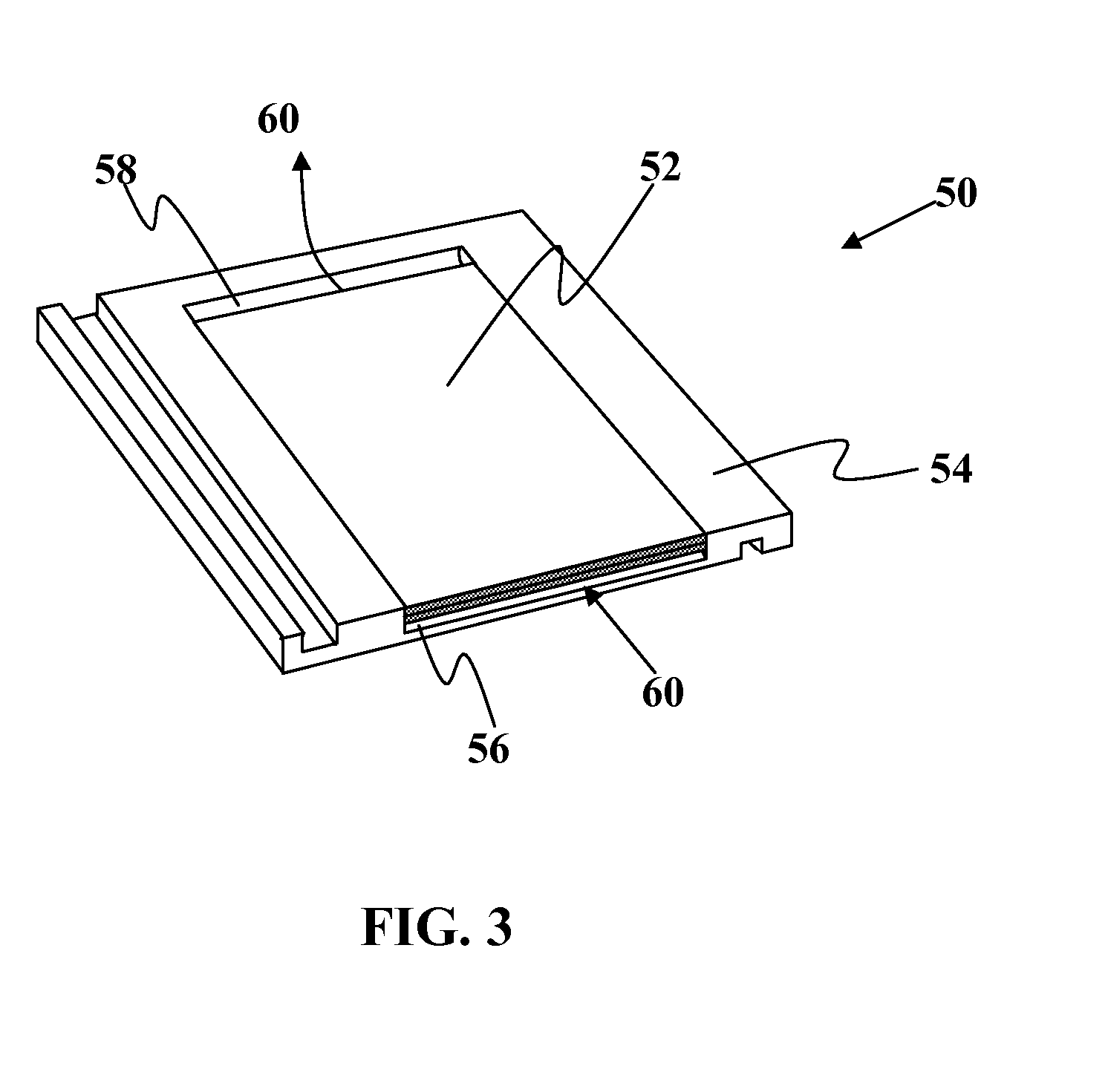

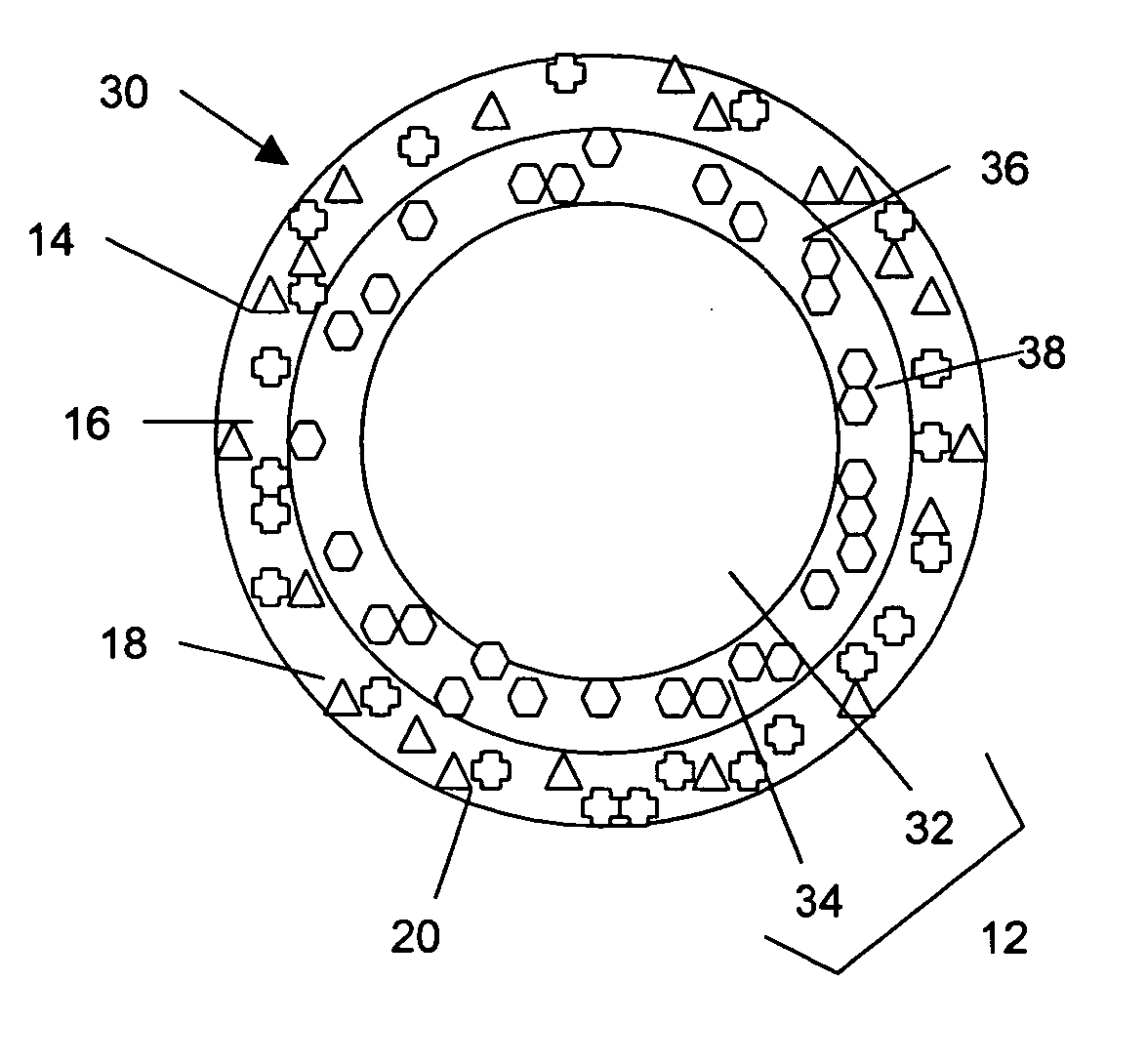

Shingle system

InactiveUS7328534B2Reduce the temperatureImprove efficiencyPhotovoltaic supportsSolar heating energyComputer moduleEngineering

A barrier, such as a PV module, is secured to a base by a support to create a shingle assembly with a venting region defined between the barrier and base for temperature regulation. Water resistant junctions may be formed between the bases of adjacent shingle assemblies of an array of shingle assemblies. The base may include an insulation layer underlying a water barrier. The base may also include a waterproofing element; the width and height of the barrier may be shorter than the width and height of the waterproofing element.

Owner:SUNPOWER CORPORATION

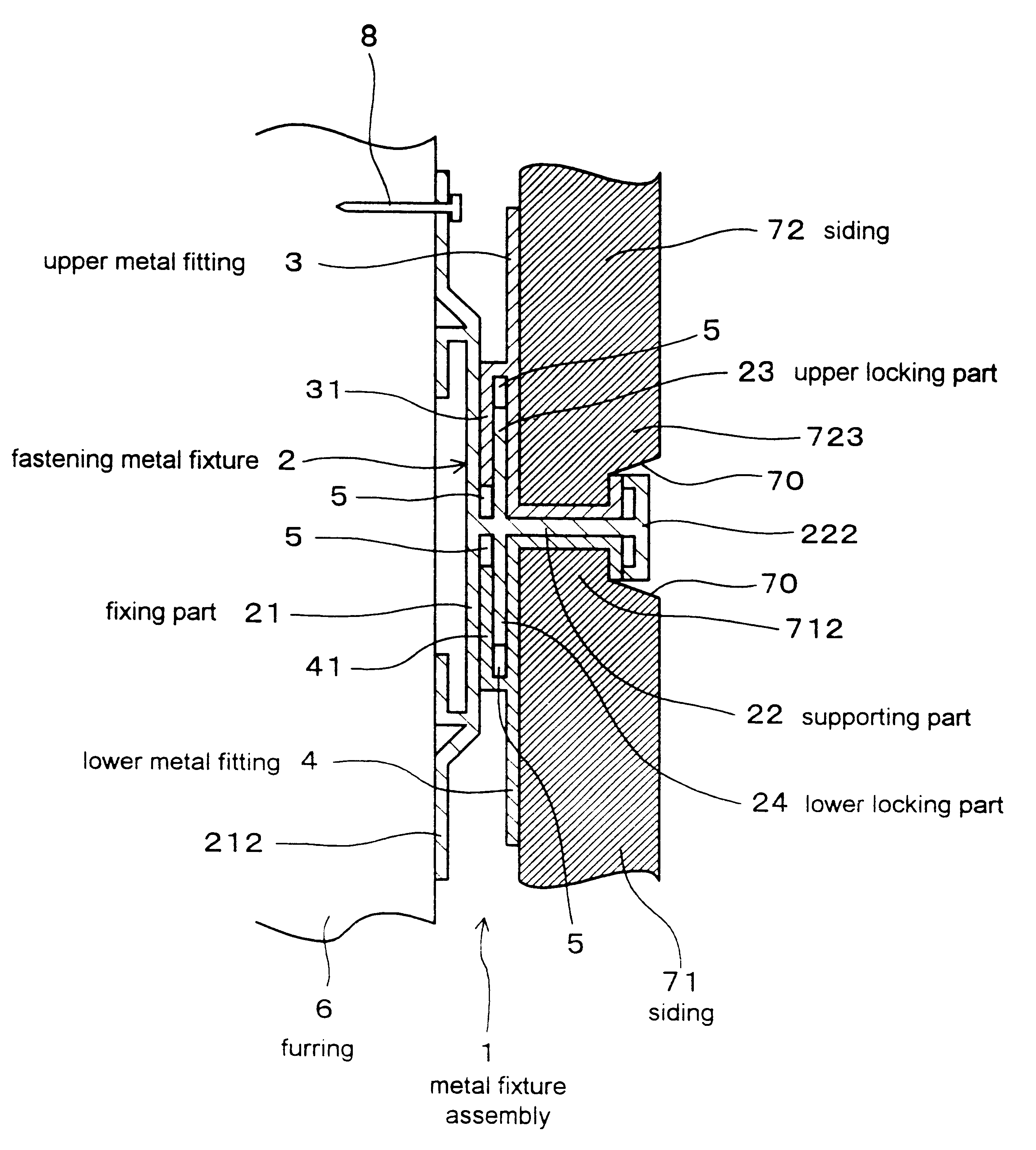

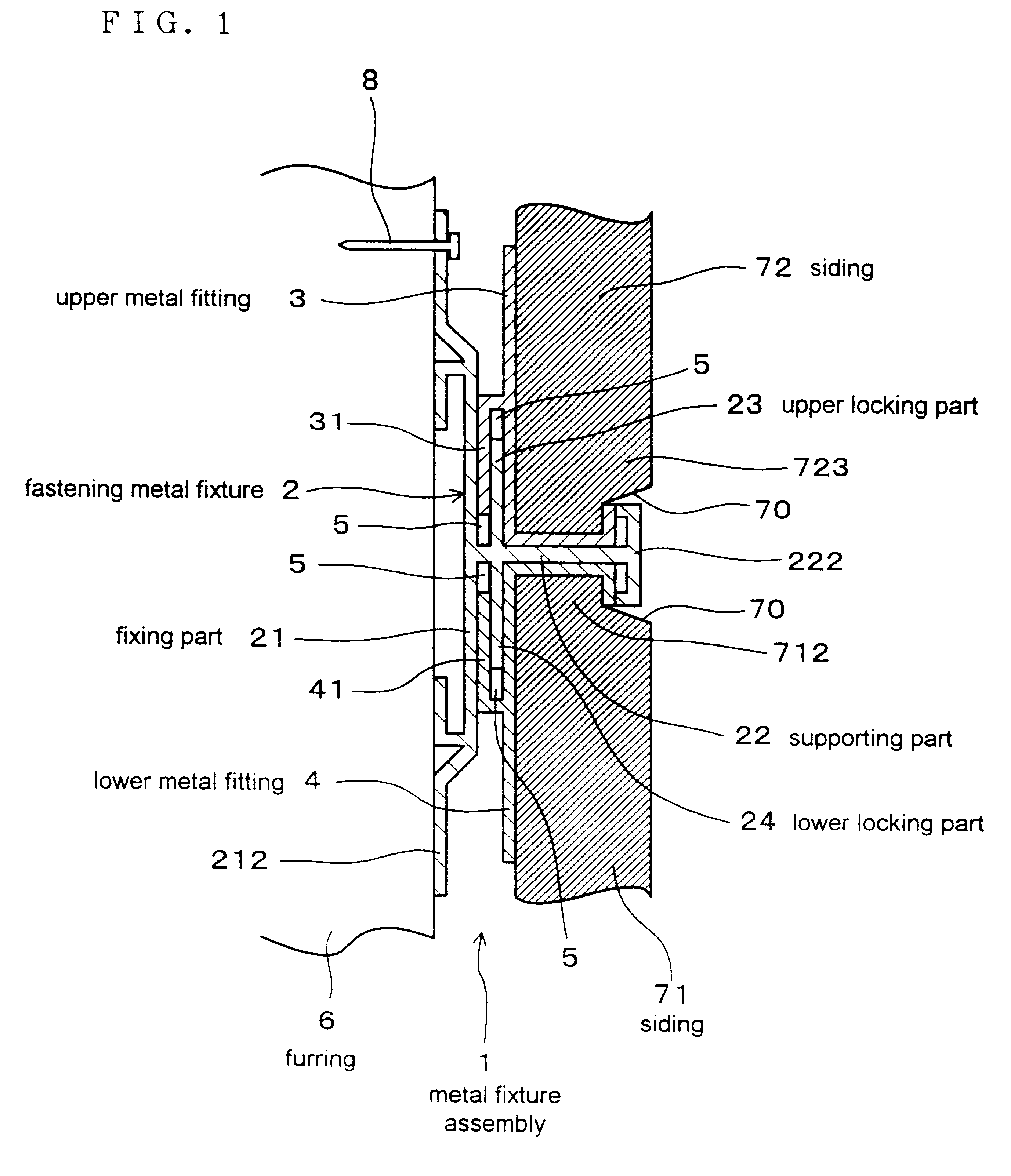

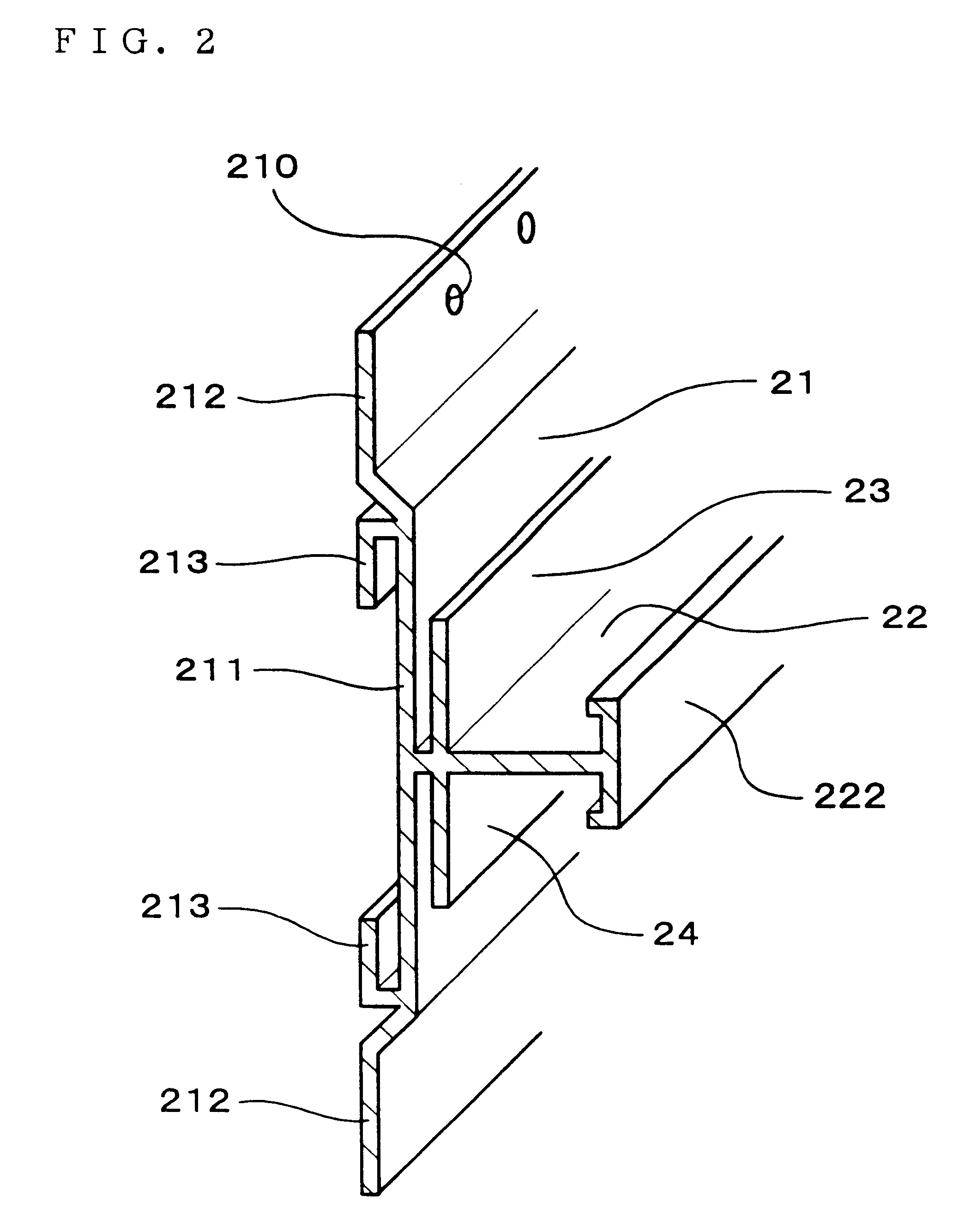

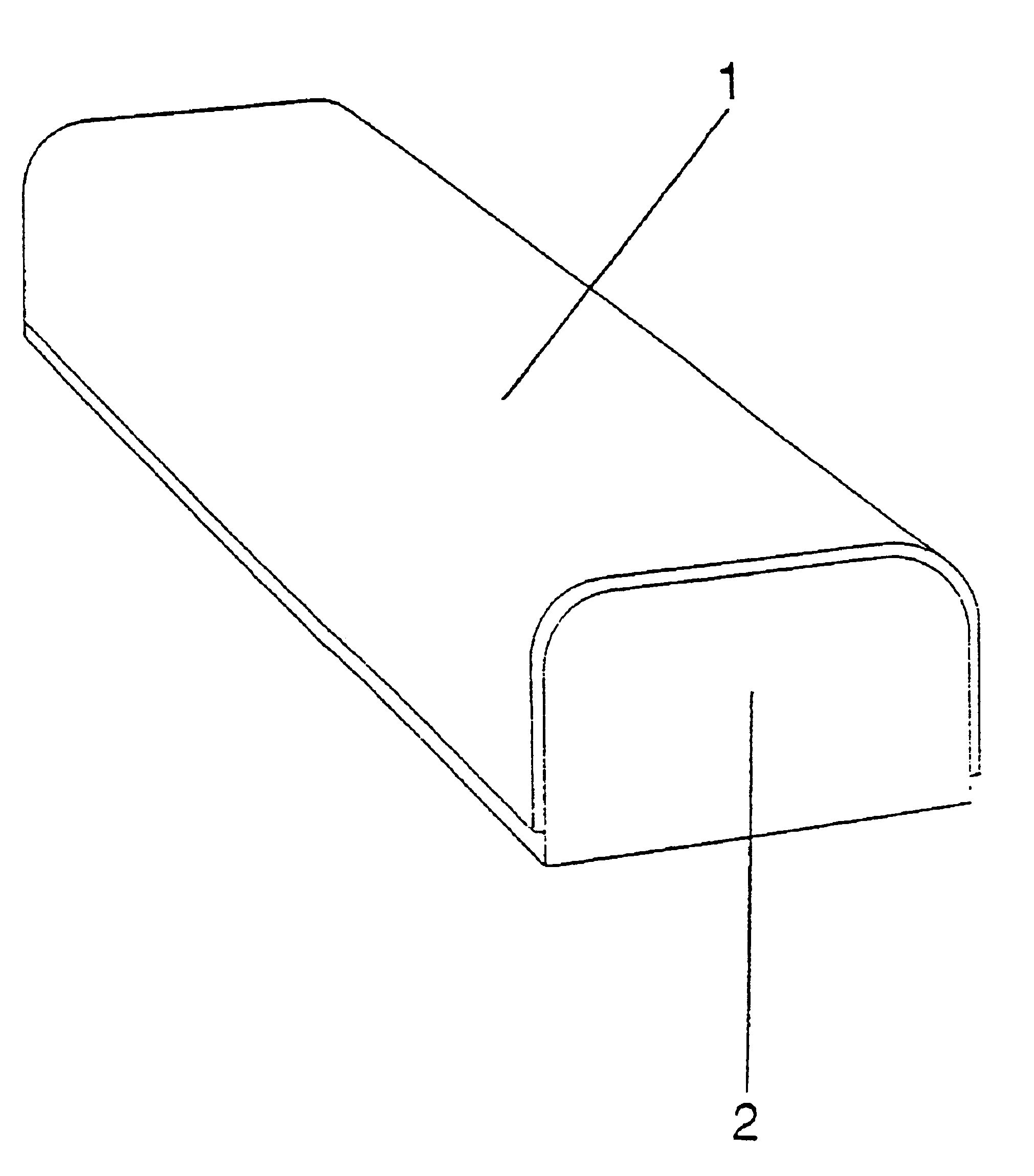

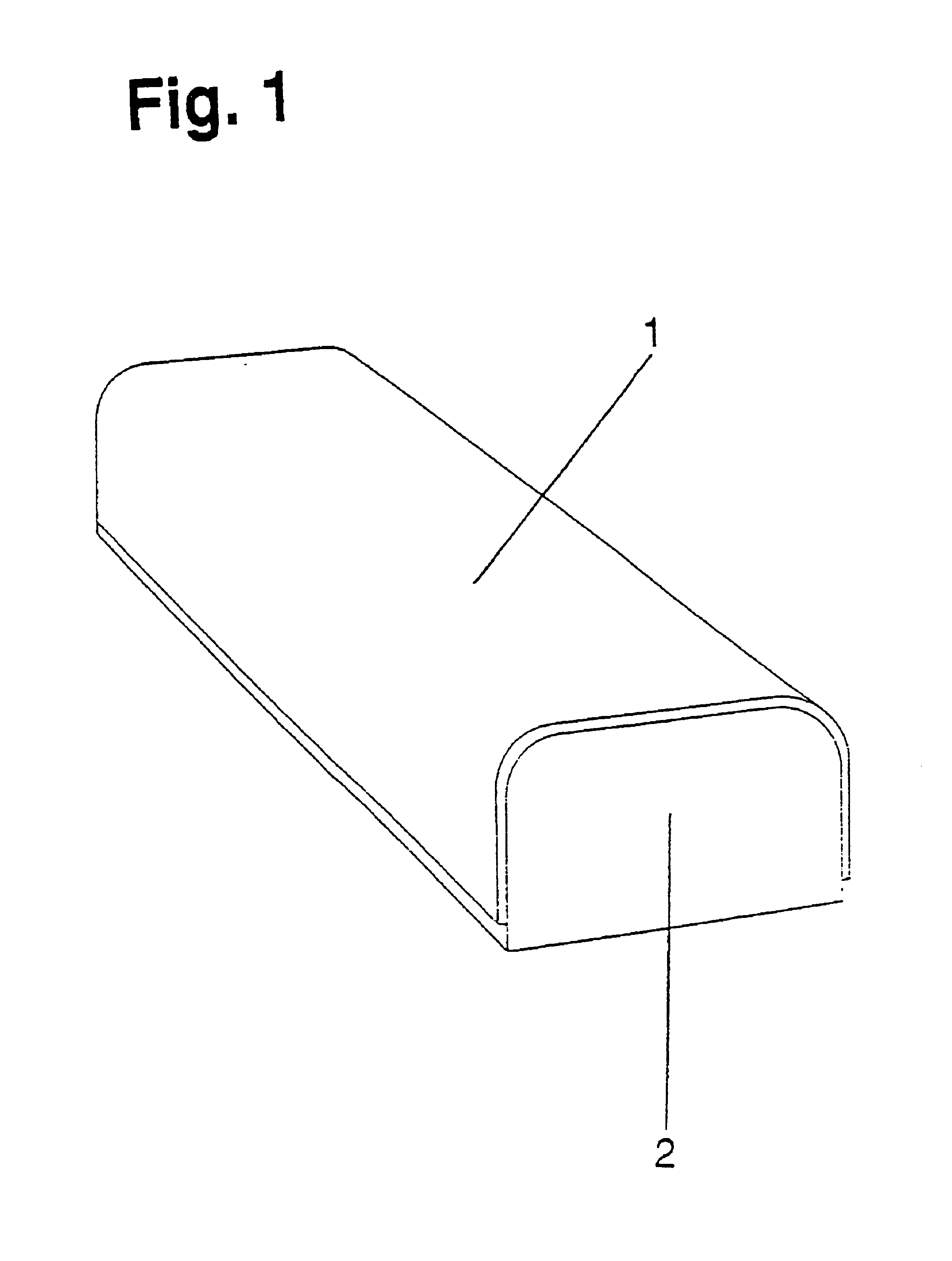

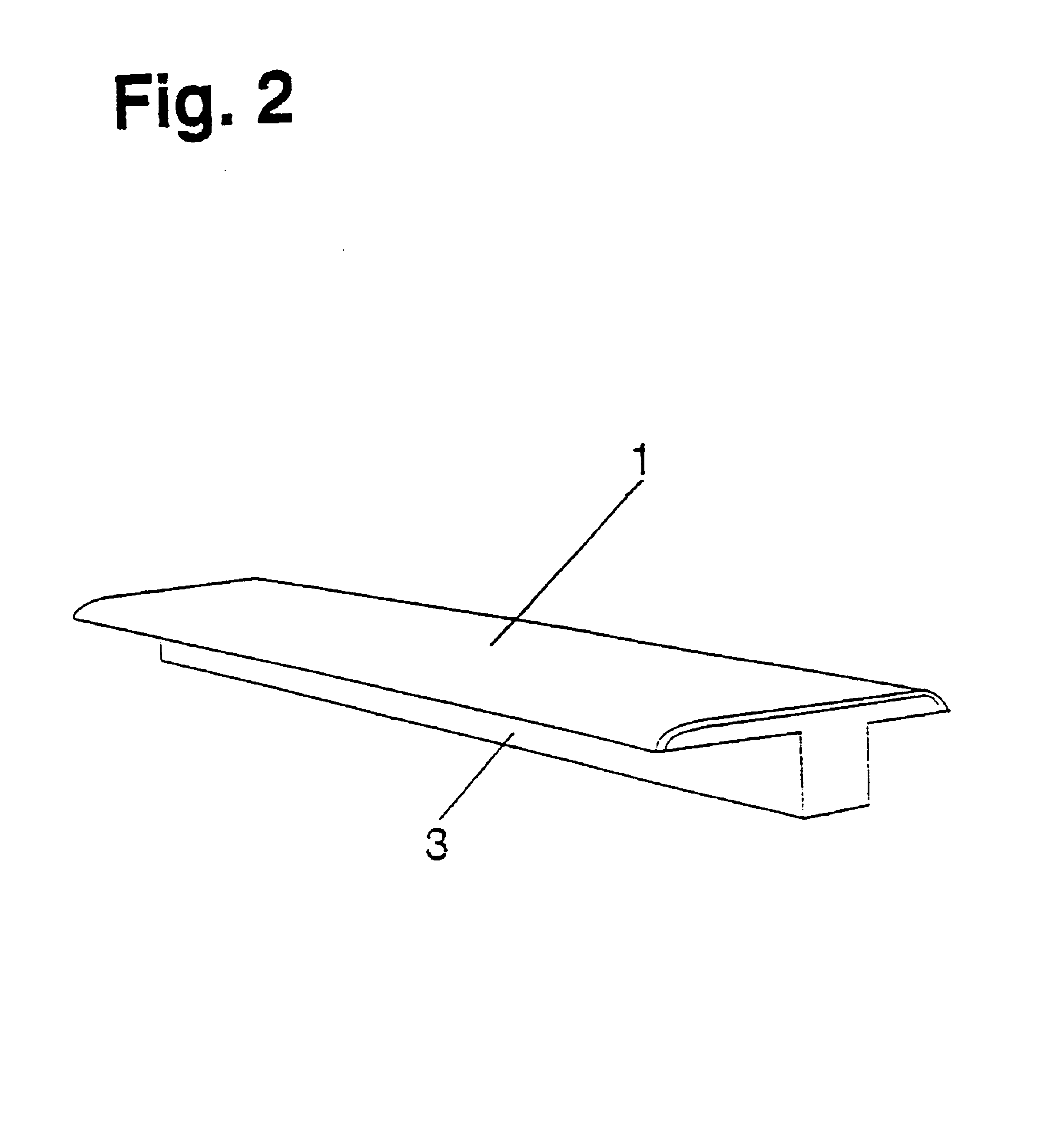

Metal fixture assembly for installation of vertical sidings, construction and method of installation

InactiveUS6289646B1Safe installationGood lookingCeilingsRoof covering using tiles/slatesArchitectural engineeringFurring

A metal fixture assembly for installation of vertical sidings to fix the siding to a furring, which is capable of providing a construction of the installation having excellent appearance and weathering, and a method using the metal fixture assembly to facilitate the installation. A metal fixture assembly for installation of a vertical lower siding and a vertical upper siding vertically adjacent to each other on a furring is positioned therebetween. The metal fixture assembly includes a fastening metal fixture to be fixed to the furring, an upper metal fitting provided between the fastening metal fixture and the upper siding and fittingly fixed on a bottom portion thereof, and a lower metal fitting provided between the fastening metal fixture and the lower siding and fittingly fixed on a top portion thereof. The fastening metal fixture has a fixing part to be fixed to the furring, a supporting part projecting from the fixing part to support the lower and upper sidings, an upper locking part provided between the fixing part and the supporting part and locking the upper metal fitting thereto, and a lower locking part provided between the fixing part and the supporting part and locking the lower metal fitting thereto.

Owner:NICHIHA CORP

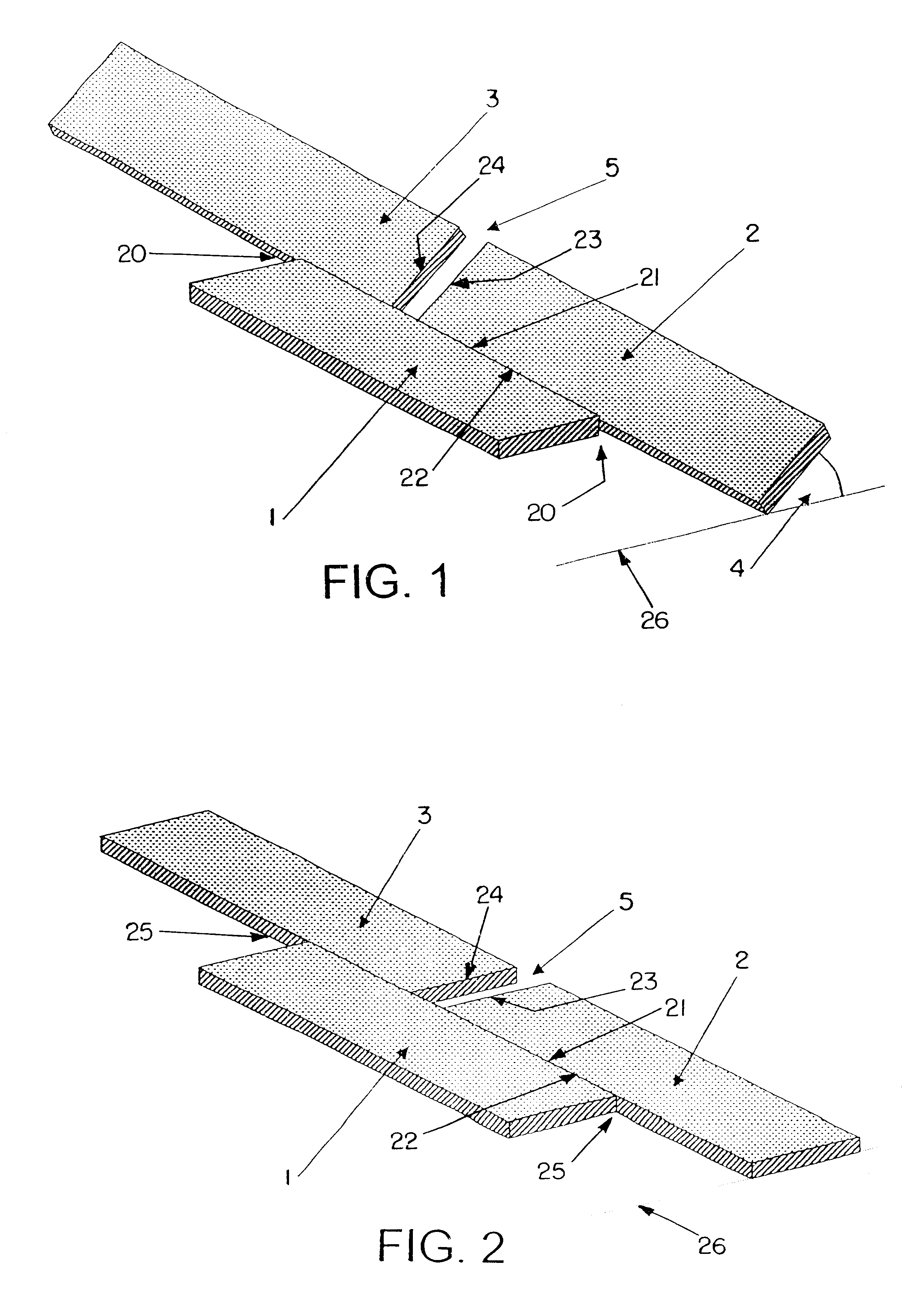

Method of laying panels

InactiveUS20020069611A1Easy to provideIncrease displacementRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

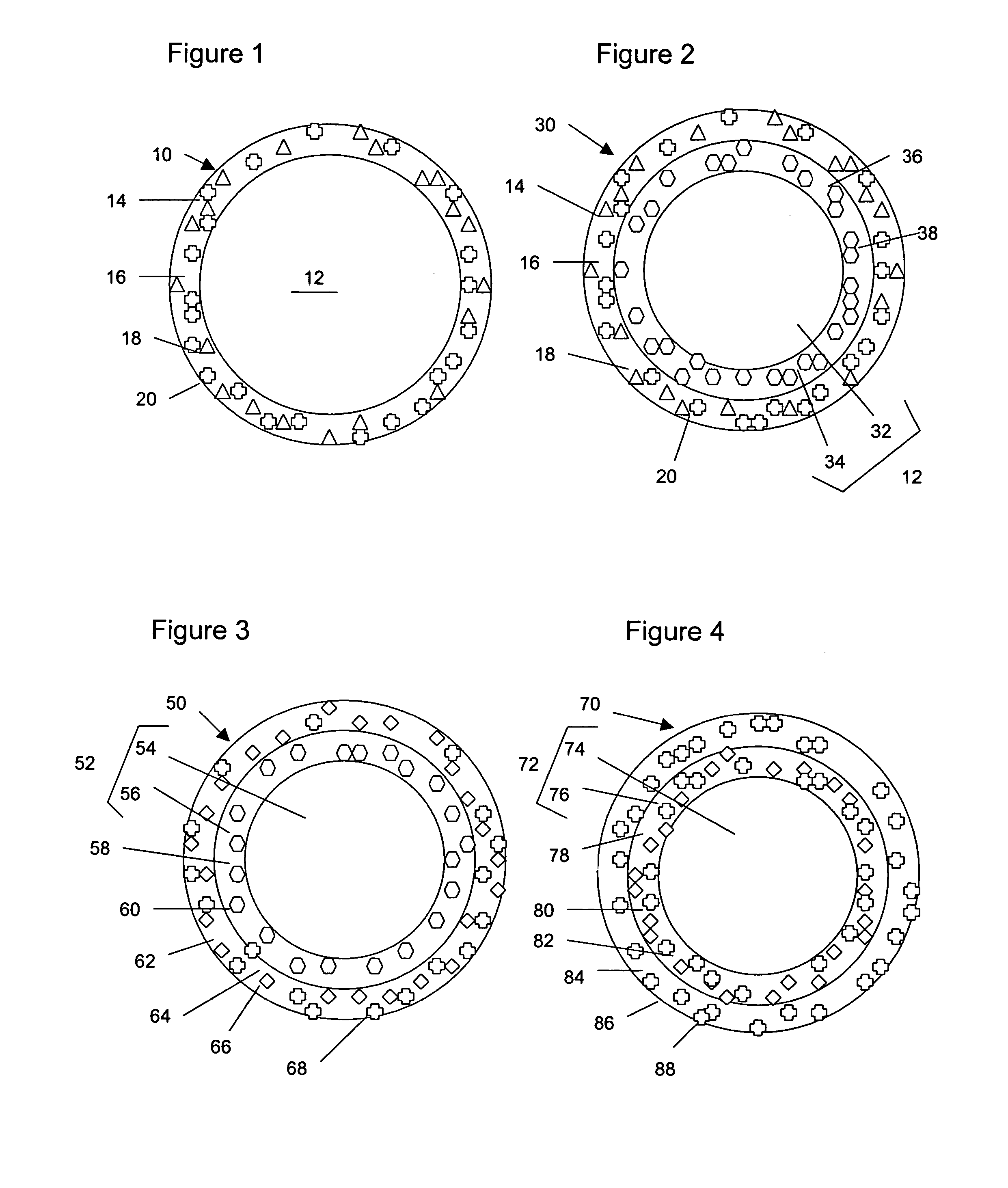

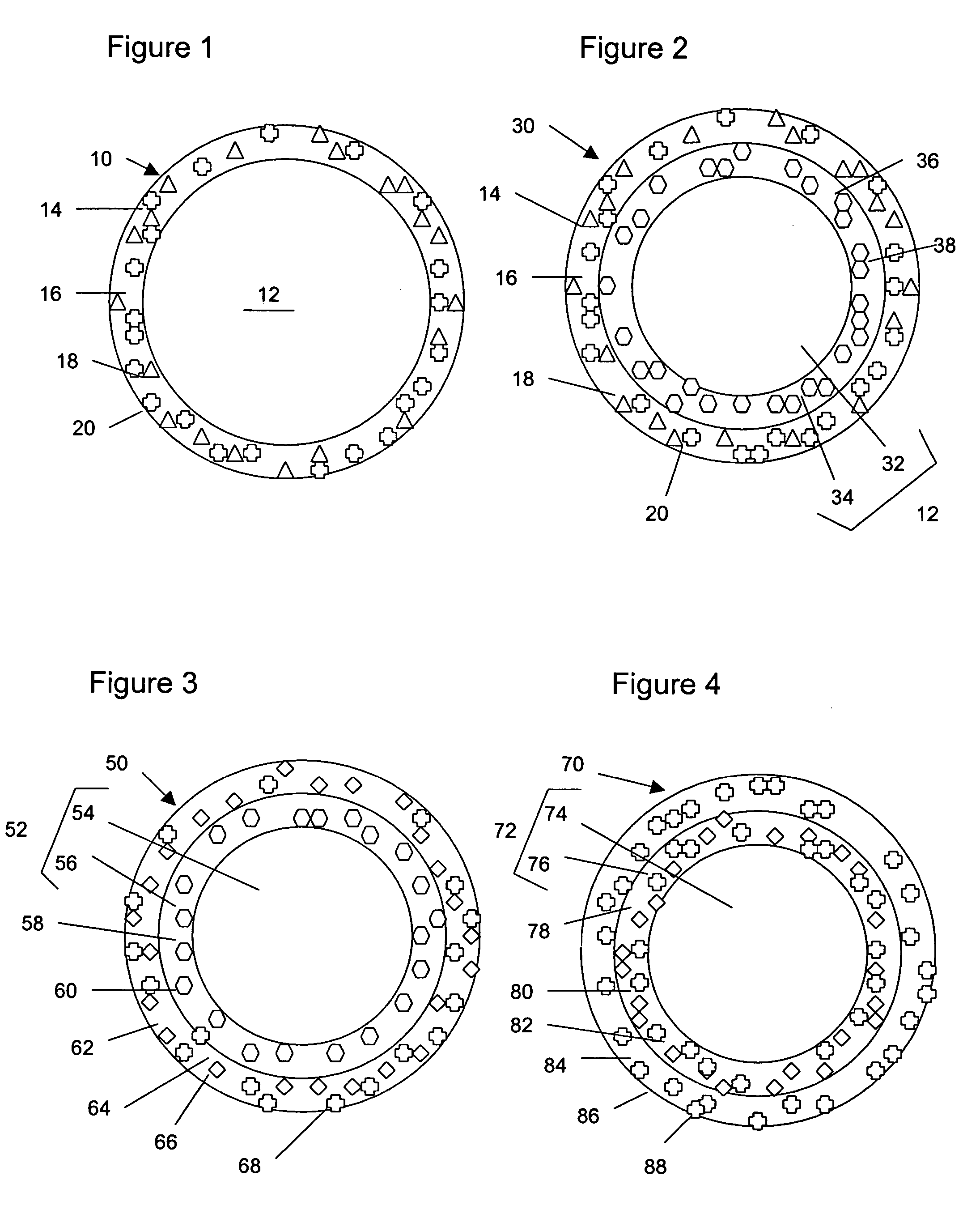

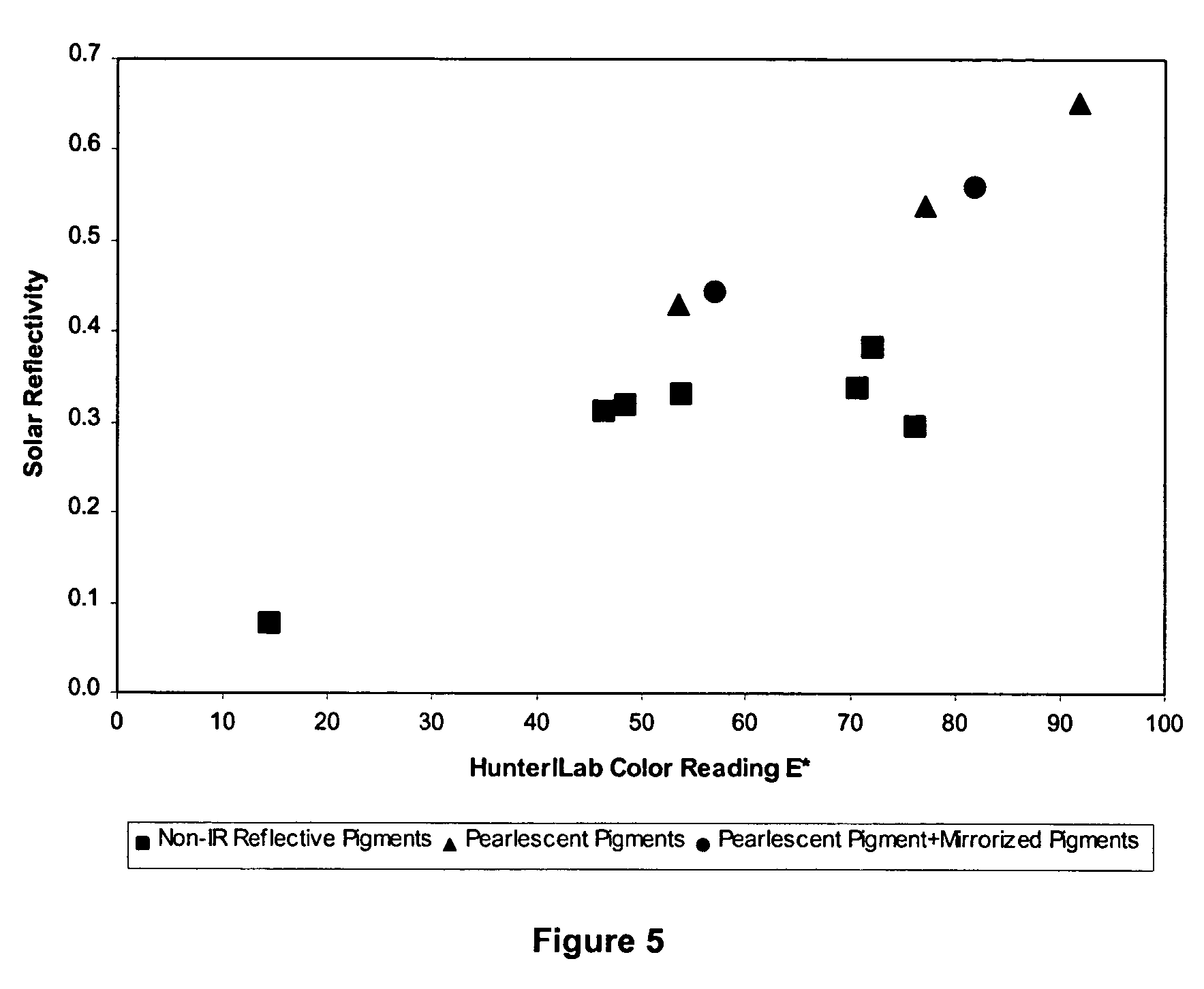

Colored roofing granules with increased solar heat reflectance, solar heat-reflective shingles, and process for producing same

ActiveUS20050072114A1Improve solar heat reflectivityRoof improvementGlass/slag layered productsMineral particlesPigment

Owner:CERTAIN TEED LLC

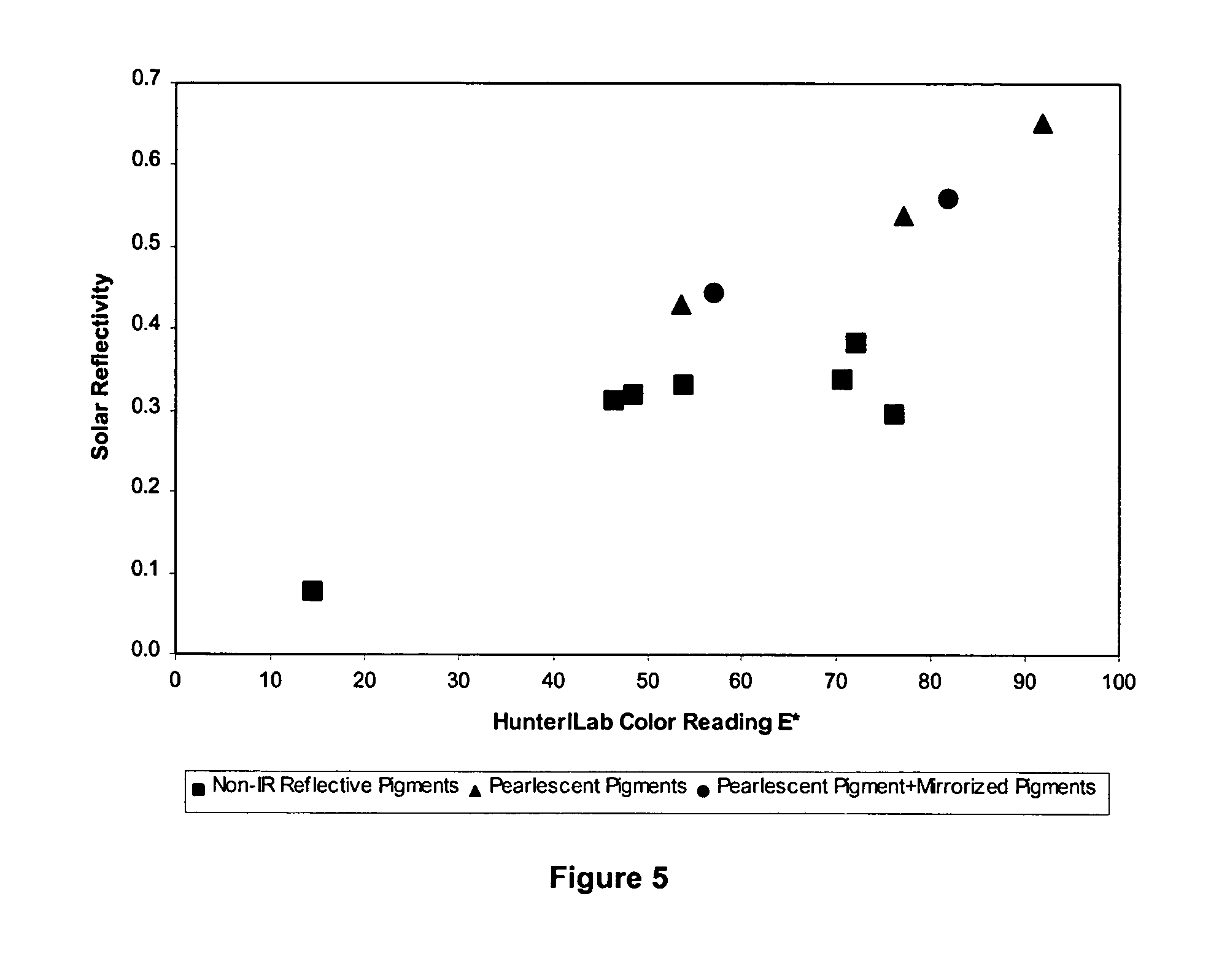

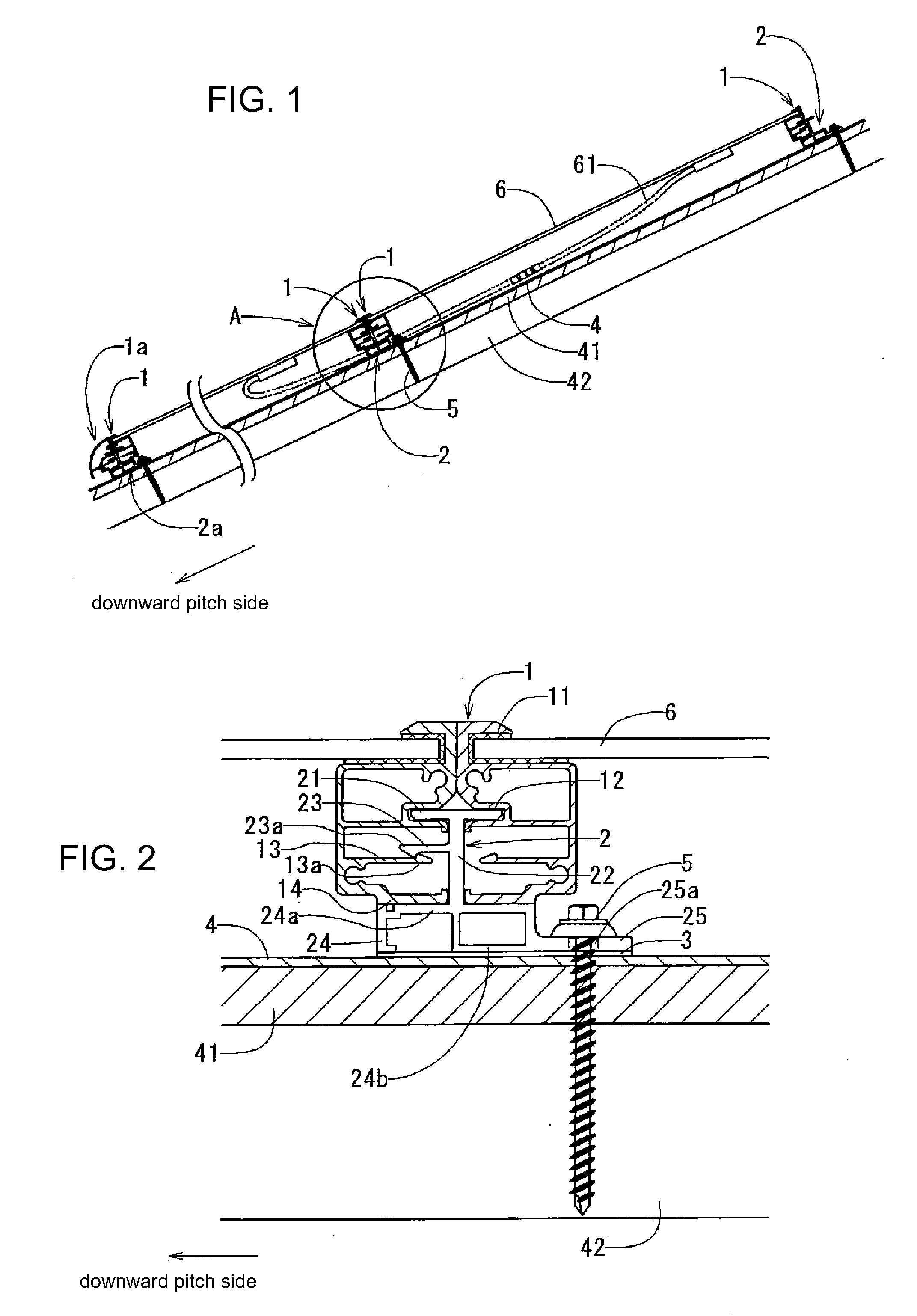

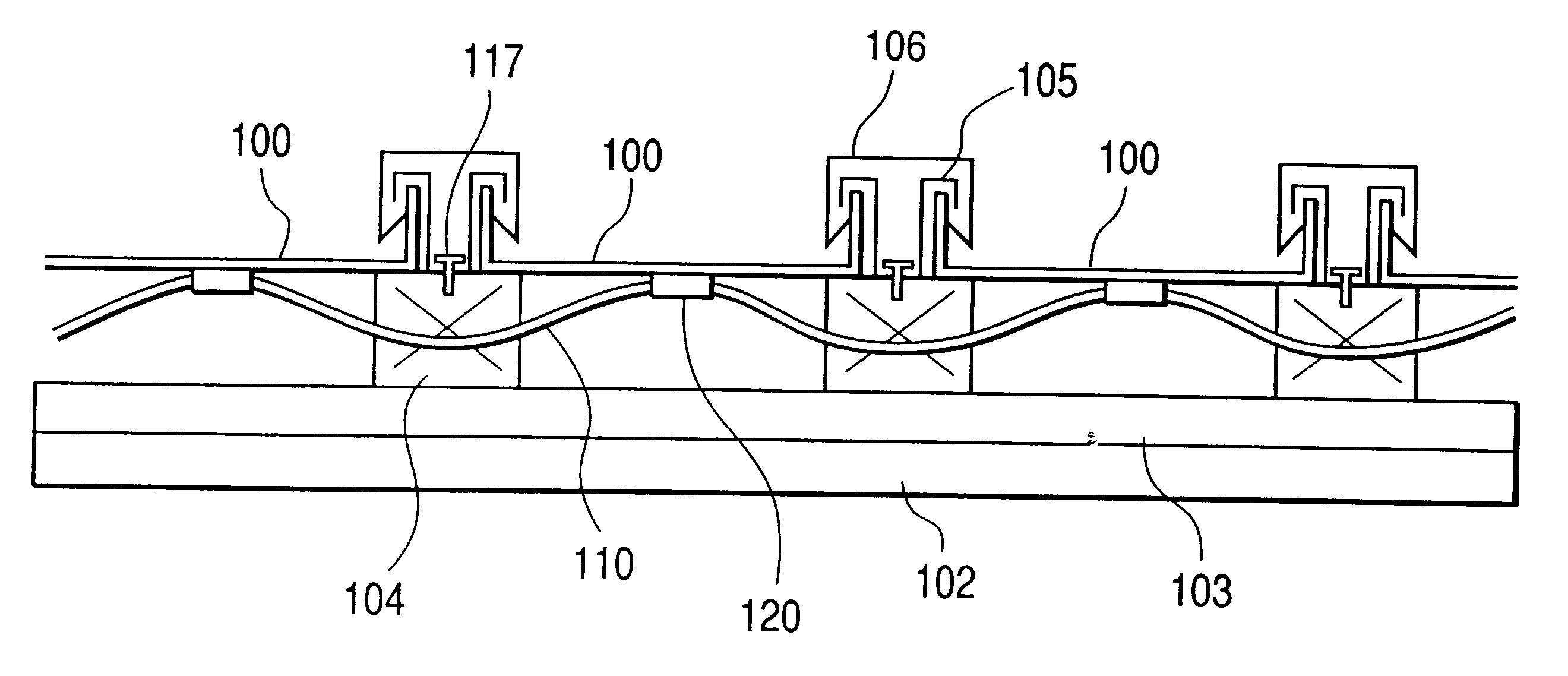

Solar cell module retaining structure, frame for solar cell module, and holding member for solar cell module

ActiveUS20080302407A1Low costEliminate gapsPhotovoltaic supportsSolar heating energyElectrical batteryComputer module

To provide the solar cell module retaining structure, the frame for the solar cell module, and the holding member for the solar cell module, which reduces the number of members relating to the solar cell module retaining structure, standardizes the installation process thereof, and reduces the cost of manufacturing and installing. The solar cell module retaining structure is to fix the solar cell module which comprises the solar cell panel body with the modular glass (6) and the frame (1) to be fixed to the solar panel body to the supporting member (42) via the holding member (2), wherein the frame (1) and the holding member (2) are for the retaining structure of the solar cell module; the holding member (2) can slide relative to the frame (1); the holding member (2) can keep two adjacent frames of two adjacent solar cell modules contacted and restrict one solar cell module from moving in the right angle direction relative to the extending direction of the frame (1); and the holding member (2) is fixed to the supporting member (42) at the lower side of the other solar cell module.

Owner:YANEGIJUTSUKENKYUJO CO LTD

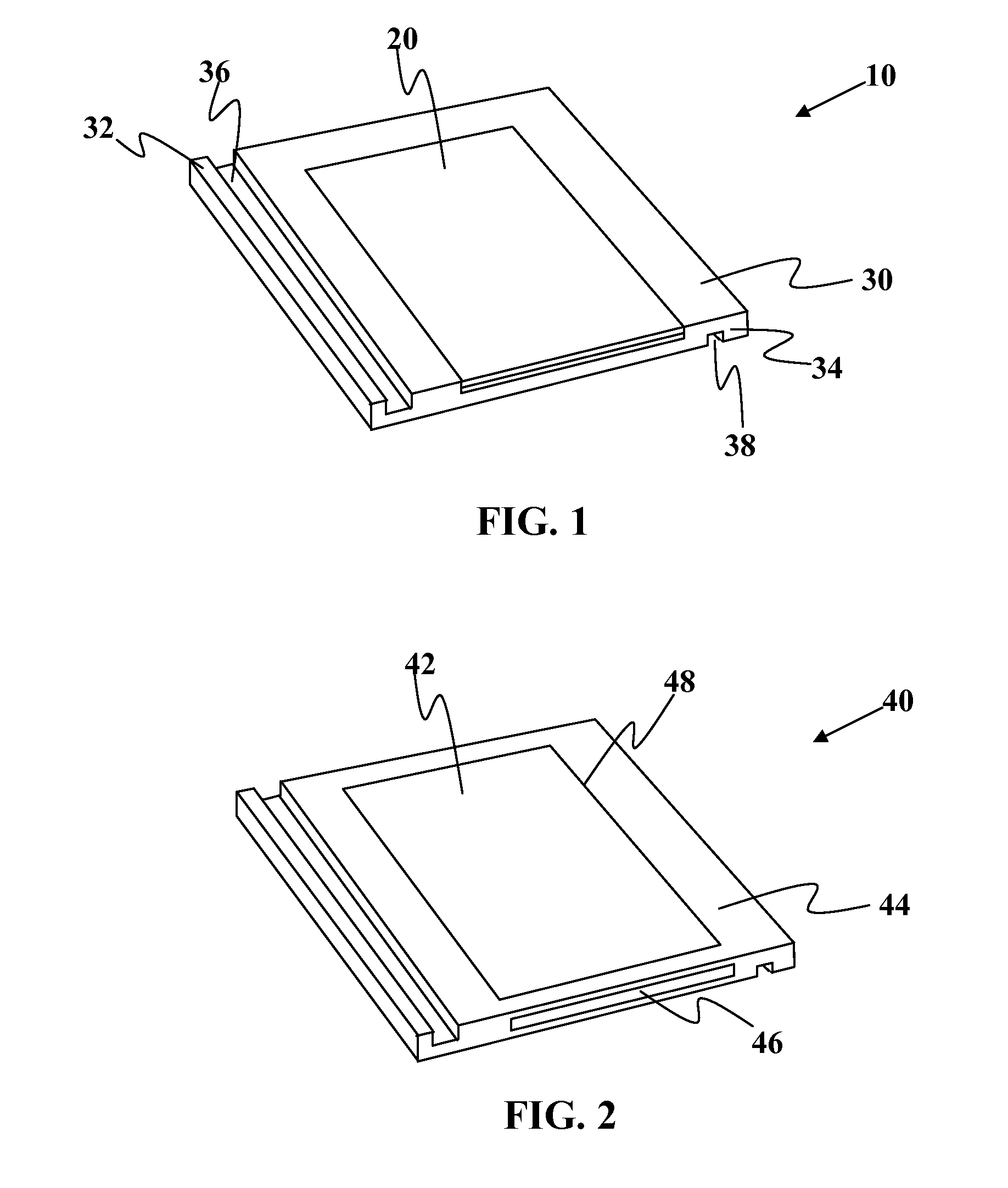

Shingle assembly

InactiveUS7178295B2Reduce wind uplift forceReduce the temperaturePhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

A barrier, such as a PV module, is secured to a base by a support to create a shingle assembly with a venting region defined between the barrier and base for temperature regulation. The first edge of one base may be interengageable with the second edge of an adjacent base to be capable of resisting first and second disengaging forces oriented perpendicular to the edges and along planes oriented parallel to and perpendicular to the base. A deflector may be used to help reduce wind uplift forces.

Owner:SUNPOWER CORPORATION

Colored roofing granules with increased solar heat reflectance, solar heat-reflective shingles, and process for producing same

ActiveUS7241500B2Improve solar heat reflectivityRoof improvementGlass/slag layered productsMineral particlesPigment

Owner:CERTAIN TEED LLC

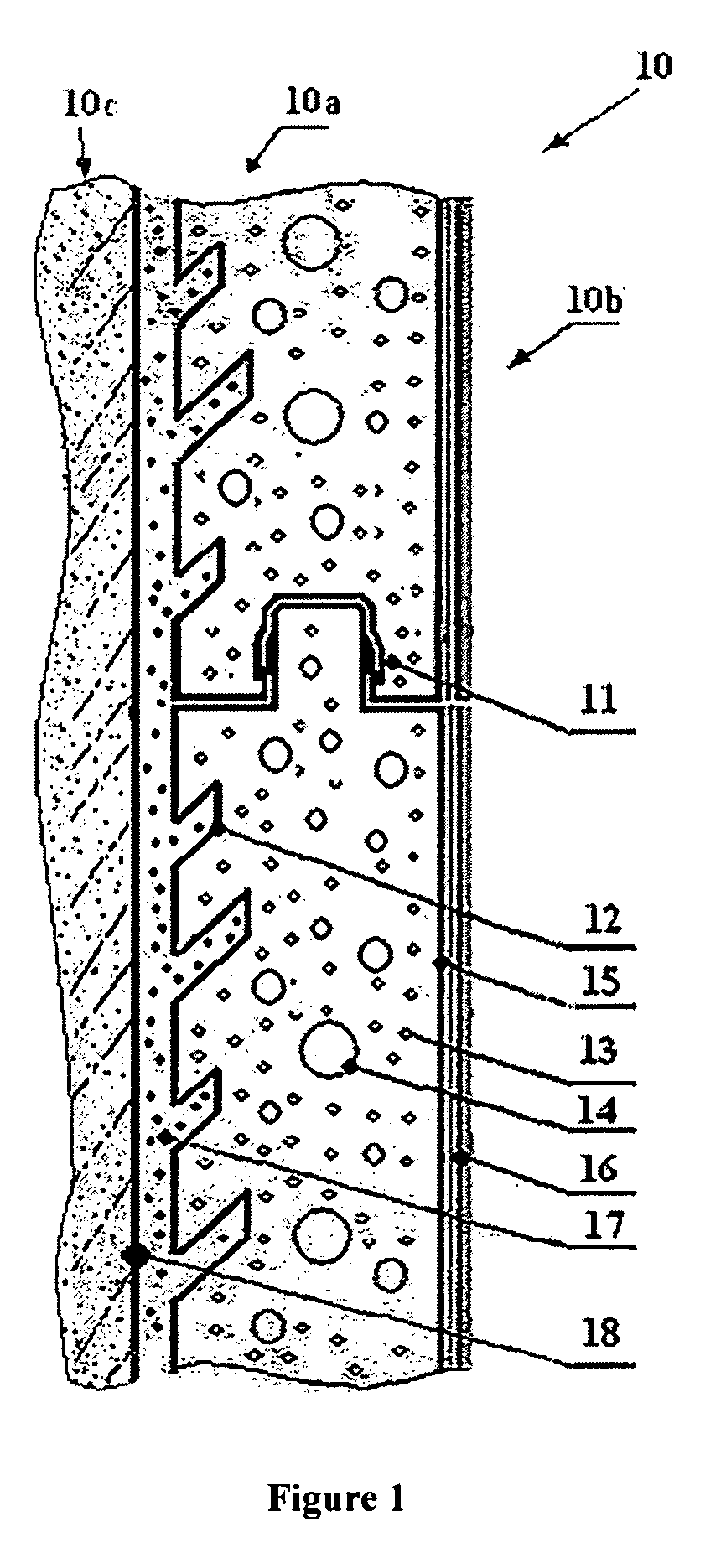

Moisture management system

InactiveUS6293064B1Improve water resistanceImprove featuresRoof covering using slabs/sheetsRoof covering using tiles/slatesAdhesiveEngineering

A moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base having weep holes therein, an upright front wall and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water entering the moisture management system through the weep holes in the base. Elongated striations in the front faces of both the front and rear upright walls as well as holes in the front upright wall provide adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

Substrate and the application

InactiveUS20090308001A1Reducing global warmingImprove energy efficiencyPhotovoltaic supportsSolar heating energyThermal energyThermal insulation

This invention relates to a substrate and the application. In particular, this invention discloses a substrate which has at least one contact structure at least on one side and at least one contact structure at least on one surface of the substrate. The substrate includes a thermal insulation material comprising at least two materials selecting from a thermal energy reflecting material, a homogeneous foam material, a heterogeneous foam material, a skin material, a skeleton structured material, an electromagnetic wave shielding material. The substrate may be used to construct various articles with different features of energy saving, decoration and protection as well as simple installation for various applications.

Owner:WU SHAOBING

Low profile hardwood flooring strip and method of manufacture

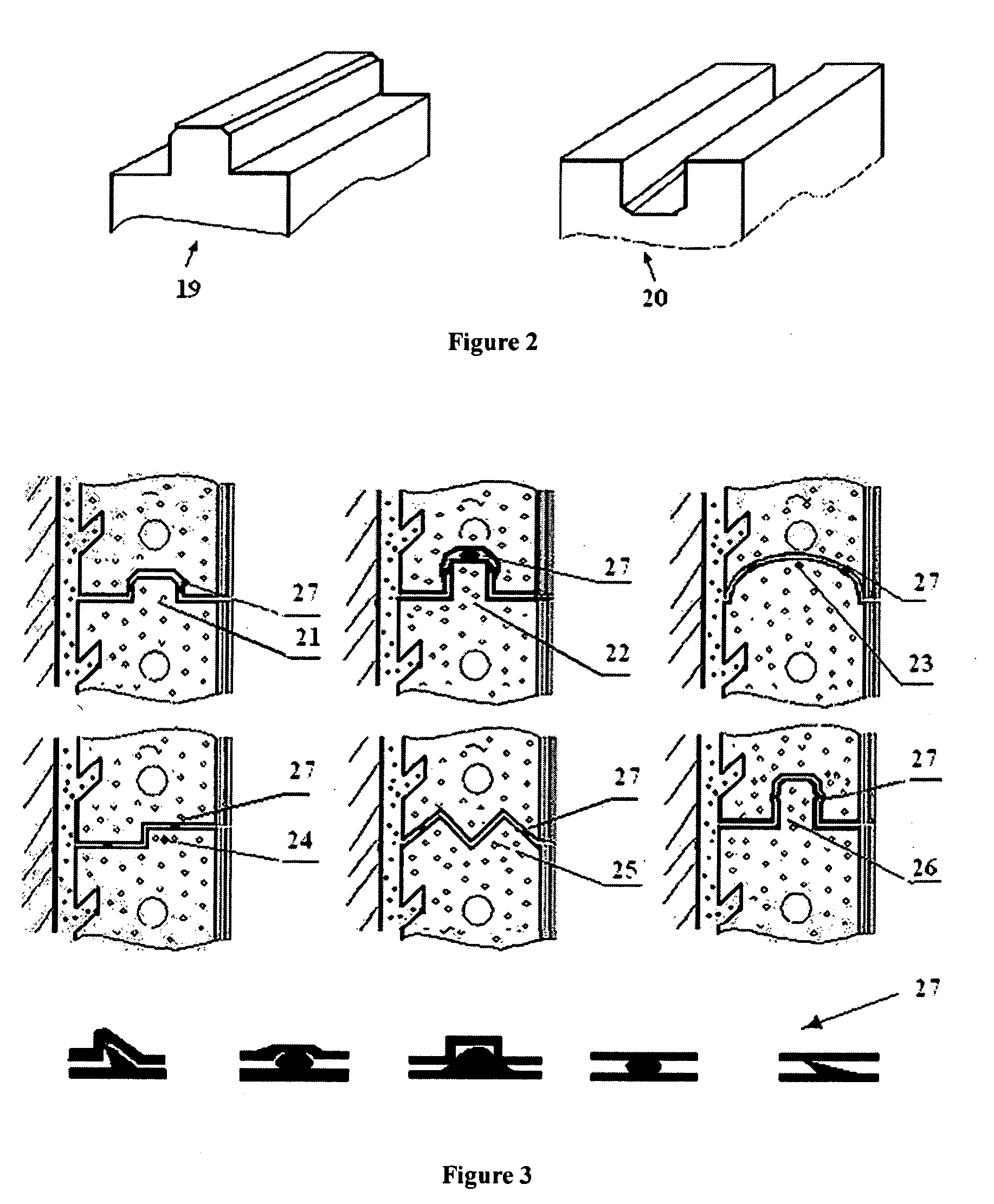

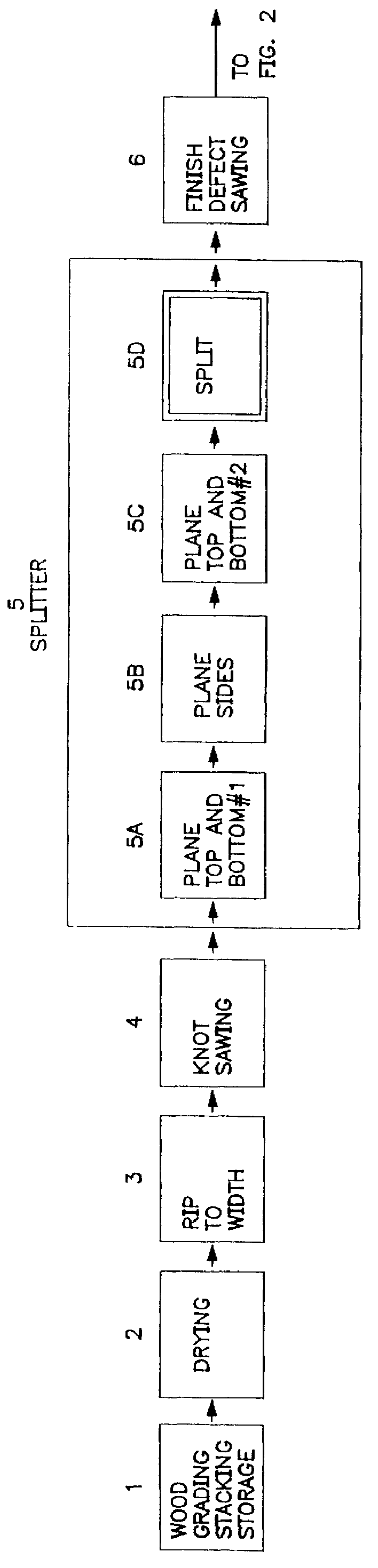

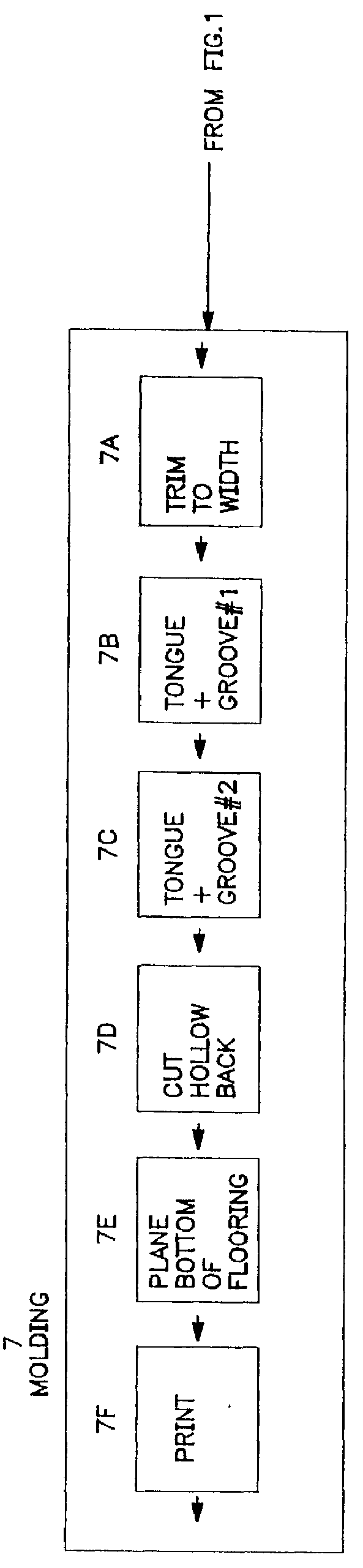

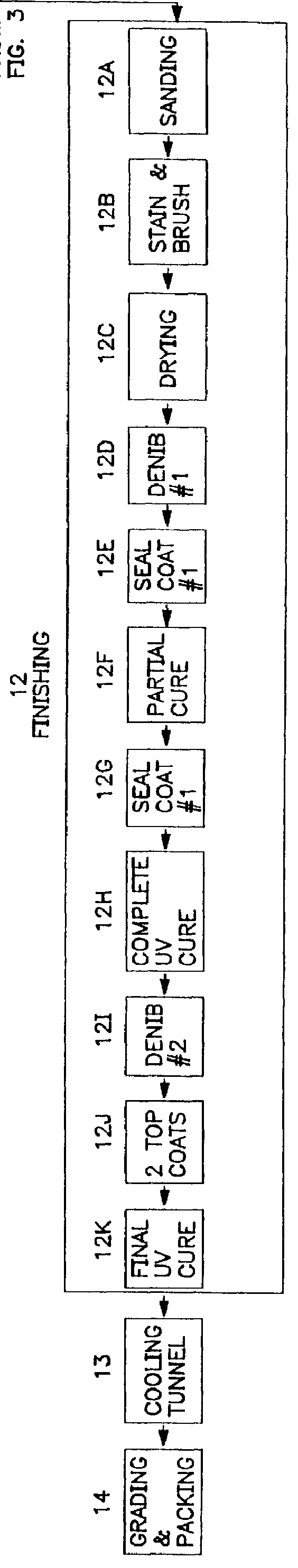

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

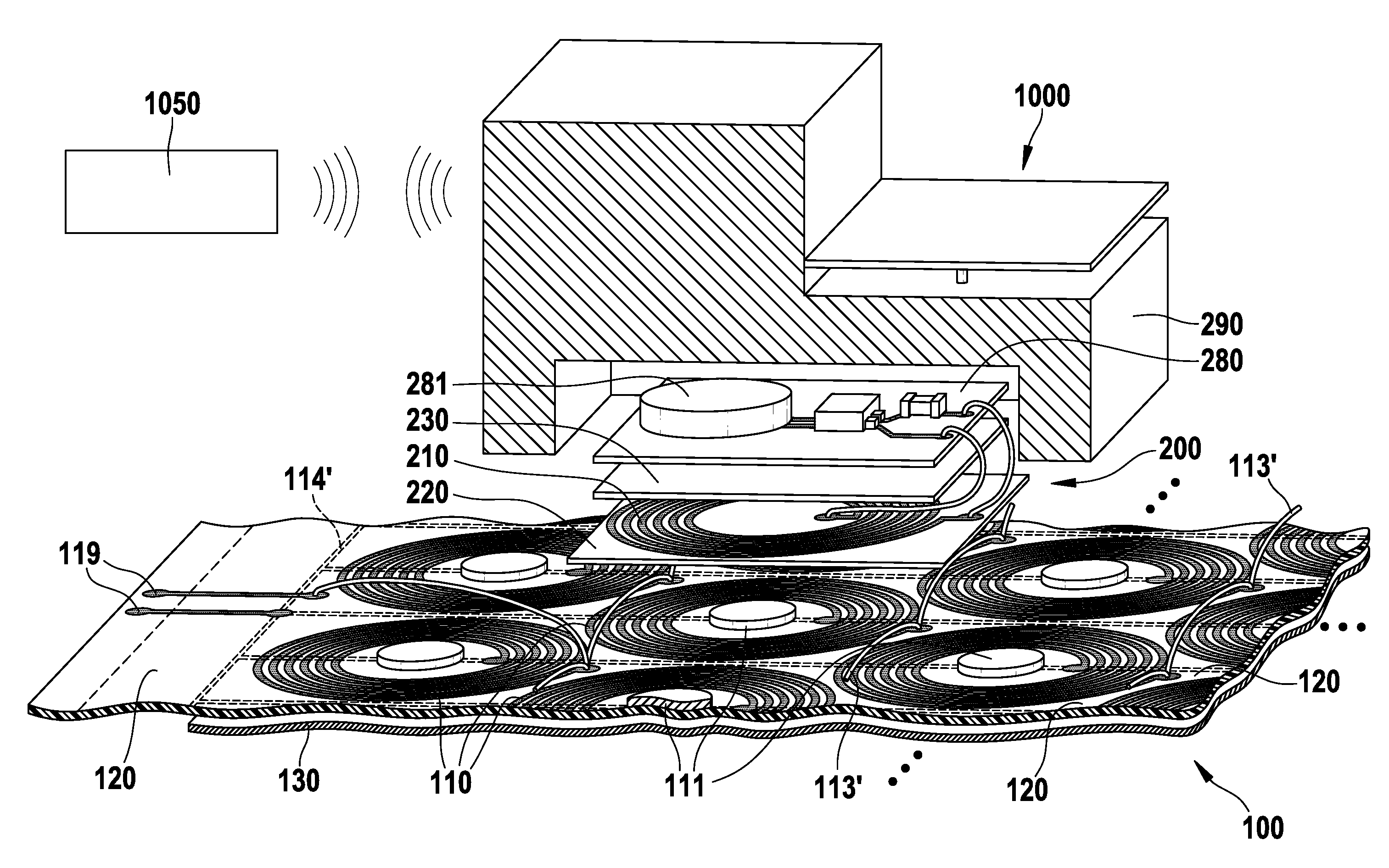

Transition molding

InactiveUS6860074B2Easy to useSmooth transitionTreadsRoof covering using tiles/slatesEngineeringSurface plate

The invention is a joint cover assembly for covering a gap adjacent an edge of a panel that covers a sub-surface, and a method of covering such a gap. The assembly includes a molding having a foot, a first arm, and a second arm. The foot is positioned along a longitudinal axis, and the first arm extends generally perpendicularly from the foot. The second arm extends generally perpendicularly from the foot. A tab depends generally perpendicularly from the first panel engaging surface. At least one of the tab and the foot engage the edge in order to tightly fit within the gap. The method includes the steps of placing the foot in the gap, pressing the respective panel engaging surfaces into contact with respective panels, and configuring at least one of the tab and the foot to cooperate to retain the molding in the gap when the assembly is in an installed condition.

Owner:PERGO

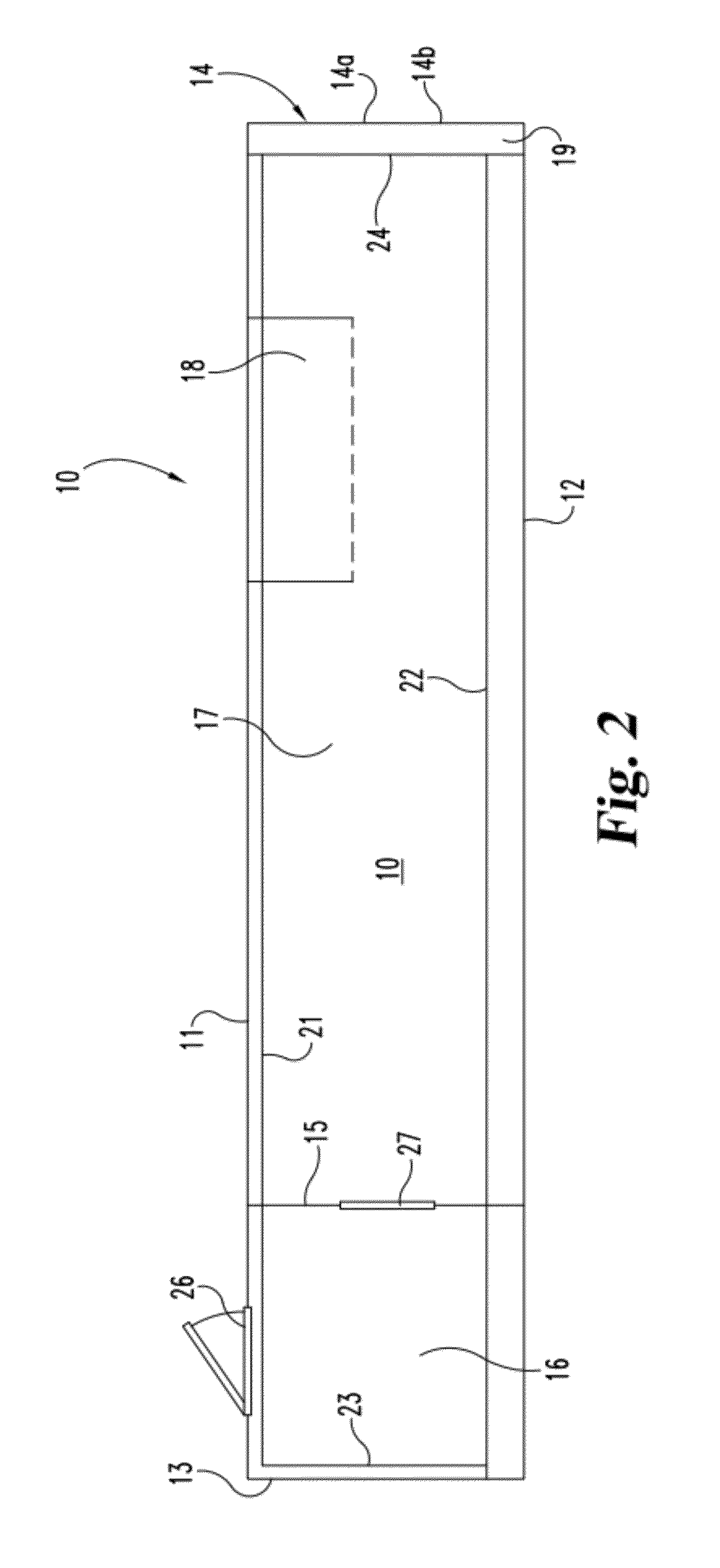

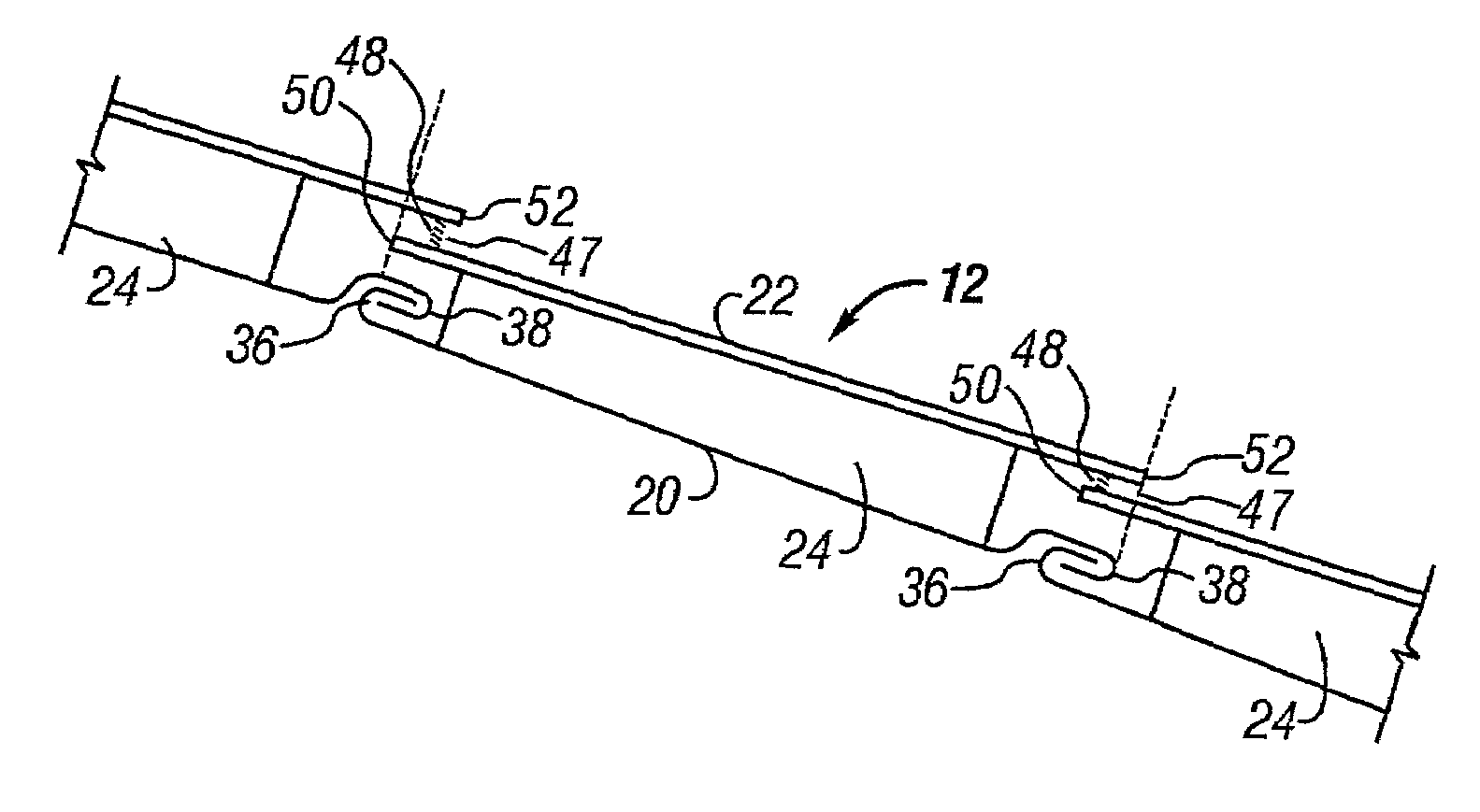

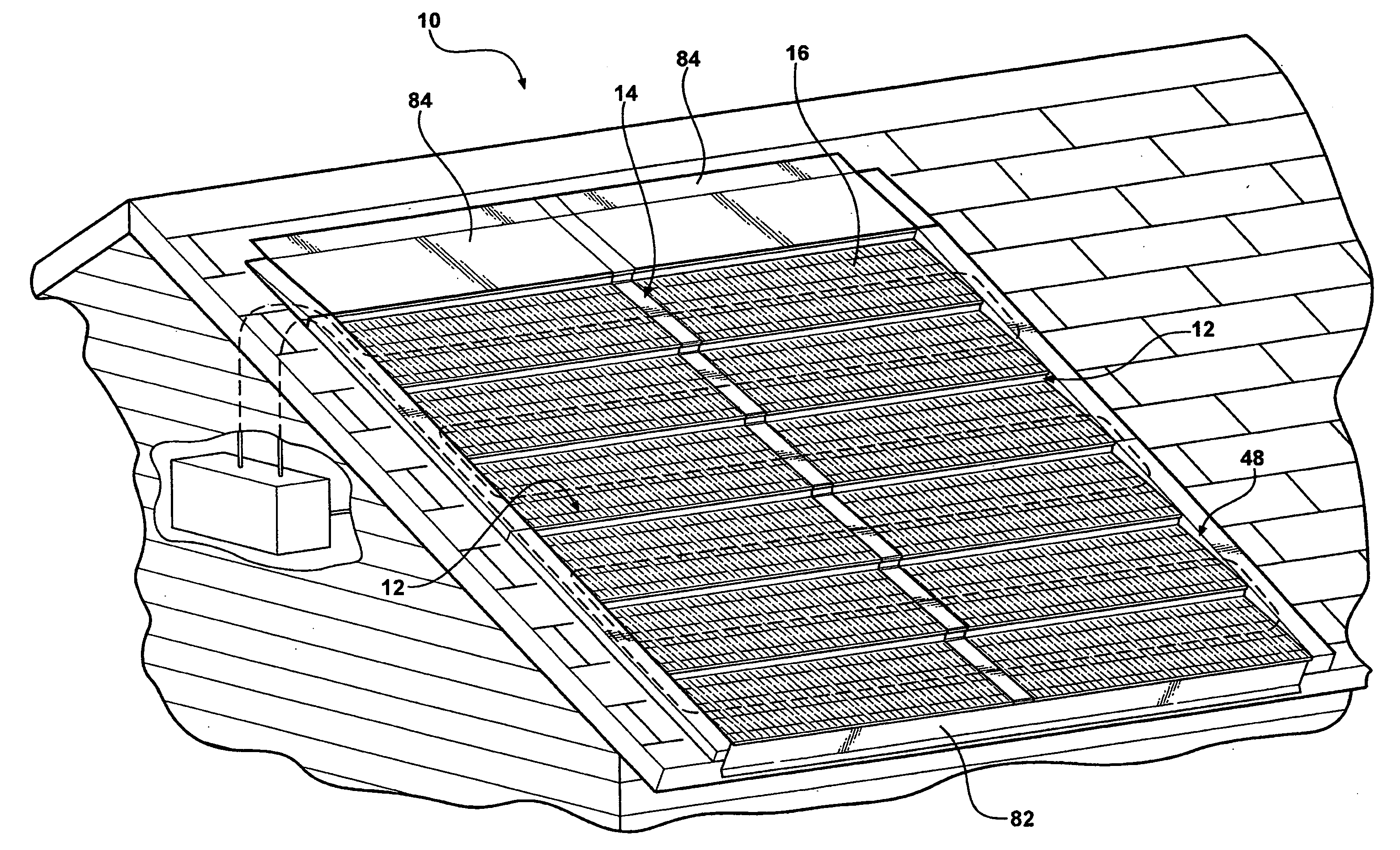

Solar Panel Roof Kit

InactiveUS20080190047A1Simplifies electrical connectionsEasy to manufacturePhotovoltaic supportsRoof covering using slabs/sheetsElectricityEngineering

A solar roofing kit for placing over a section of roof deck to generate electricity. The kit comprises at least one elongated strip of flexible photovoltaic material having a predetermined length and at least one panel supporting the strip. The panels have a riser or rib that extends generally perpendicularly away from the edge to engage and elevate a part of an adjacent panel. The kit also includes at least one side flashing for extending along and sealing at least one of the left and right edges of a panel; at least one splice plate for interconnecting adjacent left and right edges of two panels; at least one top flashing for extending along and sealing the top edge of a panel; and at least one bottom flashing for extending along and sealing the bottom edge of a panel.

Owner:LUMA RESOURCES

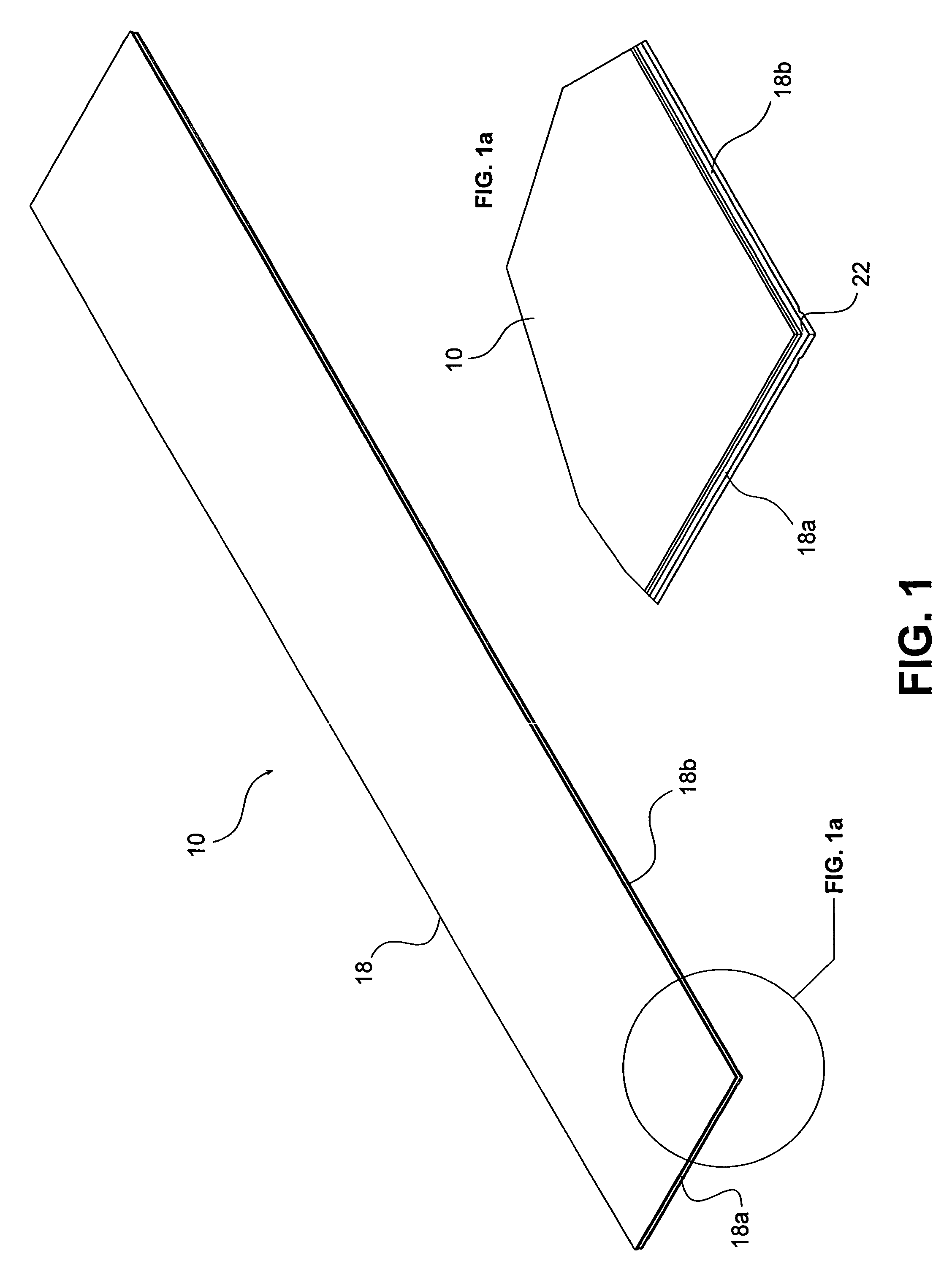

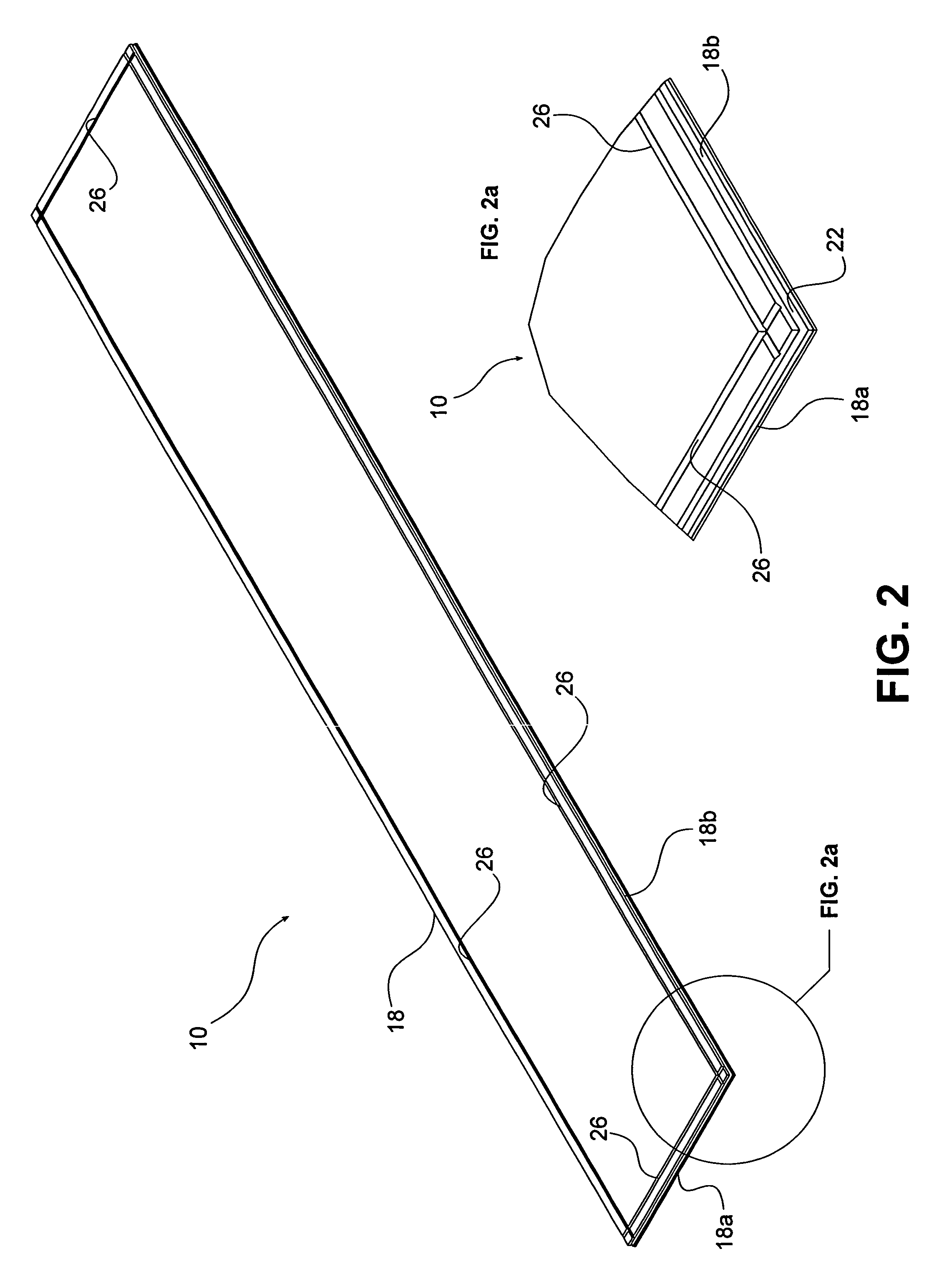

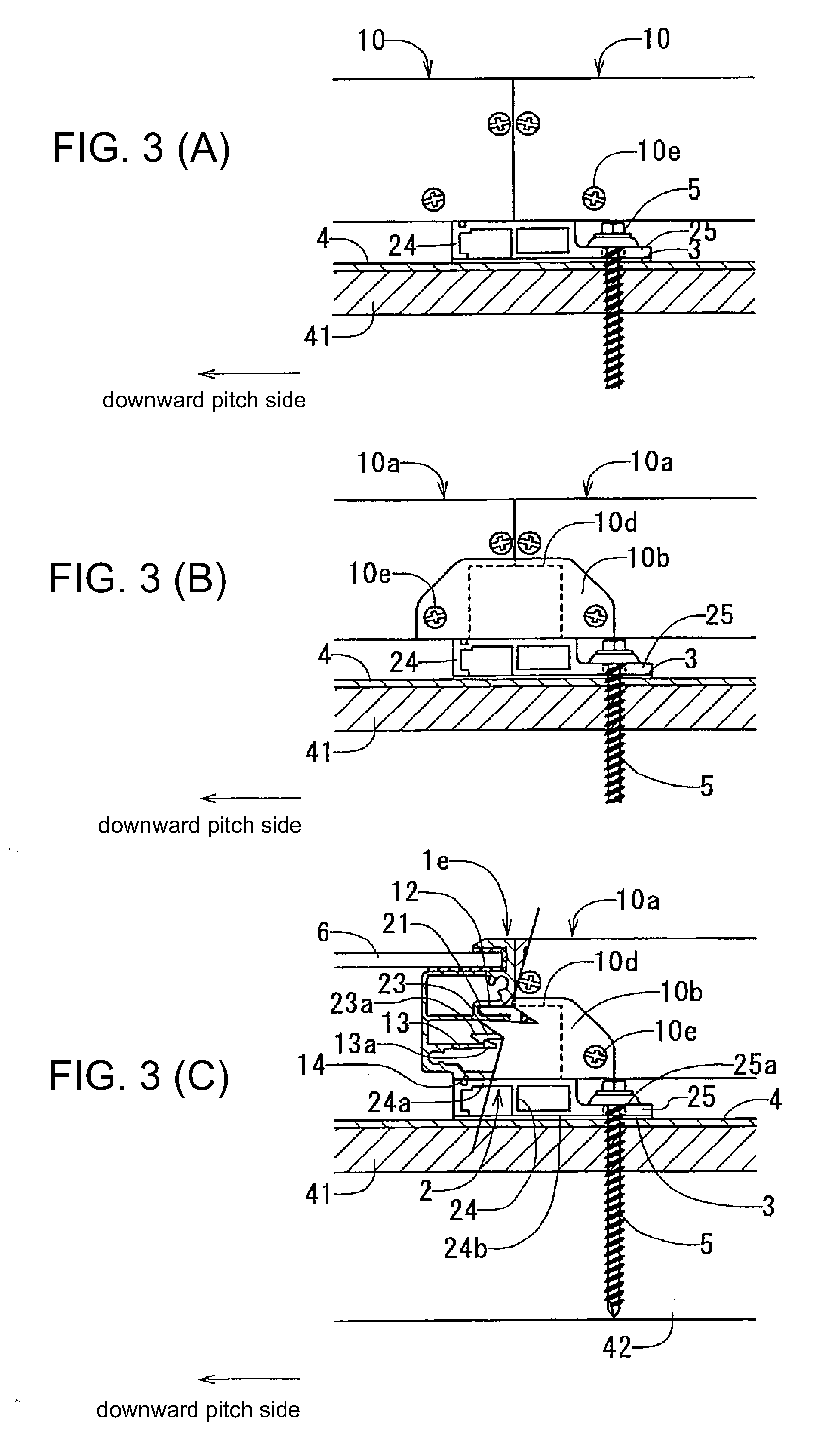

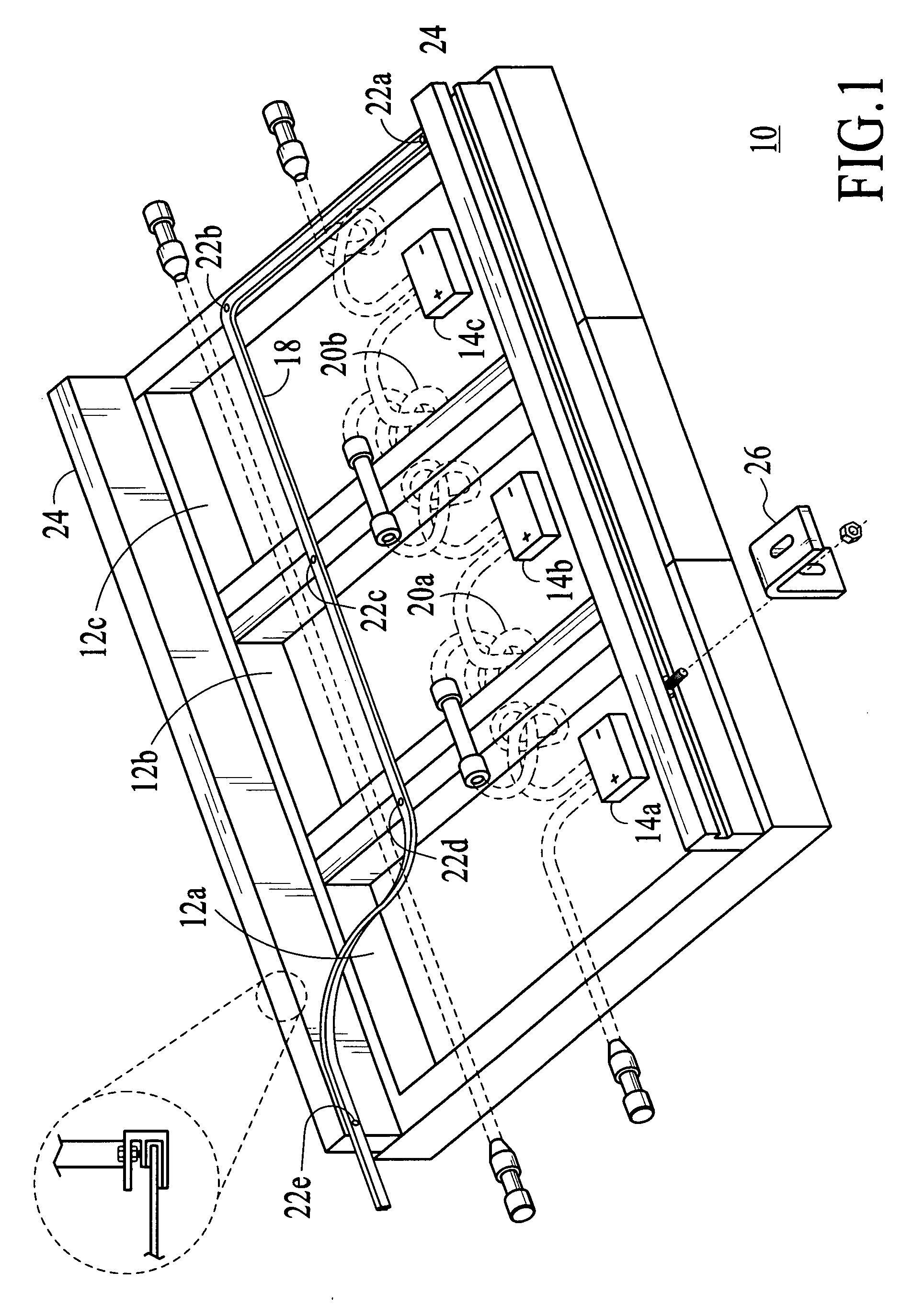

Mounting system for a solar panel

InactiveUS20050257453A1Simplify electrical assembly of moduleChange defectsPhotovoltaic supportsSolar heating energyEngineeringSolar module

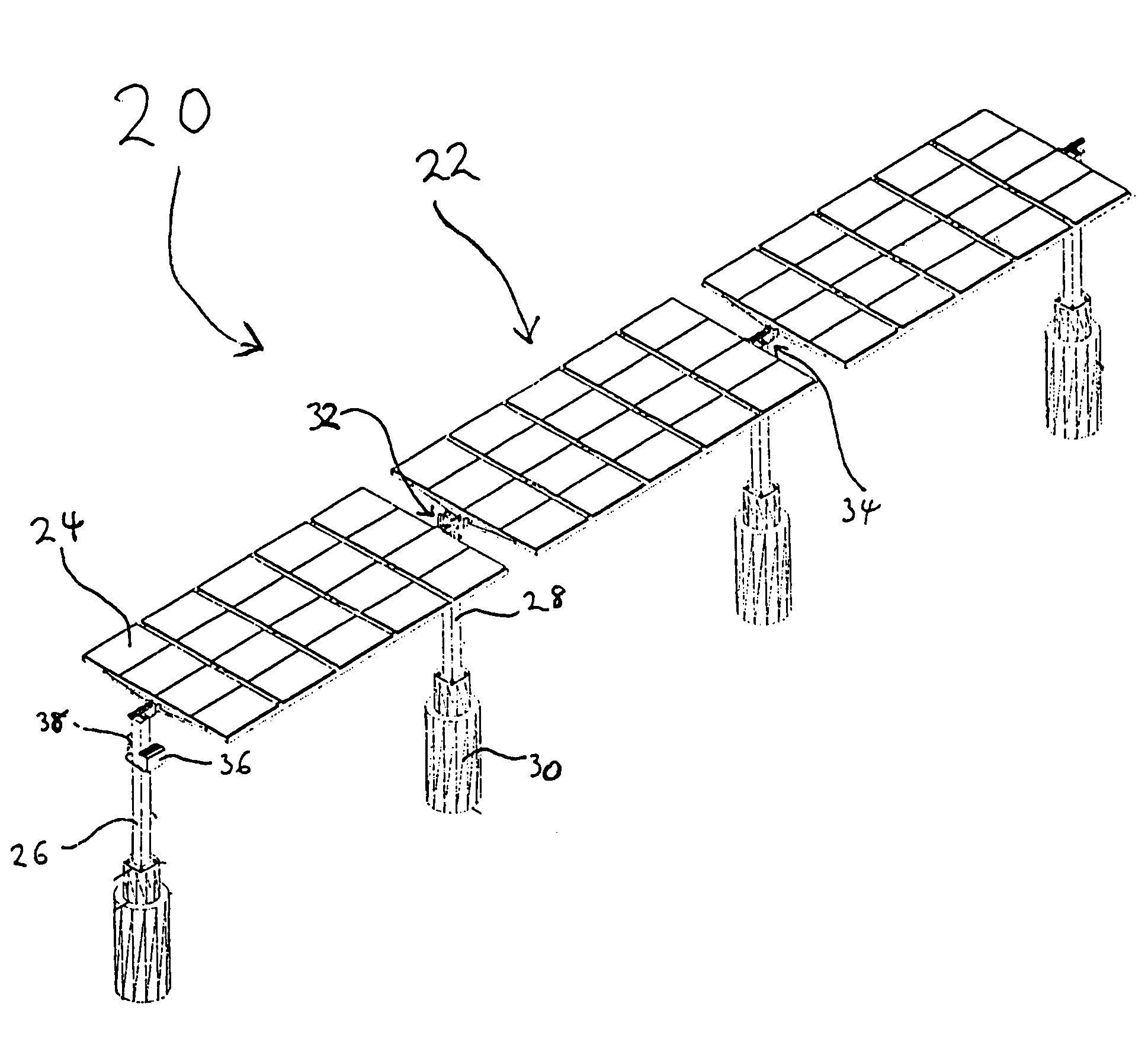

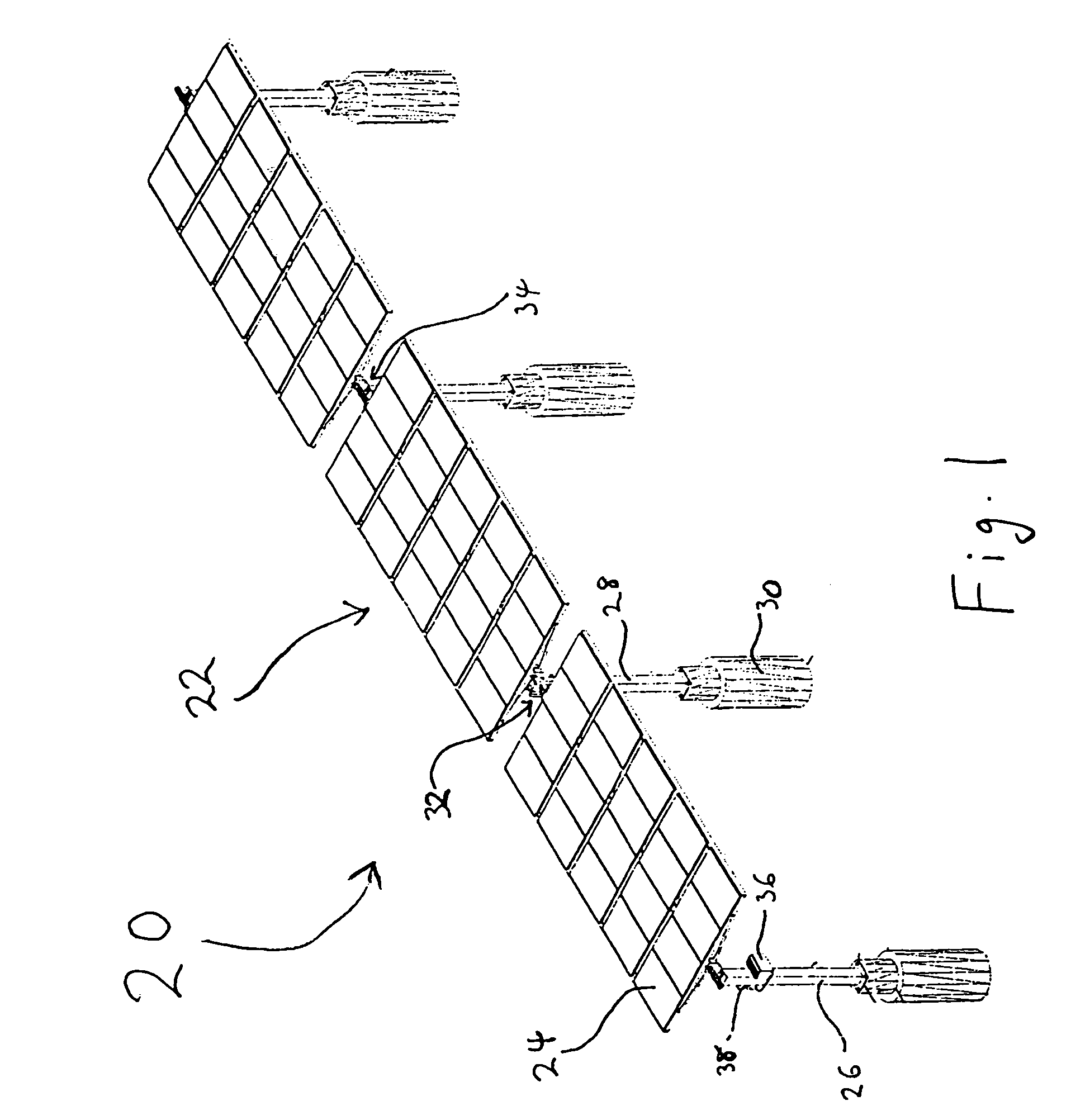

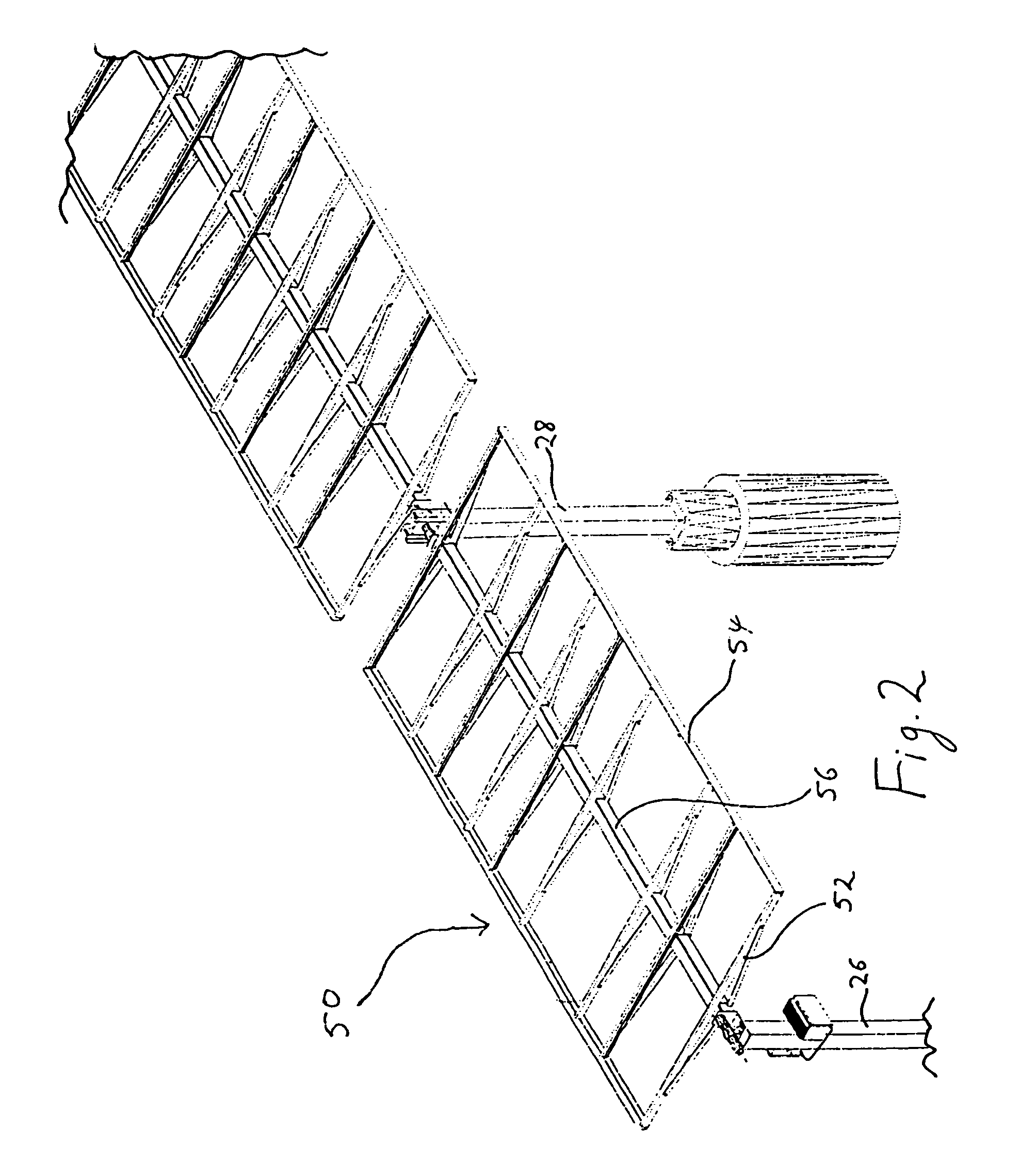

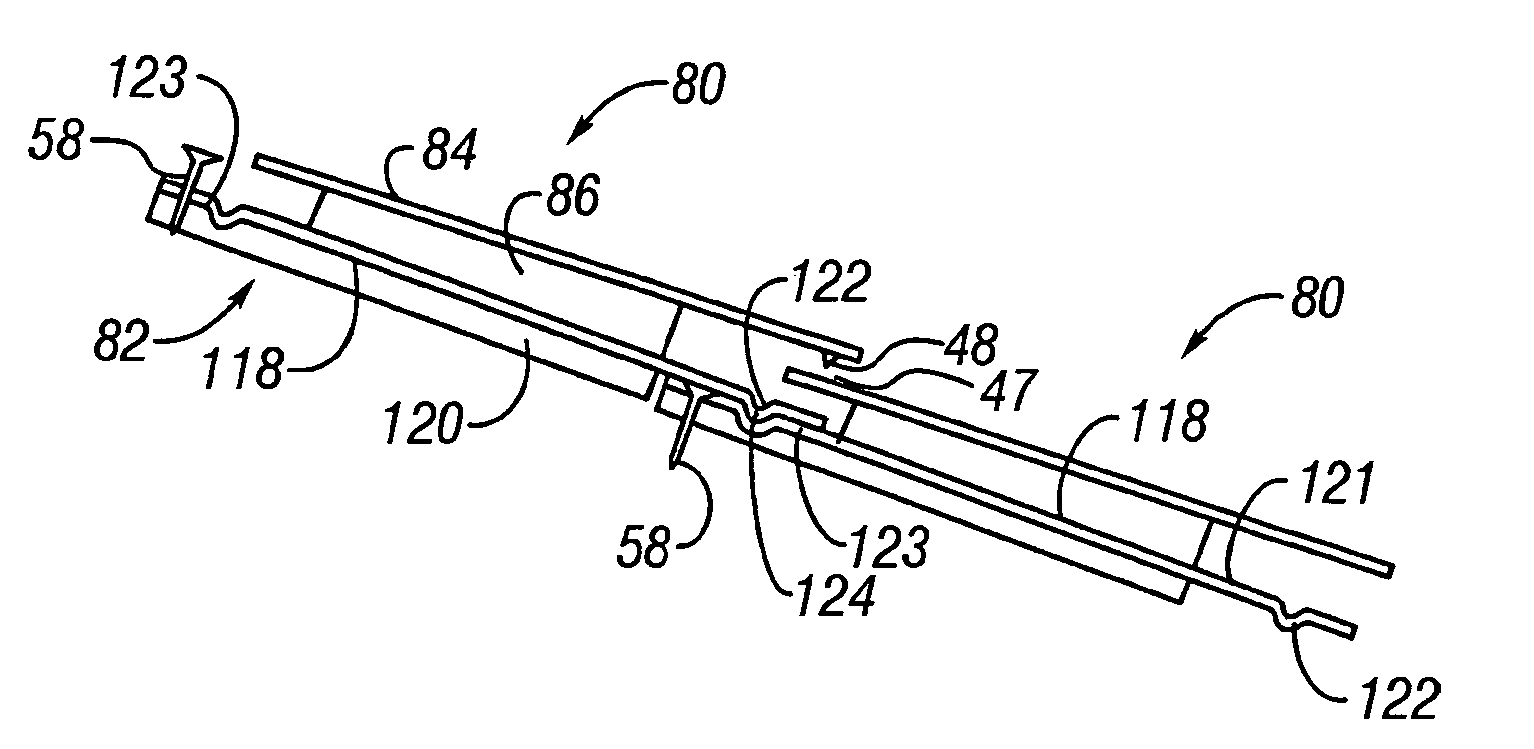

An integrated module frame and racking system for a solar panel is disclosed. The solar panel comprises a plurality of solar modules and a plurality of splices for coupling the plurality of solar modules together. The plurality of splices provide a way to make the connected modules mechanically rigid both during transport to the roof and after mounting for the lifetime of the system, provide wiring connections between modules, provide an electrical grounding path for the modules, provide a way to add modules to the panel, and provide a way to remove or change a defective module. Connector sockets are provided on the sides of the modules to simplify the electrical assembly of modules when the modules are connected together with splices.

Owner:ANDALAY SOLAR

Solar panel overlay and solar panel overlay assembly

InactiveUS20060032527A1Maintaining aesthetic appearanceKeep the lookPhotovoltaic supportsSolar heating energyEngineeringSolar energy harvesting

A solar panel overlay for mounting on an underlying roof deck comprises a substrate and at least one row of photovoltaic cells on the substrate. The photovoltaic cells define a solar collecting surface having an appearance mimicking that of the underlying roof deck. A solar panel overlay assembly comprising a plurality of interconnect solar panel overlays is also provided.

Owner:SPHERAL SOLAR POWER

Laminated shingle

Laminated shingles are manufactured from roll stock roofing material that is wider than that used to make similar laminated shingles. The roll stock includes longitudinal edge strips having a reduced thickness. The roll stock is cut into strips of tabbed top sheets and backing sheets. The strips of material used for the backing sheets are at once wider than commonly used in the industry, and include the longitudinal edge strips of reduced-thickness material. Because the backing sheet is wider two rain seal strips are laid down on the backing sheet prior to being laminated to the tabbed top sheet. The backing sheets are laminated to the tabbed top sheets with the longitudinal edges aligned. The wider backing sheet provides a substantially wider nail zone. In addition, since it allows for a second rain seal strip, provides somewhat more protection against leakage. The portion of the backing sheet that comprises the added width is relatively thinner than the remaining portions of the sheet. Paired shingles may therefore be oriented adjacent one another in opposite directions and stacked and bundled. The total thickness of the stack will be the same throughout the stack, so the stack of shingles is flat.

Owner:HERBERT MALARKEY ROOFING

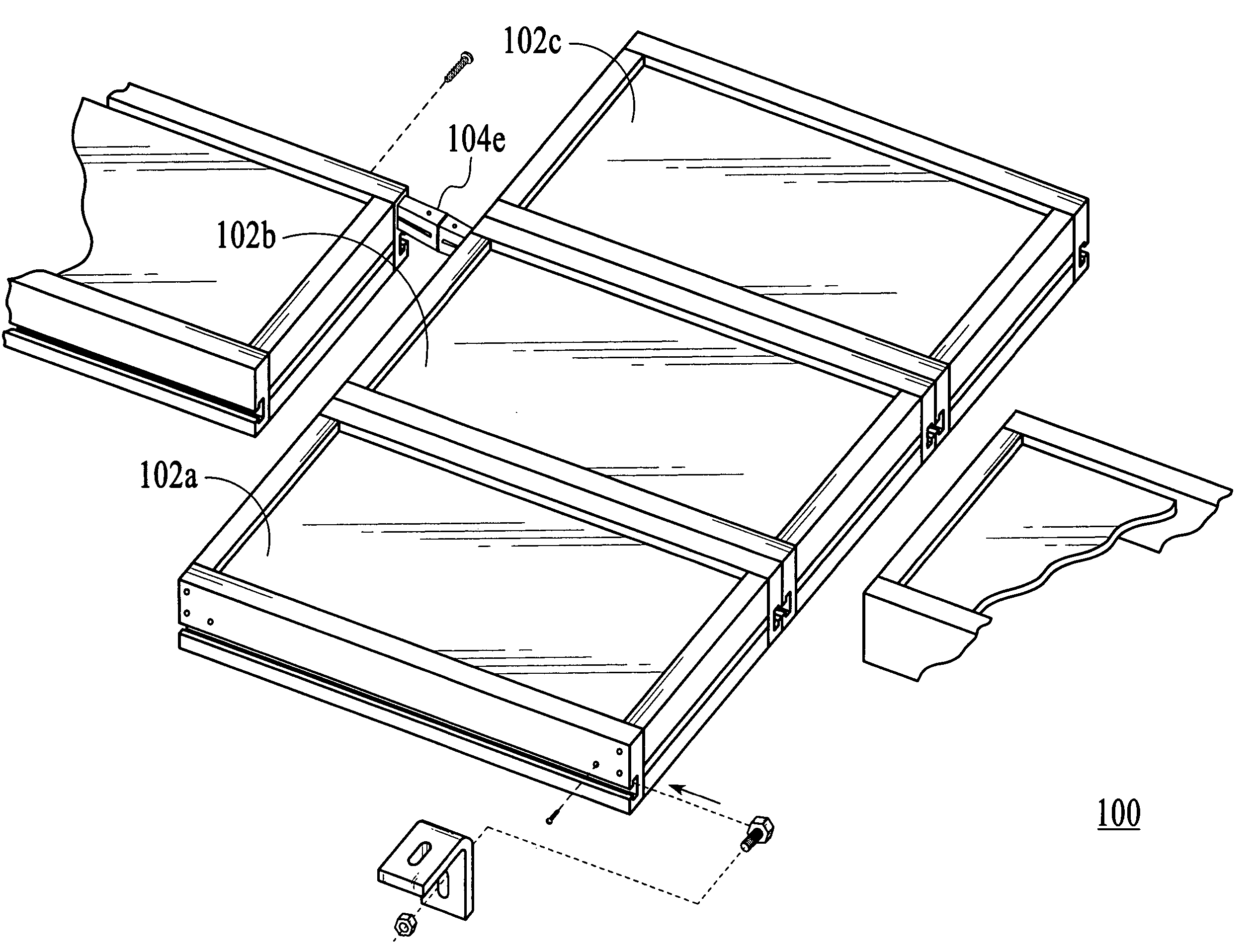

Support System for Solar Panels

ActiveUS20100236183A1Easy to deployEasy to removePhotovoltaic supportsSolar heating energySupporting systemBraced frame

Precise parameters are maintained in a support system for solar panels or other panel-like structures through use of a collapsible folding, support frame which is preassembled to precise tolerances at a convenient staging site before being collapsed for shipment. Installation on flat roofs is also facilitated through the use of a roof interface frame which rotatably supports the panel support frame of the support system and folds along with it at the assembly, staging site.

Owner:NORTHERN STATES METALS

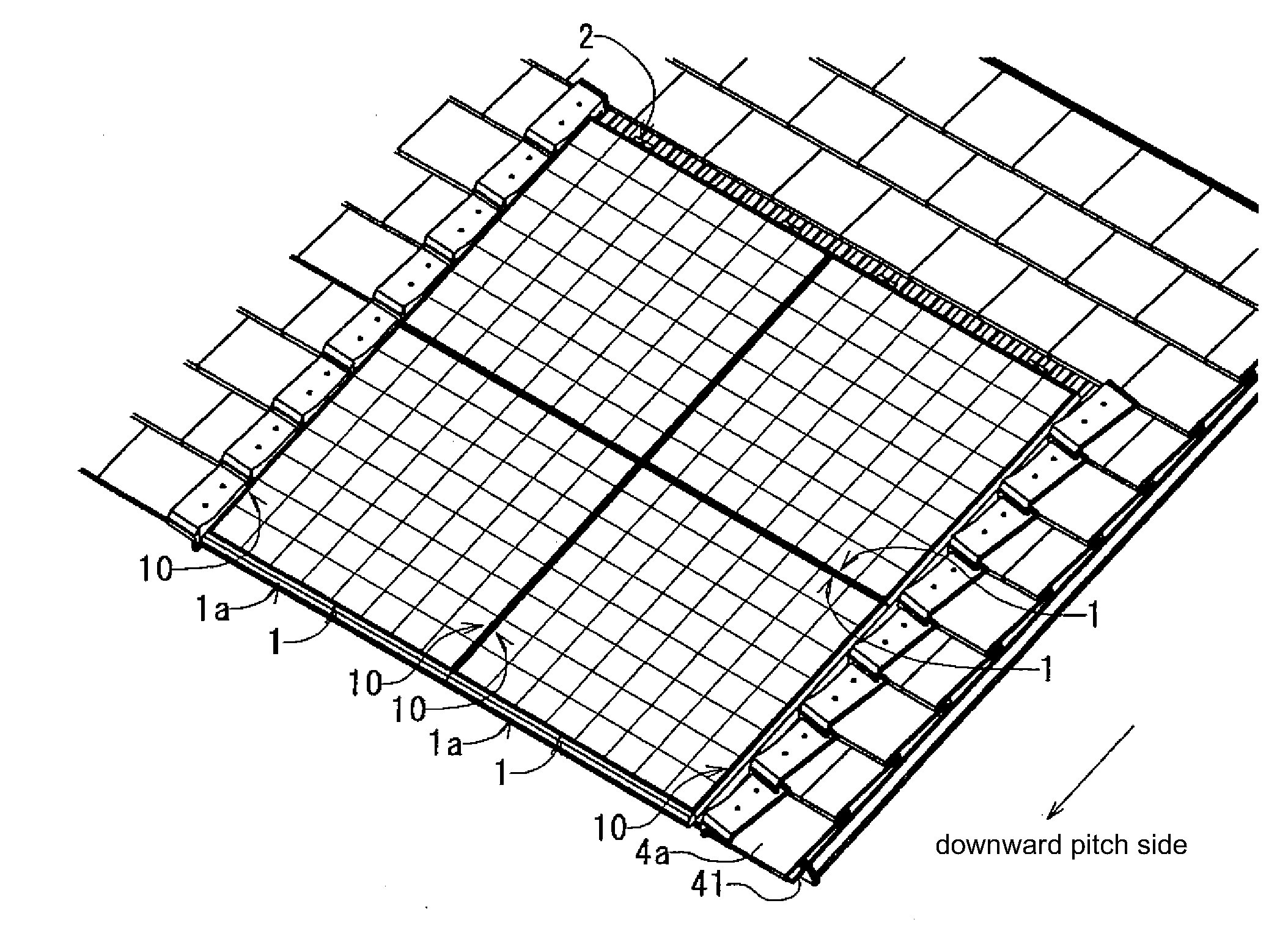

Solar cell module, enclosure with solar cells, enclosure installation method, and solar cell system

InactiveUS6245987B1Improve reliabilityAvoid crackingPhotovoltaic supportsRoof covering using slabs/sheetsElectrical batteryComputer module

By providing a non-contact means and / or a non-contact space between electric connecting members and an underlaying material and / or a substrate material and / or a rear material, the temporal degradation of a solar cell module can be prevented which is caused by a contact between the electric connecting members for the module and the underlaying material and / or the substrate material and / or the rear material.

Owner:CANON KK

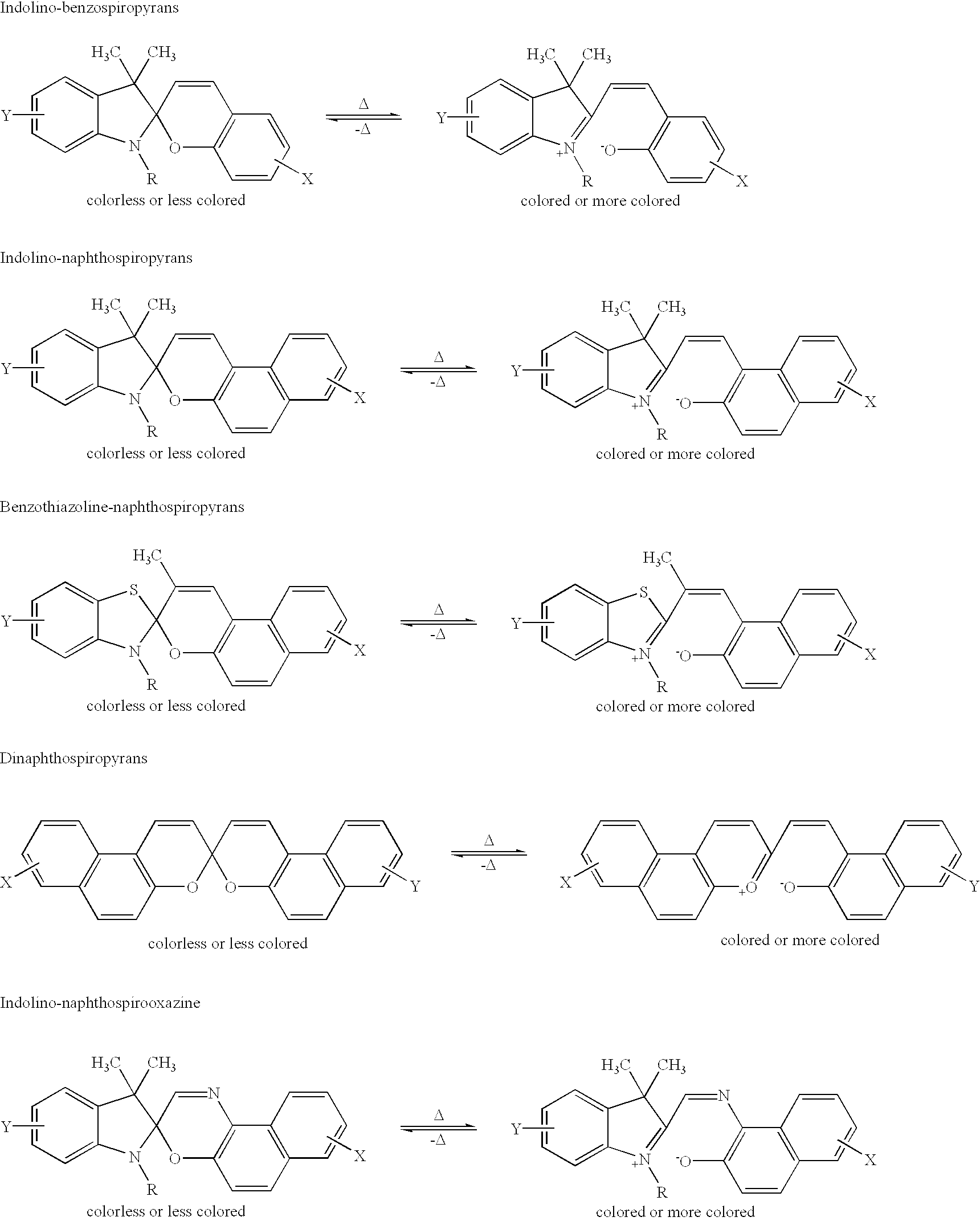

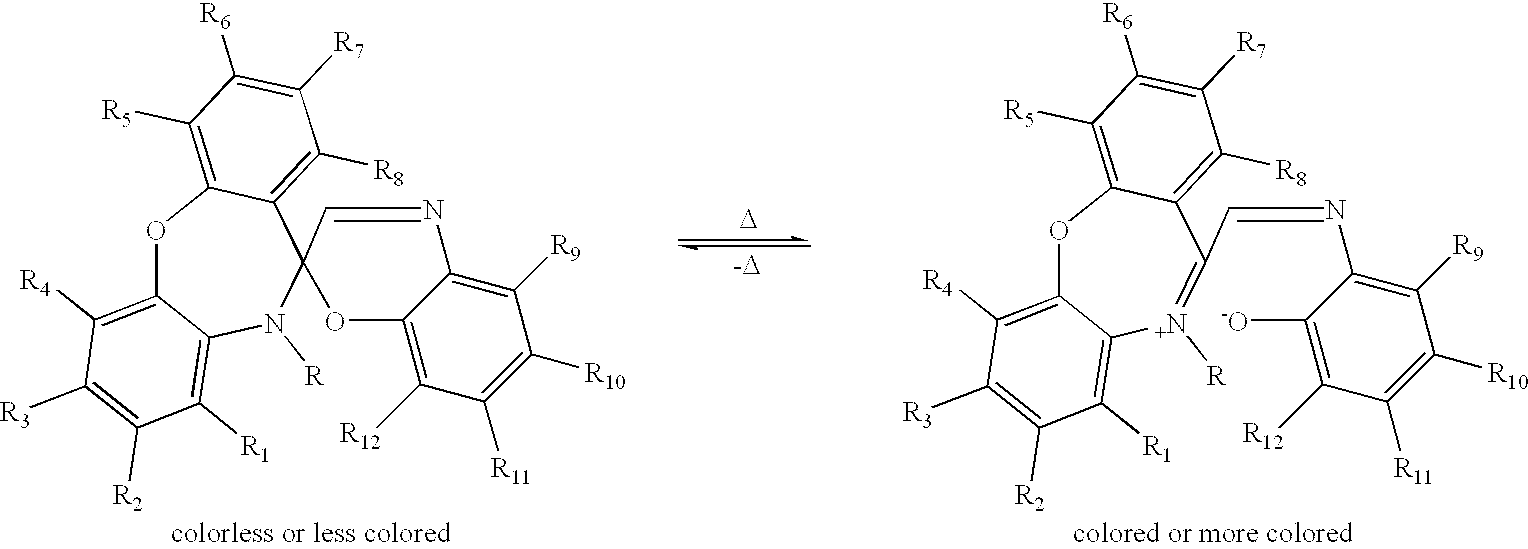

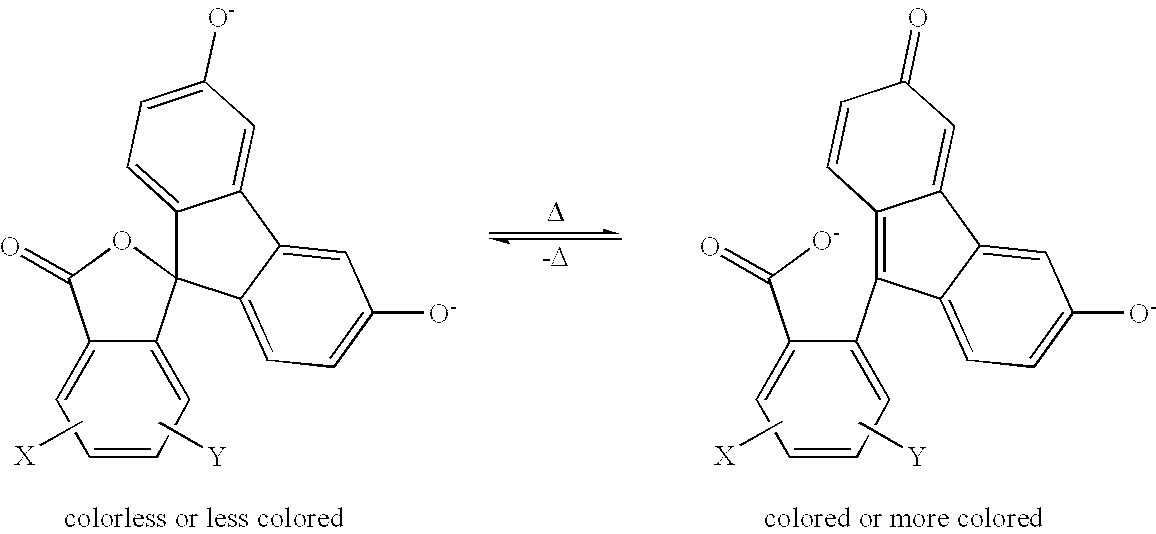

Thermochromic devices

InactiveUS6446402B1Easy to useLacking and neededPhotovoltaic supportsSolar heating energyThermochromismEngineering

The invention is an energy efficient, thermochromic device that may be used to allow sunlight or solar radiation into a building or structure when the ambient temperature is low and substantially blocks solar radiation when the ambient temperature is high, especially when sunlight is directly on the window.

Owner:BYKER HARLAN +1

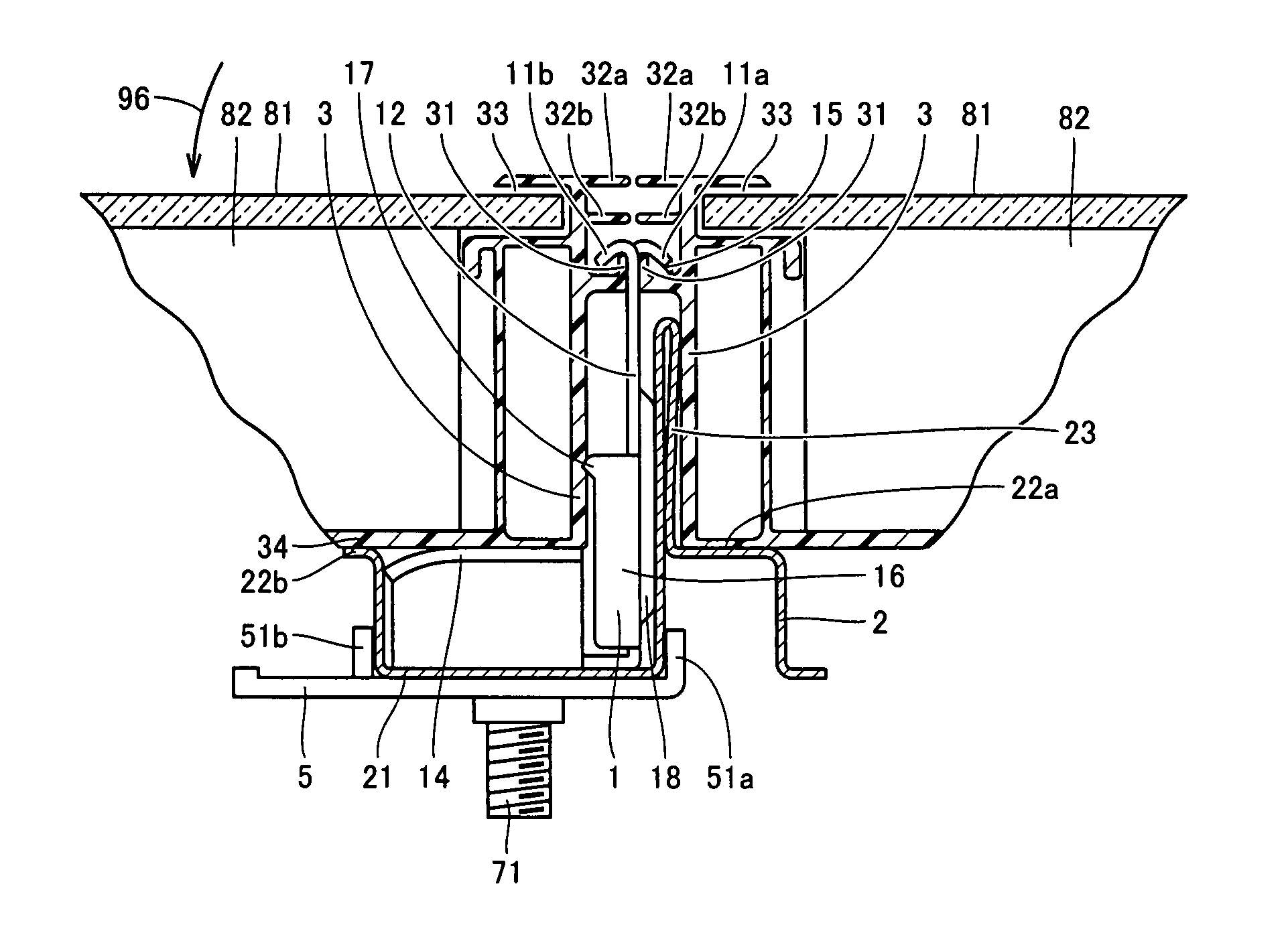

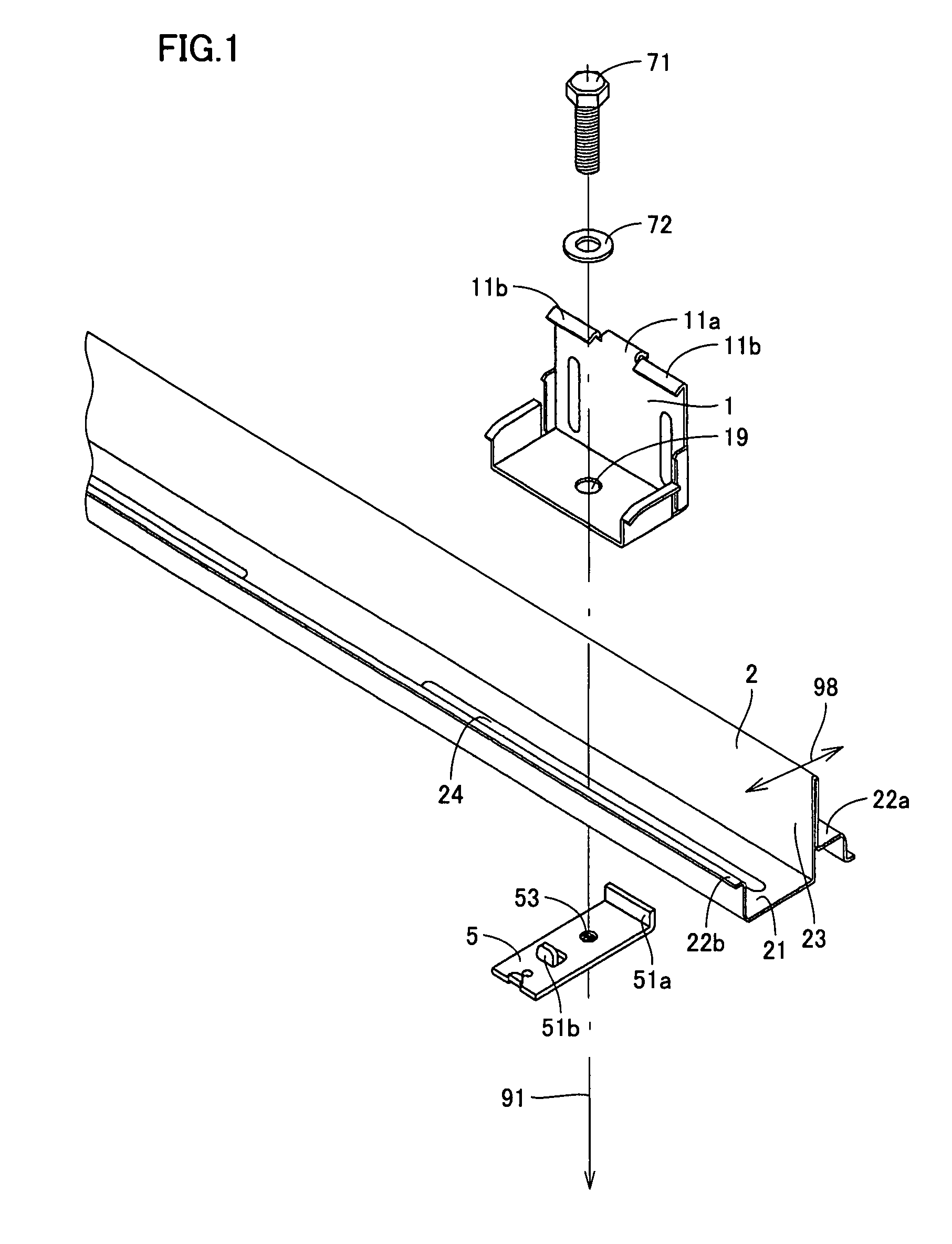

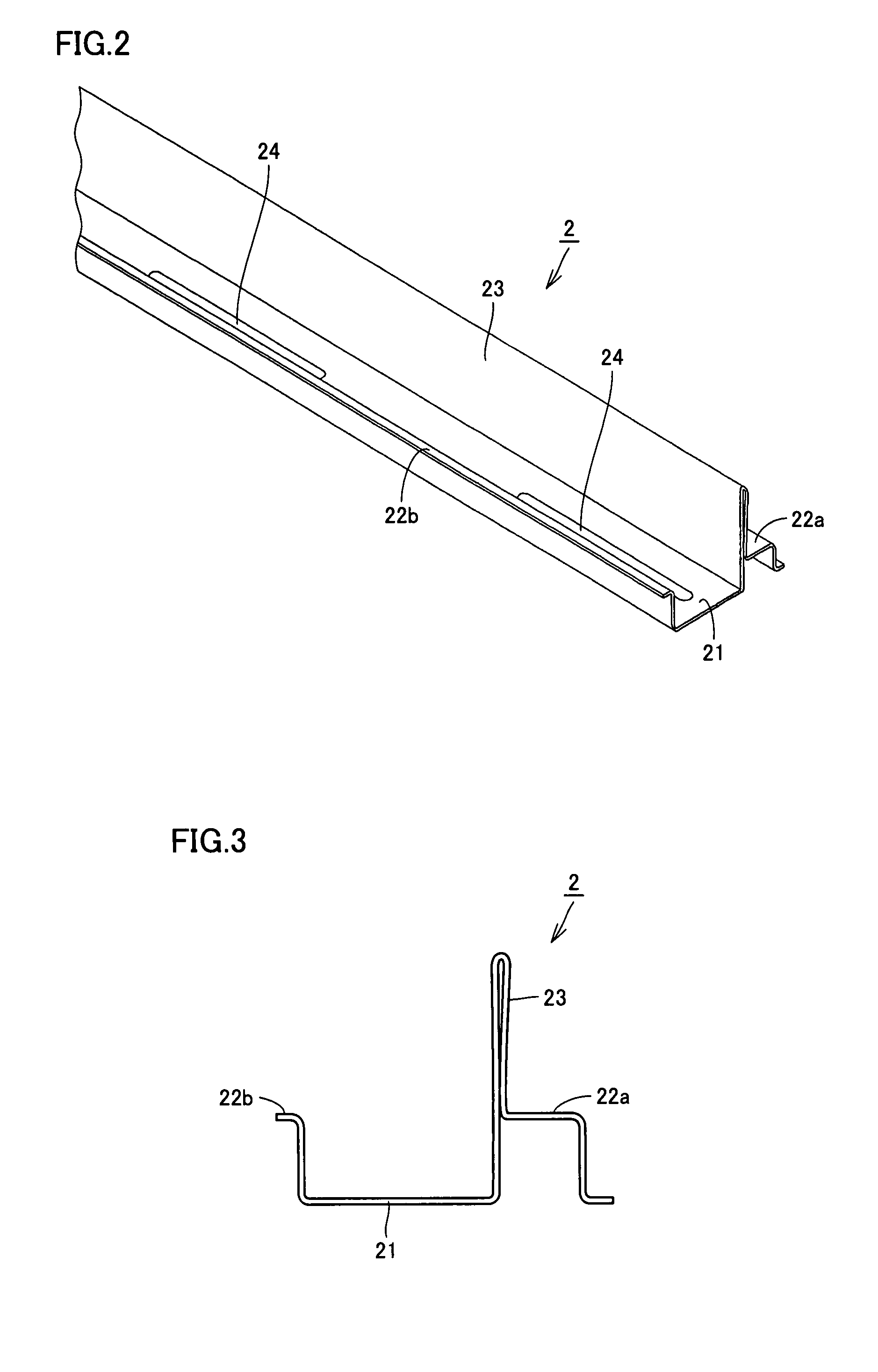

Mounting structure of solar cell module

InactiveUS7866099B2Easy to operateImprove installation efficiencySnap fastenersPhotovoltaic supportsEngineeringSolar cell

A mounting structure of a solar cell module includes a fastening for mounting the solar cell module on a lateral beam. The fastening includes a body, and a plurality of hooks formed at an end of the body. The hooks have a hook having a form bent toward one side, having an end directed downward and serving as a first hook, and a hook having a form bent away from the one side, having an end directed downward and serving as a second hook. The hooks are opposed to and engaged with a projection of a hooked and L-shaped form formed on the solar cell module.

Owner:SHARP KK

Floor strip

InactiveUS6898911B2Increase resistanceSmooth transitionWood working apparatusPaper/cardboardReducerEngineering

Owner:PERGO

Multi-use electric tile modules

InactiveUS6928775B2Eliminate needLight providedPhotovoltaic supportsCovering/liningsElectricityVisibility

A multiuse electric tile module for walling, flooring, or roofing applications having a photovoltaic cell, thermovoltaic cell, electroluminescent material, or a combination of these disposed over a rigid substrate, such as ceramic. Each tile is electrically connectable through a male-to-female connecter to at least one adjacent tile without external wiring. Preferably, a sealing layer is disposed over the electrical elements and rigid substrate to seal and protect each tile. Optionally, each tile may further include an inverter to convert direct current to alternating current or a battery to store electricity. The electroluminescent material provides light for architectural accents or nighttime visibility.

Owner:BANISTER MARK P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com