Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1634results about "Load-supporting elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

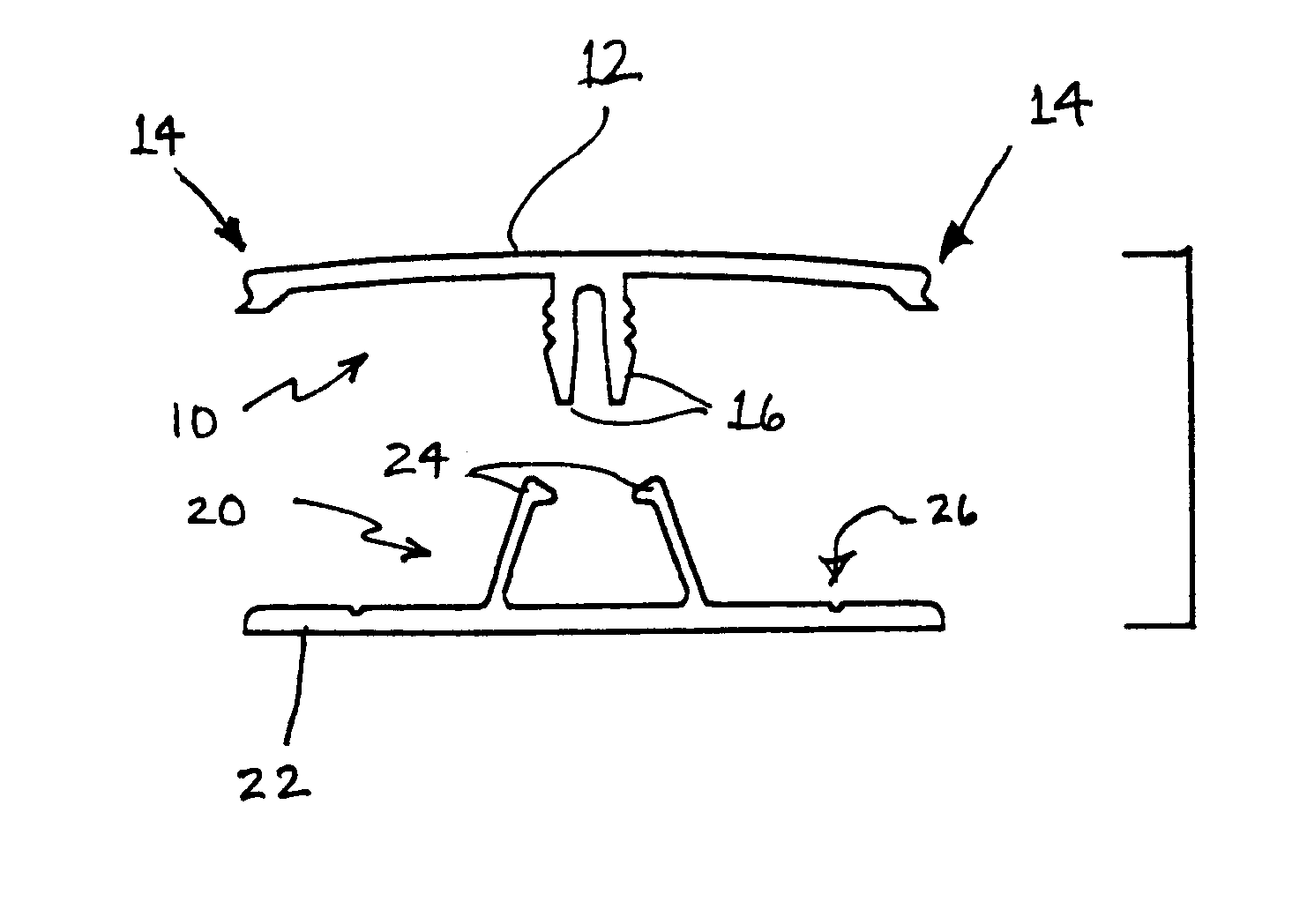

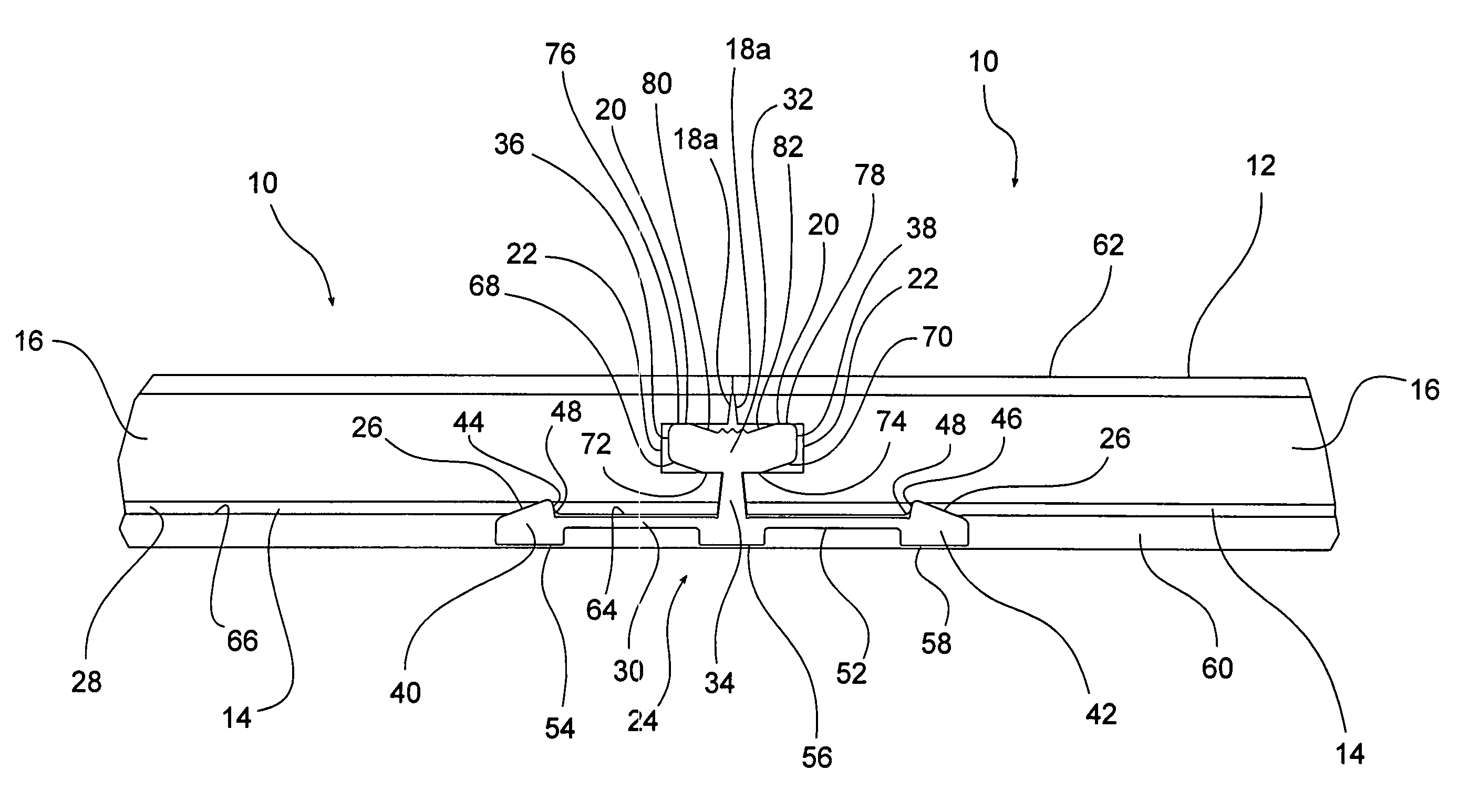

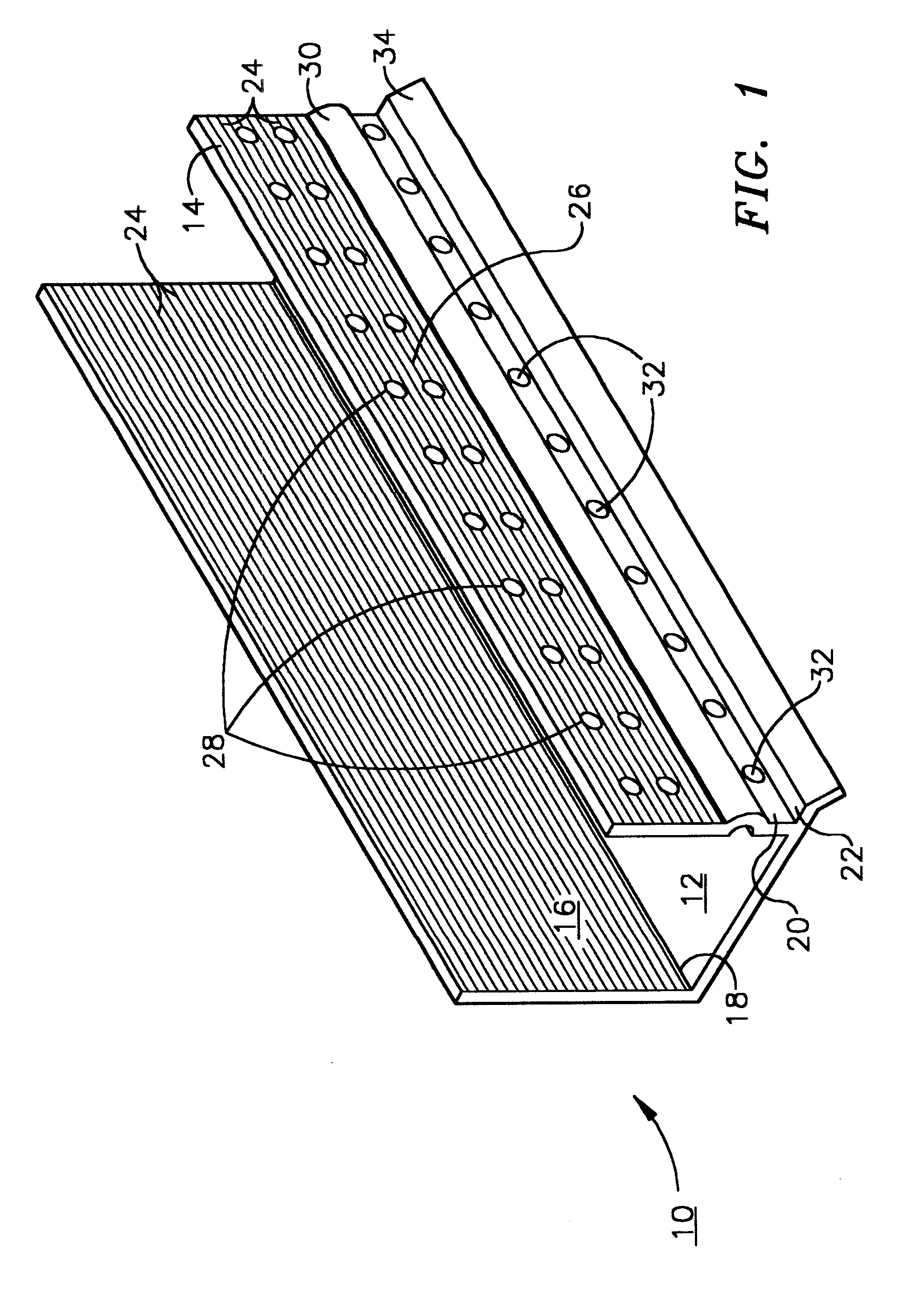

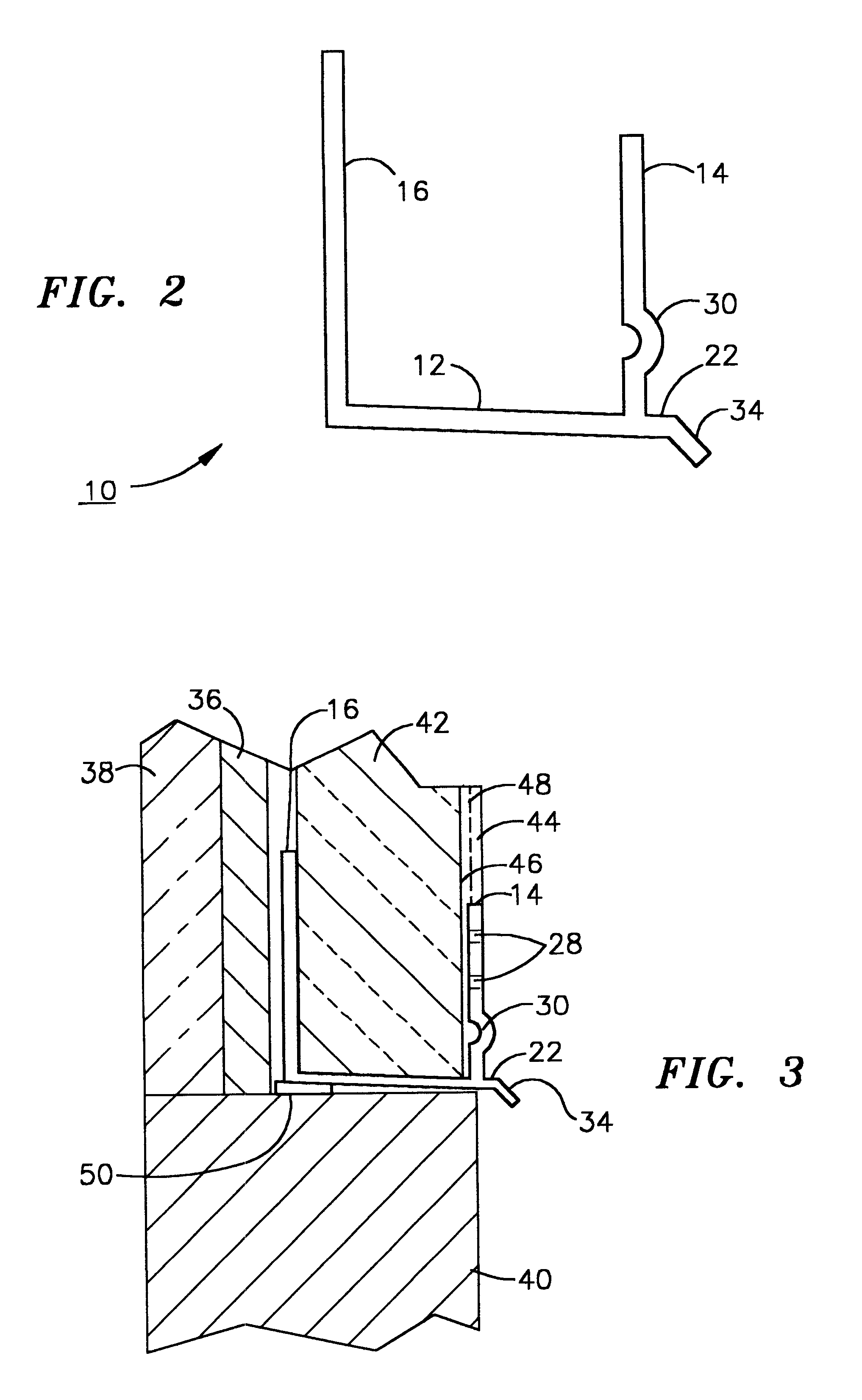

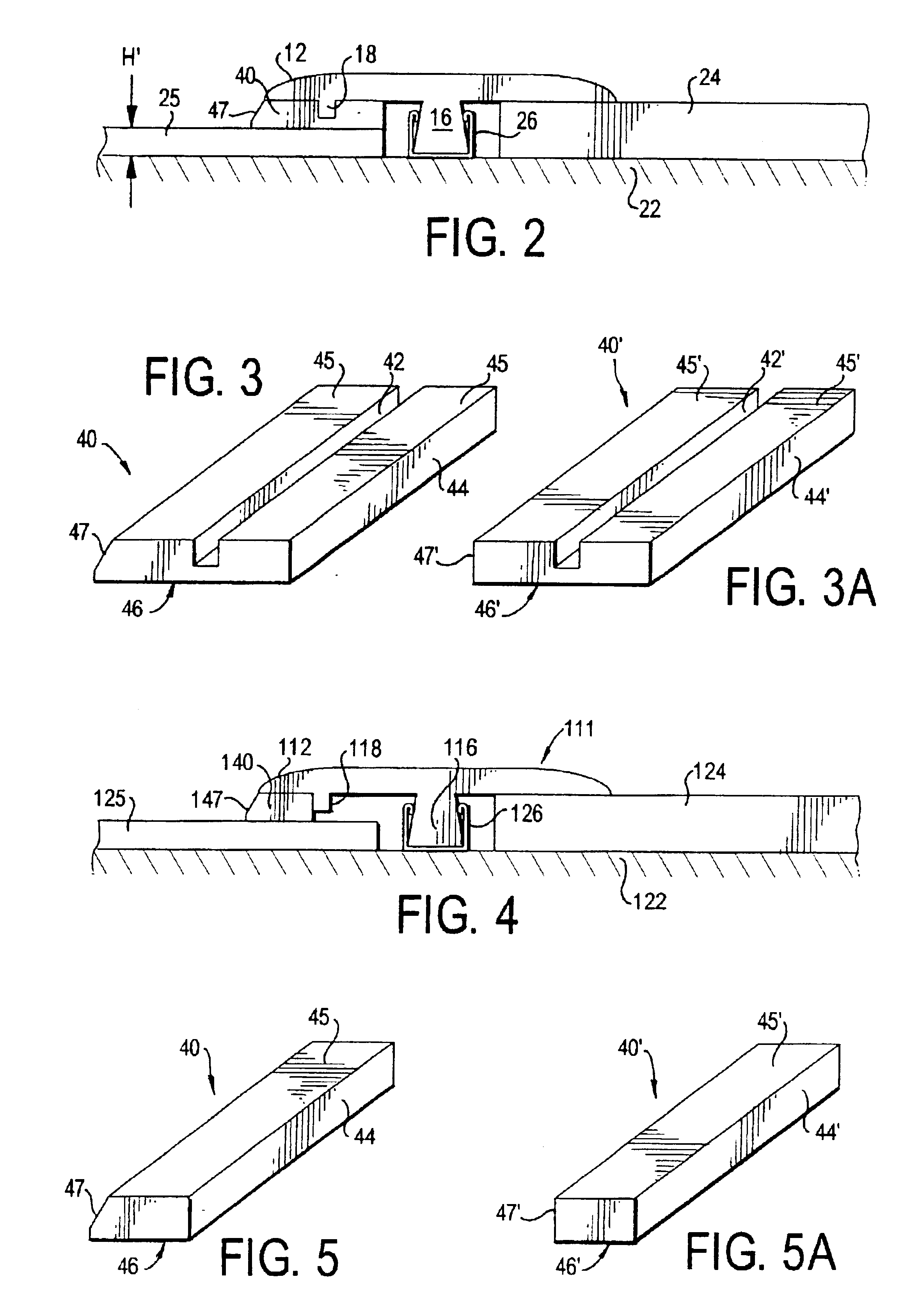

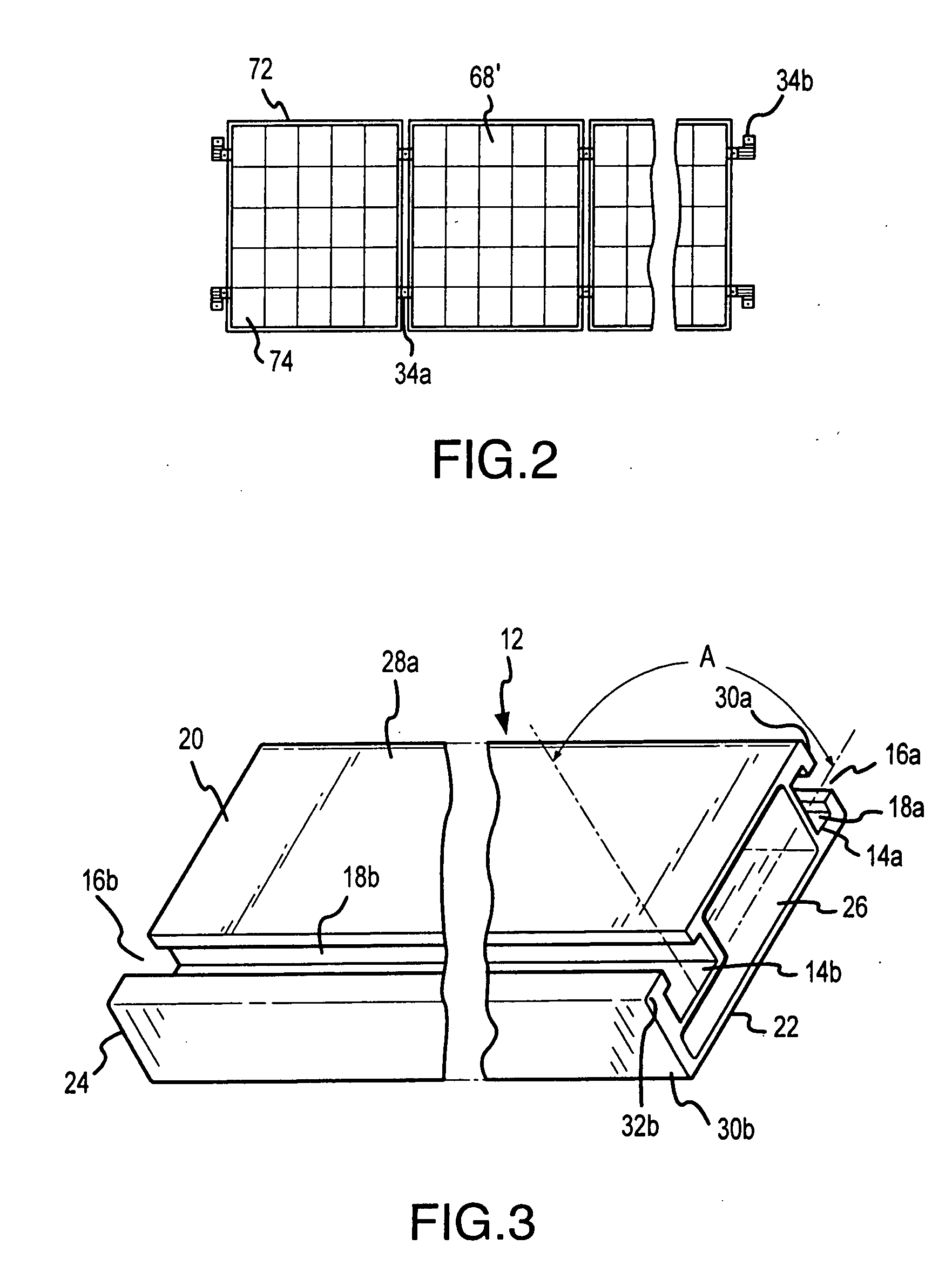

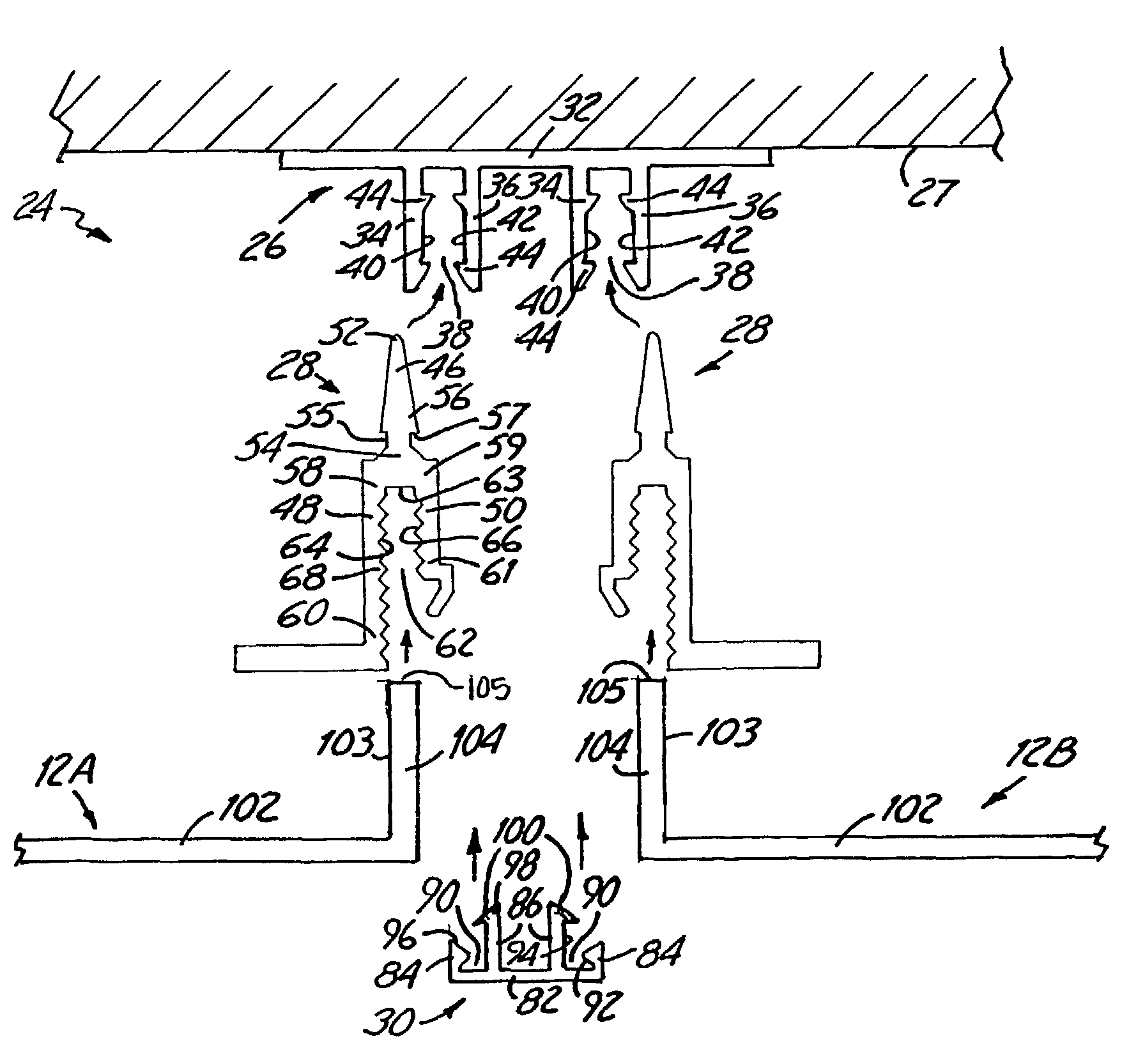

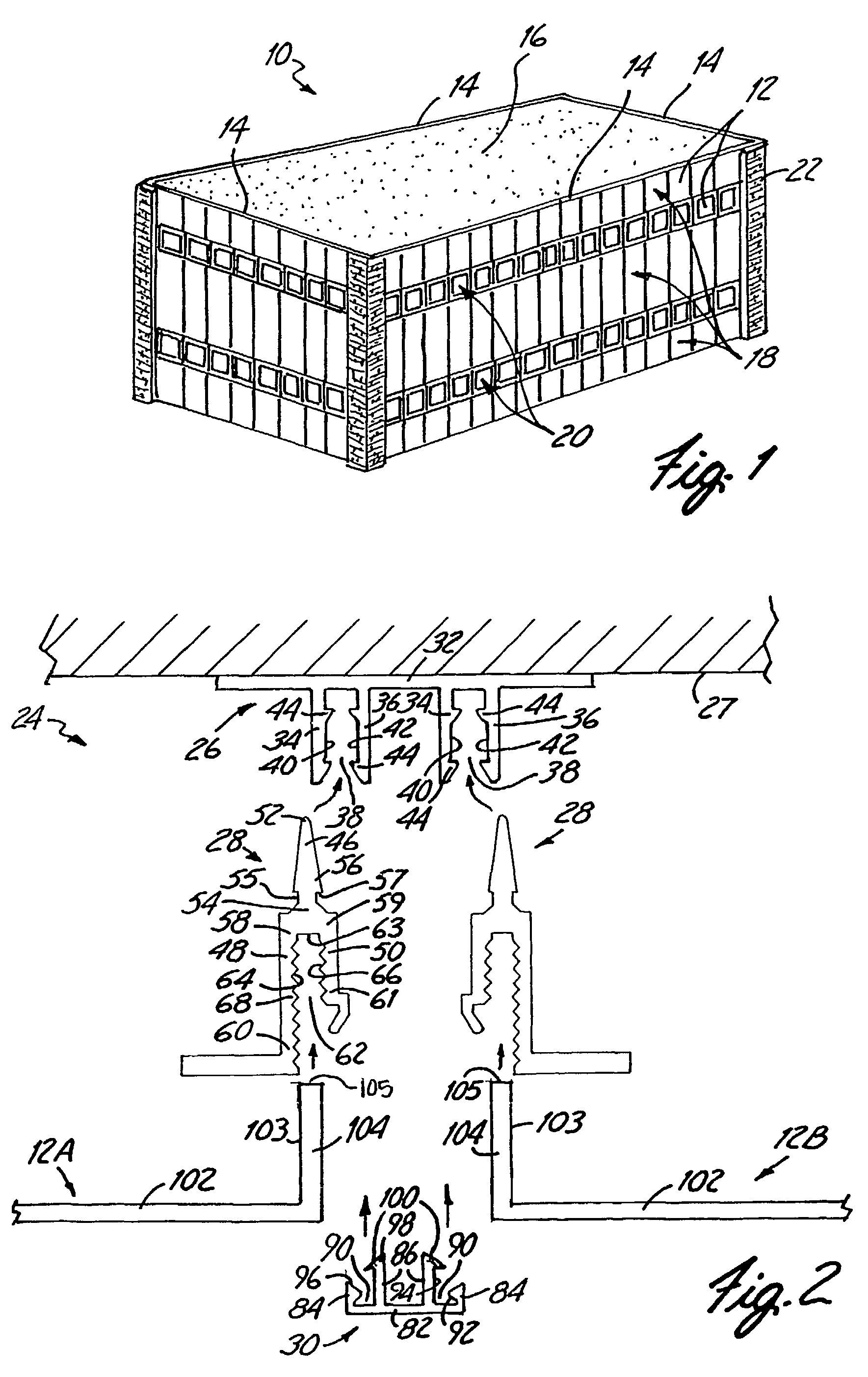

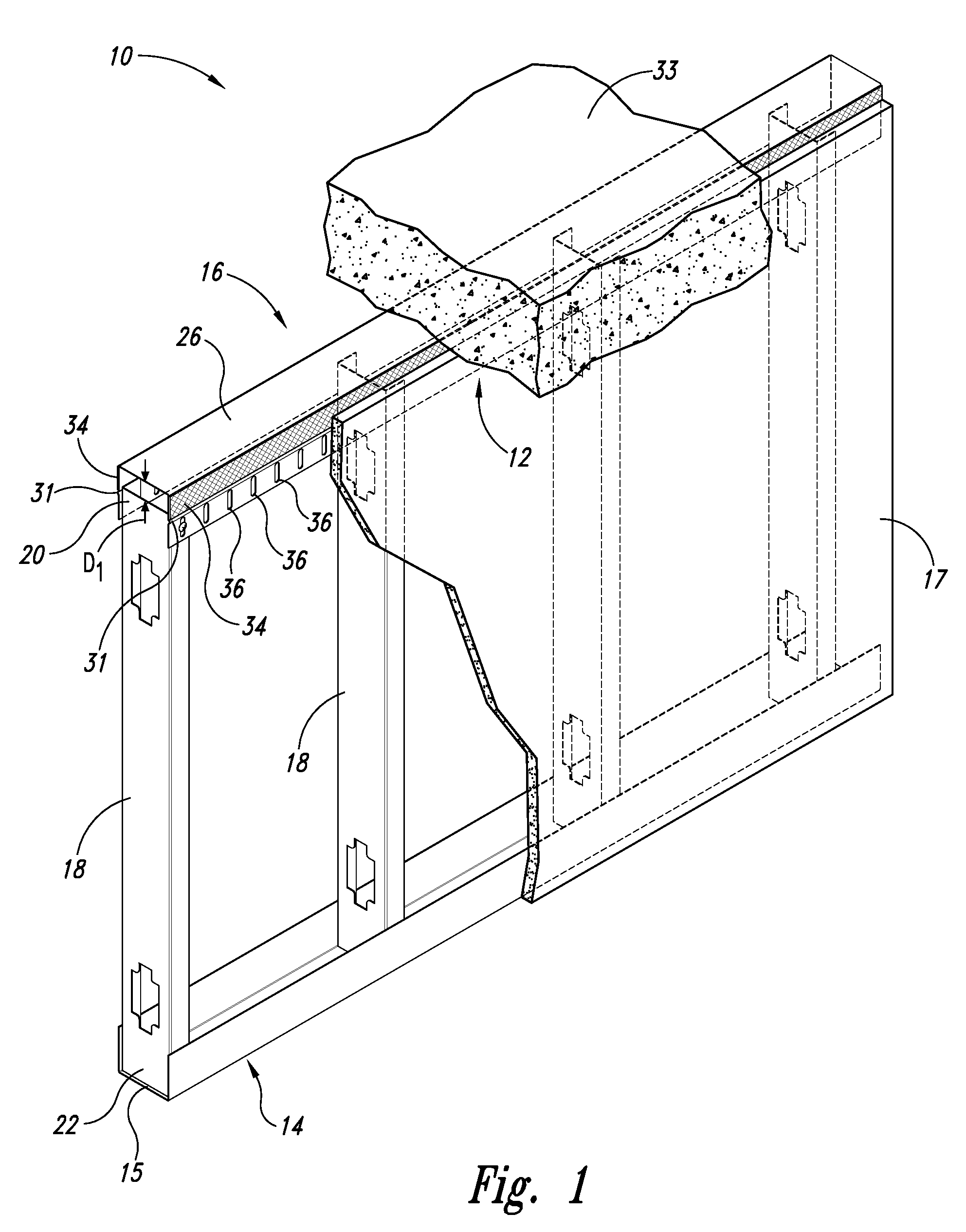

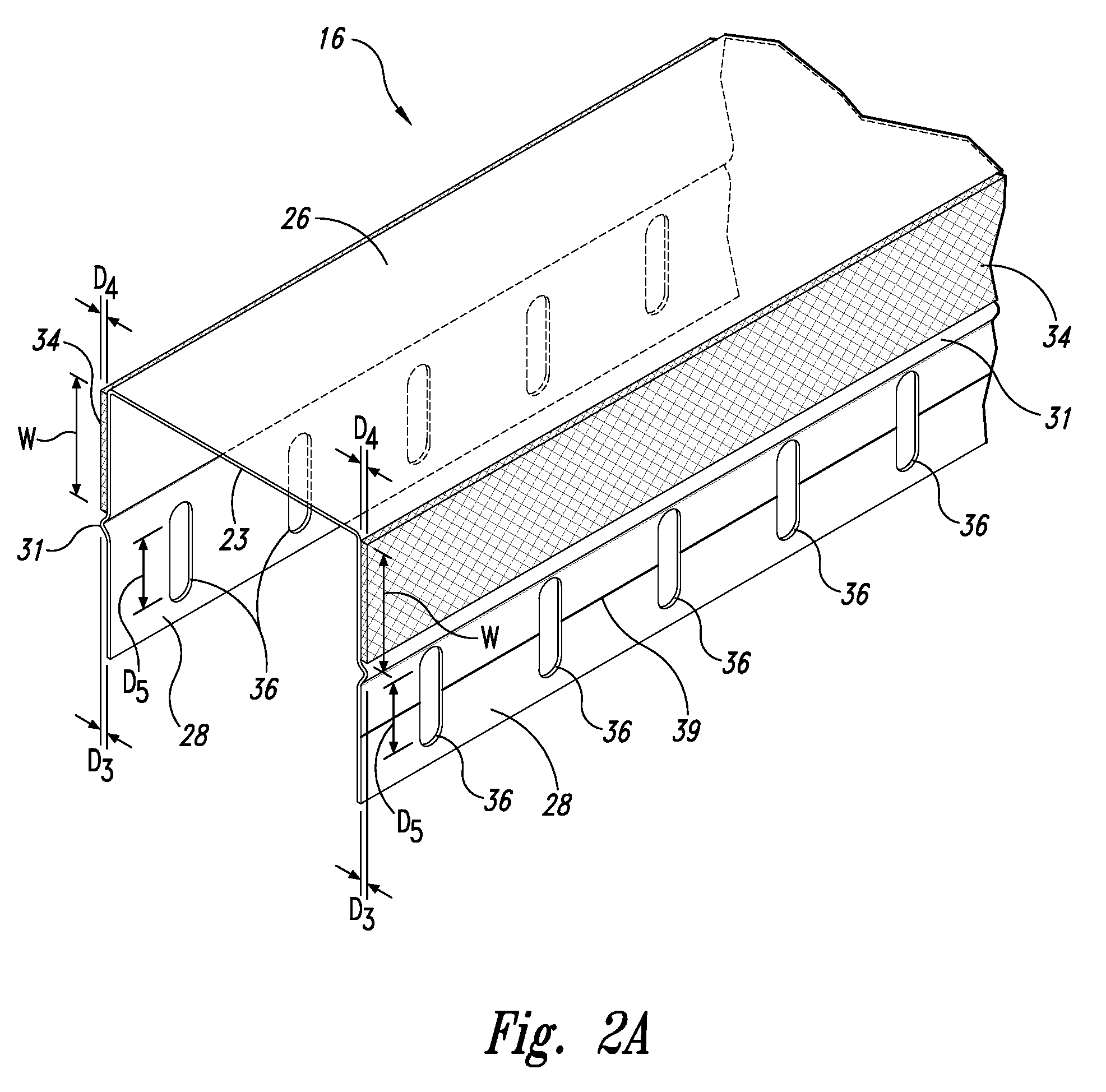

Extrusion devices for mounting wall panels

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

Laminate flooring

InactiveUS7614197B2Improve the immunityCeilingsRoof covering using tiles/slatesEngineeringSurface plate

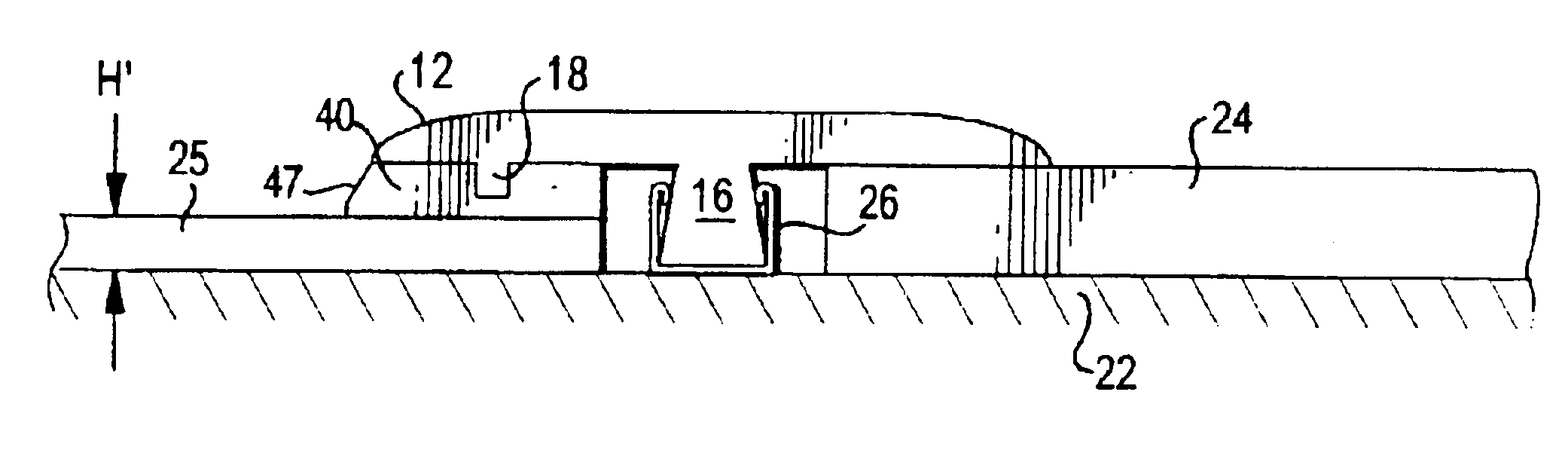

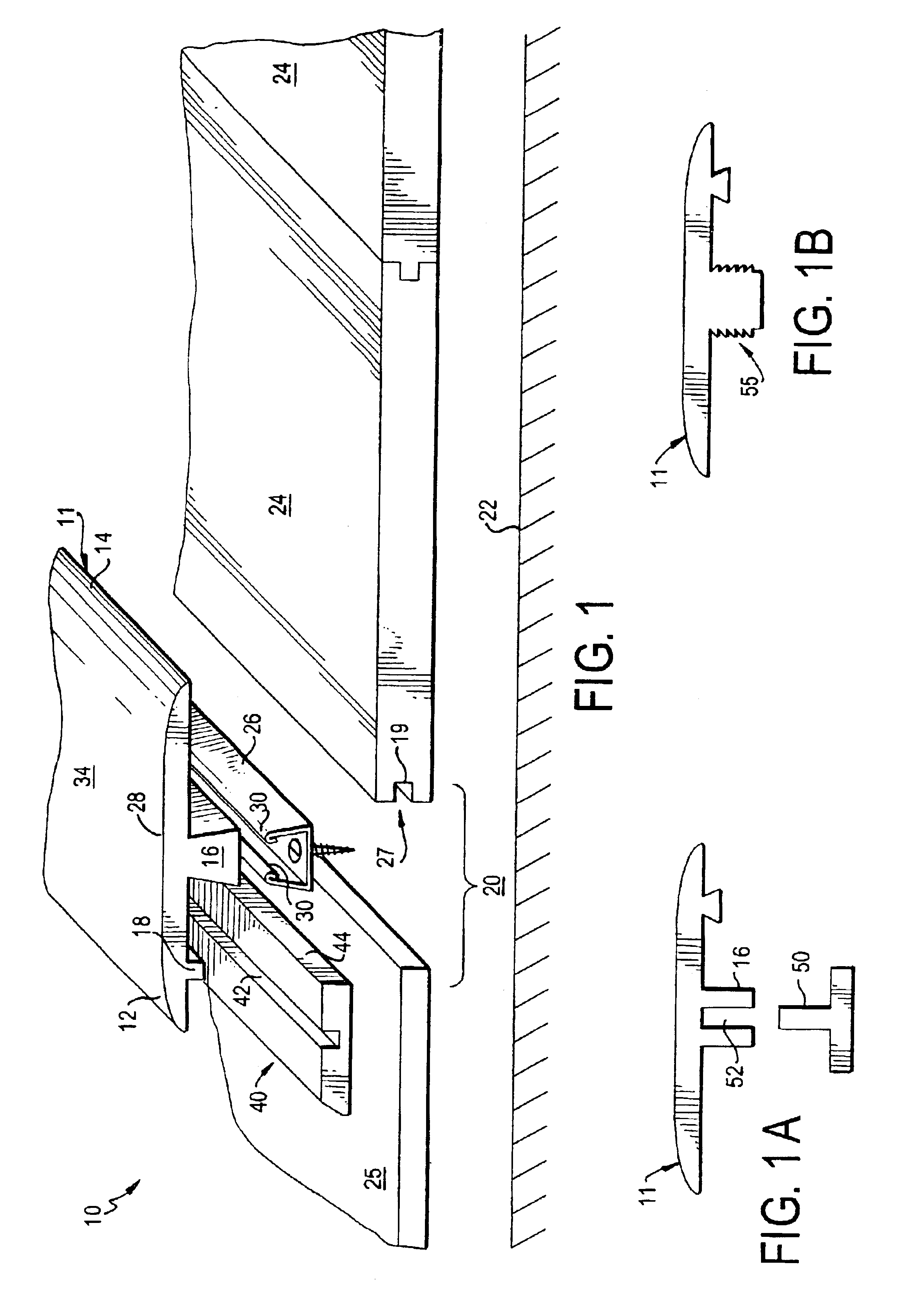

A disengageable connector for interconnecting panels includes a longitudinally extending connector body. The connector body including a base and a projection extending from the base. The base includes a top surface and a bottom surface, and at least one footing member extending downwardly from the bottom surface of the base. The footing member is shaped and dimensioned to compress the upper surface of a resilient pad positioned beneath the connector and the panels. The connector is used in conjunction with an interlocking flooring system. The interlocking flooring system includes a plurality of flooring panels, each flooring panel including a plurality of edges. A first connecting member is provided for connecting adjacent flooring panels and a second connecting member is provided for connecting adjacent flooring panels. The first connecting member is the same as the connector described above and is different from the second connecting member. The first connecting member provides greater resistance to disengagement of adjacent flooring panels when compared to the second connecting member.

Owner:WILSONART

Moisture management system

InactiveUS6470638B1Improve adhesionImprove moisture managementBuilding roofsRoof covering using slabs/sheetsAdhesiveEngineering

An improved moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base, an upright front wall that includes at its base weep holes for the removal of entrained moisture as well as a longitudinal forward extending finish stop above the weep holes, and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water exiting the moisture management system through the weep holes in the upright front wall. Preferably, elongated striations in the front faces of both the front and rear upright walls as well as holes in the upright front wall above the finish stop provide improved adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

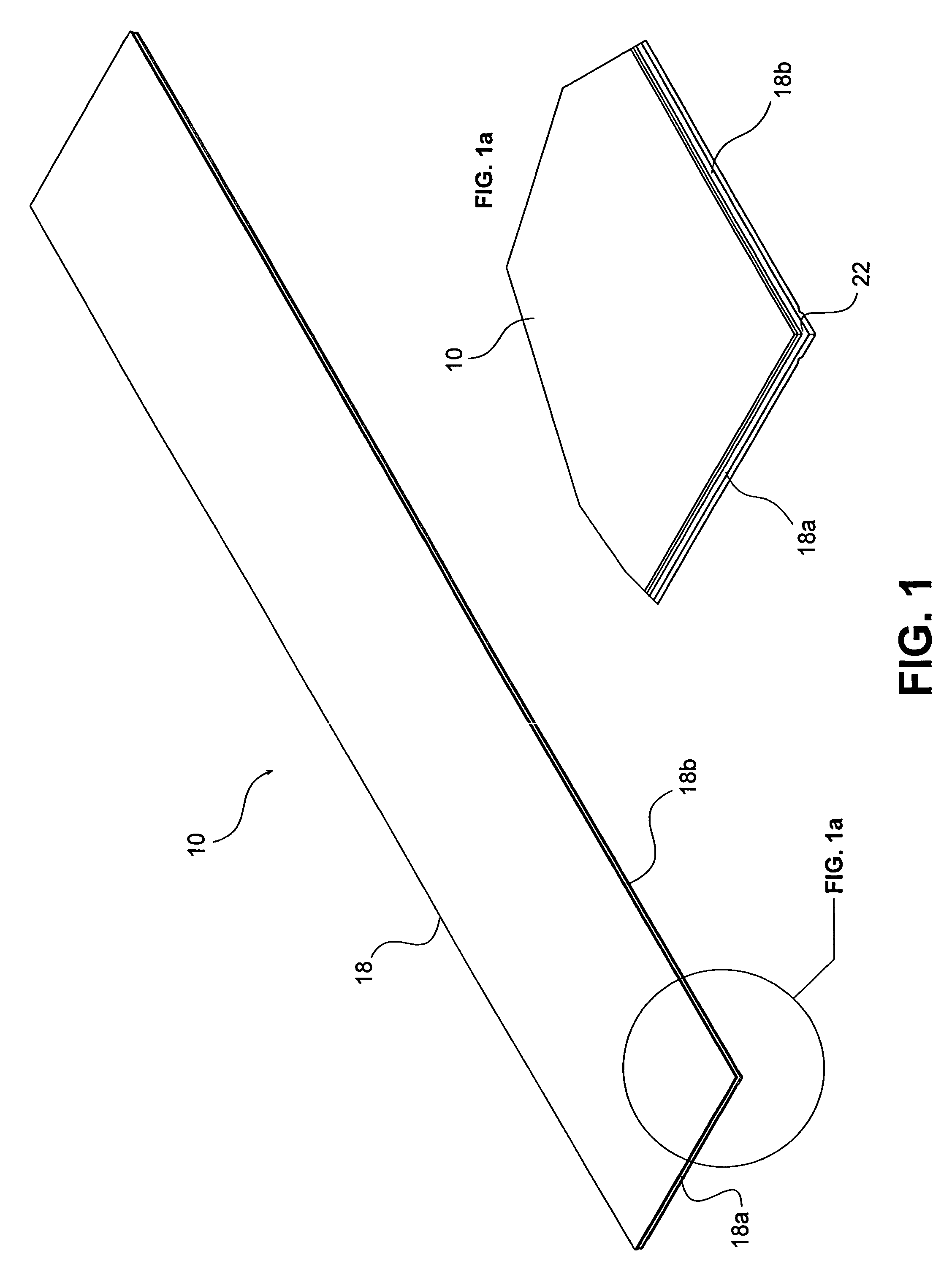

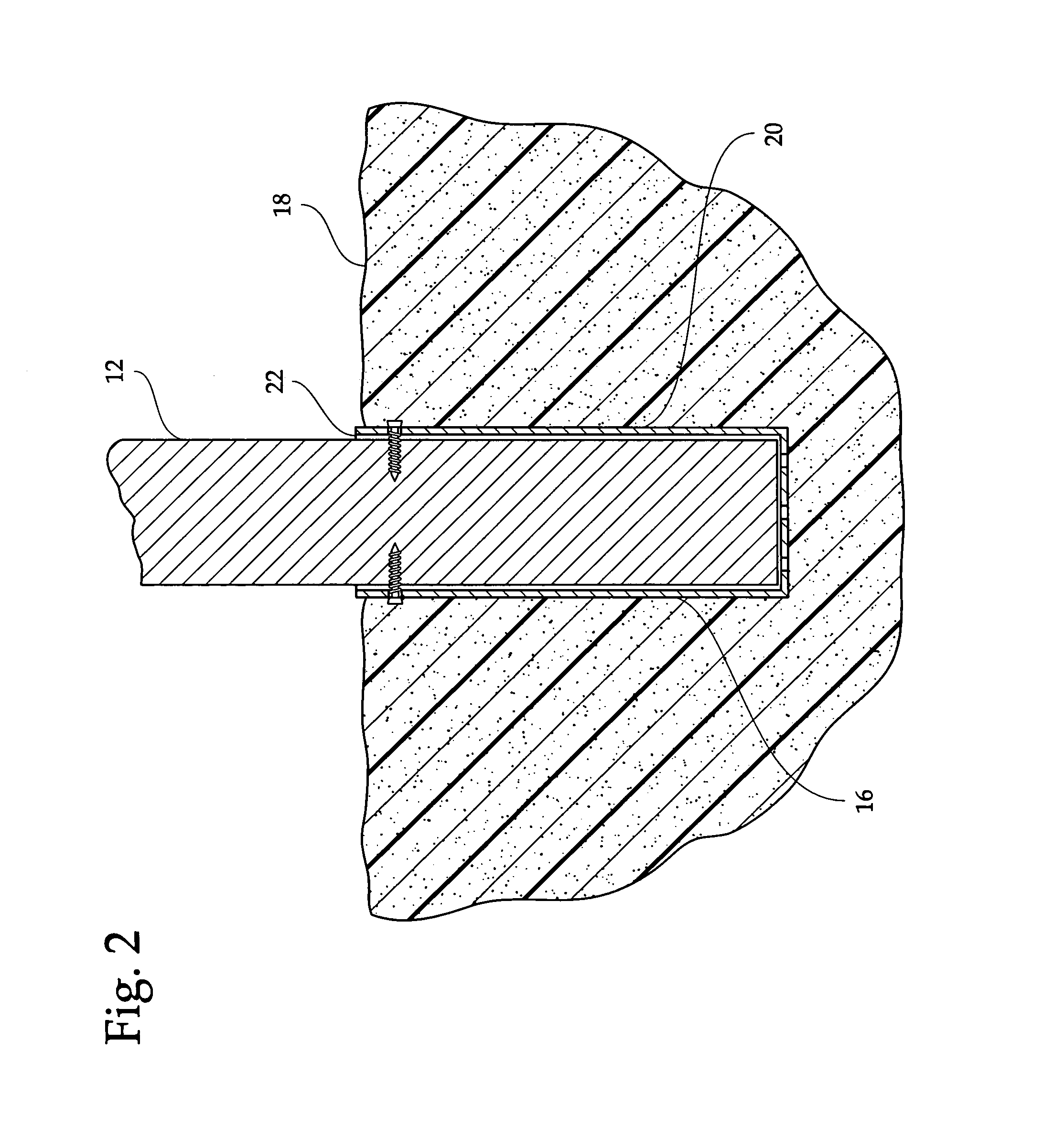

Foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6054207AHigh compressive strengthImproved fastener retentionConstruction materialLoad-supporting elementsComposite constructionThermoplastic

Advanced structural components comprising a foamed thermoplastic that can be used in virtually any application where wooden components have a use. Such structural components can comprise sized lumber, shaped trim, posts, beams or shaped structural members. An advanced profile composite structural component comprising an exterior capping layer with an interior comprising a foamed thermoplastic can be used in the assembly of fenestration units adapted to residential and commercial structures. Preferably the profile structural component can be used in a window or door assembly. The profile member is adapted for ease of construction of the fenestration units, can be easily installed in a rough opening to framing members, and can be trimmed and adjusted on site. The profile is structurally strong, thermally stable, shrink resistant and will accept and retain the insertion of fasteners such as staples, nails and screws permanently with substantial retention and little or no damage to the units. The profile structural components possess strength that permits the manufacture of a structurally sound fenestration unit from two or more foamed profile members or other conventional members.

Owner:ANDERSEN CORPORATION

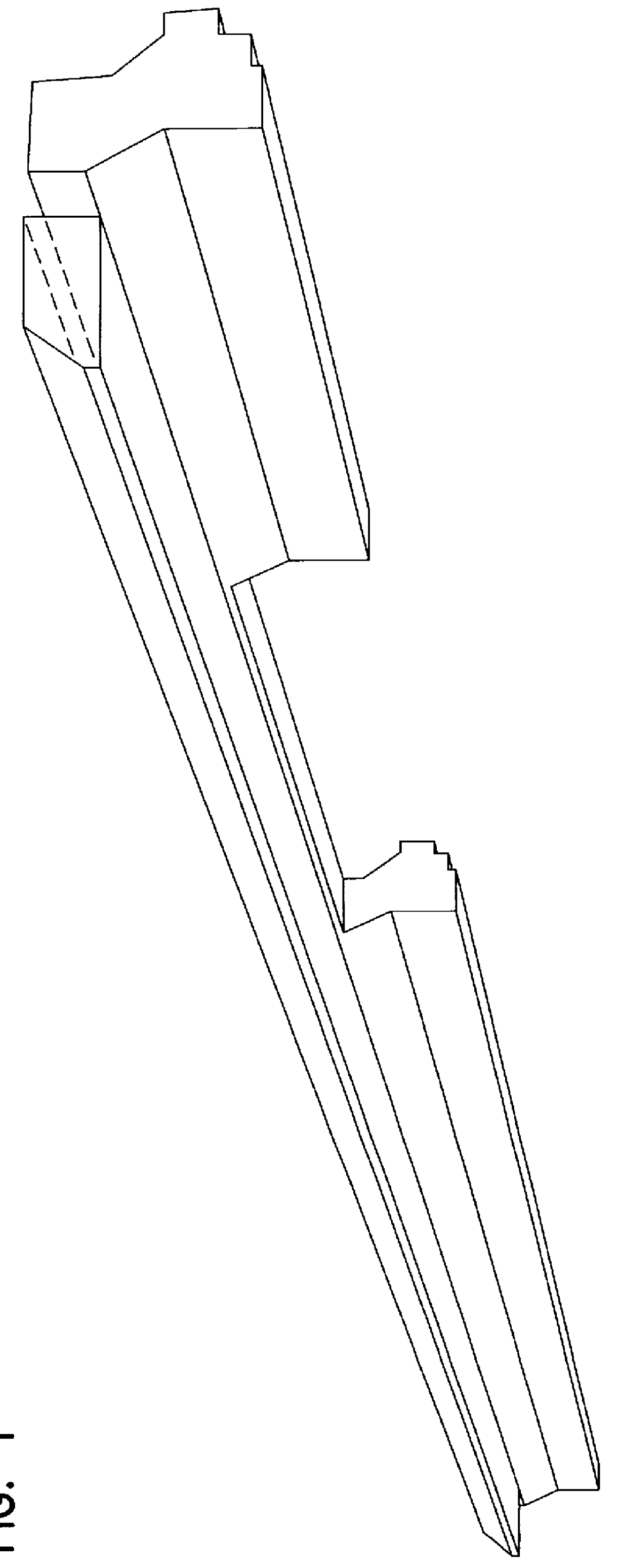

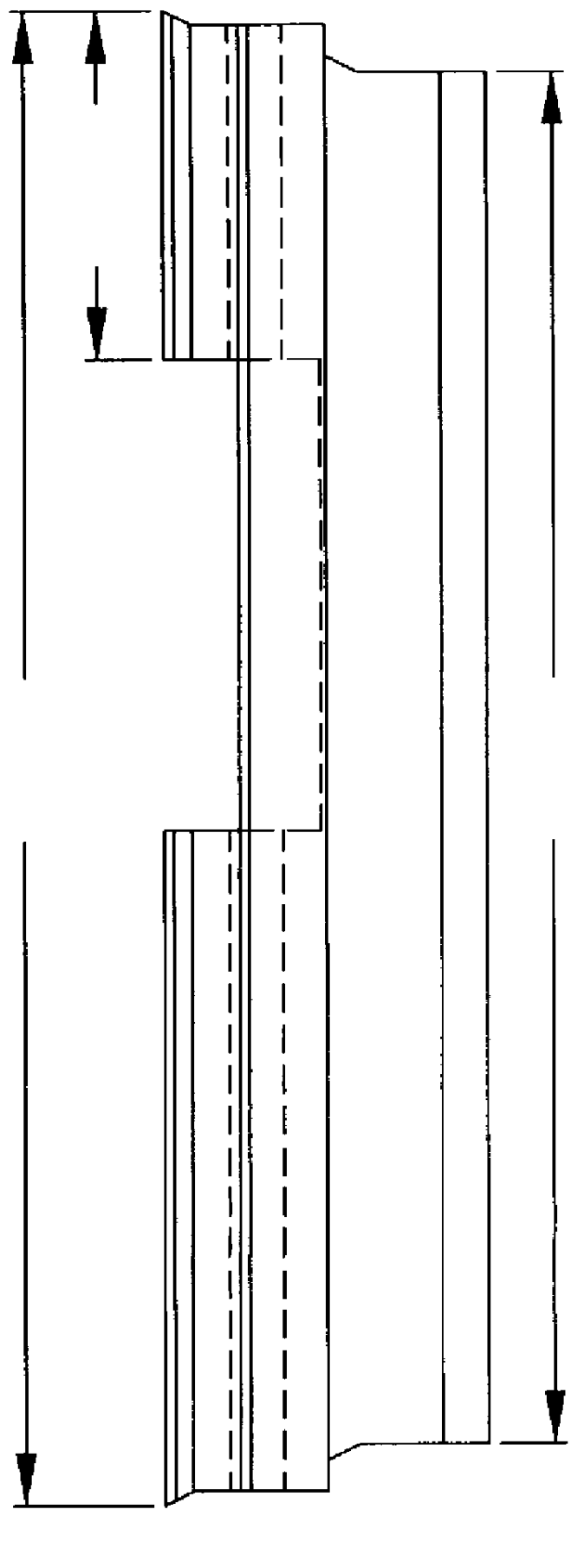

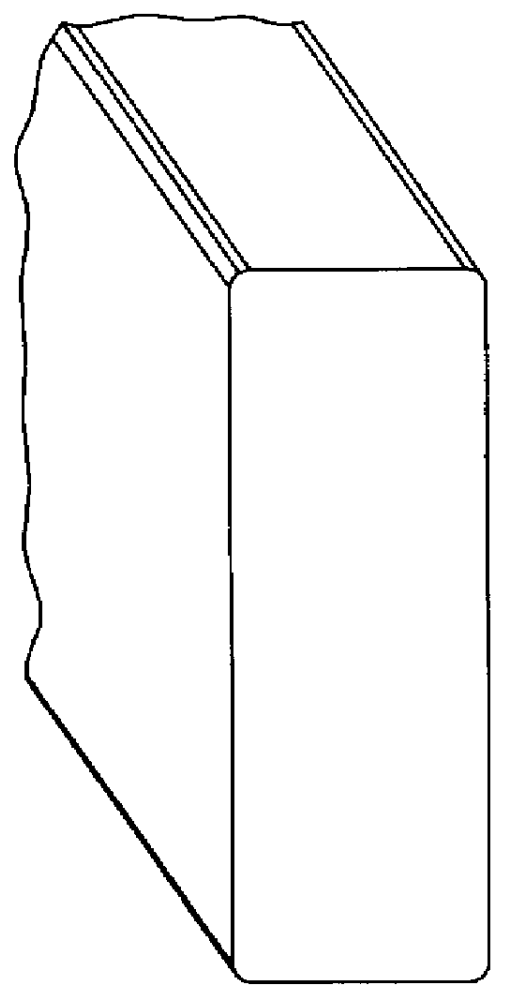

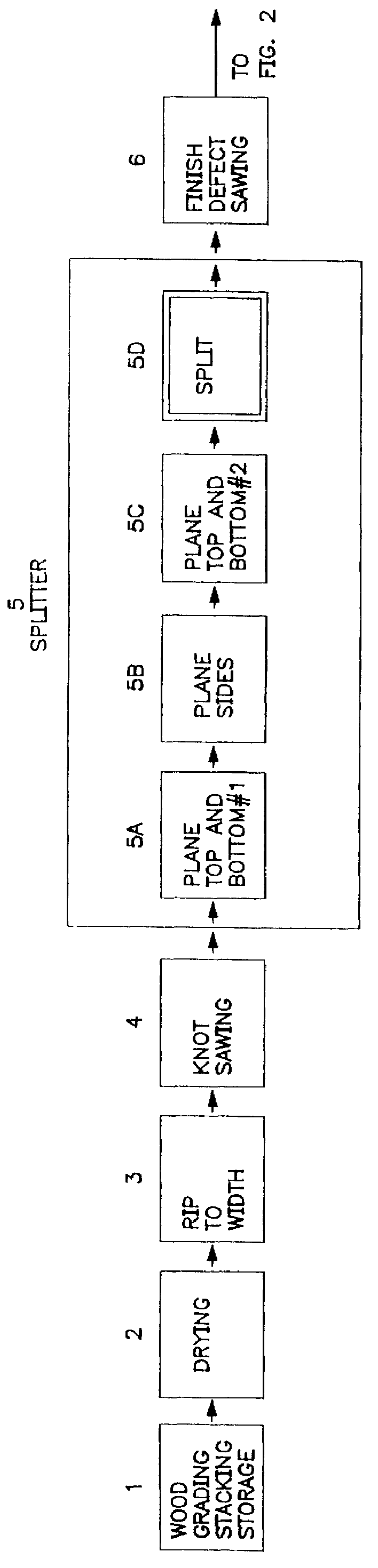

Low profile hardwood flooring strip and method of manufacture

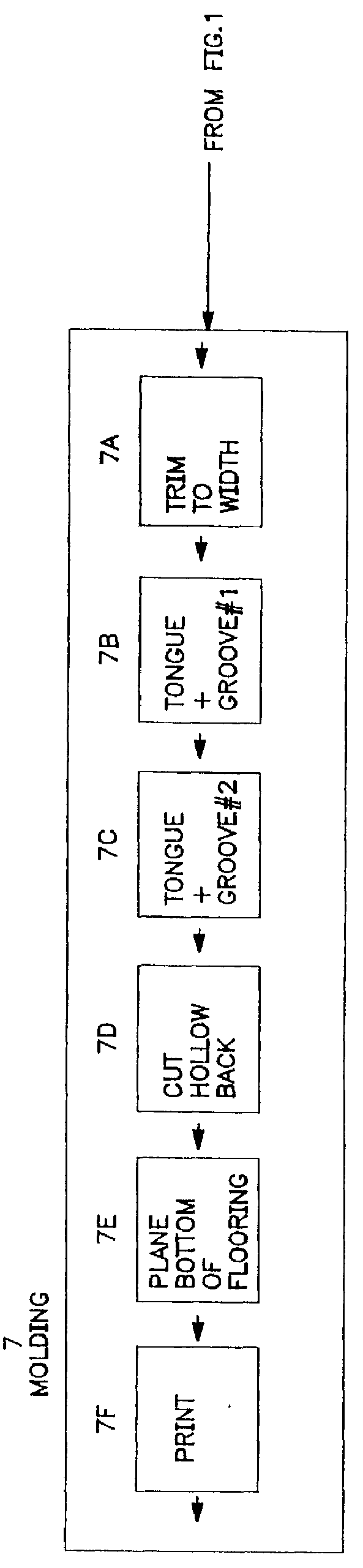

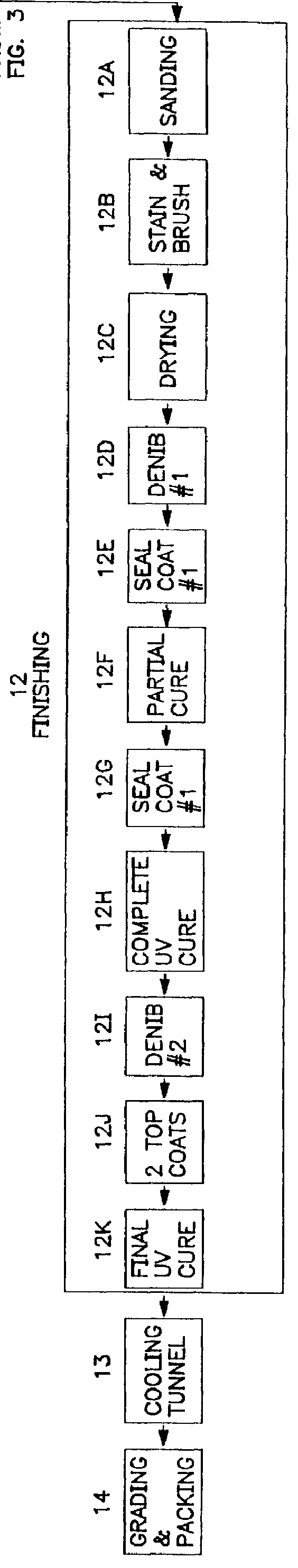

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

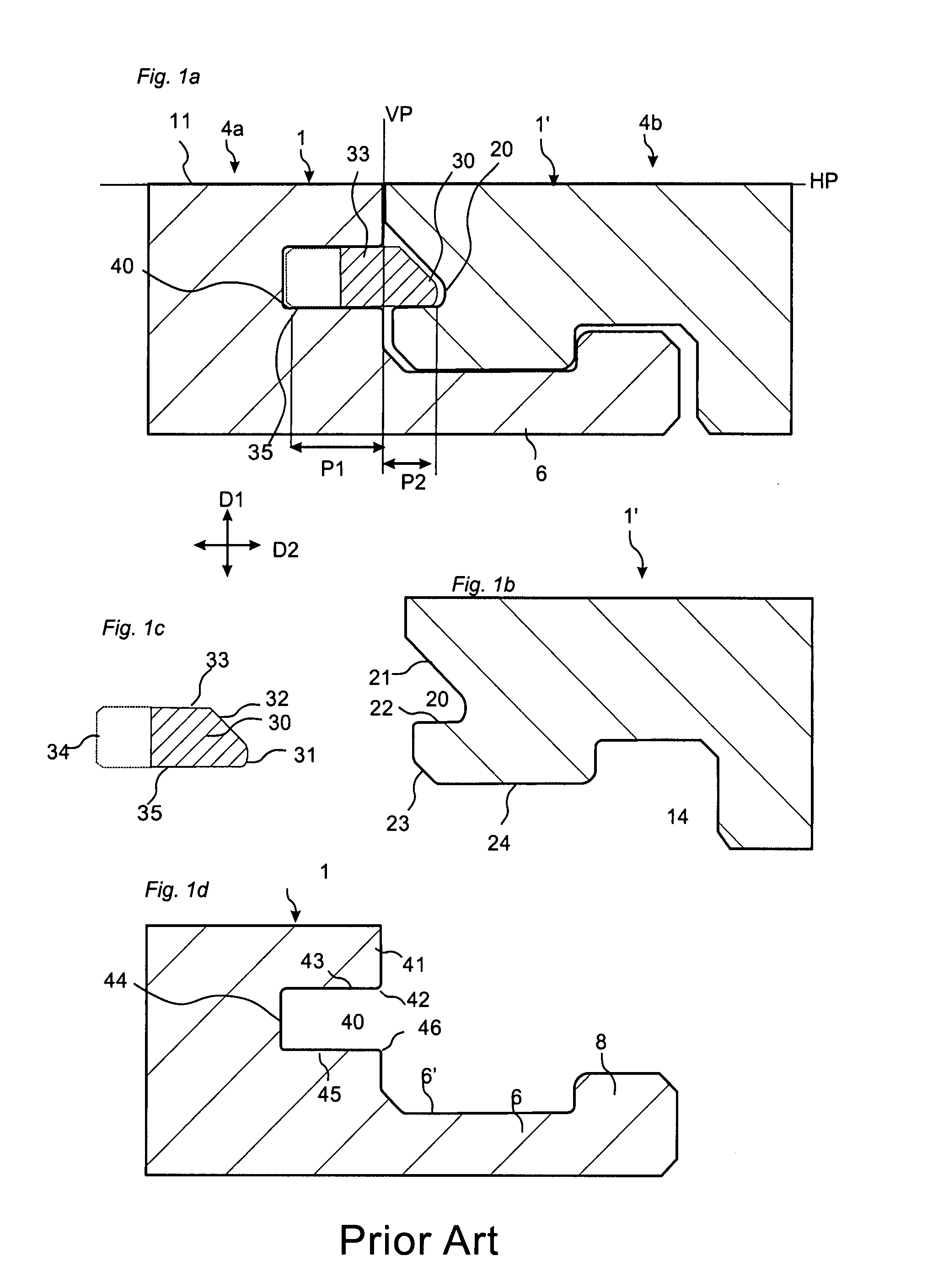

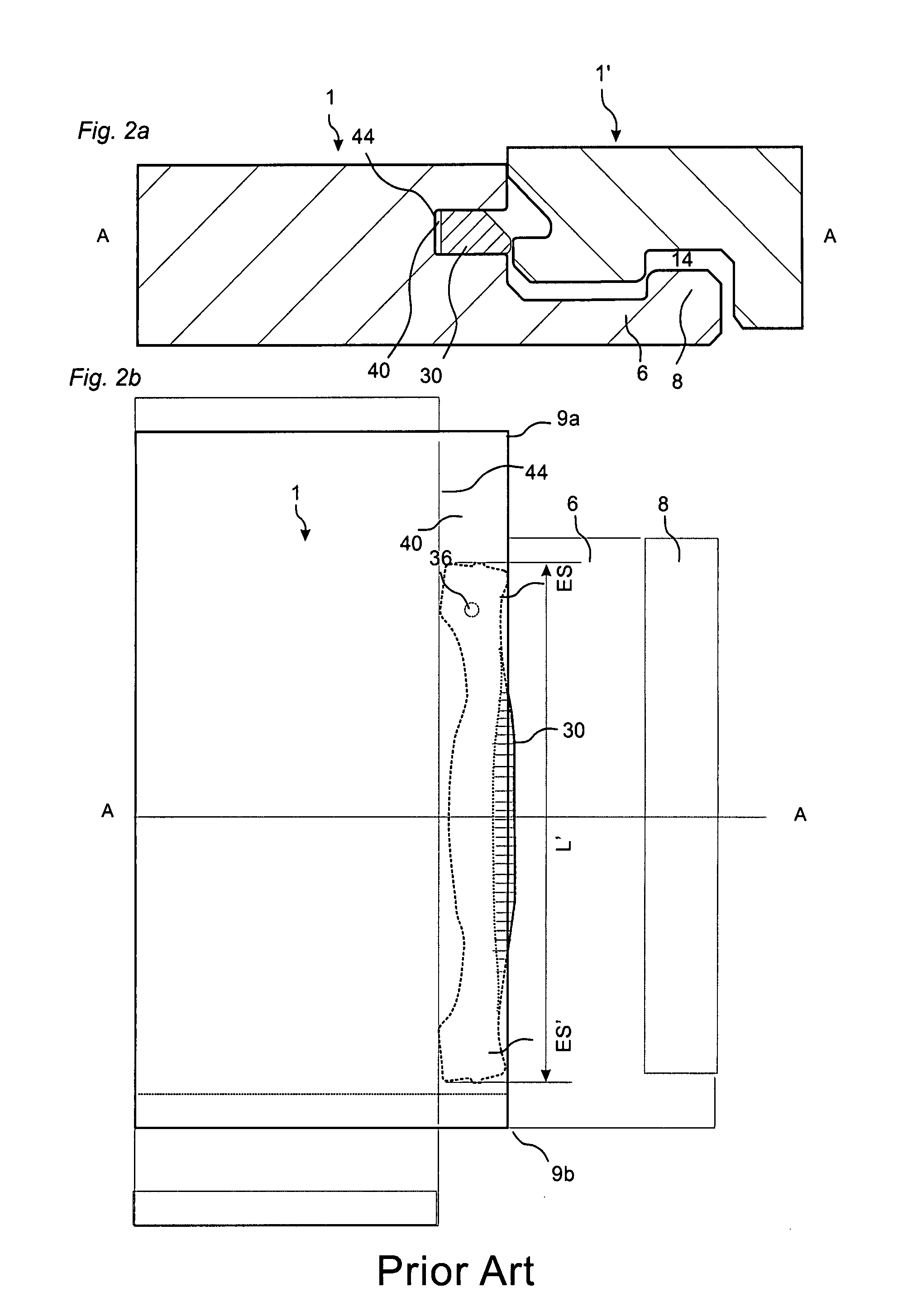

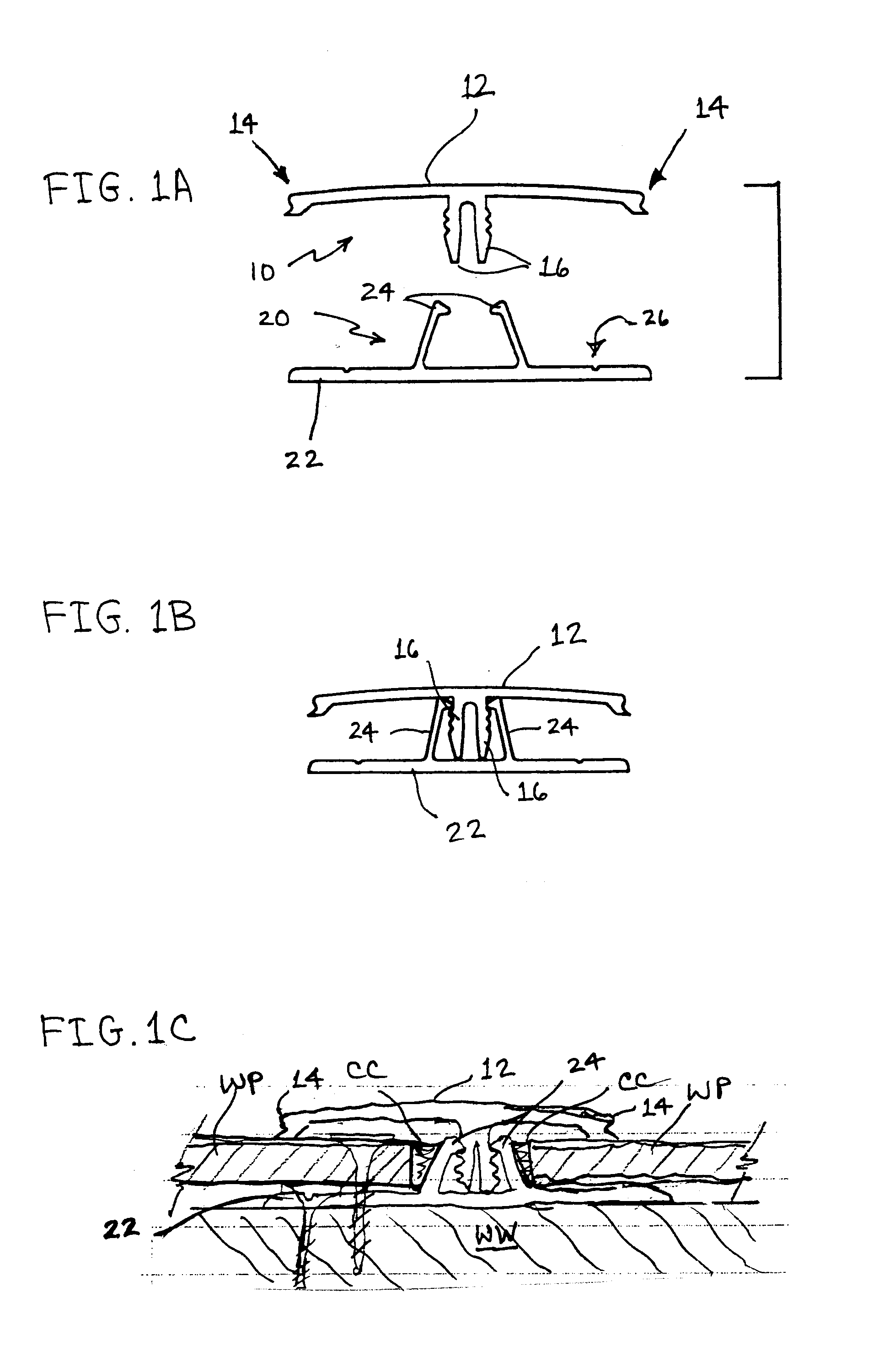

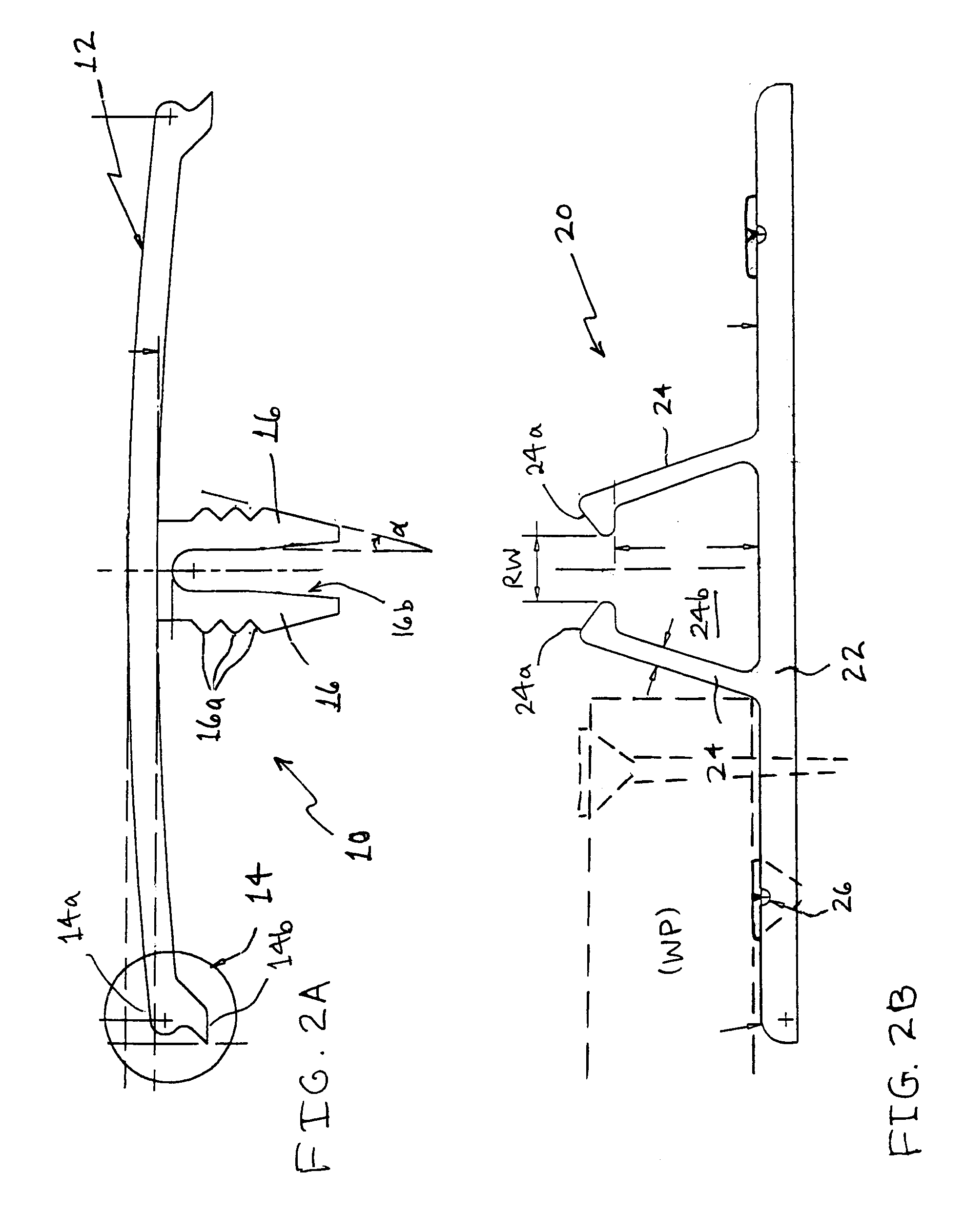

Transition molding

InactiveUS6860074B2Easy to useSmooth transitionTreadsRoof covering using tiles/slatesEngineeringSurface plate

The invention is a joint cover assembly for covering a gap adjacent an edge of a panel that covers a sub-surface, and a method of covering such a gap. The assembly includes a molding having a foot, a first arm, and a second arm. The foot is positioned along a longitudinal axis, and the first arm extends generally perpendicularly from the foot. The second arm extends generally perpendicularly from the foot. A tab depends generally perpendicularly from the first panel engaging surface. At least one of the tab and the foot engage the edge in order to tightly fit within the gap. The method includes the steps of placing the foot in the gap, pressing the respective panel engaging surfaces into contact with respective panels, and configuring at least one of the tab and the foot to cooperate to retain the molding in the gap when the assembly is in an installed condition.

Owner:PERGO

Polyolefin wood fiber composite

InactiveUS6265037B1Improve mechanical propertiesImproved chemicalConstruction materialCovering/liningsPolyolefinEngineering

An improved composite structural member comprising a complex profile structural member, made of a composite comprising a polypropylene polymer and a wood fiber. The material is useful in conventional construction applications. The complex profile, in the form of an extruded thermoplastic composite member can be used in residential and commercial structures as described. Preferably, the structural member is used in the manufacture of the fenestration components such as windows and doors. Such linear members are designed with specifically configured cross-sectional shapes to form structural elements in the fenestration units. Structural elements must possess sufficient strength, thermal stability and weatherability to permit the manufacture of a structurally sound window unit that can be easily installed into a rough opening but can maintain its attractive appearance and structural integrity over the life of the window unit often twenty years or more. The structural member comprises a hollow complex cross-section with at least one structural web or one fastener web formed within the component. The exterior of the extruded component has a visible capstock layer and is shaped and adapted for installation in rough openings. The exterior also contains shape and components capable of supporting the elements of the fenestration unit such as a window, sash or movable door unit. The improved polypropylene structural members have unique advantages and can be assembled in thermoplastic weld processes.

Owner:ANDERSEN CORPORATION

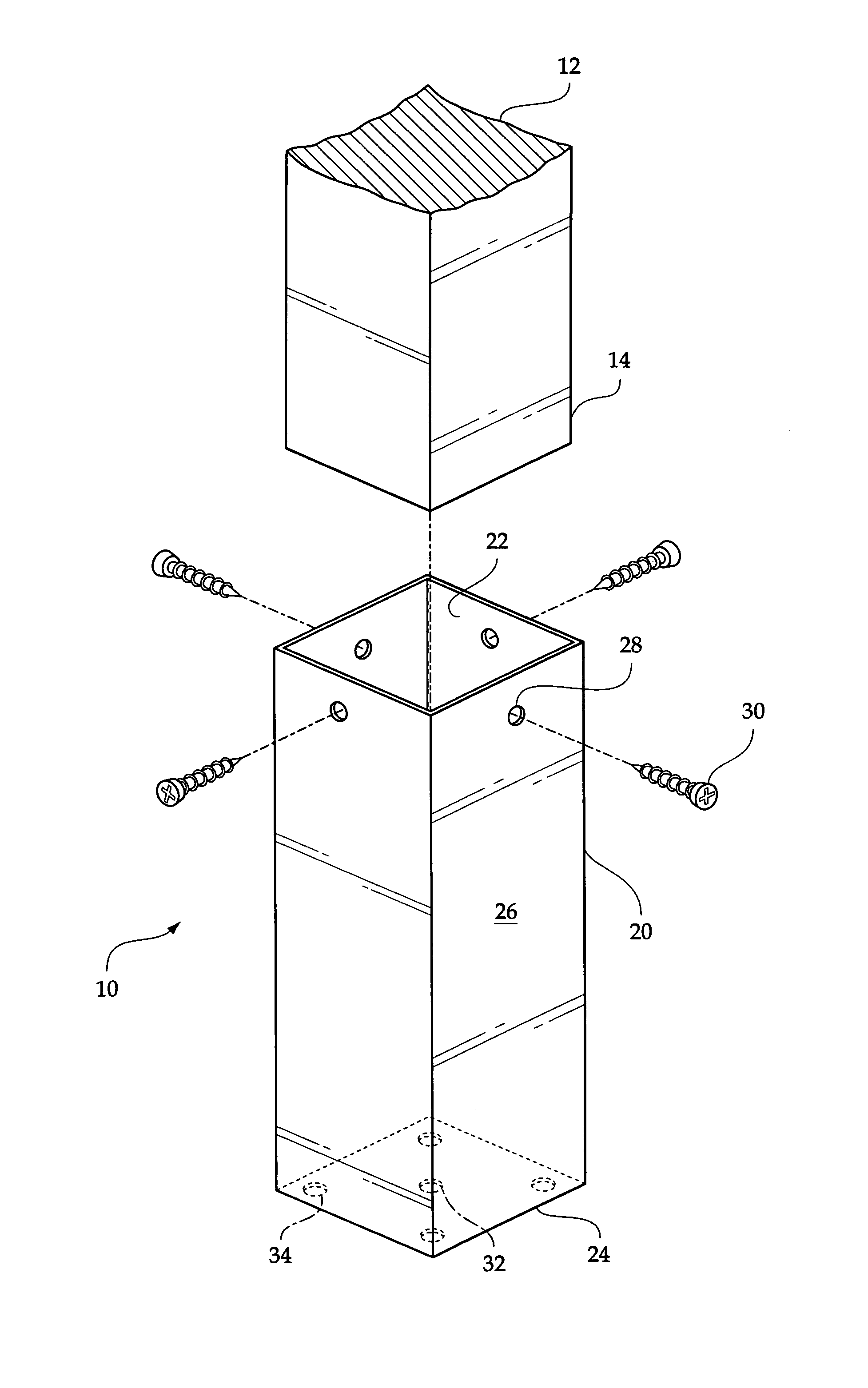

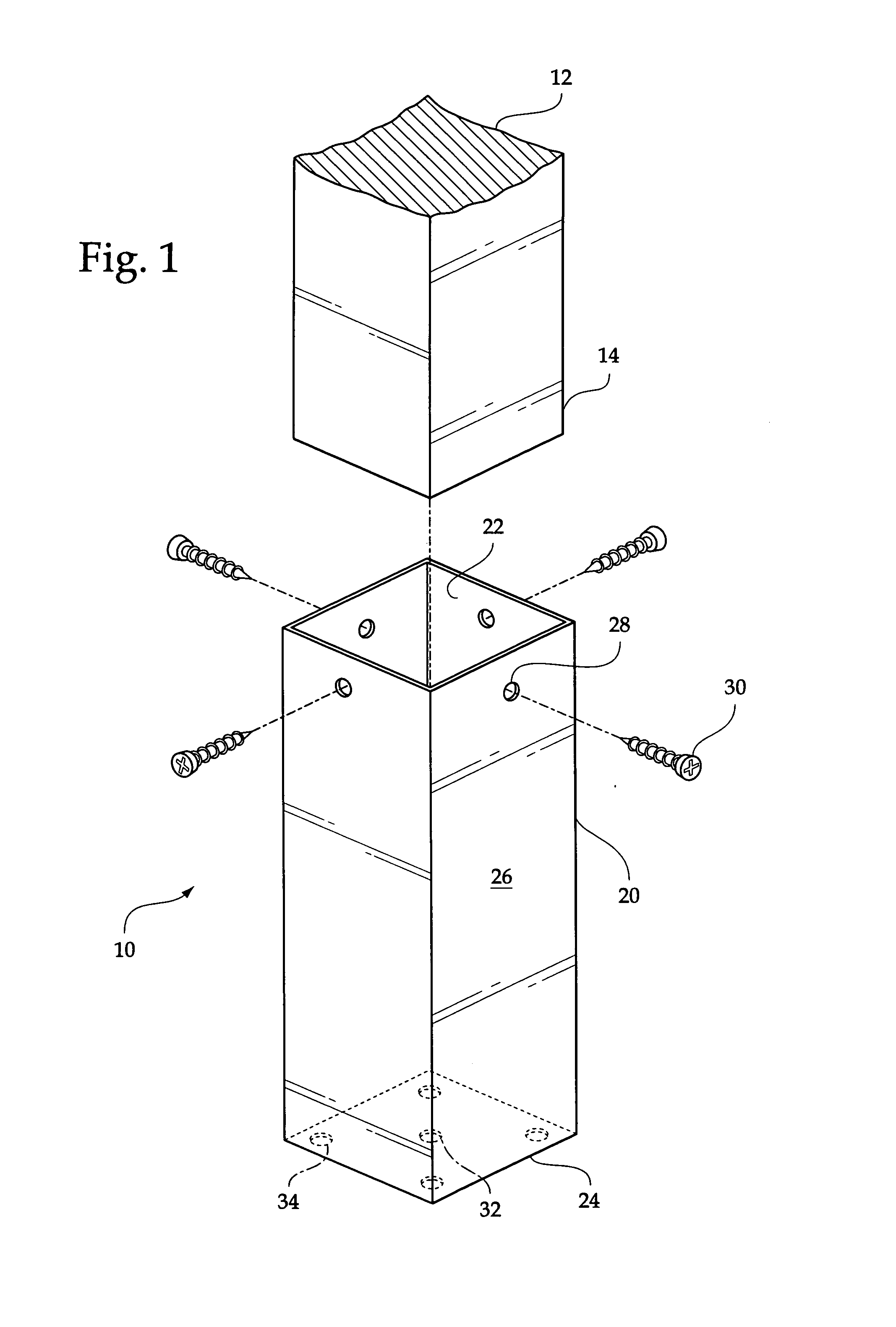

Wooden post protective sleeve

InactiveUS6886296B1Easy and efficient to manufactureDurable and reliable constructionLoad-supporting elementsStands/trestlesEngineering

A wooden post protective sleeve including a collar having an open upper end, a closed lower end, and a surrounding side wall. The open upper end is dimensioned for receiving the lower end of the wooden post therein. The surrounding side wall has a plurality of apertures therethrough downwardly of the open upper end. The apertures are dimensioned for receiving wood screws therethrough for engaging the lower end of the wooden post. The closed lower end has a plurality of drainage apertures therethrough. The drainage apertures include a central aperture and four peripheral apertures. The collar is fabricated of plastic.

Owner:JOHN MICHAEL +1

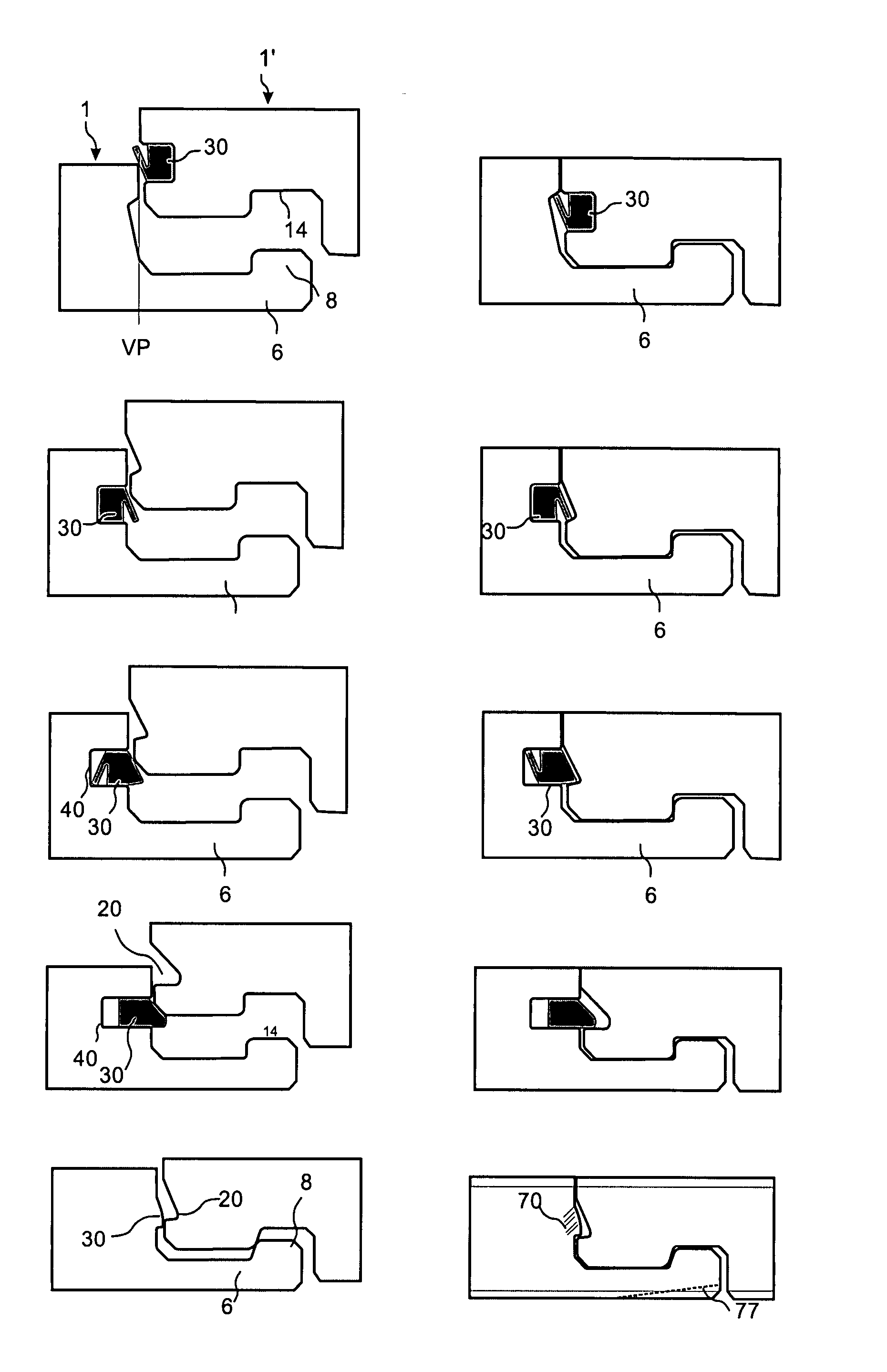

Floor strip

InactiveUS6898911B2Increase resistanceSmooth transitionWood working apparatusPaper/cardboardReducerEngineering

Owner:PERGO

Floor plank

The floor plank is a laminate of two layers of flexible plastic sheet material laminated together in offset relationship to define an offset marginal portion for each of the layers. Each of the offset marginal portions have oppositely facing adhesive coated surfaces. A foam layer and / or a fiberglass sheet can also be included in the laminate structure of the floor plank. The floor plank can conform to surface contours of a floor base. The bottom layer of the floor plank, whether it is plastic sheet or foam, is conformable to surface irregularities of the floor base. A one piece releasable packaging device covers the oppositely facing adhesive coated surfaces of the offset marginal portions.

Owner:ZHANGJIAGANG ELEGANT HOME-TECH CO LTD

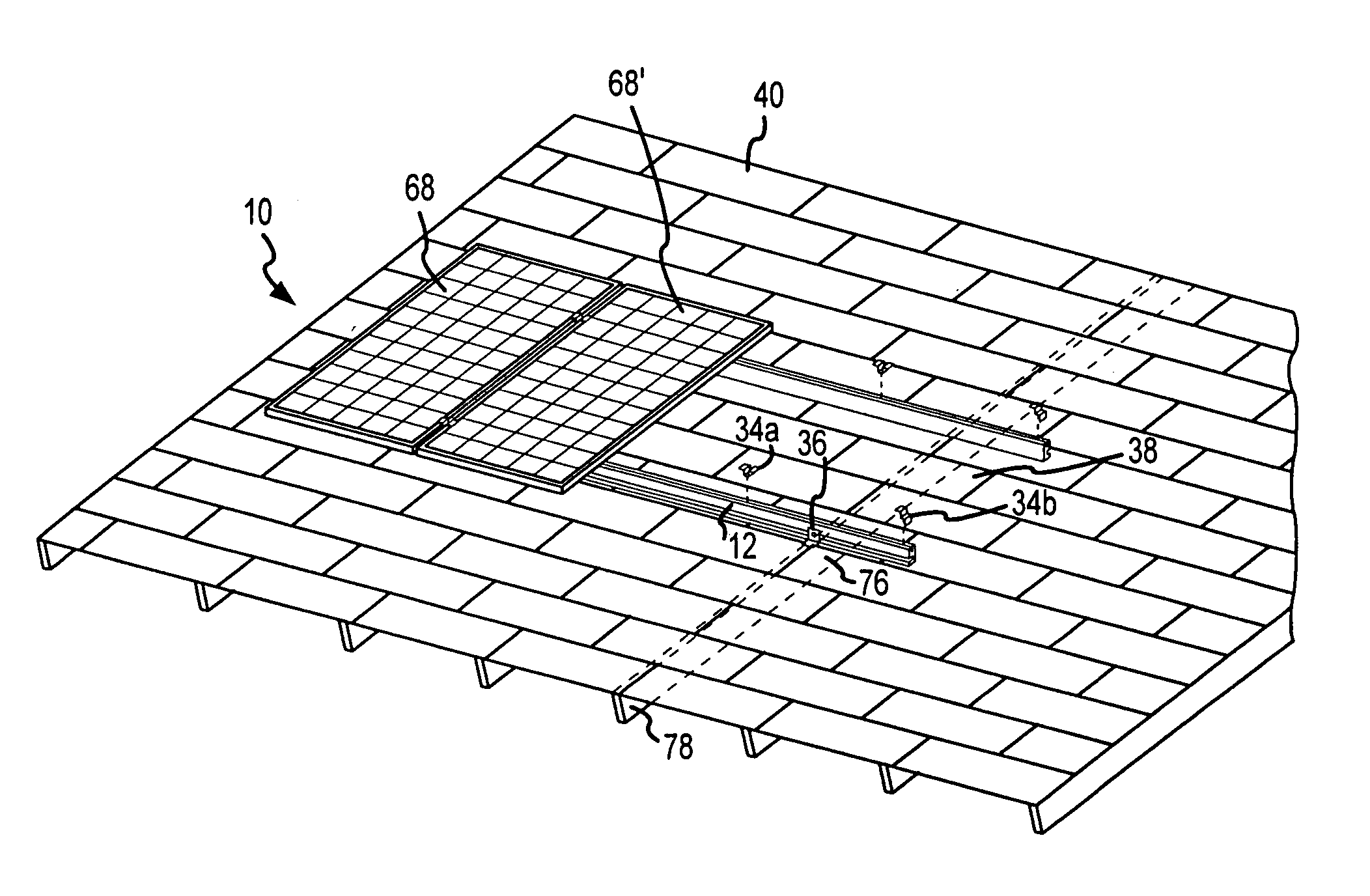

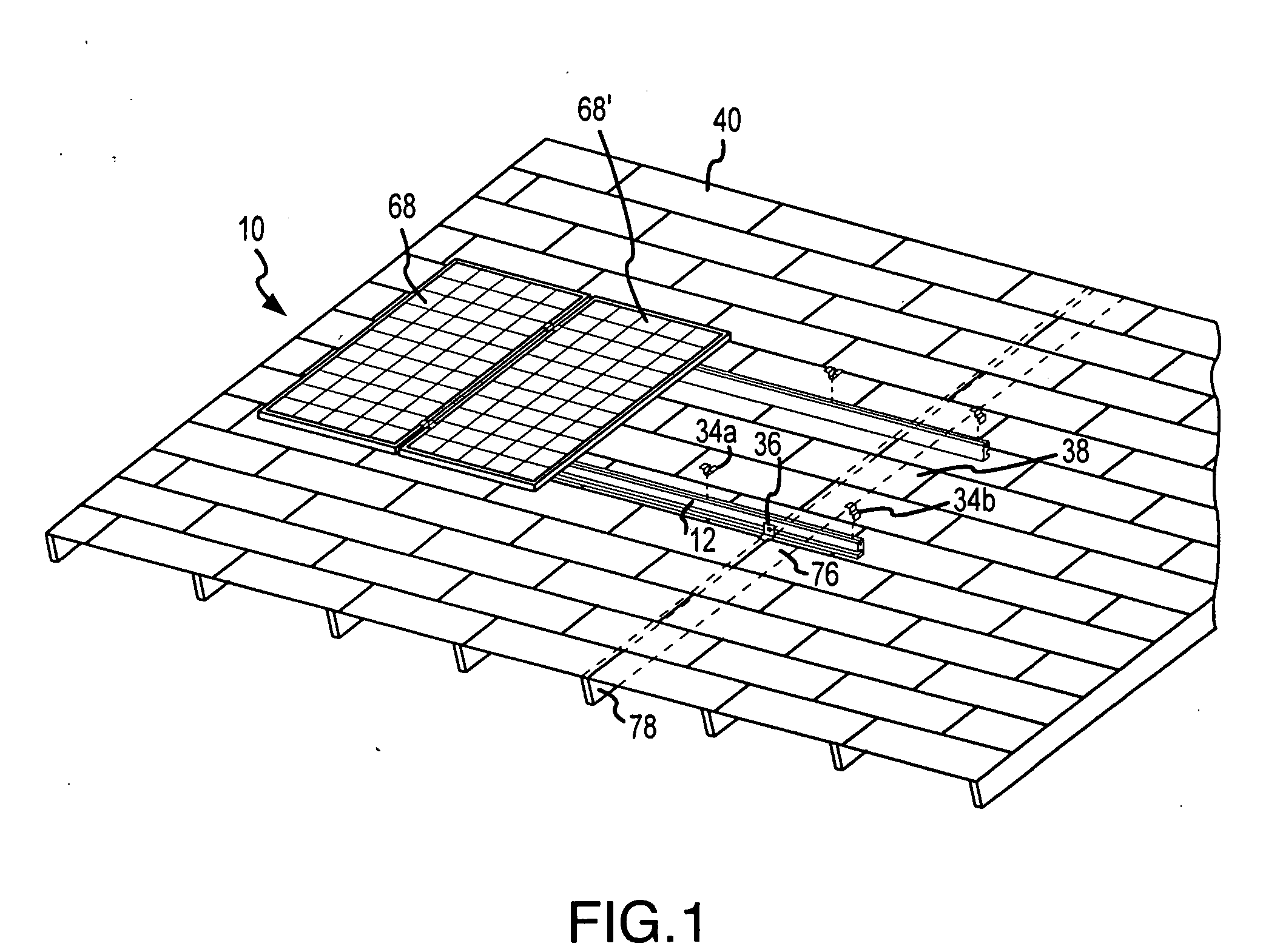

Apparatus and method for positioning a module on an object

InactiveUS20080010915A1Safe and reliable and mannerReduces number varietyPhotovoltaic supportsSolar heating energyEngineering

A system for removably and adjustably mounting a device on an object is provided. The system for removably and adjustably mounting a device on an object, according to the present invention, includes an apparatus and method useful for removably and adjustably mounting one or more photovoltaic modules on an object such as a pole or roof, and includes one or more triple track rails. Also included are one or more connector brackets that are demountably attachable to the one or more triple track rails and to the object.

Owner:UNIRAC INC

Modular construction element

InactiveUS6199340B1Easily assembled togetherEasy to assembleConstruction materialTreadsEngineeringModular structure

An elongate modular decking plank is provided for assembly on a supporting subfloor together with a plurality of like planks to form a decking structure. The decking plank has a top wall spaced-apart from a bottom wall, and opposing laterally spaced downwardly converging side walls interconnecting the top and bottom walls. An integrally-formed flange extends outwardly from the bottom wall on one of said sides of the decoding plank. The flange includes a fastening portion for receiving fasteners therethrough to the supporting subfloor to mount the decking plank on the supporting subfloor, and a connecting portion for connecting the plank to an adjacent like plank in a manner which permits limited lateral and angular adjustment between adjacent planks. The plank is preferably extruded from high-impact polymeric material, such as PVC plastic.

Owner:L B PLASTICS

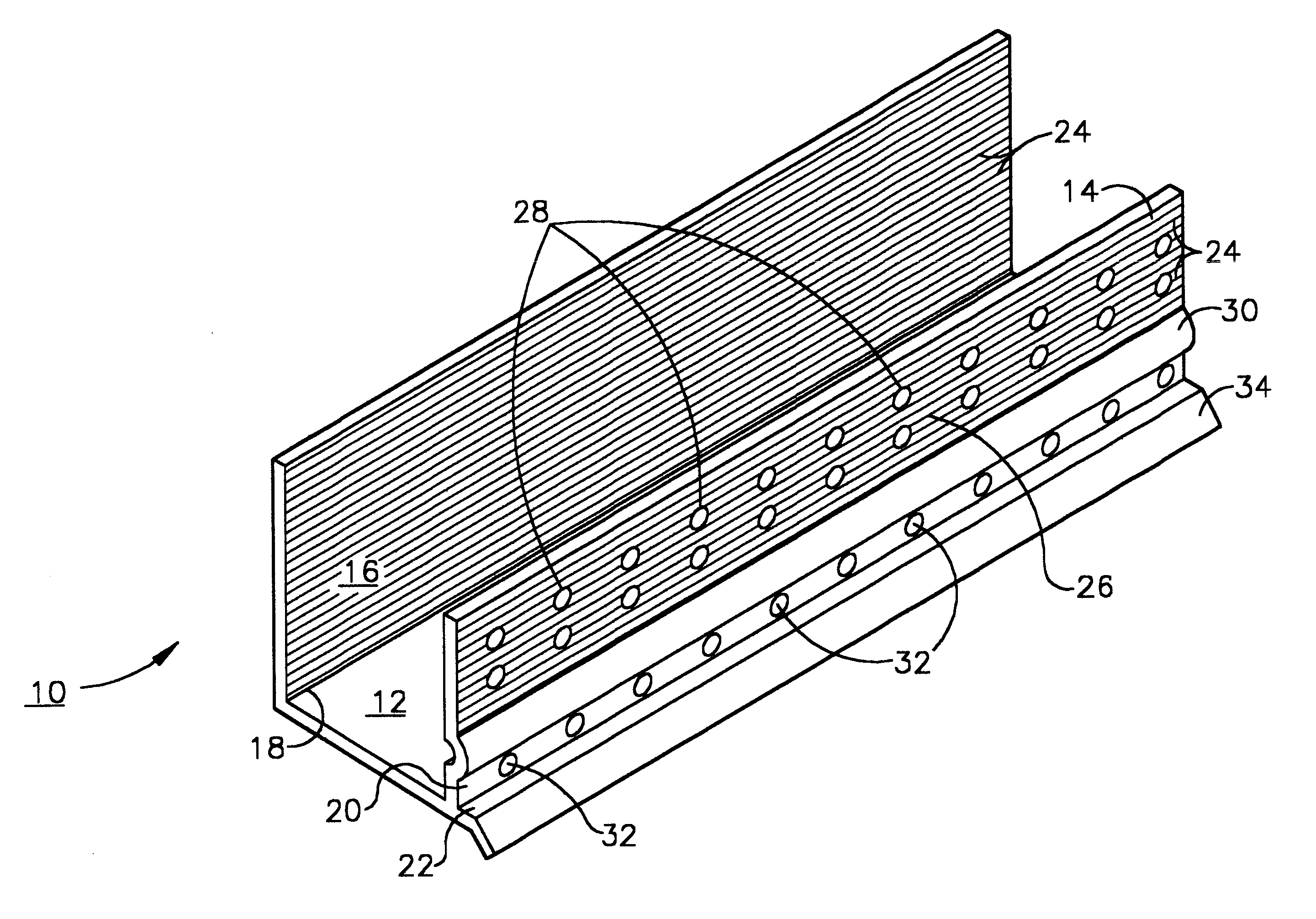

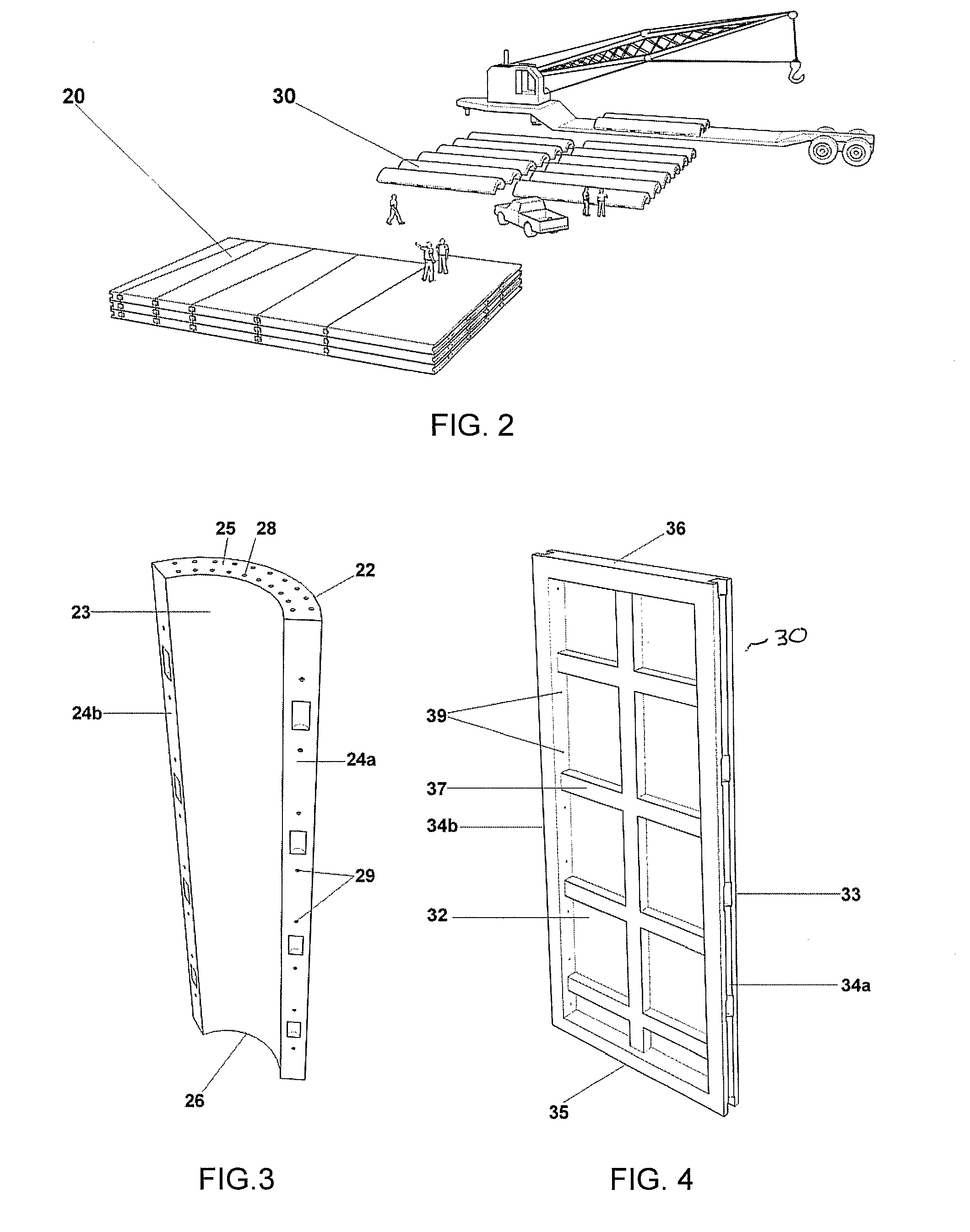

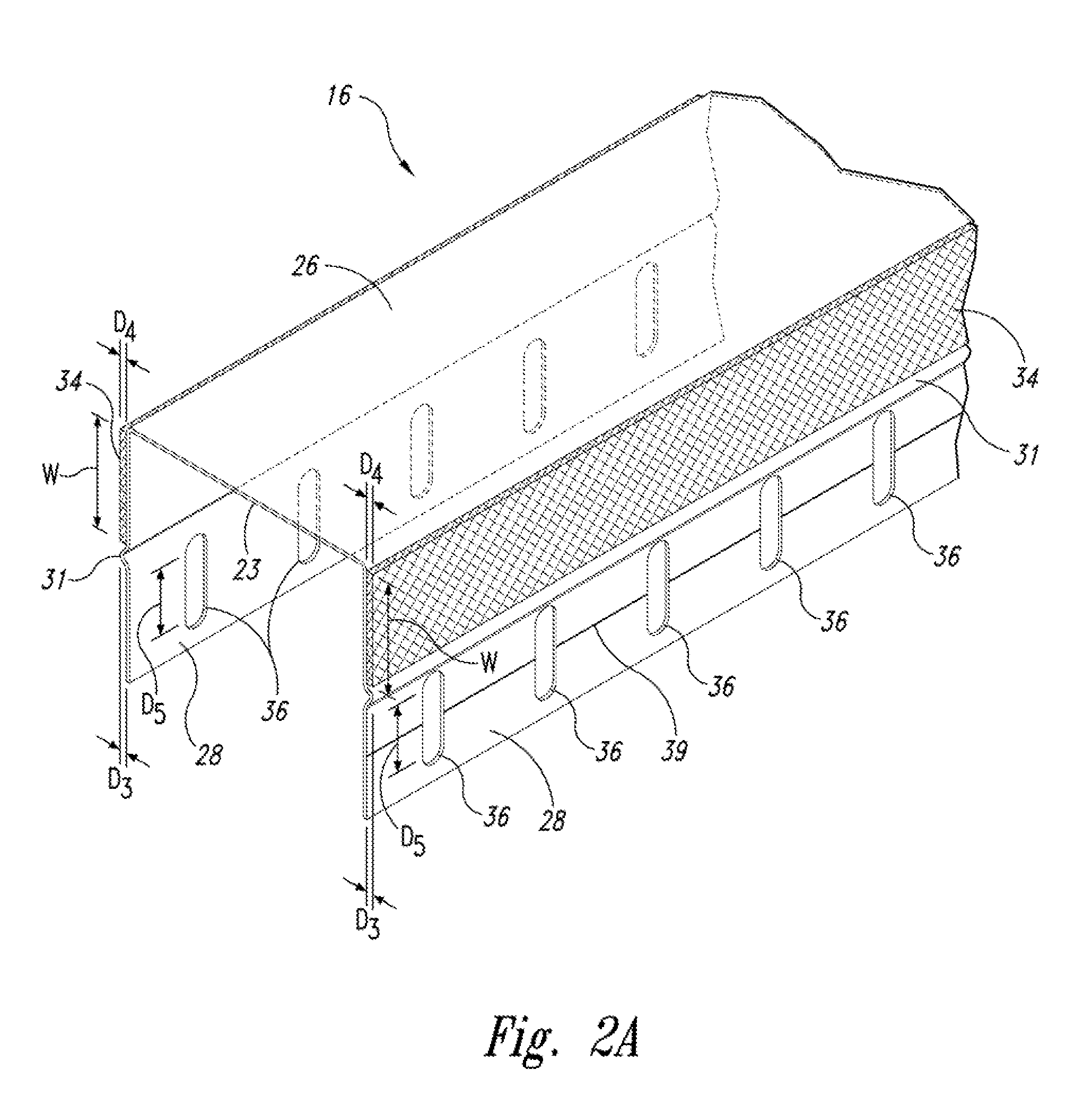

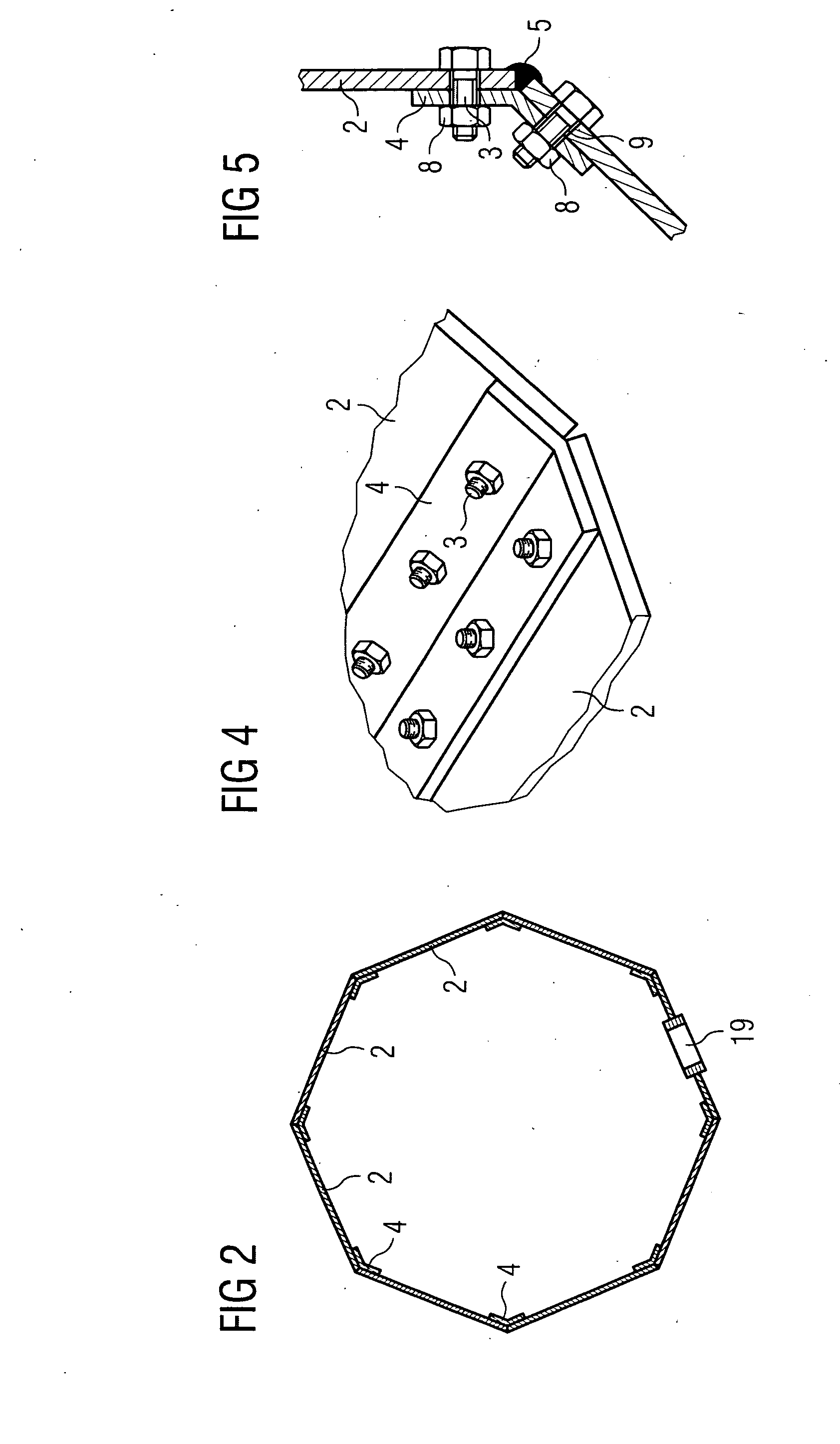

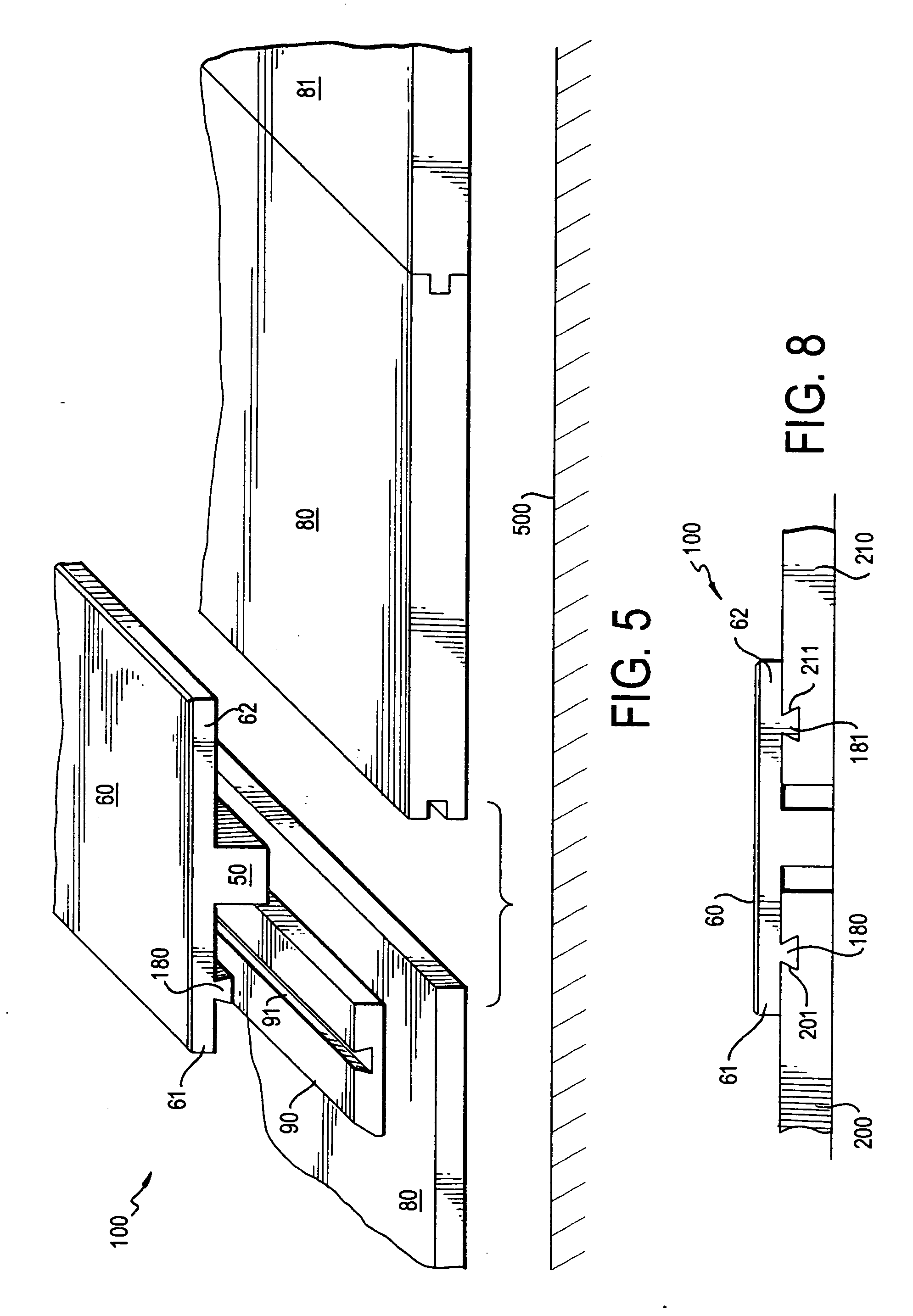

Architectural panel fabrication system

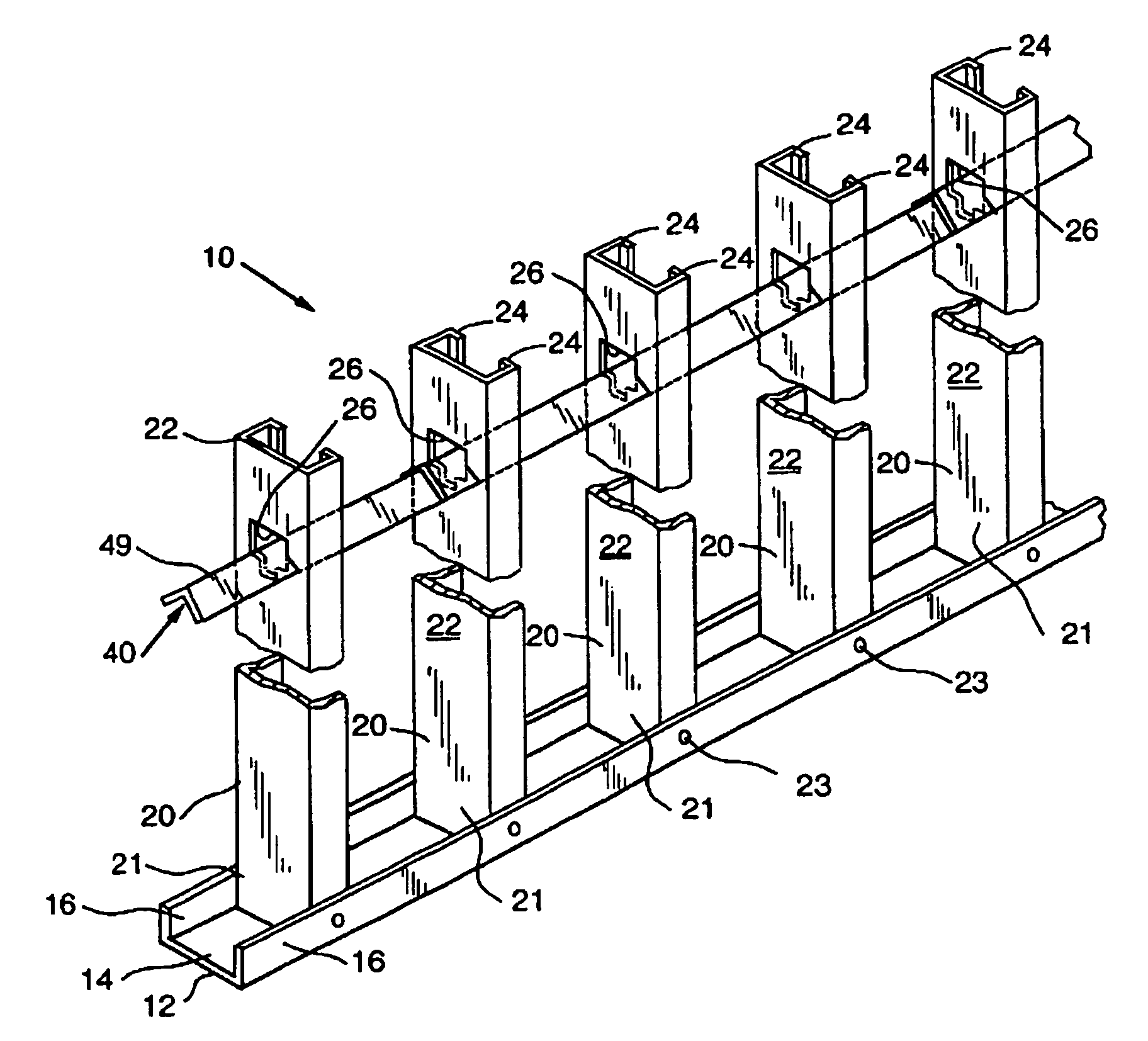

An fabrication system used for mounting a structural member to a surface including an anchor attached to the surface. The anchor has a pair of sidewalls extending substantially perpendicular therefrom and forming an anchor channel with one or more first flanges formed on at least one of the sidewalls facing the anchor channel. The fabrication system also includes a panel frame having a body for insertion into the anchor channel. The body has at least one lateral surface extending substantially perpendicularly therefrom. First and second sidewalls extend from the body to define a frame channel for receiving an edge portion of the structural member. At least one of the first and second sidewalls has a serrated inner face facing the frame channel.

Owner:WMH CONSULTING

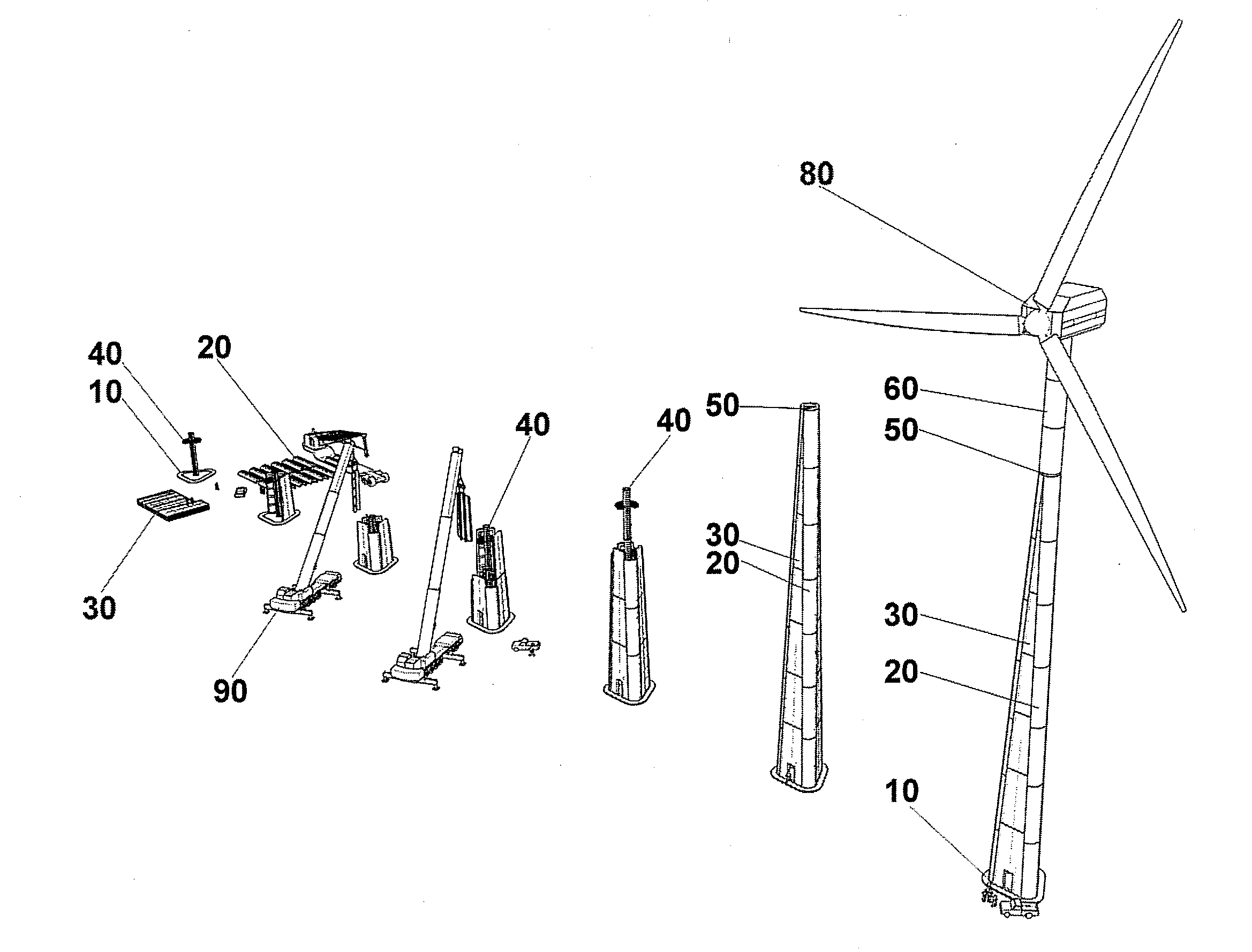

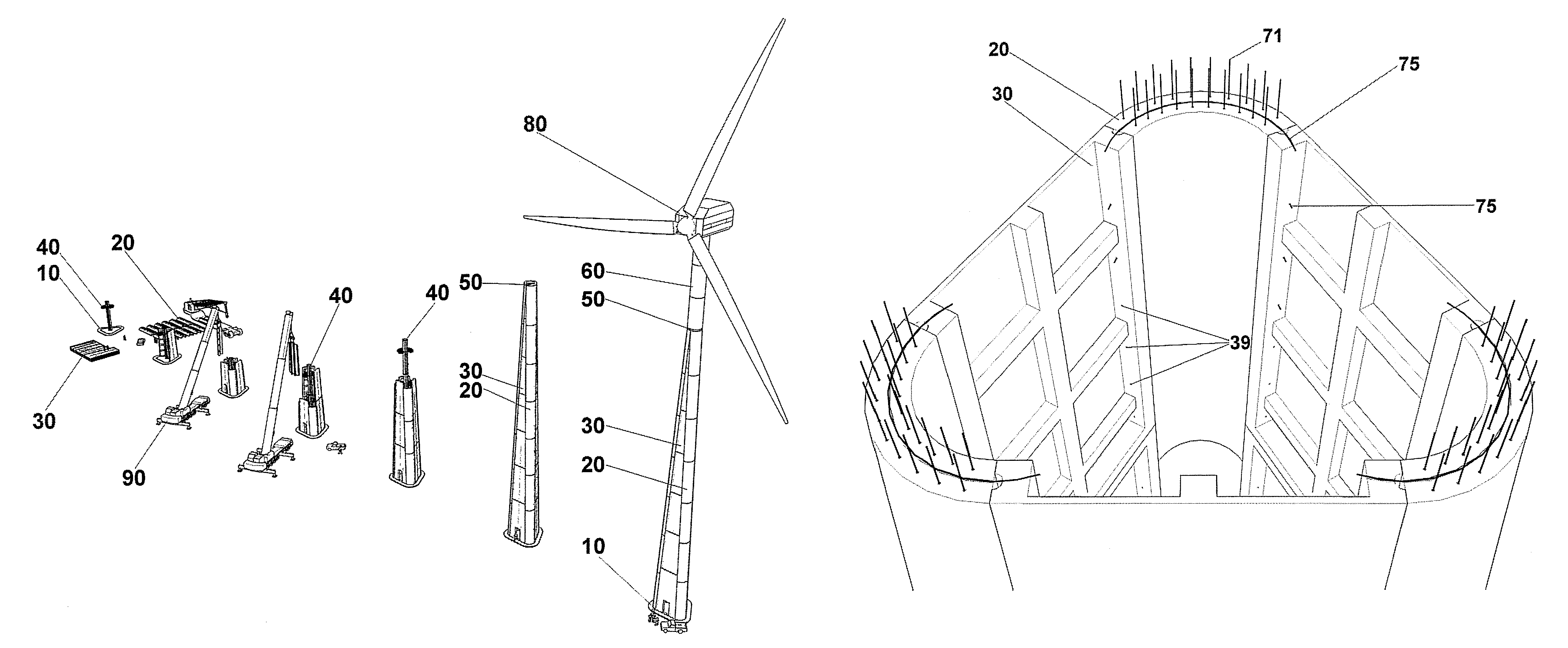

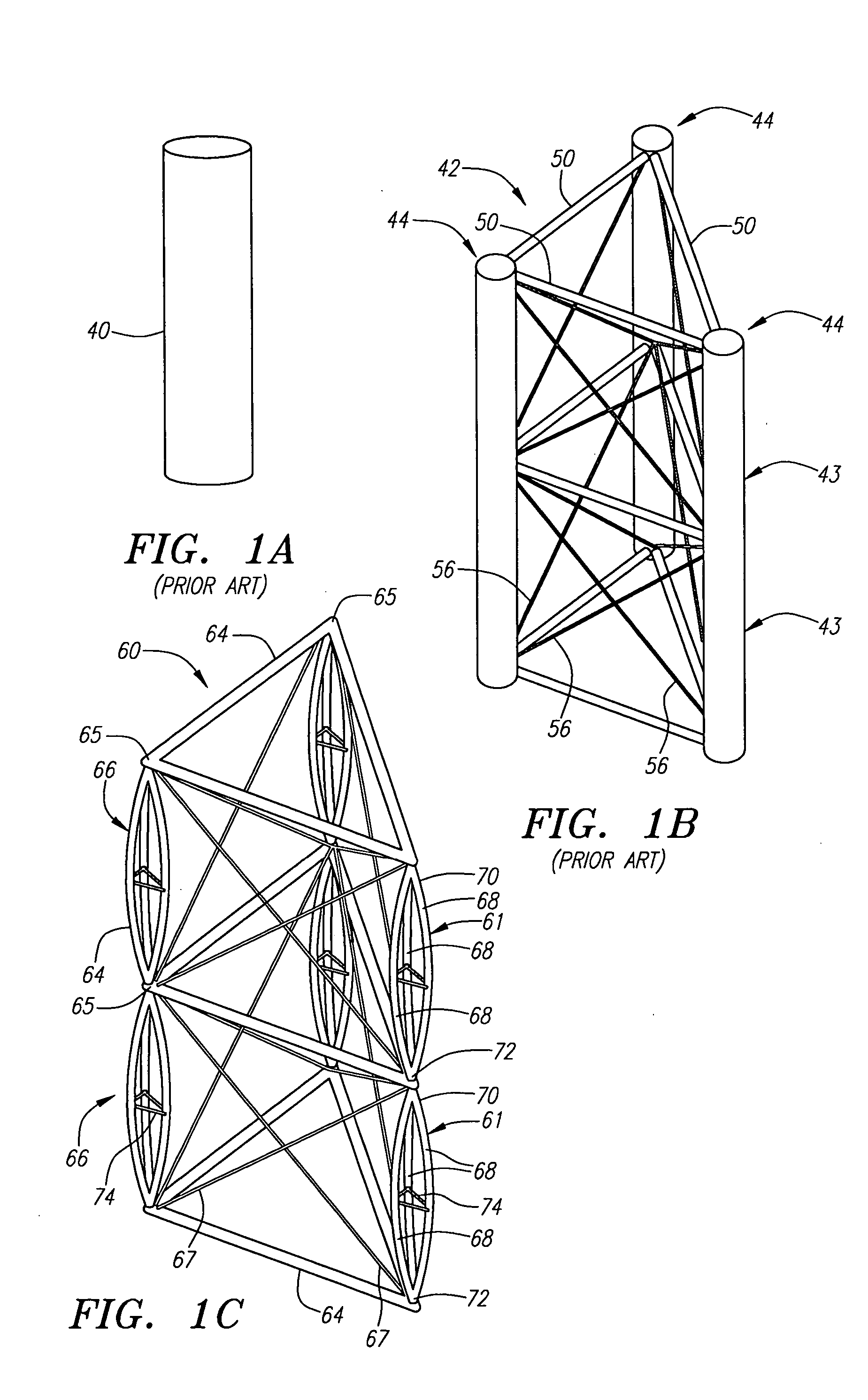

Pre-stressed concrete tower for wind power generators

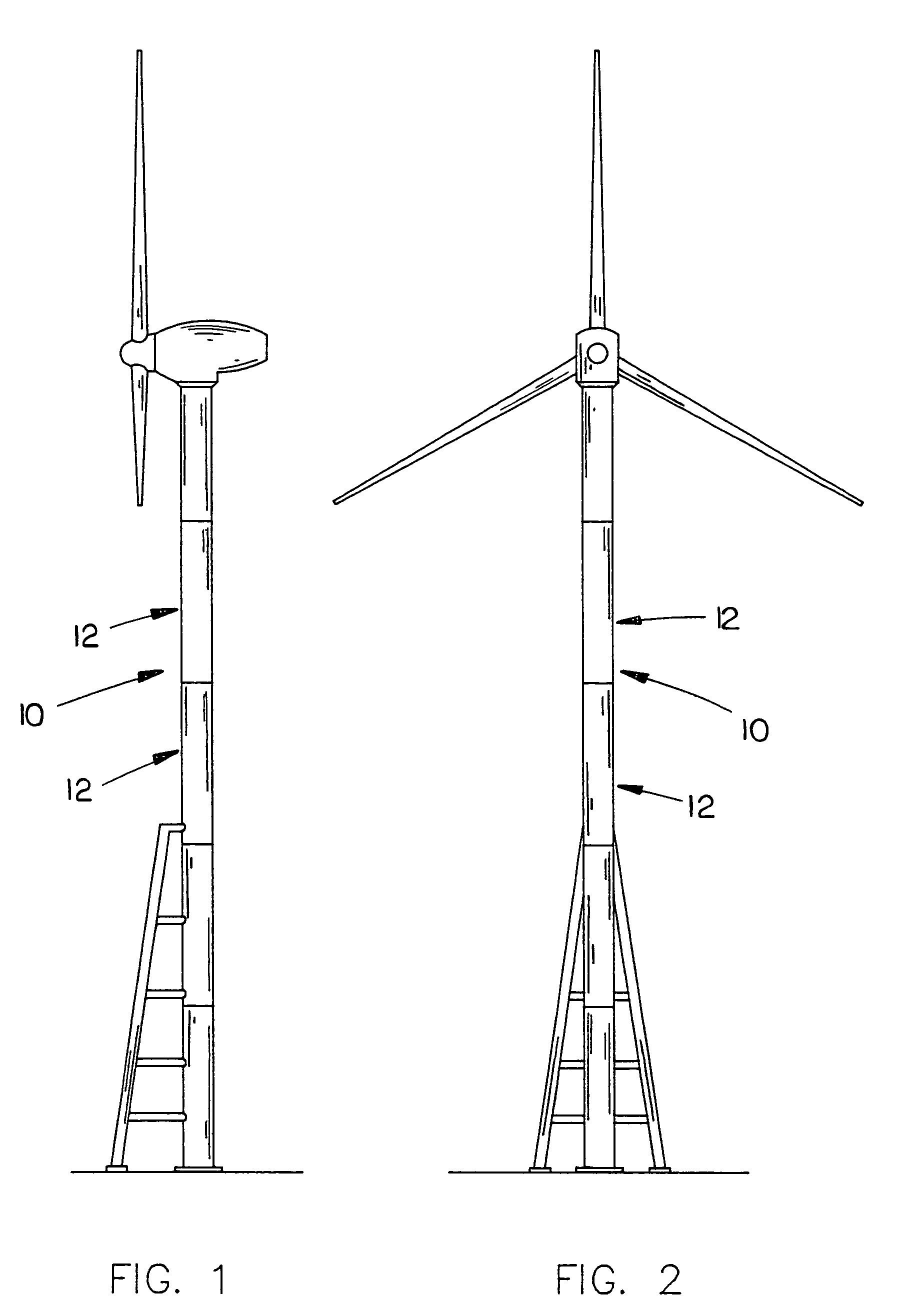

InactiveUS20090031639A1Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with circular segments, and three flat walls, formed with flat segments between the circular walls. One standard curved mold is used for the circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

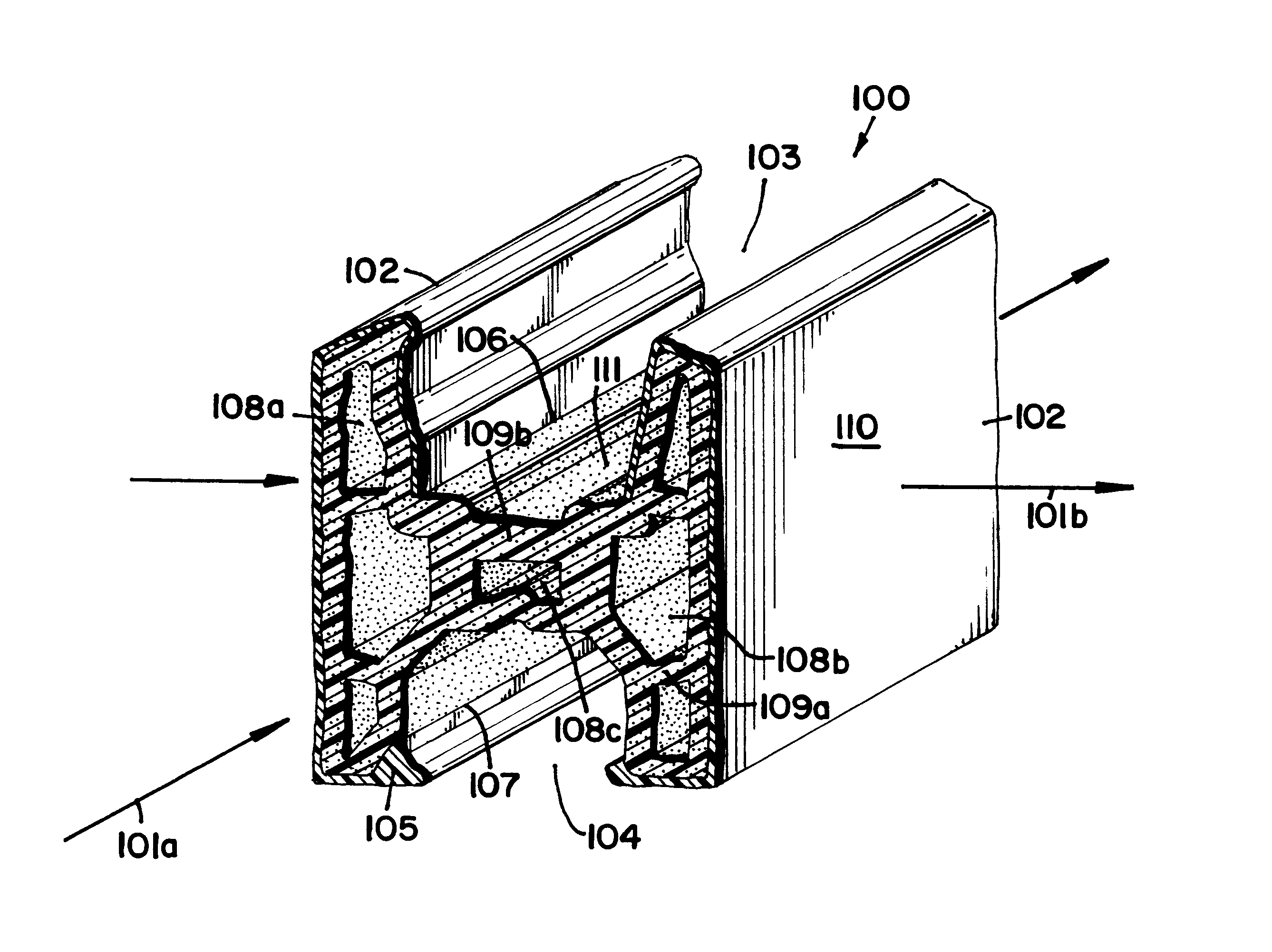

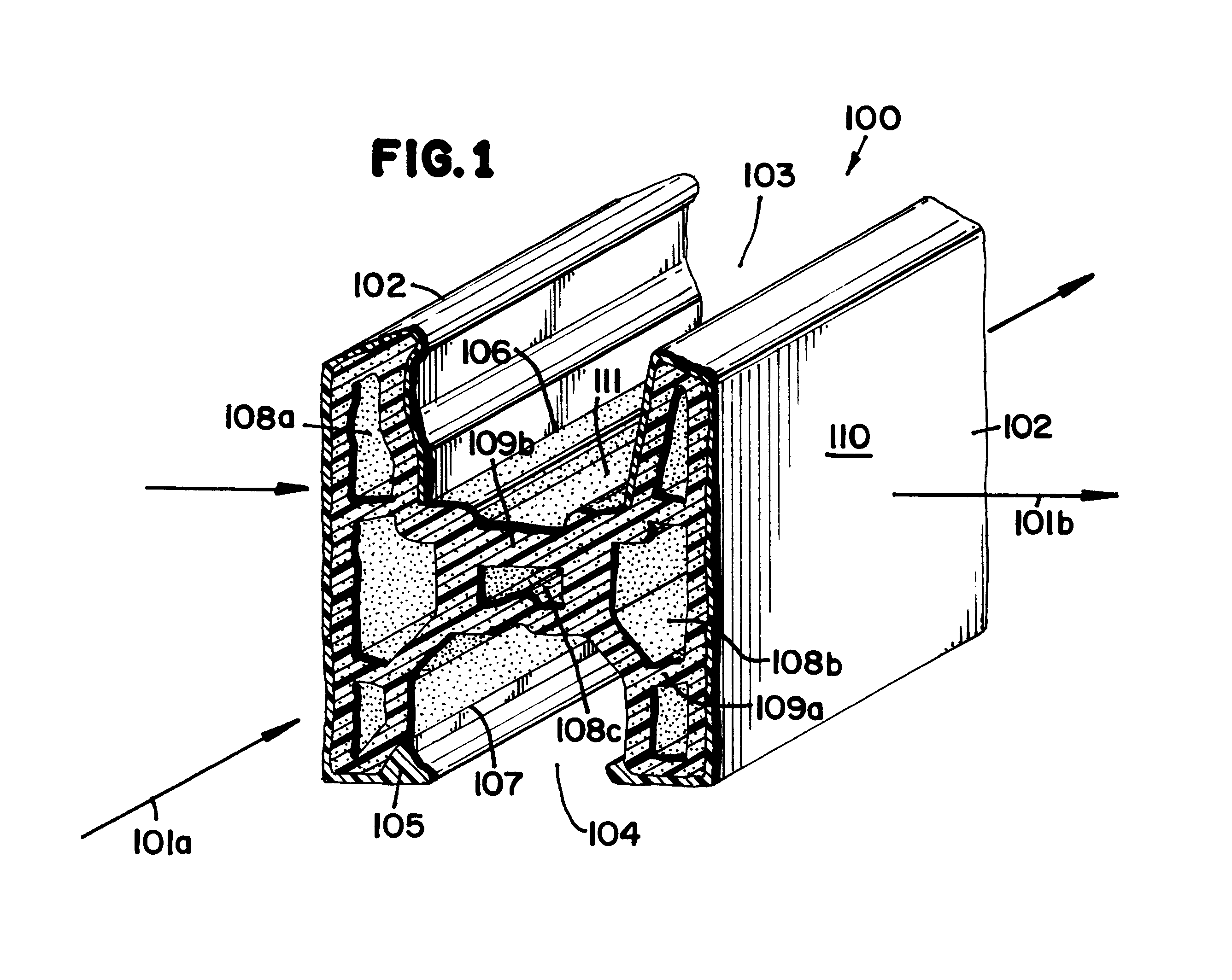

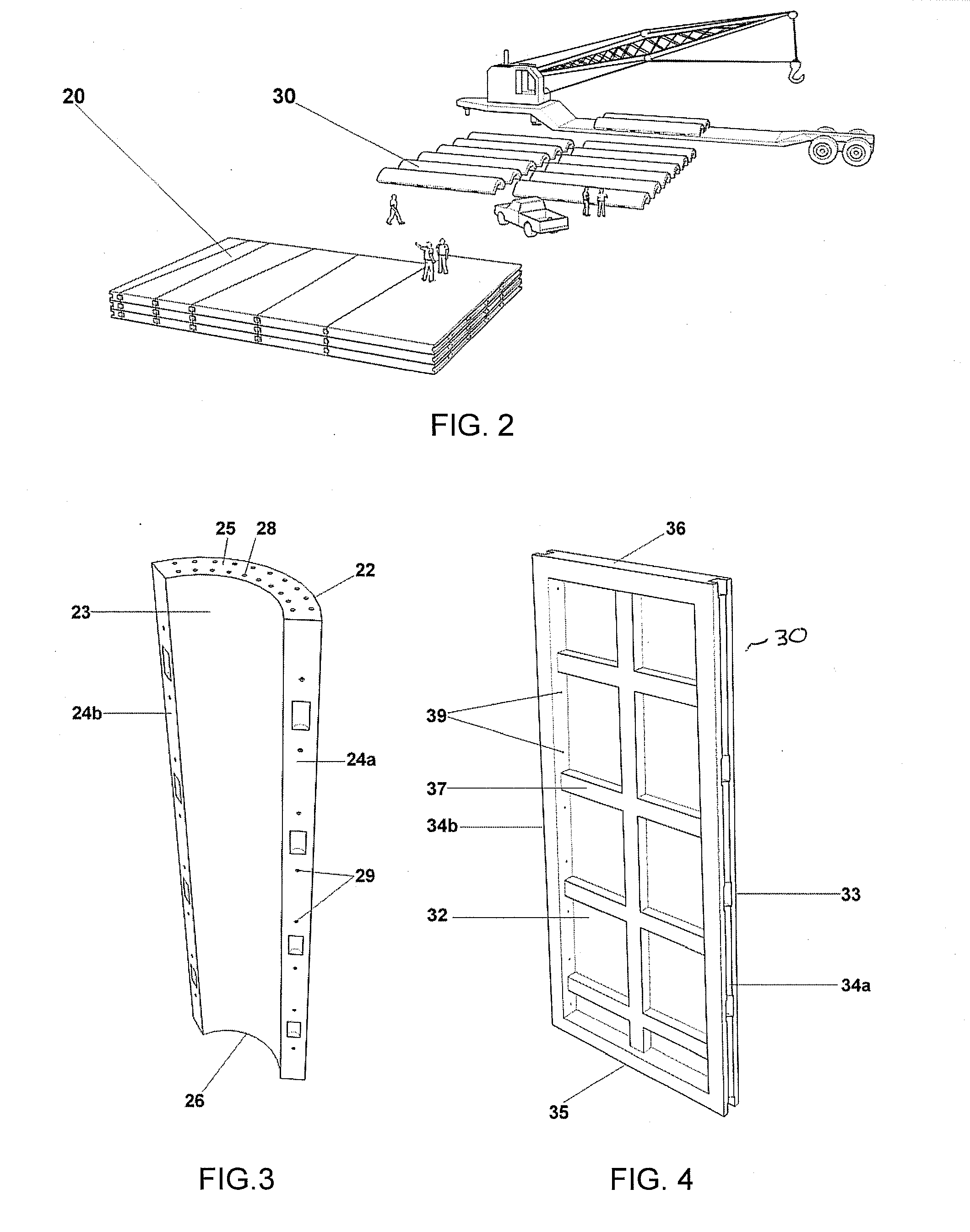

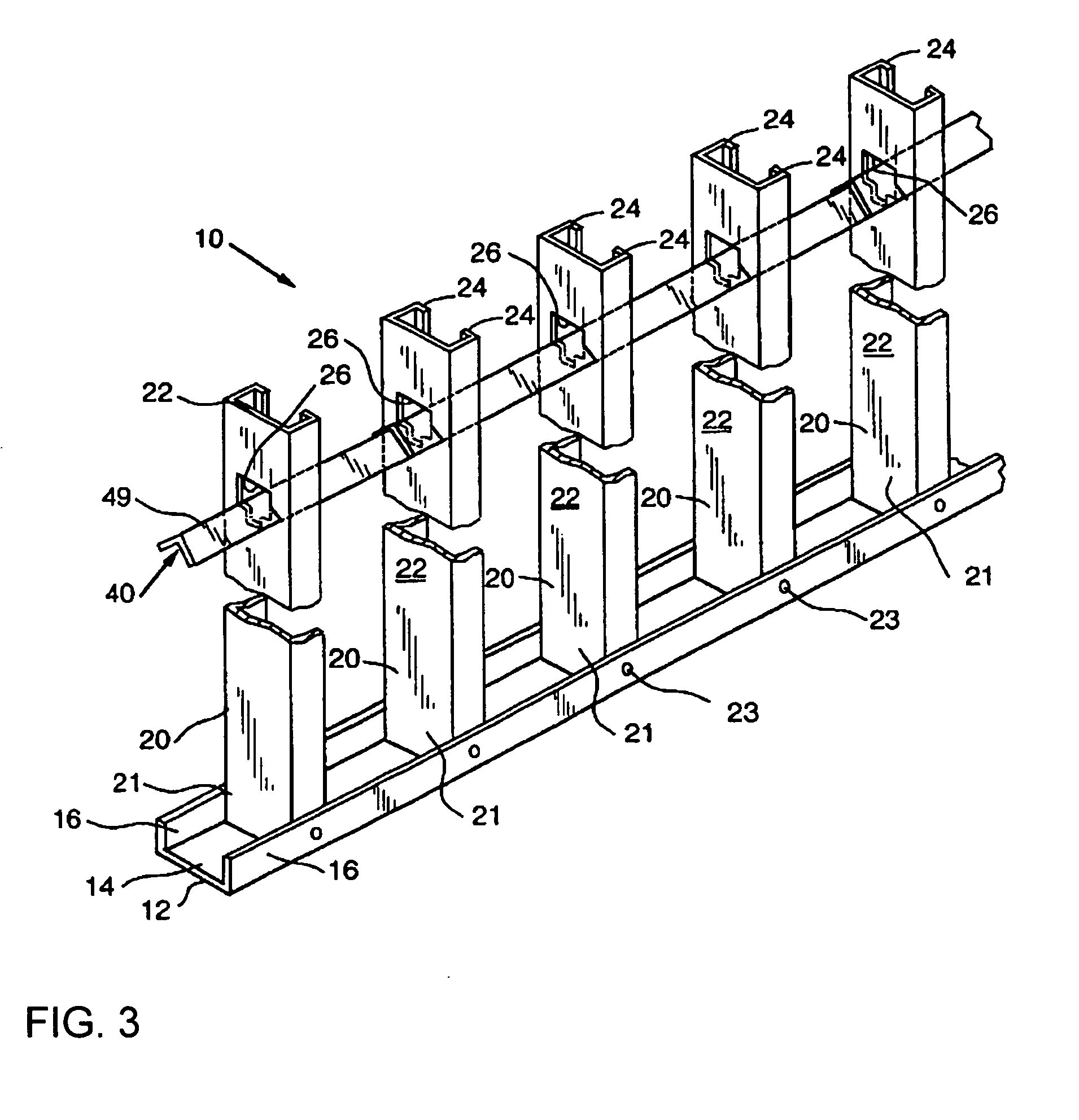

Lightweight precast concrete wall panel system

InactiveUS6837013B2Solve the lack of rigidityAvoid insufficient thicknessCeilingsConstruction materialPrecast concreteWall plate

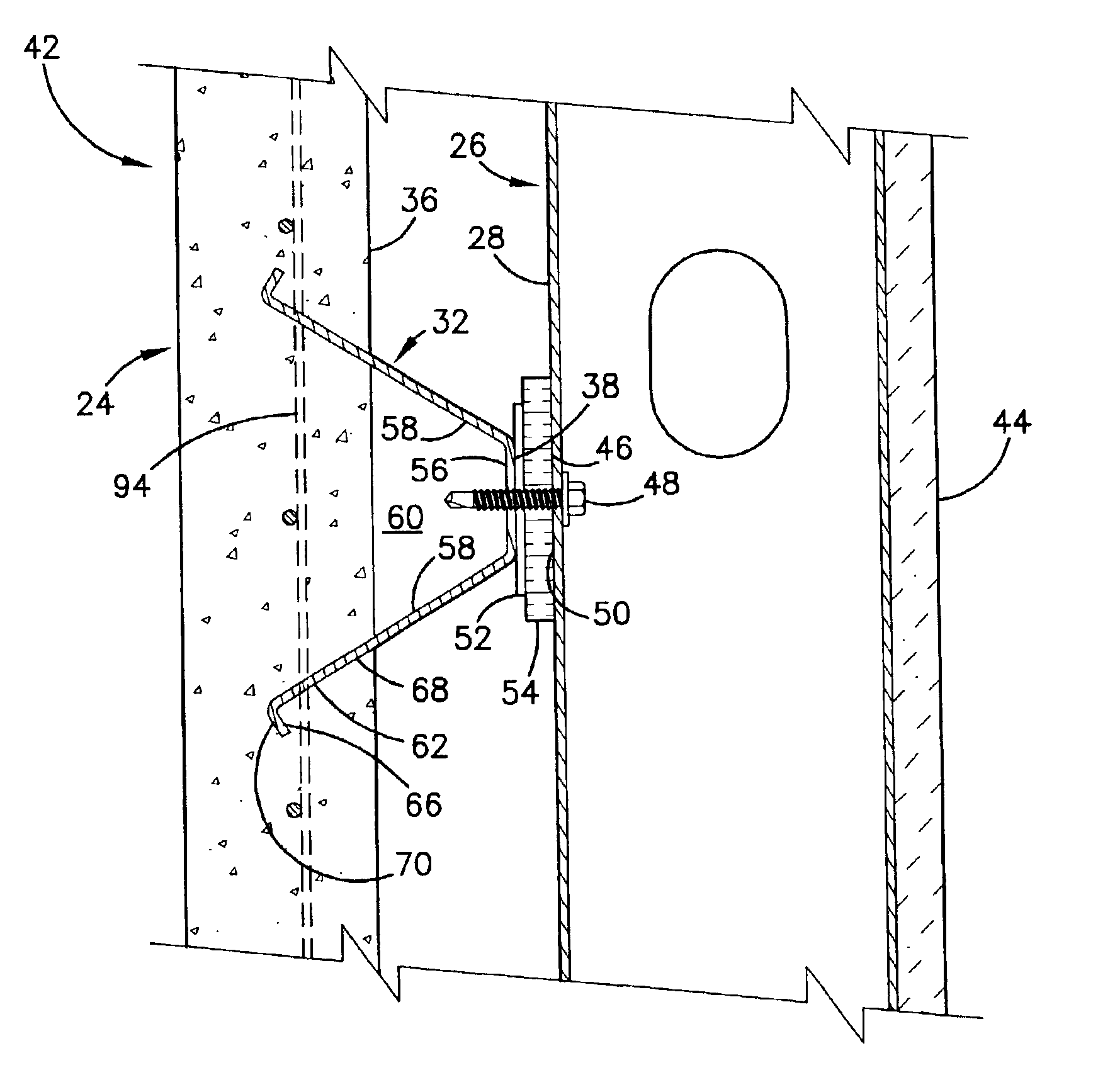

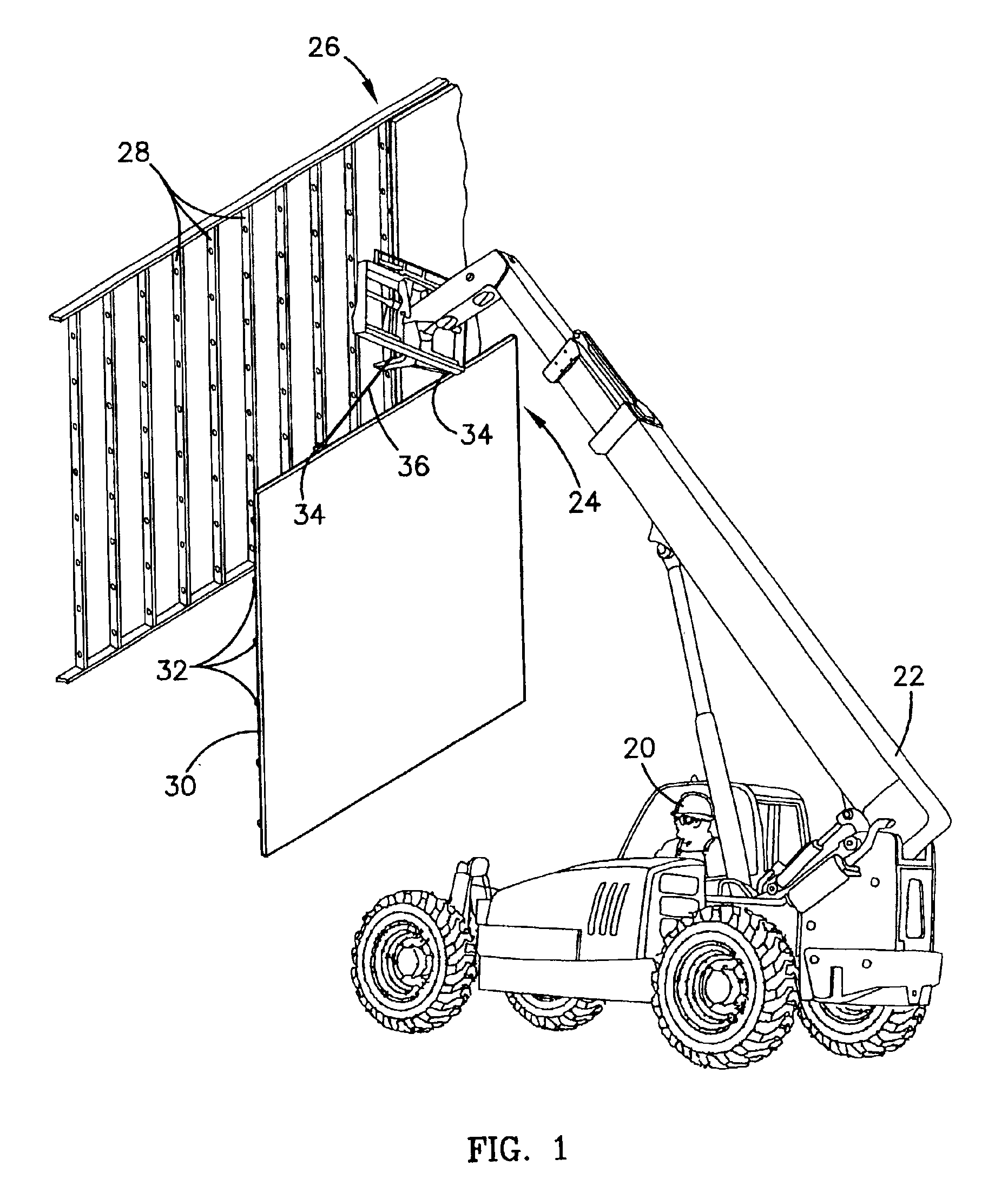

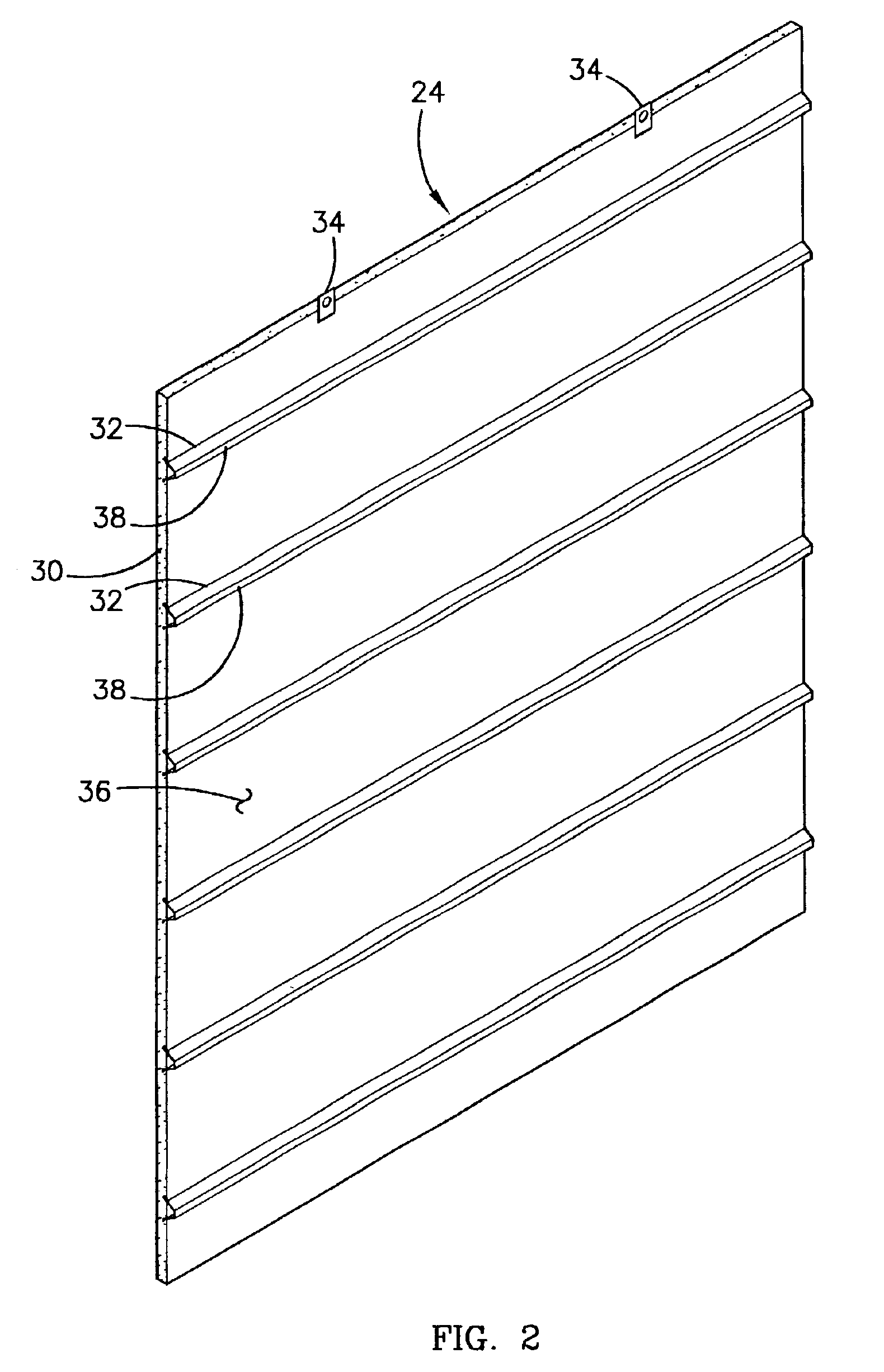

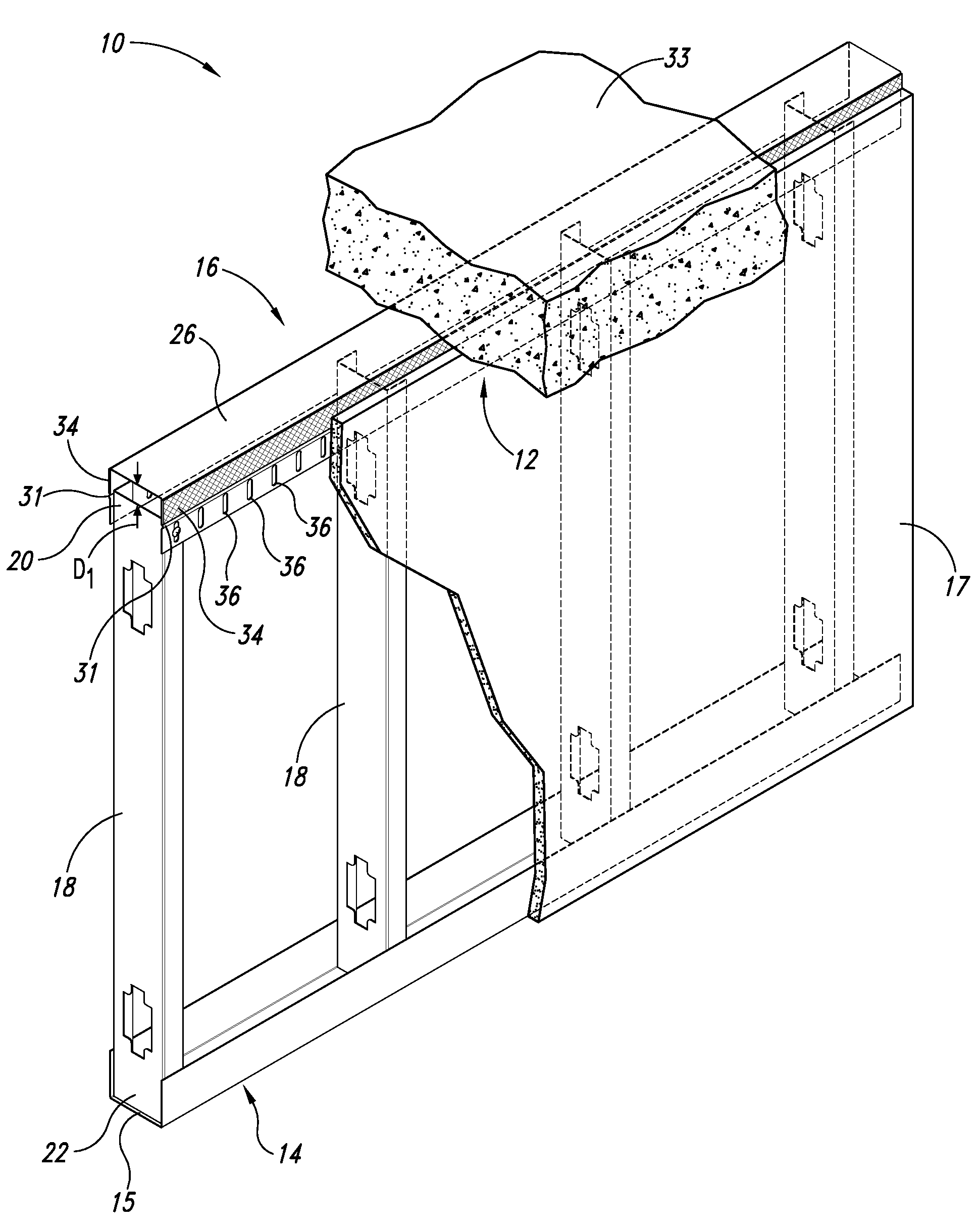

Wall system employing lightweight precast concrete wall panels. The precast wall panels include a concrete slab and a plurality of spaced-apart elongated generally parallel bent sheet metal channels that are partially embedded in the slab. Each wall panel can be coupled to a support wall by extending self-tapping screws through metallic wall framing members and the channels at locations where the framing members and channels cross.

Owner:FODERBERG JOEL +1

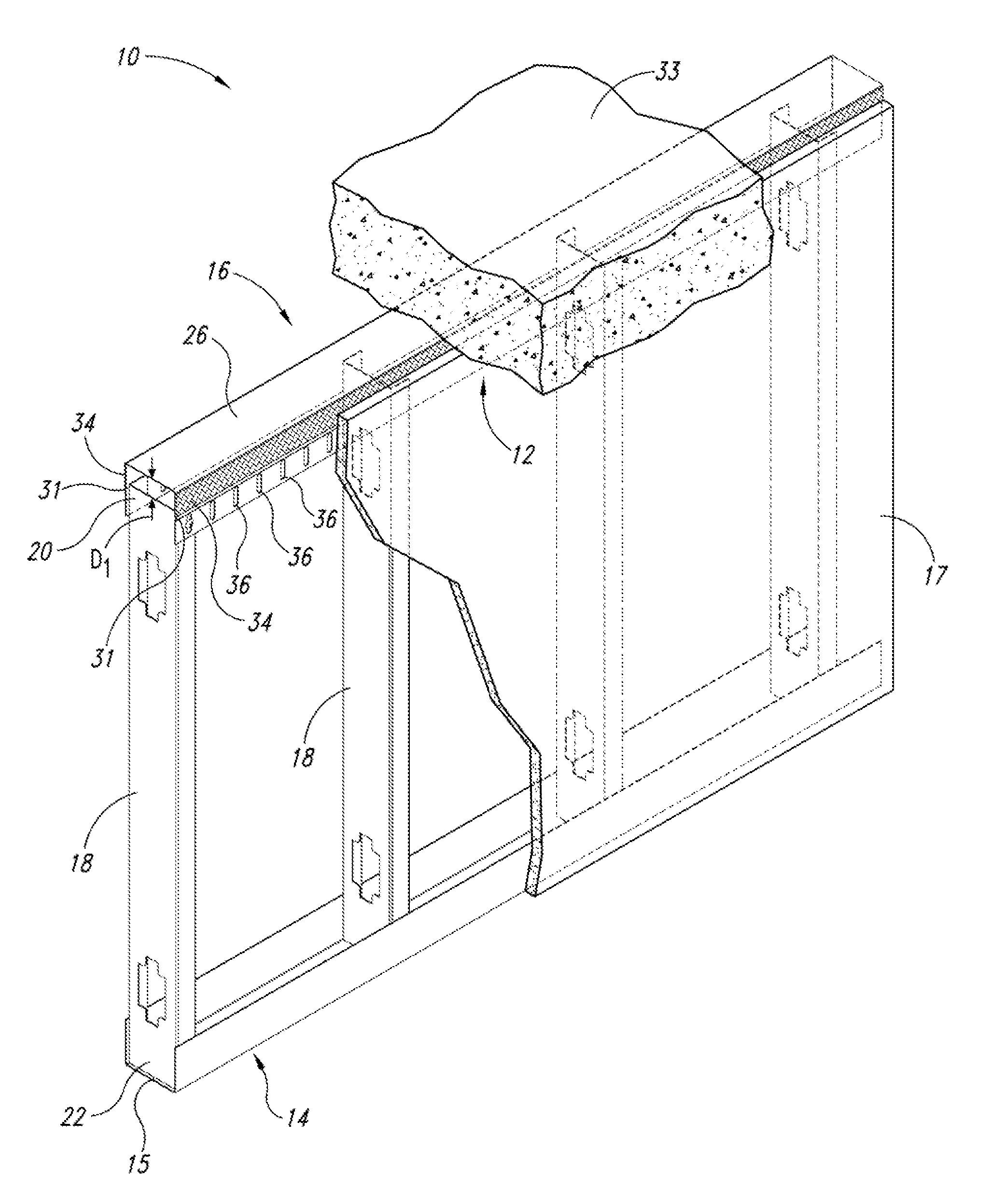

Head-of-wall fireblock systems and related wall assemblies

The invention disclosed herein is directed to a fire retardant head-of-wall assembly configured to seal a linear head-of-wall construction joint or gap when exposed to a heat source such as a building fire. The inventive fire retardant head-of-wall assembly comprises a header track having an elongated intumescent strip affixed lengthwise on at least one of the outer sidewall surfaces of the header track and above a centrally located and outwardly protruding lengthwise corrugated groove. When exposed to a heat source such as a building fire, the intumescent strip is able to expand so as to at least partially fill the head-of-wall construction joint or gap; and in so doing, retard or prevent the spread of smoke and fire. The inventive fire retardant head-of-wall assembly has been certified as complaint with respect to Underwriters Laboratories, Inc.'s standards set forth in its Tests for Fire Resistance of Building Joint Systems—UL 2079.

Owner:CEMCO LLC

Pre-stressed concrete tower for wind power generators

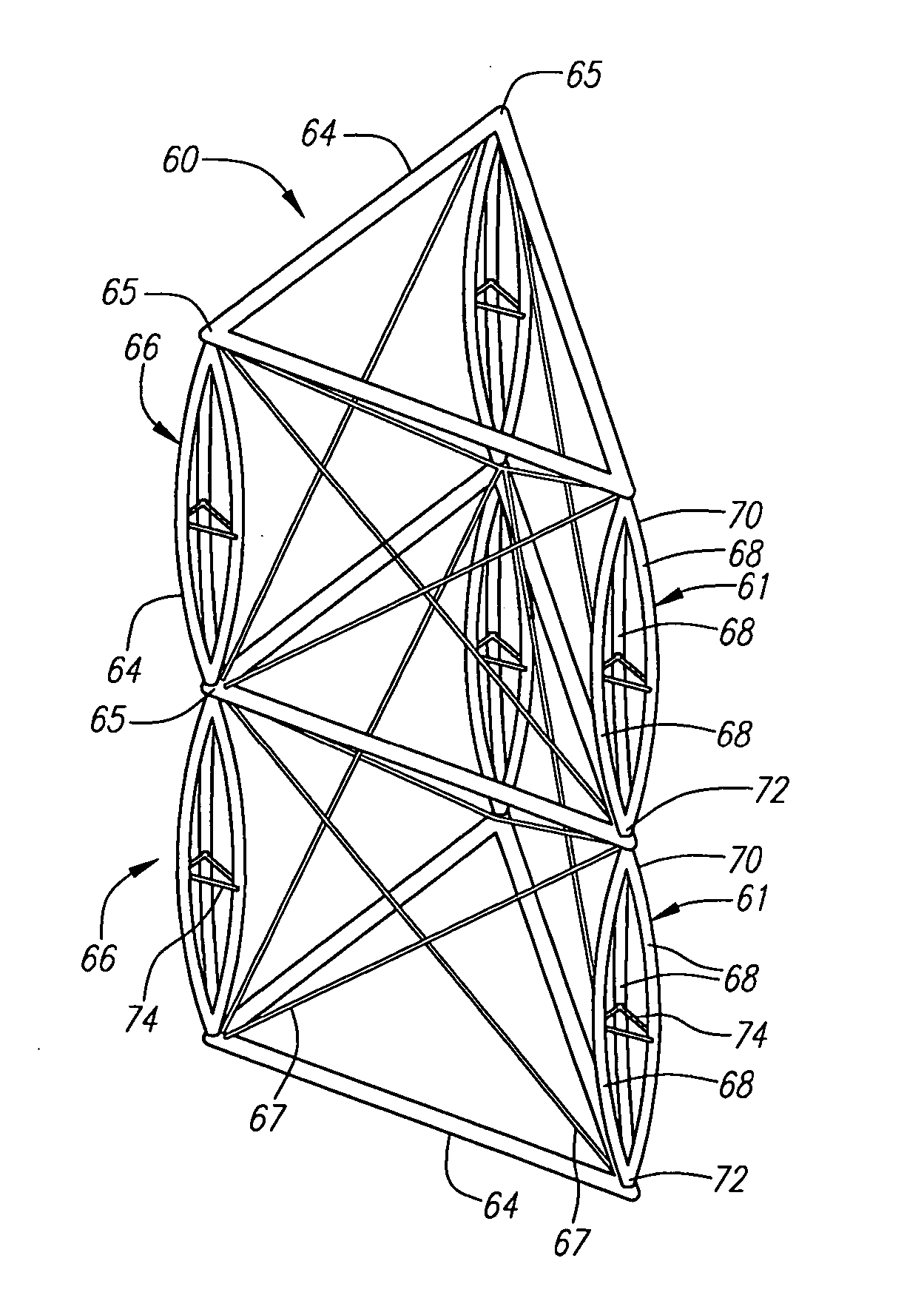

InactiveUS7739843B2Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with semi-circular segments, and three flat walls, formed with flat segments between the semi-circular walls. One standard curved mold is used for the semi-circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

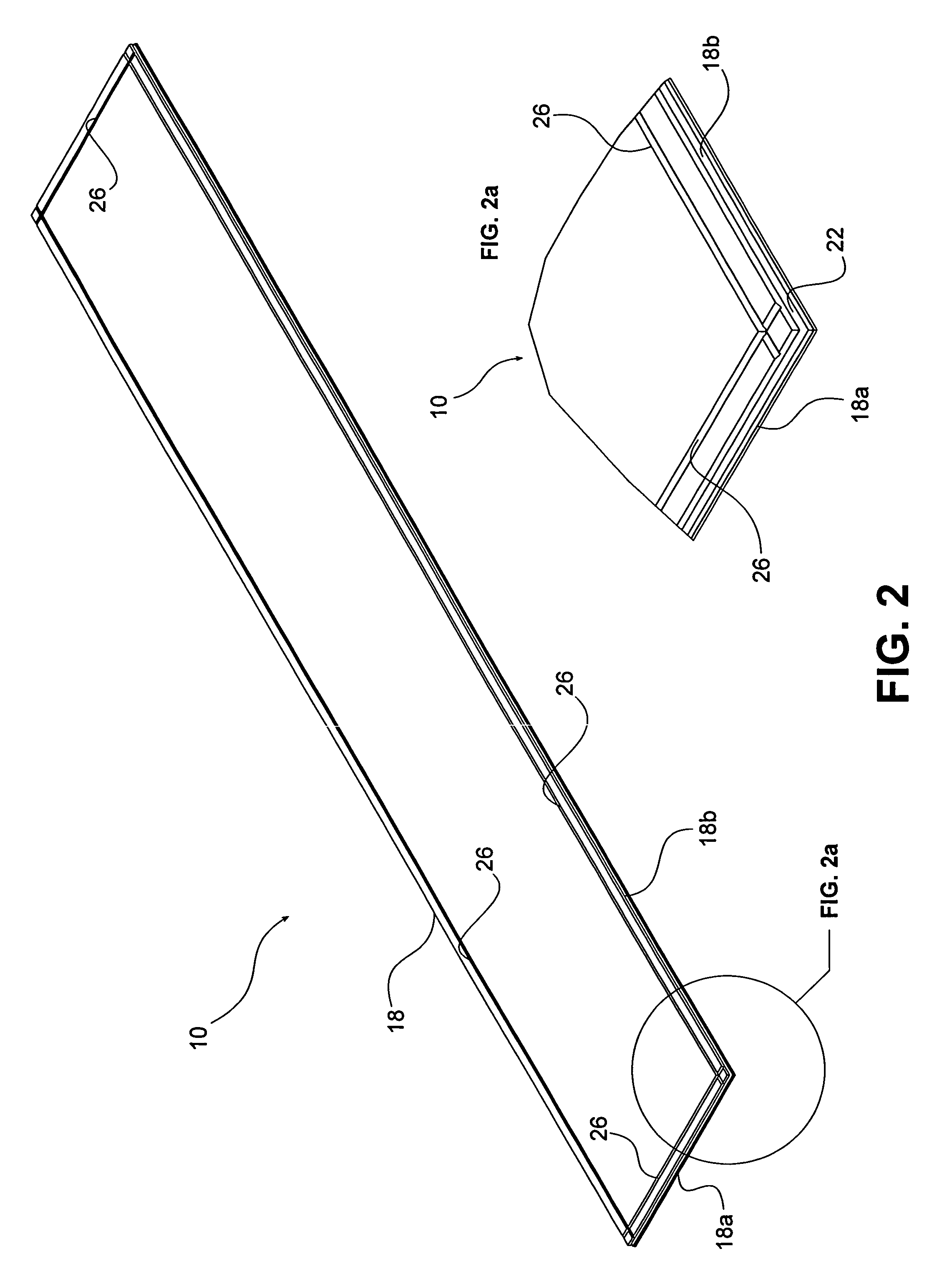

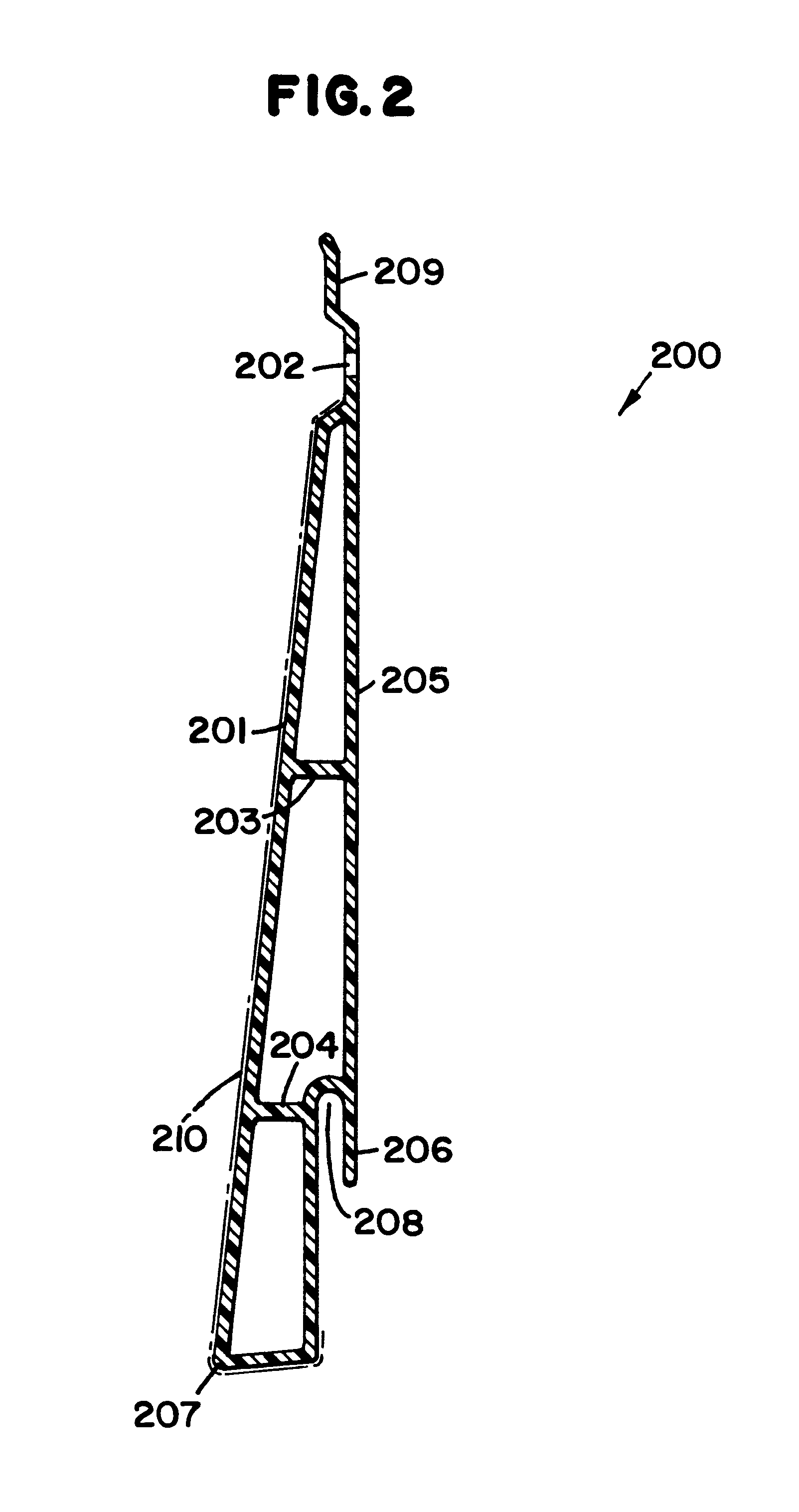

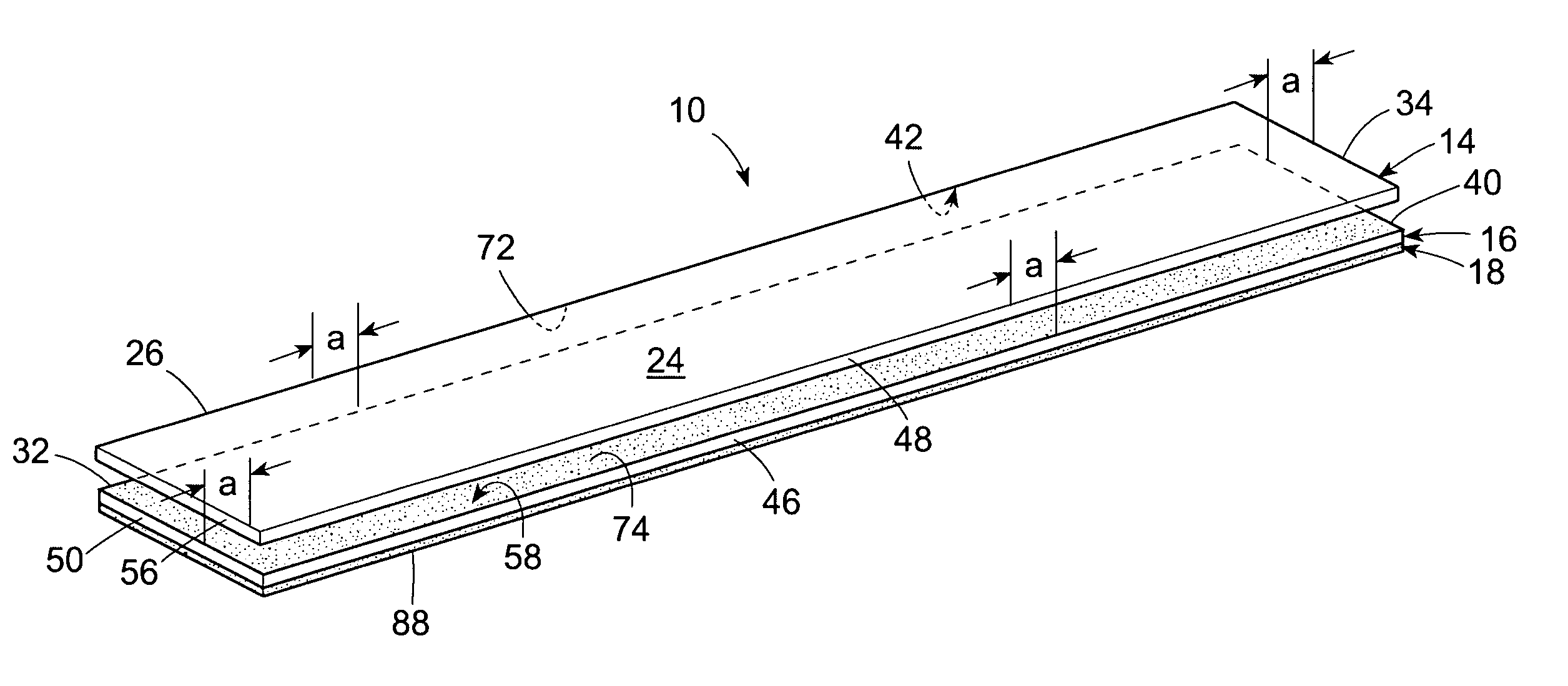

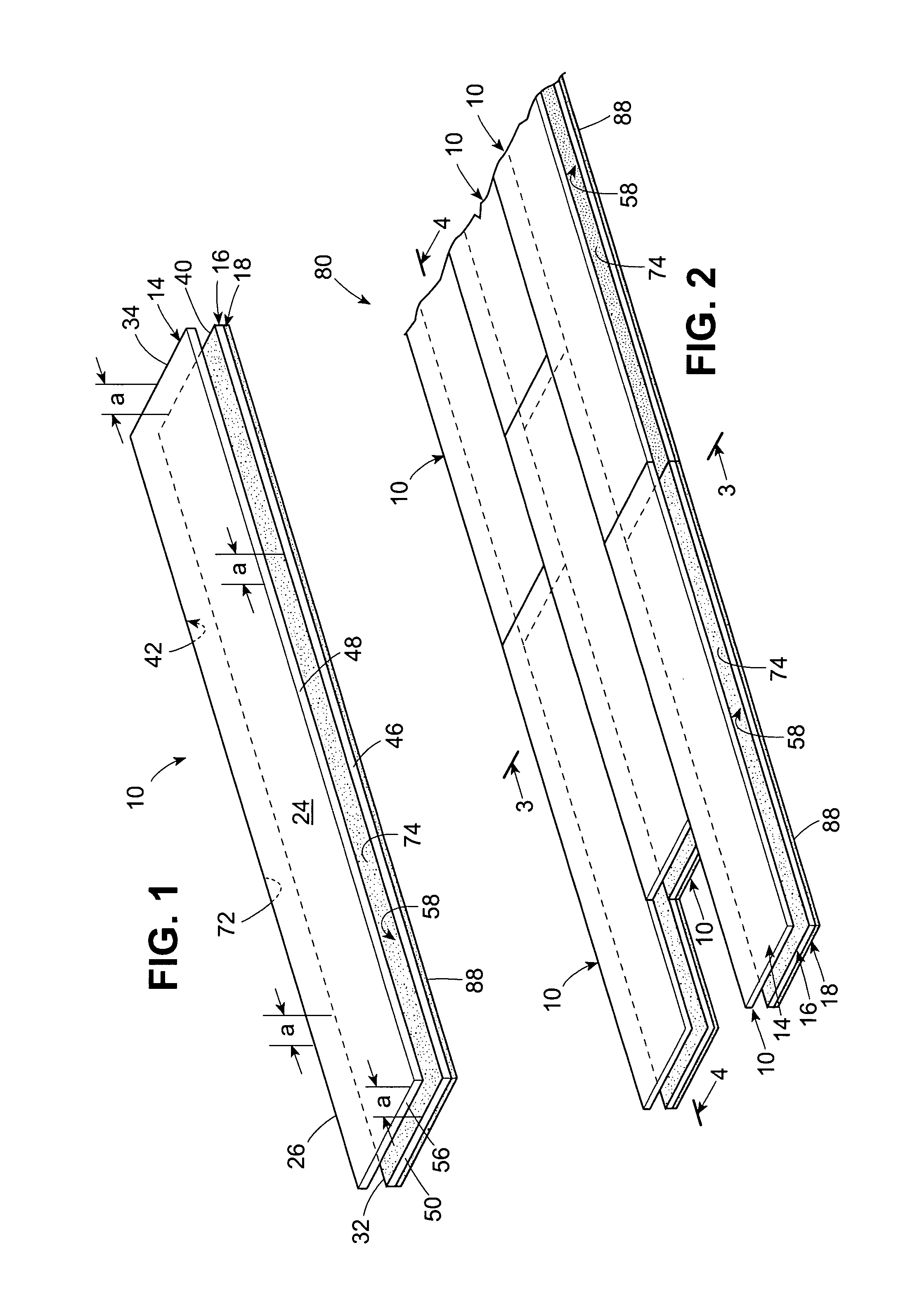

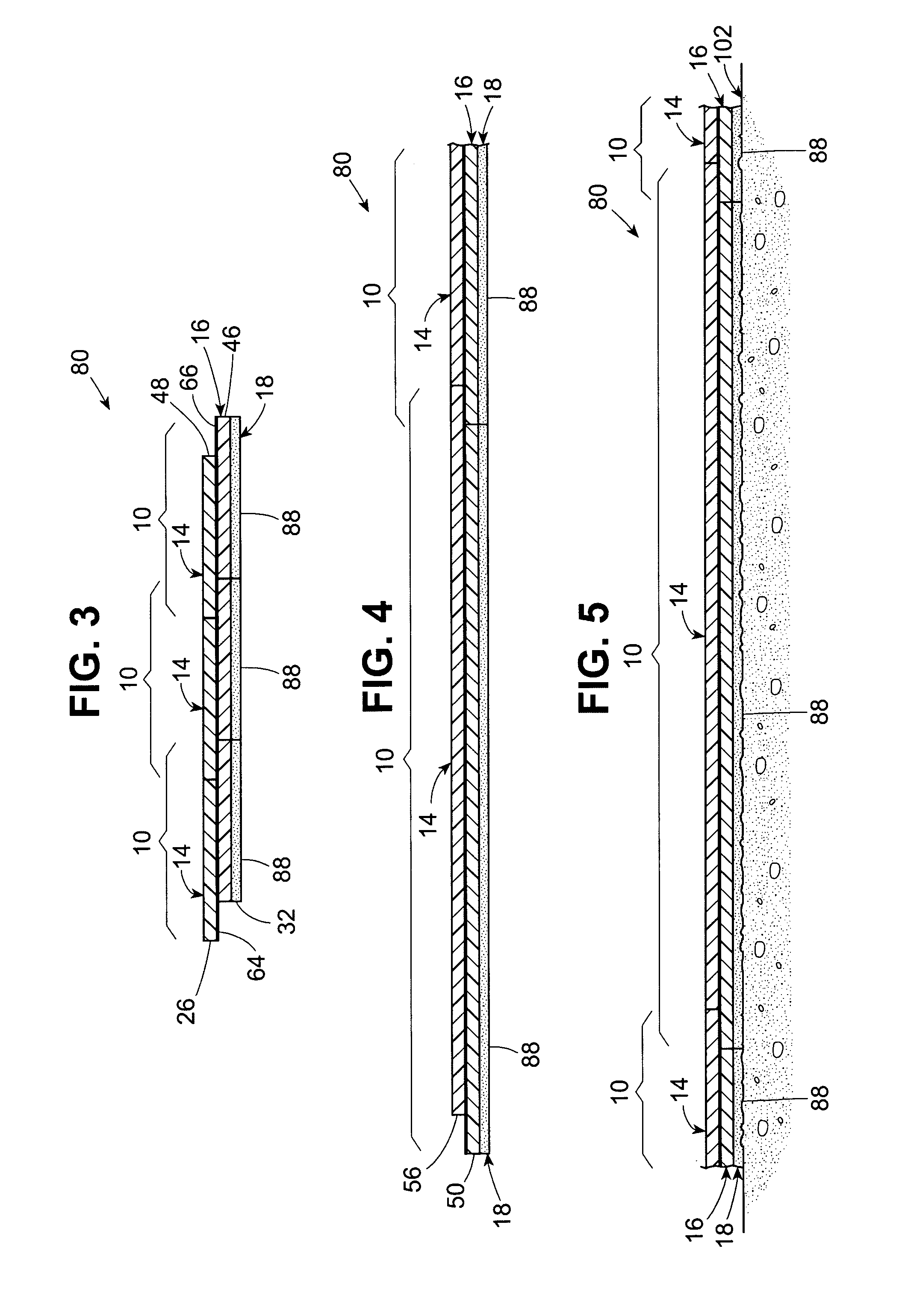

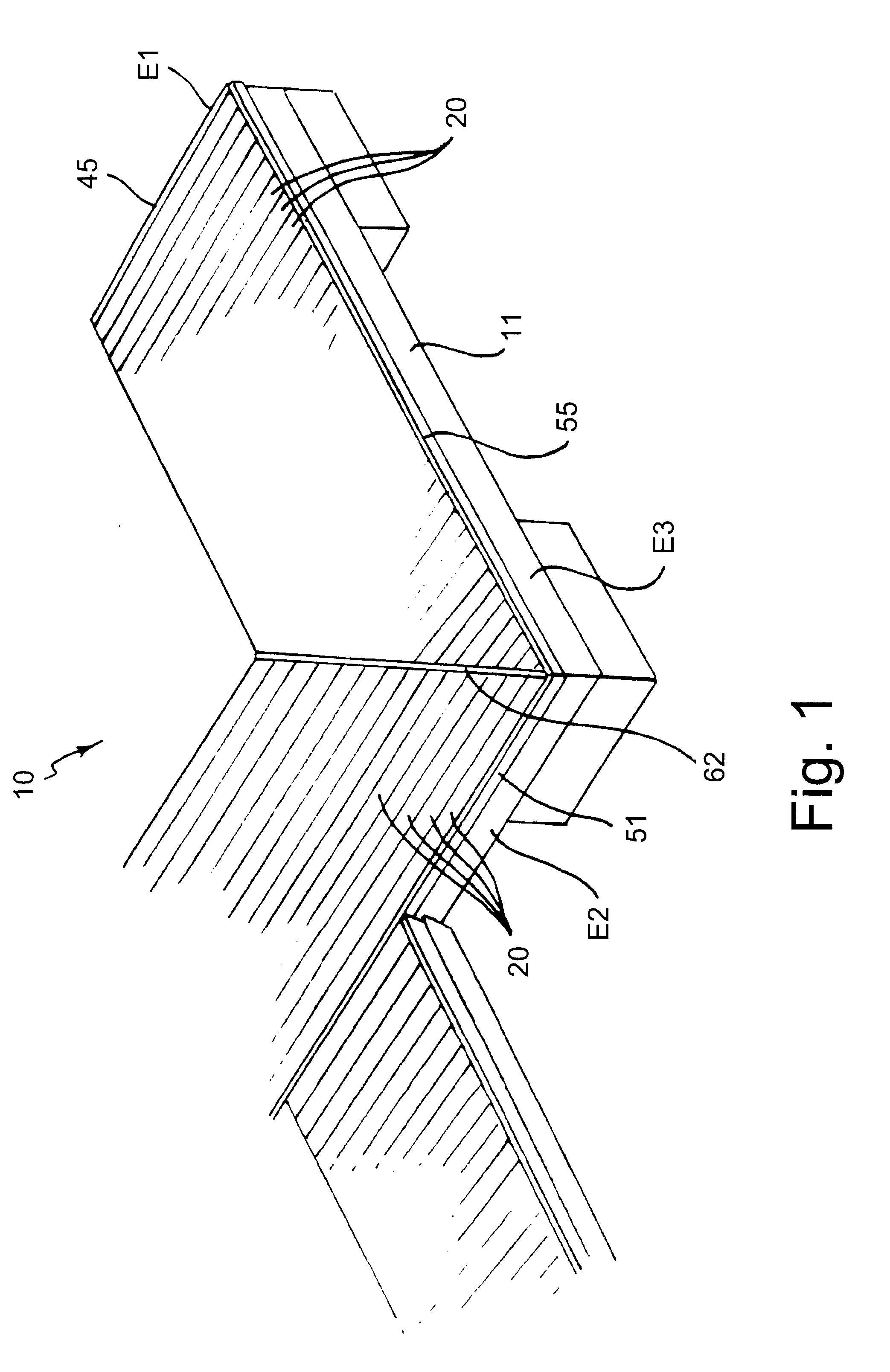

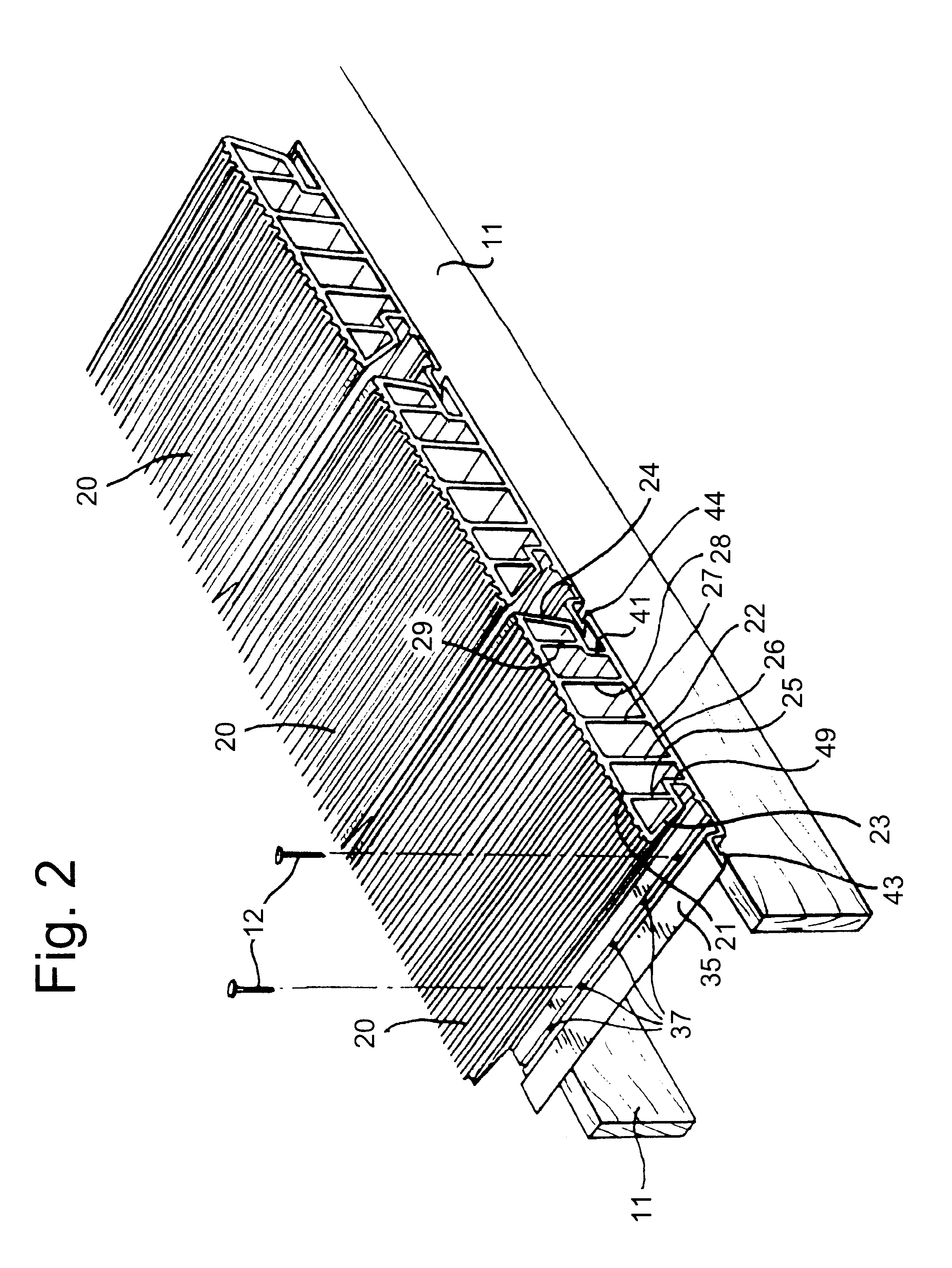

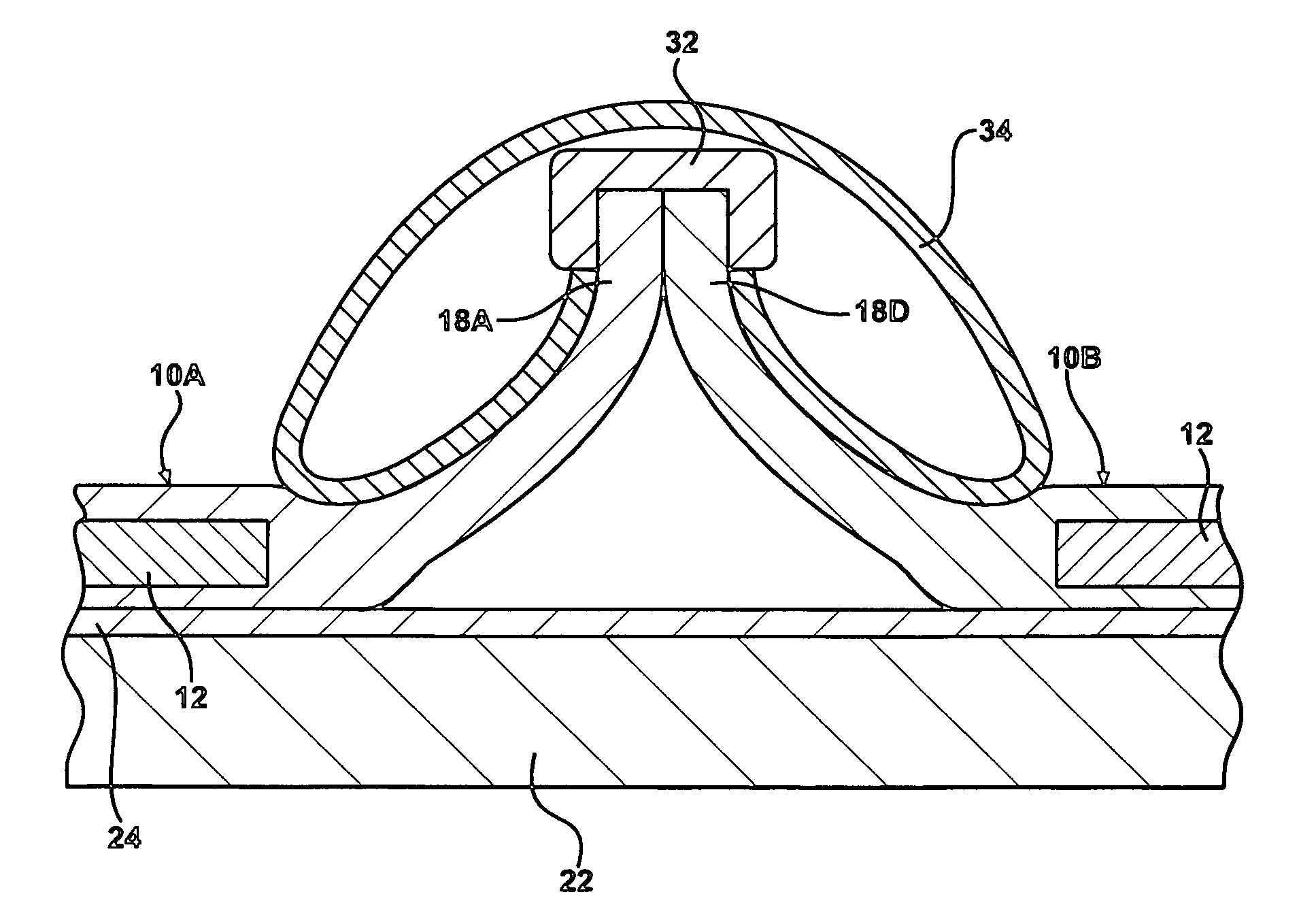

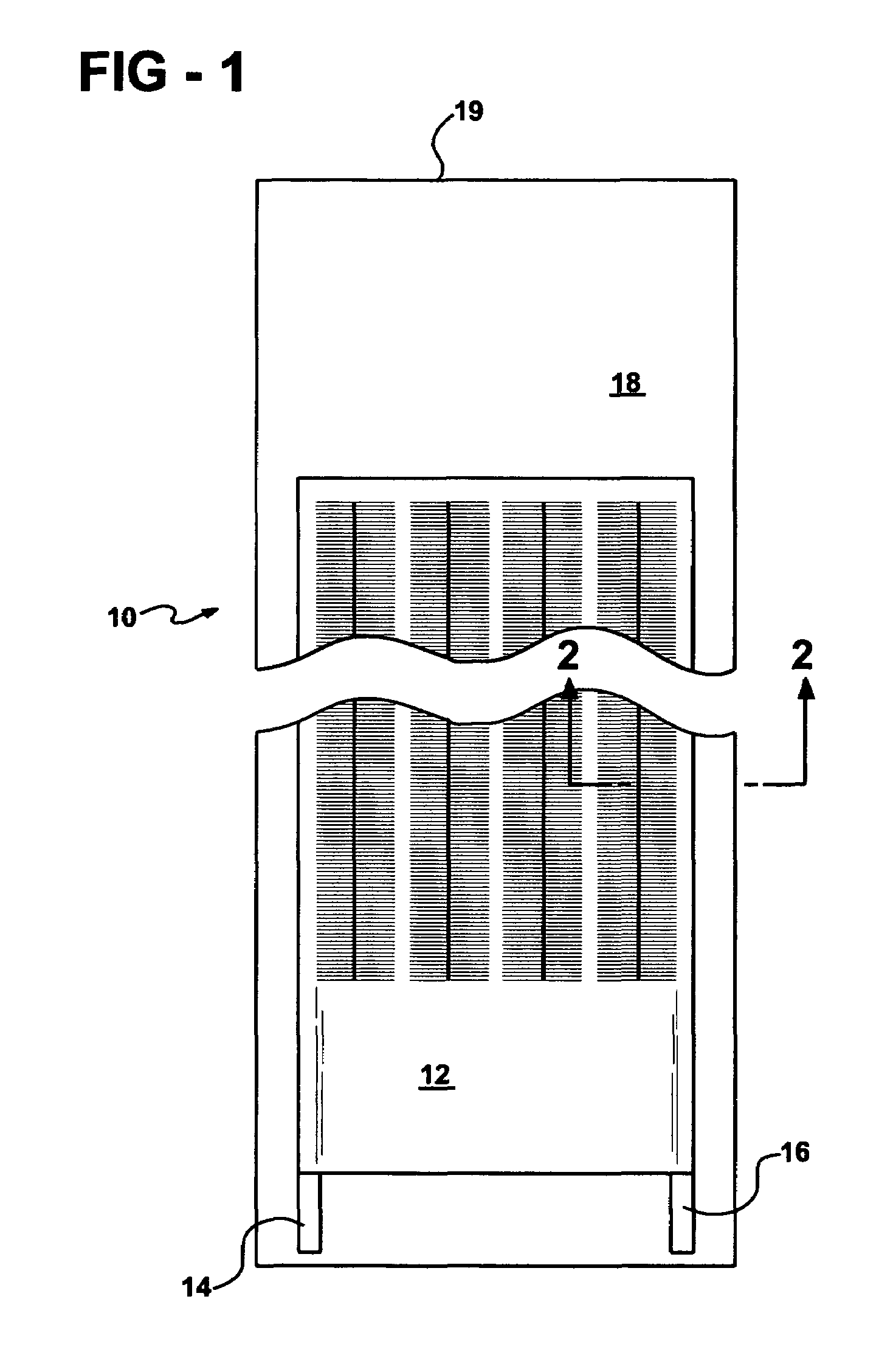

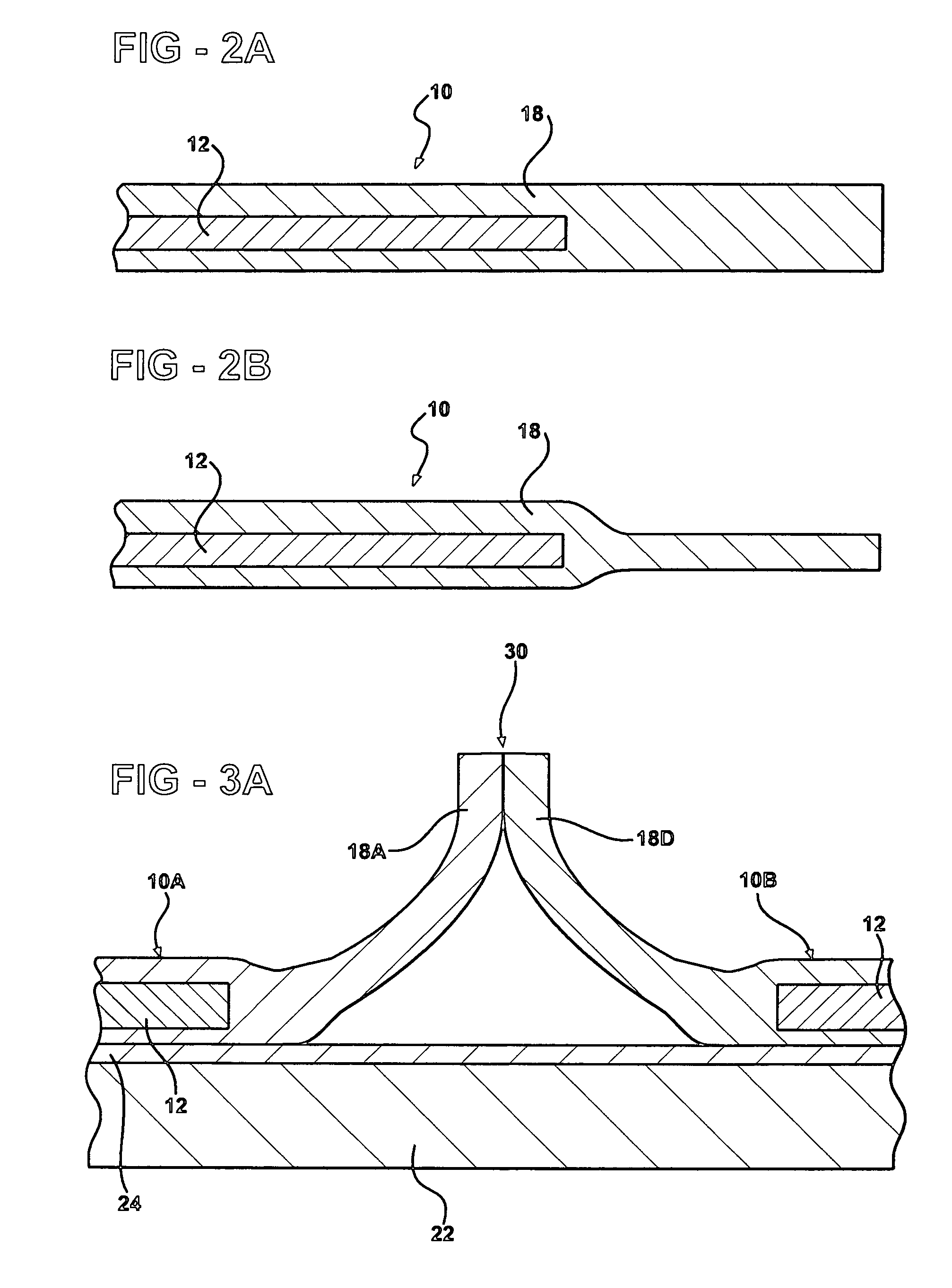

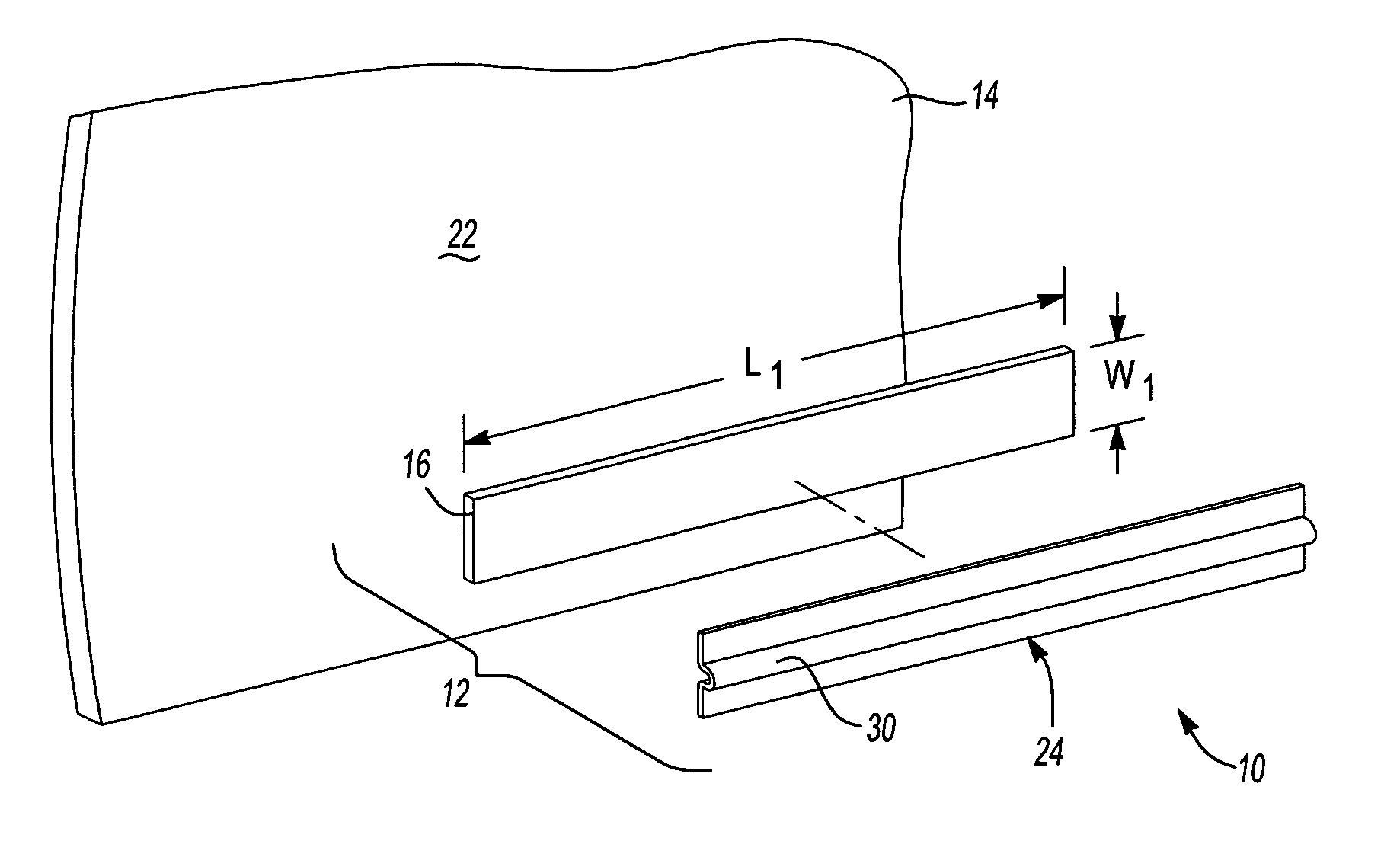

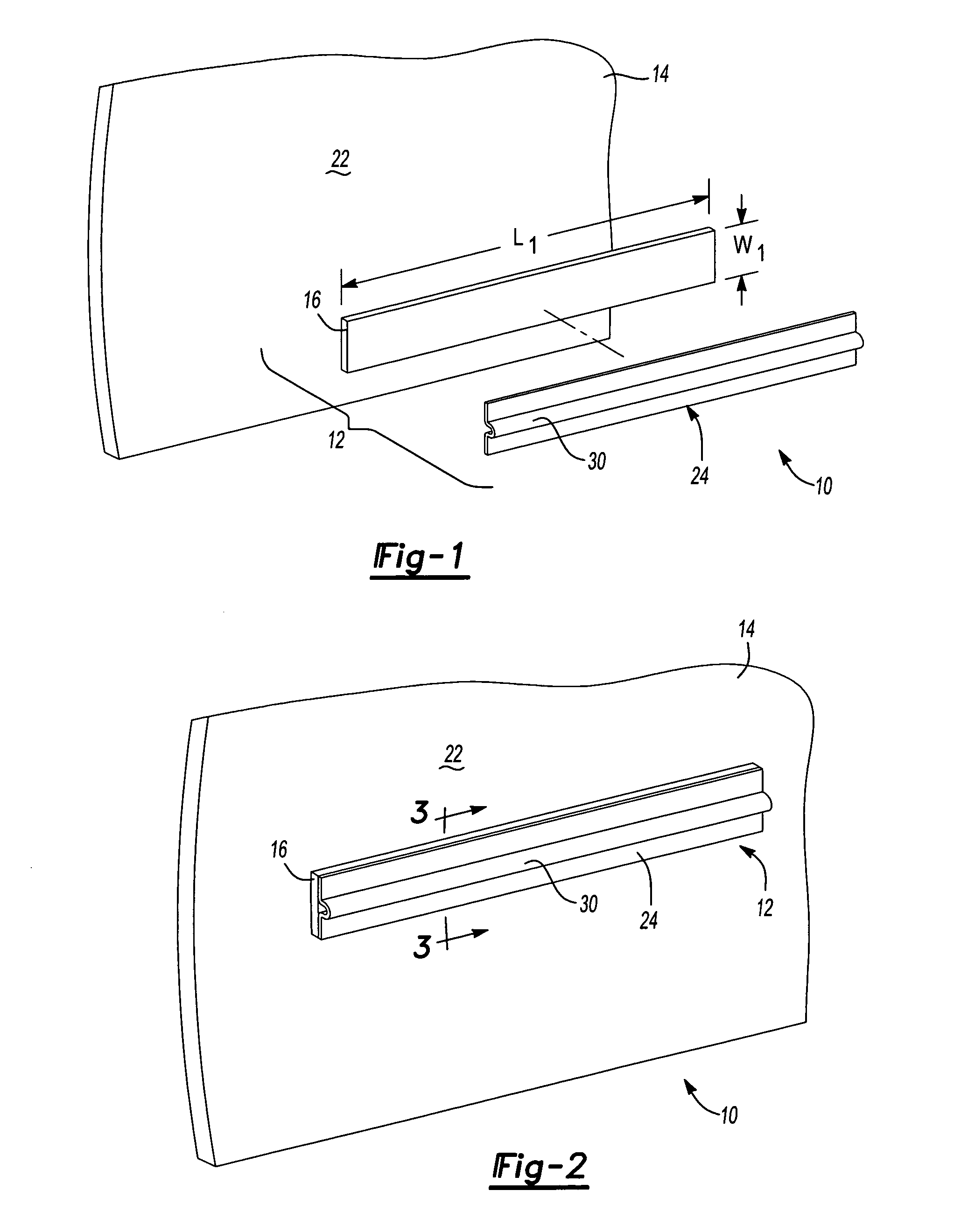

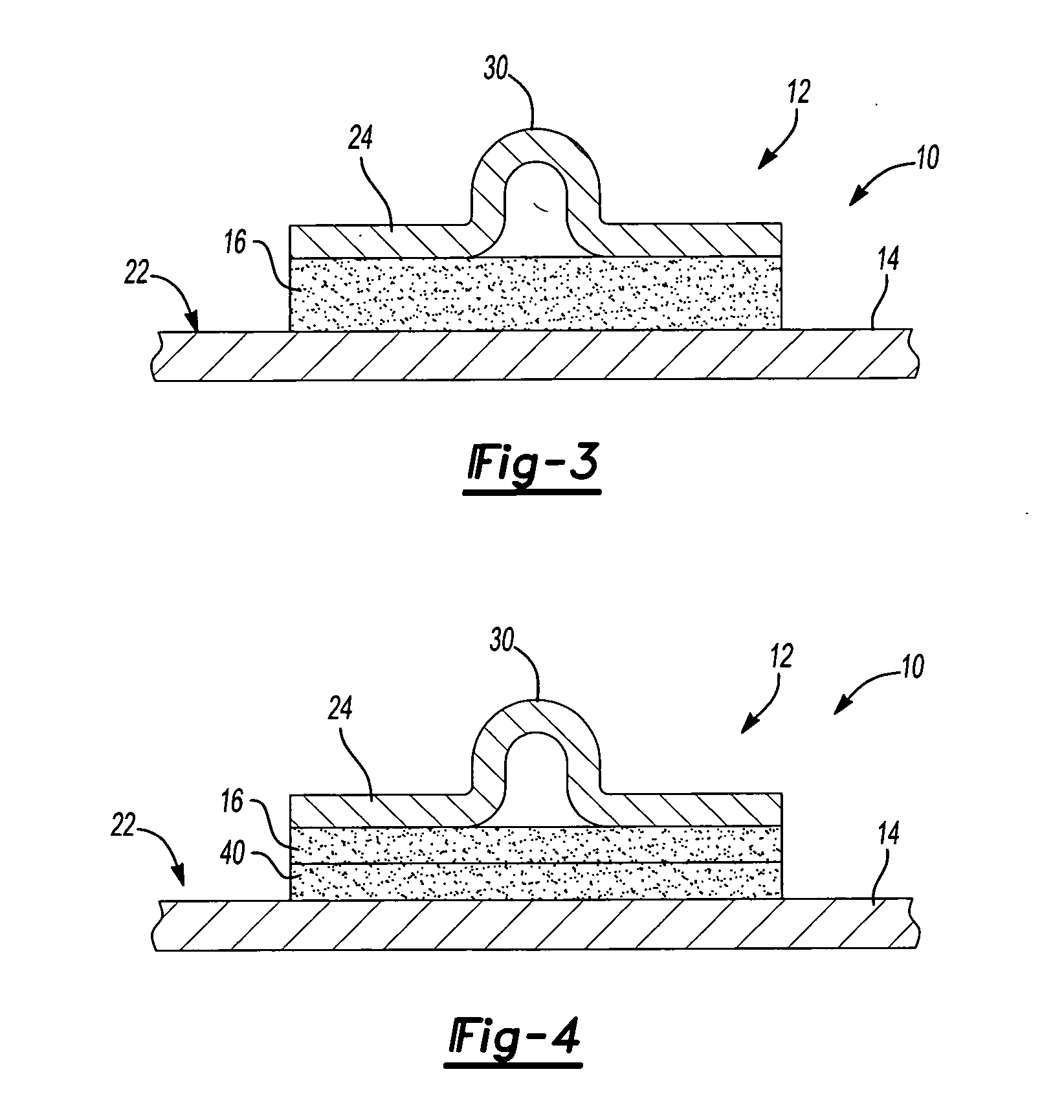

Method and system for mounting photovoltaic material

InactiveUS7365266B2Limit and eliminates useStable positionPhotovoltaic supportsCovering/liningsAdhesiveEngineering

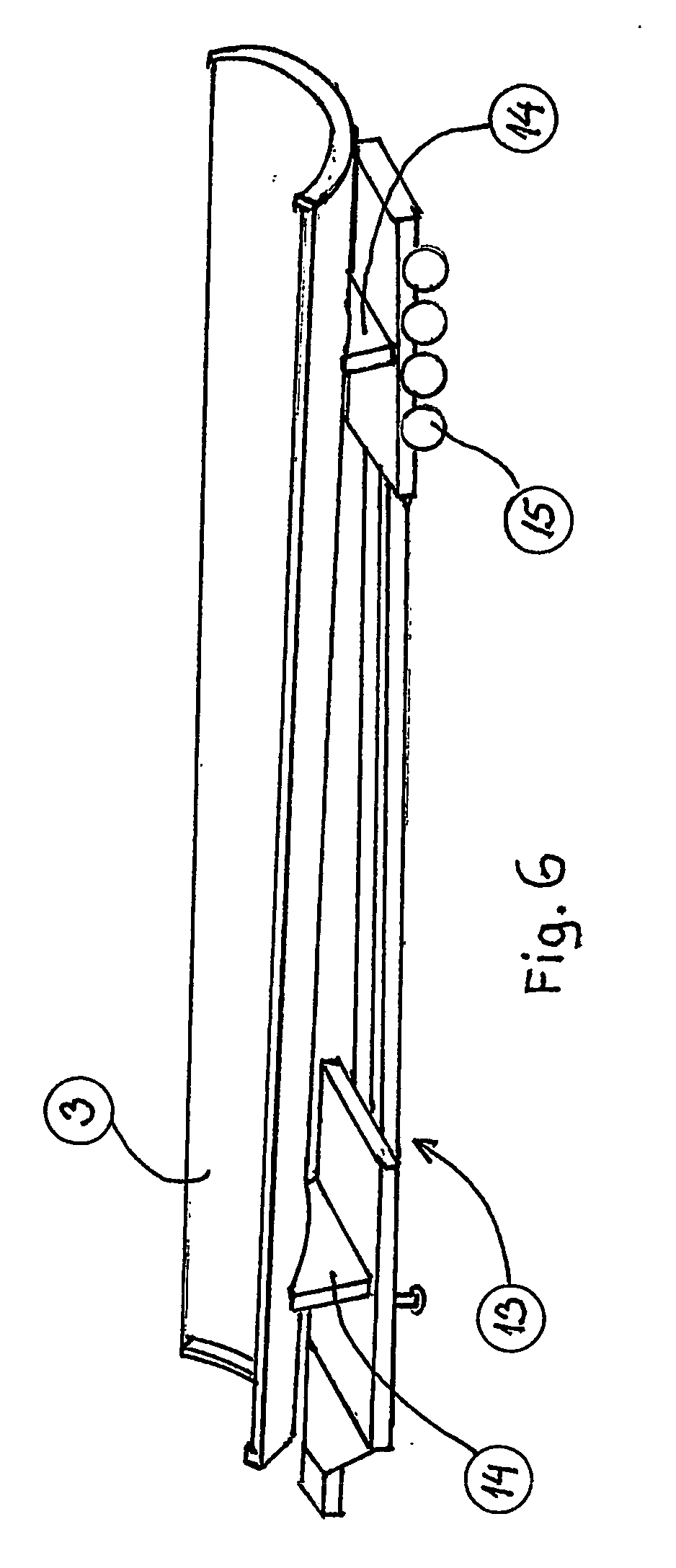

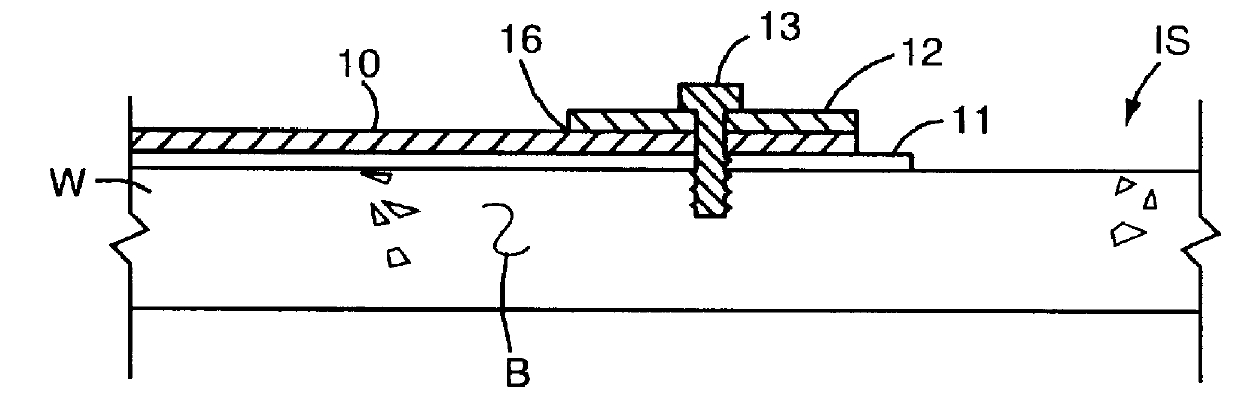

The present invention discloses a system and method for mounting a flexible material, such as a web of photovoltaic material, onto a surface, such as a roof. The system and method comprises providing a first and a second elongated web of flexible material and disposing the first and second webs on the surface in a longitudinally aligned relationship with one another, wherein a first edge of said first web abuts a first edge of said second web to form a longitudinal engagement point to produce a substantially triangular shape. At least one clamping strip is secured onto the longitudinal engagement point, wherein the clamping strip(s) is adapted to secure the longitudinal engagement point in a stable position for the length of the web. At least one batten cap is clamped onto the clamping strip(s), wherein the batten cap(s) is adapted to secure the clamping strips. Additionally, securing means, such as screws, nails or adhesives, may be incorporated to attach the sides of the substantially triangular shape to the surface.

Owner:UNITED SOLAR OVONIC

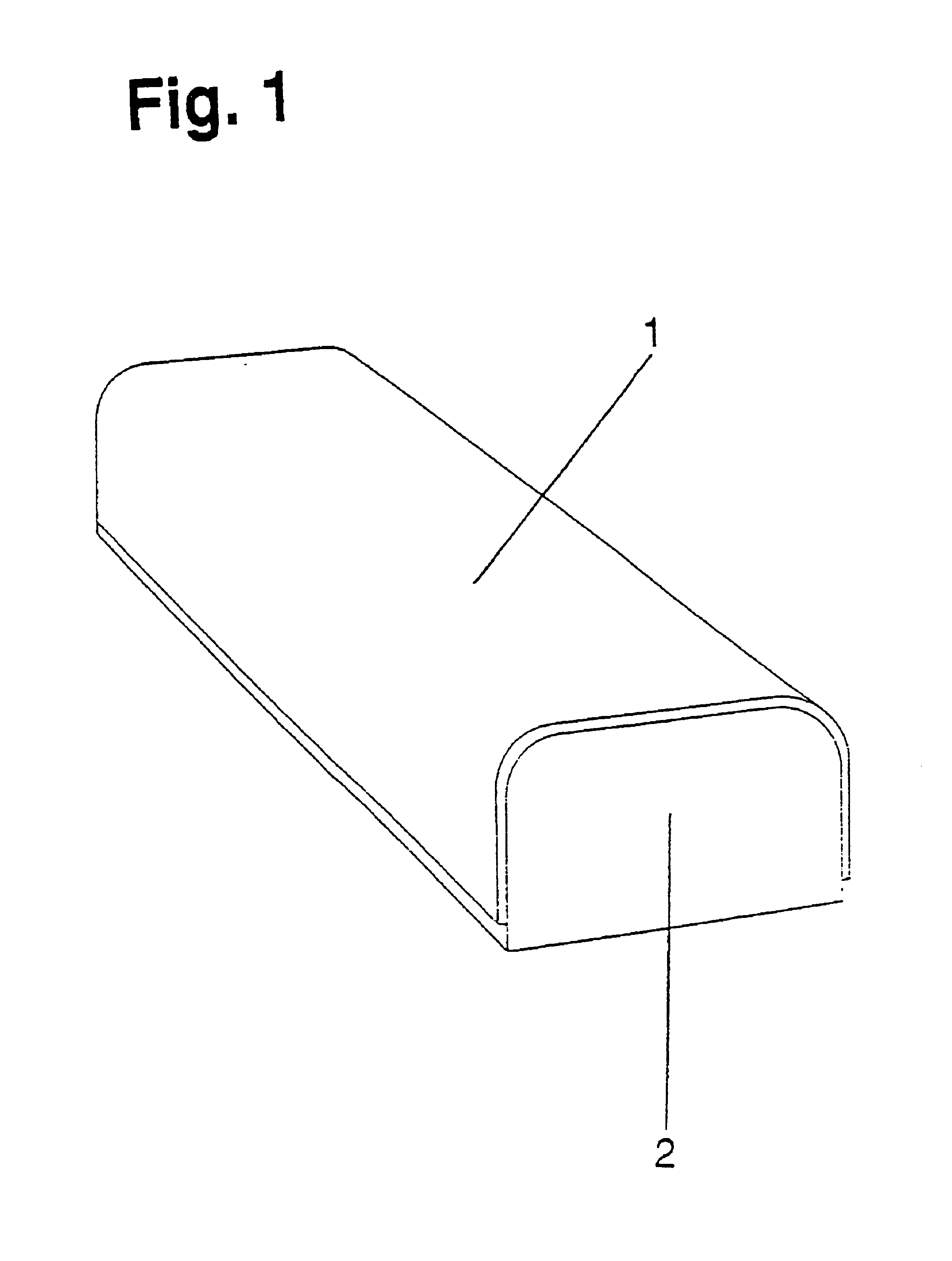

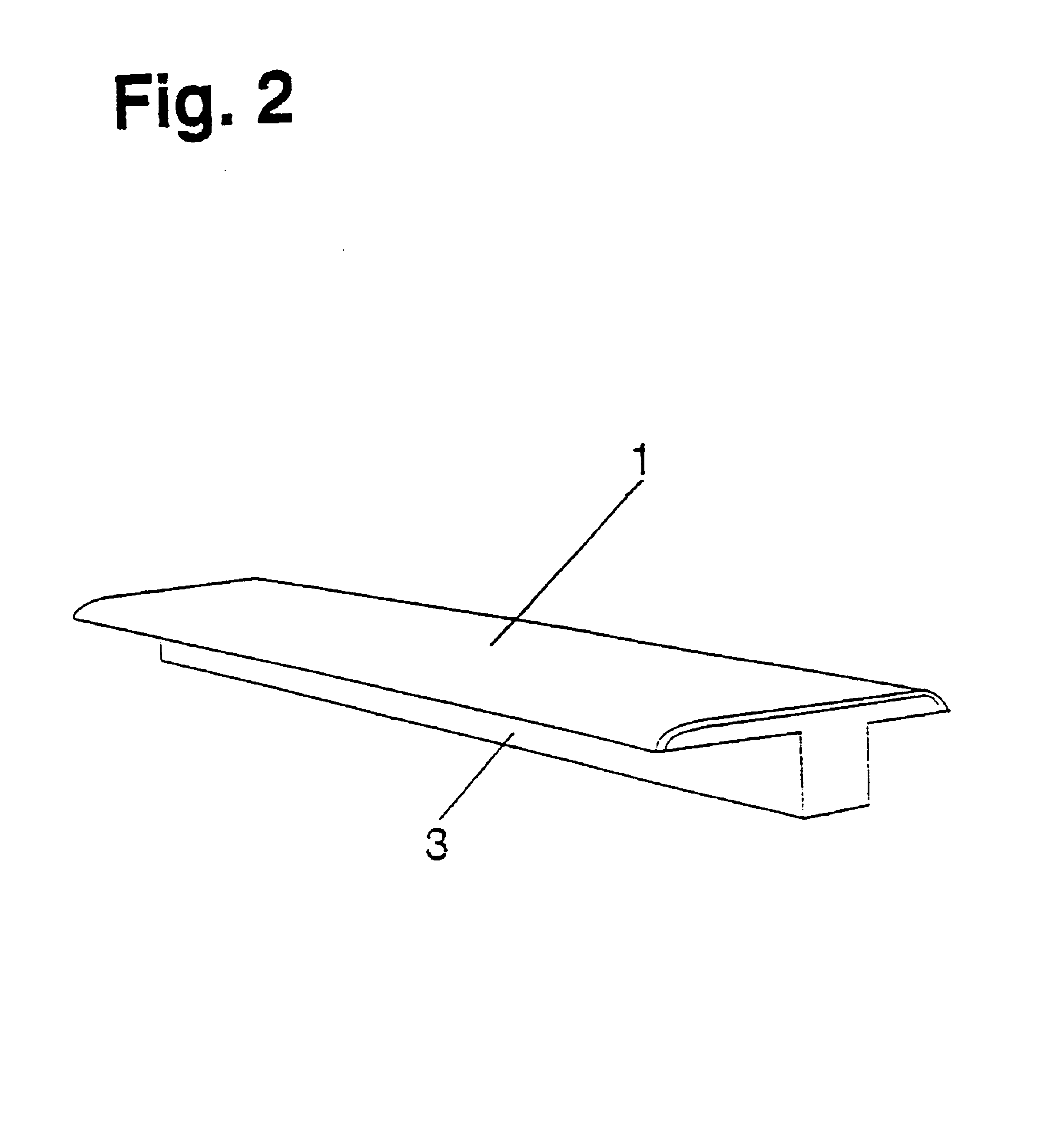

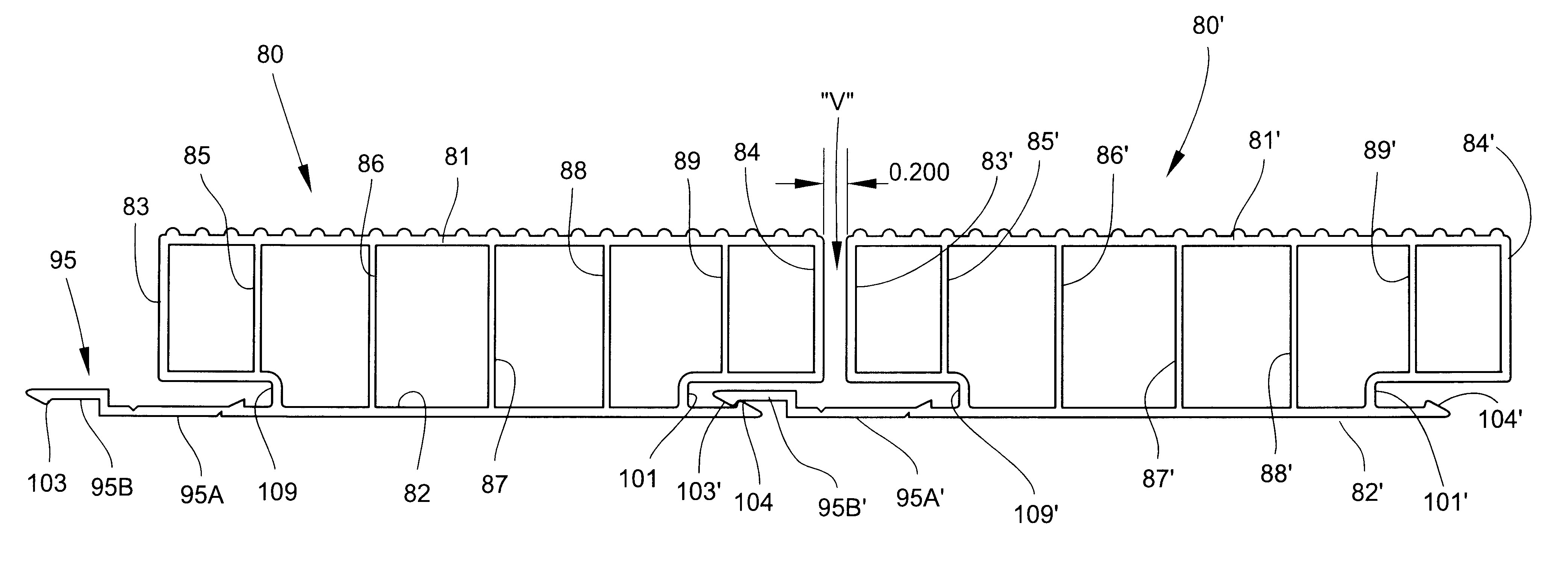

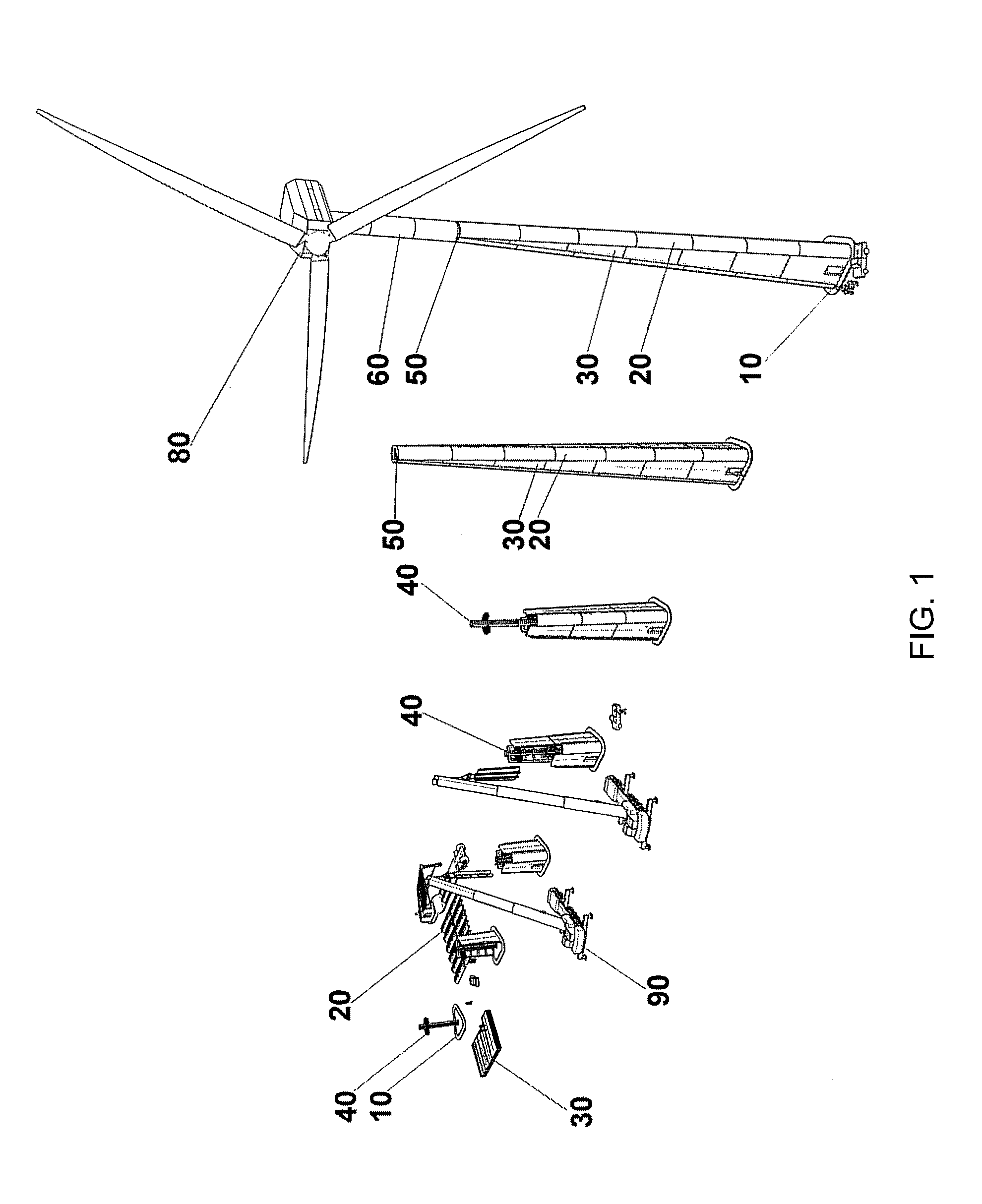

Hollow structural member

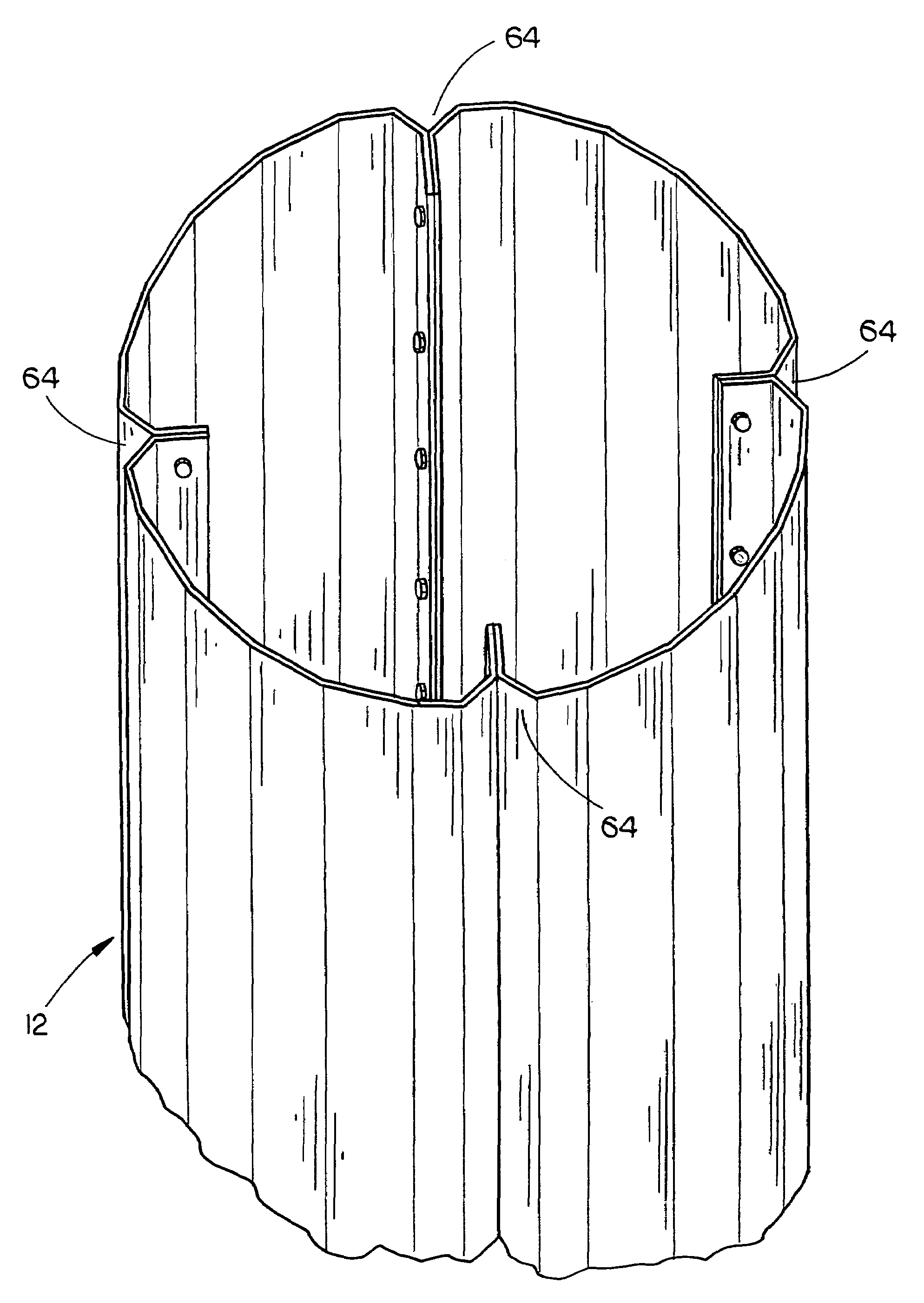

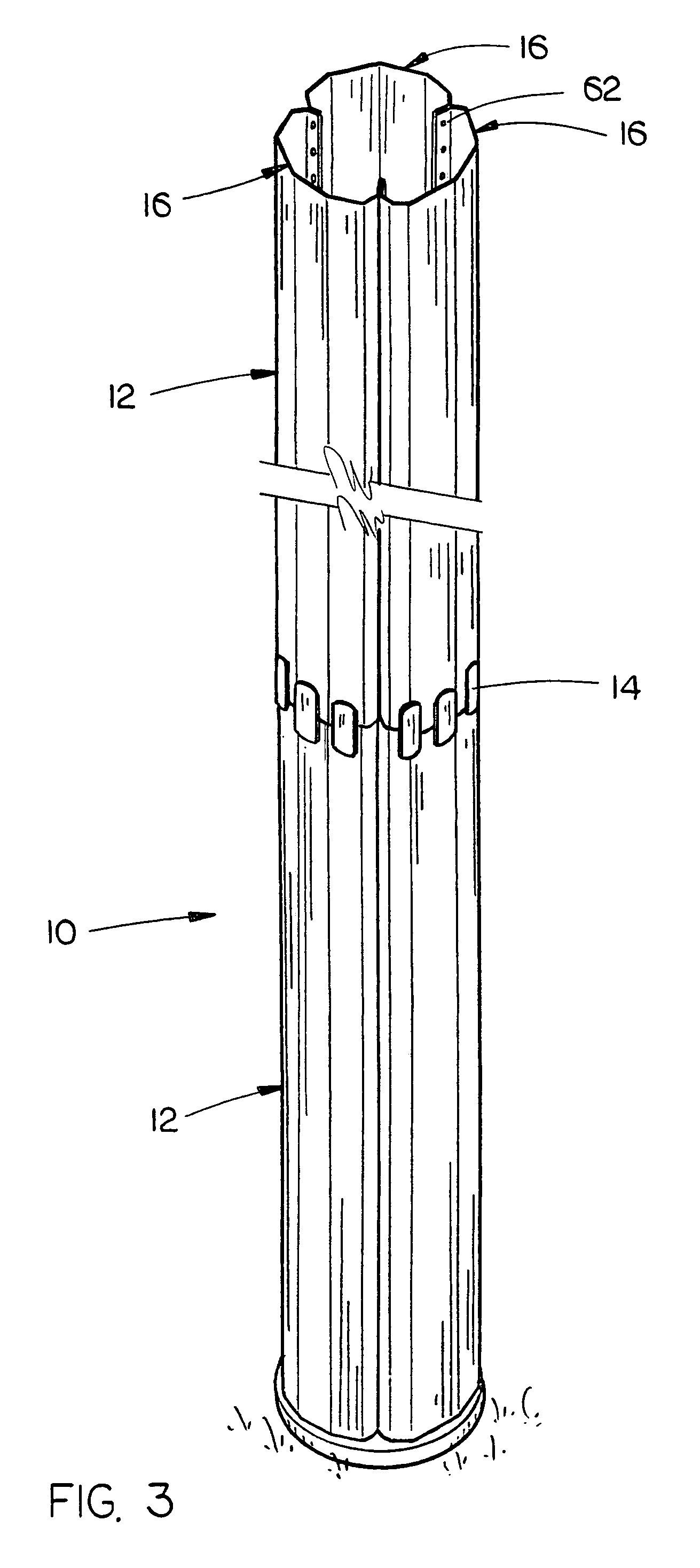

A structural member such as a wind turbine tower comprising a plurality of elongated hollow pole sections secured together in an end-to-end relationship with each of the hollow pole sections comprising a plurality of longitudinally extending peripheral sections joined together. Each of the peripheral sections is bent along at least one longitudinally extending break line to define a plurality of angled wall sections extending between longitudinally inwardly extending edge portions. The edge portions of the peripheral sections are bolted together to form a hollow pole section.

Owner:VALMONT INDUSTIES INC

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

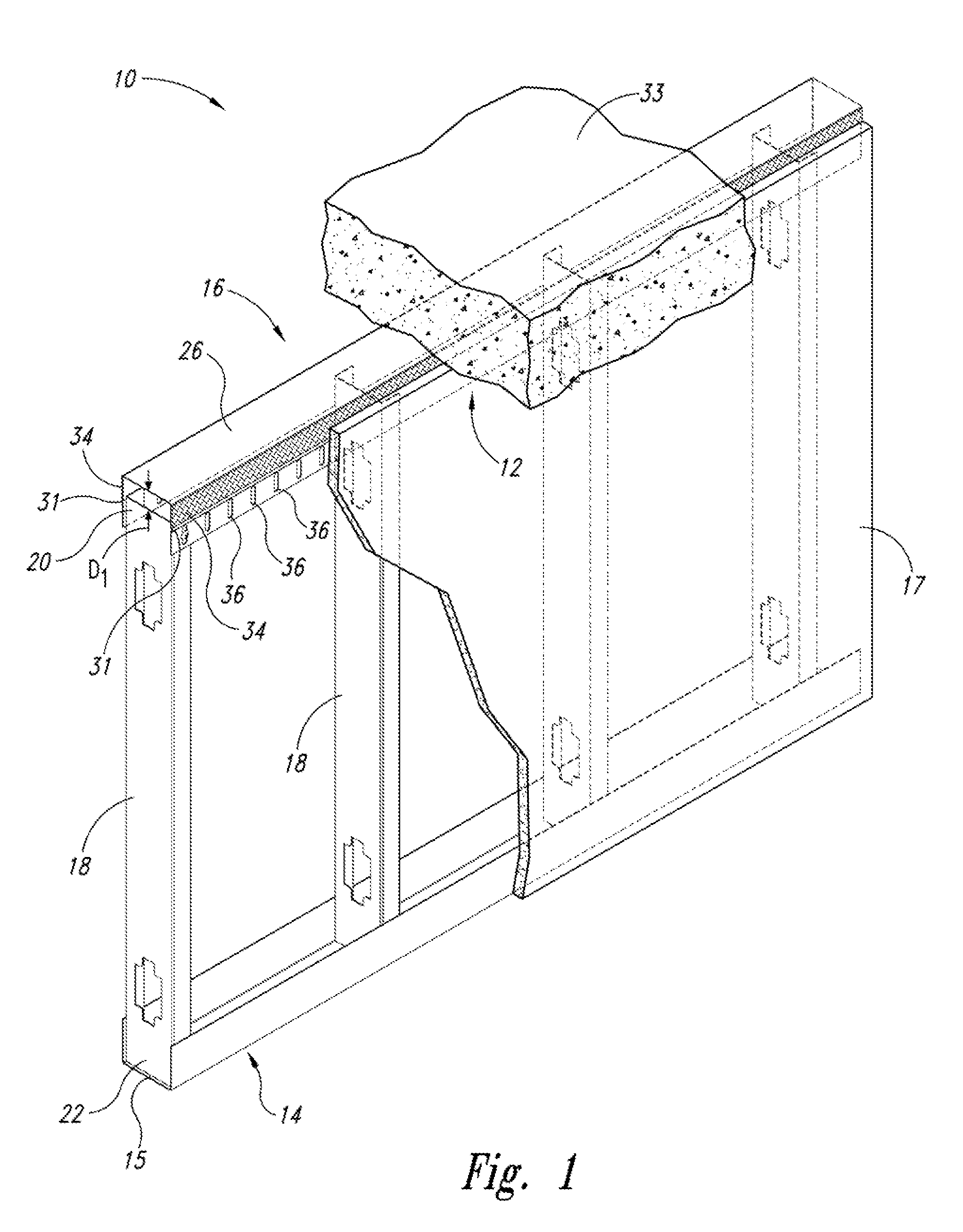

Head-of-wall fireblock systems and related wall assemblies

A fire retardant head-of-wall assembly configured to seal a linear head-of-wall construction joint or gap when exposed to a heat source such as a building fire is disclosed. The inventive fire retardant head-of-wall assembly comprises a header track having an elongated intumescent strip affixed lengthwise on at least one of the outer sidewall surfaces of the header track and above a centrally located and outwardly protruding lengthwise corrugated groove. The intumescent strip comprises expandable graphite and a fire retardant (C2-C8 alkyl diamine phosphate). When exposed to a heat source such as a building fire, the intumescent strip expands so to fill the head-of-wall construction joint or gap, thereby retarding or preventing the spread of smoke and fire. The inventive fire retardant head-of-wall assembly has been certified as complaint with respect to Underwriters Laboratories, Inc.'s standards set forth in its Tests for Fire Resistance of Building Joint Systems—UL 2079.

Owner:CEMCO LLC

Structurally reinforced panels

Owner:ZEPHYROS INC

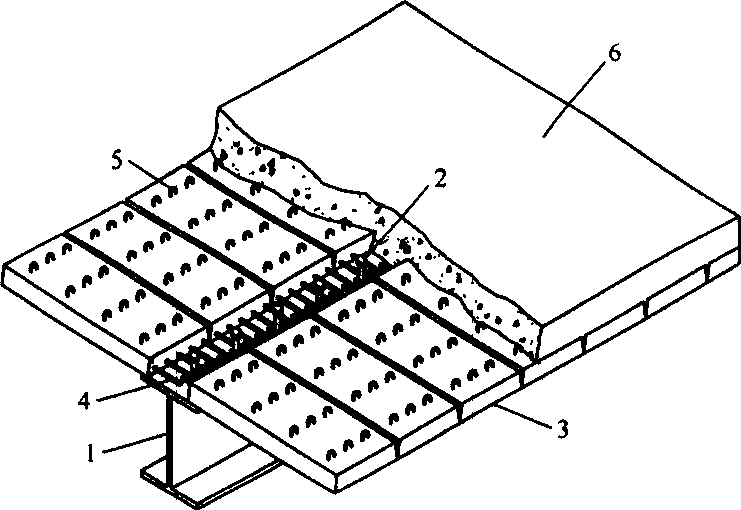

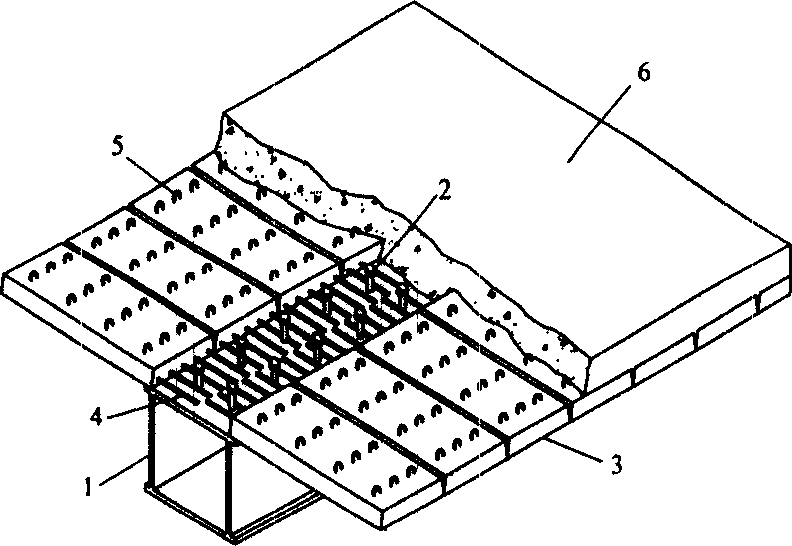

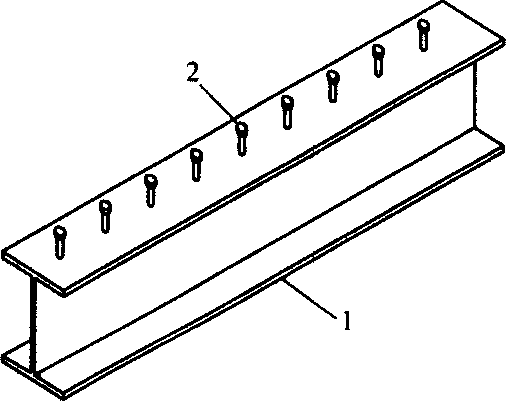

Steel-concrete folding plate combined beam

InactiveCN1587575ASolve construction difficultiesSolve complexityLoad-supporting elementsBridge structural detailsReinforced concreteEngineering

The present invention discloses one kind of combined beam of laminated steel-concrete plate for highway bridge and building as support member of bridge and building. Shear resistant connecting parts are welded to steel beam, prefabricated solid or hollow reinforced concrete boards are set on the steel beam, the steel bar tails are crossed and welded together, and the post-deposited concrete is deposited to form the combined beam. The combined beam has the advantages similar to those of in-situ deposited combined beam as well as saving in formwork and formwork supported step, simple prefabricated board structure, fast construction speed, etc. The present invention has wide application foreground in bridge structure and building structure fields.

Owner:TSINGHUA UNIV

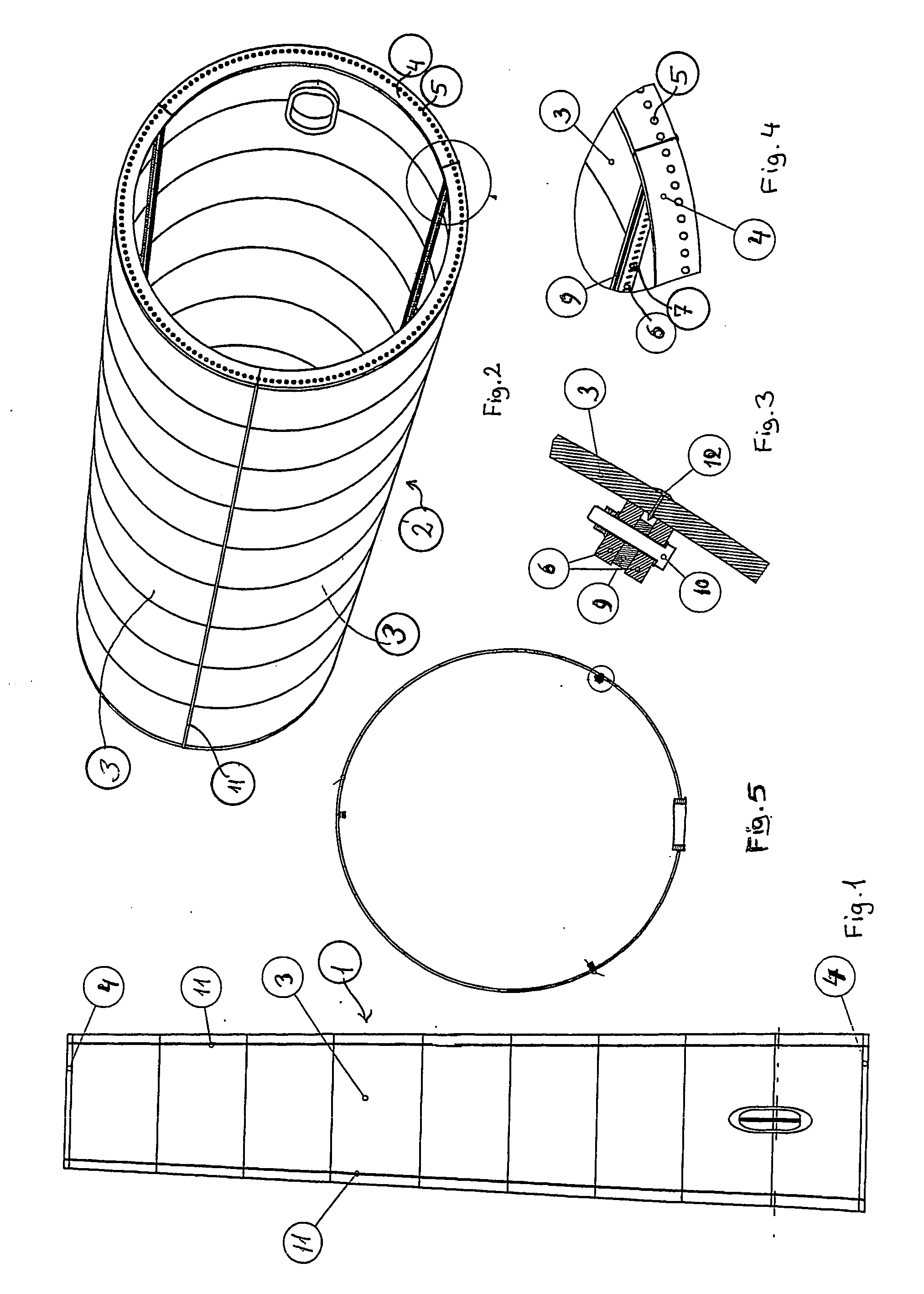

Wind turbine tower and method for constructing a wind turbine tower

ActiveUS20090021019A1Low costAvoids any rolling, bending and/or weldingEngine manufactureFinal product manufactureTowerTurbine

A wind turbine tower is provided, which comprises a number of segments with a polygonal cross section, each segment comprising a number of flat plates which are connected to each other so as to form the polygonal cross section. Further, a method for constructing a wind turbine tower which comprises segments assembled of flat plates is disclosed, wherein the flat plates are connected to each other so as to form segments with a polygonal cross section and the segments are connected to each other so as to form the tower.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

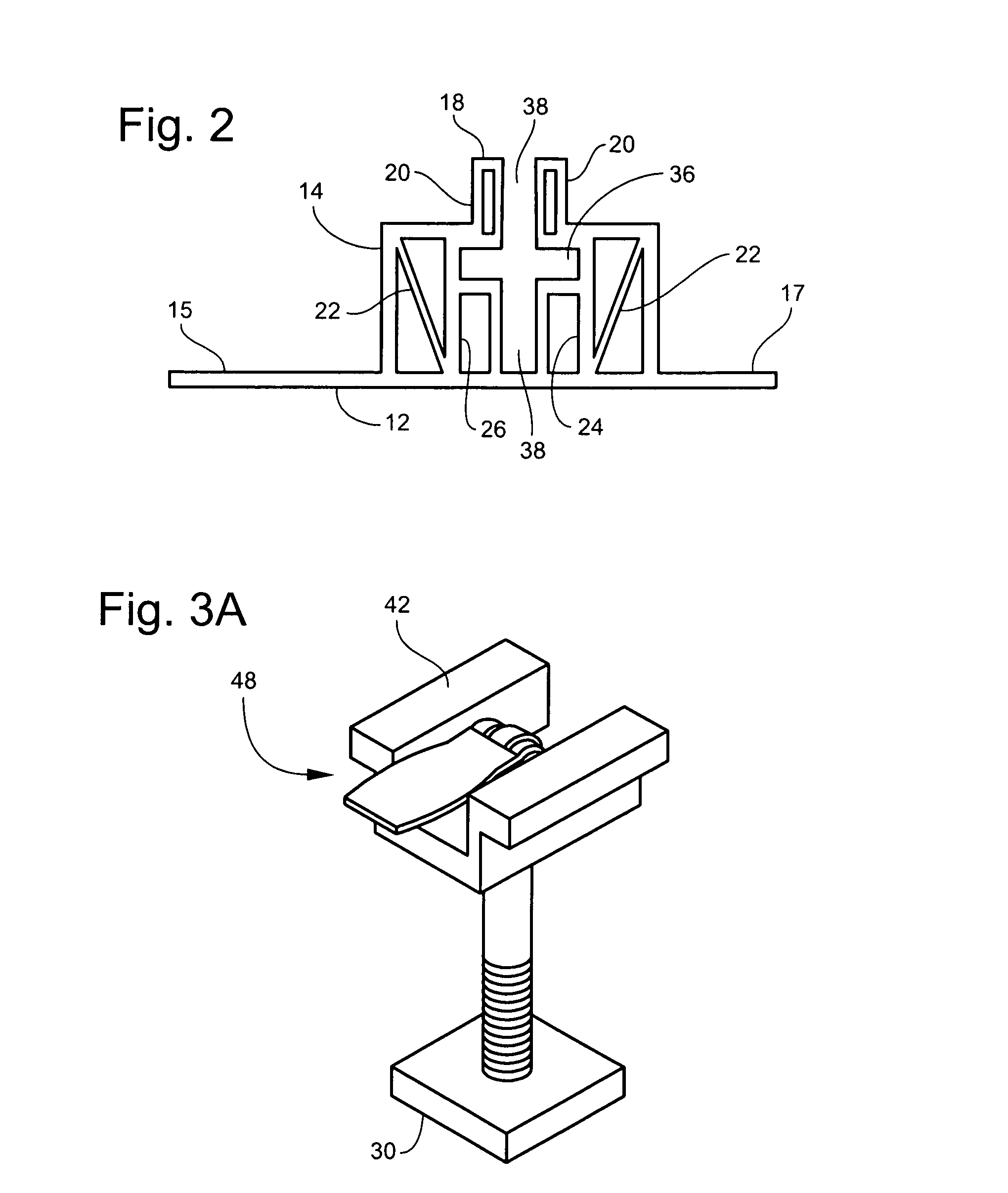

Mount for pitched roof and method of use

InactiveUS8813441B2Avoid leaningPhotovoltaic supportsSolar heating energyMechanical engineeringEngineering

In one embodiment, there is a mount for a pitched roof. The mount comprises a fastening plate. The fastening plate includes at least one support extending upwardly from the fastening plate to support a pair of mounting surfaces a predetermined distance above the pitched roof. At least a portion of the fastening plate extends laterally from the one or more supports. The pair of mounting surfaces is configured to support at least one photovoltaic panel. The mount further includes a clamp housing between the pair of mounting surfaces and receives a clamp. The clamp comprises a pair of laterally extending clamp plates and at least one clamp stabilizer configured to prevent the clamp plate from tilting when the clamping force is applied.

Owner:DYNORAXX

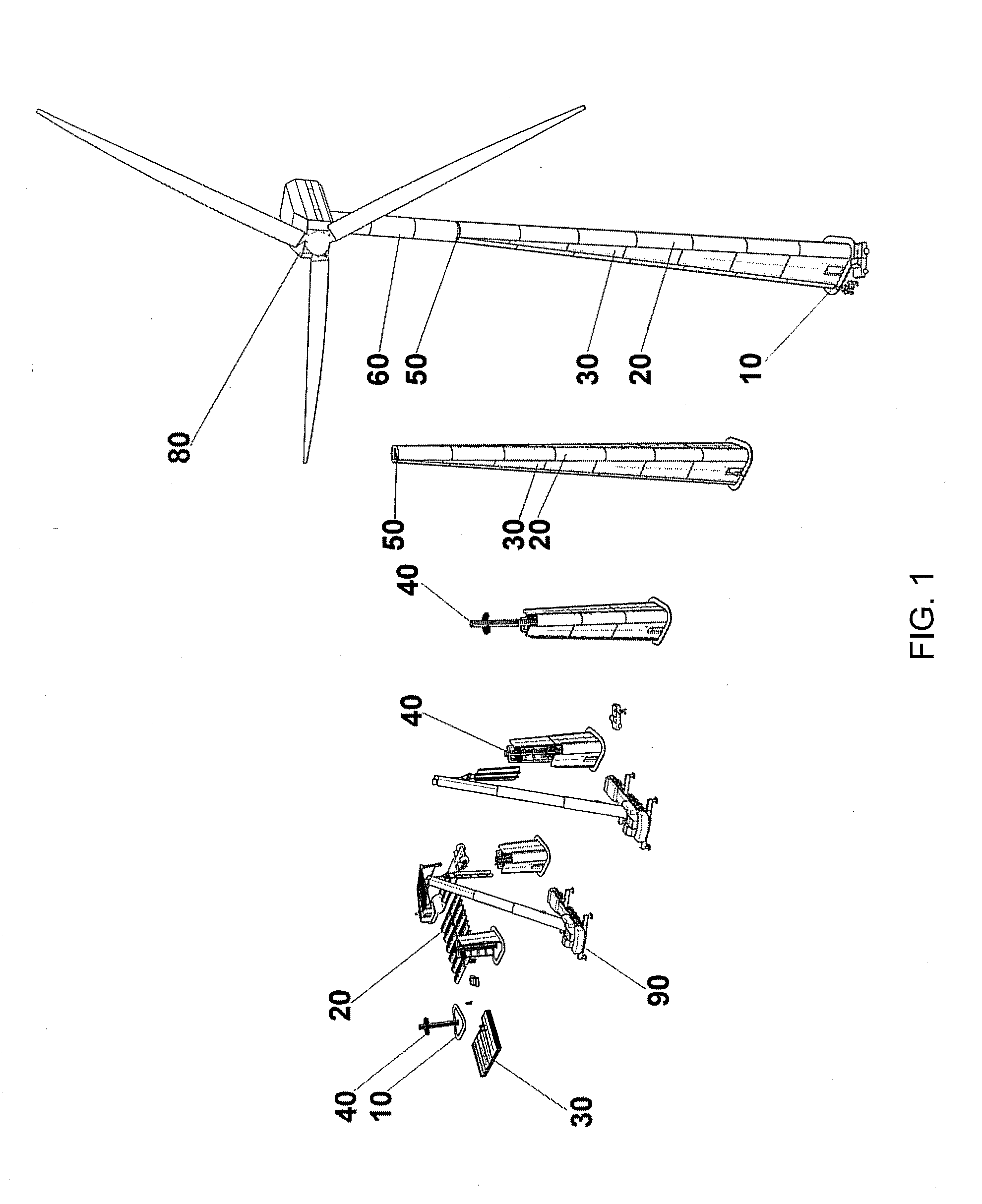

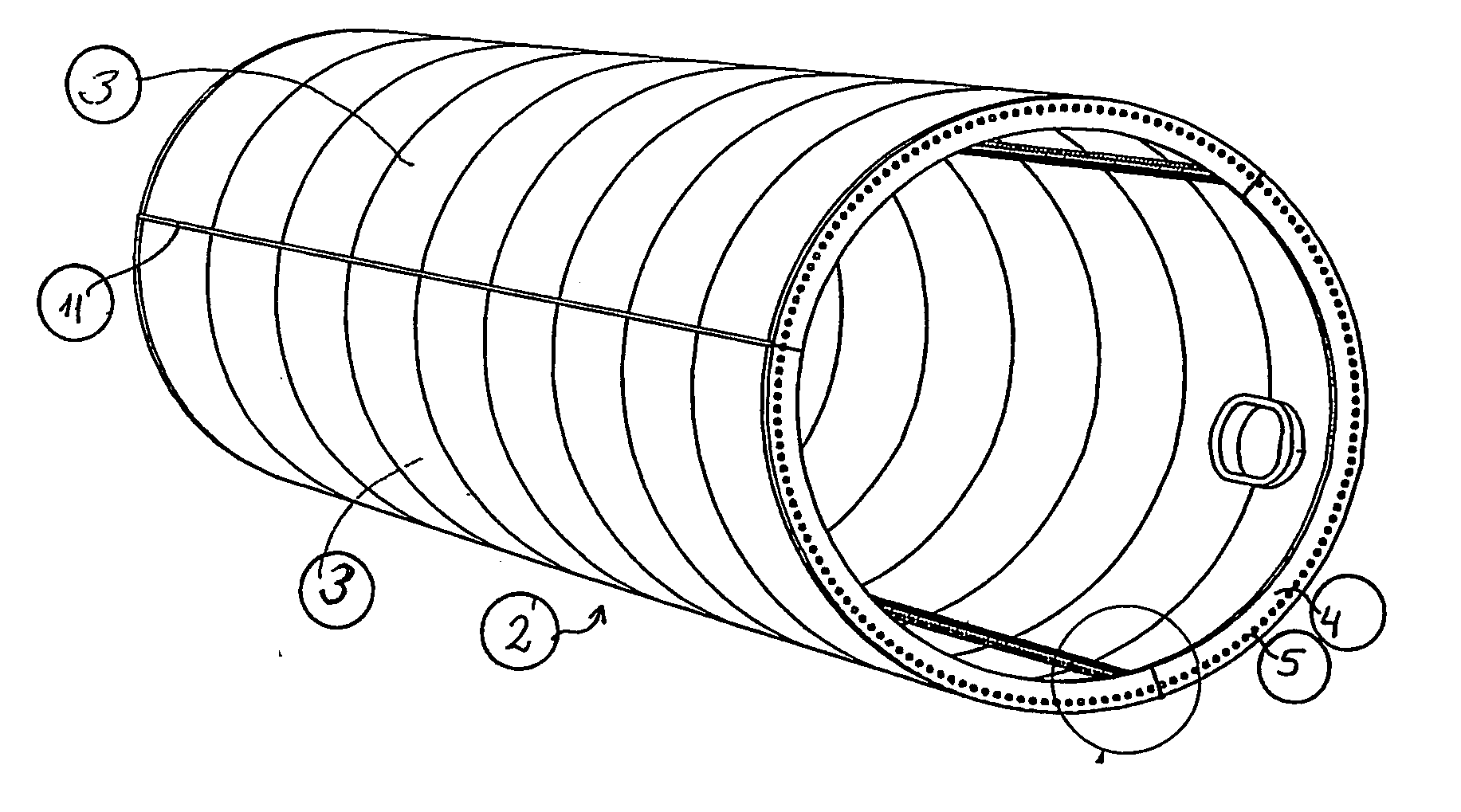

Method of contructing large towers for wind turbines

ActiveUS20060272244A1Large lengthSmooth outer surfaceWind motor assemblyWind motor supports/mountsInterconnectionTower

In order to transport large size windmill towers, the invention suggests a steel tower (1) for a windmill, comprising a number of cylindrical or tapered tower sections (2), at least the wider sections (2) of which being subdivided into two or more elongated shell segments (3), which combine into a complete tower section (2) by means of vertical flanges (6) tightened together, e.g., by bolts (10), said shells being also provided with upper and lower horizontal flanges (4), respectively, to allow interconnection of tower sections (2) one on top of the other.

Owner:VESTAS WIND SYST AS

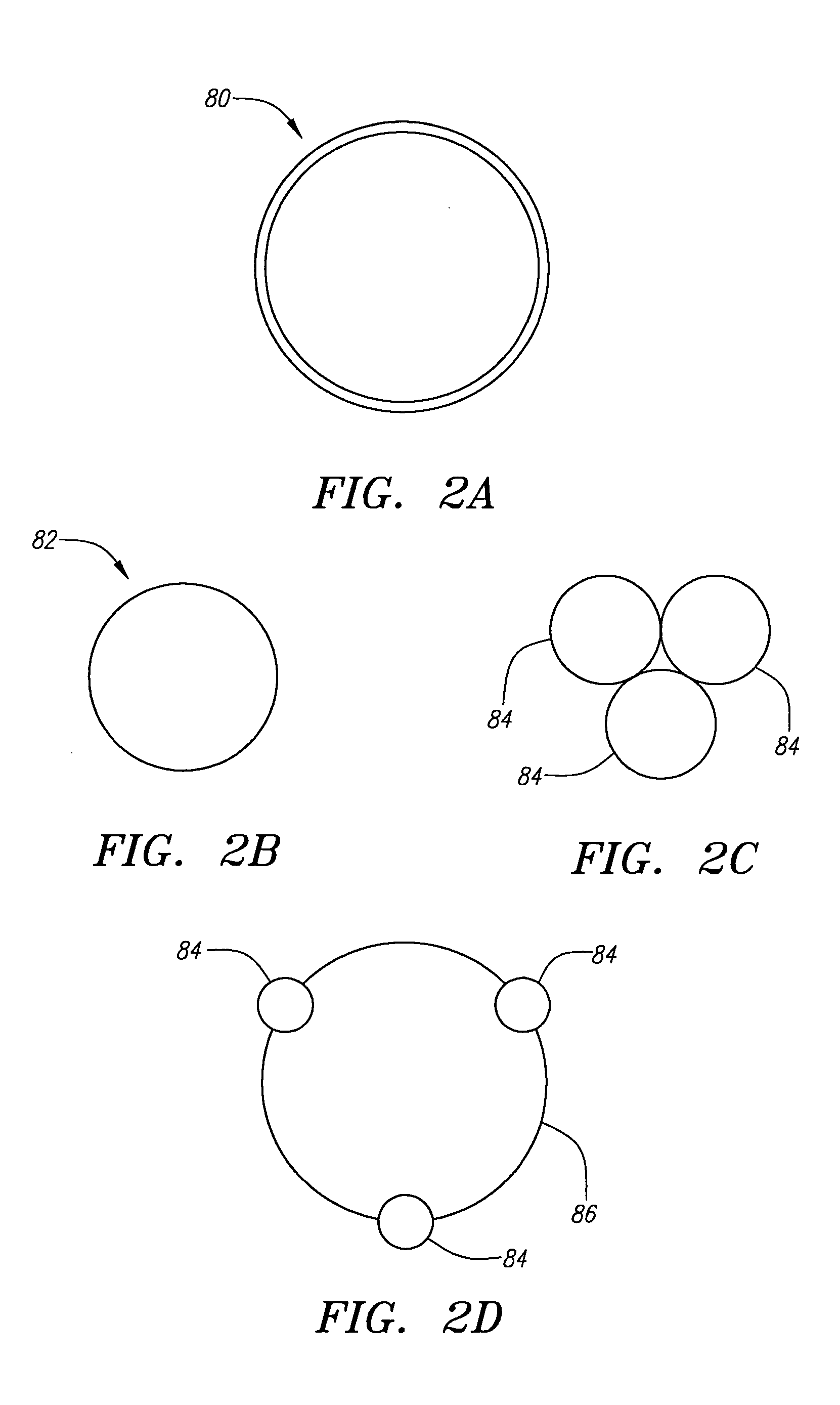

Deployable truss having second order augmentation

ActiveUS20050126106A1Decreases free buckling lengthIncrease its moment of inertiaCollapsable antennas meansCosmonautic vehiclesEngineeringMoment of inertia

A deployable truss is formed from a plurality of column members connected at their ends where at least some of the column members are formed from column assemblies, each including a plurality of strut members that are at least connected to each other at a first and second end of the column assembly. For added rigidity, strut members of a column assembly may be connected to each other between the first and second ends using, for example, a rigidizable resin, a fixed spacer, or a deployable spacer. Connecting strut members between the ends of the column assembly provides mutual bracing to the strut members and decreases the free buckling length of the individual strut members. Spacers are preferably configured to radially space the strut members away from the longitudinal centerline of the column assembly to increase its moment of inertia, and hence its buckling strength.

Owner:NORTHROP GRUMMAN SYST CORP

Wall reinforcing and waterproofing system and method of fabrication

A wall reinforcing system is provided for strengthening of walls formed of masonry or from wood, metal or other structural materials. A basic system comprises utilization of rigid, fiber reinforced polymer plates of a length to extend substantially the full vertical heigth of the wall. These plates incorporate a plurality of filamentary fibers of length to extend the full length of a plate with these fibers formed from carbon, glass or other material exhibiting high tensile strength and are affixed in a cured polymer matrix. A number of these plates are securely fixed to a wall in spaced parallel relationship by a resin bonding agent or by mechanical fastening devices, or by a combination of both. A plate may include a plurality of plates secured in stacked, superposed relationship and ridgidly secured together by a resin bonding agent into a unitary structure. A second system utilizes one or more sheets of flexible fabric-like material that is fabricated with tows of high tensile strength filamentary fibers of carbon, glass or other material. This fabric-like material is secured to the wall by a resin bonding agent with the tows vertically oriented thus utilizing their tensile strength for strengthening of the wall, either alone or in combination with the plates, and providing waterproofing.

Owner:NATIONWIDE REINFORCING +1

Floor strip

InactiveUS20050003149A1Increase resistanceSmooth transitionWood working apparatusCeramic shaping apparatusEngineeringReducer

A thin decorative thermosetting laminate of postforming quality is glued to a longitudinal carrier to form a floor strip. The laminate has a thermosetting resin as well as hard particles impregnated therein to increase the abrasion resistance of the laminate. The carrier generally has a cross section of a dilatation, transition or a finishing profile, depending on the intended use of the floor strip. The floor strip has a tab portion on a surface that engages a channel on a floor tile or a reducer. The tab portion locks the floor strip into place and prevents movement of the floor tile or the reducer with respect to the floor strip.

Owner:PERGO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com