Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

815 results about "Hardwood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardwood is wood from dicot trees. These are usually found in broad-leaved temperate and tropical forests. In temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen. Hardwood contrasts with softwood (which is from gymnosperm trees).

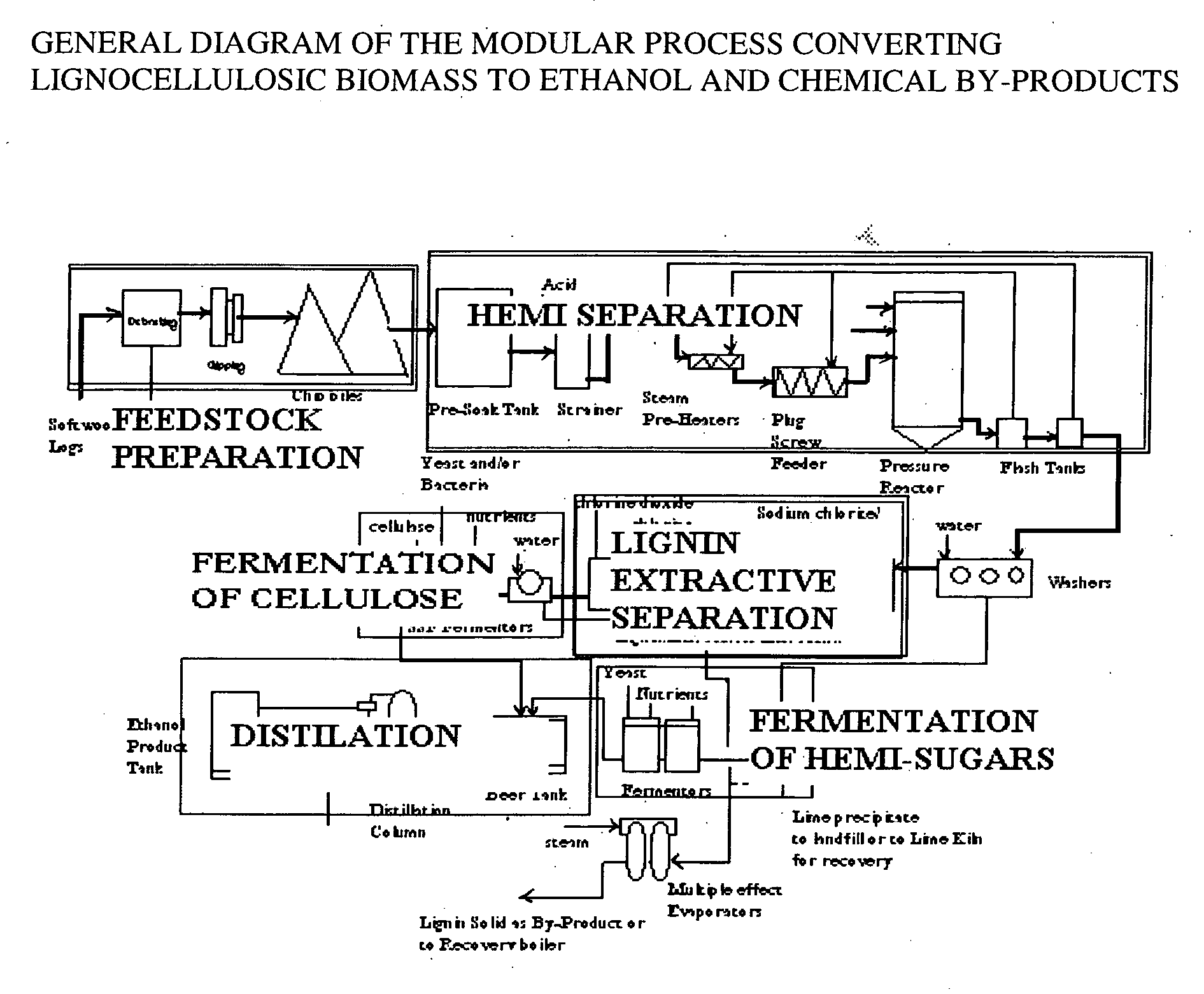

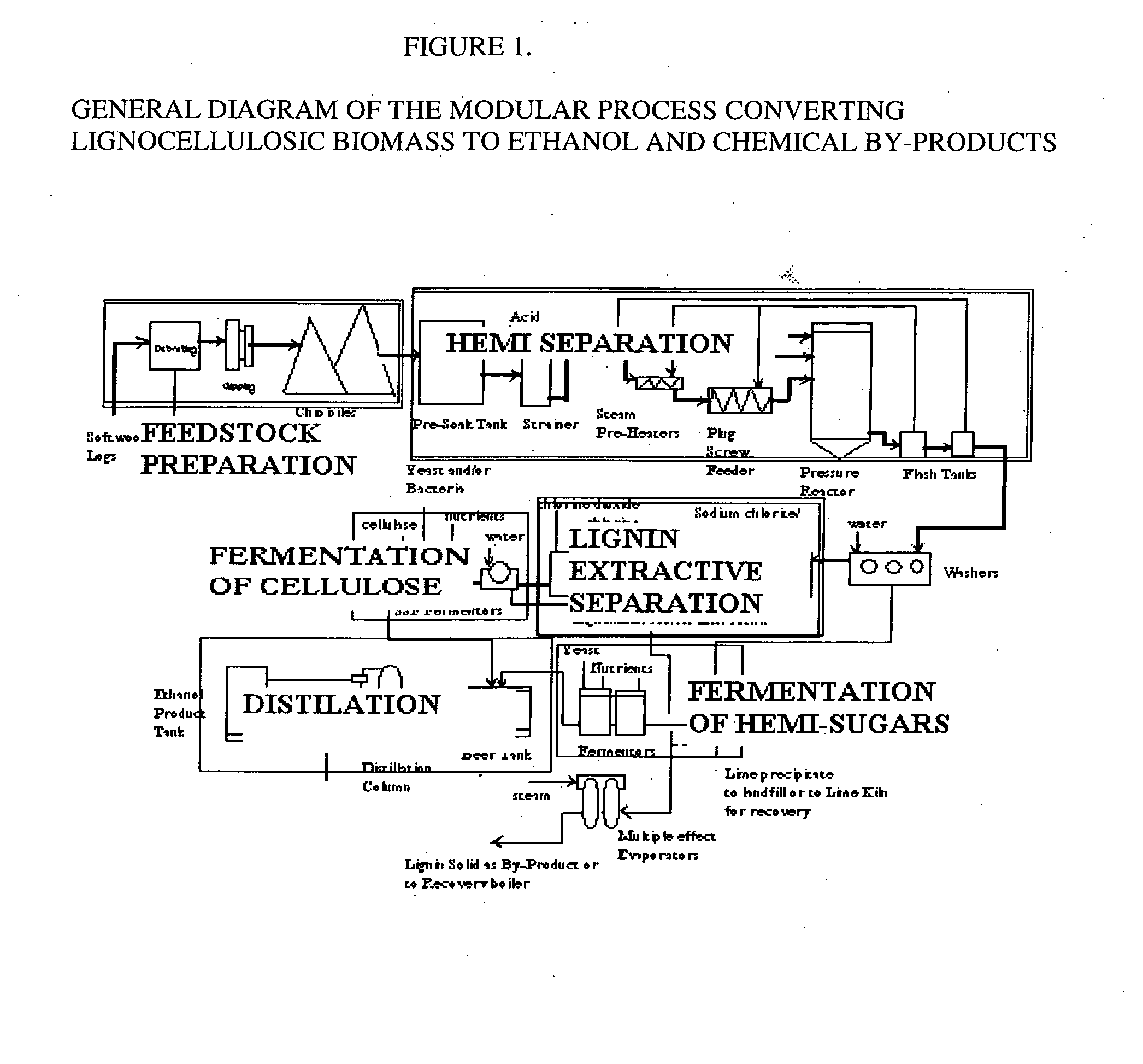

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

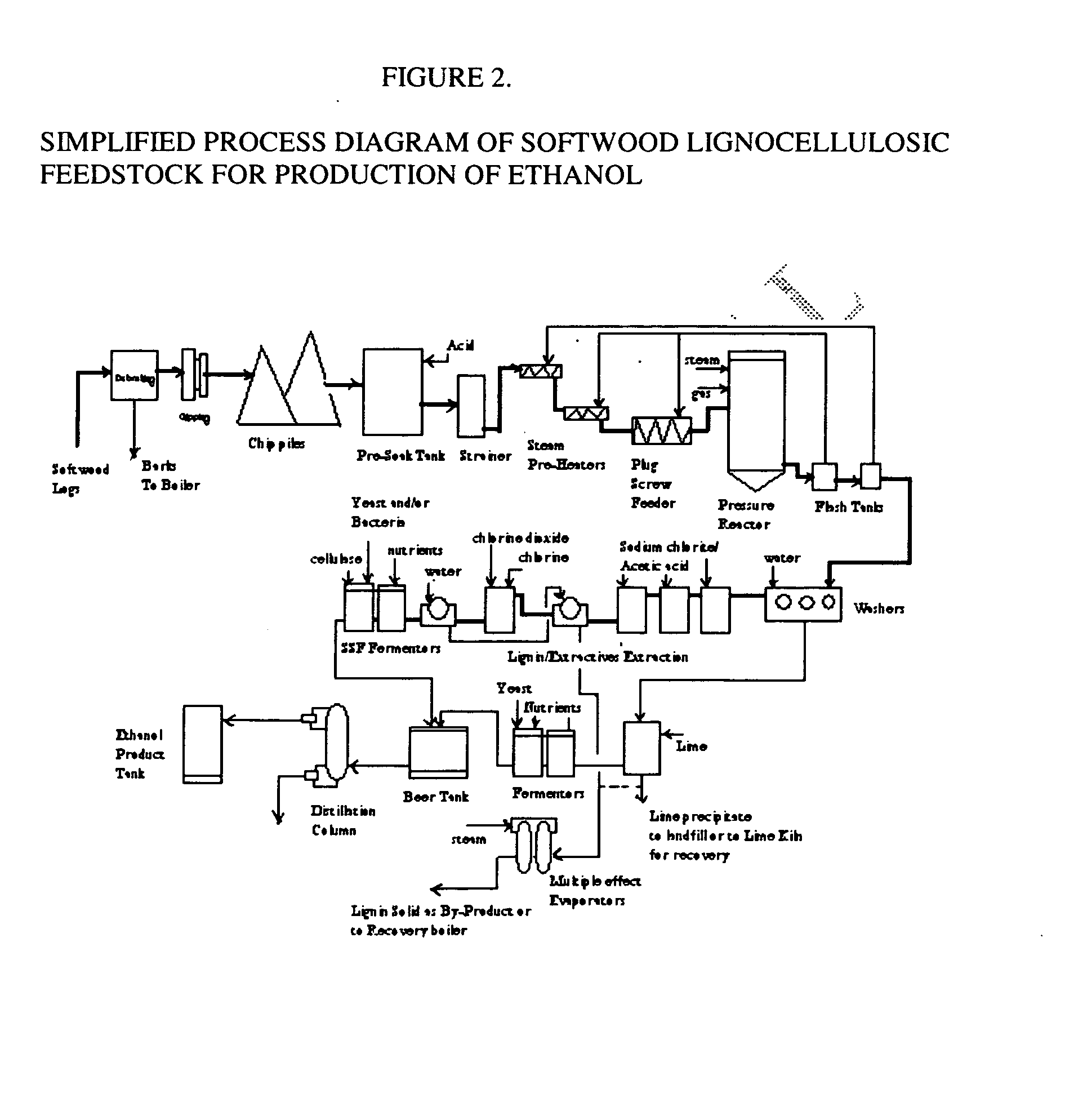

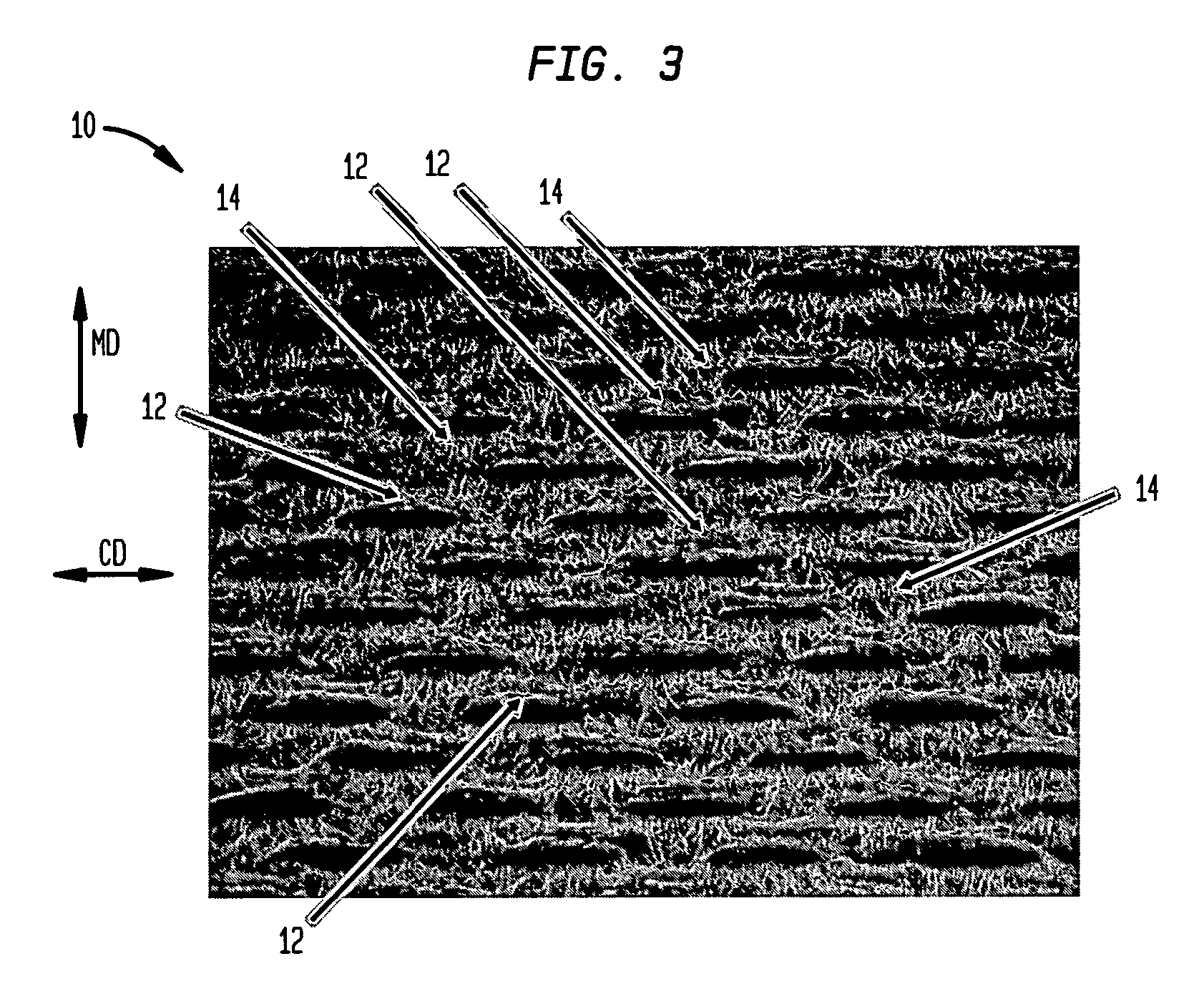

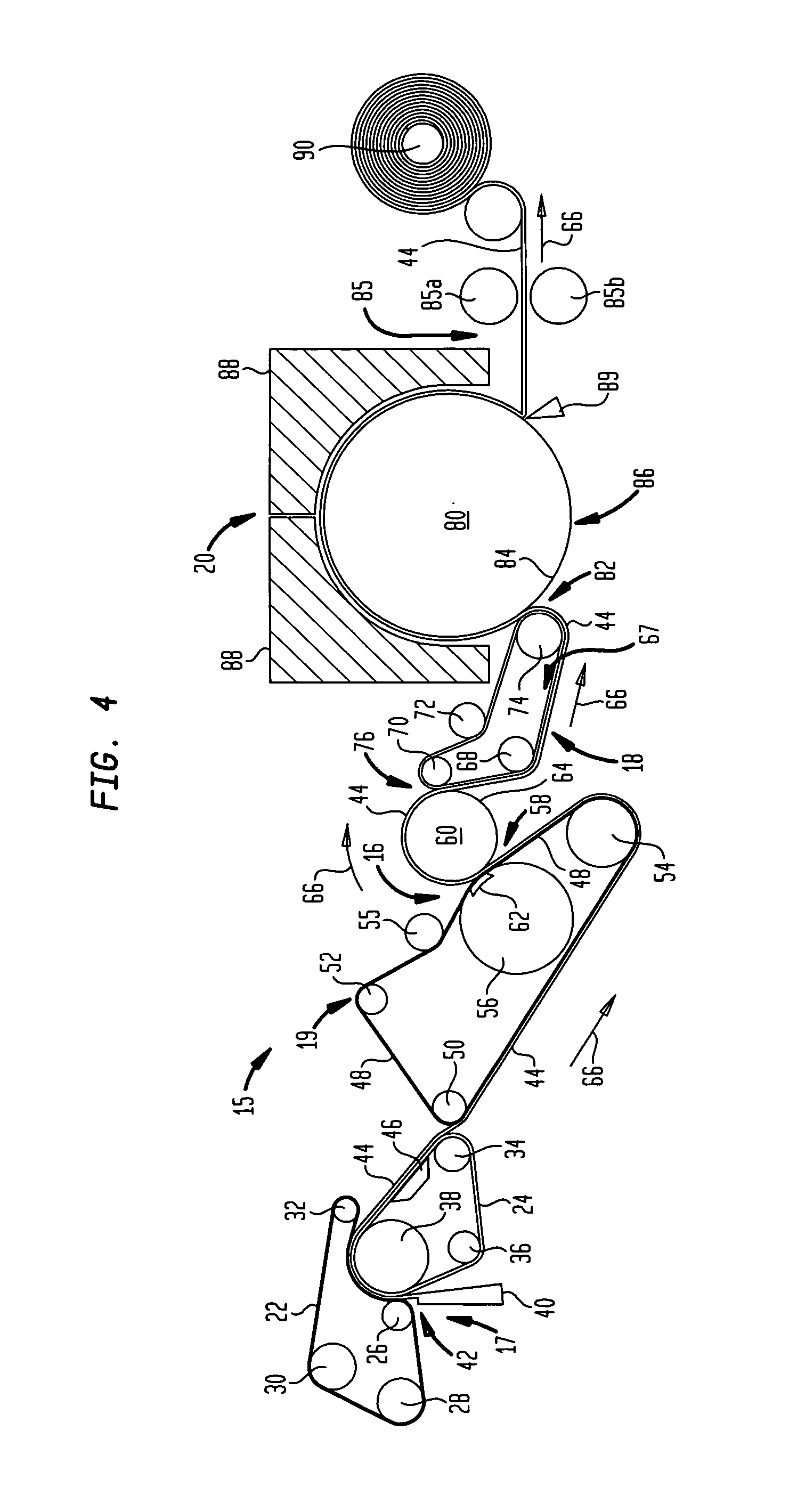

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

ActiveUS20050241786A1The implementation process is simpleNatural cellulose pulp/paperMechanical working/deformationMedicineCellulose fiber

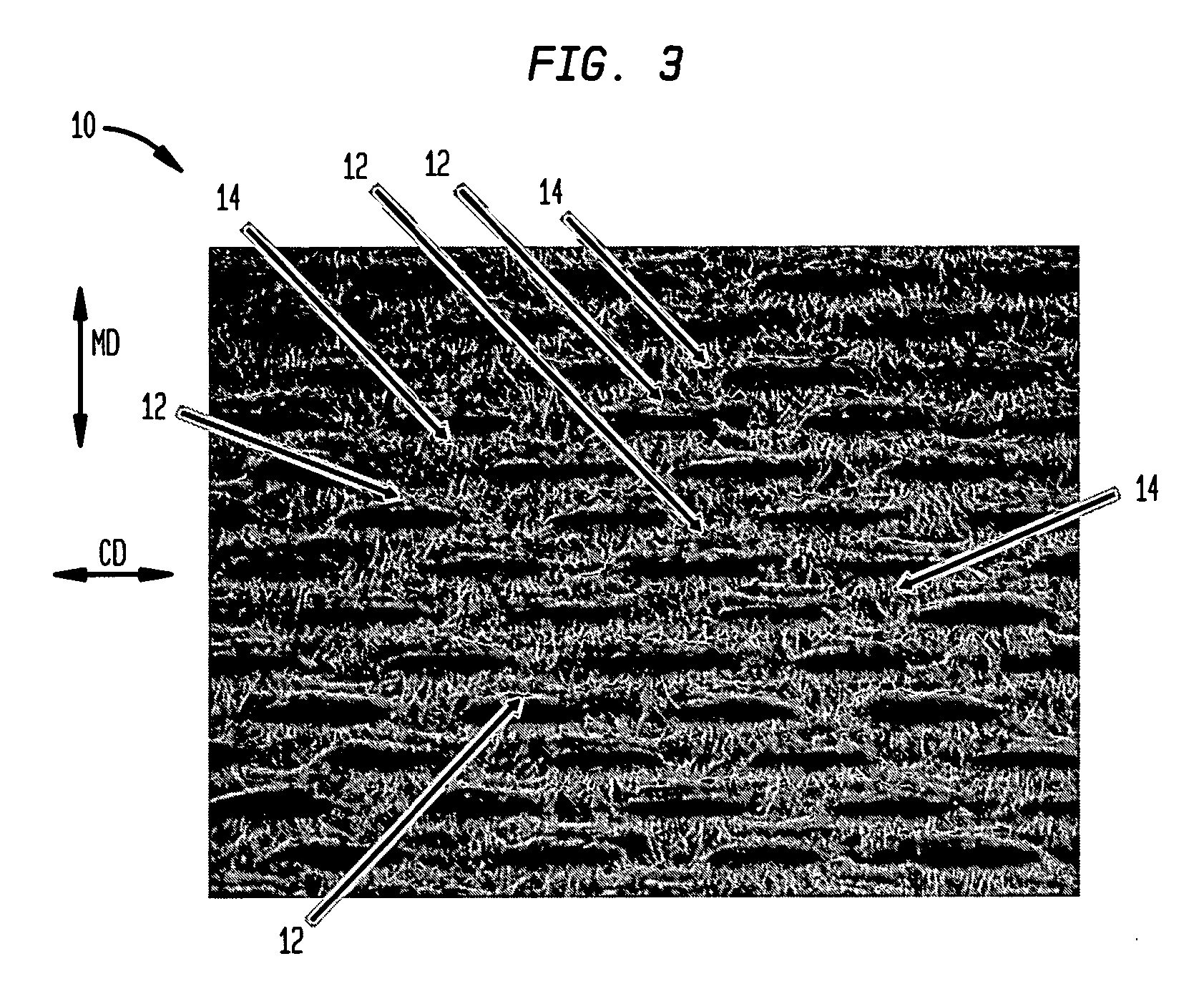

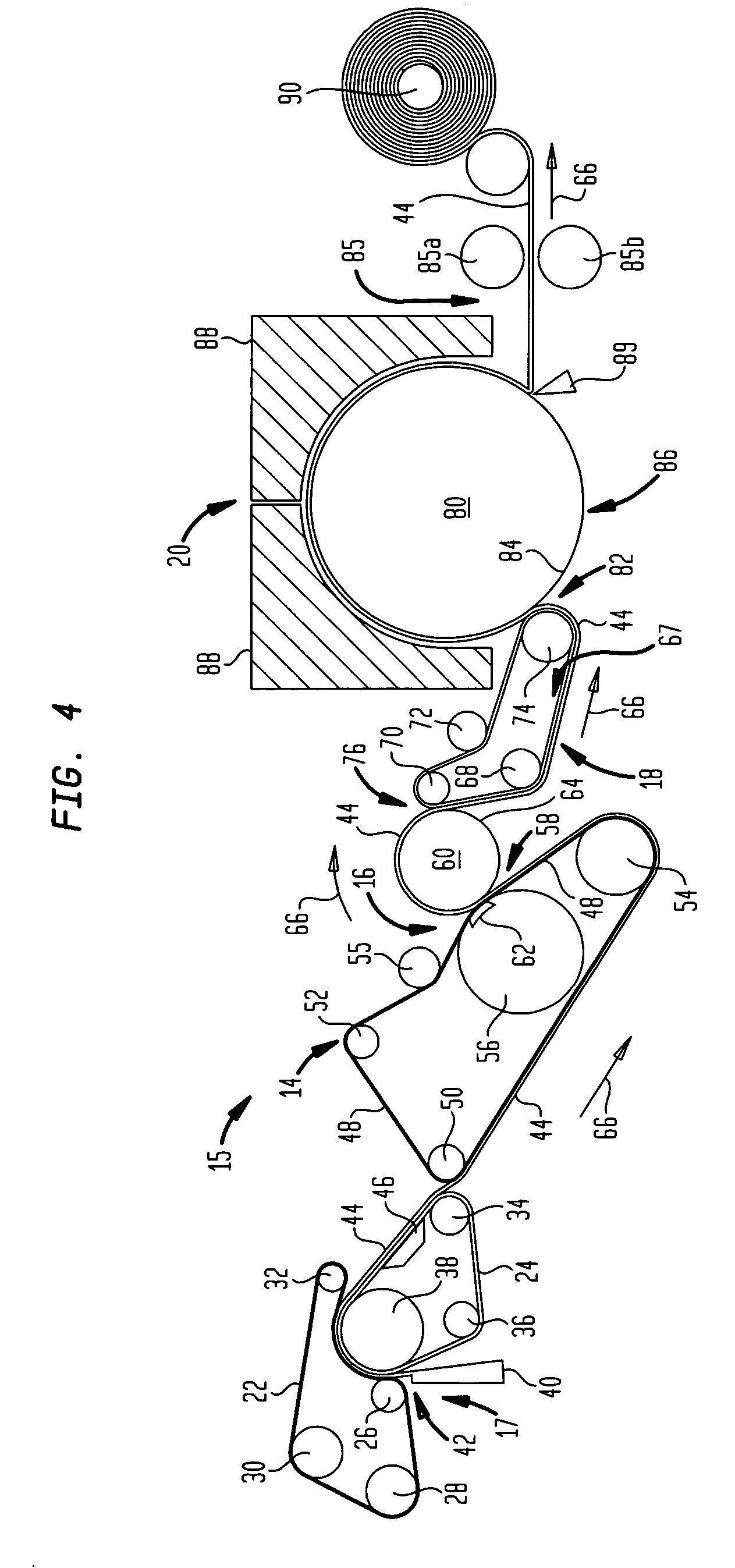

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

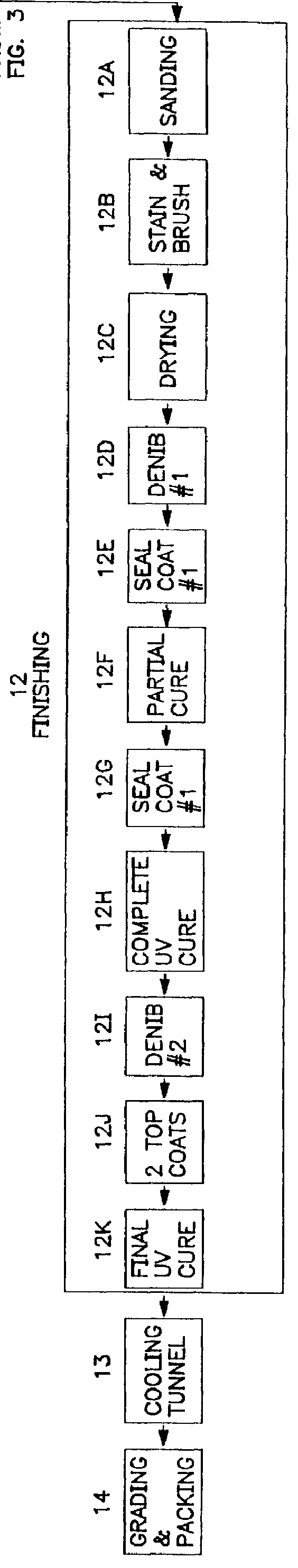

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

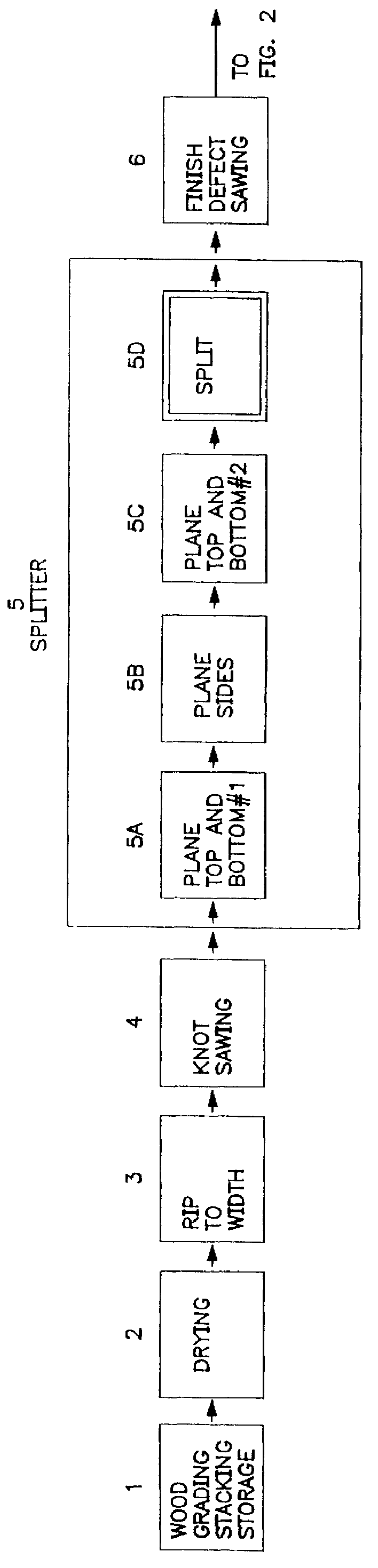

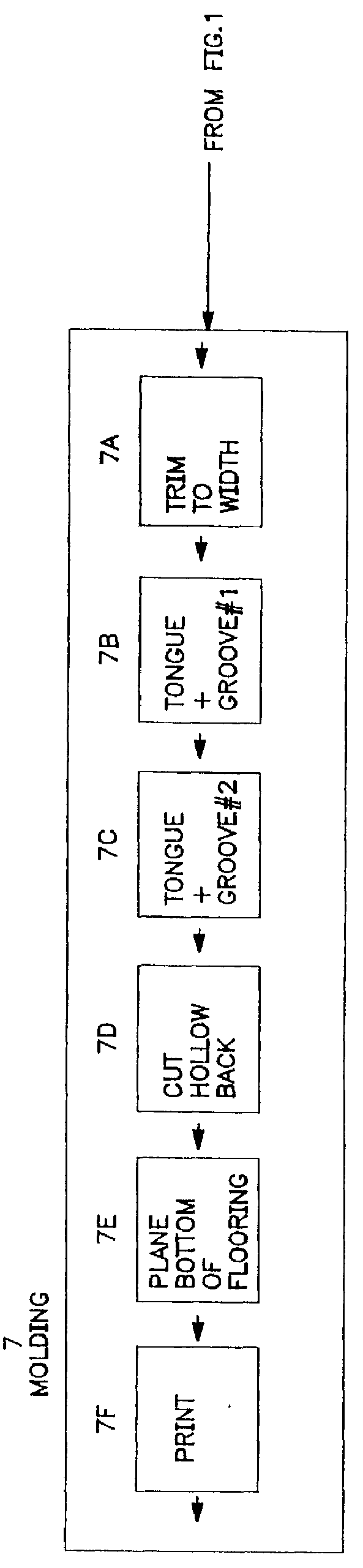

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

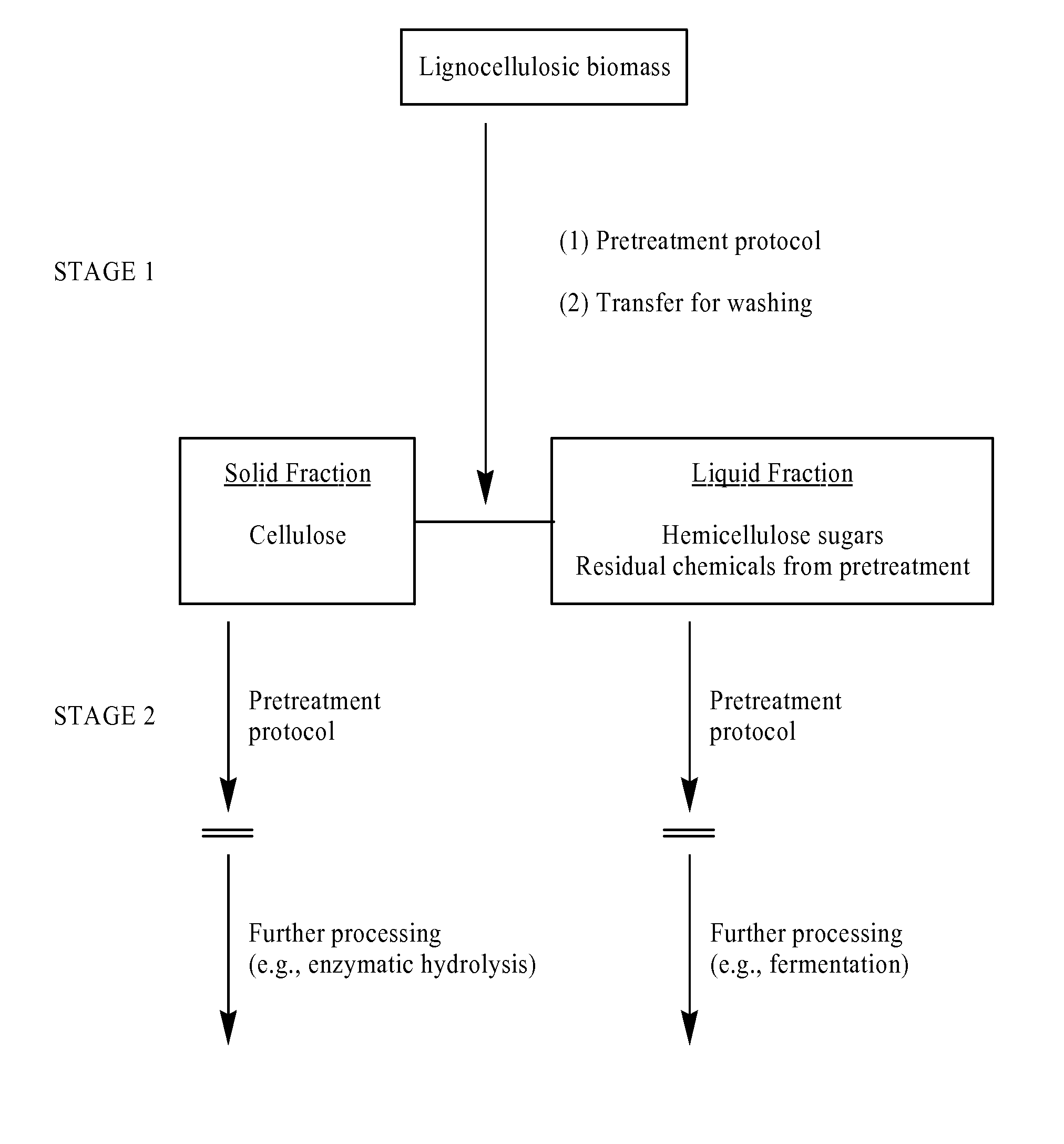

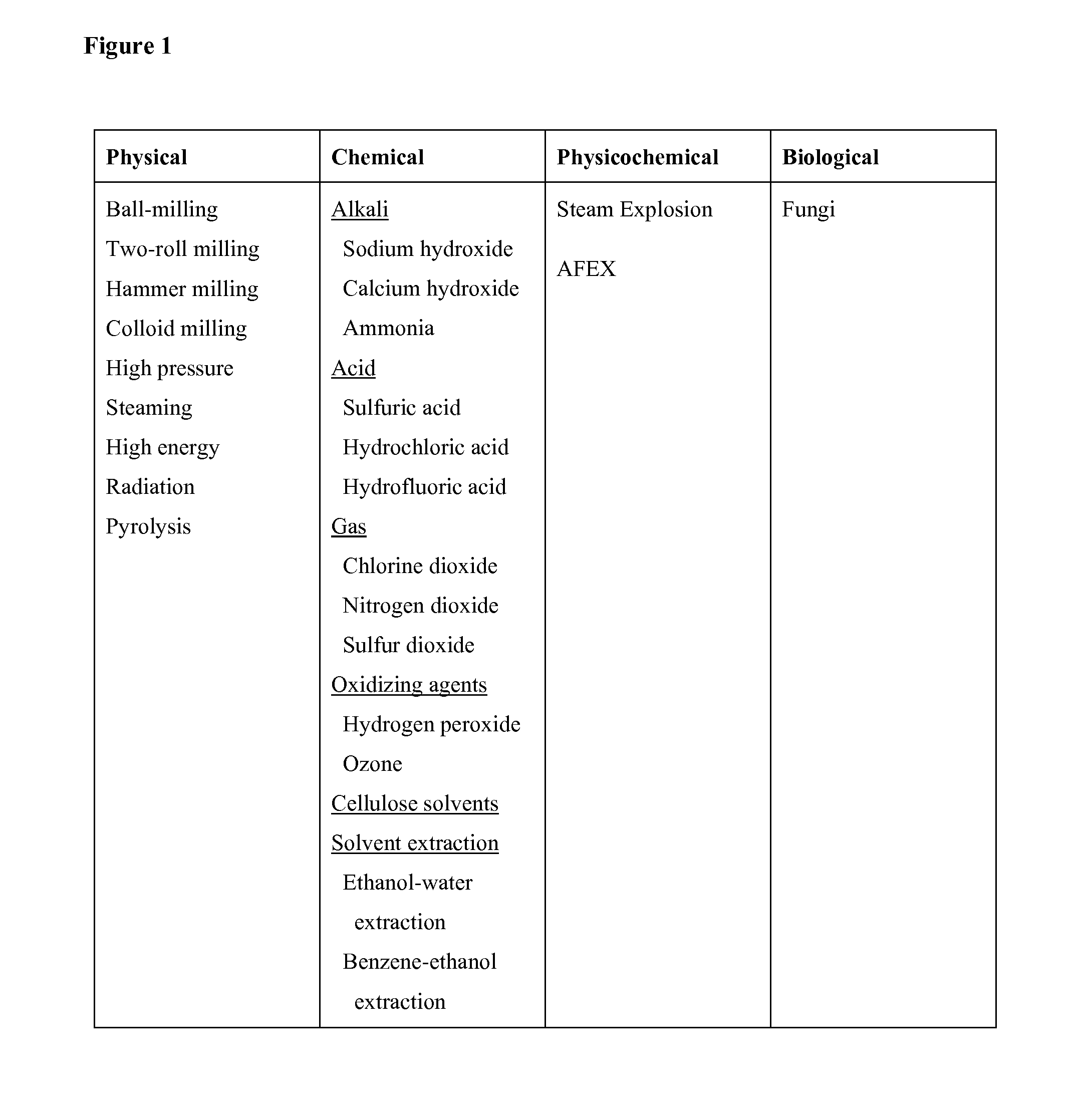

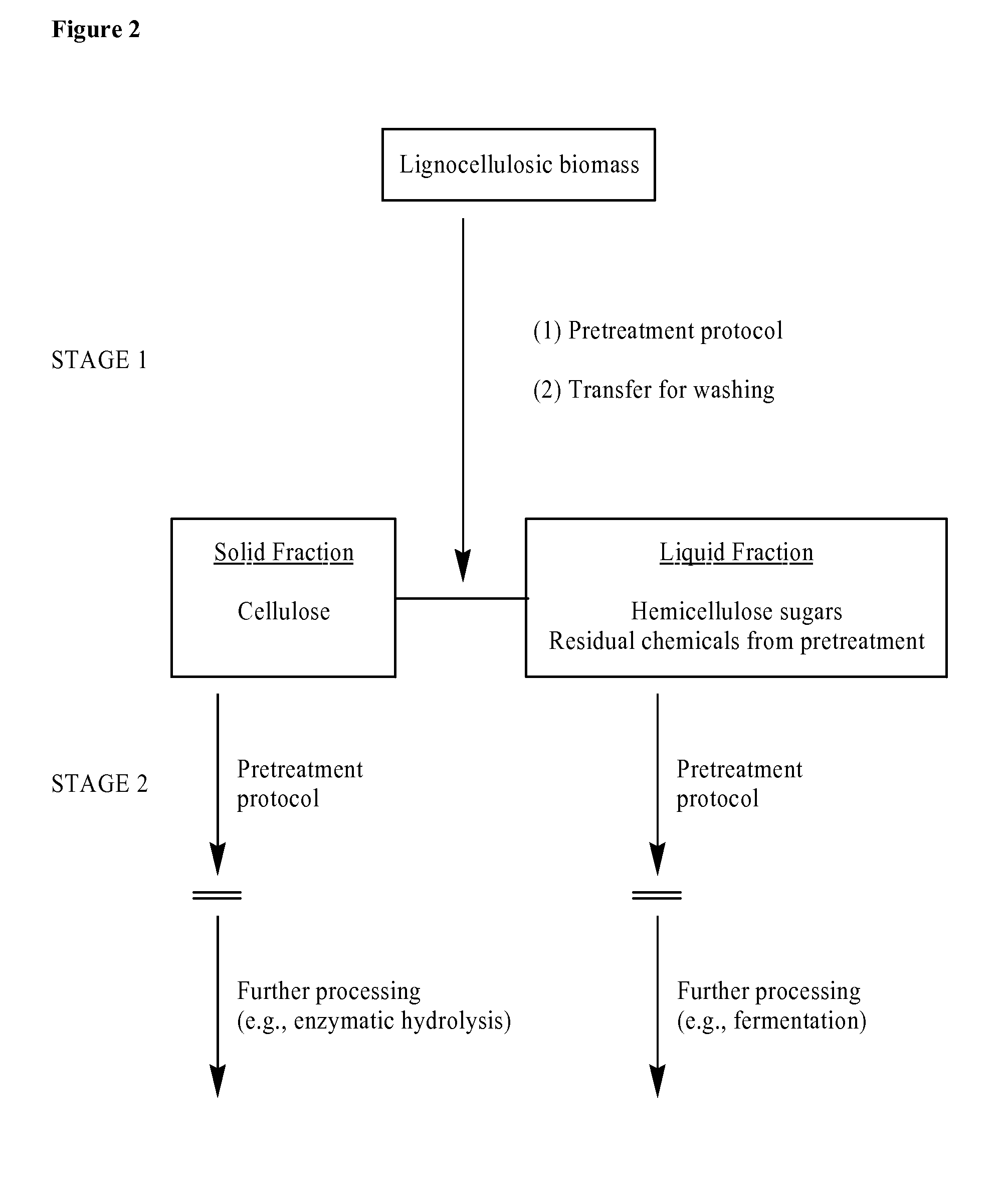

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

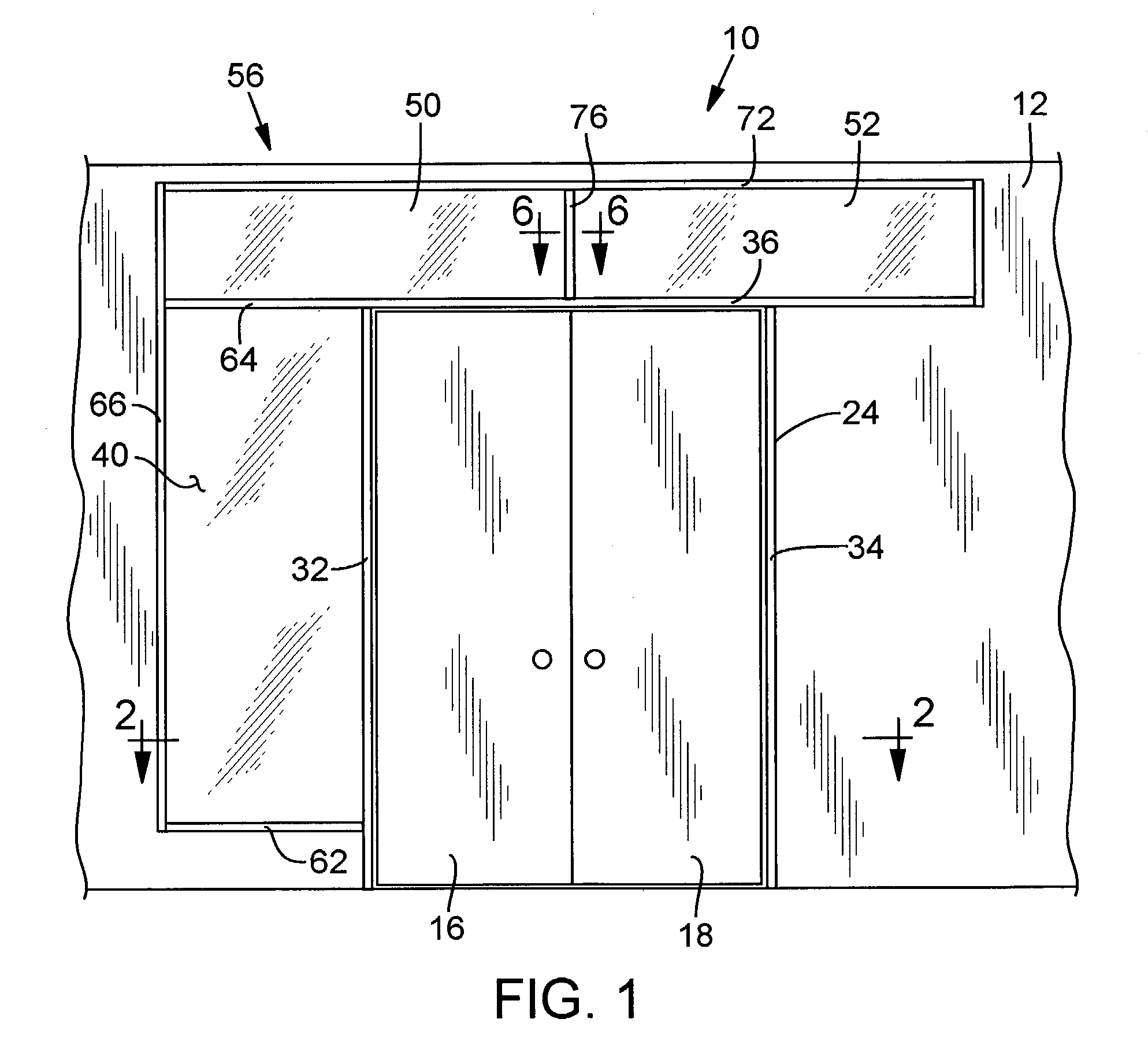

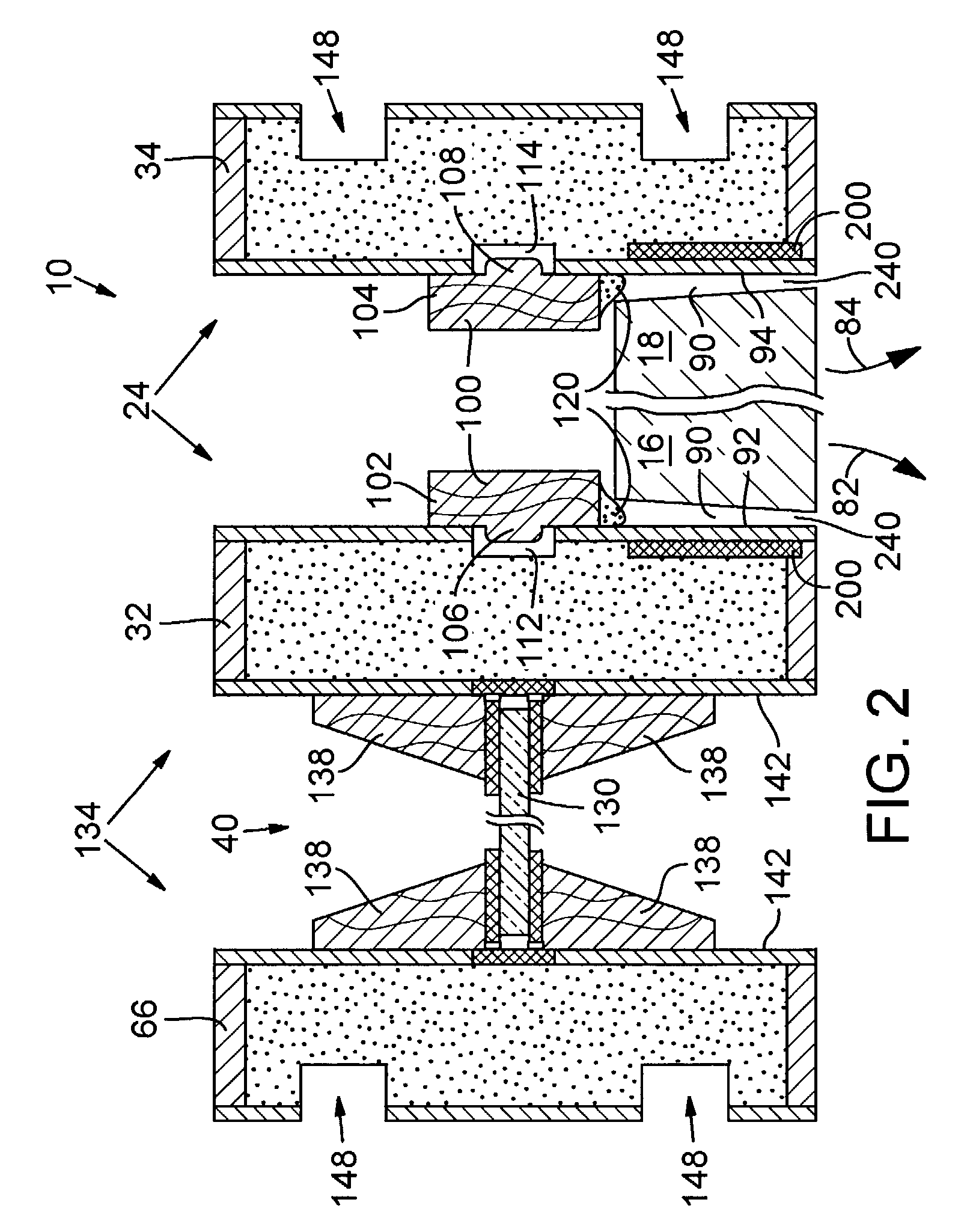

Fire-resistant wood assemblies for building

InactiveUS7059092B2Good lookingPrevent tamperingFireproof doorsWindow/door framesEngineeringWood plank

Door and glazing frames include intumescent material positioned in a dado that is formed in a jamb side surface. Trim materials are positioned over the intumescent material to improve the appearance of the frame and to prevent tampering with and damage to the intumescent material. The jamb trim is preferably made of a cut hardwood panel having a thickness that allows heat to be transmitted to the intumescent material in the event of a fire so that the intumescent material will expand and fill a clearance space between the frame and the door or glazing. The expanded intumescent material inhibits the transmission of smoke and heat between the door and door frame. After expanding, the intumescent material will char and solidify, which may provide an added benefit of structural support for the door and or glazing.

Owner:WASHINGTON HARDWOODS & ARCHITECTURAL PROD

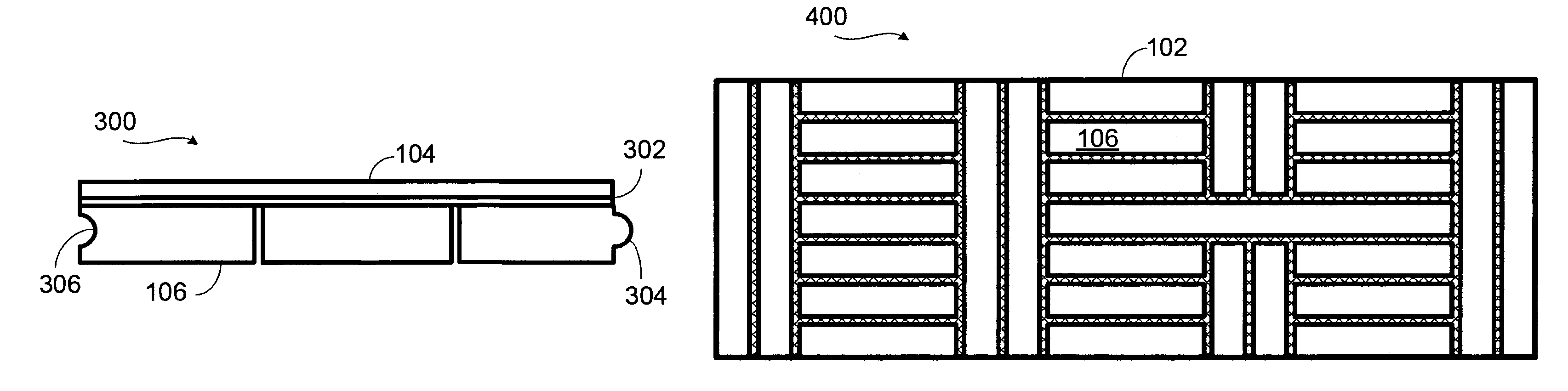

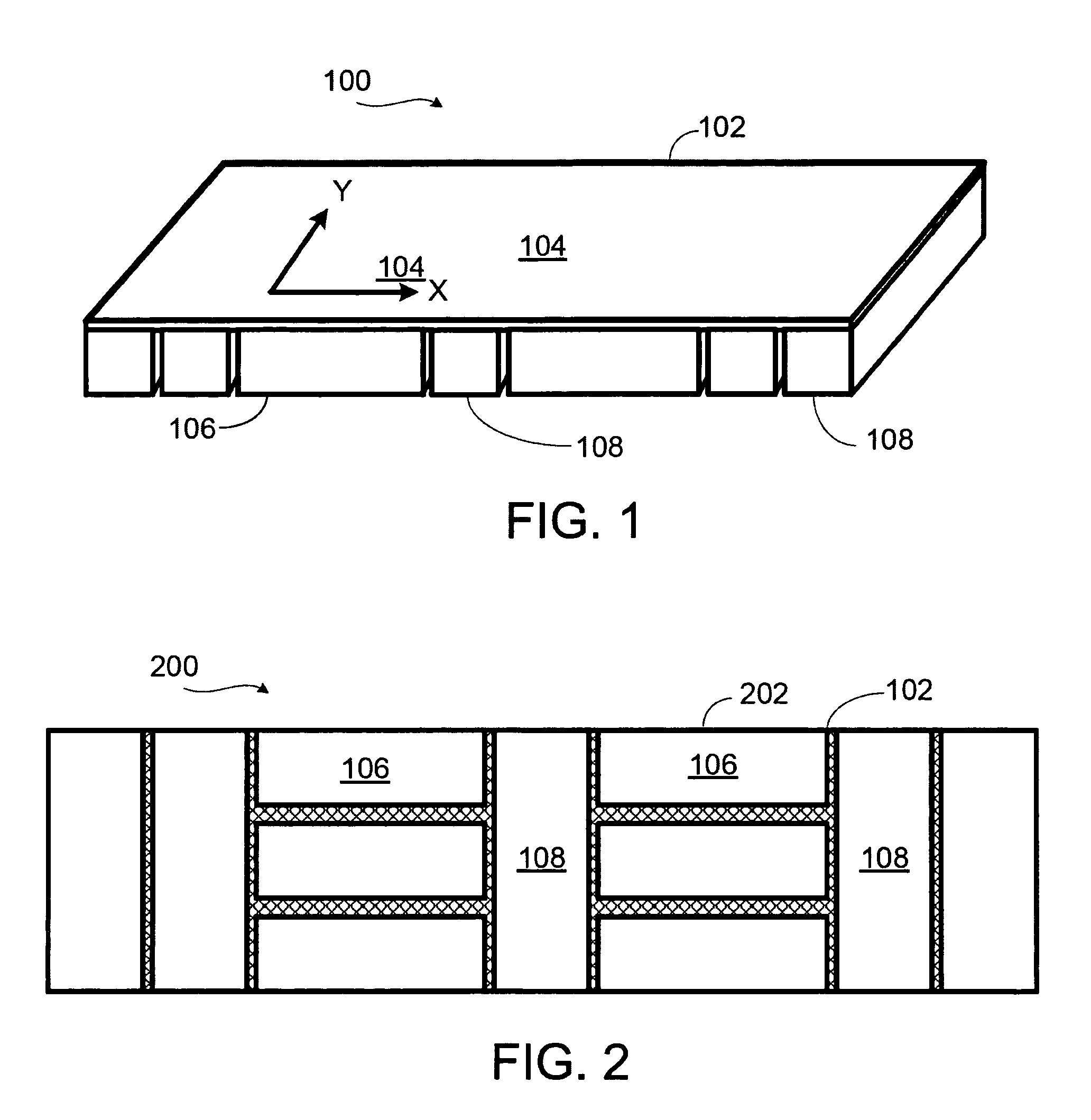

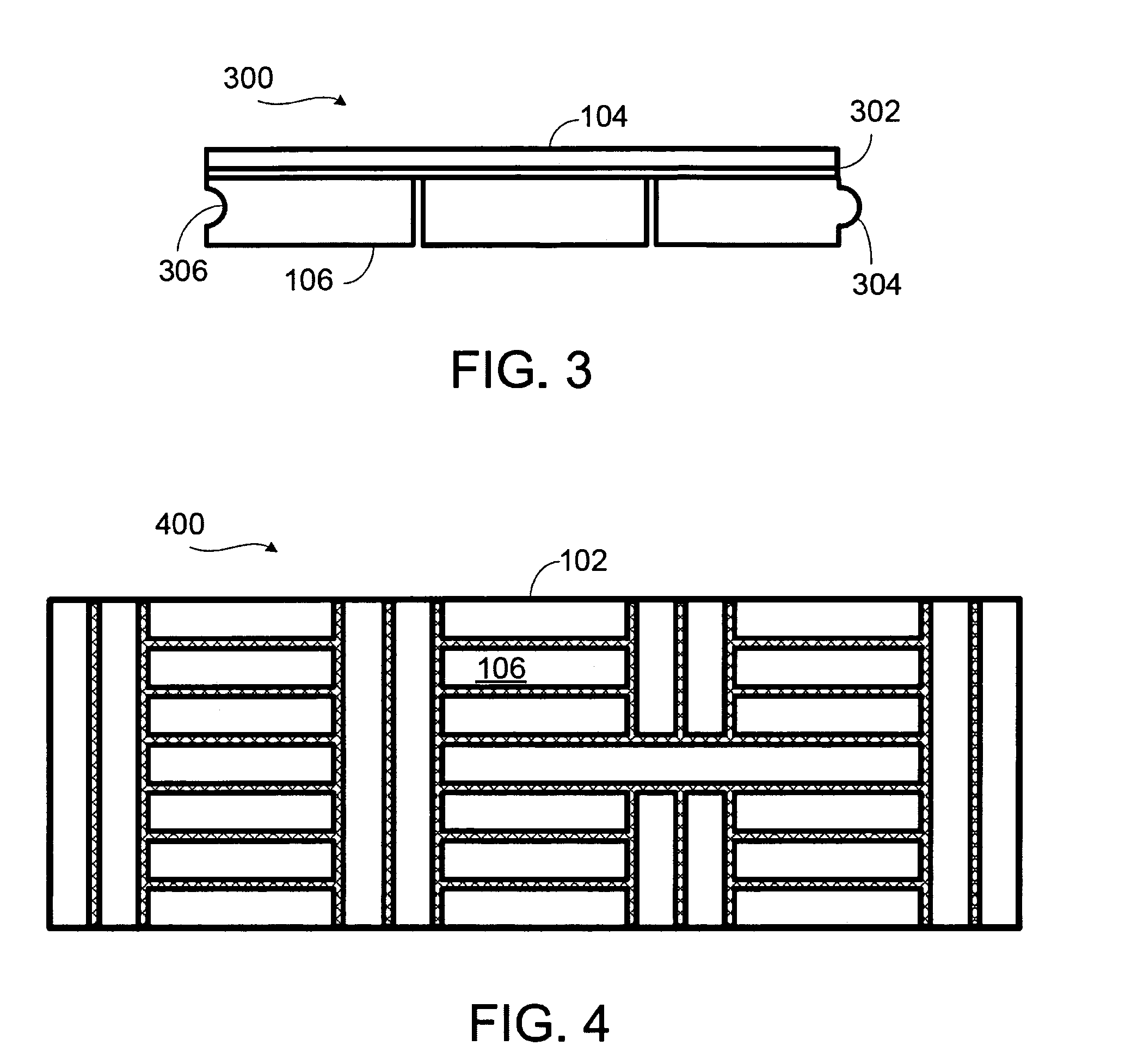

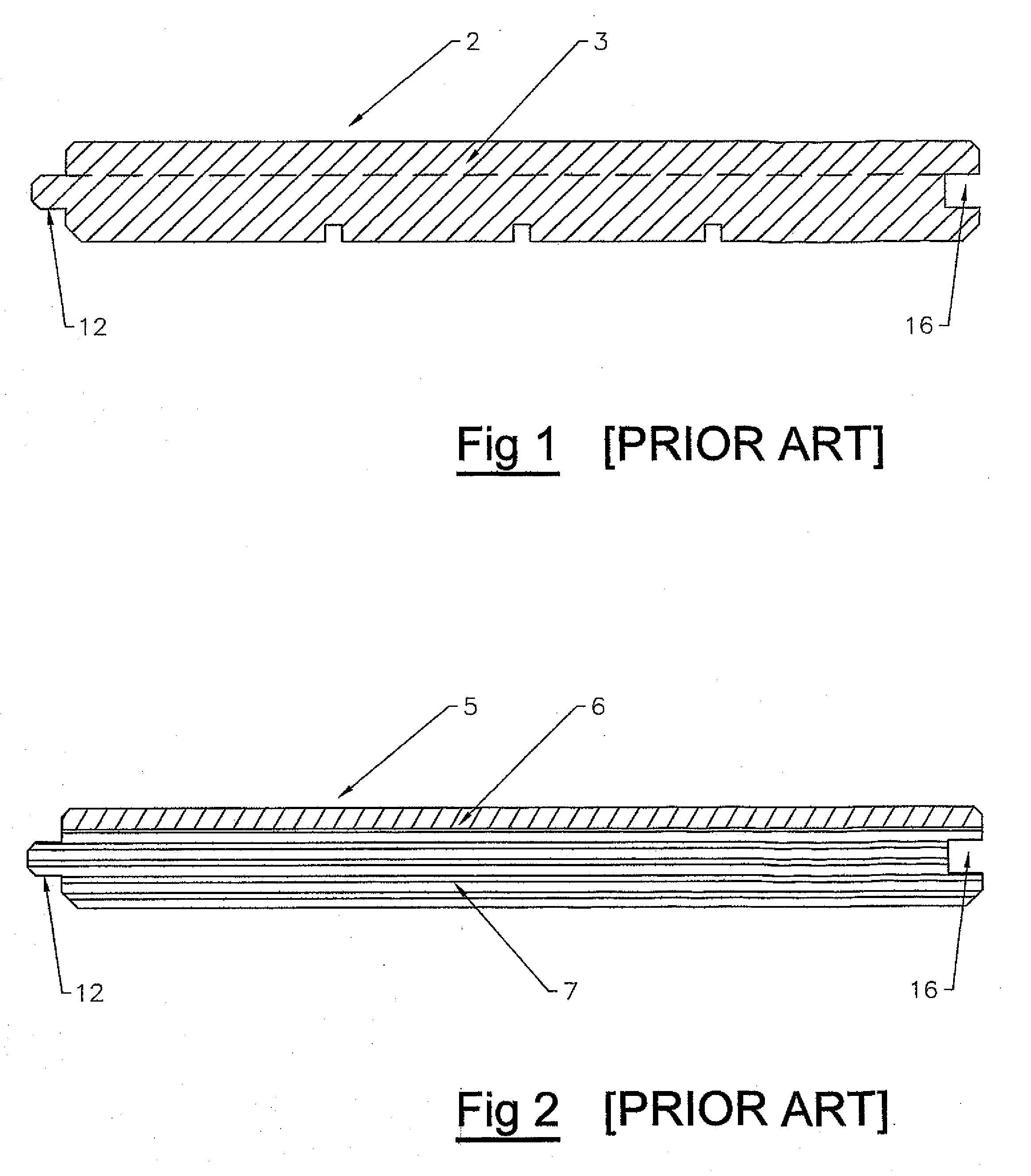

Plywood laminate having improved dimensional stability and resistance to warping and delamination

A plywood laminate having dimensional stability and resistance to warping and delamination is formed from a plurality of higher quality plies and a plurality of lower quality plies. The higher quality plies may be of hardwood and the lower quality plies may be of softwood or lower quality hardwoods, or the higher quality plies may have a veneer grade of better than ANSI / HPVA HP-1-2000 veneer grade C and the lower quality plies may have a veneer grade of no greater than ANSI / HPVA HP-1-2000 veneer grade C. The exposed plies are of the higher quality. In most embodiments, at least two adjacent interior plies are of the lower quality. In those embodiments having a tongue and groove or click-lock edge configuration, the tongue comprises portions of at least two plies and at least one of the plies is a higher quality ply.

Owner:AHF LLC

Horizontally engineered hardwood floor and method of installation

Owner:LIU DAVID C

Tie-to-tree dendrobium officinale cultivation method

InactiveCN102823401AAdaptableReduce the cost of seedling hardeningHorticultureHigh survival rateOrganic fertilizer

The invention provides a tie-to-tree dendrobium officinale cultivation method, comprising the steps of seedling tissue-culture breeding, tissue-culture seedling acclimatization and tie-to-tree cultivation of acclimatized seedlings. The step of tissue-culture seedling acclimatization comprises selection of bottled tissue-culture seedlings, selection and arrangement of a seedling acclimatization medium, selection of seedling acclimatization fertilizer, planting and after-planting management and is characterized in that the seedling acclimatization medium consists of hardwood sawdust and broken stone mixed in a mass ratio of 6.5-7.5:2.5-3.5, and the seedling acclimatization fertilizer is organic fertilizer prepared by fermenting herbivorous animal waste. The step of tie-to-tree cultivation of acclimatized seedlings comprises selection of acclimatized seedlings, selection of cultivation forest land, selection of variety of trees to be tied, seedling tying up and planting management. The tie-to-tree dendrobium officinale cultivation method provided by the invention has the advantages of low planting cost, easiness in management, high survival rate and long harvesting period; moreover, the harvest products have high quality.

Owner:RENHUA XINYU ECOLOGY DEV

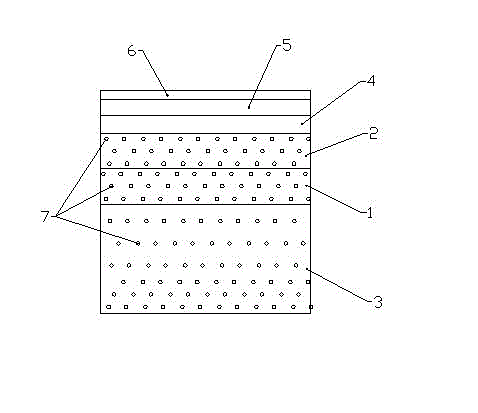

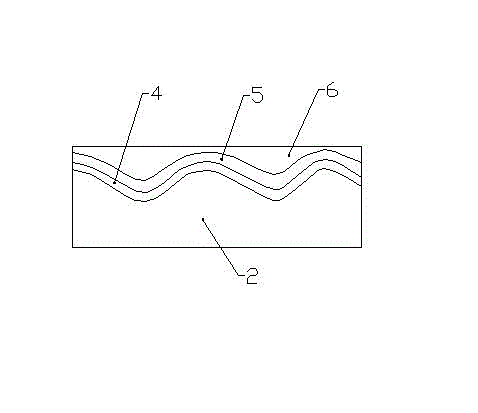

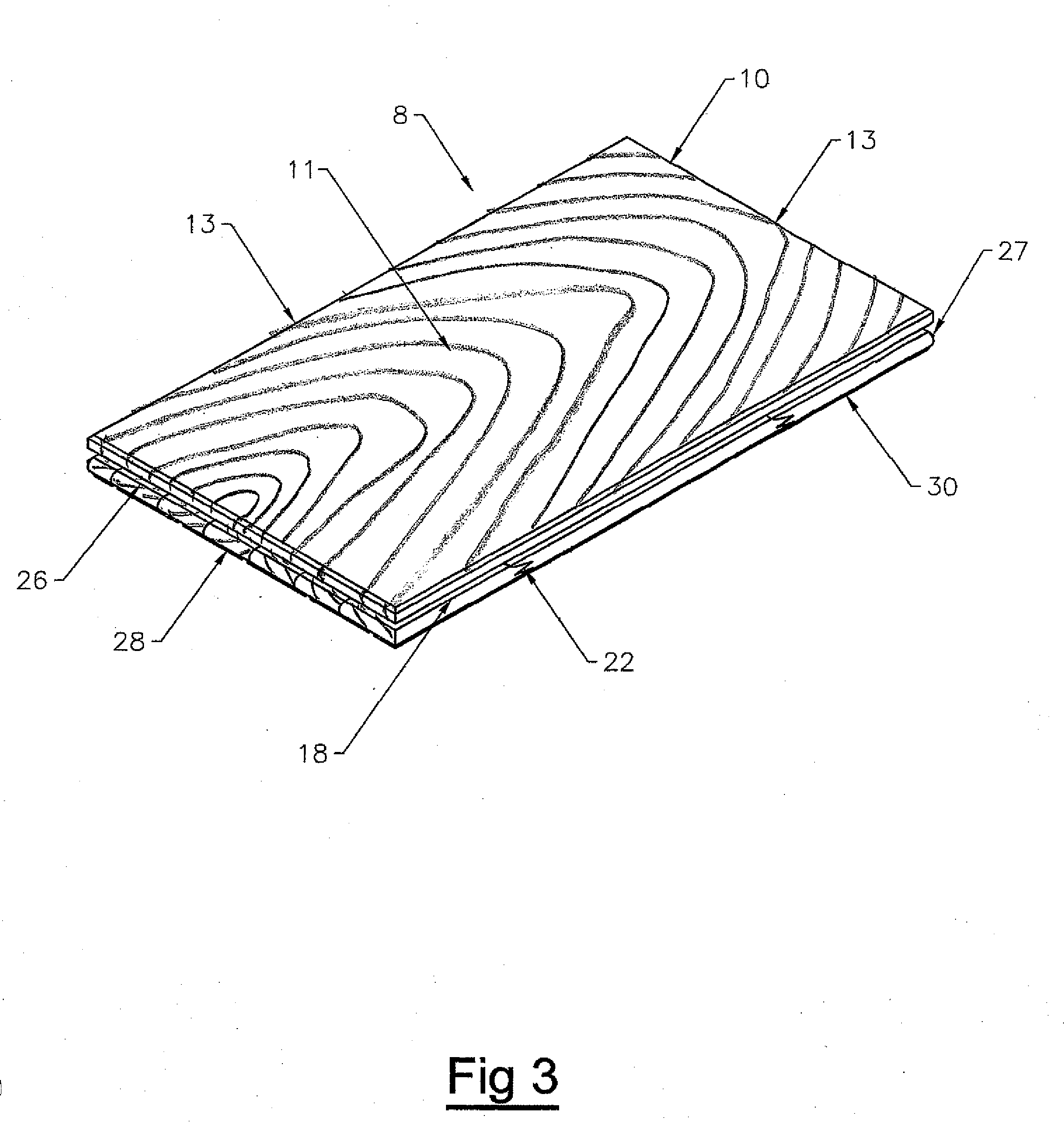

Hardwood flooring board

InactiveUS20060070325A1Maintain hardwood appearanceGood dimensional stabilityConstructions elementsWood layered productsAdhesiveEngineering

The present invention is a hardwood flooring board including a middle layer formed from a non-hardwood flooring material and a hardwood material upper layer which is secured to an upper surface of the middle layer that is thick enough to include decorative designs. The middle layer forms between 45% and 75% of the overall material of the board and enables the board to be manufactured to be more dimensionally stable, i.e., wider and longer, than conventional hardwood flooring boards such that the boards can be more uniformly constructed. Also the use of the non-hardwood material in the middle layer greatly increases the dimensional stability and long term performance of the flooring boards, while providing a genuine hardwood appearance to the floor. The board also includes a lower layer that can be formed from either a hardwood material or a non-hardwood material to function as a base for the board. The upper layer is secured to the middle layer by an adhesive that is urged into the openings or cracks in the upper layer during the assembly of the board to prevent the cracks from spreading through the upper layer when the boards are in use.

Owner:FLOORING SPECTRUM +1

Cellulosic product

InactiveUS20110088860A1Reduce liquid penetrationGood heat sealing performanceFibreboardCosmetic preparationsMicrosphereCellulose fiber

The present invention relates to a process of producing a cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide, (iii) adding thermoplastic microspheres, (iv) dewatering the suspension and forming a cellulosic product. The invention also relates to a process of producing a single layer cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide derived from softwood and / or hardwood and optionally adding thermoplastic microspheres to the suspension, (iii) dewatering the suspension and forming a cellulosic product. The invention further relates to a cellulosic product obtainable from said processes. The invention also relates to a composition comprising microfibrillar polysaccharide and thermoplastic microspheres and the use thereof.

Owner:AKZO NOBEL NV

Cutting propagation method for hard branch of Sabina przewalskii

InactiveCN101243760AShort breeding cycleNeat emergenceCultivating equipmentsHorticulture methodsGreenhousePeat

The invention discloses a method of hardwood cutting propagation of Qilian Juniper, which is characterized in that, annual hardwood of the Qilian Juniper having the age ranges from seven years to ten years is cut as branches; the average length of the branches ranges from 14.0cm to 18.0cm; the average diameter of the branches ranges from 3.0mm to 5.0mm; on the last ten days of April of each year, the branches are inserted into a greenhouse for seedling; the cutting medium is the mixture of peat and perlite mixed according to the proportion of 1:1; the cutting medium is firstly formed into a medium sausage having the length ranging from 13cm to 16cm; then the cutting medium is put in a 58 x 32cm tray and is put on the cutting bed in the greenhouse. The breeding of Qilian Juniper is realized by the method of hardwood cutting propagation. The method has the advantages of reduced seedling period of Qilian Juniper, saved cost and remarkable effect.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

Process of producing xylose and dissolving pulp

ActiveUS20110192560A1High yieldReduce the amount requiredPretreatment with water/steamWashing/displacing pulp-treating liquorsChromatographic separationXylan

The present invention relates to a process for the production of xylose and dissolving pulp from xylan-containing biomass, such as hardwood. The invention is based on prehydrolysis of the xylan-containing biomass with SO2 in specified conditions, followed by chromatographic fractionation, nanofiltration or precipitation crystallization of the xylose-containing prehydrolyzate to obtain a xylose product having a xylose content of at least 55% on DS. The dissolving pulp obtained from the process can be used for example for the production of viscose.

Owner:DUPONT NUTRITION BIOSCIENCES APS

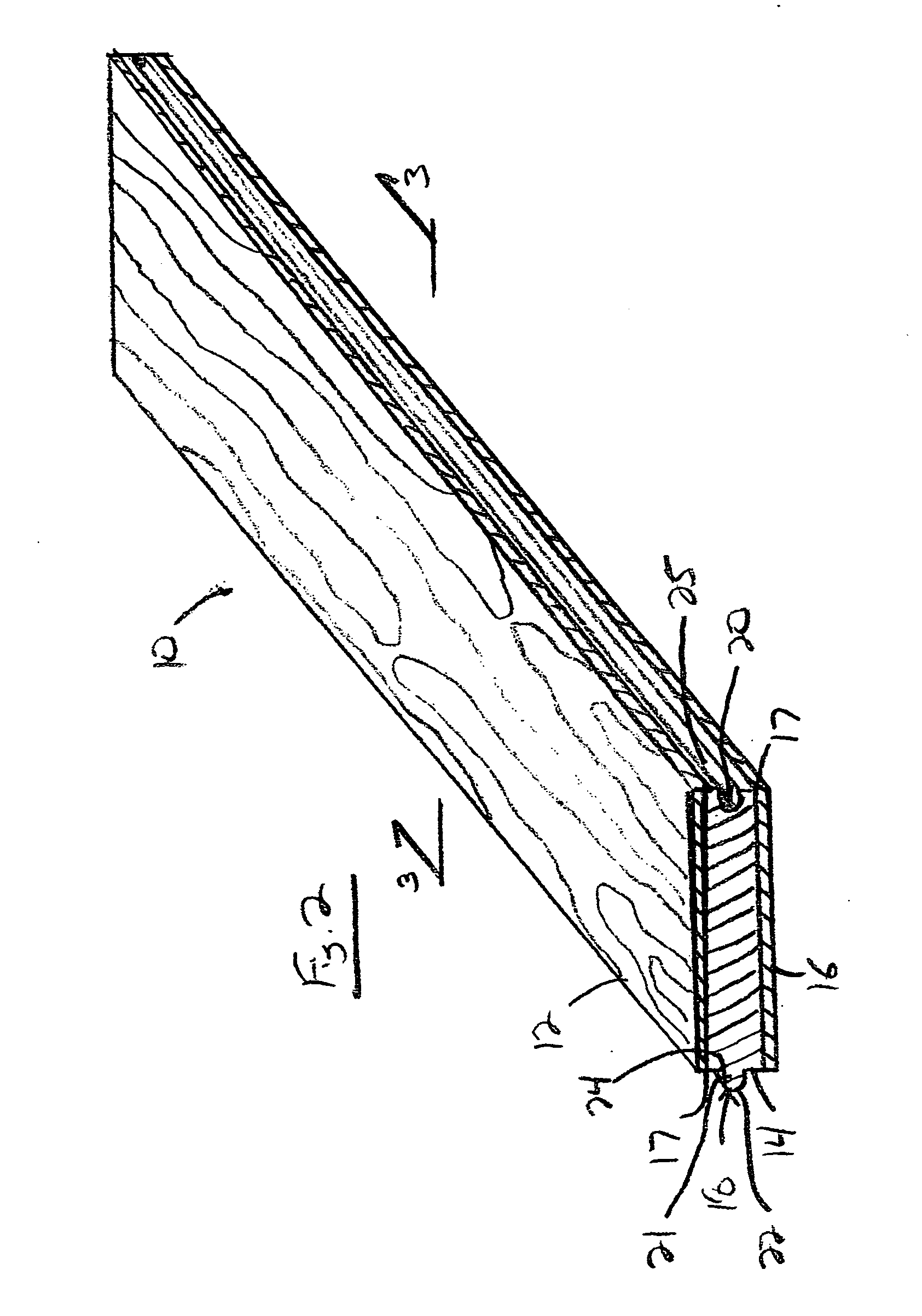

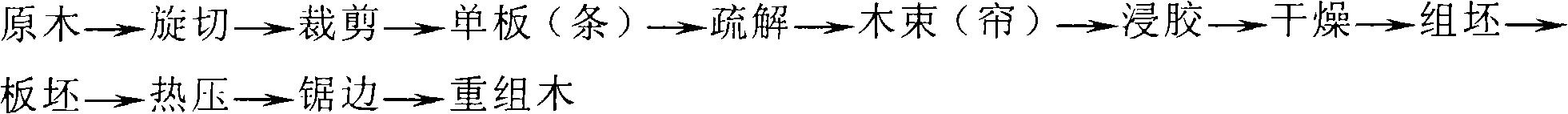

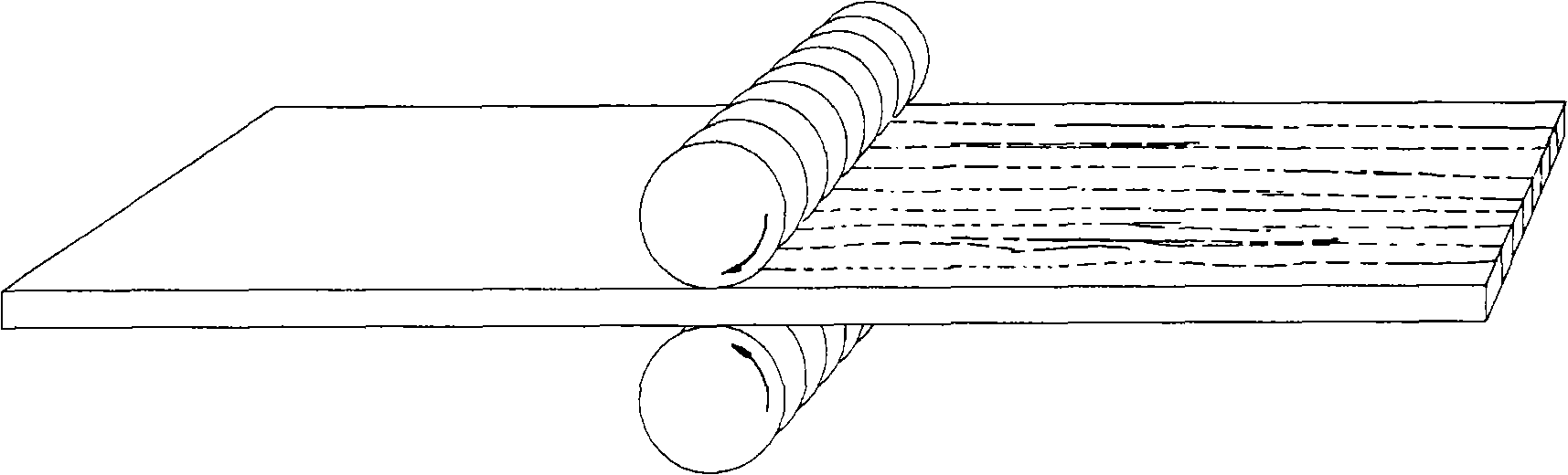

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

White-surface coated craft paper and production method thereof

ActiveCN102912689AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentRegenerating fibers

The invention discloses white-surface coated craft paper and a production method thereof. The white-surface coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer of the white-surface coated craft paper are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: mixing the bleached hardwood pulp, bleached softwood pulp and bleached regenerated fiber pulp DIP at any proportion, and manufacturing paper through a paper layer to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the white-surface coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

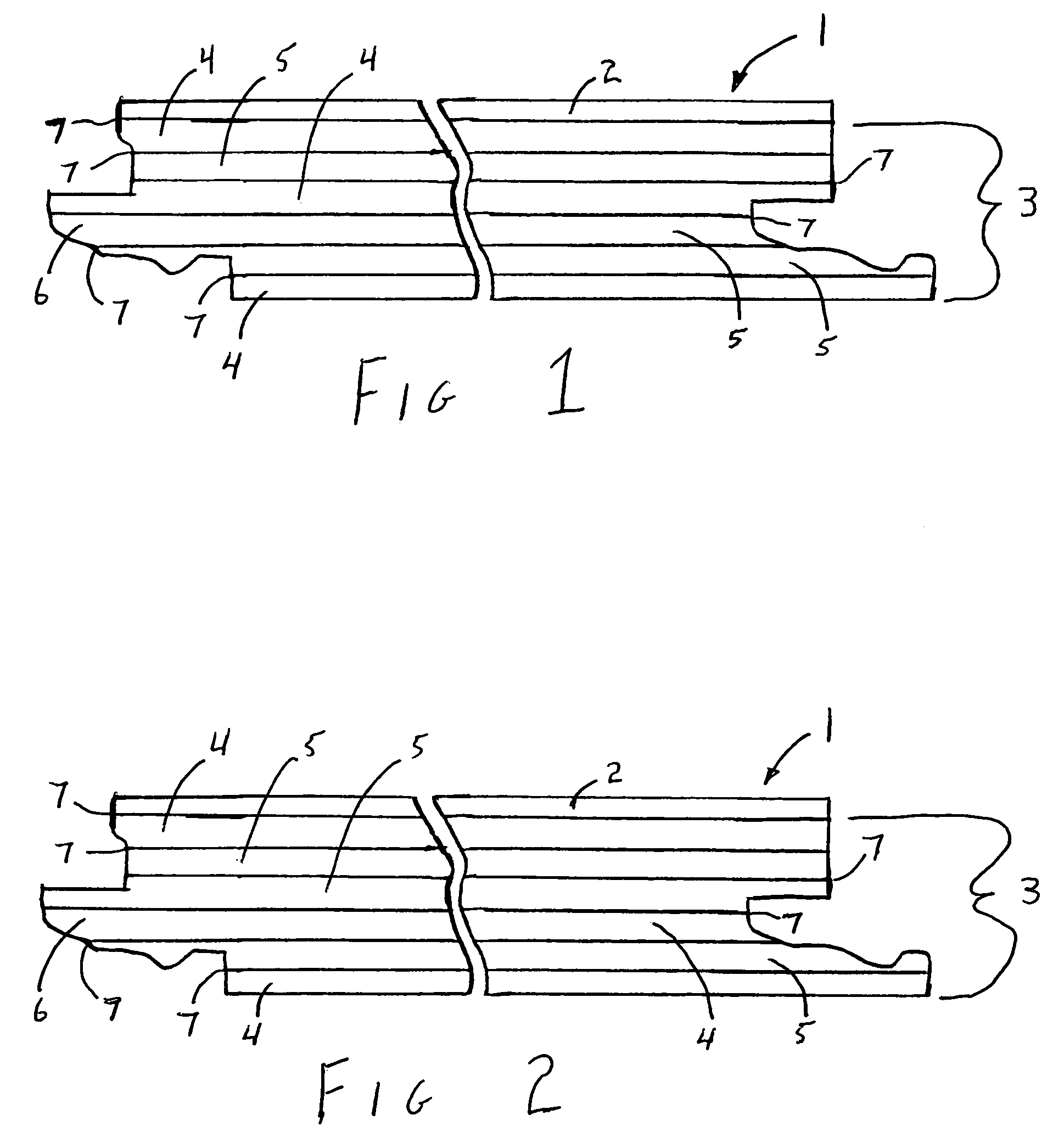

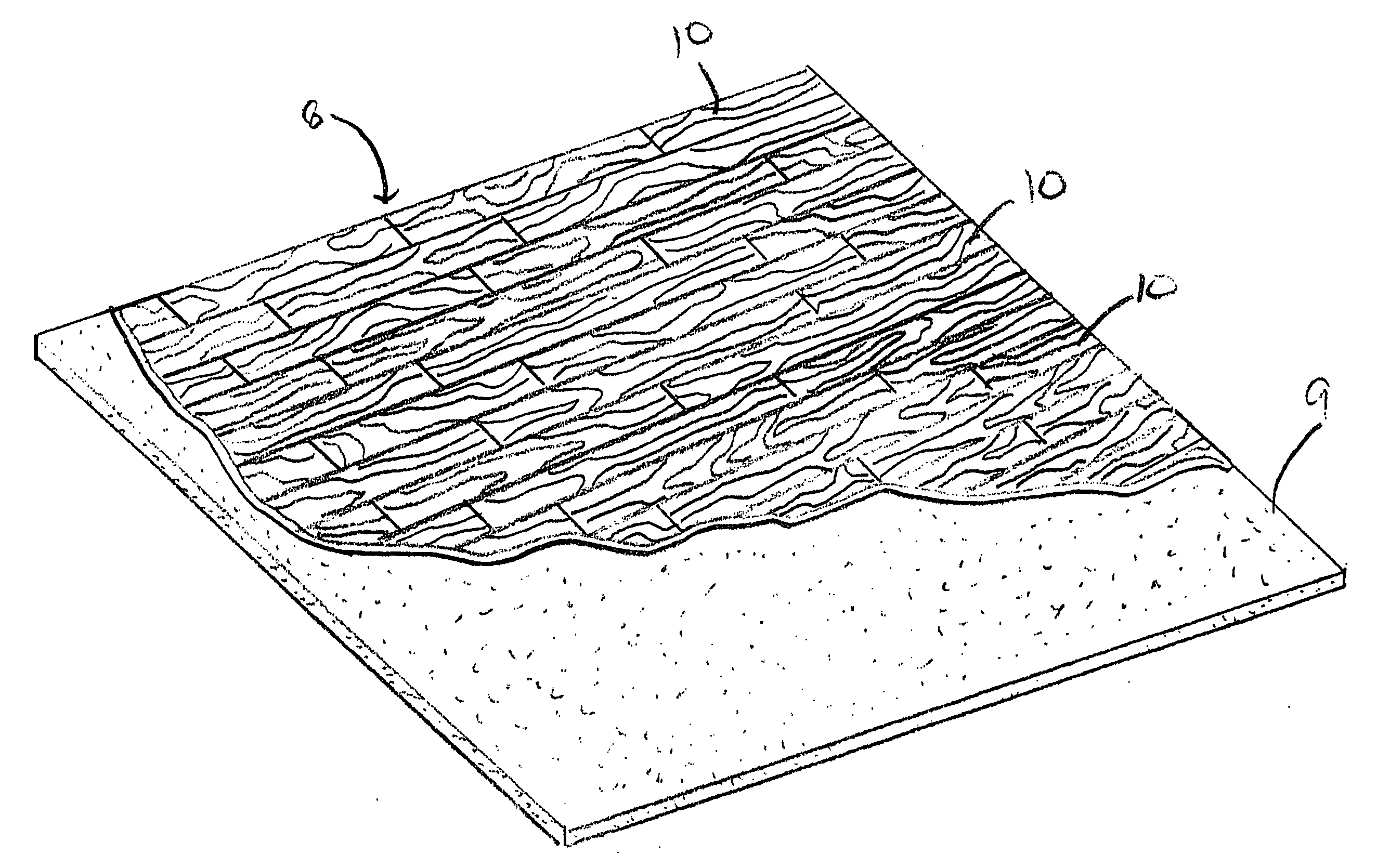

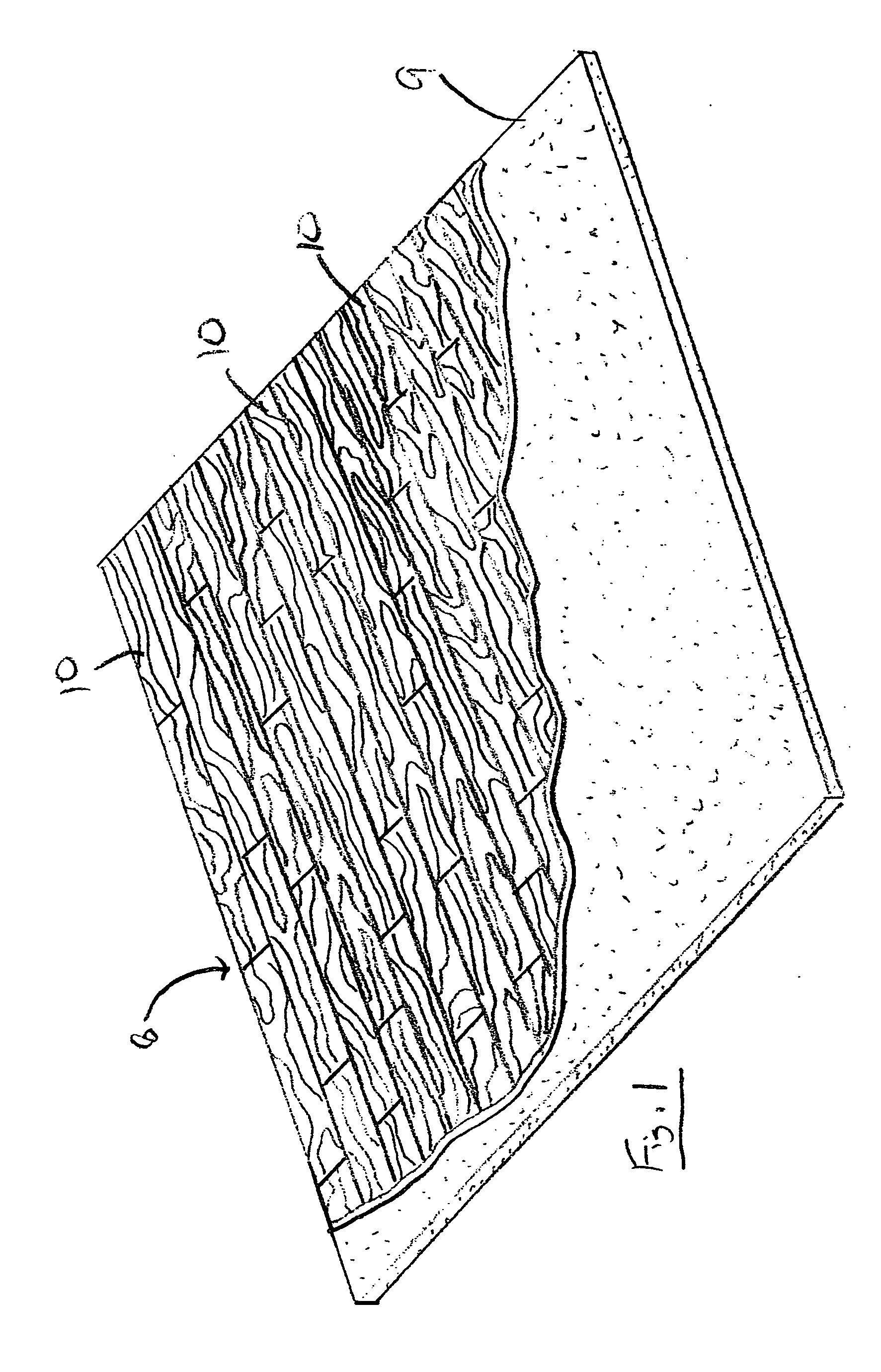

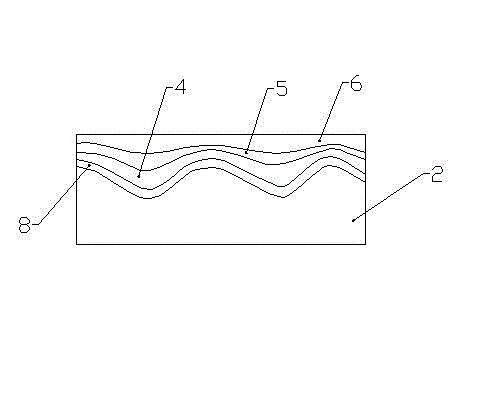

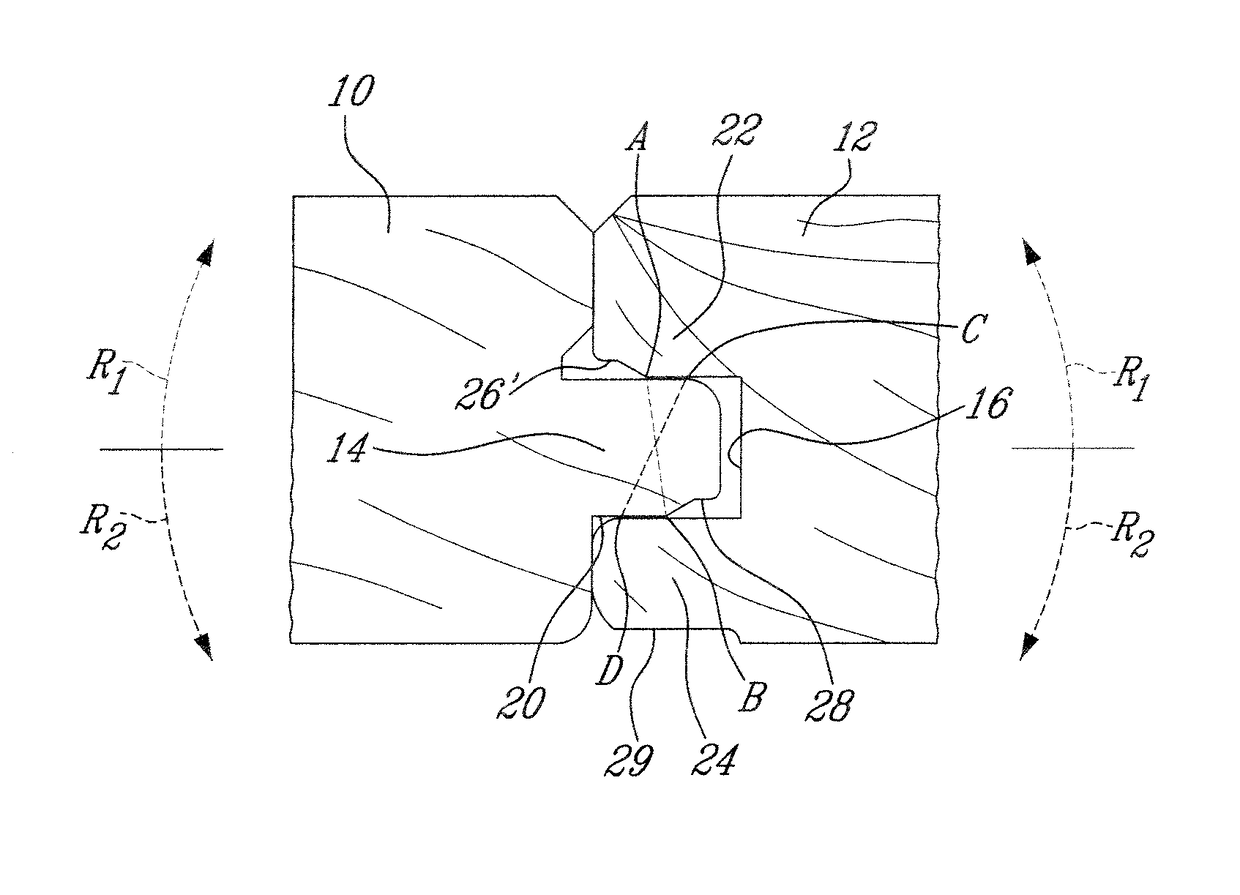

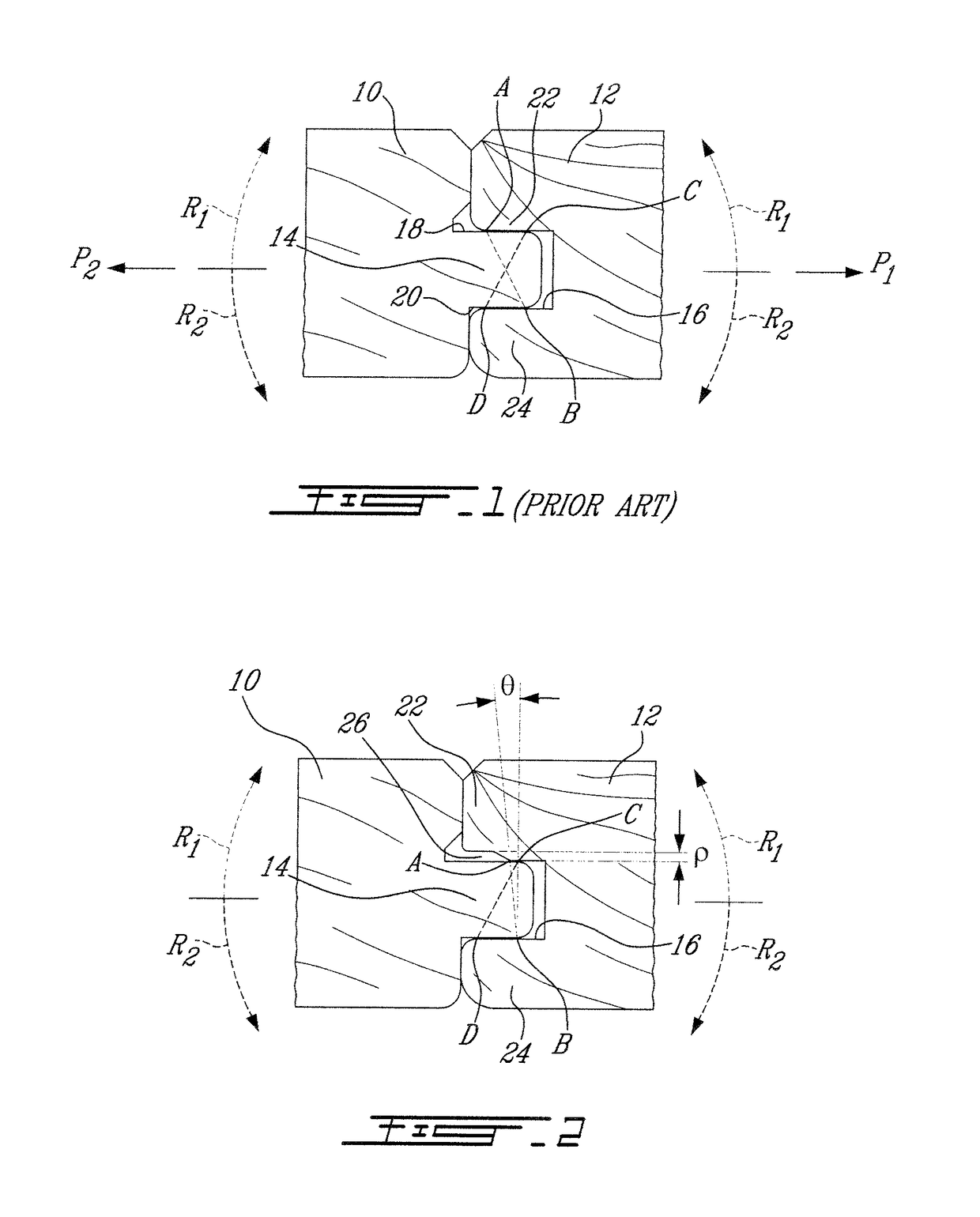

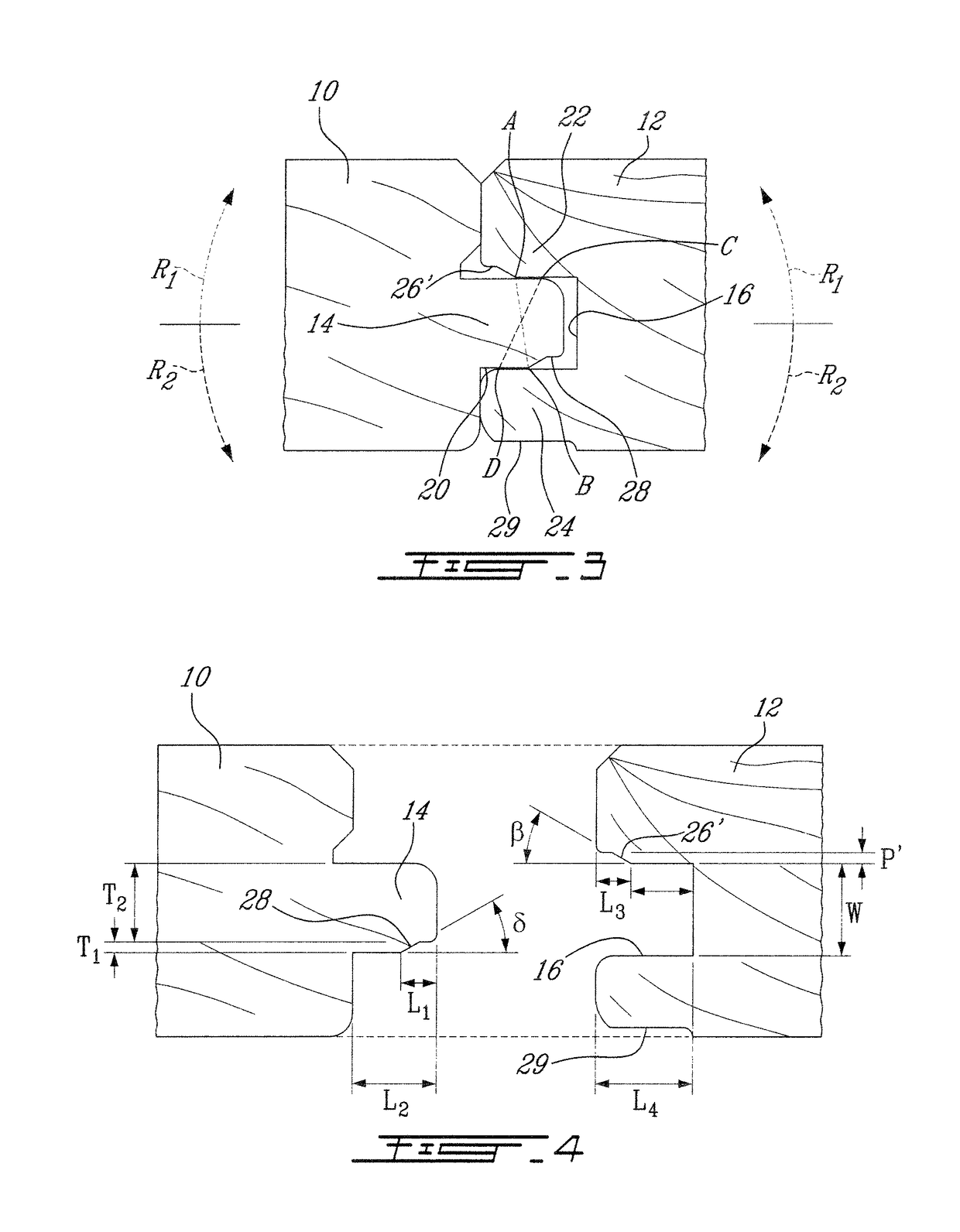

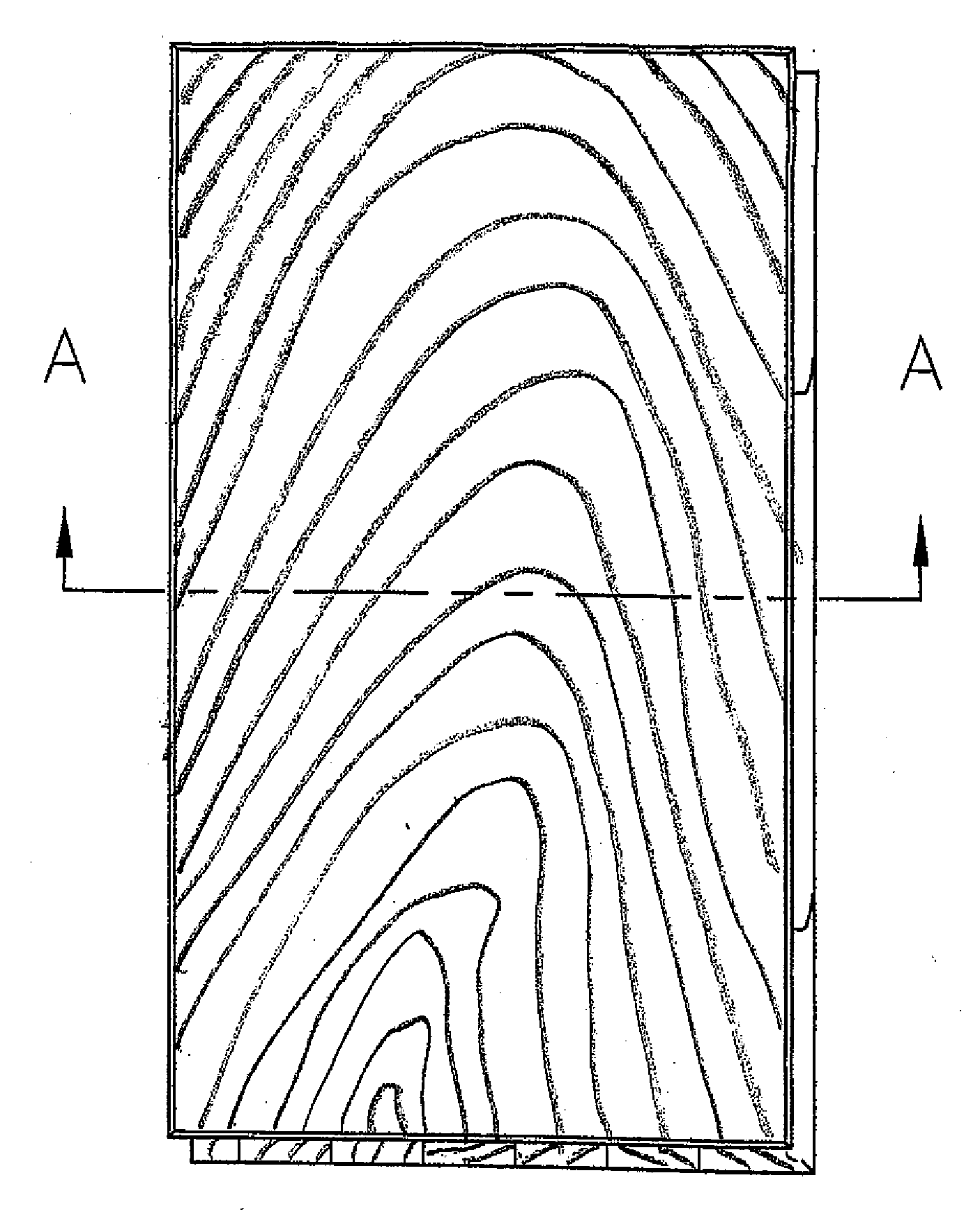

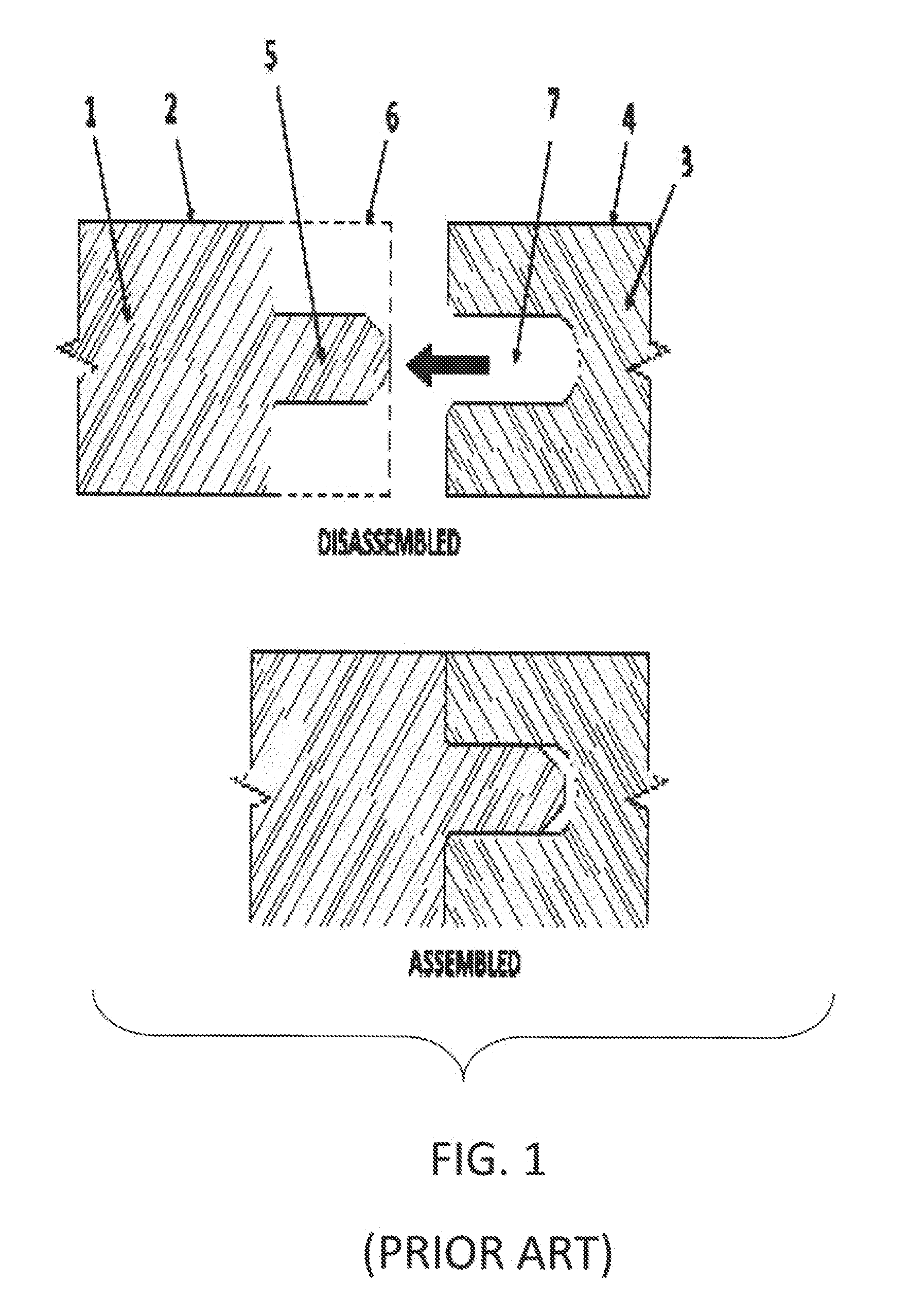

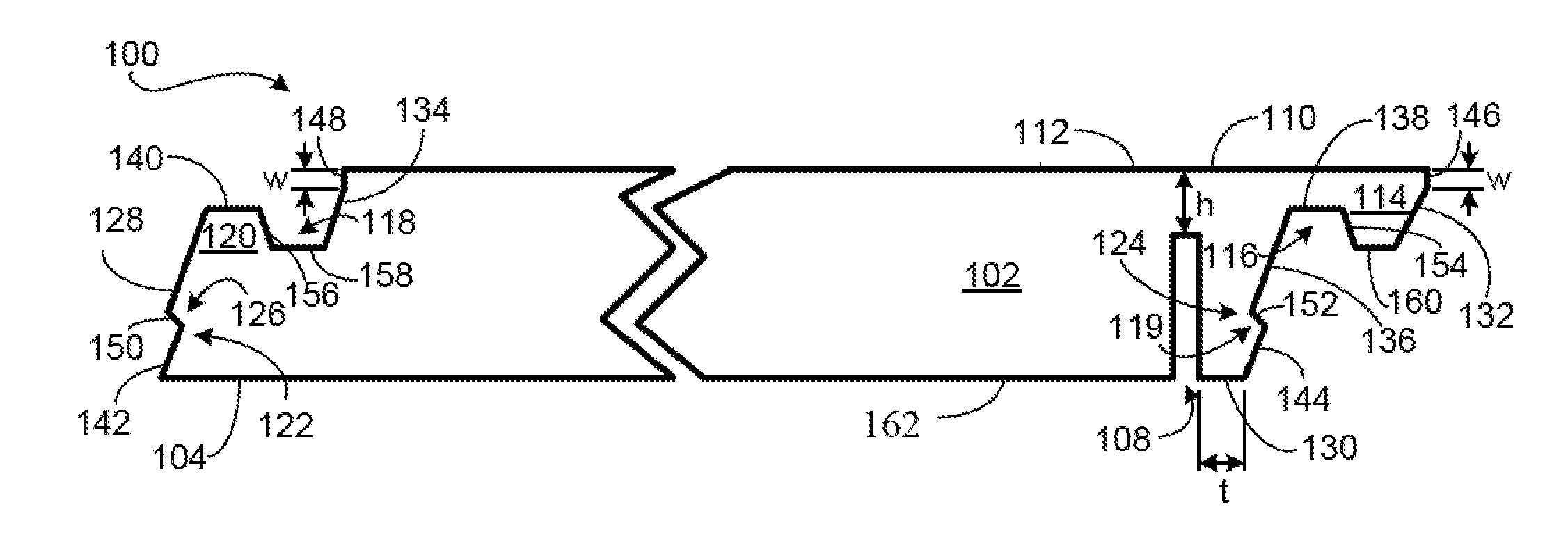

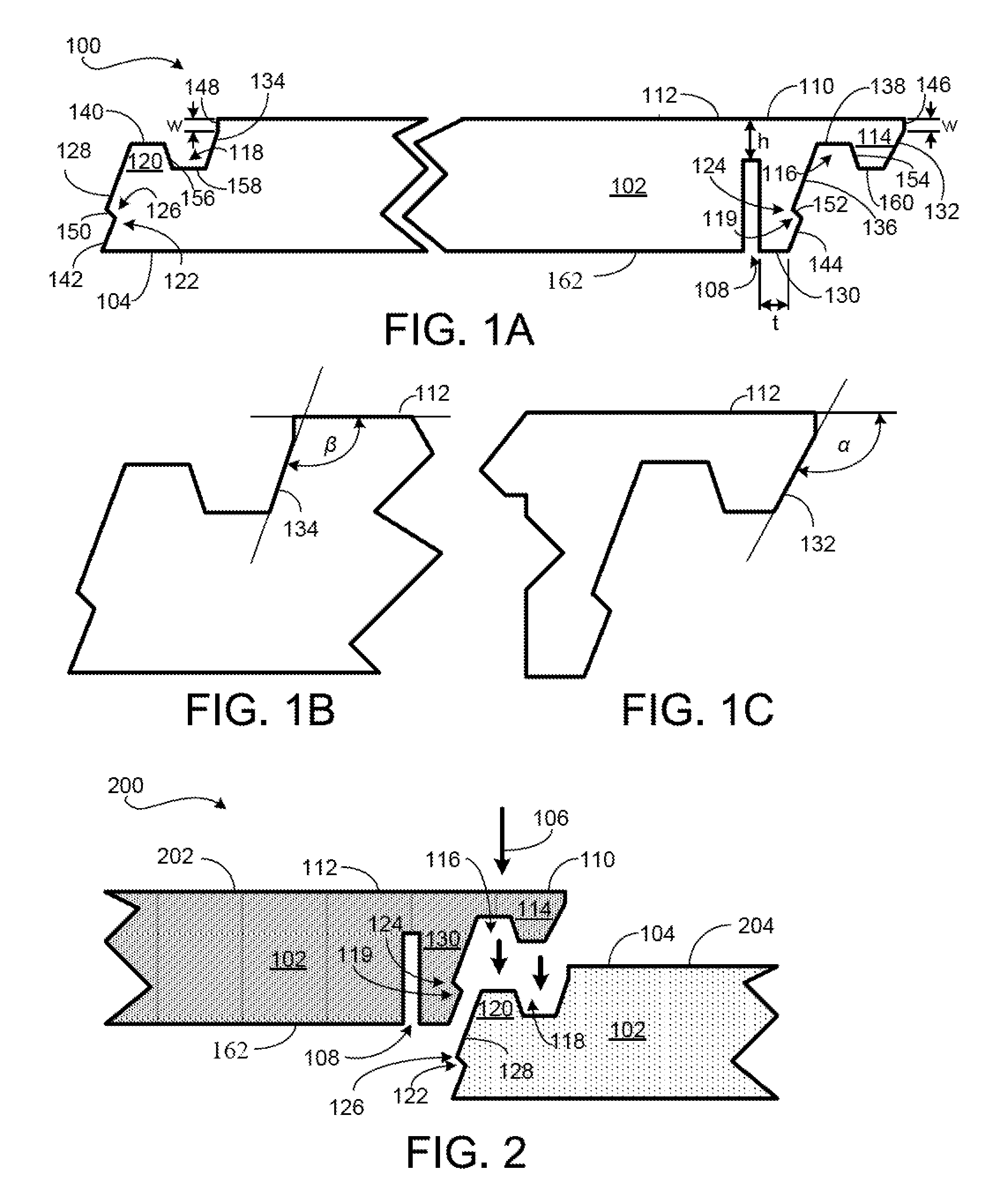

Pivotably detachable hardwood floorboards

A floorboard assembly comprises first and second solid wood floor boards (10) and (12). The first floor board (10) has a tongue (14) extending longitudinally along a first side thereof. The second floor board (12) having a groove (16) extending longitudinally along a second side thereof. The groove (16) has a width defined between a top lip (22) and a bottom lip (24). The tongue (14) is insertable in a tight fit manner in the groove (16) to prevent translational separation of the boards (10, 12) in a common plane thereof. A clearance (26, 26′, 28, 32, 32′, 32″, 36 and 38) is provided between the tongue (14) and the groove (16) at one of a tip portion of the tongue (14) and an outermost portion of the top and bottom lips (22, 24) of the groove (16). The clearance (26, 26′, 28, 32, 32′, 32″, 36 and 38) is configured to allow angular withdrawal of the tongue (14) from the groove (16) by manually pivoting the first and second floor boards (10, 12) towards one another in one of an upward and a downward direction.

Owner:RENE ST CYR 1996

Hardwood Flooring System

InactiveUS20080184647A1Superior hydroscopic dimensional stabilityProvide durabilityConstruction materialStrutsSolid woodEngineering

An improved fabricated hardwood flooring product providing the advantage of a thick wood wear layer similar to a traditional ¾ inch solid wood floor with the dimensional stability characteristics of engineered wood floor products.

Owner:BEST WOODS

Soft material solid-wood reinforced board and its producing method

ActiveCN101007415AImprove use valueOvercoming odd problemsCork treatment detailsVolumetric Mass DensityNormal conditions

A soft material quality wood material strengthening board is flat plate. It is characterized by: it has natural grains of raw wood, its color is the mixture color of raw wood self color, charring color and resin color, the density is 450-720kg / m<3>, surface hardness is 25-65MPa, vertical MOR is 35 - 90MPa, vertical elastic modulus is 1~10GPa, resin content (solid content) is 3% - 10%. The strengthening board can be produced floors or furniture raw materials after preliminary working, drying, rough planing, heating, resin soaking, hot pressing, placing in normal condition and fine finishing. The invention produces the strengthening board using soft material as raw material, covers the shortage of hardwood product raw materials, it increases the use-value of soft material, while meets the popular consumer demand of liking wood, and provides new materials for hardwood furniture and flooring manufacturing industry.

Owner:ZHEJIANG NENGFU TOURIST PRODS

Traditional Chinese medicine health-care tipping paper and production method thereof

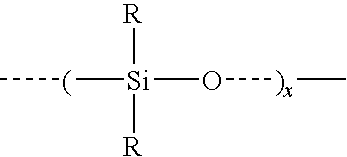

InactiveCN103741553AImprove toughnessImprove water resistanceSpecial paperNon-macromolecular organic additionSodium sulfatePaper sheet

Traditional Chinese medicine health-care tipping paper is prepared from the following raw materials in parts by weight: 90-100 parts of softwood pulp, 40-50 parts of hardwood pulp, 2-3 parts of methyltriethoxysilane, 1-2 parts of sodium lignosulfonate, 1-2 parts of aerosol-OT, 2-3 parts of ?, 1-2 parts of sodium tripolyphosphate, 4-7 parts of bentonite, 1-2 parts of ascorbic acid, 1-2 parts of chitosan, 4-6 parts of kaolin powder, 1-2 parts of bamboo charcoal powder, 2-3 parts of carboxymethyl starch, 1-2 parts of sodium persulfate, 1-2 parts of soybean oil, 1-2 parts of green tea powder, 1-2 parts of pseudo-ginseng powder, 1-2 parts of gynostemma pentaphyllum powder and 1-2 parts of castanea mollissima leaf powder. The technological effects comprise that by adding traditional Chinese medicine health-care compositions such as pseudo-ginseng, gynostemma pentaphyllum and the like, the health-care performance is increased; also when a smoker keeps a cigarette holder in mouth, harm of smoking is reduced; and also, by adding ester materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance and reduced in water absorbing property, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

A kind of food packaging paper and production method thereof

The invention discloses a food wrapping paper and a production method thereof. Poplar chemical mechanical pulp, bleached kraft softwood pulp and bleached kraft hardwood pulp are used as fiber raw materials. Sizing, desanding and degassing, sizing, fine sieving, wire dehydration forming, pressing, pre-drying, surface sizing, post-drying, calendering, coiling, and packaging to form food packaging paper. The present invention uses the surface sizing treatment method to process the product, and adds a starch surface sizing agent to the surface sizing to improve water resistance and adds a small amount of sizing agent alkyl ketene dimer to the surface sizing glue, which can Improve the retention rate, save costs, and make products more cost-effective.

Owner:YUEYANG FOREST & PAPER CO LTD

Method for raising seedlings of llex integra by cutting

The invention belongs to the technical field of plant agamous propagation and provides a method for raising seedlings of llex integra by cutting, which solves the technical problem that the conventional agamous propagation of the llex integra is difficult. The method comprises the following steps of: shearing spikes of a one-year-old half-lignified branch or an annual half-lignified hardwood branch, soaking the sheared one-year-old half-lignified branch or annual half-lignified hardwood branch into a blended hormone solution of an NAA, a DMSO and a VC or a PVP, inserting the soaked one-year-old half-lignified branch or annual half-lignified hardwood branch into a substrate prepared by mixing turf, vermiculite and perlite, and performing rooting culture management in a small sealed row cover. The technique for raising seedlings by cutting provided by the invention fulfils the aims of high rooting rate and simple operation and solves the problem that the agamous propagation of the llex integra is difficult. The obtained nursery stocks are excellent in quality and can adapt to the climatic environment in most parts of the Yangtze River Delta in China. The method of the invention has very important function and significance for the protection and reasonable development and use of the llex integra resource.

Owner:NINGBO ACAD OF AGRI SCI

Scouring process for grass pulping course

ActiveCN101082188AQuality exceedsWashing/displacing pulp-treating liquorsPulp and paper industryEngineering

The invention provides a washing process in the grass pulping. It contains the following steps: A) send the cooked pulp into the presser for pressing to get the coarse pulp. B) Process the coarse pulp through the jumping screen. C) Send the screened pulp into the pulp washer for washing. The rigidity of the screened pulp is potassium permanganate value 16-28 (equals to karber value 24-50). The washed solvent remains 90-150ppm. Take the high rigidity pulp in this invention as materials to prepare bleaching chemical pulp by pressing and washing. The whiteness of the chemical pulp is 68-82%ISO and the removal rate of the lignin is 84-98%. The quality of the bleaching chemical pulp prepared by the grass is similar, even better than that of the exciting hardwood pulp.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Embossed fibrous structure product with enhanced absorbency

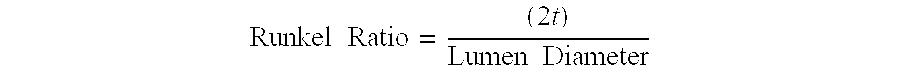

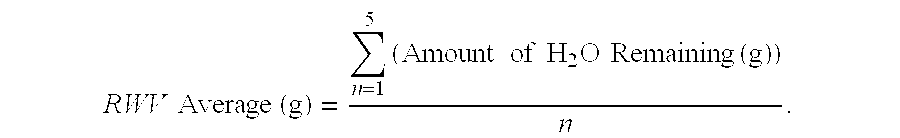

A fibrous structure product comprising one or more plies of fibrous structure; a basis weight from about 10 lbs / 3000 ft2 to about 50 lbs / 3000 ft2; from 16% to about 40% of hardwood fibers, in one embodiment eucalyptus fibers, wherein the starting hardwood fibers have a Runkel Ratio of from 4.5 to about 15 and a fiber count of from about 12 fibers / gram to about 35 fibers / gram; and a Residual Water Value from about 0.001 to about 0.18. In one embodiment the product comprises two or more plies of fibrous structure, a basis weight from about 25 lbs / 3000 ft2 to about 50 lbs / 3000 ft2 and from about 23% to about 40% of hardwood fibers. In another embodiment at least one of the piles of the fibrous structure product further comprises a plurality of embossments thereon comprising an embossment height of from about 600 μm to about 1,200 μm.

Owner:THE PROCTER & GAMBLE COMPANY

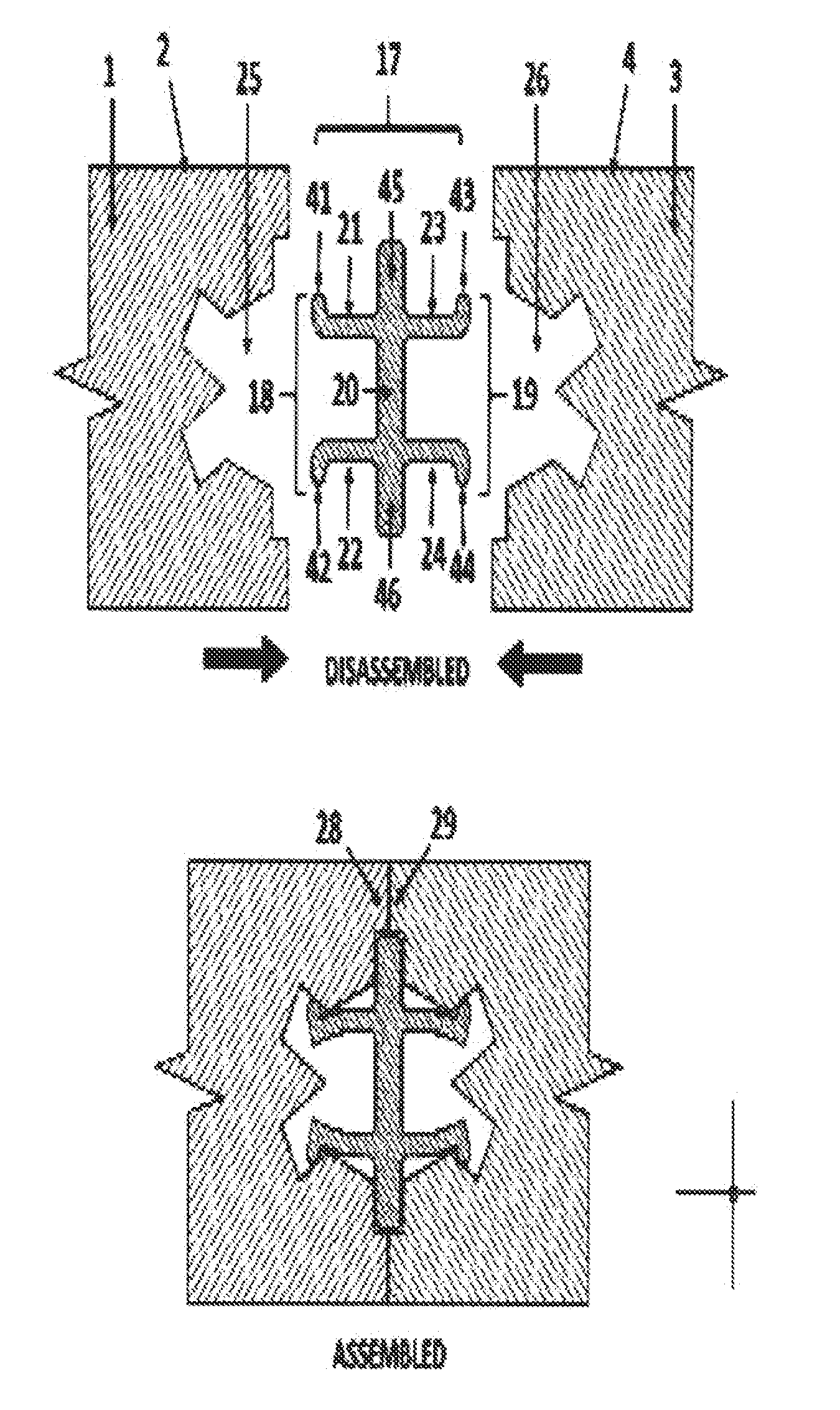

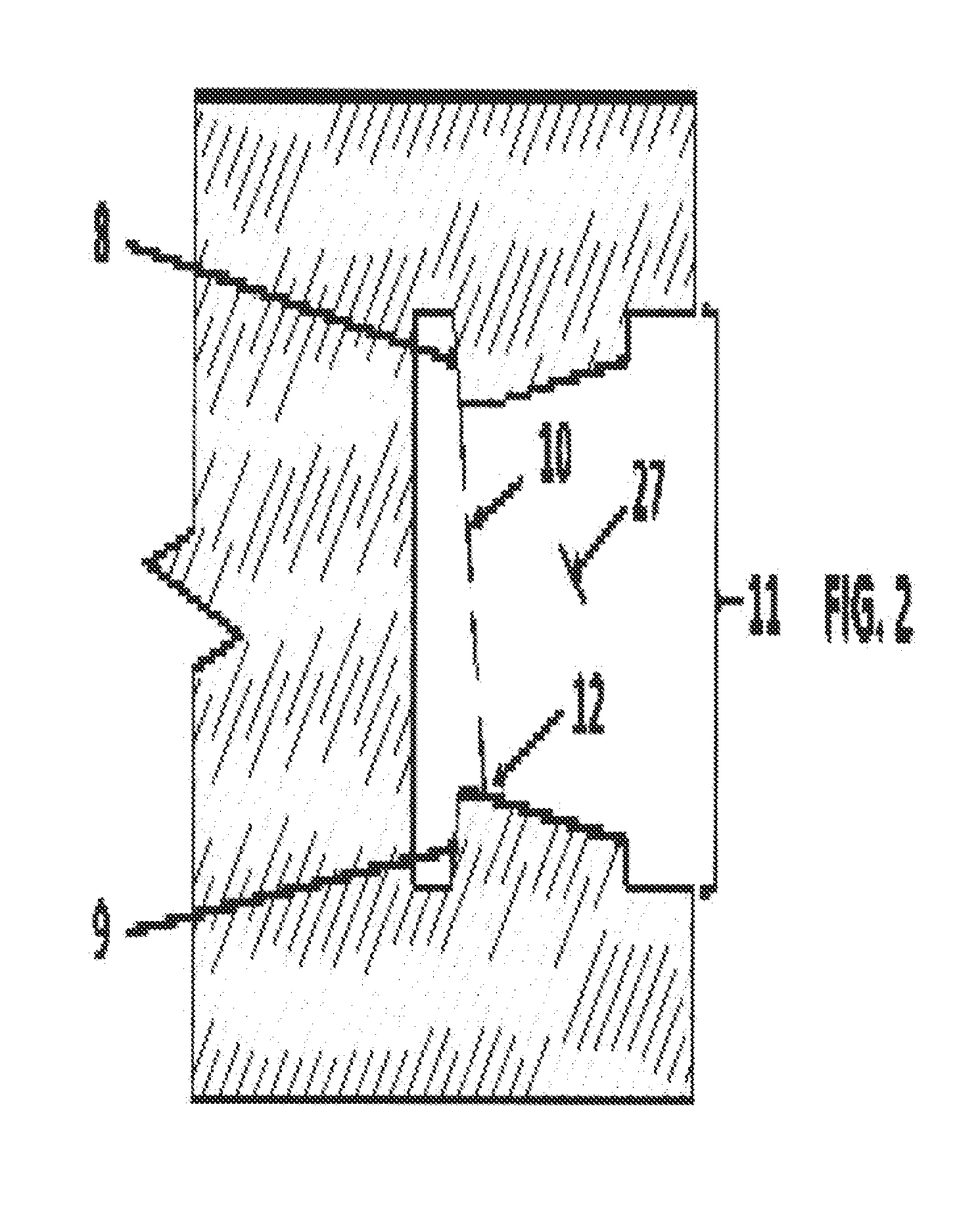

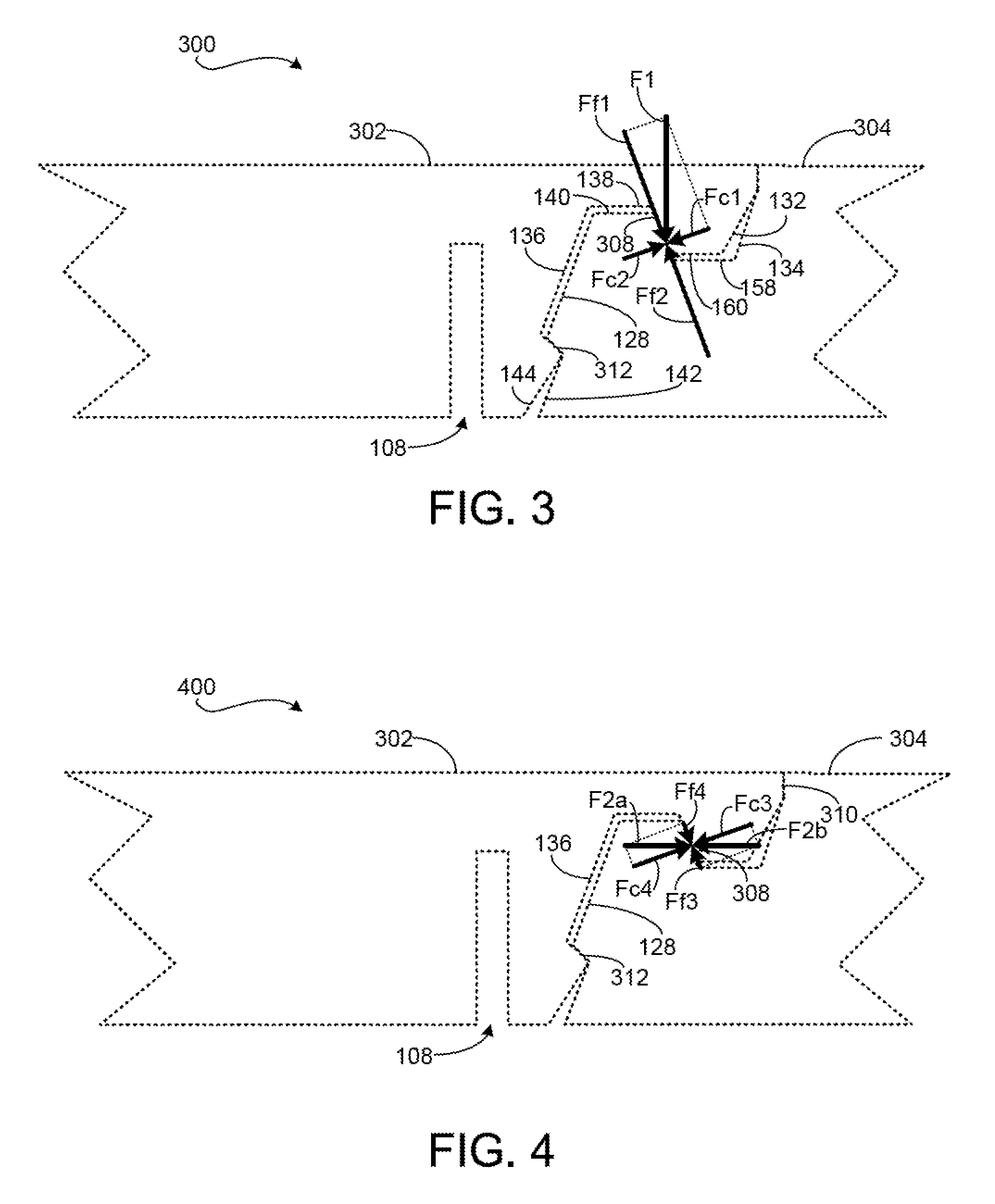

Spring-Loaded Split-Tongue Connector System

A connector system for mechanically connecting two structural elements to each other, consisting of a connector element and mating grooves in each structural element. The connector element is comprised of a base plate having a split-tongue element at each side or end of said base plate. Each joined element has a mating groove formed into its connector-receiving surface. The mating groove is designed to allow fabrication via four sequential circular saw cuts, without loss of saleable decorative surface, and at a rate consistent with economical commercial production of vinyl, laminate, or hardwood flooring. The connector element is readily extruded in a variety of polymers, including PVC. The connector and mating grooves interact so as to generate a force component acting to forcibly draw the connector into the mating grooves. The connector system operation is relatively insensitive to geometric deviations associated with normal manufacturing methods.

Owner:ENGINEERED FLOORS LLC

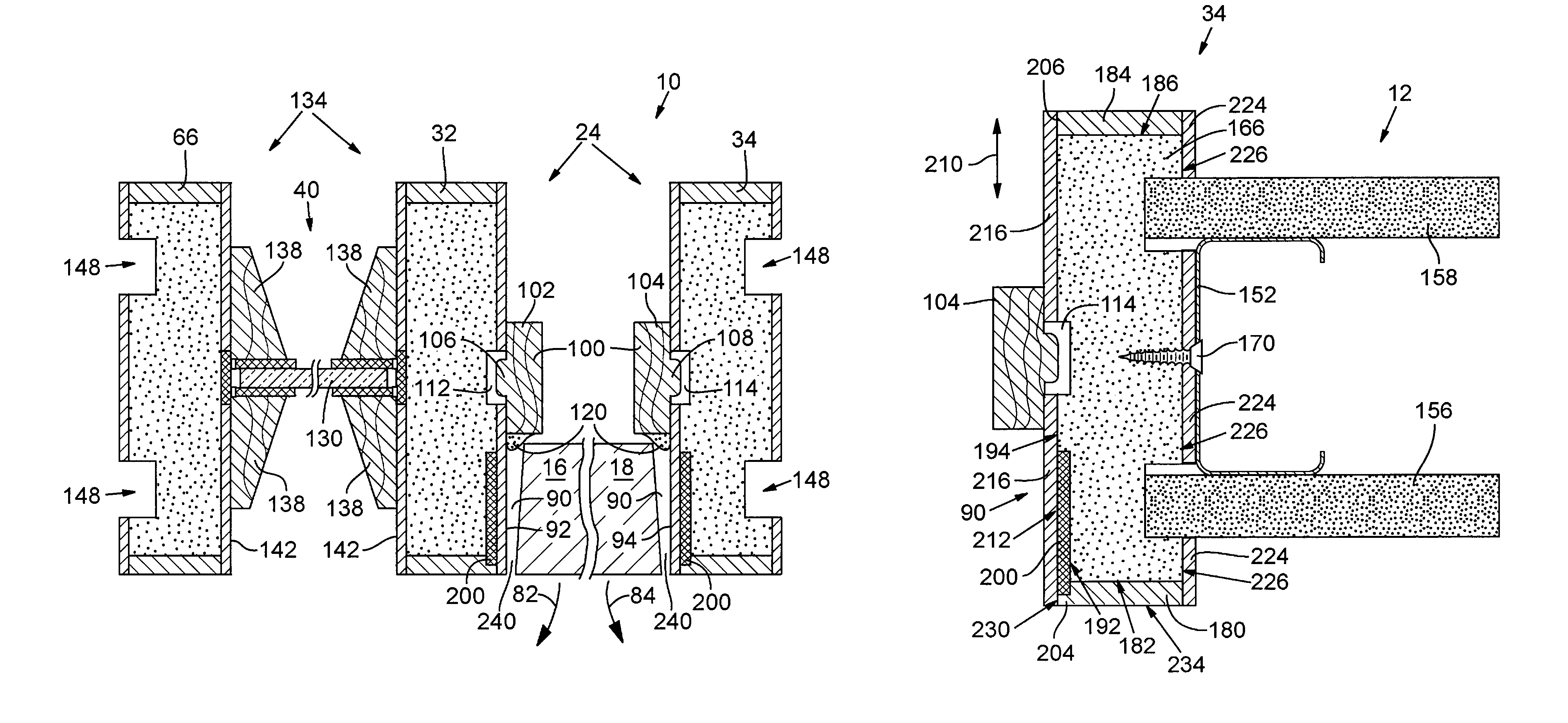

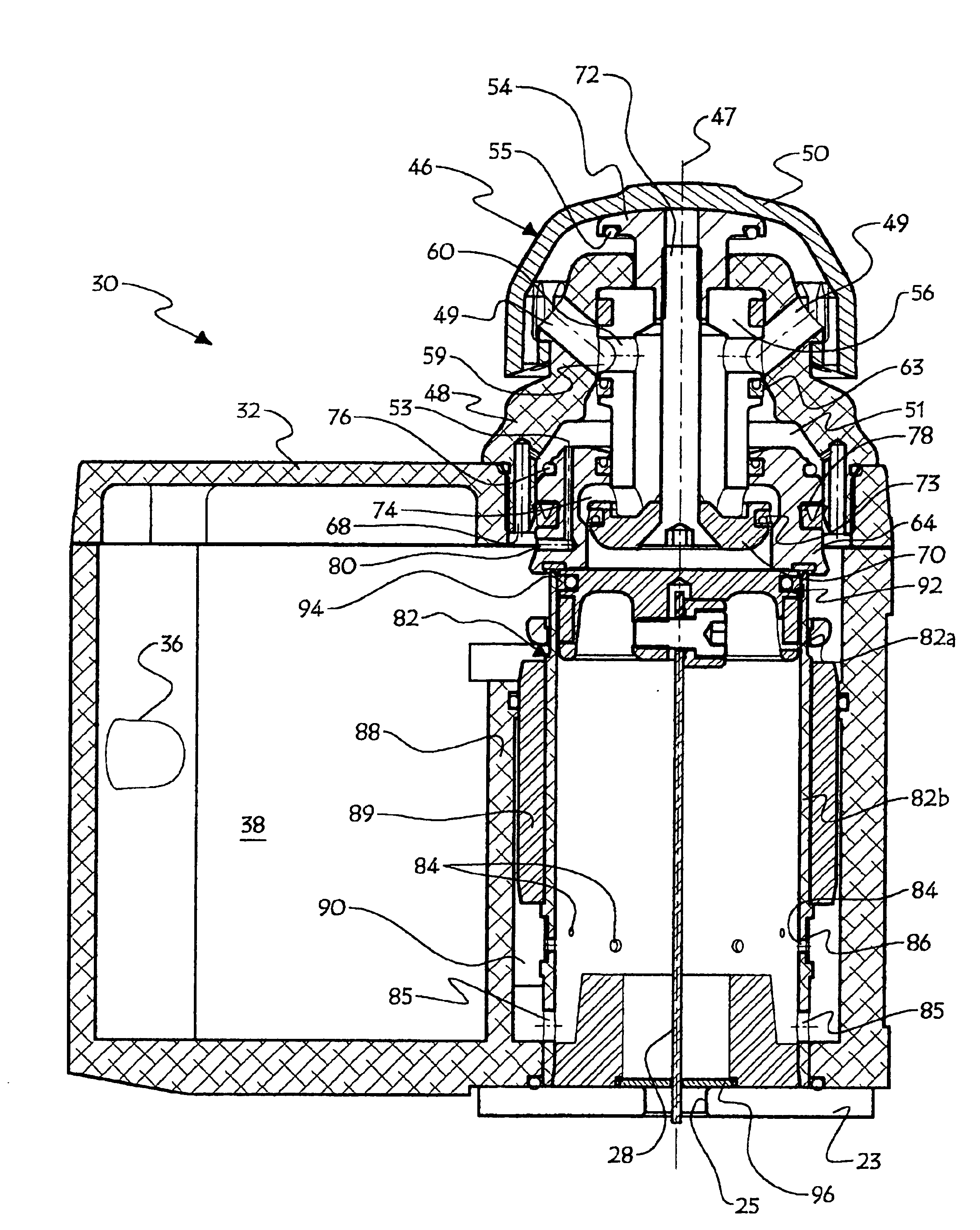

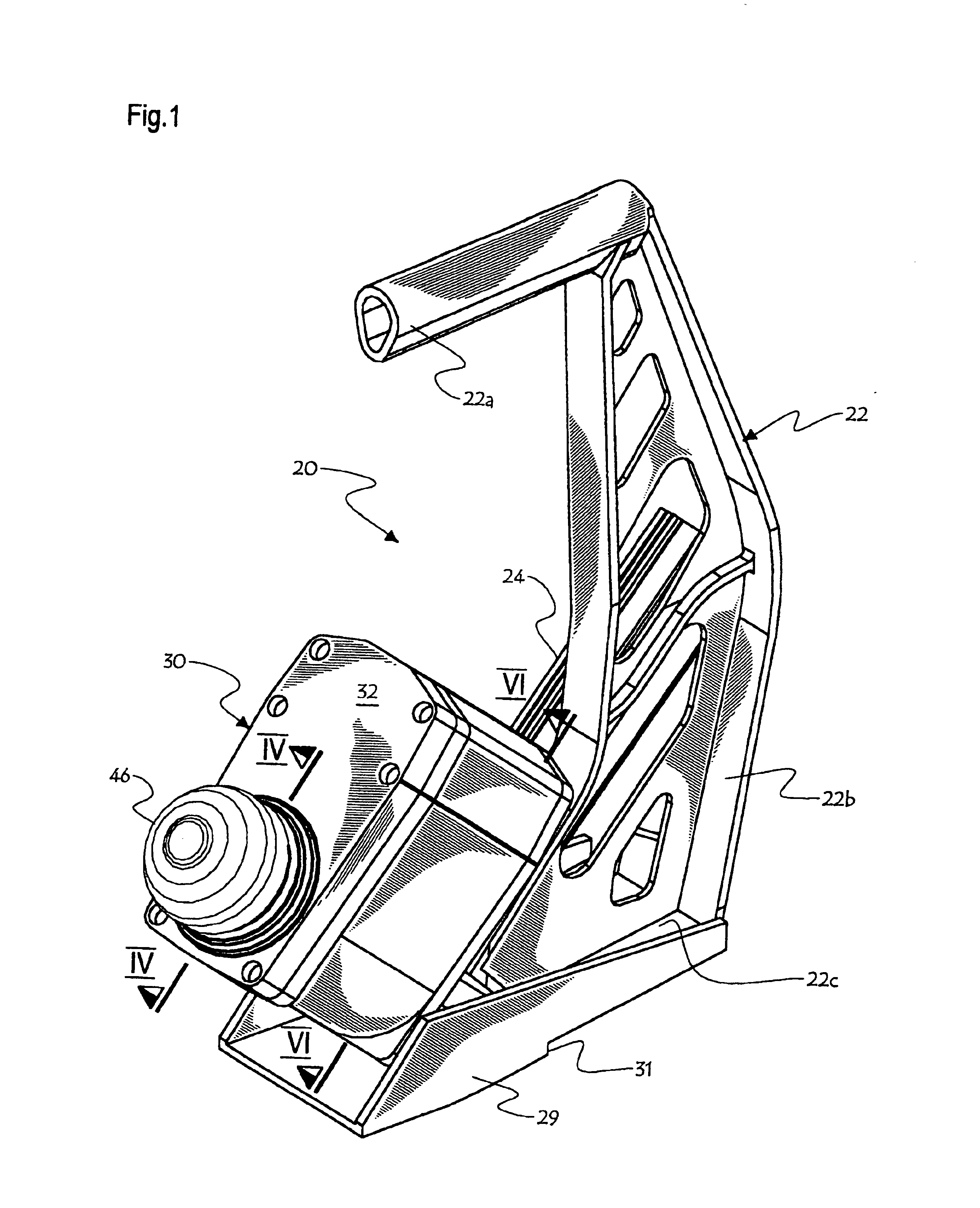

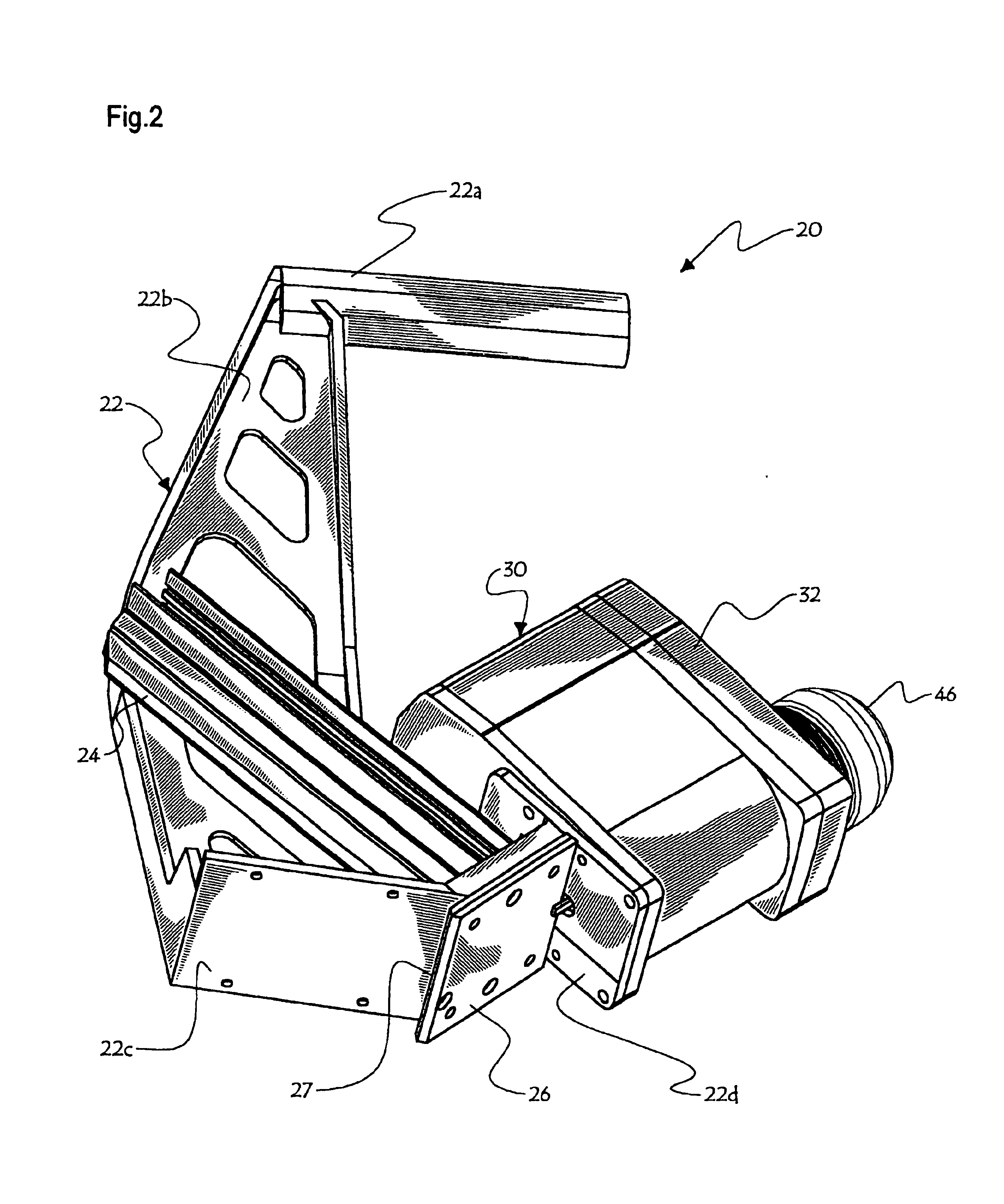

Pneumatic fastener driving tool for hardwood flooring

ActiveUS6834789B1Increase reload speedReduce labor costsStapling toolsNailing toolsCompressed fluidEngineering

A pneumatic mallet-blow operated fastener driving tool for securing hardwood planks to a subfloor, which comprises a fastener discharge mechanism in turn comprising a housing having a pressurized main chamber in direct link with a compressed air intake, a selectively depressurizable closure chamber pressurized when the tool is at rest, and a cylinder in which a piston having a plunger affixed thereto is slidably mounted. A valve, biased toward a closed position when the closure chamber is pressurized, or biased towards its open limit position if the closure chamber is depressurized, permits selective establishment of fluid communication between the inside of the cylinder and the pressurized main chamber. The piston, at a retracted limit position when the tool is at rest, is forced towards a deployed limit position when fluid communication is established between the main chamber and the inside of the cylinder, in order for its plunger to strike a fastener and drive it into an underlying plank. In use, after the mallet blow has engendered depressurizing of the closure chamber, the valve is moved in its open limit position, a fastener is discharged from the tool upon being struck by deployment of the piston by being struck by its plunger, and closure chamber starts to become pressurized again by compressed fluid flowing therein from the main chamber through a first fluid inlet, which initiates movement of the valve towards its closed position, and after such movement is initiated, a second fluid inlet port opens up to further admit compressed air into the closure chamber and thus accelerate pressurizing of the closure chamber and displacement of the valve towards its closed position.

Owner:LABE PRIMATECH

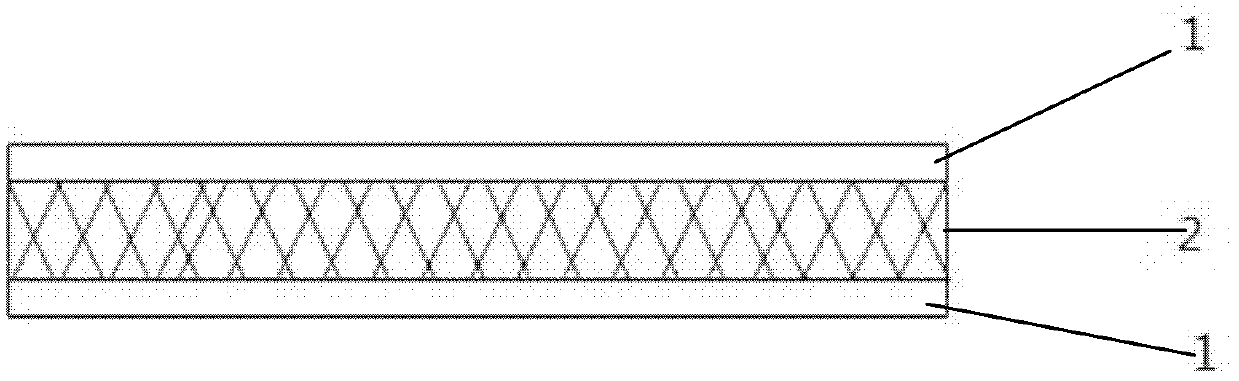

Composite material for container base plate and preparation method thereof

InactiveCN103302927AHigh strengthHigh modulusSynthetic resin layered productsLaminationAdhesiveWear resistance

The invention belongs to the technical field of material and transport, and relates to a composite material for a container base plate and a preparation method thereof. The composite material is a sandwich structure, and comprises a core layer and cover panels covering on upper and lower surfaces of the core layer, wherein the core layer is glass-felt-reinforced thermoplastic composite panel, the cover panels are thermoplastic resin and fiber reinforced thermoplastic sheets made from fibers. The composite material can reasonably select thickness and density of the covering surfaces and core materials according to actual needs, so as to reach optimum economic and weight-loss effects. The composite material is good in wear resistance, corrosion resistance, non-absorbent, and easy to clean; and compared with hardwood base plates, is greatly improved in service life. In addition, the composite material base plate is prepared all by fibers and plastic, free of corrosion and bacteria, and not damaged by insects; during preparation, no adhesive is used, and no formaldehyde is released, and thus the material is completely harmless, green and environmentally protective.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Pholiota nameko culture method

InactiveCN102613006ATake full advantage of the mushrooming effectRaw materials are easy to getHorticultureFertilizer mixturesPholiotaMycelium

The invention relates to a pholiota nameko culture method, which comprises the steps of: culture material proportioning and preparation, sterilization, inoculation and bagging, mycelium culture, summer-crossing management and primordium inducement fruiting. The pholiota nameko culture materials comprise the following recipe and mixture ratios: 30 to 50 parts of corncobs, 30 to 50 parts of soft mixed hardwood sawdust, 10 to 20 parts of bran, 2 to 4 parts of corn starch, 0.5 to 1.5 parts of gypsum and 0.5 to 1.5 parts of lime. The culture raw materials adopt the corncobs and the soft mixed hardwood sawdust as major materials, a good basis is laid for the smooth implementation of the Natural Forest Protection Projects and the pholiota nameko planting in flat areas, planting trays are omitted, the culture cost can be saved by 15 percent, the culture process is simple and is easy to implement, the work efficiency is improved, the edge fruiting effect of the pholiota nameko bag type culture is improved by 30 percent through being compared with that of the disc type culture, the edge fruiting effect of the edible fungi is sufficiently utilized, the yield can be improved by more than 10 percent, and the high-quality fruiting rate is improved by more than 40 percent.

Owner:沈阳蕈丰食用菌科技有限公司

Flooring boards with press down locking mechanism

A hardwood floor system with press down locking mechanism. Each floor board is equipped with both male and female locking mechanisms. The male locking mechanism of a floor board can be locked into the female locking mechanism of an adjacent floor board by simply exerting downward force on the floor board. The female locking mechanism is equipped with a spring slot that enables easy engagement of male and female locking mechanisms. The invention may be applied not only floor boards, but also to wall tiles and roof tiles.

Owner:LIU DAVID C +1

Method for bleaching mechanical pulp

InactiveUS20020144796A1Pulp bleachingPulping with inorganic basesAlkaline earth metalBiological activation

A method for bleaching unbleached softwood or hardwood pulps using hydrogen peroxide without added alkali for activation is described. The aqueous hydrogen peroxide solution contains an alkaline earth metal carbonate, preferably magnesium carbonate and can be used at elevated temperatures. Bleached hardwood or softwood mechanical pulps with high brightness, low yellowness (b*) and reduced reversion properties are produced.

Owner:WEST FRASER MILLS

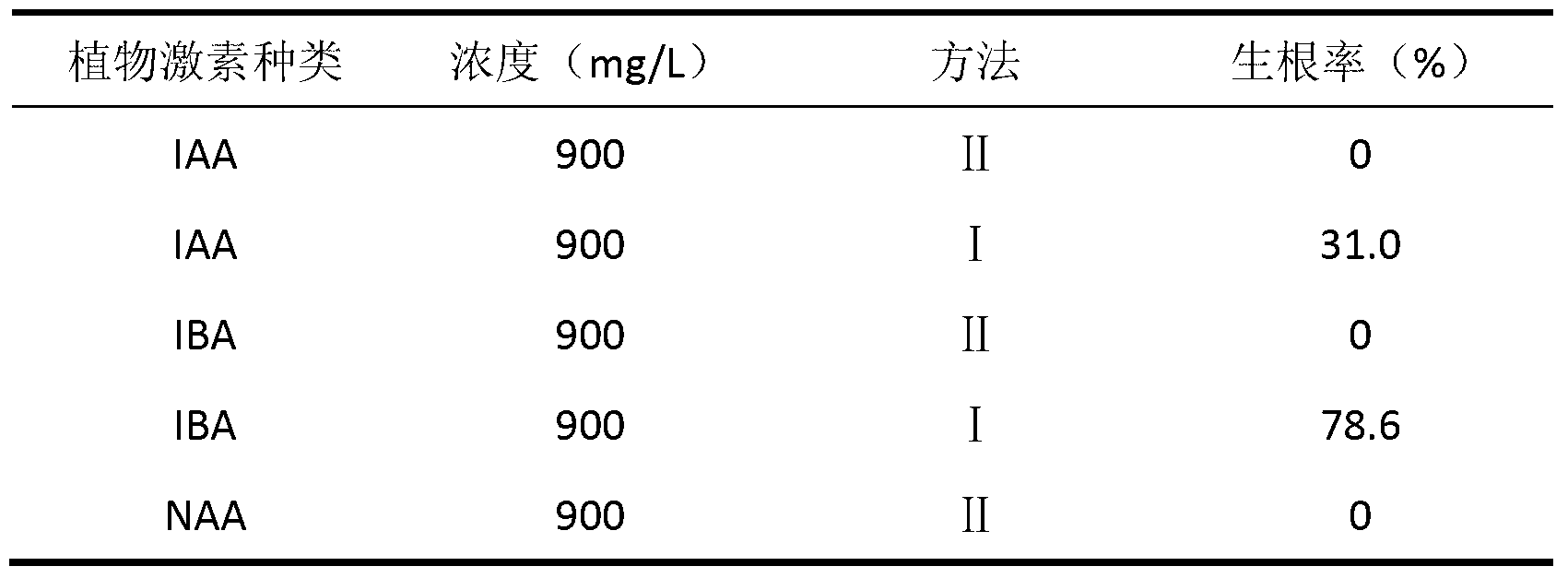

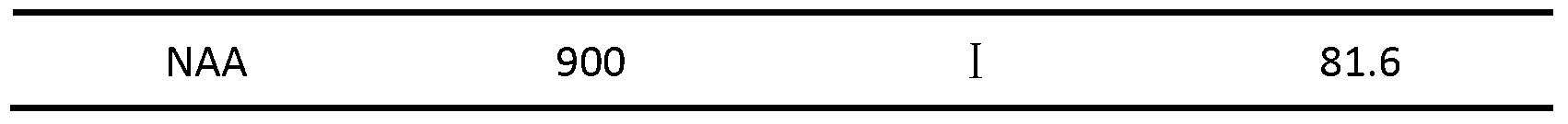

Apocarya hardwood cutting seedling raising method

ActiveCN103299812AConducive to the industrialization of cutting propagationStrong environmental conditionsHorticultureTemperature differenceTwig

The invention discloses an apocarya hardwood cutting seedling raising method. The method comprises the steps of selecting a 12cm long middle section twig and a 12cm long lower section twig of an annual apocarya seedling, soaking the trimmed twigs in a solution of phytohormone IBA (Indolebutyric Acid) or NAA (Naphthaleneacetic Acid) for 4 hours, inserting the morphological lower ends of the twigs into a matrix, laying a heating wire at the bottom of the matrix, and controlling the temperature difference between the bottom of the matrix and the outside temperature at 15 DEG C approximately, and the water content at 30% approximately. The rooting rate is counted after 60 days, and reaches above 81%. The rooting rates of a single phytohormone treatment method or a single temperature difference method are both 0%. The method effectively realizes the apocarya cutting seedling raising; seedling raising approaches of apocarya are widened; and powerful technical support is provided for the rapid propagation and industrialization of the apocarya seedlings.

Owner:南京绿宙薄壳山核桃科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com