Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4676 results about "Butanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

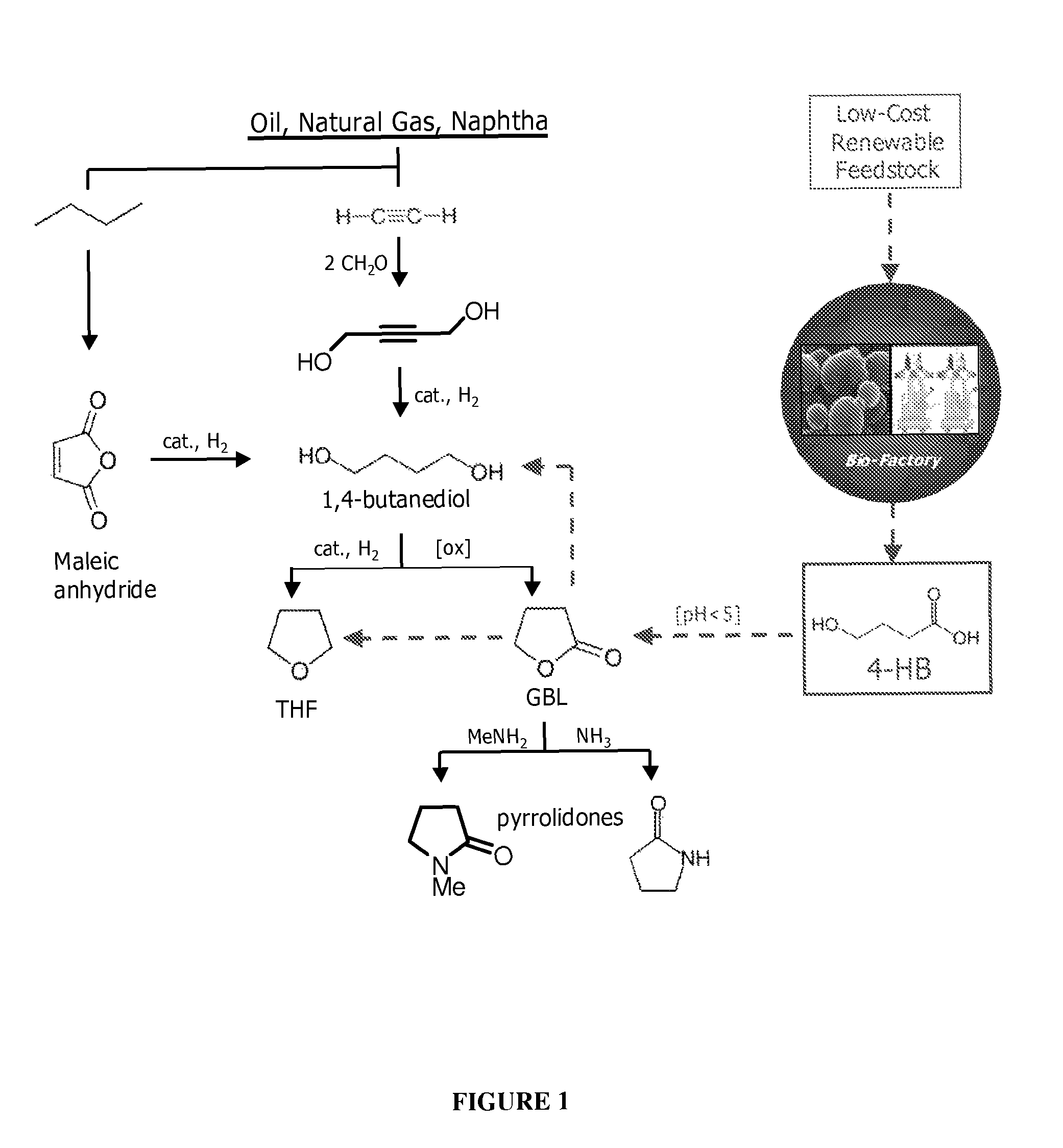

Butanediol, also called butylene glycol, may refer to: 1,2-Butanediol 1,3-Butanediol 1,4-Butanediol 2,3-Butanediol

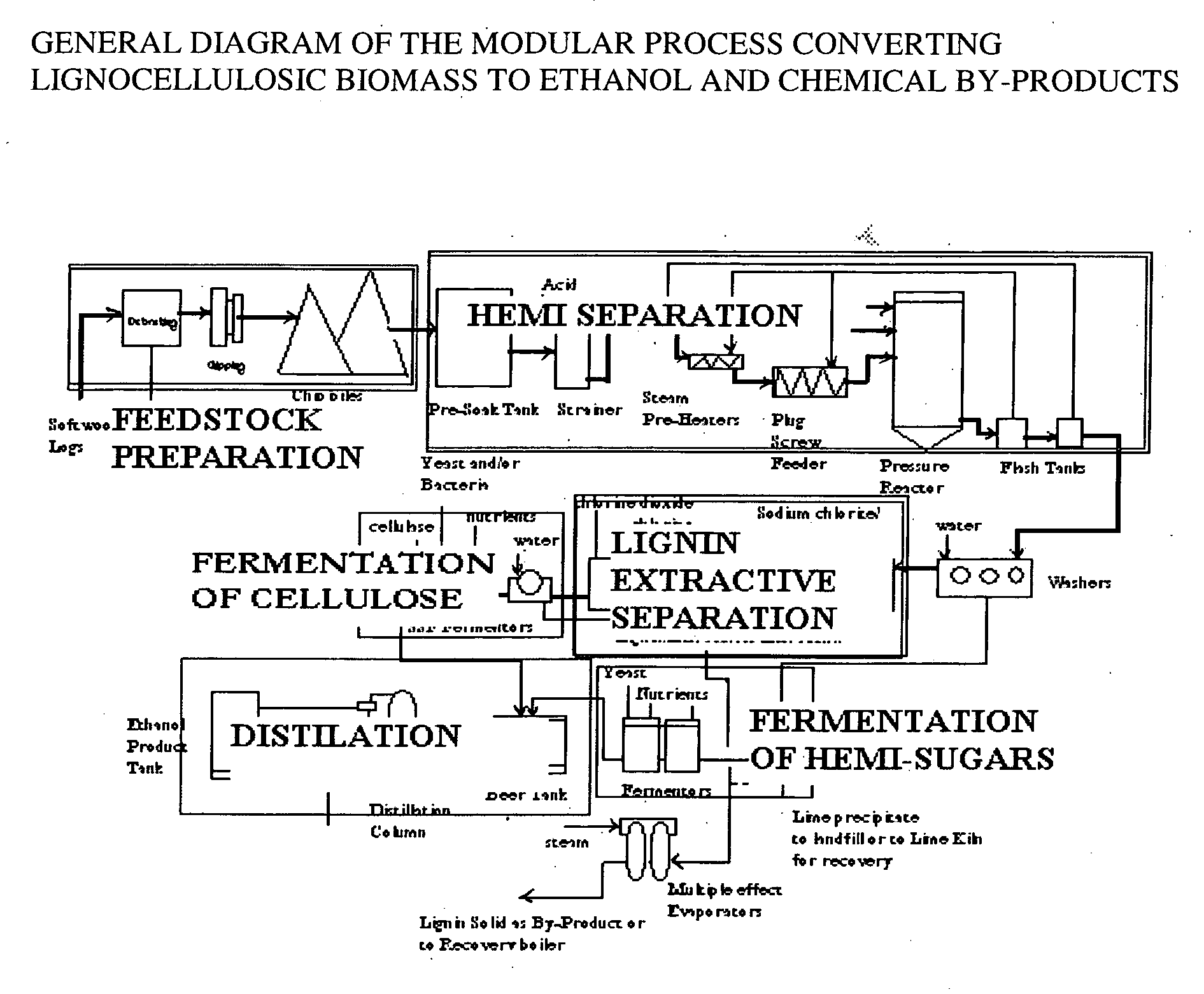

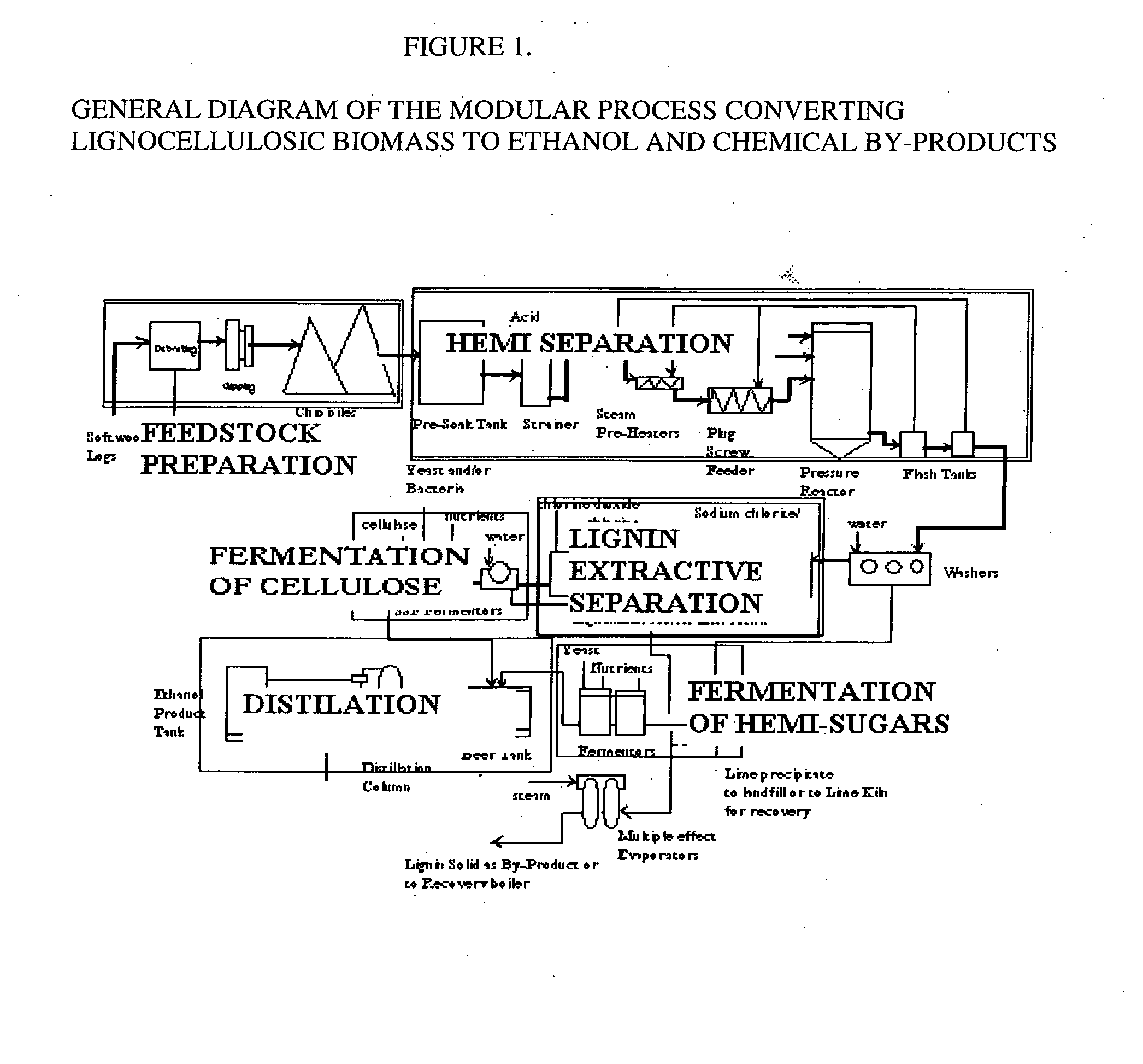

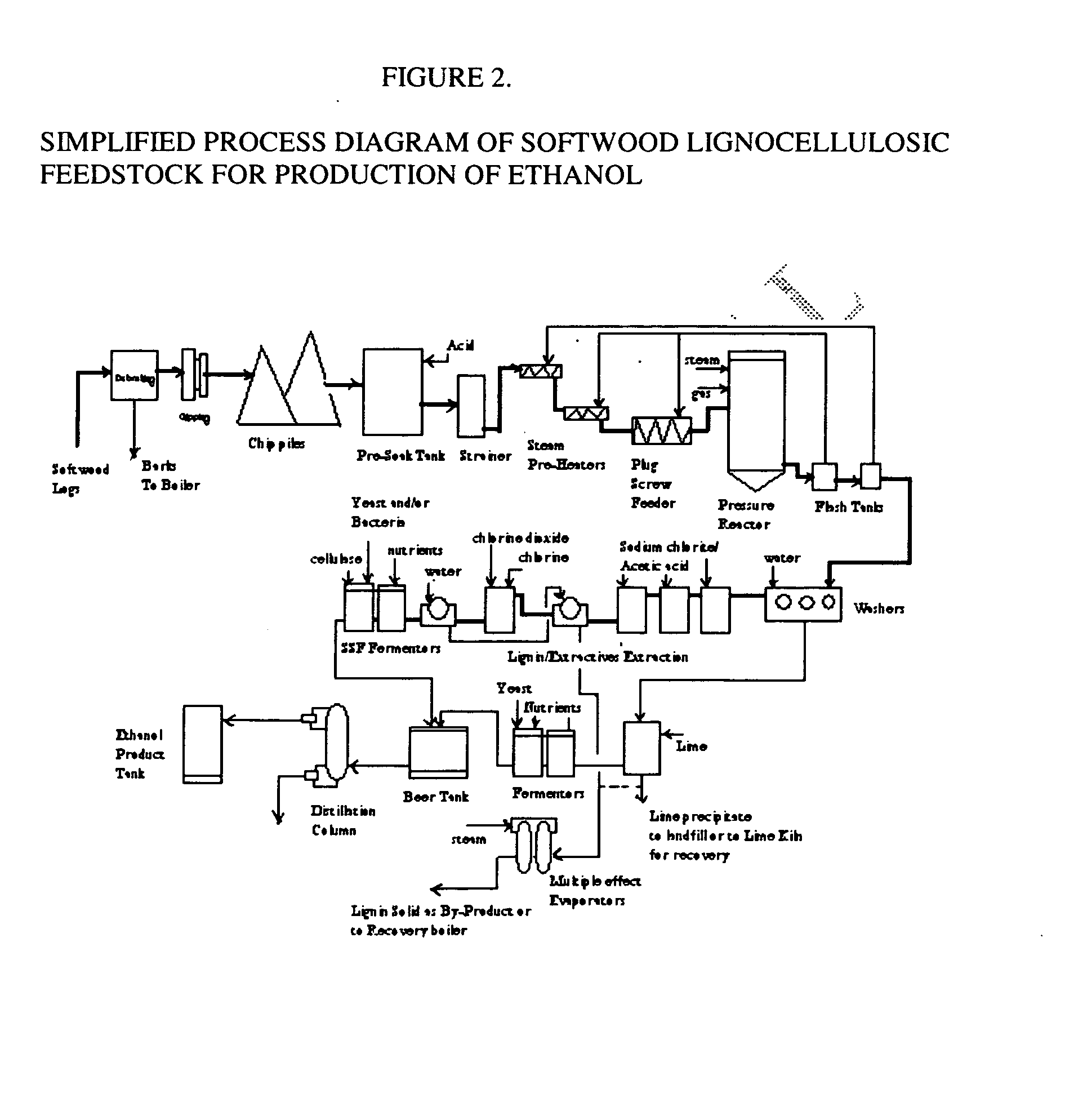

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Methods and organisms for the growth-coupled production of 1,4-butanediol

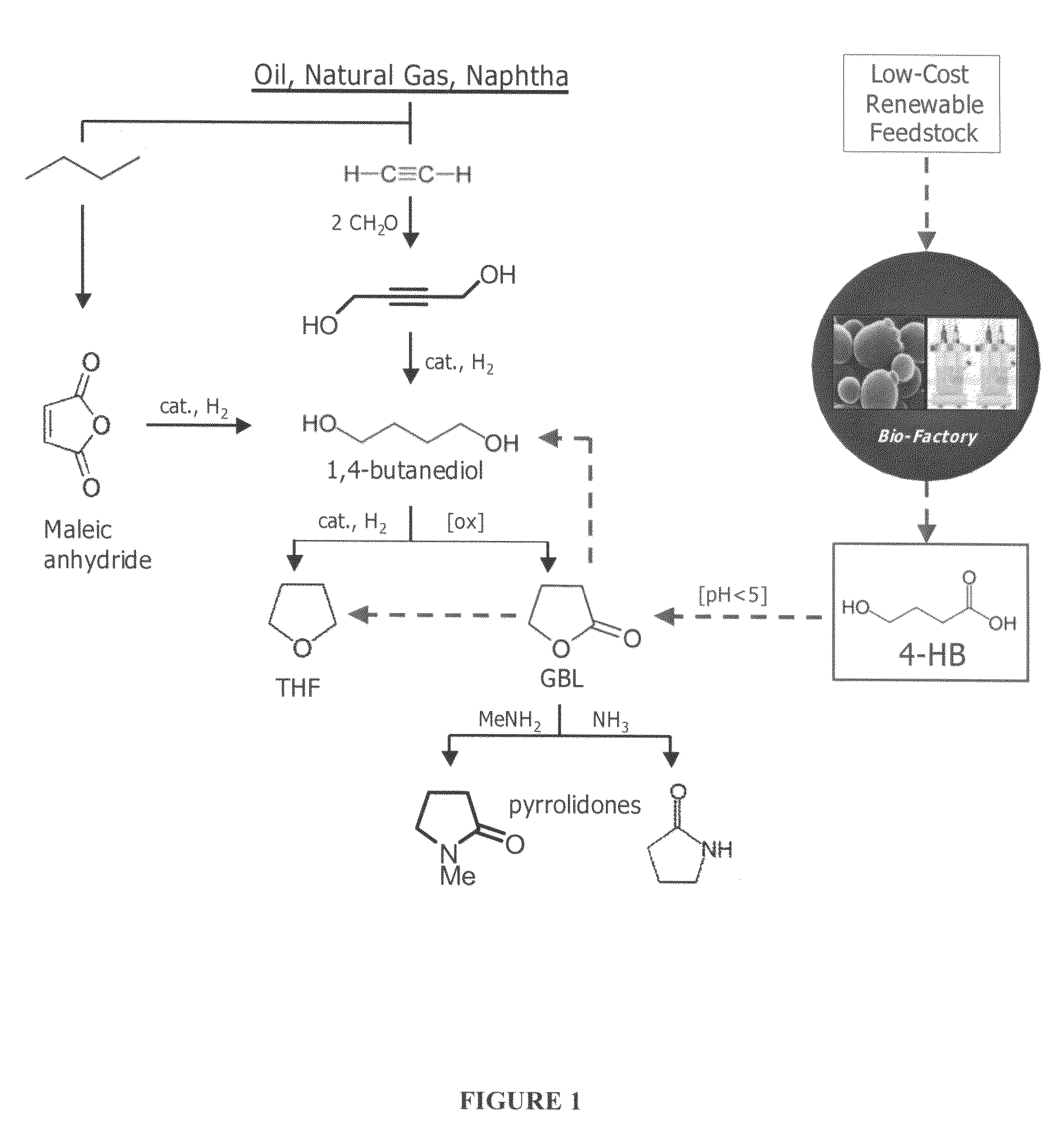

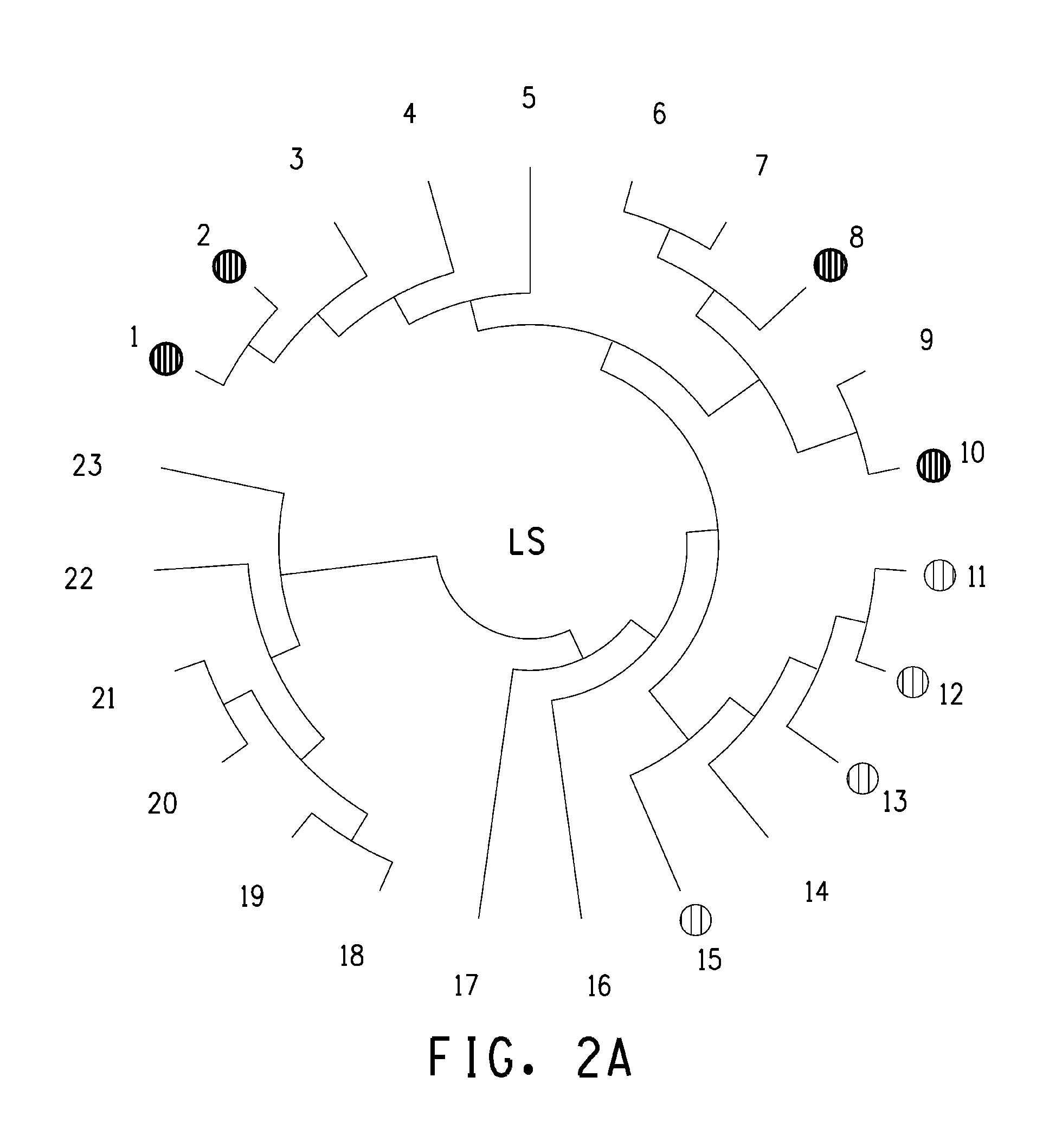

The invention provides a non-naturally occurring microorganism comprising one or more gene disruptions, the one or more gene disruptions occurring in genes encoding an enzyme obligatory to coupling 1,4-butanediol production to growth of the microorganism when the gene disruption reduces an activity of the enzyme, whereby the one or more gene disruptions confers stable growth-coupled production of 1,4-butanediol onto the non-naturally occurring microorganism. The microorganism can further comprise a gene encoding an enzyme in a 1,4-butanediol (BDO) biosynthetic pathway. The invention additionally relates to methods of using microorganisms to produce BDO.

Owner:GENOMATICA INC

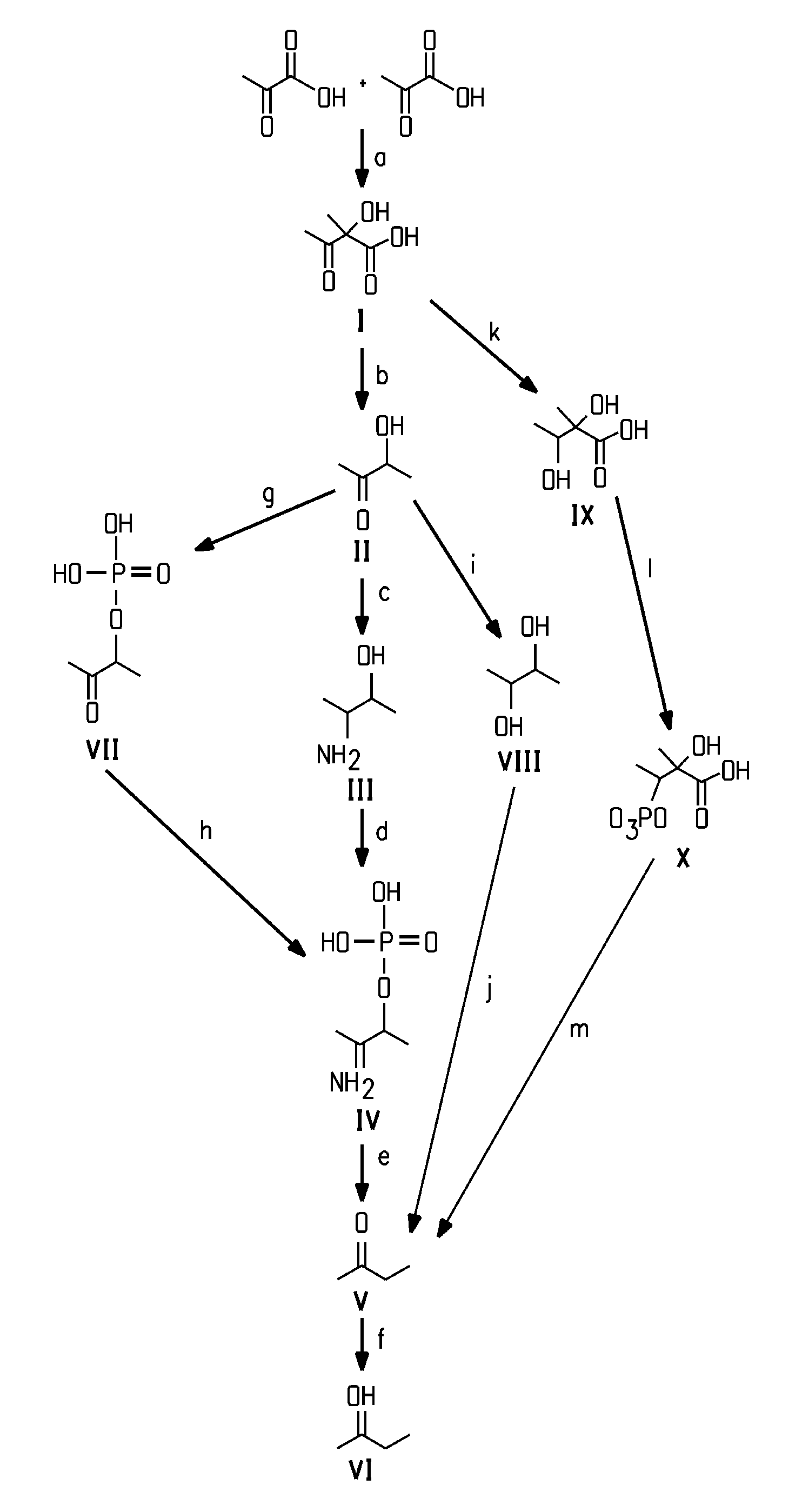

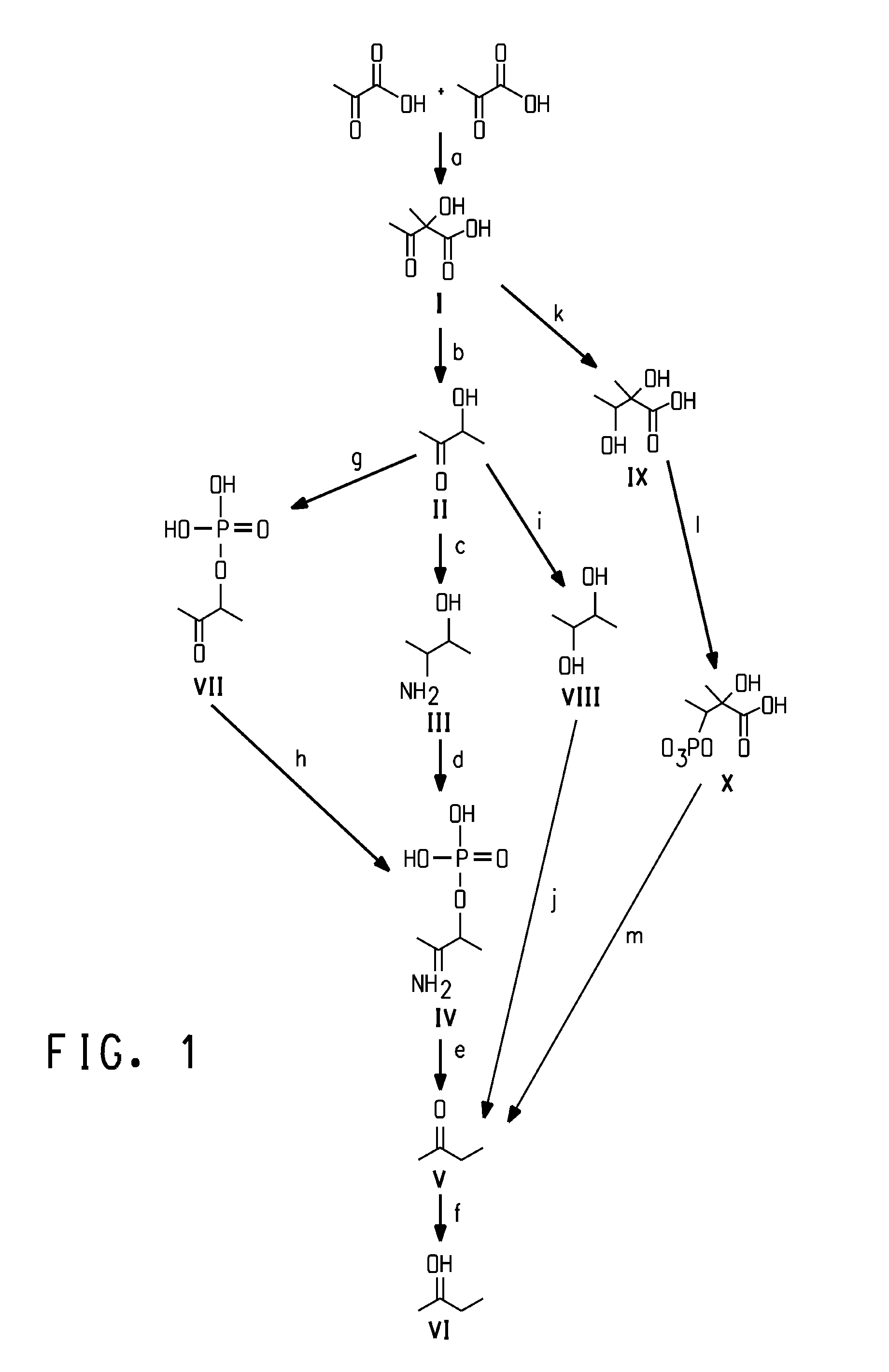

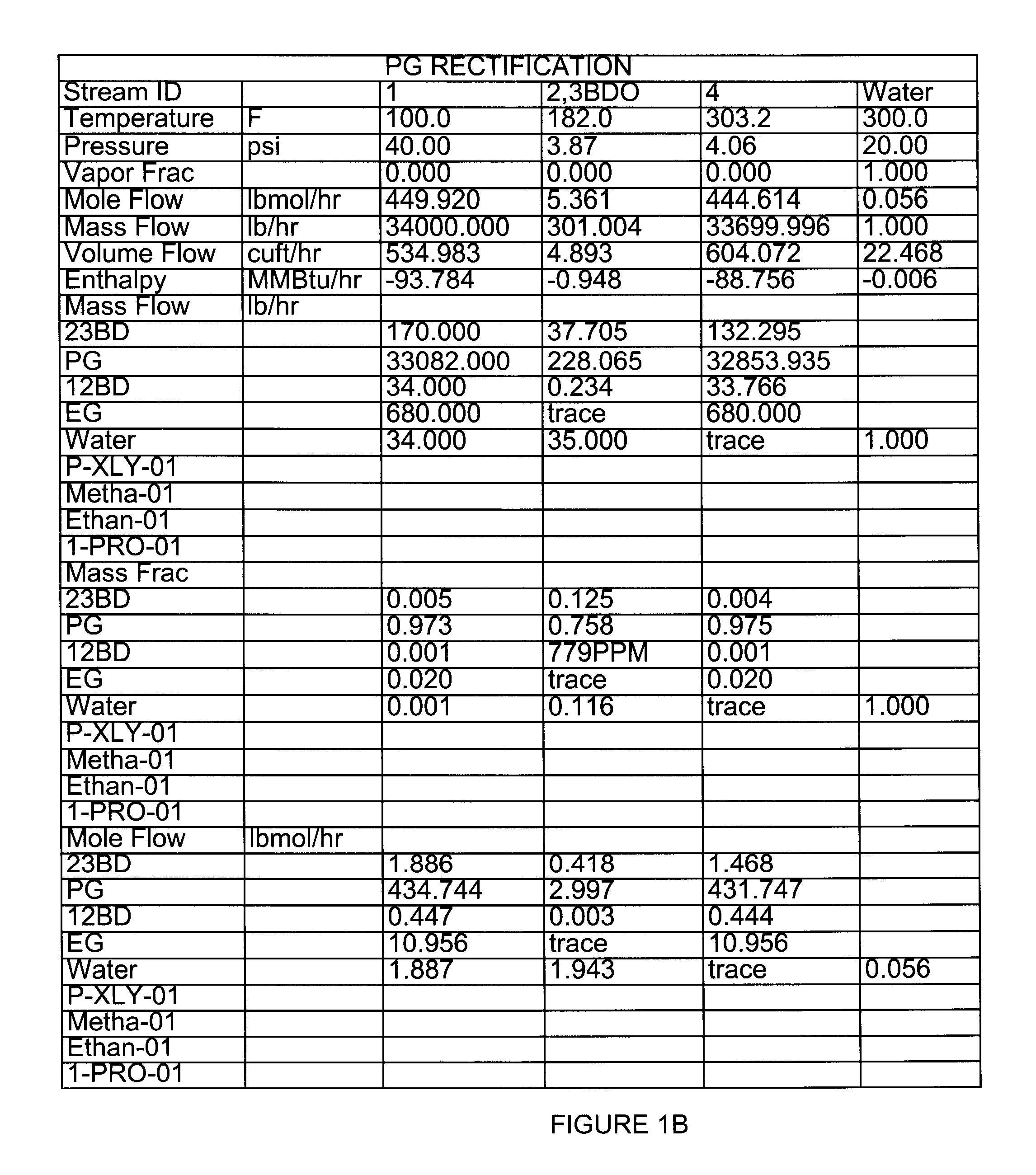

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein. Specifically disclosed herein are the use of coenzyme B12-independent butanediol dehydratases that catalyzes the substrate to product conversion of 2,3-butanediol to 2-butanone in the process of producing 2-butanol and 2-butanone.

Owner:GEVO INC

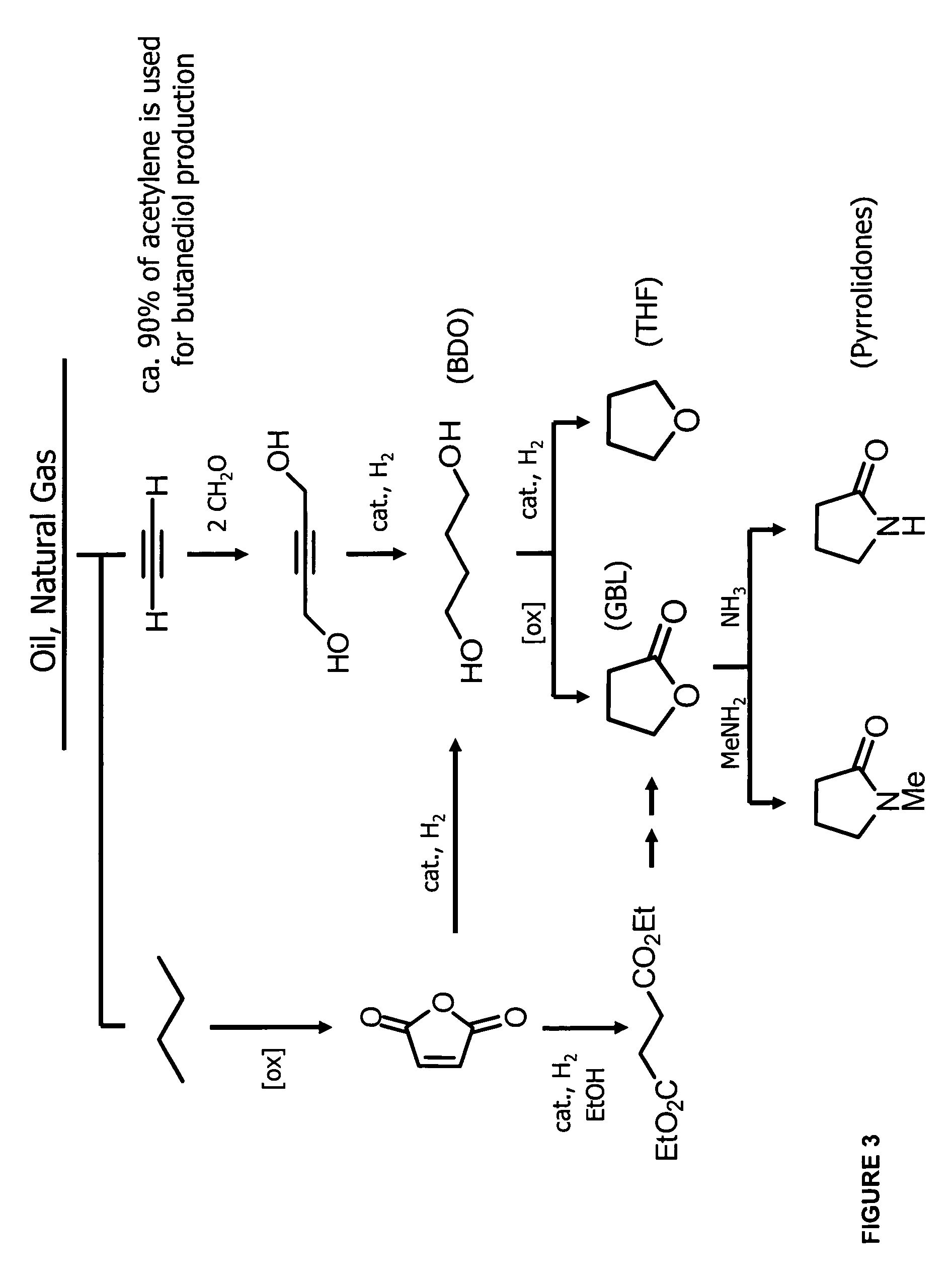

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

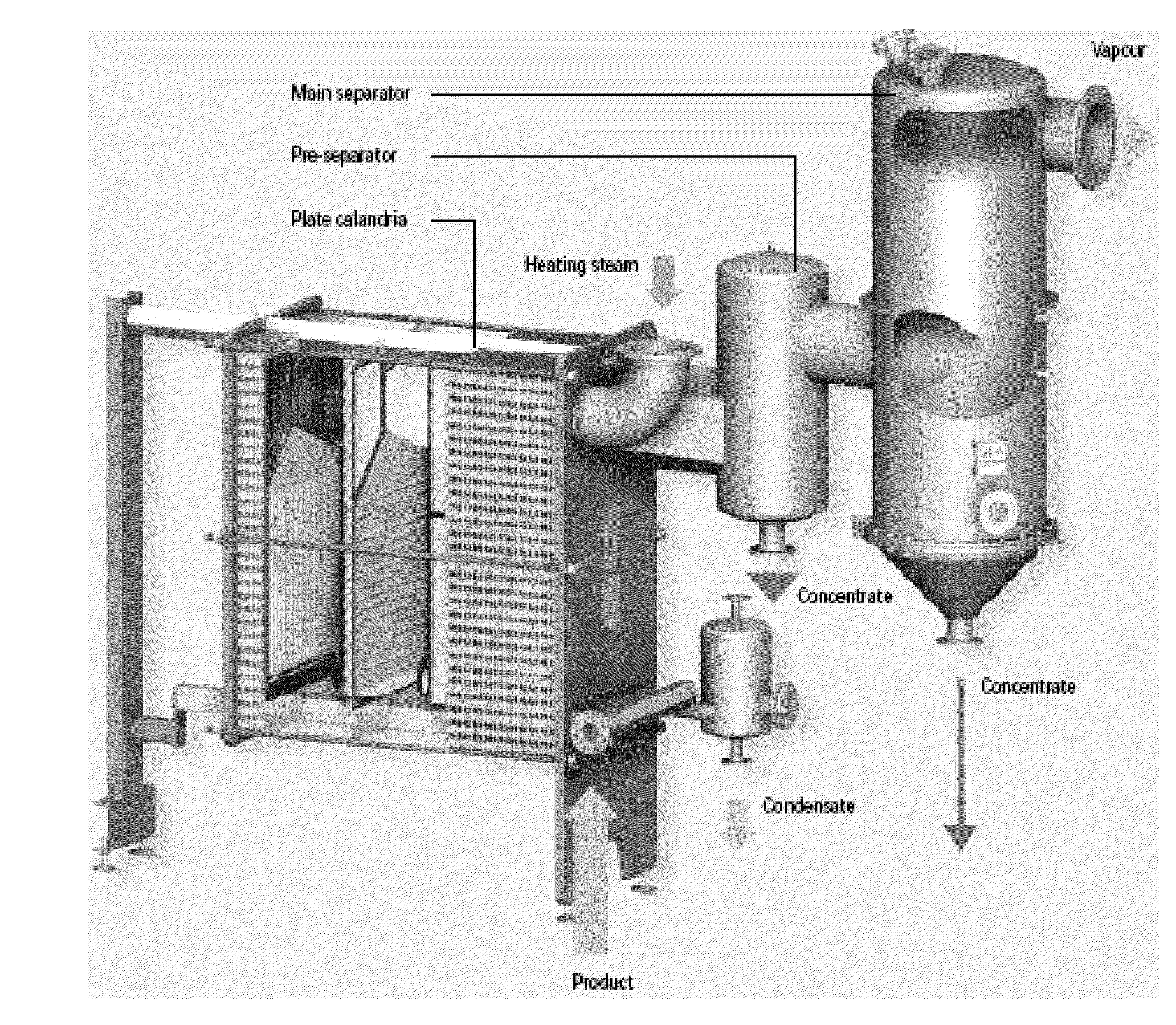

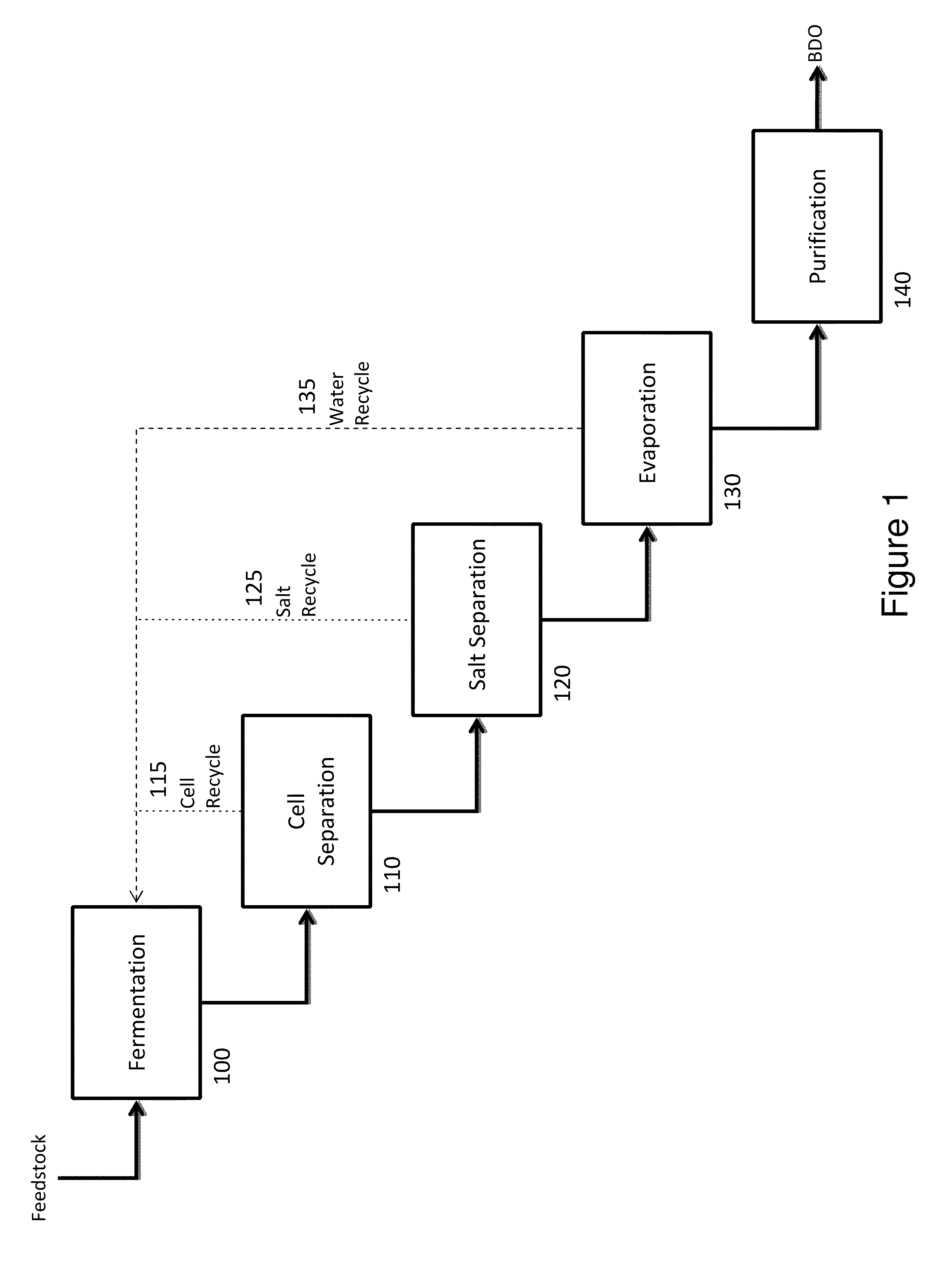

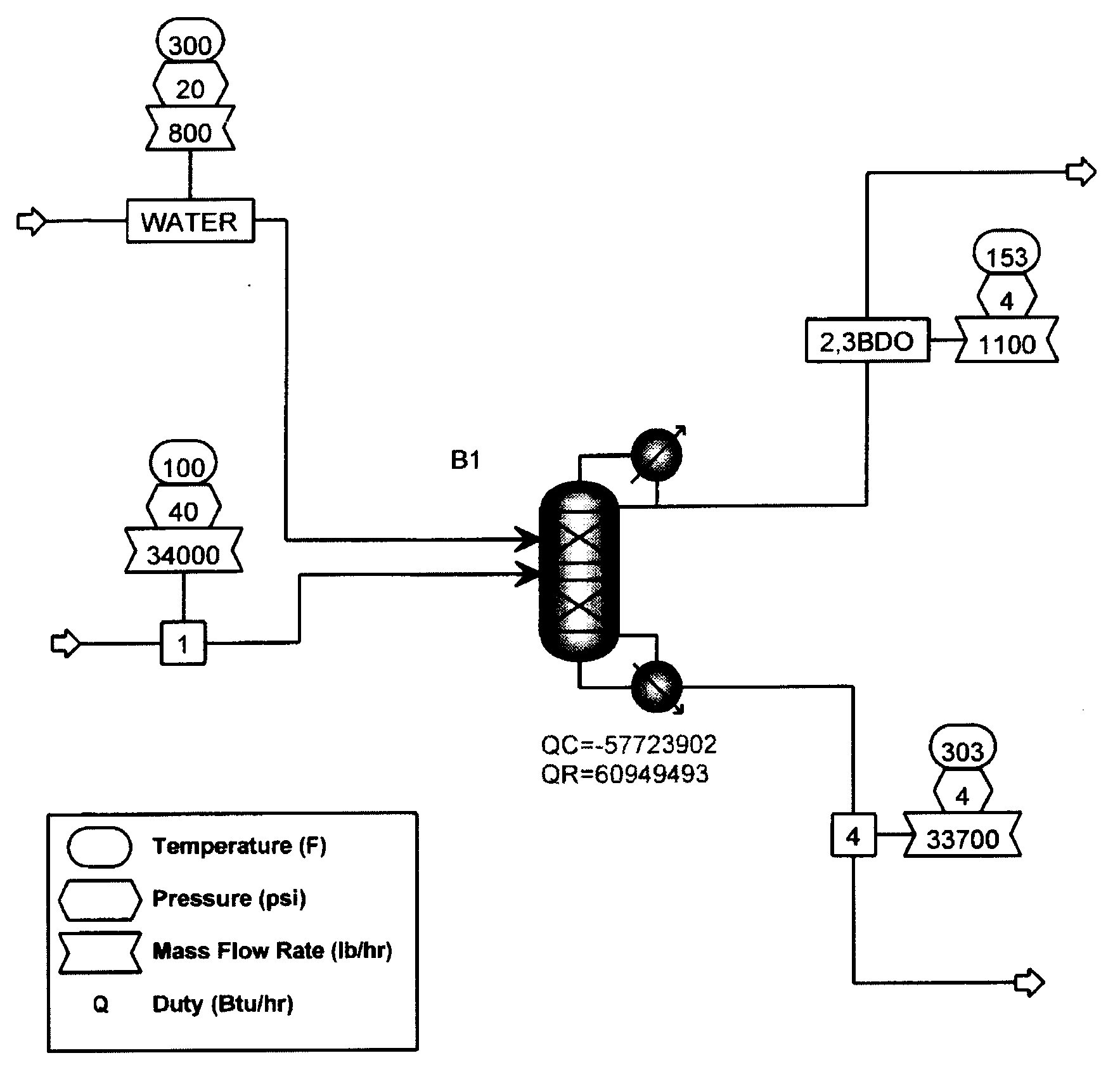

Process of separating components of a fermentation broth

ActiveUS20110003355A1Produce lotFermented solutions distillation/rectificationOrganic compound preparation1,4-ButanediolMicroorganism

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

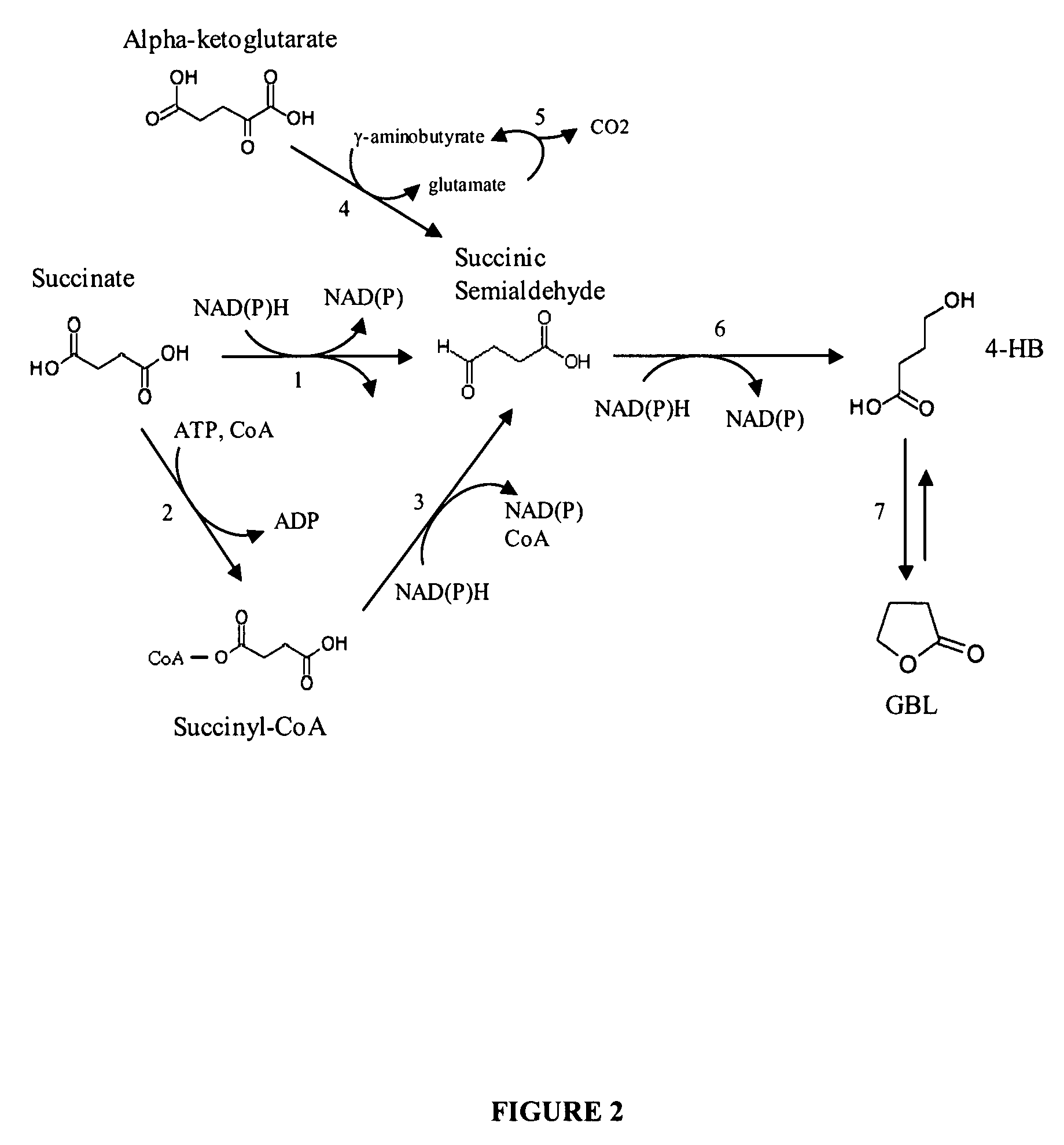

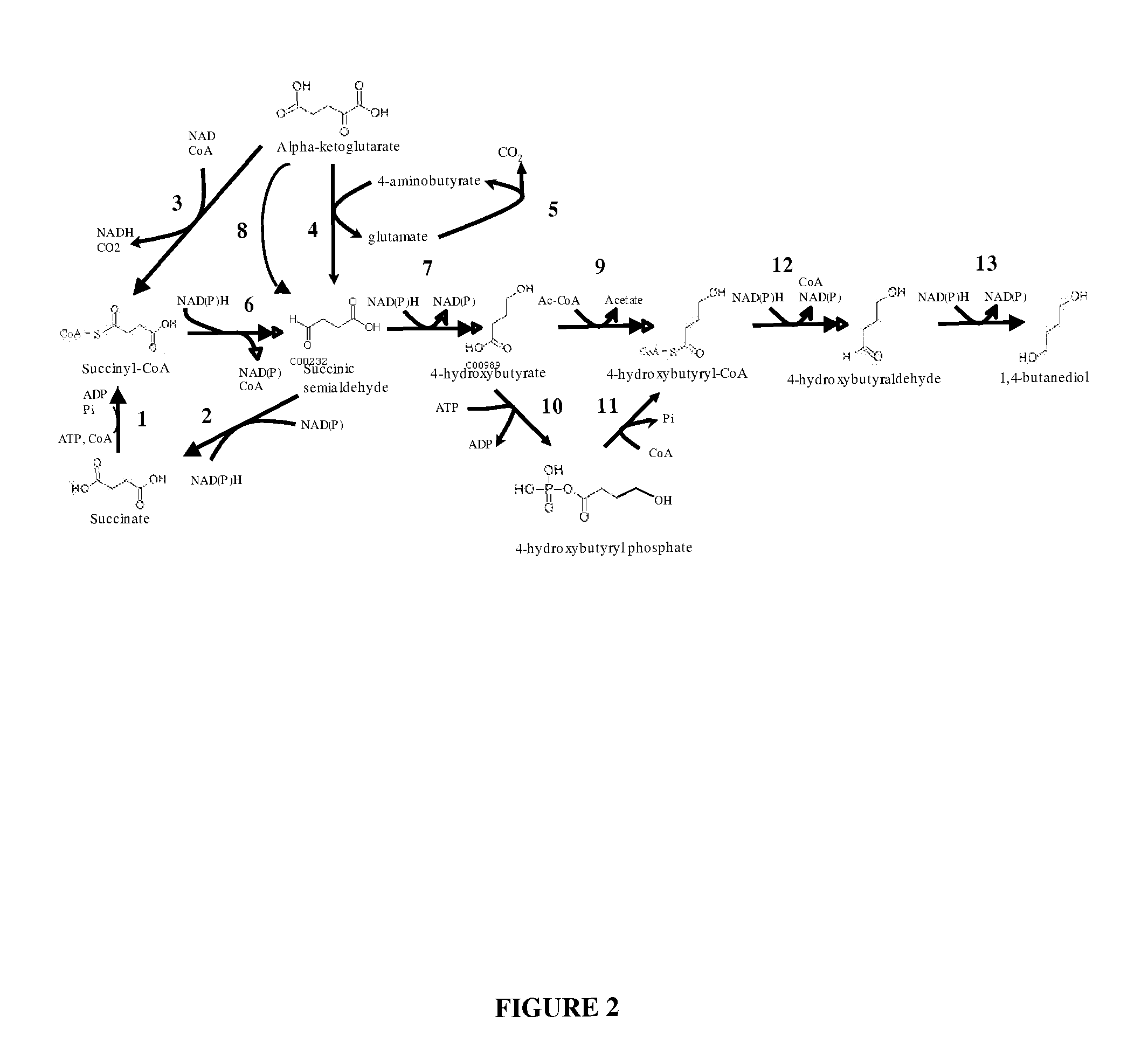

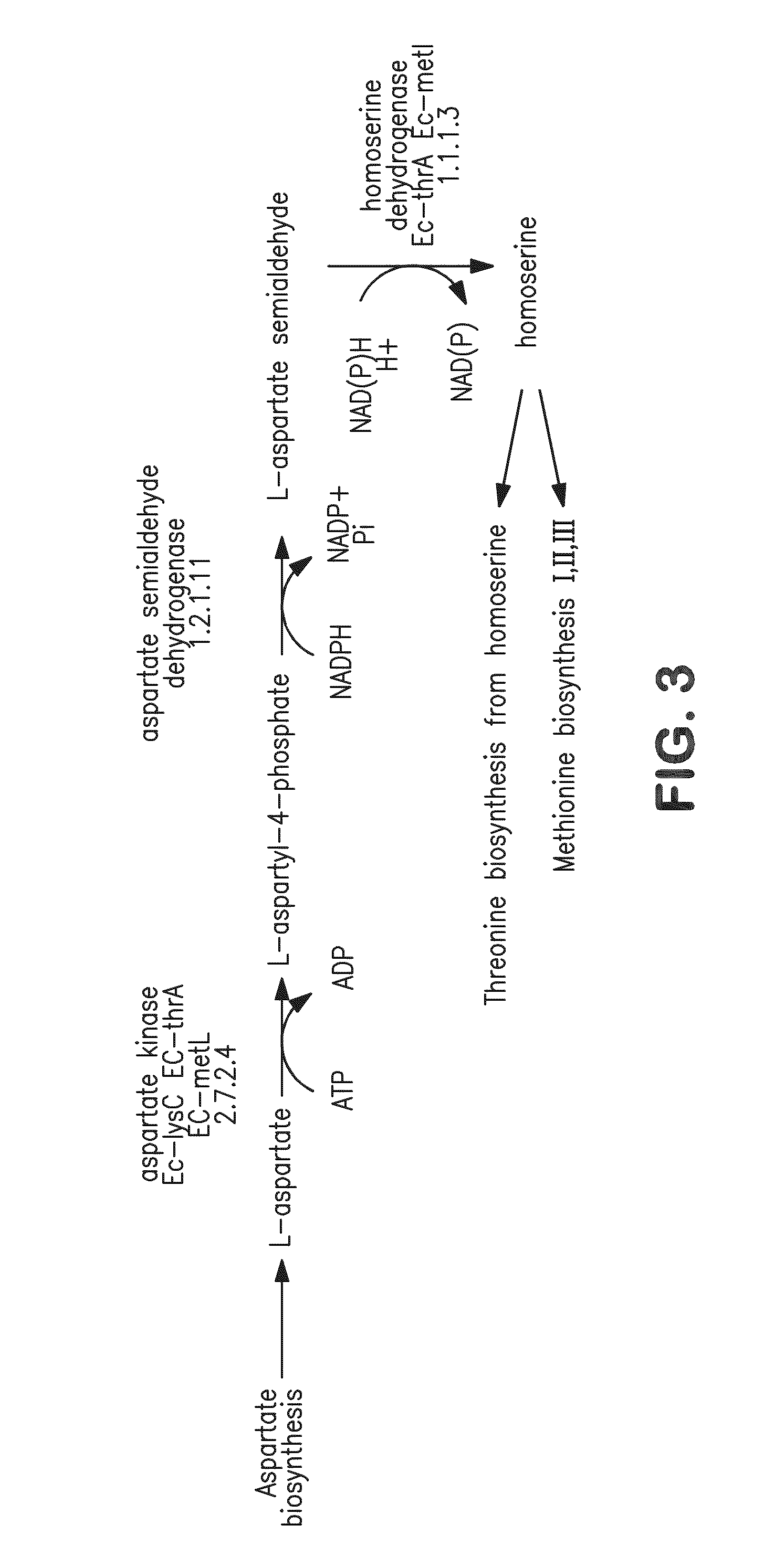

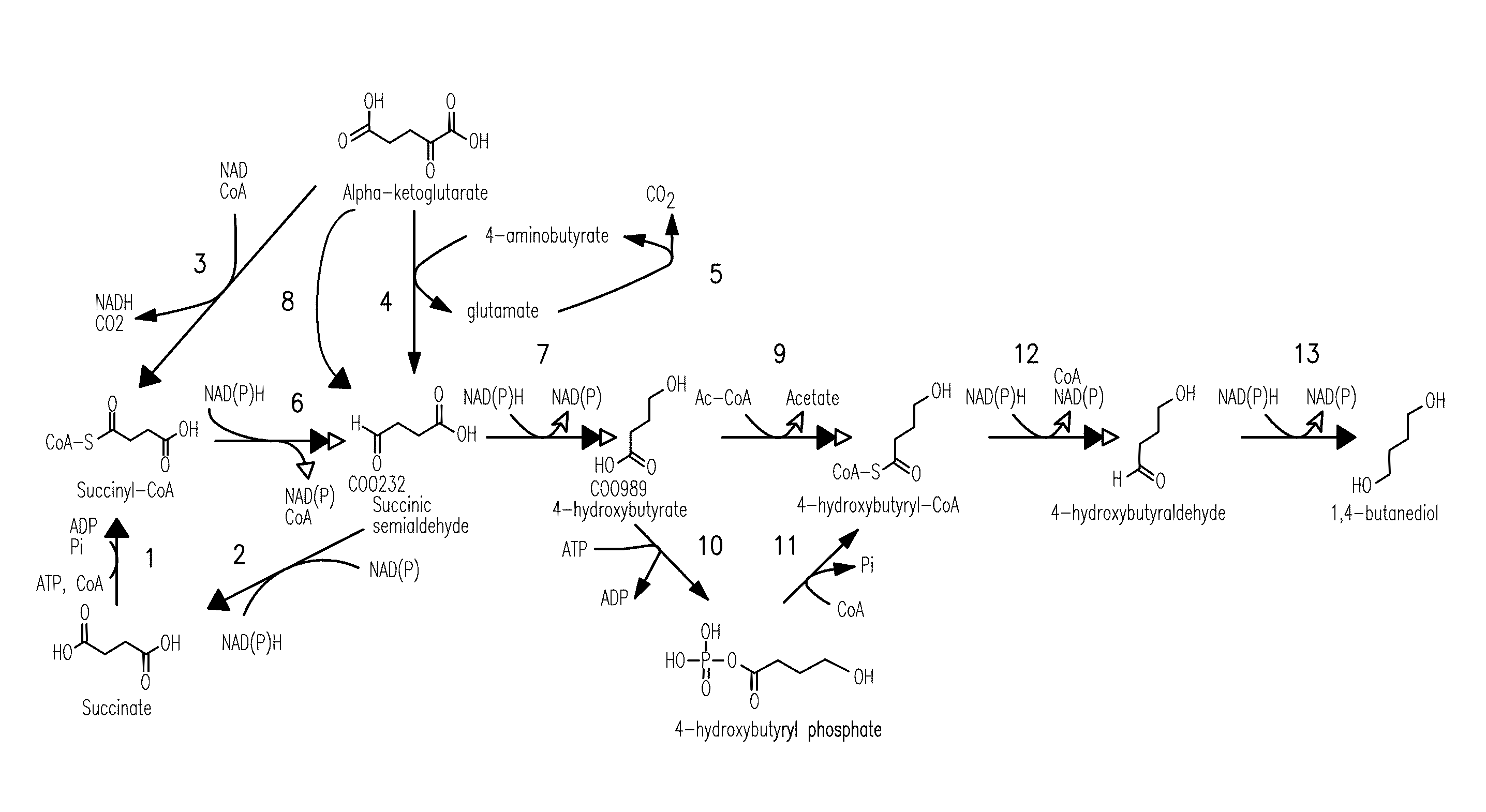

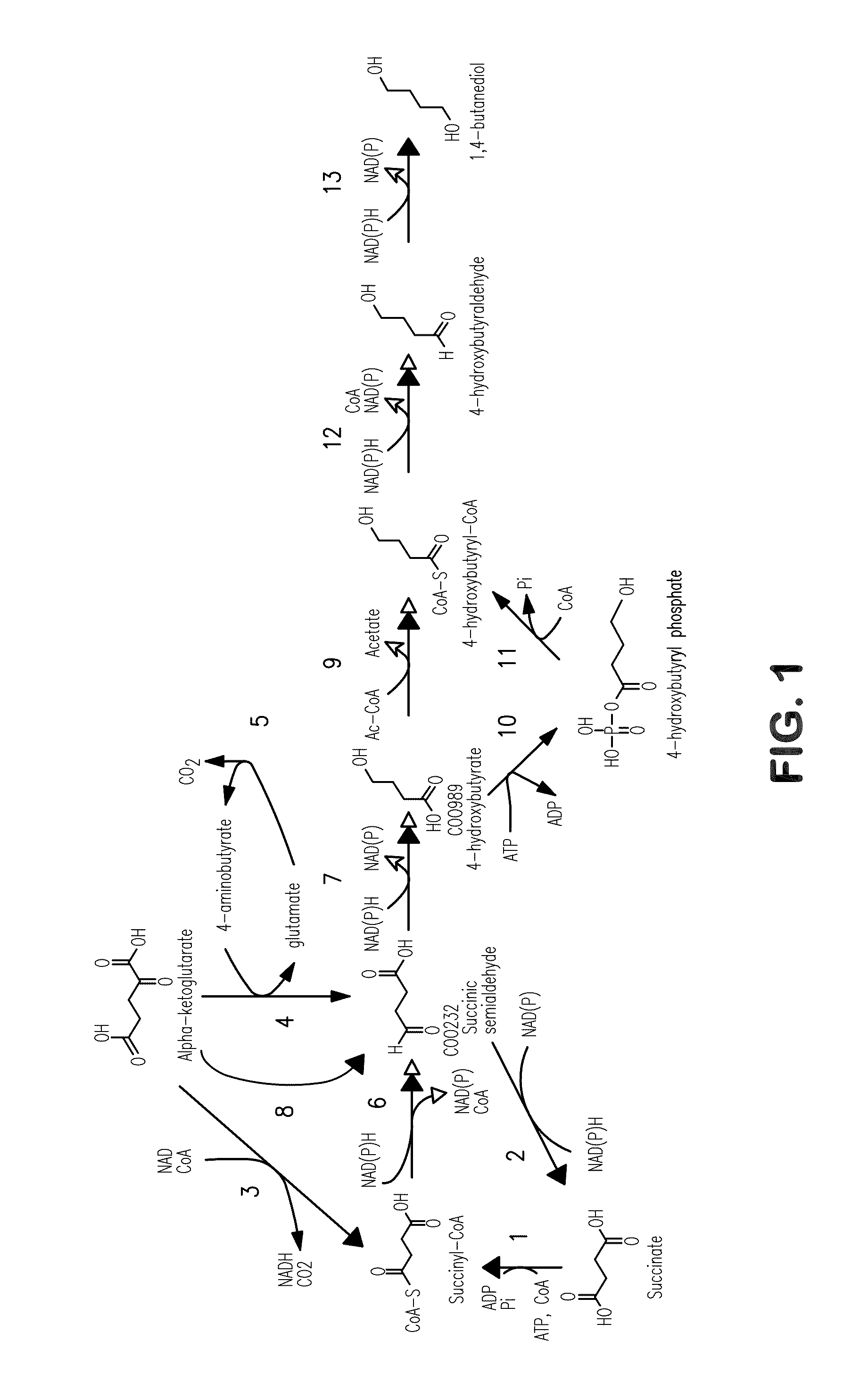

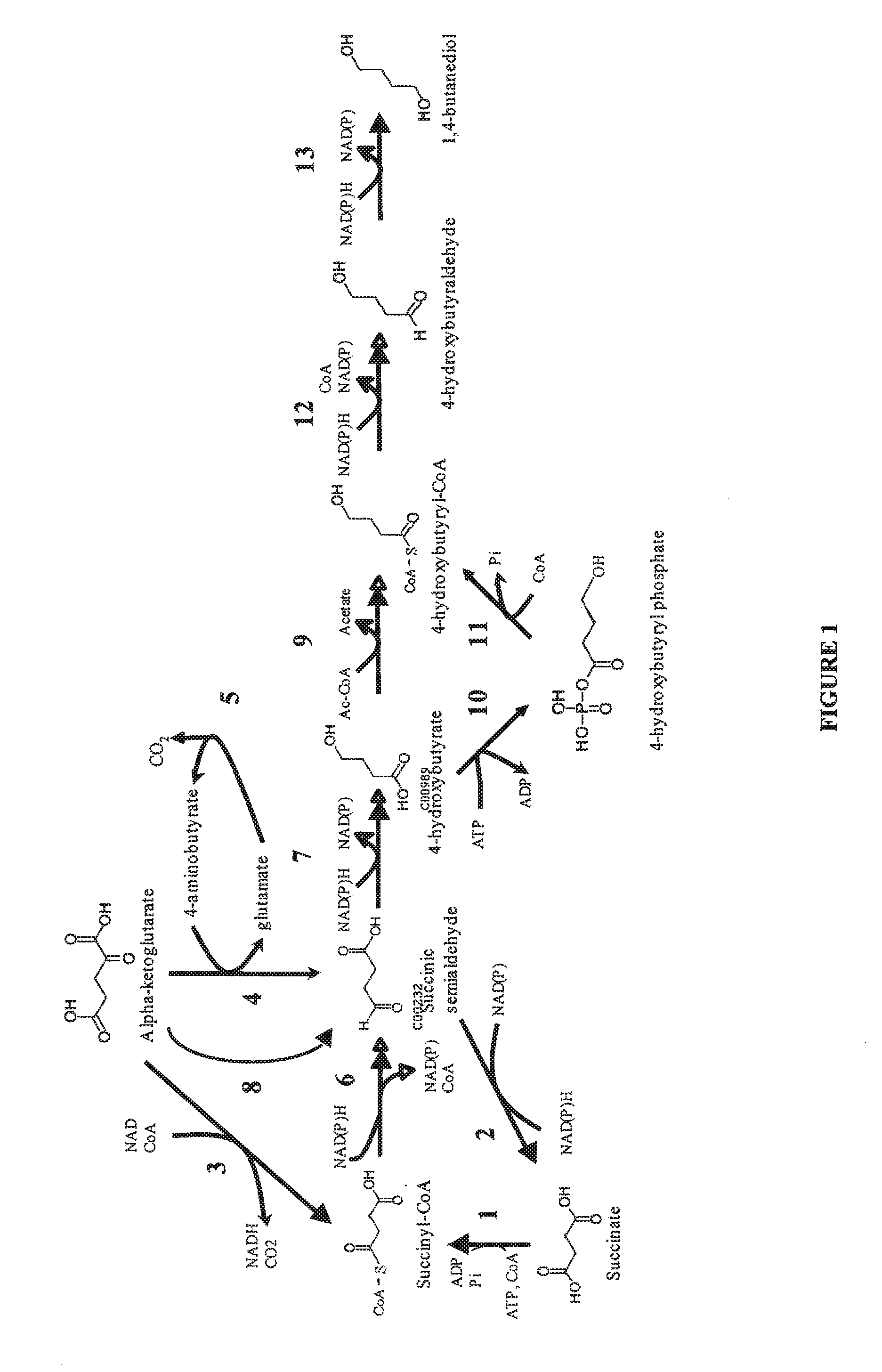

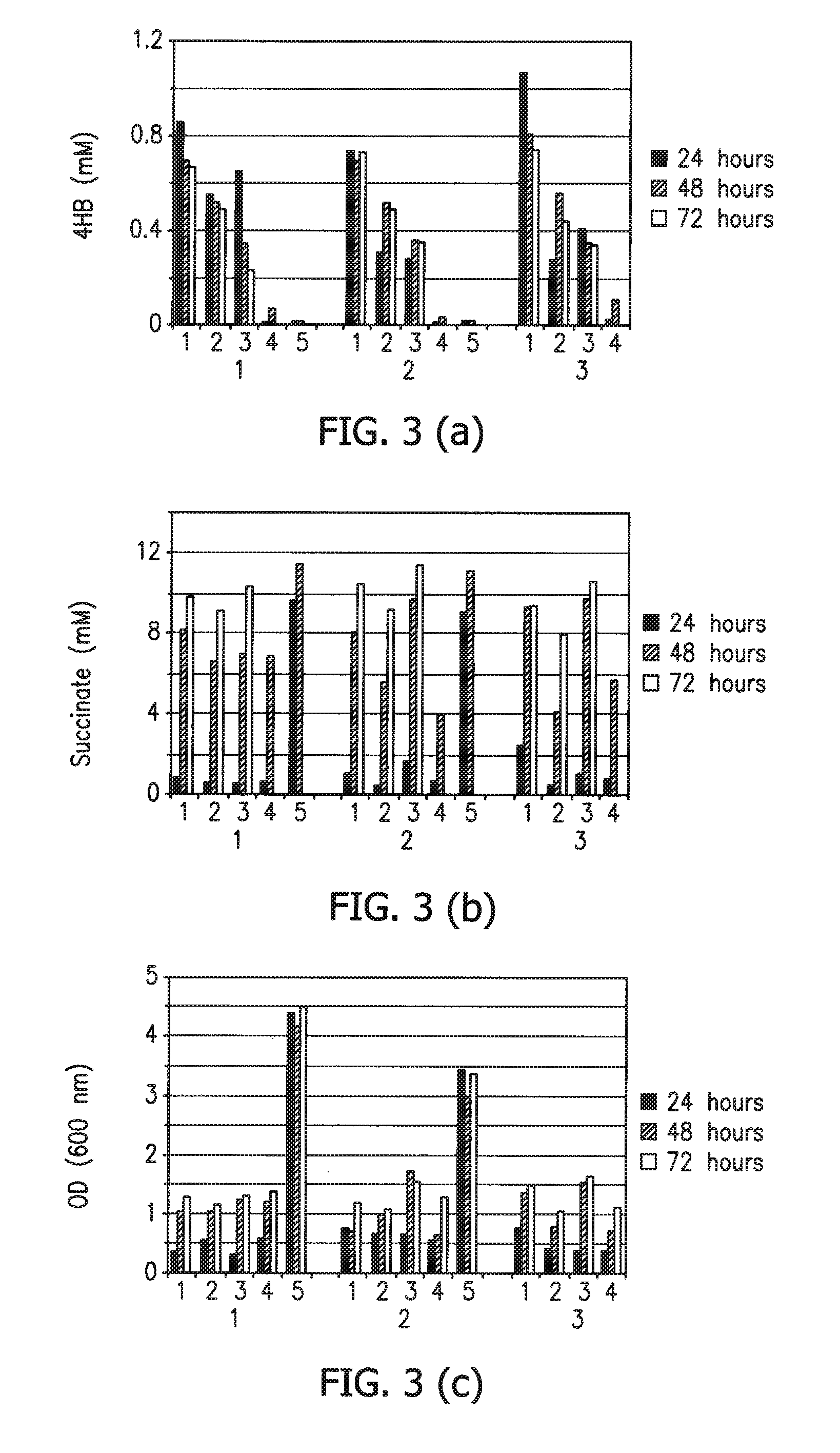

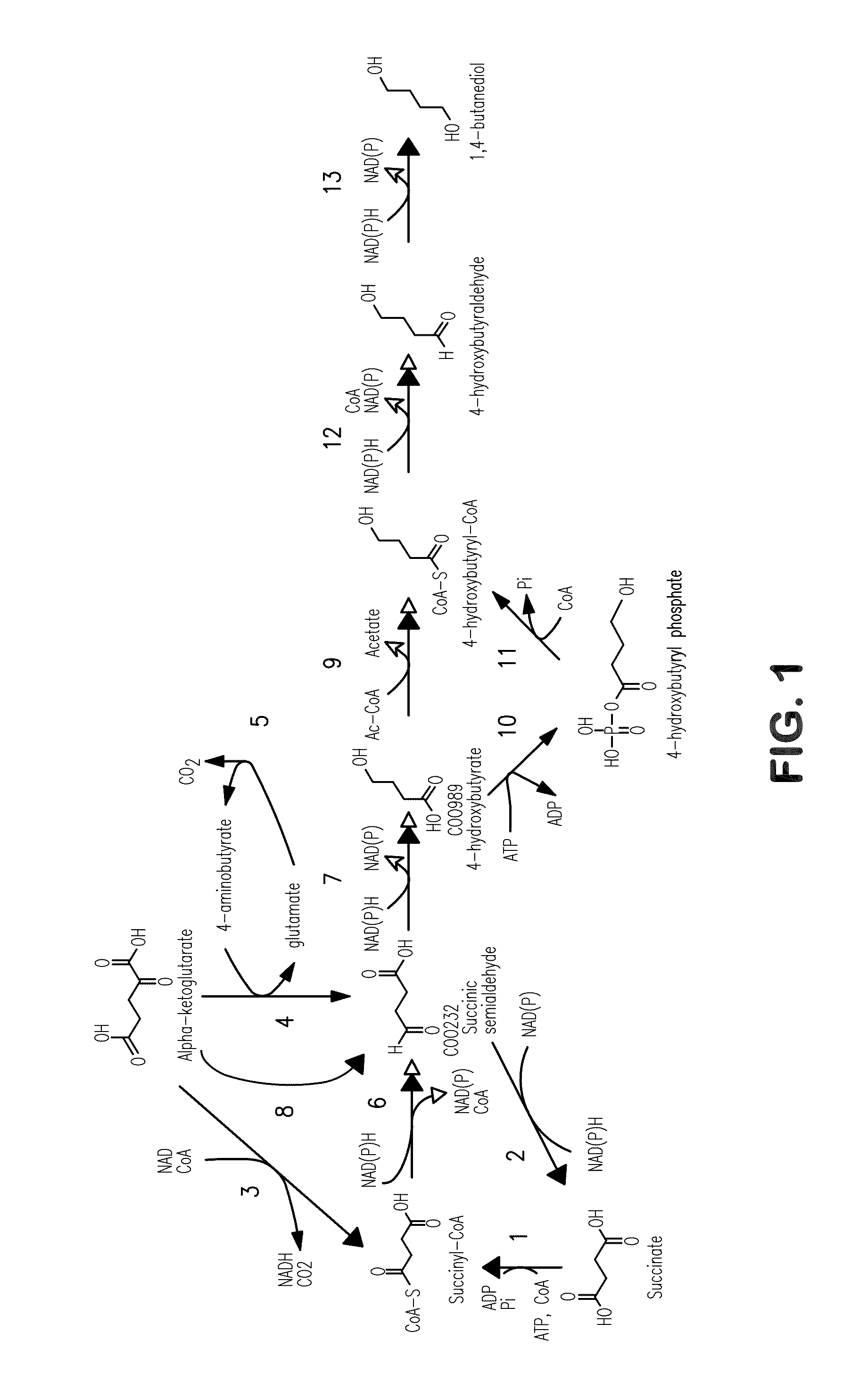

Compositions and methods for the biosynthesis of 1,4-butanediol and its precursors

The invention provides a non-naturally occurring microbial organism having 4-hydroxybutanoic acid (4-HB) and 1,4-butanediol (1,4-BDO) biosynthetic pathways. The pathways include exogenous nucleic acids encoding a) an α-ketoglutarate decarboxylase; b) a 4-hydroxybutanoate dehydrogenase; c) a 4-hydroxybutyryl-CoA:acetyl-CoA transferase or a butyrate kinase and a phosphotransbutyrylase; d) an aldehyde dehydrogenase, and e) an alcohol dehydrogenase, wherein the exogenous nucleic acids are expressed in sufficient amounts to produce 1,4-butanediol (1,4-BDO). Also provide is a method for the production of 1,4-BDO. The method includes culturing the non-naturally occurring microbial organism having 4-HB and 1,4-BDO biosynthetic pathways substantially anaerobic conditions for a sufficient period of time to produce 1,4-BDO.

Owner:GENOMATICA INC

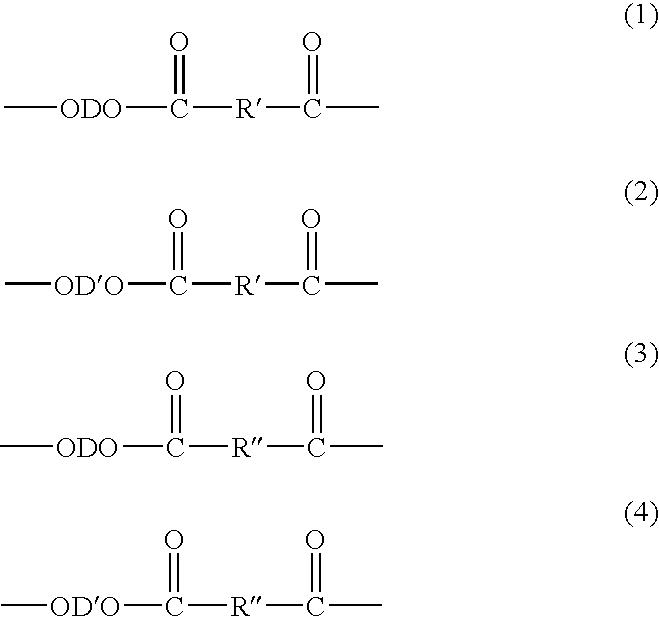

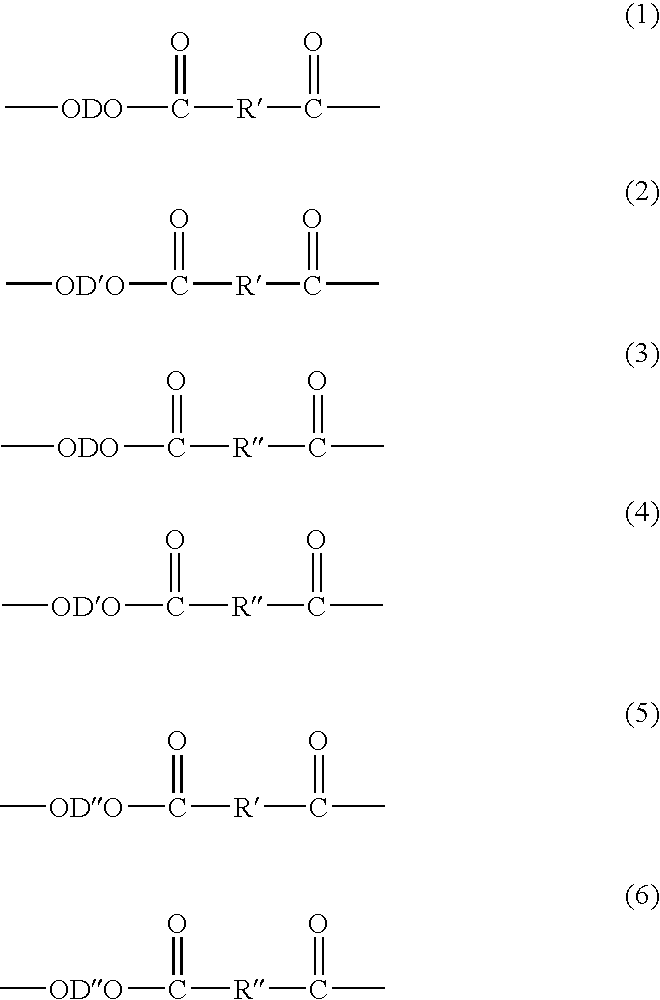

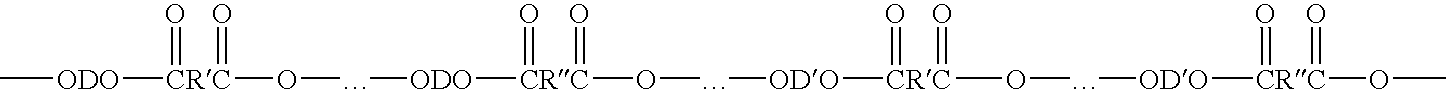

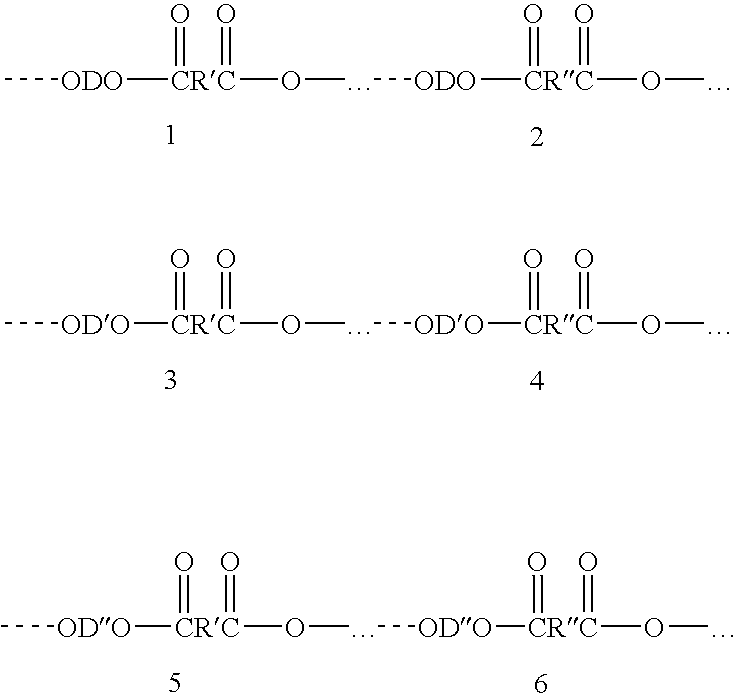

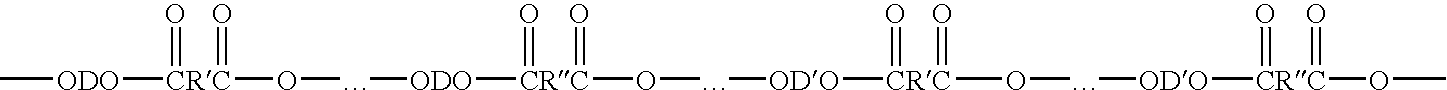

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS20050027098A1High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatusPolymer scienceCopolyester

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

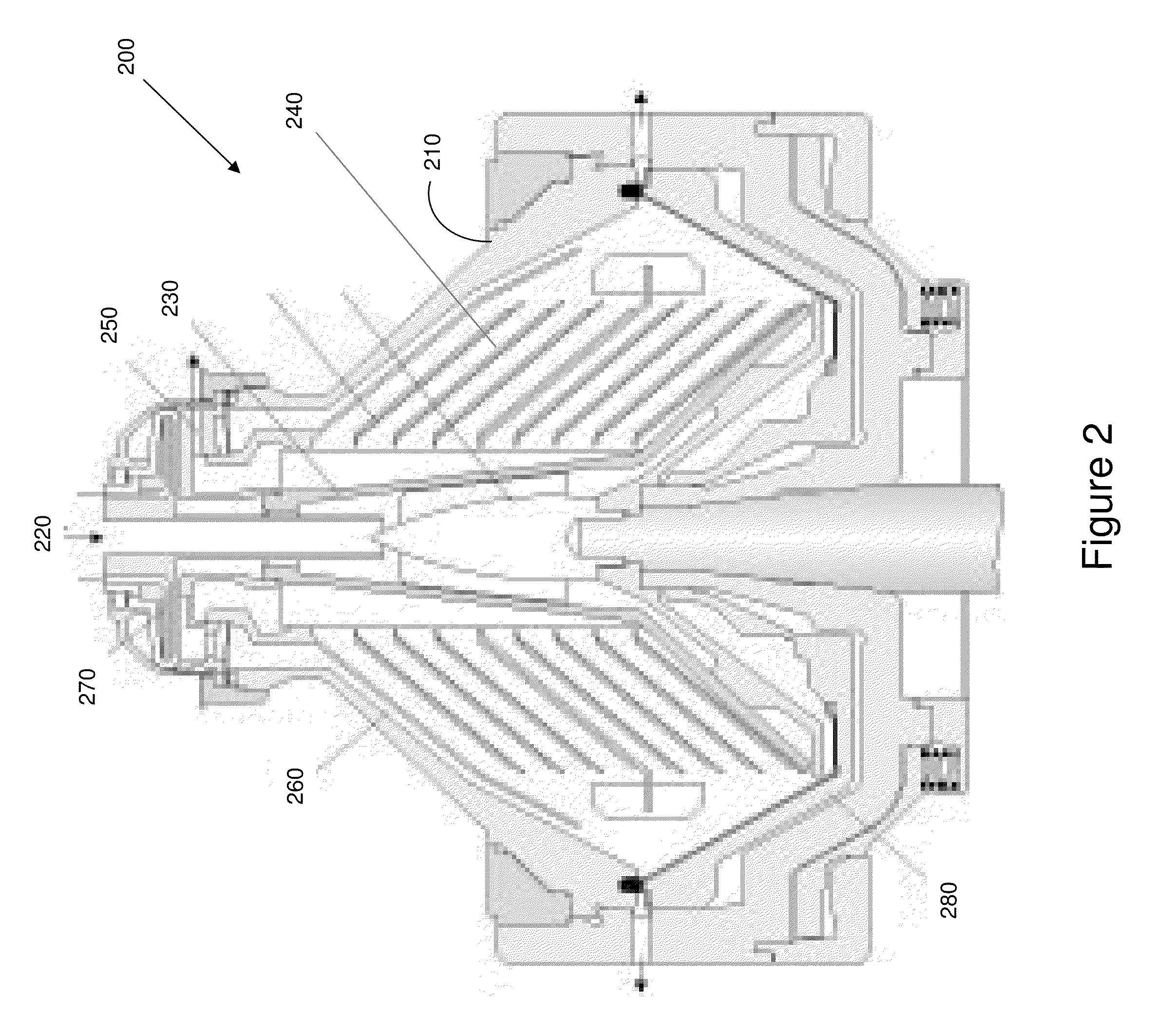

Microorganisms for the production of 1,4-butanediol and related methods

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO) pathway comprising at least one exogenous nucleic acid encoding a BDO pathway enzyme expressed in a sufficient amount to produce BDO and further optimized for expression of BDO. The invention additionally provides methods of using such microbial organisms to produce BDO.

Owner:GENOMATICA INC

Microorganisms for the production of 1,4-butanediol

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO) pathway comprising at least one exogenous nucleic acid encoding a BDO pathway enzyme expressed in a sufficient amount to produce BDO. The invention additionally provides methods of using such microbial organisms to produce BDO.

Owner:GENOMATICA INC

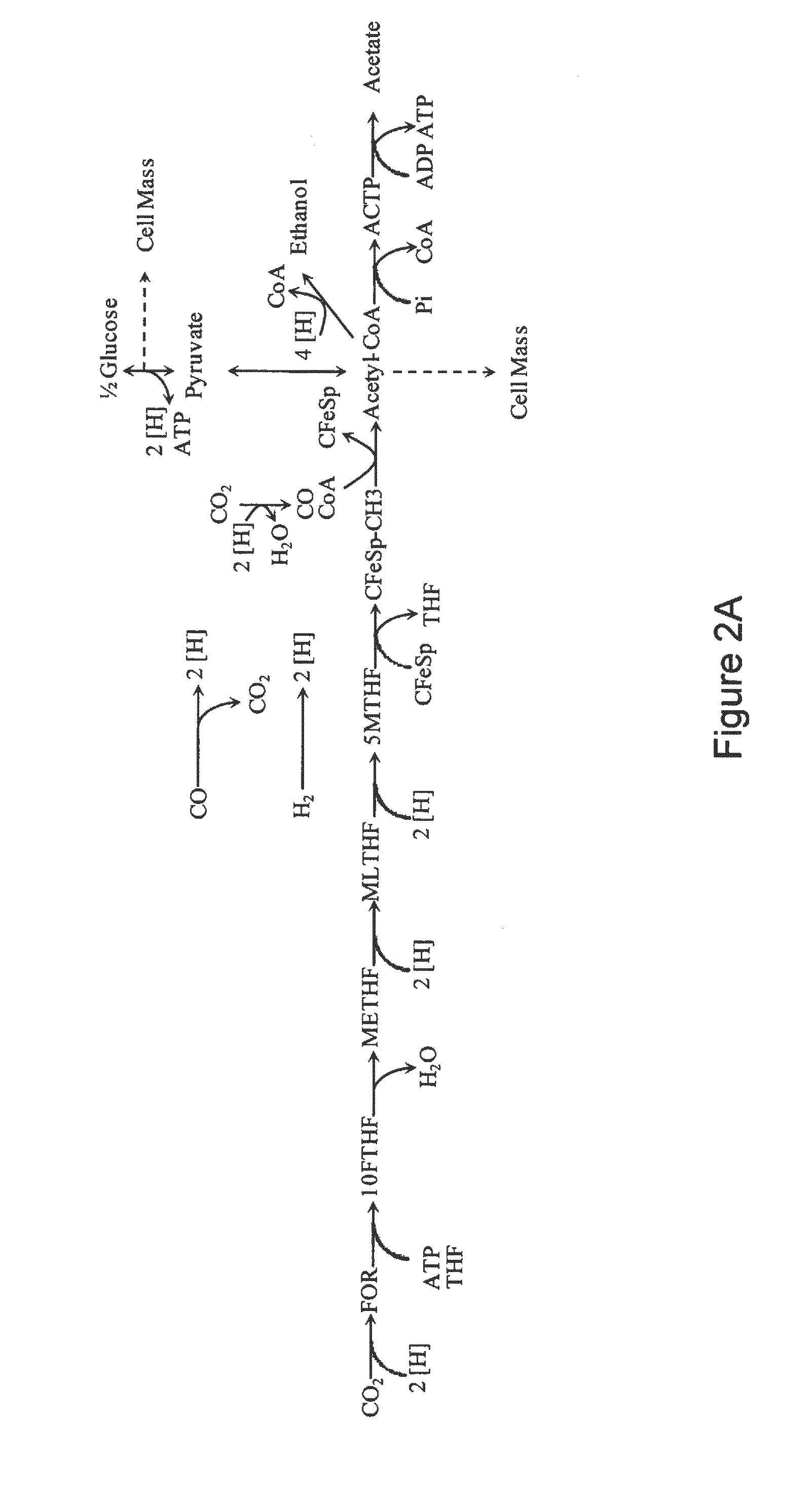

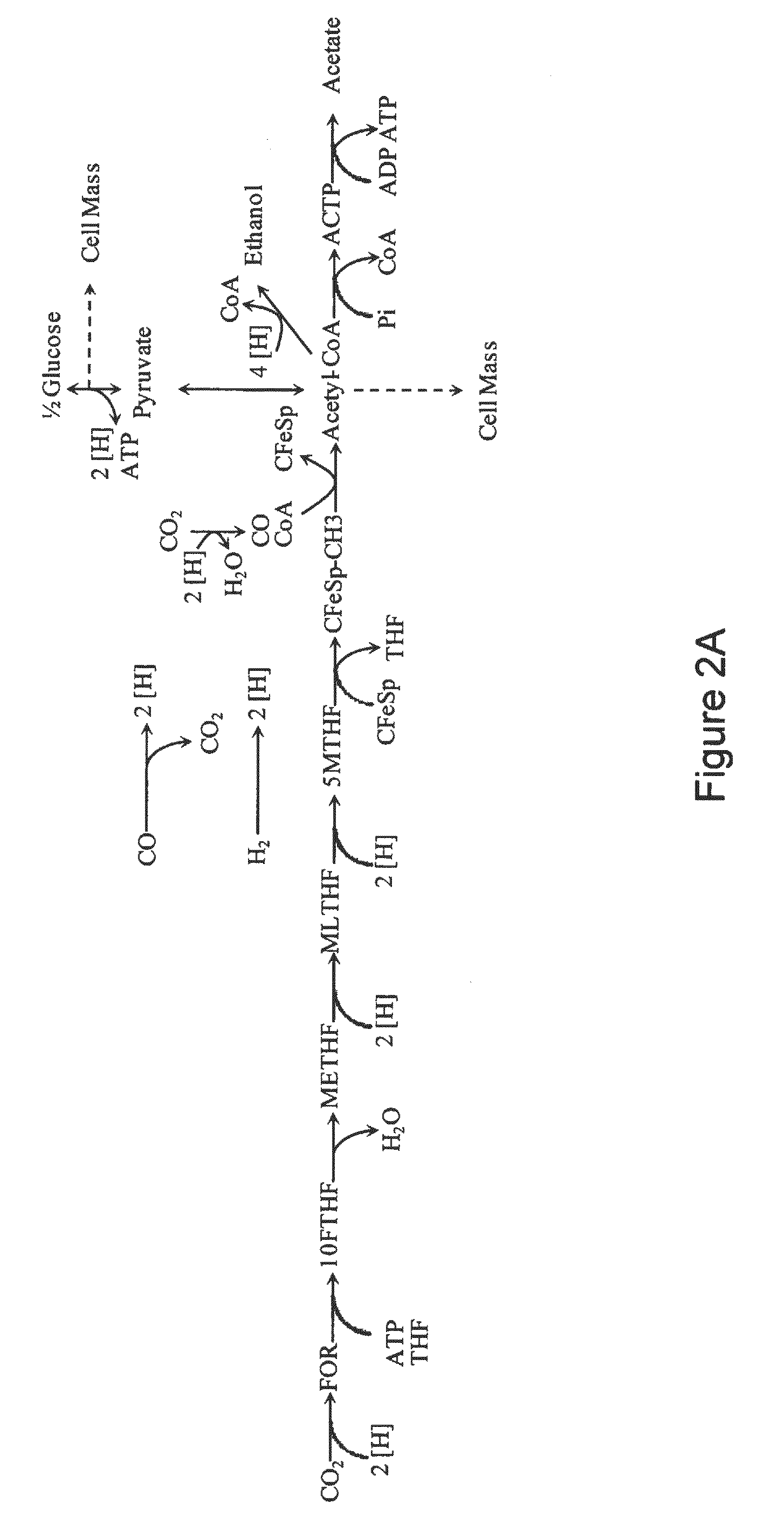

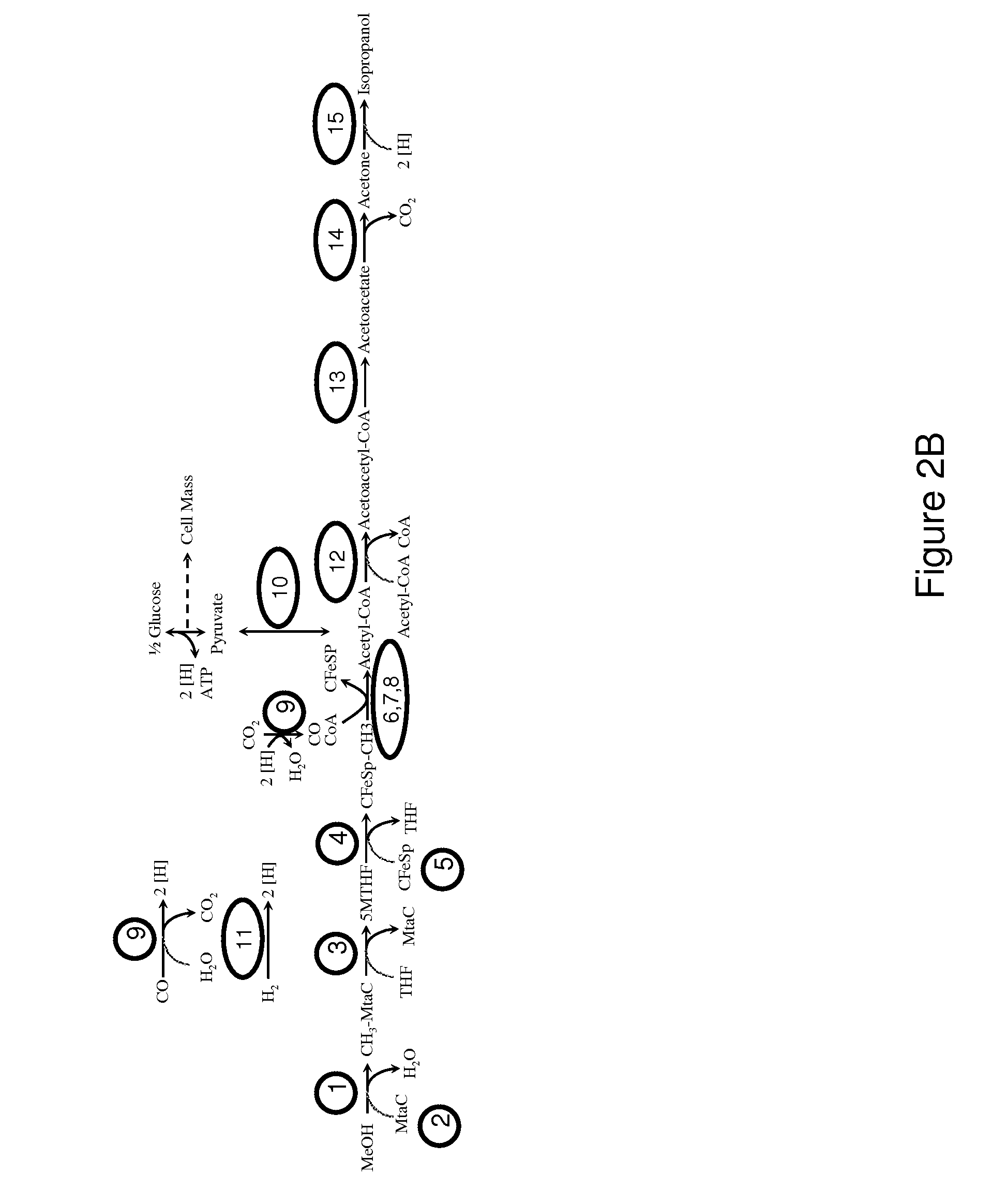

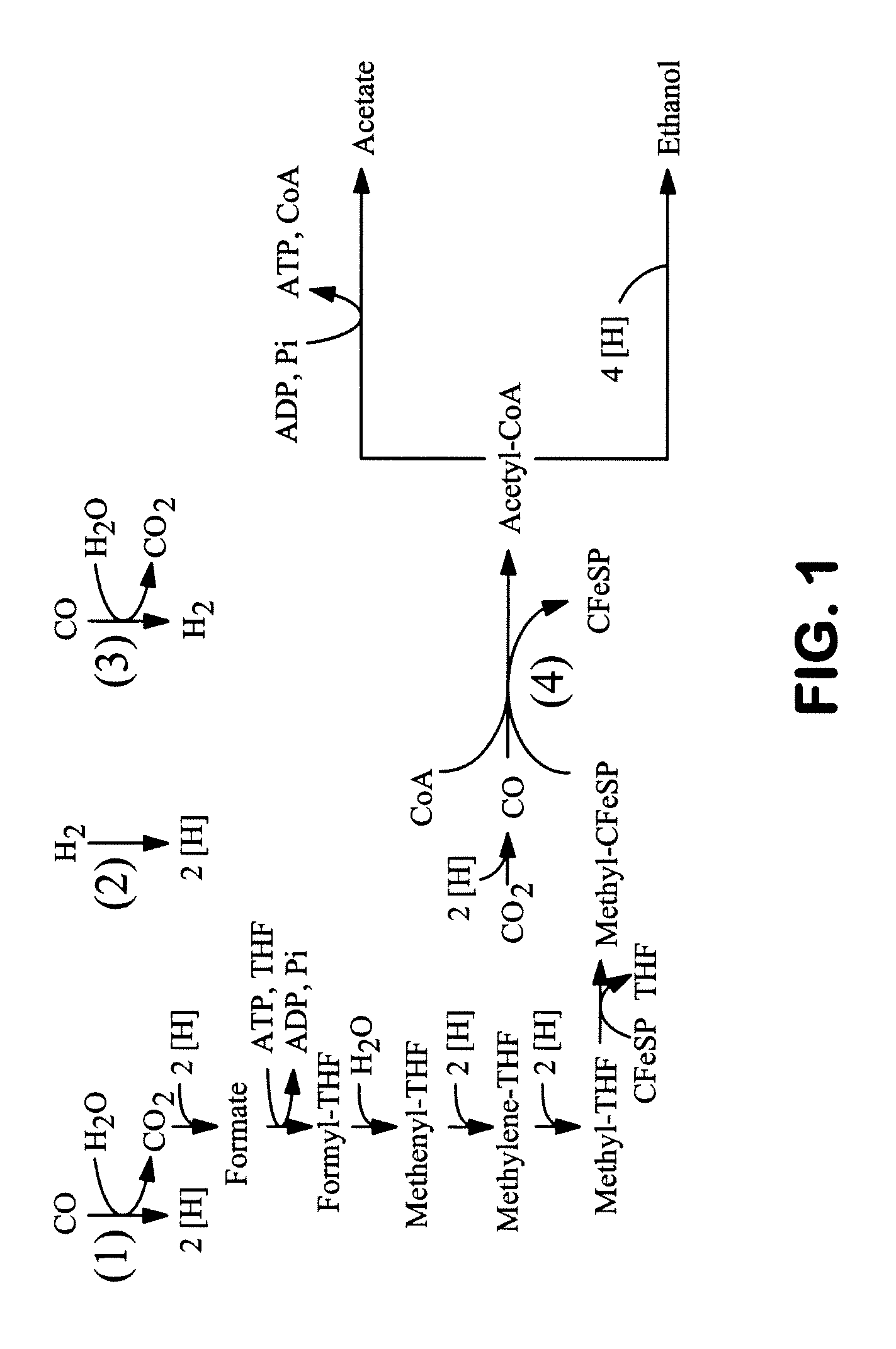

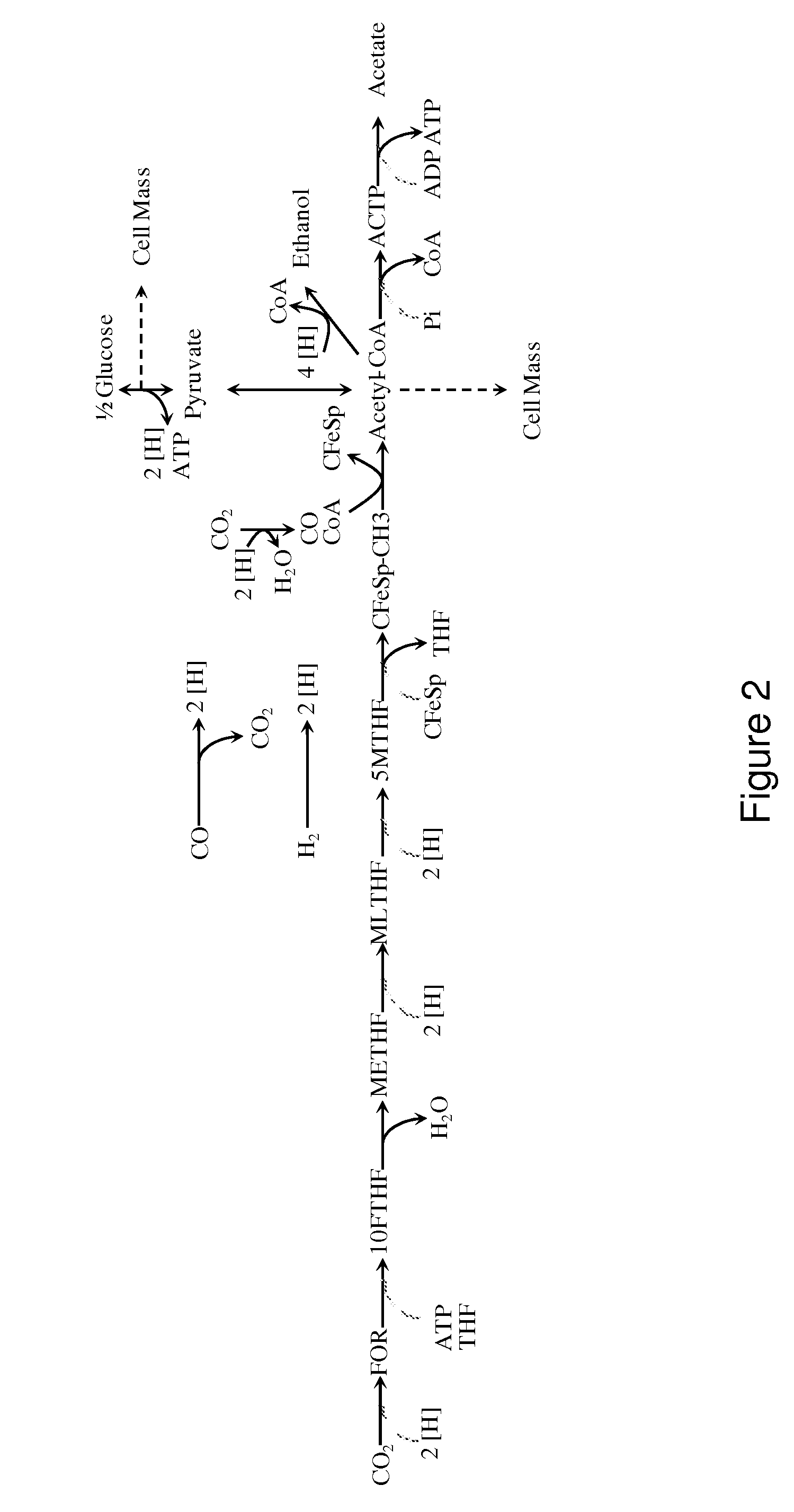

Microorganisms and methods for conversion of syngas and other carbon sources to useful products

A non-naturally occurring microbial organism having an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway includes at least one exogenous nucleic acid encoding an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway enzyme expressed in a sufficient amount to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol. The aforementioned organisms are cultured to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol.

Owner:GENOMATICA INC

Microorganisms for the production of 1,4-butanediol and related methods

Owner:GENOMATICA INC

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS7220815B2High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatus1,4-ButanediolPolymer science

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

Microorganisms and methods for conversion of syngas and other carbon sources to useful products

A non-naturally occurring microbial organism having an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway includes at least one exogenous nucleic acid encoding an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway enzyme expressed in a sufficient amount to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol. The aforementioned organisms are cultured to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol.

Owner:GENOMATICA INC

Preparation of polybutane diacid butanediol ester

A process for preparing butanediol polysuccinate able to be fully biodegradated includes such steps as adding butanediol and butanedioic acid to reactor, esterifying reacting at 150-200 deg.C, and vacuum polycondensating at 200-280 deg.C under the existance of catalyst. It is a thermoplastic resin with 100,000 of mass average molecular weight and better mechanical performance.

Owner:中科启程新材料科技(海南)有限公司

Conversion of contaminated polyethylene terephthalate to decontaminated polybutylene terephthalate

InactiveUS6518322B1Fast reaction timeCost is removed entirelyPolytetramethylene terephthalate1,4-Butanediol

Decontaminated crushed polyethylene terephthalate is converted to decontaminated PBT withtout requiring a catalyst by mixing with 1,4-butanediol under reduced pressure, transeterifying at 120-190° C., distilling off ethanediol and tetrahydrofuran under sub-atomspheric pressure. The method lowers costs, and decreases wasteful by-products and removes contaminants present in post-consumer PET, (e.g. paper, pigments, plastics, dyes, mineral sands, and clays) and chemical and water insoluble contaminants.

Owner:ALPHAPET LTD +1

Method of Making Polybutylene Terephthalate and Compositions and Articles Comprising the Same

A process for making modified polybutylene terephthalate random copolymers from a polyethylene terephthalate component includes reacting an oligomeric diol component selected from the group consisting of bis(hydroxybutyl)terephthalate, bis(hydroxybutyl)isophthalate, hydroxybutyl-hydroxyethyl terephthalate, and combinations thereof to a reactor; (i) a polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers with (ii) a diol component selected from the group consisting of 1,4-butanediol, ethylene glycol, propylene glycol, and combinations thereof, in the reactor under conditions sufficient to depolymerize the polyethylene terephthalate component into a first molten mixture; combining the first molten mixture is combined with 1,4-butanediol under conditions to form a second molten mixture; and placing the second molten mixture under conditions sufficient to produce the modified polybutylene terephthalate random copolymers. Also described are compositions and articles made from the process.

Owner:SHPP GLOBAL TECH BV

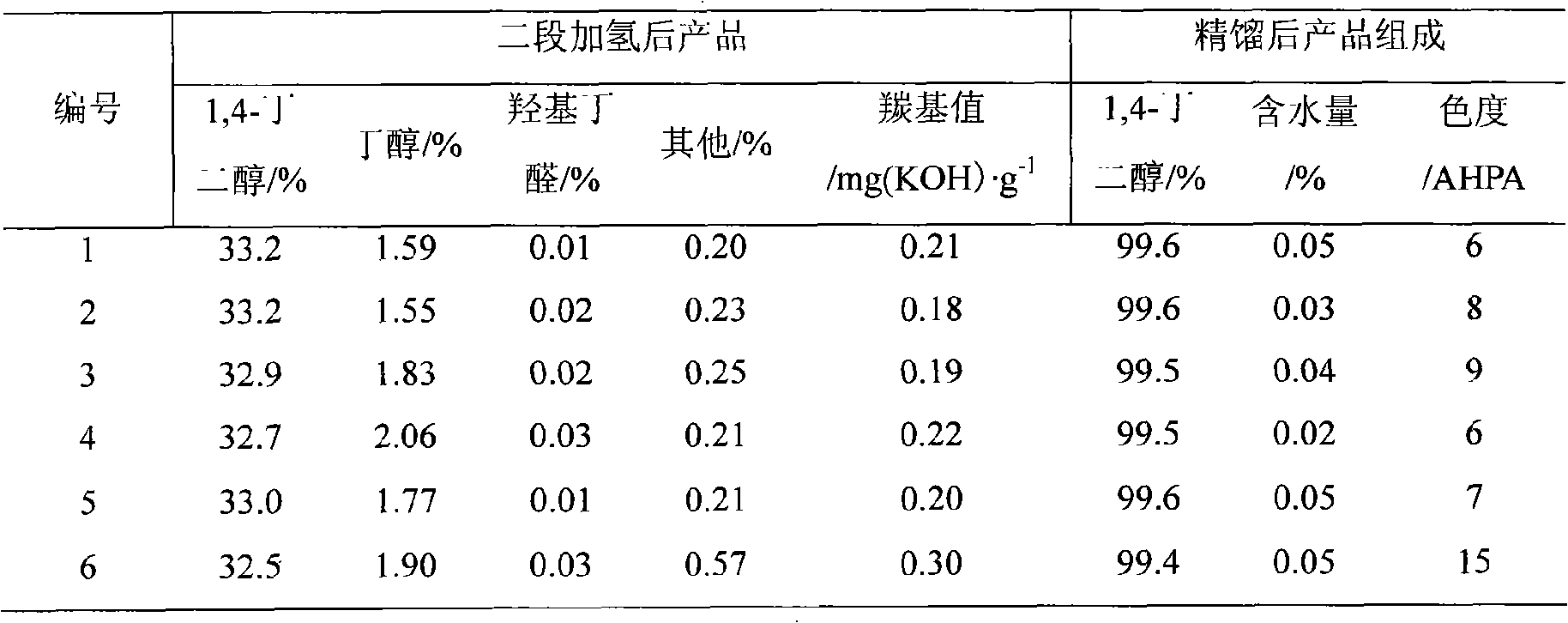

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

Process for making polybutylene terephthalate (PBT) from polyethylene terephthalate (PET)

The invention relates to a process for making modified polybutylene terephththalate random copolymers from a polyethylene terephthalate component. The invention relates to a three step process in which a diol component selected from the group consisting of ethylene glycol, propylene glycol, and combinations thereof reacts with a polyethylene terephthalate component under conditions sufficient to depolymerize the polyethylene terephthalate component into a first molten mixture; and where the first molten mixture is combined with 1,4-butanediol under conditions that create a second molten mixture that is subsequently placed under subatmospheric conditions that produce the modified polybutylene terephthalate random copolymers. The invention also relates to compositions made from the process.

Owner:SHPP GLOBAL TECH BV

Thermoplastic polyurethane elastomer and manufacturing method thereof

The invention relates to the manufacturing field of a special extrusion grade T-die thermoplastic elastomer, in particular to a manufacturing formula and a manufacturing method thereof. The formula comprises the following components: 20-40% of 4,4'-diphenylmethane-diisocyanate, 15-70% of polybutylene adipate the molecular weight of which is 1000 or 2000, 0-50% of poly butylene glycol adipate the molecular weight of which is 2000, 5-15% of 1,4-butanediol, 0-5% of glycol, 0.1-1.0% of antioxidant, 0.1-1.0% of lubricant, 0.001-0.1% of environment-friendly catalyst, 0.1-1.0% of ultraviolet absorbent, 0.1-1.0% of light stabilizer and 0.1-1.0% of hydrolysis resistant agent. Continuous production processes are used for synthesizing TPU (thermoplastic polyurethane). The product of the invention has the advantages of stable quality, excellent performance, few T-die extrusion crystal points, good transparency (more than 4mm), stable extrusion, no occurrence of separation of additives, high hydrolysis resistance and high UV (ultraviolet) resistance, and the indexes and the performance of the product can reach the indexes of international like products. The invention provides a thermoplastic polyurethane elastomer and a manufacturing method thereof.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

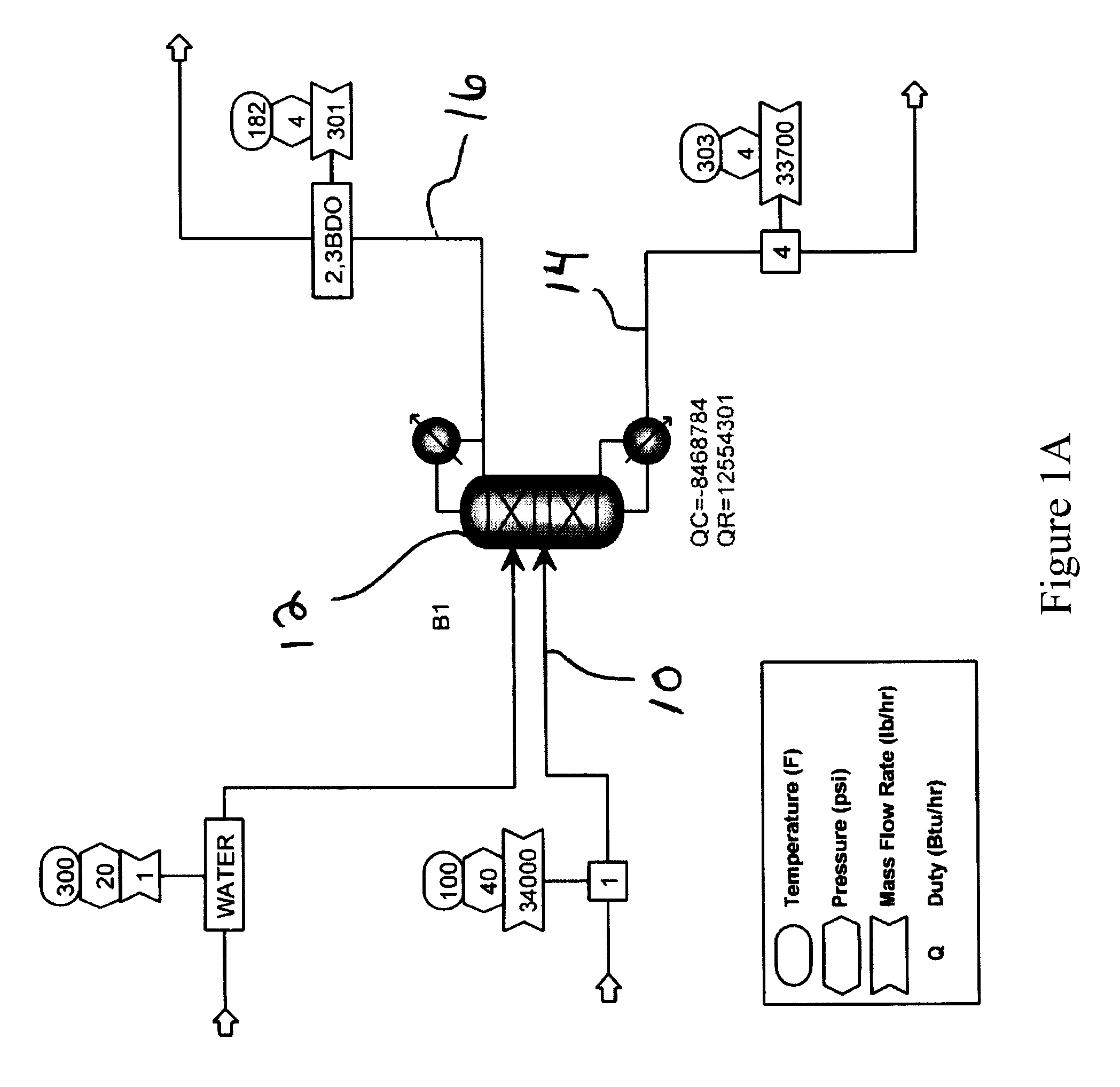

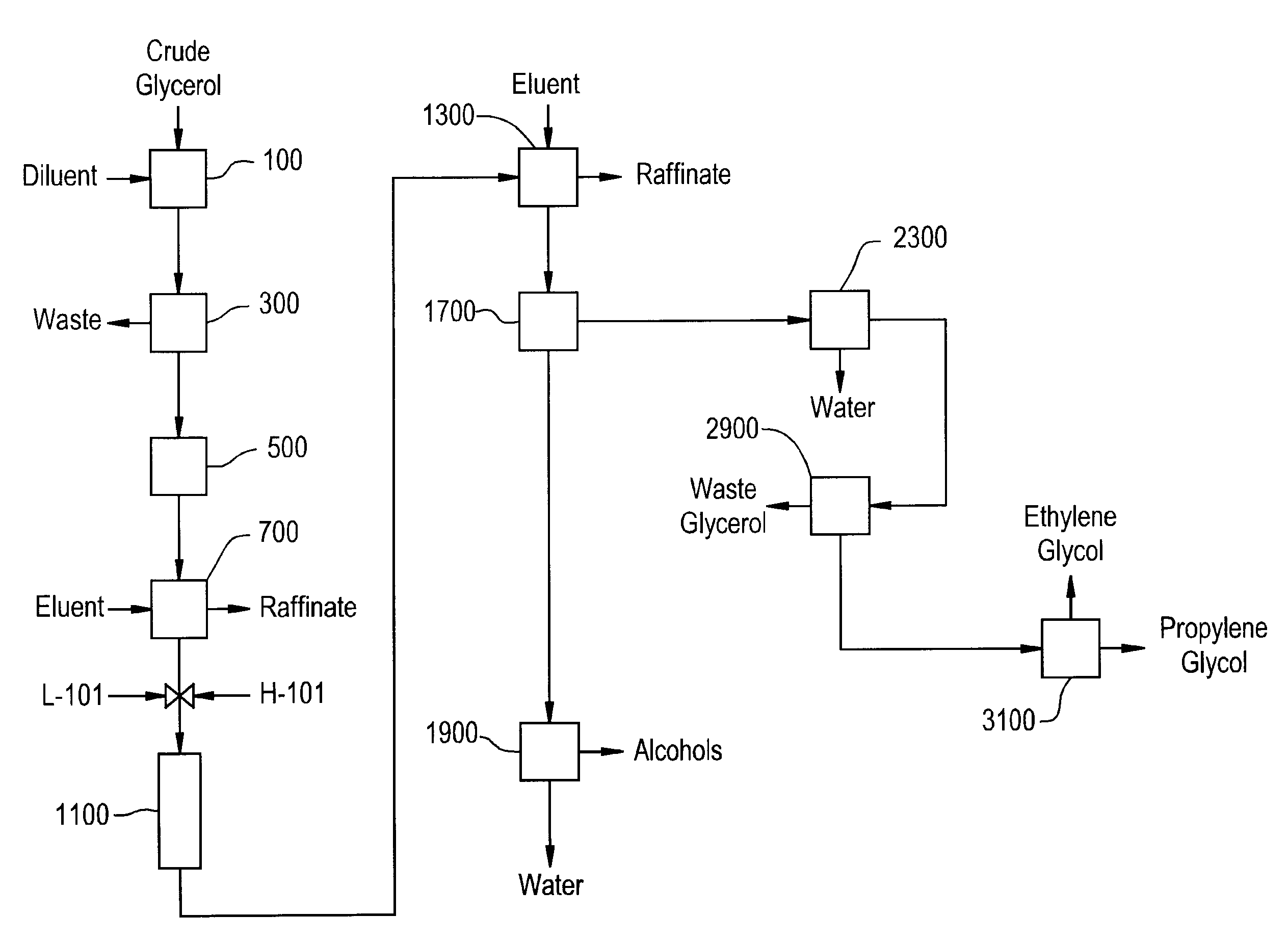

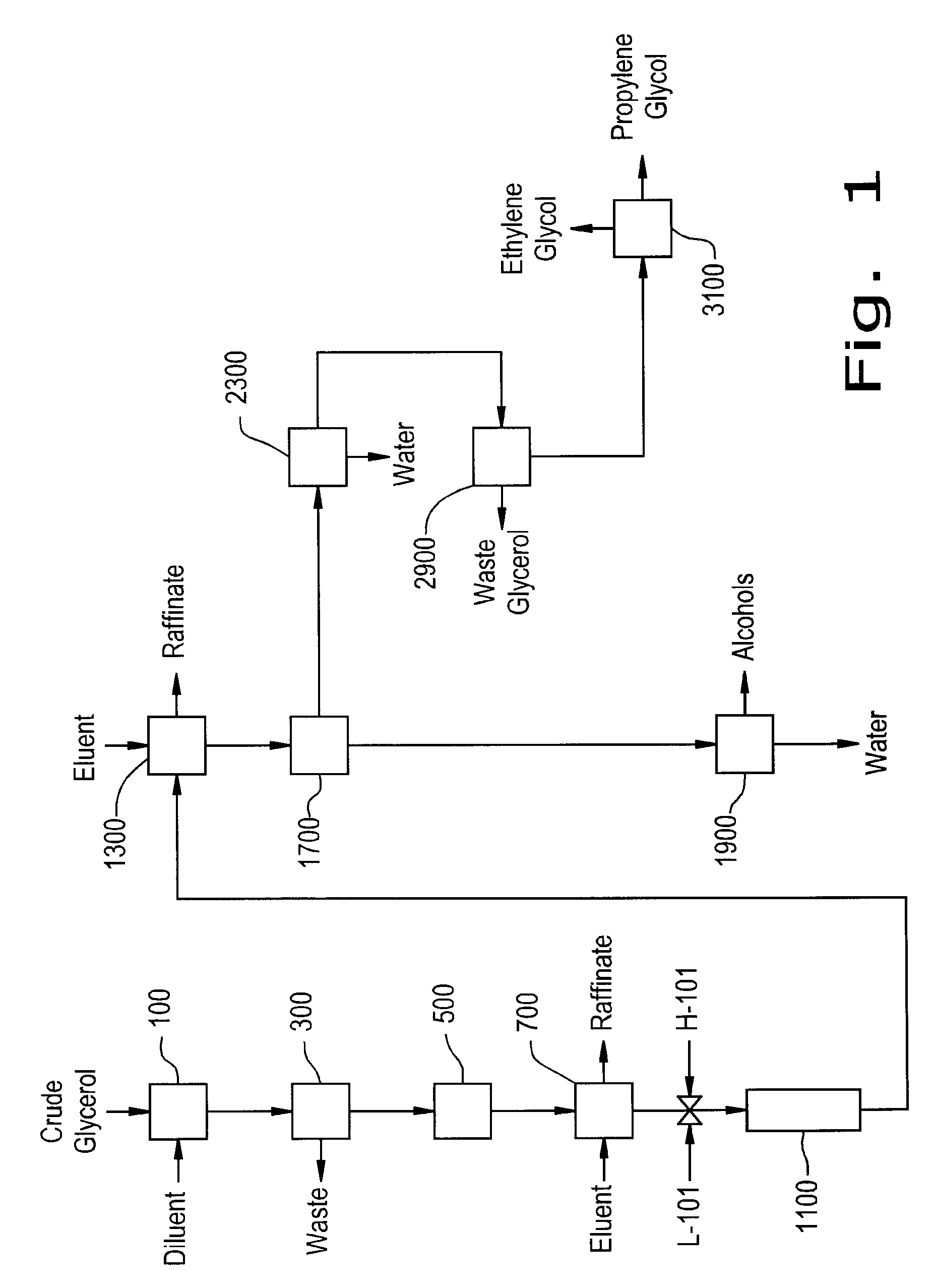

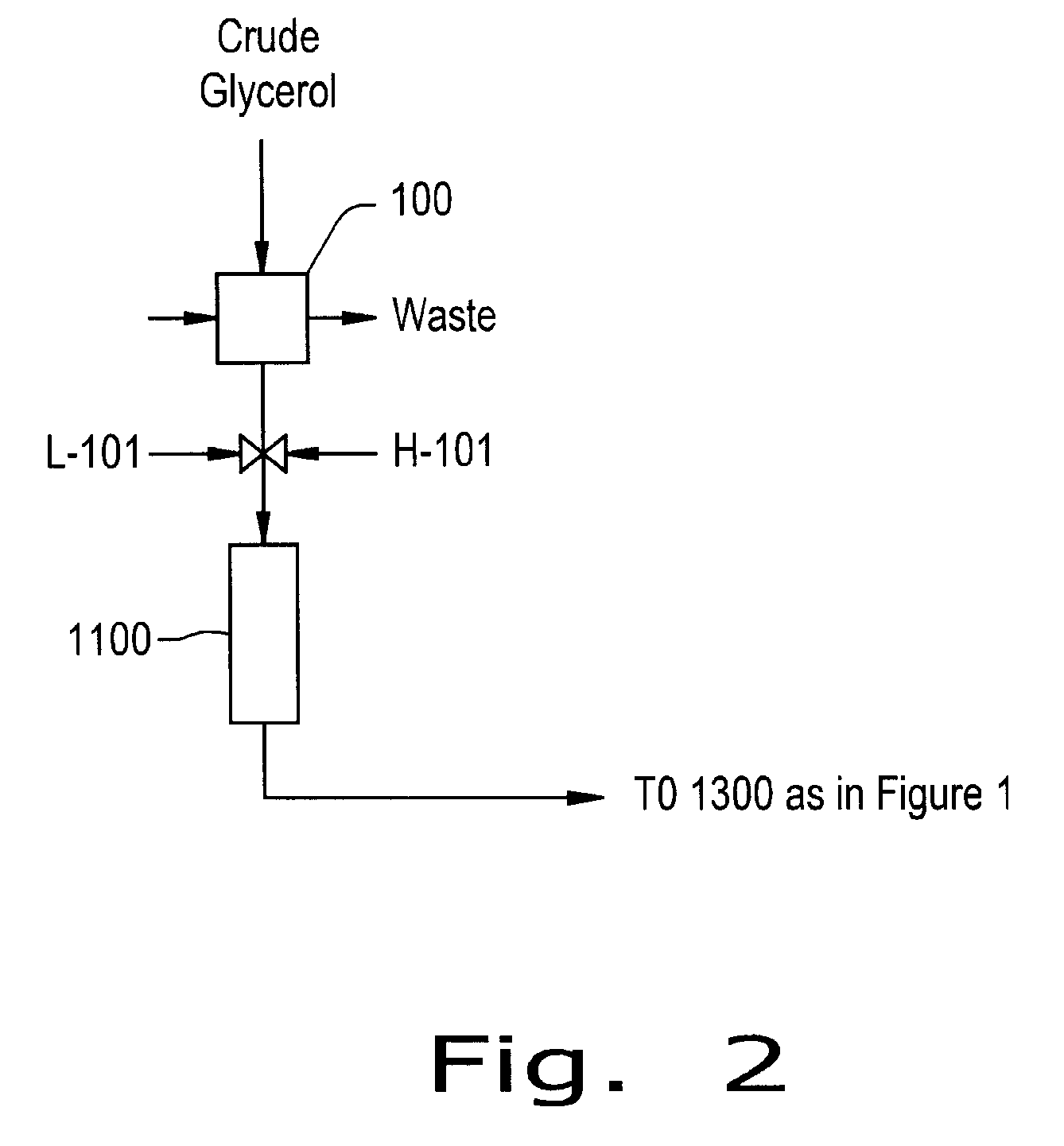

Processes for isolating or purifying propylene glycol, ethylene glycol and products produced therefrom

ActiveUS20080275277A1Organic compound preparationDetergent compounding agentsButanediolPropylene glycol

Owner:ARCHER DANIELS MIDLAND CO

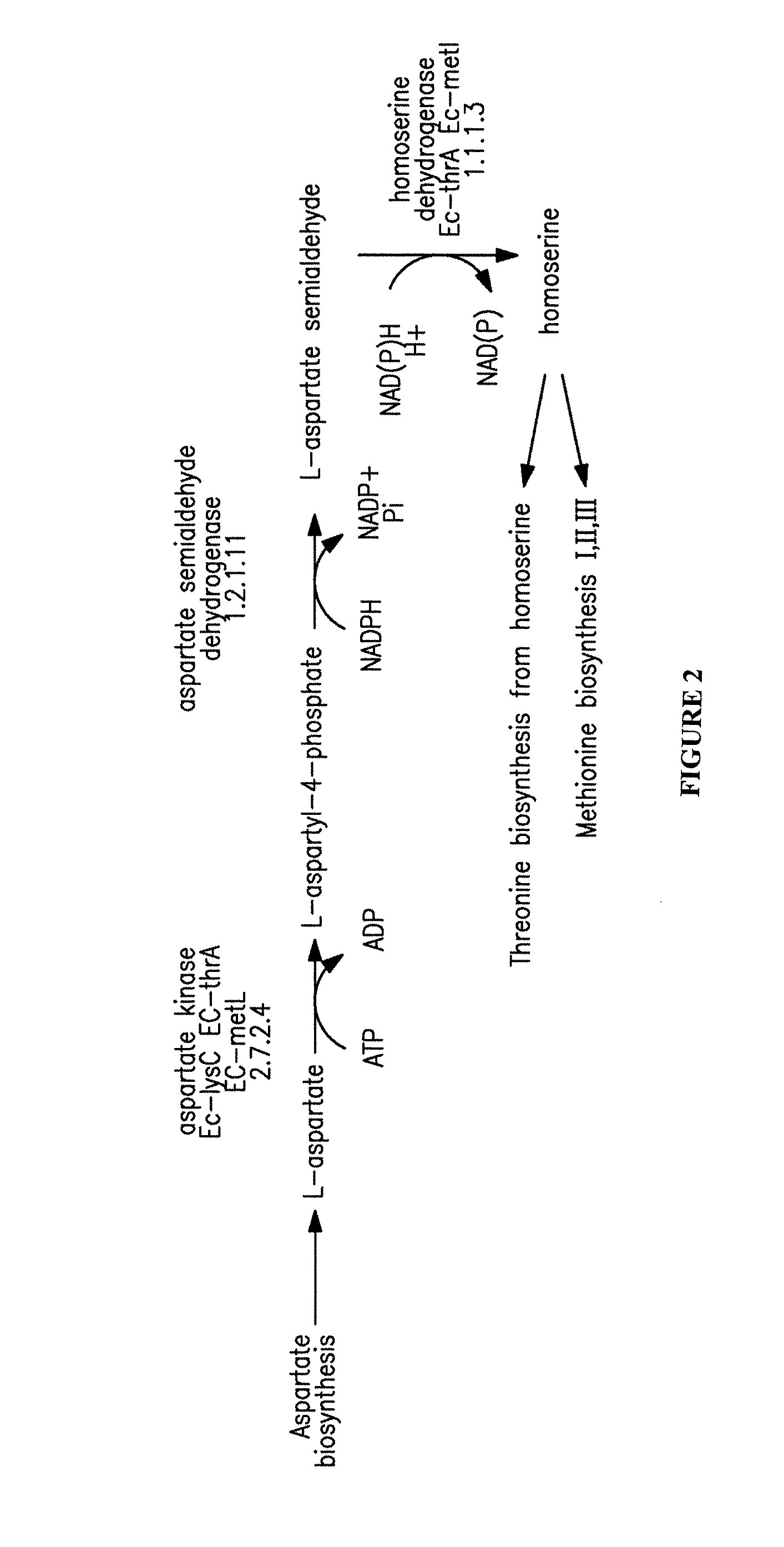

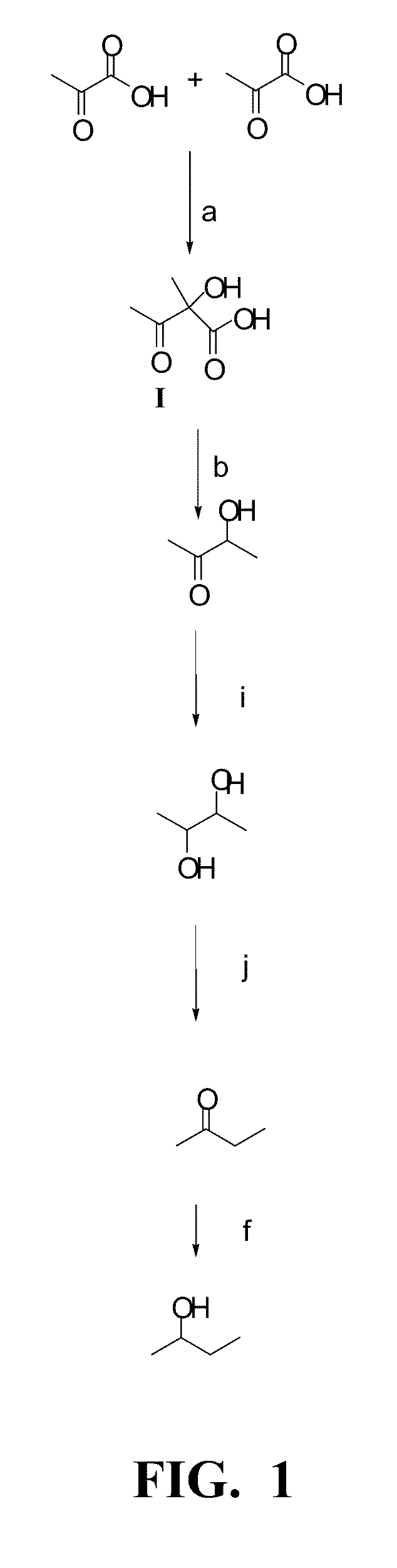

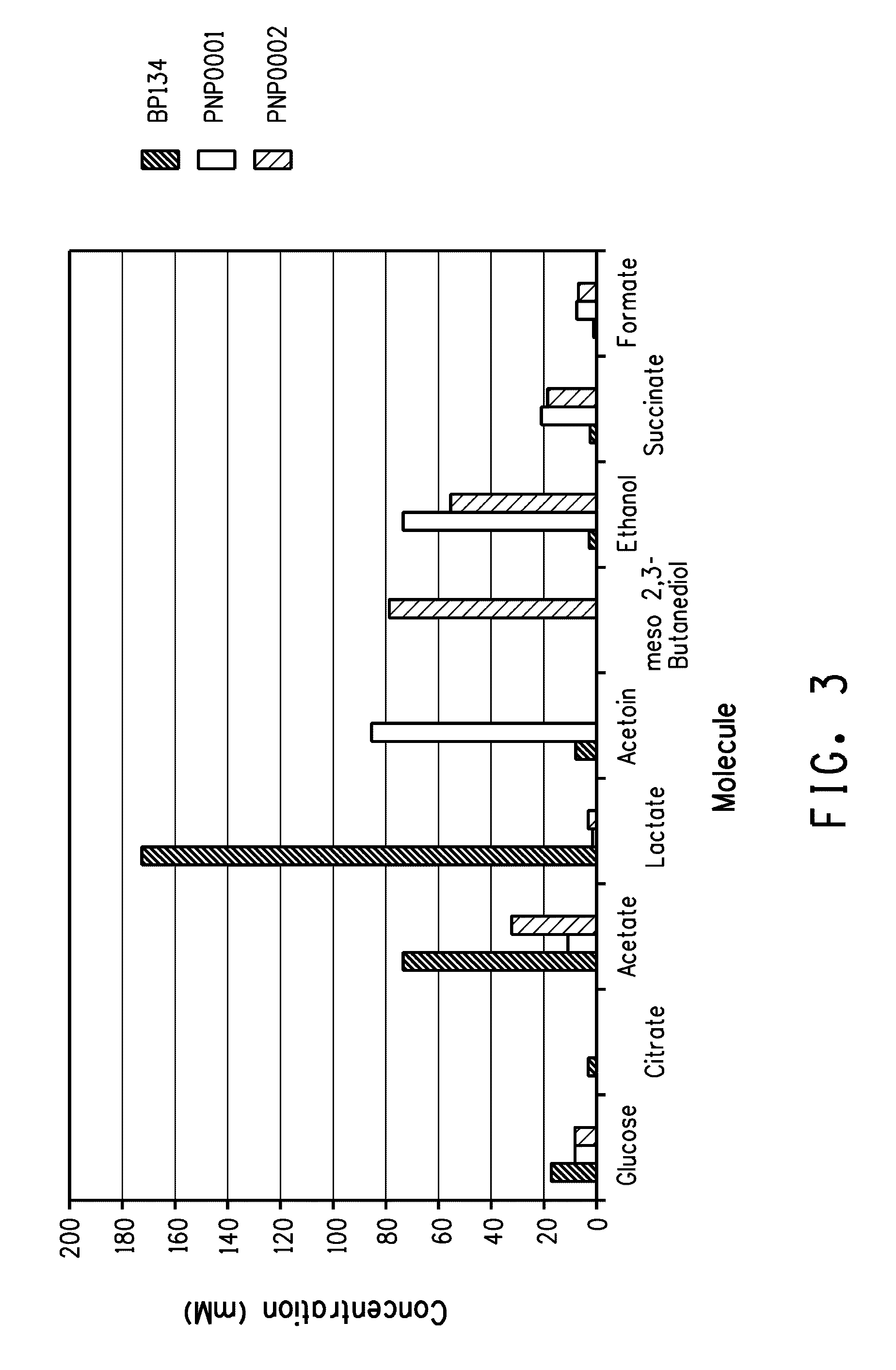

Enhanced pyruvate to 2,3-butanediol conversion in lactic acid bacteria

A high flux of metabolites from pyruvate to 2,3-butanediol in Lactobacillus plantarum was achieved through genetic engineering. Substantial elimination of lactate dehydrogenase activity in the presence of heterologously expressed butanediol dehydrogenase activity led to 2,3 butanediol production that was at least 49% of the total of major pyruvate-derived products.

Owner:GEVO INC

Preparation method of toughness enhanced and reinforced polybutanediol terephthalate nanometer composition

InactiveCN1537891AHigh surface finishImprove heat resistanceSurface finishPolytetramethylene terephthalate

A nano-class toughened and strengthened butanediol polyterephthalate composition is prepared through proportionally mixing butanediol polyterephthalate, inorganic nanoparticles, reaction compatibilizer, antioxidizing agent, and lubricant, high-speed stirring, loading it along with glass fibres in dual-screw extruder, reactive mixing and granulating. Its advantage is high high-temp resistance, strength, toughness and surface polished.

Owner:SHANGHAI JIAO TONG UNIV +1

Alumina supporter and preparation method thereof

ActiveCN101322949AHigh activityGood stabilityCatalyst carriersPreparation by hydrogenationAluminium saltsCarbon black

The invention provides an aluminum oxide carrier and a preparation method thereof. The aluminum oxide carrier takes a mixture prepared by mixing pseudo-boehmite powder prepared by the carbonization method and pseudo-boehmite powder prepared by the aluminum sulfate method according to a weight proportion of 1:0.1 to 5 as a precursor and a complex acid as a peptizing agent; substances such as zirconium, titanium, silicon, alkali metals, alkaline-earth metals, rare-earth metals, carbon black, and the like, are added during kneading process; then the aluminum oxide carrier is obtained after forming, drying and roasting. The physical properties of the carrier are as follows: pore volume is 0.4 to 1.2ml / g; specific surface area is 180 to 370m<2> / g; pores with the diameter being more than 100nm accounts for more than 90 percent of total pore volume; the amount of B acid is 0.1 to 0.3mmol / g; the amount of L acid is 0.2 to 0.5mmol / g. The carrier is especially applicable to the preparation of 1, 4-butanediol catalysts in the two-stage hydrogenation catalytic synthesis of 1, 4-butynediol.

Owner:SHANXI UNIV

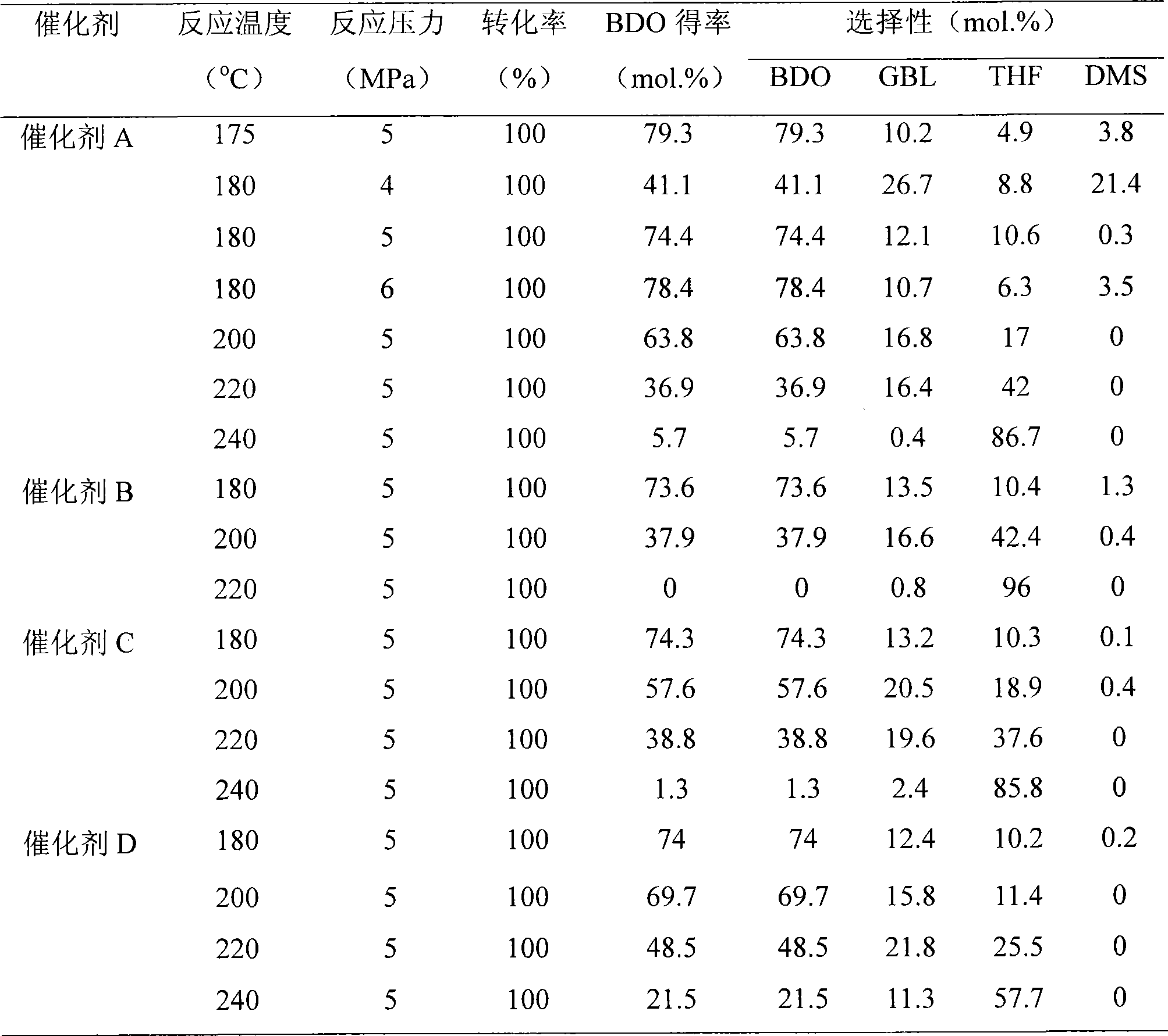

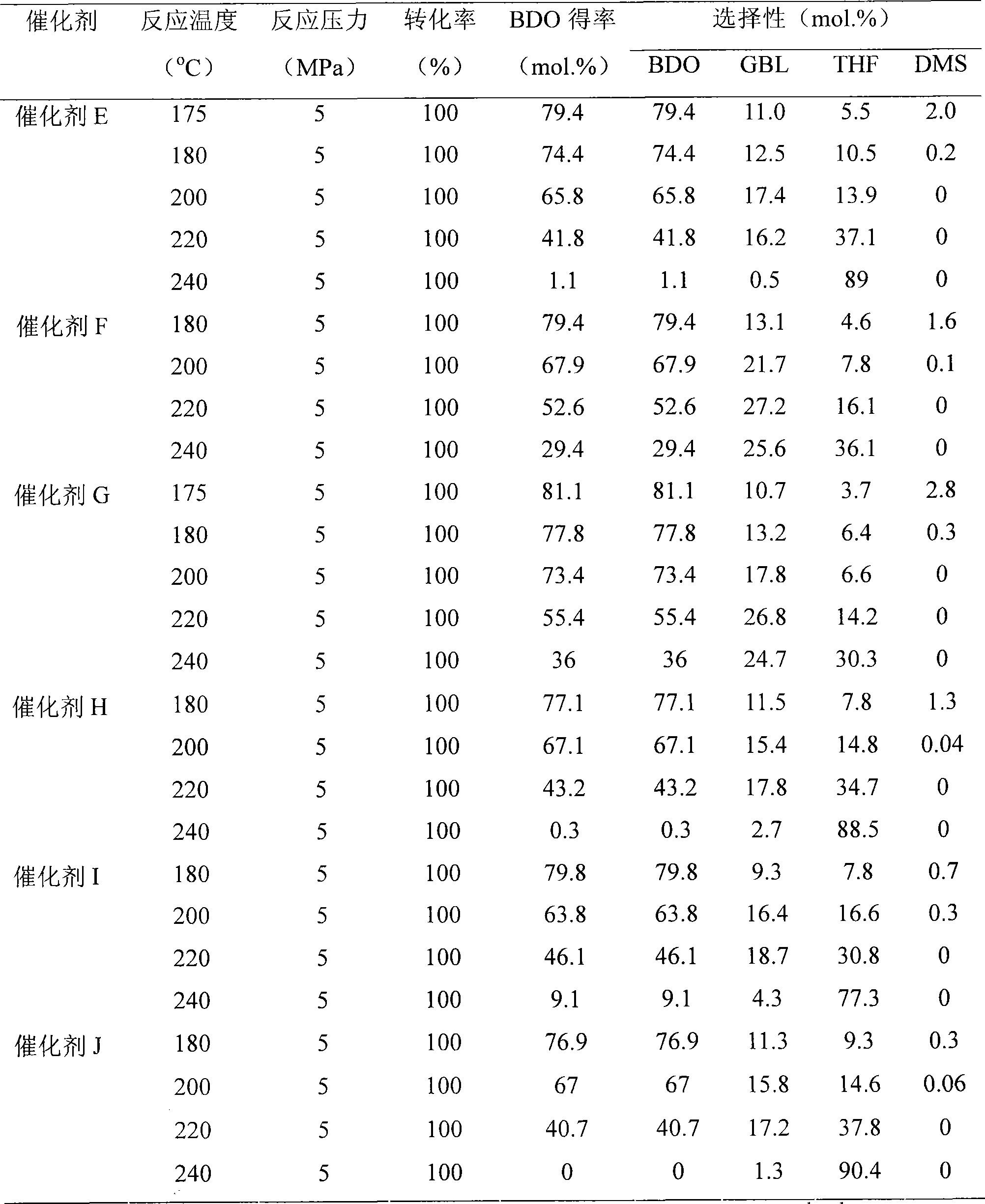

Catalyst for preparing 1,4-butanediol or tetrahydrofuran from selective hydrogenation of dimethyl maleate and preparation method thereof

ActiveCN101502803AHigh selectivitySolve filterabilityOrganic compound preparationHydroxy compound preparationMonoethyl maleateHydrogenation reaction

The invention belongs to the field of chemical technology, and in particular relates to a catalyst for preparing 1, 4-butanediol or tetrahydrofuran by selective hydrogenation of dimethyl maleate and a preparation method thereof. The catalyst consists of Cu, Zn, Al, M and O, and the mol content of each metal element is as follows: 30 to 60 percent of Cu, 10 to 50 percent of Zn, 5 to 20 percent of Al and 0 to 10 percent of M, wherein M is any one of Mn, Mg and Cr. The preparation method for the catalyst comprises precipitation, ageing, washing, drying and baking of a catalyst precursor, and reduction activation before use. The catalyst is applied to the hydrogenation reaction of the dimethyl maleate, and the yield of the 1, 4-butanediol at a reaction temperature of 180 DEG C is 73.6 percent; and the yield of the tetrahydrofuran is 96 percent at a reaction temperature of 220 DEG C. Product composition of the catalyst can be well adjusted by changing the reaction condition to adapt to different market demands, and the catalyst has extremely high industrial application value.

Owner:FUDAN UNIV +1

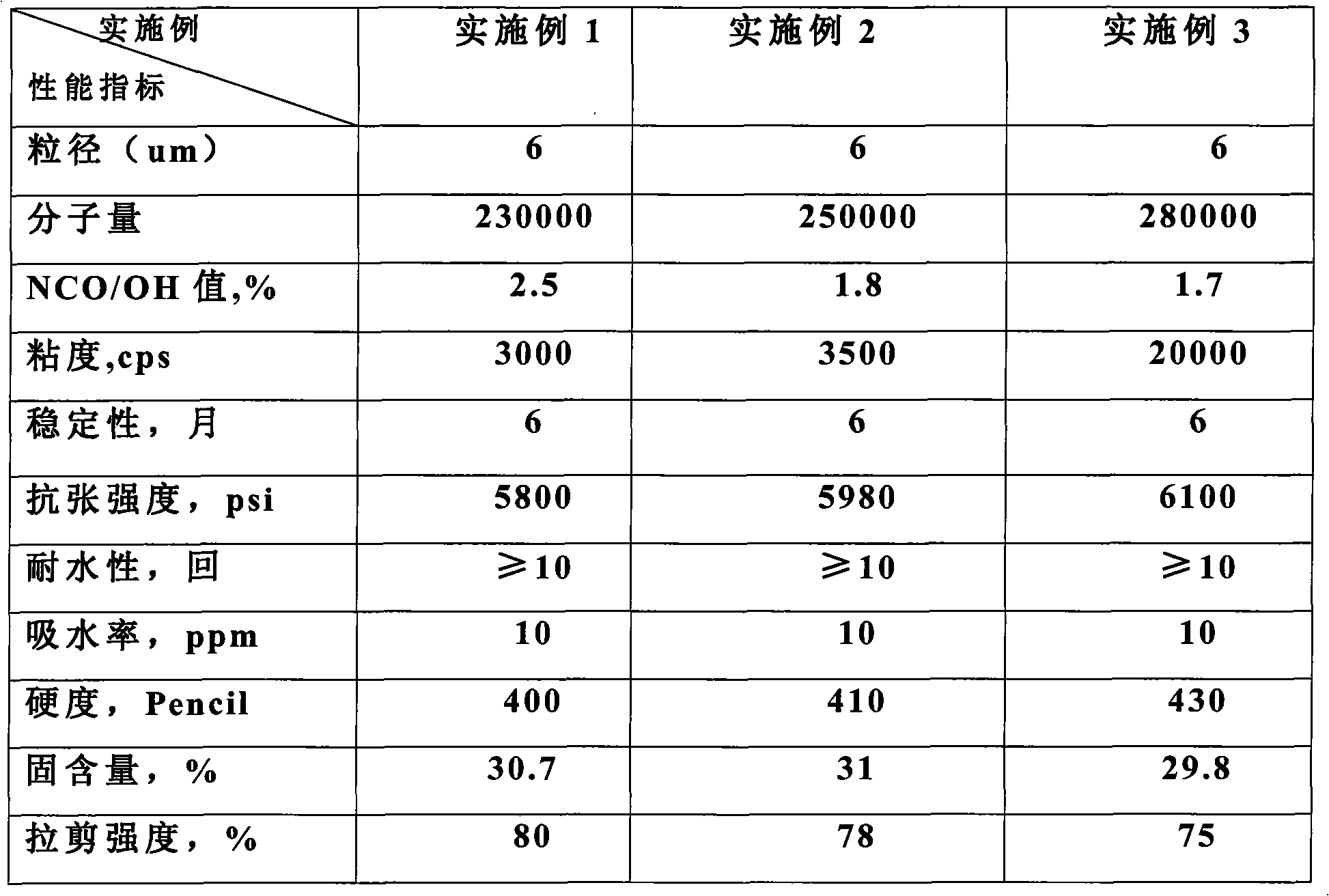

Two-package curing type polyurethane paint and preparation thereof

InactiveCN101565590ALow viscosityImprove the level ofFibre treatmentPolyurea/polyurethane coatingsApparent viscosityPolyol

The invention relates to a two-package curing type polyurethane paint and preparation thereof. The raw material system of the paint comprises a polyether polyol, a isocyanate, a small molecular chain expander and a solvent, wherein polydihydrofuran ether glycol with molecular weight between 700 to 1500 is used as the plyether polyol; methyl diphenylene diisocyanate is used as the isocyanate, 1,4-butanediol is used as the small molecular chain expander, dimethylformamide is used as the solvent. Weight proportion between the plyether polyol, the small molecular chain expander and the solvent is 1:0.7 - 0.85:8 - 15. Colloidal viscosity of the polyether polyol at 25 DEG C. is between 3000 and 2000cps. The paint is obtained by primarily charging DMF as the solvent, the polyether polyol and the chain expander into the reaction container simultaneously at one time, and then gradually charging the isocyanate for the reaction. By using MDI to substitute TDI for preparation of the polyurethane paint preparation, the invention is low in viscosity, great in levelability, easy for hardness adjustment, low in cost, safe and environment friendly in use.

Owner:顾建荣

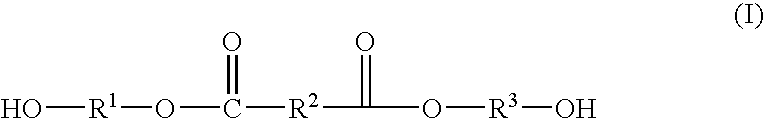

High molecular weight poly(butylene succinate) and preparation method thereof

ActiveCN101077905AHigh molecular weightNarrow molecular weight distributionPolymer scienceButanediol

The present invention relates to one kind of high molecular weight polybutanediol succinate and its preparation process, and features that bihydroxy terminated butanediol succinate, especially low molecular weight bihydroxy terminated butanediol succinate, as the pre-polymer and diisocyanate as the chain extender in 0.1-13 % are molten and reacted to prepare polybutanediol succinate with low cost, great molecular weight, narrow molecular weight distribution and excellent mechanical performance. The polybutanediol succinate has number average molecular weight greater than 5.5x10<4>, molecular weight distribution of 1.4-1.8, tensile strength of 39-58 MPa, and elongation at break of 300-700 %.

Owner:SICHUAN UNIV

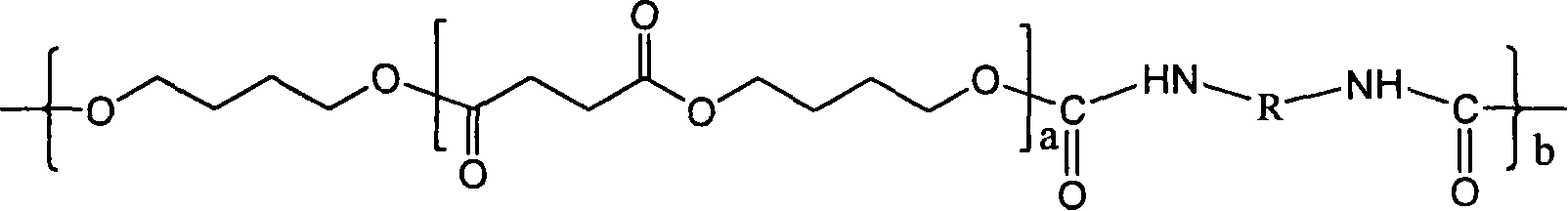

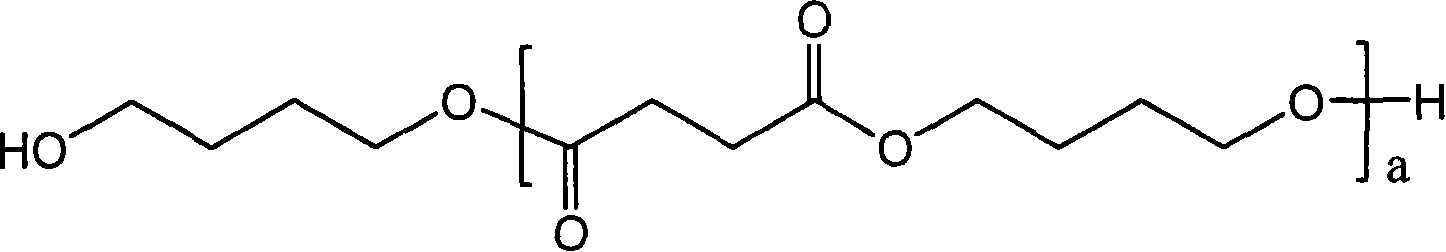

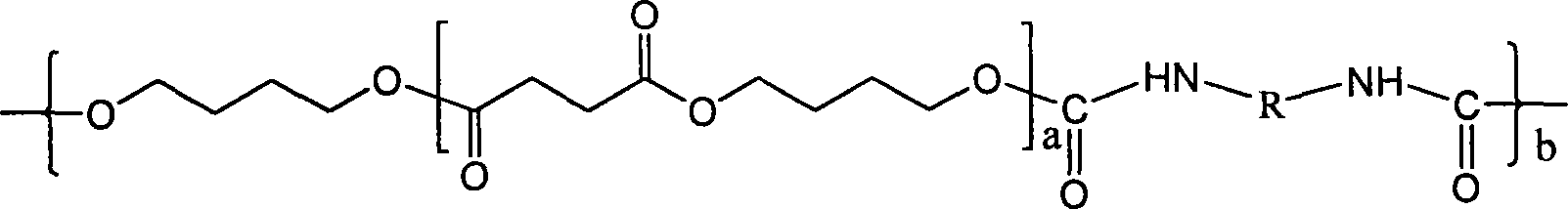

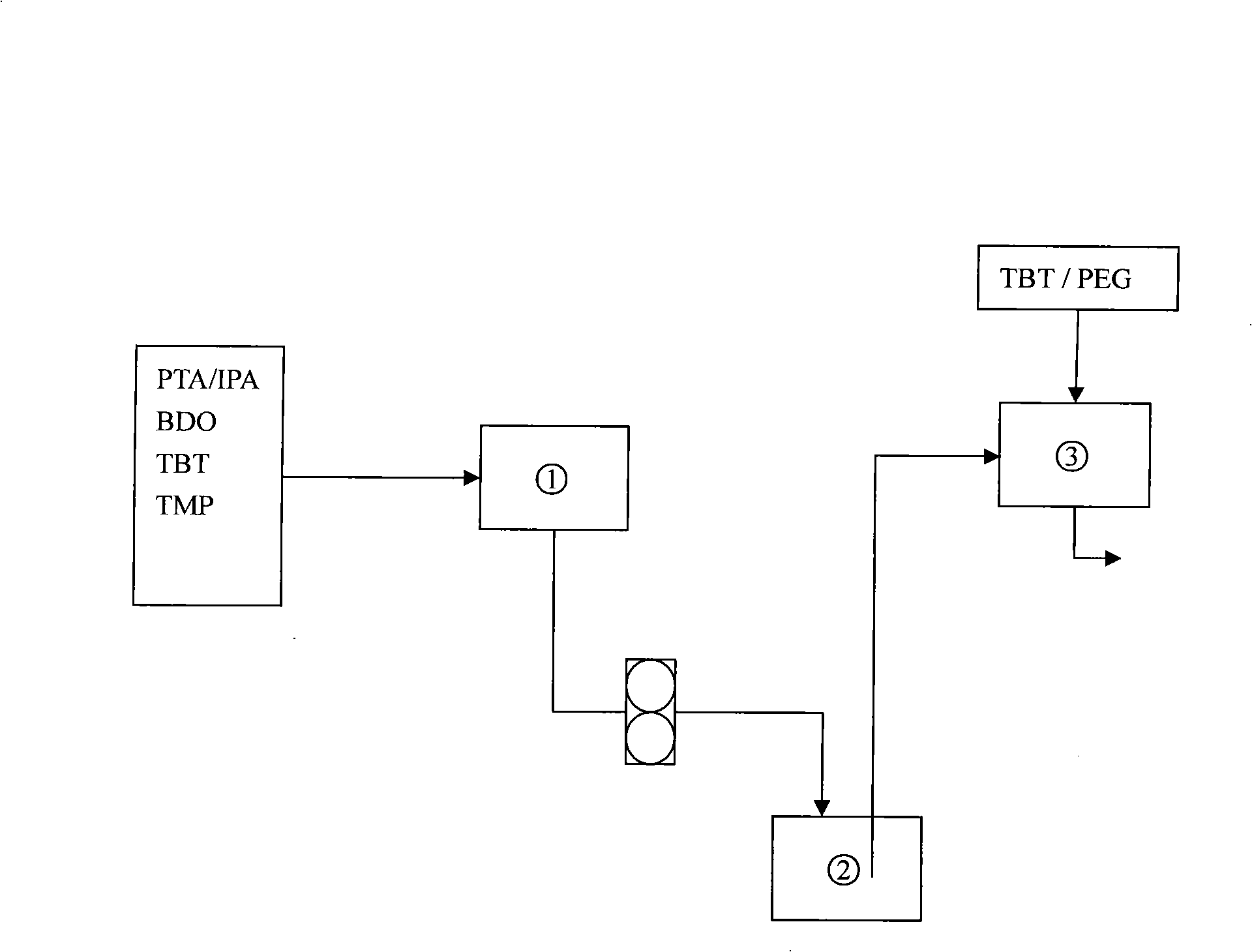

Low-melting-point copolyester and method for preparing same

InactiveCN101338023AIncrease exerciseLow melting pointMonocomponent copolyesters artificial filamentFiberPolymer science

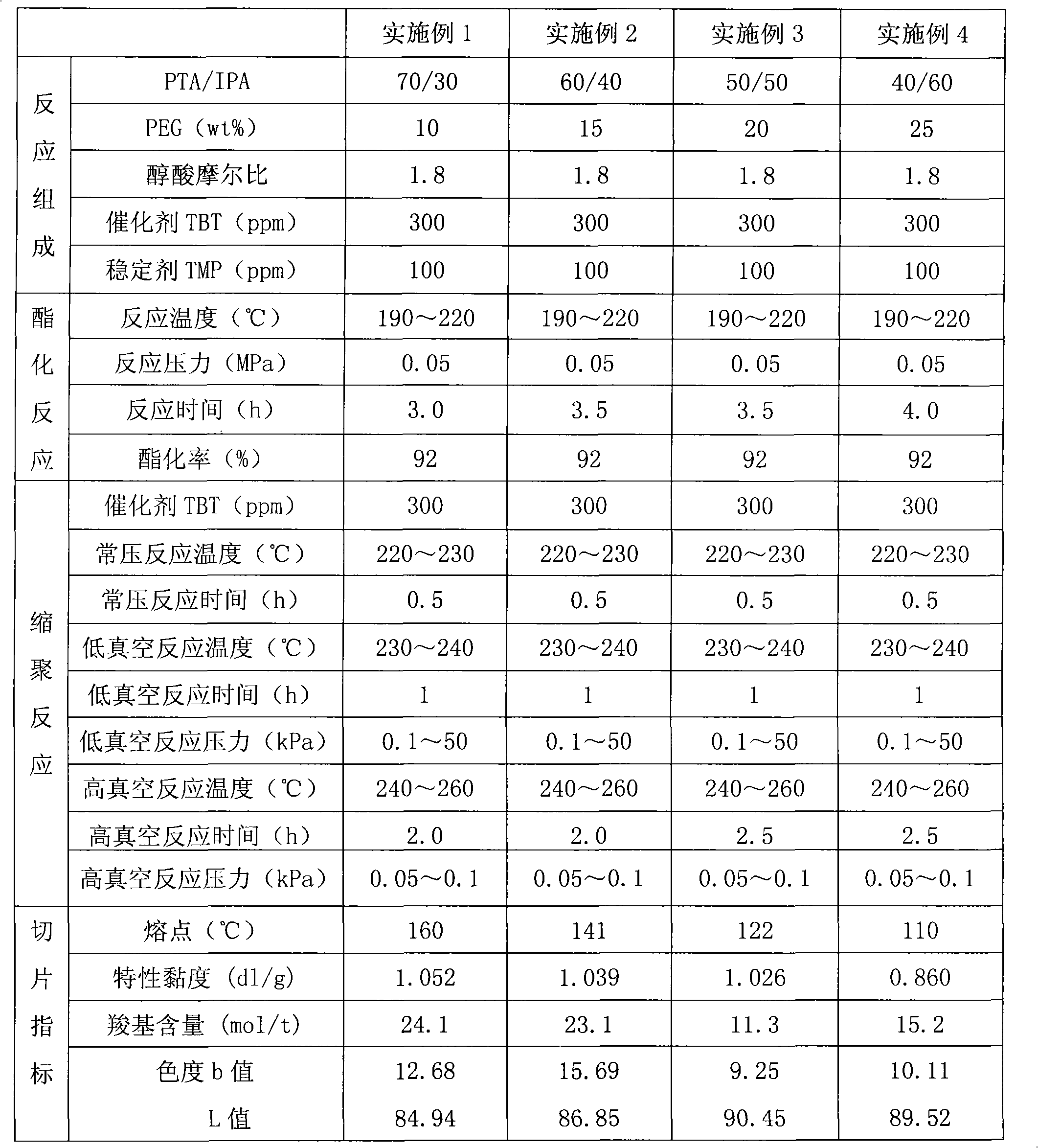

The invention relates to low melting point copolyester and a preparation method thereof. The low melting point copolyester is made from the following monomers followed by the esterification reaction and the polycondensation reaction: (a) terephthalic acid (PTA) and isophthalic acid (IPA), (b) 1, 4- butanediol (BDO) and (c) polyethylene glycol 600 to 6000 (PEG); wherein, in the a component, the feeding mass ratio of the terephthalic acid and the isophthalic acid is between 80 to 20 : 20 to 80; in the c component, the feeding weight ratio of polyethylene glycol is 1 to 30 percent based on the a; the molar ratio of the a and the b is 1:1.5 to 2.3. The preparation method comprises an esterifcation stage and a polycondensation stage. The copolyester has the characteristics of low melting point, good crystallization property, high intrinsic viscosity and difficult adhesion of particles, and is suitable for spinning the filament, the staple fibers and the non-woven fabrics.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation of Derivative of Polyhydric Alcohols

A method for converting a polyhydric alcohol into propylene glycol and butanediols is disclosed. Also disclosed are methods for converting polyhydric alcohols into three-carbon products and four-carbon products. Also disclosed are methods for maximizing conversion of polyhydric alcohols and minimizing formation of reaction products that are difficult to remove from the desired product. In other embodiments, methods are described to optimize use of reactants, including hydrogen, in hydrogenolysis of polyhydric alcohols.

Owner:ARCHER DANIELS MIDLAND CO

Polyurethane-polypeptide graft copolymer and preparation method thereof

The invention relates to a polyurethane-polypeptide graft copolymer and a preparation method thereof. The graft copolymer is a comb-shaped polymer, wherein the molecular weight of polyurethane is 10,000 to 100,000; and the molecular weight of the polypeptide chain segment is 500 to 5,000. The preparation method comprises the following steps of: 1) synthesis of polyurethane provided with lateral carboxyl on the molecular chain: adding diisocyanate, polypropylene glycol, polyethylene glycol, dibutyltin dilaurate catalyst and dimethyl formamide solvent into a dry reaction bottle, performing stirring reaction under inert atmosphere, adding dimethylolpropionic acid dissolved in dimethyl formamide to react, adding butanediol to react, finally adding butanol to react, and obtaining a target product; and 2) synthesis of the polyurethane-polypeptide graft copolymer: putting the polyurethane provided with lateral carboxyl on the molecular chain, a solvent and a condensation agent into a dry reactor, adding polypeptide homopolymer into the reactor, and performing stirring reaction under the inert atmosphere to obtain a target product with pH response.

Owner:SHANDONG UNIV OF TECH

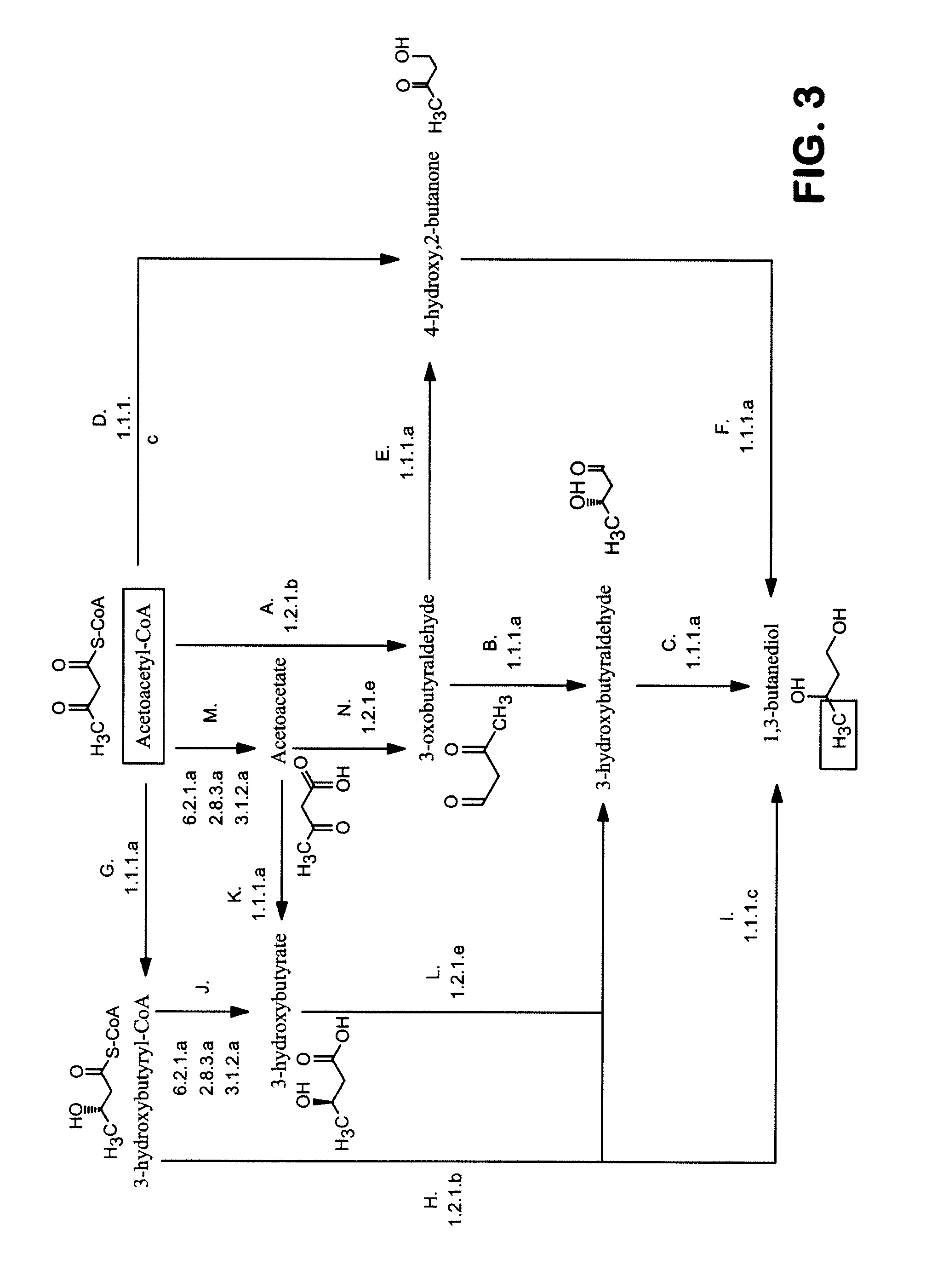

Methods and organisms for converting synthesis gas or other gaseous carbon sources and methanol to 1,3-butanediol

A non-naturally occurring microbial organism having a 1,3-butanediol (1,3-BDO) pathway includes at least one exogenous nucleic acid encoding a 1,3-BDO pathway enzyme or protein expressed in a sufficient amount to produce 1,3-BDO. A method for producing 1,3-BDO that includes culturing the this non-naturally occurring microbial organism under conditions and for a sufficient period of time to produce 1,3-BDO.

Owner:GENOMATICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com