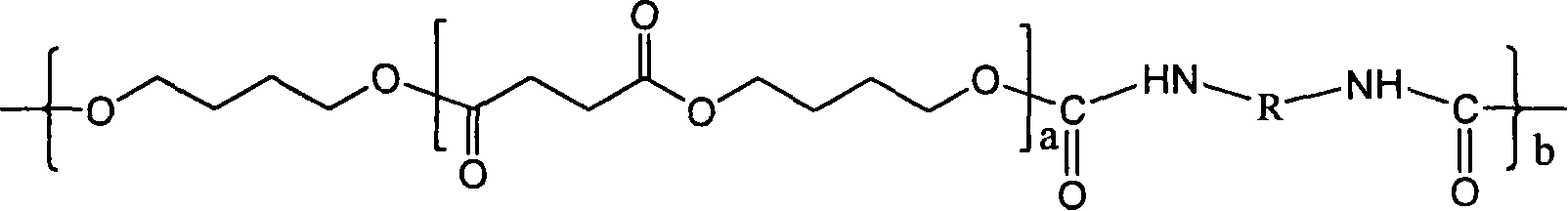

High molecular weight poly(butylene succinate) and preparation method thereof

A technology of polybutylene succinate and double-ended hydroxybutylene succinate, which is applied in the field of high molecular weight polybutylene succinate and its preparation, can solve the problem of limited application range, long production cycle, Limited strength and other issues, to achieve cost reduction, low cost, good heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

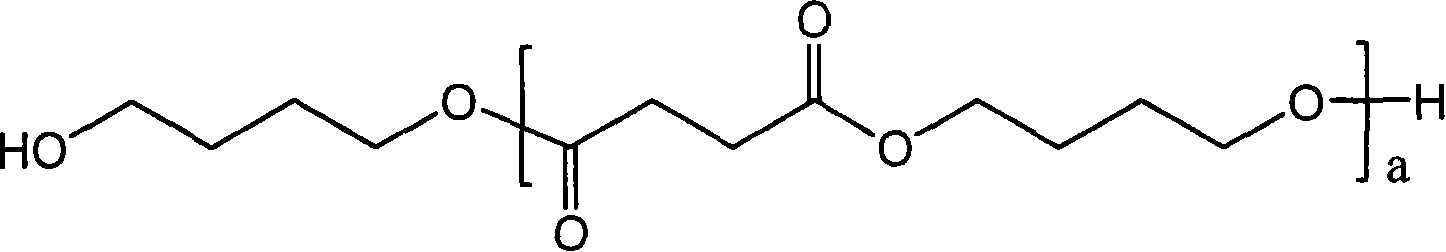

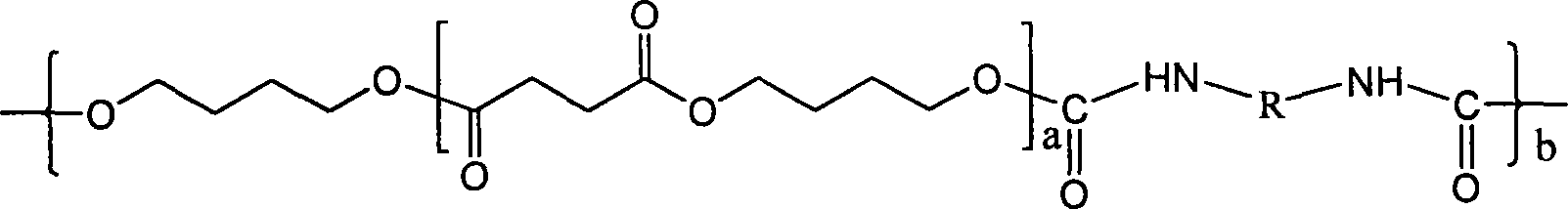

Method used

Image

Examples

Embodiment 1

[0026] Put 1,4-butanediol and succinic acid with a molar ratio of 1.5:1 in the reaction device, stir and raise the temperature to 180-190°C under the protection of nitrogen, and after esterification to remove water for 3.5 hours, add succinic acid , butanediol with a total weight of 0.01% catalyst tetrabutyl titanate, change the water separation device to a vacuum device, and react for 30 minutes at 190°C and 30Pa vacuum conditions to obtain an intrinsic viscosity of 0.08dL / g double-ended hydroxybutyrate Diacid butanediol prepolymer, its number average molecular weight recorded is 1200.

[0027] Put 87 parts of prepolymer in the reaction device first, stir and heat up to 150°C under the protection of nitrogen, after it is completely melted, add 13 parts of chain extender toluene diisocyanate, and react for 30 minutes to obtain the product. The number average molecular weight of the measured product is 5.67×10 4 , with a weight average molecular weight of 1.02×10 5 , the mole...

Embodiment 2

[0029] Put 1,4-butanediol and succinic acid with a molar ratio of 1.4:1 in the reaction device, stir and raise the temperature to 180-190°C under the protection of nitrogen, after 3.5 hours of esterification to remove water, add succinic acid The total weight of butanediol is 0.5% catalyst tin oxide, the water separation device is changed to a vacuum device, and the reaction is carried out at 200 ° C and 30 Pa for 10 minutes to obtain an intrinsic viscosity of 0.12 dL / g double-ended hydroxybutyric acid The number average molecular weight of the diol prepolymer is 2100.

[0030] Put 92 parts of prepolymer in the reaction device first, stir and heat up to 160°C under the protection of nitrogen, after it is completely melted, add 8 parts of chain extender toluene diisocyanate, and react for 30 minutes to obtain the product. The number average molecular weight of the measured product is 7.63×10 4 , with a weight average molecular weight of 1.35×10 5 , the molecular weight distri...

Embodiment 3

[0032] Put 1,4-butanediol and succinic acid with a molar ratio of 1.35:1 in the reaction device, stir and raise the temperature to 180-190°C under the protection of nitrogen, after 3.5 hours of esterification to remove water, add succinic acid , butanediol with a total weight of 2% catalyst p-toluenesulfonic acid, change the water separation device to a vacuum device, and react for 30 minutes at 210 ° C and 30 Pa vacuum conditions to obtain an intrinsic viscosity of 0.17 dL / g double-ended hydroxybutane Acid butylene glycol prepolymer, its number-average molecular weight recorded is 3100.

[0033] Put 92.5 parts of prepolymer in the reaction device first, stir and heat up to 160°C under the protection of nitrogen, and then add 7.5 parts of chain extender diphenylmethane diisocyanate after it is completely melted, and react for 30 minutes to obtain the product. The number average molecular weight of the measured product is 9.01×10 4 , with a weight average molecular weight of 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com