Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11136 results about "Titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, titanate usually refers to inorganic compounds composed of titanium oxides. In some cases, the term is used more generally for any titanium-containing anion, e.g. [TiCl₆]²⁻ and [Ti(CO)₇]²⁻. This article focuses on the oxides.

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

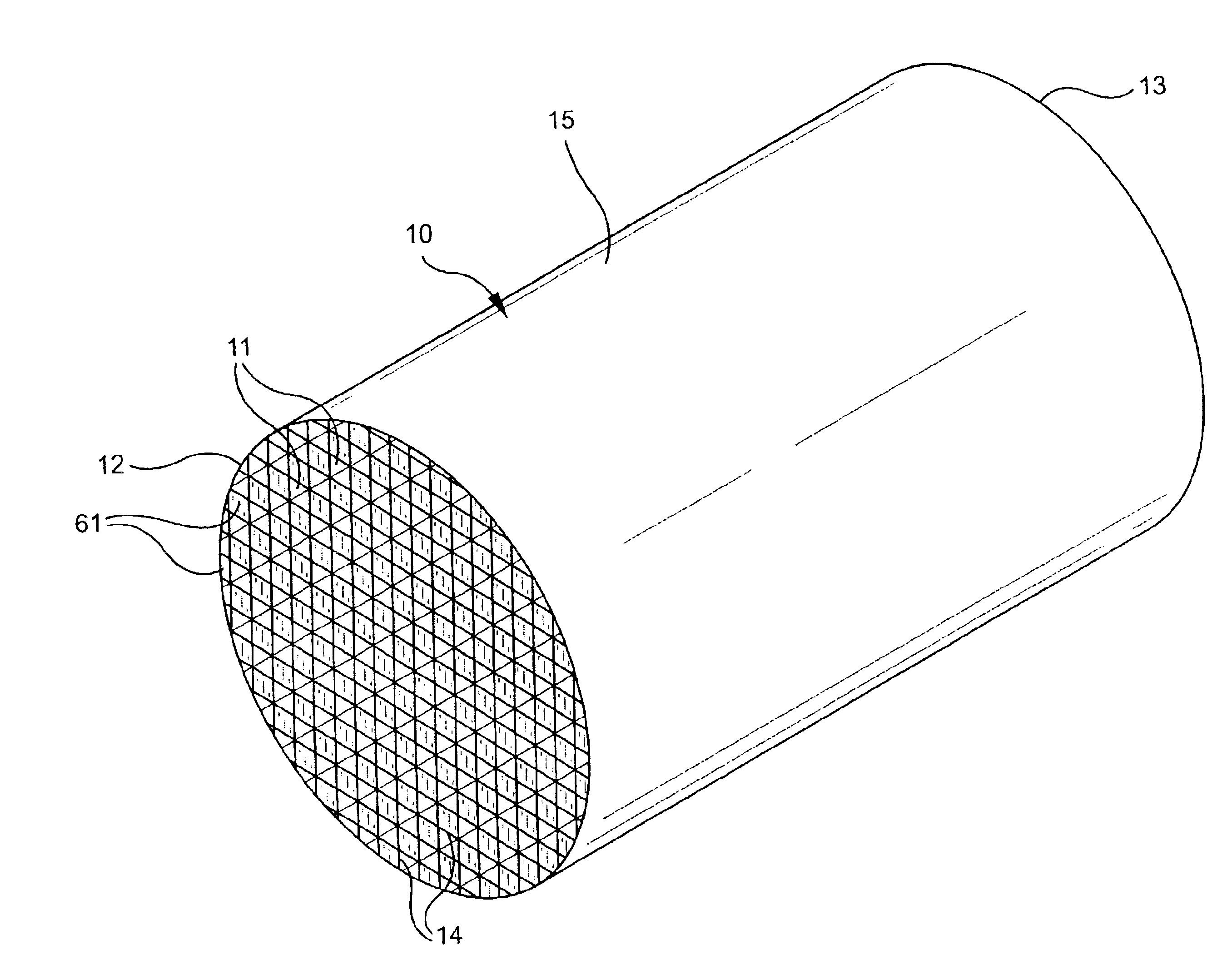

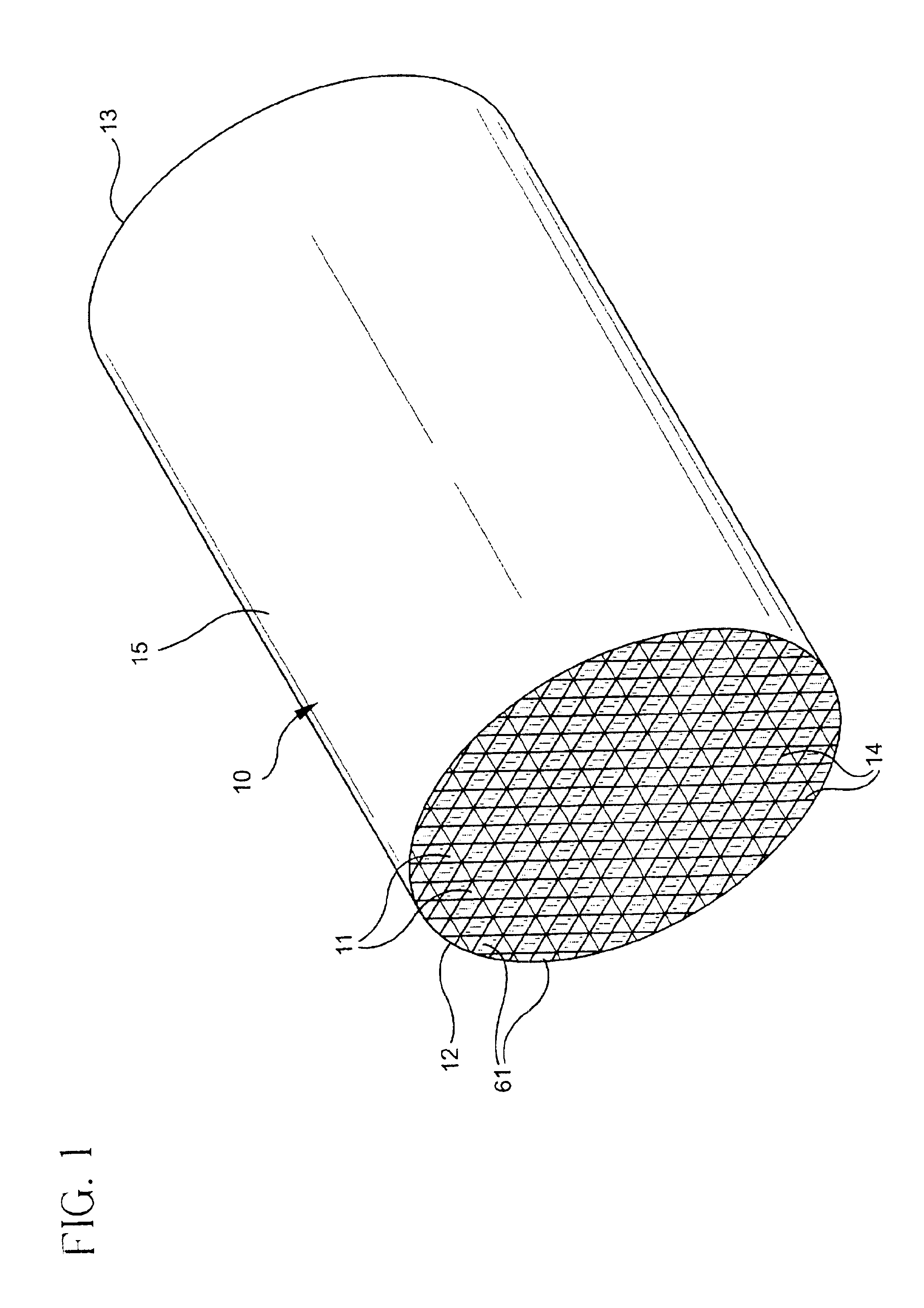

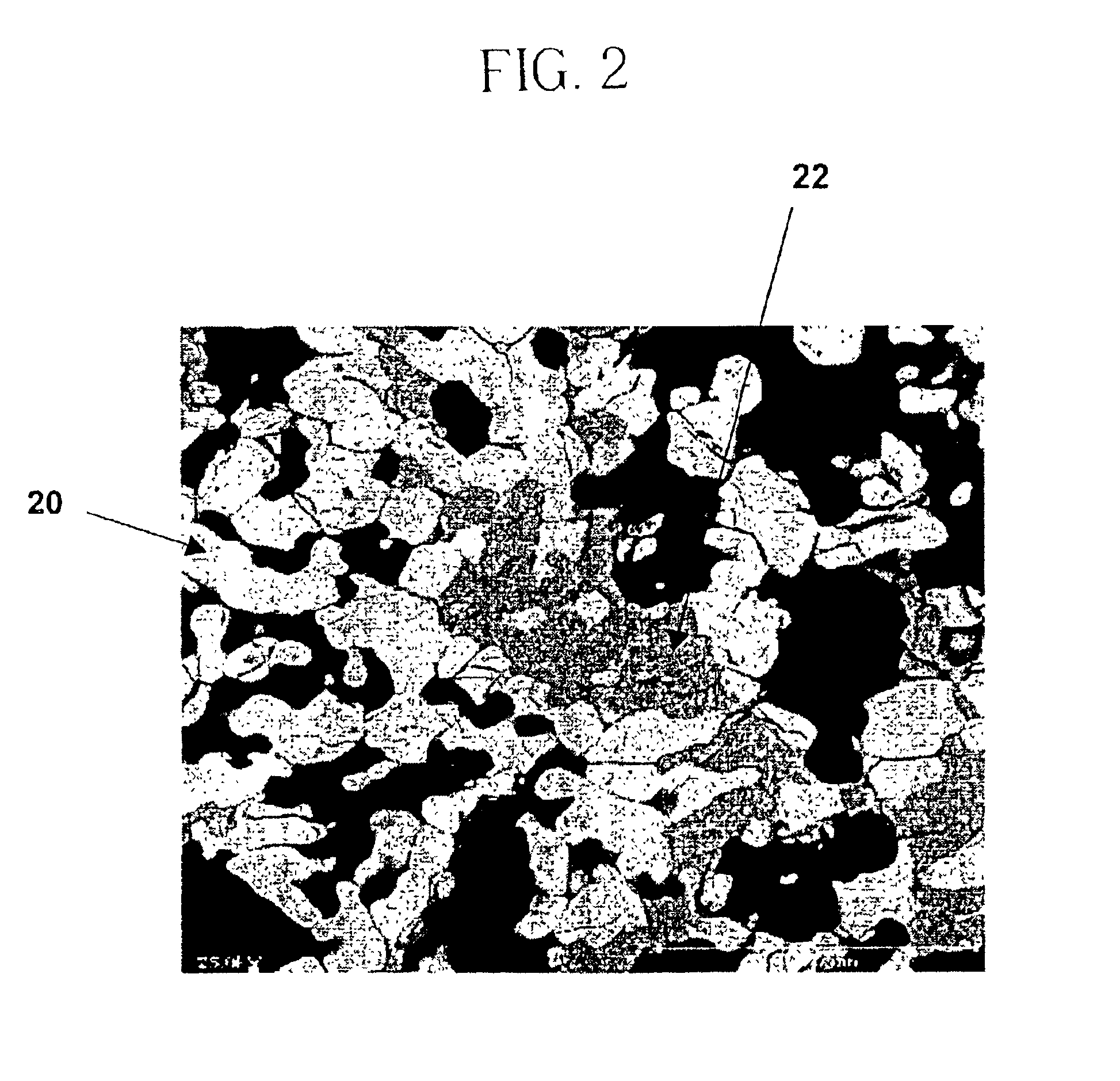

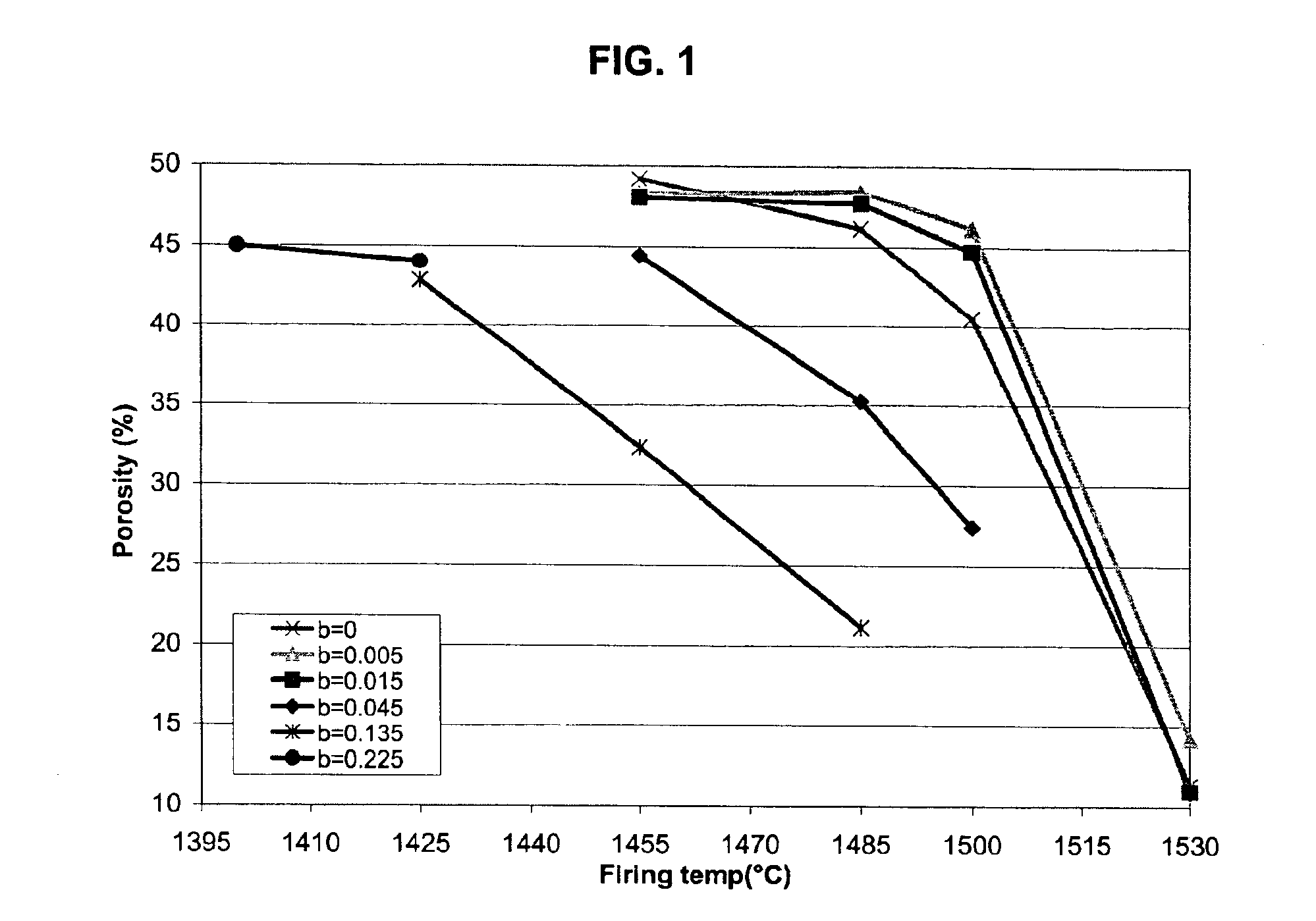

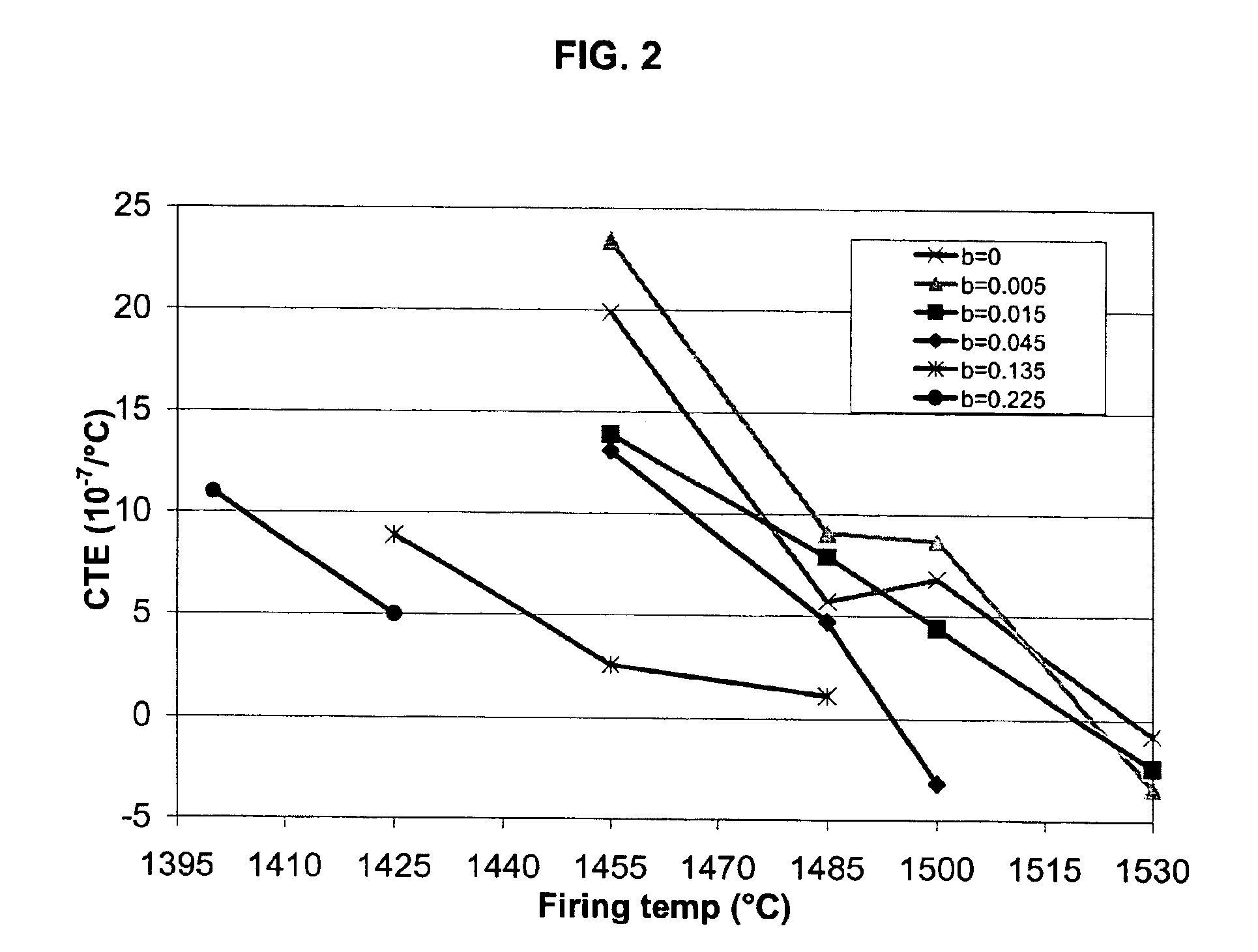

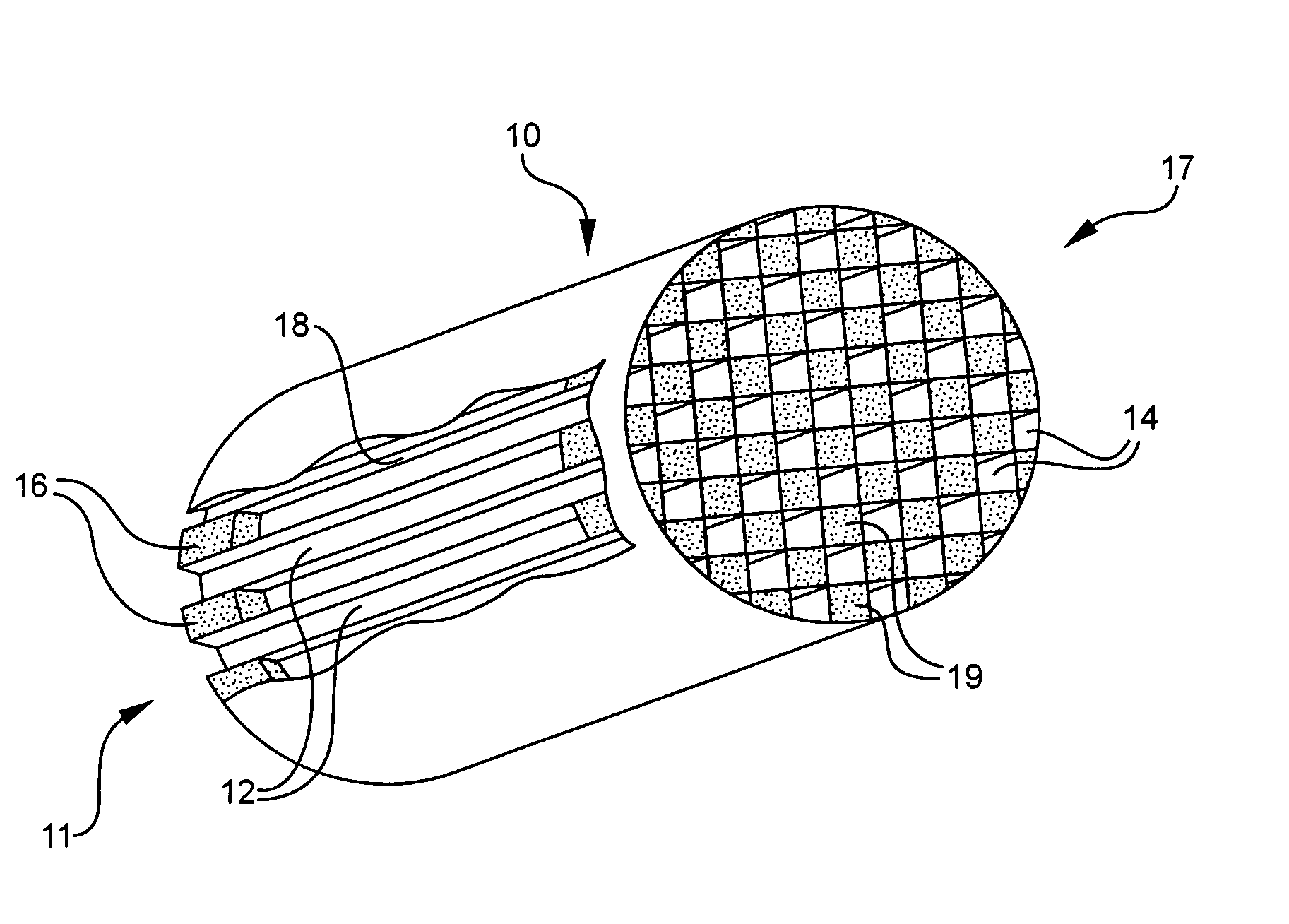

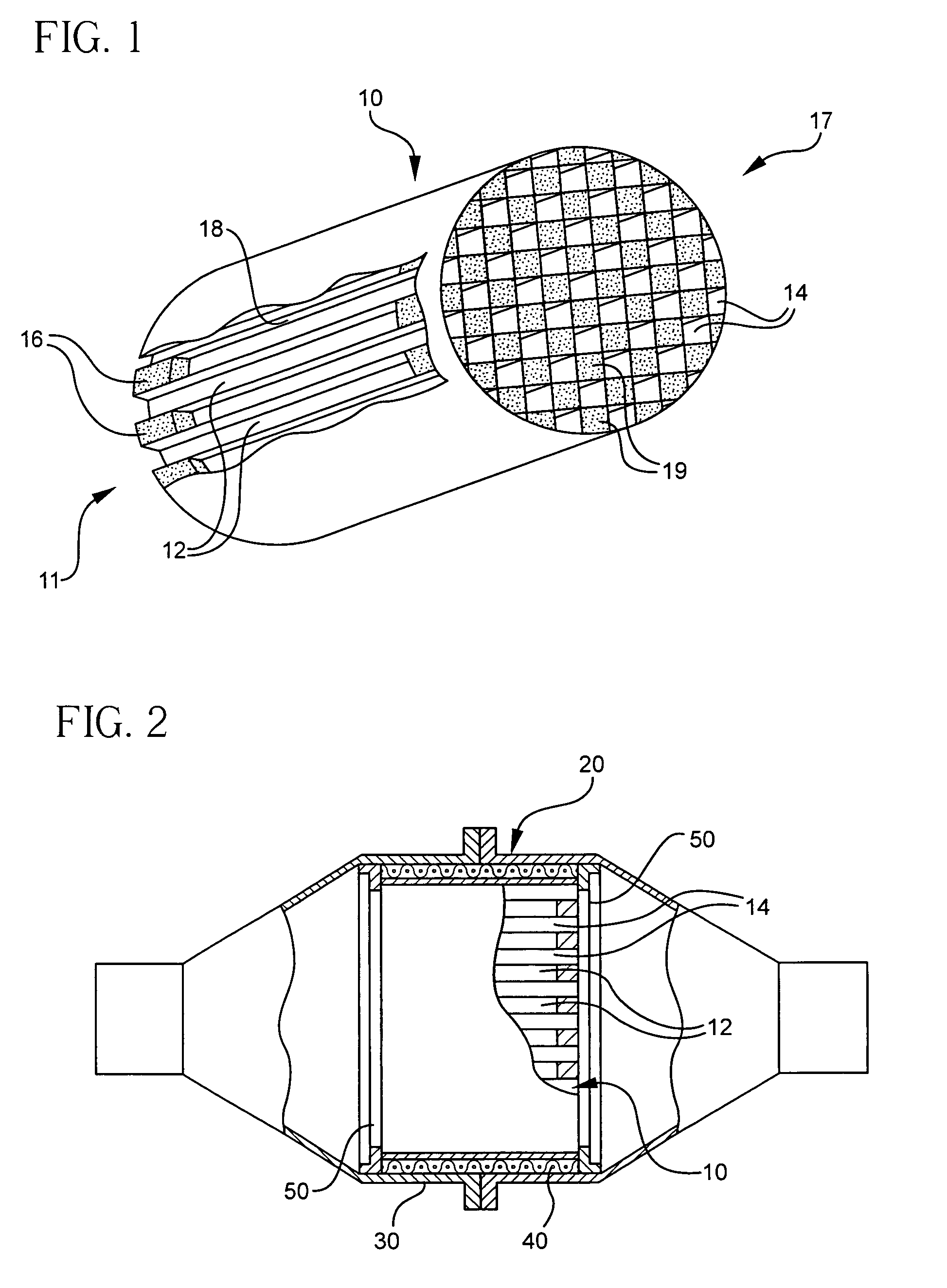

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

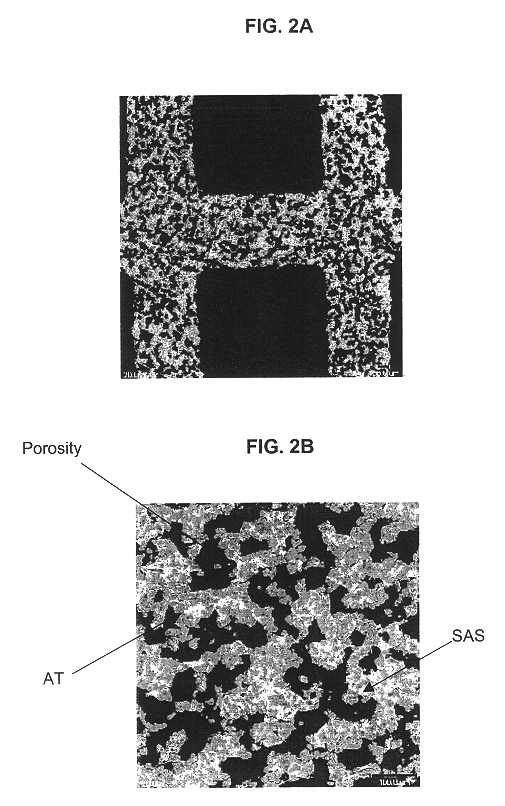

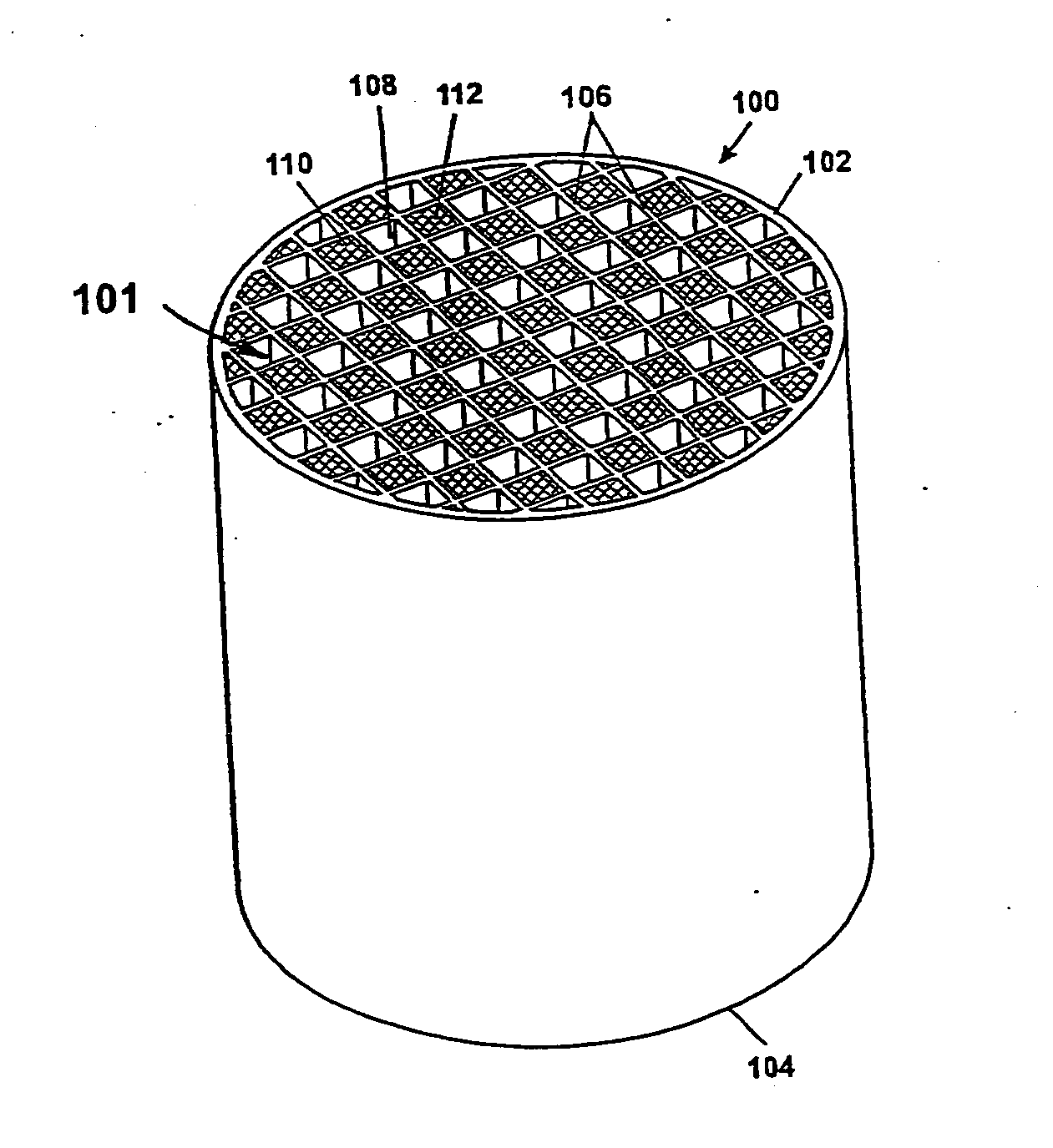

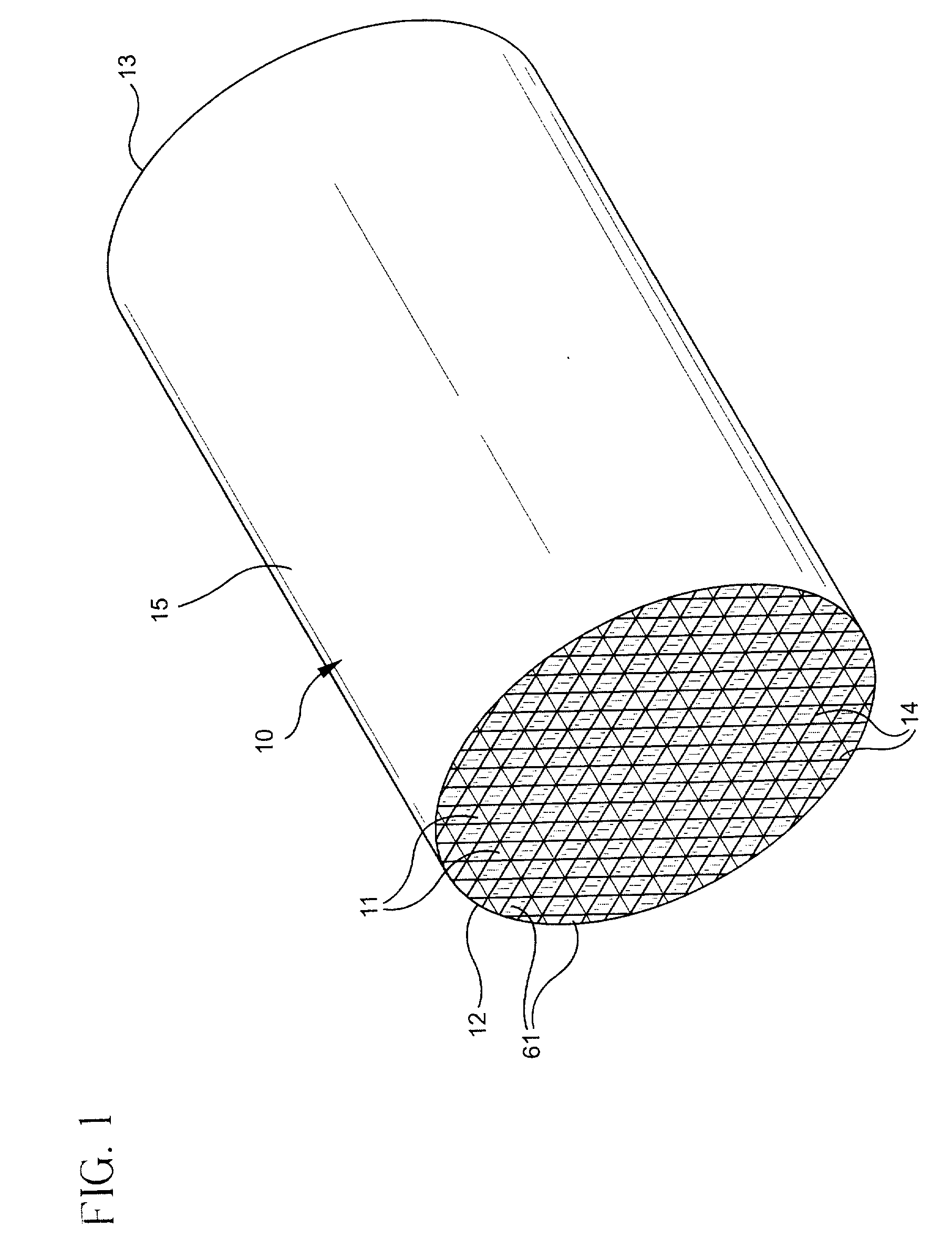

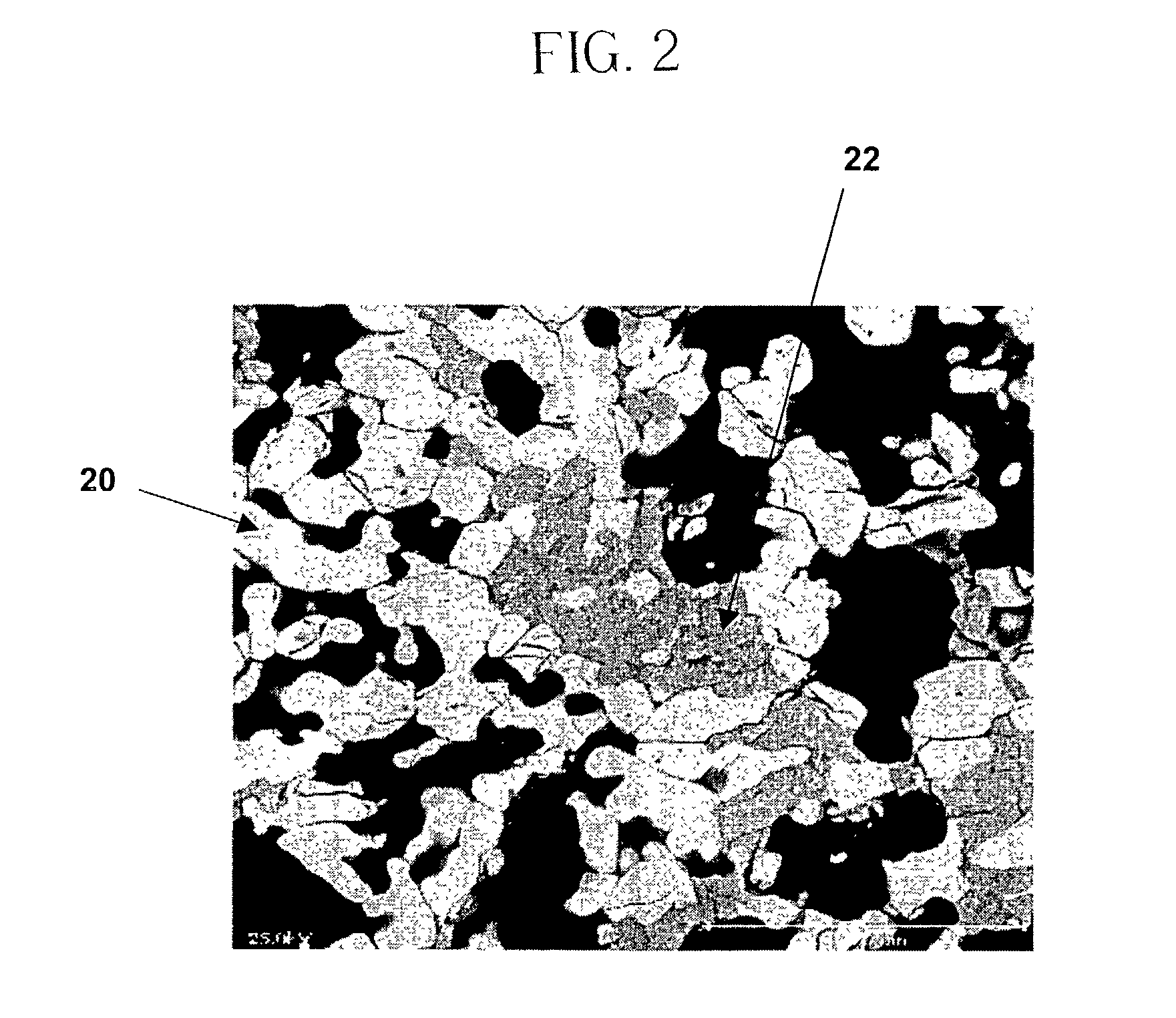

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

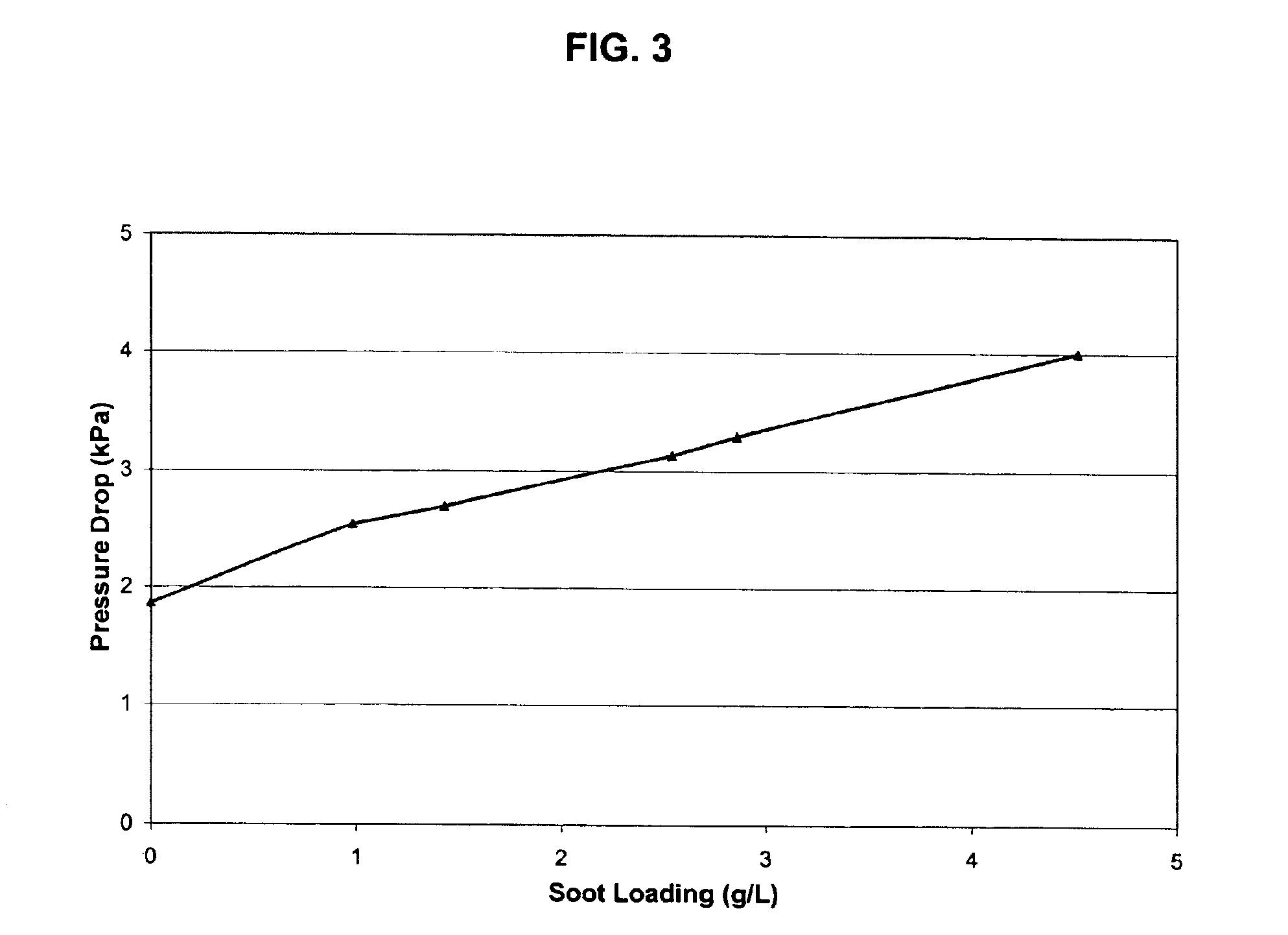

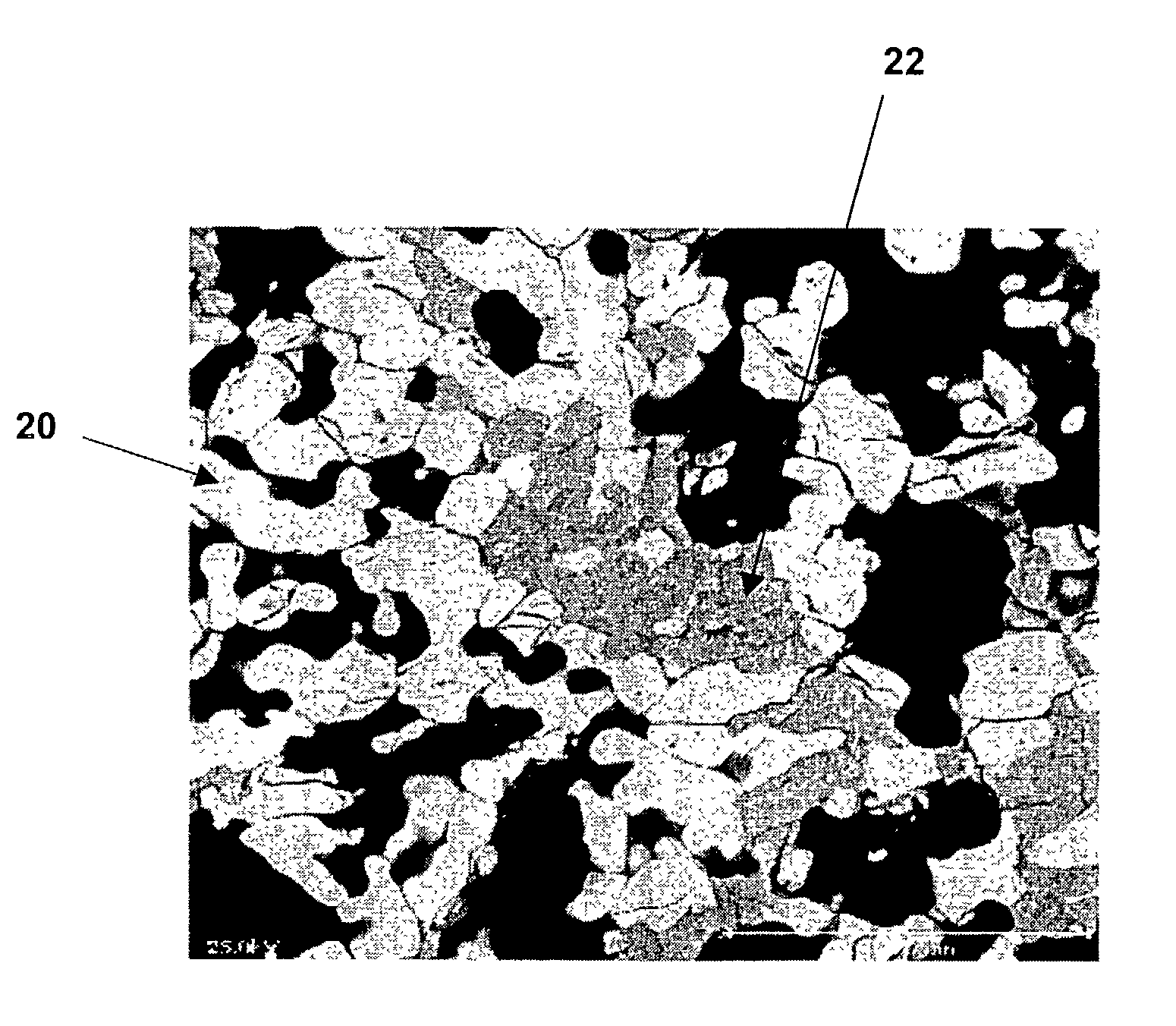

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

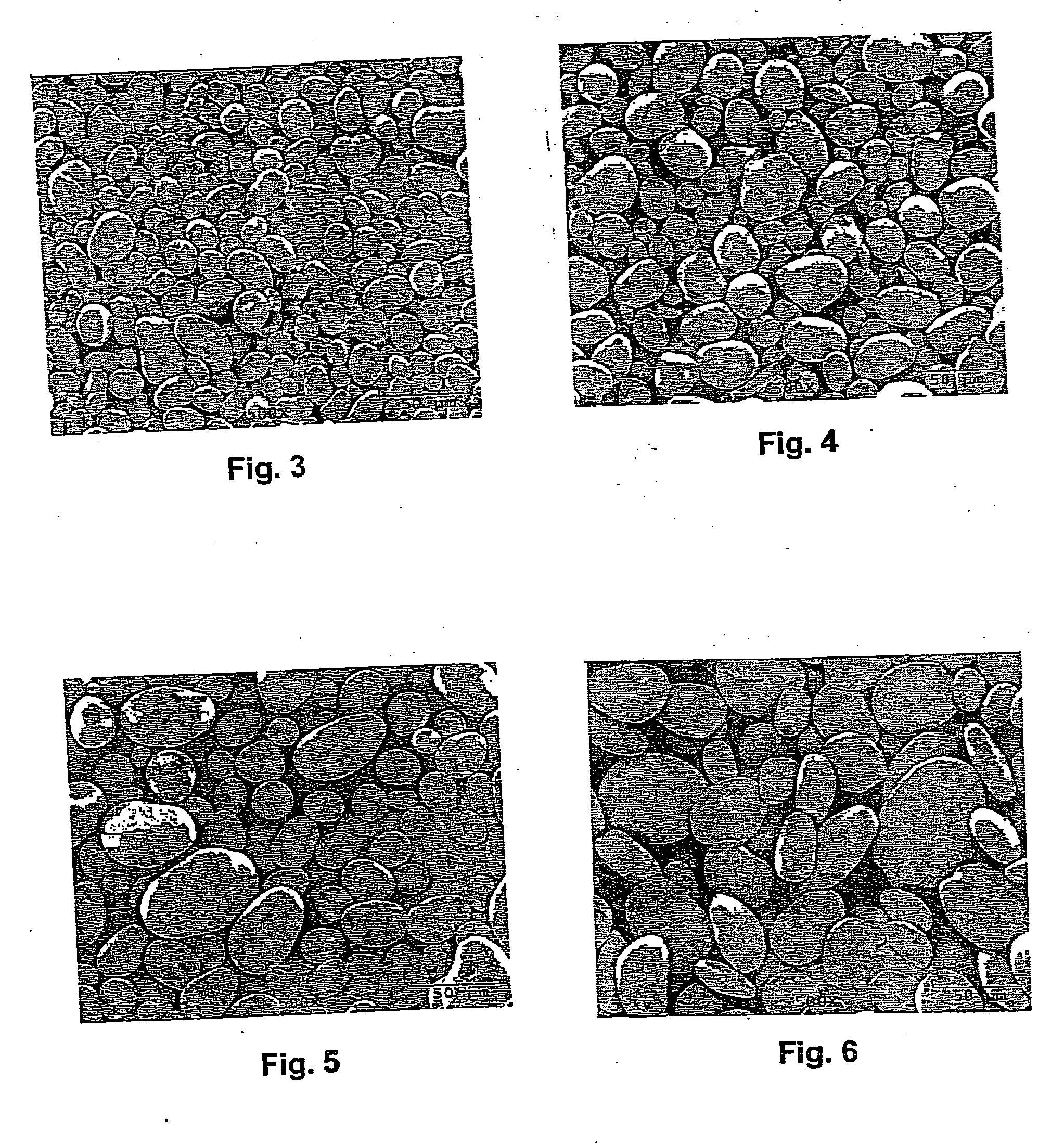

Aluminum titanate ceramic forming batch mixtures and green bodies including pore former combinations and methods of manufacturing and firing same

InactiveUS20070006561A1Low exothermic reaction and exothermic reactionReduction tendencyDispersed particle filtrationTransportation and packagingCeramic moldingSolvent

A ceramic forming batch mixture including inorganic batch materials, such as sources of alumina, titania, and silica, a pore former combination including first and second pore formers with different compositions; an organic binder; and a solvent. Also disclosed is a method for producing a ceramic article involving mixing the inorganic batch materials with the pore former combination having first and second pore formers of different composition, adding an organic binder and a solvent, forming a green body; and firing the green body. A green body having a combination of first and second pore formers with different compositions is disclosed, as are several methods for firing to produce ceramic articles such as aluminum titanate.

Owner:CORNING INC

Preparation of poly(trimethylene terephthalate)

In one embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) comprising (a) contacting terephthalic acid with 1,3-propanediol in the presence of an organic tin catalyst to form a bis(3-hydroxypropyl)terephthalate monomer; and (b) polymerizing said monomer in the presence of organic titanate polycondensation catalyst to obtain the poly(trimethylene terephthalate). In another embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) containing less than 1.6 mol % of DPG said process comprising contacting terephthalic acid with a 1.6 to 1 to 2:1 molar amount of 1,3-propanediol in the presence of 20 to 120 ppm (as tin), by weight of the poly(trimethylene terephthalate), of a organic tin catalyst, to form a bis(3-hydroxypropyl)terephthalate monomer and polymerizing said monomer to obtain the poly(trimethylene terephthalate). The invention is also directed to poly(trimethylene terephthalate) produced by the processes.

Owner:DUPONT IND BIOSCIENCES USA LLC

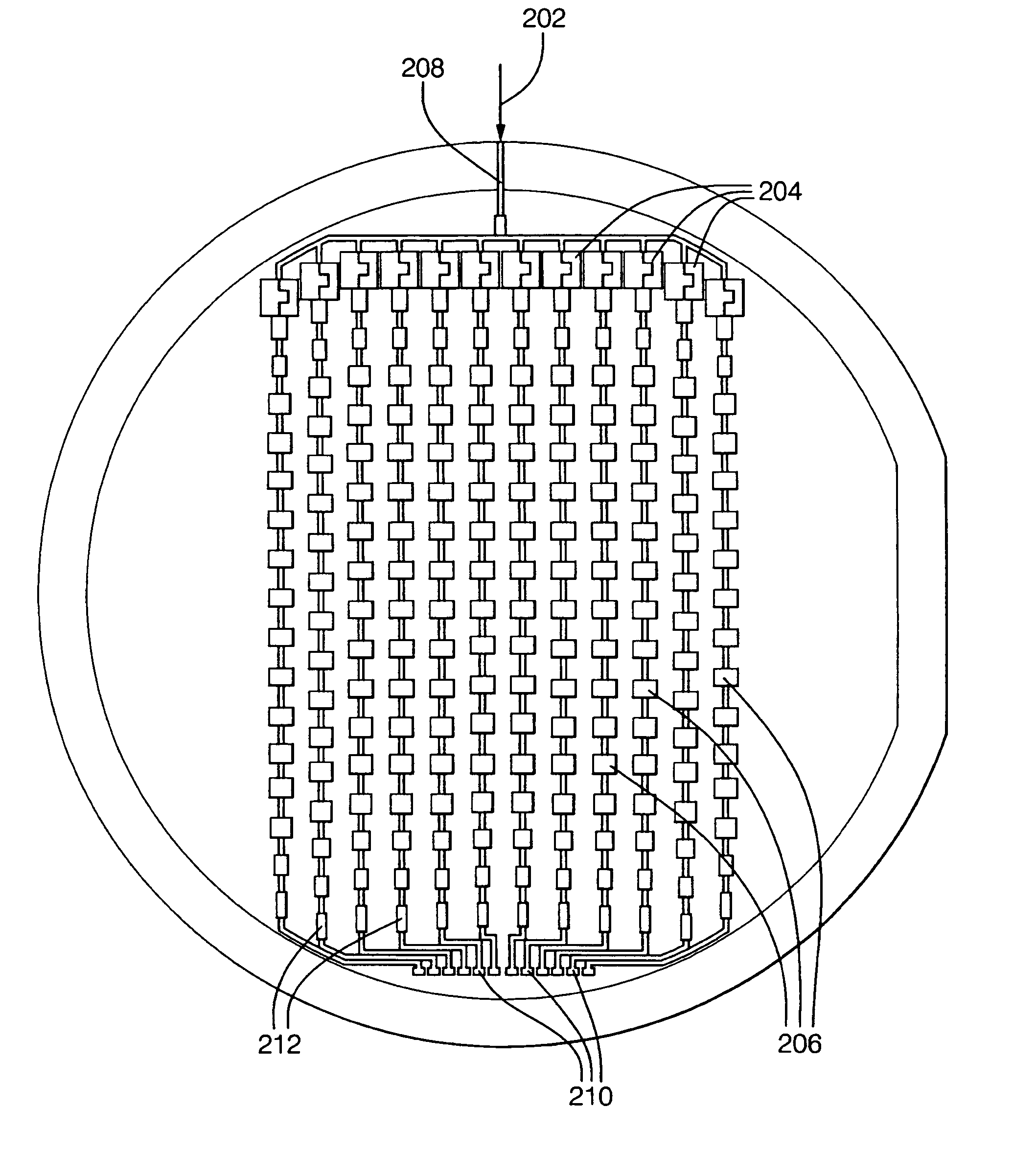

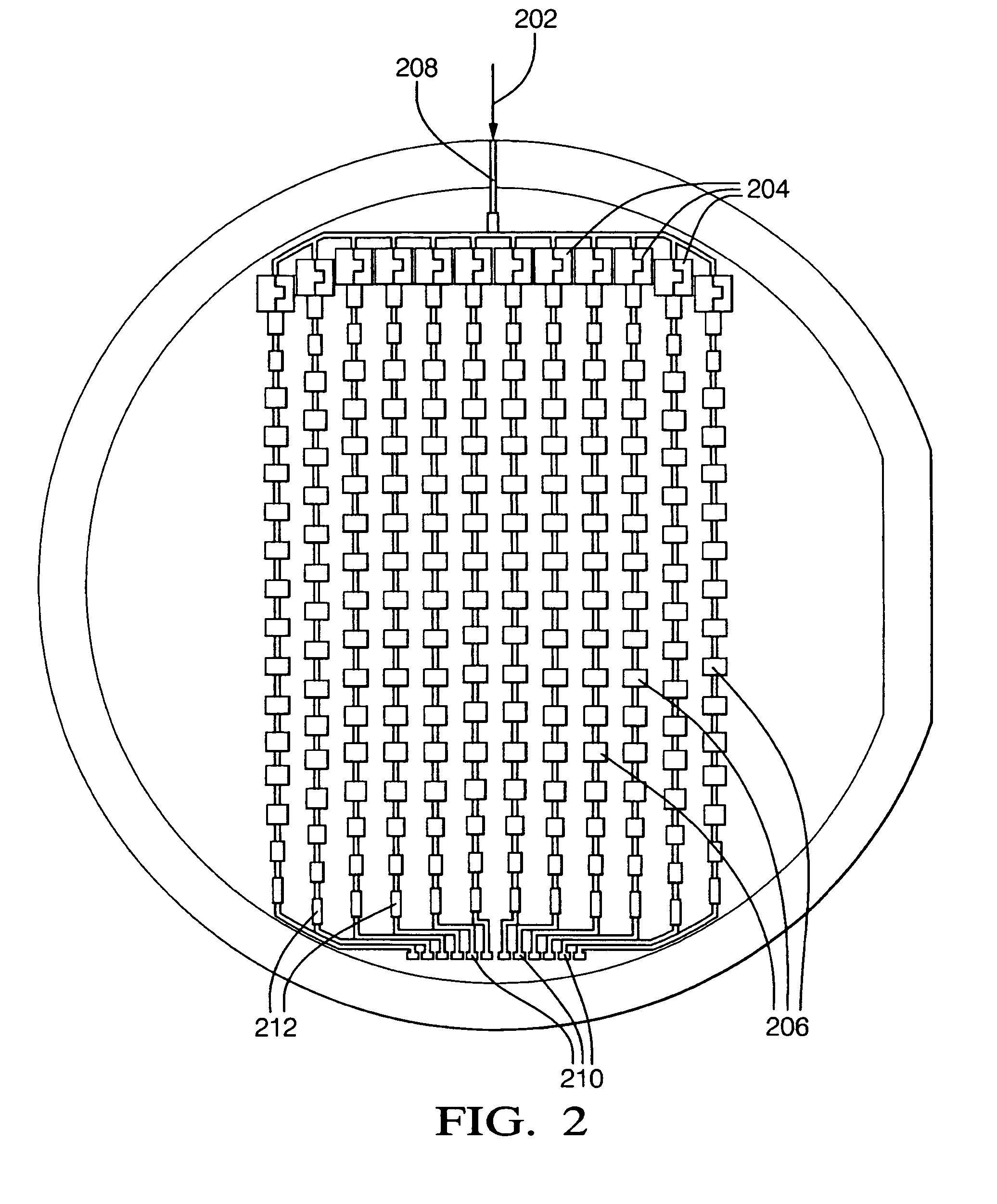

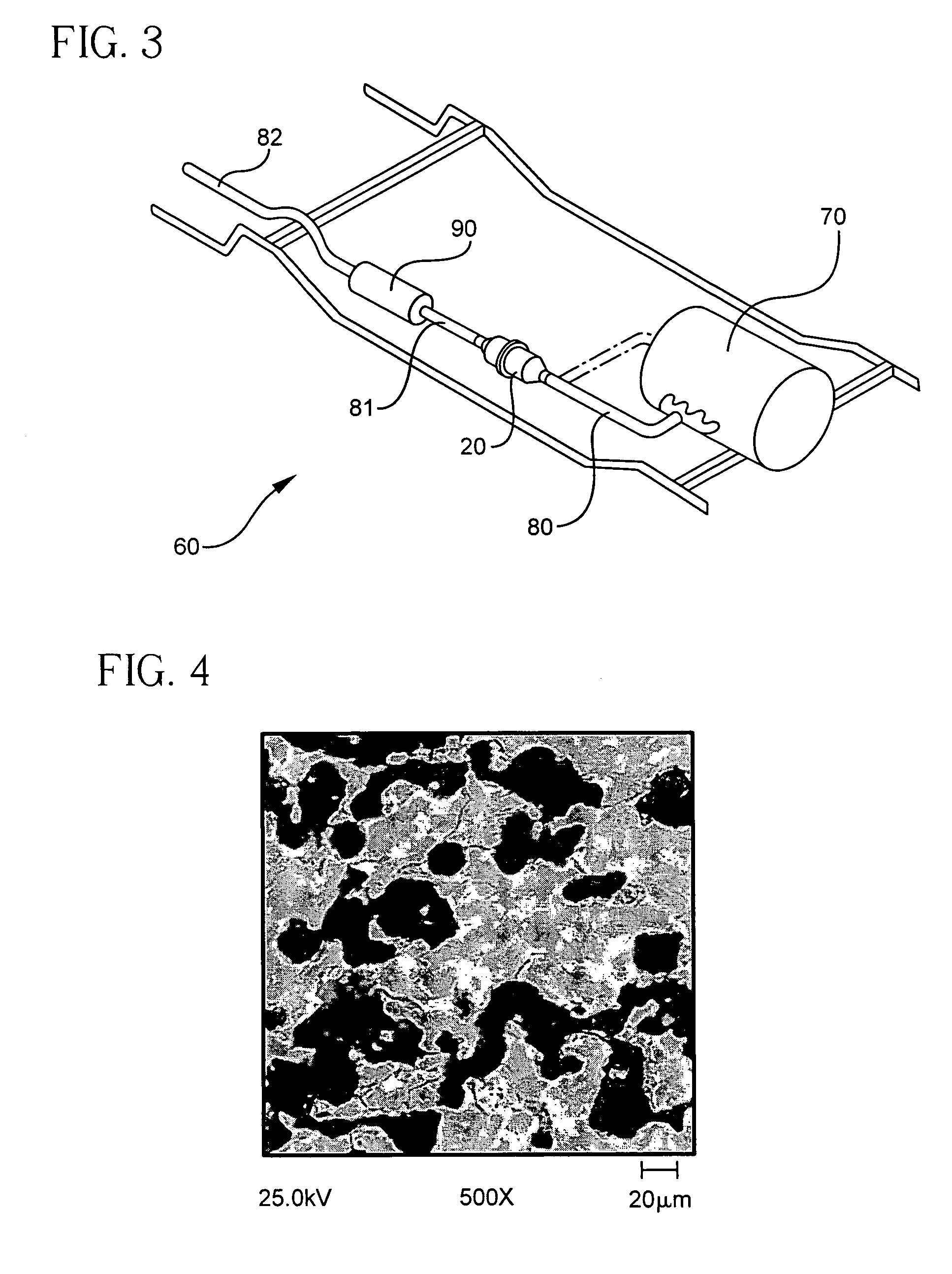

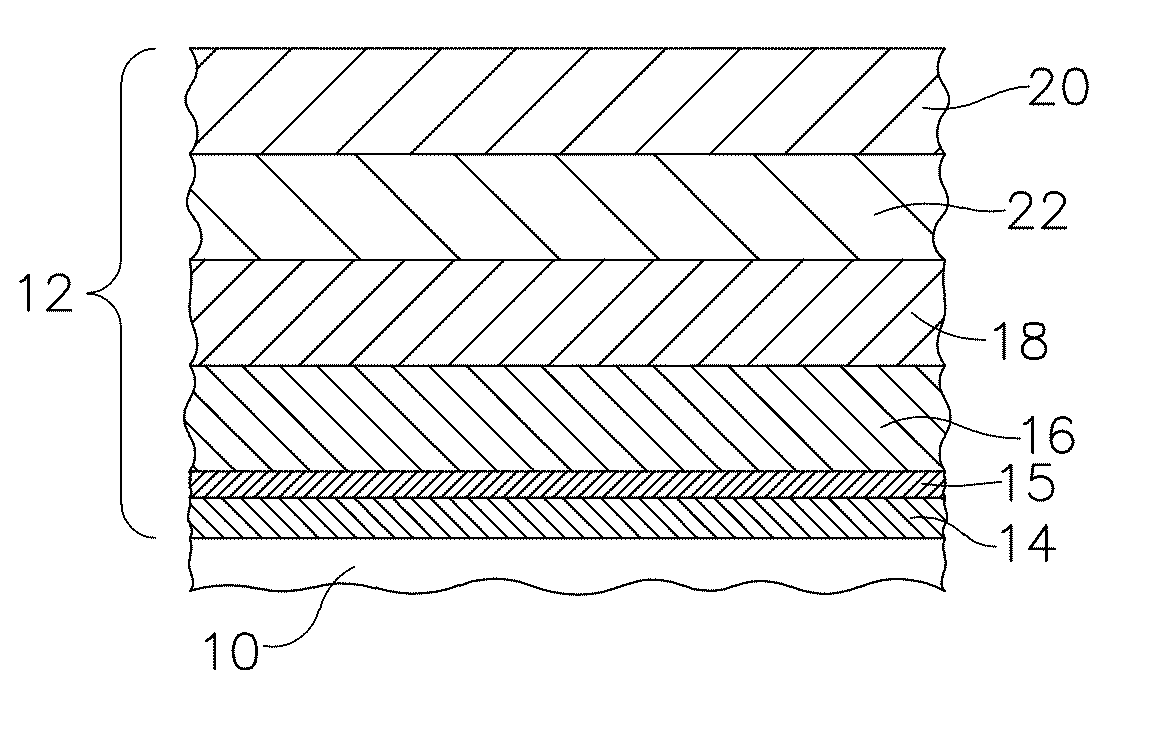

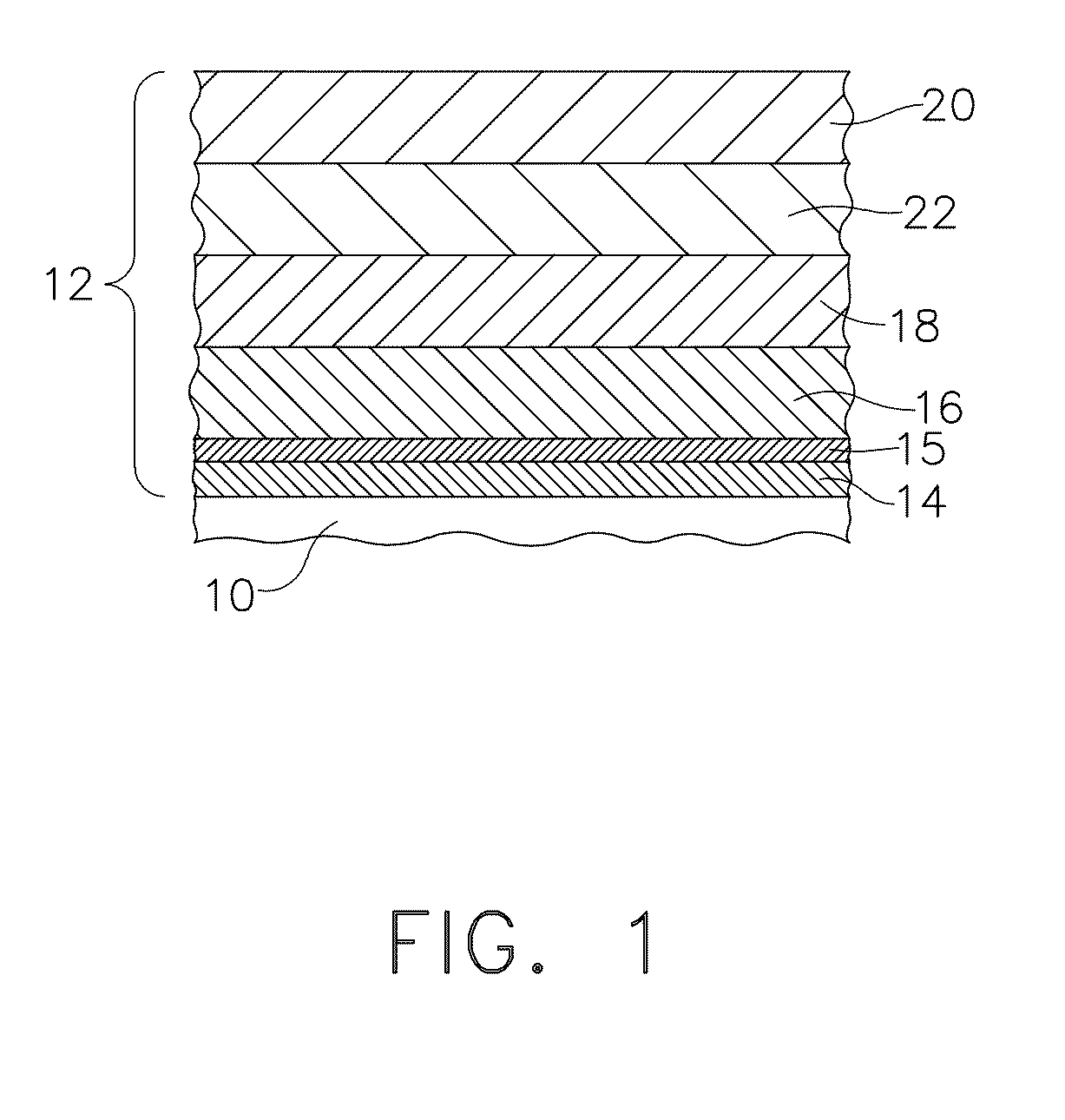

Phase shifters deposited en masse for an electronically scanned antenna

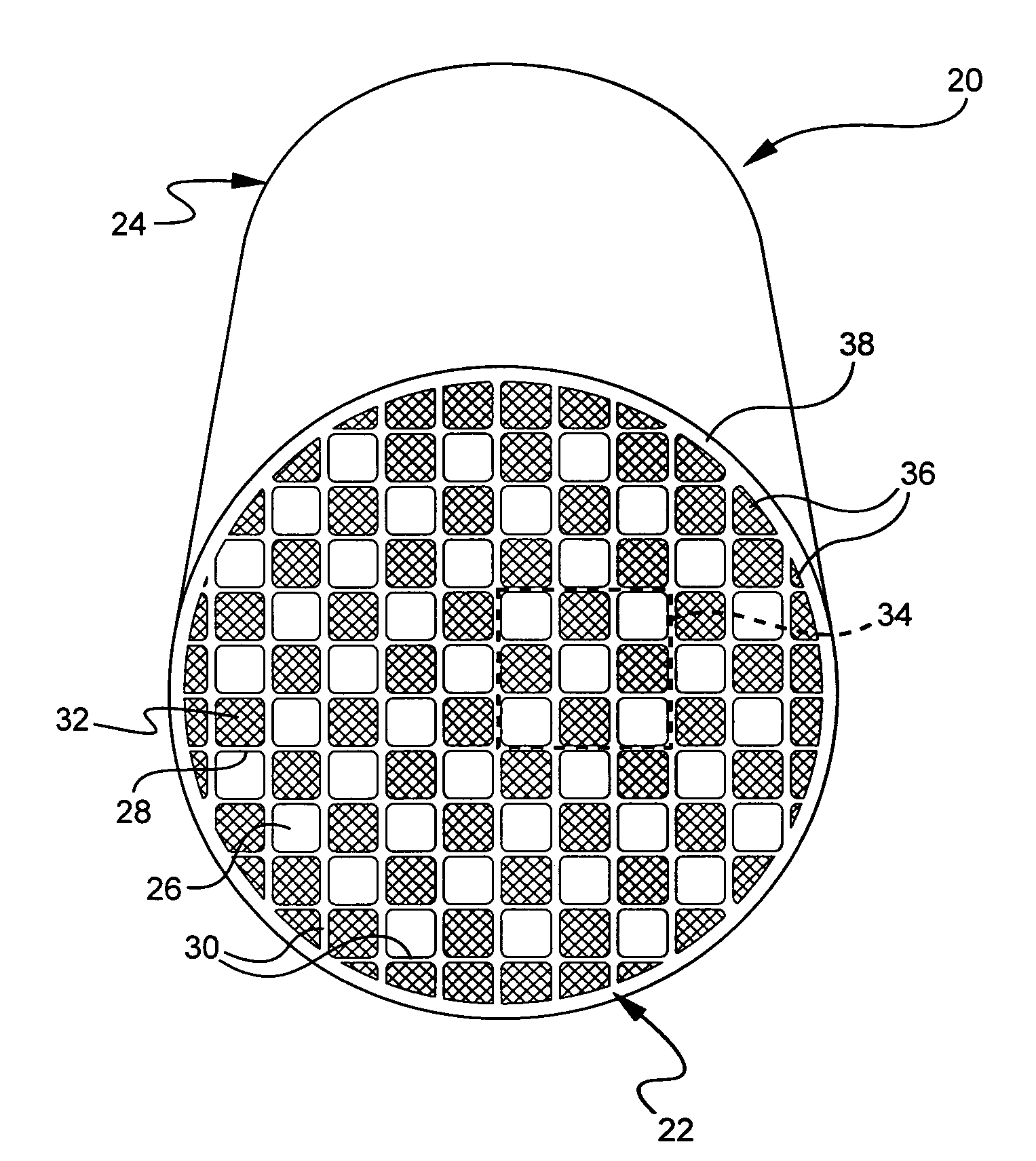

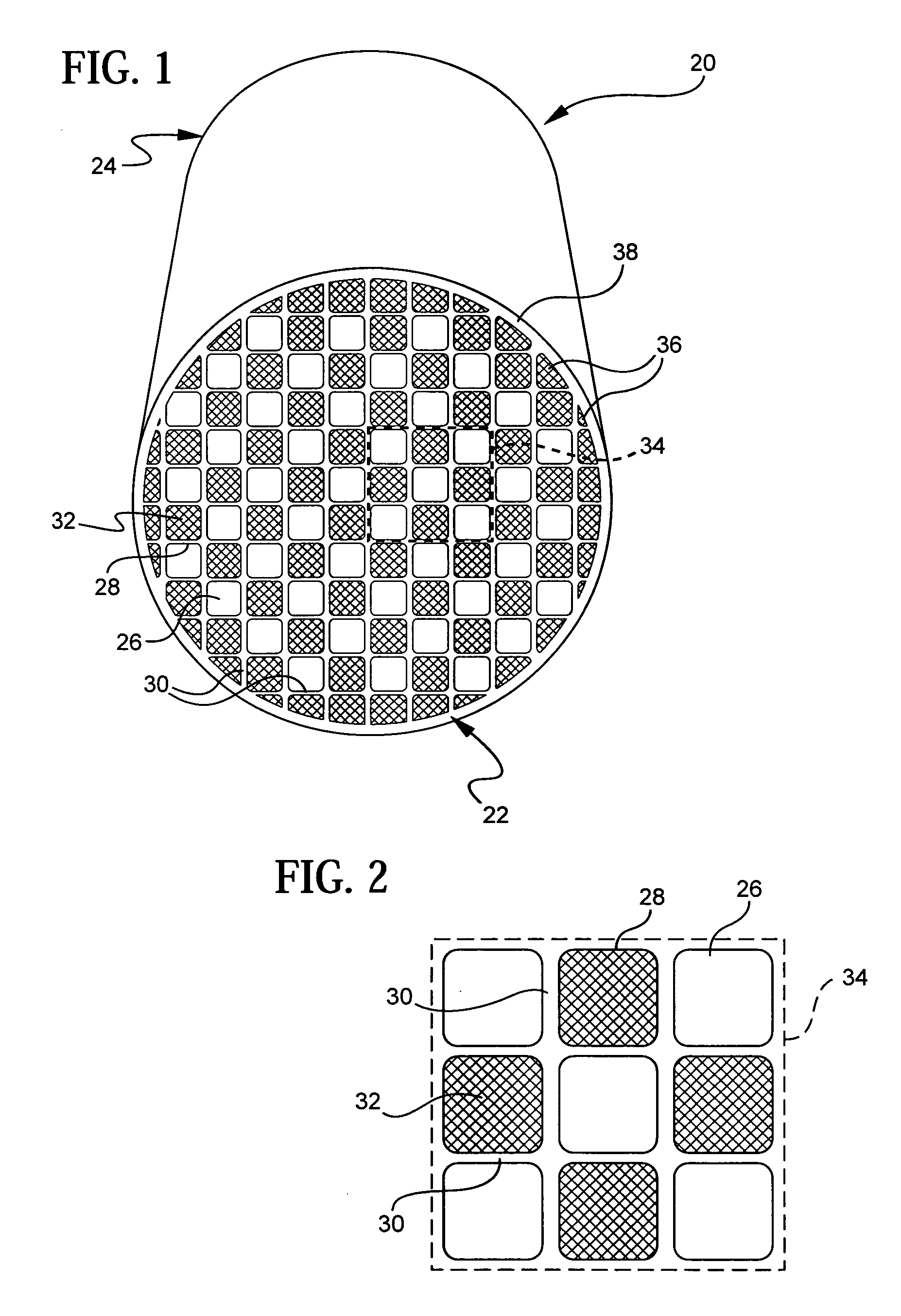

ActiveUS7324043B2Increase processing costPatterning of backsideSimultaneous aerial operationsRadiating elements structural formsDielectricEngineering

A system and method for an electronically scanned antenna is provided in which phase shifters are deposited en masse along with other electronically scanned antenna components on a wafer scale substrate using a thin film process. Alternative wafer scale sizes may be utilized to furnish a required antenna aperture area. Significant processing costs for radar and communication systems are saved utilizing the present invention as compared with contemporary discrete phase shifters that are individually mounted on an antenna. In an aspect, the phase shifter is made up of a base electrode, a barium strontanate titanate (BST) ferroelectric varactor and a top electrode. The BST ferroelectric material is a voltage variable dielectric, which generates a radiation phase. The radiation phase is regulated by a phase shifter control. The radiation phase generates an electromagnetic field about a radiating element and electromagnetic radio waves are radiated from the radiating element.

Owner:APTIV TECH LTD

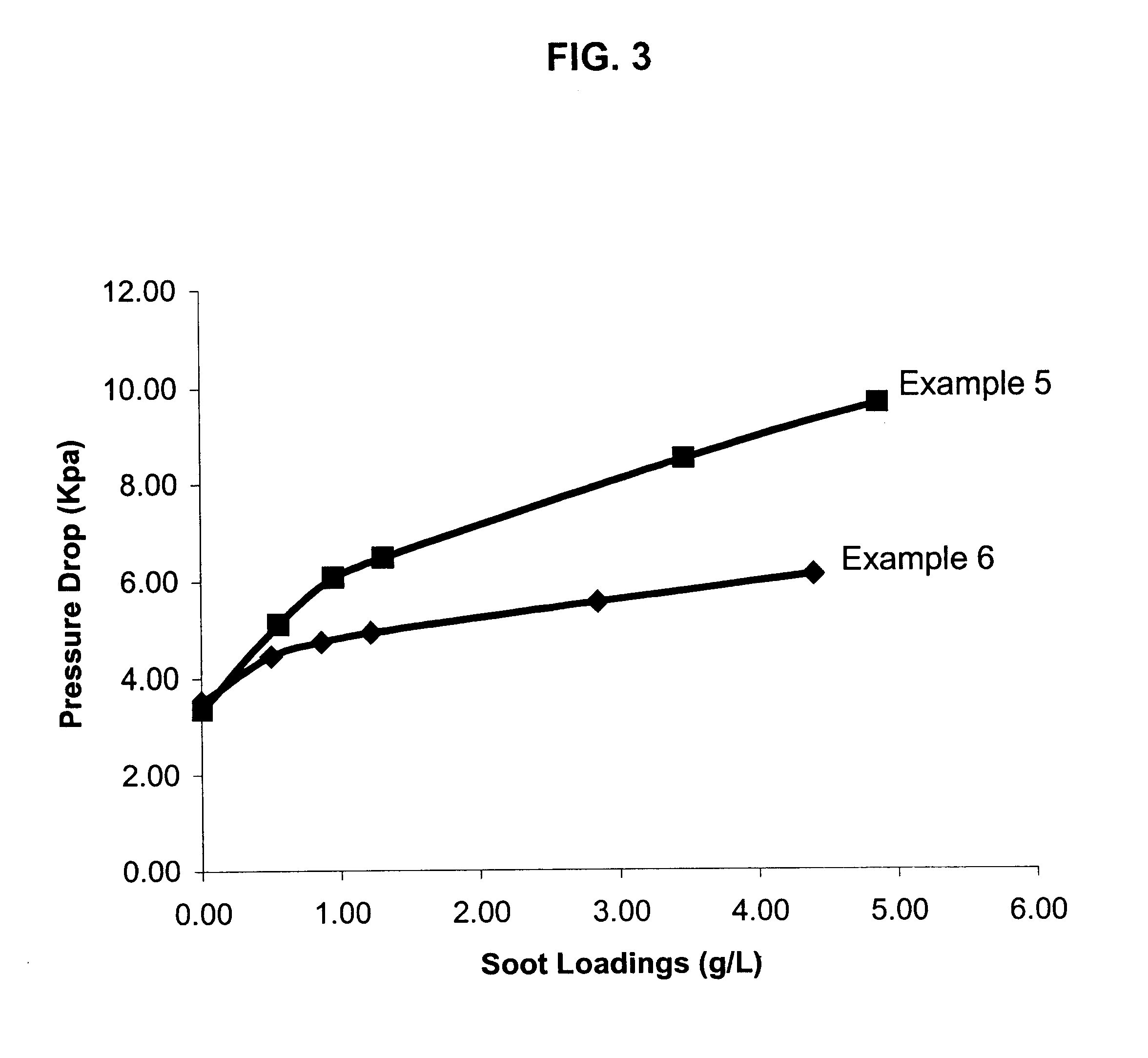

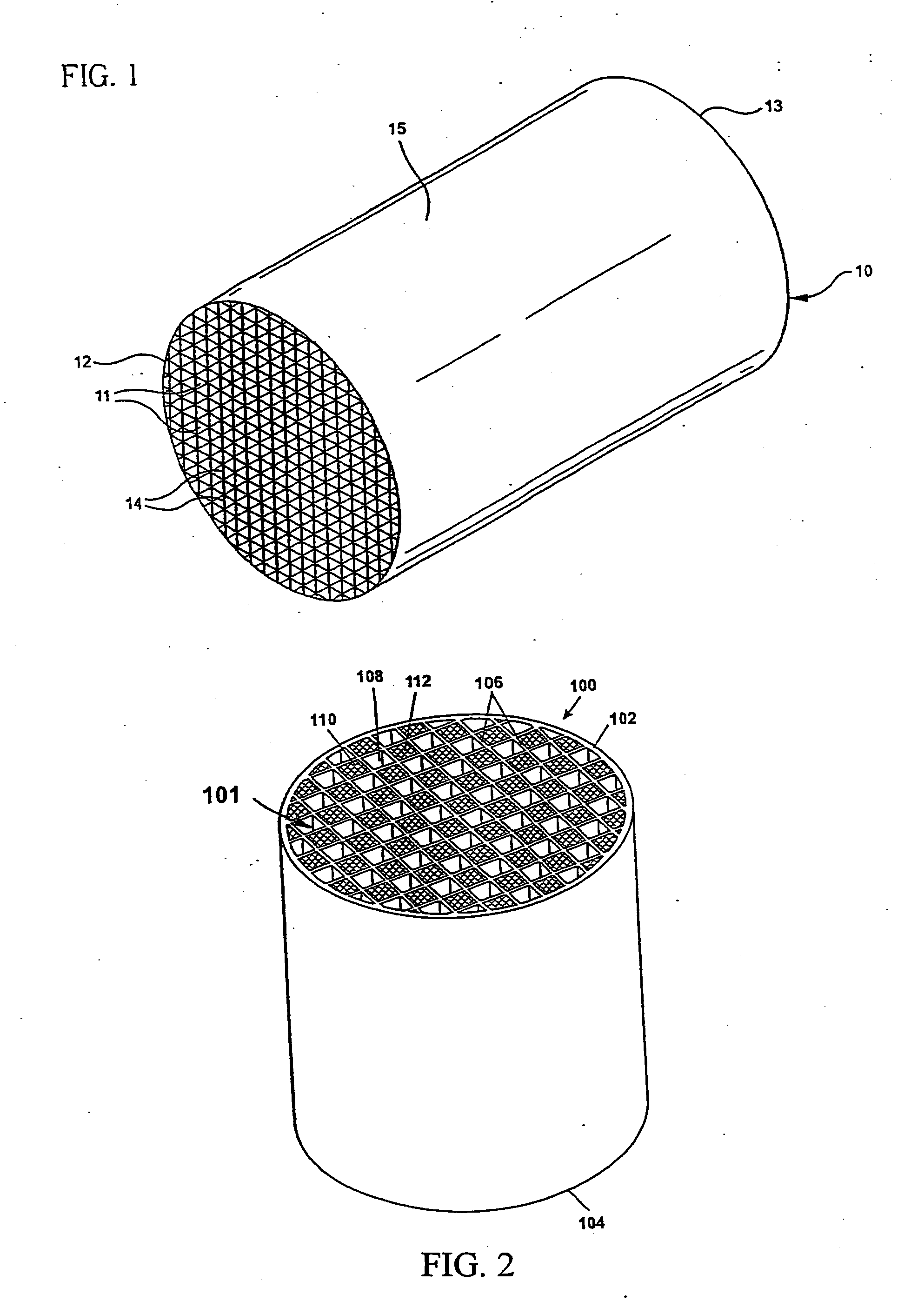

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveUS20070119135A1Lower wash-coated pressure dropQuantity minimizationCombination devicesExhaust apparatusSago palmSource material

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

Ceramic body based on aluminum titanate

An aluminum titanate-based ceramic body having a composition a formula comprising a(Al2O3.TiO2)+b(CaO.Al2O3.2SiO2)+c(SrO.Al2O3.2SiO2)+d(BaO.Al2O3.2SiO2)+e(3Al2O3.2SiO2)+f(Al2O3)+g (SiO2)+h(Fe2O3.TiO2)+i(MgO.2TiO2), wherein a, b, c, d, e, f, g, h, and i are weight fractions of each component such that (a+b+c+d+e+f+g+h+i)=1, wherein 0.5<a≦0.95; 0≦b≦0.5; 0≦c≦0.5; 0≦d≦0.5; 0<e≦0.5; 0≦f≦0.5; 0≦g≦0.1; 0≦h≦0.3; 0≦i≦0.3; b+d>0.01. A method of forming the ceramic body is provided. The ceramic body is useful in automotive emissions control systems, such as diesel exhaust filtration.

Owner:CORNING INC

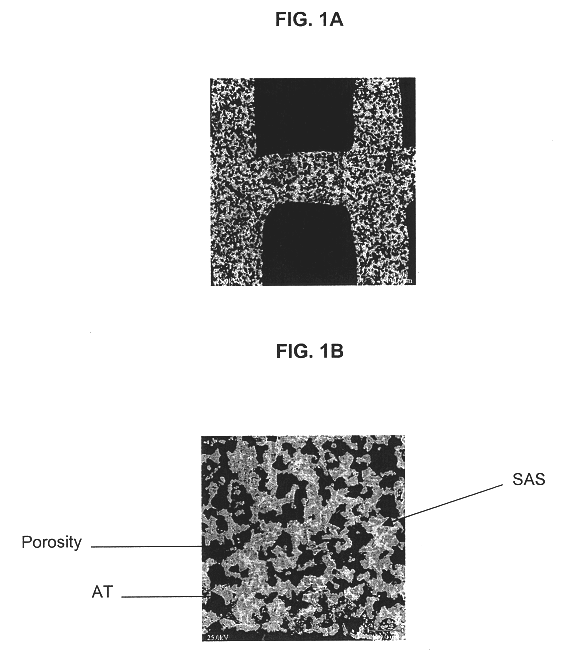

Mullite-aluminum titanate diesel exhaust filter

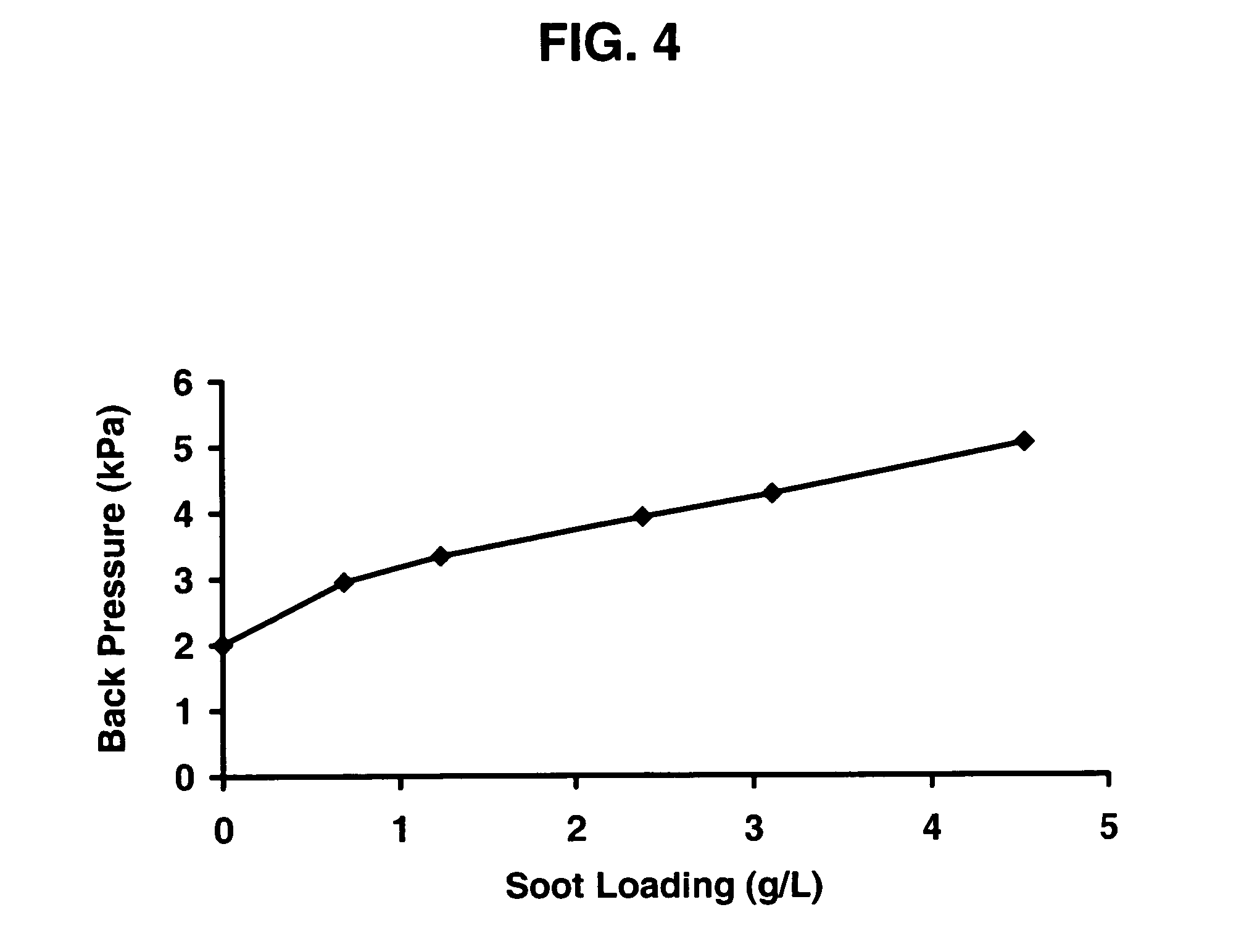

InactiveUS20040020846A1High interconnected porosityReduce back pressureIron oxides/hydroxidesExhaust apparatusFiltrationWhole body

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1-x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

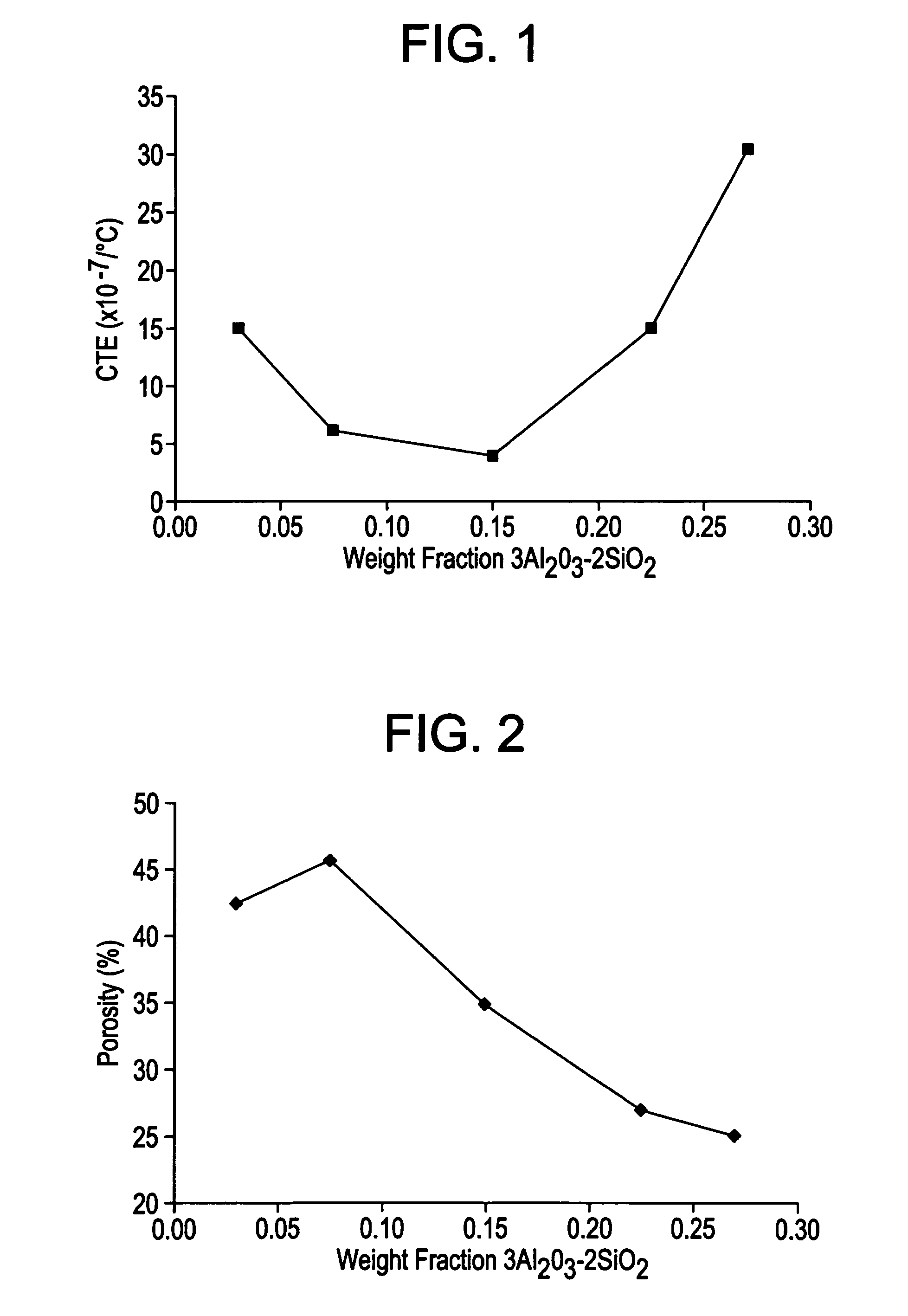

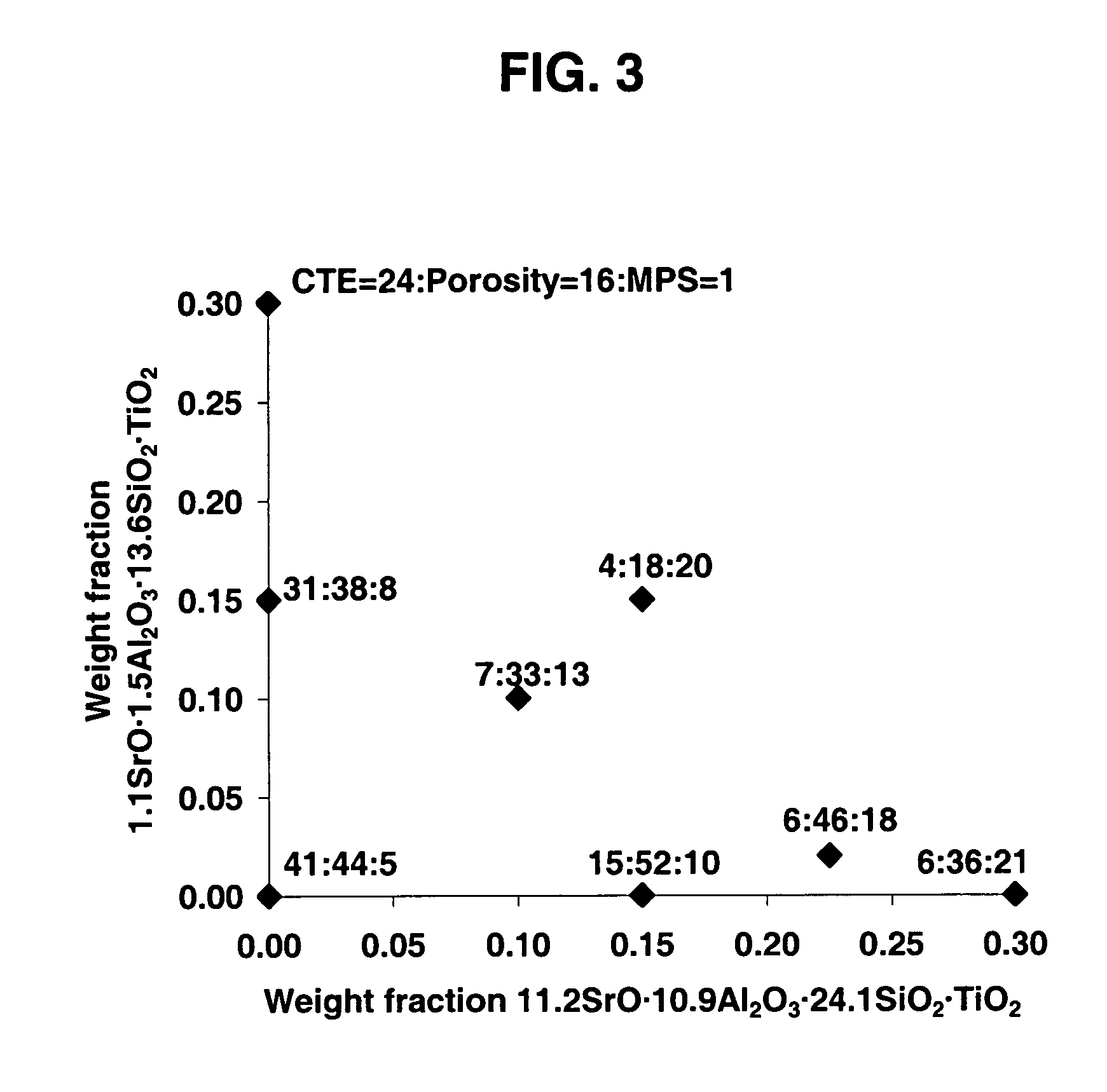

Aluminum titanate-based ceramic article

ActiveUS7001861B2Reduce manufacturing costHigh mechanical strengthDispersed particle filtrationExhaust apparatusFiltrationTitanate

An aluminum titanate-based ceramic article having a composition comprising u (Al2O3—TiO2)+v (R)+w (3Al2O3—2SiO2)+x (Al2O3)+y (SiO2)+z (1.1SrO-1.5Al2O3-13.6SiO2—TiO2)+a (Fe2O3—TiO2)+b (MgO-2TiO2), where, R is SrO—Al2O3-2SiO2 or 11.2SrO-10.9Al2O3-24.1SiO2—TiO2, where u, v, w, x, y, z, a and b are weight fractions of each component such that (u+v+w+x+y+z+a+b=1), and 0.5<u≦0.95, 0.01<v≦0.5, 0.01<w≦0.5, 0≦x≦0.5, 0≦y≦0.1, 0≦z≦0.5, 0<a≦0.3, and 0≦b≦0.3. A method of forming the ceramic article is provided. The ceramic article is useful in automotive emissions control systems, such as diesel exhaust filtration.

Owner:CORNING INC

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

Aluminum titanate ceramic articles and methods of making same

ActiveUS7259120B2Reduced strengthLower firing temperatureInternal combustion piston enginesSilencing apparatusAlkaline earth metalRare earth

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:CORNING INC

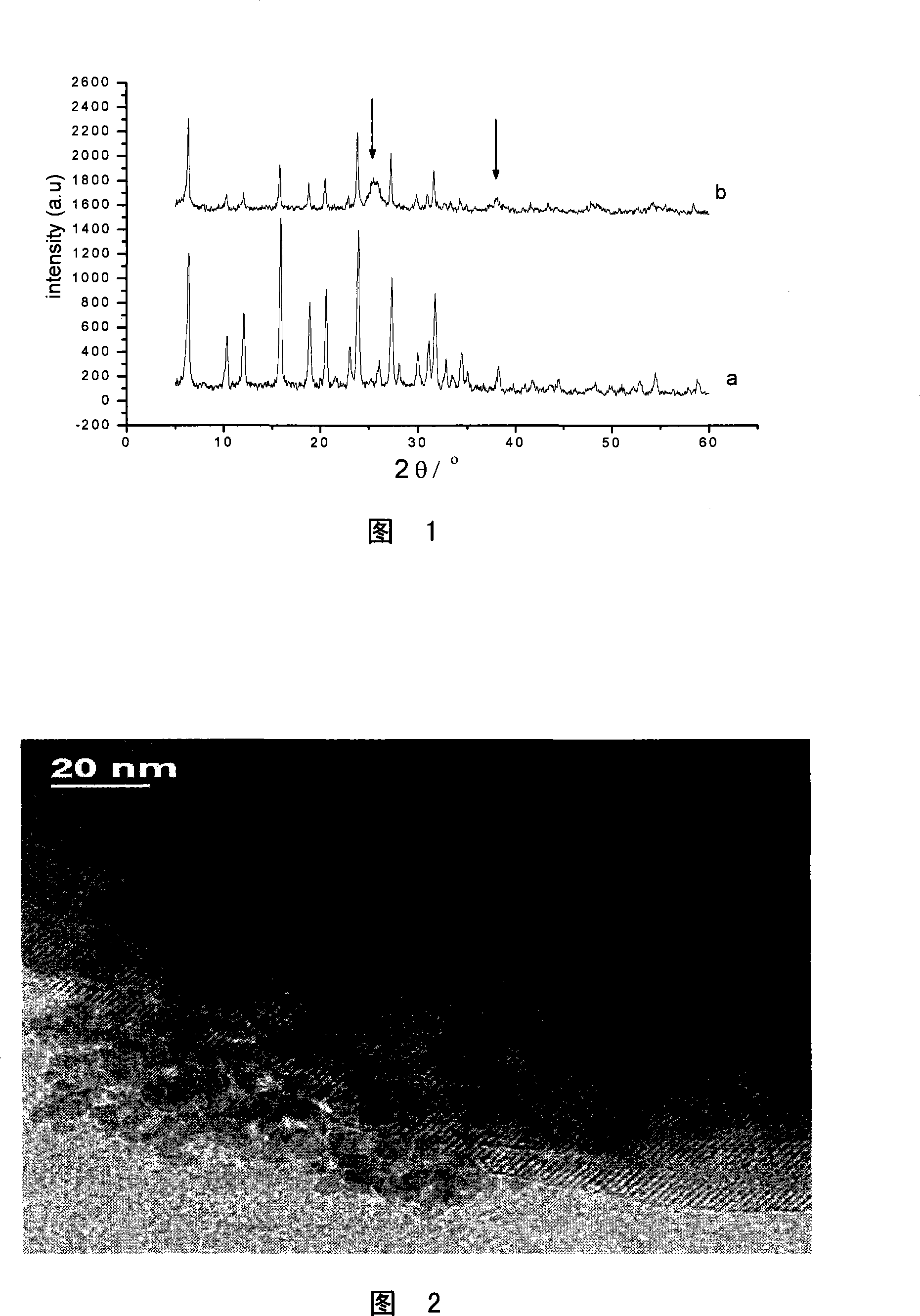

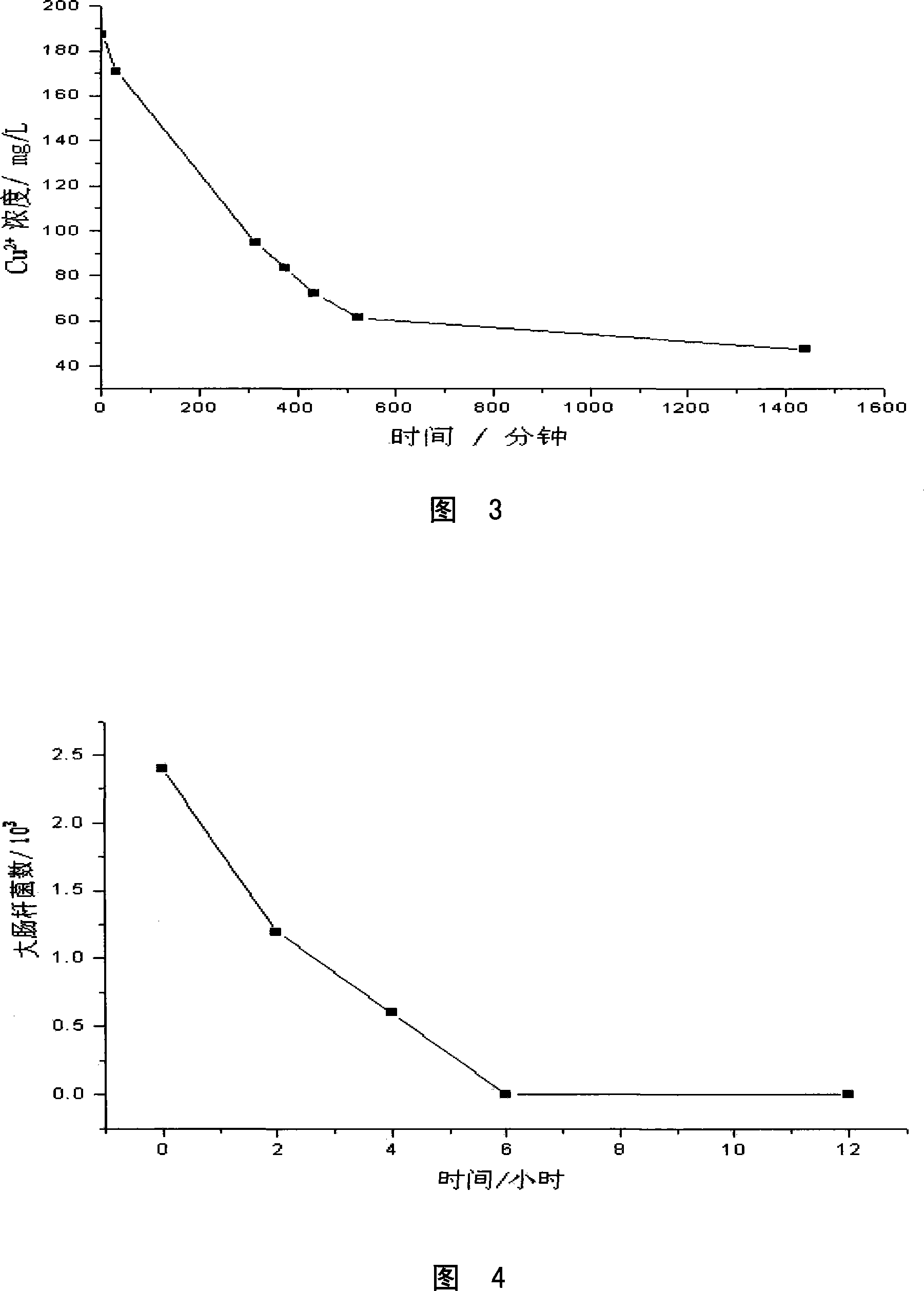

Zeolite base composite antibiotic material and its preparation method

InactiveCN101167451APrevent seepageImprove thermal stabilityBiocideDisinfectantsIon exchangeSilver ion

The invention relates to zeolite-based composite antibiotic material and a process for preparation, the material of which is low-silicon-aluminum-ratio zeolite molecular sieve which is used as the base and carrier, the outer surface of the invention is covered with nanometer titanium dioxide particles, and the pore passages or cages of the invention are provided with metallic ions which have antibiotic effect. The process for preparing the material is that low-silicon-aluminum-ratio zeolite molecular sieve absorbs organic amine to saturation and then is dipped into soluble titanates for roasting to generate nanometer titanium dioxide on the outer surface of zeolite, and metallic ions such as silver ions, copper ions and the like which have antibiotic effect are exchanged to zeolite by the ion exchange process to form the novel composite antibiotic material. The composite antibiotic material not only has the antibiotic effect of metallic ions but also has the antibiotic effect of nanometer titanium dioxide, and thereby the antibiotic effect is strengthened. The composite antibiotic material is easy to prepare, low in price and suitable for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

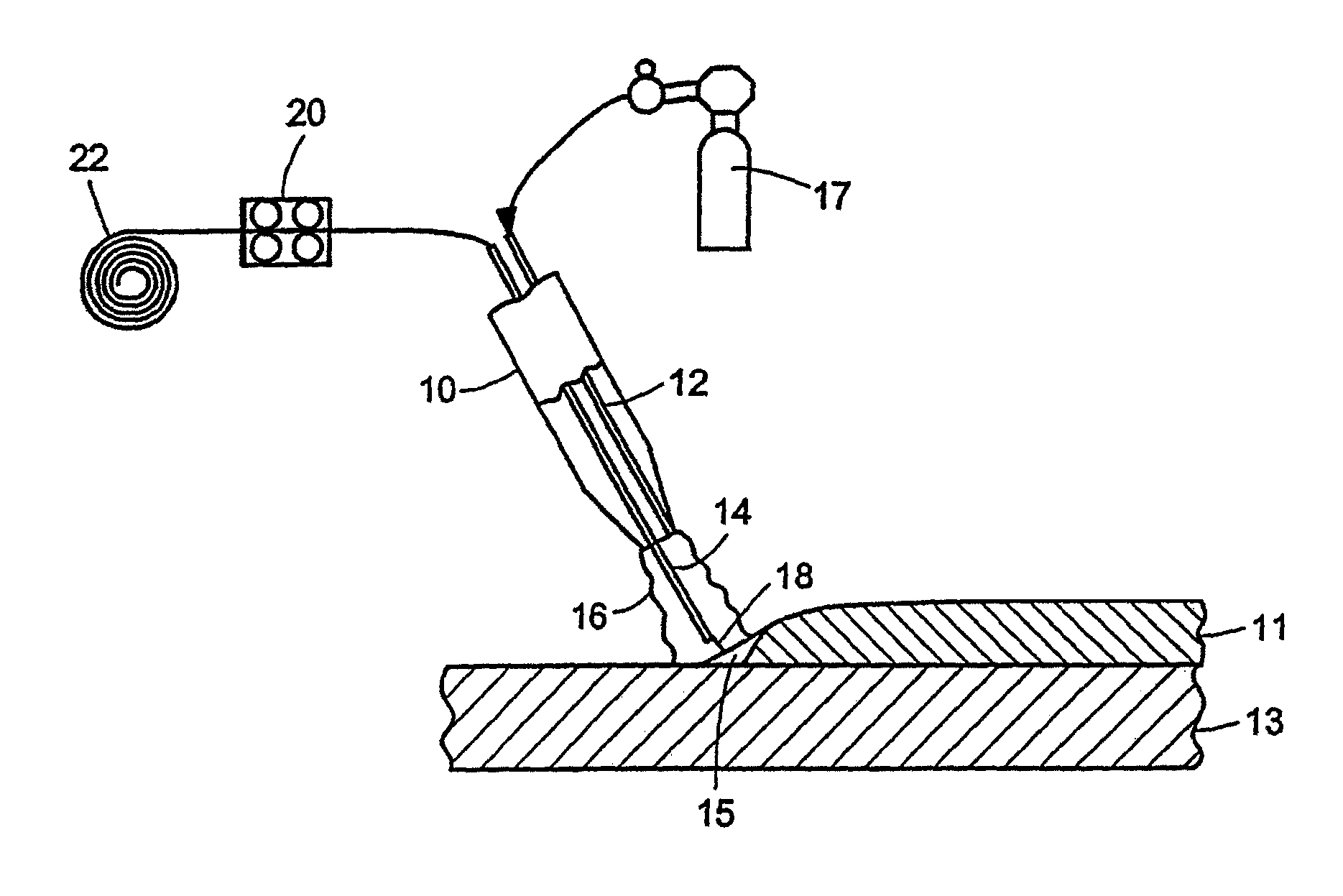

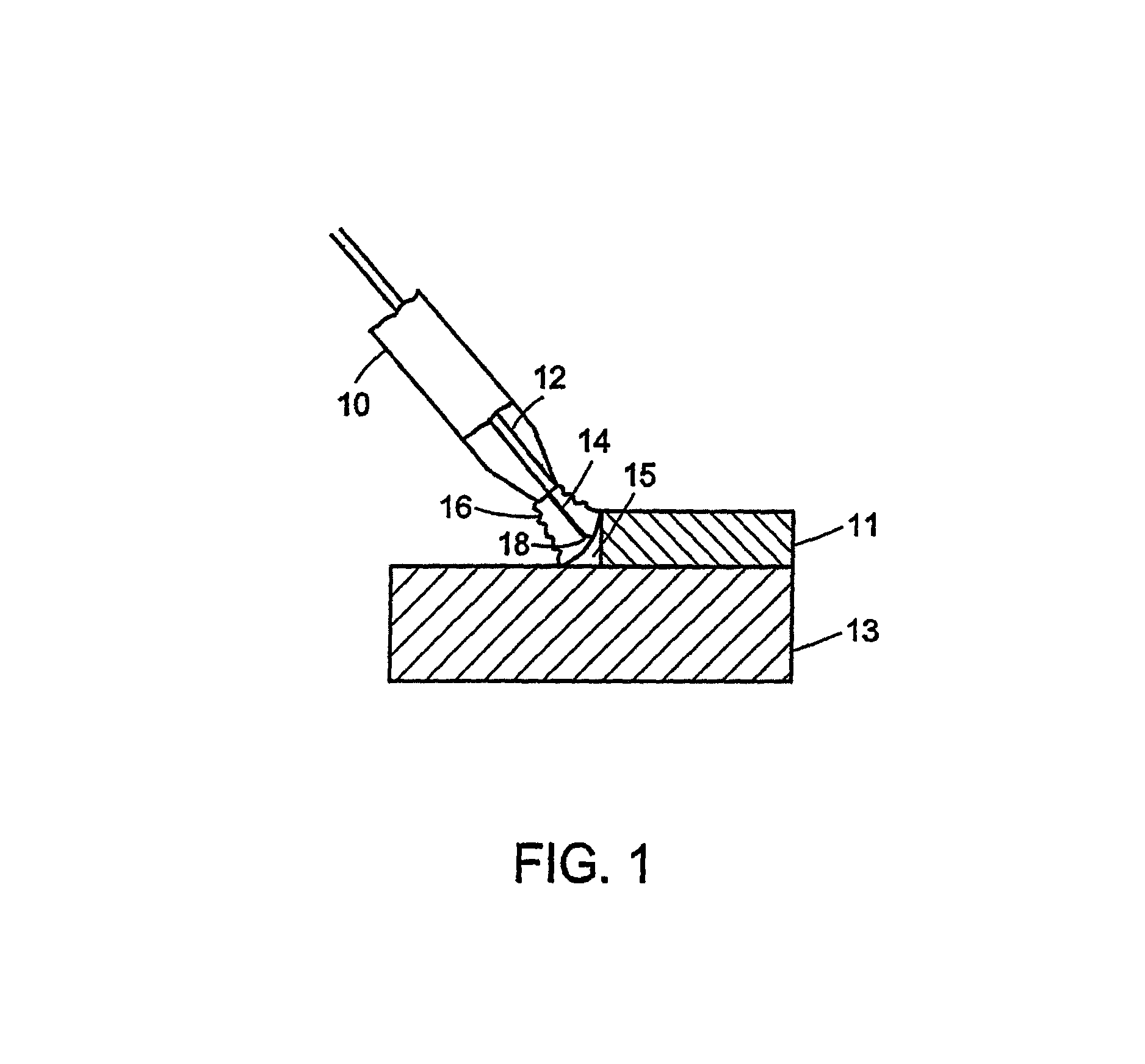

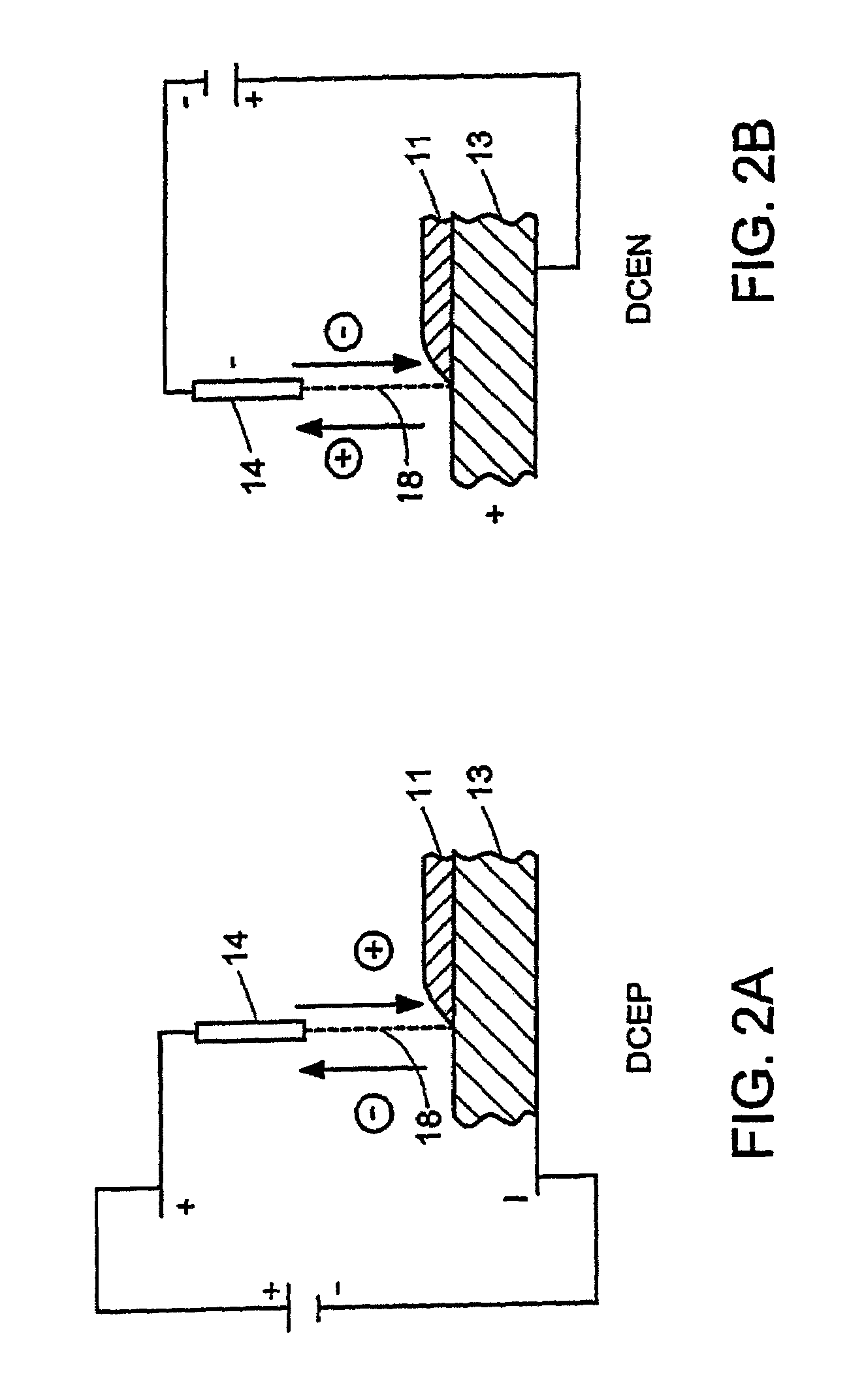

Straight polarity metal cored wires

InactiveUS7087860B2Increase deposition rateImprove welding qualityArc welding apparatusWelding/cutting media/materialsManganeseGraphite

A core composition of a metal-cored wire comprising a combination of graphite and potassium compounds has been proven to stabilize the arc in a straight polarity welding configuration. In particular, adding a combination of graphite and potassium manganese titanate (K2MnTiO4) and potassium sulfate (K2SO4) in the preferred combination of graphite and potassium compounds from the range of about 0.3% to about 5.0% wt resulted in a greatly stabilized arc, reduced spatter and reduced warpage while maintaining high deposition rates of the DCEN welding process

Owner:HOBART BROS

Novel composite carrier SCR flue gas denitration catalyst

The invention belongs to the field of environmental protection and environmental catalysis, and in particular relates to a novel composite carrier SCR flue gas denitration catalyst. An SCR flue gas denitration catalyst which takes TiO2-mesoporous SiO2 as a compound carrier is obtained by preparing the TiO2-mesoporous SiO2 by hydrolyzing tetrabutyl titanate in mesoporous SiO2 by adopting a sol-gel method, taking the TiO2-mesoporous SiO2 as the compound carrier of the SCR catalyst, supporting a cocatalyst on the TiO2-mesoporous SiO2 compound carrier, and finishing the supporting of a main catalyst. The catalyst comprises the following components in percentage by mass: 85 to 99.9 percent of the compound carrier, 0 to 5 percent of the cocatalyst and 0.1 t0 10 percent of the main catalyst, wherein the compound carrier consists 80 to 95 weight percent of the mesoporous SiO2 and 5 to 20 weight percent of the TiO2. The introduction of the mesoporous SiO2 greatly increases the specific area of the catalyst; and the catalyst has high dispersibility of active substance and high stability, contributes to a gas to enter pores to fully react with the catalyst because the carrier has regular pore structures, and has high denitration performance.

Owner:UNIV OF SCI & TECH BEIJING

SCR denitration catalyst and preparation method thereof

ActiveCN101185886AImprove structural stabilityImprove mechanical stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSilanesAmmonium paratungstate

The invention relates to a preparation method of an SCR denitration catalyst, which comprises the following steps: (1) Al2O3 sol is prepared, which comprises the steps that hot ammonia, the Al2O3 is added in drops into the ammonia and then HCI is added and the mixture is stirred; (2) Al2O3-SiO2-TiO2 composite sol is prepared, which comprises the steps that tetratethoxy-silane, butyl titanate, deionized water are sequentially put into ethanol to be aging and then the sol prepared by step (1) is adding to be stirred and aging; (3) vector is coated, which comprises the steps that cordierite honeycomb immersed into the sol of step (2) and the raffinate in a channel is cleaned, dried and roasted after being taken out; (4) active component impregnating solution is prepared, which comprises the steps that lanthanum nitrate, ammonium metavanadate and ammonium paratungstate are dissolved into the deionized water after being mixed together and oxalate acid is added to be aging; (5) the active component is loaded, which comprises the steps that the vector of the step (3) is immersed into the impregnating solution of the step (4) and then the raffinate in the channel is cleaned to be dried and roasted. The invention also relates to the denitration catalyst which is prepared by the method.

Owner:山西蒲洲博奇环保科技有限公司

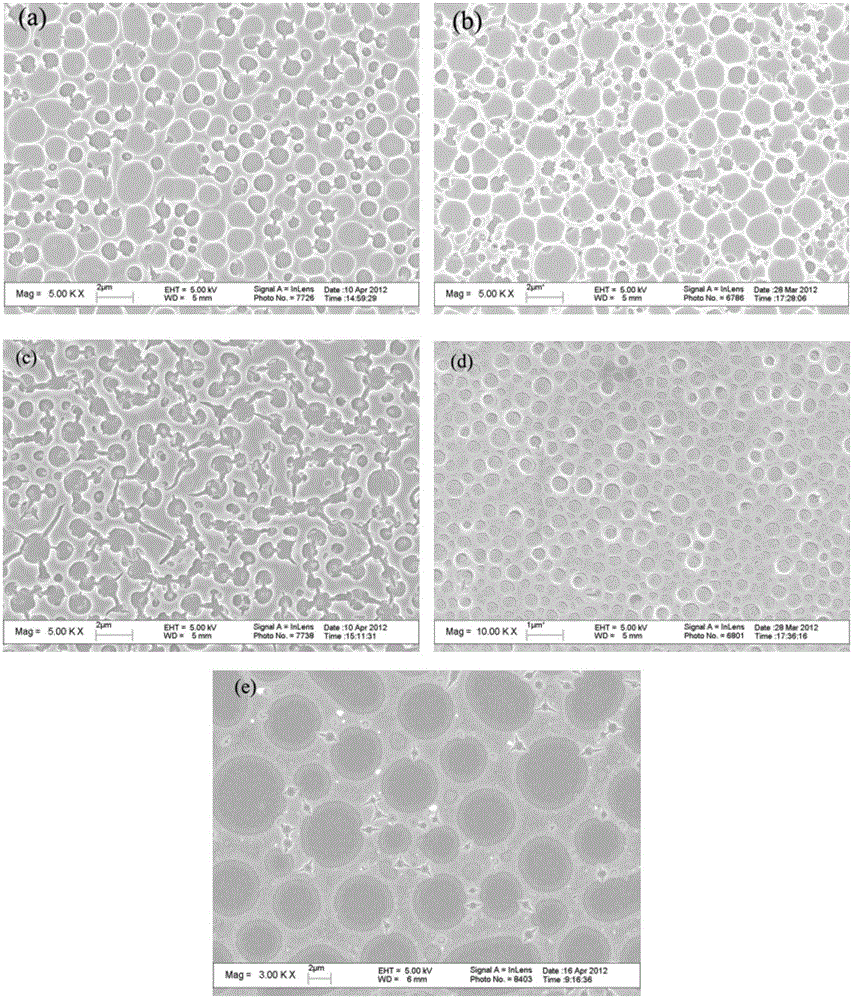

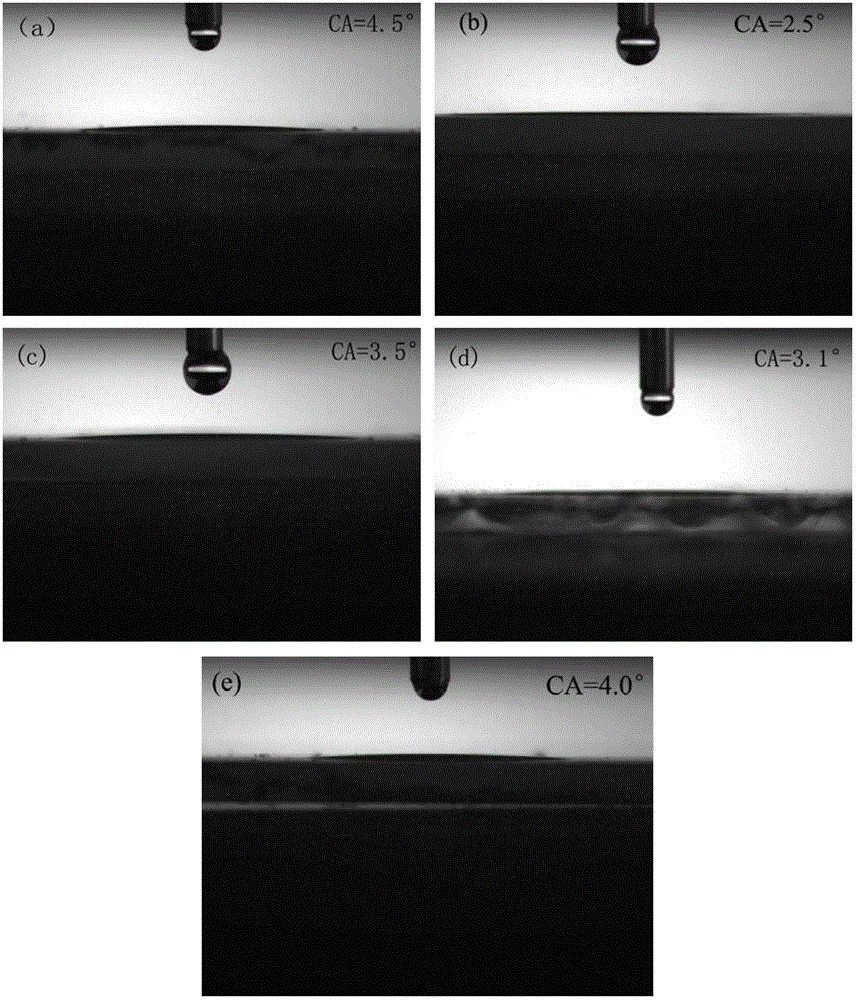

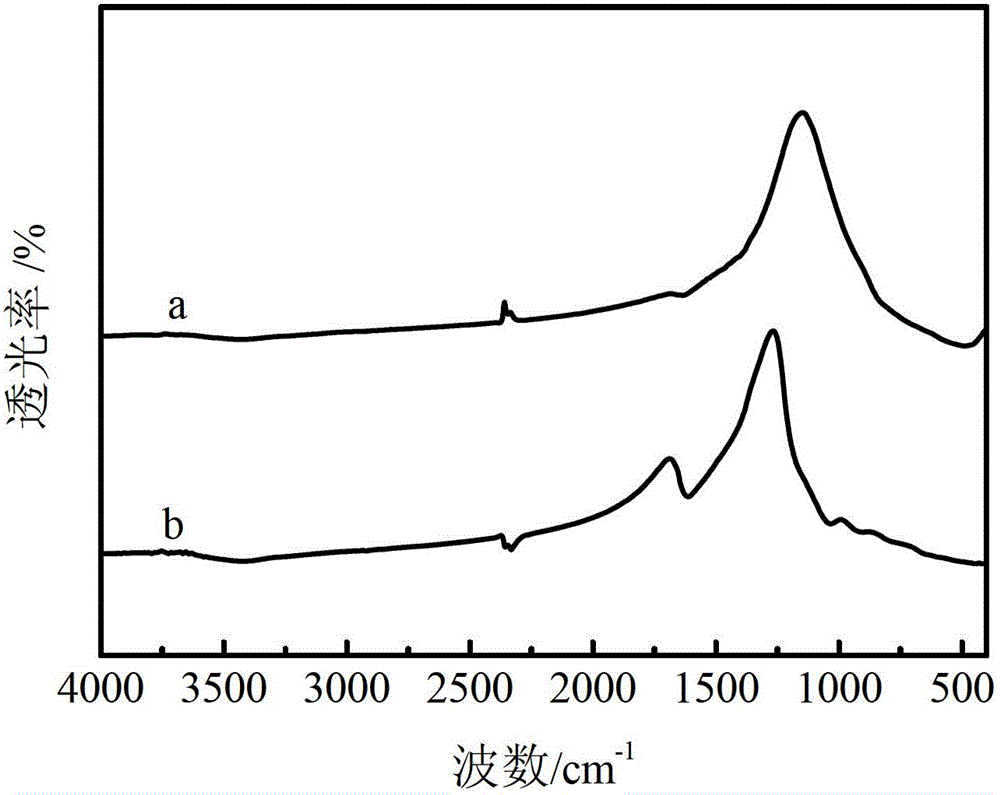

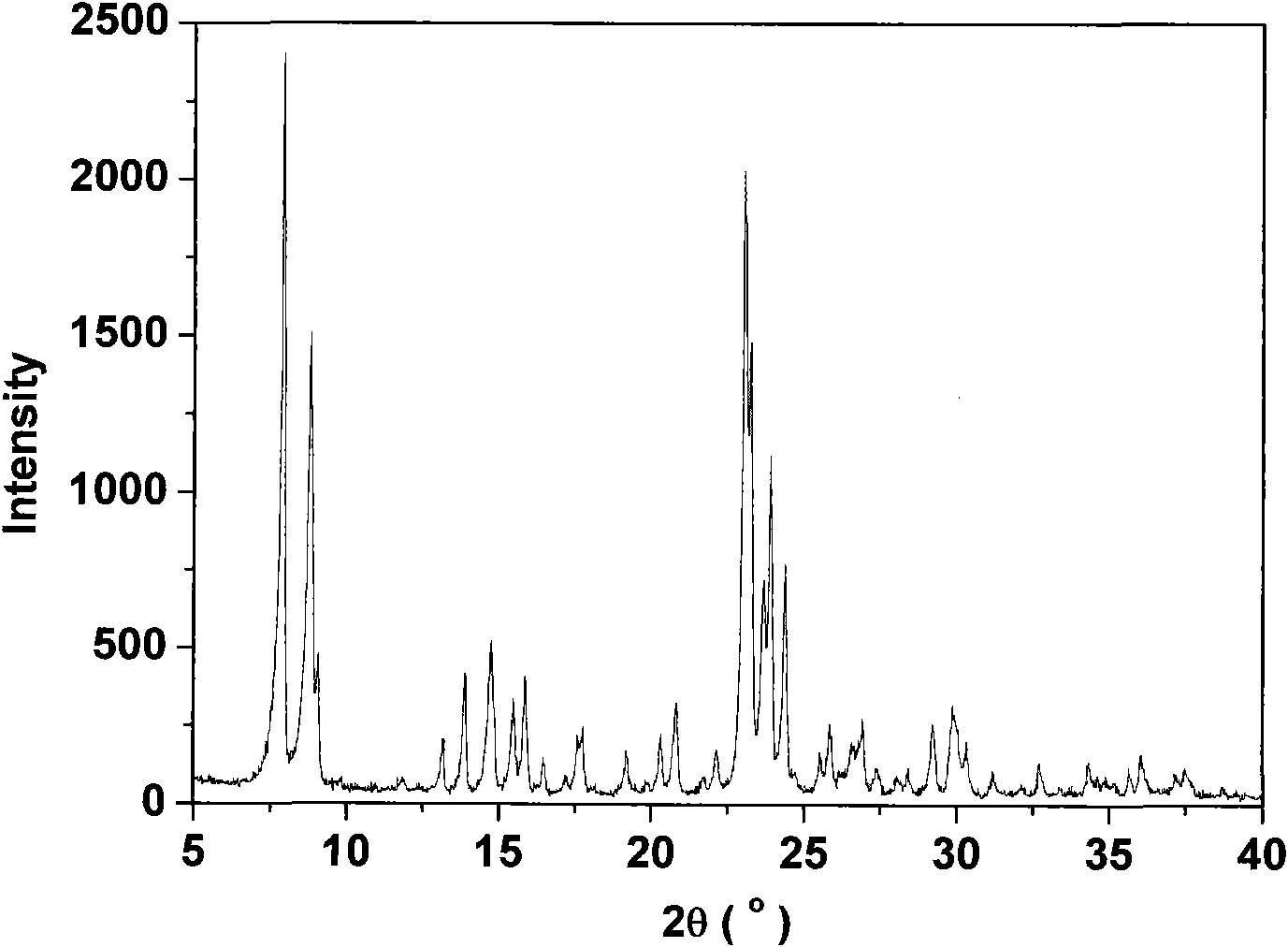

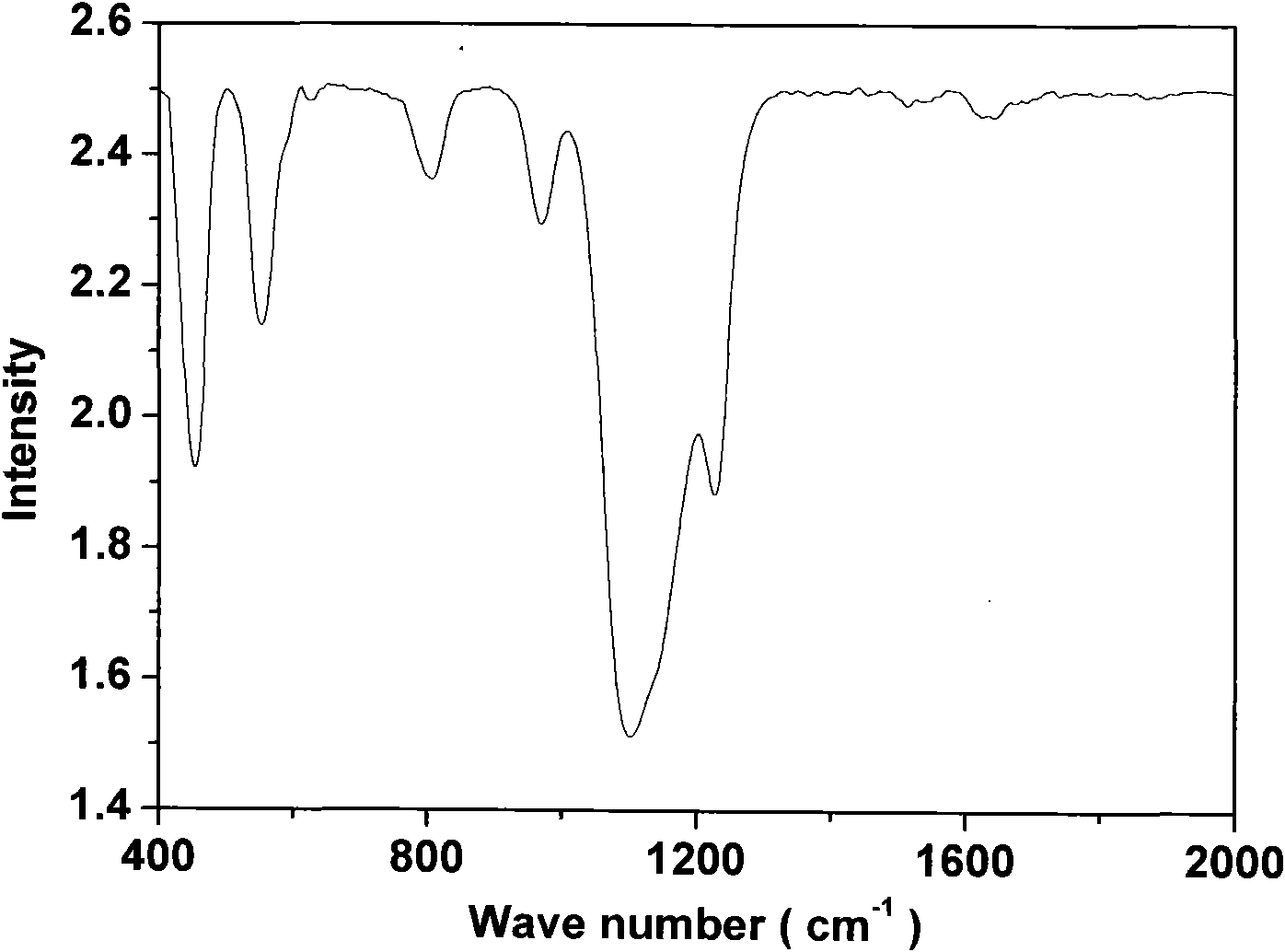

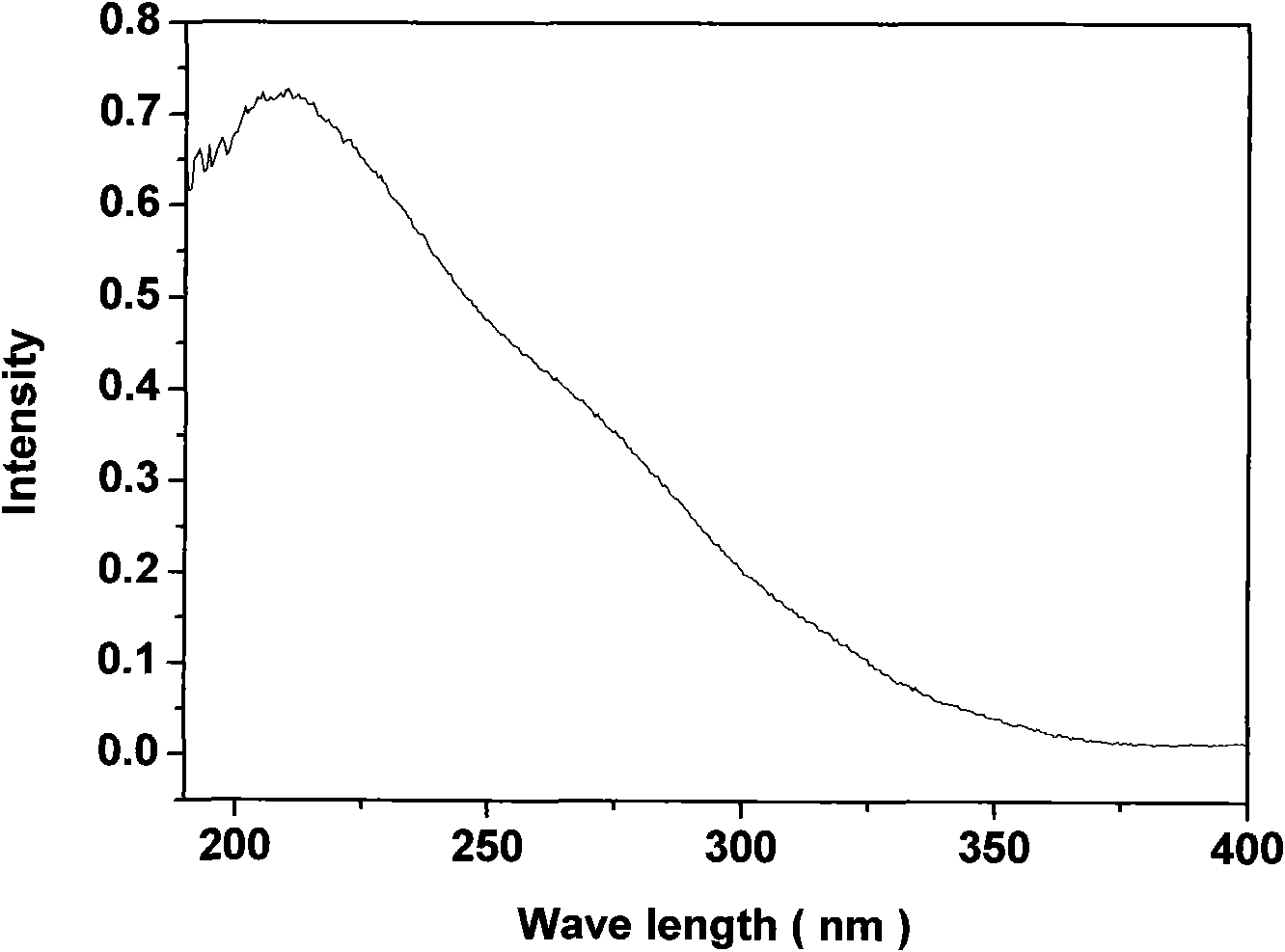

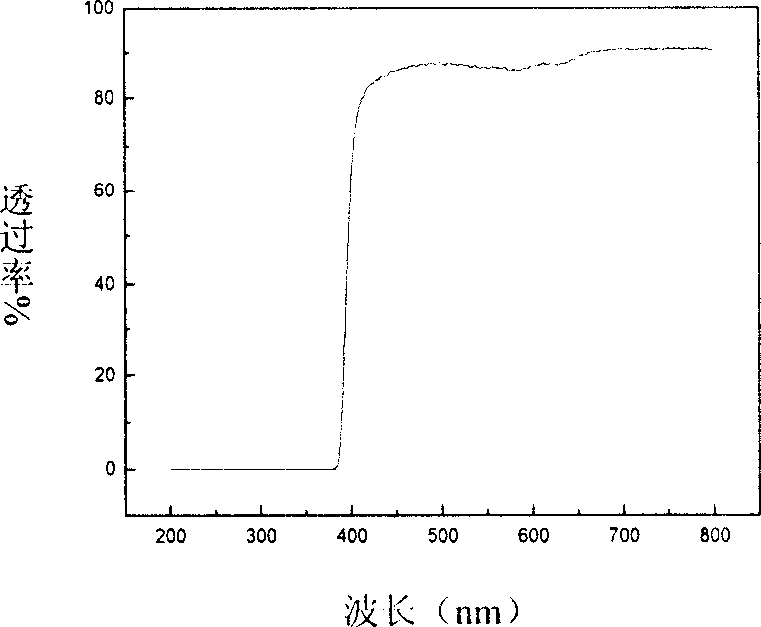

Natural super-hydrophilic porous TiO2/SiO2 composite thin film and preparation method thereof

InactiveCN102718411AImprove superhydrophilicitySolid/suspension decomposition chemical coatingComposite filmTitanate

The invention relates to a natural super-hydrophilic porous TiO2 / SiO2 composite thin film and a preparation method thereof. The preparation method comprises the following steps of: adopting a sol-gel method and respectively taking tetrabutyl titanate and ethyl orthosilicate as precursors to prepare TiO2 sol and SiO2 sol; calculating according to the molar fraction, compounding through taking the addition quantity of the SiO2 sol as 1-50 percent of total contents of SiO2 and TiO2 to obtain TiO2 / SiO2 composite sol; and coating the prepared composite sol on a substrate material, airing, calcining and cooling to obtain the super-hydrophilic thin film. The natural super-hydrophilic porous TiO2 / SiO2 composite thin film and the preparation method thereof have the beneficial effects that the thin film prepared by the method has the double effects of phase separation-induced developed hole structure and SiO2 compounding, the aperture of the thin film is within the scope of 100 nm-6 mum, the thickness of the thin film is within the scope of 200 nm-20 mum, a contact angle of the surface of the thin film with water is below 5 degrees, and the self-cleaning, antifogging and antibacterial functions are optimal.

Owner:SOUTH CHINA UNIV OF TECH

Method for quickly synthesizing small-crystallite titanium-silicon molecular sieve in cheap system

ActiveCN101913620ALower synthesis costFast crystallization rateCrystalline aluminosilicate zeolitesCyclohexanoneHigh activity

The invention provides a method for preparing a small-crystallite titanium-silicon molecular sieve in a cheap system by changing the adding mode of seed crystals and by a hydrothermal process. The titanium-silicon molecular sieve is prepared by using silicon sol as a silicon source, titanium tetrachloride or tetrabutyl titanate as a titanium source, tetrapropylammonium bromide ( TPABr) as a template agent, organic amine as an alkali source and unseparated nanoscale TS-1 mother liquor as seed crystals directly and by the hydrothermal process. The grain size of the titanium-silicon molecular sieve is less than 1 micrometer, and the titanium-silicon molecular sieve has high activity for selective oxidization reactions using hydrogen peroxide as an oxidant, such as epoxidation of olefins, hydroxylation of phenol, ammoxidation of cyclohexanone and the like. The method simplifies the synthesis process of small crystallite TS-1 in the cheap system and reduces synthesis time and cost.

Owner:DALIAN UNIV OF TECH

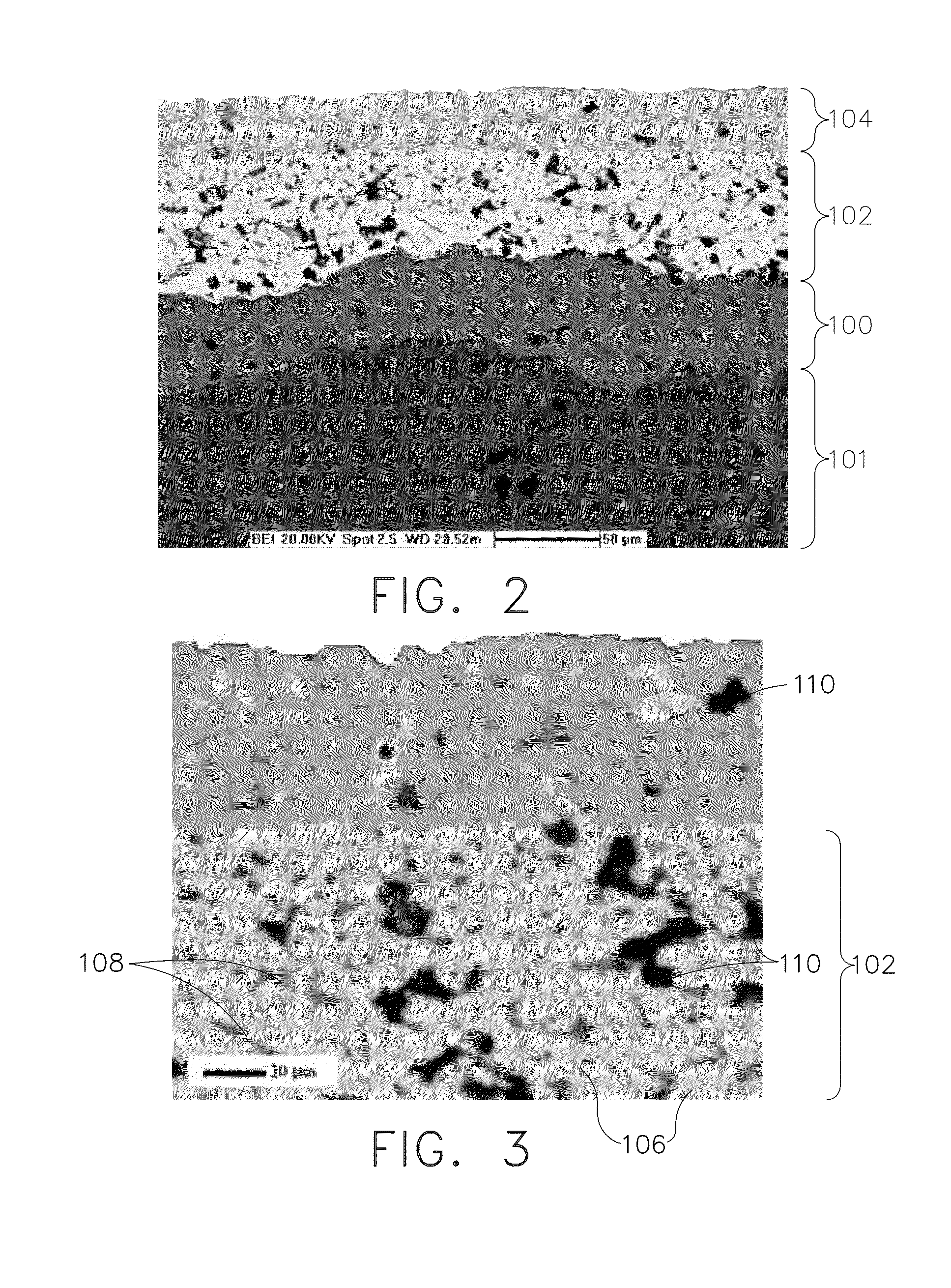

Water based environmental barrier coatings for high temperature ceramic components

Environmental barrier coatings for high temperature ceramic components including: a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material selected from a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least water, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

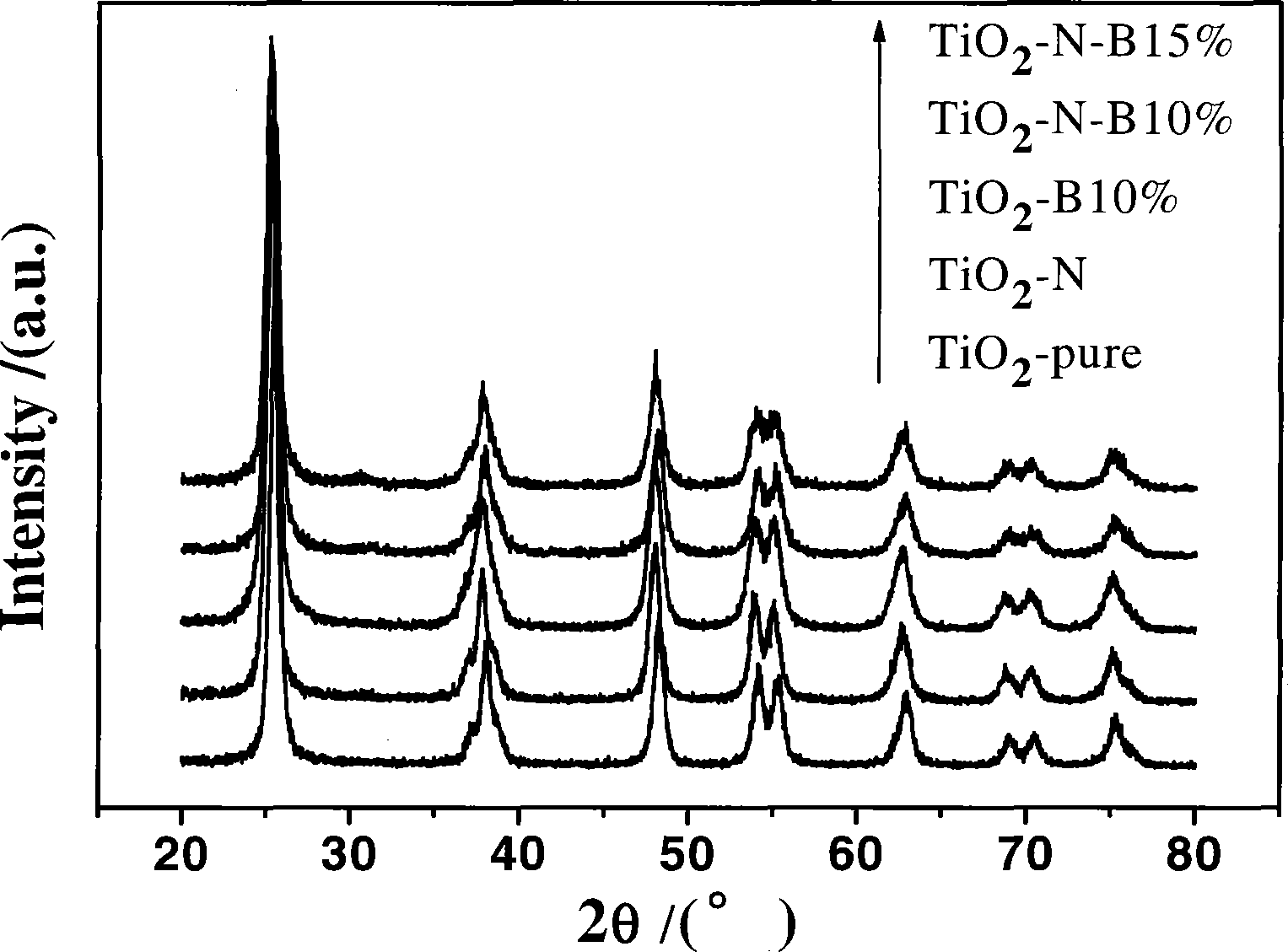

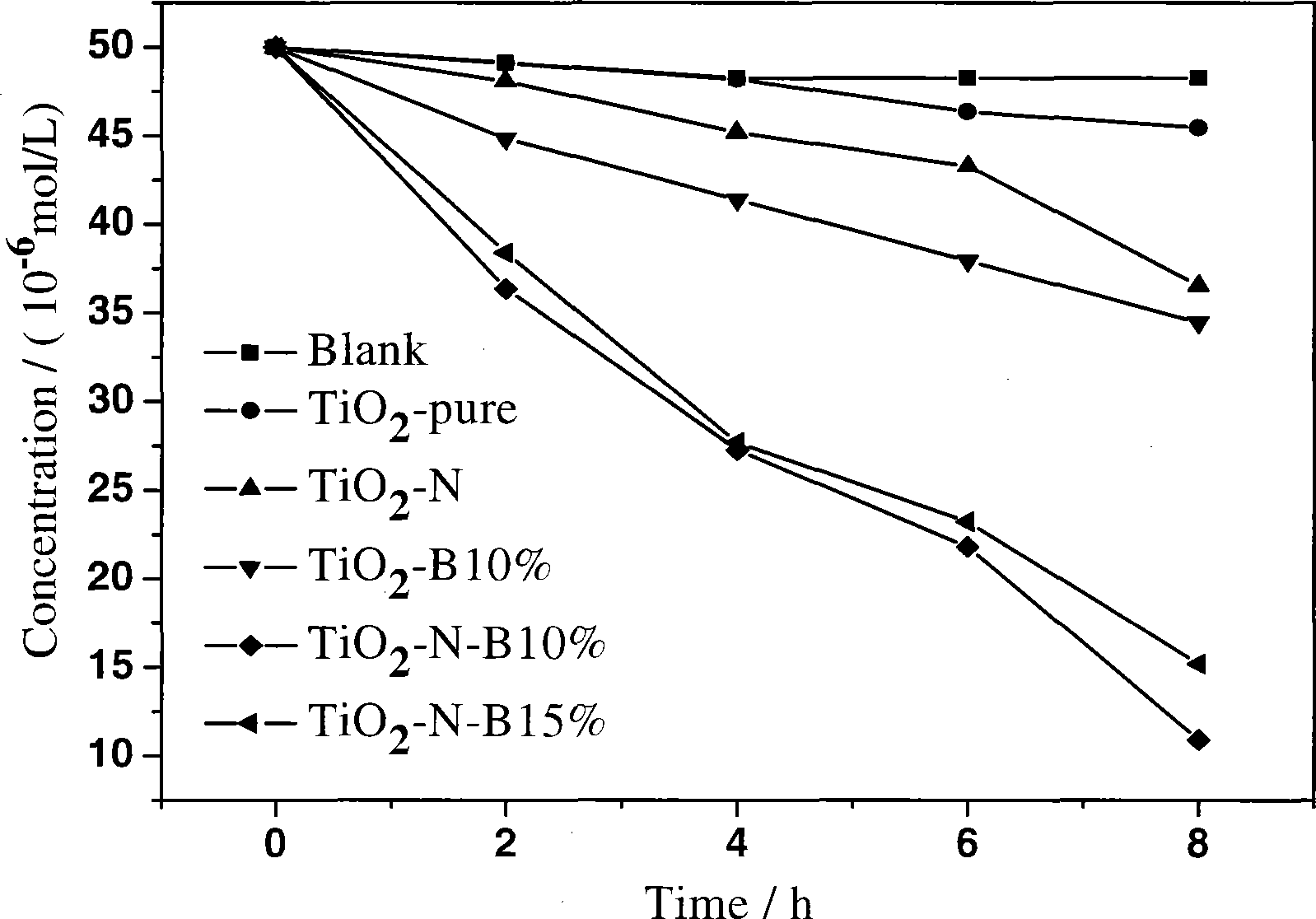

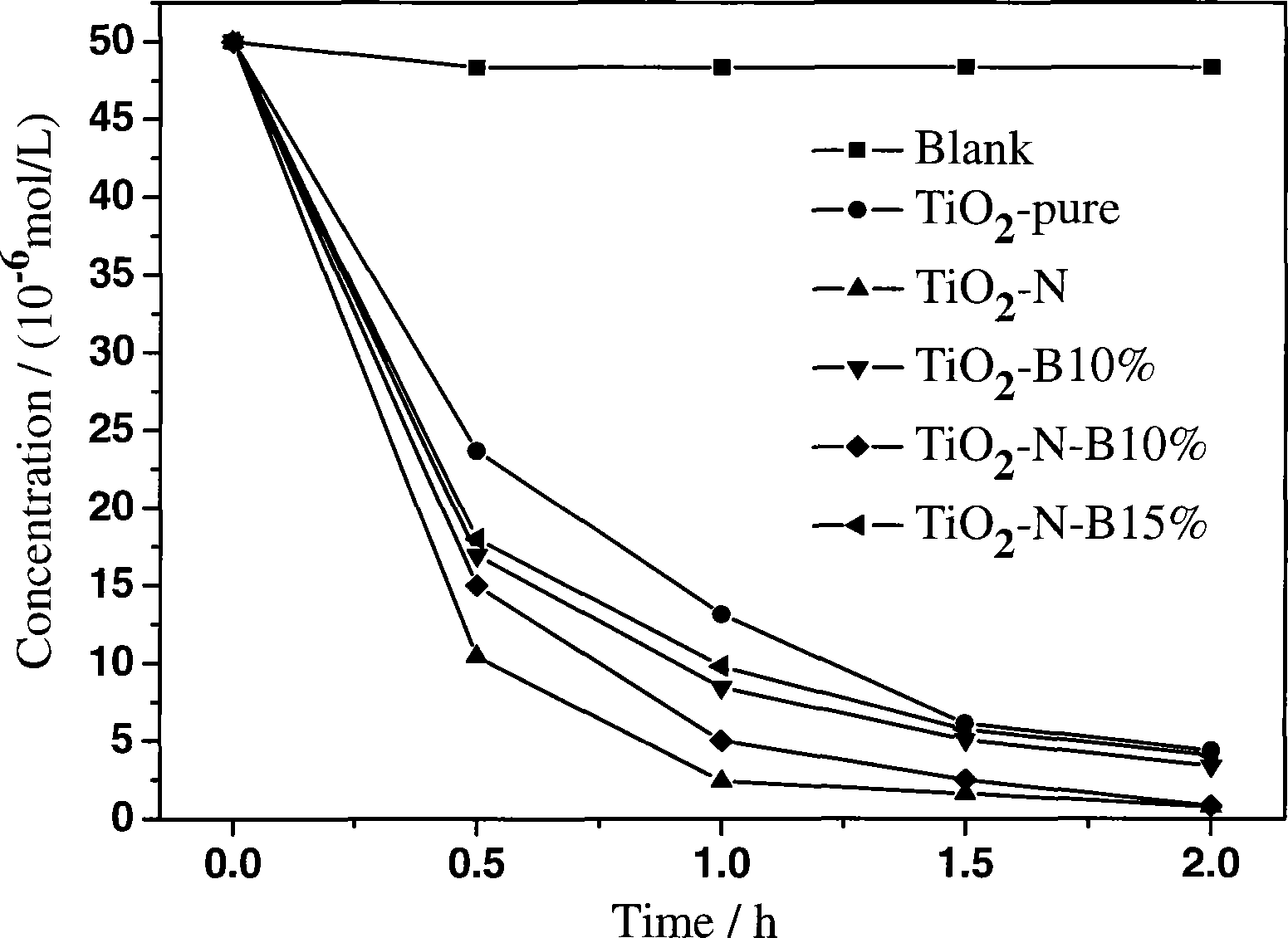

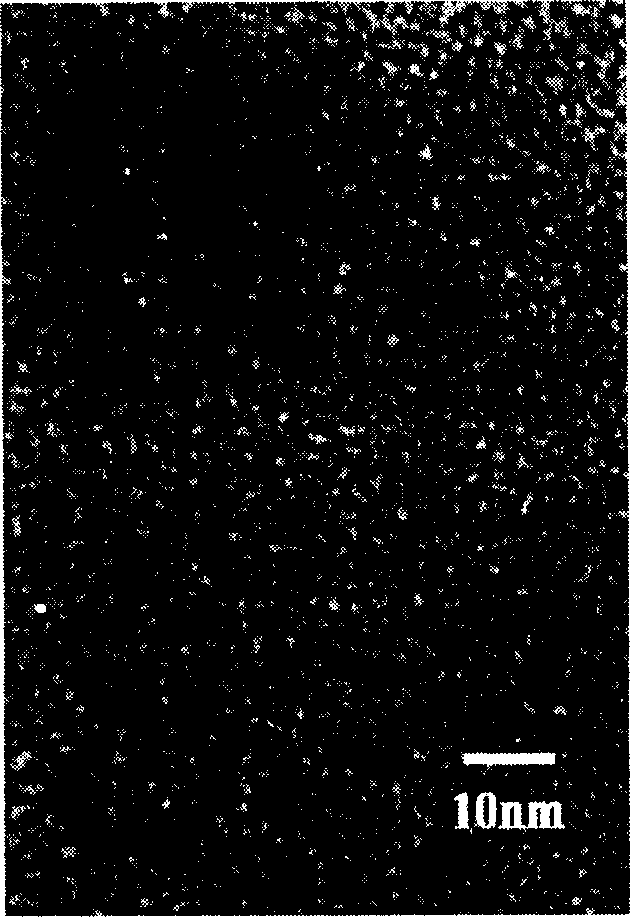

Method for preparing high activity non-metallic ion co-doped titanium dioxide photochemical catalyst

InactiveCN101444724ASimple processLow equipment requirementsPhysical/chemical process catalystsCatalyst degradationUltraviolet lights

In order to degrade the pollutants in water and atmosphere by the photocatalysis technology, the invention discloses a method for preparing a high activity non-metallic ion co-doped titanium dioxide photochemical catalyst. In the photochemical catalyst, titanium ester or titanate is used as a precursor, non-metallic compound comprising boron, carbon, nitrogen, fluorin, silicon, phosphor, sulfur, chlorine, bromine, iodine, and the like, are used as doping agents, the high activity non-metallic ion co-doped titanium dioxide photochemical catalyst is prepared by adopting the sol gel method. Compared with a titanium dioxide photochemical catalyst single-doped with pure titanium dioxide and the non-metallic irons, the visible light catalytic activity of the titanium dioxide photochemical catalyst on the degradation of parachlorophenol is greatly improved, and the ultraviolet light catalytic activity can also exceed the catalytic activity of the pure titanium dioxide catalyst. The method also has the advantages that the preparation technique is simple, the equipment requirement is low; the particle diameter of the product is small, the specific surface is relatively high, the dispersivity is good, thus having a wide application prospect in the environmental cleaning scientific field.

Owner:NANKAI UNIV

Method of manufacturing and using rod-shaped proppants and Anti-flowback additives

A sintered rod-shaped proppant and anti-flowback agent possesses high strength and high conductivity. The sintered rods comprise between about 0.2% by weight and about 4% by weight aluminum titanate. In some embodiments, the sintered rods are made by mixing bauxitic and non-bauxitic sources of alumina that may also contain several so-called impurities (such as TiO2), extruding the mixture, and sintering it. The starting material may optionally be milled to achieve better compacity and crush resistance in the final sintered rod. A fracturing fluid may comprise the sintered rods alone or in combination with a proppant, preferably a proppant of a different shape.

Owner:US CERAMICS LLC

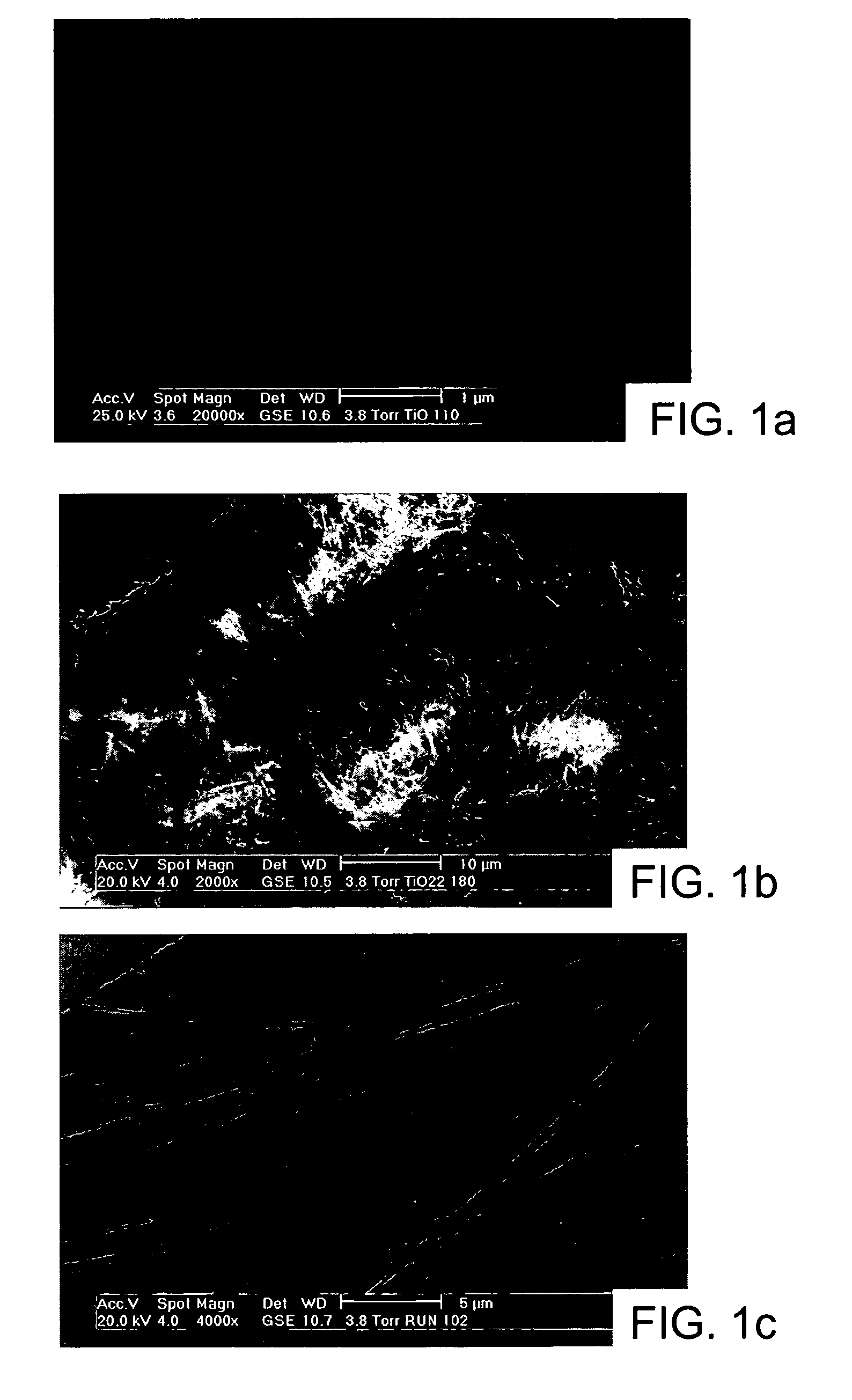

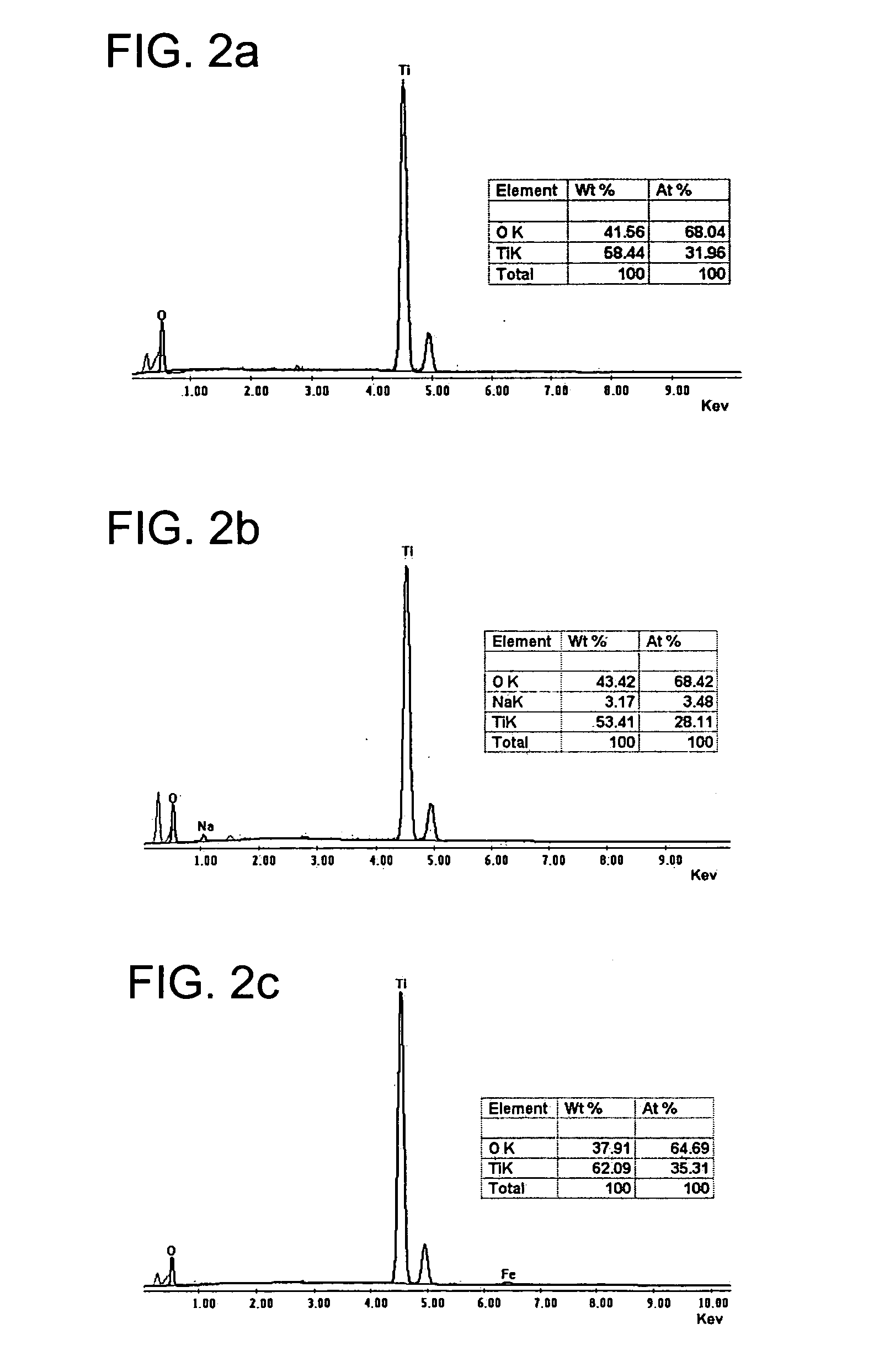

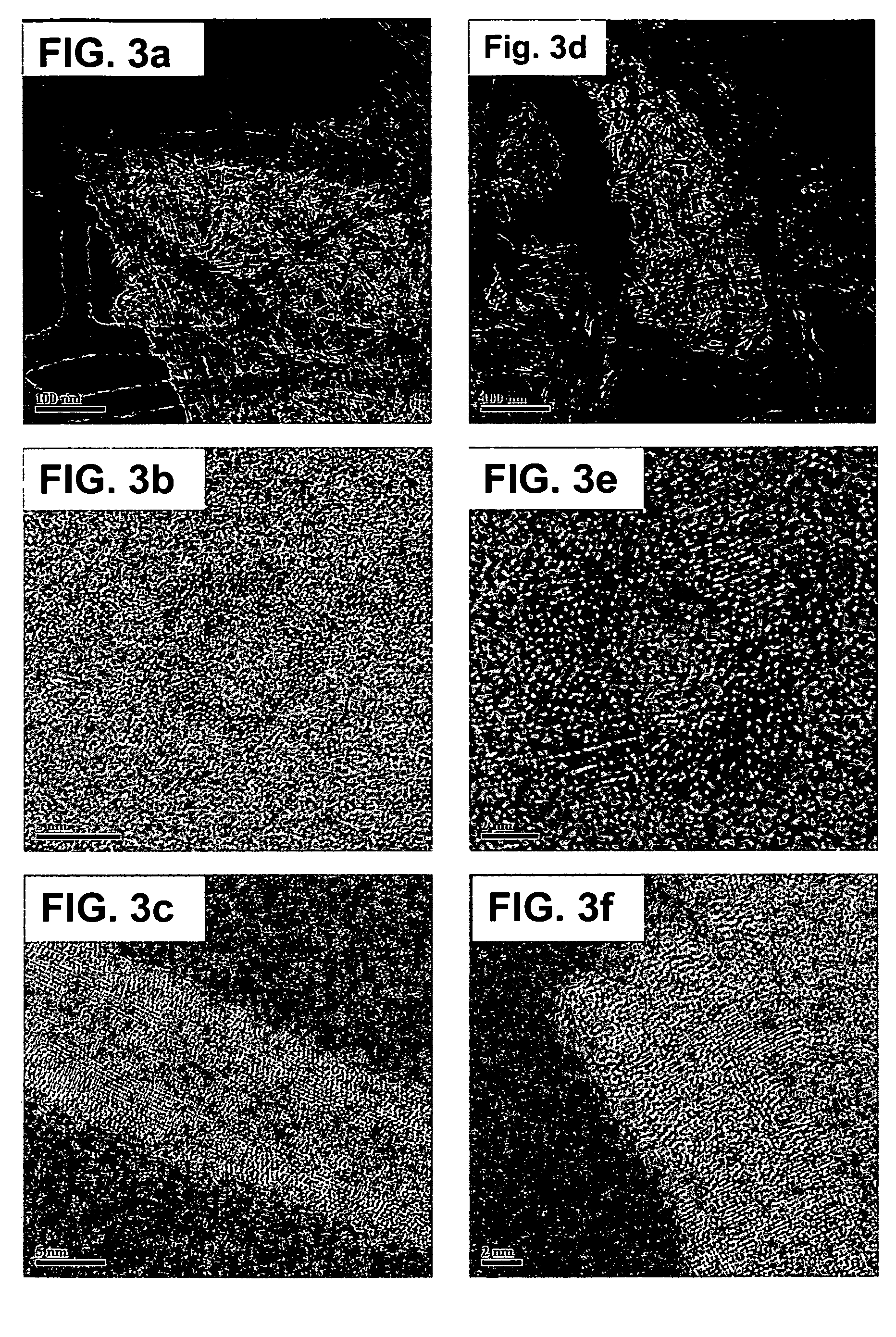

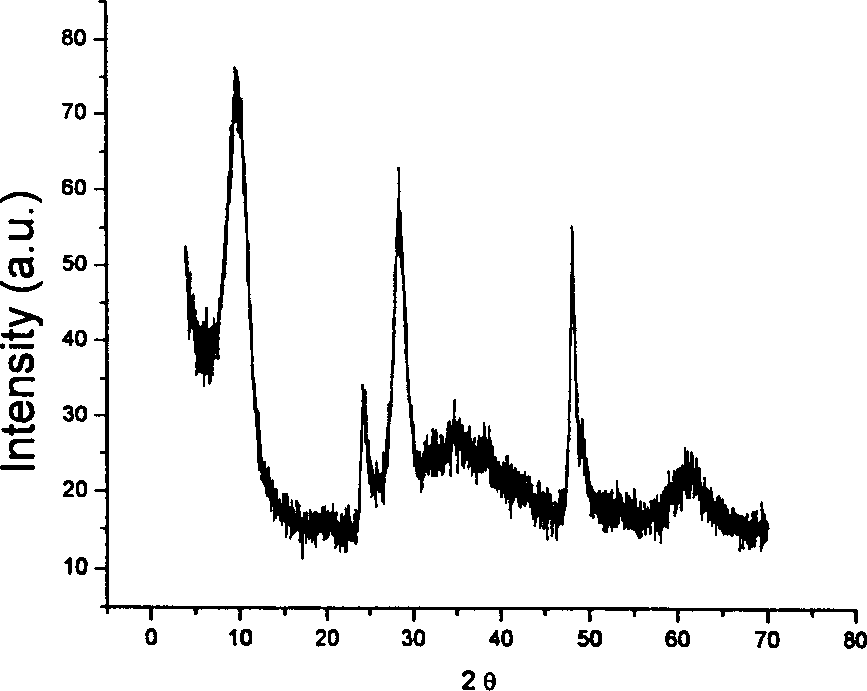

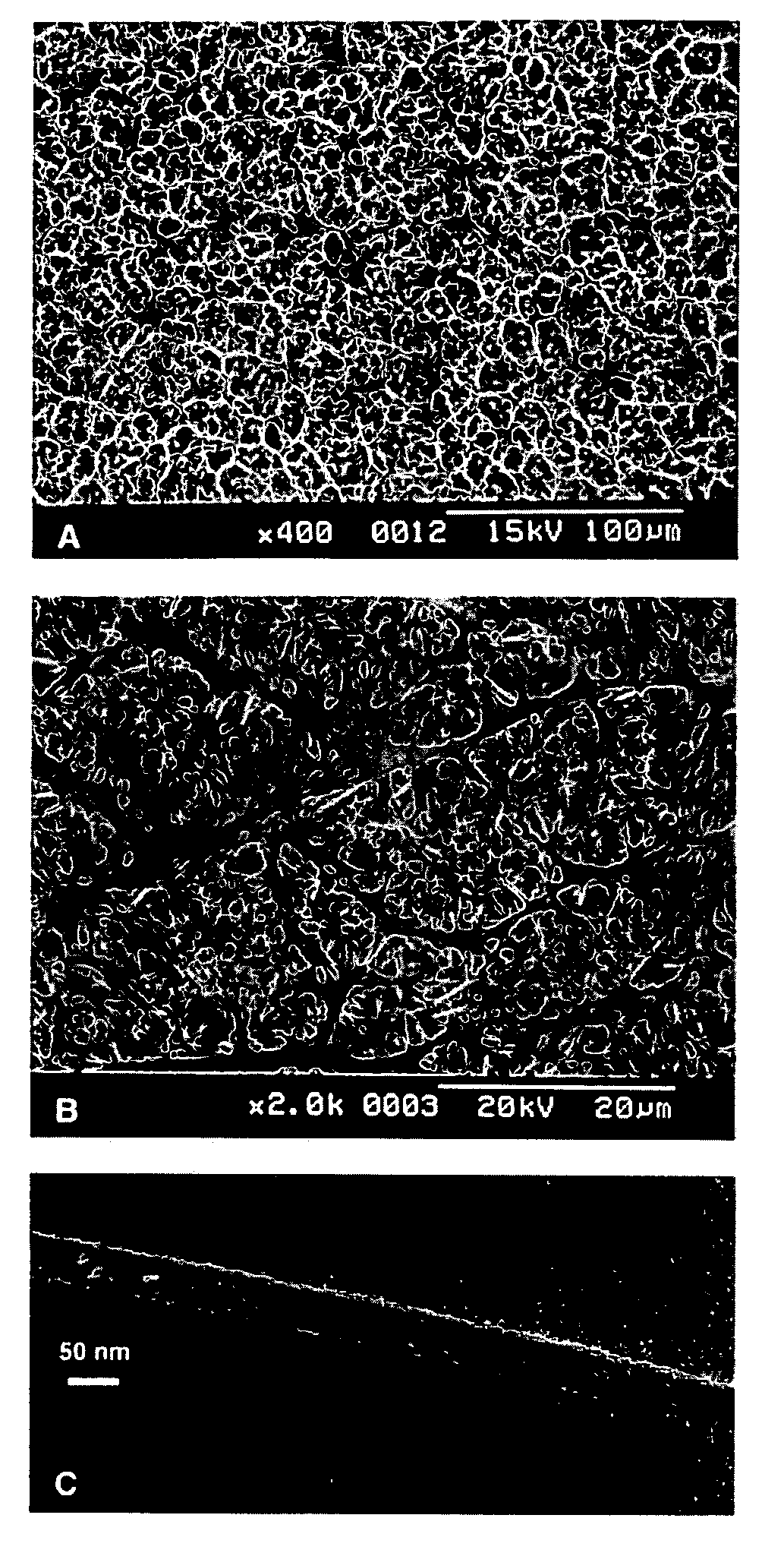

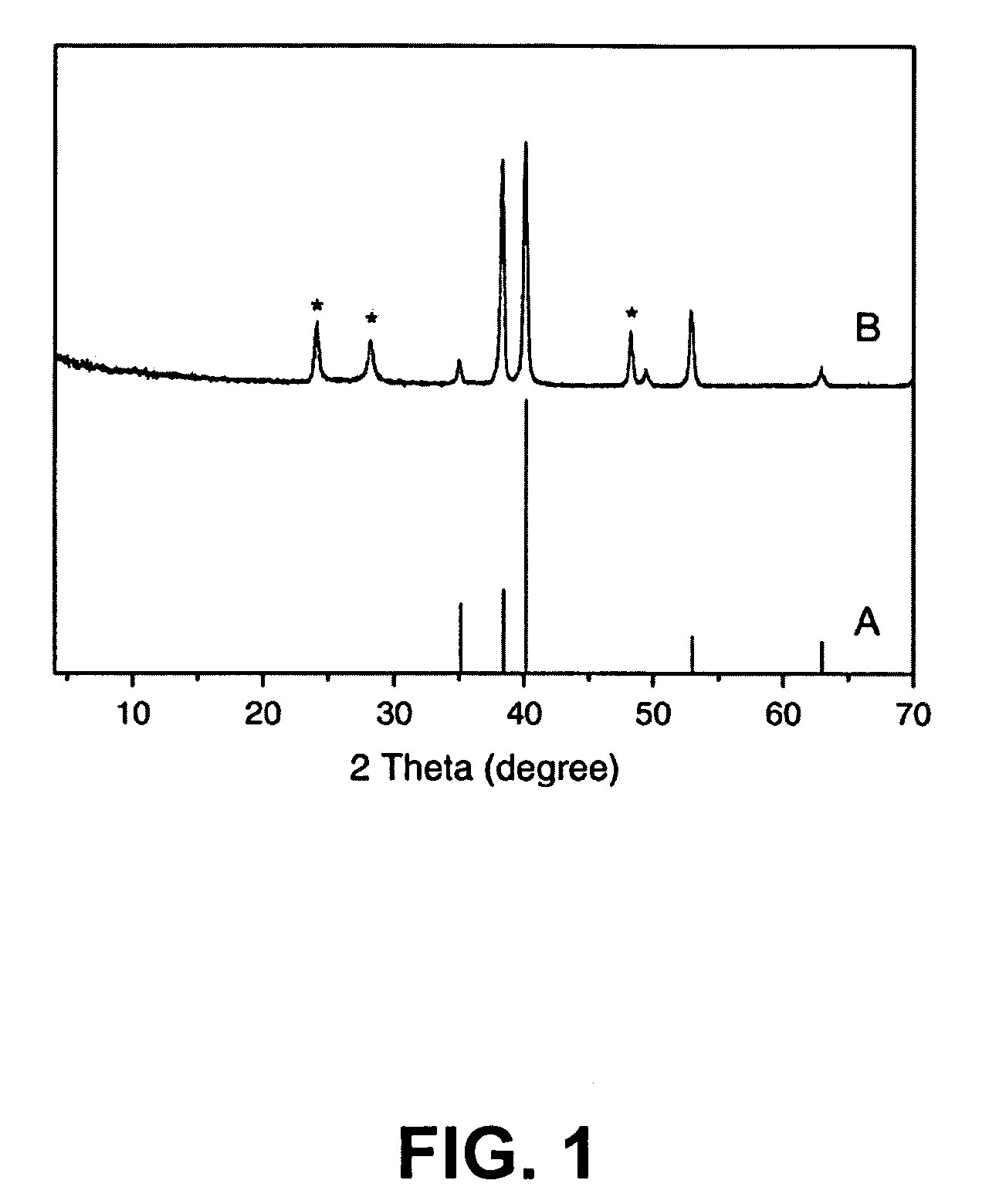

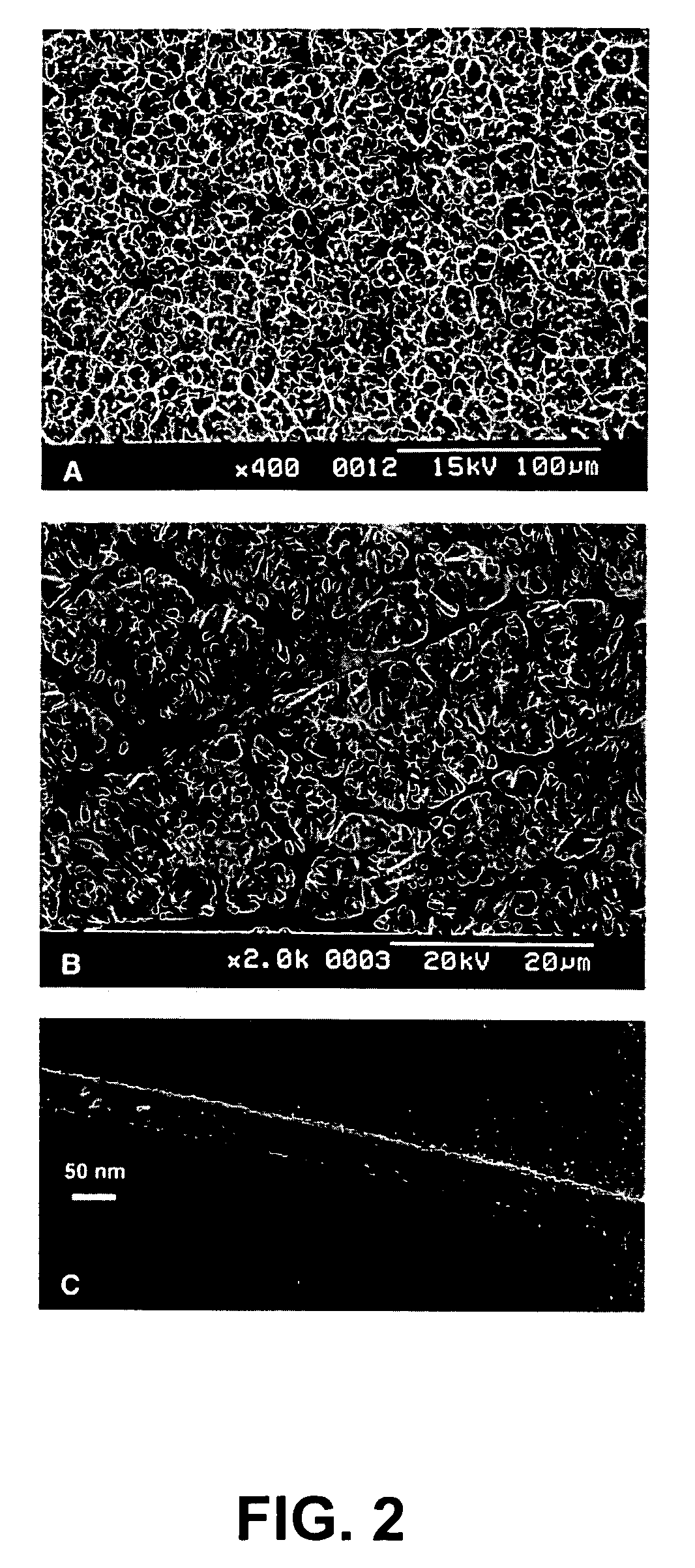

Nanostructured titanium oxide material and its synthesis procedure

ActiveUS20060078726A1Stable nanotubular structureLarge specific surface areaMaterial nanotechnologyLayered productsFiberNanowire

Nanomaterials of the JT phase of the titanium oxide TiO2-x, where 0≦x≦1 having as a building block a crystalline structure with an orthorhombic symmetry and described by at least one of the space groups 59 Pmmn, 63 Amma, 71 Immm or 63 Bmmb. These nanomaterials are in the form of nanofibers, nanowires, nanorods, nanoscrolls and / or nanotubes. The nanomaterials are obtained from a hydrogen titanate and / or a mixed sodium and hydrogen titanate precursor compound that is isostructural to the JT crystalline structure. The titanates are the hydrogenated, the protonated, the hydrated and / or the alkalinized phases of the JT crystalline phase that are obtained from titanium compounds such as titanium oxide with an anatase crystalline structure, amorphous titanium oxide, and titanium oxide with a rutile crystalline structure, and / or directly from the rutile mineral and / or from ilmenite. The titanates are submitted to dynamic thermal treatment in an inert, oxidizing or reducing atmosphere to produce the JT phase of the TiO2-x, where 0≦x≦1 with an orthorhombic structure.

Owner:INST MEXICANO DEL GASOLINEEO

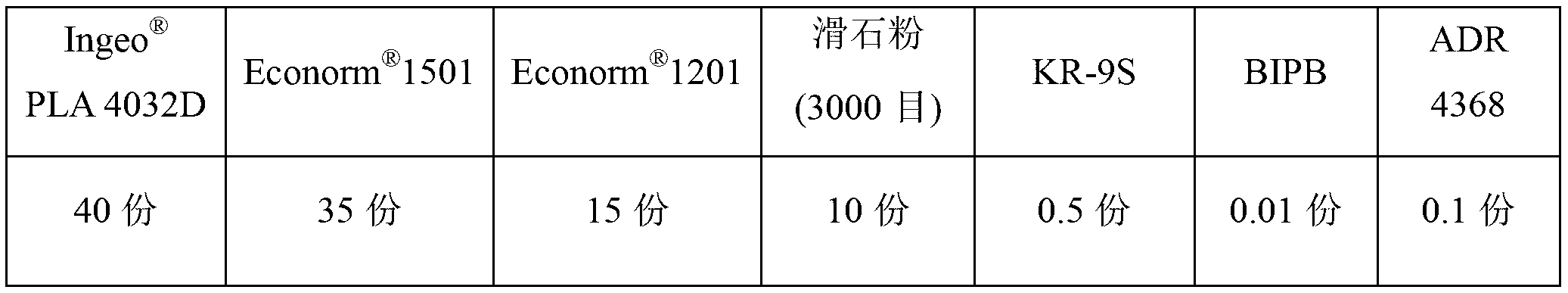

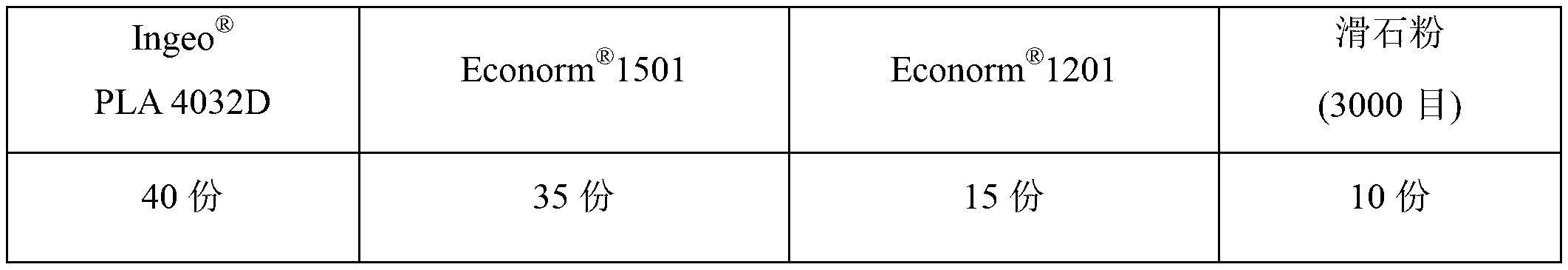

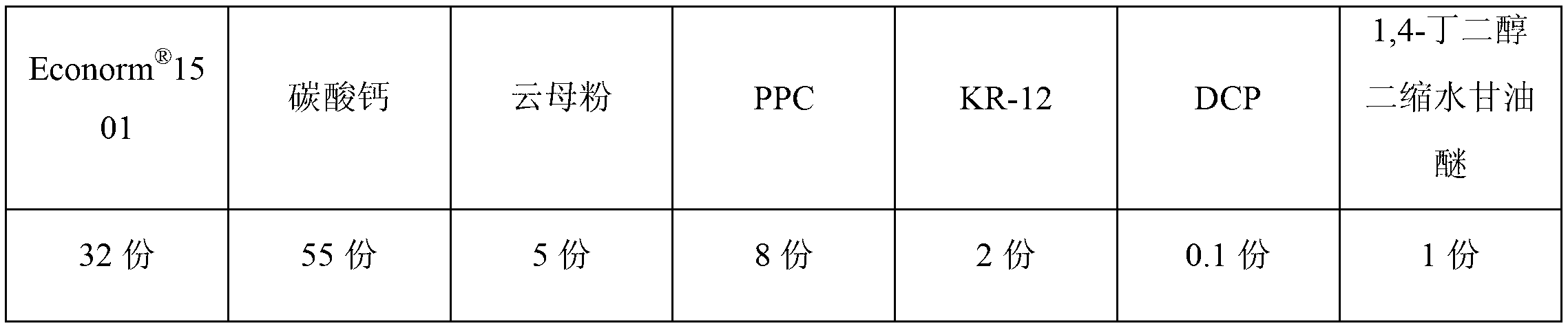

Method for increasing capacity of biodegradable polyester blend film

The invention relates to a biodegradable polyester blend film, and in particular relates to a method for increasing the capacity of a biodegradable polyester blend film. The method for increasing the capacity of the biodegradable polyester blend film comprises the steps of: adding a high-activity titanate coupling agent, a free radical cross-linking agent and a multi-epoxy group compound into a blending compound system of two or more than two biodegradable polyesters and an inorganic or organic filler; initiating and promoting transesterification, proper intermolecular cross-linking reaction and end-group chain extension in a double-screw extruder with the length-diameter ratio of more than or equal to 48 and the total kneading blocks of more than or equal to 16 under the action of high temperature and high shear strength, thus increasing the capacity of blending polyester. Through utilizing the double-screw extruder with the high length-diameter ratio and high shear strength and introducing the titanate coupling agent, the free radical cross-linking agent and the multi-epoxy group compound are introduced, on-line capacity increasing of a biodegradable polyester / filler blend compound system is carried out, so that the anisotropy of the mechanical property of the film is greatly improved.

Owner:山东悦泰生物新材料有限公司

Process for preparing hydrated sodium titanate and nano titanate tube series

InactiveCN1378977AWith ion exchangeLarge specific surface areaTitanium compoundsSodium titanateThermal stability

A process for preparing the nanometre tubes of hydrated sodium titanate and titanate series includes such steps as hydrothermal reaction of TiO2 or metatitanic acid to obtain the nanometre tubes of hydrated sodium titanate, mixing them with the solution containing one or two kinds of metal ions to convert them to the nanometre tubes of hydrated titanate or composite hydrated titanates of the saidmetal ions, and thermal dewatering to obtain the nanometre tubes of corresponding titanate or composite titanates. Its advantages are uniform shape, large specific surface area, high thermal stability and regulatable catalytic performance.

Owner:TSINGHUA UNIV

Aluminum titanate batch compositions and method

ActiveUS8974724B2Reduce amountReduce the amount requiredInternal combustion piston enginesExhaust apparatusTitanateAluminium

Aluminum titanate precursor batch compositions comprising a recycled aluminum titanate component, at least a portion of the recycled aluminum titanate component being comprised of a recycled pre-reacted aluminum titanate composition or alternatively of an un-reacted green aluminum titanate precursor composition, and methods for producing aluminum titanate ceramic articles utilizing the inventive batch compositions.

Owner:CORNING INC

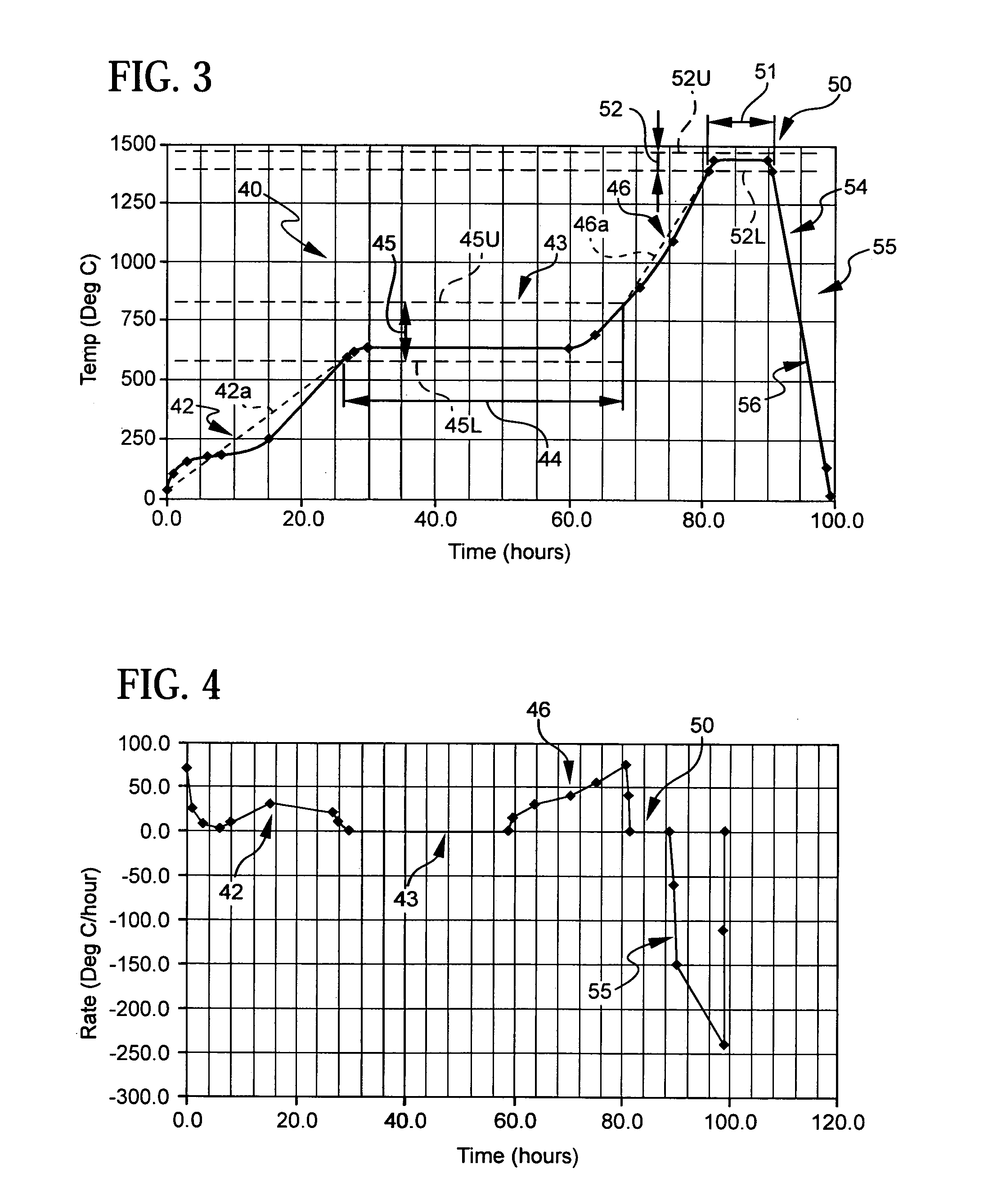

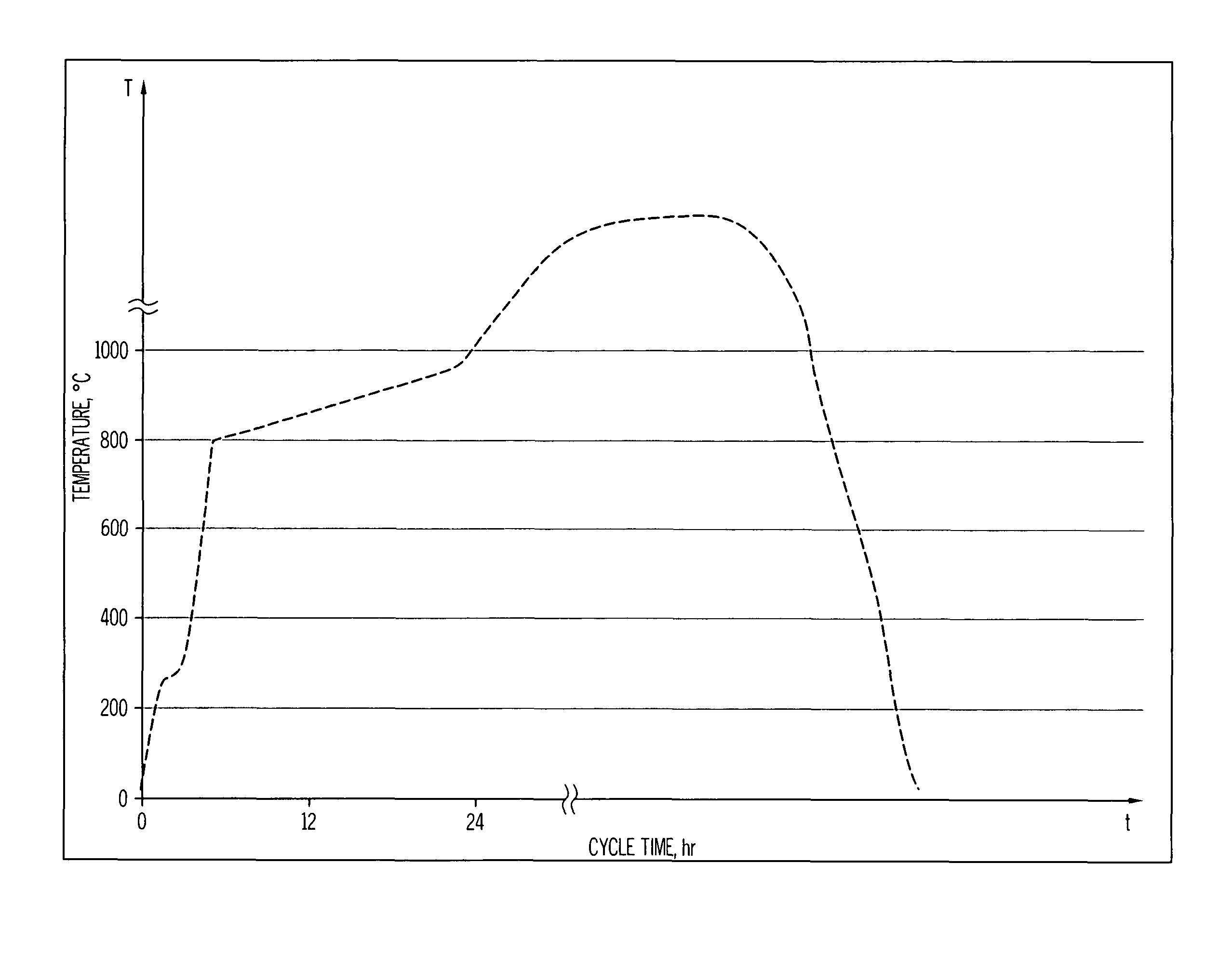

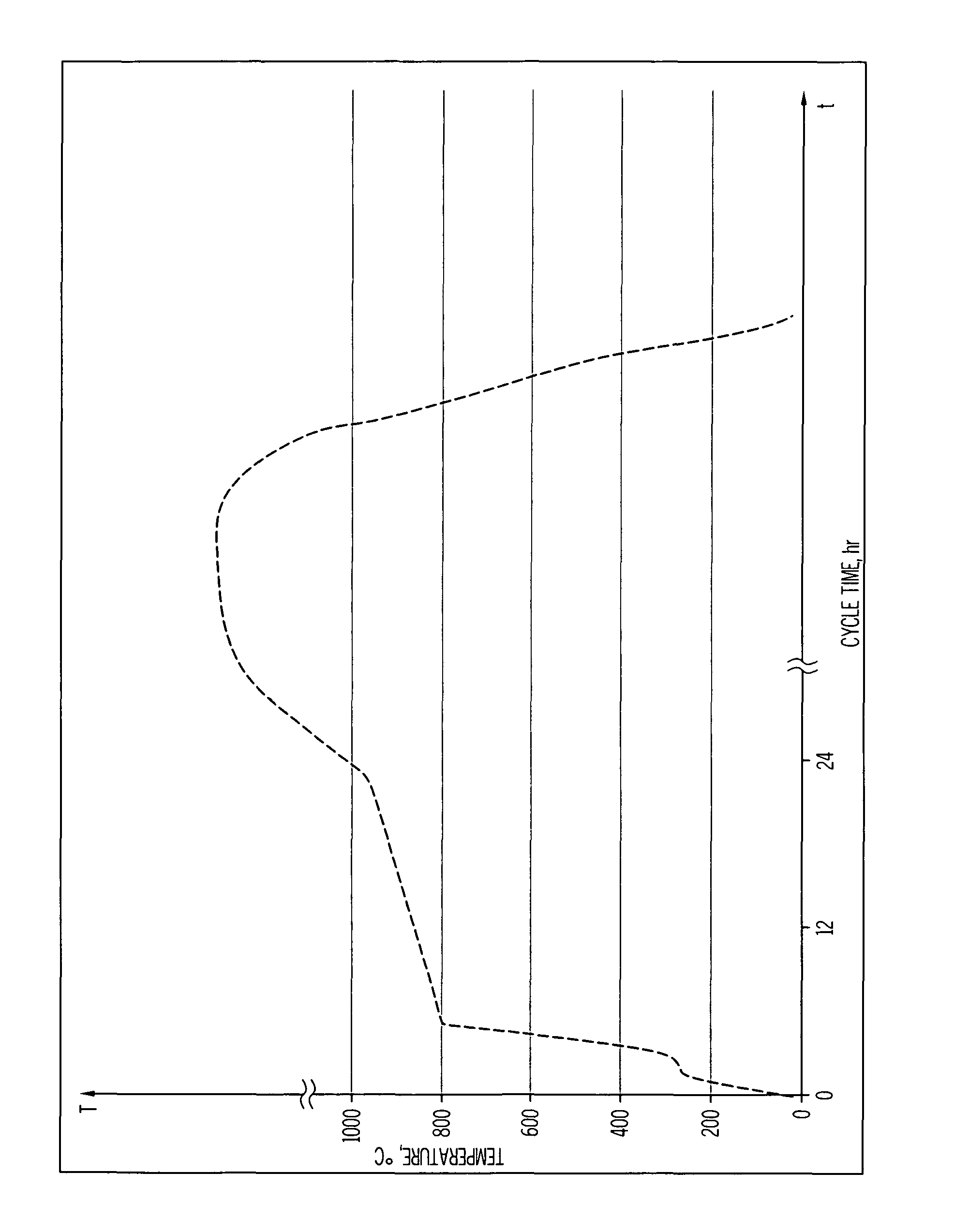

Fast firing method for high porosity ceramics

A method for firing a green honeycomb ceramic body including heating the green honeycomb ceramic body from room temperature to a first temperature of less than or equal to about 350° C. with at least one heating rate of greater than or equal to about 80° C. / hr. The green honeycomb ceramic body may be heated from the first temperature to a second temperature of greater than or equal to about 800° C. at a heating rate of greater than or equal to about 90° C. / hr. The green honeycomb ceramic body may be heated from the second temperature to a third temperature of greater than or equal to about 1000° C. The green honeycomb ceramic body may include aluminum raw materials for forming an aluminum titanate ceramic body.

Owner:CORNING INC

Titanate nanowire, titanate nanowire scaffold, and processes of making same

InactiveUS20080318044A1Synthetic resin layered productsCellulosic plastic layered productsNanowireNanoparticle

In one aspect, the present invention relates to a synthetic nanostructure. In one embodiment, the synthetic nanostructure has a top region substantially comprising titanate nanowires, a middle region substantially comprising titanate nanoparticles and titanate nanowires, and a bottom region substantially comprising titanium, wherein some of the titanate nanowires of the top region are extending into the middle region, wherein the middle region is between the top region and the bottom region, and wherein some of the titanate nanowires of the top region are substantially perpendicular to the bottom surface of the titanium substrate. At least some of the titanate nanowires in the top region form 3D macroporous scaffolds with interconnected macropores.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

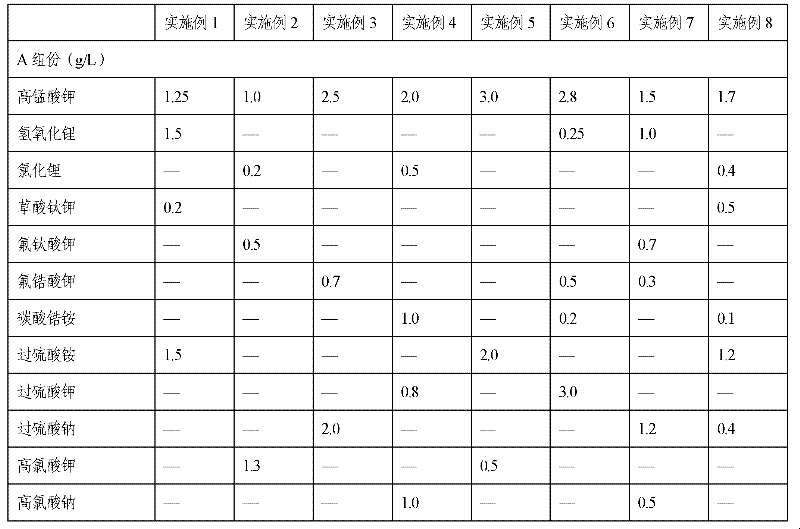

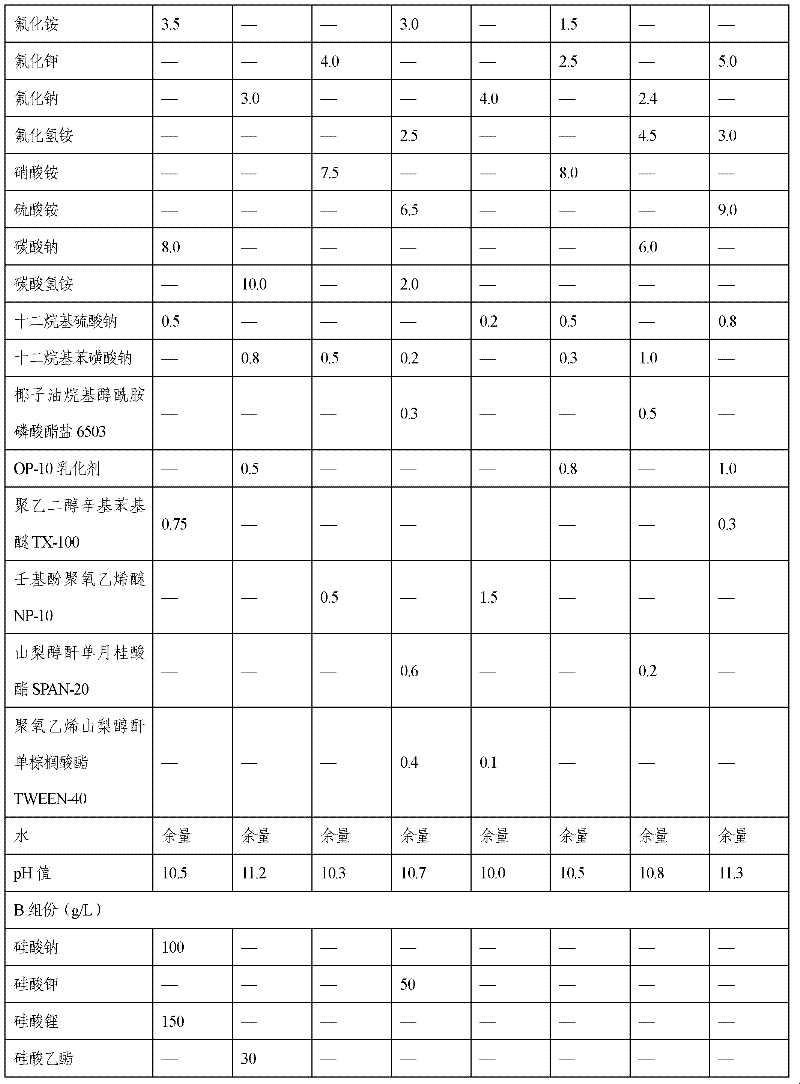

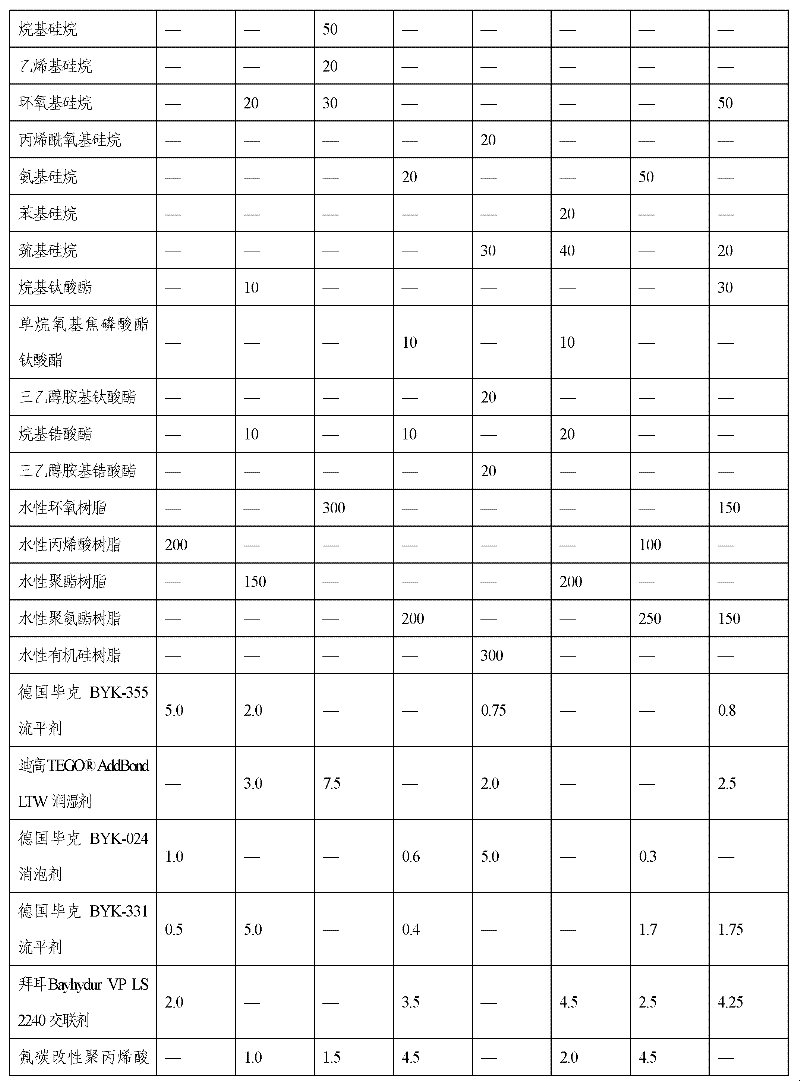

Corrosion-contamination resistant chemical conversion agent and method for preparing chromium-free chemical conversion film

InactiveCN102409332AAccelerated corrosionImprove stain resistanceMetallic material coating processesChromium freePhosphate

The invention relates to the field of aluminum alloy decoration and protection coating for ships, in particular relates to an environmentally-friendly corrosion-contamination resistant chemical conversion agent and application thereof in a chromium-free chemical conversion film, and solves the problems of poor corrosion resistance, high cost, difficulty in large-area construction and the like in the prior art. The chemical conversion agent comprises a component A and a component B. The method for preparing a chemical conversion film comprises the following steps of: forming a first inorganic chemical conversion film layer by the component A and forming an organic contamination resistant closed film by the component B. The component A is a water solution prepared from a main salt, a film-forming accelerator, a buffering agent, a surfactant and the like, and the component B is prepared from silicate, silane, a silica sol, titanate, zirconate, waterborne resins and the like. The chemicalconversion agent does not contain chromium ions and phosphates, and the chromium-free chemical conversion film prepared from the chemical conversion agent has excellent corrosion resistance and contamination resistance, can be used for construction of large-area aluminum alloy sections, and can be used as surface decoration and protection coatings for 5xxx and 6xxx series aluminum alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

InactiveCN1699488AHigh refractive indexHigh transparencyCoatingsOptical elementsComposite filmRefractive index

Owner:JILIN UNIV

Preparation method and application method of titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material

ActiveCN106238100AShape is easy to controlImprove adsorption capacityWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationWater baths

The invention relates to a preparation method and application method of a titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material, belongs to the field of titanium dioxide photocatalysis, and especially relates to the field of titanium dioxide nanosheet supported porous metal organic skeleton (MOFs) composite materials. The preparation method comprises the following steps: 1, uniformly stirring tetrabutyl titanate and hydrofluoric acid at normal temperature, putting the obtained mixture in a hydrothermal reaction kettle, carrying out a reaction, separating the obtained material, washing the separated material, and drying the washed material to obtain titanium dioxide nanosheets; and 2, uniformly dispersing the titanium dioxide nanosheets in an anhydrous ethanol solution of iron trichloride, carrying out magnetic stirring at normal temperature for 15 min, carrying out suction filtration separation to obtain a product, dispersing the product in an anhydrous ethanol solution of trimesic acid, carrying out a 50-80 DEG C water bath reaction for 20-50 min, carrying out suction filtration separation to obtain a product, and repeating above processes in step 2 2-50 times to obtain the titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material. The catalyst prepared through the method is especially suitable for catalytic degradation of high-concentration organic dyes (such as methylene blue) under visible light irritation) to reach a very high degradation rate.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com