Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

968 results about "Chromium free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Passivating solution and surface treatment method for galvanized material

InactiveCN101608306AImprove corrosion resistanceMeet the requirements of the RoHS directiveMetallic material coating processesChromium freeAlcohol

The invention relates to a passivating solution which is aqueous solution containing water-soluble molybdic compound, boric acid, water-soluble organic matter and silica sol, wherein the water-soluble organic matter is a mixture of alcohol and organic carboxylic acid. The invention also provides a surface treatment method for a galvanized material, which comprises the following step: enabling the passivating solution to be in contact with a galvanized material. A galvanized layer can be passivated by the contact between the passivating solution and the galvanized material so as to enable the galvanized material to have excellent corrosion resistance. In addition, the paint composition is chromium free and meets the requirements of a RoHS instruction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

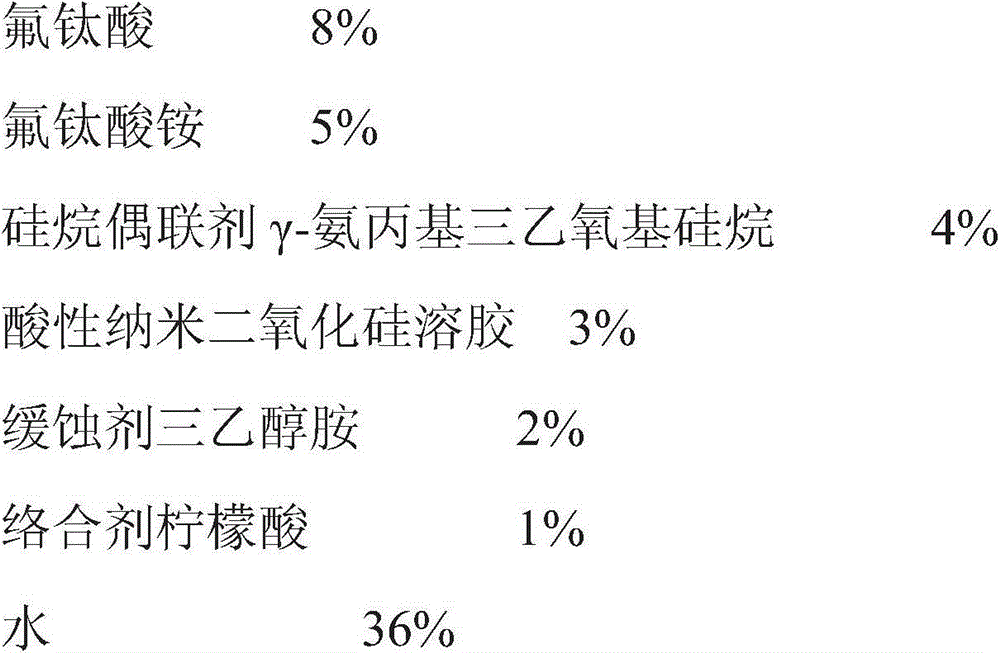

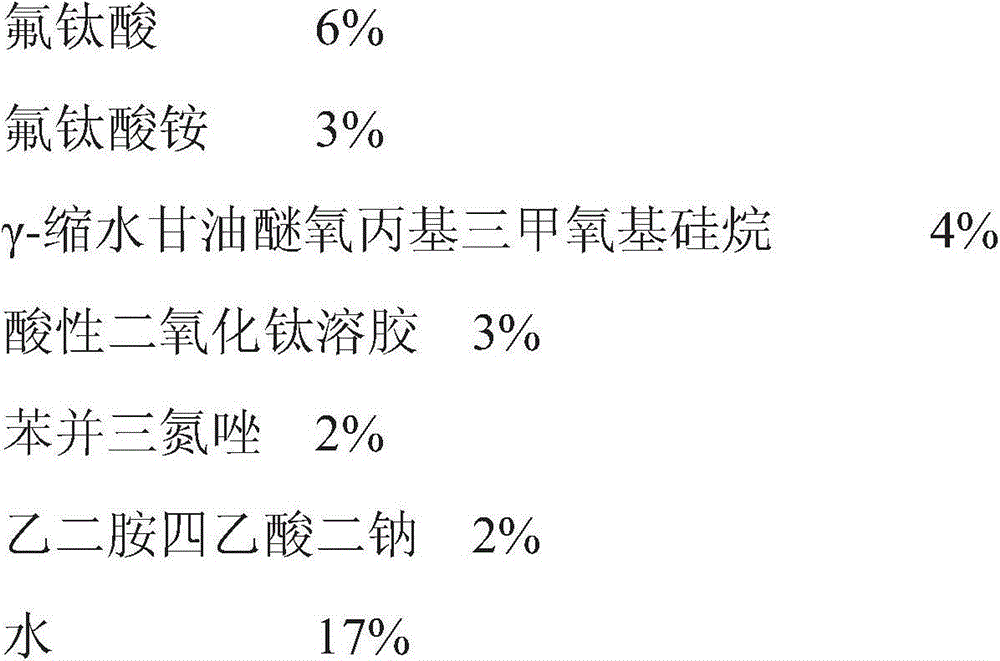

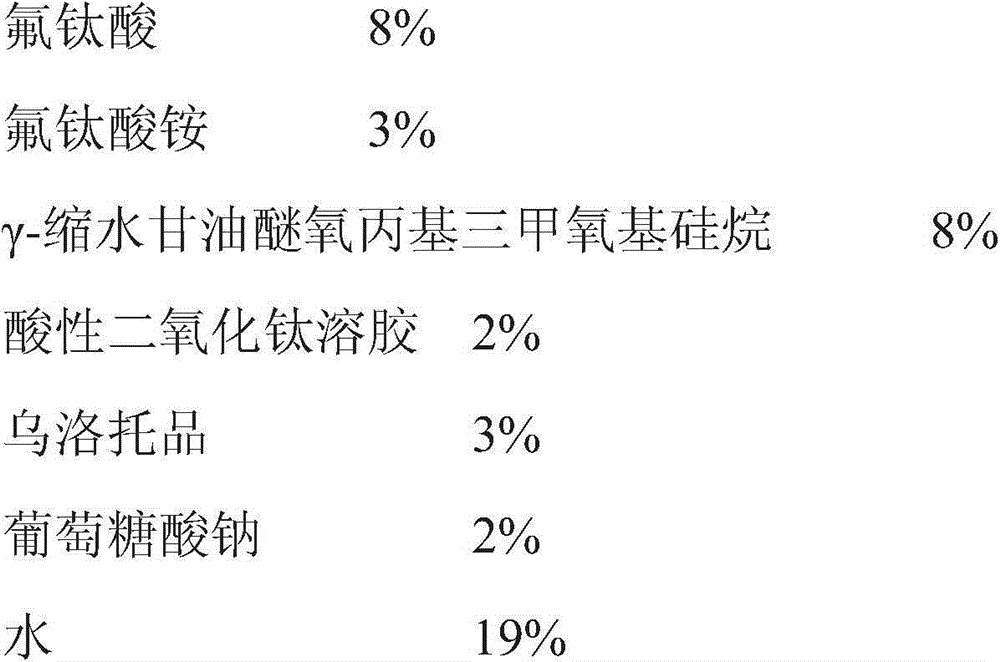

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Chromium-free passivation liquid for galvanized sheet and manufacture method thereof

InactiveCN101250699AImprove bindingImprove corrosion resistanceMetallic material coating processesChromium freeSealant

The invention in particular relates to passivation solution without chrome which is used for galvanized sheets and a method thereof. The technical scheme thereof comprises: firstly, dissolving inorganic salt corrosion inhibitor, then, adding the inorganic salt corrosion inhibitor into a stirred tank, adding dispersant, organic acid, sealant, silicone-acrylate emulsion and water while stirring, then, using inorganic acid or alkali to regulate the pH value to be 2.0-5.0, and then stirring for 1-2 hours under the condition that the temperature is 20-30 DEG C, the content of the components of each liter is: the inorganic salt corrosion inhibitor 10-55g, additive 4-10g, the organic acid 5-20g, the sealant 5-30g, the silicone-acrylate emulsion 150-300g, and the rest is the water. The method of the invention can additionally form a layer of organic resin separate layer on the basis of forming an inorganic metal compound precipitation film, additionally, since the silicon compound is added, not only the binding force between a passivation layer and zinc coating can be increased, but also the corrosion resistance, the scrubbing resistance and the wear resistance of the passivation layer can be increased, and the coating treatment after passivation can not be affected.

Owner:WUHAN UNIV OF SCI & TECH

Chromium-free pickle for plastic surfaces

ActiveUS20110140035A1Decorative surface effectsLiquid/solution decomposition chemical coatingChromium freeAlkali ions

A pickling solution for the surface pre-treatment of plastic surfaces in preparation for metallization, the solution comprising a source of Mn(VII) ions; and an inorganic acid; wherein the pickling solution is substantially free of chromium (VI) ions, alkali ions, and alkaline-earth ions.

Owner:MACDERMID ENTHONE INC

Chromium-free environment-friendly epoxy anticorrosion primer

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

A kind of aqueous chrome-free dacromet coating solution and preparation method thereof

ActiveCN102277022ANo pollution in the processWon't happenAnti-corrosive paintsChromium freeWater based

The invention discloses water-based chrome-free Dacromet coating solution. The coating solution is environment-friendly, is free of environmental pollution and simultaneously has good corrosion and weather resistance. The coating solution comprises components A, components B, a component C and components D, wherein the components A include 18-24% of zinc powder, 2-5% of aluminium powder, 28-34% of wetting and dispersing agent, 1-3% of passivator, 1-3% of corrosion inhibitor and water by mass; the components B include 5-12% of film-forming agent, 0.1-0.5% of forming auxiliaries and water by mass; the component C is 5-12% of film-forming auxiliary by mass; the components D include the balance of thickener and water; and the total mass percent of water is 18-27%.

Owner:朱承飞

Chromium-free zinc aluminum anticorrosive paint and preparation method

InactiveCN101899254AReduce microcracksImprove adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeOrganic solvent

The invention relates to a chromium-free zinc aluminum anticorrosive paint and a preparation method. The invention adopts the technical scheme that the preparation method comprises the following steps of: stirring 5 to 25 weight percent of flake zinc powder and 5 to 15 weight percent of flake aluminum powder uniformly, adding 25 to 40 weight percent of organic solvent, 1.1 to 1.8 weight percent of dispersant, 3 to 8 weight percent of corrosion inhibitor and 3 to 10 weight percent of inorganic additive into the powder, and stirring the mixture for 20 to 40 minutes to form a base material; and then stirring 5 to 15 weight percent of modified resin, 1 to 3 weight percent of organic silane coupling agent and 25 to 30 weight percent of organic solvent uniformly, and adding the mixture into the base material; or stirring the mixture for 30 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint; or stirring the mixture for 30 to 50 minutes, adding 0.05 to 0.5 weight percent of hydroxyethyl cellulose into the mixture, and stirring the mixture for 20 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint. The preparation method has the characteristics of environment friendliness, low energy consumption and low cost; and a coating coated by the prepared chromium-free zinc aluminum anticorrosive paint has high impact strength, good corrosion resistance, strong bonding force and high hardness.

Owner:襄阳普士利工程器材有限公司 +1

Corrosion-contamination resistant chemical conversion agent and method for preparing chromium-free chemical conversion film

InactiveCN102409332AAccelerated corrosionImprove stain resistanceMetallic material coating processesChromium freePhosphate

The invention relates to the field of aluminum alloy decoration and protection coating for ships, in particular relates to an environmentally-friendly corrosion-contamination resistant chemical conversion agent and application thereof in a chromium-free chemical conversion film, and solves the problems of poor corrosion resistance, high cost, difficulty in large-area construction and the like in the prior art. The chemical conversion agent comprises a component A and a component B. The method for preparing a chemical conversion film comprises the following steps of: forming a first inorganic chemical conversion film layer by the component A and forming an organic contamination resistant closed film by the component B. The component A is a water solution prepared from a main salt, a film-forming accelerator, a buffering agent, a surfactant and the like, and the component B is prepared from silicate, silane, a silica sol, titanate, zirconate, waterborne resins and the like. The chemicalconversion agent does not contain chromium ions and phosphates, and the chromium-free chemical conversion film prepared from the chemical conversion agent has excellent corrosion resistance and contamination resistance, can be used for construction of large-area aluminum alloy sections, and can be used as surface decoration and protection coatings for 5xxx and 6xxx series aluminum alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Chromium-free composite passivator for hot-dip galvanized steel sheet and preparation and application methods of composite passivator

ActiveCN104178757AImprove corrosion resistanceUniform appearanceMetallic material coating processesWater basedChromium free

The invention relates to a chromium-free composite passivator for a hot-dip galvanized steel sheet. The passivator is prepared from the following raw materials in percentage by weight: 2.20-2.30% of water-base resin, 2.60-2.65% of main salt compound, 0.10-0.15% of organic silane, 0.07-0.09% of sulfate, 0.11-0.13% of inorganic zircon salt, 0.09-0.12% of inorganic acid and the balance of water. A preparation method of the passivator comprises the following steps: firstly, dissolving the organic silane in water; stirring till the organic silane is fully dissolved and adding the main salt compound; after the main salt compound is dissolved, adding the inorganic acid to measure the pH value; then, adding the sulfate and the inorganic zircon salt in the stirring state; after the sulfate and the inorganic zircon salt are fully dissolved, adding the water-base resin; stirring till the water-base resin is fully dissolved; adjusting the pH value to 3-4 by virtue of ammonium water; and standing for later use. An application method of the passivator comprises the following steps: firstly, degreasing the hot-dip galvanized steel sheet by virtue of an alkaline degreaser during use; then, respectively washing by using tap water and deionized water; and after drying, coating the composite passivator on the surface of the hot-dip galvanized steel sheet. The passivator provided by the invention is free from chromium and non-toxic and harmless. The thickness of a passivation film can reach 8-1.0mg / m<2>, and the corrosion resistance is close to that of a hexavalent chromium passivating liquid.

Owner:唐山正元管业有限公司

Chromium-free passivation liquid for treating tin-plated steel plate

InactiveCN103805977AImprove corrosion resistanceExcellent anti-vulcanization performanceAnodisationMetallic material coating processesTinningChromium free

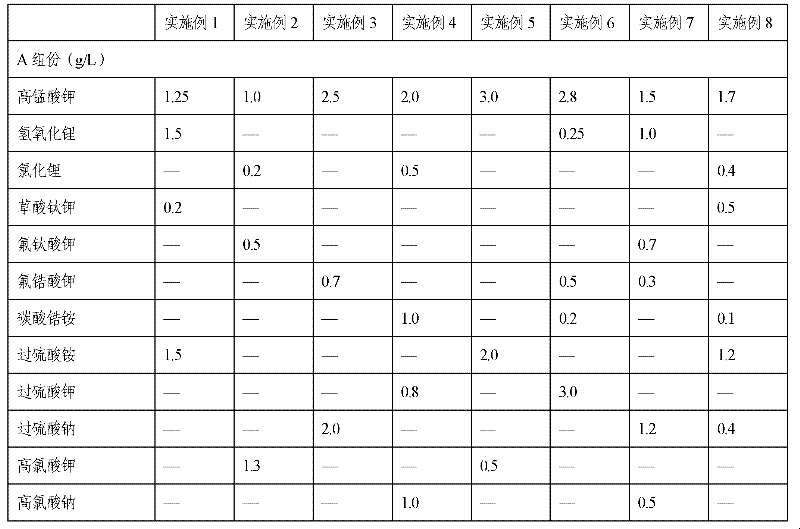

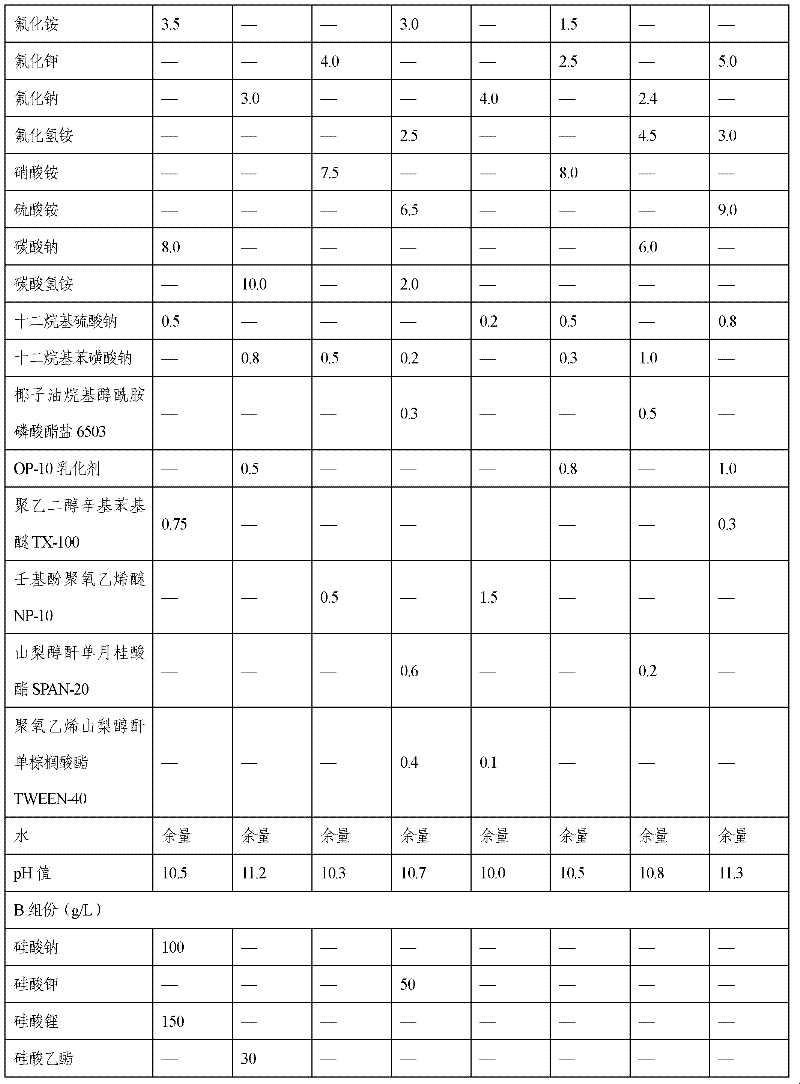

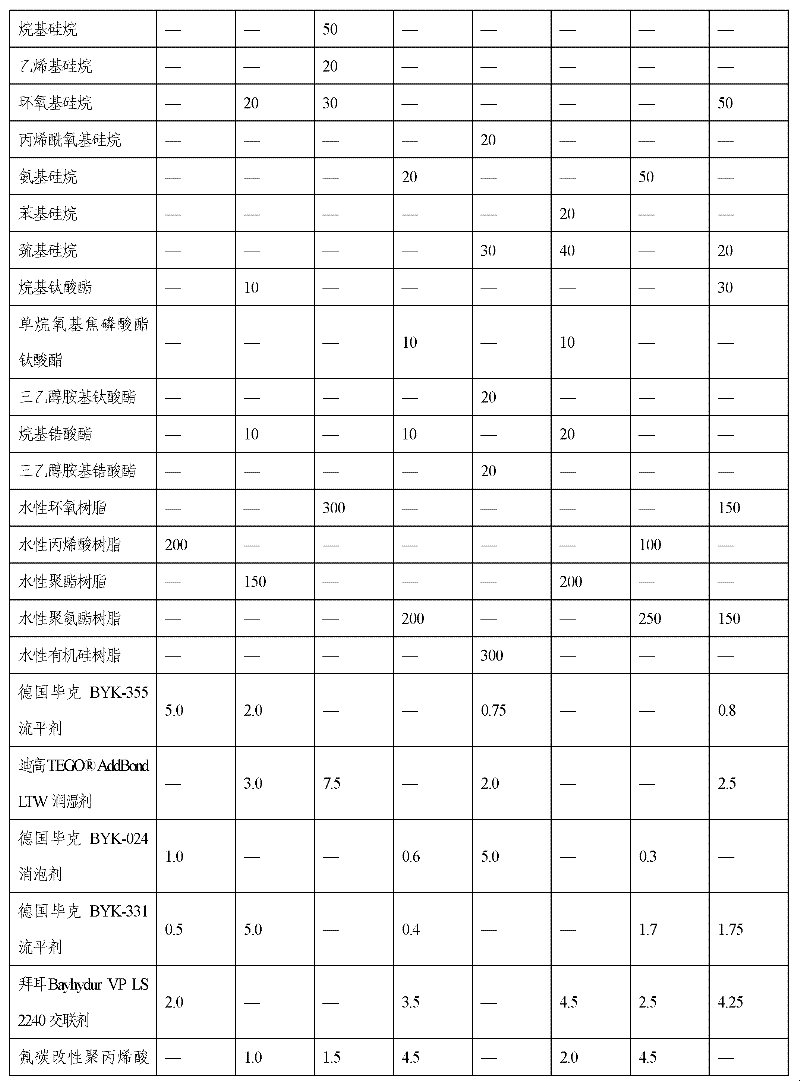

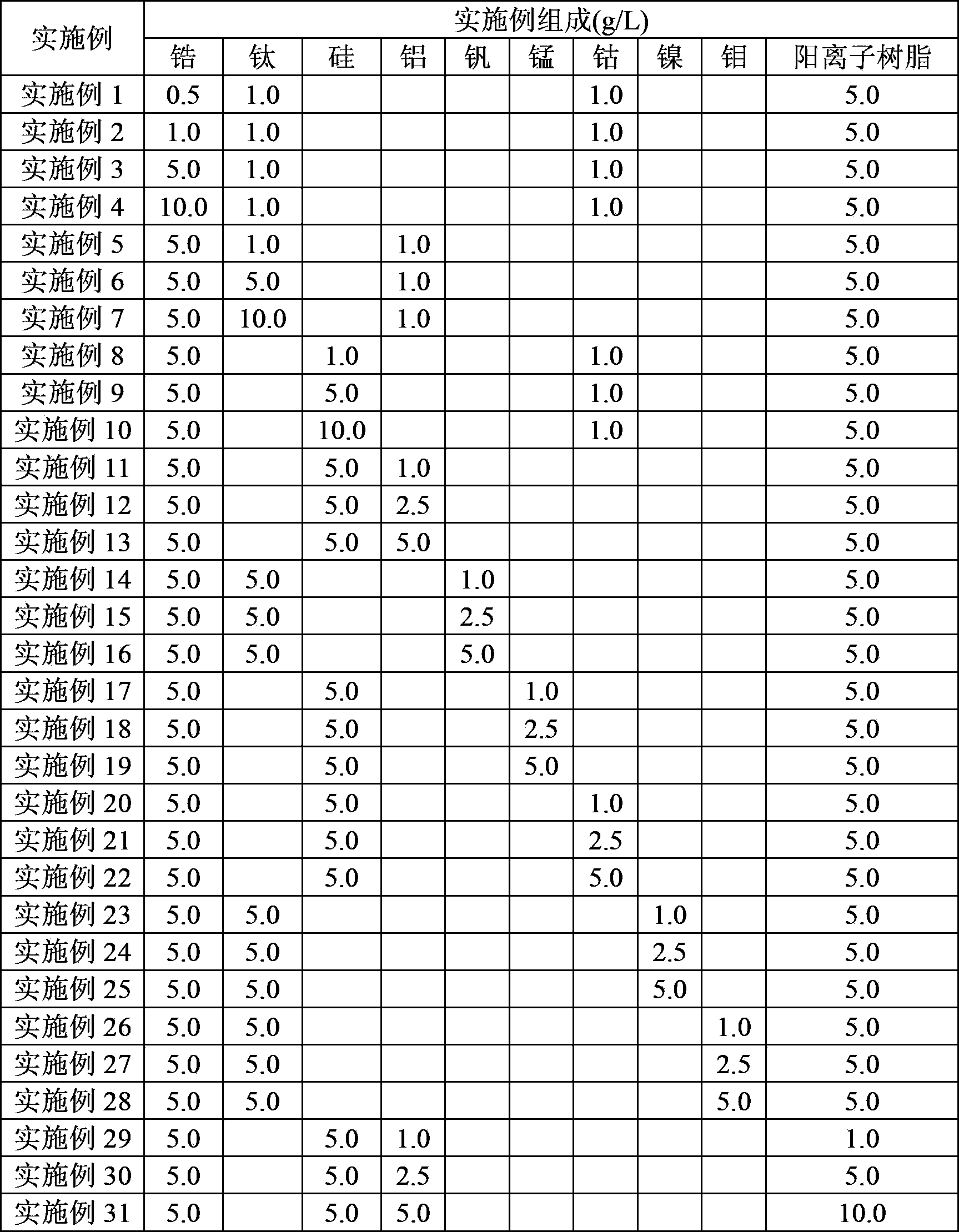

The present invention discloses a chromium-free passivation liquid for treating a tin-plated steel plate, wherein the pH value of the chromium-free passivation liquid is 3-4. The chromium-free passivation liquid comprises an inorganic compound containing at least one selected from silicon, titanium and zirconium, a metal compound containing at least one selected from aluminum, vanadium, manganese, cobalt, nickel and molybdenum, a soluble resin, an acid for adjusting the pH value of the passivation liquid to 3-4, and the balance of water and other unavoidable impurities, wherein the contents of silicon, titanium and zirconium are 0.1-20 g / L, the contents of aluminum, vanadium, manganese, cobalt, nickel and molybdenum are 0.1-20 g / L, and the soluble resin content is 0.1-20 g / L. The tin-plated steel plate treated by the chromium-free passivation liquid obtained with the technical scheme has characteristics of excellent corrosion resistance, excellent sulfurization resistance, excellent coating material adhesion and excellent processability.

Owner:上海丰野表面处理剂有限公司

Surface base-coat formulation for metal alloys

Chromium-free coating composition with anti-corrosion and anti-fingerprint properties, particularly suitable for metal alloys, especially galvanized steel, and coated articles. Composition comprises aqueous-resin emulsion, hazardous air pollutant-free co-solvent, organo-functional silane, metal chelating agent, and chromium-free corrosion inhibitor, and optionally pH adjusting agent.

Owner:LIN CHHIU TSU

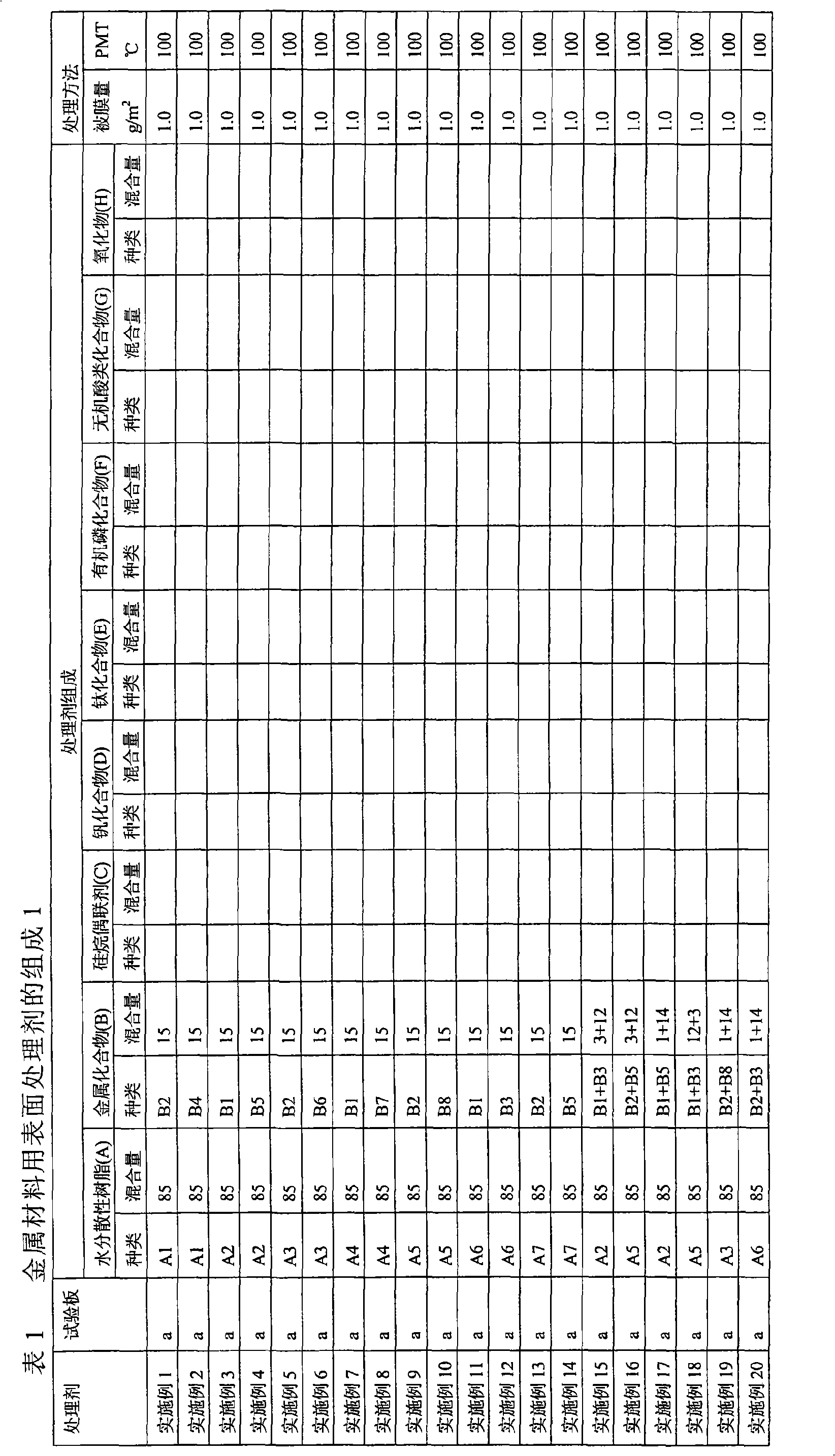

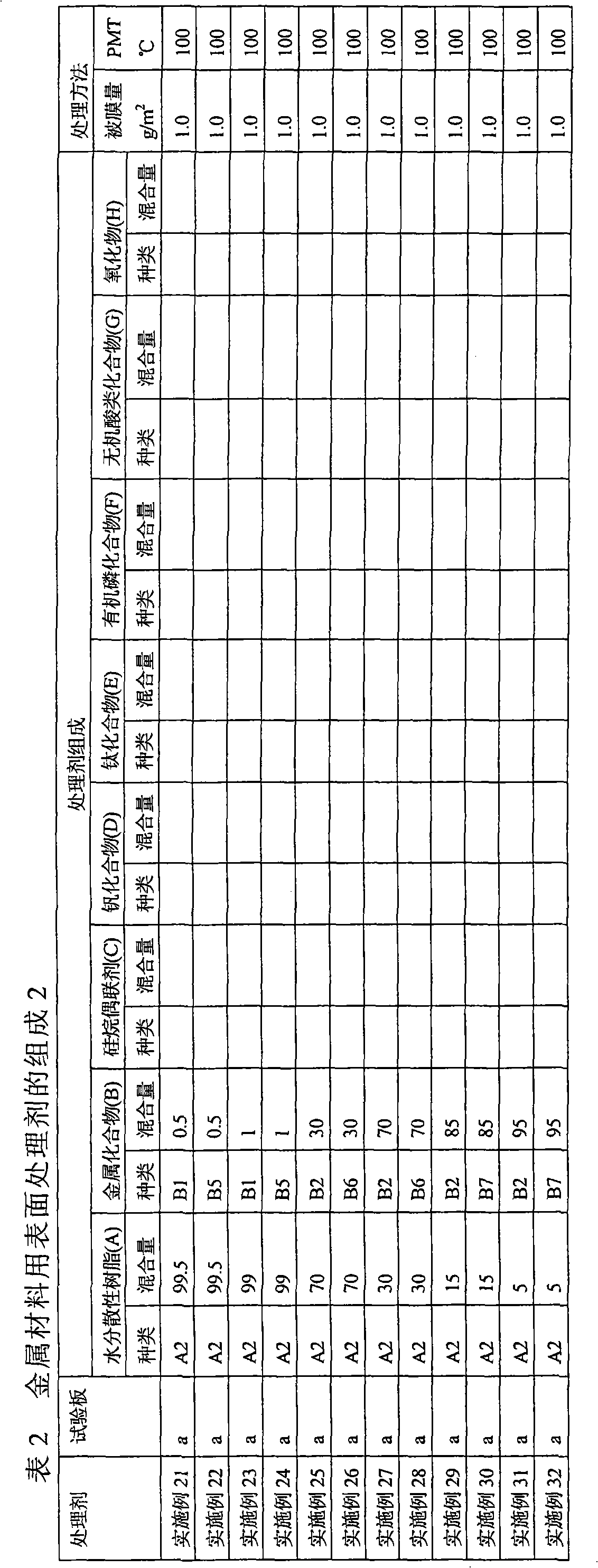

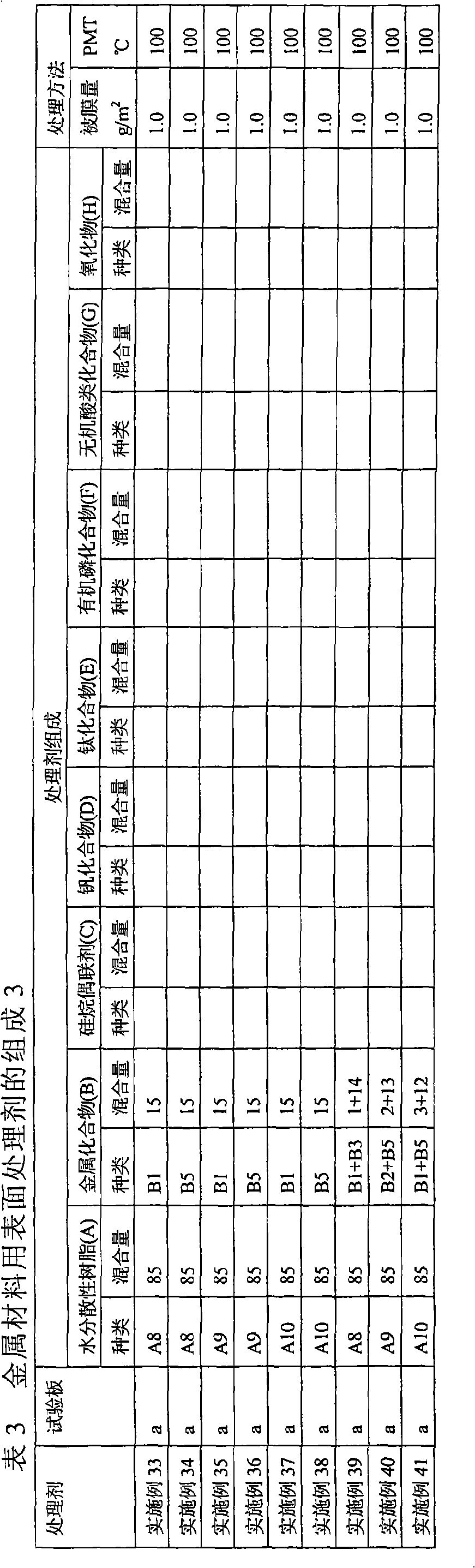

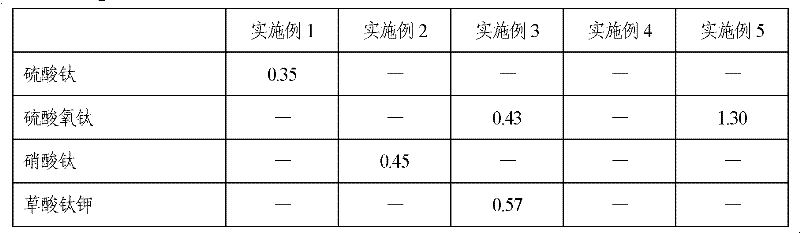

Surface treatment for metal materials, surface treatment process, and surface- treated metal materials

InactiveCN101326308AImprove use valueImprove corrosion resistanceLiquid surface applicatorsMetallic material coating processesChromium freeWater dispersible

A surface treatment for metal materials obtained by incorporating an anionic water-dispersible resin (A) having a glass transition temperature of 0 DEG C or above and at least one member (B) selected from the group consisting of alkali metal silicates and basic zirconium compounds in water, wherein the alkali metal silicates have M2O / SiO2 mass ratios of 1 / 1000 to 6 / 10 with M being at least one element selected from the group consisting of lithium, sodium and potassium; a surface treatment process; and surface-treated metal materials. The invention provides a chromium-free surface treatment for metal materials which is useful for imparting excellent corrosion resistance, chemical resistance, thermal discoloration resistance and weather resistance to metal materials. Additional incorporation of one or more members selected from among silane coupling agents, vanadium compounds, titanium compounds, organophosphonic acids, polyhydric alcohol phosphates, inorganic acids, salts thereof, metal fluorides, and metal oxides brings about further improvement in the performance of the treatment.

Owner:NIHON PARKERIZING

Graphene-modified chromium-free Dacromet coating material

ActiveCN103740152AHigh hardnessImprove corrosion resistanceAnti-corrosive paintsChromium freeFilm-forming agent

The present invention discloses a graphene-modified chromium-free Dacromet coating material, which comprises, by weight, 10-20% of zinc powder, 2-10% of aluminum powder, 2-20% of a film forming agent, 40-60.8% of a solvent, 0.1-5% of an auxiliary agent, 0.001-20% of graphene, and 0.1-5% of a filler. According to the present invention, compared with the traditional Dacromet coating, the graphene-modified chromium-free Dacromet coating material of the present invention provides substantially-increased hardness and substantially-increased adhesion, wherein the hardness of the coating of the present invention can be 7H so as to make the coating have good wear performance; the energy consumption is reduced, the conductivity of the coating is increased, and the corrosion resistance of the chromium-free Dacromet coating material is further increased; and the used raw materials do not contain substances harmful for environment and human body so as to fundamentally eliminate the pollution source.

Owner:NINGBO MORSH TECH

Chromium-free, metal surface-treating composition and surface-treated metal sheet

A chromium-free composition for treating metal surface comprising (a) a hydroxyl group-containing organic resin, (b) a phosphoric acid and (c) at least one of ions and compounds of at least one metal selected from the group consisting of Cu, Co, Fe, Mn, Sn, V, Mg, Ba, Al, Ca, Sr, Nb, Y and Zn, and (d) at least one of colloids (sol) or powders of SiO2, SnO2, Fe2O3, Fe3O4, MgO, ZrO2, Al2O3 and Sb2O5; as well as a metal sheet or metal article having thereon (i) a coating film of the chromium-free composition and optionally (ii) a coating film of a coating composition comprising an organic resin and if desired a colloid (sol) or a powder.

Owner:TOYOBO CO LTD

Steel mill continuous annealing galvanized sheet chromium-free compound passivator and preparation method thereof

InactiveCN103834938AImprove corrosion resistanceExcellent coating adhesion performanceAnti-corrosive paintsMetallic material coating processesChromium freeEnvironmental resistance

The invention discloses a steel mill continuous annealing galvanized sheet chromium-free compound passivator which comprises the following raw materials in percentage by weight: 5-20 percent by weight of a main film-forming agent, 0.1-5 percent by weight of a coupling agent, 0.1-0.5 percent by weight of inorganic complex film-forming agent, 0.1-4 percent by weight of silicate, 0.1-0.4 percent of an emulsifying agent, 0.1-0.2 percent of a dispersing agent, 0.1-0.4 percent of a corrosion inhibitor, 0.1-0.3 percent of a protective colloid, 0.1-1 percent of a nanometer sealing agent, 0.1-0.4 percent of phosphate and the balance of water. The steel mill continuous annealing galvanized sheet chromium-free compound passivator disclosed by the invention is uniform in appearance, stabilizes a liquid, has an expiration date of above 90 days, is nontoxic and environment-friendly, and accords with the ROHS (Restriction Of Hazardous Substances) requirement. The steel mill continuous annealing galvanized sheet chromium-free compound passivator is simple in preparation process; a passivated film is uniform in appearance and has certain glossness. A galvanized sheet passivated by using the passivator has the advantages that the corrosion resistance is remarkably improved, the neutral salt mist SST (Sea Surface Temperature) resistant time reaches above 72 hours, the white rust area is less than 5 percent, the blackening resistance delta E is less than 5, the yellowing resistance delta E is less than 3, the alkaline resistance delta E is less than 3, the interlamination resistance R is less than 3 omega / cm, and the conductivity is less than 1 m Omega.

Owner:NORTHEASTERN UNIV

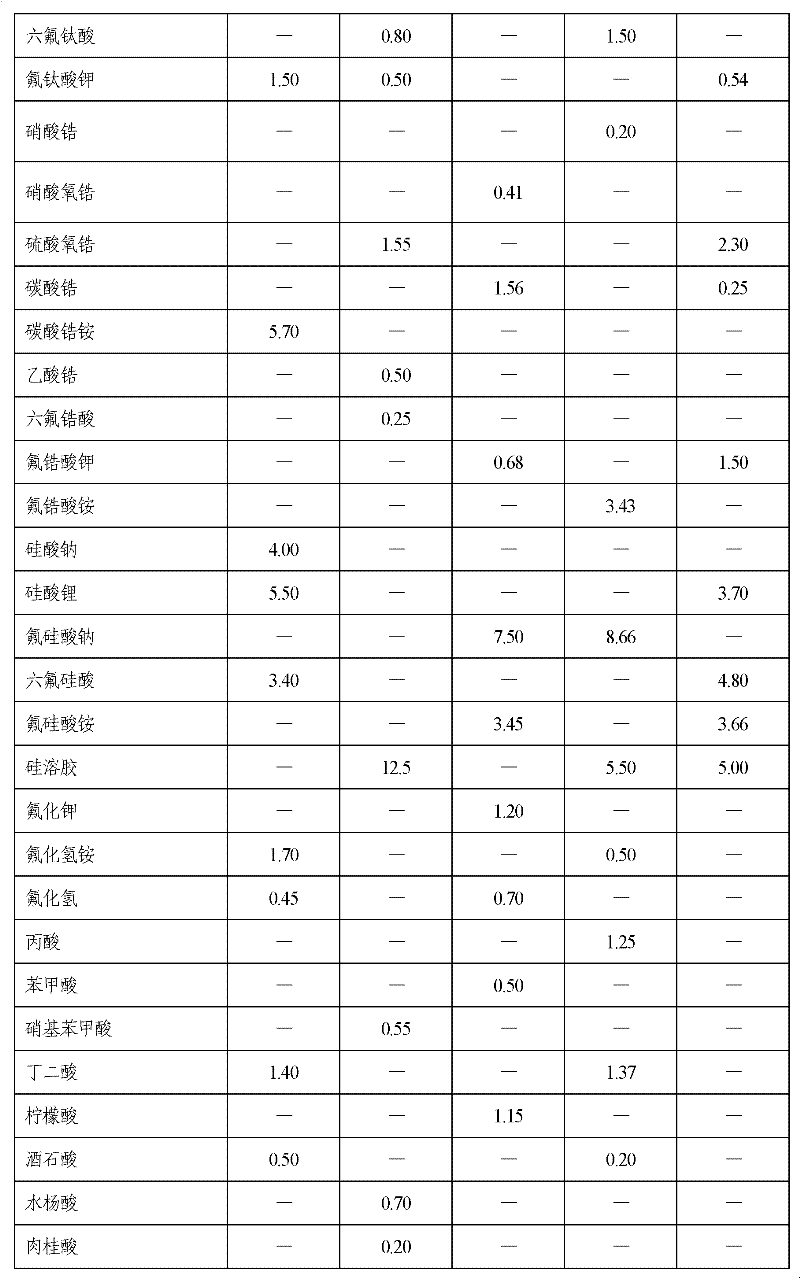

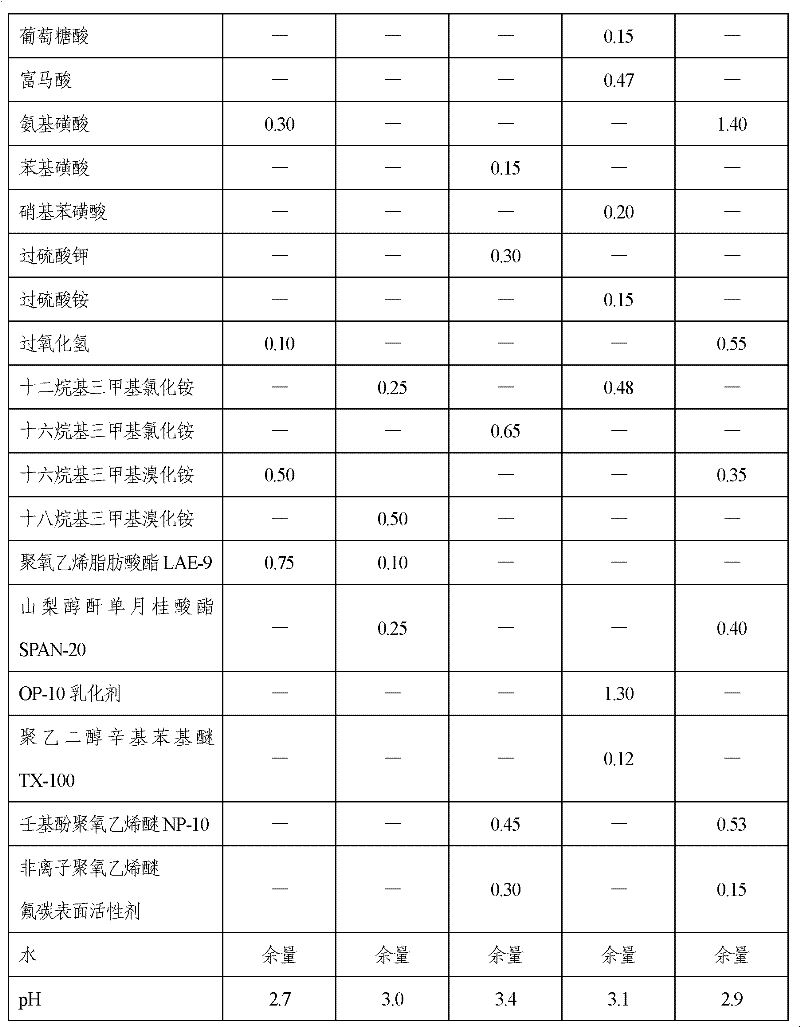

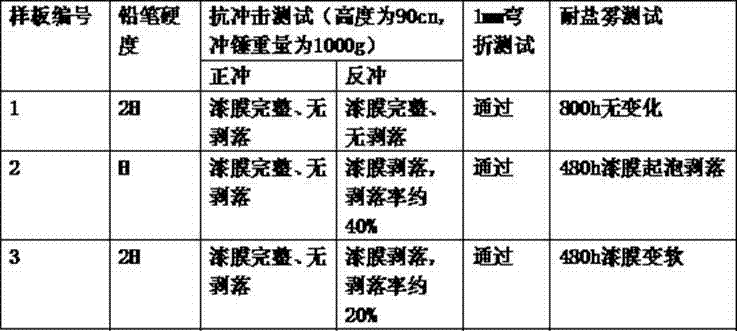

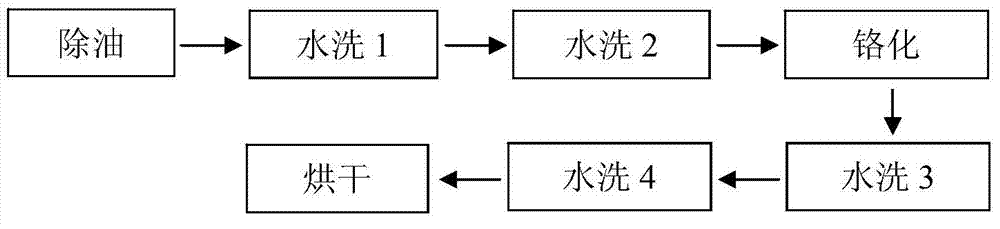

Aluminum alloy scratch resistant and fingerprint resistant chromium-free chemical conversion solution for ship and preparation method of conversion film

InactiveCN102443794AImprove corrosion resistanceImprove scratch resistanceMetallic material coating processesChromium freeTitanium

The invention relates to the field of aluminum alloy decoration and protection coatings for ships, in particular to an aluminum alloy scratch resistant and fingerprint resistant chromium-free chemical conversion solution for a ship and application of the aluminum alloy scratch resistant and fingerprint resistant chromium-free chemical conversion solution to a chemical conversion film. The chemical conversion solution contains titanium salts, zirconium salts, a silicon compound, an accelerator, a surfactant and the balance water, wherein the concentration of the titanium salts in the chromium-free chemical conversion solution ranges from 0.02 to 10g / L; the concentration of the zirconium salts in the chromium-free chemical conversion solution ranges from 0.1-10 g / L; the concentration of thesilicon compound in the chromium-free chemical conversion solution ranges from 2 to 25g / L; the concentration of the accelerator in the chromium-free chemical conversion solution ranges from 0.5-12 g / L; and the concentration of the surfactant in the chemical conversion solution ranges 0.1 to 10g / L. Chemical conversion films are formed on the surfaces of 5xxx or 6xxx series aluminum alloys by adopting an impregnating, brush coating, roller coating or spraying mode; and the chemical conversion films have favorable corrosion resistance, scratch resistance and fingerprint resistance and can be used as the surface decoration and protection coating of the aluminum alloy for the ship.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminium alloy chromium-free chemical converting liquid and its using method

The present invention relates to surface treatment of aluminum alloy, and especially a kind of chromium-free chemical aluminum alloy converting solution capable of endowing aluminum alloy surface with excellent corrosion resistance and its usage. The chromium-free chemical aluminum alloy converting solution consists of silicate, titanium salt, peroxide, fluoride, and water solution of sulfuric acid. The solution is used in 50-99 deg.c and pH 4-9 and has aluminum alloy contacting time of 2-20 min. The solution contains no hexavalent chromium and potassium ferricyanate, and has less environmental pollution, low cost, easy filming and high corrosion resistance.

Owner:郭瑞光

High temperature resistant annealing treated single-component chromium-free water-based silicon steel sheet insulating coating solution

InactiveCN101486866AGood coating appearanceGood adhesionEpoxy resin coatingsPolyester coatingsChromium freeWater based

A high-temperature annealing treatment resistant single-component chromium-free aqueous silicon steel sheet insulated masking liquid is characterized in that the main ingredients include organic resin, inorganic water dispersion liquid, curing agent and other additives. The weight ratio of the components is as follows: 100 parts of the organic resin, 100-400 parts of inorganic matter, 5-30 parts of the curing agent, 1-20 parts of additive surface active agent and the rest of water, and the solid content of the masking liquid is 30-50 percent. The masking liquid does not contain toxic organic solvent and chromate, has excellent performances of coating appearance, adhesion, salt spray resistance, insulativity and the like, and can still keep good insulativity after going through high-temperature stress annealing process. After a high-temperature annealing experiment (nitrogen atmosphere, 750 DEG C / 2h), the interface resistance retention value is more than 70 percent. The curing speed of the masking liquid is fast, the curing is thorough, and the surface of the membranous layer does not turn sticky for a long time of placement after curing. The masking liquid is in the form of single component, has convenient use and can be stored for long time.

Owner:NANJING UNIV +1

Chromium-free waterborne epoxy anticorrosion primer with excellent solvent oil resistant performance

ActiveCN102559010AImprove anti-corrosion performanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeEmulsion

The invention discloses chromium-free waterborne epoxy anticorrosion primer with excellent solvent oil resistant performance. The chromium-free waterborne epoxy anticorrosion primer comprises a component A and a component B, wherein the component A is a dispersoid formed by waterborne epoxy emulsion, pigment filler, and the like and the component B comprises a curing agent, cosolvent and the like. The chromium-free waterborne epoxy anticorrosion primer disclosed by the invention has the characteristics of good anticorrosion performance, large cohesive force, high strength, good water resistant performance, good solvent oil resistant performance, excellent mechanical performance, excellent flexibility, steady storage, and the like, can bear the influence of high-low temperature cycling, uses water as a dispersion medium, does not contain heavy metal such as chromium, is pollution-free to the environment, has low probability of shedding off and is convenient to construct.

Owner:MARINE CHEM RES INST CO LTD

Chromium-free Dyclo paint

InactiveCN101260252AGood effectNo pollution in the processLiquid surface applicatorsAnti-corrosive paintsChromium freeZinc

The invention relates to a non-chromate Dacromet paint belonging to the metal anticorrosion technical field. The non-chromate Dacromet paint is prepared by the following steps that: after mixing a component B with a component C based on the weight ratio of 3-5:1.5-2.4, mixing the mixture with a component A based on the weight ratio of 1:16-32, stirring evenly and controlling pH value between 3.5 and 5.5; the non-chromate Dacromet paint has the characteristics of non-environmental pollution and non-public nuisance, high permeability, high adhesion, high antifriction, high weatherability, high chemical stability and so on. And the anticorrosion of the non-chromate Dacromet paint improves 7-10 folds of zinc electroplating.

Owner:SHANDONG UNIV

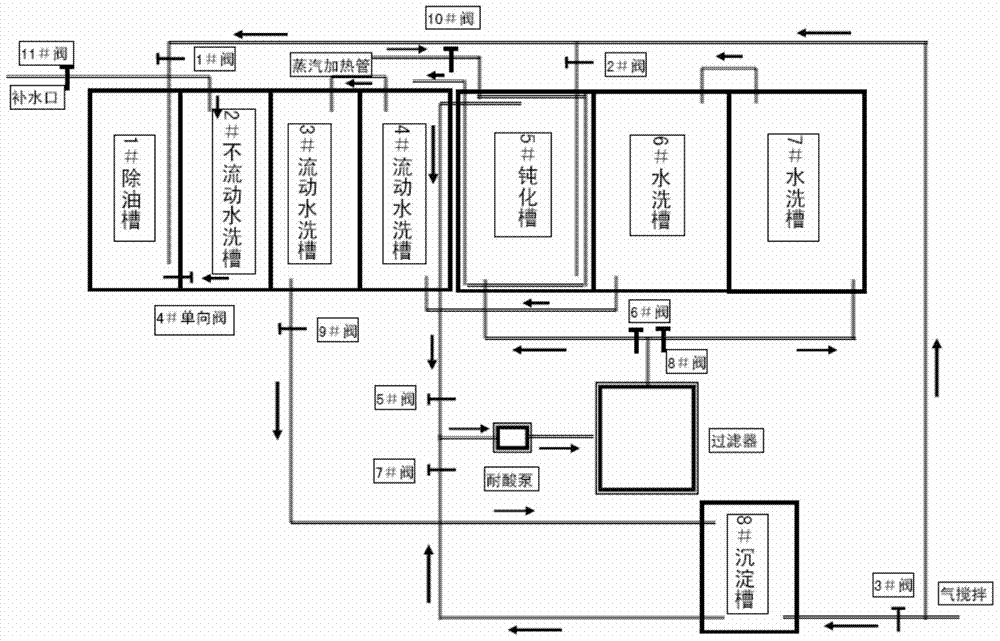

Aluminium alloy chromium-free passivating agent and aluminium alloy chromium-free passivating treatment system

ActiveCN103757624AEliminate pollutionExtend your lifeMetallic material coating processesChromium freeWater quality

The invention discloses an aluminium alloy chromium-free passivating agent. The aluminium alloy chromium-free passivating agent comprises fluotitanic acid, fluozirconic acid, a corrosion inhibitor and a chelating agent, wherein the concentrations of the fluotitanic acid and the fluozirconic acid (50wt.%) are 2.0-3.0g / L, the concentration of the corrosion inhibitor is 4.0-6.0g / L, and the concentration of the chelating agent is 6.0-8.0g / L. The aluminium alloy chromium-free passivating agent has the advantages that the pollution of chromium salt to water is completely eliminated from the source; the aluminium solving amount is reduced, powder applied to the surface of the aluminum alloy is reduced, and the service life of passivating liquid is prolonged; the passivation speed of the passivating agent is more than three times of that of chromium salt, and the production efficiency is improved. Meanwhile, the invention discloses an aluminium alloy chromium-free passivating treatment system. The aluminium alloy chromium-free passivating treatment system is simple to operate, energy-saving and environmentally-friendly, can be used for easily treating wastewater and facilitates large-scale production. The aluminium alloy chromium-free passivating treatment system is used for completely avoiding chromium pollution generated in processes of treating surfaces of building aluminium profiles, using the building aluminium profiles and treating wasted building aluminium profiles and solving the bottleneck problem of restricting the development of industries.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

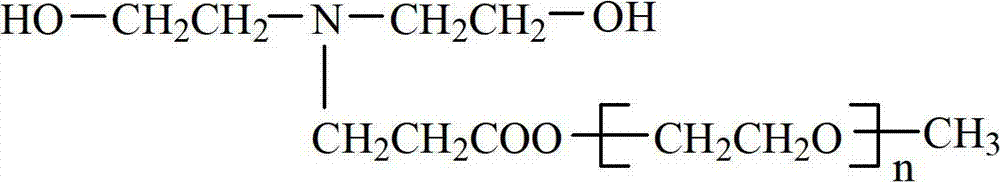

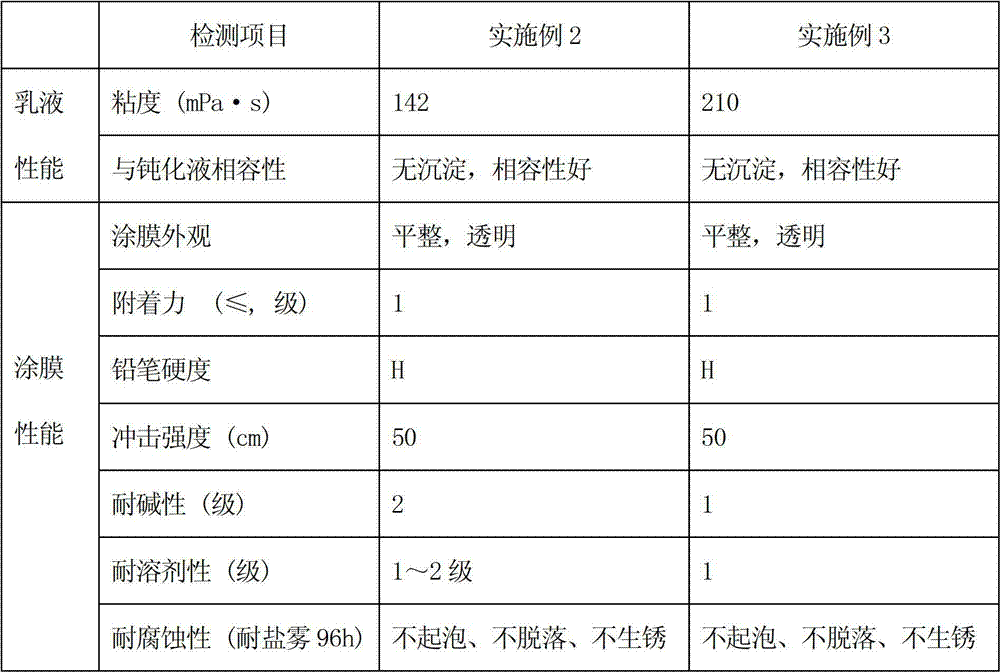

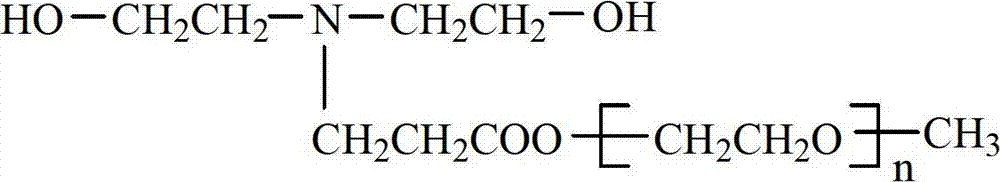

Cation-nonionic mixed aqueous polyurethane emulsion and preparation method thereof

ActiveCN102775578AGood chemical resistanceImprove corrosion resistancePolyurea/polyurethane coatingsChromium freePropanoic acid

The invention relates to a cation-nonionic mixed aqueous polyurethane emulsion and a preparation method thereof. The emulsion is aqueous polyurethane which has a cation hydrophilic group and a nonionic hydrophilic side chain. The preparation method comprises the steps of firstly introducing the nonionic hydrophilic side chain by using a specific nonionic hydrophilic chain extender; and introducing the cation hydrophilic group by using a cation hydrophilic chain extender, wherein the amounts of the nonionic hydrophilic chain extender and the cation hydrophilic chain extender respectively account for 1-10 percent and 1-8 percent according to the total weight of the raw materials, and the specific nonionic hydrophilic chain extender is 3-(N,N-dihydroxyethyl) amino-propionic acid polyethyleneglycol monomethyl ether ester which is prepared by heating and reacting methoxy polyethylene glycol single methyl acrylate and diethanol amine in a molar ratio of 1:1. By using the emulsion, the defect of the existing emulsion is overcome, and the requirement of zinc-plating steel plate chromium-free passivation pretreatment on aqueous polyurethane resins are met, so that the cost is reduced.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Two-stage conversion treatment

InactiveUS20070017602A1Shorten the process chainReduce in quantitySolid state diffusion coatingSpecial surfacesChromium freeZinc alloys

The invention relates to a chromium-free, corrosion prevention treatment for steel, zinc or zinc alloys, aluminum, magnesium or alloys thereof in which the metal surfaces are contacted in a first step with a first aqueous solution having a pH of 1.5 to 5 which contains Ti and / or Zr and / or Si ions and at least such a quantity of fluoride that the atomic ratio of Ti to F and / or Zr to F and / or Si to F is in the range from 1:1 to 1:6 and then, optionally after rinsing with water, and thereafter in a second step are contacted with a second aqueous solution having a pH of 1.5 to 5 which contains Ti and / or Zr and / or Si ions and at least such a quantity of fluoride that the atomic ratio of Ti to F and / or Zr to F and / or Si to F is in the range from 1:1 to 1:6, and which additionally contains such a quantity of soluble anions of oxo acids of Mo (VI) and / or W (VI) that the total concentration of molybdenum and / or tungsten is in the range from 5 to 1500 mg / l.

Owner:HENKEL KGAA

Batch hot-dip galvanizing chromium-free passivator and application method thereof

ActiveCN104018148AAchieve qualityAchieve corrosion resistanceMetallic material coating processesOrganic filmChromium free

The invention discloses a batch hot-dip galvanizing chromium-free passivator and an application method thereof. According to the invention, toxic and harmful hexavalent chromium and trivalent chromium used in a traditional passivation process are replaced with an organic film-former, so that a chromium-free passivator which does not contain chromates, can be used at room temperature, is low in cost, good in corrosion resistance and easy to use, and can be practically applied to industrial production is provided for passivation treatment in the batch hot-dip galvanizing industry. The chromium-free passivator mainly comprises an organic film-former, an organic corrosion inhibitor, an oxidant, a surfactant and water. The chromium-free passivator disclosed by the invention is easy to use and simple in operation, and has no change in existing processes.

Owner:宁波华印表面工程材料科技有限公司 +1

Chromium-free metal surface treatment agent

InactiveUS20050037227A1Improve adhesionAvoid performanceLiquid surface applicatorsSynthetic resin layered productsChromium freeSolvent

Provided is a chromium-free metal surface treatment agent excellent in rust inhibitive performance which can be used in a surface treatment of metal products, in particular, galvanized metal products. The metal surface treatment agent consists essentially of a siliceous binder solution comprising water and / or alcohol as a solvent, and the concentration of the silica component is 8 to 25% by weight. In particular, a metal surface treatment agent containing an alcoholic solution of alkoxysilane oligomer having a weight averaged molecular weight of 1000 to 10000, which is obtained by hydrolyzed condensation polymerization of alkoxysilane, can suppress the occurrence of white rusting for a long time. It is preferred that 3 to 25 parts by weight of a dispersed nano-sized titanium dioxide powder having an average primary particle size of not more than 70 nm, per 100 parts by weight of the silica component be suspended in the siliceous binder solution. The rust inhibitive performance of the metal surface treatment agent can be further improved by using an alcohol-soluble polyvinyl butyral resin and by adding a silane coupling agent having a vinyl or epoxy group as a functional group, in combination with a dispersed nano-sized powder of titanium dioxide.

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

Chromium-free passivation solution and hot-dip galvanized metal material

InactiveCN102373453AImprove corrosion resistanceImprove water resistanceHot-dipping/immersion processesChromium freeSilanes

The invention relates to a chromium-free passivation solution and a hot-dip galvanized metal material. The chromium-free passivation solution is prepared from a raw material mixture through uniform mixing. The raw material mixture contains one or more silane coupling agents and water. The chromium-free passivation solution is characterized in that the raw material mixture also contains one or more titanium compounds, one or more inorganic silicon compounds, one or more water-soluble film-forming agents and tannic acid or phytic acid, wherein the one or more titanium compounds are selected from hexafluorotitanic acid, ammonium hexafluorotitanate, potassium hexafluorotitanate, metatitanic acid and titanyl sulfate and the one or more inorganic silicon compounds are selected from nanoscale silica powder, silica sol and sodium silicate. The chromium-free passivation solution has good corrosion resistance, good water resistance, good heat resistance, good fingerprint resistance and excellent roller coating performances. A passivation method adopting the chromium-free passivation solution can greatly shorten treatment time, can be utilized for passivation plate production in a spray mode or a roller coating mode, and also can avoid an oiling process in galvanized plate production.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Chromium-free composite passivator and preparation method thereof

InactiveCN102168265AReduce pollutionBreak through performance bottlenecksMetallic material coating processesChromium freeEpoxy

The invention relates to the technical field of metal passivators, and particularly relates to a chromium-free composite passivator and a preparation method thereof. The chromium-free composite passivator provided by the invention is prepared from the following components in percentage by mass: 3.0-10% of gamma-methylacryloyloxytrimethoxy silane, 0.1-3.0% of sodium molybdate, 0.1-5.0% of cerium chloride, 0.5-4.0% of phosphoric acid, 0.5-4.0% of acetic acid, 15-20% of water-soluble epoxy resin, 5-15% of water-soluble acrylic resin, 10-30% of water and 20-40% of ethanol. The chromium-free composite passivator is suitable for treating steel, zinc and zinc alloy, or aluminum and aluminum alloy. The chromium-free composite passivator contains the water-soluble high-molecular resins and inorganic corrosion inhibitor, and is mixed with ethanol to form a colorless, innoxious, environment-friendly, transparent and clear solution. At room temperature, the chromium-free composite passivator is applied on the surface of steel, hot-galvanized zinc and zinc alloy, or aluminum and aluminum alloy to generate chemical crosslinking reaction, and is cured to form a film.

Owner:NORTHEASTERN UNIV

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Chromium free hardfacing materials

Disclosed are embodiments of Fe-based alloys for use as a hardfacing material having high hardness while avoiding the use of chromium. The alloys can be twin arc or thermally sprayed as coatings on different types of equipment. In some embodiments, the alloys can be readable even after heating of the alloys.

Owner:SCOPERTA INC

Water-based chromium-free fingerprint-resistant paint for galvanized steel plate

InactiveCN104449154AReduce consumptionWeather resistantAntifouling/underwater paintsPaints with biocidesWater basedPhosphate

The invention discloses water-based chromium-free fingerprint-resistant paint for a galvanized steel plate. The paint comprises raw materials in parts by weight as follows: 30.0-55.0 parts of a fluorine-modified water-based self-crosslinking acrylate emulsion, 0.1-1.5 parts of a neutralizer, 0.5-1.0 part of a silane coupling agent, 0.1-0.2 parts of laurocapram, 0.6-1.0 part of chlorinated paraffin, 4.0-8.0 parts of inorganic sol, 1.5-3.5 parts of metal salt, 0.1-0.3 parts of glycerin, 0.1-0.2 parts of sodium carboxymethylcellulose, 0.1-0.2 parts of polydimethylsiloxane, 1.5-5.5 parts of a cosolvent, 1.0-2.5 parts of aluminium dihydrogen phosphate and 40-50 parts of water; the curing temperature is as low as 40-60 DEG C, and energy consumption is reduced. The fluorine-modified water-based self-crosslinking acrylate emulsion is adopted to enable a film to have weather-resistant, waterproof and self-cleaning performance and the like, the film has a self-repairing function when damaged, and the forming processability is greatly improved. Low VOC (volatile organic compounds) emission is realized, and the problem of chromium passivation pollution is solved.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com