Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

A magnesium-aluminum alloy, chromium-free passivation technology, applied in the direction of metal material coating process, etc., can solve the problem that the corrosion resistance of the silane film and the phosphating film are quite different, the corrosion resistance and corrosion resistance are far different, and the To problems such as corrosion resistance, high hardness, reduced agglomeration, and excellent acid and alkali resistance are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution prepared according to the following proportions and methods:

[0036] Prepare material A and material B respectively according to the mass ratio,

[0037] 1) Material A:

[0038] Water-based resin pure acrylic emulsion 20%

[0039] Rare earth catalyst titanyl sulfate 1%

[0040] water 20%

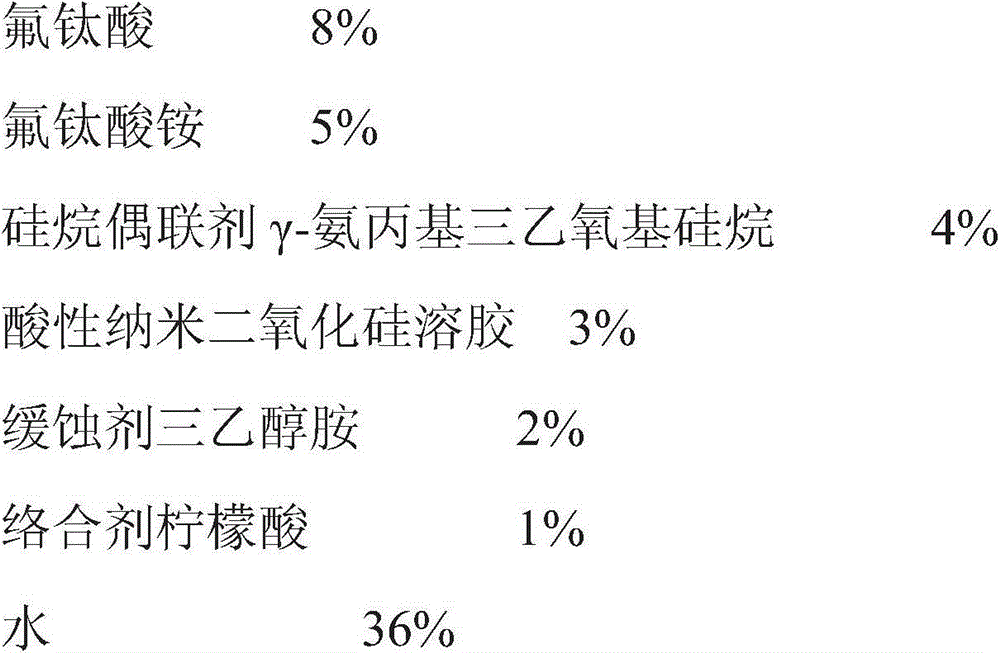

[0041] 2) Material B

[0042]

[0043] Mix material A and material B evenly to obtain a concentrated sample of corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution.

[0044] Dilute the corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution 15 times with water for later use.

[0045] First clean the surface of the magnesium-aluminum parts with an acidic or neutral cleaning solution to remove oil and dust on the surface of the magnesium-aluminum parts; then clean other impurities remaining on the surface of the magnesium-aluminum parts with water...

Embodiment 2

[0047] Preparation of corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution:

[0048] Prepare material A and material B respectively according to the mass ratio,

[0049] 1) Material A:

[0050] Silicone acrylic emulsion 30%

[0051] Ammonium Metavanadate 3%

[0052] water 30%

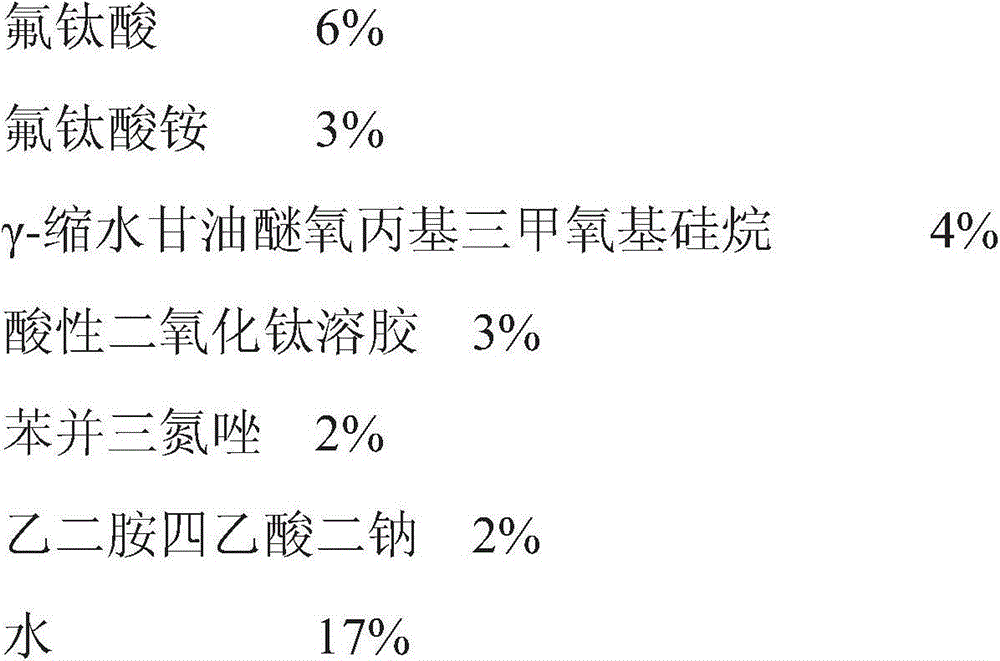

[0053] 2) Material B

[0054]

[0055] Mix material A and material B evenly to obtain a concentrated sample of corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution.

[0056] Dilute the corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution 15 times with water for later use.

[0057] First clean the surface of the magnesium-aluminum parts with an acidic or neutral cleaning solution to remove the oil and dust on the surface of the magnesium-aluminum parts; Alloy chromium-free passivation liquid dilution, the passivation temperature is 25 ° C, the passivation time is about 2 minutes, dried at 100-120 ° C, or at room tem...

Embodiment 3

[0059] Preparation of corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution:

[0060] Prepare material A and material B respectively according to the mass ratio,

[0061] 1) Material A:

[0062] Styrene Acrylic Emulsion 25%

[0063] Vanadium acetylacetonate 5%

[0064] water 25%

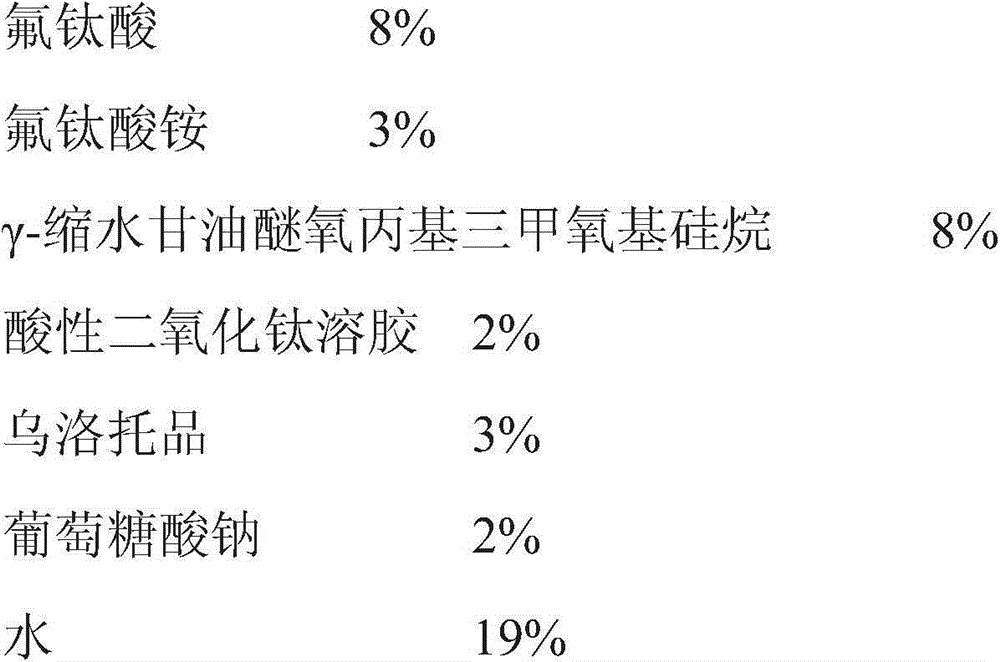

[0065] 2) Material B

[0066]

[0067] Mix material A and material B evenly to obtain a concentrated sample of corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution.

[0068] Dilute the corrosion-resistant magnesium-aluminum alloy chromium-free passivation solution 15 times with water for later use.

[0069] First clean the surface of the magnesium-aluminum parts with an acidic or neutral cleaning solution to remove the oil and dust on the surface of the magnesium-aluminum parts; Alloy chromium-free passivation liquid dilution, the passivation temperature is 25 ° C, the passivation time is about 2 minutes, dried at 100-120 ° C, or at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com