Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

571 results about "Pitting corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pitting corrosion, or pitting, is a form of extremely localized corrosion that leads to the creation of small holes in the metal. The driving power for pitting corrosion is the depassivation of a small area, which becomes anodic while an unknown but potentially vast area becomes cathodic, leading to very localized galvanic corrosion. The corrosion penetrates the mass of the metal, with a limited diffusion of ions. The mechanism of pitting corrosion is probably the same as crevice corrosion.

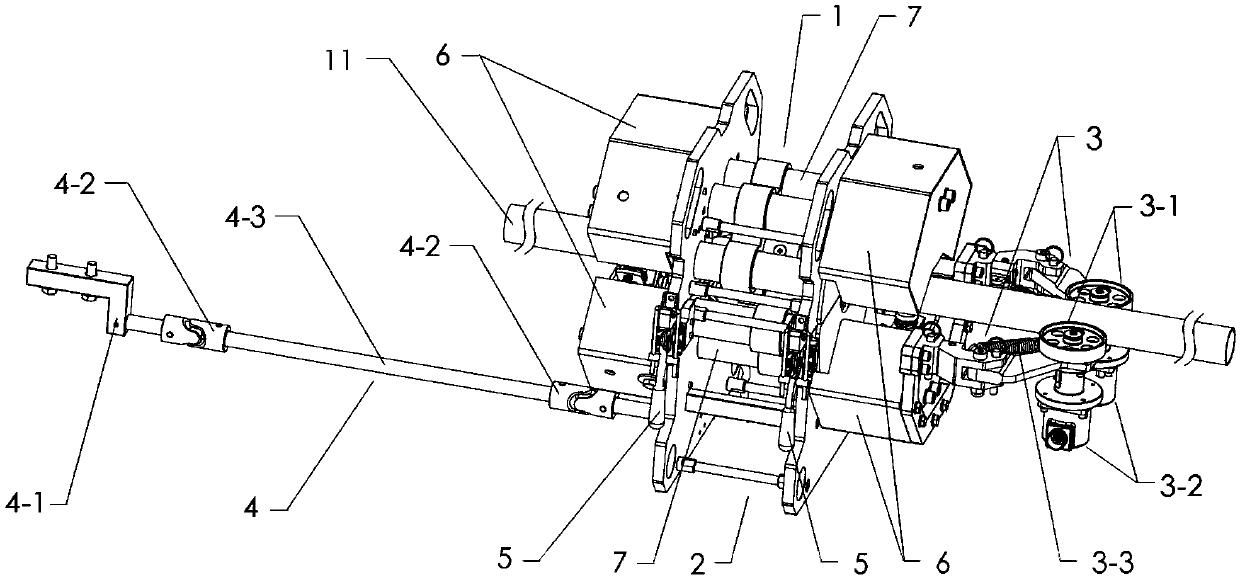

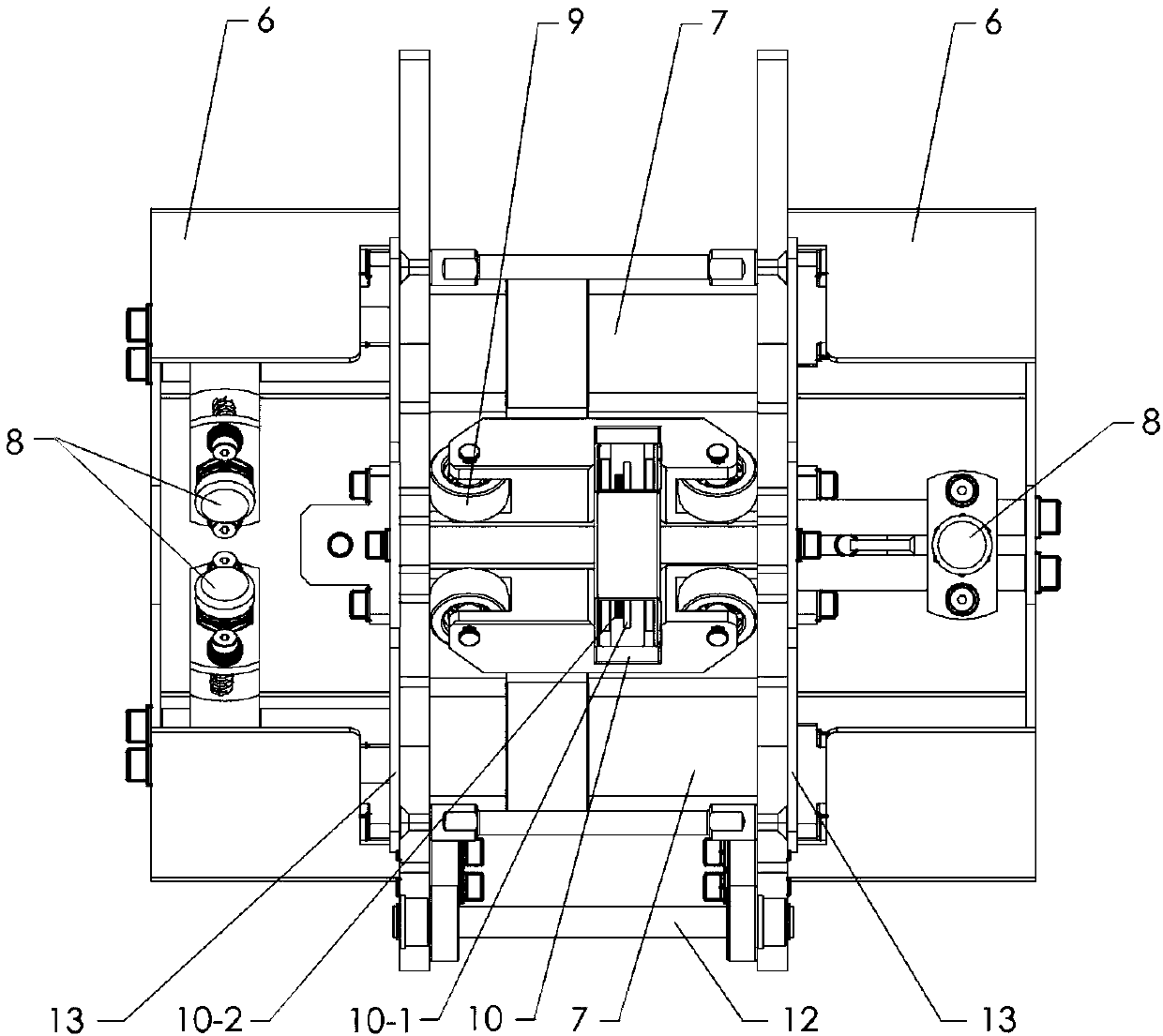

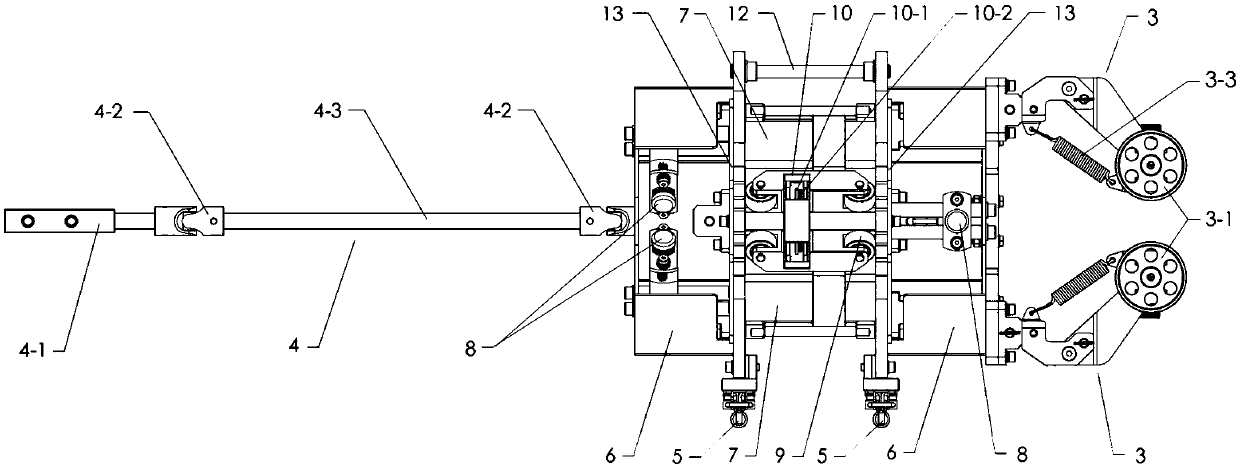

Integrated coiled tubing defect detection device

PendingCN109682881AAccurate defect detectionAccurate detection of wall thicknessElectric/magnetic contours/curvatures measurementsUsing electrical meansCoiled tubingEngineering

The invention provides an integrated coiled tubing defect detection device. The coiled tubing defect detection device comprises an upper half detection unit and a lower half detection unit, and a passage for coiled tubing to pass through is formed between the two detection units after the two detection units are matched and assembled with each other, and internally provided with a magnetism generating device, a magnetism leakage detection probe, an ellipticity detection probe and a guide device which are arranged on the two detection units; a measuring arm assembly kit for guiding the two detection units in moving along the coiled tubing is connected to the outsides of the detection units. The device can achieve real-time and precise detection of the wall thickness, outer diameter, ovalityand various physical defects such as corrosion, cracks, mechanical damage and pitting corrosion of coiled tubing columns.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

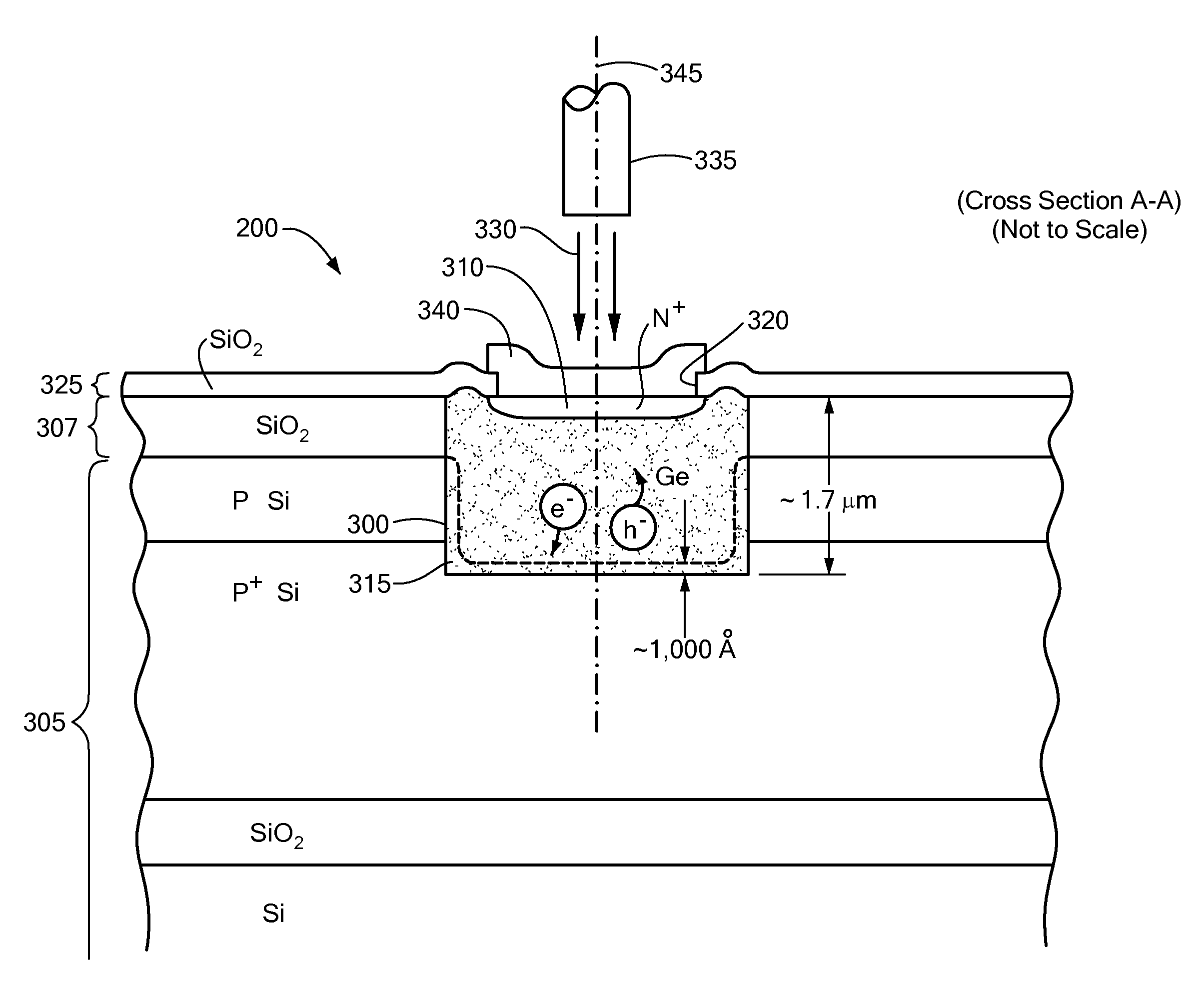

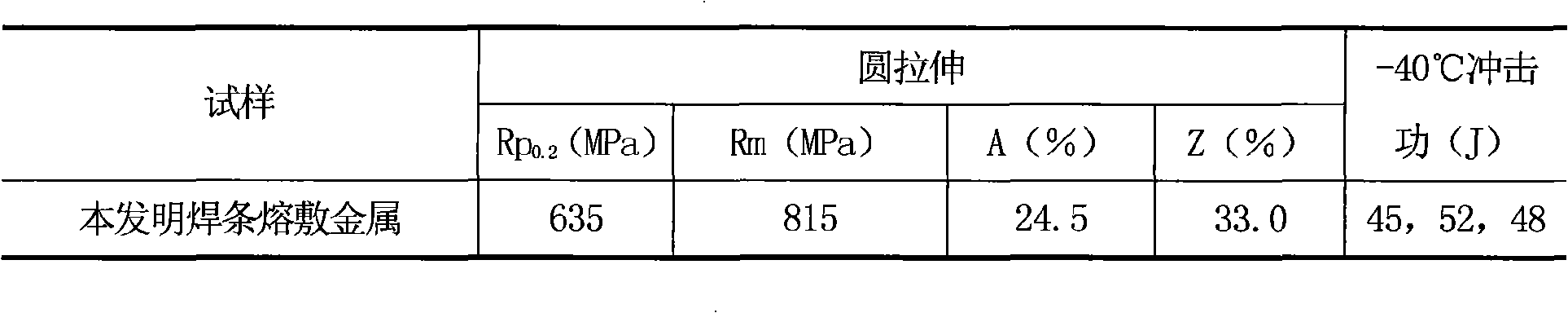

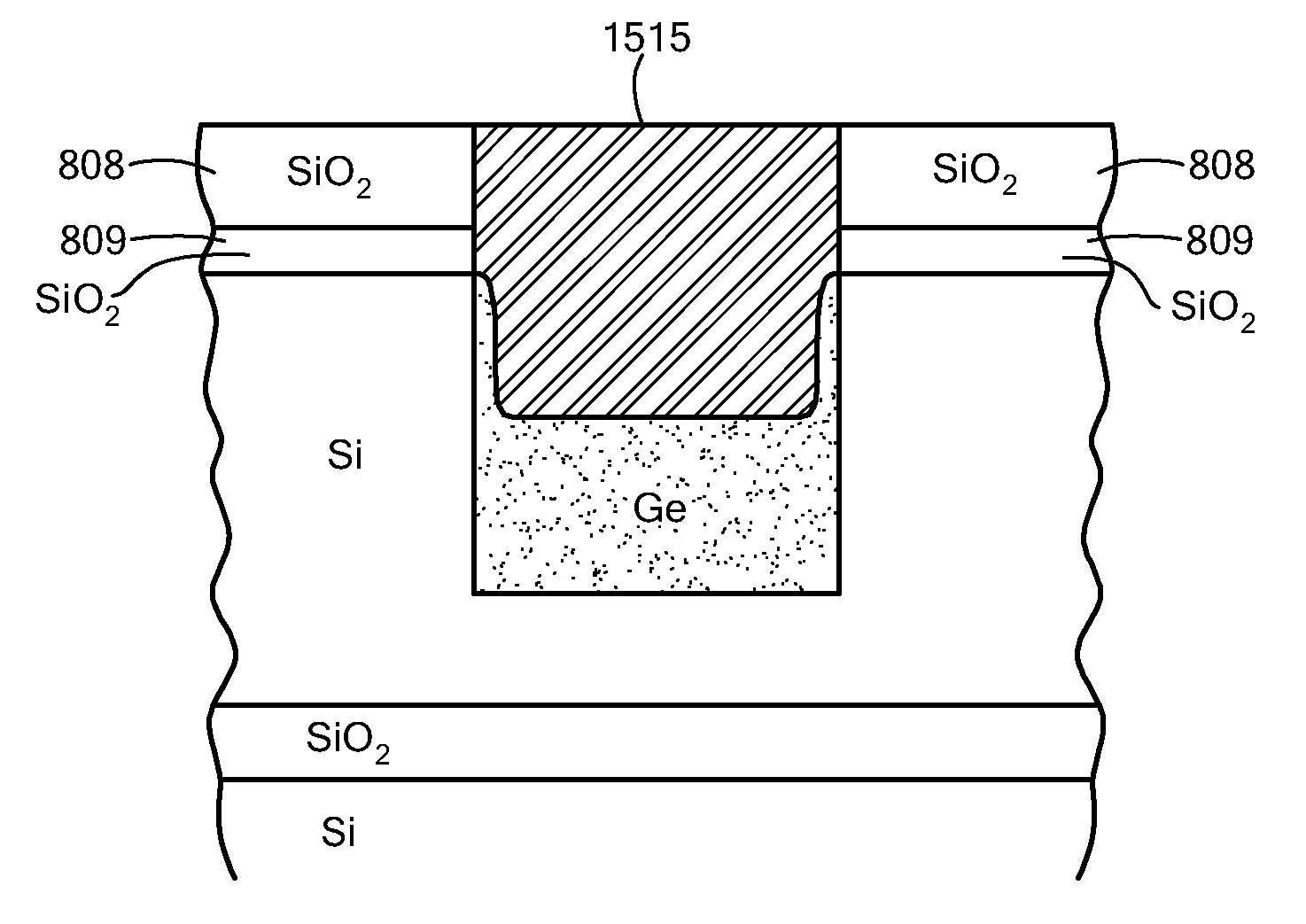

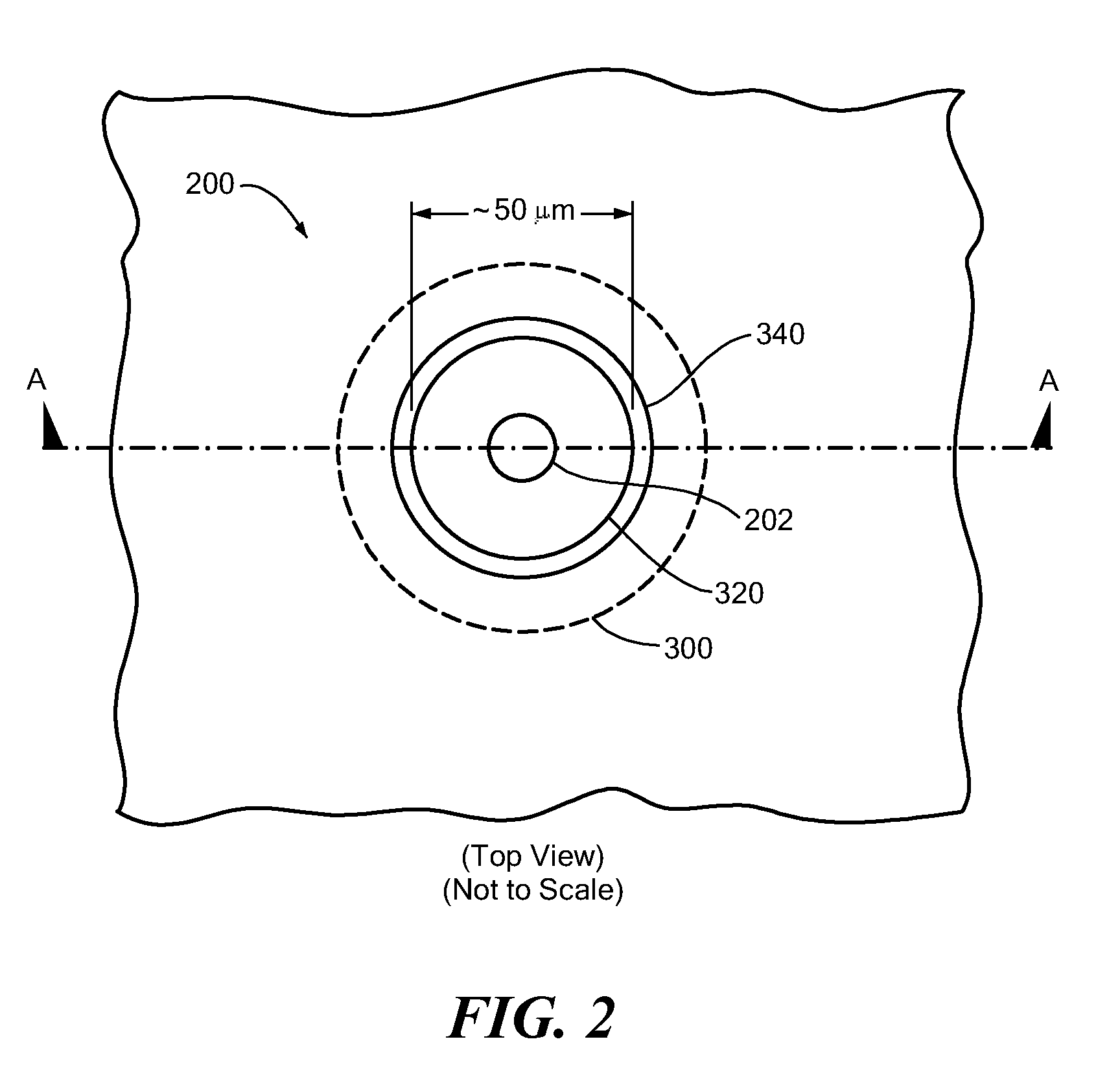

Recessed Germanium (Ge) Diode

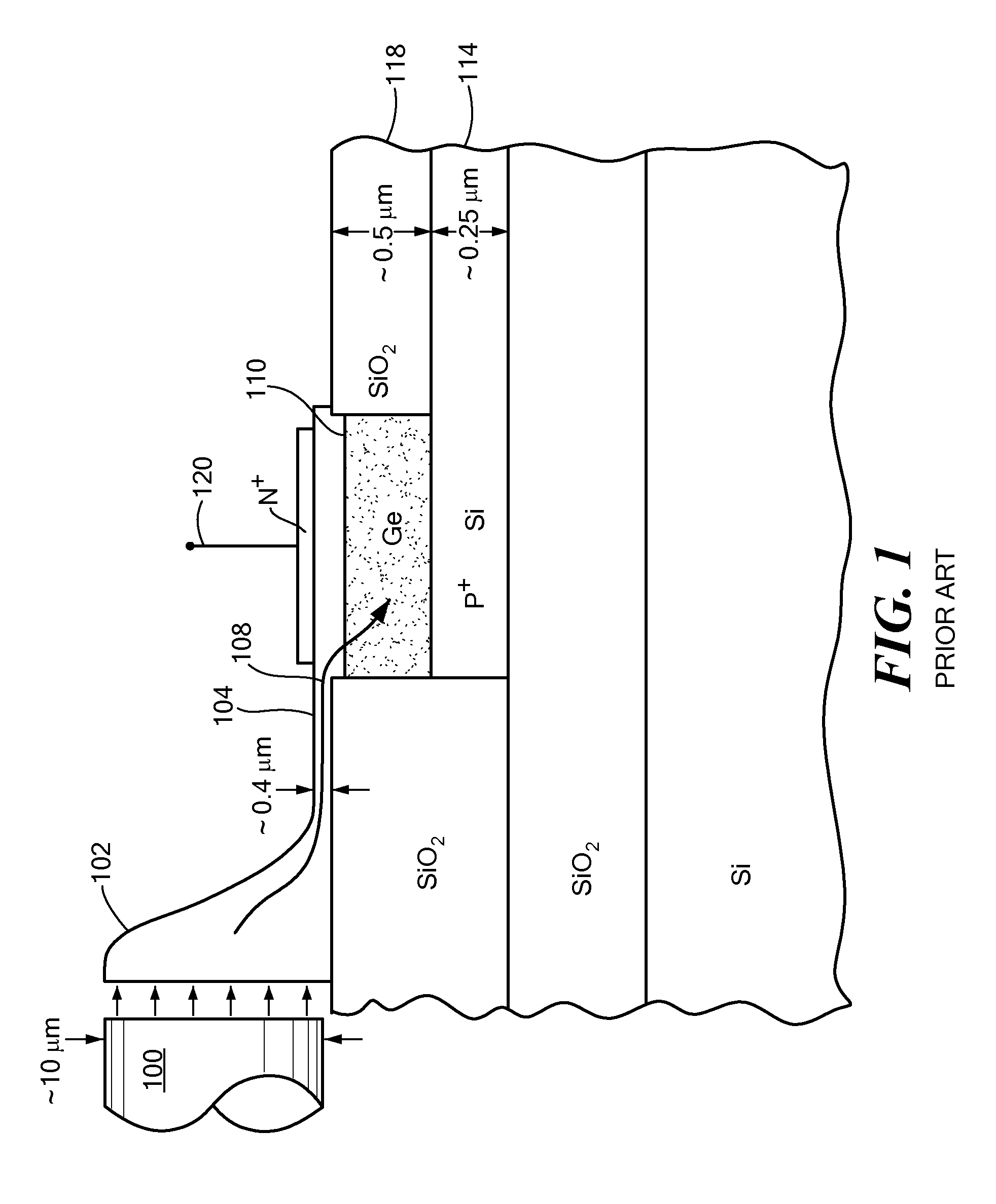

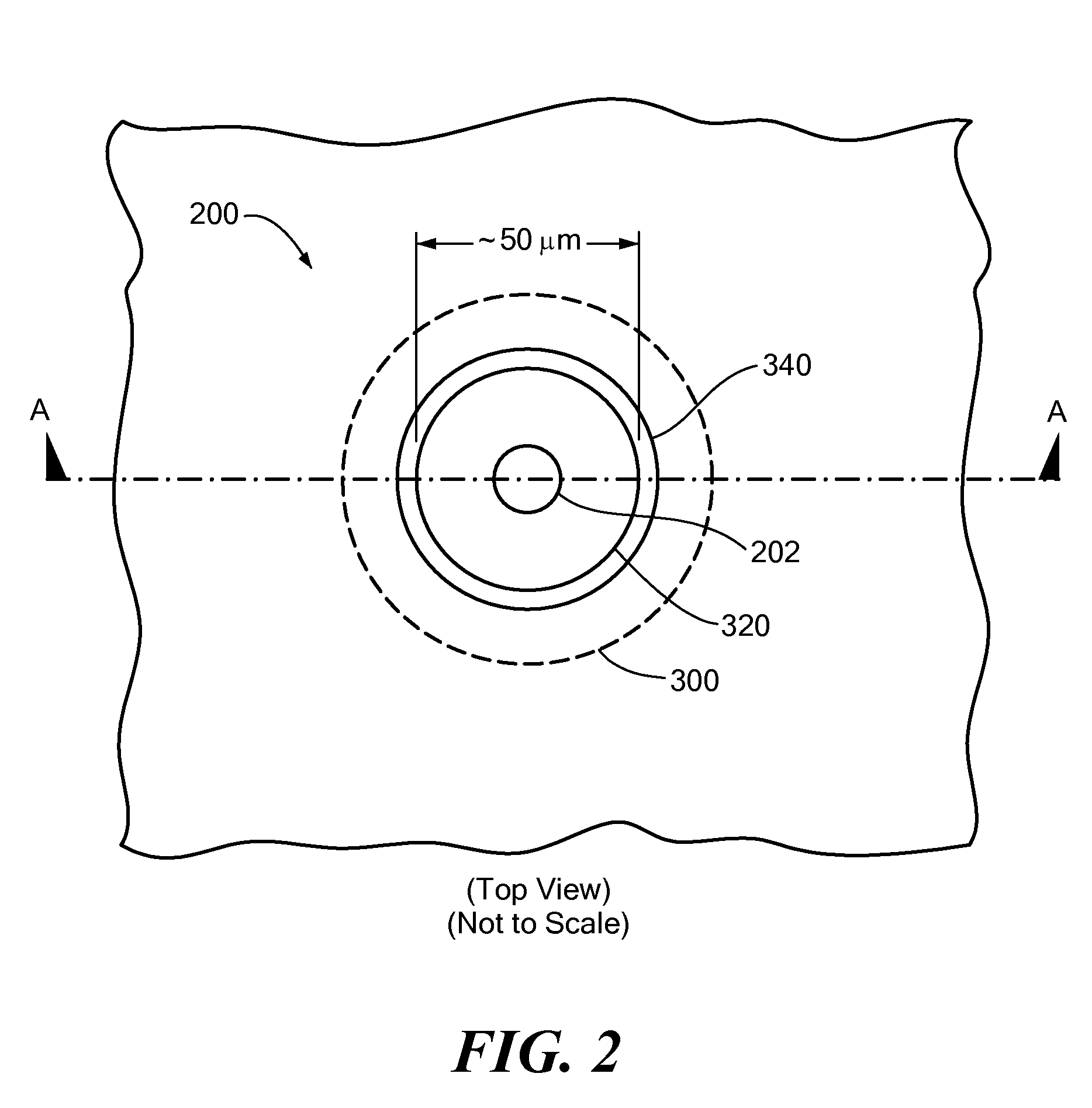

InactiveUS20100006961A1Reduce the overall heightSolid-state devicesSemiconductor/solid-state device manufacturingPhotodiodeCoupling efficiency

A photodiode is formed in a recessed germanium (Ge) region in a silicon (Si) substrate. The Ge region may be fabricated by etching a hole through a passivation layer on the Si substrate and into the Si substrate and then growing Ge in the hole by a selective epitaxial process. The Ge appears to grow better selectively in the hole than on a Si or oxide surface. The Ge may grow up some or all of the passivation sidewall of the hole to conformally fill the hole and produce a recessed Ge region that is approximately flush with the surface of the substrate, without characteristic slanted sides of a mesa. The hole may be etched deep enough so the photodiode is thick enough to obtain good coupling efficiencies to vertical, free-space light entering the photodiode.

Owner:ANALOG DEVICES INC

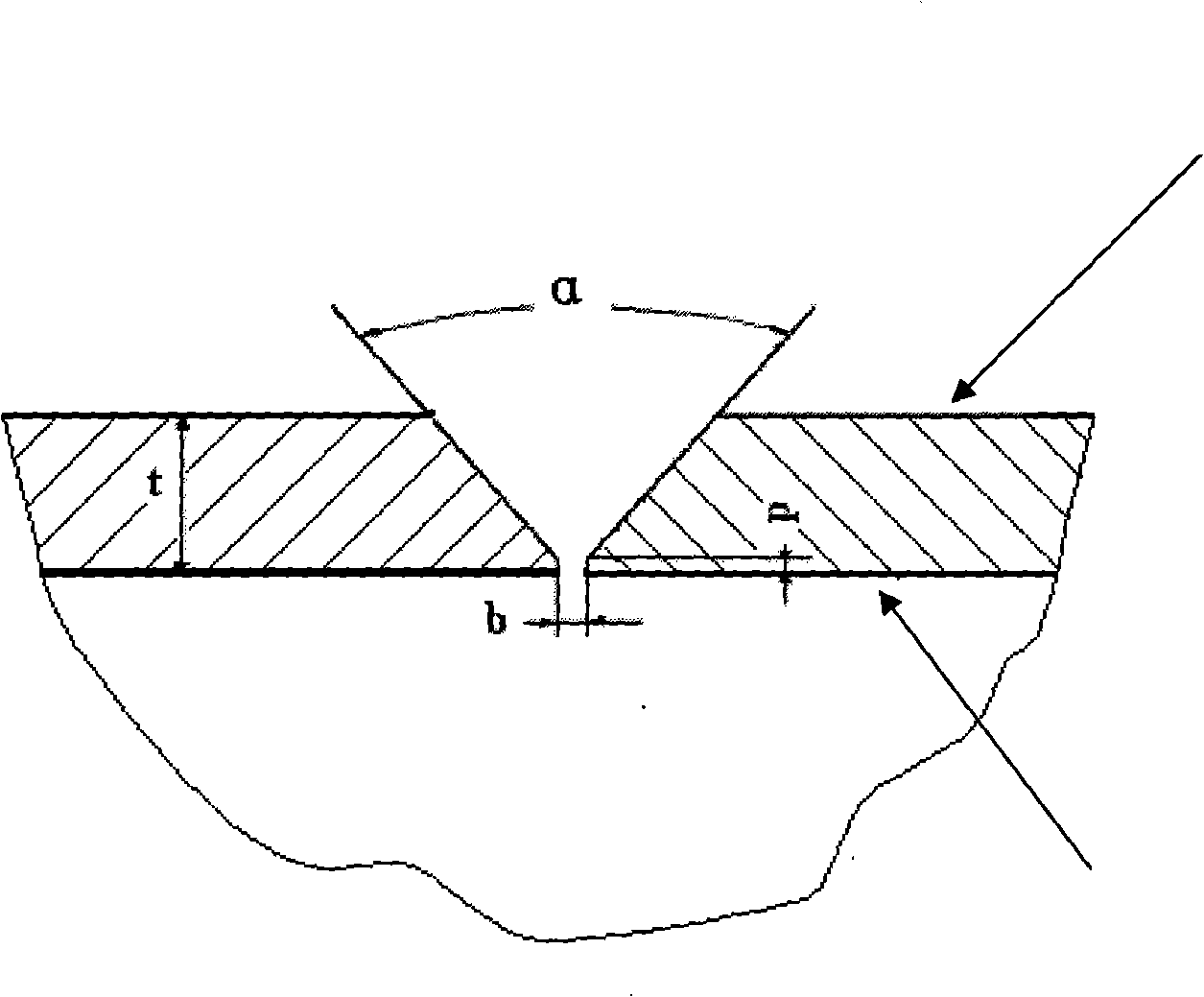

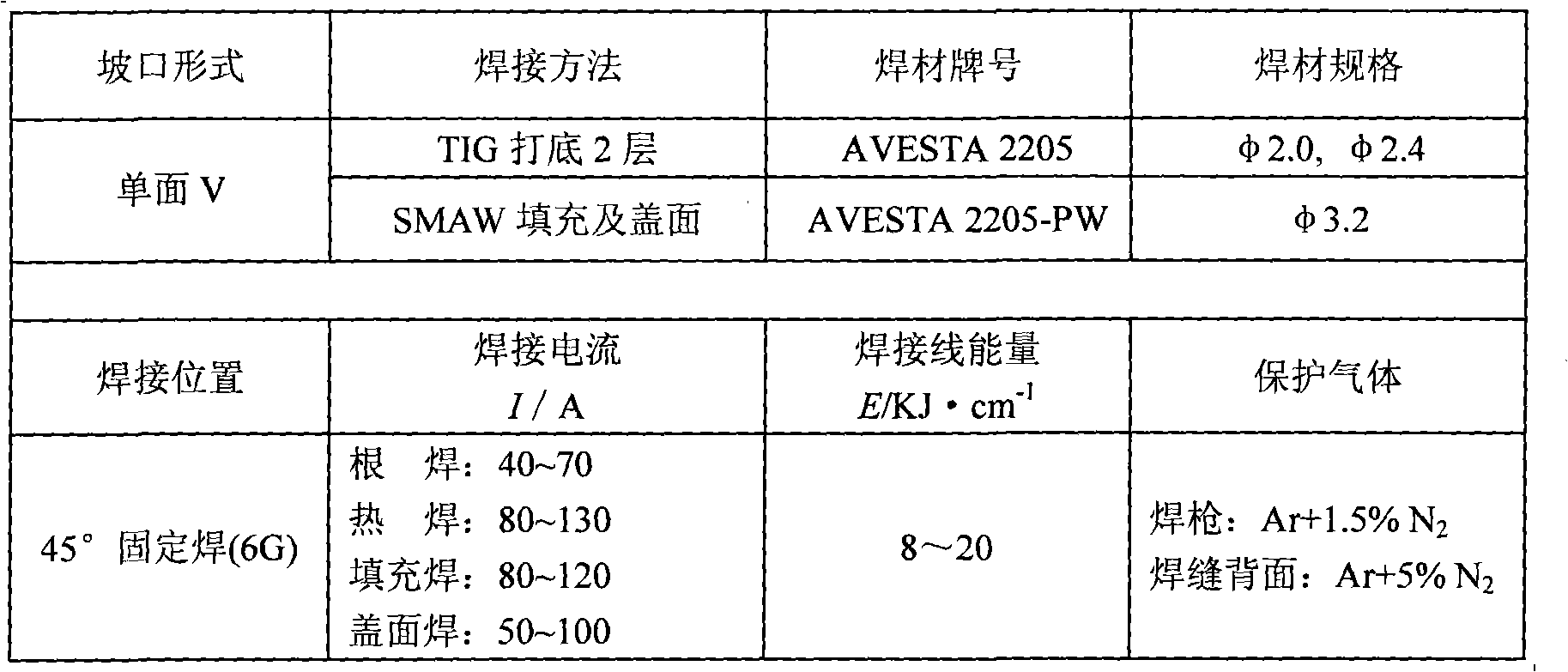

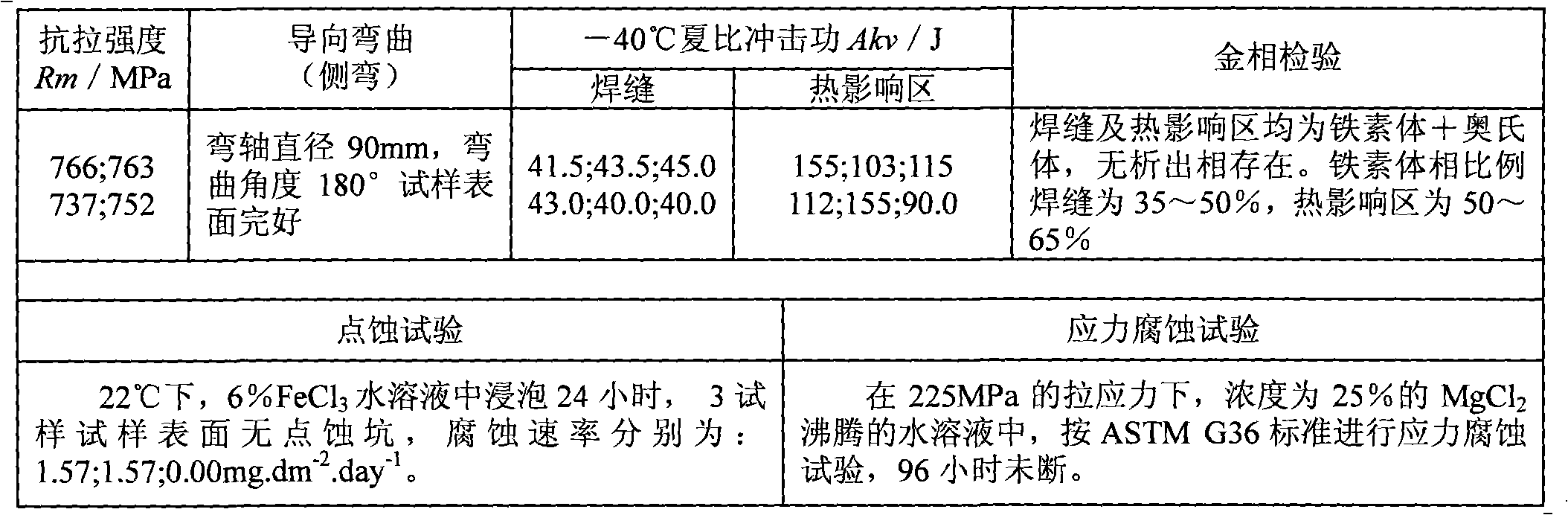

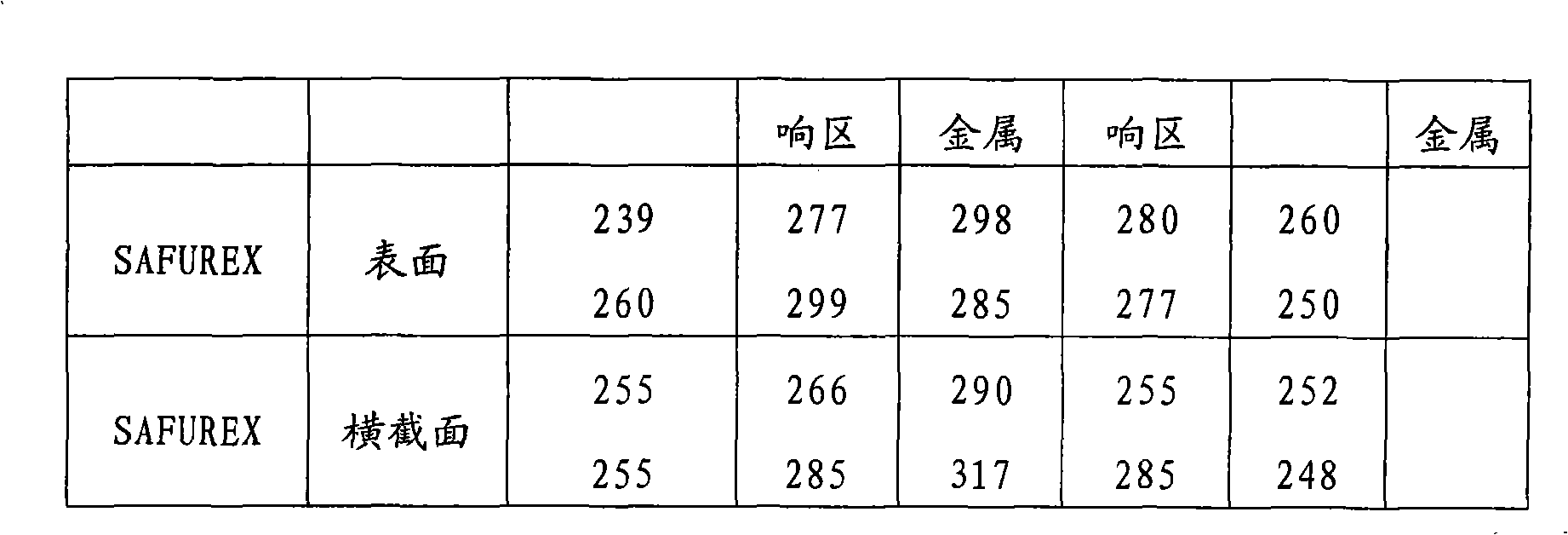

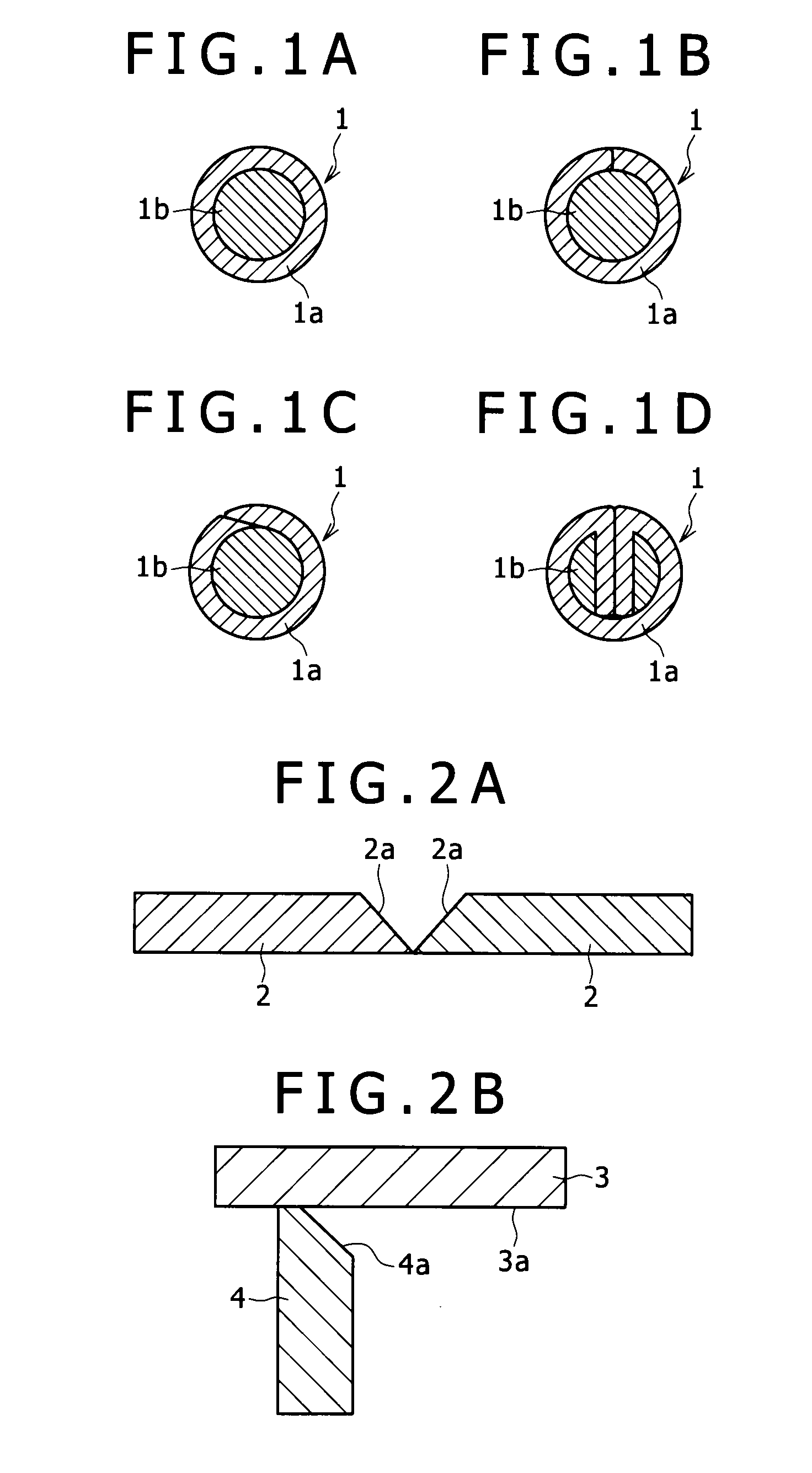

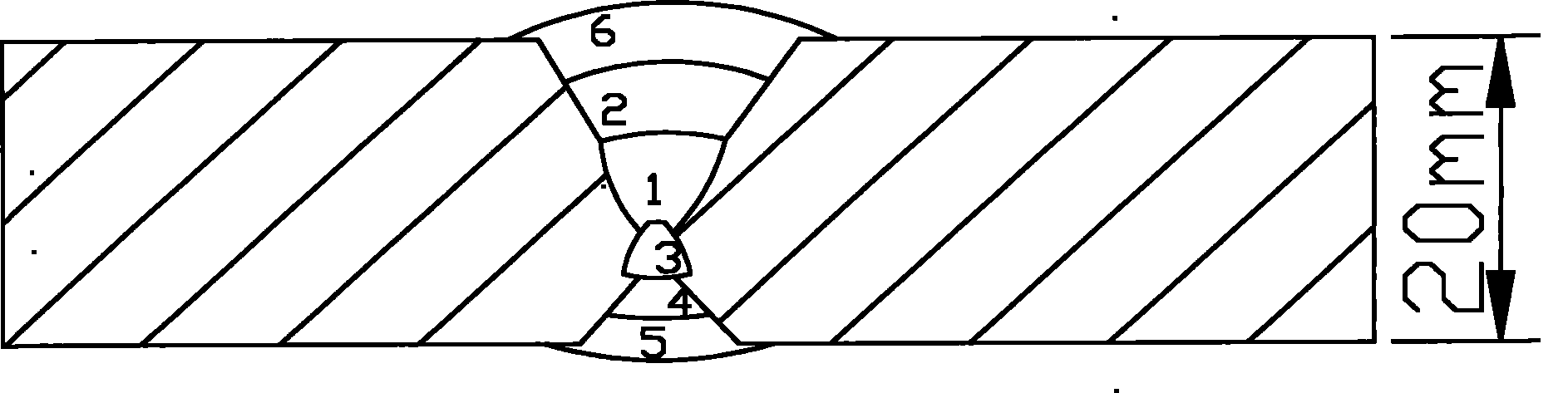

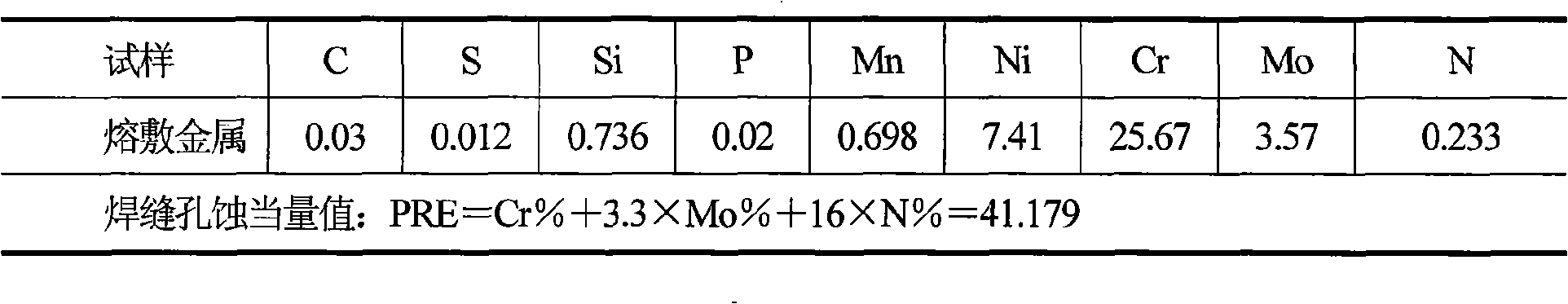

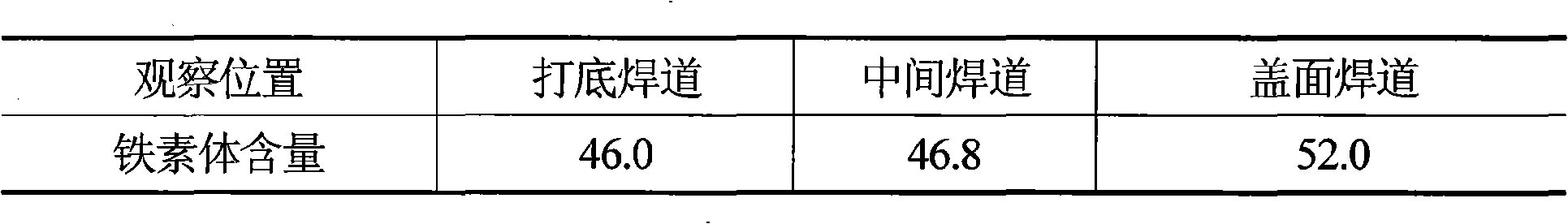

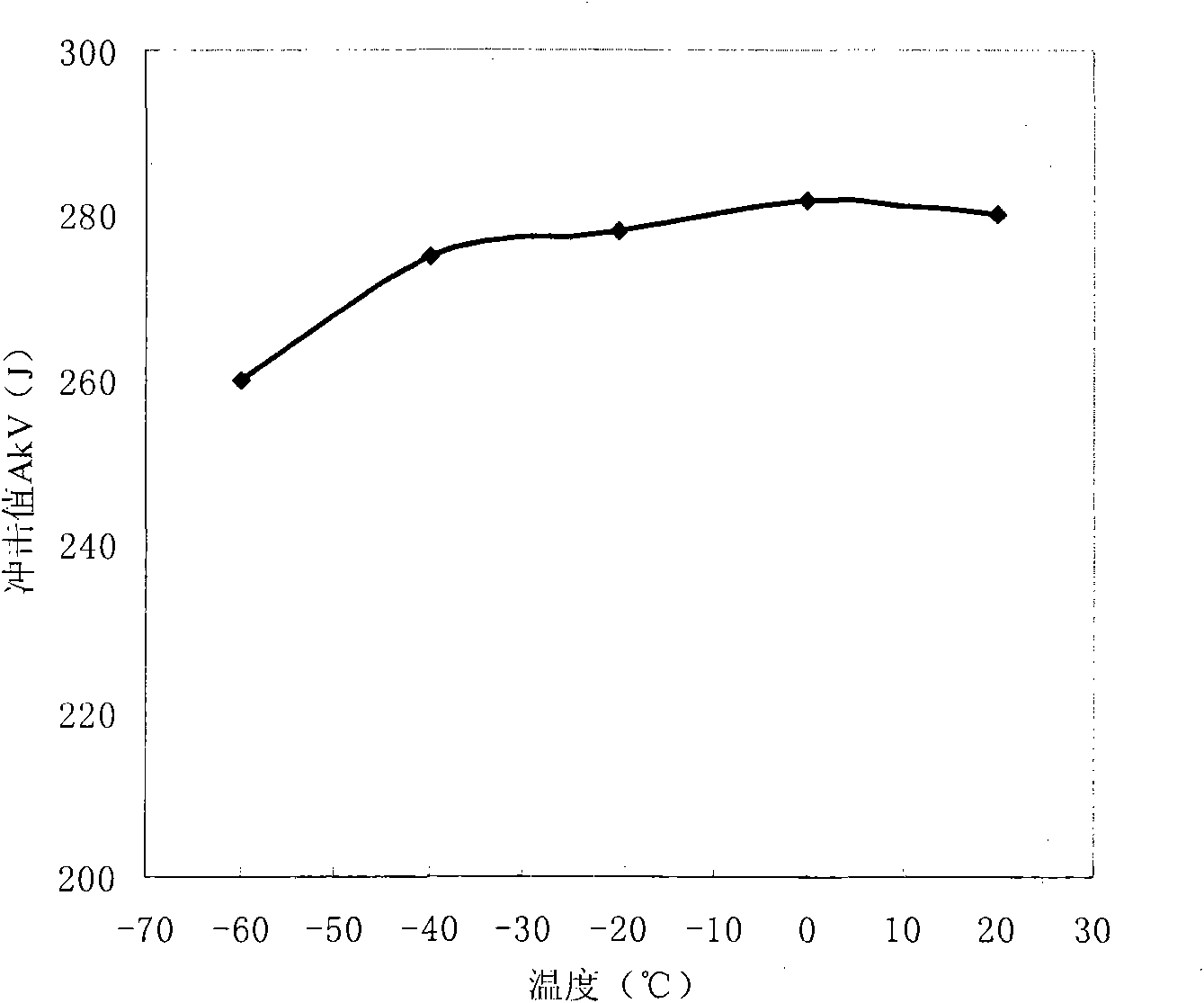

22Cr duplex phase stainless tube welding method

InactiveCN101288918AImprove tensile propertiesImprove low temperature impact toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesMicrostructurePitting corrosion

The invention relates to a welding method of 22Cr duplex stainless steel corrosion resistant alloy pipe, which adopts a gas mixture of 99.995 percent pure Ar and 98 to 99 percent Ar plus 2 percent N2 or a gas mixture of 90 to 95 percent of N2 plus 5 to 10 percent H2 to weld the two laterals within the range equal to or more than 100mm inside the pipe; back welding, fill welding and cap welding are implemented when the oxygen content is equal to or less than 50ppm; the welding and filling metal deposit includes the following components according to the weight percentage: C is equal to or less than 0.04, Cr is 22.0 to 23.5, Ni is 8.5 to 10.5, Mo is 3.0 to 3.5, Mn is 0.5 to 2.0, Si is equal to or less than 0.9, P is equal to or less than 0.04, S is equal to or less than 0.03, N is 0.15 to 0.20 and Cu is equal to or less than 0.75. A balanced austenitic-ferritic microstructure is obtained with good joint tensility and low-temperature shock toughness, as well as good corrosion performances of anti-pitting corrosion of chloride, stress corrosion and simulated environment medium corrosion resistance.

Owner:CNPC TUBULAR GOODS RES INST

Process for welding duplex stainless steel

ActiveCN101972878AOvercome adverse defectsGood welding effectArc welding apparatusShielding gasPetrochemical

The invention relates to a process for welding duplex stainless steel, in particular to the process for welding the duplex stainless steel used for high-sulfur content refining equipment, highly-corrosive petrochemical equipment and pipelines, high-parameter power devices, and the chloridion-corroded environments of seawater and the like. In the process, a specific protective gas favorable for the welding of the duplex stainless steel is adopted, and simultaneously limited linear energy and inter-layer temperature are regulated in the welding process, so that the unfavorable defects of the conventional welding process can be overcome, and a metallographic structure with the ferrite content of 30 to 70 percent and a ferritic phase in percentage equivalent to that of an austenitic phase is obtained. A welding joint obtained by the welding process has high mechanical properties, high strength and hardness, particularly high yield strength which is about twice that of austenitic stainless steel, high thermal fatigue resistance, pitting corrosion resistance, crevice corrosion resistance, intercrystalline corrosion resistance and high weldability.

Owner:CHINA NAT CHEM ENG NO 7 CONSTR

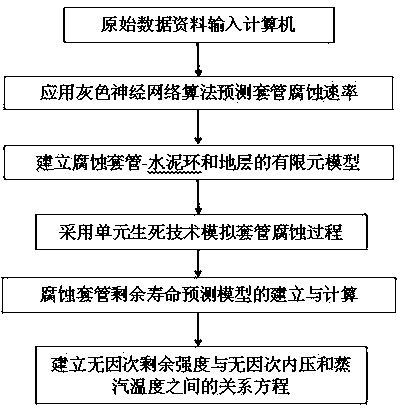

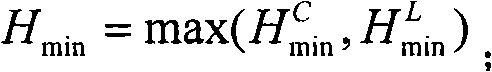

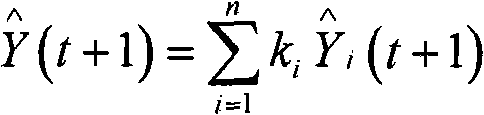

Method for predicting residual life of corroded casing of high-temperature and high-pressure well

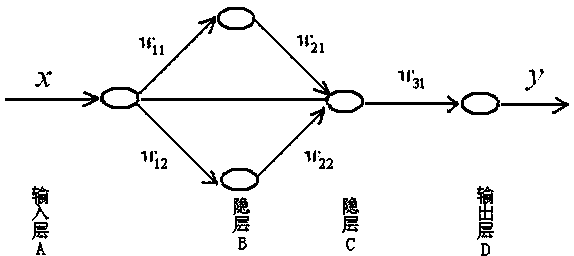

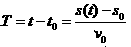

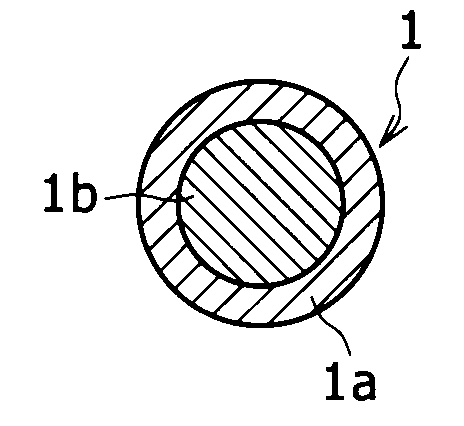

ActiveCN103455682AGuaranteed accuracyEasy to adjust process parametersSpecial data processing applicationsInternal pressureElement model

A method for predicting the residual life of a corroded casing of a high-temperature and high-pressure well mainly comprises the following steps: (1) predicting the inner average corrosion rate and the outer average corrosion rate of the casing by adopting the gray neural network algorithm; (2) establishing an finite element model for the corroded casing, and simulating the corrosion process of the casing by utilizing the element birth-death technology, so as to acquire the critical failure wall thickness of the casing when the casing loses efficacy; (3) establishing a residual life prediction model for the corroded casing, and computing the residual life of the casing subjected to uniform corrosion, local corrosion and pitting corrosion by utilizing the approximate analytical method; (4) establishing a relation equation for zero dimension residual intensity and zero dimension internal pressure and steam temperature by utilizing the regression analysis method. Aiming at the limitation of the theoretical study, laboratory test and field data on prediction of the service life of the casing, the method can effectively predict the residual life of the casing in shorter time, and the established residual intensity relation equation enables the engineering personnel to perform comprehensive evaluation on the service capability of the casing.

Owner:SOUTHWEST PETROLEUM UNIV

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

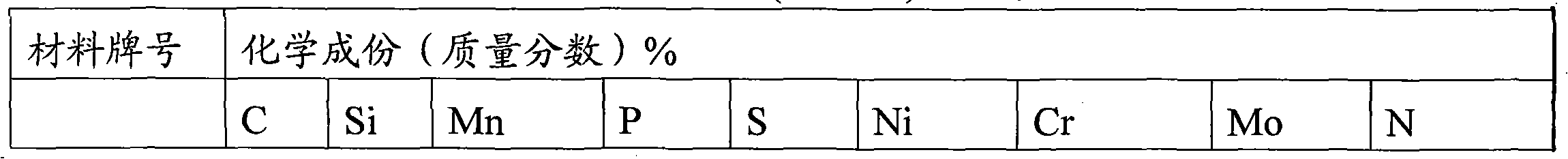

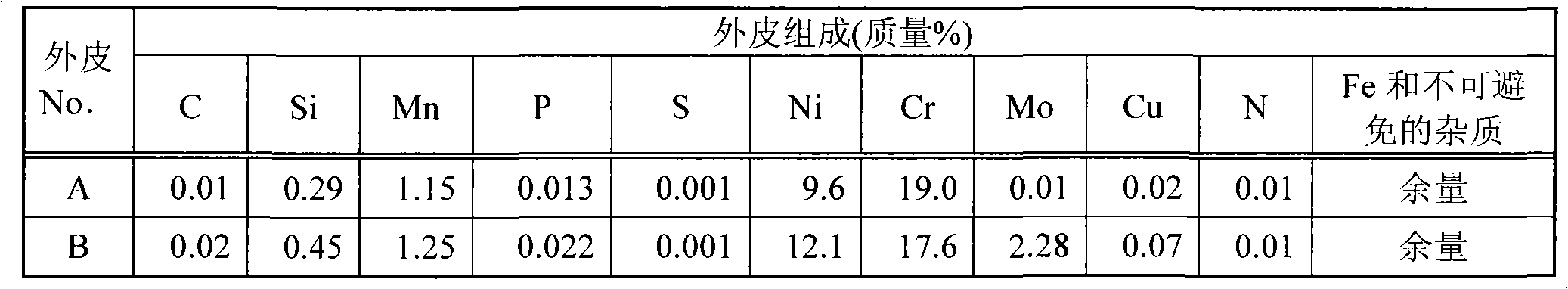

Flux-cored wire for stainless steel arc welding

ActiveUS20110139761A1Guaranteed Low Temperature ToughnessImprove corrosion resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementMetallurgy

A flux-cored wire for stainless steel arc welding including an outer sheath made of stainless steel and flux filled up in the outer sheath contains, as percentage to the total mass of the wire, Cr: 22.0-30.0 mass %, Ni: 6.0-12.0 mass %, Mo: 2.0-5.0 mass %, N: 0.20-0.35 mass %, TiO2: 4.0-9.0 mass %, SiO2: 0.1-2.0 mass %, ZrO2: 0.5-4.0 mass %, total of Li2O, Na2O and K2O: 0.50-1.50 mass %, metal fluoride in terms of fluorine amount: 0.10-0.90 mass %, and rare earth element component: 0.10-1.00 mass %, limits C to 0.04 mass % or below, W to 4.0 mass % or below, Cu to 2.0 mass % or below, Bi2O3 to 0.01 mass % or below, and limits oxides other than the above to 3.0 mass % or below. With such a composition, it is possible to obtain a weld bead which is excellent in the weldability in welding in all attitudes and is more excellent in the low temperature toughness while keeping excellent pitting corrosion resistance in arc welding of duplex stainless steel and the like.

Owner:KOBE STEEL LTD

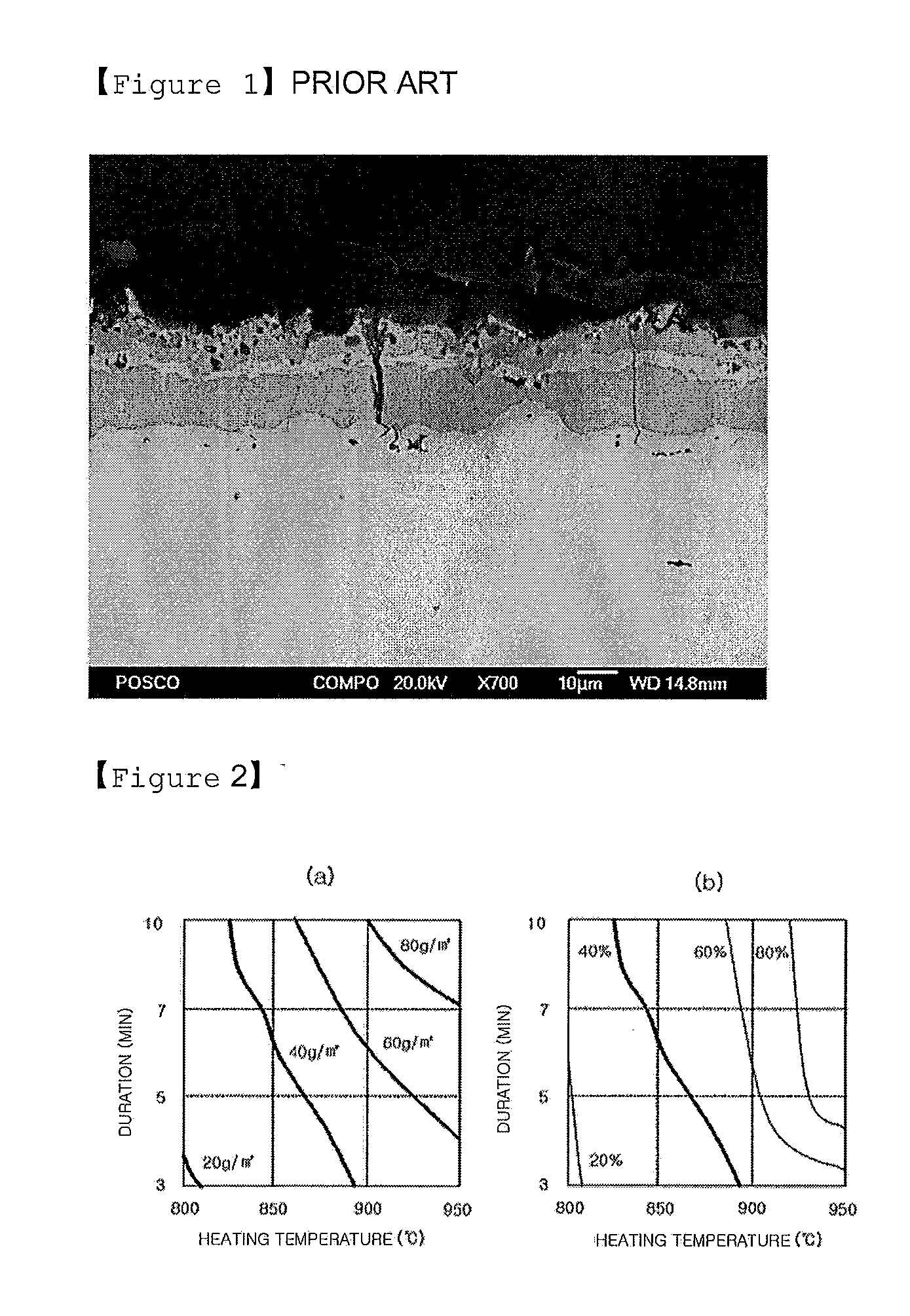

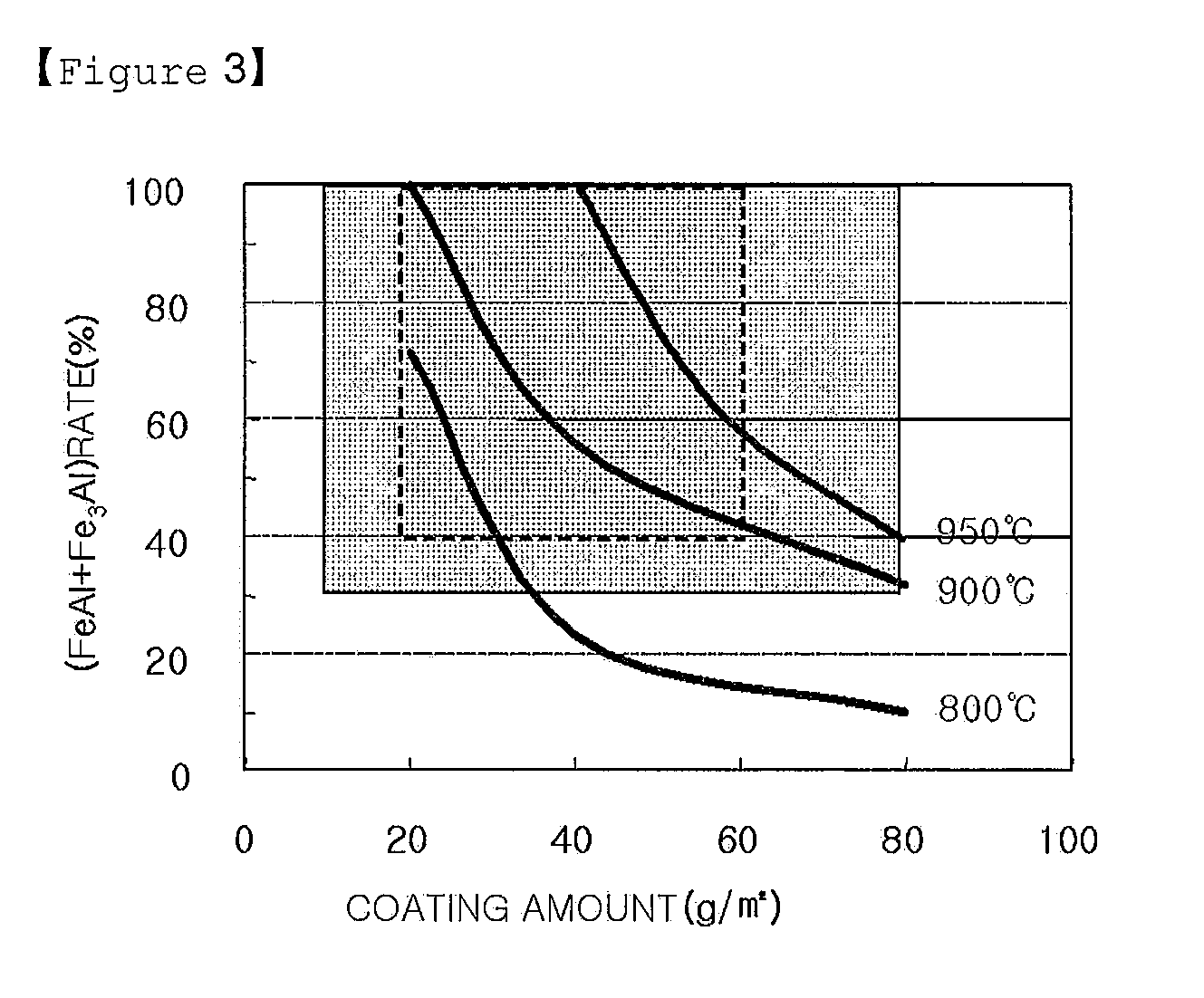

Aluminum-Plated Steel Sheet Having Superior Corrosion Resistance, Hot Press Formed Product Using the Same, and Method for Production Thereof

InactiveUS20110300407A1Easy to produceSimple production conditionsHot-dipping/immersion processesPretreated surfacesProduction rateDip-coating

Provided are a coated steel sheet, a hot press formed product using the steel sheet, and a producing method thereof. Conditions for hot-dip coating bath are optimized when an aluminum-coated steel sheet is produced using a hot rolled steel sheet or a cold rolled steel sheet, and processes are controlled during production of a hot press formed product from the steel sheet, thereby forming a coating layer having a high ratio of (Fe3Al+FeAl) compound layer on the surface of the steel sheet. In cases where the (Fe3Al+FeAl) compound layer has an appropriate occupancy ratio with respect to the whole thickness of the coating layer, good resistance against crack and corrosion can be achieved to improve a local corrosion resistance of the hot press formed product, particularly, a pitting corrosion resistance. Therefore, high-quality hot press formed products can be produced with high productivity and lower costs.

Owner:POHANG IRON & STEEL CO LTD

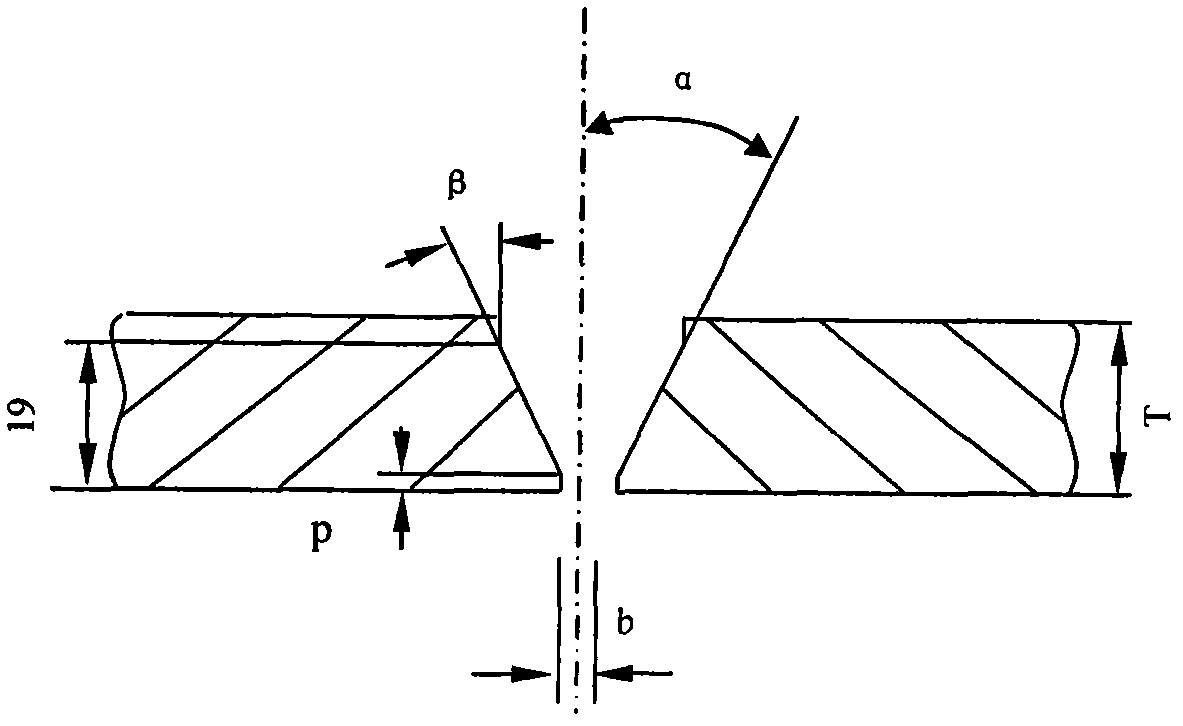

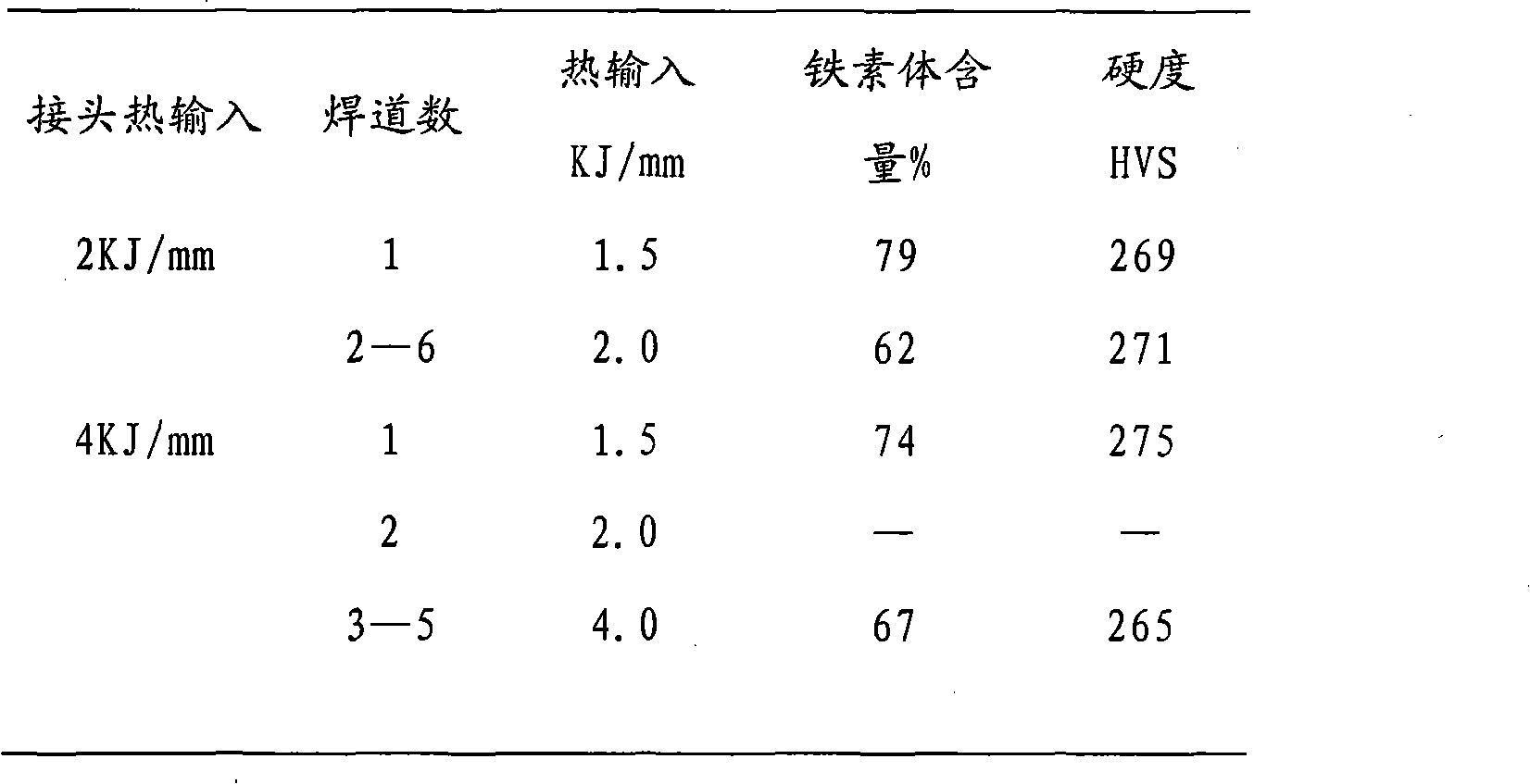

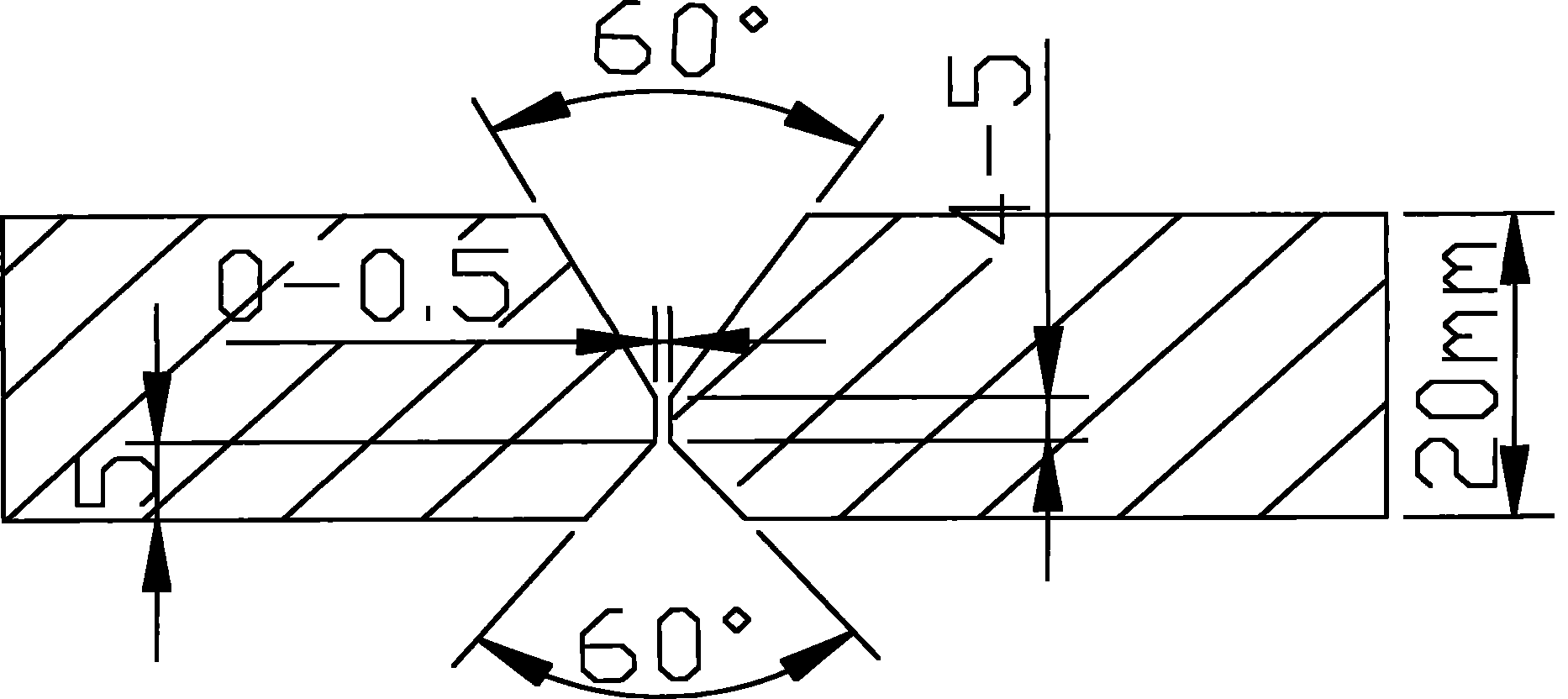

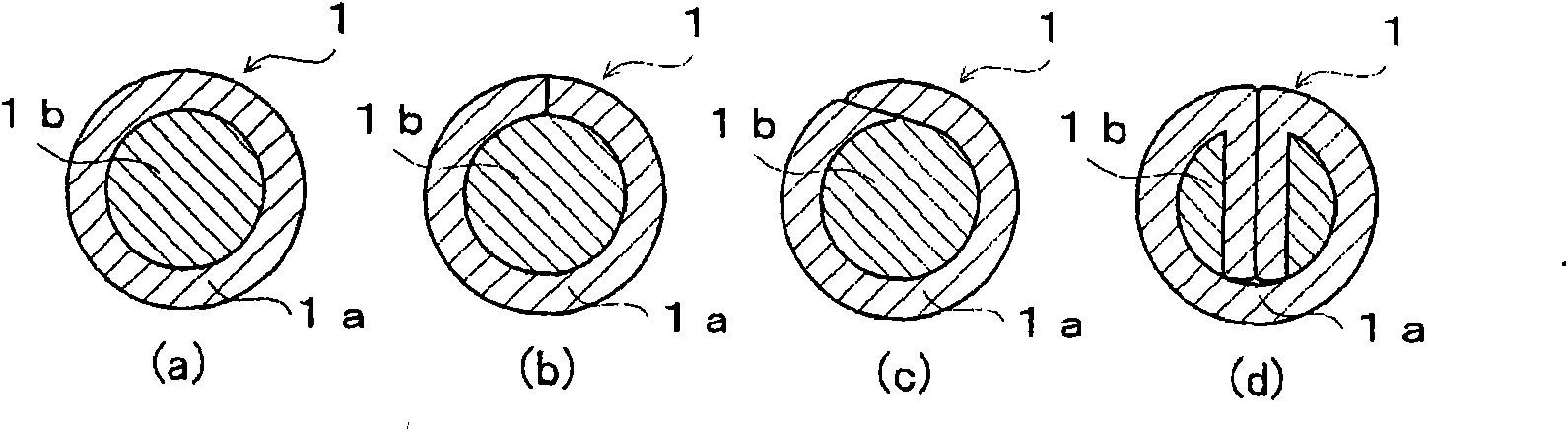

Two phase stainless steel submerged-arc welding SAW welding procedure

ActiveCN101913012AGood academic performanceImprove corrosion resistanceArc welding apparatusMechanical propertyWeld line

The invention relates to an economic and practical submerged arc welding procedure applicable to welding of common two phase stainless steel 022CrNi5Mo3(S31803 and S2205). The invention is characterized in that the procedure includes the following steps: 1) the performance characteristics of two phase stainless steel are researched; 2) welding material is selected and welding procedure is determined; 3) welding edge preparation is carried out; 4) clean-up and final inspection are carried out on the surface of work piece to be welded; 5) submerged arc welding is carried out on the common two phase stainless steel. The invention is based on research of chemical constituents and performance characteristics of common two phase stainless steel, economic and practical domestic submerged arc welding material combination applicable to common two phase stainless steel and reasonable submerged arc welding procedure are selected, and the invention has the advantage that efficient welding of two phase stainless steel is realized by adopting high line energy submerged arc welding. Welding of common two phase stainless steel is carried out by adopting the invention, the chemical constituents of welding line can be ensured to meet standard requirement, ferrite content of welding joint (including welding line and heat affected zone) is controlled to be 30-65%, and the welding joint has good mechanical properties and pitting corrosion resistance.

Owner:NANJING BAOSE

Flux-cored wire for stainless steel arc welding

ActiveCN102091881AImprove pitting resistanceImprove low temperature toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementFluoride

A flux-cored wire for stainless steel arc welding including an outer sheath made of stainless steel and flux filled up in the outer sheath contains, as percentage to the total mass of the wire, Cr: 22.0-30.0 mass %, Ni: 6.0-12.0 mass %, Mo: 2.0-5.0 mass %, N: 0.20-0.35 mass %, TiO2: 4.0-9.0 mass %, SiO2: 0.1-2.0 mass %, ZrO2: 0.5-4.0 mass %, total of Li2O, Na2O and K2O: 0.50-1.50 mass %, metal fluoride in terms of fluorine amount: 0.10-0.90 mass %, and rare earth element component: 0.10-1.00 mass %, limits C to 0.04 mass % or below, W to 4.0 mass % or below, Cu to 2.0 mass % or below, Bi2O3 to 0.01 mass % or below, and limits oxides other than the above to 3.0 mass % or below. With such a composition, it is possible to obtain a weld bead which is excellent in the weldability in welding in all attitudes and is more excellent in the low temperature toughness while keeping excellent pitting corrosion resistance in arc welding of duplex stainless steel and the like.

Owner:KOBE STEEL LTD

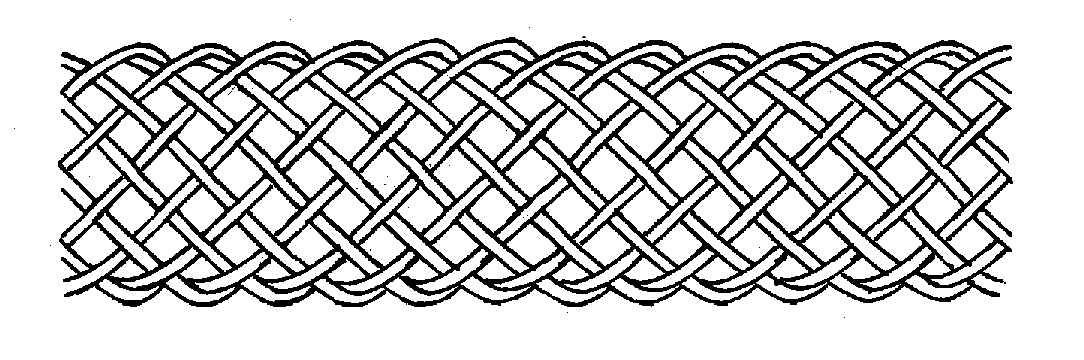

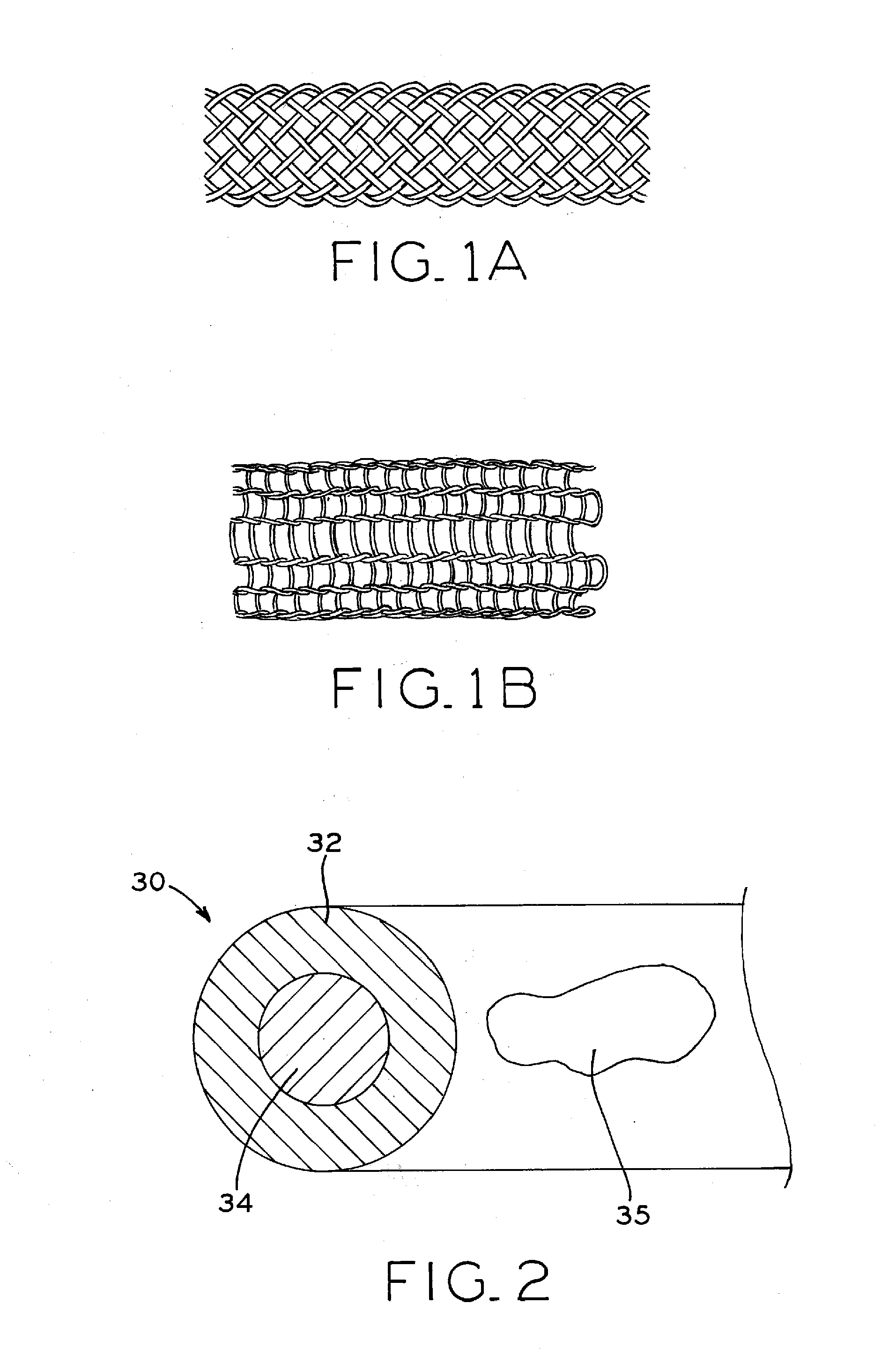

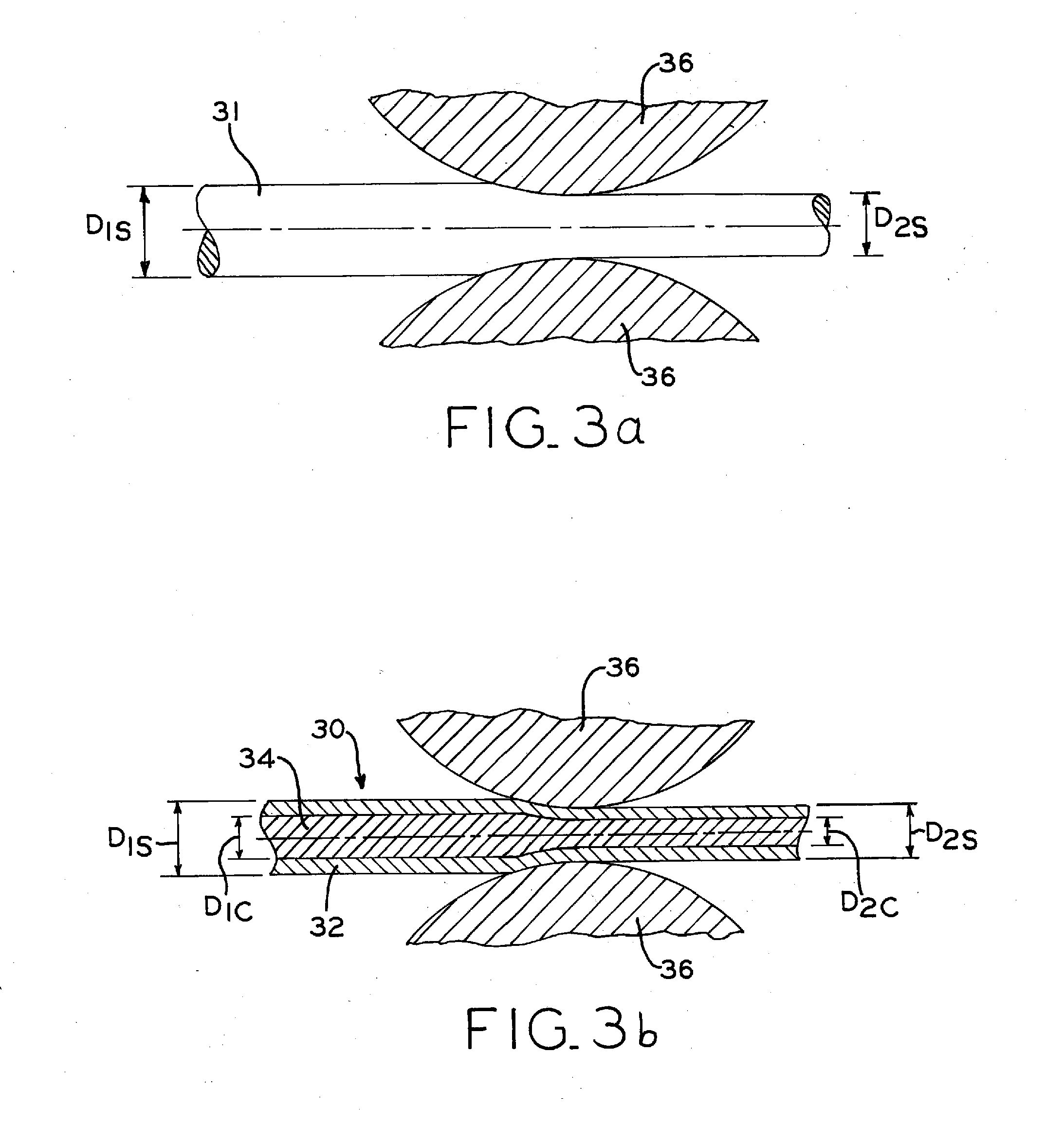

Biodegradable composite wire for medical devices

A bioabsorbable wire material includes manganese (Mn) and iron (Fe). One or more additional constituent materials (X) are added to control corrosion in an in vivo environment and, in particular, to prevent and / or substantially reduce the potential for pitting corrosion. For example, the (X) element in the Fe—Mn—X system may include nitrogen (N), molybdenum (Mo) or chromium (Cr), or a combination of these. This promotes controlled degradation of the wire material, such that a high percentage loss of material the overall material mass and volume may occur without fracture of the wire material into multiple wire fragments. In some embodiments, the wire material may have retained cold work for enhanced strength, such as for medical applications. In some applications, the wire material may be a fine wire suitable for use in resorbable in vivo structures such as stents.

Owner:FORT WAYNE METALS RES PROD CORP

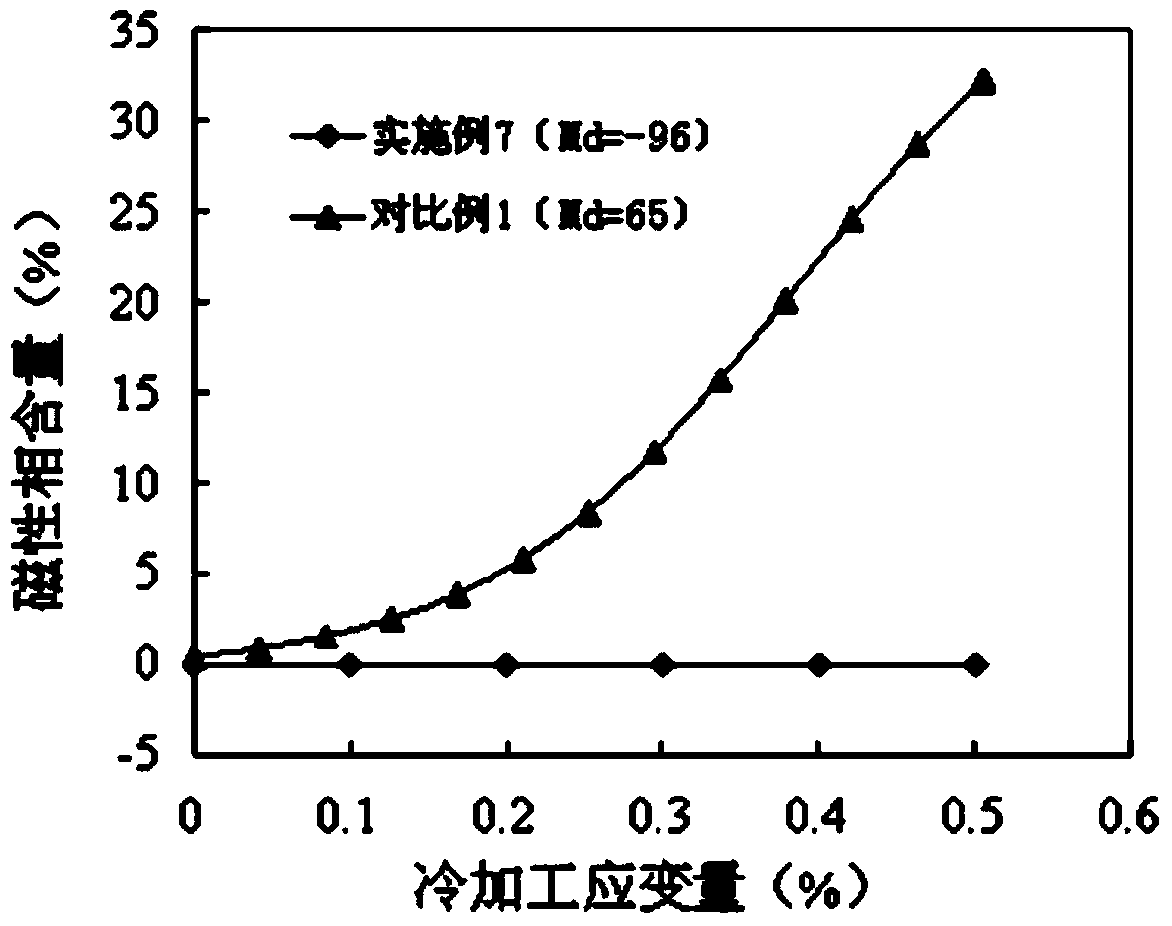

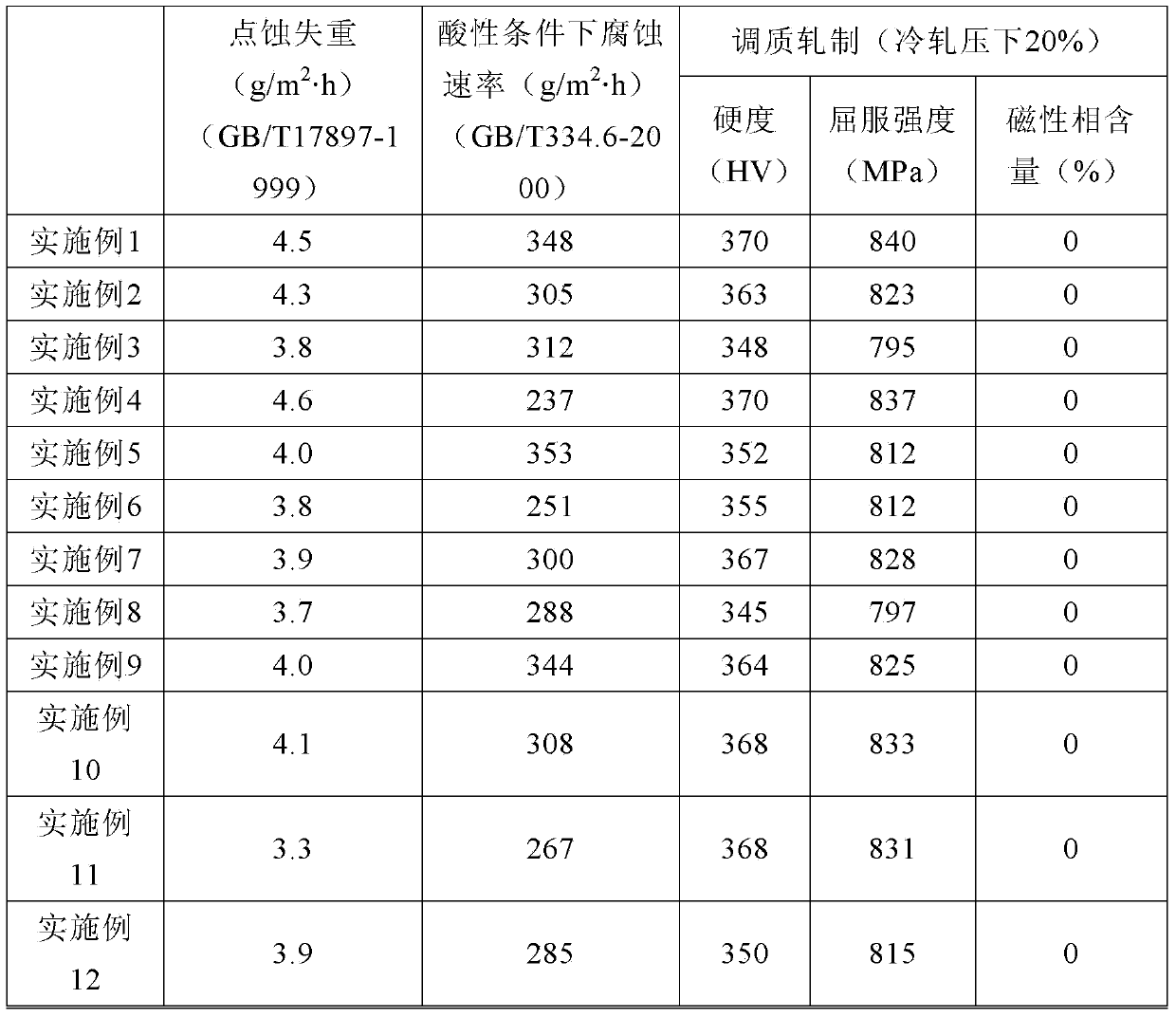

Non-magnetic hard austenitic stainless steel for precision electron and manufacturing method thereof

The invention relates to a non-magnetic hard austenitic stainless steel for precision electron and a manufacturing method thereof. The stainless steel comprises the following chemical components by weight percent: 0.06% to 0.10% of C, 0.51% to 0.8% of Si, 11.5% to 12.5% of Mn, 17.0% to 18.0% of Cr, 2.51% to 3.50% of Ni, 0.15% to 0.20% of N, 0.15% to 0.50% of Sn, 0.30% to 0.50% of Mo, 0.30% to 0.75% of Mo and W / 2, 2.0% to 2.5% of Cu and the balance of Fe and inevitable impurities, wherein at least one of the components as follows is selected: less than or equal to 0.1% of V and less than or equal to 0.1% of Nb; and 30Sn%+5Mo%+2.5W%+Ni%+Cu%+0.5Si%-0.25Mn% is greater than or equal to 9.0. Based on the Cu-Mo-Sn-Si alloying, the adverse effect to the corrosion resistance of the stainless steel in which the Ni is reduced and the Mn is added is eliminated, so that the stainless steel has the pitting corrosion resistance superior to 304 and can be prevented from being corroded by a reducing acid. Meanwhile, the temperature of Md30 / 50 is controlled to be lower than -75 DEG C and the austenitic stability is controlled to be superior to 304 and 305, so that the magnetic martensite phase transformation is avoided when the deformation of the stainless steel in cold machining is less than or equal to 50%. Thus, the non-magnetic performance of the hard austenitic stainless steel is also maintained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Recessed Germanium (Ge) Diode

InactiveUS20100151619A1Reduce the overall heightSolid-state devicesSemiconductor/solid-state device manufacturingPhotodiodeDiode

A photodiode is formed in a recessed germanium (Ge) region in a silicon (Si) substrate. The Ge region may be fabricated by etching a hole through a passivation layer on the Si substrate and into the Si substrate and then growing Ge in the hole by a selective epitaxial process. The Ge appears to grow better selectively in the hole than on a Si or oxide surface. The Ge may grow up some or all of the passivation sidewall of the hole to conformally fill the hole and produce a recessed Ge region that is approximately flush with the surface of the substrate, without characteristic slanted sides of a mesa. The hole may be etched deep enough so the photodiode is thick enough to obtain good coupling efficiencies to vertical, free-space light entering the photodiode.

Owner:ANALOG DEVICES INC

Metal sheet with anticorrosive coating

InactiveUS20020160180A1Improve corrosion resistanceSynthetic resin layered productsRecord information storageSheet steelPhosphate

Disclosed herein is a metal sheet with anticorrosive coating which exhibits outstanding corrosion resistance, pitting corrosion resistance, and red rust resistance. It has the anticorrosive coating on at least one side thereof. The anticorrosive coating is formed from an anticorrosive paint which contains a metallic zinc powder and at least one kind of metal salt rust inhibitor. The metal salt is a salt of a metal which is more base than zinc. The metal sheet may be a steel sheet. The metal salt rust inhibitor may be a phosphate or a phosphomolybdate.

Owner:KOBE STEEL LTD

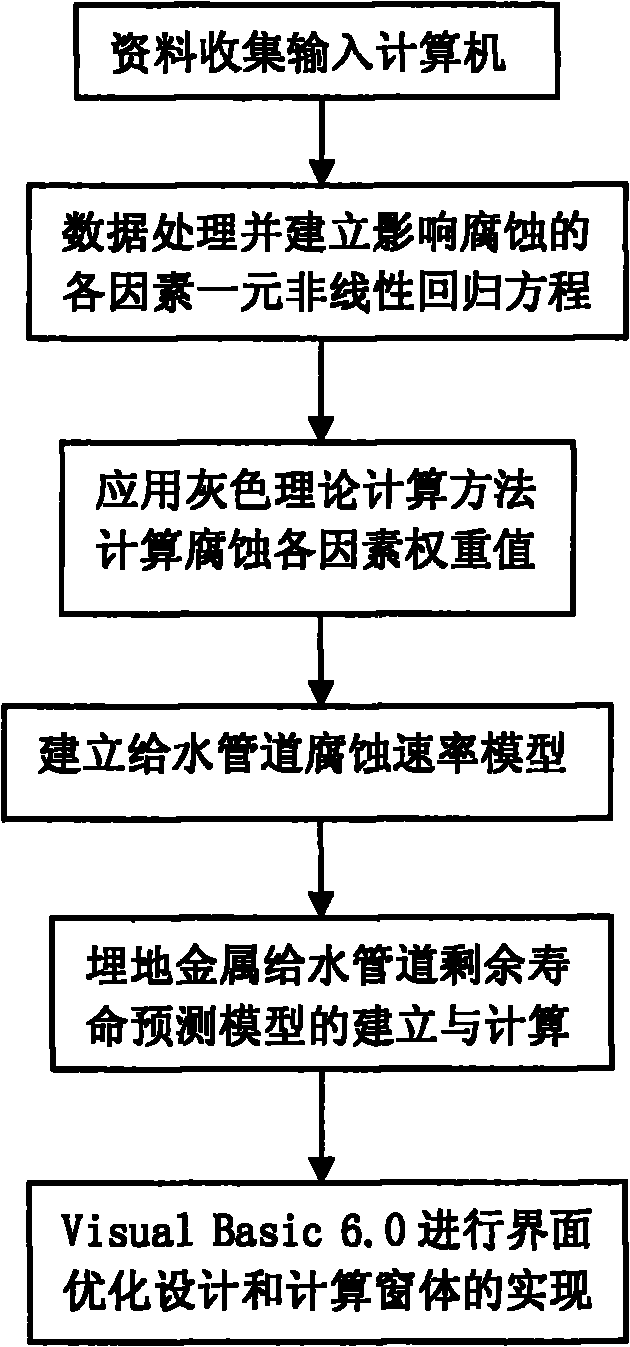

Testing method for predicting residual service life of buried metal water supply pipeline

InactiveCN101915728ABig interestEfficient prediction of remaining lifeWeather/light/corrosion resistanceSpecial data processing applicationsWater qualityProcess engineering

The invention discloses a testing method for predicting the residual service life of a buried metal water supply pipeline, which relates to a testing method comprising the following steps: (1) inputting testing data of environmental factors affecting the corrosion of the buried metal water supply pipeline and water quality change conditions in the pipeline in different periods of time into a computer; (2) respectively computing the collected data in the computer by a mathematical statistics method, and establishing a nonlinear regression equation in one unknown; (3) computing the weighted value of each factor affecting pipeline corrosion by a grey theory computing method; (4) establishing corrosion rate models (an internal corrosion model and an external corrosion model) of the buried metal water supply pipeline; and (5) according to an electrochemical model of the soil corrosion rate, respectively establishing prediction models for the residual service life of the buried metal water supply pipeline by uniform corrosion, local corrosion and pitting corrosion, and computing the residual service life of the buried metal water supply pipeline by an approximate analytical method. The invention provides a technical reference for carrying out transformation and renovation of pipelines and improving the safety of a water supply system.

Owner:SHENYANG JIANZHU UNIVERSITY

Nondestructive flaw detector for steel wire ropes

InactiveCN103994998AHigh speed online high speedHigh-speed detectionOptically investigating flaws/contaminationUsing optical meansFeature extractionMetallurgy

The invention provides a nondestructive flaw detector for steel wire ropes, and solves the problem that quantitative detection of wire break and wear in steel wire ropes cannot be realized by the prior art. The nondestructive flaw detector for steel wire ropes comprises a steel wire rope walking positioning mechanism, a magnetic leakage flux detector, an optical detector, a photoelectric encoder, and an embedded signal processing system. The steel wire rope walking positioning mechanism is provided with a steel wire rope channel, the inner wall surface of which is fixed with the magnetic leakage flux detector, the optical detector and the photoelectric encoder. The embedded signal processing system is fixed on the steel wire rope walking positioning mechanism, and the magnetic leakage flux detector, the optical detector and the photoelectric encoder are connected to the embedded signal processing system. By combining a magnetic leakage flux technology and an optical determination technology to perform signal feature extraction and quantitative analysis on wire break, pitting corrosion, wear and other defects of steel wire ropes, the nondestructive flaw detector realizes online high speed and high accuracy detection of the steel wire ropes.

Owner:YANTAI JIUXIN PRECISE MECHANICAL EQUIP

Time-varying Reliability Determination Method of Prestressed Concrete Box Girder Bridge

ActiveCN102286916AImprove analysis efficiencyBridgesSpecial data processing applicationsCarbonizationStress relaxation

A method for determining the time-varying reliability of prestressed concrete box girder bridges based on the stochastic finite element method. For prestressed concrete box girders that are widely used in highway bridge systems and have common early-stage diseases, by combining degenerate shell elements, material constitutive relations and The crack model simulates the nonlinear characteristics of the box girder in the cracking stage, and the embedded concrete creep, shrinkage and steel strand stress relaxation model considers the deformation, prestress loss and internal force redistribution of the box girder during its entire life, through the reinforcement The uniform corrosion model and the pitting corrosion model calculate the section loss of steel bars (steel strands) in carbonization environment and chloride ion environment respectively. Finally, through the definition of random variables, sampling, calling finite element program calculation and extracting stress and strain results, the reliability calculation of the box girder bridge is realized and used to guide the subsequent maintenance and reinforcement work.

Owner:SOUTHEAST UNIV

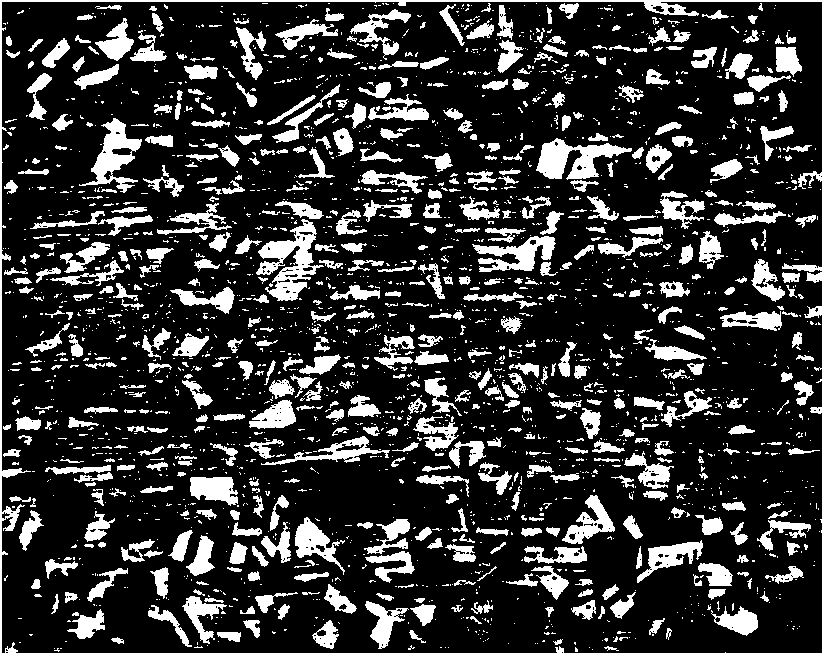

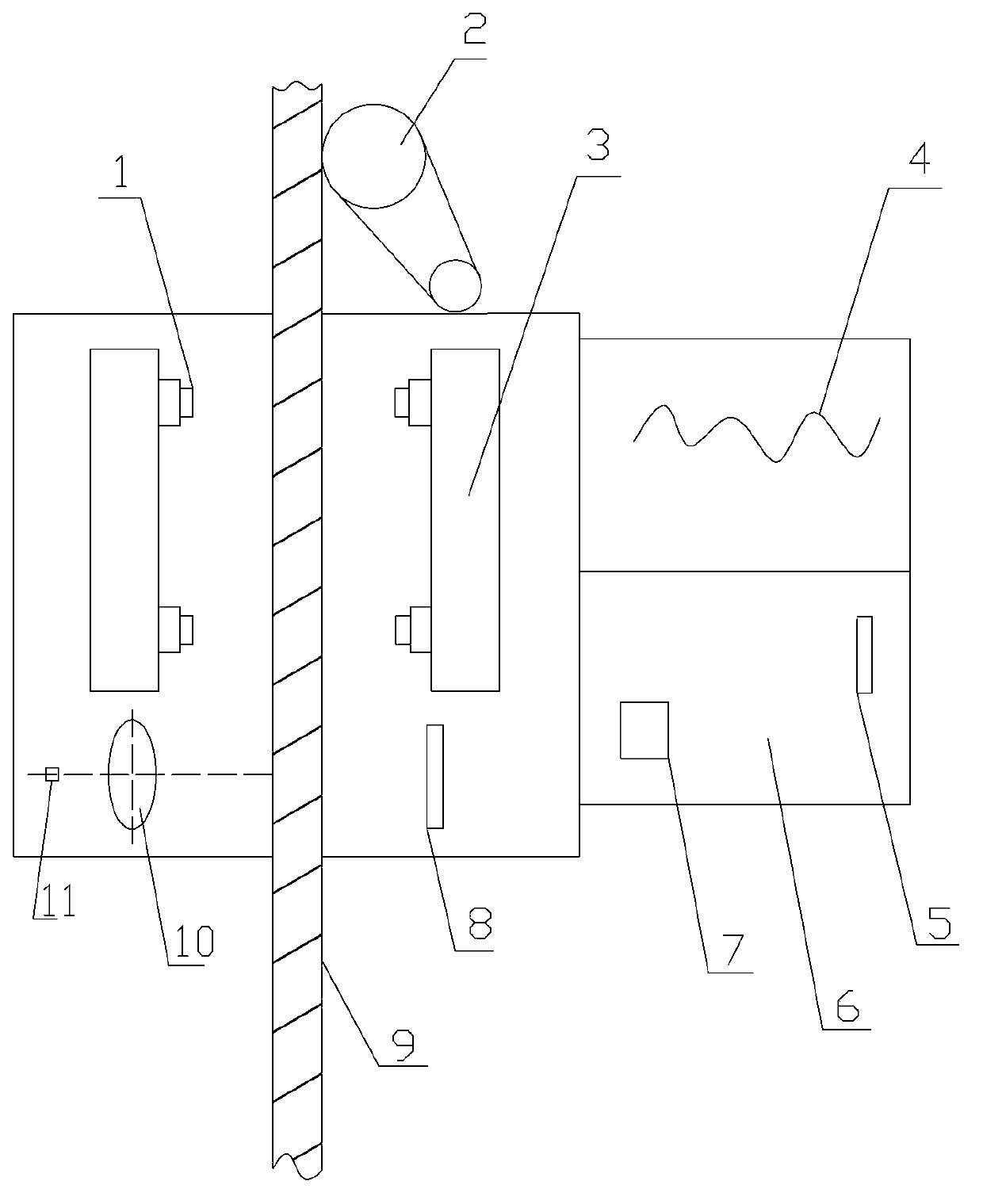

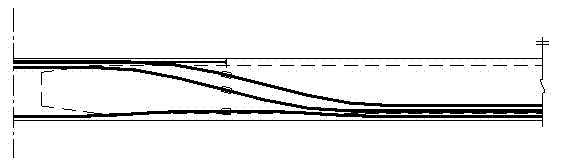

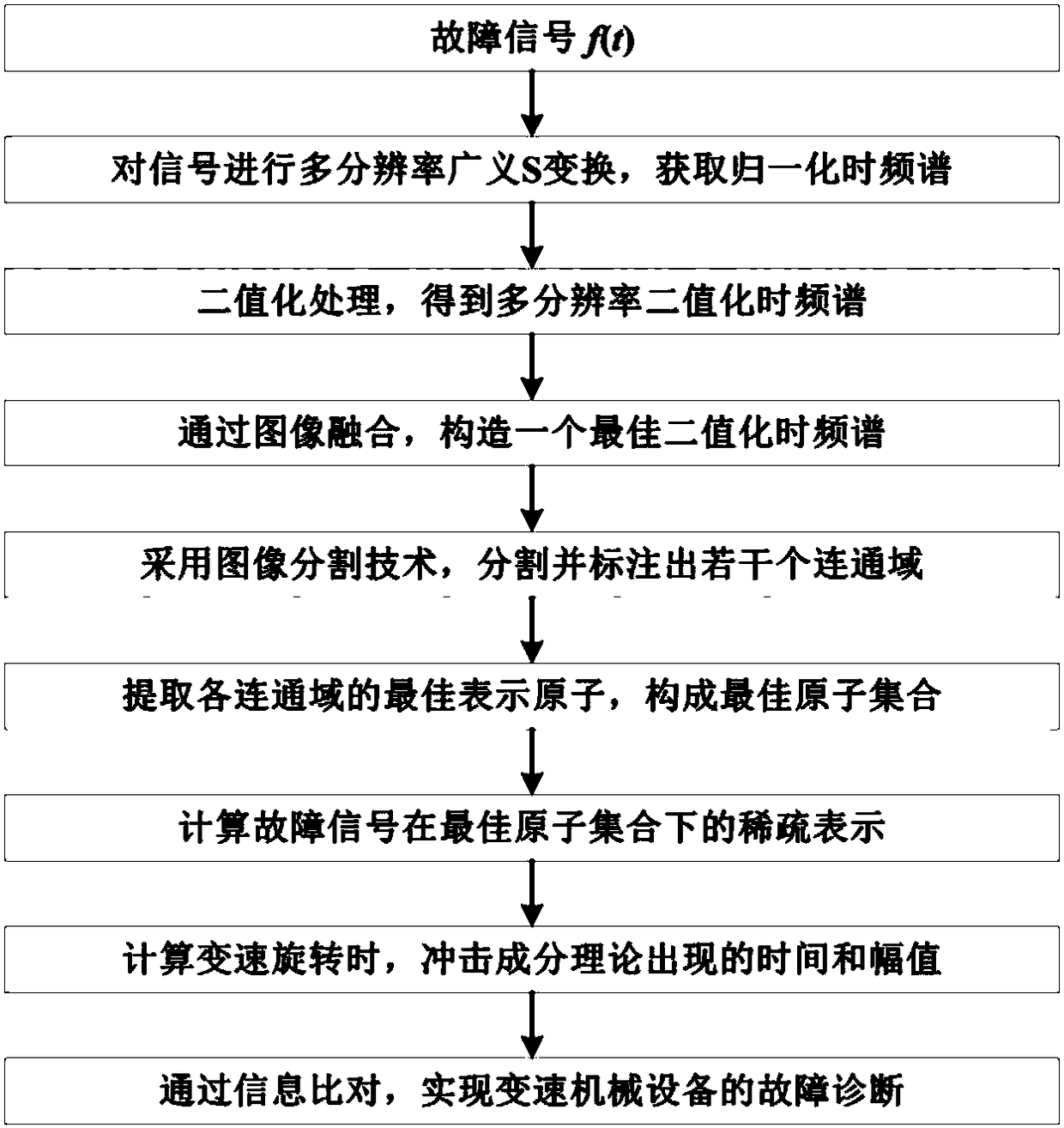

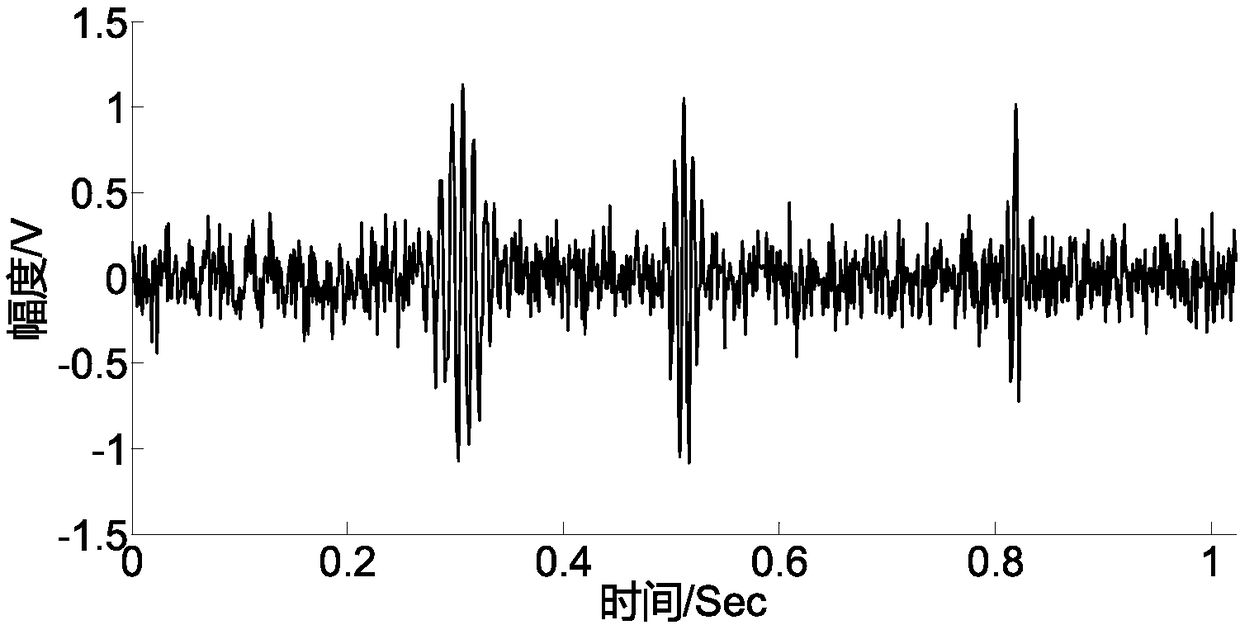

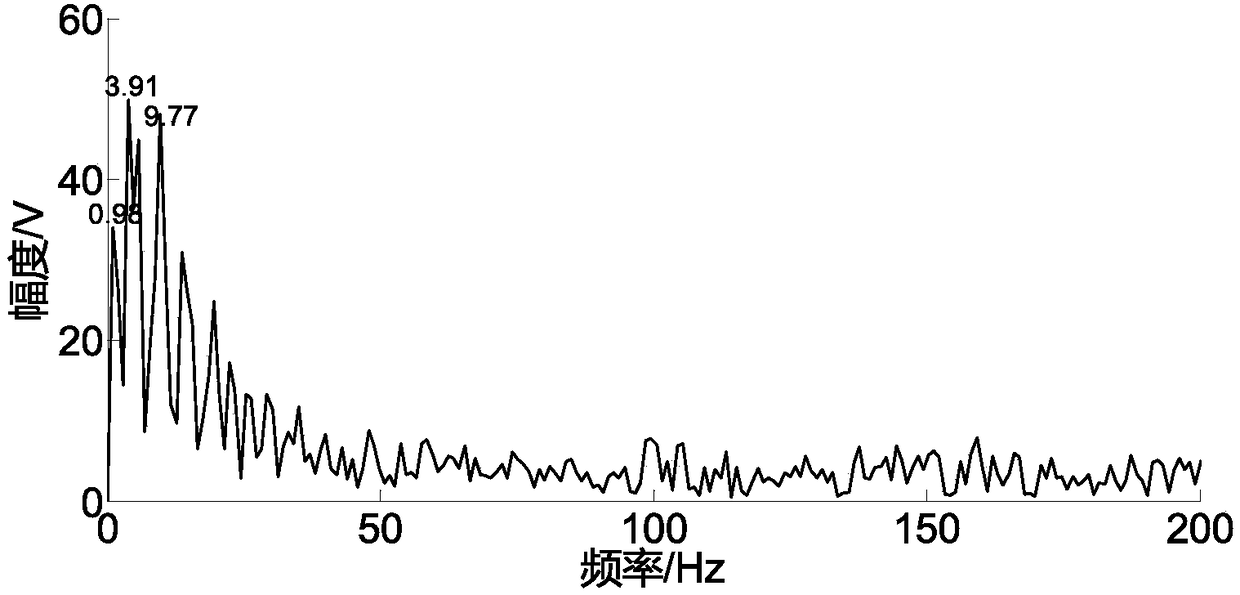

Fault diagnosis method of variable-speed rotation machine based on time-frequency spectrum segmentation

ActiveCN108106830AQuick TroubleshootingFilter out strong background noiseMachine part testingFrequency spectrumTime frequency spectrum

The invention provides a fault diagnosis method of a variable-speed rotation machine based on time-frequency spectrum segmentation. The method includes following steps: step 1, obtaining normalized time-frequency spectrums of signals through multi-resolution generalized S transform, and generating multi-resolution binarized time frequency spectrums; step 2, combining the binarized time-frequency spectrums with all resolutions, and obtaining an optimal binarized time-frequency spectrum; step 3, segmenting the optimal binarized time-frequency spectrum into a plurality of connected domains, and performing information annotation on each connected domain; step 4, extracting an optimal expression atom of each connected domain, forming an optimal atom set, and calculating the expression of a fault signal in the optimal atom set; and step 5, calculating the appearance time and amplitude of an impact theory, and realizing fault diagnosis of variable-sped mechanical equipment through informationcomparison. According to the method, most strong background noises can be filtered, and fault diagnosis of impact type faults including cracking, pitting corrosion or spalling etc. of the variable-speed rotation machine can be realized.

Owner:WUHAN UNIV OF SCI & TECH +1

Sapphire substrate ultraprecision machining method based on fixed abrasive pad

ActiveCN103252708AFast processingEfficient processingLapping machinesLapping toolsMachining timeUltra precision

The invention discloses a sapphire substrate ultra-precision machining method based on a fixed abrasive pad. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad mainly relates to three steps of rough grinding, accurate grinding and polishing, namely, rough grinding is conducted on a cut sapphire substrate semi-finished product through a W75 nickel plated diamond FAP; then accurate grinding is conducted on a workpiece after rough grinding through a W28 nickel plated diamond FAP; last, polishing is conducted on the workpiece after accurate grind through a W5 diamond FAP, and grinding and polishing processes are finished. According to the sapphire substrate ultra-precision machining method based on the fixed abrasive pad, a sapphire substrate is machined, the time cost in the whole process is shortened within two hours, machining time of sapphire is greatly shortened, the sapphire substrate with the workpiece surface roughness (Ra) is smaller than 3nm can be finally obtained, surface defects such as pitting corrosion and scratches can be effectively removed, the damage of a subsurface is reduced and the quality of the surface is good. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad improves machining efficiency of the substrate and the quality of the surface of the substrate, and is low in cost and pollution-free.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Blade surface pitting corrosion resistant coating and preparation method thereof

InactiveCN102392217AReduce coefficient of frictionHigh hardnessBlade accessoriesVacuum evaporation coatingLarge particleBlocking layer

The invention discloses a blade surface pitting corrosion resistant coating and preparation method thereof. The coating comprises a bonding layer, a blocking layer, and a surface layer from the inside to the outside, wherein, the bonding layer consists of pure metal Ti, the blocking layer consists of TiN and TiC from the inside to the outside, and the surface layer consists of TiCN. The preparation method is characterized by using an arc ion plating machine to successively depositing the bonding layer, the blocking layer, and the surface layer on the blade matrix. The multi-layer pitting corrosion resistant coating structure disclosed herein has low friction coefficient, high hardness, good wear resistance, good bonding force between the coating and the substrate, and excellent pitting corrosion resistance. According to the invention, in the preparation process, vacuum degree of the furnace body is at least 6.7*10<-3> Pa, the temperature of the furnace body is 250-450 DEG C, so that the marked impact on blade matrix material microstructure in the deposition process can be reduced; by using specific arc current, large particles, liquid drop and cavity on the coating surface in the deposition process can be reduced, so that the coating surface is smooth, compact, and uniform, and the corrosion resistance is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

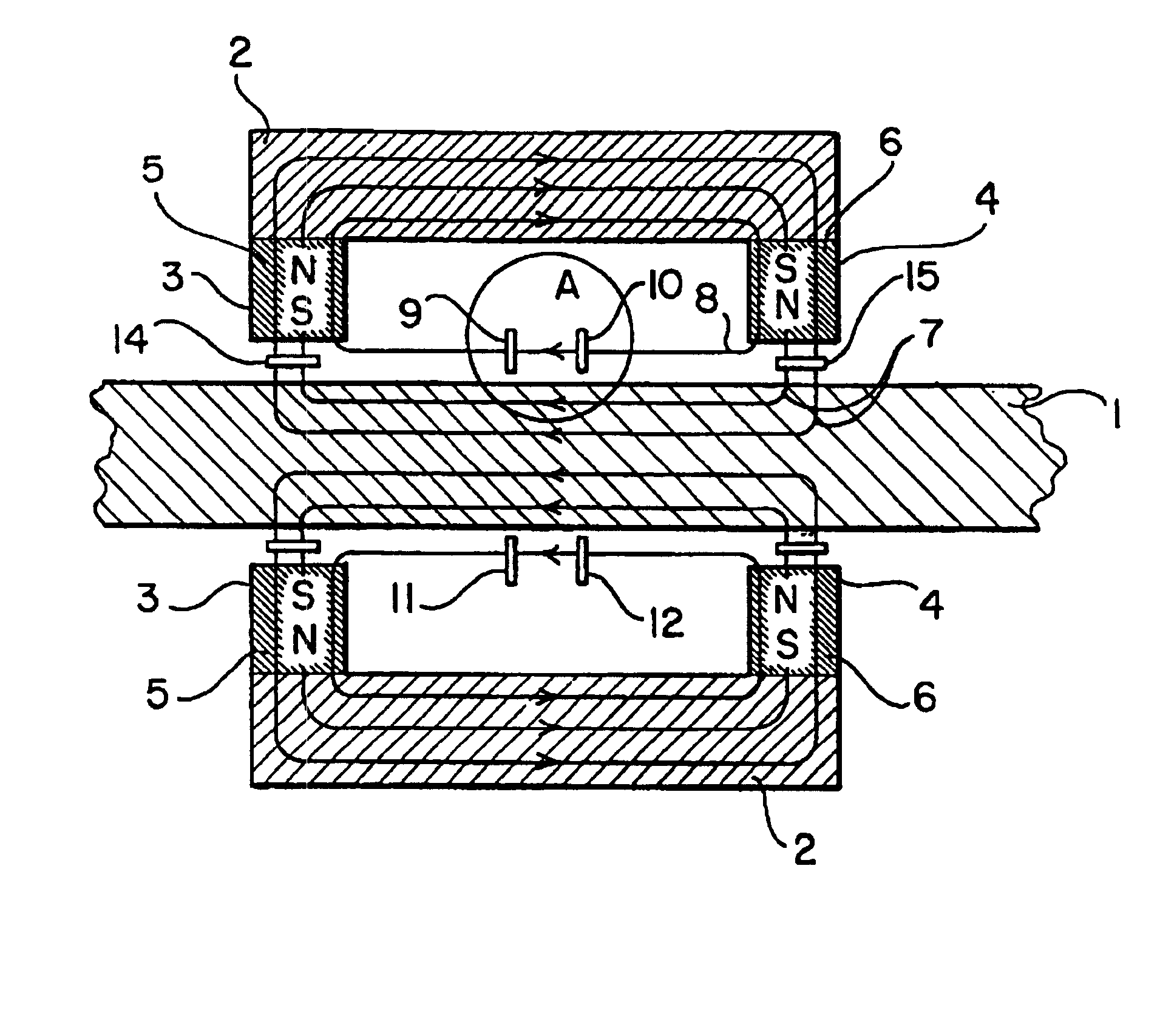

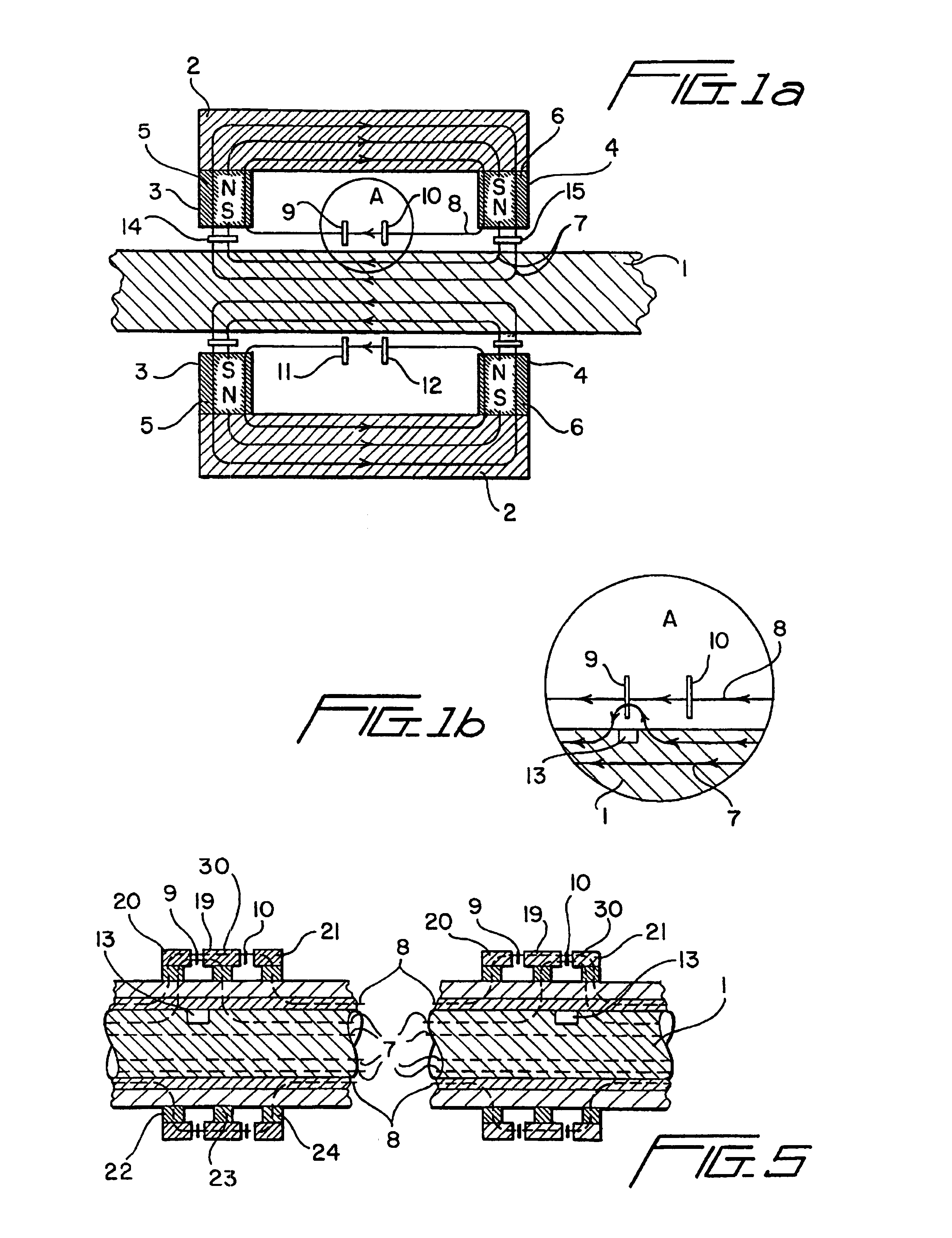

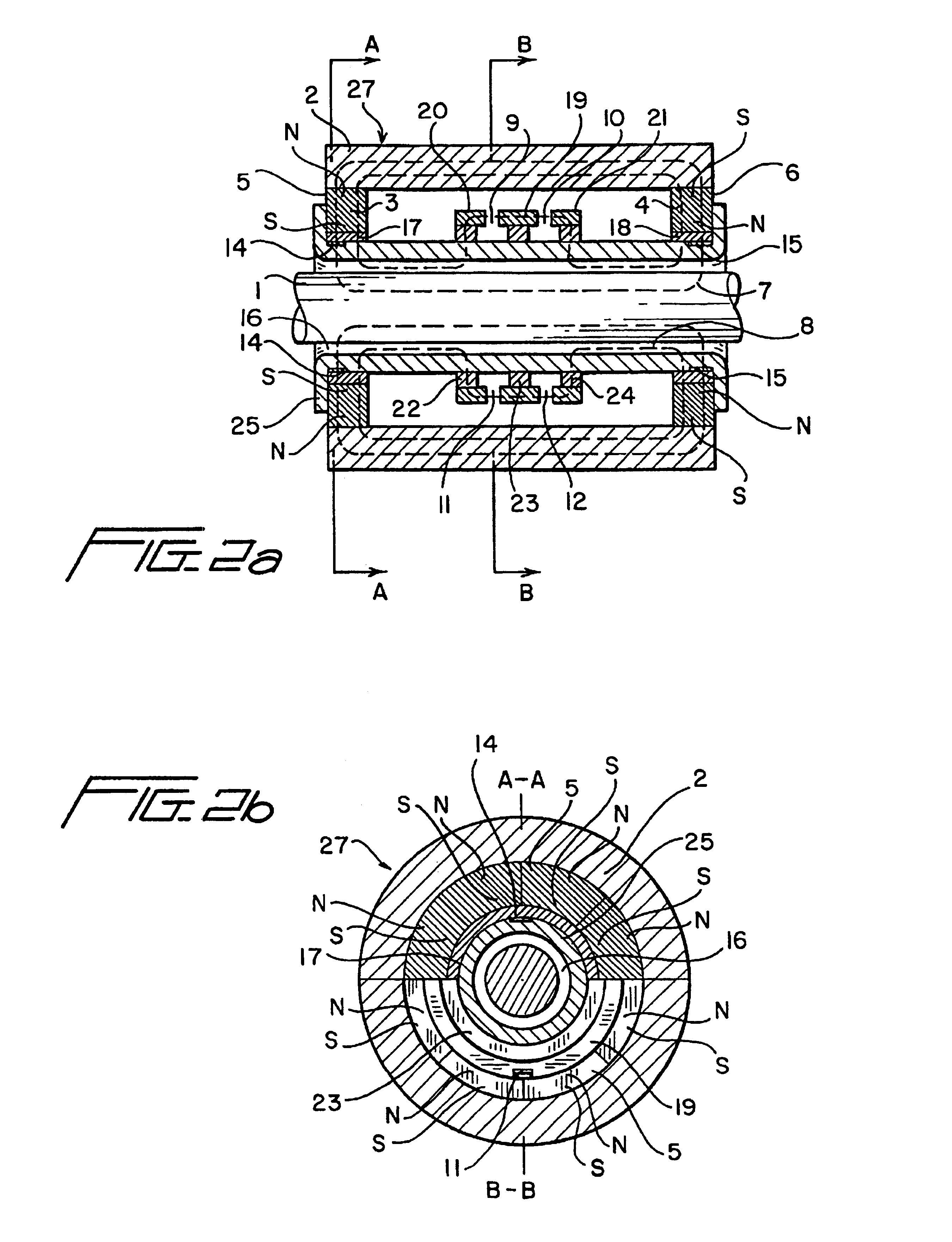

Magnetic non-destructive method and apparatus for measurement of cross sectional area and detection of local flaws in elongated ferrous objects in response to longitudinally spaced sensors in an inter-pole area

InactiveUSRE40166E1Improve reliabilityImprove accuracyMagnetic property measurementsMaterial magnetic variablesNon destructiveWeight coefficient

A magnetic non-destructive method and an apparatus for measurement of cross sectional area of elongated ferrous objects such as steel wire ropes and for detecting local flaws is disclosed. A section of a wire rope is magnetized by longitudinally spaced magnetic poles. A magnetic field parameter, e.g. magnetic flux density, is measured in, by at least, one pair of points between the poles of magnetizing device (in an inter-pole area) at the object under test surface. The pair of points is formed by two sensors placed in the inter-pole area along a direct line parallel to the rope axis. The rope cross sectional area corresponds to a sum of the sensor pair signals. Local flaws, such as broken wires and pitting corrosion in the rope, is detected by a first differences of signals of the sensor pair. At least one additional magneto-sensitive sensor is located radially inward of the poles and weight coefficient A depending on a nominal value of the rope cross sectional area is subtracted from the sum of signals of the sensor pair thereby providing a second difference of the signals corresponding to the rope cross sectional area. The coefficient A value is chosen to get the minimum value of the second signal difference while the magnetizing device and all the sensors are placed onto the rope having a nominal value of a cross sectional area. A sensor unit in the inter-pole area includes a magnetic core in form of three longitudinally spaced ferrous elements. Pairs of the sensors are located in the gaps along a direct line parallel to the rope. Two embodiments of the magnetic heads are disclosed: the hollow cylinder-shaped one and the U-shaped one.

Owner:INTRON PLUS

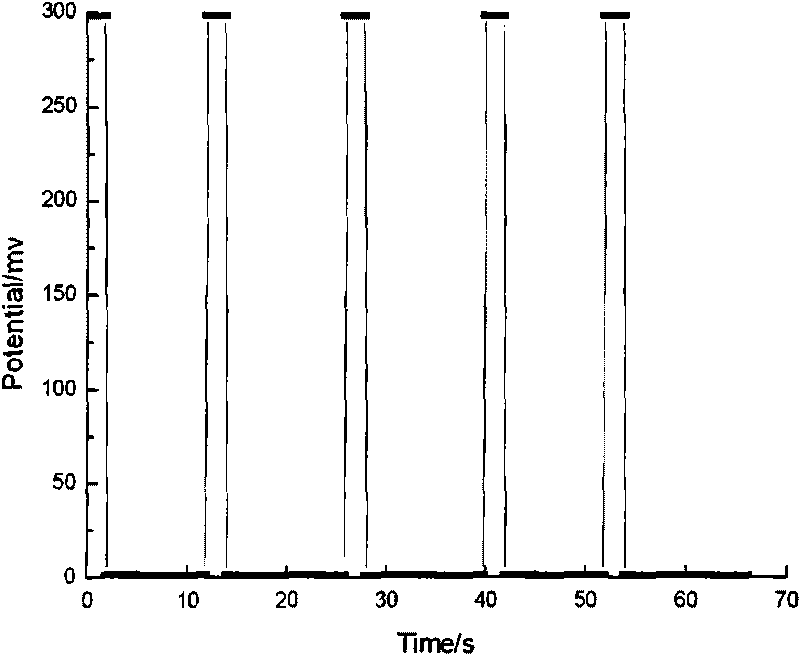

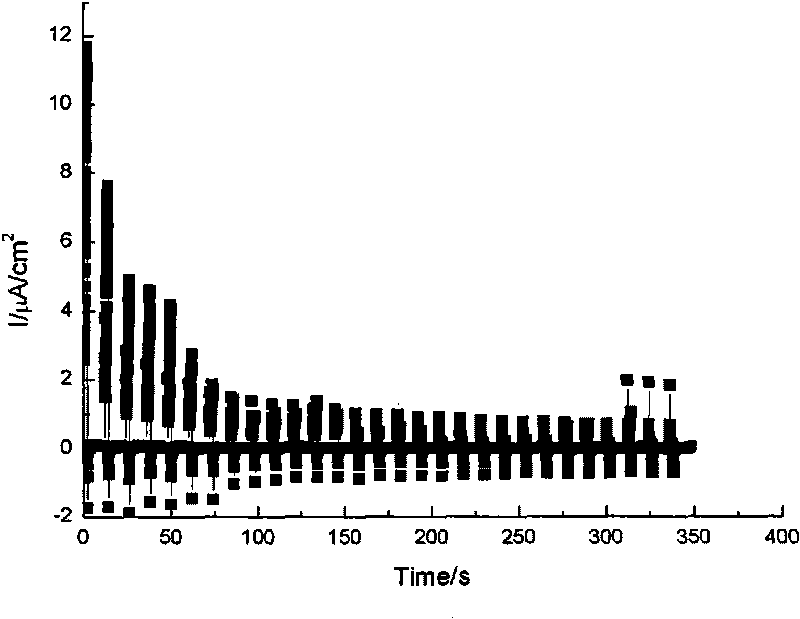

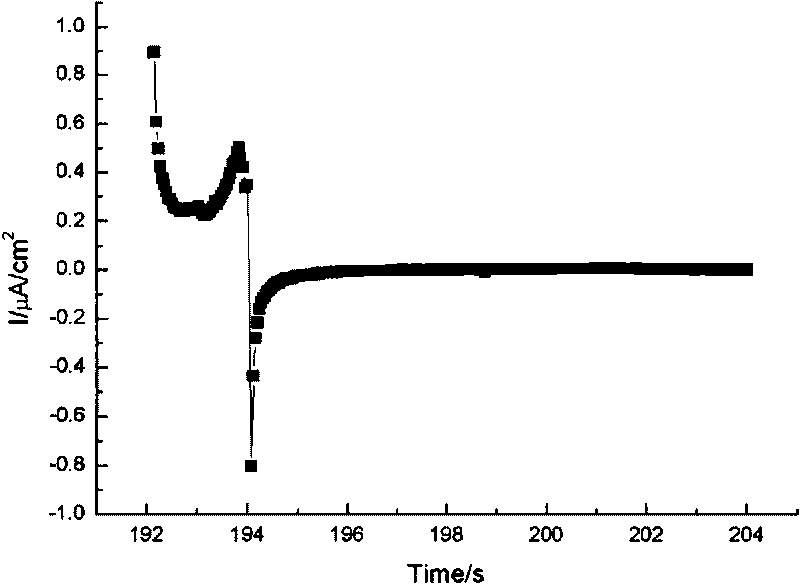

Electrochemical method for evaluating pitting resistance of stainless steel

InactiveCN101762449AWeather/light/corrosion resistanceMaterial electrochemical variablesElectrochemistryPulse waveform

The invention belongs to the technical field of pitting corrosion evaluation of stainless steel and relates to a method for controlling and evaluating occurrence and development of pitting corrosion of the stainless steel, in particular to an electrochemical method for evaluating pitting resistance of the stainless steel. In the method, by adopting rotary pulse technique, selecting a proper temperature and medium, controlling pulse waveform and the number of pulses and effectively controlling the quantity and the size of pitting corrosion on the surface of the stainless steel, the evaluation of development positions, quantity, size and shape of corrosion pit and the like of the pitting corrosion in the stainless steel is realized. By the method, a large amount of information on the pitting corrosion is qualitatively and quantitatively obtained, and an important basis is provided for the research on the corrosion resistance of the stainless steel, so that the method has great research and application significance.

Owner:FUDAN UNIV

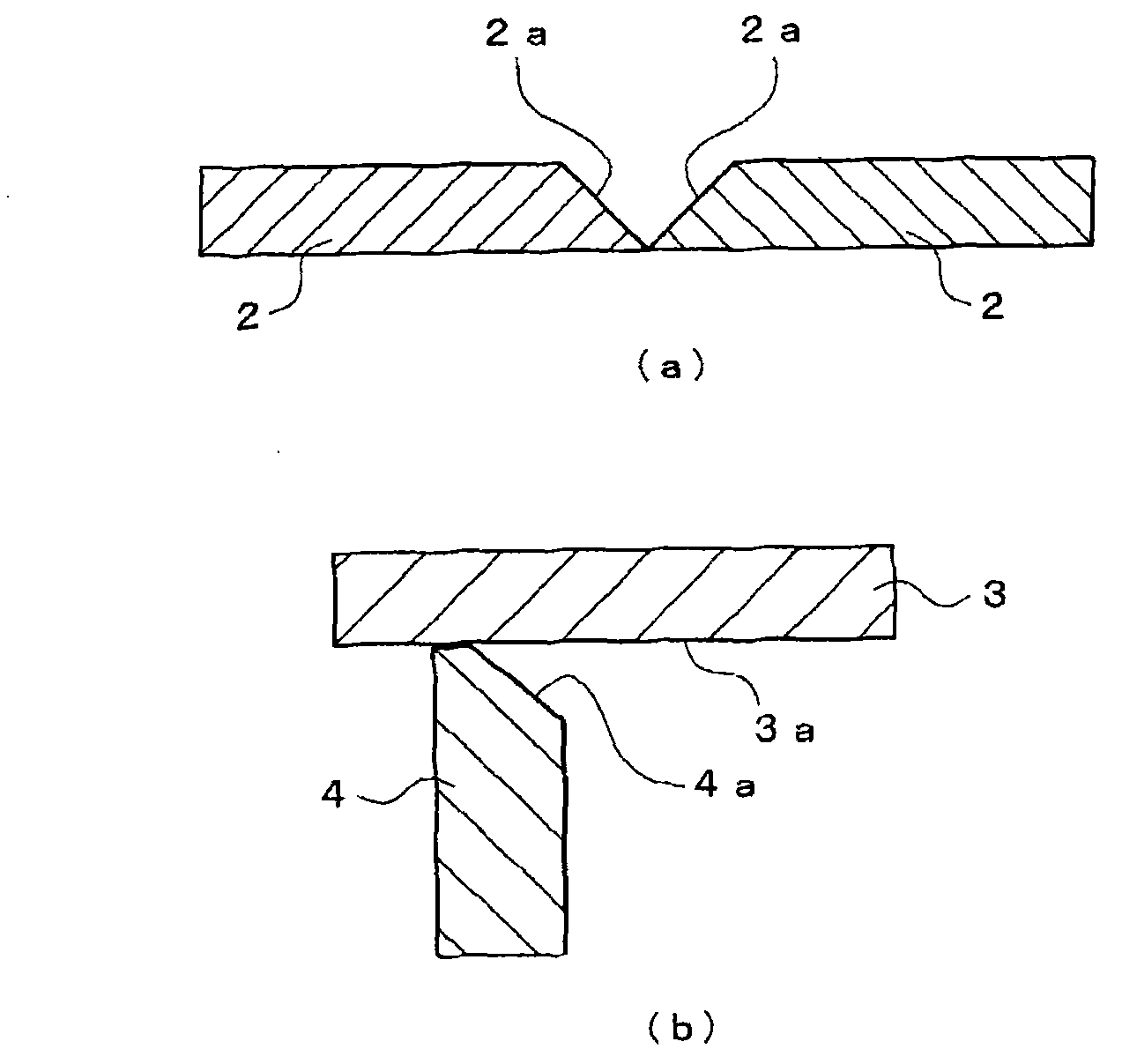

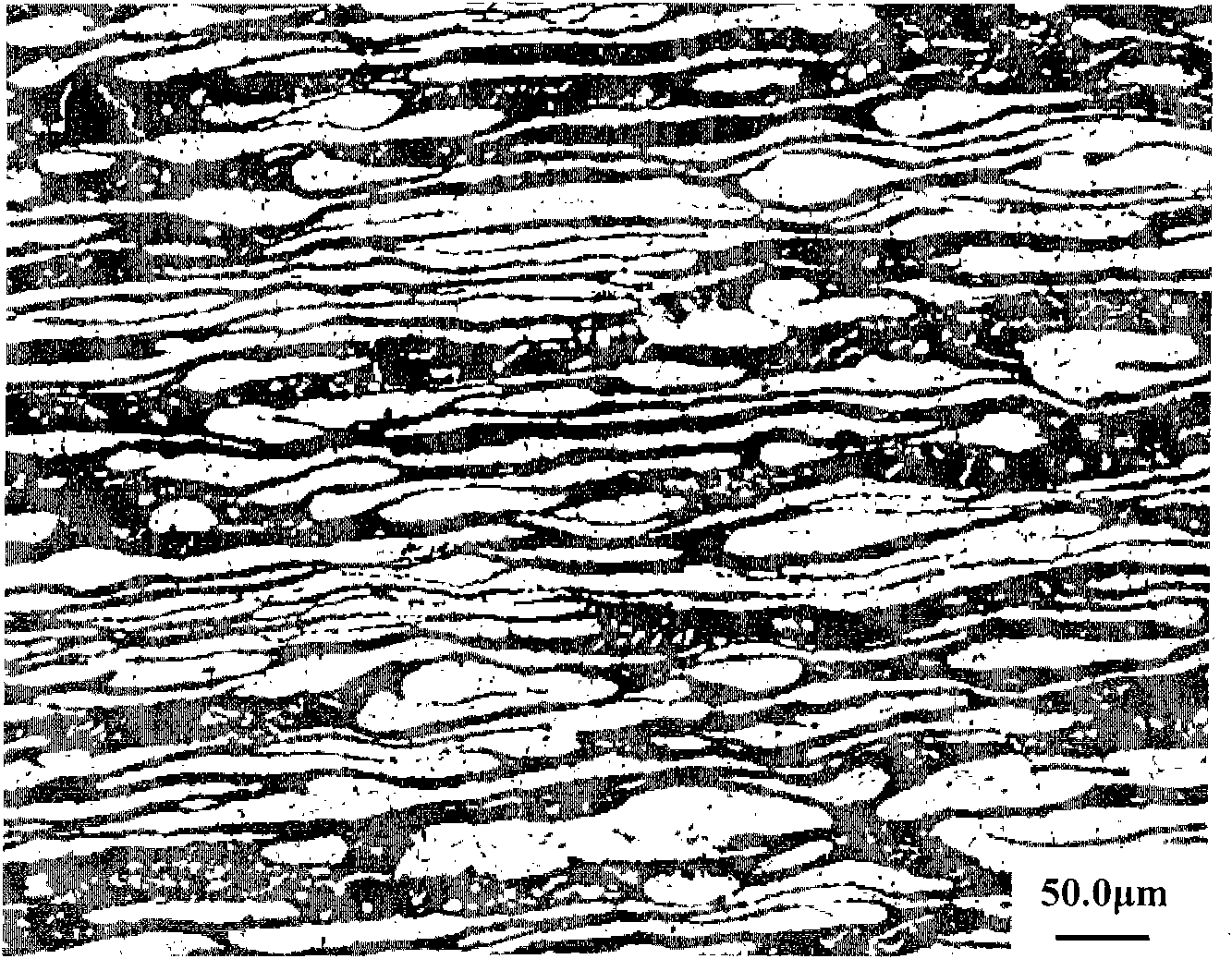

Duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and manufacturing method thereof

InactiveCN101684542AImprove solubilityDecreased low temperature toughnessChemical compositionRoom temperature

The invention discloses a duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and a manufacturing method thereof. The duplex stainless steel comprisesthe following components in mass percentage: 0.01-0.10% of C, 0.2-1.0% of Si, more than 0% and less than 1.5% of Mn, 20.0-22.0% of Cr, 1.8-4.0% of Ni, 0.08-0.2% of N, more than 0% and less than 0.5% of Mo, less than or equal to 1.0% of one or more than one of W and Cu and the balance Fe and inevitable impurities. The invention controls Mn content below 1.5% until zero and simultaneously adjusts the content of elements of N, Ni and the like to ensure that steel has high strength, favourable corrosion resistance and favourable impact toughness at room temperature and low temperature when steel contains no or small amount of noble element Mo; meanwhile, the duplex stainless steel has low cost and small hot working difficulty, can be largely applied in the fields of buildings along the coast,petrochemical industry and the like and can replace 304 austenitic stainless steel of which the nickel content is above 8% at room temperature and lower temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

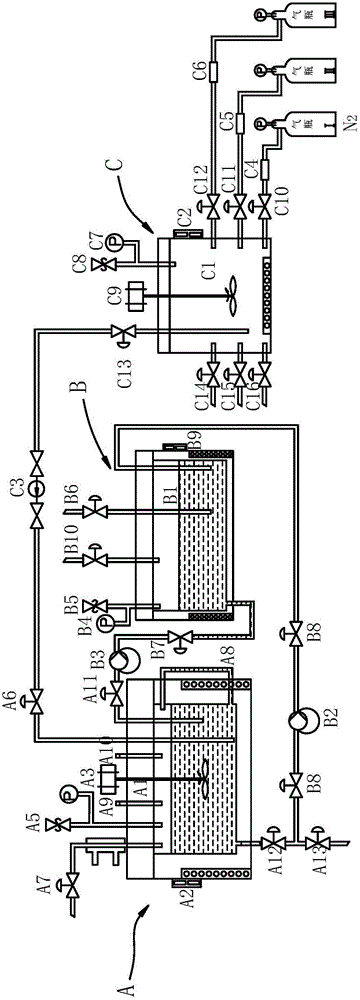

Corrosion testing device capable of simulating complex environment and testing method thereof

ActiveCN105891094AGuaranteed accuracyEnsure scientificWeather/light/corrosion resistanceTemperature controlGas composition

The invention discloses a corrosion testing device capable of simulating the complex environment and a testing method thereof. The device comprises a dynamic high-temperature autoclave system, a medium circulation system and a gas mixing system which can be used for conducting corrosion tests on a sample; the medium circulation system cooperates with the dynamic high-temperature autoclave system so that the medium in the testing environment can be replaced or circulated, and thus the solution medium or flow velocity under the actual working condition is simulated; the gas mixing system is communicated with and cooperate with the dynamic high-temperature autoclave system to simulate the gas composition and pressure environment required by the tests; the dynamic high-temperature autoclave system is internally provided with a medium temperature controller which is used for simulating the temperature under the actual working condition. According to the testing device, multiple types of testing parameters are considered comprehensively, an expansion interface is provided, multiple types of actual working conditions can be effectively simulated, corrosion performance evaluation and research of multiple types of materials, such as stress corrosion, uniform corrosion, erosion corrosion, pitting corrosion, crevice corrosion, electrochemical corrosion, coating corrosion resistance evaluation and corrosion inhibitor efficiency evaluation, in the complex environment are completed, and correctness and scientificity of the test result are guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

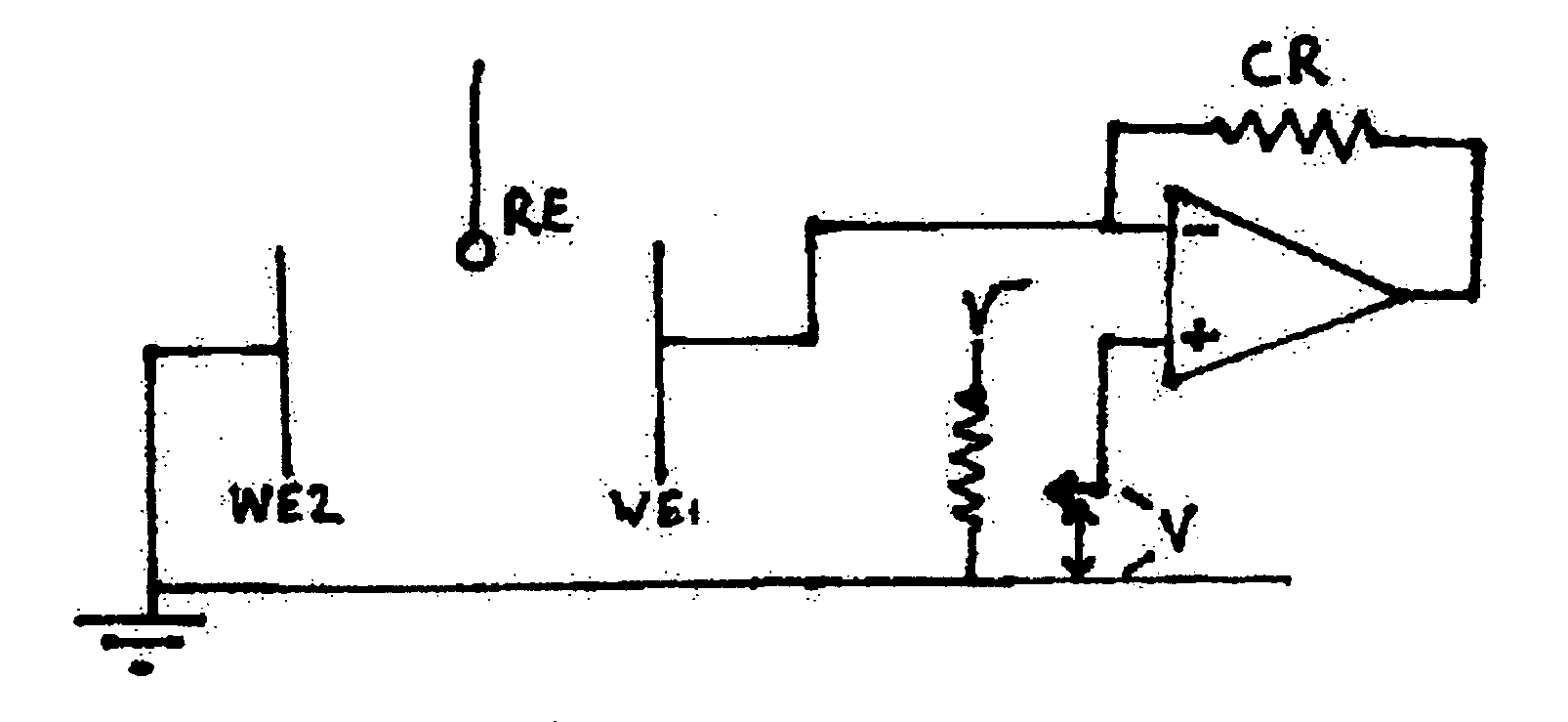

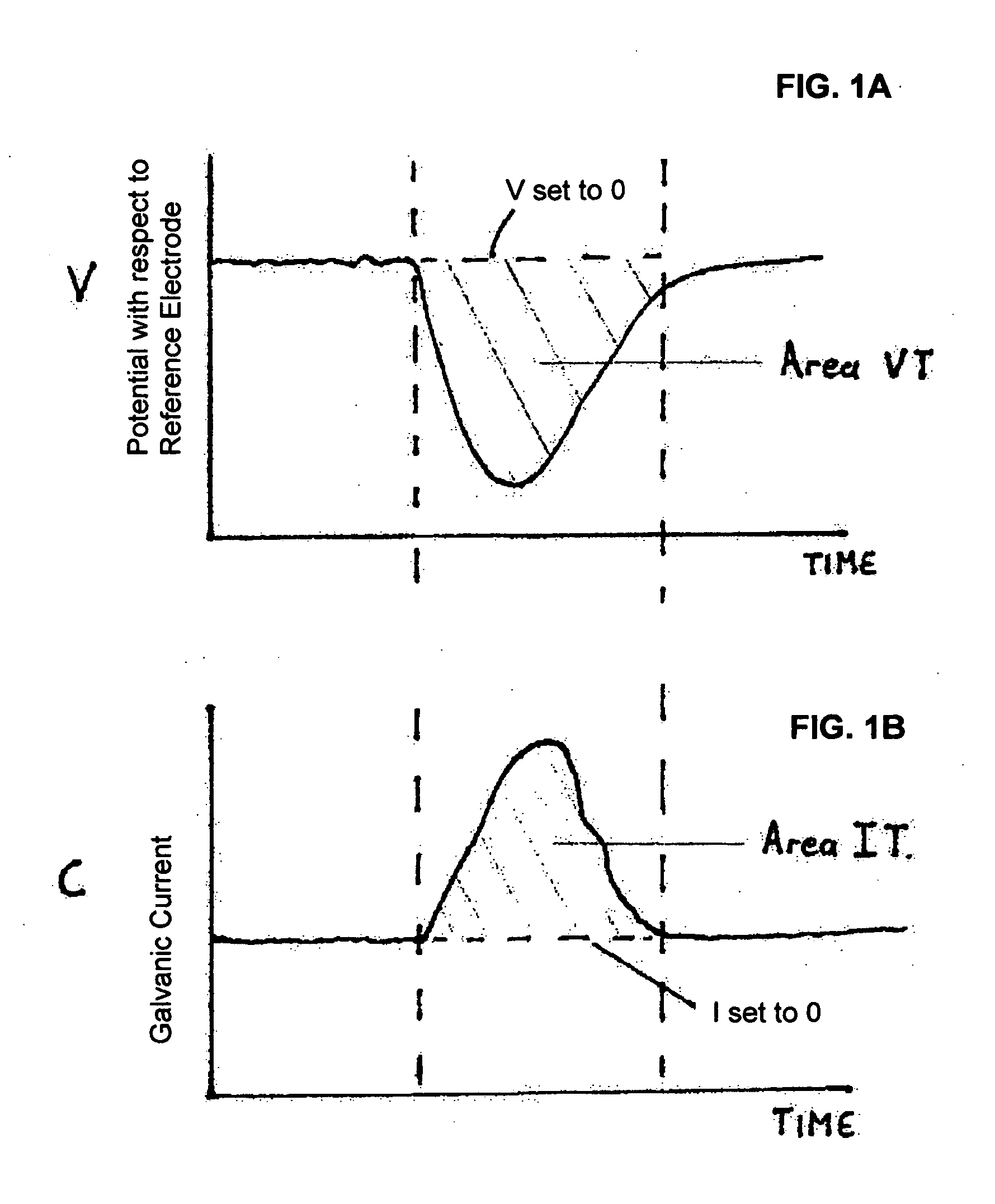

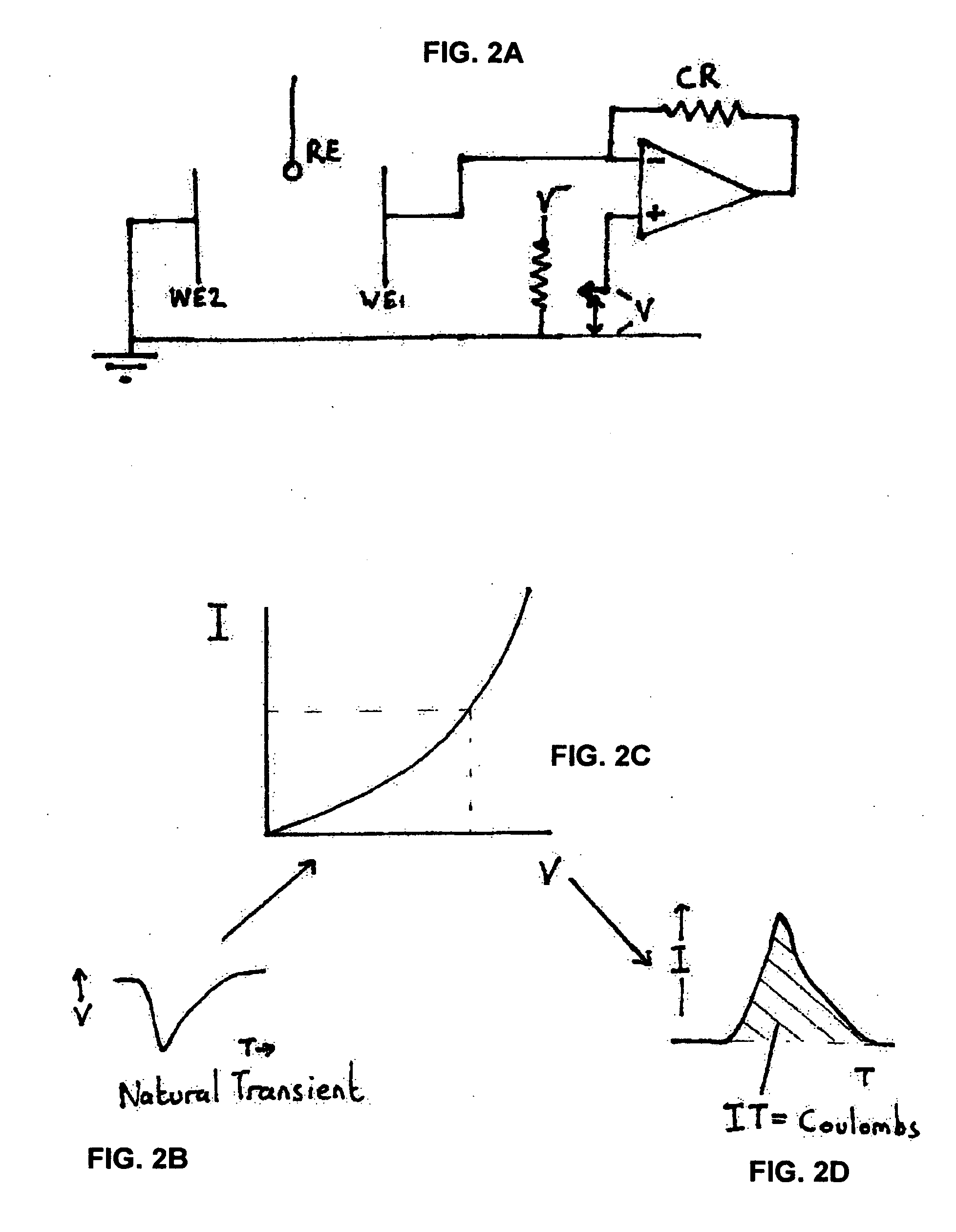

General and localized corrosion rate measurements

InactiveUS20070017822A1Weather/light/corrosion resistanceResistance/reactance/impedenceElectrical resistance and conductanceElectricity

Simultaneous determination of general corrosion and localized corrosion rate measurements is achieved with polarization applied by the electrodes themselves rather than externally applied polarization. Two or more working electrodes may be galvanically coupled. A localized pitting corrosion event on one of the electrodes will lead to a potential transient. The area within the potential transient is measured with the baseline being the initial starting potential. This gives localized corrosion as a function of time. The relationship Rp=ΔV / ΔI is calculated, where Rp is the polarization resistance of the working electrodes and is a measure of generalized corrosion rate.

Owner:BAKER HUGHES INC

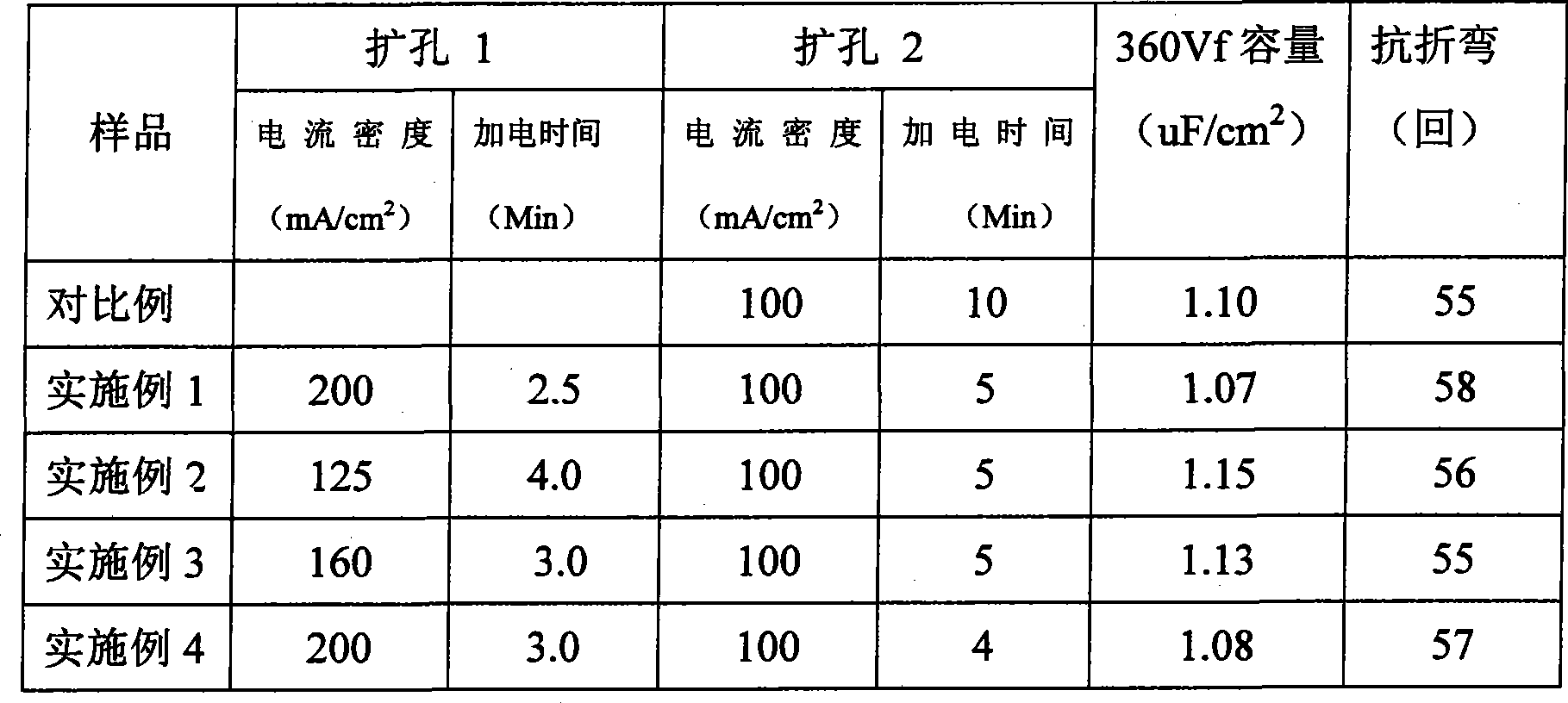

Medium high voltage anode aluminum foil corrosion method

Owner:DONGGUAN HEC CONDENSER CO LTD

Method of preventing corrosion degradation using ni or ni-alloy plating

ActiveUS20090252883A1Prevent degradationPretreated surfacesLiquid/solution decomposition chemical coatingMachine partsPetrochemical

Disclosed herein is a method of preventing corrosion degradation in a defective region including an expansion transition region and / or an expansion region of a heat transfer tube of a steam generator in a nuclear power plant by using nickel (Ni) plating or nickel (Ni) alloy plating. The method can prevent various types of corrosion damage, such as pitting corrosion, abrasion, stress corrosion cracking, lead-induced stress corrosion cracking and the like, occurring during the operation of the steam generator, and particularly, pitting corrosion or primary and secondary stress corrosion cracking, so that the life span of the steam generator is increased, maintenance costs are reduced, and the operation rate of a nuclear power plant is increased, with the result that the unit cost of the production of electric power can be decreased, thereby improving economic efficiency. Further, the method can be usefully used to prevent the corrosion damage of parts and equipment of nuclear, hydroelectric or thermoelectric power plants or of petrochemical plants, and that of industrial and machine parts and equipment, and parts and equipment in a defense industry.

Owner:KOREA ATOMIC ENERGY RES INST +1

Acid-mixed reaming corrosion method for high-voltage anode foil in aluminum electrolysis

ActiveCN108538600AGood effectIncrease specific volumeElectrolytic capacitorsSpecific volumePre treatment

The invention relates to the technical field of anode foil corrosion for aluminum electrolytic capacitors, in particular to an acid-mixed reaming corrosion method for high-voltage anode foil in aluminum electrolysis. The method comprises six steps of pre-treatment, first-stage pitting corrosion, second-stage reaming corrosion, third-stage reaming corrosion, post-treatment and formation treatment,and is characterized in that the aluminum foil after the first-stage pitting corrosion is subjected to second-stage and third-stage acid-mixed reaming corrosion, respective characteristics of hydrochloric acid and nitric acid are fully utilized for common reaming, so that defects of single acid reaming corrosion can be overcome; 520 Vt specific volume of the aluminum foil is 0.750-0.799 uF / cm<2>,which is increased by 1.57%-3.03% than the specific volume of the aluminum foil in single acid reaming corrosion; 375 Vt specific volume is 1.265-1.293 uF / cm<2>, which is increased by 1.59%-3.60% thanthe specific volume of the aluminum foil in single acid reaming corrosion.

Owner:新疆广投桂东电子科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com