Process for welding duplex stainless steel

A duplex stainless steel, welding process technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effect of excellent welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

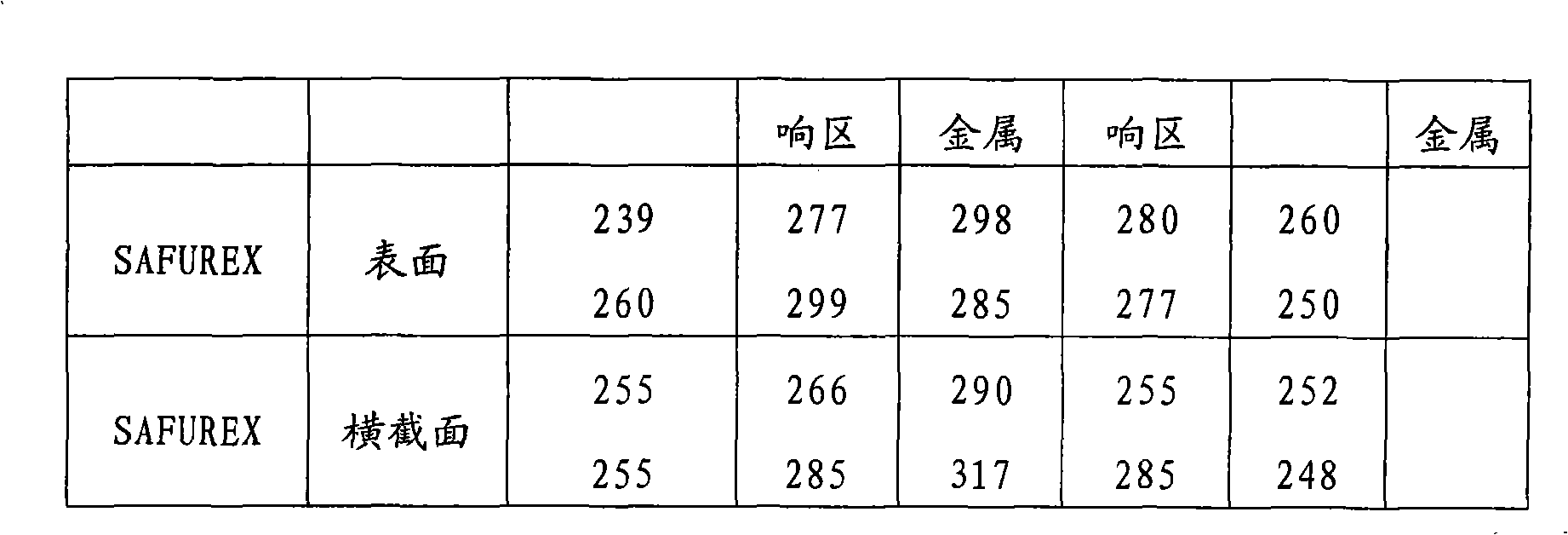

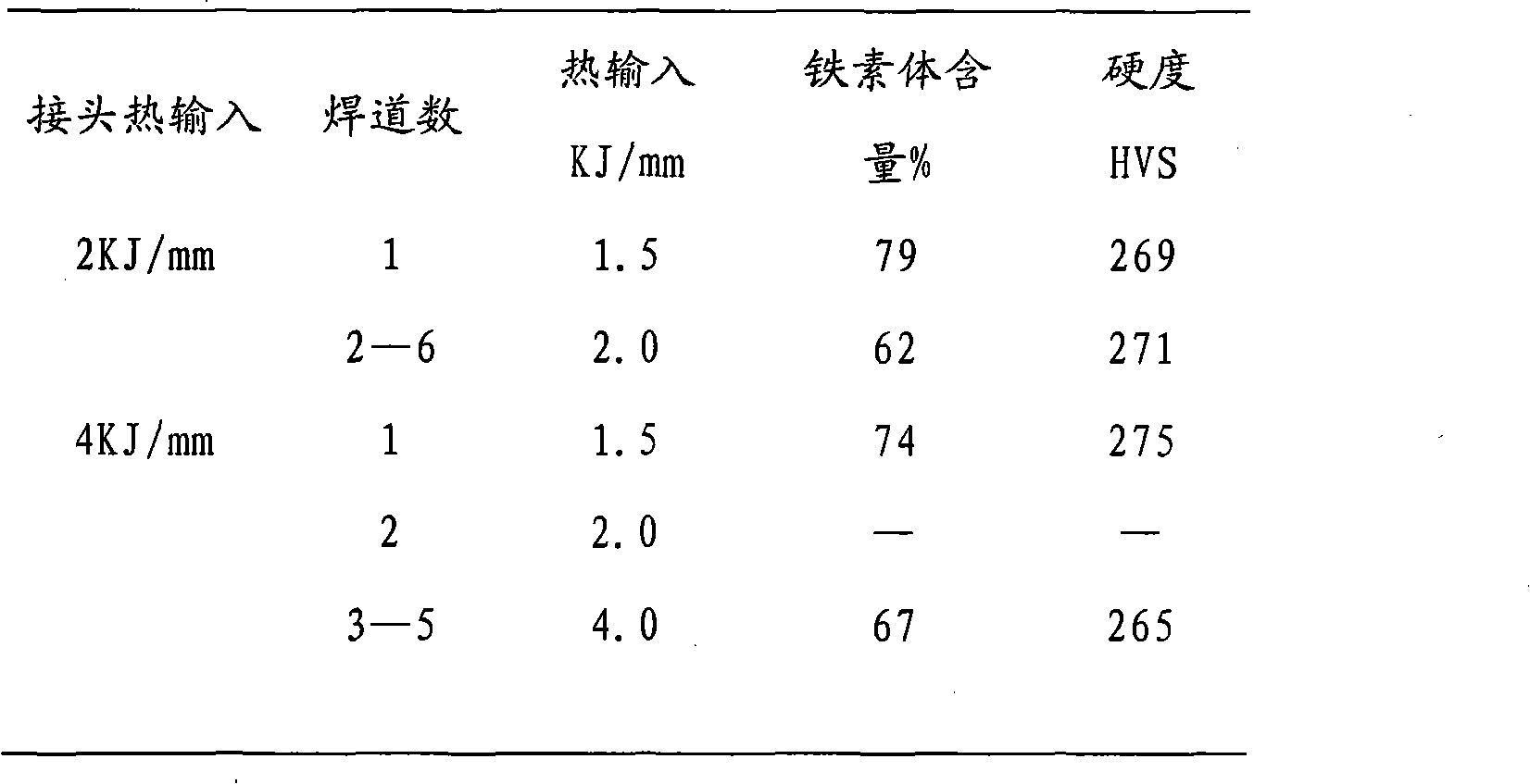

[0061] Example 1. Welding of duplex stainless steel SAFUREX and duplex stainless steel SAFUREX

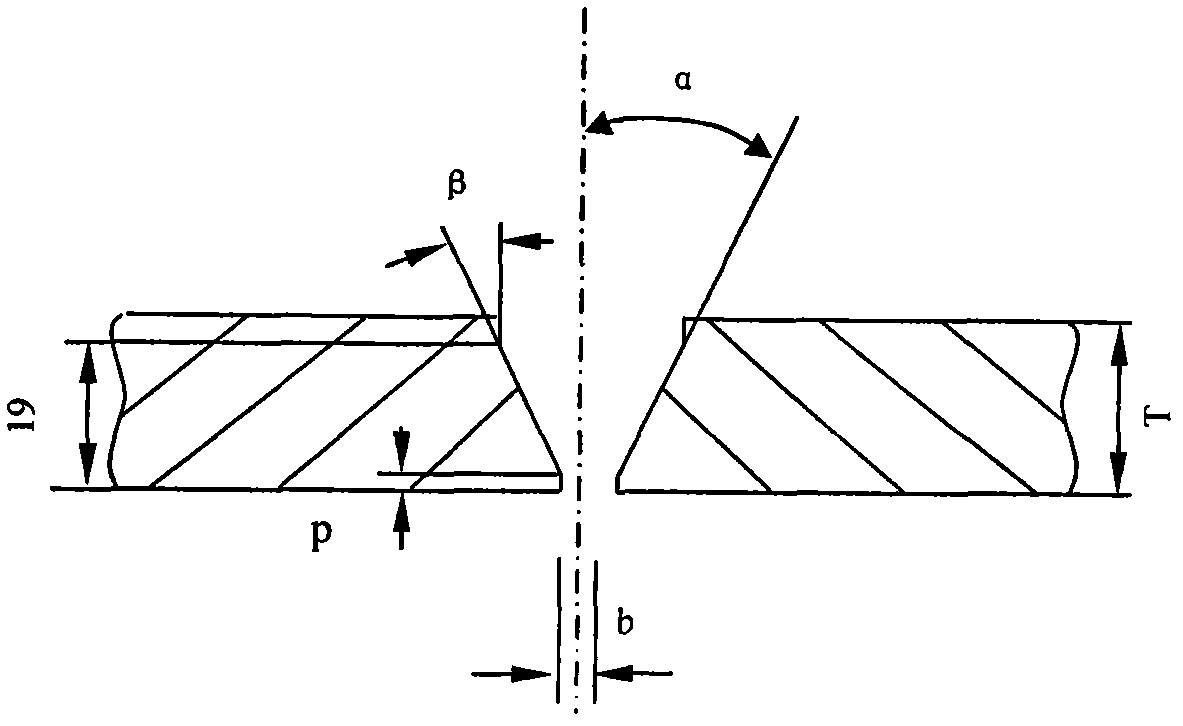

[0062] 1. Adopt single V-shaped butt weld. Groove angle α: 35±2.5°; gap b: 2-4mm; blunt edge p: 0.8-2.5mm, for assembly, welding position is 6G (45°fixed welding).

[0063] 2. Duplex stainless steel is welded without preheating and post-weld heat treatment.

[0064] 3. The bottom welding and the second layer of welding bead are welded by tungsten argon arc welding, and the argon arc welding machine is WS-400IGBT, and the polarity of the power supply is DC positive connection. For the back protection gas, the flow rate is 6-10L / min; for the front side, a mixture of 98% argon + 2% nitrogen is used as the protection gas, and the flow rate is 8-15L / min. The welding wire is Swedish SAFUREXφ2.4 or AWS: ER2209, when the wall thickness is ≤3mm, the line energy is 10-20KJ / cm; when the wall thickness is 3-12mm, the line energy is 20-30KJ / cm; welding by certified welders, And measure the i...

example 2

[0083] Example 2. Welding of duplex stainless steel and carbon steel

[0084] There are two ways: one is to surfacing a transition layer on one side of the carbon steel with a transition electrode E309L before formal welding, and then smooth it and pair it with the duplex stainless steel on the other side for welding. details as follows:

[0085] 1. Adopt single V-shaped butt weld. Groove angle α: 35±2.5°; gap b: 2-4mm; blunt edge p: 0.8-2.5mm. The welding position is 6G (45° fixed welding).

[0086] 2. Duplex stainless steel welding does not require preheating and post-weld heat treatment.

[0087] 3. The bottom welding and the second layer of welding bead are welded by tungsten argon arc welding. The argon arc welding machine is WS-400IGBT, the polarity of the power supply is DC positive connection, and 100% nitrogen or 90% nitrogen + 10% hydrogen ( volume percentage) as the back protection gas, the flow rate is 6-10L / min, and the front side uses a mixture of 98% argon +...

example 3

[0113] Example 3. Welding of duplex stainless steel and 316L

[0114] 1. Adopt single V-shaped butt weld. Groove angle α: 35±2.5°; gap b: 2-4mm; blunt edge p: 0.8-2.5mm, for grouping, welding position is 6G (45°fixed welding).

[0115] 2. Duplex stainless steel welding does not require preheating and post-weld heat treatment.

[0116] 3. The bottom welding and the second layer of welding bead are welded by tungsten argon arc welding. The argon arc welding machine is WS-400IGBT, the polarity of the power supply is DC positive connection, and 100% nitrogen or 90% nitrogen + 10% hydrogen ( volume percentage) as the back protection gas, the flow rate is 6-10L / min, and the front side uses a mixture of 98% argon + 2% nitrogen as the protection gas, the flow rate is 8-15L / min. The welding wire is Swedish φ2.4, ER316L or Sandvik25, 22, 2L Mn welding wire. When the wall thickness is ≤3mm, the line energy is 10-20KJ / cm; when the wall thickness is 3-12mm, the line energy is 20-30KJ / cm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com