Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12133 results about "Argon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in the Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice as abundant as water vapor (which averages about 4000 ppmv, but varies greatly), 23 times as abundant as carbon dioxide (400 ppmv), and more than 500 times as abundant as neon (18 ppmv). Argon is the most abundant noble gas in Earth's crust, comprising 0.00015% of the crust.

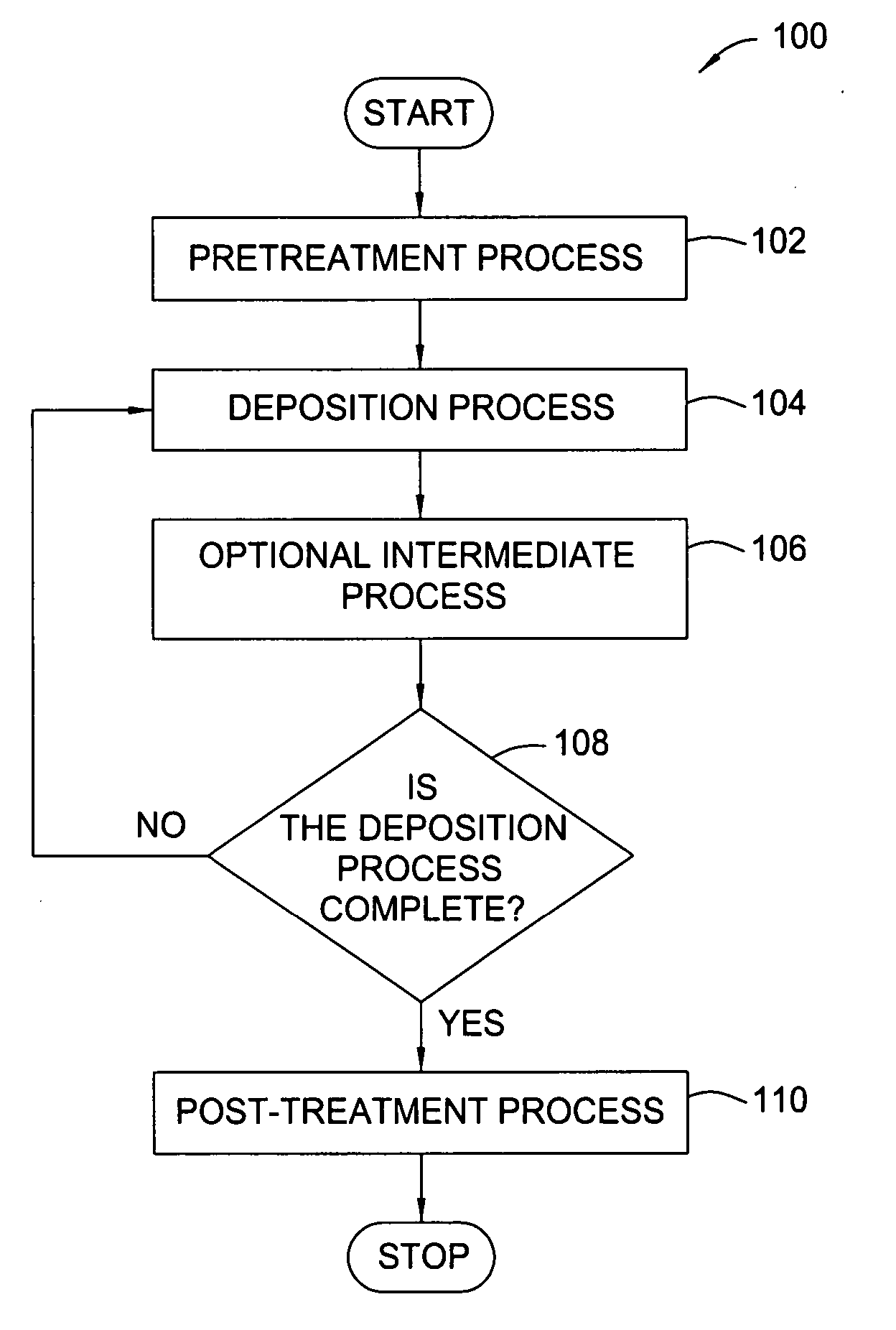

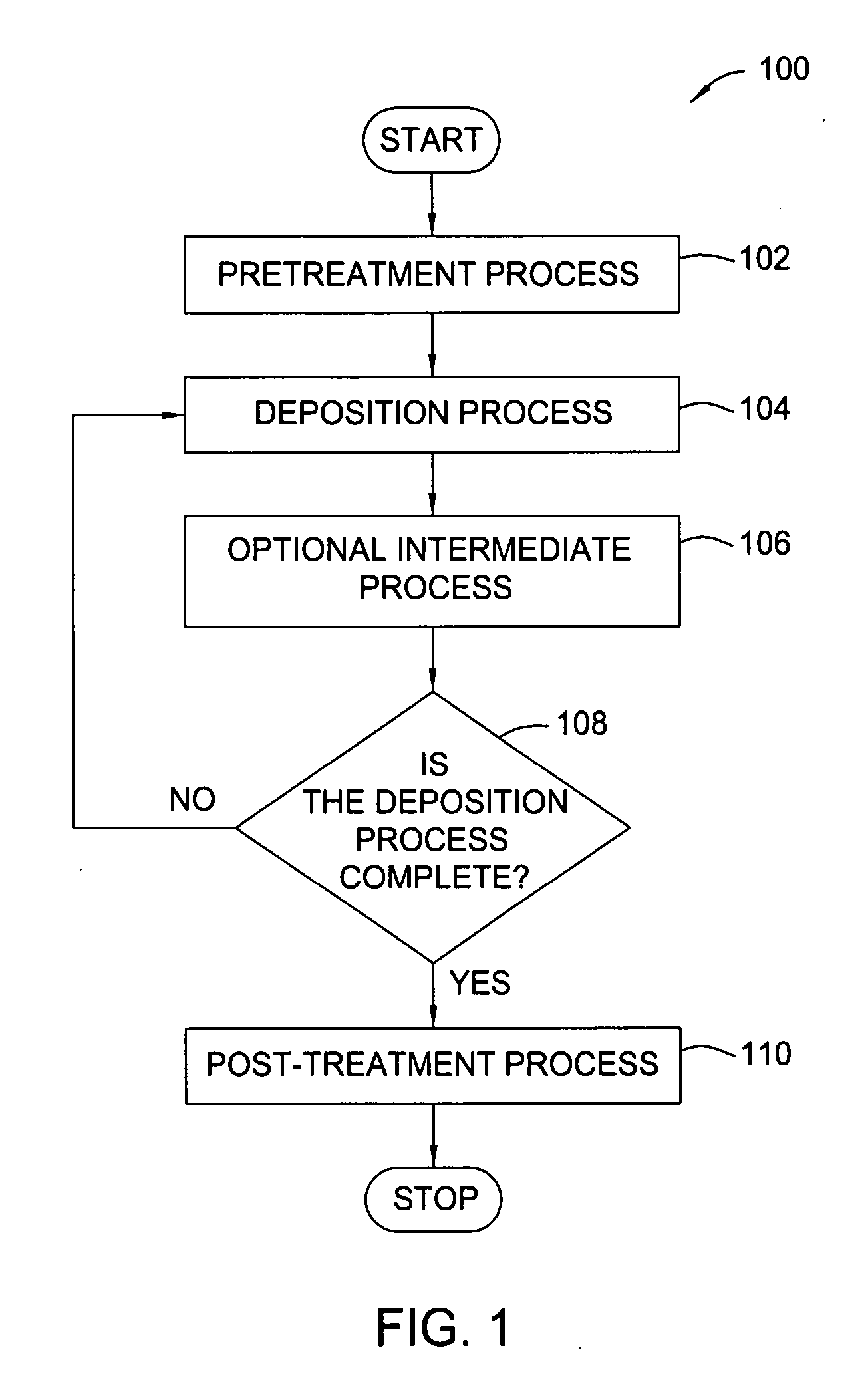

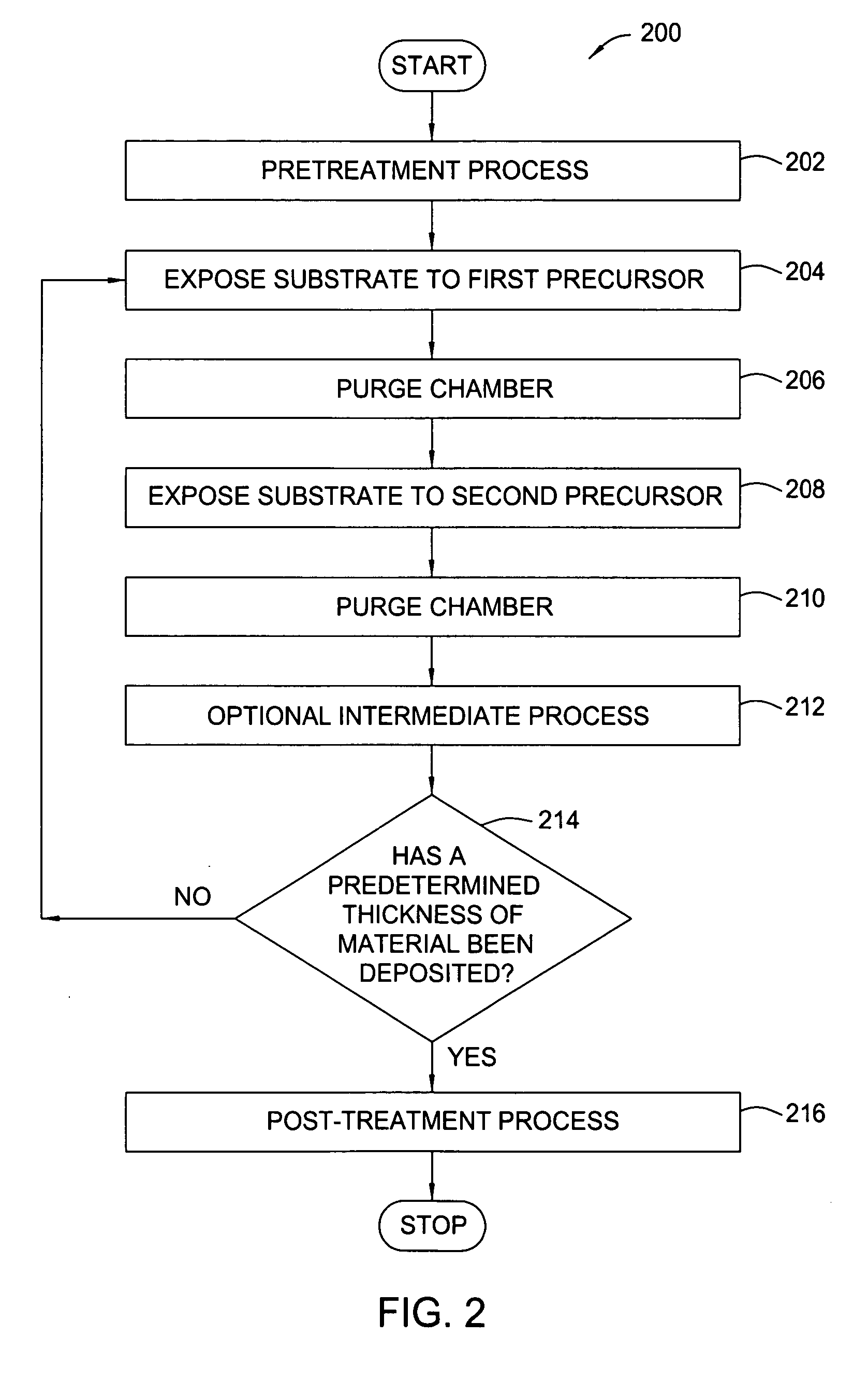

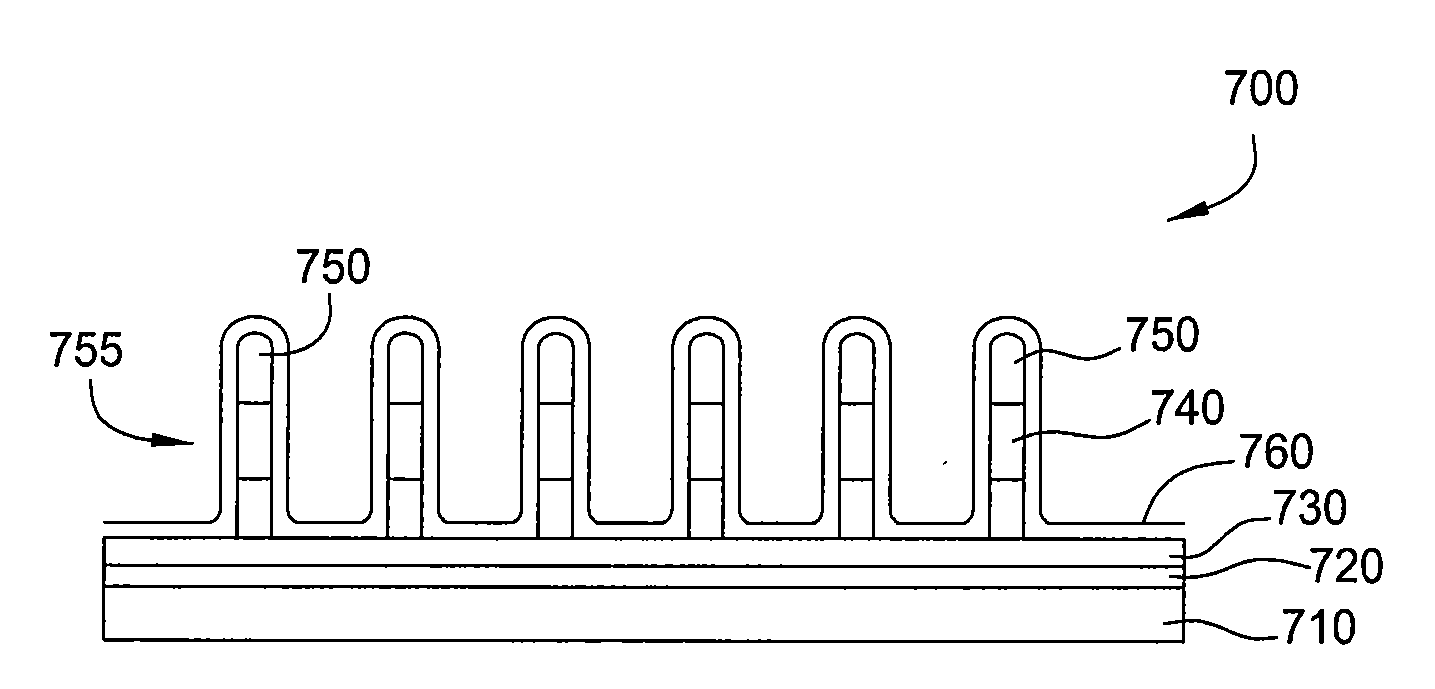

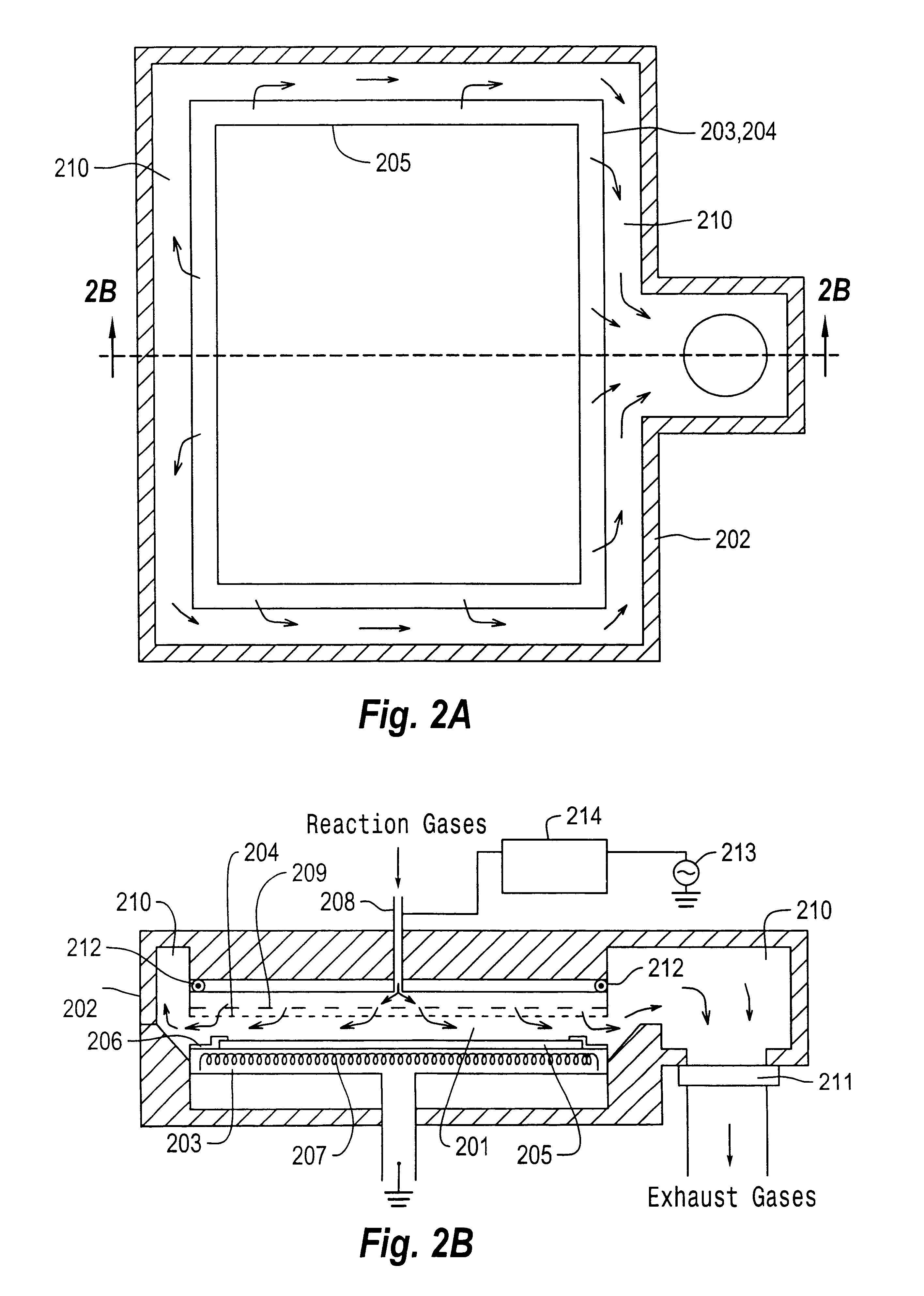

Treatment processes for a batch ALD reactor

Embodiments of the invention provide treatment processes to reduce substrate contamination during a fabrication process within a vapor deposition chamber. A treatment process may be conducted before, during or after a vapor deposition process, such as an atomic layer deposition (ALD) process. In one example of an ALD process, a process cycle, containing an intermediate treatment step and a predetermined number of ALD cycles, is repeated until the deposited material has a desired thickness. The chamber and substrates may be exposed to an inert gas, an oxidizing gas, a nitriding gas, a reducing gas or plasmas thereof during the treatment processes. In some examples, the treatment gas contains ozone, water, ammonia, nitrogen, argon or hydrogen. In one example, a process for depositing a hafnium oxide material within a batch process chamber includes a pretreatment step, an intermediate step during an ALD process and a post-treatment step.

Owner:APPLIED MATERIALS INC

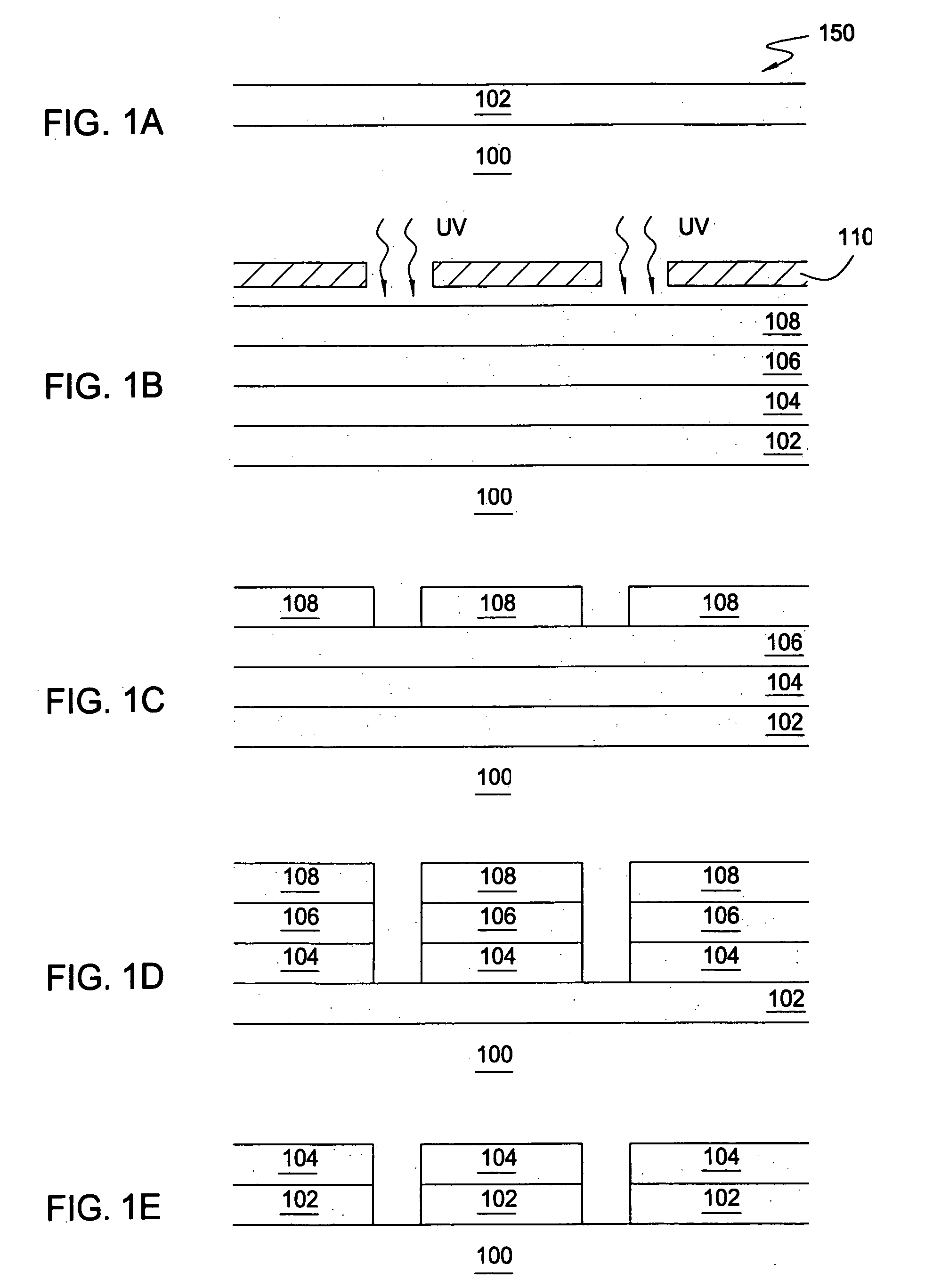

Method for Depositing Conformal Amorphous Carbon Film by Plasma-Enhanced Chemical Vapor Deposition (PECVD)

ActiveUS20100093187A1Good shape retentionHighly conformalSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerNitrogen gas

Methods and apparatus for depositing an amorphous carbon layer on a substrate are provided. In one embodiment, a deposition process includes positioning a substrate in a substrate processing chamber, introducing a hydrocarbon source having a carbon to hydrogen atom ratio of greater than 1:2 into the processing chamber, introducing a plasma initiating gas selected from the group consisting of hydrogen, helium, argon, nitrogen, and combinations thereof into the processing chamber, with the hydrocarbon source having a volumetric flow rate to plasma initiating gas volumetric flow rate ratio of 1:2 or greater, generating a plasma in the processing chamber, and forming a conformal amorphous carbon layer on the substrate.

Owner:APPLIED MATERIALS INC

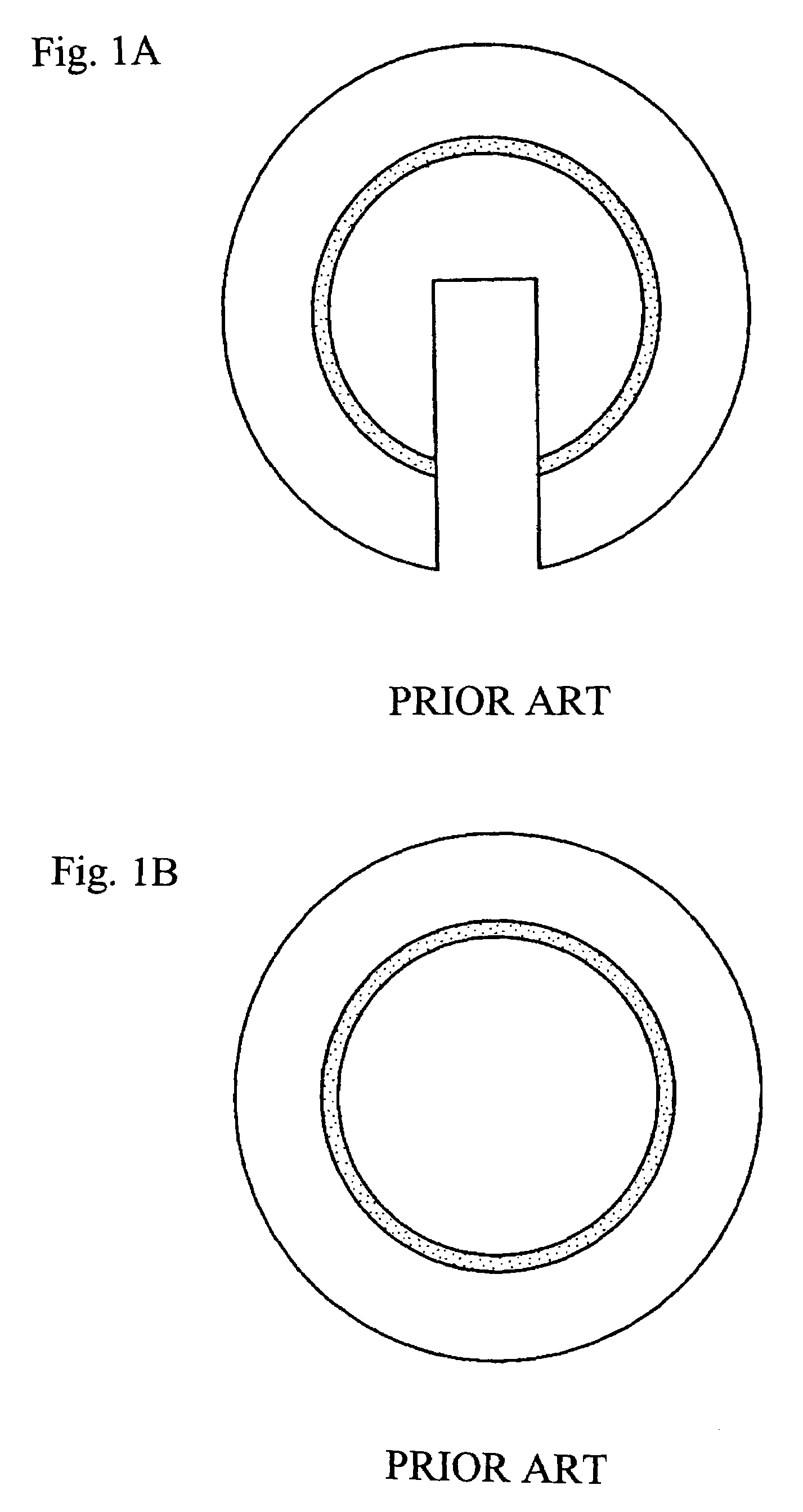

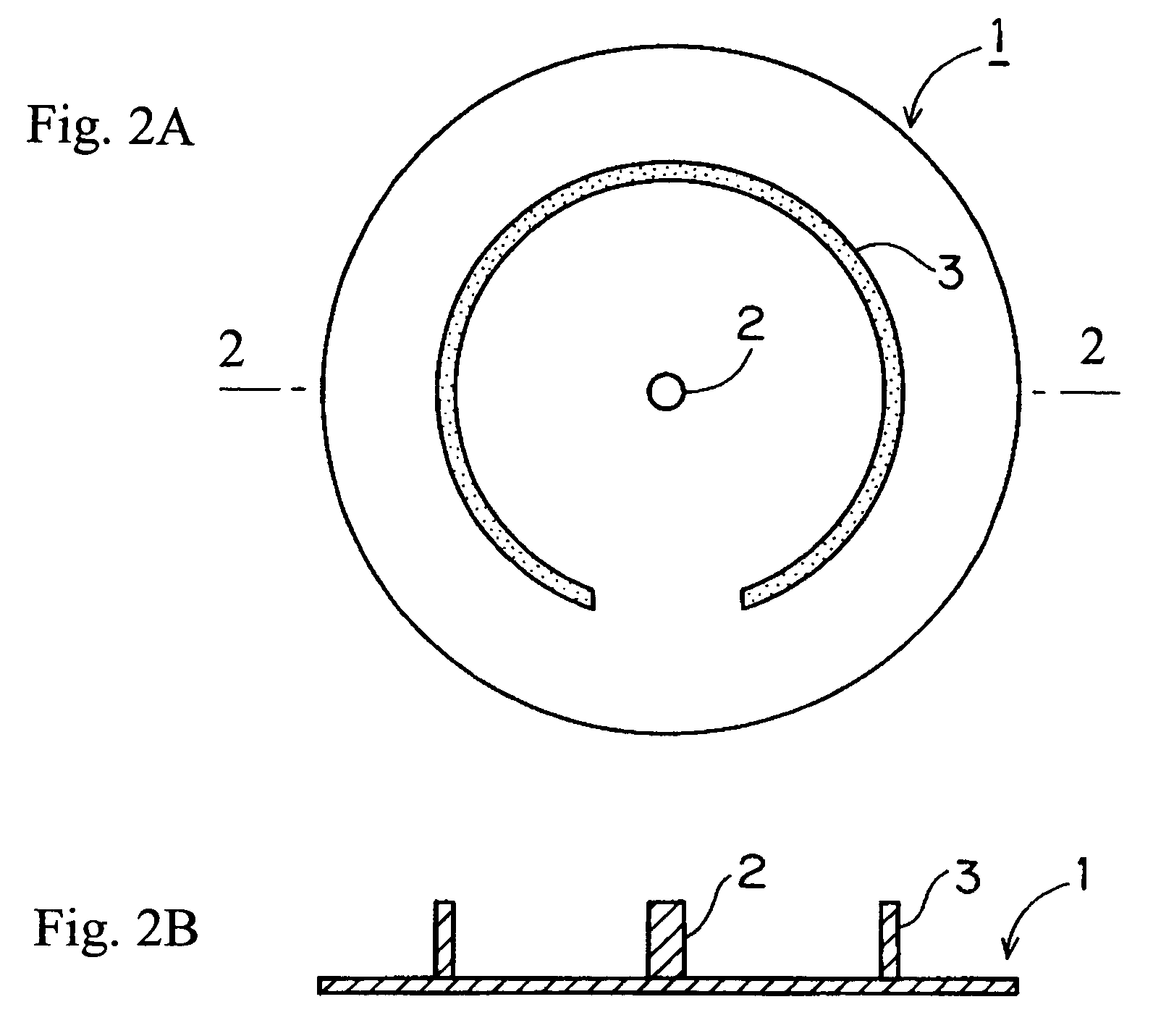

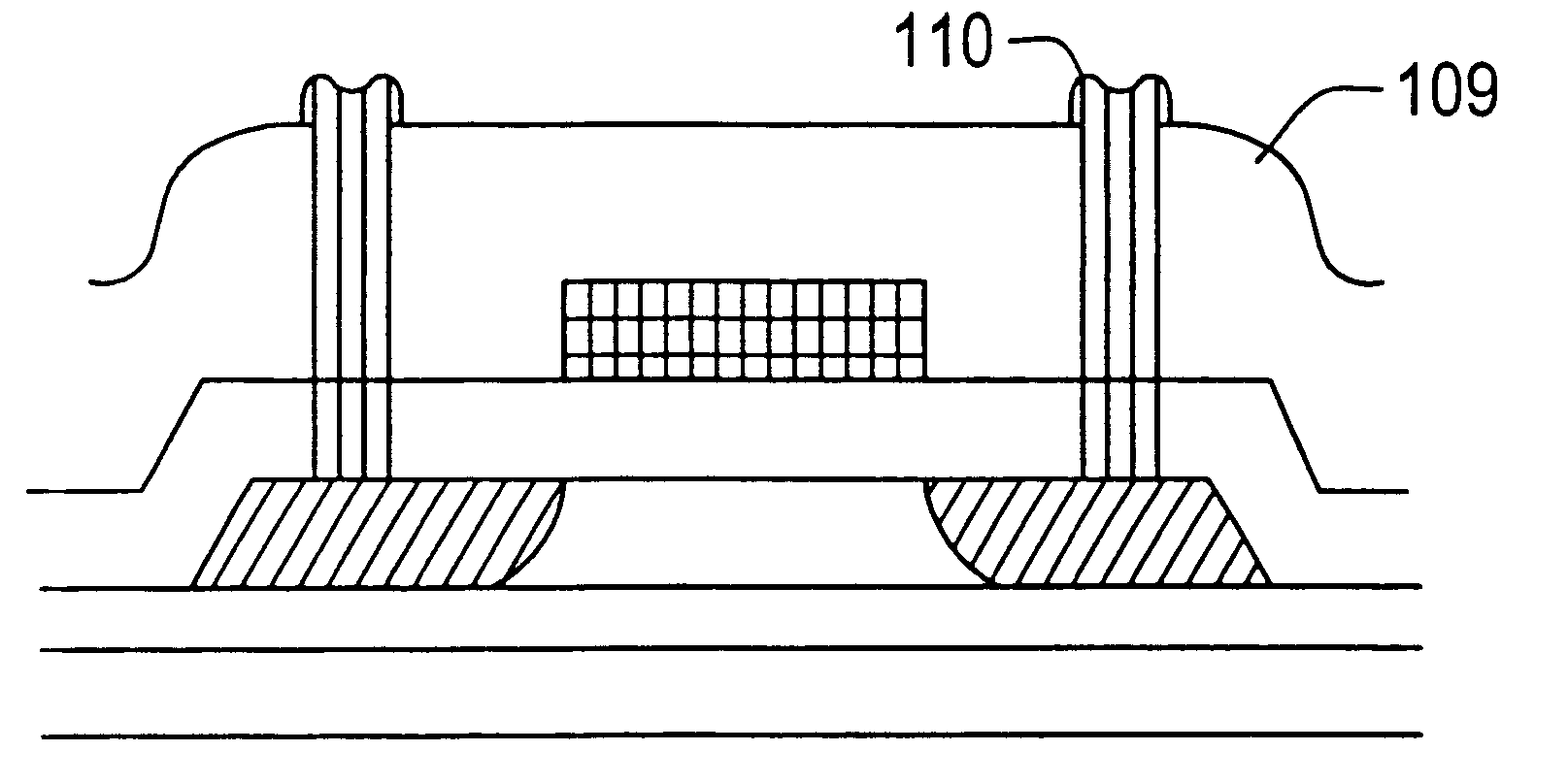

Method of forming an oxide film

InactiveUS6960812B2Improve performanceReduce the temperatureSolid-state devicesVacuum evaporation coatingAlkali ionsSputtering

A method of forming an oxide film and a method of manufacturing an electronic device utilizing the oxide film is disclosed. A silicon oxide film is formed on a substrate by sputtering. Therefore, the film formation is carried out at a low temperature. The sputtering atmosphere comprises an oxidizing gas and an inert gas such as argon. In order to prevent fixed electric charges from being generated in the film and to obtain an oxide film of good properties, the proportion of argon is adjusted to 20% or less. Alternatively, a gas including halogen elements such as fluorine is added to the above sputtering atmosphere at a proportion less than 20%. Hereupon, alkali ions and dangling bonds of silicon in the oxide film are neutralized by the halogen elements, whereby a fine oxide film is obtained.

Owner:SEMICON ENERGY LAB CO LTD

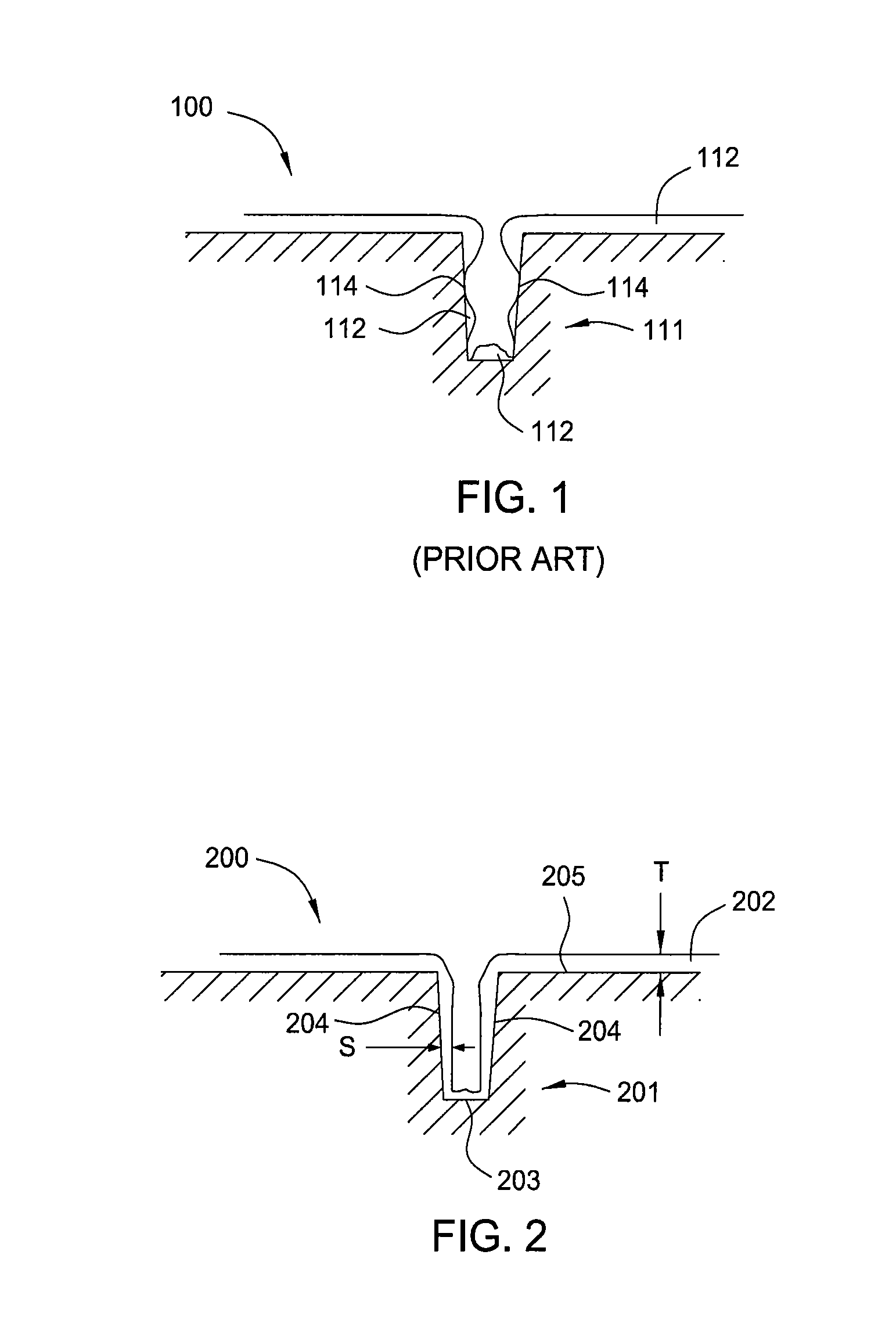

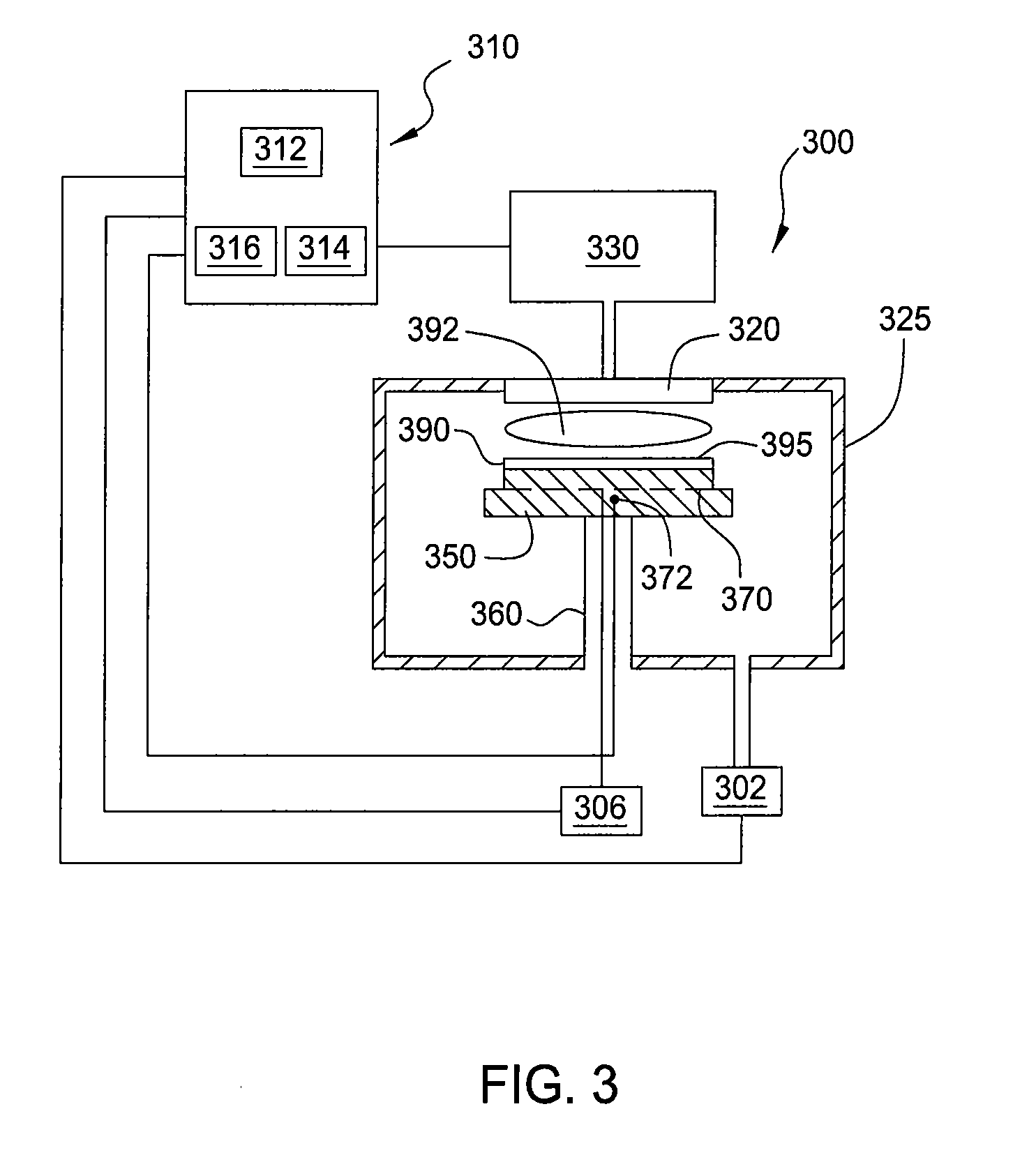

Heat treatment jig for semiconductor silicon substrate

ActiveUS7163393B2Charge supportsSemiconductor/solid-state device manufacturingDislocationHydrogen annealing

Owner:SUMITOMO MITSUBISHI SILICON CORP

Hydrogen ashing enhanced with water vapor and diluent gas

ActiveUS20080261405A1Decorative surface effectsSemiconductor/solid-state device detailsWater vaporOxygen

An oxygen-free hydrogen plasma ashing process particularly useful for low-k dielectric materials based on hydrogenated silicon oxycarbide materials. The main ashing step includes exposing a previously etched dielectric layer to a plasma of hydrogen and optional nitrogen, a larger amount of water vapor, and a yet larger amount of argon or helium. Especially for porous low-k dielectrics, the main ashing plasma additionally contains a hydrocarbon gas such as methane. The main ashing may be preceded by a short surface treatment by a plasma of a hydrogen-containing reducing gas such as hydrogen and optional nitrogen.

Owner:APPLIED MATERIALS INC

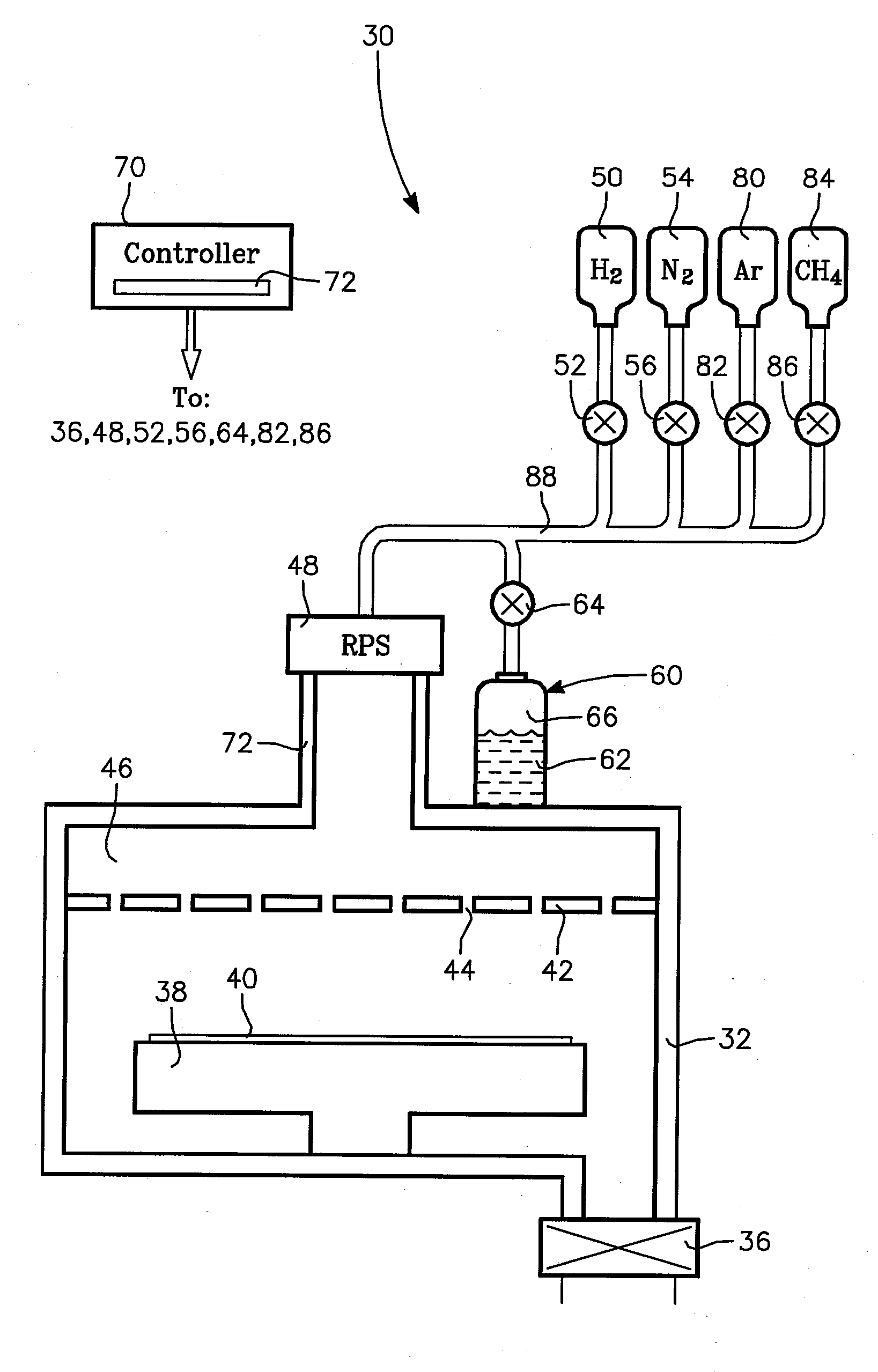

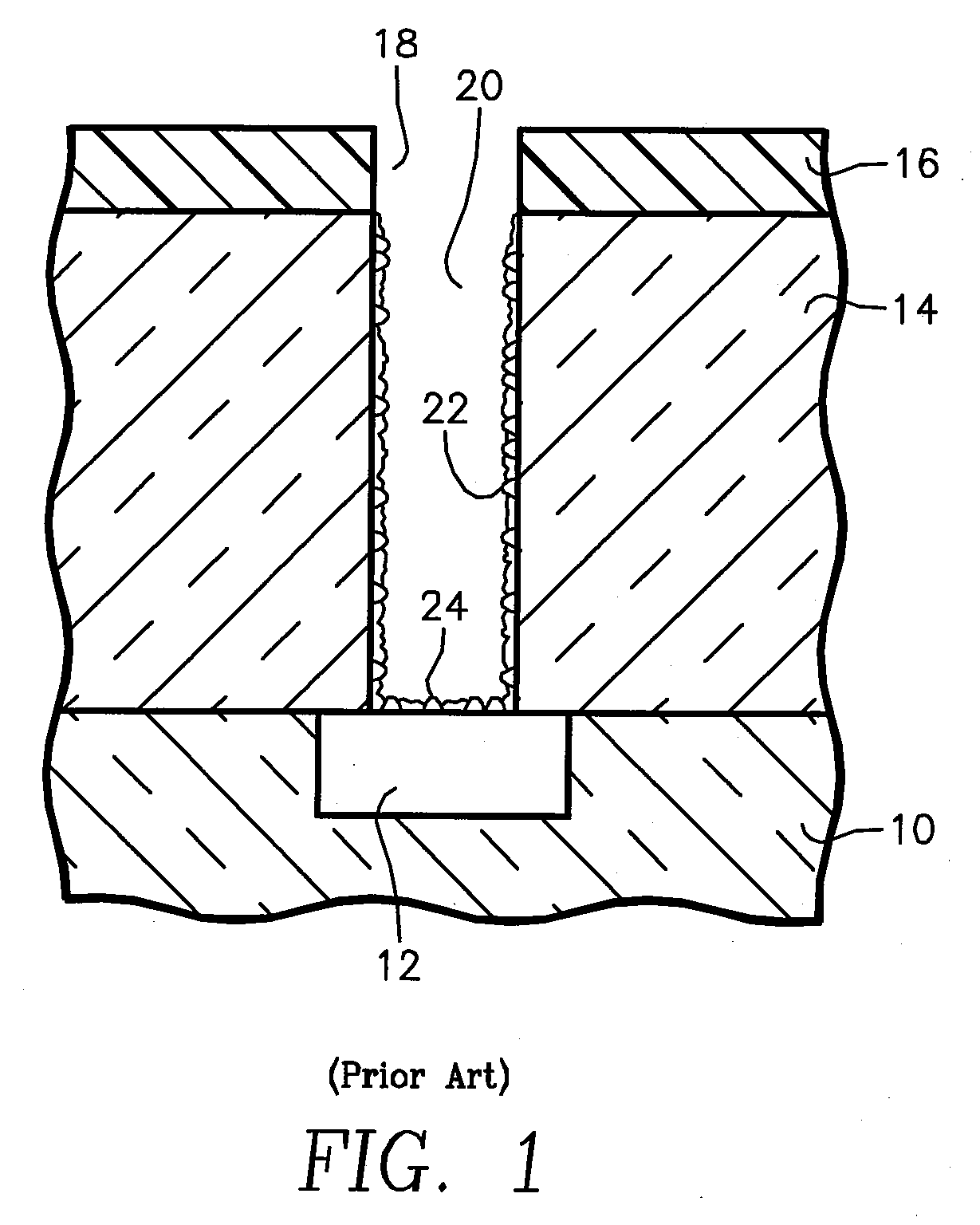

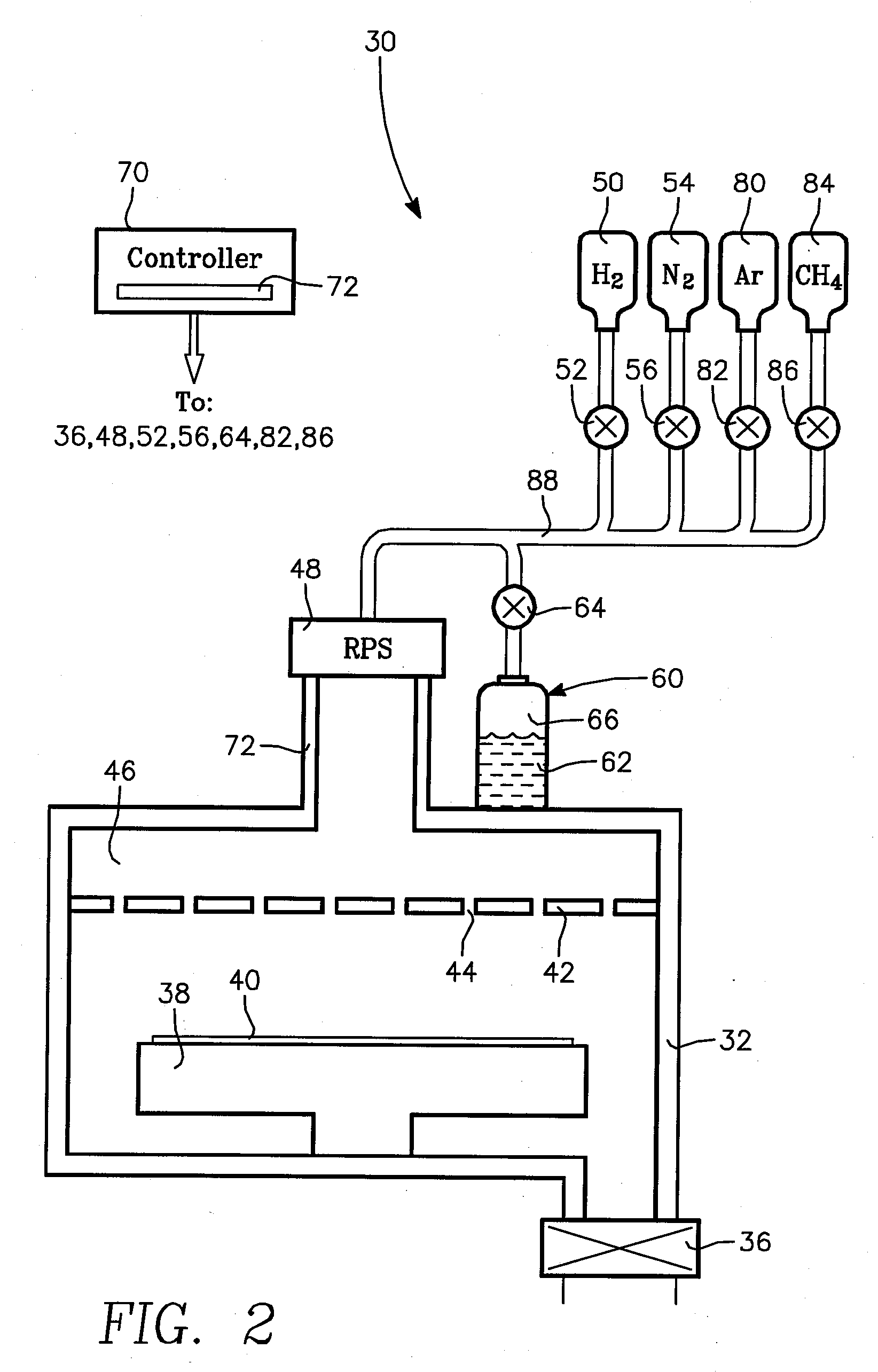

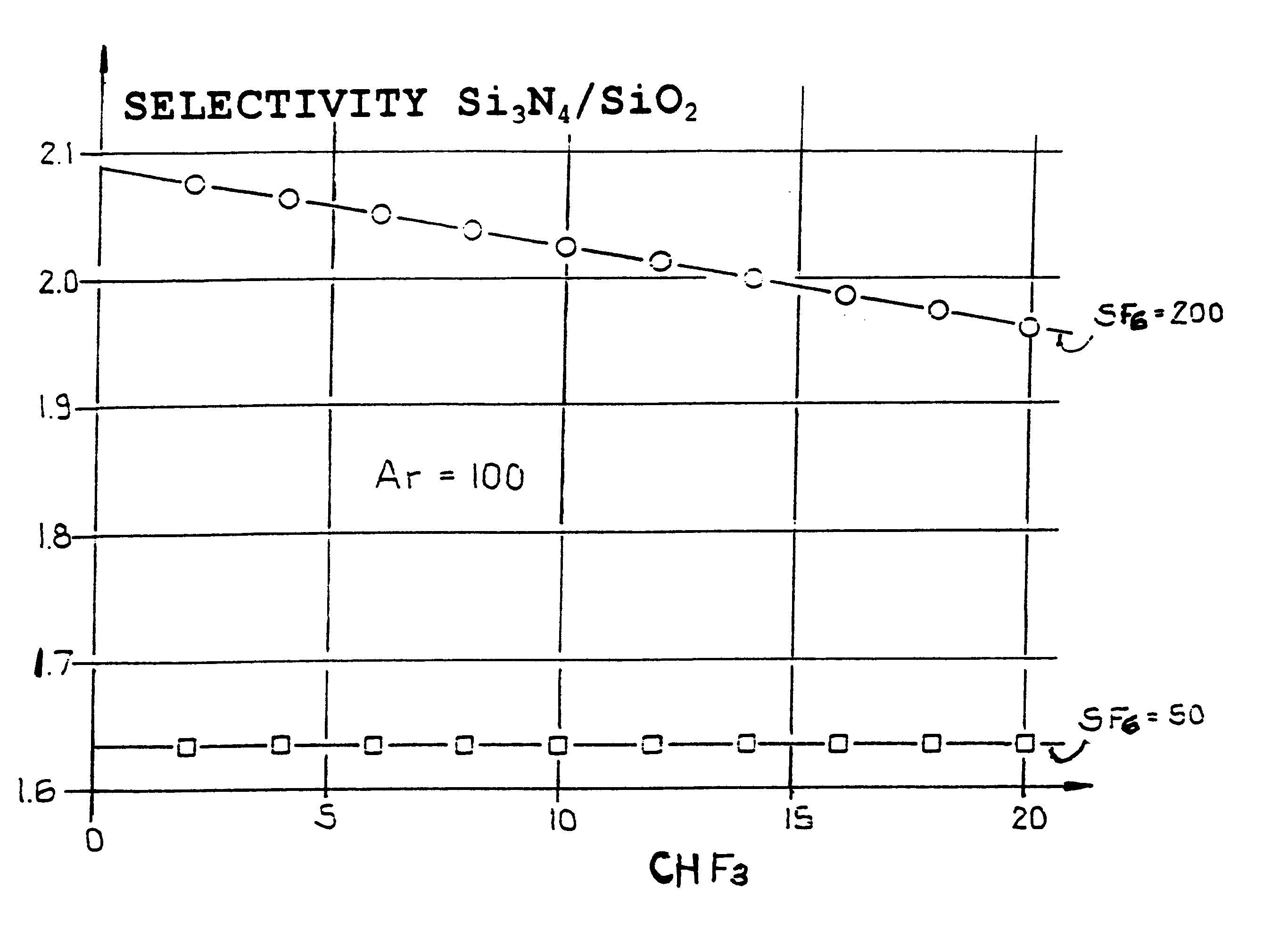

Method for anisotropic plasma-chemical dry etching of silicon nitride layers using a gas mixture containing fluorine

InactiveUS6569773B1Improve uniformityHigh atomic weightSemiconductor/solid-state device manufacturingSilicon oxideOxygen

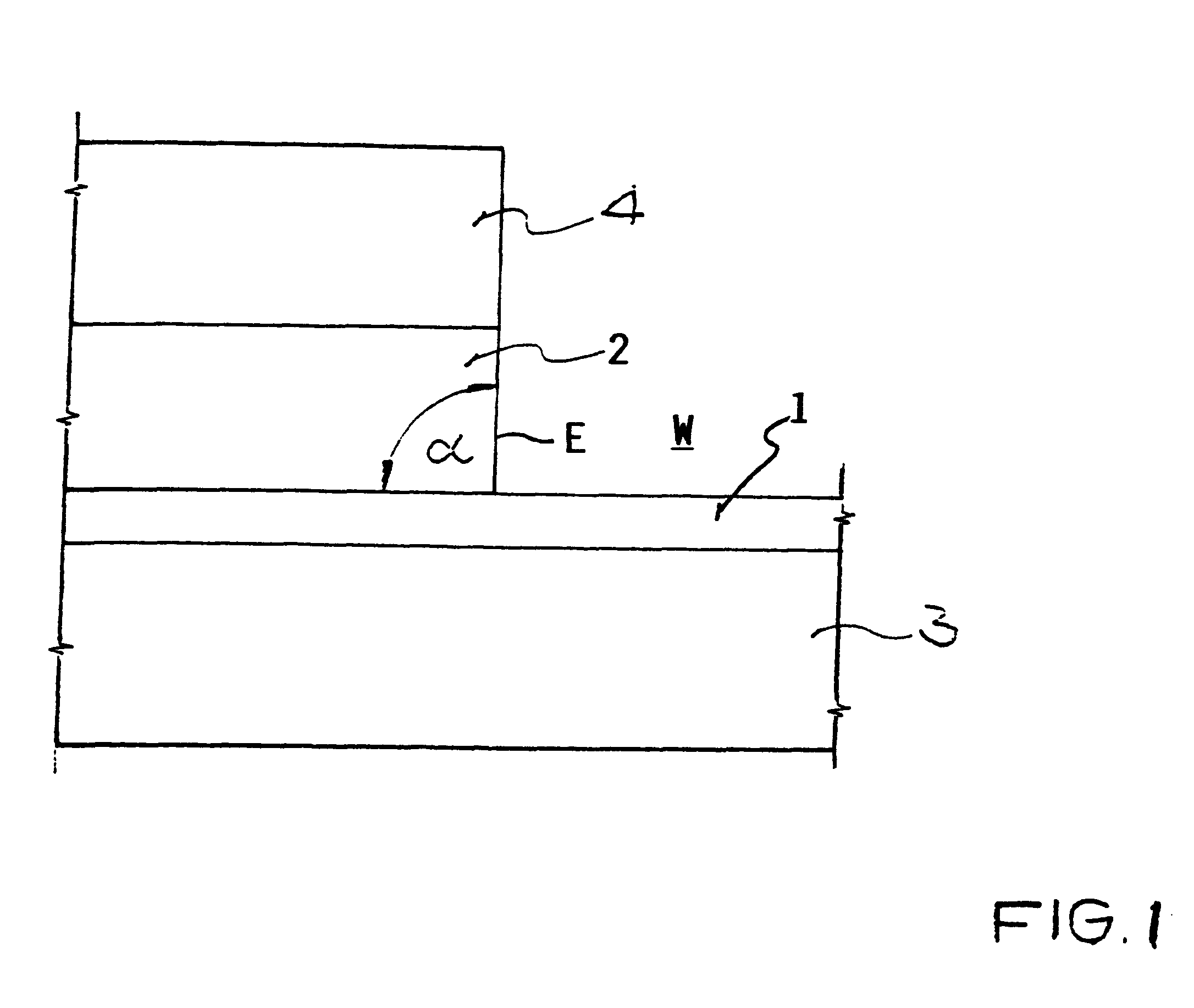

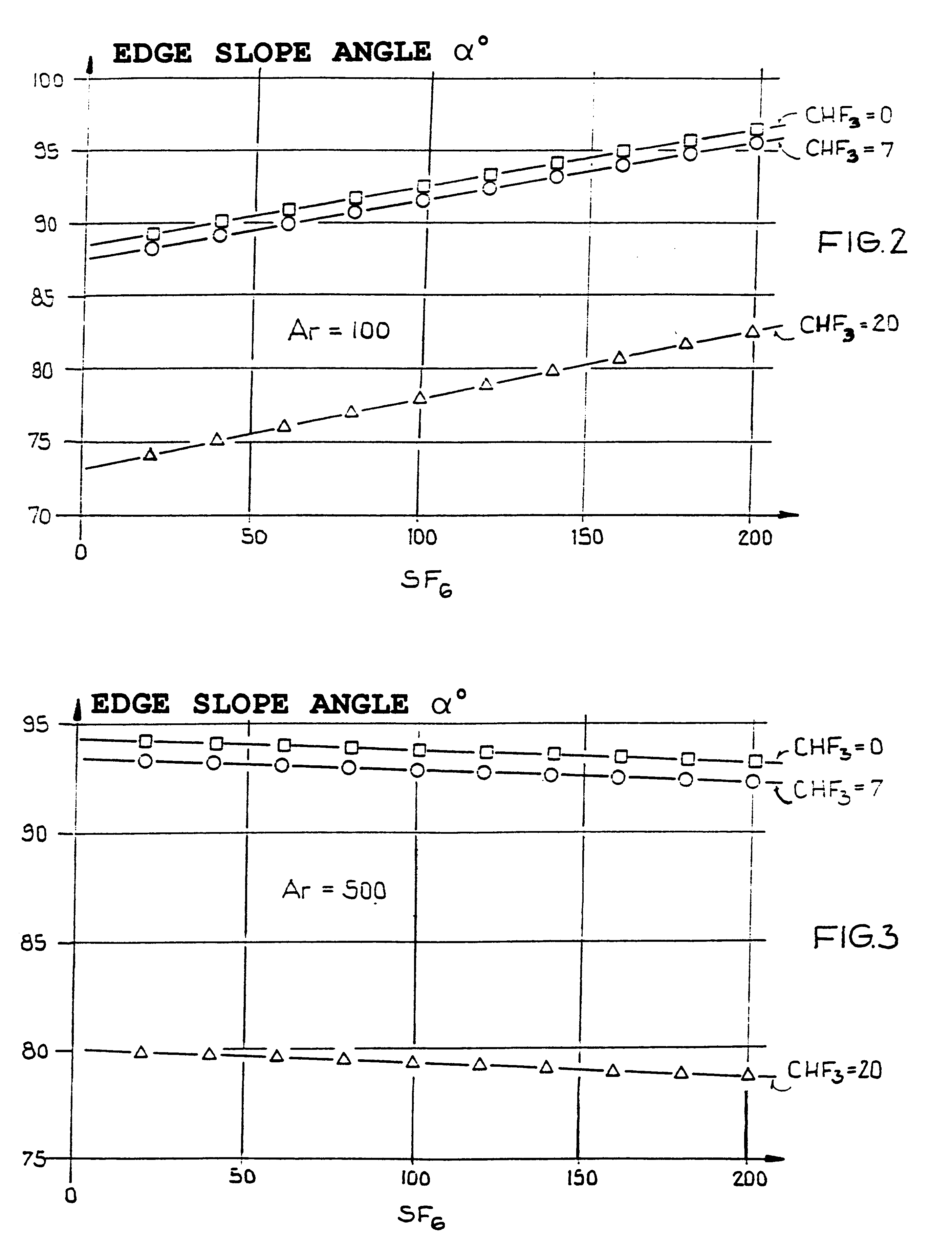

An etching gas mixture containing CHF3, SF6 and a non-oxidizing gas such as Ar is used as an etching gas mixture for the anisotropic plasma-chemical dry-etching of a silicon nitride layer differentially or selectively relative to a silicon oxide layer. The gas mixture does not contain oxygen, chlorine, bromine, iodine or halides in addition to the above mentioned constituents, so that the process can be carried out in reactor systems equipped with oxidizable electrodes. By adjusting the gas flow rates or composition ratios of CHF3, SF6, and argon in the etching gas mixture, it is possible to adjust the resulting etching selectivity of silicon nitride relative to silicon oxide, and the particular edge slope angle of the etched edge of the remaining silicon nitride layer. A high etch rate for the silicon nitride is simultaneously achieved.

Owner:ATMEL CORP +1

Method of aligning nanowires

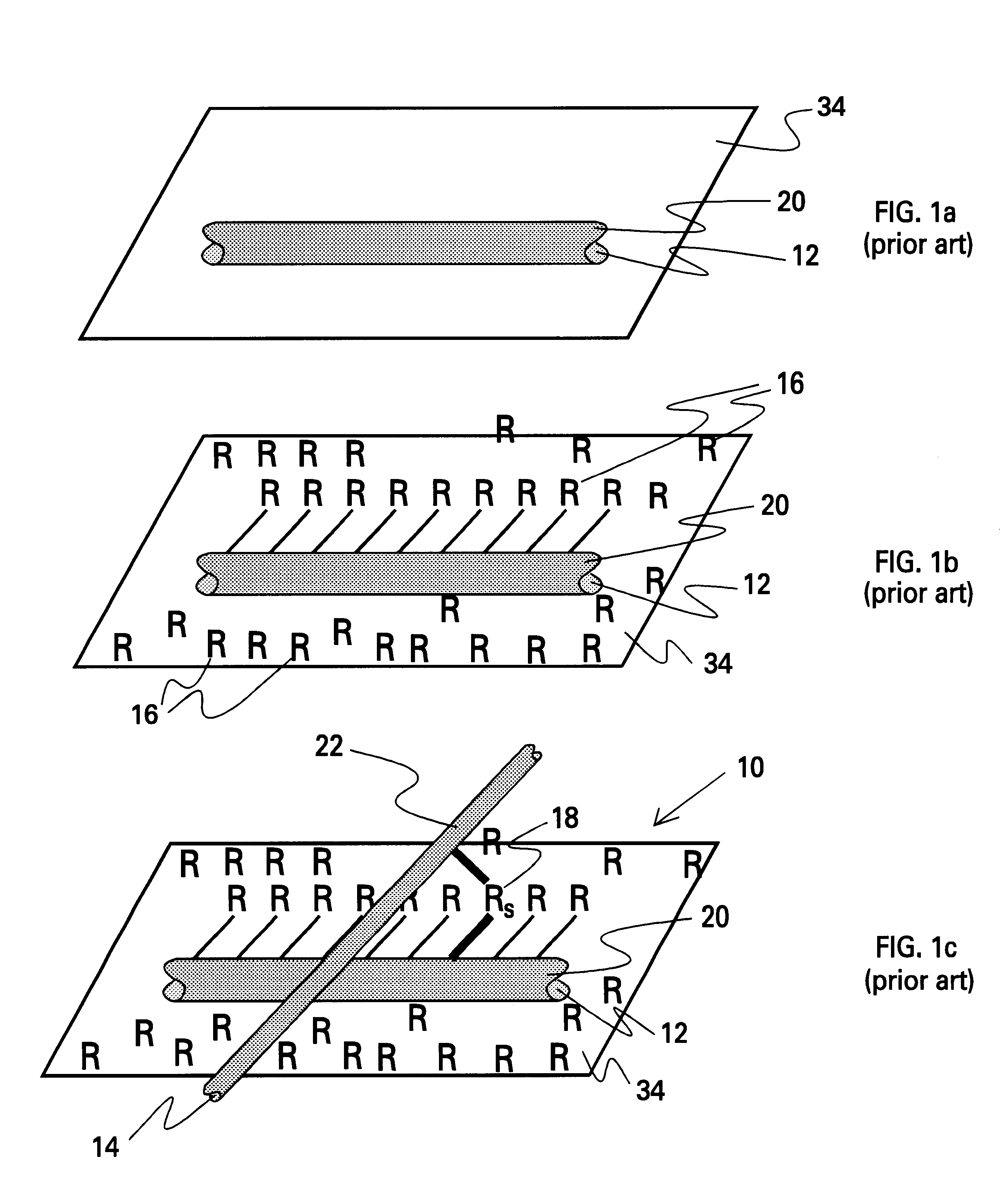

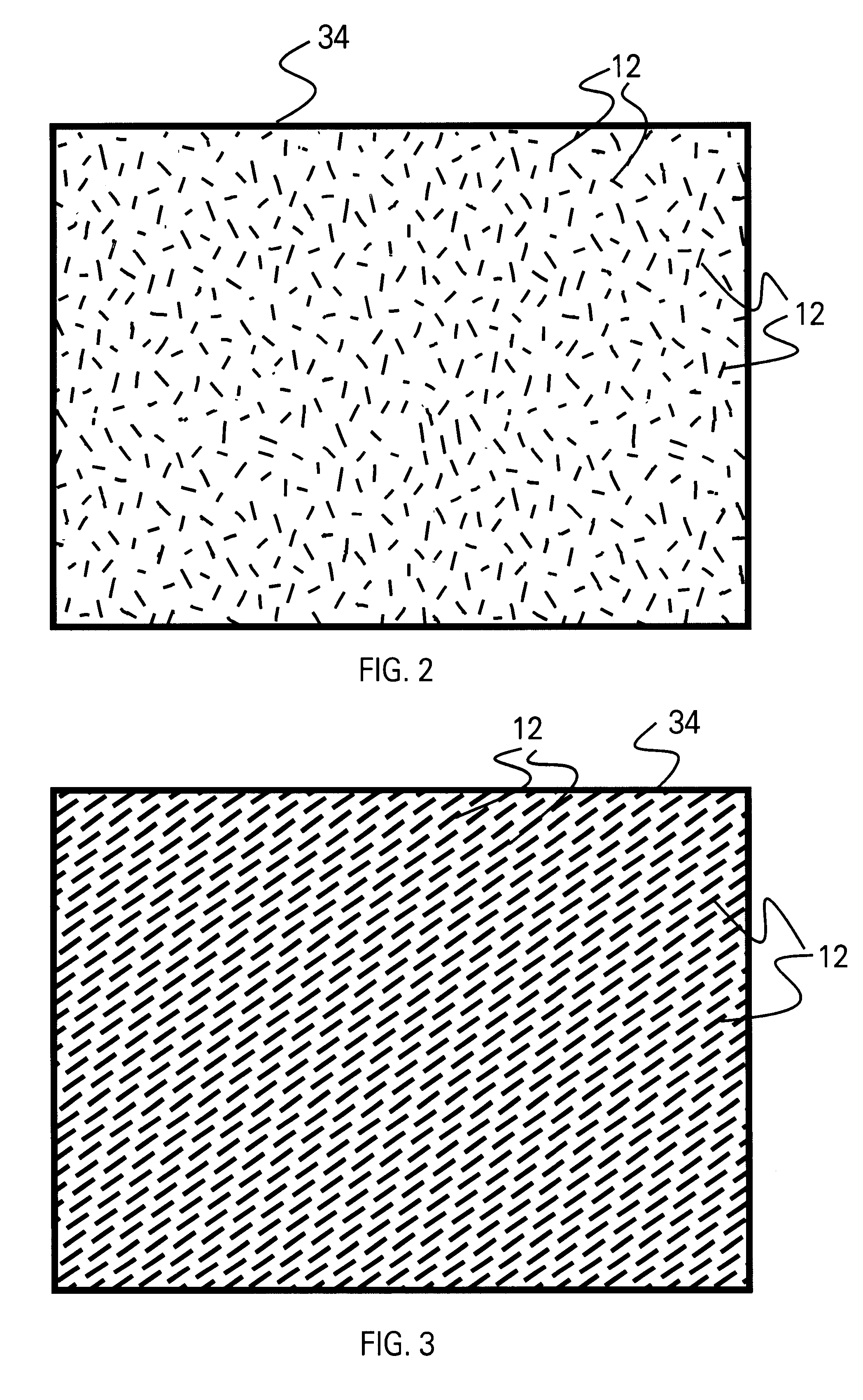

A method of aligning nanowires on a substrate is provided. First, a plurality of the nanowires is formed on the substrate, then the plurality of nanowires is exposed to a flux of energetic ions, e.g., argon at an ion energy of 5 KV and an integrated flux density of about 6x1015 ions / cm2. The flux of energetic ions serves to align the nanowires parallel to each other. The flux of energetic ions may also be used to align the nanowires parallel to the substrate surface.

Owner:SAMSUNG ELECTRONICS CO LTD

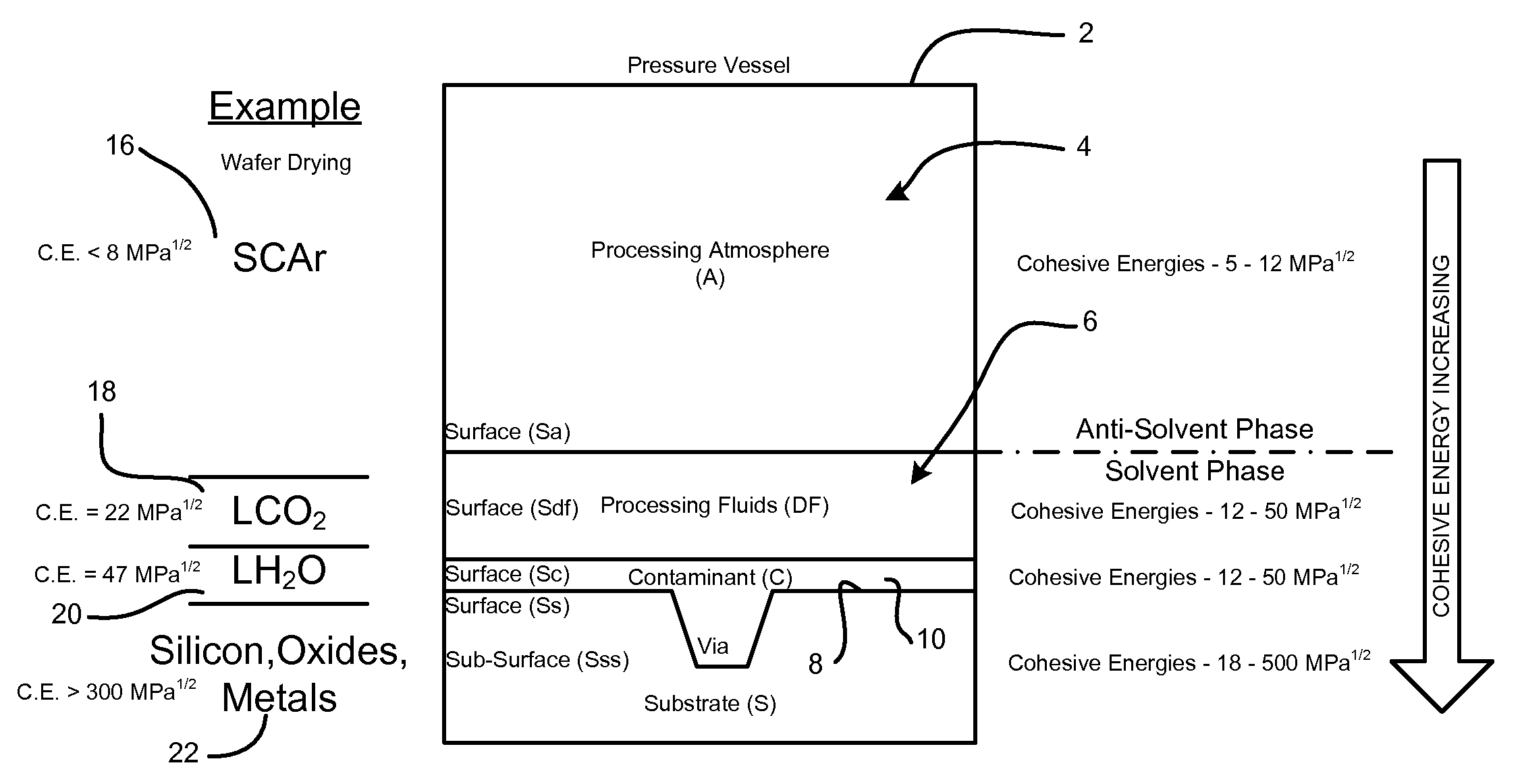

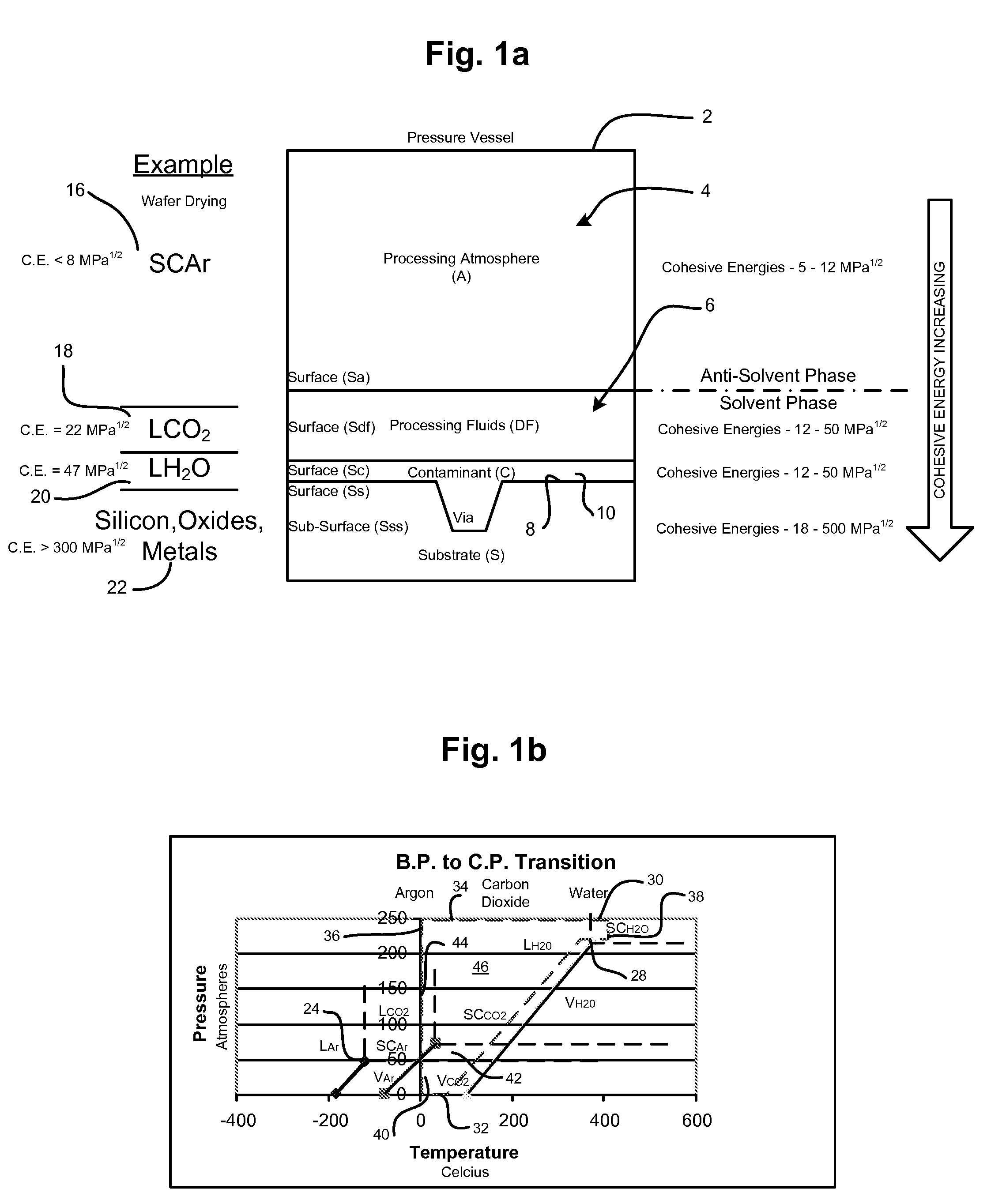

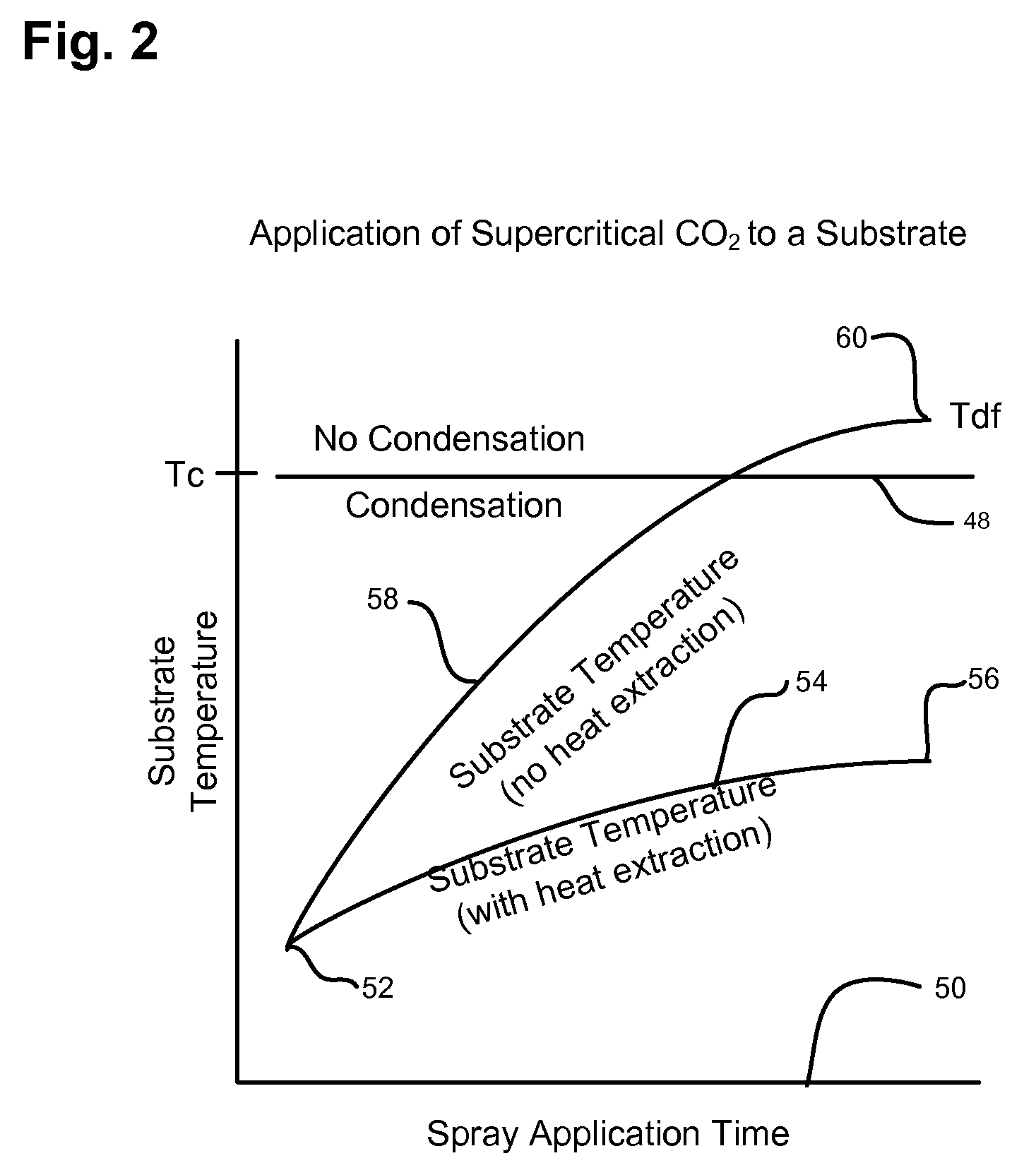

Precision surface treatments using dense fluids and a plasma

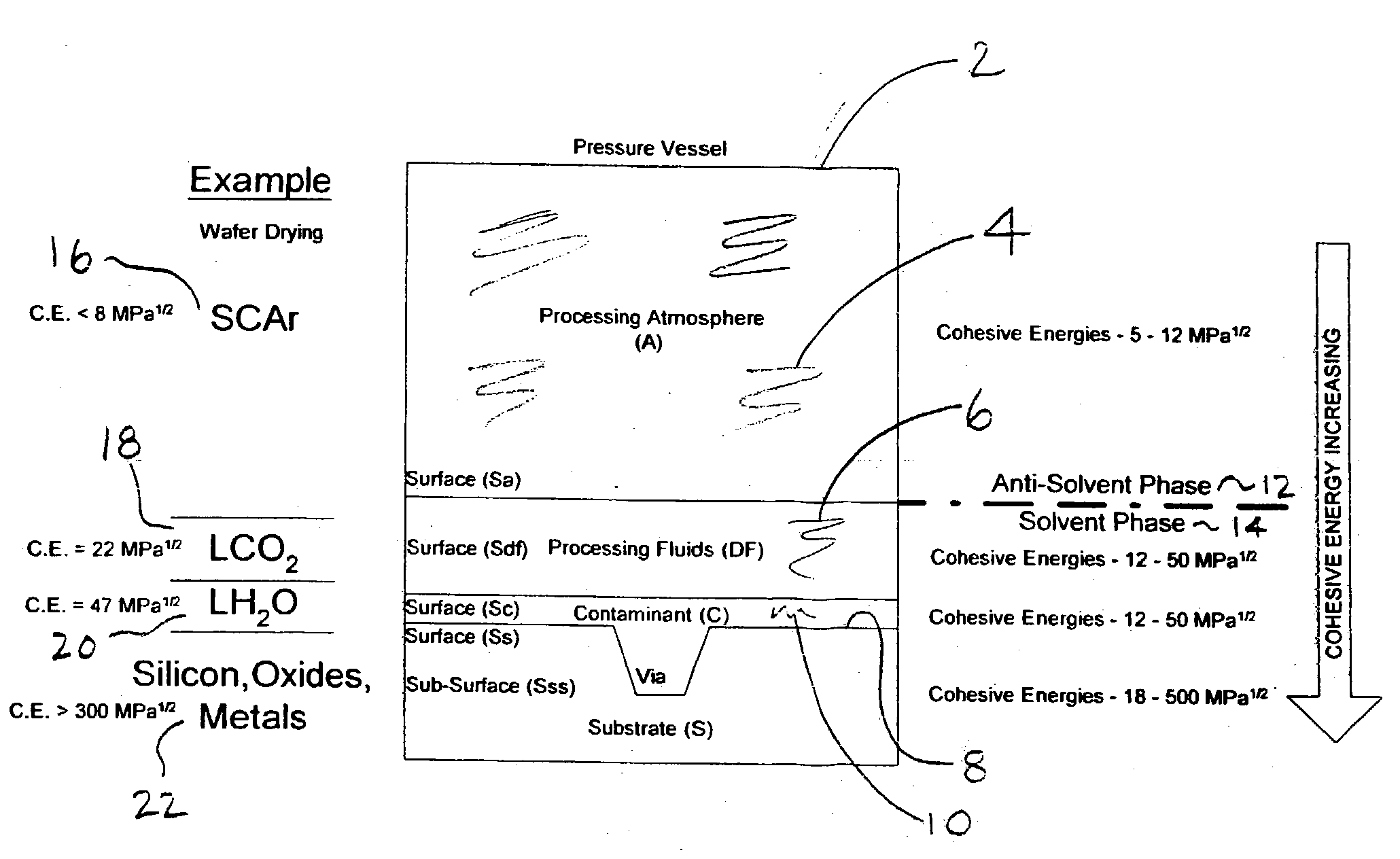

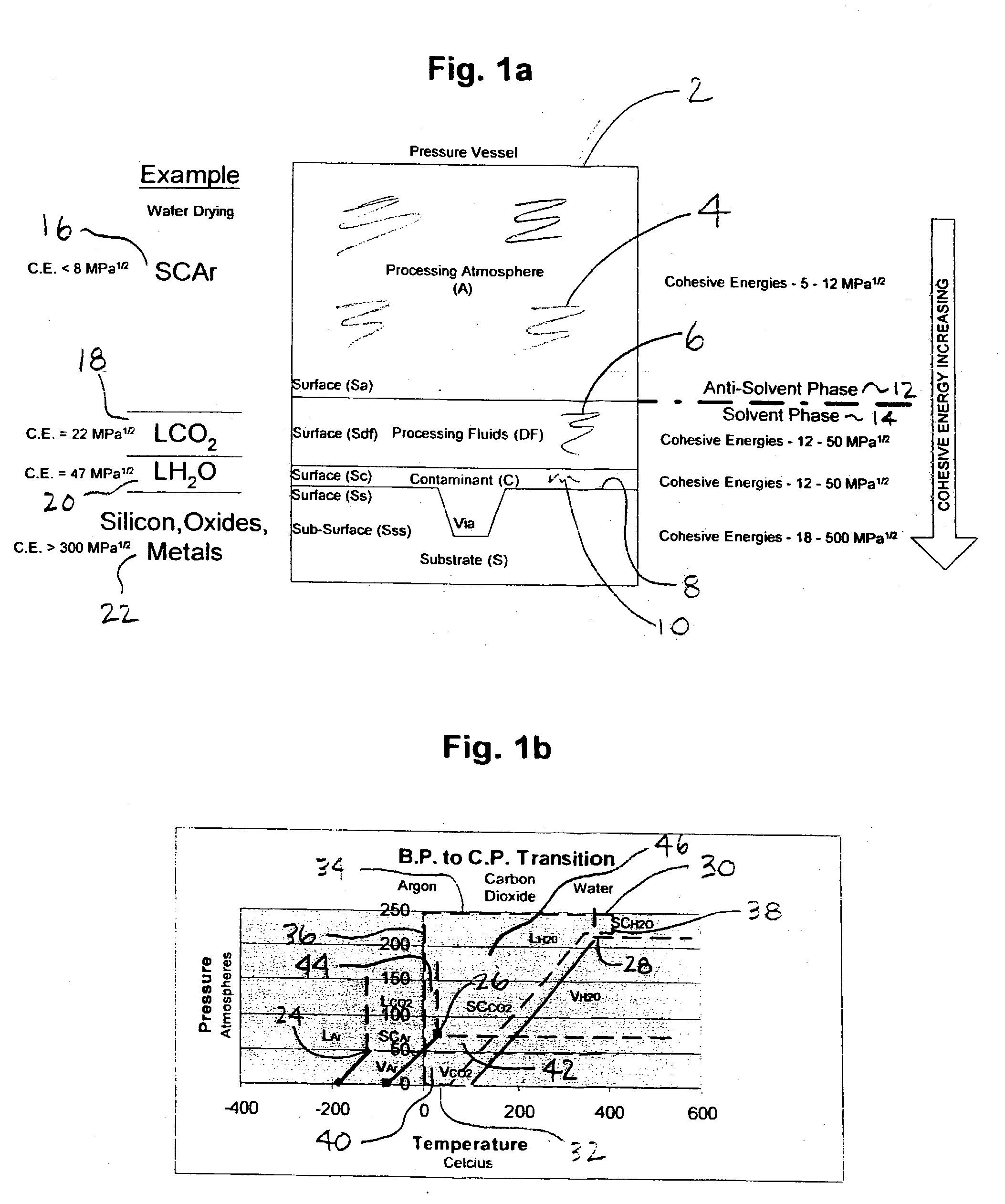

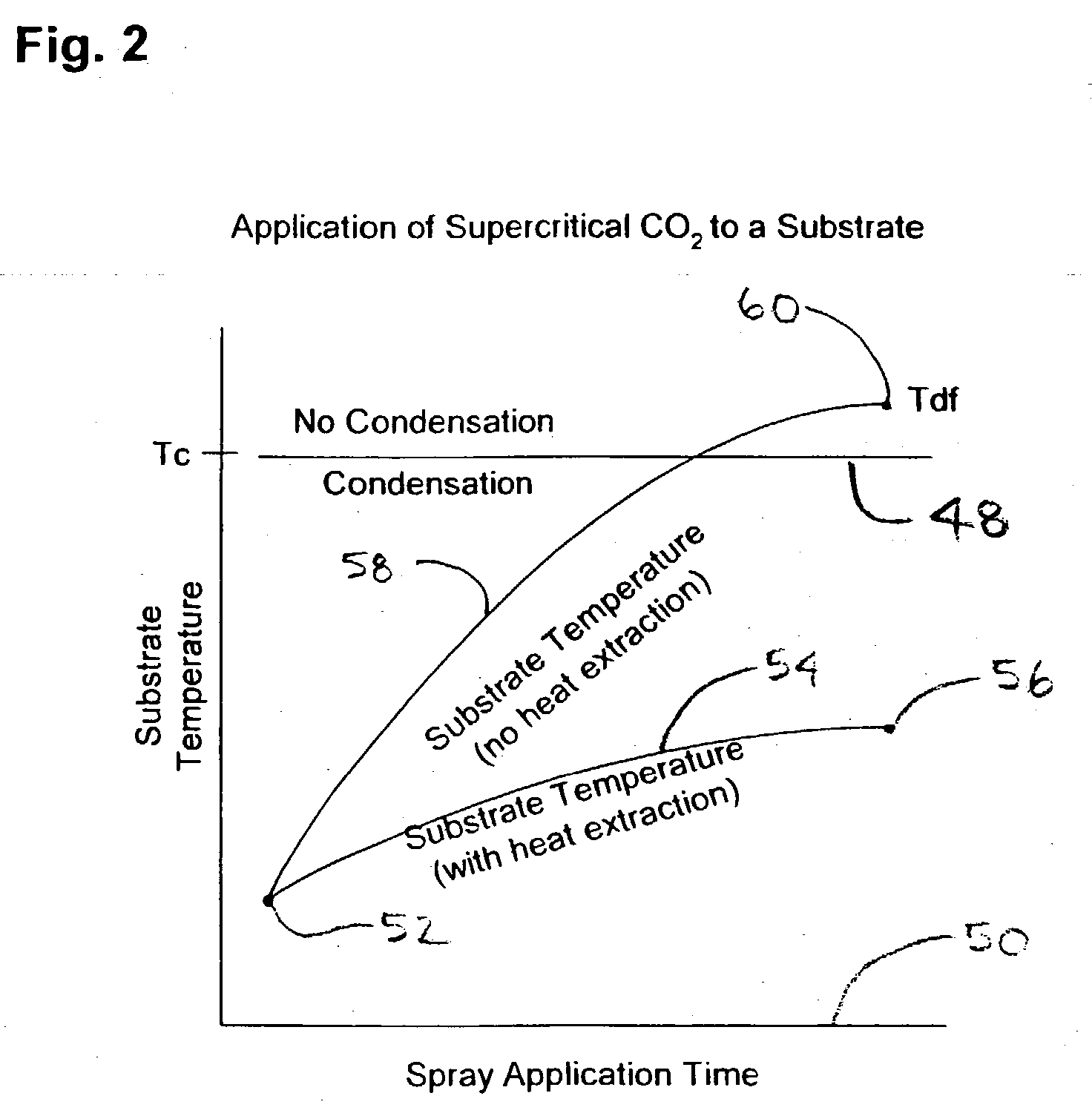

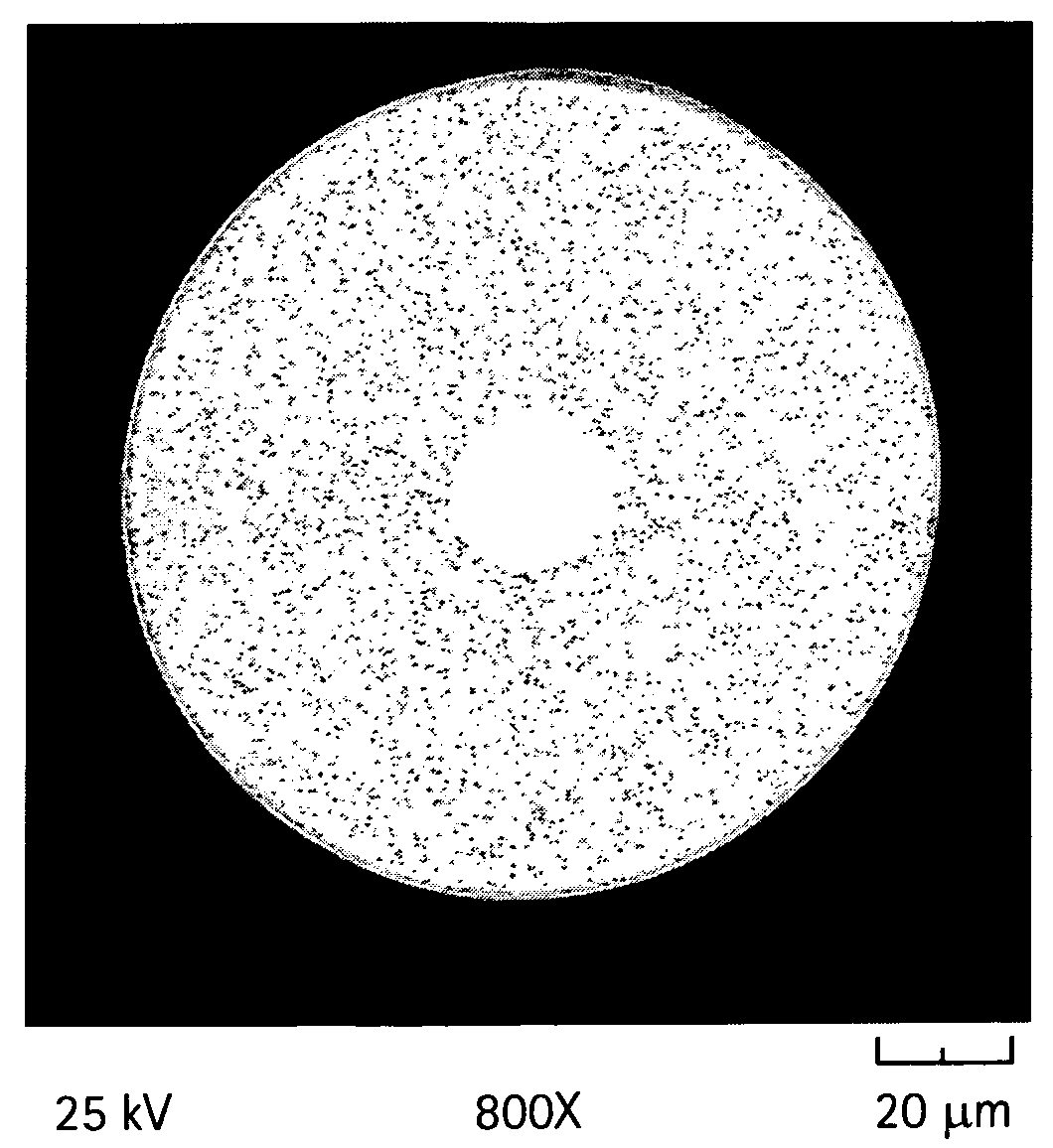

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

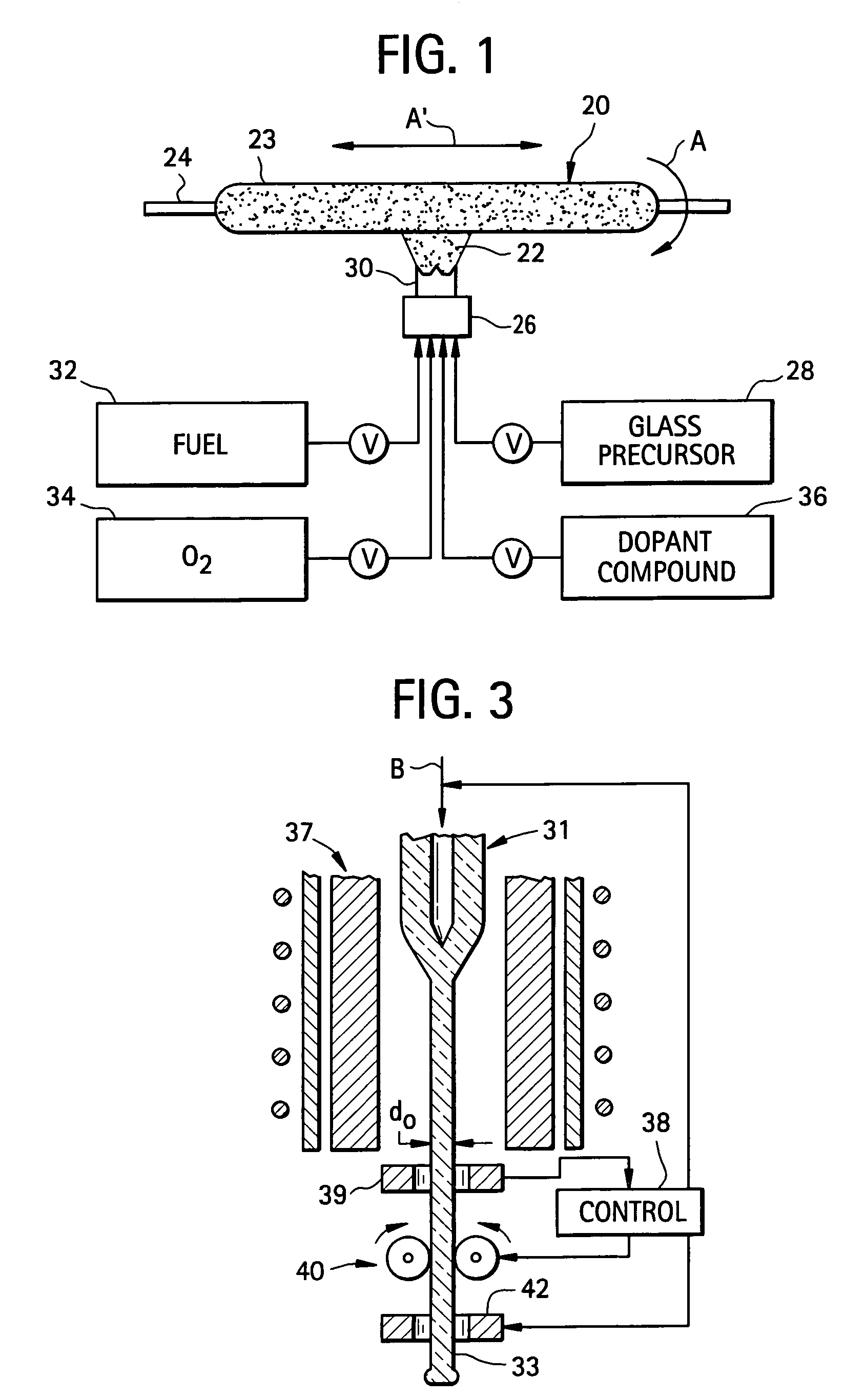

Microstructured optical fibers and methods

InactiveUS7450806B2Improve bending performanceLower refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogenNitrogen gas

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

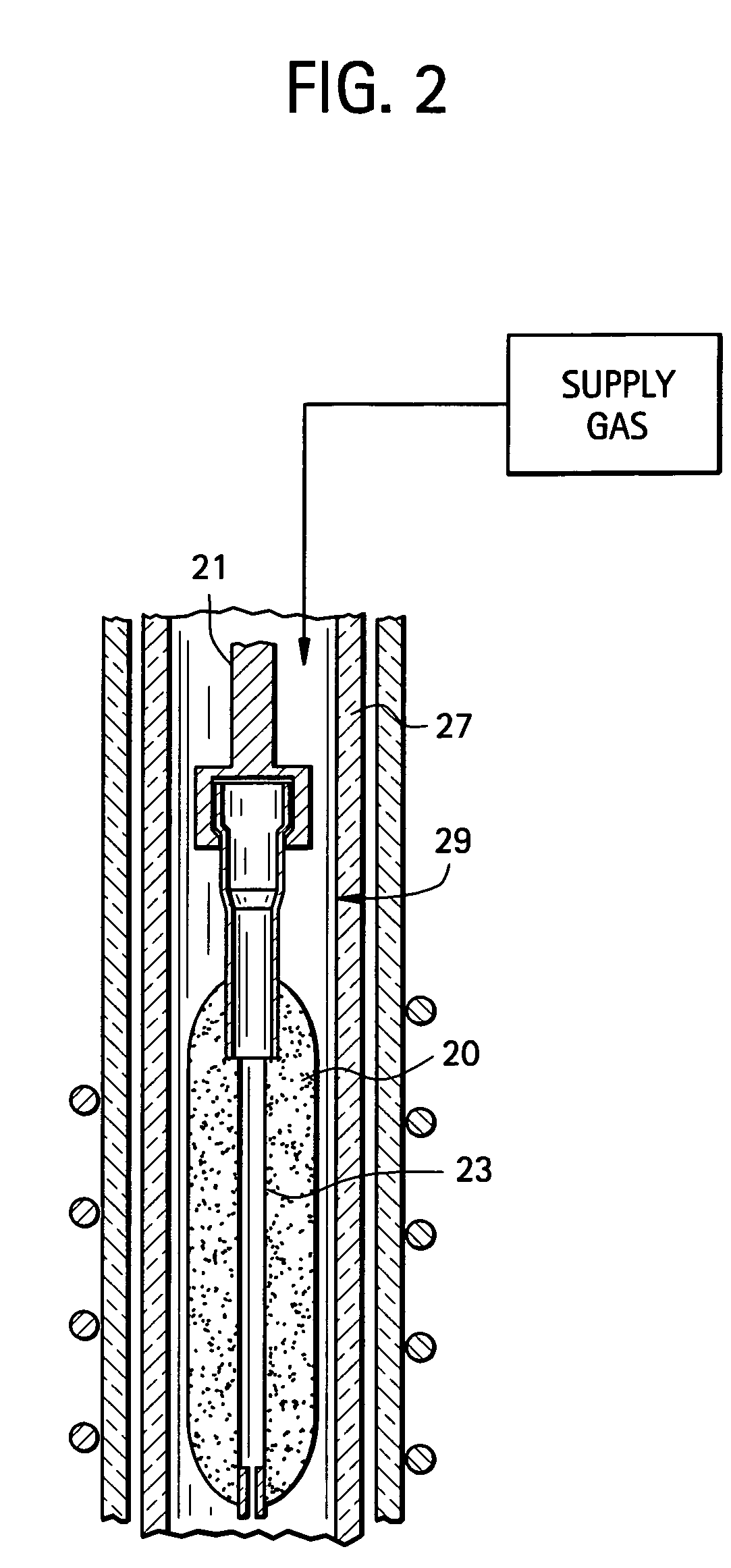

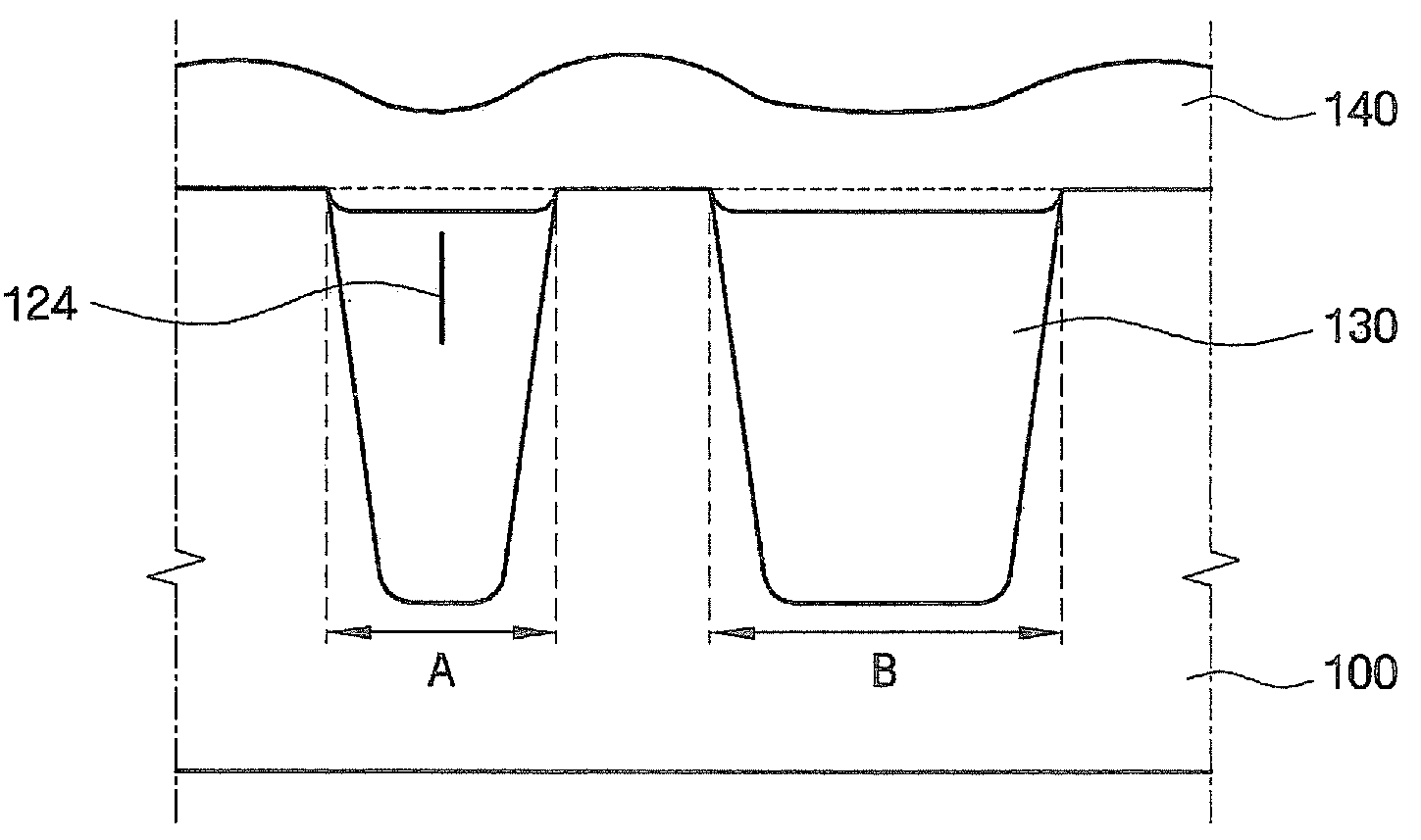

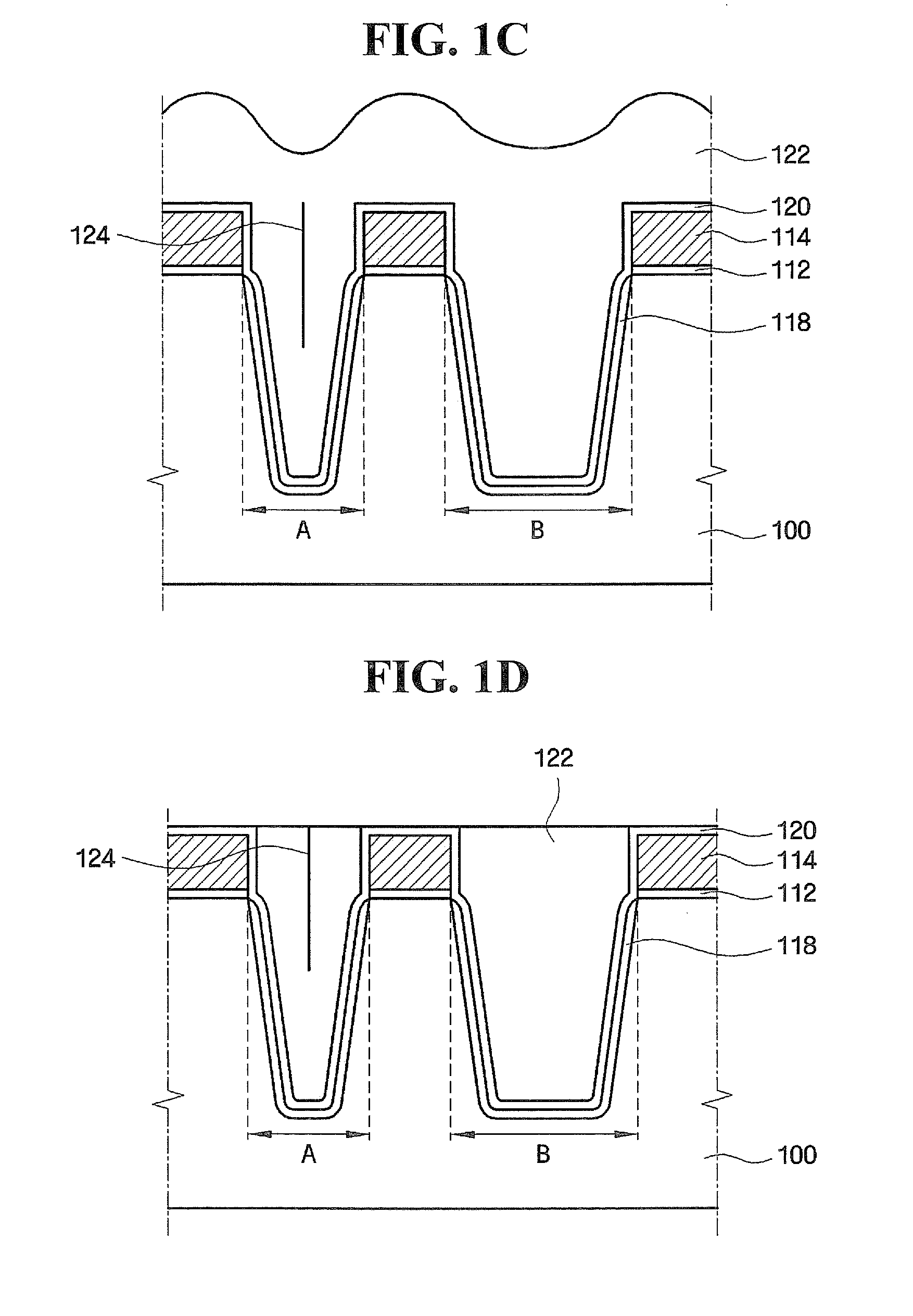

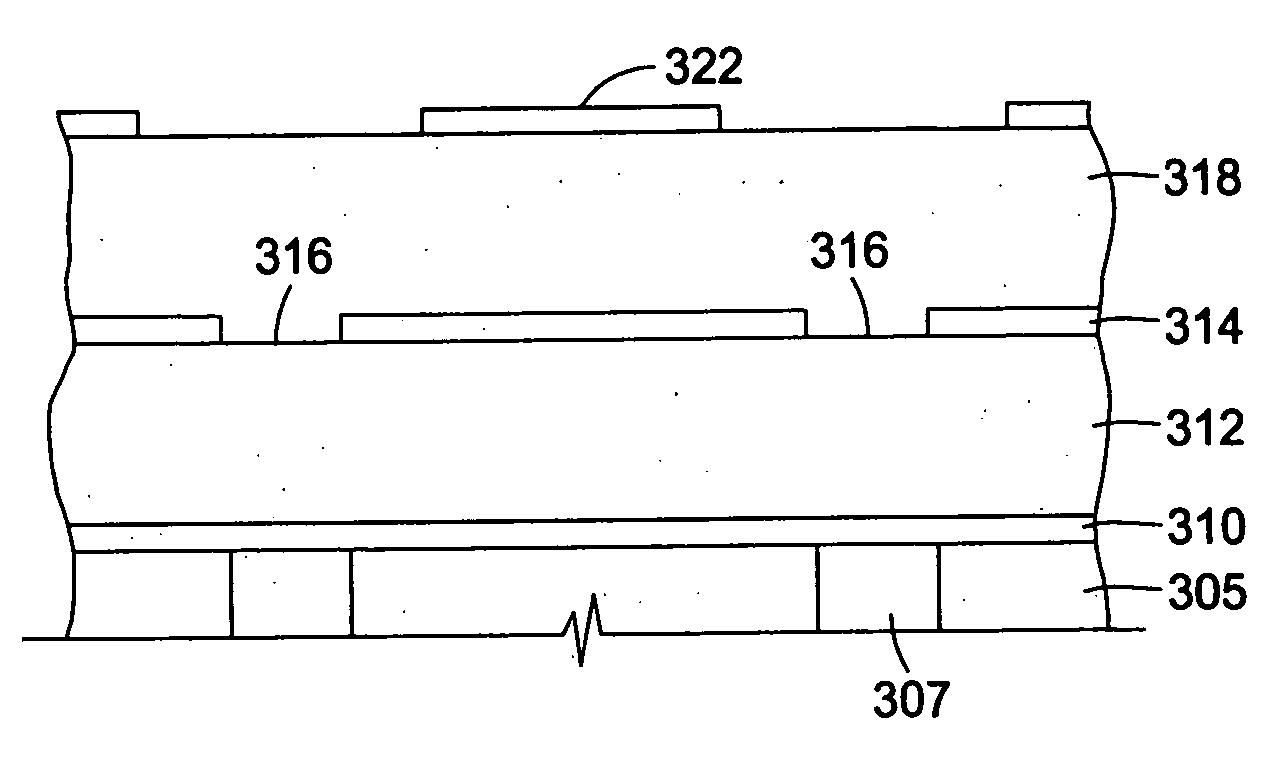

Methods of Forming Integrated Circuit Devices Having Ion-Cured Electrically Insulating Layers Therein

ActiveUS20090098706A1Quality improvementDegree of reductionSemiconductor/solid-state device manufacturingAtomic orderEngineering

Methods of forming integrated circuit devices include forming a trench in a surface of semiconductor substrate and filling the trench with an electrically insulating region having a seam therein. The trench may be filled by depositing a sufficiently thick electrically insulating layer on sidewalls and a bottom of the trench. Curing ions are then implanted into the electrically insulating region at a sufficient energy and dose to reduce a degree of atomic order therein. The curing ions may be ones selected from a group consisting of nitrogen (N), phosphorus (P), boron (B), arsenic (As), carbon (C), argon (Ar), germanium (Ge), helium (He), neon (Ne) and xenon (Xe). These curing ions may be implanted at an energy of at least about 80 KeV and a dose of at least about 5×1014 ions / cm2. The electrically insulating region is then annealed at a sufficient temperature and for a sufficient duration to increase a degree of atomic order within the electrically insulating region.

Owner:IBM CORP +2

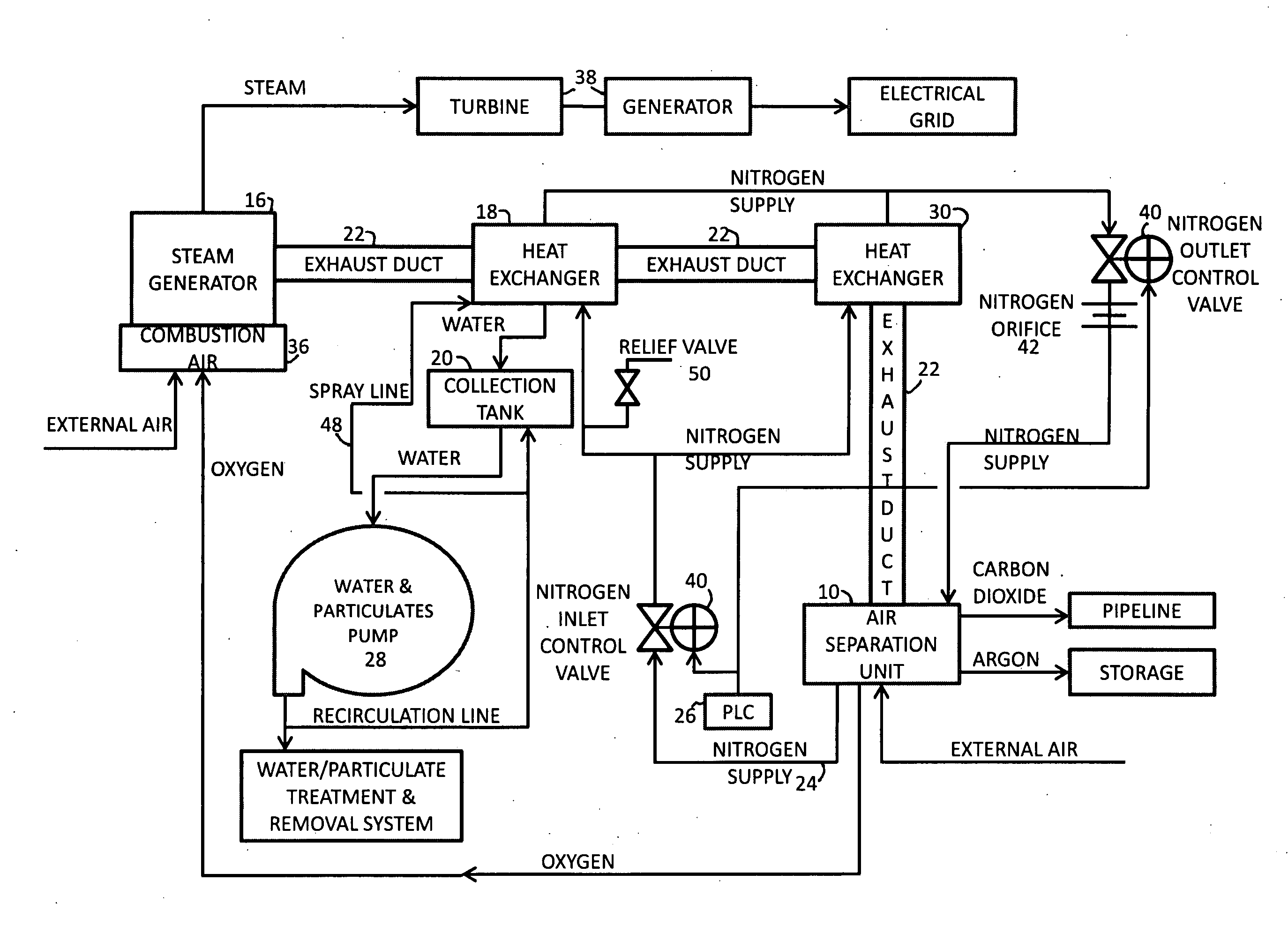

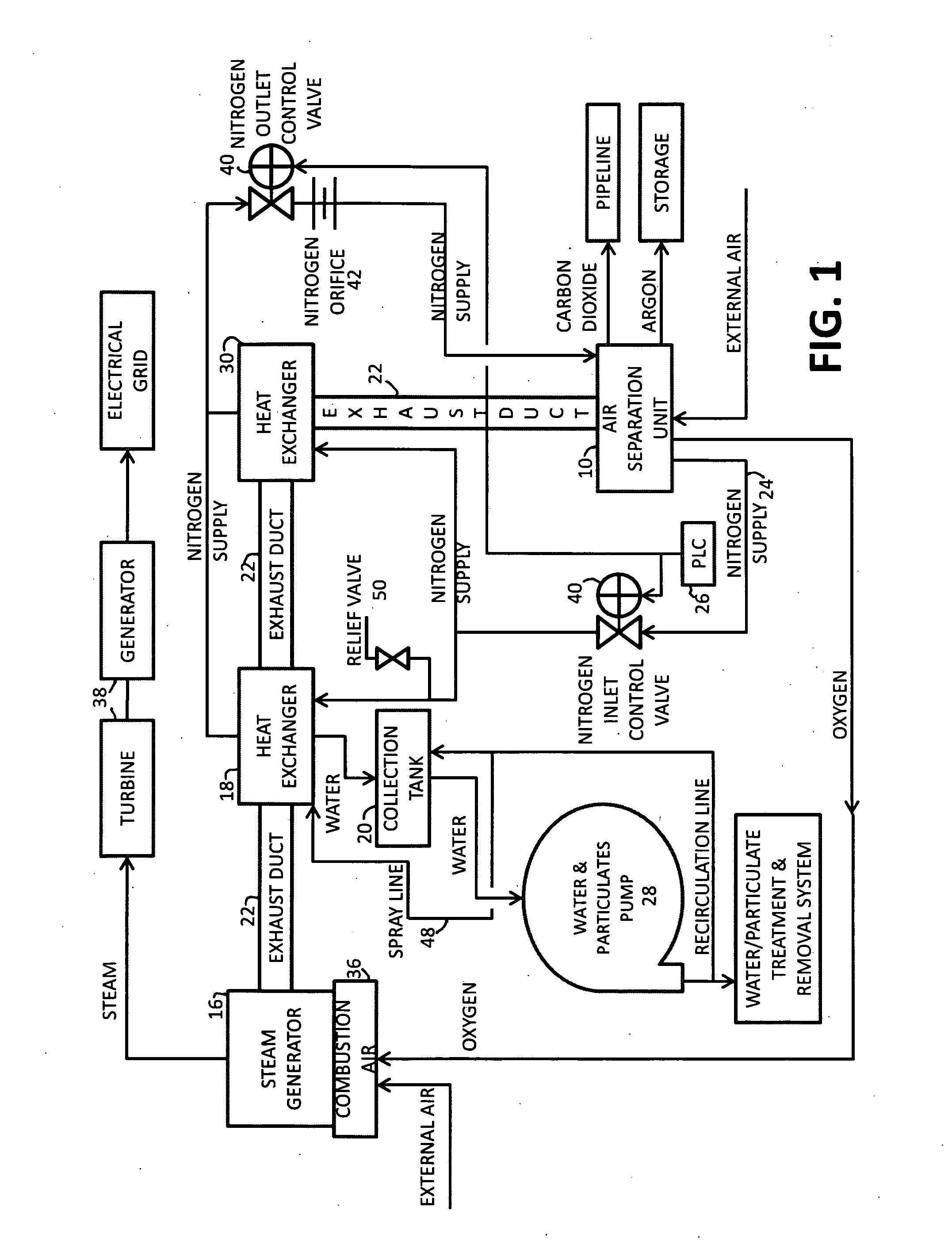

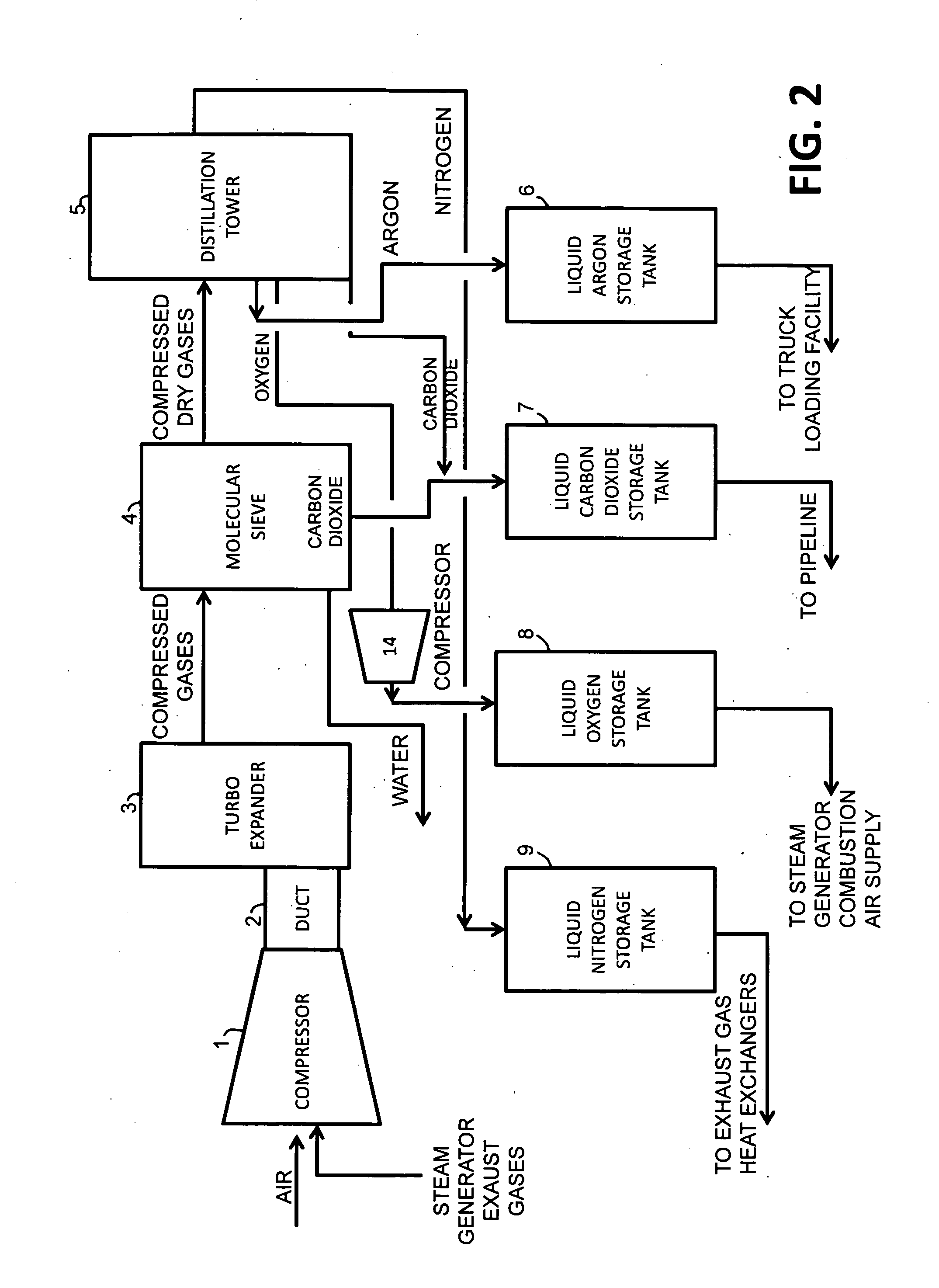

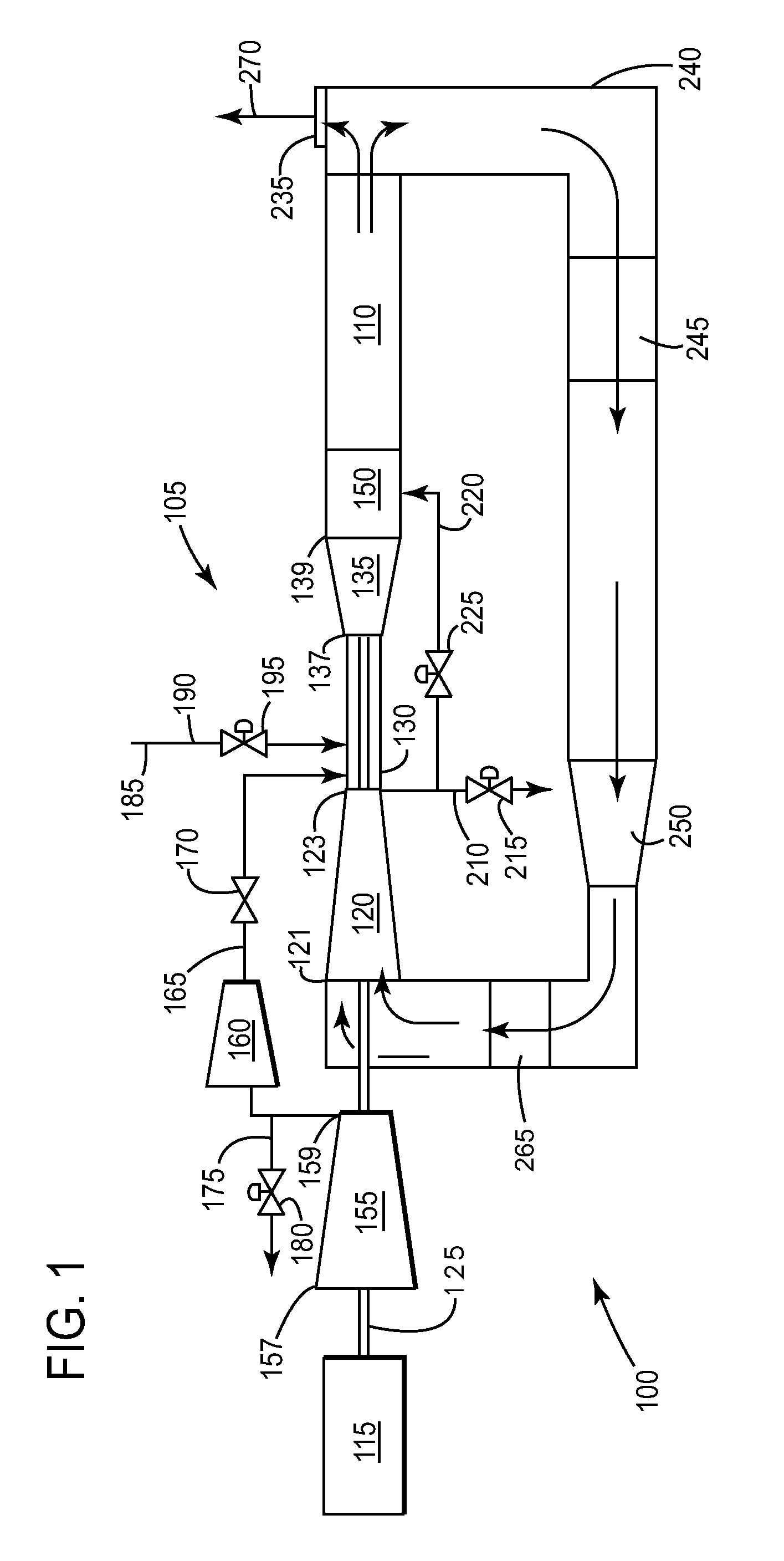

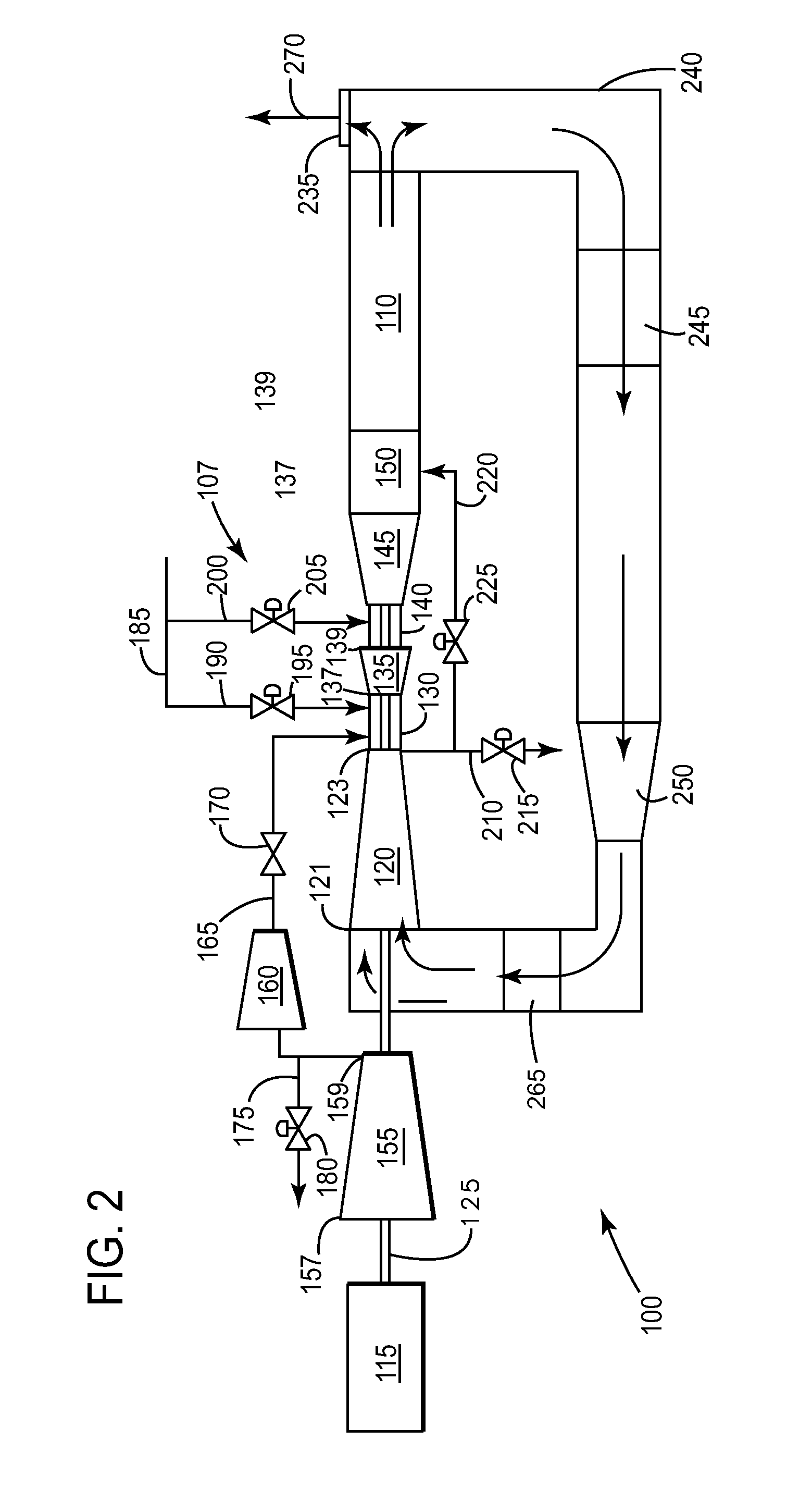

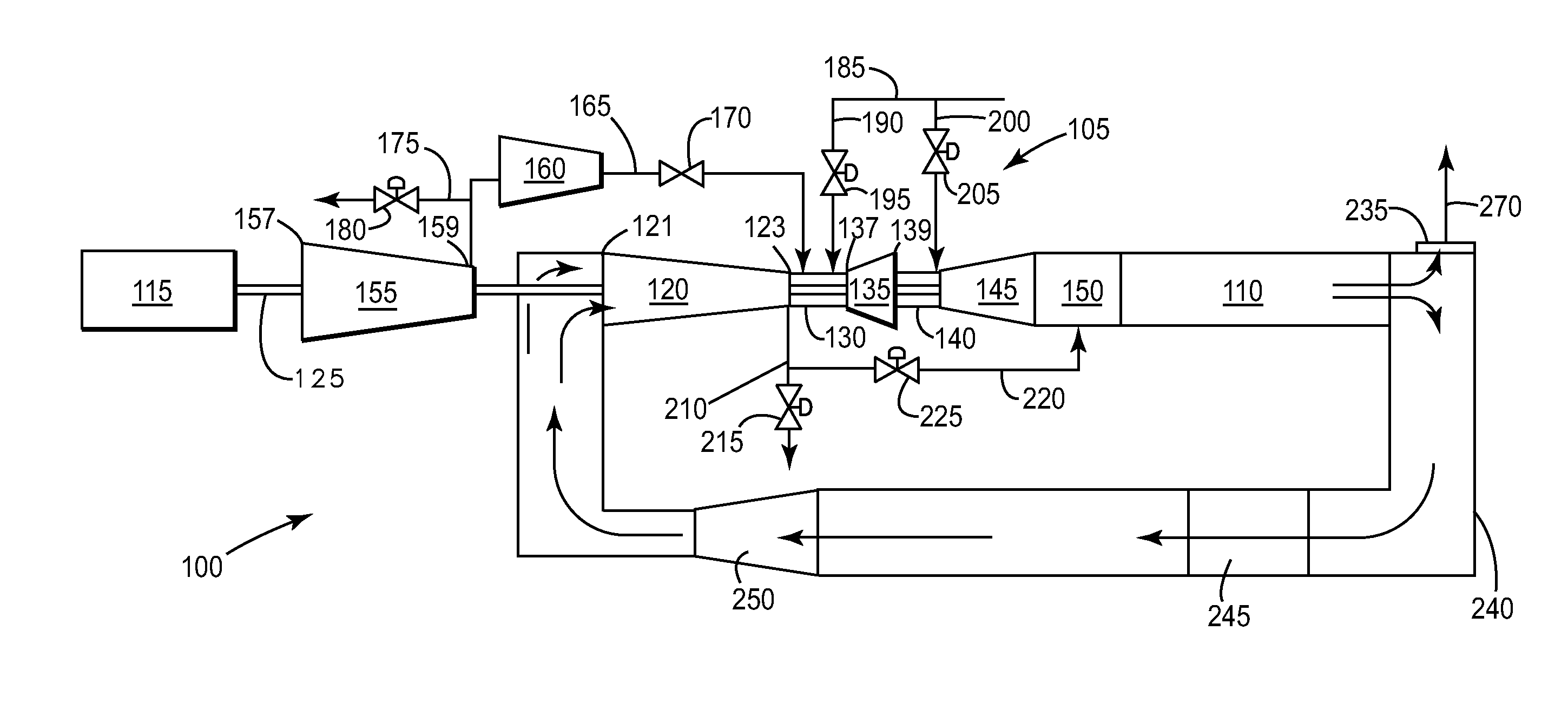

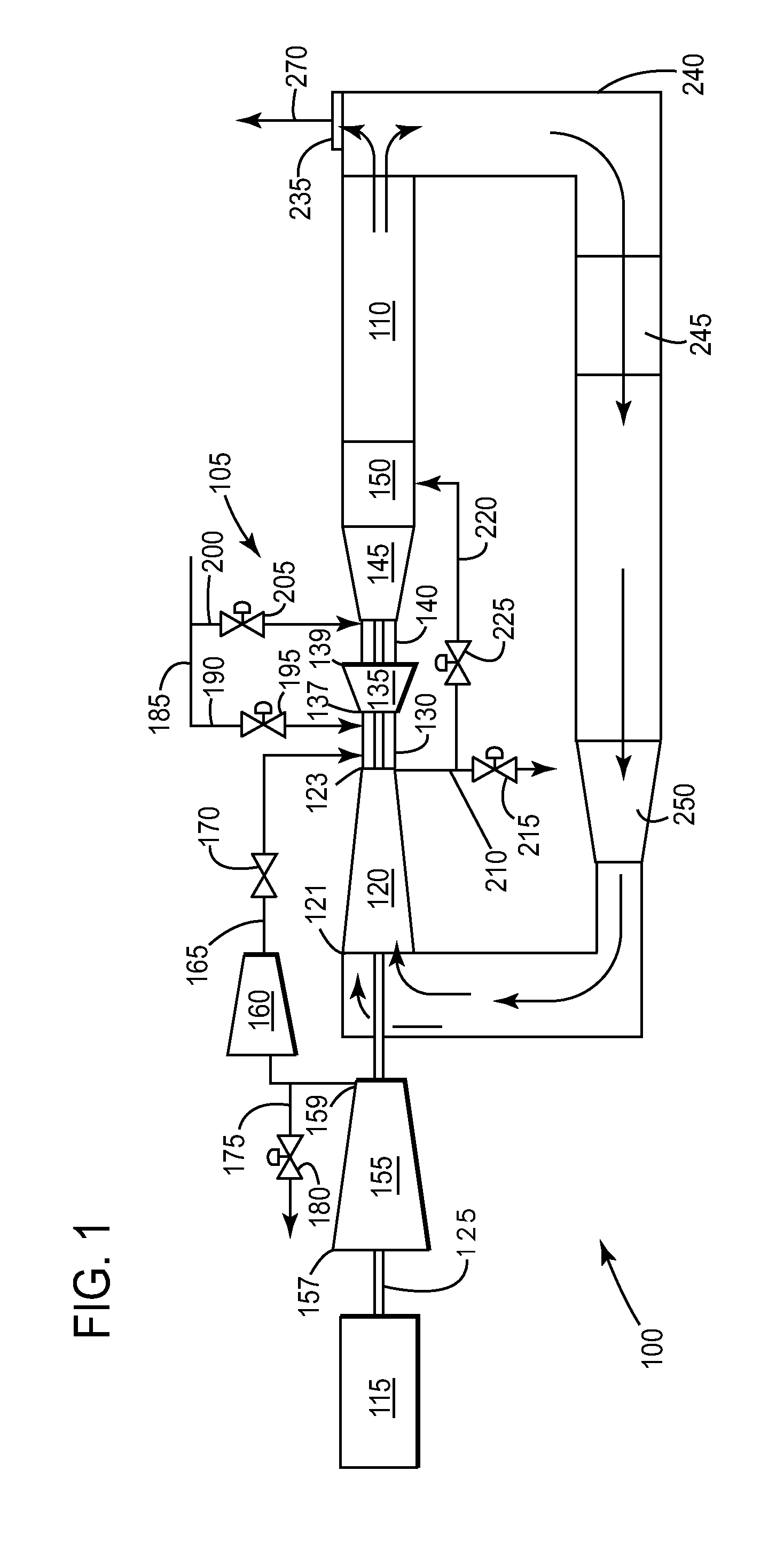

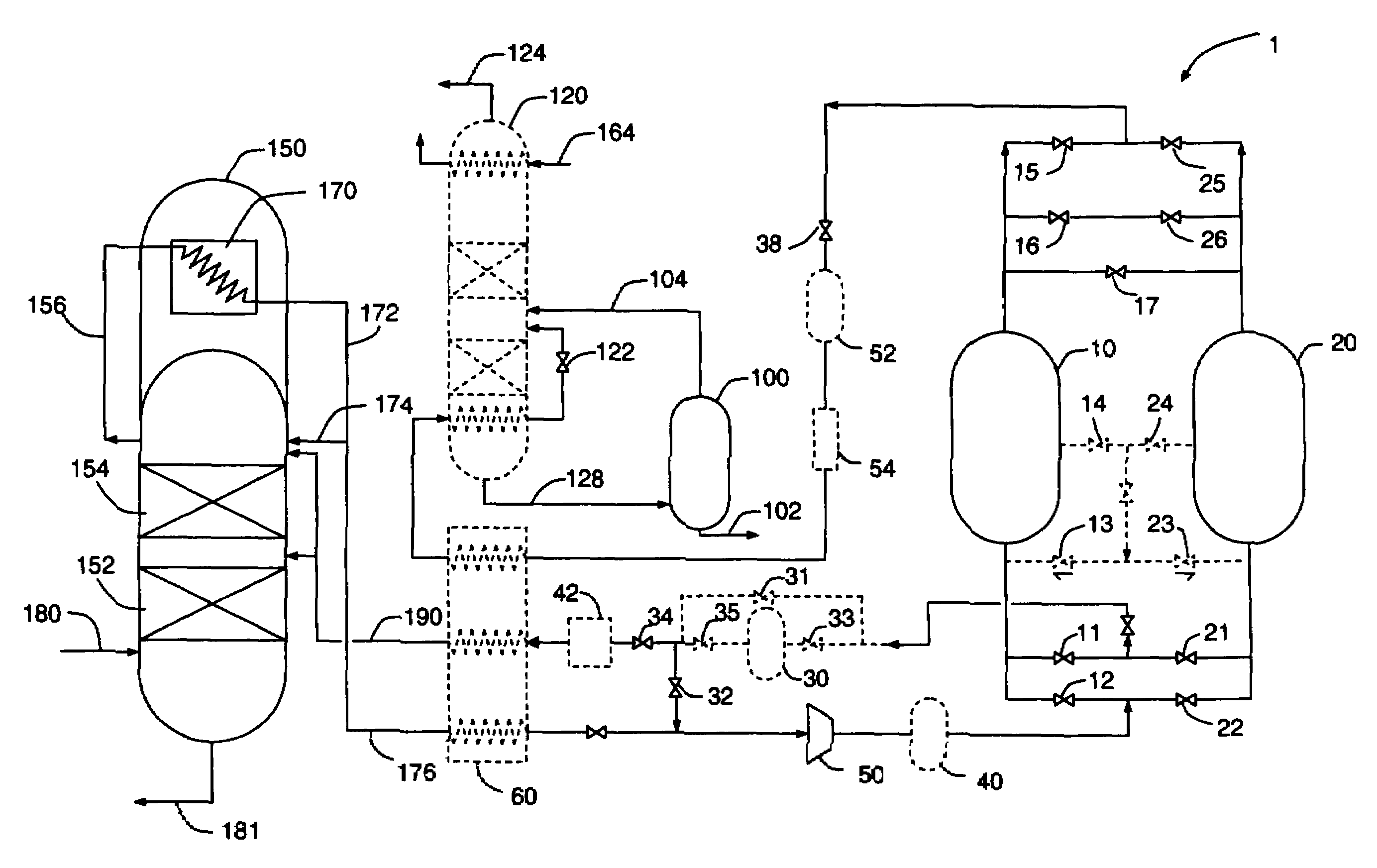

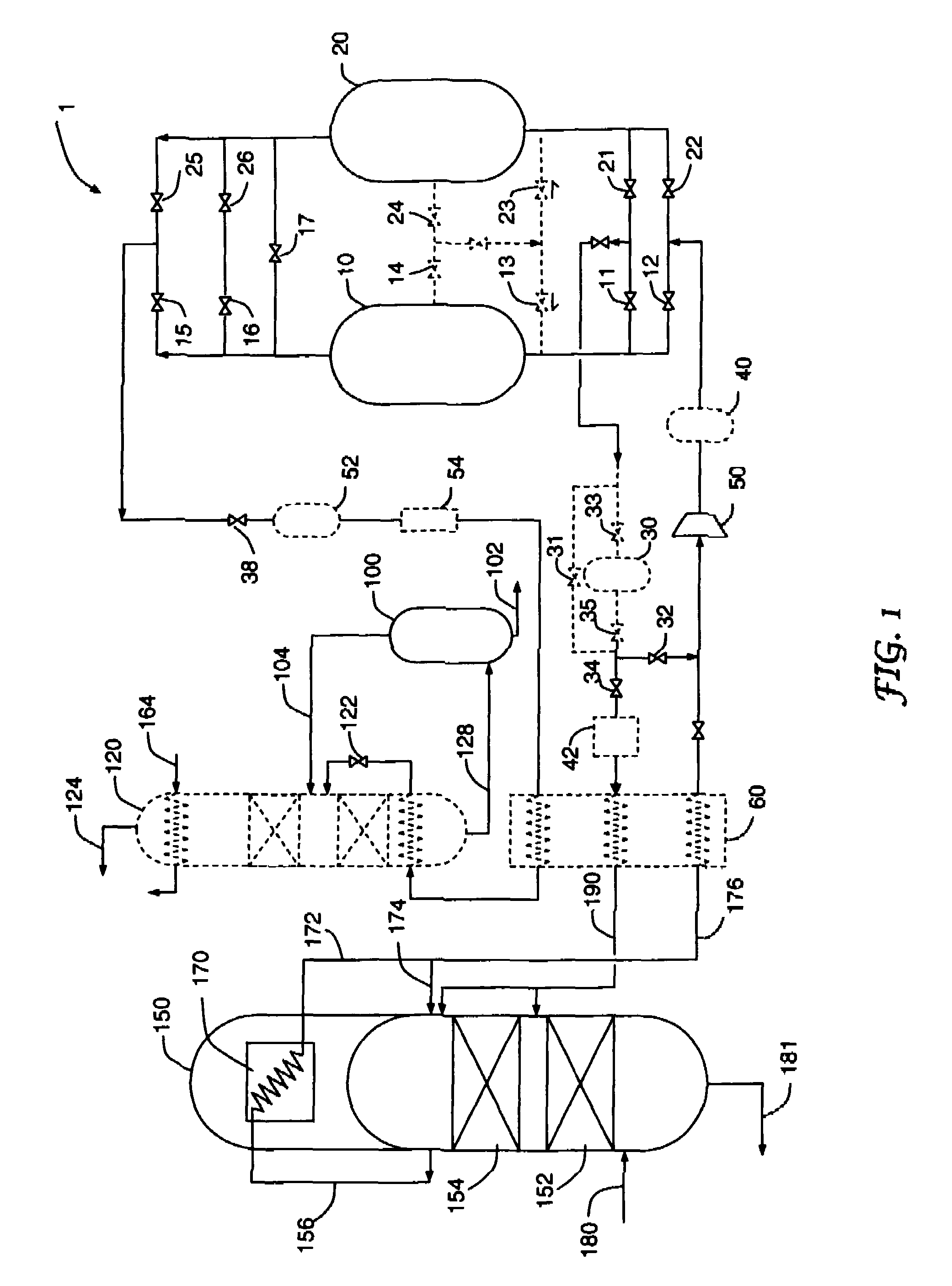

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

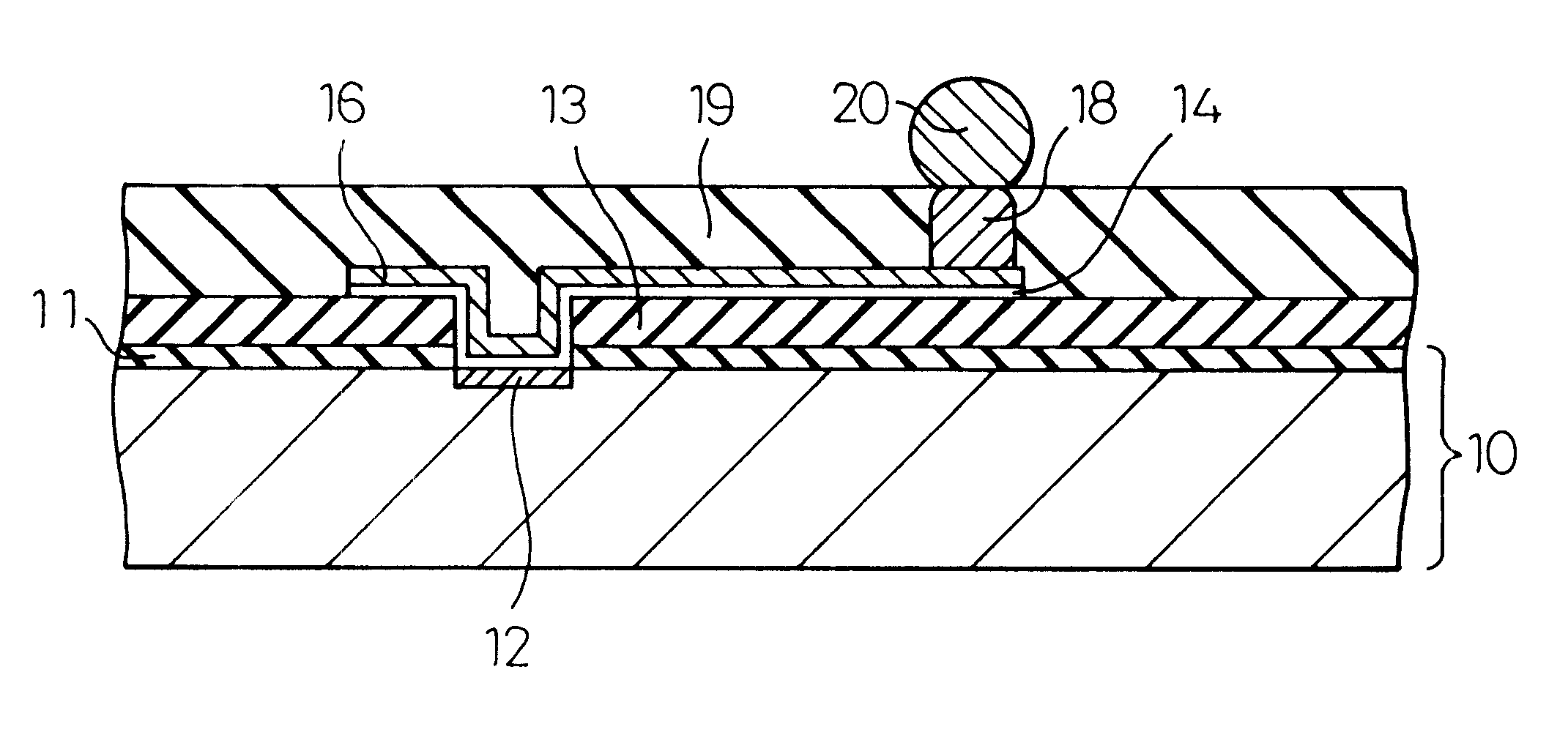

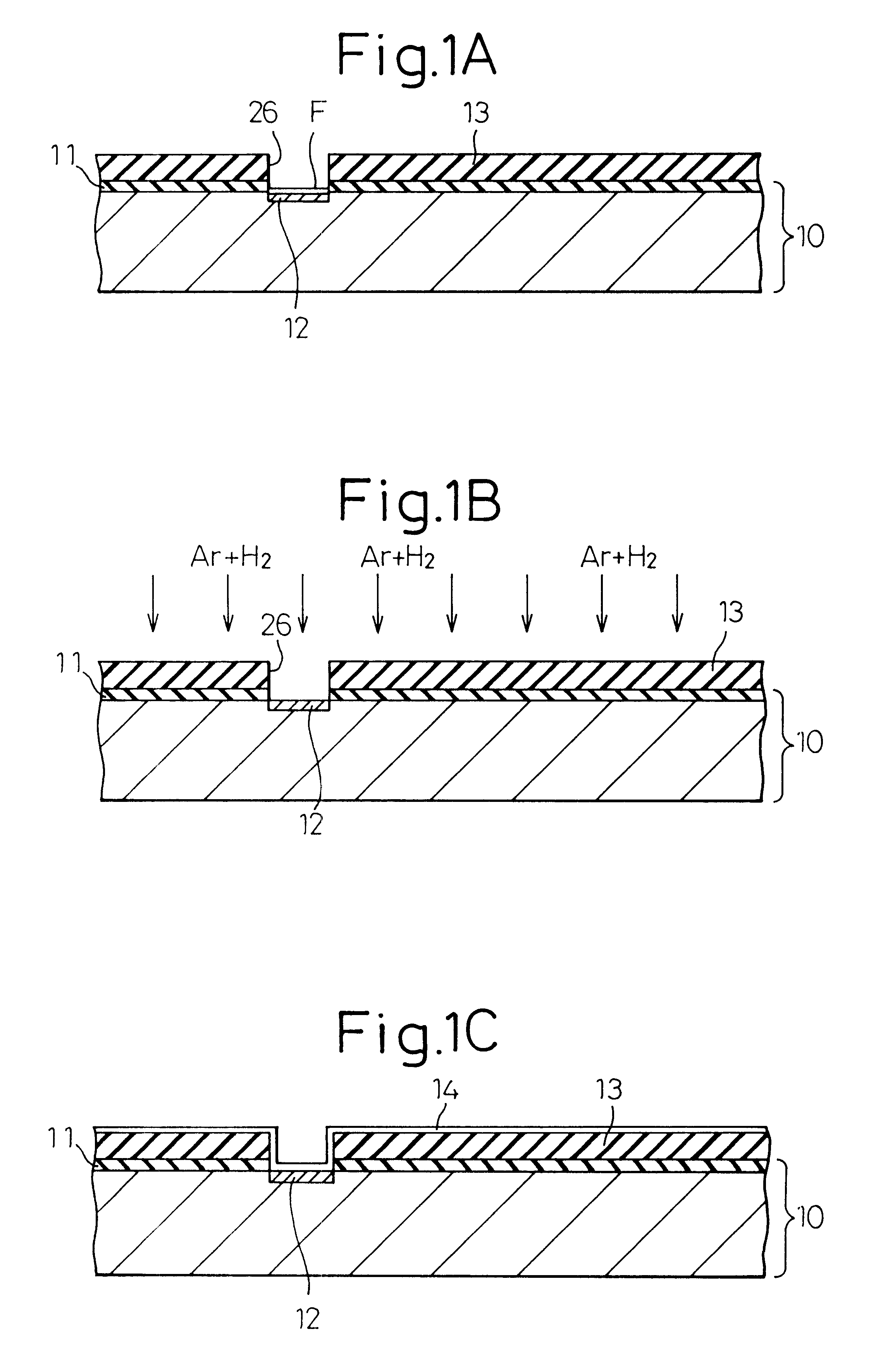

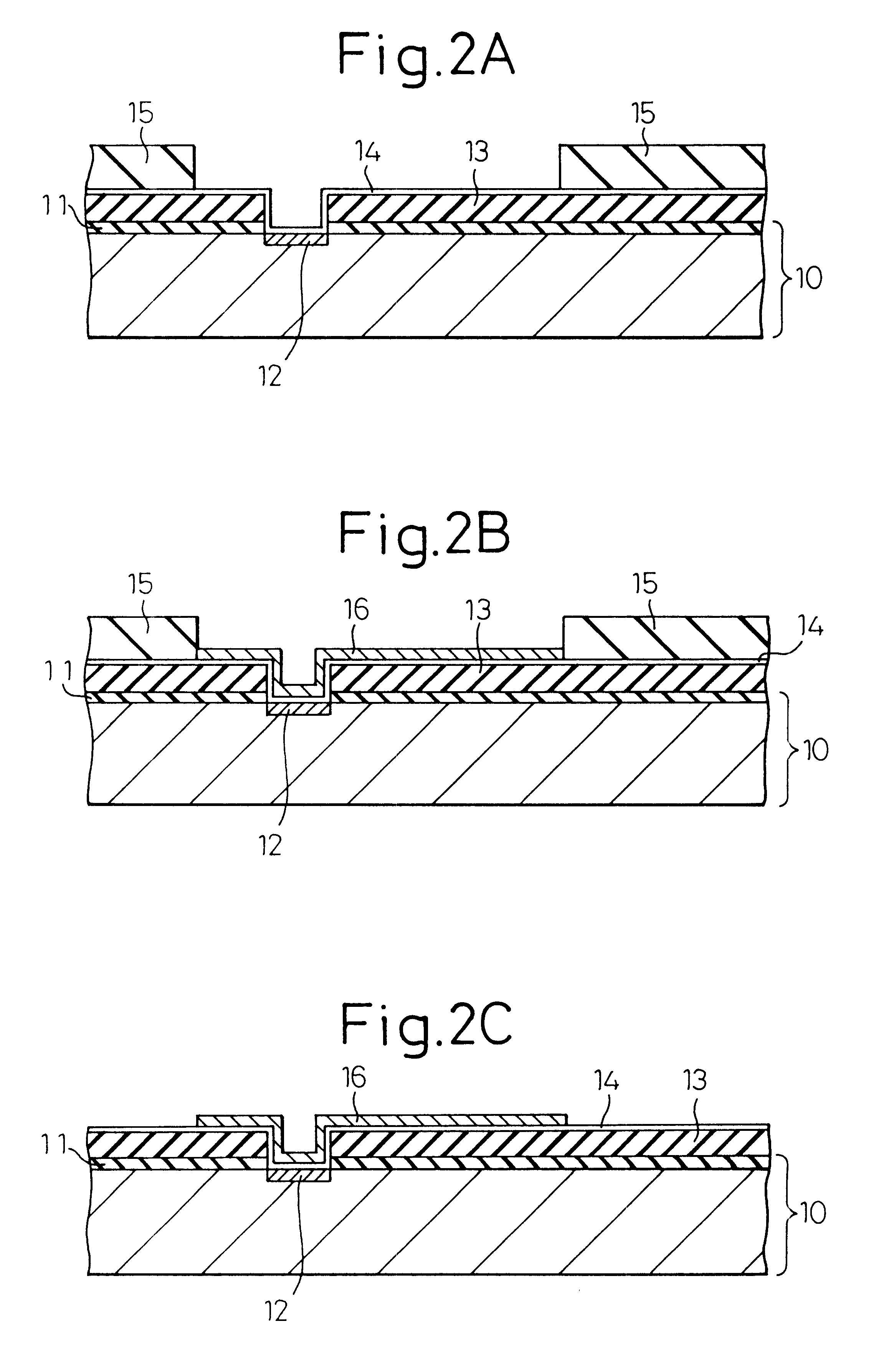

Method of producing semiconductor device comprising insulation layer having improved resistance and semiconductor device produced thereby

InactiveUS6200888B1Satisfactory electrical connectionReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

Owner:SHINKO ELECTRIC IND CO LTD

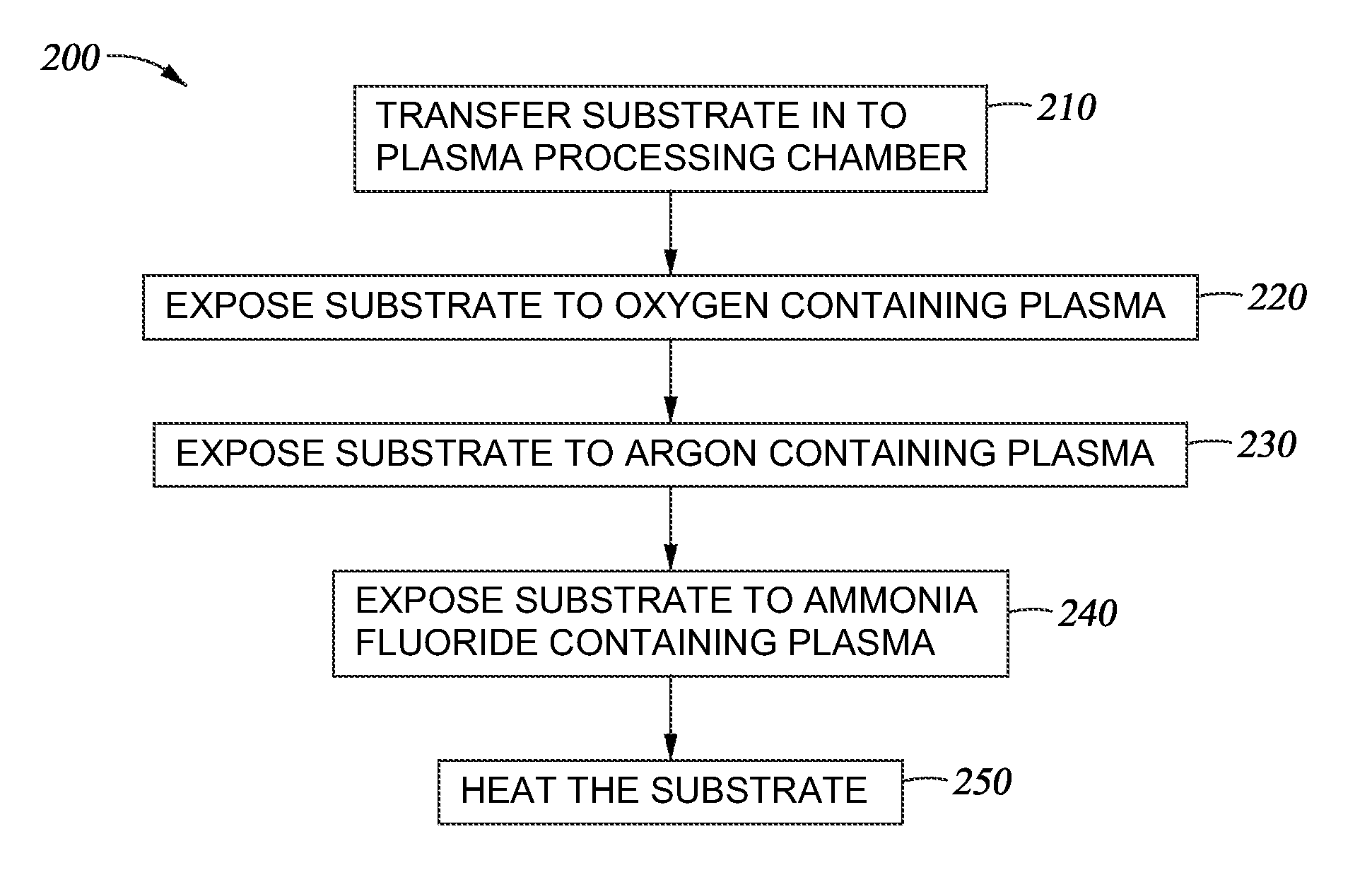

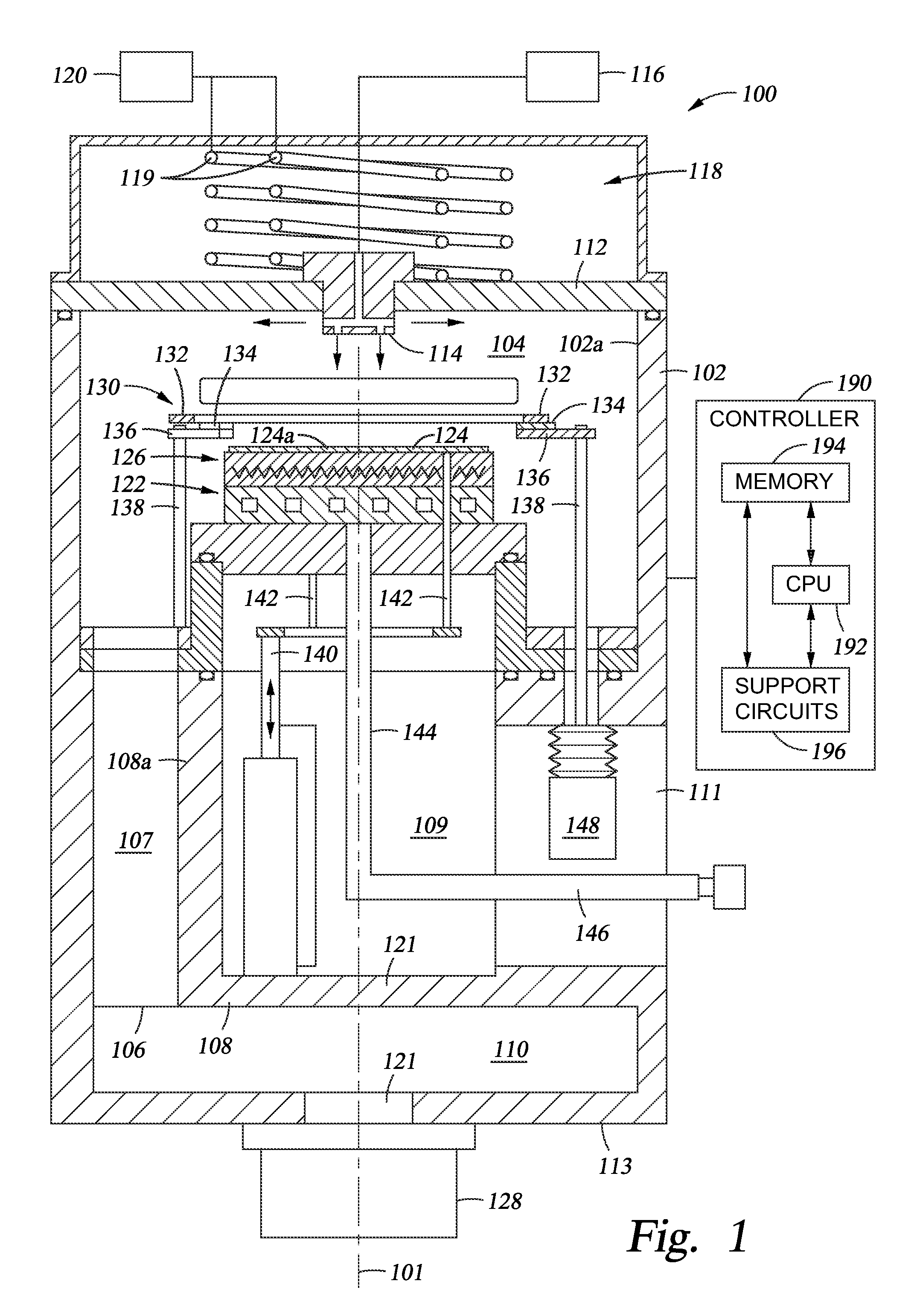

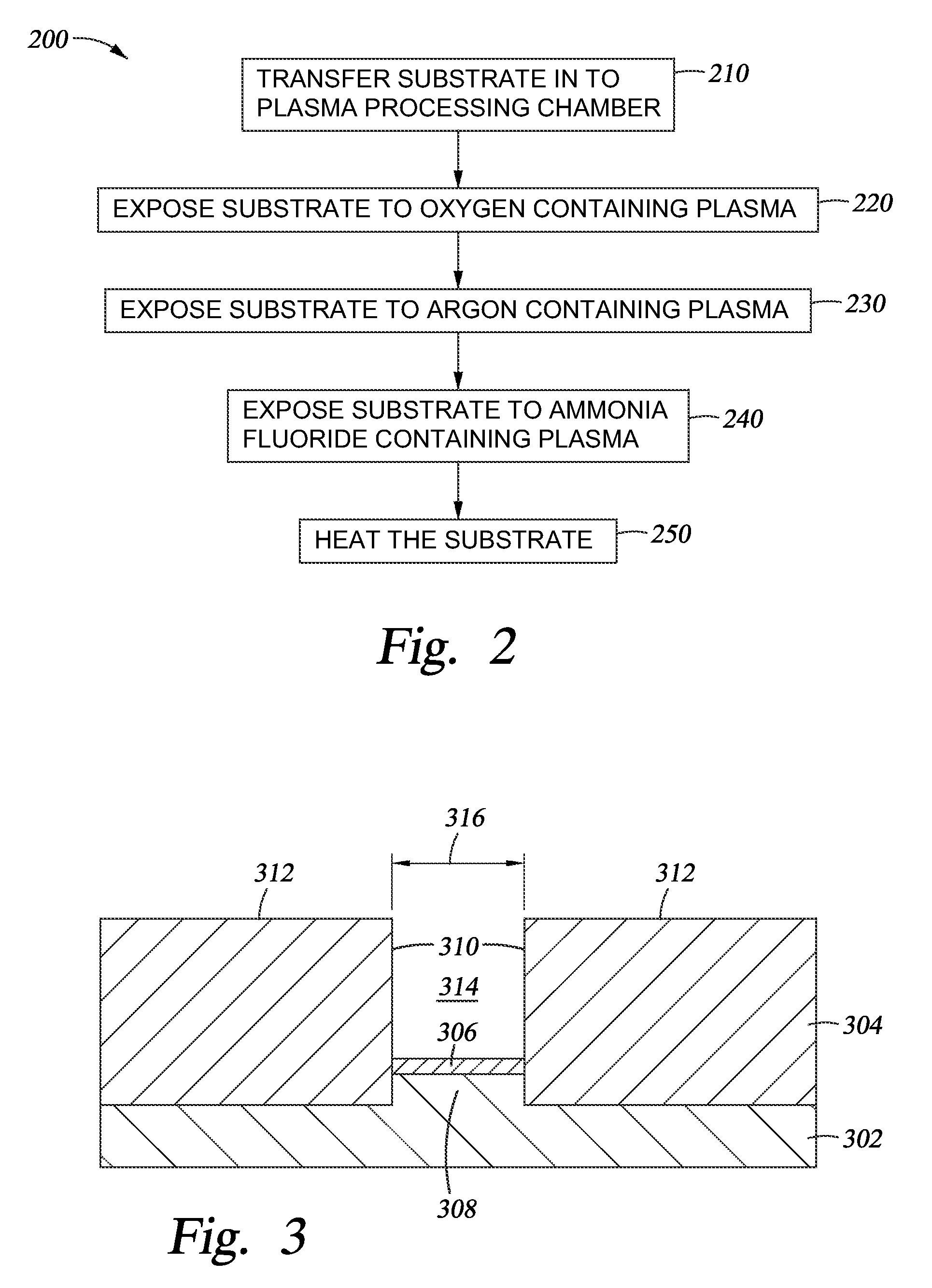

CVD oxide surface pre-conditioning by inductively coupled O2 plasma

A method and apparatus for conditioning an oxide surface during a semiconductor device formation process is provided herein. One or more plasma processing operations are performed on a substrate having a fin structure and shallow trench isolation structure (STI) formed thereon. An oxygen containing plasma process may modify surfaces of the STI structure in preparation for an argon containing plasma process. The argon containing plasma process may form a first layer on the fin structure and STI structure and an ammonia fluoride containing plasma process may form a second layer on the first layer. The first and second layers may be removed from the substrate during a subsequent heating process to provide a cleaned fin structure suitable for subsequent processing operations.

Owner:APPLIED MATERIALS INC

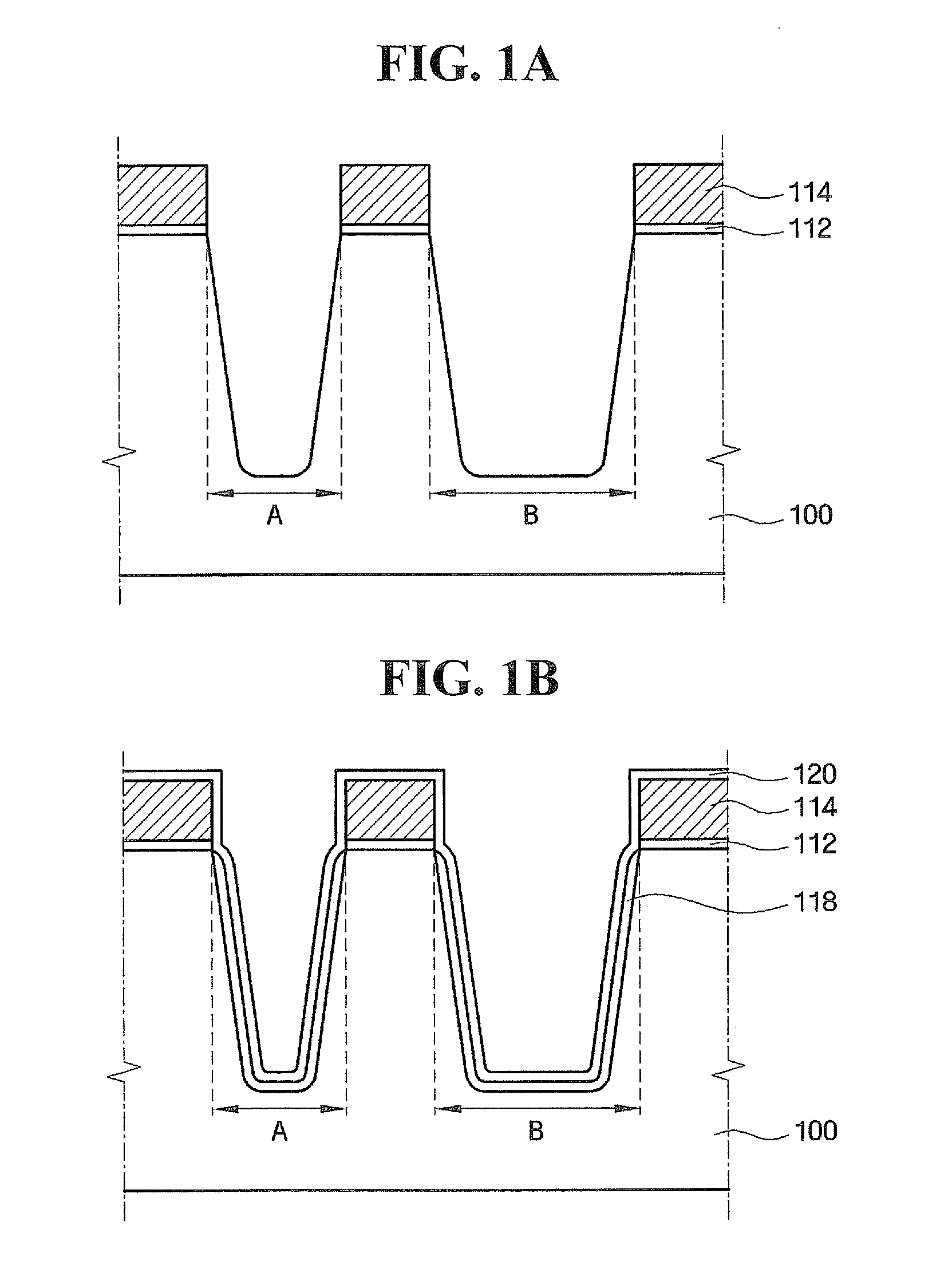

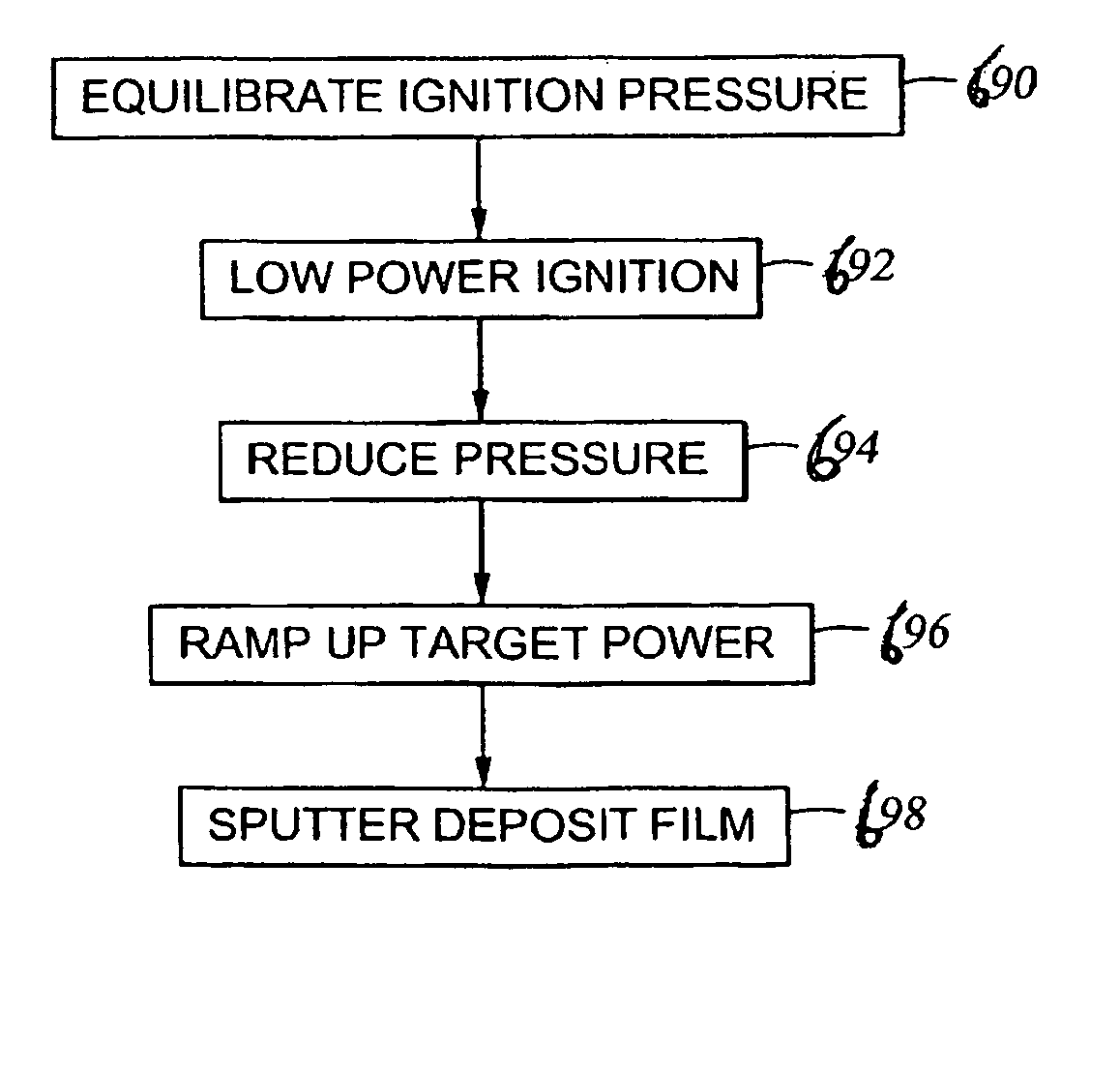

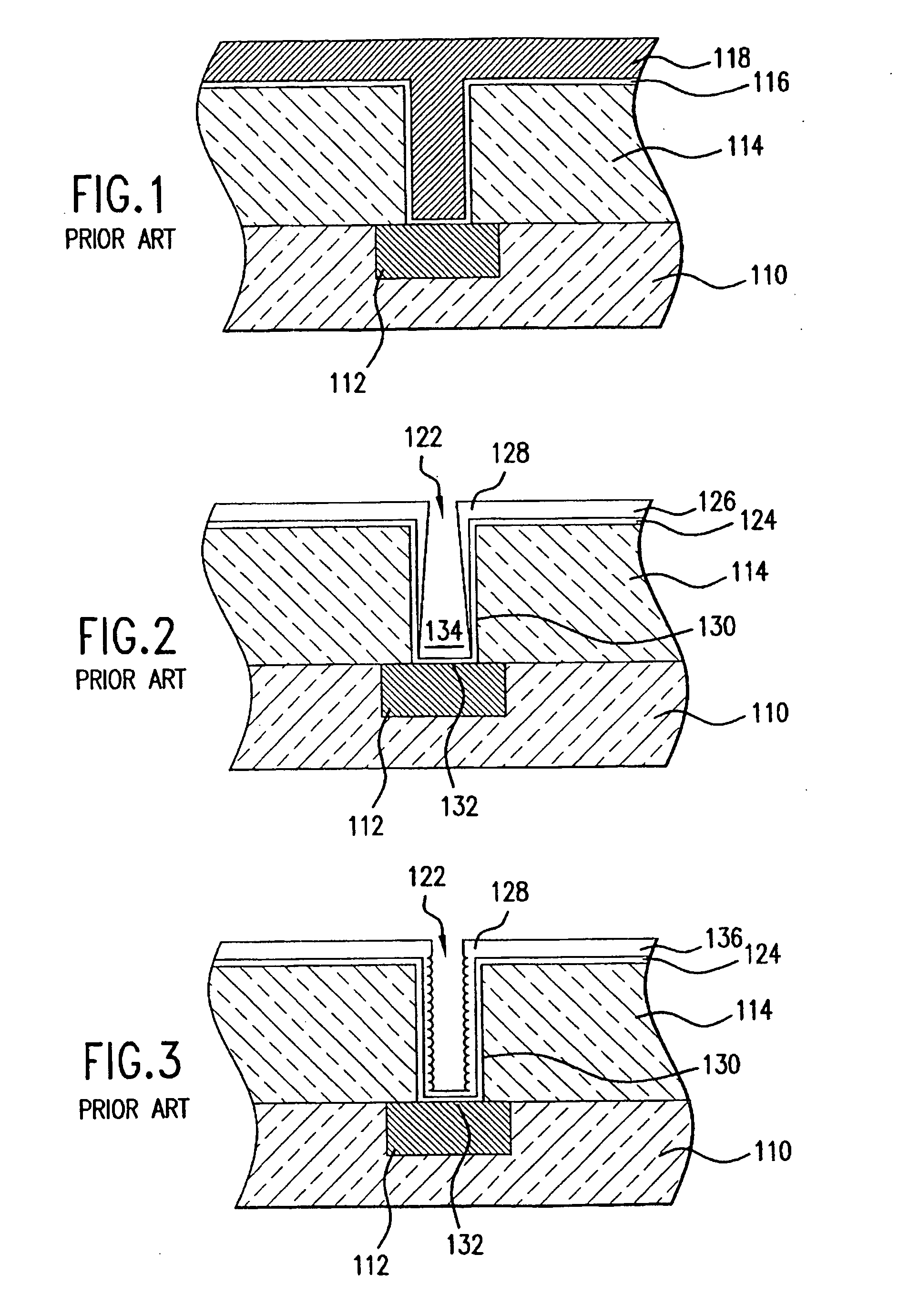

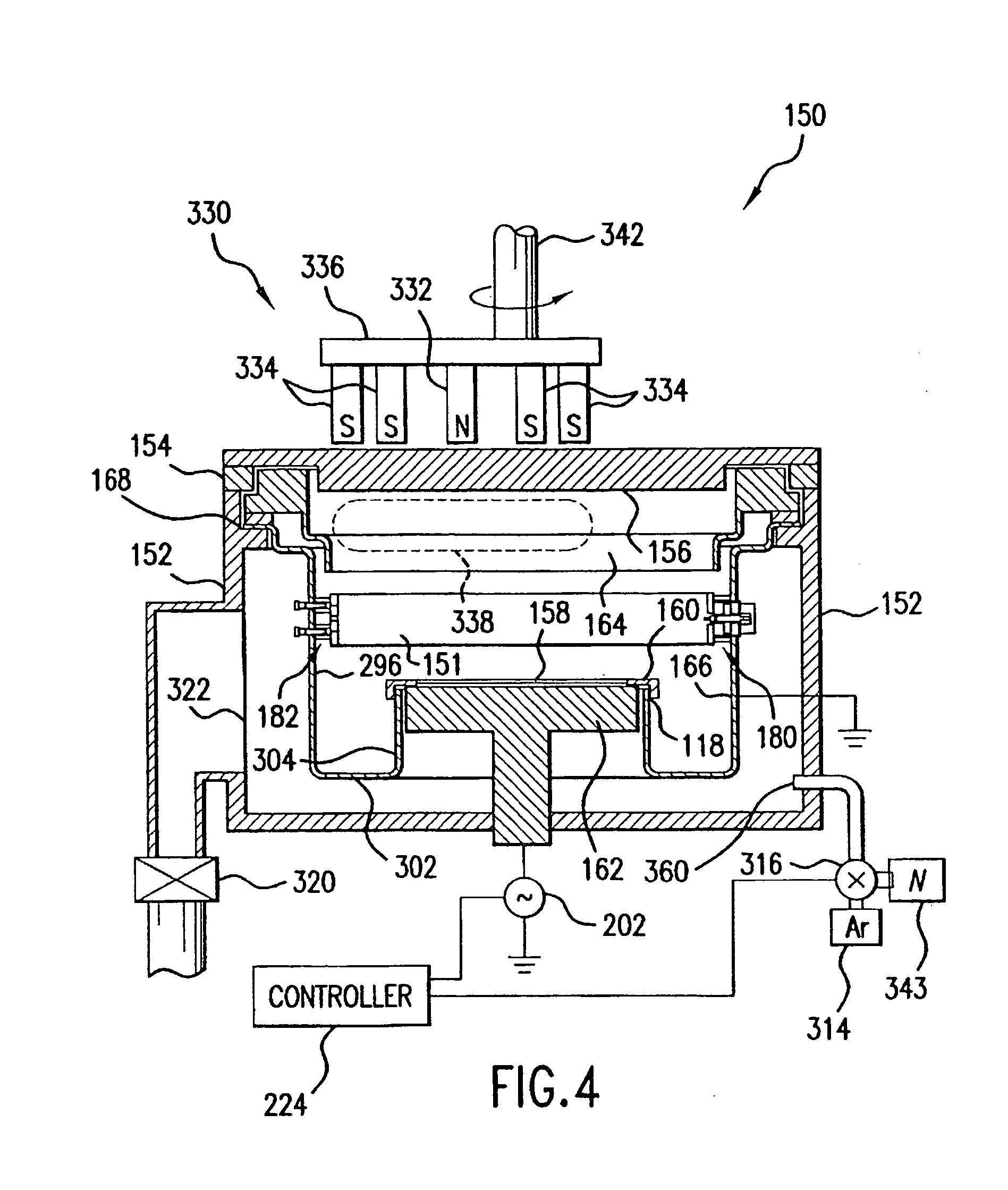

Self-ionized and inductively-coupled plasma for sputtering and resputtering

InactiveUS20050006222A1Raise the ratioReduce layer thicknessCellsElectric discharge tubesSputteringInductively coupled plasma

A magnetron sputter reactor (410) and its method of use, in which SIP sputtering and ICP sputtering are promoted is disclosed. In another chamber (412) an array of auxiliary magnets positioned along sidewalls (414) of a magnetron sputter reactor on a side towards the wafer from the target is disclosed. The magnetron (436) preferably is a small one having a stronger outer pole (442) of a first polarity surrounding a weaker inner pole (440) of a second polarity all on a yoke (444) and rotates about the axis (438) of the chamber using rotation means (446, 448, 450). The auxiliary magnets (462) preferably have the first polarity to draw the unbalanced magnetic field (460) towards the wafer (424), which is on a pedestal (422) supplied with power (454). Argon (426) is supplied through a valve (428). The target (416) is supplied with power (434).

Owner:APPLIED MATERIALS INC

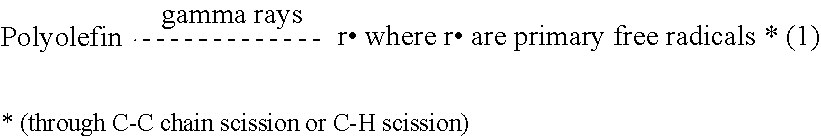

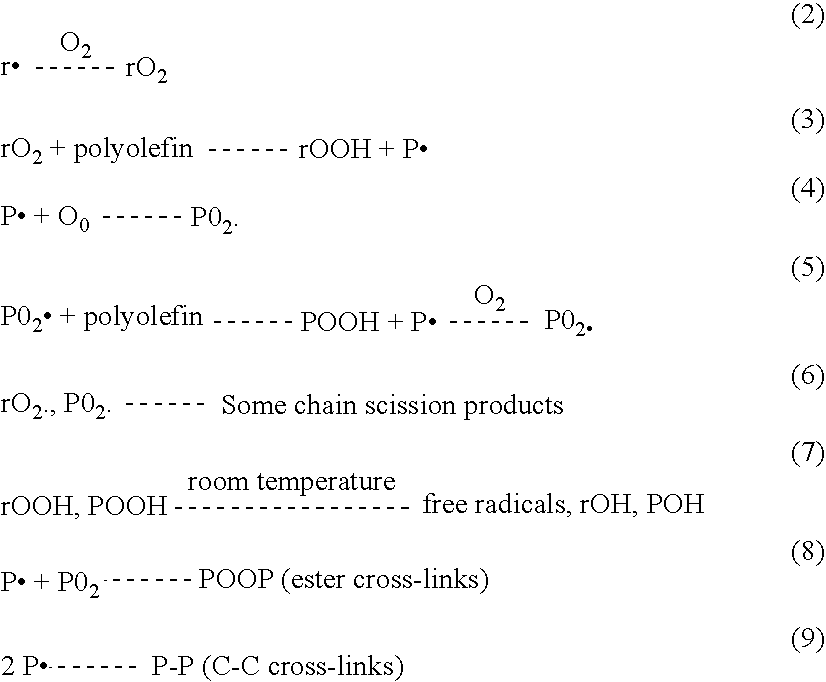

Non-oxidizing polymeric medical implant

InactiveUS20050059750A1Improve antioxidant capacityPrevent further oxidationSurgeryPharmaceutical containersCross-linkNitrogen gas

A medical implant made of polymeric material having an increased oxidation resistance is formed by a method including the steps of placing a resin powder in a sealed container. A substantial portion of the oxygen is removed from the sealed contained by either a vacuum, an oxygen absorbent or by flushing with inert gas. The container is then repressurized with a gas such as nitrogen, argon, helium or neon so that long term storage may be possible. On use, the resin in transferred to a forming device which both melts and forms the resin in an oxygen reduced atmosphere to produce a polymeric raw material such as a rod or bar stock. The medical implant is then formed from this raw material annealed and sealed in an airtight package in an oxygen reduced atmosphere. The implant is then radiation sterilized and thereafter annealed in the package for a predetermined time and temperature sufficient to form cross-links between any free radicals in neighboring polymeric chains.

Owner:HOWMEDICA OSTEONICS CORP

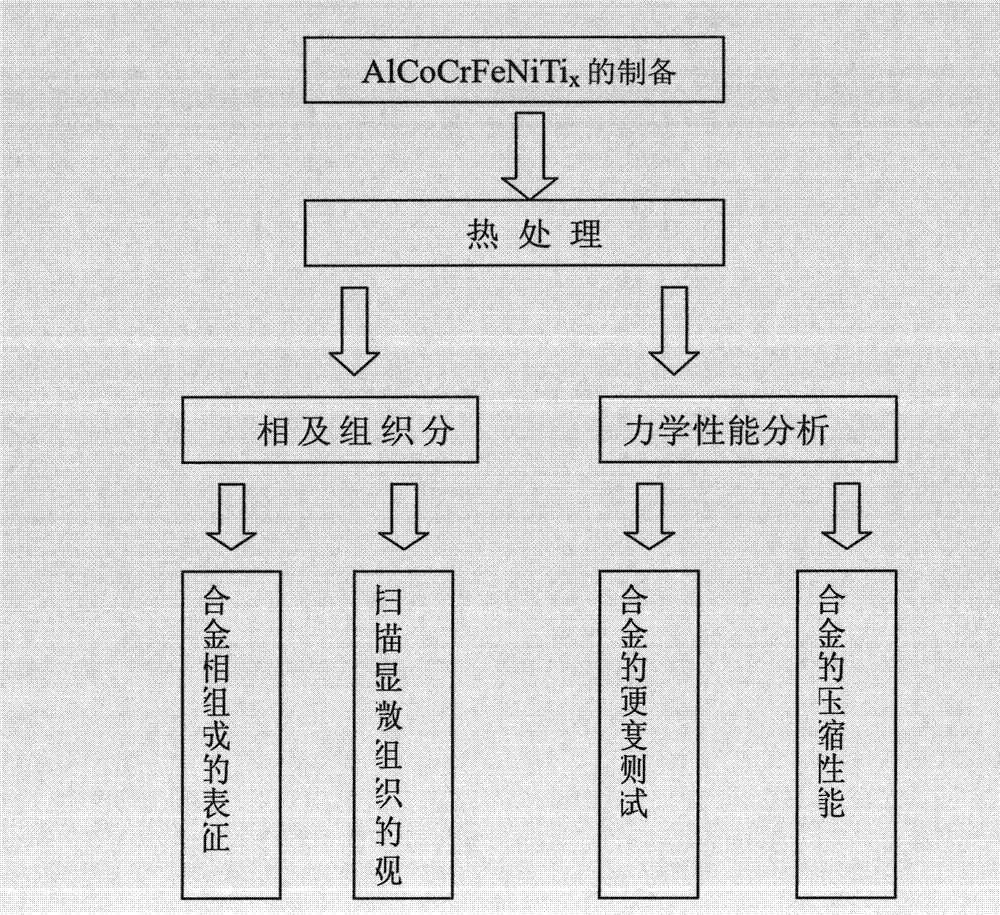

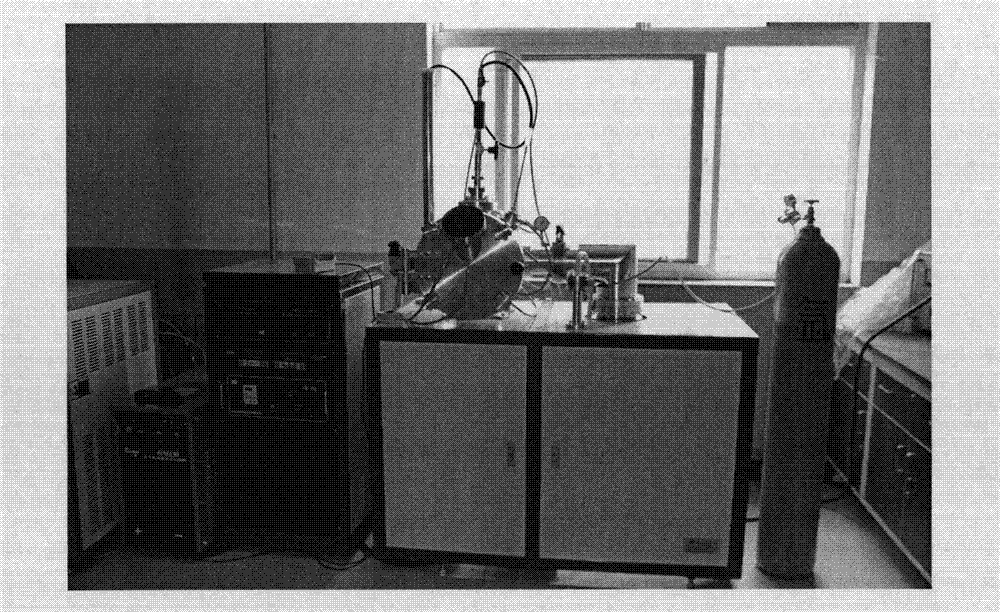

AlCoCrFeNiTix high-entropy alloy material and method for preparing same

The invention relates to a high-entropy alloy material and a method for preparing the same. The component of the high-entropy alloy material is AlCoCrFeNiTix, wherein x represents a molar ratio, and the value range is between 0.1-0.4. The method for preparing the material comprises: preparing raw materials, adopting the alloy smelting raw materials including Al, Co, Cr, Fe, Ni and Ti, and accurately weighing and proportioning according to the molar ratio; then, purifying oxide on a metal surface; putting the prepared raw materials into a tank in a water-cooling copper-formed mold smelting pool, vacuumizing, filling argon, controlling smelting current to be at about 250 ampere and smelting time for 30-60 seconds, turning an alloy block after alloys are fully mixed, putting an alloy ingot into a tank of a water-cooling copper-formed mold, regulating the smelting current, opening a suction casting air suction valve after the alloys are uniformly smelted, utilizing the negative pressure in a pump for suction casting, and taking out the alloy ingot after an alloy mould is cooled. Compared with the conventional crystalline state alloy, the high-entropy alloy material has relative high thermal stability, hardness, yield strength, breaking tenacity, plastic deformation and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

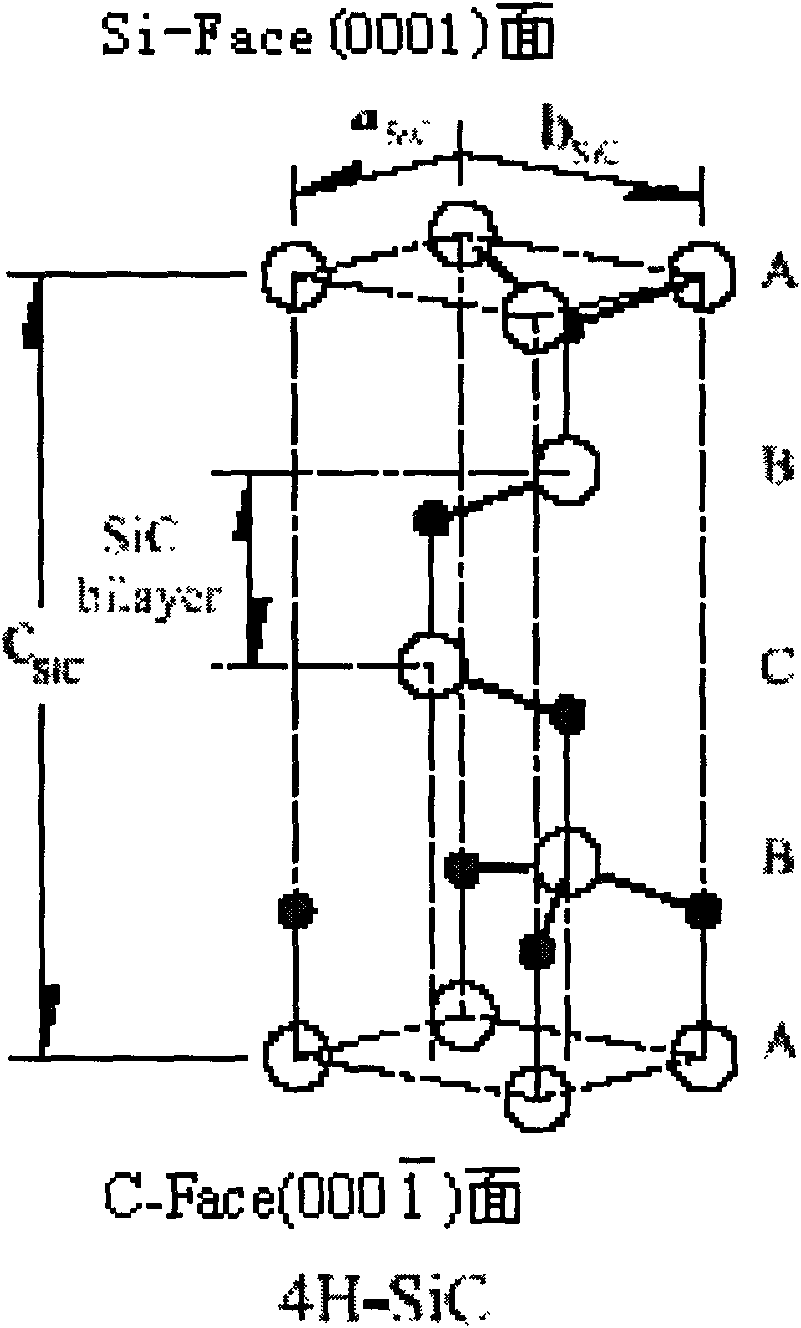

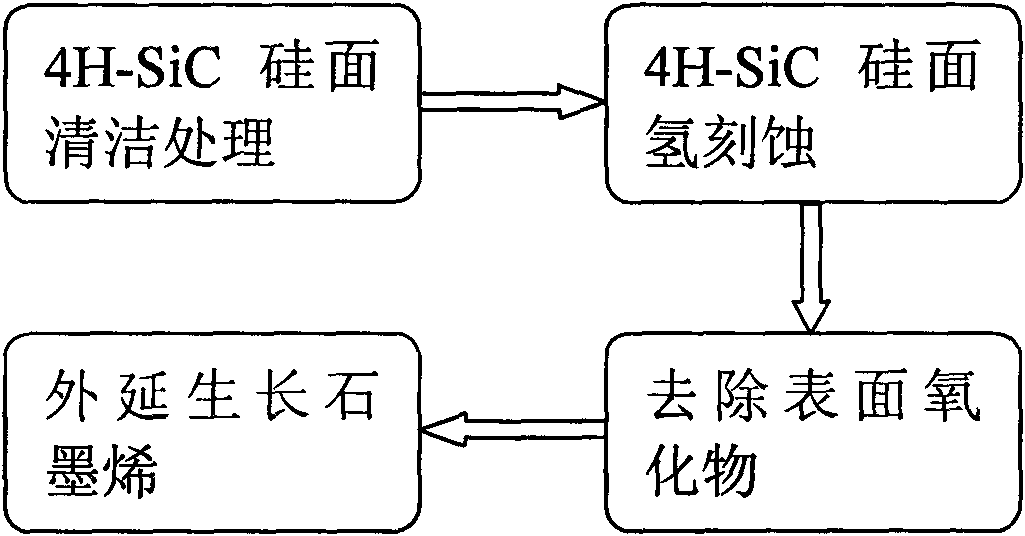

Method for graphene epitaxial growth on 4H-SiC silicon surface

InactiveCN101602503AIncrease the areaImprove uniformityPolycrystalline material growthSingle crystal growth detailsHydrogenSilanes

The invention discloses a method for graphene epitaxial growth on 4H-SiC silicon surface, mainly solving the problems of small graphene area and poor homogeneity during graphene epitaxial growth on the 4H-SiC silicon surface. The method is as follows: a 4H-SiC silicon surface is cleaned to remove organic remains and ionic contaminants on the surface; hydrogen and propane are led in to carry out hydrogen corrosion to the 4H-SiC silicon surface to remove surface scratches so as to form regular step-shaped stripes; silane is led in to remove oxide formed by hydrogen corrosion on the surface; under the circumstance of argon, silicon atoms are evaporated to ensure carbon atom to reconstruct and form epitaxial graphene in the form of sp by heating. The invention can be used for manufacturing epitaxial graphene materials.

Owner:XIDIAN UNIV

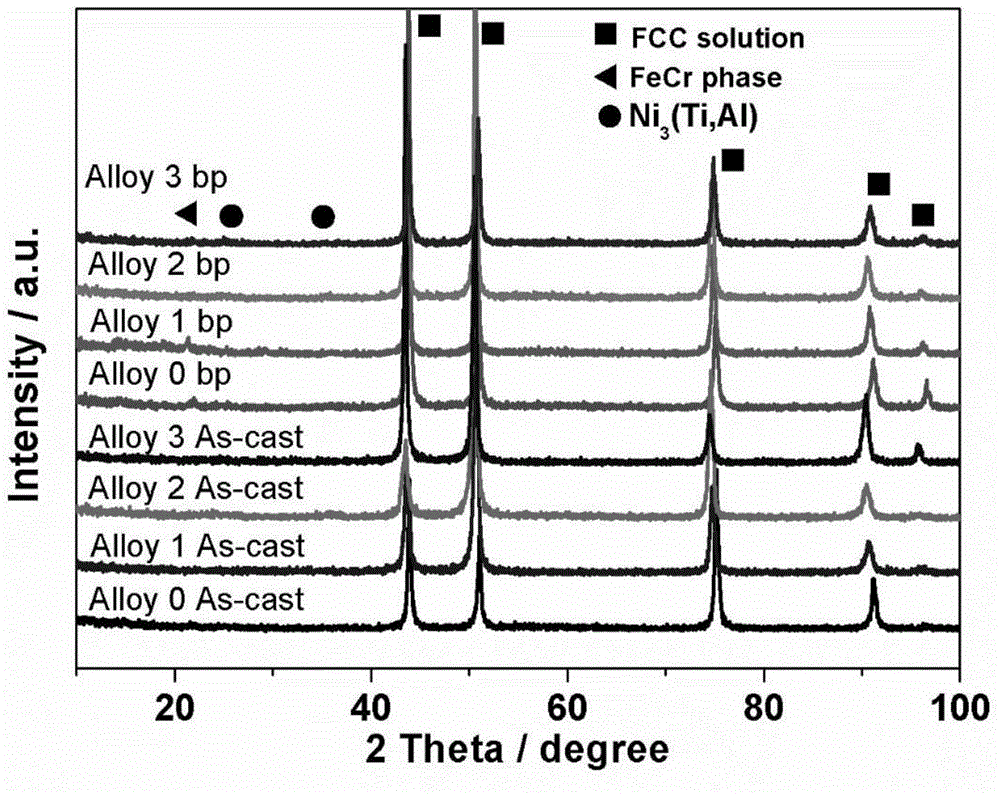

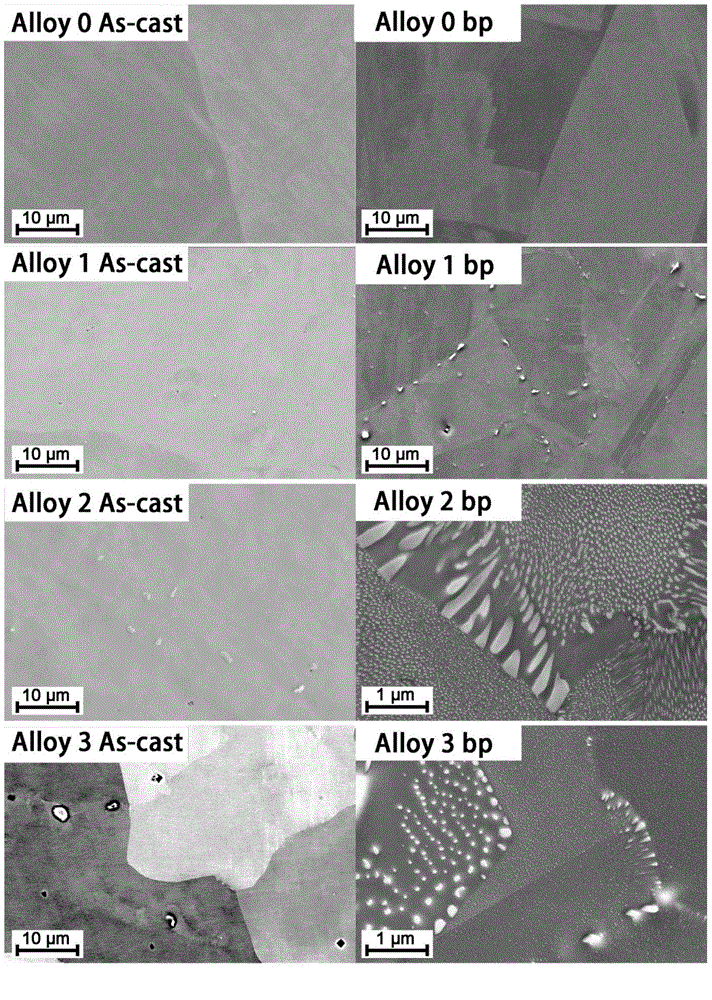

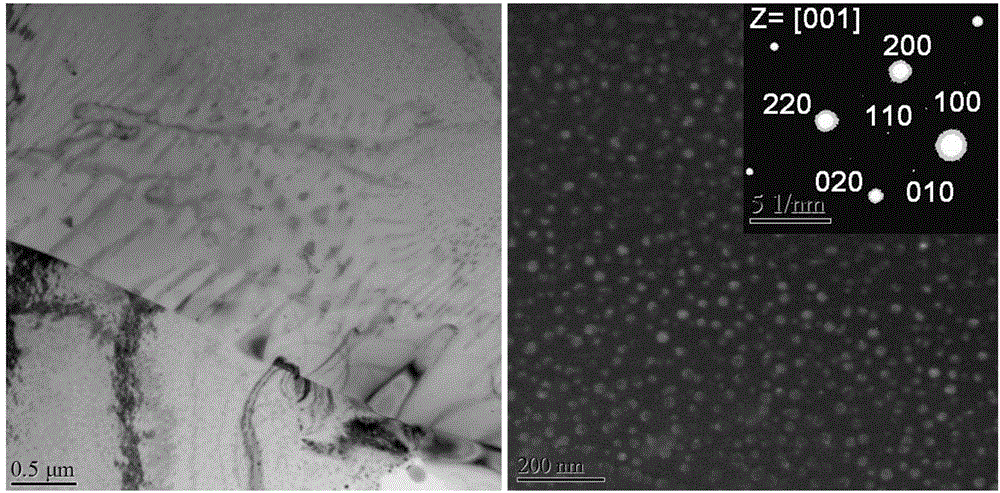

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

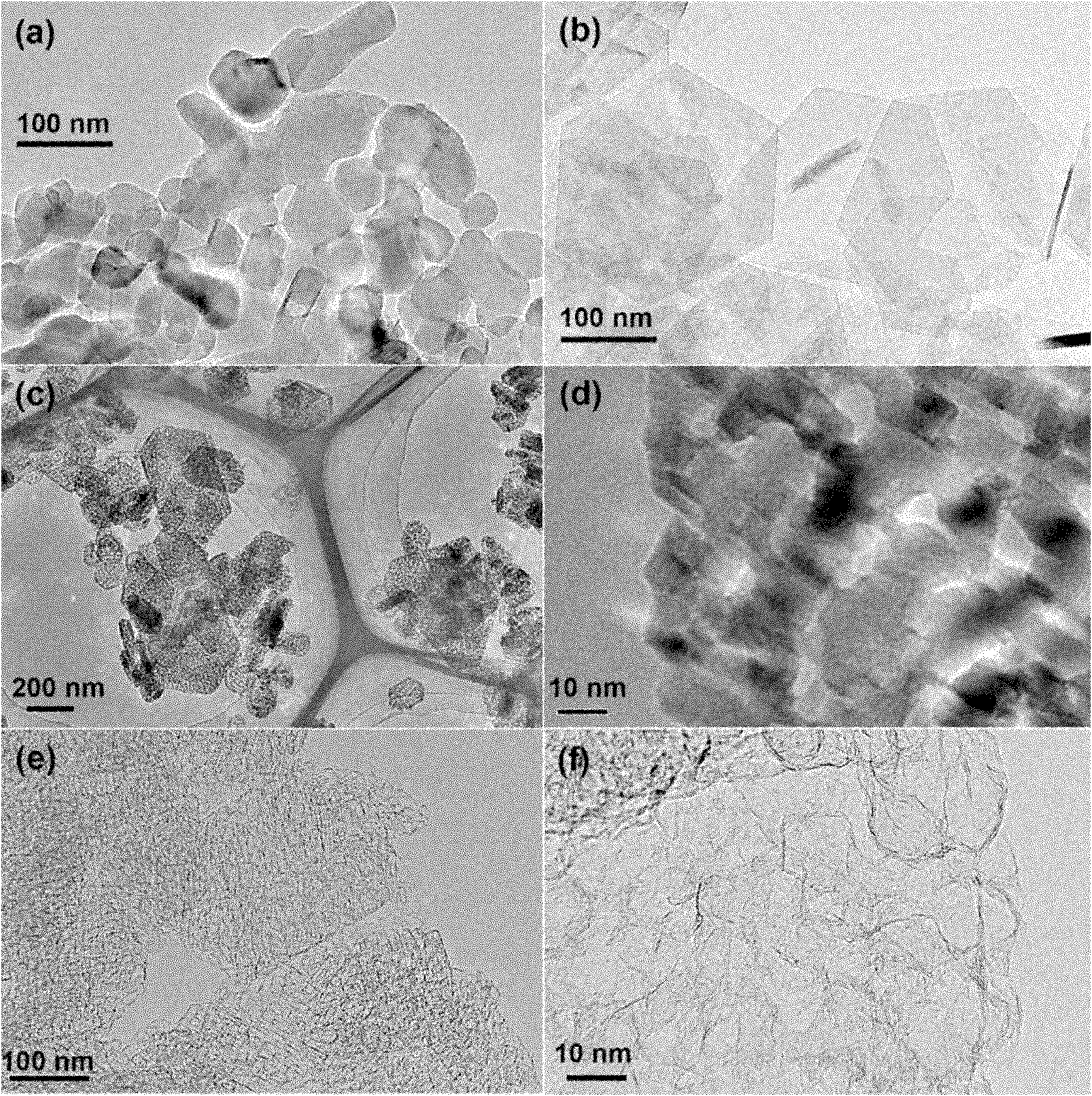

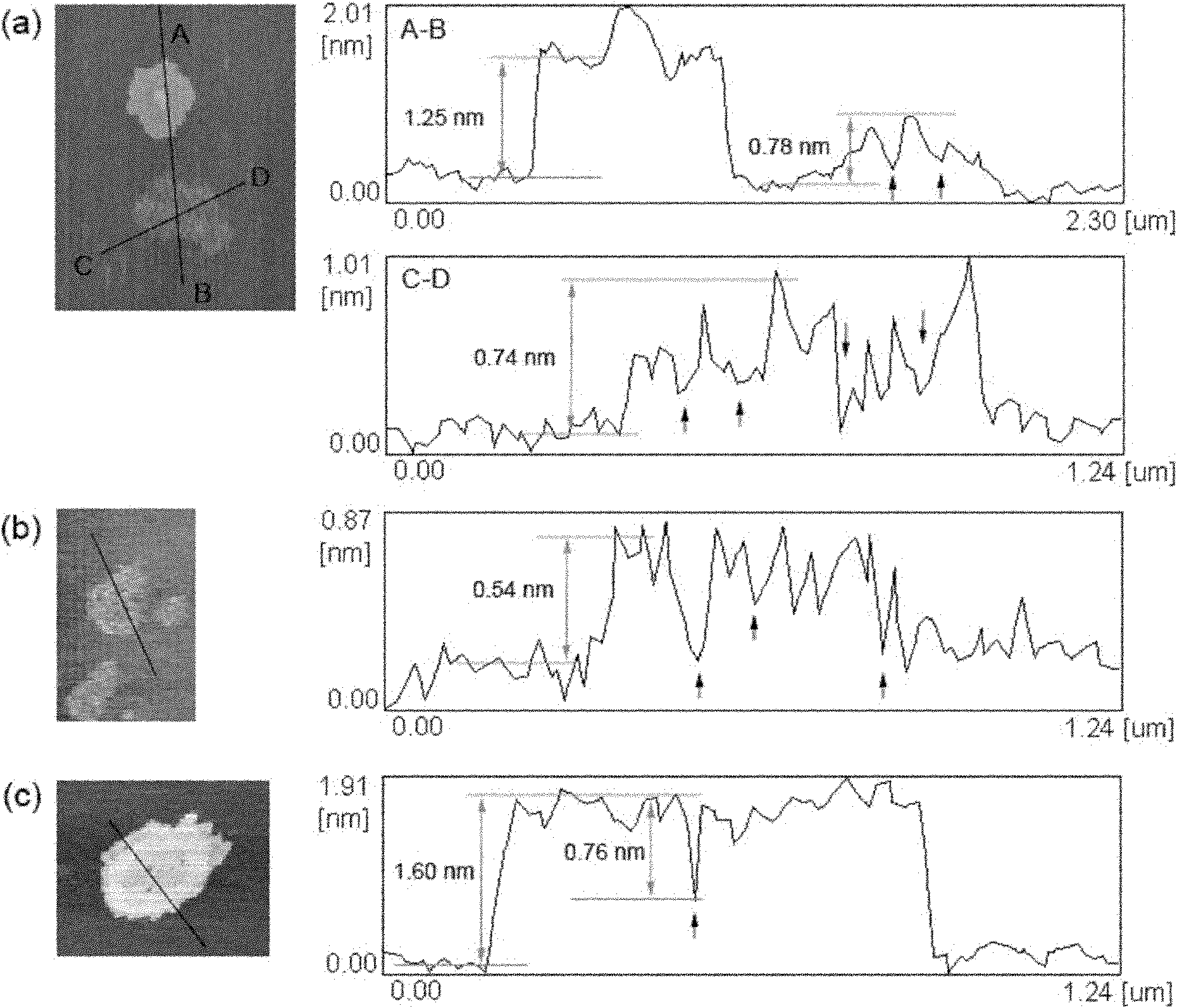

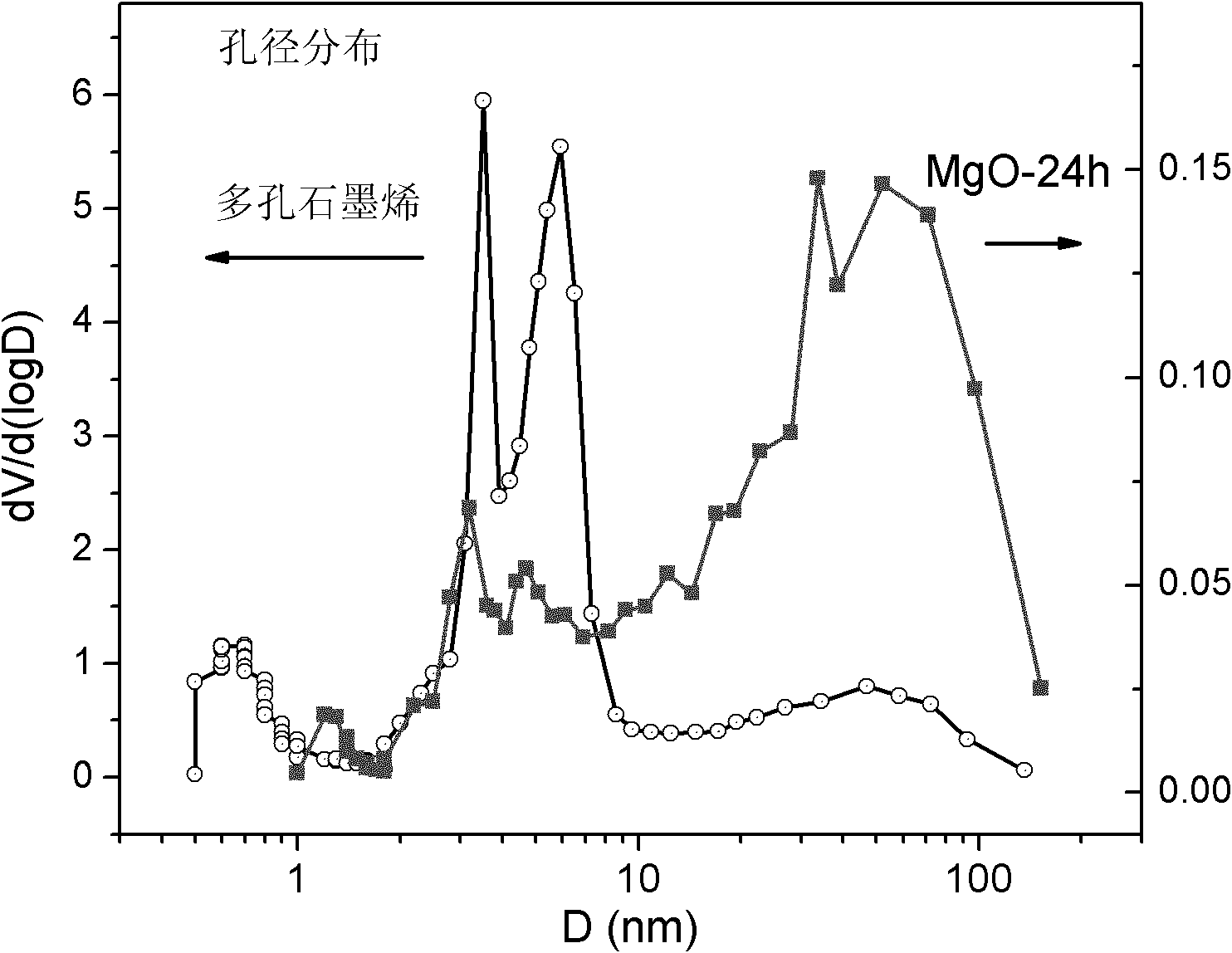

Graphene with porous structure and preparation method of graphene

The invention discloses a graphene with a porous structure and a preparation method of the graphene. The porous grapheme consists of a single-layer or multi-layer graphene structure unit, the single-layer or multi-layer grapheme structure unit has a pore-shaped structure (pore diameter is 0.1-200 nm) and a large specific surface area (300-2000 m<2> / g), thus the graphene has potential application value in the aspects of super-capacitors, conductive filling materials and the like. The preparation method of the porous grapheme is characterized in that MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as catalysts, or MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as carriers so as to further load one or more active components of Fe, Co, Ni and Mo and then the obtained substance is used as the catalyst ( the pore diameter of the catalyst is 1-200 nm, and the specific surface area is 10-300 m<2> / g); and then at the temperature of 300-1000 DEG C, the graphene is prepared by using inert gases such as nitrogen, argon, helium and the like and using a hydrocarbon chemical gas phase deposition method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

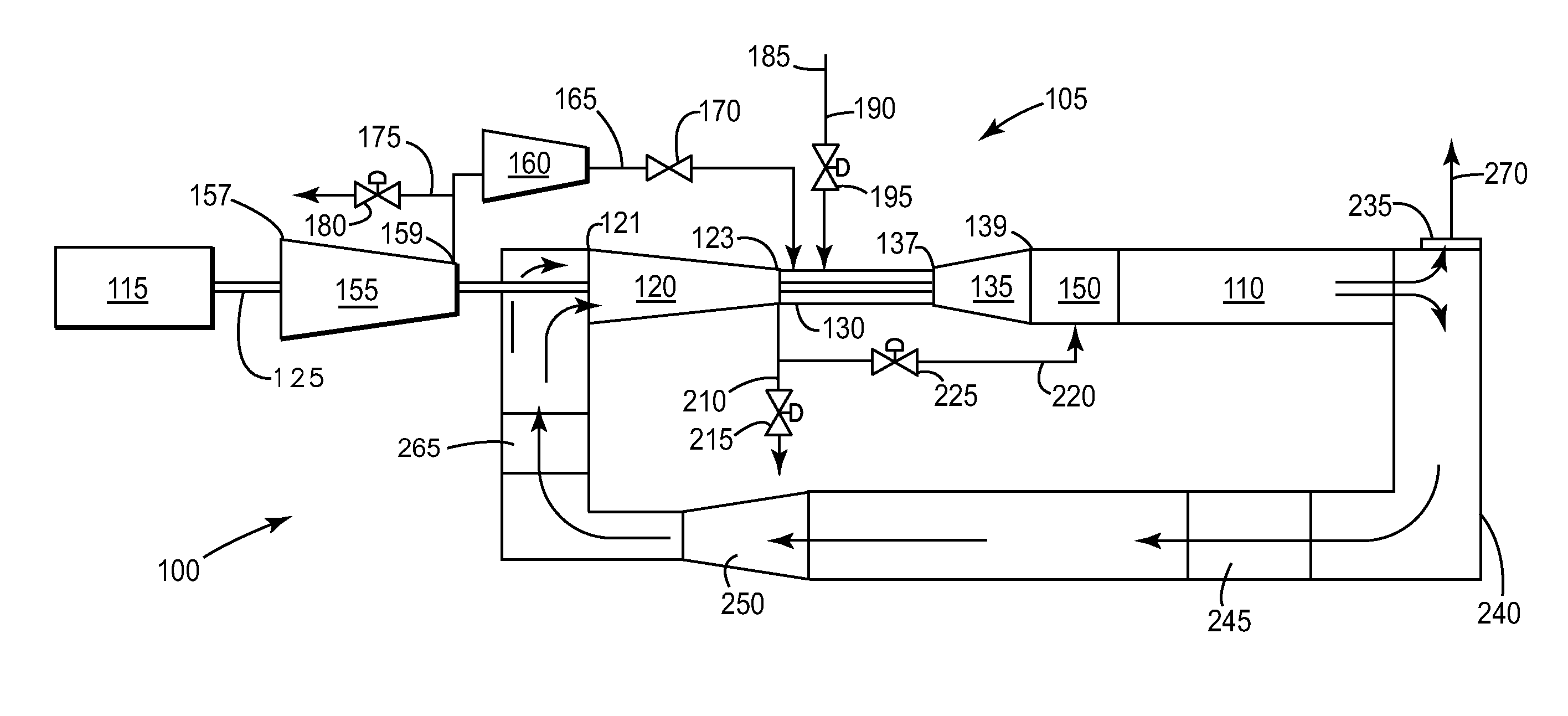

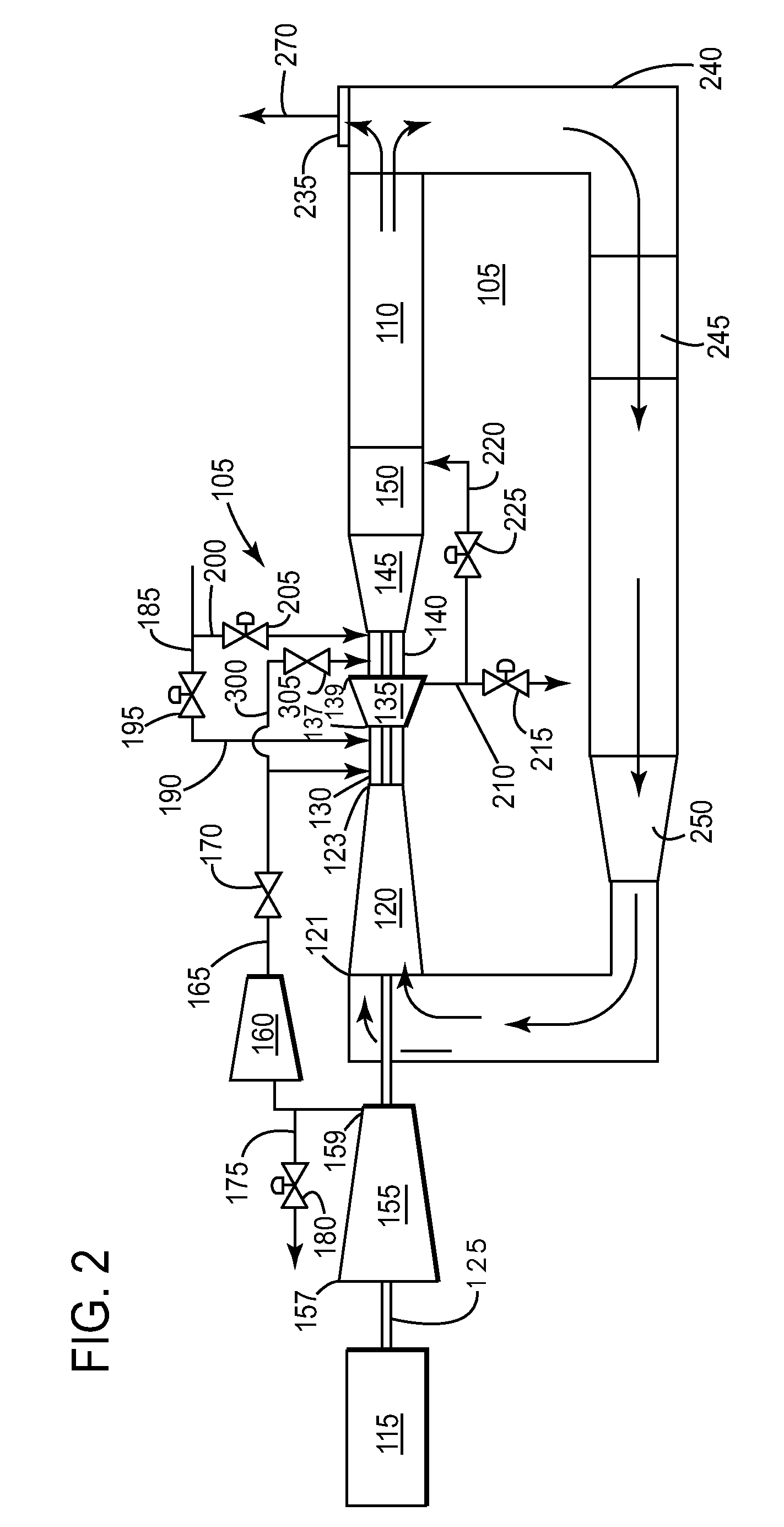

Method and system for controlling an extraction pressure and temperature of a stoichiometric egr system

The present invention provides a system and method that yields an exhaust stream that includes a relatively high concentration of a desirable gas and is also substantially oxygen-free. This desirable gas includes, but is not limited to: Carbon Dioxide (CO2), Nitrogen (N2), or Argon. The present invention also provides a way to control the physical property of the exhaust stream.

Owner:GENERAL ELECTRIC CO

Method and system for controlling a stoichiometric egr system on a regenerative reheat system

Embodiments of the present invention provide a S-EGR process that yields an exhaust stream that includes a relatively high concentration of a desirable gas and is also substantially oxygen-free. This desirable gas includes, but is not limited to: Carbon Dioxide (CO2), Nitrogen (N2), or Argon.

Owner:GENERAL ELECTRIC CO

Method and apparatus for treating a substrate with dense fluid and plasma

ActiveUS20060278254A1High densityDivergent cohesion energyElectric discharge tubesElectric arc lampsSolid phasesWet cleaning

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid anti-solvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:HITACHI HIGH-TECH CORP

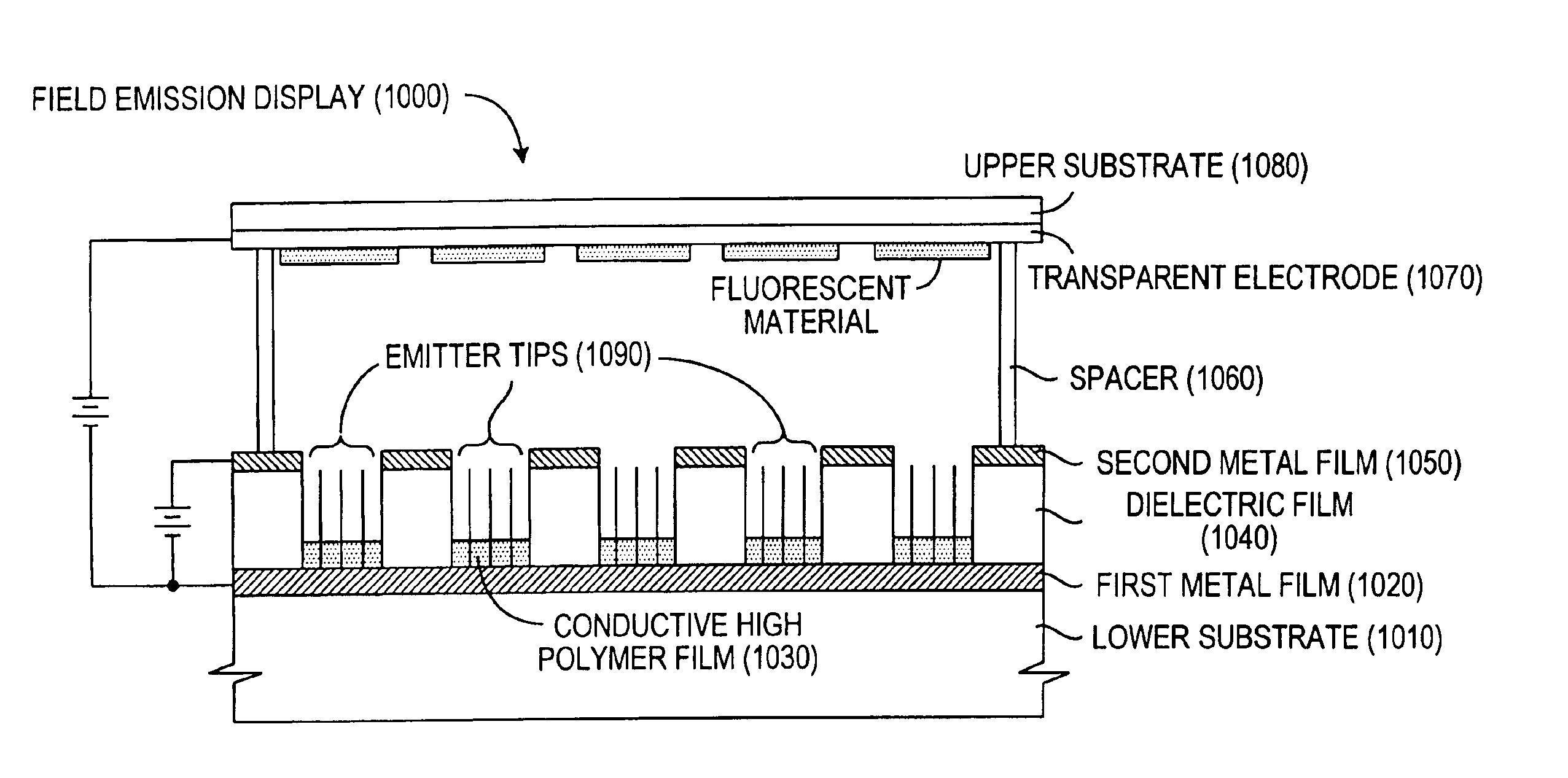

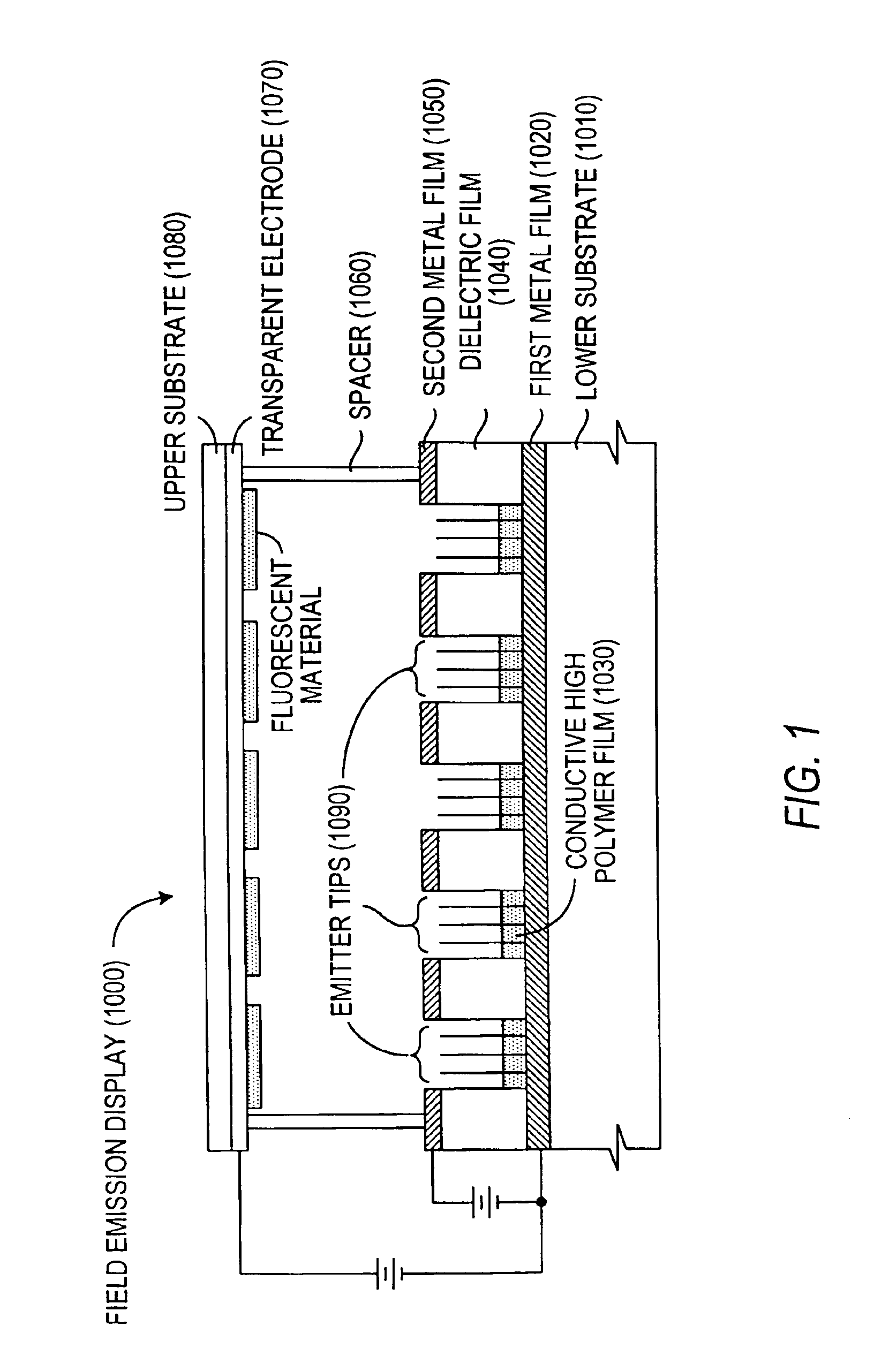

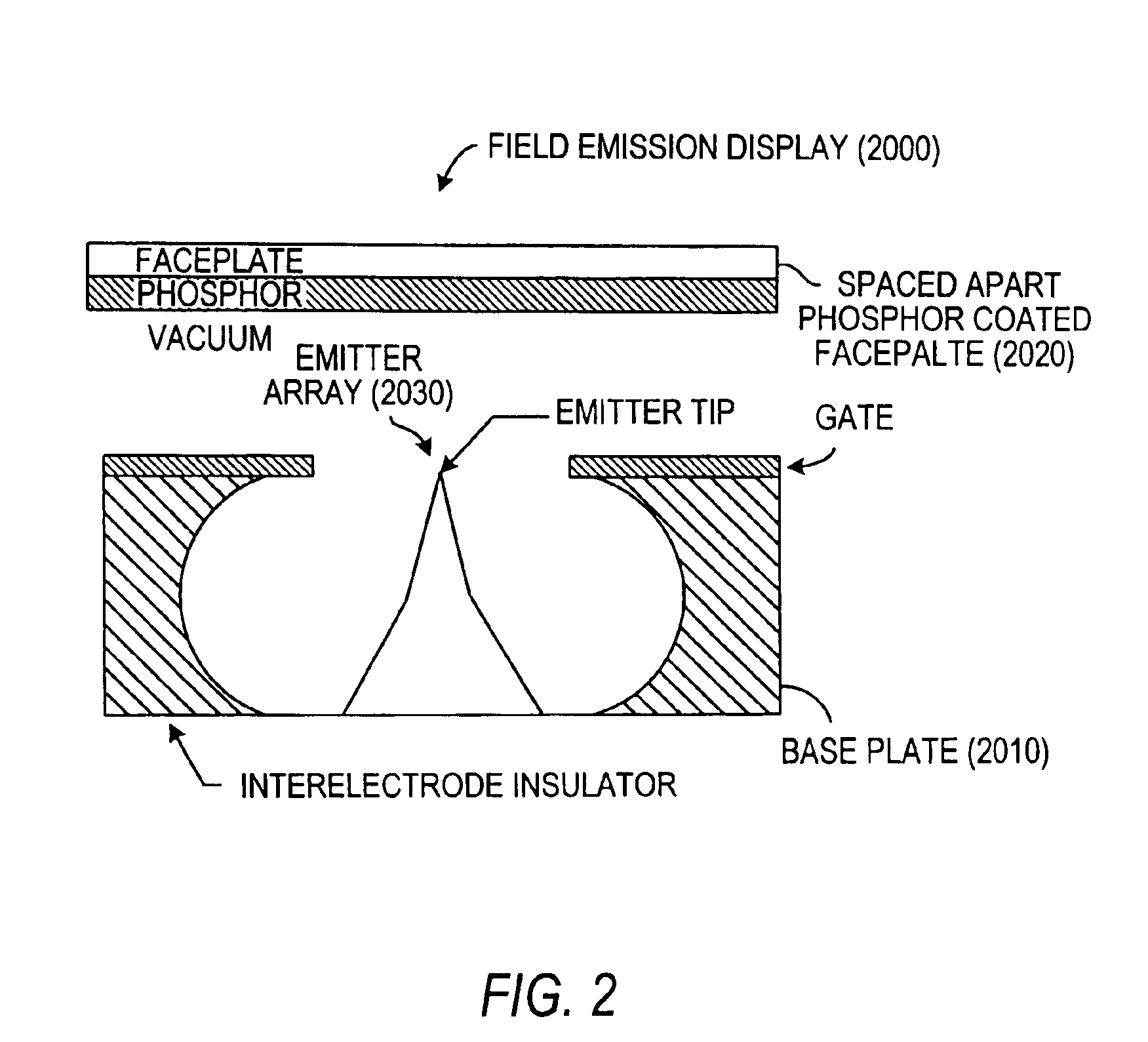

Field emission devices using ion bombarded carbon nanotubes

InactiveUS6911767B2Reduce voltageAccelerate emissionsCathode ray tubes/electron beam tubesNanoinformaticsField emission deviceOxygen

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes which have been treated with an ion beam. The ion beam may be any ions, including gallium, hydrogen, helium, argon, carbon, oxygen, and xenon ions. The present invention also relates to a field emission cathode comprising carbon nanotubes, wherein the nanotubes have been treated with an ion beam. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been treated with an ion beam is further disclosed.

Owner:HYPERION CATALYSIS INT

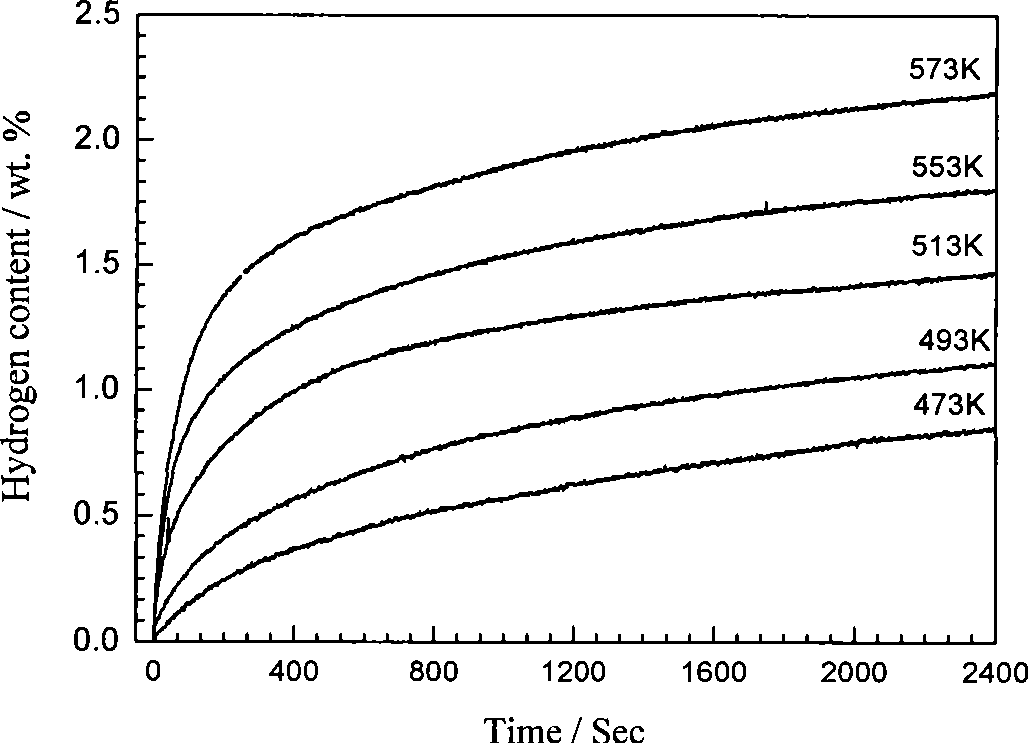

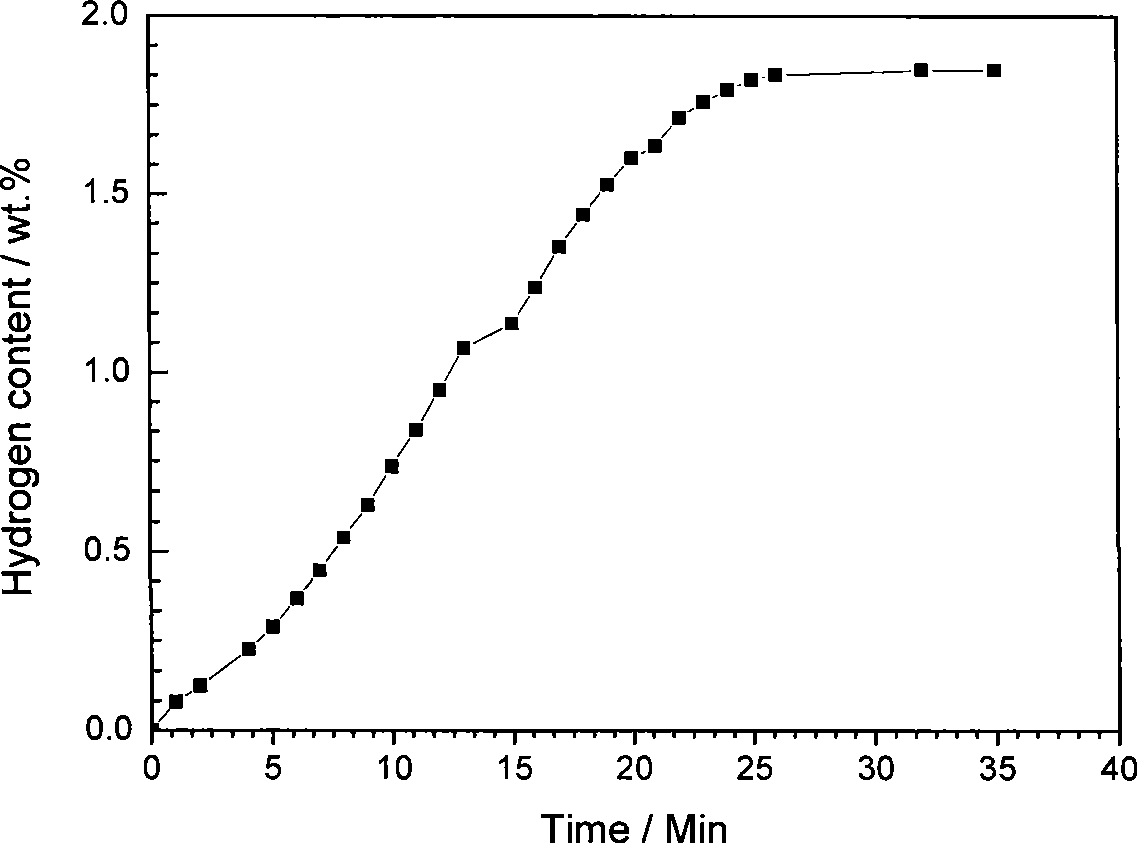

Magnesium base composite hydrogen storage material and preparation method

The invention discloses a magnesium-based composite hydrogen storage material comprising the following compositions by weight percent: 1.0-10.0% of Al, 1.0-5.0% of Ni, and the balance of Mg. A preparation method thereof comprising the following steps: at first, smelting block-shaped metal Mg and Al by a medium frequency induction to prepare Mg17Al12 alloy which is crushed to 300 meshes; hydrogenising Mg powder at 340 DEG C under a hydrogen atmosphere of 4.0MPa to prepare MgH2; then blending Mg17Al12, MgH2, Ni powder in accordance with contents by weight percent for ball-grinding for 60 to 100 hours under an atmosphere of argon. The magnesium-based composite hydrogen storage material can reversely absorb and release hydrogen at low temperature, and has high hydrogen storage capacity, excellent activation performance and superior hydrogen absorbing and releasing kinetics property. The magnesium-based composite hydrogen storage material can be used for manufacturing hydrogen source to facilitate purification and storage and transportation of hydrogen, and can also used for hydrogen storage material for fuel cells.

Owner:ZHEJIANG UNIV

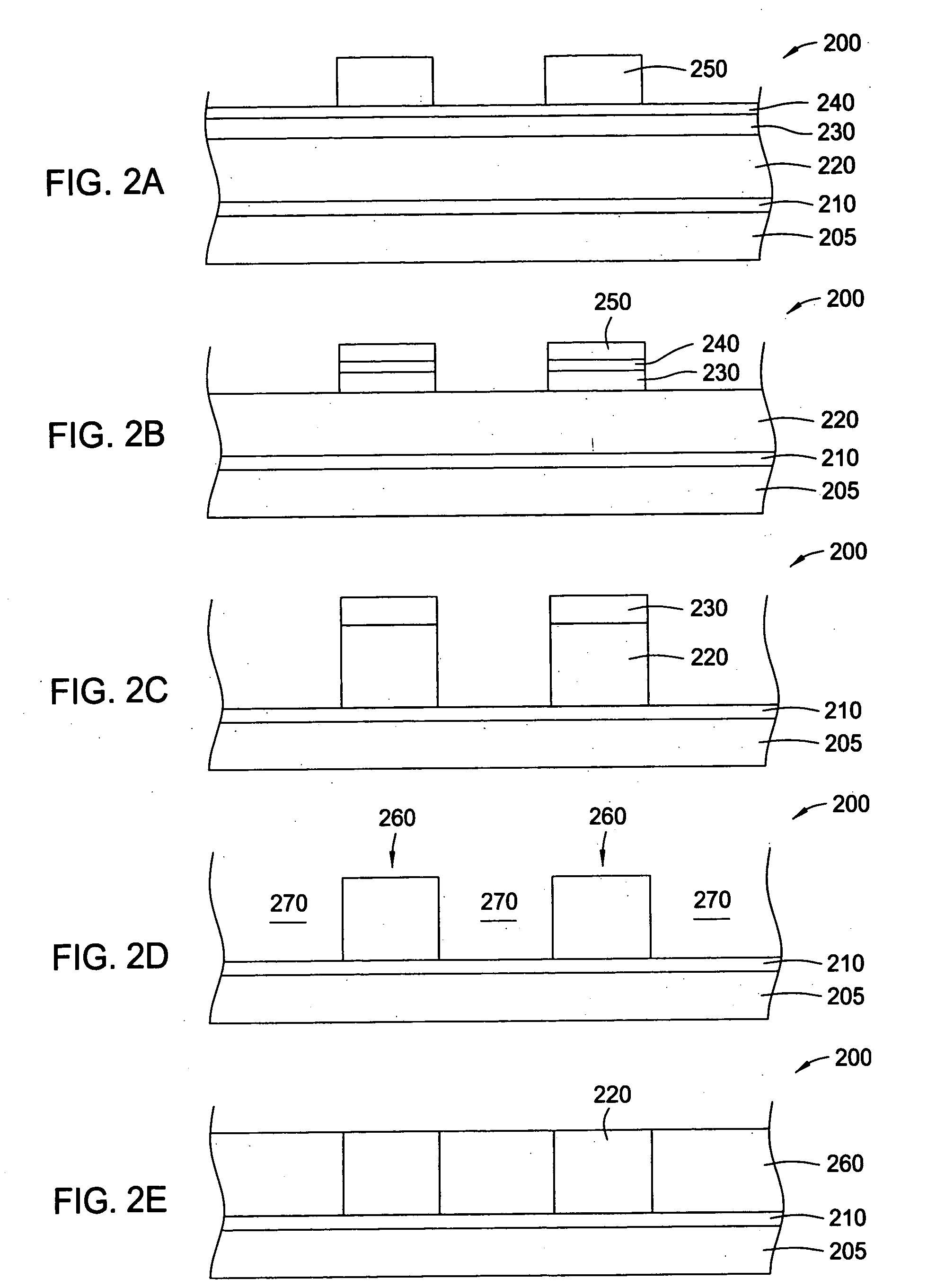

Method of depositing an amorphous carbon film for etch hardmask application

InactiveUS20050202683A1Photomechanical apparatusSemiconductor/solid-state device manufacturingDual frequencyAnti-reflective coating

Methods are provided for depositing amorphous carbon materials. In one aspect, the invention provides a method for processing a substrate including forming a dielectric material layer on a surface of the substrate, depositing an amorphous carbon layer on the dielectric material layer by introducing a processing gas comprises one or more hydrocarbon compounds and an argon carrier gas, and generating a plasma of the processing gas by applying power from a dual-frequency RF source, etching the amorphous carbon layer to form a patterned amorphous carbon layer, and etching feature definitions in the dielectric material layer corresponding to the patterned amorphous carbon layer. The amorphous carbon layer may act as an etch stop, an anti-reflective coating, or both.

Owner:APPLIED MATERIALS INC

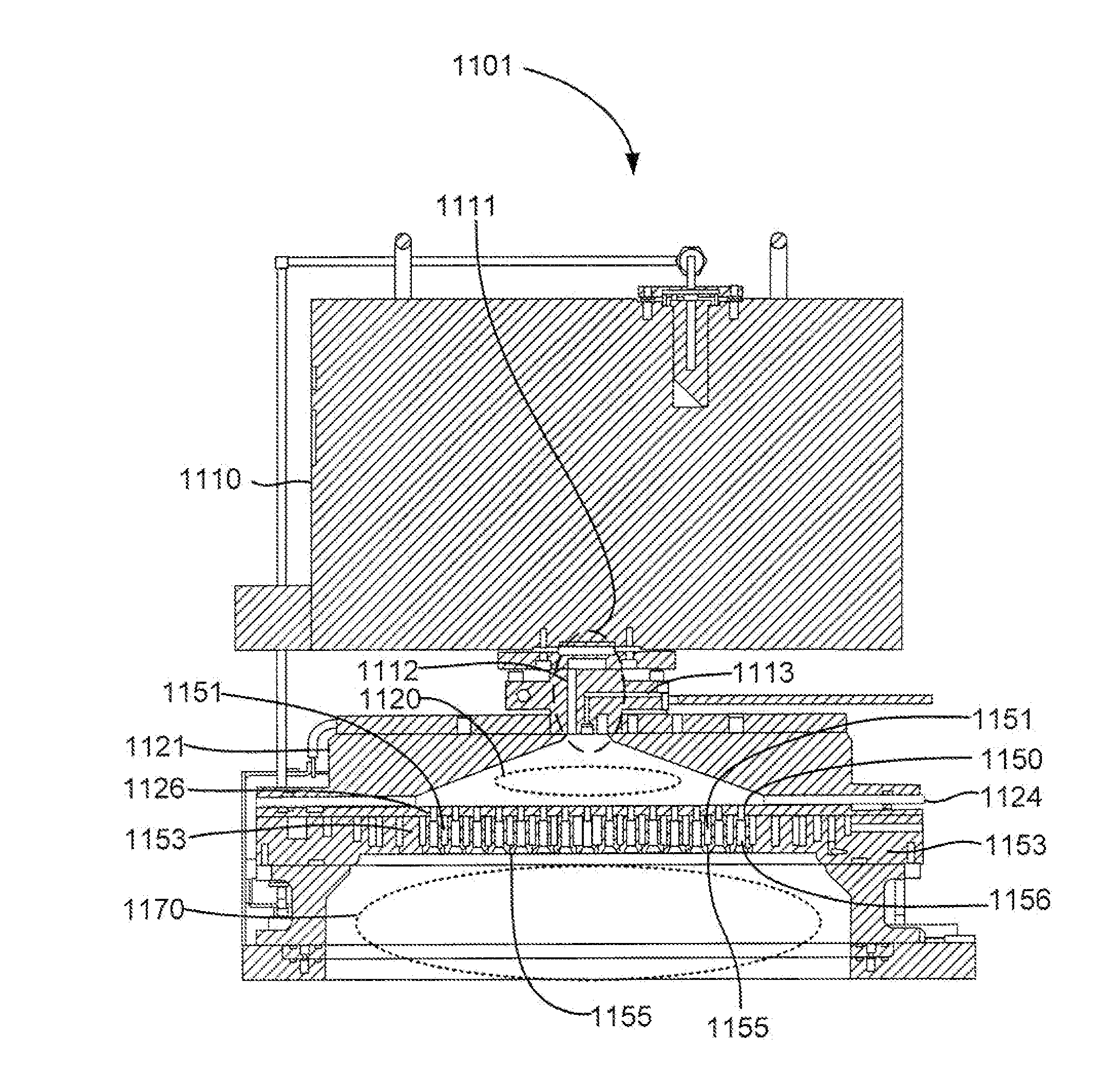

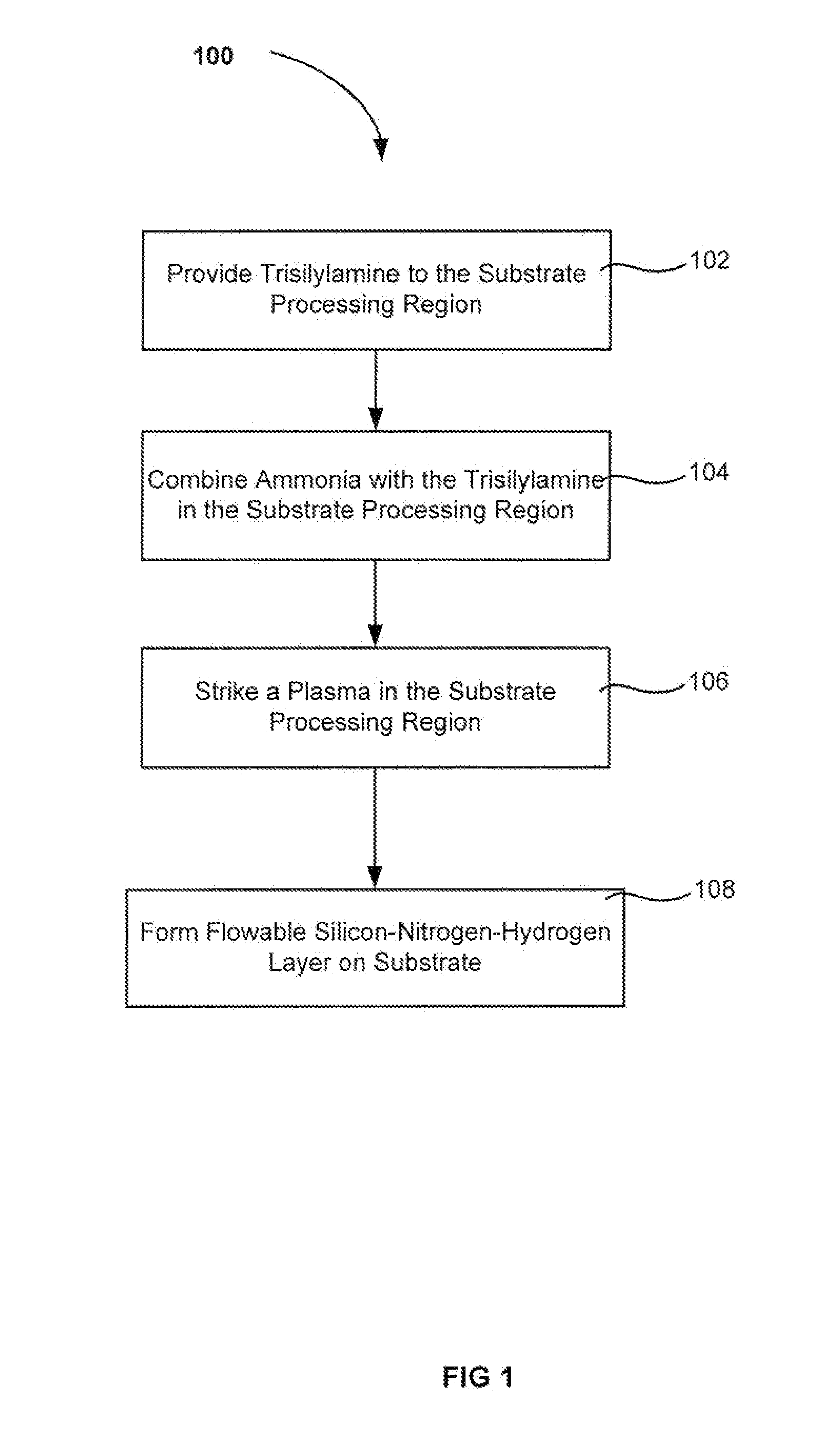

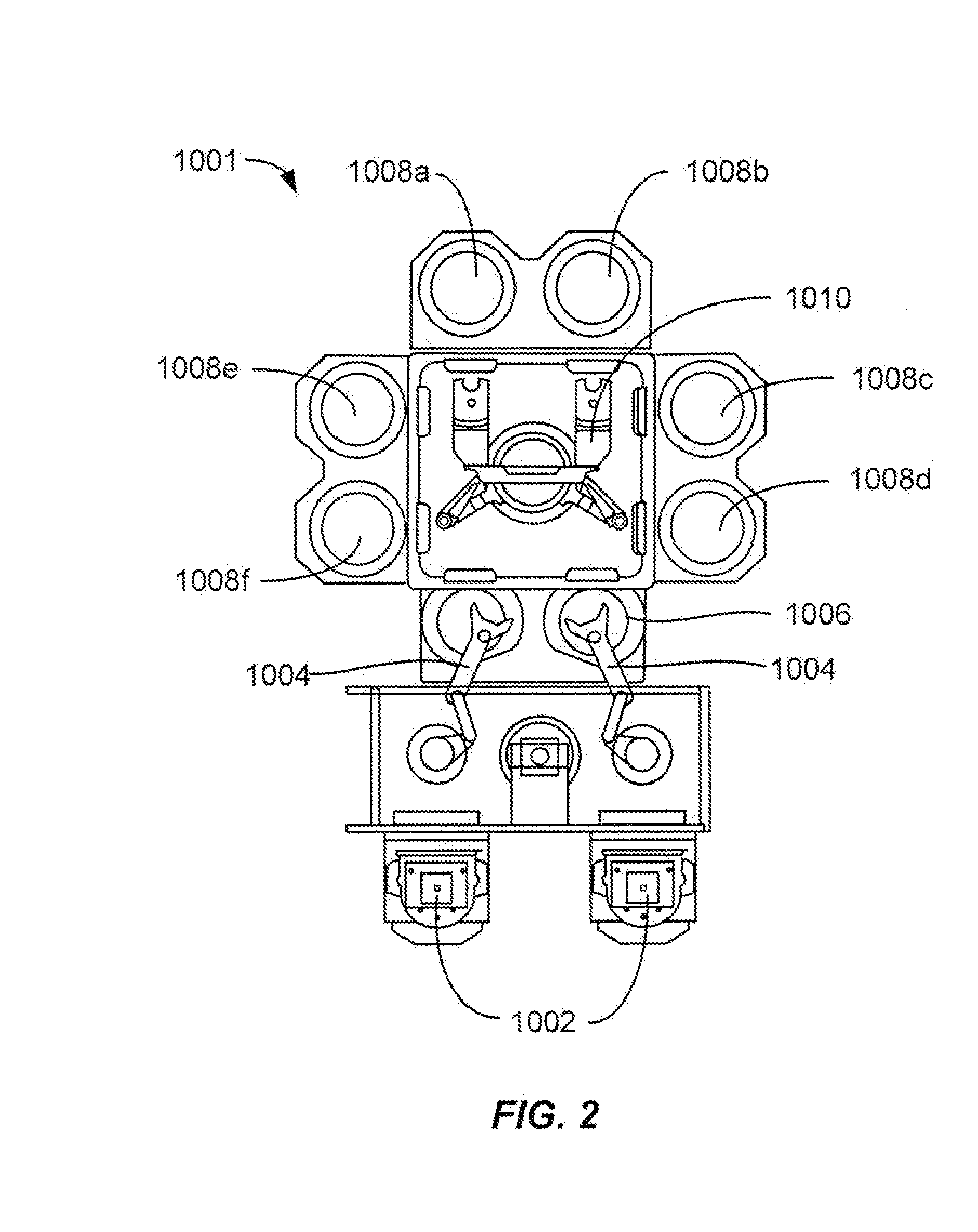

Low cost flowable dielectric films

ActiveUS20140073144A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilyleneSilanes

A method of forming a dielectric layer is described. The method deposits a silicon-containing film by chemical vapor deposition using a local plasma. The silicon-containing film is flowable during deposition at low substrate temperature. A silicon precursor (e.g. a silylamine, higher order silane or halogenated silane) is delivered to the substrate processing region and excited in a local plasma. A second plasma vapor or gas is combined with the silicon precursor in the substrate processing region and may include ammonia, nitrogen (N2), argon, hydrogen (H2) and / or oxygen (O2). The equipment configurations disclosed herein in combination with these vapor / gas combinations have been found to result in flowable deposition at substrate temperatures below or about 200° C. when a local plasma is excited using relatively low power.

Owner:APPLIED MATERIALS INC

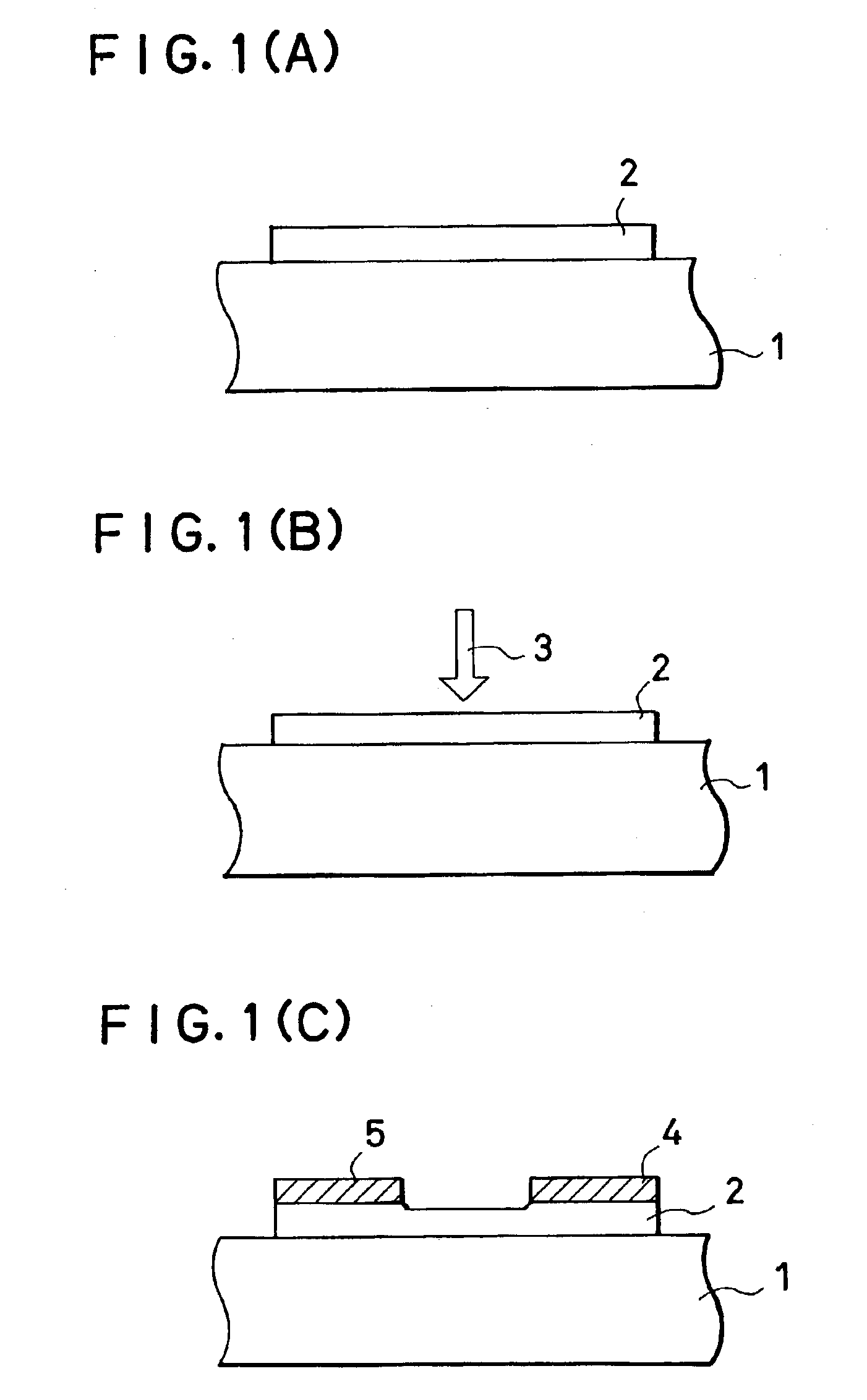

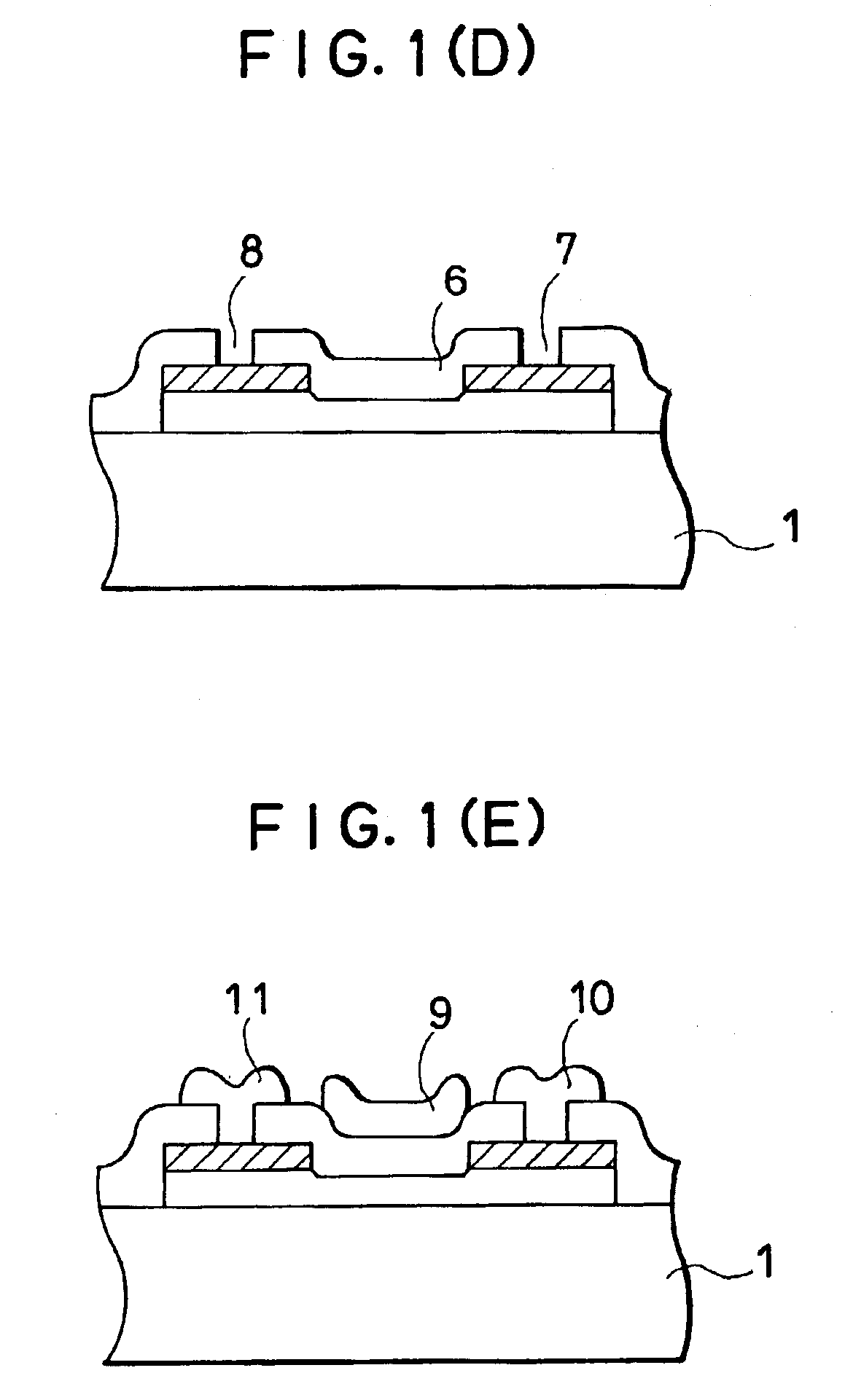

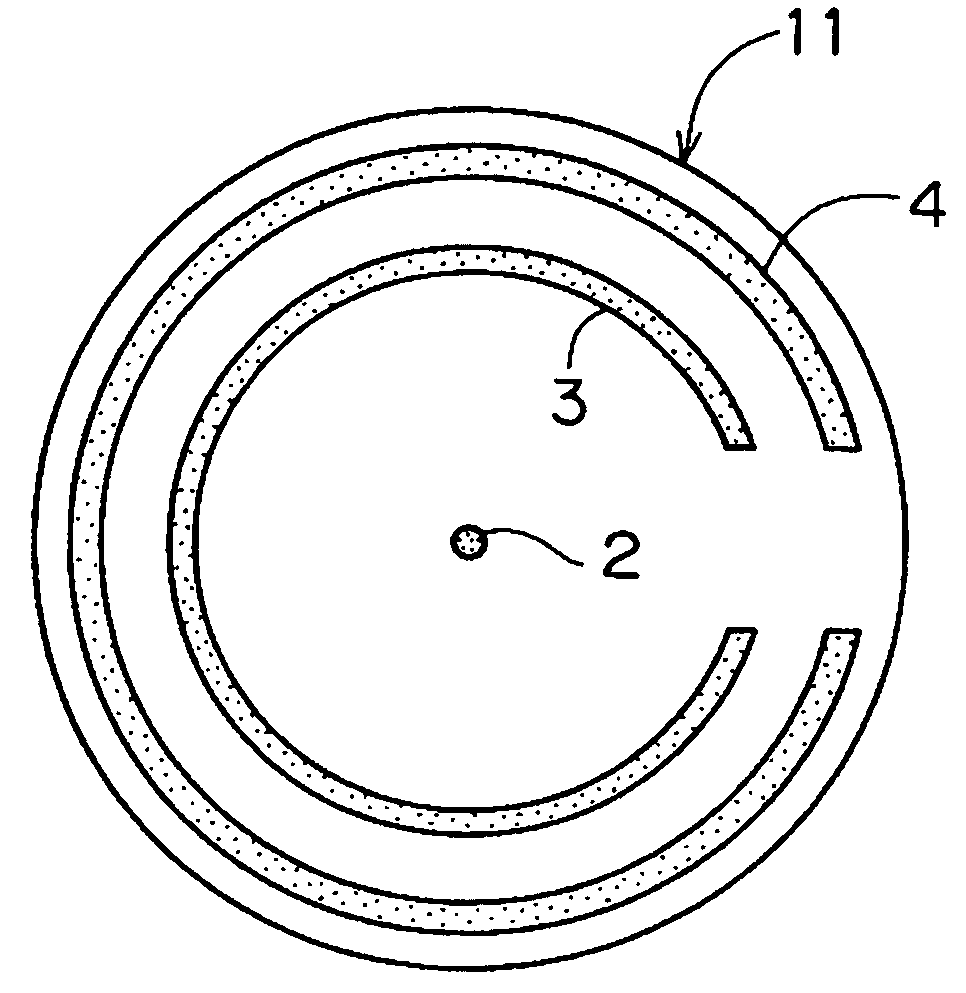

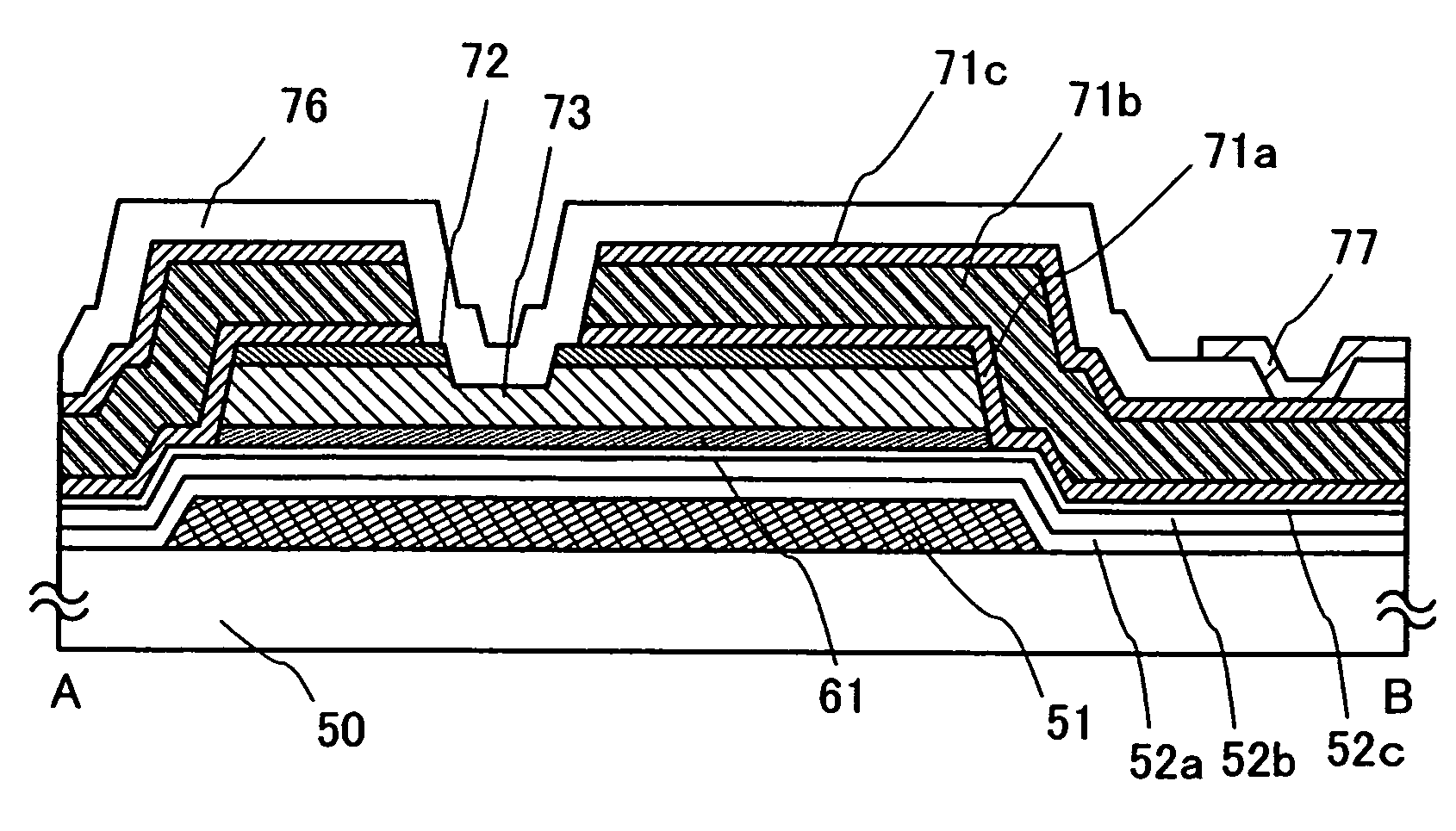

Method for manufacturing semiconductor device

InactiveUS20090047759A1Increase display contrastQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasHydrogen

After a gate insulating film is formed over a gate electrode, in order to improve the quality of a microcrystalline semiconductor film which is formed in an early stage of deposition, a film near an interface with the gate insulating film is formed under a first deposition condition in which a deposition rate is low but the quality of a film to be formed is high, and then, a film is further deposited under a second deposition condition in which a deposition rate is high. Then, a buffer layer is formed to be in contact with the microcrystalline semiconductor film. Further, plasma treatment with a rare gas such as argon or hydrogen plasma treatment is performed before formation of the film under the first deposition condition for removing adsorbed water on a substrate.

Owner:SEMICON ENERGY LAB CO LTD

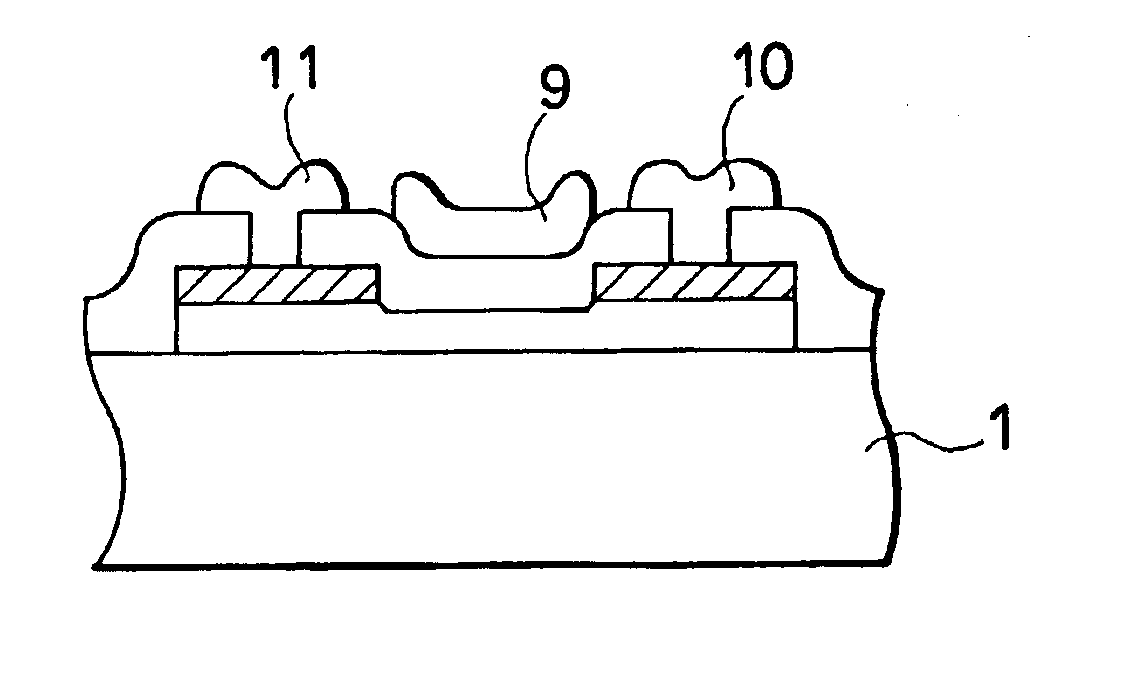

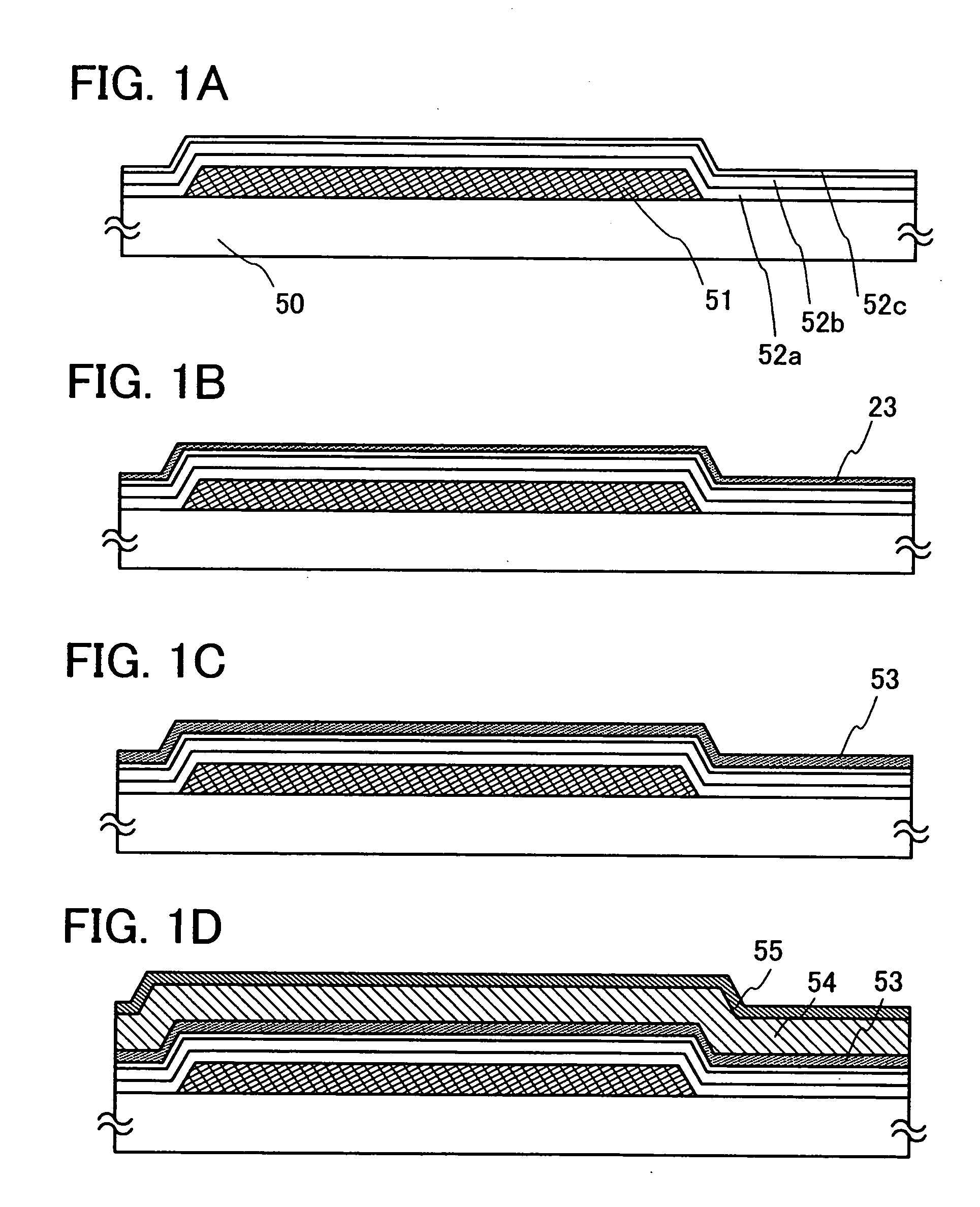

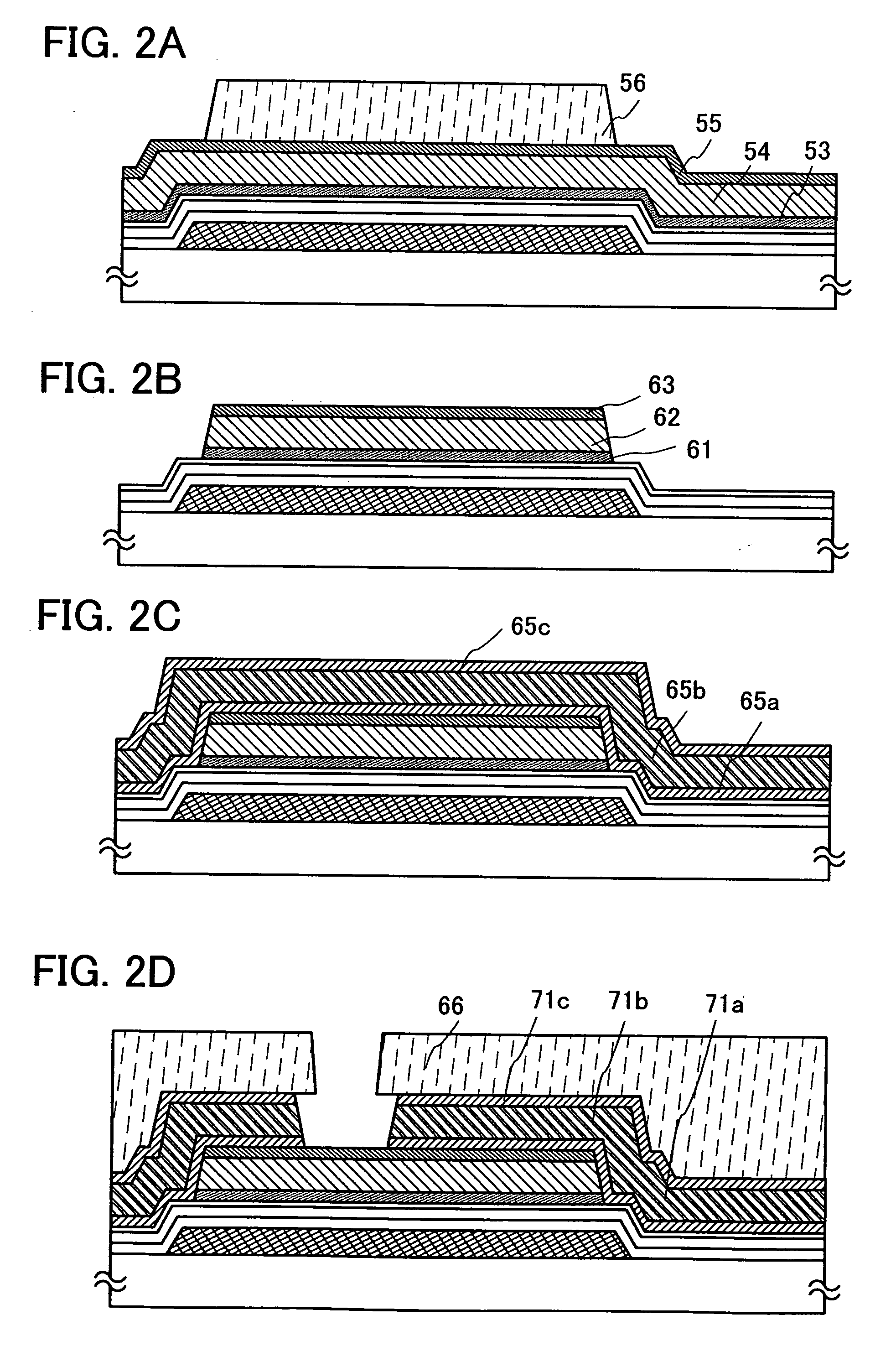

Thin film semiconductor device and method for producing the same

Owner:SEIKO EPSON CORP

Combined cryogenic distillation and PSA for argon production

ActiveUS7501009B2Improvements in the refining of crude argonSpeed up the processSolidificationLiquefactionParticulatesFiltration

A method and apparatus for producing high purity argon by combined cryogenic distillation and adsorption technologies is disclosed. Crude argon from a distillation column or a so-called argon column is passed to a system of adsorption vessels for further purification. Depressurization gas from adsorption is introduced back, in a controlled manner, to the distillation column and / or a compressor or other means for increasing pressure. Particulate filtration and getter purification may optionally be used.

Owner:AIR PROD & CHEM INC

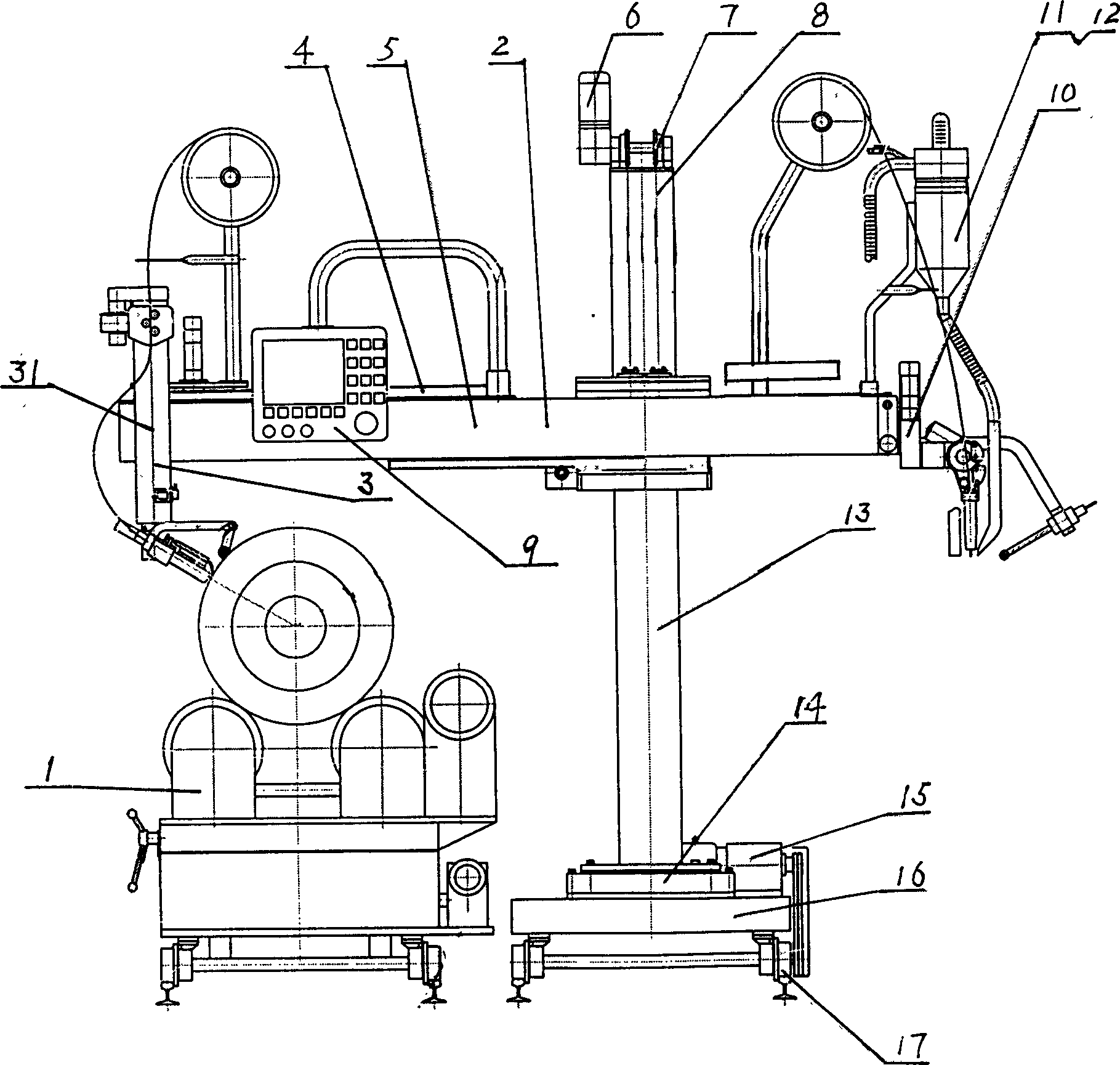

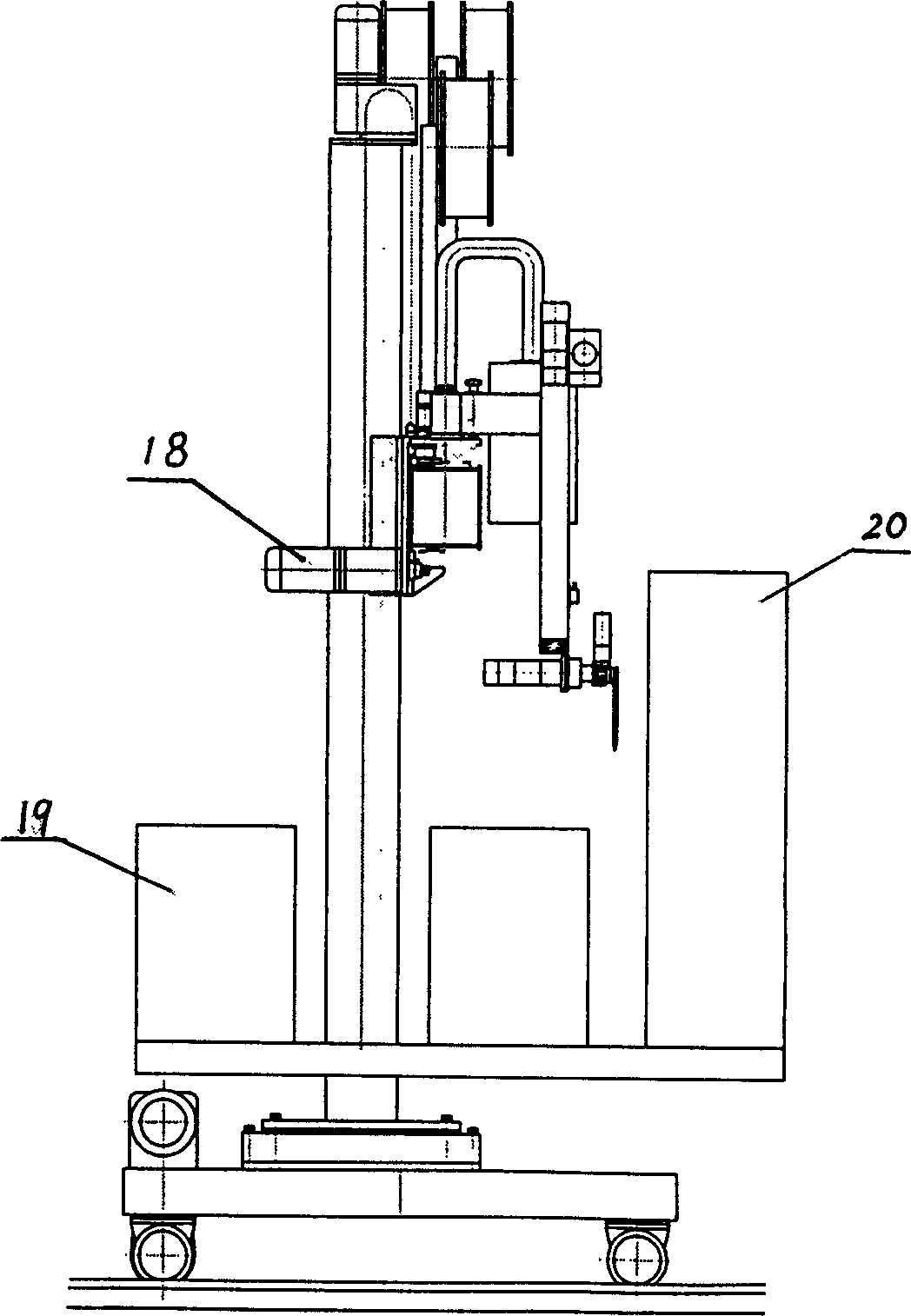

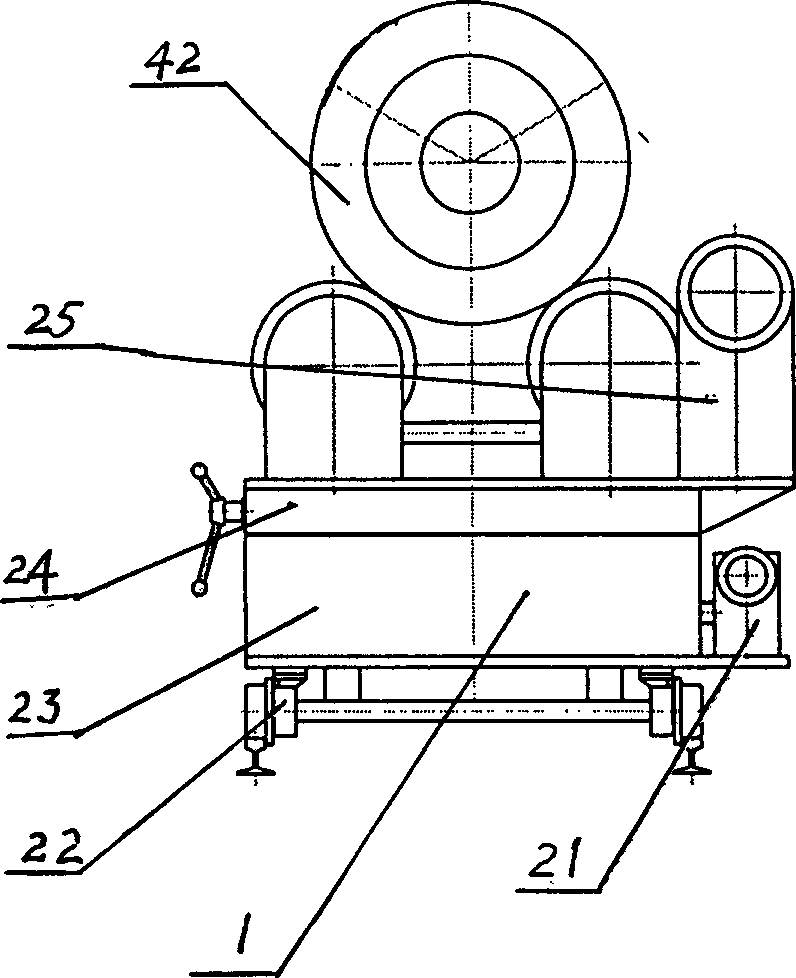

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN1714978AAutomatically calculate relative coordinate origin positionEnsure shapeArc welding apparatusBogieEngineering

The automatic argon arc welding and narrow gas submerged arc welding process for circular pipe header seam features the first horizontal and vertical welding with immobile workpiece and using automatic cold welding TIG wire until completing over one third of circle; the subsequent welding in the other two thirds of circle with automatically rotating welding roller frame; and the performing in the identical site of the annular seam assembling and the welding. The welding apparatus for the said technological process consists of roller device and welding frame bogie, and the welding frame bogie on some tracks parallel to roller frame tracks is movable. The present invention has the advantages of automatic operation, raised welding quality, etc.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com