Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1364results about How to "Good shape retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

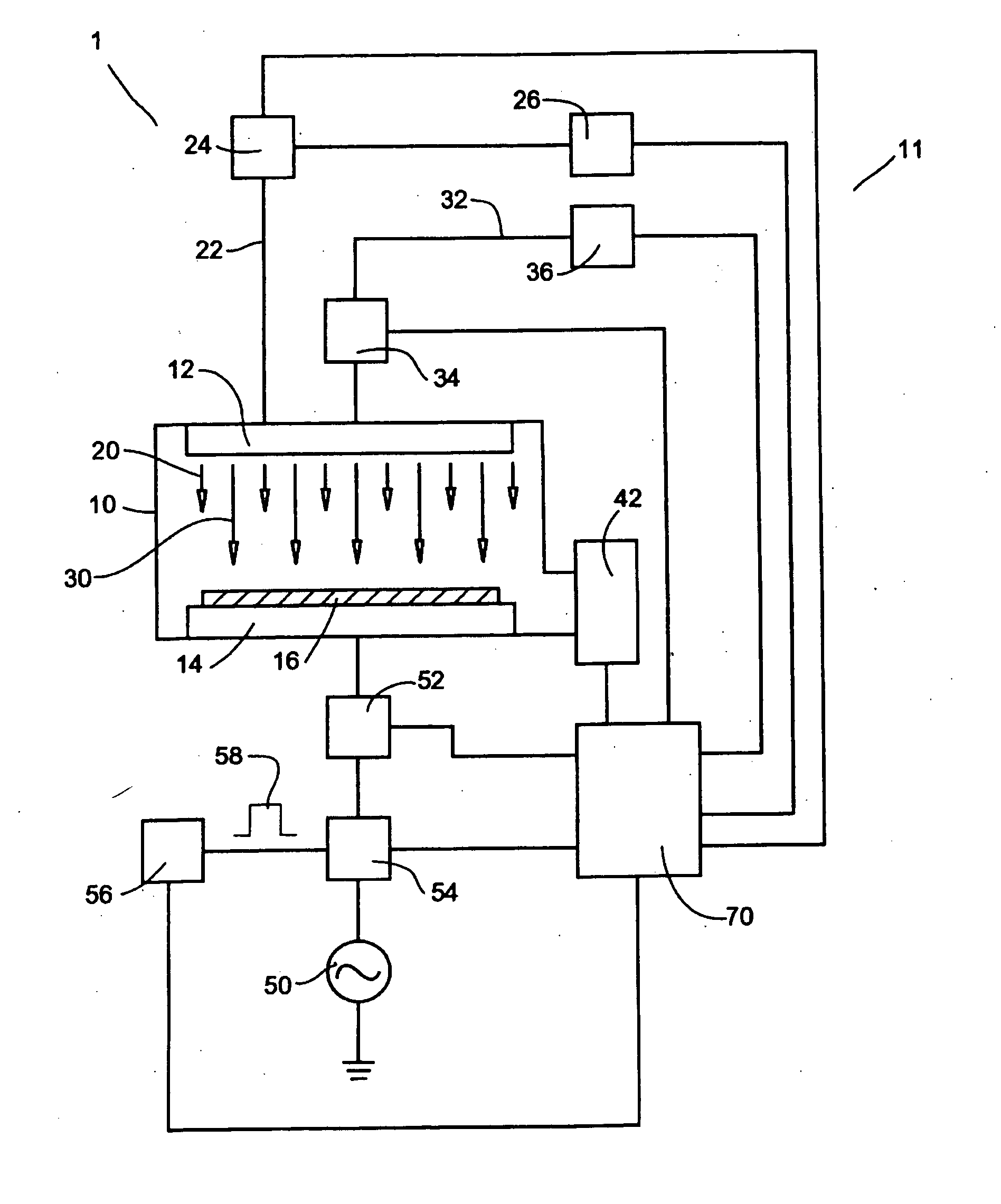

Method for Depositing Conformal Amorphous Carbon Film by Plasma-Enhanced Chemical Vapor Deposition (PECVD)

ActiveUS20100093187A1Good shape retentionHighly conformalSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerNitrogen gas

Methods and apparatus for depositing an amorphous carbon layer on a substrate are provided. In one embodiment, a deposition process includes positioning a substrate in a substrate processing chamber, introducing a hydrocarbon source having a carbon to hydrogen atom ratio of greater than 1:2 into the processing chamber, introducing a plasma initiating gas selected from the group consisting of hydrogen, helium, argon, nitrogen, and combinations thereof into the processing chamber, with the hydrocarbon source having a volumetric flow rate to plasma initiating gas volumetric flow rate ratio of 1:2 or greater, generating a plasma in the processing chamber, and forming a conformal amorphous carbon layer on the substrate.

Owner:APPLIED MATERIALS INC

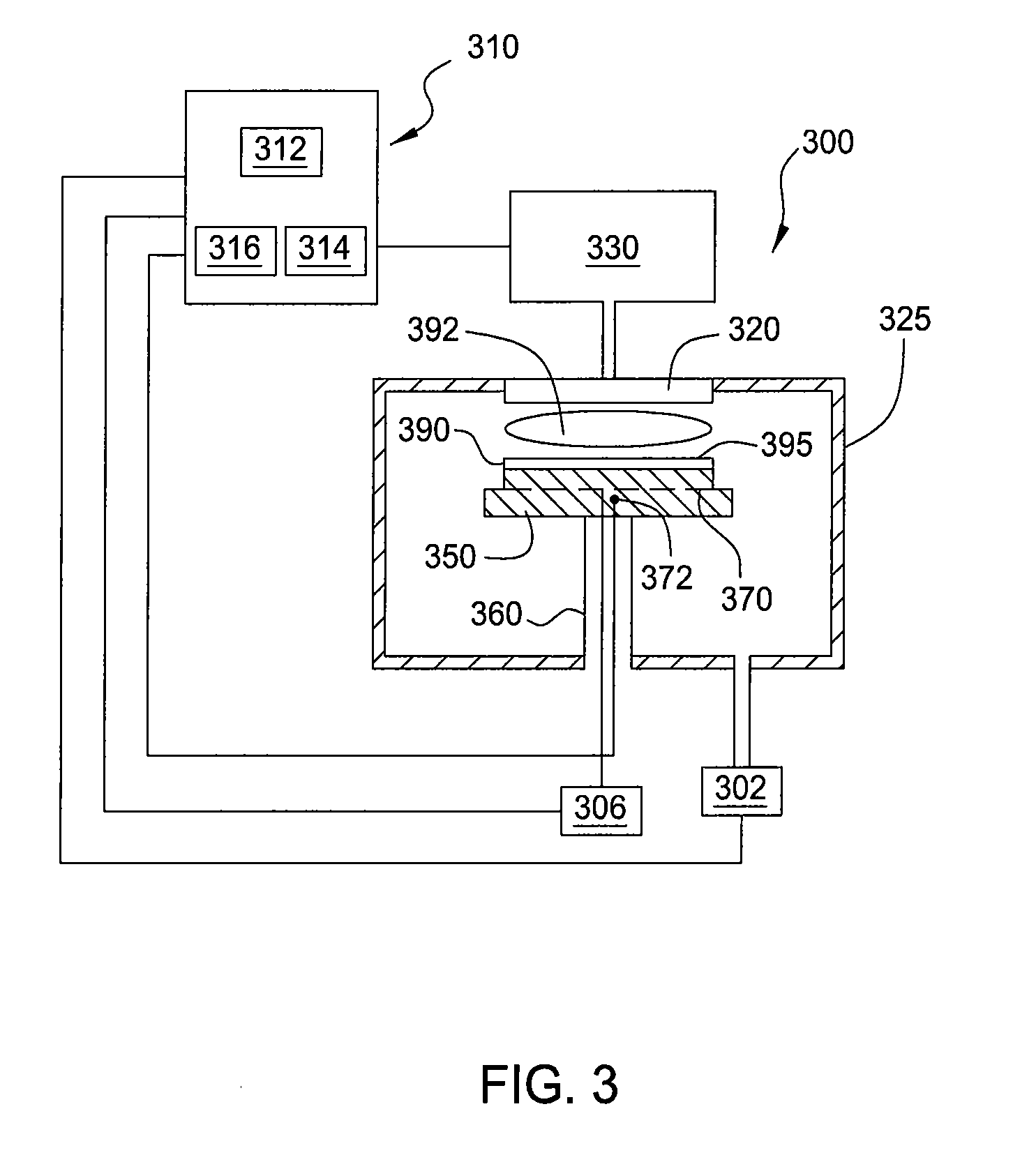

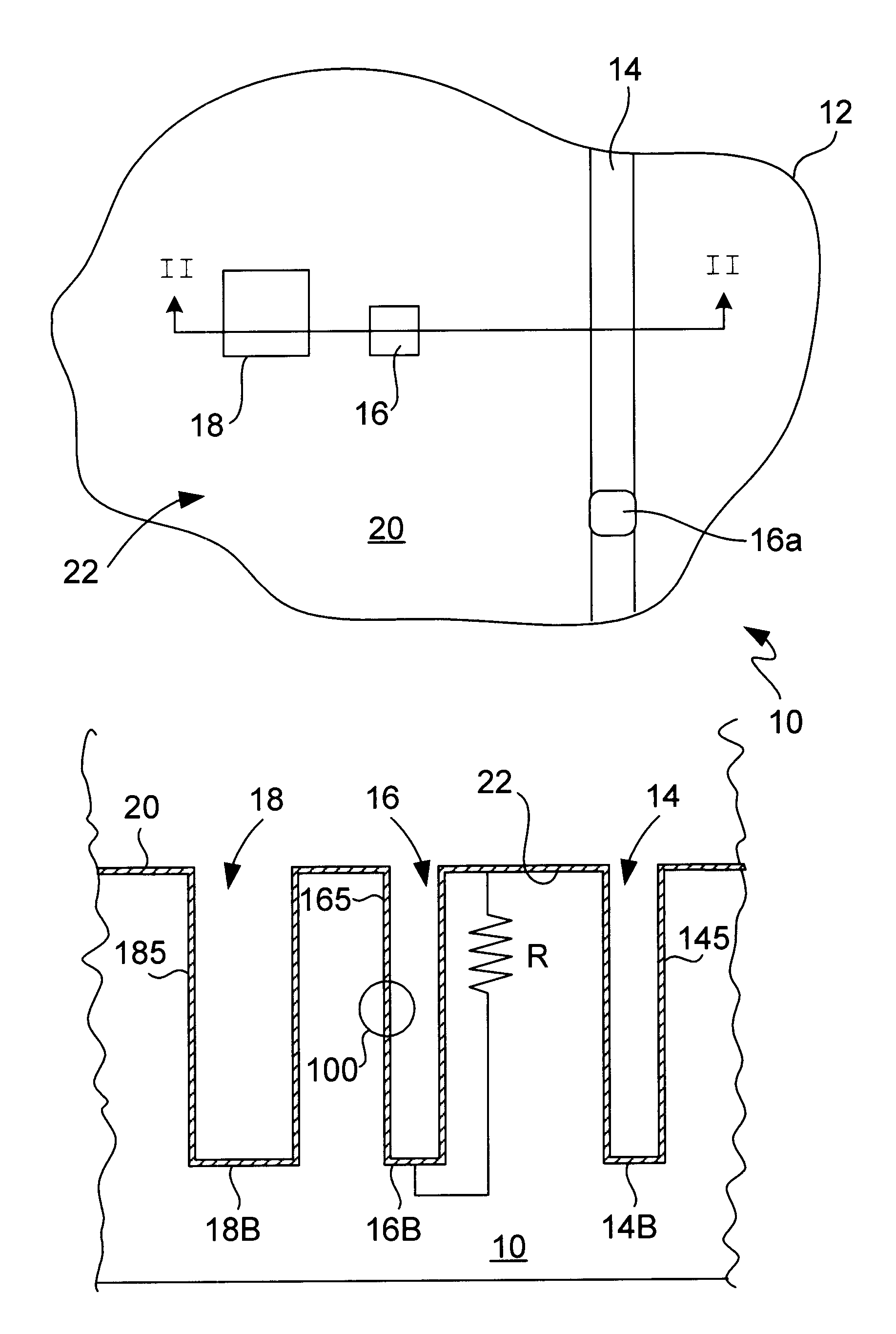

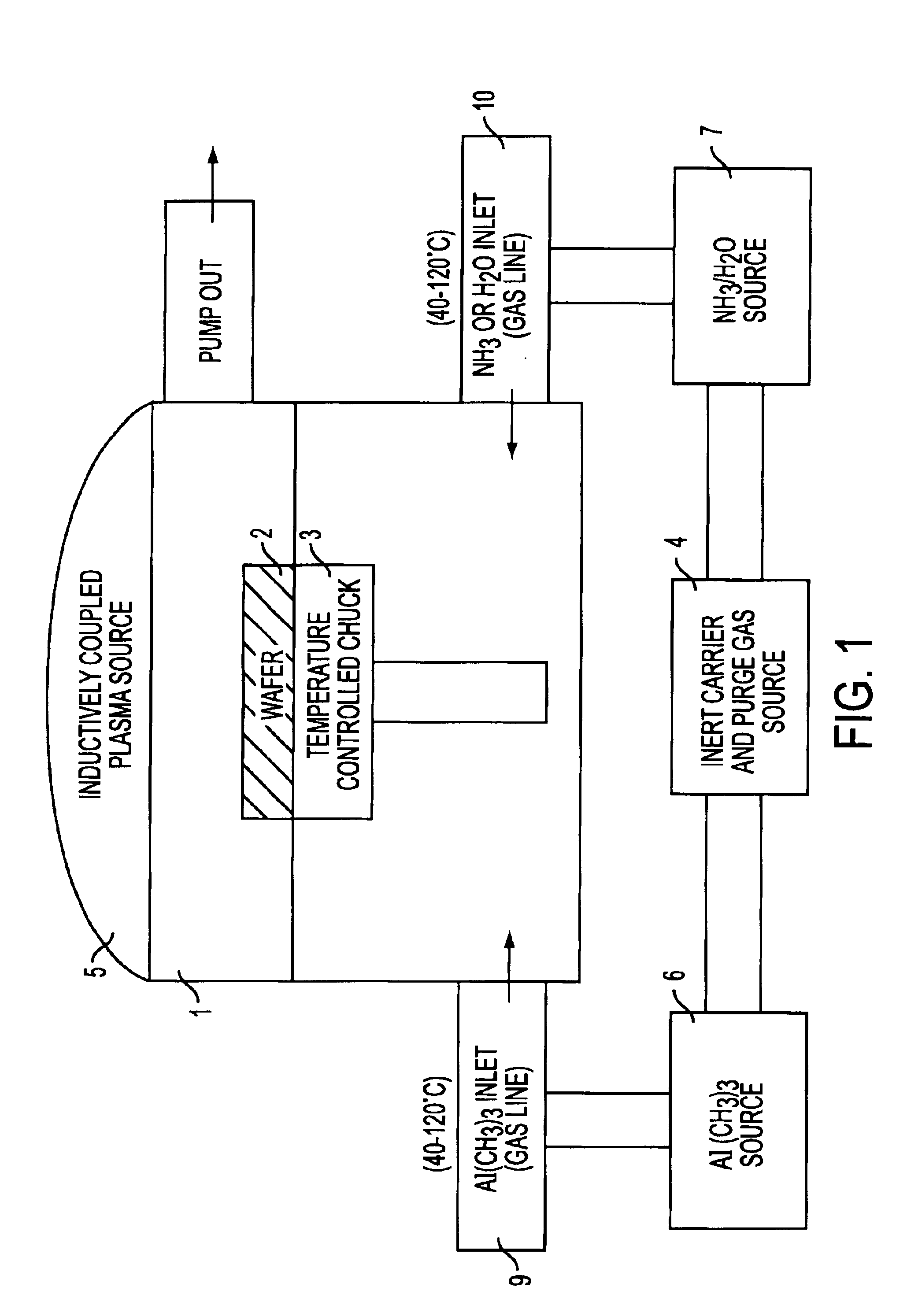

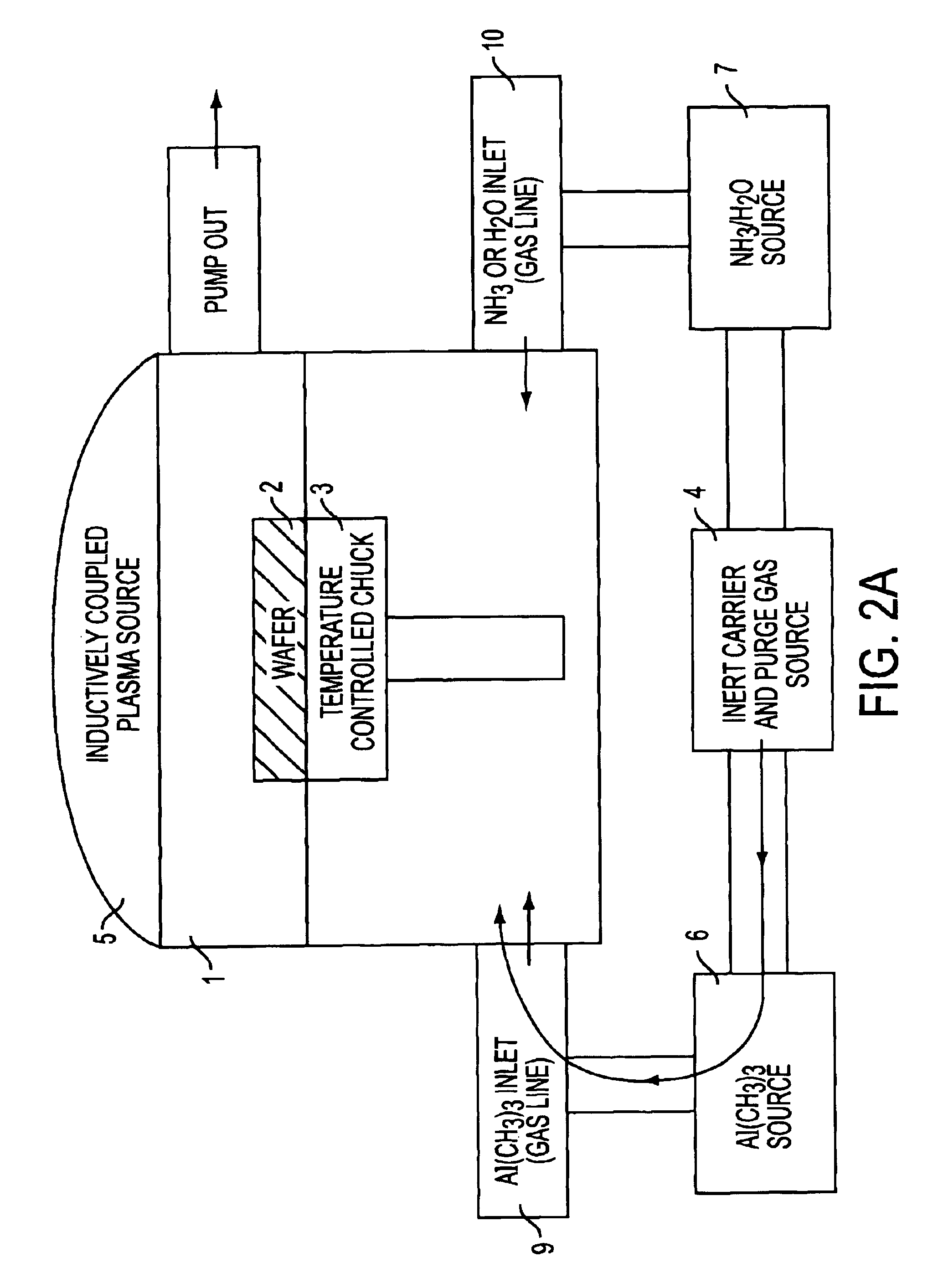

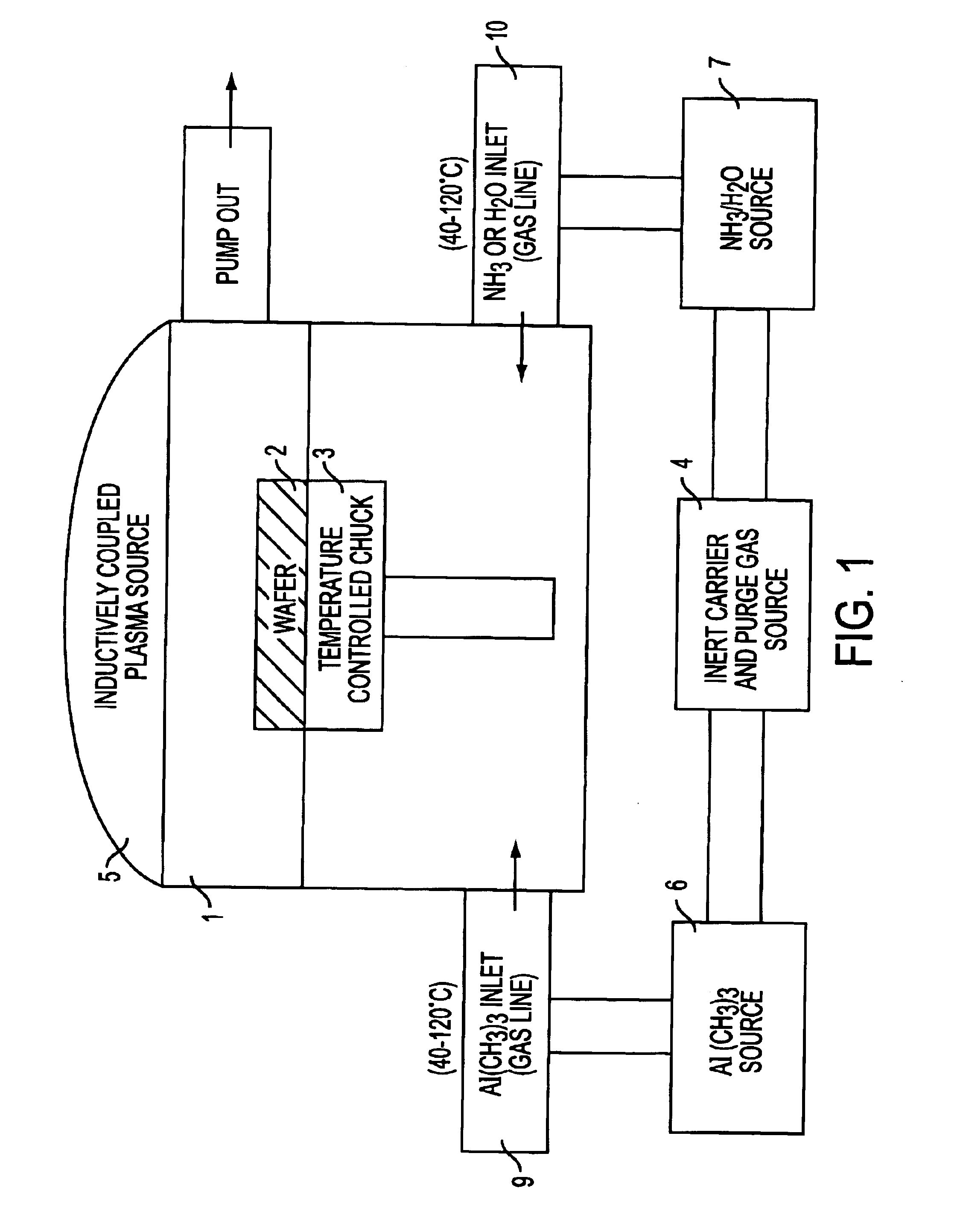

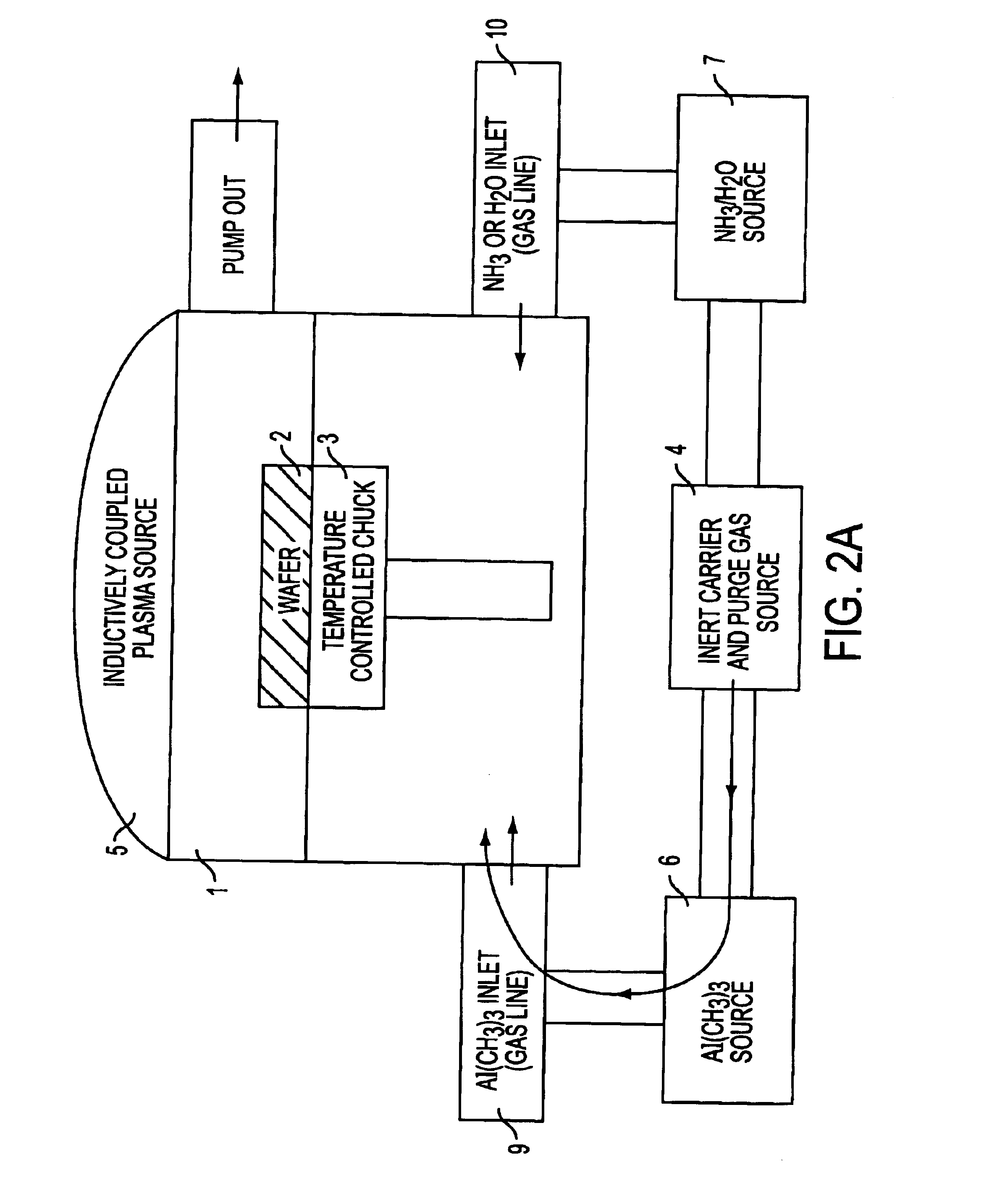

Method and system for performing atomic layer deposition

InactiveUS20050221021A1Improved deposition characteristicsGood shape retentionElectric discharge tubesChemical vapor deposition coatingProcess engineeringAtomic layer deposition

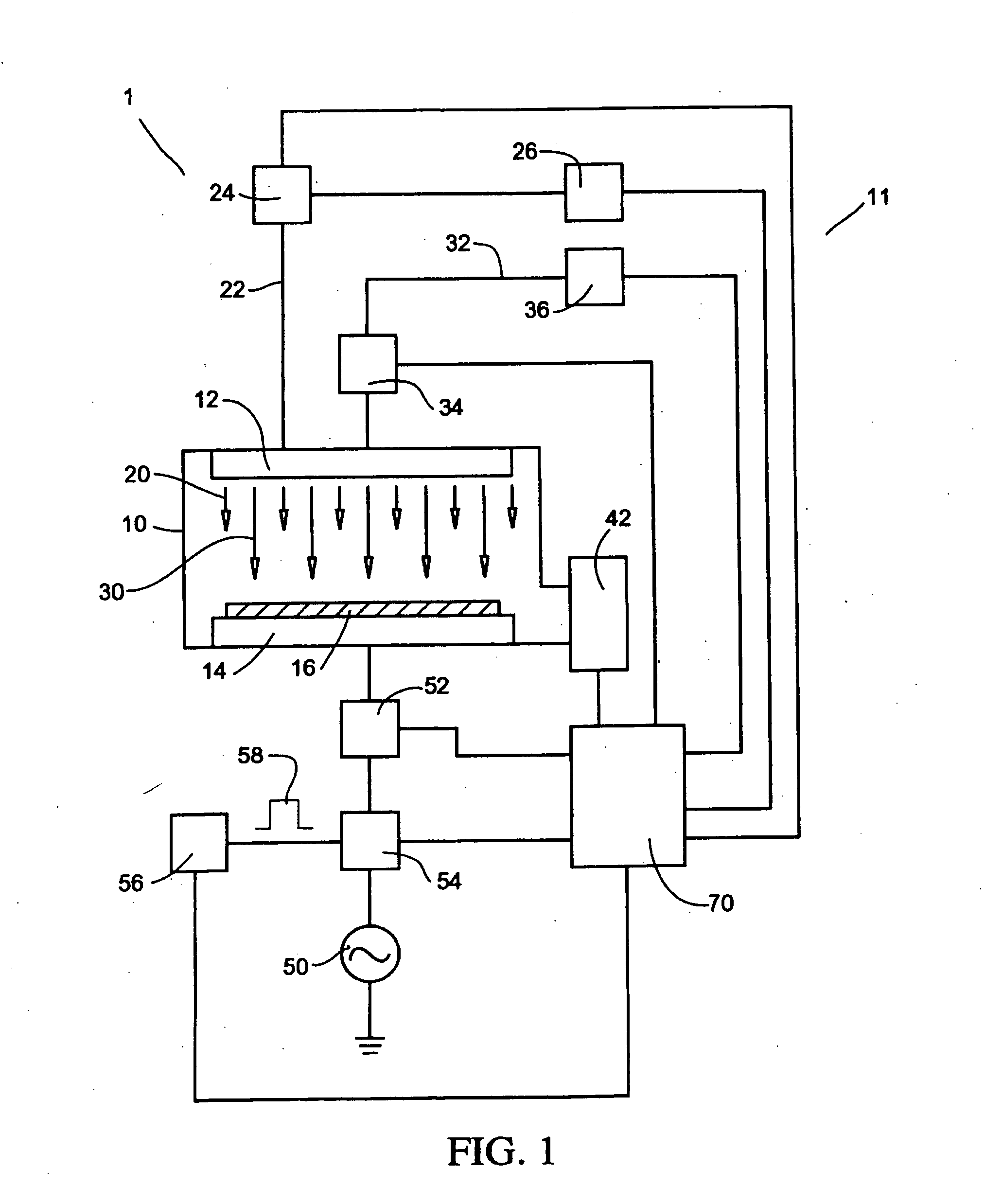

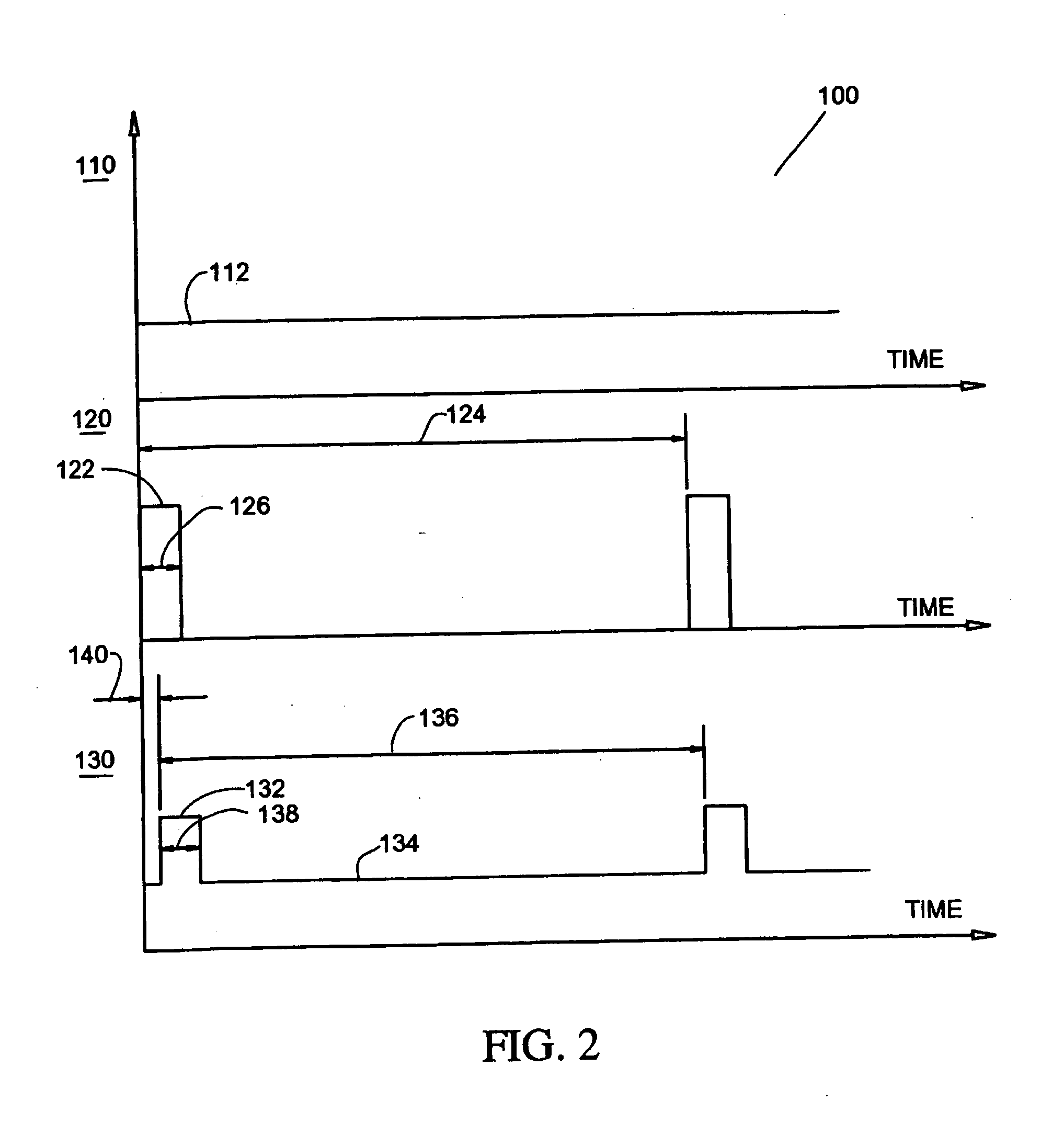

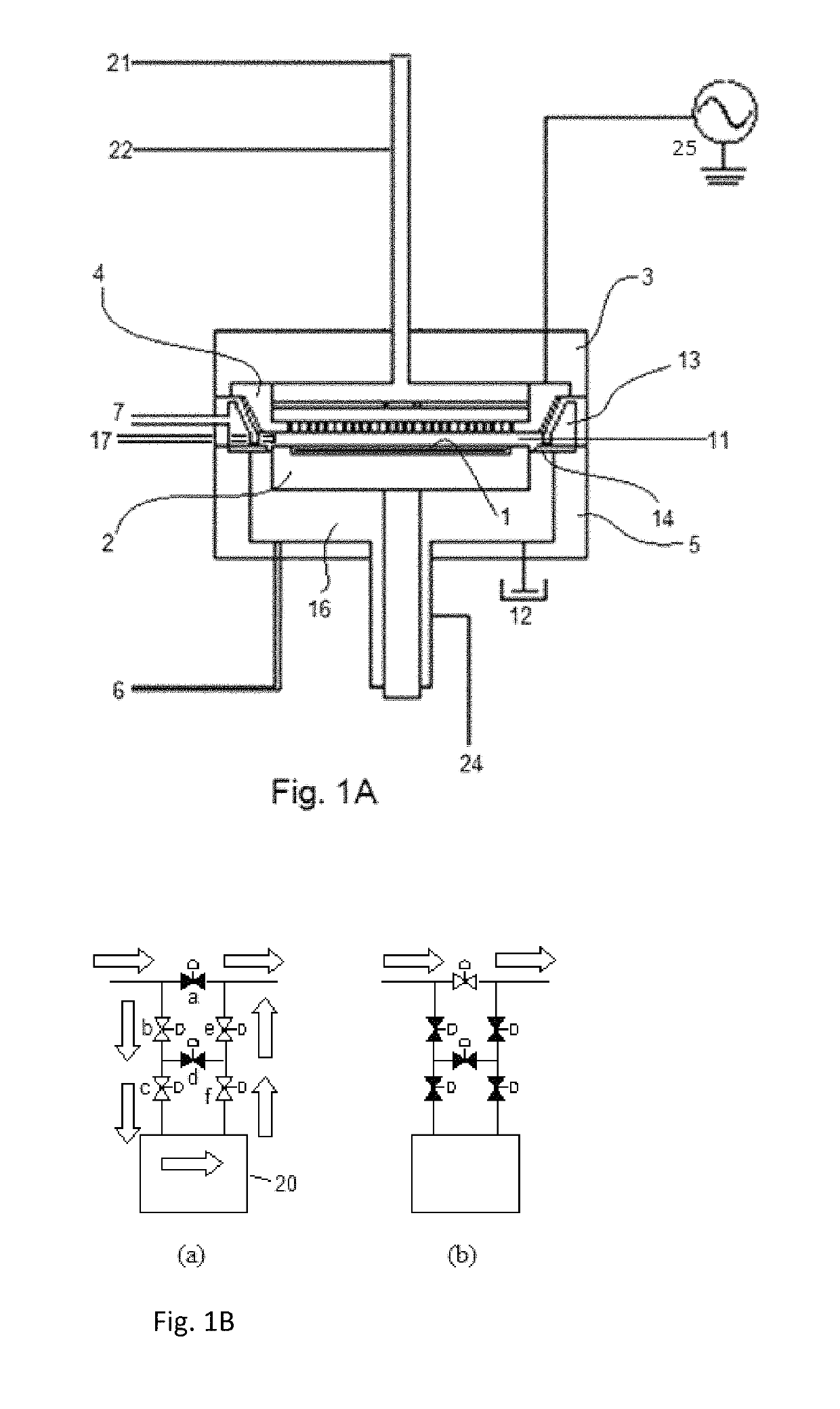

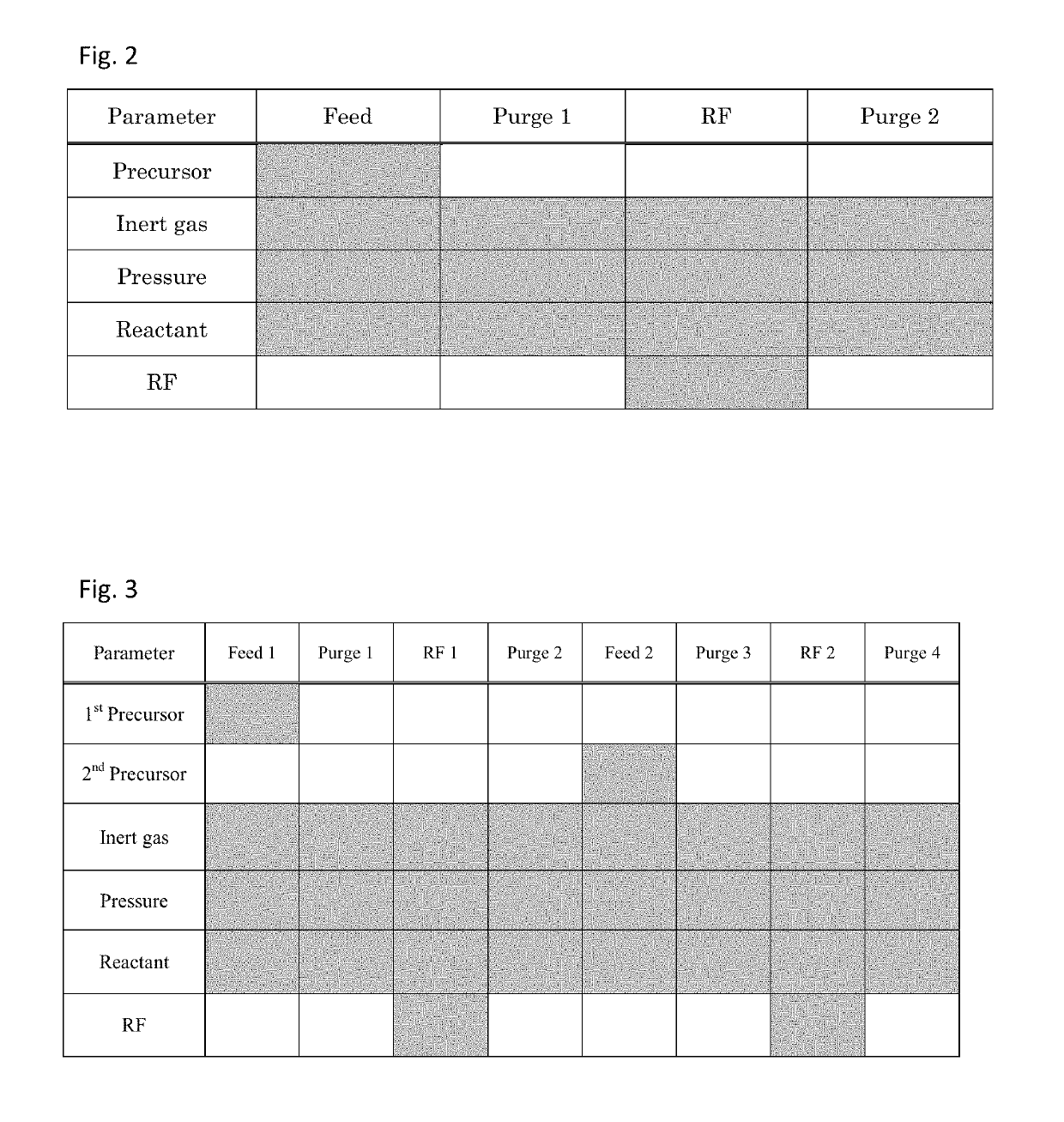

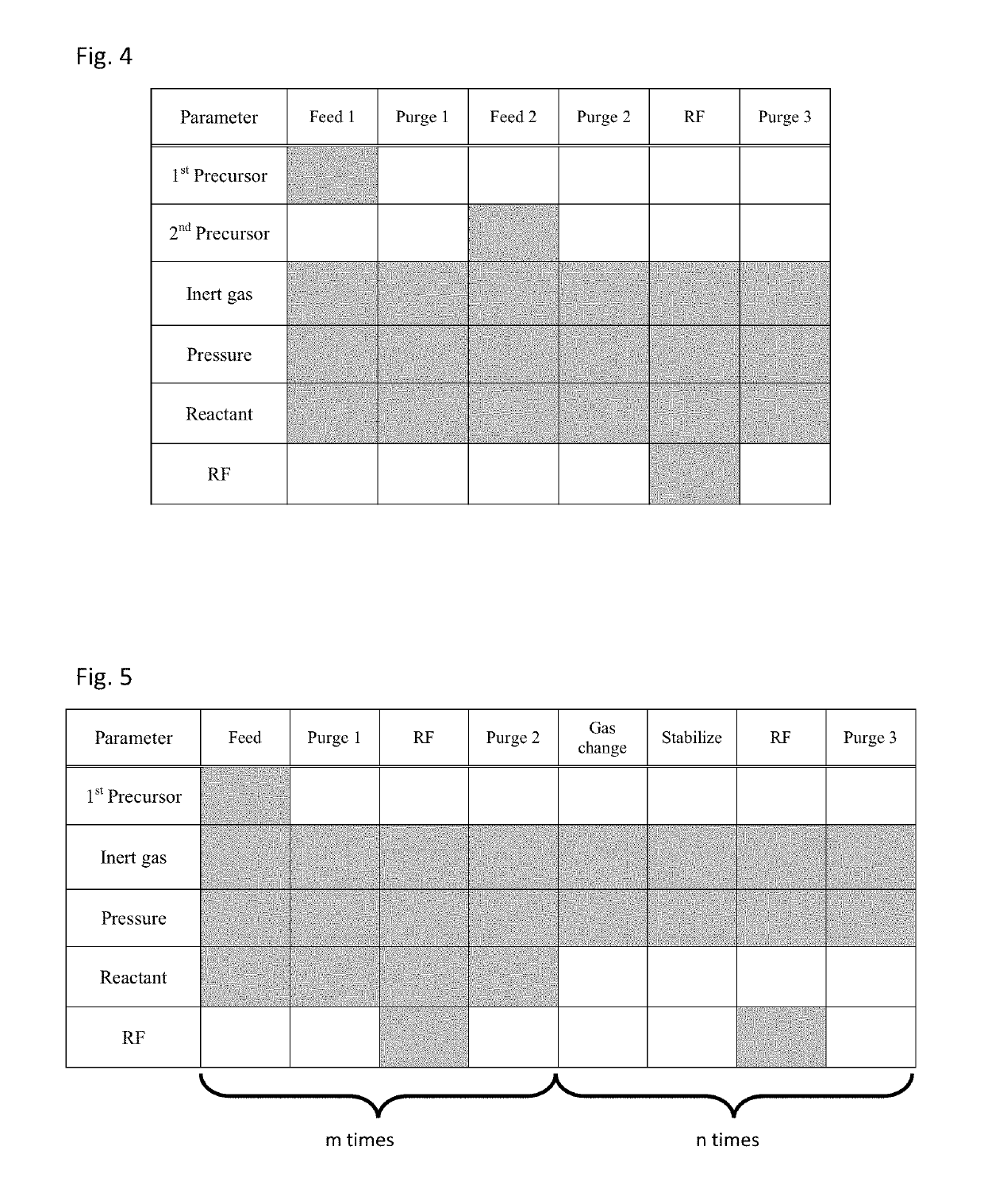

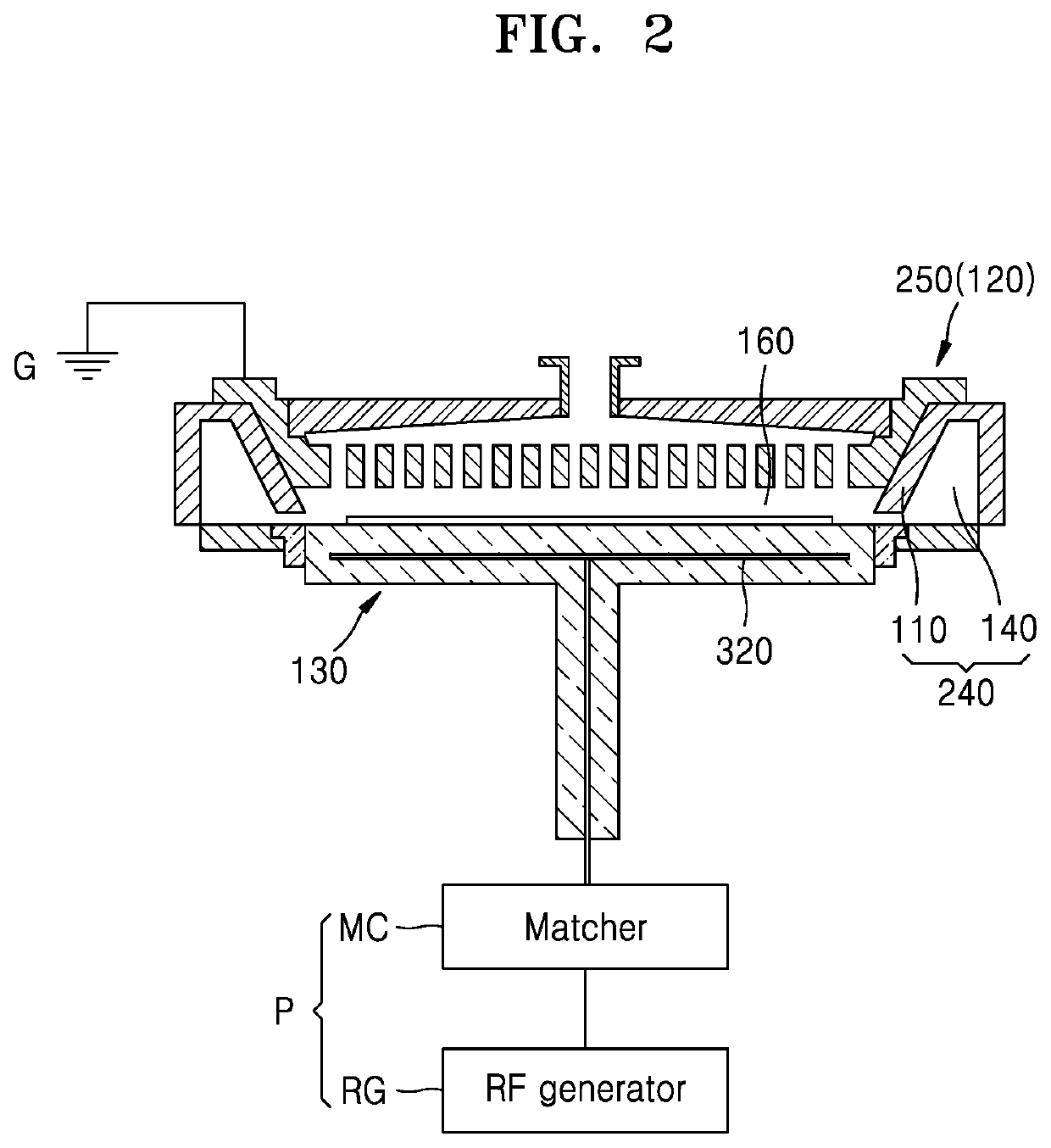

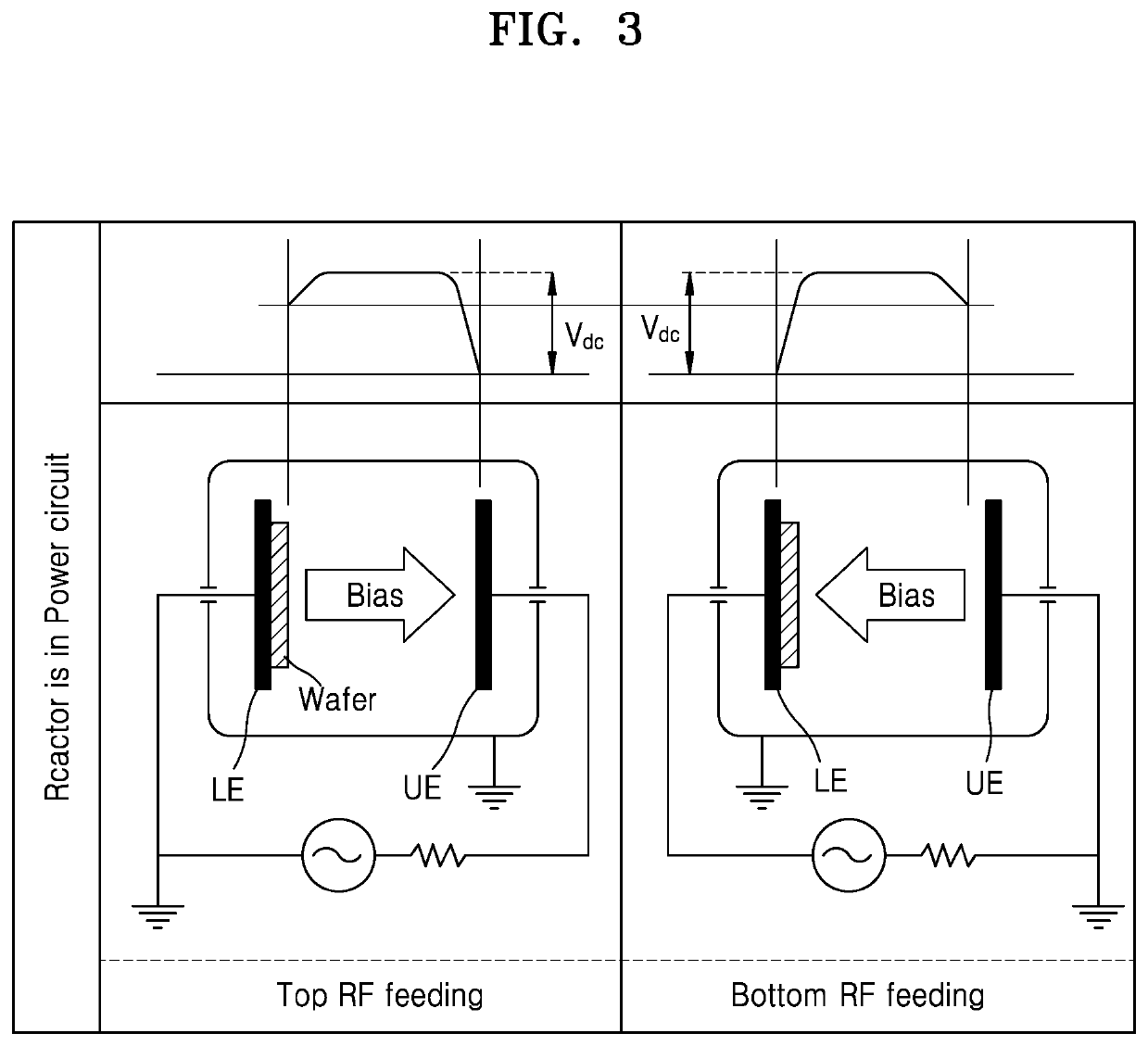

A plasma processing system for performing atomic layer deposition (ALD) including a process chamber, a substrate holder provided within the process chamber, and a gas injection system configured to supply a first gas and a second gas to the process chamber. The system includes a controller that controls the gas injection system to continuously flow a first gas flow to the process chamber and to pulse a second gas flow to the process chamber at a first time. The controller pulses a RF power to the substrate holder at a second time. A method of operating a plasma processing system is provided that includes adjusting a background pressure in a process chamber, where the background pressure is established by flowing a first gas flow using a gas injection system, and igniting a processing plasma in the process chamber. The method includes pulsing a second gas flow using the gas injection system at a first time, and pulsing a RF power to a substrate holder at a second time.

Owner:TOKYO ELECTRON LTD

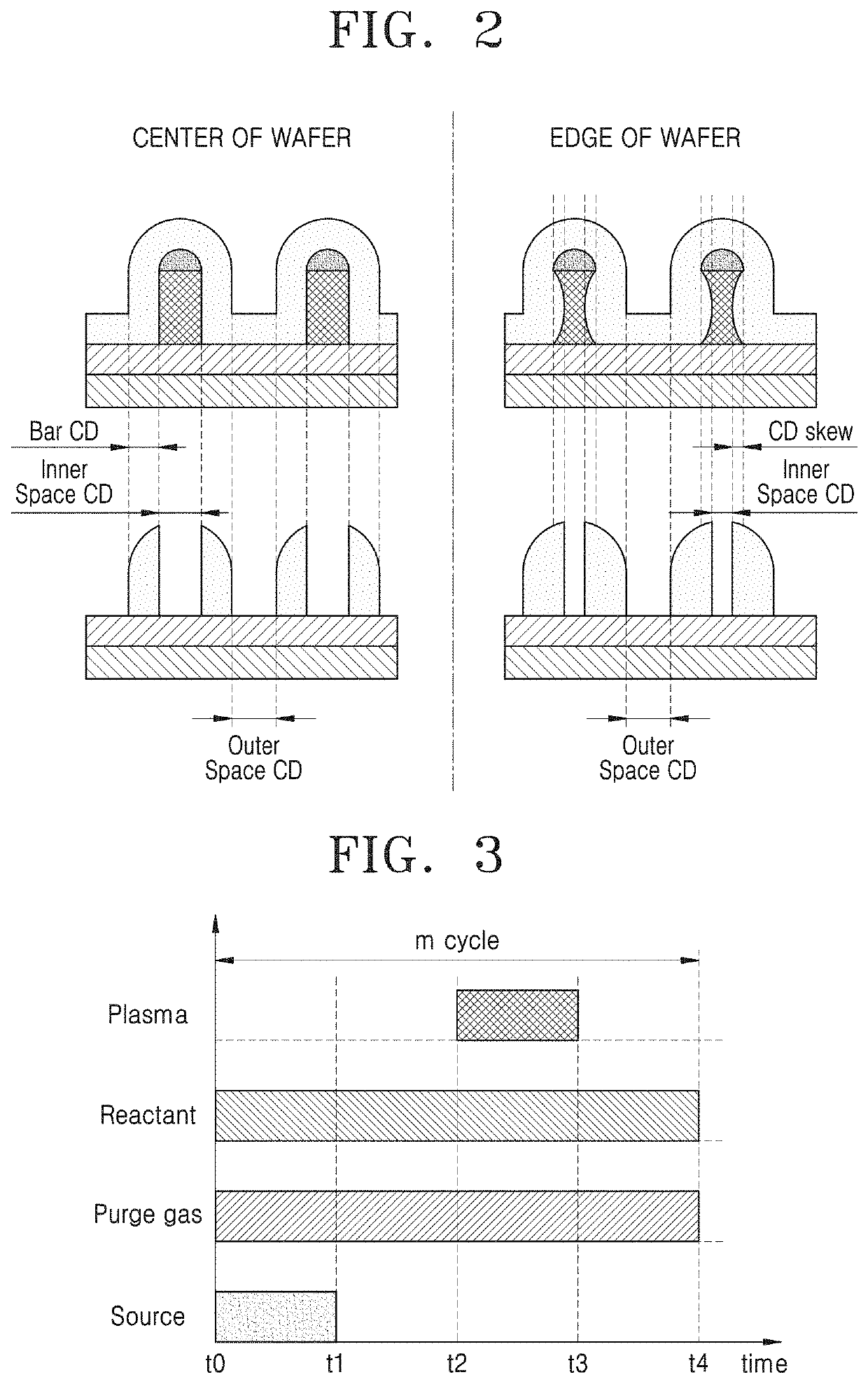

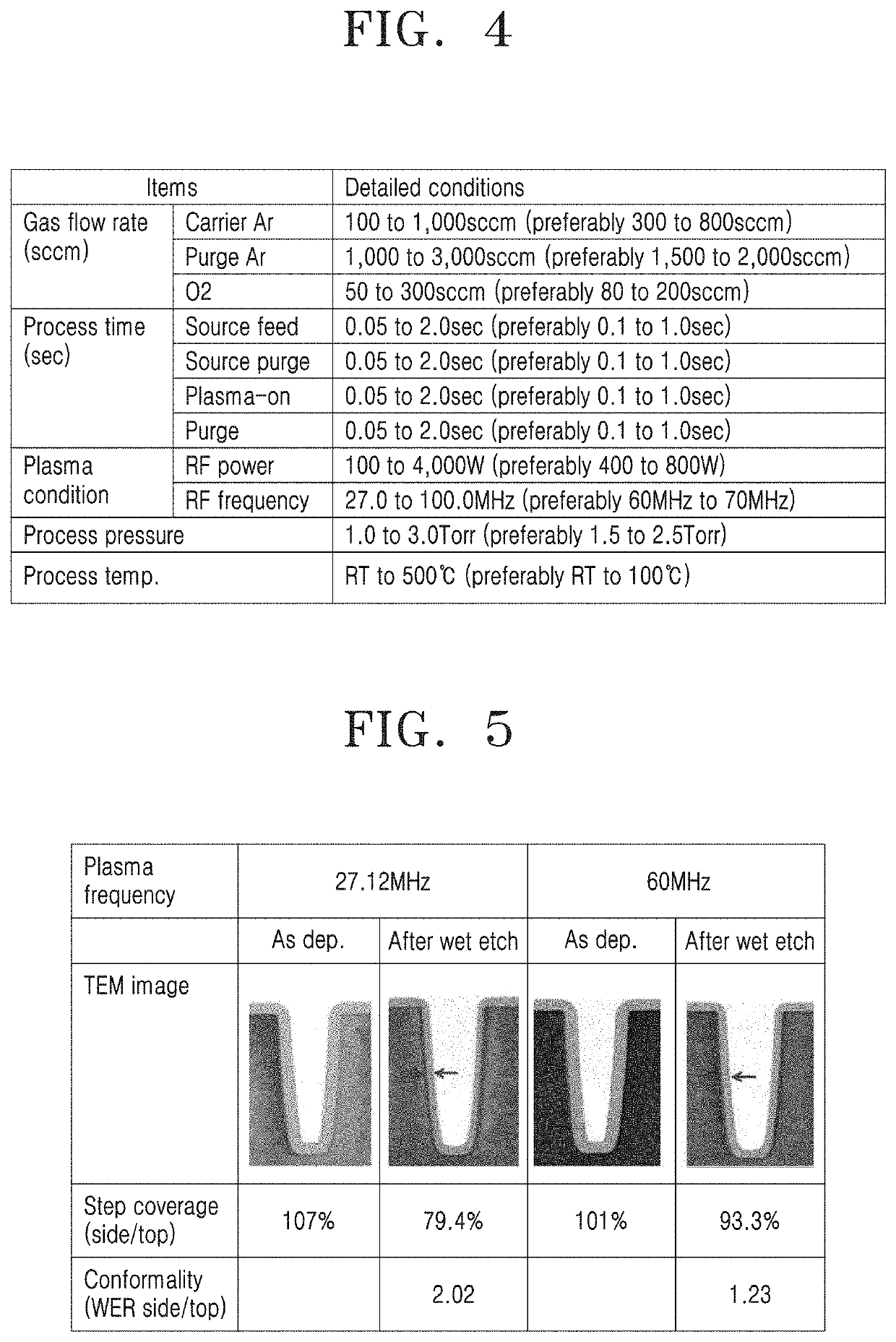

Method of depositing thin film and method of manufacturing semiconductor device

ActiveUS20190115206A1Good shape retentionAvoid damageElectric discharge tubesSemiconductor/solid-state device manufacturingReactive gasEngineering

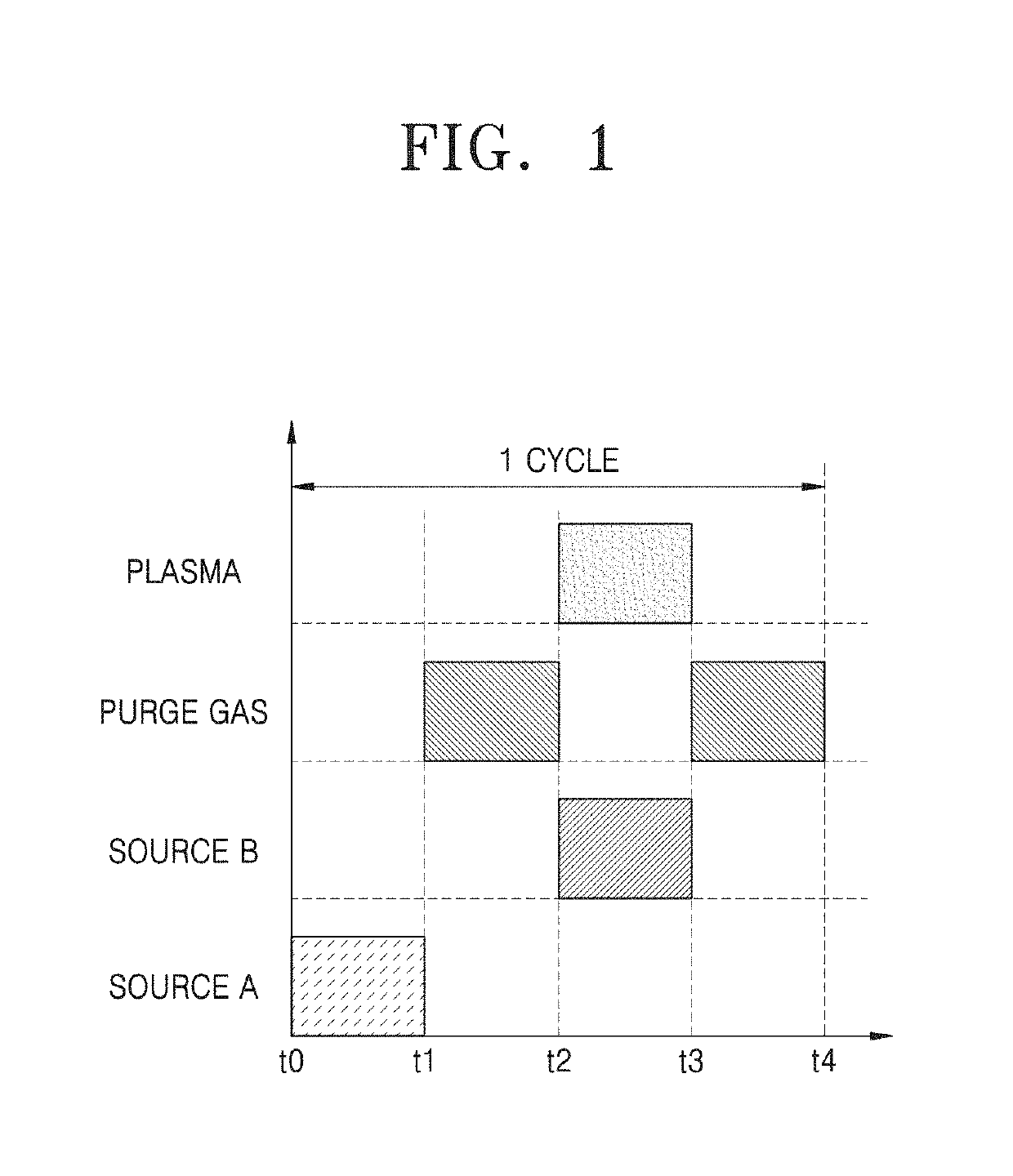

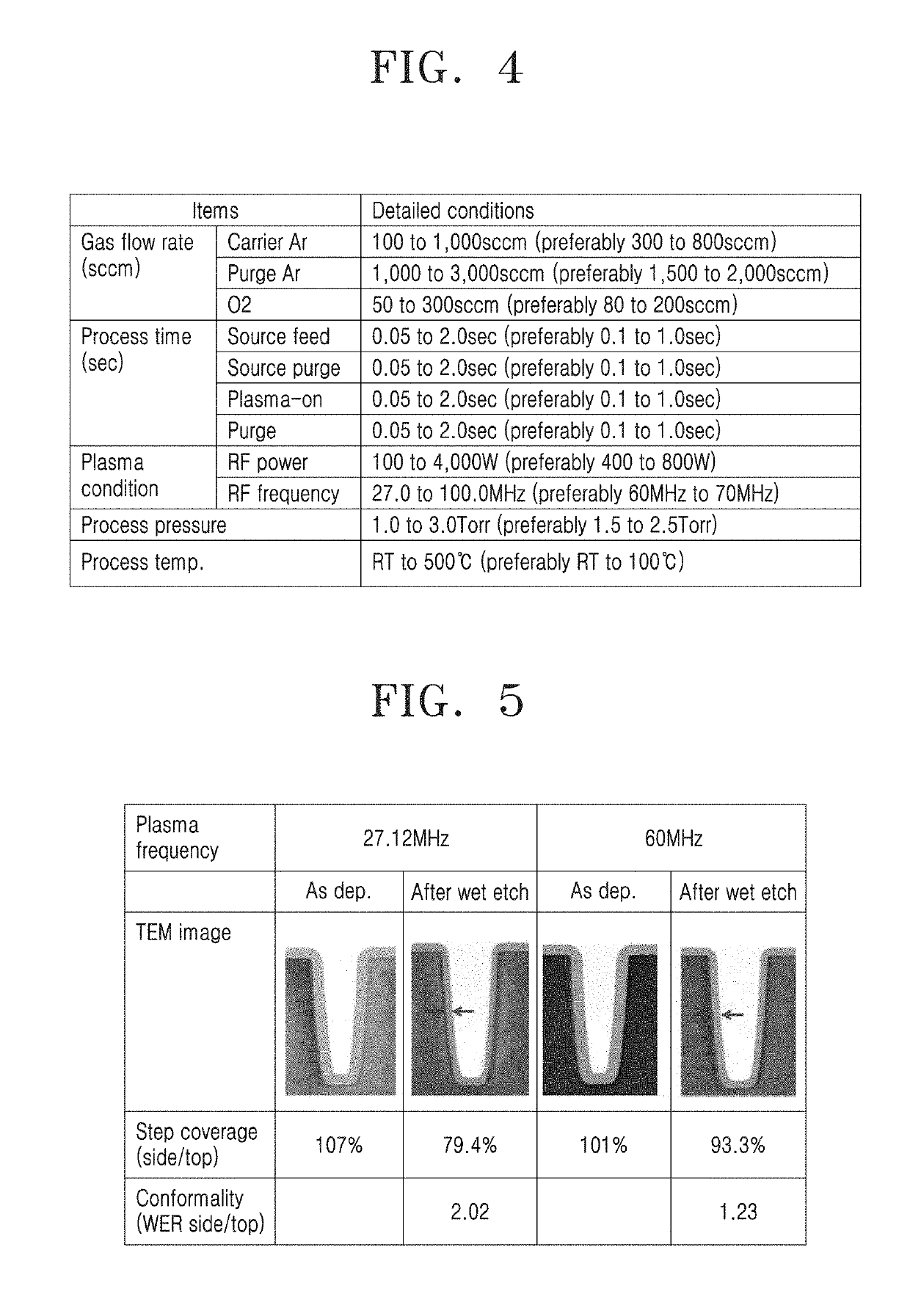

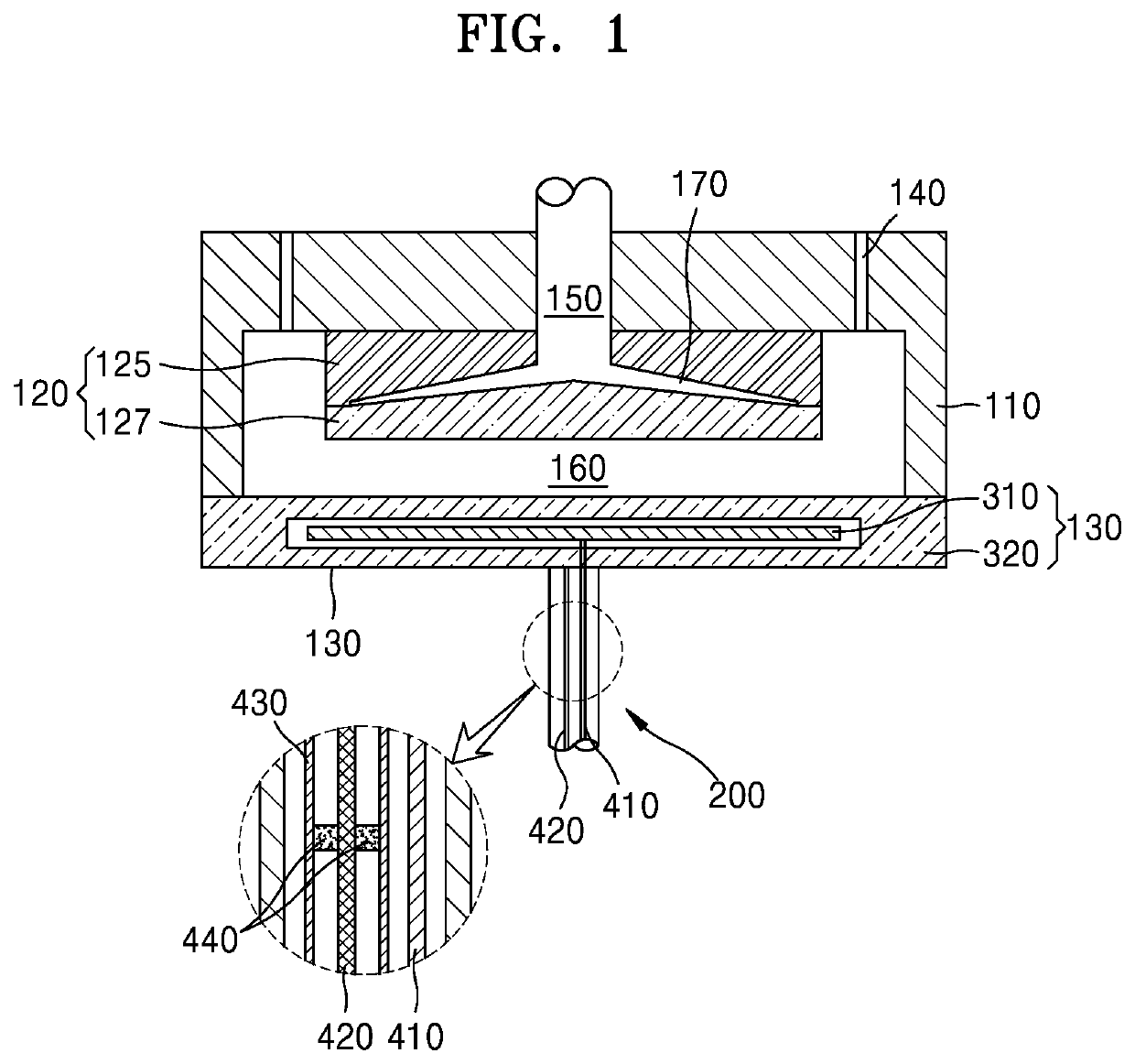

Provided is a method of depositing a thin film on a pattern structure of a semiconductor substrate, the method including (a) supplying a source gas; (b) supplying a reactive gas; and (c) supplying plasma, wherein the steps (a), (b), and (c) are sequentially repeated on the semiconductor substrate within a reaction space until a desired thickness is obtained, and a frequency of the plasma is a high frequency of 60 MHz or greater.

Owner:ASM IP HLDG BV

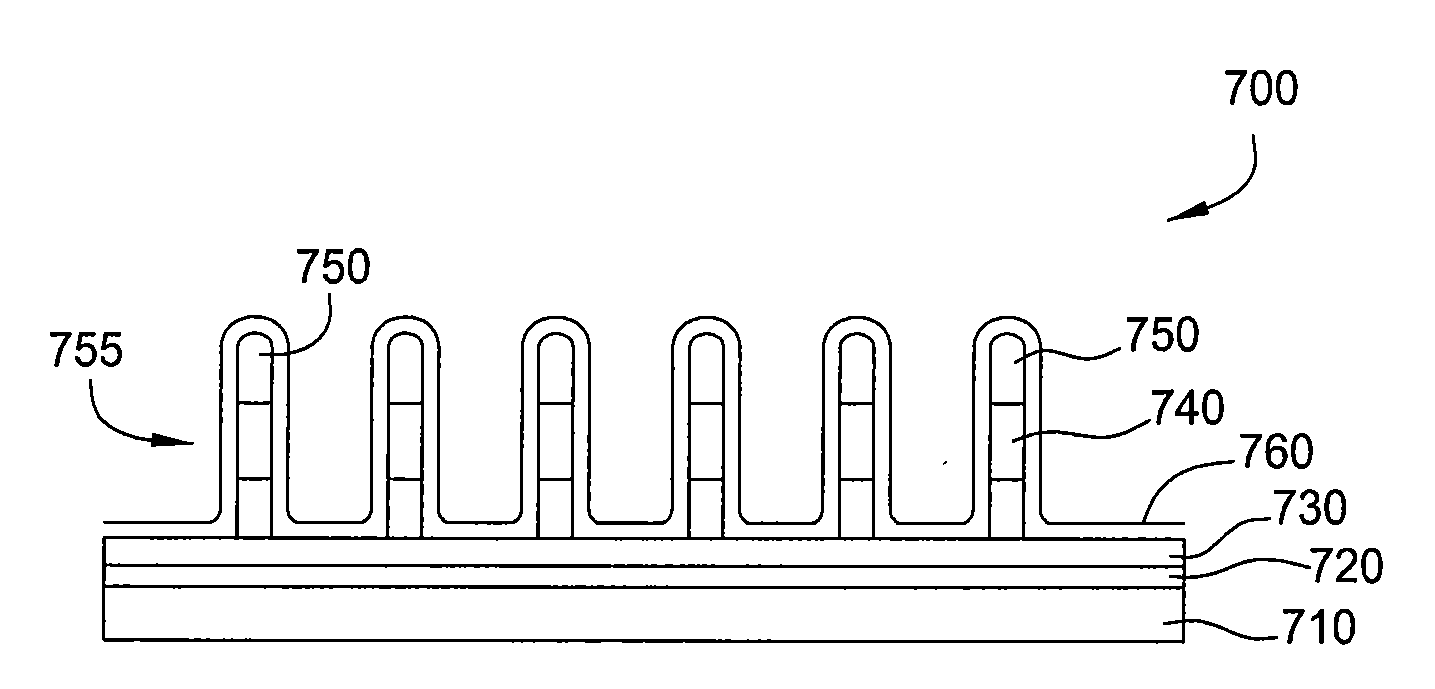

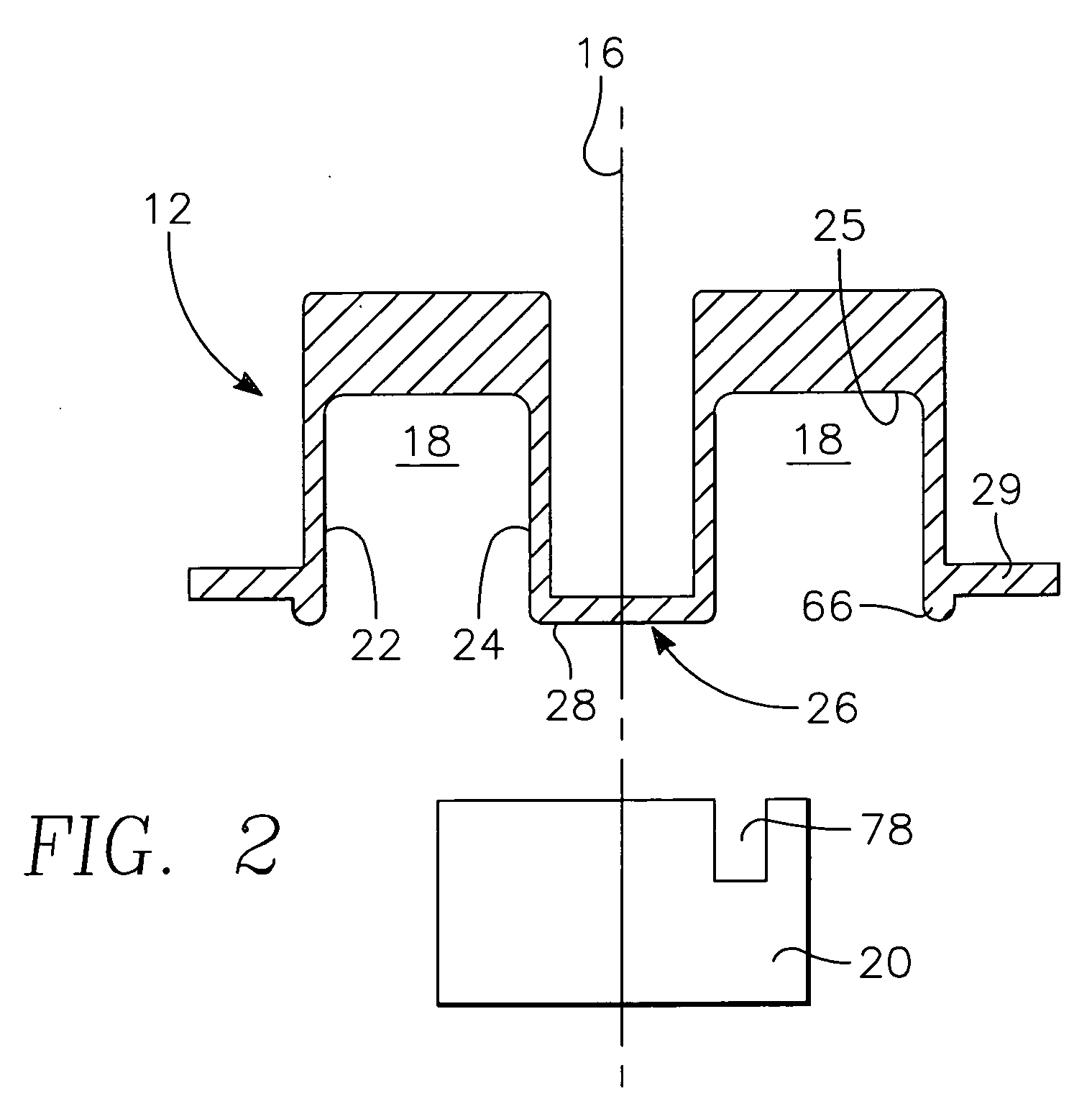

Method of subatmospheric plasma-enhanced ALD using capacitively coupled electrodes with narrow gap

ActiveUS10435790B2Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

Thin film deposition method

ActiveUS20200080200A1Low mobilityWeakening rangeElectric discharge tubesSemiconductor/solid-state device manufacturingThin membraneComposite material

Owner:ASM IP HLDG BV

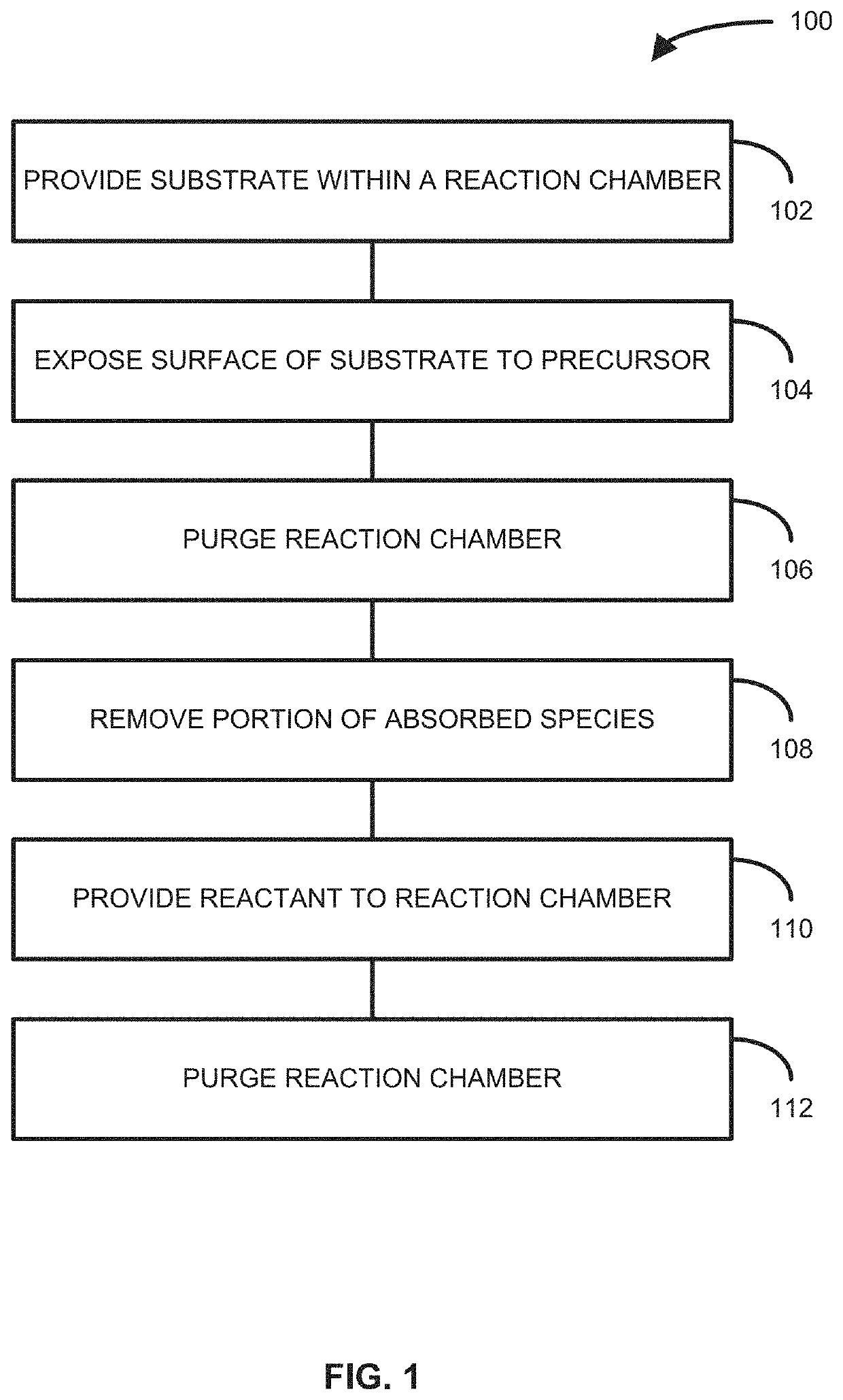

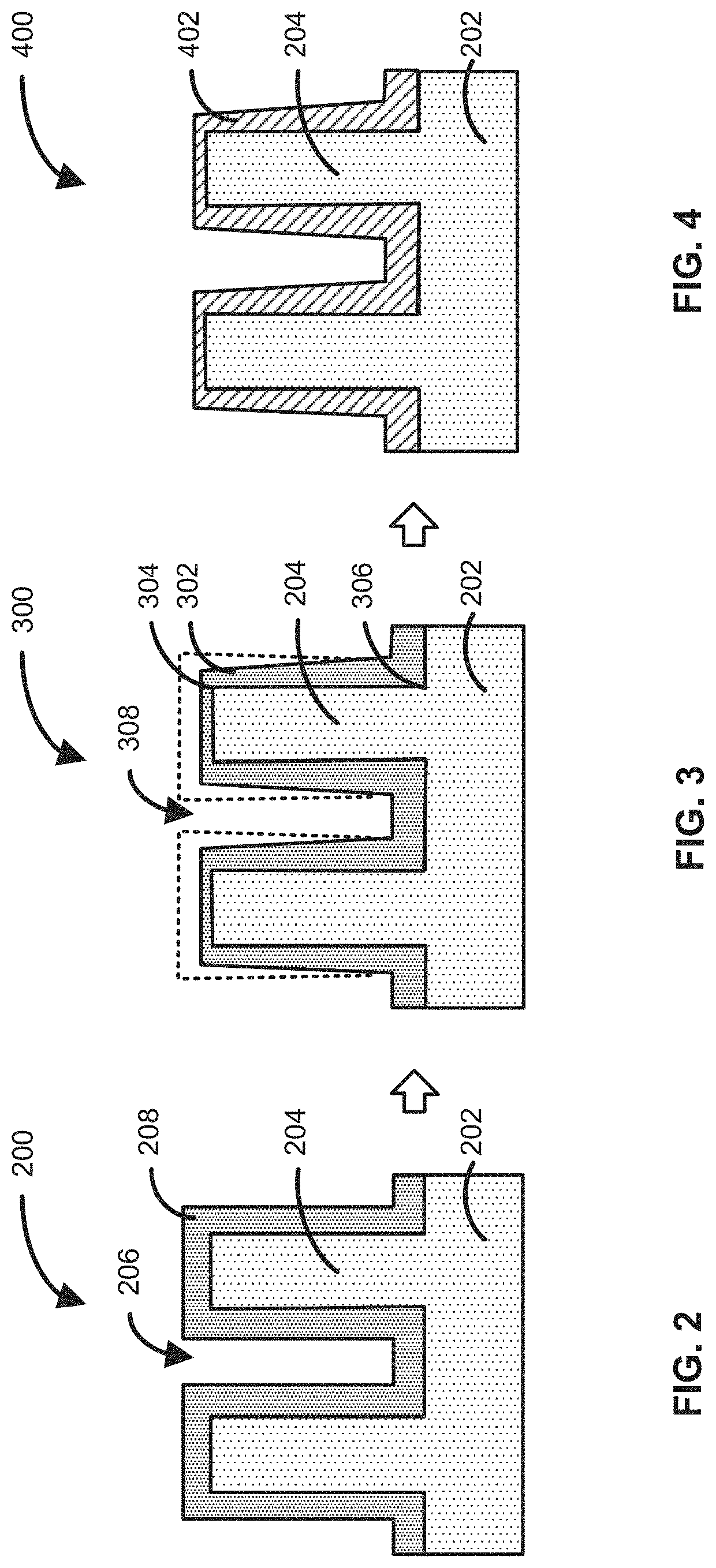

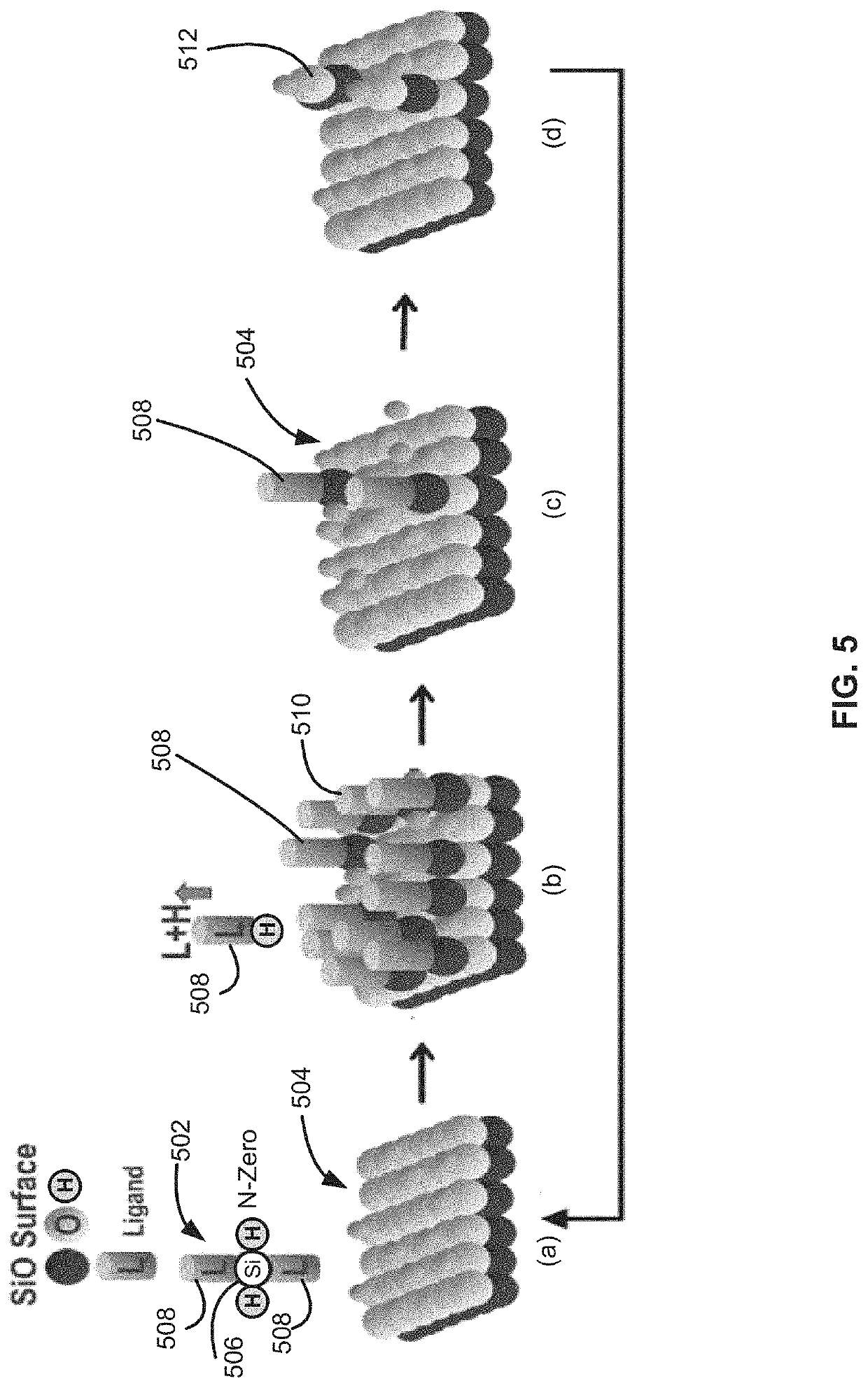

Method of depositing material onto a surface and structure formed according to the method

ActiveUS20200357631A1Reduce harmSimple methodElectric discharge tubesVacuum evaporation coatingPhysical chemistryEngineering

Methods of depositing material on a surface of a substrate are disclosed. The methods include exposing a surface of the substrate to a precursor within a reaction chamber to form adsorbed species on the surface and removing at least a portion of the adsorbed species prior to introducing a reactant to the reaction chamber.

Owner:ASM IP HLDG BV

Method of depositing thin film and method of manufacturing semiconductor device

ActiveUS10714335B2Good shape retentionAvoid damageElectric discharge tubesSemiconductor/solid-state device manufacturingDevice materialReactive gas

Provided is a method of depositing a thin film on a pattern structure of a semiconductor substrate, the method including (a) supplying a source gas; (b) supplying a reactive gas; and (c) supplying plasma, wherein the steps (a), (b), and (c) are sequentially repeated on the semiconductor substrate within a reaction space until a desired thickness is obtained, and a frequency of the plasma is a high frequency of 60 MHz or greater.

Owner:ASM IP HLDG BV

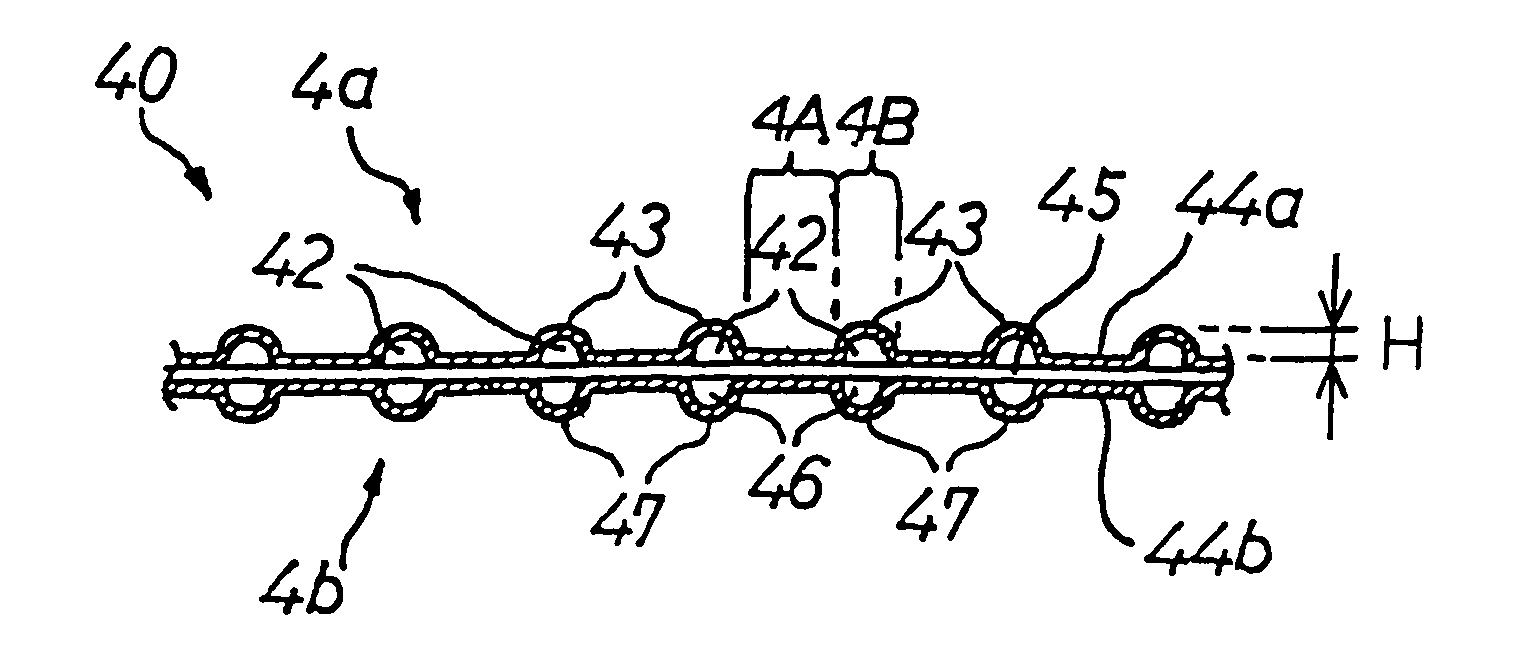

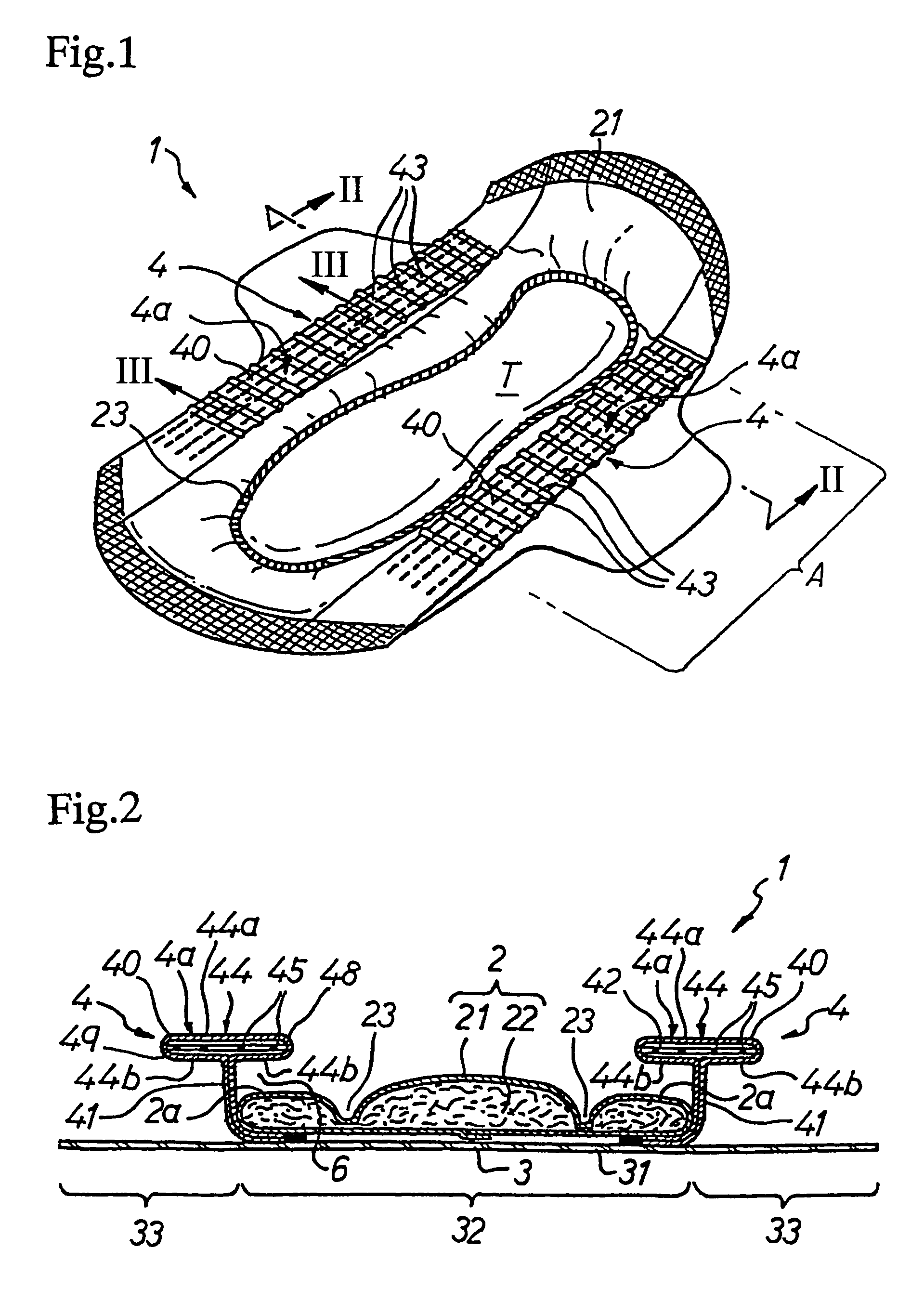

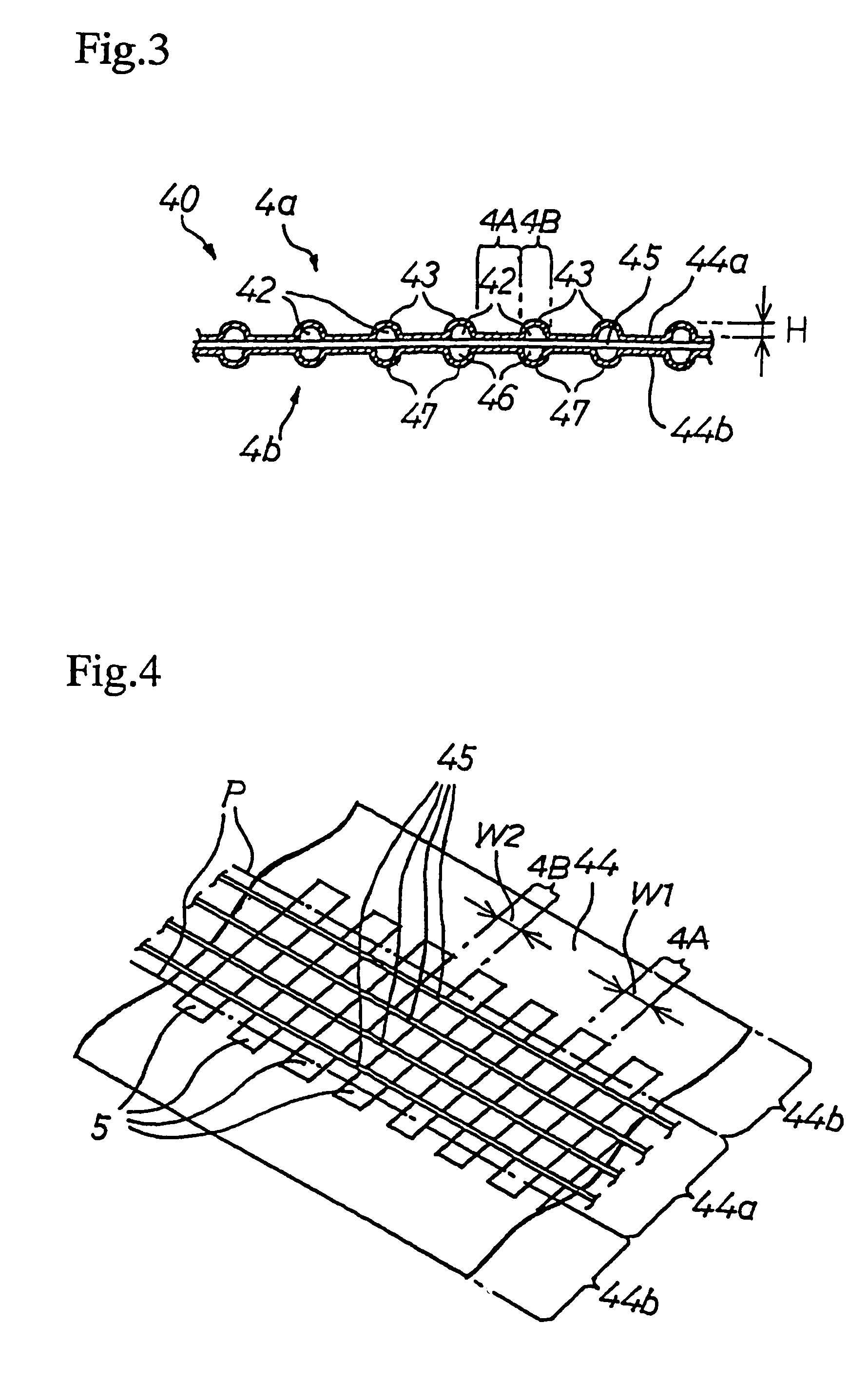

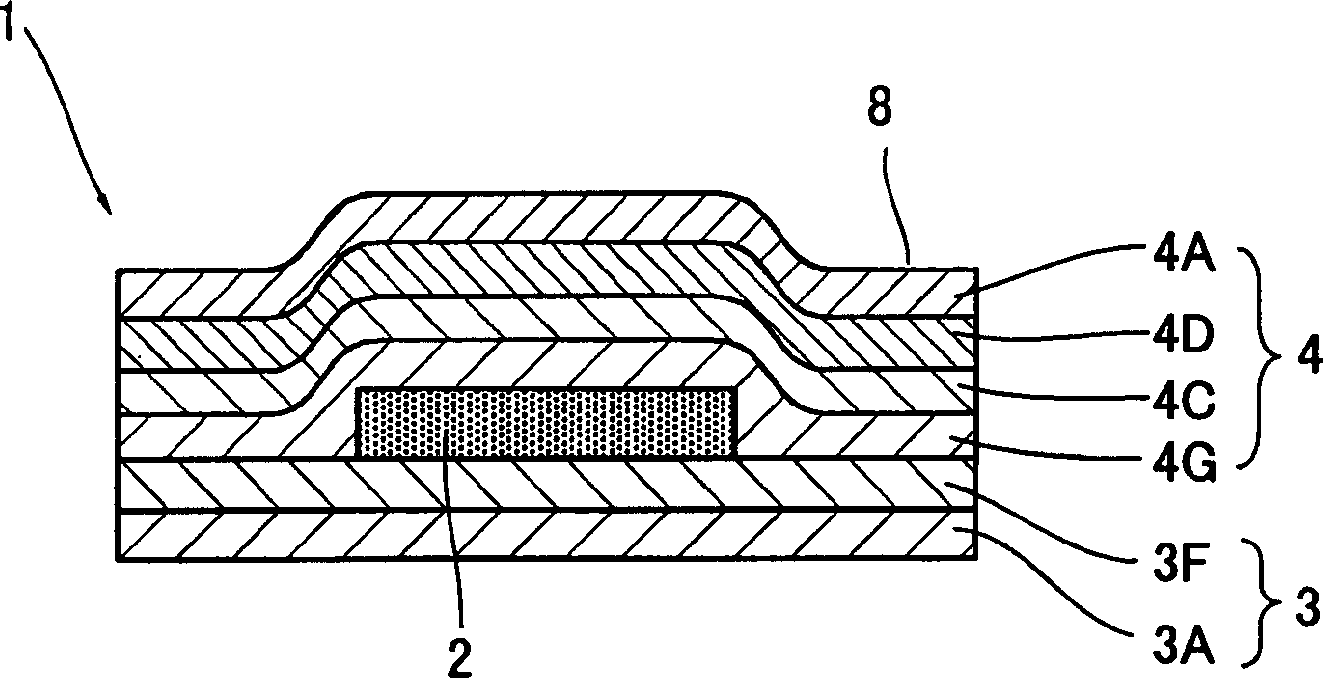

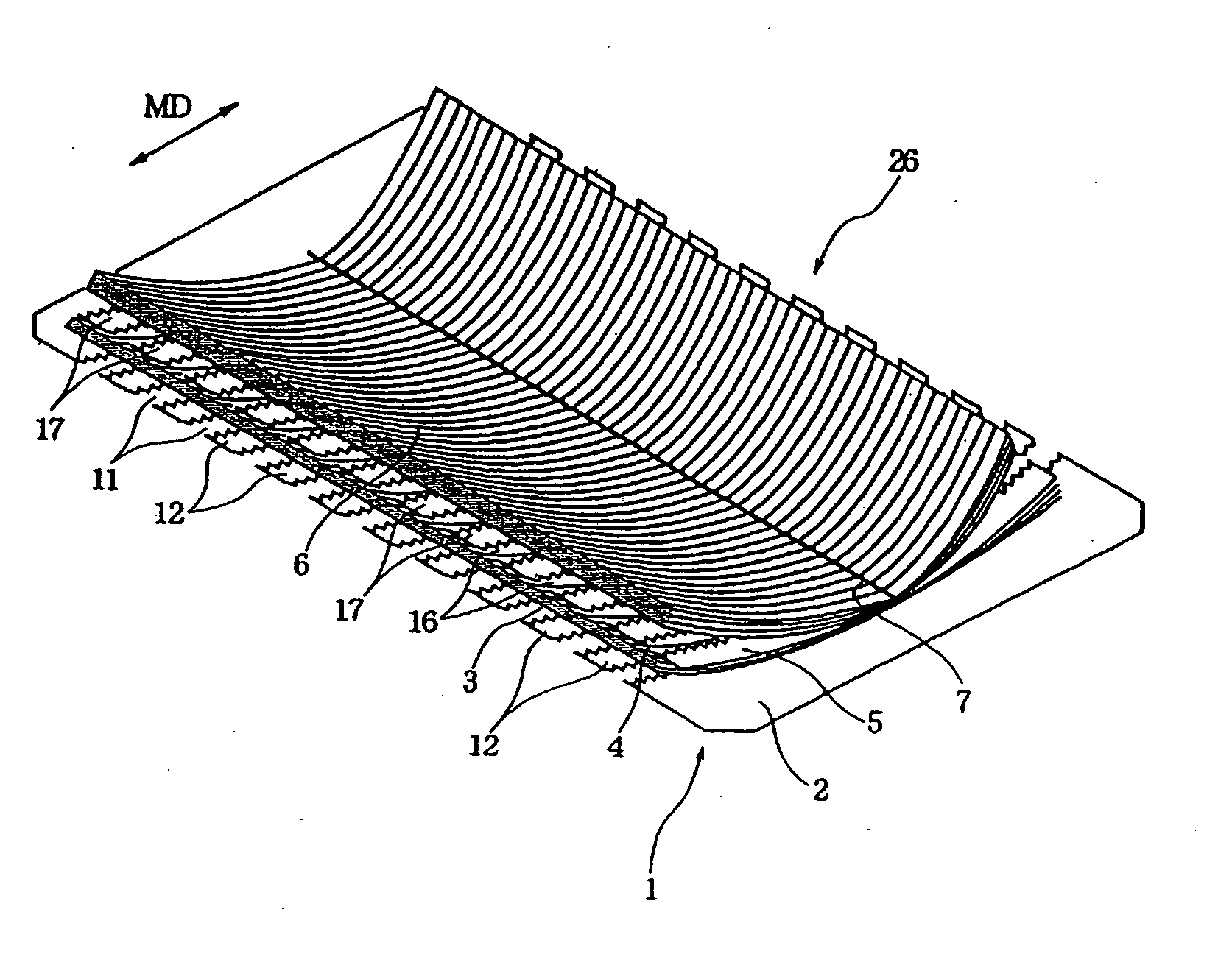

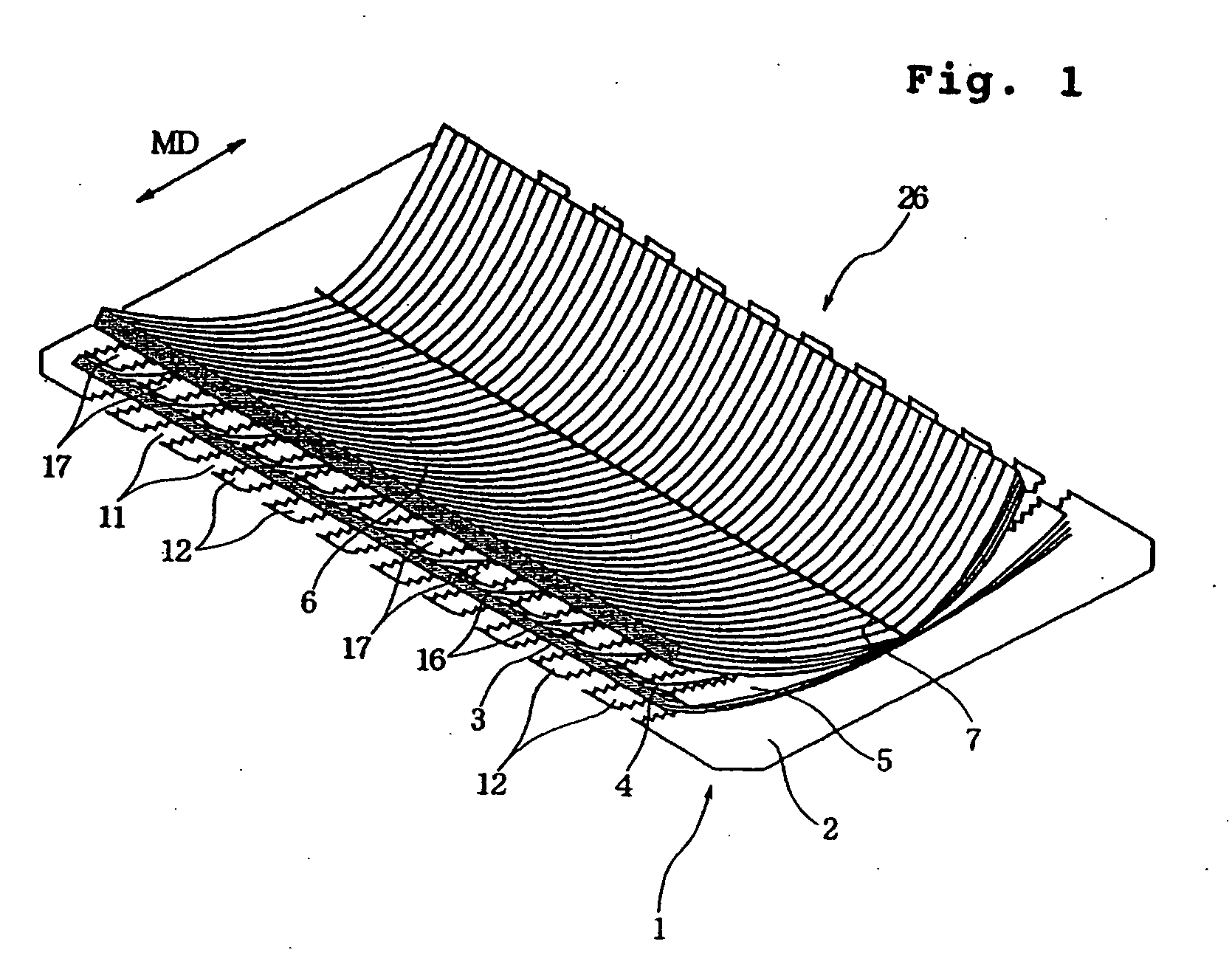

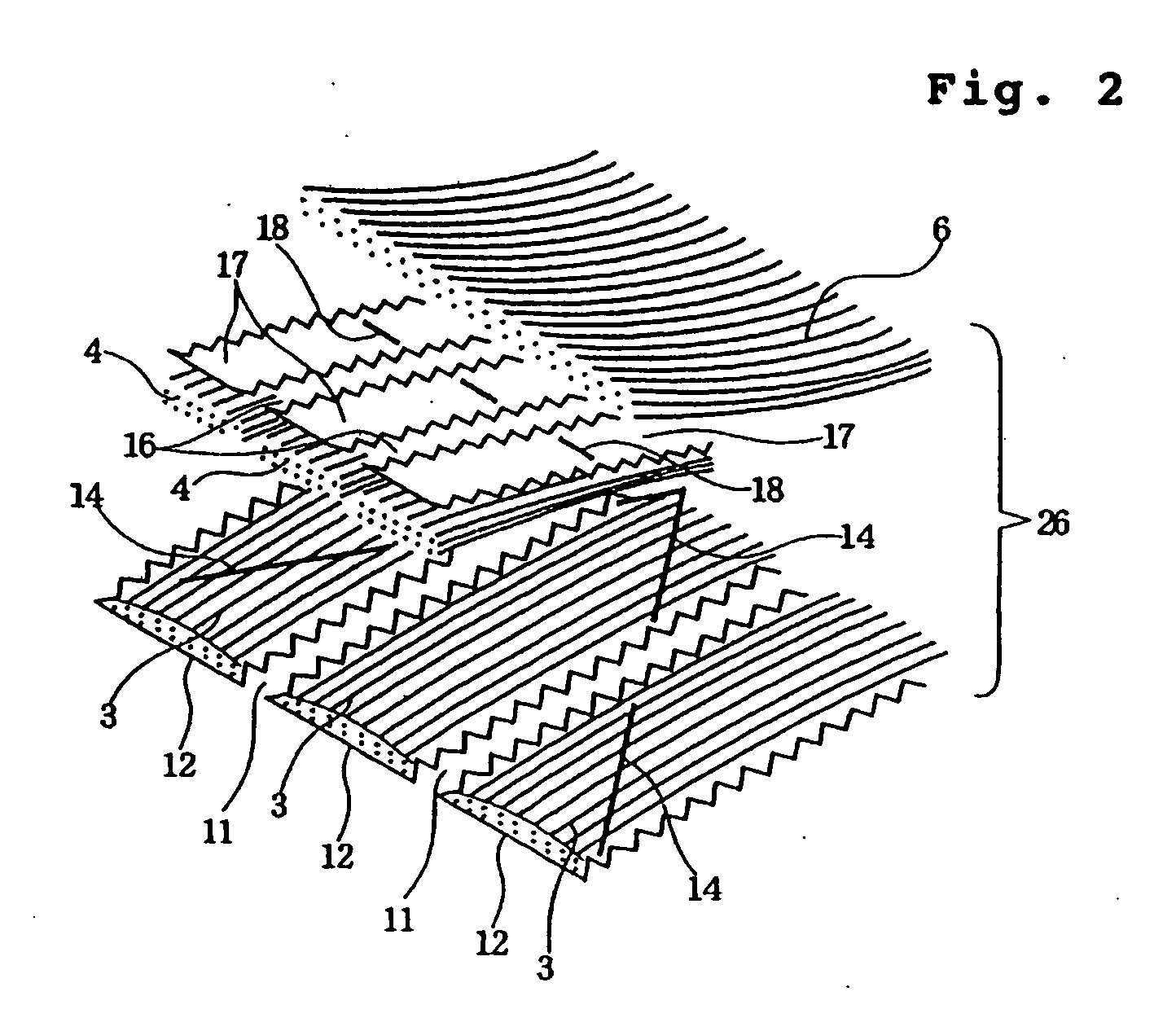

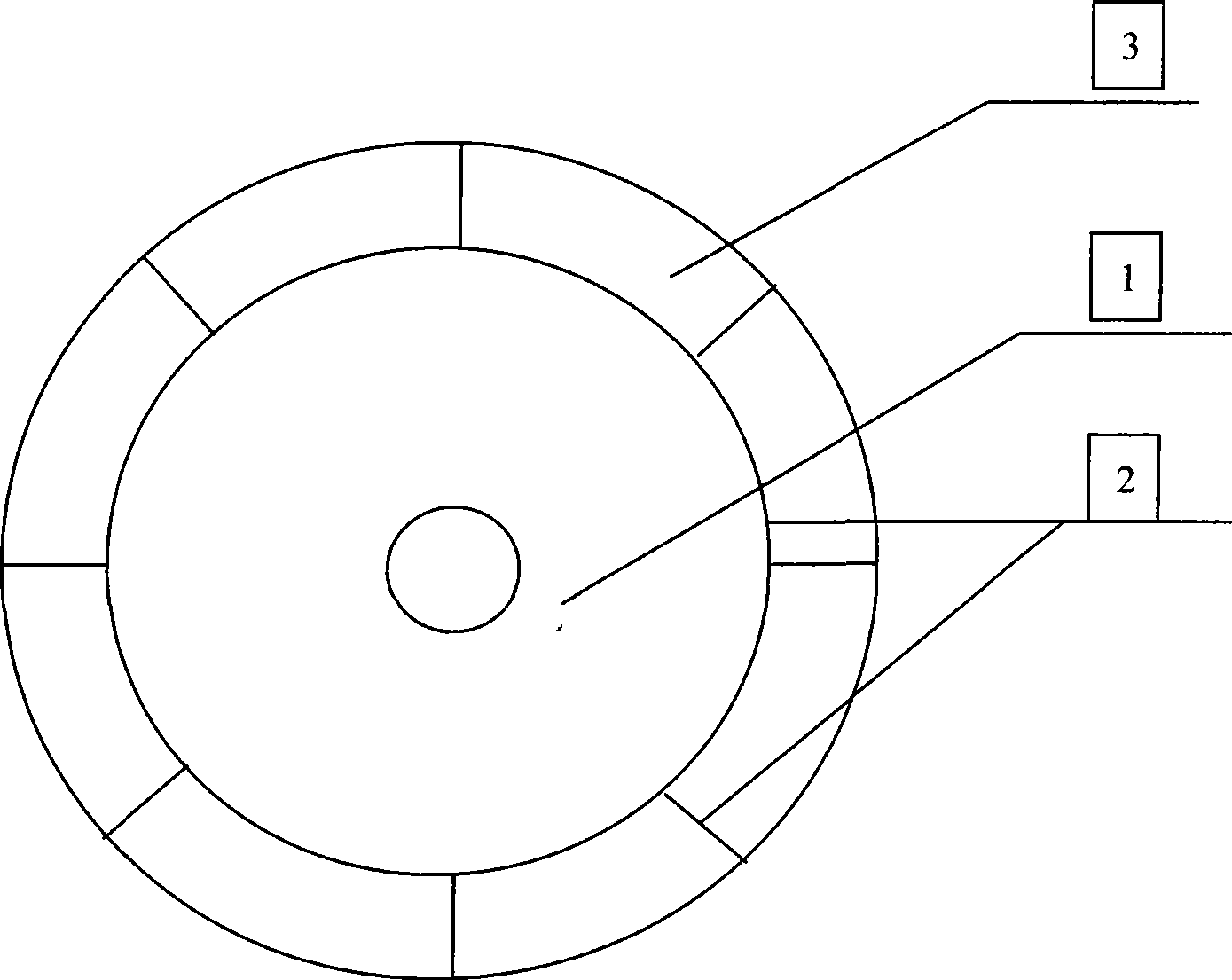

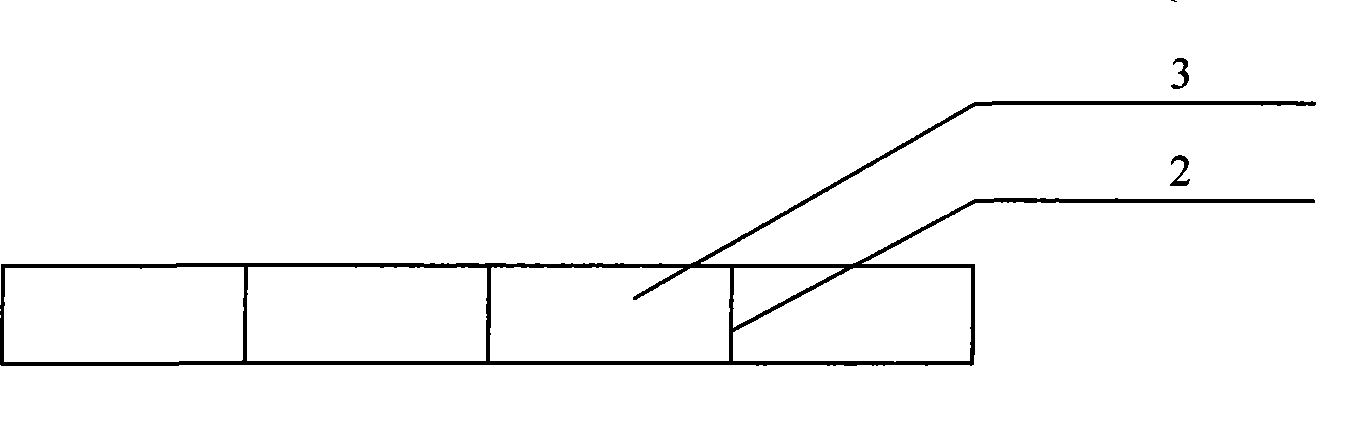

Absorbent article

An absorbent article (1) having a liquid-retentive absorbing layer (2), a liquid-impermeable leakproof layer (3), and standing gathers (4) on each side. The gathers have an elastically extensible portion (40) coming into planar contact with the wearer's skin while worn. The elastically extensible portion (40) is made of a sheet (44) and at least one elastic member (45), the elastic member (45) being fixed to the sheet (44) discretely in the longitudinal direction in its stretched state, and the parts of the sheet where the elastic member (45) is not fixed are raised by contraction of the elastic member (45) to form a plurality of hollow ridges (43) on the side of the elastically extensible portion (40) to be brought into contact with the wearer's skin.

Owner:KAO CORP

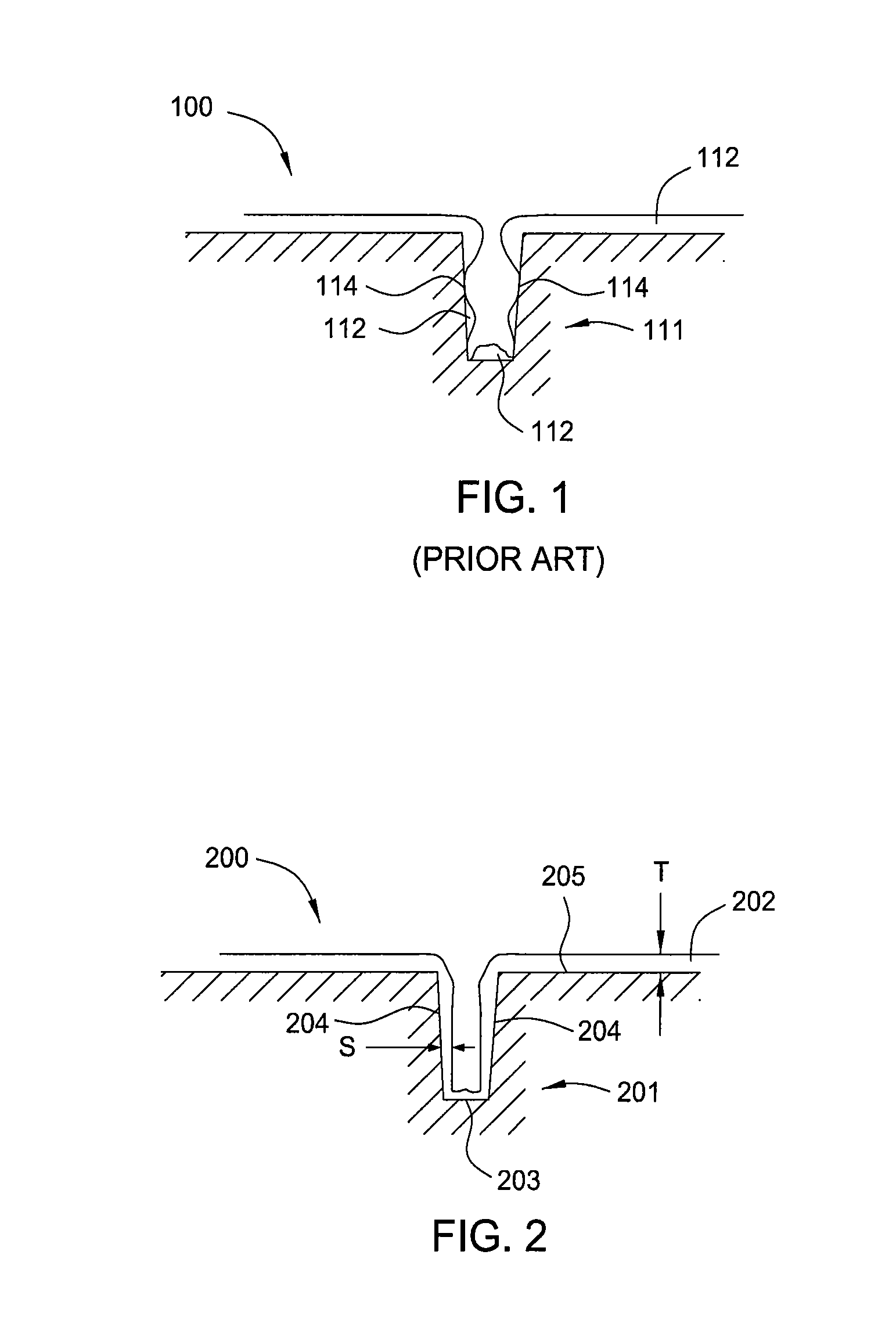

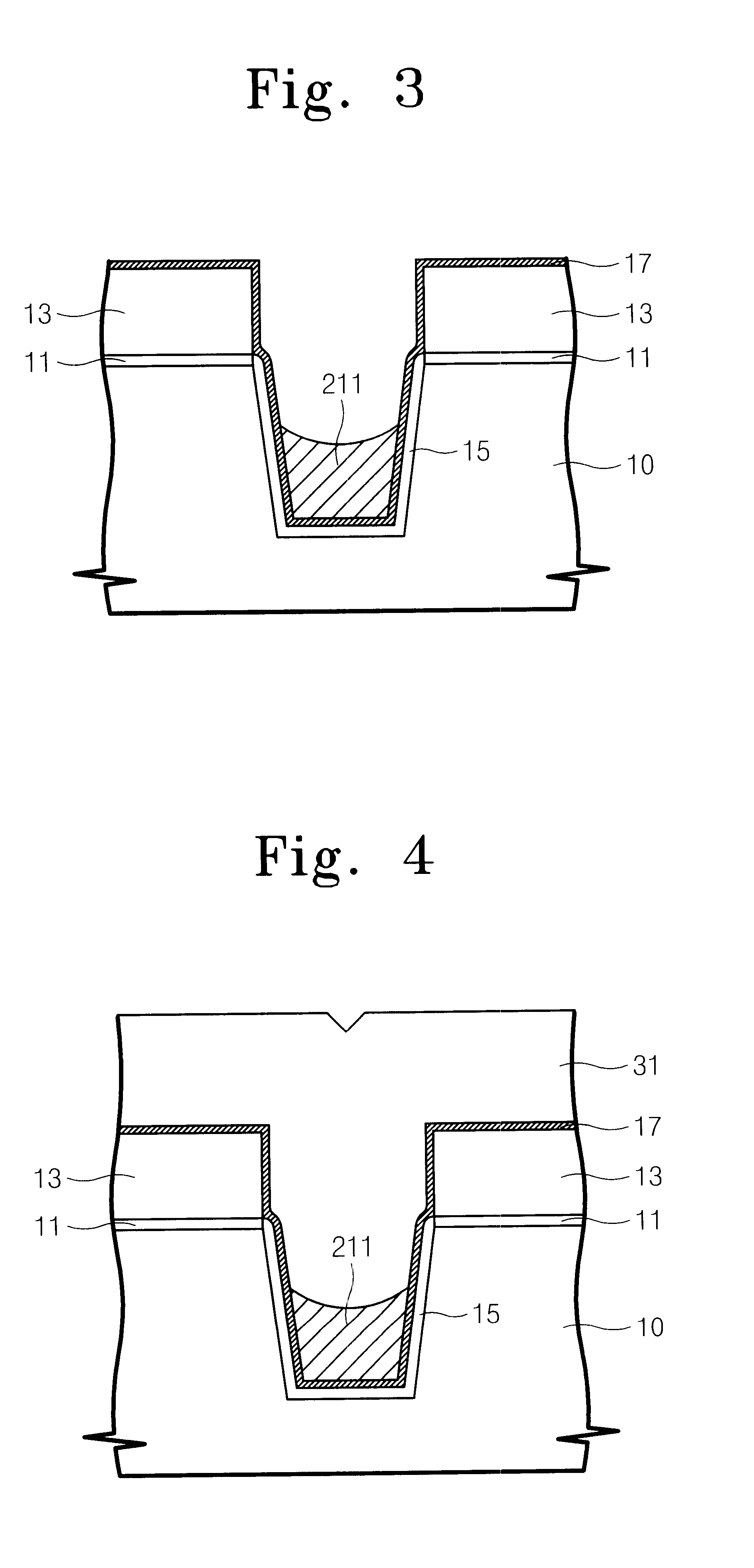

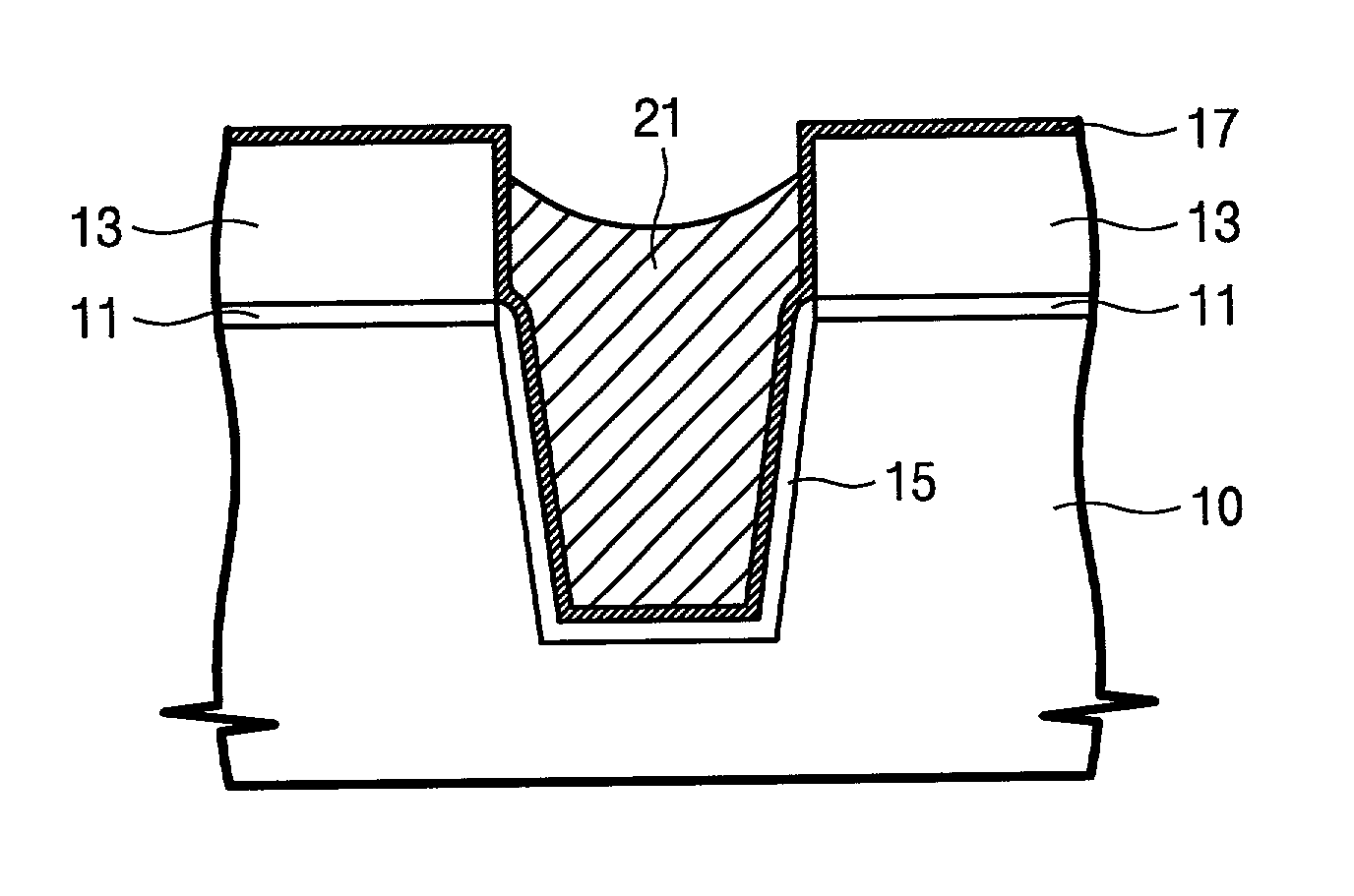

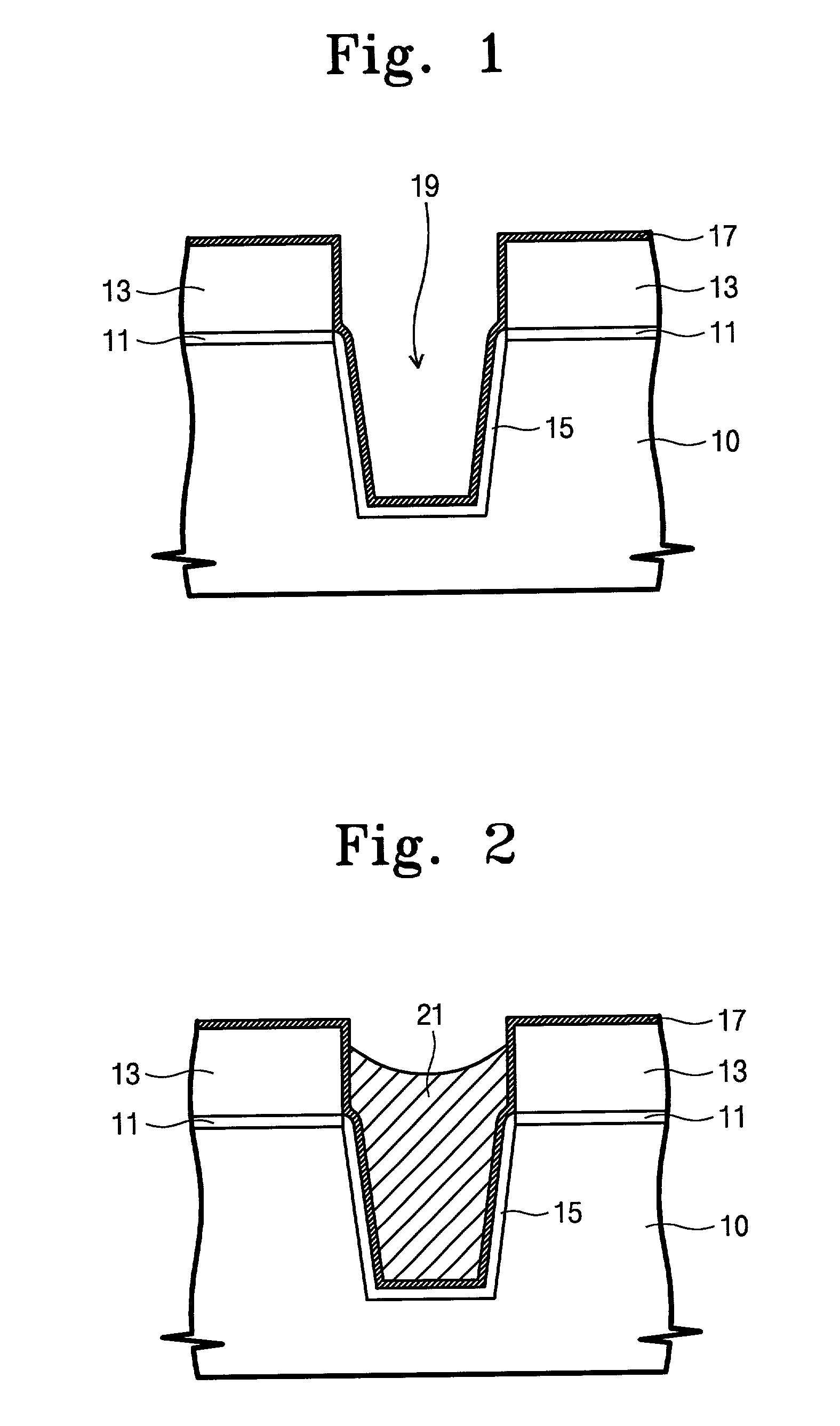

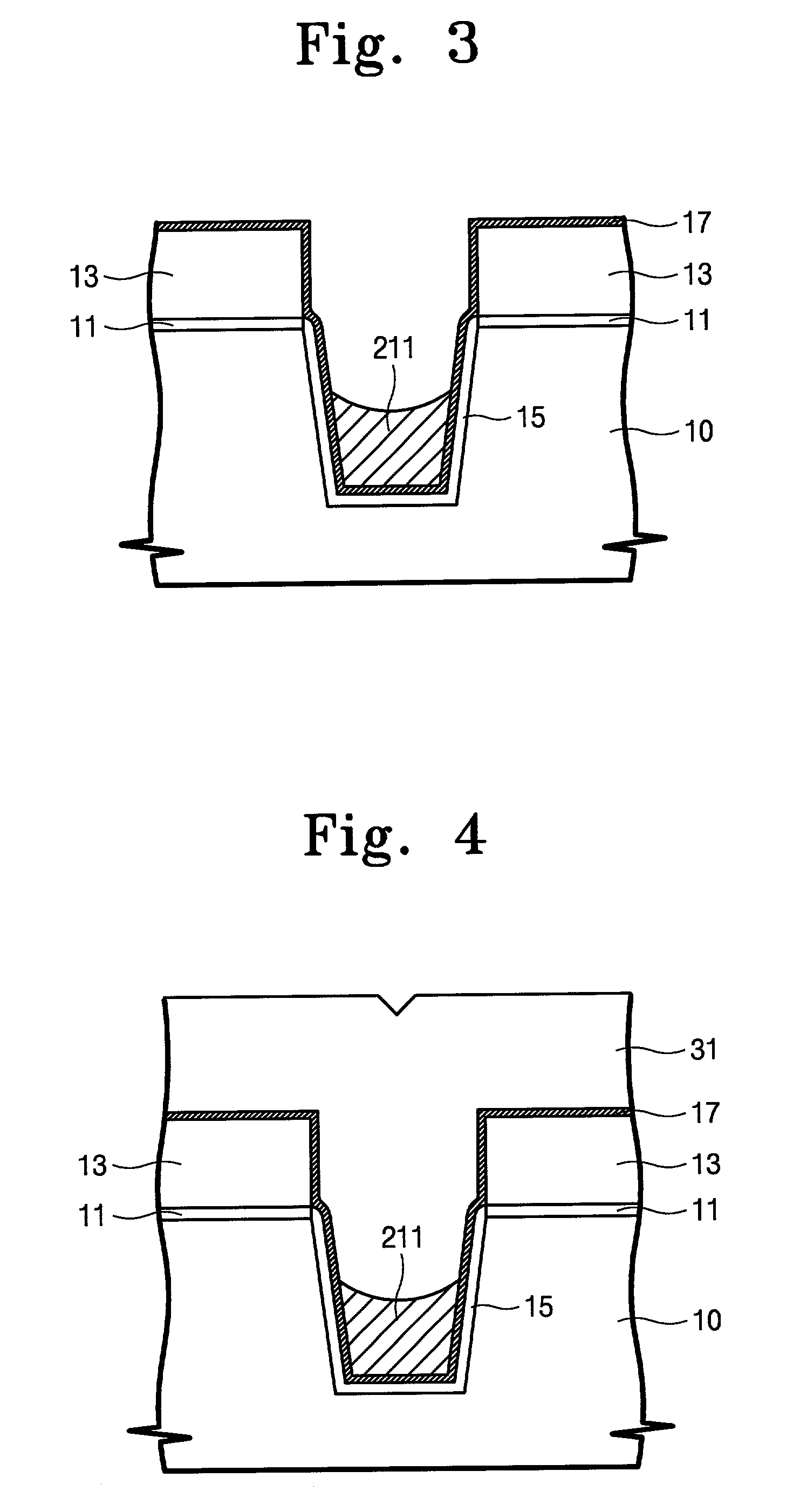

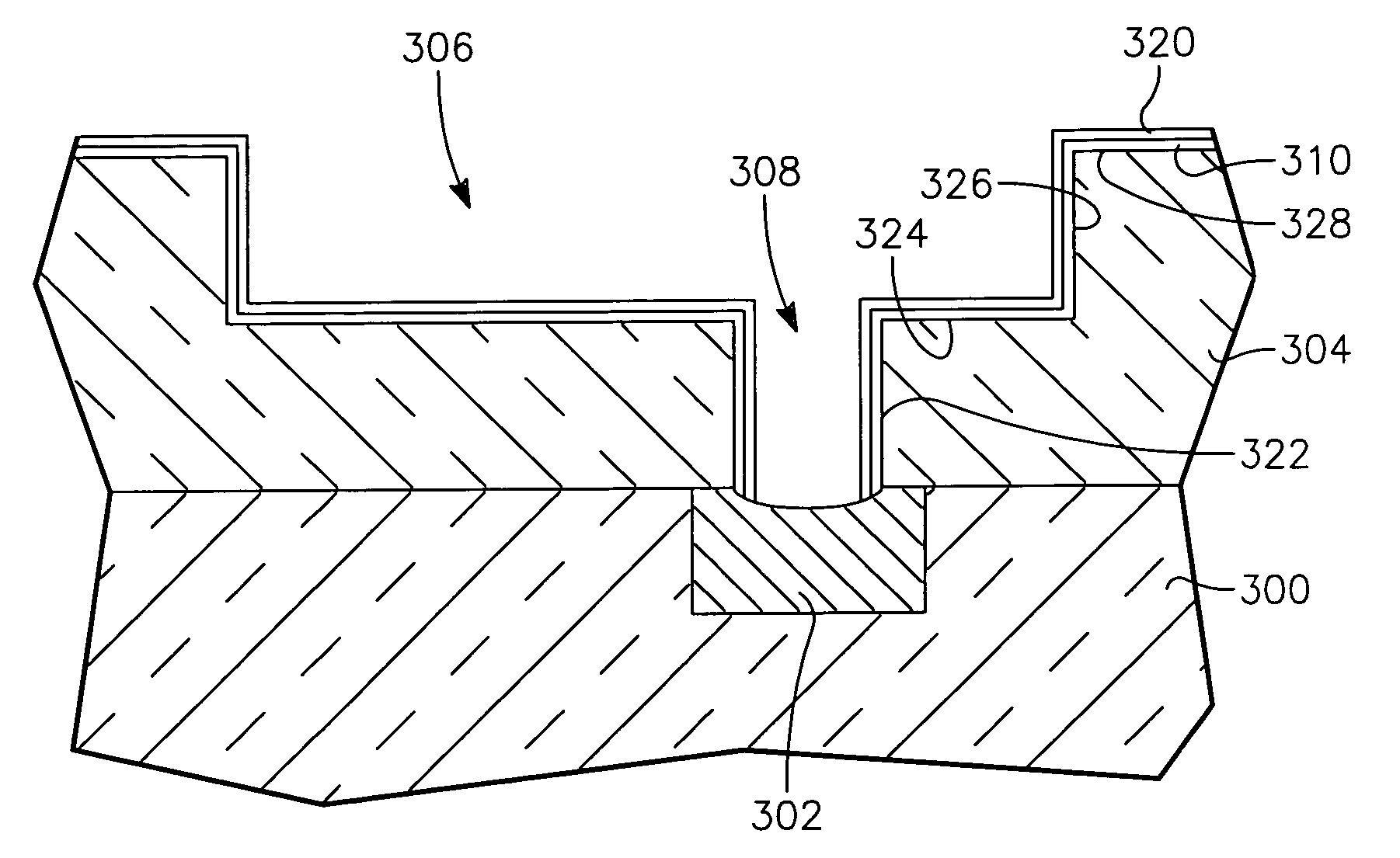

Method of forming an insulating layer in a trench isolation type semiconductor device

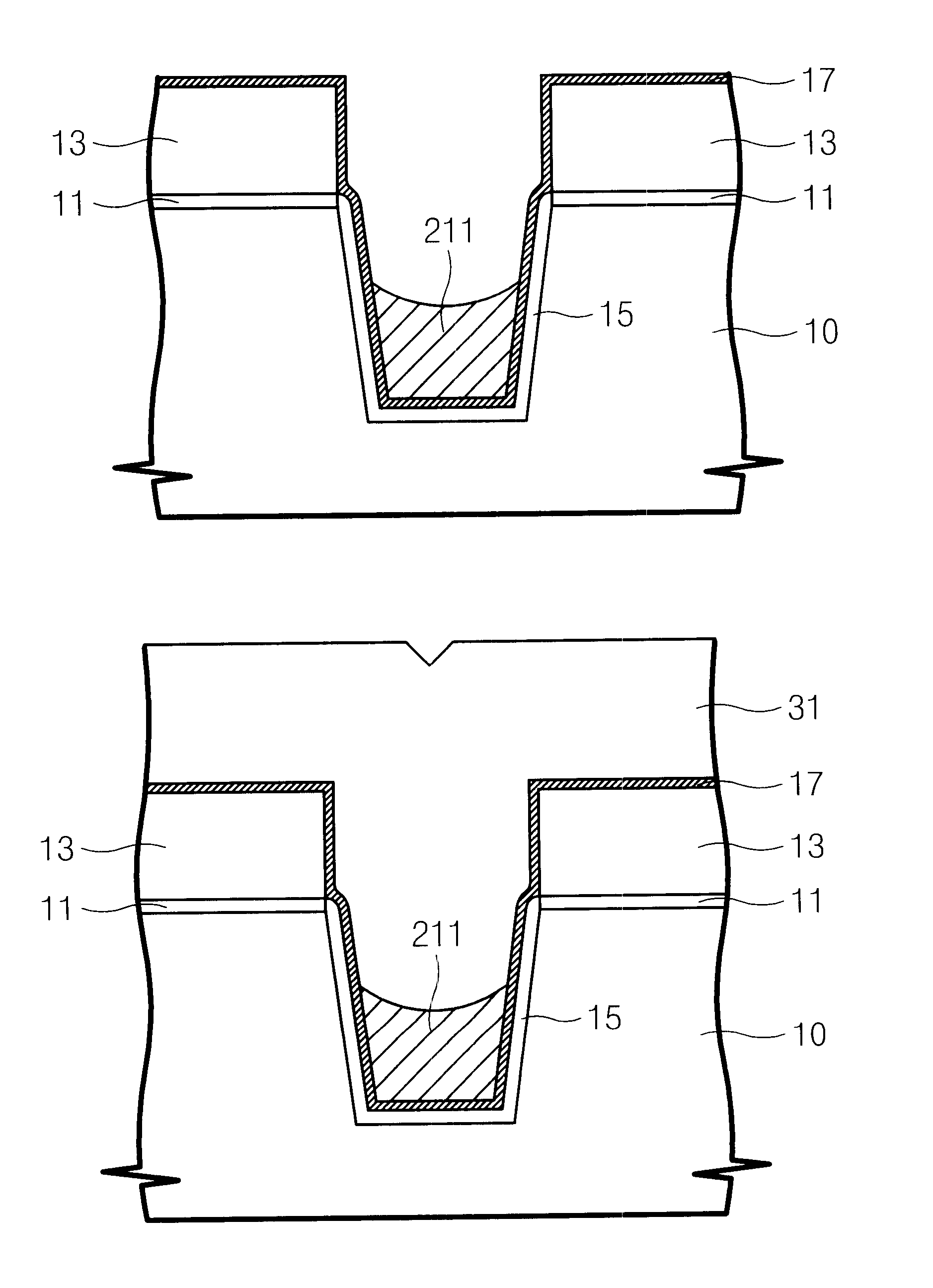

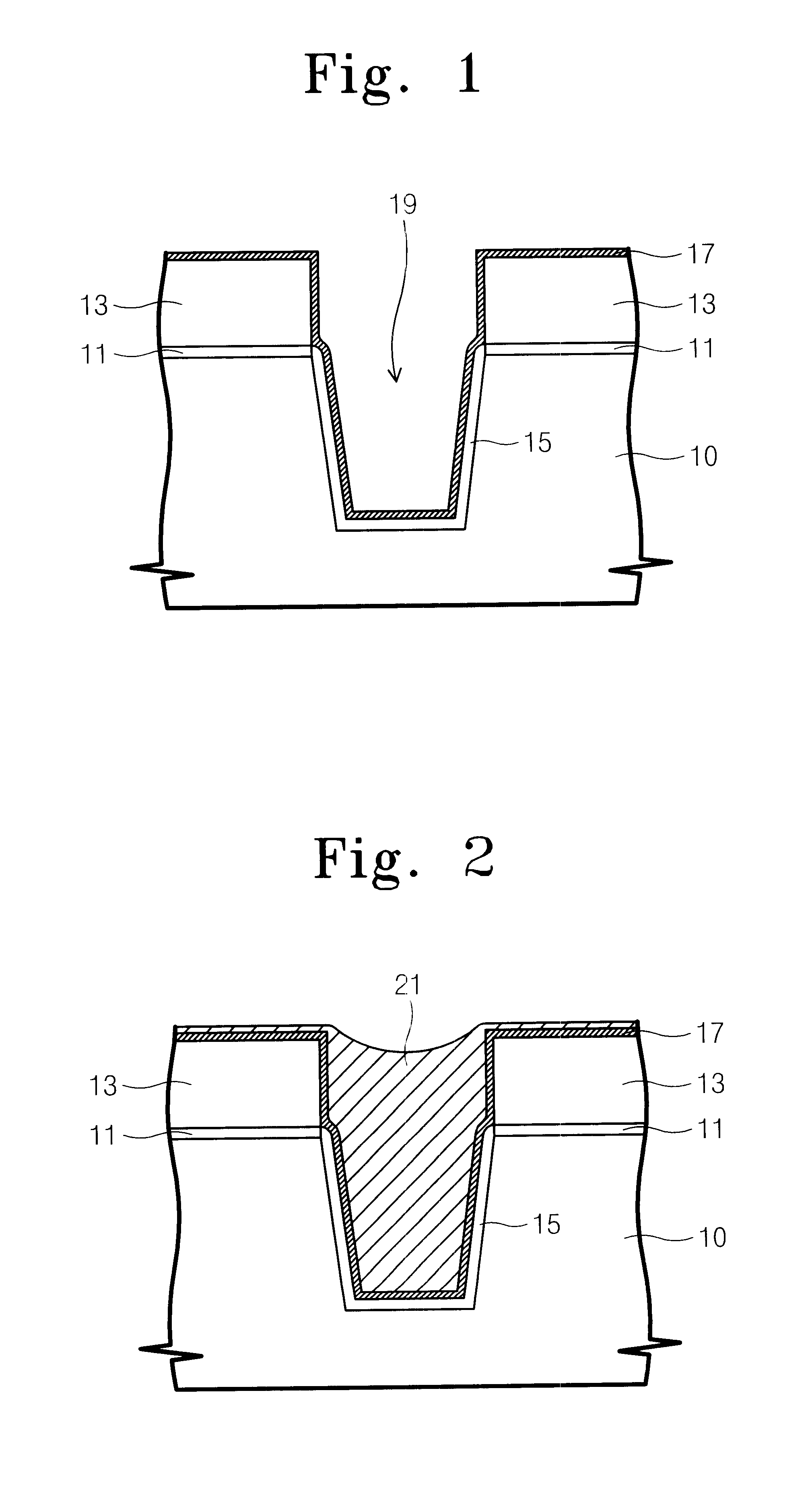

InactiveUS6566229B2Good shape retentionEasy annealingSemiconductor/solid-state device manufacturingDevice materialPolysilazane

A method of forming a trench-type device isolation layer in which a trench is filled through two steps, wherein a polysilazane solution is coated on a semiconductor substrate, in which a trench for device isolation layer is formed, in a spin on glass (SOG) manner to form an SOG layer filling a predetermined portion of the trench. In order to maintain a conformal coating thickness without overfilling the trench, the polysilazane solution preferably has a solid-state perhydro polysilazane ([SiH2NH]n) of between about 5 to about 15 percent by weight. Following formation of the SOG layer, a subsequent annealing process is carried out. The SOG layer is etched to make a top surface of the remaining SOG layer recessed down to a degree of about 1000 Å from an inlet of the trench, and a remaining space of the trench is filled with an ozone TEOS USG layer or an HDP CVD layer.

Owner:SAMSUNG ELECTRONICS CO LTD

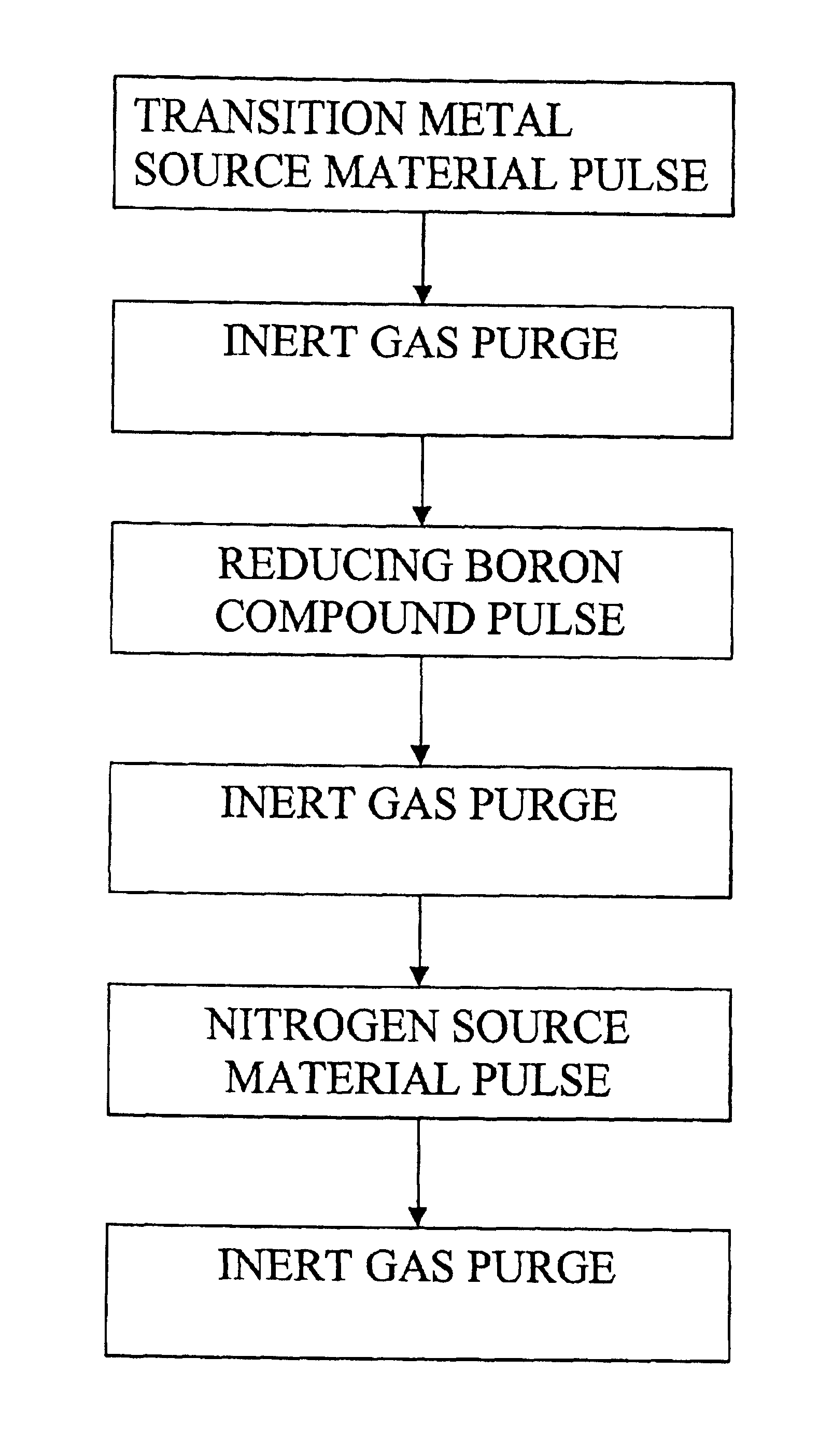

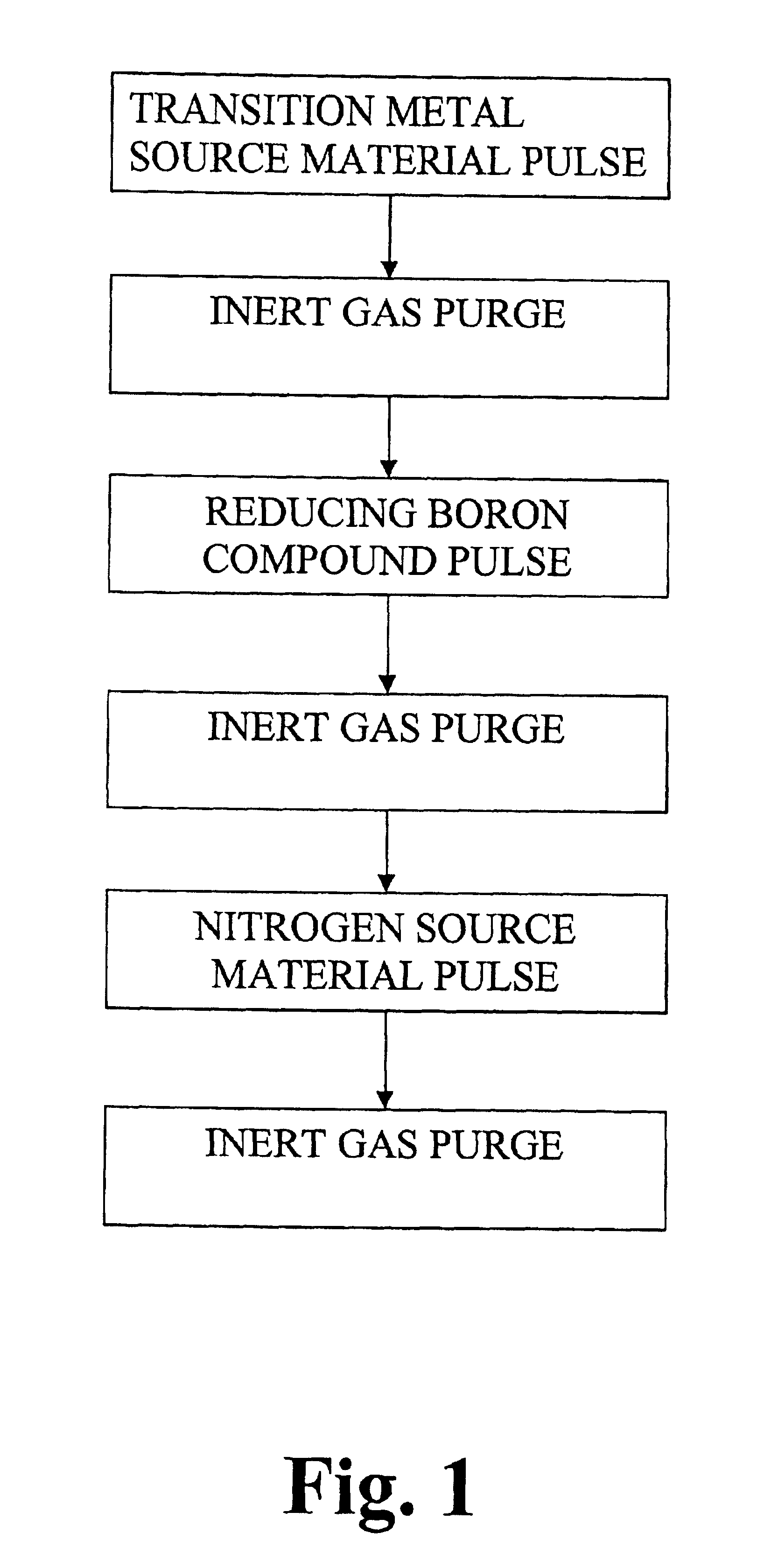

Method of depositing transition metal nitride thin films

InactiveUS6863727B1Low resistivityEasy to disassemblePolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseSource material

This invention concerns a method for depositing transition metal nitride thin films by an Atomic Layer Deposition (ALD) type process. According to the method vapor-phase pulse of a source material, a reducing agent capable of reducing metal source material, and a nitrogen source material capable of reacting with the reduced metal source material are alternately and sequentially fed into a reaction space and contacted with the substrate. According to the invention as the reducing agent is used a boron compound which is capable of forming gaseous reaction byproducts when reacting with the metal source material.

Owner:ASM INTERNATIONAL

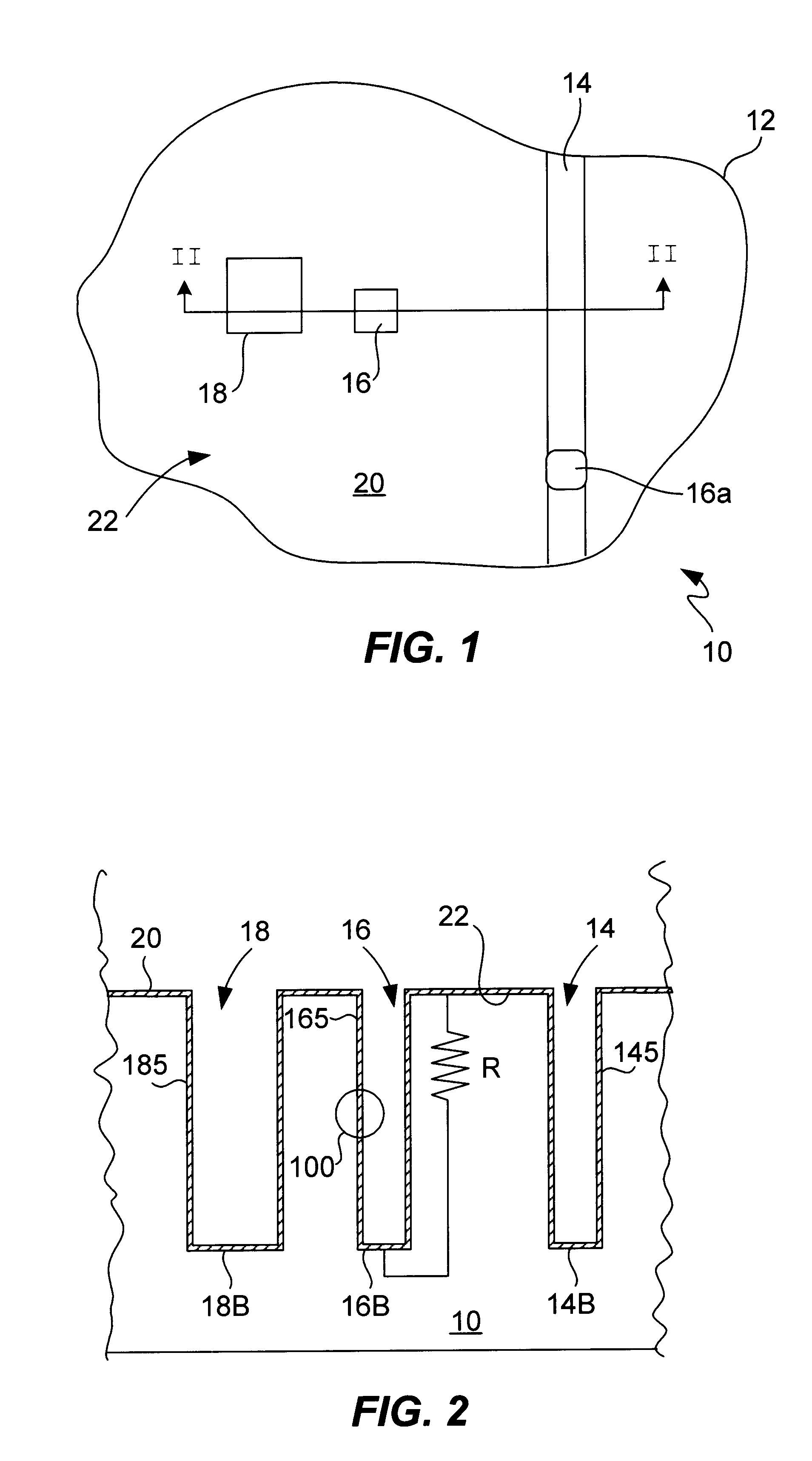

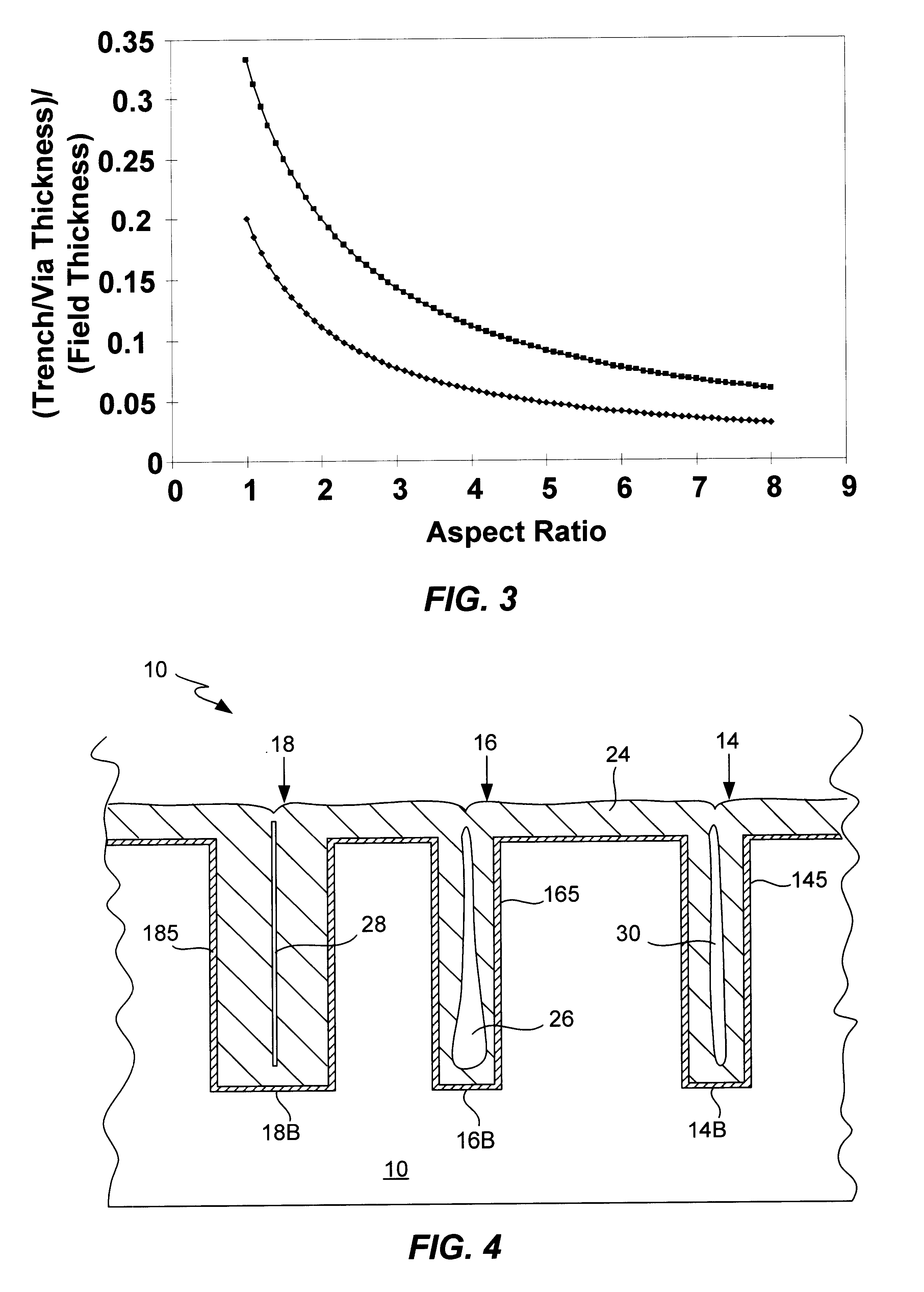

Process for electroplating metal into microscopic recessed features

InactiveUS6946065B1High aspect ratioSmall additive depletion effectAnodisationSemiconductor/solid-state device manufacturingEngineeringCathodic polarization

Several techniques are described for reducing or mitigating the formation of seams and / or voids in electroplating the interior regions of microscopic recessed features. Cathodic polarization is used to mitigate the deleterious effects of introducing a substrate plated with a seed layer into an electroplating solution. Also described are diffusion-controlled electroplating techniques to provide for bottom-up filling of trenches and vias, avoiding thereby sidewalls growing together to create seams / voids. A preliminary plating step is also described that plates a thin film of conductor on the interior surfaces of features leading to adequate electrical conductivity to the feature bottom, facilitating bottom-up filling.

Owner:NOVELLUS SYSTEMS

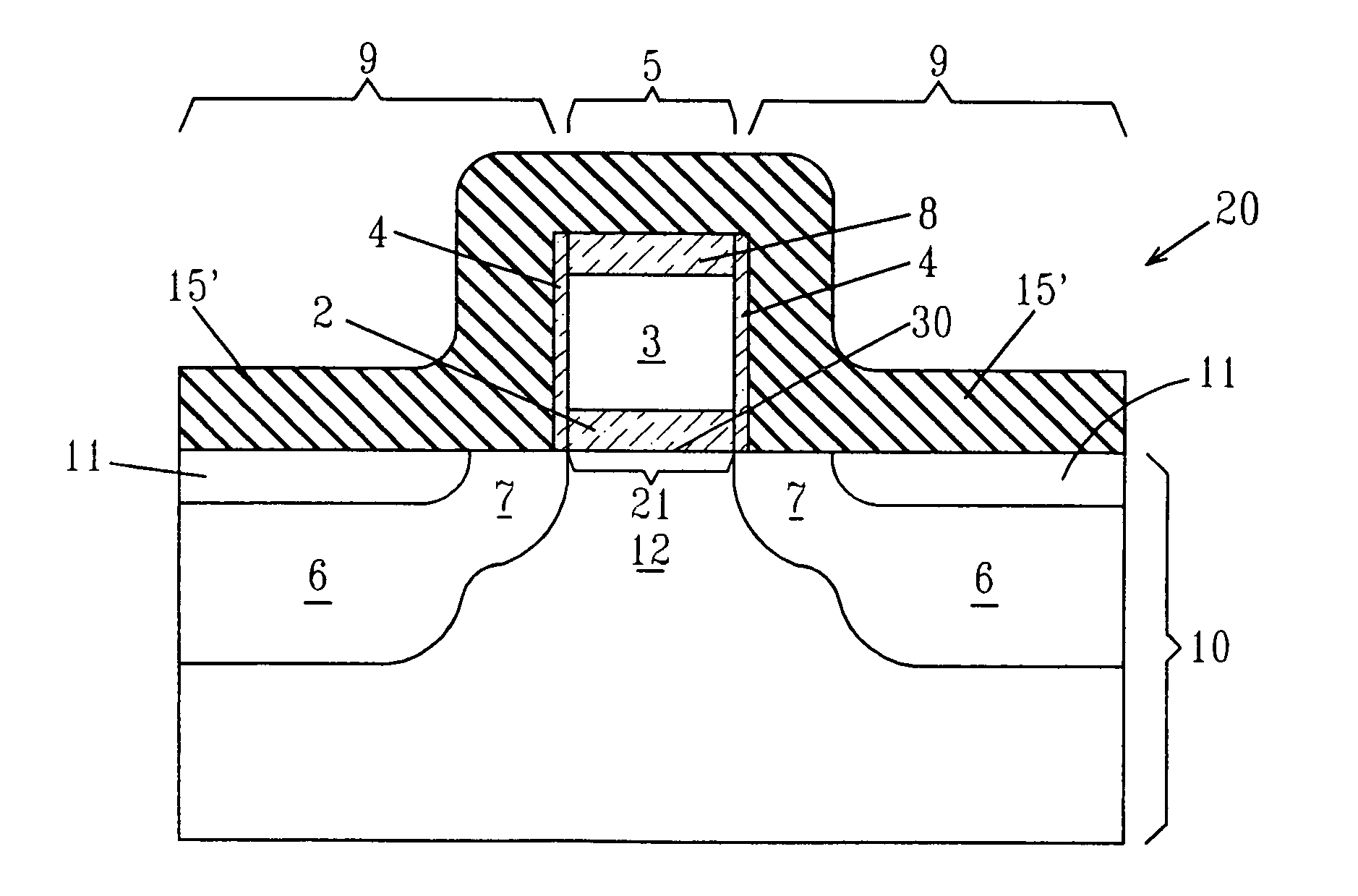

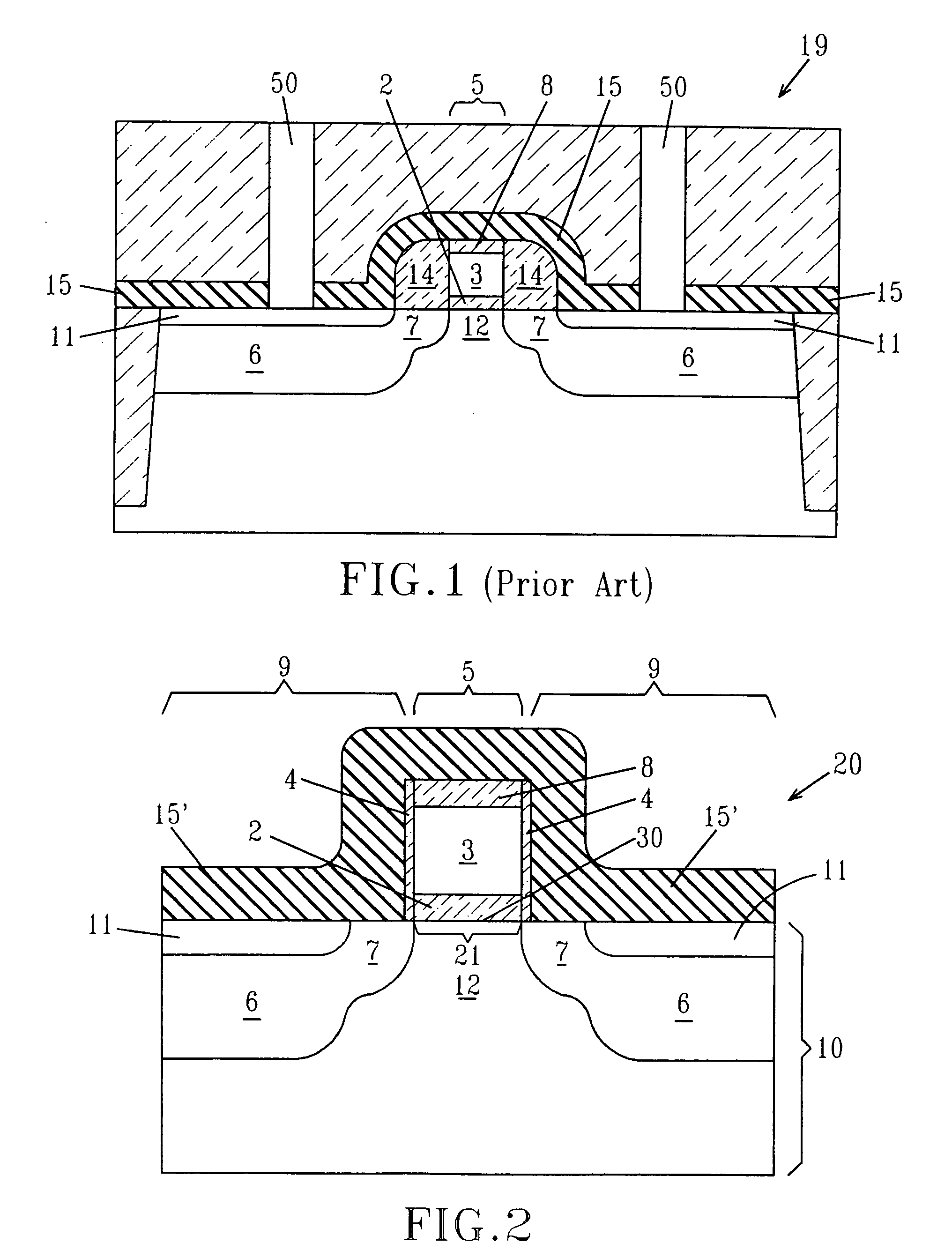

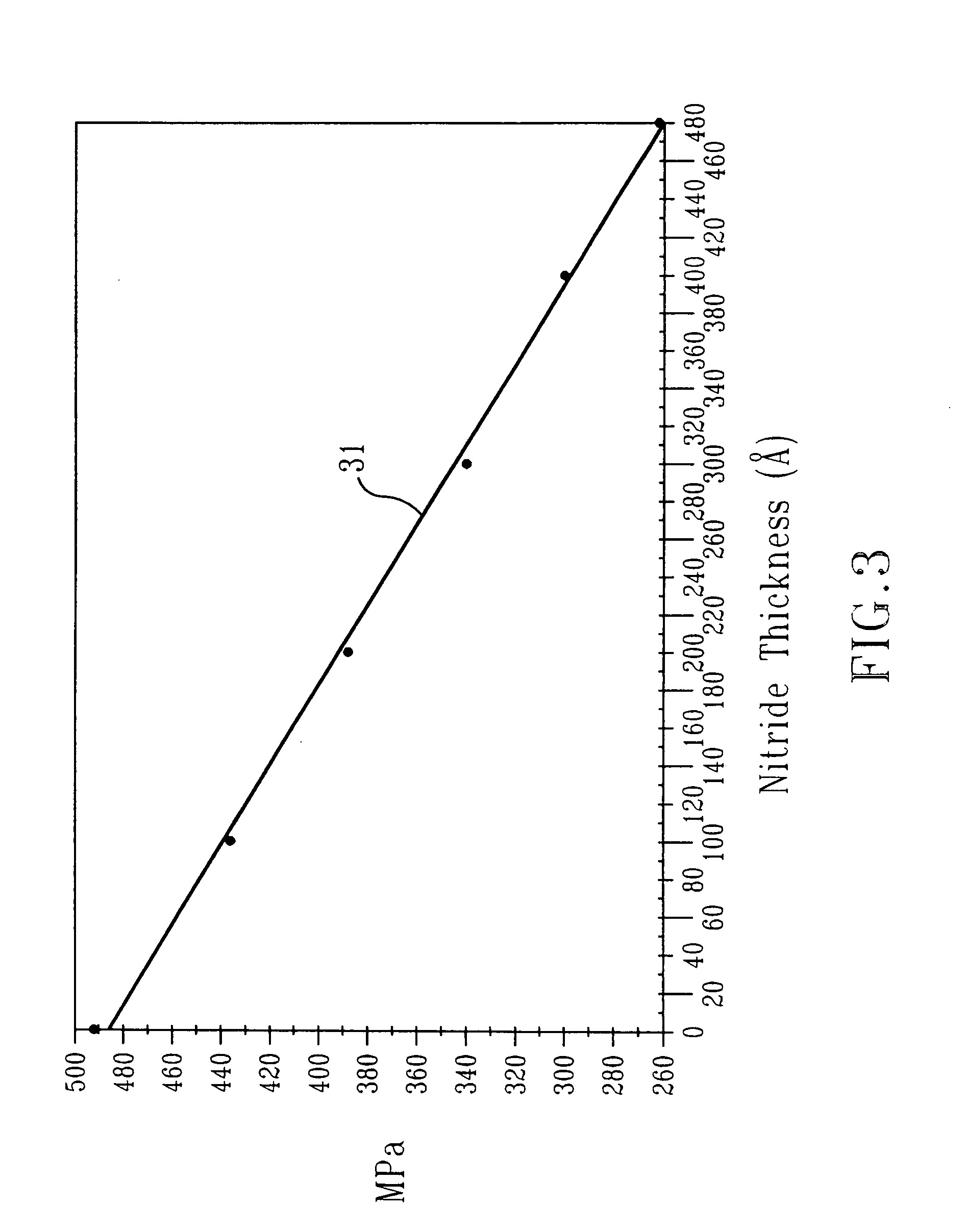

MOSFET structure with high mechanical stress in the channel

ActiveUS7002209B2Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingMOSFETStress induced

The present invention provides a semiconducting device including at least one gate region including a gate conductor located on a surface of a substrate, the substrate having an exposed surface adjacent the gate region; a silicide contact located adjacent the exposed surface; and a stress inducing liner located on the silicide contact, the exposed surface of the substrate adjacent to the gate region and the at least one gate region, wherein the stress inducing liner provides a stress to a device channel portion of the substrate underlying the gate region. The stress produced on the device channel is a longitudinal stress on the order of about 200 MPa to about 2000 MPa. The present invention also provides a method for forming the above-described semiconducting device.

Owner:AURIGA INNOVATIONS INC

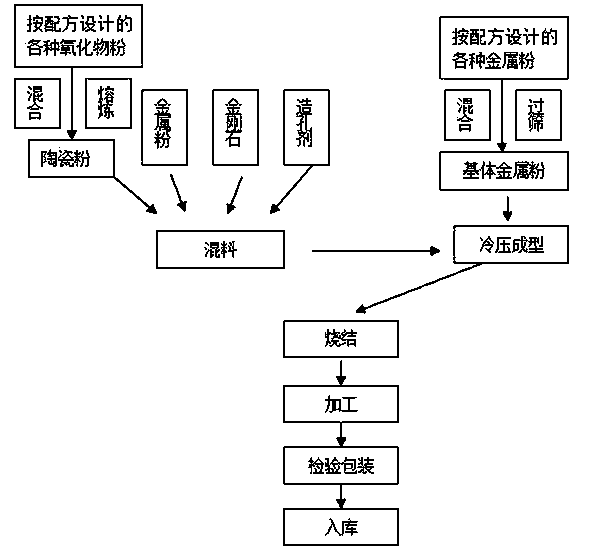

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

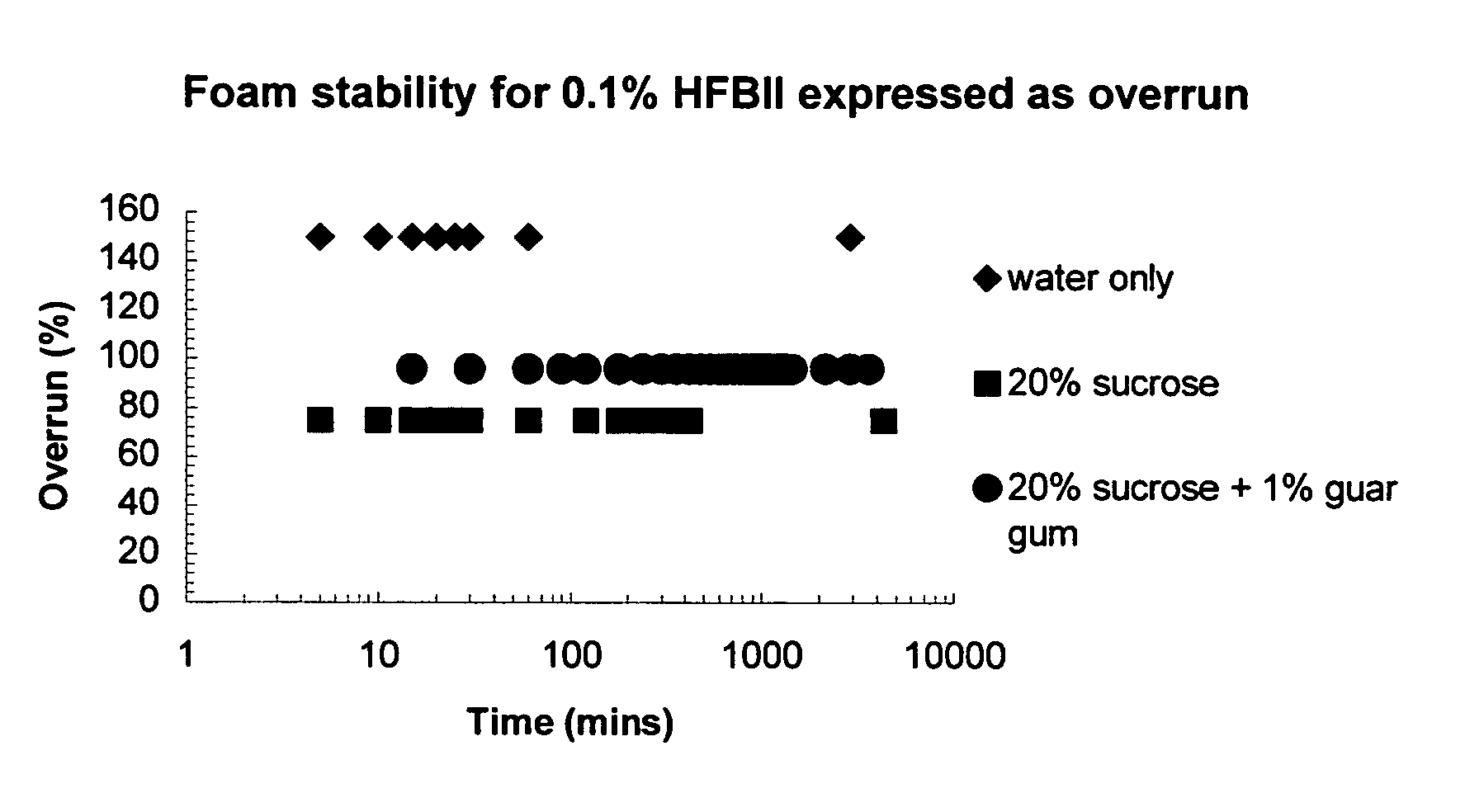

Aerated food products

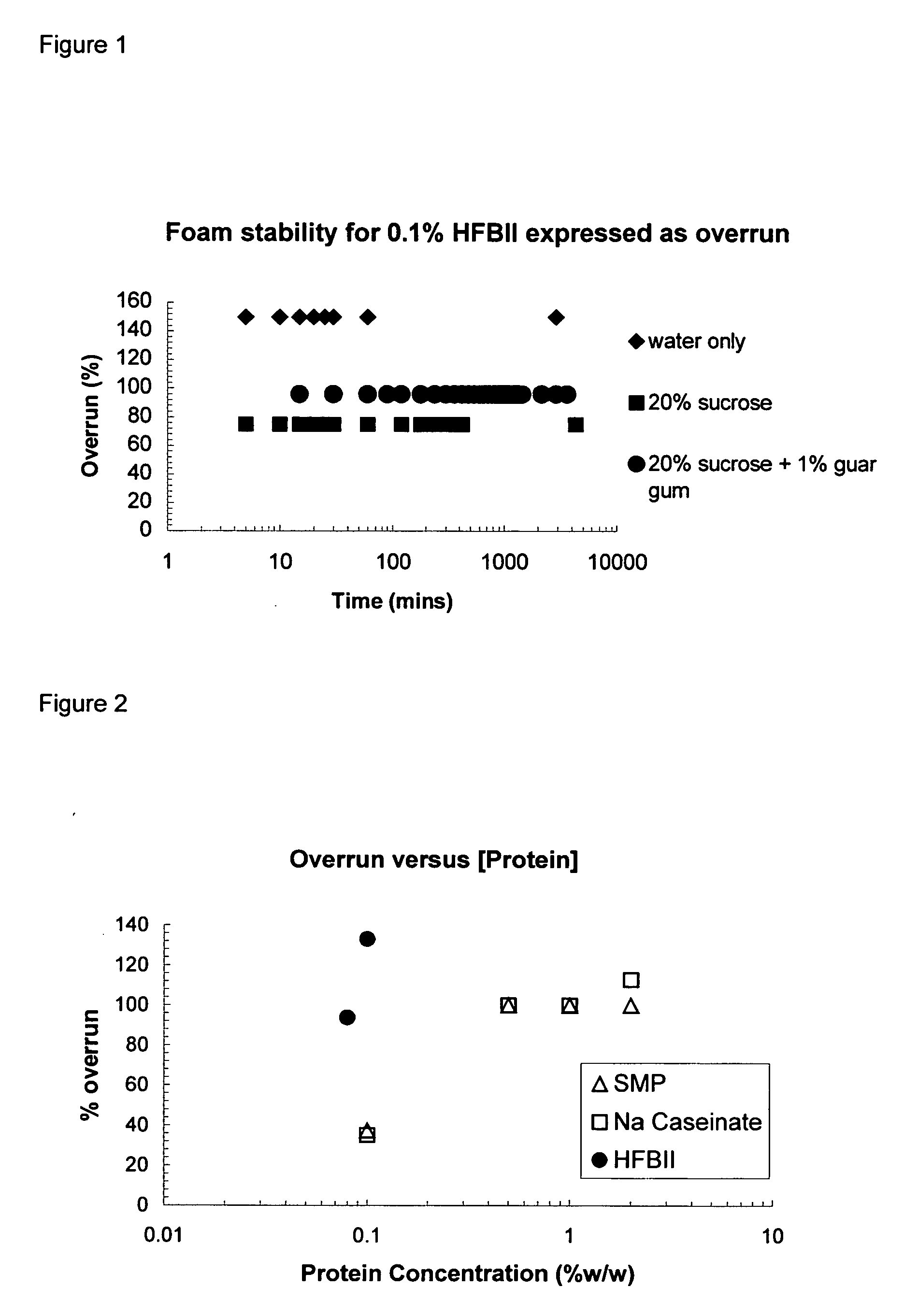

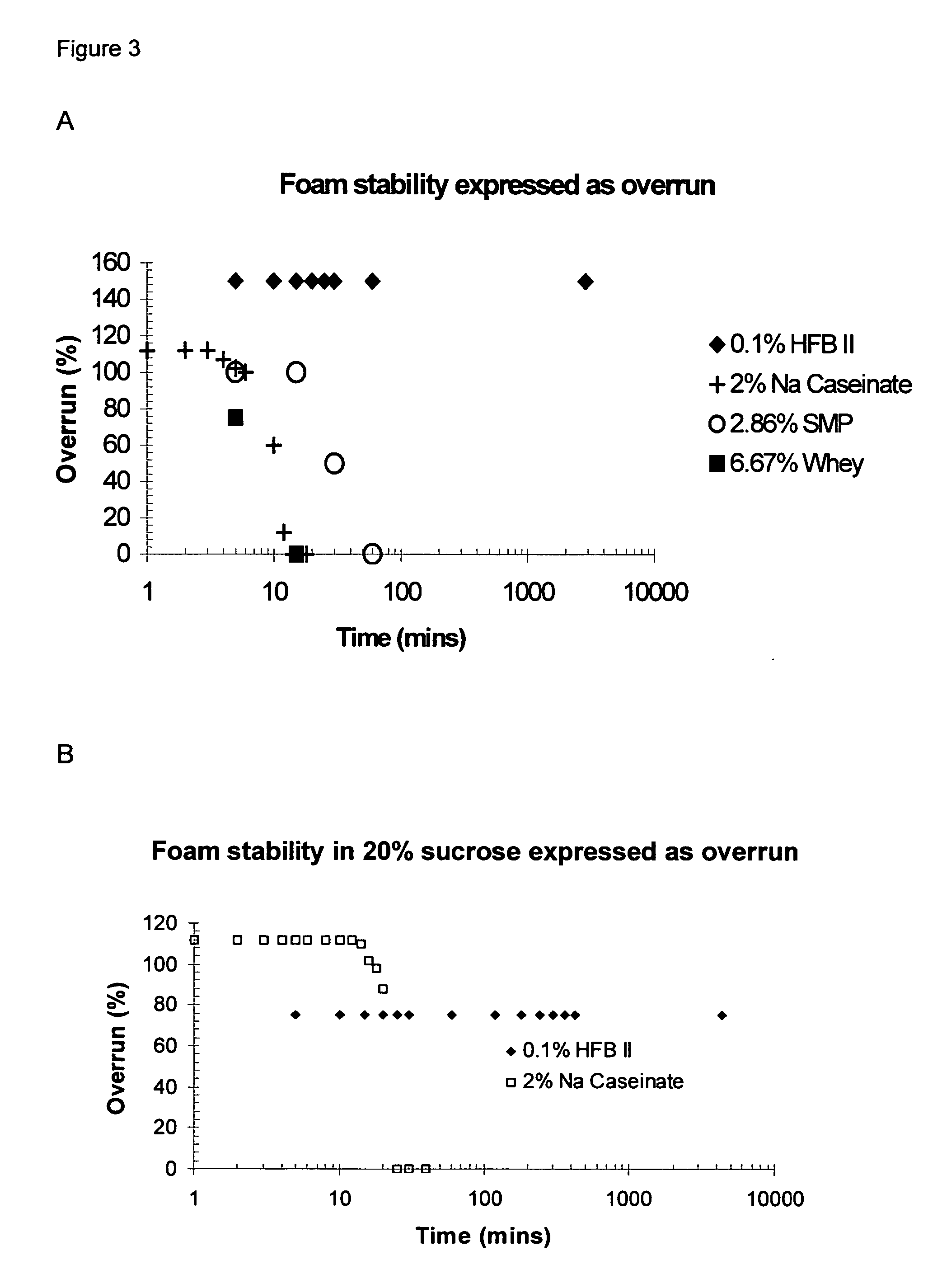

ActiveUS20060024417A1Improve rigidityGood shape retentionMilk preparationFrozen sweetsChemistryFood products

An aerated food product is provided which includes hydrophobin. Also provided is the use of a hydrophobin in a method of inhibiting bubble coarsening in aerated food products.

Owner:CONOPCO INC D B A UNILEVER

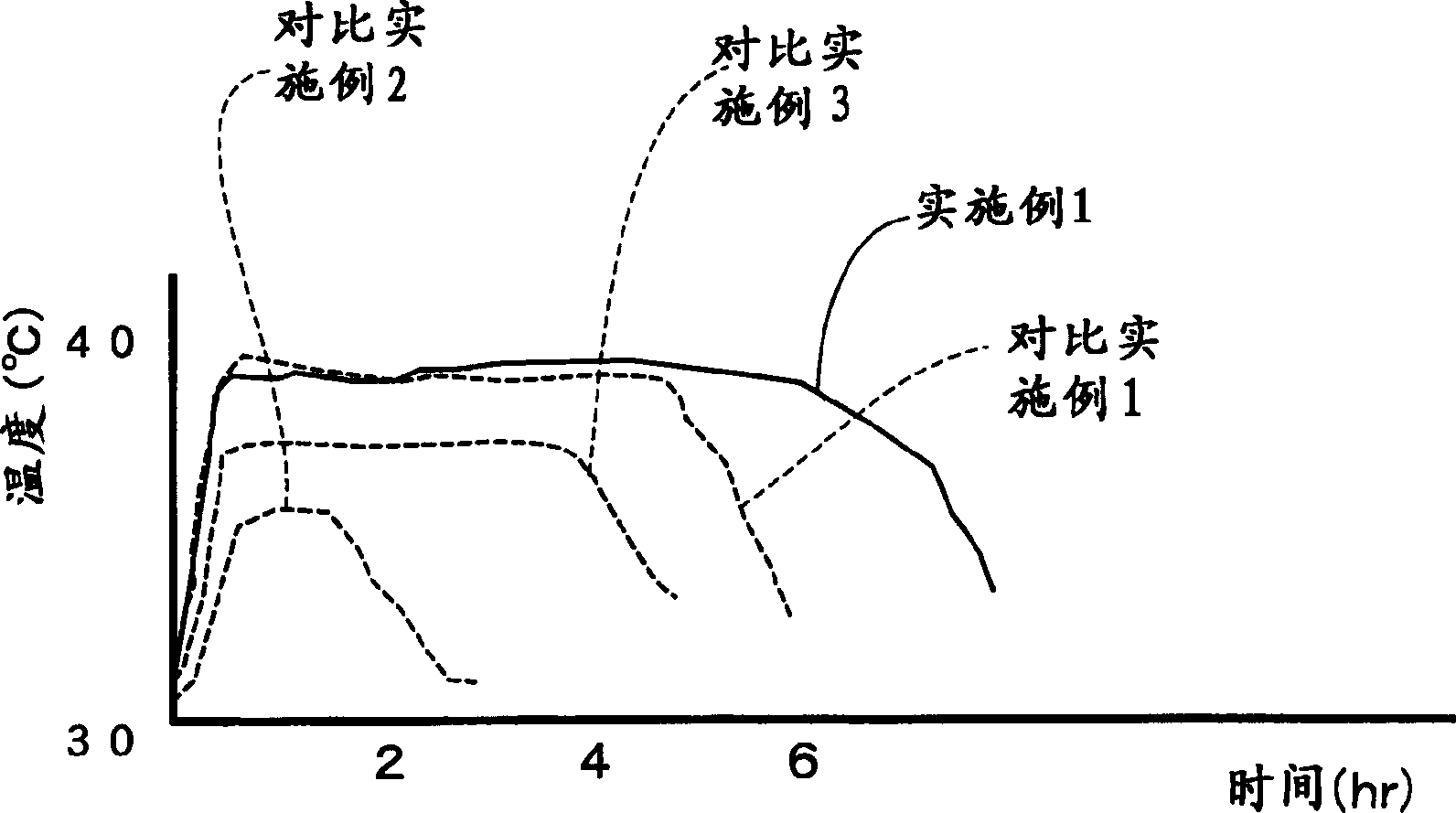

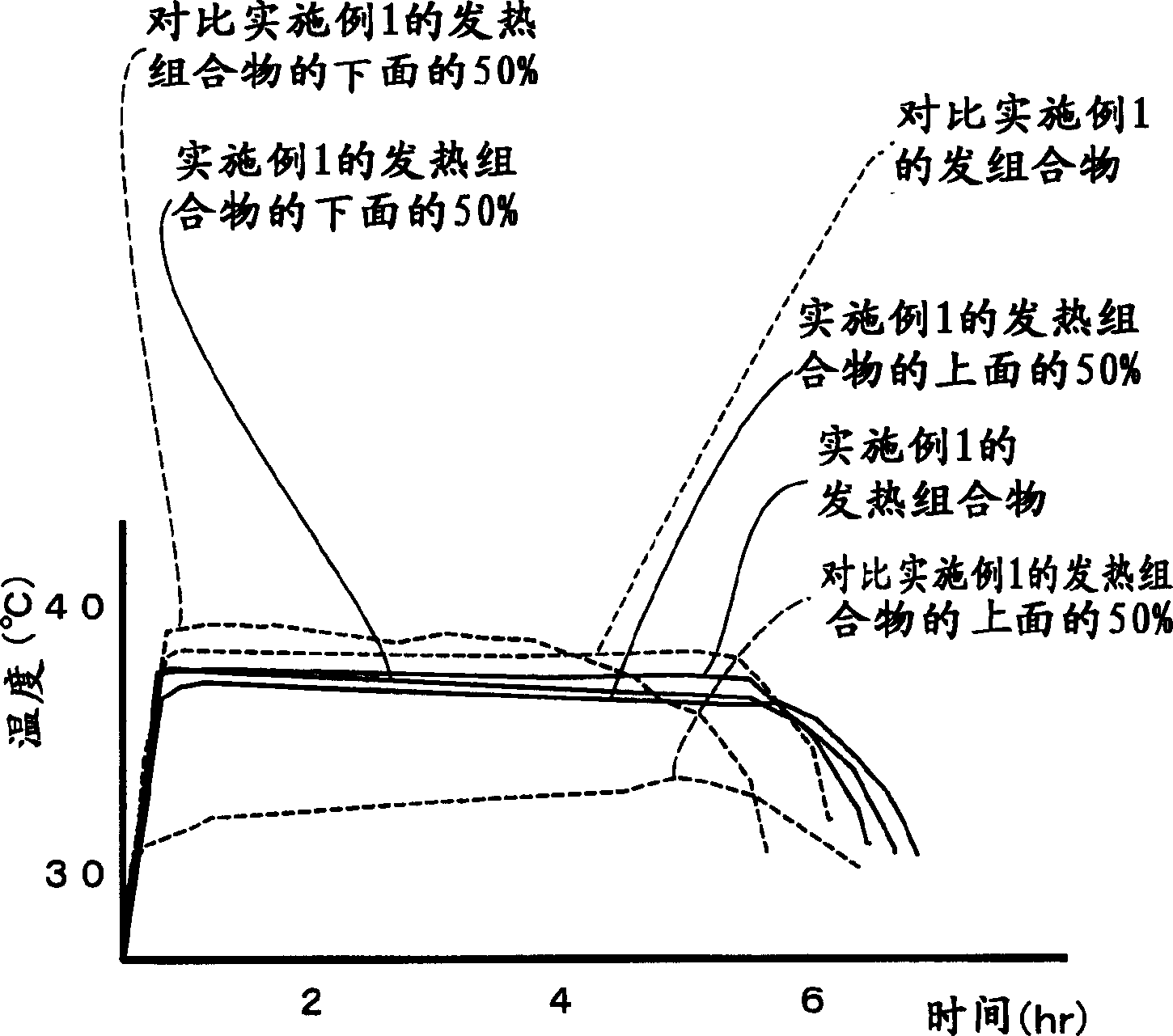

Exothermic composition and exothermic article using composition, and method for producing exothermic article

InactiveCN1491271AAccurate Guaranteed QuantityHas dispersion stabilityExothermal chemical reaction heat productionHeat-exchange elementsDispersion stabilityChemical composition

It relates to a heat-generating composition having such dispersion stability that withstands continuous molding, and has excellent drainage property, excellent heat-generating characteristics, excellent molding property and excellent shape retaining property, without becoming viscous, and relates to a heat-generating body using the same and a process for producing the heat-generating body. It contains, as essential components, a heat-generating substance generating heat upon reaction with oxygen, a carbon component, an oxidation promoter and water, characterized in that the composition further contains a water separation-preventing stabilizer in a proportion of from 0.001 to 0.25 part by mass per 100 parts by mass of the heat-generating composition, and has a water mobility value of from 7 to 40 and a separation degree of from 0 to 30.

Owner:MYCOAL

Cleaning article

InactiveUS20050097695A1Improve collection effectLow costCarpet cleanersKitchenware cleanersFiber bundleEngineering

Owner:UNI CHARM CORP

Method of forming an insulating layer in a trench isolation type semiconductor device

InactiveUS20020123206A1Good shape retentionEasy annealingSemiconductor/solid-state device manufacturingSolid-stateEngineering

A method of forming a trench-type device isolation layer in which a trench is filled through two steps, wherein a polysilazane solution is coated on a semiconductor substrate, in which a trench for device isolation layer is formed, in a spin on glass (SOG) manner to form an SOG layer filling a predetermined portion of the trench. In order to maintain a conformal coating thickness without overfilling the trench, the polysilazane solution preferably has a solid-state perhydro polysilazane ([SiH2NH]n) of between about 5 to about 15 percent by weight. Following formation of the SOG layer, a subsequent annealing process is carried out. The SOG layer is etched to make a top surface of the remaining SOG layer recessed down to a degree of about 1000 Å from an inlet of the trench, and a remaining space of the trench is filled with an ozone TEOS USG layer or an HDP CVD layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Cationically modified, anionic polyurethane dispersions

InactiveUS20050153865A1Enhance deposition and retentionImprove the level ofOrganic detergent compounding agentsCross-linked polyethyleneMeth-

Owner:BASF SE

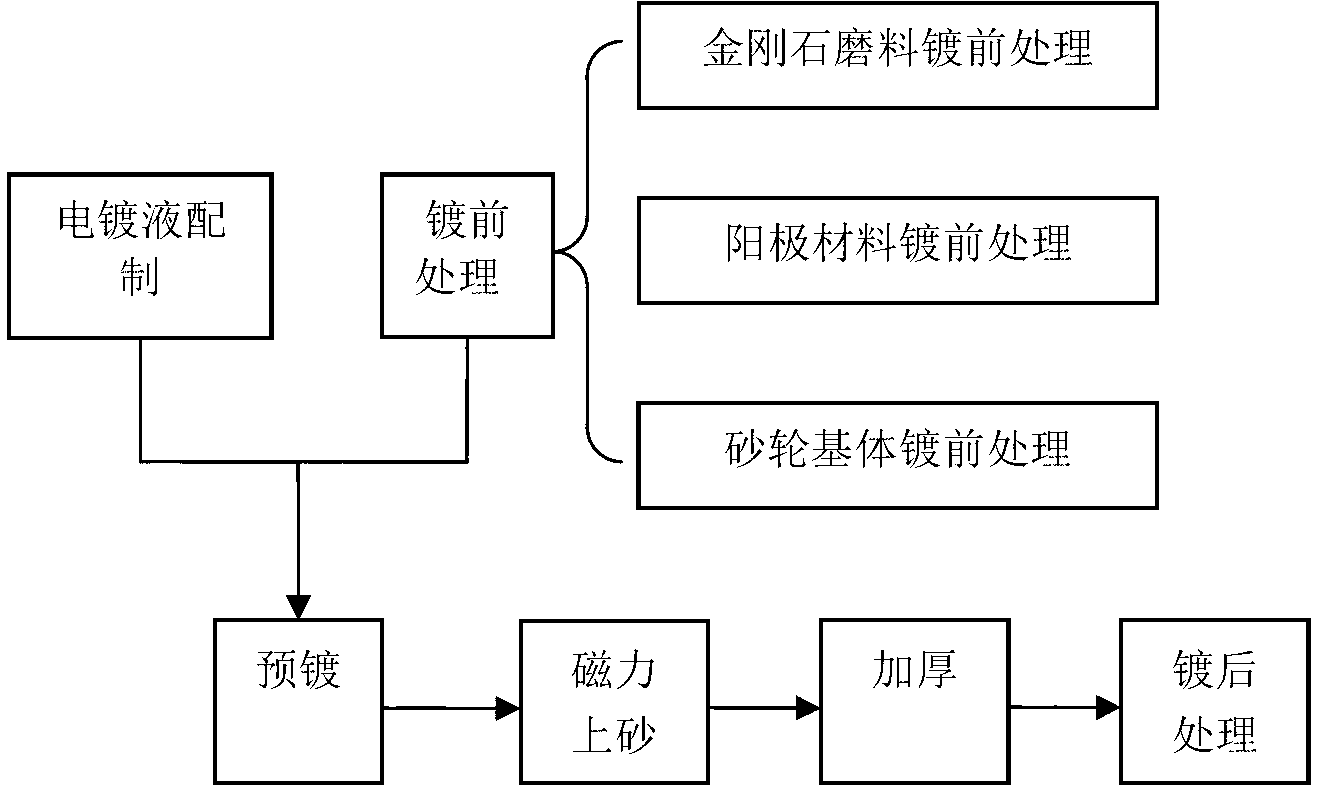

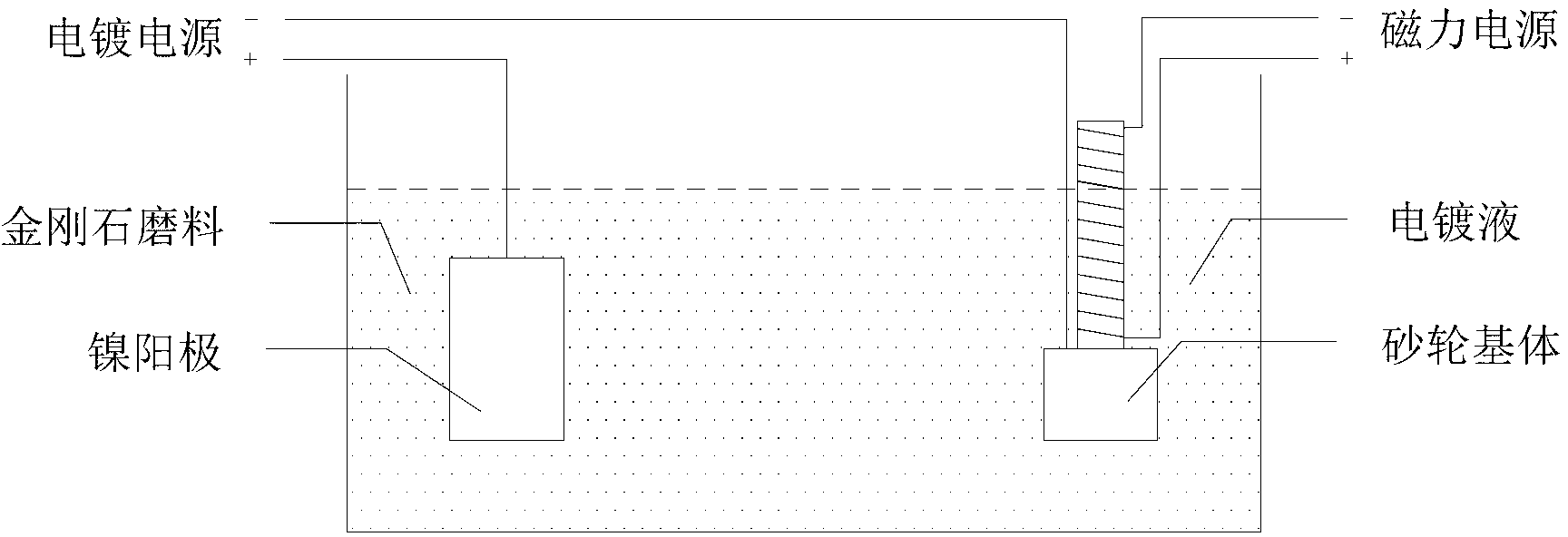

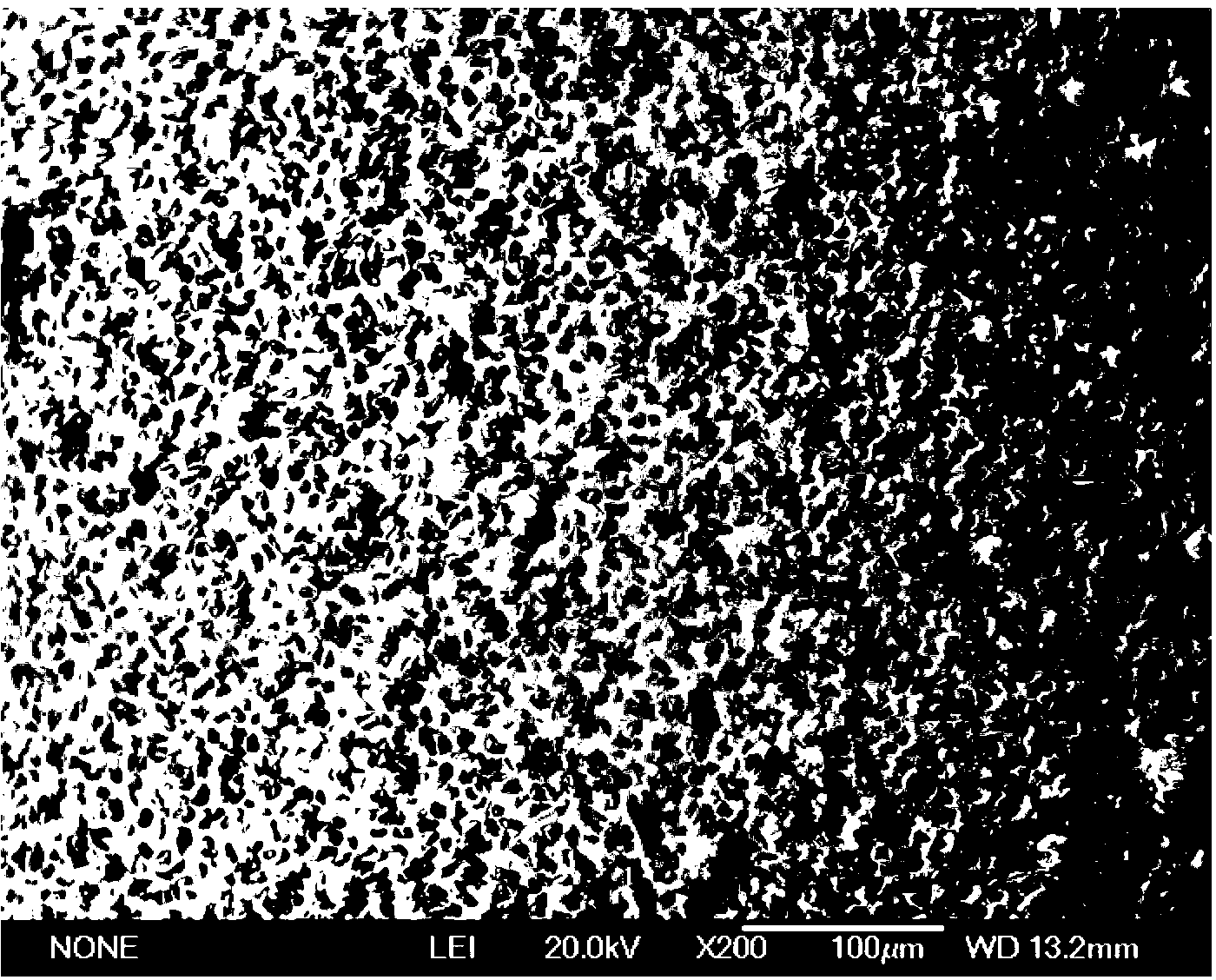

Method for producing grinding electroplated diamond wheel

ActiveCN103173840AControl sedimentation rateEvenly distributedCellsElectrolytic coatingsGranularityGrinding wheel

The invention discloses a method for producing a grinding electroplated diamond wheel. The method comprises the steps of: 1, preparing an electroplating bath; 2, pre-treating before plating; 3, pre-plating, wherein the current density is 1.2-1.8A / dm<2>, and the thickness of a pre-plating layer is 7-10micrometers; 4, magnetically sand feeding, namely applying magnetic induction intensity of 400-1000mT on a plating surface of a grinding wheel base body so as to absorb a diamond abrasive through the plating surface of the grinding wheel base body, and depositing an electroplating layer through electrifying, wherein the sand feeding current density is 0.5-0.8A / dm<2>, and the thickness of the plating layer is 15% of the average particle size of the diamond abrasive; 5, thickening, wherein the current density is 1.6-2.0A / dm<2>, and the thickness of the thickened plating layer is 65% of the average particle size of the diamond abrasive; and 6, treating after the plating so as to obtain the grinding electroplated diamond wheel. By utilizing the method for producing the grinding electroplated diamond wheel, the abrasive with fine granularity can be uniformly solidified on the plating surface, and the produced grinding wheel has good shape retention performance and satisfies grinding requirements on high precision and high efficiency.

Owner:白鸽磨料磨具有限公司

Metal injection molding product and carbon control method thereof in manufacturing process

The invention relates to a metal injection molding product which contains material ingredients and a molding agent ingredient, wherein the material ingredients comprise 90-95 percent of iron powder, 2-5 percent of nickel powder and 0.5-1 percent of molybdenum powder; the molding agent ingredient contains paraffin wax, low density polyethylene, polypropylene, carnauba wax and stearic acid; and theadjustment range of the molding agent content is 6.0 percent to 8.0 percent. The carbon content range of a finally-sintered product can be effectively controlled by adopting the percentages and the contents of the materials, and therefore, the carbon content is controlled easily and accurately. In addition, the molding agent has the advantages of easy removal, environment protection, good fluidityand shaping effect, and the like, therefore, the quenched product has even and uniform internal and external hardness, and the processed product is ensured not to deform easily; and due to appropriate temperature, push speed and gas flow adopted on a thermal adsorption process as well as skilled drive to the ambient humidity, the stability of the process sand and the carbon content can be ensured, and the product with optimal performance is prepared.

Owner:深圳市注成科技股份有限公司

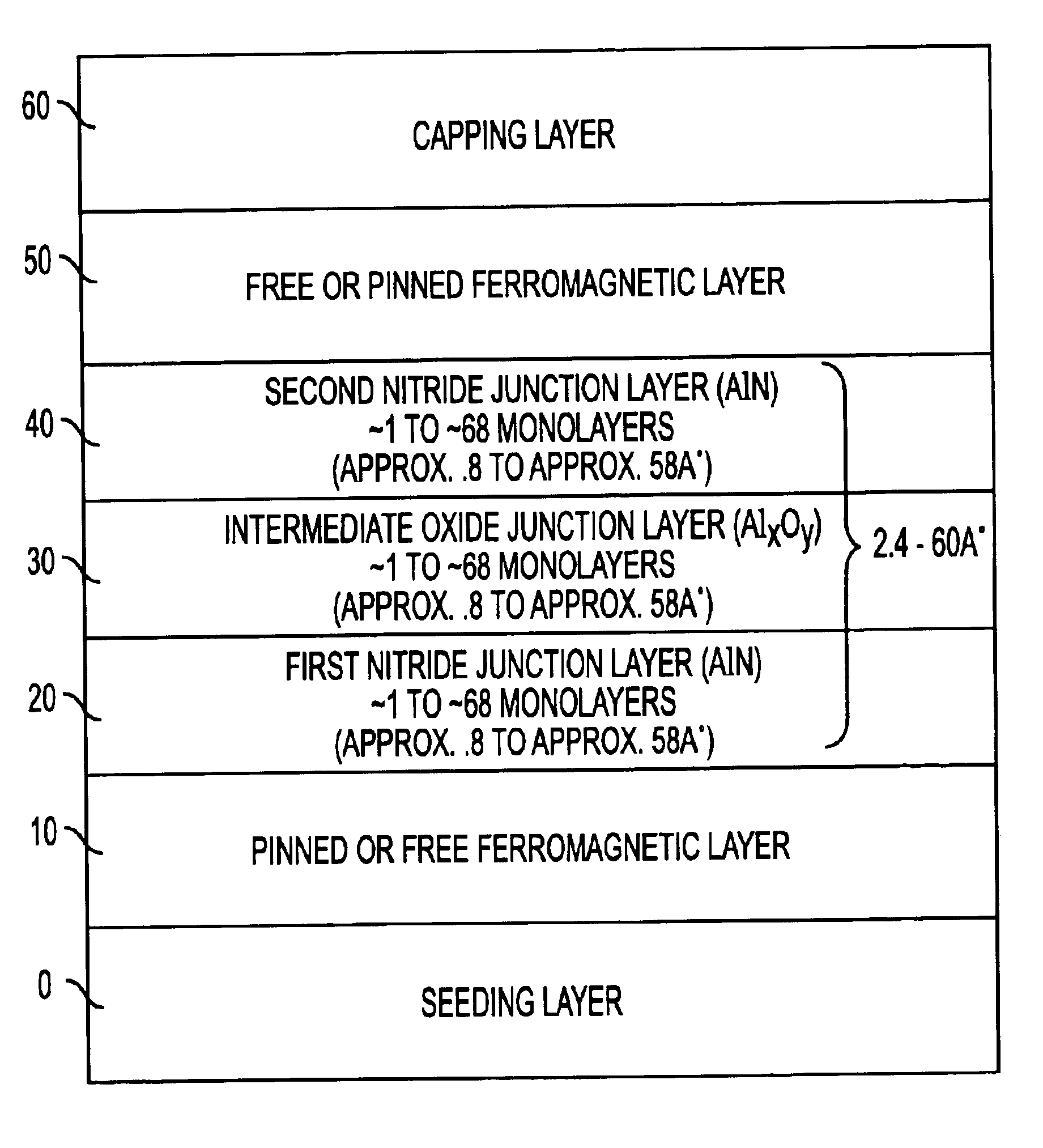

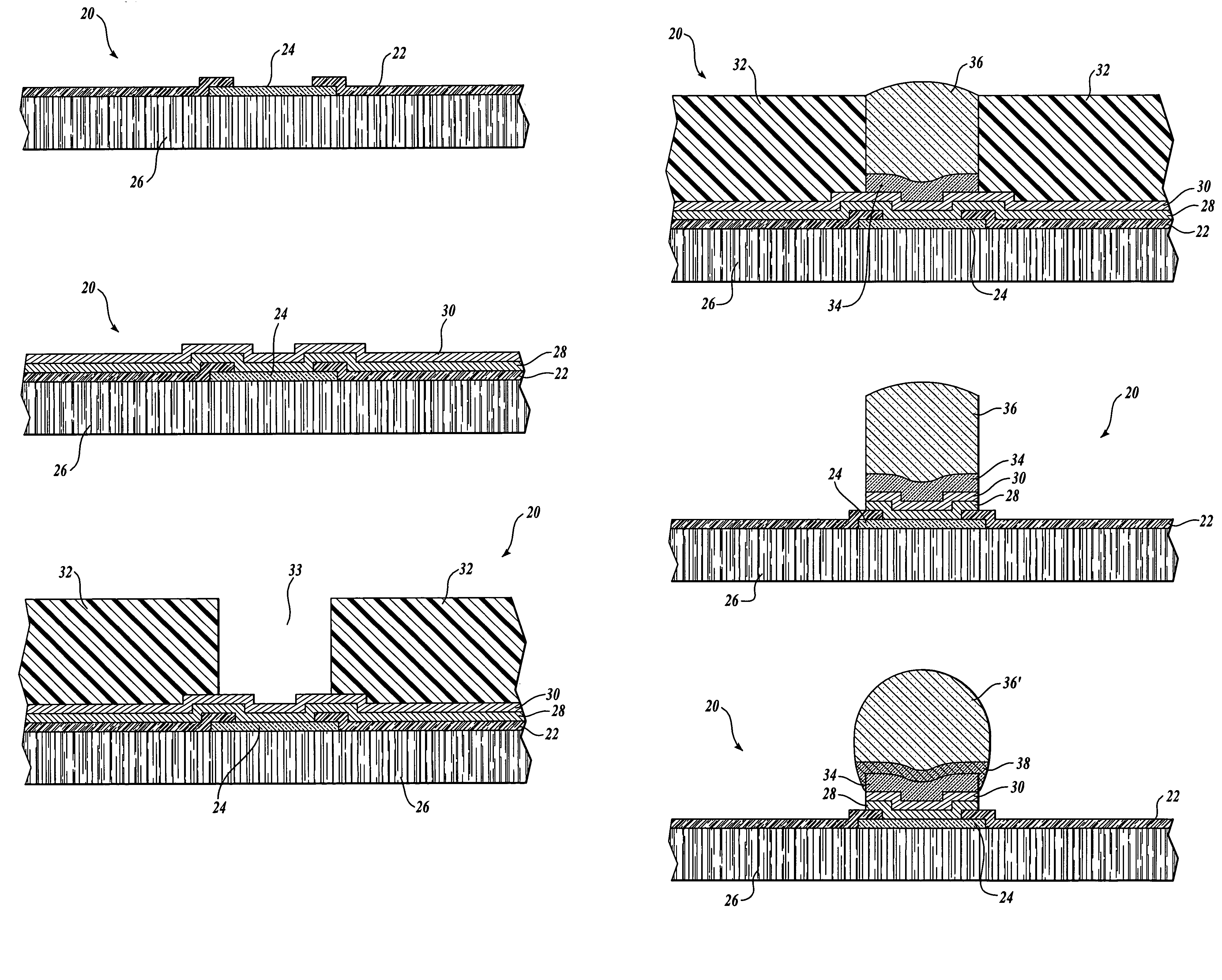

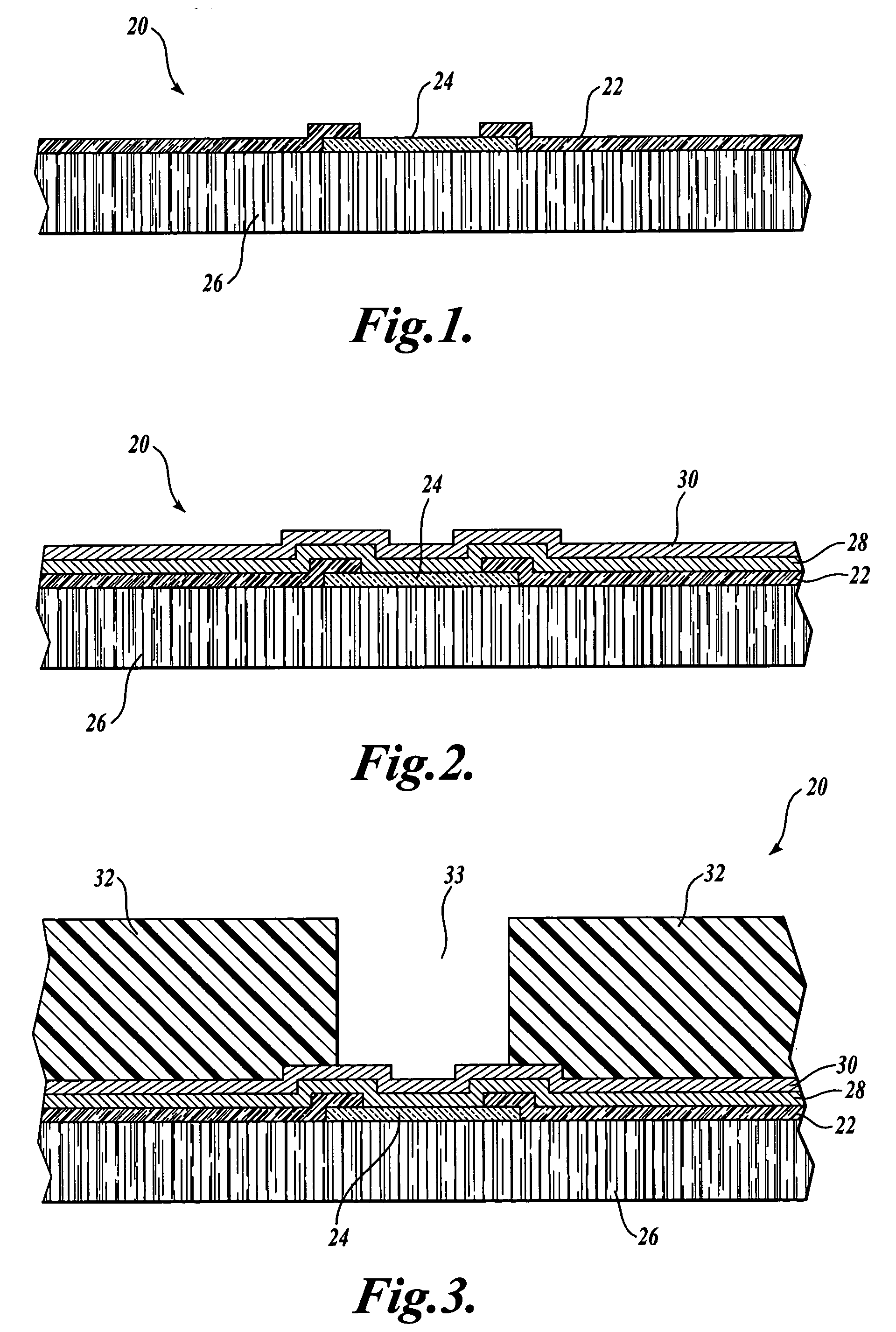

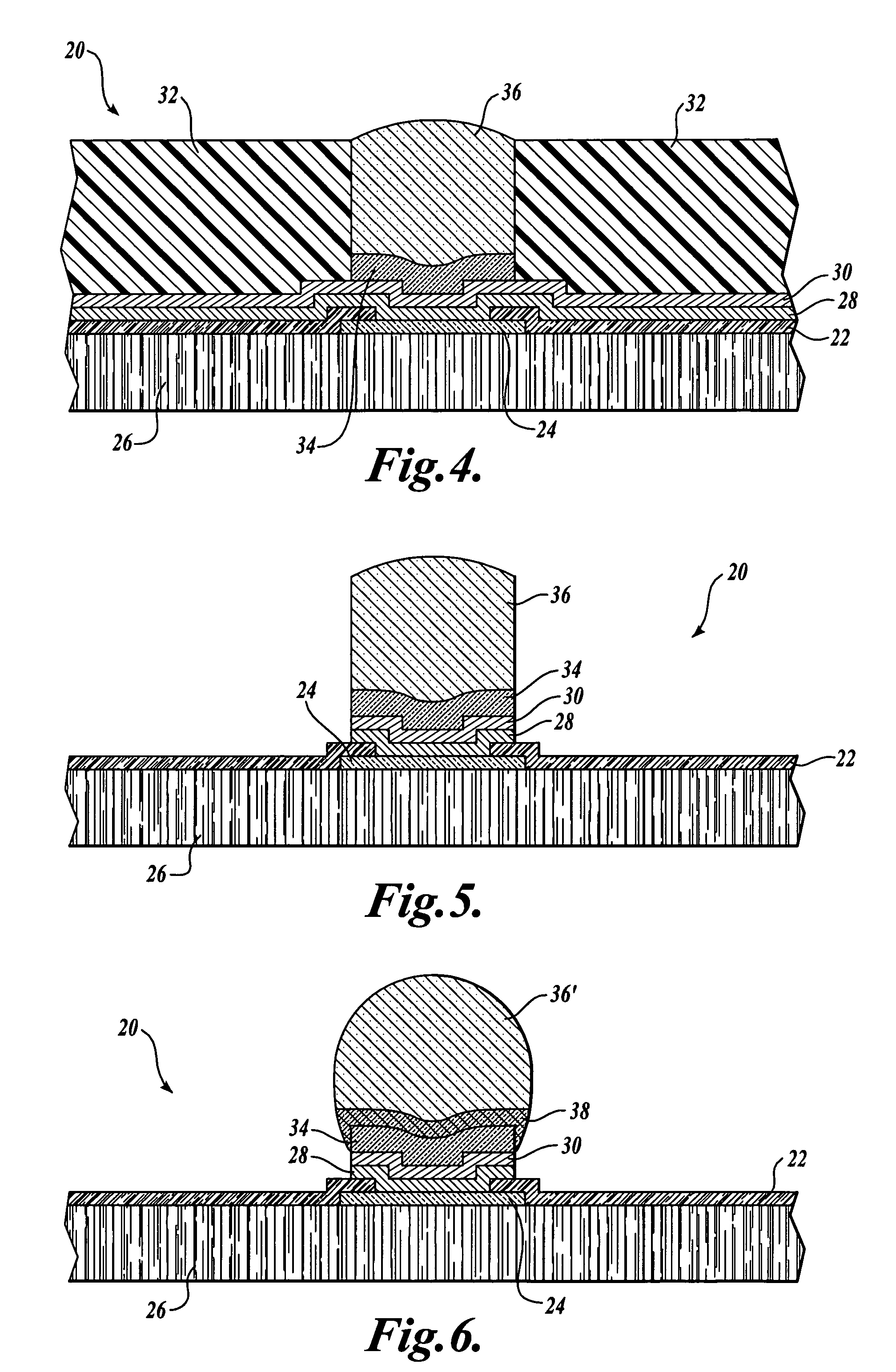

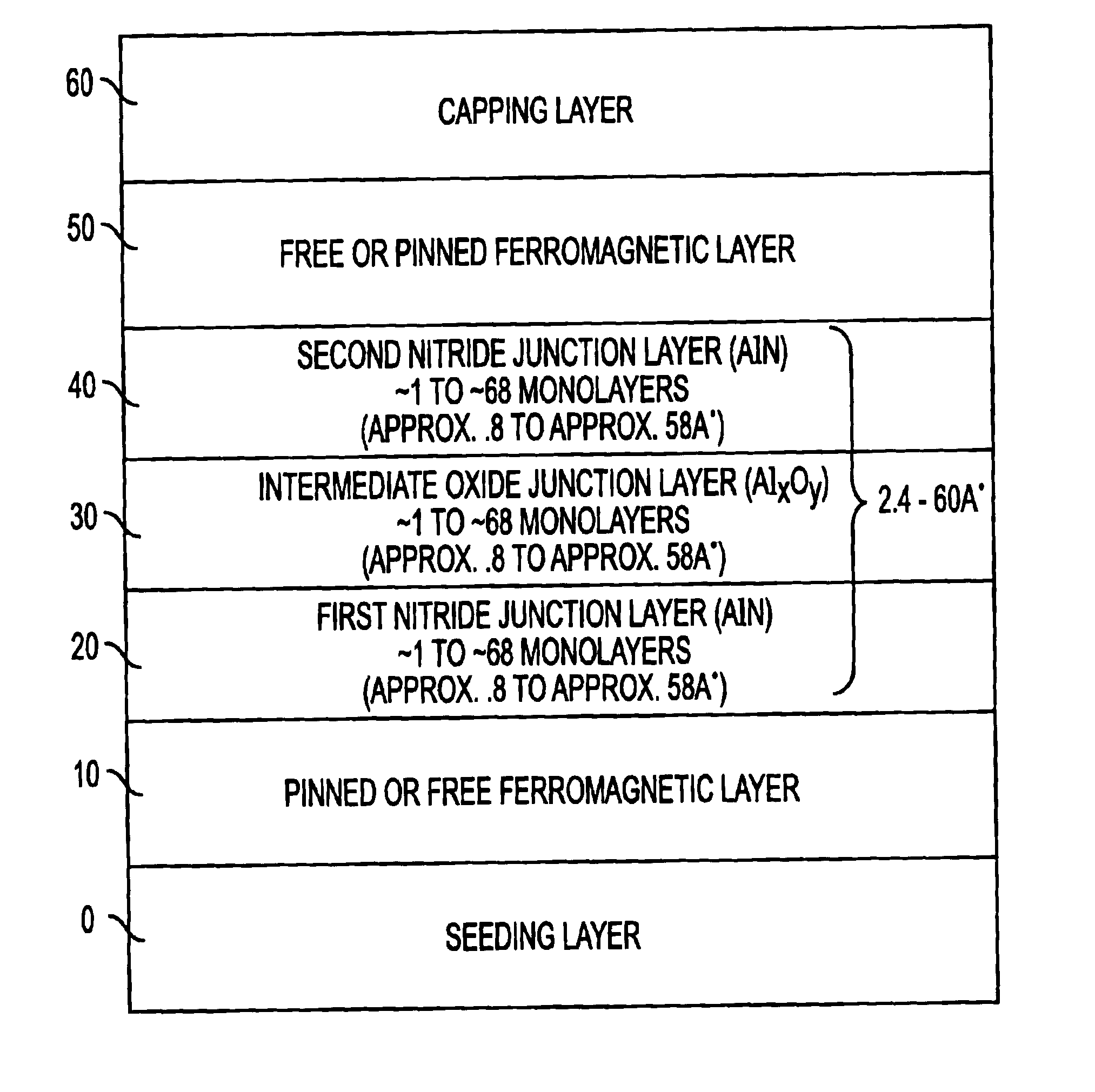

Method of fabricating a multilayer dielectric tunnel barrier structure

InactiveUS6849464B2Reduce resistanceGood shape retentionNanomagnetismChemical vapor deposition applicationMagnetic memoryNitride

A multilayer dielectric tunnel barrier structure and a method for its formation which may be used in non-volatile magnetic memory elements comprises an ALD deposited first nitride junction layer formed from one or more nitride monolayers i.e., AlN, an ALD deposited intermediate oxide junction layer formed from one or more oxide monolayers i.e., AlxOy, disposed on the first nitride junction layer, and an ALD deposited second nitride junction layer formed from one or more nitride monolayers i.e., AlN, disposed on top of the intermediate oxide junction layer. The multilayer tunnel barrier structure is formed by using atomic layer deposition techniques to provide improved tunneling characteristics while also providing anatomically smooth barrier interfaces.

Owner:MICRON TECH INC

Bath and method for high rate copper deposition

InactiveUS20050092611A1Small sizeReduce surface tensionConductive materialSolid-state devicesHigh rateWetting

A plating bath for electroplating copper on a microelectronic workpiece in a through-mask plating application at a rate of at least 2 μm / min where the bath includes: (a) 50-85 g / L of Cu2+; (b) 50-100 g / L of H2SO4; (c) 30-150 ppm of Cl—; (d) a brightener; (e) a wetting agent; (f) optionally a leveler; and (g) water. A process for electroplating copper on a microelectronic workpiece in a through-mask plating application at a rate of at least 2 μm / min where the process includes the steps of: (a) providing the plating bath described above; (b) providing a workpiece which has one or more through-mask openings having a conductive layer at the bottom of the openings; (c) contacting the conductive layer with the plating bath; and (d) providing electroplating power between the conductive layer and an anode disposed in electrical contact with the bath, whereby copper is deposited onto the conductive layer at a rate of at least 2 μm / min.

Owner:SEMITOOL INC

Multilayer dielectric tunnel barrier used in magnetic tunnel junction devices, and its method of fabrication

InactiveUS6900455B2Reduce resistanceGood shape retentionNanomagnetismChemical vapor deposition applicationDielectricMagnetic memory

Owner:MICRON TECH INC

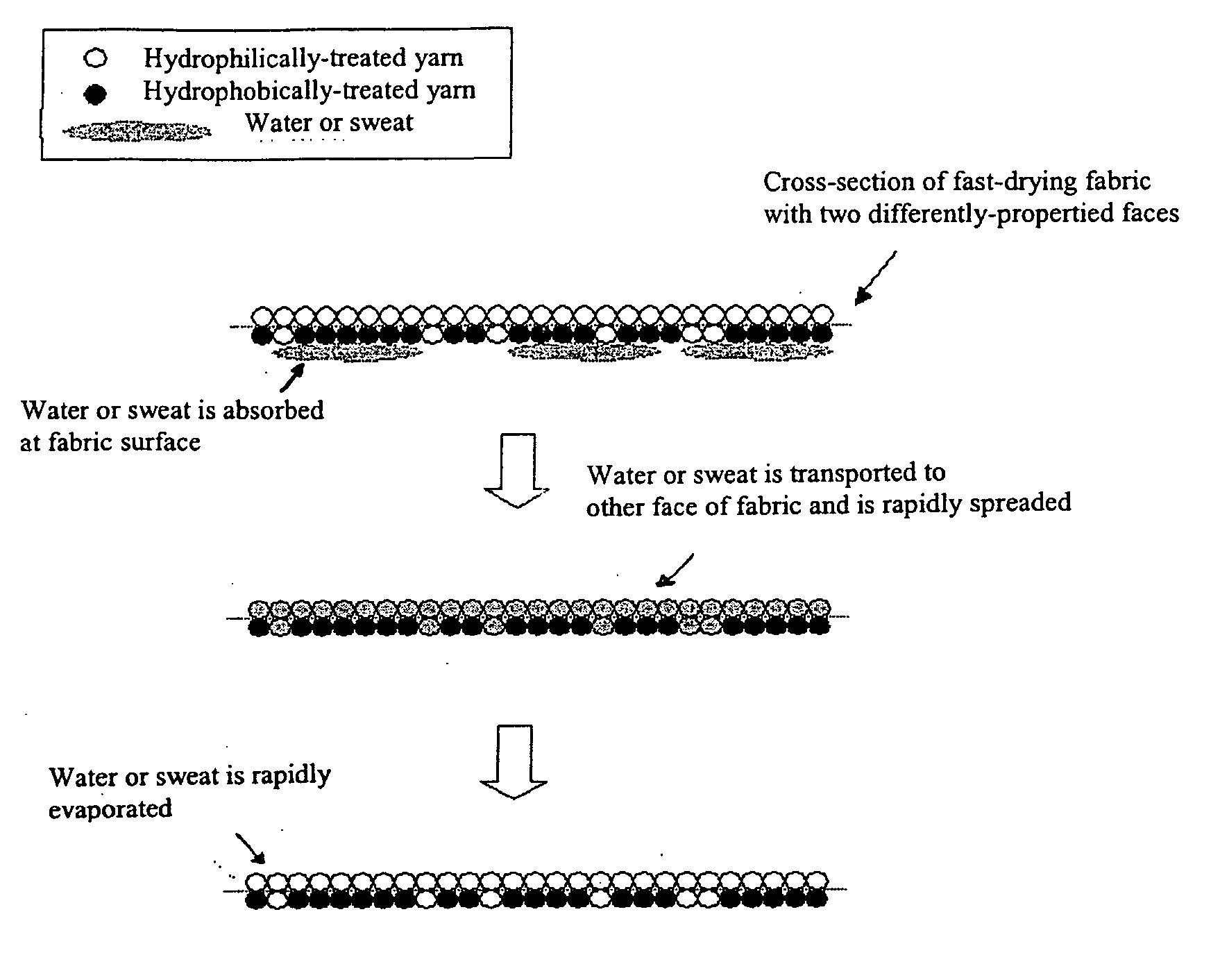

Quick-drying pure cotton fabric with two faces having different properties and a method of producing same

InactiveUS20060148356A1Quick drying-whilePleasing to touchGarment special featuresOrnamental textile articlesYarnCivil engineering

The present invention is a quick-drying pure cotton fabric whose two faces have different properties and a method of producing same. One face of said fabric is a hydrophobic face formed largely or entirely from hydrophobic pure cotton, and the other face is a hydrophilic face formed largely or entirely from hydrophobic pure cotton. Moreover, said fabric is capable of unidirectional transportation of water. The method of producing said fabric consists mainly of separate hydrophobic treatments of pure cotton yarn. The result is hydrophilically-treated yarn and hydrophobically treated yarn. Then the two types of yarn are knit according to a certain knitting process to produce a fabric whose two faces have different properties: hydrophilicity and hydrophobicity. The fabric is also comfortable and has moisture management and fast-drying functions.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

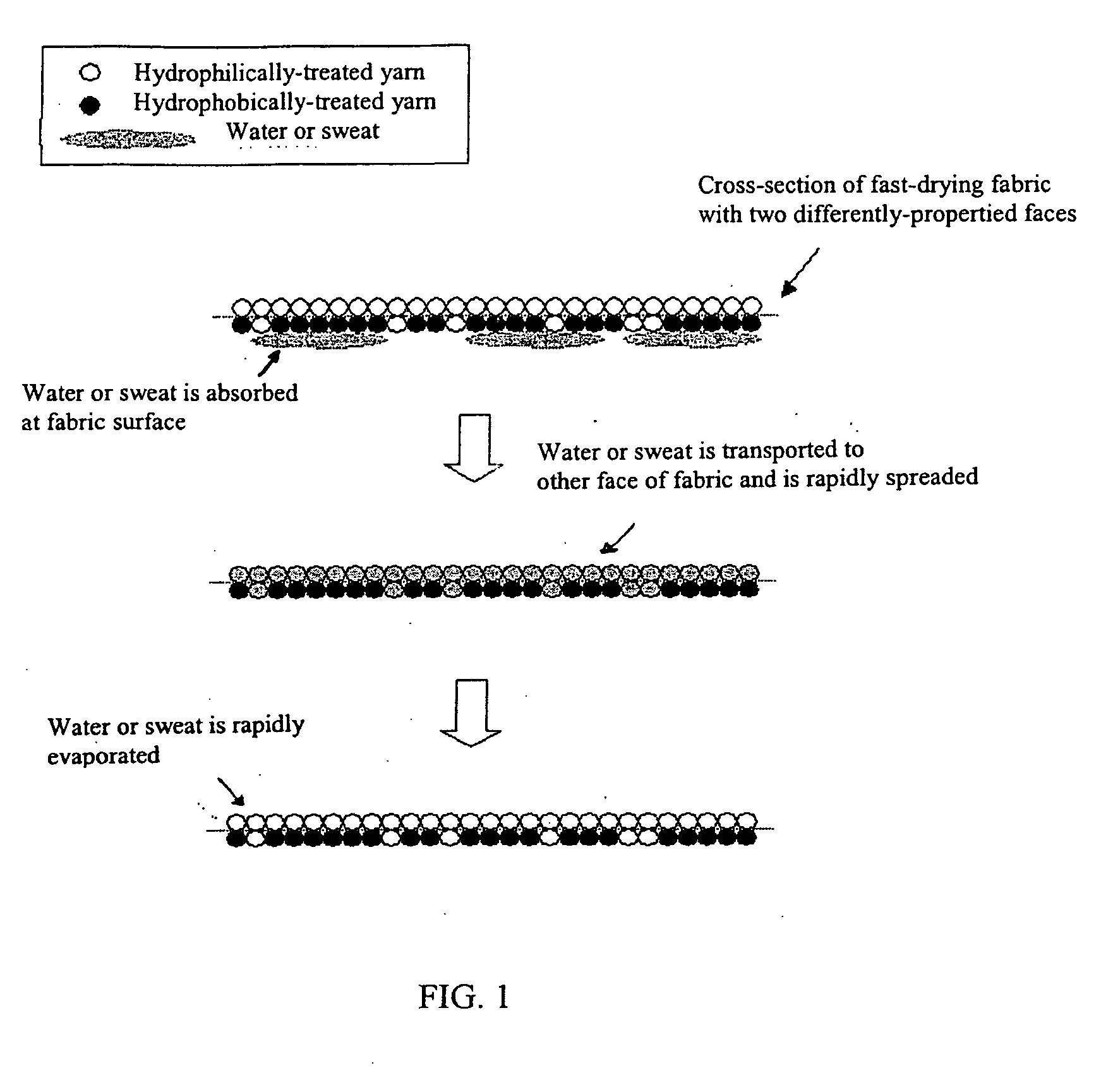

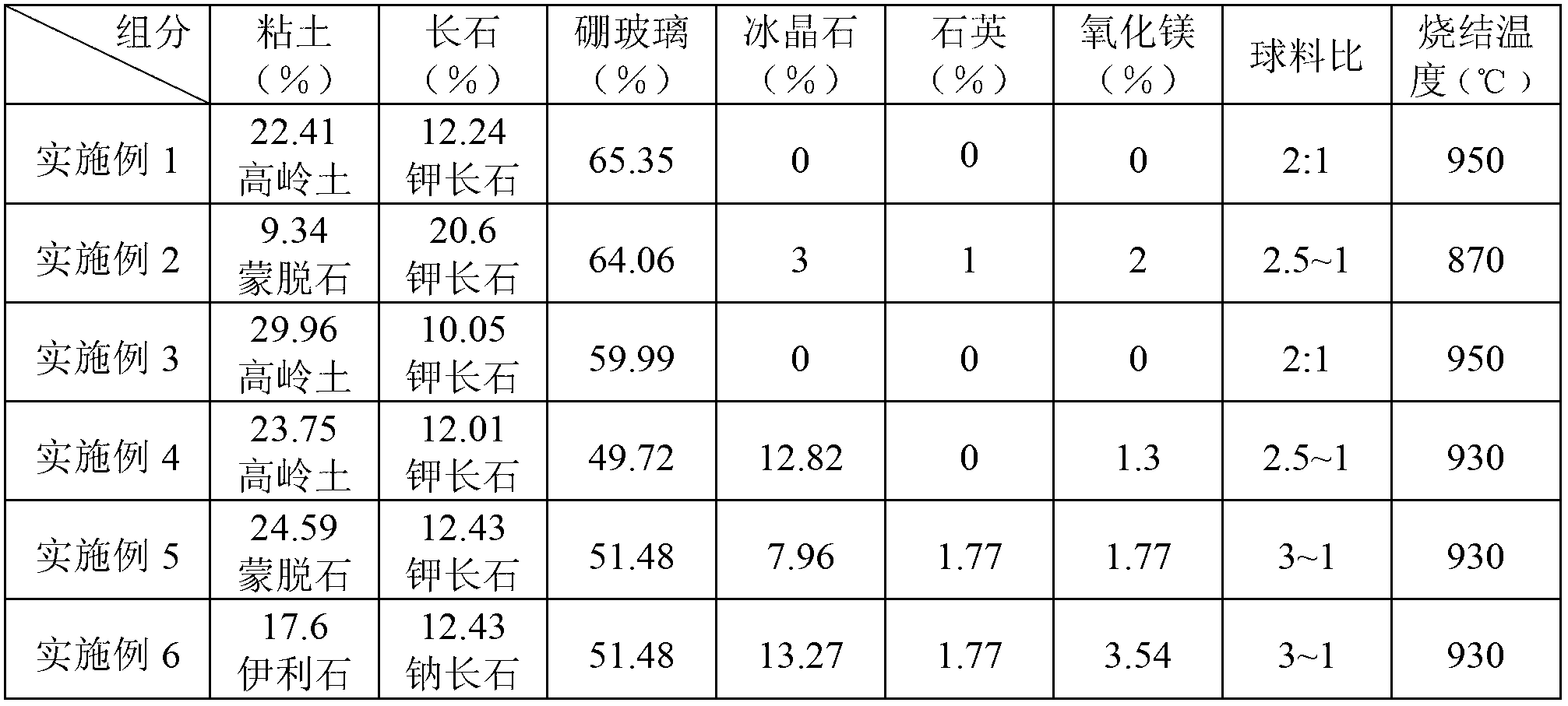

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Copolymer, rubber composition, cross-linked rubber, cross-linked foam, and uses thereof

ActiveUS9193856B2Adequate foamabilityLarge expansion ratioBuilding constructionsCross-linkActivation energy

The present invention provides a rubber composition having adequate foamability, uses thereof, a copolymer contained in the rubber composition, a rubber composition capable of providing a cross-linked foam, which has a low specific gravity and an excellent shape-retaining property even when the usage of a nonconjugated polyene is reduced, and a cross-linked rubber and a cross-linked foam, which are produced from the rubber composition. A copolymer (A) according to the present invention is a copolymer including structural units derived from ethylene [A], an α-olefin [B], a nonconjugated polyene [C-1], in which one carbon-carbon double bond (C═C) polymerizable with a metallocene catalyst is present in one molecule, and a nonconjugated polyene [C-2], in which two bonds of C═C polymerizable with the metallocene catalyst are present in one molecule, and being synthesized with the metallocene catalyst, wherein (1) the units derived from the component [B] constitute 10 to 50 percent by mole, (2) the total of the units derived from the component [C-1] and the units derived from the component [C-2] is 1.0 to 6.0 percent by mole, (3) the molar ratio of the units derived from the component [C-1] to the units derived from the component [C-2] is 75 / 25 to 99.5 / 0.5, (4) [ML (1+4) 100° C.] is 10 to 200, and (5) 50>activation energy of fluidization (kJ / mol)>35 is satisfied.

Owner:MITSUI CHEM INC

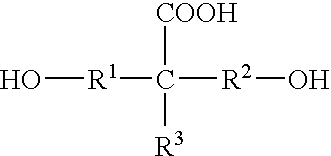

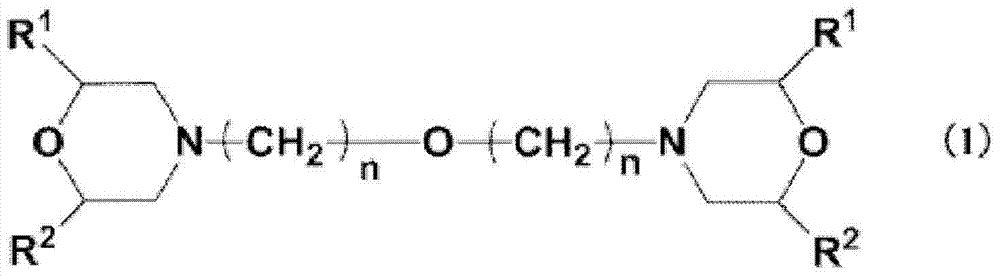

Moisture-curable polyurethane hot melt resin composition, adhesive and article

ActiveCN104245769AImprove waterproof performanceExcellent fast curingNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterFiber

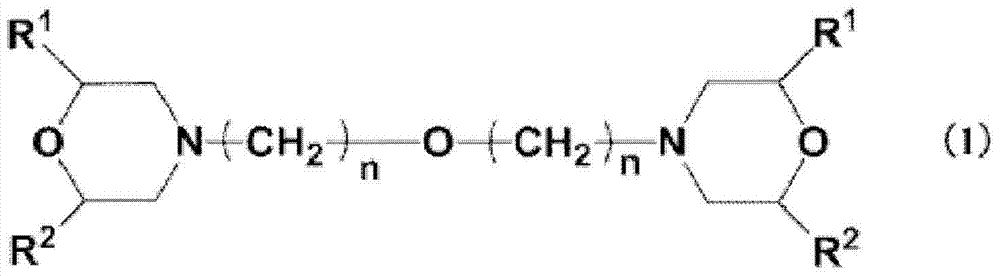

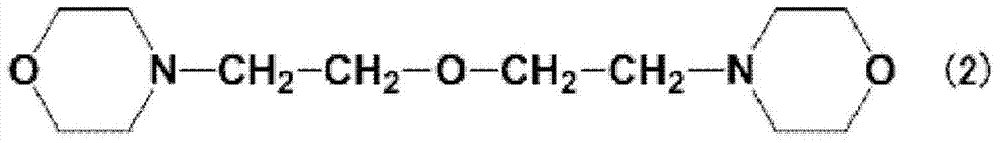

The present invention addresses the problem of providing a moisture-curable polyurethane hot melt resin composition which has excellent waterproof properties, fast curing properties, flexibility and the like. The present invention provides: a moisture-curable polyurethane hot melt resin composition which is characterized by containing (i) a urethane prepolymer having an isocyanate group, which is obtained by reacting (A) a polyol that contains (A-1) a polyether polyol, (A-2) a crystalline polyester polyol, (A-3) an amorphous polyester polyol and (A-4) an acrylic polyol with (B) a polyisocyanate, and (ii) a curing catalyst that is represented by general formula (1); an adhesive which is obtained using the moisture-curable polyurethane hot melt resin composition; and an article. An adhesive that is obtained using the moisture-curable polyurethane hot melt resin composition of the present invention is suitable not only for use in fiber bonding and building material lamination but also for use in bonding of optical members.

Owner:DIC CORP

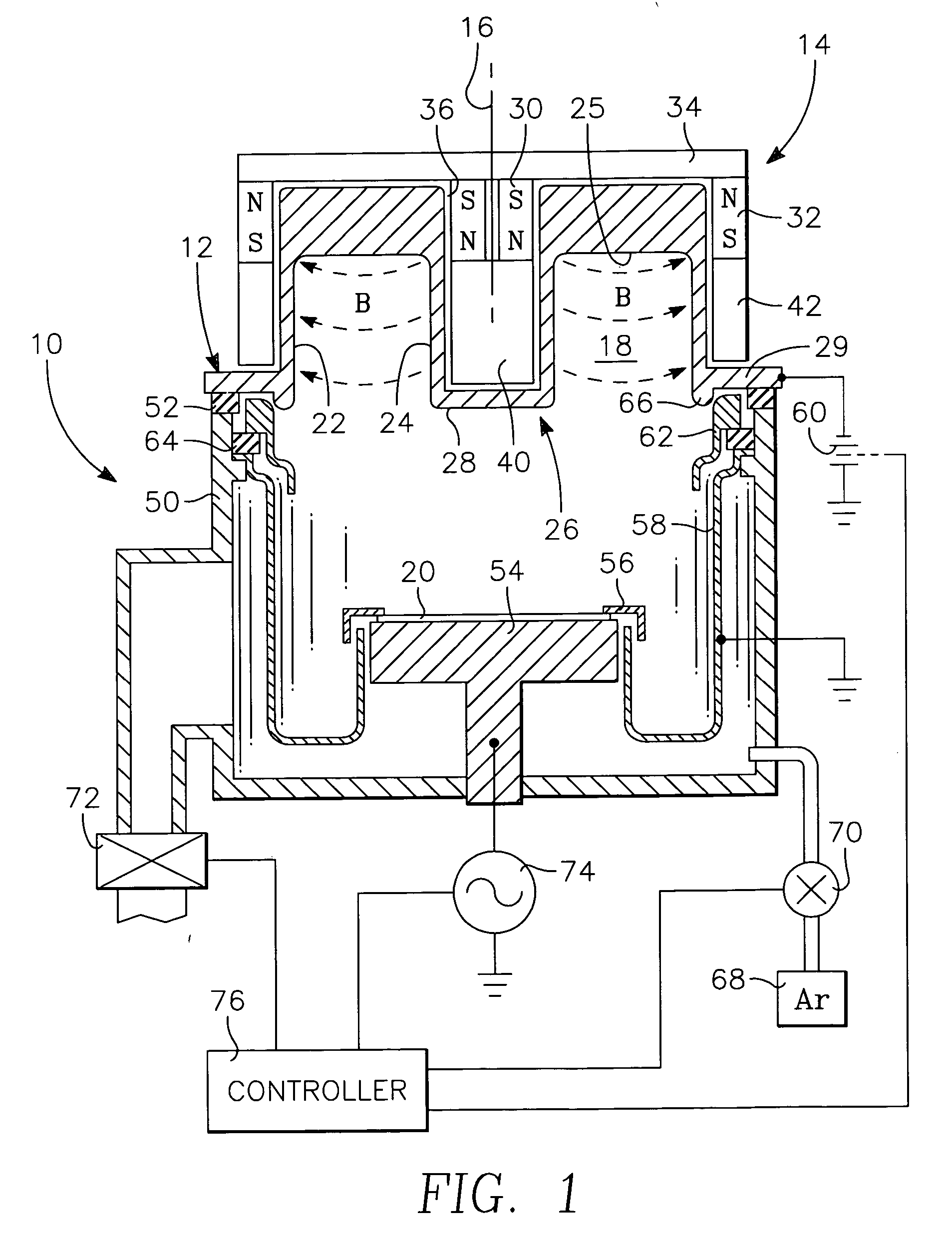

Controlled multi-step magnetron sputtering process

InactiveUS20050255700A1Eliminating any yoke sputteringLarge sputtering of the sidewallsElectric discharge tubesSolid-state devicesEngineeringCopper

A multi-step sputtering process in plasma sputter reactor having target and magnetron operable in two modes, for example, in a substrate sputter etch and a substrate sputter deposition. The target has an annular vault facing the wafer to be sputter coated. Various types of magnetic means positioned around the vault create a magnetic field supporting a plasma extending over a large volume of the vault. An integrated copper via filling process with the inventive reactor or other reactor includes a first step of highly ionized sputter deposition of copper, which can optionally be used to remove the barrier layer at the bottom of the via, a second step of more neutral, lower-energy sputter deposition of copper to complete the seed layer, and a third step of electroplating copper into the hole to complete the metallization. The first two steps can be also used with barrier metals.

Owner:GOPALRAJA PRABURAM +6

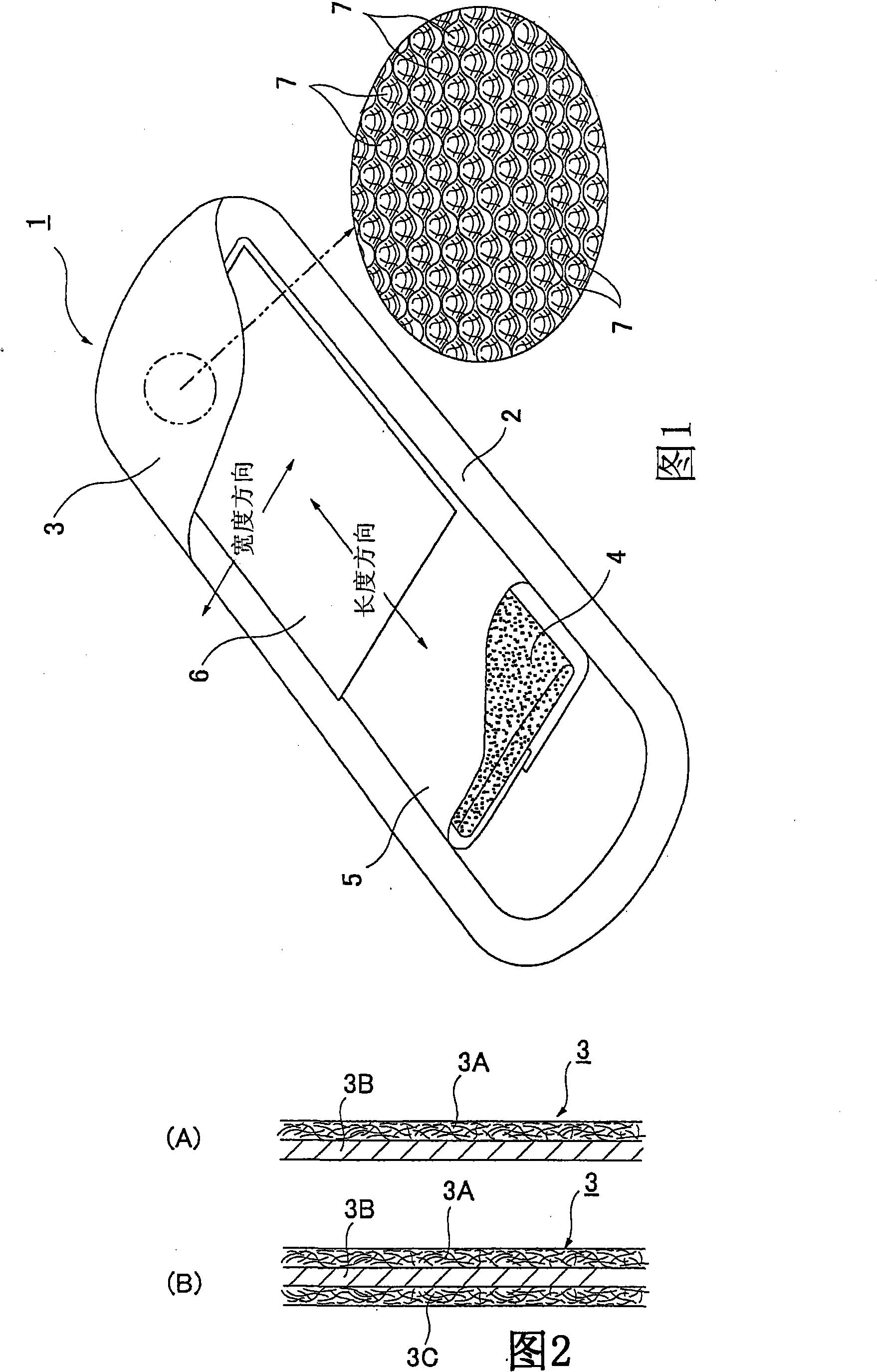

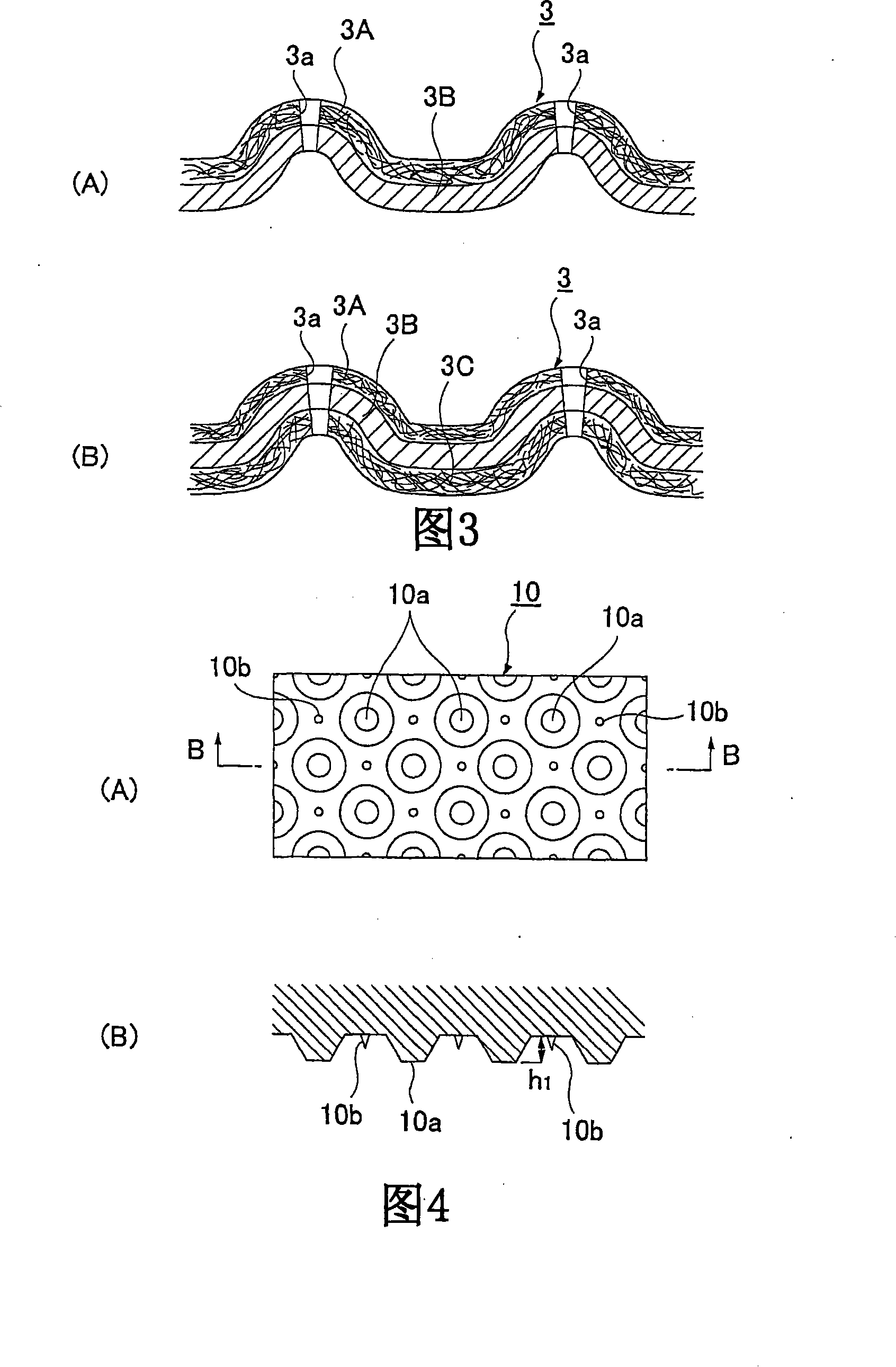

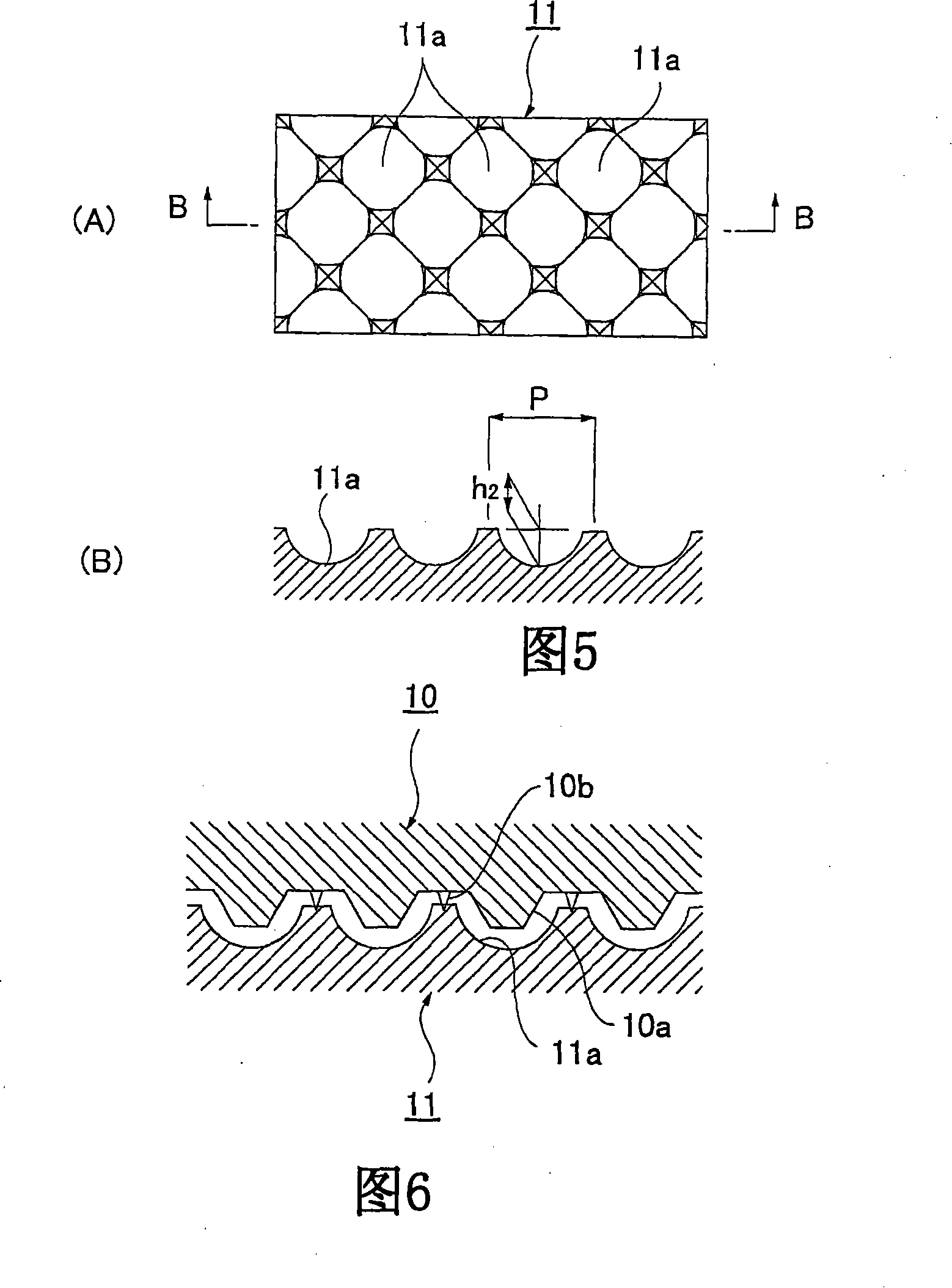

Absorbency substance

ActiveCN101152114AHolds shape firmlyGuaranteed cushioning effectAbsorbent padsBaby linensSkin contactPlastic film

The present invention provides an absorbability article which has cubic effect, high buffering property, and can keep concave-convex form not only under drying condition but also under the condition of absorbing sap by improving the form retentivity of concave-convex embossed pattern. The absorbability article (1) is provided with an absorbing body (4) between permeating front side and back side thin sheets (3) and (2), wherein, the front side thin sheet (3) is a multi-layer sheet which at least comprises a nonwoven cloth layer (3A) forming the skin contacting surface and a plastic film layer(3B) laminated on the non skin contacting surface of the nonwoven cloth layer, the plastic film layer (3B) is composed of material with a melting point lower than the nonwoven cloth. Under the heating condition with a melting point higher than the melting point of the plastic film layer (3B) and lower than the melting point of the nonwoven cloth layer (3A), the concave-convex embossing process composed of a plurality of projecting parts (7, 7......) projecting outside is executed to the front side thin sheet (3), and the hole making process is executed to the top of the convex embossed pattern or the bottom of the concave embossed pattern of the concave-convex embossed pattern.

Owner:DAIO PAPER CORP

Low-temperature high-strength devitrified glass ceramics bond cubic boron nitride grinding wheel

InactiveCN101362316AHigh hardnessImprove grinding abilityBonded abrasive wheelsNumerical controlBoron nitride

The invention discloses a cubic boron nitride grinding wheel with low-temperature and high-strength microcrystalline glass ceramic binder. The cubic boron nitride grinding wheel consists of a matrix, a binding course and a grinding wheel block. The grinding wheel block is a cubic boron nitride grinding wheel block, and adopts the following raw materials (according to the weight percentage of the content): 45 to 80 percent of cubic boron nitride abrasive, 0 to 20 percent of corundum, and 20 to 35 percent of ceramic binder; the ceramic binder is the microcrystalline glass ceramic binder, and the raw material composition and the weight percentage content is as follows: 40 to 70 percent of SiO2, 5 to 25 percent of B2O3, 2 to 5 percent of Al2O3, 2 to 15 percent of Na2O, 2 to 5 percent of K2O, 2 to 4 percent of MgO, 2 to 4 percent of CaO, 1 to10 percent of Li2O, 2 to 5 percent of ZrO2 and 2 to 5 percent of Sb2O3. The invention provides a high efficiency grinding tool which has the advantages that the using linear speed of the grinding wheel can be 160 m / s, the process precision is high, the service life is long, the environment pollution is avoided, and the high efficiency grinding tool can be matched with a high speed high efficiency numerical control crankshaft grinder and is mainly used in the grinding machining of car crank shafts and various numerical control.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com