Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26010results about How to "Improve waterproof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

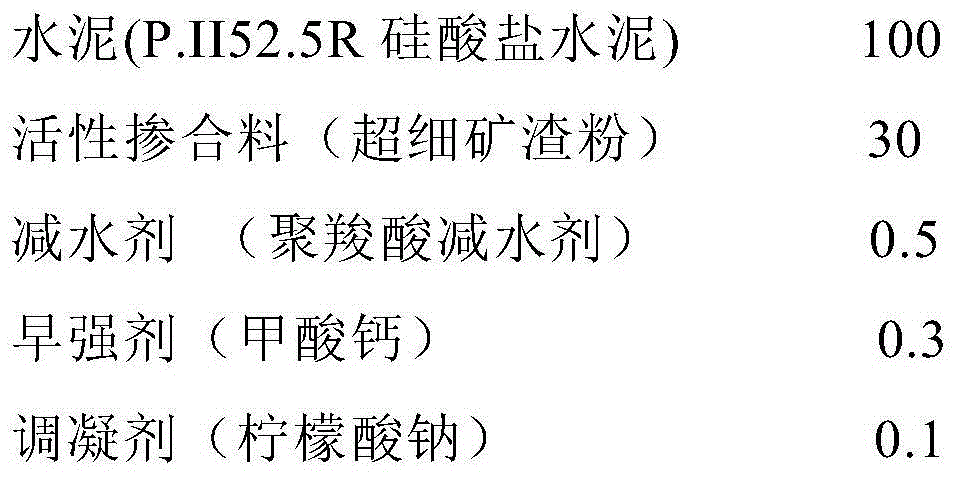

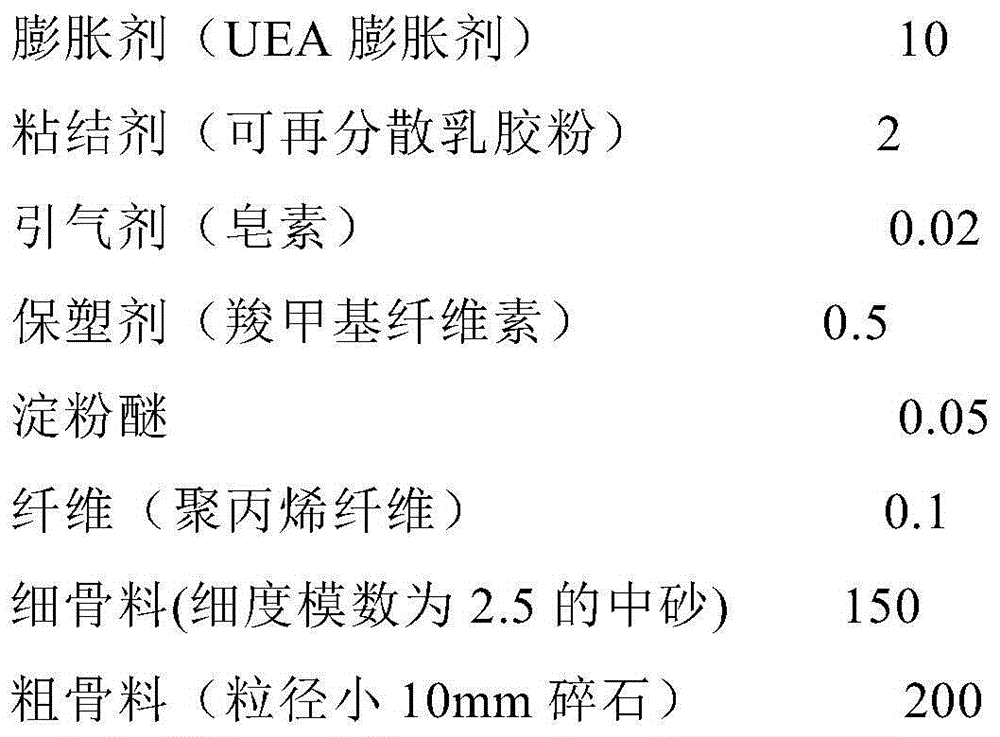

3D printing cement-based material and preparation method thereof

The invention relates to a 3D printing cement-based material and a preparation method thereof. The 3D printing cement-based material is composed of a powder form gelling material and an aggregate, the powder form gelling material is composed of cement, an active admixture, a water reducer, a hardening accelerator, an adjustable solidification agent, an expanding agent, a binder, an air-entrainer, a plasticity-maintaining agent, a water repellent, starch ether, a powder filling material and fiber, and the aggregate is composed of a fine aggregate and a crude aggregate. Compared with prior art, the 3D printing cement-based material has the advantages of good work performance, constructability performance, mechanical property and endurance performance.

Owner:TONGJI UNIV

Plant-level comprehensive supervision platform

InactiveCN105187771ARealize centralized managementQuality improvementClosed circuit television systemsTransmissionVideo monitoringIntelligent lighting

The invention relates to a monitoring system and specifically relates to a plant-level comprehensive supervision platform. The plant-level comprehensive supervision platform comprises a front-end system, a transmission network and a master station system, wherein the front-end system is integrated with subsystems of video monitoring, environmental monitoring, security guard, fire alarm, one-card-through, entrance and exit control, maloperation prevention, gps positioning, intelligent lighting, intelligent control and the like in a thermal power plant; the transmission network functions as a bridge for connecting the front end and the platform; the master station system comprises a local monitoring center, a cloud computing system, an application platform and a whole network operation and maintenance platform. The comprehensive supervision platform is a large online monitoring system integrated with hardware, software and network; the platform software is taken as the core to realize centralized management on all zones; besides, centralized monitoring and uniformed management on the front-end system can be realized at a regulation and control center; in short, the plant-level comprehensive supervision platform escorts the smart grid.

Owner:SHANDONG CHUANGDE SOFTWARE TECH

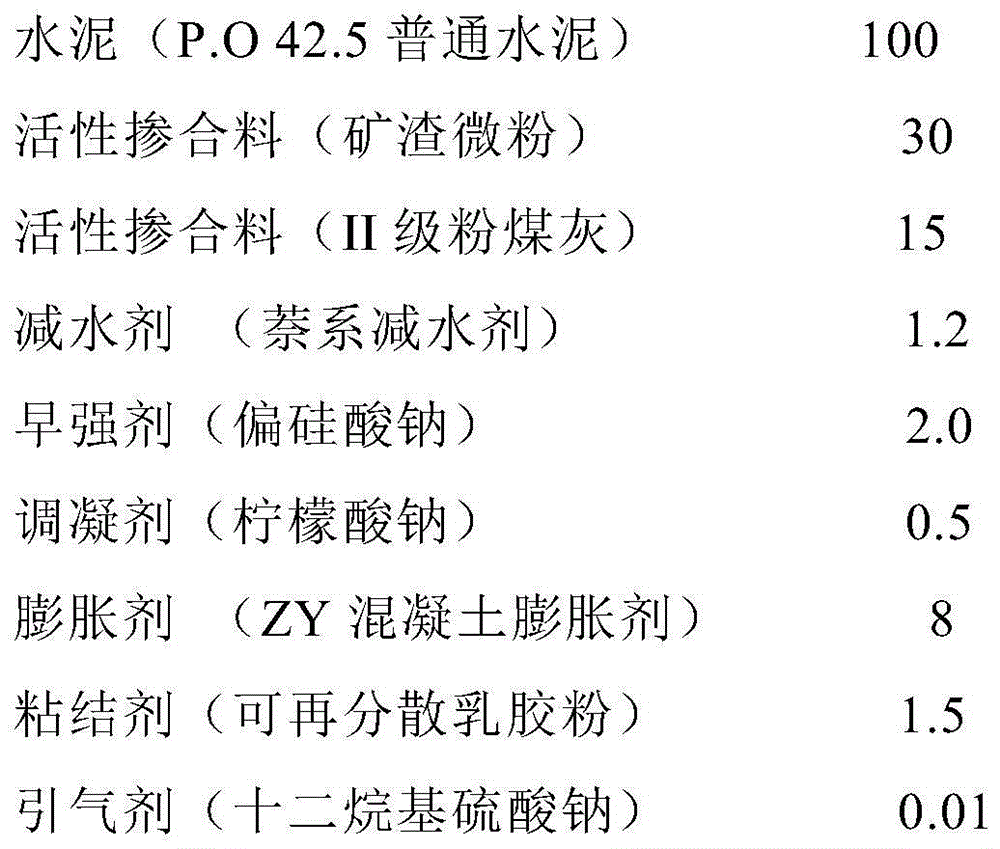

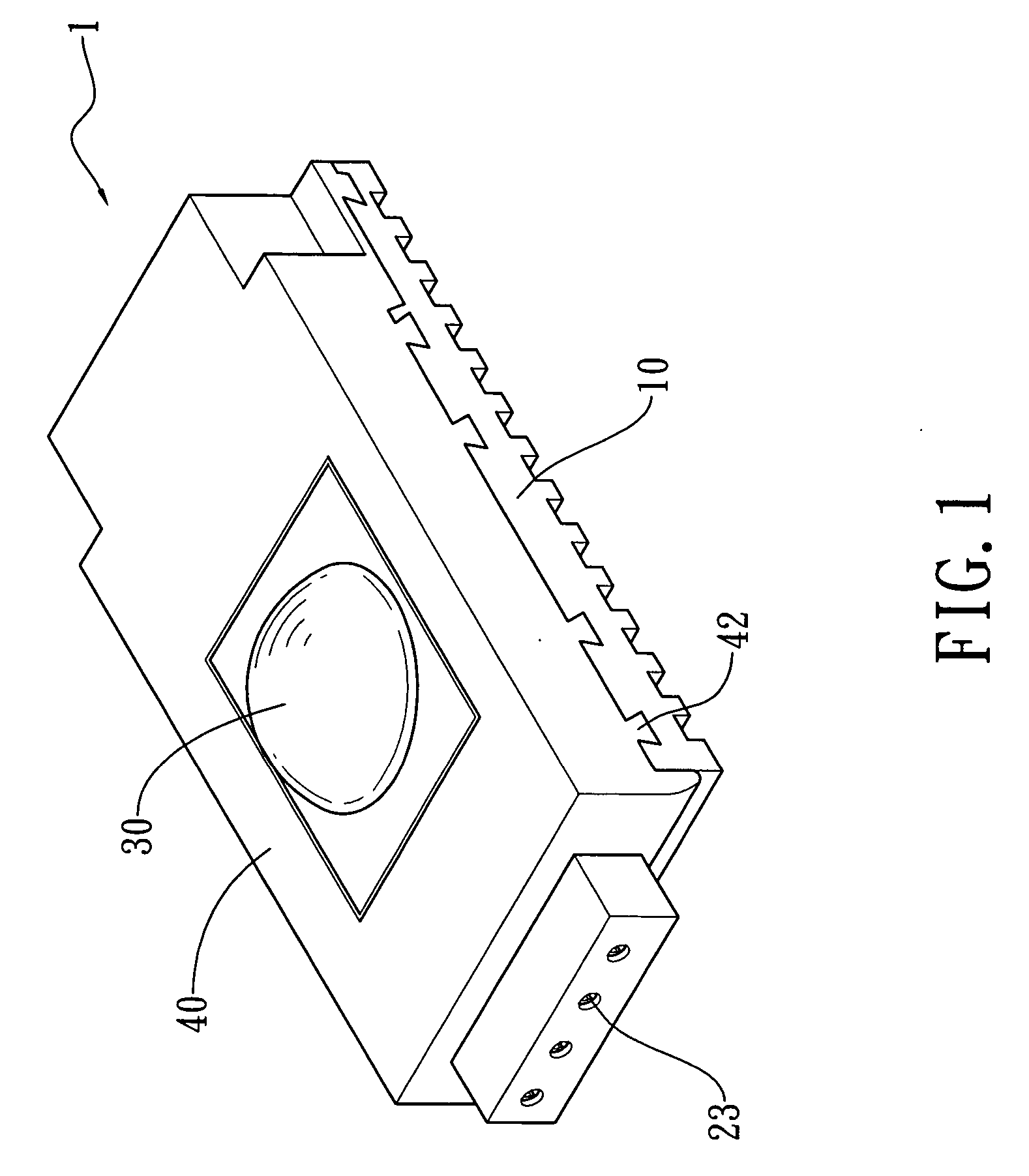

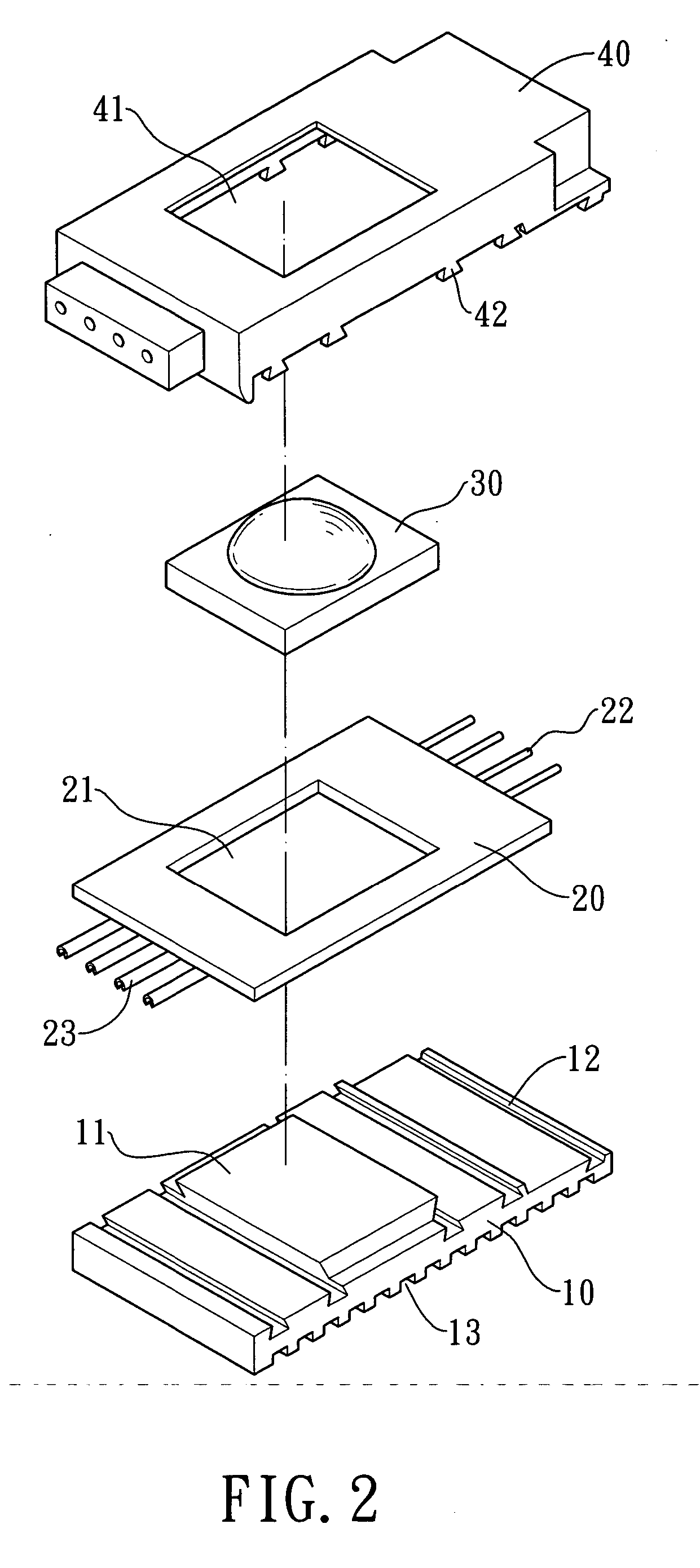

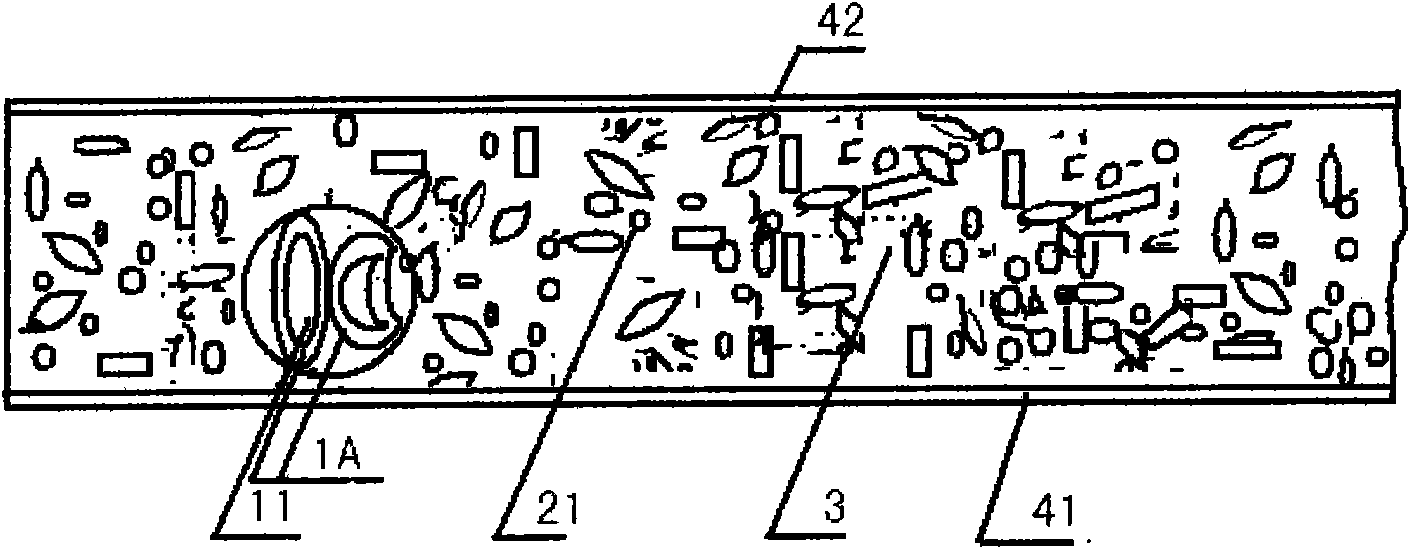

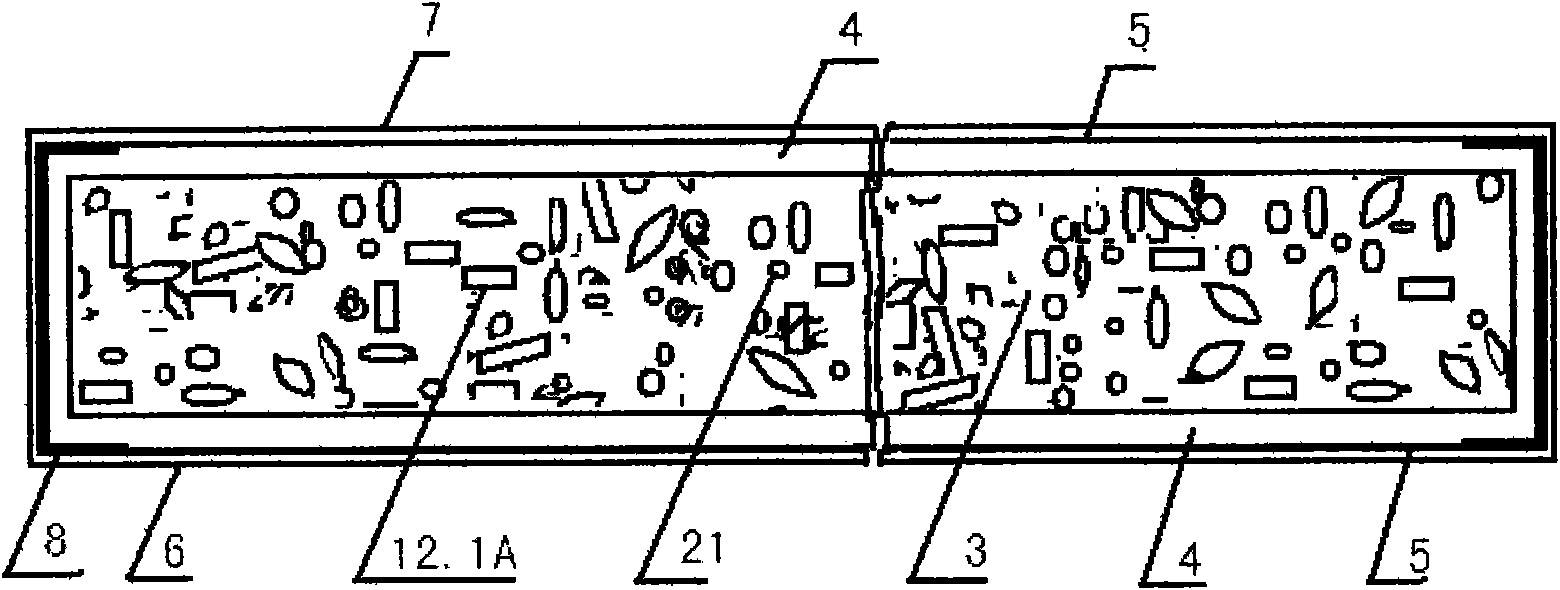

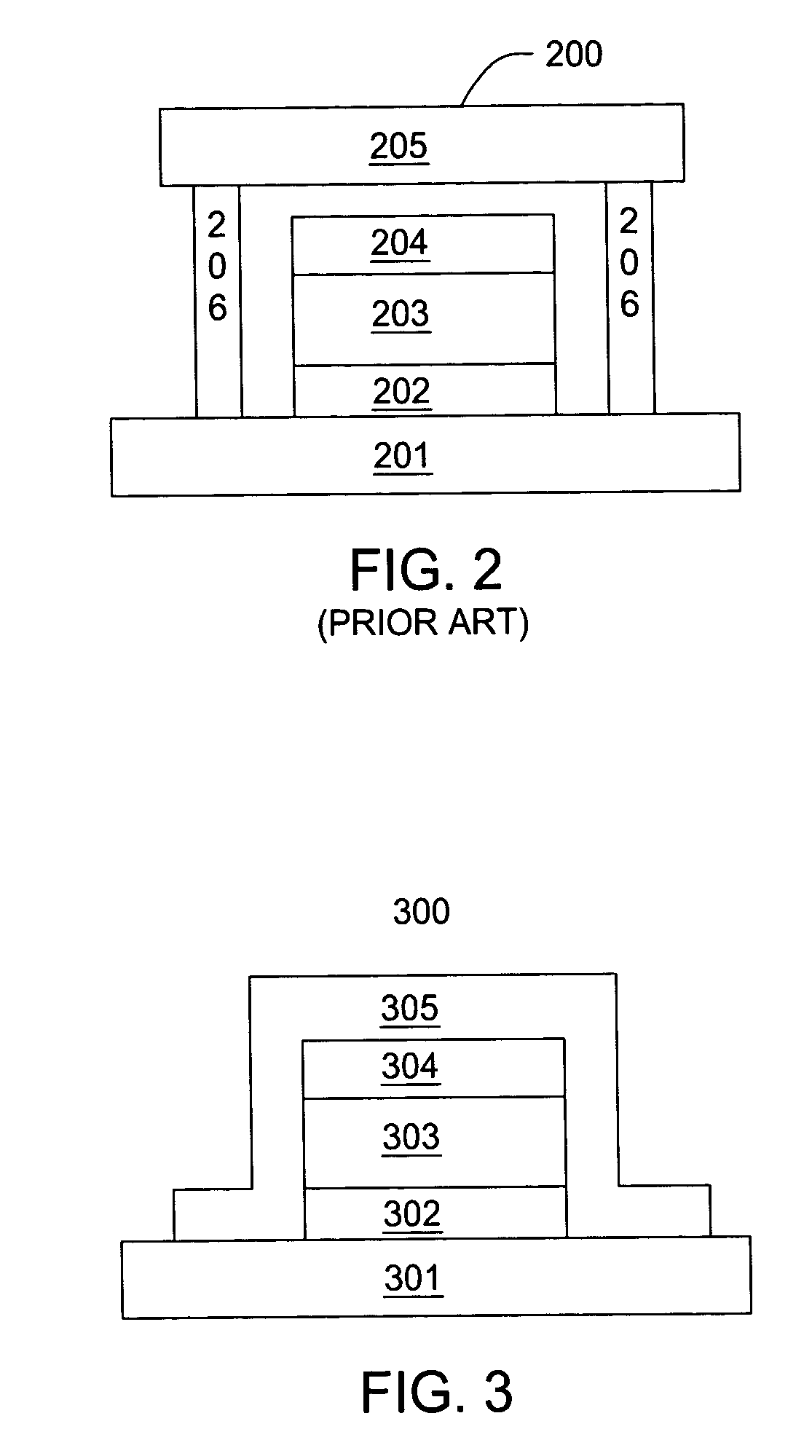

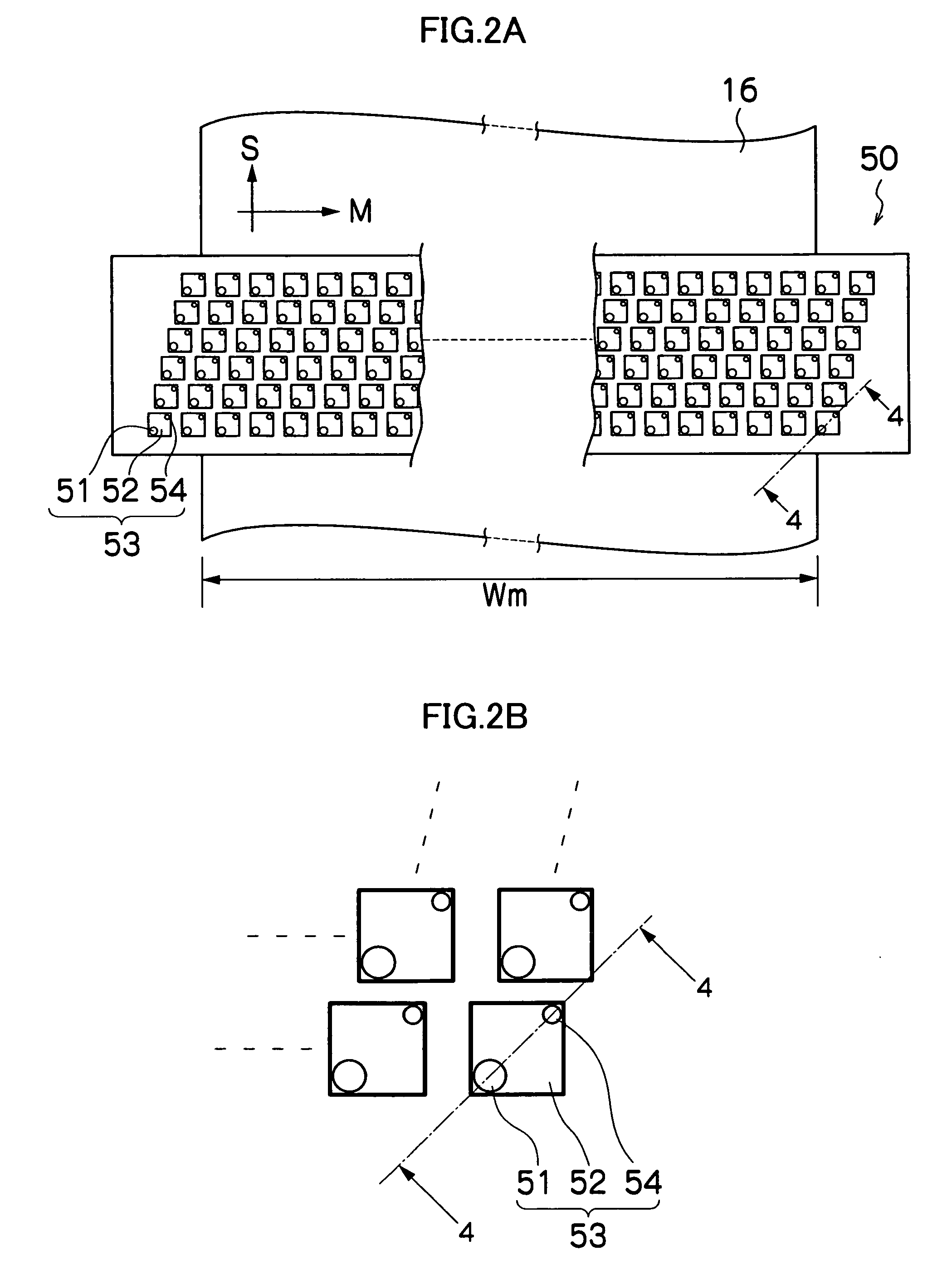

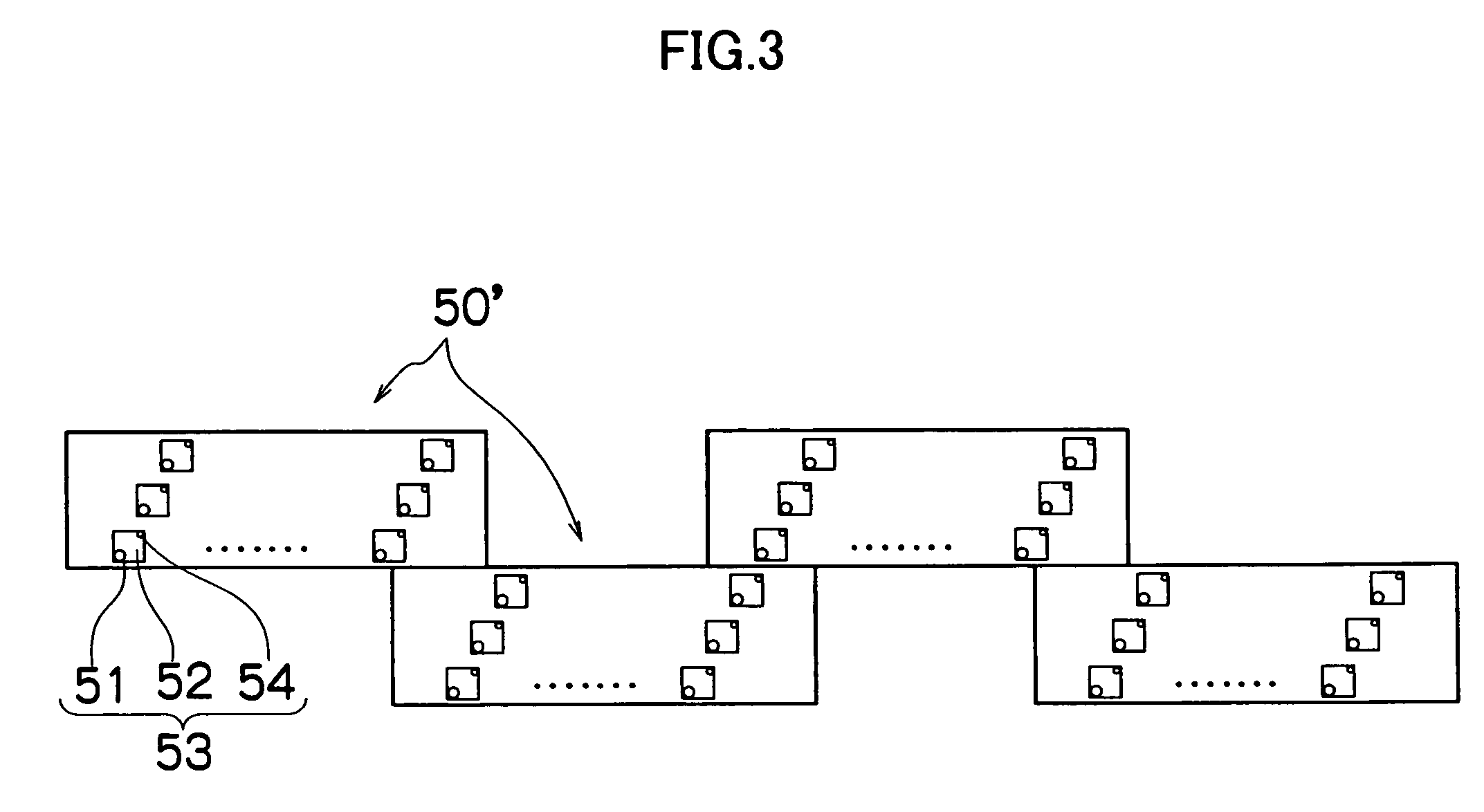

Modular light emitting diode

InactiveUS20060262533A1Improve waterproof performanceHeat dissipation fastLighting support devicesPoint-like light sourceEngineeringLight-emitting diode

A modular light emitting diode is disclosed. The modular light emitting diode comprises a heat-sinking base, a circuit board, a LED light emitting device, and a waterproofing layer. A protrudent portion and a plurality of trenches are formed on the surface of the heat-sinking base. Waterproof connection terminals are mounted on both sides of the circuit board. The LED light emitting device is mounted on and connected to the circuit board so as to form a complete circuit. Thereafter, the circuit board on which the LED light emitting device is mounted is stacked on the heat-sinking base to allow the LED light emitting device to be mounted on the protrudent portion of the heat-sinking base. These three stacked components are locally packaged by a waterproofing layer to complete the modular light emitting diode having the advantages of good waterproofing, rapid heat sinking, and flexible assembly.

Owner:PARA LIGHT ELECTRONICS

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

Fiberglass nonwoven binder

A fiberglass non-woven binder composition containing a carboxy-functional copolymer binder crosslinker and a compound capable of forming a hydrogen-bonding complex with the carboxy-functional copolymer binder. The binder composition provides a strong, yet flexible bond that allows a compressed fiberglass mat to easily expand once the compression is released. The binder composition is capable of being cured at lower cure temperatures than those binders prepared using conventional crosslinkers.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

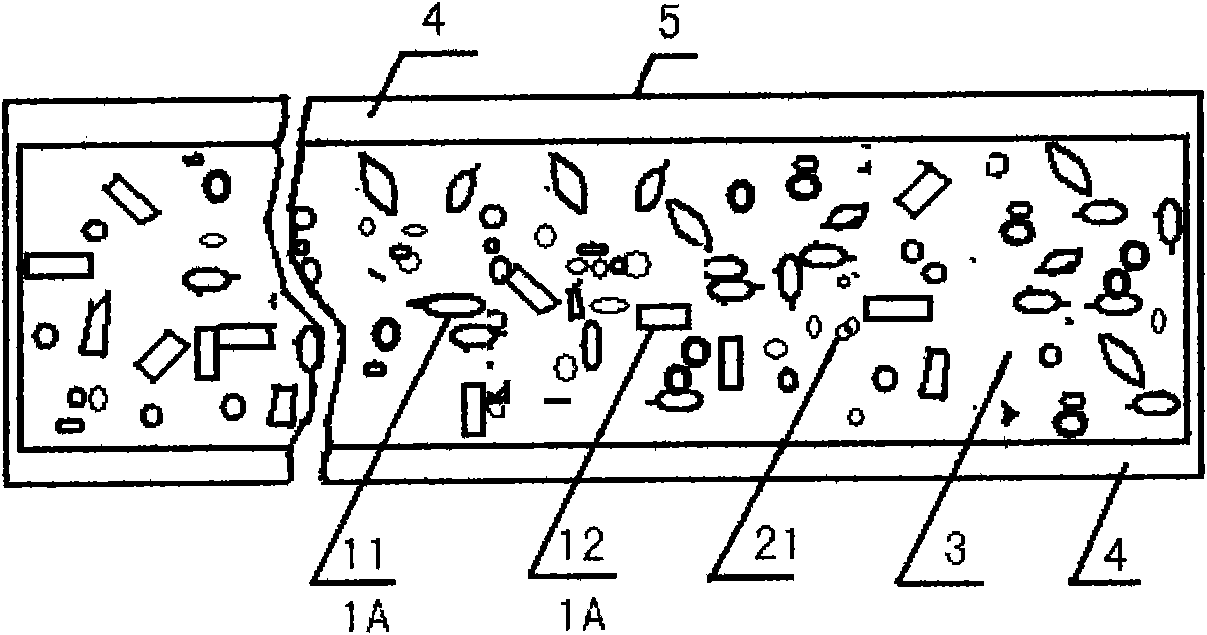

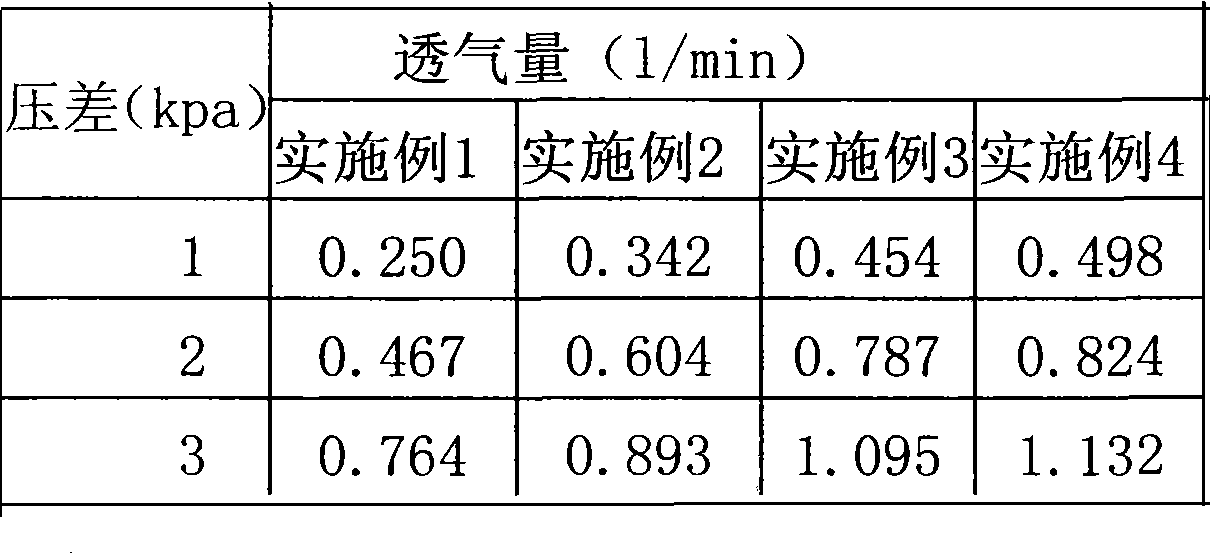

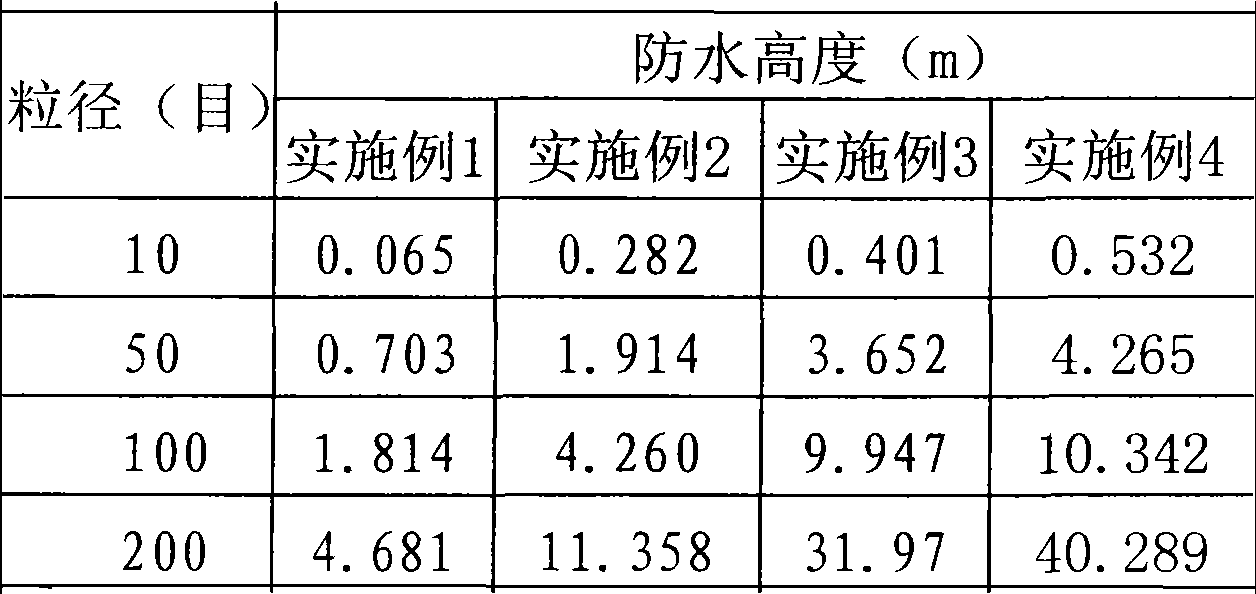

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

Porous films, process for producing the same, and laminate films and recording sheets made with the use of the porous films

InactiveUS6177181B1High in transparency and ink absorptionImprove waterproof performanceMembranesSemi-permeable membranesBoiling pointOptical transmittance

Porous membranes having a micro phase separation structure and showing a light transmittance at the wavelength of 400 nm of not less than 30% are obtained by the dry phase conversion method comprising drying a coating layer of a dope containing a polymer, a good solvent for the polymer and a poor solvent for the polymer which solvent has a higher boiling point than the good solvent. The polymer includes cellulose derivatives, vinyl-series polymers such as acrylonitrile-series polymers and (meth)acrylic acid ester-series polymers, polysulfone-series polymers, and the like. The porous polymer membranes have a porosity of 10 to 60%, a mean pore size of about 0.002 to 0.35 mum and a maximum pore size of not greater than 0.4 mum. These porous membranes shows not only excellent transparency but also high productivity.

Owner:DAICEL CHEM IND LTD

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

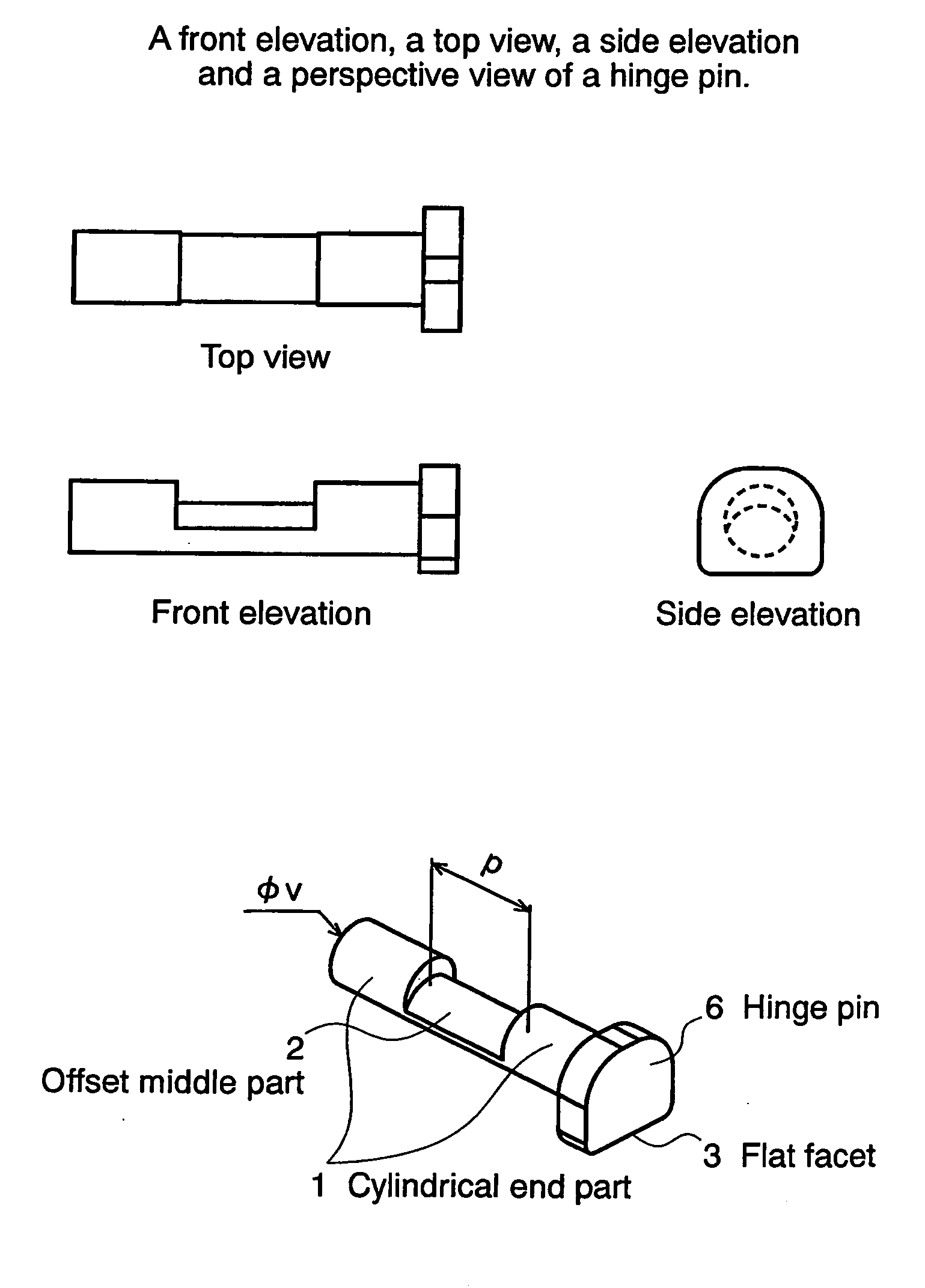

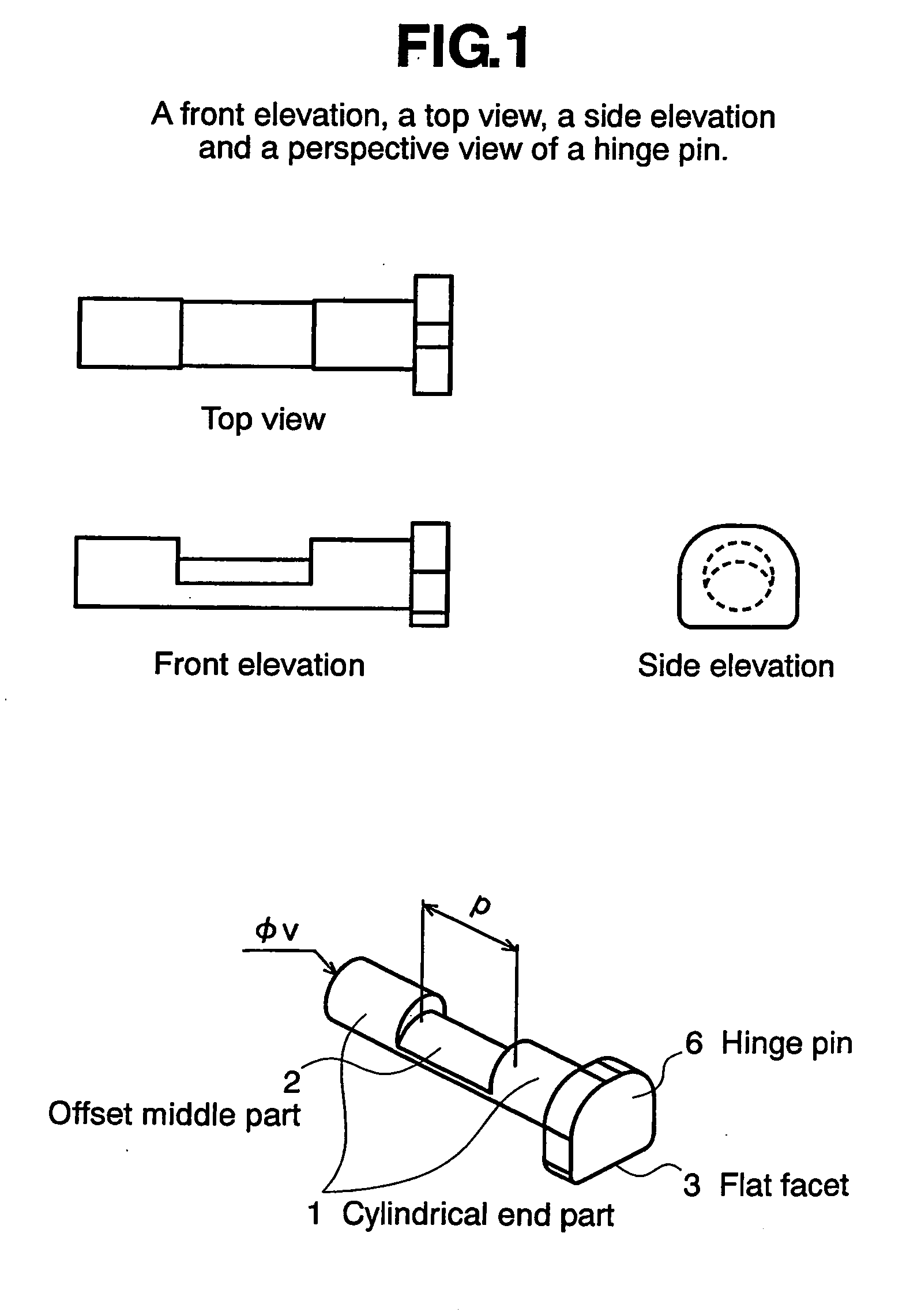

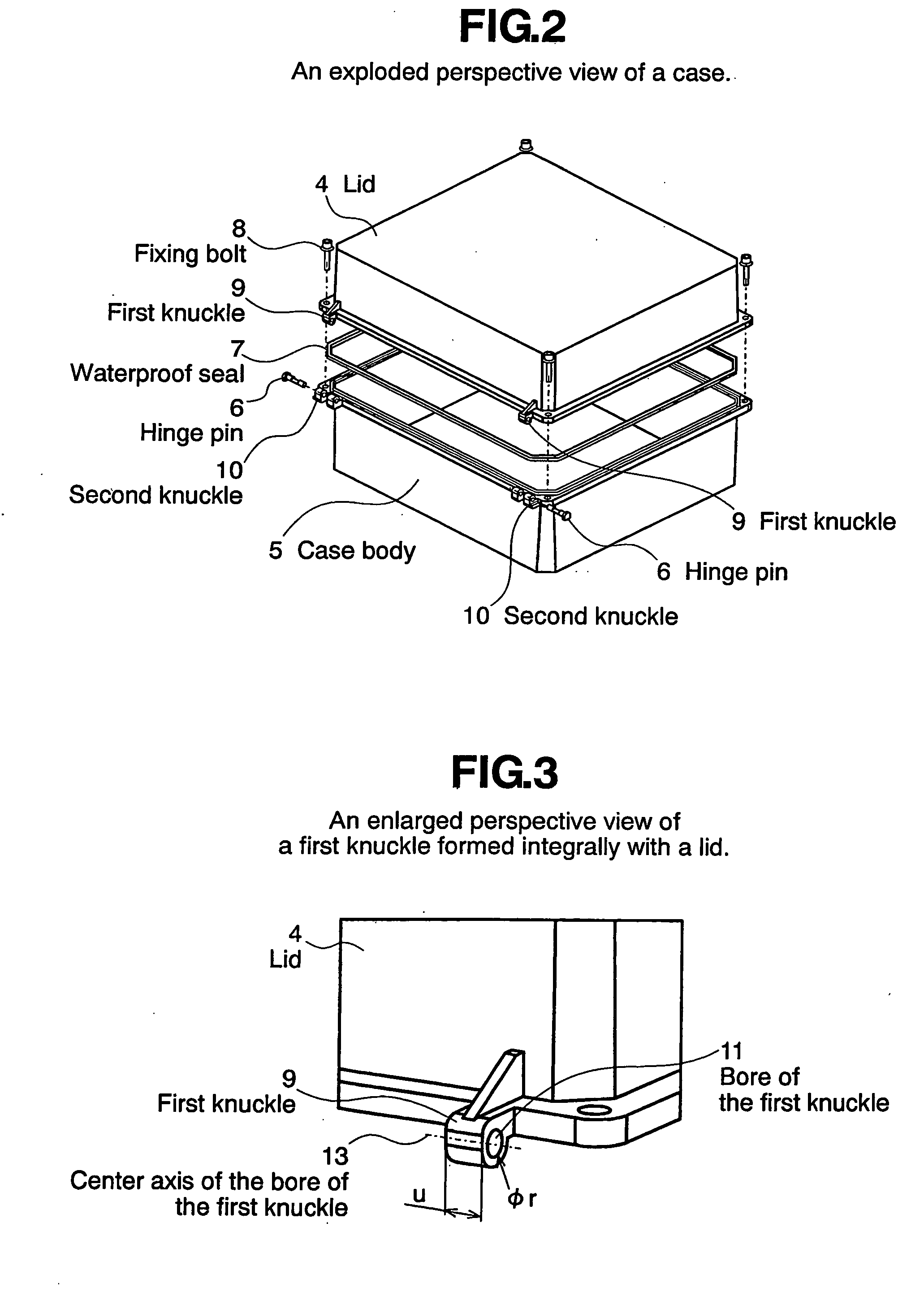

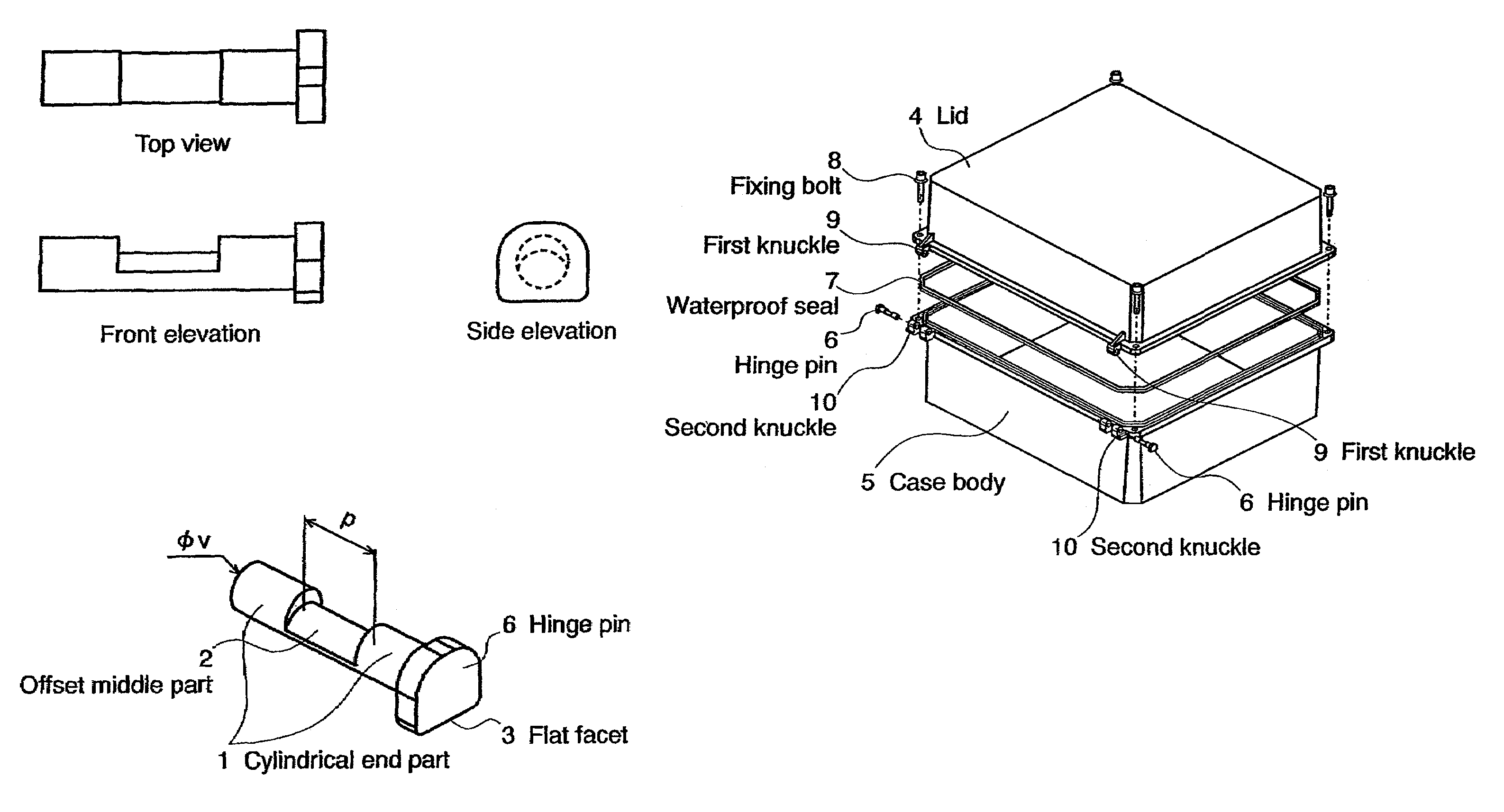

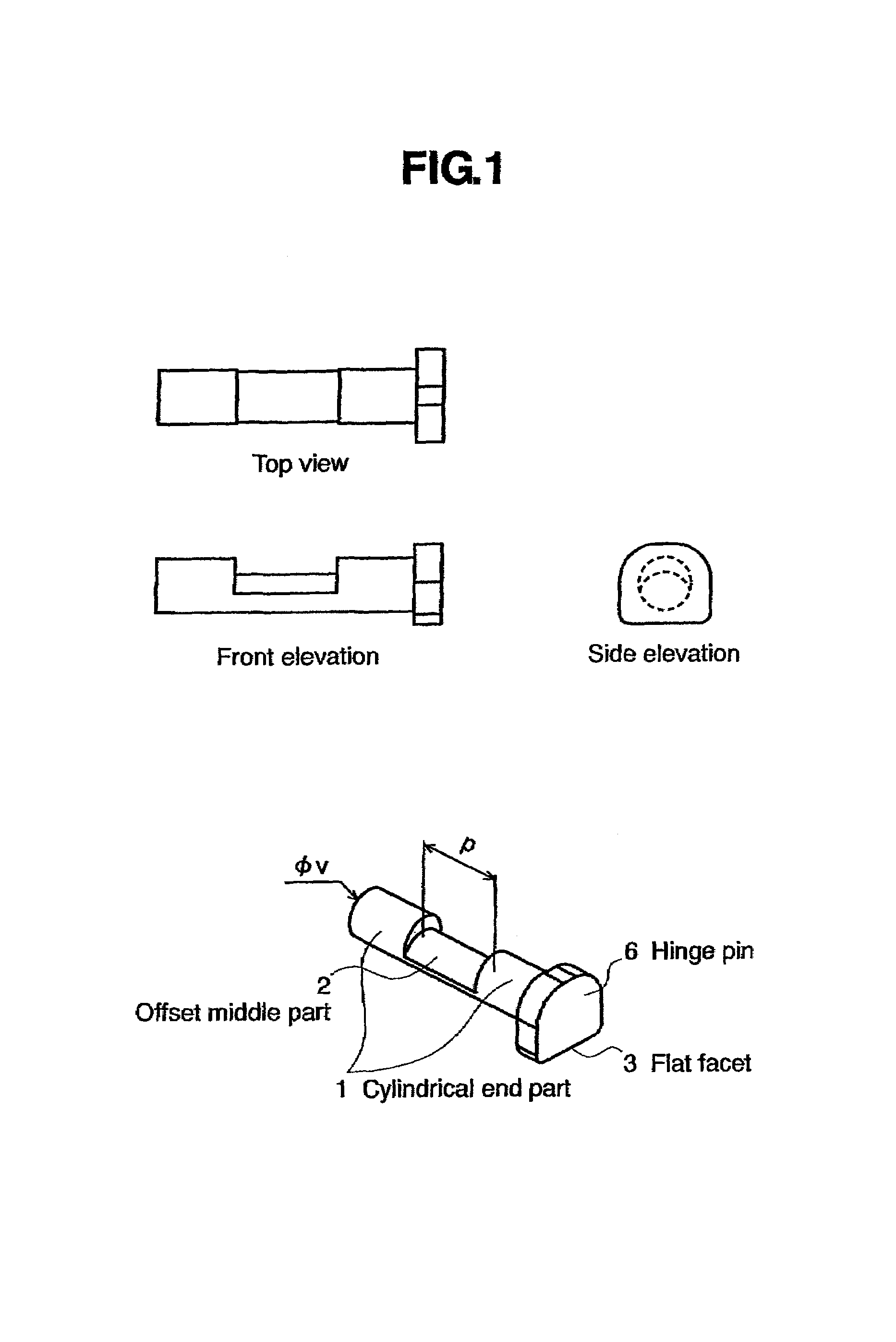

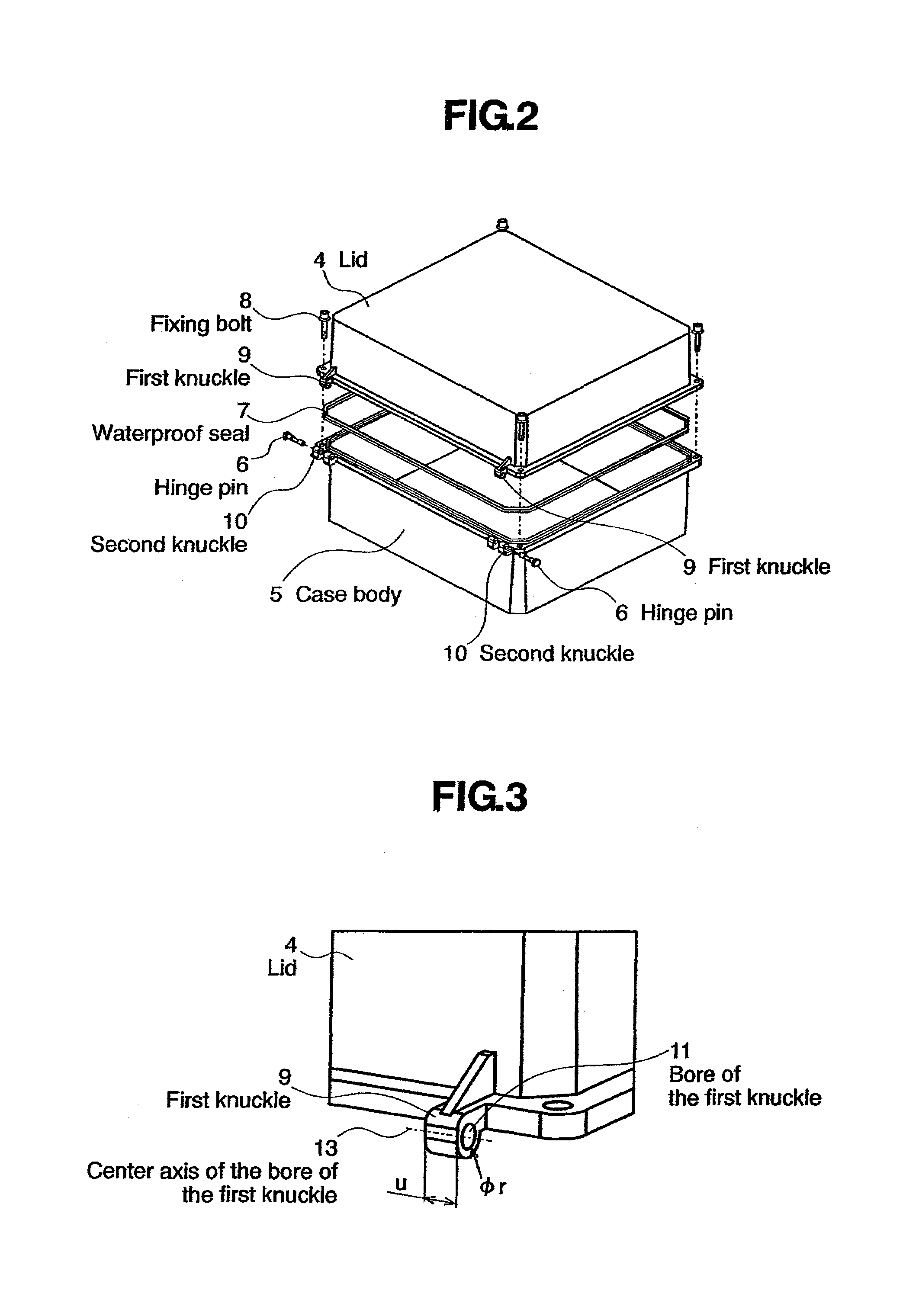

Case with hinged lid

InactiveUS20050224508A1Avoid Sealing ProblemsImprove waterproof performanceWing accessoriesCasings/cabinets/drawers detailsSacroiliac jointHinge angle

Owner:HITACHI LTD

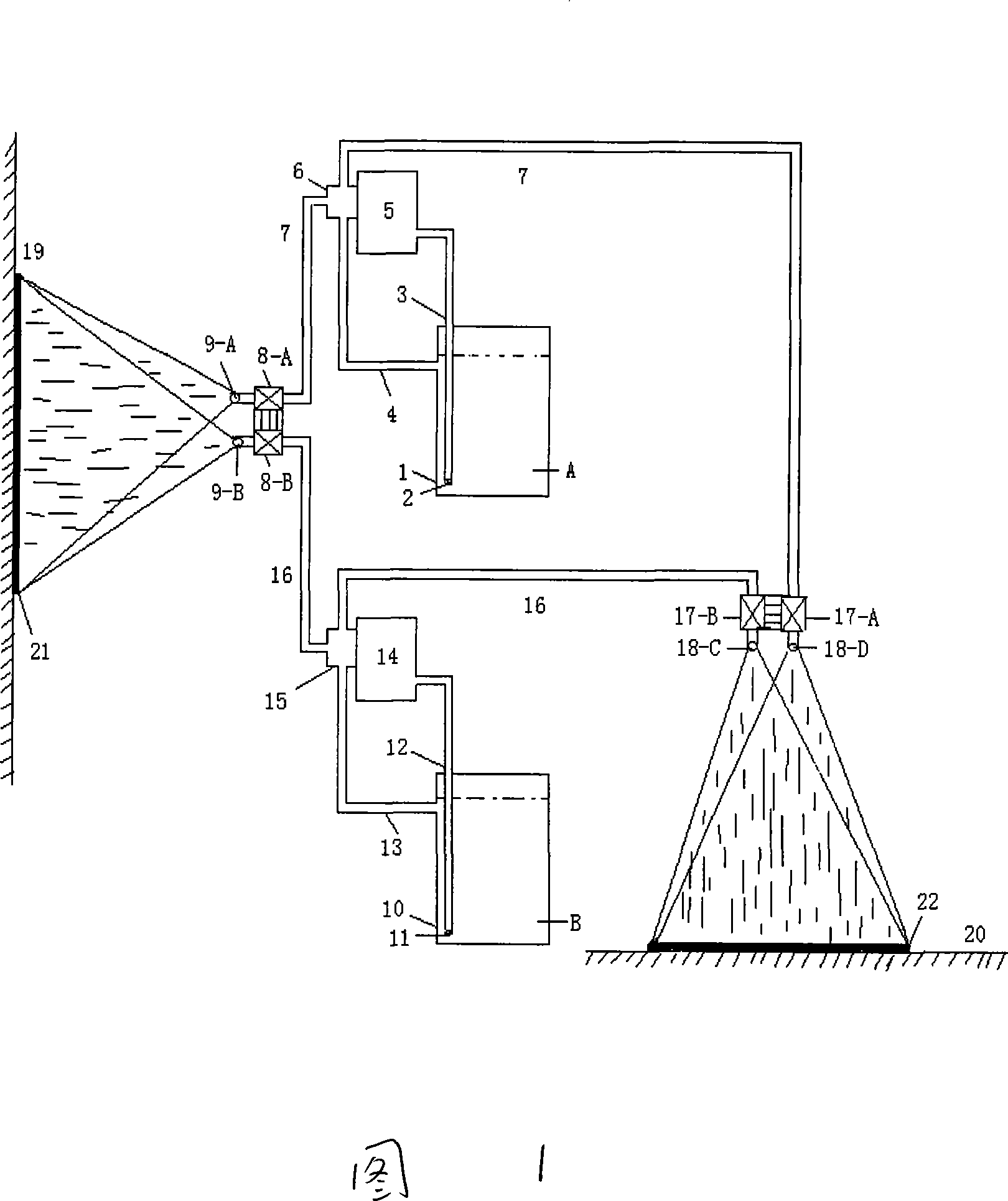

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

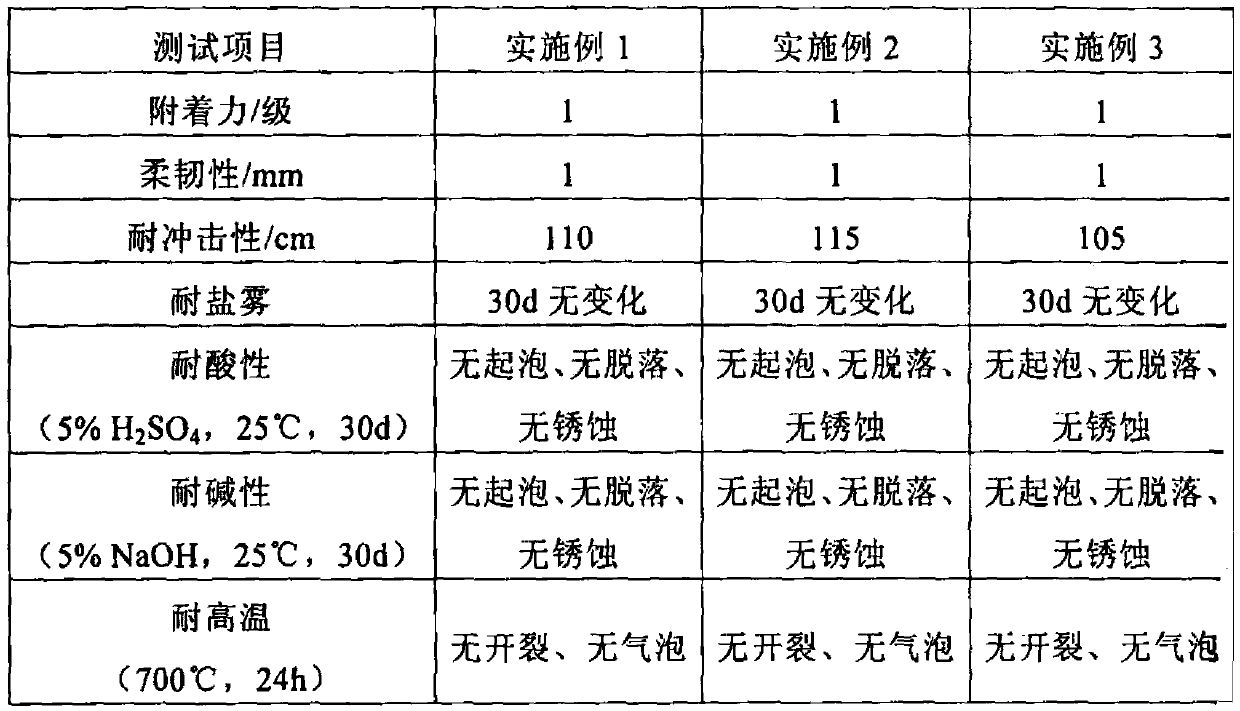

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Low-dielectric-constant glass fiber and glass fiber fabric made thereof

InactiveUS20030054936A1Maintain good propertiesImprove meltabilityWoven fabricsCircuit susbtrate materialsProduction rateTO-18

Disclosed are a low-dielectric-constant glass fiber having a glass composition comprising, by weight %, 50 to 60% of SiO2, 10 to 18% of Al2O3, 14% to less than 20% of B2O3, 1% to less than 6% of MgO, 2 to 5% of CaO, 0.5 to 5% of TiO2, 0 to 0.3% of Li2O, 0 to 0.3% of Na2O, 0 to 0.5% of K2O and 0 to 2% of F2, the content of MgO+CaO being 4 to 11% and the content of Li2O+Na2O+K2O being 0 to 0.6%, and a glass fiber fabric made of the low-dielectric-constant glass fiber. The glass fiber of the present invention has a low dielectric constant and a low dielectric tangent, is excellent in productivity and workability and is also excellent in water resistance, and the glass fiber is suitable for reinforcing printed wiring boards for high-density circuits.

Owner:NITTO BOSEIKI CO LTD

Hydrophobic modified alkali-activated inorganic polymer coating restoration material

InactiveCN104291741AFirmly connectedImprove waterproof performanceBuilding materialPolymer chemistry

The invention relates to a hydrophobic modified alkali-activated inorganic polymer coating restoration material, and belongs to the field of building materials. The hydrophobic modified alkali-activated inorganic polymer coating restoration material is used for the surface restoration and protection of building engineering, and is especially suitable for the restoration and protection of concrete of walls, water conservancy engineering, tunnels, bridges, roads, docks and water pools. The hydrophobic modified alkali-activated inorganic polymer coating restoration material comprises water, an alkali activator, a gelling base material, a water repellent and an assistant.

Owner:吕孟龙

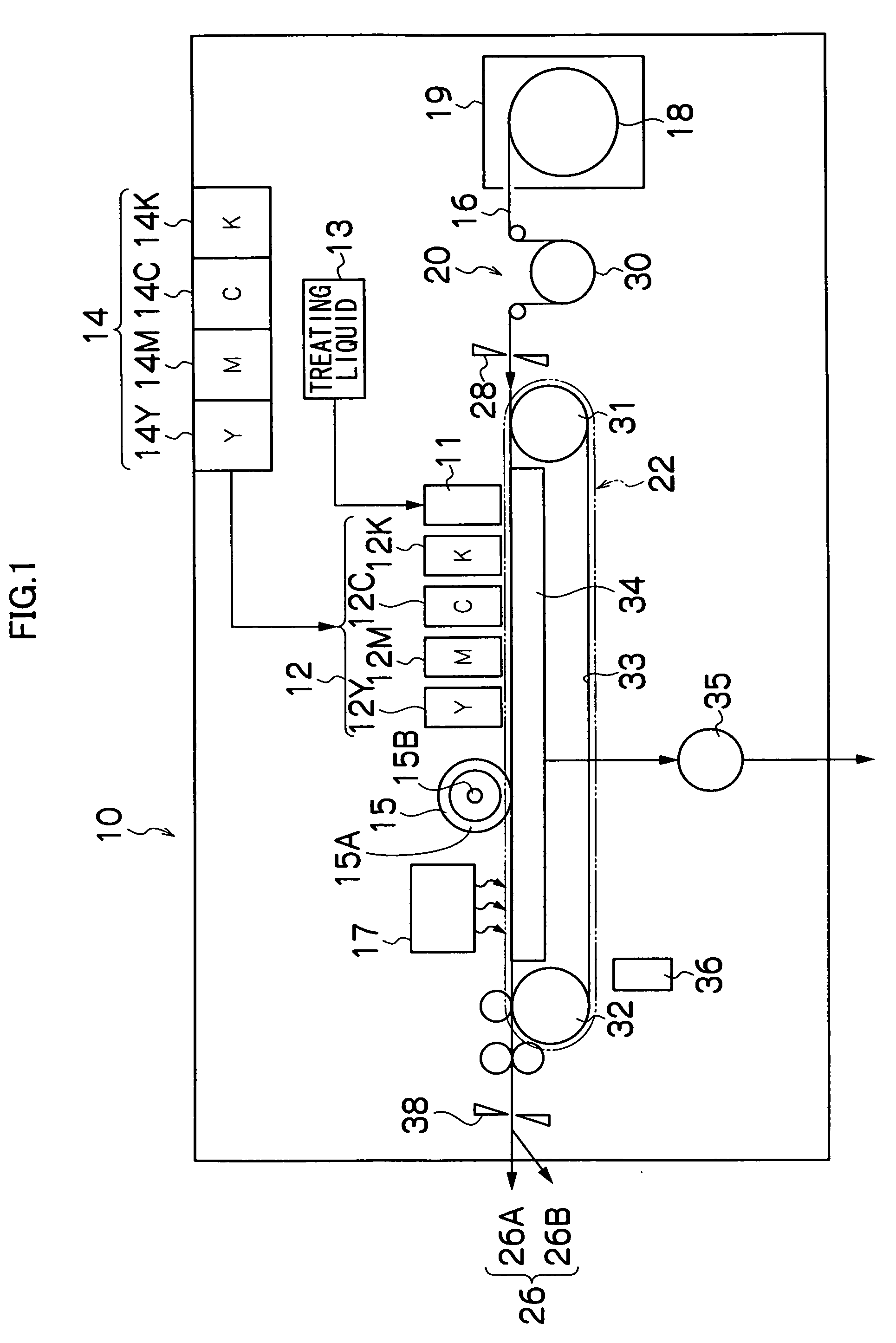

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS6695443B2Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksPolyolImaging quality

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which includes (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6% by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS20030107632A1Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksImaging qualityEngineering

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which comprises (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6 % by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

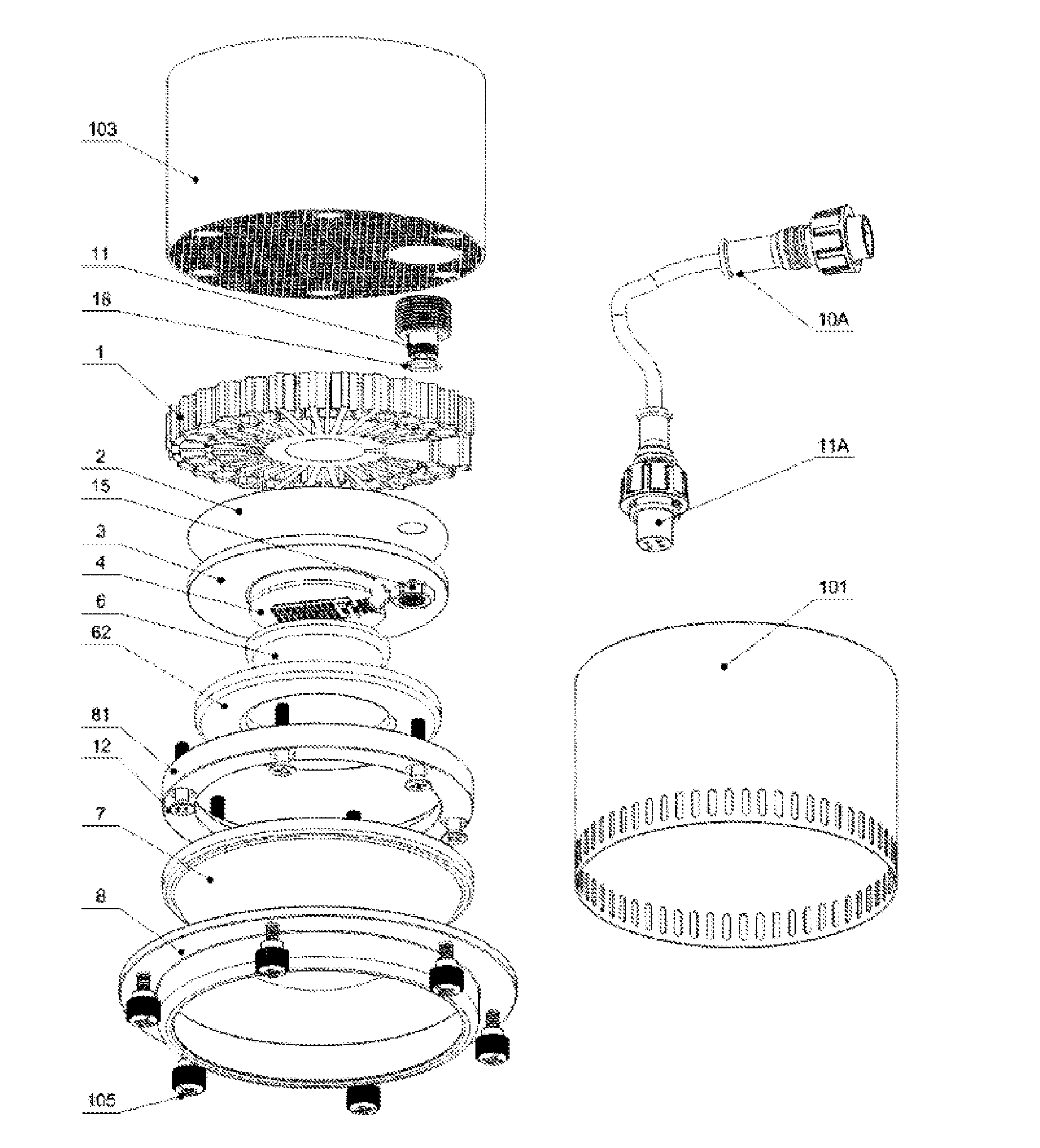

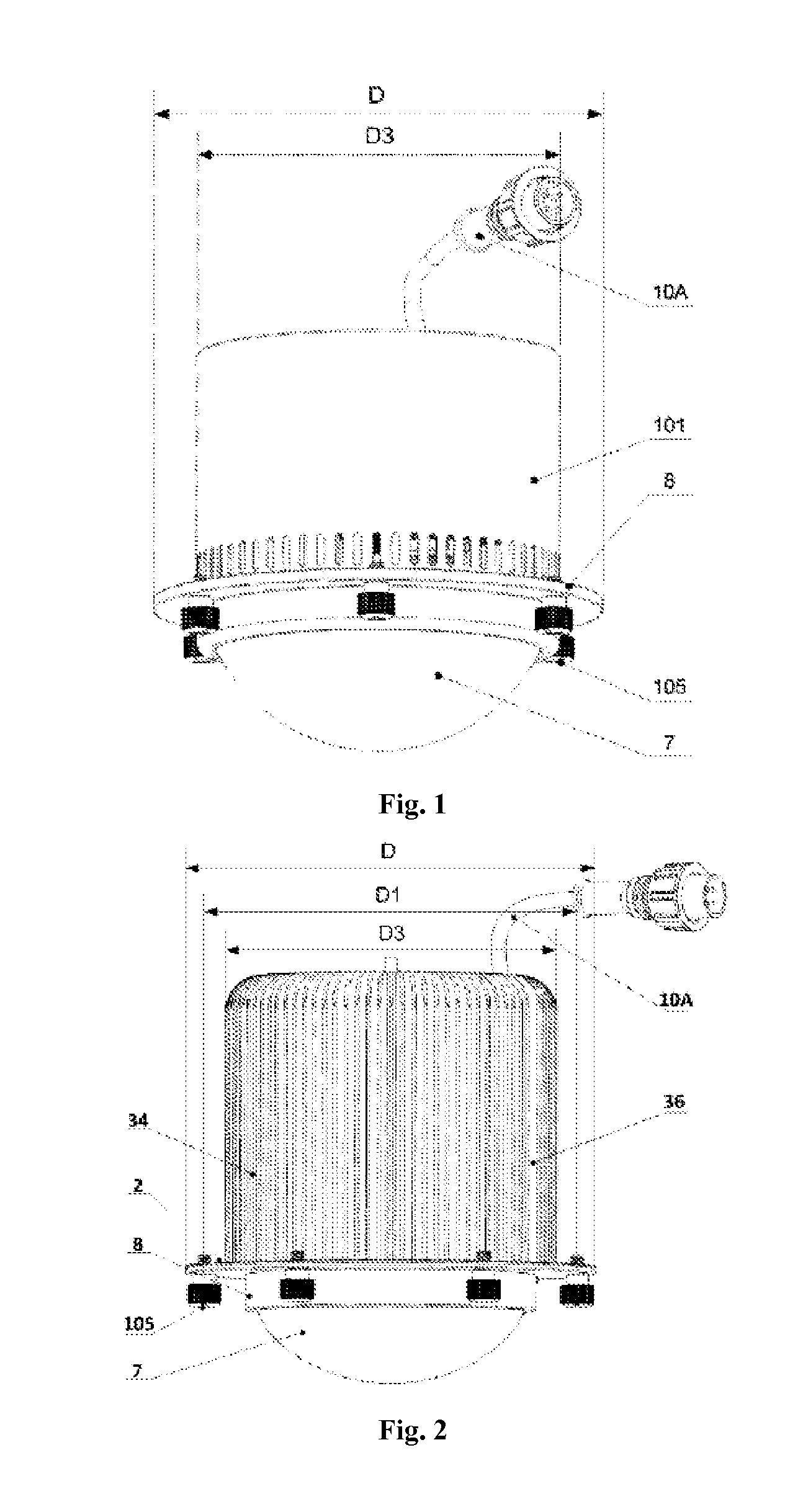

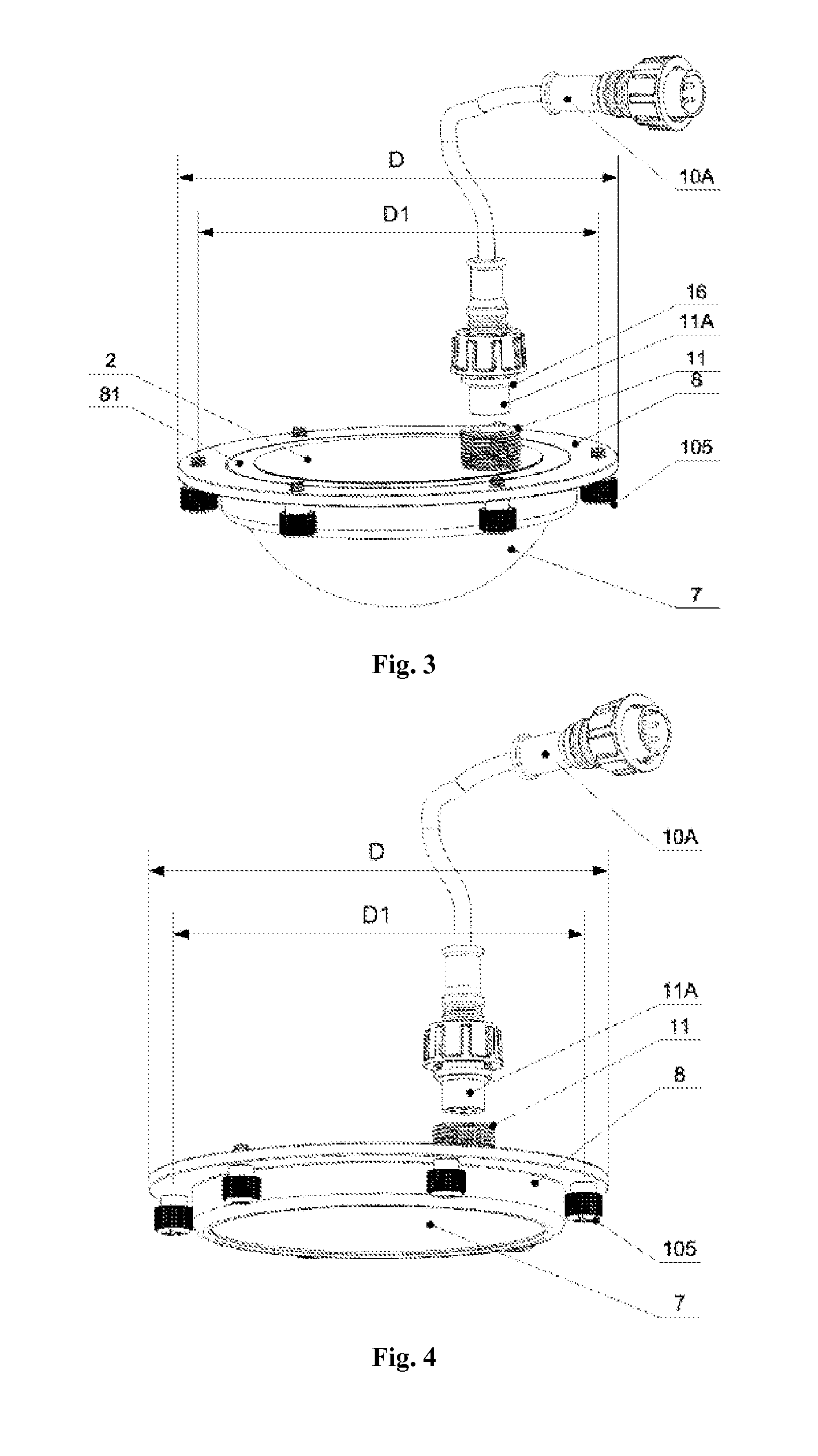

Method for constructing universal LED bulb, snap ring structured LED bulb and LED lamp

InactiveUS20150184837A1Reduce production proceduresImprove mass productionMechanical apparatusLight source combinationsEngineeringLED lamp

The present invention provides a method for constructing a universal LED bulb, a snap ring structured LED bulb and a lamp. The constructing method comprises: supporting an optical engine core member of the LED bulb in the lens snap ring (8) using a lens snap ring (8) as a supporting main body, using an inner snap ring (81) provided on the inner side of a light distribution optical lens (7) in the optical engine core member as an auxiliary supporting structure, and further using the inner snap ring (81) as an installation base of an optical engine module (4) and a heat conductive bracket (3) or an installation base of an LED bulb radiator (103); the optical engine core member of the LED bulb is composed of the heat conductive bracket (3), the optical engine module (4), the inner snap ring (81) and the light distribution optical lens (7).

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

Case with hinged lid

InactiveUS7341144B2Avoid Sealing ProblemsSeal the joint of the case body and the lid satisfactorilyWing accessoriesCasings/cabinets/drawers detailsEngineeringSacroiliac joint

Owner:HITACHI LTD

Pressure-sensitive adhesive tape and pressure-sensitive adhesive composition for medical adhesive tape

InactiveUS20060216523A1Good moisture permeabilityLess generationSurgical adhesivesPolyureas/polyurethane adhesivesVitrificationOligomer

An adhesive composition for medical adhesive tapes, comprising a base polymer containing a pressure-sensitive adhesive polymer obtained by crosslinking or curing a precursor containing a urethane acrylate oligomer and an ultraviolet (UV) initiator, the base polymer having a glass transition temperature (Tg) of 0° C. or less.

Owner:3M INNOVATIVE PROPERTIES CO

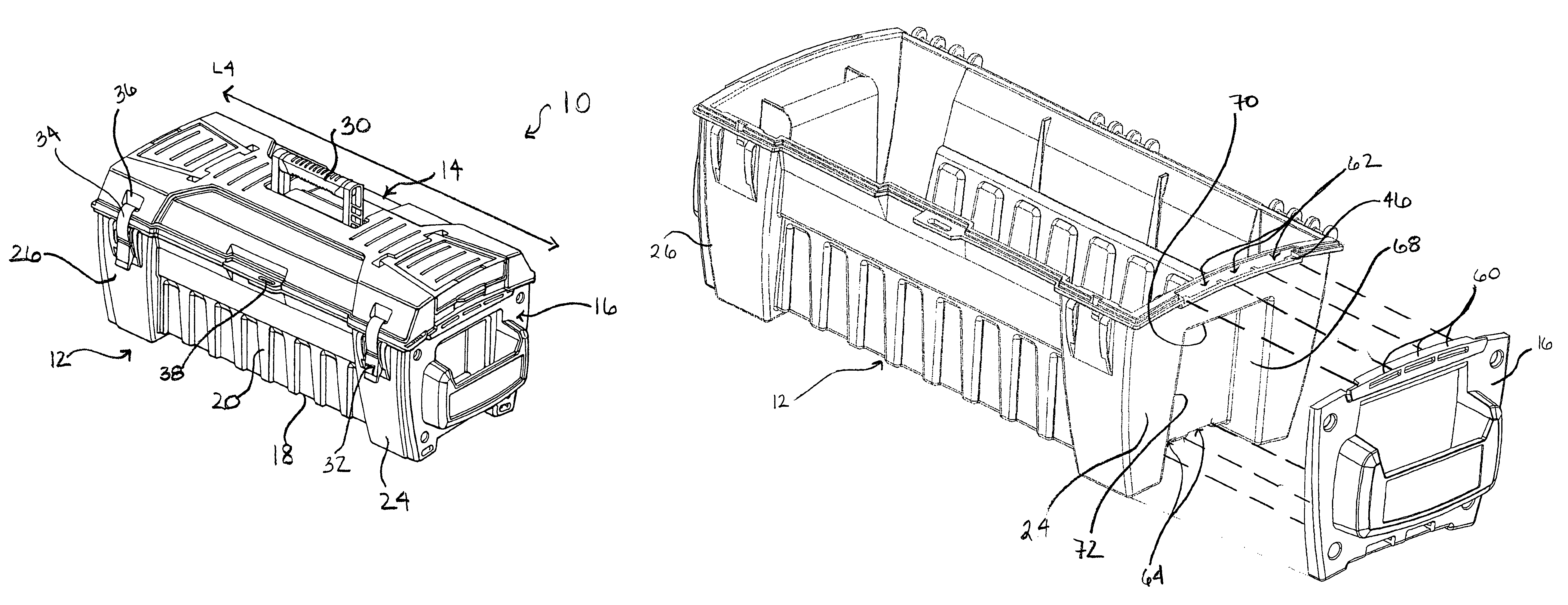

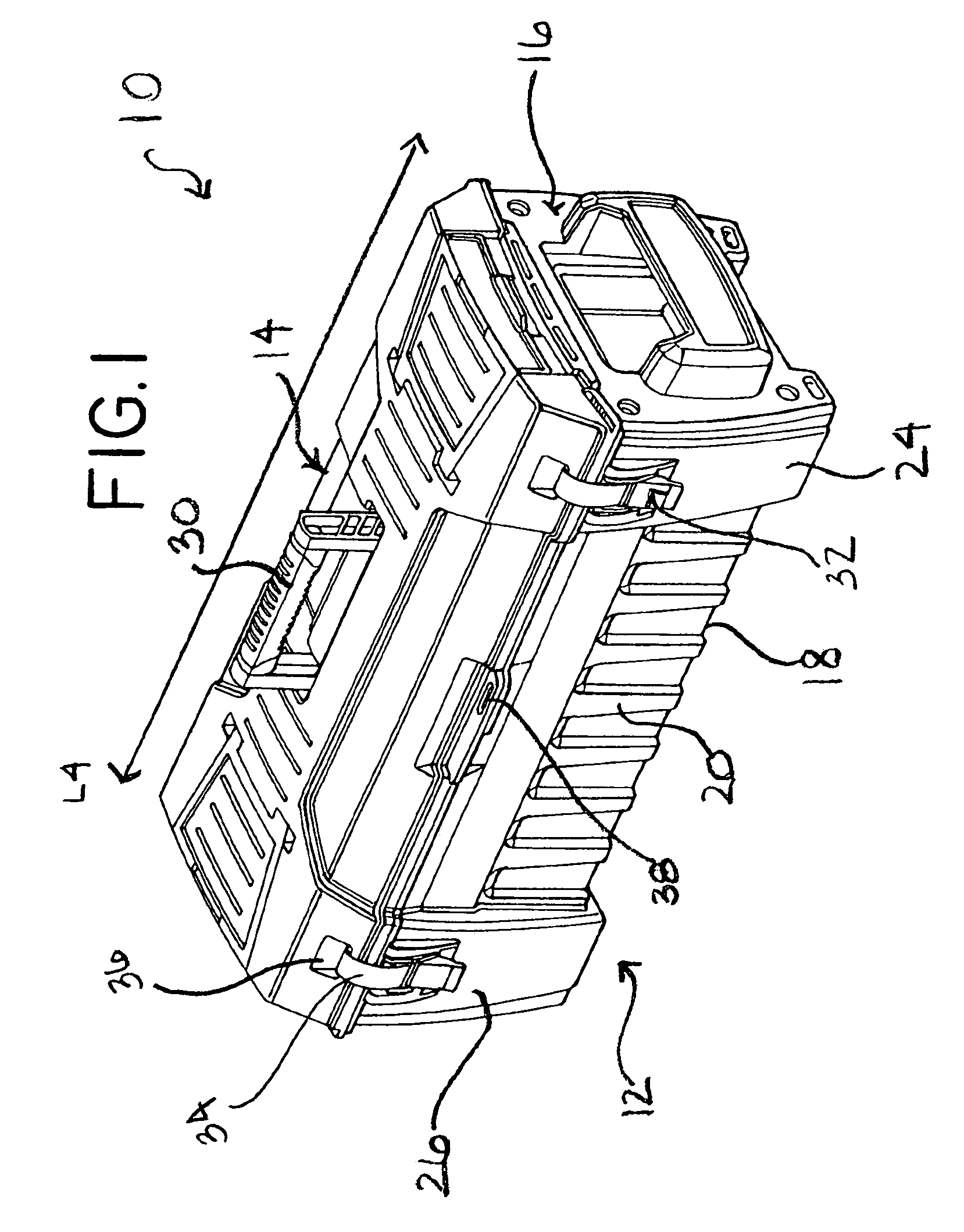

Modular toolbox system

InactiveUS7334680B2Improve waterproof performanceEliminate needMachine supportsTable equipmentsModularityEngineering

A toolbox having modular components for additional storage and functionality includes modular attachments that are adapted to removably fit various attachments, such as a cooler, cup holder, saw blades holder, drill bit holders, and the like. In addition, the toolbox includes a three-quarter length tray that allows the craftsman to overstuff the inside of the toolbox and additional storage compartments in the lid of the toolbox.

Owner:BLACK & DECKER INC

Low Weight and Density Fire-Resistant Gypsum Panel

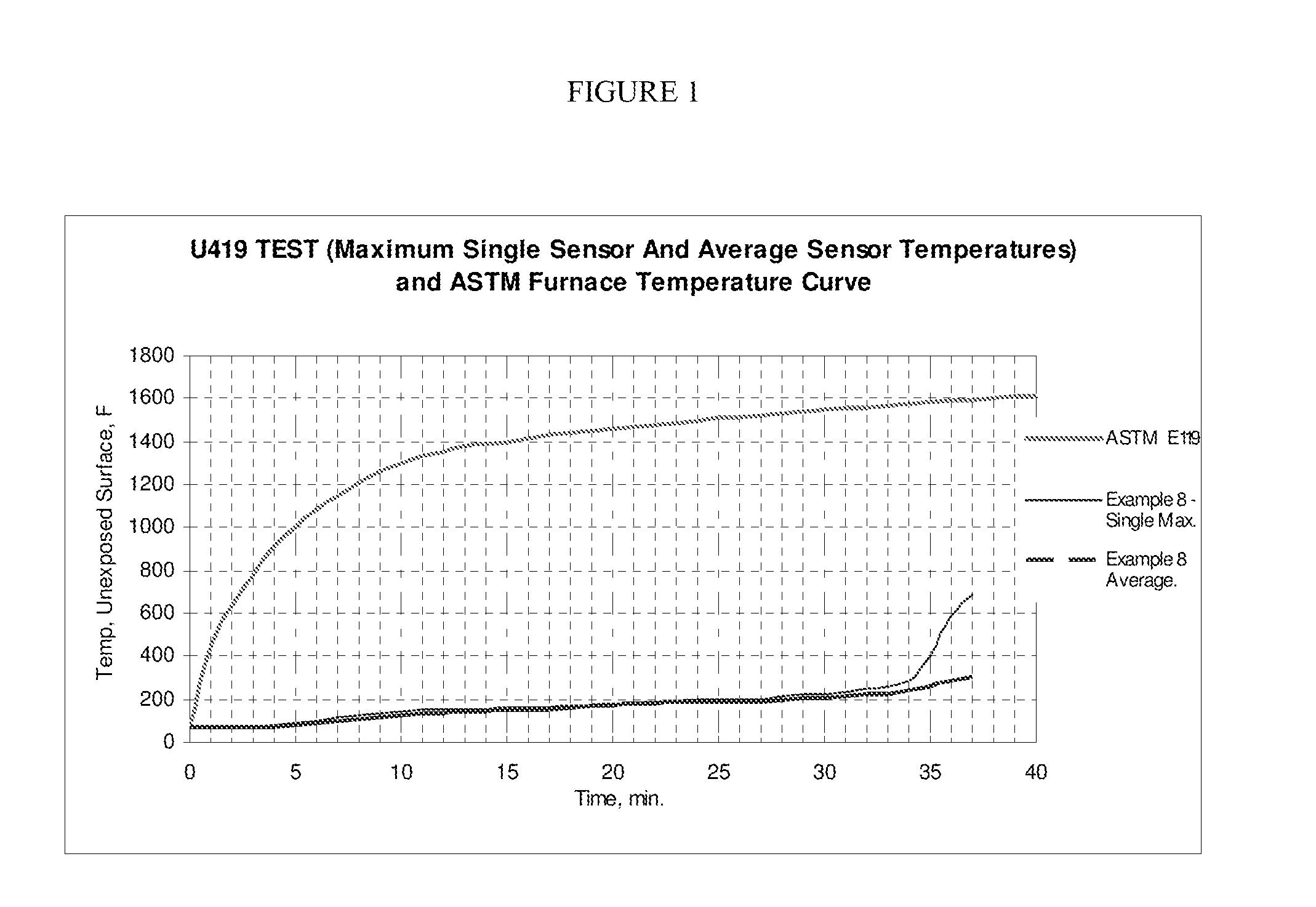

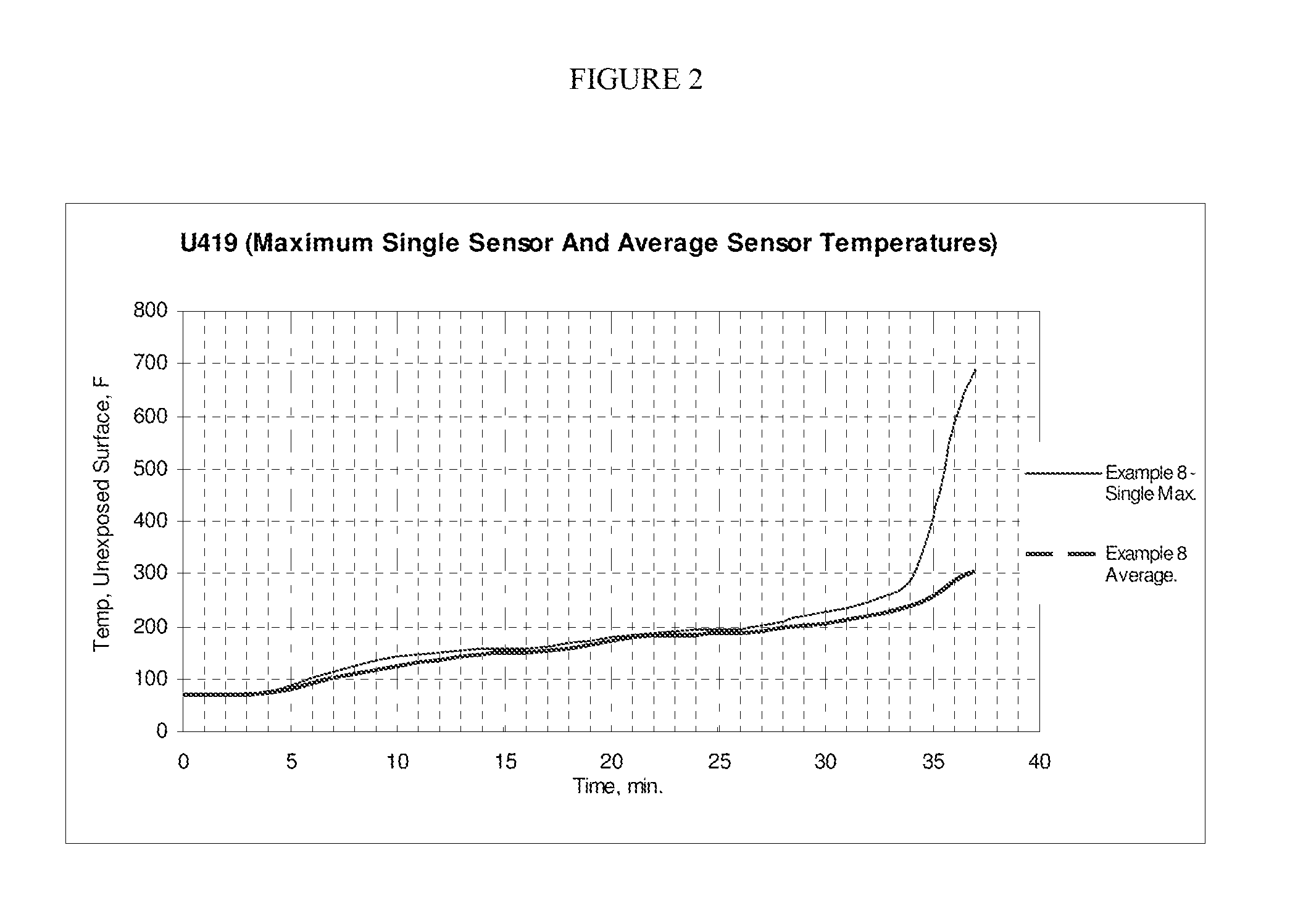

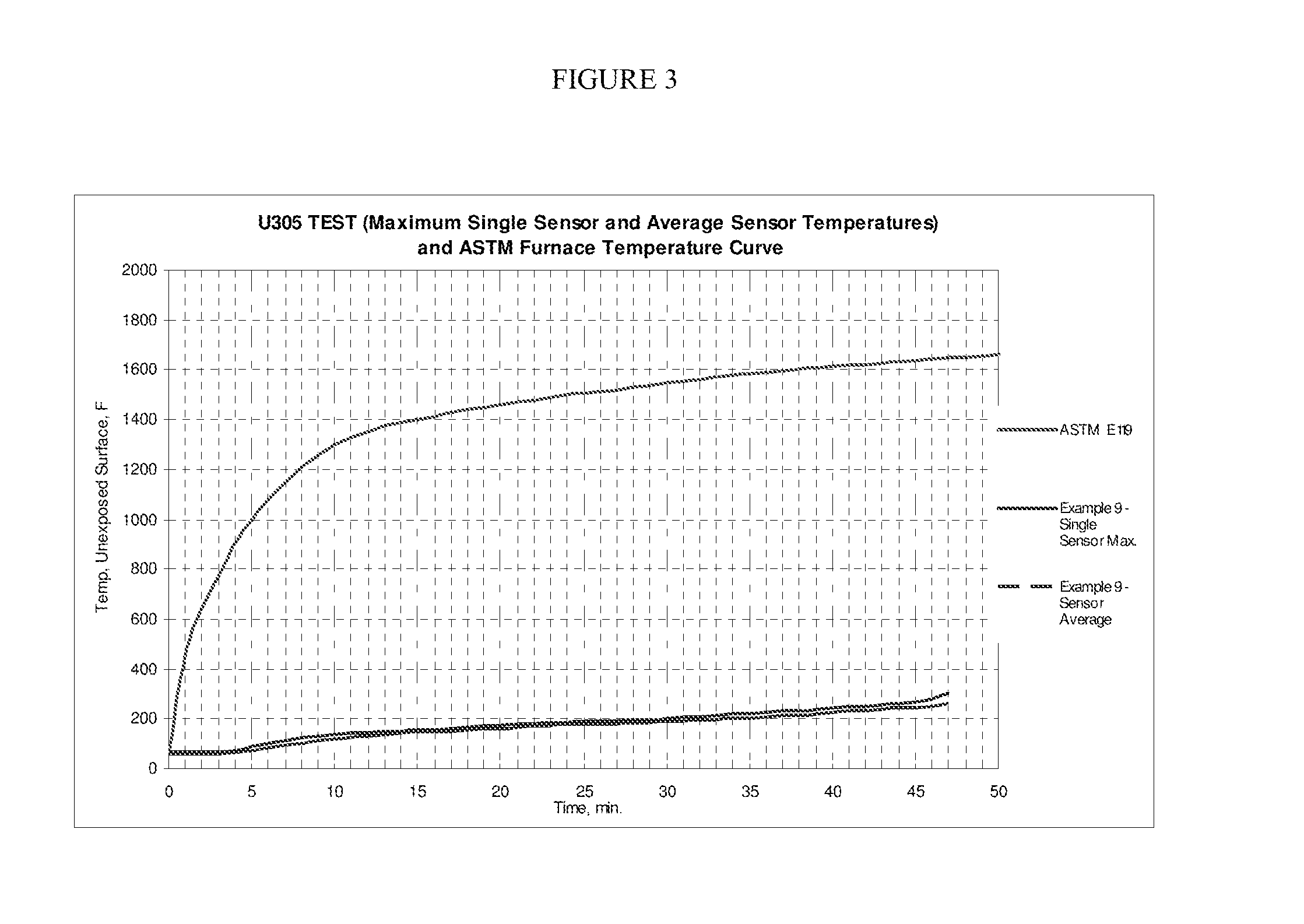

InactiveUS20110195241A1Small expansionReduce Shrinkage ProblemsSolid waste managementWood layered productsThermal insulationVolumetric Mass Density

An about ⅝ inch to ¾ inch thick low weight, low density gypsum panel with fire resistance capabilities sufficient to provide a Thermal Insulation Index of at least 17.0 minutes which when subjected to U419 test procedures will not fail for at least 30 minutes and, in selected embodiments, also has outstanding water resistance properties.

Owner:UNITED STATES GYPSUM CO

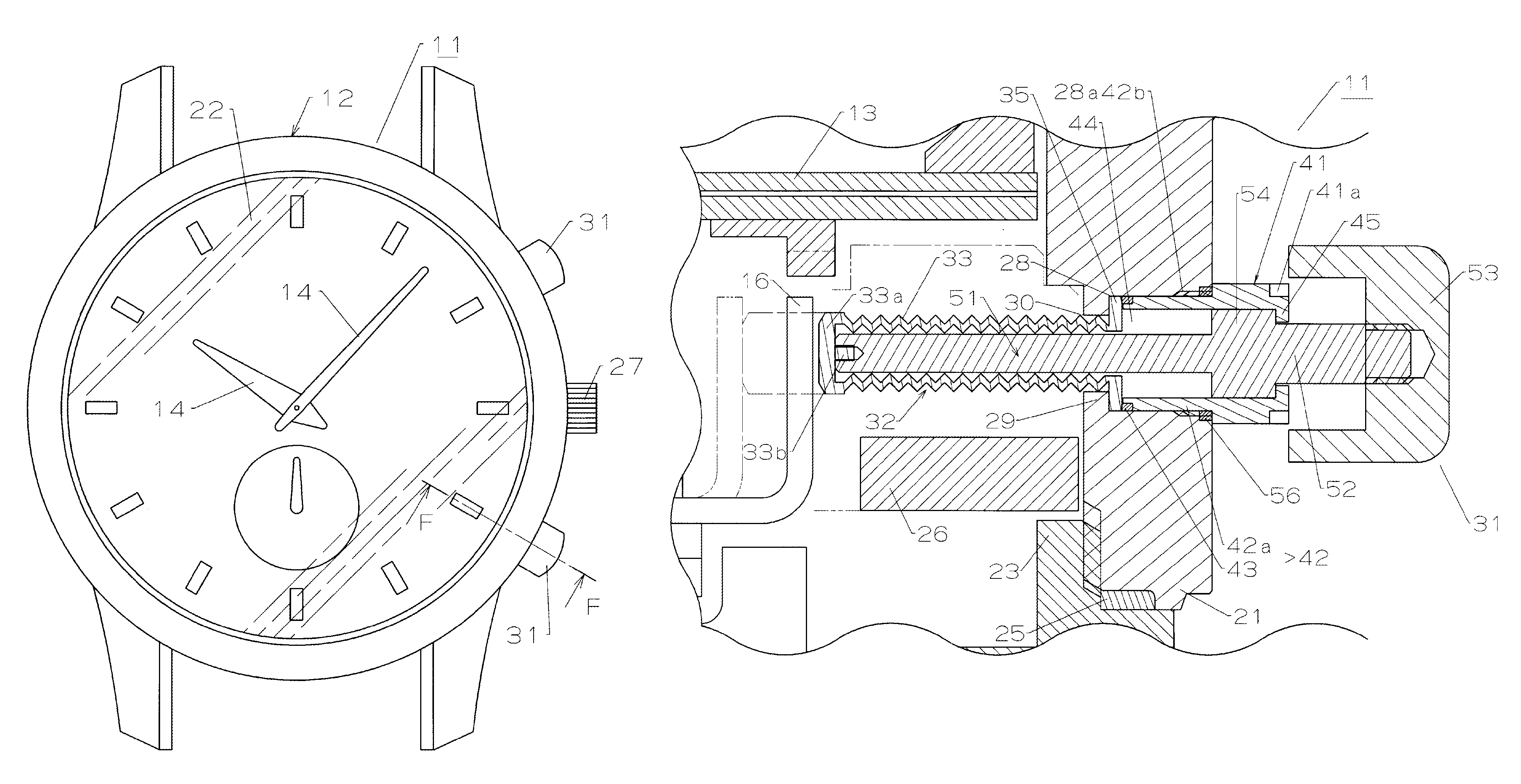

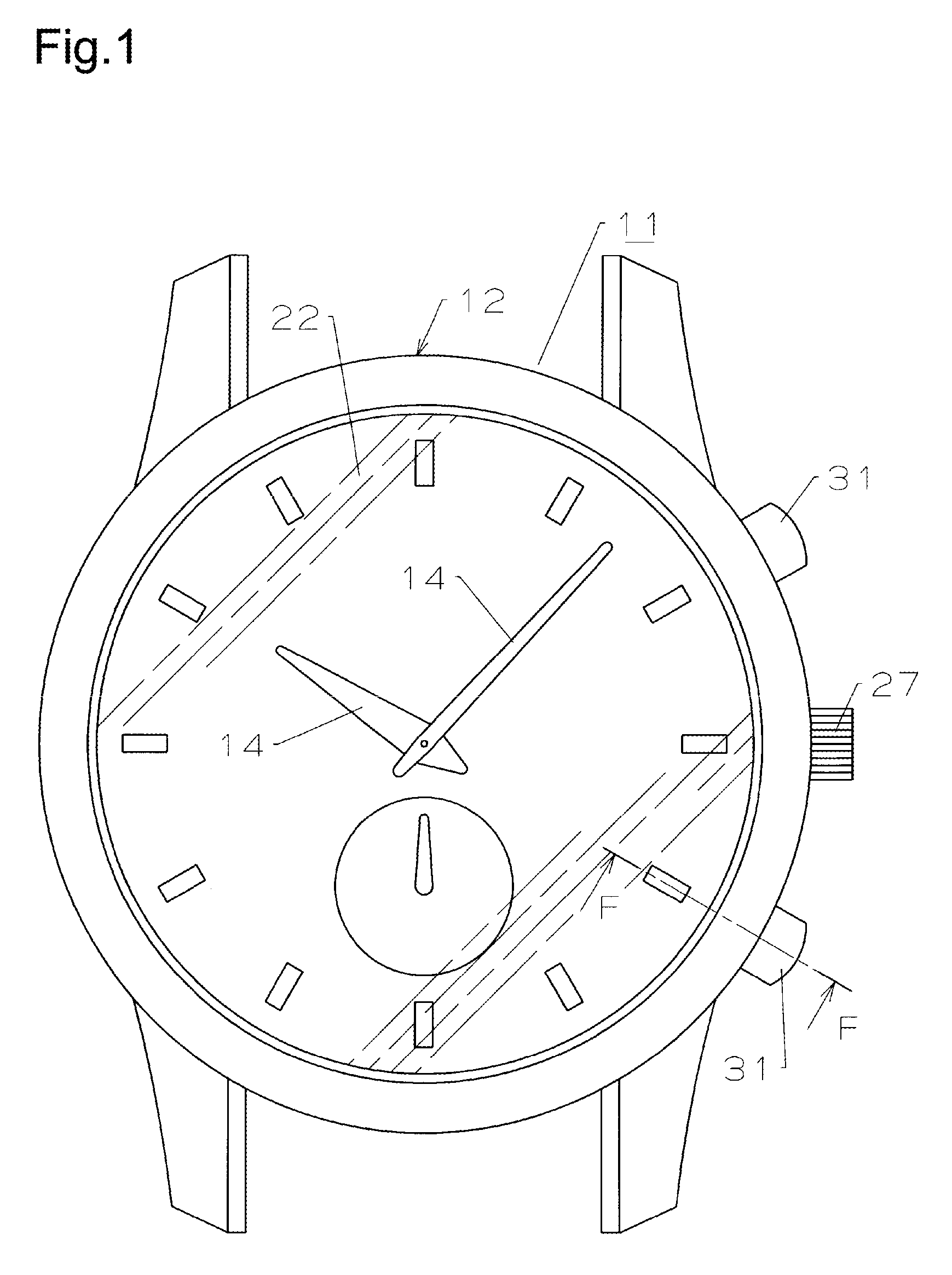

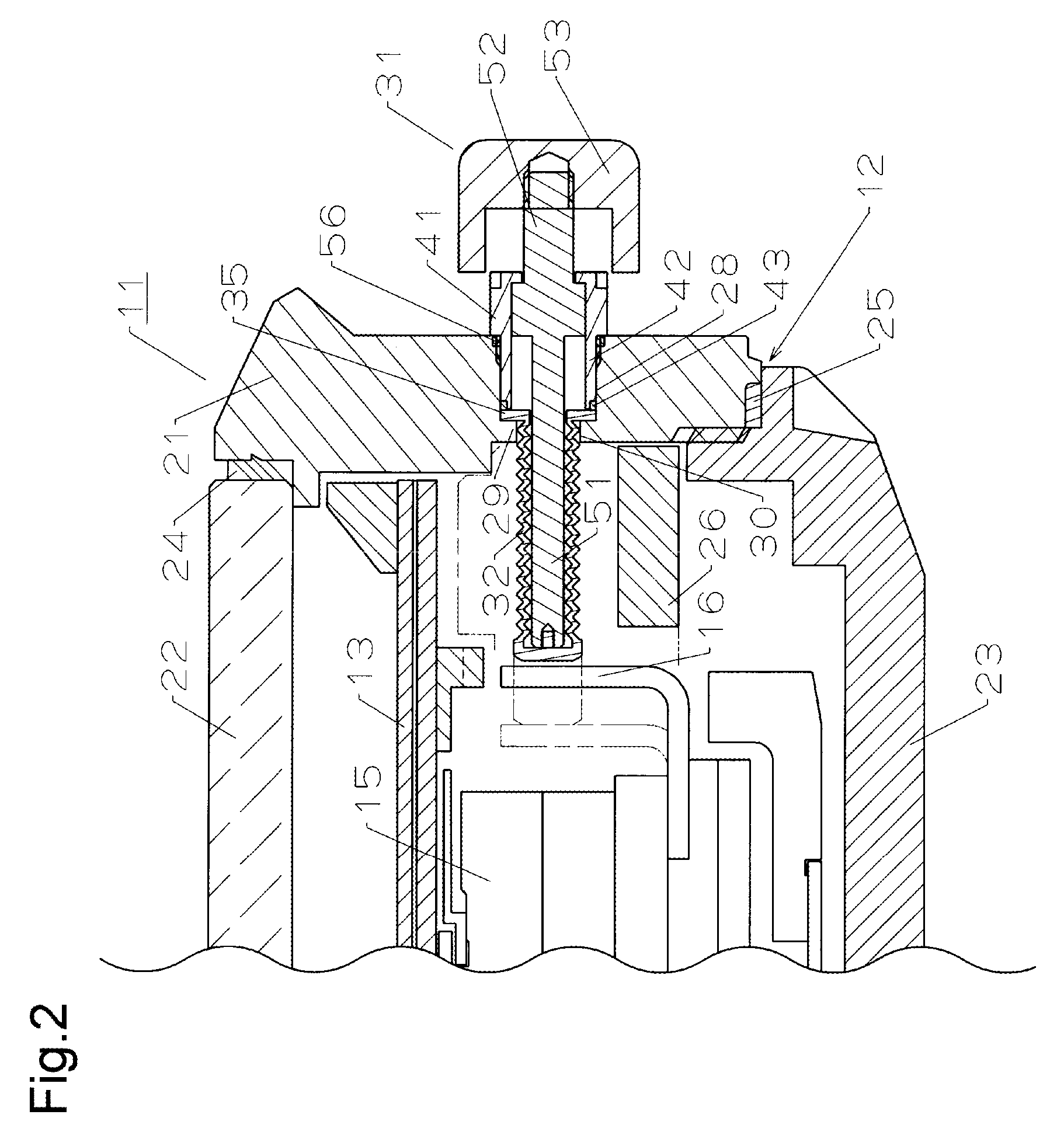

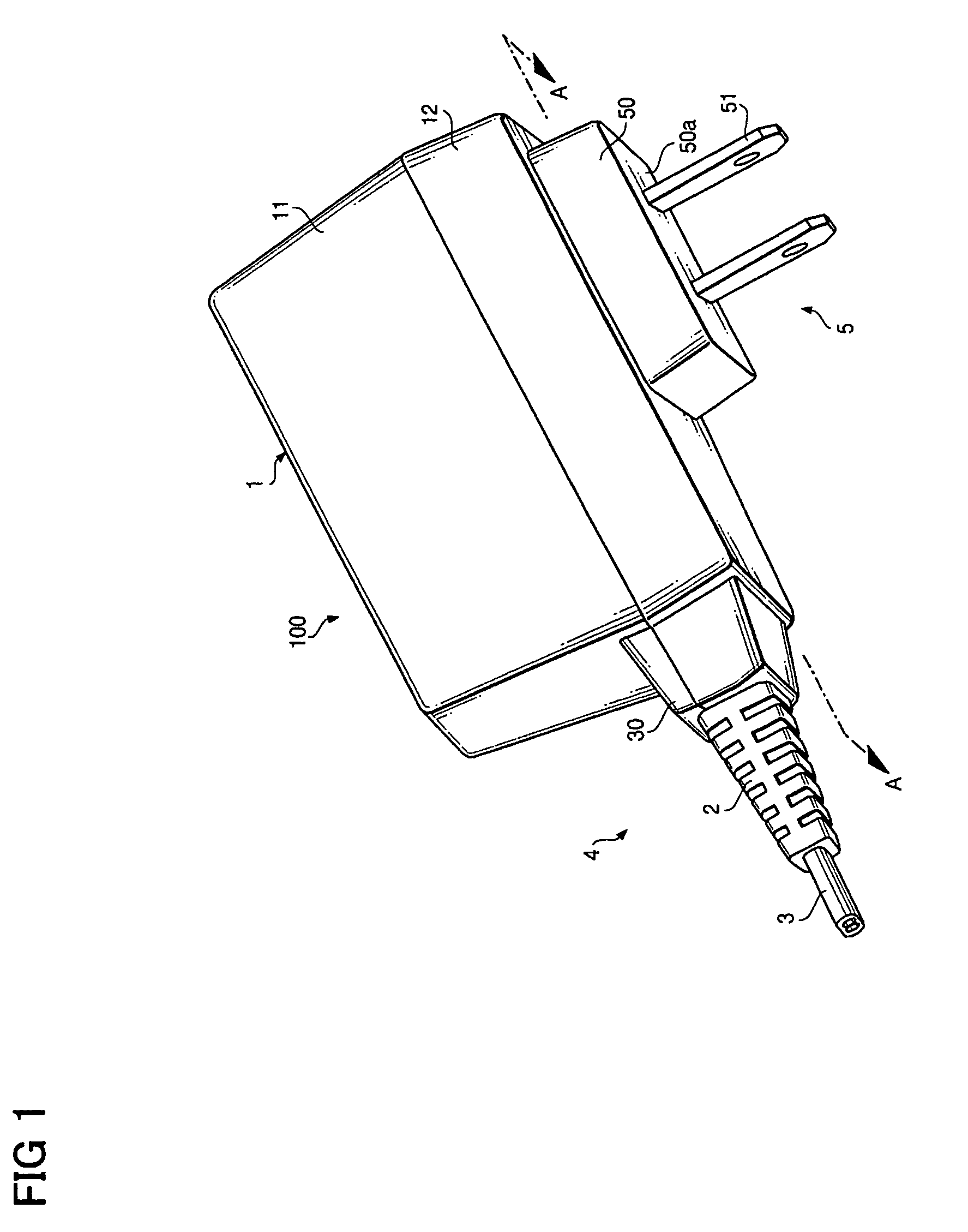

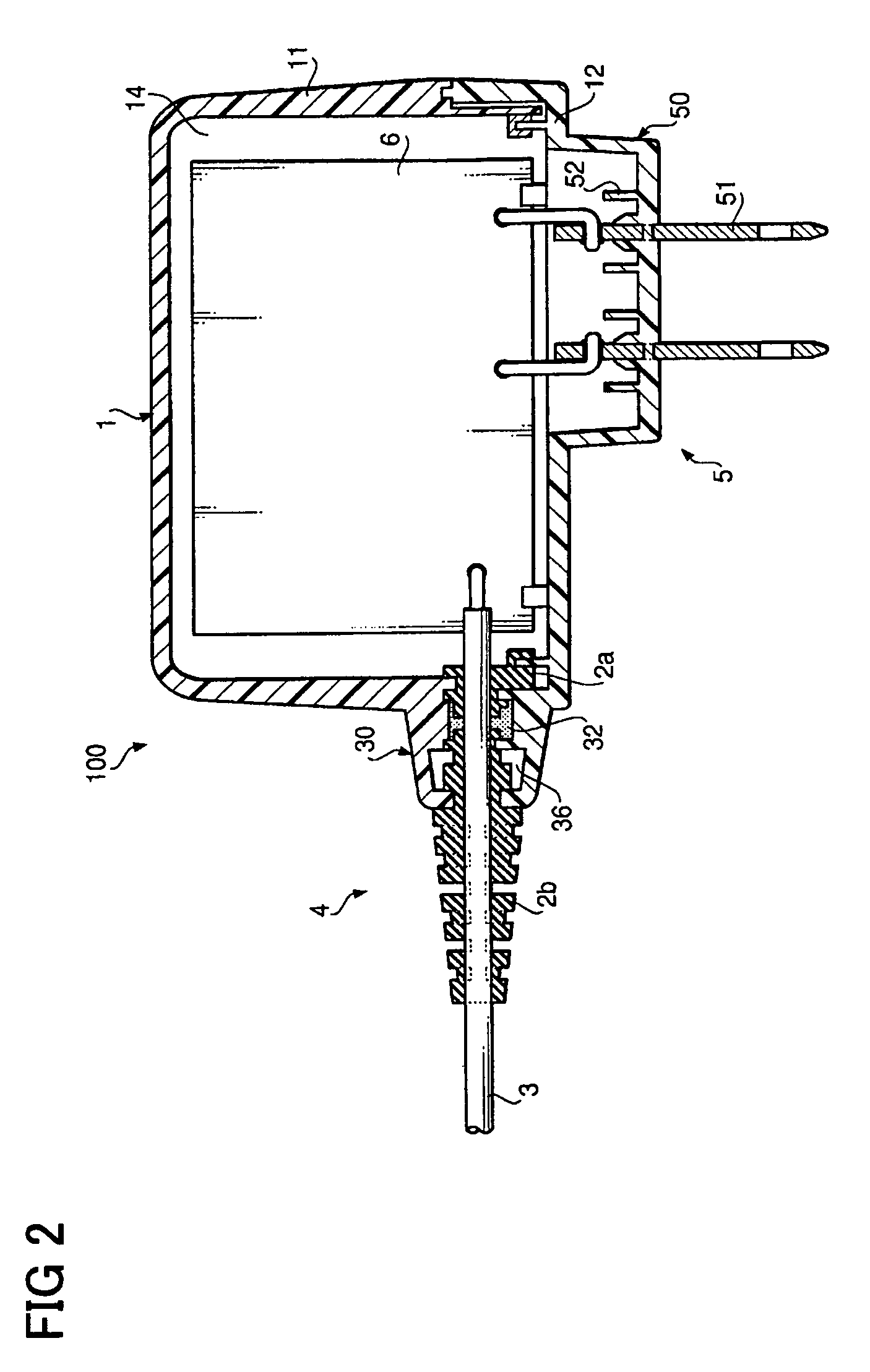

Waterproof device and portable timepiece

Provision of a waterproof device capable of improving waterproof property in a push-in operation portion formed by including an extensible member, a holding member and an operation shaft. A wrist watch (portable device) 11 includes an outer case (device outer housing) 12, an extensible member 32 with waterproof property, a holding member 41 attached to the case 12 and an operation shaft 51. The case 12 includes a seating portion 29 and a hole 30. The extensible member 32 includes a cylindrical portion 33 which can be extended / retracted in an axial direction, closing one end as well as opening the other end, and inserted into the hole 30, and a flange 35 projecting integrally from an outer periphery of the other end portion of the cylindrical portion and seated on the seating portion 29. The holding member 41 includes a presser portion 42 sandwiching the flange 35 with the seating portion 29 to thereby secure the waterproofing around the flange, and a through hole 44 connecting to the opening of the cylindrical portion 33. The operation shaft 51 includes a shaft end portion 52 protruding to the outside of the holding member 41 through the through hole 44. The operation shaft 51 is inserted into the cylindrical portion 33 and arranged in a state of being able to be pushed from the outside of the case 12 so as to allow the cylindrical portion 33 to extend.

Owner:SEIKO INSTR INC

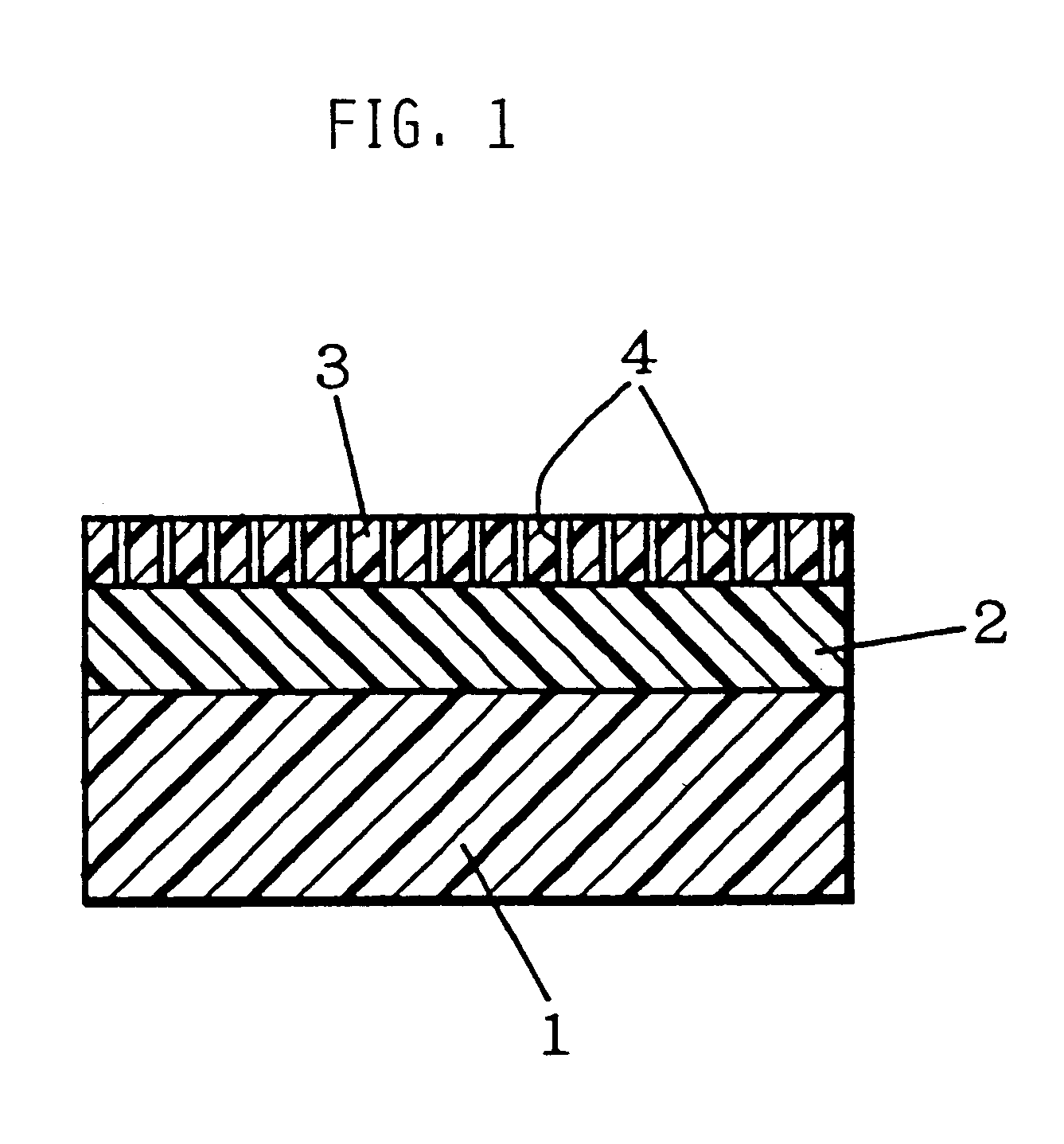

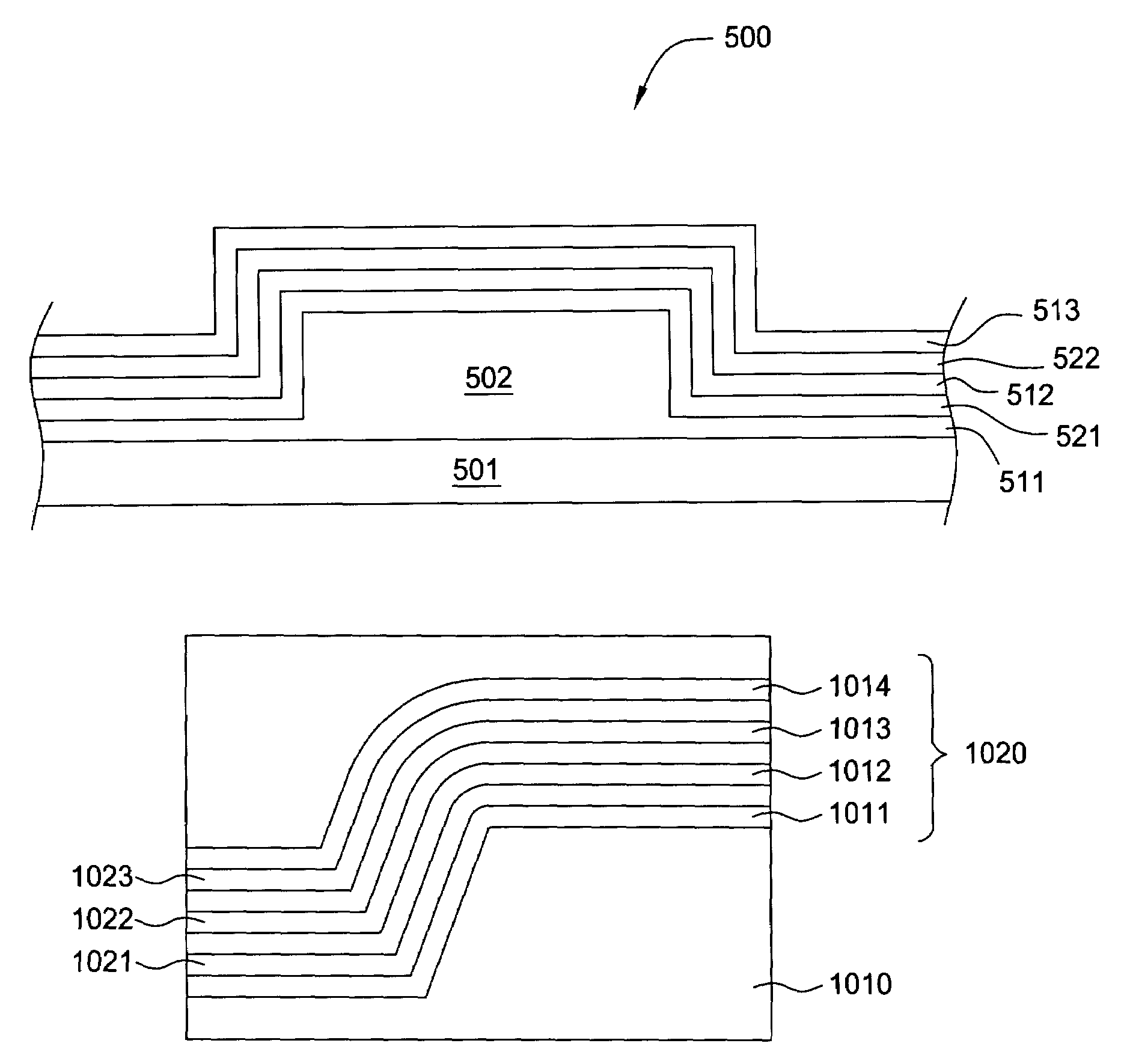

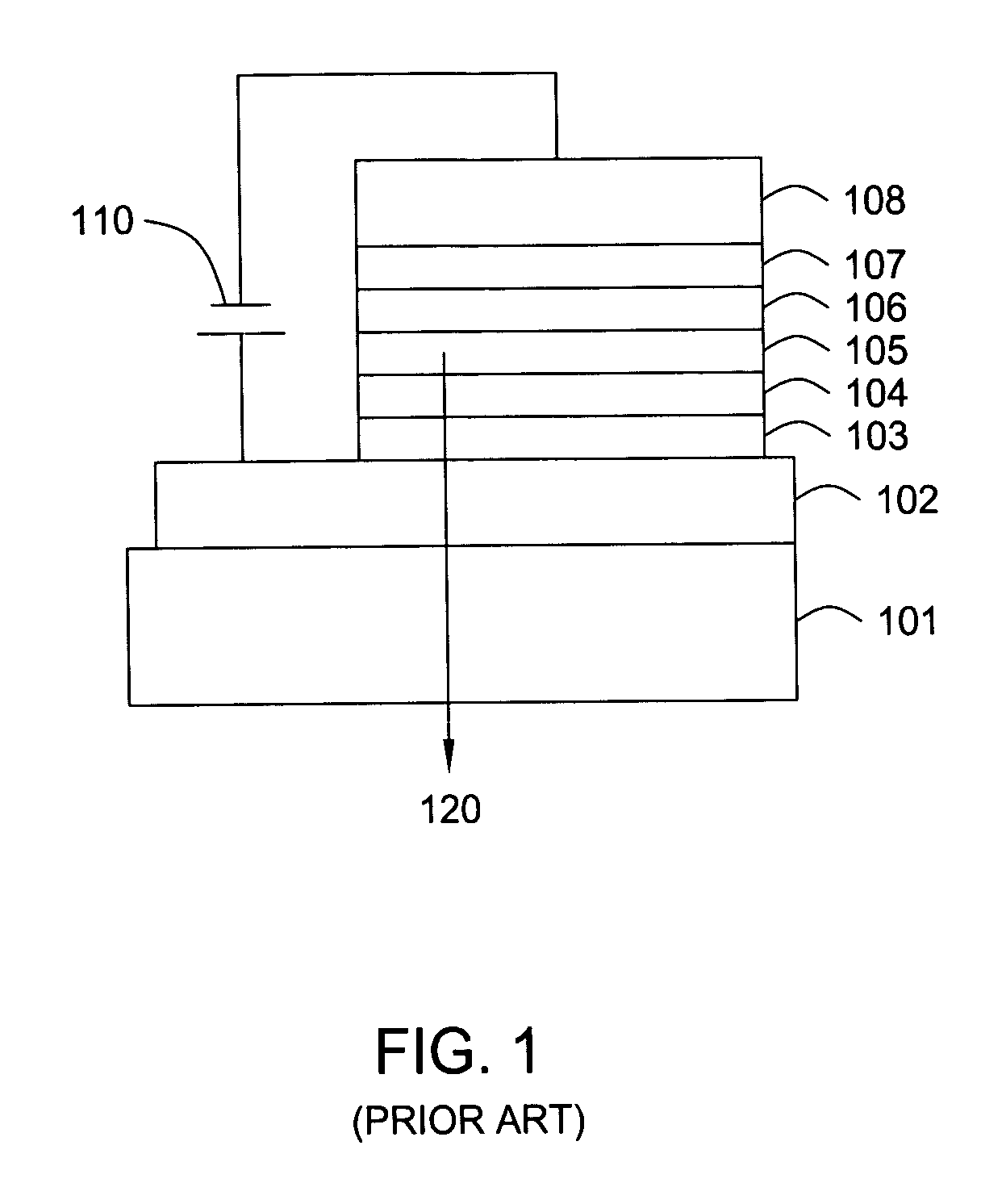

Water-barrier performance of an encapsulating film

ActiveUS7183197B2Improve waterproof performanceGood film uniformityTransistorSemiconductor/solid-state device manufacturingLow temperature depositionSubstrate type

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

Coating composition containing a low MFI ethylene acrylic acid copolymer

InactiveUS6852792B1Improve water resistanceLow sealing temperatureEmulsion paintsMelt flow indexSolvent

This invention is directed to the discovery that ethylene-acid copolymers that have low melt flow index MFI (namely less than 100 g / 10 min measured according to ASTM D1238 at 190° C., 2.16 kg) even with low acid content (such as less than 20 wt. %) can provide stable aqueous dispersions directly in aqueous media (i.e. free from any other solvent) with less than 1 wt. % non-dispersibles in single bases even at mild dispersion process conditions, at temperature less than 100°C., atmospheric pressure, and with low agitation speed.

Owner:PERFORMANCE MATERIALS NA INC +1

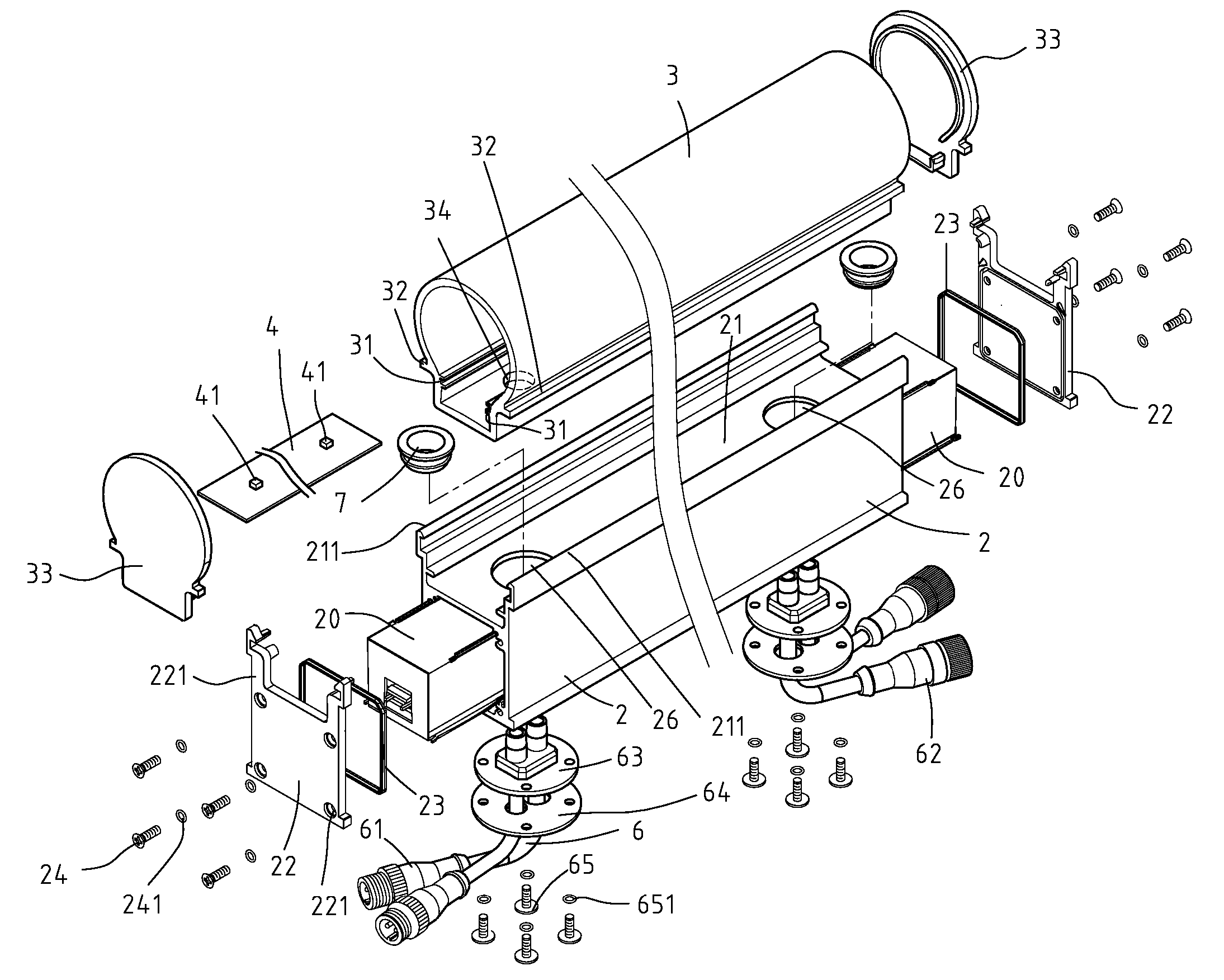

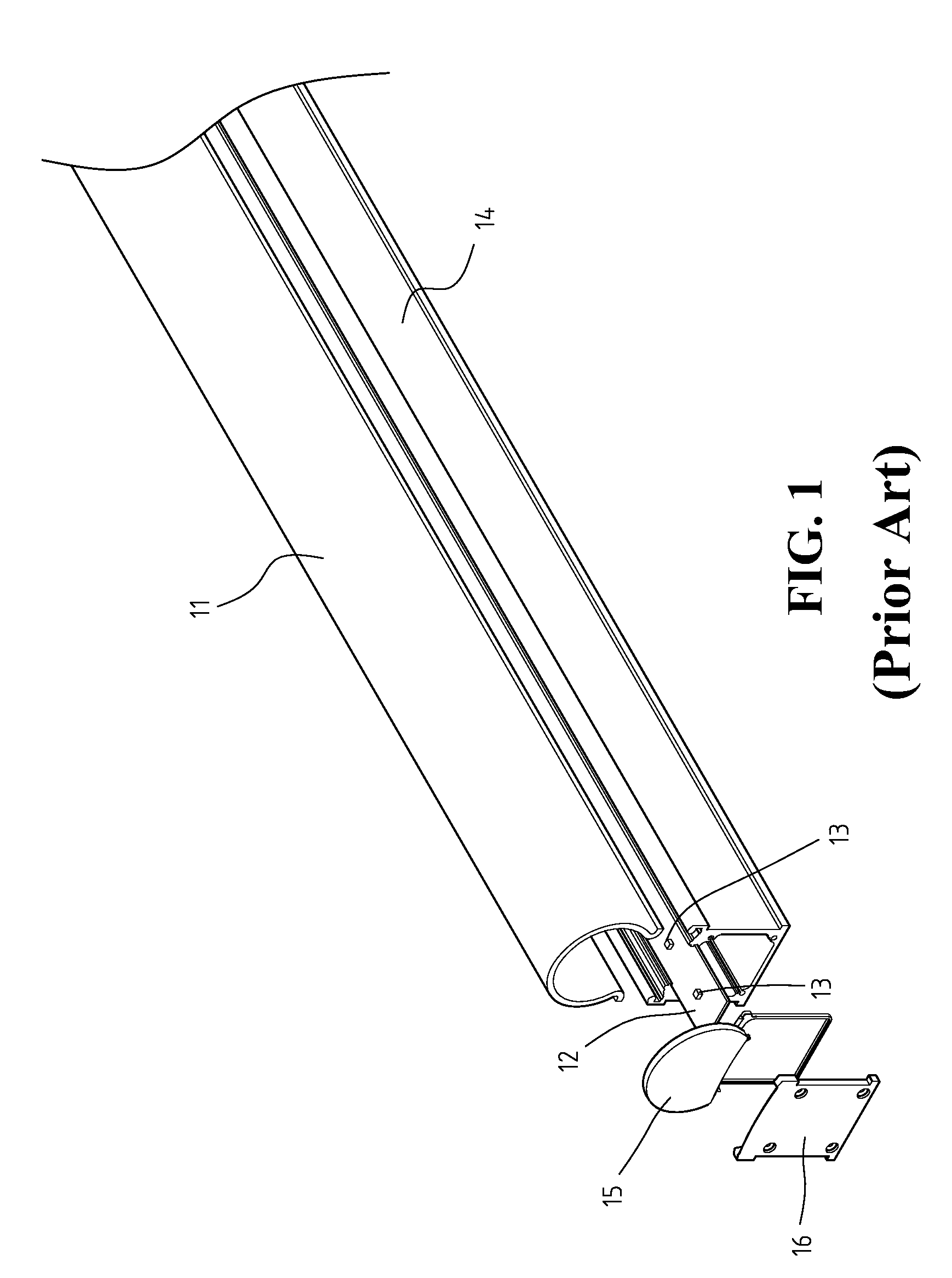

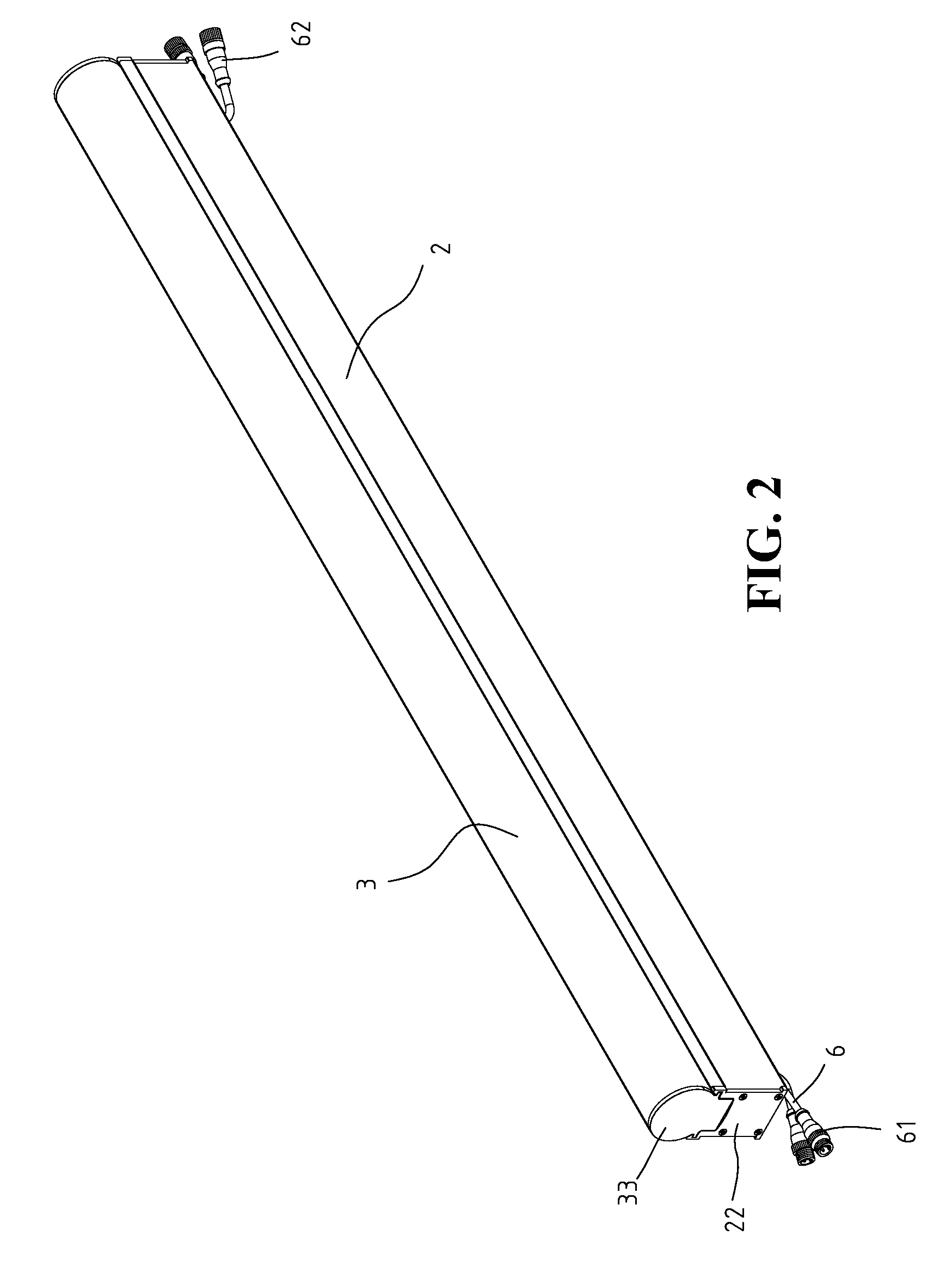

Structure for a high efficiency and water-proof lighting device

InactiveUS7303310B2Enhanced water-proof glueImprove waterproof performancePoint-like light sourceElongate light sourcesEffect lightEngineering

A structure for a high diffuse efficiency and water-proof lighting device is provided, including a light tube and a base holder. The light tube and the base holder are each an enclosed structure. The light tube includes a circuit substrate inside the enclosed structure. The circuit substrate includes a plurality of LEDs. The light tube and the base holder each include two holes close to both ends. When the light tube and the base holder are assembled, the holes match so that the wire connecting the circuit substrate can go through the holes to enter the base holder. A water-proof and highly pull-resistant glue is used to fill the overlapping of the holes. A resilient element is used to connect the neighboring circuit substrates, the resilient element can absorb the deformation caused by the temperature changes so that the light diffusion remains uniform. Therefore, the lighting device can perform well even when operating in an environment with drastic temperature changes.

Owner:OPTO TECH

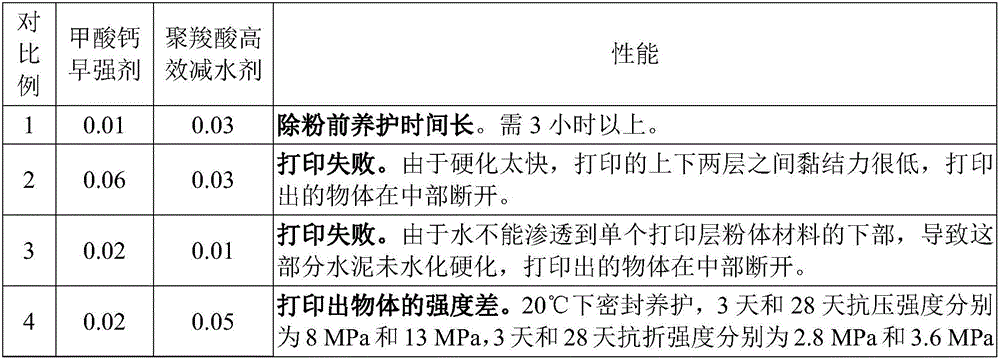

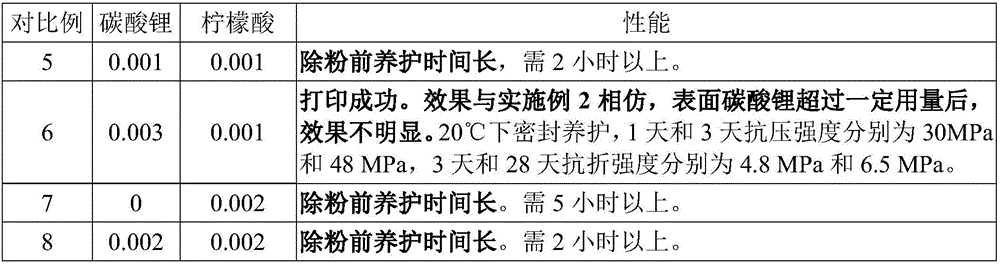

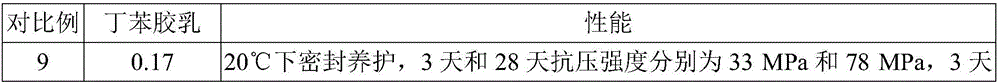

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

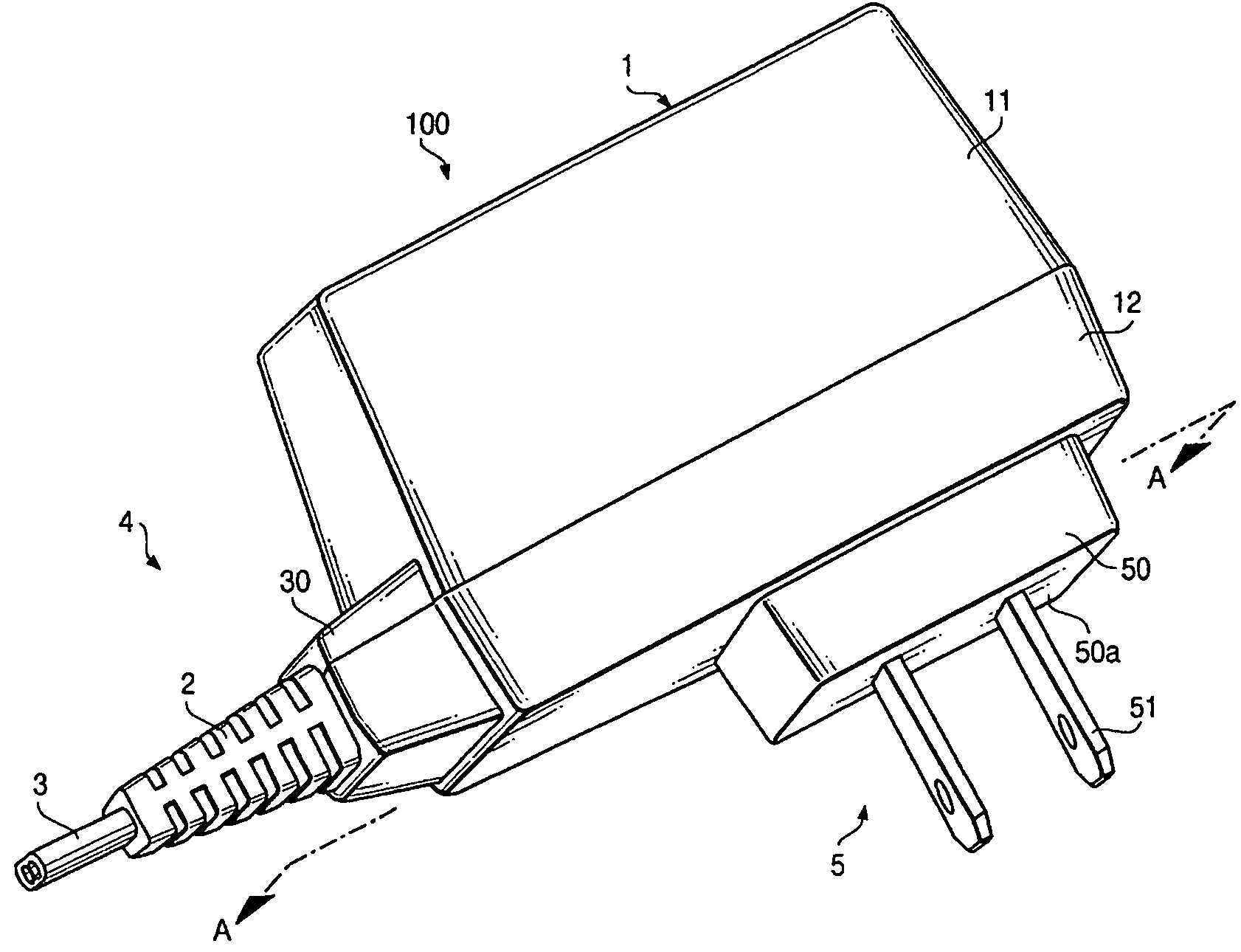

Waterproof case for electrical apparatus

InactiveUS7789696B2Reduce component countSimplify workWave amplification devicesCouplings bases/casesMechanical engineeringEngineering

A drawing part of a cable 3 in a waterproof case for an electrical apparatus is sealed. On an outer circumferential part of the cable 3, a first bushing member 2a and a second bushing member 2b are formed by injection molding to be spaced with respect to each other. A box part 35 of the waterproof case is located between the first busing member 2a and the second bushing member 2b. After locating the cable 3 in the waterproof case, a filling material 40, such as epoxy resin or urethane resin, is filled into the inside of the box part 35.

Owner:TAMURA KK

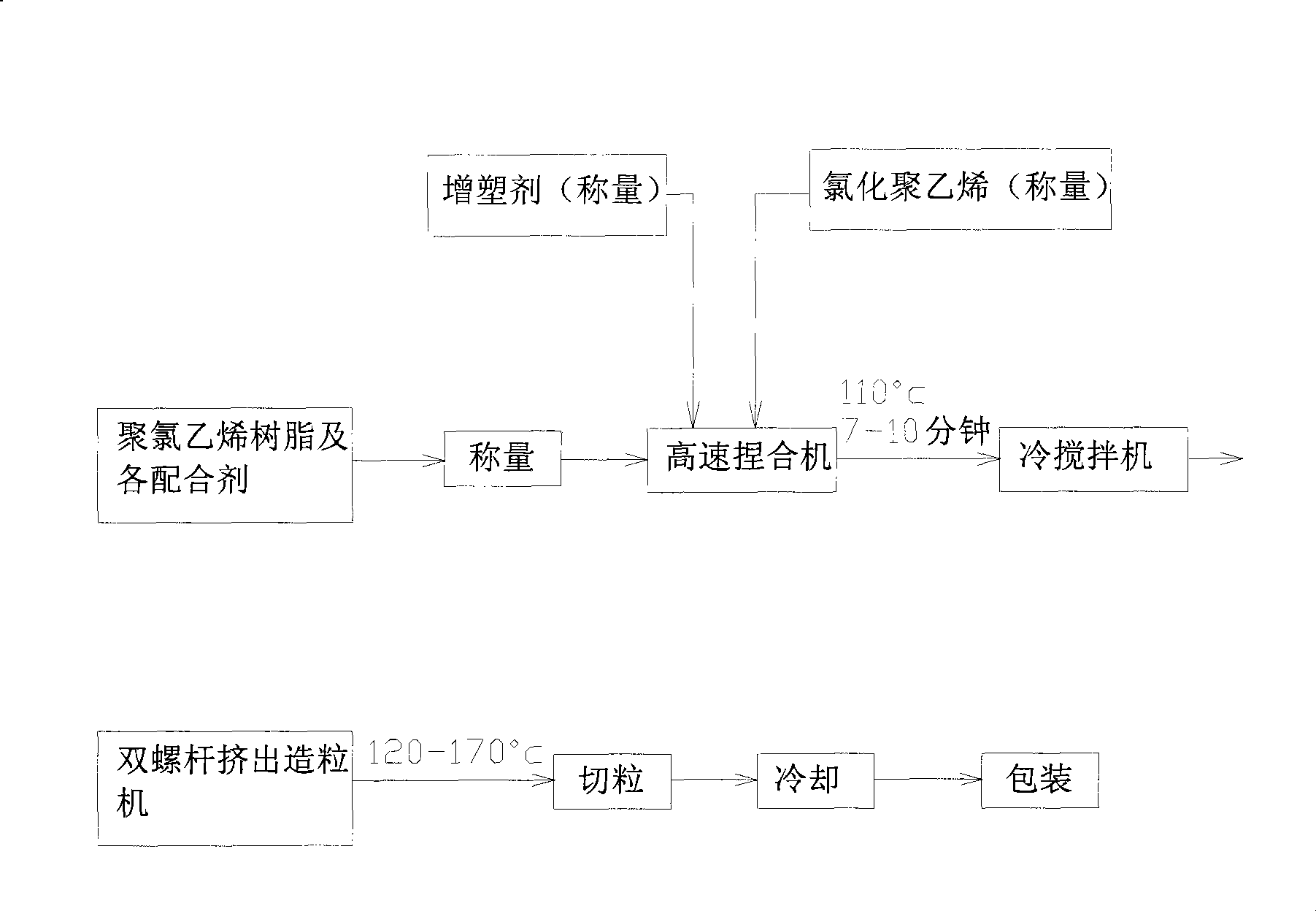

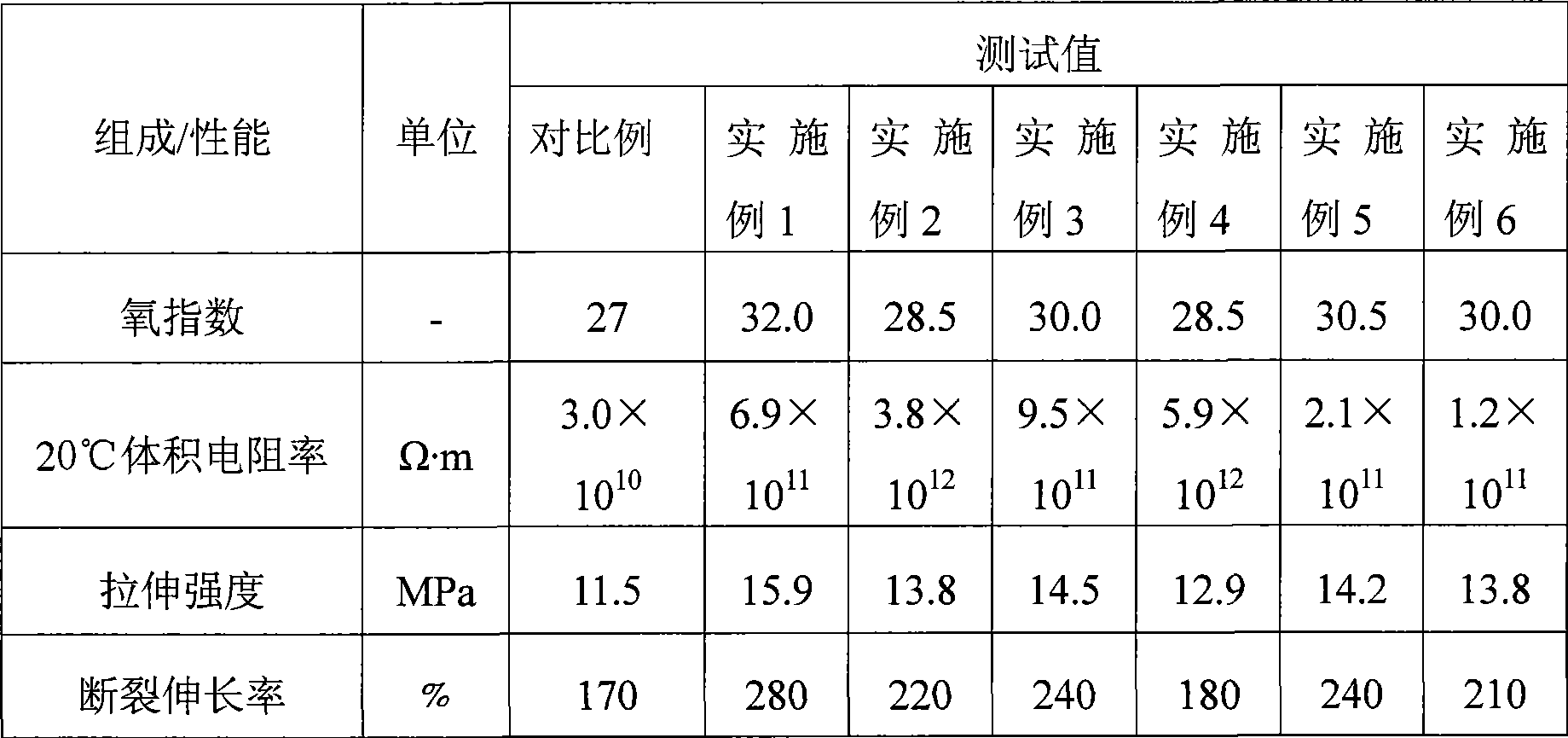

Waterproof cold resistant heatproof flame-retardant polychloroethylene insulation material

ActiveCN101481480AGood effectExcellent resistance to low temperature embrittlementPlastic/resin/waxes insulatorsInsulated cablesHeat resistancePlasticizer

The invention provides a waterproof cold resistance temperature resistance inflaming retarding polyvinyl chloride insulating material, which comprises the following components according to the parts by weight mixture ratio: 100 of polyvinyl chloride resin, 20-70 of thermal stability plasticizer, 1-7 of cold tolerance plasticizer, 5-15 of modifier, 3-9 of stabilizing agent, 4-30 of flame retardant, 5-70 of filling agent, and 0.5-3.5 of lubricant. The insulating material has excellent waterproof performance, temperature resistant cold resistance and insulating performance, also has good soft performance and good processing performance.

Owner:ZHENG WEI TECH SHEN ZHEN LTD

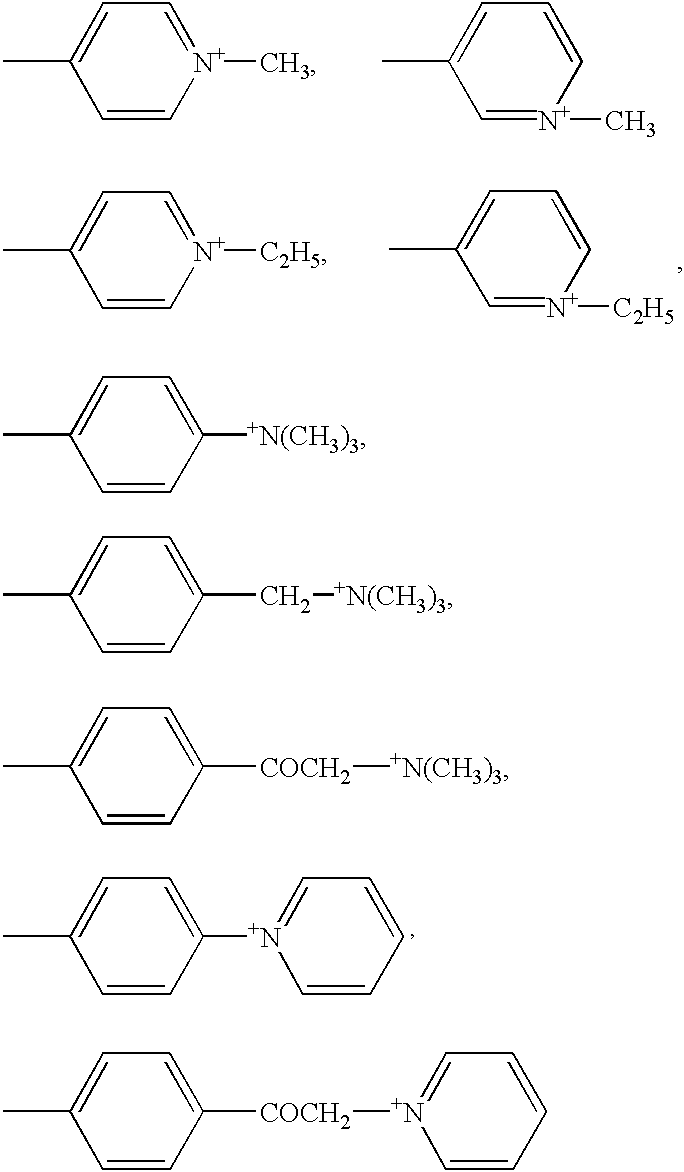

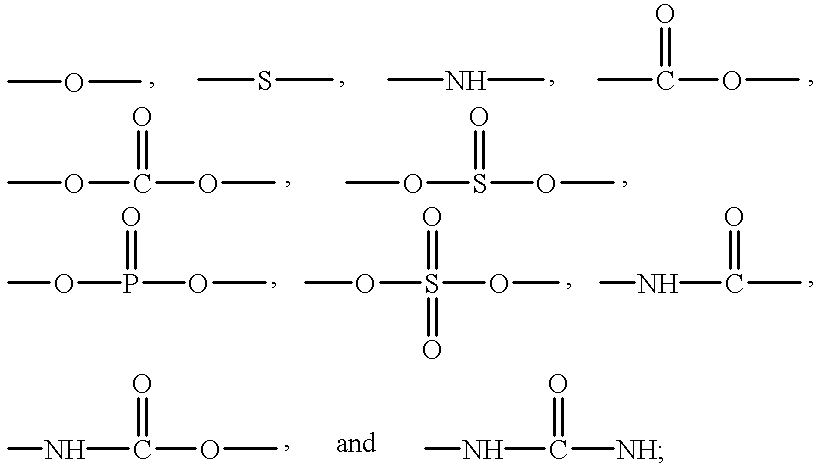

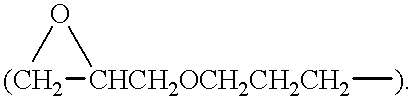

Addition crosslinkable epoxy-functional organopolysiloxane polymer coating compositions

The present invention pertains to an epoxy-functional organopolysiloxane resin, and an epoxy-functional organopolysiloxane coating composition comprising the epoxy-functional organopolysiloxane resin. The epoxy-functional organopolysiloxane resin which contains repeating units having the formulae:whereinE is an epoxy-functional C1-18 hydrocarbon group containing one or more oxygen atoms, provided that no oxygen atom is directly bonded to a Si- atom; andR1 and R2 are independently a C1-20 hydrocarbon, optionally interspersed with a heteroatom linking group,a is an integer of 0, 1, or 2, preferably 0 or 1;b is an integer of 0, 1, 2 or 3, preferably 0, 1, or 2;c is an integer of 0, 1, 2 or 3, preferably 0, 1, or 2; andin M units, a+b+c=3,in D units, a+b+c=2,in T units, a+b+c=1,with the proviso that the molecule, on average, contain at least two E components.

Owner:WACKER SILICONES

Ink set and method and apparatus for recording image

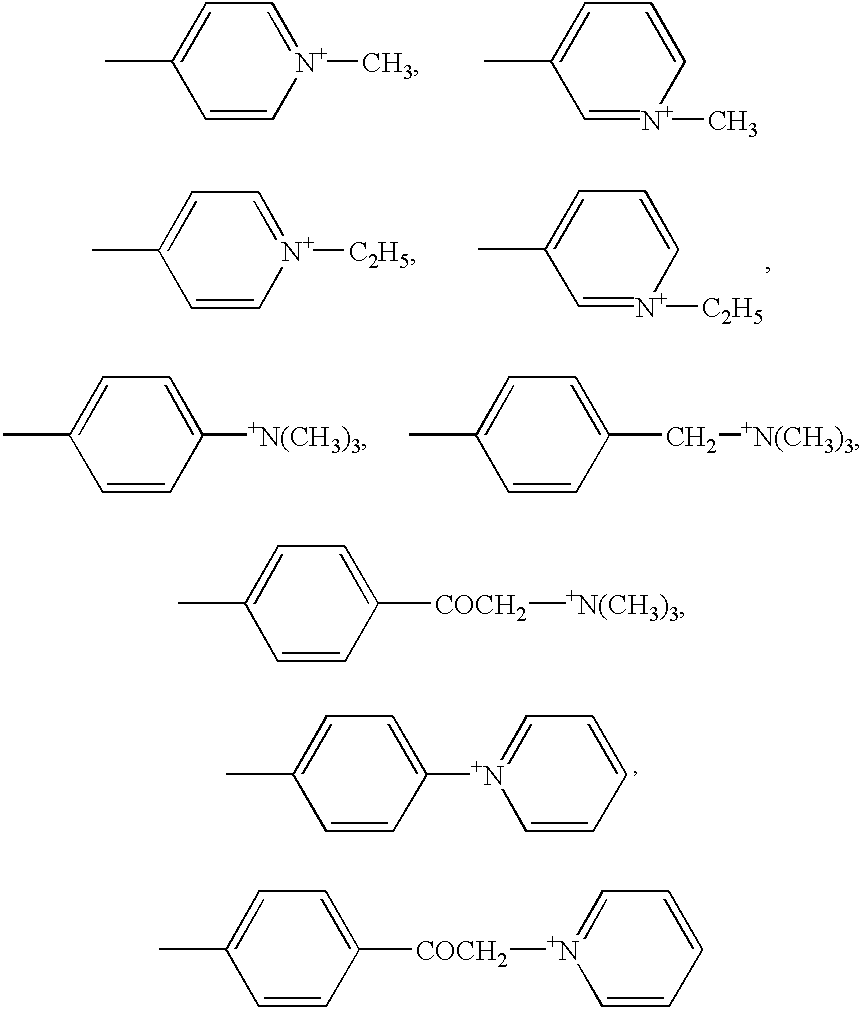

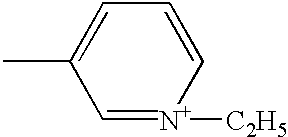

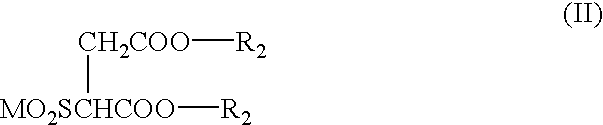

InactiveUS20070054981A1Improve scratch resistanceImprove waterproof performanceInksCoatingsOrganic solventWater soluble

An ink set comprising an ink containing at least an organic pigment, a water-soluble organic solvent and water and a treating liquid which is applied to a recording medium before applying the ink to the recording medium and produces an agglomerate upon contact with the ink, the ink containing a low molecular weight dispersant having a molecular weight of 2000 or lower and polymer fine particles.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com