Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Low sealing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating composition containing a low MFI ethylene acrylic acid copolymer

InactiveUS6852792B1Improve water resistanceLow sealing temperatureEmulsion paintsMelt flow indexSolvent

This invention is directed to the discovery that ethylene-acid copolymers that have low melt flow index MFI (namely less than 100 g / 10 min measured according to ASTM D1238 at 190° C., 2.16 kg) even with low acid content (such as less than 20 wt. %) can provide stable aqueous dispersions directly in aqueous media (i.e. free from any other solvent) with less than 1 wt. % non-dispersibles in single bases even at mild dispersion process conditions, at temperature less than 100°C., atmospheric pressure, and with low agitation speed.

Owner:PERFORMANCE MATERIALS NA INC +1

Heat sealable biaxially oriented polypropylene film

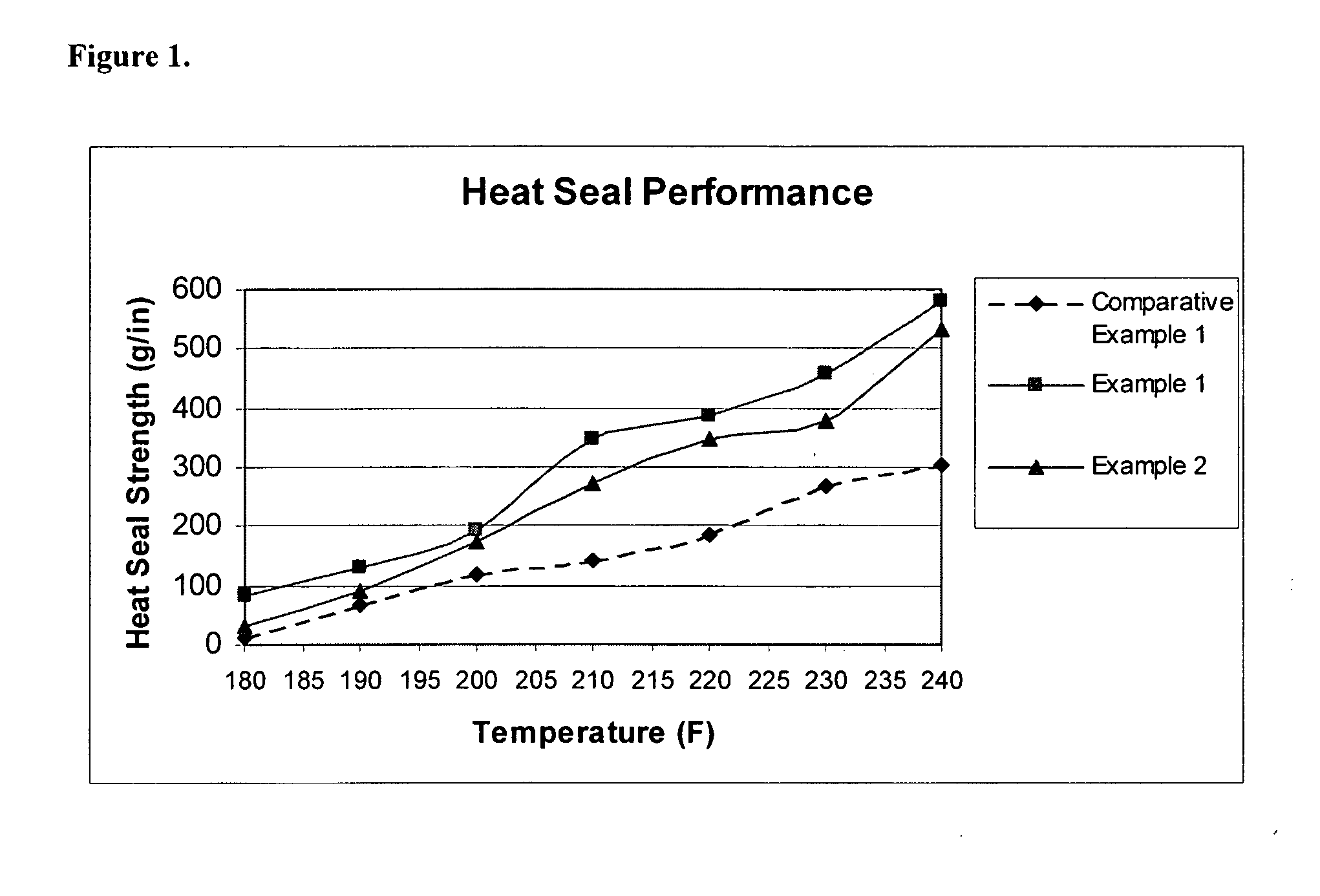

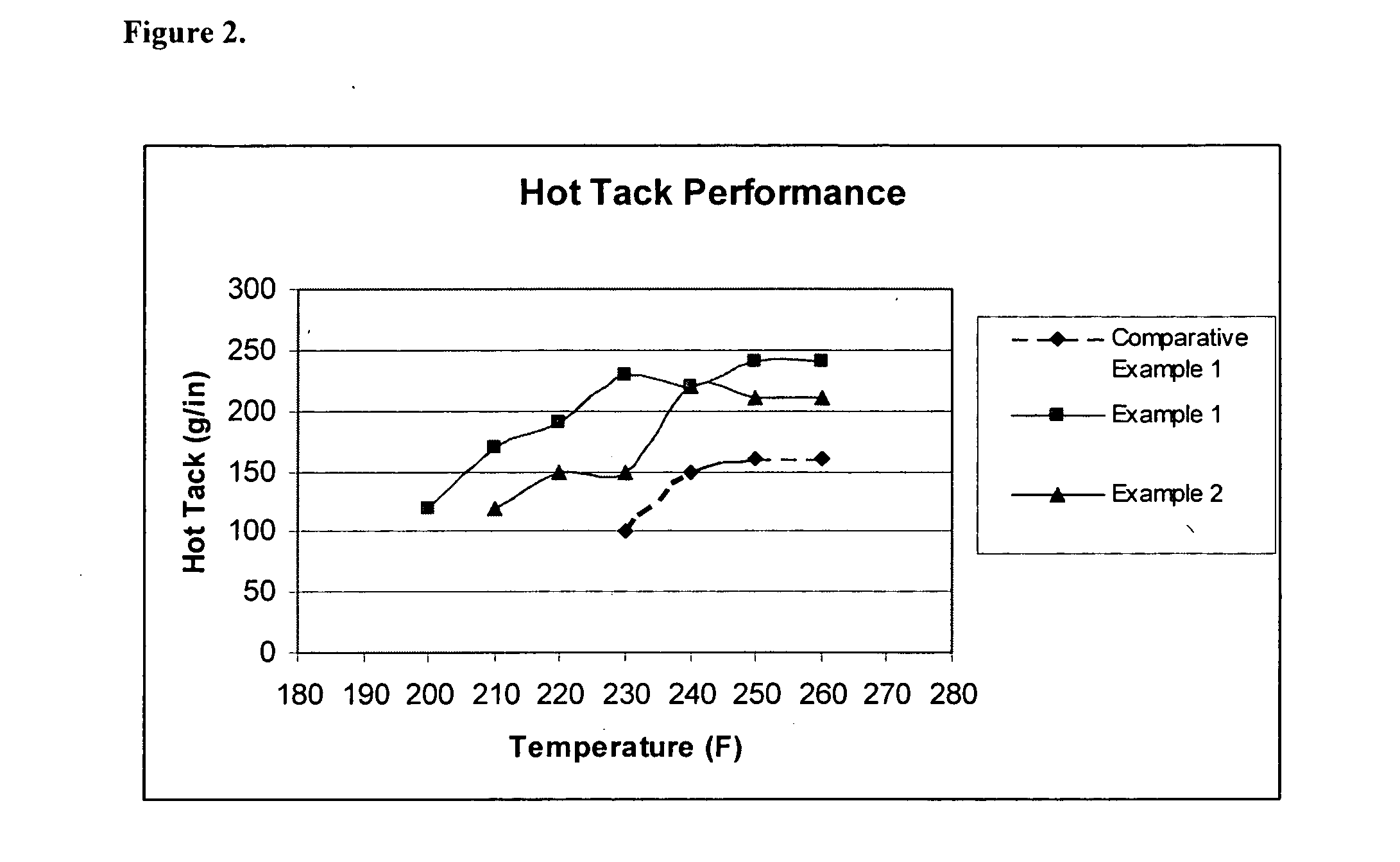

InactiveUS20050142367A1Low sealing temperatureSeal contaminationSynthetic resin layered productsDomestic containersButenePolyolefin

A polyolefin multilayer film comprising (a) a polyolefinic core layer and (b) at least one skin layer adjacent to the care layer comprising about 30%-90% by weight of a propylene-ethylene-butene terpolymer and about 10%-70% by weight of a metallocene catalyzed polyethylene or a metallocene catalyzed ethylene copolymer is disclosed. Preferably, a propylene-ethylene-butene terpolymer-containing component and a metallocene catalyzed polyethylene-containing component or a metallocene catalyzed ethylene copolymer-containing component are in distinct separate phases in an incompatible blend of the propylene-ethylene-butene terpolymer-containing component and the metallocene catalyzed polyethylene-containing component or the metallocene catalyzed ethylene copolymer-containing component.

Owner:TORAY PLASTICS AMERICA

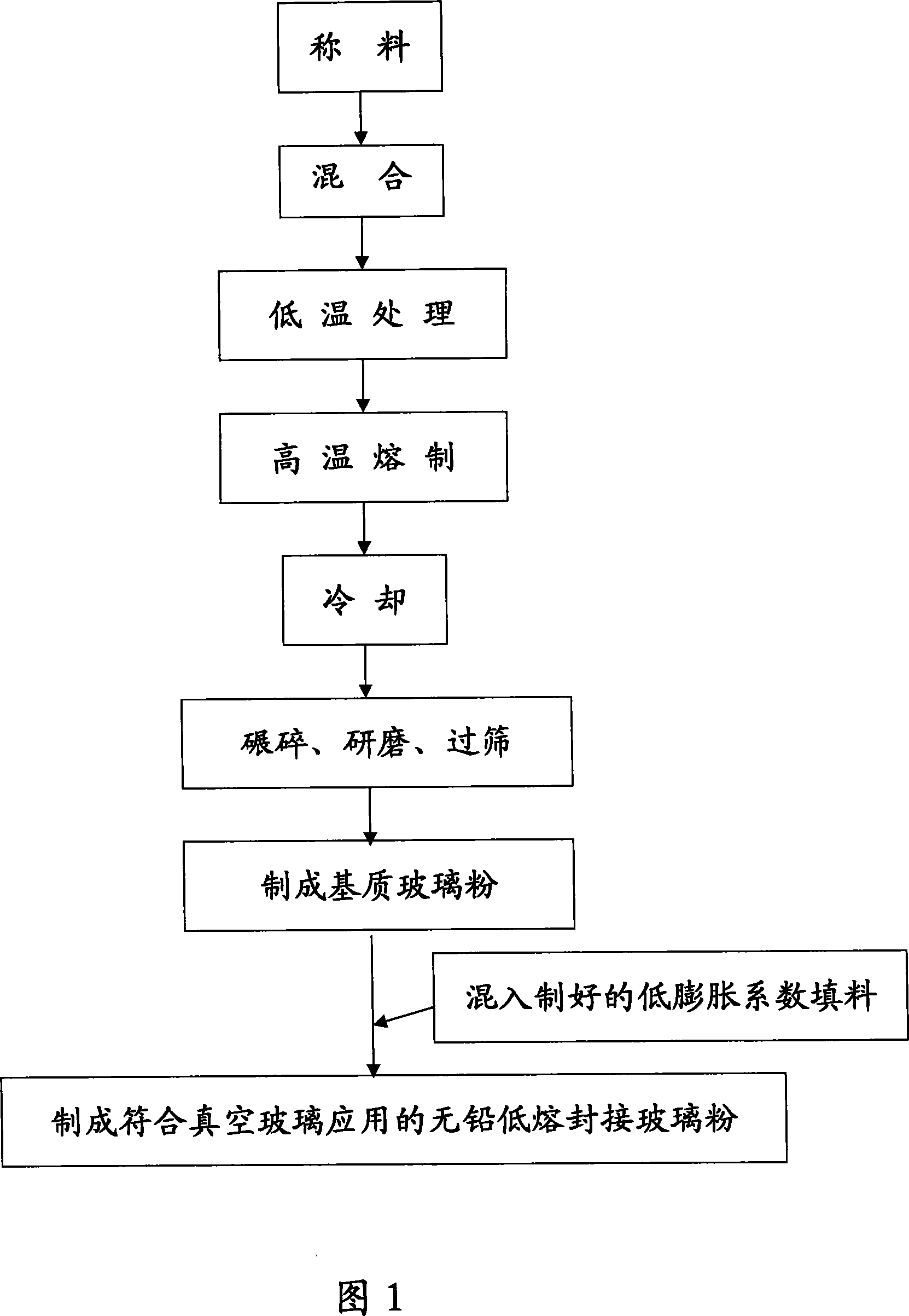

No-lead RE doped sealing glass powder with low smelting point and its production process

The present invention discloses one kind of no-lead RE doped sealing glass powder with low smelting point for vacuum glass sealing and its preparation process. The no-lead sealing glass powder has P2O5, SnO and ZnO as basic glass oxides and mixed RE oxide of La, Yt and Nd added, with the weight ratio between the basic glass oxides and the mixed RE oxide being (30.0-381.5) to (0.12-19.0). The no-lead sealing glass powder of the present invention with doping mixed RE oxide has lowered glass smelting and sealing temperature, raised chemical stability and lowered thermal expansion coefficient of glass as well as lowered environmental pollution. It is used in sealing electronic device and element and vacuum glass.

Owner:CHINA BUILDING MATERIALS ACAD

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

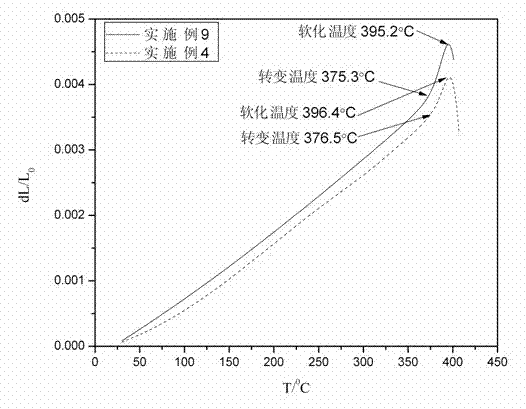

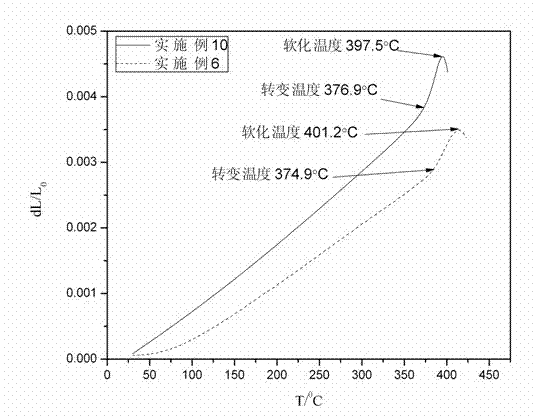

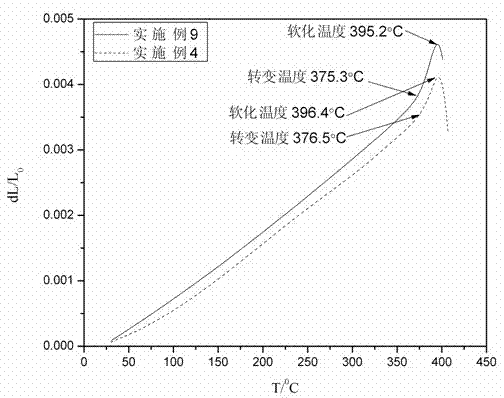

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

Low-temperature heat-seal acrylic emulsion for coating and preparation method thereof

The invention relates to a low-temperature heat-seal acrylic emulsion for coating and a preparation method thereof. The paint is prepared from the following raw materials in percentage by mass: 85-95% of modified acrylic emulsion and 5-15% of ethylene-acrylic acid copolymer emulsion (EAA emulsion for short). The modified acrylic emulsion is prepared from the following raw materials in percentage by mass: 11-18% of methacrylate, 3-6% of acrylate, 0.1-1% of acrylic acid, 0.01-0.2% of emulsifier, 0.01-0.1% of electrolyte, 0.4-0.6% of initiator, 1-4% of neutralizer, 72-80% of deionized water and 0.05-0.3% of bactericide. The emulsion can be coated on a biaxially-oriented polypropylene (BOPP) film to prepare a coating film for low-temperature heat seal, wherein the initial seal temperature can be lowered to 80 DEG C, and the heat-seal strength is 1.8-2.2N / 15mm (the heat-seal conditions are 80 DEG C, 0.14 MPa and 0.75s). The low-temperature heat-seal acrylic emulsion can be used for quickly packaging some candy products of which the packaging temperature is controlled at 85 DEG C below.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Low-melting point glass powder and manufacturing method thereof

The invention provides low-melting point glass powder and a manufacturing method thereof; on a weight basis, the low-melting point glass powder comprises: 20-55% of Bi2O3, 10-30% of B2O3, 5-15% of ZnO, 15-40% of BaO, 0.5-5% of CuO, 0.5-2% of MgO, and 0.2-5% of halide. The low-melting point glass powder does not contain harmful elements of lead, vanadium, thallium, tellurium, and the like, has a low thermal expansion coefficient, good chemical stability, wetability and fluidity. In addition, the low-melting point glass powder has low Bi2O3 content, and thus has low manufacturing cost.

Owner:天津北旭新材料有限公司

Low-temperature heat-seal high-separating coating thin film and production method thereof

ActiveCN102848671AIncreased sealing temperatureThe sealing temperature is 80-85℃, and the heat sealing strength is improvedFlexible coversWrappersChewing gumHigh heat

The invention relates to a low-temperature heat-seal high-separating coating thin film. The low-temperature heat-seal high-separating coating thin film comprises a base material, an upper coating layer and a lower coating layer arranged on the upper and lower surfaces of the base material, an upper bottom glue layer arranged between the base material and the upper coating layer and a lower bottom glue layer arranged between the base material thin film and the lower coating layer, wherein the upper coating layer is an acrylic acid coating layer; the lower coating layer is a polyvinylidene chloride (short for PVDC as below) coating layer; the acrylic acid coating layer is a low-temperature heat-seal layer; the PVDC coating layer is a high-separating layer; and during sealing, the acrylic acid coating layer and the PVDC coating layer are sealed in a heating manner, namely sealed in a lapping manner from inside and outside, and the heat-seal strength can reach 3.6N / 15mm. The coating thin film has the advantages of low heat-seal temperature, high heat-seal strength and high separating performance, and is particularly suitable for packaging chewing gum and chocolates sensitive to temperature at high speed.

Owner:HAINAN SHINER IND

Bismuthate lead-free sealing glass material with low melting point and preparation method thereof

The invention discloses a bismuthate lead-free sealing glass material with low melting point and a preparation method thereof, and belongs to the technical field of electronic materials. The bismuthate lead-free sealing glass material with the low melting point comprises the following main components in percentage by mass: 71 to 91 percent of Bi2O3, 5 to 25 percent of B2O3, 2 to 20 percent of ZnO and 0.5 to 5 percent of Sb2O3. The preparation method for the material comprises the following steps: weighing the components in percentage by mass as raw materials, and mixing the raw materials evenly; putting the evenly-mixed raw materials into a crucible; preserving the heat for 0.5 to 1 hour at the temperature of between 200 and 300 DEG C; continuously heating the raw materials to between 1,000 and 1,200 DEG C at the heating rate of 10 DEG C per minute; covering a crucible cover on the crucible to prevent bismuth trioxide from volatilizing; preserving the heat for 0.5 to 2 hours, and melting glass liquid; and taking the well melted glass liquid out, and water-quenching, drying, ball-milling and sieving the glass liquid to obtain bismuthate lead-free sealing glass powder with low melting point. The material has the advantages that the material can be used for long-time stable sealing operation at relatively low temperature, and the sealing process does not crystallize and has good liquidity.

Owner:CHINA JILIANG UNIV

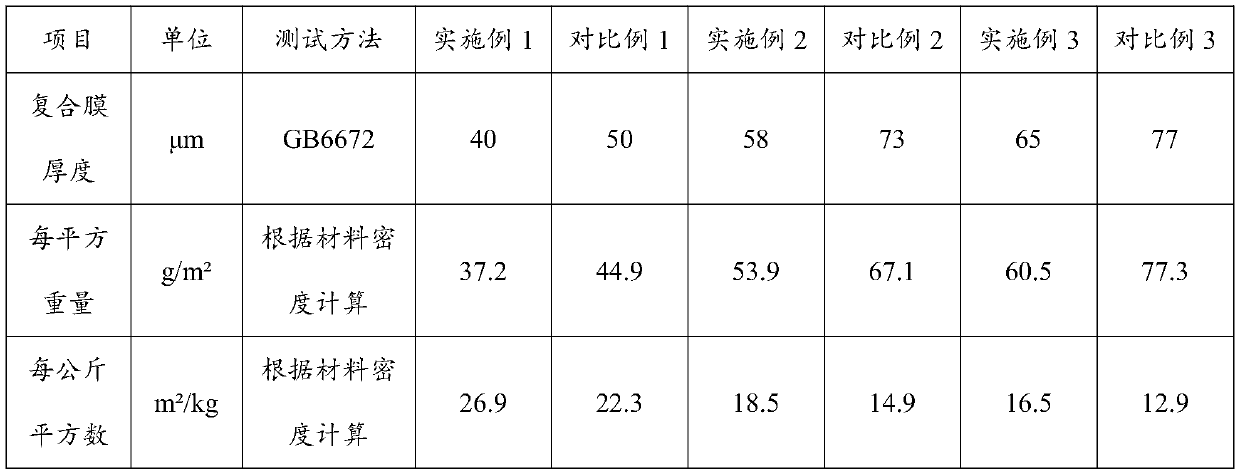

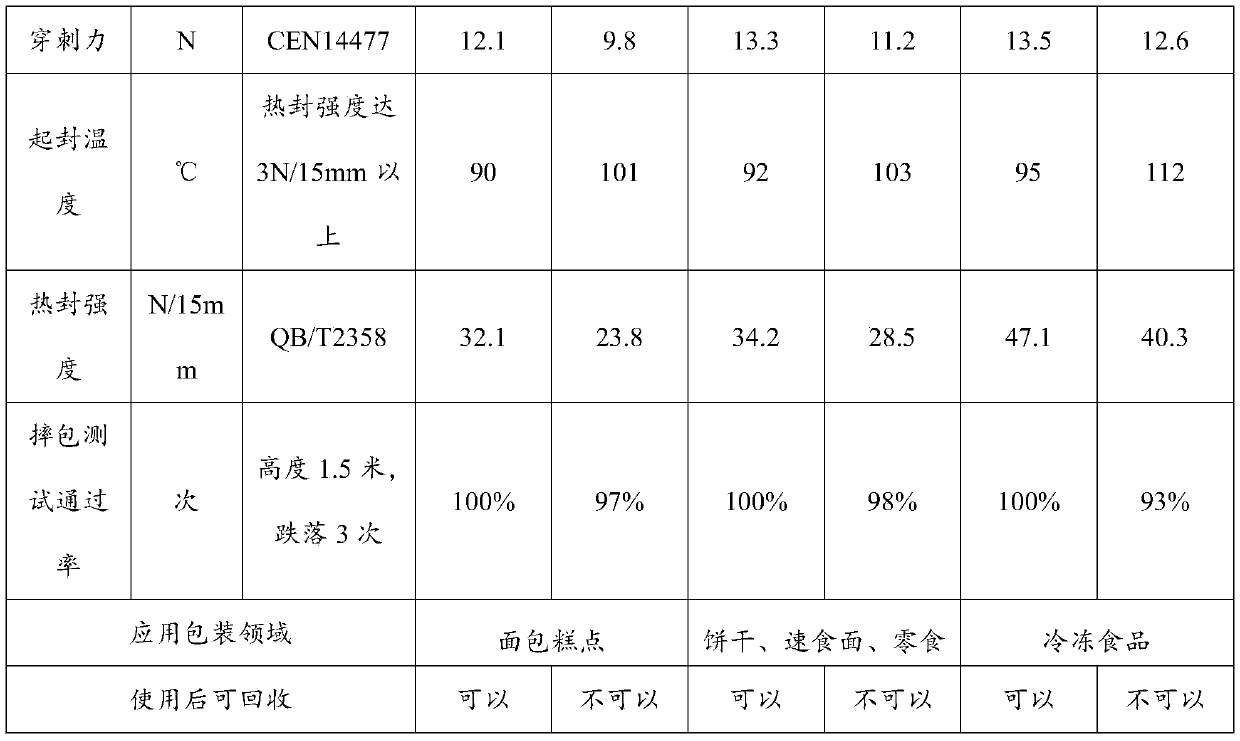

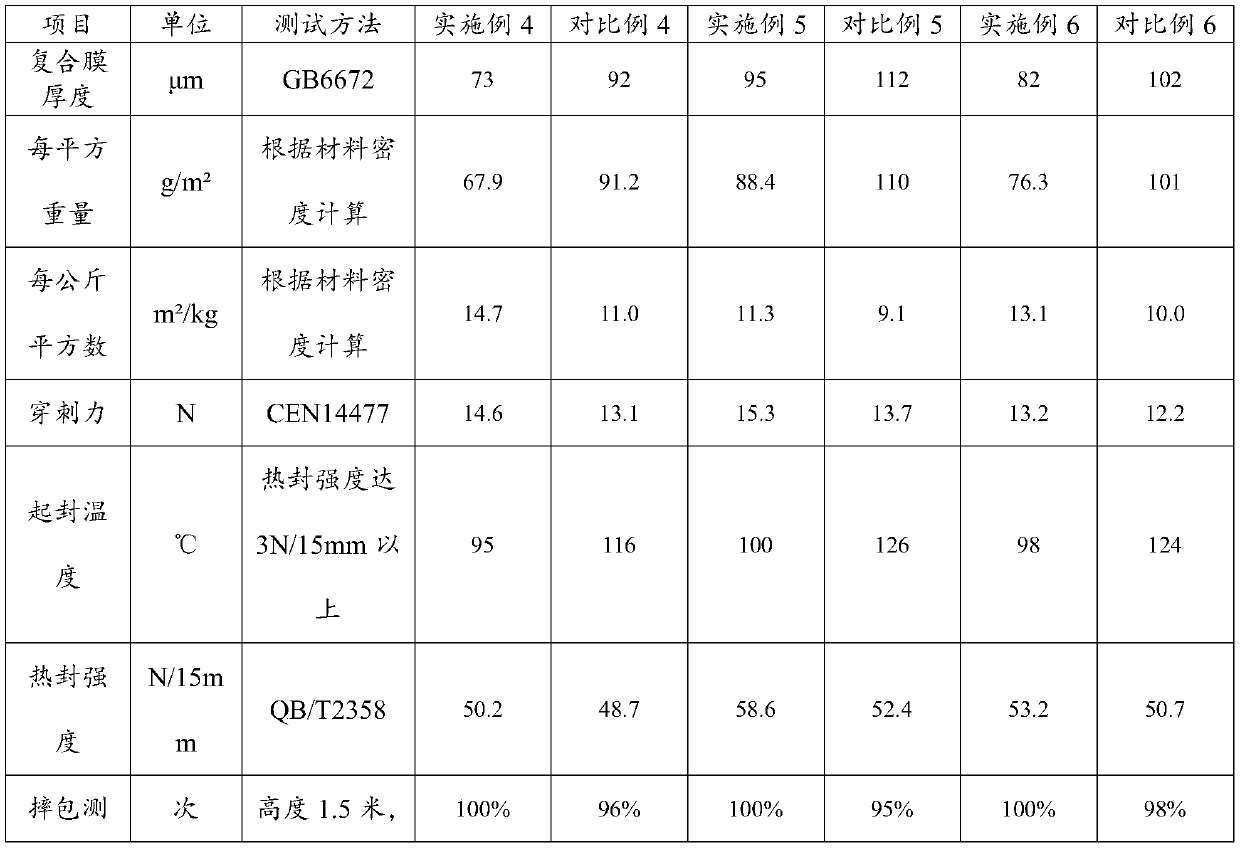

Polyethylene composite film capable of 100% recovery as well as preparation method and application thereof

ActiveCN111531991AGood printabilityGood optical performancePackage recyclingFlexible coversLow-density polyethylenePolymer science

The invention belongs to the technical field of polyethylene materials, and particularly relates to a polyethylene composite film capable of 100% recovery as well as a preparation method and application thereof. The provided polyethylene composite film comprises a composite printing layer, a bonding layer and a composite heat-seal layer which are bonded in sequence, wherein the composite printinglayer is a longitudinally-stretched polyethylene printing film; the direction from the composite printing layer to the composite heat sealing layer is from outside to inside, and the composite printing layer comprises a printing layer outer layer, a printing layer middle layer and a printing layer inner layer in sequence; the bonding layer is a low-density polyethylene film or a solvent-free gluelayer; the composite heat-seal layer is a multi-layer co-extrusion polyethylene heat-seal film and comprises a heat-seal layer outer layer, a heat-seal layer middle layer and a heat-seal layer inner layer in sequence. Experimental results show that the polyethylene composite film capable of 100% recovery can be recycled by 100%, and has the characteristics of small thickness, low density, punctureresistance and low unsealing temperature.

Owner:江门市华龙膜材股份有限公司

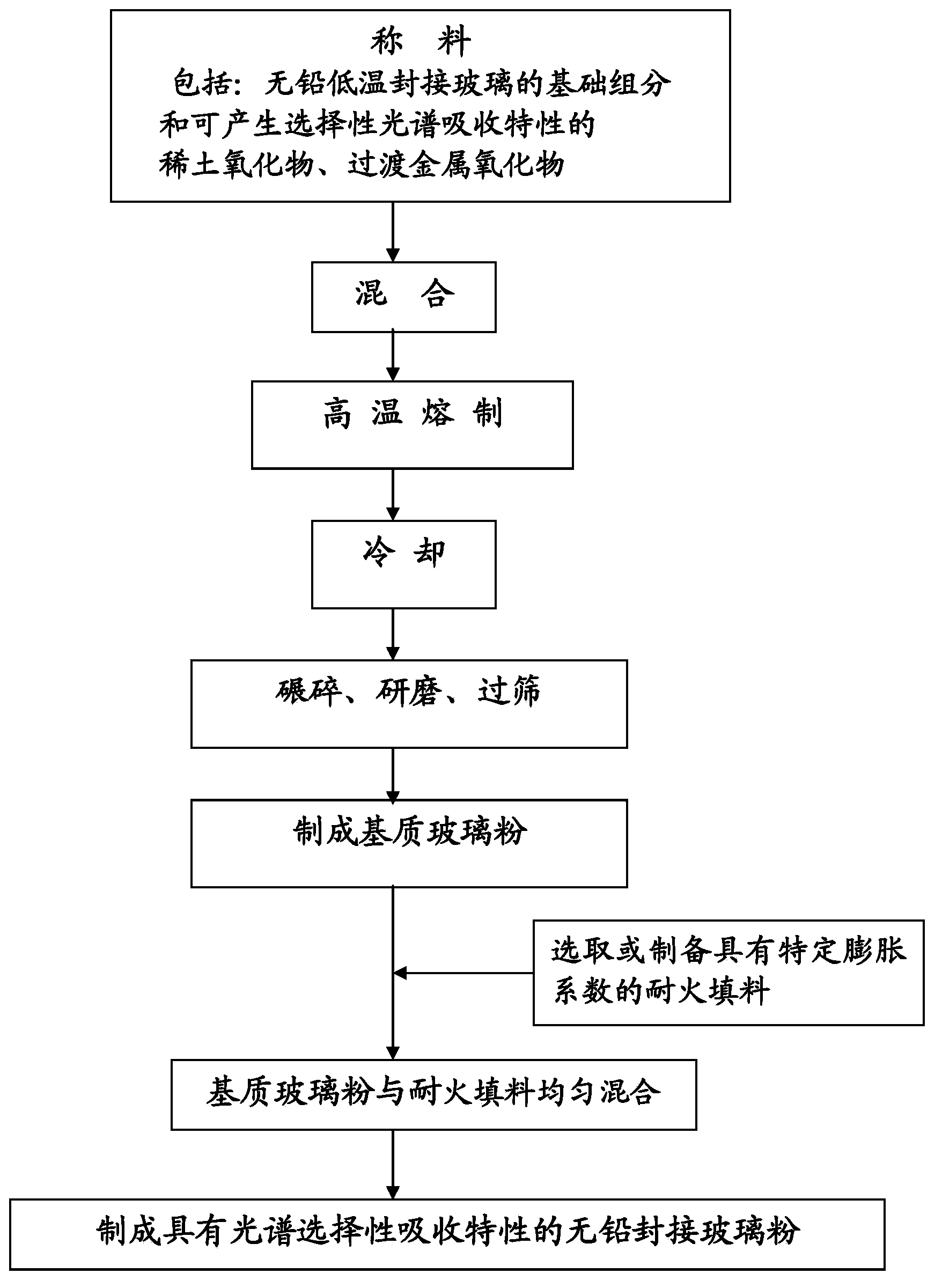

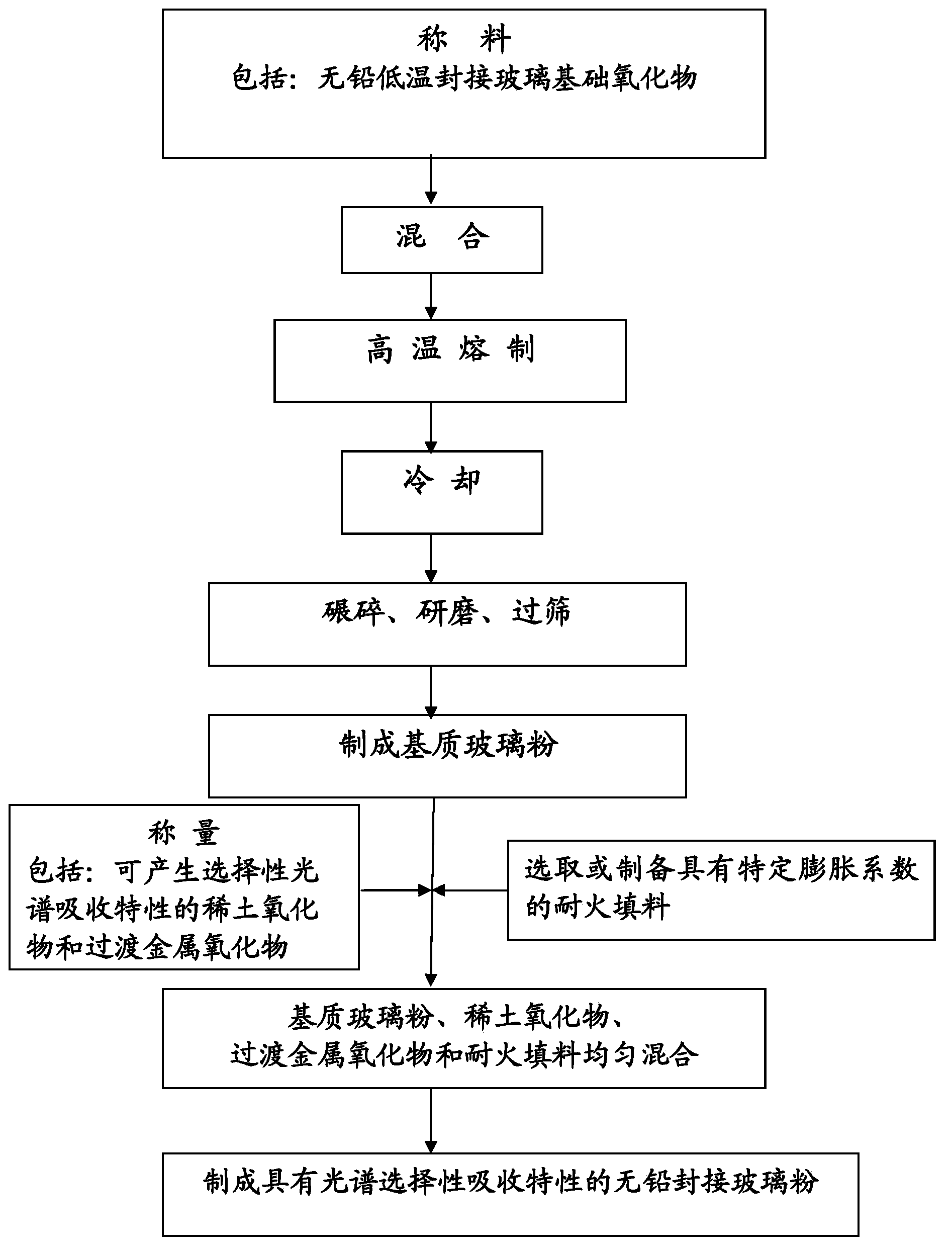

Lead-free sealing glass powder having selective spectrum absorption characteristic, and manufacturing method thereof

ActiveCN103910490AHas spectrally selective absorption propertiesLow sealing temperatureElectricityUltraviolet lights

The present invention discloses lead-free sealing glass powder having a selective spectrum absorption characteristic, and a preparation method thereof, wherein a lead-free low temperature sealing glass system is adopted as a base component, and is added with a rare earth oxide capable of making the sealing glass produce the selective spectrum absorption characteristic and a transition metal oxide, and the weight percentage ratio of the total amount of the base component to the total amount of the rare earth oxide and the transition metal oxide in the lead-free sealing glass is 100:0.1-20.0. The lead-free sealing glass powder prepared according to the method has the selective spectrum absorption characteristic, is applicable for the light radiation heating sealing processes adopting ultraviolet light, visible light or infrared light as the heating source, can be used for insulating sealing or air tightness sealing of electrical vacuum devices, electronic components or vacuum insulating glasses, and has advantages of low sealing temperature, good chemical stability, appropriate expansion coefficient, easy preparation, continuous large-scale industrial production and the like.

Owner:CHINA BUILDING MATERIALS ACAD +1

Laminates comprising a low temperature heat sealable layer containing poly(trimethylene succinate) or poly(trimethylene terephthalate-co-succinate)

InactiveUS20140363546A1Improve performanceStiffnessDomestic containersGlass/slag layered productsPolyethylene terephthalatePolytrimethylene terephthalate

The present invention relates to laminates comprising at least one structural layer and a heat sealable layer, wherein the heat sealable layer comprises or is produced from polytrimethylene succinate, poly(trimethylene terephthalate-co-succinate), or blends thereof. This invention also relates to packages comprising the laminates, said package is heat sealable at a heat sealing temperature below 100° C. to provide a heat sealing strength of 10 N / 15 mm or higher.

Owner:EI DU PONT DE NEMOURS & CO

Anodizing-assisted low-temperature glass brazing method

The invention discloses an anodizing-assisted low-temperature glass brazing method which aims at mainly solving the problem that in the process of using low-temperature glass brazing for brazing, spreading wetting is insufficient due to poor chemical compatibility of the brazing and base metal or low brazing temperatures and large fused glass brazing viscosity. The brazing method comprises the steps that firstly, low-temperature sealing ground glass is put into a mold to be smelted into a block, and a low-temperature glass block is obtained; secondly, the low-temperature sealing glass block is cut into slices, and base metal to be brazed is cut and molded; thirdly, a brazing piece is subjected to ultrasonic cleaning and grinding; fourthly, the brazing piece is subjected to anodizing and hole sealing treatment; fifthly, the slice-shaped low-temperature glass brazing is put at the to-be-connected position of the brazing piece; and sixthly, heating is conducted for melting brazing paste, heat preservation is carried out, and then the brazing piece is cooled along with a furnace. The slice-shaped low-temperature glass used in the method is low in sealing temperature and small in coefficient of linear expansion, an obtained brazing connector is free of macroscopic defects such as cracks and air holes and high in strength, and meanwhile an oxidation film formed through anodizing has a good protection effect on the base metal.

Owner:HARBIN INST OF TECH

Low-temperature low expansion coefficient high-rigidity lead-free electronic glass powder and preparation method thereof

The invention relates to a low-temperature low expansion coefficient high-rigidity lead-free electronic glass powder and a preparation method thereof. The electronic glass powder comprises, by weight, 30-80 parts of Bi2O3, 10-30 parts of ZnO, 10-30 parts of B2O3, 3-5 parts of CaF2, 2-8 parts of MoO3, 1-5 parts of Al2O3, 0-10 parts of SiO2, 0-5 parts of P2O5, 0-5 parts of Sb2O3 and 0-5 parts of WO3. According to the low-temperature low expansion coefficient high-rigidity lead-free electronic glass powder and the preparation method thereof, lead-free environment-friendly materials are used, and during production, the materials have no harm on human bodies and don't generate harmful waste gases, waste water and waste residues, so that the materials are new materials which are environment-friendly in raw materials, production processes and products; the glass powder is good in electrical performance, low in melting point, small in coefficient of thermal expansion, high in rigidity and low in leakage current; temperatures of sealing-in are low, and the sealing-in can be achieved at temperatures of 450 DEG C + / - 10 DEG C; and the expansion coefficient of the materials is 5.85ppm, and the materials are matched with lightning arrester valve block matrixes.

Owner:西安宏星电子浆料科技股份有限公司

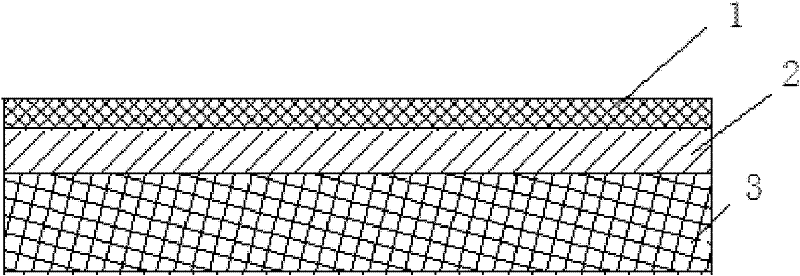

Thinning lightweight packaging material and preparation method thereof

ActiveCN102303436AExcellent transparency and brightnessHigh tensile strengthFlexible coversWrappersPolyesterPolyethylene terephthalate glycol

The invention discloses a thinning lightweight packaging material and a preparation method thereof. The packaging material comprises a PET (Polyethylene Terephthalate) polyester film layer, a functional polyethylene film layer and a polypropylene and polyethylene co-extruded and blended film layer from outside to inside, respectively. Compared with the prior art, the invention has the following advantages of: (1) clear and bright appearance, good effect on shelves and capability of improving product grades; (2) low temperature, short heat-sealing time, high sealing strength and capability of reducing packaging cost; (3) small friction coefficient, applicability for modern rapid automatic packaging equipment, fast packaging speed and high efficiency; (4) high performance and good weather resistance; (5) low-temperature heat-sealing formula; the heat-sealing temperature of the ordinary packaging material for washing powder is 120-130 DEG C, and the heat-sealing temperature of the thinning lightweight packaging material disclosed by the invention can be controlled at 100-110 DEG C; and (6) on the premise of improving the performance, the weight per unit and the produced quantity of the wastes are reduced and the trend to thinning, lightweight and multifunctional packaging is realized.

Owner:HUANGSHAN NOVEL

Ce and Y codoped modified sealing-in microcrystalline glass

The invention discloses Ce and Y codoped modified sealing-in microcrystalline glass, which comprises the following ingredients through being metered by mole percentage: 0 to 10 percent of B2O3, 0 to 10 percent of Al2O3, 30 to 40 percent of SiO2, 20 to 40 percent of MO (one or several materials from MgO, CaO, SrO and BaO) and 15 to 40 percent of RO (CeO2 and Y2O3). The Ce and Y codoped modified sealing-in microcrystalline glass has the advantages that preparing raw materials are simple and can be easily obtained, the process is stable, the cost is low, the process is simple and feasible, and the practical and industrialized conditions are reached.

Owner:FUZHOU UNIV

Heat shrinkable film applicable to automatic quick packaging on production line

ActiveCN107696623AImprove packaging efficiencyEasy to operateSynthetic resin layered productsSacksLinear low-density polyethyleneInter layer

The invention relates to the field of heat shrinkable films, in particular to a heat shrinkable film applicable to automatic quick packaging on a production line. The heat shrinkable film comprises anouter surface layer, a heat seal layer on the inner surface and a barrier layer between the outer surface layer and the heat seal layer. The barrier layer comprises an EVOH (ethylene-vinyl alcohol) barrier interlayer, at least one side of the EVOH barrier interlayer is provided with a barrier layer protecting layer which is a PA (polyamide) layer, the surface layer is a PA layer, and the heat seal layer is a POP (polyether polyol) layer or one of an mLLDPE (metallocene linear low density polyethylene) layer, a ULDPE (ultralow-density polyethylene) layer and a Surlyn resin layer or a POP and mLLDPE mixed layer. The surface layer and the barrier layer as well as the barrier layer and the heat seal layer are connected through adhesive resin. The heat shrinkable film is high in strength, great in barrier and heat seal performance, excellent in machinability and suitable for full-automatic online packaging. By the heat shrinkable film, the shrinkable bag packaging modes and packaging efficiency can be changed.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Cast polypropylene membrane

ActiveCN105172287AImprove air tightnessHigh transparencyFlexible coversWrappersElastomerModified atmosphere

A cast polypropylene (CPP) membrane is formed by performing three-layer co-extrusion by a casting machine, and possesses a three-layer structure comprising an outer layer, a middle layer and an internal layer. The internal-layer material is formed by blending 50% by weight of terpolymerization polypropylene, 40% by weight of allyl elastomer and 10% by weight of vinyl-vinyl acetate copolymer. The middle-layer material is formed by blending allyl elastomer and metallocene polyethylene, wherein allyl elastomer accounts for 60%-90% by weight. The outer-layer material employs homopolymerization polypropylene or random copolymerization polypropylene resin. The fusion index of all of the above resin is 3-8, the inner-layer thickness is 10 mu m or more, the cast polypropylene membrane is formed through three-layer co-extrusion casting equipment and forms a composite packaging membrane. The airtightness, and toughening and compatibility technical problems of a conventional CPP material are solved. The modified atmosphere packaging high airtightness and high-speed pillow-type automatic packaging (HFFS) requirements are satisfied, and the membrane is especially suitable for baking foodstuff inflation pressure-resistant packaging.

Owner:湖北宏裕新型包材股份有限公司

Hole sealing treatment method for aluminum and aluminum alloy anodized films

ActiveCN102677120ASimple processEasy to operateSurface reaction electrolytic coatingAlloyTherapeutic effect

The invention provides a hole sealing treatment method for aluminum and aluminum alloy anodized films. The hole sealing treatment method for the aluminum and aluminum alloy anodized films is characterized by taking an aqueous solution of an aqueous nano-coating or an alcohol solution of organic sol gel as a hole sealing solution, and hole sealing treatment is performed on the aluminum and aluminum alloy anodized films according to the following specific process: soaking an anodized aluminum or aluminum alloy workpiece into the aqueous solution of the aqueous nano-coating or the alcohol solution of the organic sol gel for the hole sealing treatment, wherein the treatment temperature is 20-25 DEG C and the treatment time is 10-20 seconds; and then taking out and baking the aluminum alloy workpiece for 30 minutes at 110-150 DEG C. The hole sealing treatment method for the aluminum and aluminum alloy anodized films is simple in process, relatively low in energy consumption, and accordant with requirements on environmental protection; and after the hole sealing treatment on aluminum and aluminum alloy workpieces, the corrosion resistance of surfaces of the aluminum and aluminum alloy workpieces are relatively high, water marks are avoided and the dyeing treatment effect of the anodized films is not affected.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Special functional material for food package and preparation method of special functional material

The invention discloses a special functional material for a food package and a preparation method of the special functional material. The special functional material is prepared from the following components in percentage by weight: 20-22 percent of matrix resin, 46-50 percent of barium sulfate, 1.0-1.5 percent of stearic acid coupling agent, 21-23 percent of titanium dioxide and 3-6 percent of lubricant, wherein the matrix resin is metallocene linear low-density polyethylene (mLLDPE) with the solution flow rate of 2.0-3.0 and the density of 0.915-0.920, and the lubricant is paraffin and zinc stearate. With the adoption of the special functional material, the content of n-hexane as master batch evaporated residues is far lower than that in the industrial standard, the consumption of potassium permanganate is low, and all physical properties and sensory indexes are good. The special functional material is simple and economic in the preparation process, is environment-friendly and energy-saving and has wide market prospects.

Owner:上海三承高分子材料科技有限公司

High-temperature resistant metal sealing material for mixed conductor oxygen permeable ceramic membrane and application method thereof

InactiveCN101928855AGood chemical inertnessReduce chemical reactionsElectrical conductorRoom temperature

The invention relates to a preparation method of a high-temperature resistant metal sealing material for a compact mixed conductor oxygen permeable ceramic membrane and a sealing application method of the material, in particular to a preparation method of the sealing material between a compact mixed conductor oxygen permeable ceramic membrane piece and a supporting component thereof and an application method of the sealing material, belonging to the technical field of a special ceramic welding material. The high-temperature resistant metal sealing material comprises the following components in weight percentage: 92-95% of Cu, 4-7% of Sn, 0-0.005% of Al, 0.1-0.3% of Zn, 0-0.05% of Fe, 0.04-0.2% of Pb, 0.1-0.3% of Ni and 0.1-0.5% of P. The preparation method comprises the following steps: weighing raw materials according to the formula for blending; placing the mixed materials in a vacuum induction furnace the vacuum degree of which is less than 2Pam for smelting at the temperature of 1100-1150 DEG C for 3-5 minutes until the materials are molten; and cooling to room temperature, and then taking out molten blocks to finally obtain the high-temperature resistant sealing material. The sealing material obtained by the method of the invention has very high sealing tightness as well as good chemical stability on the oxygen permeable ceramic membrane.

Owner:SHANGHAI UNIV

High-barrier BOPP aluminum-plated film and preparation method thereof

ActiveCN107553941AImprove barrier propertiesGood adhesionSynthetic resin layered productsLaminationWater vapor permeabilityOxygen transmission rate

The invention discloses a high-barrier BOPP aluminum-plated film and a preparation method thereof. The preparation method comprises the steps of: raw material treatment; feeding and fusion plastifying; extrusion; casting cooling; longitudinal stretching; transverse stretching; corona treatment; traction coiling; ageing treatment; slitting; and vacuum aluminum plating. Under the conditions of 38 DEG C and relative humidity of 90%, the high-barrier BOPP aluminum-plated film prepared by the preparation method reaches the water vapor permeability of not more than 0.2 g / (m2.24h) and the oxygen permeability of not more than 25 cm3 / (m2.24h); the hot sealing strength of a hot sealing surface of the prepared high-barrier BOPP aluminum-plated film is not less than 3.0 N / 15 mm; and the sealing temperature is not higher than 115 DEG C. The high-barrier BOPP aluminum-plated film prepared by the preparation method can synchronously reach the composite flexible packing bag and label printing industrystandard and the YY0236-1996 industry standard, and can be used for packing materials in such fields as foods and medicines with high-barrier packing requirements.

Owner:SHANGHAI RADIX VACUUM METALIZING

Lead-free low-melting-point sealing glass doped with fusible metal alloy and preparation method of lead-free low-melting-point sealing glass

The invention relates to lead-free low-melting-point sealing glass doped with fusible metal alloy and a preparation method thereof. The glass comprises the following components in percentage by weight: 60-85% of lead-free low-melting-point sealing glass; 8%-20% of a low-expansion filler; and 7%-20% of fusible metal alloy. The expansion coefficient of the lead-free low-melting-point sealing glass is matched with that of platinum group glass, the sealing temperature is smaller than or equal to 420 DEG C, and the lead-free low-melting-point sealing glass is good in chemical stability, high in sealing strength and easy to prepare. According to different characteristic index requirements, the proportion of each component can be flexibly adjusted, the formula of the glass is optimized, and the specific requirements of the market on the lead-free low-melting-point sealing glass are met.

Owner:CHINA BUILDING MATERIALS ACAD

Low-temperature glass brazing method aided by micro-arc oxidation

ActiveCN105499733AReduce complexityLow connection temperatureSoldering ironMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a low-temperature glass brazing method aided by micro-arc oxidation. The invention aims at solving the problems that the spreadability and the wettability are insufficient and the strength of a brazed joint is relatively low due to poor chemical compatibility or low brazing temperature between a brazing material and masterbatch and high viscosity of a molten glass brazing material in a process of brazing using the low-temperature glass brazing material. The brazing method comprises the following steps: 1, mixing low-temperature sealing glass powder and an adhesive to obtain brazing paste; 2, carrying out cutting molding on masterbatch to be brazed; 3, carrying out ultrasonic cleaning and polishing on a weldment; 4, carrying out micro-arc oxidation and hole sealing on the weldment; 5, coating the surface of the weldment subjected to micro-arc oxidation with the brazing paste; 6, constituting a piece to be brazed; 7, carrying out high-pressure brazing in an argon atmosphere or under a negative pressure condition. The low-temperature sealing glass used in the brazing process is low in sealing temperature and small in linear expansion coefficient; the obtained brazed joint has no cracks and pores, and has small residual stress, high strength and good air tightness; meanwhile, a compact ceramic film layer formed by micro-arc oxidation has a favorable protection effect on the masterbatch.

Owner:HARBIN INST OF TECH

Co-Ni co-doping anti-corrosion glass and preparation and use methods thereof

The invention discloses Co-Ni co-doping anti-corrosion glass and preparation and use methods thereof. The Co-Ni co-doping anti-corrosion glass is prepared from the following raw materials including B2O3, SiO2, Na2O, K2O, Co2O3 and Ni2O3 according to a mol ratio of (0 to 15):(20 to 40):(10 to 30):(10 to 30):(5 to 25):(5 to 25). High-concentration Na2O and K2O are added; the compatibility of the glass and the concrete is improved; the heat expansion coefficient of the glass is increased; the sealing and connecting temperature of the glass is obviously reduced; the SiO2 is used as main ingredients for making a resistant net; the anti-corrosion performance of the glass is improved; the SiO2 takes a reaction with CaO in concrete to generate a compact CaSiO3 layer on the surface of a steel bar, so that the corrosion of the steel bar is inhibited; high-concentration Co2O3 in the glass and Ni2O3 generate solid solutions of spinel structures; the tight lap joint is realized with an oxide layer on the surface of the steel bar; the adhesion force of the glass and the steel bar is obviously enhanced. The Co-Ni co-doping anti-corrosion glass has the advantages that the raw material price is low; the process is stable; the conditions of practicability and industrialization are reached.

Owner:FUZHOU UNIV

Preparation method of lead-free electronic glass

The invention relates to a preparation method of lead-free electronic glass. Lead-free electronic glass is developed at home and abroad, and has a main systems comprising Bi2O3-B2O3-SiO2, Bi2O3-B2O3-ZnO, V2O5-B2O3-ZnO, BaO-B2O3-ZnO, and the like. The front three system raw materials have overhigh cost, and the cost of the materials is above 100 yuan per kilogram, and the expansion coefficient of the fourth material system is too large. If the expansion coefficient is wanted to be lowered, a melting point of the materials is needed to rise. The lead-free electronic glass is prepared from the following raw materials by weight portion: 30 to 80 portions of B2O3, 10 to 30 portions of ZnO, 5 to 10 portions of NaCO3, 1 to 10 portions of CaCO3 and 1 to 5 portions of feldspar. The lead-free electronic glass has excellent electrical performance, small dieletric constant, little medium loss as well as high volume resistivity and breakdown strength, and cannot generate damage to a human body during production or generate harmful waste gas, waste water and waste slag.

Owner:西安创联宏晟电子有限公司

Lead-free bismuthate glass powder used for bonding electronic ceramics

The invention relates to a lead-free bismuthate glass powder used for bonding electronic ceramics. The lead-free bismuthate glass powder comprises the following raw materials in percentage by weight: 65 to 85 percent of bismuth oxide (Bi2O3), 1 to 30 percent of boric oxide (B2O3), 1 to 20 percent of zinc oxide (ZnO), 1 to 10 percent of aluminum oxide (Al2O3), 1 to 5 percent of magnesium oxide (MgO), 1 to 5 percent of vanadium pentoxide (V2O5), 1 to 5 percent of lithium oxide (Li2O), 1 to 5 percent of tungsten trioxide (WO3), 1 to 3 percent of phosphorus pentoxide (P2O5), and 1 to 3 percent of strontium oxide (SrO), wherein the total weight percentage of the Bi2O3, the B2O3 and the ZnO is 70 to 90 percent; the total weight percentage of the Al2O3, the MgO and the WO3 is 5 to 13 percent; and the total weight percentage of the V2O5, the Li2O3 and the P2O5 is 4 to 10 percent. The lead-free bismuthate glass powder used for bonding the electronic ceramics one another has the characteristics of no lead, high air tightness, high sealing fluidity and low sealing temperature, and can be used for bonding electronic ceramics one another.

Owner:郑庆云

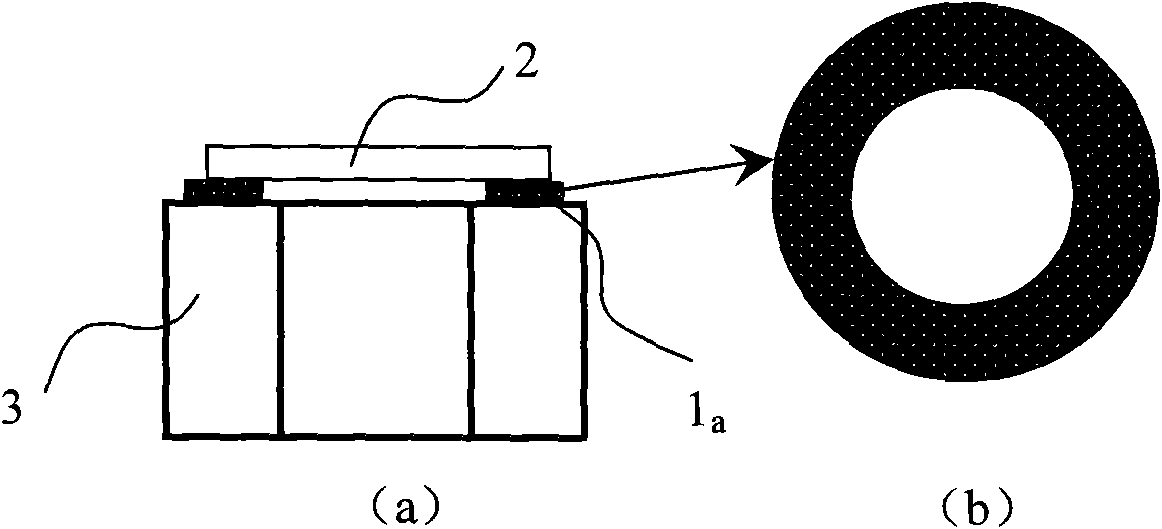

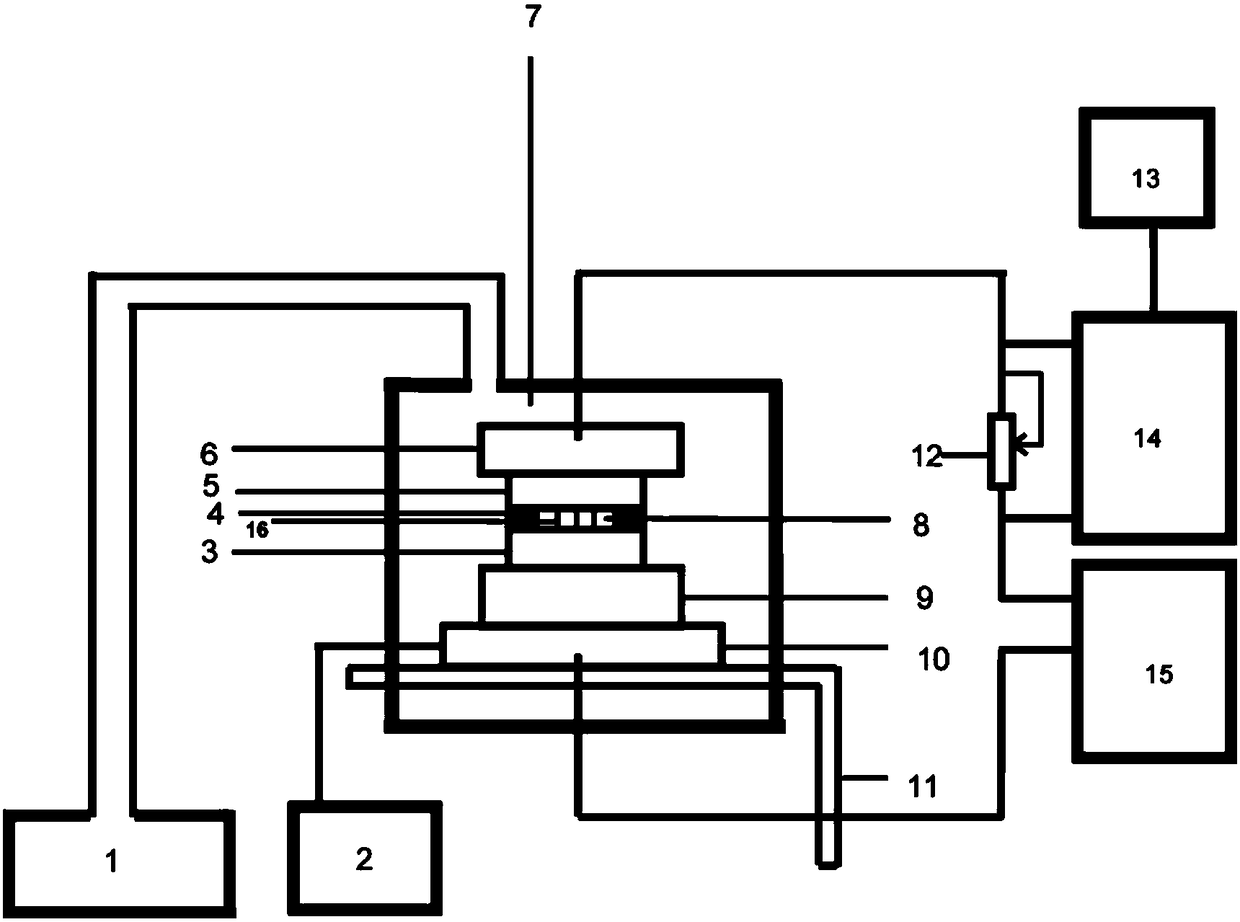

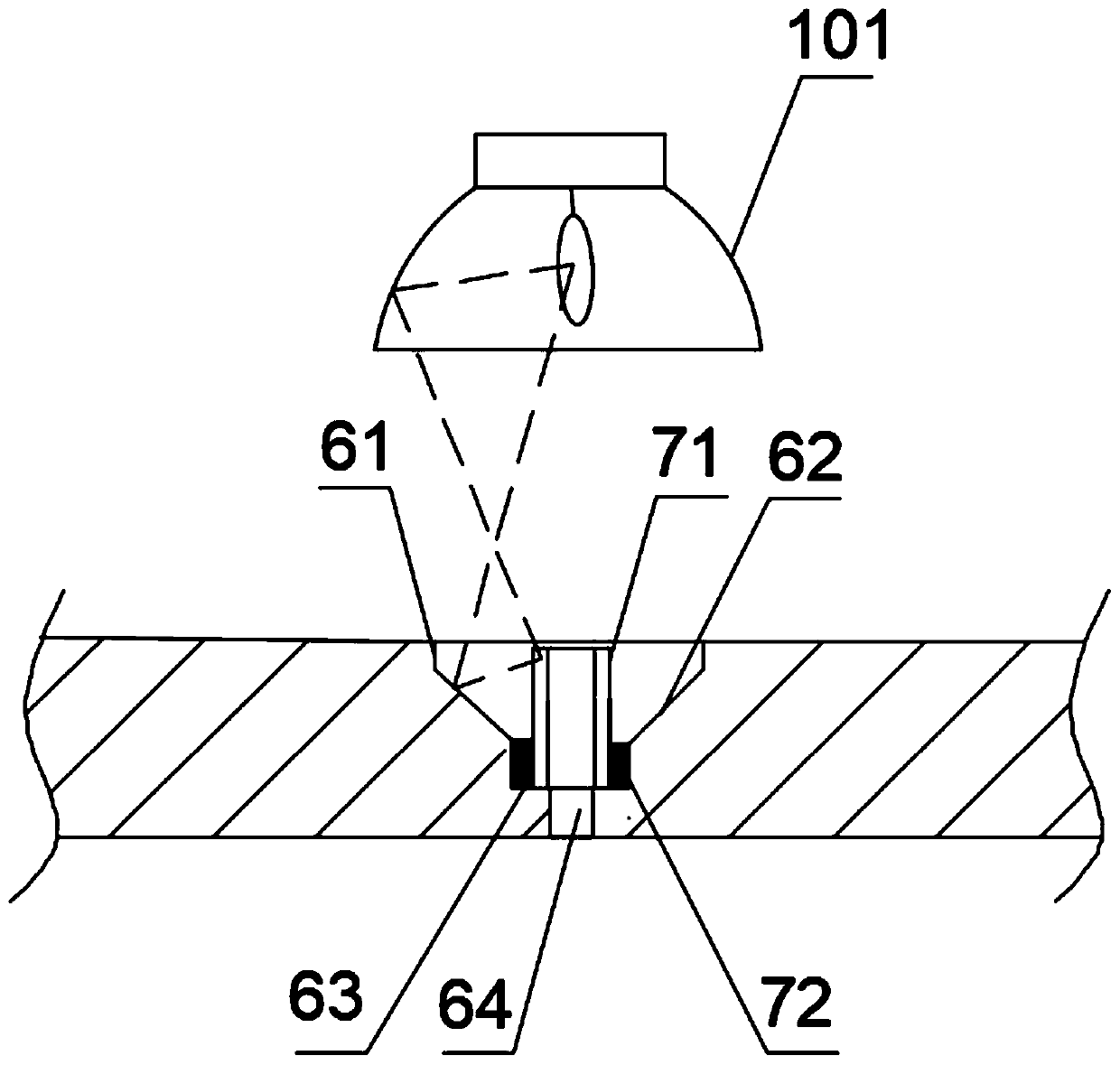

Anodic bonding method and anodic bonding device for vacuum glass sealing

ActiveCN108328912ASimple preparation processLow costGlass reforming apparatusEnvironmental resistanceThermal expansion

The invention discloses an anodic bonding method and an anodic bonding device for vacuum glass sealing. The anodic bonding method includes selecting appropriate glass powder with a low melting point and manufacturing sealing materials; coating edge sealing layers and intermediate support dot matrixes on glass substrates at one step; laminating each glass substrate with another blank glass substrate, placing the glass substrates and the blank glass substrates in the anodic bonding device, vacuumizing the anodic bonding device until the pressure of the anodic bonding device reach 5.0*10<-2>-1.0*10<-4> Pa and carrying out effective anodic bonding in states of bonding temperatures of 300-500 DEG C and bonding voltages of 400-800 V. The anodic bonding method and the anodic bonding device have the advantages that vacuum glass can be vacuumized and sealed in the anodic bonding device at the low bonding temperatures at one step, and accordingly vacuum glass with excellent performance can be prepared by the aid of the anodic bonding method and the anodic bonding device; glass composition with the low melting point is free of lead, is green and environmentally friendly and is matched with thermal expansion coefficients of the glass substrates; preparation processes are simple and are low in cost and high in efficiency, the anodic bonding method and the anodic bonding device are suitablefor industrial production and high in efficiency, and energy can be saved; the vacuum glass is high in sealing strength, good in stability and long in service life as compared with the traditional vacuum glass sealing methods.

Owner:WUHAN UNIV OF TECH

Tempered vacuum glass and manufacturing method thereof

InactiveCN111499223AFully sinteredLower sintering temperatureGlass tempering apparatusLaser beam welding apparatusToughened glassLaser drilling

The invention discloses tempered vacuum glass and a manufacturing method thereof. The tempered vacuum glass comprises upper tempered glass, lower tempered glass and a vacuum area therebetween, whereina ceramic glaze supporting object is arranged between the two pieces of glass; low-temperature welding flux used for edge sealing is arranged in gaps of the four edges, and air exhaust parts with airexhaust pipes and reflecting surfaces are arranged at the corners of the upper piece of glass. The method for manufacturing the toughened vacuum glass comprises the following steps: S1, laser drilling; S2, support arrangement; S3, toughening and support sintering; S4, solder coating; S5, glass lamination; S6, edge sealing; and S7 exhaustion and sealing. In the invention, the ceramic glaze supporthas the advantages that the ceramic glaze support and the glass are sintered together; the glass is not prone to falling off, the reflection face of the glass is beneficial to concentration of sealing heat, the air suction pipe is arranged in the glass after sealing, use is safer, low-temperature welding flux and the rapid heating and cooling technology are adopted for edge sealing in the step S6, and the glass surface stress attenuation is smaller than or equal to 5%, so that the glass surface flatness is good, and the production efficiency is high.

Owner:李长征

Blister packaging film for gamma ray disinfection and preparing method thereof

ActiveCN105216418AGood compatibilityGood heat sealing performanceLamination ancillary operationsLayered product treatmentLow-density polyethyleneLinear low-density polyethylene

The invention discloses a blister packaging film for gamma ray disinfection. The blister packaging film comprises seven layers, wherein the layer A is made from polyamide 6, the layer B is made from bonding resin, the layer C is made from 60-80% linear low-density polyethylene and 20-40% low-density polyethylene, the layer D is made from bonding resin, the layer E is made from polyamide resin, the layer F is made from bonding resin, and the layer G is made from 60-80% linear low-density polyethylene and 20-40% metallocene polyethylene; the thickness of the layer A accounts for 5-10% of the total thickness of the blister packaging film, the thickness of the layer B accounts for 5-10% of the total thickness of the blister packaging film, the thickness of the layer C accounts for 20-30% of the total thickness of the blister packaging film, the thickness of the layer D accounts for 5-10% of the total thickness of the blister packaging film, the thickness of the layer E accounts for 5-10% of the total thickness of the blister packaging film, the thickness of the layer F accounts for 5-10% of the total thickness of the blister packaging film, and the thickness of the layer G accounts for the rest of the total thickness of the blister packaging film. The blister packaging film is obtained through extrusion, film blowing, air cooling, water-cooling setting, surface treatment and coiling, integration of different layers is good, biphase separation does not occur during blister forming, the mechanical strength of products is high, polyethylene (PE) and medical dialyzing paper heat sealing effect is good, sealing starting temperature is low, heat sealing strength is high, and the blister packaging film is especially suitable for gamma ray disinfection.

Owner:FUZHOU GREEN SAIL PACKAGE MATERIAL

Ce and La codoped modified sealing-in microcrystalline glass

ActiveCN104876445AEnhanced network structureImprove insulation performanceHigh concentrationNetwork structure

The invention discloses Ce and La codoped modified sealing-in microcrystalline glass, which comprises the following ingredients through being metered by mole percentage: 0 to 10 percent of B2O3, 0 to 10 percent of Al2O3, 30 to 40 percent of SiO2, 20 to 40 percent of MO (one or several materials from MgO, CaO, SrO and BaO) and 15 to 40 percent of RO (CeO2 and La2O3). Through the design of invert glass, the sealing-in glass (greater than 15 mole percent) with high concentration Ce and La is obtained. Through the cooperated effect of the Ce and the La, the network structure of the glass can be obviously enhanced, and the insulation performance and the high-temperature chemical stability are effectively improved. The Ce and La codoped modified sealing-in microcrystalline glass has the advantages that preparing raw materials are simple and can be easily obtained, the process is stable, the cost is low, the process is simple and feasible, and the practical and industrialized conditions are reached.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com