Special functional material for food package and preparation method of special functional material

A functional material and food packaging technology, applied in the field of food packaging, can solve problems such as economic losses, achieve low consumption, stable quality, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1. Preparation of special functional material for food packaging one

[0050] (1) Barium sulfate pretreatment, first dehumidify the filler barium sulfate in an oven at 80°C until the water content of the filler drops below 0.5%, then put 49.5 parts of the filler into a high-speed kneader at a temperature of about 100°C, Add stearic acid coupling agent at 1.0%, adjust the speed to 250r min -1 , stirring at high speed for 10 minutes. It should be noted that when the stearic acid coupling agent is used, there must be no water in the system, and the barium sulfate must be dried before treatment;

[0051](2) 21 parts of metallocene linear low density polyethylene HPR18H27DX, 49.5 parts of barium sulfate after step (1) pretreatment, 22.5 parts of titanium dioxide titanium dioxide, 3 parts of lubricant paraffin, 3 parts of lubricant hard Zinc fatty acid is added to a high-speed kneader and stirred, the temperature does not exceed 80 degrees, and the stirring time ...

Embodiment 2

[0055] Embodiment 2. Preparation two of special functional materials for food packaging

[0056] (1) Barium sulfate pretreatment, first dehumidify the filler barium sulfate in an 80°C oven until the water content of the filler drops below 0.5%, then put 48 parts of the filler into a high-speed kneader at a temperature of about 100°C, Add stearic acid coupling agent at 1.2%, adjust the speed to 250r min -1 , stirring at high speed for 10 minutes. It should be noted that when the stearic acid coupling agent is used, there must be no water in the system, and the barium sulfate must be dried before treatment;

[0057] (2) 22 parts of metallocene linear low density polyethylene HPR18H27DX, 48 parts of barium sulfate after step (1) pretreatment, 23 parts of titanium dioxide titanium dioxide, 2.4 parts of lubricant paraffin, 3.4 parts of lubricant hard Zinc fatty acid is added to a high-speed kneader and stirred, the temperature does not exceed 80 degrees, and the stirring time is ...

Embodiment 3

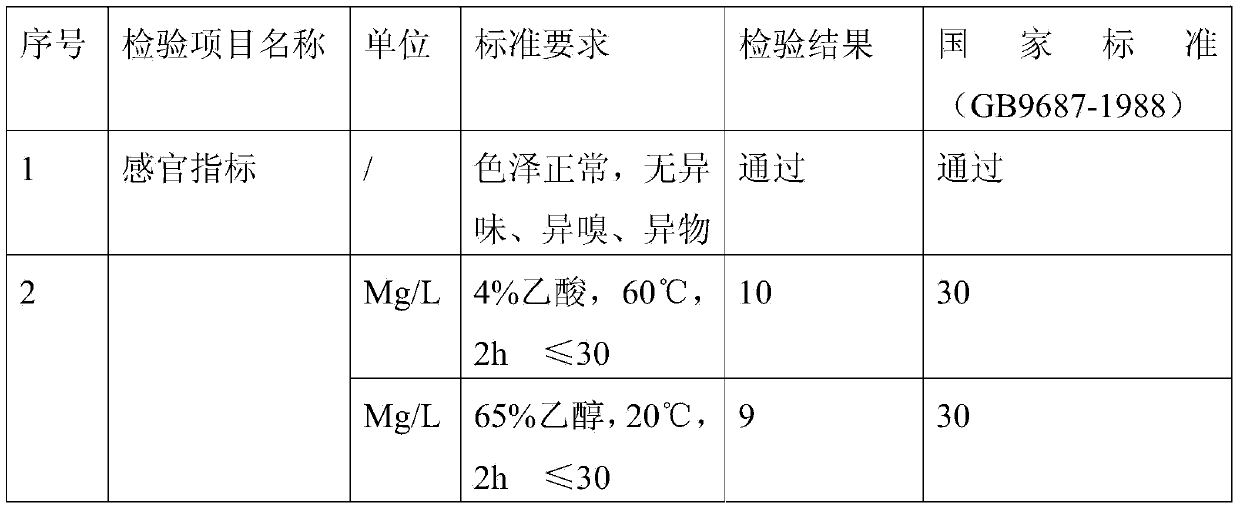

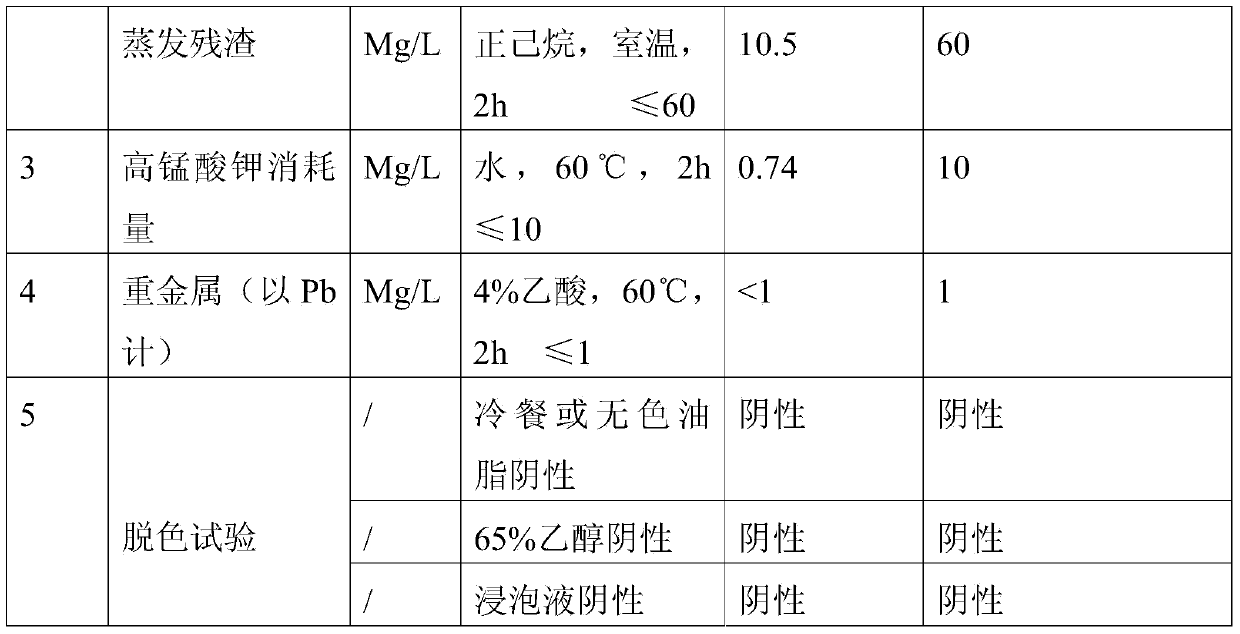

[0059] Embodiment 3. Performance testing

[0060] The detection of food packaging materials is generally to simulate different foods, prepare several soaking solutions, and measure the samples after soaking them at a certain temperature for a certain period of time.

[0061] Common soaking liquids are: water (represents neutral food and beverage)

[0062] 4% acetic acid (represents acidic food and beverage)

[0063] 20% or 60% ethanol (represents alcohol and alcoholic beverages)

[0064] n-Hexane (represents oily food)

[0065] Detection method:

[0066] (1) Sampling method: The sampling quantity of each batch shall not be less than 10, each 500ML, respectively indicate: product name, batch number, sampling date.

[0067] (2) Soaking conditions:

[0068] Distilled water: 60°C, keep warm for 2 hours;

[0069] 4% acetic acid: 60°C, keep warm for 2h;

[0070] 65% ethanol: soak at room temperature (20°C) for 2 hours;

[0071] n-Hexane: soak at room temperature (20°C) for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com