Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3791 results about "Linear low-density polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear low-density polyethylene (LLDPE) is a substantially linear polymer (polyethylene), with significant numbers of short branches, commonly made by copolymerization of ethylene with longer-chain olefins. Linear low-density polyethylene differs structurally from conventional low-density polyethylene (LDPE) because of the absence of long chain branching. The linearity of LLDPE results from the different manufacturing processes of LLDPE and LDPE. In general, LLDPE is produced at lower temperatures and pressures by copolymerization of ethylene and such higher alpha-olefins as butene, hexene, or octene. The copolymerization process produces an LLDPE polymer that has a narrower molecular weight distribution than conventional LDPE and in combination with the linear structure, significantly different rheological properties.

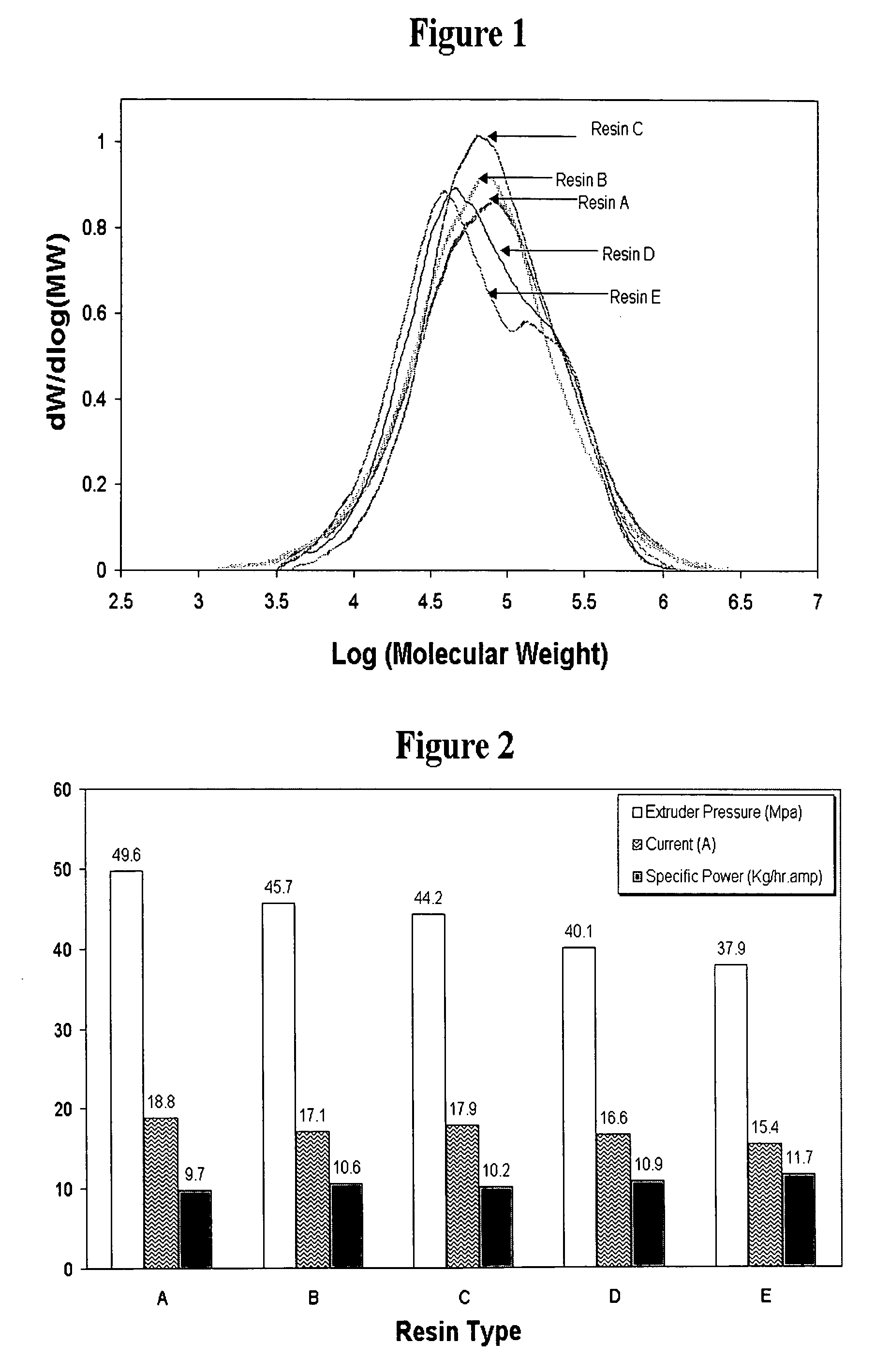

Linear low density polymer blends and articles made therefrom

ActiveUS20070260016A1Synthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

This invention relates to blends of linear low density polyethylene copolymers with other linear low density polyethylenes or very low density, low density, medium density, high density, and differentiated polyethylenes. The invention also includes articles produced from the linear low density polyethylene and polyethylene blends described.

Owner:EXXONMOBIL CHEM PAT INC

Linear low density polymer blends and articles made therefrom

ActiveUS7951873B2Synthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

This invention relates to blends of linear low density polyethylene copolymers with other linear low density polyethylenes or very low density, low density, medium density, high density, and differentiated polyethylenes. The invention also includes articles produced from the linear low density polyethylene and polyethylene blends described.

Owner:EXXONMOBIL CHEM PAT INC

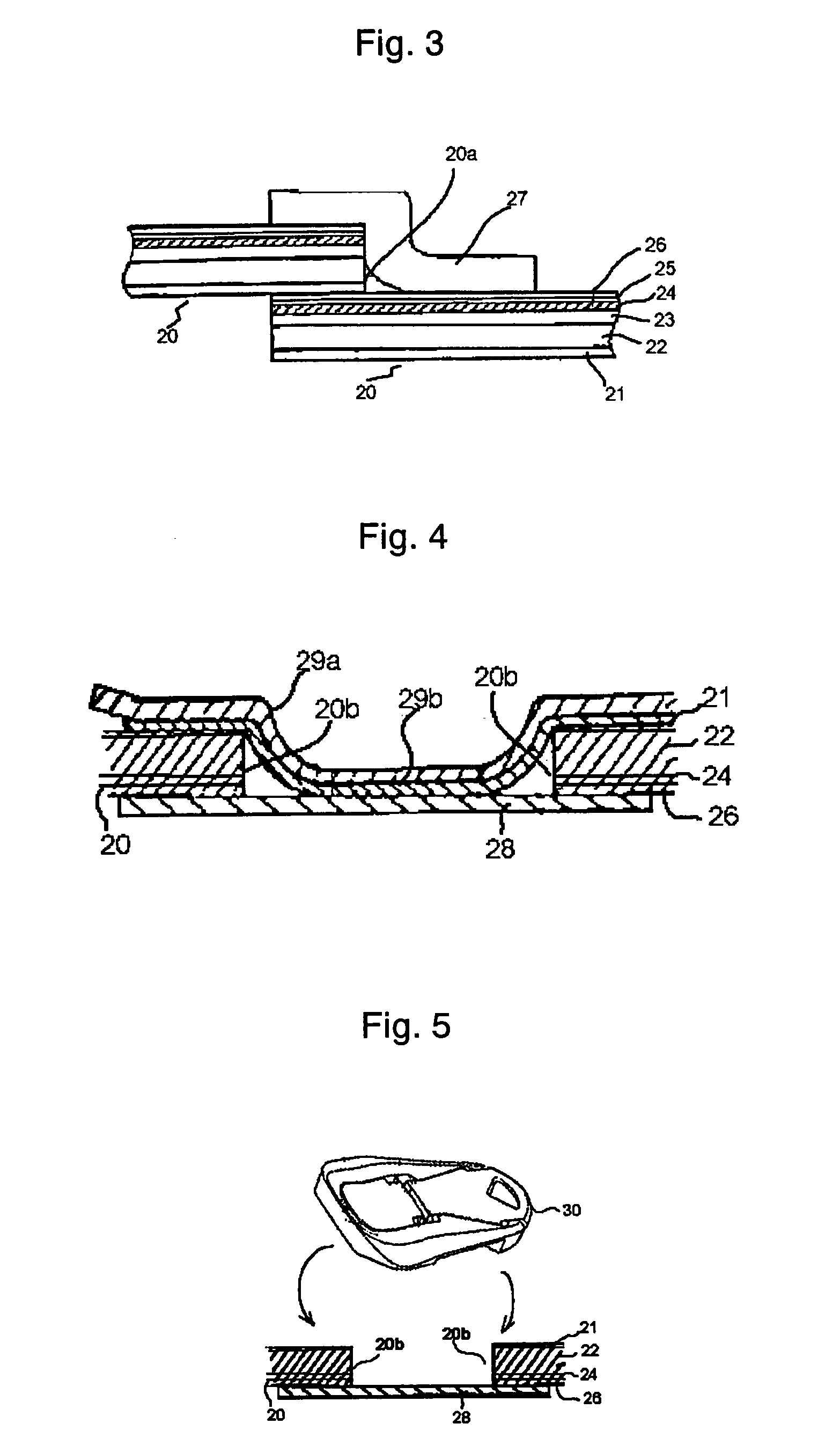

Laminated packaging material for paper container

InactiveUS6974612B1Easy to manufactureQuick heat sealEnvelopes/bags making machineryFlexible coversLow-density polyethyleneLinear low-density polyethylene

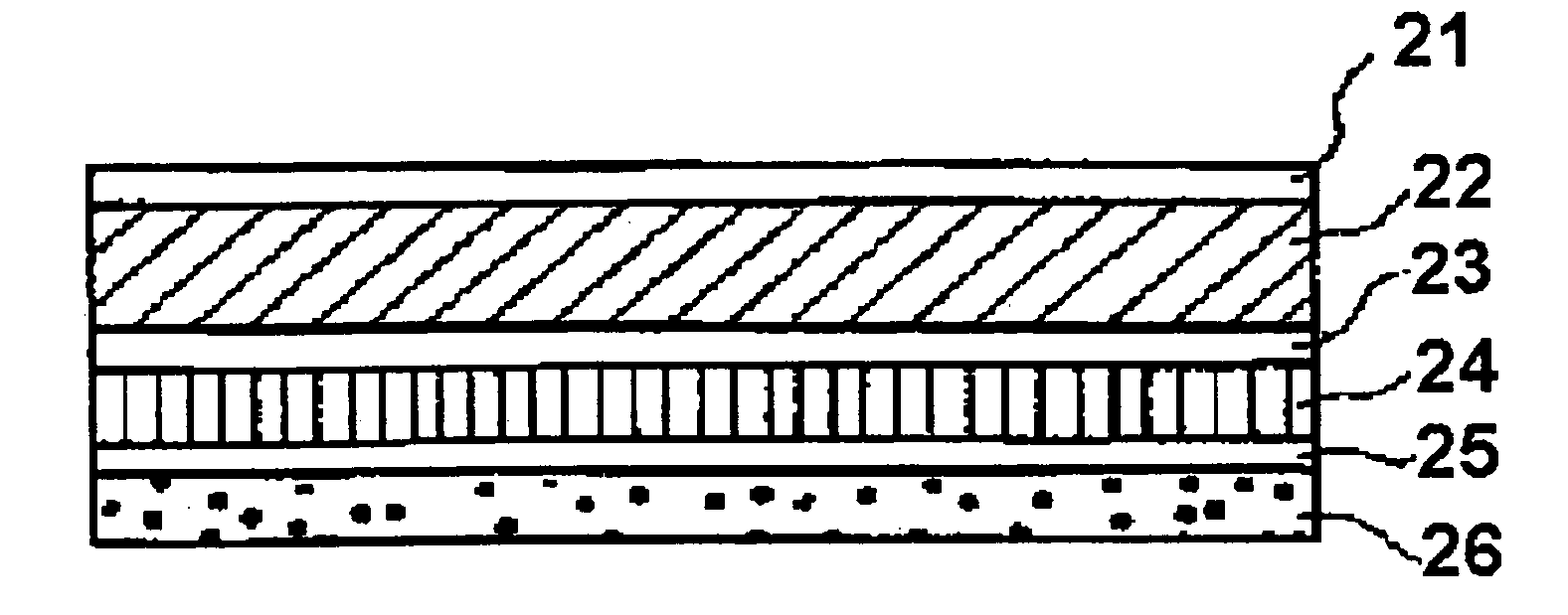

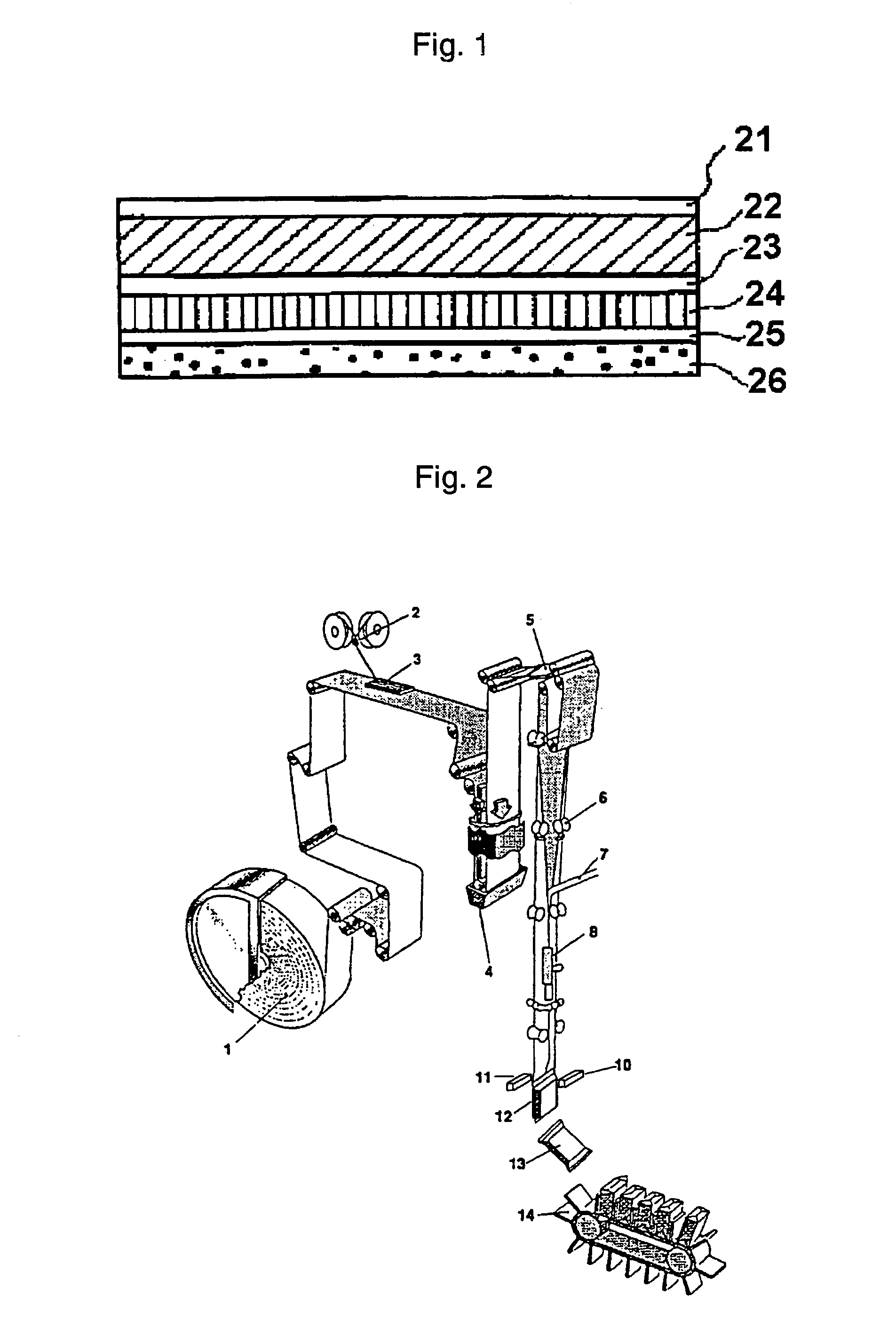

A paper packaging container is formed from the packaging material comprising constitution layers of at least an outside thermoplastic material layer, a paper substrate layer, and an inside thermoplastic material layer, wherein the inside thermoplastic material layer contains at least a linear low density polyethylene, and has properties parameters of an average density of 0.900–0.930, a predetermined peak melting point, a melt flow index of 5–15, and a swelling ratio of 1.3–1.8. The use of the packaging material allows easy filling and packaging to the packaging container and quick heat sealing, and results in more toughly and strongly sealed container, and the material can be used for achieved good sealing independently of the temperature of food contents and thus maintaining the non-scalping and quality preservability of the content product.

Owner:TETRA LAVAL HLDG & FINANCE SA

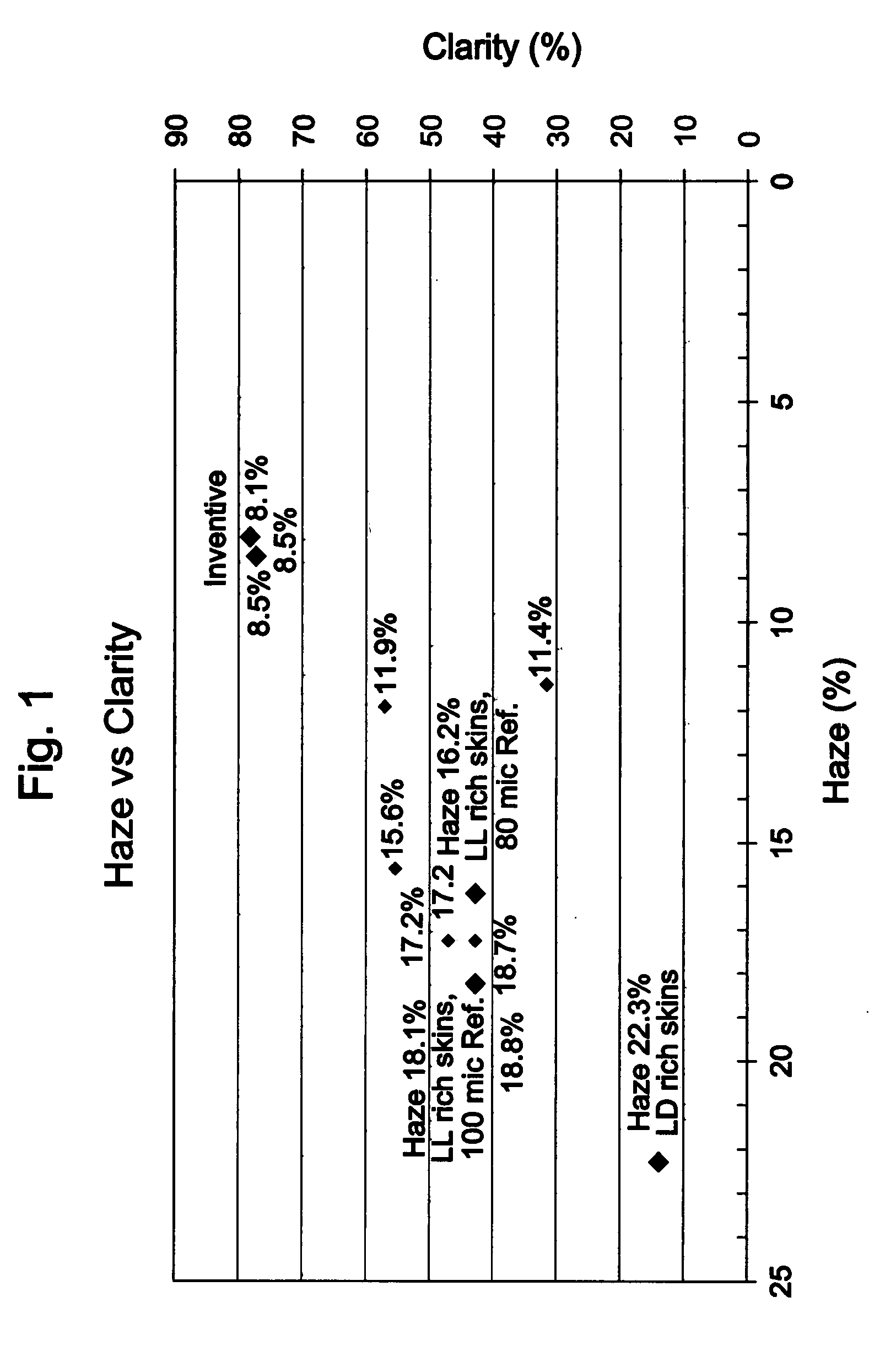

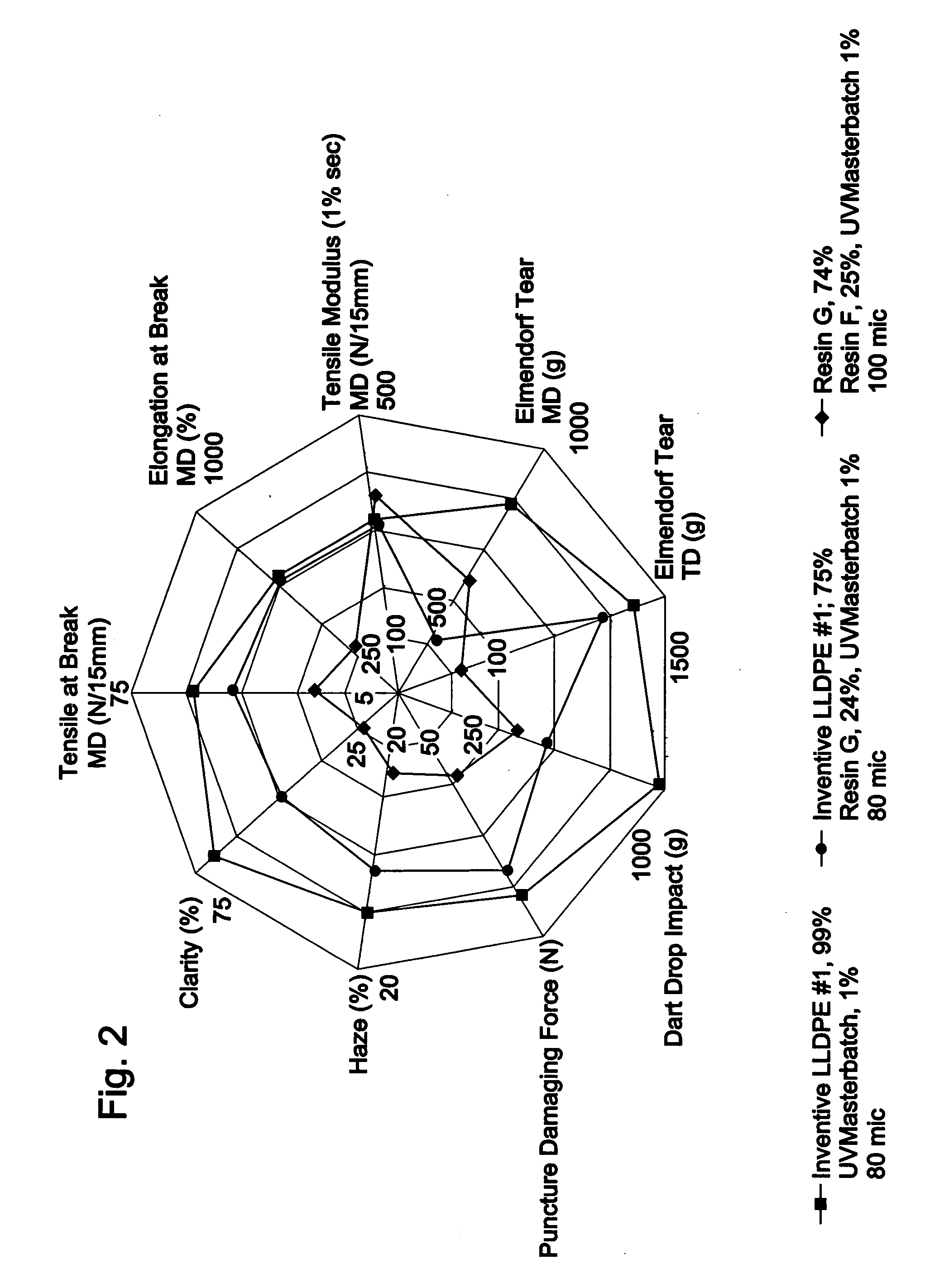

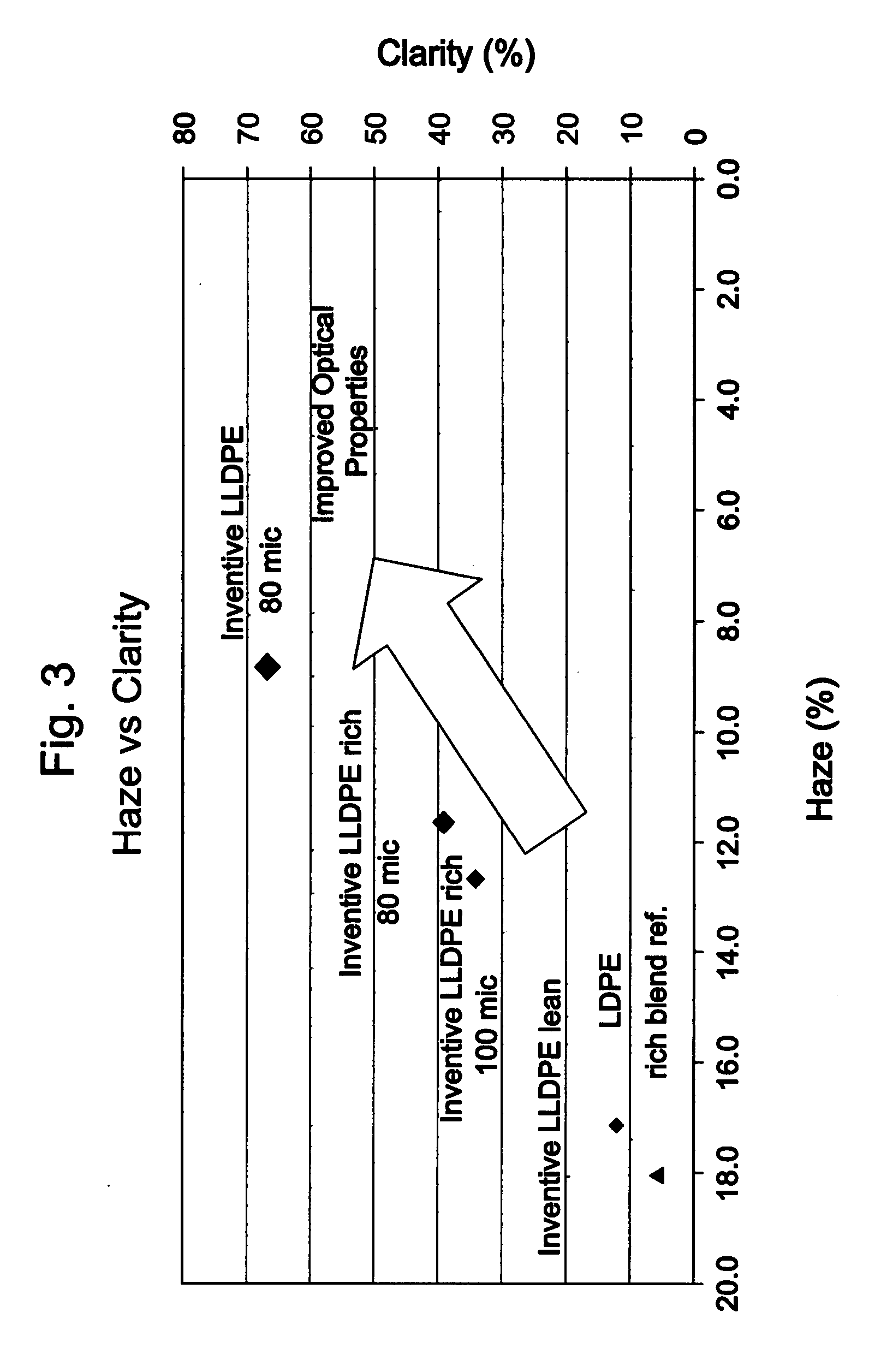

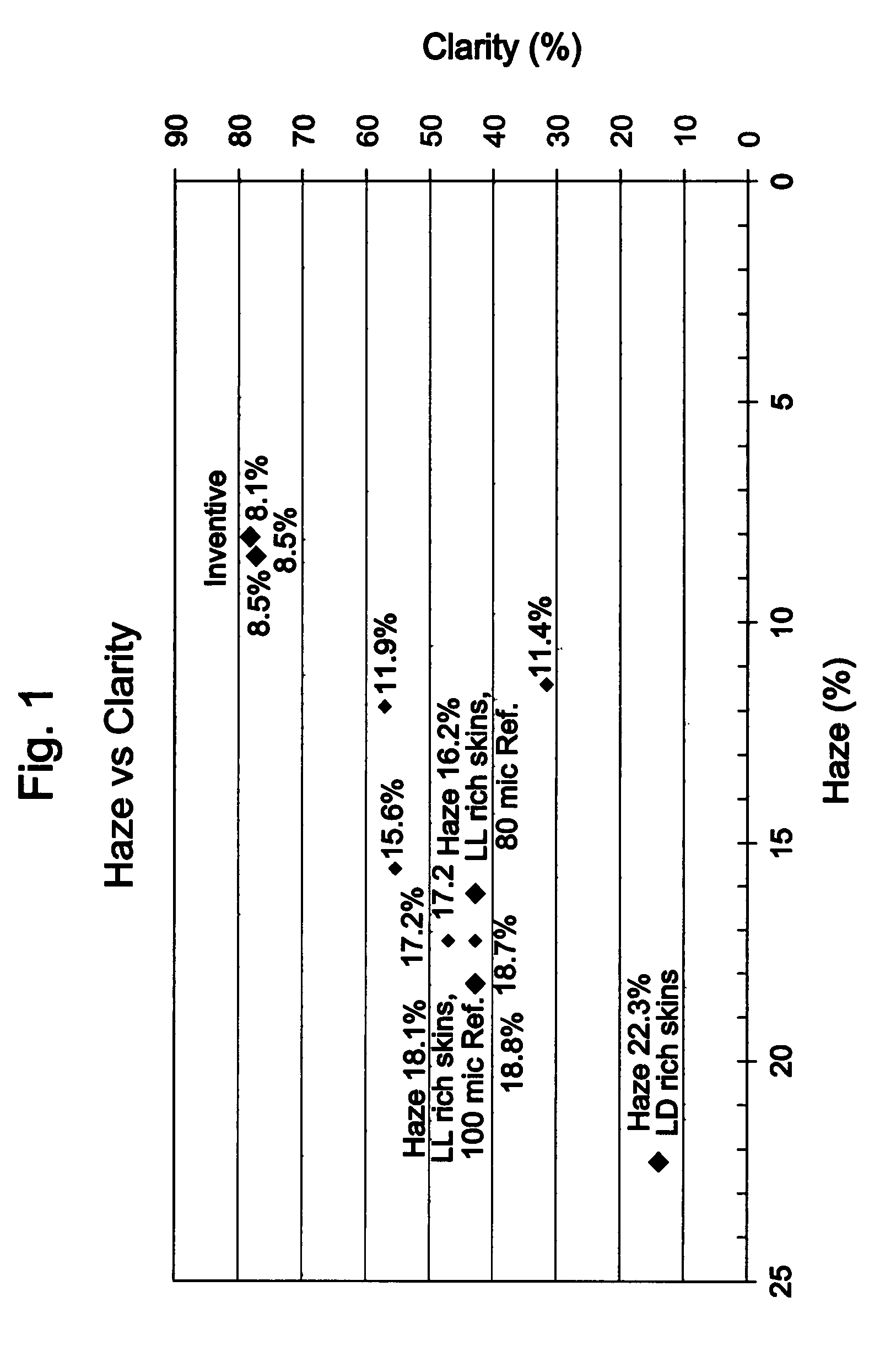

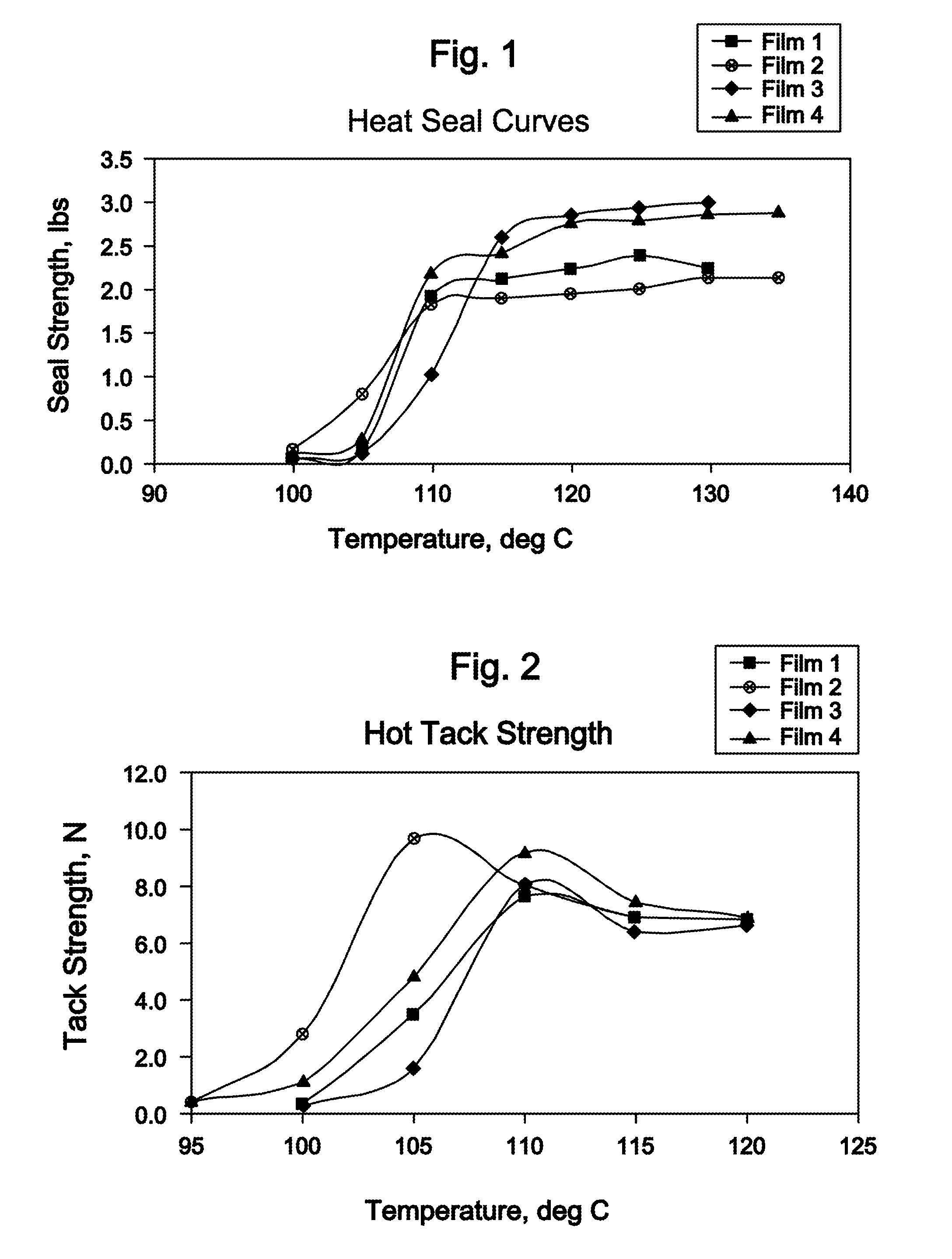

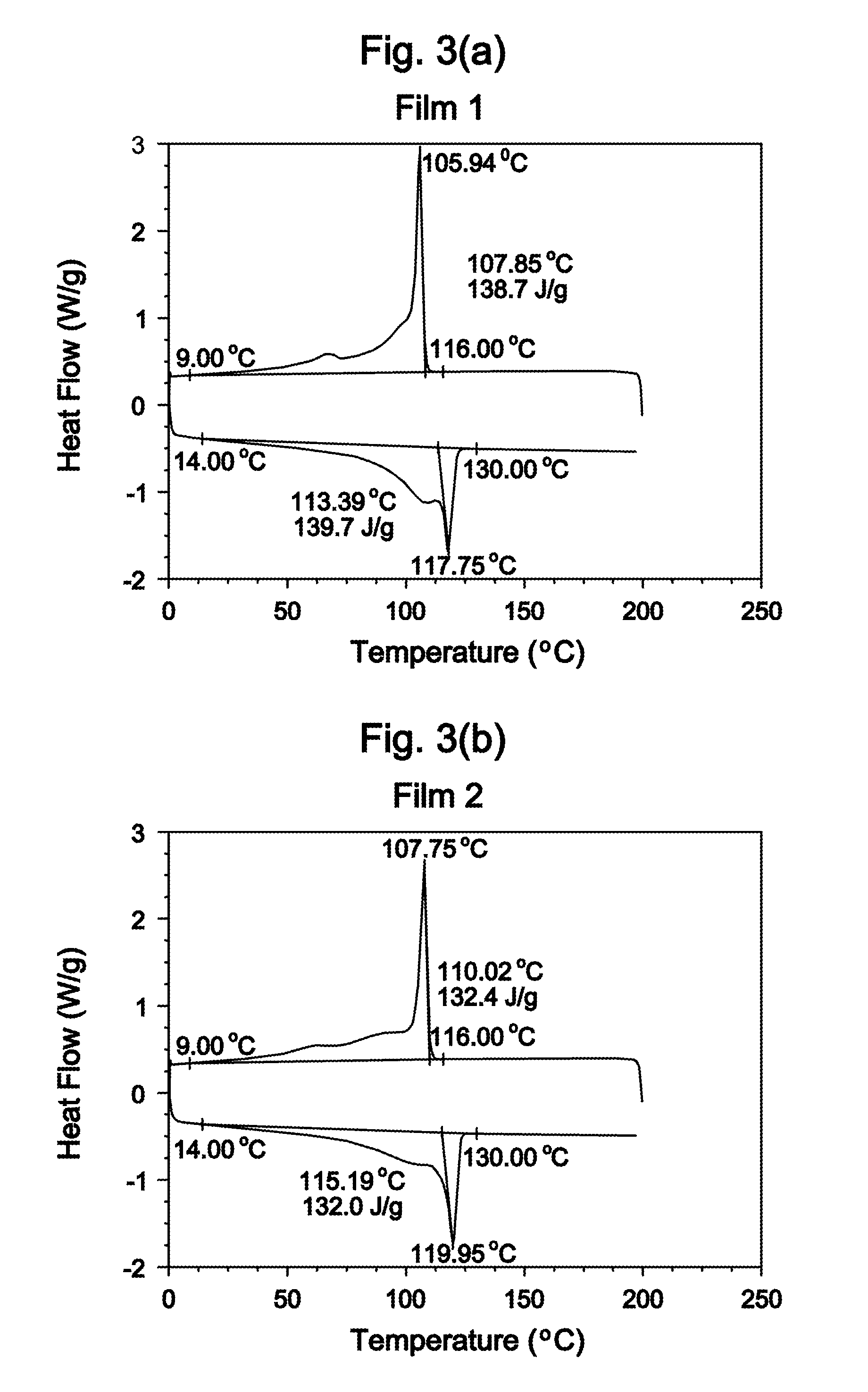

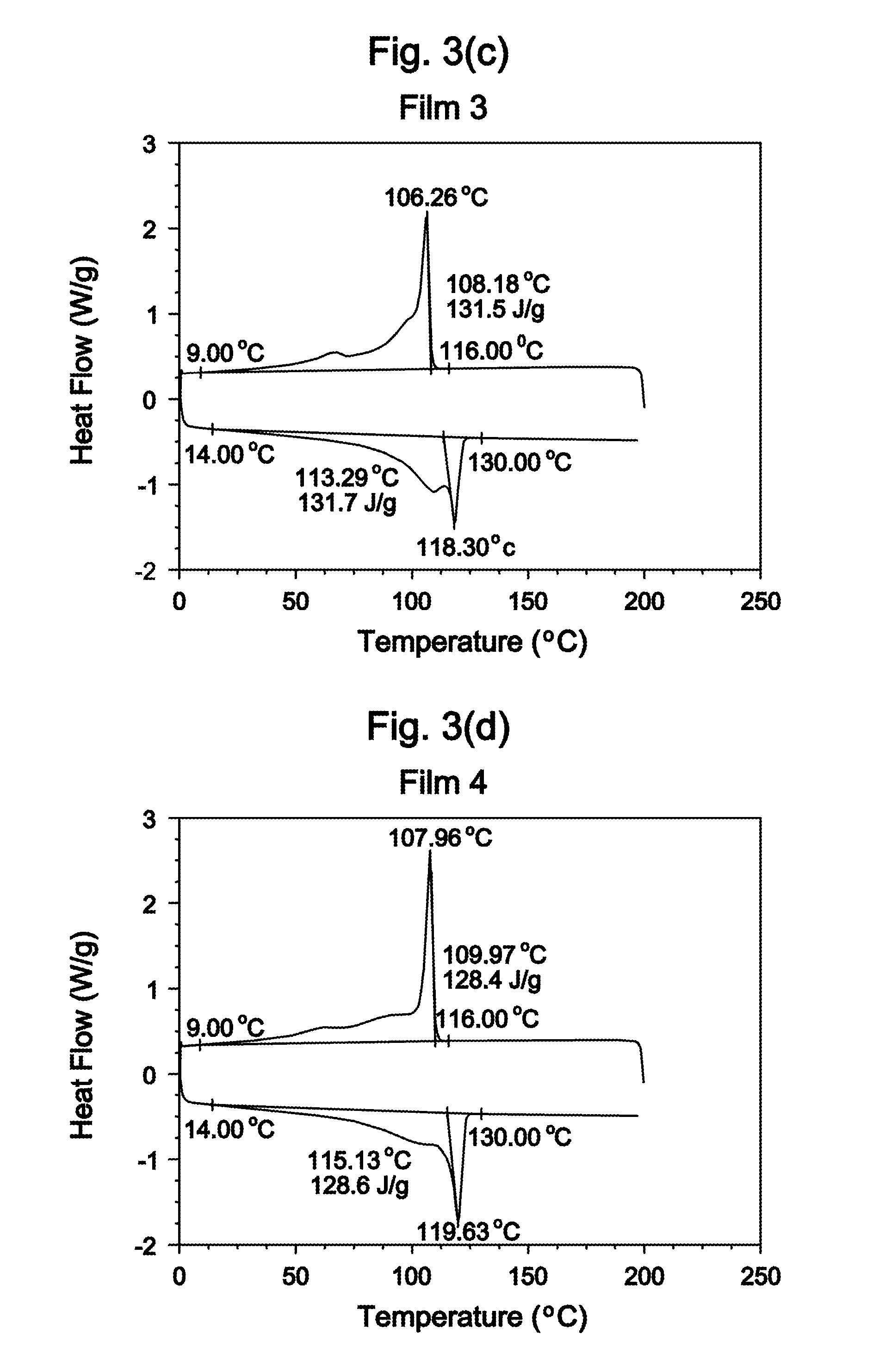

Ethylene-Based Polymers And Articles Made Therefrom

ActiveUS20090192270A1Good physical propertiesDrop clarityPersonal careSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

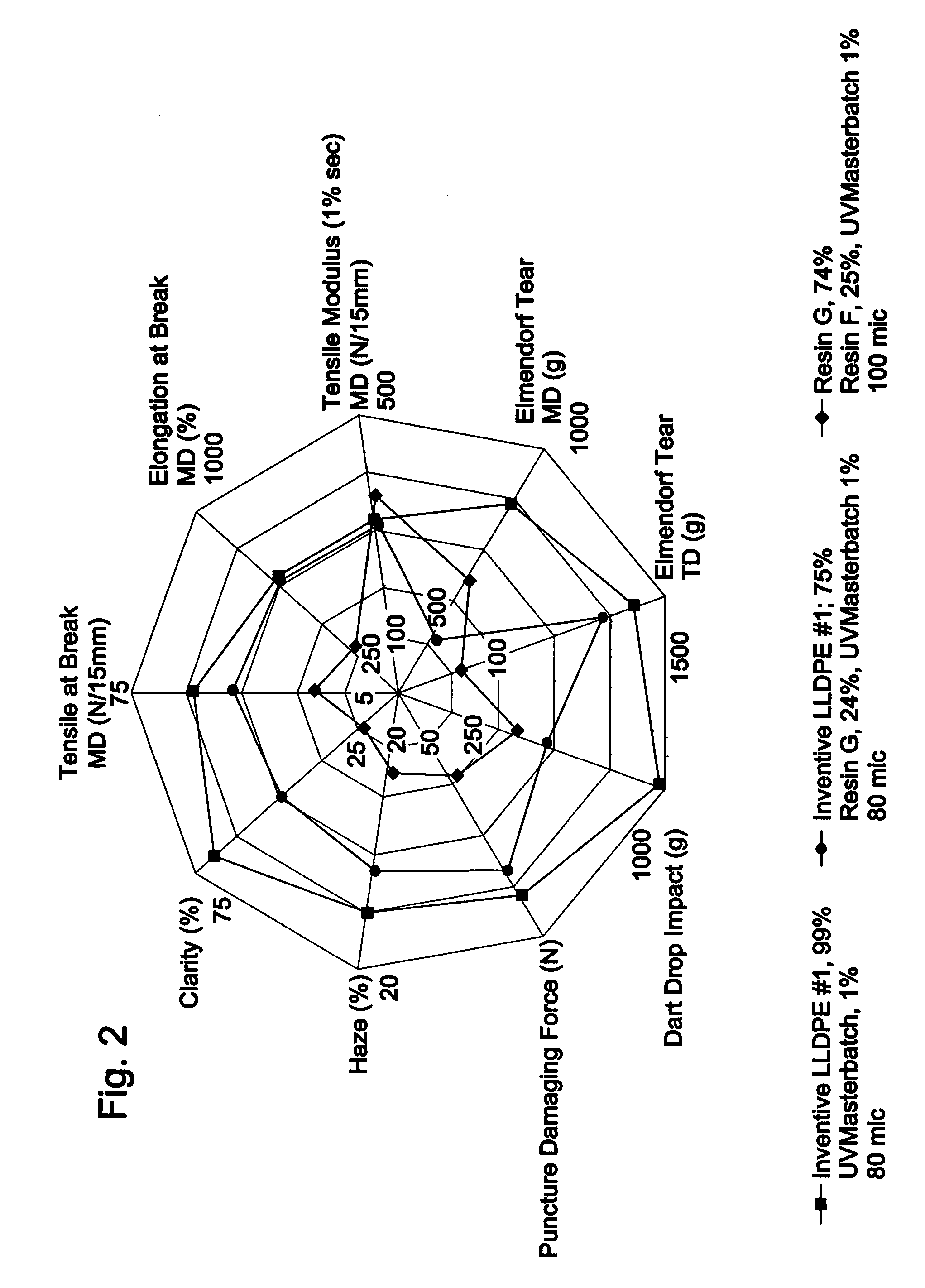

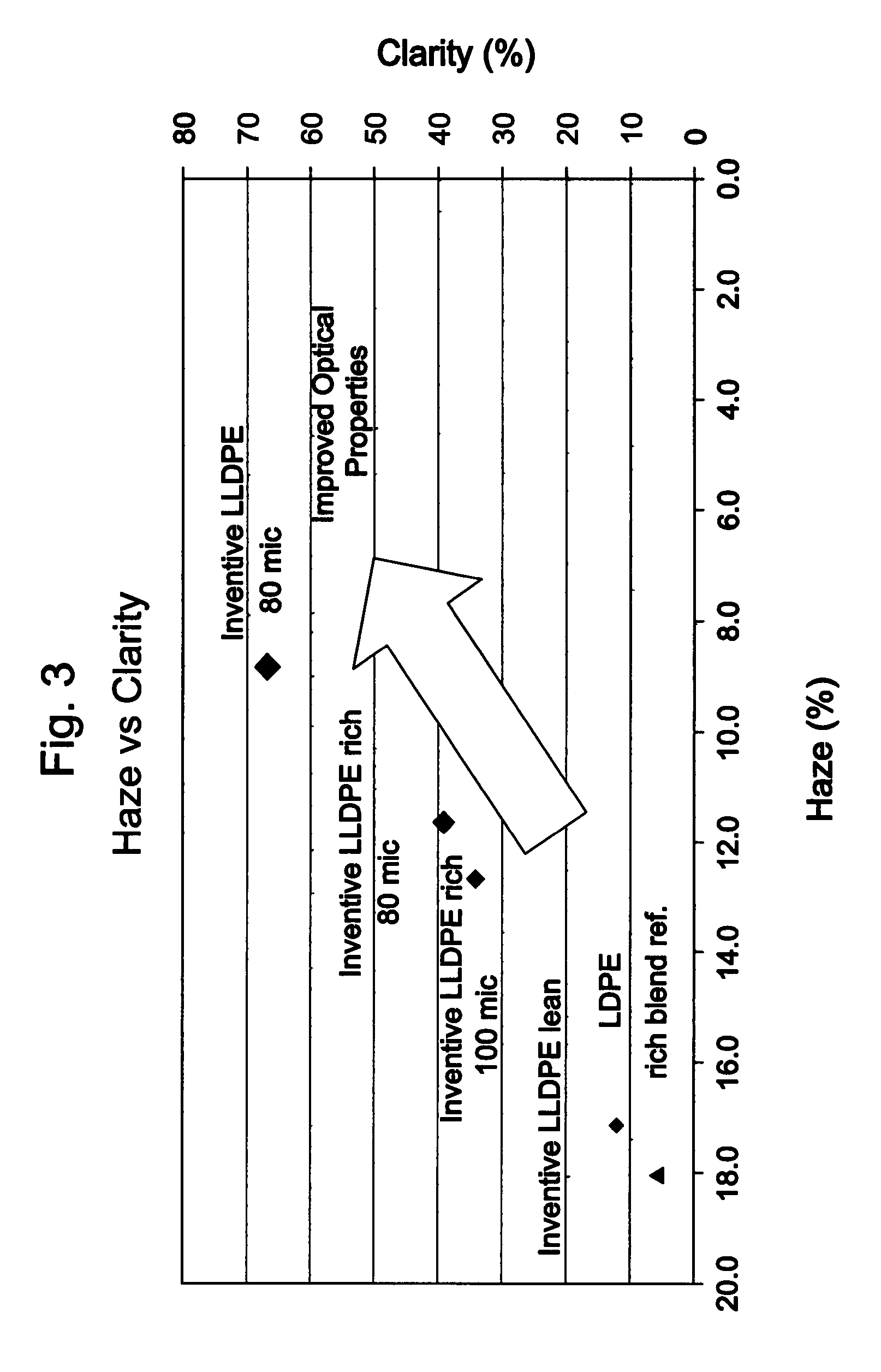

Provided are ethylene-based polymer compositions, articles made therefrom, and methods of making the same. Ethylene-based polymer compositions include blends of a linear low density polyethylene prepared with metallocene catalyst and a low density polyethylene. The linear low density polyethylene may optionally have about five mole percent or less of monomer units derived from an alpha-olefin comonomer. Articles composed of such ethylene-based polymer compositions, such as blown films, exhibit favorable physical properties, including excellent optical properties and retained strength i.e., mitigation of expected decline in physical strength due to LDPE addition.

Owner:EXXONMOBIL CHEM PAT INC

Glycosaminoglycan and Synthetic Polymer Material for Blood-Contacting Applications

ActiveUS20150196688A1Improve surface chemistryFeasible at commercial productionSuture equipmentsOrganic active ingredientsLow-density polyethyleneLinear low-density polyethylene

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), and polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

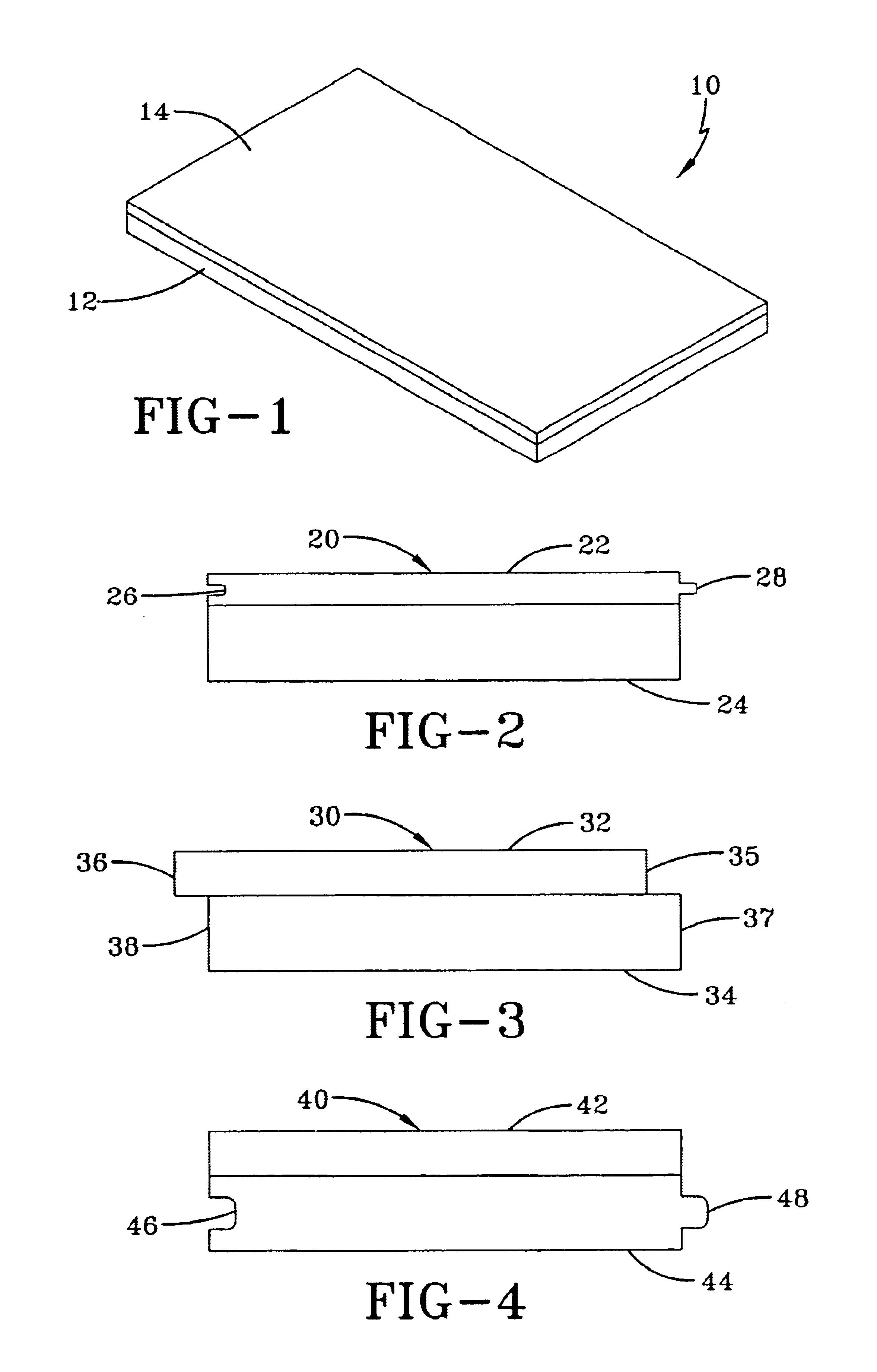

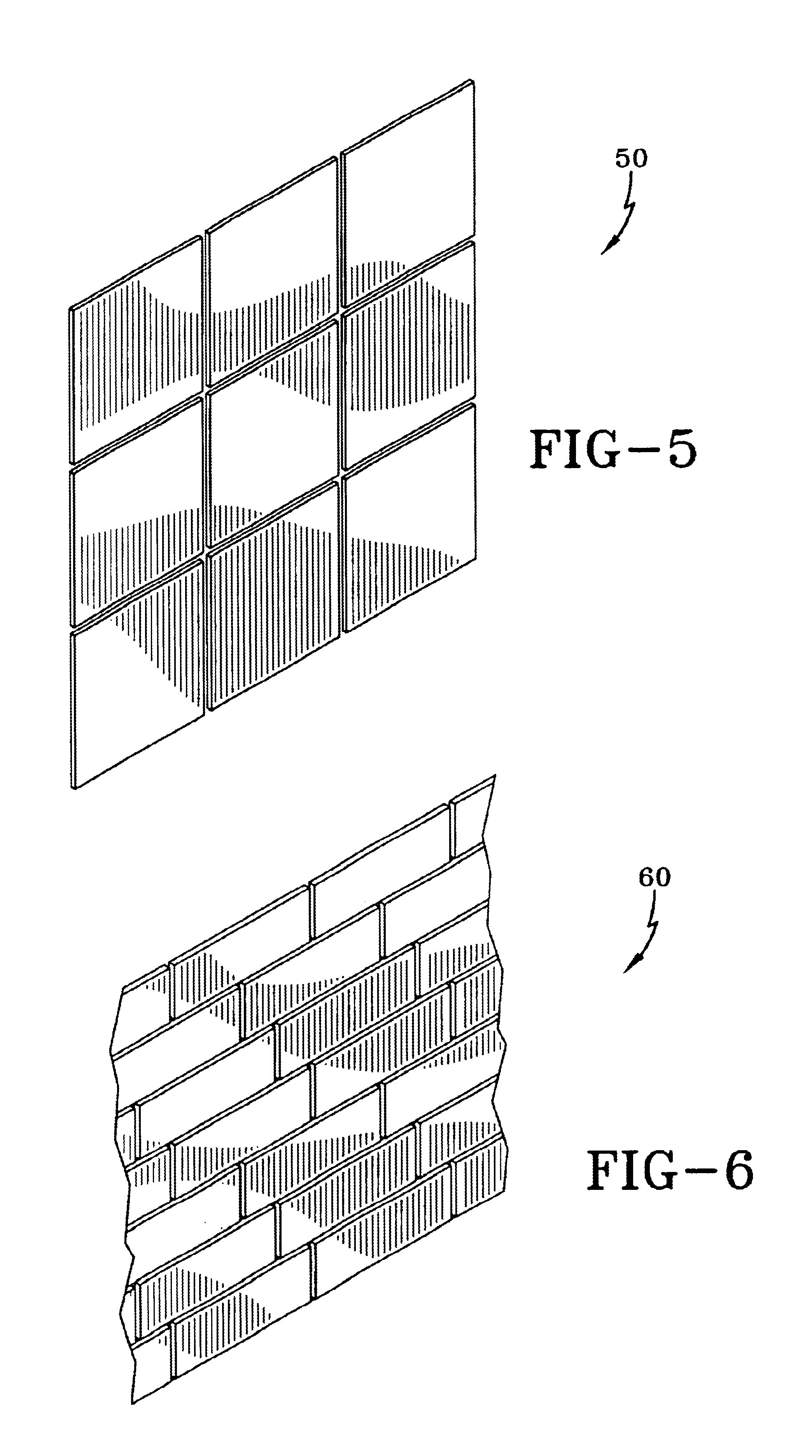

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

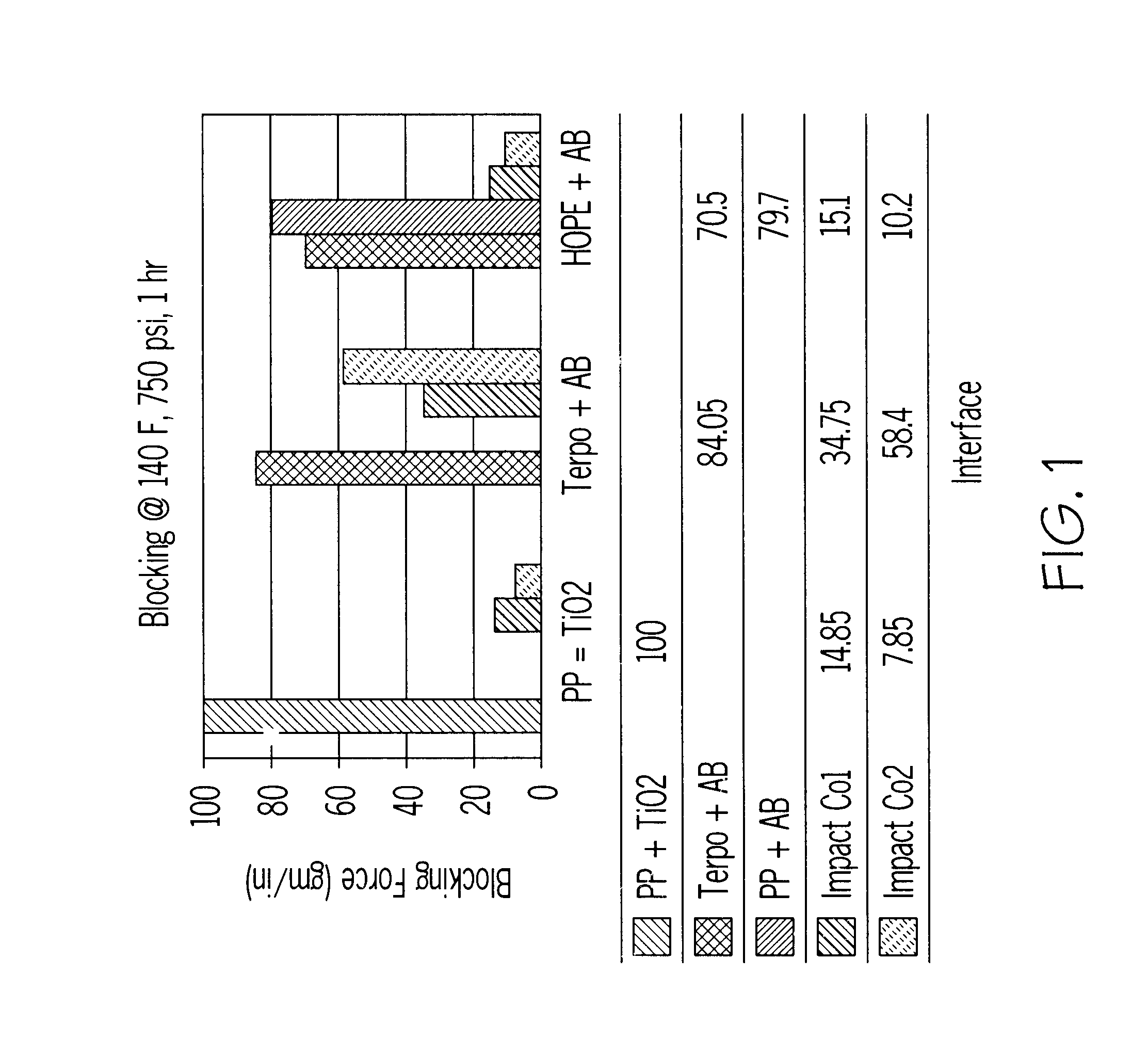

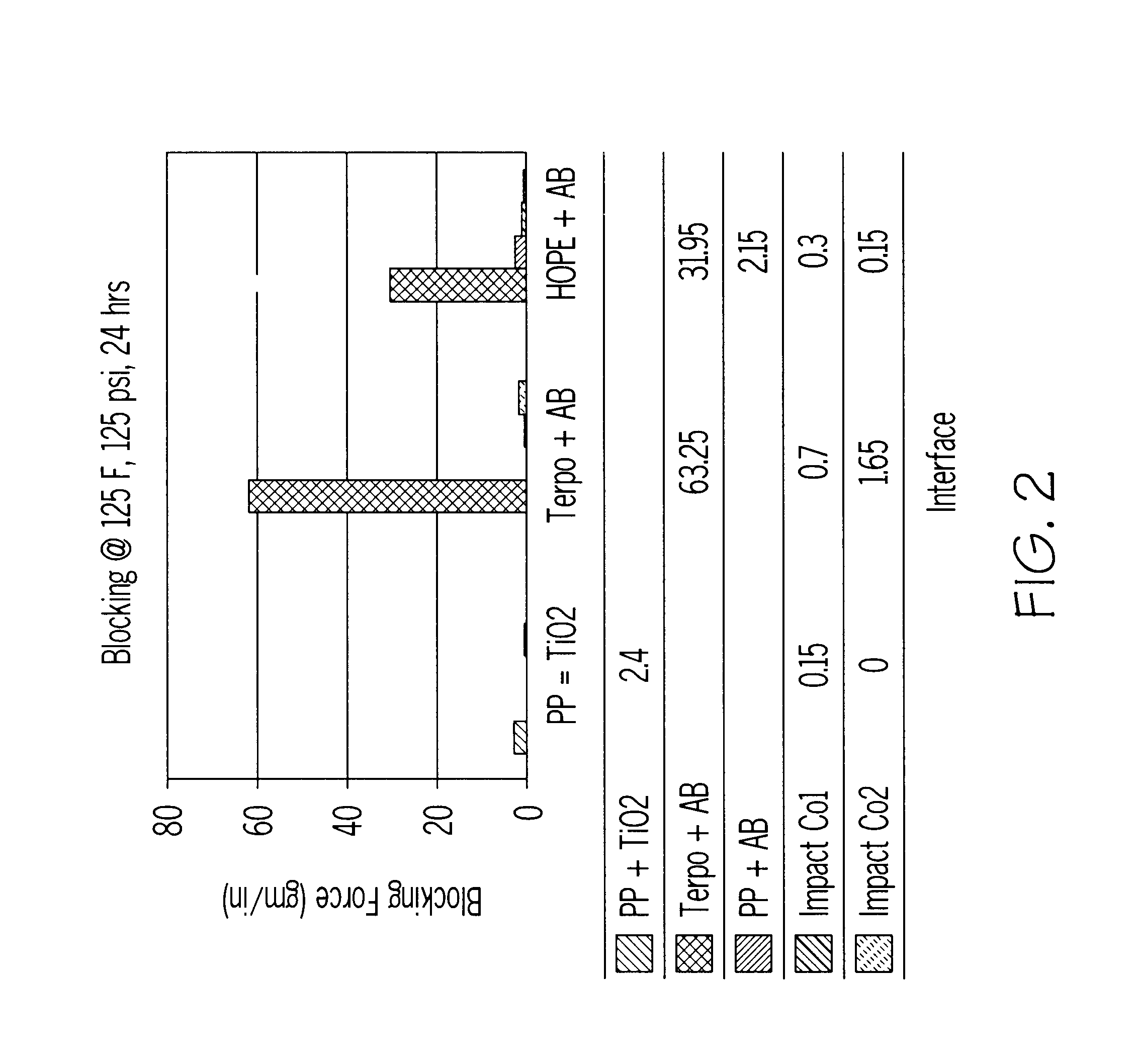

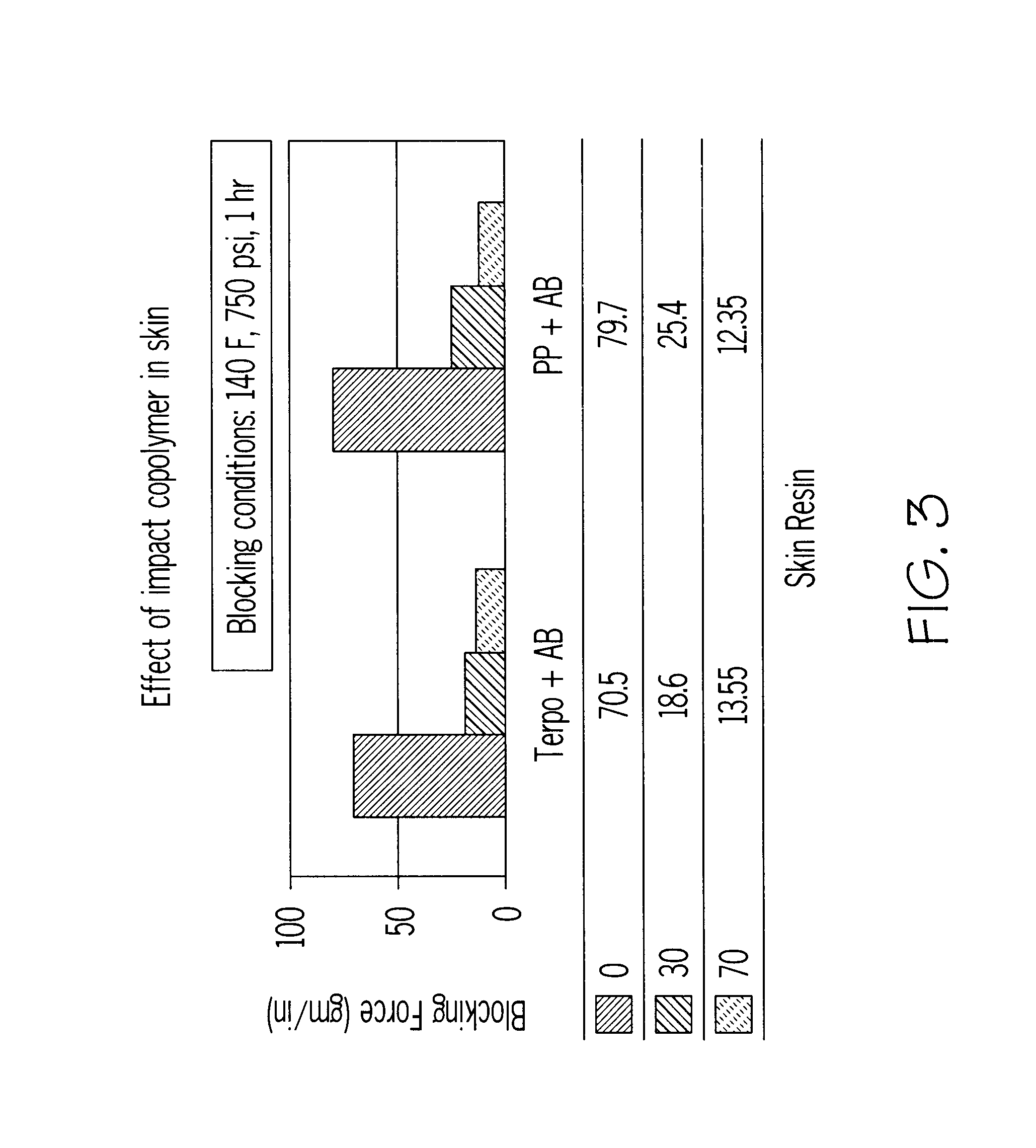

Films with improved blocking resistance and surface properties

InactiveUS6495266B1Lamination ancillary operationsSynthetic resin layered productsLinear low-density polyethylenePolypropylene

The invention discloses methods of improving blocking resistant properties and reducing the coefficient of friction of a multilayer film comprising providing at least one layer of an ethylene-propylene impact copolymer having from about 3% to about 30% by weight ethylene, wherein said copolymer has no more than two peaks in the melting curve within the range from about 110° C. to about 165° C., and wherein said layer is non-heat sealable, to a multilayer film having a core layer comprising polypropylene, high density polyethylene (HDPE) or linear low density polyethylene (LLDPE), whereby anti-blocking and coefficient of friction characteristics of said film is improved without necessity of adding an antiblock or slip agent.

Owner:JINDAL FILMS AMERICAS LLC

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

Low density paperboard articles

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

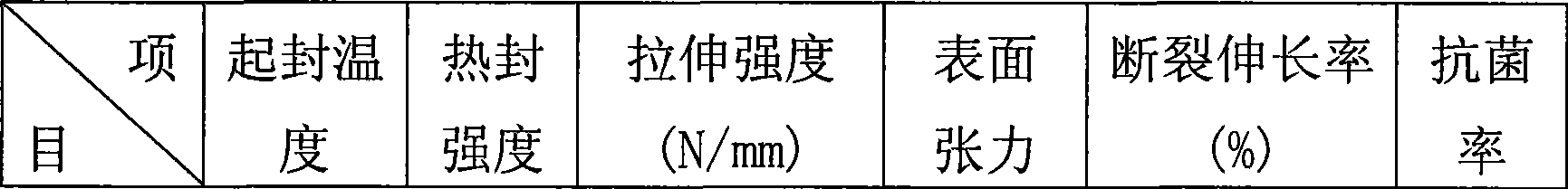

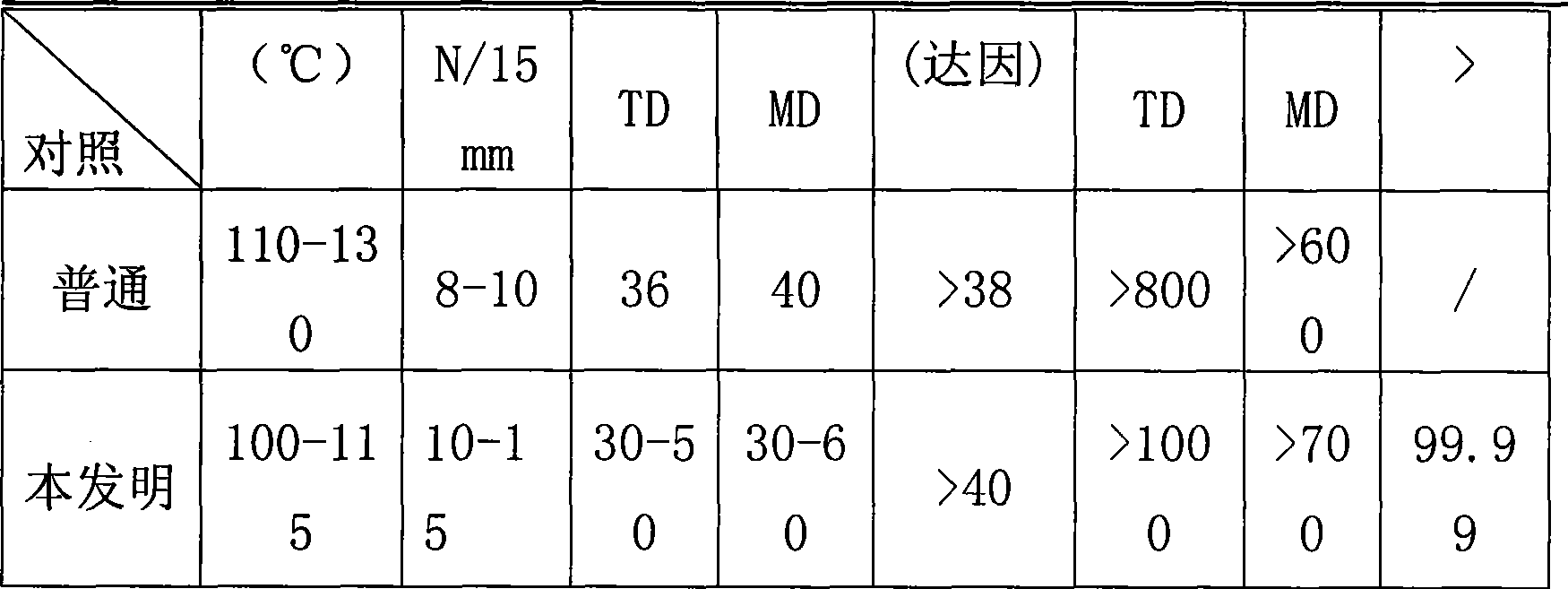

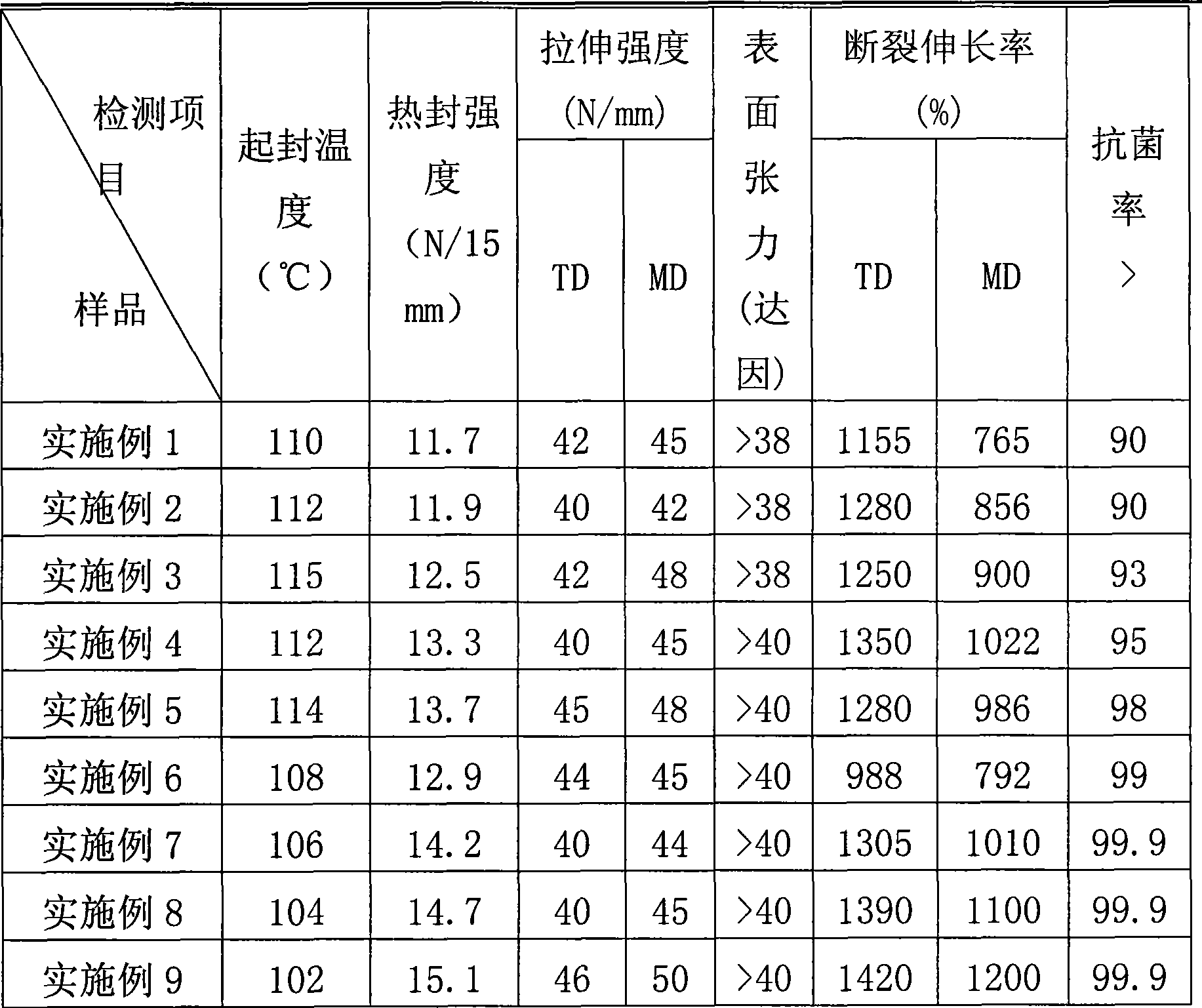

Antimicrobial polyethylene film and preparing technique thereof

ActiveCN101367283APlay a protective effectImprove antibacterial propertiesFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antibacterial polyethylene film and a method for preparing the same. The film consists of an outer layer, a middle layer and an inner layer; the outer layer consists of low-density polyethylene and linear low-density polyethylene; the middle layer consists of low-density polyethylene and linear low-density polyethylene; and the inner layer comprises low-density polyethylene, linear low-density polyethylene, metallocene linear low-density polyethylene, a slipping agent and an antibacterial agent. Compared with the prior art, the antibacterial polyethylene film has the characteristics of broad-spectrum sterilization, lasting antibacterial effect, good safety, no toxicity, no side effects and uneasy discoloration, thereby really achieving the protective function on packaged foods.

Owner:HUANGSHAN NOVEL

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

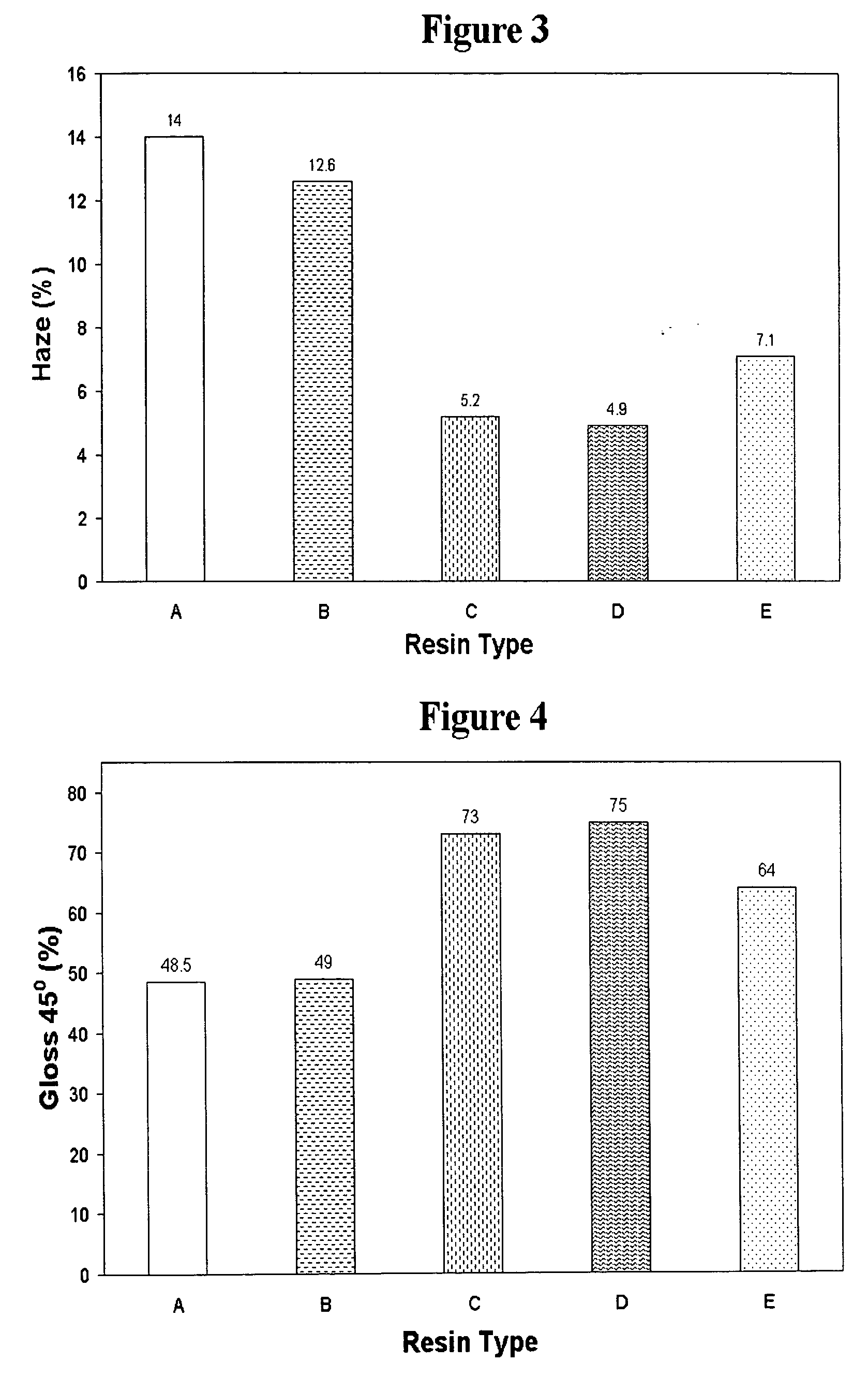

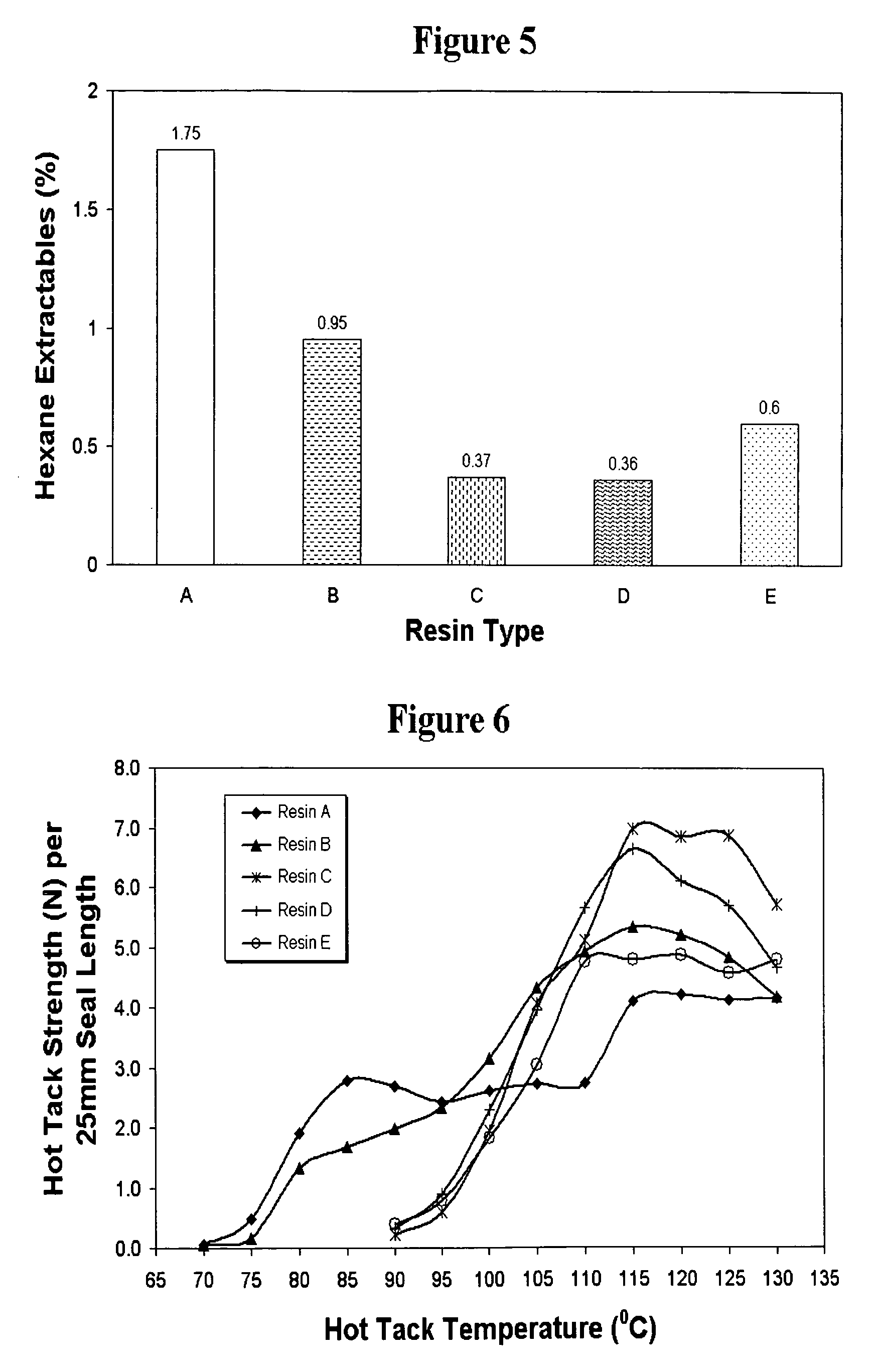

Dual reactor polyethylene resins for electronic packaging-films, tapes, bags and pouches

InactiveUS20060247373A1Good optical performanceHeat sealabilityLinear low-density polyethylenePolymer science

Owner:NOVA CHEM (INT) SA

Soft low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

InactiveCN101817952ABright surfaceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses a soft low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable material comprises the following components (based on by mass part ratio): 80-90 parts of copolymer of ethylene-vinylacetate, 10-20 parts of linear low-density polyethylene, 65-130 parts of an inorganic fire retardant through surface treatment, 10-30 parts of high-effective flame retardant synergist, 10-20 parts of high molecular compatilizer, 0.9-1.5 parts of antioxidant and 1-2 parts of processing aid. The preparation method comprises the steps of resin blending extrusion; surface treatment of the inorganic fire retardant; batching, mixing, extrusion, granulation and the like. Compared with the prior art, the invention has the characteristics of predominant flame retardation (an oxygen index up to 36), excellent toughness, excellent bending resistance, low density (density is only 1.28g / cm<3>), low smoke, low corrosion, low toxicity, environmental protection, good processability, bright surface of extrudates and the like.

Owner:XI AN JIAOTONG UNIV +1

Multilayer high clarity shrink film comprising monovinylarene-conjugated diene copolymer

InactiveUS20050166551A1Wrappers shrinkageSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

We disclose a shrink film comprising a first layer comprising a monovinylarene-conjugated diene copolymer; a second layer comprising low density polyethylene (LDPE) and linear low density polyethylene (LLDPE); and a third layer comprising a monovinylarene-conjugated diene copolymer; wherein the second layer is disposed between the first layer and the third layer. We also disclose methods of using the shrink film to prepare bundled or fully enclosed groups of objects.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP +1

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

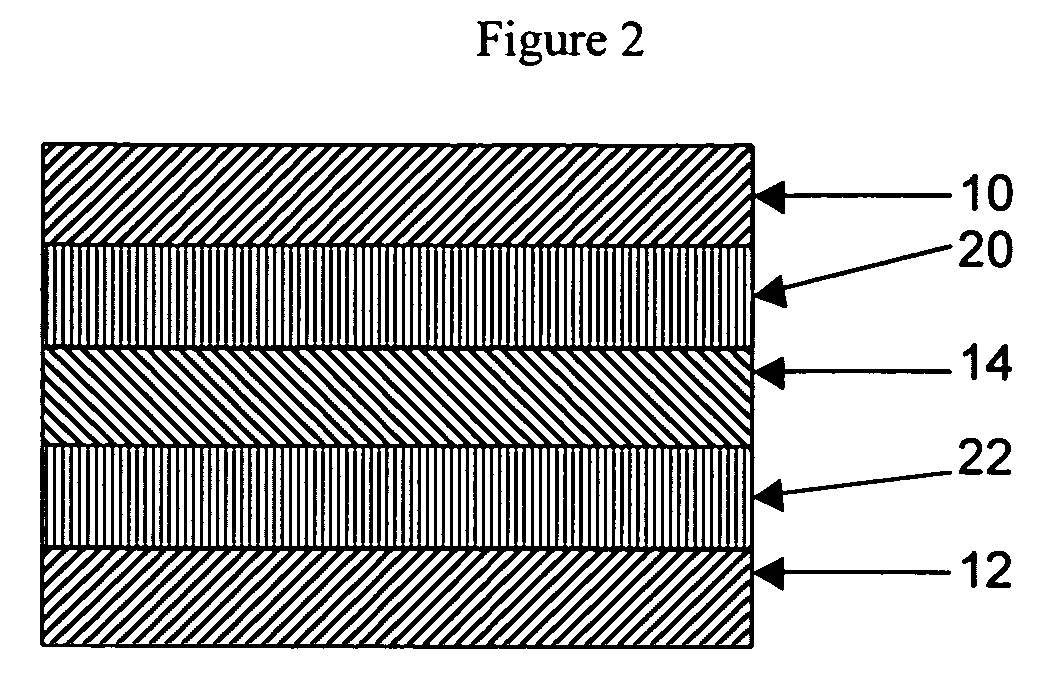

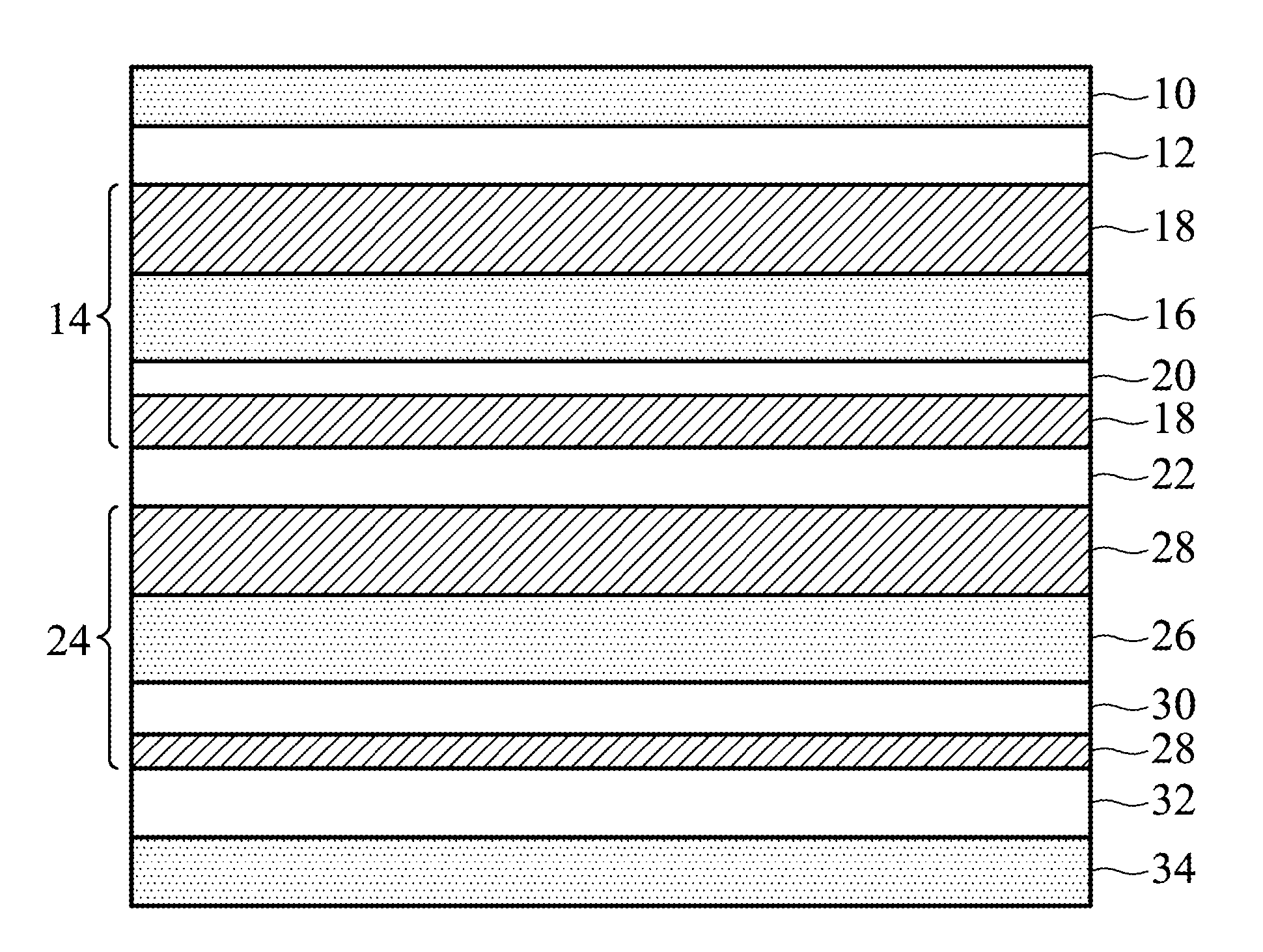

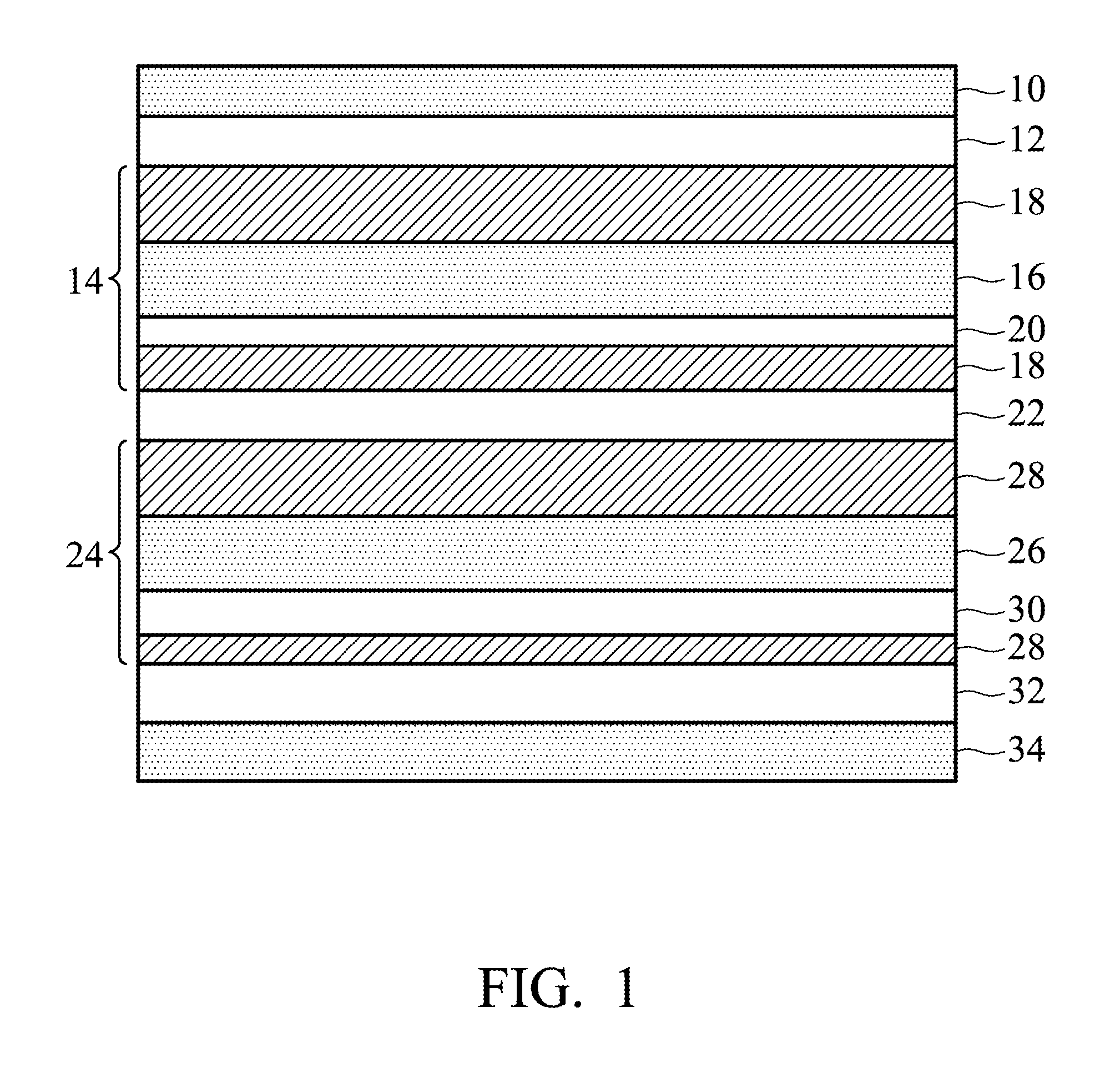

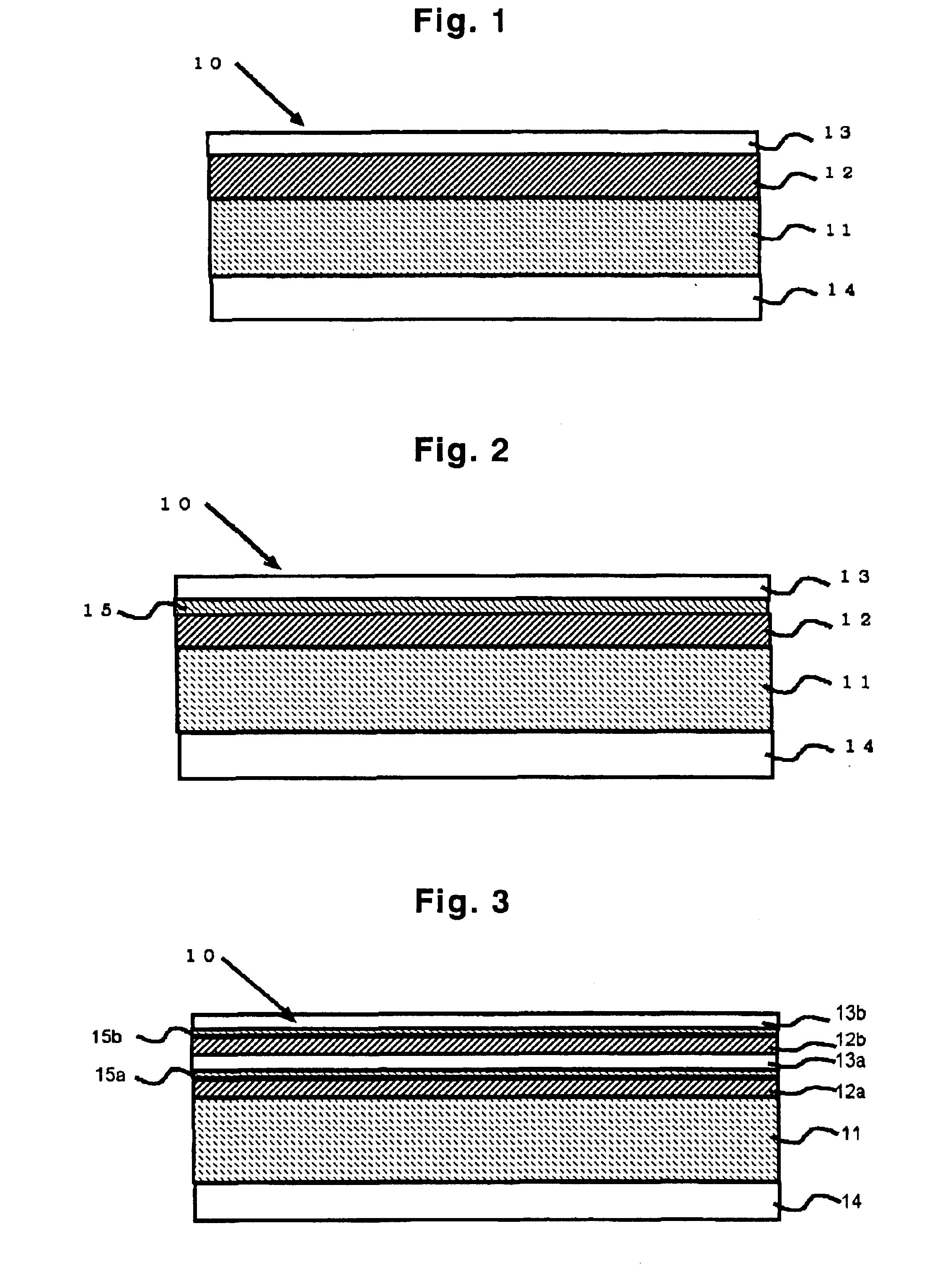

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

Flexible poly(arylene ether)composition and articles thereof

A flexible thermoplastic composition comprises poly(arylene ether); a plasticizer having an affinity for polyolefin; a polyolefin and a hydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene, wherein the polyolefin comprises (i) an ethylene / C7-C20 alpha olefin copolymer having an alpha olefin content greater than or equal to about 10%, (ii) a thermoplastic vulcanizate (iii) a combination of linear low density polyethylene and a thermoplastic vulcanizate, (iv) a combination of an ethylene / C7-C20 alpha olefin copolymer having an alpha olefin content greater than or equal to about 10%, a linear low density polyethylene, and a thermoplastic vulcanizate, (v) a combination of an ethylene / C7-C20 alpha olefin copolymer having an alpha olefin content greater than or equal to about 10% and a thermoplastic vulcanizate or (vi) a combination of an ethylene / C7-C20 alpha olefin copolymer having an alpha olefin content greater than or equal to about 10% and linear low density polyethylene.

Owner:SHPP GLOBAL TECH BV

Thermoplastic oil-resistant halogen-free low-smoke flame-retardant polyolefin cable material and preparation method thereof

ActiveCN102731891AMitigates melt fractureHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a thermoplastic oil-resistant halogen-free low-smoke flame-retardant polyolefin cable material. The material is characterized in that: the material is prepared from raw materials of: substrate resin, a fire retardant, a lubricating agent, and an anti-oxidant. The substrate resin is composed of metallocene linear low-density polyethylene (MLLDPE), an ethylene-vinyl acetate polymer, and an interface compatibilizing agent. The preparation method comprises the steps that: the raw materials are well mixed in a high-speed mixing machine; the mixture is subjected to mixed extrusion under a processing temperature of 125-145 DEG C on a same-direction double-screw extruder; and the material is subjected to hot-cut granulation, such that a finished product is obtained. Compared with a traditional thermoplastic halogen-free low-smoke flame-retardant polyolefin cable material, the cable material provided by the invention has good oil resistance. When the cable material is soaked in mineral oil, the change rates in tensile strength and breaking elongation are low.

Owner:中广核三角洲(江苏)塑化有限公司 +1

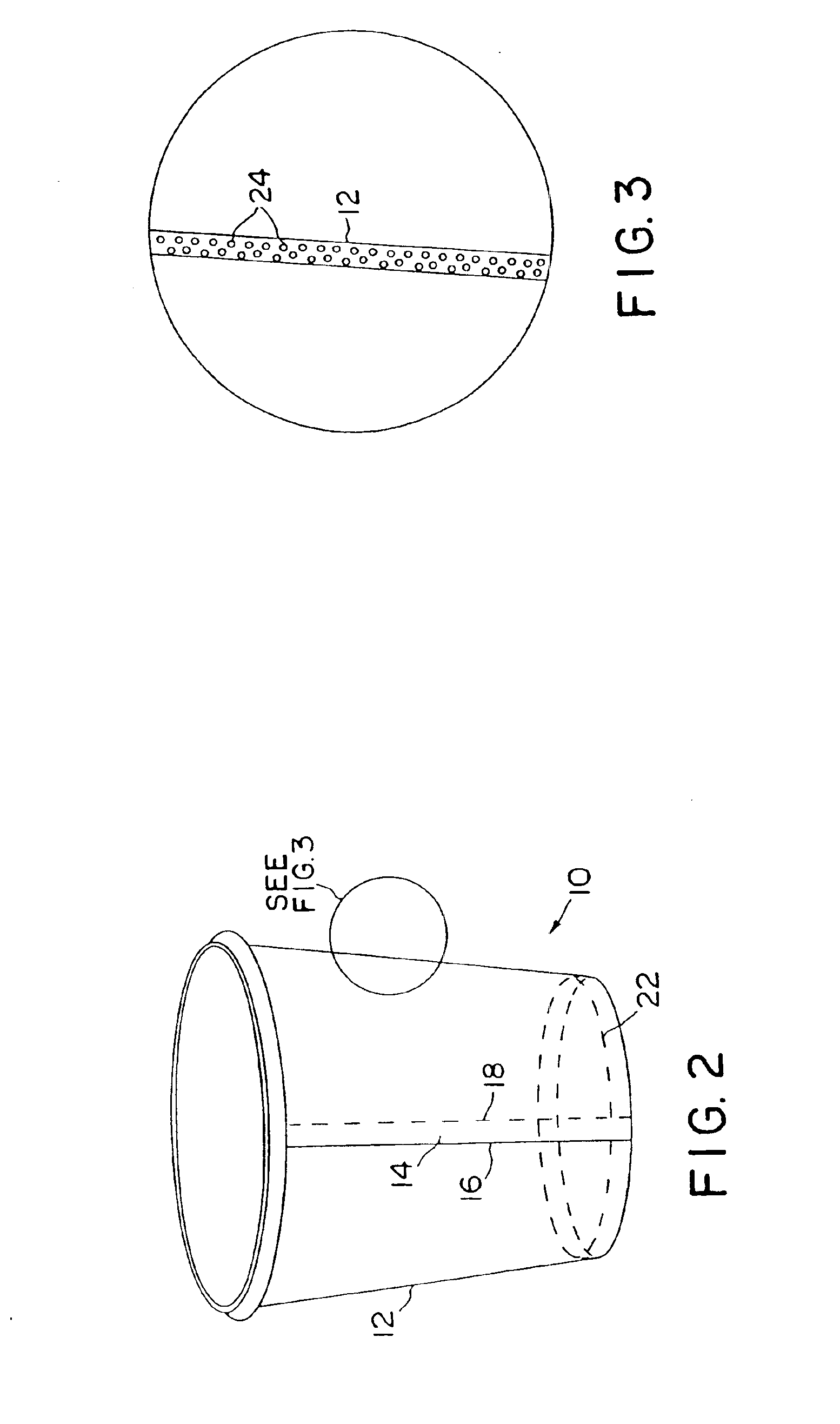

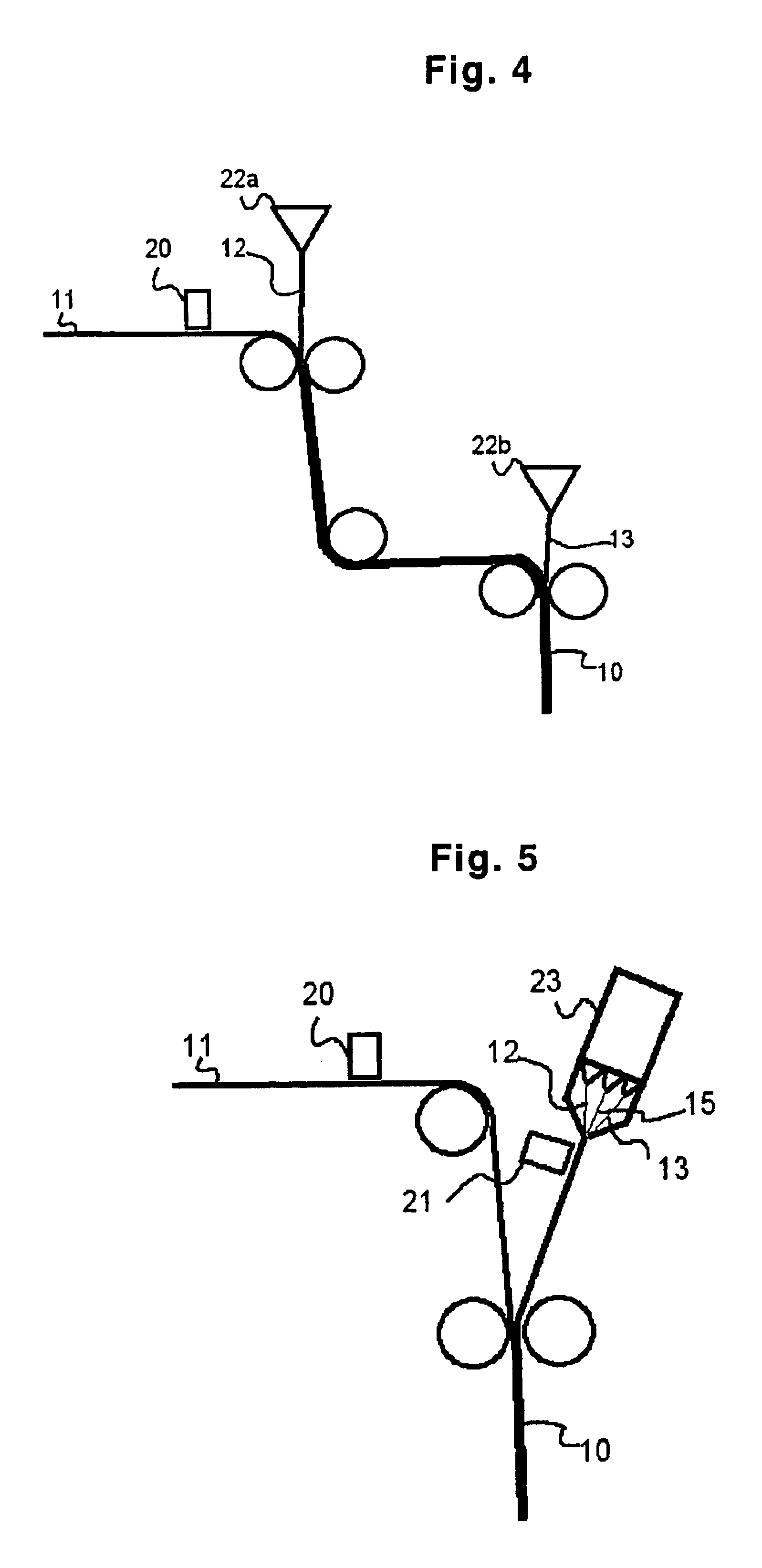

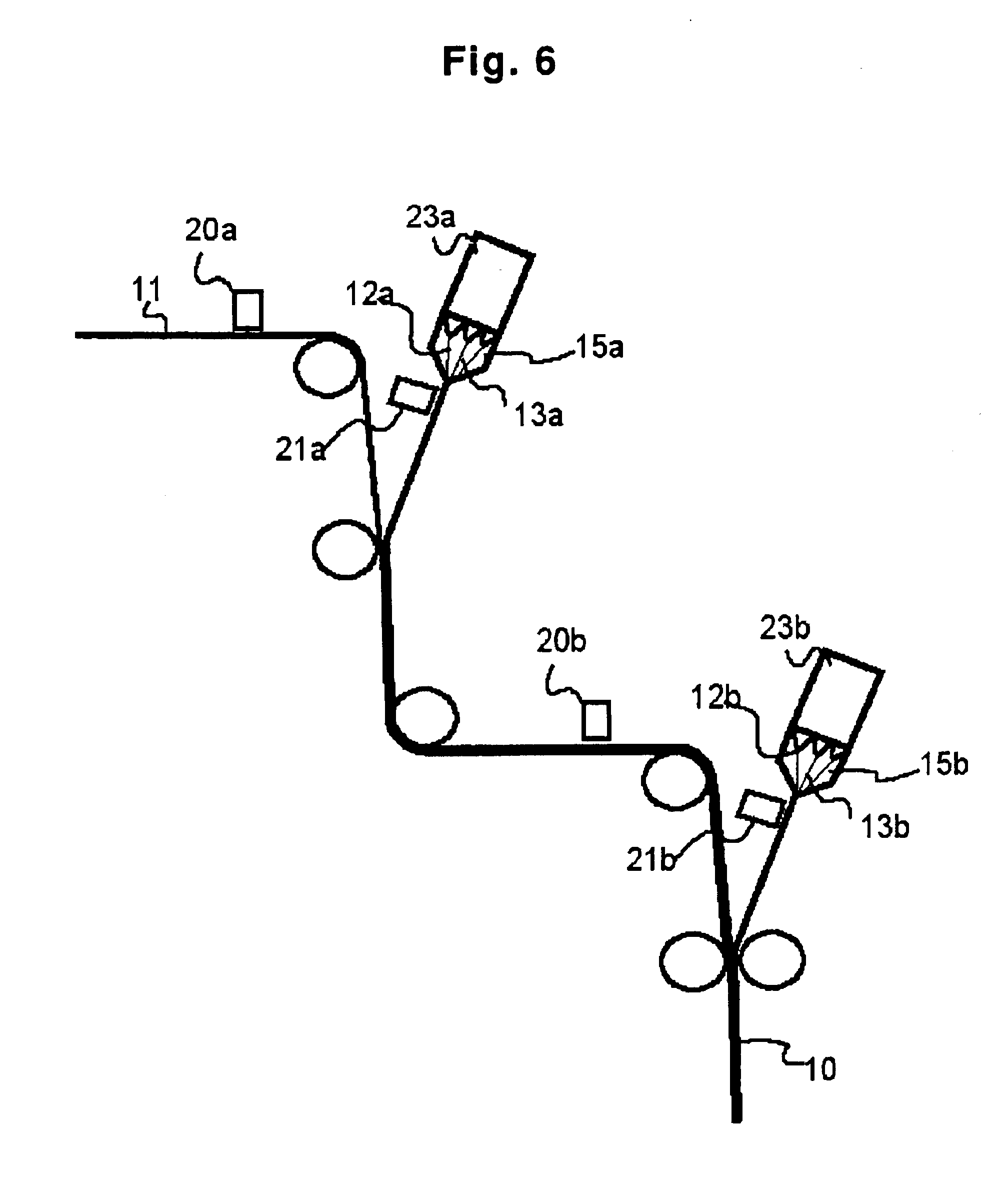

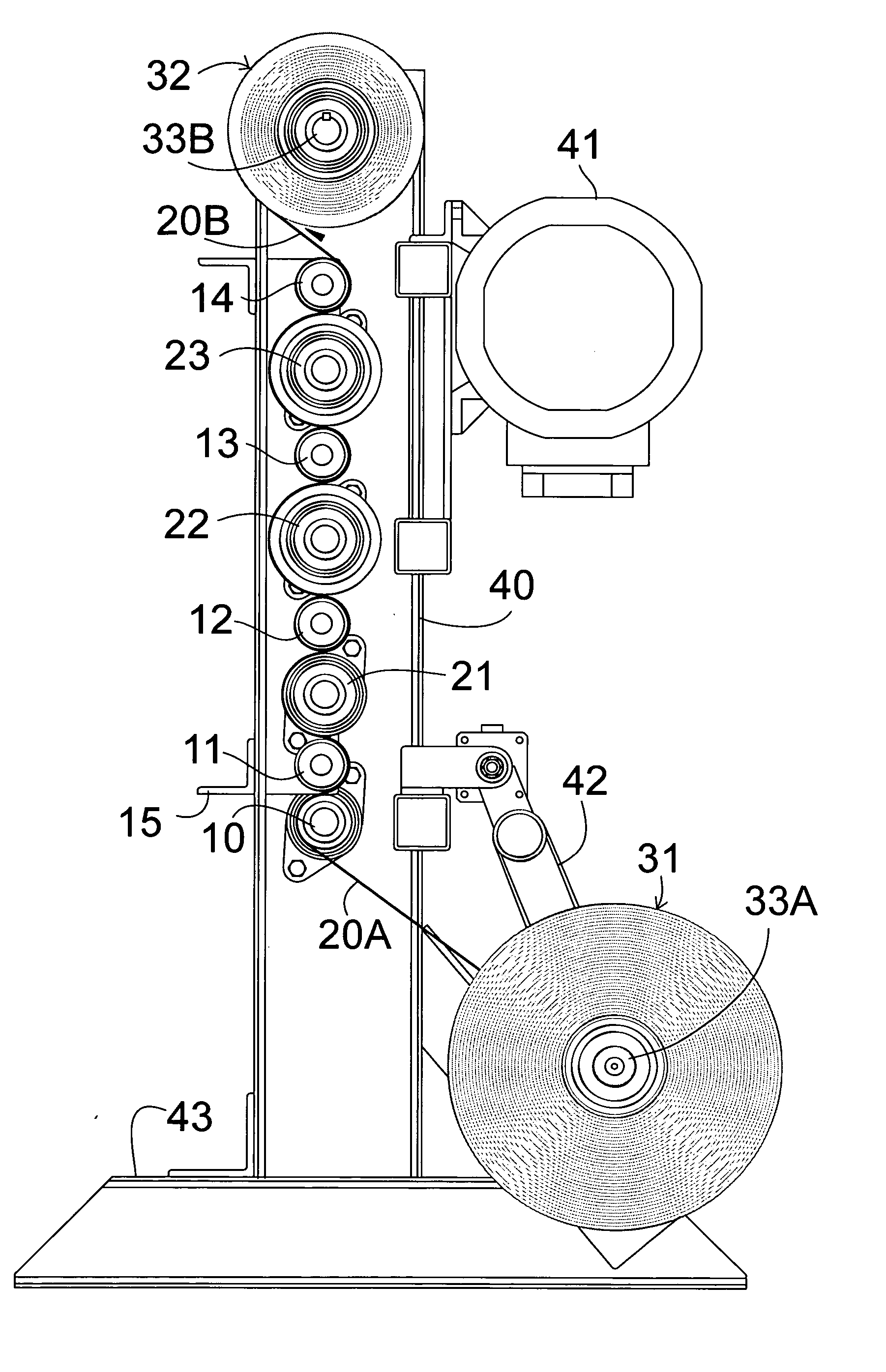

Laminated packaging material and method for producing the same

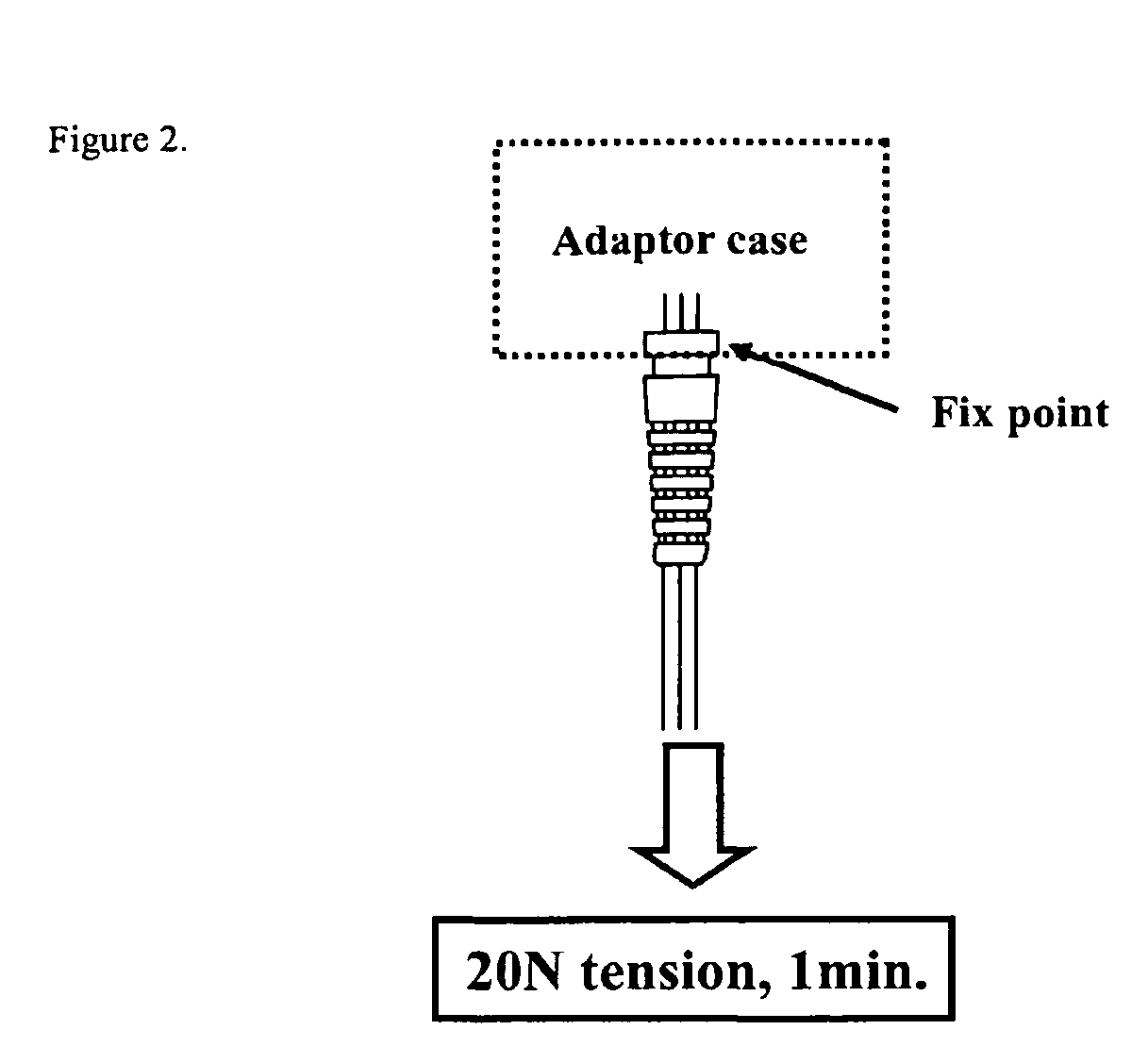

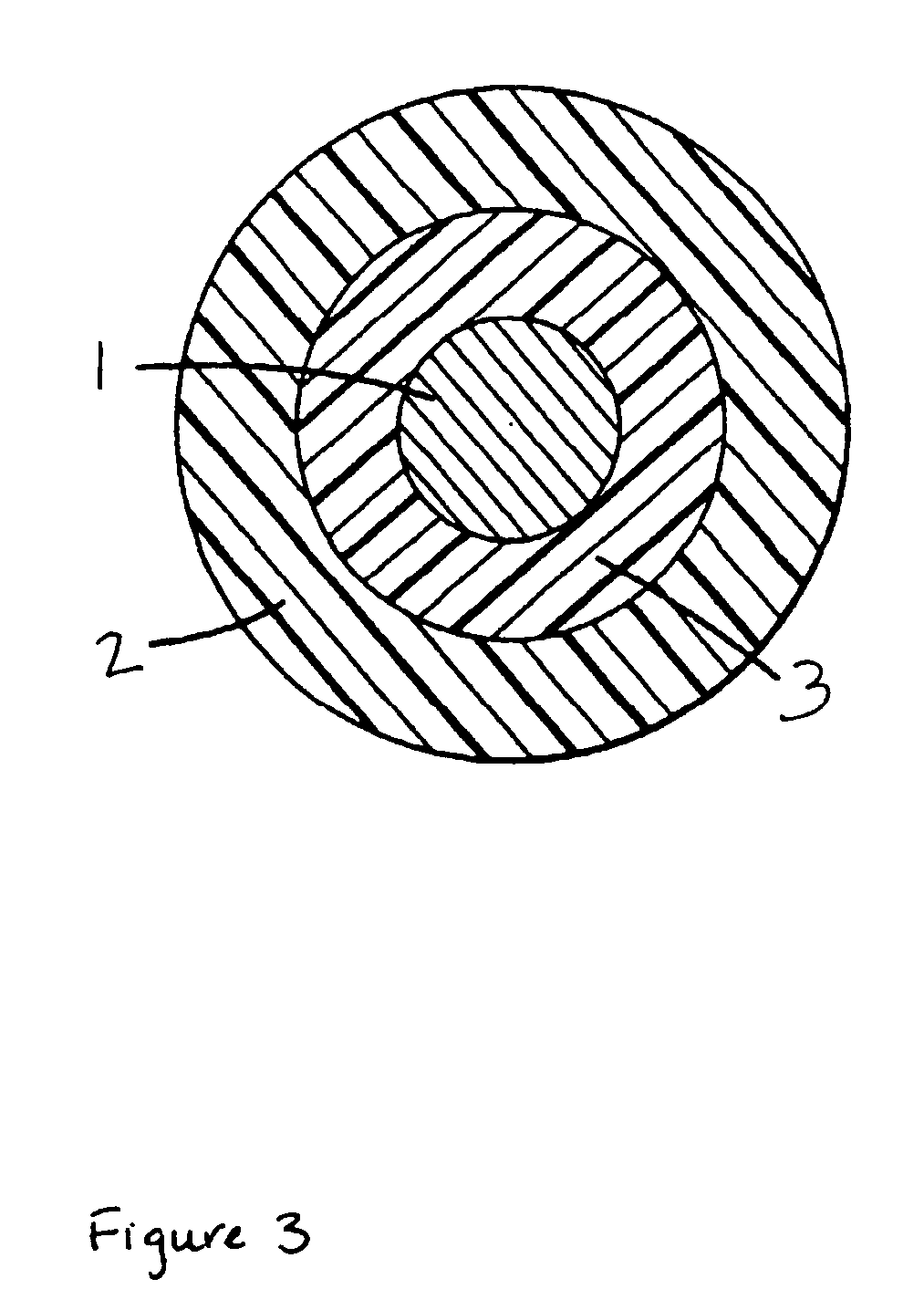

InactiveUS6872459B1Valid conversionExcellent in non-scalping and gas barrierLamination ancillary operationsLayered product treatmentLinear low-density polyethyleneSwelling ratio

This invention relates to the laminated material for food packaging, and its manufacturing process. The laminated material (10) consists of the quality keeping intermediate layer (12) laminated inside the paper core layer (11) and the core layer and the heat sealable innermost layer (13). The quality keeping intermediate layer comprises of an extrusion coatable blend polymer consisting of polymer component A 50-95% of nylon-MXD6 or EVOH and, polymer component B 5-50% of nylon 6, nylon 6, the blends or PET. The quality keeping intermediate layer is extruded and laminated directly in the core layer, the innermost layer contains at least the linear low density polyethylene which has a narrow molecular weight distribution, and has the properties parameter of mean density of 0.910-0.925, 100-122 degrees C. peak melting point, melt flow index of 5-20, swelling ratio (SR) of 1.4-1.6, and 5-50 micrometer layer thickness.The hardness, production efficiency, and cost performance of the barrier packaging container formed by the packaging material are improved.

Owner:TETRA LAVAL HLDG & FINANCE SA

Materials for making shoe soles and processing method

The invention discloses a novel sole material and a processing method for manufacturing the sole material. The main raw materials of the raw material formula are poly vinyl acetate and linear low density polyethylene, wherein, the main function of POE polyene elastomer or SBS thermoplastic rubber is to render soles elastic and malleable; the main function of a foaming agent is to act on the foaming performance of the soles so that the soles have softness; the main function of a cross-linking agent is the generation of effects of lubrication, softness and no sticky mold. During processes of material mixing, performing plastication and the extrusion granulation, various process conditions can be well handled so that the physical and chemical properties of materials can be well embodied. The soles manufactured with the material formula and the manufacturing method has the advantages of high strength, good tenacity, enough flexibility, being free-crack, good stability and comfortable wearing.

Owner:牟海妲

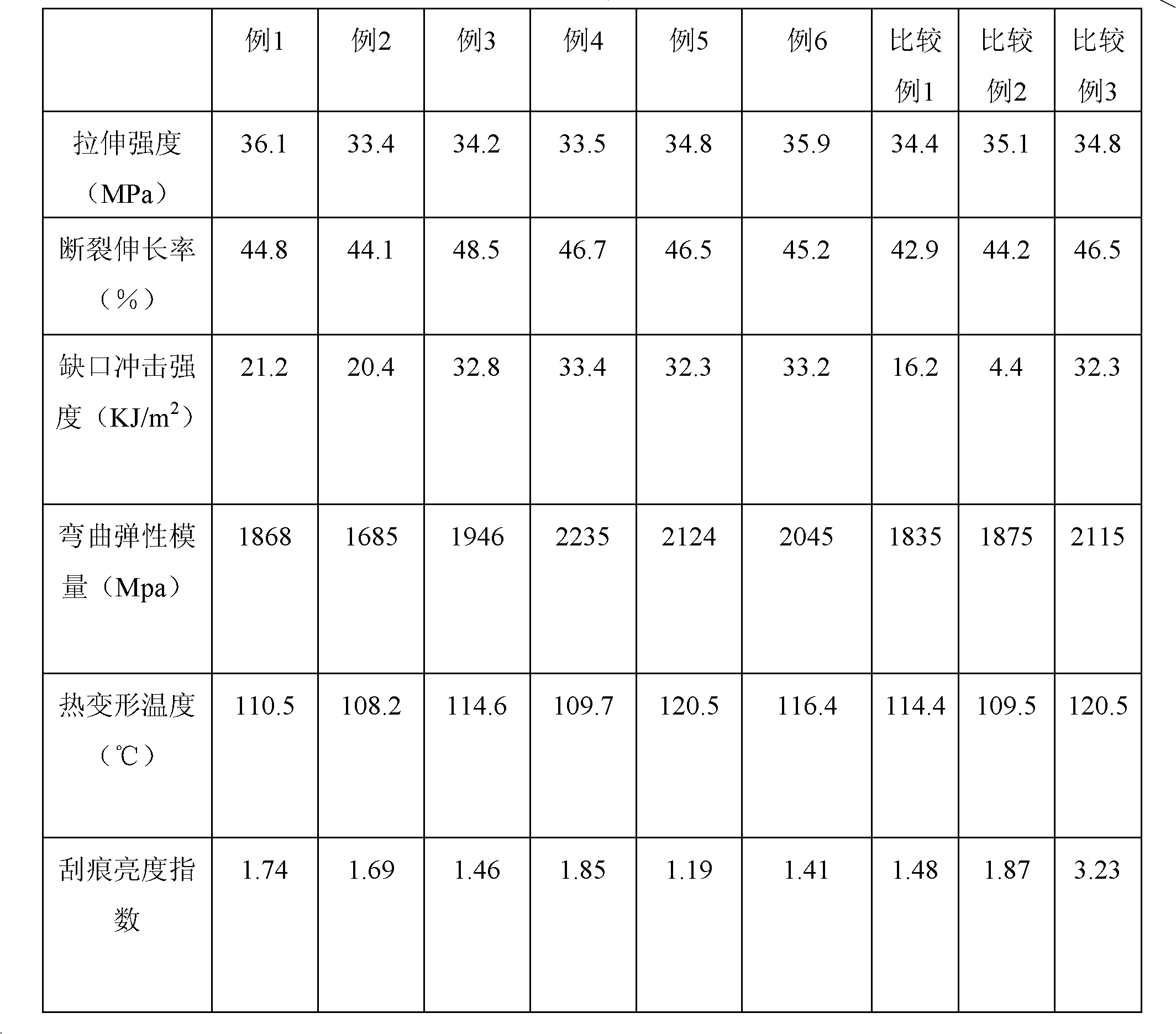

Modified polypropylene material as well as preparation method and application thereof

InactiveCN102464830AImprove rigidityNo lack of resilienceLinear low-density polyethyleneAging resistance

The invention belongs to the technical field of high molecule modification and processing and relates to a modified polypropylene material as well as a preparation method and application thereof. The material provided by the invention comprises the following components in parts by weight: 40-50 parts of bulk polypropylene, 20-35 parts of co-polypropylene, 15-24 parts of toughening agent, 0-15 parts of linear low-density polyethylene, 8-15 parts of filler retention aid, 6-12 parts of compatilizer, 0-8 parts of scratch-resistant smoothing agent, 0.5-1 part of lubricating agent, 3.5-5 parts of composite antioxidant and 1.5-3 parts of coupling agent. Compared with the prior art, the modified polypropylene material provided by the invention has the advantages of good rigidity, ductility, improvement on impact strength, heat resistance, ageing resistance, scratch resistance and excellent processing performance. The material provided by the invention can be widely applied to various interior trim parts of automobiles.

Owner:华砻树脂股份有限公司 +1

Preparation method of self-adhesive polyethylene base protection film

InactiveCN1597304AFilm/foil adhesivesSynthetic resin layered productsLow-density polyethyleneTectorial membrane

A process for preparing self-adhesive polyethene-base protecting film includes such steps as extruding out basic film, middle layer and self-adhesive layer, and blowing film to obtain a composite film. Said basic film is prepared from low-density polyethene and low-density linear polyethene. Said middle layer is prepared from the polyethene of basic film and ethene-vinyl acetate. Said self-adhesive layer is prepared from 6 chemicals including ethene-vinyl acetate, polyethene of basic film, dioctyl adiptate, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

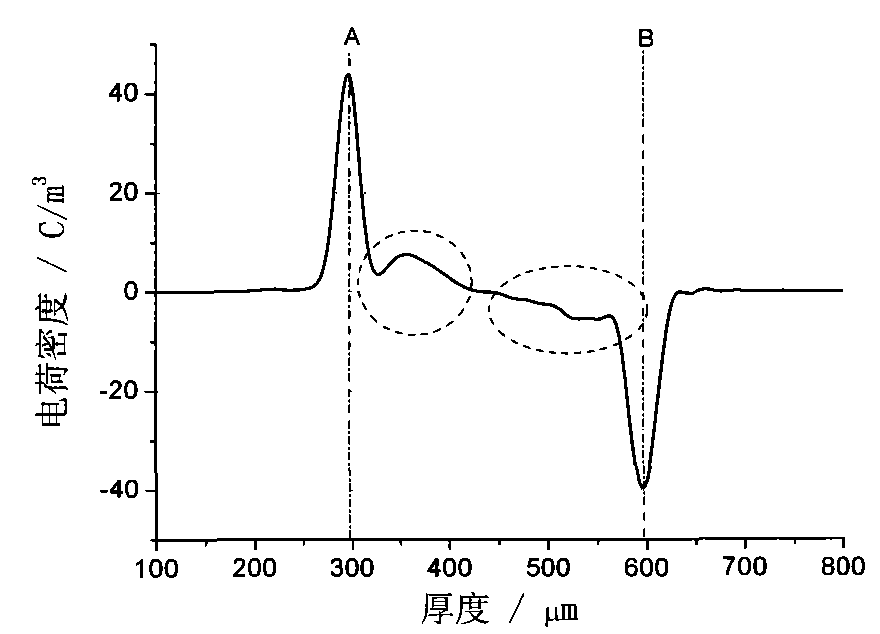

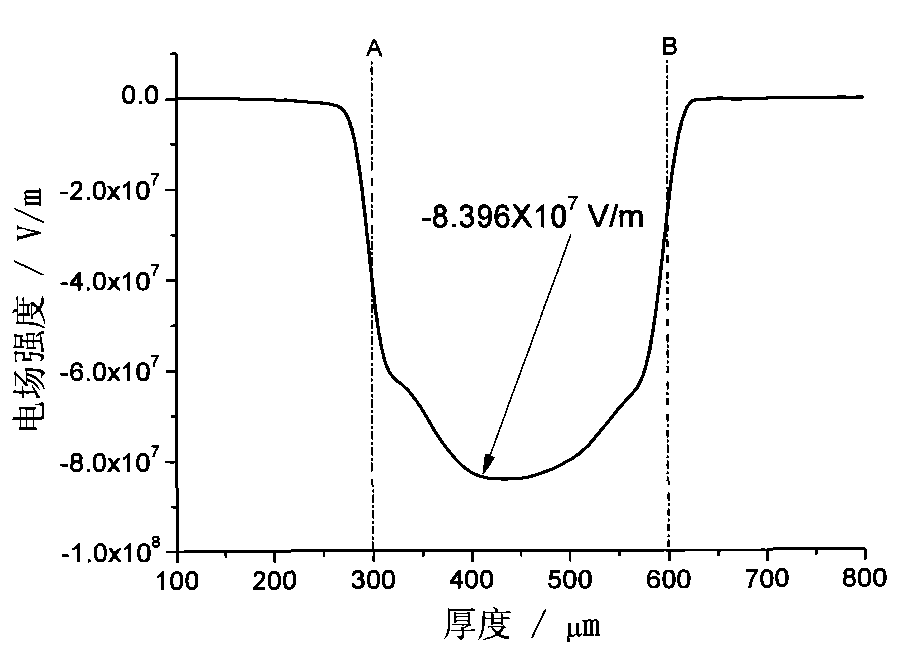

Cable semi-conductive shielding material and preparation method thereof

InactiveCN101585943AAvoid accumulationReduces the effect of increased conductivityPower cables with screens/conductive layersLinear low-density polyethyleneCross linker

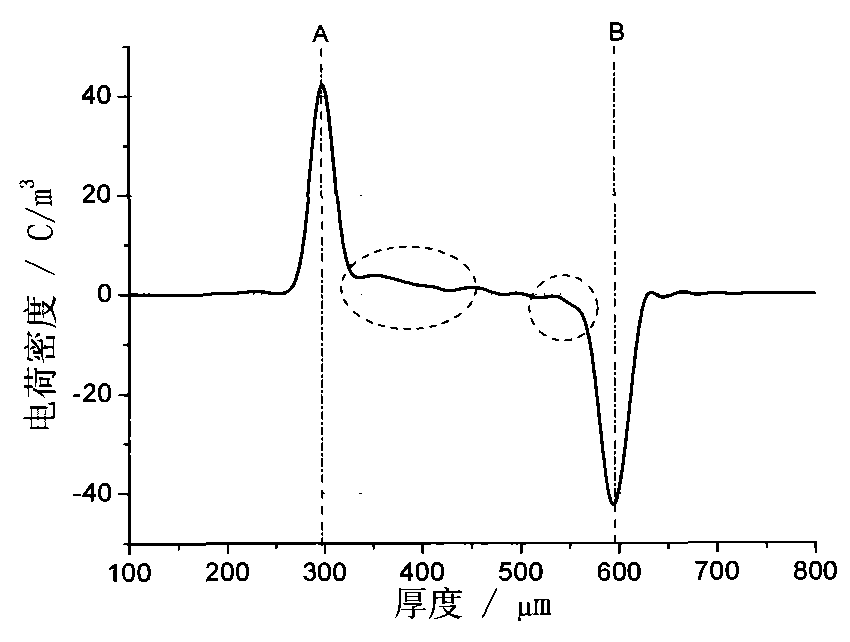

The invention provides a cable semi-conductive shielding material which belongs to the field of electric cable fabrication technique and a preparation method thereof, and the components of the material and the content thereof are as follows: ethylene-vinyl acetate copolymer or linear low density polyethylene 100 proportion by weight, black carbon 10-50 proportion by weight, anti-oxidant 0.1-5 proportion by weight as well as cross linker 0.1-5 proportion by weight. The method provided by the invention can effectively inhibit accumulation of space charges in insulation material, and improves electric field threshold value of injected space charge, which reduces insulation material electric conductivity increased effect induced by space charge-limited current (SCLC), and the electric field distortion rate in XLPE is only 14-19% under -60kV / mm extra electric field for 60 minutes.

Owner:SHANGHAI JIAO TONG UNIV

Rotational molding wear-resistant polyolefin resin and preparation method thereof

InactiveCN101735505AImprove wear resistanceImprove friction and wear propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a rotational molding wear-resistant polyolefin resin and a preparation method thereof. In the rotational molding wear-resistant polyolefin resin, raw materials commonly used in the rotational molding process, namely linear low-density polyethylene, high-density polyethylene or polypropylene is taken as a matrix material; and by adding components of an inorganic filler, ultrahigh molecular weight polyethylene and a lubricant, the wear resistance of the matrix resin is improved. The rotational molding wear-resistant polyolefin resin consists of the following components in percentage by mass: 70 to 80 percent of matrix resin, 10 to 15 percent of inorganic filler subjected to surface treatment, 4 to 13 percent of ultrahigh molecular weight polyethylene and 1.5 to 2 percent of lubricant, wherein the matrix resin is the linear low-density polyethylene, the high-density polyethylene or the polypropylene; and a range of a melt flow rate of the matrix resin is between 2g / 10min and 15g / 10min.

Owner:江苏吉星管业科技有限公司

Polyethylene repackaging film material composition

ActiveCN101255249AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

A polyethylene heavy packaging film composite can be widely used for producing blisterpack, such as FFS package, large goods package, tray package and so on, which can effectively improve the all round performance of packaging film, and make the package of goods more beauty, firm, green and effective. The film composite comprises: linear low density polyethylene accounting for 60-80% of the sum of the material, low density polyethylene accounting for 5-25% of the sum of the material, metallocene linear low density polyethylene accounting for 10-30% of the sum of the material, additive accounting for 3-7% of the sum of the material. An automatic feed proportioning system feeds the material of three extruders to die head and the heavy packaging film combination is obtained after three-layer extruding and mixing. The additive is combination of one or several kinds of slippery agent, antistatic agent, antioxidant, opening agent, thermal stabilizer.

Owner:SINOPEC YANGZI PETROCHEM

Antistatic adhesion-resistant slippery linear low density polyethylene composition and method of making the same

ActiveCN101012322AGuaranteed performanceMeet production requirementsLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antistatic blocking resistant smooth linear low-density polyethylene composition based on LLDPE as base, which comprises the following parts: 0.05-0.2% opening agent, 0.05-0.3% smooth agent, 0.05-0.3% antistatic agent, 0.05-0.2% anti-oxidant and 0.05-0.2% manufacturing and heat stabilizer, wherein the opening agent contains inorganic blocking resistant agent or organic opening agent; the smooth agent is amide, soap or organic silicane; the main auxiliary anti-oxidant is hindered phenol and phosphorus anti-oxidant; the antistatic agent adopts composite pattern of non-ionic typed antistatic agent and ion-typed antistatic agent. The making method compress the following steps: adopting LLDPE as base; adding blended auxiliary material into graining stage; or graining auxiliary agent into mother grain; adding mother grain; manufacturing specific material.

Owner:SINOPEC YANGZI PETROCHEM

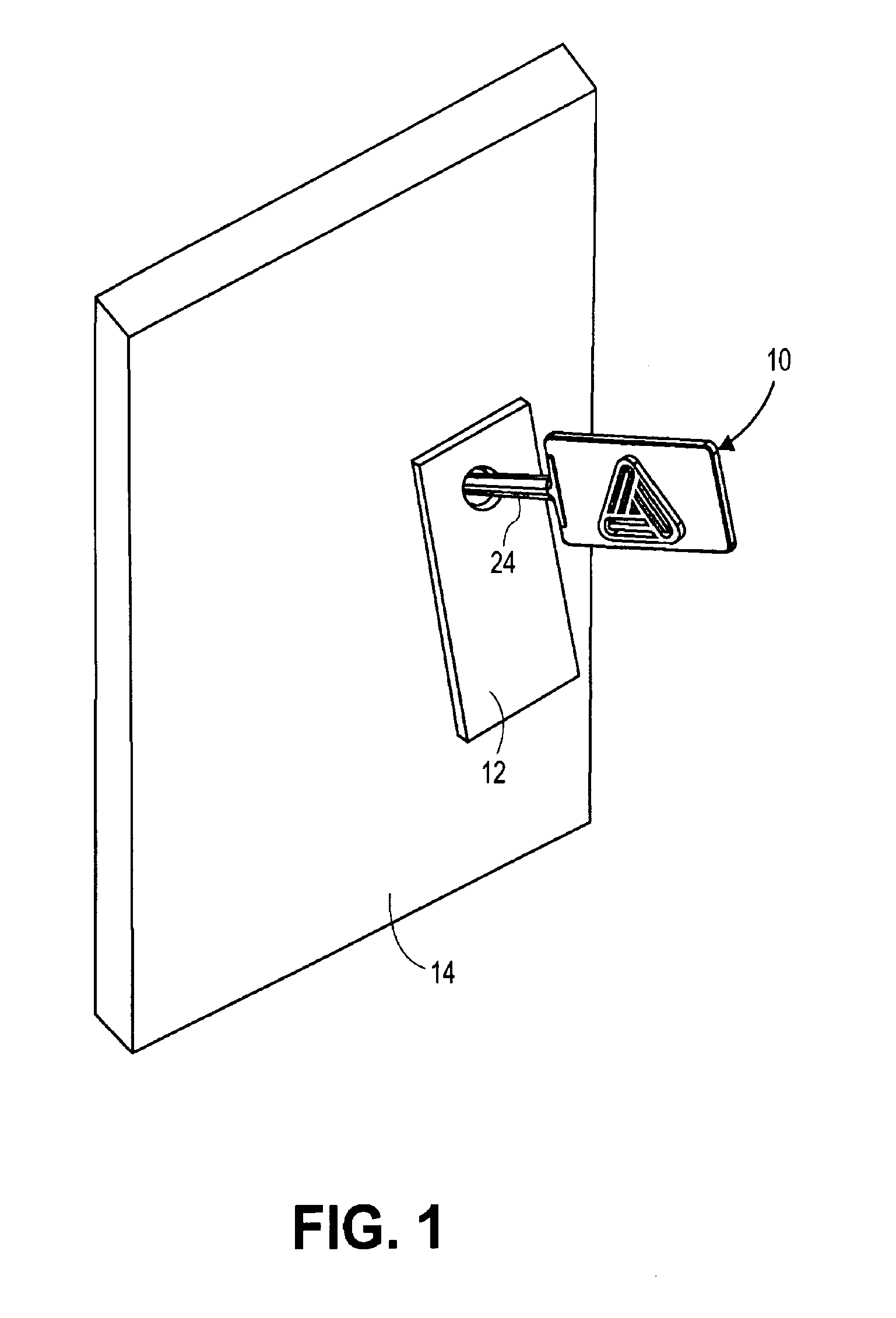

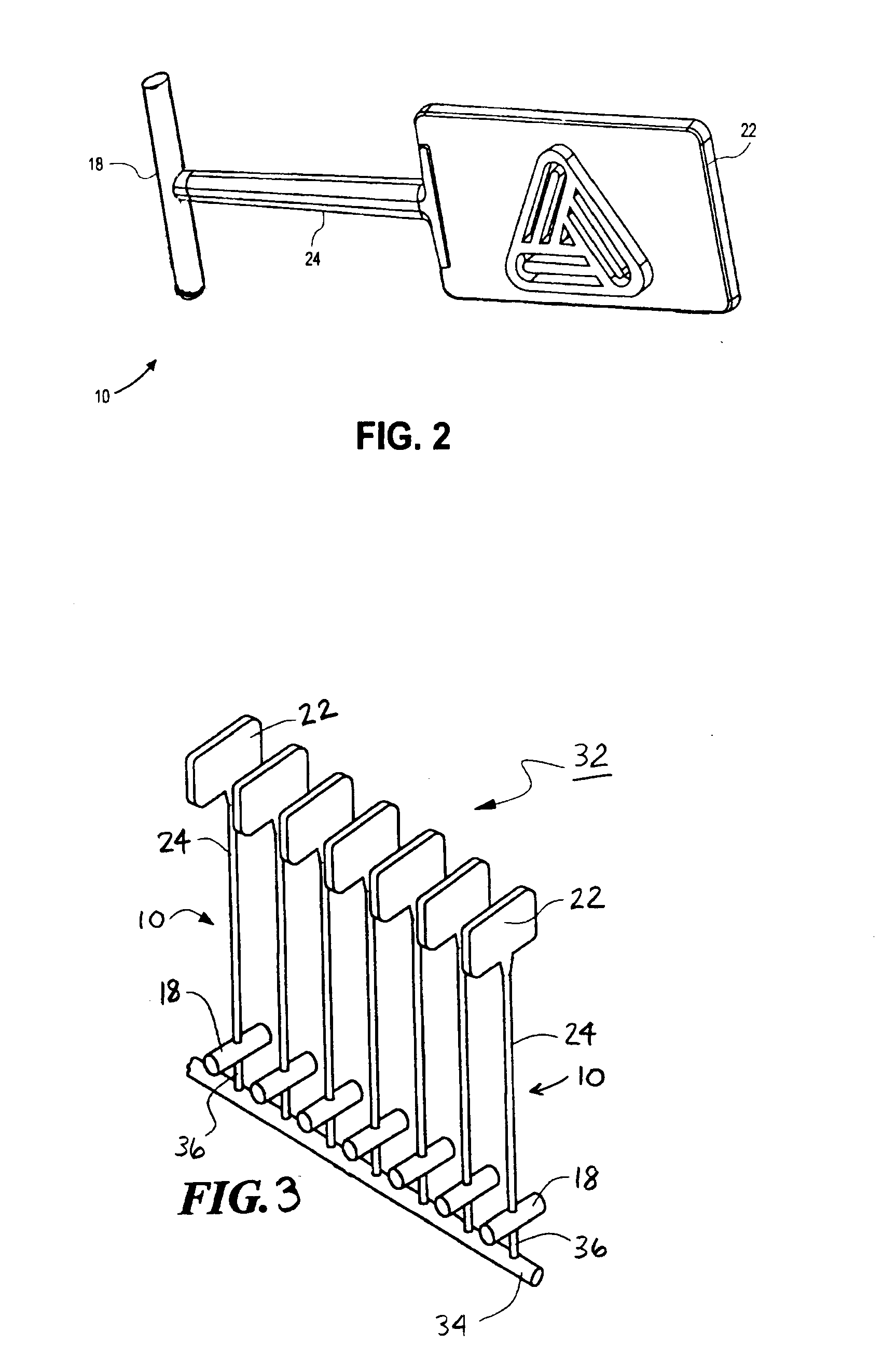

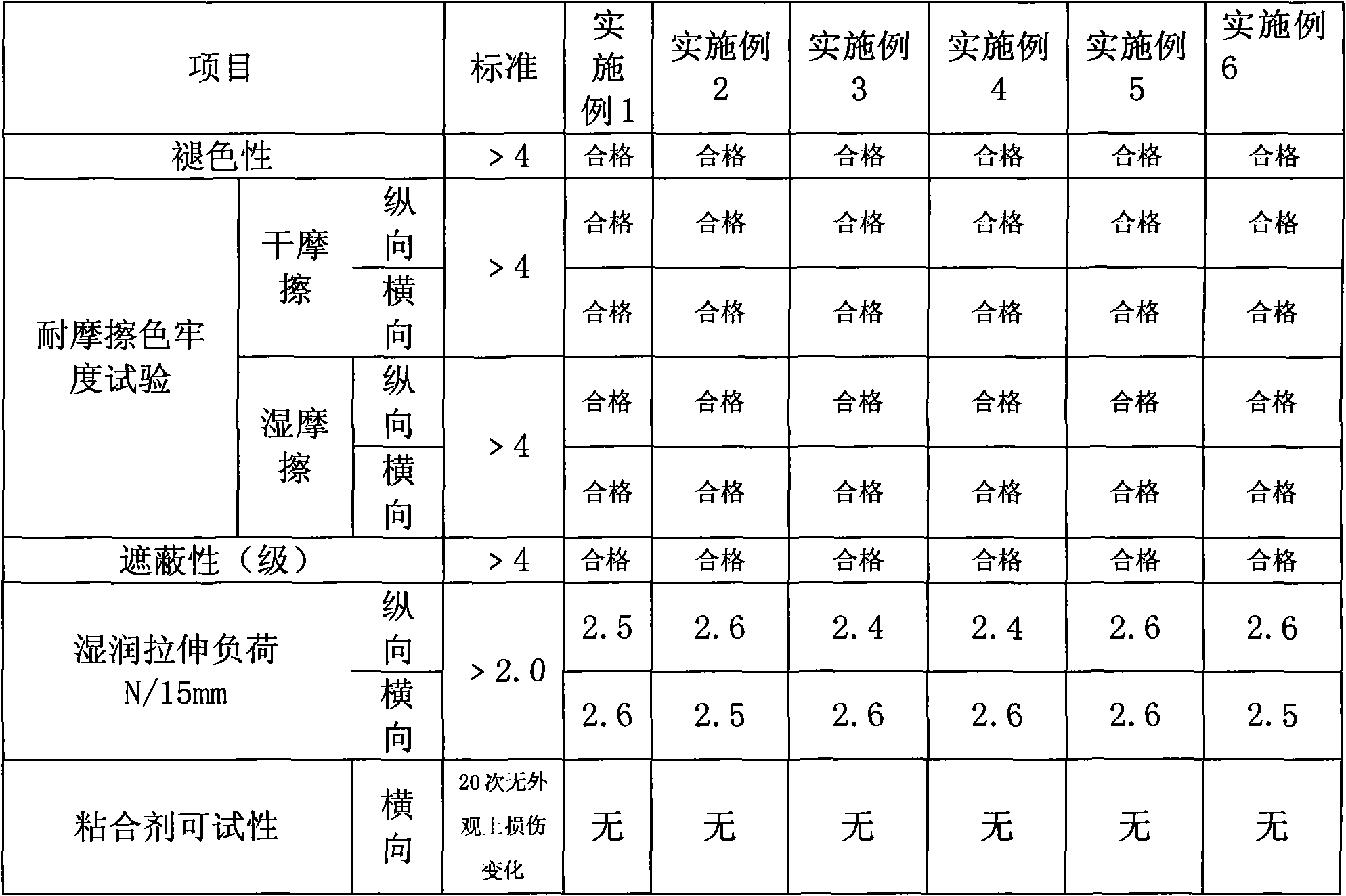

Plastic Fastening Device Comprising a Recycled Thermoplastic Resin

InactiveUS20120279023A1Improve compatibilityStampsArtificial filament recoveryLow-density polyethyleneThermoplastic

A plastic fastening device that includes a recycled material. In one embodiment, at least a portion of the fastening device includes a blend of two or more thermoplastic resins, at least one of which is a recycled material. The blend may include, for example, a fresh thermoplastic resin and a recycled thermoplastic resin. The fresh thermoplastic resin may include, for example, one or more of a polyethylene (PE), a polyamide (PA), or a polycarbonate (PC). The recycled thermoplastic resin may include, for example, a recycled polyethylene terephthalate (rPET). In a preferred embodiment, the blend of two or more thermoplastic resins includes a blend of (i) rPET and (ii) one of a low-density polyethylene (LDPE), a LDPE / LLDPE (linear low-density polyethylene) blend and LLDPE, (iii) wherein the rPET constitutes about 88% to 98% of the total material content and the LDPE, the LDPE / LLDPE blend, or the LLDPE constitutes the balance.

Owner:AVERY DENNISON CORP

Stone paper and manufacturing method thereof

The invention provides stone paper and a manufacturing method thereof. The stone paper comprises the following components in part by weight: 6 to 12 parts of low-density polyethylene, 6 to 12 parts of linear low-density polyethylene, 3 to 6 parts of hot melt adhesive, 5 to 10 parts of titanium dioxide, 65 to 75 parts of heavy calcium carbonate, 3 to 5 parts of silane coupling agent, 0.5 to 1.5 parts of stearic acid, 0.5 to 1.5 parts of epoxy plasticizer, and 0.2 to 0.6 part of polyethylene wax. In the method, high polymer is used as a base material, the calcium carbonate is subjected to compound modification, other additives are added, the characteristics of the surface chemical principle and modification of the high polymer are used and a special process is adopted; and the stone paper is prepared by mixing the polymer, performing composite modification on the filler, plasticizing the filler and polymer, extruding and casting, and performing calendaring molding. The stone paper and the method have great significance for saving energy, protecting natural resources and improving environment.

Owner:山东高旭新材料有限公司

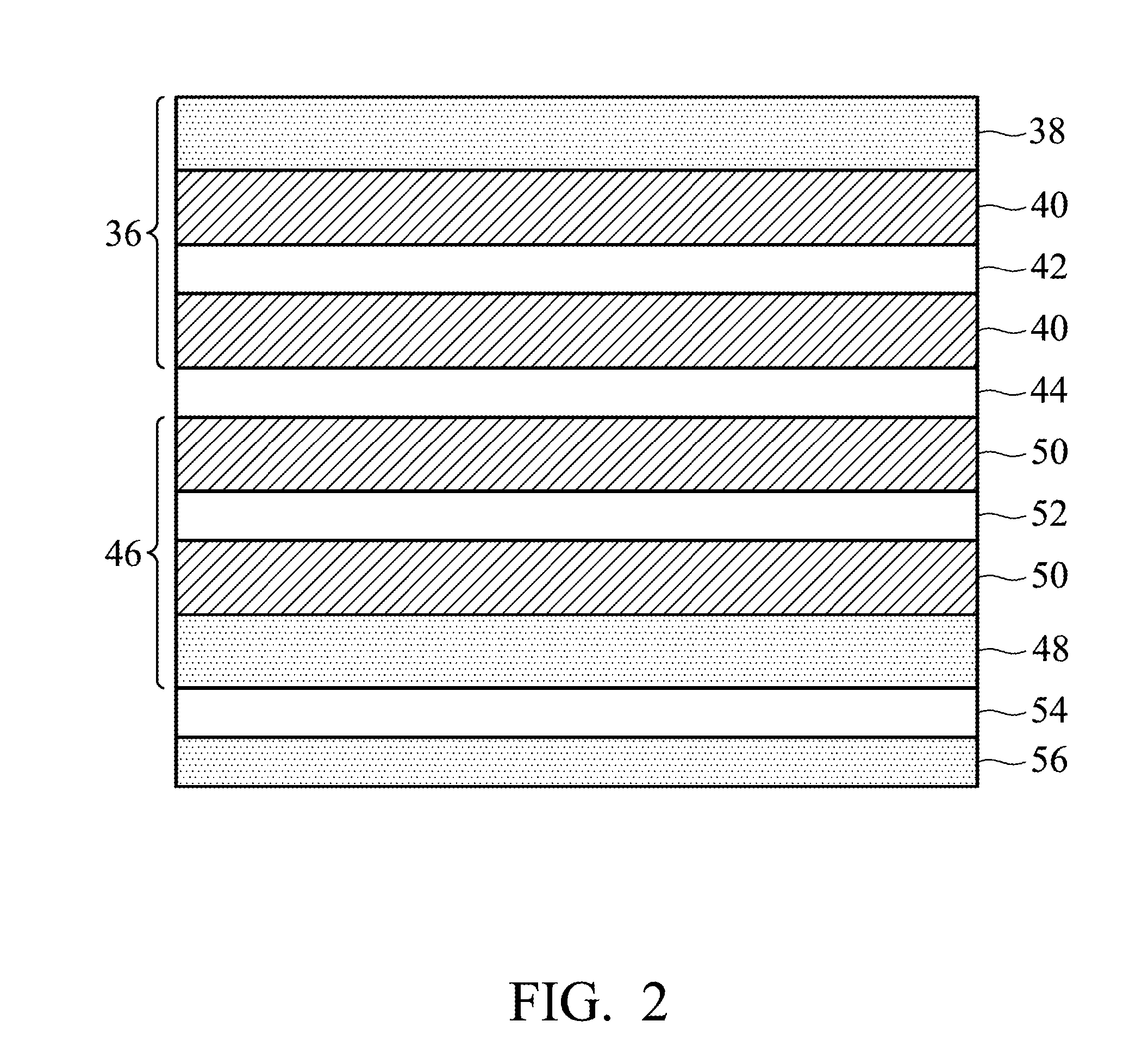

Pre-stretched wrapping film roll with entrapped air and method

InactiveUS20060243842A1Easy and fast loadingLayered productsFunction indicatorsLinear low-density polyethyleneAir entrainment

A pre-stretched film roll of a mono orientated linear low density polyethylene (LLDPE) is stretched between 30% and 320% depending on the final product that is required. Stretching is in the machine direction (MD) at a controlled rate in two stages. Differentially rewinding the film entraps air between the layers of the roll and creates soft overlapping edges around the roll to produce a spongy, “soft” roll that prevents and resists drop damage due to its shock absorbent characteristic.

Owner:MARTIN GUILLERMO DURAN ESPINOZA & ANGEL GERARDO SANTILLAN DIAZ DE LEON

Polymer adhesive resin for corrosion-prevention of steel pipe and preparation process thereof

InactiveCN1754932AHigh bonding strengthSimple technical solutionAdhesivesNon-disconnectible pipe-jointsLow-density polyethyleneLinear low-density polyethylene

The invention relates to adhesive resin with antiseptic function for steel pipe, which is prepared by HDPE, LLDPE, LDPE, PP, maleic anhydride, initiator, EVA, tackifier, antioxidant, color filler, and structural modifying agent with double-screws extruder. The product has high joint strength, and friend environment.

Owner:赵璐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com