Modified polypropylene material as well as preparation method and application thereof

A technology of polypropylene material and bulk polypropylene, which is applied in the field of polymer modification, can solve the problems of reducing the aesthetics of products, poor surface scratch resistance, and poor impact resistance of PP, so as to save resource consumption, scratch resistance and Excellent processability and vehicle weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

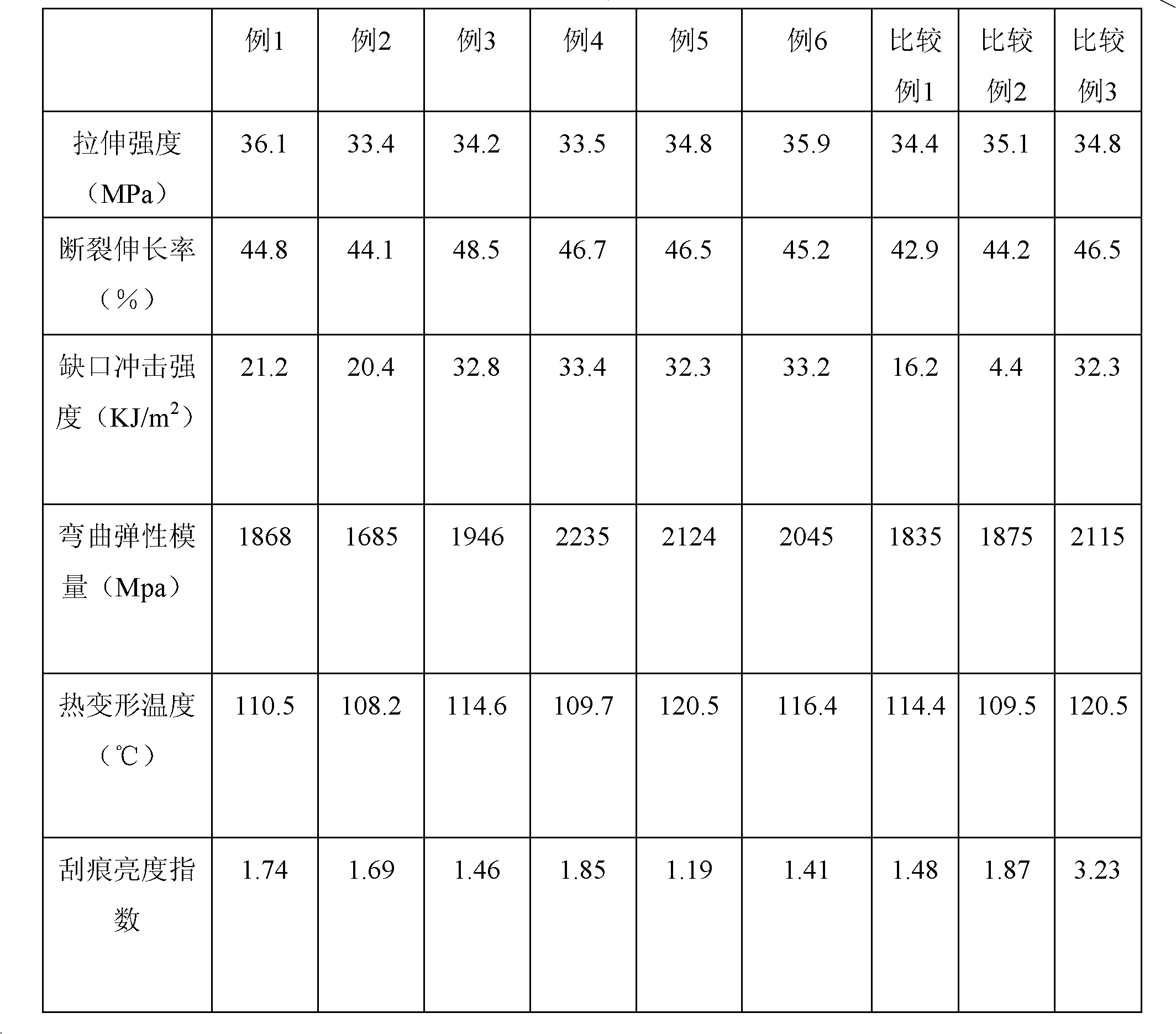

Examples

Embodiment 1

[0034] 48 parts of bulk polypropylene powder, 21 parts of copolymerized polypropylene, 20 parts of polyolefin elastomer, 8 parts of linear low density polyethylene, 10 parts of wollastonite, 8 parts of maleic anhydride grafted polypropylene, reactive polymer Add 4 parts of siloxane, 0.6 parts of calcium stearate, 4 parts of composite antioxidant 2246 / DLTP (the mass ratio of composite antioxidant 2246 / DLTP is 1.5:1), and 1.8 parts of aluminate coupling agent into the reactor in sequence Stir in medium for 12 minutes; then mix in a high-speed mixer for 8 minutes, the speed of the mixer is 4000-6000r / min, and the heating temperature is 100-120°C; The diameter is 68mm, the length-to-diameter ratio is 25:1, the screw speed is 80r / min, and the extrusion temperature is 180-230°C; after cooling to room temperature, and then drying for 20-30min, injection molding samples are prepared, and the injection temperature is 190-220°C. Pressure: 40~80MPa, back pressure: 0.7MPa, exhaust port de...

Embodiment 2

[0036]42 parts of bulk polypropylene powder, 22 parts of copolymerized polypropylene, 15 parts of polyolefin elastomer, 6 parts of linear low density polyethylene, 8 parts of wollastonite, 8 parts of maleic anhydride grafted polypropylene, reactive polymer Add 5 parts of siloxane, 0.5 parts of calcium stearate, 3.5 parts of composite antioxidant 2246 / DLTP (the mass ratio of composite antioxidant 2246 / DLTP is 1.5:1), and 1.5 parts of aluminate coupling agent into the reactor in sequence Stir in medium for 10 minutes; then mix in a high-speed mixer for 6 minutes, the speed of the mixer is 4000-6000r / min, and the heating temperature is 100-120°C; The diameter is 68mm, the length-to-diameter ratio is 20:1, the screw speed is 60r / min, and the extrusion temperature is 180-230°C; after cooling to room temperature and drying for 20-30min, injection molding samples are prepared, and the injection temperature is 190-220°C. Pressure: 40~80MPa, back pressure: 0.7MPa, exhaust port depth: 0...

Embodiment 3

[0038] 42 parts of bulk polypropylene powder, 33 parts of copolymerized polypropylene, 18 parts of polyolefin elastomer, 15 parts of linear low density polyethylene, 8 parts of wollastonite, 6 parts of maleic anhydride grafted polypropylene, reactive polymer 6 parts of siloxane, 0.8 parts of calcium stearate, 4.4 parts of composite antioxidant 2246 / DLTP (the mass ratio of composite antioxidant 2246 / DLTP is 1.5:1), and 2.1 parts of aluminate coupling agent are added to the reactor in sequence Stir in medium for 15 minutes; then mix in a high-speed mixer for 5 minutes, the speed of the mixer is 4000-6000r / min, and the heating temperature is 100-120°C; The diameter is 68mm, the length-to-diameter ratio is 26:1, the screw speed is 90r / min, and the extrusion temperature is 180-230°C; after cooling to room temperature and drying for 20-30min, injection molding samples are prepared, and the injection temperature is 190-220°C. Pressure: 40~80MPa, back pressure: 0.7MPa, exhaust port de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com