Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8909 results about "Toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toughening refers to improving the fracture resistance of a given material. The material's toughness is described by irreversible work accompanying crack propagation. Designing against this crack propagation leads to toughening the material.

Process for applying a streamable epoxy adhesive

InactiveUS20050070634A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesBENZYL ALCOHOL/WATERViscosity

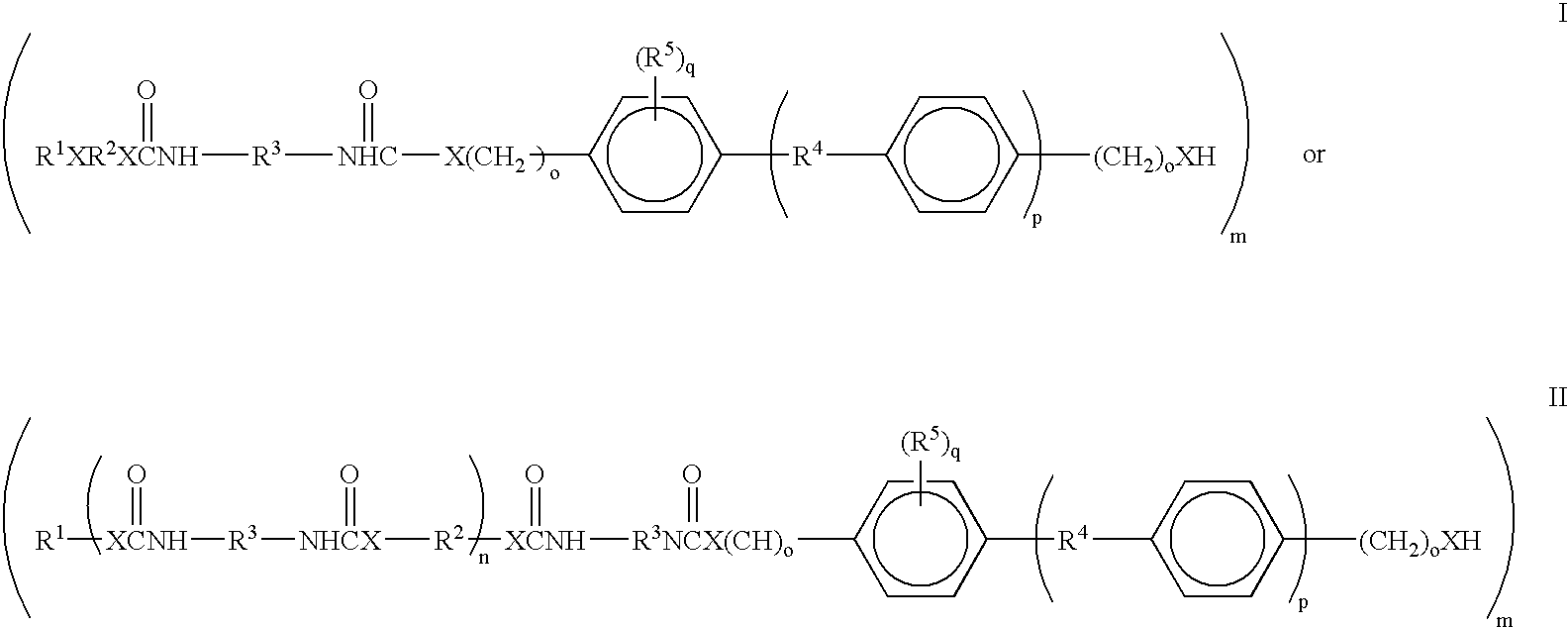

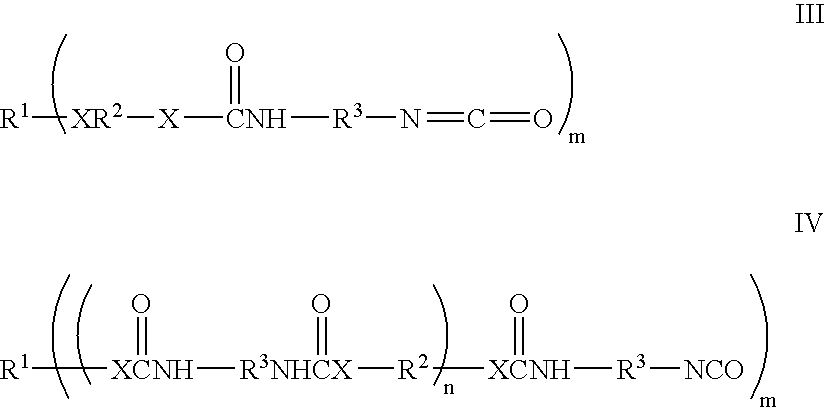

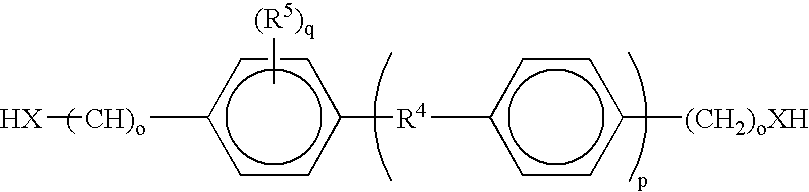

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa.s to about 400 Pa.s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

Epoxy coating

InactiveUS7037958B1Improve adhesionAvoid corrosionLiquid surface applicatorsAircraft carriersEpoxyGlass fiber

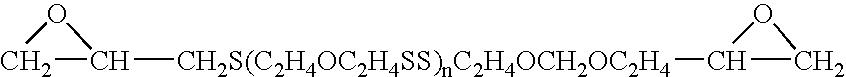

This invention concerns an epoxy coating for use as a non-skid surface for applications such as the deck of an aircraft carrier. The epoxy coating can be formulated from (a) an amine curing agent, (b) an epoxide-containing toughening agent such as a polysulfide and / or a polythioether, (c) an epoxy resin, (d) a rubber toughening agent, and (e) an optional fire retardant, a glass fiber thixotrope and impact toughening agent, an optional pigment, an optional corrosion inhibitor, an optional moisture penetration inhibitor, an optional ultraviolet light stabilizer, an optional abrasive aggregate, or a combination thereof.

Owner:TEXAS RES INT

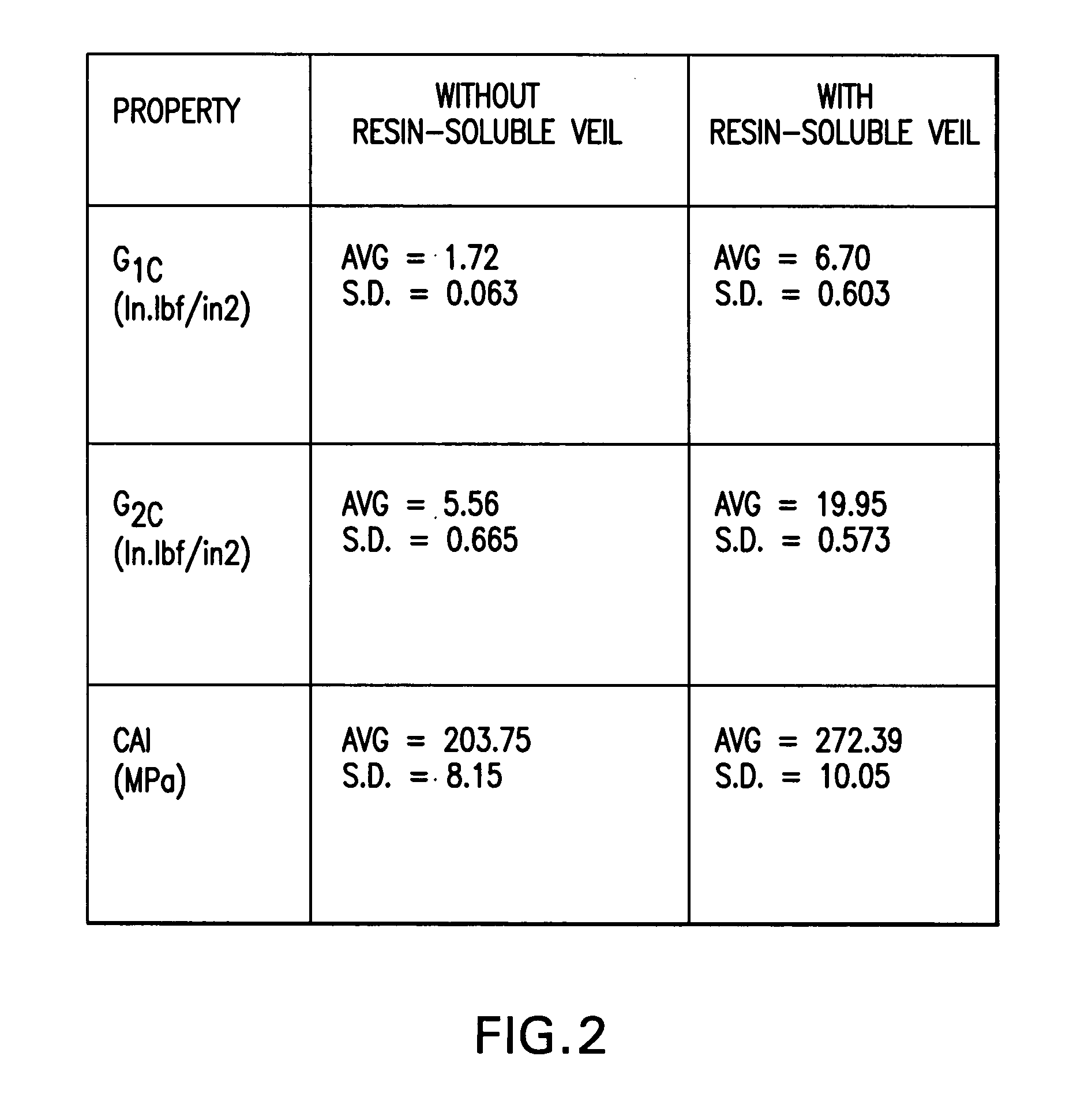

Resin-soluble thermoplastic veil for composite materials

ActiveUS20060252334A1Improve the level ofImprove toughnessWood working apparatusVehicle componentsFiberResin matrix

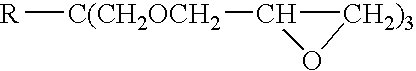

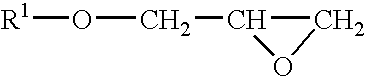

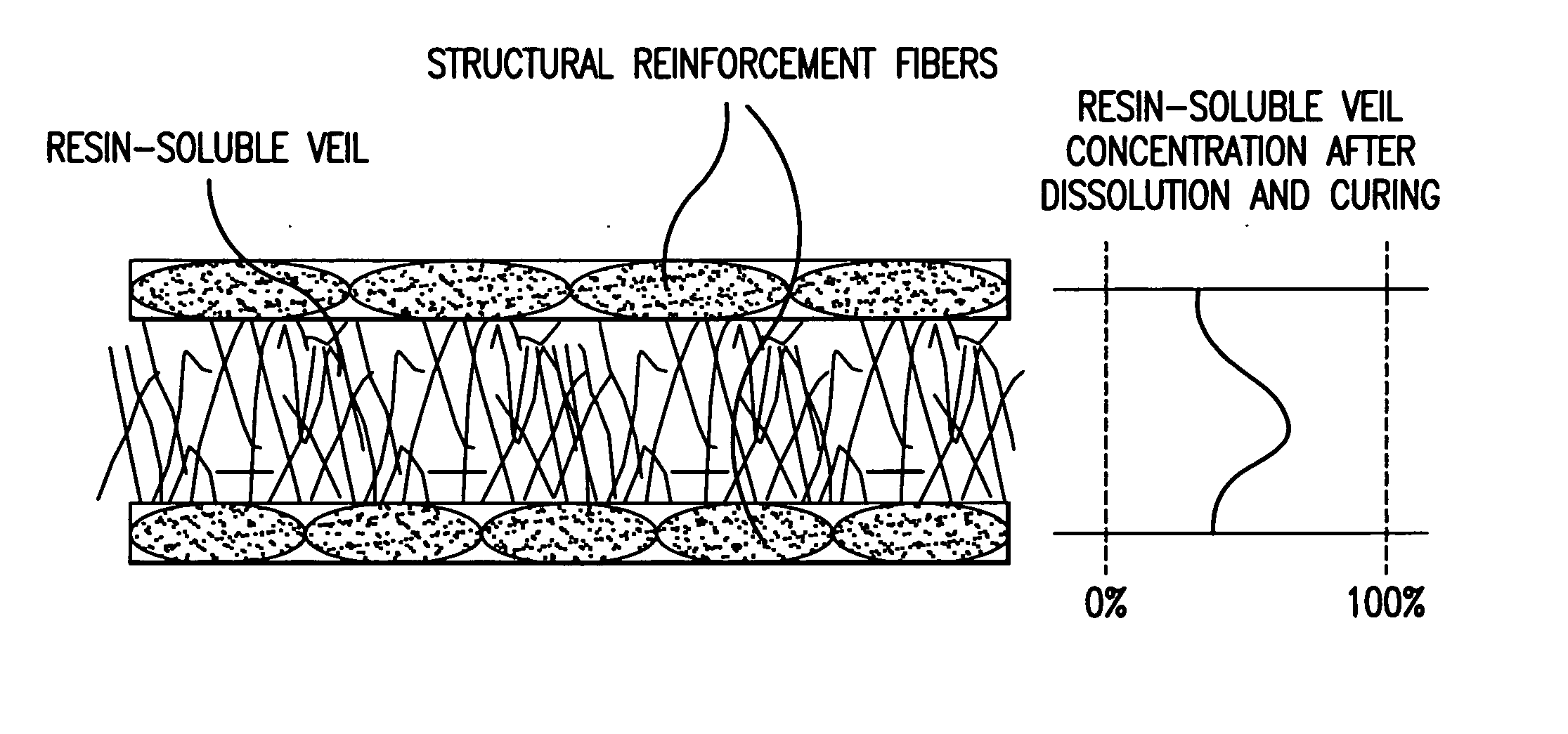

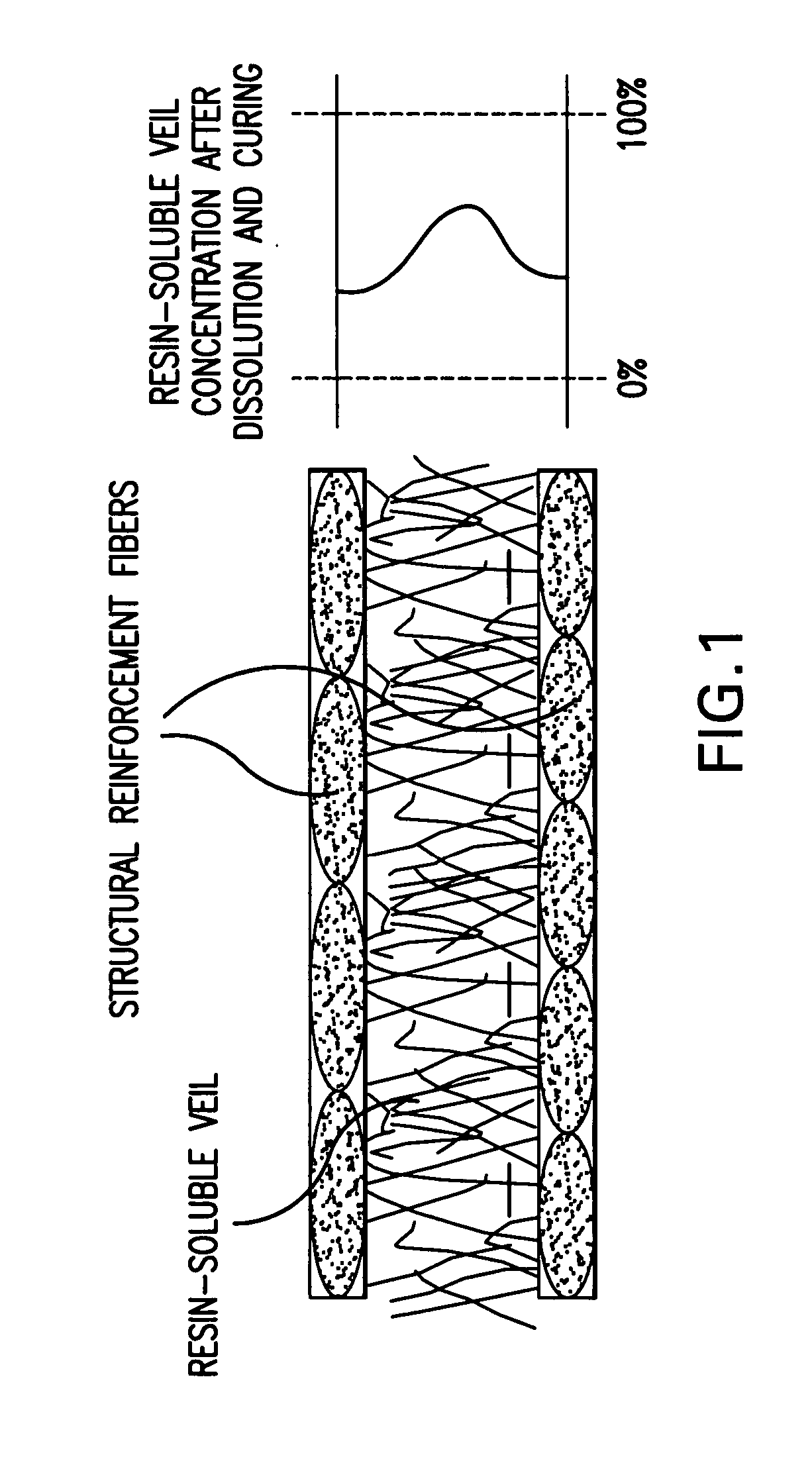

A resin-soluble thermoplastic polymer veil toughening element for a curable composition wherein the polymer element is a non-woven veil in solid phase adapted to undergo at least partial phase transition to fluid phase on contact with a component of the curable resin matrix composition in which it is soluble at a temperature which is less than the temperature for substantial onset of gelling and / or curing of the curable composition and which temperature is less than the polymer elements melt temperature; a method for the preparation thereof, a preform support structure for a curable composition comprising the at least one thermoplastic veil element together with structural reinforcement fibers, methods for preparation thereof, a curable composition comprising the at least one thermoplastic veil element or the support structure and a curable resin matrix composition, a method for preparation and curing thereof, and a cured composite or resin body obtained thereby, and known and novel uses thereof.

Owner:CYTEC TECH CORP

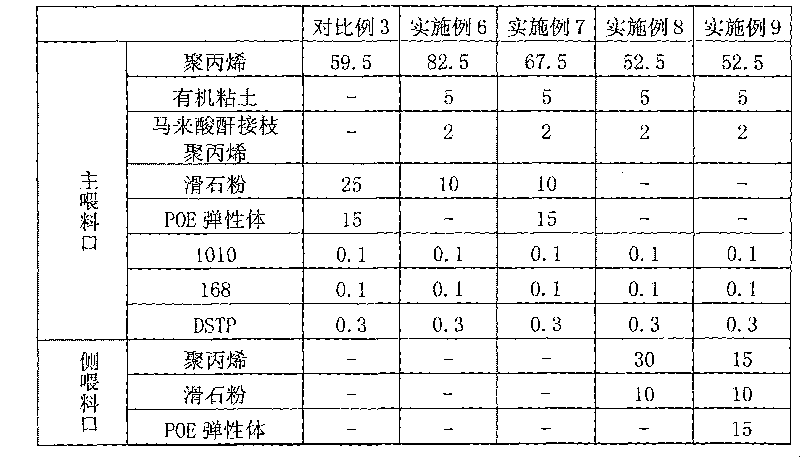

High strength and high toughness modified poly-propylene material

The present invention belongs to the field of polymer material technology, and is especially one kind of modified polypropylene material comprising at least polymer base, strengthening agent and toughening agent. The polymer base may be polypropylene or polypropylene composition; the strengthening agent is inorganic or organic matter with great aspect ratio, such as inorganic or organic crystal whisker, fiber, mica, etc; and the toughening agent may be polypropylene beta-nucleater, rubber elastomer, etc. The modified polypropylene material has high strength, high toughness, etc and may be applied widely in automobile, pipeline, electric appliance and other fields.

Owner:FUDAN UNIV

Repairing damage to low-k dielectric materials using silylating agents

ActiveUS20050095840A1Reduce hydrophobicityImprove hydrophobicitySemiconductor/solid-state device manufacturingStress inducedSilicate glass

A method for restoring hydrophobicity to the surfaces of organosilicate glass dielectric films which have been subjected to an etchant or ashing treatment. These films are used as insulating materials in the manufacture of integrated circuits to ensure low and stable dielectric properties in these films. The method deters the formation of stress-induced voids in these films. An organosilicate glass dielectric film is patterned to form vias and trenches by subjecting it to an etchant or ashing reagent in such a way as to remove at least a portion of previously existing carbon containing moieties and reduce hydrophobicity of said organosilicate glass dielectric film. The vias and trenches are thereafter filled with a metal and subjected to an annealing treatment. After the film is subjected to the etchant or ashing reagent, but before being subjected to an annealing treatment, the film is contacted with a toughening agent composition to restore some of the carbon containing moieties and increase the hydrophobicity of the organosilicate glass dielectric film.

Owner:HONEYWELL INT INC

Low-density, high-rigidity and high-tenacity polypropylene nano composite material and preparation method thereof

InactiveCN101712780ALow content of inorganic componentsLow densityVolumetric Mass DensityLow density

The invention discloses a low-density, high-rigidity and high-tenacity polypropylene nano composite material and a preparation method thereof. The low-density, high-rigidity and high-tenacity polypropylene nano composite material consists of the following raw materials in percentage by weight: 55 to 98 percent of polypropylene, 1 to 15 percent of organic clay, 0 to 30 percent of inorganic filler, 0.1 to 10 percent of compatilizer, 0 to 20 percent of toughening agent, 0.2 to 2 percent of stabilizing agent, and 0 to 5 percent of other additives. The low-density, high-rigidity and high-tenacity polypropylene nano composite material and the preparation method have the following advantages that: 1, the density and the weight of a product are reduced for the help of reducing the weight and the energy consumption of a finished product; 2, the rigidity and the tenacity are higher; 3, the process flow is simplified and the production cost is reduced effectively; and 4, the influences on the cutting of nano clay and the dispersion process caused by other components are avoided to the utmost extent to further improve the performance of the composite material.

Owner:SHANGHAI PRET COMPOSITES

PVC fine foaming wood-plastic coiled material and method of preparing the same

The invention discloses a PVC micro-foaming wood-plastic coiled material, including the following materials by weight portion:100 portions of PVC, 70-80 portions of waste vegetable fibers, 10-30 portions of CaCO3, 1-4 portions of coupling agent, 2-8 portions of heat stabilizer, 3-9 portions of lubricant, 7-12 portions of toughening agent, 3-7 portions of plasticizer, 0.6-1.2 portions of composite foaming agent and 2-3 portions of titanium pigment powder. Compared with the prior art, the composite material prepared by the method has high toughness, the disadvantages of high resin content, little filler and high cost of common PVC coiled materials are avoided. The coiled materials can be used as the coating materials of indoor floor, peripheries and walls with sophisticated shapes.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD +1

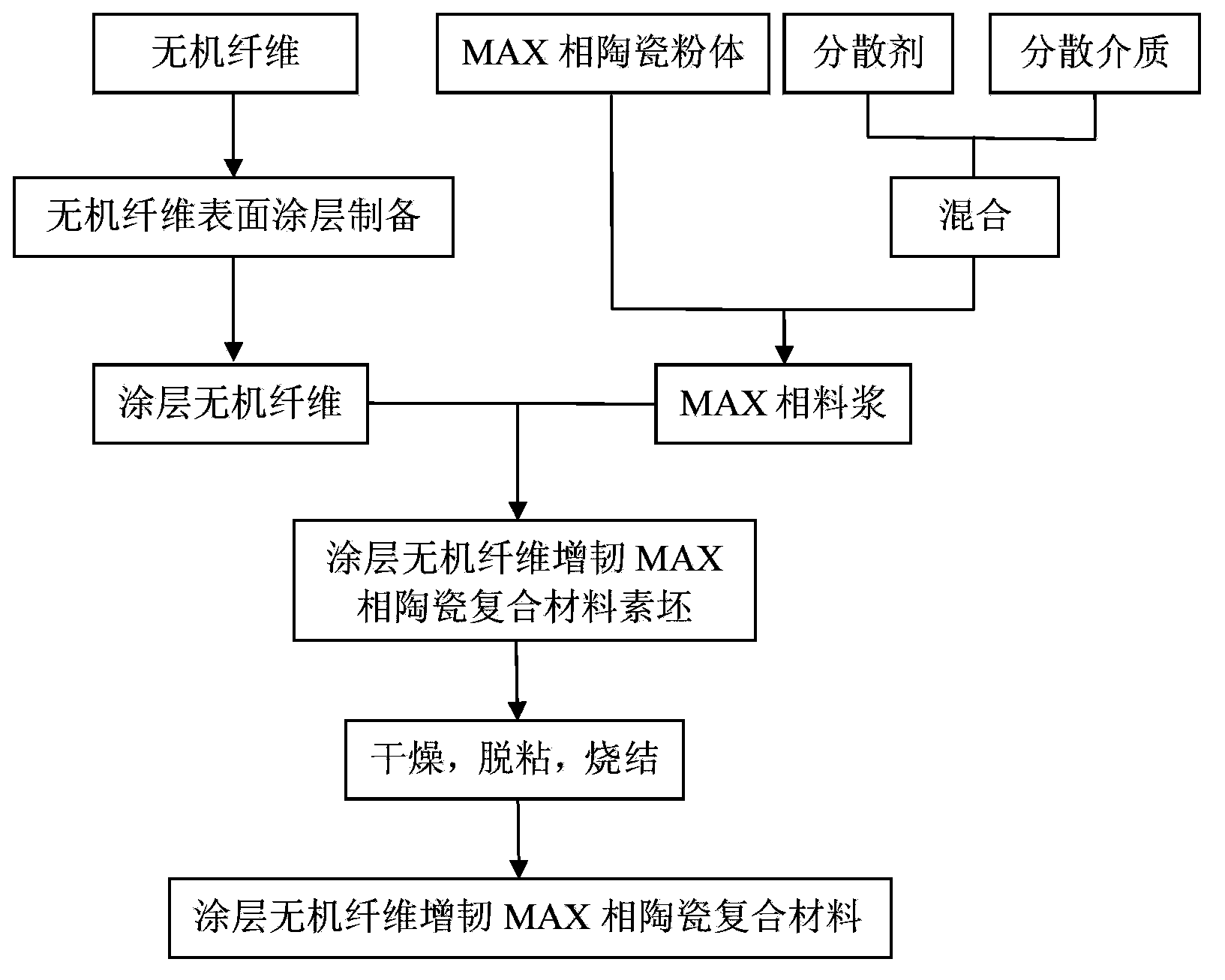

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

PP composite material of low VOC interior trim parts for automobiles and preparation method thereof

ActiveCN101570612AEfficient decompositionLow VOC contentVehicle componentsPolypropylene compositesAntioxidant

The invention relates to the field of automobiles, and belongs to a PP composite material special for low VOC (volatile organic compounds) high performance automobile interior trim parts and a preparation method thereof. The special material is prepared from the following compositions by mass portion: 60 to 80 portions of polypropylene (PP), 10 to 25 portions of reinforcing filler, 10 to 15 portions of toughening agent, 0.5 to 2 portions of inorganic photocatalyst, 0.2 to 0.5 portion of antioxidant and 0.1 to 0.5 portion of light stabilizer. The prepared polypropylene composite material has TVOC less than 40 mu gC / g, the notch impact strength of a cantilever beam at 23 DEG C between 10 and 42KJ / m, bending modulus between 1,000 and 2,400 MPa, and the melt index at 230 DEG C and 2.16 Kg between 10 and 30g / 10min. The PP composite material of the low VOC interior trim parts for the automobiles has low cost, good stability and the function of self-purification of VOC, and can be widely applied to production of the automobile interior trim parts.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

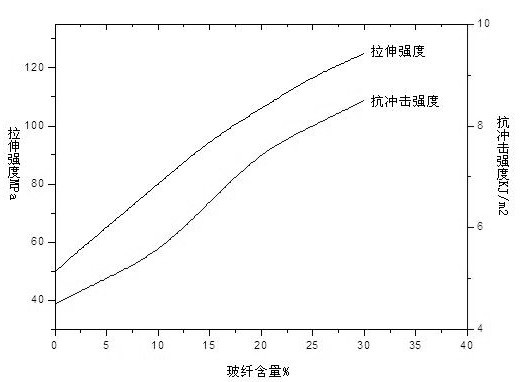

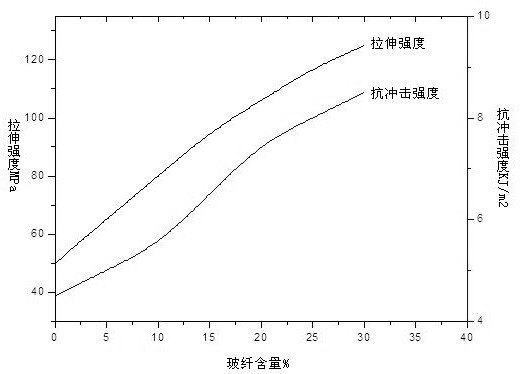

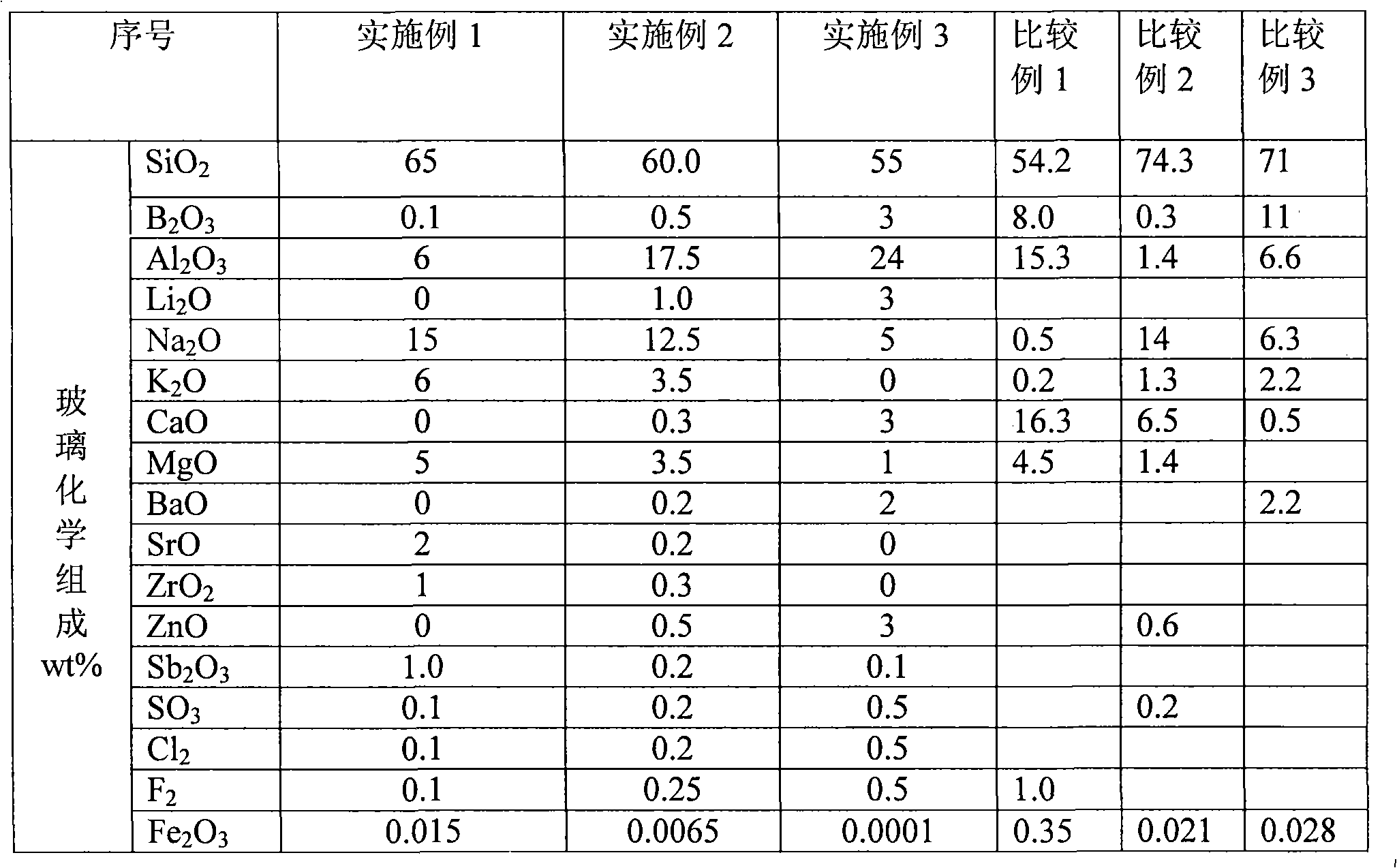

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

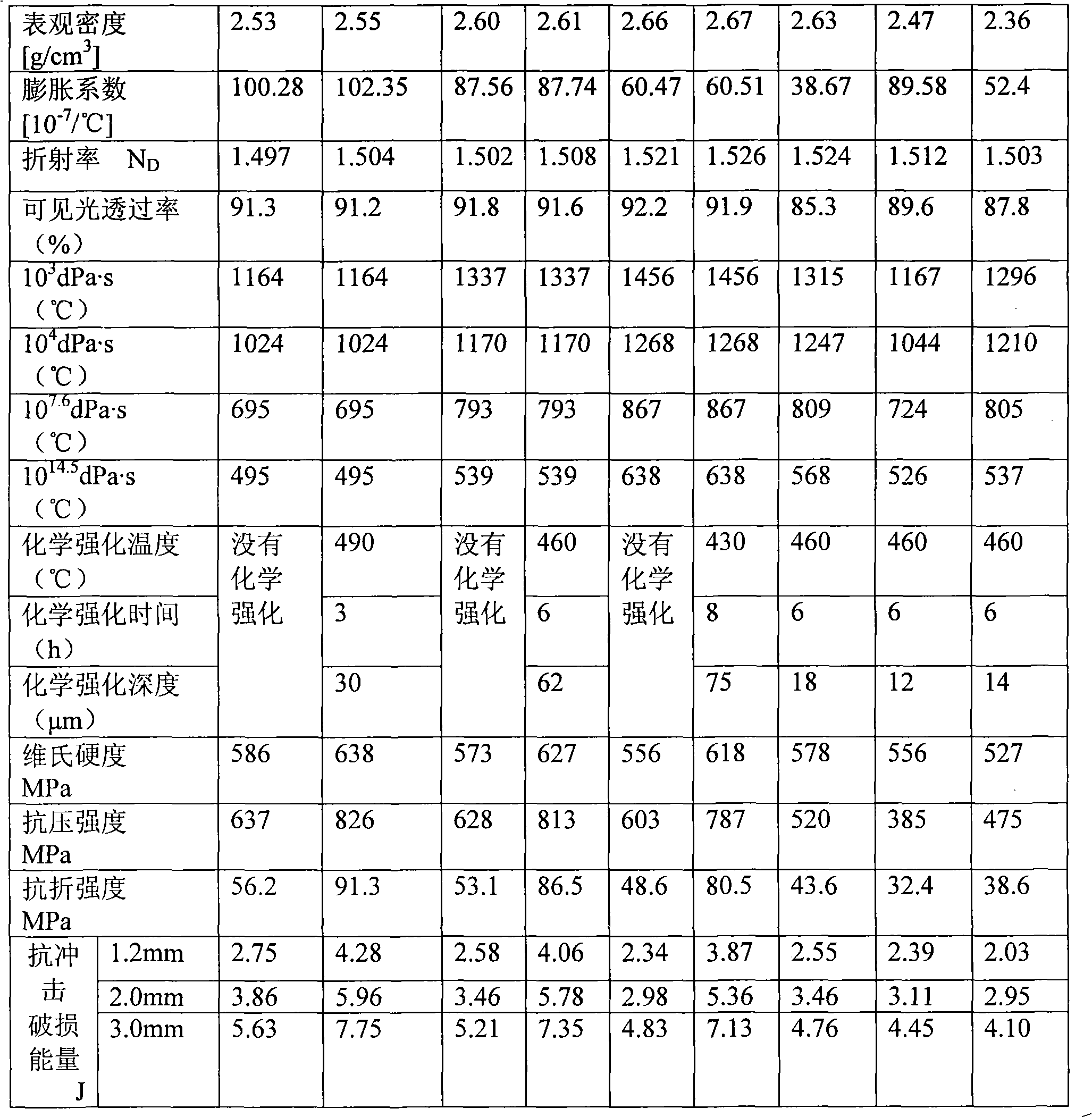

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

Materials for selective deposition modeling

InactiveUS6133355AHandling dimensionalToughness handlingAdditive manufacturing apparatusPaper coatingParaffin waxMicrocrystalline wax

A novel thermopolymer material adapted for use in thermal stereolithography. More particularly, a thermopolymer material comprising a mixture of: a low shrinkage polymer resin; a low viscosity material such as paraffin wax; at least one microcrystalline wax; a toughening polymer; a plasticizer. Alternative embodiments further include components to improve the materials ability to transfer heat and to improve strength. The subject material, together with the described process greatly reduce part building distortions while retaining desirable toughness, strength and jetting properties.

Owner:3D SYST INC

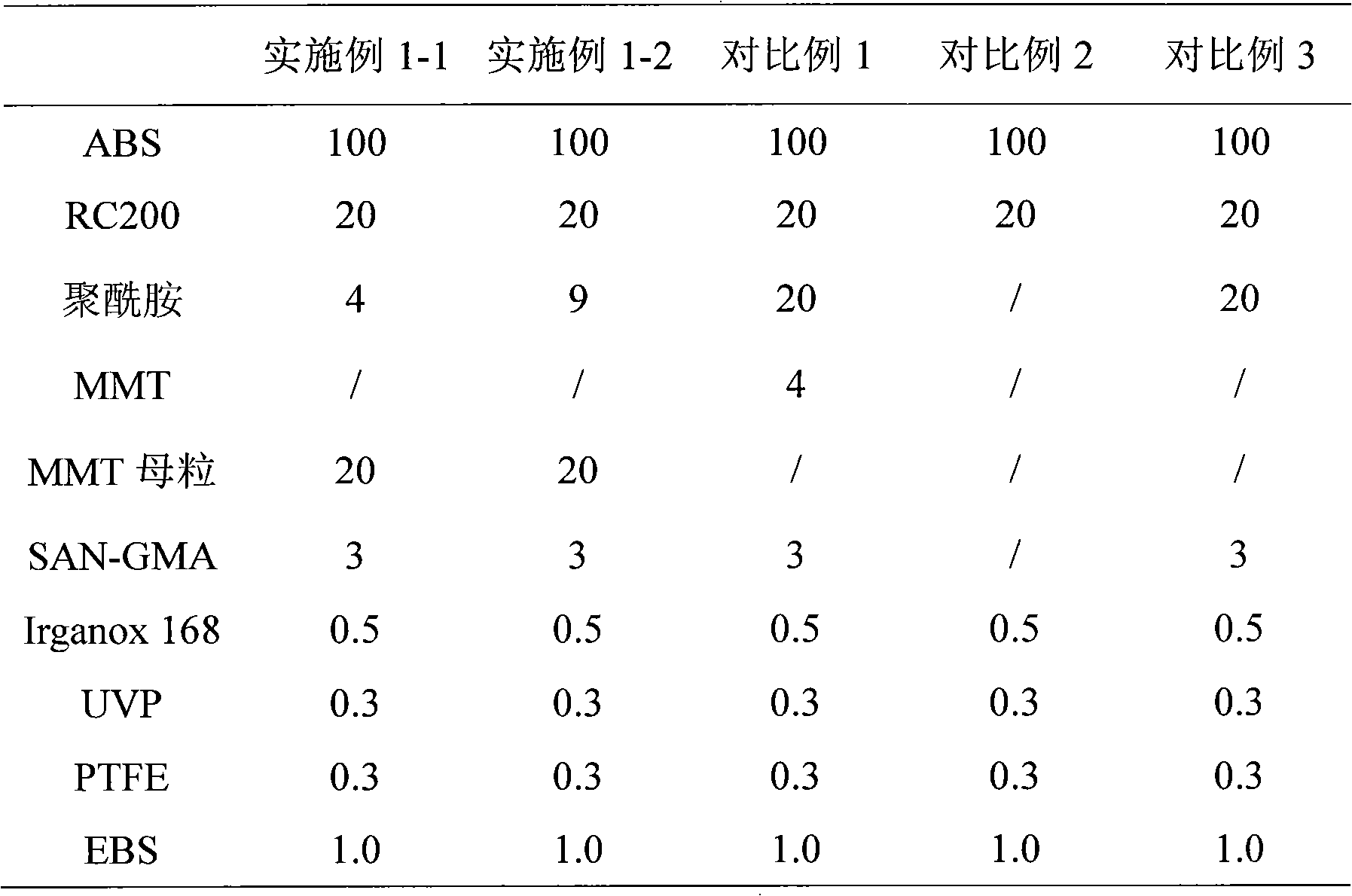

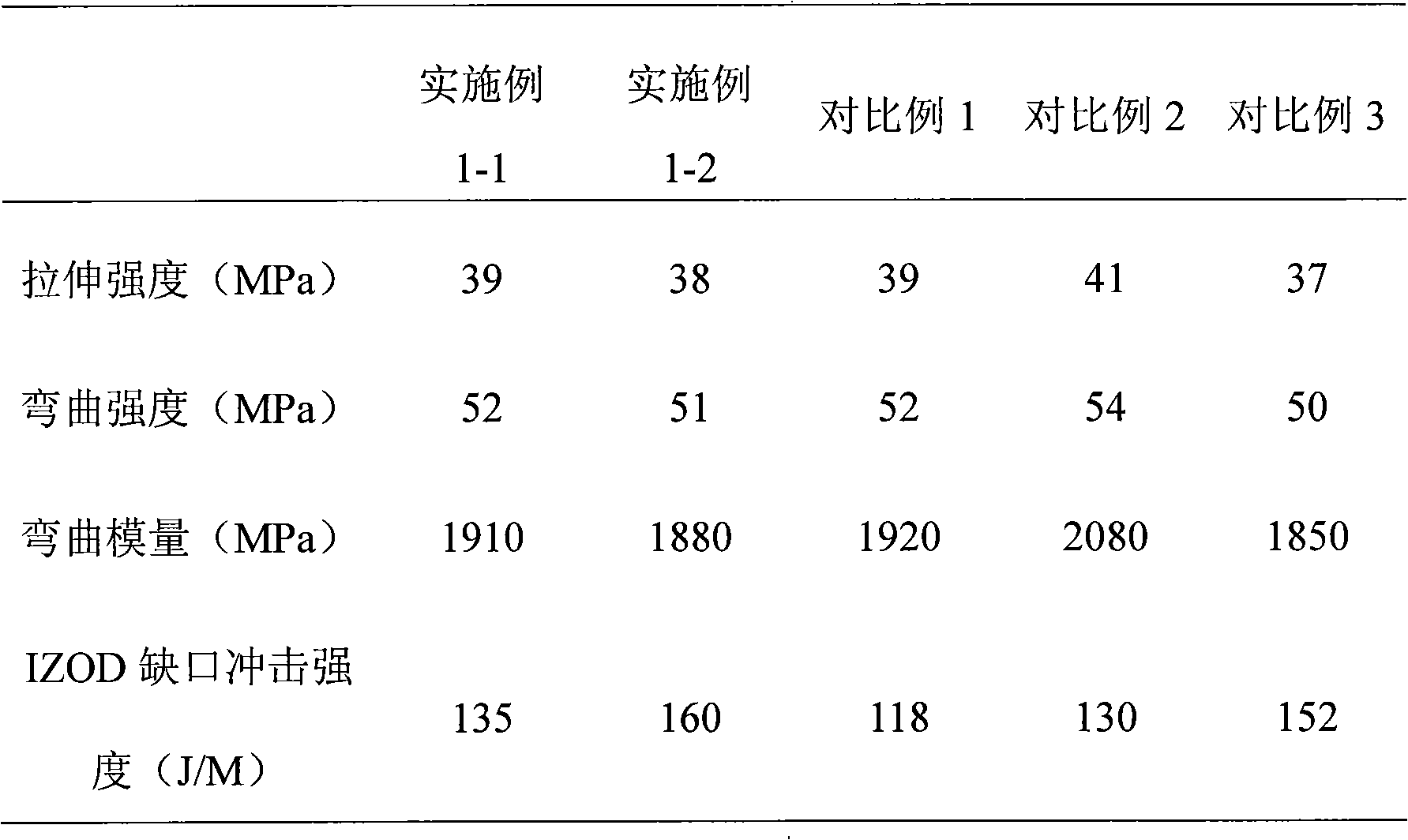

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

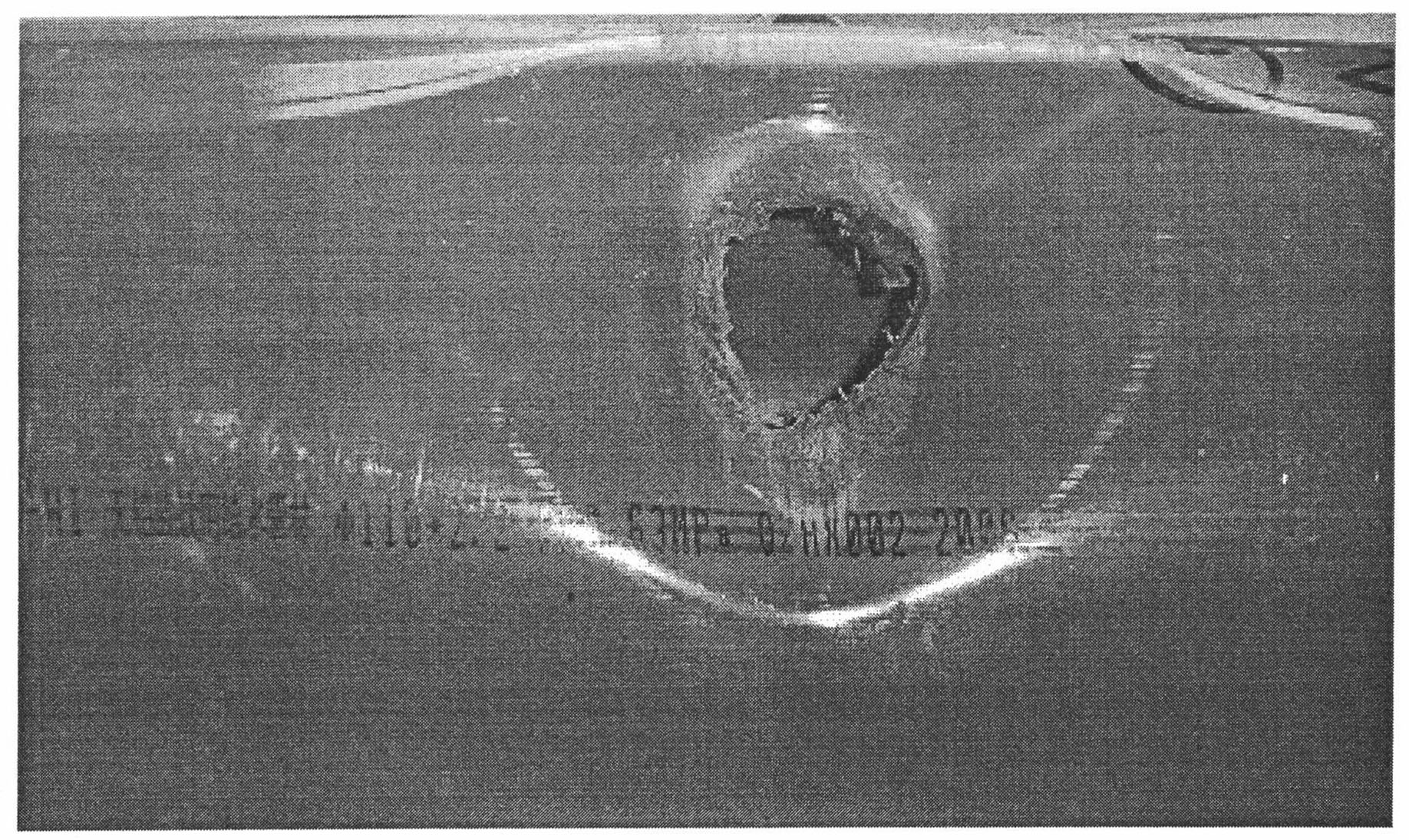

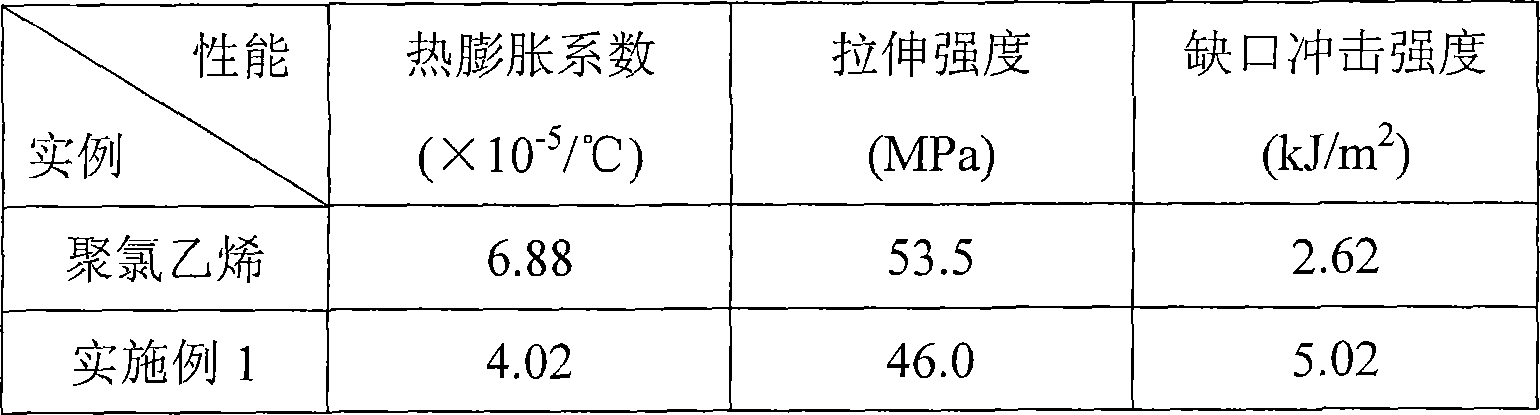

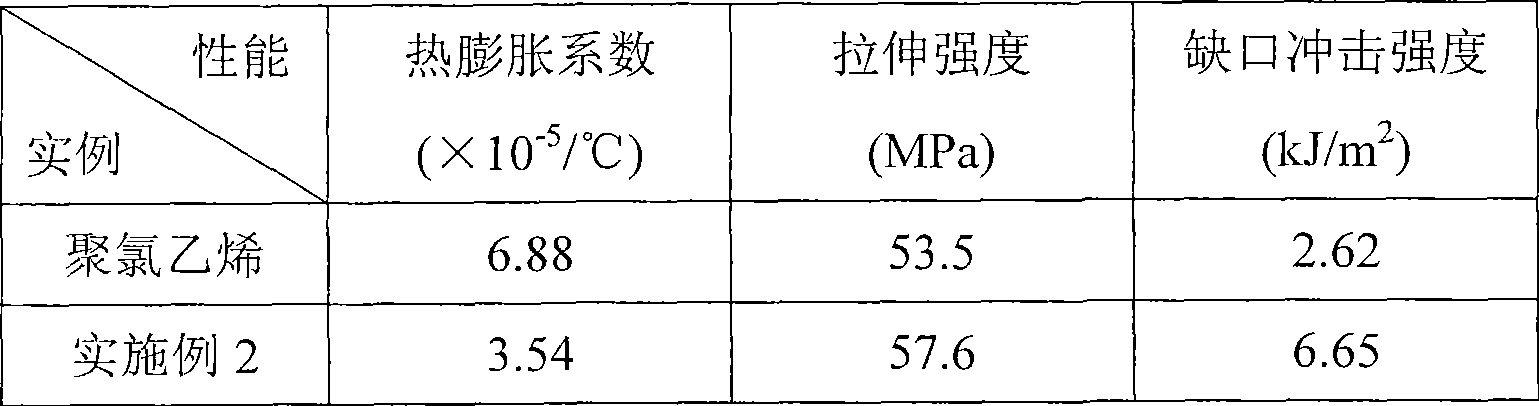

Impact-resistant modified polyvinyl chloride tube material and preparation process thereof

ActiveCN101775180AImprove mechanical propertiesCrack terminationRigid pipesAntioxidantPolyvinyl chloride

The invention discloses an impact-resistant modified polyvinyl chloride tube material, which is prepared from the following components in part by weight: 100 parts of polyvinyl chloride resin, 0.4 to 4.0 parts of stabilizing agent, 2 to 8 parts of toughening agent, 2 to 8 parts of rigid particles, 0.5 to 3.0 parts of processing aid, 1.1 to 2.5 parts of lubricant, 0.05 to 0.5 part of antioxidant, 0.03 to 3 parts of coloring agent and 0 to 5 parts of filling agent. A preparation process for the tube material comprises the following steps: mixing the components uniformly in a high-speed mixer, extruding the mixture to form the tube material by using a double-host single-screw extruder after the components are mixed uniformly in a cooling mixer, and modularizing, vacuuming and cooling-molding the tube material; and cutting and packing the tube material with fixed length. The impact-resistant modified polyvinyl chloride tube material uses a method of cooperative toughening of the toughening agent and the rigid particles, and solves the problem that the impact-resistant PVC tube material difficultly realizes rigidity balance so that the toughness of the tube material is obviously improved while the rigidity of the hard PVC tube material is kept.

Owner:山东华信塑胶股份有限公司

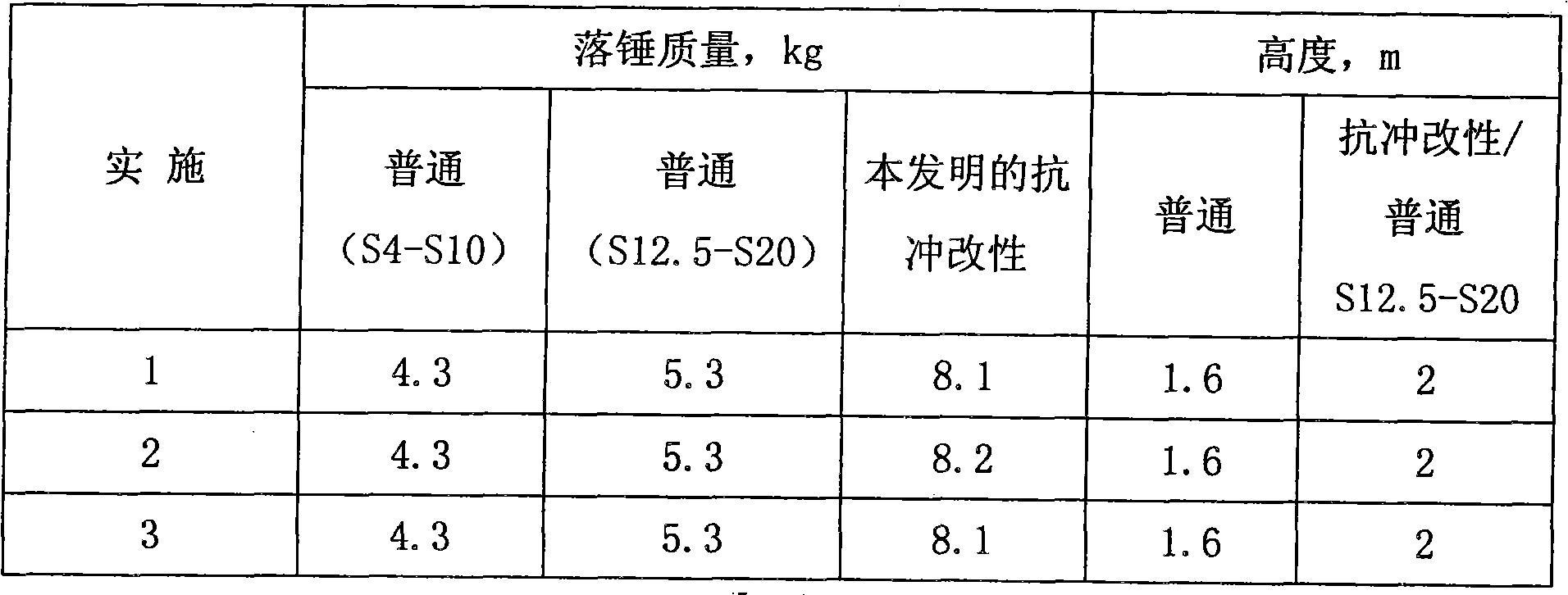

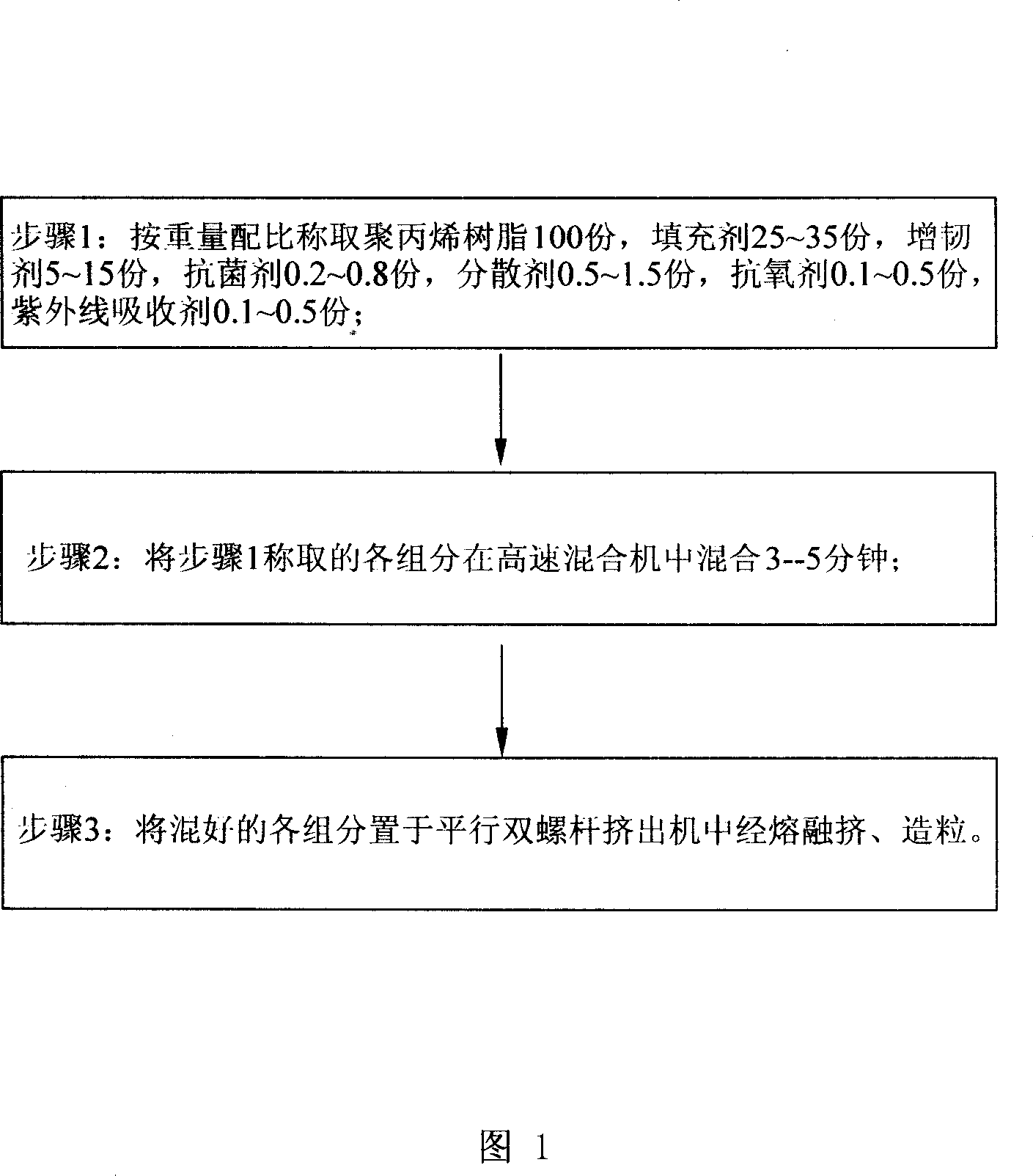

Antibacterial polypropylene material and its prepn process

InactiveCN101089038AReduce manufacturing costHigh surface glossBiocideAnimal repellantsUltravioletPolypropylene

The antibacterial polypropylene material consists of polypropylene resin 100 weight portions, stuffing 25-35 weight portions, toughening agent 5-15 weight portions, antiseptic 0.2-0.8 weight portion, dispersant 0.5-1.5 weight portions, antioxidant 0.1-0.5 weight portion and ultraviolet absorber 0.1-0.5 weight portion. The polypropylene resin is homopolypropylene, and the antiseptic is compounded with nanometer silver and organosilicon antiseptic. The present invention also provides the preparation process of the antibacterial polypropylene material with low production cost, excellent antiseptic performance.

Owner:SHENZHEN KEJU NEW MATERIAL

Modified polypropylene material for thin-wall bumper and preparation method thereof

The invention discloses a modified polypropylene material applicable for a thin-wall bumper and a preparation method thereof. The material comprises the following components in parts by weight: 50 to 90 parts of polypropylene, 5 to 20 parts of toughening agent, 10 to 15 parts of inorganic mineral, 5 to 15 parts of mineral fiber, 1 to 5 parts of compatibilizer and 1 to 5 parts of processing aid. The product of the invention has the characteristics of high fluidity, high toughness and high rigidity, simultaneously has the characteristics of high surface activity, low shrinkage, low linear thermal expansion and shrinkage rate, heat resistance and low temperature resistance and efficiently satisfies the requirement of a vehicle bumper material.

Owner:NANJING JULONG SCI&TECH CO LTD

Modified, weather resisting polypropylene material

This invention discloses a modified polypropylene material used as elements of home appliances, such as outdoor hulls of air-conditioners and panels of automobiles. The modified polypropylene material comprises: polypropylene resin 65-85 wt.%, toughening modifier 1-18 wt.%, mineral reinforcer 0-25 wt.%, coupler 0.1-0.8 wt.%, processing auxiliary 0.2-2 wt.%, photostabilizer 0.2-2 wt.% and colorant 0.1-1.5 wt.%. Compared with present polypropylene material, the modified polypropylene material has improved weathering resistance and anti-aging property.

Owner:CGN JUNER NEW MATERIALS

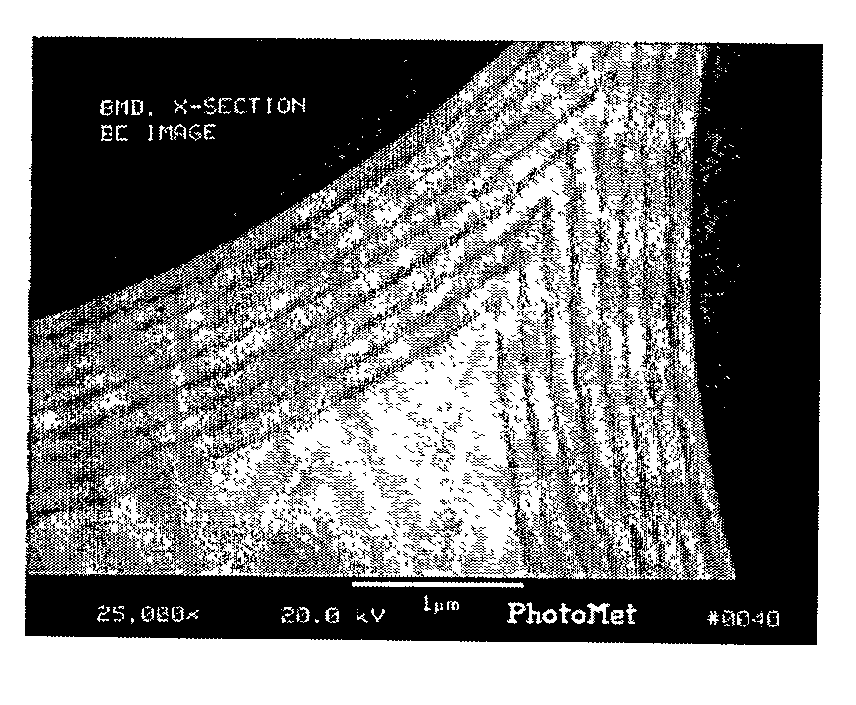

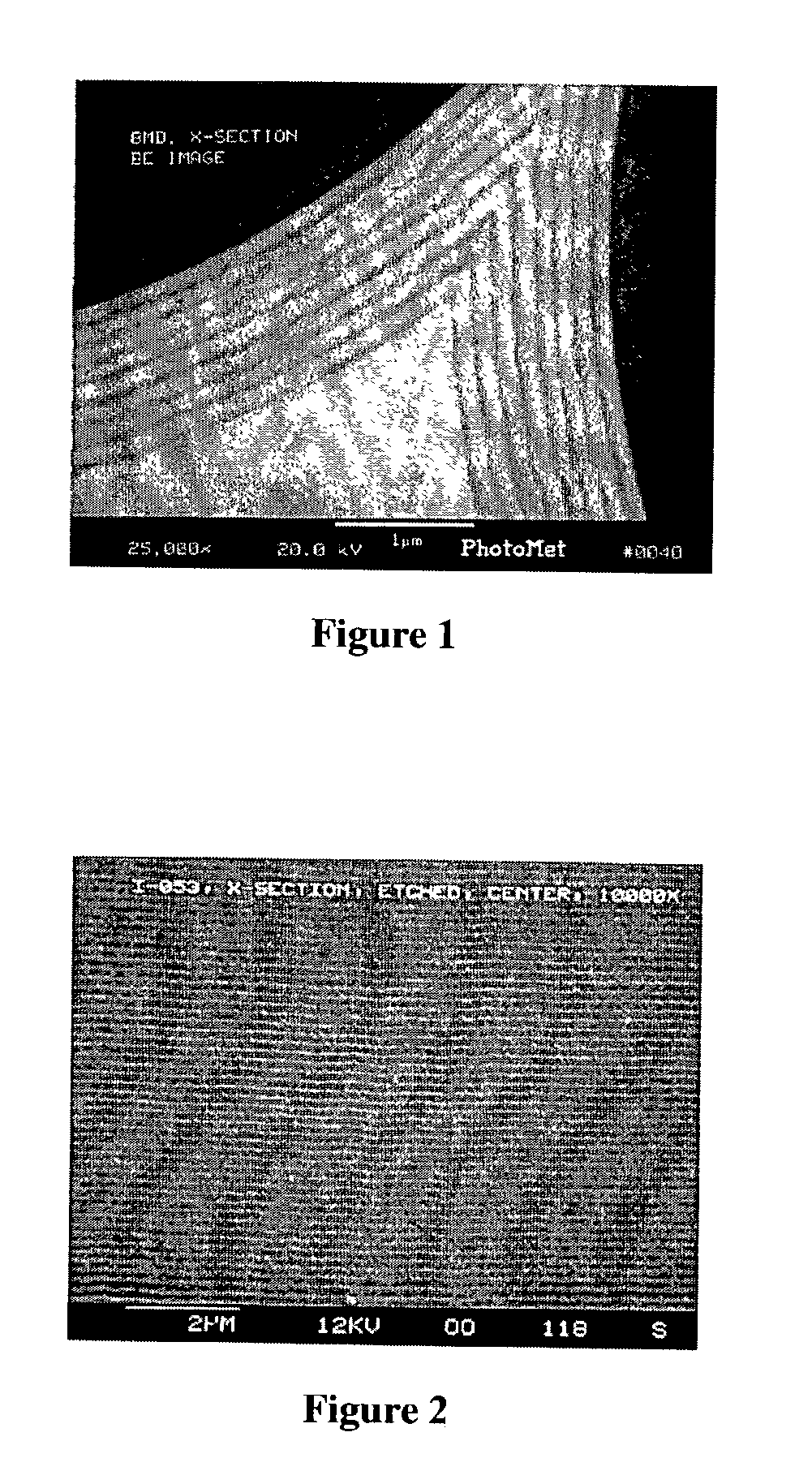

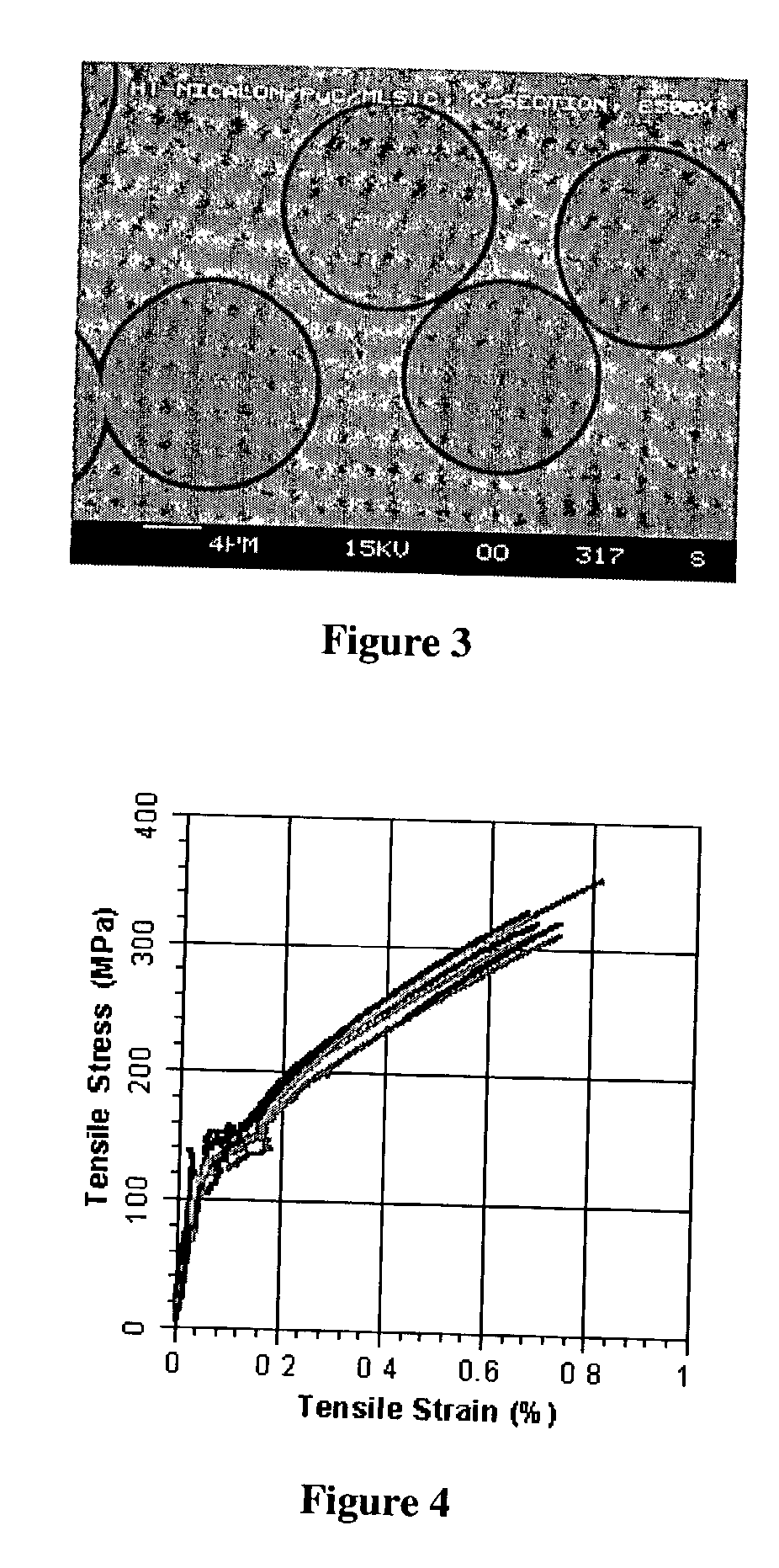

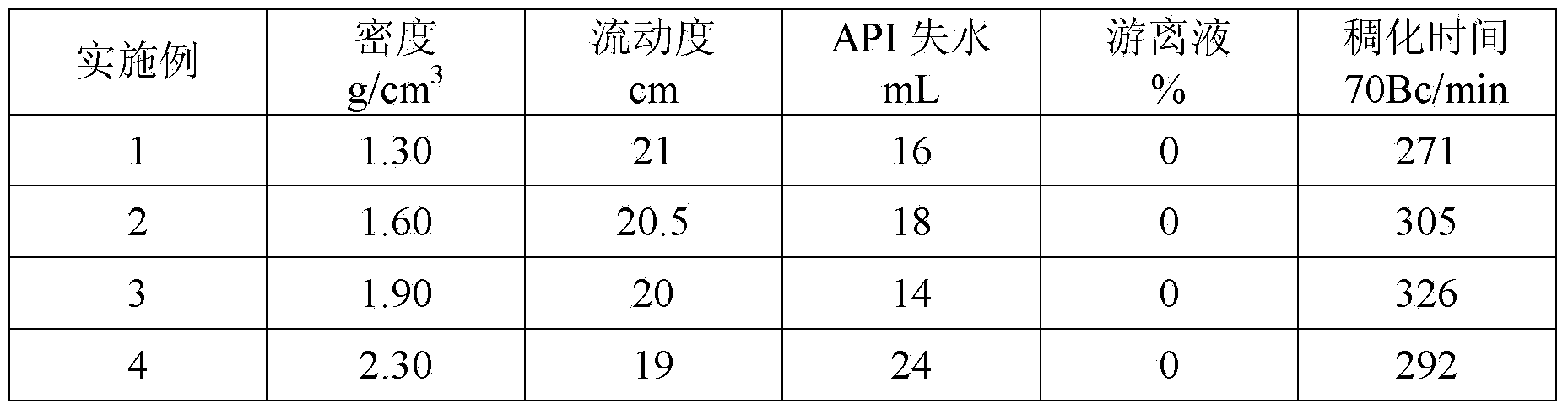

Fiber-reinforced ceramic composite material comprising a matrix with a nanolayered microstructure

InactiveUS20050181192A1Improve the immunityHigh strengthSynthetic resin layered productsCeramic layered productsCeramic compositeToughening

A fiber-reinforced ceramic matrix composite material exhibiting increased matrix cracking strength and fracture toughness is produced by sequentially depositing a plurality of 5-500 nanometer-thick layers of a primary ceramic matrix material phase periodically separated by 1-100 nanometer-thick intermediate layers of a secondary matrix material phase onto the reinforcing fibers upon their consolidation. The resultant nanolayered matrix enhances the resistance to the onset of matrix cracking, thus increasing the useful design strength of the ceramic matrix composite material. The nanolayered microstructure of the matrix constituent also provides a unique resistance to matrix crack propagation. Through extensive inter-layer matrix fracture, debonding and slip, internal matrix microcracks are effectively diverted and / or blunted prior to their approach towards the reinforcing fiber, thus increasing the apparent toughness of the matrix constituent. This unique toughening mechanism serves to dampen energetic co-planar macrocrack propagation typically observed in conventionally manufactured ceramic matrix composites wherein matrix cracks are usually deflected at the fiber / matrix interphase region.

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

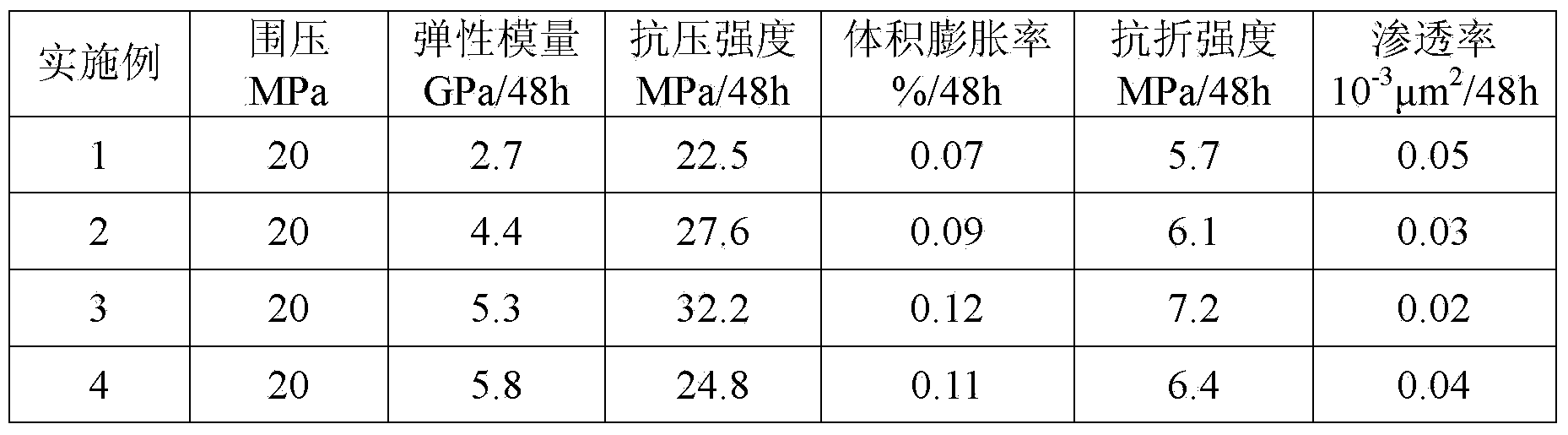

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Dendritic polyester macromolecule in thermosetting resin matrix

A partially or fully cured thermosetting product which includes a cured and molded product of a thermosetting composition. The composition includes 70% to 99% by weight of at least one thermosetting resin or compound and 1% to 30% by weight of at least one toughening agent. The toughening agent is at least one hyperbranched dendritic macromolecule formed of ester units, optionally in combination with ether units.

Owner:PERSTORP AB

Engineered crosslinked thermoplastic particles for interlaminar toughening

ActiveUS20100304118A1Increase damage toleranceImprove toughnessThin material handlingRubber layered productsTougheningPolymer chemistry

Engineered crosslinked thermoplastic particles are useful for interlaminar toughening of pre-pregs and composite materials.

Owner:CYTEC TECH CORP

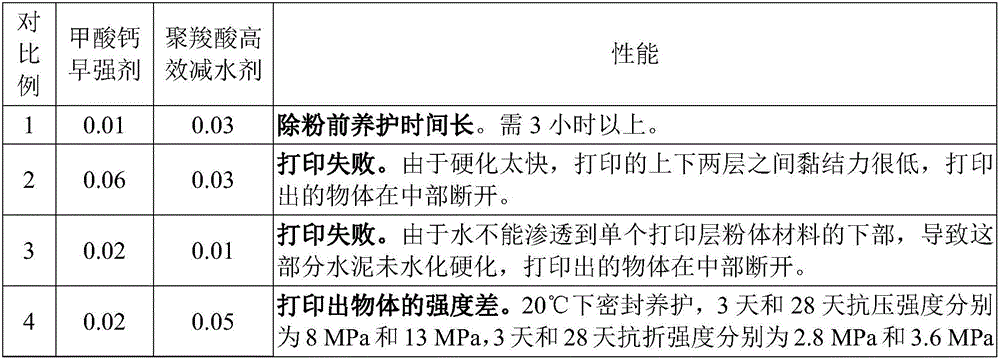

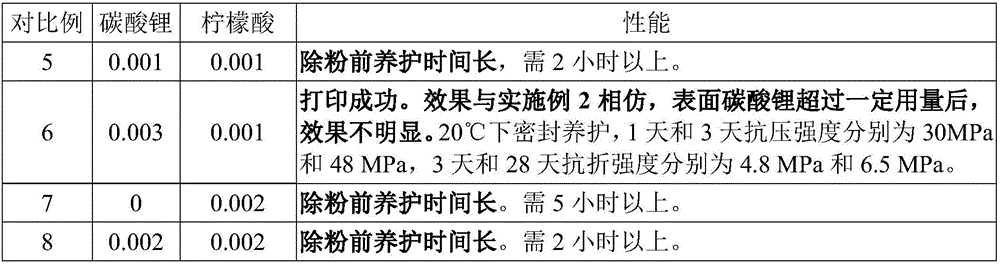

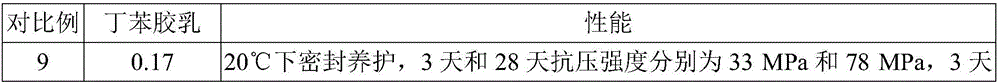

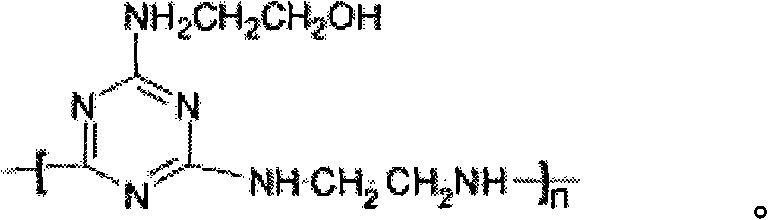

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

Natural fiber reinforcement halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN101418099AImprove flame retardant performanceImprove mechanical propertiesGlass fiberHeat deflection temperature

The invention provides a natural fiber reinforced halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing assistant, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of compatilizer, and 5 to 30 portions of natural fiber. The invention also provides a method for preparing the material. The composite material has the advantages that the composite material has excellent flame-retardant effect and excellent comprehensive mechanical property; the flame-retardant property of the composite material can reach 1.6mm V0; the tensile strength is more than or equal to 60MPa; the bending modulus is more than or equal to 4,000MPa; the gap impact strength is more than or equal to 10KJ / m<2>; the shrinkage ratio is between 4 and 6 per thousand; the heat distortion temperature is more than or equal to 140 DEG C; and the composite material is a novel environment-friendly material, and has no safety and health problems of glass fibers.

Owner:SHANGHAI KINGFA SCI & TECH +1

Halogen-free expansion type flame-retardant and preparation thereof

The invention relates to a halogen-free intumescent flame-retardant polypropylene composite and a preparation method thereof. Calculated by weight percentage, the composite comprises 35 to 80 percent of polypropylene, 5 to 30 percent of coated poly-ammonium phosphate, 1 to 20 percent of melamine and the derivatives, 1 to 15 percent of halogen-free macromolecular char forming flame retardant, 0.1 to 5 percent of flame retardant synergist, 1 to 20 percent of rigid inorganic particle, 0.05 to 5 percent of coupling agent, 0.1 to 10 percent of compatilizer, 1 to 20 percent of toughening agent and 0.01 to 4 percent of antioxidant. Compared with the prior art, the material of the invention has good toughness, high strength and environment-protecting flame retardance, and the composite can be widely applied in the fields such as automobile and electronic appliances.

Owner:SHANGHAI RES INST OF CHEM IND +1

Nylon modified plastic

The invention discloses a nylon modified plastic which comprises the following raw materials in parts by weight: (1) 20-80 parts of nylon resin; and (2) one or more of 15-45 parts of reinforcer, 5-20 parts of toughener or 9-15 parts of compound flame retardant, wherein the nylon resin is prepared from pentamethylene diamine and aliphatic dibasic acid used as raw materials, and at least one of the pentamethylene diamine and the aliphatic dibasic acid is prepared through a biological method. The nylon modified particle prepared by the invention has excellent properties of reinforcing, toughening, flame retardance and the like, can be further used in the fields of automobile industry, electronic / electric apparatus industry, mechanical equipment and the like, and has wide industrial application prospects.

Owner:CATHAY R&D CENT CO LTD +1

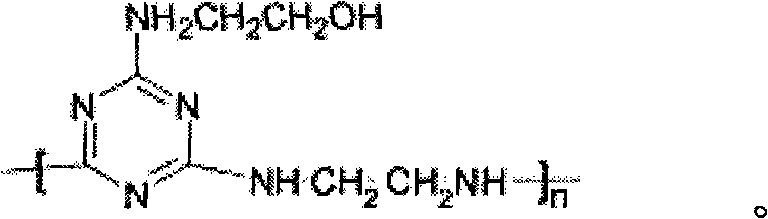

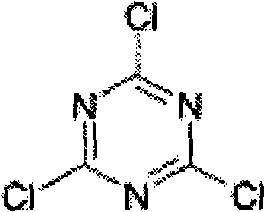

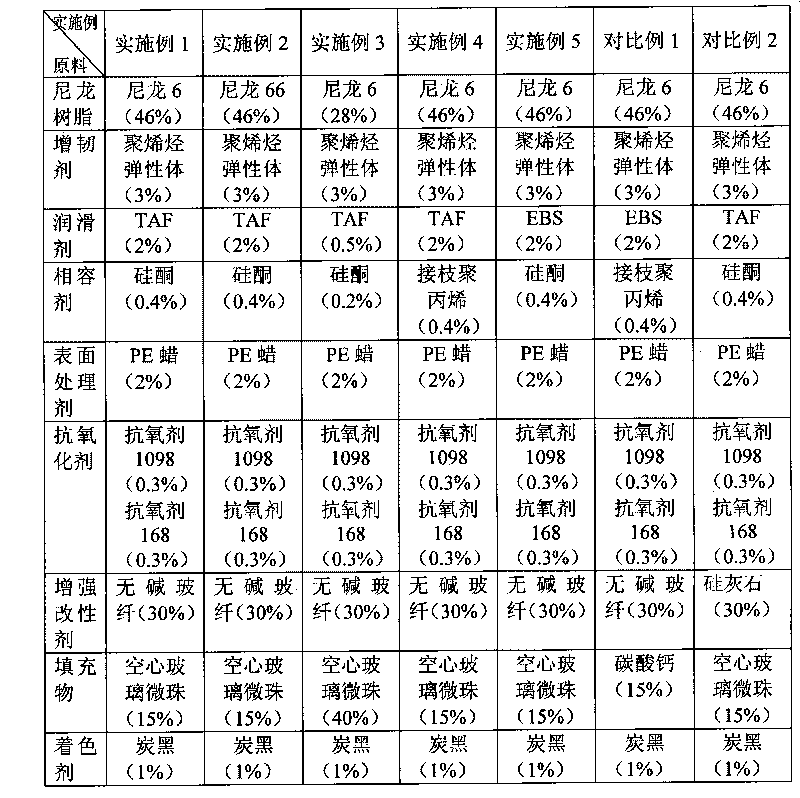

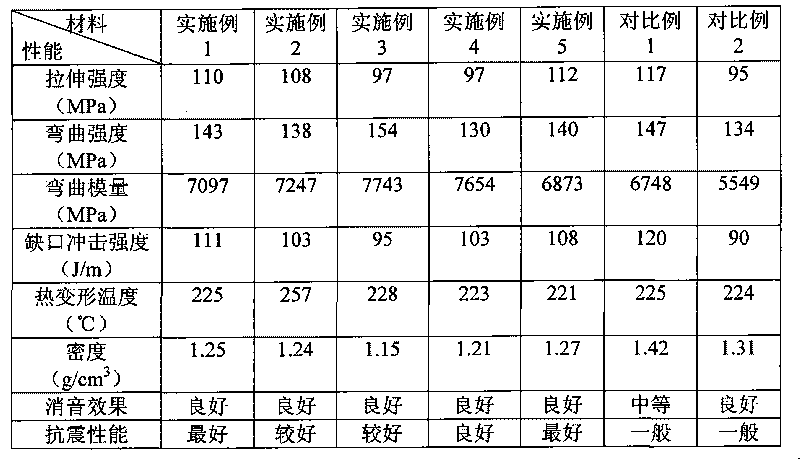

Nylon composition, method for preparing same and application thereof

The invention provides a nylon composition and a method for preparing the same. The raw materials of the nylon composition comprise nylon resin, a toughening agent, a lubricant, a compatilizer, a surface treating agent, an antioxidant, a reinforced modifying agent which is fiber, and filling materials which are hollow glass microspheres. The nylon composition, provided by the invention, can lower the warpage of the materials, prevent the glass fiber from being exposed to the outside, make the surface of the injection moulding piece more smooth and clean, reduce the weight of the injection moulding piece and simultaneously achieves good silencing and shock resistant effects.

Owner:BYD CO LTD

A kind of polybutene alloy material and preparation method thereof

The invention discloses a polybutene alloy material and a preparation method thereof, and belongs to the field of polyolefin material, specifically relates to a polybutene alloy material and a preparation method thereof. The polybutene alloy material provided by the present invention comprises, by mass, 50-99% of poly-1-butene, 1-40% of polypropylene and 0-10% of a butane-propylene copolymer. Thepreparation method is characterized by: adopting a TiCl4 / MgCl2 supported titanium catalyst for synthesis of the polybutene alloy material through a two-phase polymerization method. The polybutene alloy material provided by the present invention has a core-shell structure, and has advantages of the combination of the excellent impact resistance of the poly-1-butene, the heat resistance and creep property of the poly-1-butene, the low shrinkage rate of the poly-1-butene, the high modulus of the polypropylene, the high surface hardness of the polypropylene, the rapid shaping of the polypropylene, and the like, such that the polybutene alloy material can replace the partial use of the poly-1-butene and the polypropylene. In addition, the polybutene alloy material can be applicable for preparation of the pipe and the pipe fitting, toughening modification of the polypropylene, or the polybutene alloy material can be used as the general polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +1

Anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material and preparation method thereof

The invention discloses an anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material, which comprises the following components in parts by mass: 25-70 parts of plastic resin, 10-50 parts of plant fiber powder, 5-10 parts of camphor wood powder, 0.5-20 parts of a compatibilizer, 0-15 parts of a toughening agent, 10-35 parts of a flame retardant and a synergist, 2-5 parts of a thermal stabilizer, 0-1 part of an antioxidant and 1-4 parts of a lubricating agent. According to a method for preparing the wood-plastic composite material with a two-step fusion method disclosed by the invention, the interfacial compatibility can be improved effectively, and the flame retardance of the wood-plastic composite material is enhanced on the premise of keeping high mechanical property; and moreover, the using amount of ammonium polyphosphate serving as a major flame retardant is reduced. Compared with the conventional wood-plastic composite material, the wood-plastic composite material disclosed by the invention has a simple production flow, has the technical effects of flame retardance, smoke suppression and mildew resistance, and is widely applied to occasions such as indoor and outdoor architectural decoration, and the like.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE +1

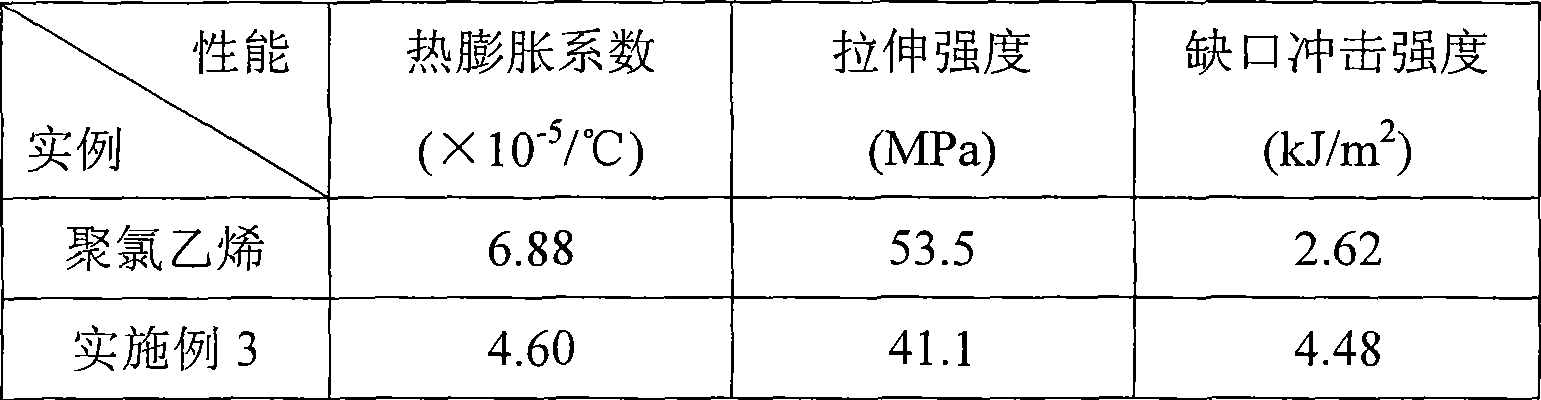

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com