Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1316 results about "Silicate glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Common silicate glass, the material used in window panes and iced tea glasses, is a mixture of sand, sodium-carbonate and limestone. Add boric oxide to it and, you guessed it, borosilicate glass is created.

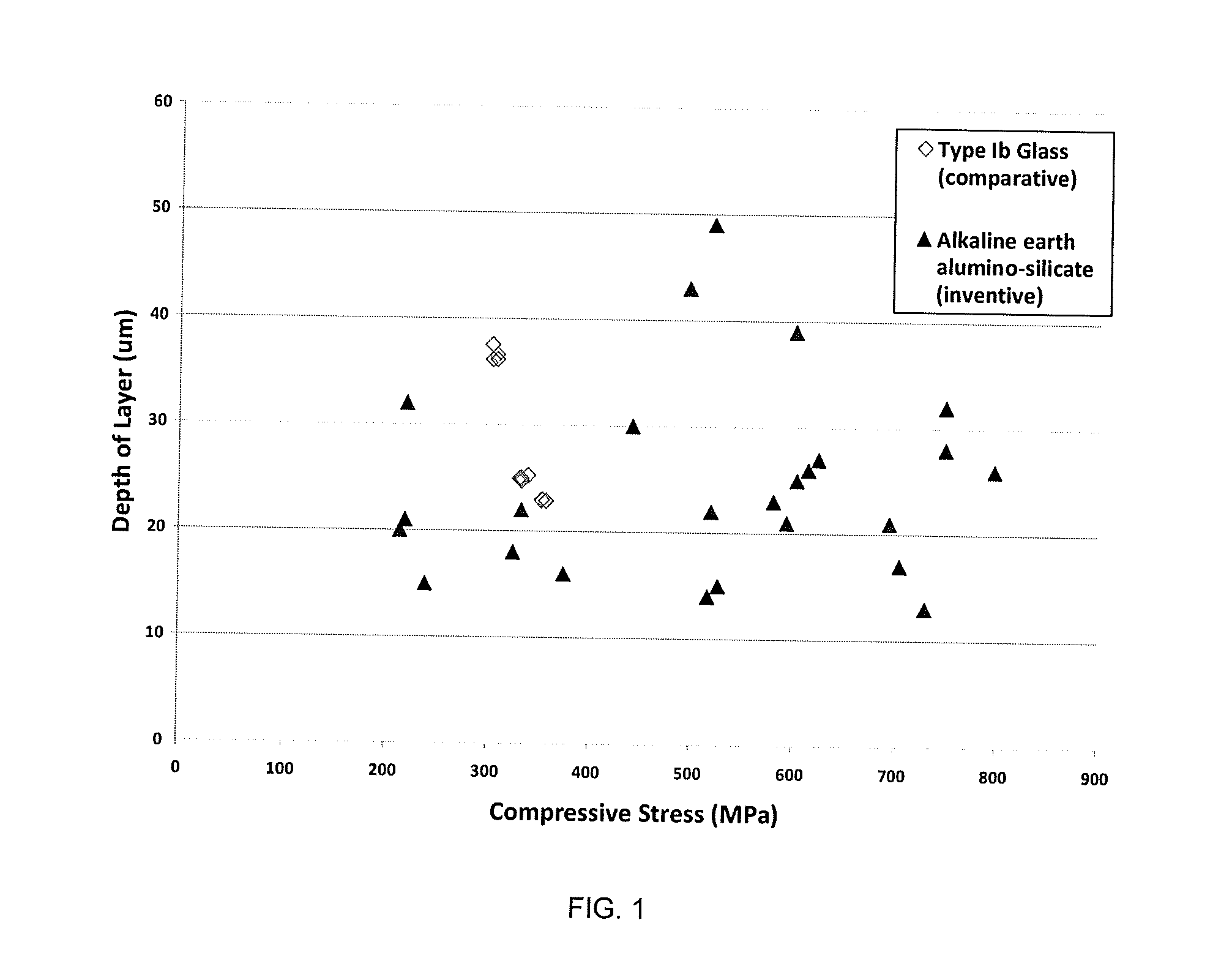

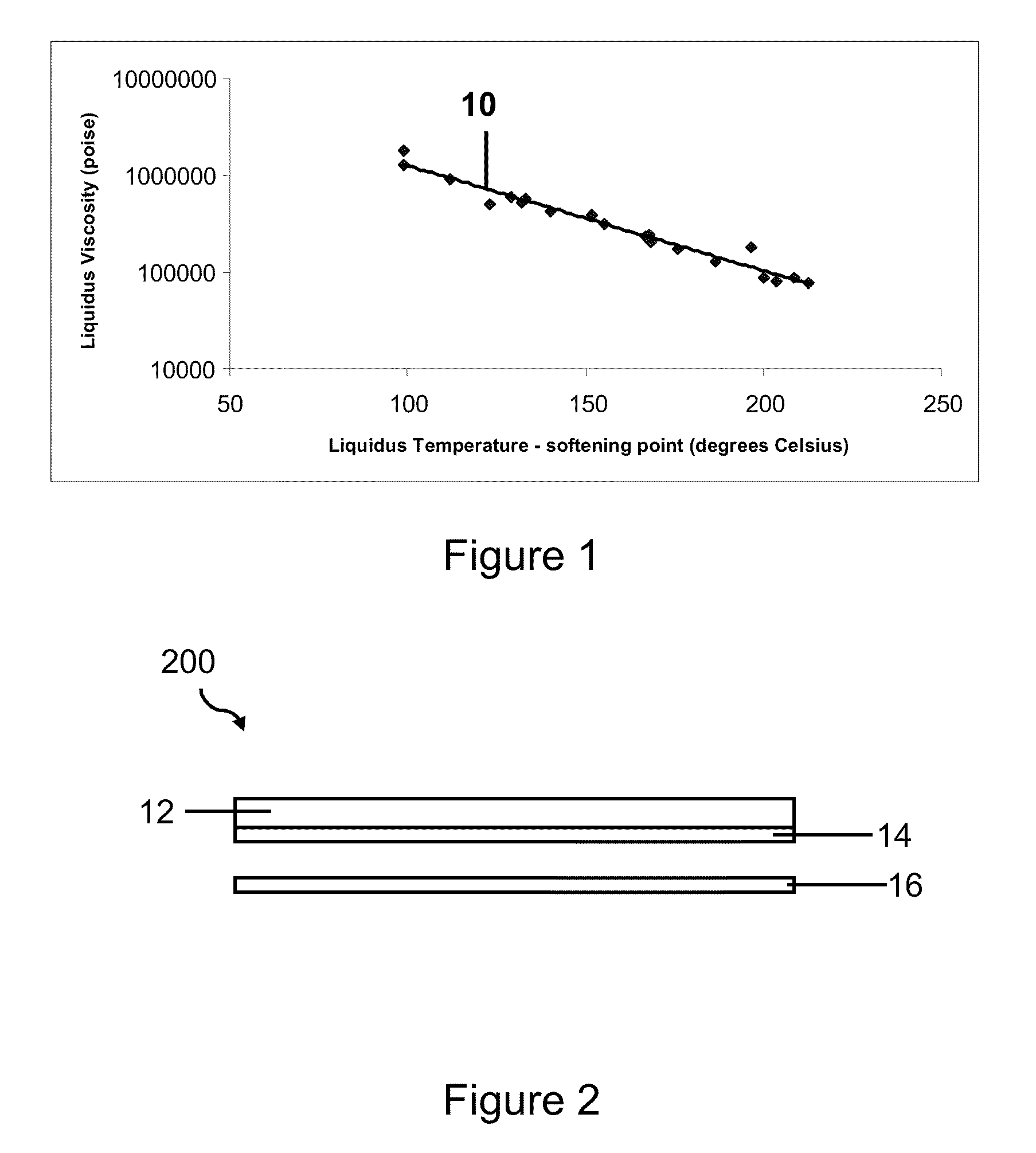

Down-drawable, chemically strengthened glass for cover plate

An alkali aluminosilicate glass that is chemically strengthened and has a down-drawable composition. The glass has a melting temperature less than about 1650° C. and a liquidus viscosity of at least 130 kpoise and, in one embodiment, greater than 250 kpoise. The glass undergoes ion exchange at relatively low temperatures to a depth of at least 30 μm.

Owner:CORNING INC

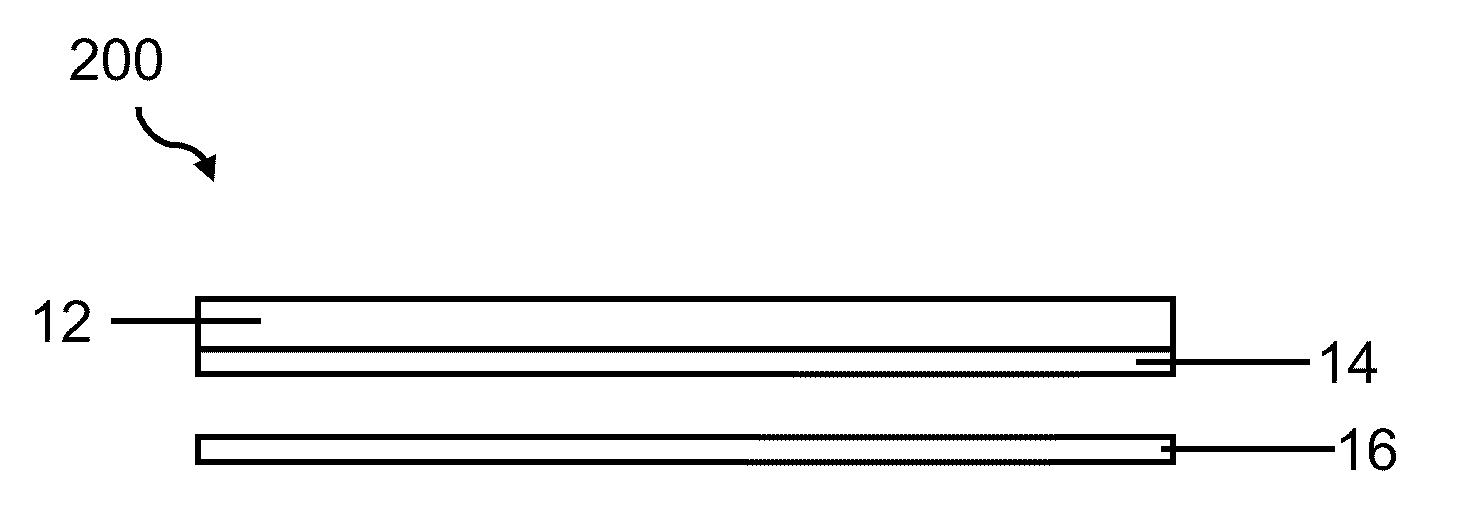

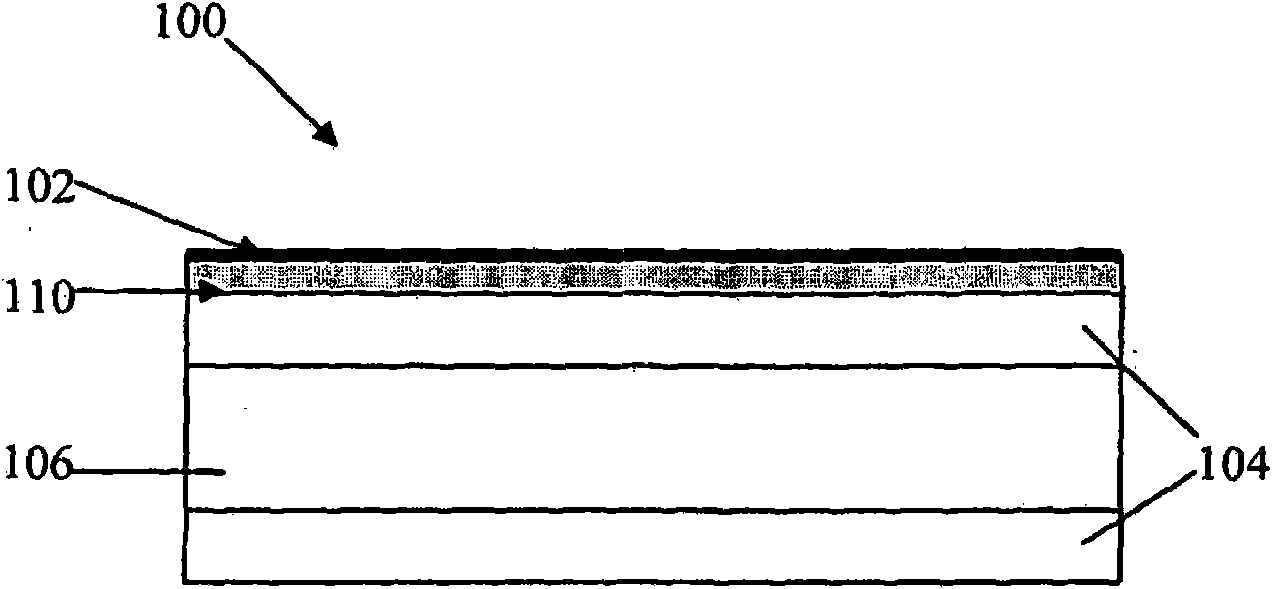

Damage resistant glass article for use as a cover plate in electronic devices

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

Method for forming silicon oxide cap layer for solid state diffusion process

ActiveUS9607837B1Avoid dissipationQuality improvementSemiconductor/solid-state device manufacturingPlasma techniqueMetallurgySilicate glass

Owner:ASM IP HLDG BV

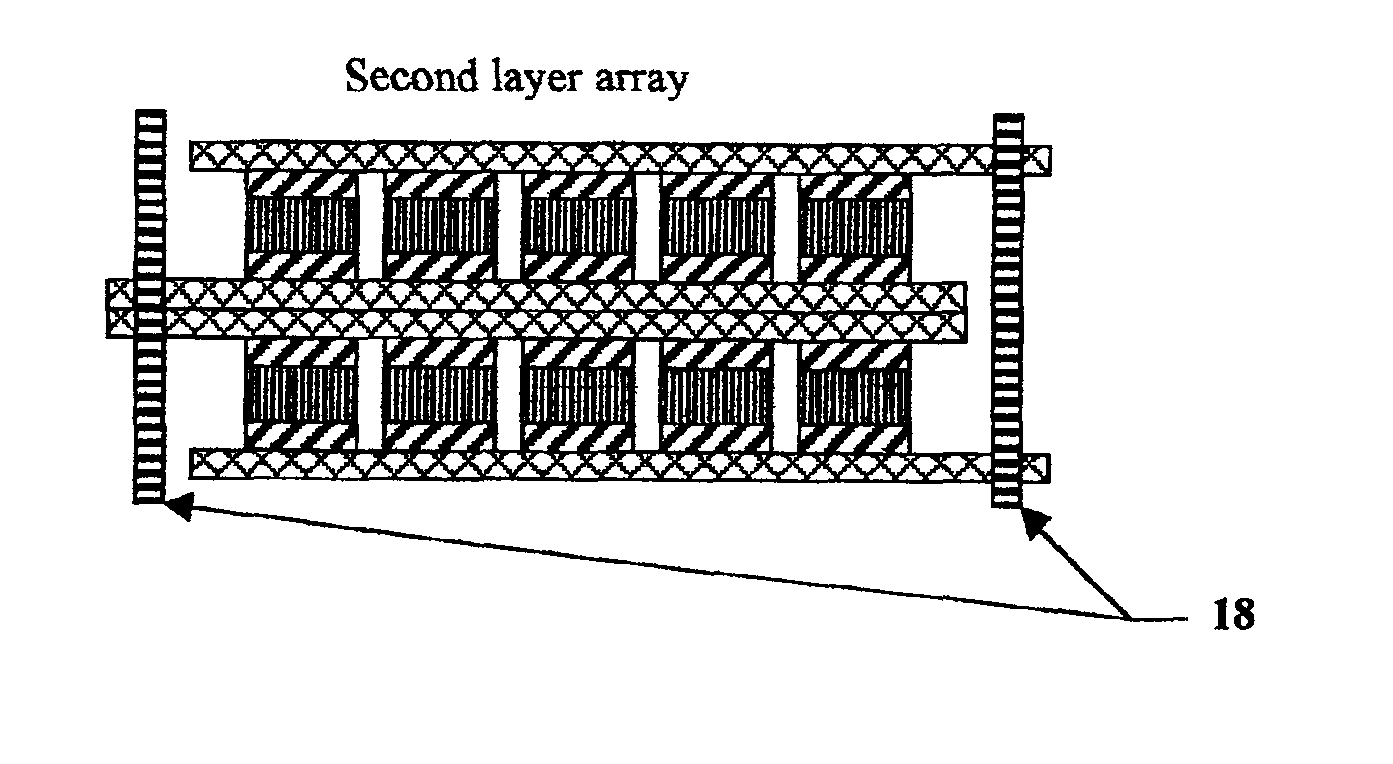

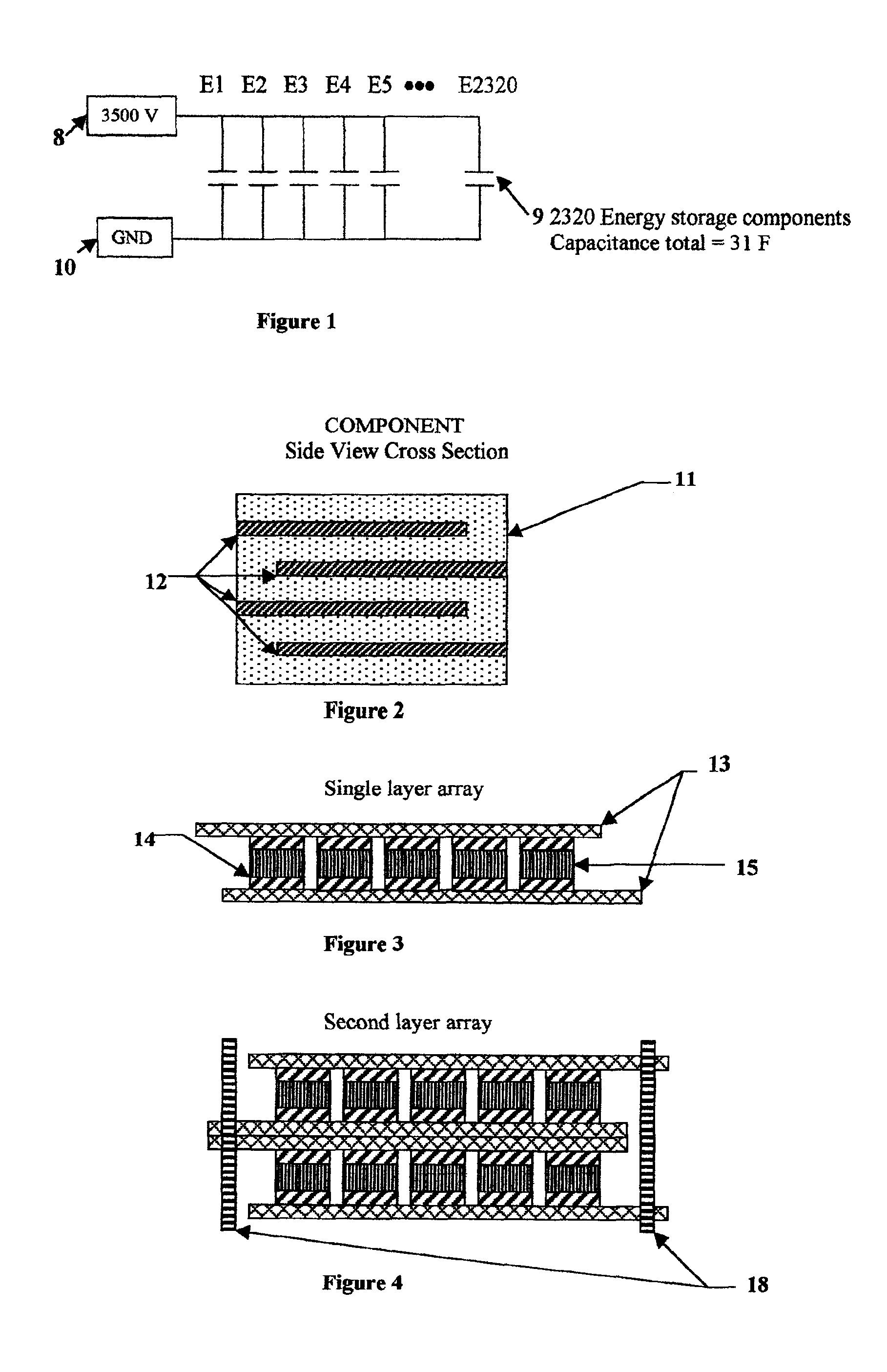

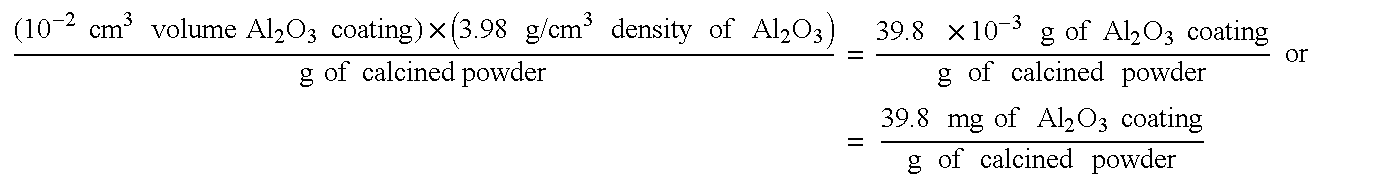

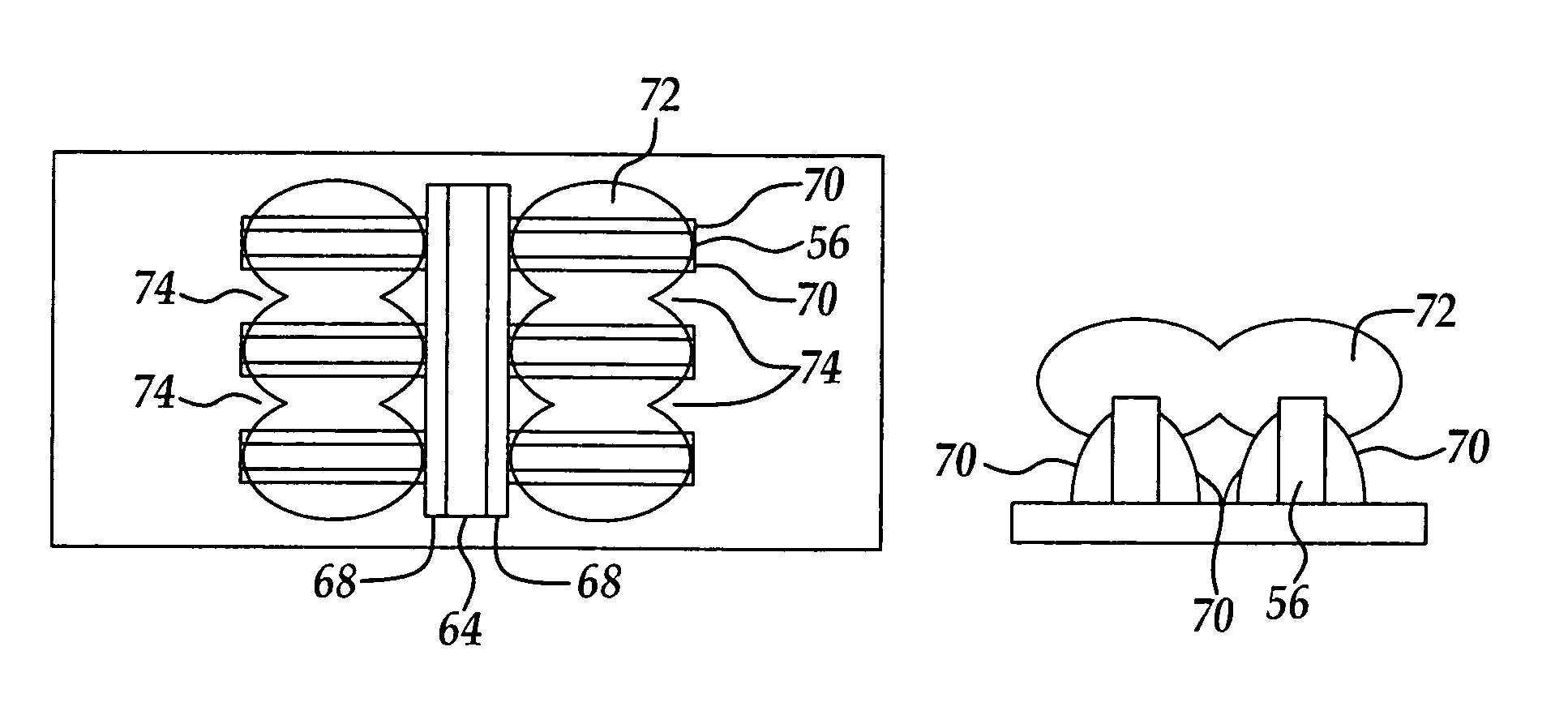

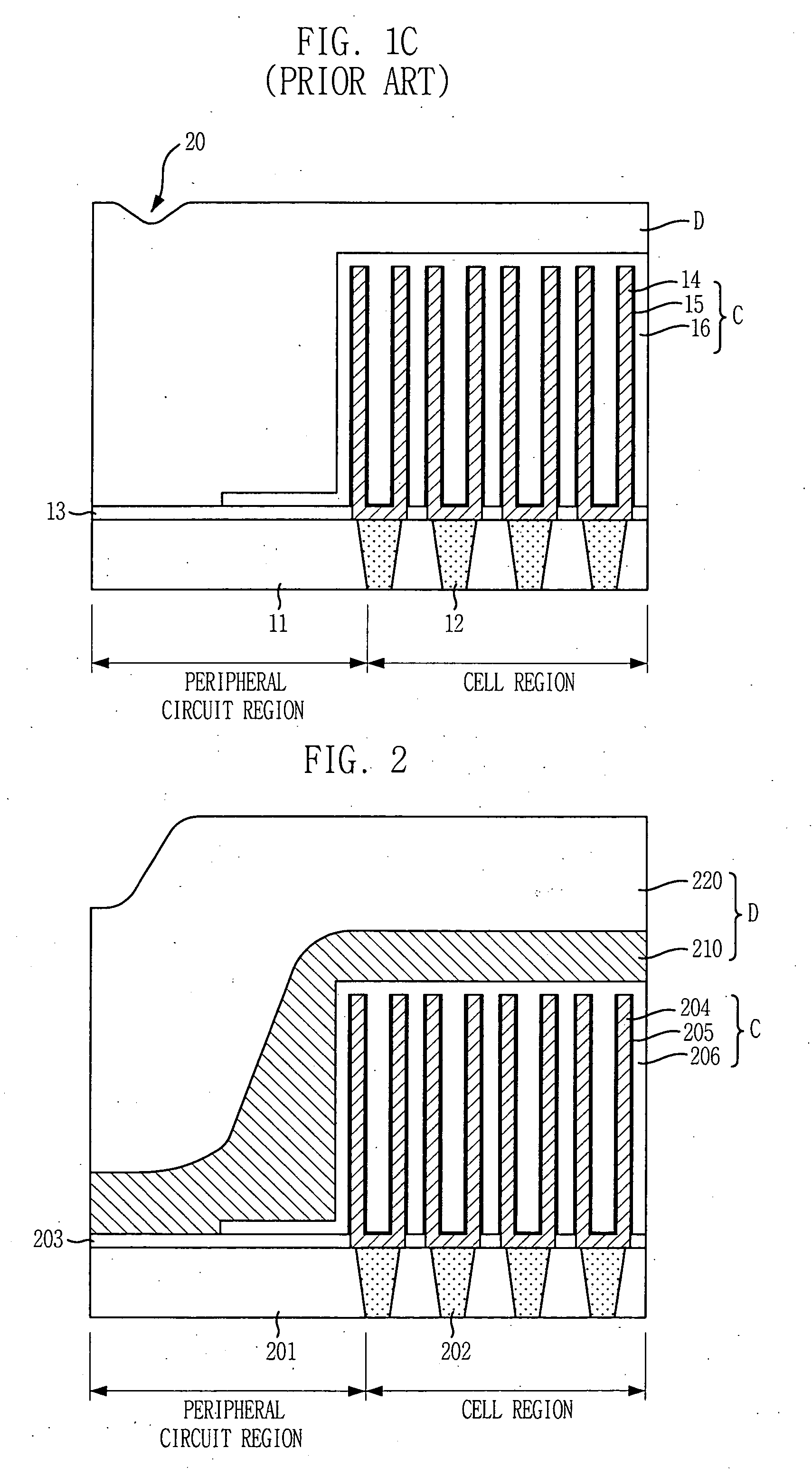

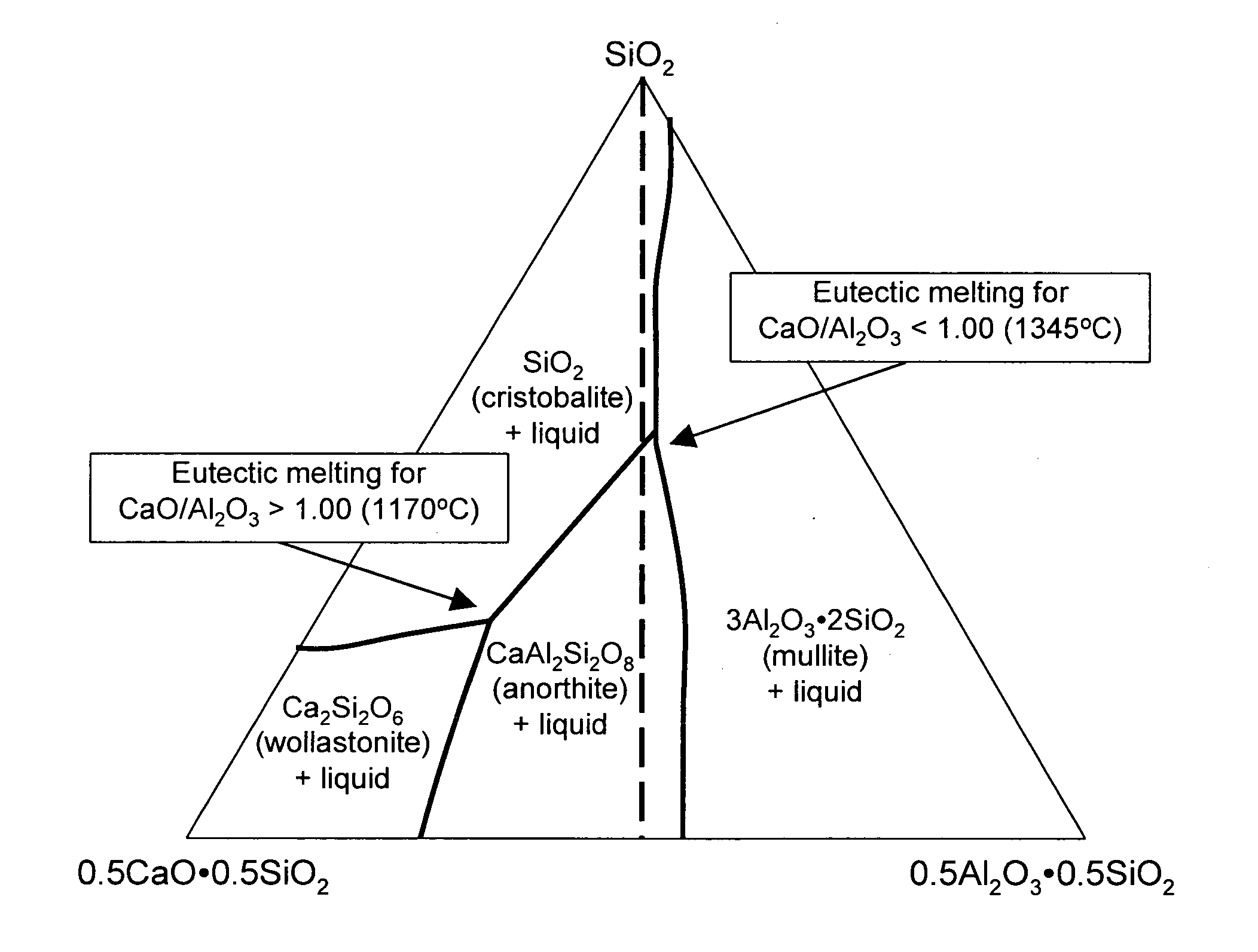

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS7033406B2Reduce sinteringLowering hot-isostatic-pressing temperatureElectrical storage systemFixed capacitor electrodesBarium titanatePermittivity

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

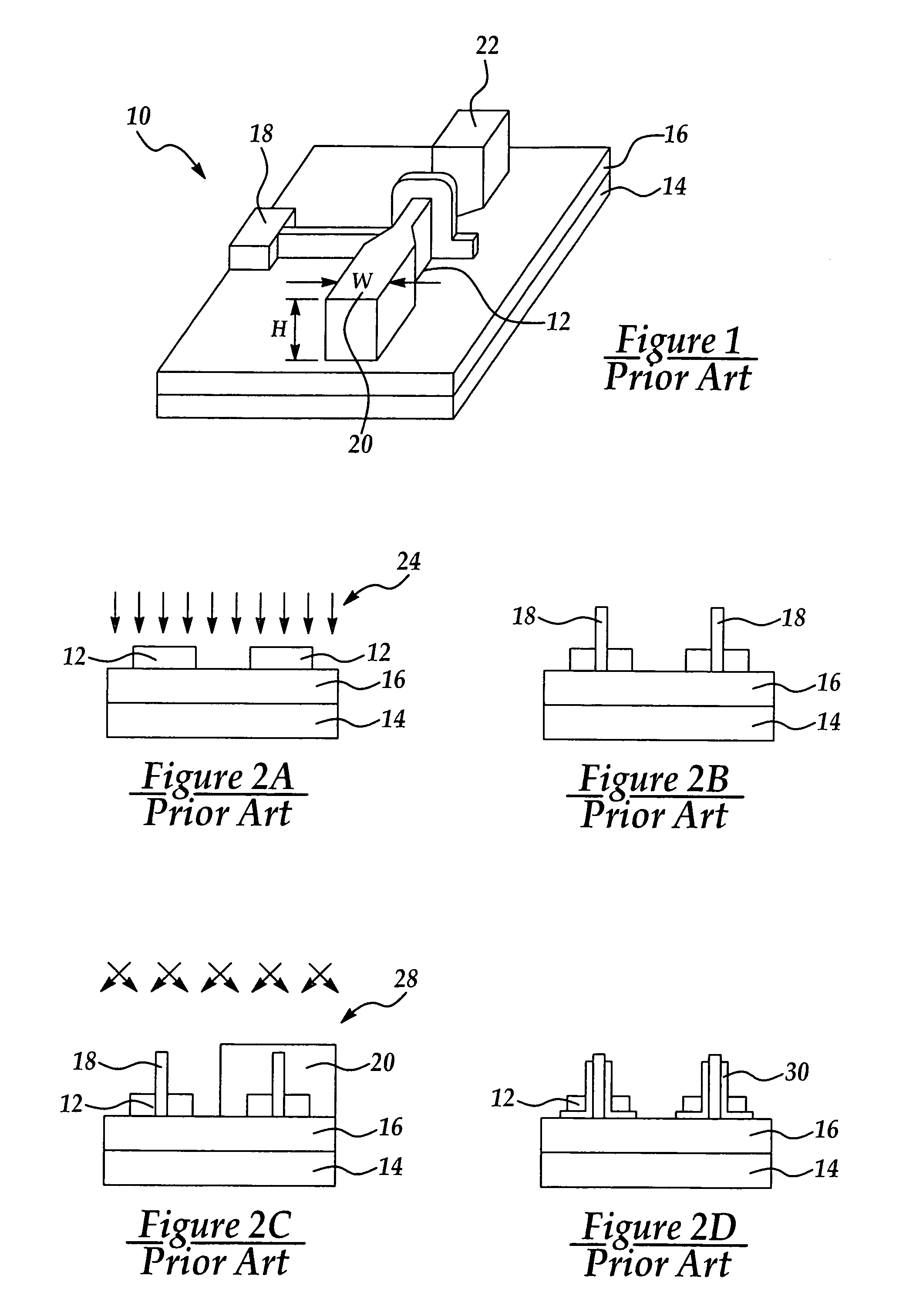

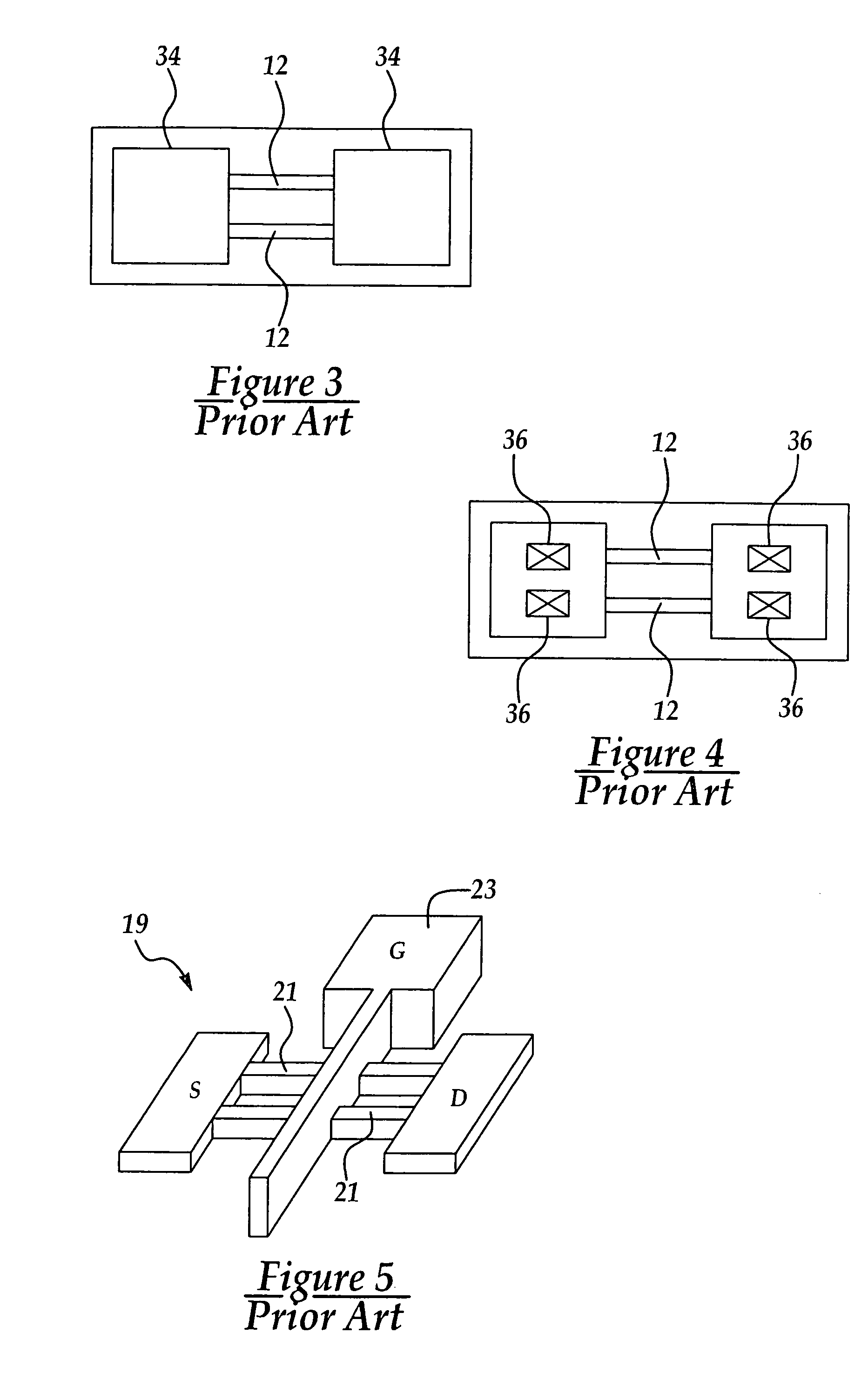

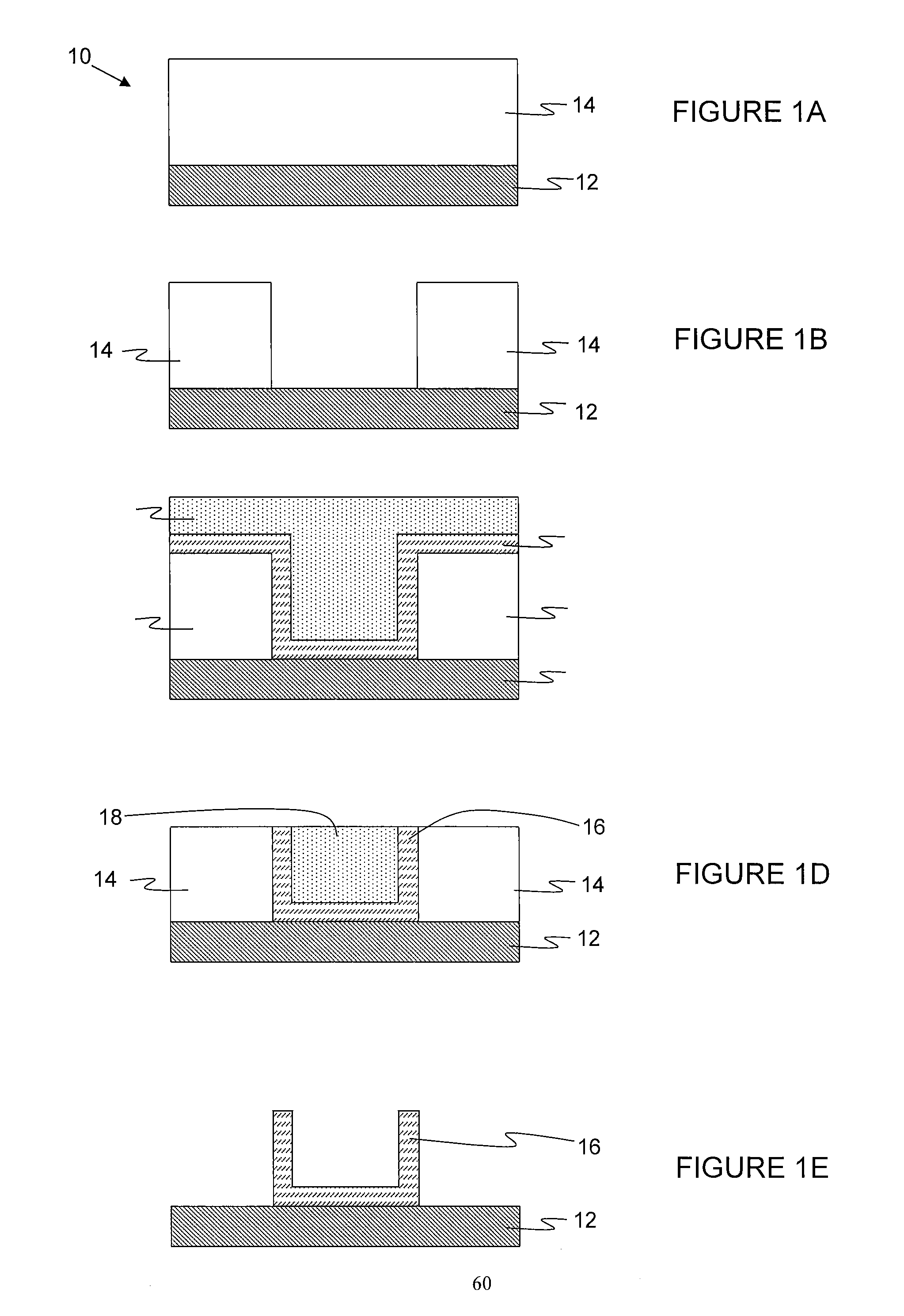

FinFET transistor device on SOI and method of fabrication

ActiveUS7300837B2Thin body”Reduce contact resistanceTransistorSolid-state devicesSilicate glassEngineering

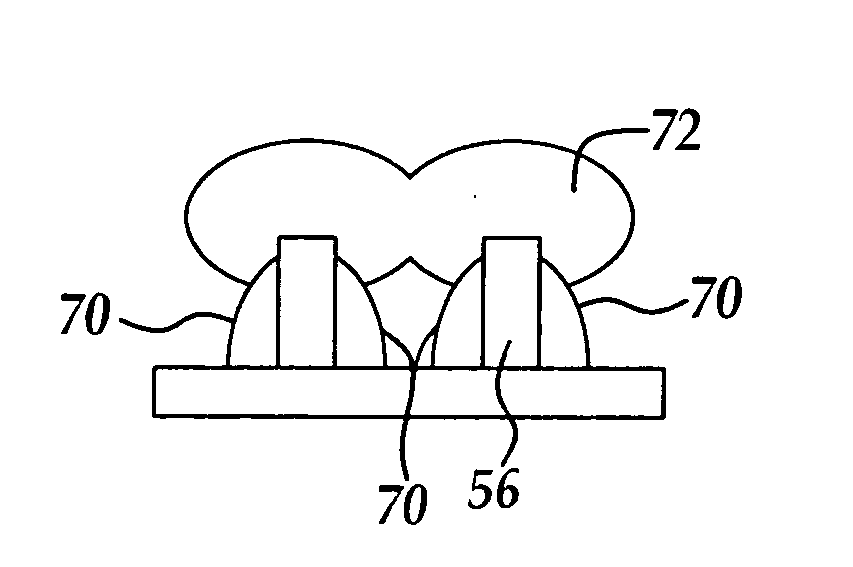

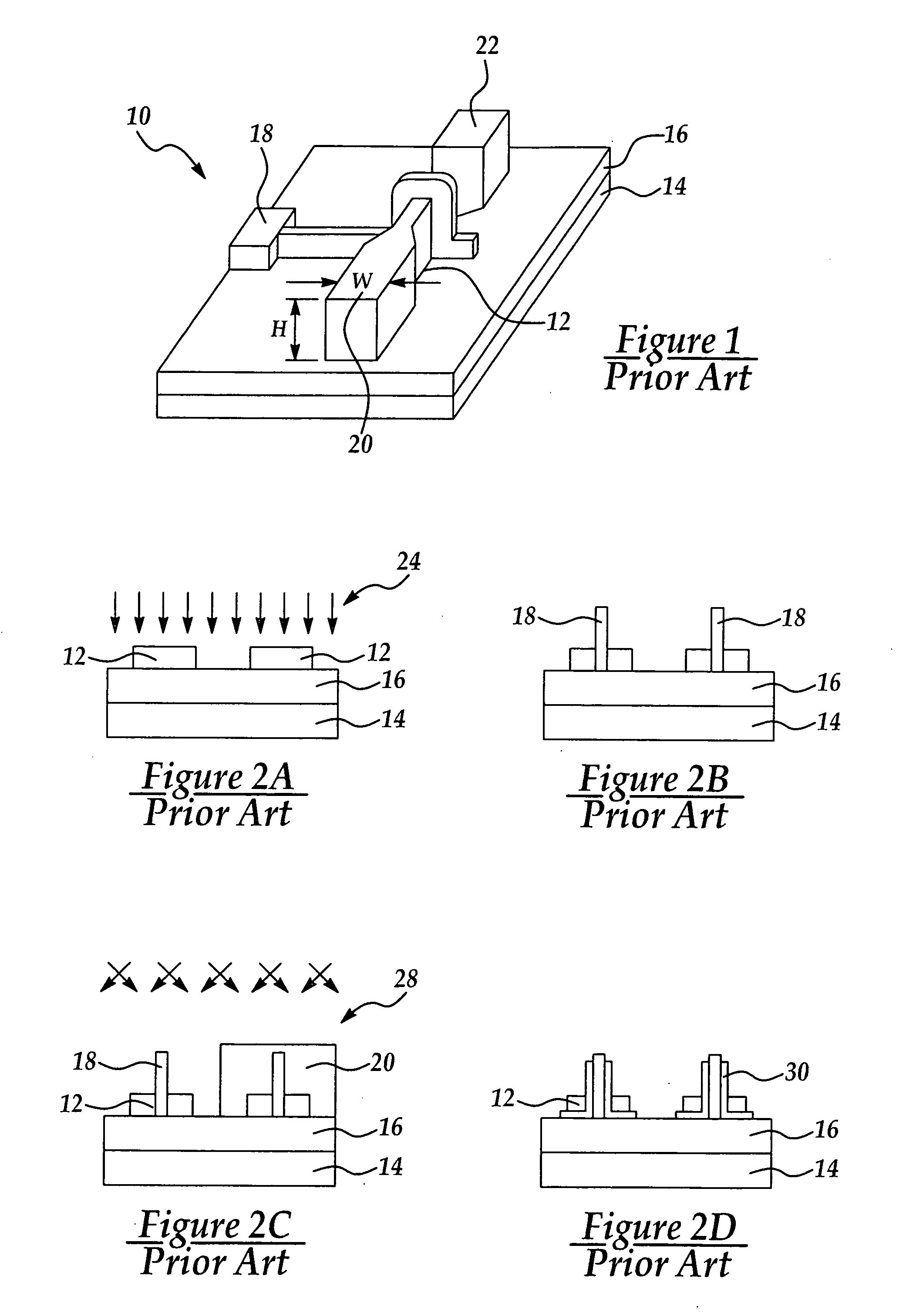

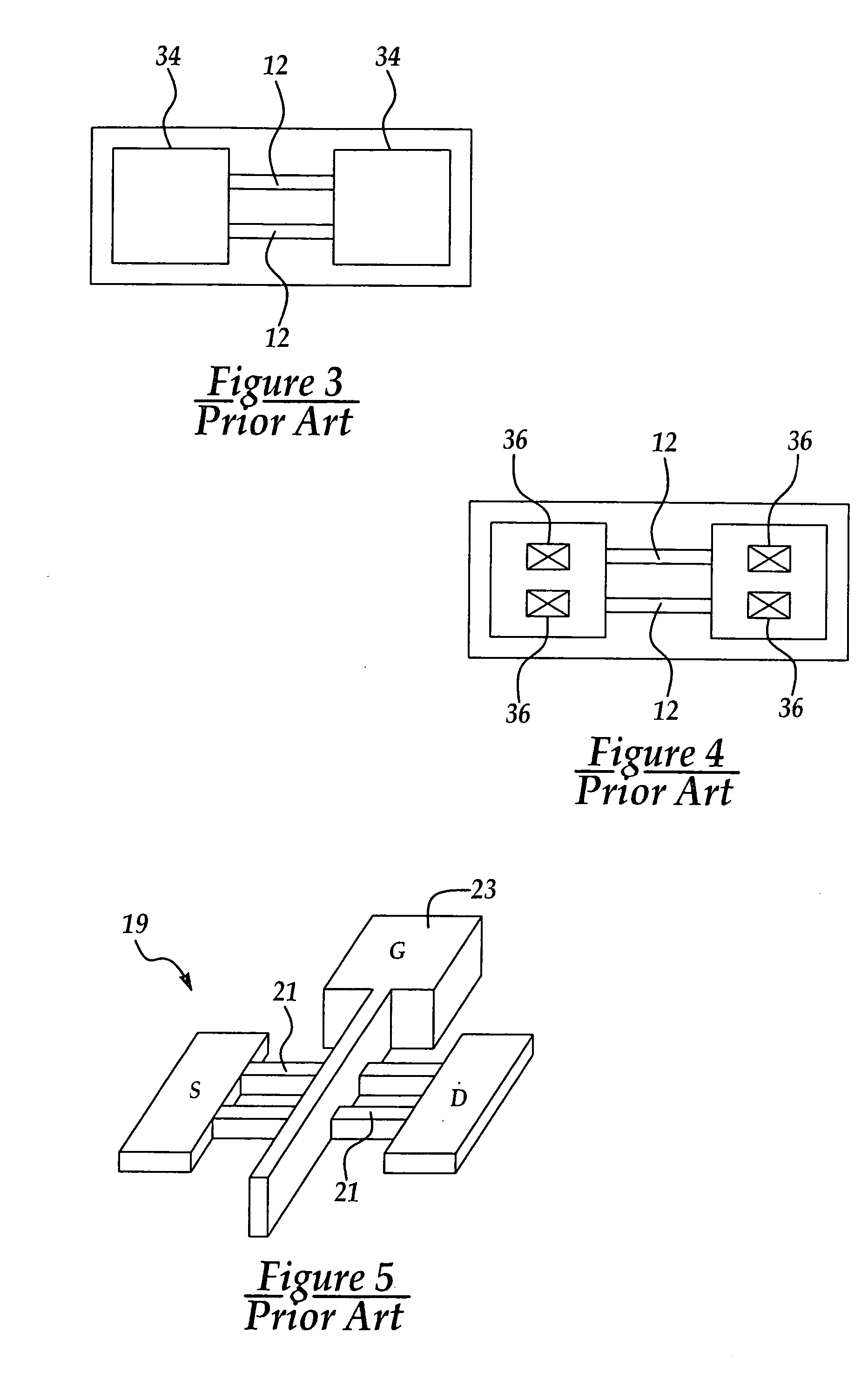

A FinFET transistor on SOI device and method of fabrication is provided. At least two FinFET fins each having an upper poly-silicate glass portion and a lower silicon portion are formed using spacer patterning technology. Each fin is formed on a sacrificial SiN mask layer having a sacrificial support structure. The SiN mask is removed and then a breakthrough etch is applied to remove an underlying pad oxide layer. A PSG layer defining a width of each of the fins on a sidewall of each of the support structures is deposited on each of the support structures. At least two fins each having a narrow fin pitch of about 0.25 μm. are formed. The fins provide a seed layer for at least two selective epitaxially raised source and drain regions, wherein each raised source-drain associated with each fin are interconnected thus forming a source pad and a drain pad.

Owner:TAIWAN SEMICON MFG CO LTD

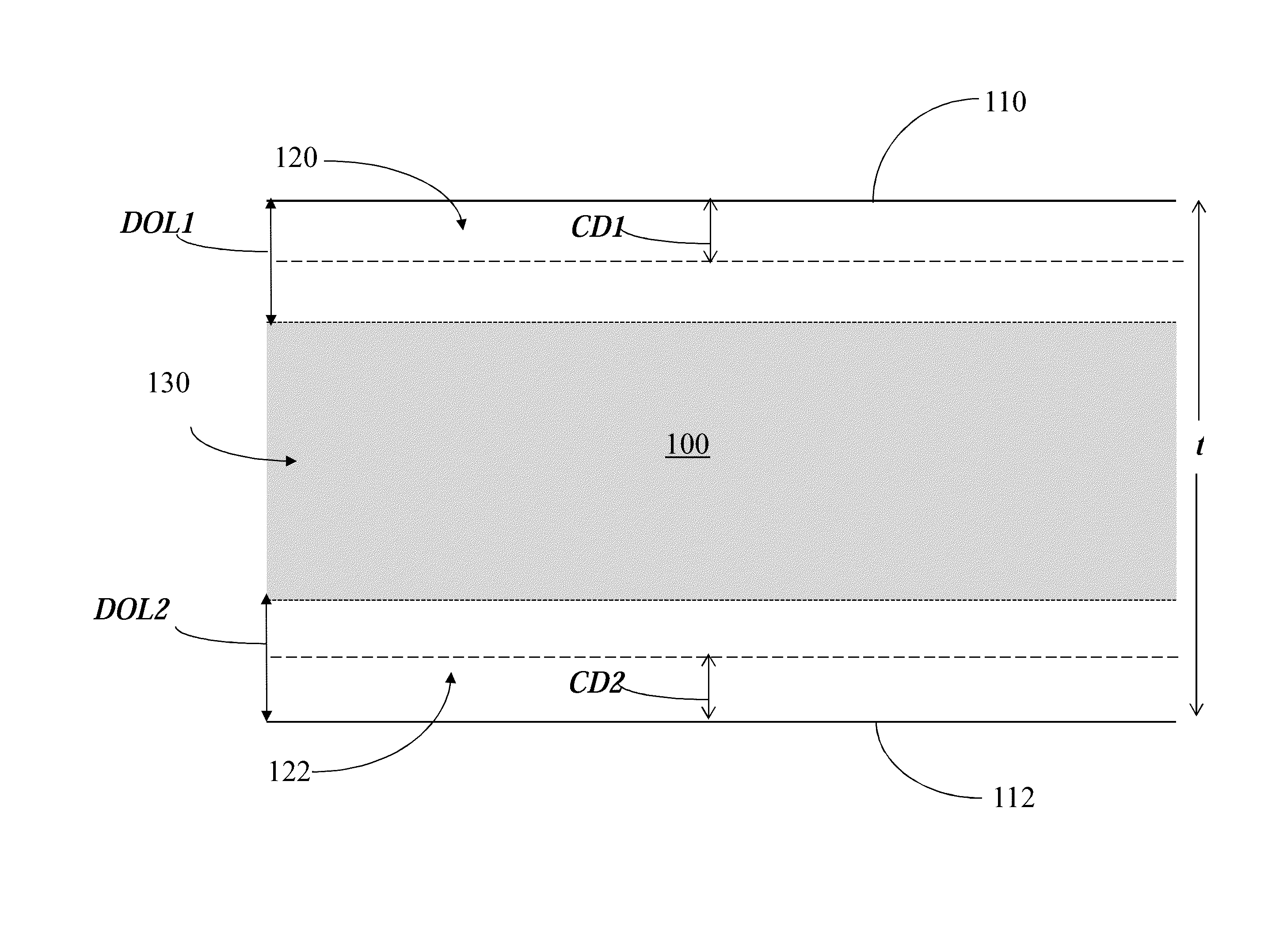

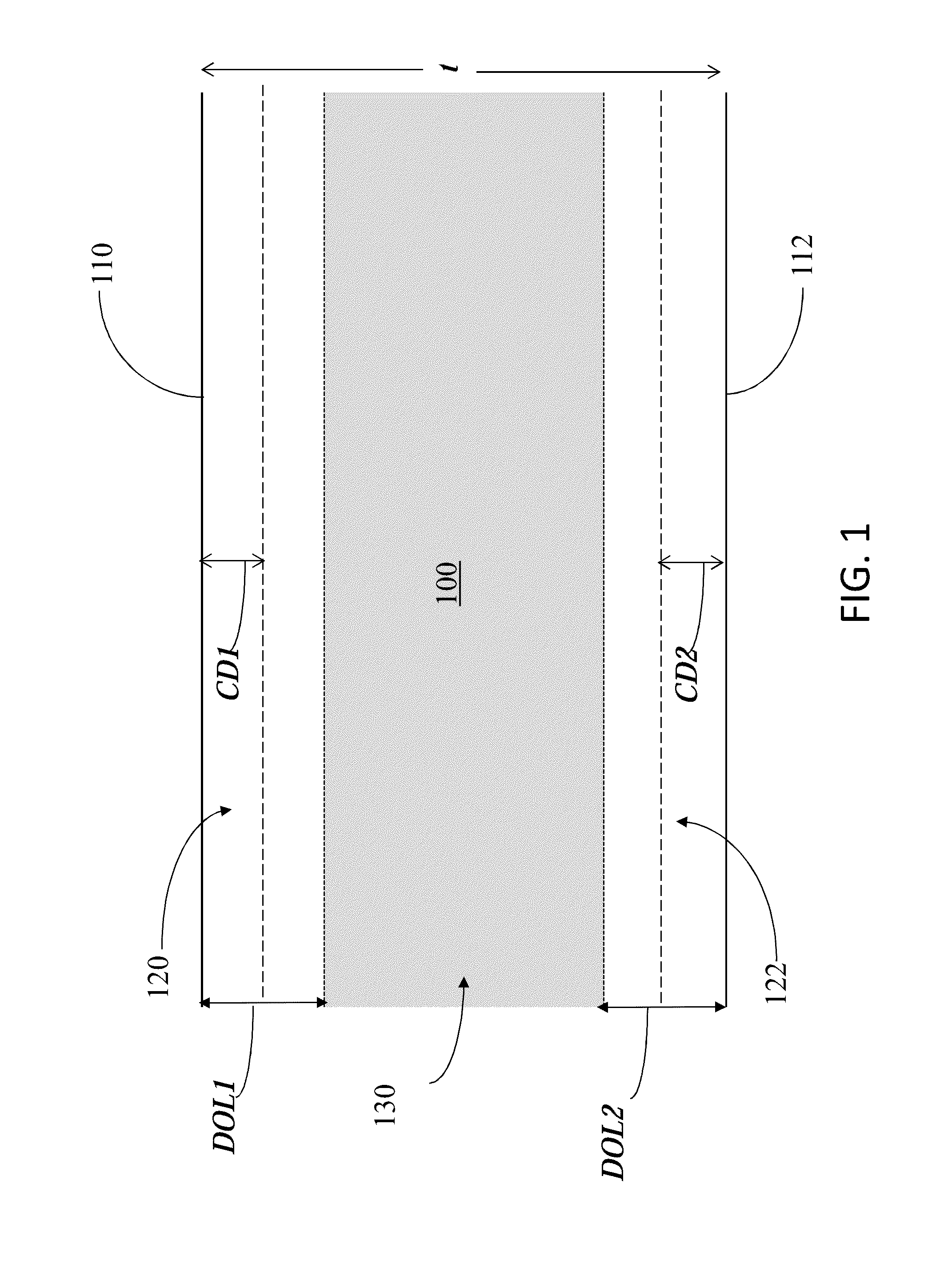

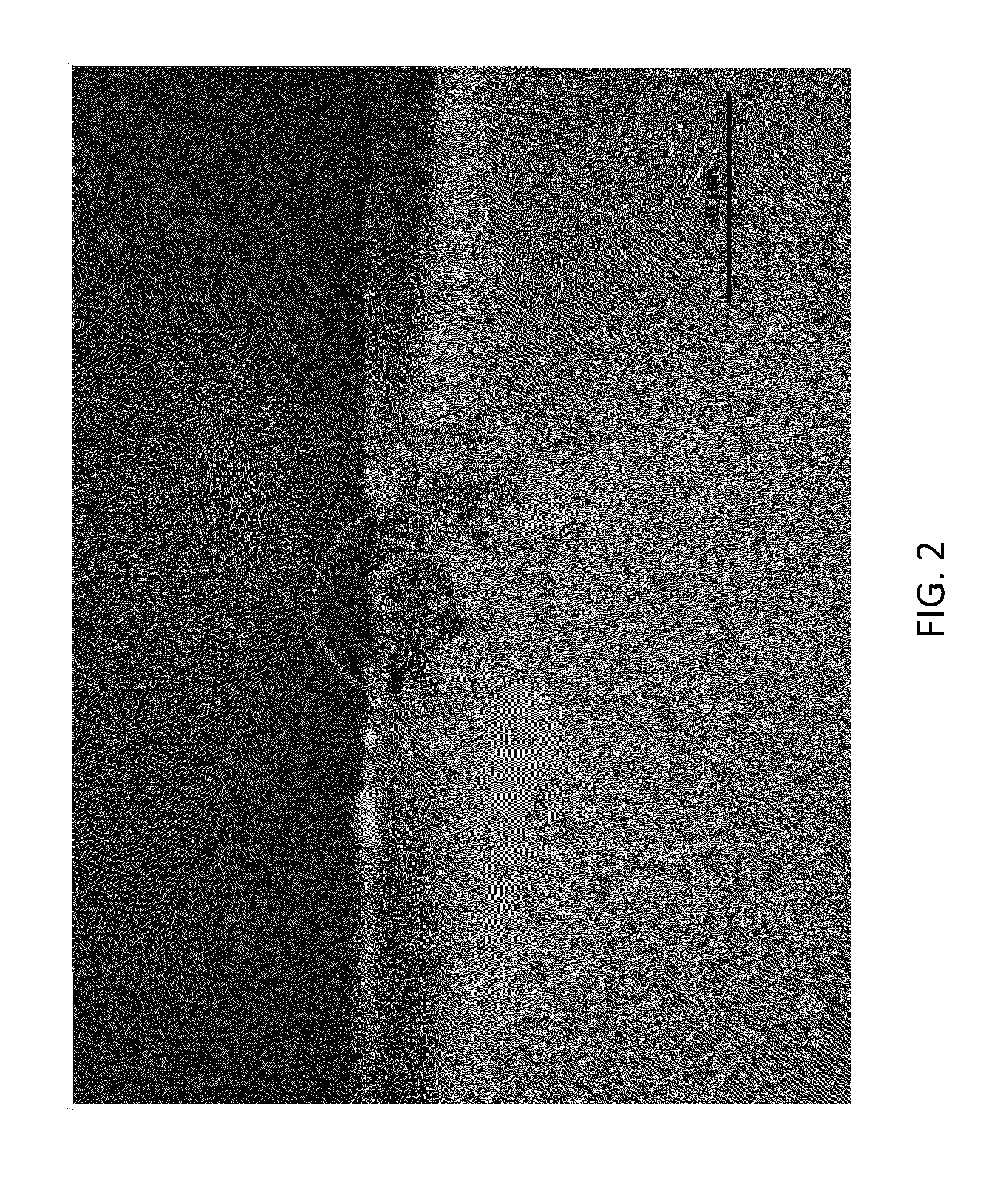

Strengthened glass articles having improved survivability

ActiveUS20150030834A1Increase drop heightSynthetic resin layered productsUsing mechanical meansSurvivabilitySilicate glass

Embodiments are directed to strengthened glass articles comprising a thickness t≦1 mm (1000 μm), an inner region under a central tension CT (in MPa), and at least one compressive stress layer adjacent the inner region and extending within the strengthened glass article from a surface of the strengthened glass article to a depth of layer DOL (in μm), wherein the strengthened glass article is under a compressive stress at the surface CSs (in MPa), wherein the strengthened glass article is an alkali aluminosilicate glass article comprising 0-5 mol % Li2O, and at least 3 mol % Al2O3, and wherein the DOL≧70 μm, and a CSs / DOL ratio≧2.5 MPa / μm.

Owner:CORNING INC

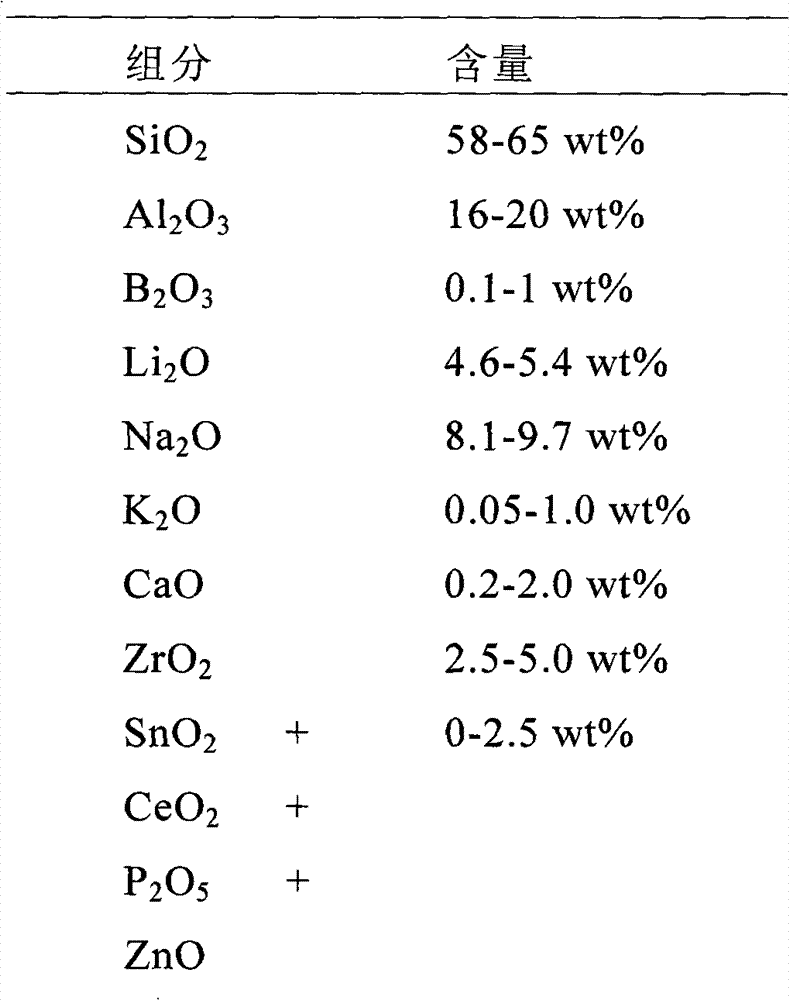

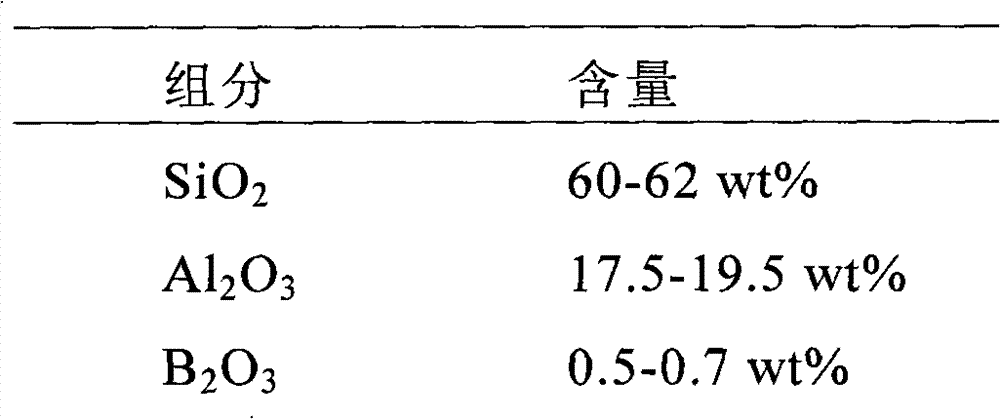

Glass-ceramic materials, precursor glass thereof and process-for making the same

The present invention relates to: novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and ithium alumino-silicate glasses, which are precursors of said novel glass-ceramics; methods of preparing said novel glass-ceramics and articles made from said novel glass-ceramics. The present invention relates to the use of SnO2 and of Br, as an agent for fining the glass-ceramic glass precursor.

Owner:EUROKERA SOC & NOM COLLECTIF

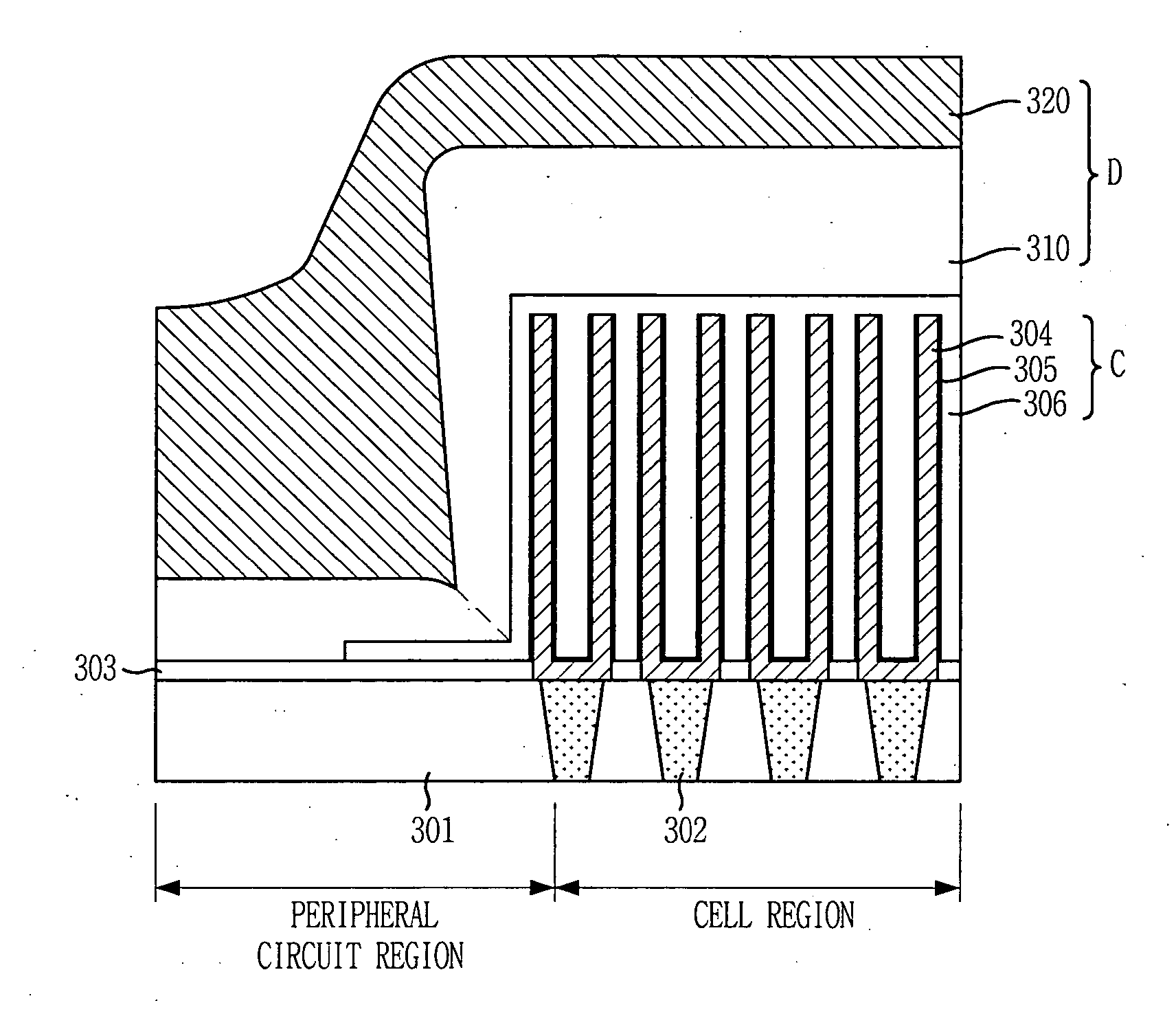

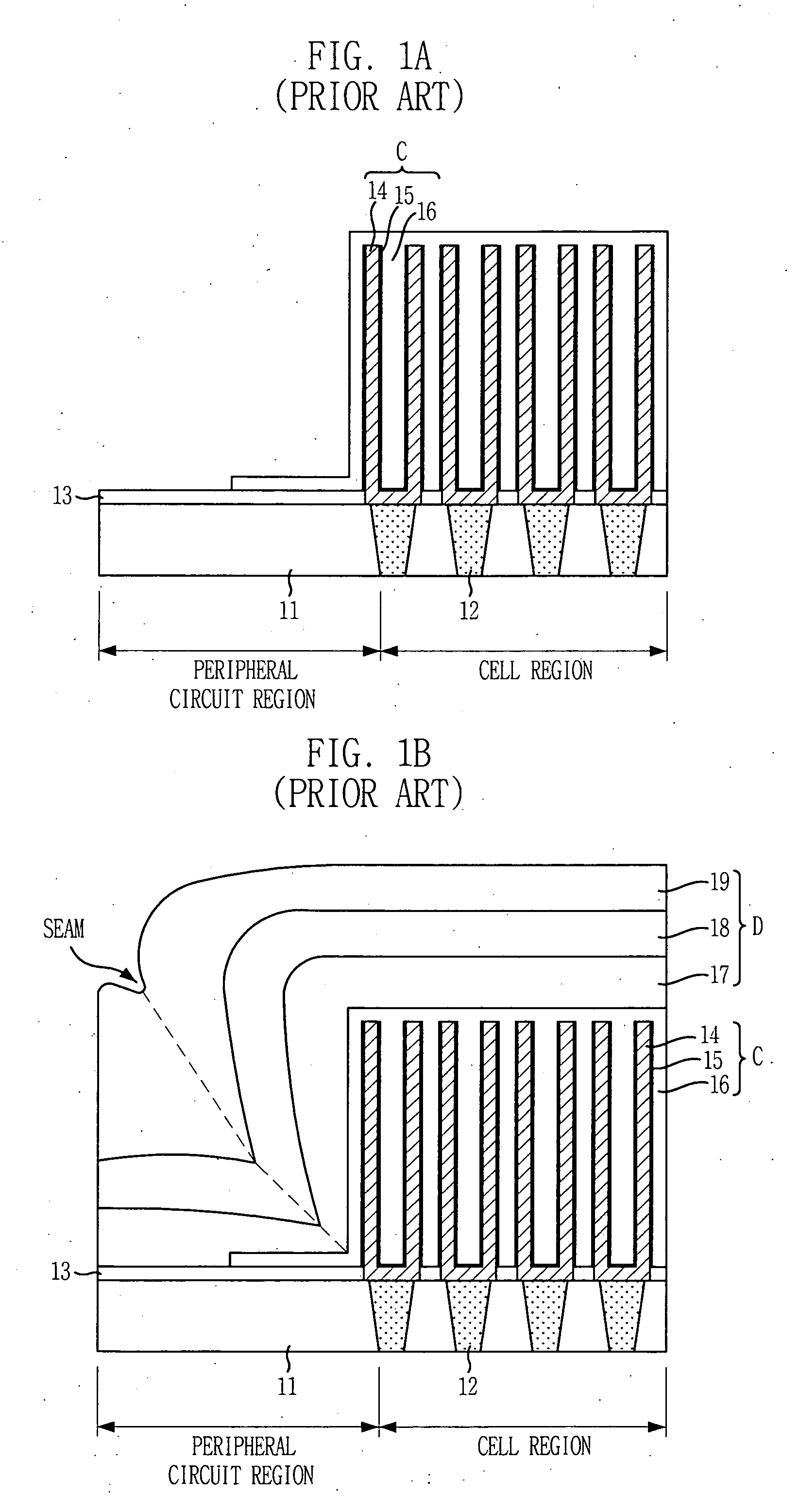

Semiconductor device with flowable insulation layer formed on capacitor and method for fabricating the same

ActiveUS20050266650A1Good planarization characteristicWithout degrading characteristicTransistorSemiconductor/solid-state device detailsMetal interconnectInsulation layer

Disclosed is a semiconductor device with a flowable insulation layer formed on a capacitor and a method for fabricating the same. Particularly, the semiconductor device includes: a capacitor formed on a predetermined portion of a substrate; an insulation layer formed by stacking a flowable insulation layer and an undoped silicate glass layer on a resulting substrate structure including the substrate and the capacitor; and a metal interconnection line formed on the insulation layer. The method includes the steps of: forming a capacitor on a predetermined portion of a substrate; forming an insulation layer by stacking a flowable insulation layer and an undoped silicate glass layer on a resulting substrate structure including the substrate and the capacitor; and forming a metal interconnection line on the insulation layer.

Owner:SK HYNIX INC

Fining of boroalumino silicate glasses

ActiveUS20060293162A1Pot furnacesGlass furnace apparatusActive-matrix liquid-crystal displaySilicate glass

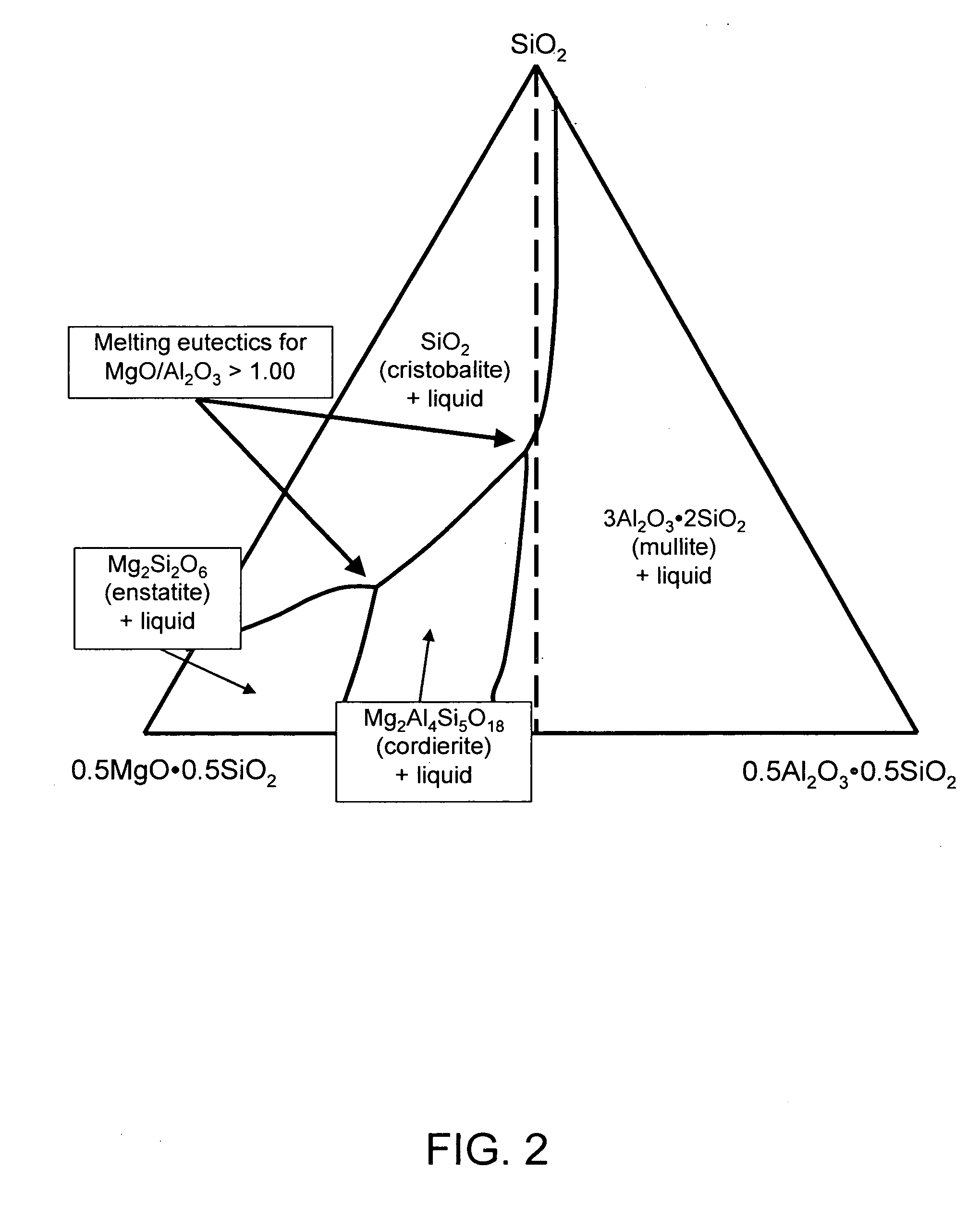

Glasses are disclosed which can be used to produce substrates for flat panel display devices, e.g., active matrix liquid crystal displays (AMLCDs). The glasses have MgO concentrations in the range from 1.0 mole percent to 3.0 mole percent and Σ[RO] / [Al2O3] ratios greater than or equal to 1.00, where [Al2O3] is the mole percent of Al2O3 and Σ[RO] equals the sum of the mole percents of MgO, CaO, SrO, and BaO. These compositional characteristics have been found to improve the melting properties of batch materials used to produce the glass, which, in turn, allows the glasses to be fined (refined) with more environmentally friendly fining agents, e.g., tin as opposed to arsenic and / or antimony.

Owner:CORNING INC

Optical switch and method for assembling the same

An optical switch includes a substrate having therein optical waveguides made of silicon and a silicon layer deposited on its top surface. A space is formed in the crossing portion of the optical waveguides which is covered with a lid, preferably made of low alkali borosilicate glass, and which is bonded to the silicon layer by anodic bonding. Preferably, a groove is formed in a surface of the optical waveguide substrate or a bonding surface of the lid. The groove, after the lid has been bonded, makes a passage which communicates between the space and an outside. The passage is a pouring slit for pouring an index-matching liquid and is connected to the space which acts as a driving slit in which the index-matching liquid moves. In one embodiment, the width of the pouring slit is smaller than that of the driving slit. The optical switch can be manufactured by providing an optical waveguide substrate and a lid substrate, one of which is formed with a groove in its surface on which the two substrates are bonded. The optical waveguide substrate and the lid substrate are bonded together by anodic bonding to make a passage which communicates between the space formed in a crossing portion of the optical waveguides and an outside. The regulation of the volume of the index-matching liquid is time-, temperature-, or pressure-based regulation.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

FinFET transistor device on SOI and method of fabrication

ActiveUS20050242395A1Reduce contact resistanceReduce channel resistanceTransistorSolid-state devicesSilicate glassAdemetionine

A FinFET transistor on SOI device and method of fabrication is provided. At least two FinFET fins each having an upper poly-silicate glass portion and a lower silicon portion are formed using spacer patterning technology. Each fin is formed on a sacrificial SiN mask layer having a sacrificial support structure. The SiN mask is removed and then a breakthrough etch is applied to remove an underlying pad oxide layer. A PSG layer defining a width of each of the fins on a sidewall of each of the support structures is deposited on each of the support structures. At least two fins each having a narrow fin pitch of about 0.25 μm. are formed. The fins provide a seed layer for at least two selective epitaxially raised source and drain regions, wherein each raised source-drain associated with each fin are interconnected thus forming a source pad and a drain pad.

Owner:TAIWAN SEMICON MFG CO LTD

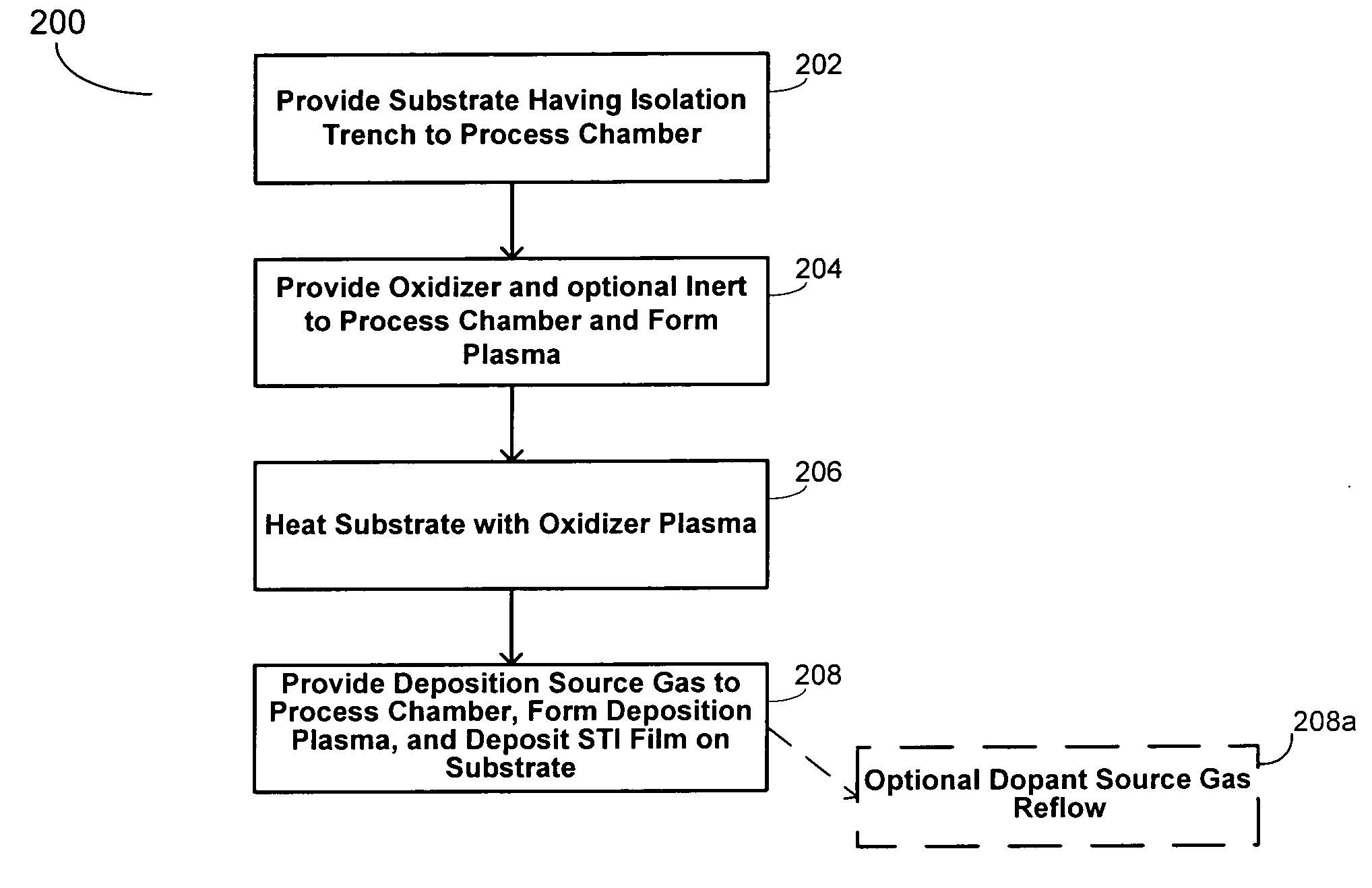

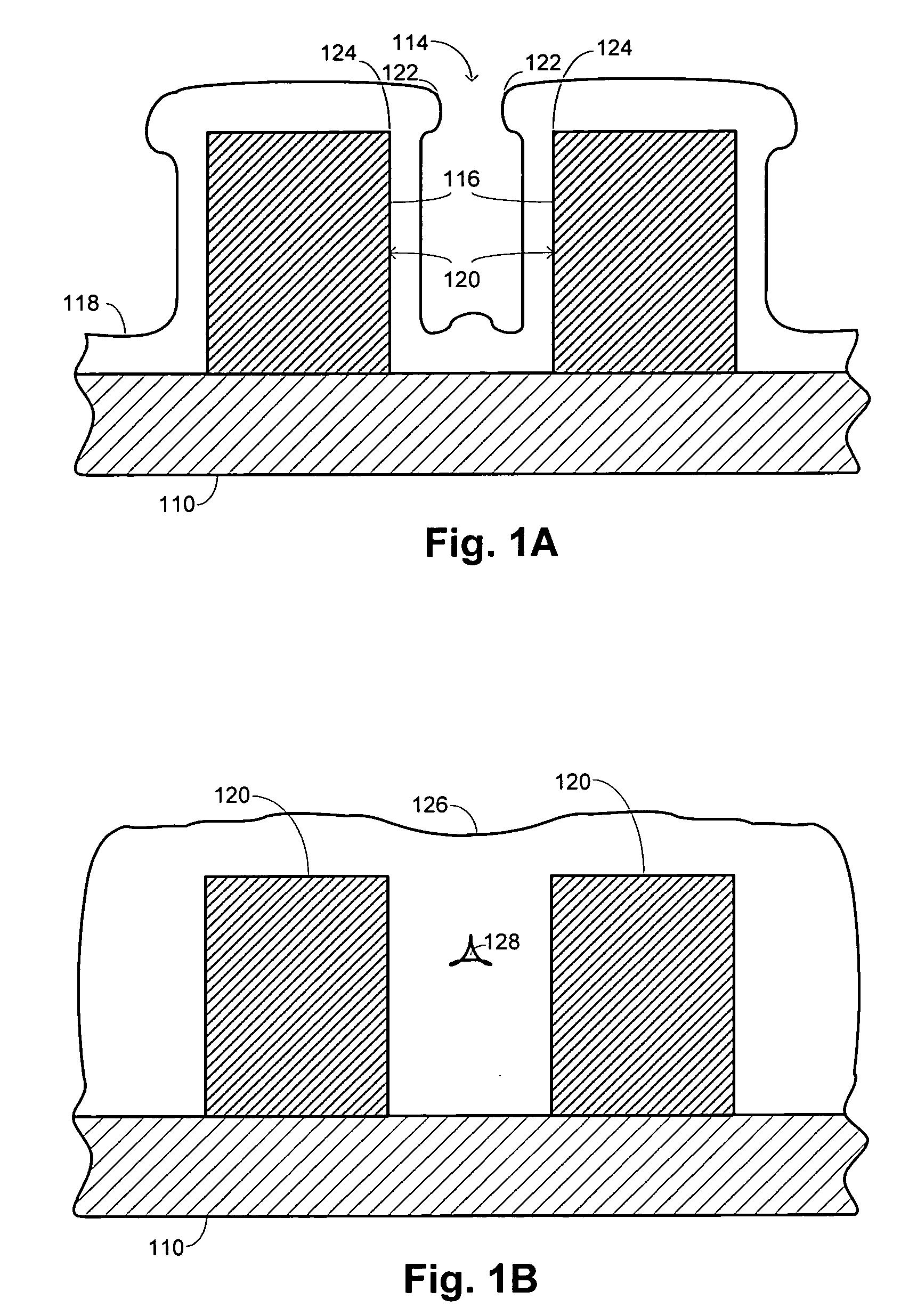

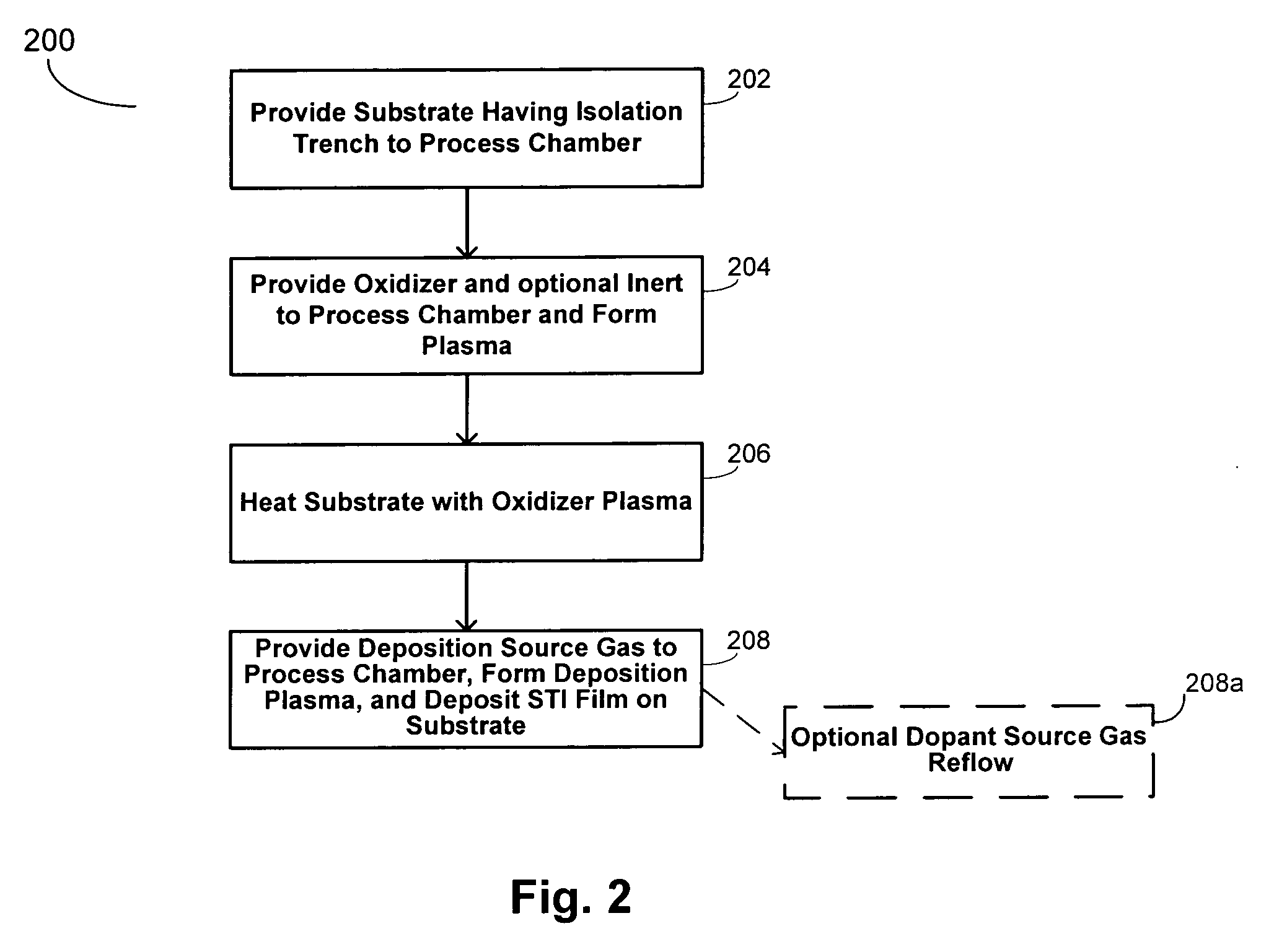

Low stress STI films and methods

InactiveUS20070087515A1Reduce compressive stressGood gap fill characteristicSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSilicate glass

The present invention generally relates to low compressive stress doped silicate glass films for STI applications. By way of non-limited example, the stress-lowering dopant may be a fluorine dopant, a germanium dopant, or a phosphorous dopant. The low compressive stress STI films will generally exhibit a compressive stress of less than 180 MPa, and preferably less than about 170 MPa. In certain embodiment, the STI films of the invention will exhibit a compressive stress less than about 100 MPa. Further, in certain embodiments, the low compressive stress STI films of the invention will comprise between about 0.1 and 25 atomic % of the stress-lowering dopant.

Owner:APPLIED MATERIALS INC

Alkaline earth alumino-silicate glass compositions with improved chemical and mechanical durability

Owner:CORNING INC

Repairing damage to low-k dielectric materials using silylating agents

ActiveUS20050095840A1Reduce hydrophobicityImprove hydrophobicitySemiconductor/solid-state device manufacturingStress inducedSilicate glass

A method for restoring hydrophobicity to the surfaces of organosilicate glass dielectric films which have been subjected to an etchant or ashing treatment. These films are used as insulating materials in the manufacture of integrated circuits to ensure low and stable dielectric properties in these films. The method deters the formation of stress-induced voids in these films. An organosilicate glass dielectric film is patterned to form vias and trenches by subjecting it to an etchant or ashing reagent in such a way as to remove at least a portion of previously existing carbon containing moieties and reduce hydrophobicity of said organosilicate glass dielectric film. The vias and trenches are thereafter filled with a metal and subjected to an annealing treatment. After the film is subjected to the etchant or ashing reagent, but before being subjected to an annealing treatment, the film is contacted with a toughening agent composition to restore some of the carbon containing moieties and increase the hydrophobicity of the organosilicate glass dielectric film.

Owner:HONEYWELL INT INC

Fusion formable silica and sodium containing glasses

ActiveUS20110017297A1Point becomes highImprove battery efficiencyPhotovoltaic energy generationSemiconductor devicesSilicate glassThermal expansion

Sodium containing aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates or superstrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points≧535° C., for example, ≧570° C., thermal expansion coefficients of from 8 to 9 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

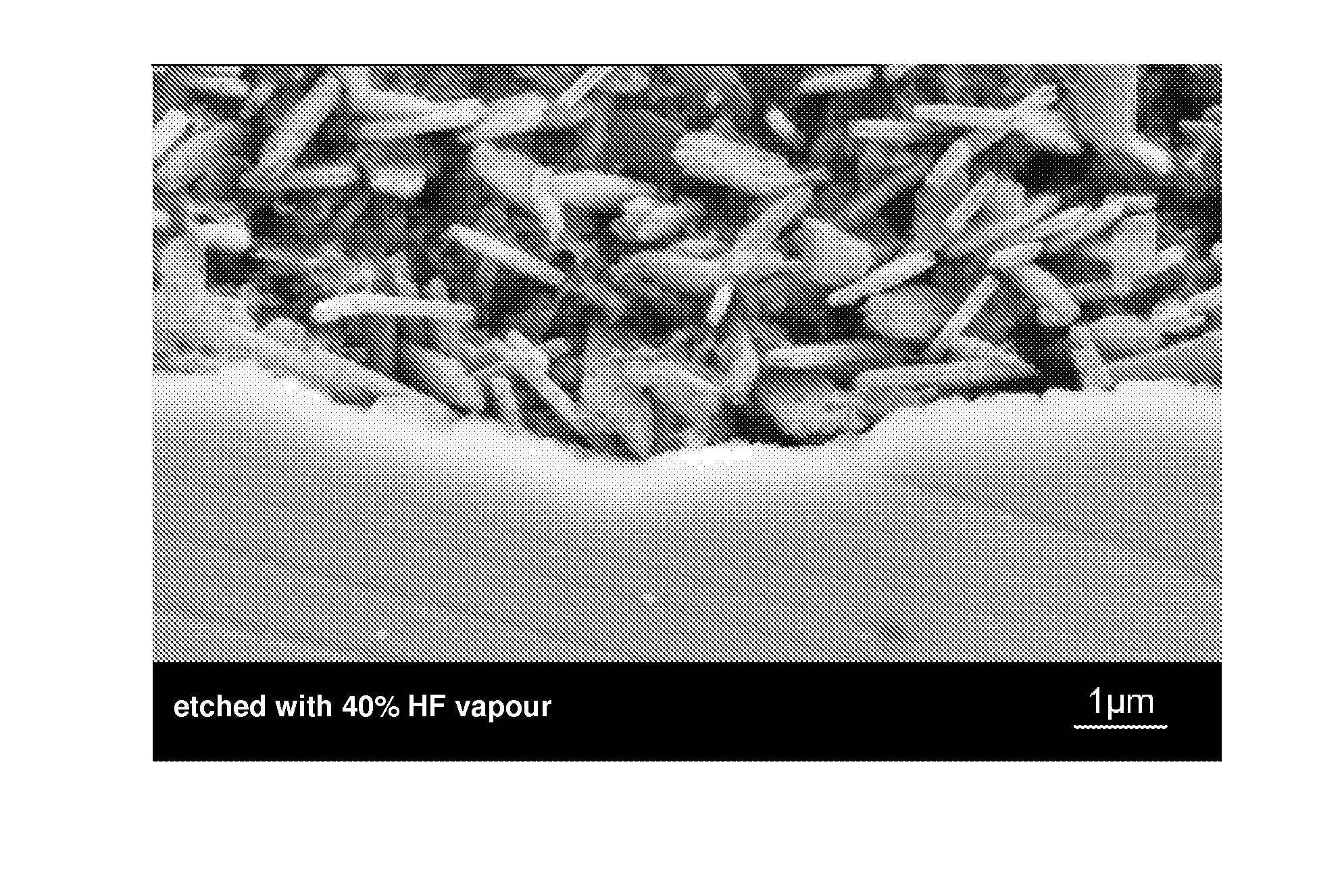

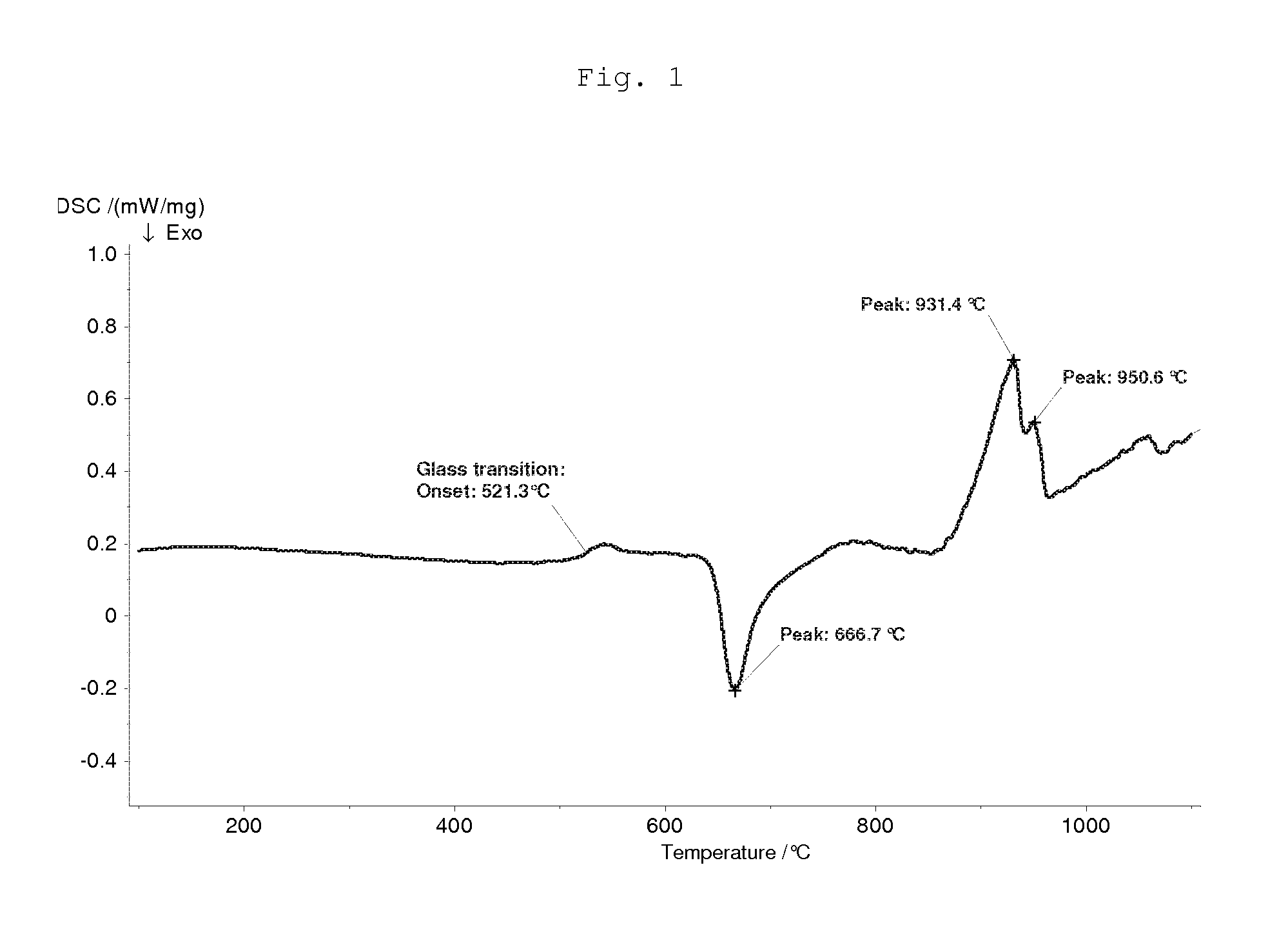

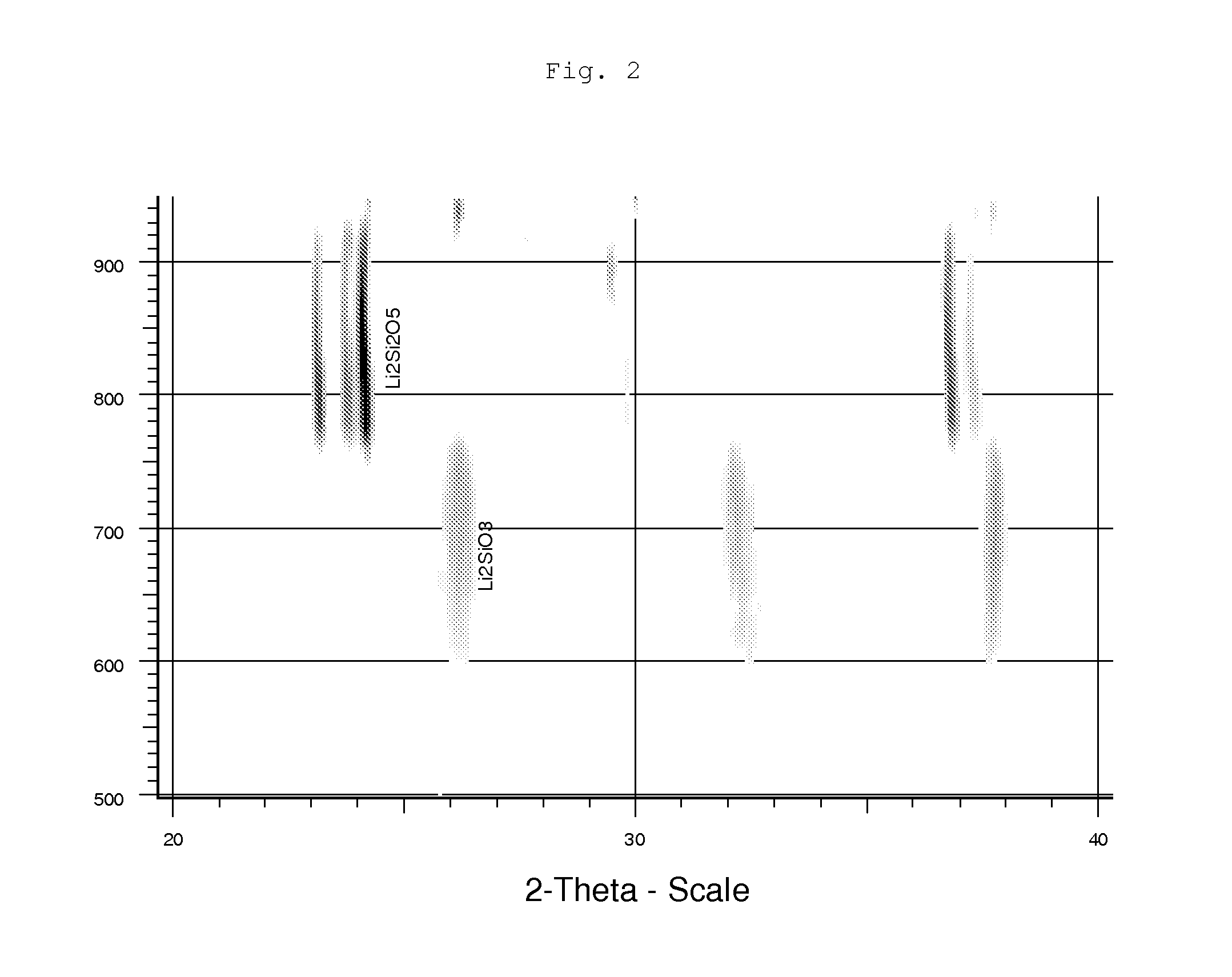

Lithium Silicate Glass Ceramic and Glass With ZrO2 Content

ActiveUS20110256409A1Substantial deterioration in translucencyInhibition formationPretreated surfacesTooth crownsLithiumSolid Bond

Owner:IVOCLAR VIVADENT AG

Method for producing tempered glass with plurality of surface stress layers and tempered glass product

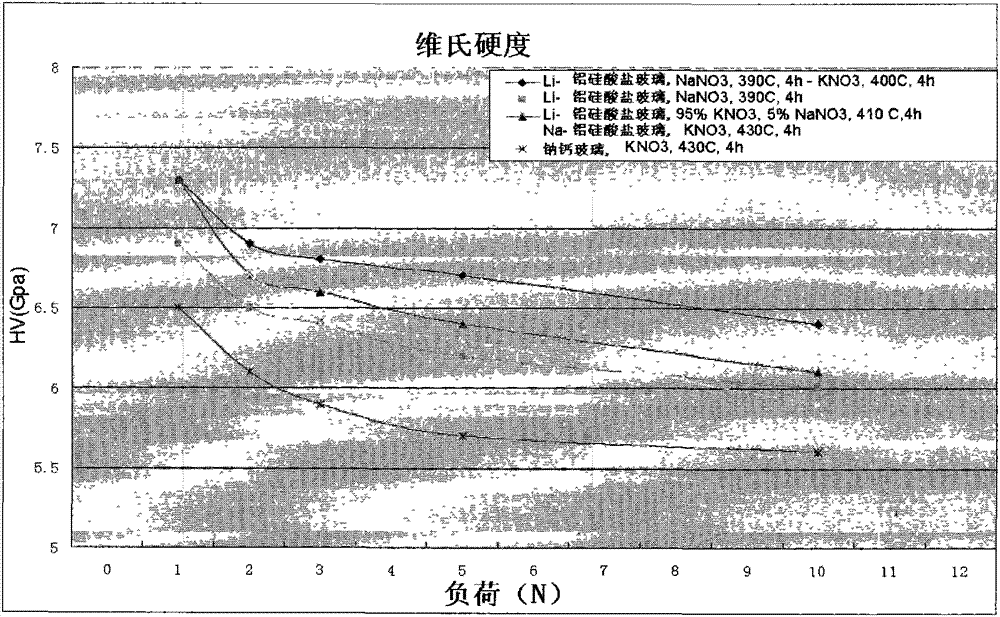

The invention discloses a method for producing tempered glass with a plurality of surface stress layers and a tempered glass product and particularly relates to a method for producing tempered lithium glass with a plurality of surface stress layers. The method comprises that a mixed salt bath is used for conducting ion exchange in a step, or various mixed salt baths are used for conducting several ion exchange in a plurality of steps. By the aid of the novel chemical tempered lithium aluminosilicate glass and the treatment method of relative glass products, glass with the plurality of surface stress layers and products of the glass are obtained, and the product serves as a high-strength cover plate in electronic devices, household appliances and vehicles. Compared with the prior art, the tempered glass with the plurality of surface stress layers can protect electronic devices, household appliances and vehicles reliably.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Intermediate Thermal Expansion Coefficient Glass

ActiveUS20100084016A1High pull rateLower melting temperaturePV power plantsPhotovoltaic energy generationSilicate glassEffect light

Aluminoborosilicate glasses which may be useful in photovoltaic, photochromic, electrochromic, or Organic Light Emitting Diode (OLED) lighting applications are described.

Owner:CORSAM TECH

Thin lithium-aluminosilicate glass for three dimensional precision molding

ActiveUS20130189486A1Easily D shapedLower TgSynthetic resin layered productsRecord information storageThermodynamicsSilicate glass

A thin lithium-aluminosilicate glass is provided. The glass is suitable for three dimensional precision molding and suitable for toughening, wherein after toughening, the glass has a center tension smaller than 50 Mpa, a surface compressive stress of 600-1200 Mpa, and a bending strength of up to 500 MPa. The glass also has a transition point lower than 550° C.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

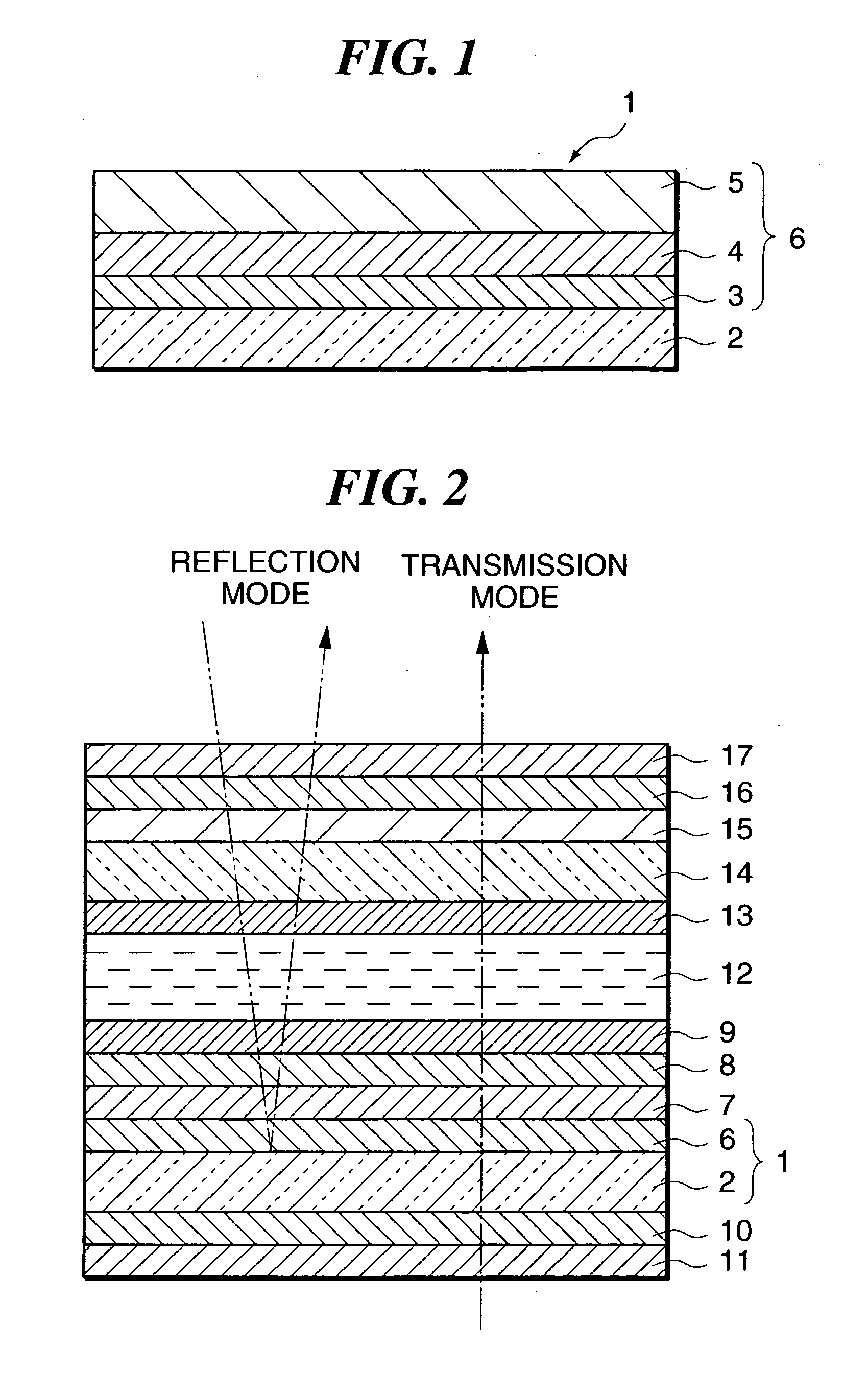

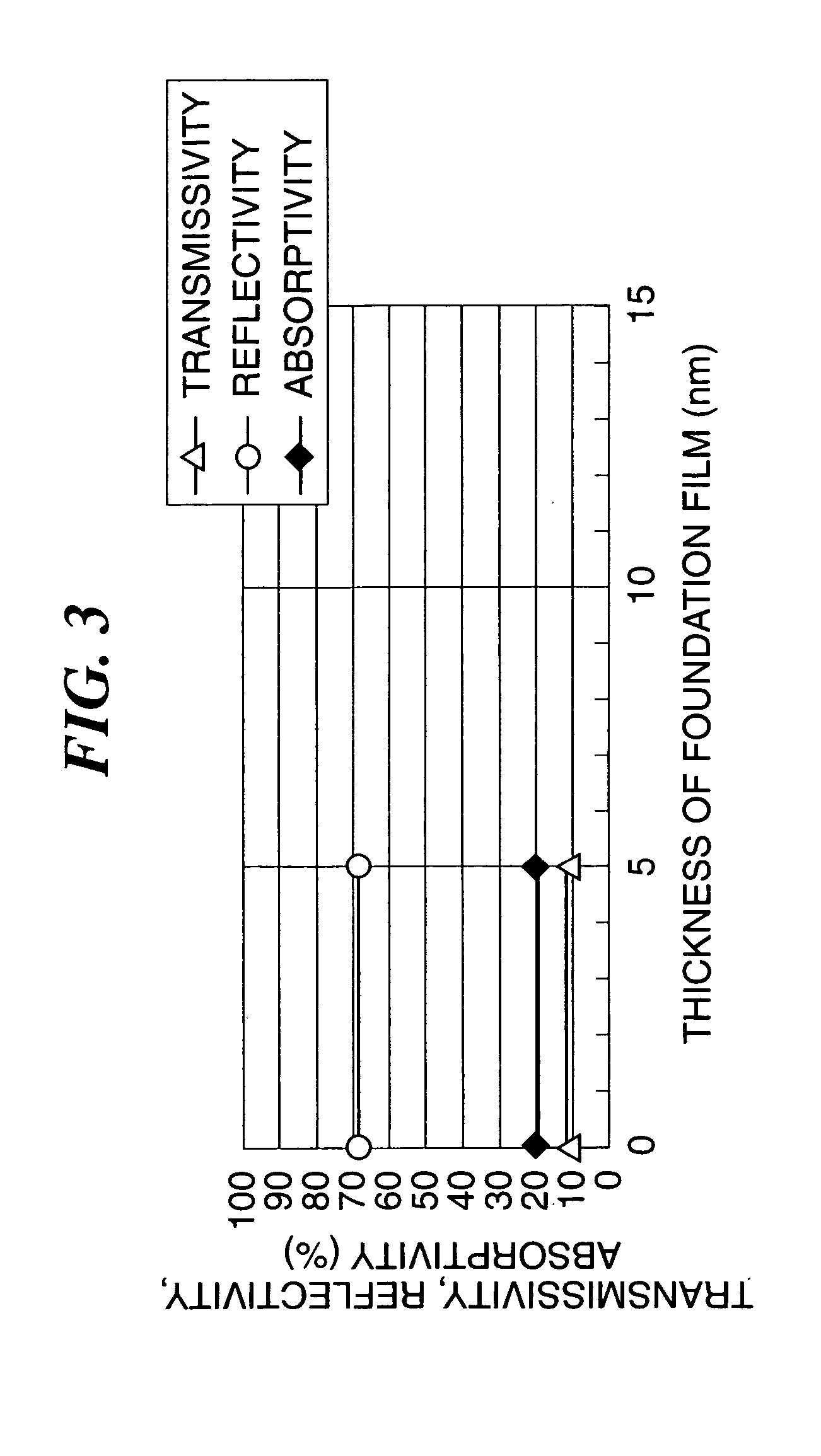

Semi-transmitting mirror-possessing substrate, and semi-transmitting type liquid crystal display apparatus

There is provided a semi-transmitting mirror-possessing substrate that has high reflectivity while maintaining high transmissivity, whereby transmission display performance and reflection display performance can both be improved. The semi-transmitting mirror-possessing substrate 1 has a transparent glass substrate 2 made of a soda lime silicate glass, a foundation film 3 made of silicon oxide (SiOx) formed on the glass substrate 2, a semi-transmitting reflective film 4 made of aluminum (Al) formed on the foundation film 3, and a protective film 5 made of silicon dioxide (SiO2) formed on the semi-transmitting reflective film 4. The film thickness of the SiOx used as the foundation film 3 is in a range of 0 to 8 nm. Moreover, the chemical composition ratio x of oxygen (O) to silicon (Si) in the SiOx is in a range of 1.5 to 2.0.

Owner:NIPPON SHEET GLASS CO LTD

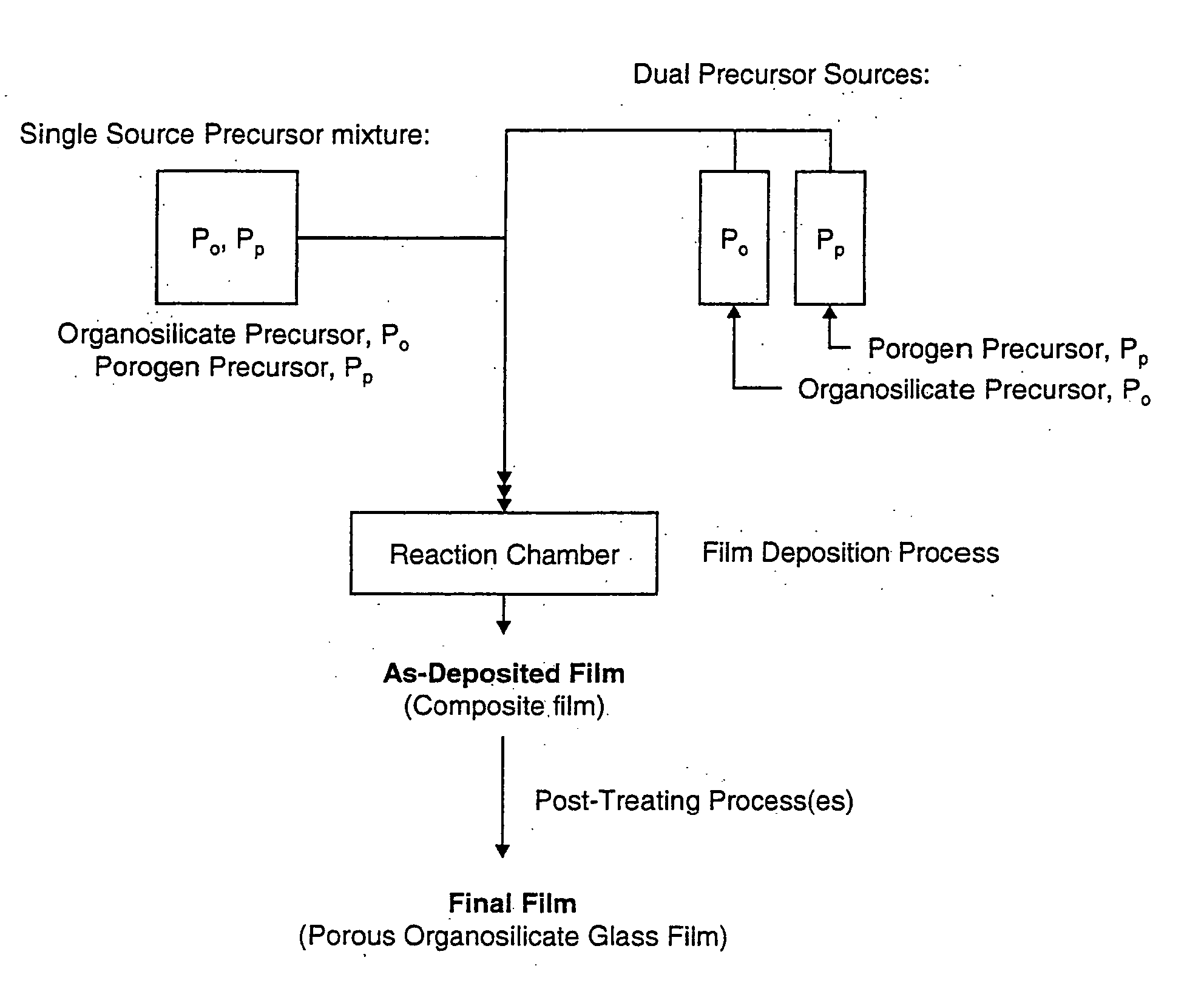

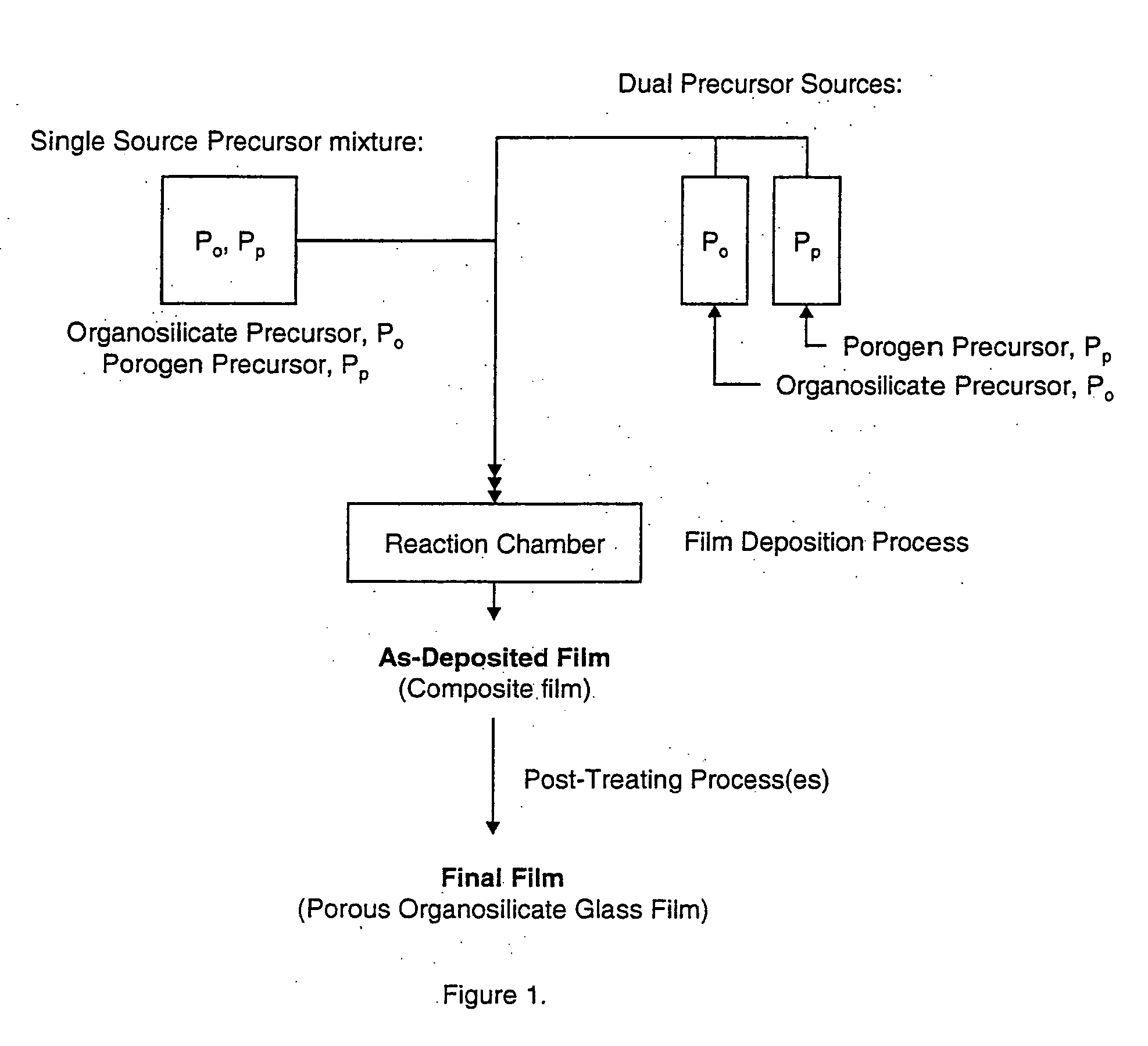

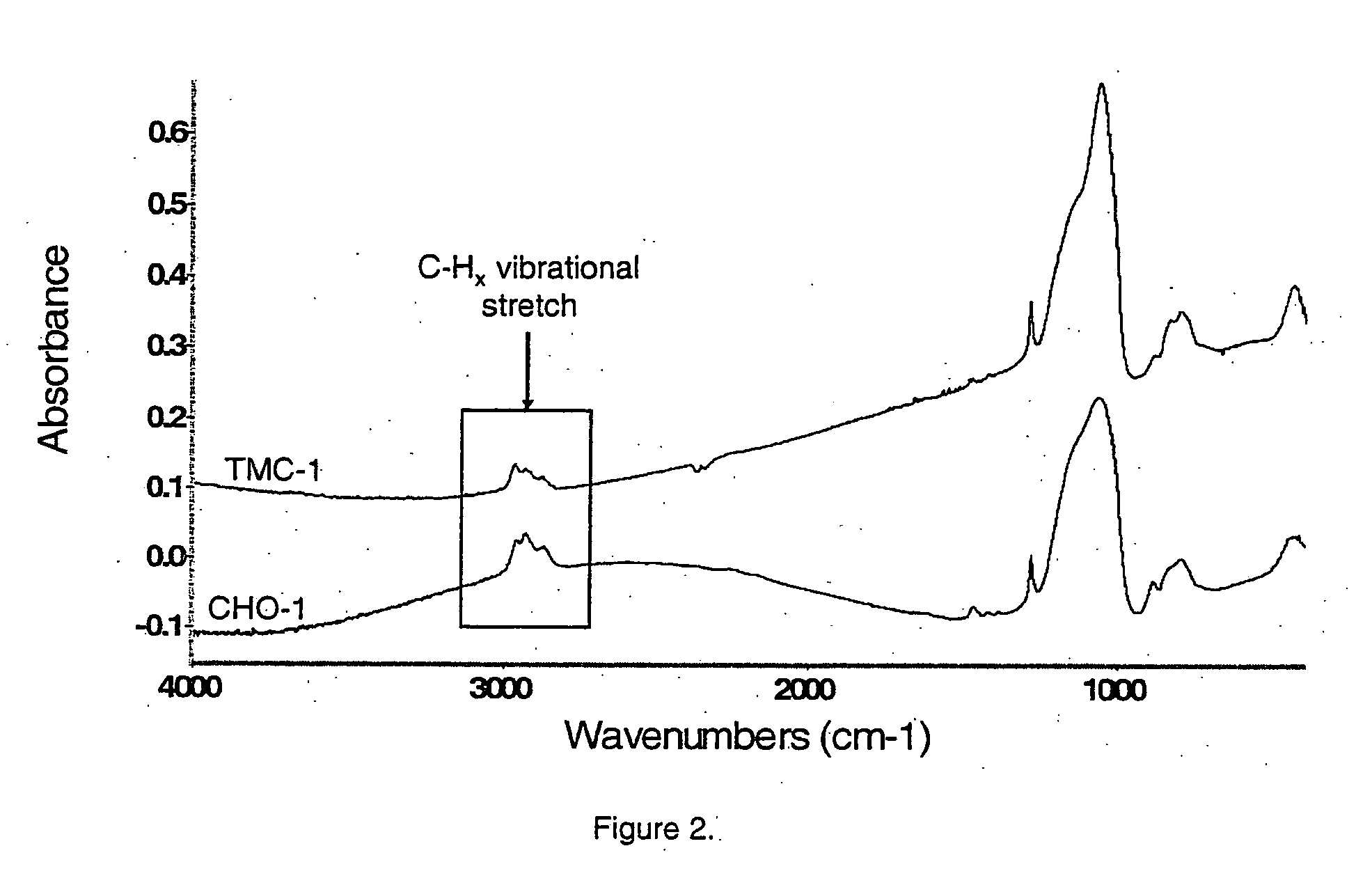

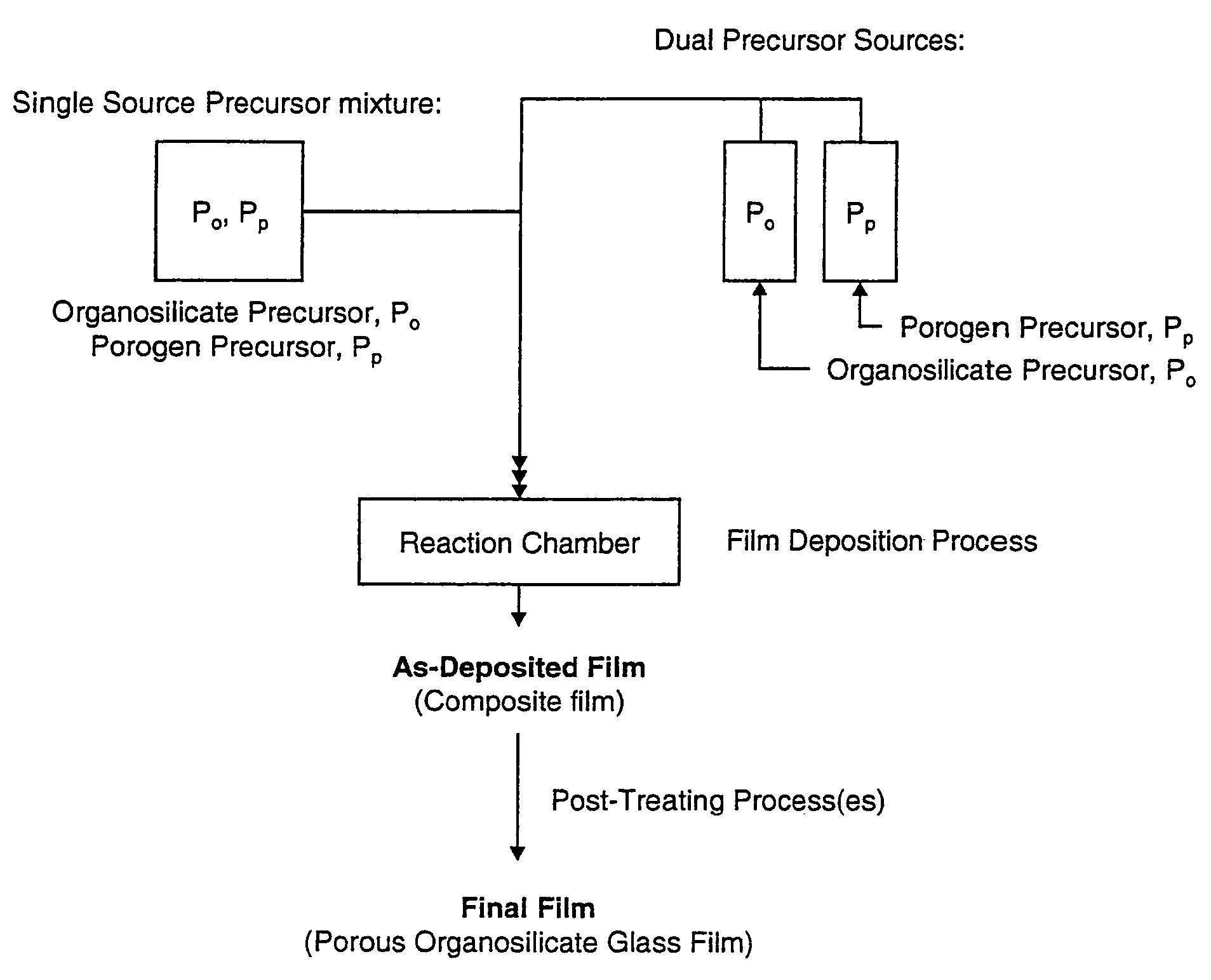

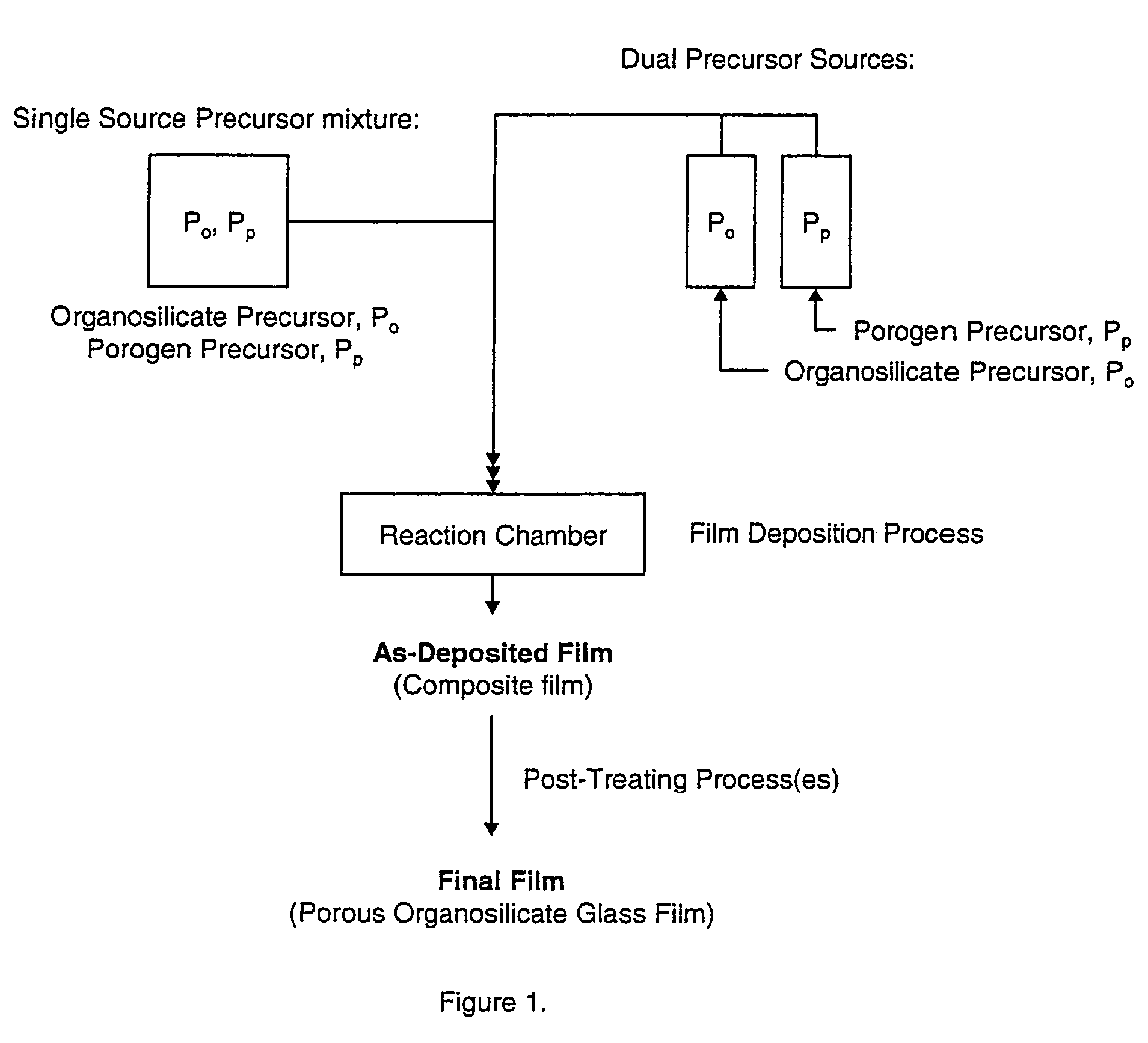

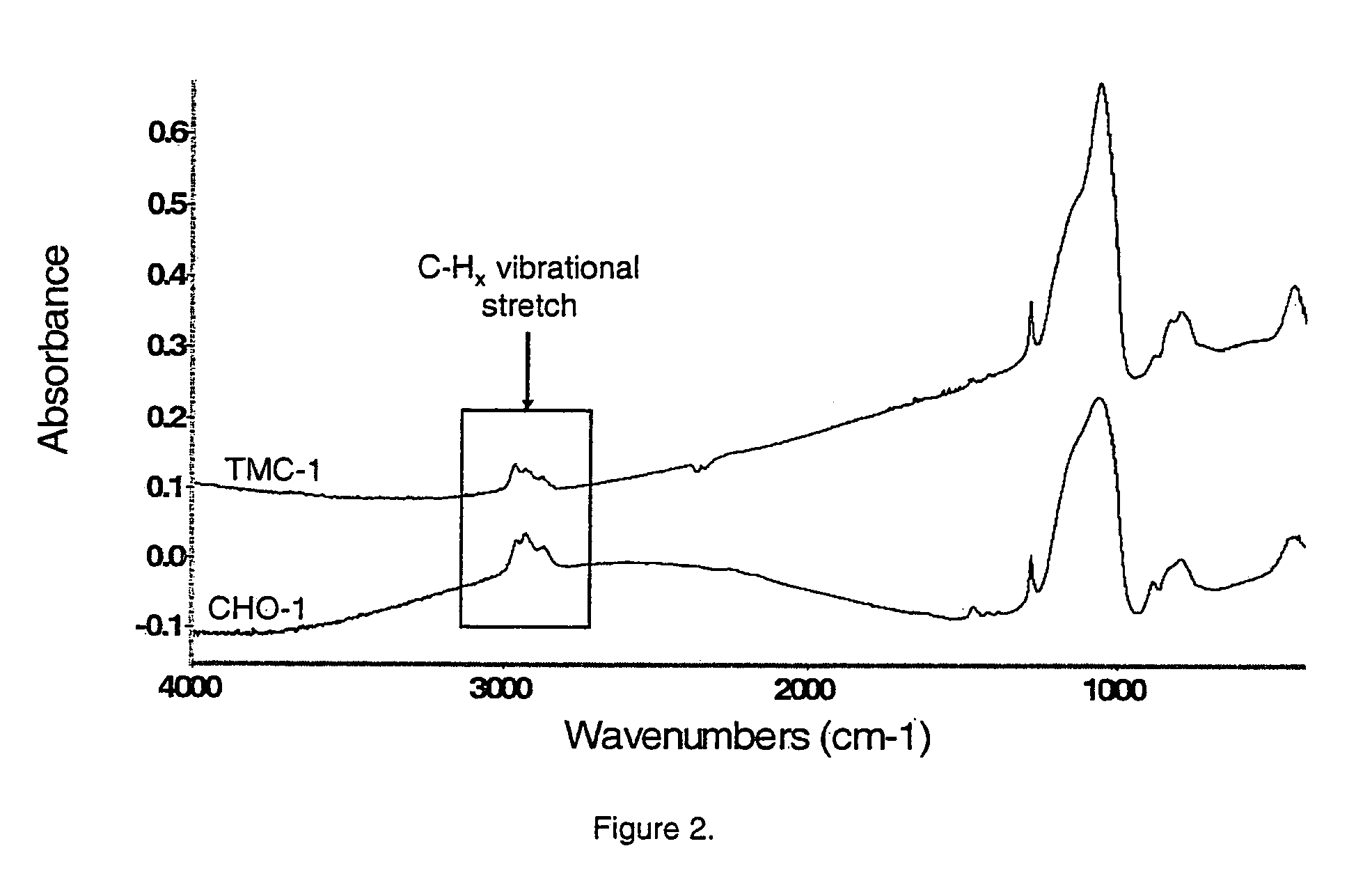

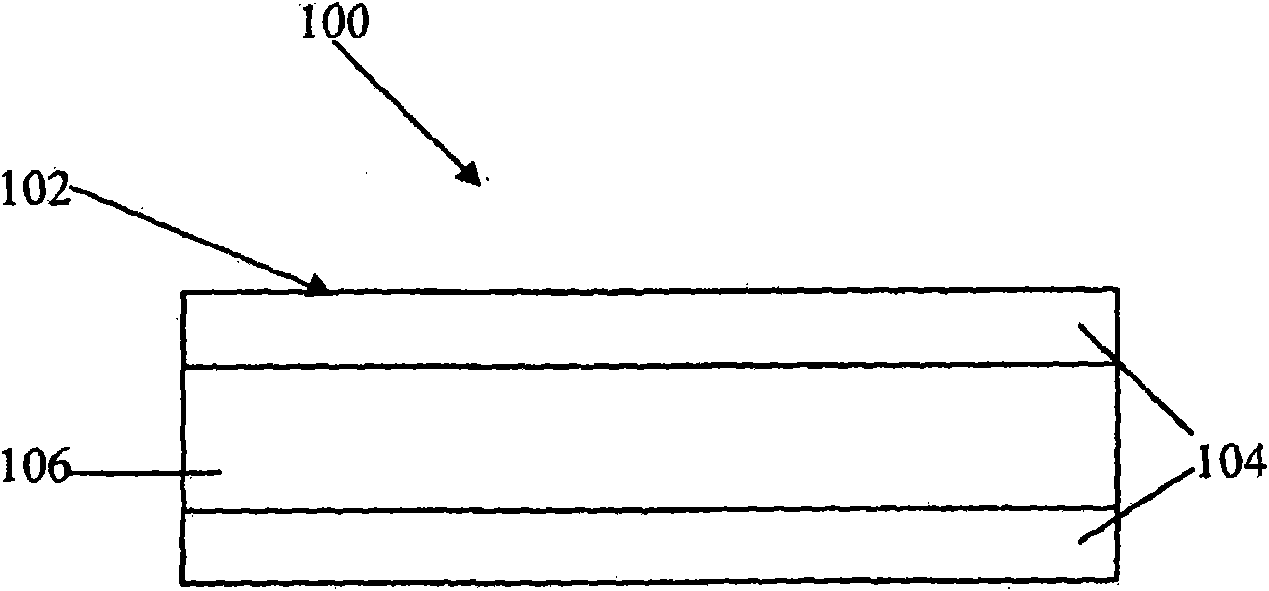

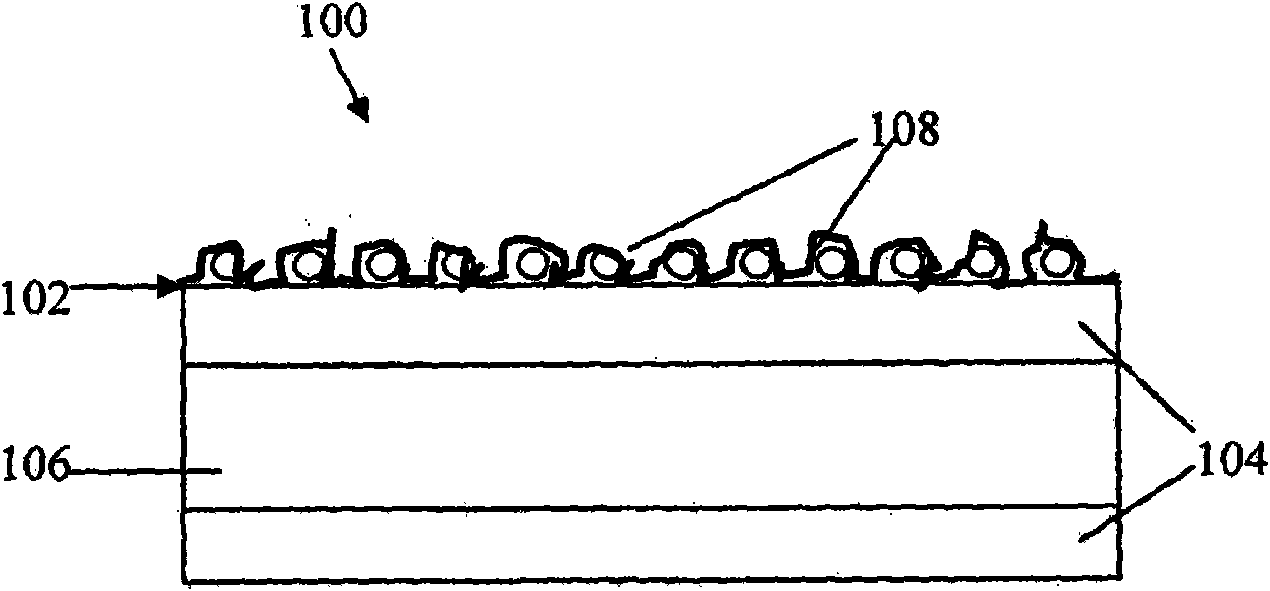

Porous low dielectric constant compositions and methods for making and using same

ActiveUS20060078676A1Semiconductor/solid-state device manufacturingPretreated surfacesConstant compositionCarboxylic acid

A porous organosilicate glass (OSG) film: SivOwCxHyFz, where v+w+x+y+z=100%, v is 10 to 35 atomic %, w is 10 to 65 atomic %, x is 5 to 30 atomic %, y is 10 to 50 atomic % and z is 0 to 15 atomic %, has a silicate network with carbon bonds as methyl groups (Si—CH3) and contains pores with diameter less than 3 nm equivalent spherical diameter and dielectric constant less than 2.7. A preliminary film is deposited by a chemical vapor deposition method from organosilane and / or organosiloxane precursors, and independent pore-forming precursors. Porogen precursors form pores within the preliminary film and are subsequently removed to provide the porous film. Compositions, film forming kits, include organosilane and / or organosiloxane compounds containing at least one Si—H bond and porogen precursors of hydrocarbons containing alcohol, ether, carbonyl, carboxylic acid, ester, nitro, primary amine, secondary amine, and / or tertiary amine functionality or combinations.

Owner:VERSUM MATERIALS US LLC

Soda-lime-silicate glass composition

A neutral-colored soda-lime-silicate glass with high light transmission in the visible region. The glass has a basic composition which contains at least the following constituents: SiO2, 66-75 weight %; Na2O, 10-20 weight %; CaO, 5-15 weight %; MgO, 0-6 weight %; Al2O3, 0-5 weight %; and K2O, 0-5 weight %; and incorporates a colorant portion comprising the following constituents: Co, 0.1-1 ppm; Fe2O3, <=0.03 weight % (total iron content); and FeO / Fe2O3, >0.4. The glass possesses a light transmittance (illuminant D 65 according to DIN 67 507) of at least 89% at a reference thickness of 4 mm.

Owner:PILKINGTON DEUTLAND

Formulations for cleaning memory device structures

InactiveUS20080125342A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBorophosphosilicate glassSilicon oxide

A removal composition and process for removing silicon-containing layers from a microelectronic device having said layers thereon. The removal composition selectively removes layers including, but not limited to, silicon oxide, plasma enhanced tetraethyl orthosilicate (P-TEOS), borophosphosilicate glass (BPSG), plasma enhanced oxide (PEOX), high density plasma oxide (HDP), phosphosilicate glass (PSG), spin-on-dielectrics (SOD), thermal oxide, updoped silicate glass, sacrificial oxides, silicon-containing organic polymers, silicon-containing hybrid organic / inorganic materials, organosilicate glass (OSG), TEOS, fluorinated silicate glass (FSG), hemispherical grain (HSQ), carbon-doped oxide (CDO) glass, and combinations thereof, relative to lower electrode, device substrate, and / or etch stop layer materials.

Owner:ADVANCED TECH MATERIALS INC

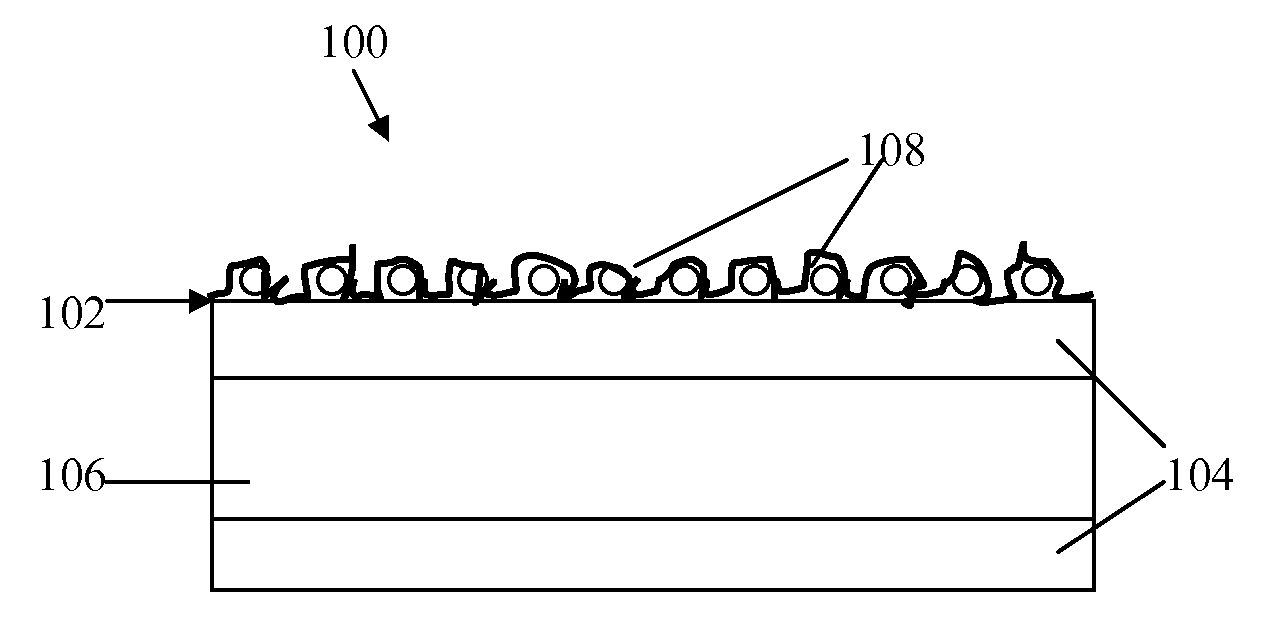

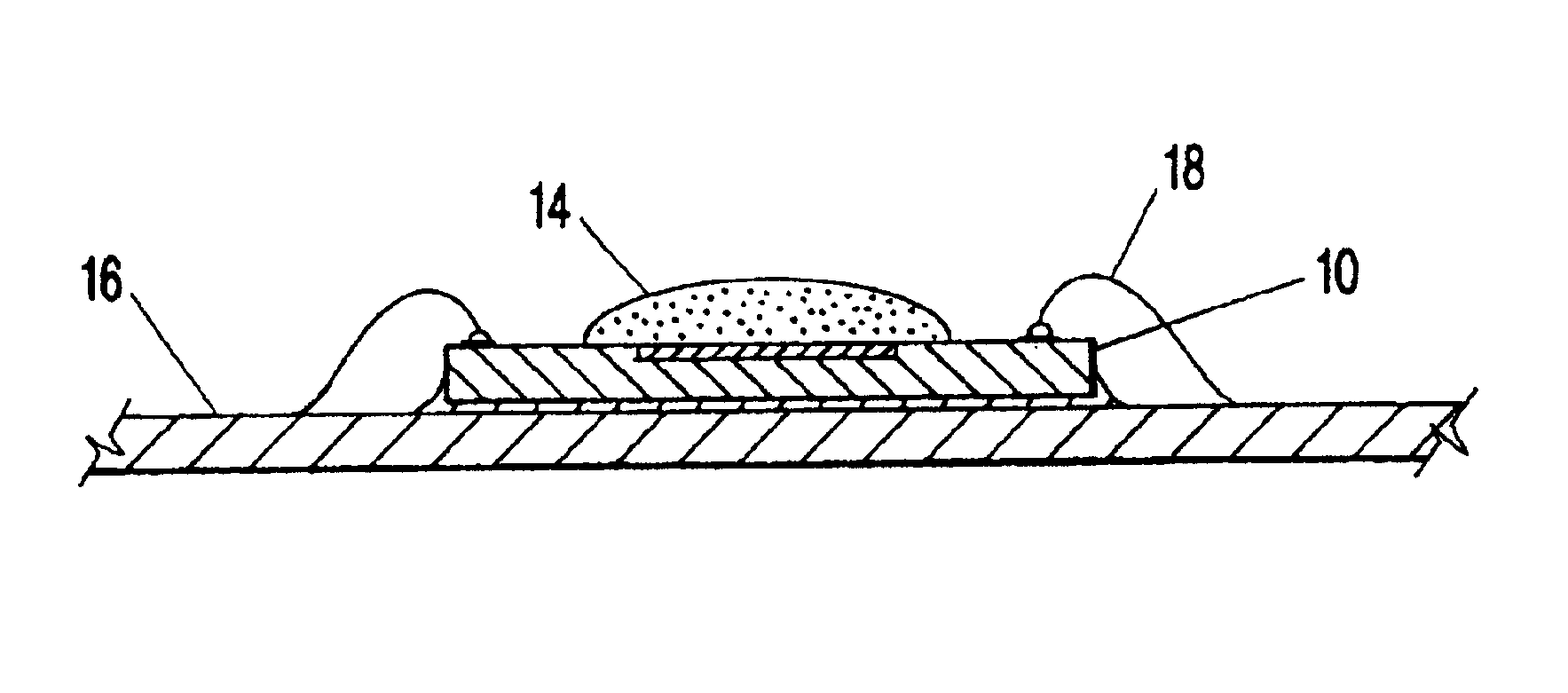

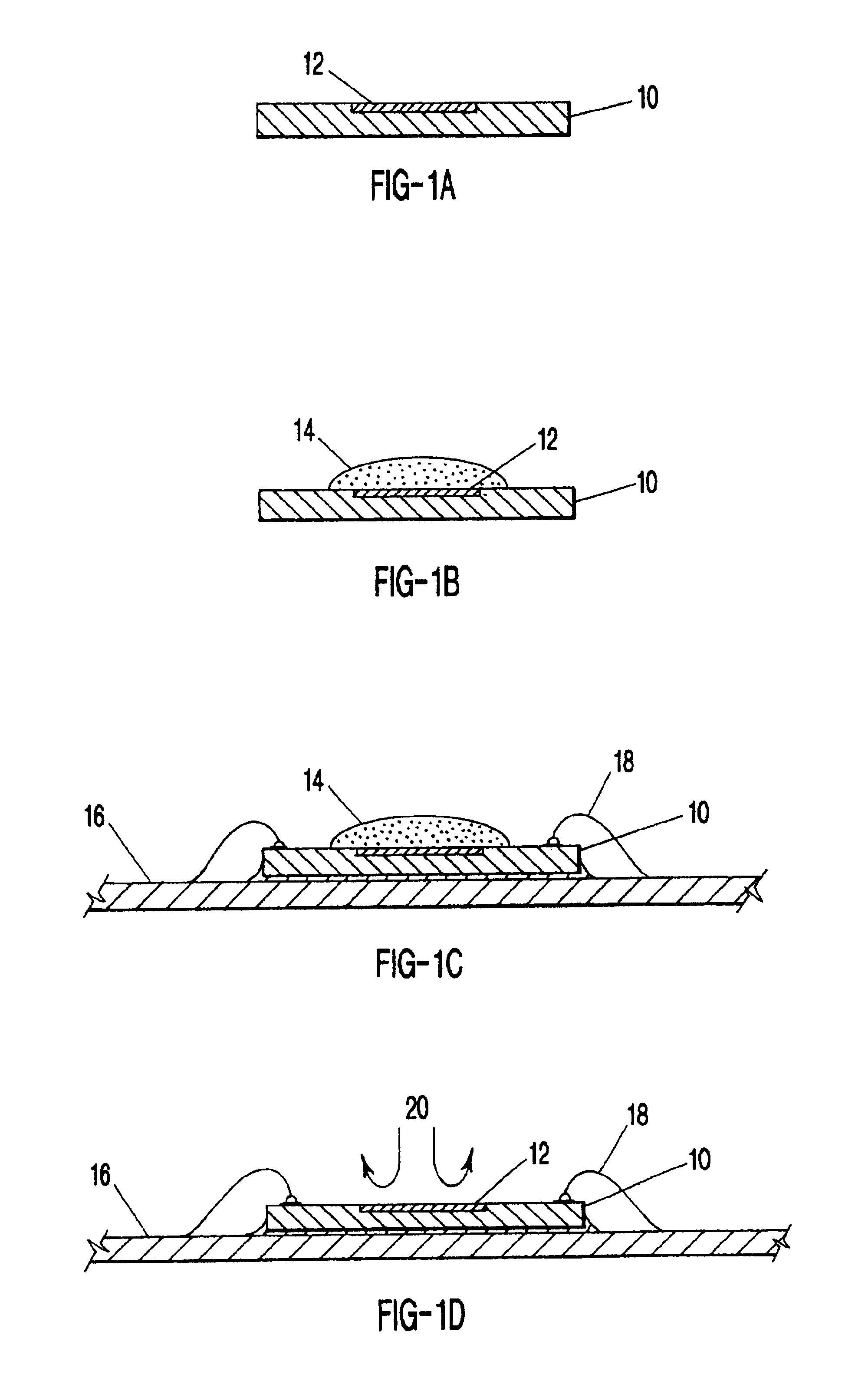

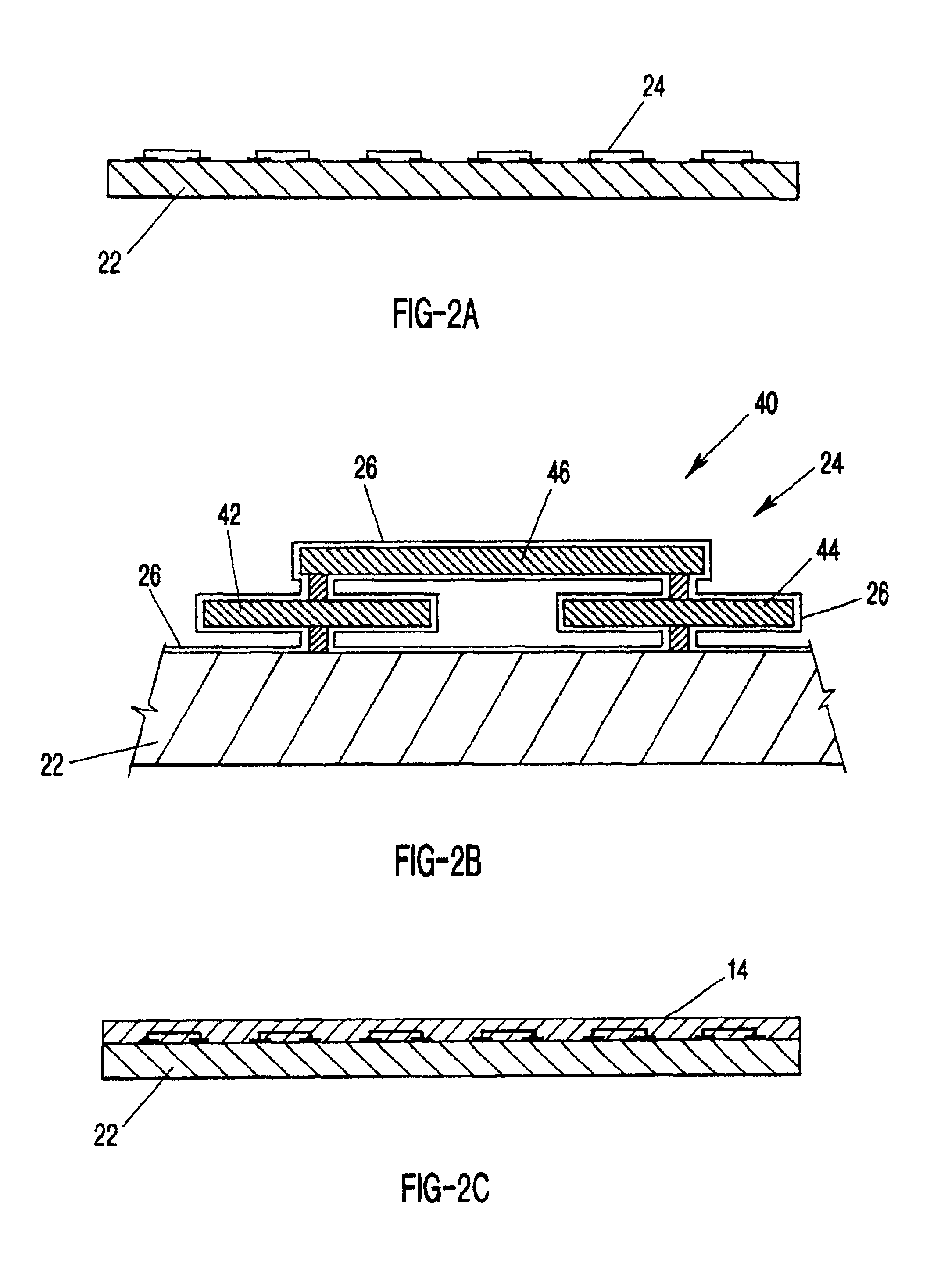

Temporary coatings for protection of microelectronic devices during packaging

InactiveUS6844623B1Decorative surface effectsSemiconductor/solid-state device detailsCarbon filmParylene

The present invention relates to a method of protecting a microelectronic device during device packaging, including the steps of applying a water-insoluble, temporary protective coating to a sensitive area on the device; performing at least one packaging step; and then substantially removing the protective coating, preferably by dry plasma etching. The sensitive area can include a released MEMS element. The microelectronic device can be disposed on a wafer. The protective coating can be a vacuum vapor-deposited parylene polymer, silicon nitride, metal (e.g. aluminum or tungsten), a vapor deposited organic material, cynoacrylate, a carbon film, a self-assembled monolayered material, perfluoropolyether, hexamethyldisilazane, or perfluorodecanoic carboxylic acid, silicon dioxide, silicate glass, or combinations thereof. The present invention also relates to a method of packaging a microelectronic device, including: providing a microelectronic device having a sensitive area; applying a water-insoluble, protective coating to the sensitive area; providing a package; attaching the device to the package; electrically interconnecting the device to the package; and substantially removing the protective coating from the sensitive area.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

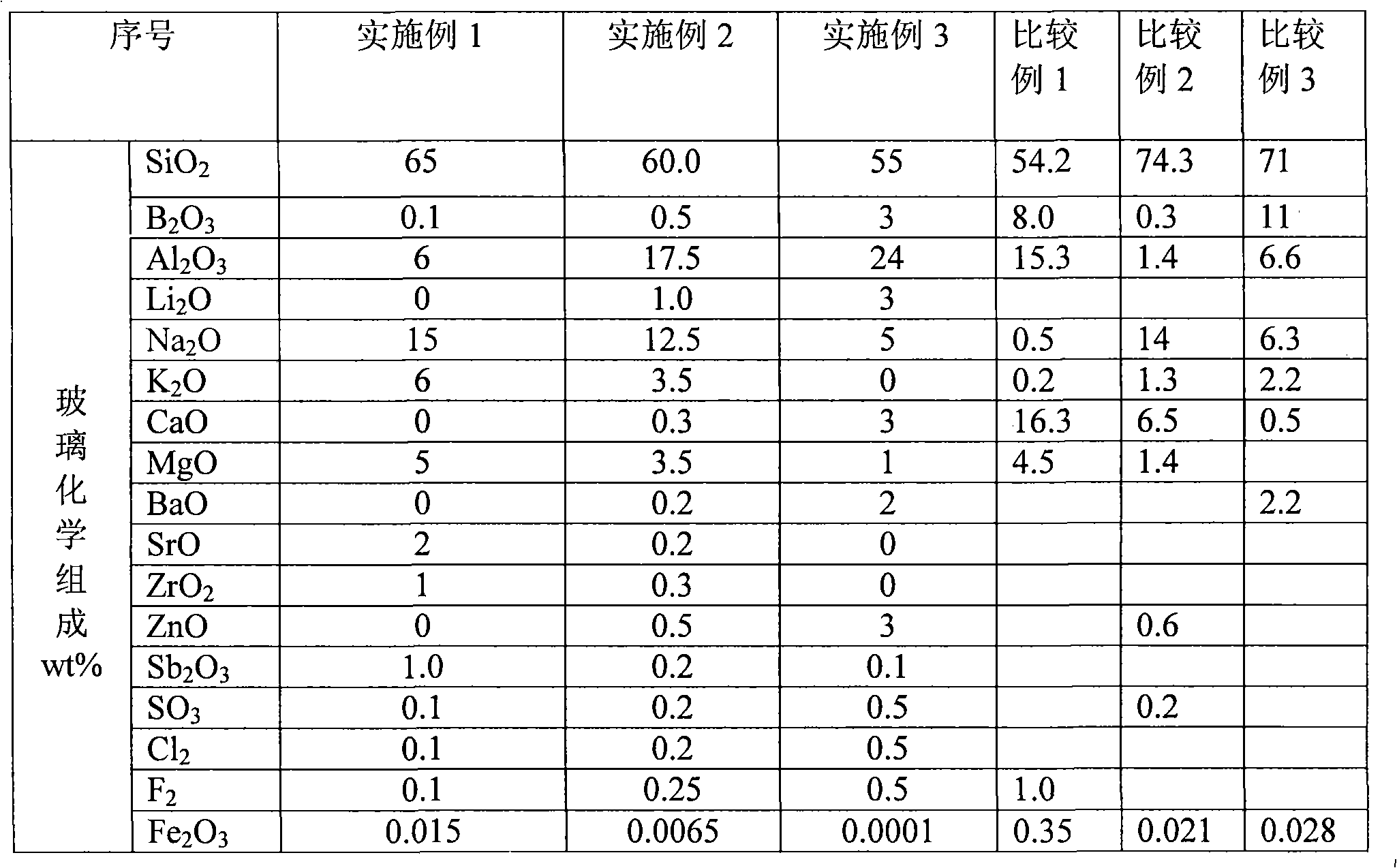

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

Lithium silicate glass ceramic and glass with ZrO2 content

ActiveUS20120248642A1Substantial deterioration in translucencyInhibition formationDental implantsWristbandsLithiumSolid Bond

Owner:IVOCLAR VIVADENT AG

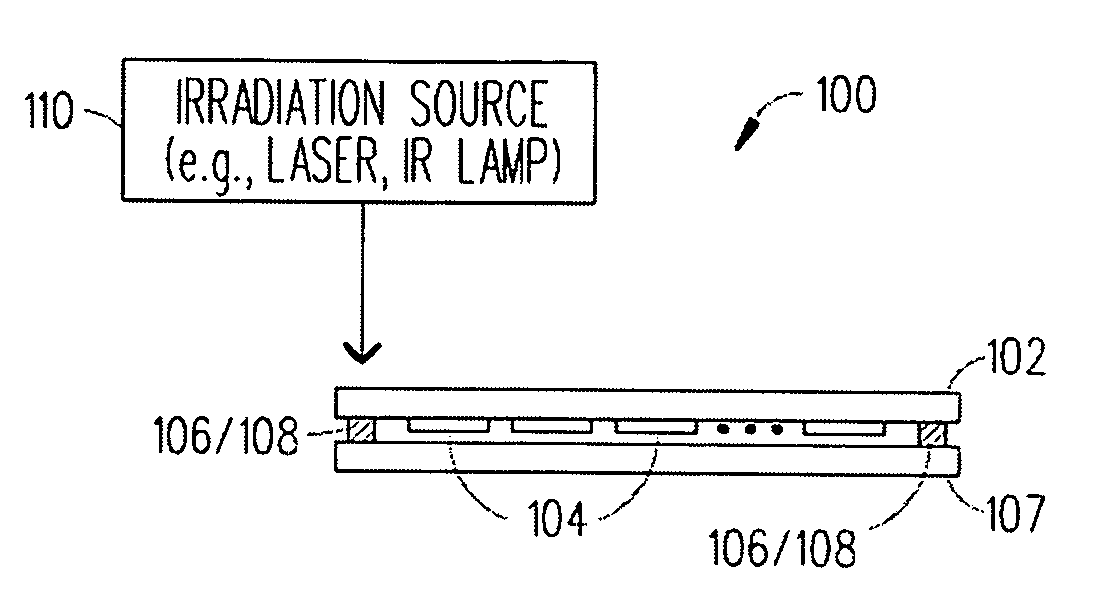

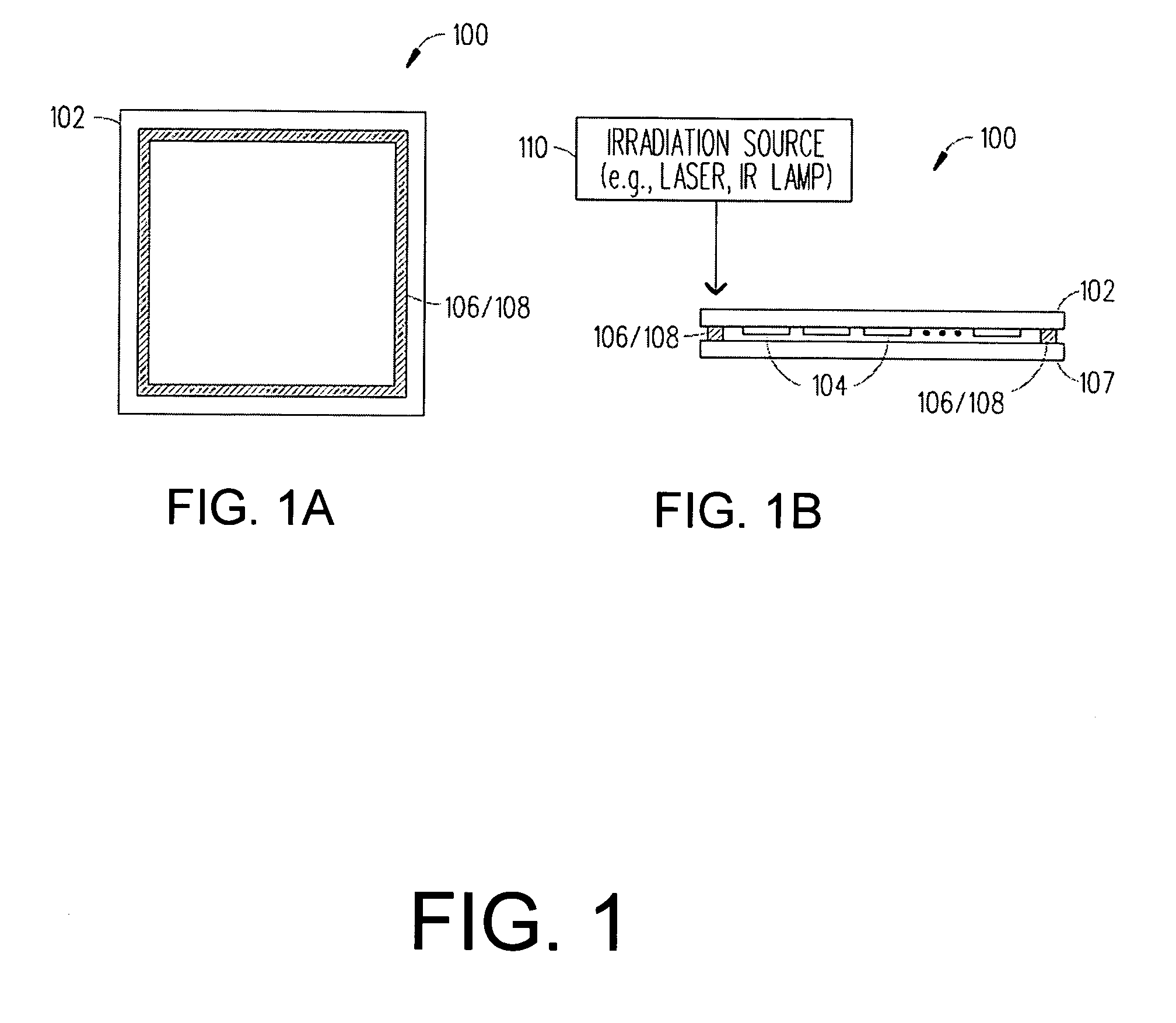

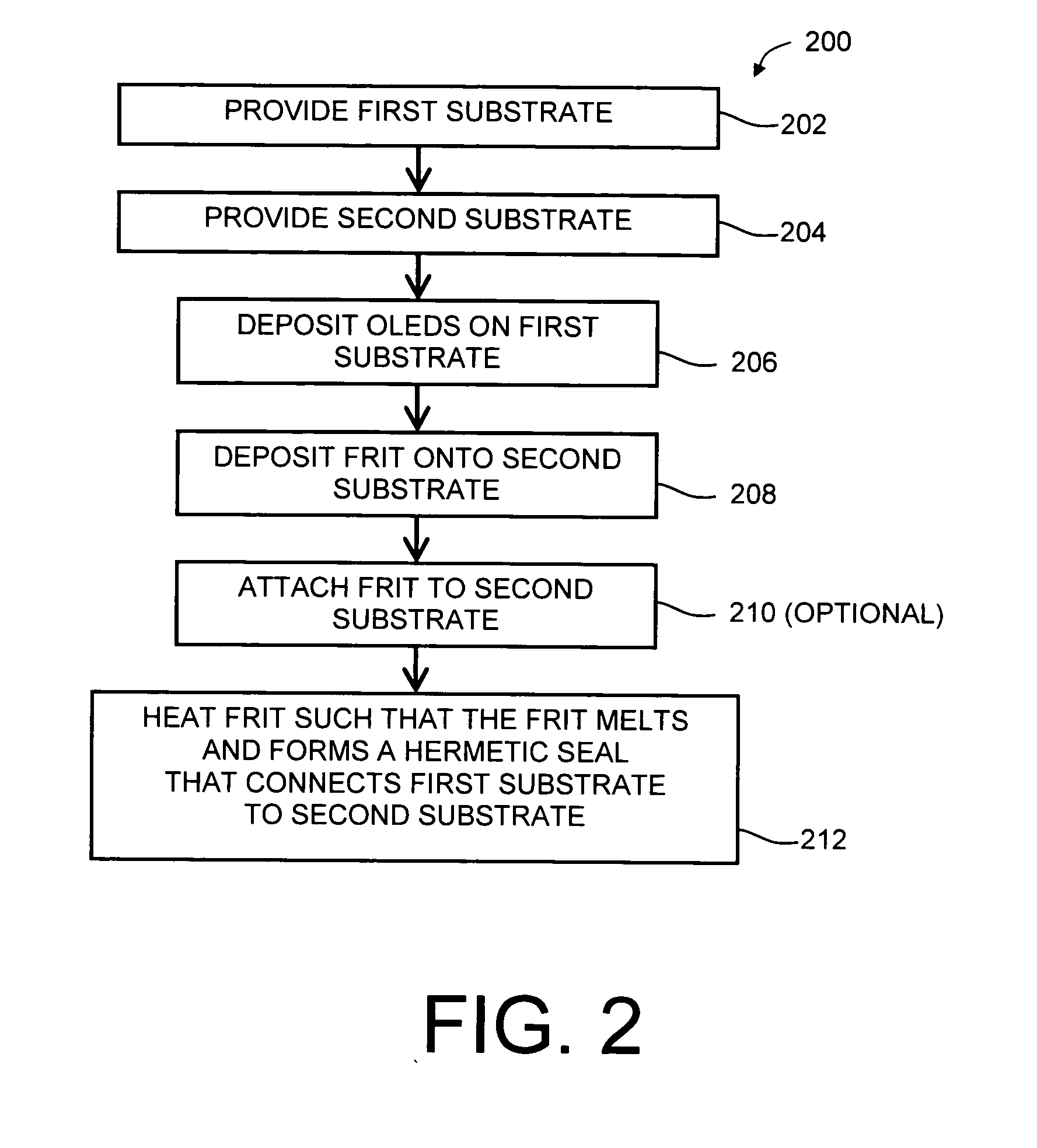

Boro-silicate glass frits for hermetic sealing of light emitting device displays

InactiveUS20080124558A1Problem be addressLamination ancillary operationsSolid-state devicesFritSilicate glass

A frit composition useful for sealing a light emitting device is disclosed. The frit composition comprises a glass portion comprising a base component and at least one absorbing component. The glass portion of the frit comprises silica, boron oxide, optionally alumina, and (a) cupric oxide and / or a (b) combination of ferric oxide, vanadium pentoxide, and optionally titanium dioxide. Also disclosed is an article comprising a substrate and a frit, and a glass package comprising two substrates and a frit positioned between the substrates. A method for manufacturing a hermetically sealed glass package comprising the deposition of a glass frit and heating of the glass frit to form a hermetic seal is also disclosed.

Owner:CORNING INC

Porous low dielectric constant compositions and methods for making and using same

Owner:VERSUM MATERIALS US LLC

Antimicrobial, water-insoluble silicate glass powder and mixture of glass powders

An antimicrobial, water-insoluble silicate glass powder is provided. The starting glass includes 30 to 70 weight percent SiO2, 0 to 1 weight percent Na2O, 0 to 1 weight percent K2O, 0 to 40 weight percent MgO, 0 to 40 weight percent CaO, 0 to 40 weight percent SrO, 0 to 40 weight percent BaO, 0 to 25 weight percent Al2O3, 0 to 20 weight percent P2O5, 0 to 20 weight percent B2O3, wherein the sum of the alkali oxide contents is less than 1.5 weight percent in the total composition of the starting glass. The starting glass also includes, as biocidally active components, ions or atoms of the elements Ag, Zn, Cu, Ce, Te, or I with total proportions of greater than 2.5 weight percent.

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com