Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

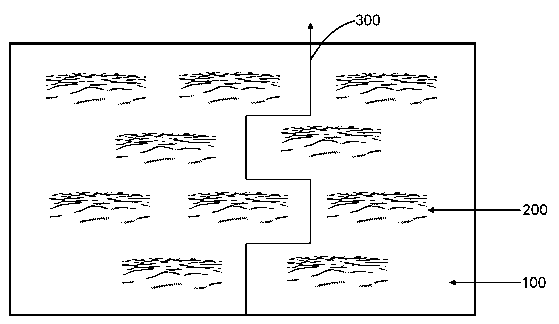

651results about How to "Improve battery efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

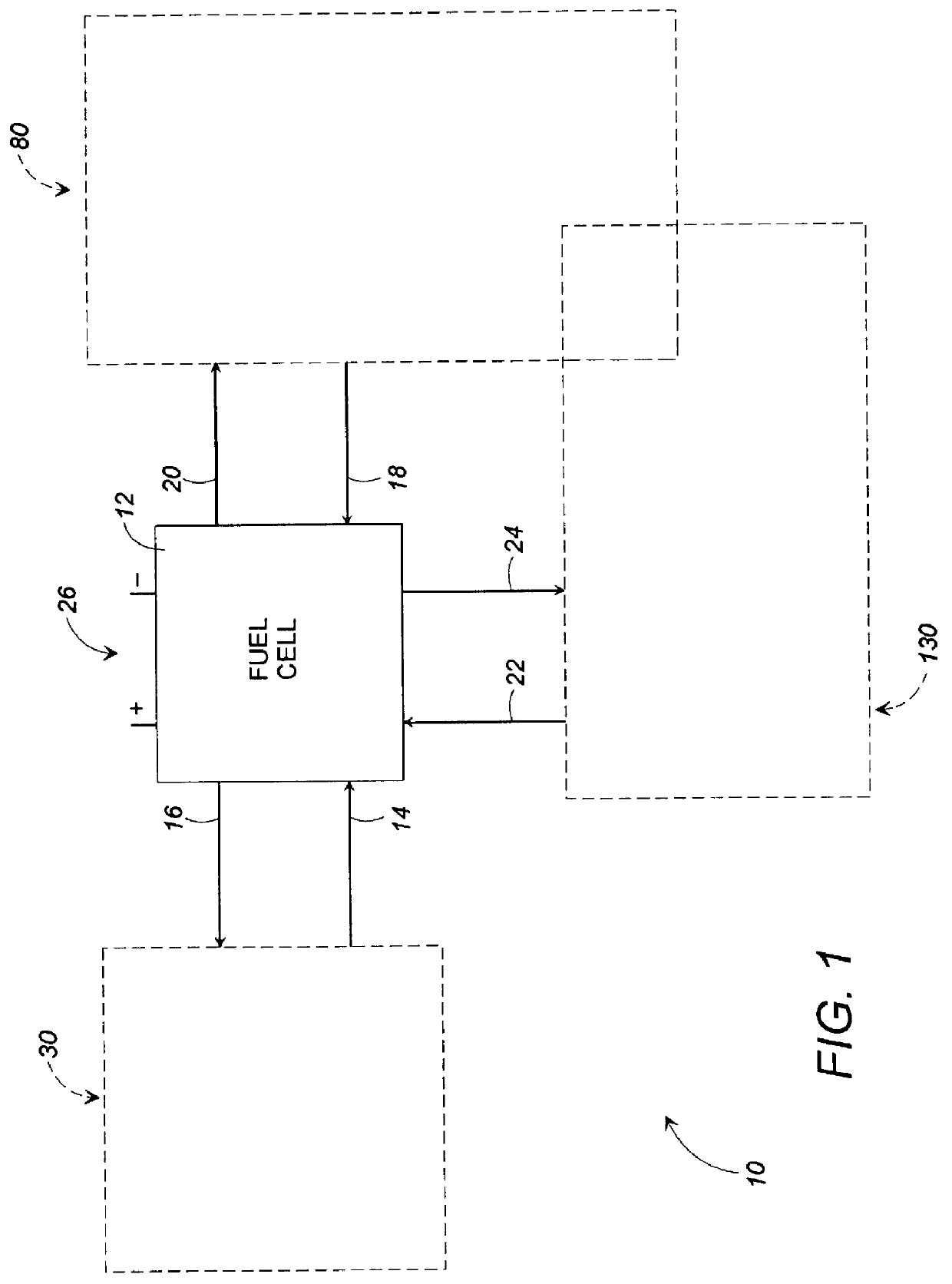

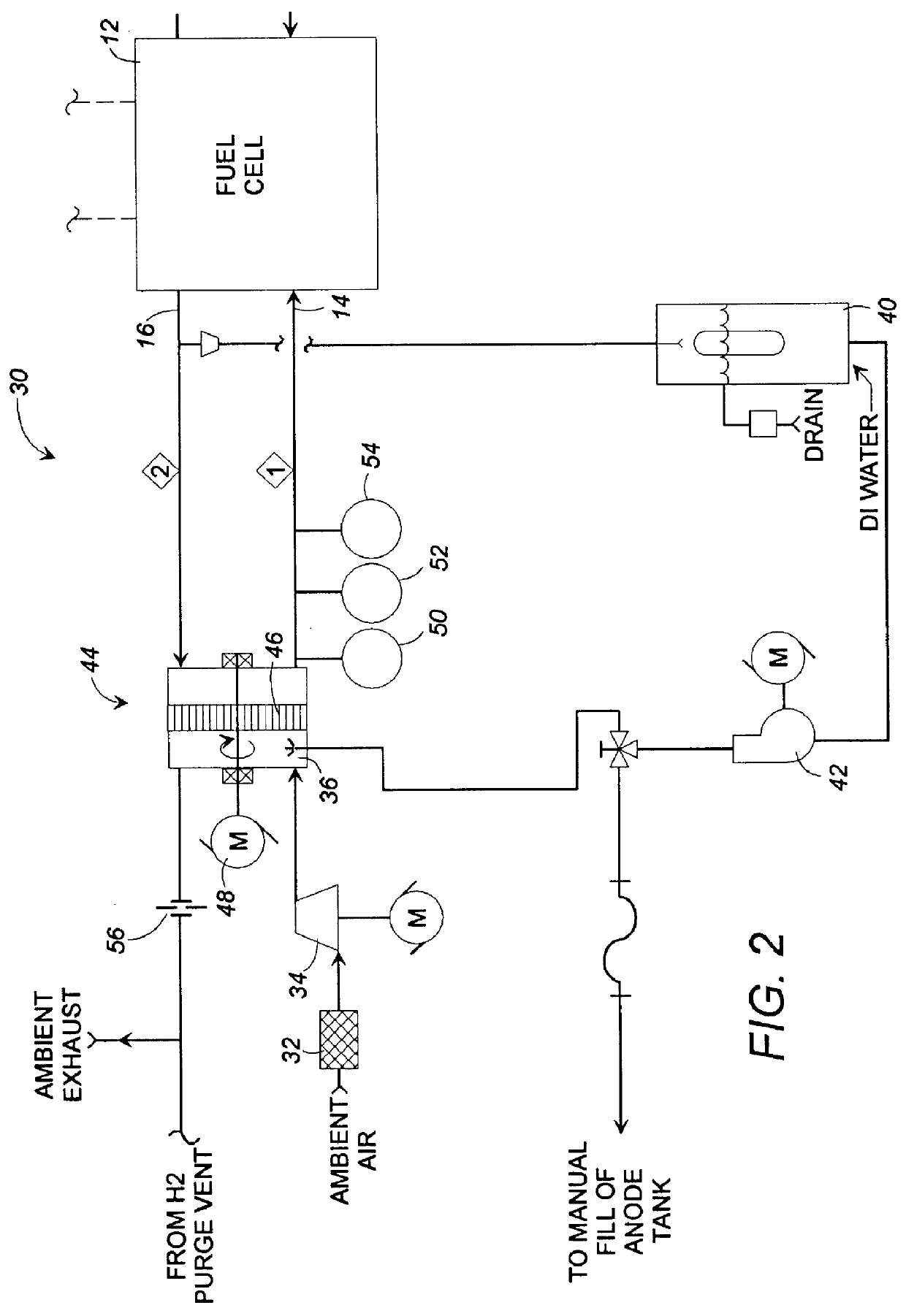

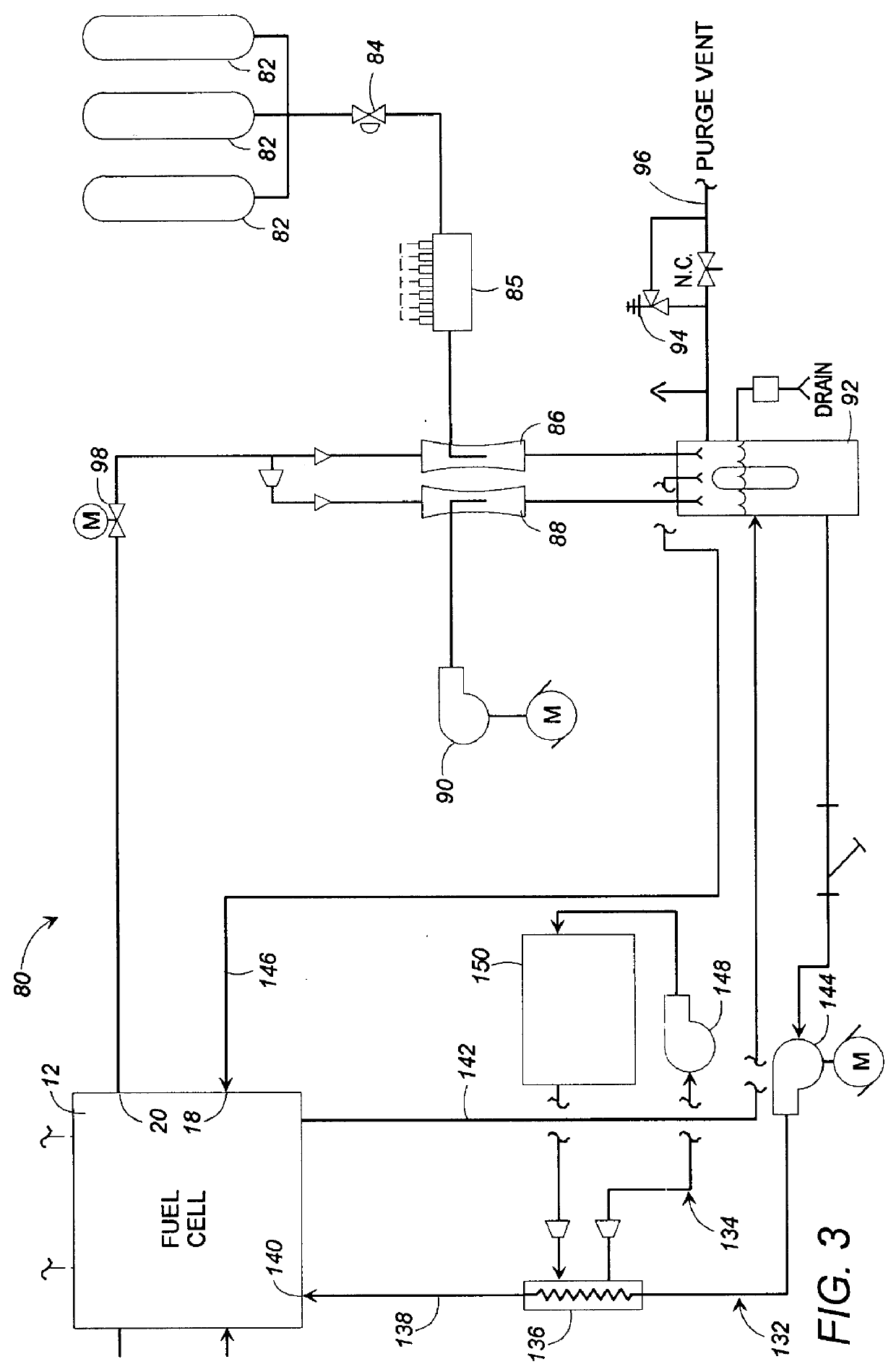

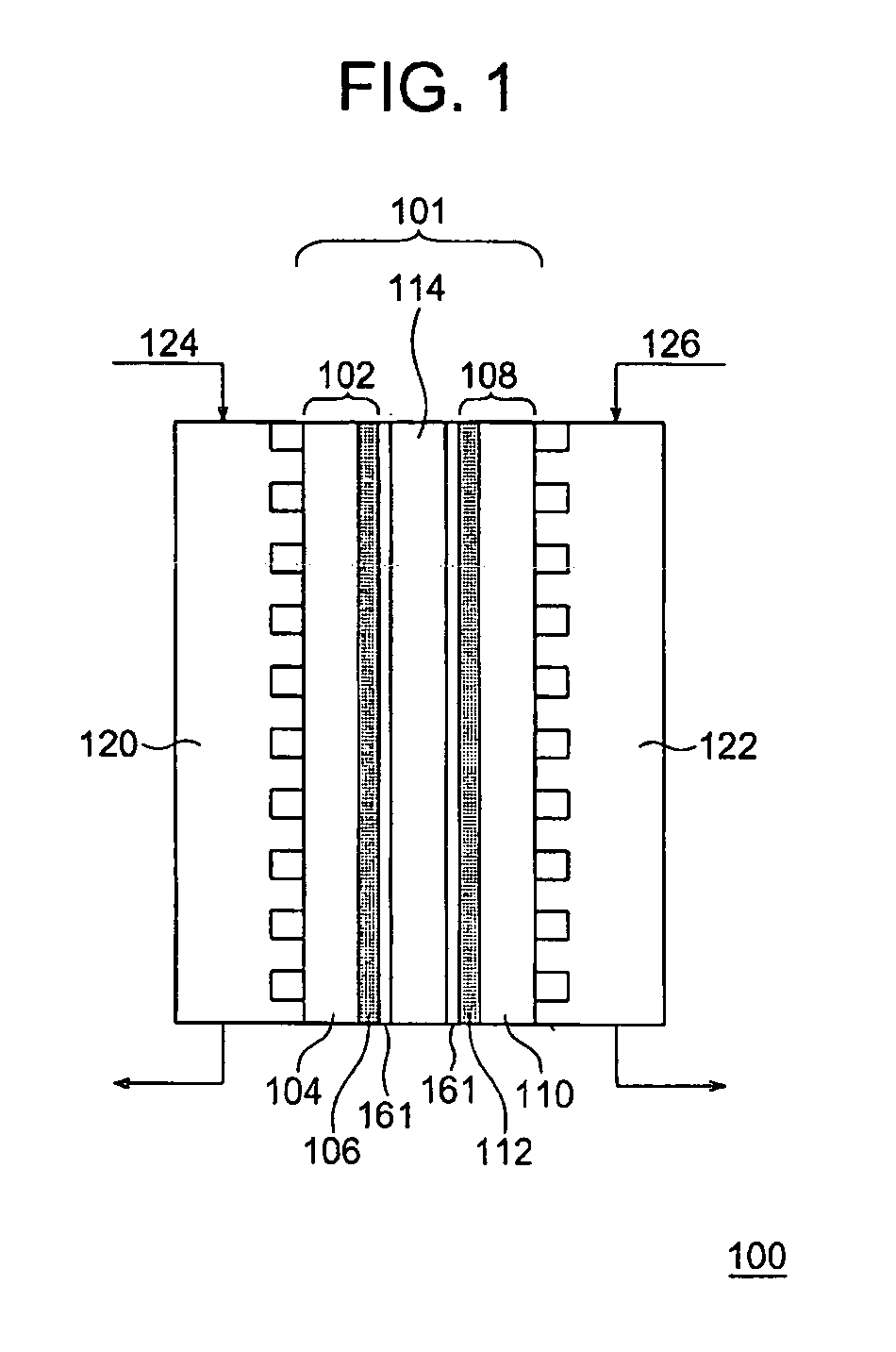

Fuel cell gas management system

InactiveUS6013385AImprove battery efficiencyMinimize the possibilityFuel cell heat exchangeFuel cell controlIonEnthalpy

A fuel cell gas management system including a cathode humidification system for transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell equal to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

Thick Film Pastes For Fire Through Applications In Solar Cells

InactiveUS20090056798A1Improve battery efficiencyFinal product manufactureConductive materialEngineeringMetal

Formulations and methods of making solar cell contacts and cells therewith are disclosed. The invention provides a photovoltaic cell comprising a front contact, a back contact, and a rear contact. The back contact comprises, prior to firing, a passivating layer onto which is applied a paste, comprising aluminum, a glass component, wherein the aluminum paste comprises, aluminum, another optional metal, a glass component, and a vehicle. The back contact comprises, prior to firing, a passivating layer onto which is applied an aluminum paste, wherein the aluminum paste comprises aluminum, a glass component, and a vehicle.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

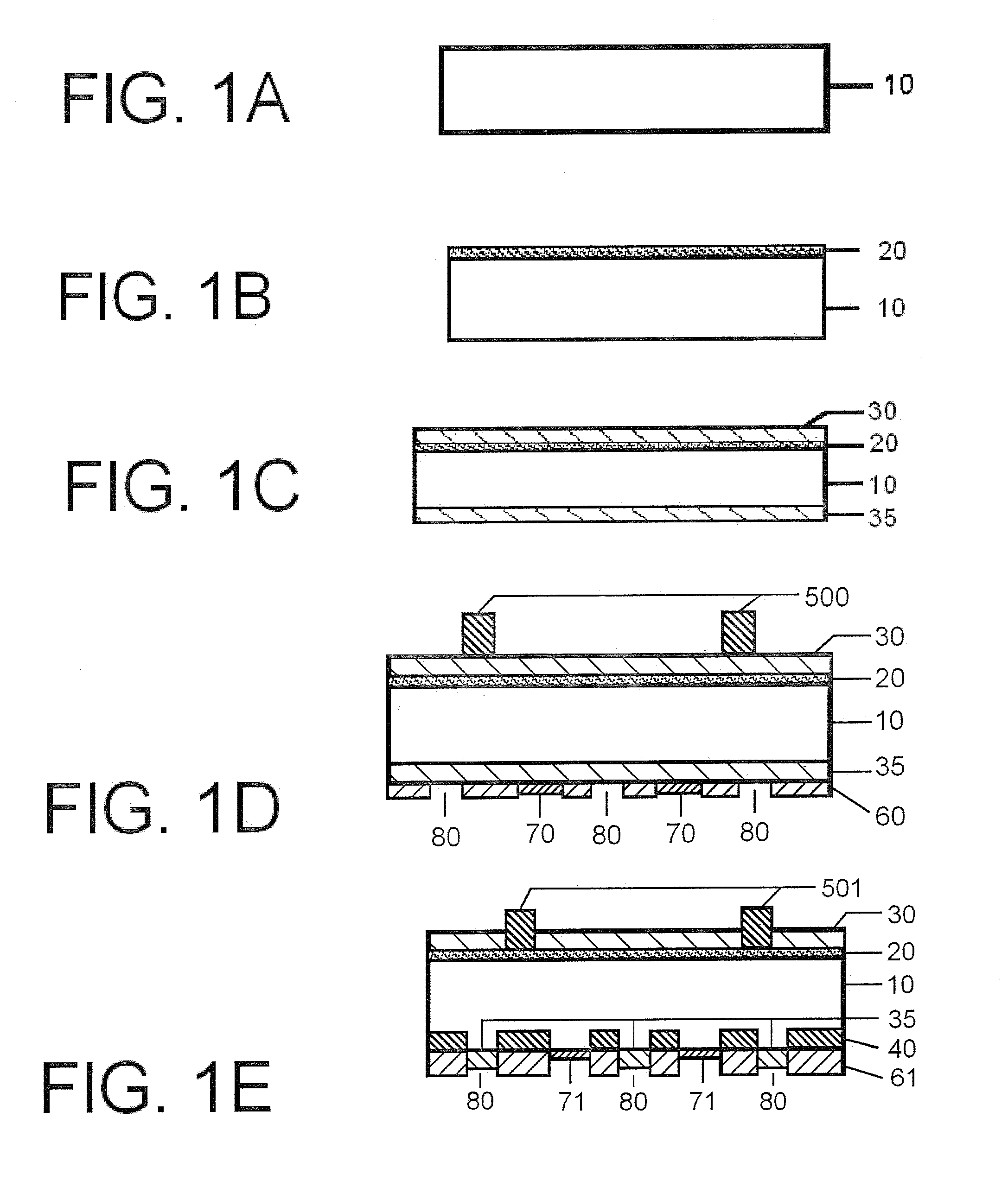

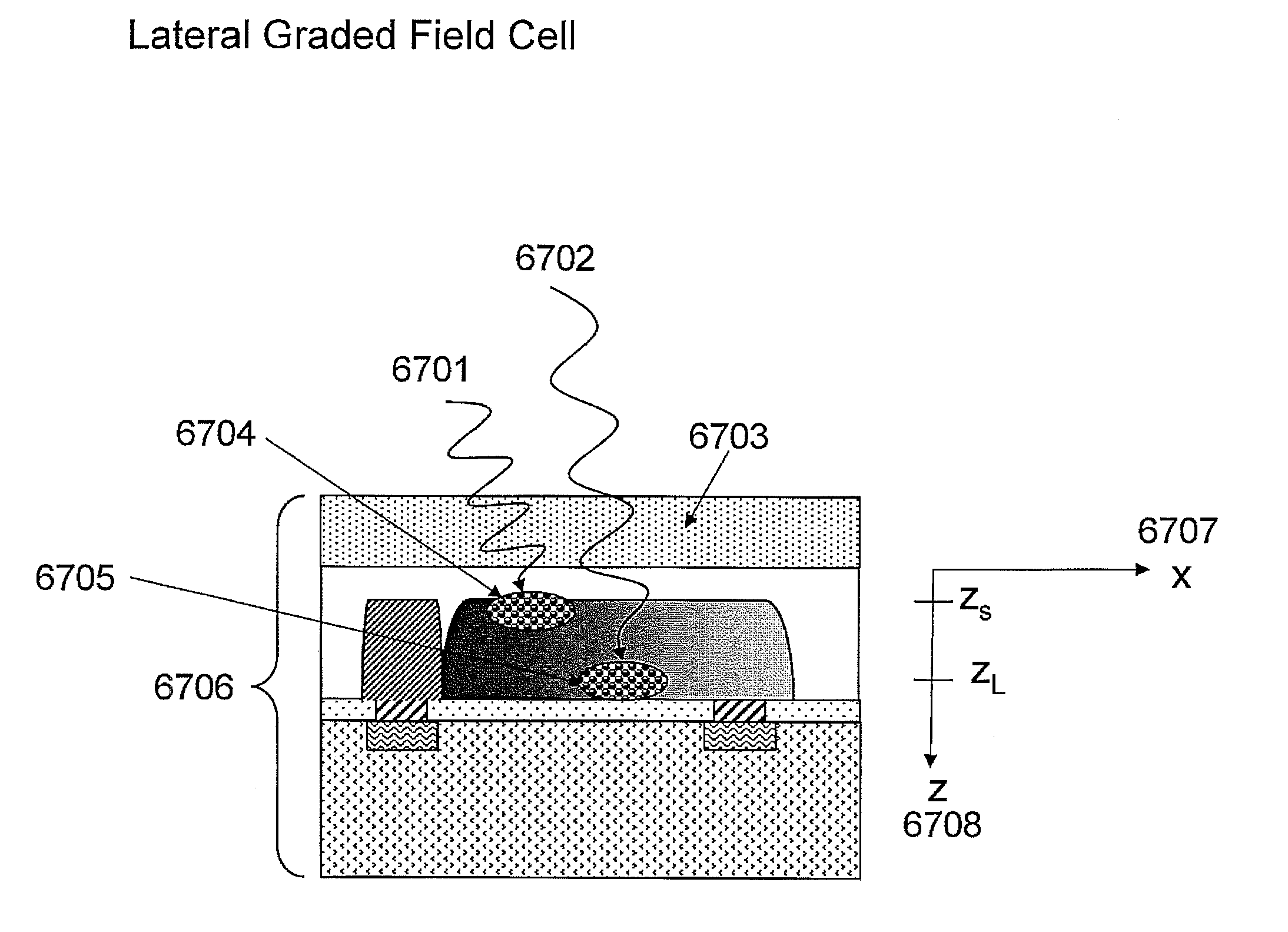

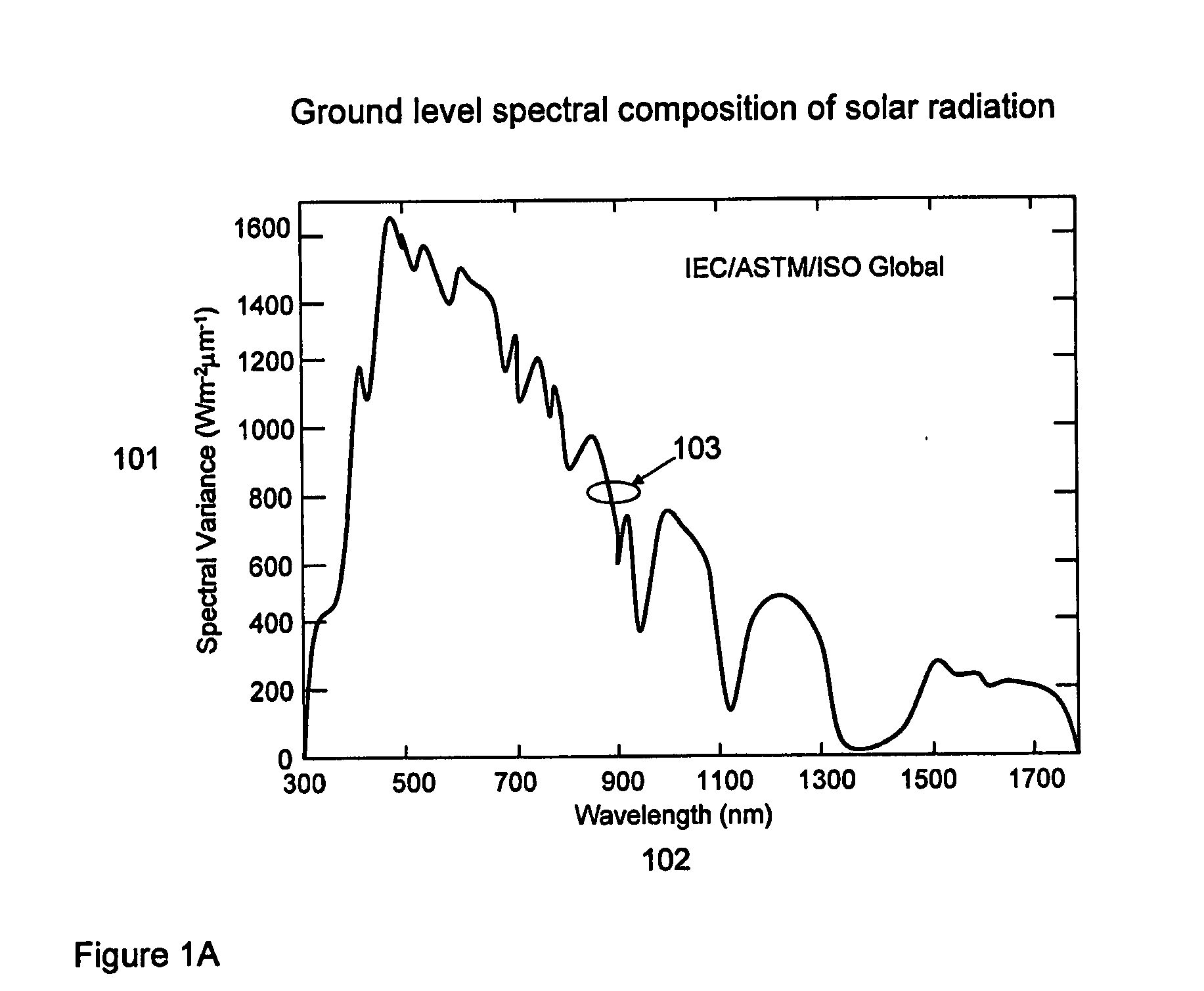

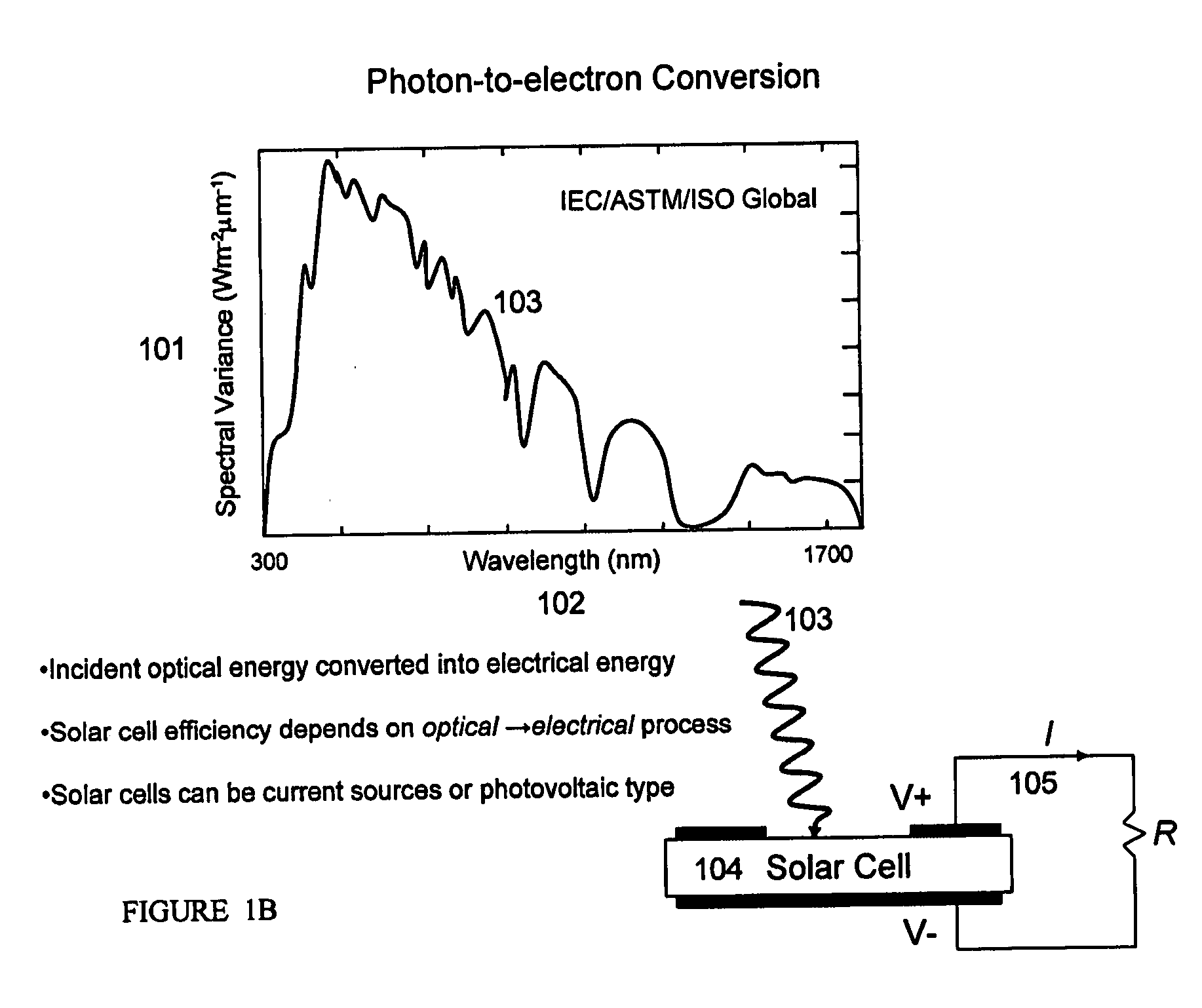

Thin film solar cell

InactiveUS20080078444A1Good choiceImprovement factorPhotovoltaic energy generationSemiconductor devicesHigh energyUltraviolet

Optimal structures for high efficiency thin film silicon solar energy conversion devices and systems are disclosed. Thin film silicon active layer photoelectron conversion structures using ion implantation are disclosed. Thin film semiconductor devices optimized for exploiting the high energy and ultraviolet portion of the solar spectrum at the earths surface are also disclosed. Solar cell fabrication using high oxygen concentration single crystal silicon substrates formed using in preference the CZ method are used advantageously. Furthermore, the present invention discloses optical coatings for advantageous coupling of solar radiation into thin film solar cell devices via the use of rare-earth metal oxide (REOx), rare-earth metal oxynitride (REOxNy) and rare-earth metal oxy-phosphide (REOxPy) glasses and or crystalline material. The rare-earth metal is chosen from the group commonly known in the periodic table of elements as the lanthanide series.

Owner:IQE

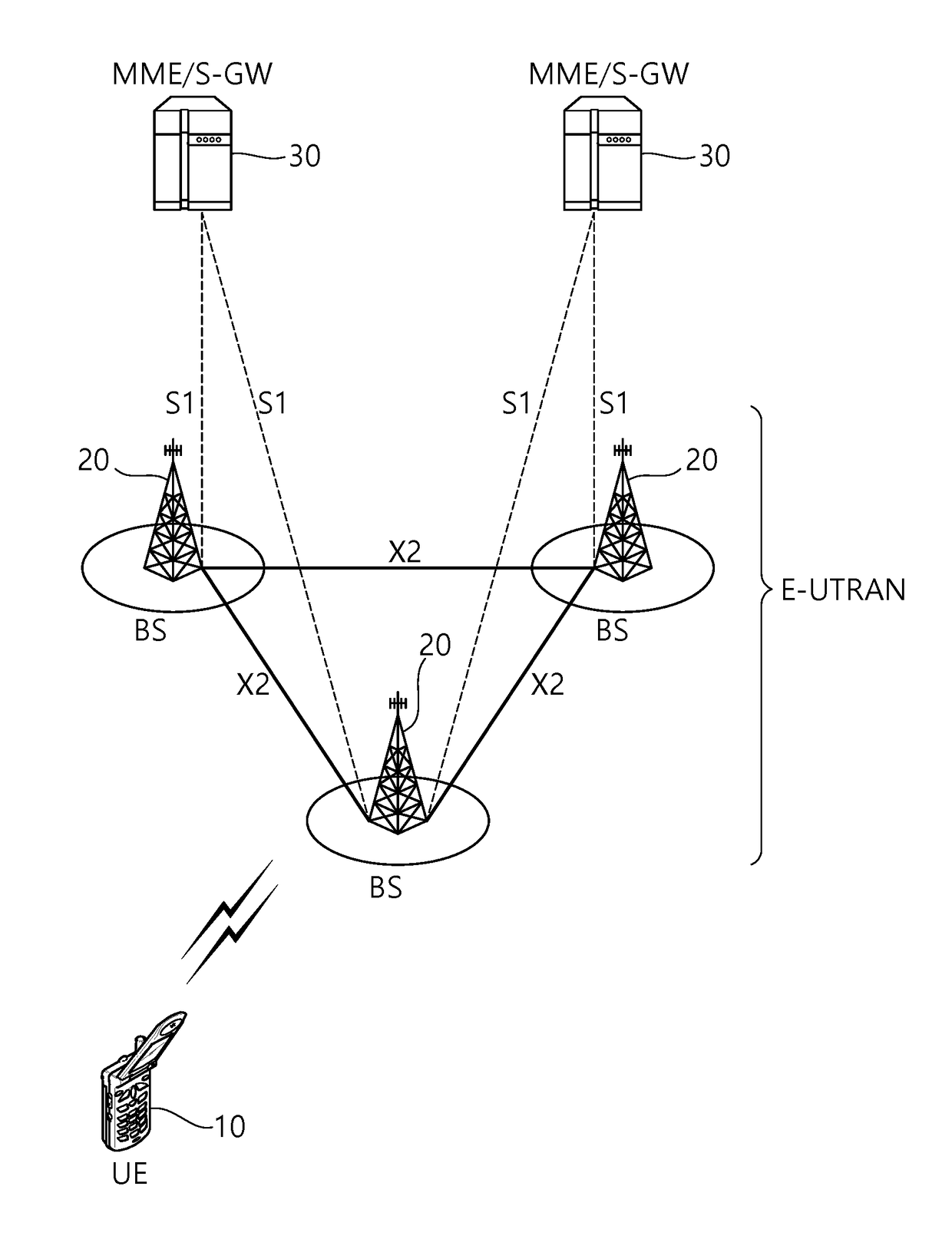

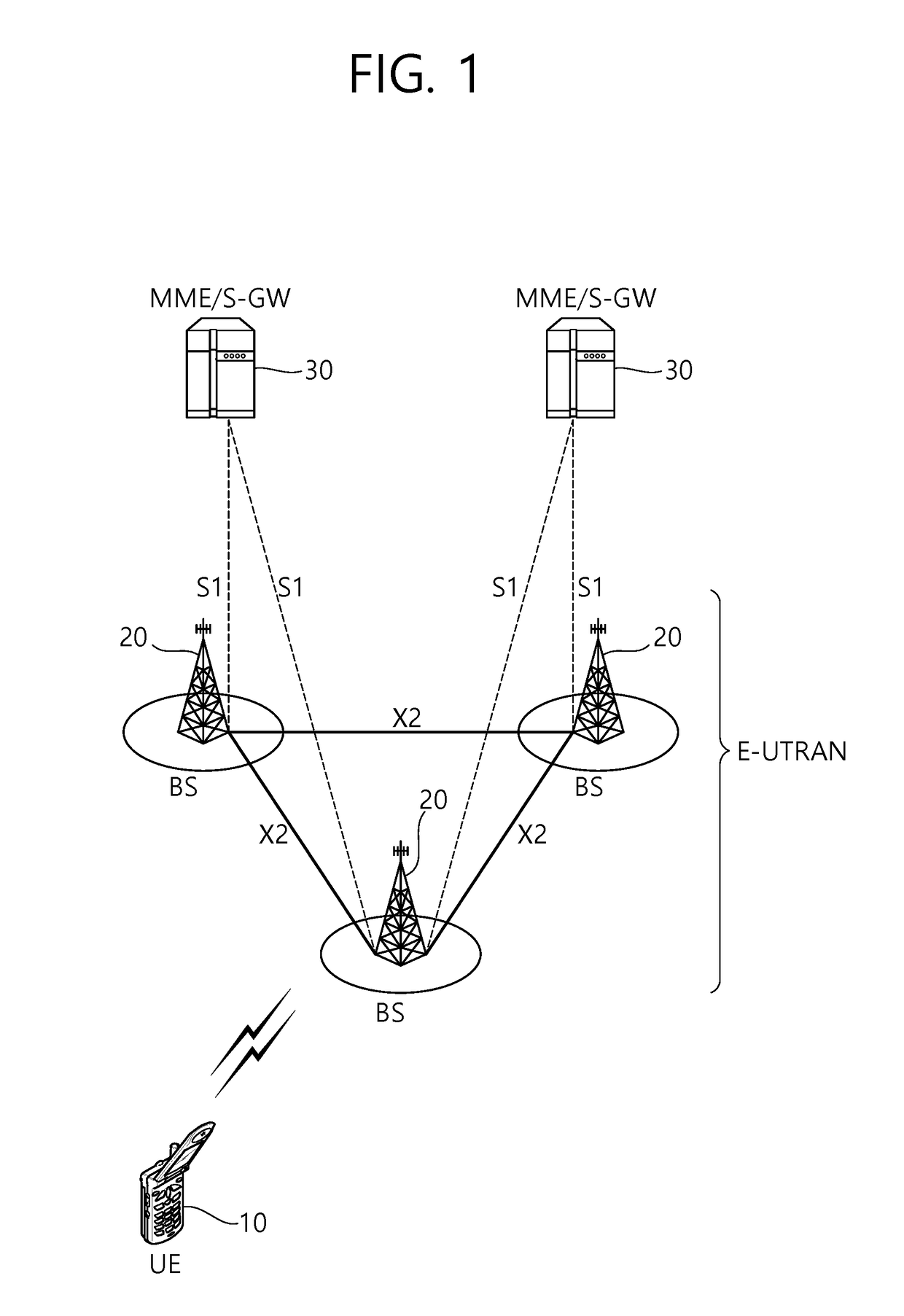

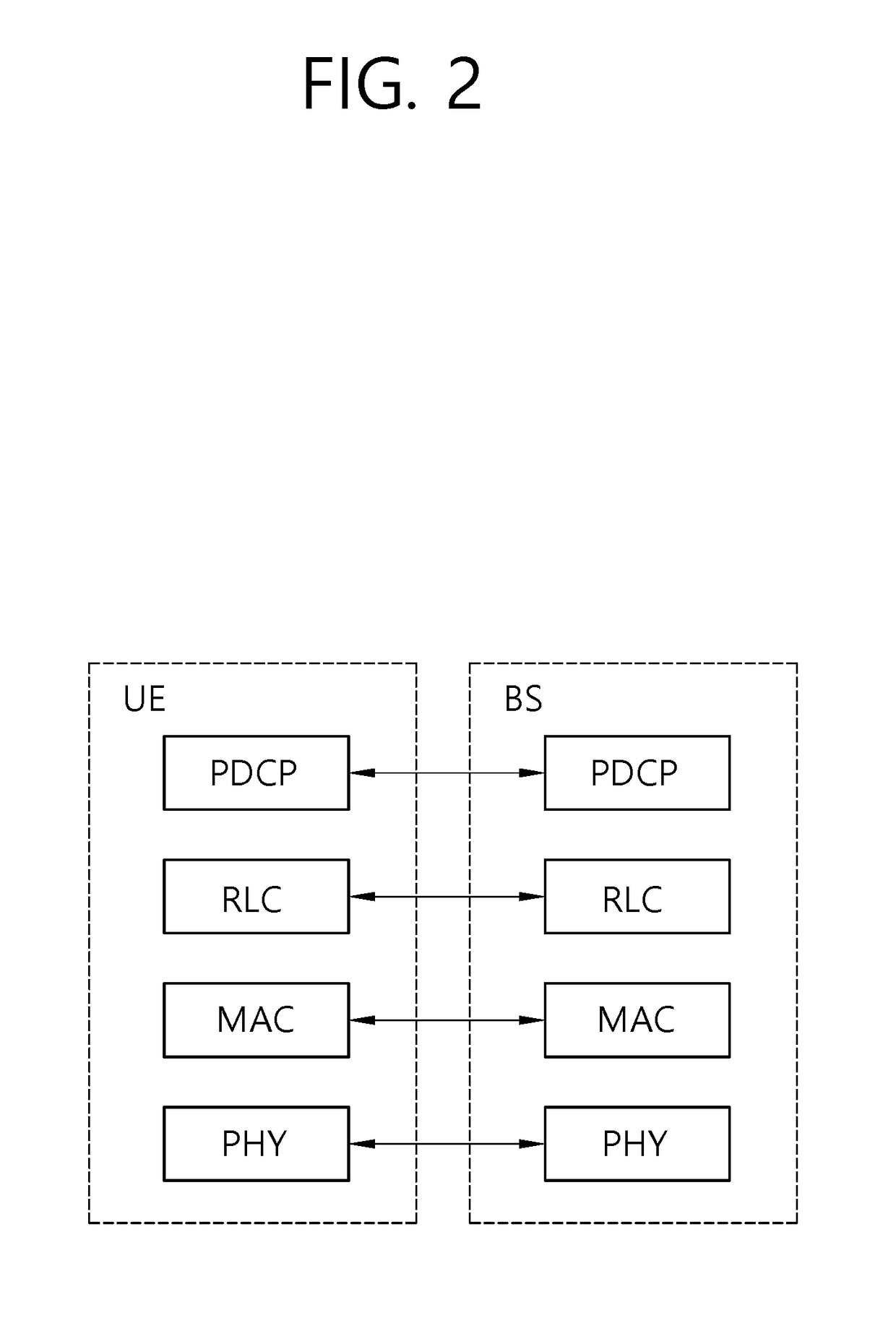

Method for acting as paging proxy in wireless communication system and terminal utilizing the method

ActiveUS20180077624A1Save powerImprove battery efficiencyPower managementNetwork topologiesCommunications systemPaging

The present invention, a method for carrying out a proxy operation executed by a second terminal in a wireless communication system, comprises the steps of: determining whether the second terminal is to act as a proxy for carrying out a paging-associated procedure for a first terminal; on the basis of the determination, acting as a proxy for carrying out the paging-associated procedure for the first terminal, wherein the second terminal monitors the paging of the first terminal at paging occasions of the first terminal.

Owner:LG ELECTRONICS INC

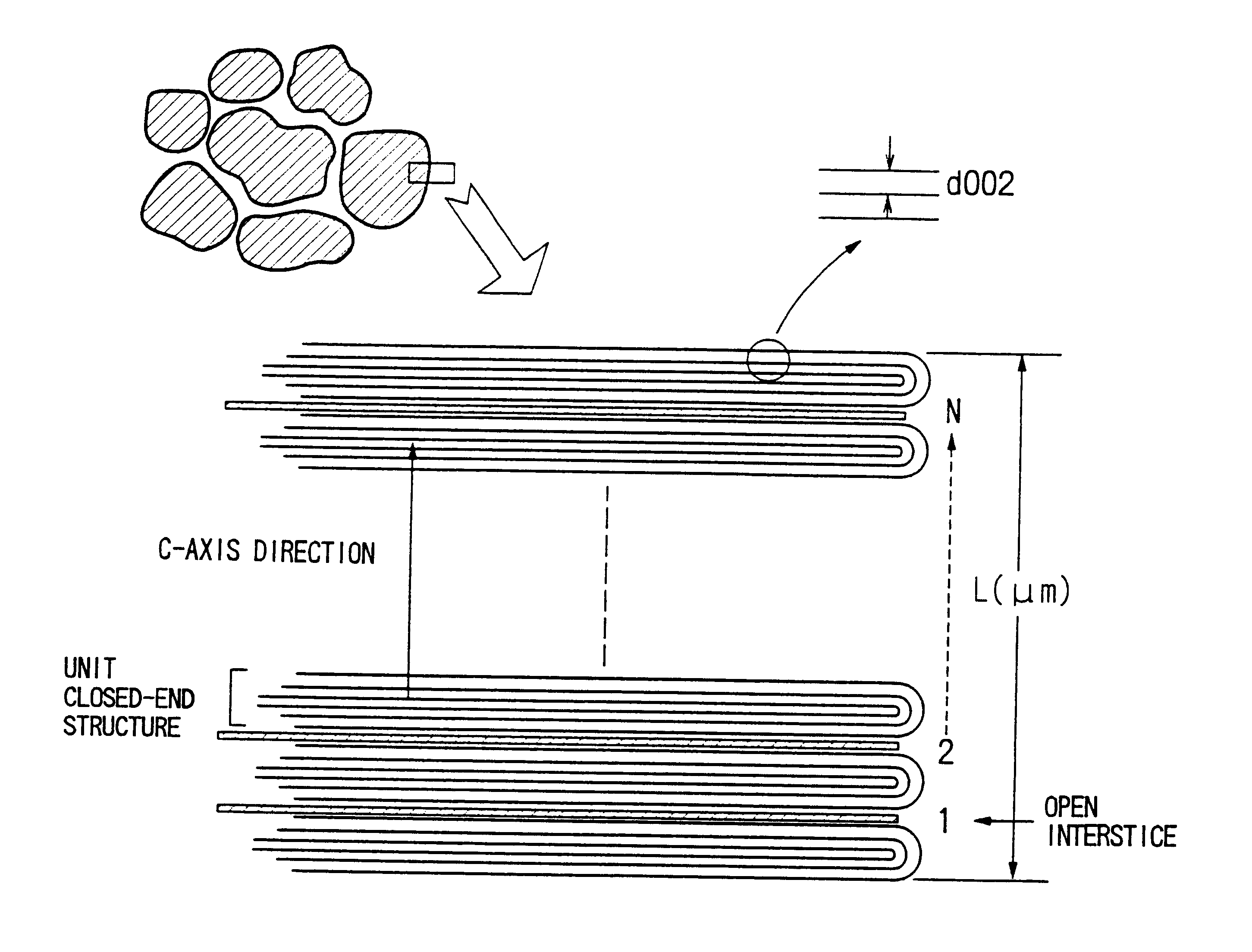

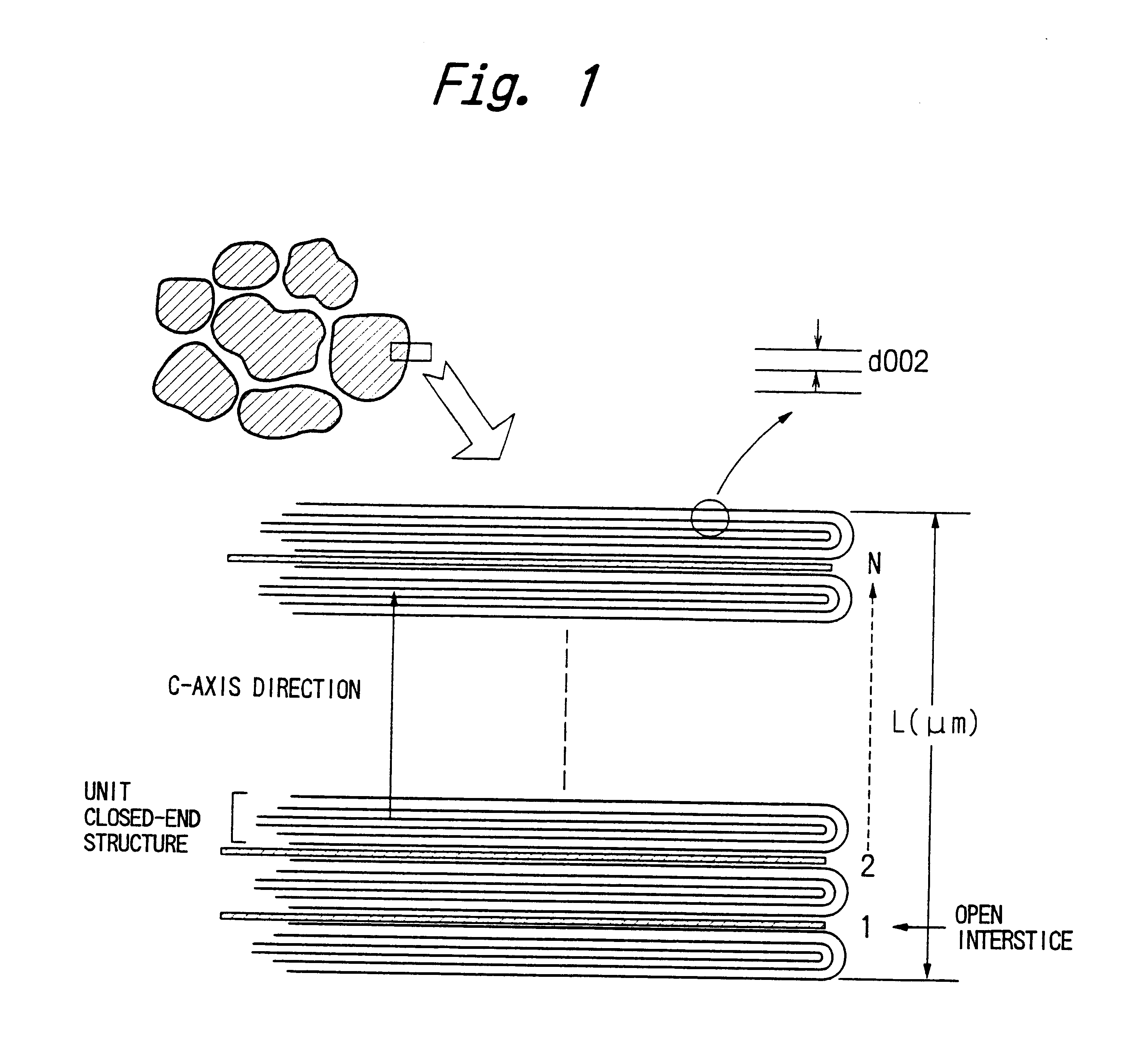

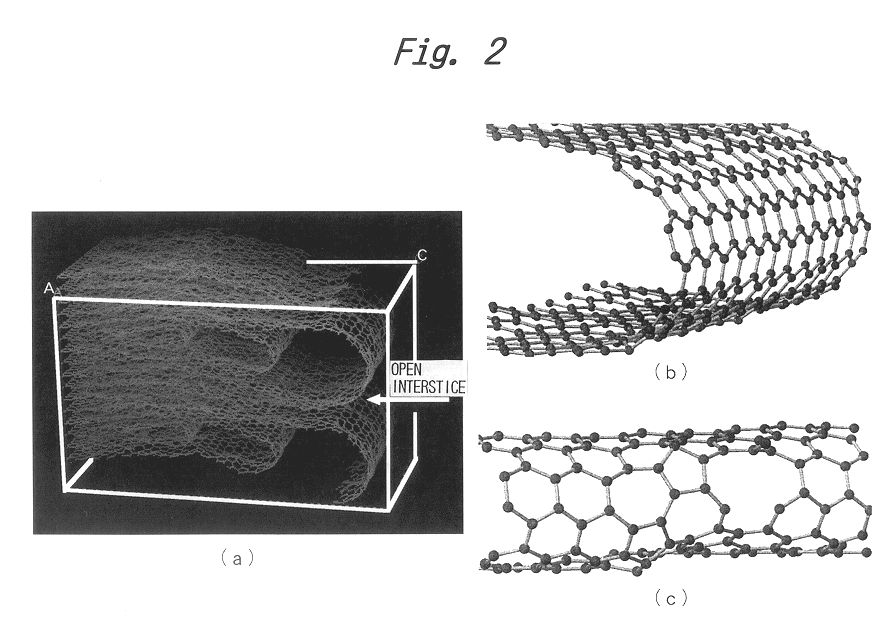

Graphite powder suitable for negative electrode material of lithium ion secondary batteries

InactiveUS6576369B1Improve discharge capacityImprove Coulombic efficiencyNon-aqueous electrolyte accumulatorsGraphiteLithiumMicrometer

A graphite powder has surface closed-end structures in which the graphite c-plane layers of the graphite layer crystal lattices have closed-ends on the surface of the graphite powder by linking the ends of one or more pairs of the c-plane layers, leaving interstices which are open on the surface of the graphite. The number of open interstices is at least 100 and at most 1500 per micrometer in a c-axis direction of the graphite. Preferably, the graphite powder has a specific surface area of 1.0 m2 / g or less. Such a graphite powder can be prepared either by graphitizing a carbon material, which has been pulverized at a high speed under well-controlled conditions before and / or after the carbonization, or by subjecting a carbon material, which has been pulverized under well-controlled conditions before and / or after the carbonization, to graphitization and then to oxidative heat treatment at a temperature of 600-800° C. and finally to heat treatment at a temperature of 800° C. or higher in an inert gas. The graphite powder can be used to produce negative electrodes of lithium ion secondary batteries having a high discharge capacity of at least 320 mAh / g and a high charge / discharge coulombic efficiency of at least 90%.

Owner:NIPPON DENKO CO LTD +1

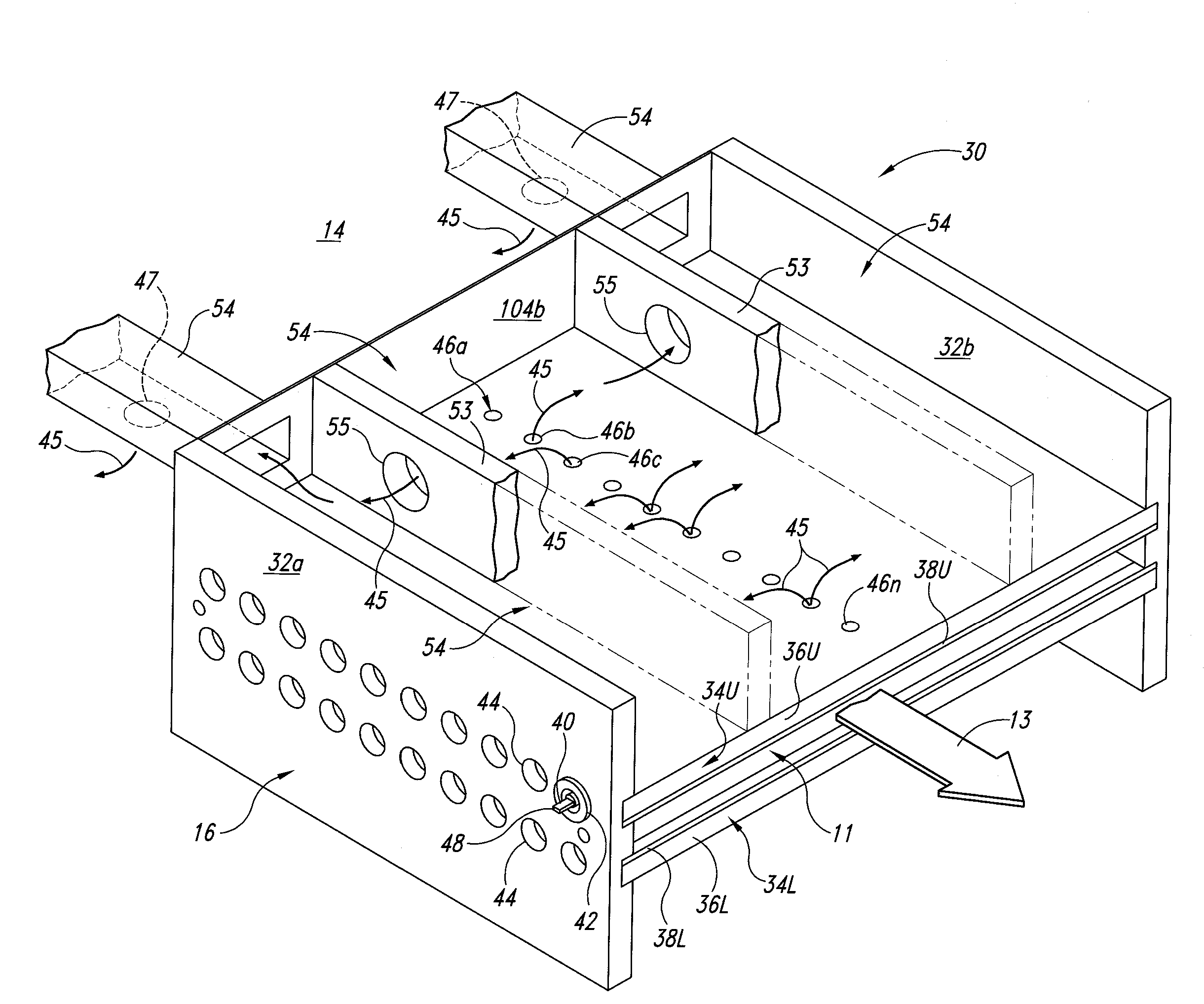

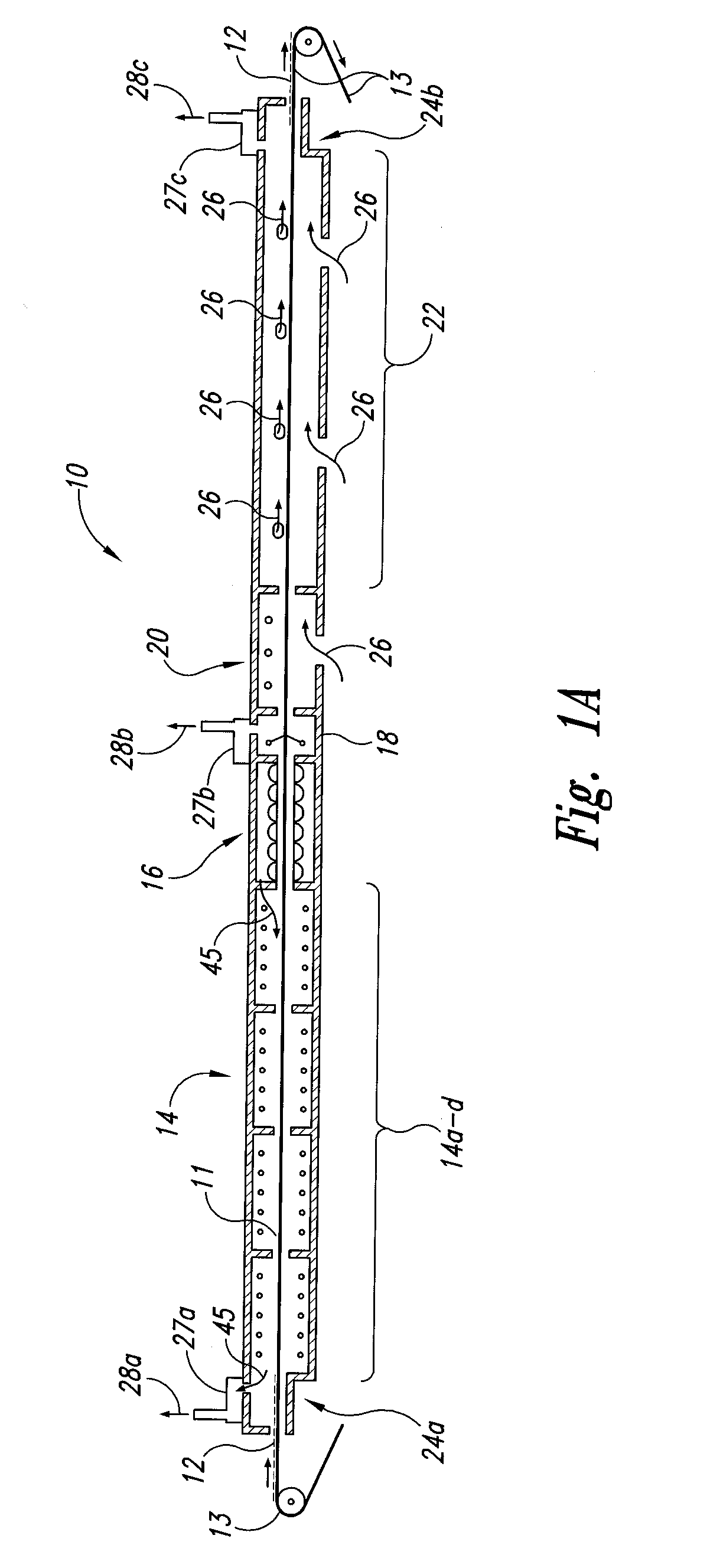

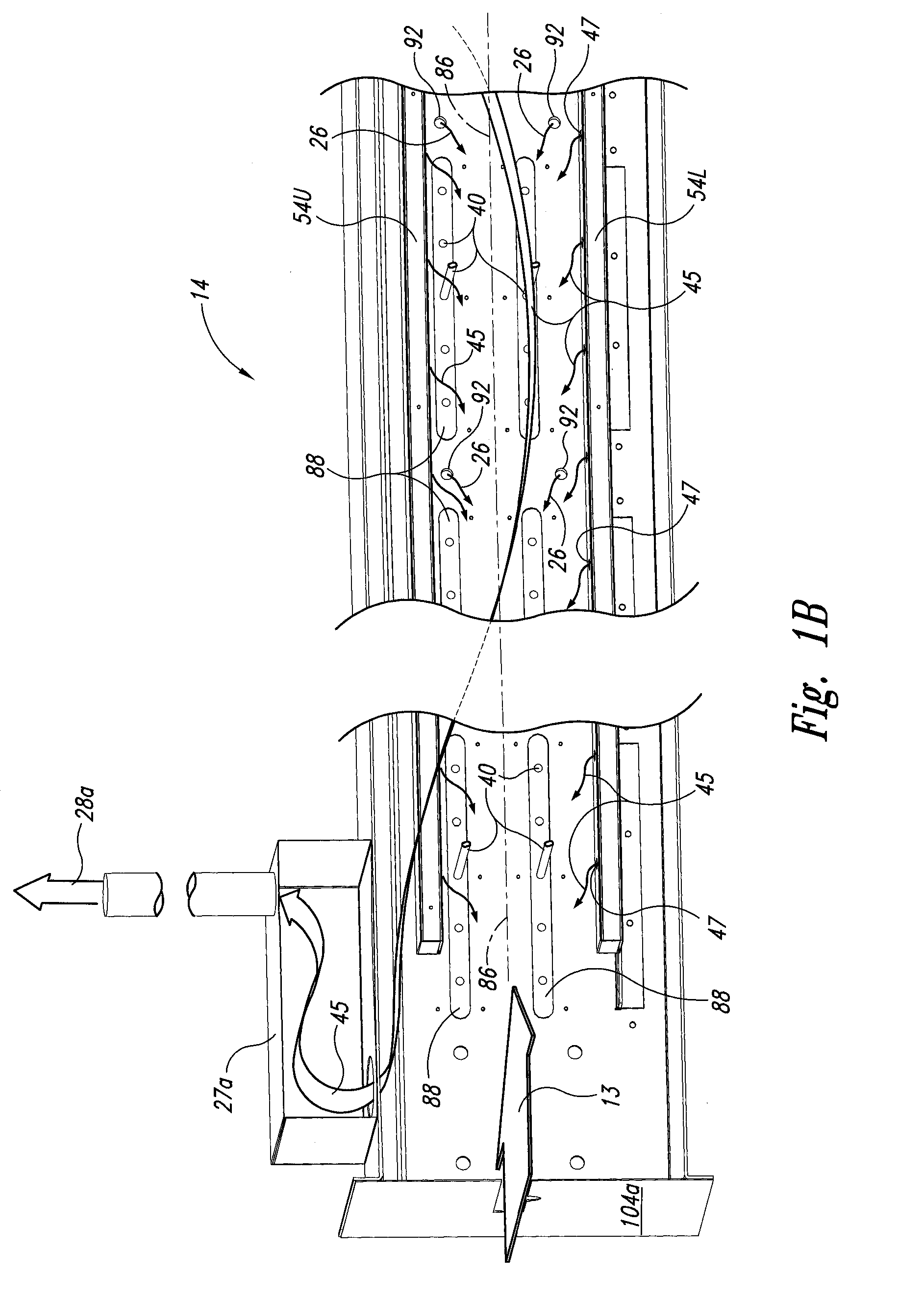

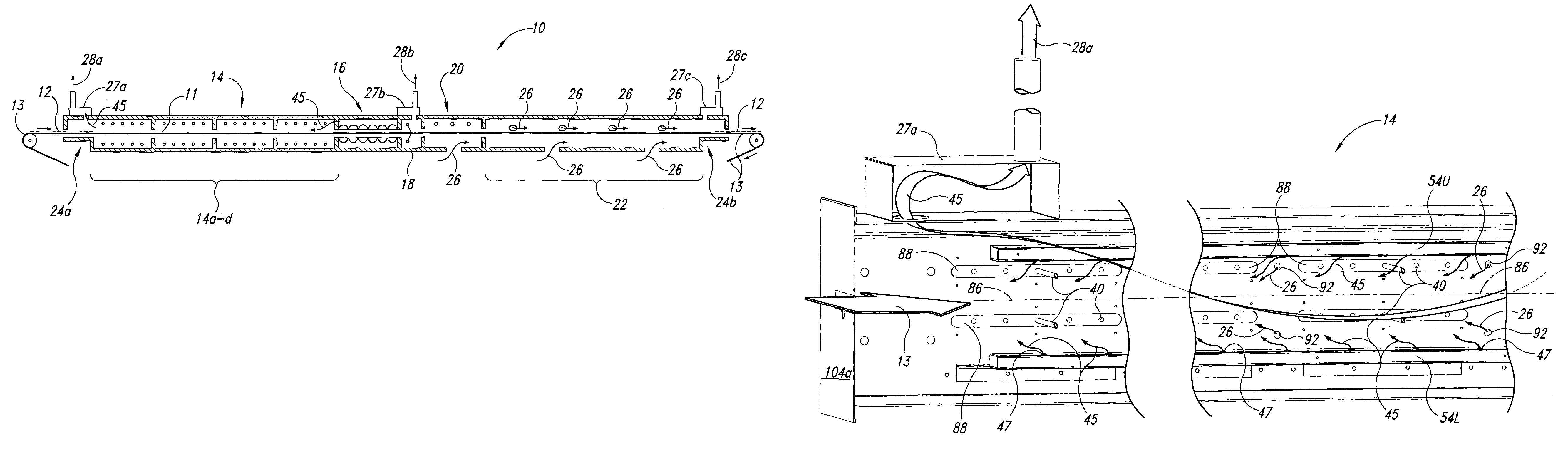

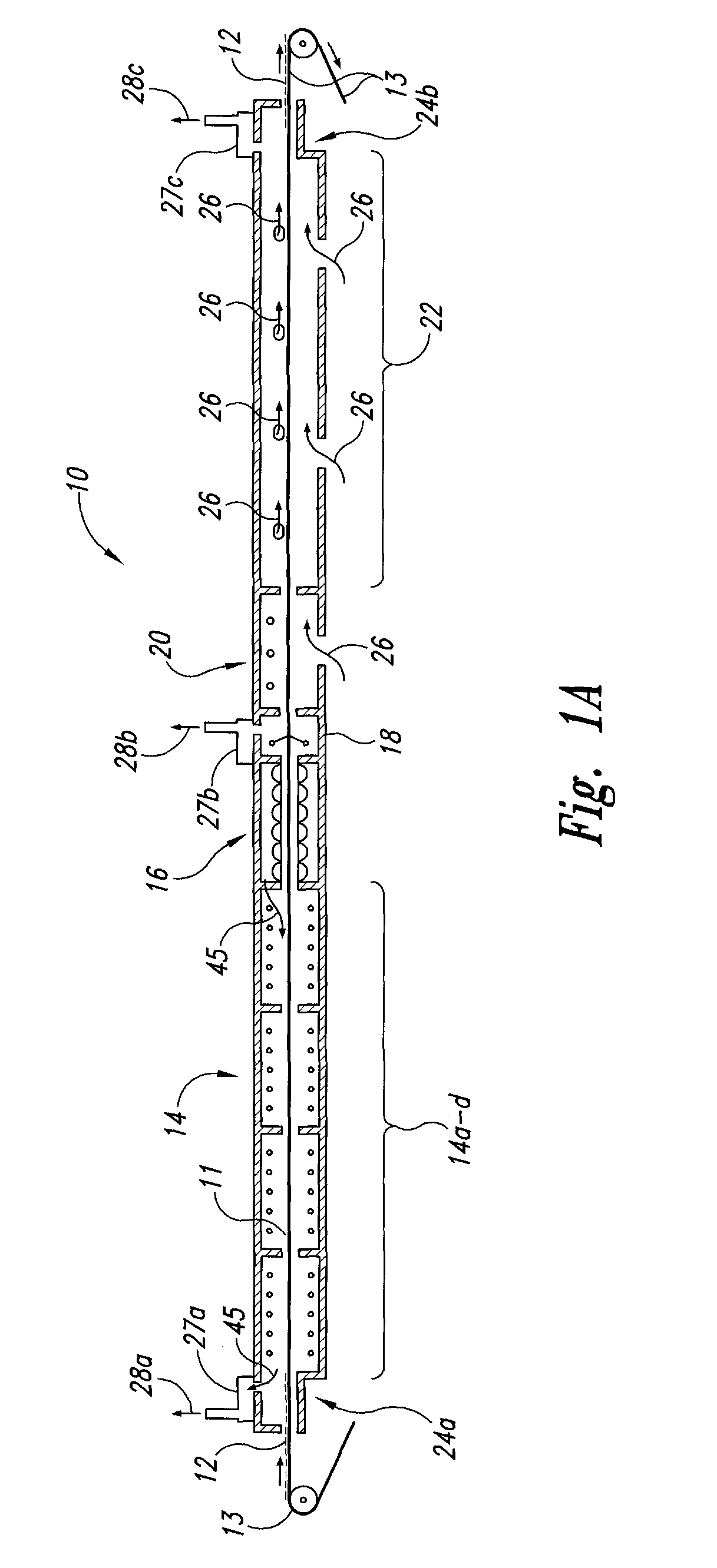

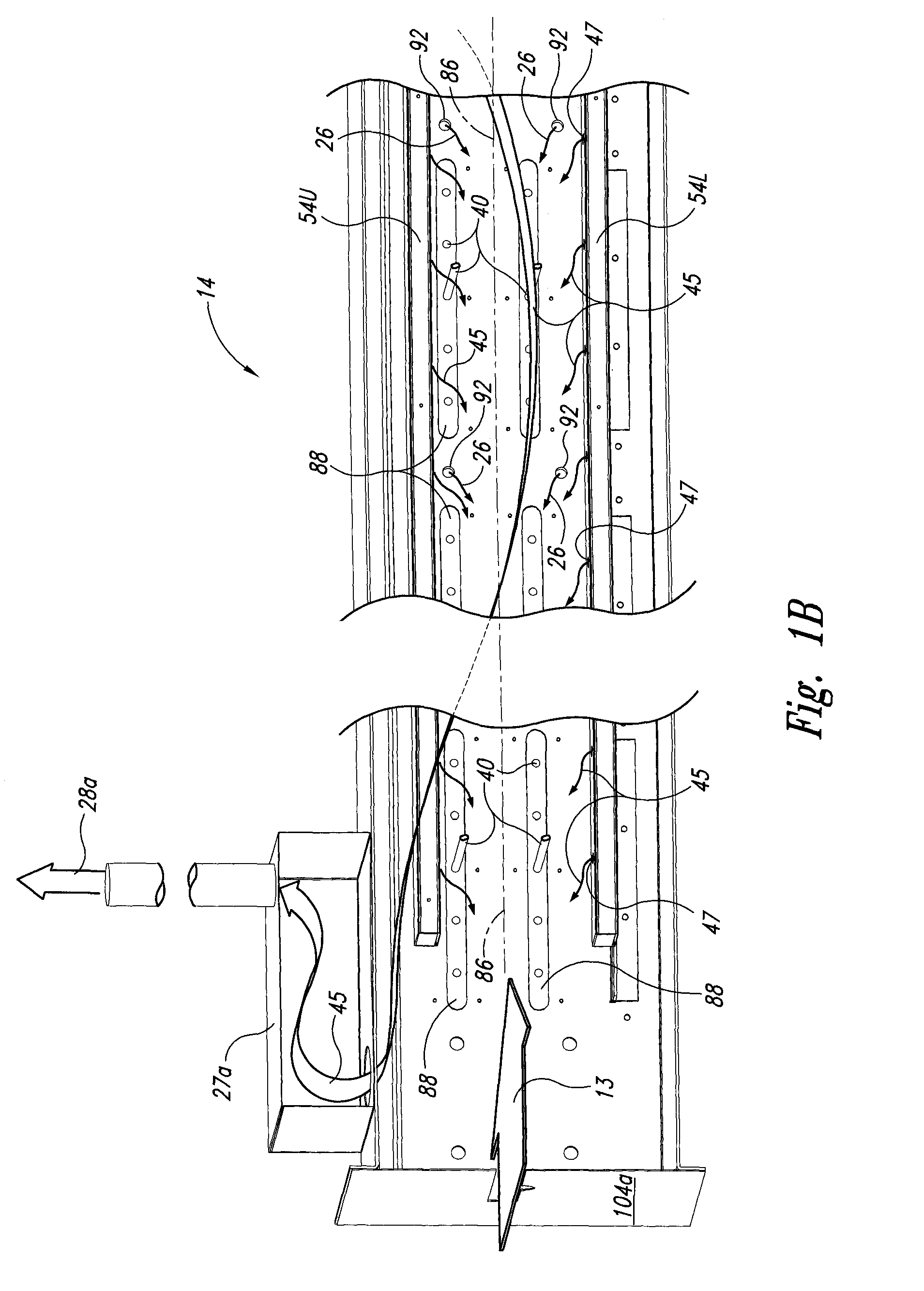

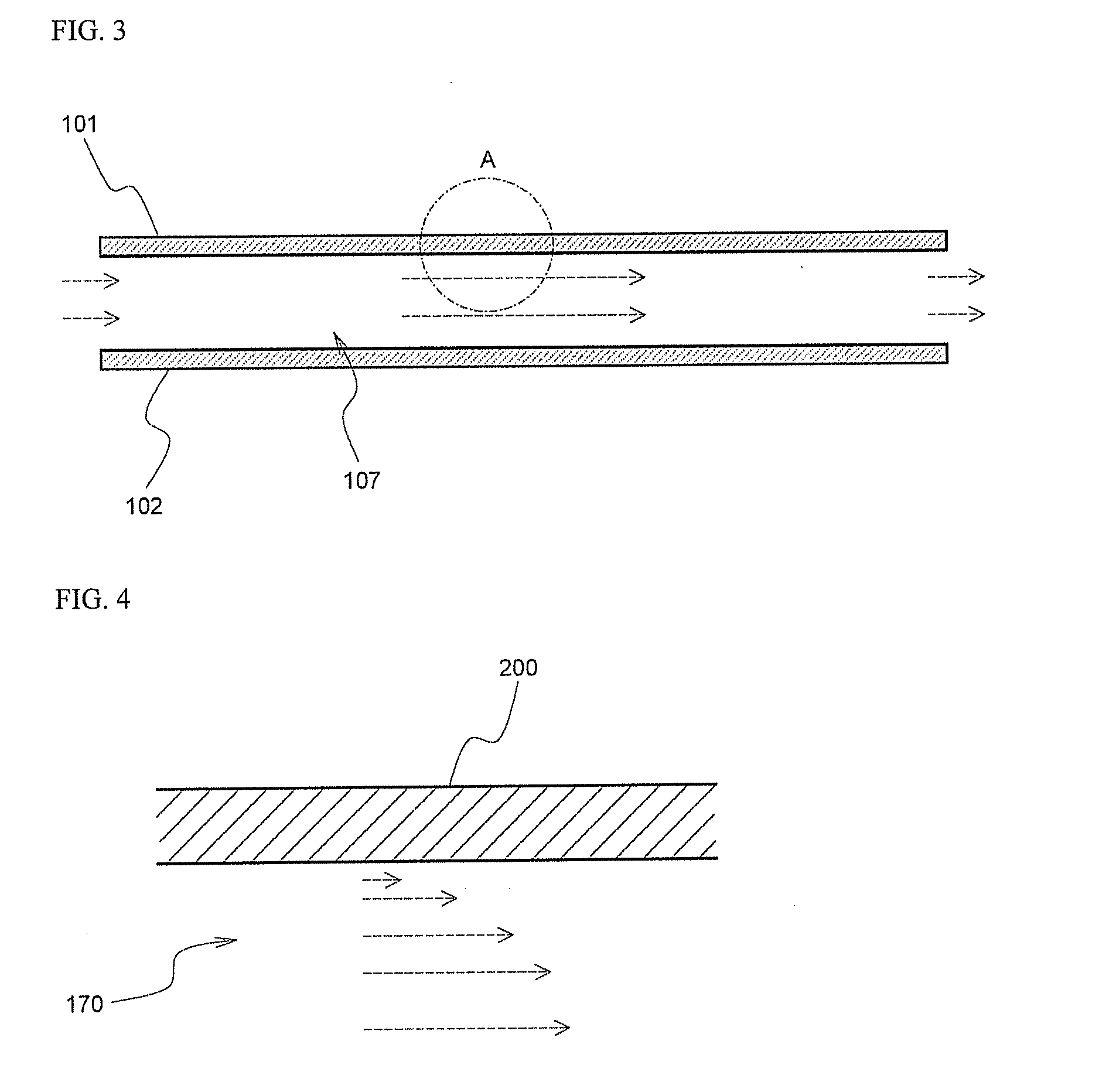

Rapid Thermal Firing IR Conveyor Furnace Having High Intensity Heating Section

InactiveUS20080012499A1Effectively doubling heating rate and furnace processing throughputIncrease productionSoldering apparatusSemiconductor/solid-state device manufacturingNameplate capacityCooling curve

Isolation IR heat lamp module and method of firing multi-zone IR furnaces for solar cell processing comprising lamps disposed in individual parallel channels in a reflector / insulator body to provide a cooling air channel surrounding each tube; the channels are covered with IR-transmissive plate material to isolate each lamp from adjacent lamps and the process zone. Cooling air is exhausted and recycled upstream for energy conservation. Lamp spacing can be varied and power to each lamp individually controlled to provide infinite control of temperature profile in each heating zone. For a spike zone, and in combination with downstream quench control and annealing zones, steep heating and cooling curves with very short dwell (sharp) peak temperature profiles permit faster throughput due to operation of the lampsm at essentially 100% rated capacity, at a 2× or greater heating and throughput rate without compromising lamp life, while producing solar cells with improved output efficiency.

Owner:TP SOLAR OF USA

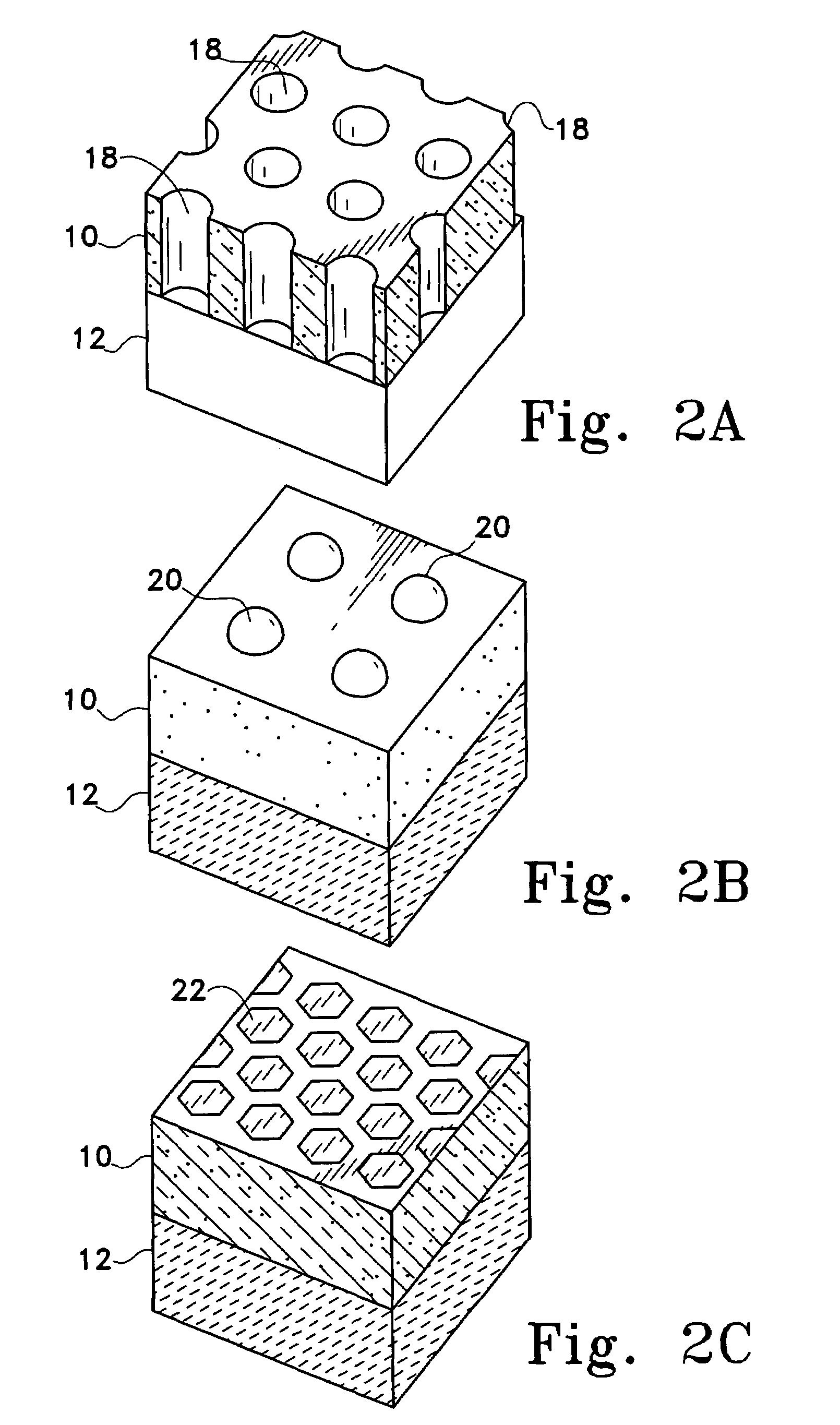

Metal catalyst technique for texturing silicon solar cells

InactiveUS6329296B1Improve throughputDiminish current extractionDecorative surface effectsSemiconductor/solid-state device manufacturingManufacturing technologySilicon solar cell

Textured silicon solar cells and techniques for their manufacture utilizing metal sources to catalyze formation of randomly distributed surface features such as nanoscale pyramidal and columnar structures. These structures include dimensions smaller than the wavelength of incident light, thereby resulting in a highly effective anti-reflective surface. According to the invention, metal sources present in a reactive ion etching chamber permit impurities (e.g. metal particles) to be introduced into a reactive ion etch plasma resulting in deposition of micro-masks on the surface of a substrate to be etched. Separate embodiments are disclosed including one in which the metal source includes one or more metal-coated substrates strategically positioned relative to the surface to be textured, and another in which the walls of the reaction chamber are pre-conditioned with a thin coating of metal catalyst material.

Owner:SANDIA NAT LAB

Method for improving performance of light absorption layer of perovskite solar cell

ActiveCN103956394AImprove performanceImprove battery efficiencyFinal product manufacturePhotovoltaic energy generationPerovskite solar cellThermal treatment

The invention relates to a method for improving the performance of a light absorption layer of a perovskite solar cell. The method includes the steps that an additive is added into a reactant of perovskite to form a perovskite precursor solution; then a base coated with an electron transport material or a hole transport material is coated with the precursor solution in a rotating mode, and a perovskite light absorption layer film is formed after thermal treatment. The additive comprises one or more of CnH2n+1NH3B and an AB compound, wherein n is equal to 0-3, A is selected from monovalent metal, and B is F or C1 or Br or I. The light absorption layer, prepared through the method, of the perovskite solar cell enables the battery efficiency to be increased to over 10 percent from less than 6 percent. The method is simple and effective, simplifies the preparation process, and can save production cost. Therefore, the method for improving the performance of the light absorption layer of the perovskite solar cell has extremely high industrial application value.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

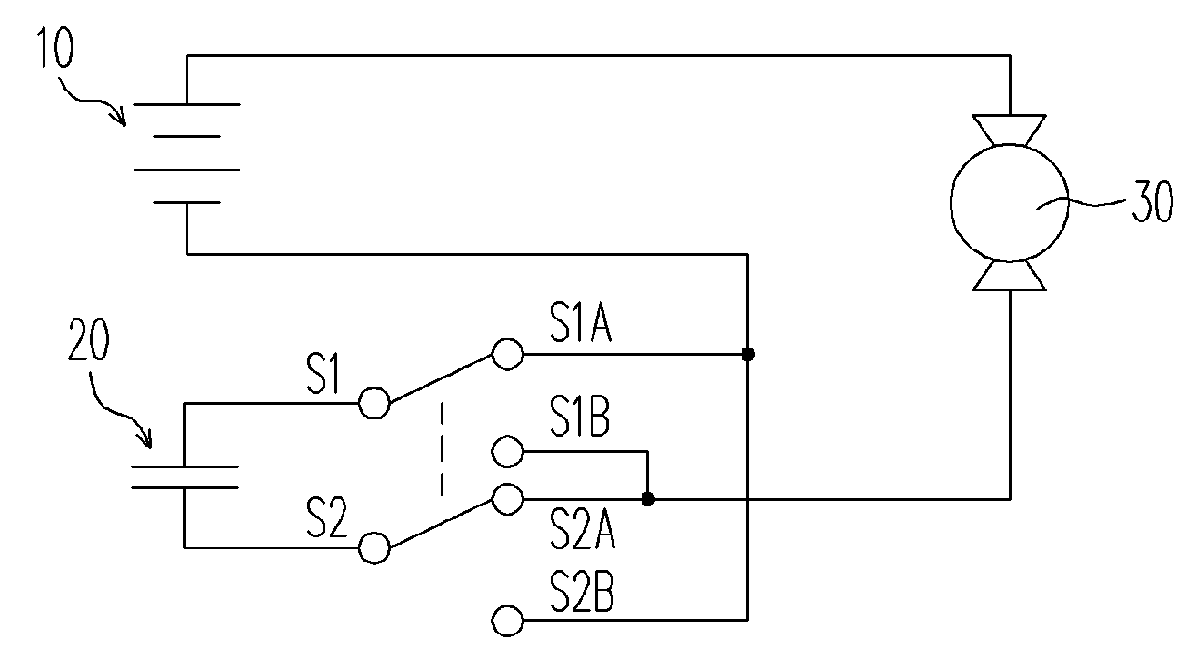

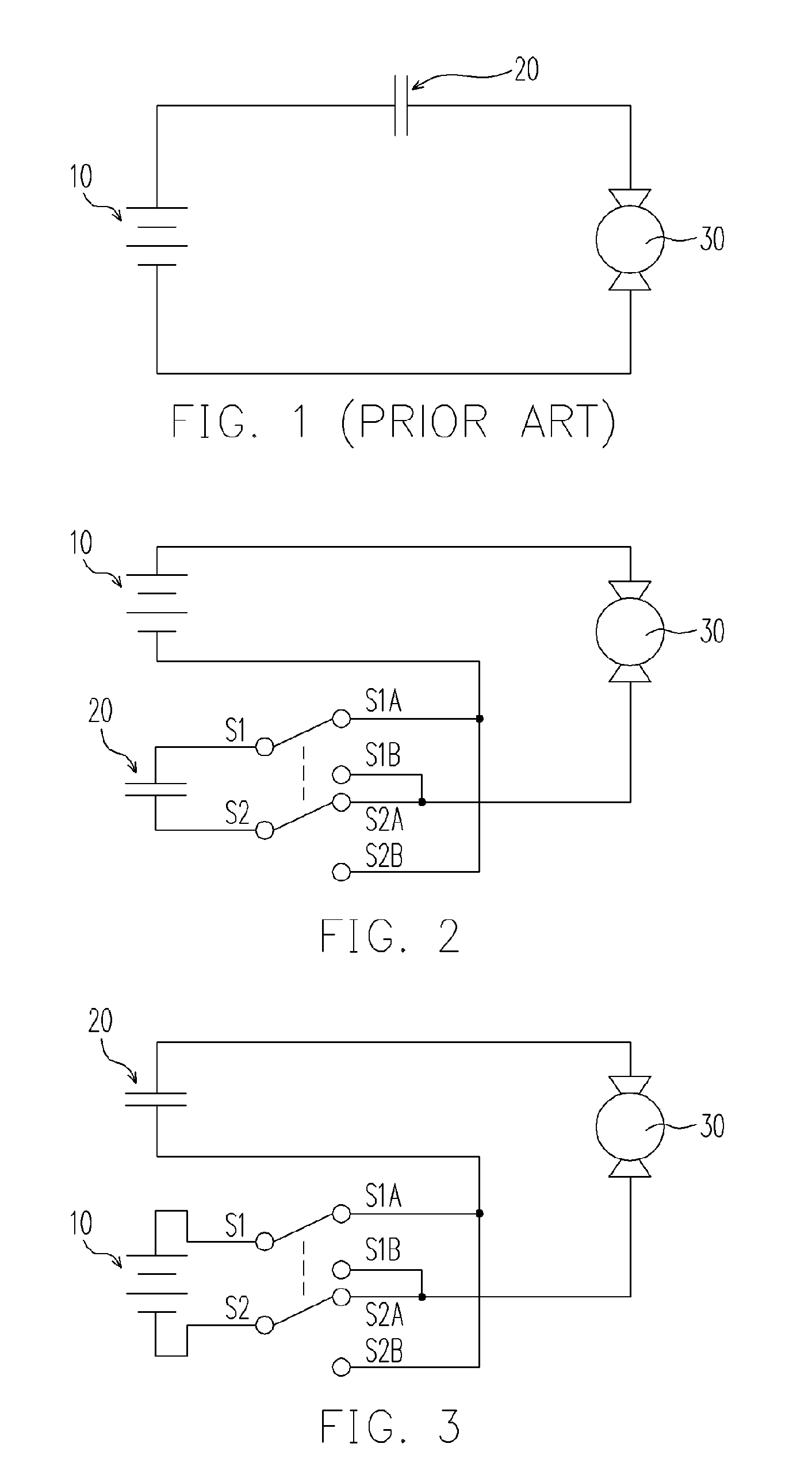

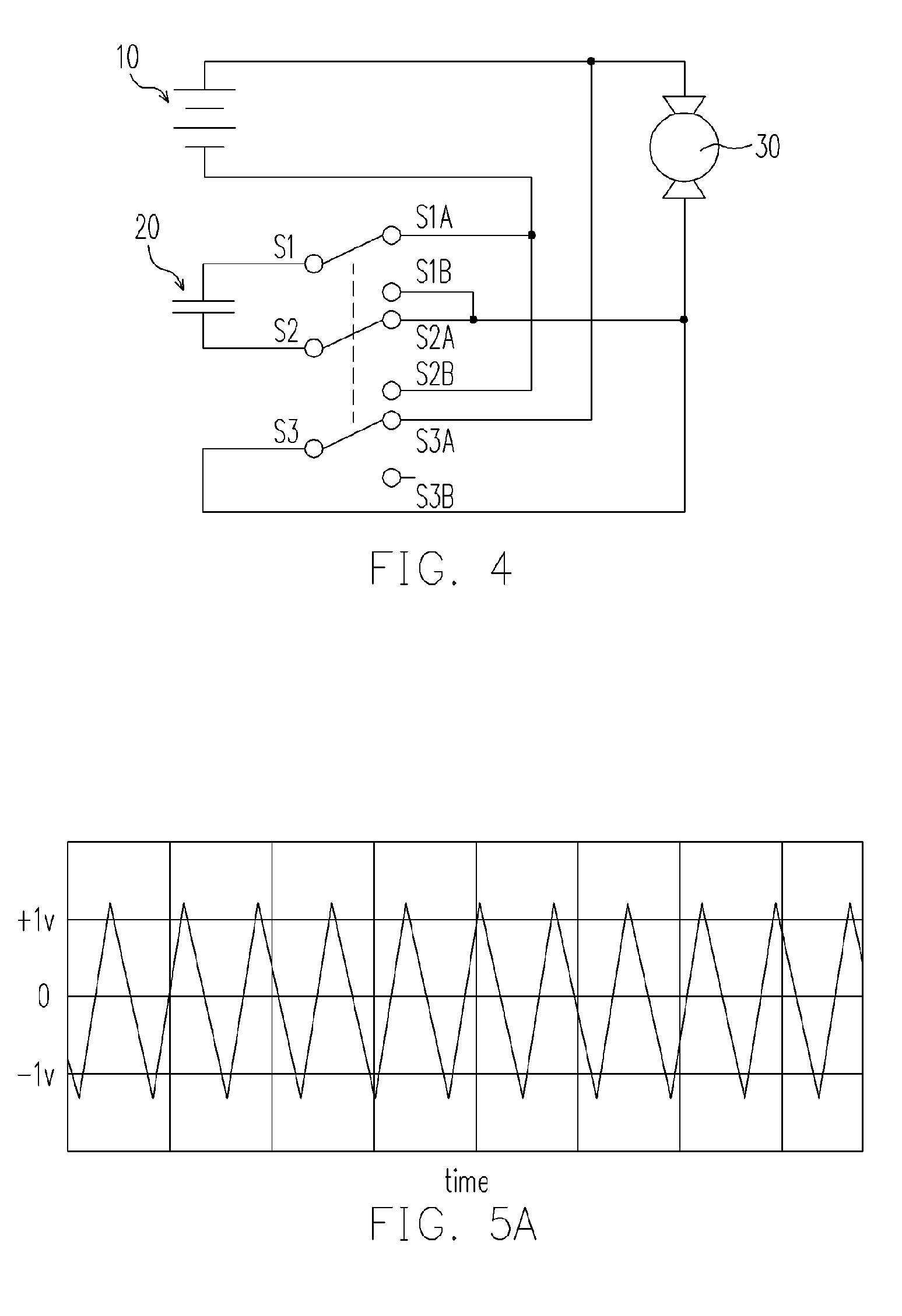

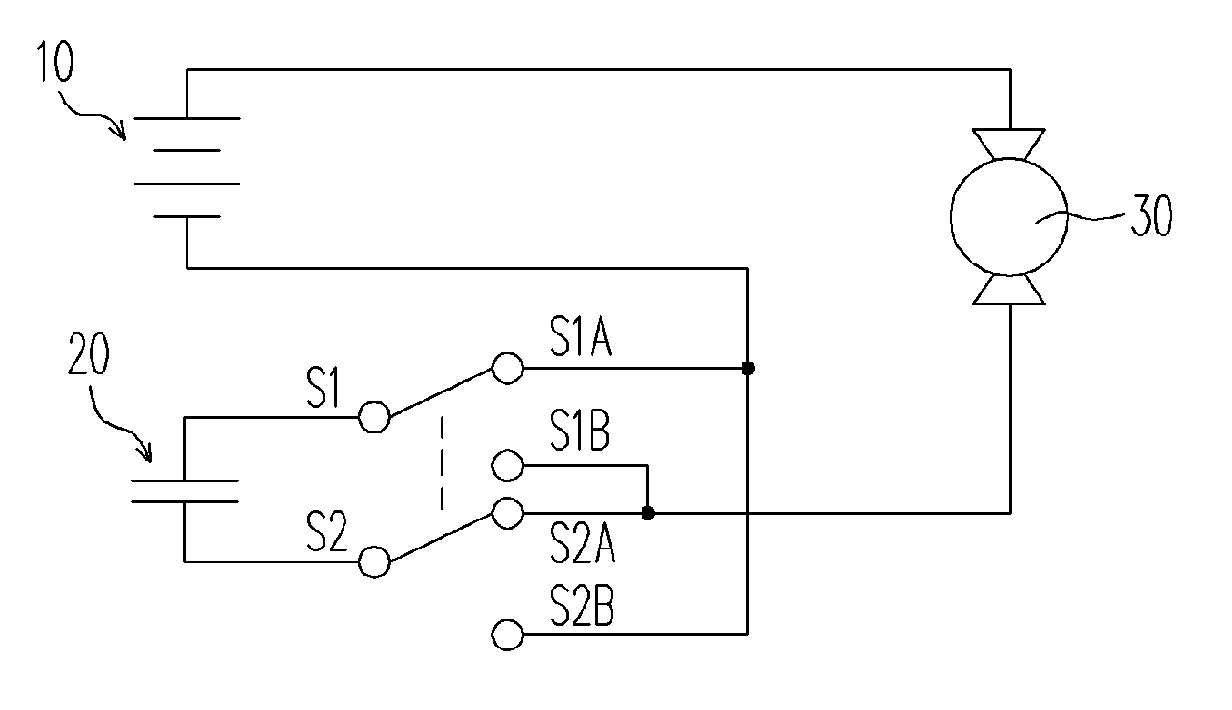

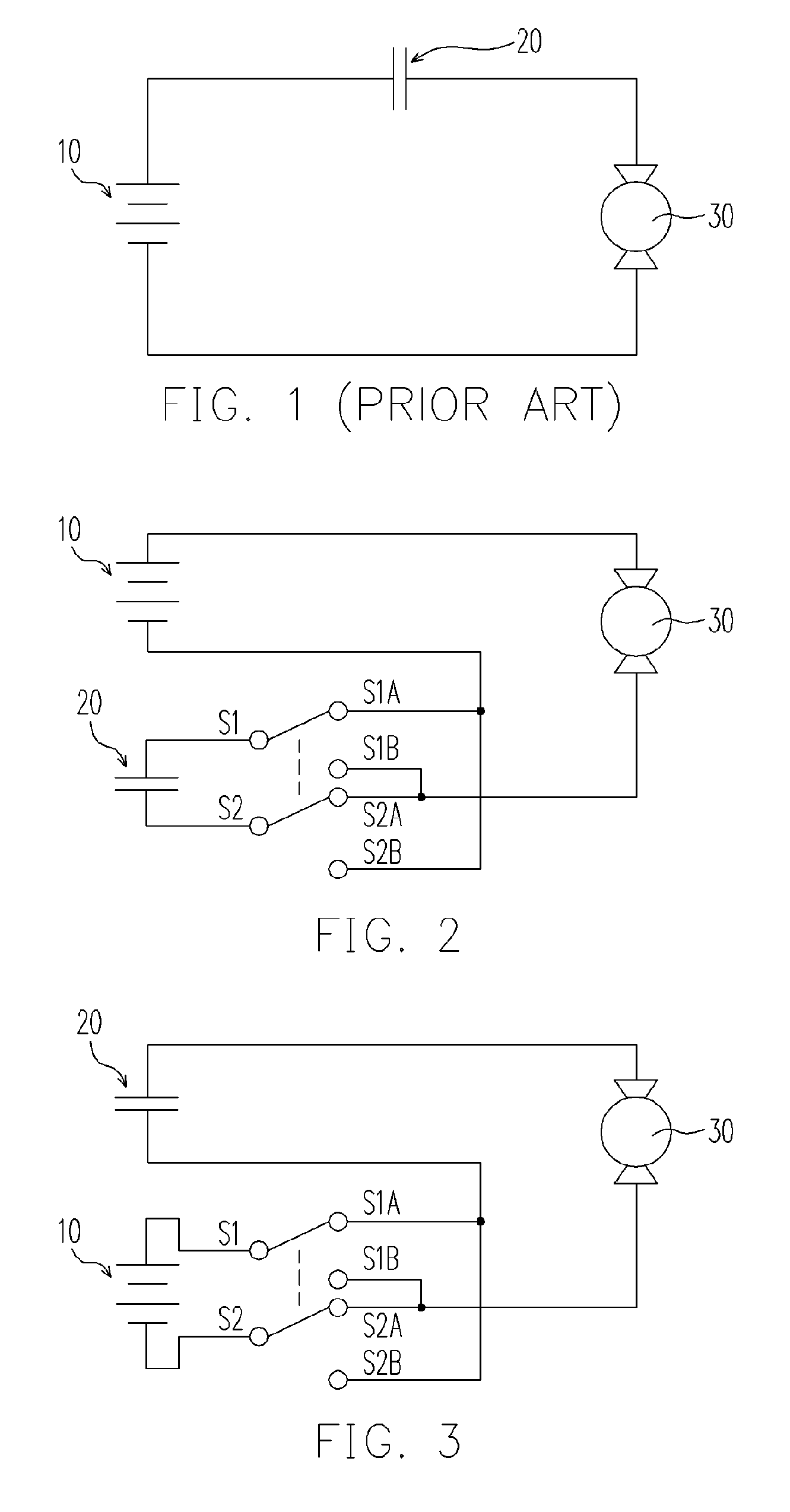

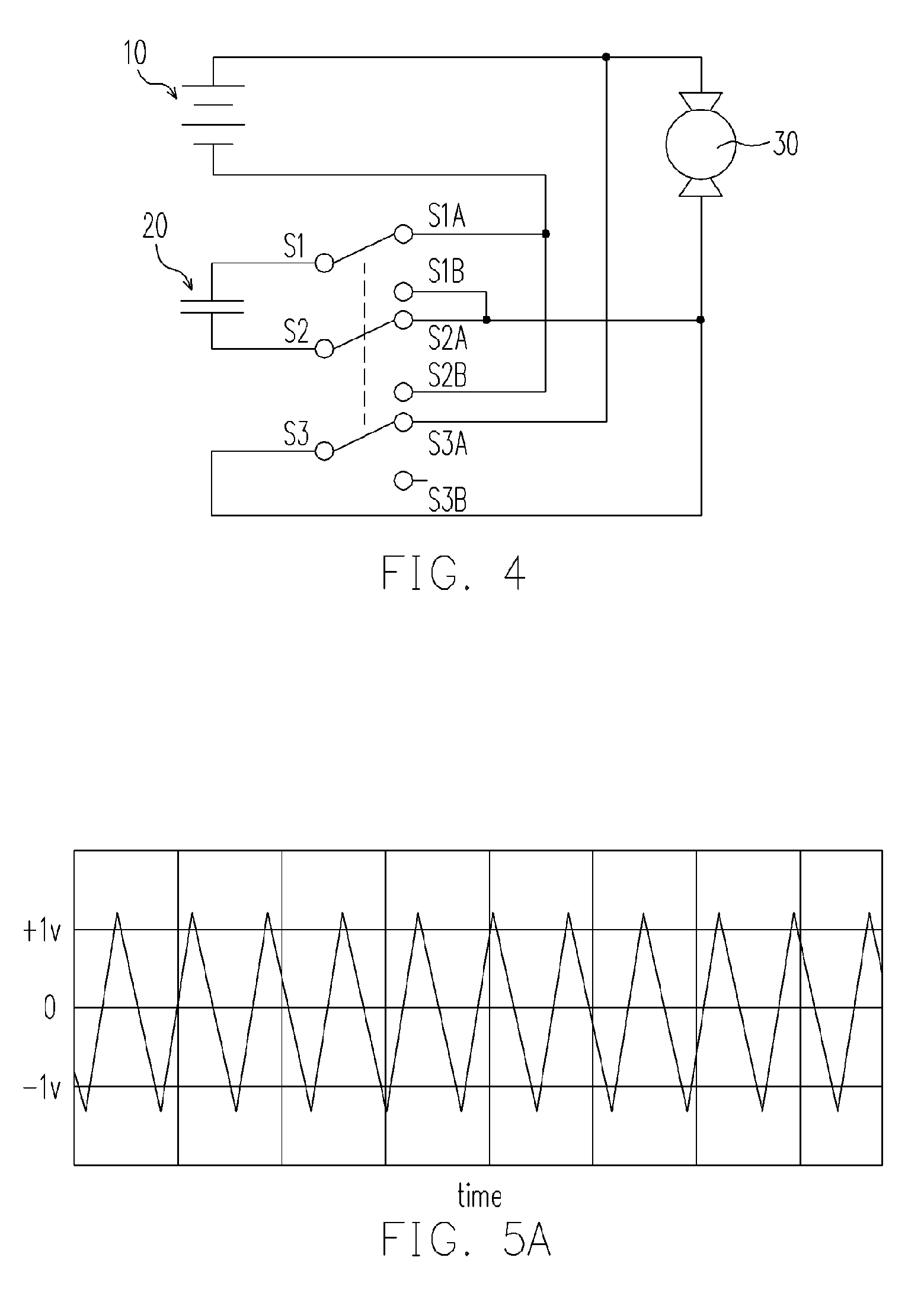

Power supply apparatus and power supply method

ActiveUS7085123B2Improve performanceHigh dischargeBatteries circuit arrangementsElectrolytic capacitorsEngineeringCapacitor

A power supply apparatus and a power supply method are described, wherein the non-polar characteristics of the electrodes of a capacitor is utilized to improve the energy utilization efficiency of a battery through reciprocating switches of polarity connection between the battery and the capacitor. The voltages of the capacitors can also stay at a near constant level using the polarity reversal mechanism.

Owner:POWER REGENERATION

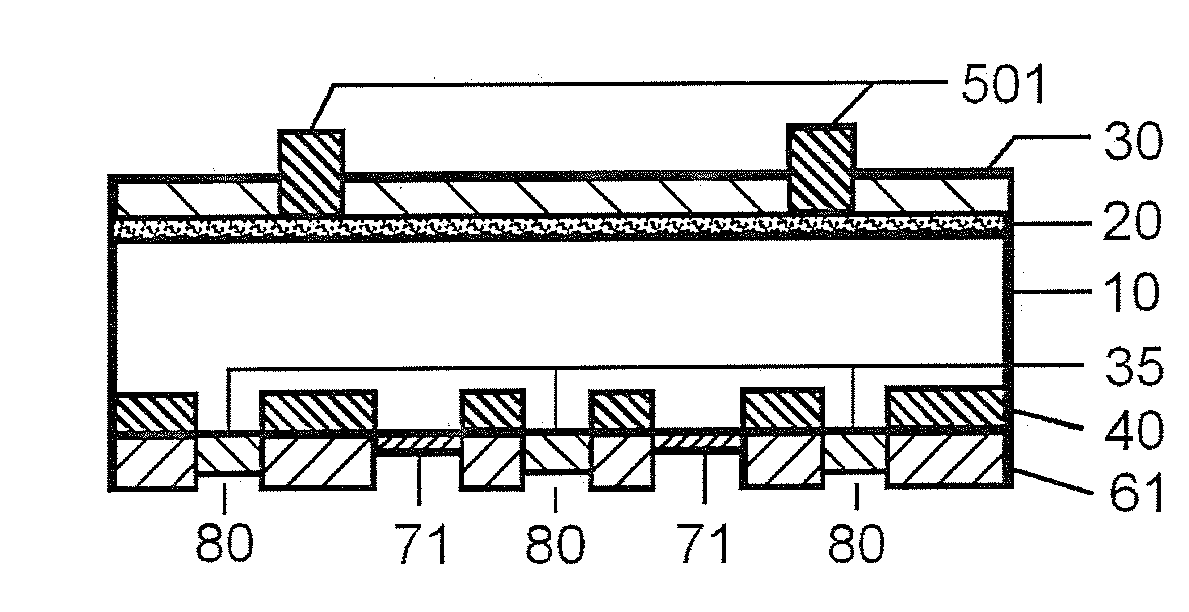

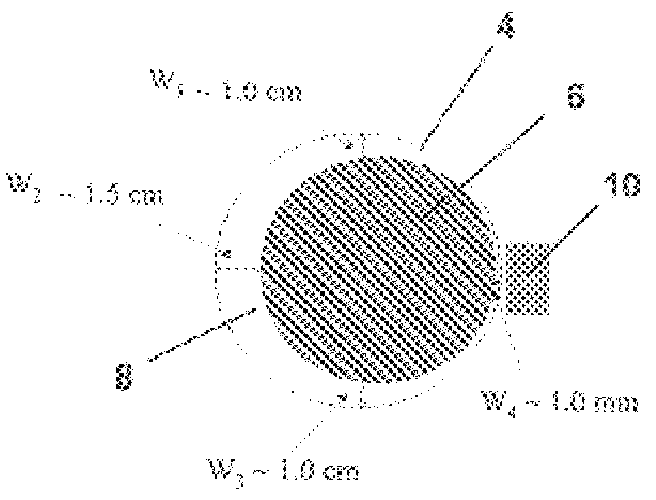

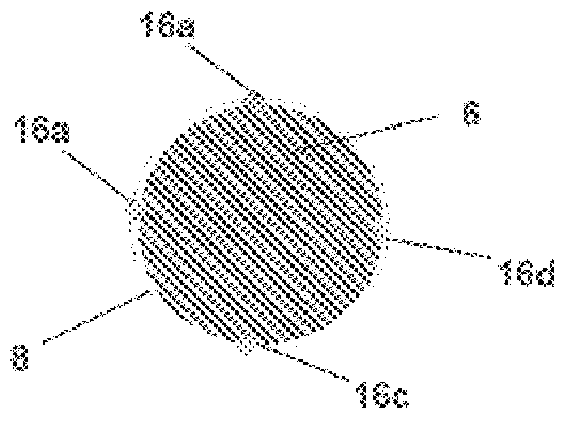

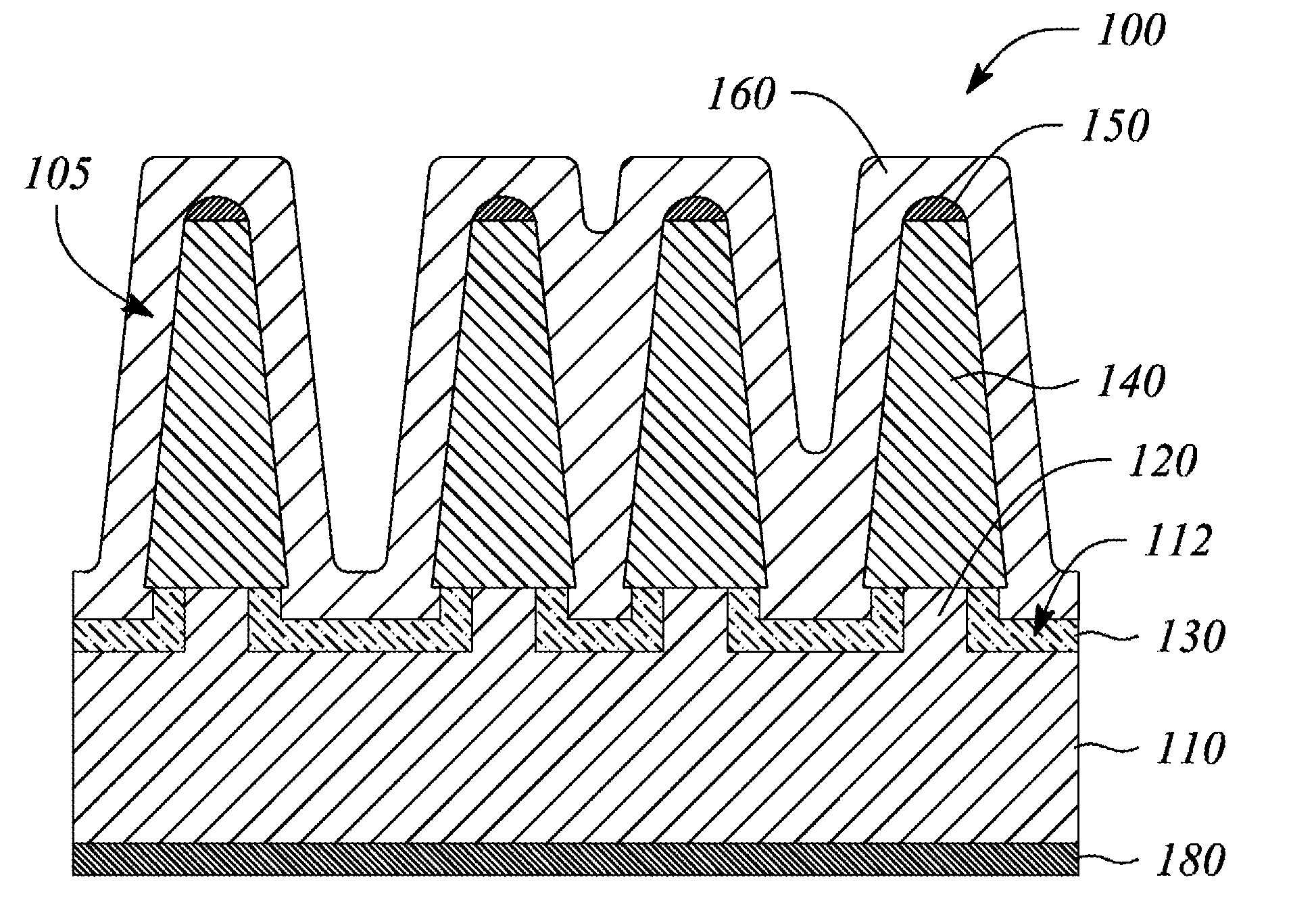

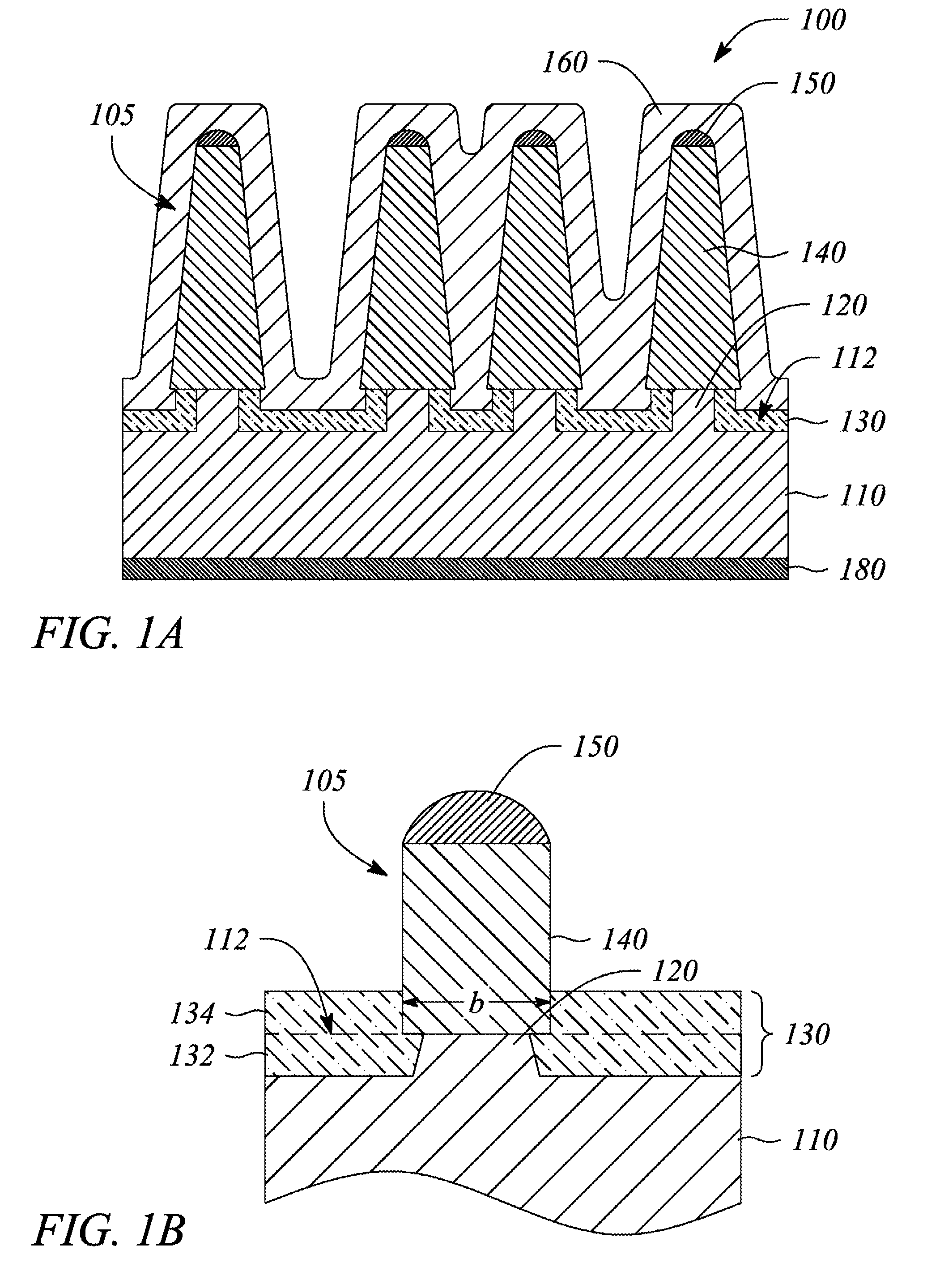

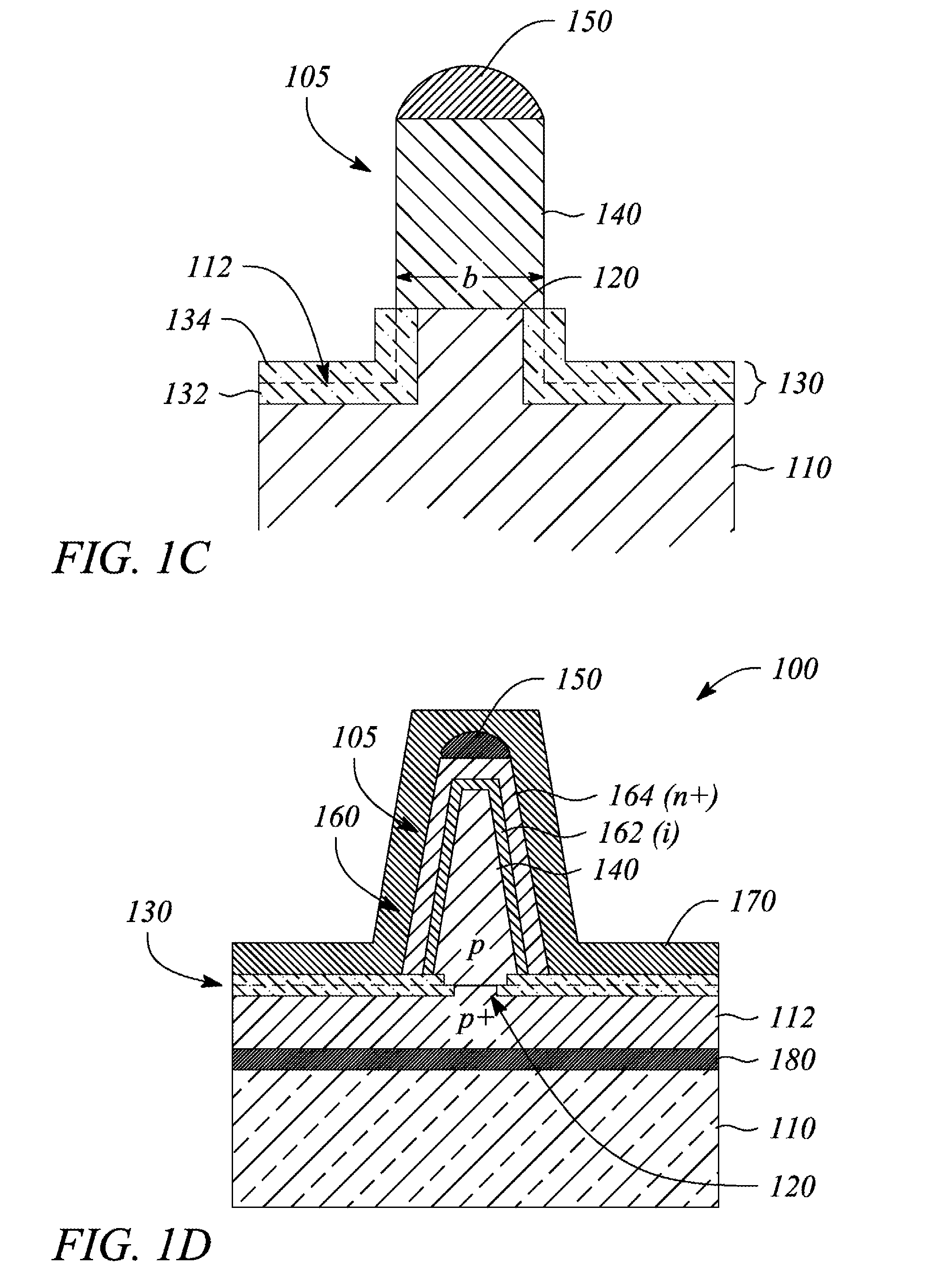

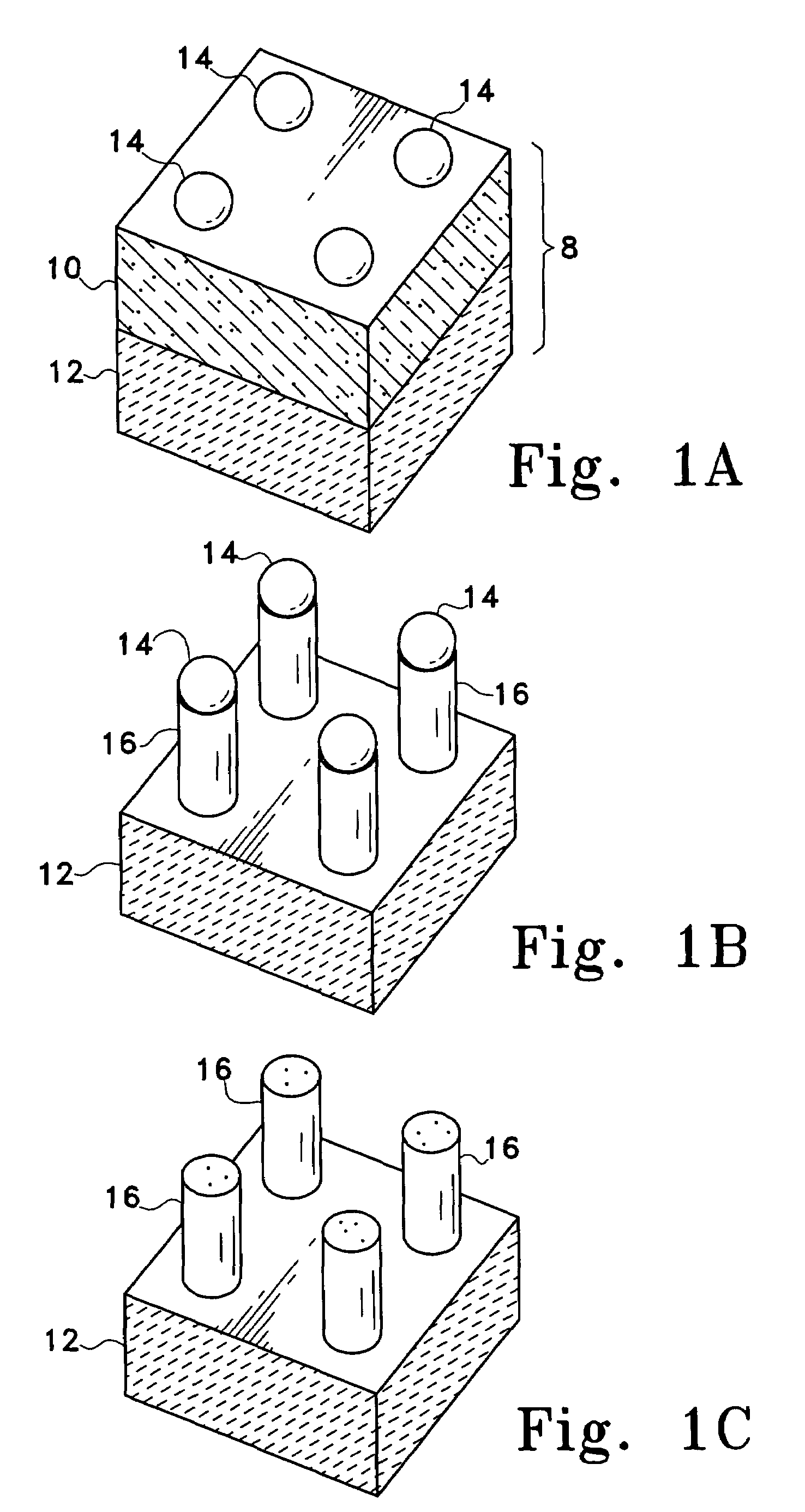

Photovoltaic Structure And Method Of Fabication Employing Nanowire In Stub

InactiveUS20110272014A1Cost and manufacturing advantagePerformance advantageFinal product manufactureSemiconductor/solid-state device manufacturingNanowireNanoparticle

A photovoltaic structure of a photovoltaic cell and a method of fabricating a photovoltaic structure, employ a nanowire having a base connected to a stub and an electrical isolation layer surrounding the stub. The stub is a constituent of a substrate surface. The nanowire extends away from the substrate surface and is wider than the stub. The nanowire base overlies a part of the isolation layer that is adjacent to the stub. A semiconductor junction comprises the nanowire. The method includes forming the stub; growing the nanowire from the stub; and conformally coating the nanowire. A nanoparticle is applied to the substrate surface. The isolation layer is created on and embedded in the substrate surface using the nanoparticle as a mask. A portion of the substrate surface underlying the nanoparticle forms the stub. The nanoparticle catalyzes nanowire growth on the stub. The stub is narrower than the nanoparticle.

Owner:HEWLETT PACKARD DEV CO LP

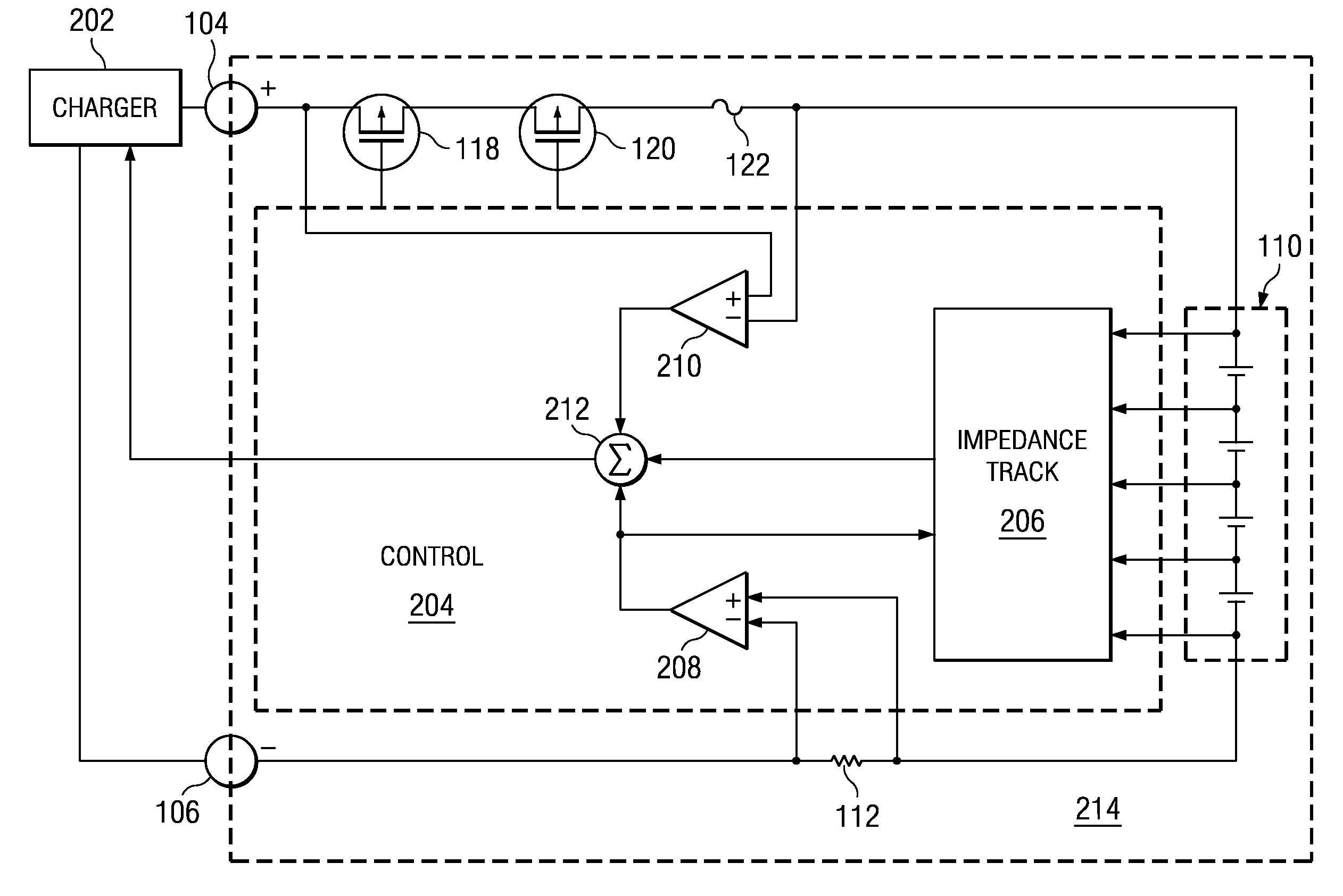

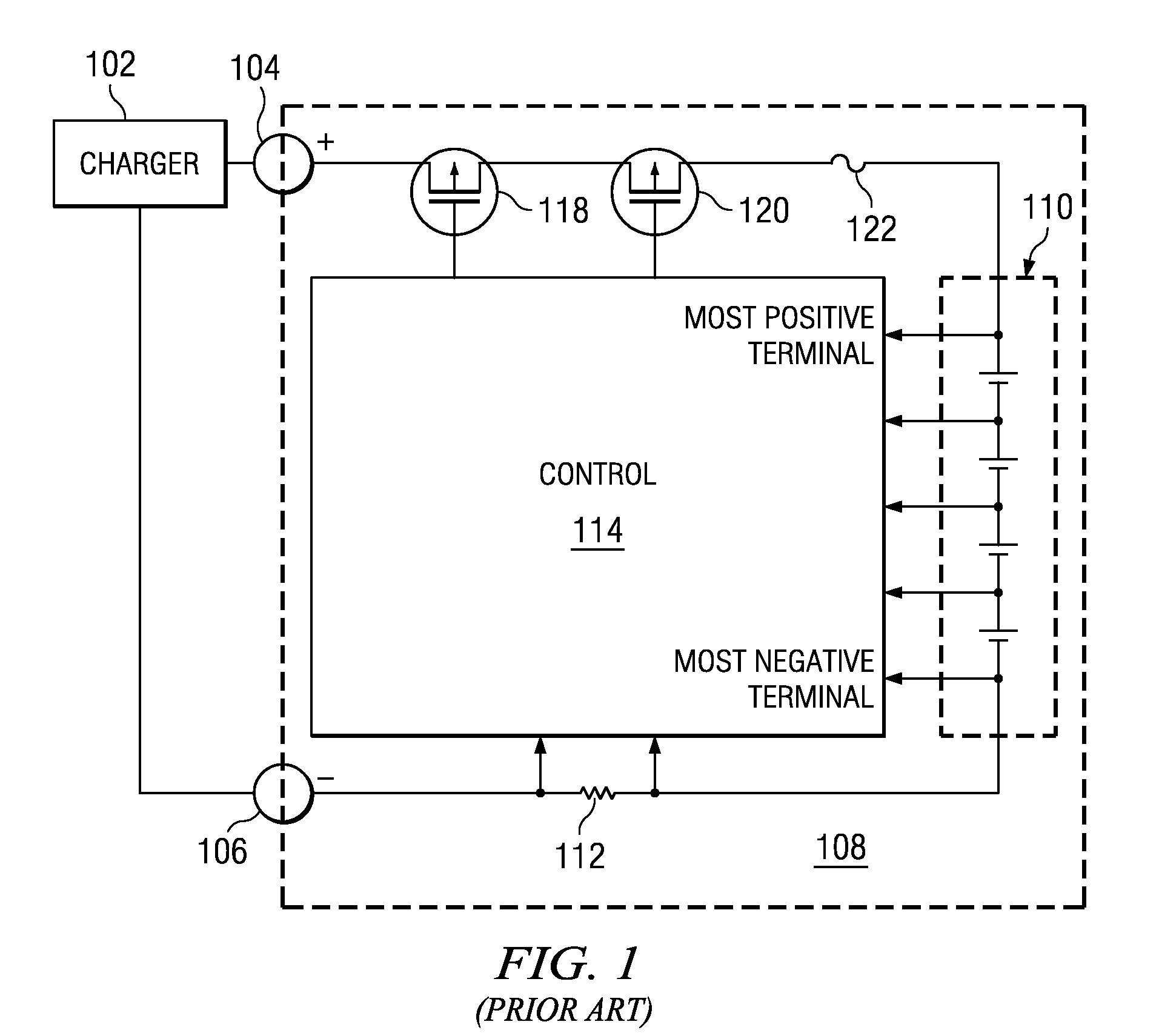

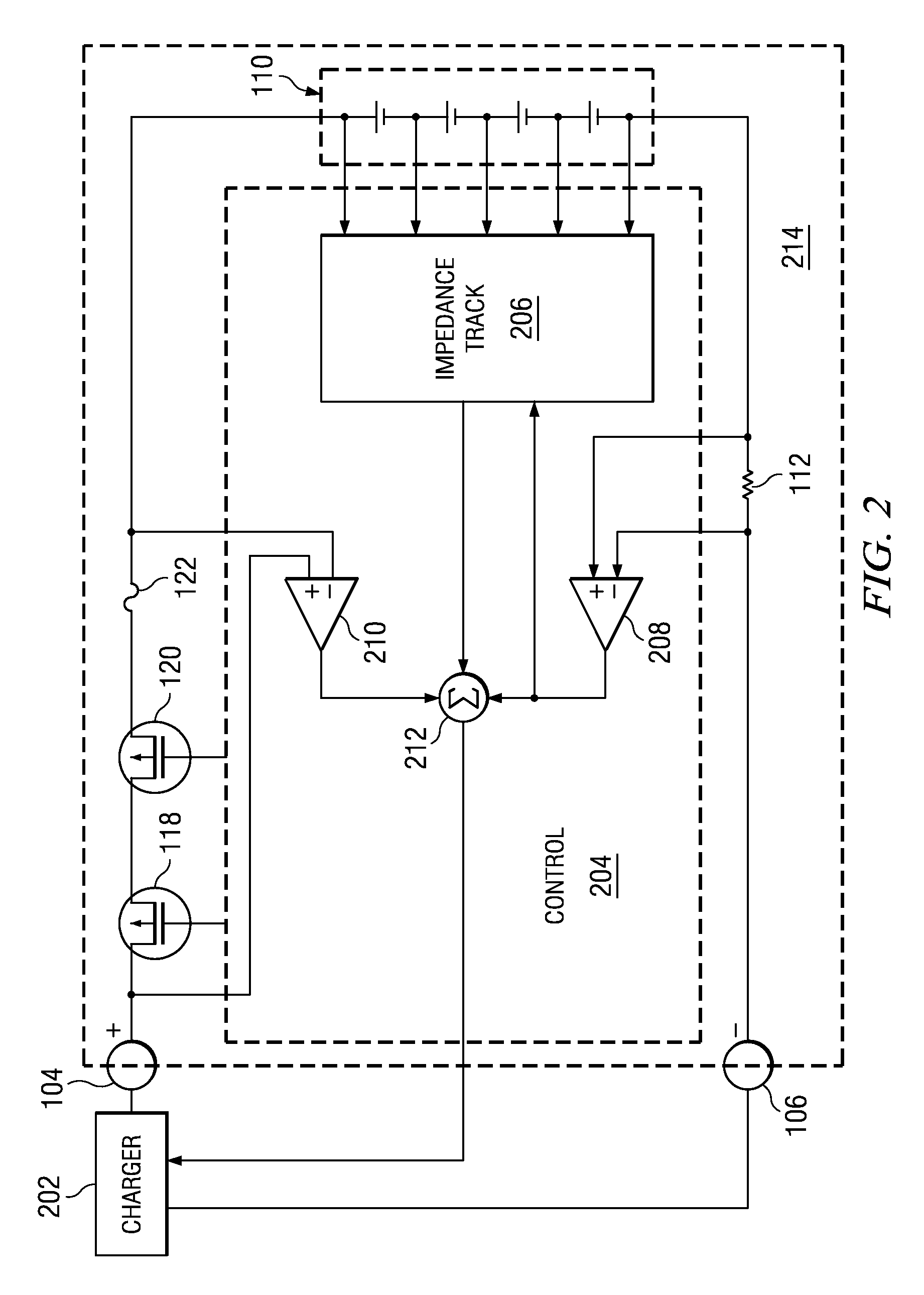

Battery charge compensation

ActiveUS20090261786A1Improve charging efficiencyImprove battery efficiencyBatteries circuit arrangementsMaterial analysis by electric/magnetic meansBattery chargeCharge current

A battery charger and method for a rechargeable battery pack which includes various elements in series with the cells to be charged, including but not limited to current control FETs, a fuse, current sense resistor, and internal series impedance of the series connected cells to be charged. The charging current Ichg flowing through these series elements reduces the voltage applied to the cells, thus lengthening charging time. A compensation voltage Vcomp, which when added to the nominal charging voltage for the series connected cells overcomes these voltage drops, facilitates more efficient charging while avoiding over-voltage damage to the cells. Three voltages representing substantially all of the voltage drops reducing the charging voltage on the cells, are summed, and the result is a compensation voltage which is utilized to change the nominal charge voltage for the battery to overcome these voltage drops.

Owner:TEXAS INSTR INC

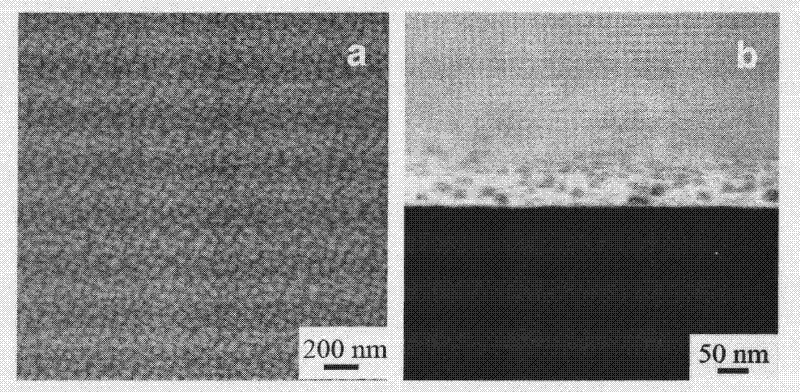

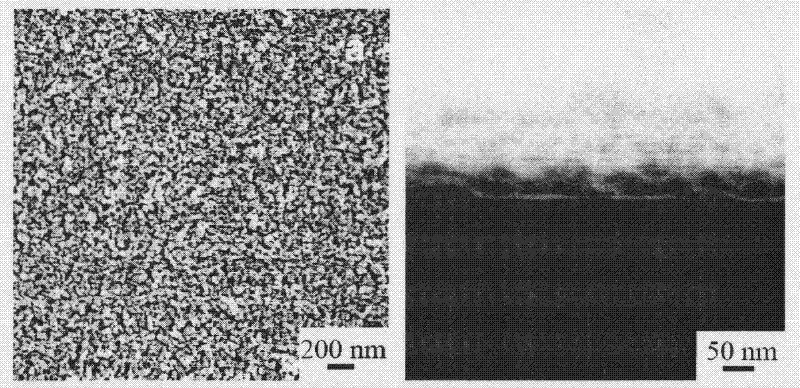

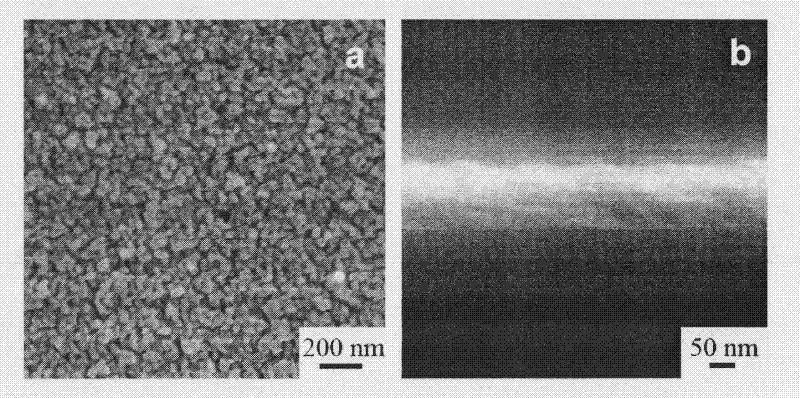

Anti-reflection coating and super-hydrophobic self-cleaning anti-reflection coating and preparation method thereof

The invention relates to an anti-reflection coating and a super-hydrophobic self-cleaning anti-reflection coating and a preparation method thereof. The anti-reflection coating is formed by a SiO2 ball-shaped nanoparticle layer with the particle size of 10-100 nm, and the surface of the coating has a rough structure. The super-hydrophobic self-cleaning anti-reflection coating is formed by providing a low surface energy substance on the surface of the anti-reflection coating, and the surface of the low surface energy substance has a rough structure. The coatings are obtained by using layer-by-layer electrostatic self-assembly technique. The light transmittance of the glass coated with the super-hydrophobic self-cleaning anti-reflection coating can increase to 99.1 from 91.3%, and the single-side reflectivity of the glass can reduce lowest to 0.3%. Compared with a solar cell coated with a common glass flake, a standard mono-silicon solar cell panel coated with a glass with the super-hydrophobic self-cleaning anti-reflection coating can utilize solar energy more effectively, and the efficiency can be improved to more than 6.6%.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Fusion formable sodium free glass

ActiveUS20100300536A1Improve battery efficiencyImprove film adhesionFinal product manufactureSynthetic resin layered productsSilicate glassThermal expansion

A compositional range of fusion-formable, high strain point sodium free, silicate, aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points≧540° C., thermal expansion coefficient of from 6.5 to 10.5 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

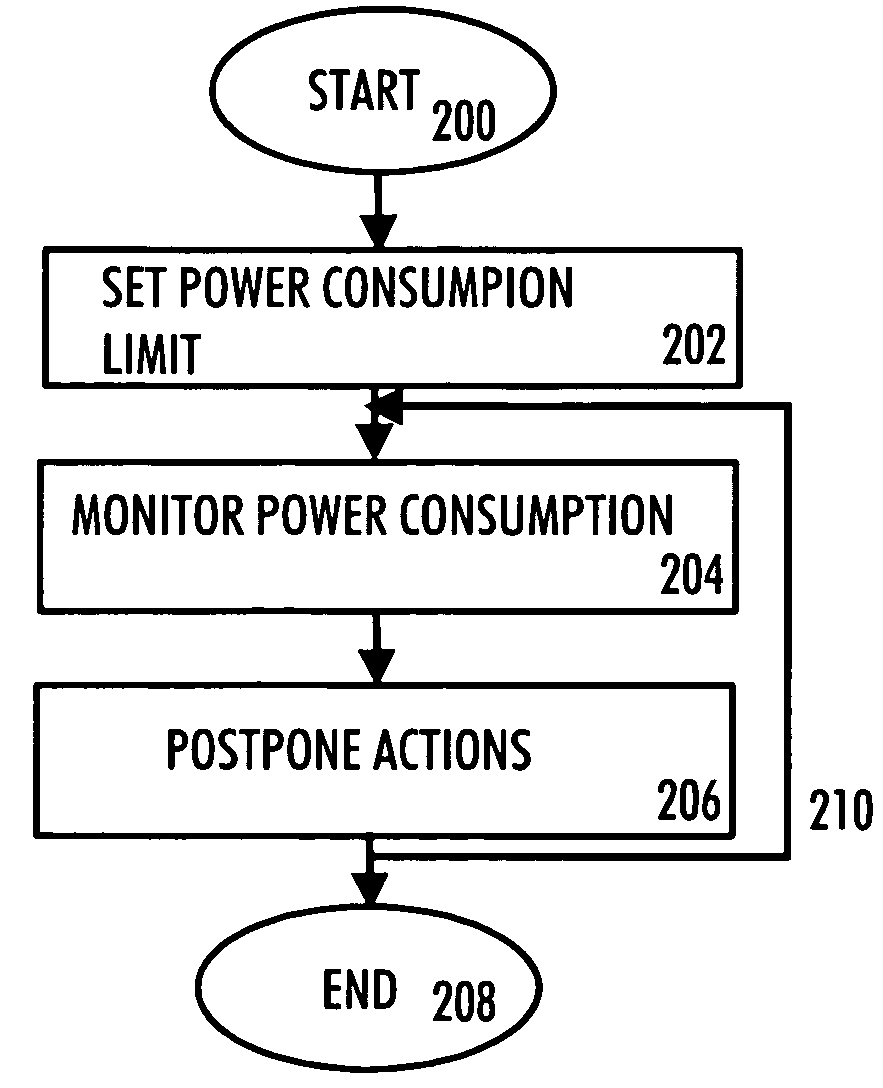

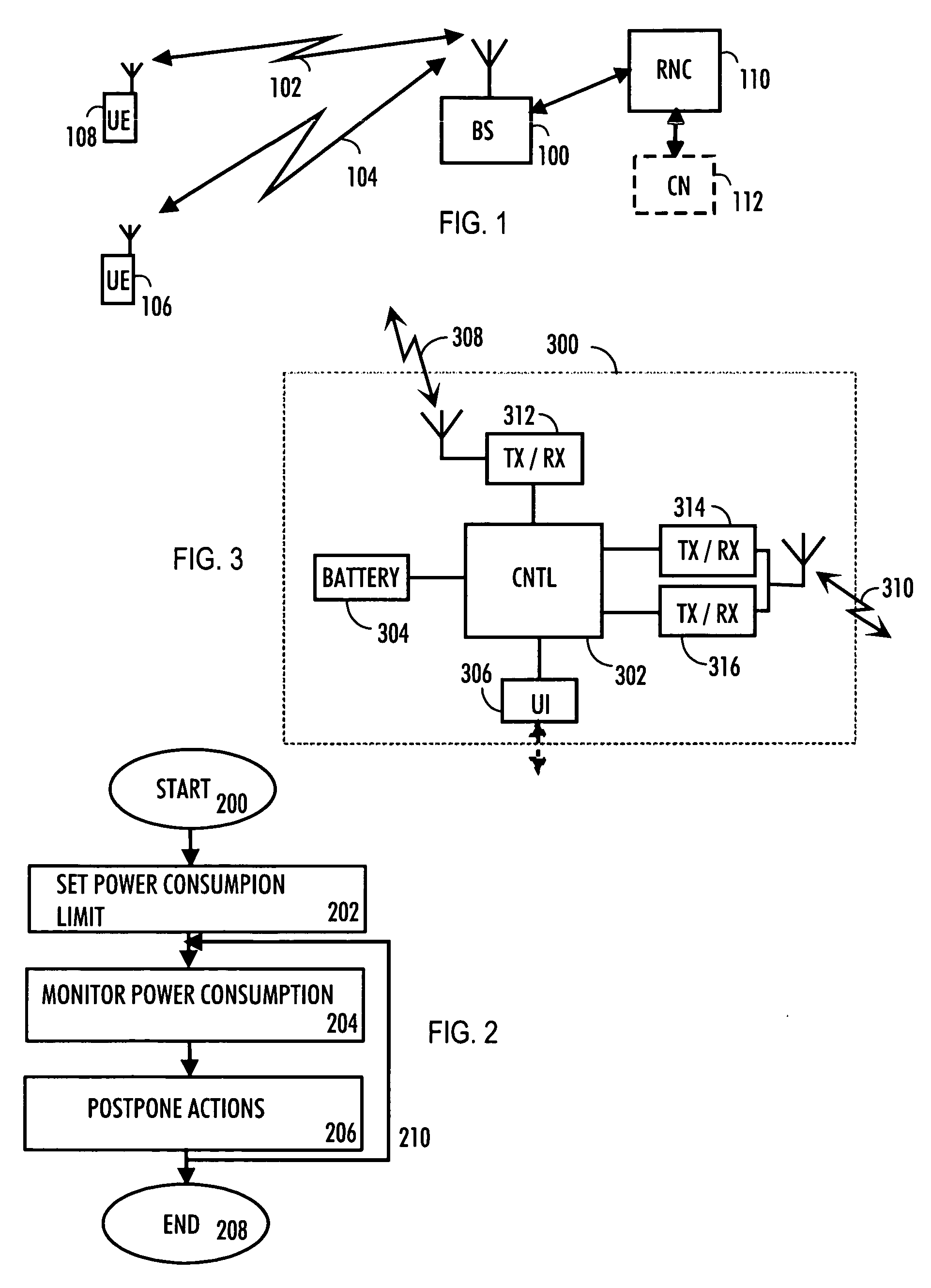

Power consumption control method, power consumption control apparatus, computer program product, computer program distribution medium and communication device

ActiveUS20080004063A1Avoid overuseIncreasing effect on power consumption of the communication devicePower managementResonant long antennasControl communicationsEngineering

The invention relates to a power consumption control apparatus configured to receive messages or commands which have an increasing effect on power consumption of a communication device; monitor the power consumption of the communication device; and control the power consumption of the communication device by applying at least one predetermined power consumption limit in such a way that if the monitored power consumption reaches the at least one power consumption limit or if actions according to the received messages or commands will make the power consumption reach the at least one power consumption limit, the actions according to the received messages or commands are postponed.

Owner:NOKIA TECHNOLOGLES OY

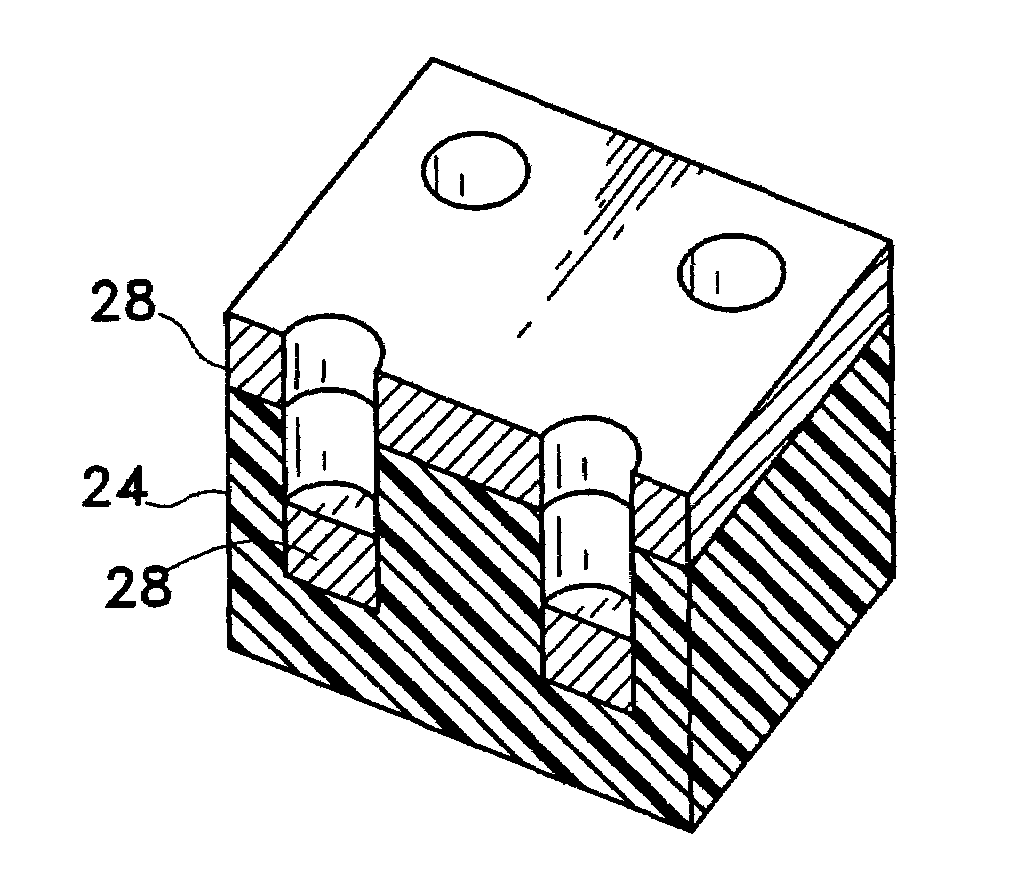

Imprinting nanoscale patterns for catalysis and fuel cells

ActiveUS7445742B2Improve battery efficiencyEfficient andMaterial nanotechnologyElectrode manufacturing processesElectrochemistryNanostructure

Owner:SAMSUNG ELECTRONICS CO LTD

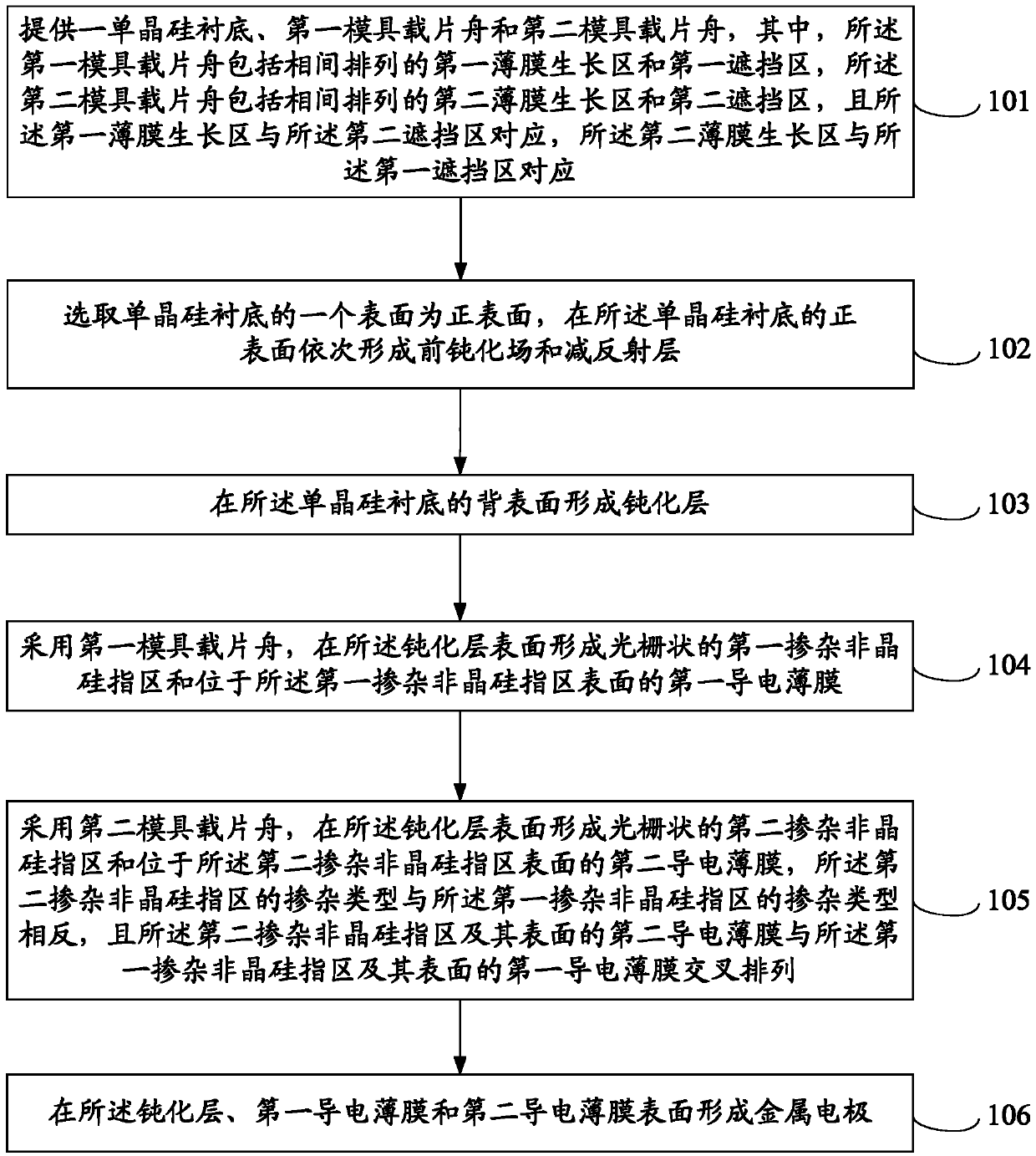

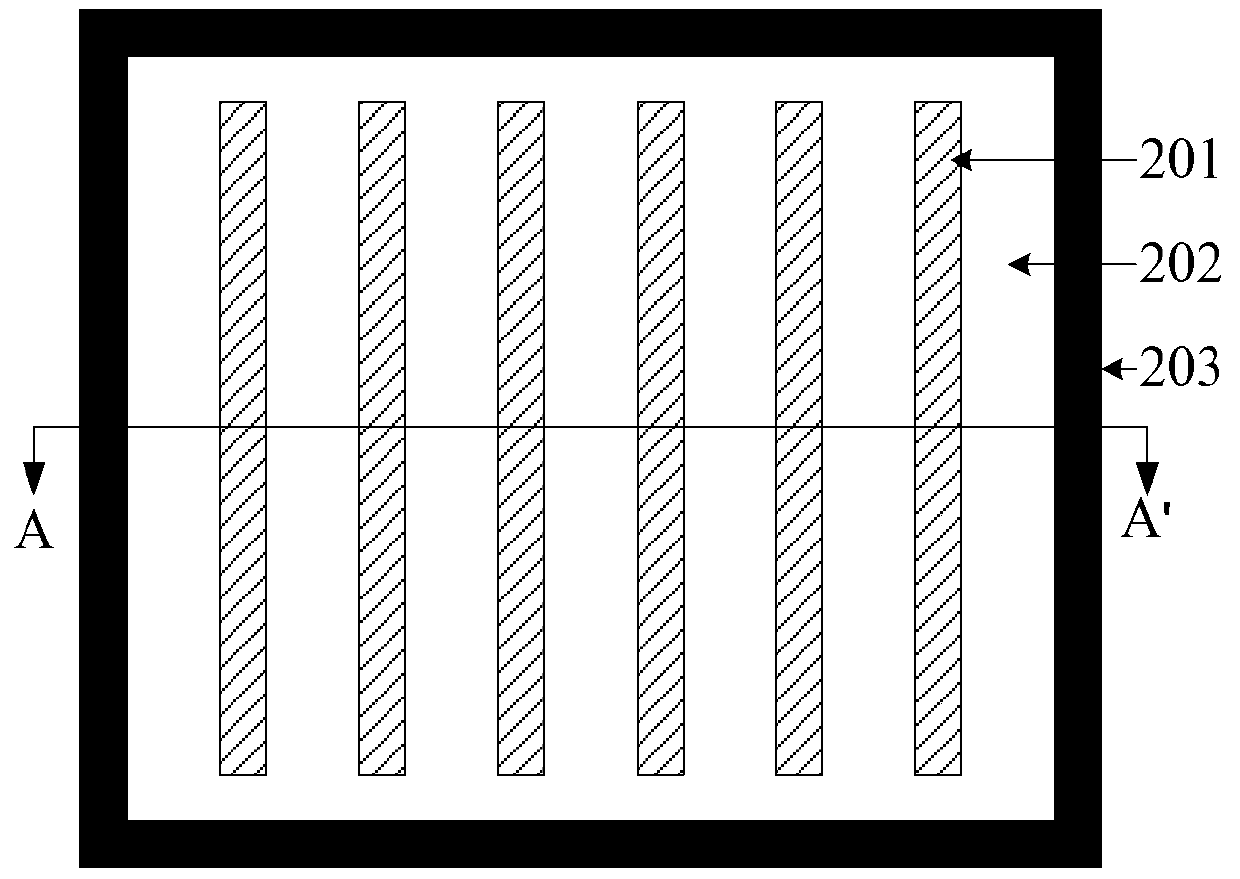

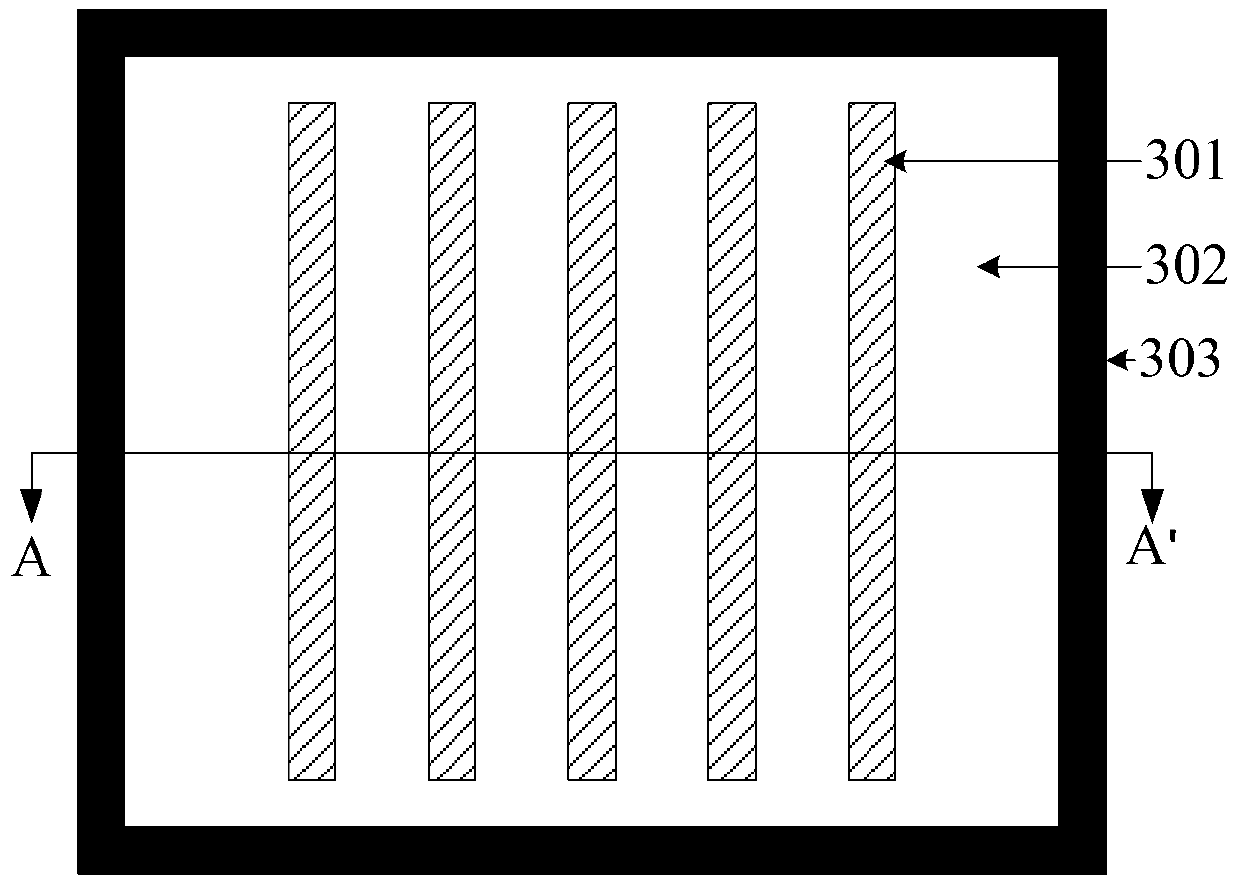

Back contact solar battery and preparing method thereof

ActiveCN103346211ASimple manufacturing methodImprove electrical performancePhotovoltaic energy generationSemiconductor devicesAmorphous siliconEngineering

The invention provides a back contact solar battery and a preparing method of the back contact solar battery. The preparing method of the back contact solar battery includes the steps of providing a first mould slide boat and a second mould slide boat, wherein the first mould slide boat comprises first film growing areas and first shielding areas which are distributed alternatively, and the second mould slide boat comprises second film growing areas and second shielding areas which are distributed alternatively, the first film growing areas correspond to the second shielding areas, and the second film growing areas correspond to the first shielding areas. First doped amorphous silicon indication areas and second doped amorphous silicon indication areas are formed on the surfaces, with passivated layers, of monocrystalline silicon substrates through the mould slide boats, wherein the first doped amorphous silicon indication areas and the second doped amorphous silicon indication areas are opposite in doping type and crossed in distribution. By means of the preparing method, a fork structure of a back field of the back contact solar battery is achieved simply at low cost, additional manufacturing process of forming the passivated layers is needless, and the preparing method of the back contact solar battery is simplified.

Owner:YINGLI GRP +2

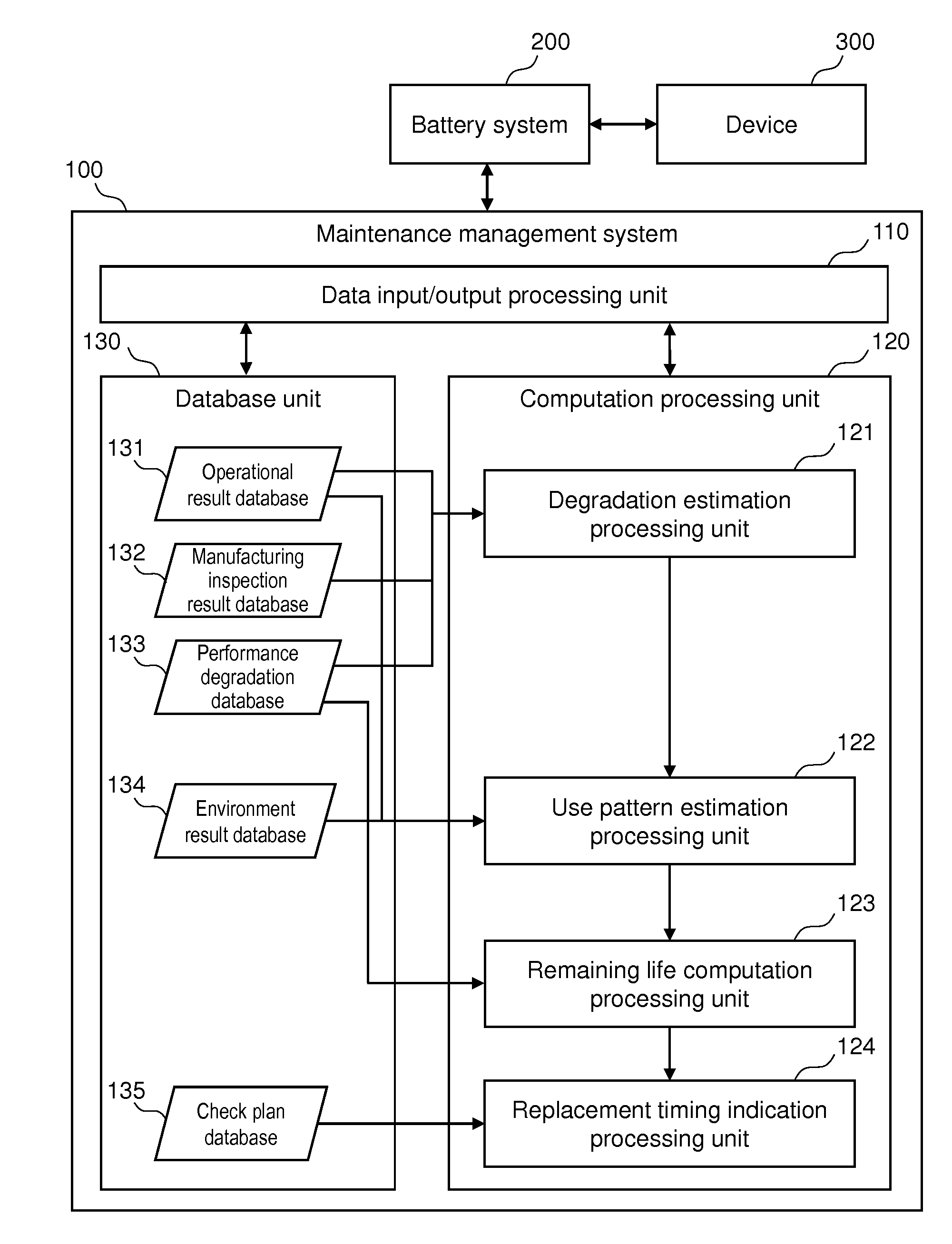

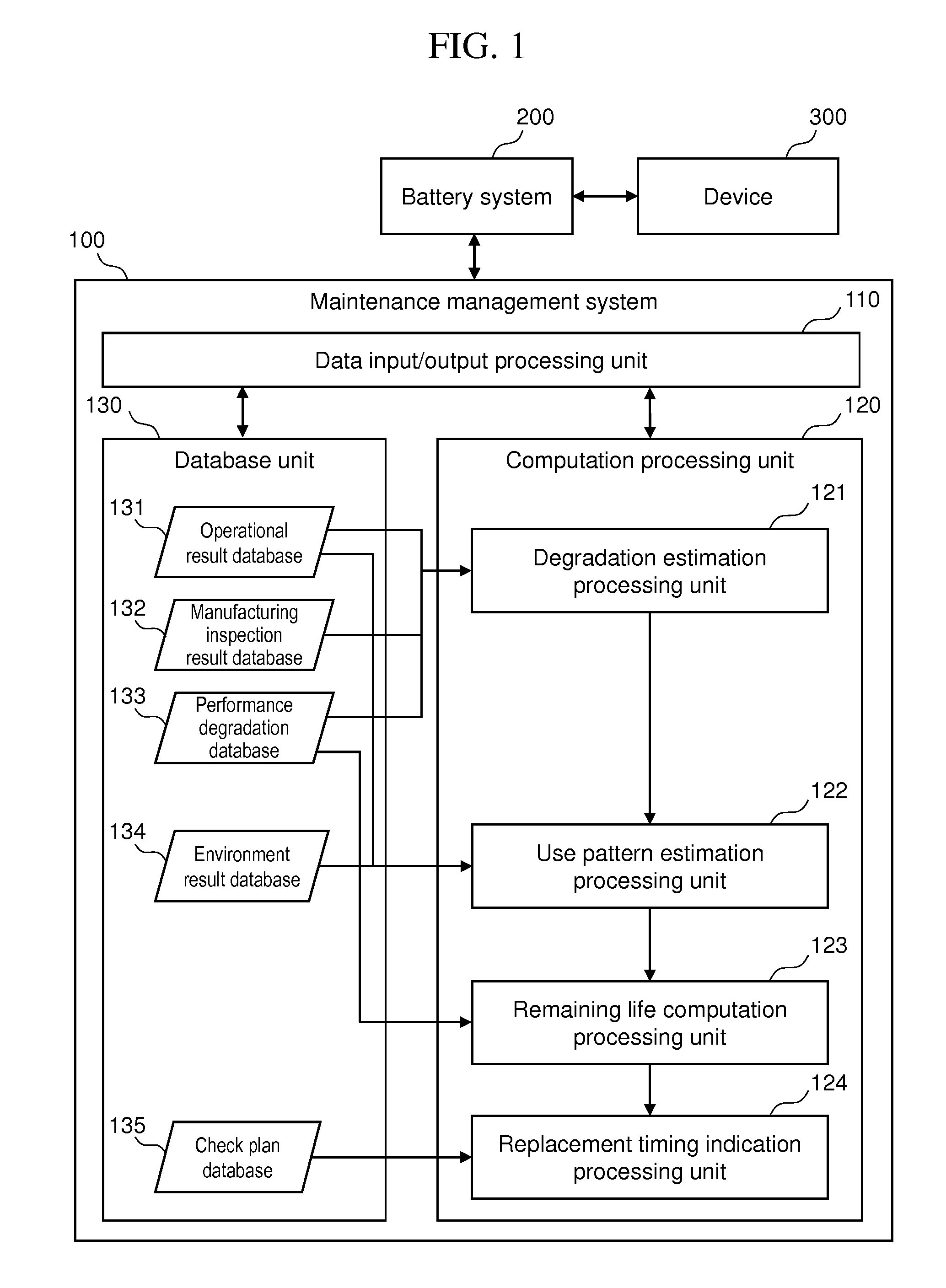

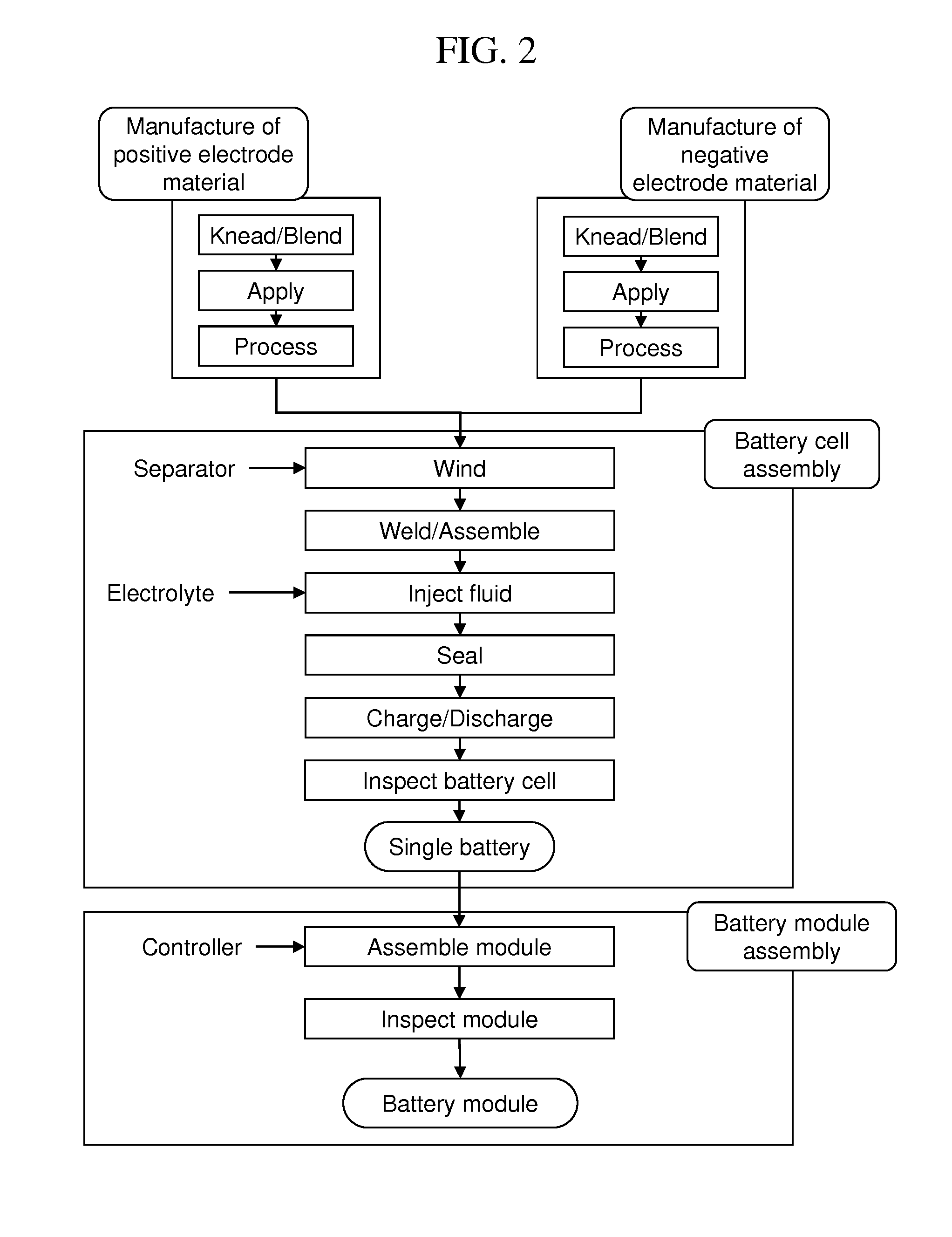

Battery system maintenance management system and method

InactiveUS20150046109A1Improve battery efficiencyEasy to operateElectrical testingSecondary cellsElectrical batteryMaintenance management

Proposed is a method for efficiently indicating the replacement timing of each battery module which is a constituent element of a battery system on the basis of operational results information of the battery system without lowering the operating ratio of the battery system. First, capacity-voltage profile data of the battery module according to manufacturing state and degradation state, capacity-voltage profile data at the time of shipping of the battery module, and most recent capacity-voltage profile data of the battery module are collated to estimate the degradation degree of the battery module of the battery system. Then, based on past charge / discharge results data of the battery module, a future use pattern is estimated. Thereafter, remaining operating life is computed based on the degradation degree, the use pattern of the battery module, and characteristics degradation data. Finally, based on the remaining operating computed for the life battery module, the replacement timing of the individual battery module is indicated.

Owner:HITACHI LTD

Rapid thermal firing IR conveyor furnace having high intensity heating section

InactiveUS7805064B2Effectively doubling heating rate and furnace processing throughputIncrease productionSoldering apparatusSemiconductor/solid-state device manufacturingNameplate capacityCooling curve

Isolation IR heat lamp module and method of firing multi-zone IR furnaces for solar cell processing comprising lamps disposed in individual parallel channels in a reflector / insulator body to provide a cooling air channel surrounding each tube; the channels are covered with IR-transmissive plate material to isolate each lamp from adjacent lamps and the process zone. Cooling air is exhausted and recycled upstream for energy conservation. Lamp spacing can be varied and power to each lamp individually controlled to provide infinite control of temperature profile in each heating zone. For a spike zone, and in combination with downstream quench control and annealing zones, steep heating and cooling curves with very short dwell (sharp) peak temperature profiles permit faster throughput due to operation of the lampsm at essentially 100% rated capacity, at a 2× or greater heating and throughput rate without compromising lamp life, while producing solar cells with improved output efficiency.

Owner:TP SOLAR OF USA

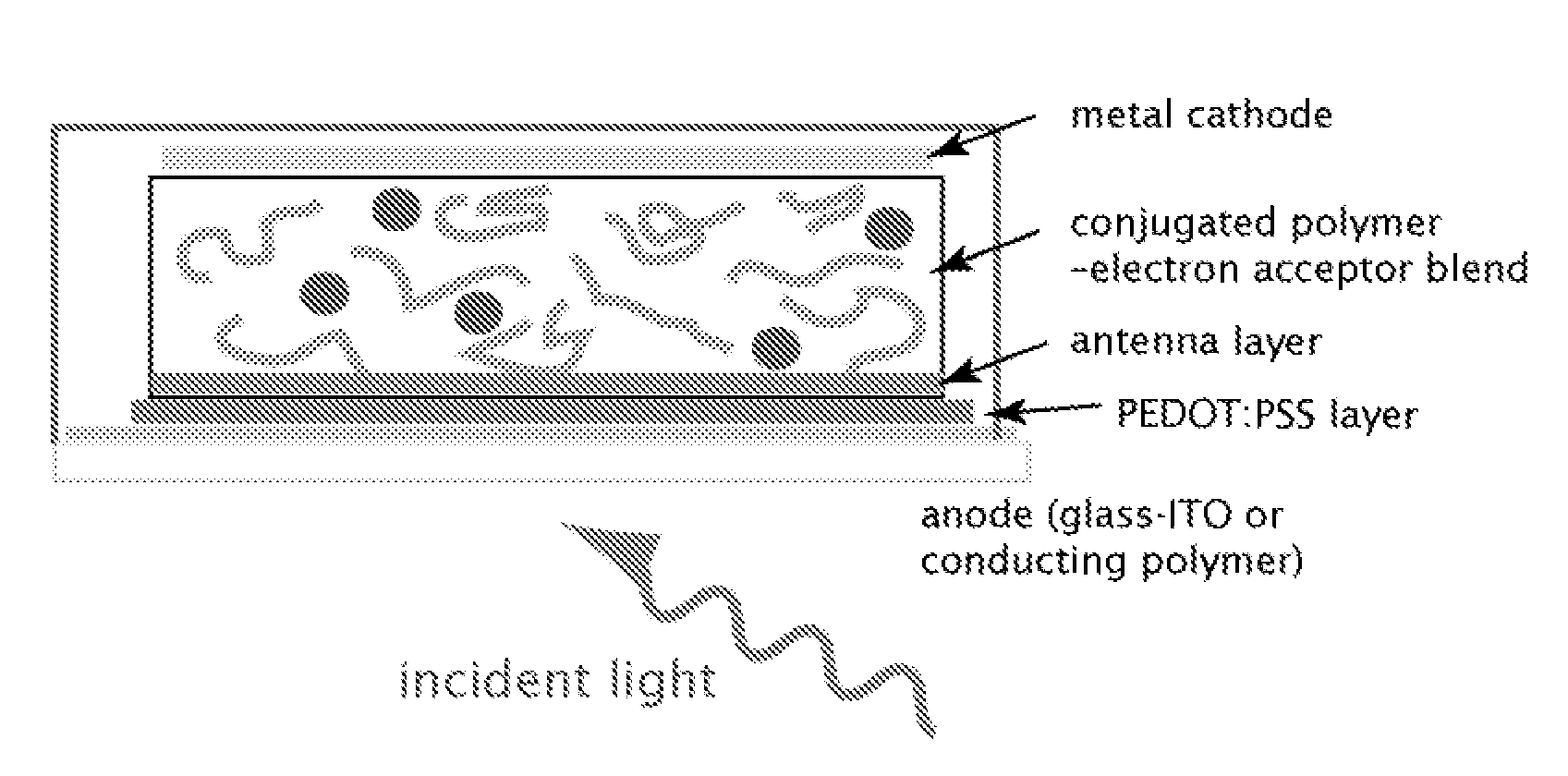

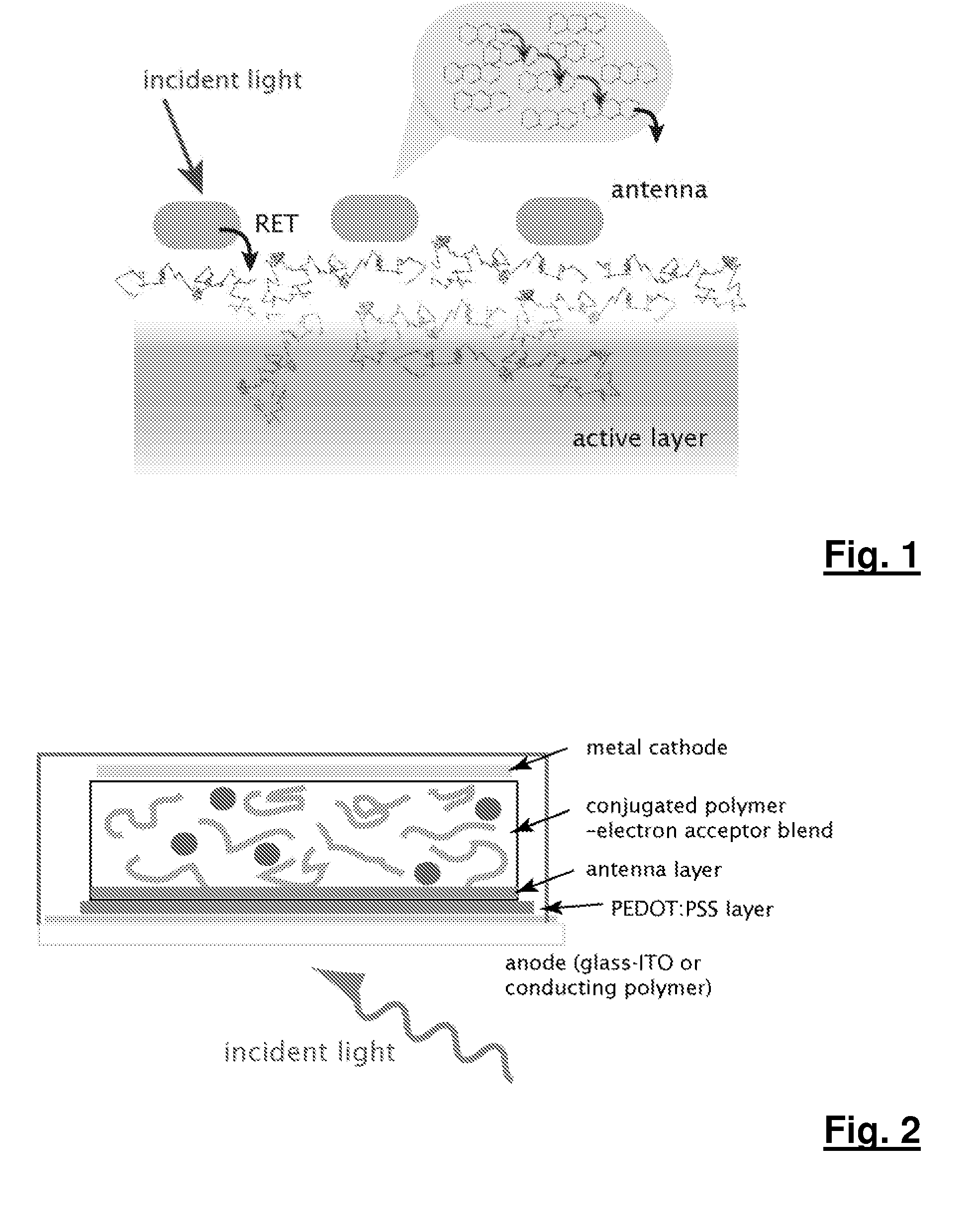

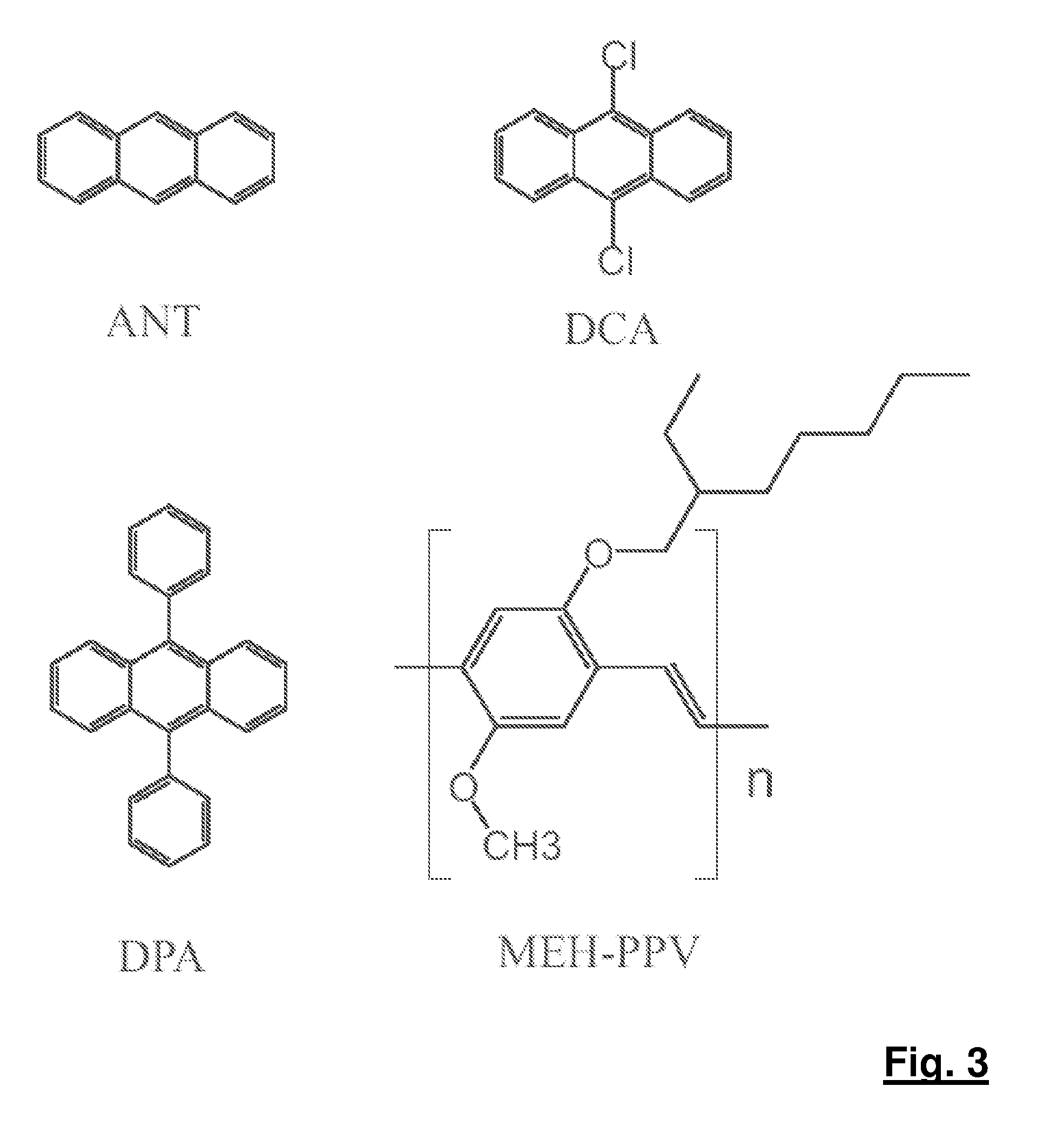

Light-harvesting antennae for organic solar cells

InactiveUS20080087326A1Improve energy conversion efficiencyReduce photodegradationNanoinformaticsSolid-state devicesOrganic solar cellUltraviolet

An antenna layer is provided separate from an active layer in a solar cell device based on organic materials, enabling improved energy conversion in the solar cell devices by increasing the efficiency and spectral cross-section for the capture of incident light. The antenna layer may be anthracene or an anthracene derivative, for example. The antenna layer is operable to harvest light and transfer captured excitation energy to the active layer of the solar cell device using an energy transfer mechanism, wherein the charge separation and / or the formation of free carriers takes place. The antenna layer also limits the ultraviolet exposure of the active layer thus extending the operating life of the solar cell. The active layer and the antenna layer of a solar cell device may be independently optimized such that there is an increased spectral range and / or cross-section of light absorption and thus a higher photovoltaic efficiency.

Owner:SCHOLES GREGORY DENTON +2

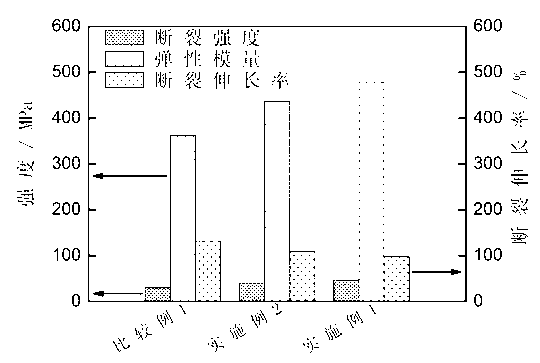

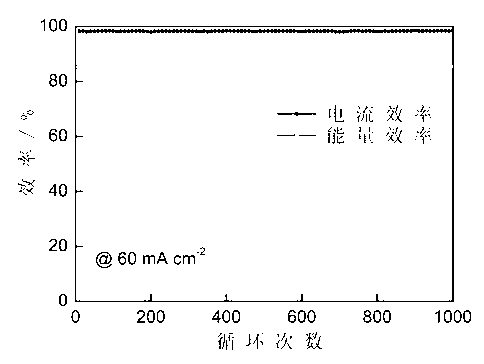

A composite ion-exchange membrane and a preparation method thereof, and a redox flow battery

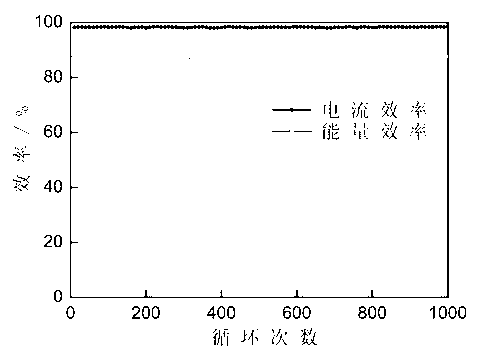

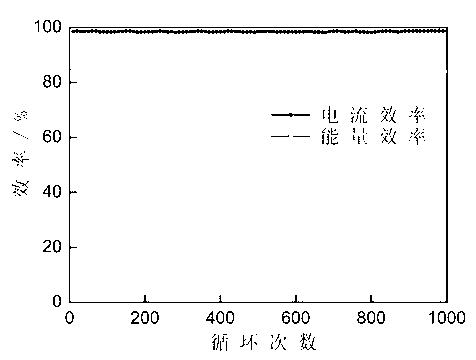

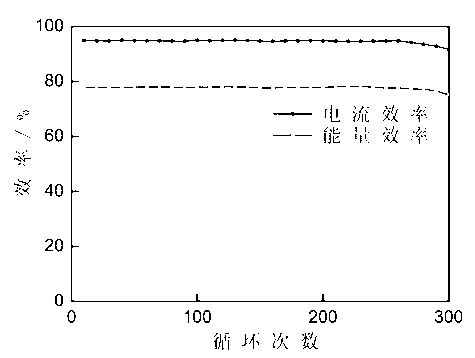

ActiveCN103236553AHigh ion selectivityLow costCell electrodesRegenerative fuel cellsPolymer scienceSulfonated polymer

The present invention discloses a composite ion-exchange membrane and a preparation method thereof, and a redox flow battery. The composite ion-exchange membrane is prepared by using a sulfonated polymer as a matrix, incorporating inorganic materials into the matrix, and mixing the sulfonated polymer and the inorganic materials uniformly. The ion-exchange capacity of the sulfonated polymer is 0.1-5mmol / g, the mass percentage of the sulfonated polymer is 80-99.99wt%, the mass percentage of the inorganic materials is 0.01-20wt%, and the mass percentagesof the sulphonated polymer and the inorganic materials sum to 100wt%. According to the present invention, by introducing a certain amount of inorganic materials into a certain amount of the sulfonated polymer matrix for modification, the composite ion-exchange membrane is allowed to both have a high ionic selectivity and a high stability. By applying the prepared composite ion-exchange membrane in the redox flow cell, higher battery efficiency and more stable battery performance can be achieved. The preparation method of the composite ion-exchange membrane is simple and is conducive to promoting the industrial development of redox flow batteries.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

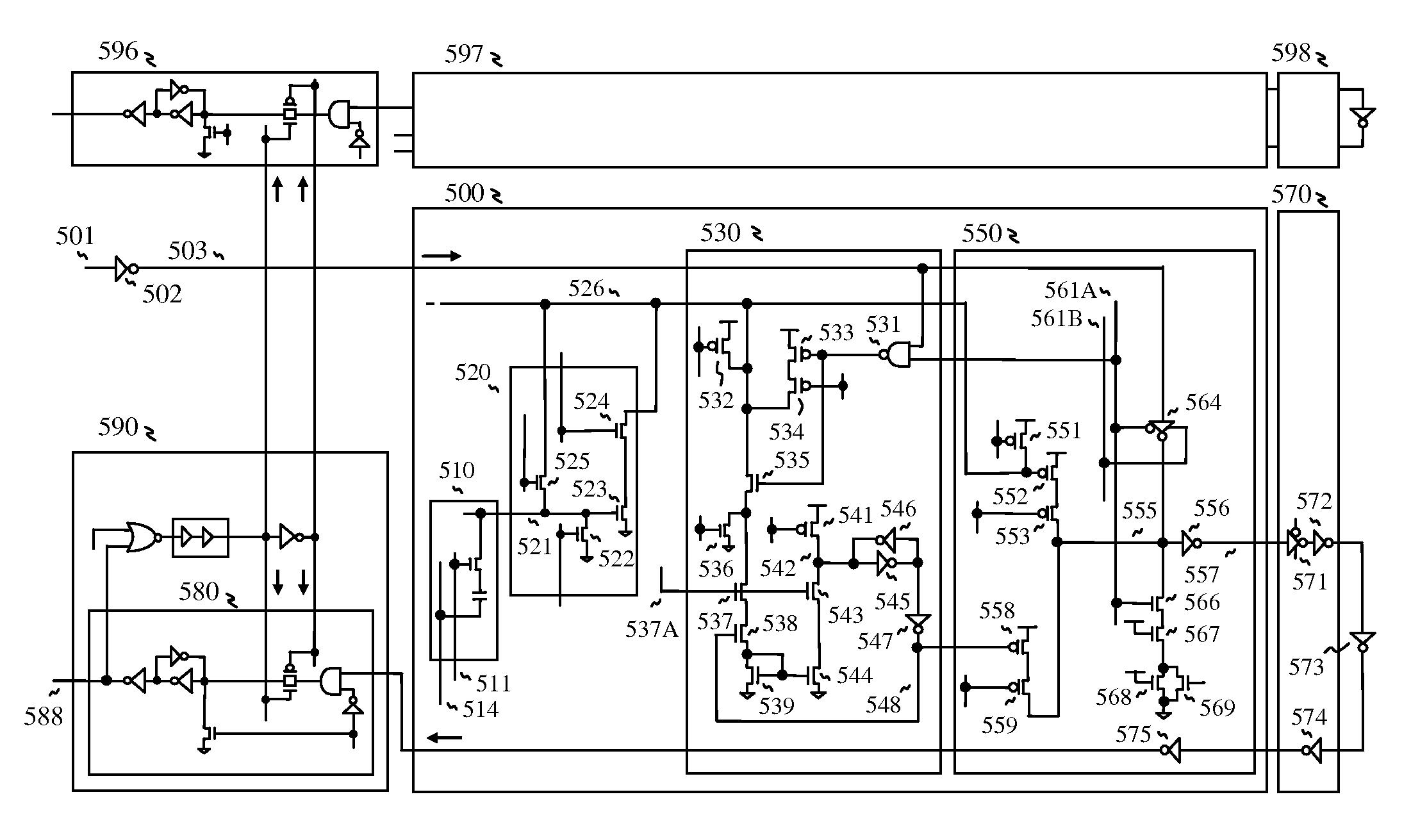

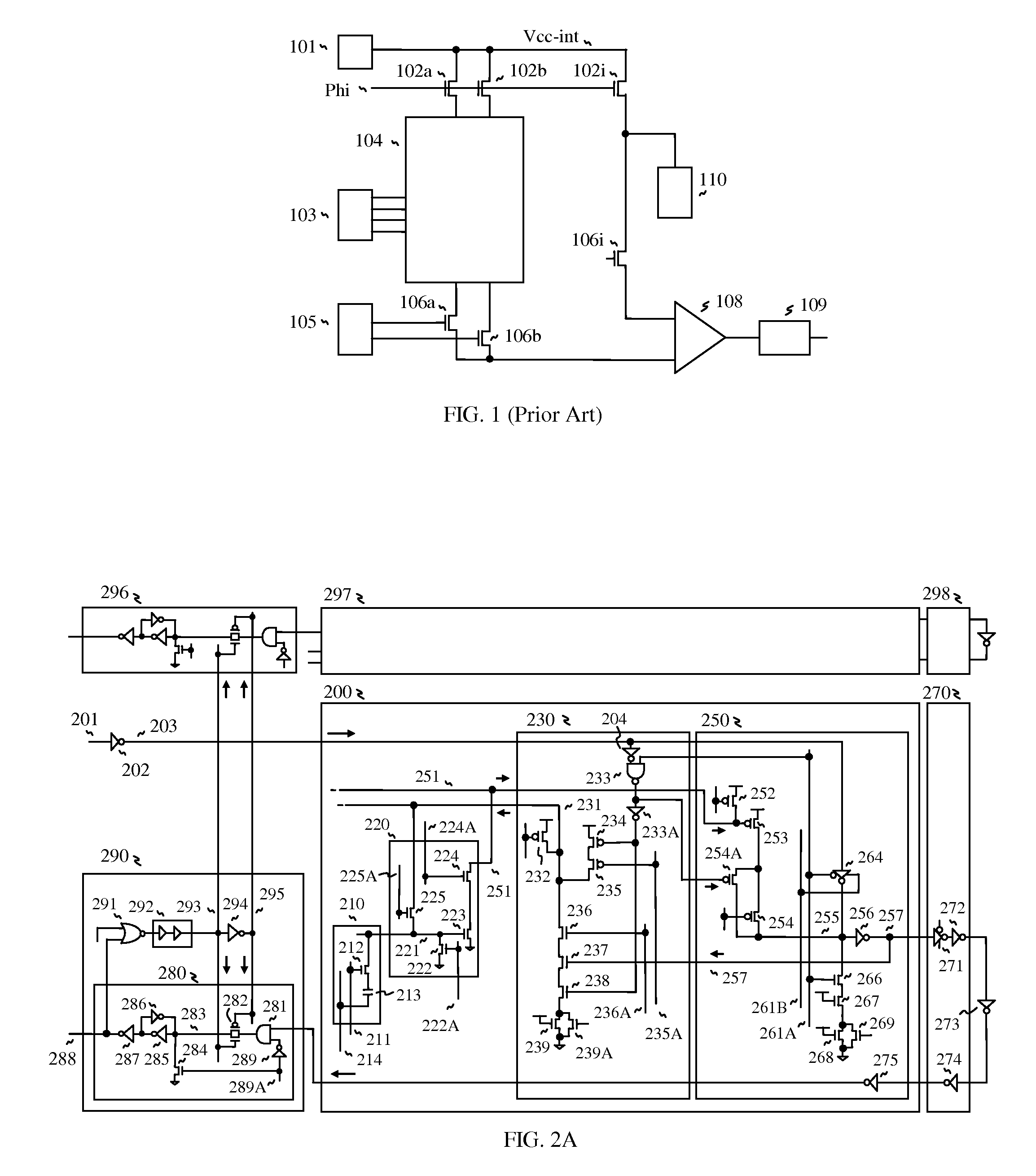

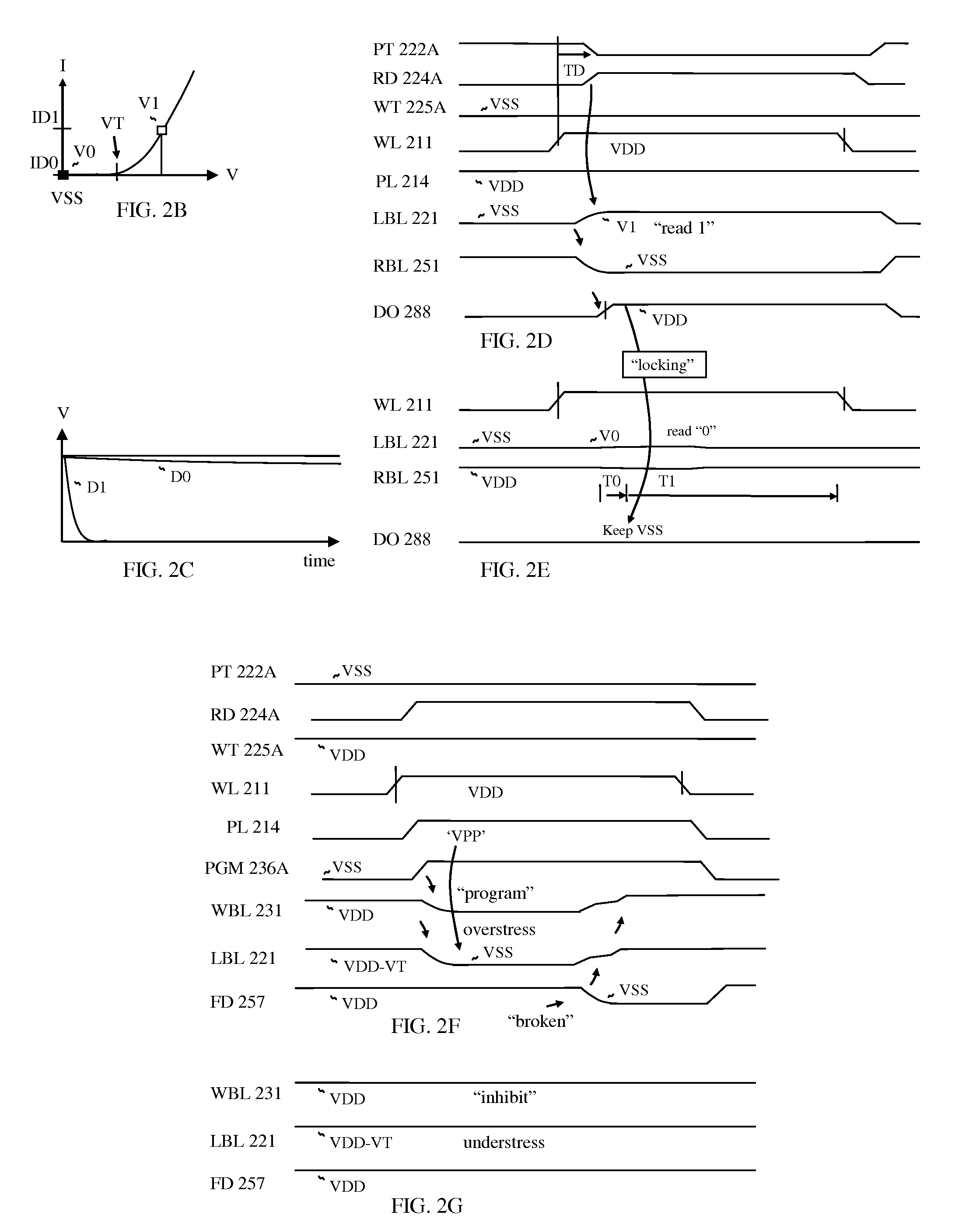

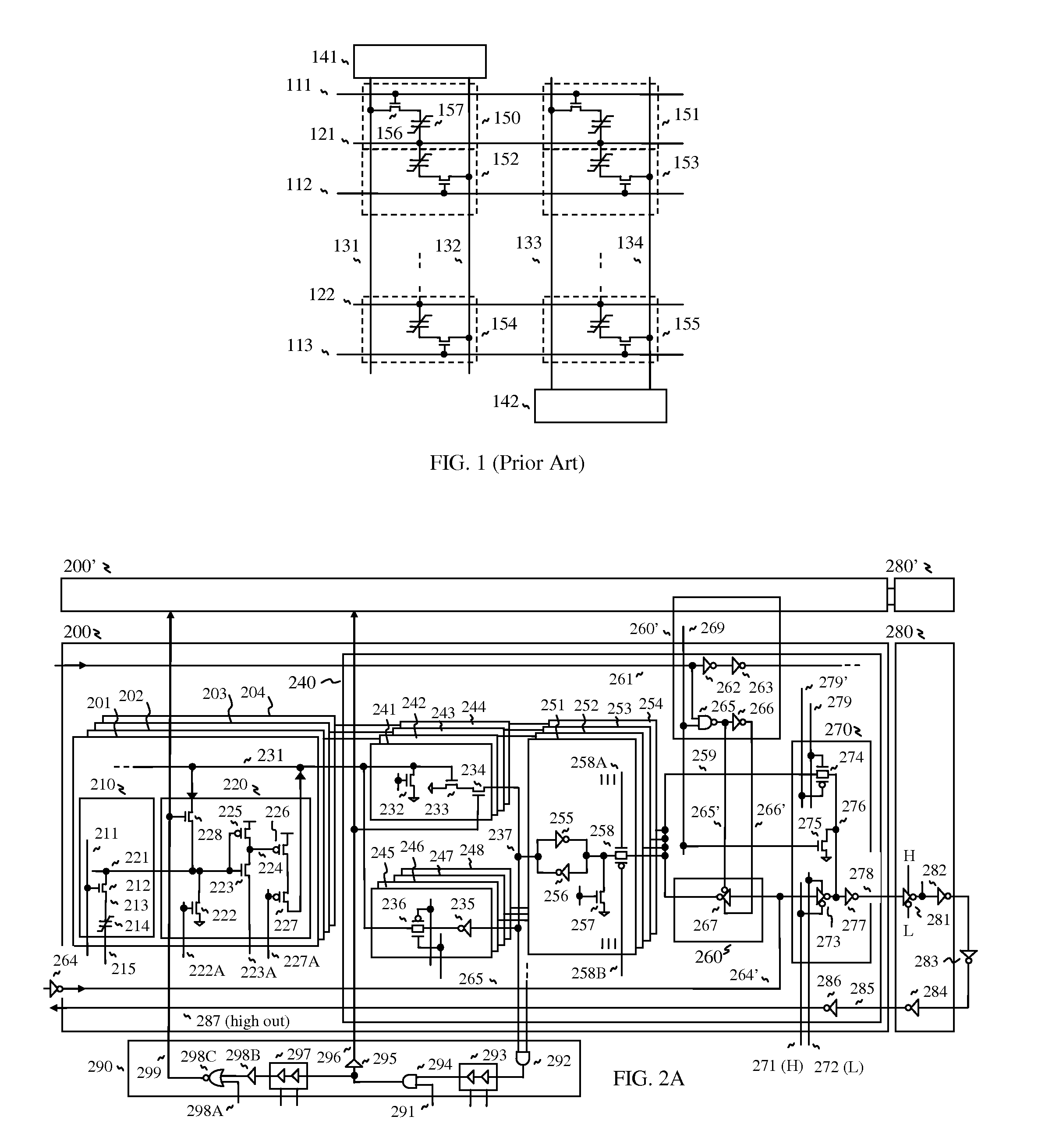

Mask ROM with light bit line architecture

InactiveUS7715246B1Configuring memory is more flexibleReduce in quantityTransistorSolid-state devicesCapacitanceBit line

For improving performance of mask ROM, bit line is multi-divided for reducing capacitance, so that multi-stage sense amps are used for reading, wherein a local sense amp receives an output from a memory cell through the bit line, and a global sense amp receives the local sense amp output. By the sense amps, a voltage difference in the bit line is converted to a time difference for differentiating data “1” and data “0”. For example, data “1” is quickly transferred to an output latch circuit through the sense amps with high gain, but data “0” is rejected by a locking signal based on data “1” as a reference signal. Furthermore, a buffered data path is used for transferring data wherein the buffered data path includes a forwarding write line and a returning read line. Additionally, alternative circuits and memory cell structures for implementing the mask ROM are described.

Owner:KIM JUHAN

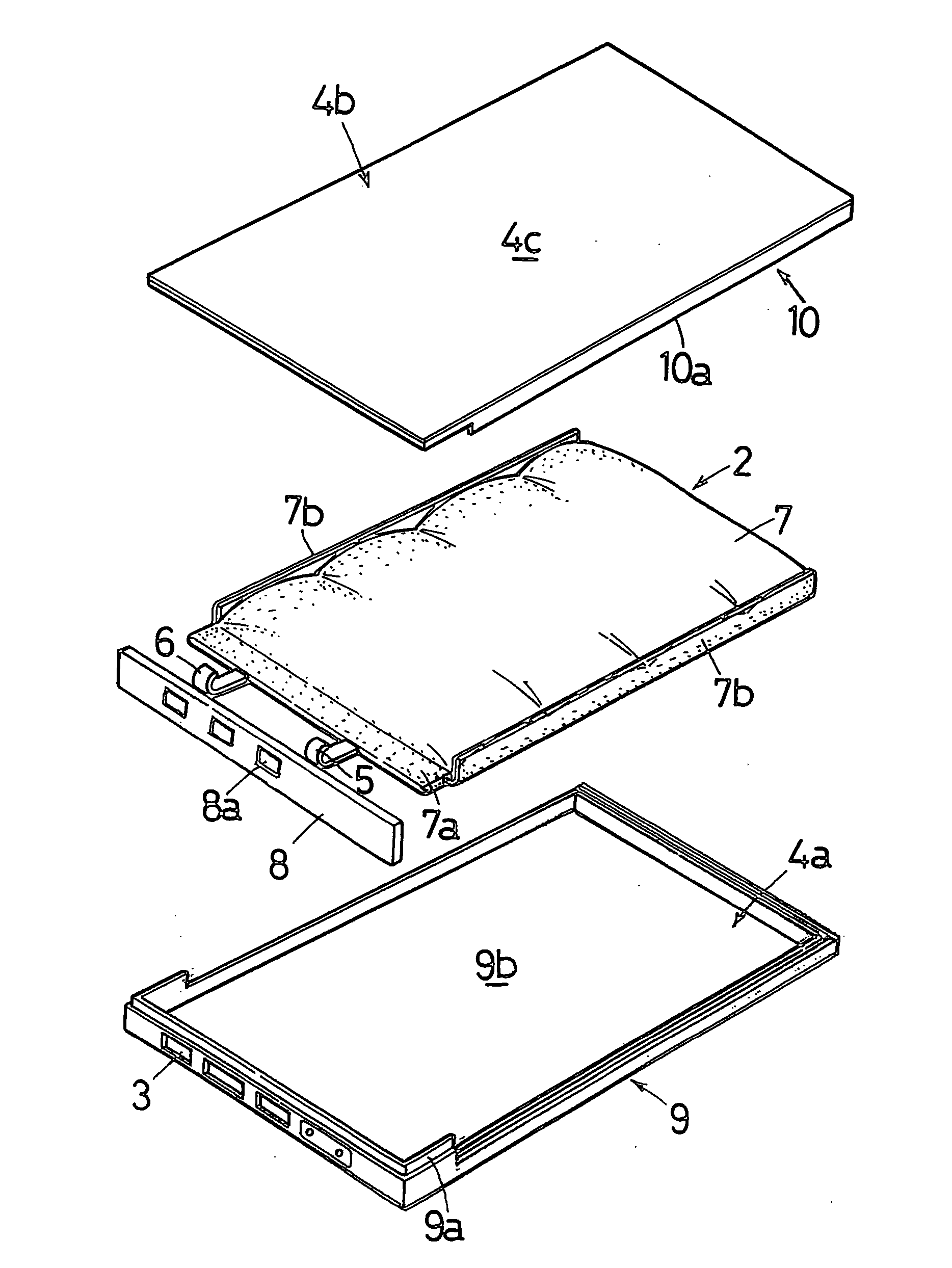

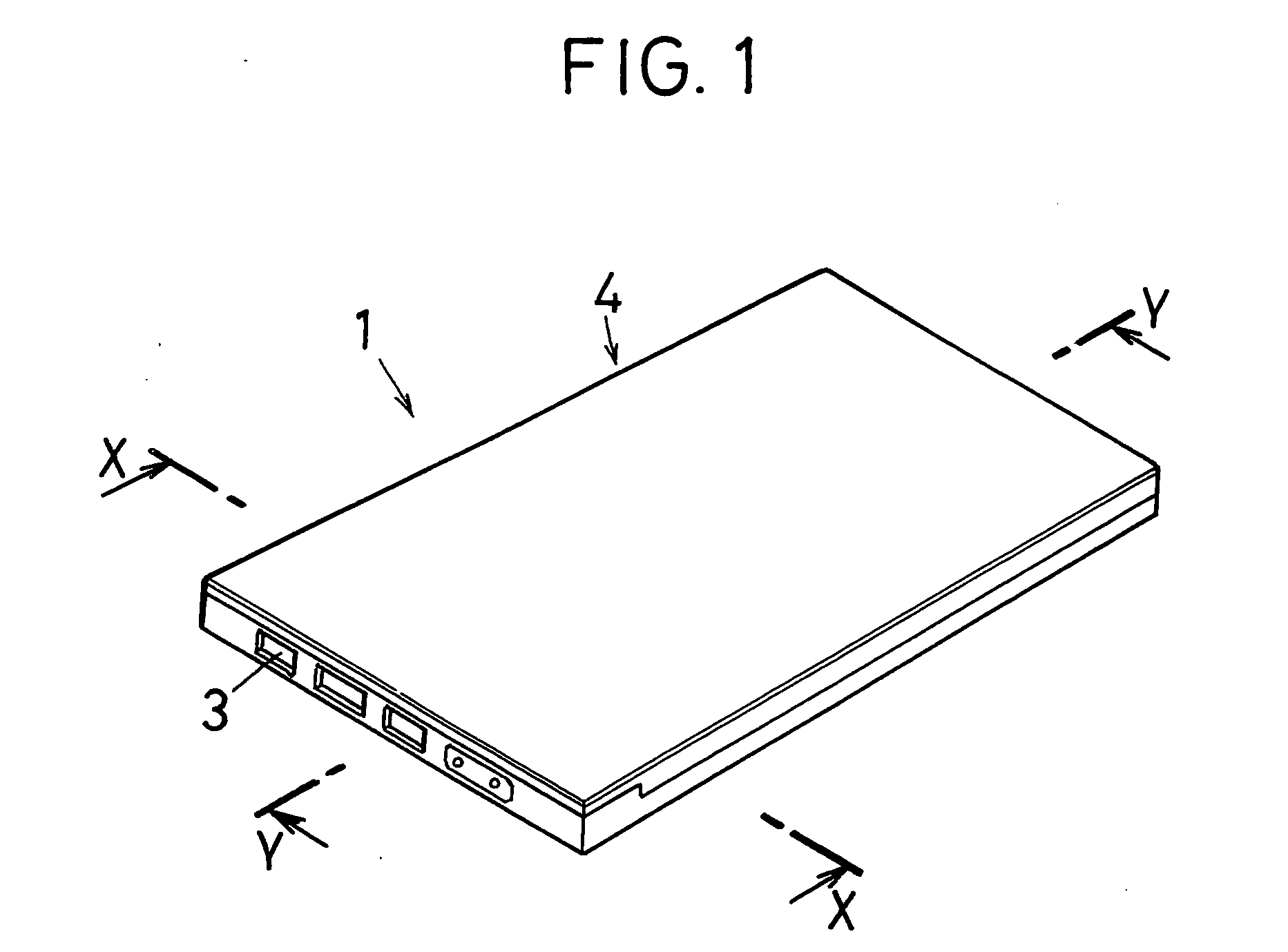

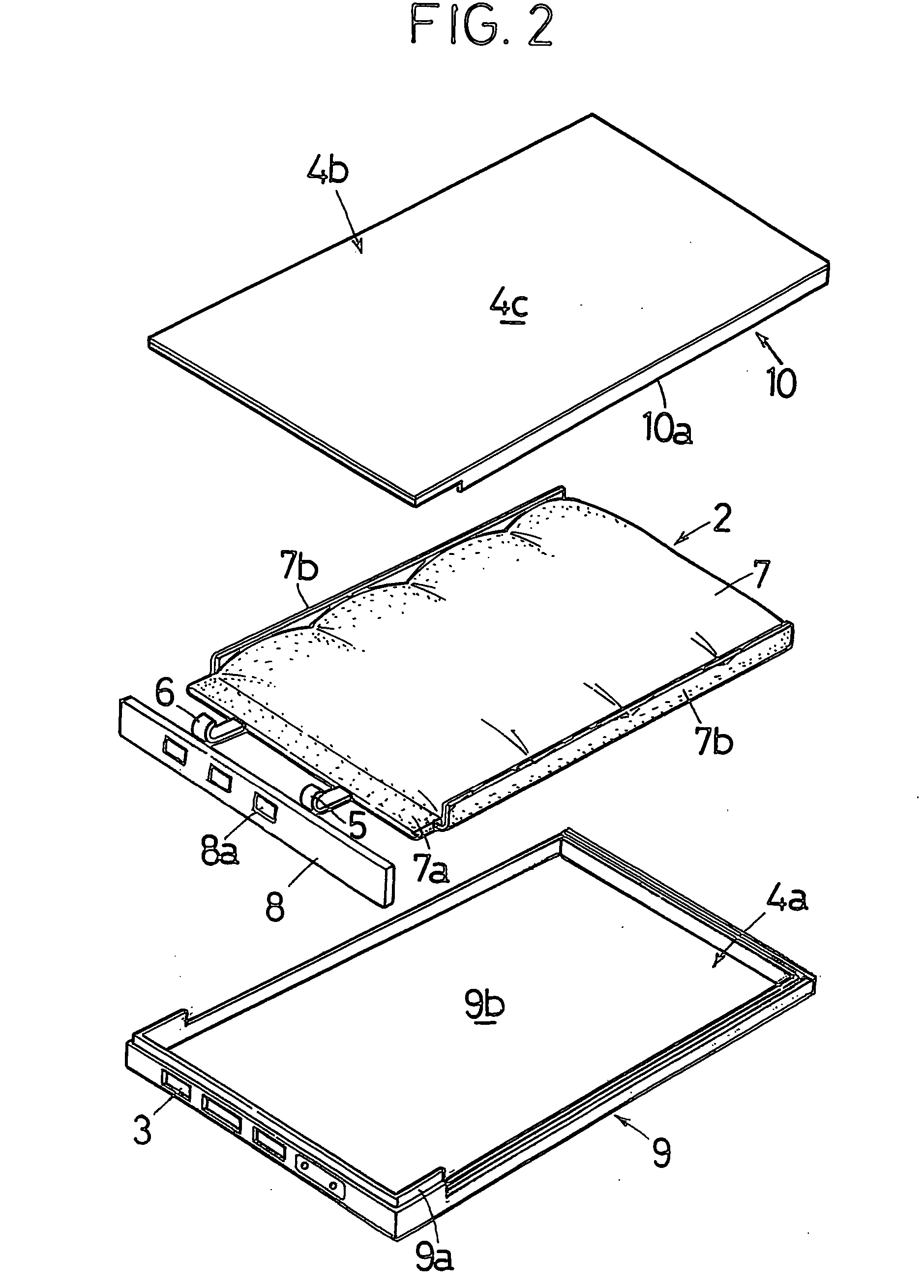

Outer case for non-aqueous electrolyte battery and method of producing the same

InactiveUS20060068281A1Satisfactory mechanical strengthThin formPrimary cellsElectrode carriers/collectorsEngineeringSynthetic resin

An outer casing of a non-aqueous electrolyte battery is capable of being mass-produced as well as thin and resistant to damage. The outer casing 4 comprises a casing body 4a and a cover 4b. After being internally packaged, a non-aqueous electrolyte battery 2, e.g. a lithium-ion polymer secondary battery, is sandwiched between the casing body 4a and the cover 4b, which are then joined together integrally. The cover 4b is formed from a film-shaped sheet material 4c of a synthetic resin to make the outer casing 4 thin. The casing body 4a and the cover 4b have a casing body outer peripheral frame 9 and a cover outer peripheral frame 10, respectively, formed by injection molding. Joint portions of the casing body 4a and the cover 4b have stepped portions 9a and 10a, respectively. The stepped portions ensure the mechanical strength against shock and impact. With this structure, the outer casing 4 is resistant to damage.

Owner:SONY CORP +1

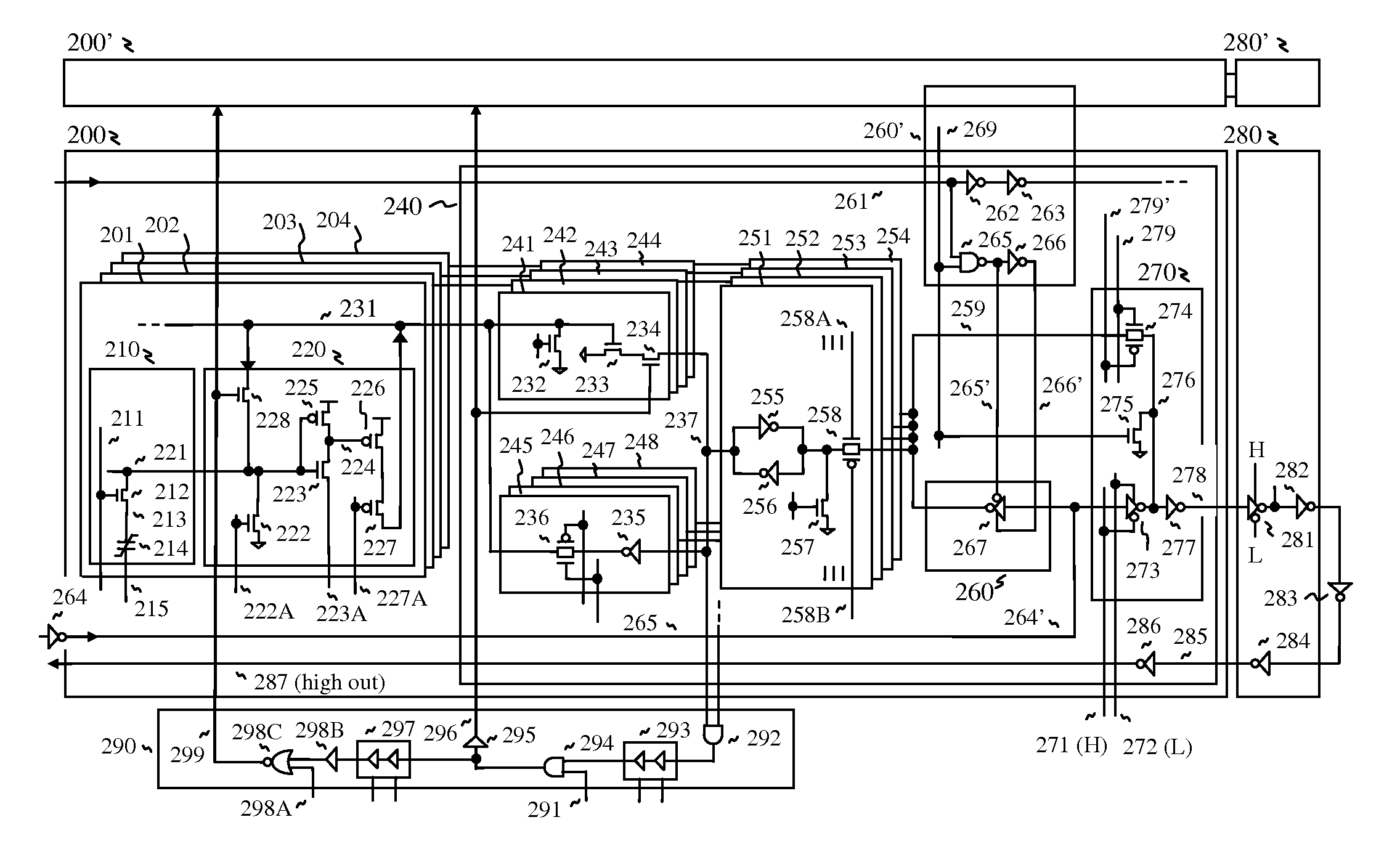

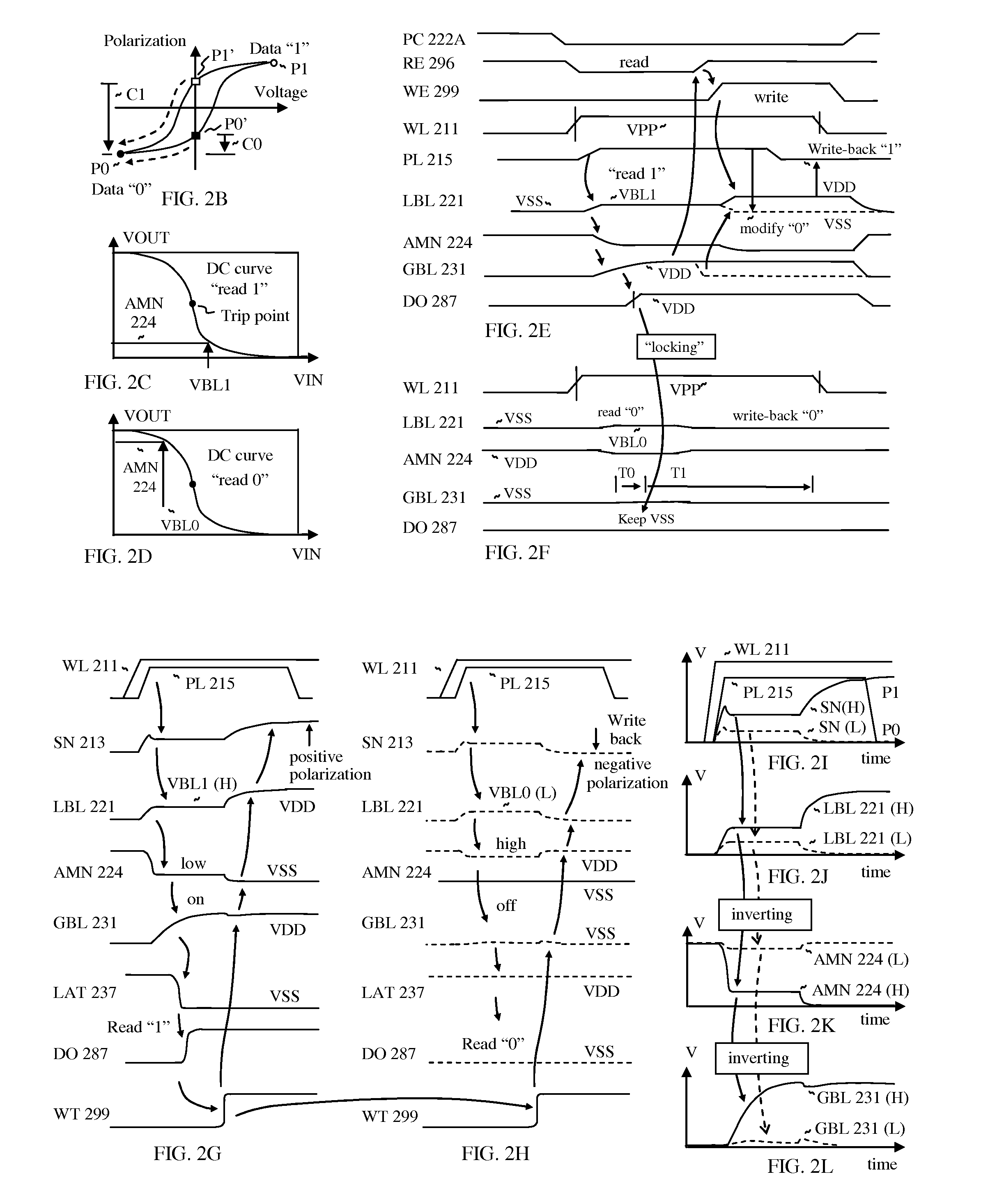

High speed ferroelectric random access memory

For realizing high speed ferroelectric random access memory, bit line is multi-divided for reducing parasitic capacitance, so that the bit line is quickly charged or discharged by a memory cell including a ferroelectric capacitor when reading. Particularly, a non-inverting local sense amp is devised for reducing area, such that the memory cell is read by the local sense amp through a lightly loaded local bit line, and the local sense amp is read by a global sense amp through a global bit line. By the sense amps, a voltage difference in the local bit line is converted to a time difference for differentiating data “1” and data “0”, and buffered data path is used for achieving fast data transfer. Additionally, various alternative circuits and memory cell structures for implanting the memory are described.

Owner:KIM JUHAN

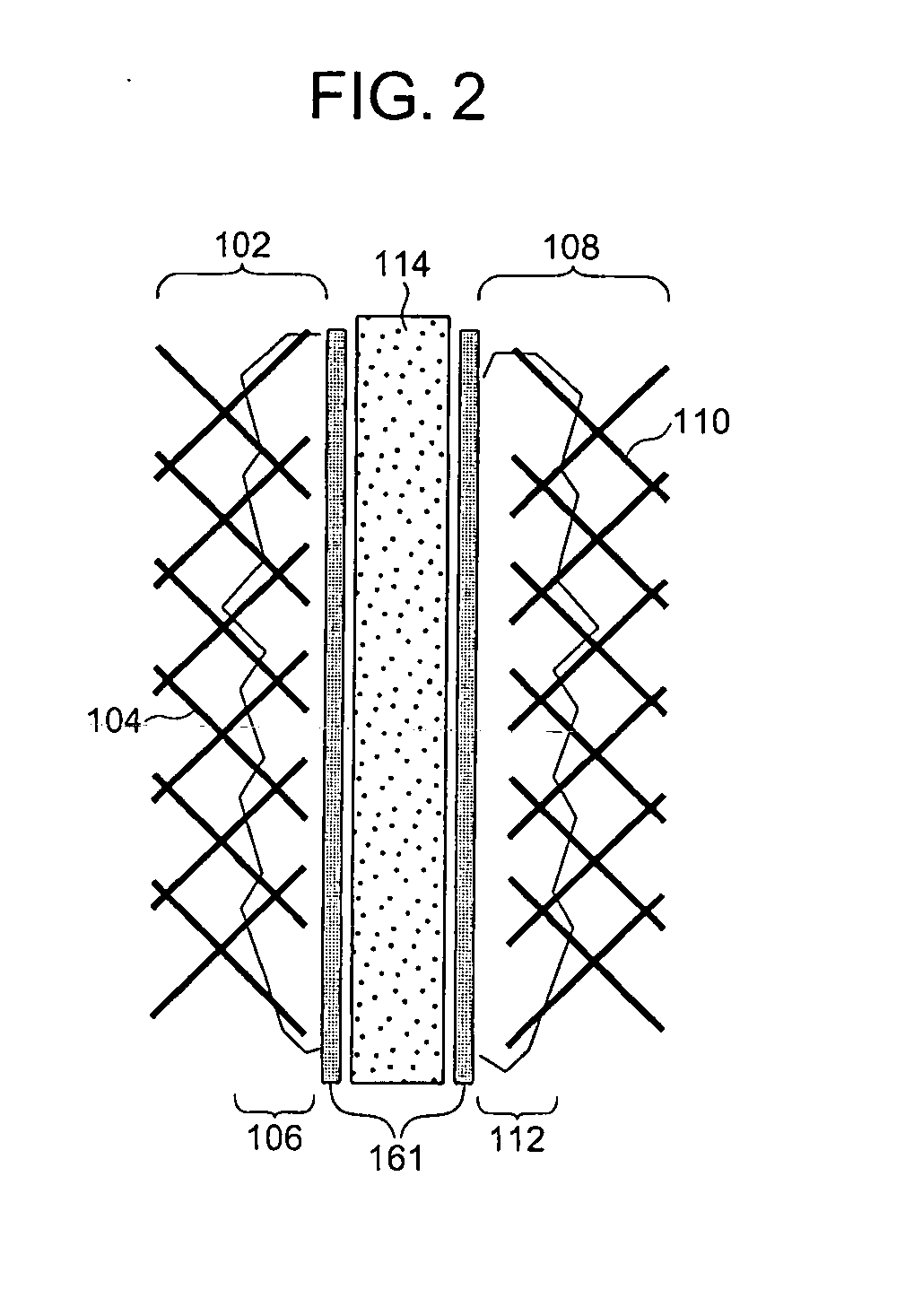

Fuel cell, fuel cell electrode and method for fabricating the same

InactiveUS20050112448A1Improve battery efficiencyCrossover of the liquid fuel is suppressedElectrolyte holding meansSolid electrolytesPolymer electrolytesFuel cells

An adhesion layer containing a second solid polymer electrolyte is disposed between a solid polymer electrolyte membrane and a fuel electrode and / or an oxidant electrode containing a first solid polymer electrolyte and a catalyst substance. The solid polymer electrolyte membrane and the adhesion layer are made of the same solid polymer electrolyte. In this manner, the adhesion at the interface between the electrode surface and the solid polymer electrolyte membrane is enhanced to implement the elevation of the cell characteristics and the elevation of the reliability of the cell.

Owner:NEC CORP

Composite graphene ion exchange membrane for flow battery and preparation method thereof

ActiveCN103219533AImprove stabilityHigh selectivityCell component detailsFuel cell detailsGraphene derivativesRedox

The invention discloses a composite graphene ion exchange membrane for a flow battery and a preparation method thereof. The composite graphene ion exchange membrane comprises a sulfonation polymer which serves as an ion exchange membrane matrix and graphene and / or graphene derivatives doped in the ion exchange membrane matrix. The preparation method is a method for preparing the composite graphene ion exchange membrane. Compared with the prior art, the graphene and / or graphene derivatives are introduced into the sulfonation polymer for modification, and the graphene with a two-dimensional lamellar structure and / or graphene derivatives can improve the stability of the composite ion exchange membrane through the interaction between the graphene and the polymer molecules, and can serve as an obstacle (barrier) of active substance penetration in the ion exchange membrane so as to improve the ion selectivity of the composite ion exchange membrane. The sulfonation polymer-composite graphene ion exchange membrane is applied to the flow battery, particularly an all vanadium redox flow battery, and high battery efficiency and stable battery performance can be obtained.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Power supply apparatus and power supply method

ActiveUS20060133007A1Improve performanceHigh dischargeBatteries circuit arrangementsElectrolytic capacitorsEngineeringCapacitor

A power supply apparatus and a power supply method are described, wherein the non-polar characteristics of the electrodes of a capacitor is utilized to improve the energy utilization efficiency of a battery through reciprocating switches of polarity connection between the battery and the capacitor. The voltages of the capacitors can also stay at a near constant level using the polarity reversal mechanism.

Owner:POWER REGENERATION

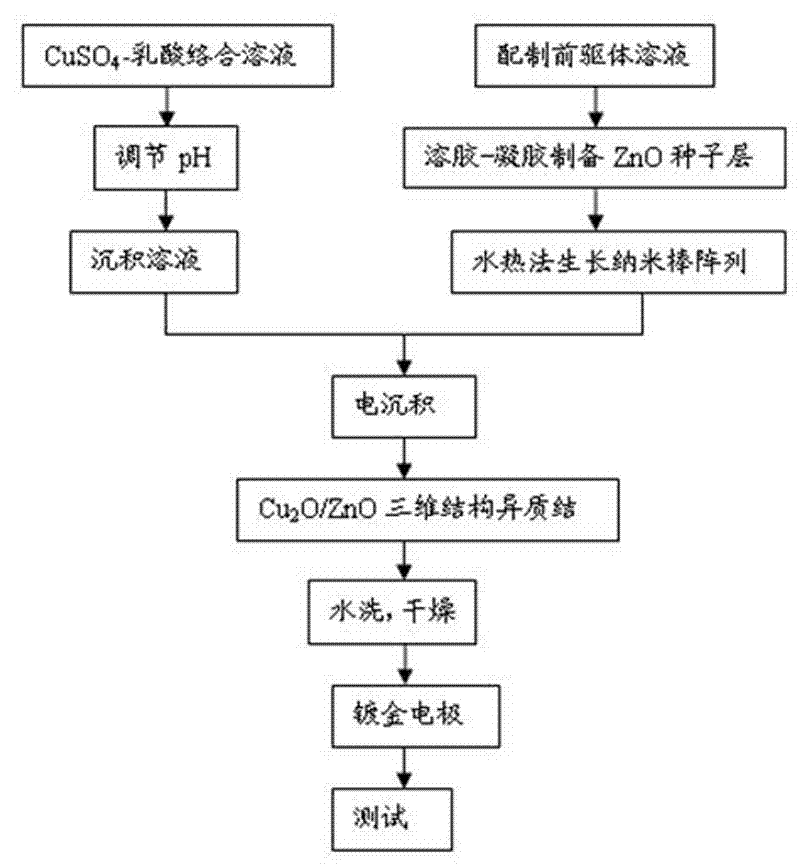

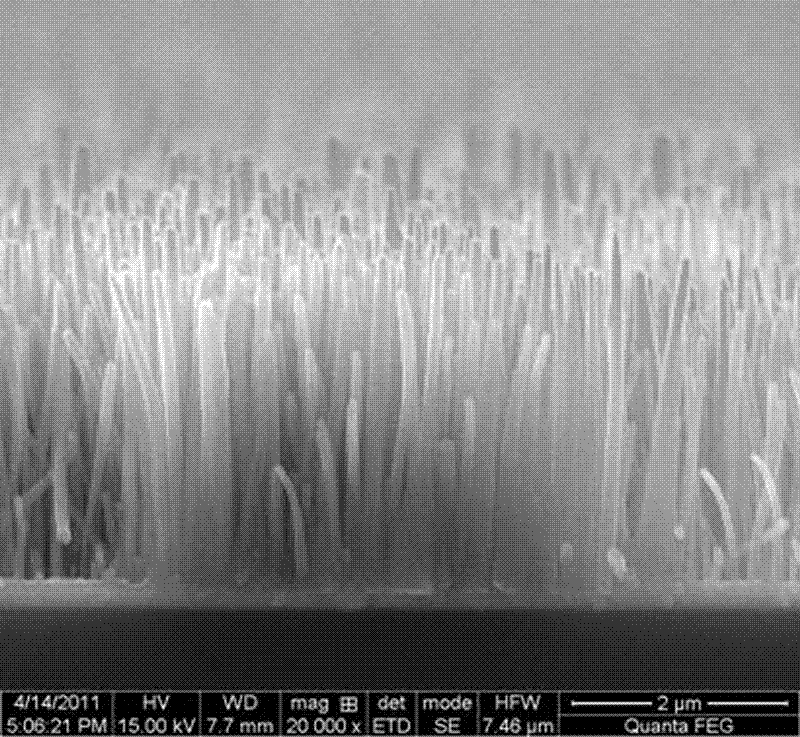

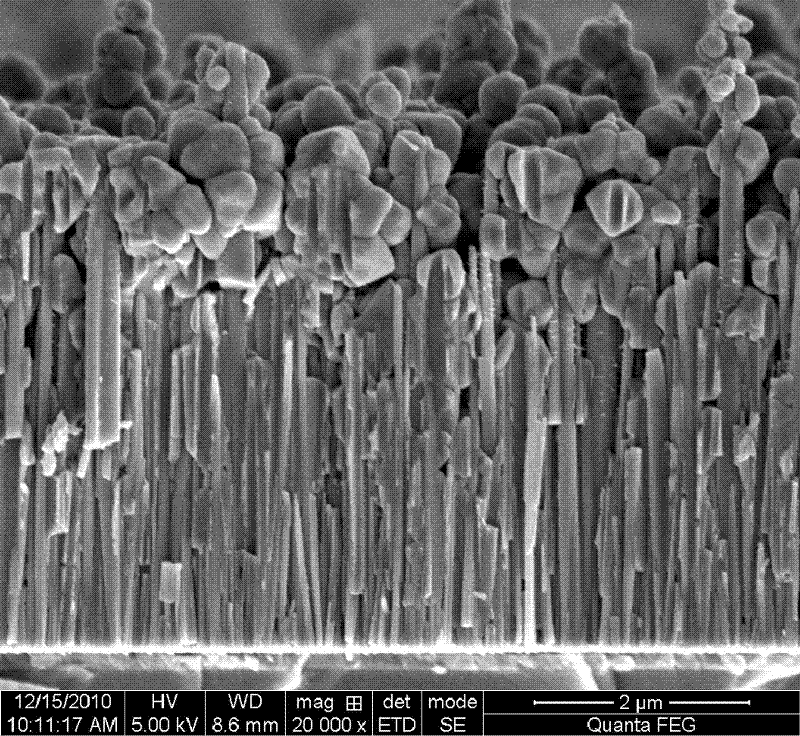

Method for preparing zno/cu2o heterojunction material and zno/cu2o three-dimensional structure heterojunction solar cell

InactiveCN102268706AReduce chance of recombinationImprove coverage uniformityFinal product manufactureSemiconductor devicesHeterojunctionElectrolytic agent

The invention discloses a method for preparing a ZnO / Cu2O heterojunction material and a ZnO / Cu2O three-dimensional structure heterojunction solar cell. The preparation method of the heterojunction material includes growing an n-type ZnO nanorod array on a substrate by a liquid phase growth method. Thin film, use alkaline copper salt solution as electrolyte, deposit at a deposition potential of -0.4~-0.6V for 60-150s, electrochemically deposit p-type Cu2O on the surface of ZnO nanorods to form a Cu2O seed layer; use alkaline copper The salt solution is a deposition solution, and the electrochemical deposition method is again used at a deposition potential of -0.05 to -0.3V to fully fill Cu2O from bottom to top into the gaps of the nanorod array to form a ZnO / Cu2O three-dimensional structure heterojunction material. The filling depth and density of the Cu2O semiconductor film of the present invention are increased, interface defects are reduced, and the heterojunction battery produced has high battery efficiency.

Owner:UNIV OF JINAN

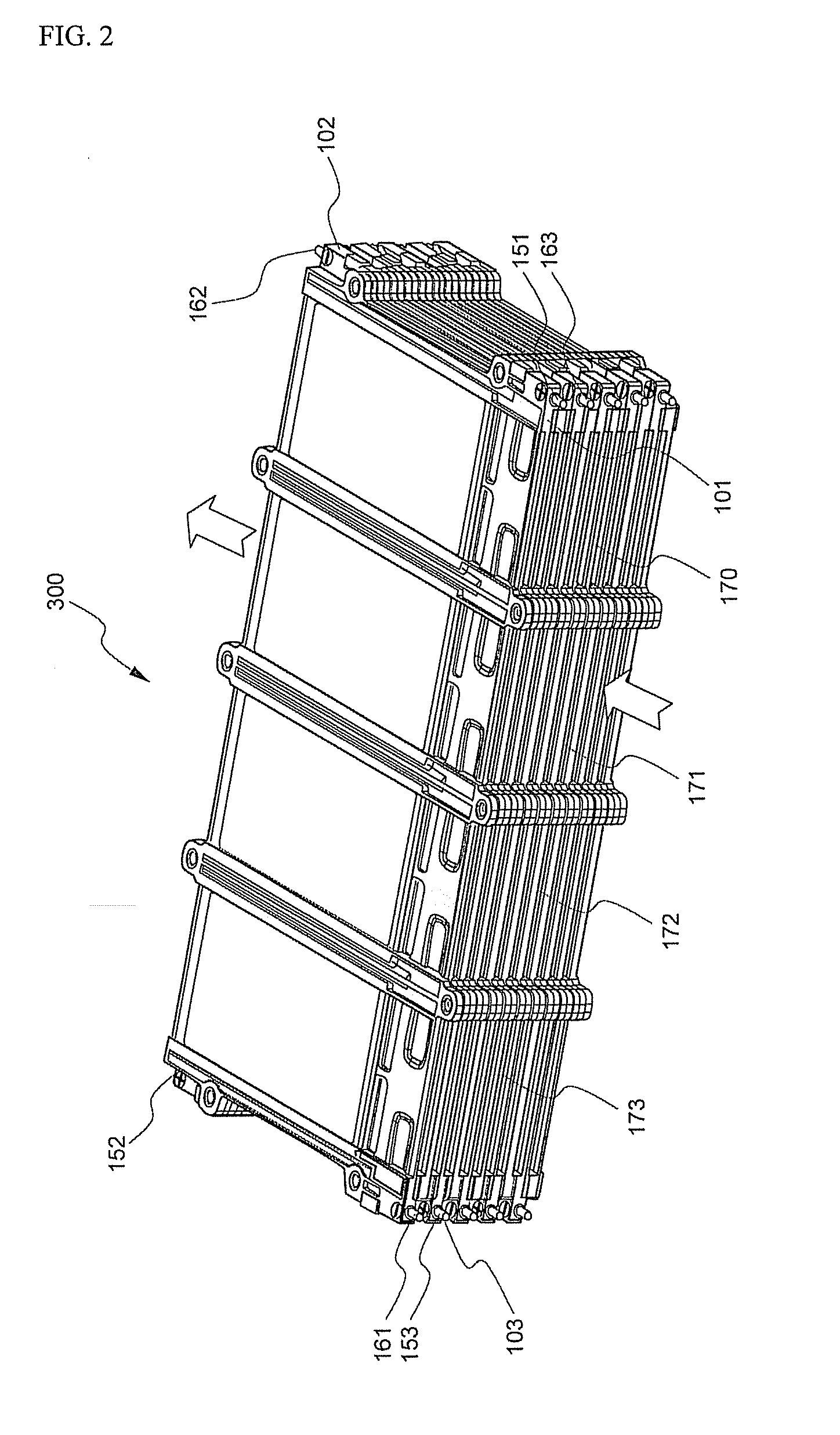

Battery module of high cooling efficiency

ActiveUS20070126396A1High efficiencyCool efficiency be highBatteries circuit arrangementsCells cooling/heatingElectric vehicleCoolant flow

Disclosed herein is a battery module including a plurality of unit cells stacked one on another. The battery module has a cooling system that accomplishes contact type cooling by a coolant flowing through gaps (flow channels) defined between the unit cells, and the flow channels defined between the unit cells are at a predetermined angle to the flowing direction of the coolant at inlet ports of the flow channels. The contact rate of the coolant to the unit cells in the battery module is increased and a large number of turbulent flows are created by the changing the flow channel through which the coolant flows. Consequently, the occurrence of the velocity gradient of the coolant in the flow channel defined between the unit cells is prevented, and therefore, the cooling efficiency of the battery module is improved. Furthermore, a battery pack including the battery module has high cooling efficiency although the overall structure of the battery pack is not greatly changed, or a large-sized cooling fan or a string driving unit is not used. Consequently, the battery pack is preferably used as a power source for electric vehicles or hybrid electric vehicles.

Owner:LG ENERGY SOLUTION LTD

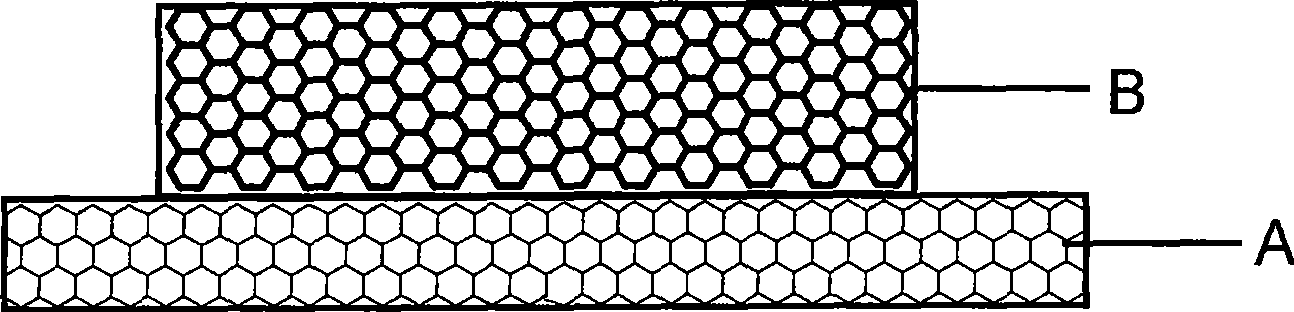

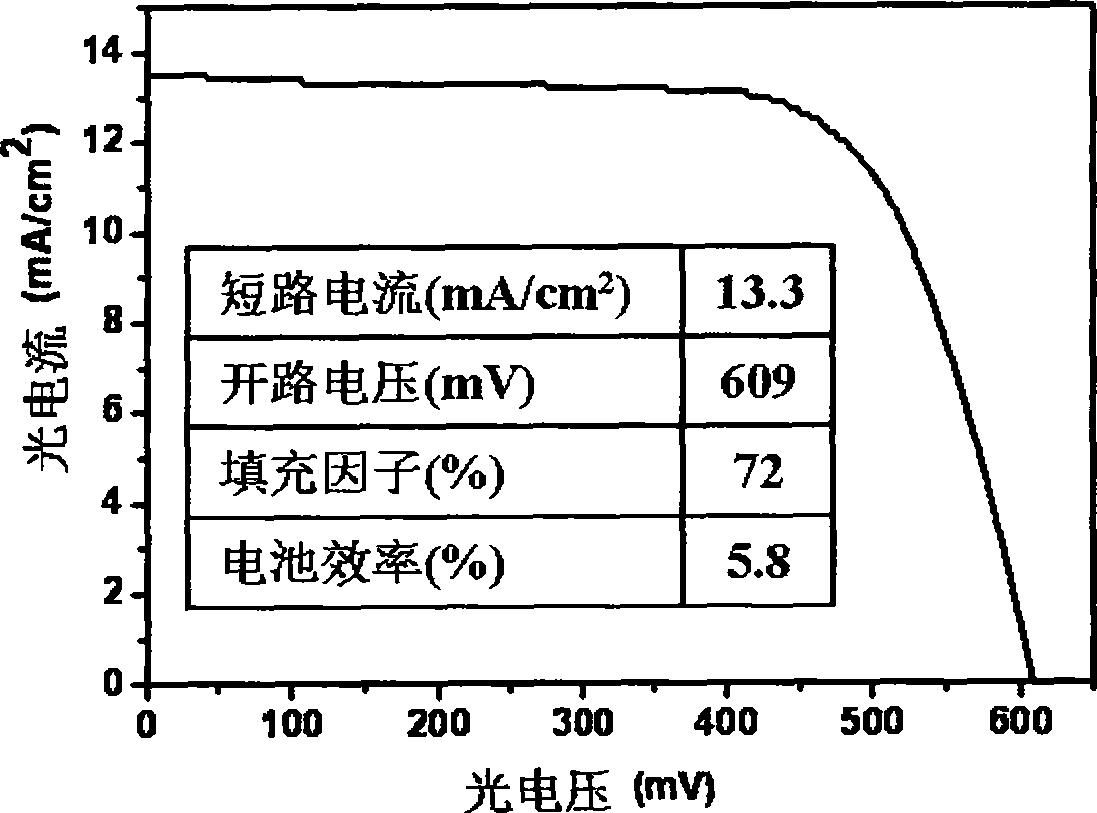

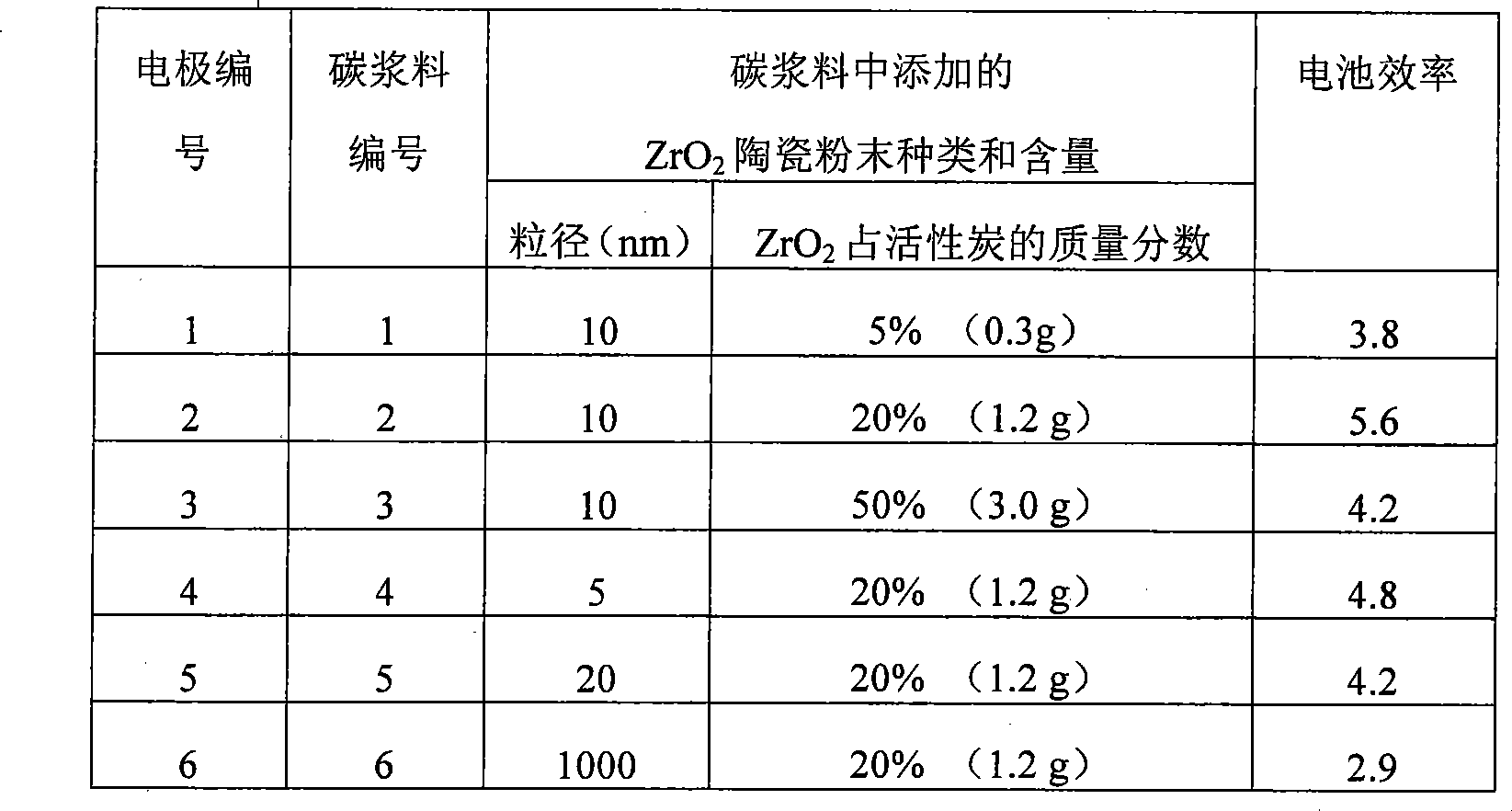

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

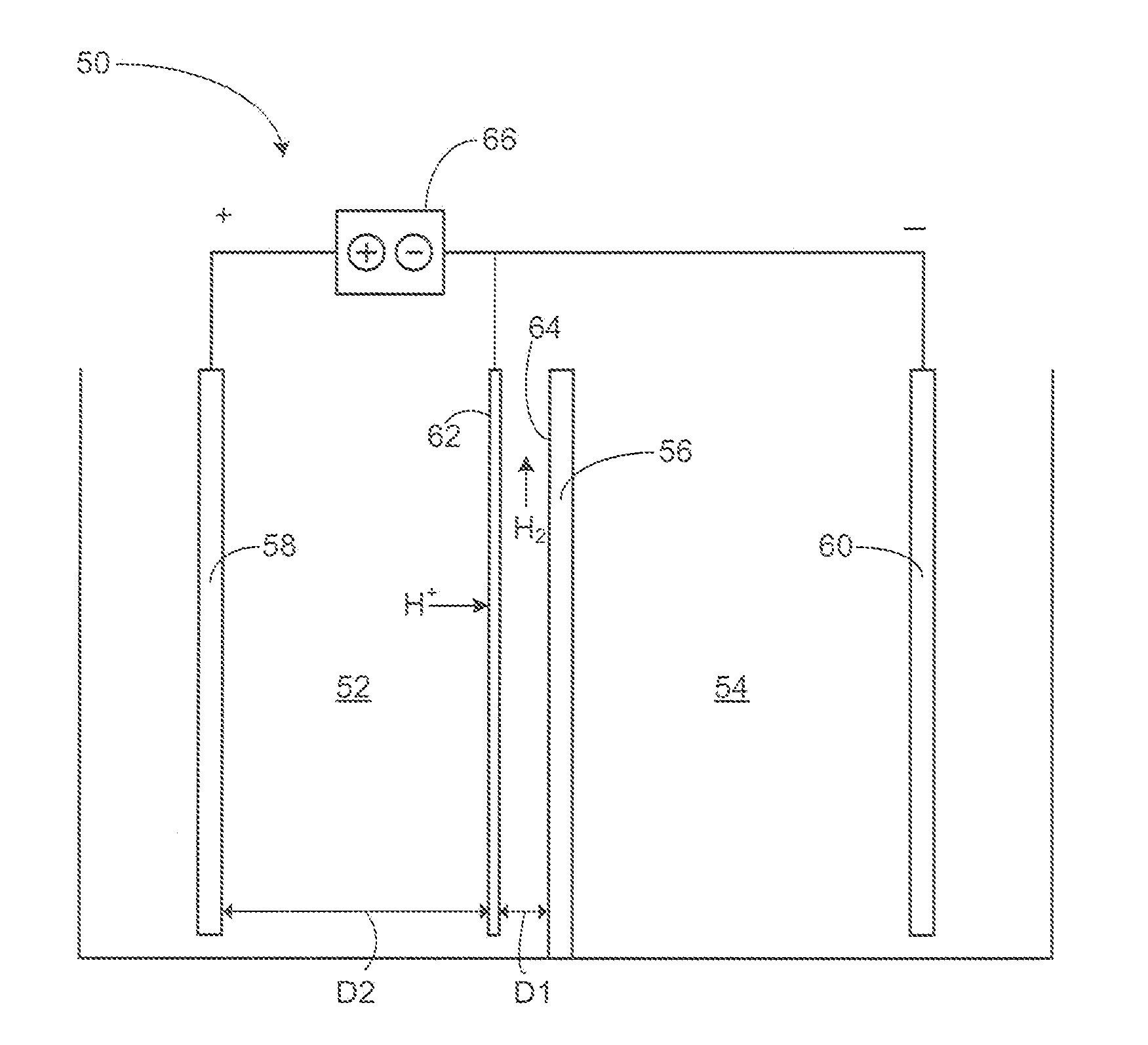

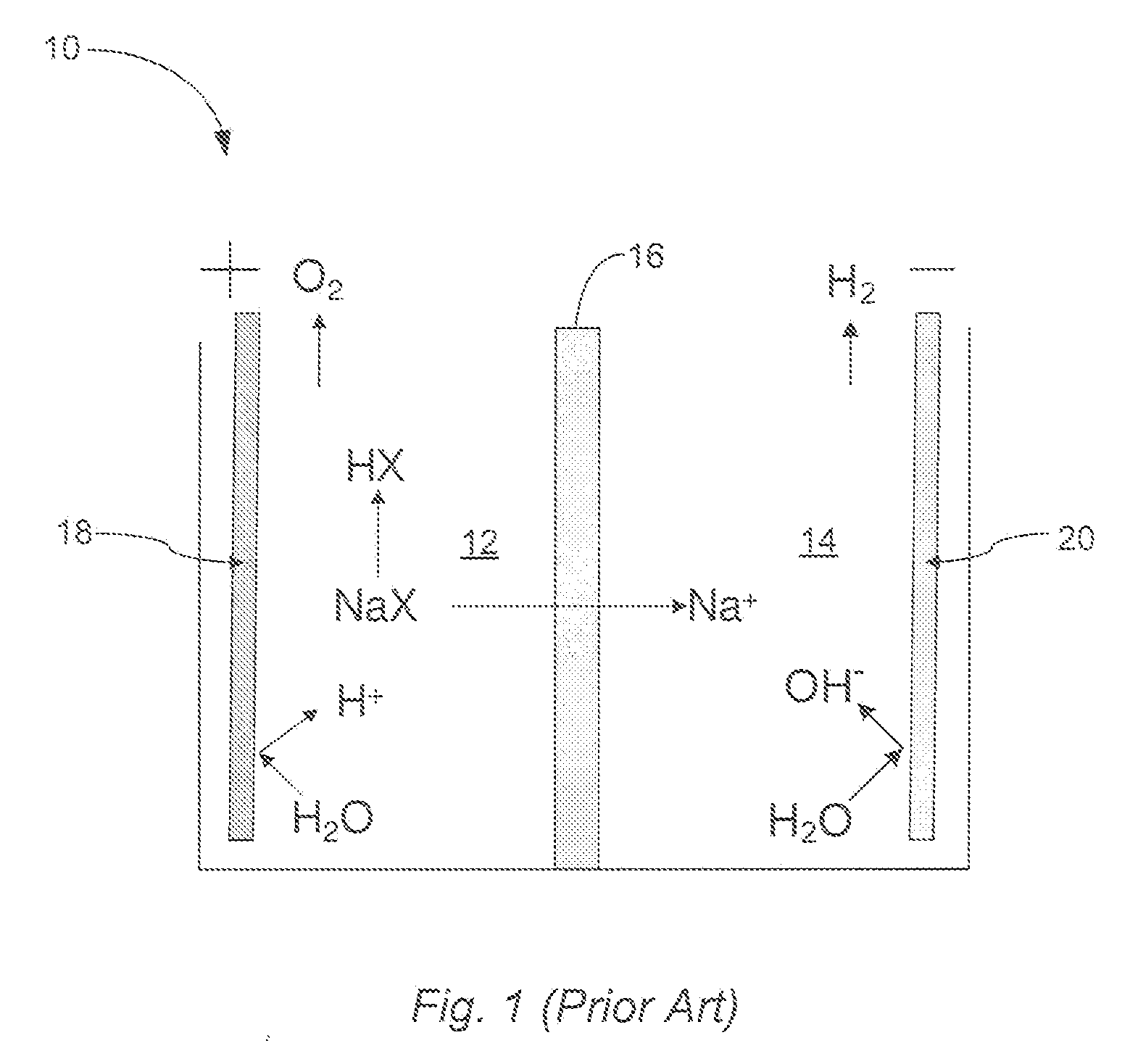

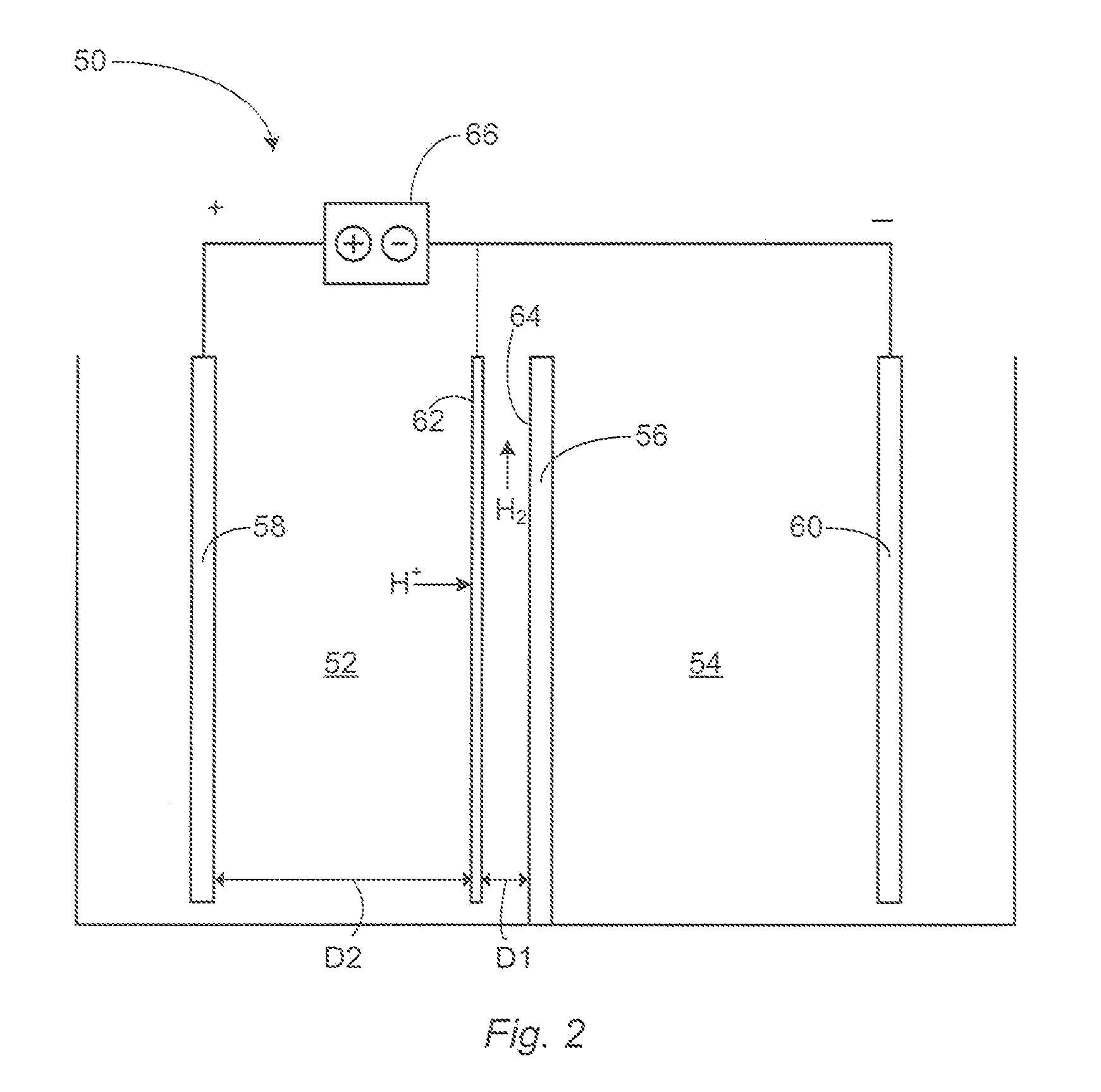

Electrochemical systems and methods for operating an electrochemical cell with an acidic anolyte

ActiveUS20120085658A1Cut surfaceObstruction is producedCellsWater treatment parameter controlHydrogenCeramic membrane

An electrochemical cell having a cation-conductive ceramic membrane and an acidic anolyte. Generally, the cell includes a catholyte compartment and an anolyte compartment that are separated by a cation-conductive membrane. While the catholyte compartment houses a primary cathode, the anolyte compartment houses an anode and a secondary cathode. In some cases, a current is passed through the electrodes to cause the secondary cathode to evolve hydrogen gas. In other cases, a current is passed between the electrodes to cause the secondary cathode to evolve hydroxyl ions and hydrogen gas. In still other cases, hydrogen peroxide is channeled between the secondary cathode and the membrane to form hydroxyl ions. In yet other cases, the cell includes a diffusion membrane disposed between the secondary cathode and the anode. In each of the aforementioned cases, the cell functions to maintain the pH of a fluid contacting the membrane at an acceptably high level.

Owner:ENLIGHTEN INNOVATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com