Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2366results about "Graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

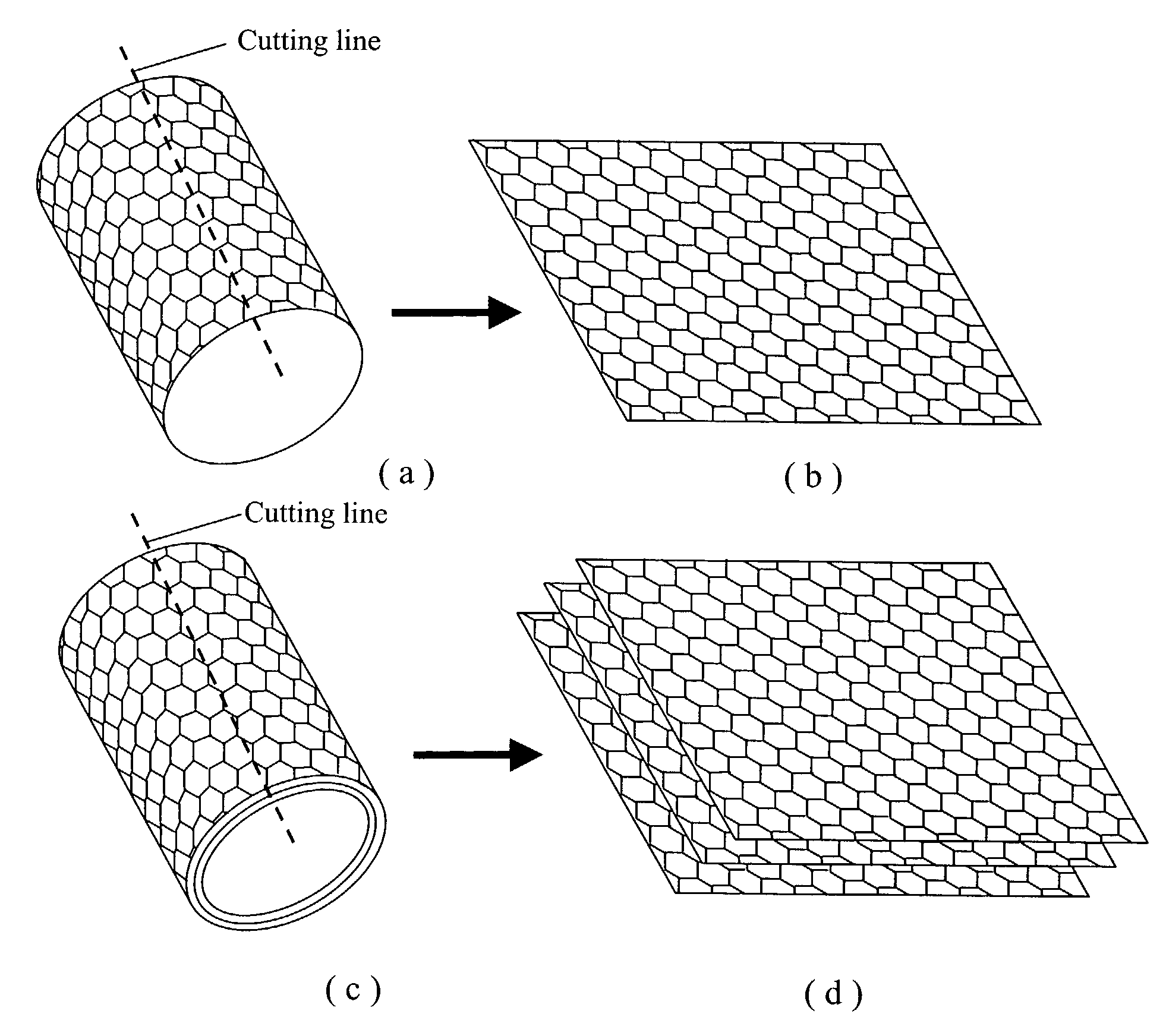

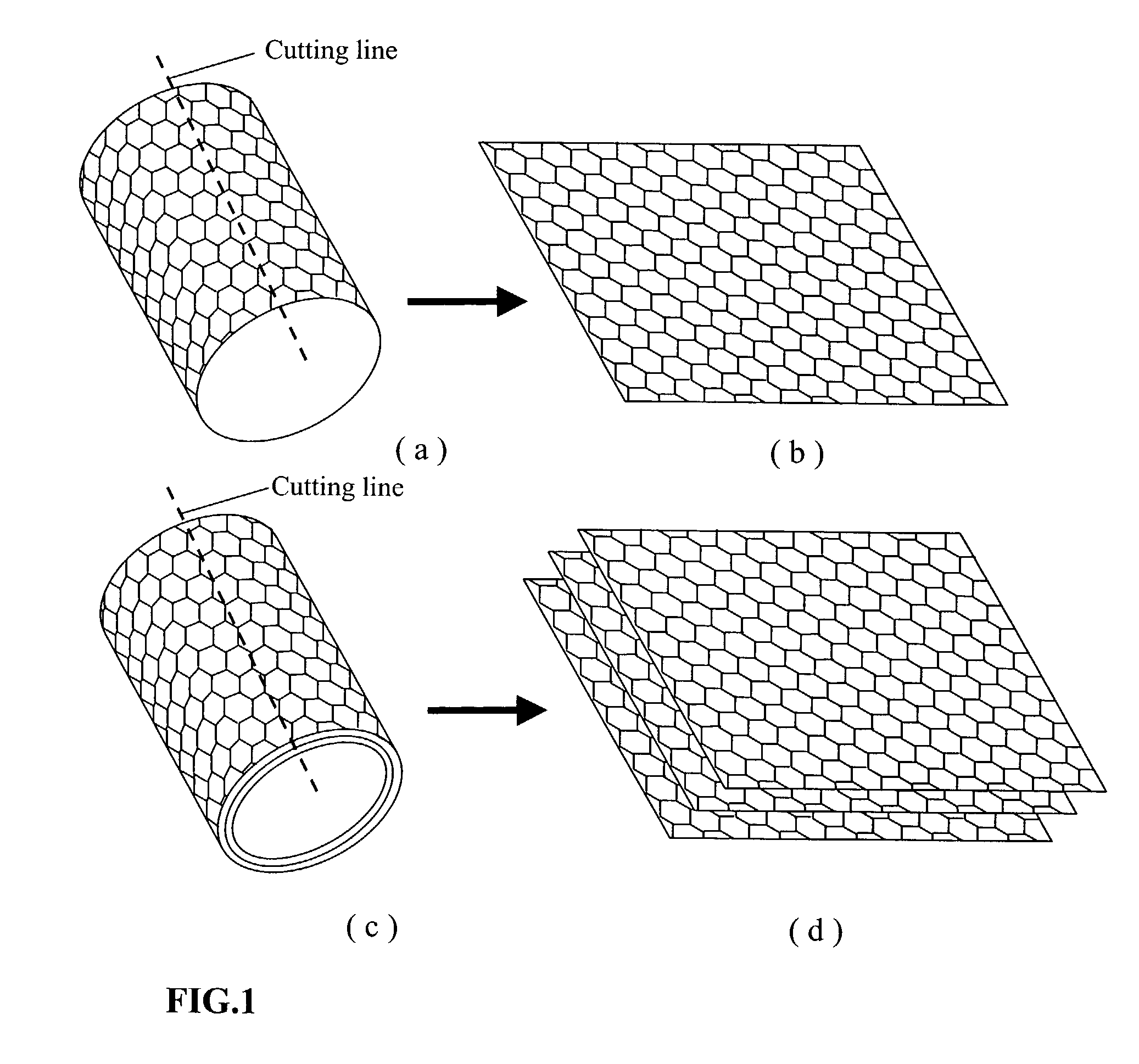

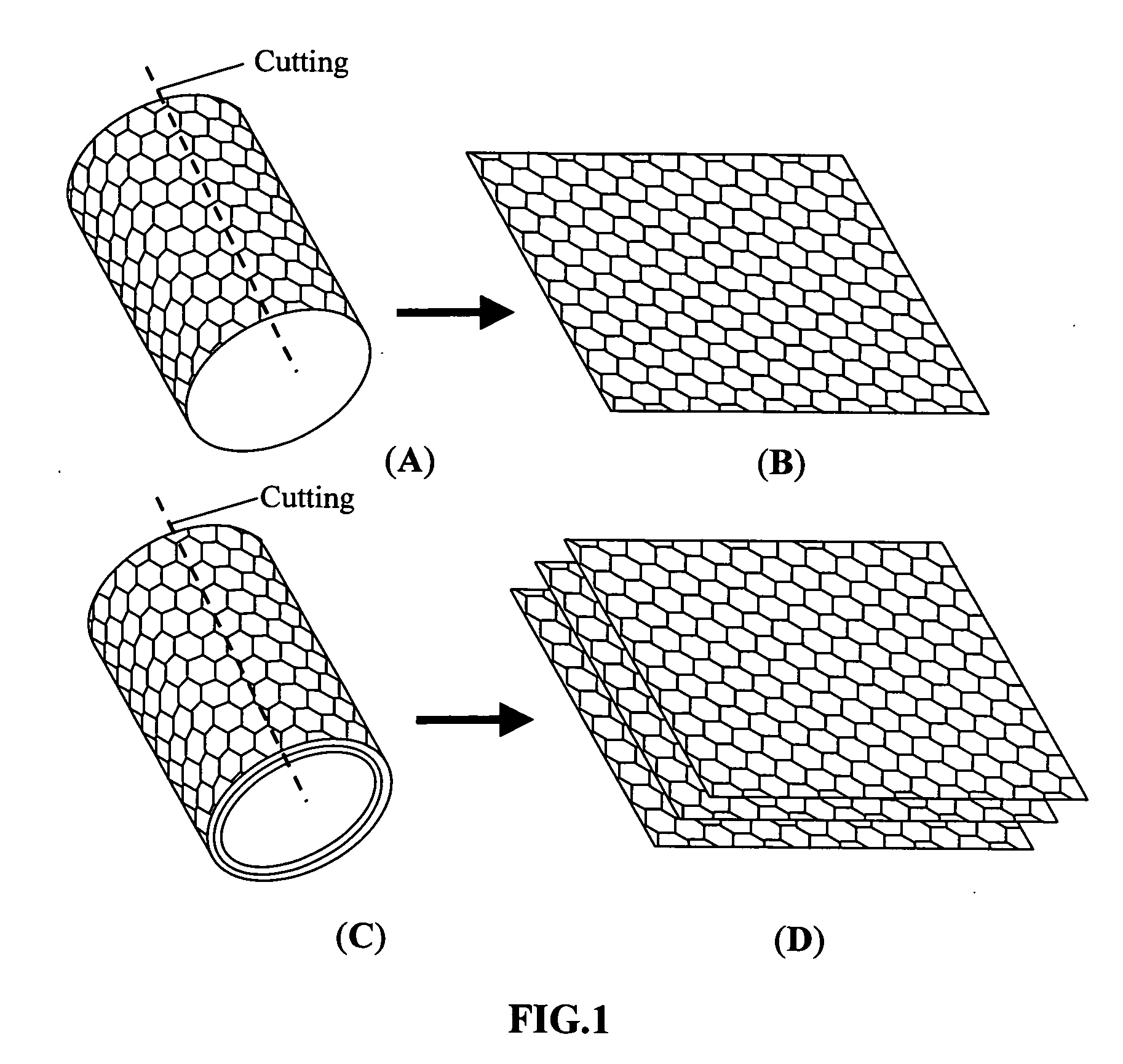

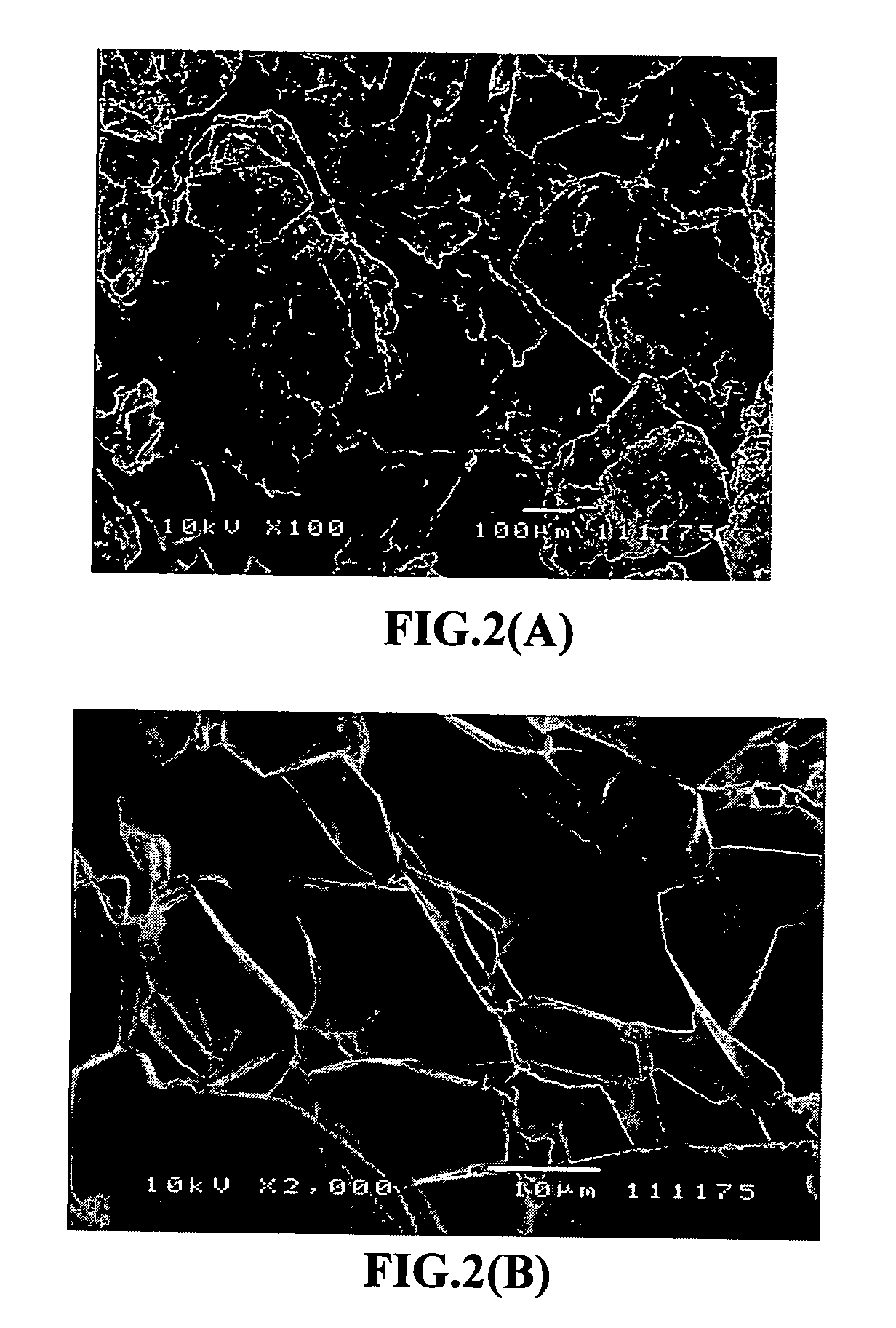

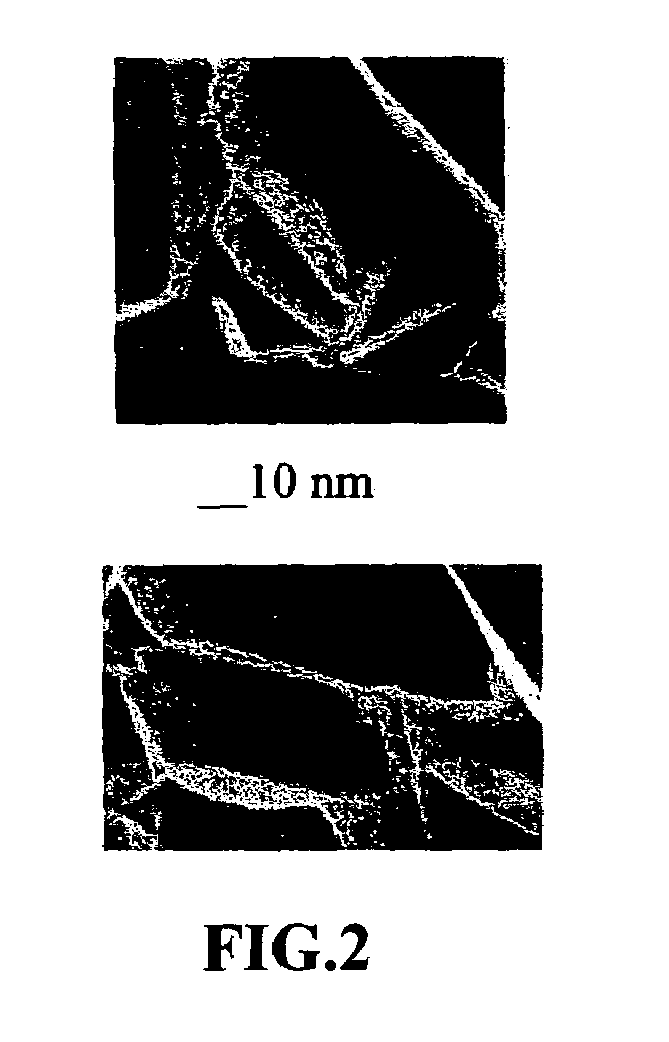

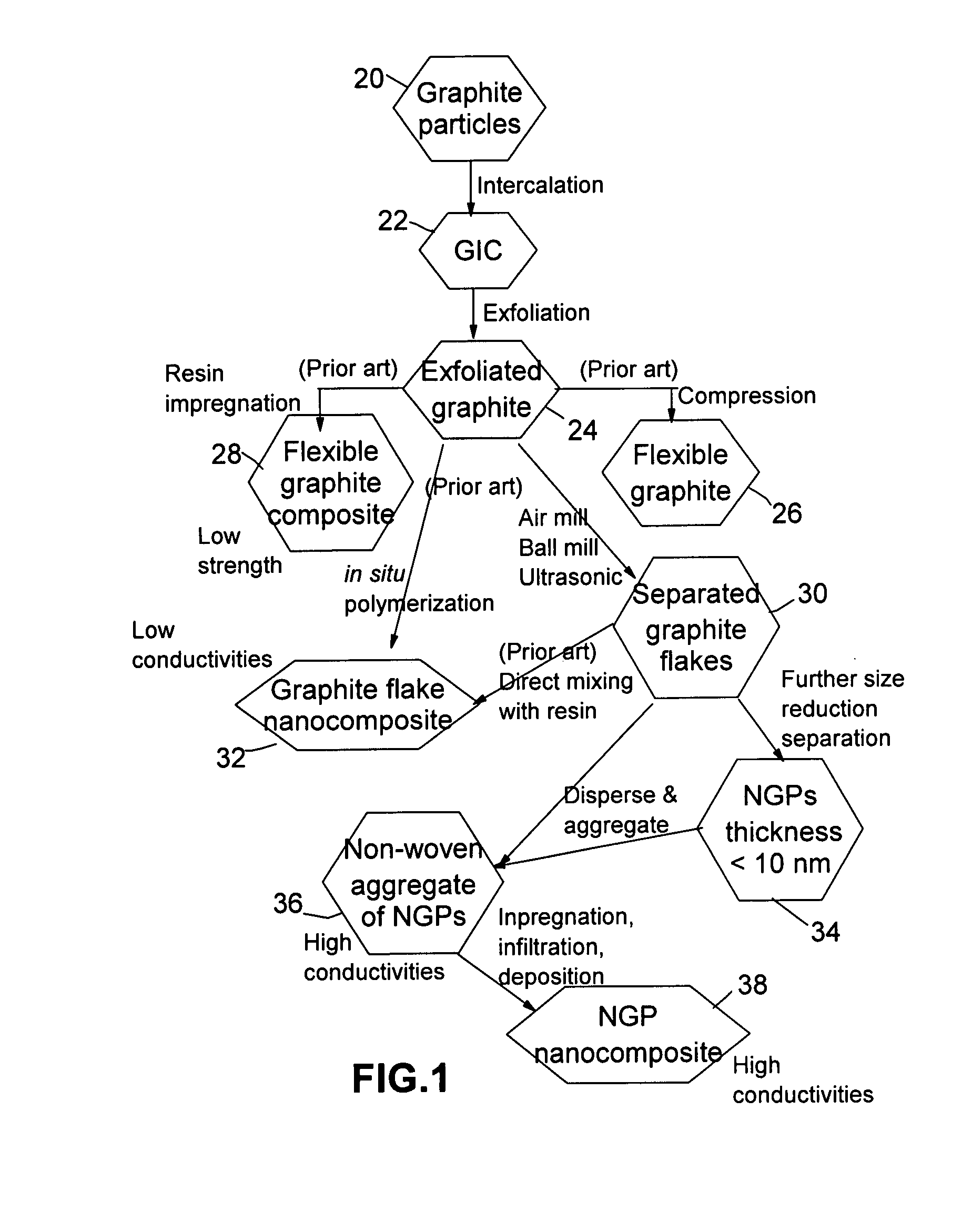

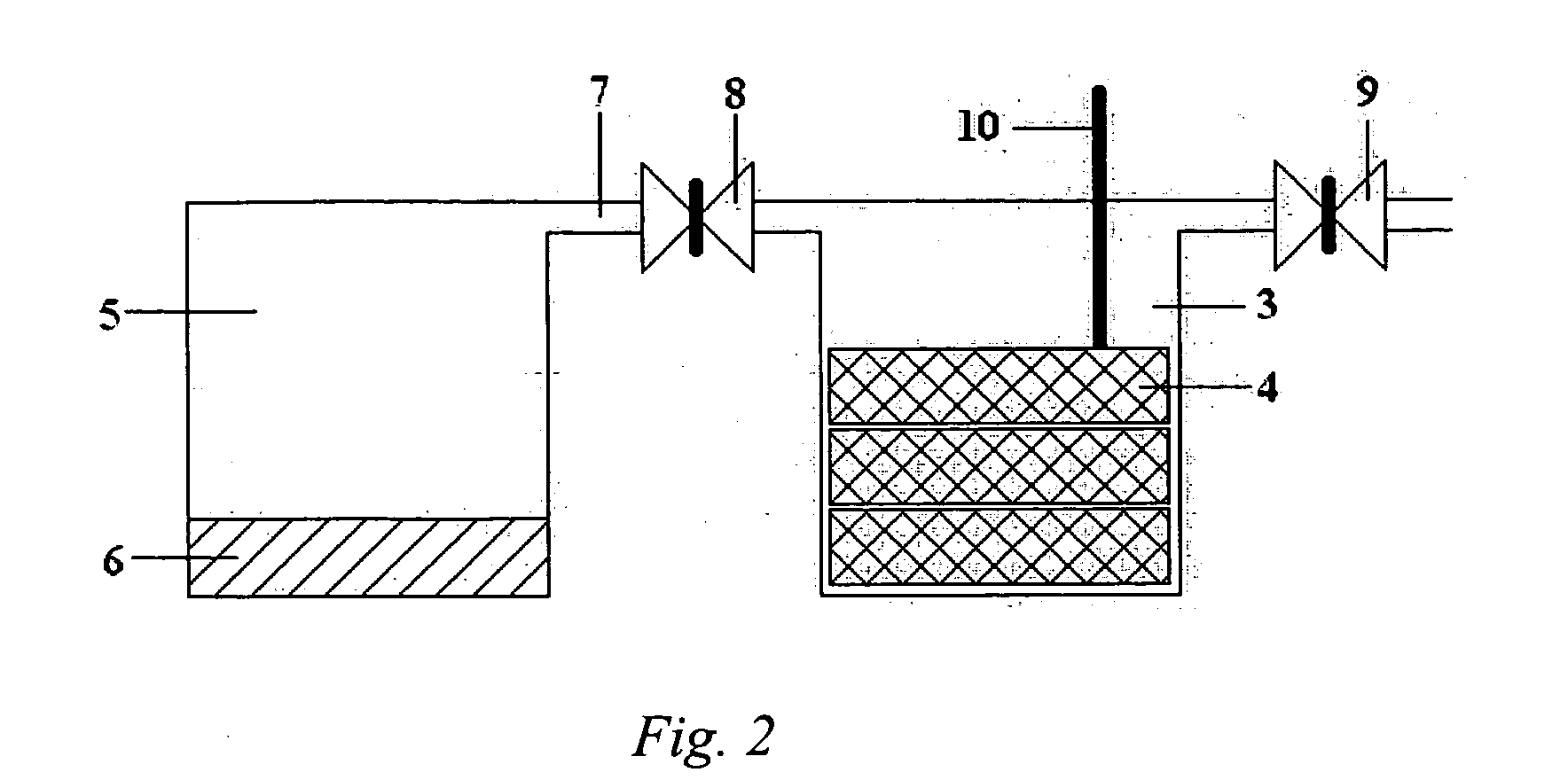

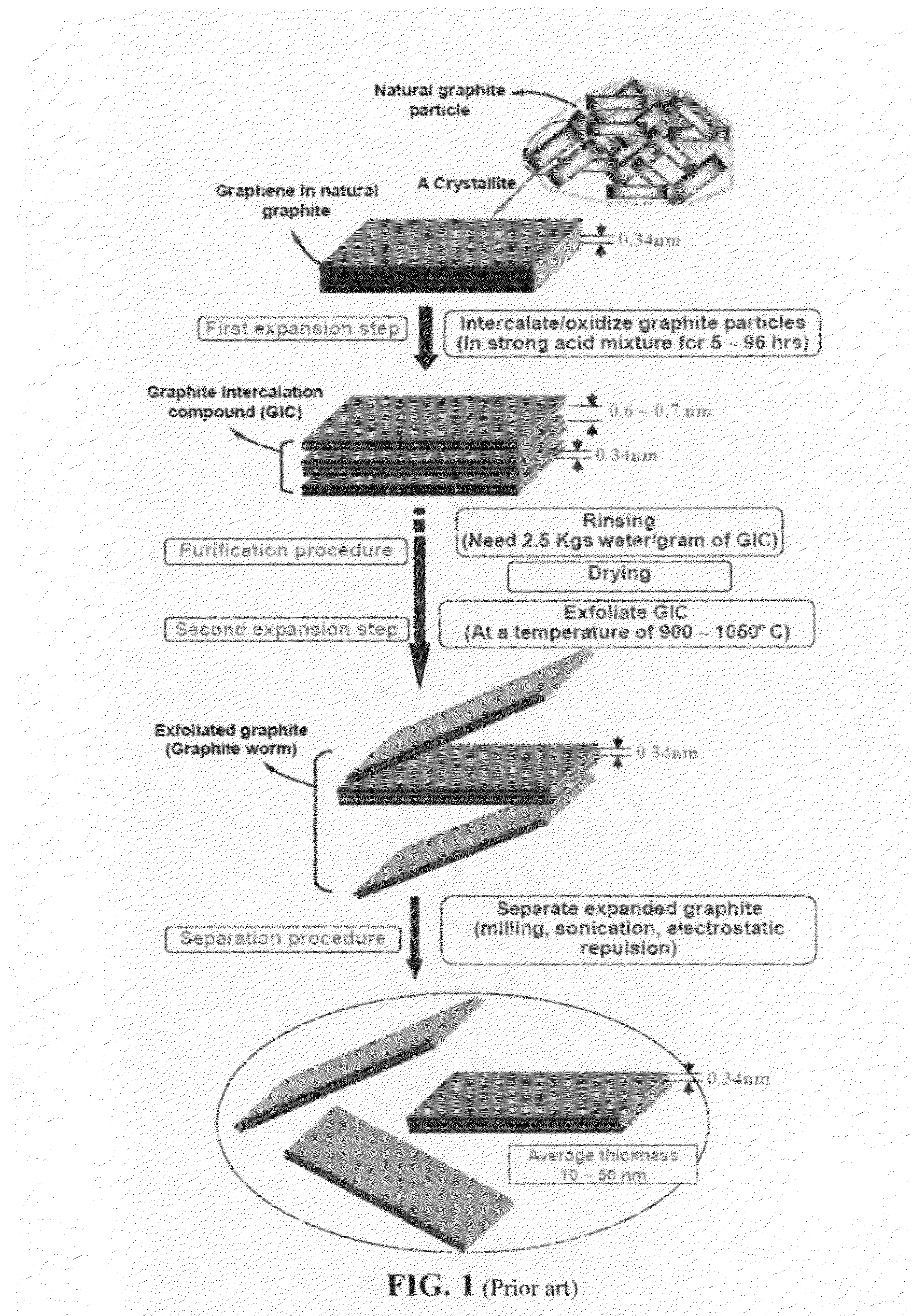

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

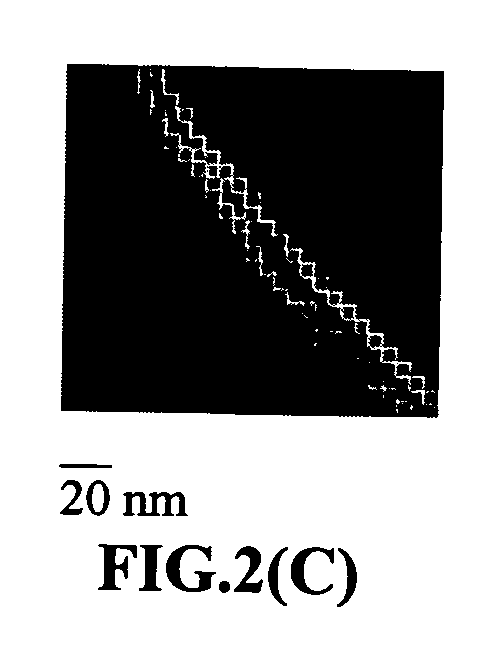

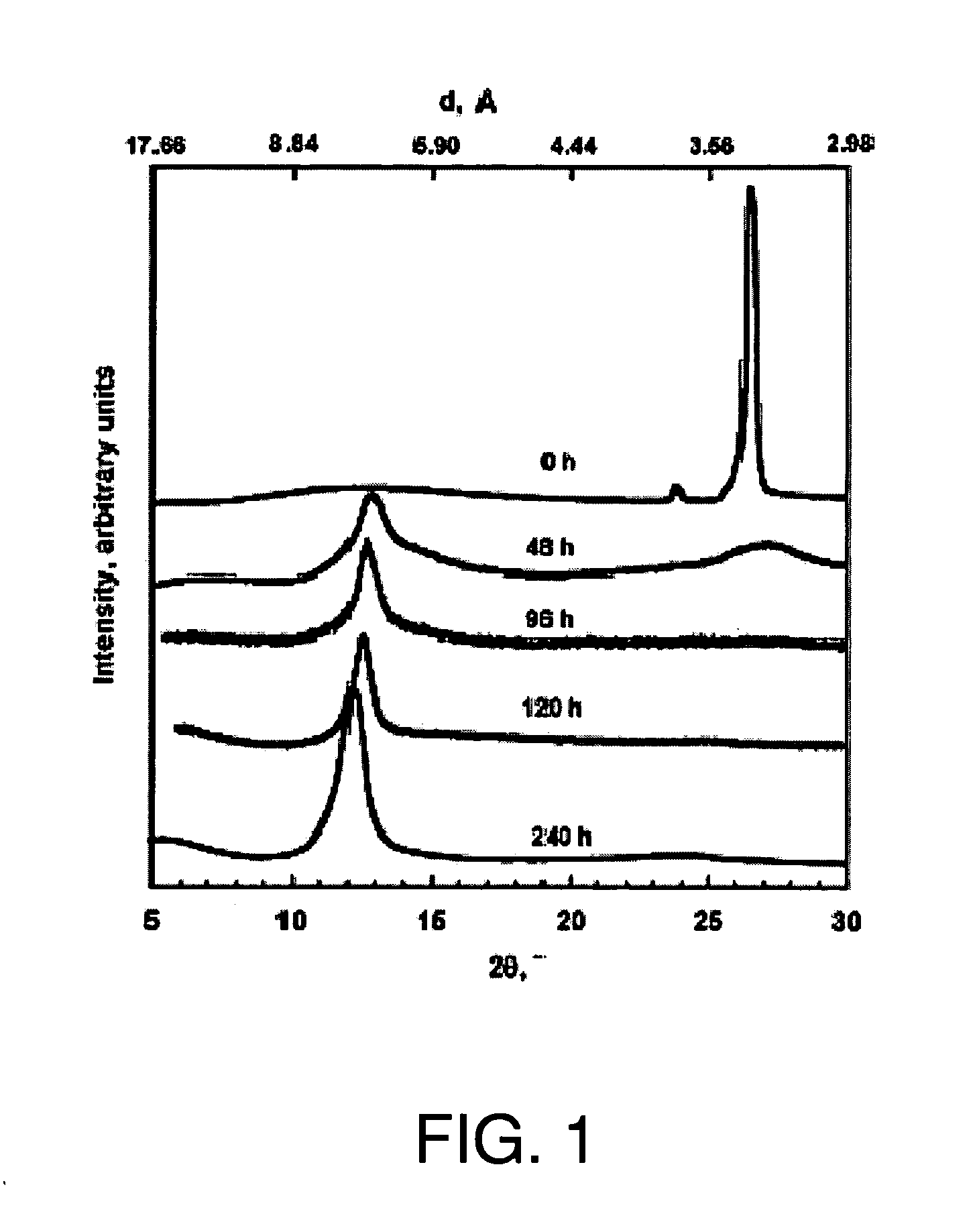

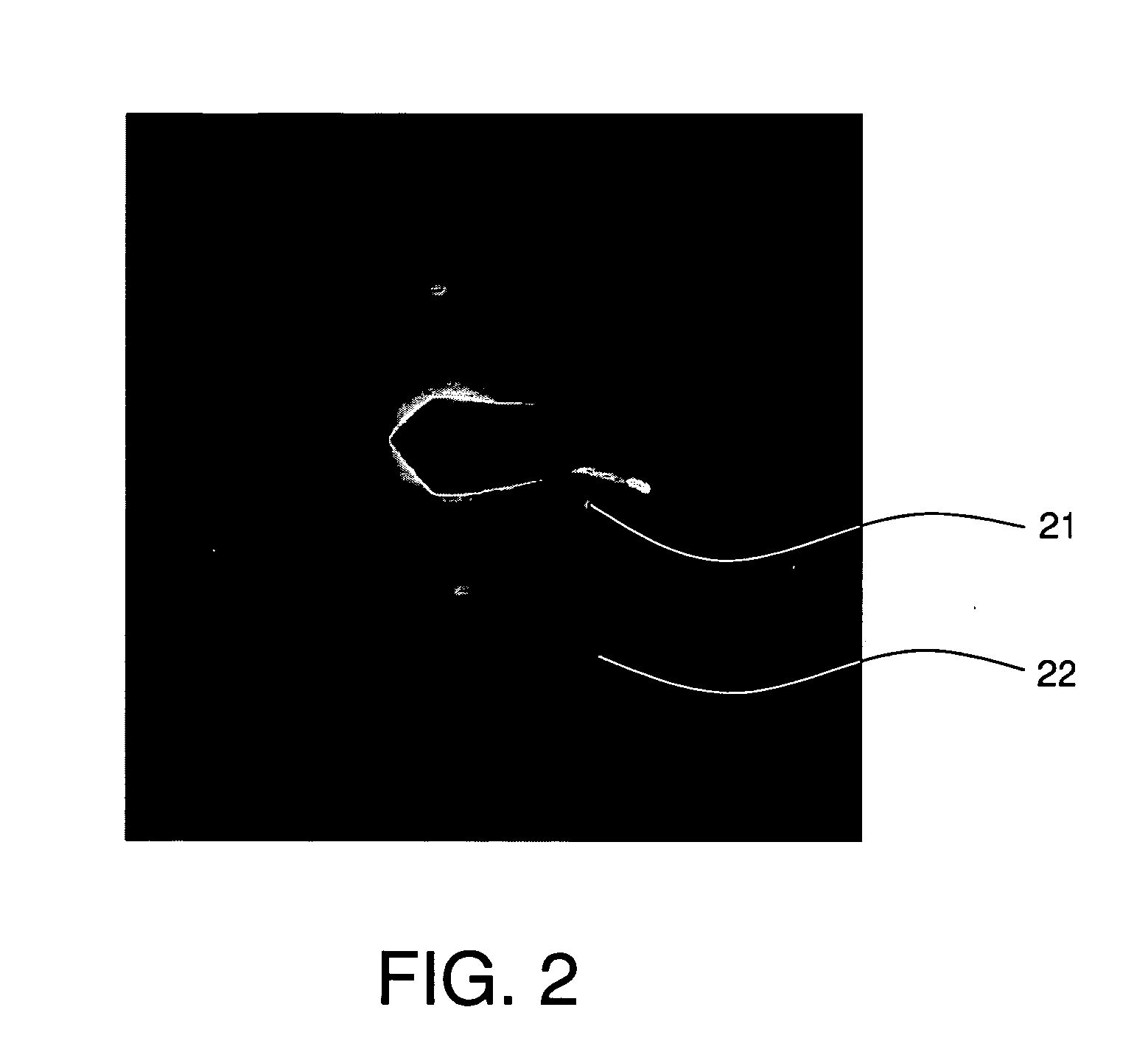

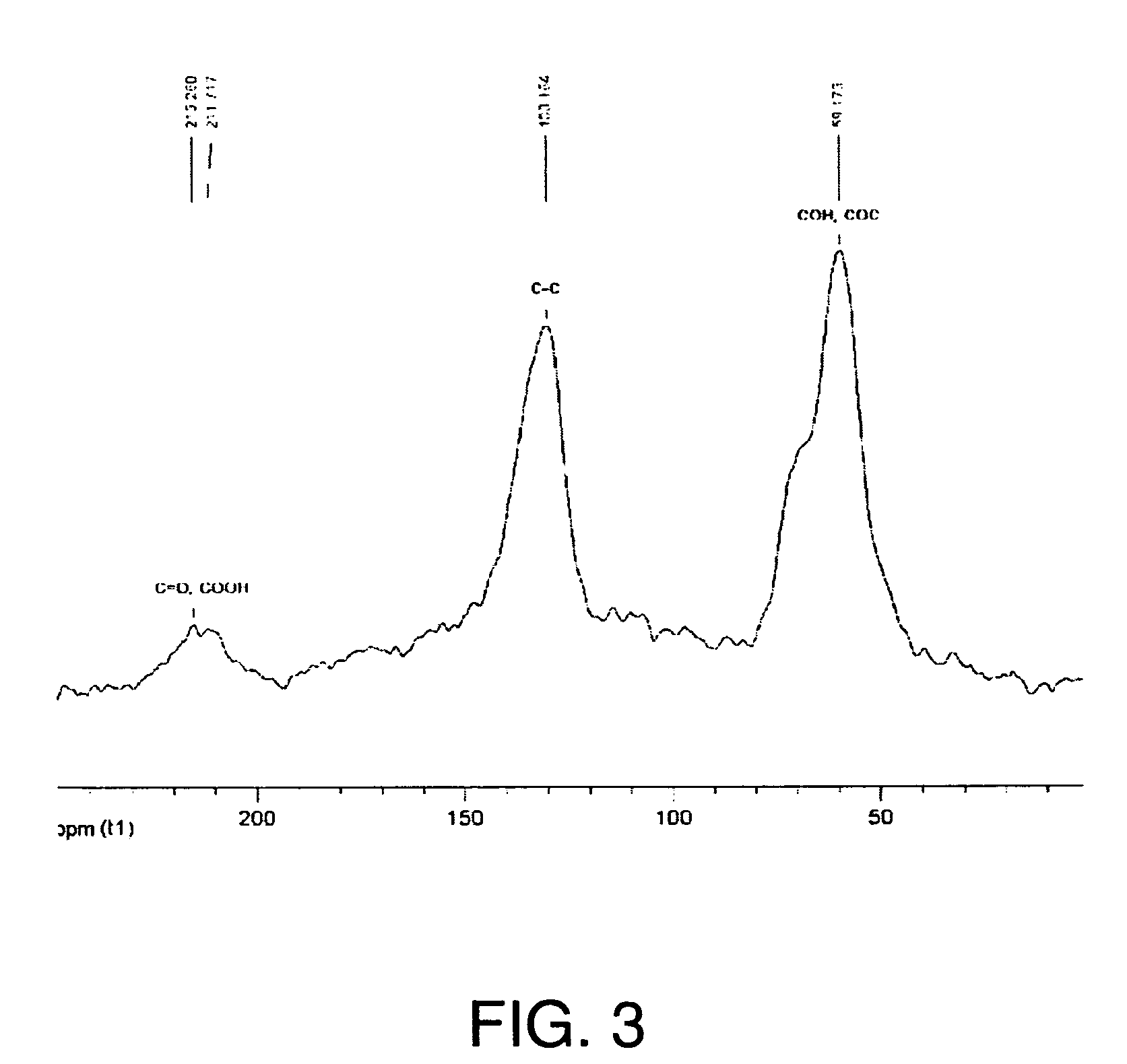

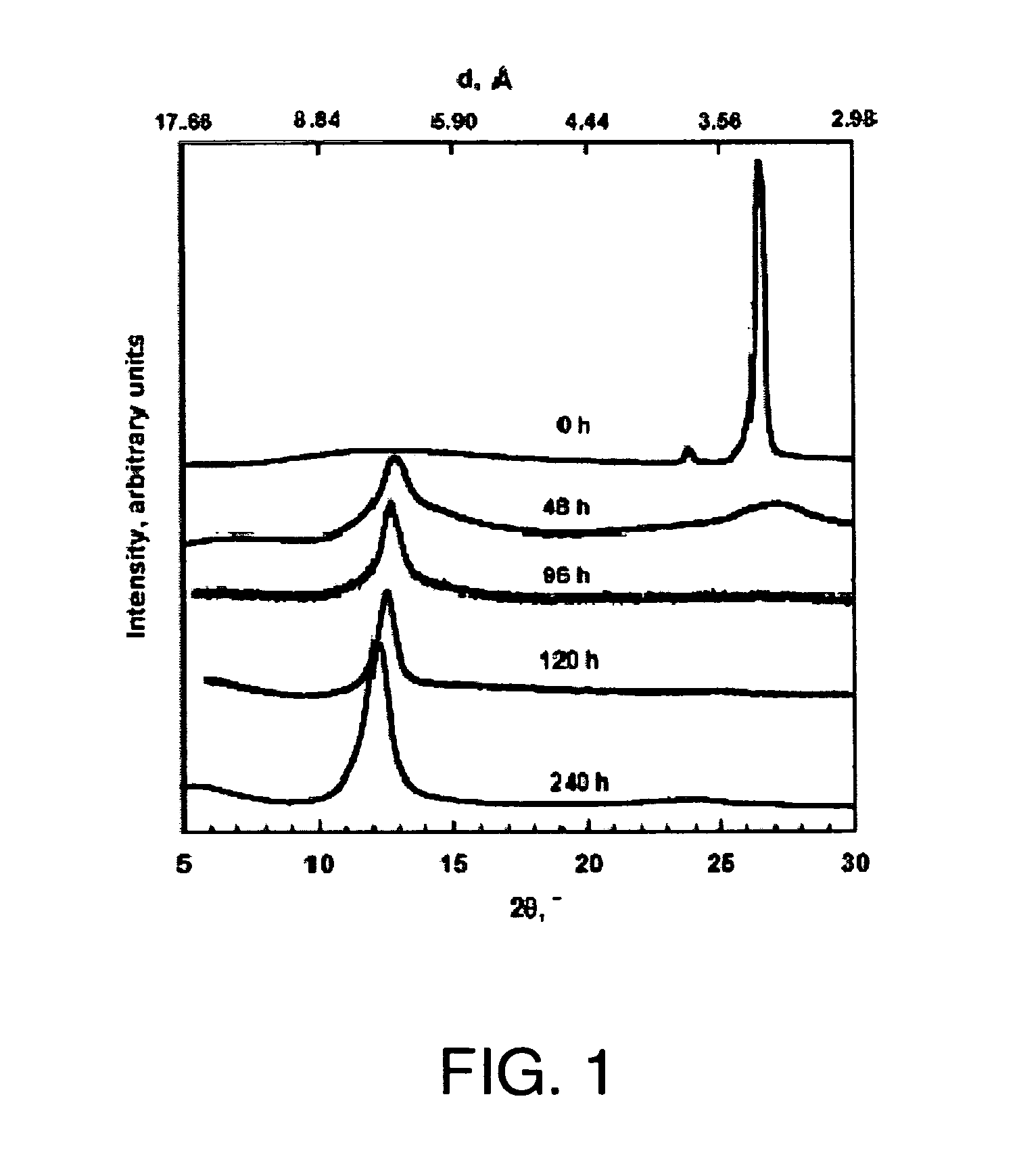

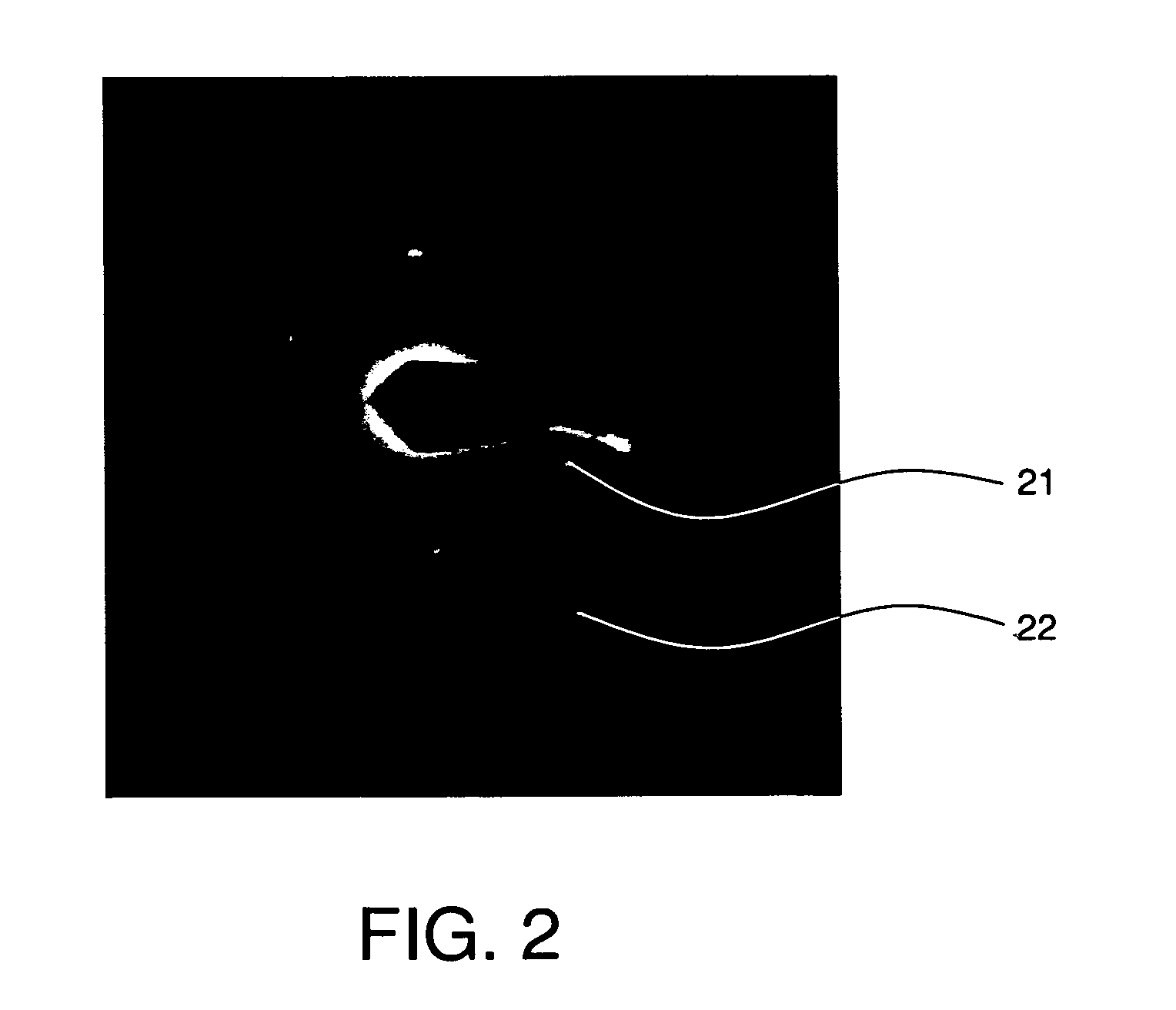

Thermally exfoliated graphite oxide

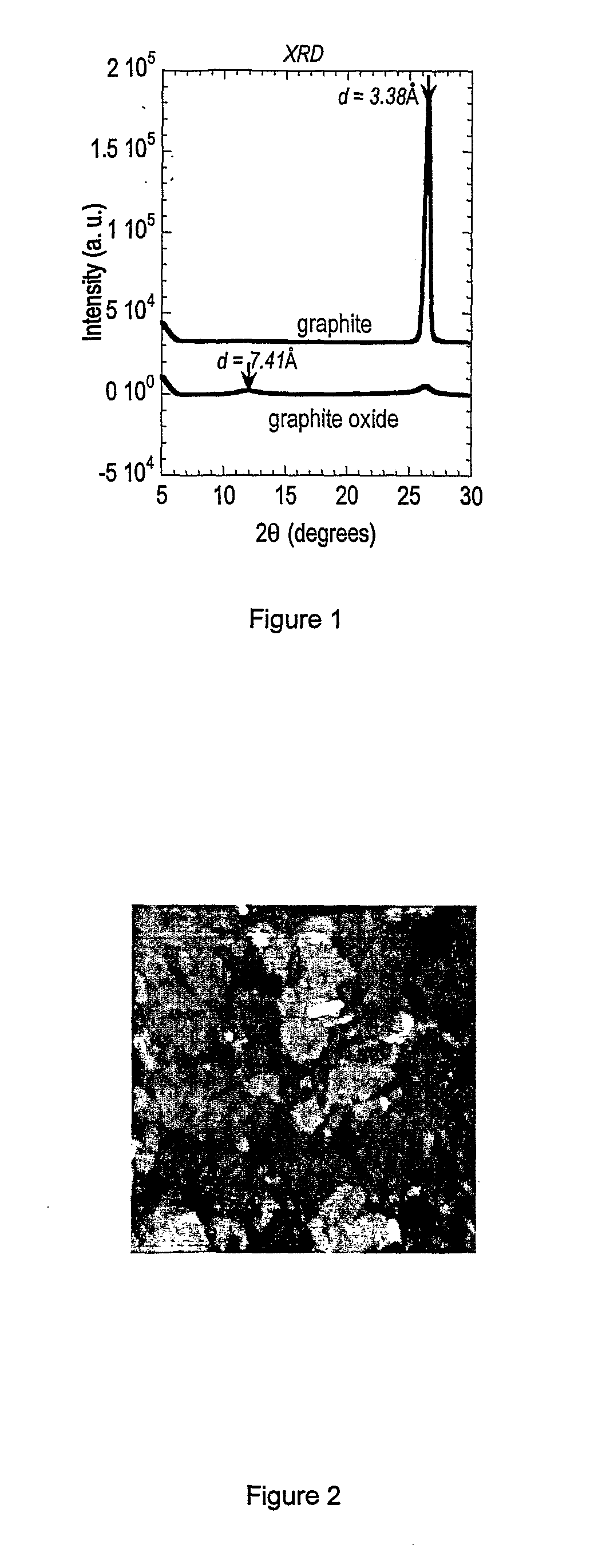

ActiveUS20070092432A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphiteX-rayMaterials science

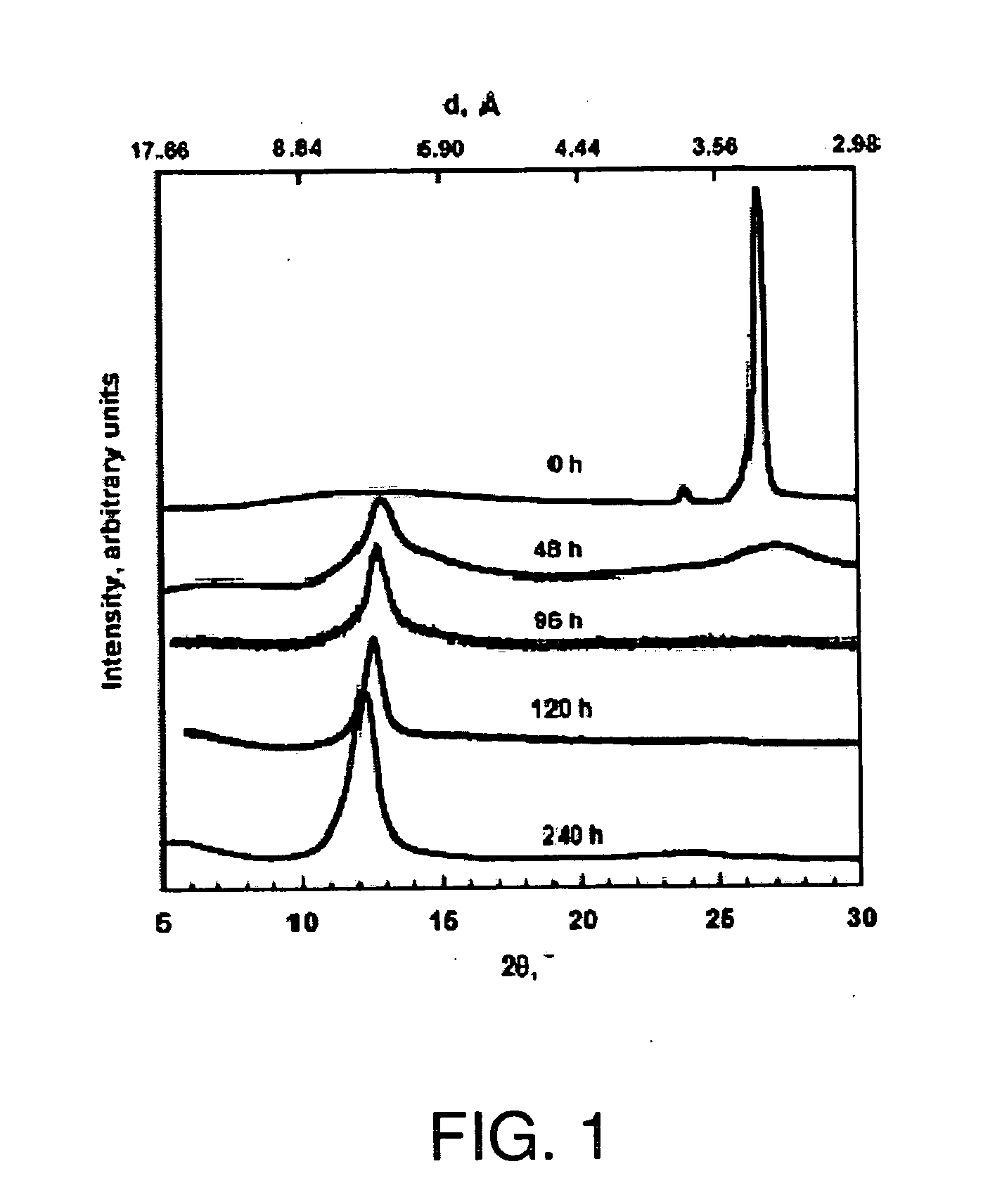

A modified graphite oxide material contains a thermally exfoliated graphite oxide with a surface area of from about 300 m2 / g to 2600 m2 / g, wherein the thermally exfoliated graphite oxide displays no signature of the original graphite and / or graphite oxide, as determined by X-ray diffraction.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Process for producing nano-scaled platelets and nanocompsites

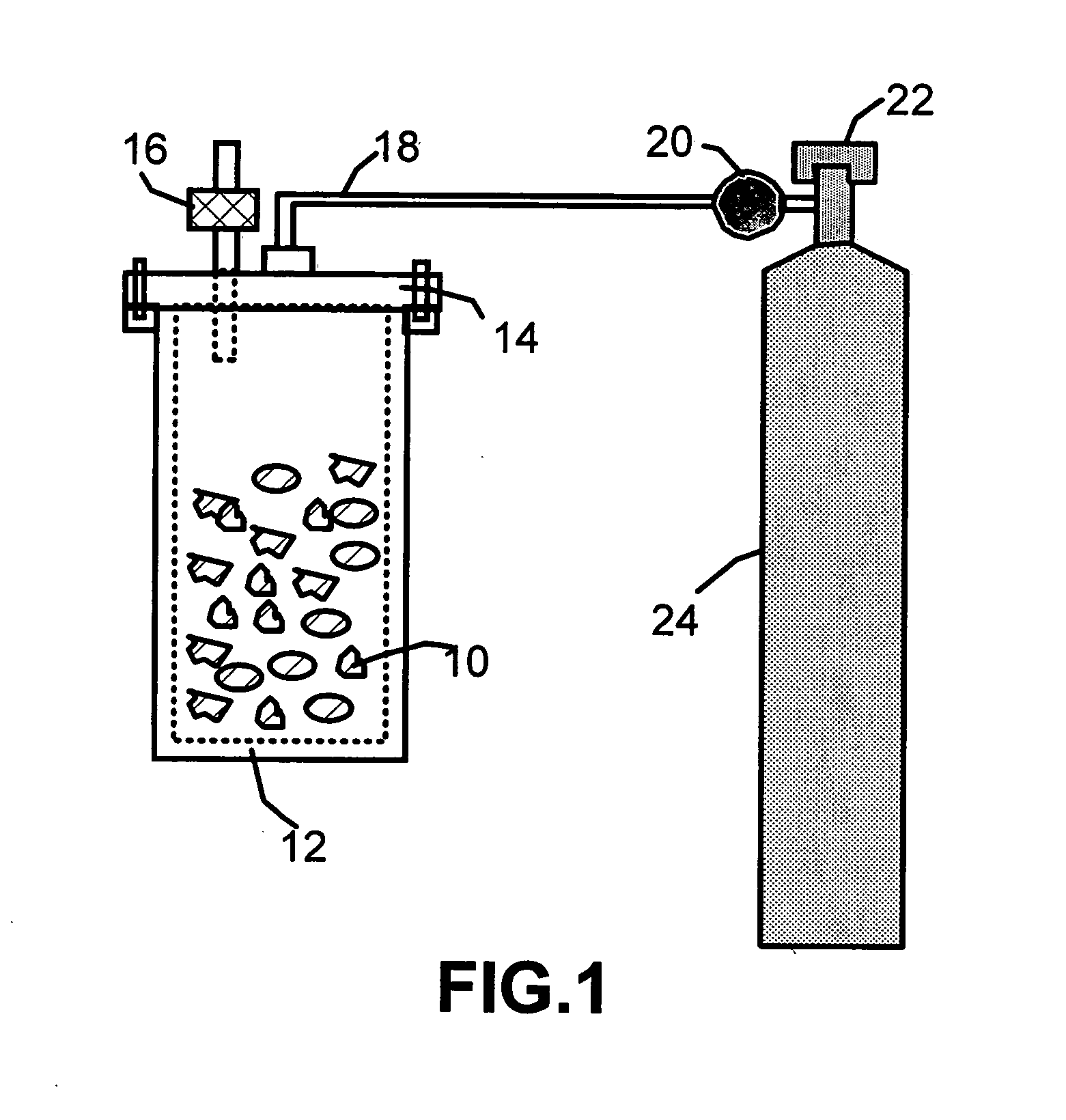

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) subjecting a layered material to a gaseous environment at a first temperature and first pressure sufficient to cause gas species to penetrate between layers of the layered material, forming a gas-intercalated layered material; and (b) subjecting the gas-intercalated layered material to a second pressure, or a second pressure and a second temperature, allowing gas species to partially or completely escape from the layered material and thereby exfoliating the layered material to produce partially delaminated or totally separated platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can also include dispersing the platelets in a matrix material to form a nanocomposite.

Owner:GLOBAL GRAPHENE GRP INC

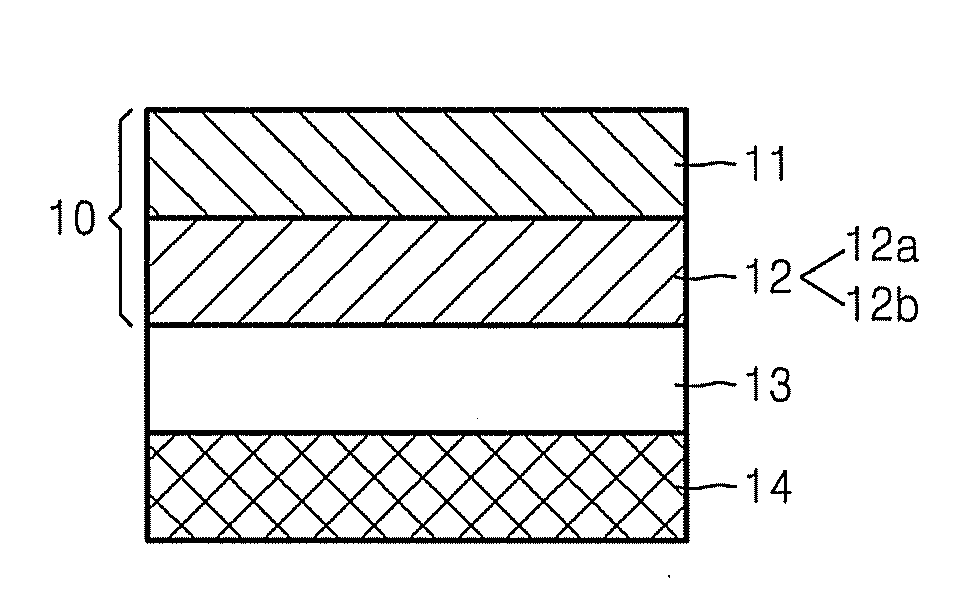

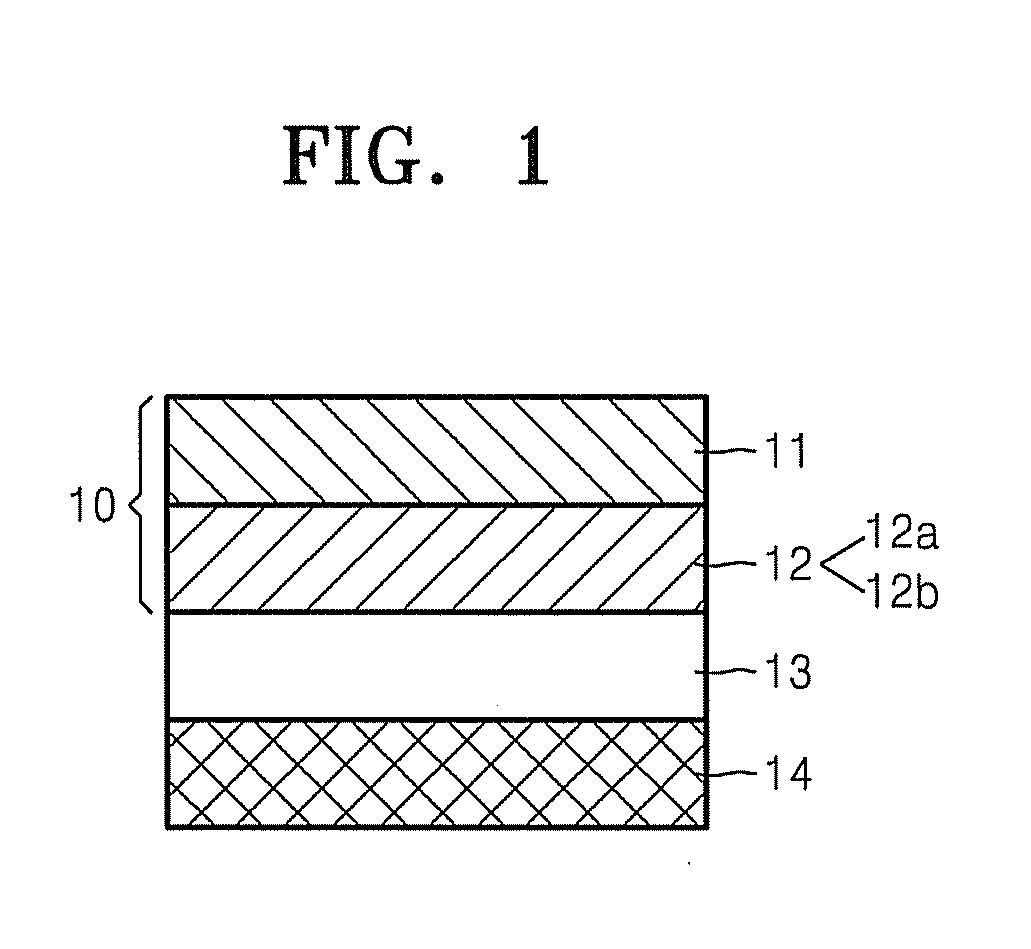

Nano-scaled graphene plate films and articles

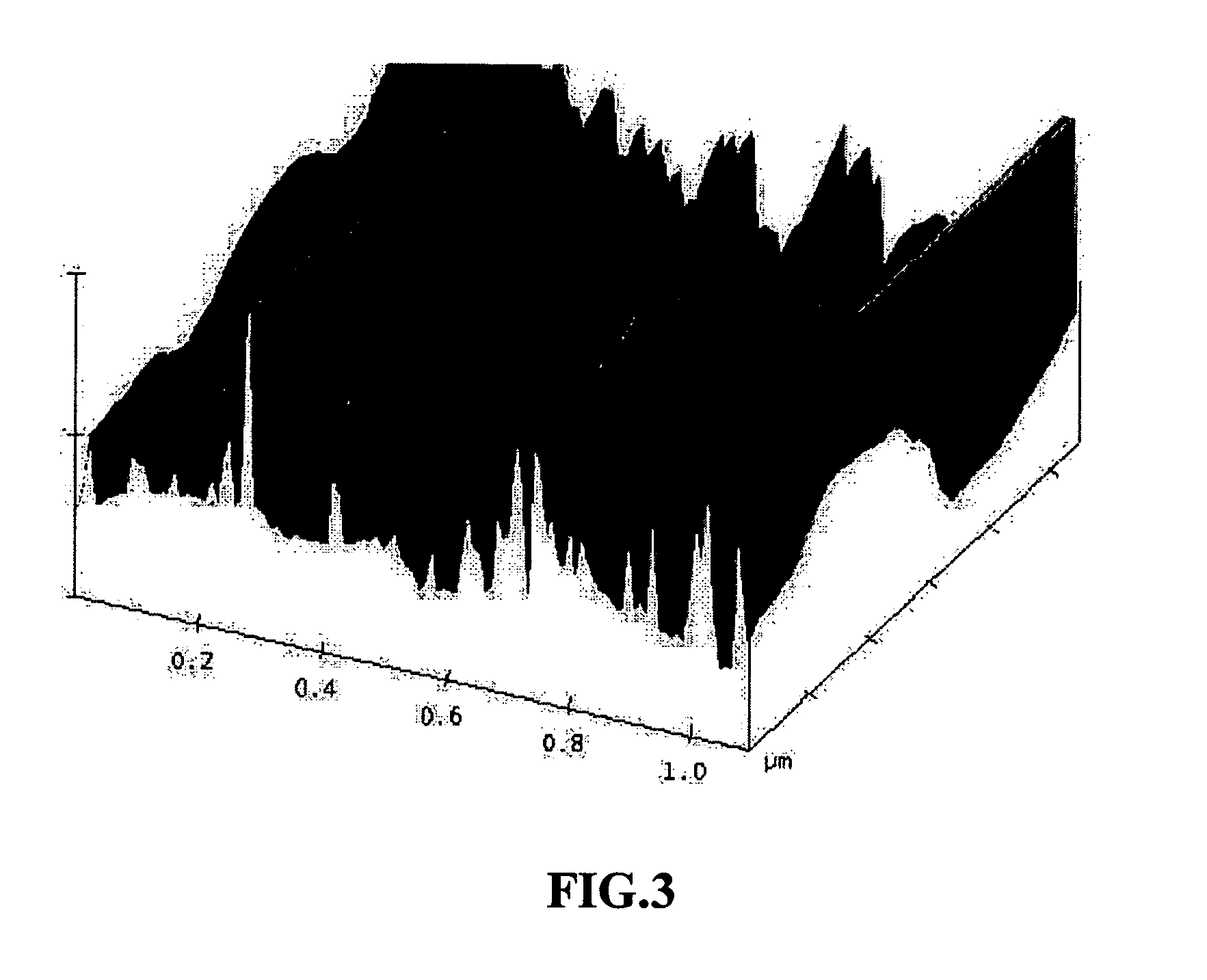

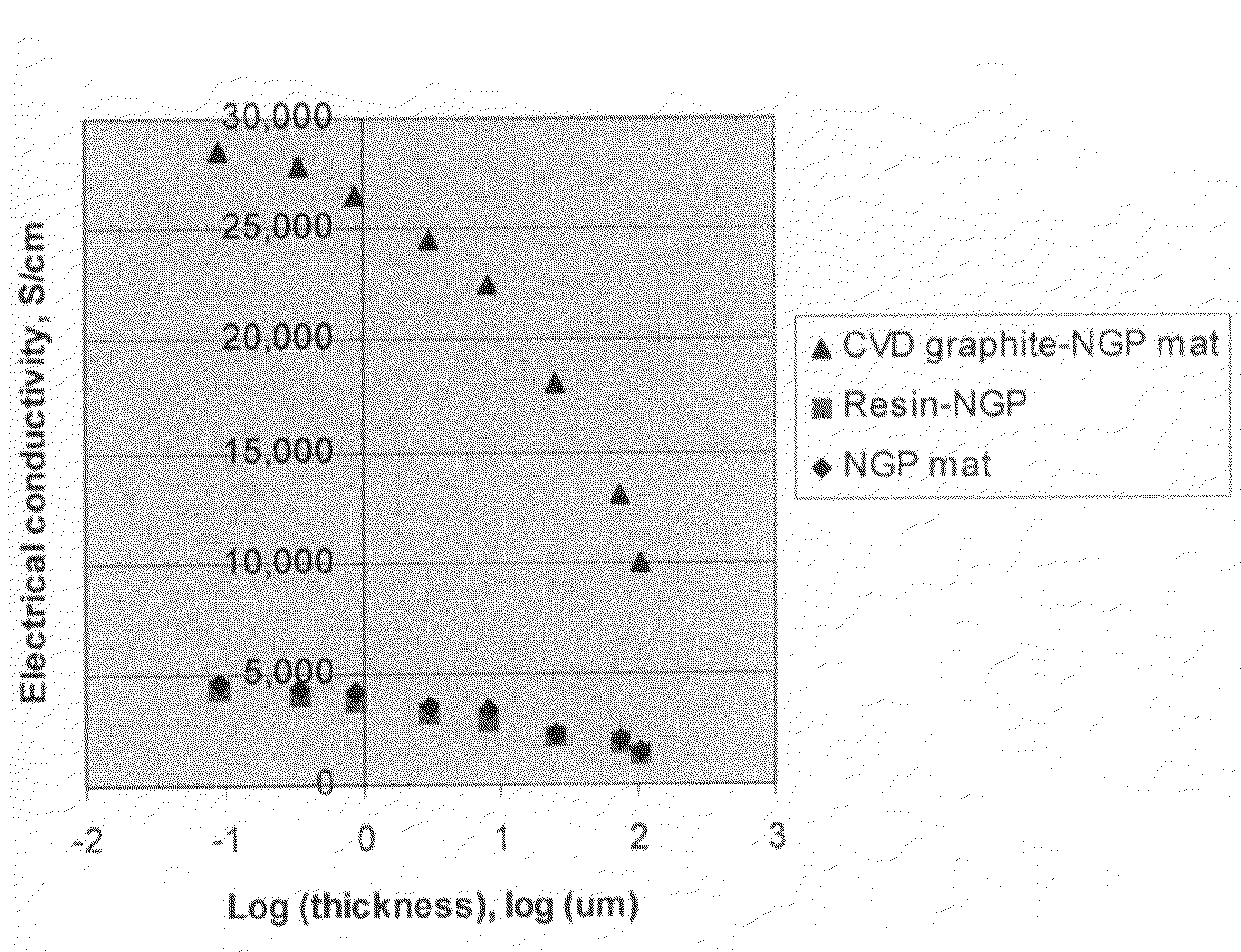

ActiveUS20080248275A1Improve thermal conductivityNon-metal conductorsMaterial nanotechnologyLightning strikePlatelet

Disclosed is a nano-scaled graphene article comprising a non-woven aggregate of nano-scaled graphene platelets wherein each of the platelets comprises a graphene sheet or multiple graphene sheets and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and platelets contact other platelets to define a plurality of conductive pathways along the article. The article has an exceptional thermal conductivity (typically greater than 500 Wm−1K−1) and excellent electrical conductivity (typically greater than 1,000 S / cm). Thin-film articles of the present invention can be used for thermal management in micro-electronic devices and for current-dissipating on an aircraft skin against lightning strikes.

Owner:GLOBAL GRAPHENE GRP INC

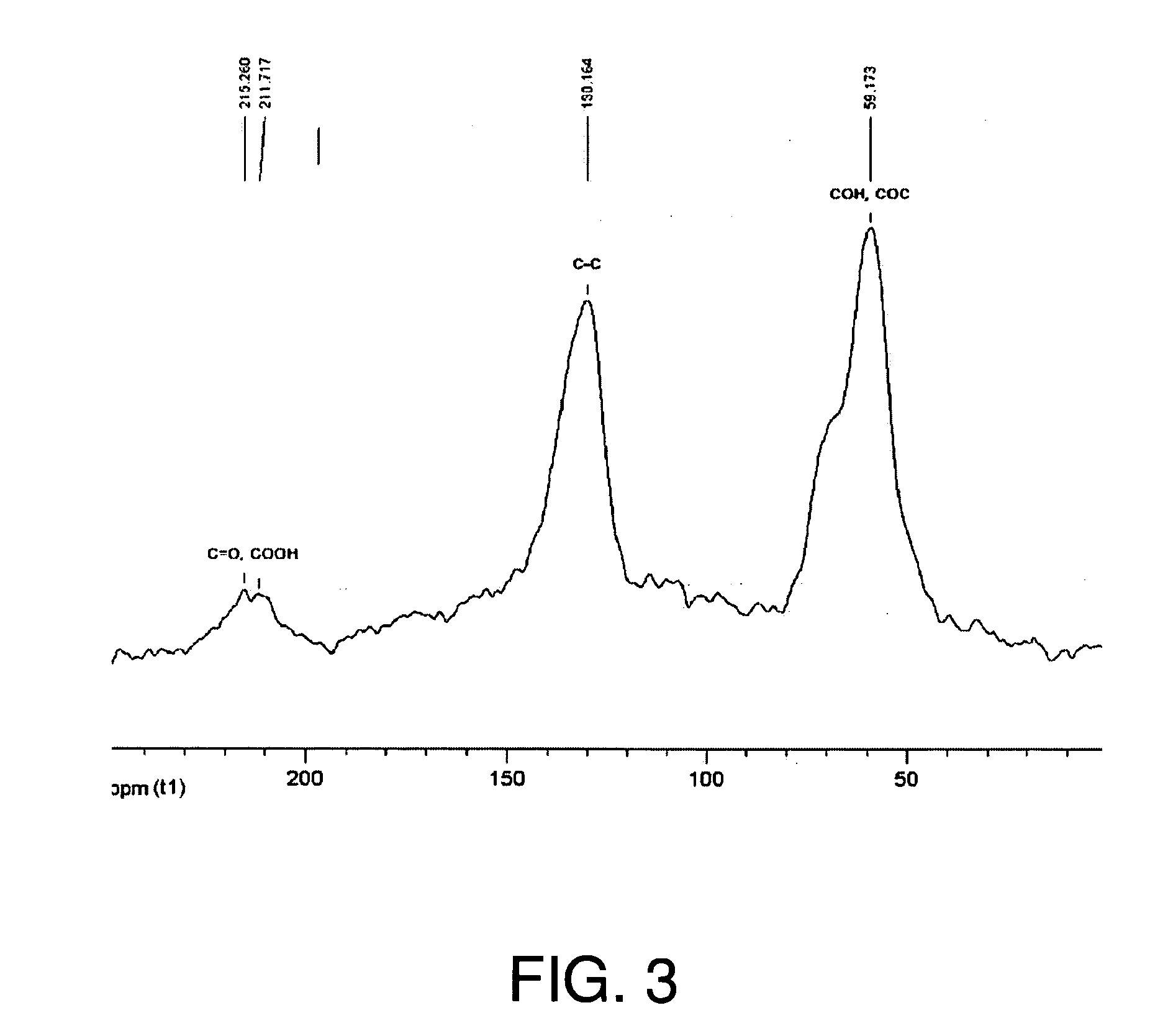

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveUS20100096595A1Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologyNanostructure manufactureNano compositesX-ray

Owner:THE TRUSTEES FOR PRINCETON UNIV

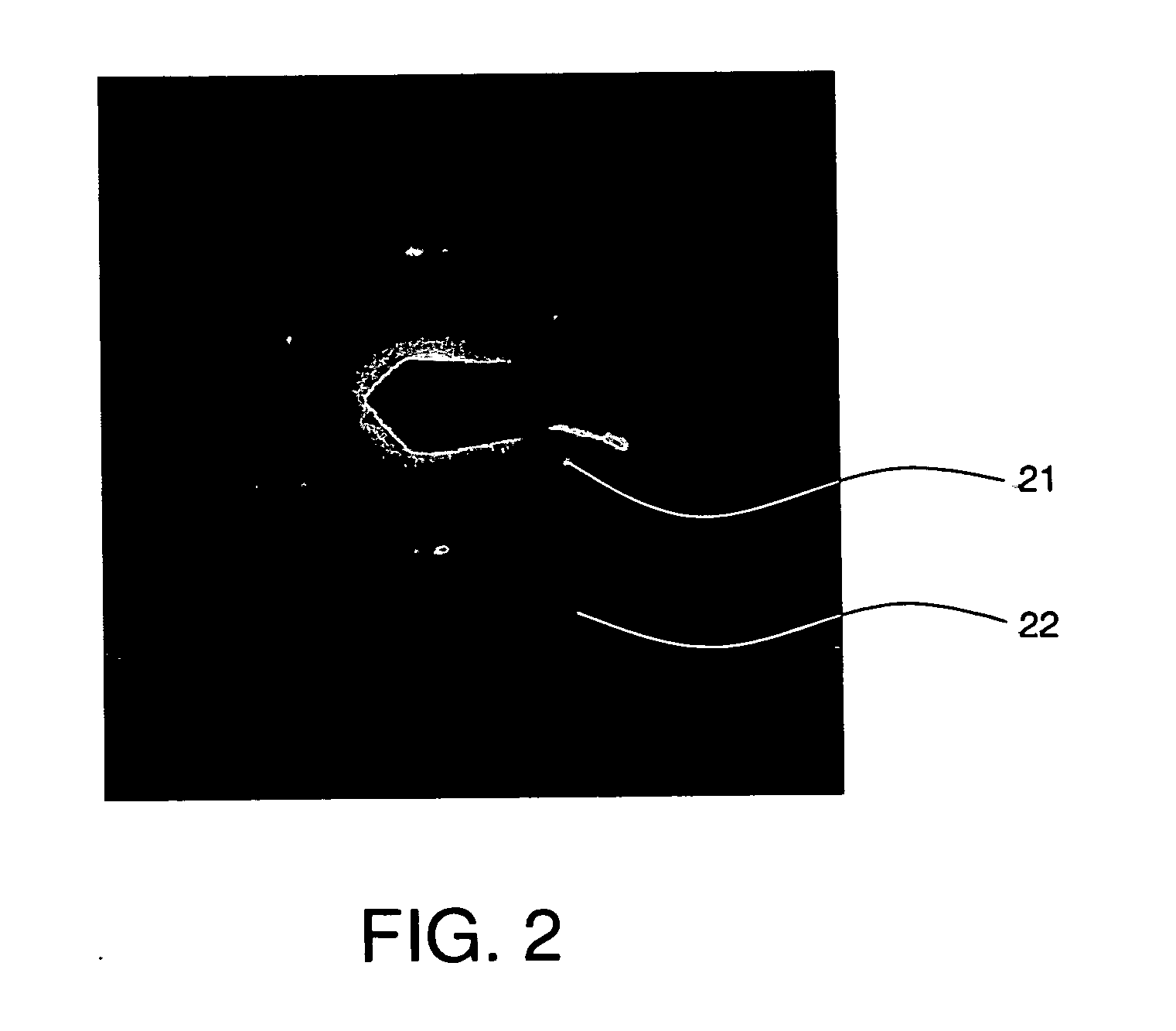

Reduced graphene oxide doped with dopant, thin layer and transparent electrode

InactiveUS20090146111A1Improve electrical performanceMaterial nanotechnologyNon-metal conductorsDopantDisplay device

Disclosed herein is a reduced graphene oxide doped with a dopant, and a thin layer, a transparent electrode, a display device and a solar cell including the reduced graphene oxide. The reduced graphene oxide doped with a dopant includes an organic dopant and / or an inorganic dopant.

Owner:SAMSUNG ELECTRONICS CO LTD

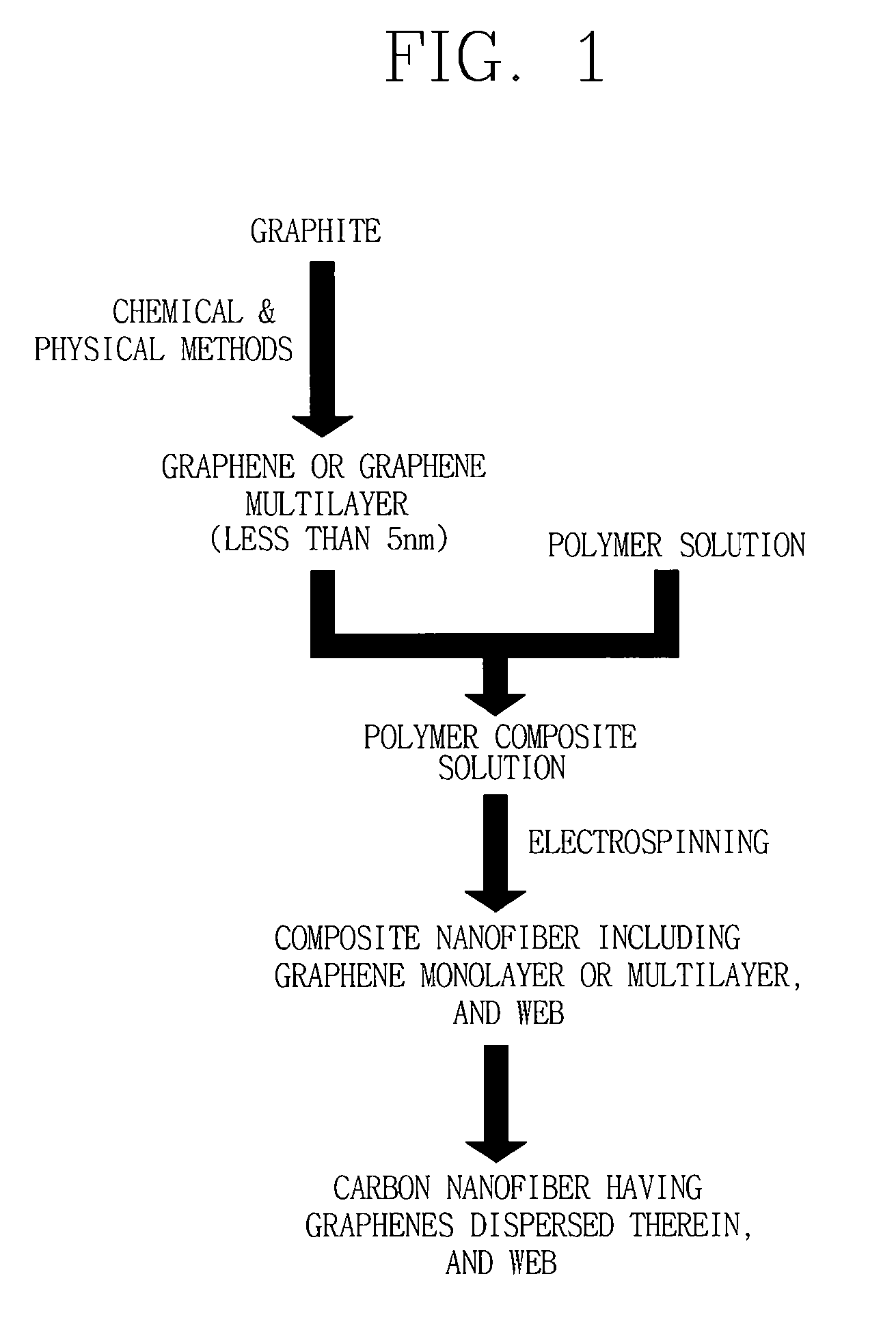

Graphene composite nanofiber and preparation method thereof

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

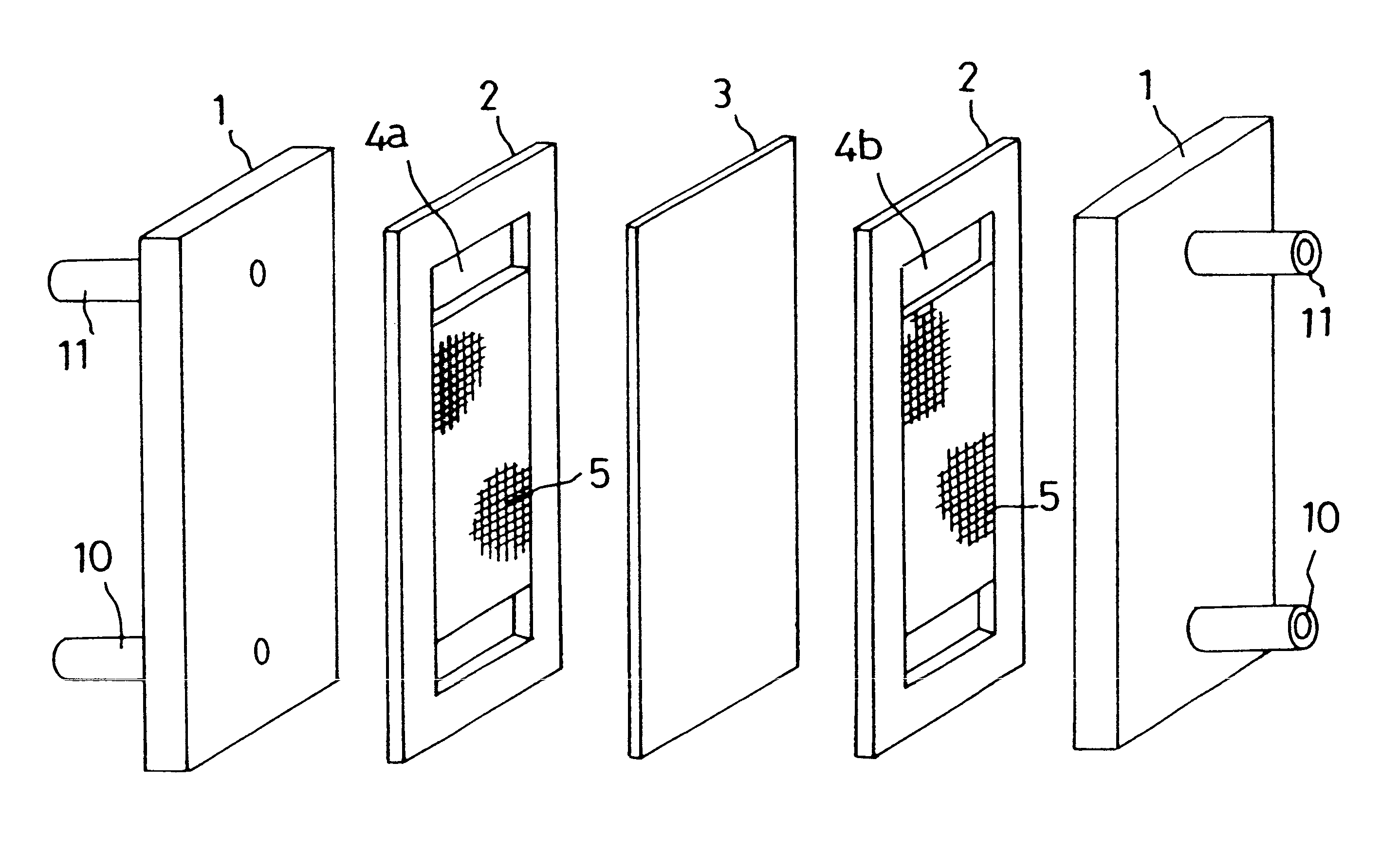

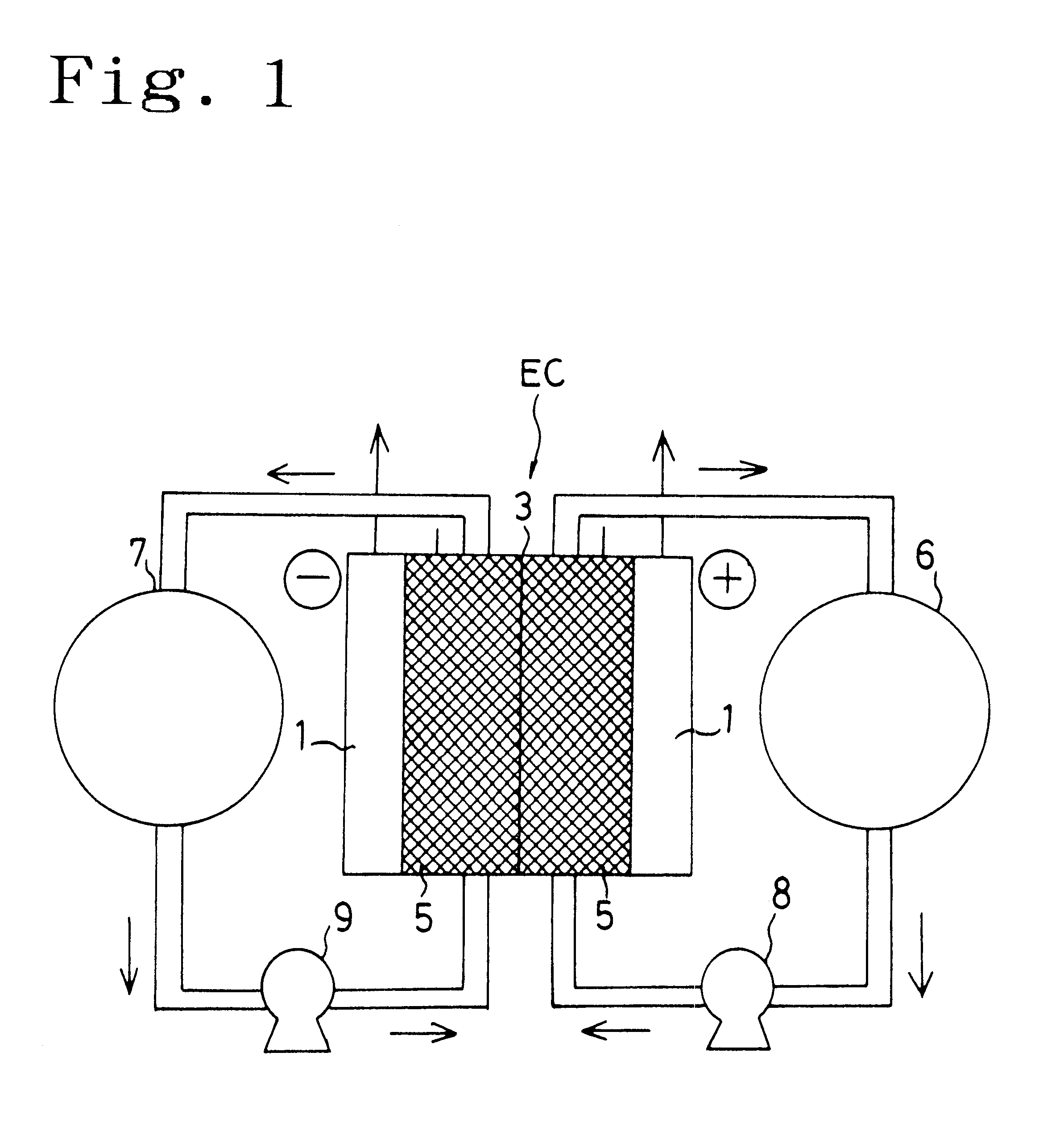

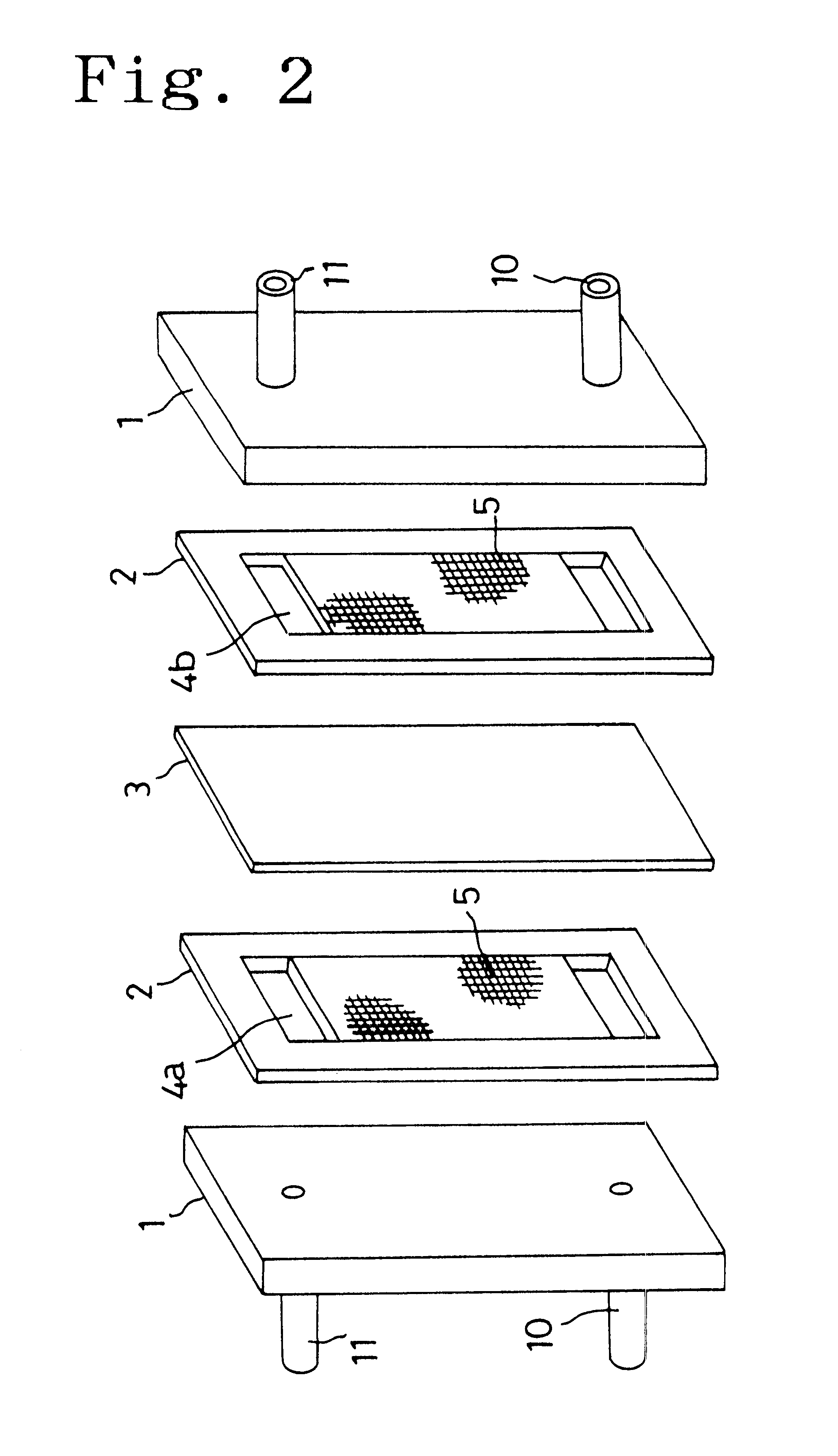

Carbon electrode material for a vanadium-based redox-flow battery

The carbon electrode material of the present invention is used for a vanadium redox-flow cell. The carbon electrode material has quasi-graphite crystal structure in which <002> spacing obtained by X-ray wide angle analysis is 3.43 to 3.60 Å, size of a crystallite in c axial direction is 15 to 33 Å and size of crystallite in a axial direction is 30 to 70 Å. In addition, an amount of surface acidic functional groups obtained by XPS surface analysis is 0.1 to 1.2% and total number of surface bound-nitrogen atoms is 5% or smaller relative to total number of surface carbon atoms. The carbon electrode materials formed of a non-woven fabric of a carbonaceouss fiber is preferable.

Owner:TOYO TOYOBO CO LTD

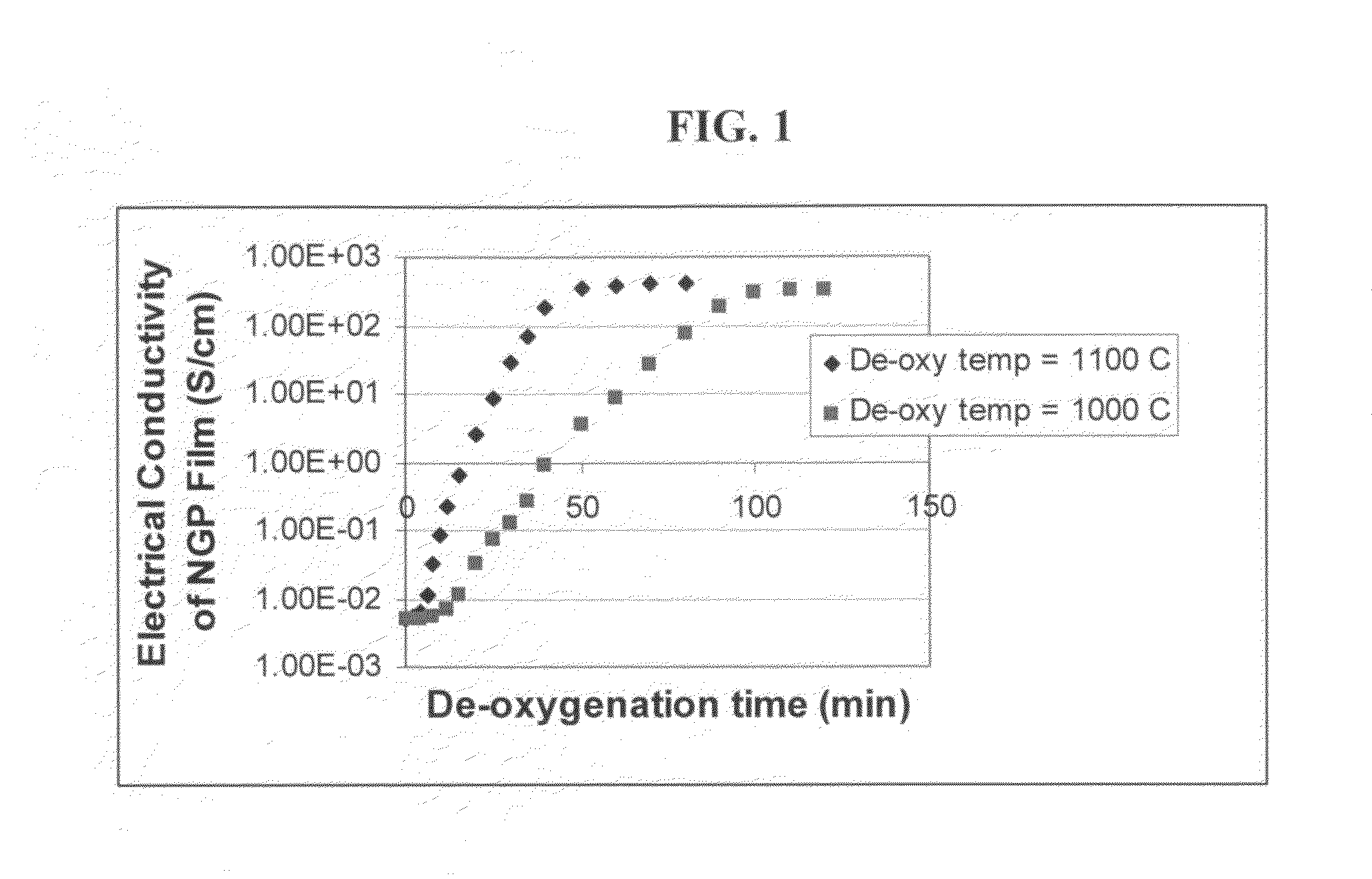

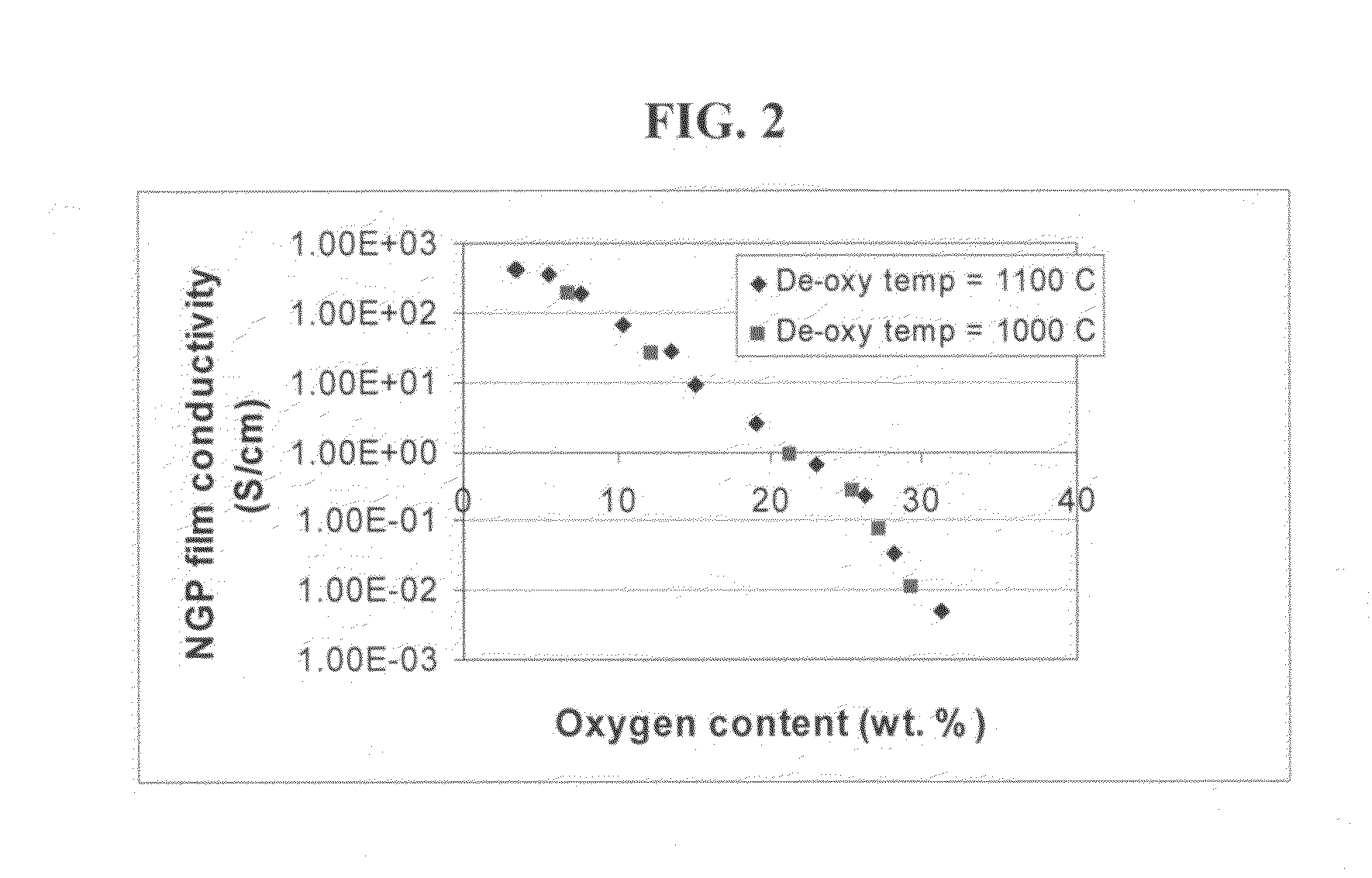

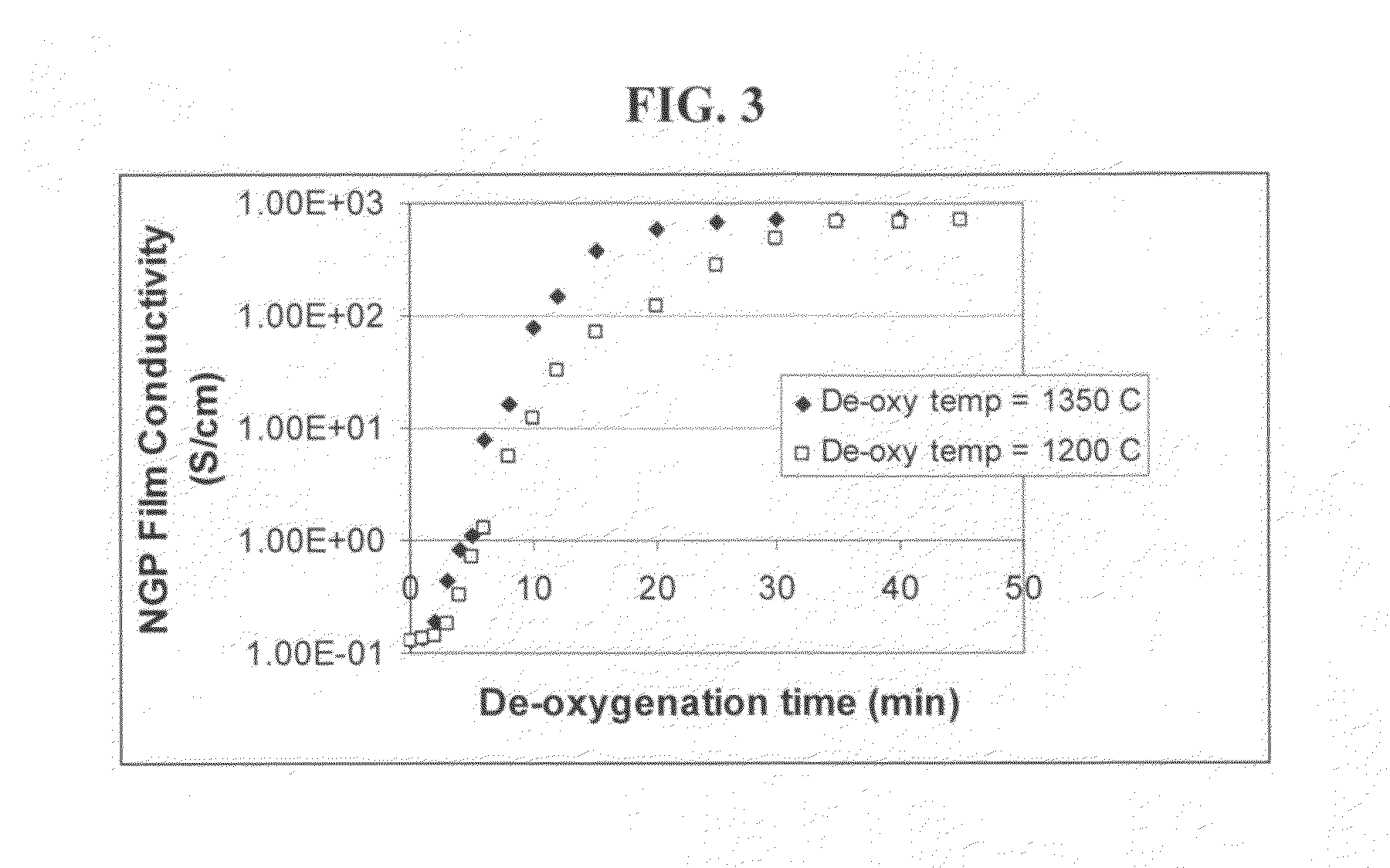

Process for producing dispersible Nano Graphene Platelets from oxidized graphite

The present invention provides a process for producing nano graphene platelets (NGPs) that are dispersible and conducting. The process comprises: (a) preparing a graphite intercalation compound (GIC) or graphite oxide (GO) from a laminar graphite material; (b) exposing the GIC or GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time to obtain the desired dispersible nano graphene platelet with an oxygen content no greater than 25% by weight, preferably below 20% by weight, further preferably between 5% and 20% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

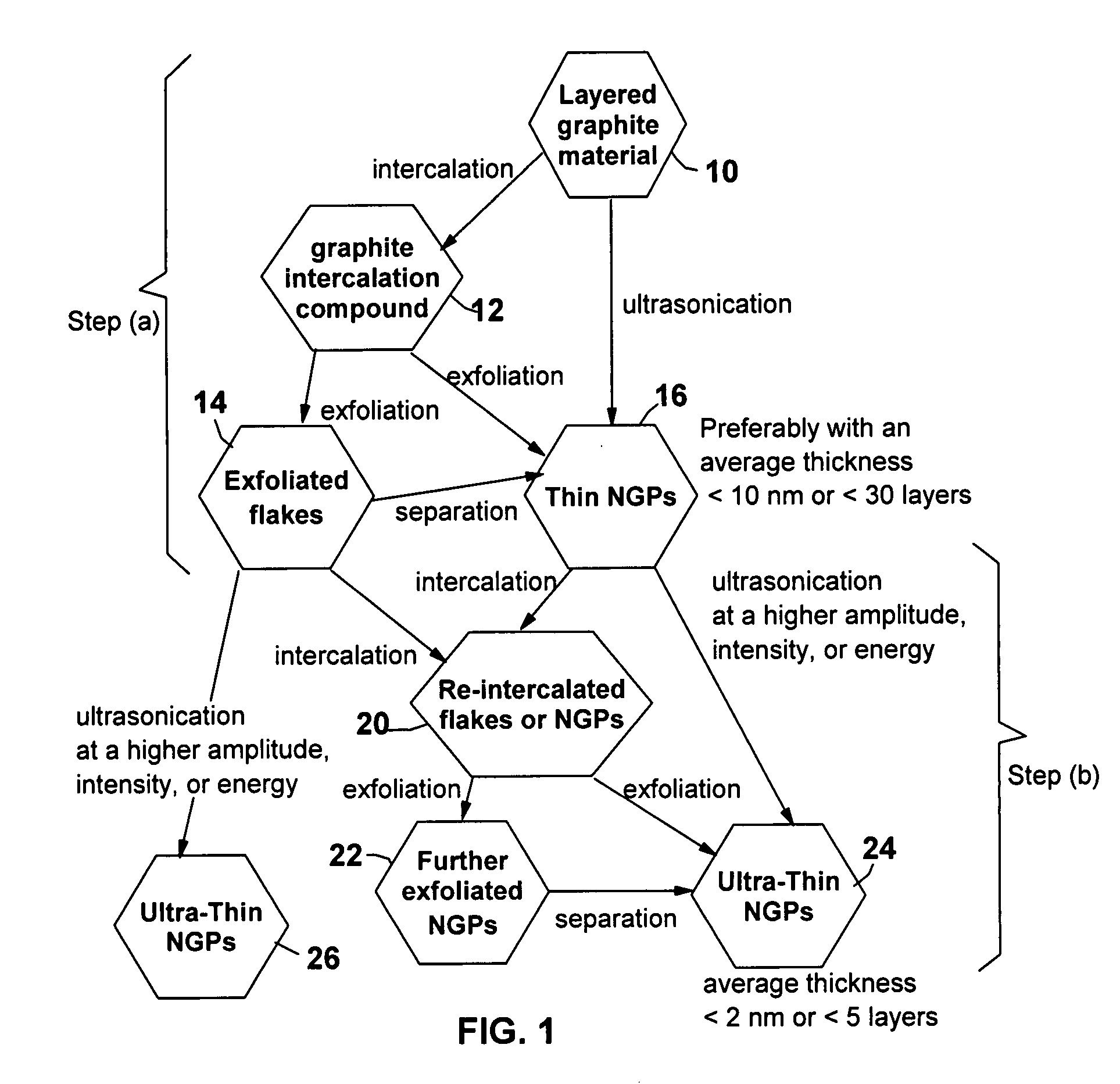

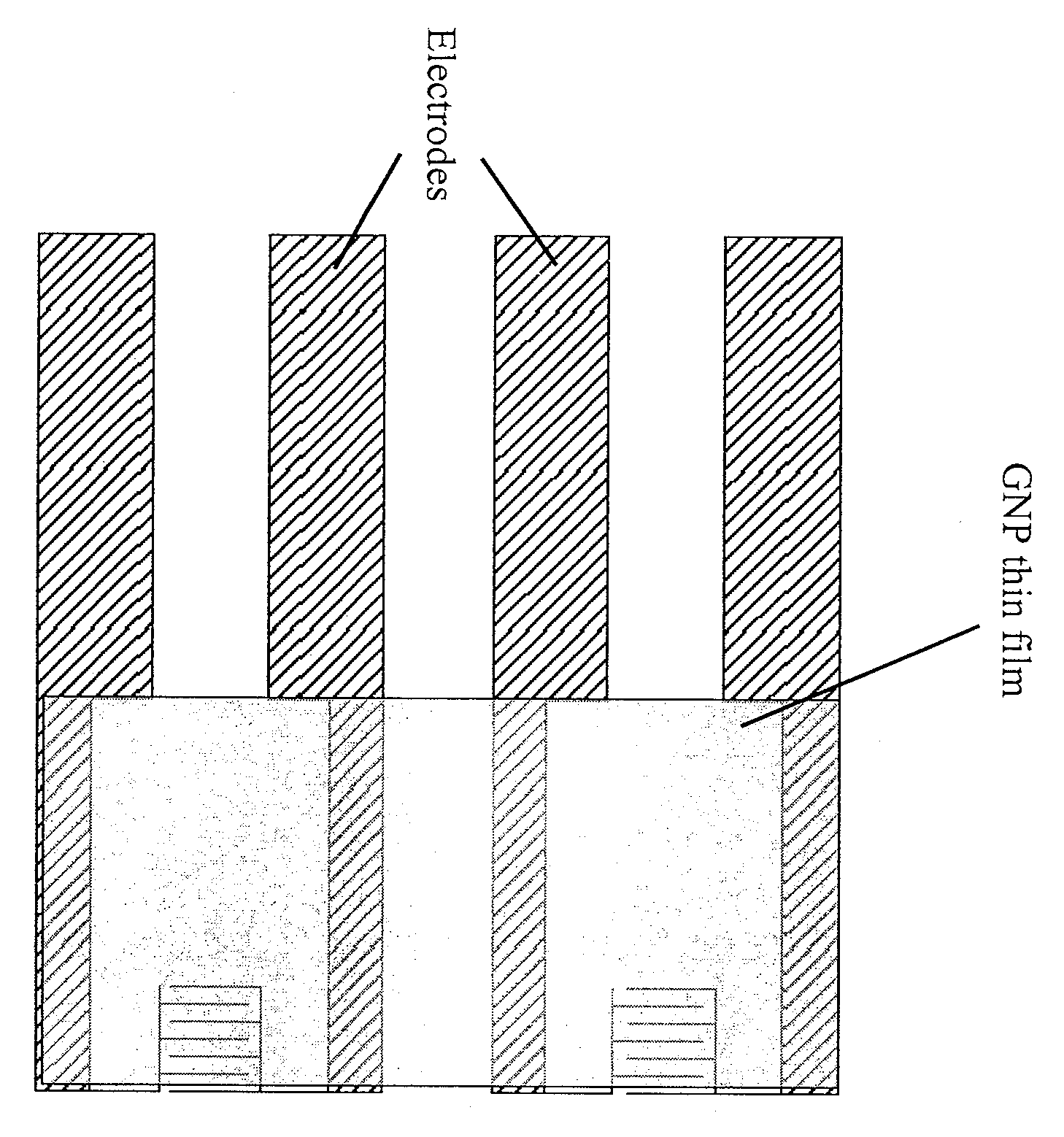

Graphene Nanoelectric Device Fabrication

Embodiments of the present invention provide methods for fabricating graphene nanoelectronic devices with semiconductor compatible processes, which allow wafer scale fabrication of graphene nanoelectronic devices. Embodiments of the present invention also provide methods for passivating graphene nanoelectronic devices, which enable stacking of multiple graphene devices and the creation of high density graphene based circuits. Other embodiments provide methods for producing devices with graphene layer segments having multiple thicknesses.

Owner:LOCKHEED MARTIN CORP

Functionalised graphene oxide

ActiveUS20110052813A1Good dispersionReadily deoxidised to grapheneMaterial nanotechnologyOrganic chemistryHigh concentrationRoom temperature

A functionalised graphene oxide and a method of making a functionalised graphene oxide comprising: (i) oxidizing graphite to form graphite oxide wherein the graphene sheets which make up the graphite independently of each other have a basal plane fraction of carbon atoms in the sp2-hybridised state between 0.1 and 0.9, wherein the remainder fraction comprises sp3-hybridised carbon atoms which are bonded to oxygen groups selected from hydroxyl and / or epoxy and / or carboxylic acid; and (ii) exfoliating and in-situ functionalizing the graphite oxide surface with one or more functional groups such that functionalisation of the surface is effected at a concentration greater than one functional group per 100 carbon atoms and less than one functional group per six carbon atoms. The functionalised graphene oxide is dispersible at high concentrations in appropriate solvents without aggregating or precipitating over extended periods at room temperature.

Owner:NAT UNIV OF SINGAPORE

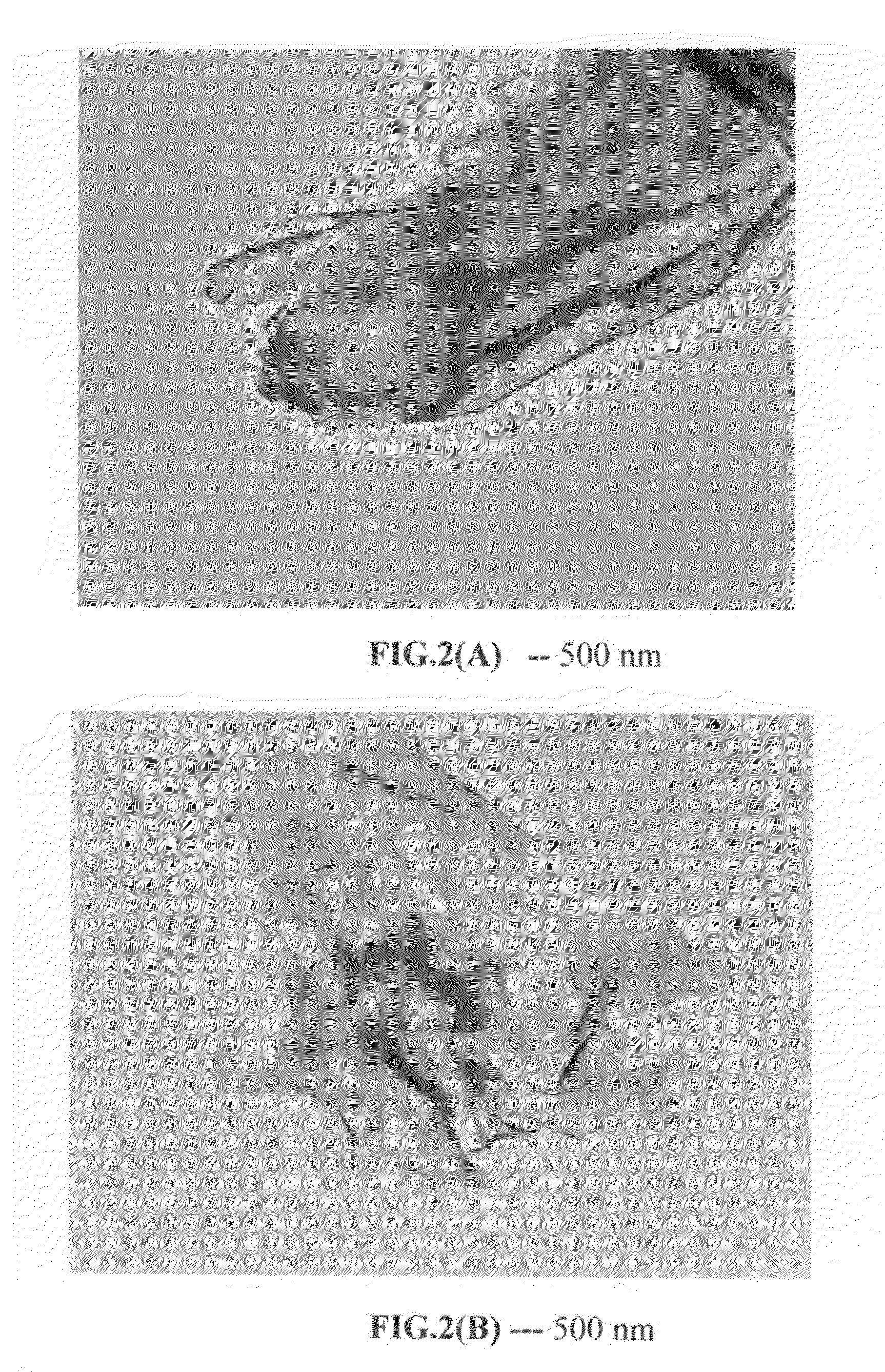

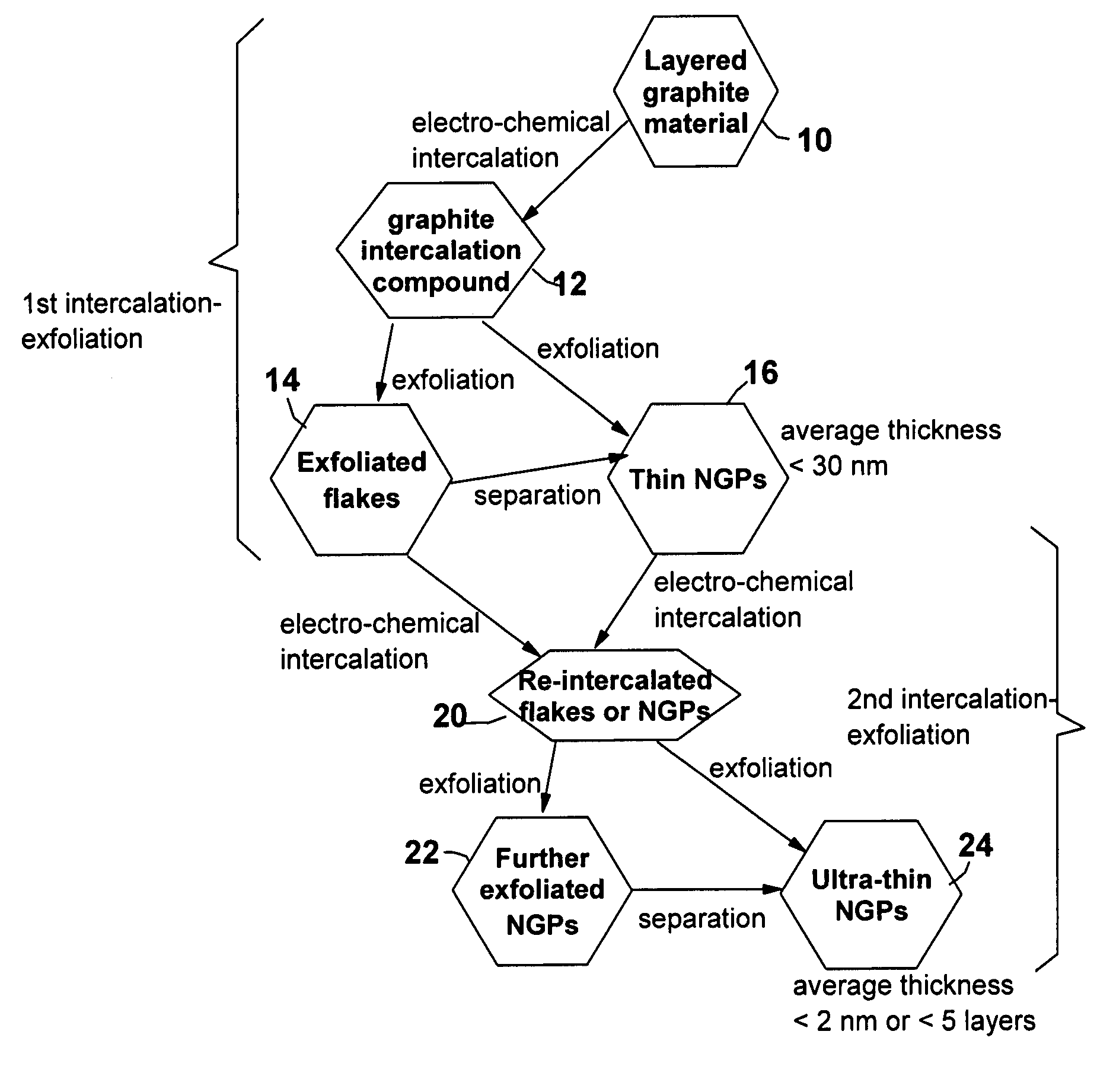

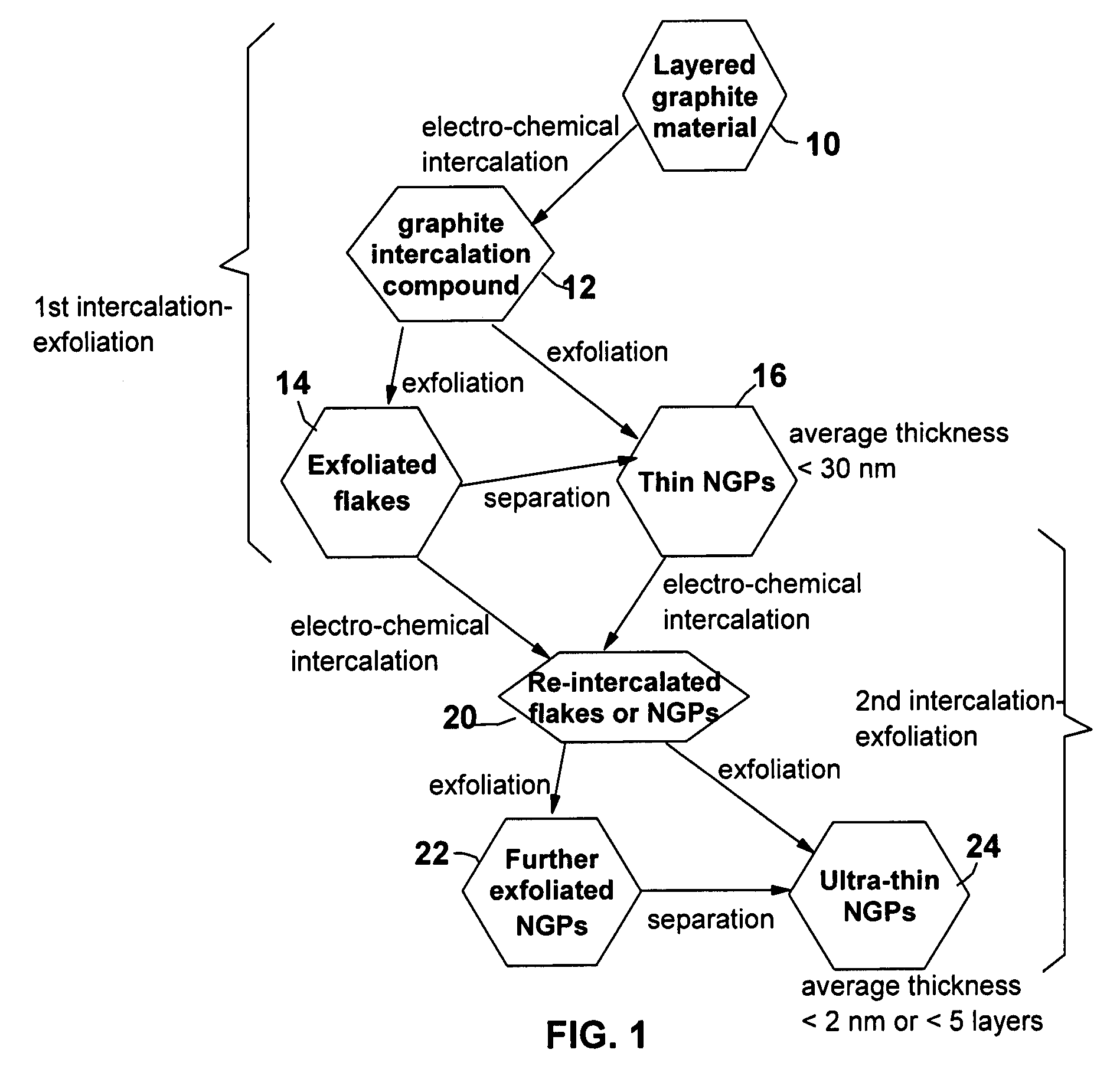

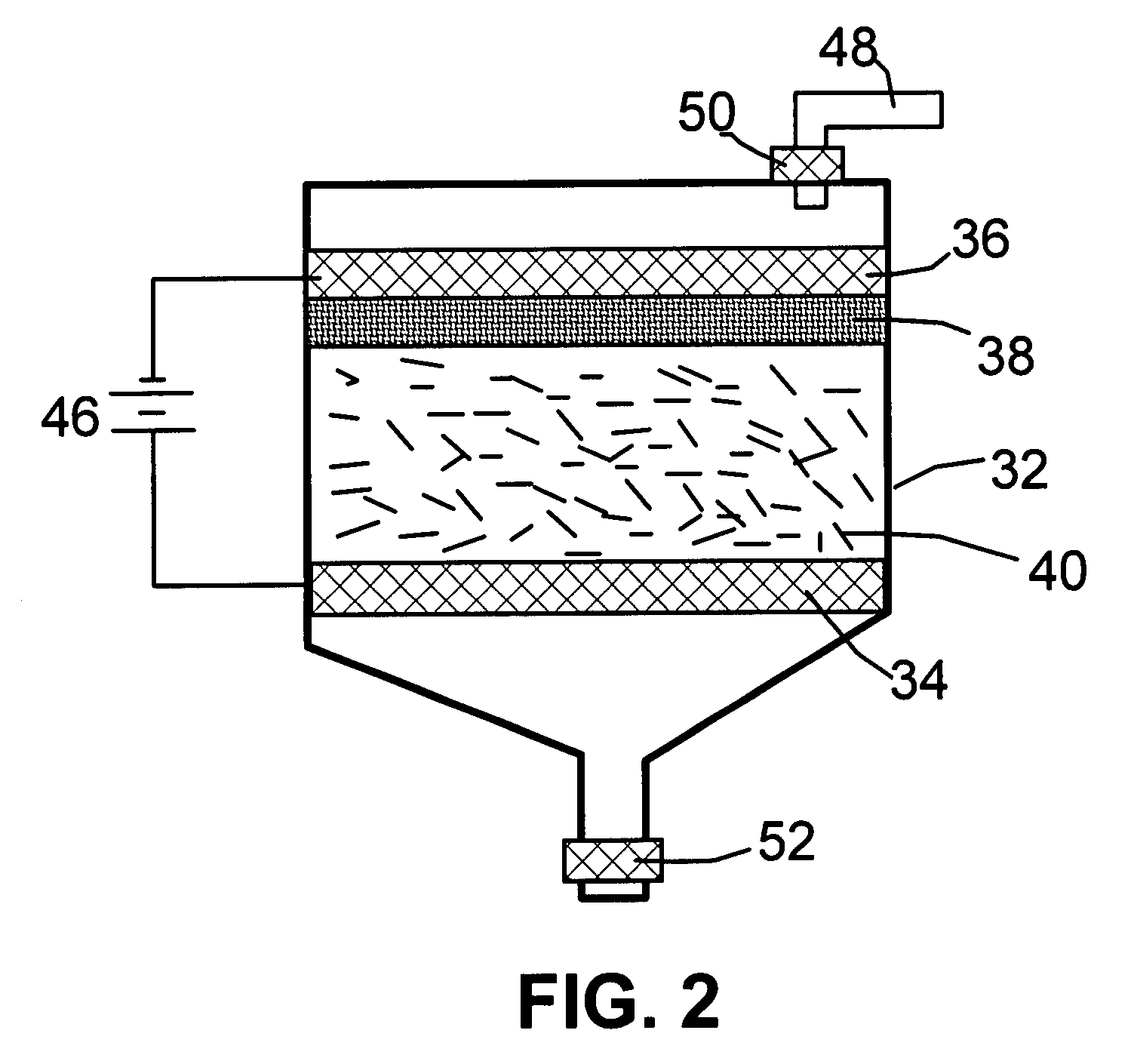

Method for producing ultra-thin nano-scaled graphene platelets

InactiveUS20090022649A1Good dispersionImprove conductivityMaterial nanotechnologyGraphiteFiberCarbon nanotube

A method of producing ultra-thin, separated nano-scaled platelets having an average thickness no greater than 2 nm or comprising, on average, no more than 5 layers per platelet from a layered graphite material. The method comprises: (a) providing a supply of nano-scaled platelets with an average thickness of no more than 10 nm or having, on average, no more than 30 layers per platelet; and (b) intercalating the supply of nano-scaled platelets to produce intercalated nano platelets and exfoliating the intercalated nano platelets at a temperature and a pressure for a sufficient period of time to produce the ultra-thin nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:NANOTEK INSTR

Functional graphene-rubber nanocomposites

ActiveUS7745528B2Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerX-ray

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Functional graphene-rubber nanocomposites

ActiveUS20100096597A1Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerPolymer science

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Process for nano-scaled graphene plates

A process for producing a nano-scaled graphene plate. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:JANG BOR Z

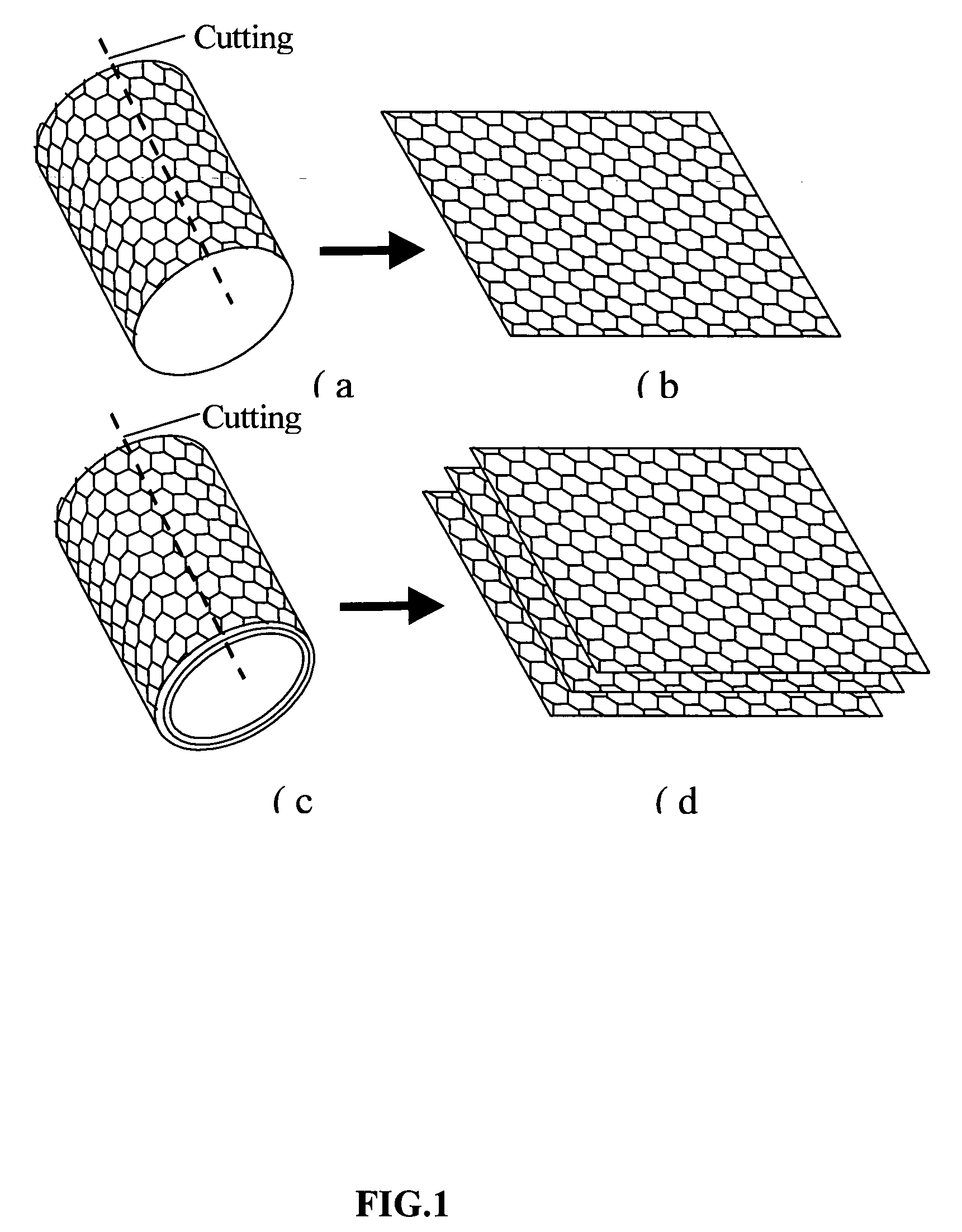

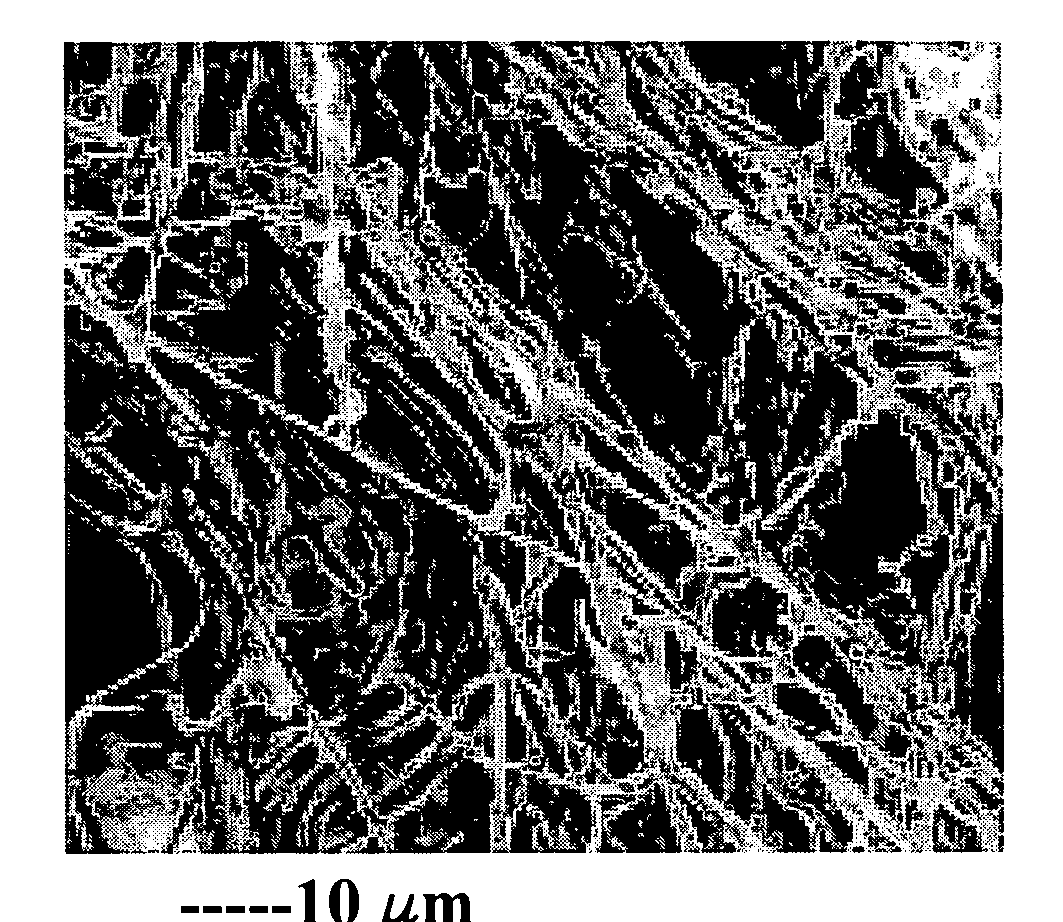

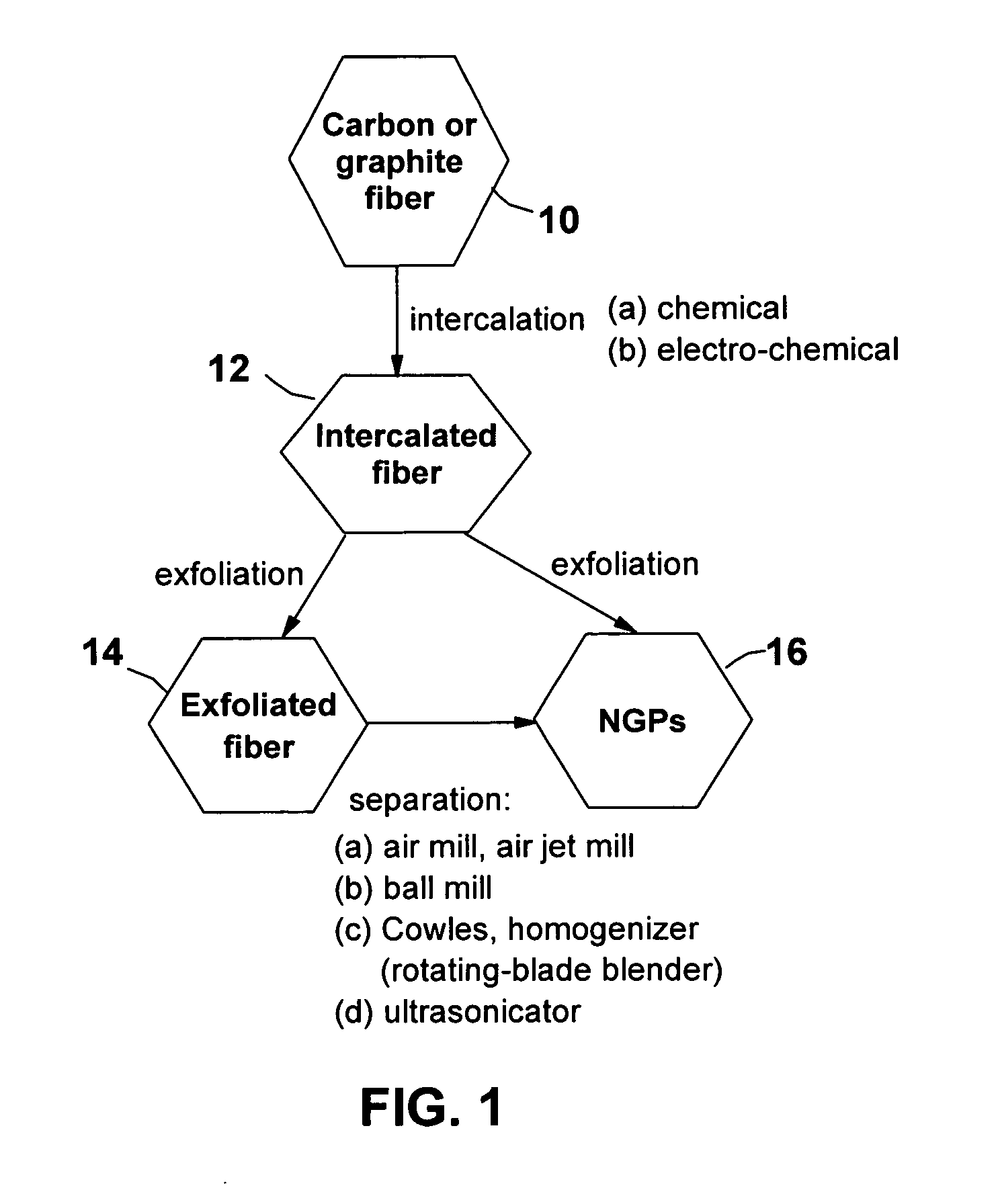

Nano-scaled graphene platelets with a high length-to-width aspect ratio

ActiveUS20090155578A1High aspect ratioHigh stiffnessMaterial nanotechnologyShielding materialsFiberCarbon fibers

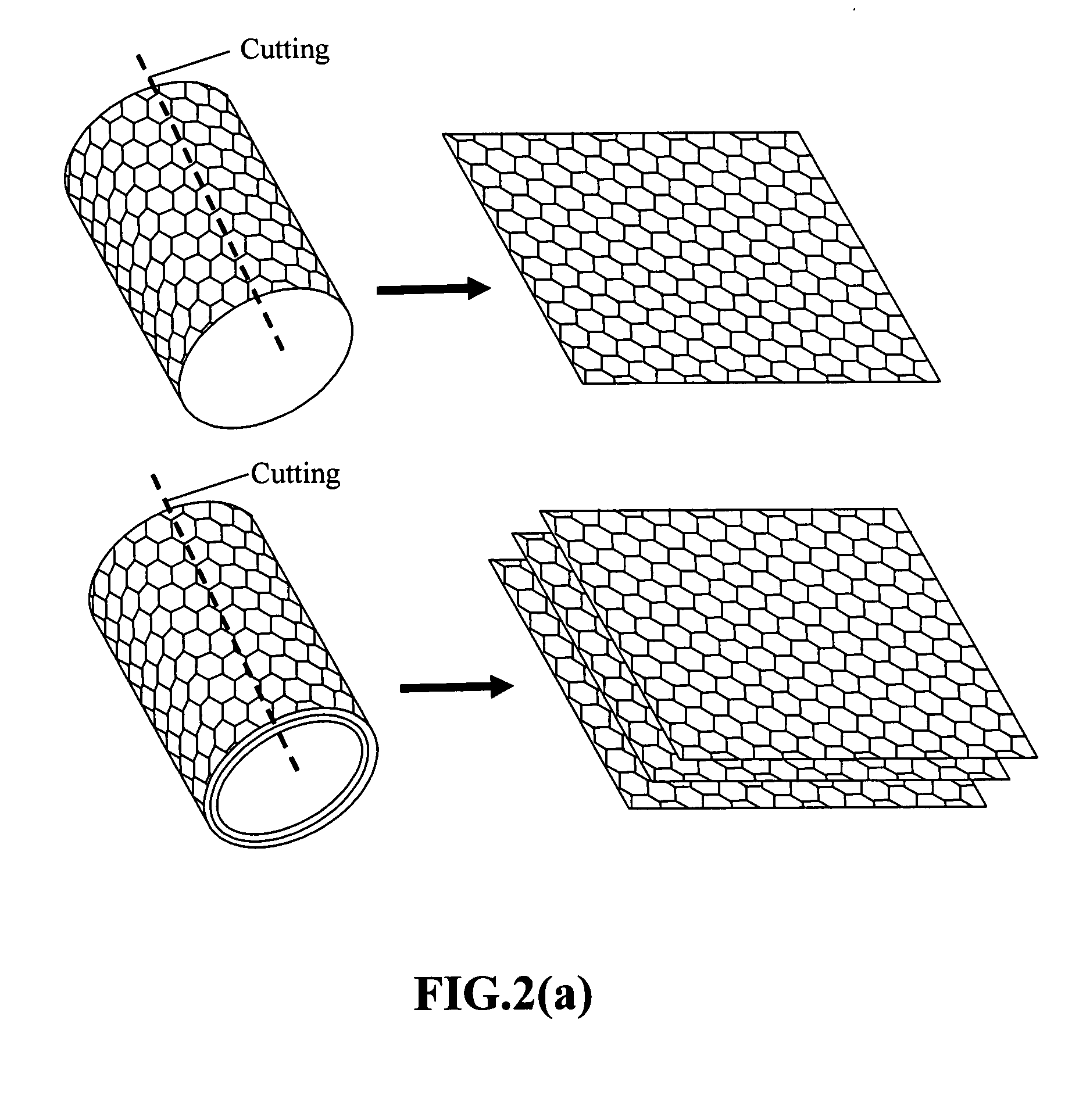

This invention provides a nano-scaled graphene platelet (NGP) having a thickness no greater than 100 nm and a length-to-width ratio no less than 3 (preferably greater than 10). The NGP with a high length-to-width ratio can be prepared by using a method comprising (a) intercalating a carbon fiber or graphite fiber with an intercalate to form an intercalated fiber; (b) exfoliating the intercalated fiber to obtain an exfoliated fiber comprising graphene sheets or flakes; and (c) separating the graphene sheets or flakes to obtain nano-scaled graphene platelets. The invention also provides a nanocomposite material comprising an NGP with a high length-to-width ratio. Such a nanocomposite can become electrically conductive with a small weight fraction of NGPs. Conductive composites are particularly useful for shielding of sensitive electronic equipment against electromagnetic interference (EMI) or radio frequency interference (RFI), and for electrostatic charge dissipation.

Owner:GLOBAL GRAPHENE GRP INC

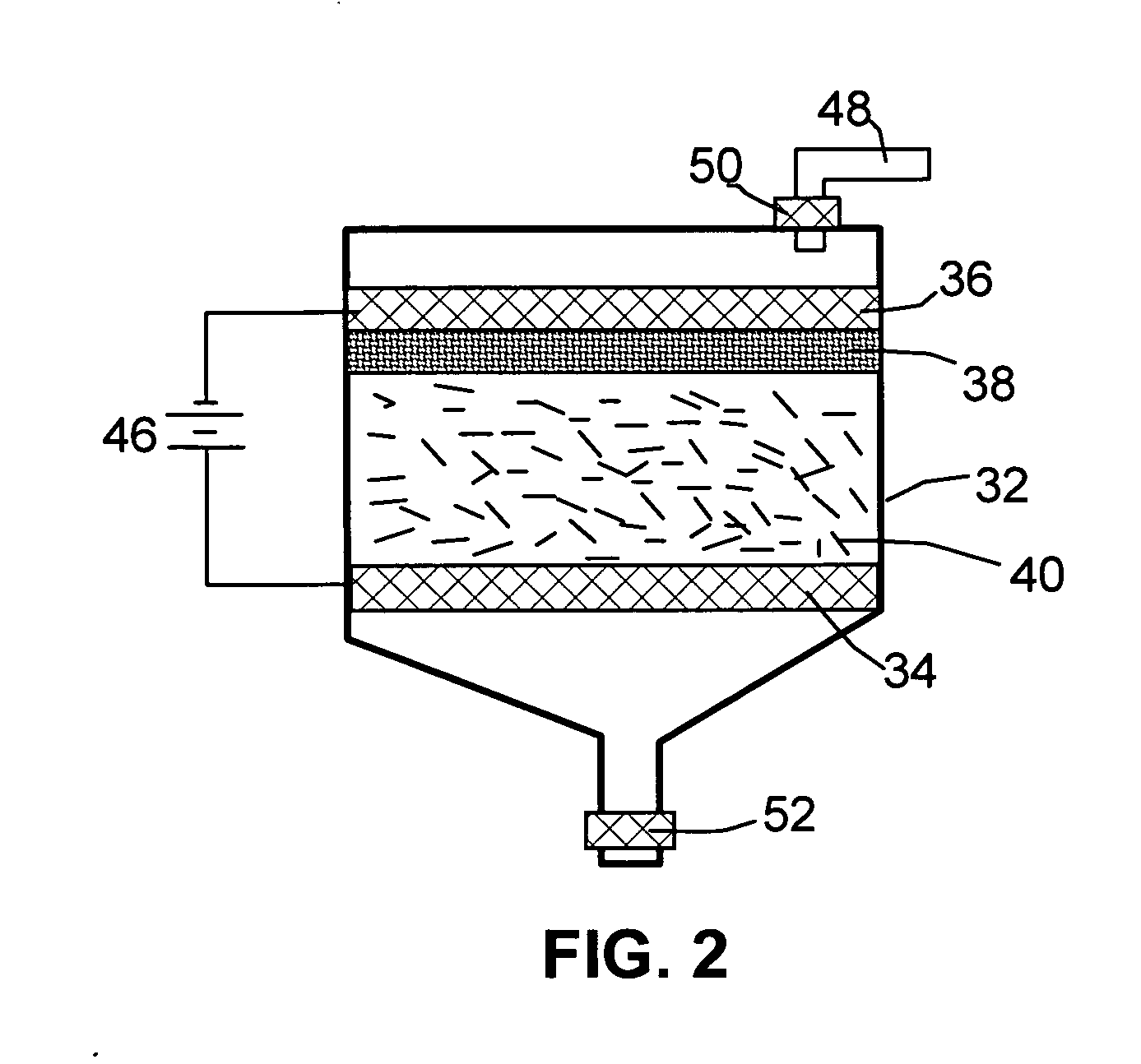

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

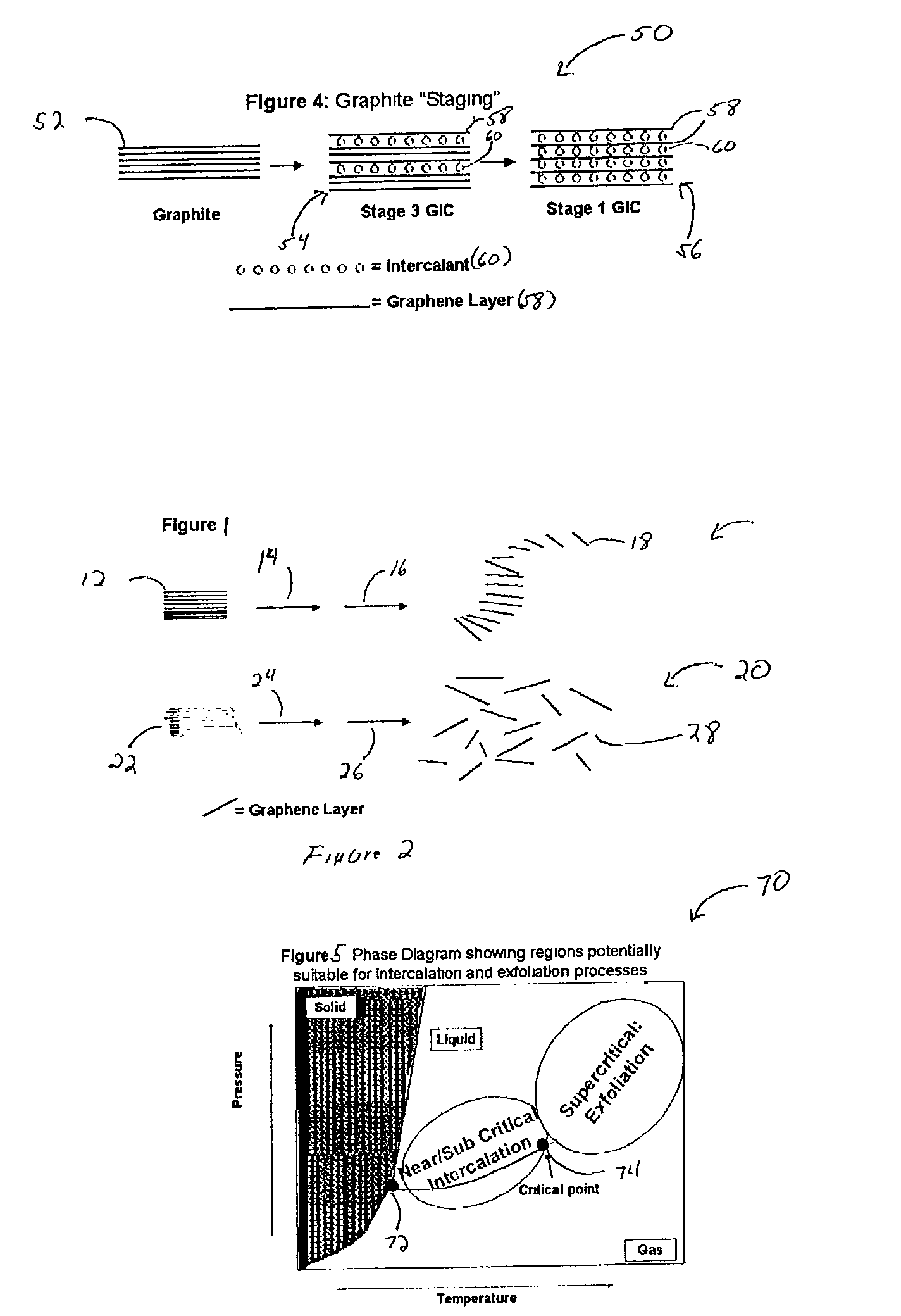

Graphite intercalation and exfoliation process

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

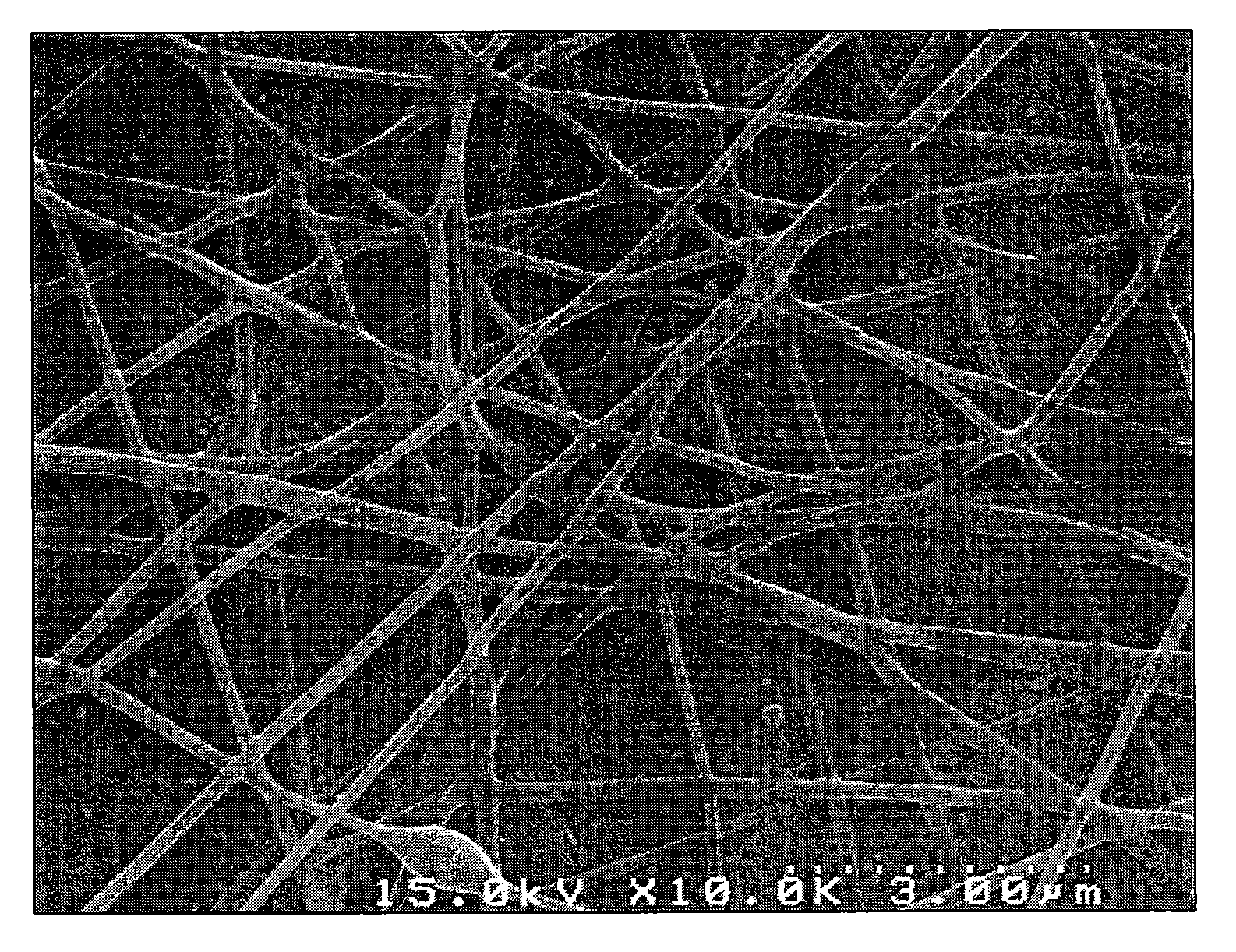

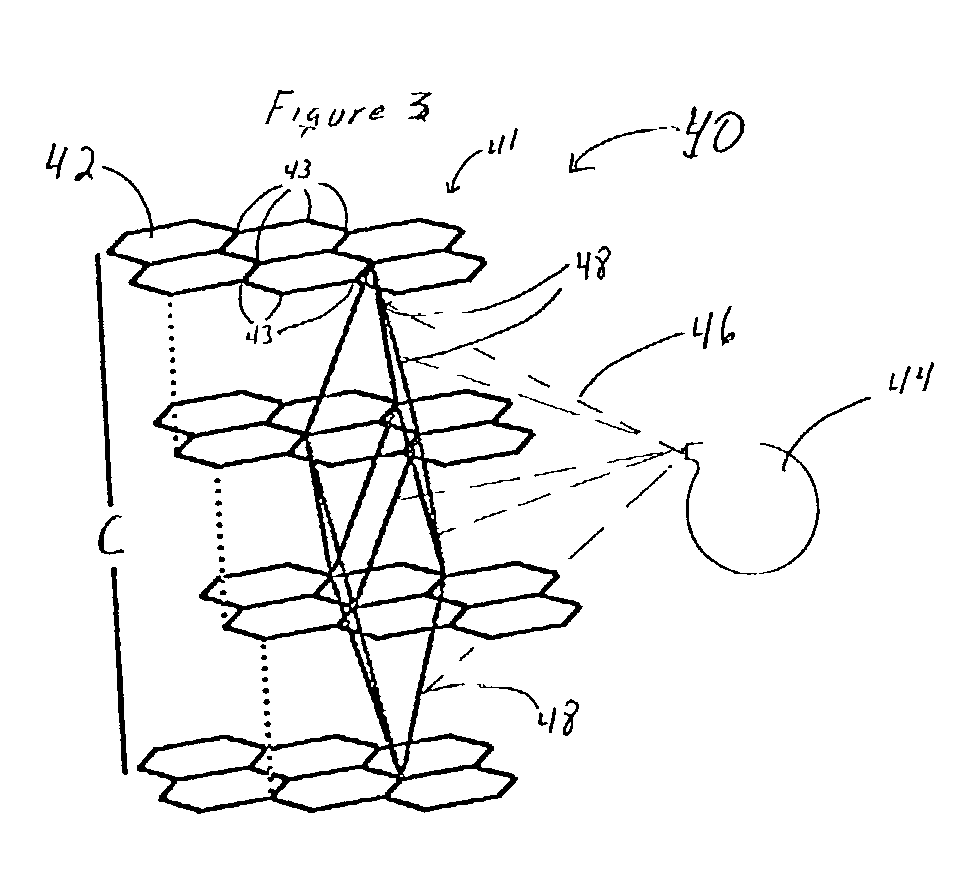

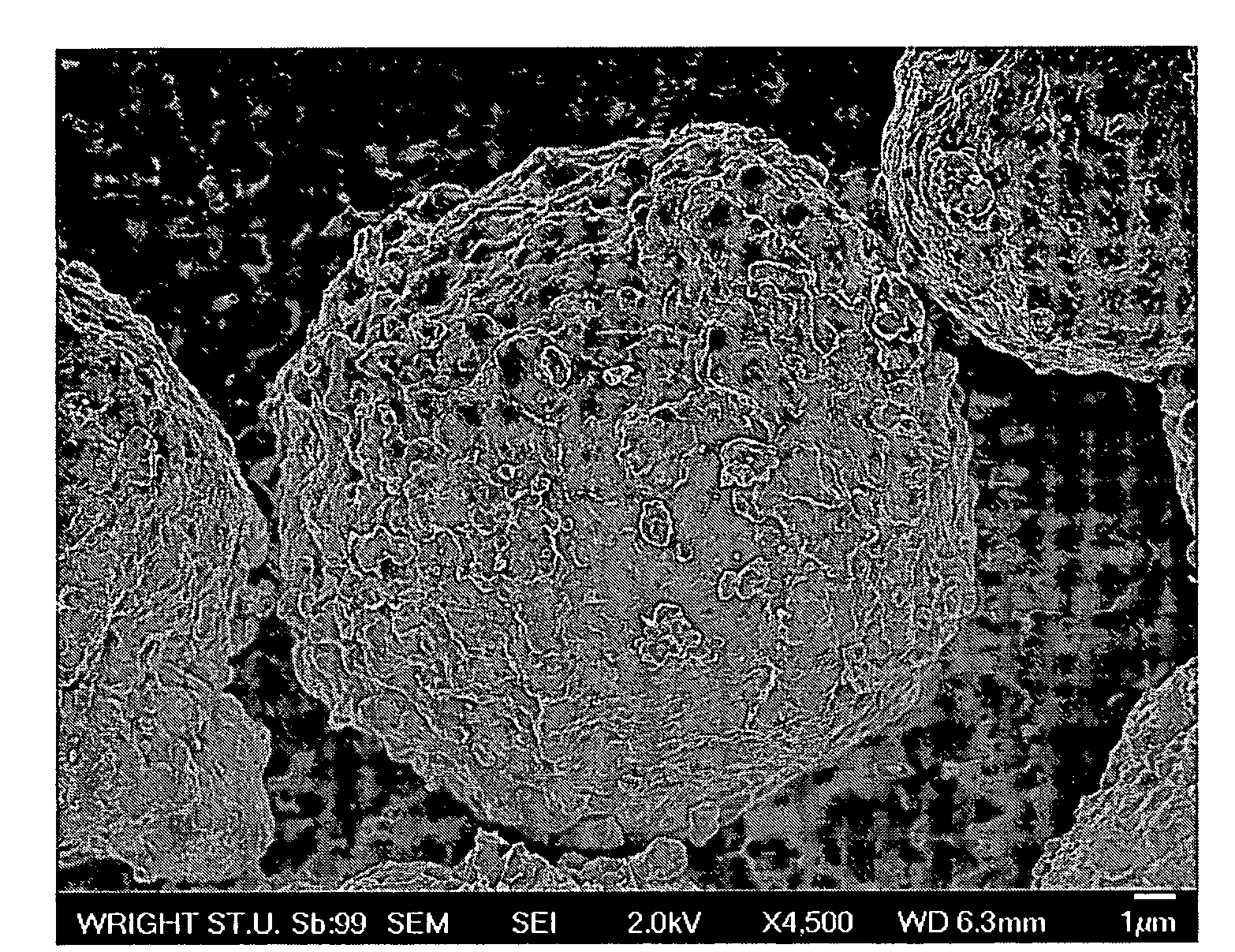

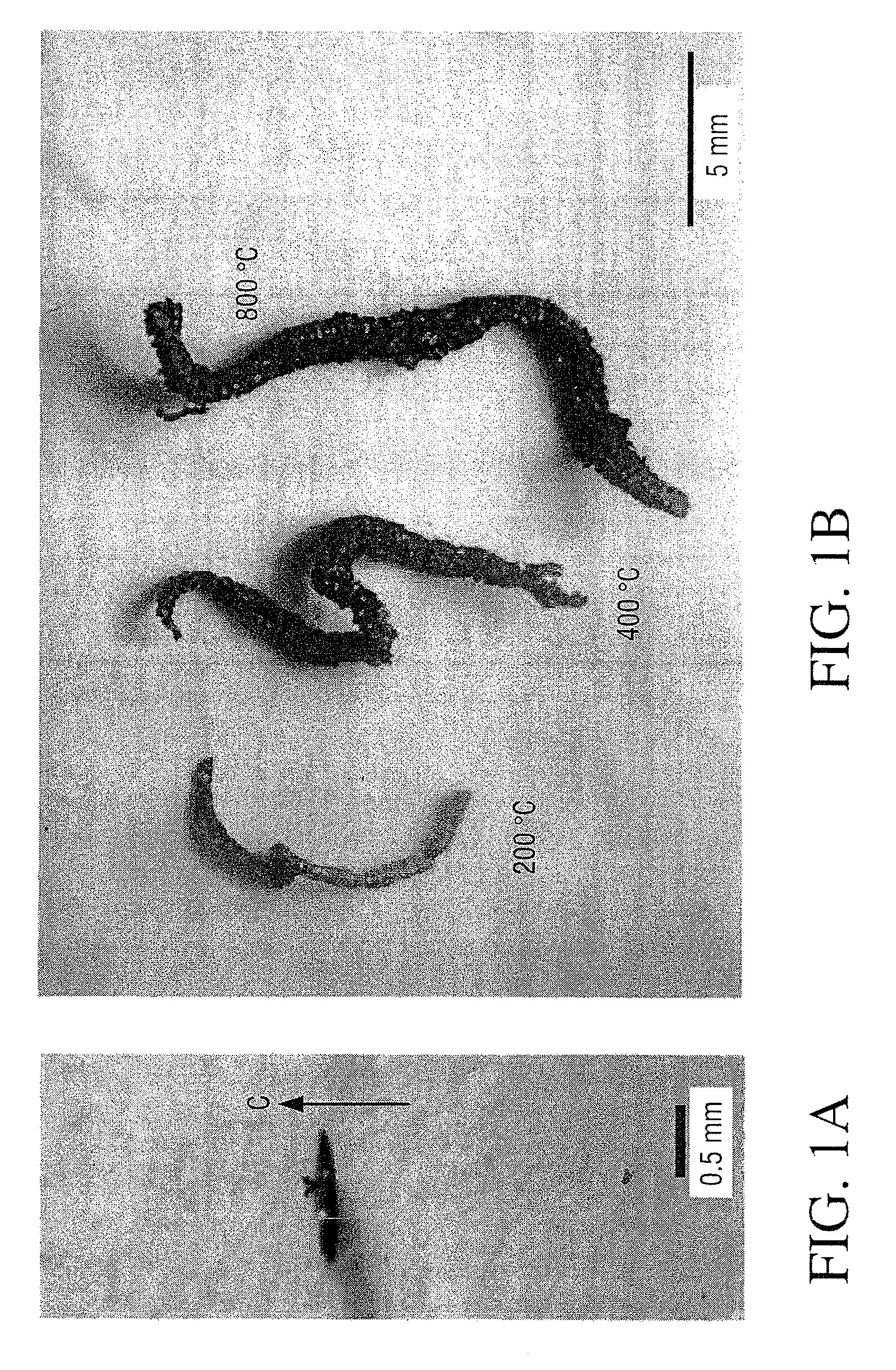

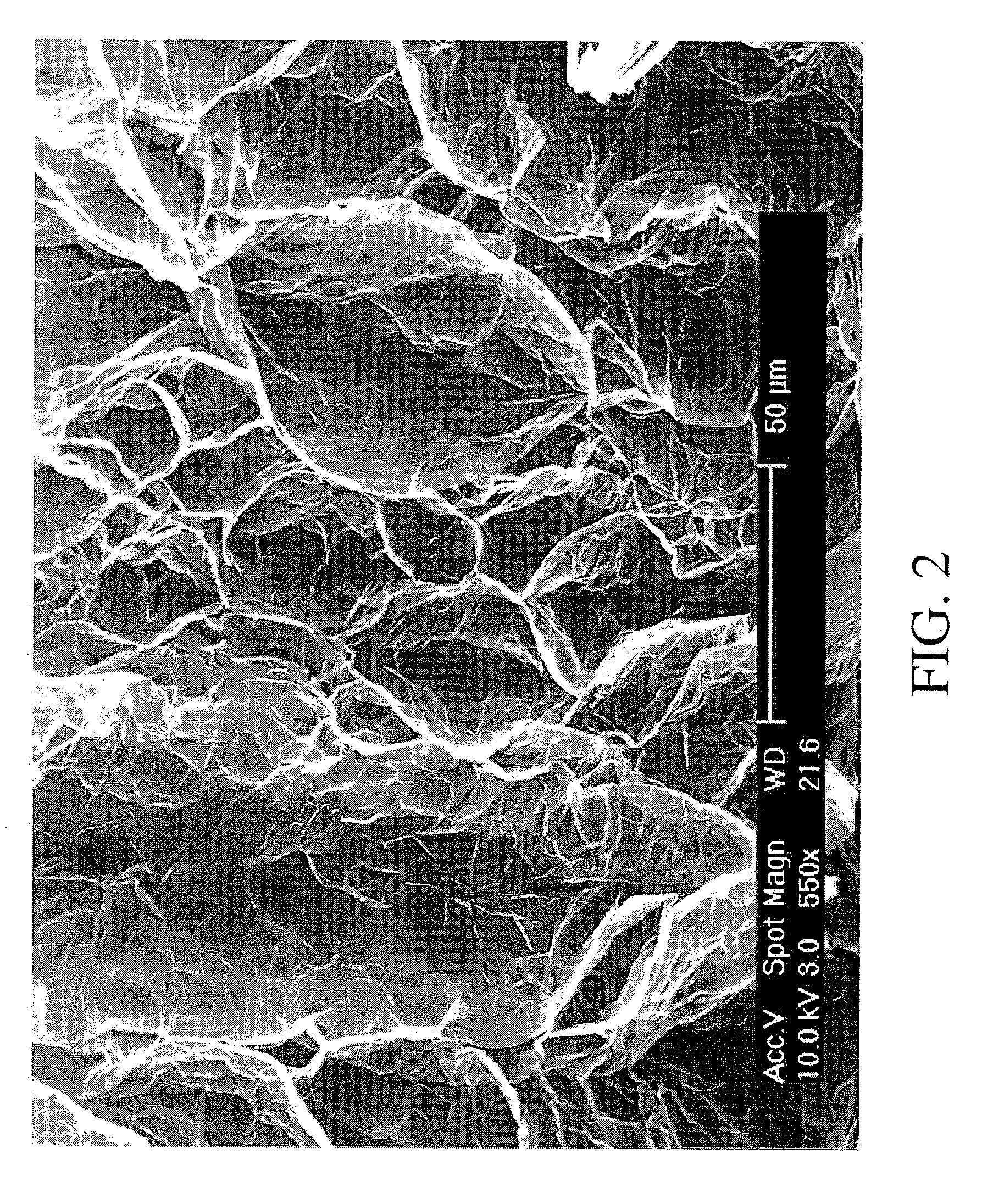

Production of ultra-thin nano-scaled graphene platelets from meso-carbon micro-beads

ActiveUS20090169467A1Improve permeabilityPromote quick completionMaterial nanotechnologyPigmenting treatmentFiberMetallurgy

A method of producing nano-scaled graphene platelets (NGPs) having an average thickness no greater than 50 nm, typically less than 2 nm, and, in many cases, no greater than 1 nm. The method comprises (a) intercalating a supply of meso-carbon microbeads (MCMBs) to produce intercalated MCMBs; and (b) exfoliating the intercalated MCMBs at a temperature and a pressure for a sufficient period of time to produce the desired NGPs. Optionally, the exfoliated product may be subjected to a mechanical shearing treatment, such as air milling, air jet milling, ball milling, pressurized fluid milling, rotating-blade grinding, or ultrasonicating. The NGPs are excellent reinforcement fillers for a range of matrix materials to produce nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

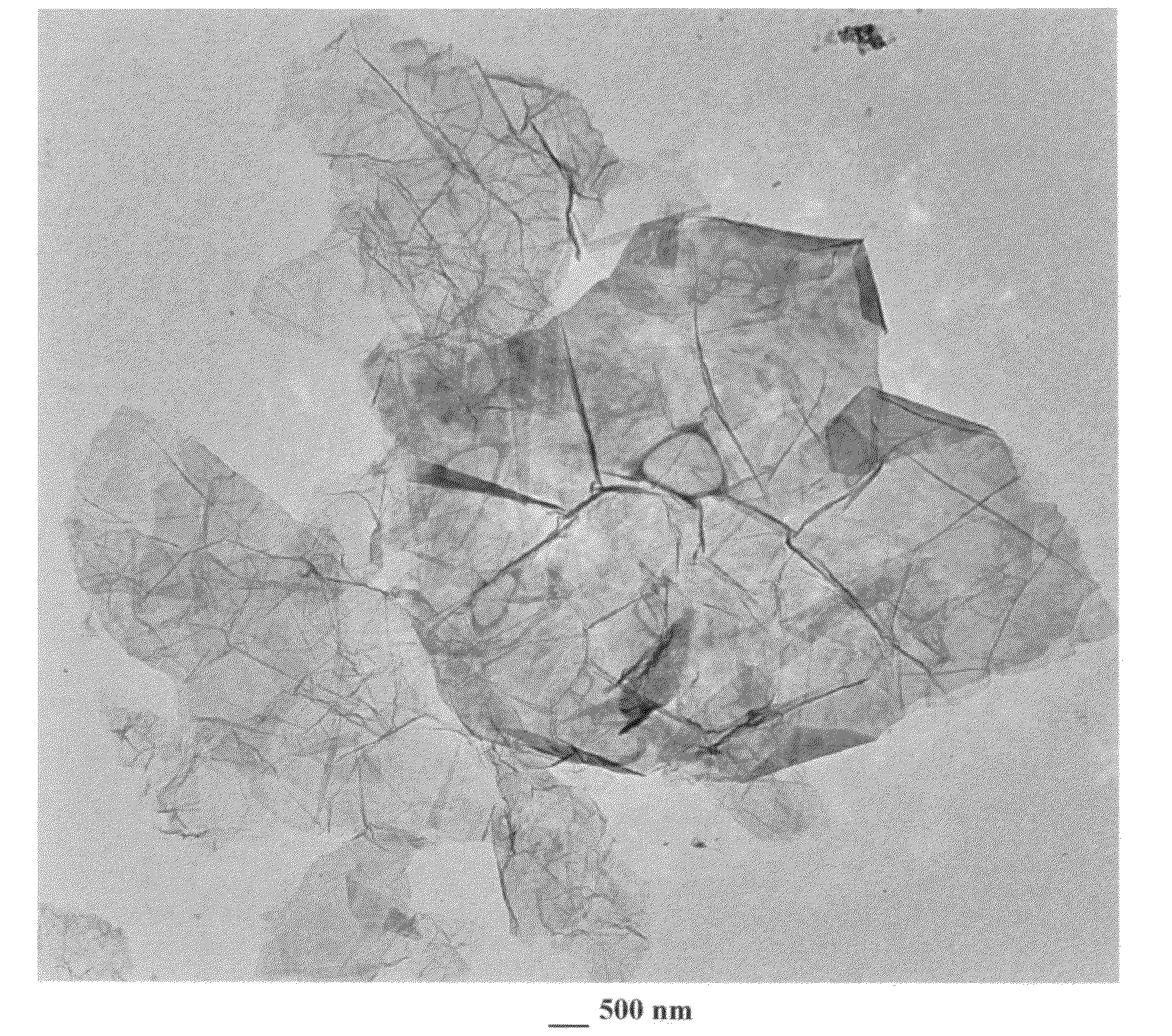

Graphite nanoplatelets for thermal and electrical applications

This disclosure concerns a procedure for bulk scale preparation of high aspect ratio, 2-dimensional nano platelets comprised of a few graphene layers, Gn. n may, for example, vary between about 2 to 10. Use of these nano platelets in applications such as thermal interface materials, advanced composites, and thin film coatings provide material systems with superior mechanical, electrical, optical, thermal, and antifriction characteristics.

Owner:RGT UNIV OF CALIFORNIA

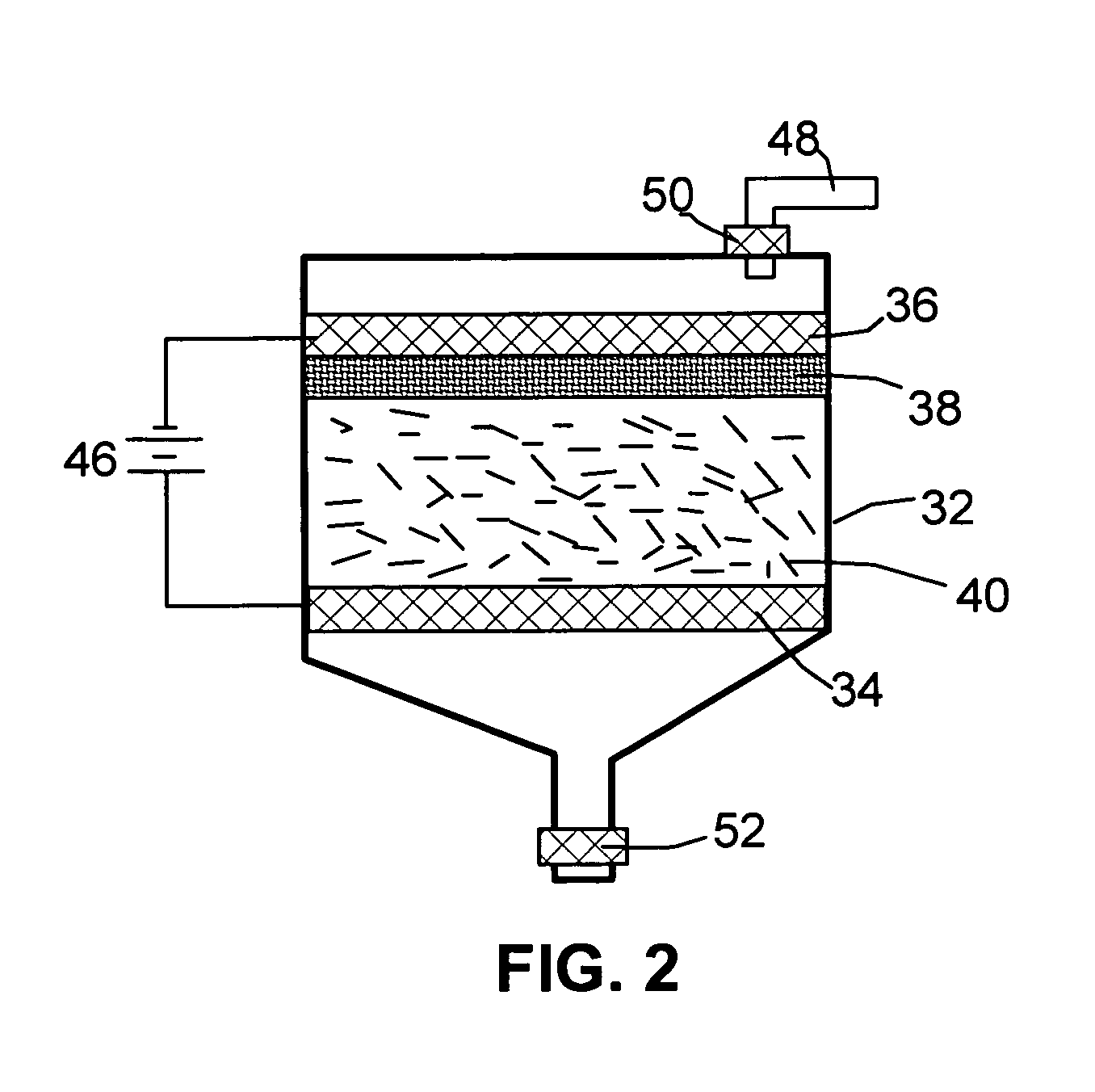

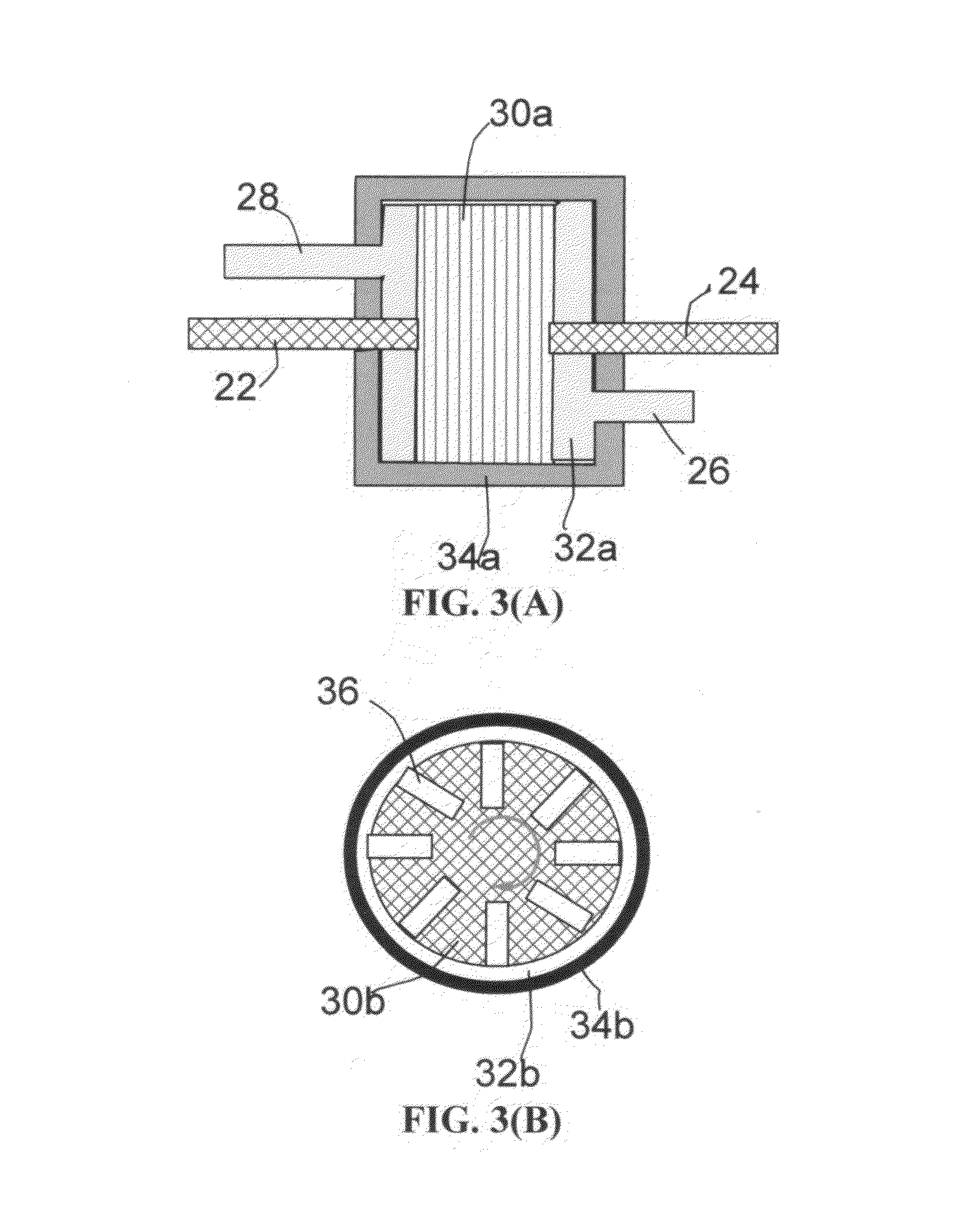

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

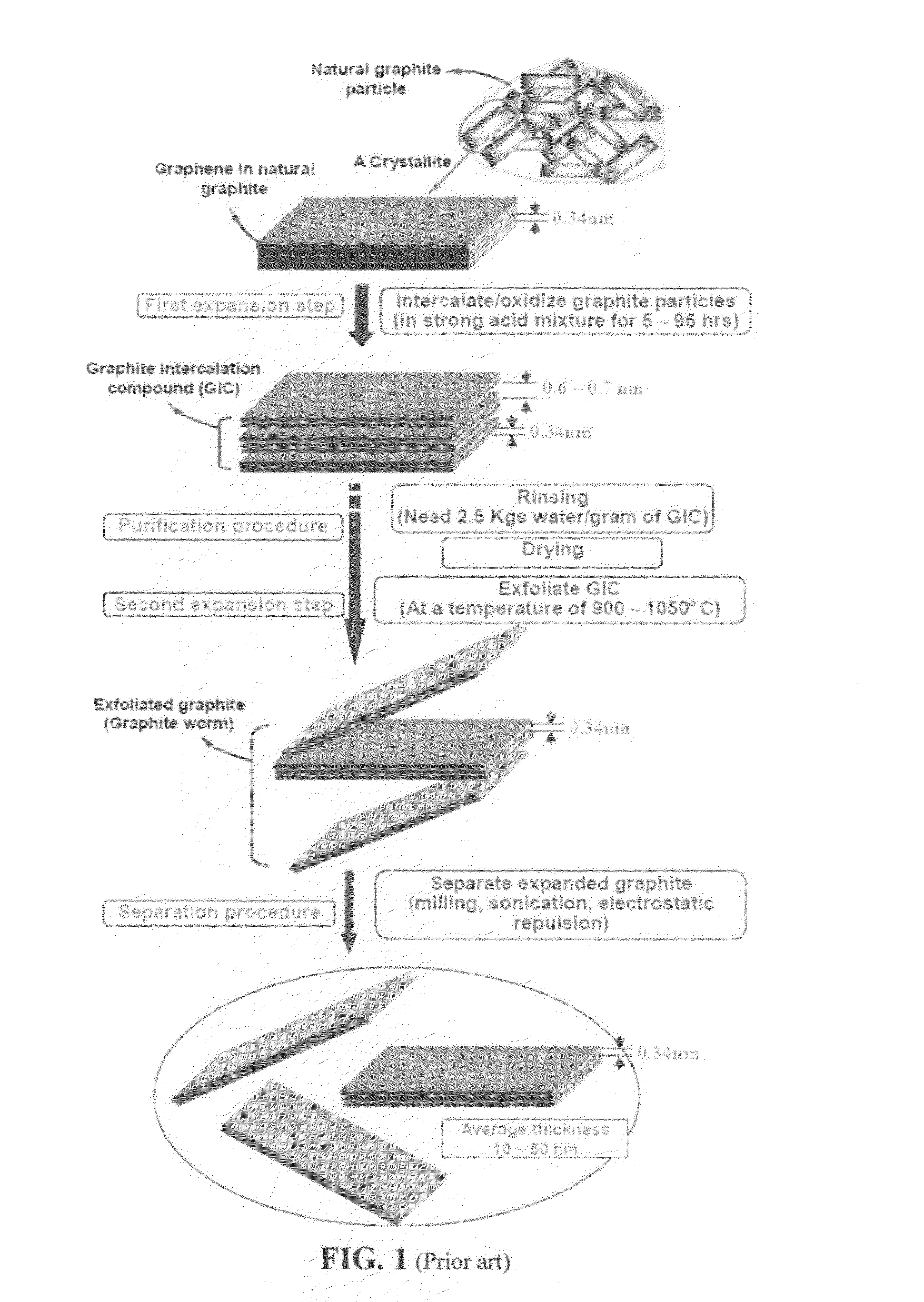

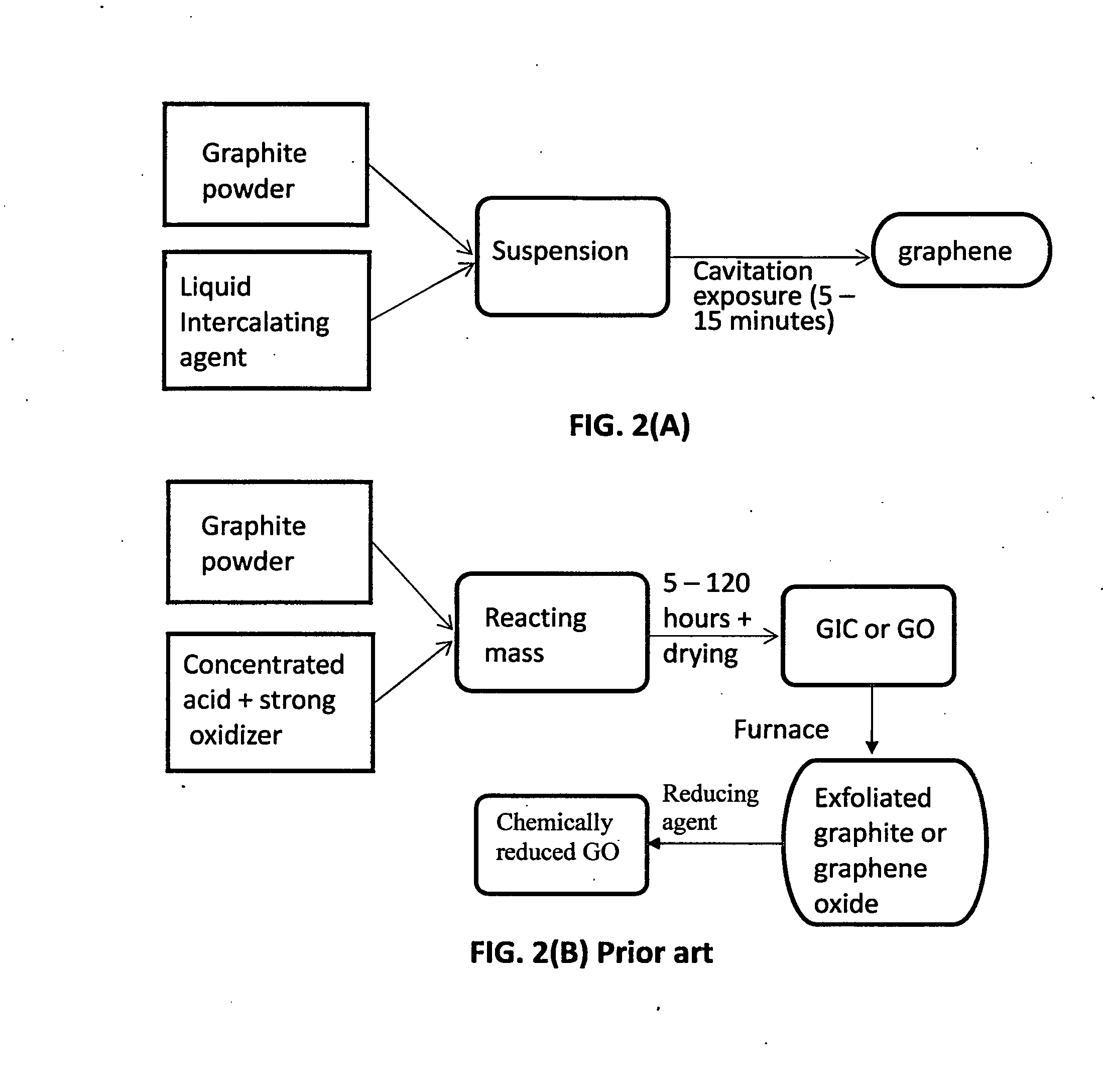

Production of graphene materials in a cavitating fluid

ActiveUS20150239741A1Shorten the timeReduce lossesCarboxylic acid nitrile preparationGraphiteCavitationLiquid medium

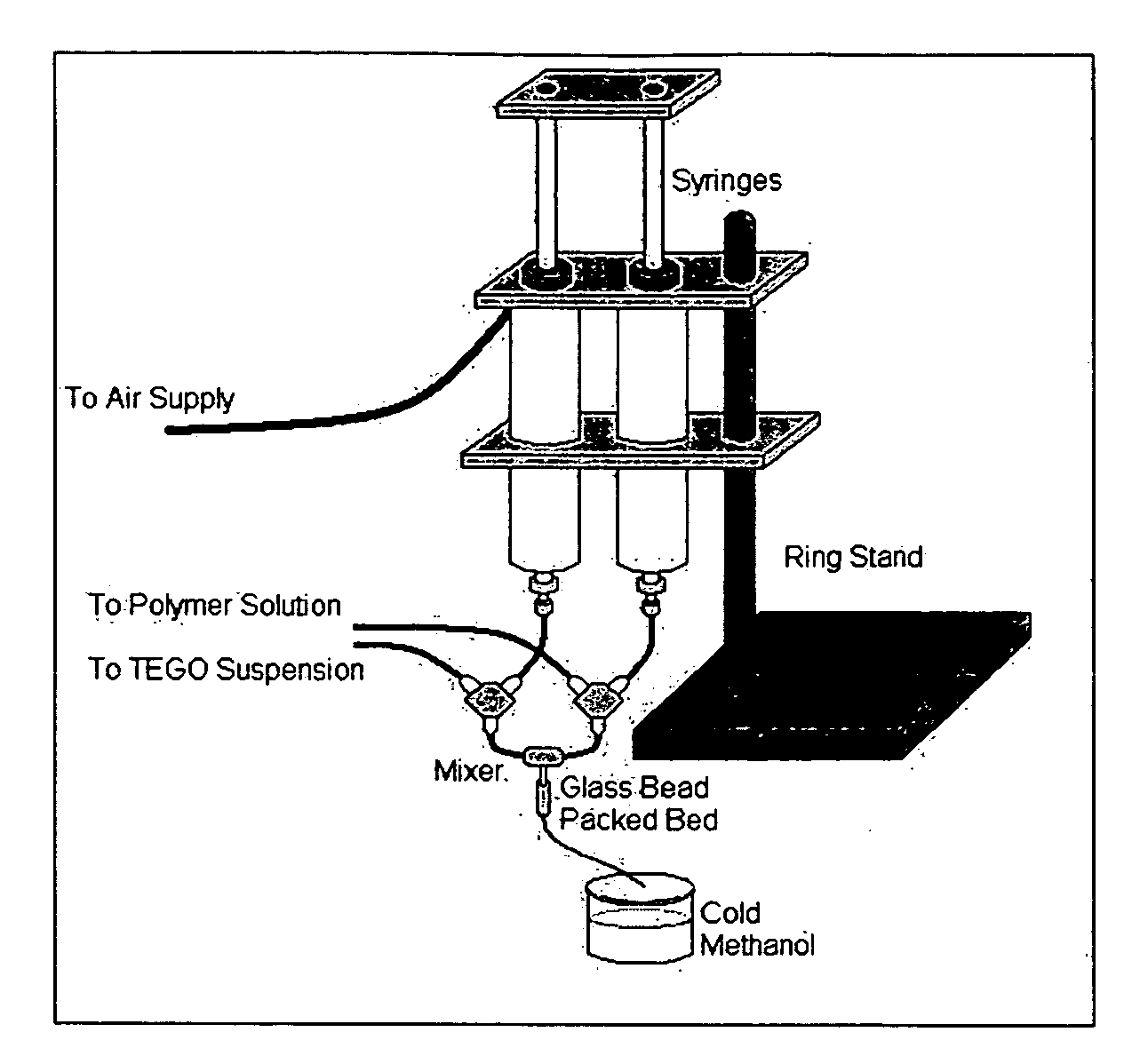

The invention provides a method of producing a graphene material from a starting graphitic material. In an embodiment, the method comprises: (a) dispersing the starting graphitic material in a liquid medium to form a graphite suspension; and (b) introducing the graphite suspension into a hydrodynamic cavitation reactor that generates and collapses cavitation or bubbles in the liquid medium to exfoliate and separate graphene planes from the starting graphitic material for producing the graphene material. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable. The reactor can concurrently perform the functions of graphene production, chemical functionalization, dispersion, and mixing with a polymer to make a composite.

Owner:GLOBAL GRAPHENE GRP INC

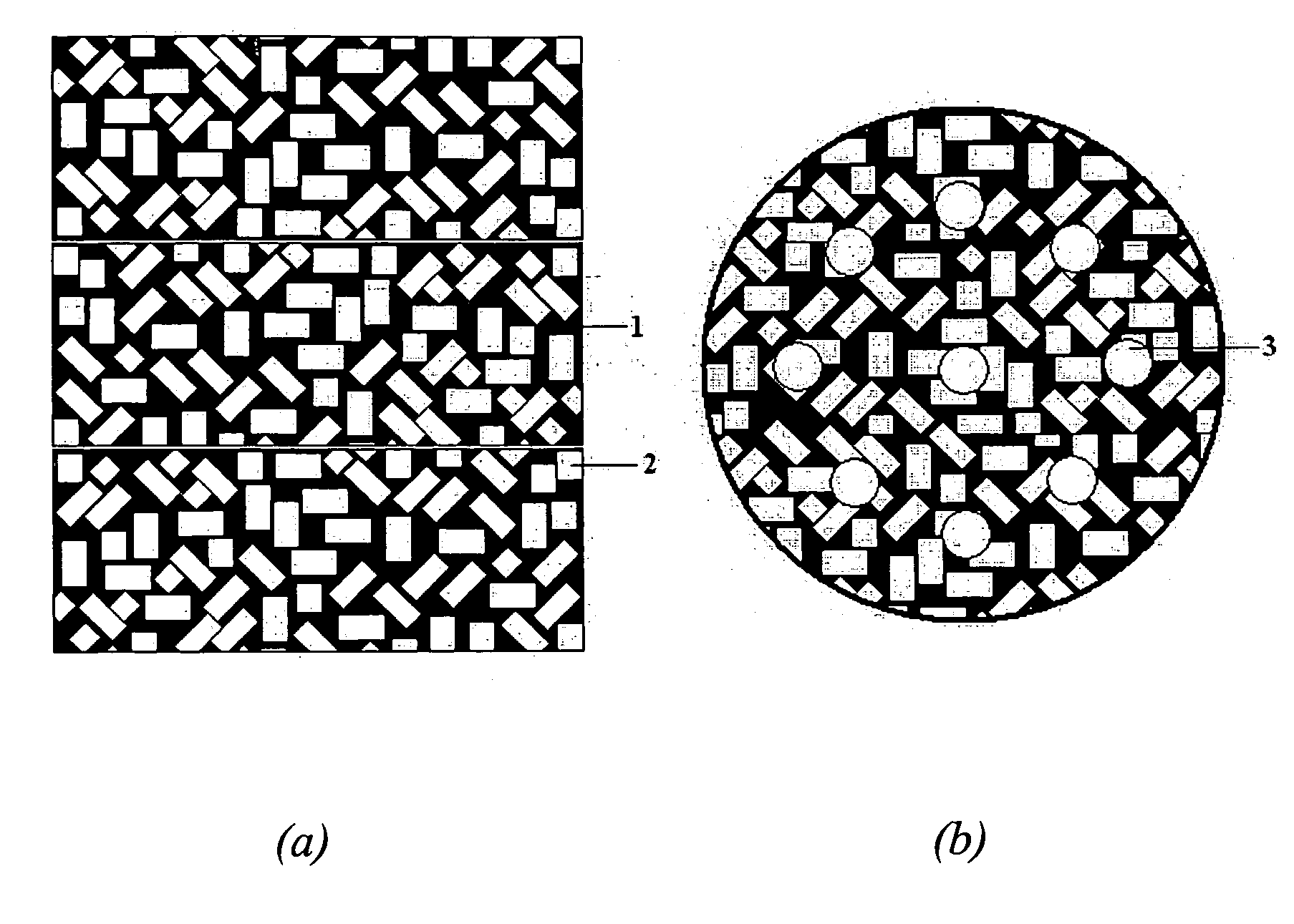

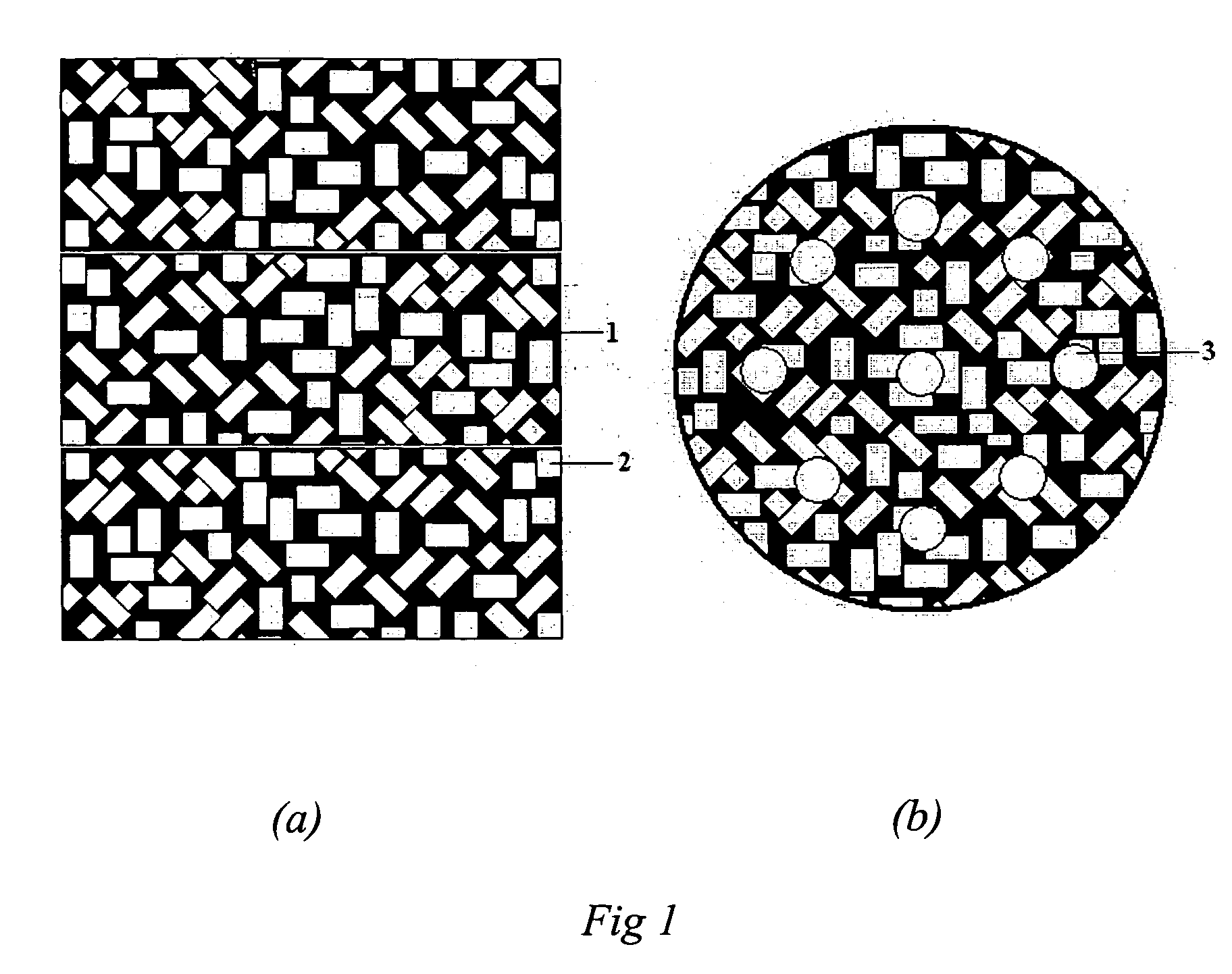

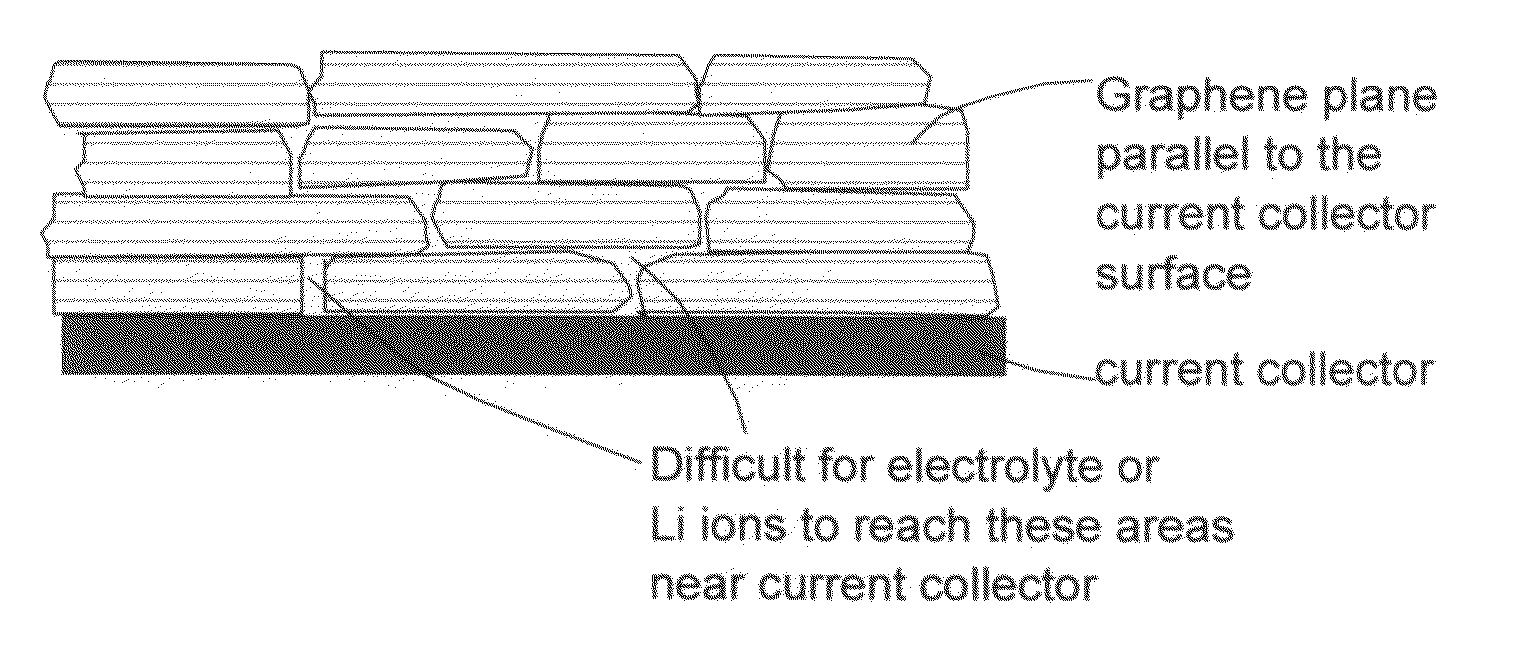

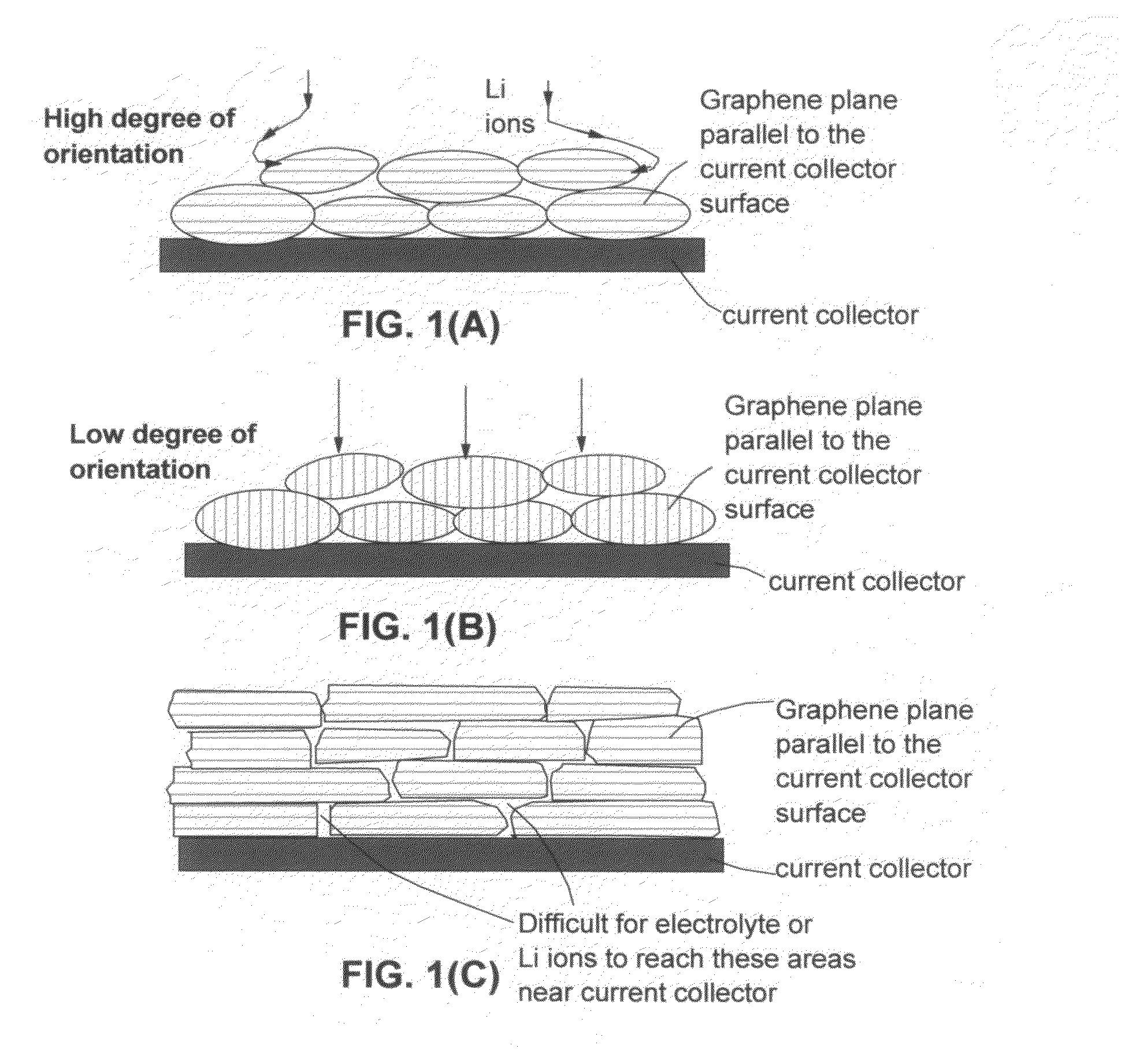

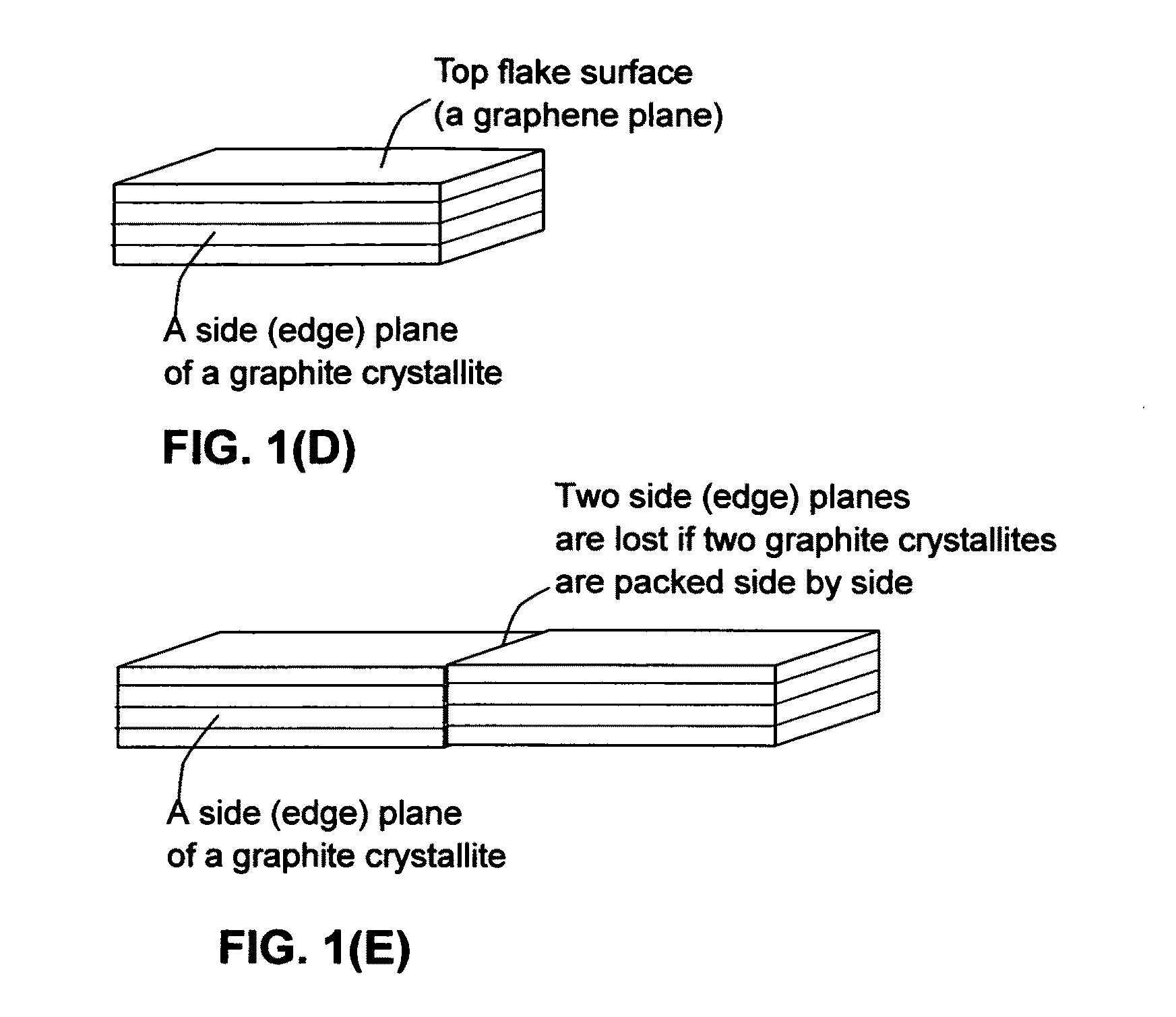

Graphite or carbon particulates for the lithium ion battery anode

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

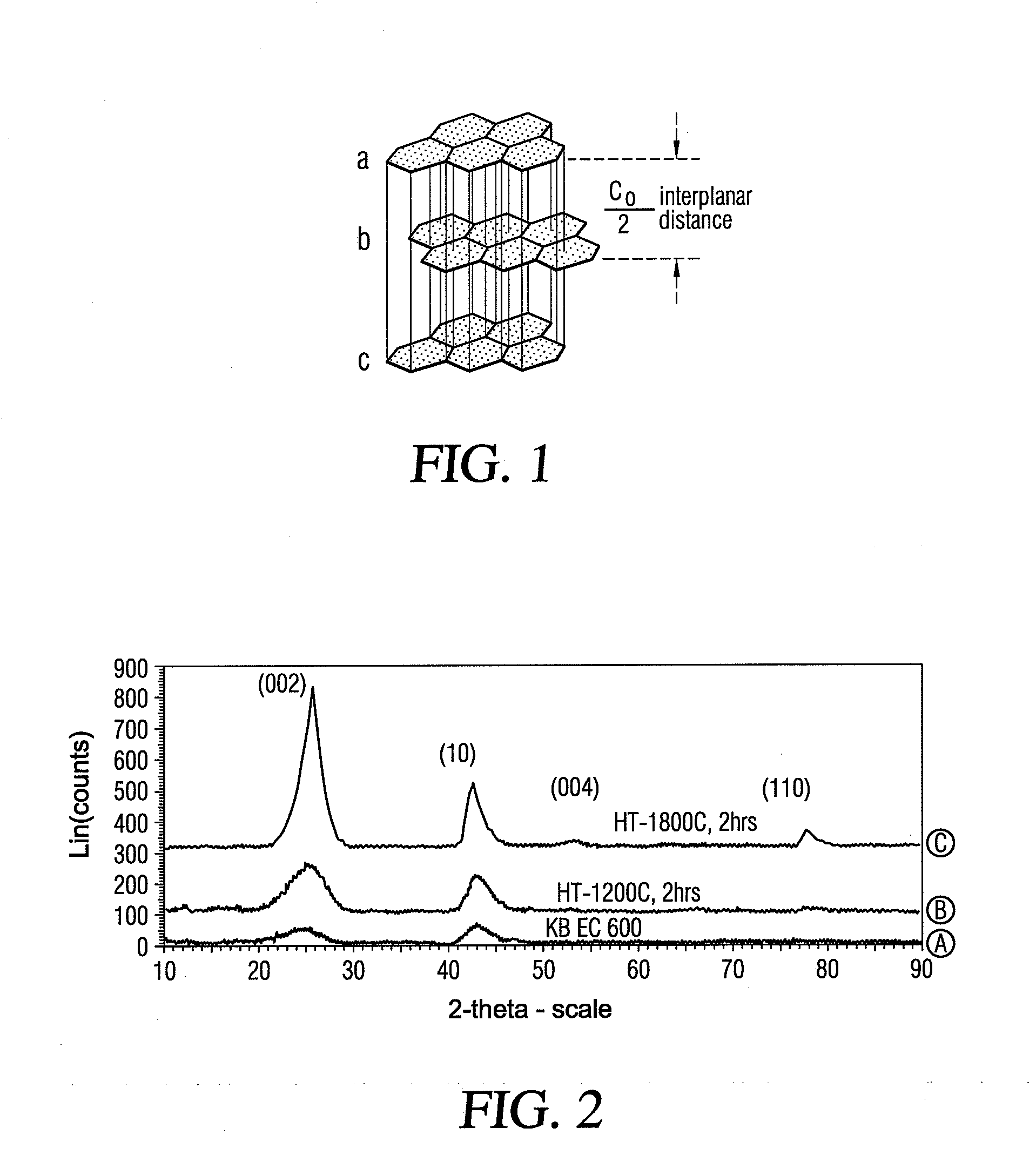

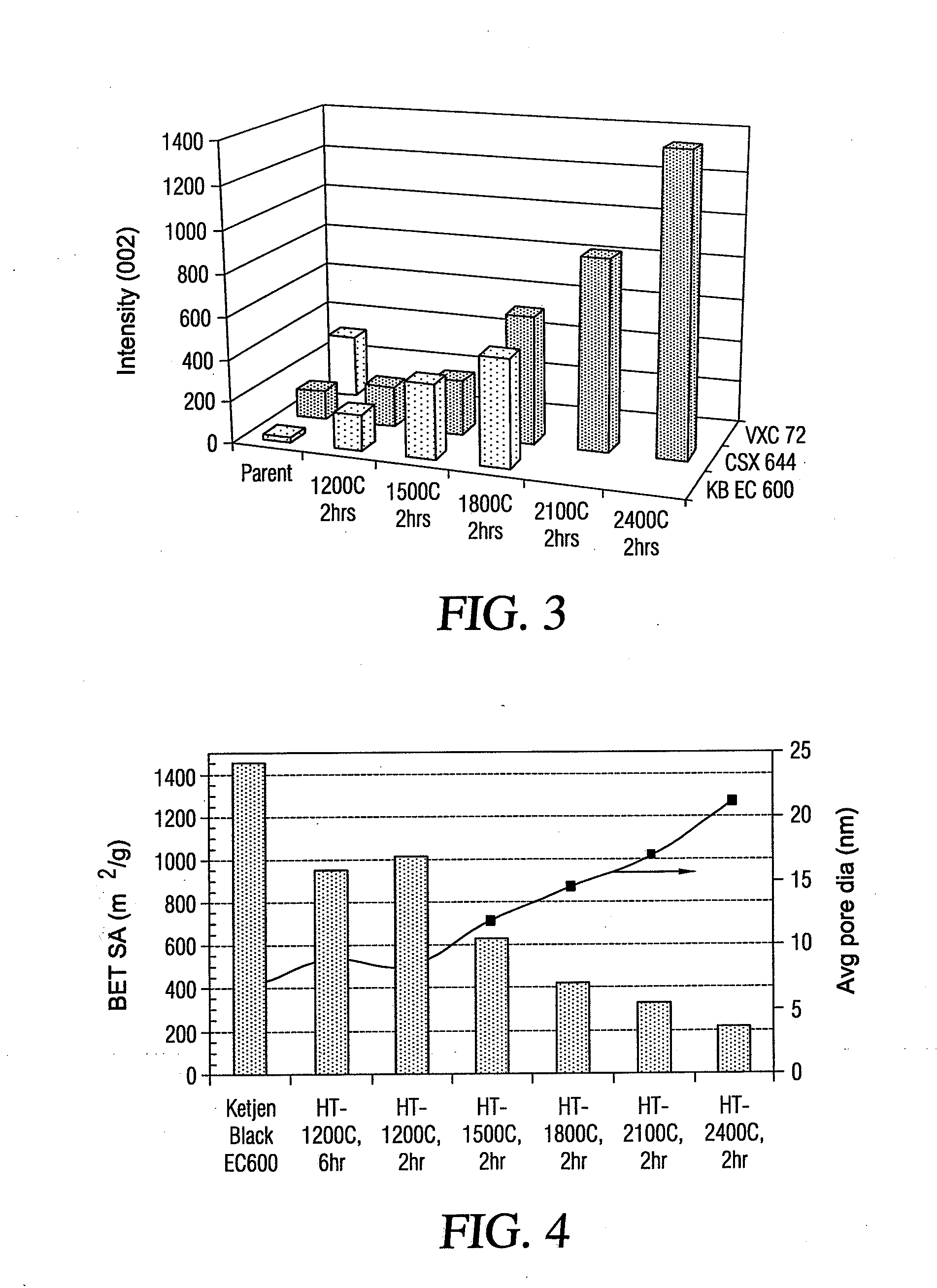

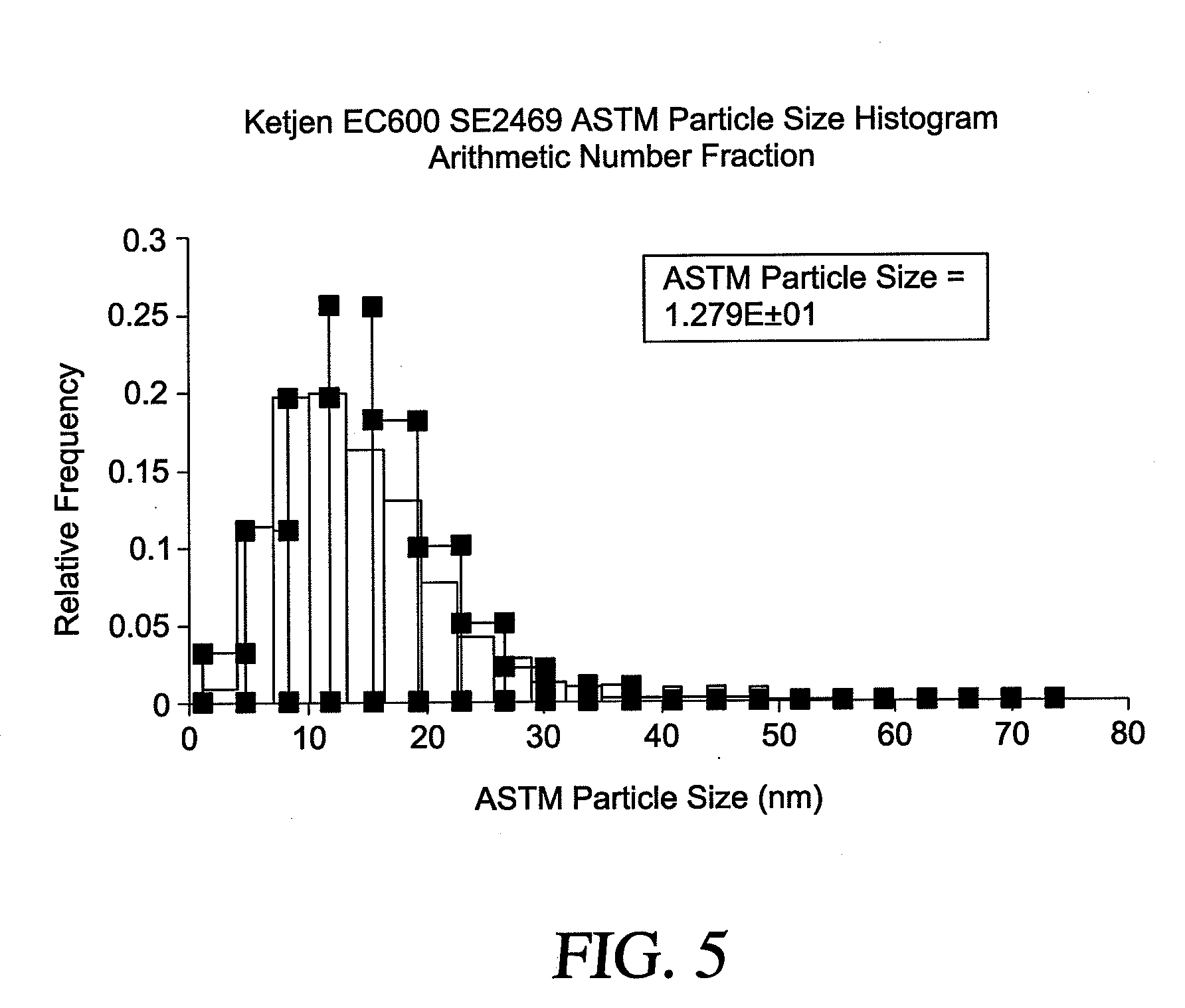

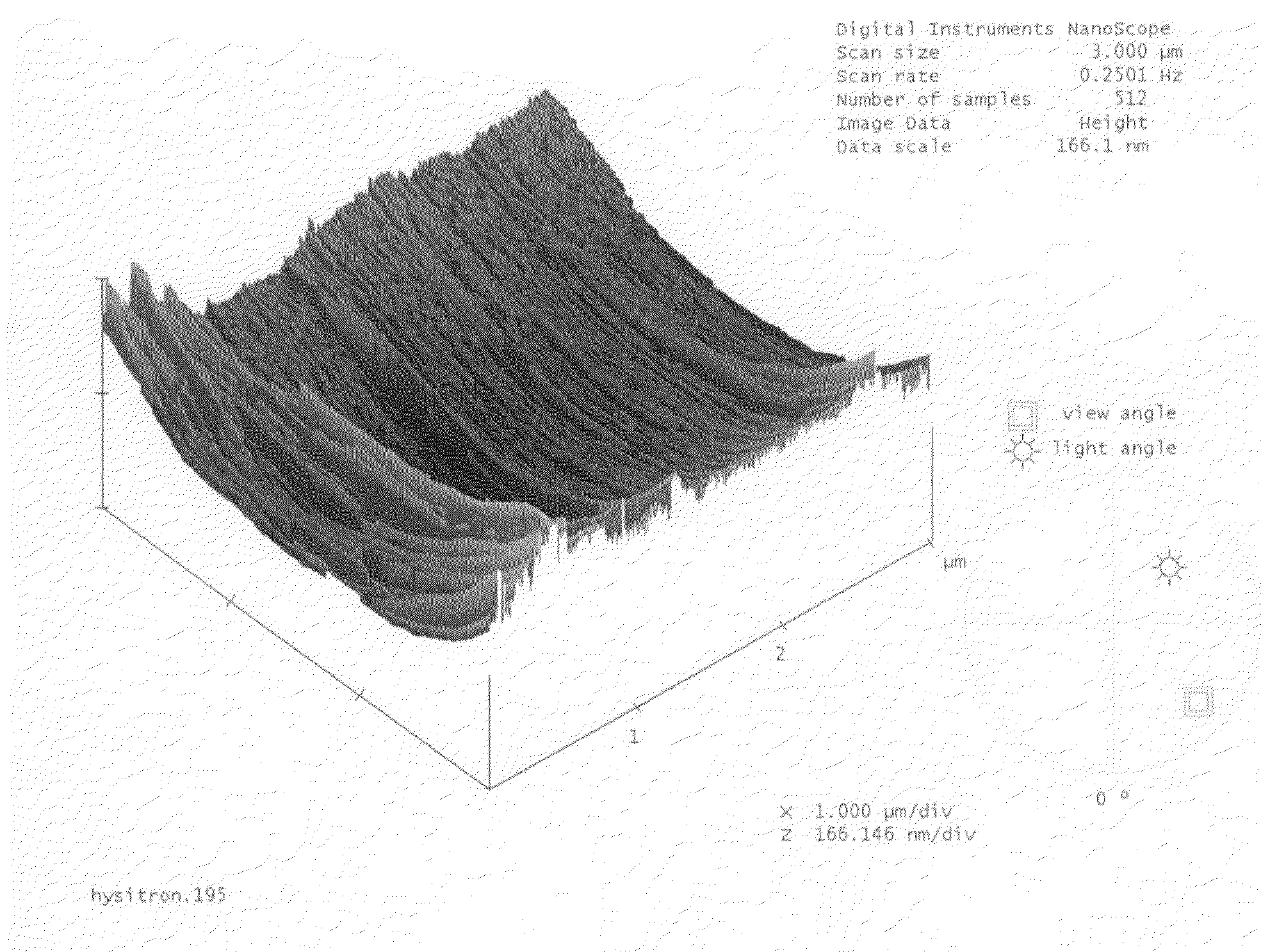

High surface area graphitized carbon and processes for making same

The invention is directed to high surface area graphitized carbon and to processes for making high surface area graphitized carbon. The process includes steps of graphitizing and increasing the surface area of (in either order) a starting carbon material to form high surface area graphitized carbon. The step of increasing the surface area optionally comprises an oxidizing step (e.g., through steam etching) or template removal from composite particles. The invention is also directed to catalyst particles and electrodes employing catalyst particles that are formed from the high surface area graphitized carbon.

Owner:CABOT CORP

Low-temperature method of producing nano-scaled graphene platelets and their nanocomposites

A method of exfoliating a layered material to produce separated nano-scaled platelets having a thickness smaller than 100 nm. The method comprises: (a) providing a graphite intercalation compound comprising a layered graphite containing expandable species residing in an interlayer space of the layered graphite; (b) exposing the graphite intercalation compound to an exfoliation temperature lower than 650° C. for a duration of time sufficient to at least partially exfoliate the layered graphite without incurring a significant level of oxidation; and (c) subjecting the at least partially exfoliated graphite to a mechanical shearing treatment to produce separated platelets. The method can further include a step of dispersing the platelets in a polymer or monomer solution or suspension as a precursor step to nanocomposite fabrication.

Owner:GLOBAL GRAPHENE GRP INC

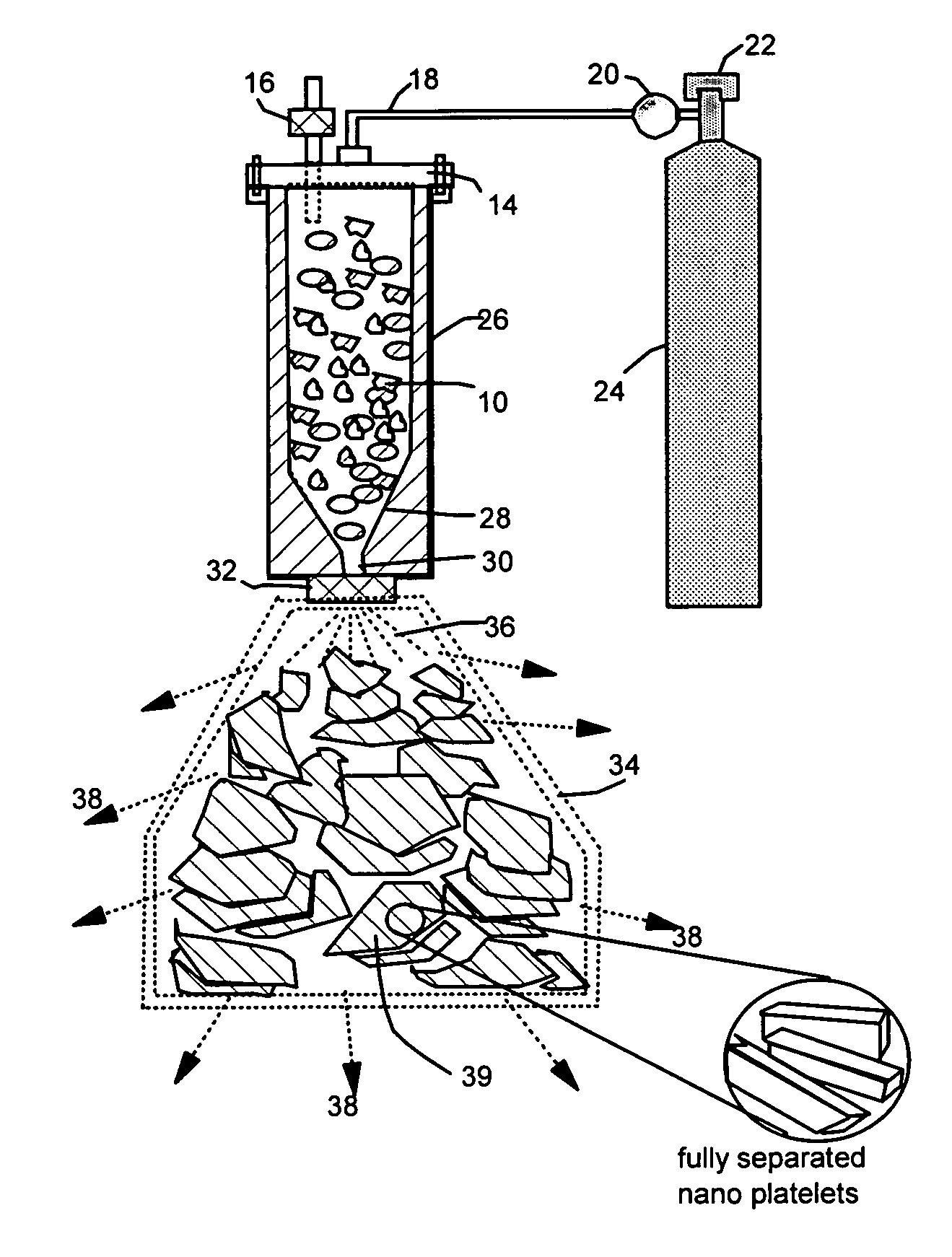

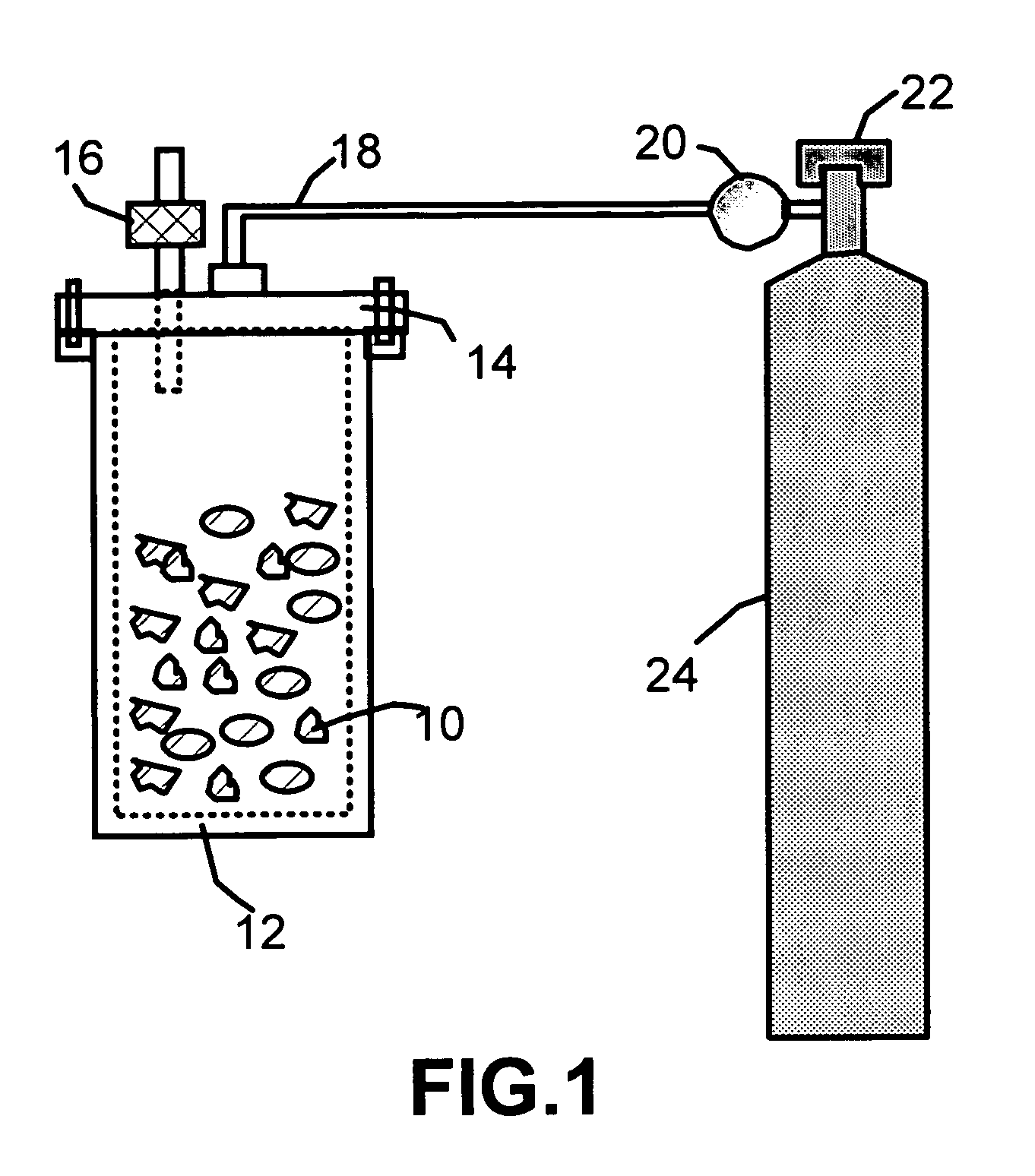

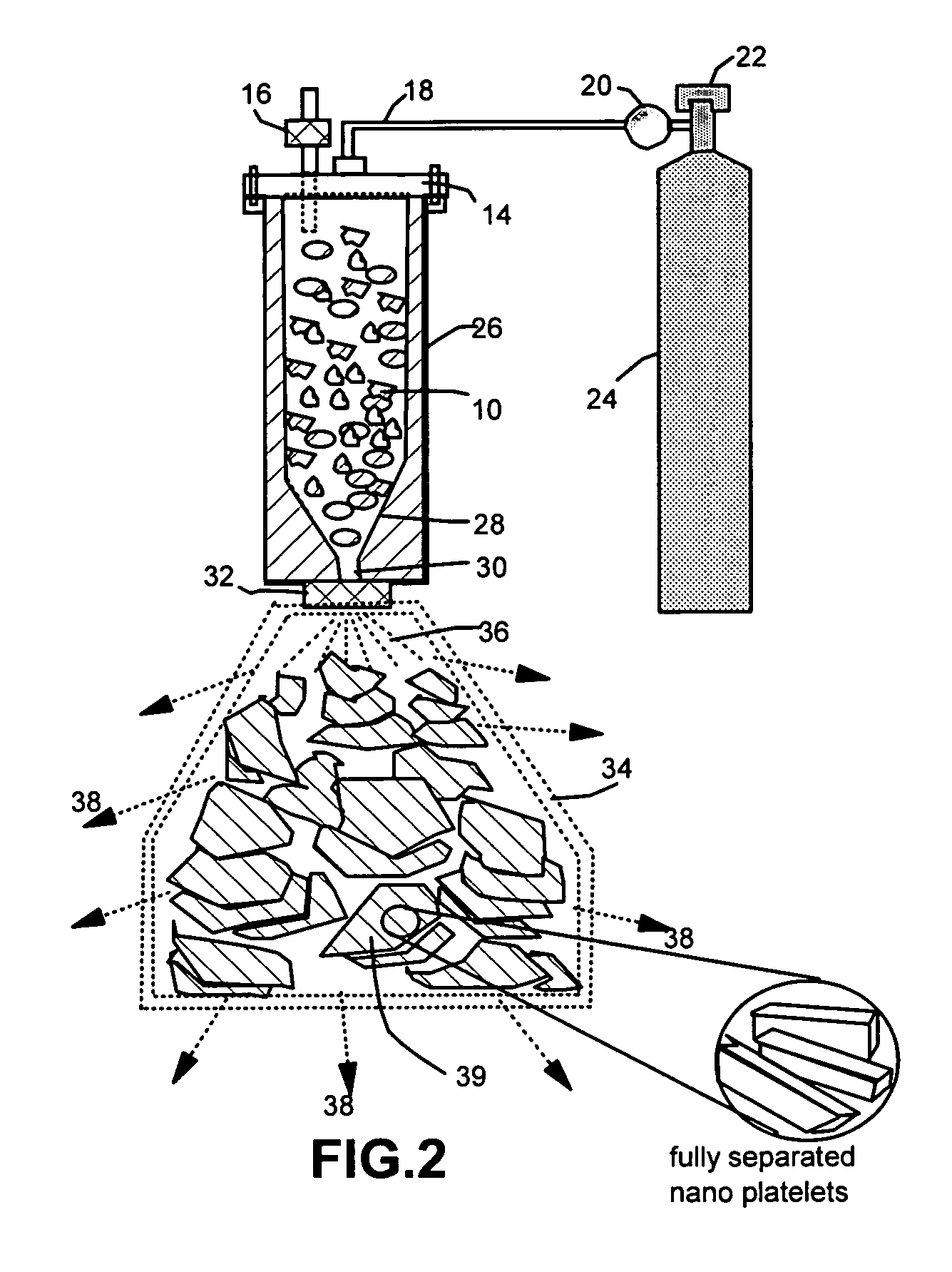

Mass production of nano-scaled platelets and products

ActiveUS7785492B1Reduce necessary intercalation timeSmall thicknessMaterial nanotechnologyGraphiteNoble gasGraphite

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) charging a layered material to an intercalation chamber comprising a gaseous environment at a first temperature and a first pressure sufficient to cause gas species to penetrate into the interstitial space between layers of the layered material, forming a gas-intercalated layered material; and (b) operating a discharge valve to rapidly eject the gas-intercalated layered material through a nozzle into an exfoliation zone at a second pressure and a second temperature, allowing gas species residing in the interstitial space to exfoliate the layered material to produce the platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can additionally include dispersing the platelets in a matrix material to form a nanocomposite. The process also can include an additional process of re-compressing the nana-scaled platelets into a product such as a flexible graphite sheet.

Owner:GLOBAL GRAPHENE GRP INC

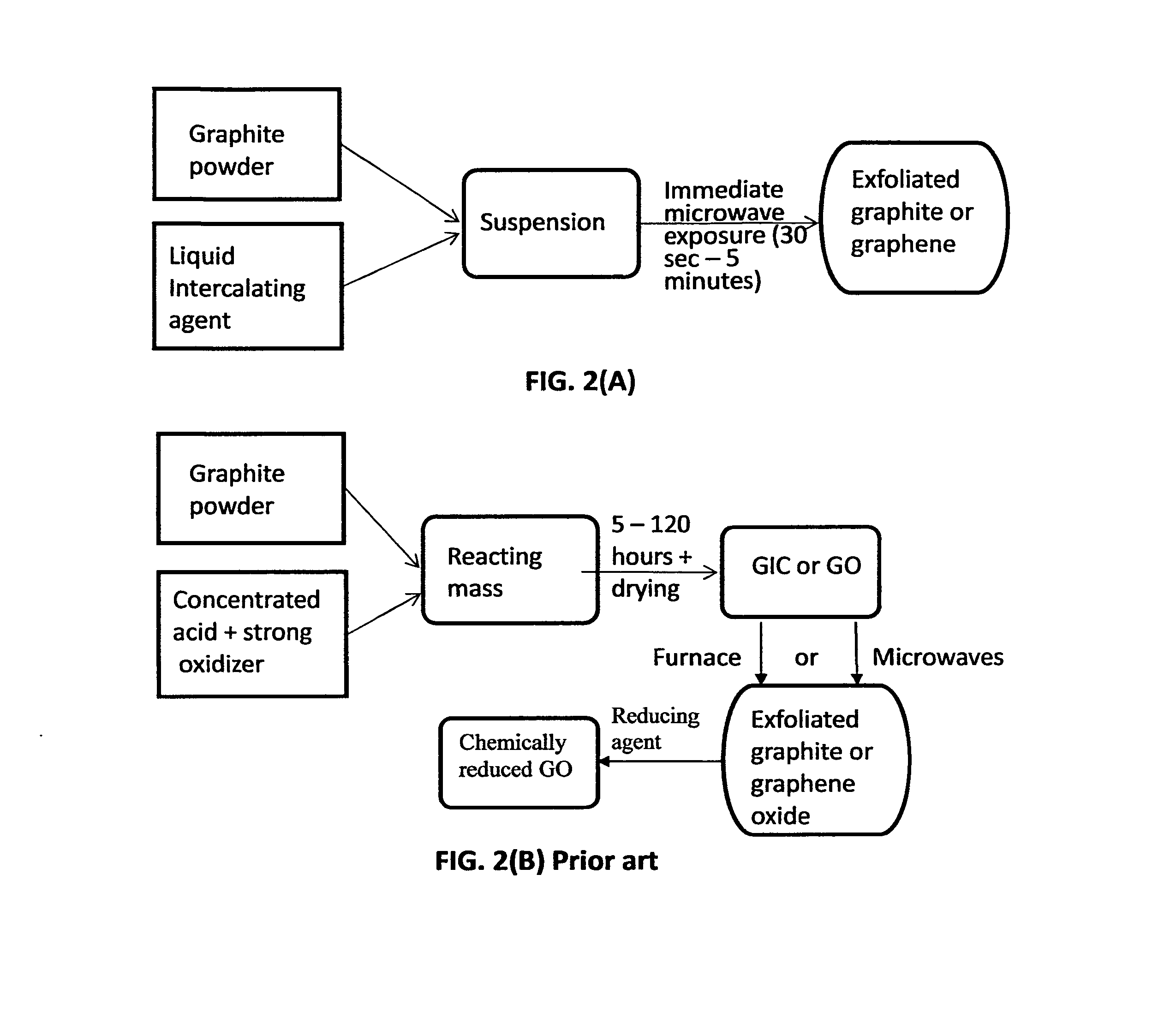

One-step production of graphene materials

InactiveUS20130087446A1Simple and short processSimply replace furnace heatingMaterial nanotechnologyGraphiteMicrowaveGraphite

A method of producing exfoliated graphite or graphene from a graphitic or carbonaceous material. The method includes: (a) dispersing a graphitic material in a liquid intercalating agent to form a suspension; and (b) subjecting the suspension to microwave or radio frequency irradiation for a length of time sufficient for producing the exfoliated graphite or graphene. In one preferred embodiment, the intercalating agent is an acid or an oxidizer, or a combination of both. The method enables production of more electrically conducting graphene sheets directly from a graphitic material without going through the chemical intercalation or oxidation procedure. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable.

Owner:GLOBAL GRAPHENE GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com