Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2135 results about "Platelet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Platelets, also called thrombocytes (from Greek θρόμβος, "clot" and κύτος, "cell"), are a component of blood whose function (along with the coagulation factors) is to react to bleeding from blood vessel injury by clumping, thereby initiating a blood clot. Platelets have no cell nucleus: they are fragments of cytoplasm that are derived from the megakaryocytes of the bone marrow, and then enter the circulation. Circulating unactivated platelets are biconvex discoid (lens-shaped) structures, 2–3 µm in greatest diameter. Activated platelets have cell membrane projections covering their surface. Platelets are found only in mammals, whereas in other animals (e.g. birds, amphibians) thrombocytes circulate as intact mononuclear cells.

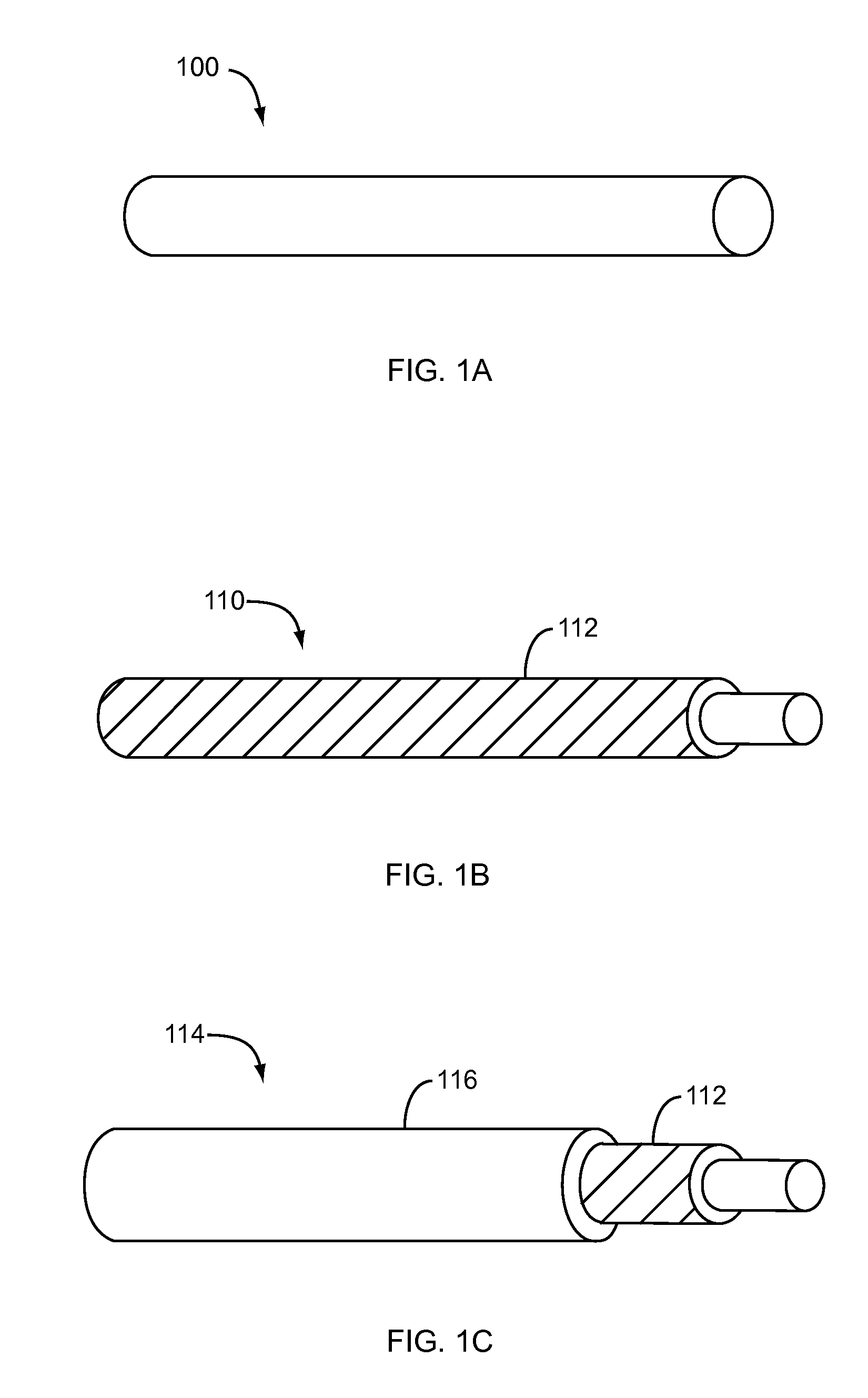

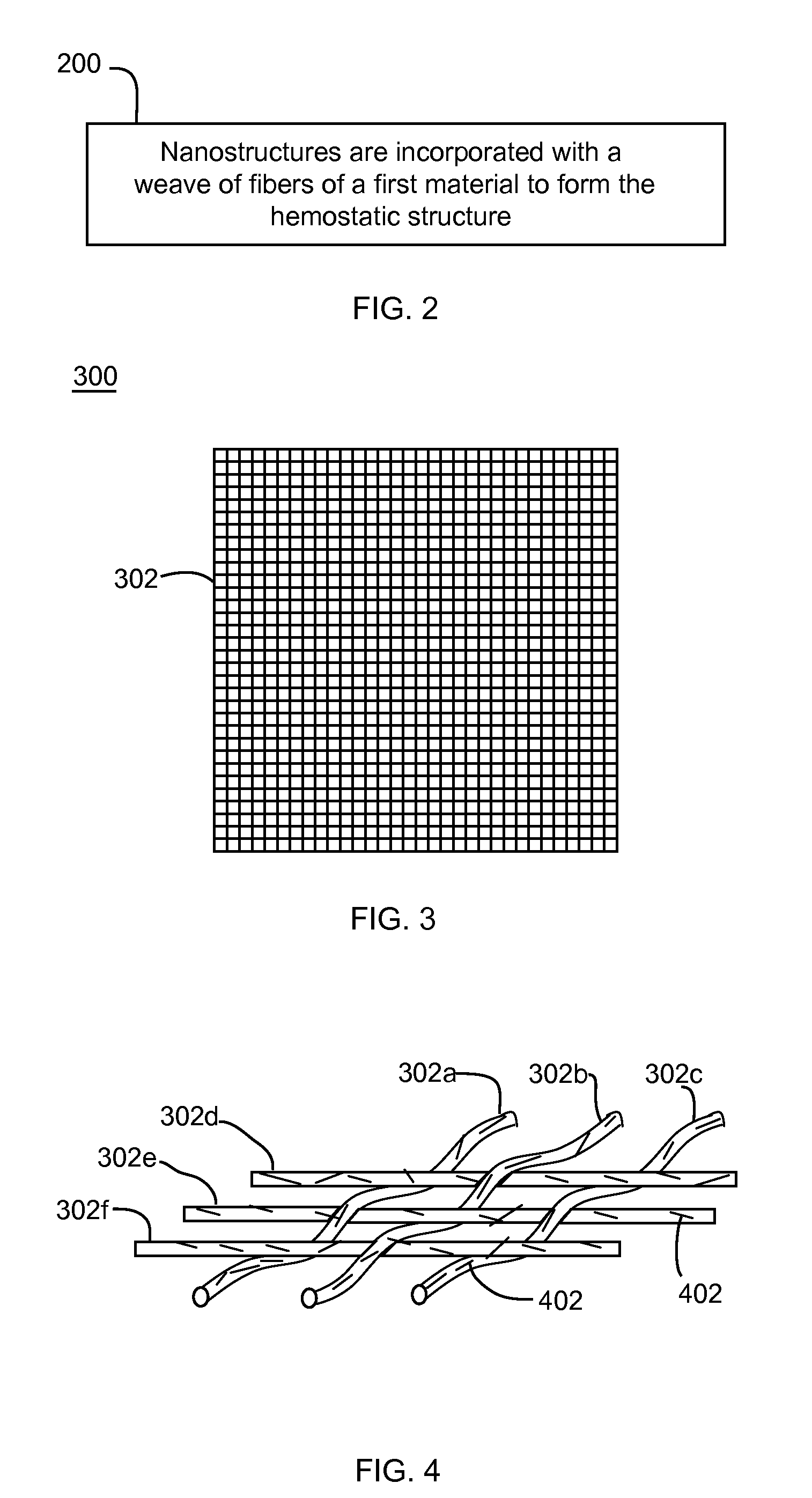

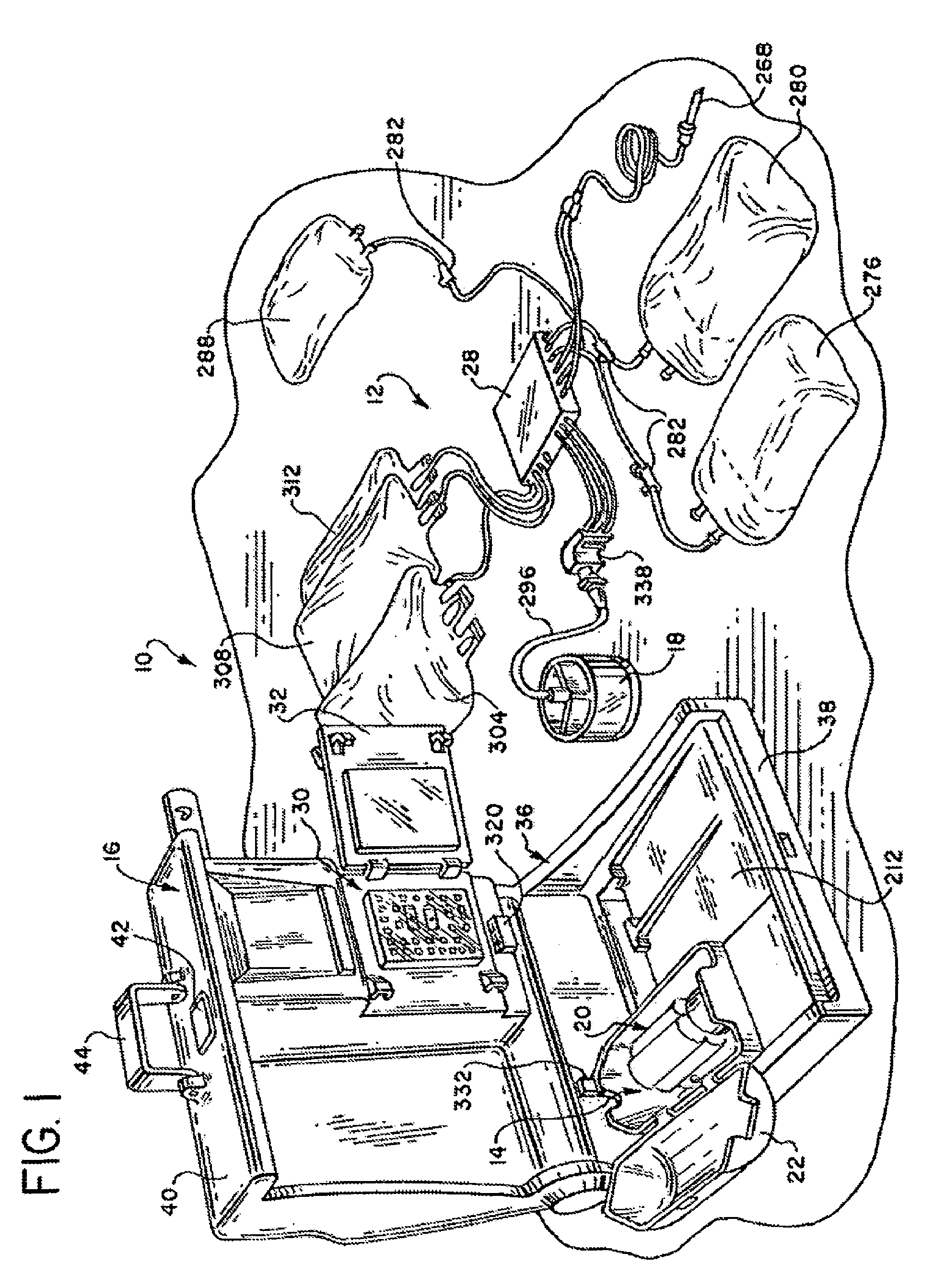

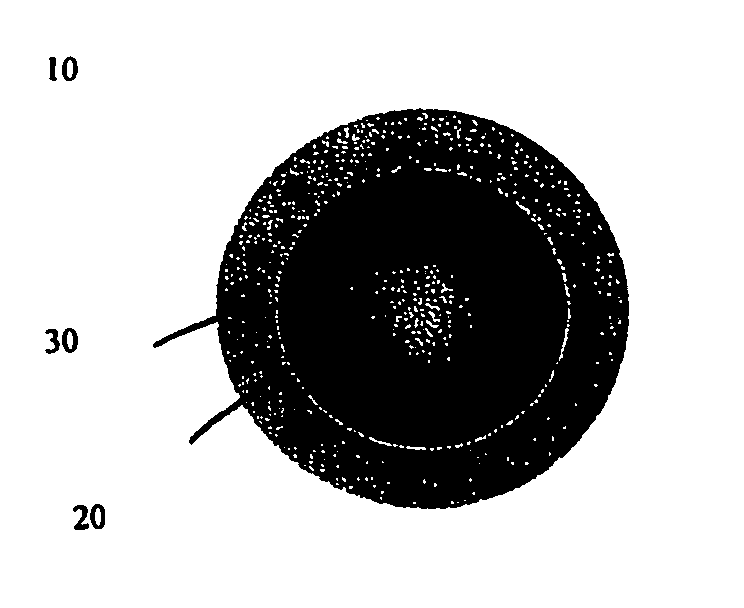

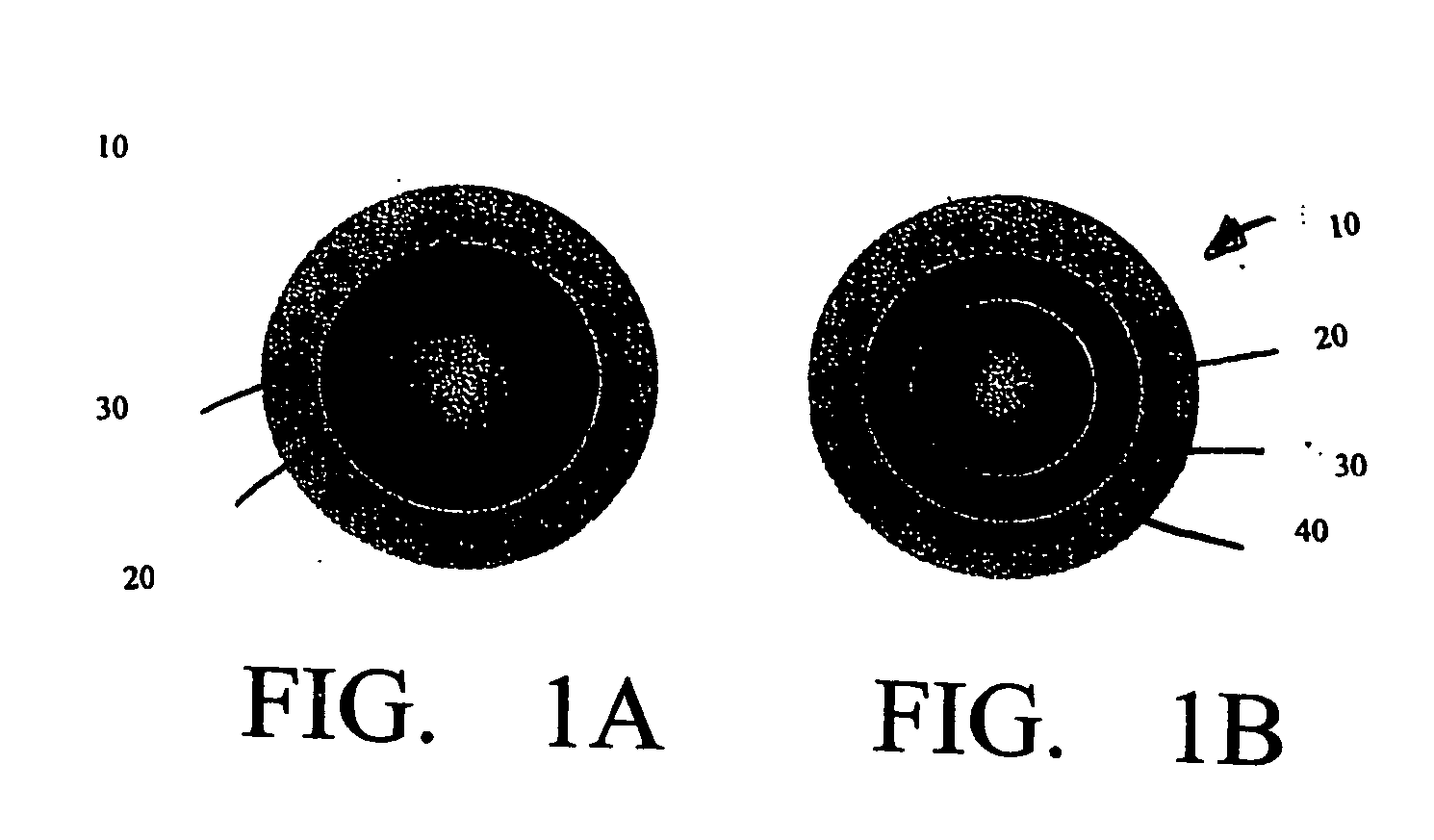

Nanostructure-enhanced platelet binding and hemostatic structures

InactiveUS8319002B2Enhancing overall rate and strengthInduce platelet binding and efficient hemostasisBiocideSurgical adhesivesPlateletNanofiber

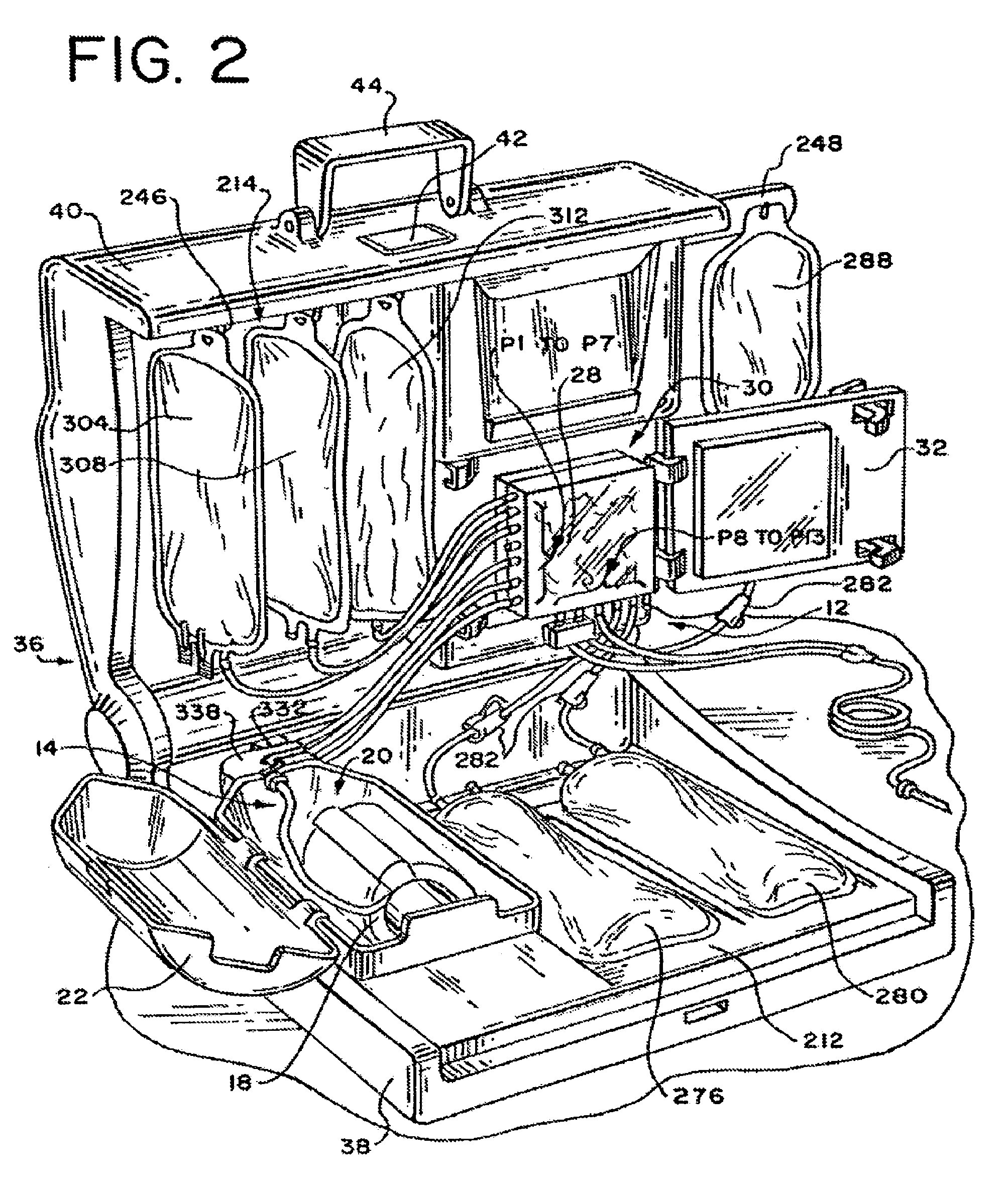

Methods, systems, and apparatuses for nanomaterial-enhanced platelet binding and hemostatic medical devices are provided. Hemostatic materials and structures are provided that induce platelet binding, including platelet binding and the coagulation of blood at a wound / opening caused by trauma, a surgical procedure, ulceration, or other cause. Example embodiments include platelet binding devices, hemostatic bandages, hemostatic plugs, and hemostatic formulations. The hemostatic materials and structures may incorporate nanostructures and / or further hemostatic elements such as polymers, silicon nanofibers, silicon dioxide nanofibers, and / or glass beads into a highly absorbent, gelling scaffold. The hemostatic materials and structures may be resorbable.

Owner:NANOSYS INC

Particulate acellular tissue matrix

A method of processing an acellular tissue matrix to give a particulate acellular tissue matrix includes: cutting sheets of dry acellular tissue matrix into strips; cryofracturing the dry acellular tissue matrix strips at cryogenic temperatures; separating the resulting particles by size at cryogenic temperatures; and freeze drying the fraction of particles desired size to remove any moisture that may have been absorbed to give a dry particulate acellular tissue matrix. Rehydration of the dry particulate acellular tissue matrix may take place just prior to use. The particulate acellular tissue may be applied to a recipient site, by way of injection, spraying, layering, packing, in-casing or combinations thereof. The particulate acellular tissue may further include growth and stimulating agents selected from epidermal growth factor, fibroblast growth factor, nerve growth factor, keratinocyte growth factor, platelet derived growth factor, vasoactive intestinal peptide, stem cell factor, bone morphogetic proteins, chondrocyte growth factor and combinations thereof. Other pharmaceutically active compounds may be combined with the rehydrated particulate material including: analgesic drugs; hemostatic drugs; antibiotic drugs; local anesthetics and the like to enhance the acceptance of the implanted particulate material. The particulate material product may also be combined with stem cells selected from mesenchymal stem cells, epidermal stem cells, cartilage stem cells, hematopoietic stem cells and combinations thereof.

Owner:LIFECELL

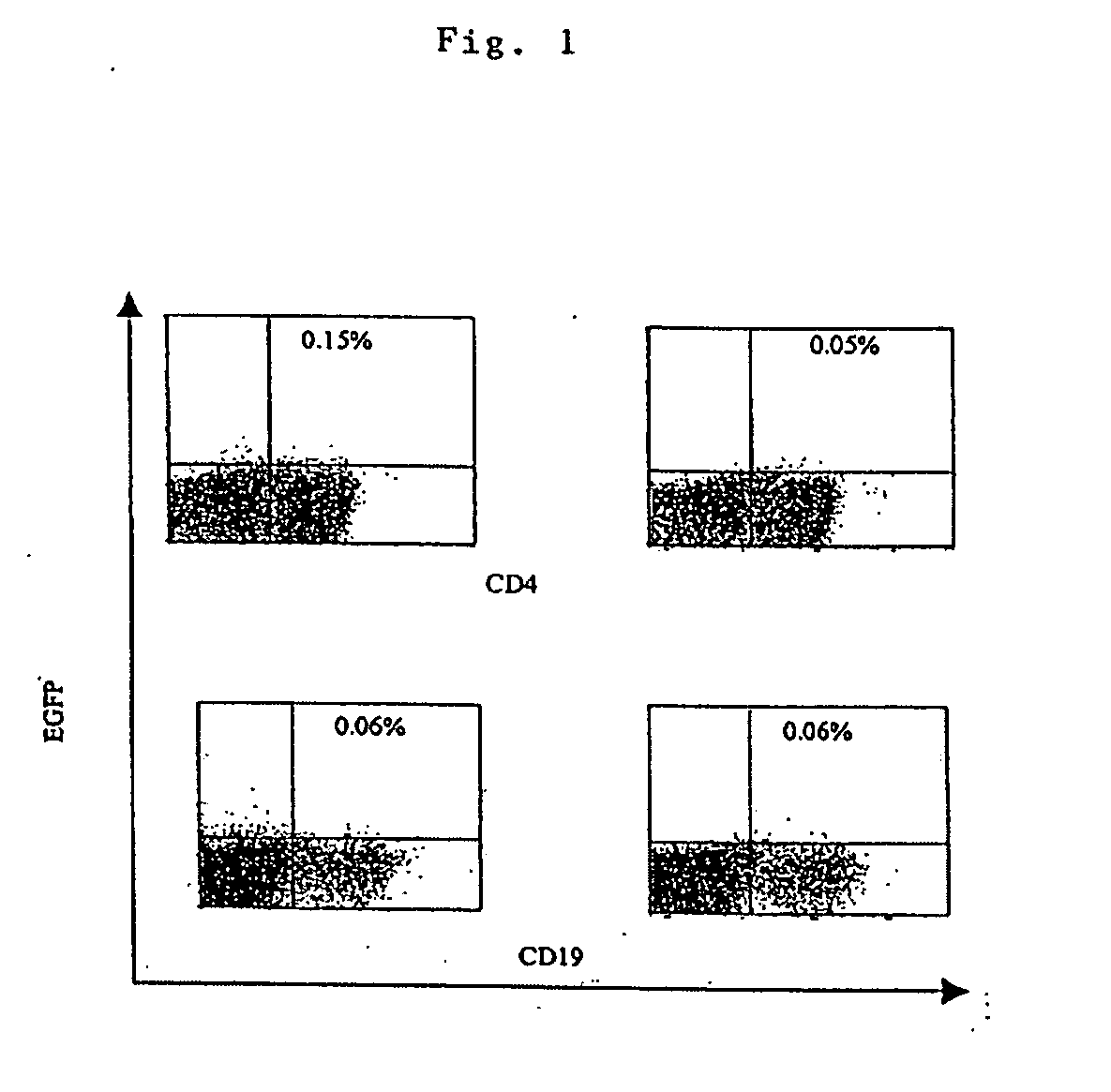

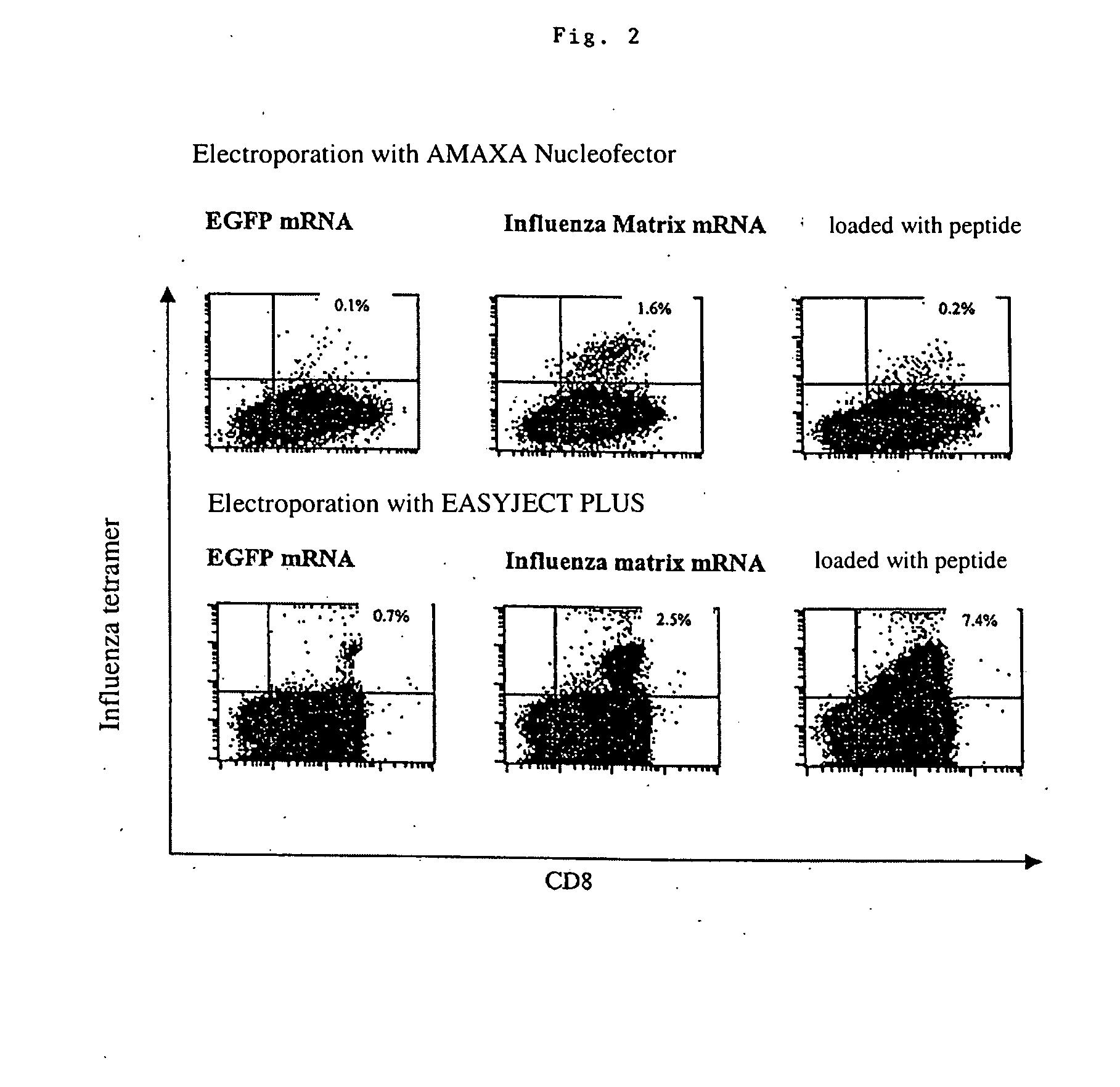

Transfection of blood cells with mRNA for immune stimulation and gene therapy

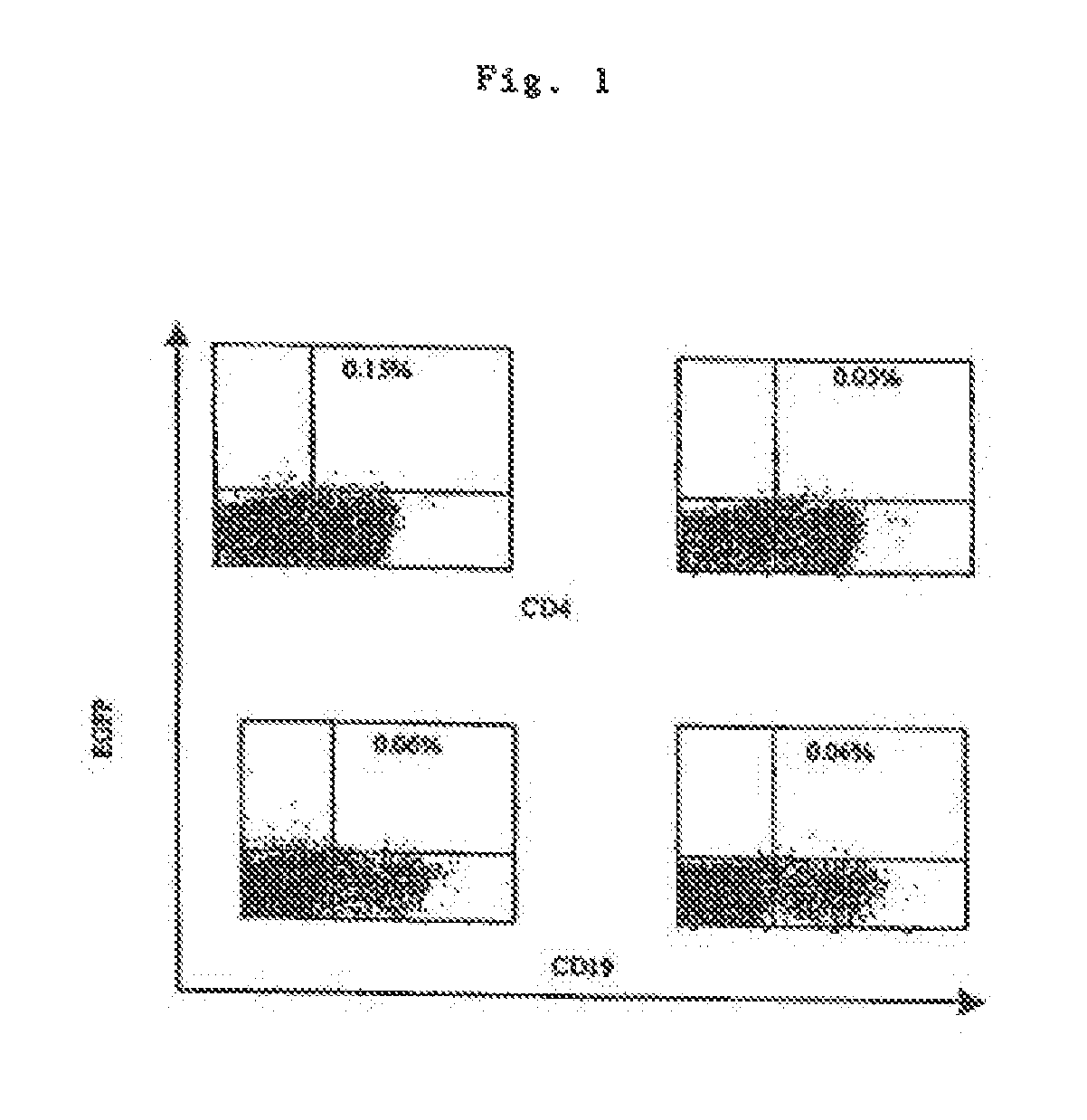

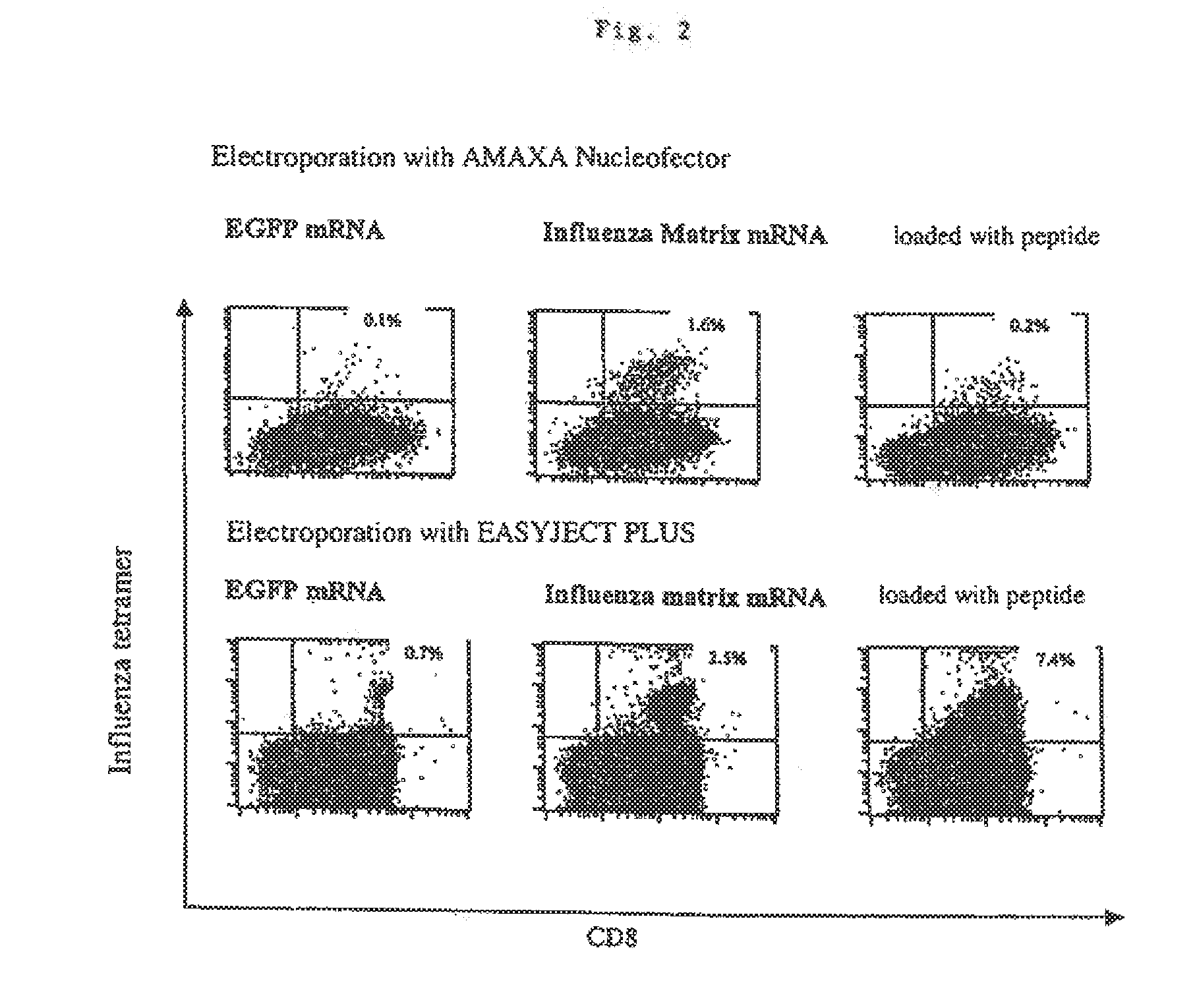

InactiveUS20060188490A1Improve stabilityIncrease transfectionSsRNA viruses negative-senseBiocideAntigenCancer prevention

The present invention relates to a pharmaceutical composition containing blood cells or haemopoietic cells, e.g. red blood cells (erythrocytes), granulocytes, mononuclear cells (PBMCs) and / or blood platelets, in combination with a pharmaceutically acceptable excipient and / or vehicle, wherein the cells are transfected with at least one mRNA comprising at least one region coding for at least one antigen. The invention further discloses a method of preparing the aforesaid pharmaceutical composition and the use of blood cells transfected in this way for the preparation of drugs or pharmaceutical compositions for immune stimulation against the antigens encoded by the mRNA. The subjects according to the invention are used especially for the therapy and / or prophylaxis of carcinoses or infectious diseases and can also be employed in gene therapy.

Owner:CUREVAC AG

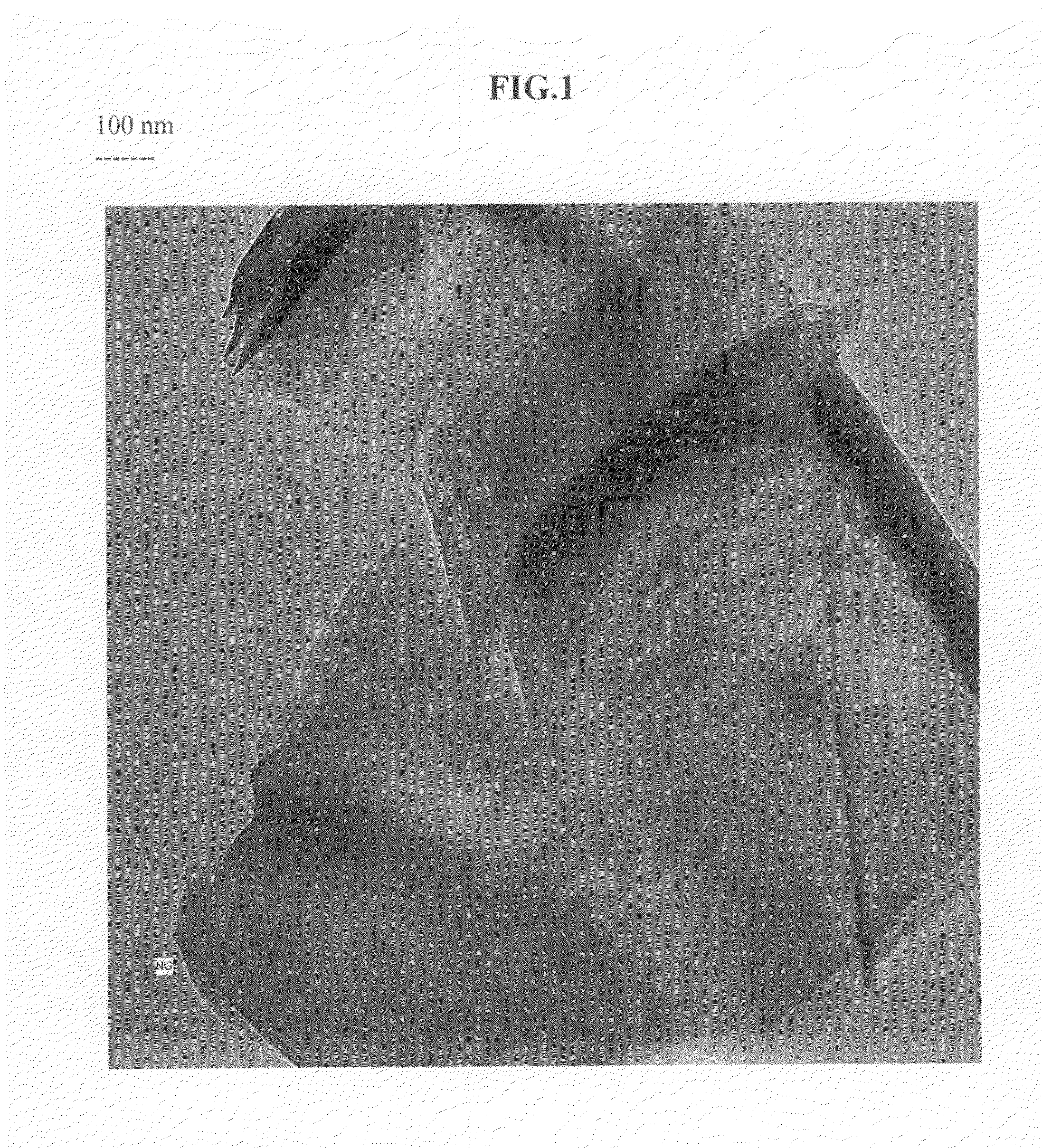

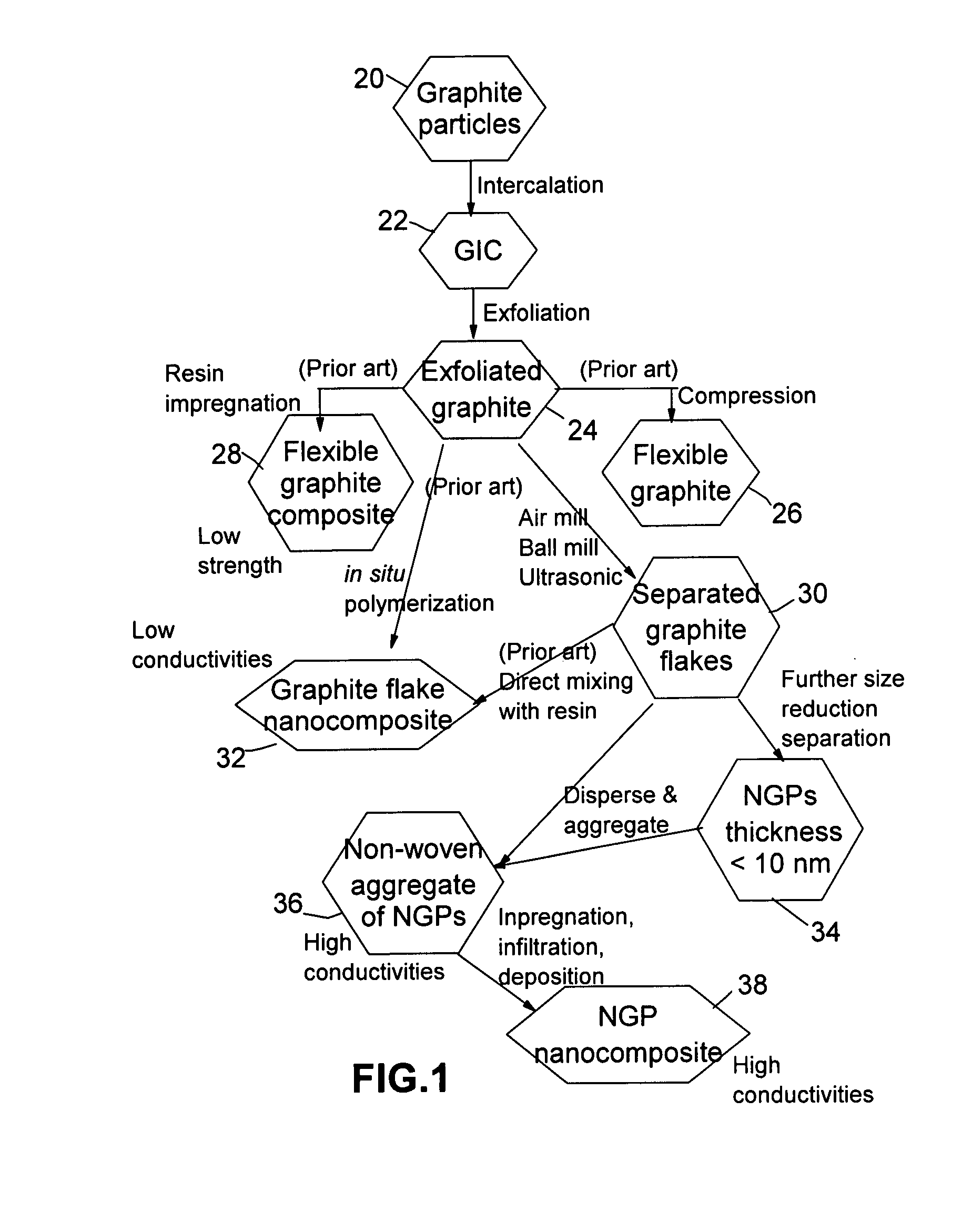

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

ActiveUS20080279756A1Good dispersionImprove conductivityCarbon compoundsFibre chemical featuresFiberLiquid medium

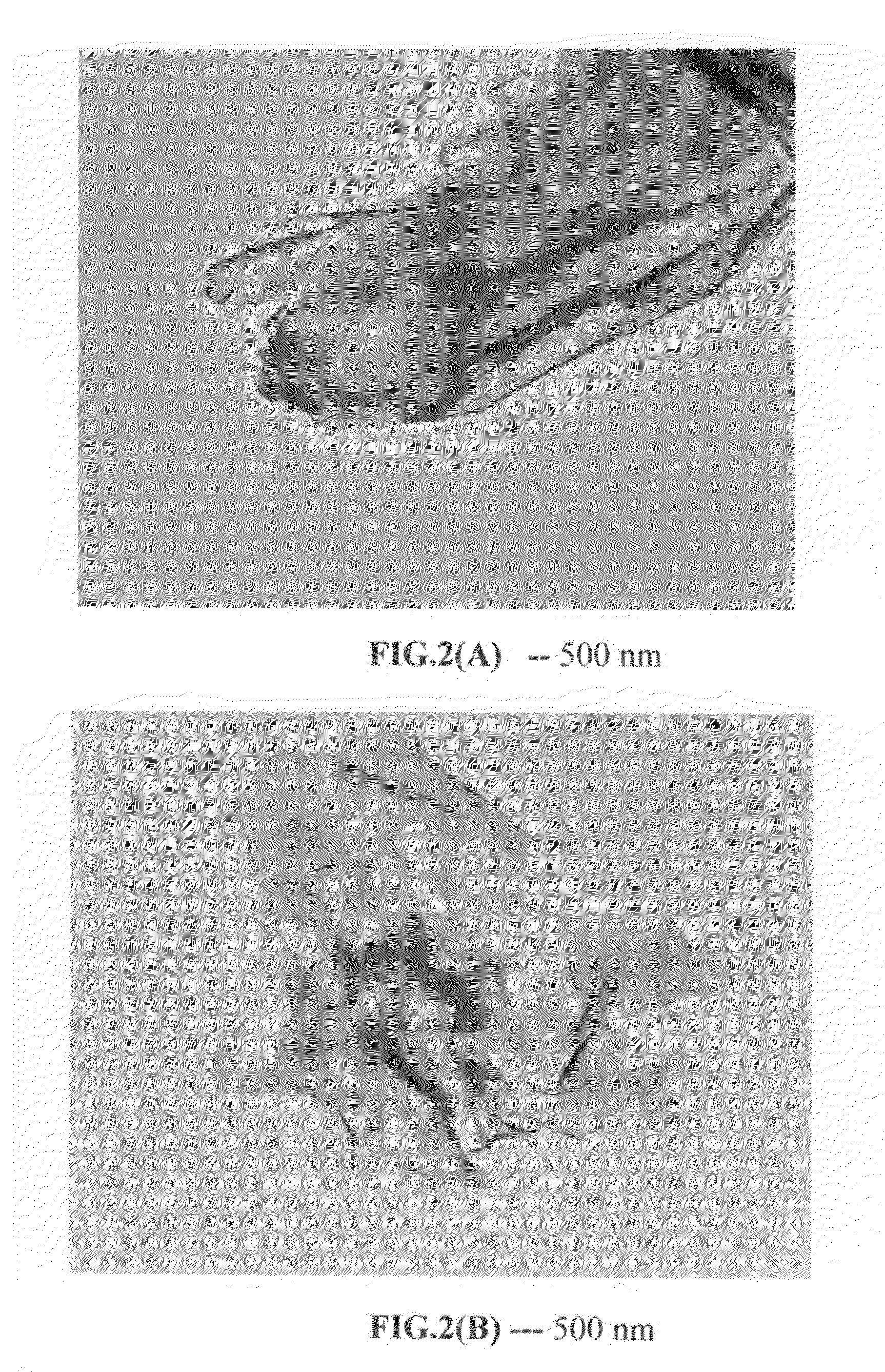

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

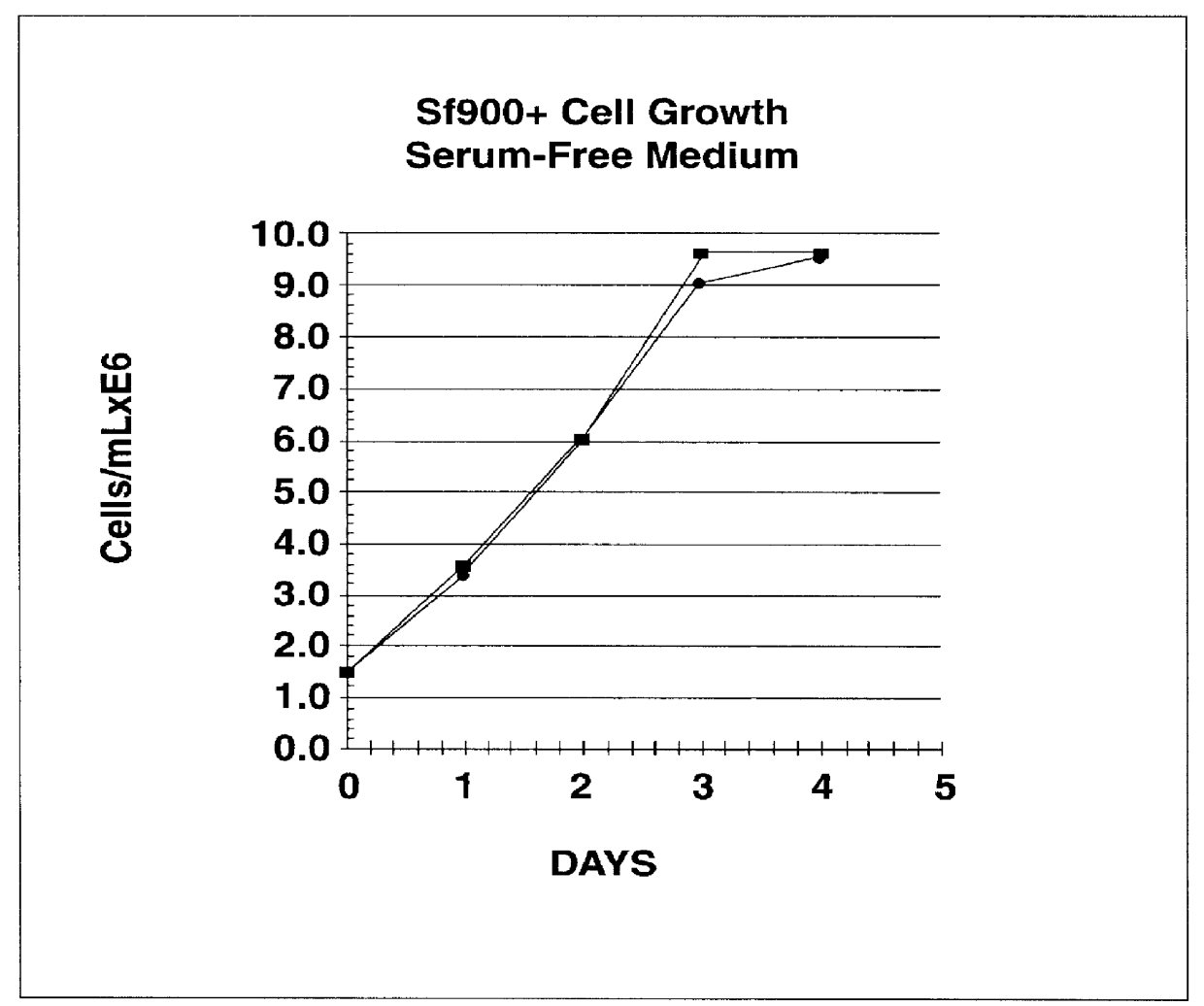

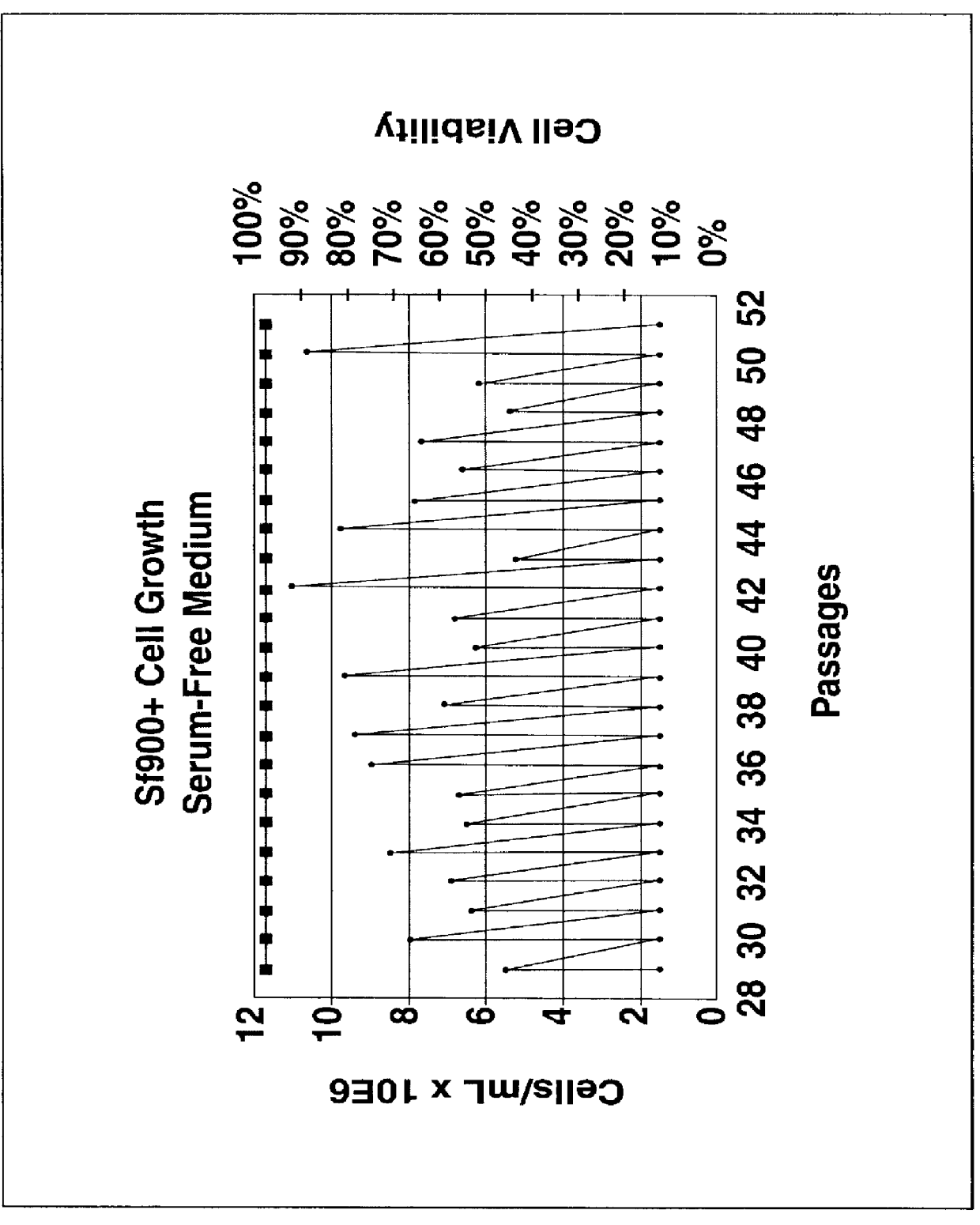

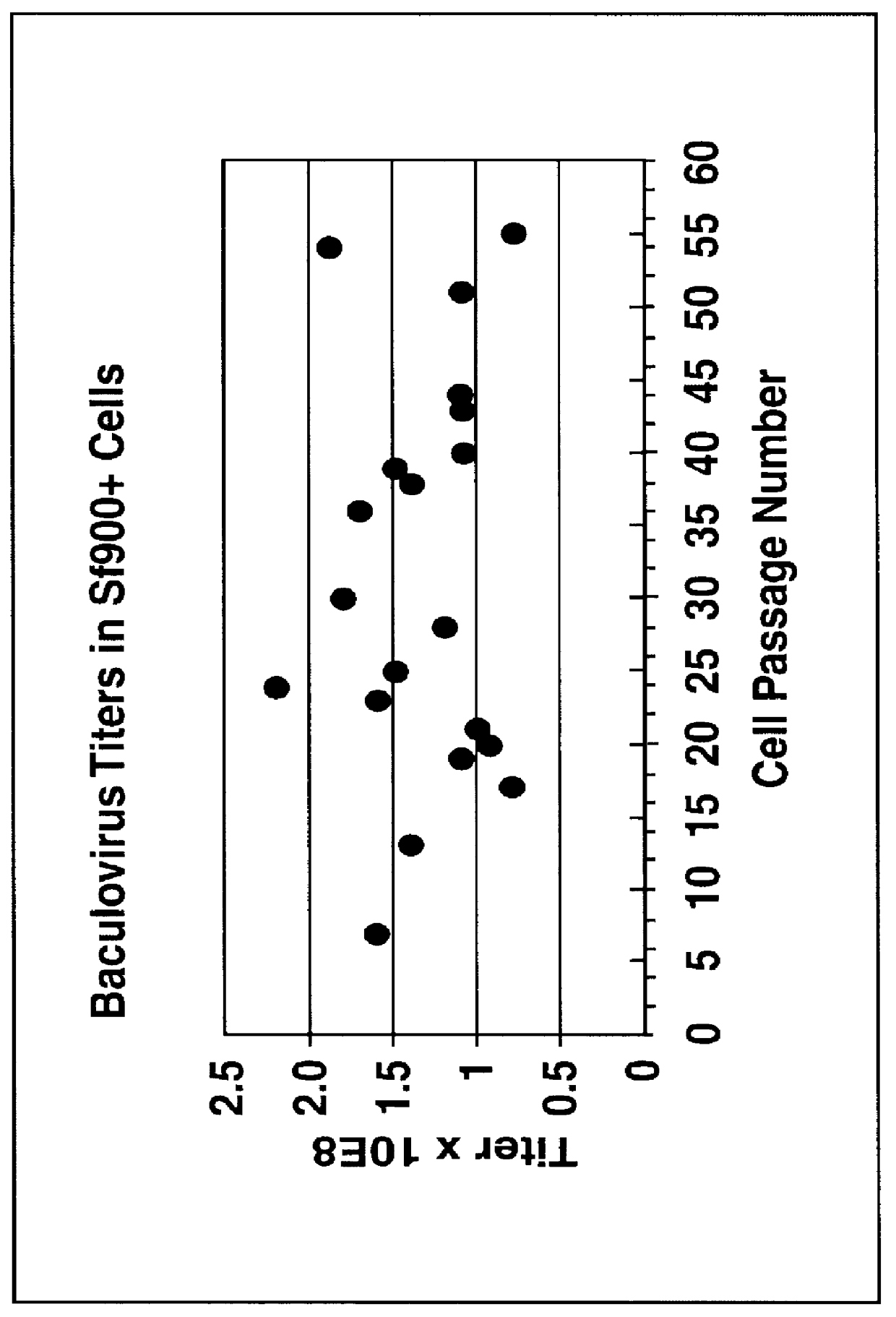

Spodoptera frugiperda single cell suspension cell line in serum-free media, methods of producing and using

InactiveUS6103526AAvoid infectionHigh densityConnective tissue peptidesInvertebrate cellsSerum free mediaAdjuvant

Disclosed and claimed is a new insect cell line, Sf900+, ATCC CRL-12579. The insect cell line was established from Lepidoptera, Noctuidae, Spodoptera frugiperda Sf-9 (ATCC CRL-1711) through multiple rounds of limiting dilution and selection in a serum-free insect medium supplemented with added human insulin. The insect cell line is useful in BEVS or as an adjuvant and has many characteristics and advantages. Also disclosed and claimed are recombinant proteins from recombinant baculovirus expression in insect cells such as Sf900+ cells, for instance, HA, NA, EPO, CD4, CEA, and thrombospondin.

Owner:PROTEIN SCI

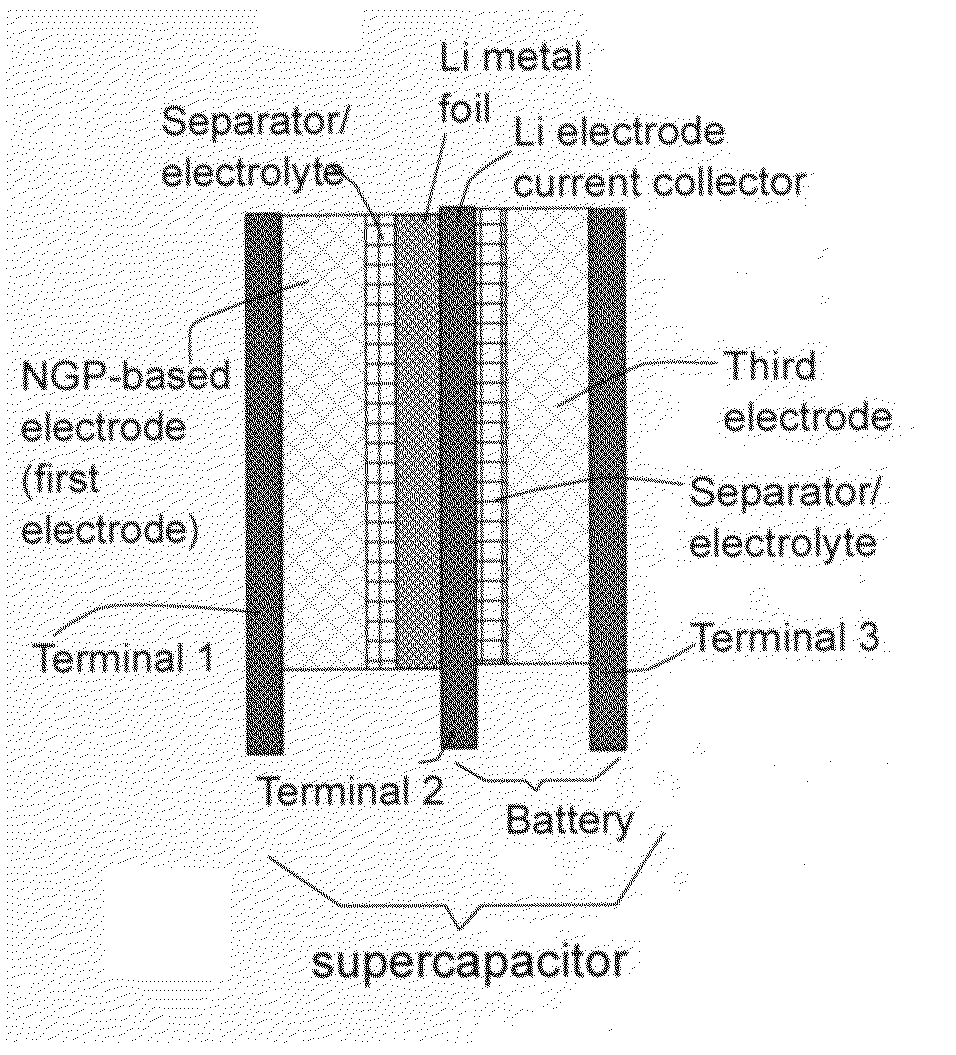

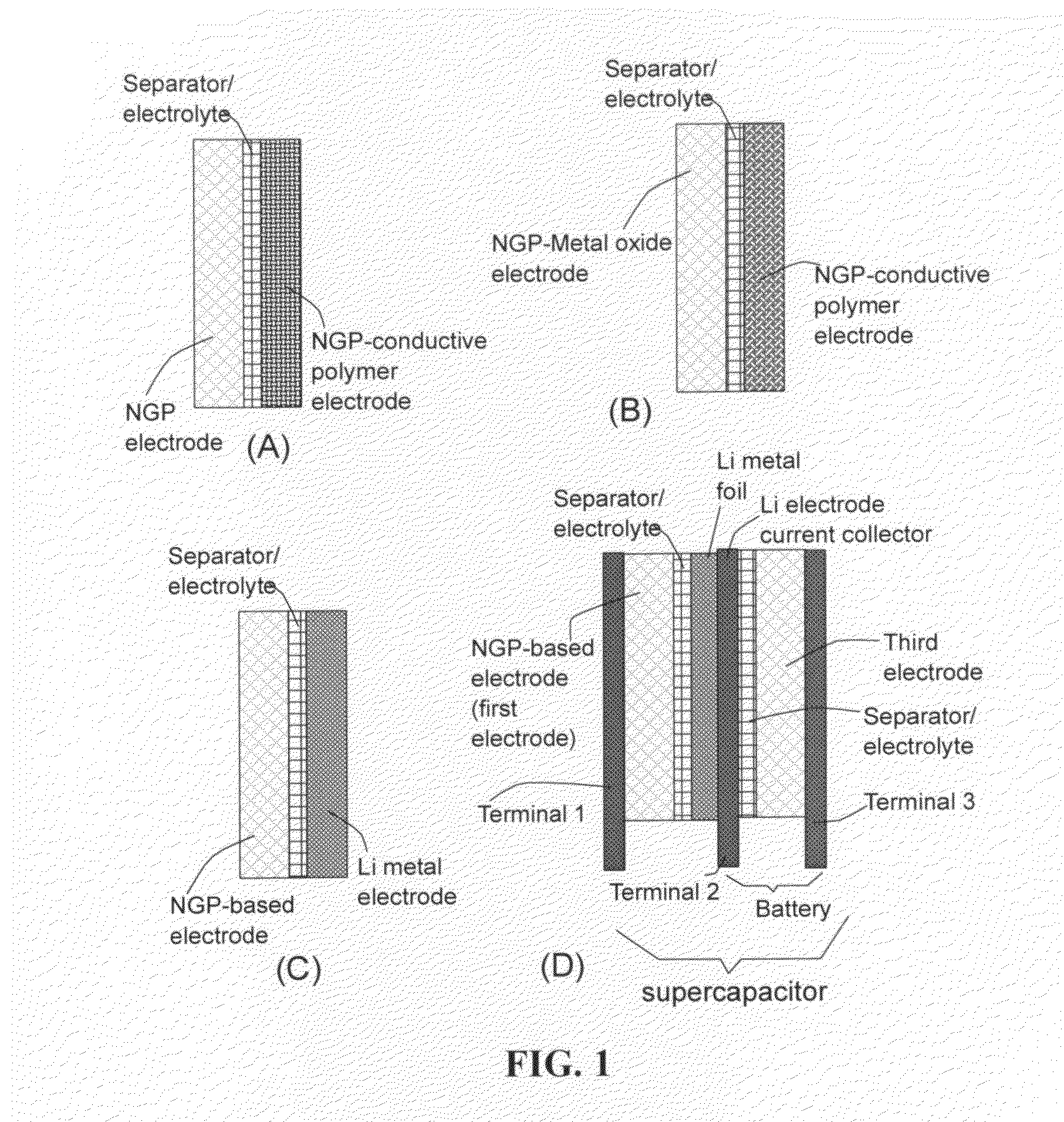

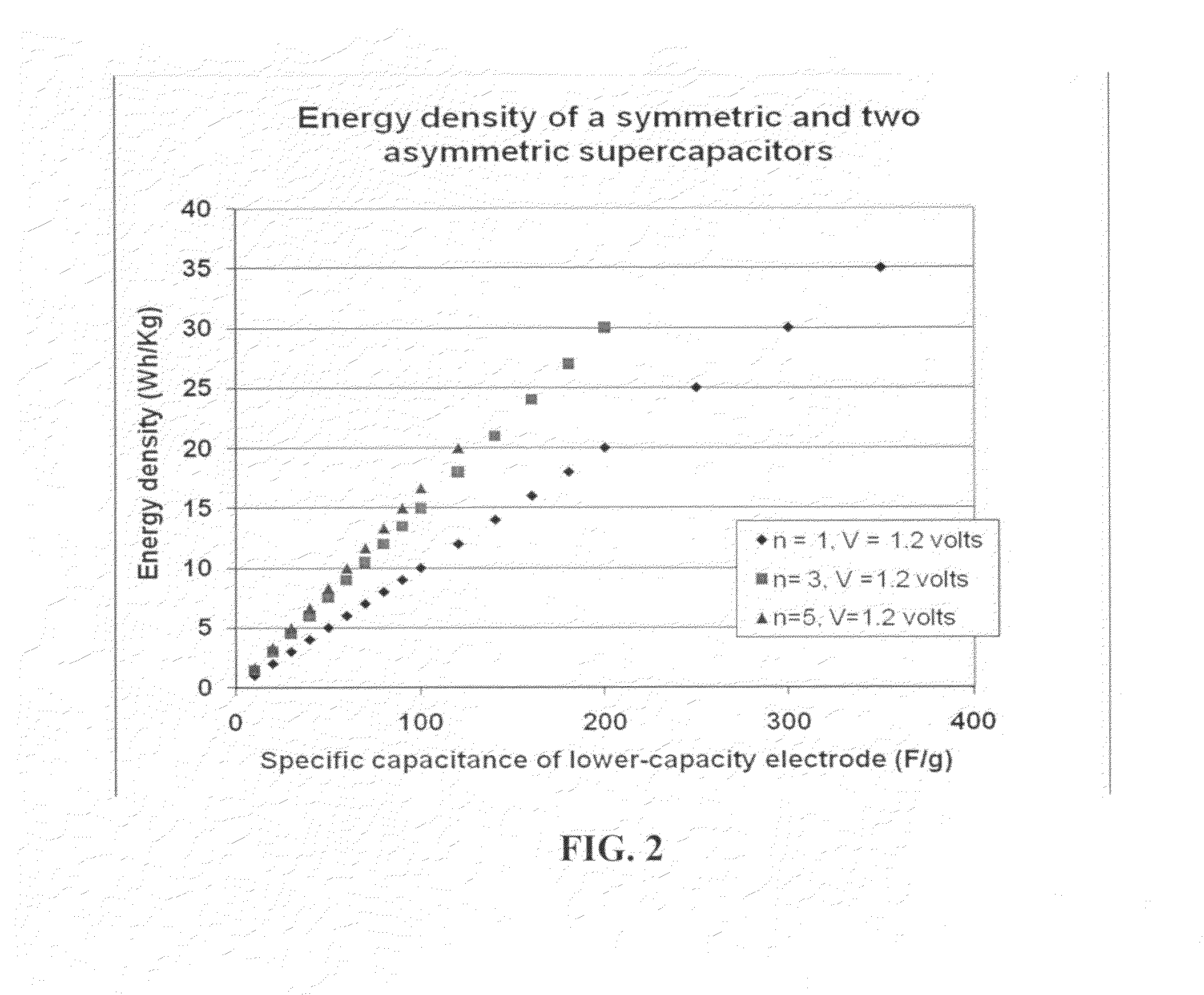

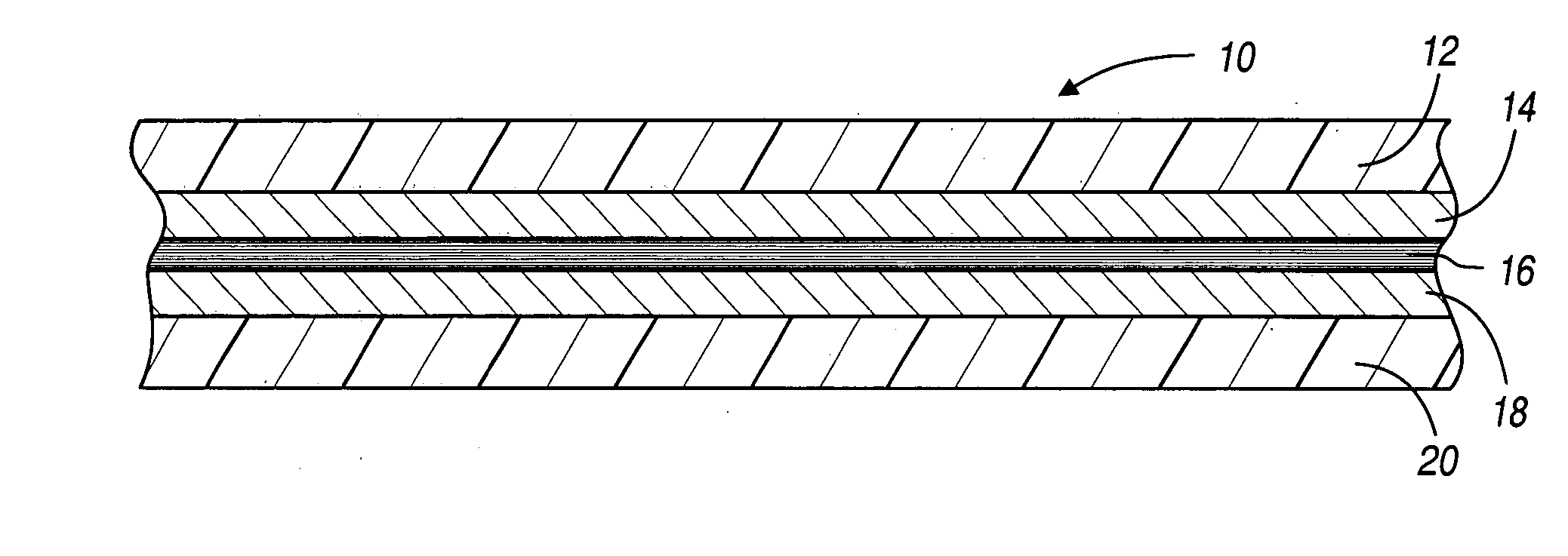

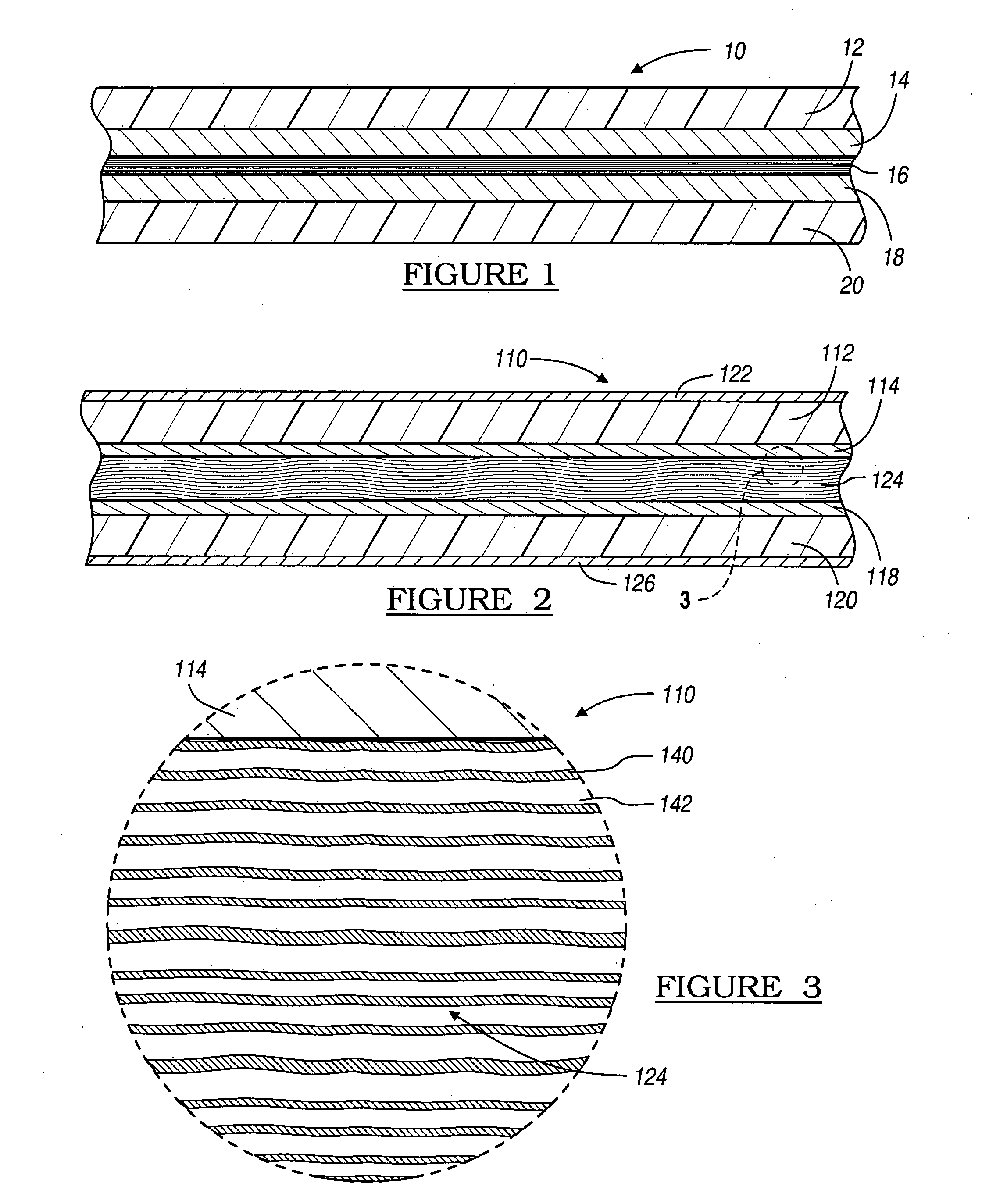

Flexible asymmetric electrochemical cells using nano graphene platelet as an electrode material

InactiveUS20110183180A1Excellent specific capacitanceLarge specific surface areaElectrochemical generatorsHybrid capacitor separatorsPlateletGraphene

A flexible, asymmetric electrochemical cell comprising: (A) A sheet of graphene paper as first electrode comprising nano graphene platelets having a platelet thickness less than 1 nm, wherein the first electrode has electrolyte-accessible pores; (B) A thin-film or paper-like first separator and electrolyte; and (C) A thin-film or paper-like second electrode which is different in composition than the first electrode; wherein the separator is sandwiched between the first and second electrode to form a flexible laminate configuration. The asymmetric supercapacitor cells with different NGP-based electrodes exhibit an exceptionally high capacitance, specific energy, and stable and long cycle life.

Owner:NANOTEK INSTR GRP LLC

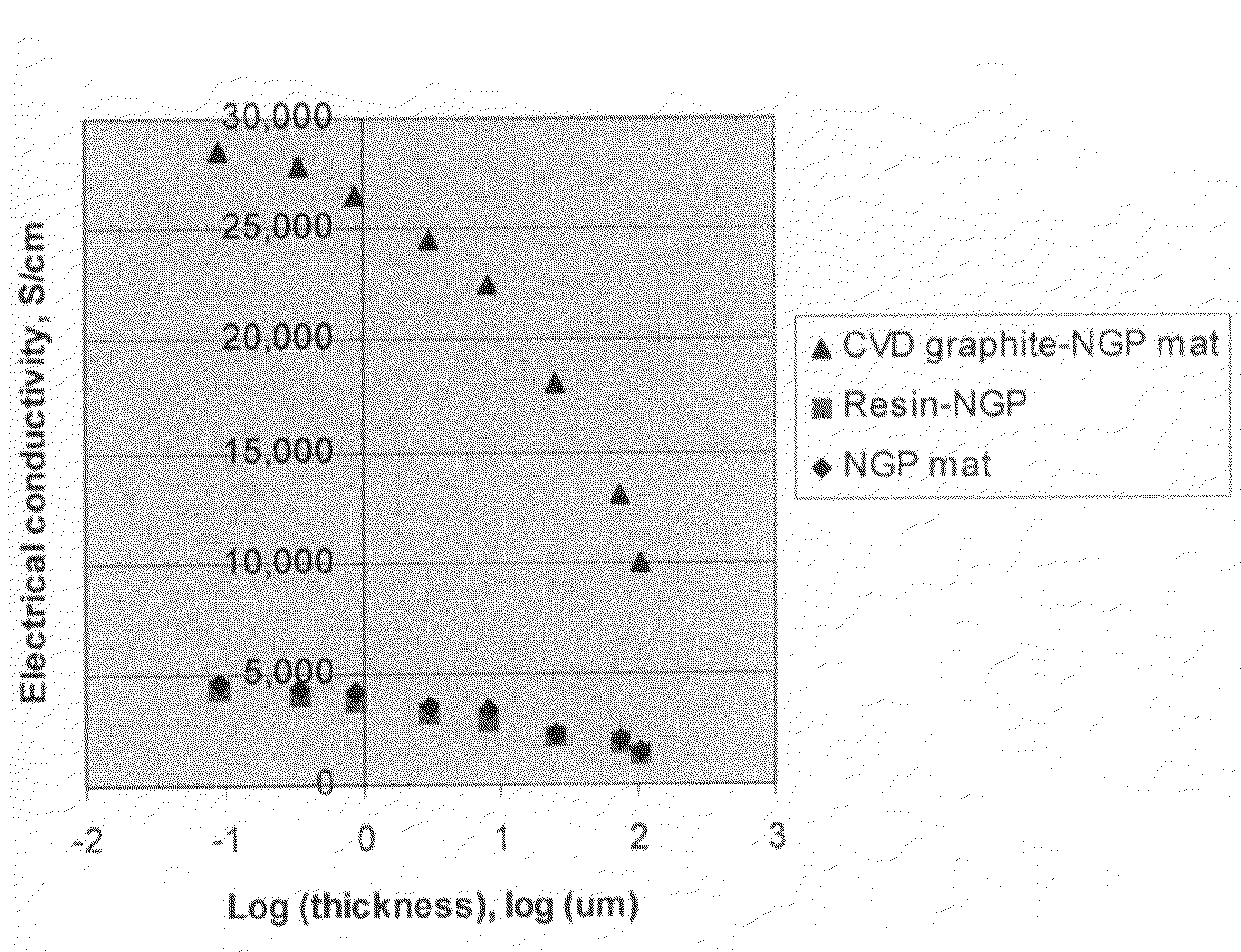

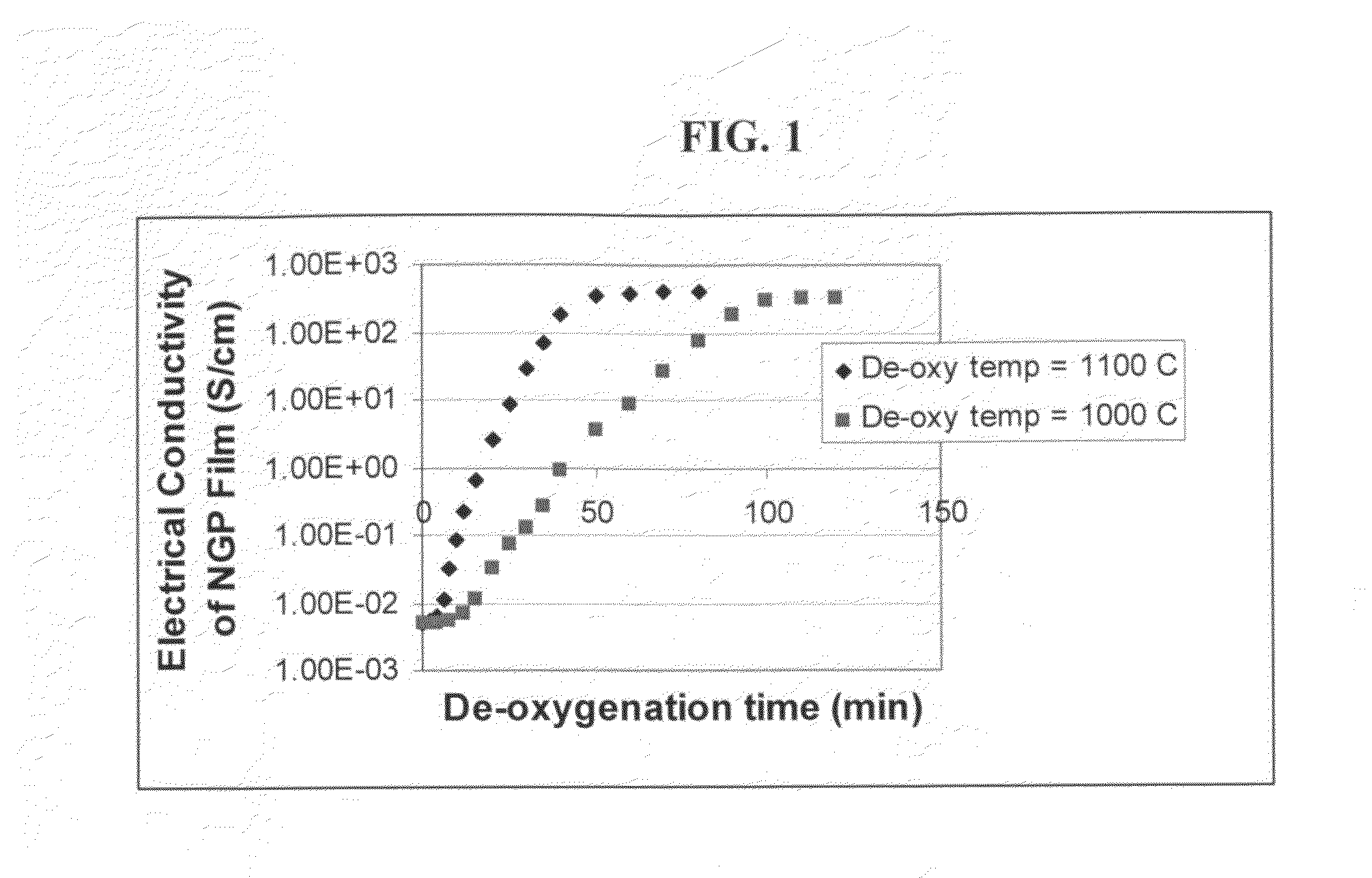

Nano-scaled graphene plate films and articles

ActiveUS20080248275A1Improve thermal conductivityNon-metal conductorsMaterial nanotechnologyLightning strikePlatelet

Disclosed is a nano-scaled graphene article comprising a non-woven aggregate of nano-scaled graphene platelets wherein each of the platelets comprises a graphene sheet or multiple graphene sheets and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and platelets contact other platelets to define a plurality of conductive pathways along the article. The article has an exceptional thermal conductivity (typically greater than 500 Wm−1K−1) and excellent electrical conductivity (typically greater than 1,000 S / cm). Thin-film articles of the present invention can be used for thermal management in micro-electronic devices and for current-dissipating on an aircraft skin against lightning strikes.

Owner:GLOBAL GRAPHENE GRP INC

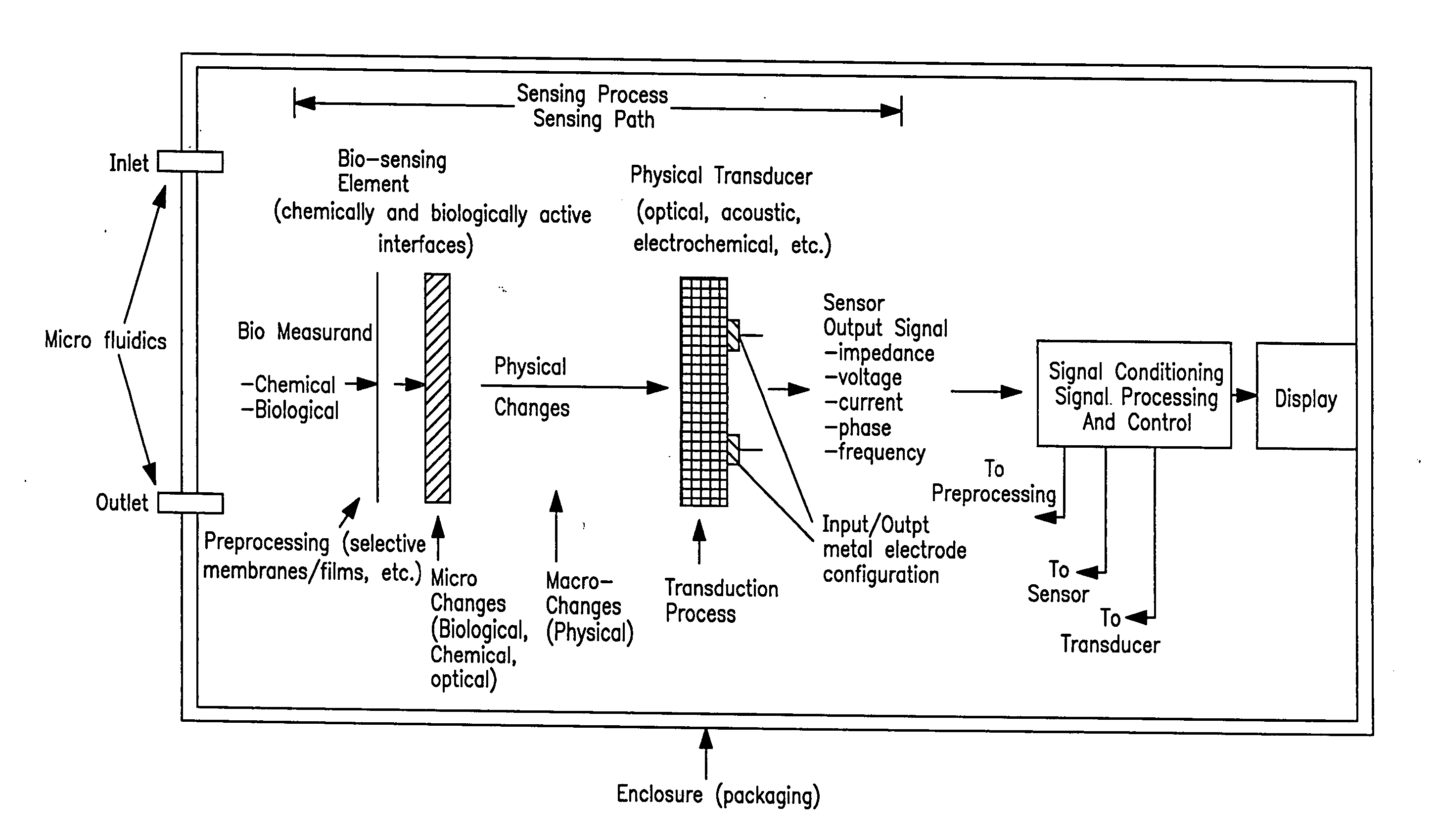

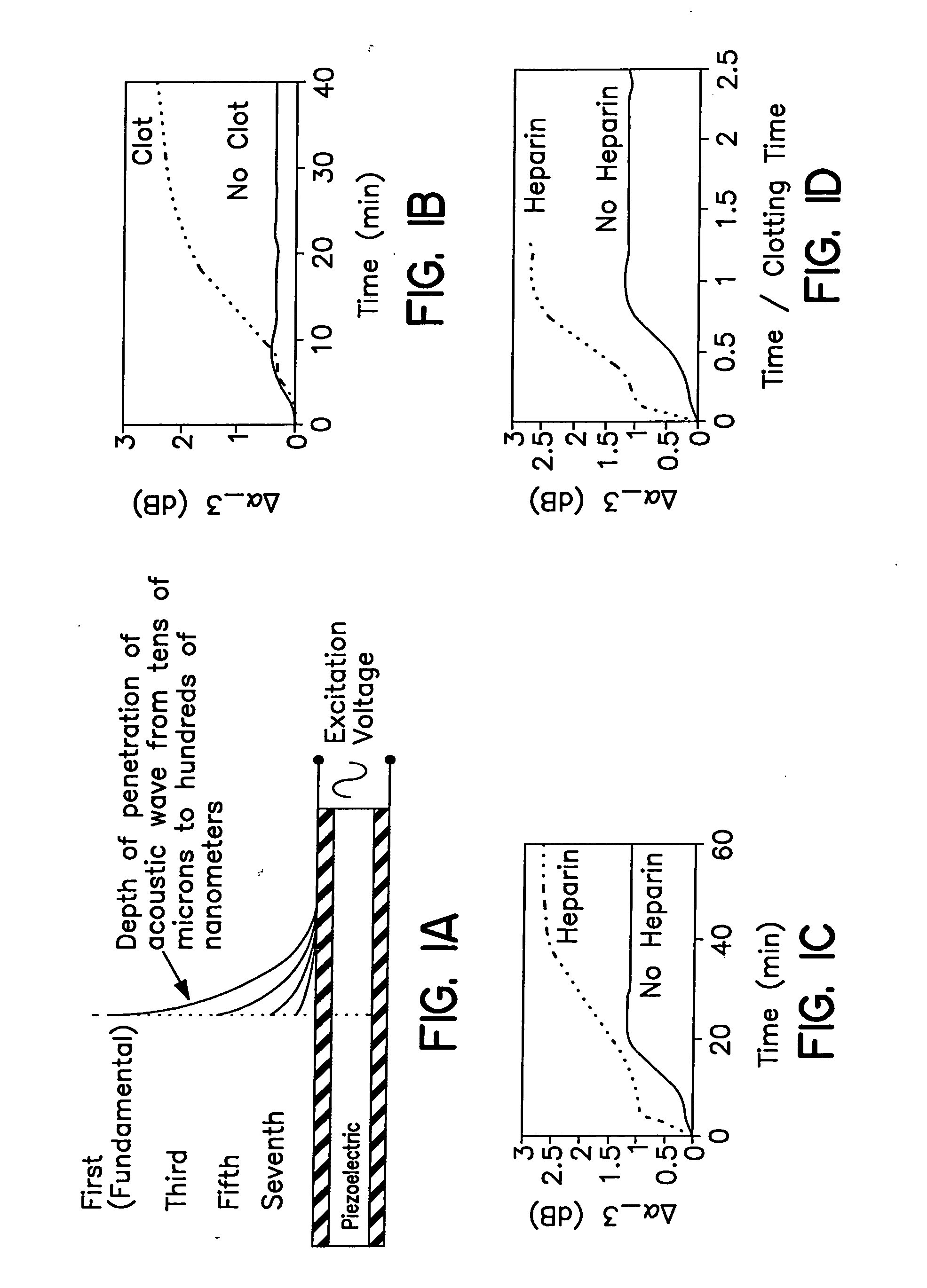

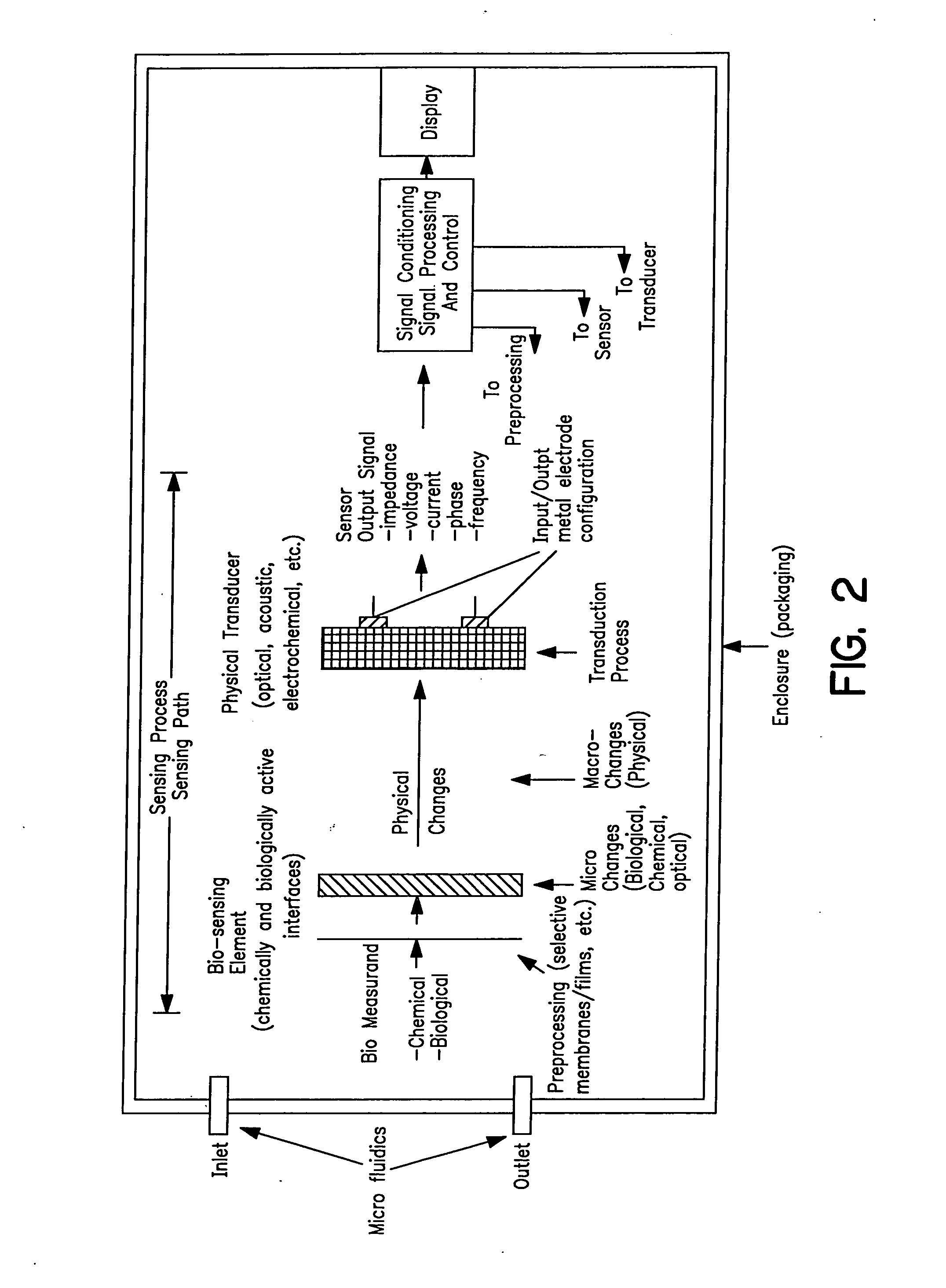

Acoustic blood analyzer for assessing blood properties

InactiveUS20050015001A1Ultrasonic/sonic/infrasonic diagnosticsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMedicinePlatelet

An acoustic blood analyzer with a transducer section of acoustic biosensors for measurement of blood properties including, but not limited to blood coagulation, platelet function and various blood disorders in a blood sample is provided. Methods for use of the blood analyzer in measurement of blood properties are also provided.

Owner:DREXEL UNIV

Transfection of blood cells with mRNA for immune stimulation and gene therapy

InactiveUS20120009221A1Improve stabilityIncrease transfectionSsRNA viruses negative-senseViral antigen ingredientsAntigenPharmaceutical medicine

The present invention relates to a pharmaceutical composition containing blood cells or haemopoietic cells, e.g. red blood cells (erythrocytes), granulocytes, mononuclear cells (PBMCs) and / or blood platelets, in combination with a pharmaceutically acceptable excipient and / or vehicle, wherein the cells are transfected with at least one mRNA comprising at least one region coding for at least one antigen. The invention further discloses a method of preparing the aforesaid pharmaceutical composition and the use of blood cells transfected in this way for the preparation of drugs or pharmaceutical compositions for immune stimulation against the antigens encoded by the mRNA. The subjects according to the invention are used especially for the therapy and / or prophylaxis of carcinoses or infectious diseases and can also be employed in gene therapy.

Owner:CUREVAC AG

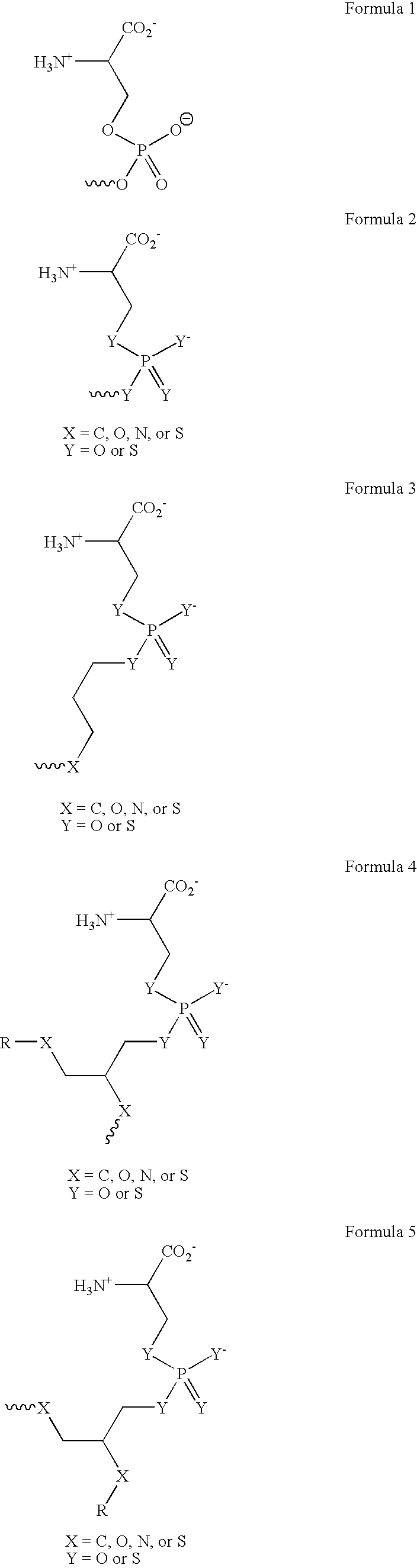

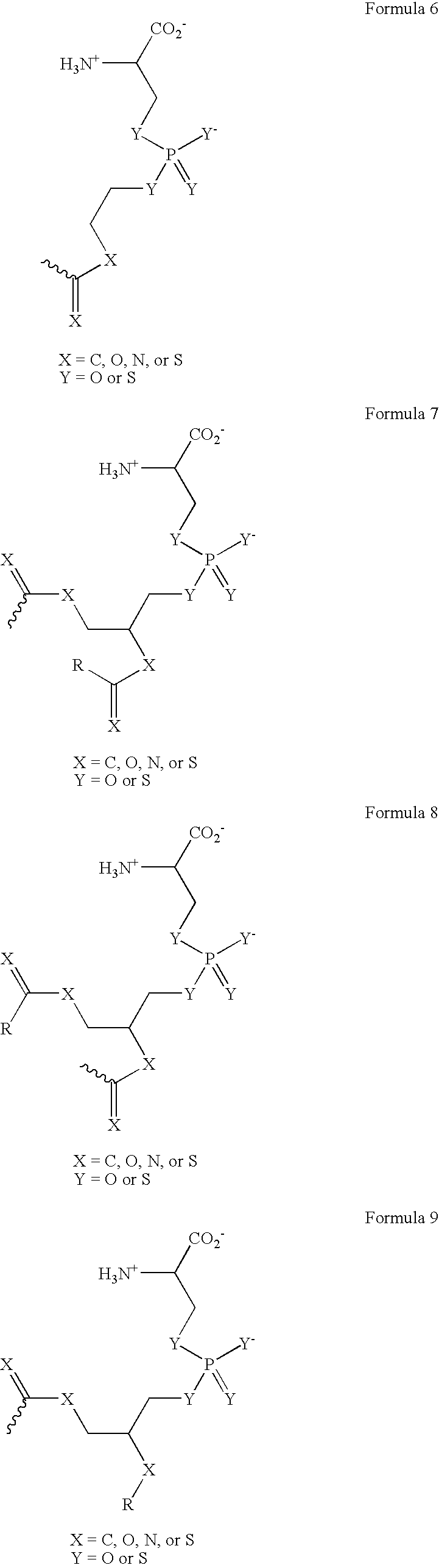

Compositions and methods for enhancing phagocytosis or phagocyte activity

ActiveUS20050113297A1Enhances and incites phagocytosisBetter targets for phagocytosisSenses disorderPeptide/protein ingredientsWhite blood cellCell type specific

The present invention provides a system for enhancing clearance or destruction of undesirable cells or noncellular molecular entities by tagging such cells or noncellular molecular entities with a marker that targets the cells or noncellular molecular entities for phagocytosis (phagocytic marker). The target cells can be, for example, endothelial cells, tumor cells, leukocytes, or virus-infected cells. In certain embodiments of the invention the tagging is accomplished by administering a composition comprising an antibody or ligand linked to the phagcytotic marker, wherein the antibody or ligand binds to a cell type specific marker present on or in the cell surface of a target cell. In preferred embodiments of the invention, the phagocytic marker comprises phosphatidylserine or a group derived from phosphatidylserine, thrombospondin-1, annexin I, or a derivative of any of these.

Owner:APELLIS PHARMA

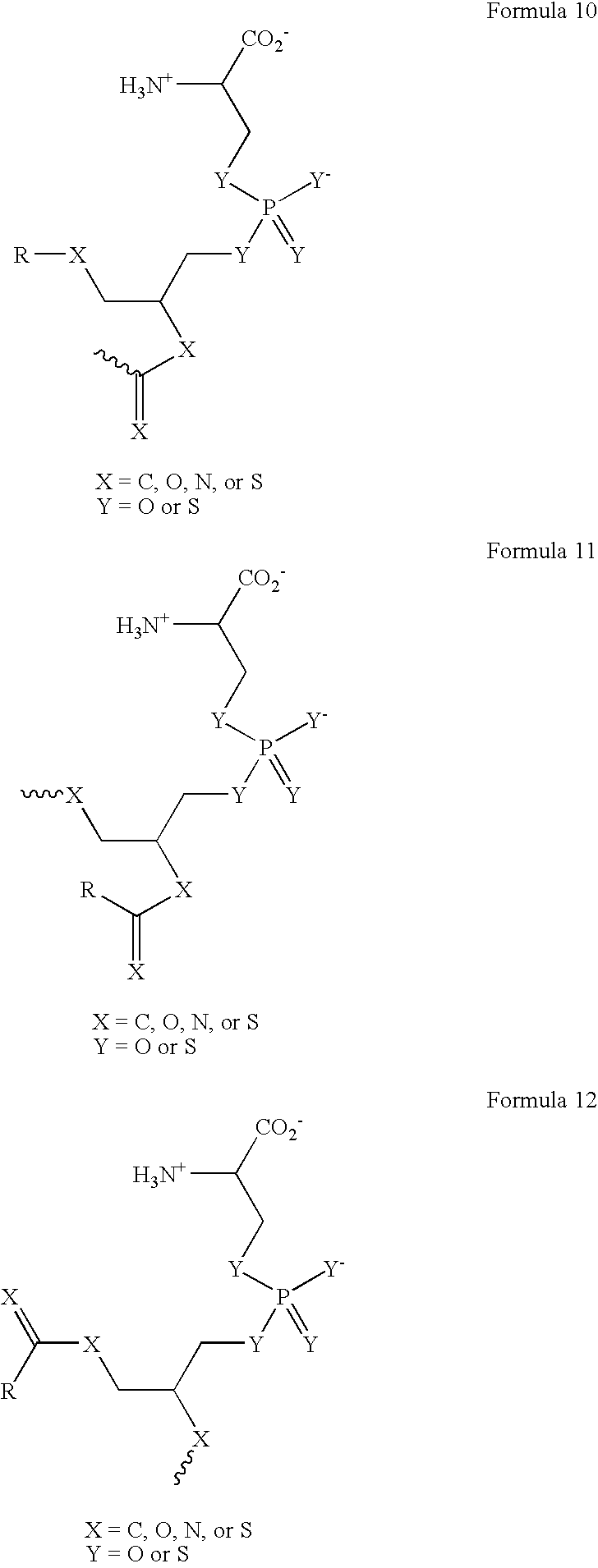

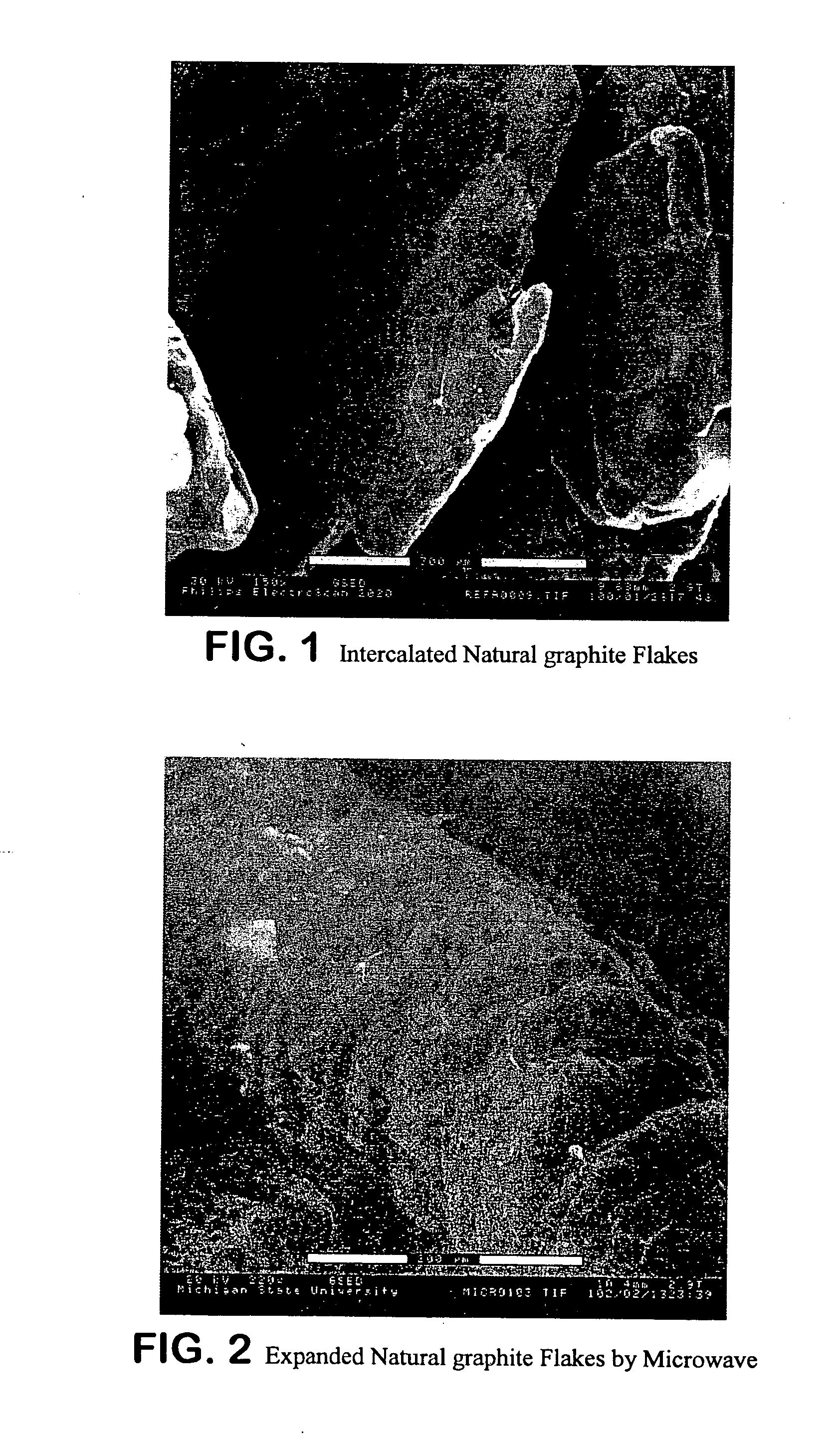

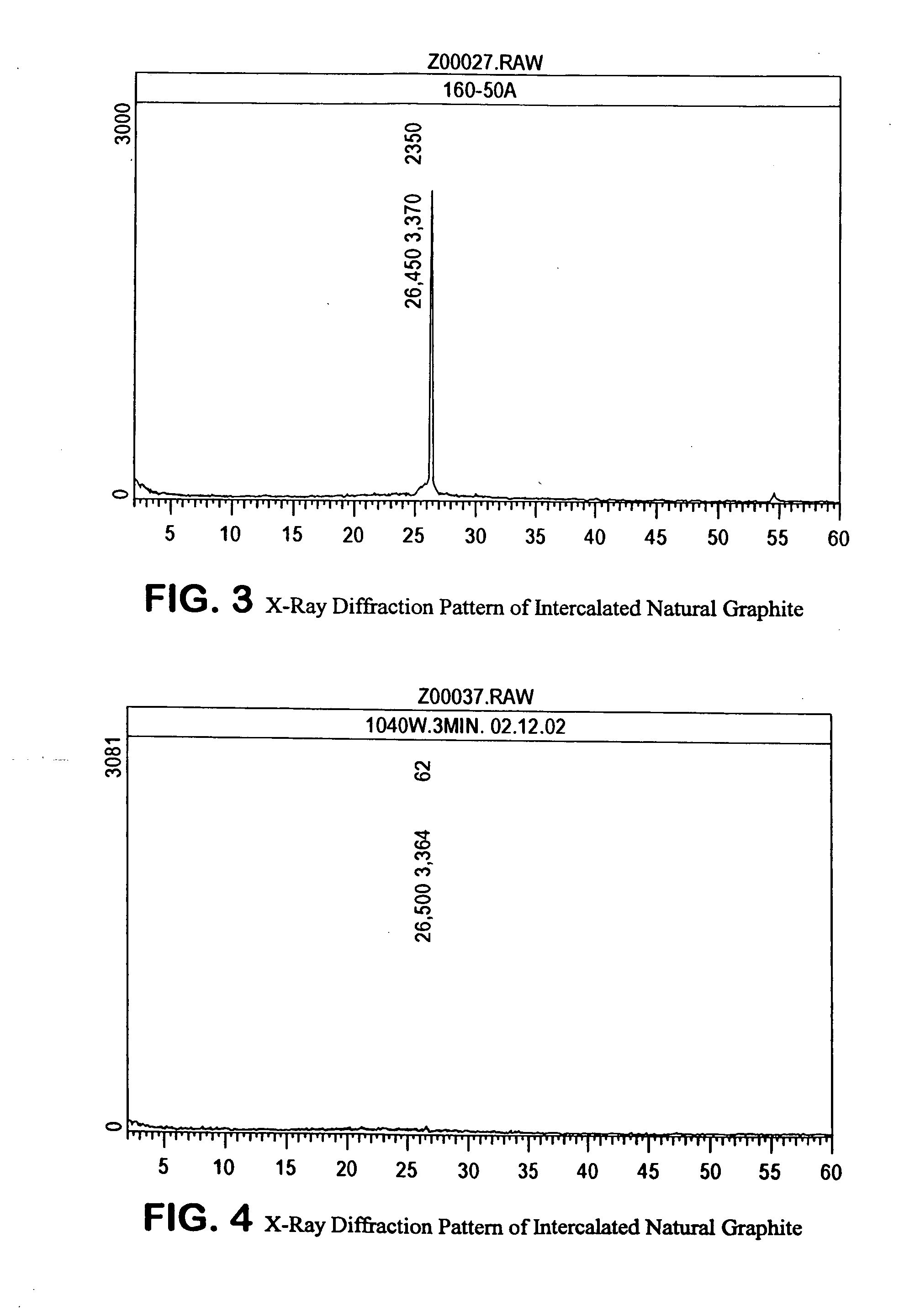

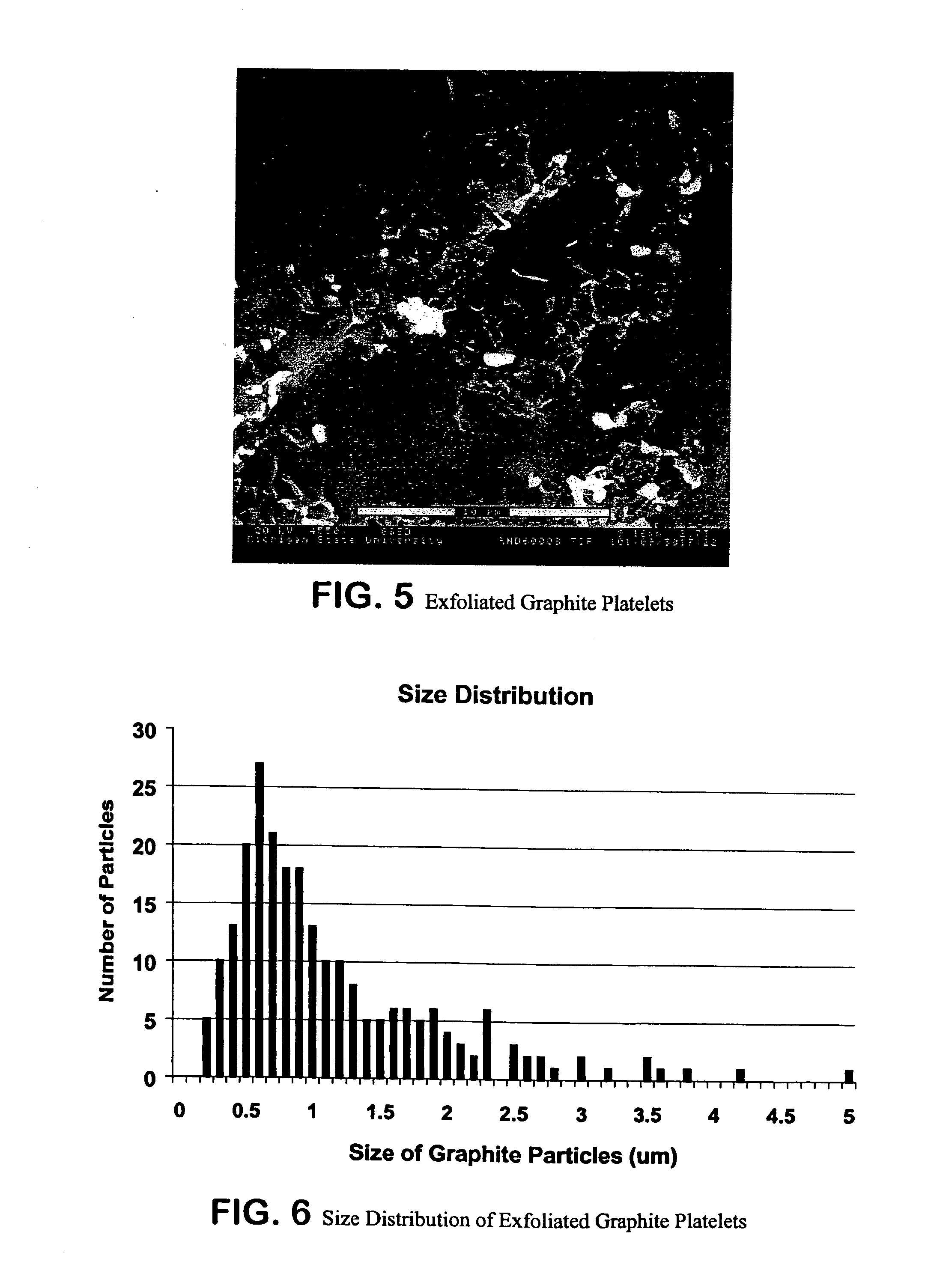

Continuous process for producing exfoliated nano-graphite platelets

InactiveUS20060241237A1Improve mechanical propertiesImprove thermal conductivitySpecial tyresMicrowavePlatelet

Graphite nanoplatelets of expanded graphite and composites and products produced therefrom are described. The graphite is expanded by microwaves or radiofrequency waves in the presence of a gaseous atmosphere. Various devices are described for expanding the intercalated graphite by means of microwaves or other radiofrequency waves to produce the expanded graphite. These devices can be used in a continuous process.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

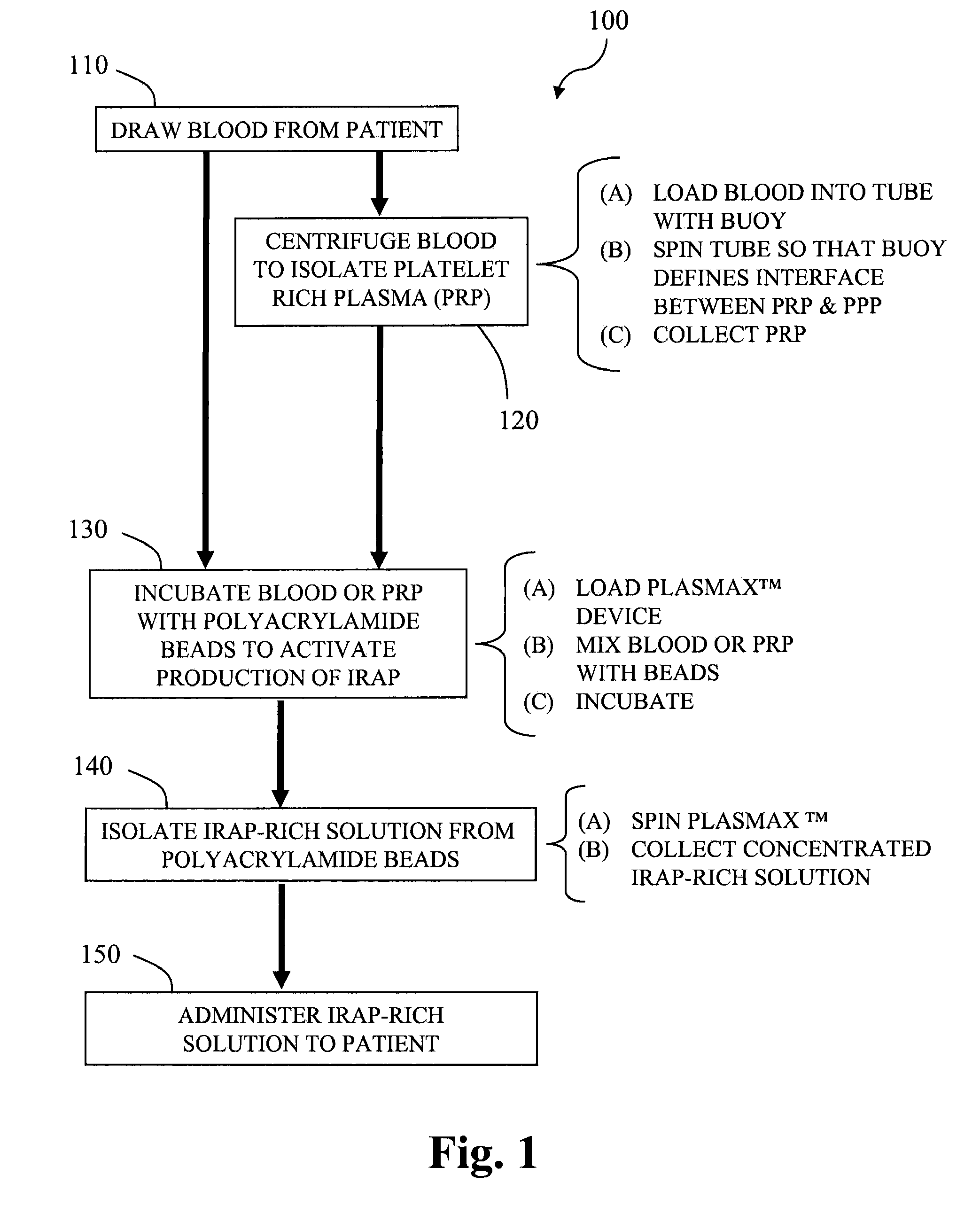

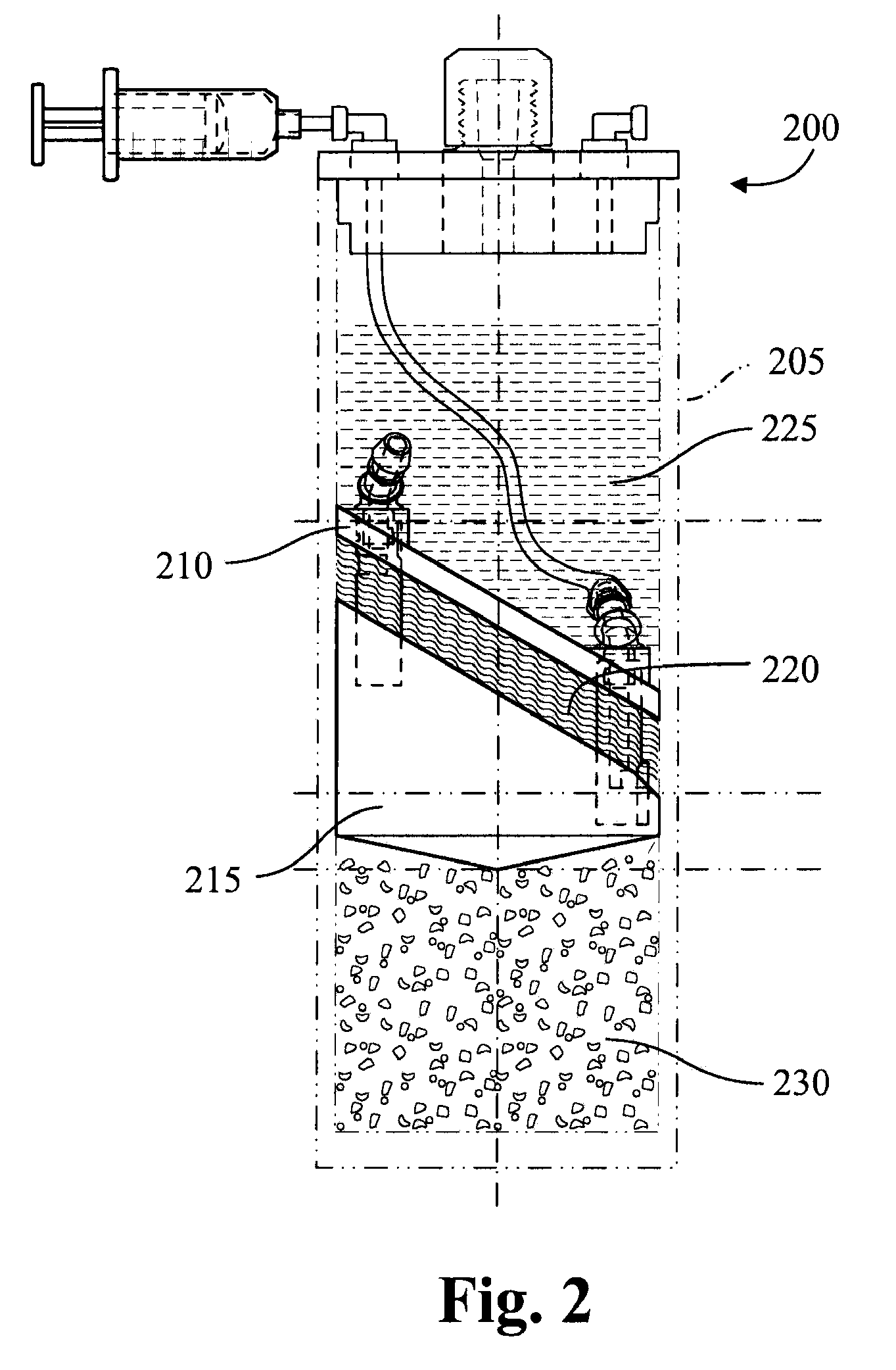

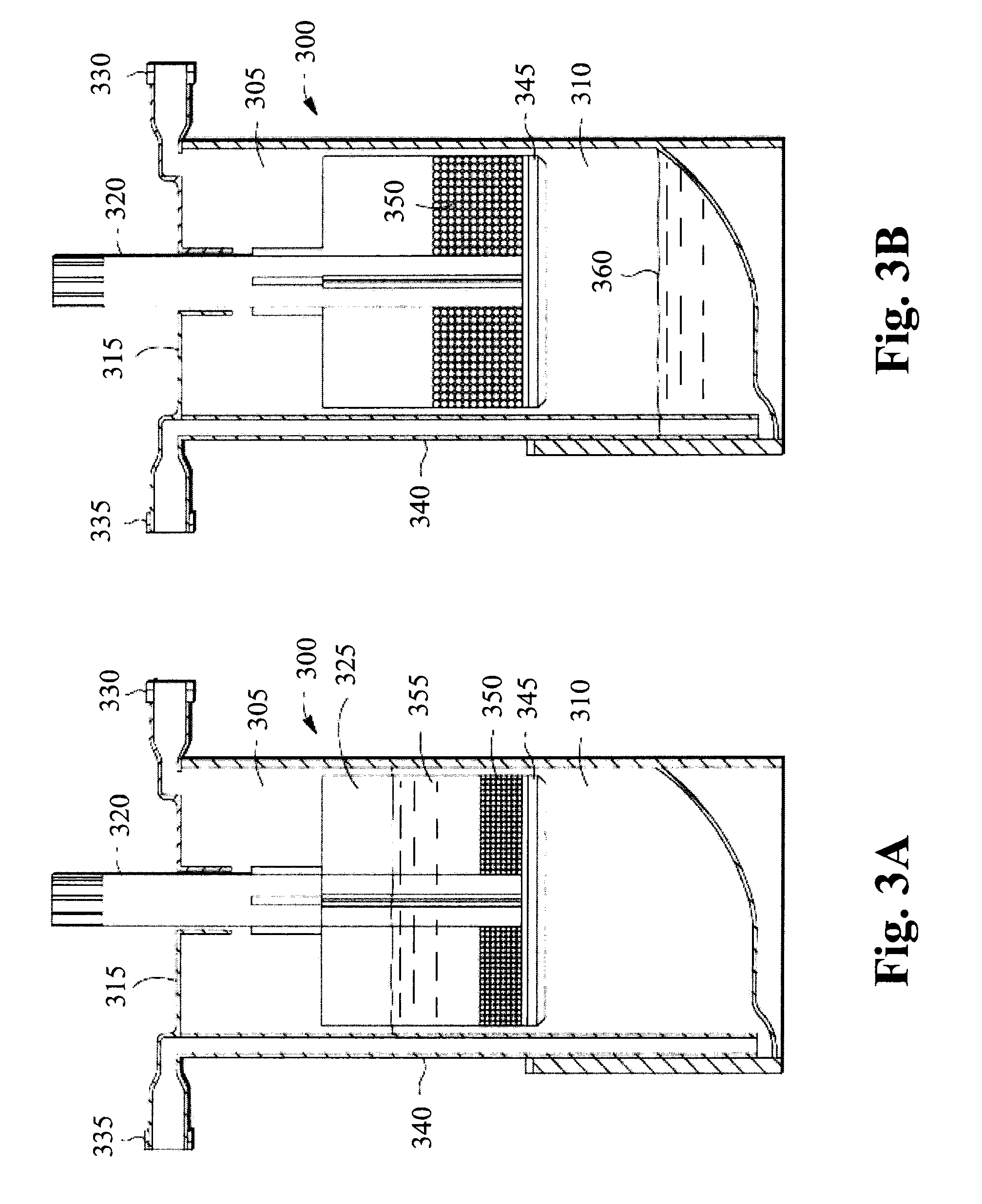

Methods and compositions for delivering interleukin-1 receptor antagonist

ActiveUS20090220482A1Contribute to degenerationIncrease productionPeptide/protein ingredientsPharmaceutical delivery mechanismWhite blood cellPlatelet

Methods and compositions generating and using an interleukin-1 receptor antagonist (IL-1ra)-rich solution. Methods for generating and isolating interleukin-1 receptor antagonist include incubating a liquid volume of white blood cells and platelets with polyacrylamide beads to produce interleukin-1 receptor antagonist. The interleukin-1 receptor antagonist is isolated from the polyacrylamide beads to obtain the solution rich in interleukin-1 receptor antagonist. Methods for treating a site of inflammation in a patient include administering to the site of inflammation the solution rich in interleukin-1 receptor antagonist.

Owner:BIOMET MFG CORP

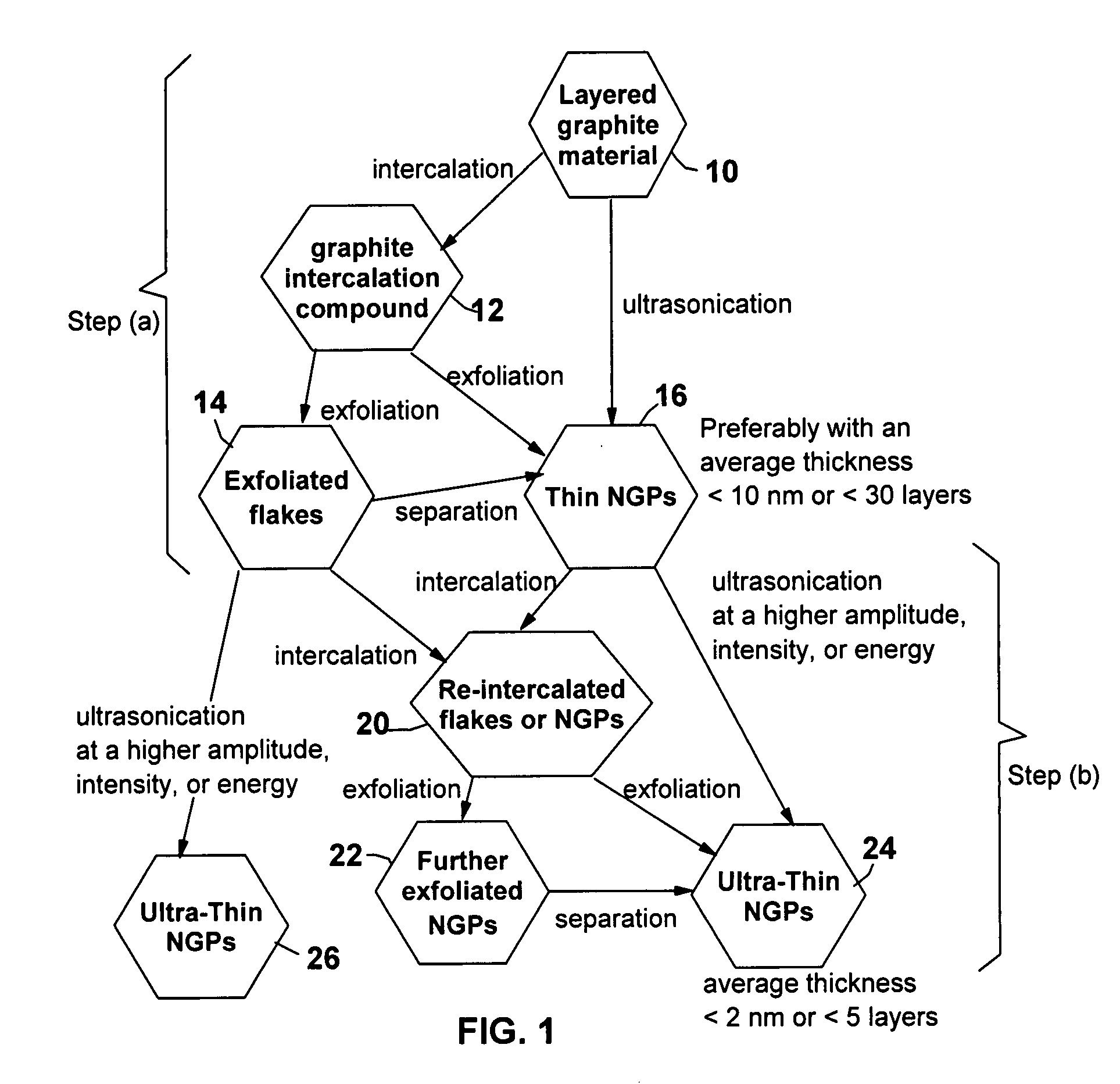

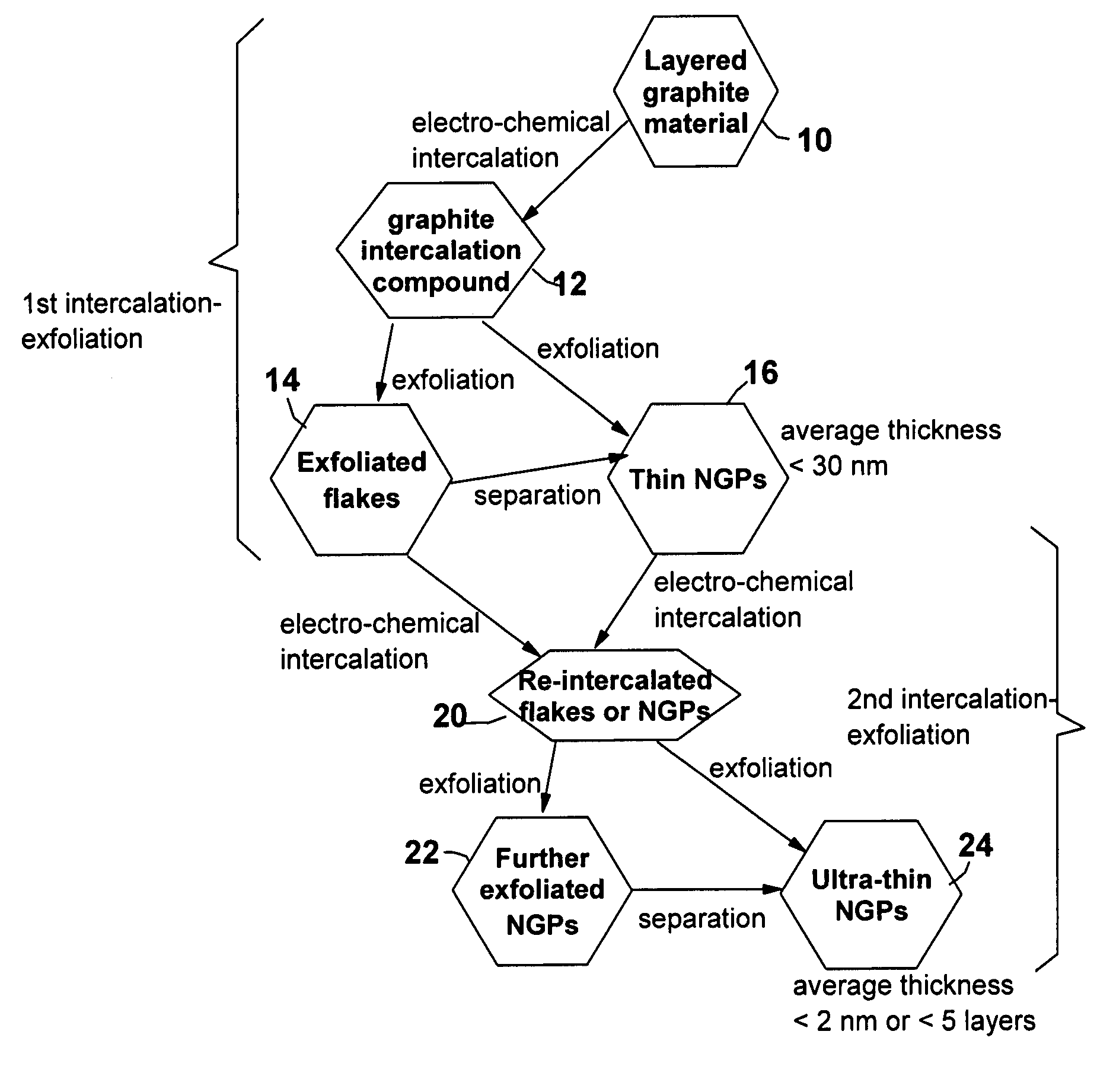

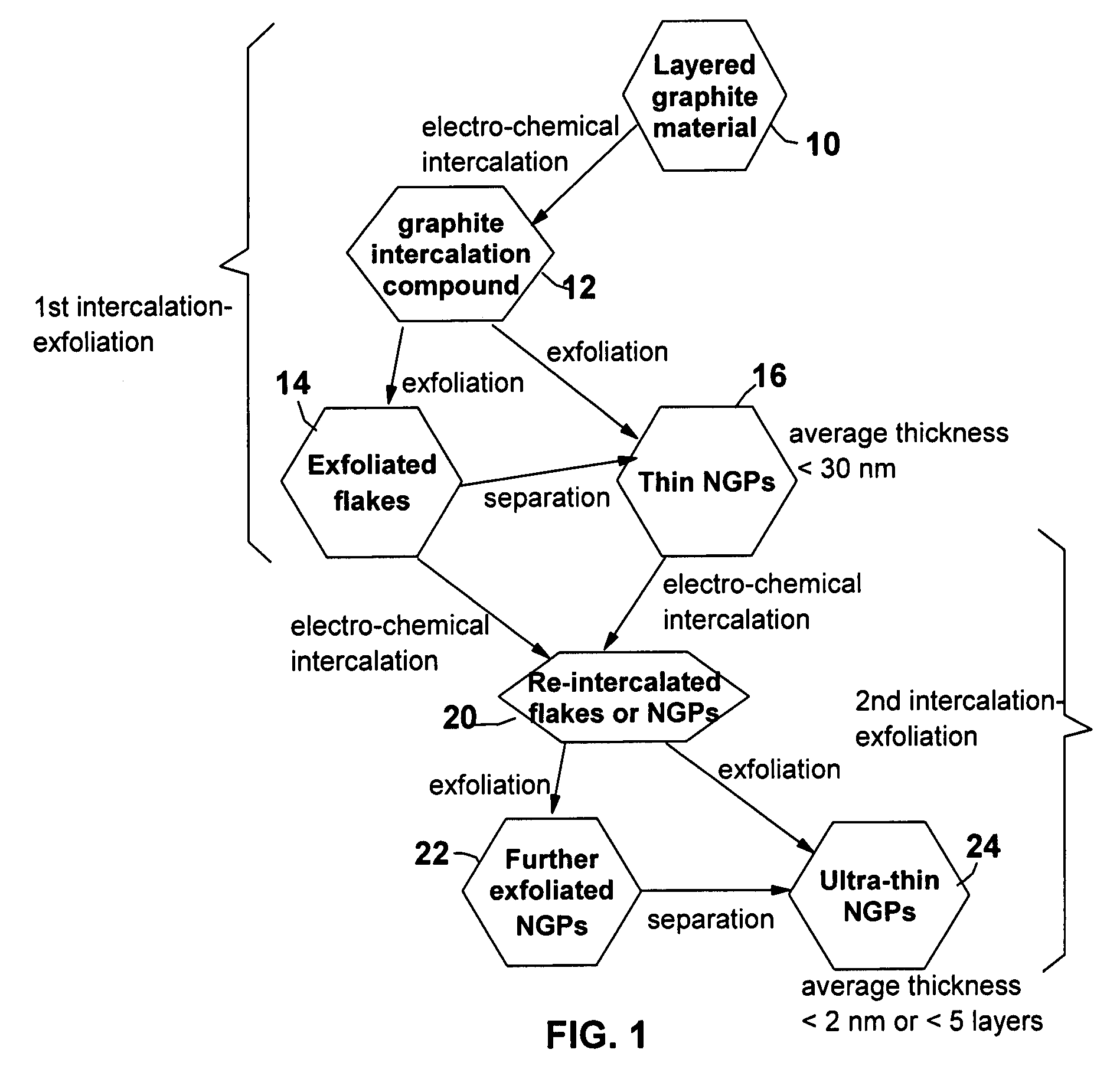

Method for producing ultra-thin nano-scaled graphene platelets

InactiveUS20090022649A1Good dispersionImprove conductivityMaterial nanotechnologyGraphiteFiberCarbon nanotube

A method of producing ultra-thin, separated nano-scaled platelets having an average thickness no greater than 2 nm or comprising, on average, no more than 5 layers per platelet from a layered graphite material. The method comprises: (a) providing a supply of nano-scaled platelets with an average thickness of no more than 10 nm or having, on average, no more than 30 layers per platelet; and (b) intercalating the supply of nano-scaled platelets to produce intercalated nano platelets and exfoliating the intercalated nano platelets at a temperature and a pressure for a sufficient period of time to produce the ultra-thin nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:NANOTEK INSTR

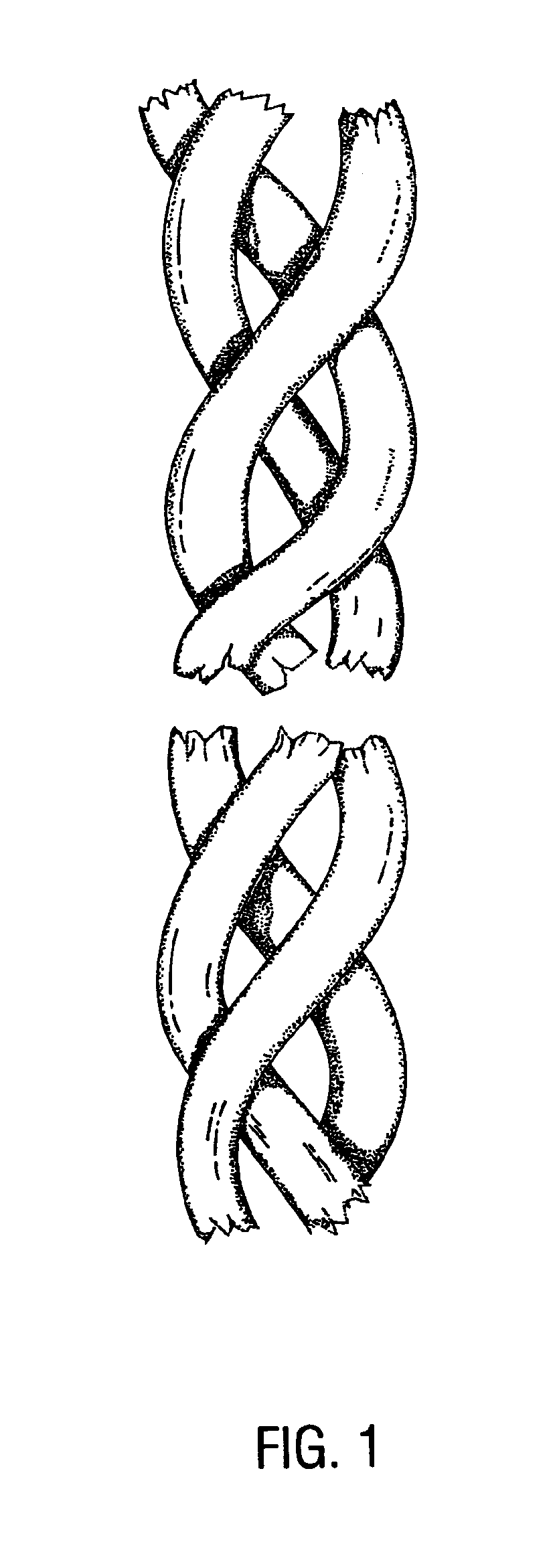

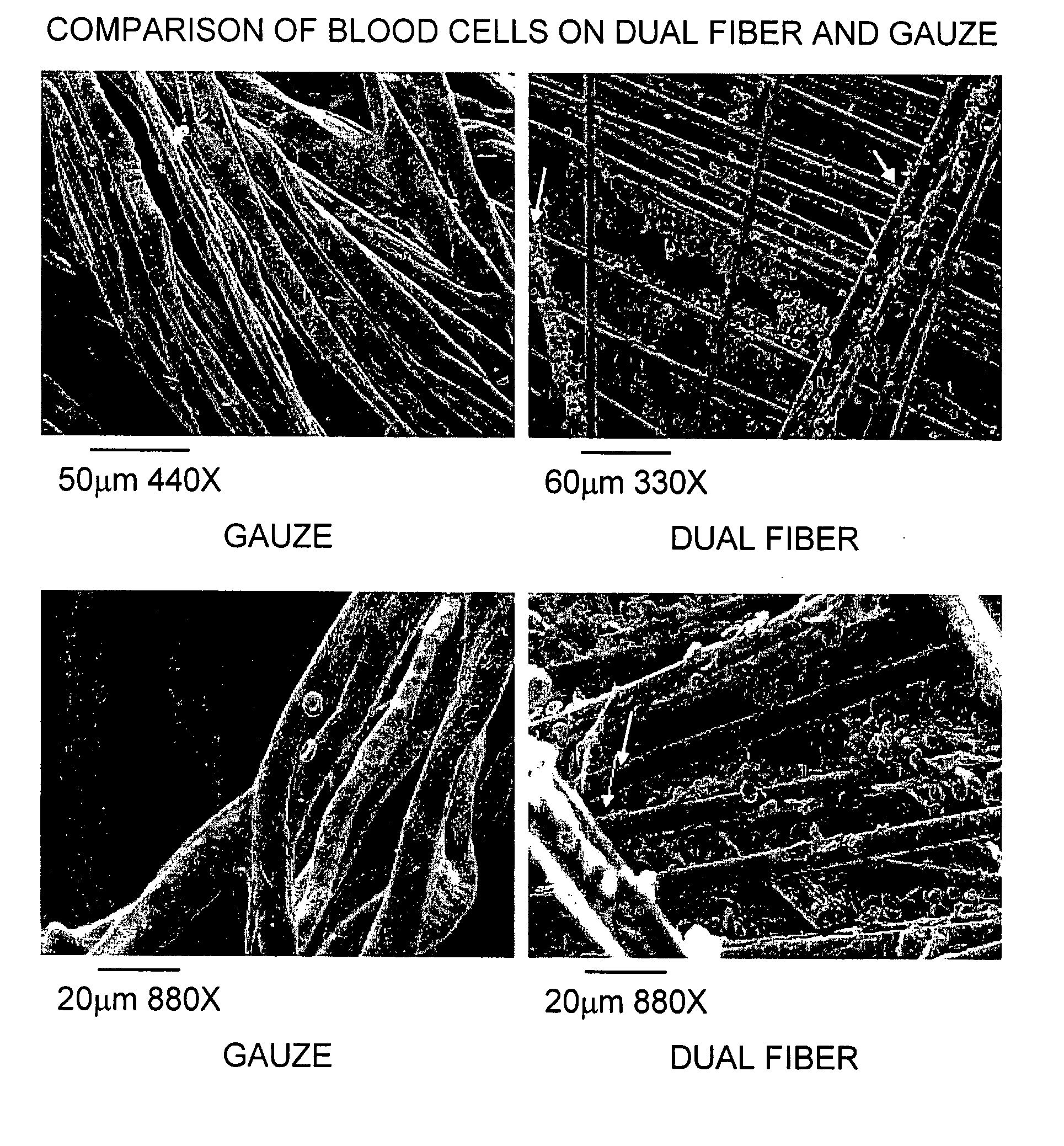

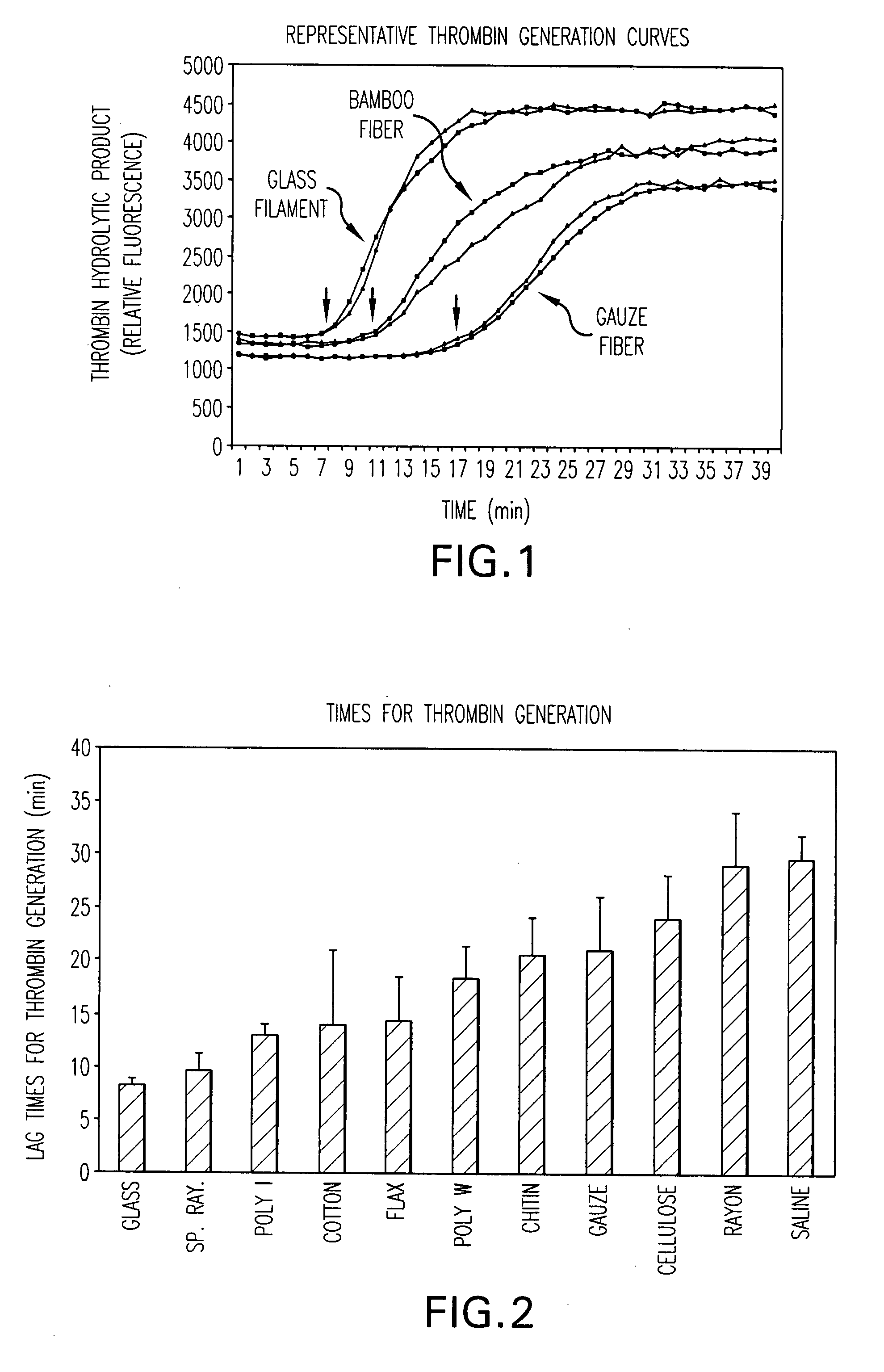

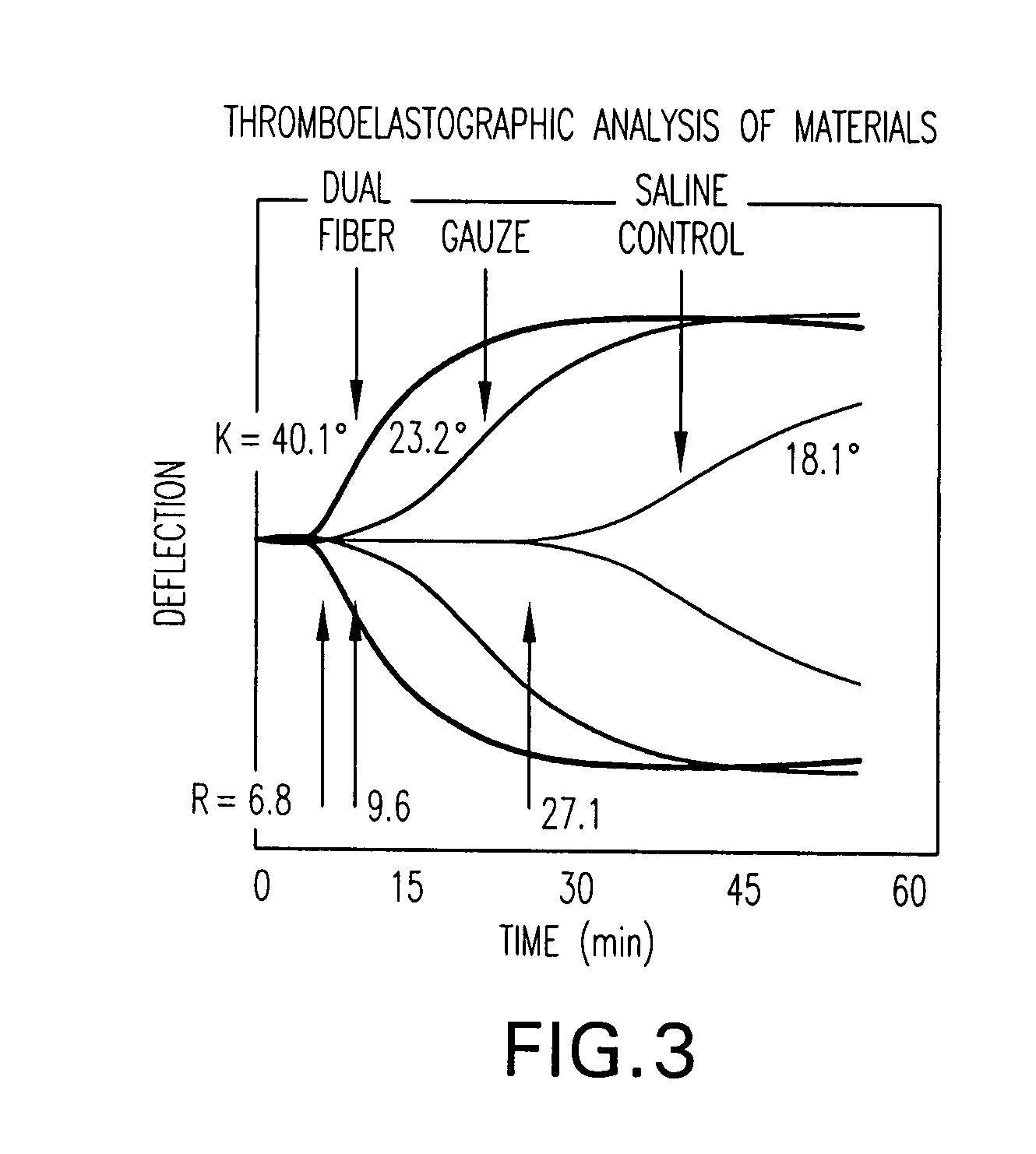

Hemostatic textile

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

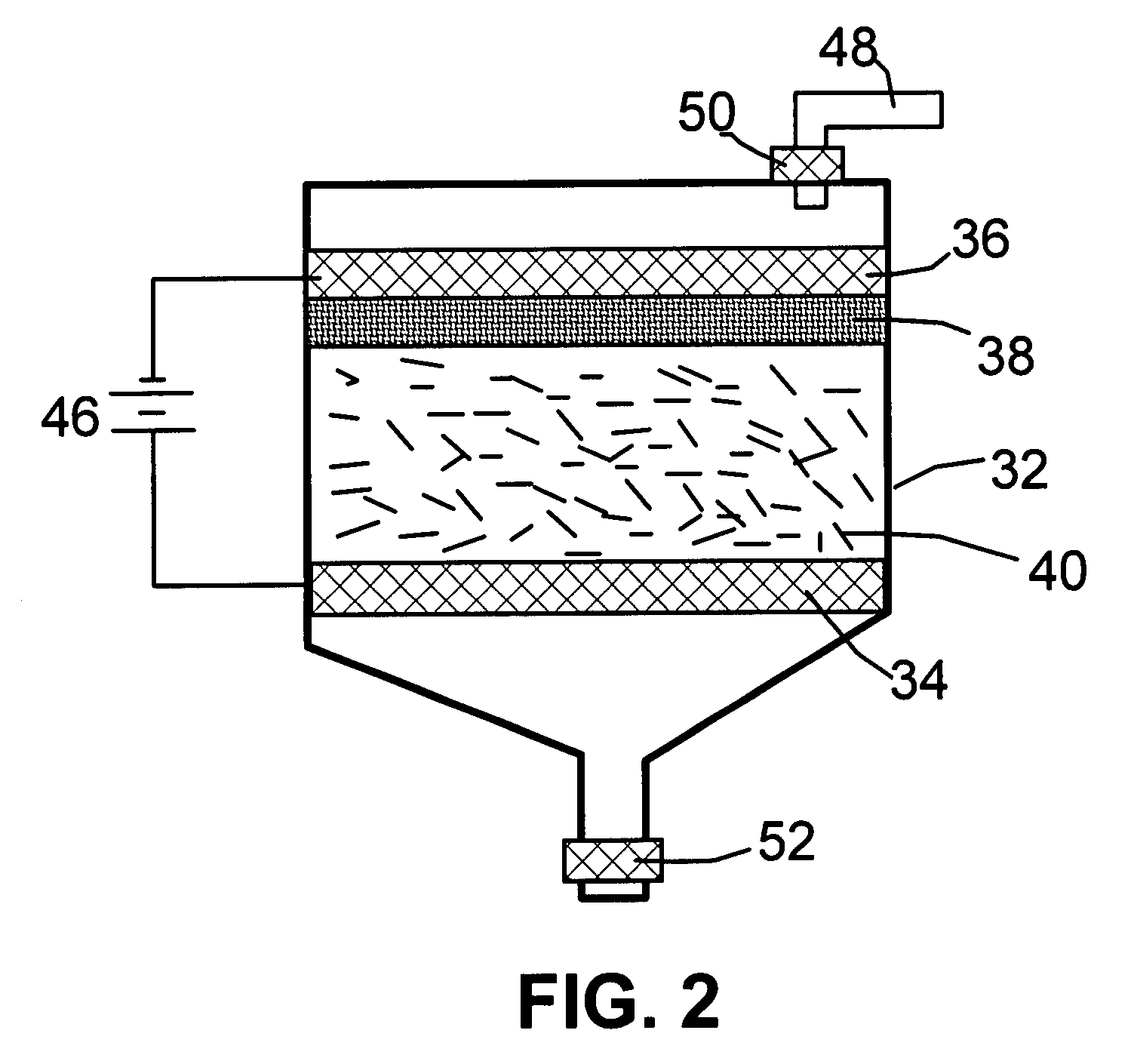

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

Systems and methods for mid-processing calculation of blood composition

Blood separation methods are provided for mid-processing calculation of blood composition. Blood is conveyed into a device having an outlet line and the device is spun to separate platelets from the blood. A flow of platelets is conveyed from the device by the outlet line and the platelets in the outlet line are optically measured. With said optical measurement, a current platelet yield, a platelet pre-count, the volume of blood to process to collect a target amount of platelets, and / or the processing time required to collect a target amount of platelets is calculated. The optical measurement can also be used to calculate an amount of storage fluid to convey into a collection container with the platelets.

Owner:FENWAL

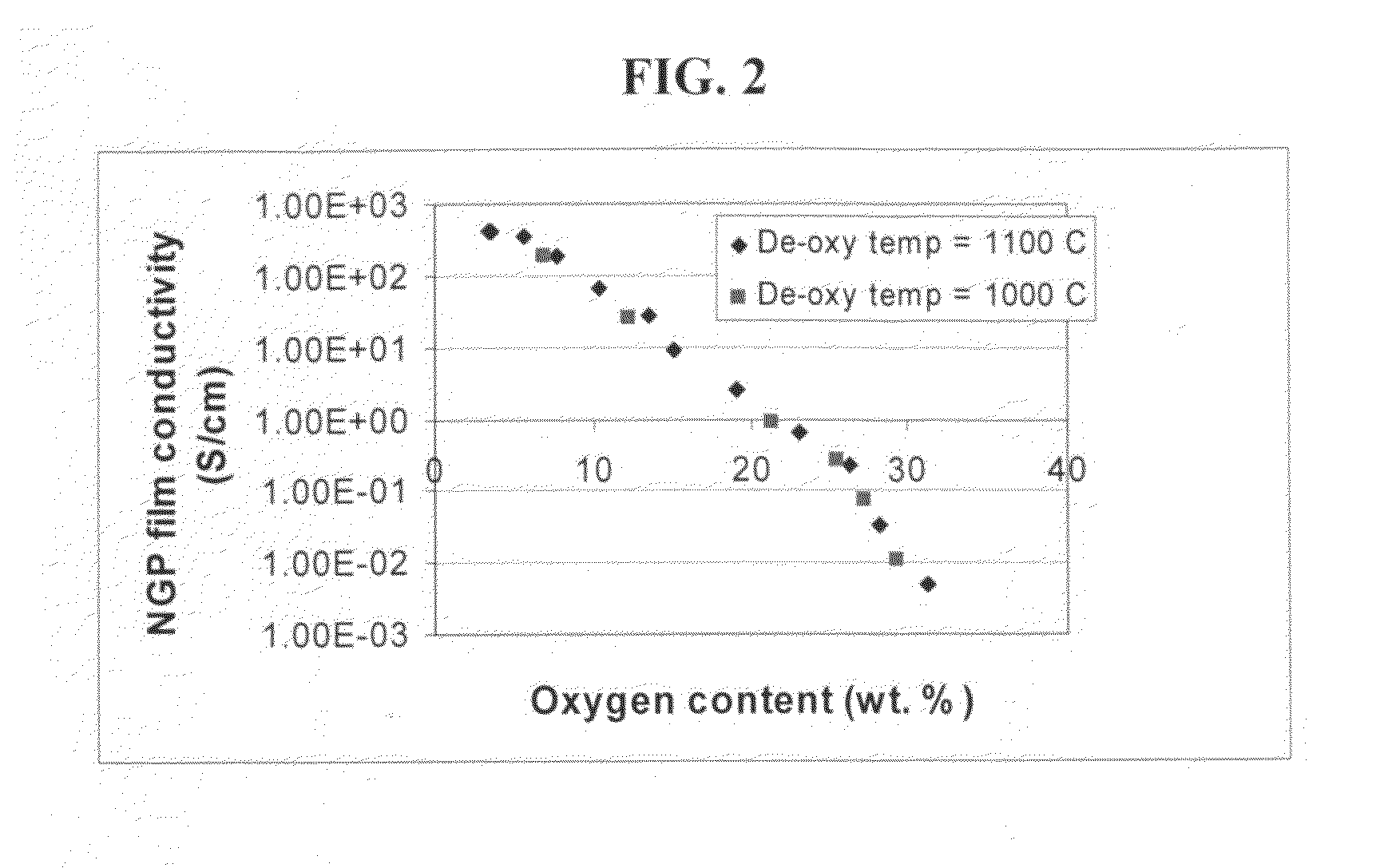

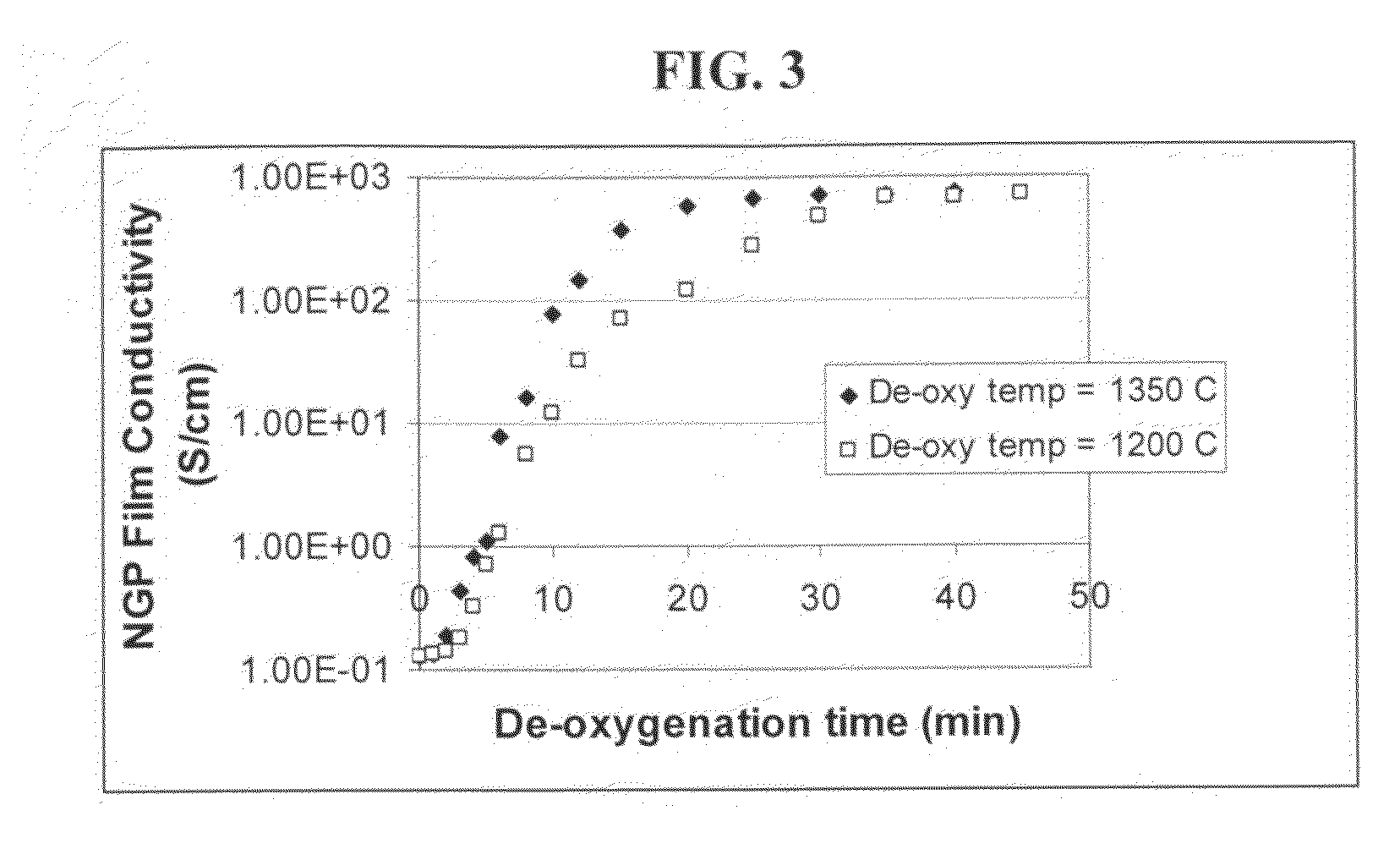

Process for producing dispersible and conductive Nano Graphene Platelets from non-oxidized graphitic materials

ActiveUS20100056819A1Impart dispersibilityImpart solubilityMaterial nanotechnologyPigmenting treatmentDisplay deviceSolar cell

The present invention provides a process for producing nano graphene platelets (NGPs) that are both dispersible and electrically conducting. The process comprises: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment to obtain the dispersible NGP material, wherein the NGP material has an oxygen content no greater than 25% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

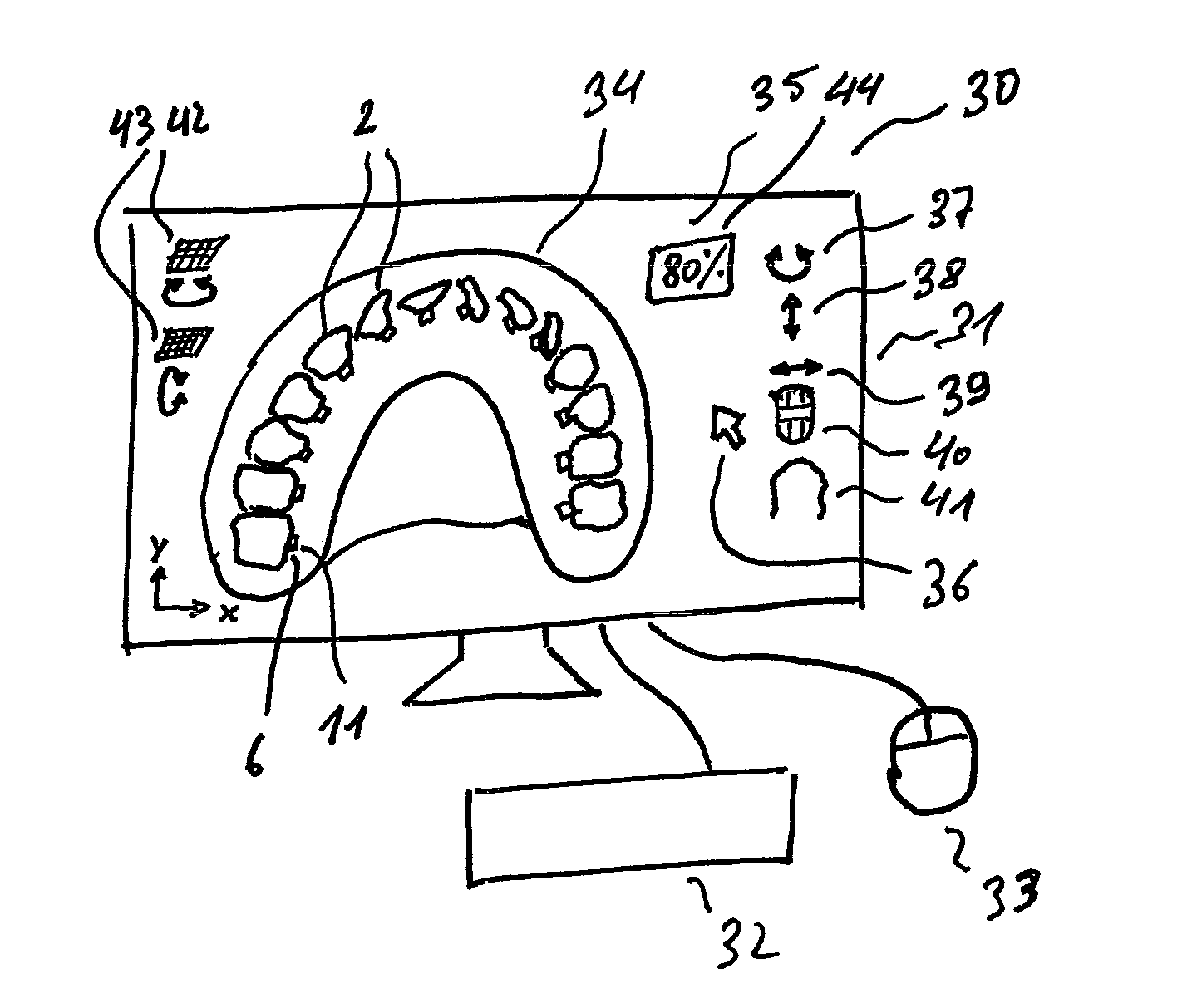

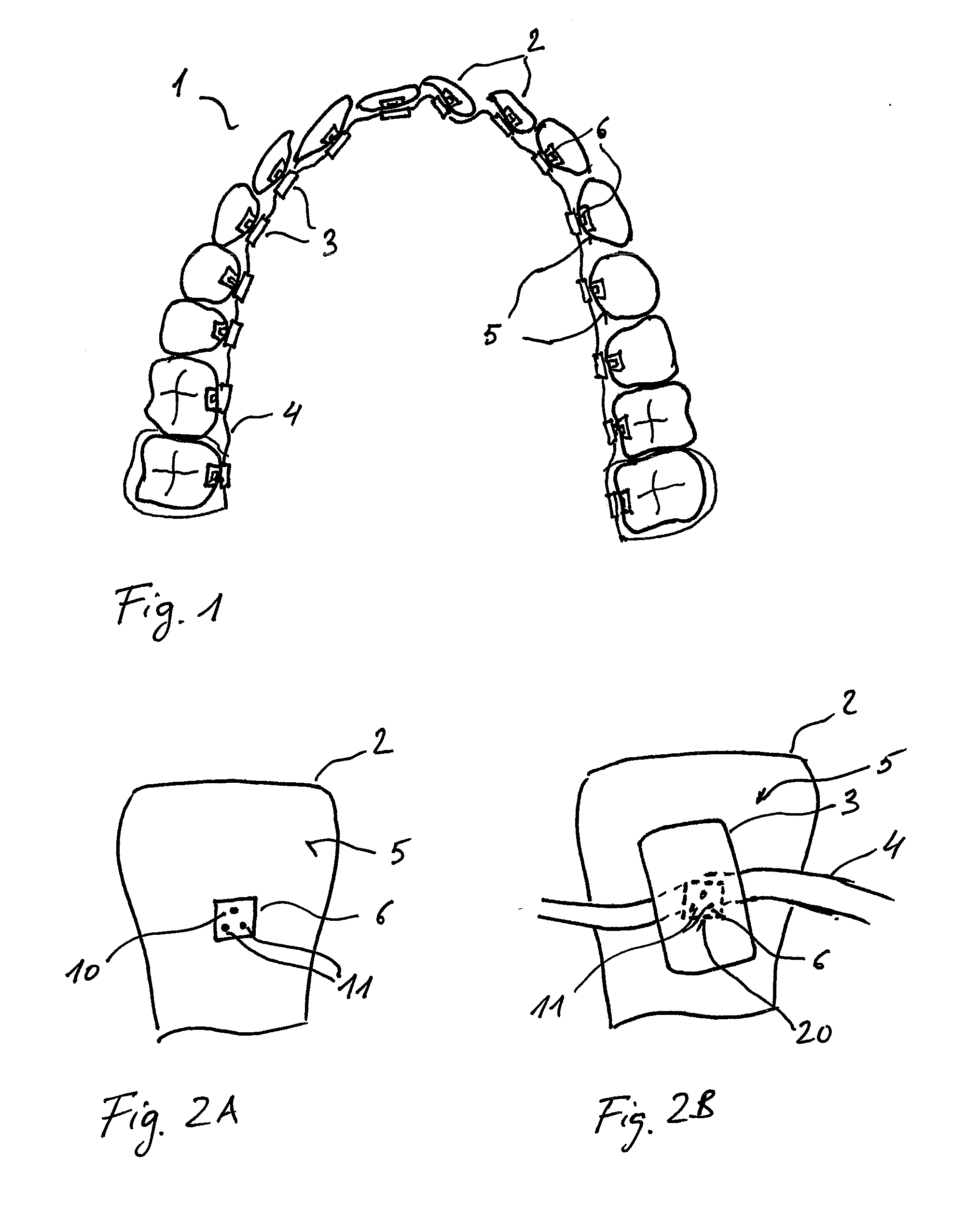

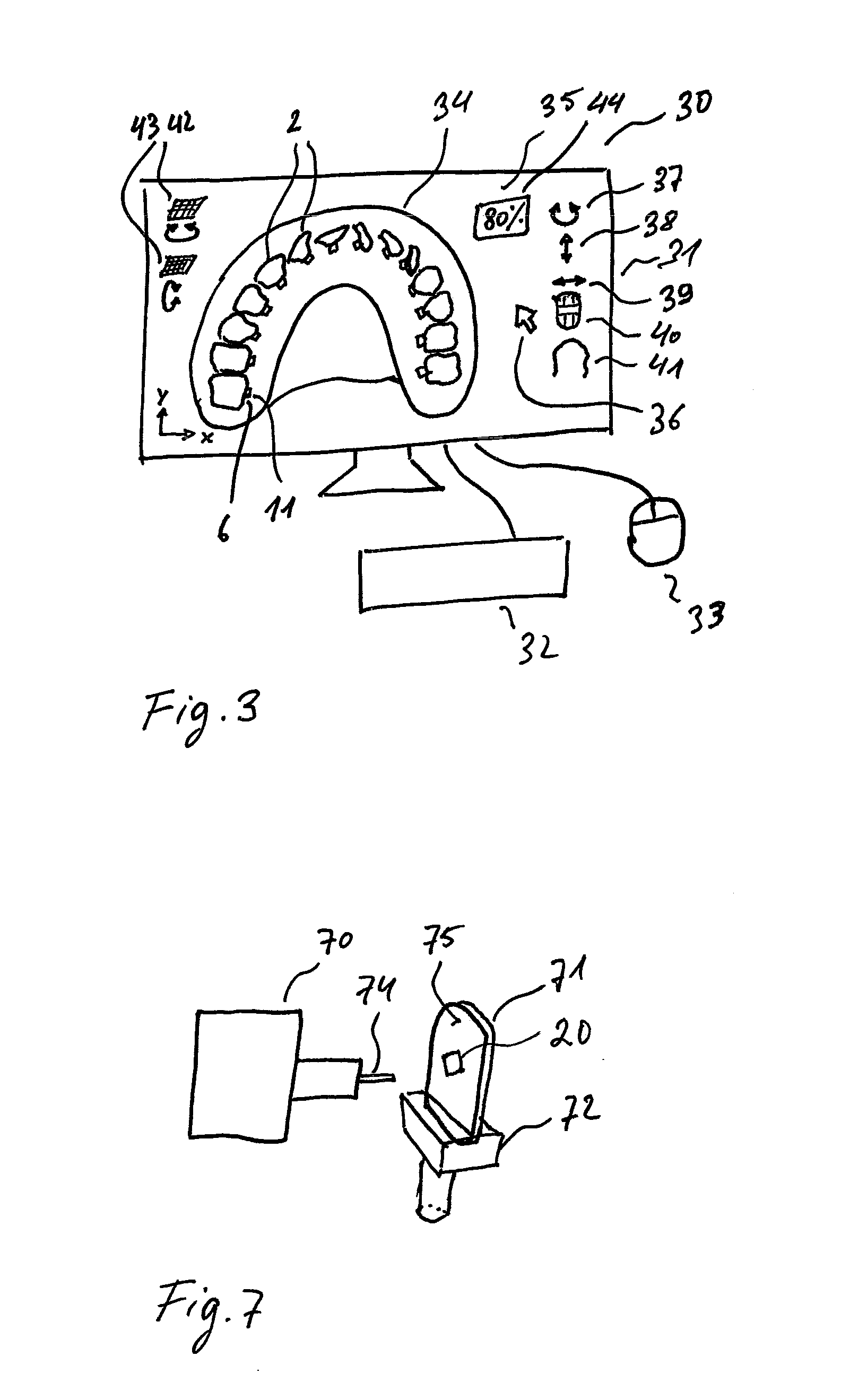

Bracket system and method for planning and producing a bracket system for the correction of tooth malpositions

The invention relates to a method for planning a bracket system (1) for the correction of malpositions of teeth (2), comprising a plurality of brackets (3) and an arch (4) wherein at least one platelet (6) per tooth is mounted on certain tooth surfaces (5) of the teeth to be corrected (2), a three-dimensional optical image (50) of the tooth region to be treated is created, the platelets (6) have registration elements (10) comprising registration points (11) and the registration points (11) have a characteristic form for registration in the three-dimensional optical image (50)

Owner:SIRONA DENTAL SYSTEMS

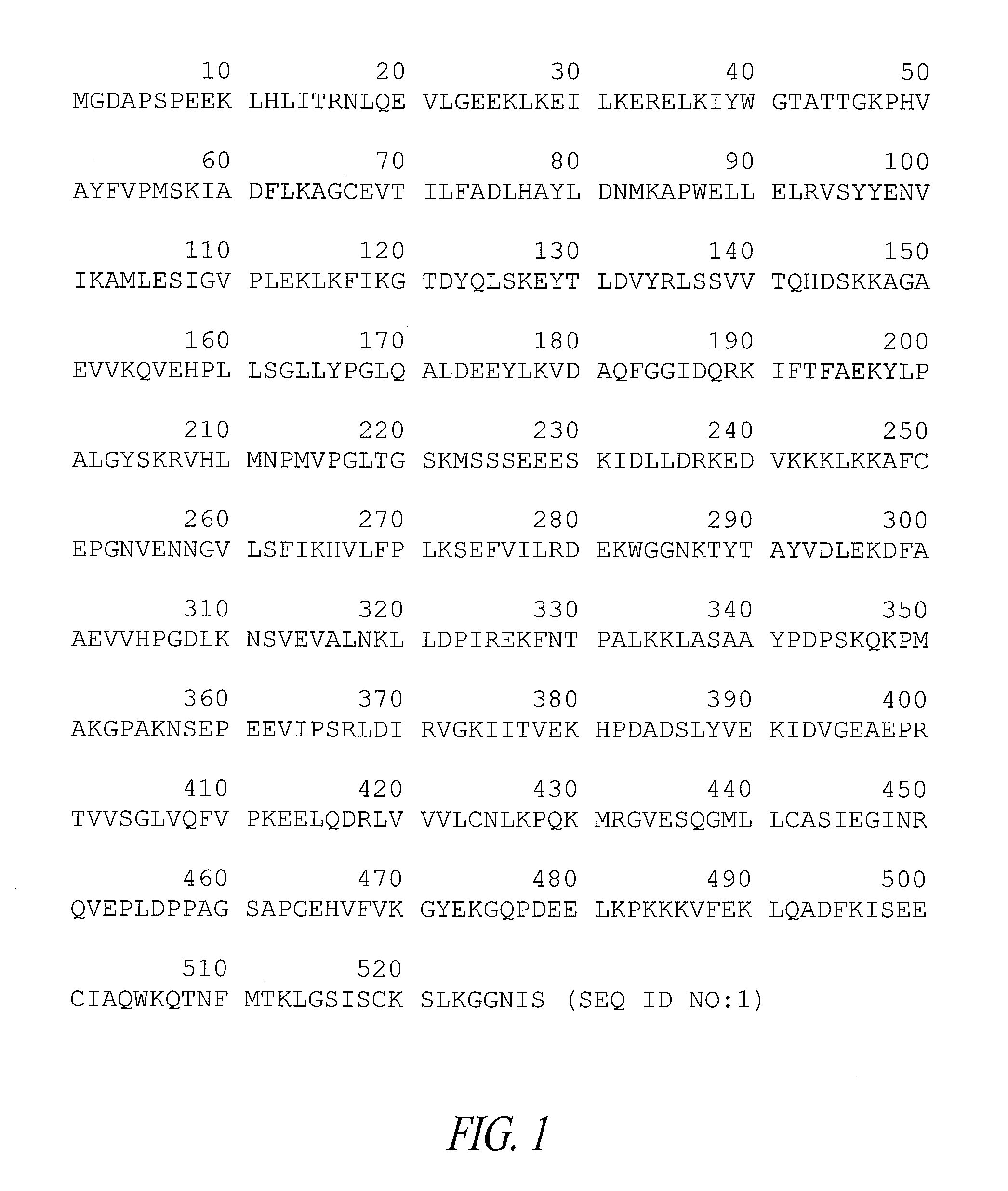

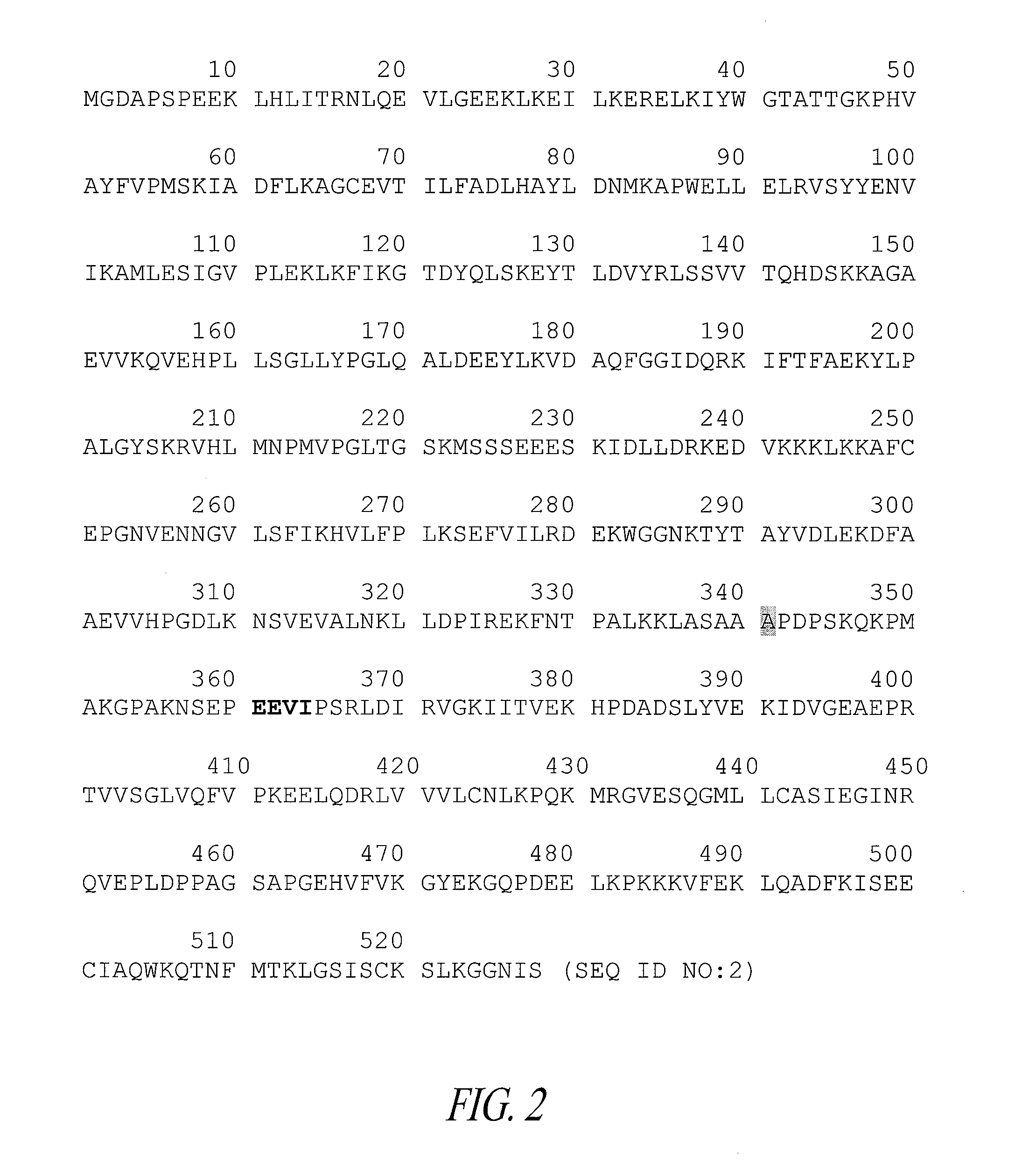

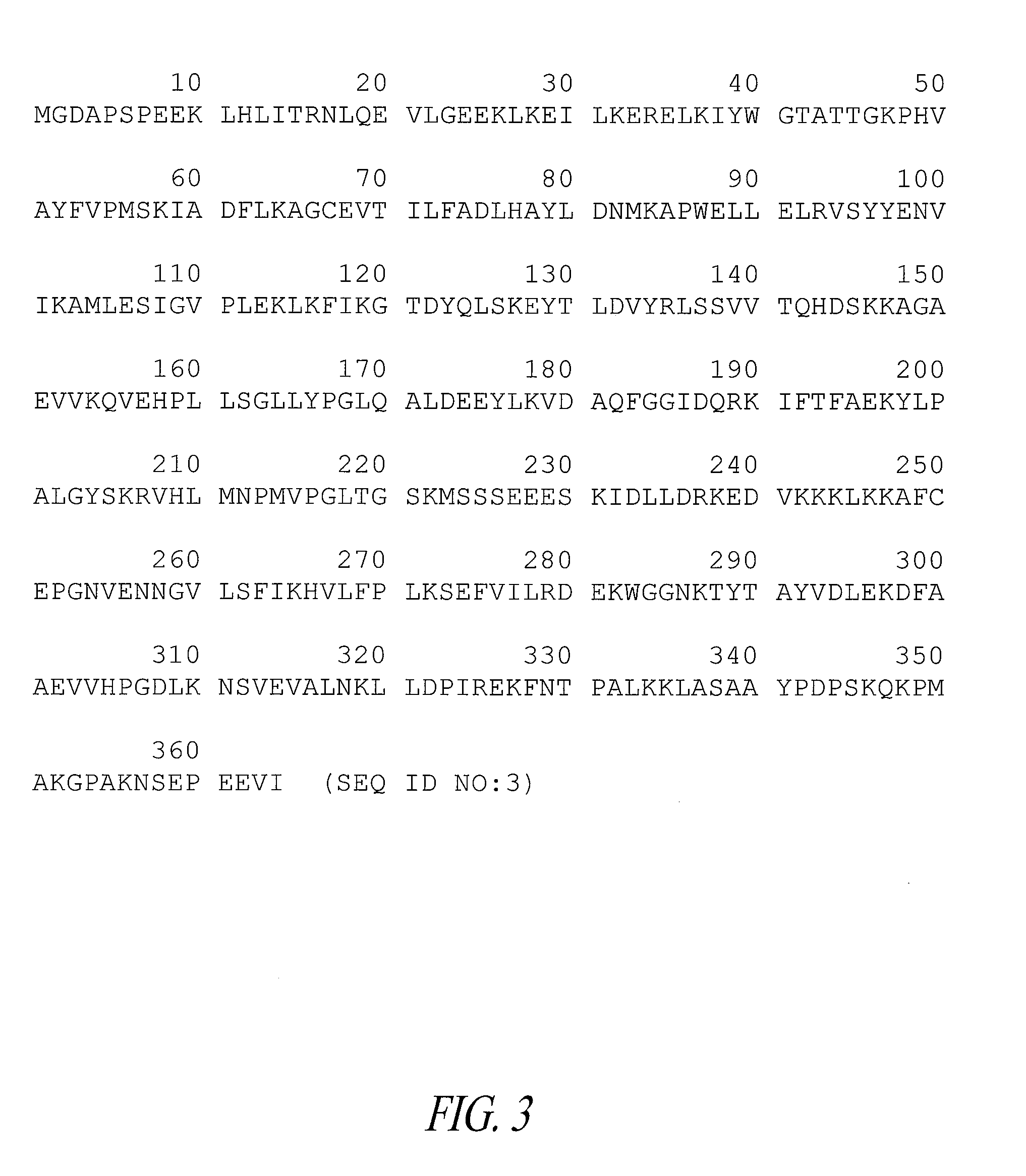

Thrombopoietic activity of tyrosyl-trna synthetase polypeptides

InactiveUS20100092434A1Reduce lung inflammationReduce inflammationBiocidePeptide/protein ingredientsTyrosyl-tRNA SynthetaseIncreased Thrombopoiesis

Thrombopoietic compositions are provided comprising tyrosyl tRNA synthetase polypeptides, including truncations and / or variants thereof. Also provided are methods of using such compositions in the treatment of conditions that benefit from increased thrombopoiesis, such as thrombocytopenia.

Owner:ATYR PHARM INC

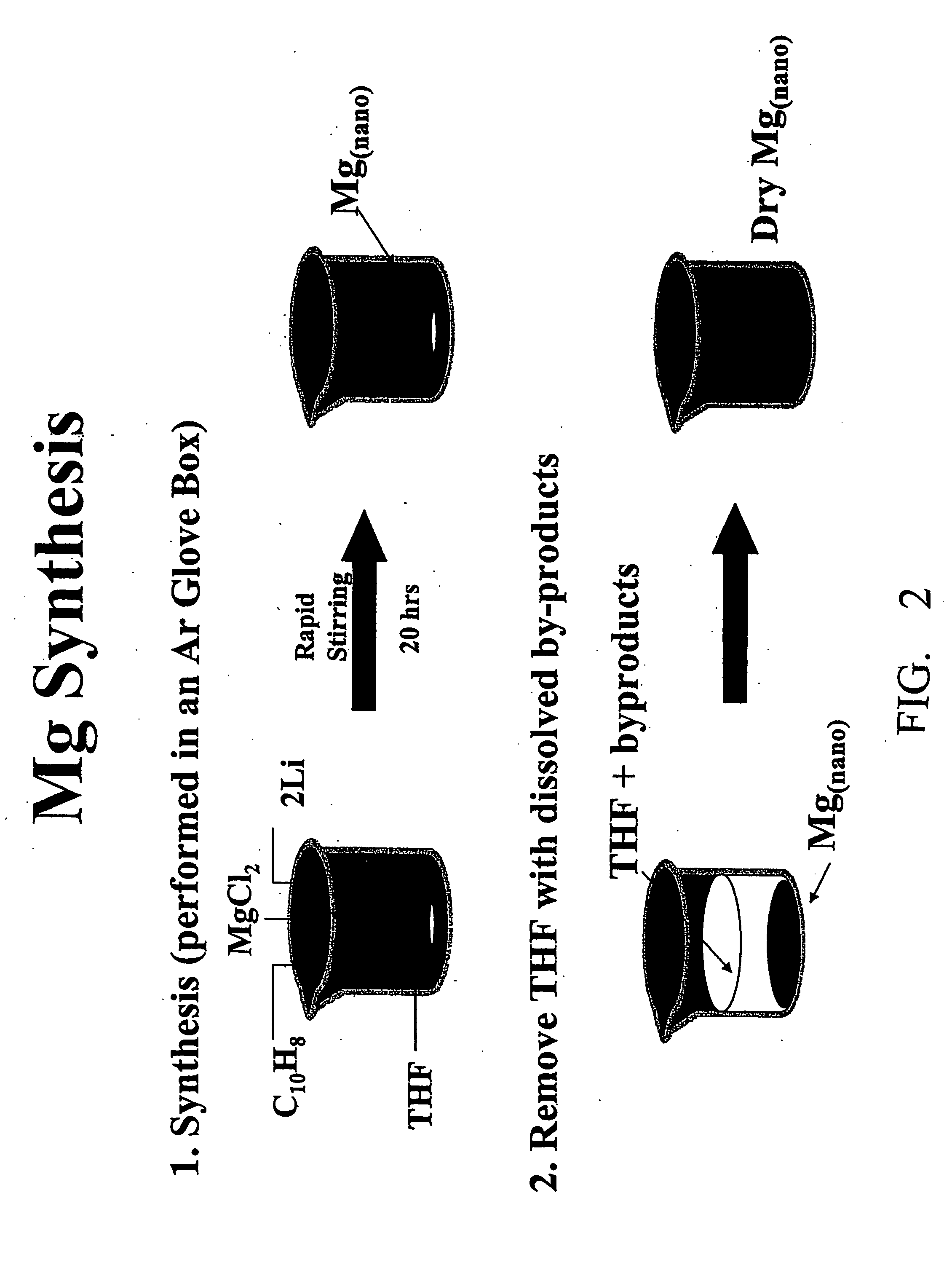

Hydrogen storage material based on platelets and/or a multilayered core/shell structure

A hydrogen storage material includes a nano size material that can be formed in a multi-layered core / shell structure and / or in a nanotabular (or platelet) form.

Owner:PENNSYLVANIA STATE UNIVERSITY

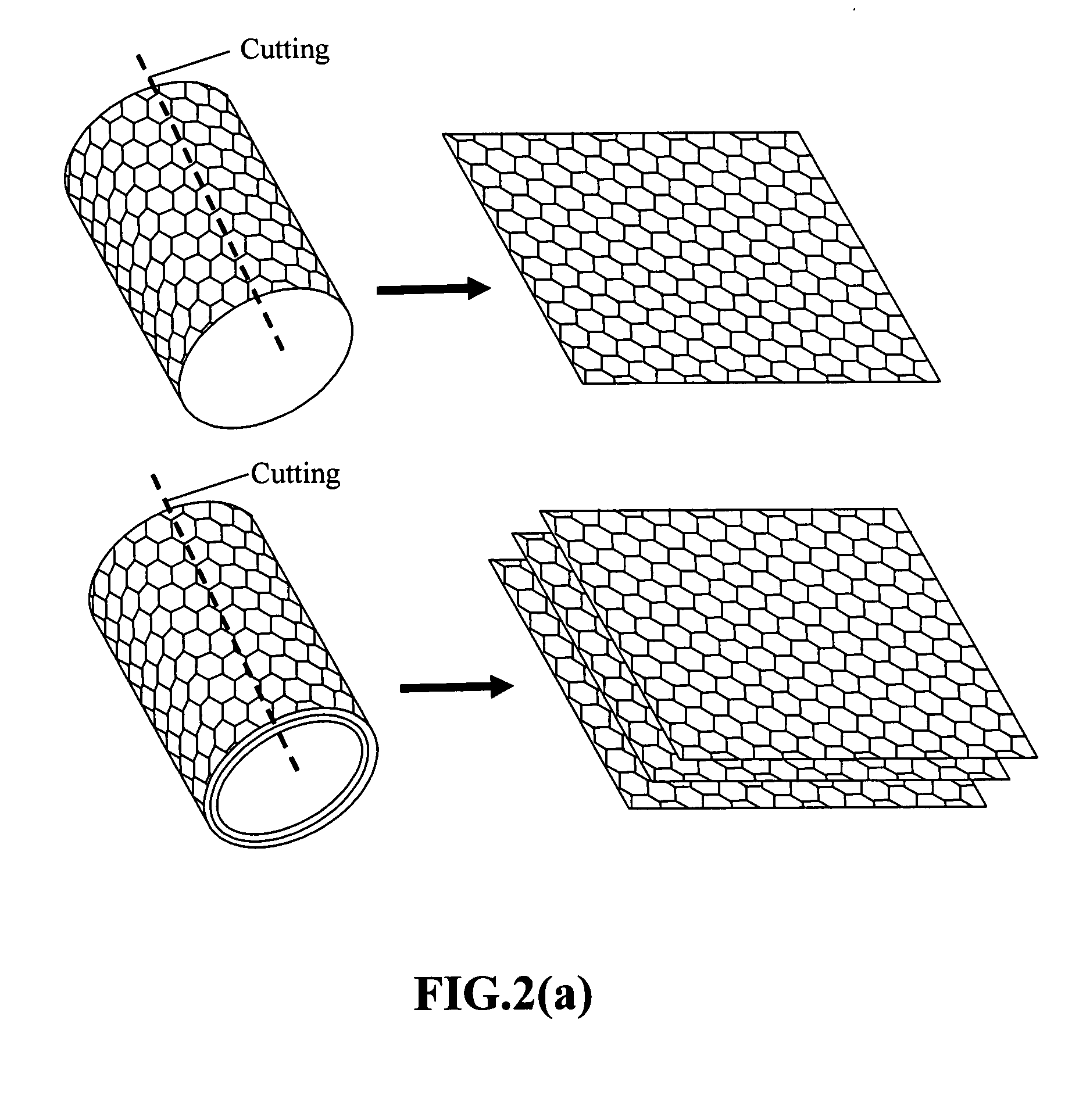

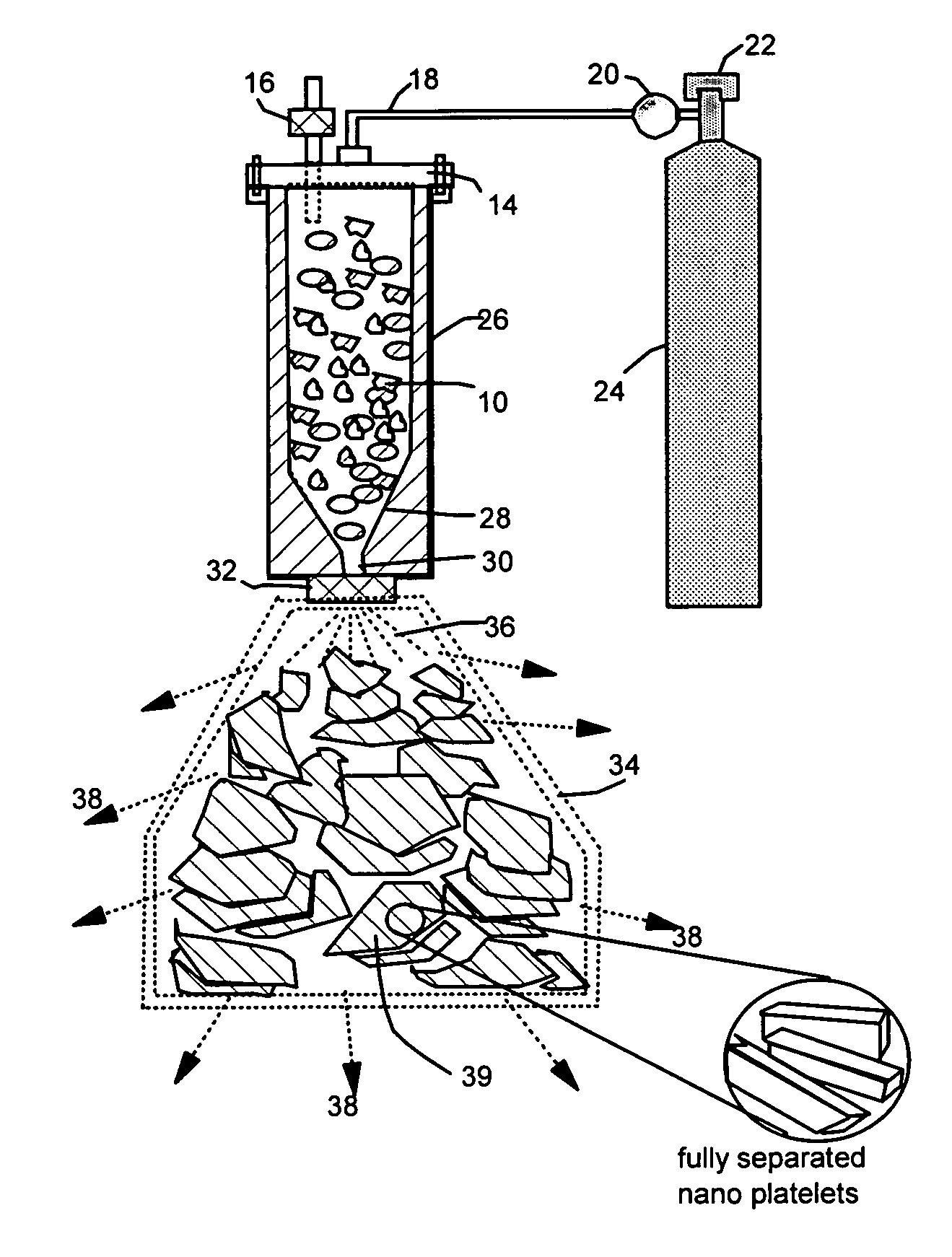

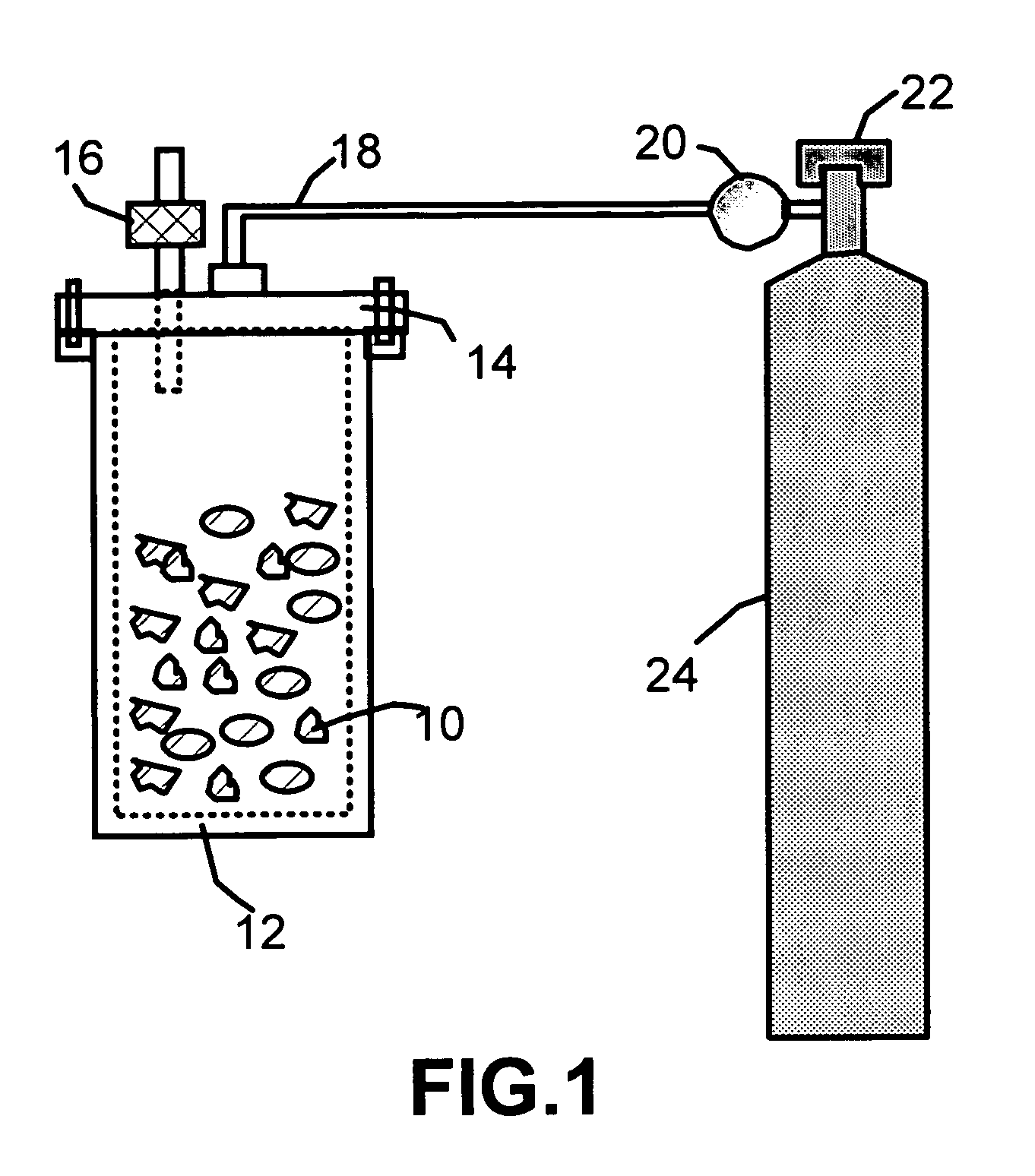

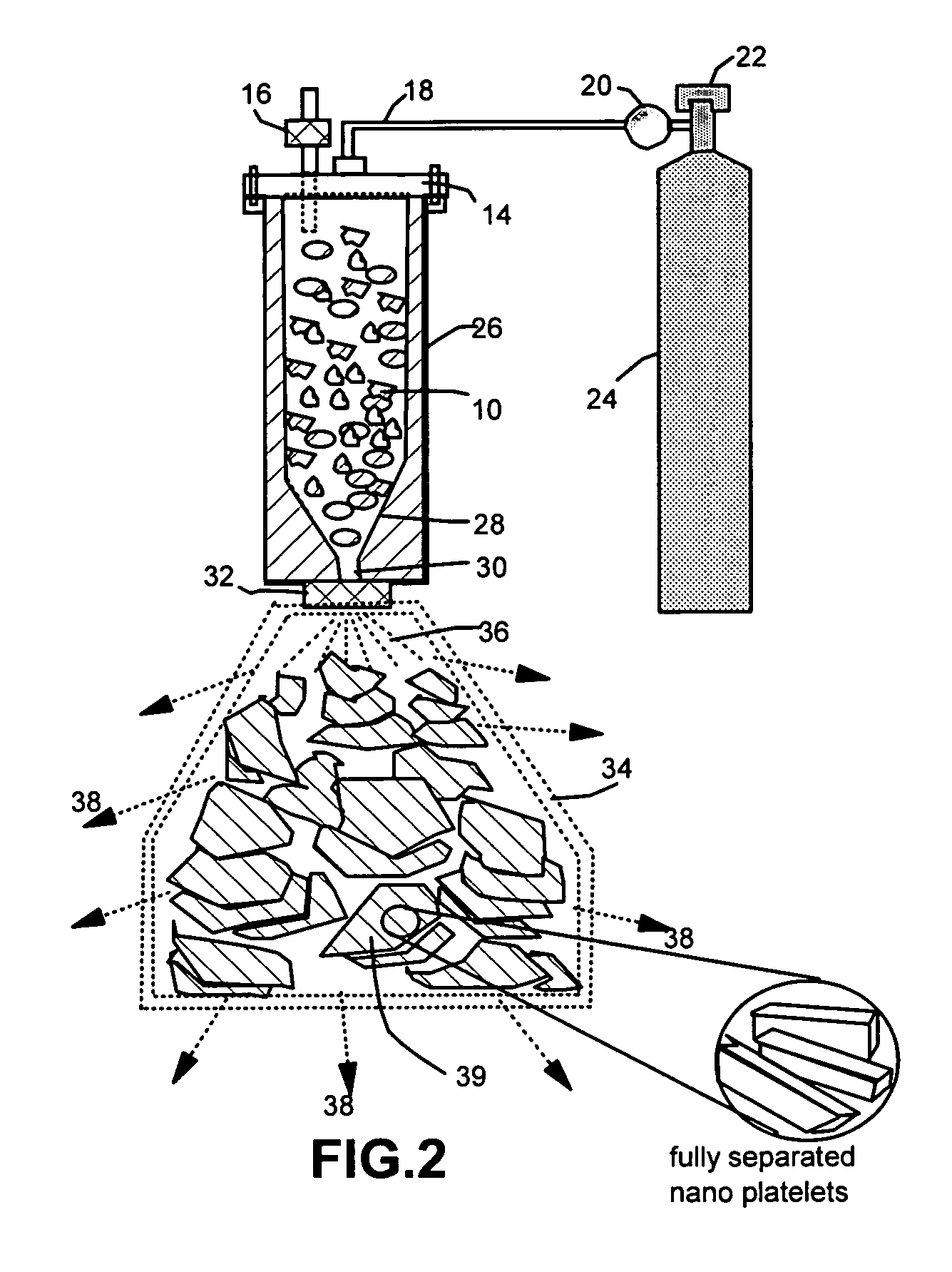

Mass production of nano-scaled platelets and products

ActiveUS7785492B1Reduce necessary intercalation timeSmall thicknessMaterial nanotechnologyGraphiteNoble gasGraphite

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) charging a layered material to an intercalation chamber comprising a gaseous environment at a first temperature and a first pressure sufficient to cause gas species to penetrate into the interstitial space between layers of the layered material, forming a gas-intercalated layered material; and (b) operating a discharge valve to rapidly eject the gas-intercalated layered material through a nozzle into an exfoliation zone at a second pressure and a second temperature, allowing gas species residing in the interstitial space to exfoliate the layered material to produce the platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can additionally include dispersing the platelets in a matrix material to form a nanocomposite. The process also can include an additional process of re-compressing the nana-scaled platelets into a product such as a flexible graphite sheet.

Owner:GLOBAL GRAPHENE GRP INC

Membranes with fluid barrier properties and articles containing such membranes

InactiveUS20050031816A1Increases ability of to preventReduce reboundMaterial nanotechnologySolesElastomerPlatelet

A membrane comprising at least one elastomeric material, at least one polymeric fluid barrier material, and a laminar nano-filler having an average platelet thickness of up to about 10 nanometers and an average aspect ratio of at least about 200 provides desirable appearance and low gas transmission characteristics. The membrane may be a single layer, but preferably the membrane includes at least one layer of an elastomeric material and at least one layer of a polymeric barrier material, in which the elastomeric material layer and / or the polymeric barrier material layer comprises the laminar nano-filler.

Owner:NIKE INTERNATIONAL LTD

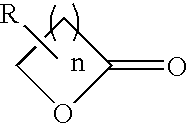

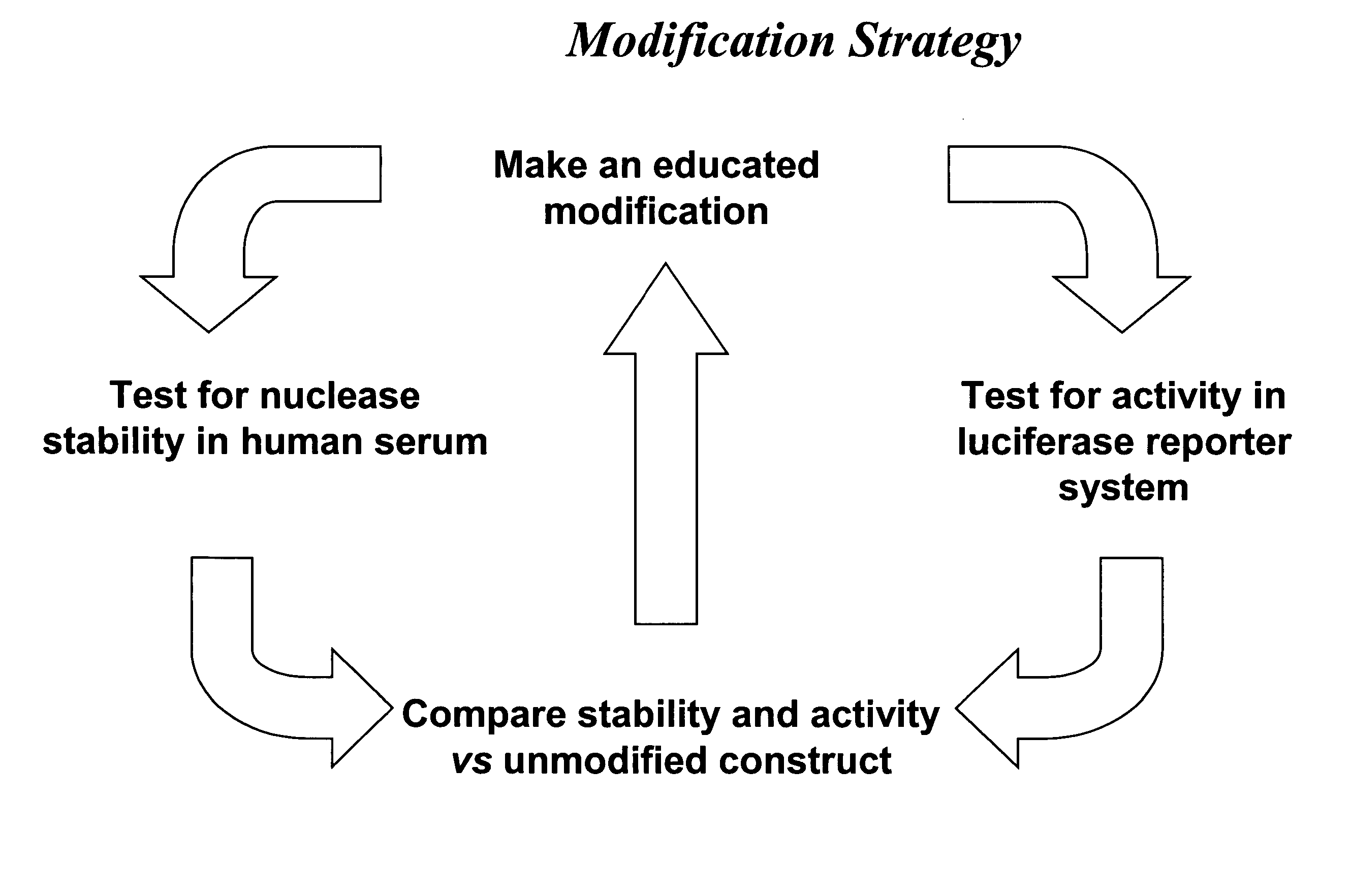

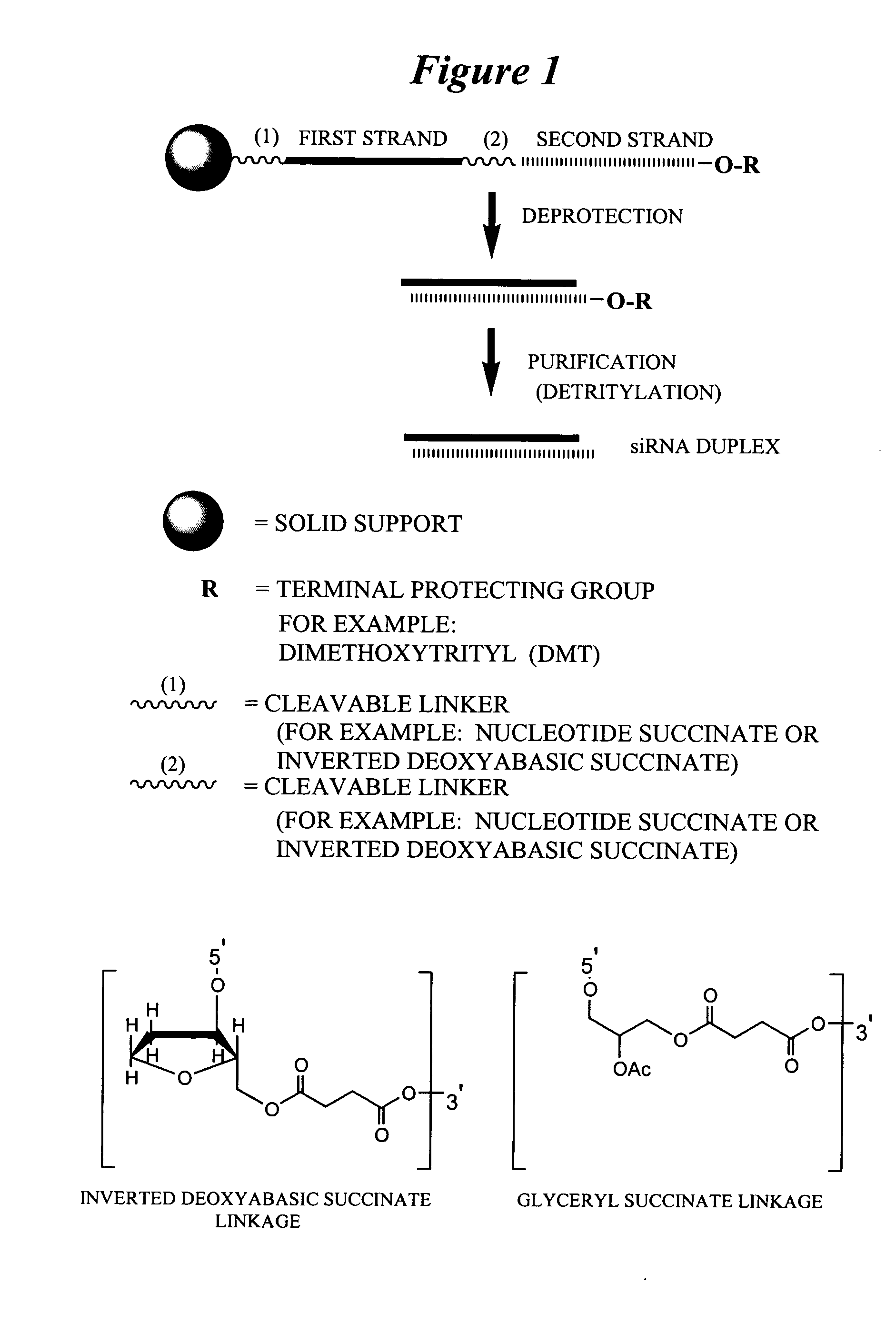

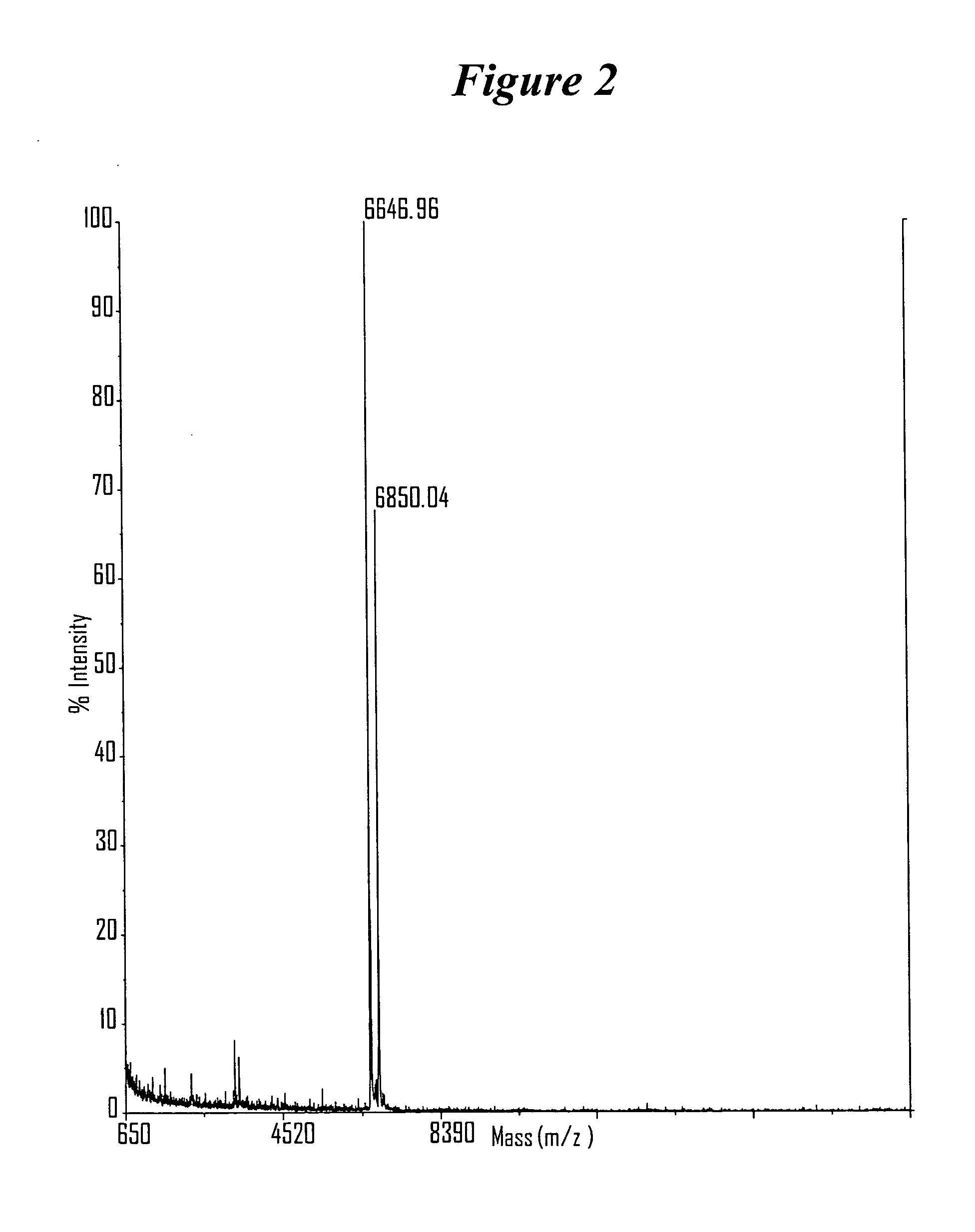

RNA interference mediated inhibition of platelet-derived endothelial cell growth factor (ECGF1) gene expression using short interfering nucleic acid (siNA)

InactiveUS20050106726A1Strong specificityIncrease serum stabilitySugar derivativesActivity regulationDiseaseDiabetic retinopathy

The present invention concerns methods and reagents useful in modulating platelet-derived endothelial cell growth factor (ECGF1) and / or platelet-derived endothelial cell growth factor receptor (e.g., ECGF1r) gene expression in a variety of applications, including use in therapeutic, diagnostic, target validation, and genomic discovery applications. Specifically, the invention relates to small nucleic acid molecules, such as short interfering nucleic acid (siNA), short interfering RNA (siRNA), double-stranded RNA (dsRNA), micro-RNA (miRNA), and short hairpin RNA (shRNA) molecules capable of mediating RNA interference (RNAi) against ECGF1 and / or ECGF1r gene expression and / or activity. The small nucleic acid molecules are useful in the diagnosis and treatment of cancer, proliferative diseases, macular degeneration, diabetic retinopathy, and any other disease or condition that responds to modulation of ECGF1 and / or ECGF1r expression or activity.

Owner:SIRNA THERAPEUTICS INC

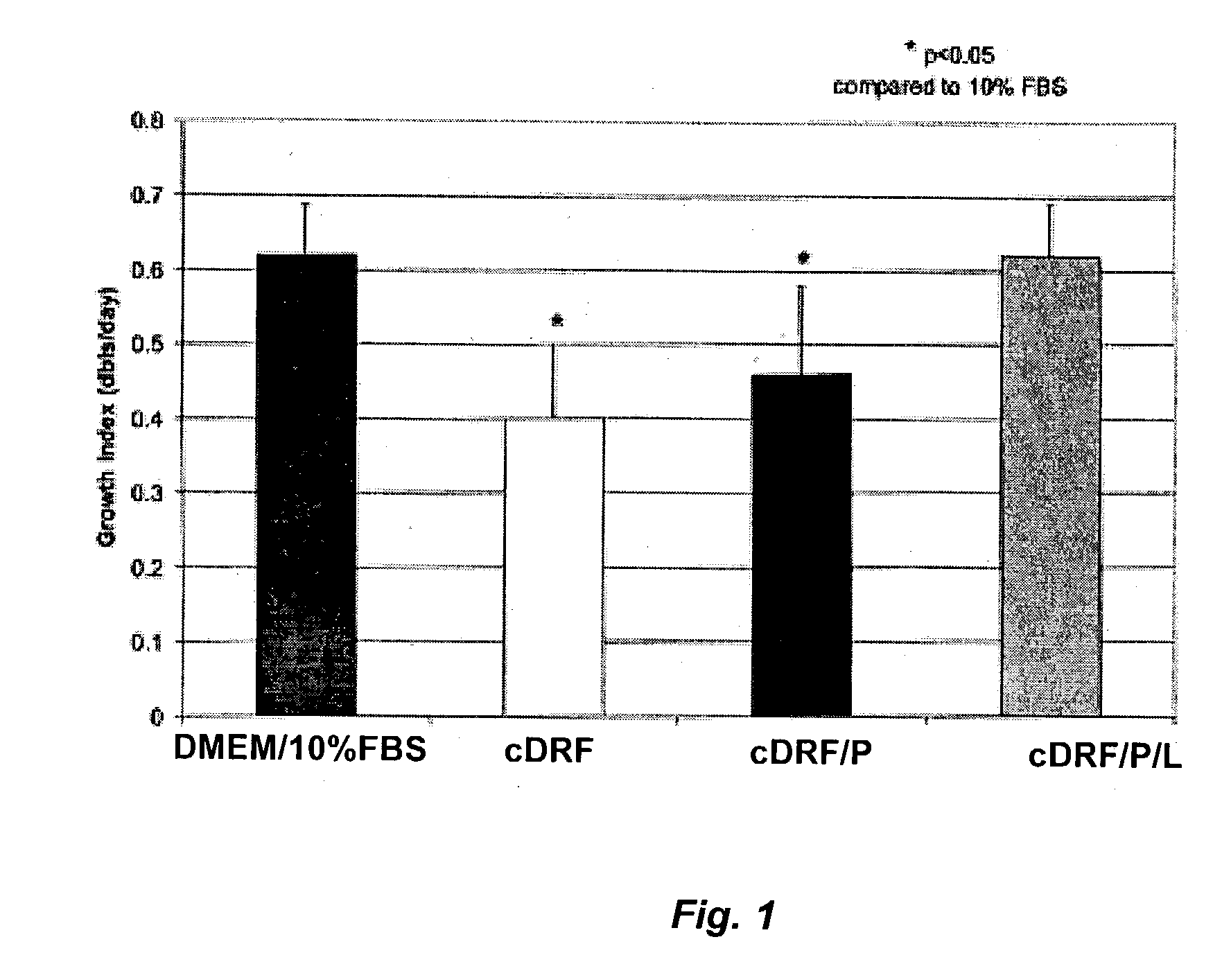

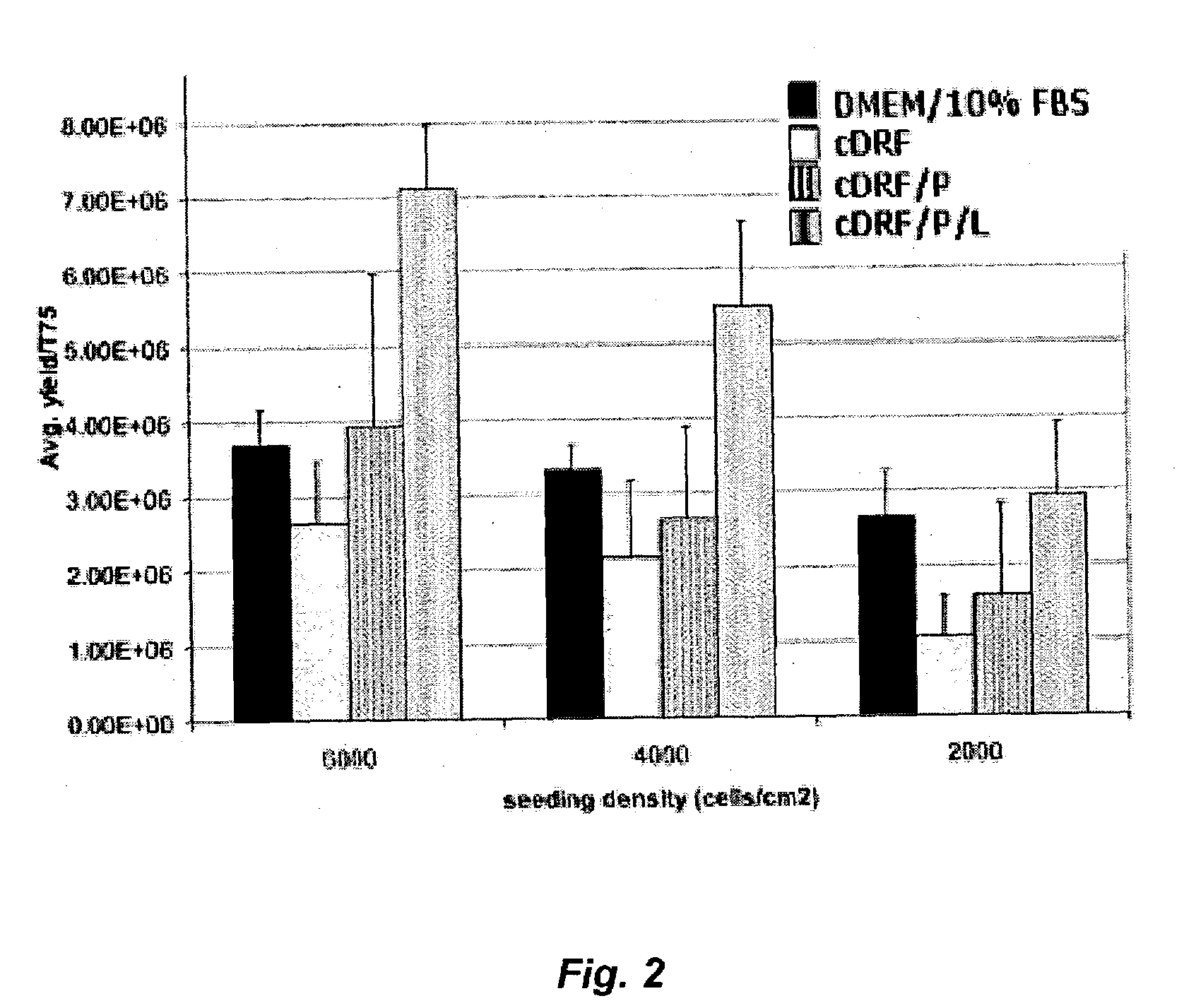

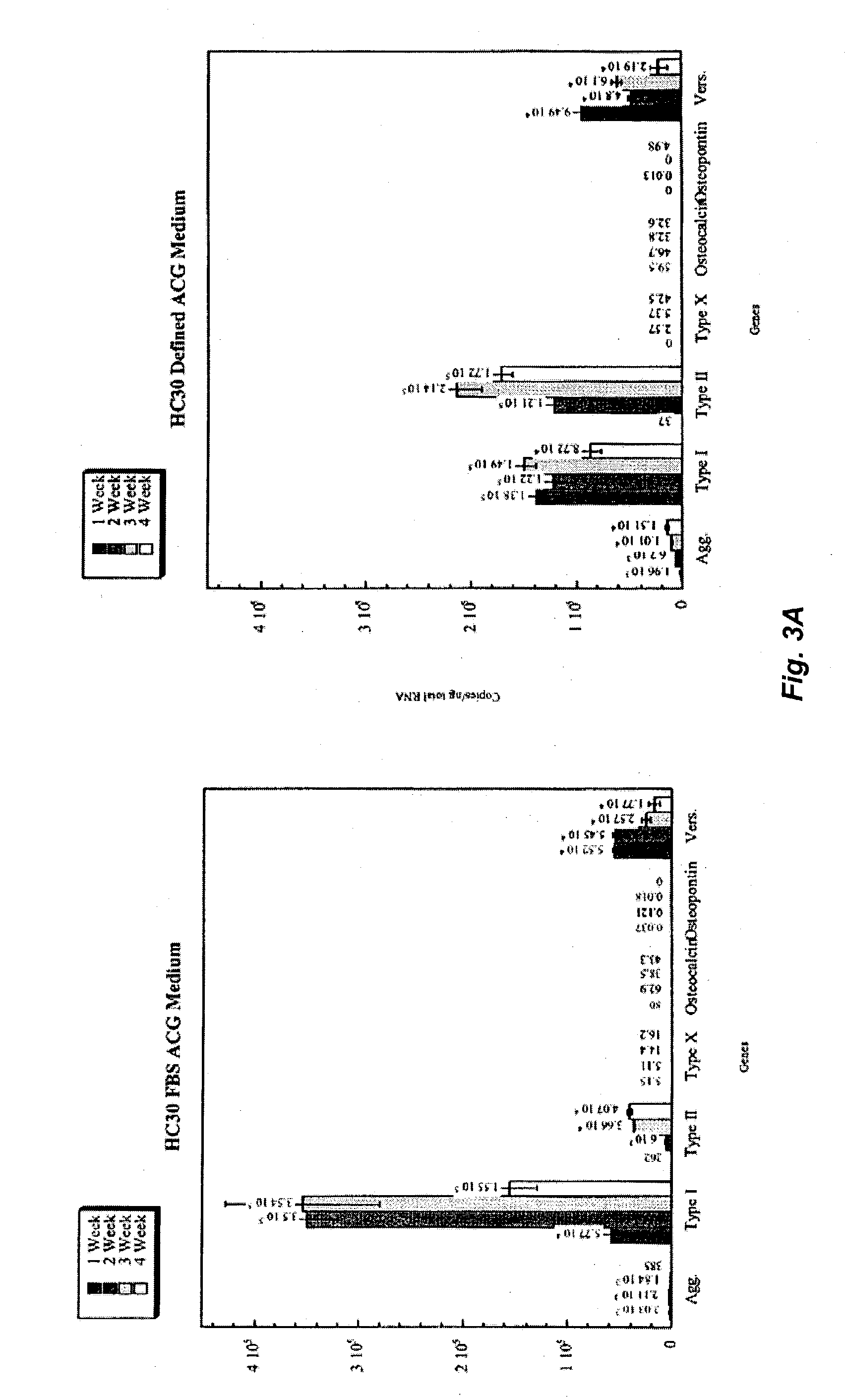

Serum-free media for chondrocytes and methods of use thereof

InactiveUS7169610B2Safe effective inexpensiveSafe and effective and inexpensiveCulture processArtificial cell constructsLipid formationSerum free media

The present invention provides defined serum-free cell culture media useful in culturing fibroblasts, especially articular chondrocytes, that avoids problems inherent in the use of serum-containing media. The defined media comprise platelet-derived growth factor (PDGF), and chemically defined lipids, or combinations of these compounds. In another aspect, the present invention also provides tissue culture methods that comprise incubating chondrocytes in the defined serum free media. The methods enhance attachment and proliferative expansion of chondrocytes seeded at low density while maintaining their redifferentiation potential.

Owner:GENZYME CORP

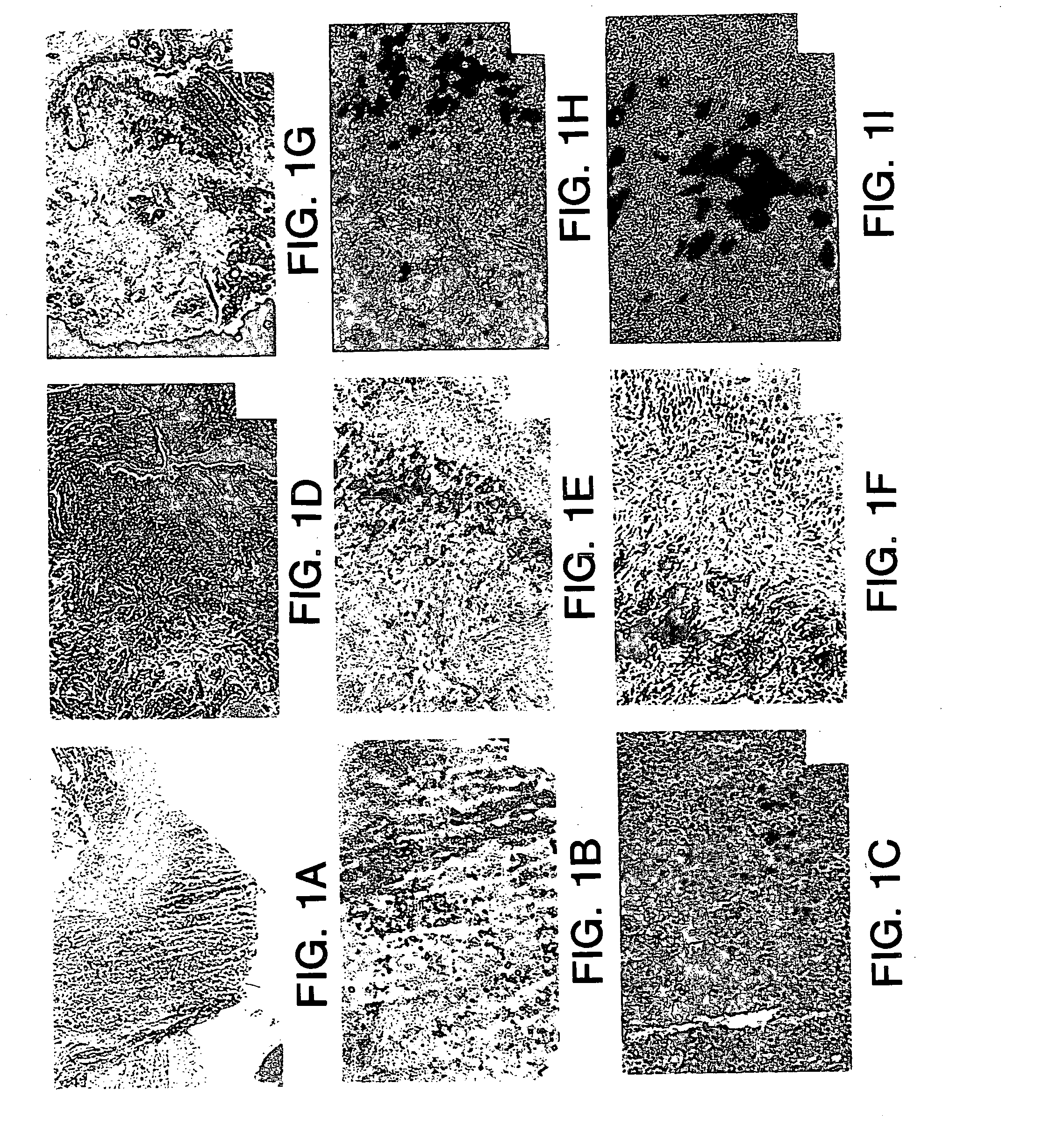

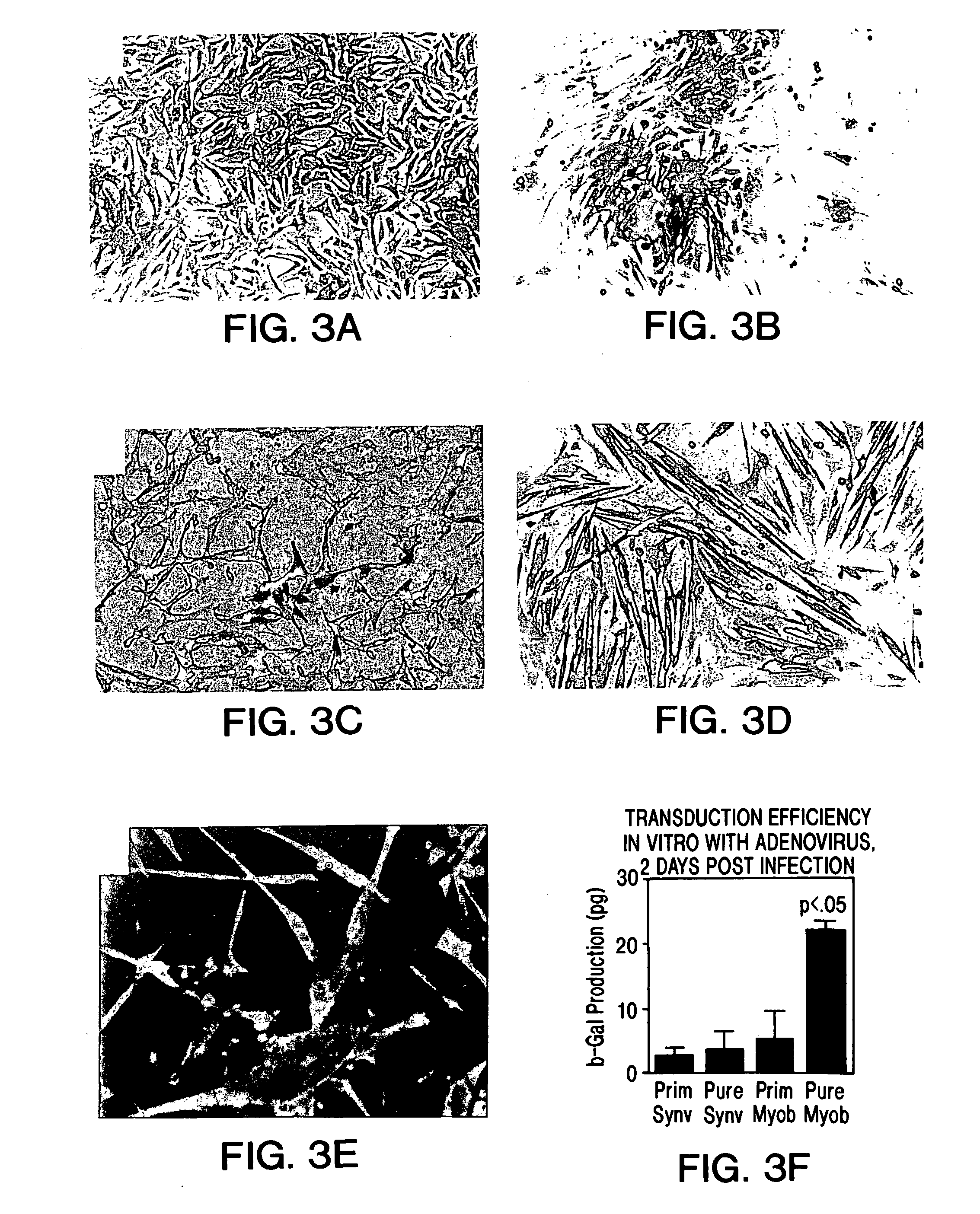

Muscle-derived cells (MDCs) for treating muscle- or bone-related injury or dysfunction

The present invention provides muscle-derived cells, preferably myoblasts and muscle-derived stem cells, genetically engineered to contain and express one or more heterologous genes or functional segments of such genes, for delivery of the encoded gene products at or near sites of musculoskeletal, bone, ligament, meniscus, cartilage or genitourinary disease, injury, defect, or dysfunction. Ex vivo myoblast mediated gene delivery of human inducible nitric oxide synthase, and the resulting production of nitric oxide at and around the site of injury, are particularly provided by the invention as a treatment for lower genitourinary tract dysfunctions. Ex vivo gene transfer for the musculoskeletal system includes genes encoding acidic fibroblast growth factor, basic fibroblast growth factor, epidermal growth factor, insulin-like growth factor, platelet derived growth factor, transforming growth factor-β, transforming growth factor-α, nerve growth factor and interleukin-1 receptor antagonist protein (IRAP), bone morphogenetic protein (BMPs), cartilage derived morphogenetic protein (CDMPs), vascular endothelial growth factor (VEGF), and sonic hedgehog proteins.

Owner:UNIVERSITY OF PITTSBURGH

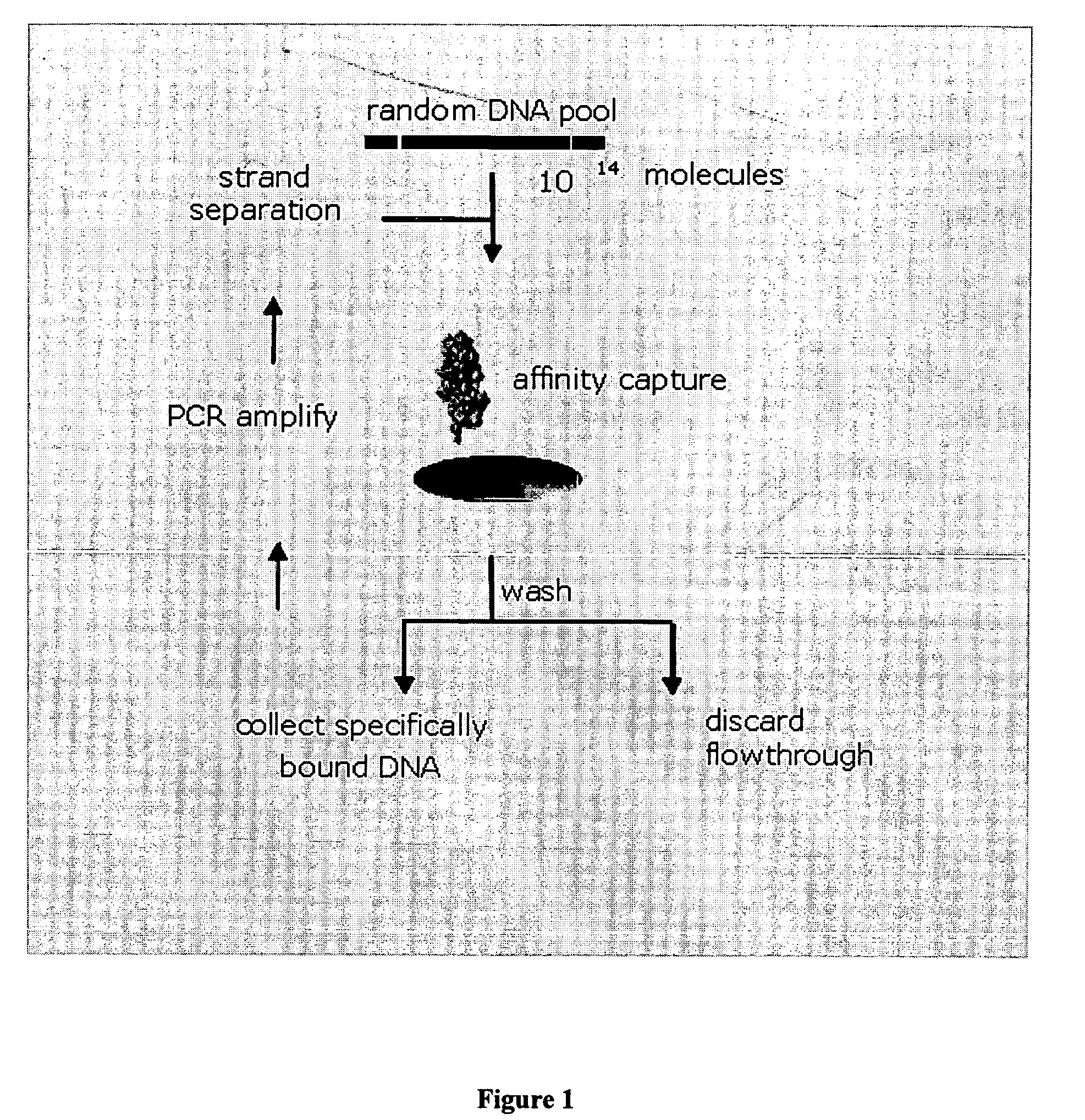

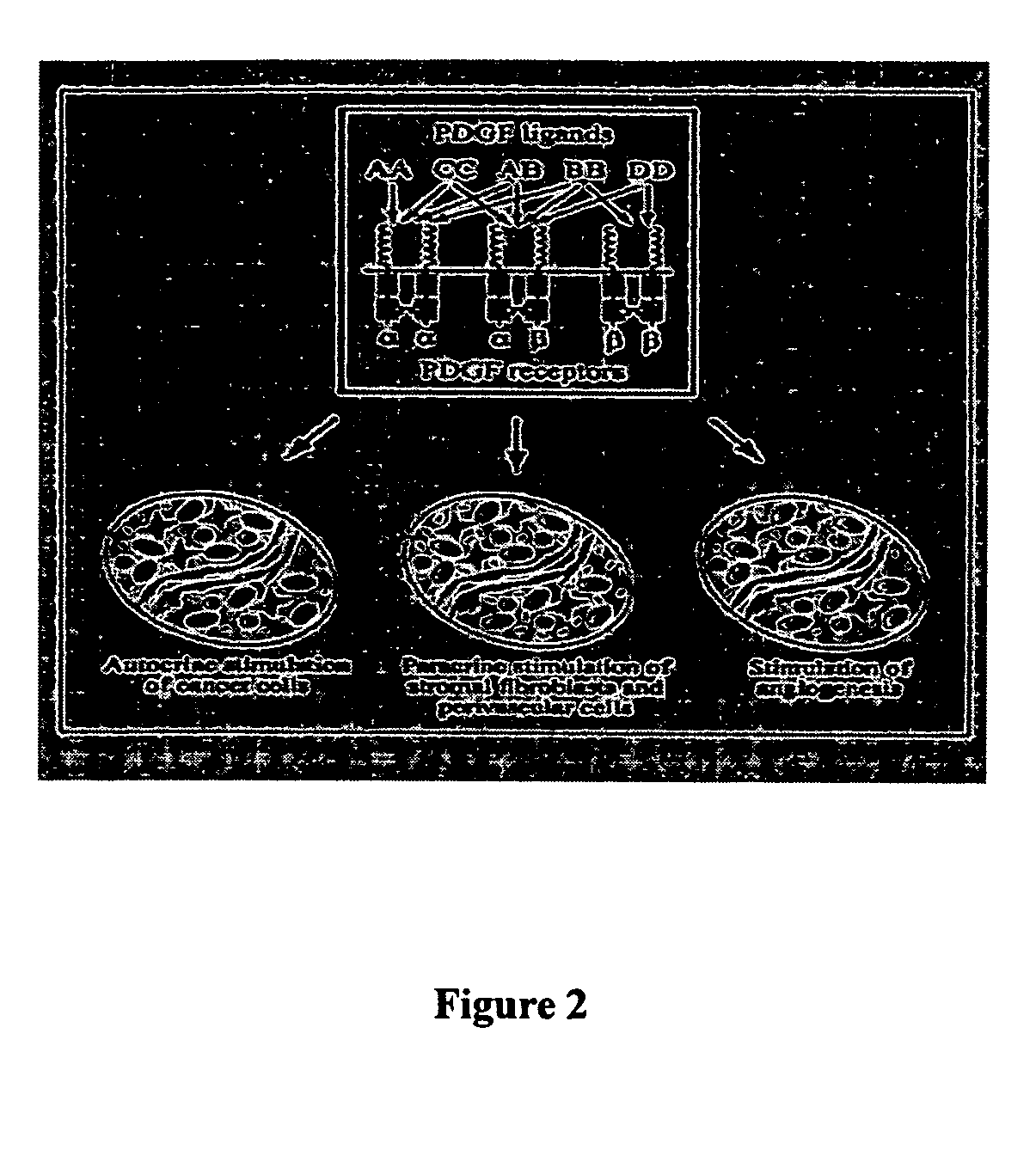

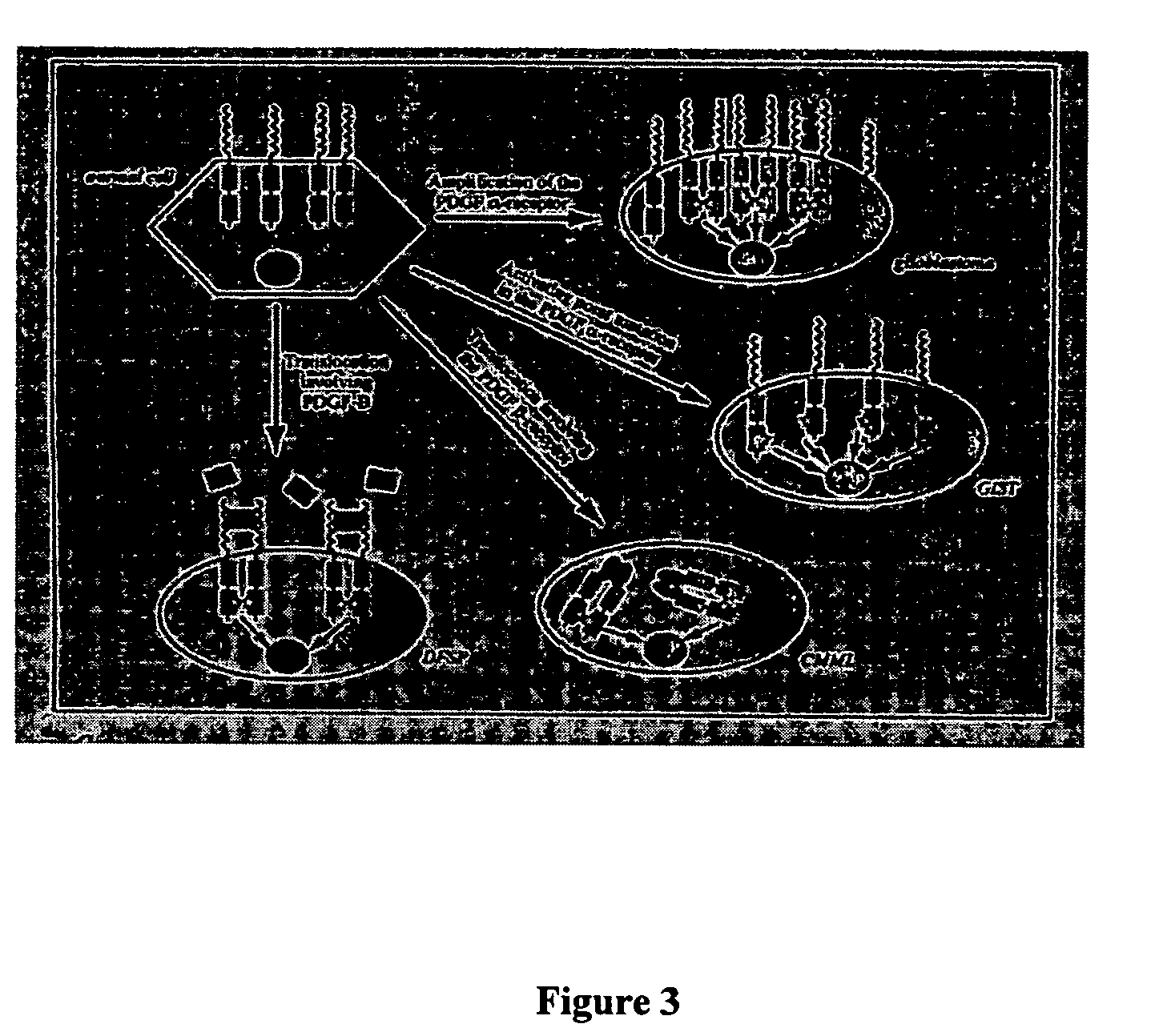

Stabilized aptamers to platelet derived growth factor and their use as oncology therapeutics

Materials and methods are provided for producing and using aptamers useful as oncology therapeutics capable of binding to PDGF, PDGF isoforms, PDGF receptor, VEGF, and VEGF receptor or any combination thereof with great affinity and specificity. The compositions of the present invention are particularly useful in solid tumor therapy and can be used alone or in combination with known cytotoxic agents for the treatment of solid tumors. Also disclosed are aptamers having one or more CpG motifs embedded therein or appended thereto.

Owner:ARCHEMIX CORP

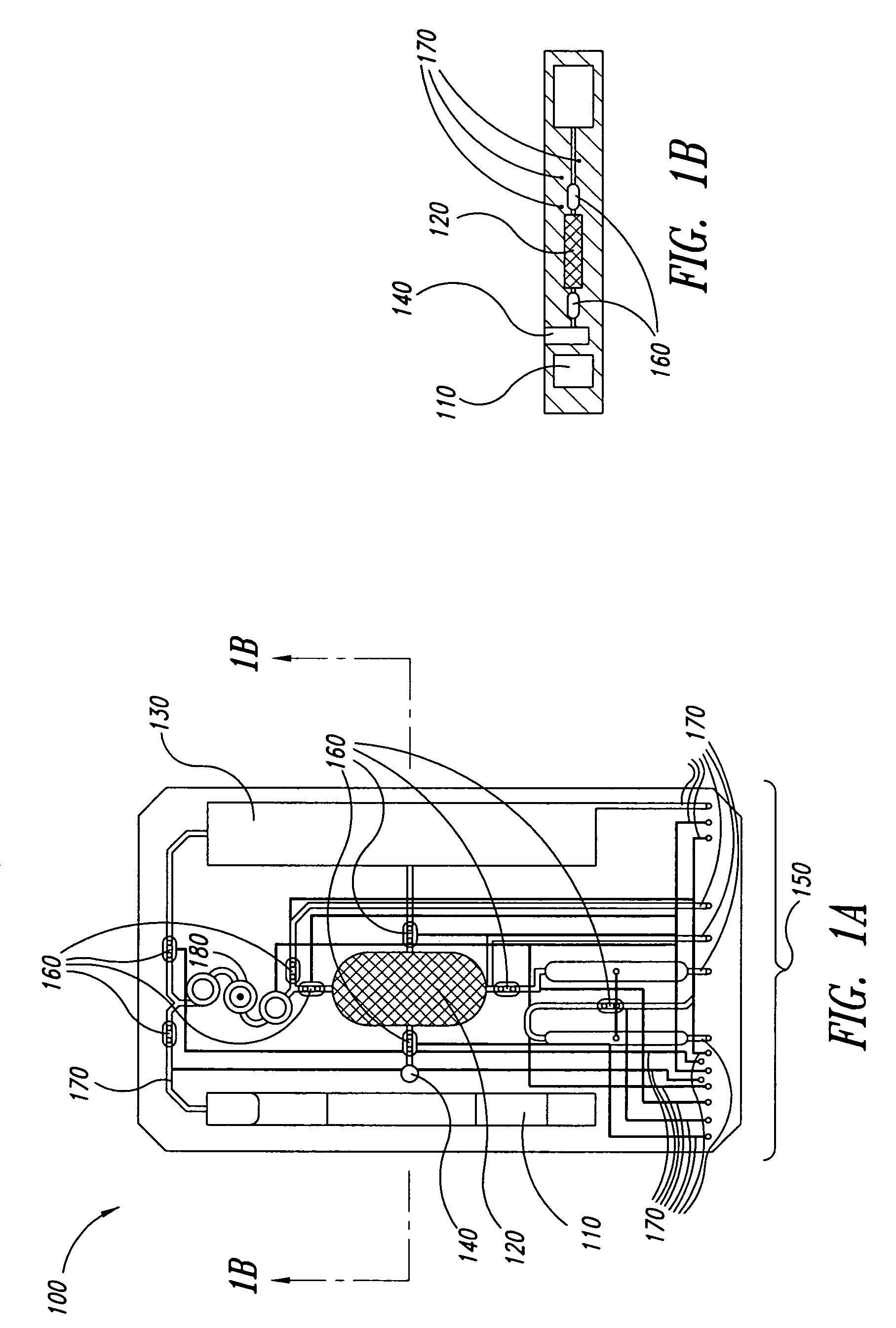

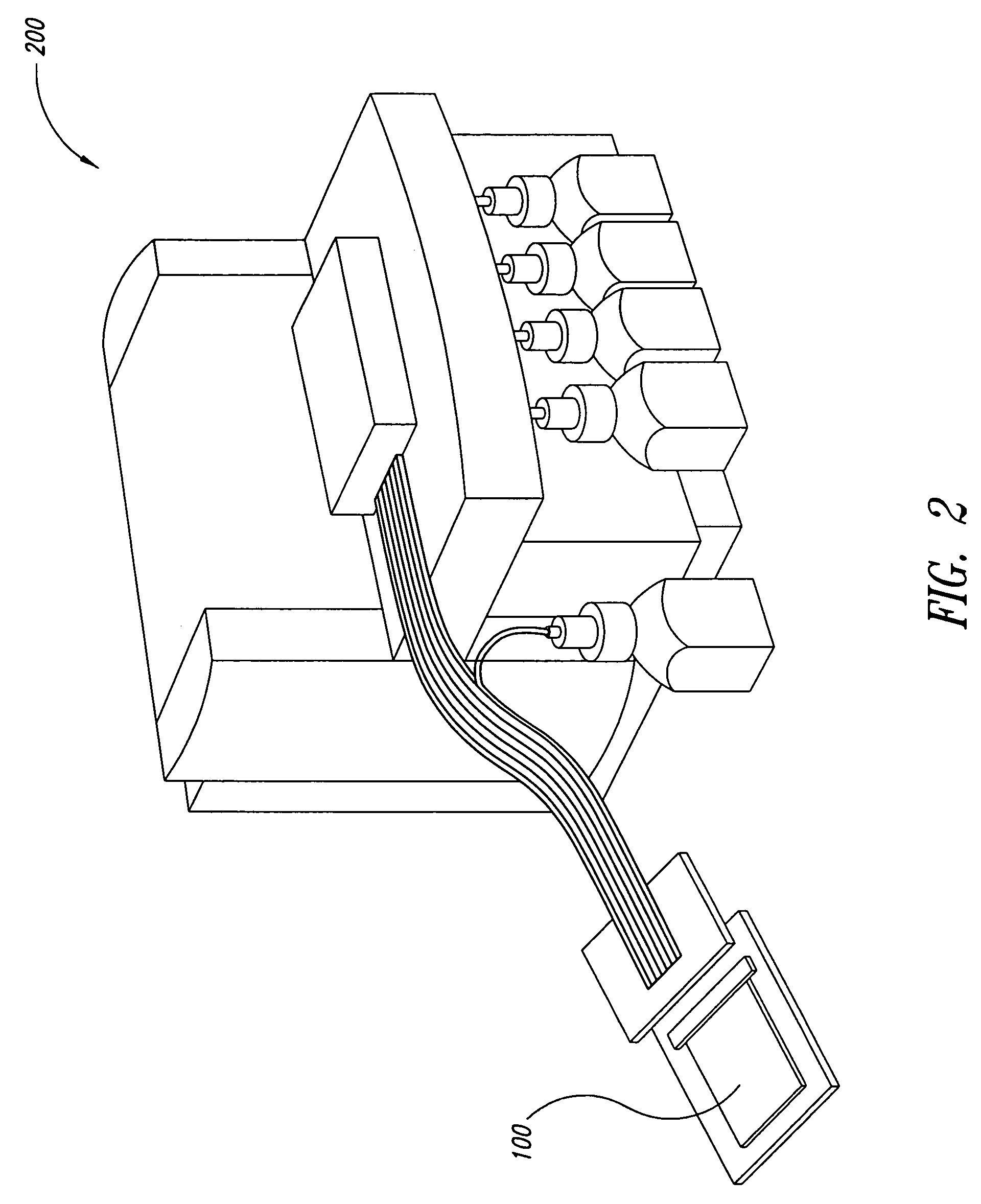

Method and system for microfluidic manipulation, amplification and analysis of fluids, for example, bacteria assays and antiglobulin testing

Owner:PERKINELMER HEALTH SCIENCES INC

Personal care compositions containing hydrophobically modified non-platelet particles

A rinsable personal care composition includes (a) 0 to 75 weight percent of a composition surfactant; (b) 0.01 to 99 weight percent of a skin benefit agent or emollient; (c) 0.01 to 20 weight percent of a hydrophobically modified non-platelet particle; and (d) 0 to 99% water.

Owner:THE PROCTER & GAMBLE COMPANY

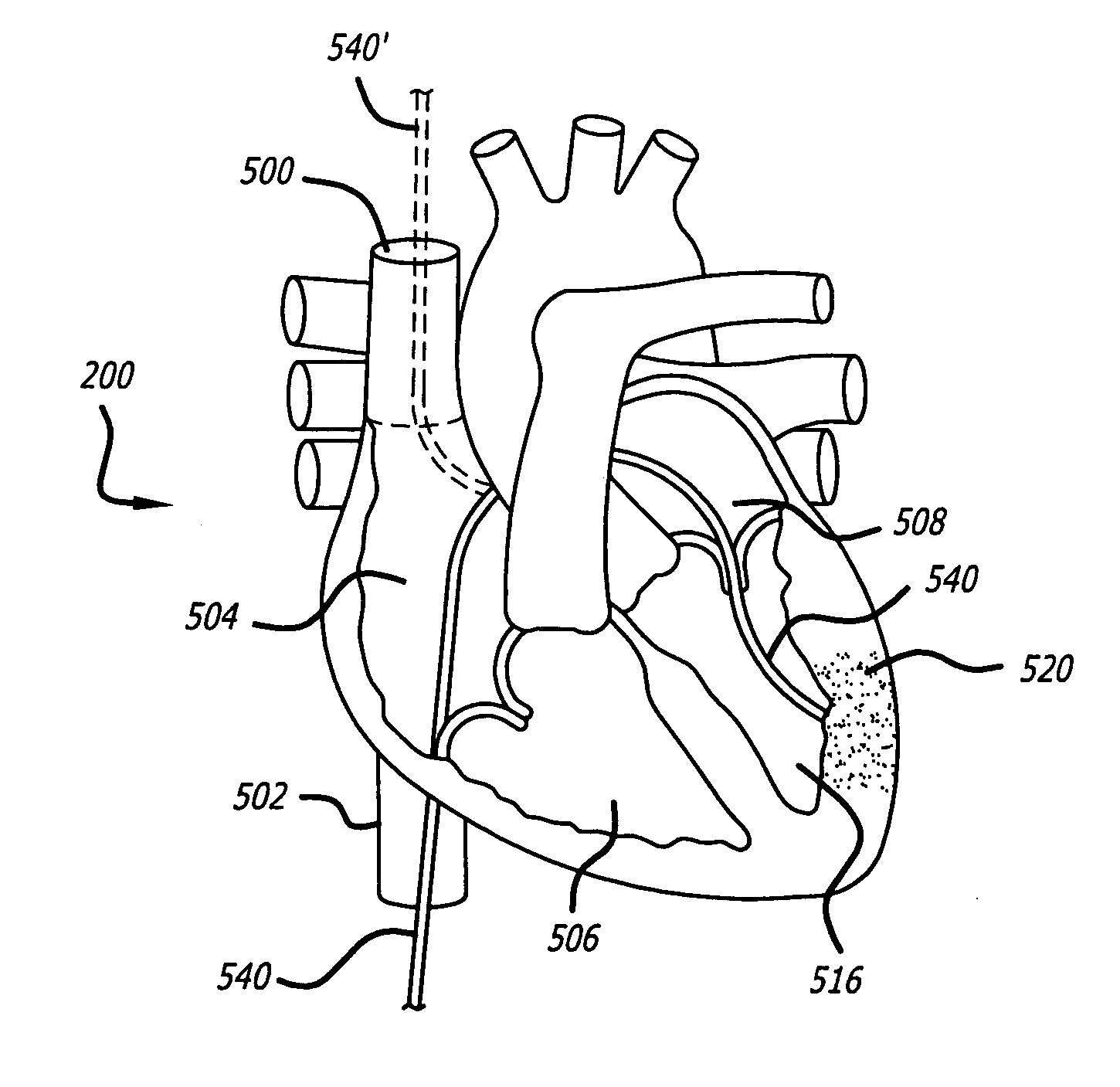

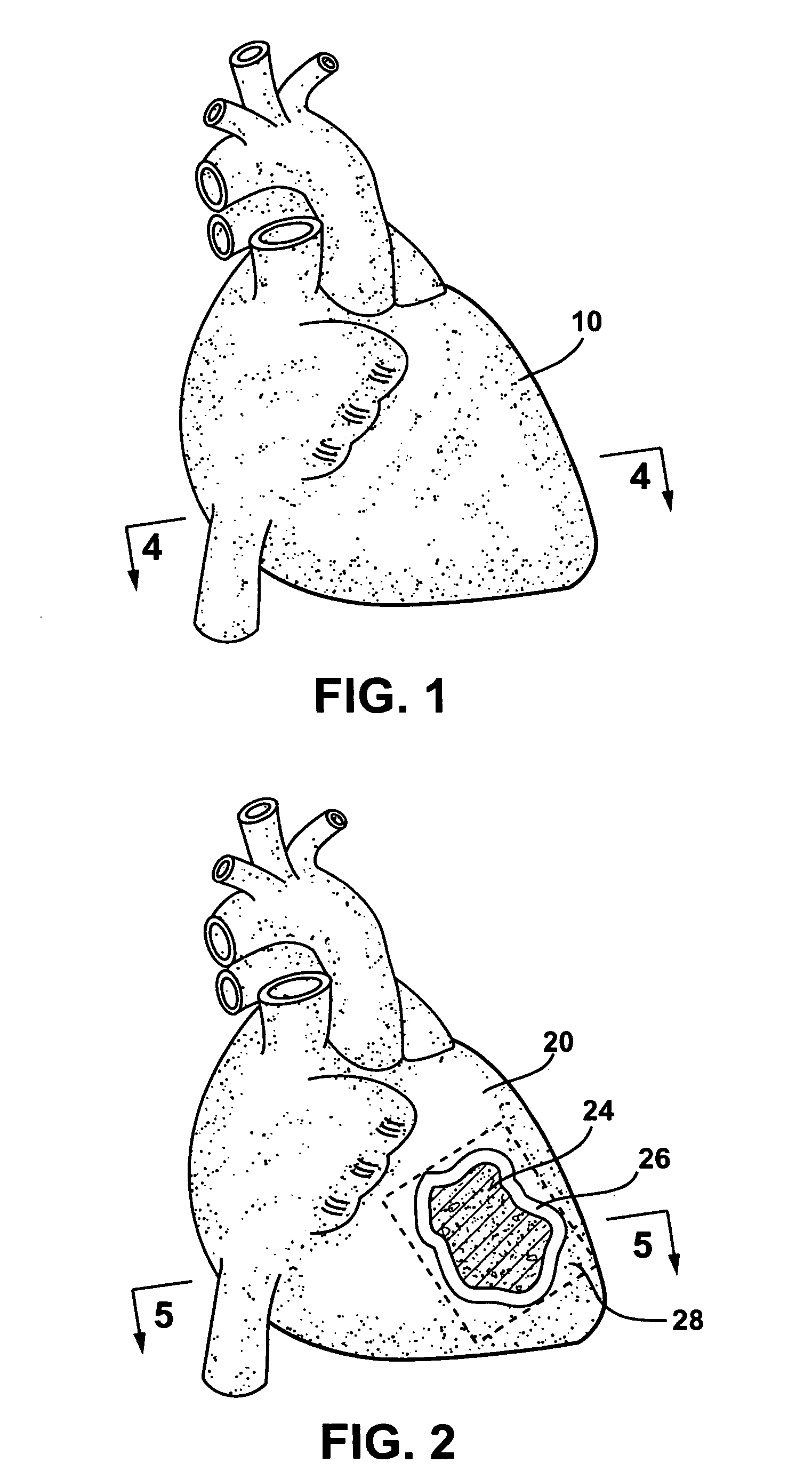

Methods and systems for treating injured cardiac tissue

InactiveUS20070093748A1Simple processReduce riskElectrotherapySurgical needlesAutologous plateletThinning

Methods and systems are disclosed for treating injury to cardiac tissue by delivering a composition which provides structural support to the cardiac tissue. The composition helps to prevent chamber remodeling by providing structural reinforcement of the tissue or structural reinforcement of the tissue combined with biological therapy. The structurally reinforcing composition can thicken the wall of a heart, or act to prevent further thinning and thereby provide resistance against further remodeling. A number of compositions are disclosed, including multi-component substances such as autologous platelet gel, and other substances. The compositions disclosed can contain additives to augment / enhance the desired effects of the injection.

Owner:MEDTRONIC VASCULAR INC

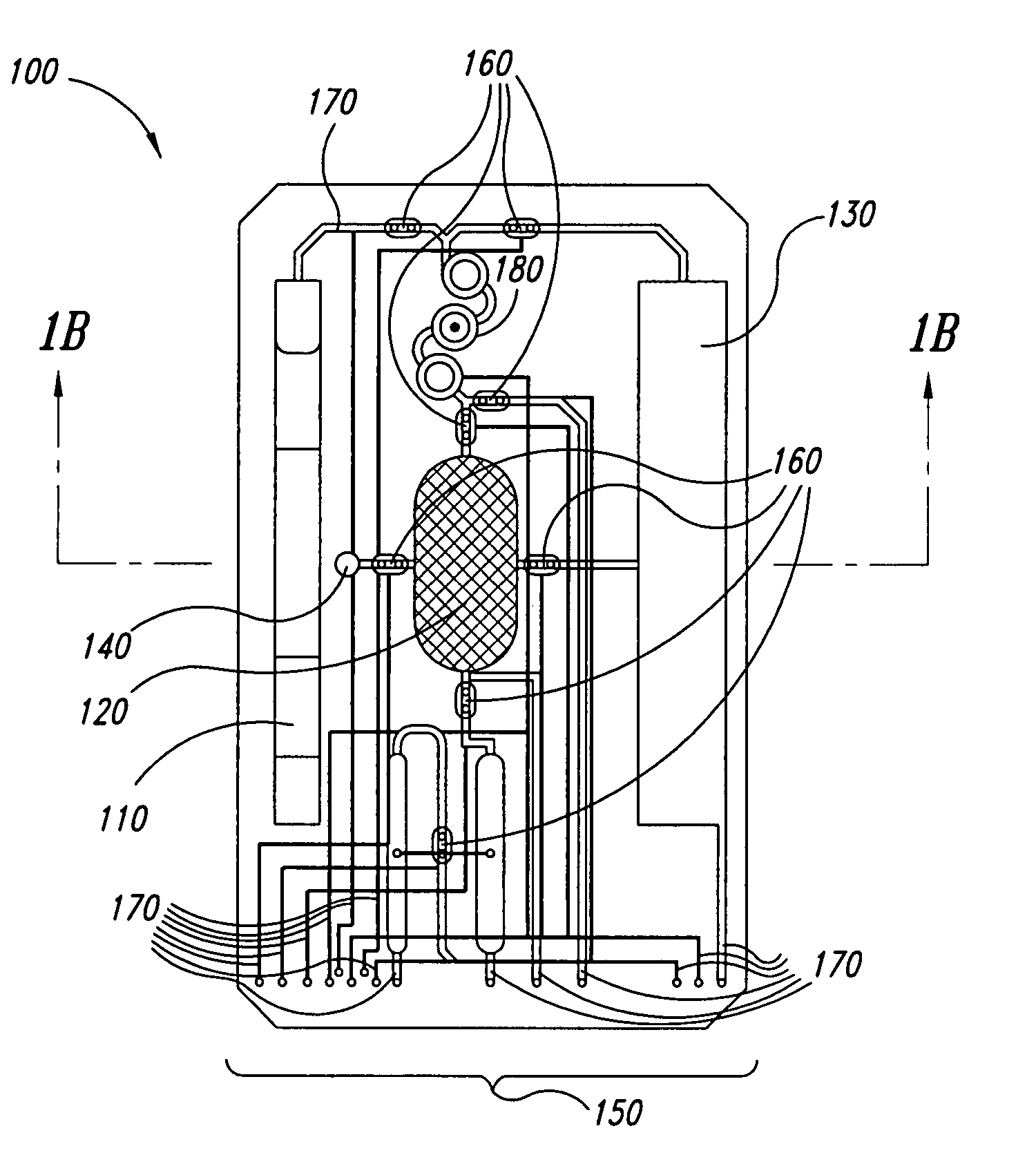

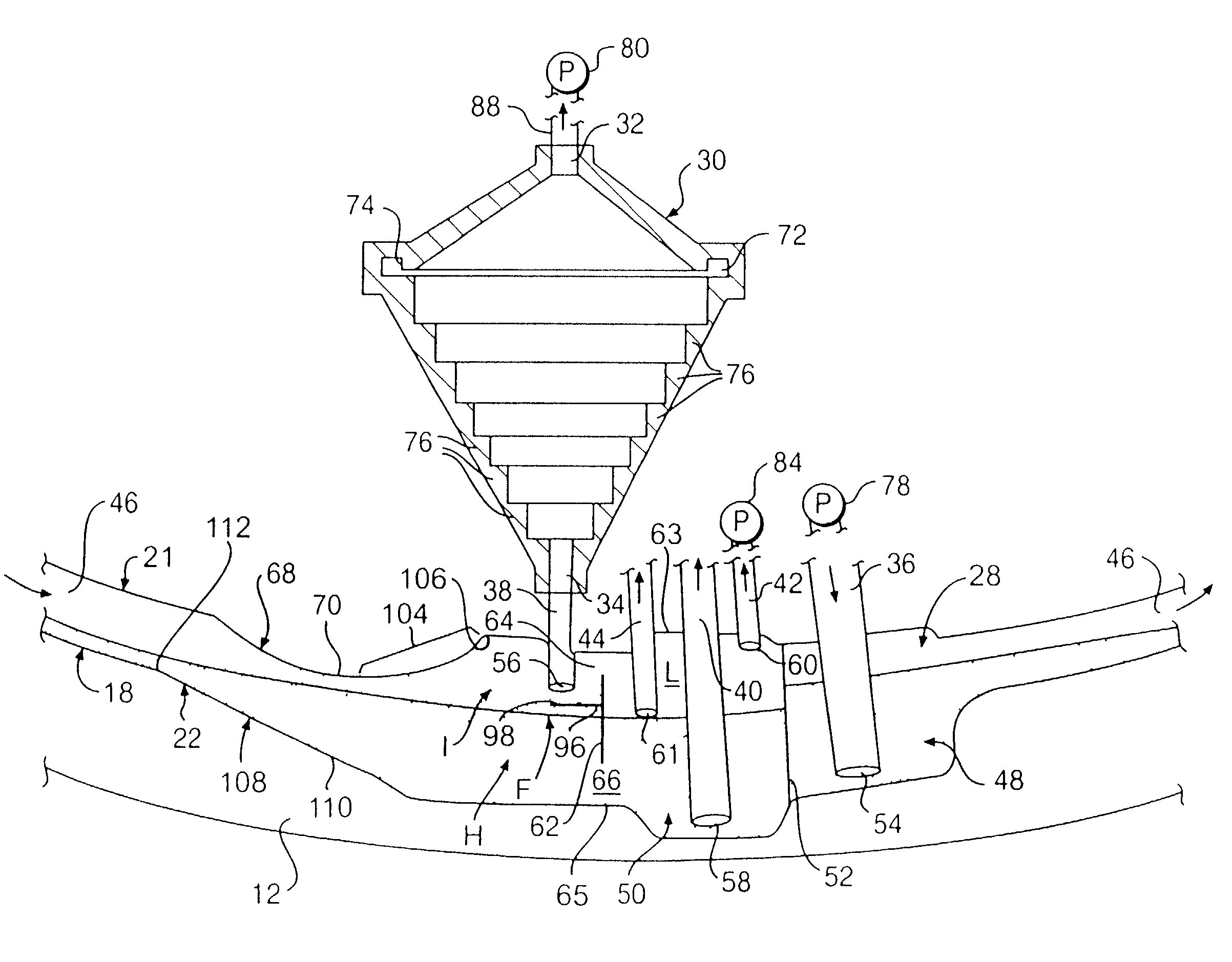

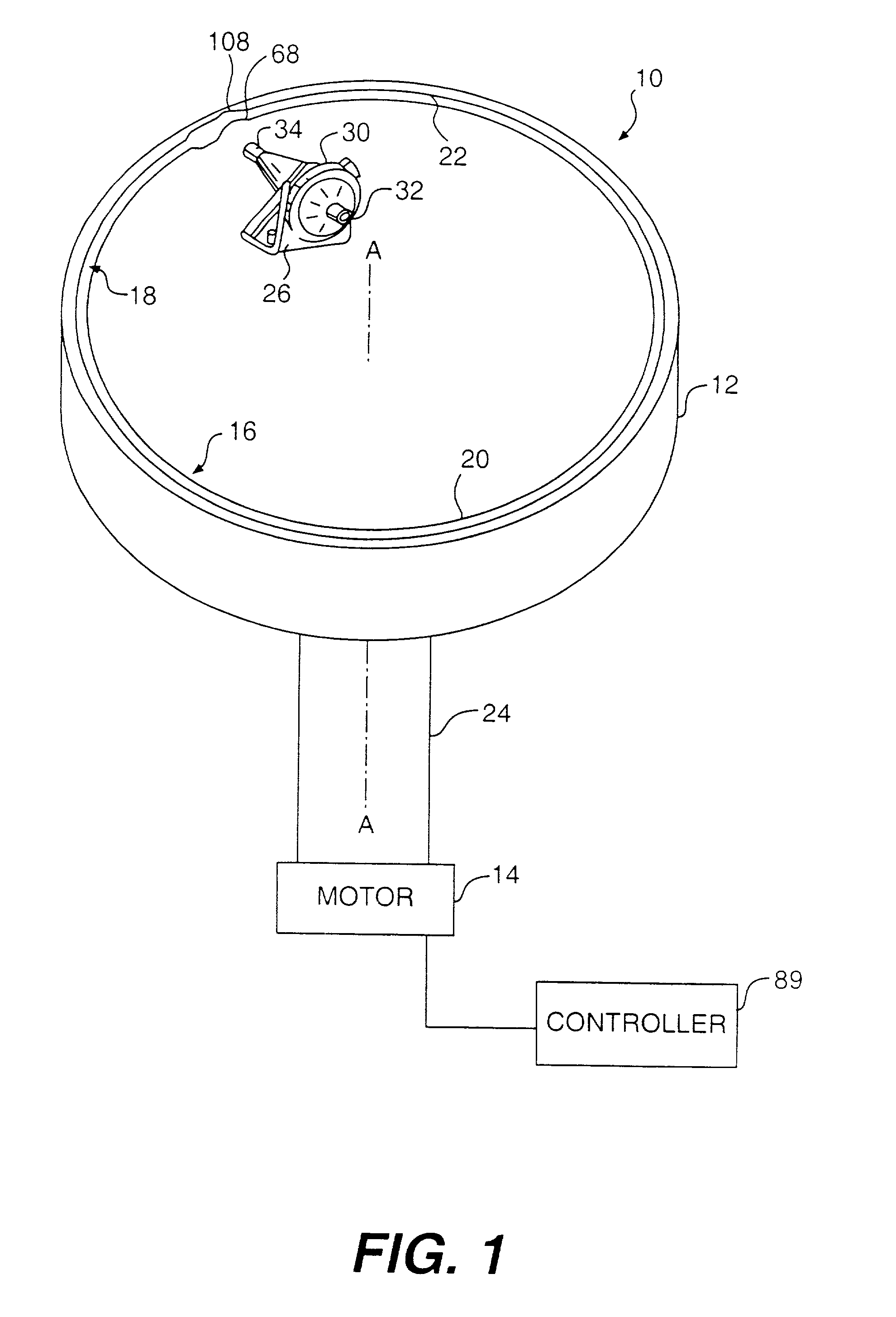

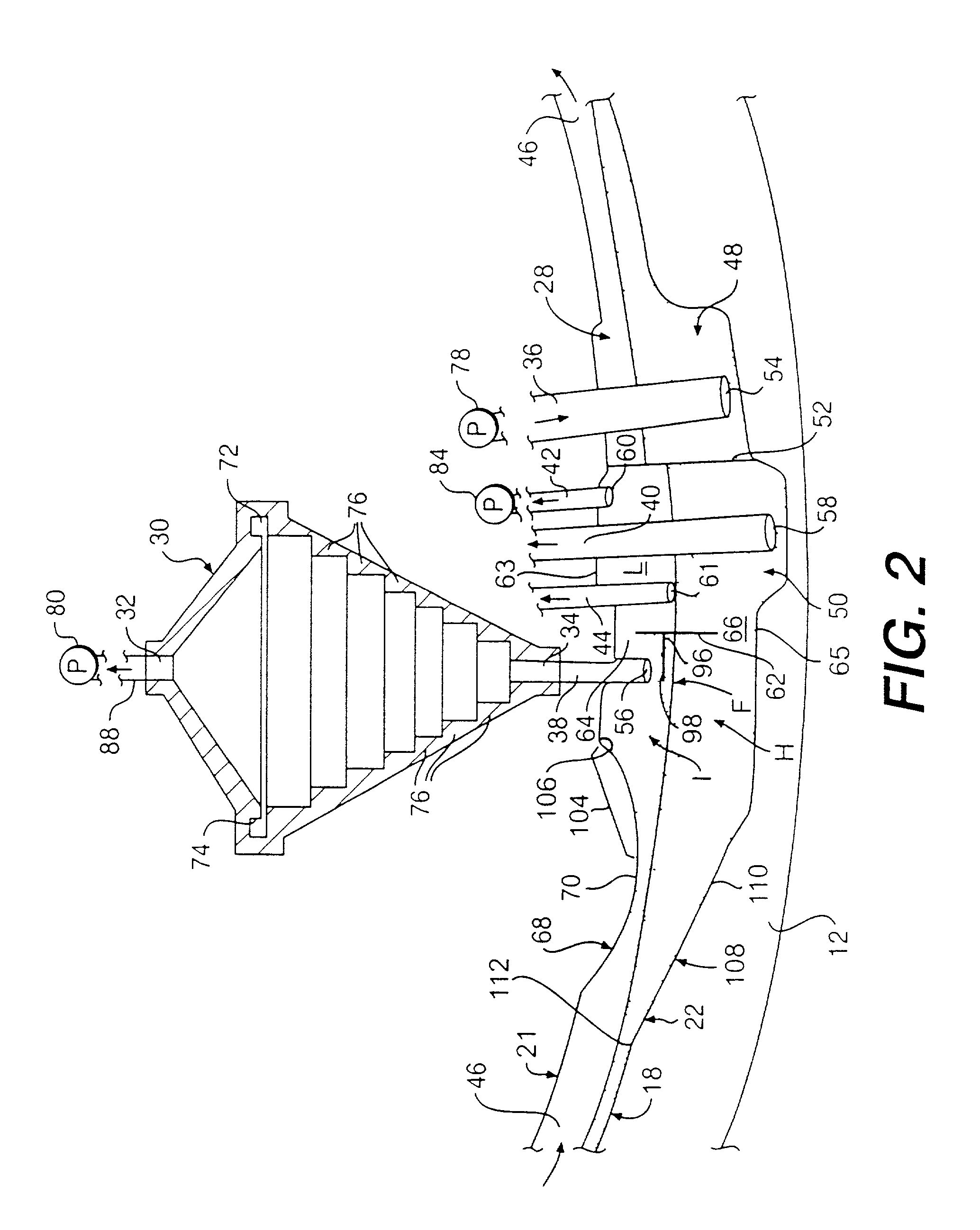

Centrifugal separation apparatus and method for separating fluid components

InactiveUS7029430B2Reduce cakingReduces platelet clumpingOther blood circulation devicesWithdrawing sample devicesHigh densityRed blood cell

An apparatus and method are provided for separating components of a fluid or particles. A separation vessel having a barrier dam is provided to initially separate an intermediate density components of a fluid, and a fluid chamber is provided to further separate these intermediate density components by forming an elutriative field or saturated fluidized particle bed. The separation vessel includes a shield for limiting flow into the fluid chamber of relatively high density substances, such as red blood cells. The separation vessel also includes a trap dam with a smooth, gradually sloped downstream section for reducing mixing of substances. Structure is also provided for adding additional plasma to platelets and plasma flowing from the fluid chamber. The system reduces clumping of platelets by limiting contact between the platelets and walls of the separation vessel.

Owner:TERUMO BCT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com