Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9904 results about "Wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wool is the textile fiber obtained from sheep and other animals, including cashmere and mohair from goats, qiviut from muskoxen, from hide and fur clothing from bison, angora from rabbits, and other types of wool from camelids; additionally, the Highland and the Mangalica breeds of cattle and swine, respectively, possess wooly coats.

Hemostatic textile

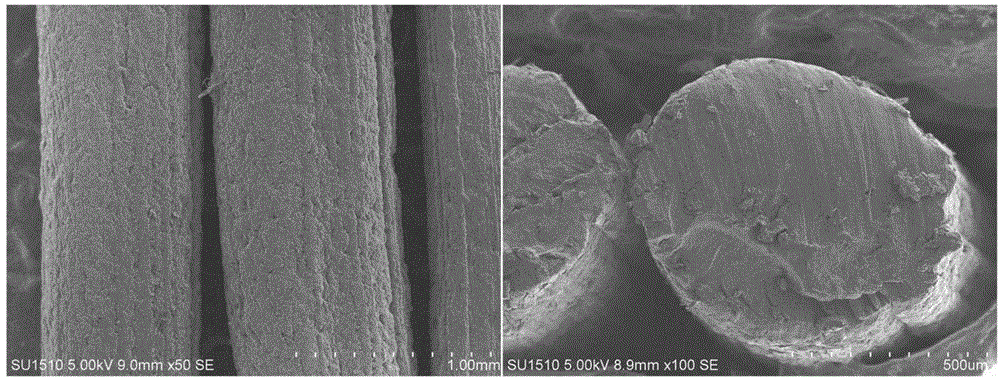

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

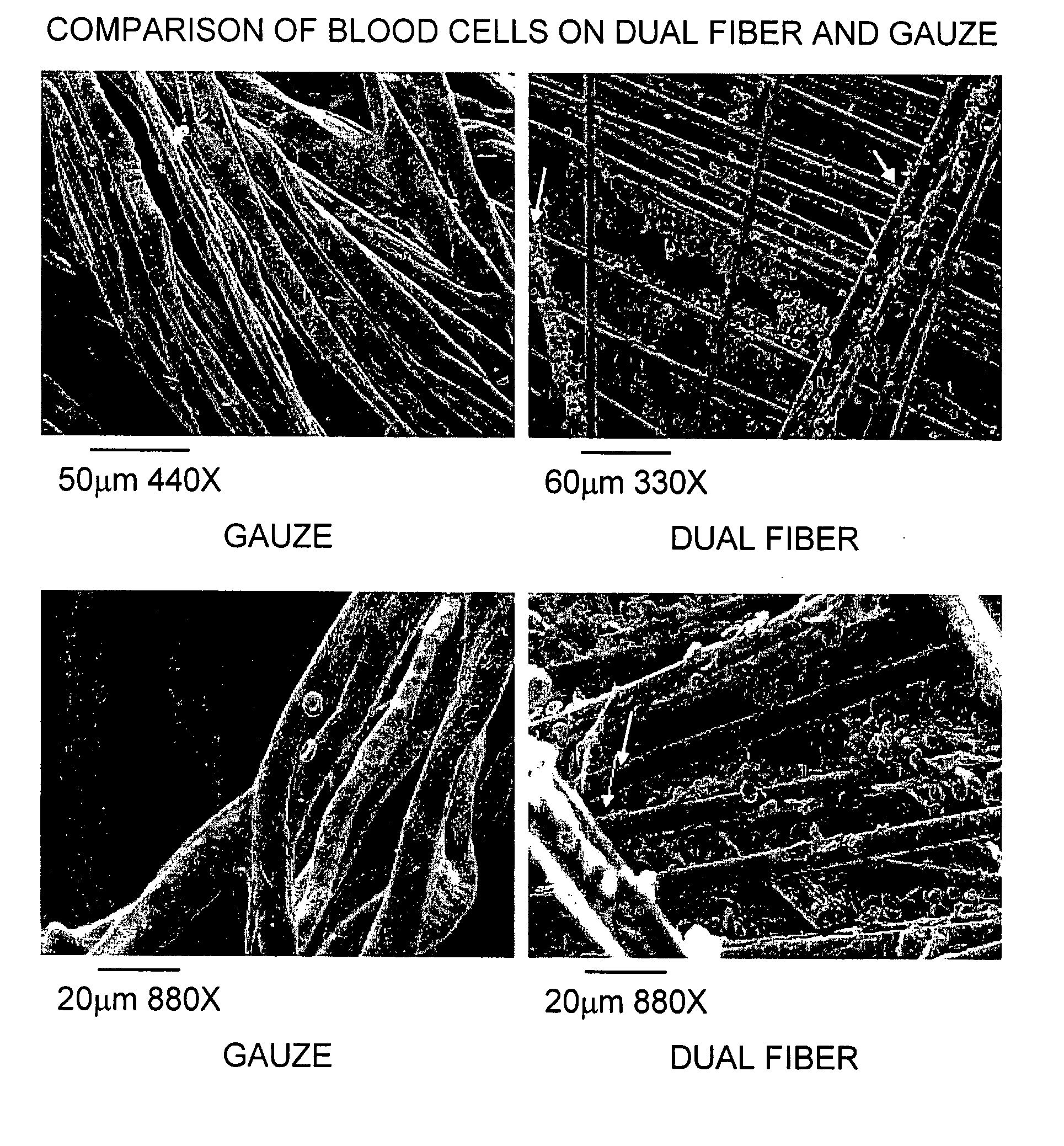

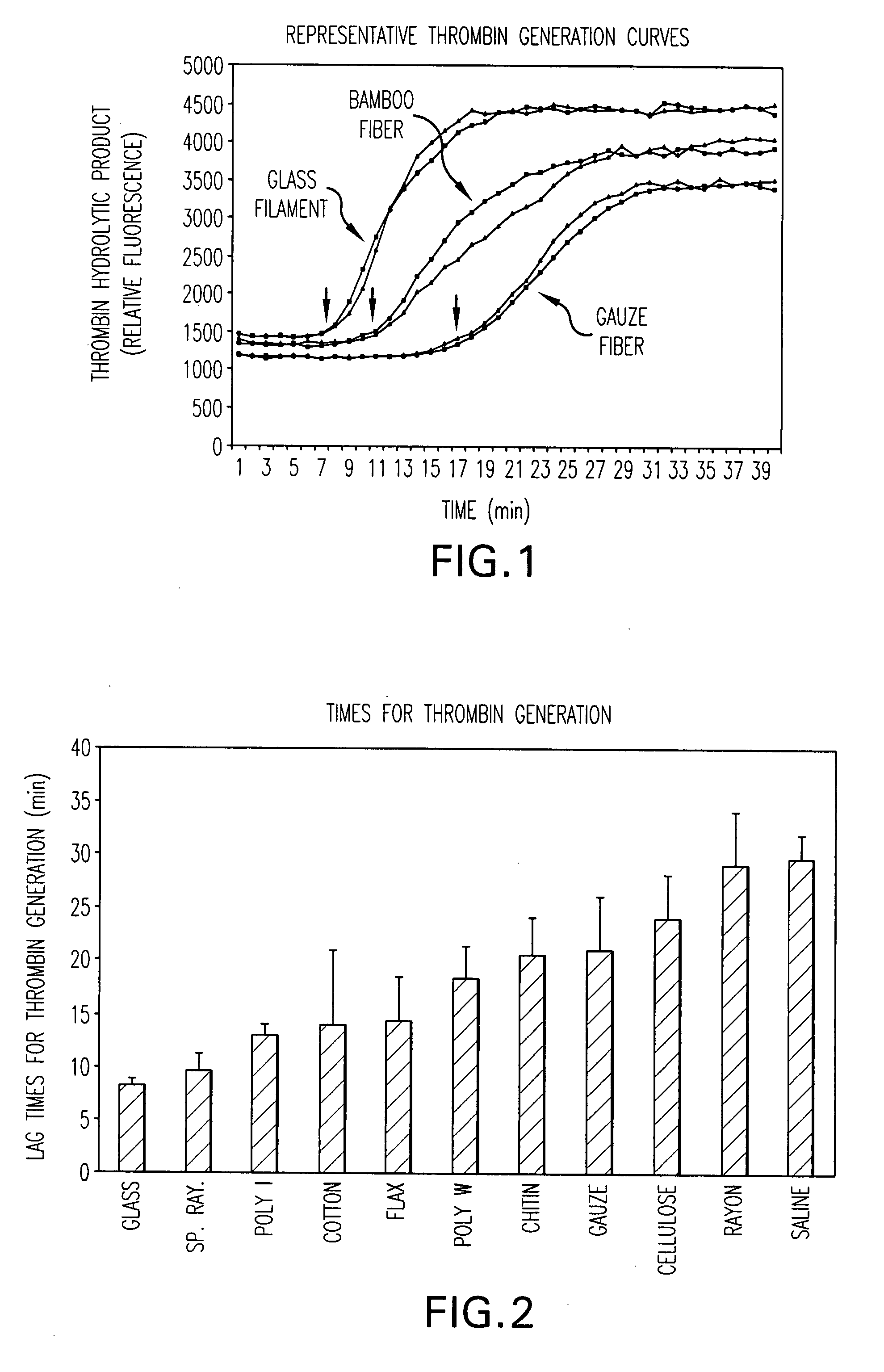

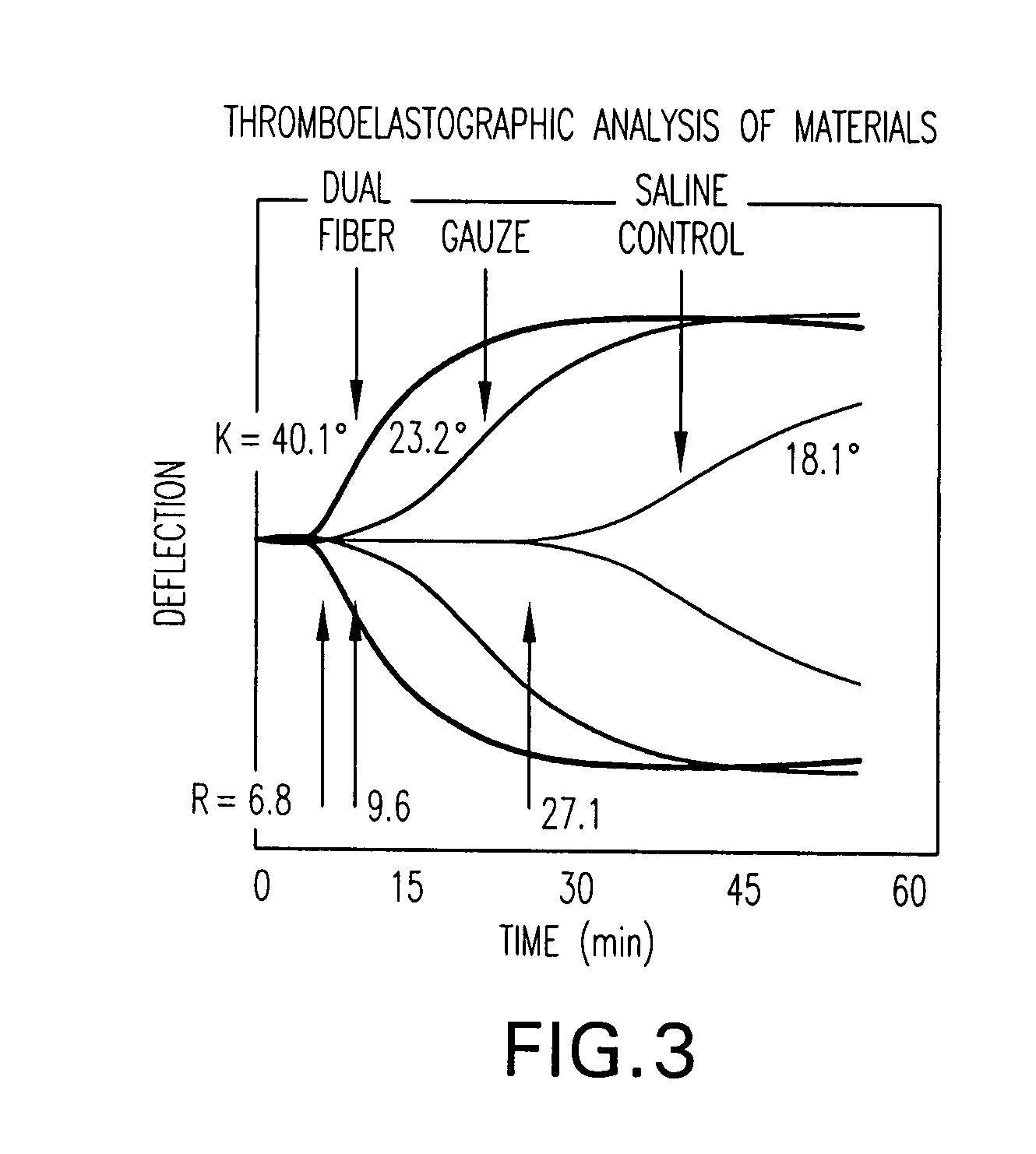

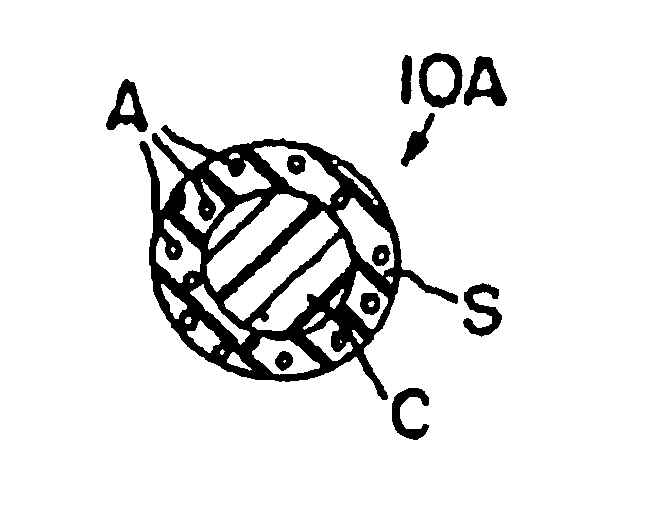

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Air filtration media

A glass fiber composite air filtration media is fabricated from glass fibers and plastic-containing boding fibers. The glass fibers may be virgin rotary fibers, loose-fill blowing wool insulation, bindered glass fibers such as batting insulation, or scrap rotary fibers.

Owner:CERTAINTEED CORP

Anti-microbial fiber and fibrous products

InactiveUS6841244B2Resistant to washing off and wearing offLow costGarment special featuresDispersed particle filtrationPolyesterMicroorganism

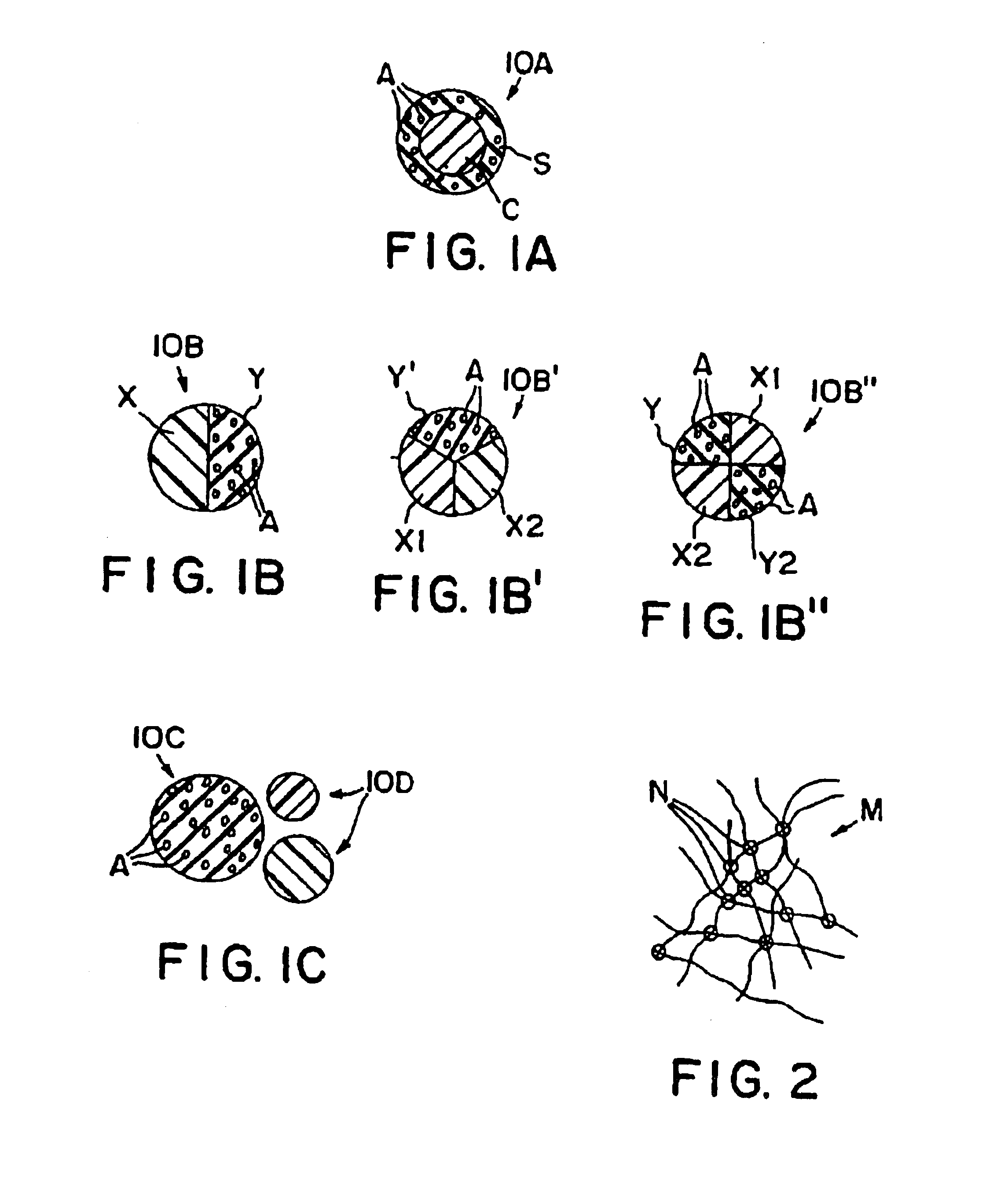

An anti-microbial and / or anti-fungal synthetic fiber that comprises various thermoplastic polymers and additives in a bi-component form in either a core-sheath or side-by-side configurations. The anti-microbial synthetic fibers comprise inorganic anti-microbial additives, distributed in certain areas to reduce the amount of the anti-microbial agents being used, and therefore the cost of such fibers. The fibers can incorporate anti-microbial additives so that they are not removed by repeating washing in boiling water and in dry clean cycles and become ineffective and conversely enhance access to the additives by washing or the like. The fibers comprise high tenacity polymers (e.g. PET) in one portion and hydrolysis resistance polymers (e.g. PCT) in another portion with the additives. The fibers can further be blended with non-anti-microbial fibers such as cotton, wool, polyester, acrylic, nylon etc. to provide anti-microbial finished fabrics. In one such embodiment, binder fibers are used which are mixed with other fibers.

Owner:FOSS PERFORMANCE MATERIALS LLC

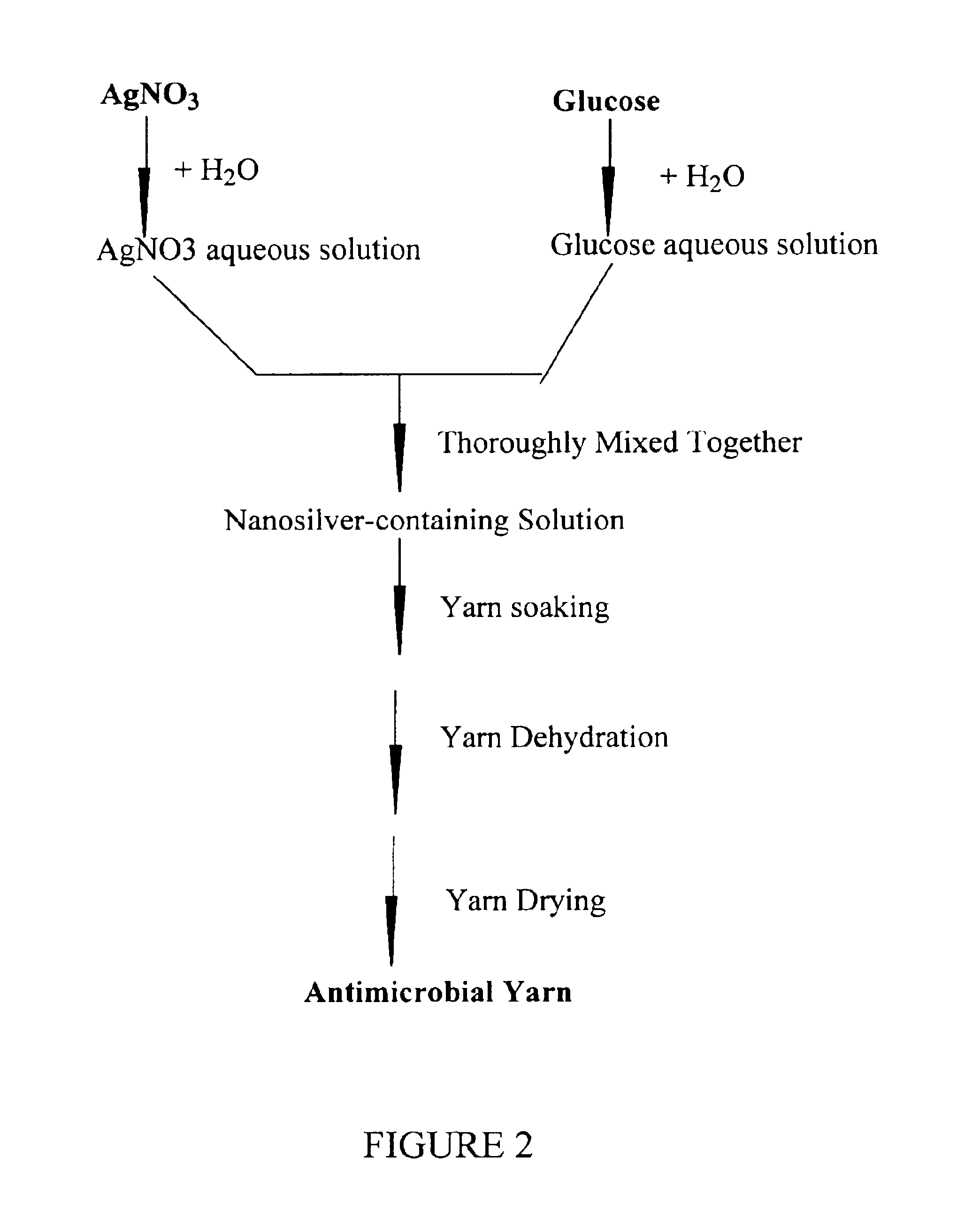

Antimicrobial yarn having nanosilver particles and methods for manufacturing the same

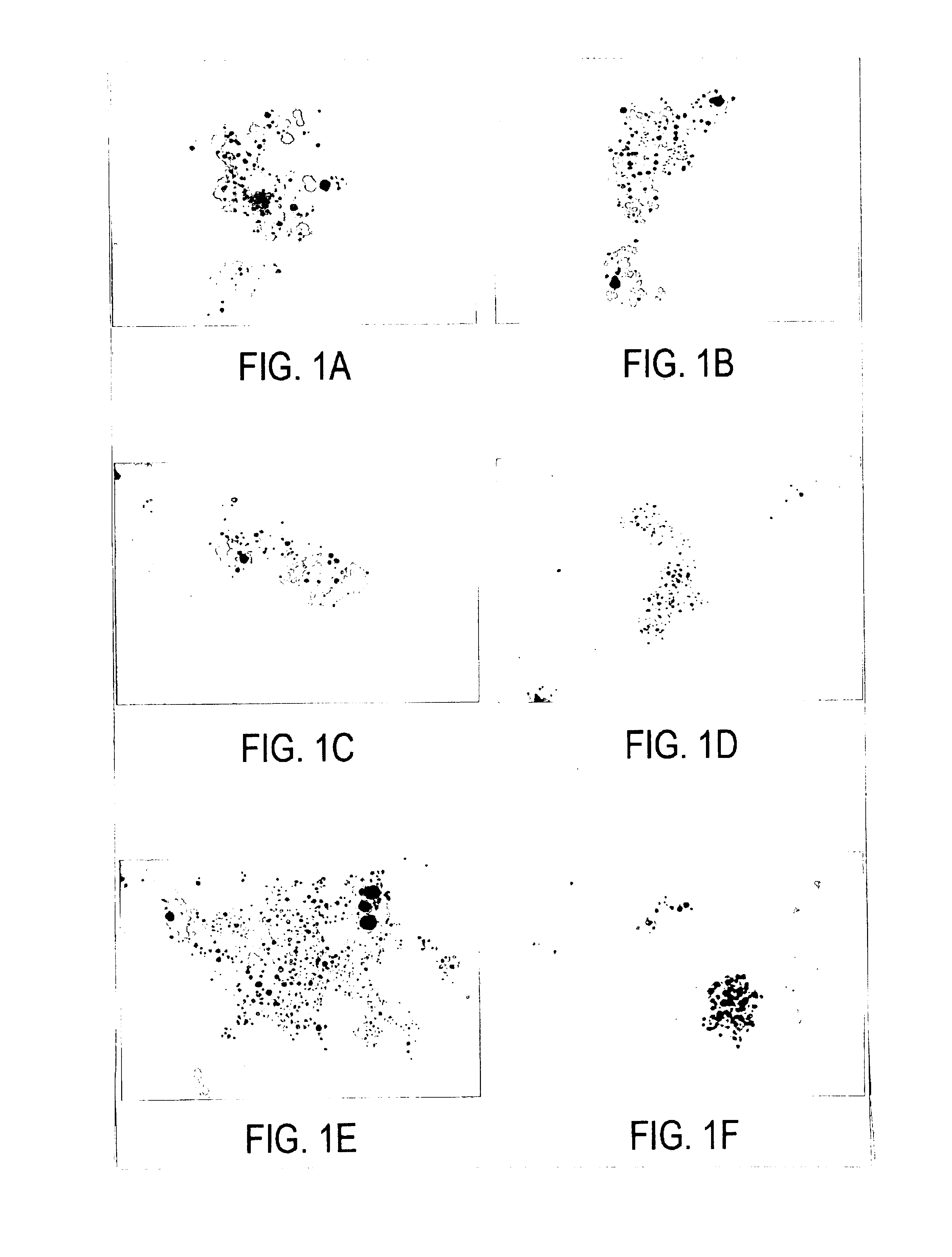

InactiveUS6979491B2The process is simple and fastEasy to carryYarnConductive materialsYarnEngineering

The present invention provides a yarn with antimicrobial effects. The antimicrobial antifungal effect of the yarn is derived from nanosilver particles (diameter between 1 and 100 nm) which are adhered to the yarn. The yarn contains fibers which are made of cotton, linen, silk, wool, leather, blending fabric, synthetic fiber, or any combination thereof. The yarn can be used to make cloth to be used particularly for treating patients with burns or wound. The cloth made from the antimicrobial yarn can be further used to make clothes such as underwears, socks, shoe cushions, shoe linings, bed sheets, pillow cases, towels, women hygiene products, laboratory coats, and medical robes. The present invention also provides a method for making the antimicrobial yarn.

Owner:CC TECH INVESTMENT

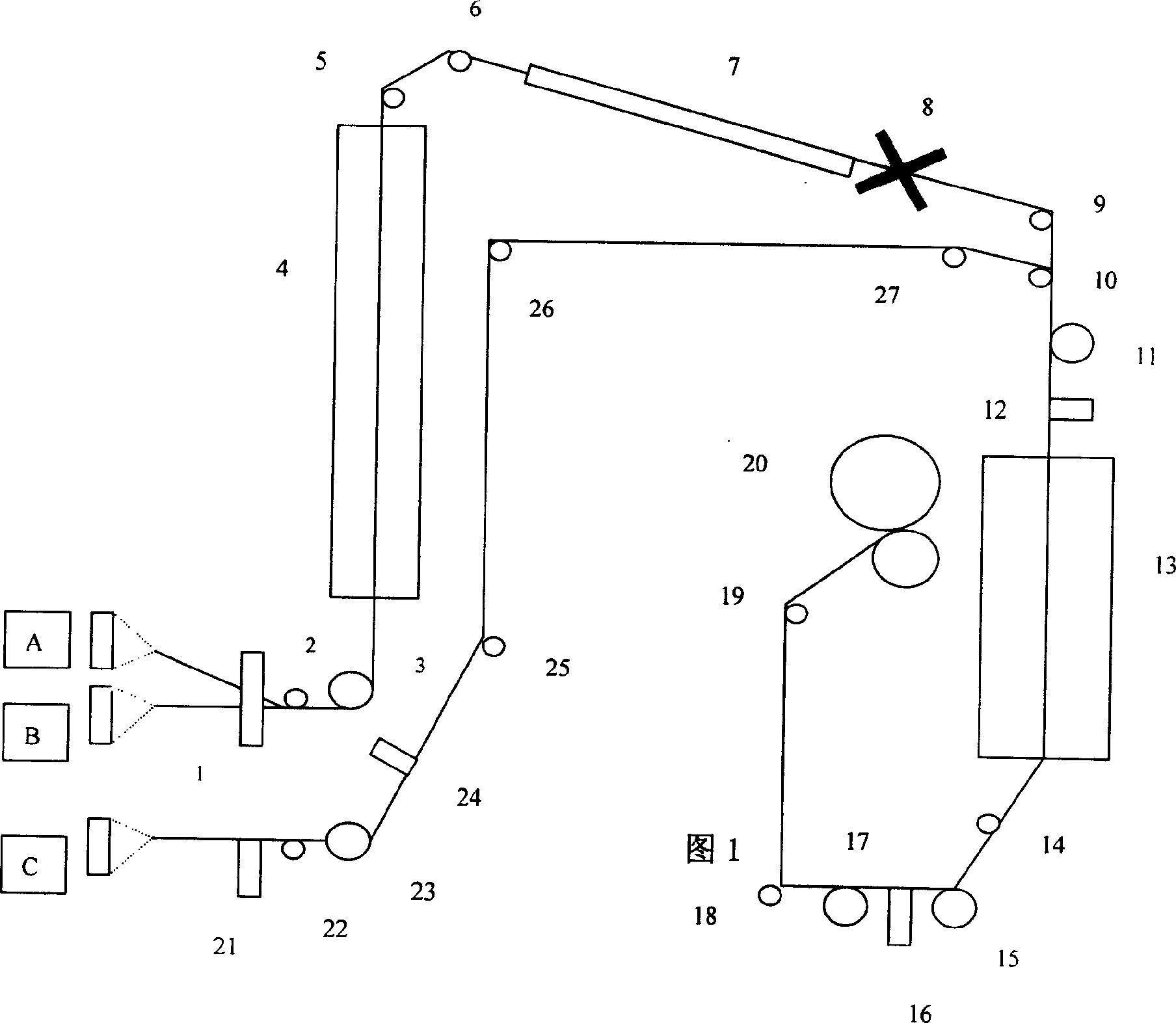

Chemical etching, cleaning and drying method of single-crystal silicon solar battery and integrated processing machine

InactiveCN101087007AImprove reflective effectAvoid secondary pollutionFinal product manufactureSemiconductor devicesEtchingWater source

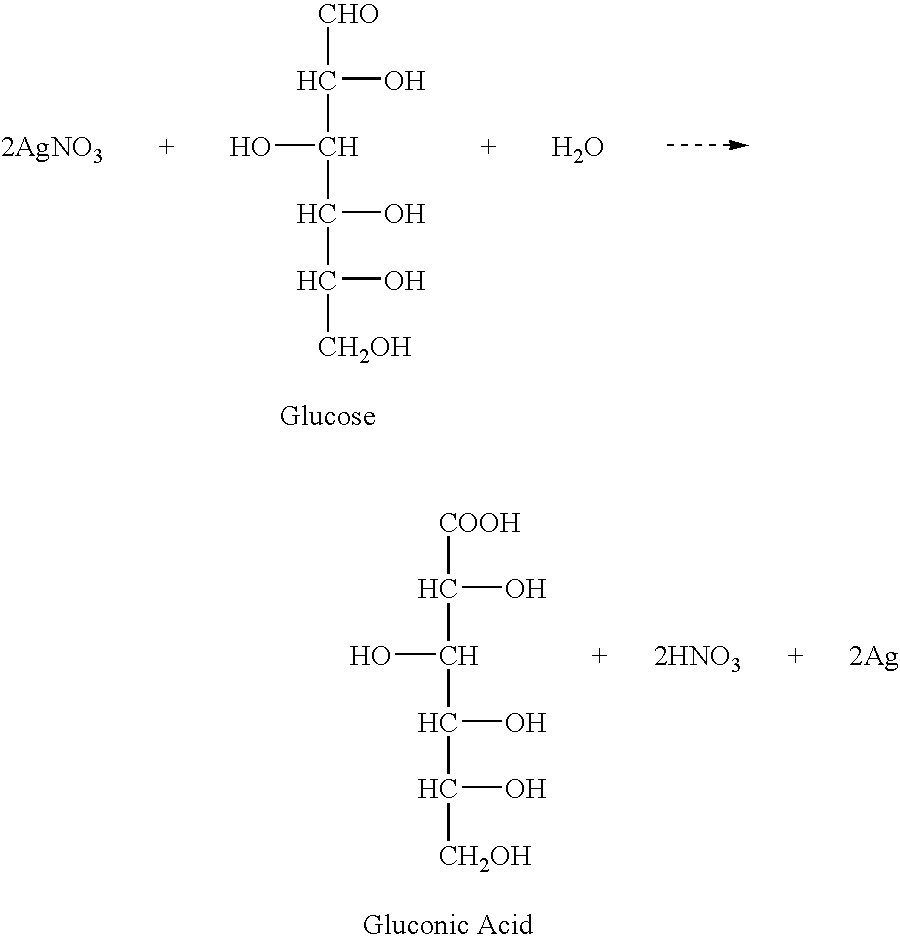

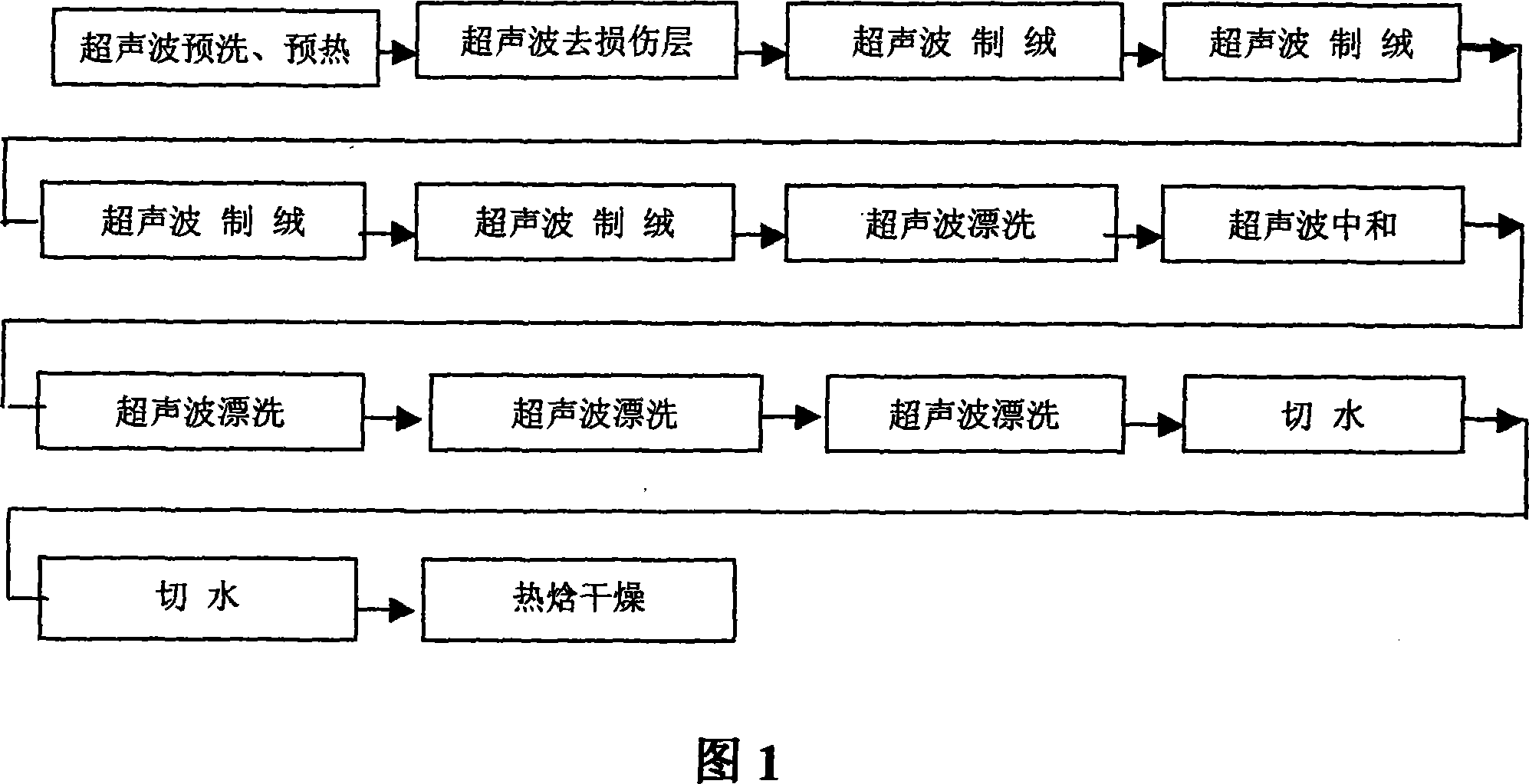

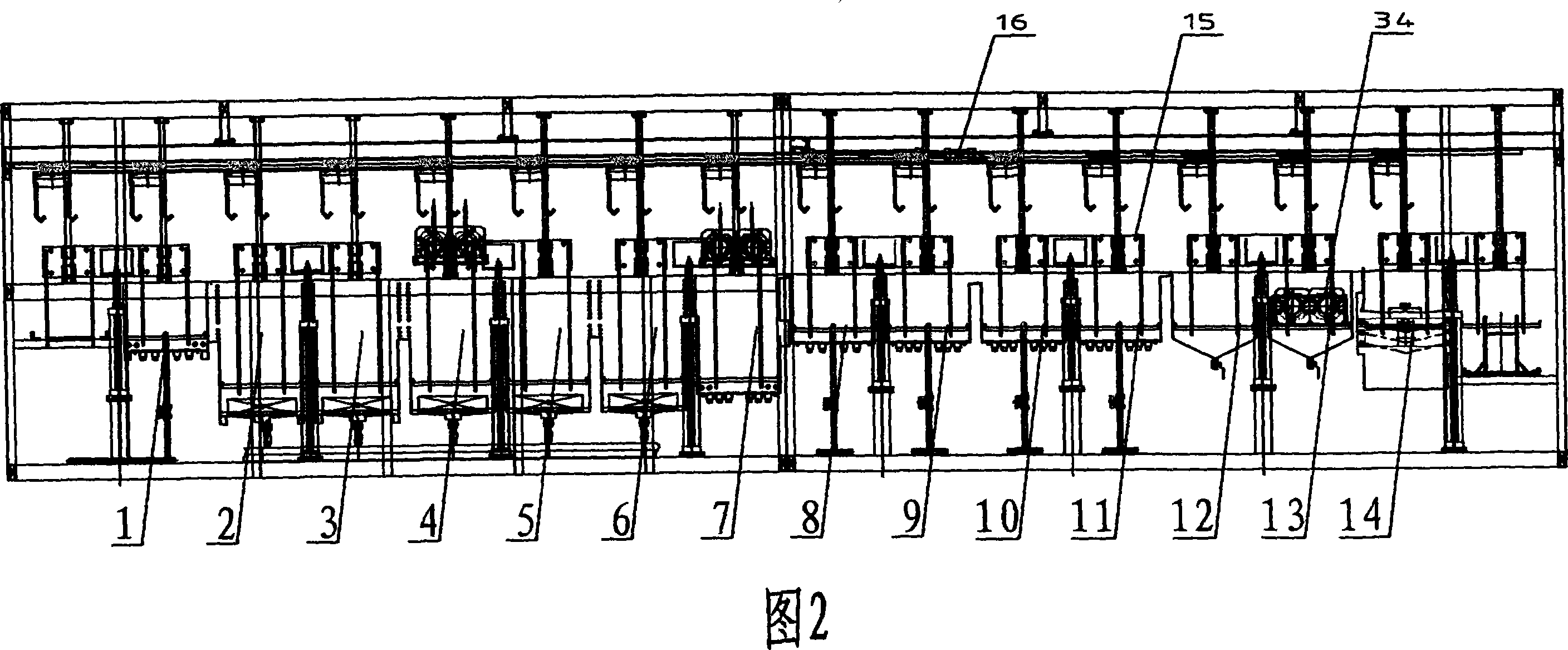

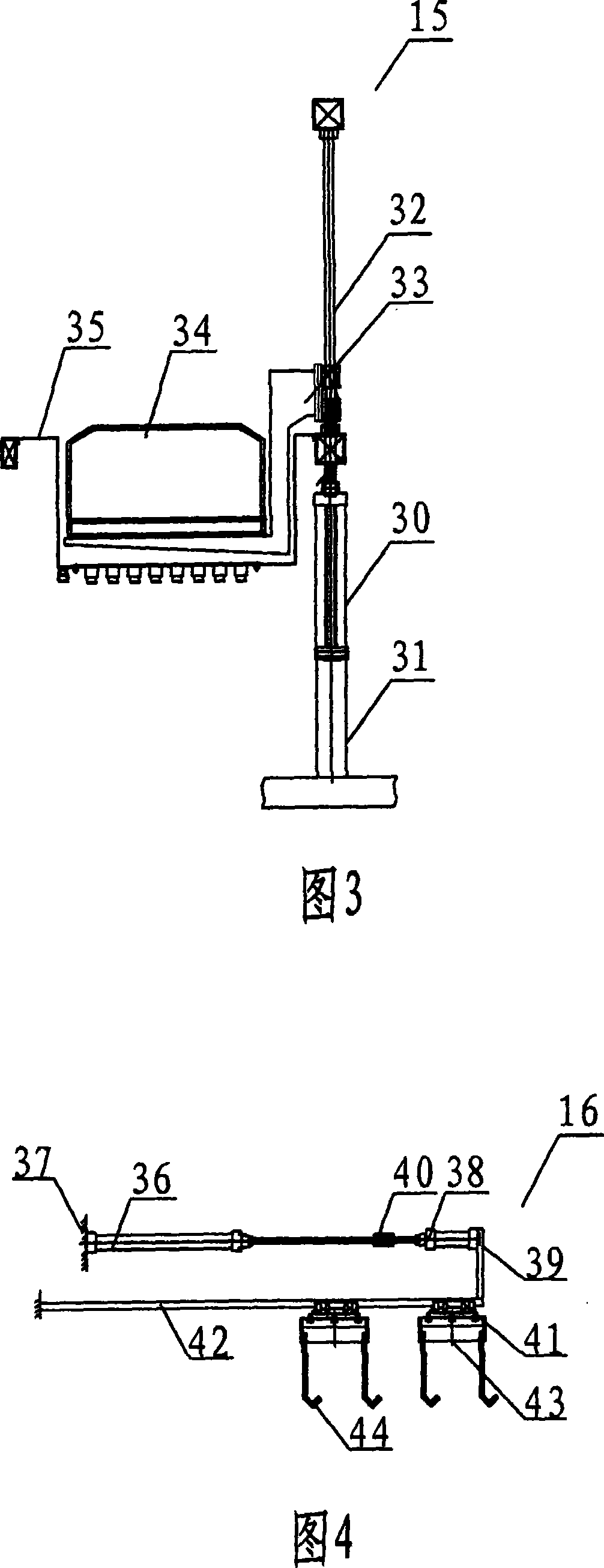

Monocrystalline silicon solaode chemical etching, washing, drying method and integral processor belong to technique field of chemical etching technique and washing. It characterized in that it not only includes water, acid, alkali, but also ultrasonic participates in etching and washing course: it includes following steps: (1) ultrasonic washes and heats in advance, (2) ultrasonic removes damnification layer, (3) ultrasonic makes herbs into wool, (4) ultrasonic rinses, (5) washing with acid to counteract, (6) ultrasonic rinses, (7) cutting water, (8) hot enthalpy to dry. Positive effects of the invention are: adopting ultrasonic to etch and wash, liquid of making wool can be acted with silicon piece, similar coarseness degree can be generated on surface, perfect pyramid pattern can be obtained; it also eliminates kalium, natrium ion from alkalescent solution, and extends service life of silicon piece; pollution can be decreased, energy consumption and water source can be saved greatly, it is a practical invention.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH +2

Tubular solid oxide fuel cell stack

This invention relates to a stack comprising a continuous solid-phase matrix and tubular fuel cells embedded in the matrix. Each fuel cell comprises an inner electrode layer, an outer electrode layer, and an electrolyte layer sandwiched between the inner and outer electrode layers. The matrix is sufficiently porous to allow a first reactant to flow through the matrix and to the outer electrode of each fuel cell, and have sufficient mechanical strength to support the fuel cells in the stack. The fuel cells are embedded such that a second reactant may be flowed through the inside of each tubular fuel cell and to the inner electrode thereof. Alternatively, a stack of tubular separation membranes or a stack of tubular membrane reactors may be embedded in the matrix. The matrix material may comprise solid state foam, metal filament, or metal, cermet, or ceramic wool.

Owner:INNOTECH ALBERTA INC

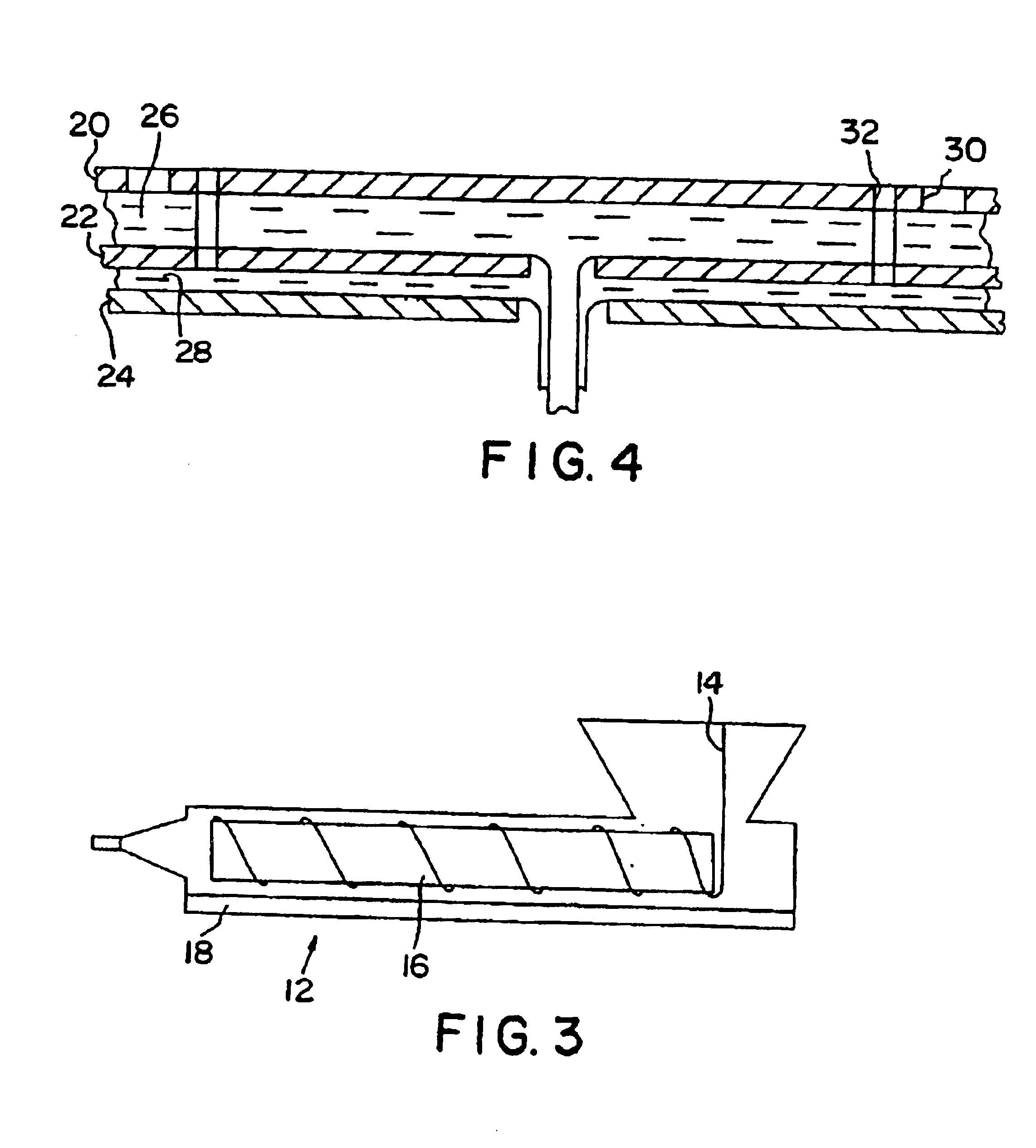

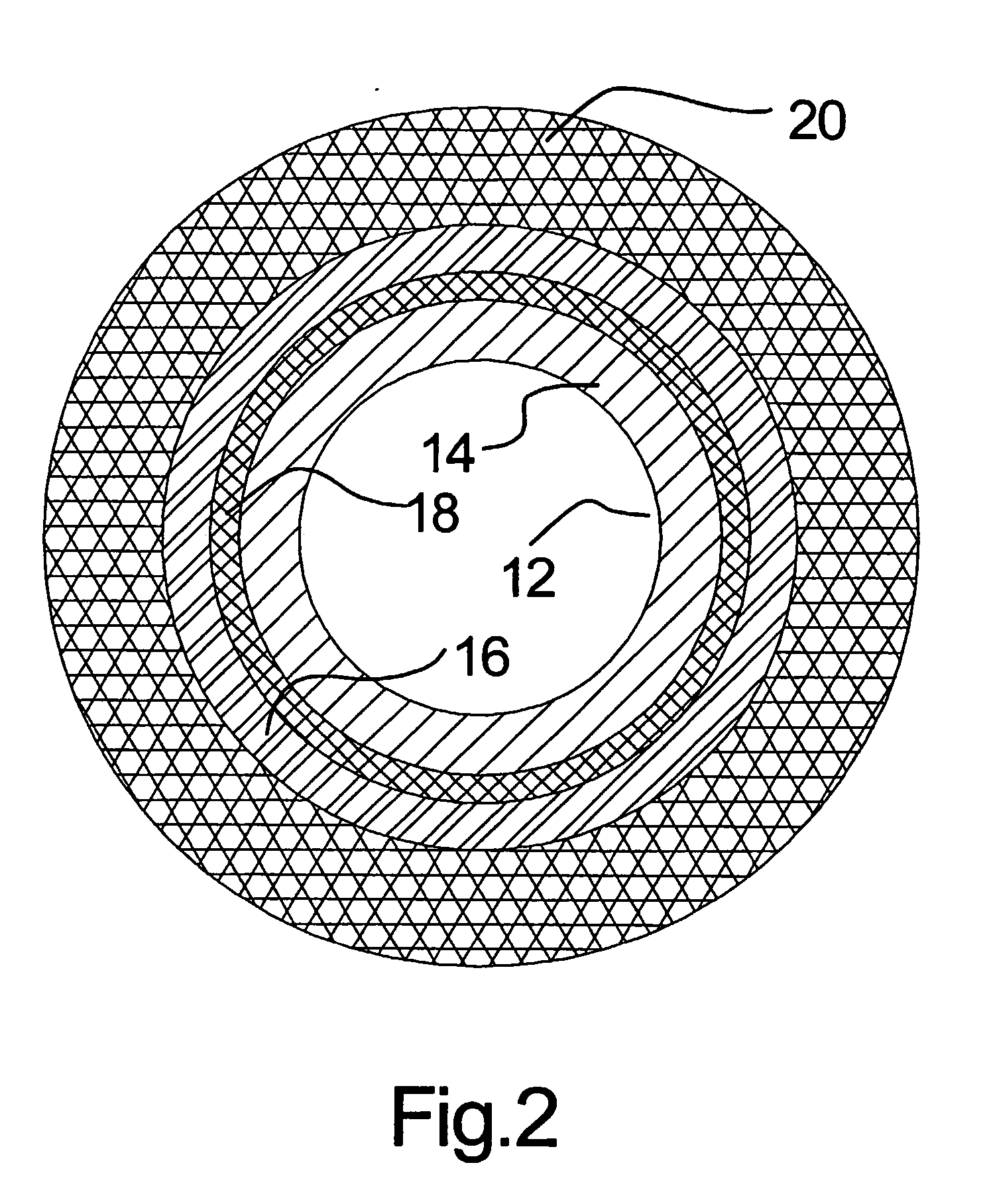

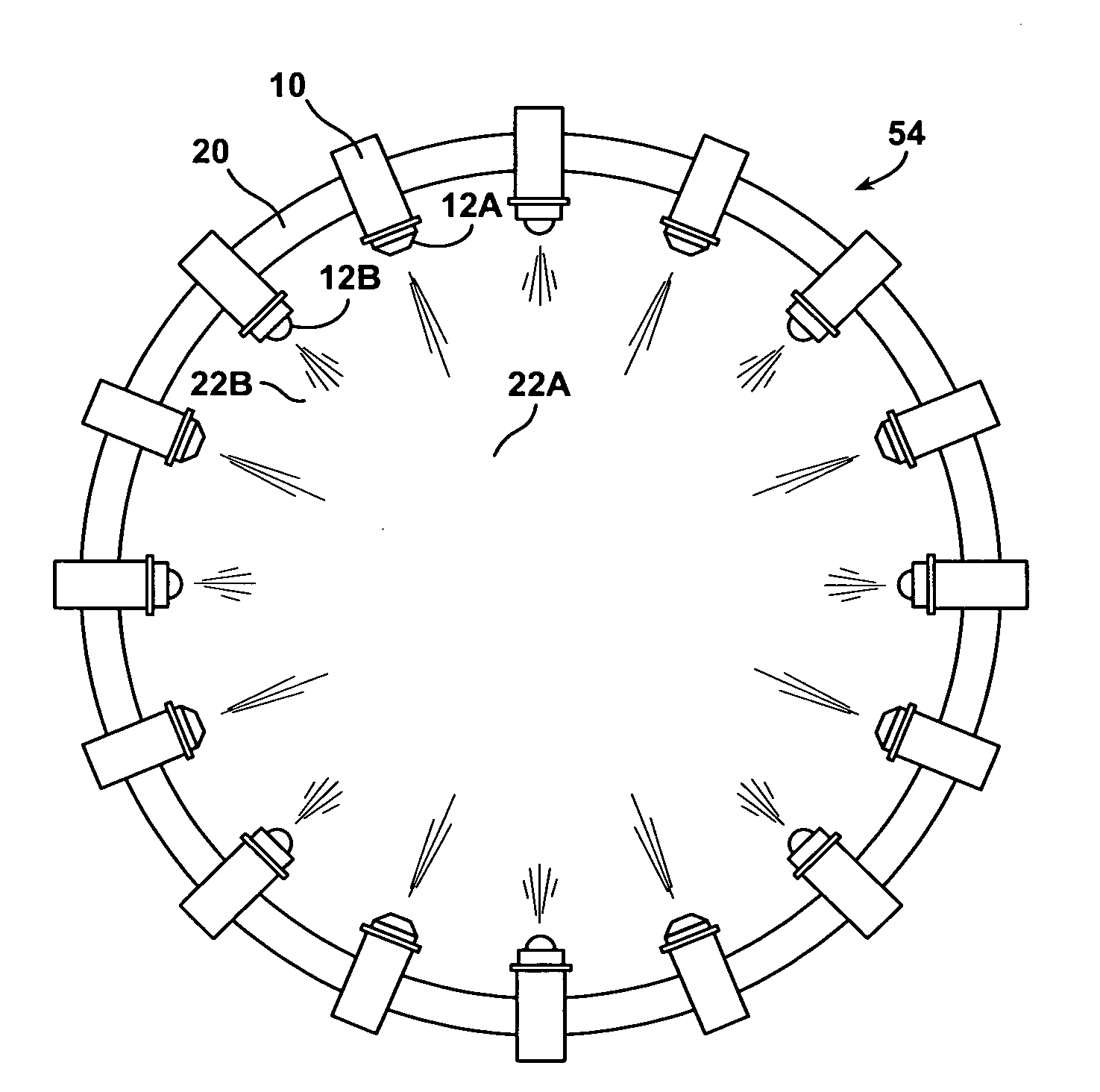

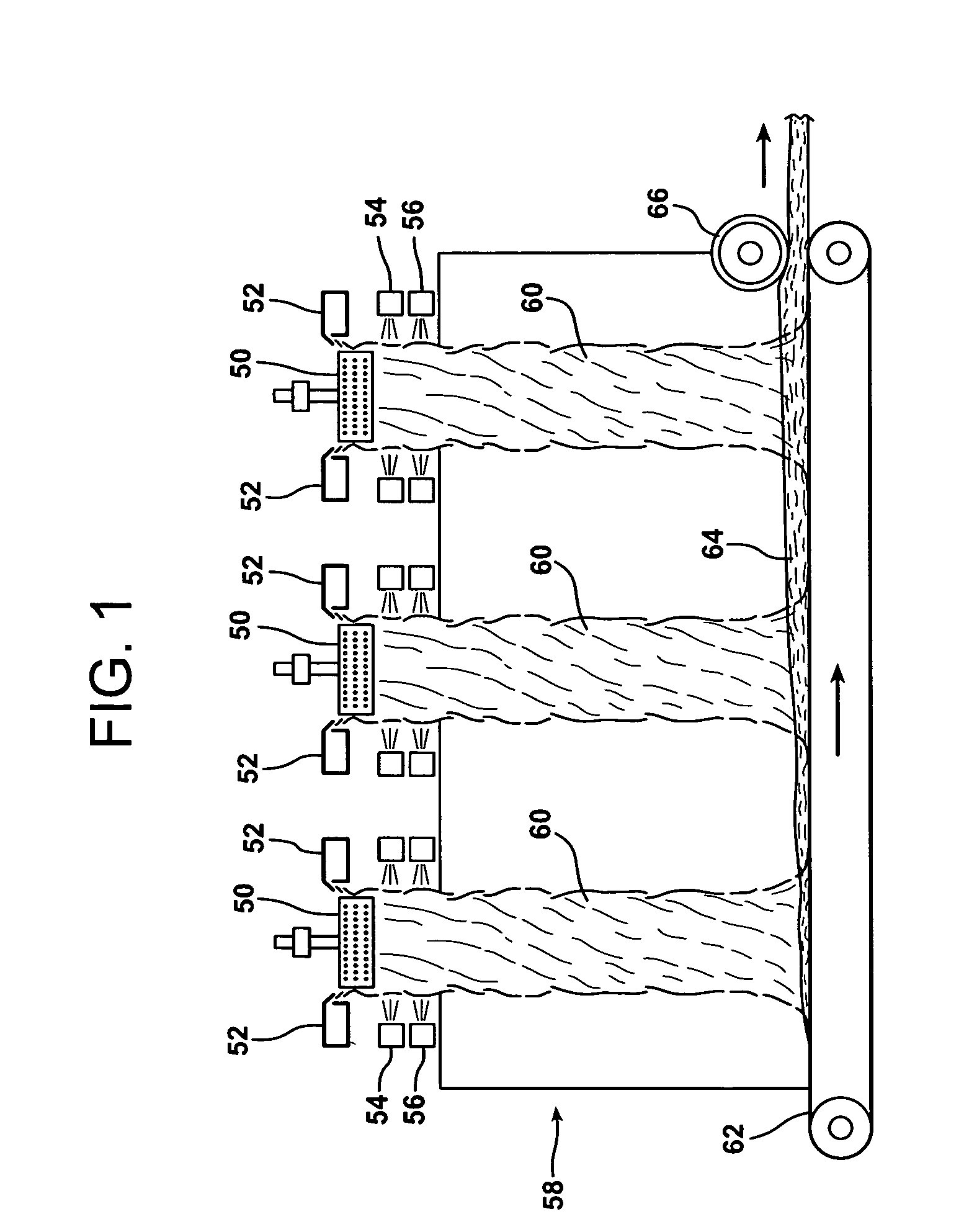

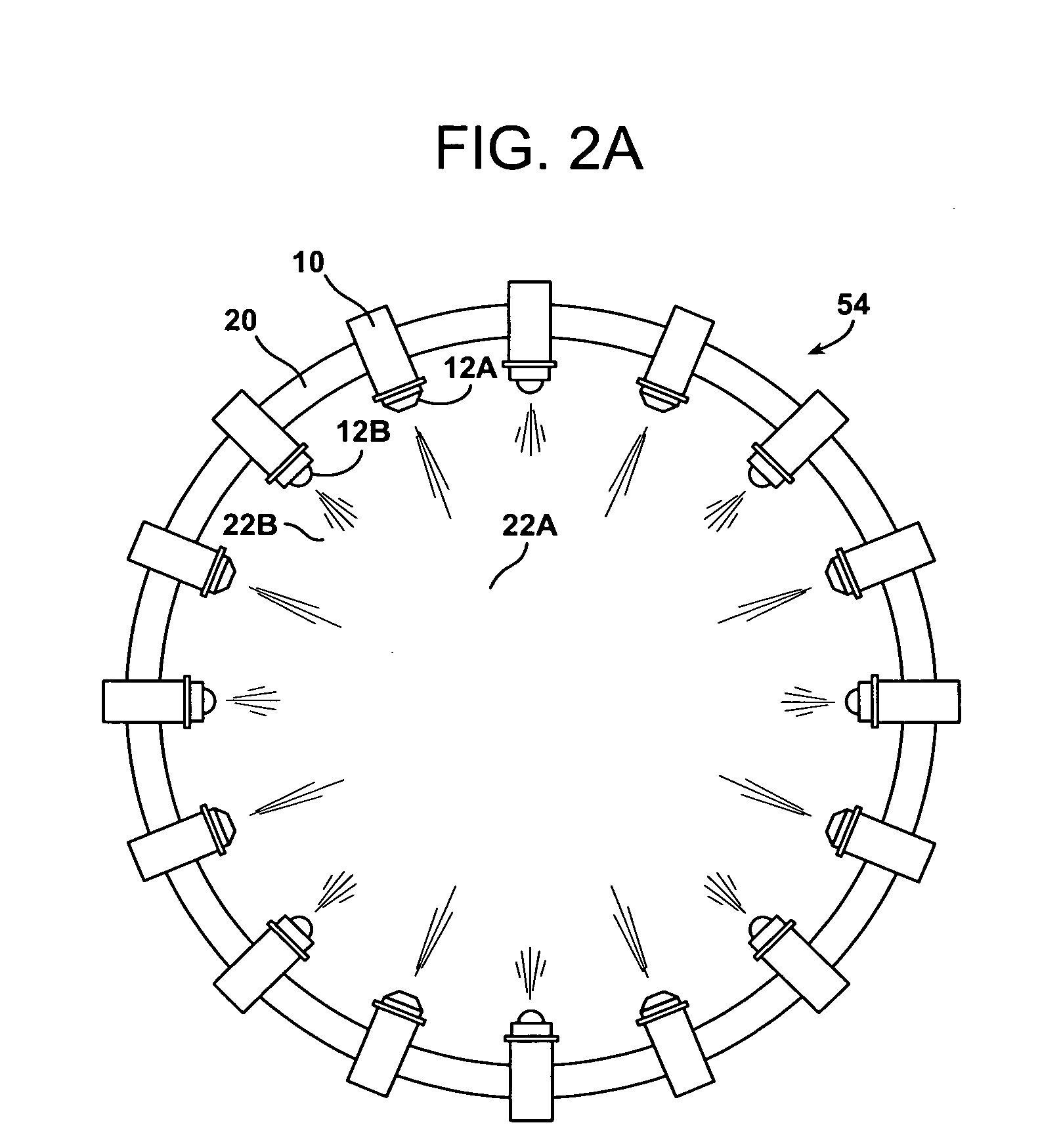

Cooling ring for use in manufacturing of fiberglass wool

InactiveUS20080156041A1Improve cooling effectImprove cooling efficiencyGlass furnace apparatusRotary drum furnacesGlass fiberFiber

The present invention provides improved cooling of a veil of glass fibers by using a combination of nozzle assemblies. The nozzle assemblies include air caps of differing configurations to control the penetration of the spray into the veil. One suitable spray configuration is a nozzle assembly having punch air cap that creates a narrow exit angle, high velocity flow of droplets to penetrate the veil to cool the fibers at the interior. Another suitable configuration is a nozzle assembly having a flat air cap that creates a wide exit angle, low velocity, dispersed spray pattern to cool the exterior of the veil. Preferably, the flat air cap creates a very fine particle size to increase the cooling efficiency of the spray. By using the cooling ring of the present invention, lower levels of binder to be applied to the fibers and environmental emissions from the plant may be reduced.

Owner:OWENS CORNING FIBERGLAS TECH INC

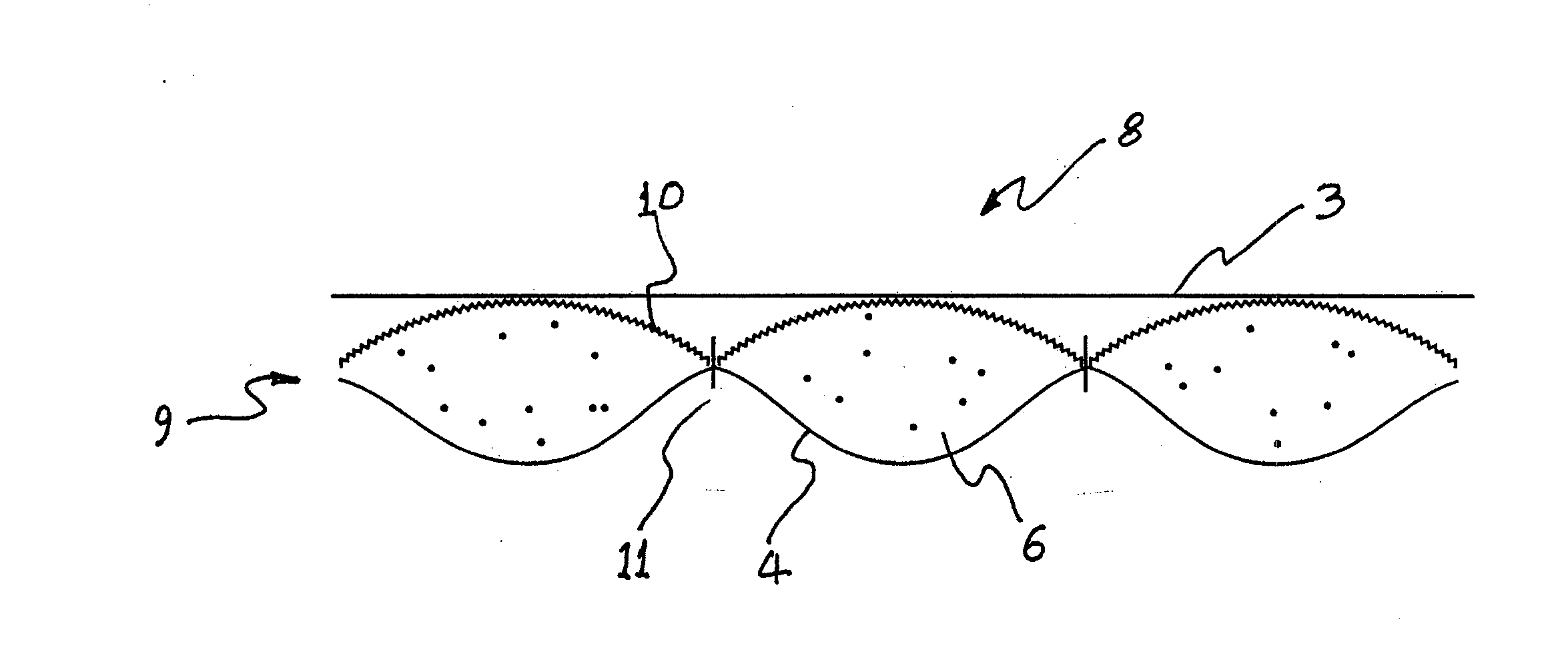

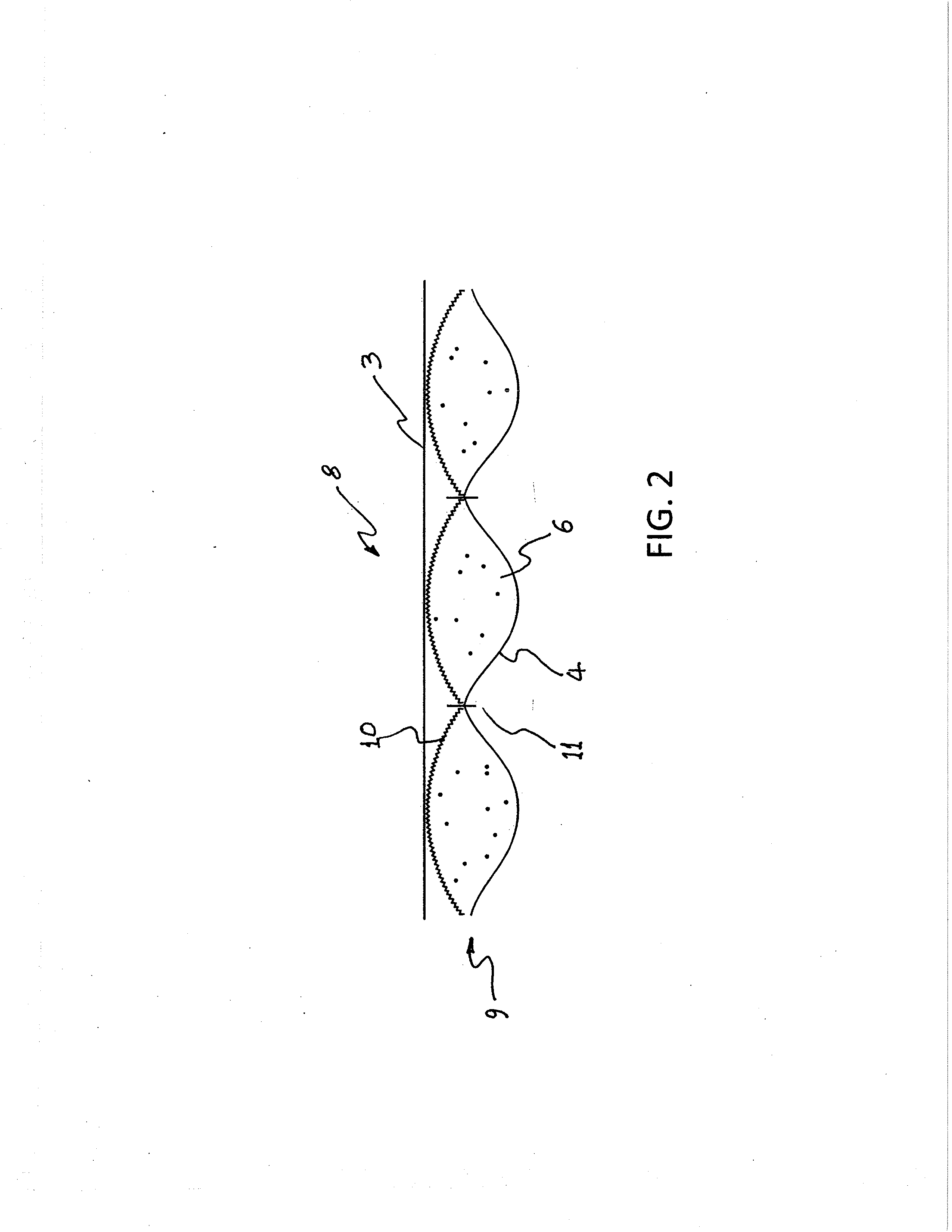

Thermal insulation structure and products made therefrom

InactiveUS20130177731A1Eliminates and lessensReduce weightGarment special featuresBaby linensInter layerThermal insulation

A thermal insulating structure, and products made therefrom. The insulation structure includes an insulation-containing substructure that includes an inner and intermediate layers forming a plurality of successive compartments, the compartments containing insulation material, such as down or loose synthetic material. The intermediate layer is a batting of insulation, such as fiberfill or fleece. An outer layer, such as a waterproof material, extends over the substructure.

Owner:ARCTERYX EQUIP

Process for producing wool-like polyester composite filament yarn

The present invention discloses the production process of composite wool-like polyester filament yarn. Very fine sea island polyester fiber and conventional polyester fiber are stretched, false twisted and combined to form composite fiber filament, and the composite fiber filament is then combined with high shrinkage polyester fiber with boiling water shrinkage over 20 % via air spray twisting to form the composite wool-like polyester filament yarn. The composite filament yarn is woven, and processed through fiber opening, post finishing and light roughing to form soft and fine wool-like fabric with excellent rebound resilience.

Owner:厦门翔鹭化纤股份有限公司

SiO2 aerogel/inorganic cotton compound thermal insulation felt and preparation method thereof

The invention relates to a SiO2 aerogel / inorganic cotton compound thermal insulation felt and a preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The method comprises the following steps of: compounding silica sol and inorganic cotton; ageing the silica sol and the inorganic cotton; carrying out modification and solvent replacement processing; and drying at normal pressure to obtain the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt, which is disclosed by the invention, is characterized in that cheap and easily-obtained industrial raw materials, such as industrial sodium silicate, industrial silica sol, glass wool, rock wool and mineral wool are adopted, the production cost can be lowered, and the ordinary pressure drying technology is convenient and easy to realize, is simple to operate and is suitable for large-scale industrial production. Meanwhile, the product is nontoxic and harmless and does not pollute the environment.

Owner:DALIAN POLYTECHNIC UNIVERSITY

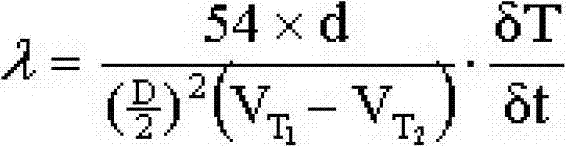

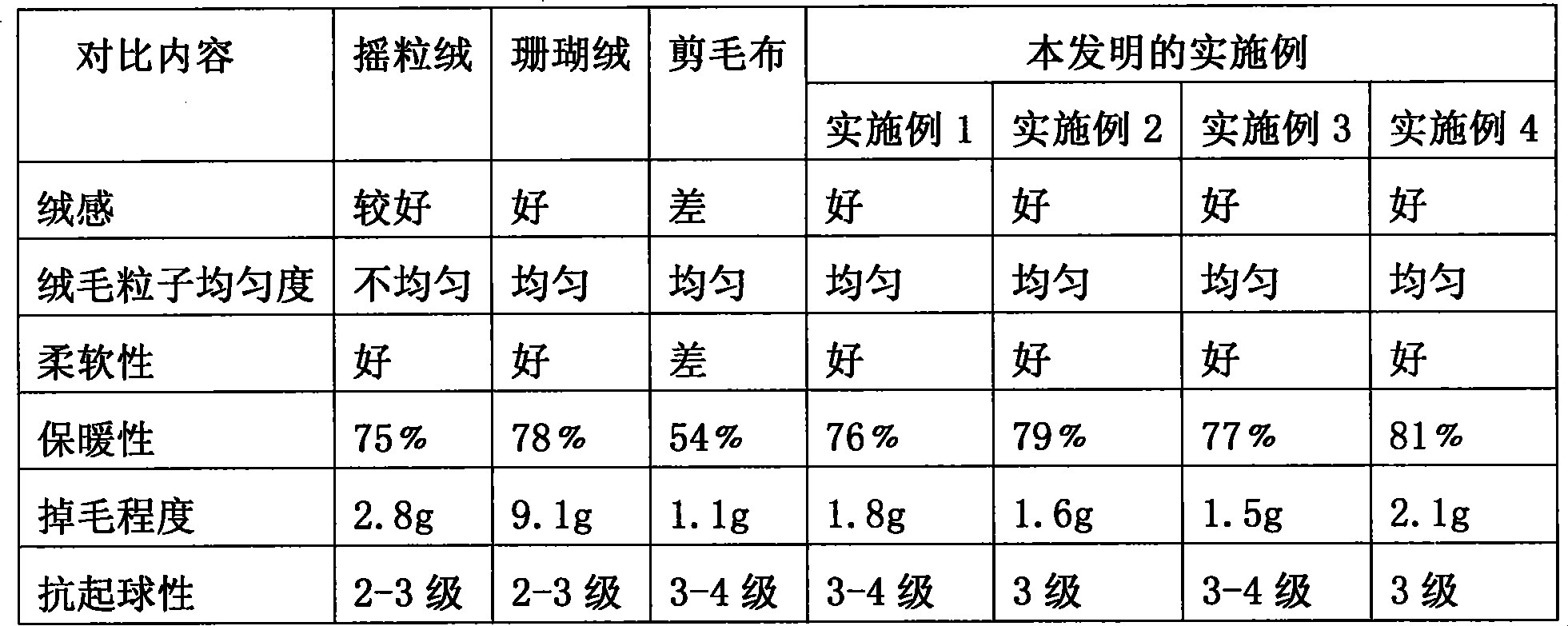

Total polyester superfine denier fabric and its processing method

InactiveCN101423997AInsufficiency to avoid strong influenceSoft touchTextile selvedgesHeating/cooling textile fabricsPolyesterFiber

The invention relates to superfine full-polyester denier fabrics and a processing method thereof, which belong to the technical field of polyester fiber products. The superfine full-polyester denier fabrics comprise surface threads and bottom threads, wherein the surface threads use 150D / 288F or 100D / 144F DTY polyester threads as raw materials, and the bottom threads use 100D / 36F DTY polyester threads as raw materials; and the content of the surface threads occupies 60 to 70 percent of the total compositions, and the content of the bottom threads occupies 40 to 30 percent of the total compositions. The invention has the advantages that the raw materials of the surface threads and the bottom threads are reasonablely selected; full polyester obtained is superfine, light and fluffy, and has soft hand feeling, plump fluffy feeling, good warmth retention property and uniform particle size; small fiber clearance is guaranteed, and the superfine full-polyester denier fabrics have the function of isolating inner air and outer air and preventing heat energy loss as dresses; the processing method forms texture surfaces without texturing, prevents the phenomenon of wool falling when people wear and repeatedly wash the texture due to the fact that fibers are broken by ruleless mechanical external force to form a hairy surface, and prevents the phenomena of pilling and grinning; and the technological steps are simple.

Owner:常熟市东方染整有限公司

Highly effective straw decomposition composite flora

The invention relates to a biotechnology dealing agricultural discard stem with an highly effective stem decomposing composite bacterial, which dissolves the problem of single species of applying microbiological bacterial, weak breaking up, low total degradability rate of cellulose, long developmental cycle. The composite bacterial comprises the following parts: yellow archespore wool bacterium leather bacterial, mushroom bacterial, haci trichoderma, green trichoderma, coninic trichoderma, aspergillus niger, bacillus subtilis, feed bacillus, bacillus megaterium, candida, distillery yeast, food-yeast, brown sphere azotobacter, thermoactinomyces, and so on. The composite bacterial can overall degrade lignin, cellulose, hemicellulose and other organic material in the stem, has a more than 80% degrading rate, a 10-15 days short cycle, keeps a long time for providing a solid bacteria.

Owner:韩农

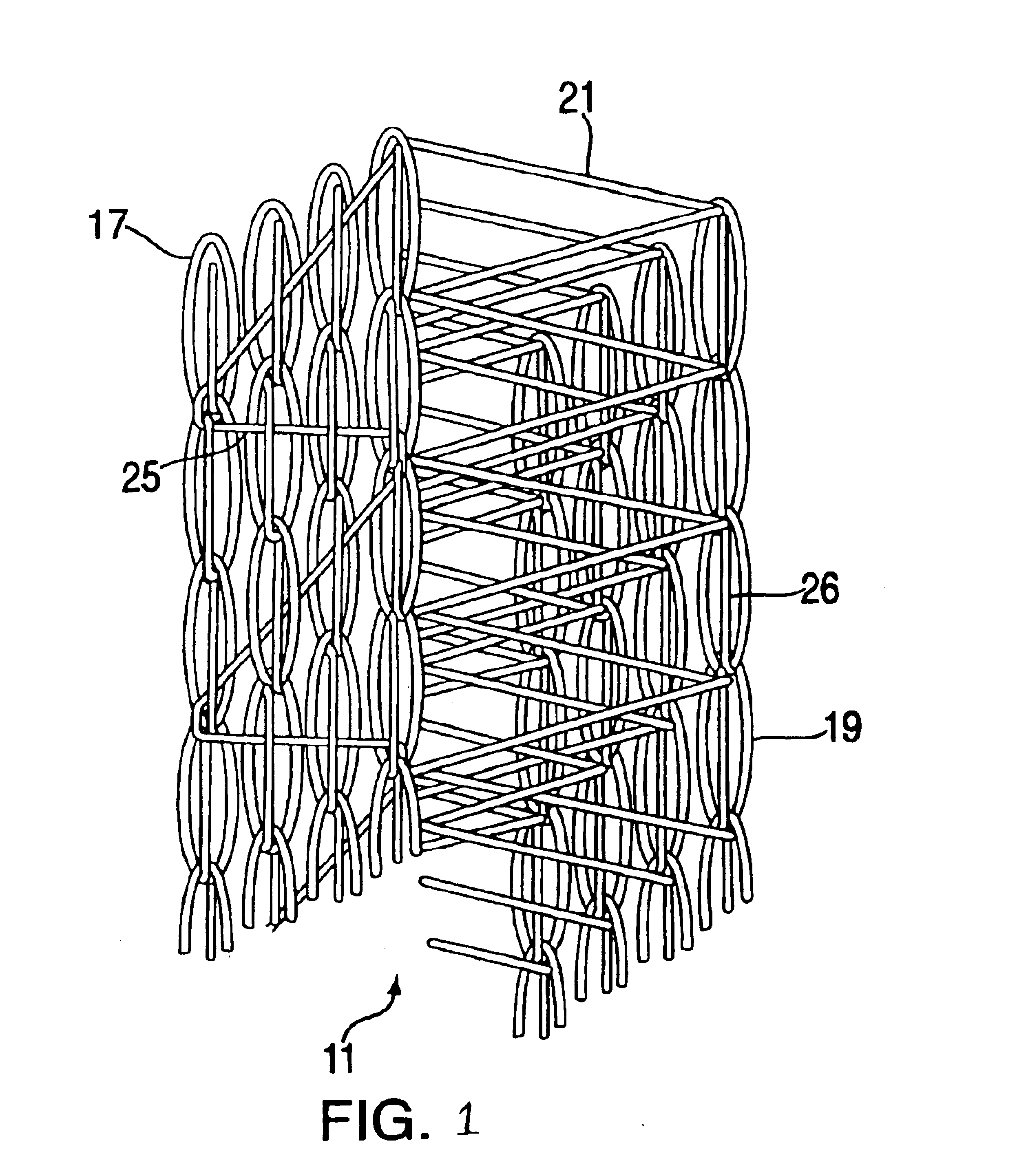

Knit fabrics with face-to-back differentiation

ActiveUS6837078B1Improve the level ofReduce convective heat lossOrnamental textile articlesWarp knittingWoolYarn

A double face knit fabric has a technical face with a velour or fleece surface and a first set of appearance characteristics and a technical back with a velvet surface and a second set of appearance characteristics. The first set of appearance characteristics is different from the second set of appearance characteristics. Pile yarns are processed by napping or raising to form the velour or fleece surface at the technical face and the pile yarns are processed to form the velvet surface at the technical back. The pile yarns include first yarns formed of materials having the first set of appearance characteristics selected from the group of consisting of: depth of color upon dyeing, degree of raising, degree of air permeability, susceptibility to selected dye formulation, reaction to heat, and degree of coarseness, bulk, cross-section and / or denier and second pile yarns formed of materials having the second set of appearance characteristics selected from among the group of consisting of: depth of color upon dyeing, degree of fiber straightness, degree of fiber curl, degree of fiber shrinkage, degree of fiber crimp degree of raising, reaction to heat, degree of yarn coarseness, bulk, cross-section and / or denier.

Owner:MMI IPCO

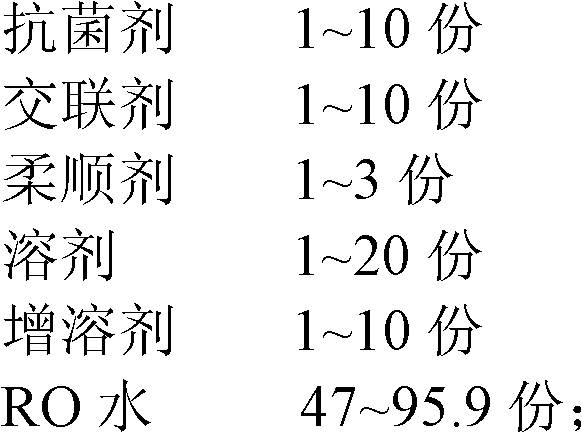

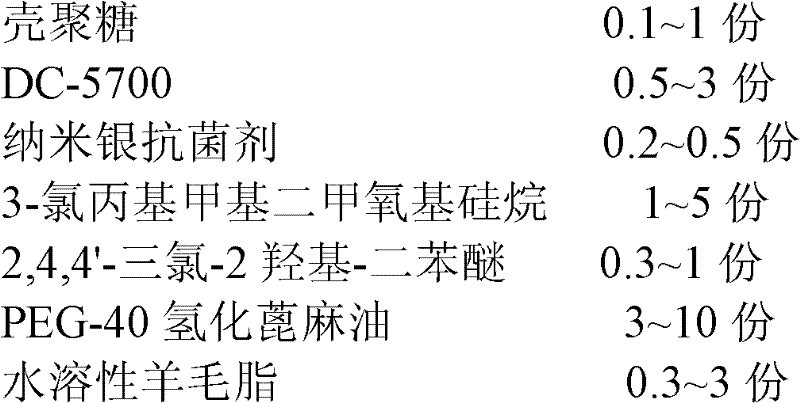

Finishing liquor for realizing antibiosis of fabrics and preparation method of finishing liquor

ActiveCN102505467APromote degradationGood biocompatibilityFibre treatmentPolyethylene glycolReverse osmosis

The invention discloses finishing liquor for realizing antibiosis of fabrics and a preparation method of the finishing liquor. The finishing liquor consists of raw materials including, by weight, 0.1 part of chitosan, 0.5 part of DC-5700, 0.2 part of nanometer silver antibacterial agent, 1 part of 3-chloropropylmethyldimethoxysilanes, 0.3 part of 2, 4, 4'-trichlorine-2 hydroxy-diphenyl ether, 3 parts of PEG (polyethylene glycol)-40 hydrogentated castor oil, 0.3 part of water-soluble wool oil, 10 parts of ethanol and 84.6 parts of RO (reverse osmosis) water. Compared with other bacteriacide, the antibacterial agent has high safety and a good long-term sterilizing effect, and does not affect processability of materials and other application performances. The finishing liquor for the fabrics not only has an antibacterial effect, but also has a special effect of being capable of guaranteeing that finished fabrics can keep original softness. In addition, the finishing liquor for the fabrics is temperate, is not irritative, does not contain formaldehyde, is environment-friendly, and does not have any side effects when used for a long time.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

Production of soluble keratin derivaties

InactiveUS7148327B2Low costReduce impactPeptide/protein ingredientsPeptide preparation methodsSulfurIntermediate Filament Protein

A process for the preparation of soluble proteins of high molecular weight with little or no damage to the structural integrity of the proteins. The process is economically and environmentally acceptable by virtue of the cost of reagents that are used, and the recycling of some of those reagents, and is suitable for the production of soluble proteins on a large scale. The process includes a first stage using oxidative sulfitolysis followed by a second stage using mild conditions to extract the soluble protein. In the case of wool as the protein source the process leads to the production of soluble keratin proteins fractionated into the classes S-sulfonated keratin intermediate filament proteins and S-sulfonated keratin high sulfur proteins.

Owner:KERATEC LTD

Fabric capable of preventing electromagnetic radiation

InactiveCN101942729AElastic fit and comfortableHarm reductionWeft knittingWarp knittingYarnSilver plate

The invention relates to a fabric capable of preventing electromagnetic radiation, which is knitted or weaved. The warp and the abb of the fabric comprise covering yarn. The covering yarn takes one of silver plating fiber, carbon fiber and carbon black organic fiber as core yarn and takes comfortable fiber as skin yarn; the silver plating fiber is formed by carrying out silver plating on synthetic fiber; the weight ratio of the corn yarn to the skin yarn is 10-70:30-90; and the comfortable fiber is one of cotton, wool, silk, hemp, viscose, bamboo fiber, bamboo carbon fiber, soybean fiber, PLA fiber, alginate fibre, milk fiber and pearl fiber. The invention can shield electromagnetic wave, and the shield effect is above 99%. The skin yarn in the covering yarn adopts natural fiber, and the natural fiber on the outer layer has the characteristics of moisture absorption, ventilation and comfort.

Owner:汕头市奥山服饰有限公司

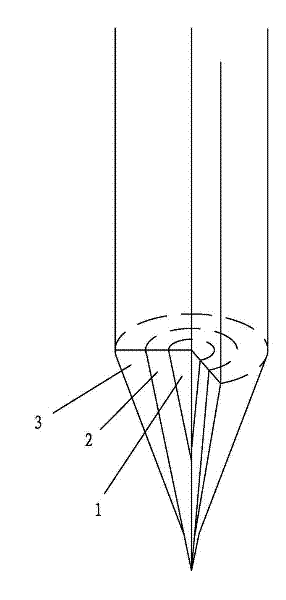

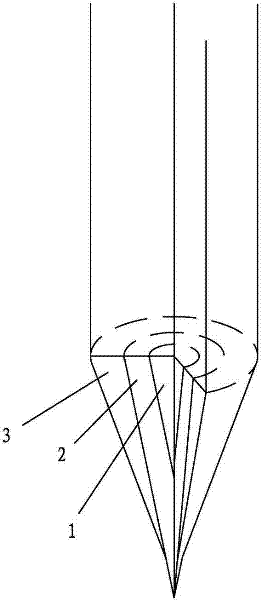

Writing brush and manufacturing method thereof

The invention relates to a writing brush and a manufacturing method for the writing brush. The brush head consists of wool and other animal hair; the other animal hair is selected from one of raccoon hair, badger hair, dressed water badger hair, broom corn millet fiber, bristle and wolf tail hair; the brush head is divided into a middle area, a modified area and a hair area; and the middle area is provided with a central brush core formed by one animal hair, the modified area is formed by the other animal hair and has conical structure with annular bottom, the hair area is positioned outside the modified area, the hair area is formed by wool, and the hair of the hair area is not arranged at the top. The invention belongs to the technical field of manufacturing of writing brushes. Compared with the conventional writing brush produced in Huzhou, the writing brush has the advantage of higher elasticity by adopting a technology of combining multiple kinds of hair.

Owner:湖州市善琏鑫利湖笔厂

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

Flame-resistant, high visibility, anti-static fabric and apparel formed therefrom

InactiveUS20060068664A1Optimal static dissipationBig contrastWarp knittingCircular knitting machinesPolyesterYarn

A fabric is provided for use in safety apparel, including a first yarn type comprising at least about 60 percent modacylic fibers and a second yarn type comprising an intimate blend of anti-static fibers and other fibers selected from the group of fibers consisting of polyester, nylon, rayon, modacrylic, cotton, wool, and combinations thereof. The fabric meets the American Society for Testing and Materials standard ASTM F-1506 for flame resistance, Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Multifunctional aromatic type element fiber fabric protective clothing

ActiveCN103233287ASpinning solutions preparationArtifical filament manufactureAcute hyperglycaemiaSesamum orientale

The invention discloses multifunctional aromatic type element fiber fabric protective clothing. The multifunctional aromatic type element fiber fabric protective clothing comprises vitamin mineral substance nutrient element group, a free radical-scavenging anti-electromagnetic wave energy-accumulated heat-insulating material, natural antibiosis mite-proof traditional Chinese medicine fluid extract aroma nano microcapsule, and cotton, sesame, silk, wool, polypropylene fiber, nylon, acrylic fiber and a terylene viscose fiber spinning solution. The multifunctional aromatic type element fiber fabric protective clothing can entirely supplement and regulate the element balance of a human body, as well as the vitamin balance, release trace element negative ions, purify air, resist heavy metal elements and air, powerfully scavenge free radicals, enhance the immunity of the human body, and prevent electromagnetic wave pollution, is energy-accumulated, cold-proof and heat-insulating, as well as antimicrobial and mite-proof, can effectively prevent the infection of various pathogenic bacteria, influenza and skin pruritus, is anti-cancer, and resists hypertension, hyperlipidemia, hyperglycemia, cerebral thrombosis and the like, thus building the human body, and enabling the human body to emit natural and pleasant aroma.

Owner:中山巨邦科技集团有限公司

Preparation method of keratin complex fiber

InactiveCN104862818AReduce pollutionTime-consuming and laborious to solveConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberSolvent

The invention relates to a preparation method of keratin complex fiber, which comprises the following steps: 1, mixing the dried keratin powder, high polymer for fiber forming, ionic liquid and the like, and mechanically stirring and dissolving to obtain a keratin complex solution at certain temperature; (2) preparing a keratin complex fiber by using a dry jet wet spinning process. According to the invention, the keratin used according to the invention comes from leftovers of processing industry such as chicken feather, drake feather, goose feather and wool, and as for the recycle of the waste, on one hand, the economic benefit is increased, on the other hand, the environment pollution can be reduced. The selected high polymer for fiber forming and keratin can dissolve together in the same ionic liquid, so that the characteristics of high efficiency, simpleness and convenience can be achieved. Compared with the pure keratin fiber, the strength and elongation at break of the spun regenerated keratin can be improved greatly, the practical use value can be increased; the keratin complex fiber has wide potential application in the fields of clothing, wig, tissue engineering and the like. In addition, the solvent ionic liquid can be completely recycled, can not pollute the environment and has the meaning of sustainable development.

Owner:JIANGNAN UNIV

Multifilament blending knitted fabric

The invention discloses a multifilament blending knitted fabric which comprises the following components in parts by weight: 5-20 parts of mulberry silk, 10-30 parts of a bamboo fiber, 15-25 parts of an acetate fiber; 10-15 parts of a copper ammonia fiber; 8-32 parts of a corn fiber, 6-18 parts of a cotton fiber, 7-21 parts of a conductive fiber, 10-30 parts of mercerized wool, 6-25 parts of polyester cotton, 20-40 parts of polyester, 10-30 parts of chinlon, 15-28 parts of tencel, 4-26 parts of cashmere wool and 25-35 parts of woolen plush. With the adoption of the scheme disclosed by the invention, the multifilament blending knitted fabric can improve the comfort and practicability of the fabric through advantage complementation of multiple fibers.

Owner:YANGZHOU GUANGHONG STEEL STRUCTURE METAL IND

Mercerization and shrinkproof finishing method for woven fabric

InactiveCN101418515AReduce yellowingGood reproducibilityAnimal fibresBiochemical engineeringReducing agent

The invention discloses a mercerizing and shrinkproof finishing method for a wool fabric, which comprises the following steps of: step one, washing fluffiness of the wool fabric; step two, scale stripping by chloridizing or chloridizing plus oxidizing; step three, reduction dechlorination, in which a reducing agent is added into a container; step four, alkali washing neutralization; step five, water washing; step six, softening and fluid removal; and step seven, dehydration and drying. The method is characterized in that: 1. the whole process of the process is finished in water environment, which is suitable for uniform processing of ready-made clothes and has good reproducibility; 2. the appropriate stripping of wool scales improves dimensional stability and achieves the aim of machine washing; 3. the method combining the chlorination and the oxidization greatly reduces the yellowing of the fabric; and 4. the method greatly improves hand feel and luster, and meets the requirement of people on the comfort and beauty.

Owner:ZHEJIANG QUEPING TEXTILE CHEM

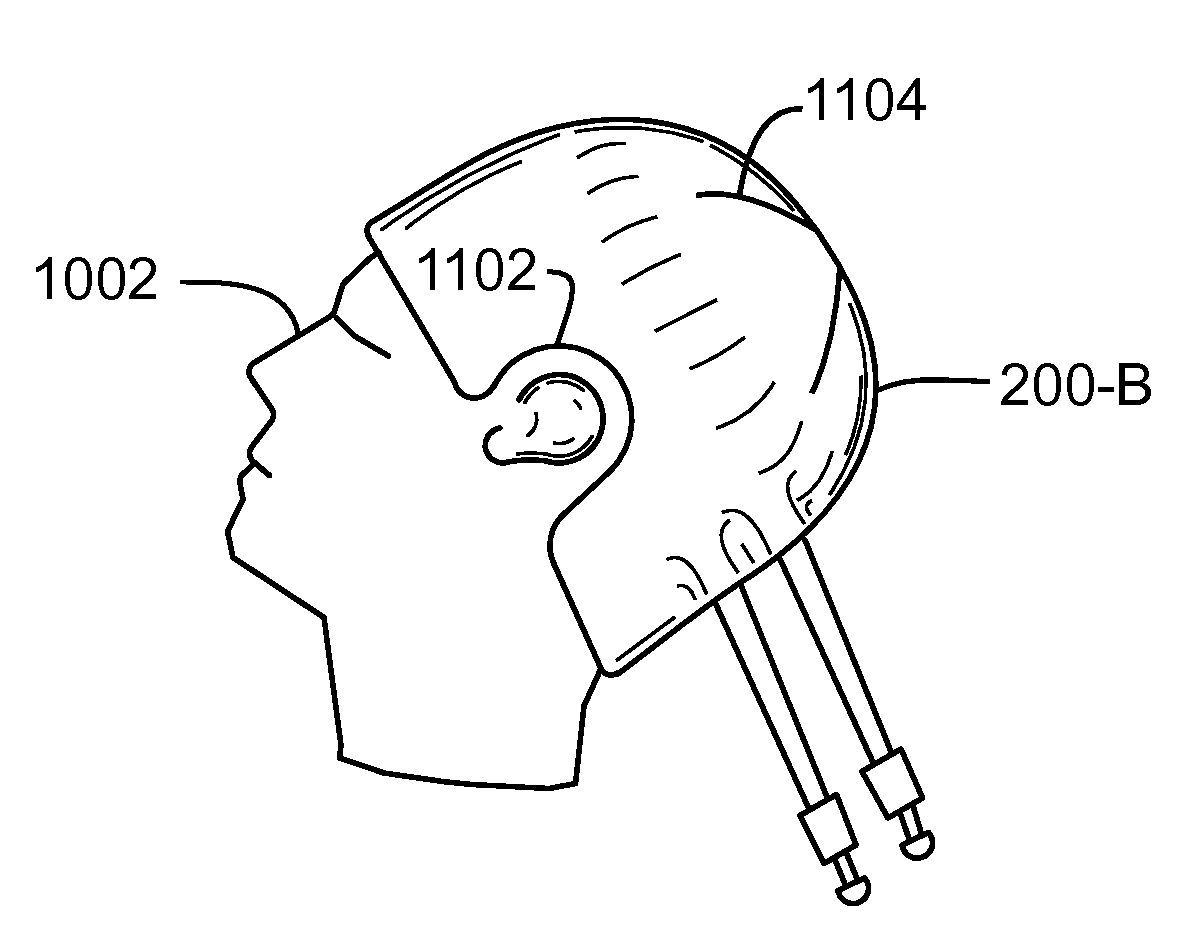

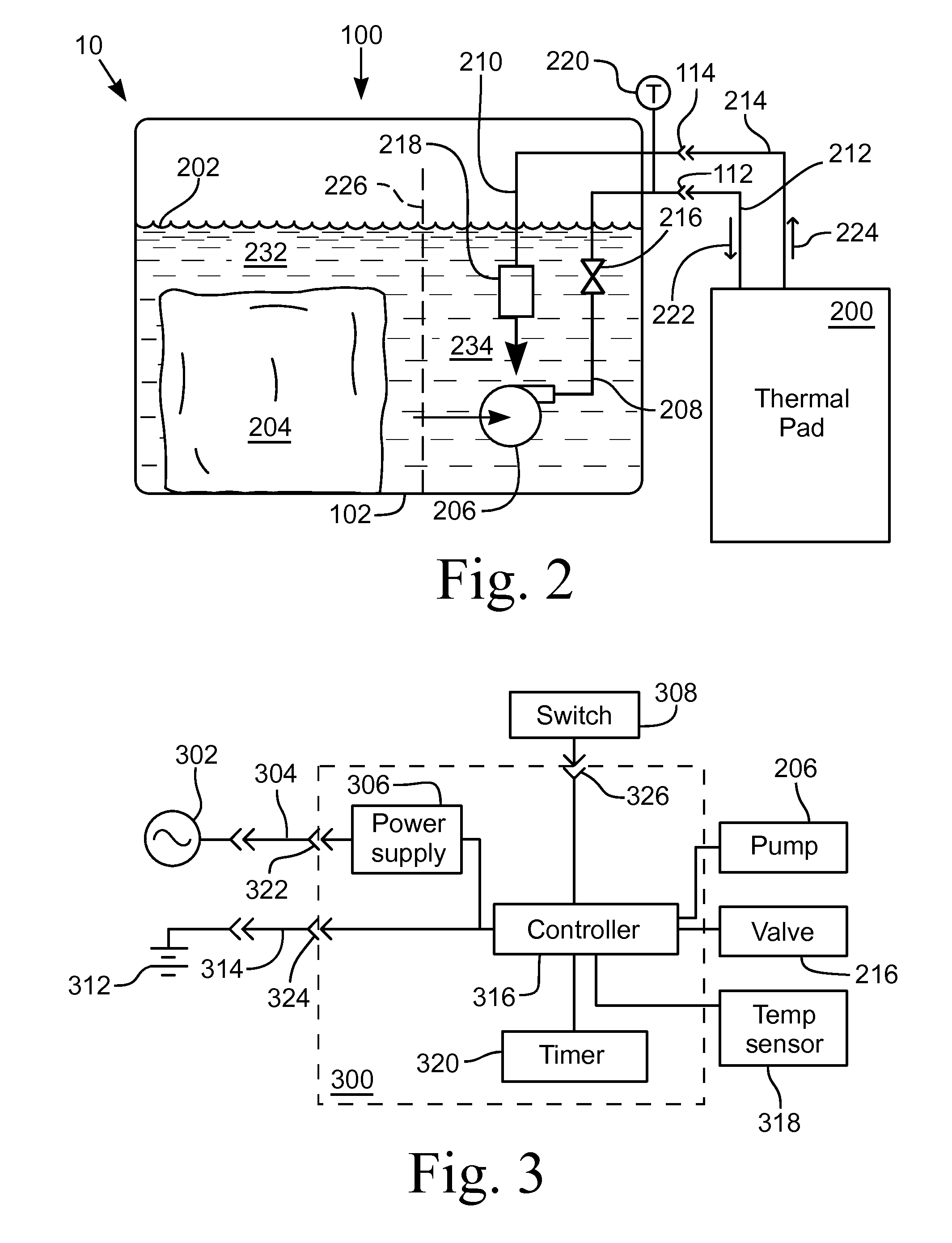

Thermal skull pads for coolant system

A bonnet-shaped pad configured to fit a skull is formed from a rectangular thermal pad. A rectangular pad has creases that allow the pad to conform to the shape of a human skull. The pad defines a cavity. The pad proximate the cavity includes a serpentine conduit configured to allow conditioned fluid to flow from an inlet to an outlet. The pad is configured such that fluid flow is not unduly restricted proximate the creases in the pad, thereby allowing the fluid to flow through the portion of the pad configured to be proximate the skull. The pad is connected to a cool water supply that pumps wool water through the pad at preselected intervals. In one configuration a remote, tethered switching unit controls the duty cycle of the pump, enabling cool water to flow through the pad after a selected time.

Owner:ADROIT MEDICAL SYST

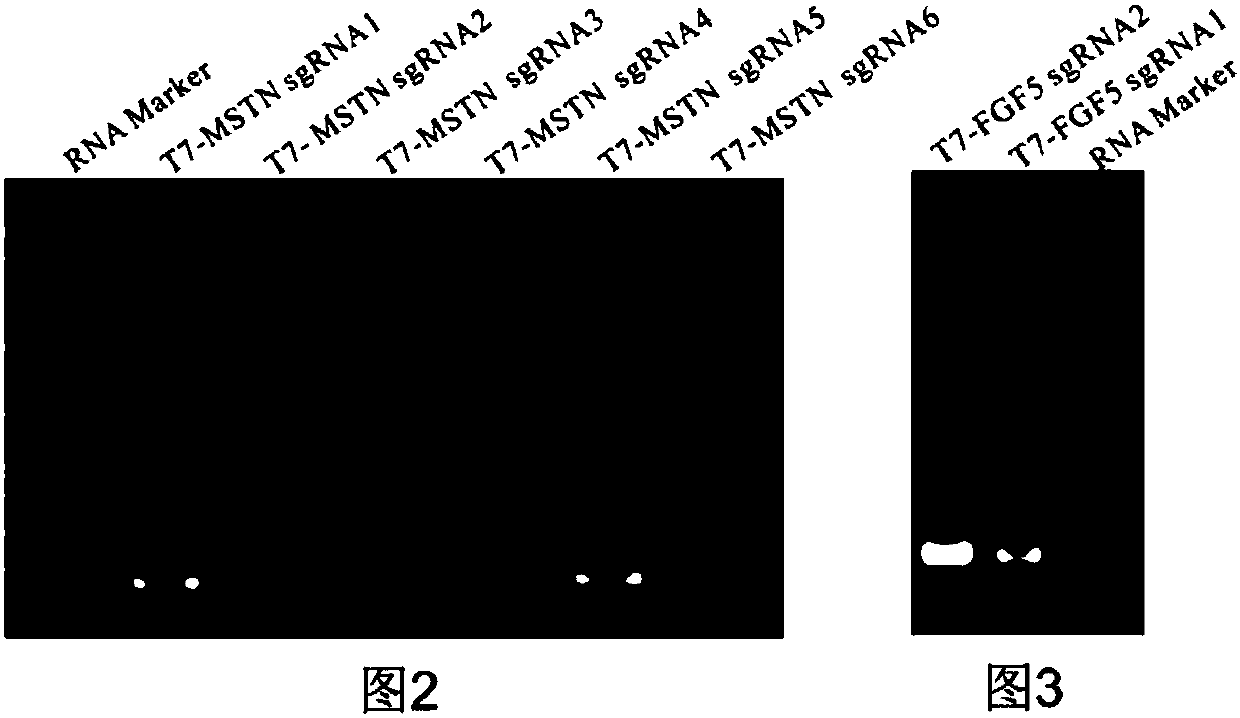

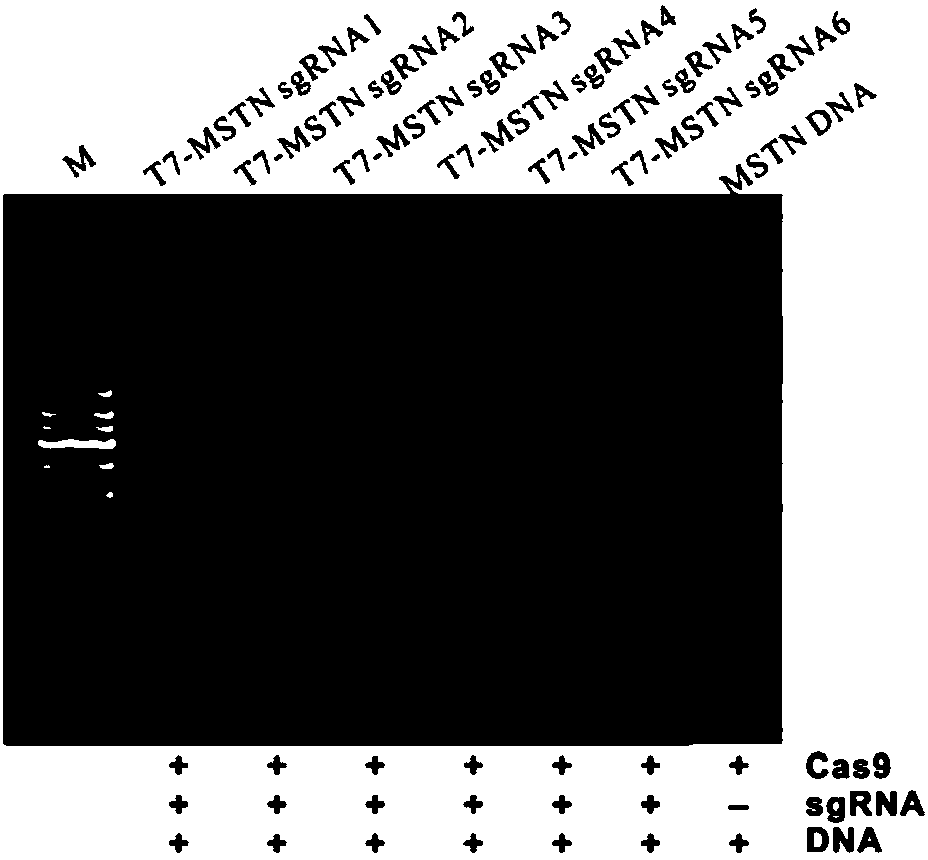

Method for acquiring gene editing sheep by RNA-mediated specific double-gene knockout and special sgRNA for method

ActiveCN105132427AStrong specificityPrecise targeted modificationArtificial cell constructsVertebrate cellsAnimal scienceGenome editing

The invention discloses a method for acquiring gene editing sheep by RNA-mediated specific double-gene knockout and special sgRNA for the method. The sgRNA combination consists of sgRNAMSTN-1 and sgRNAFGF5-1, wherein sgRNAMSTN-1 is sgRNA which can realize specific targeted modification of sheep MSTN gene and is RNA shown in the second to 21st nucleotides in a sequence 6 or RNA with the second to 21st nucleotides of the sequence 6; sgRNAFGF5-1 is sgRNA which can realize specific targeted modification of sheep FGF5 gene and is RNA shown in the second to the 21st nucleotides in a sequence 8 or RNA with the second to 21st nucleotides of the sequence 8. According to the method for acquiring gene editing sheep by RNA-mediated specific double-gene knockout and special sgRNA for the method, the CRISPR / Cas9 genome editing technology and the micro-injection technology are combined, so that the sheep targeting efficiency is higher and more accurate, sheep double-gene knockout is realized for the first time in the generation, improvement on sheep meat production and wool production is greatly promoted, and a larger space and a more effective technical tool are provided for breeding of new sheep varieties.

Owner:新疆畜牧科学院生物技术研究所

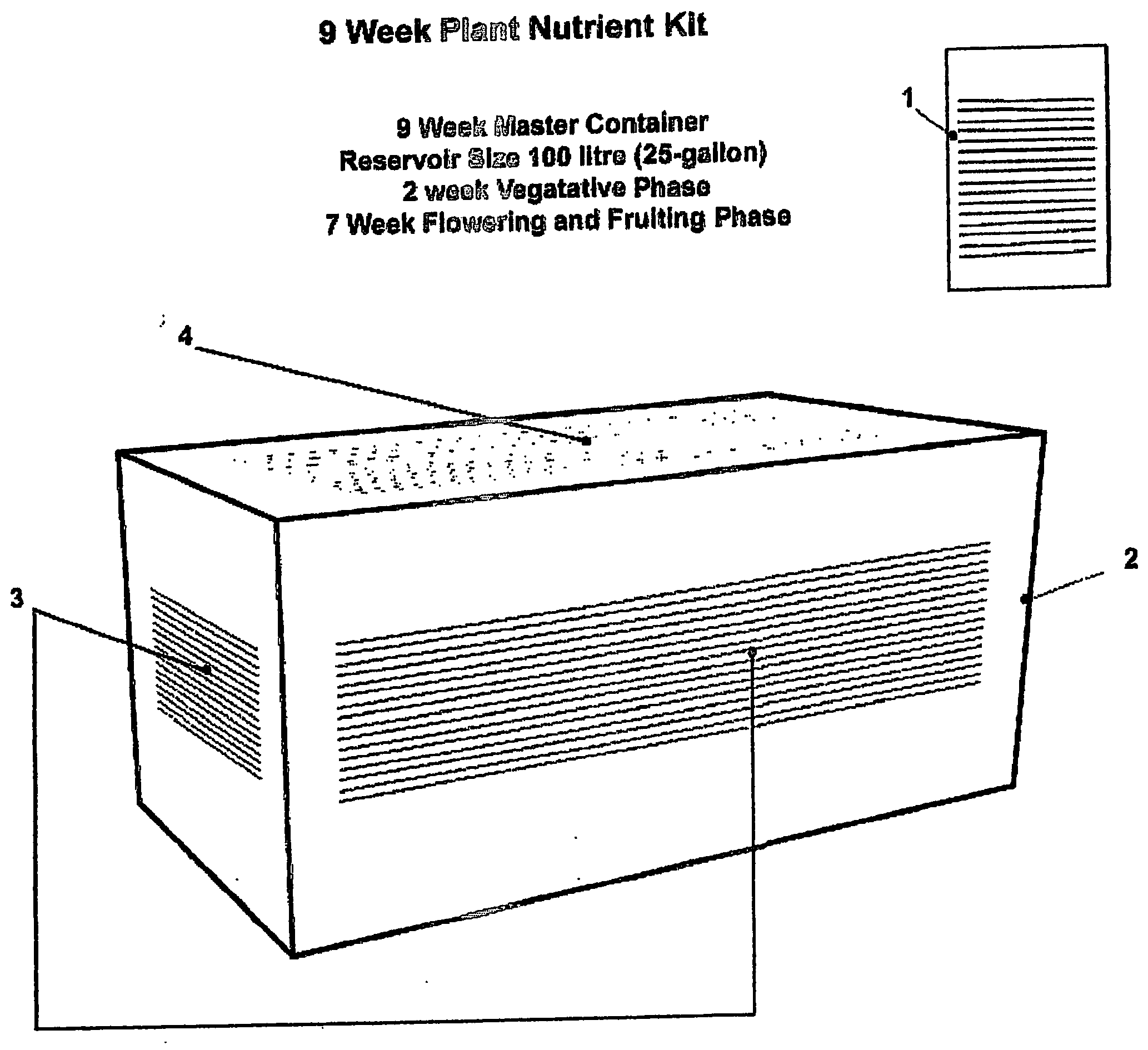

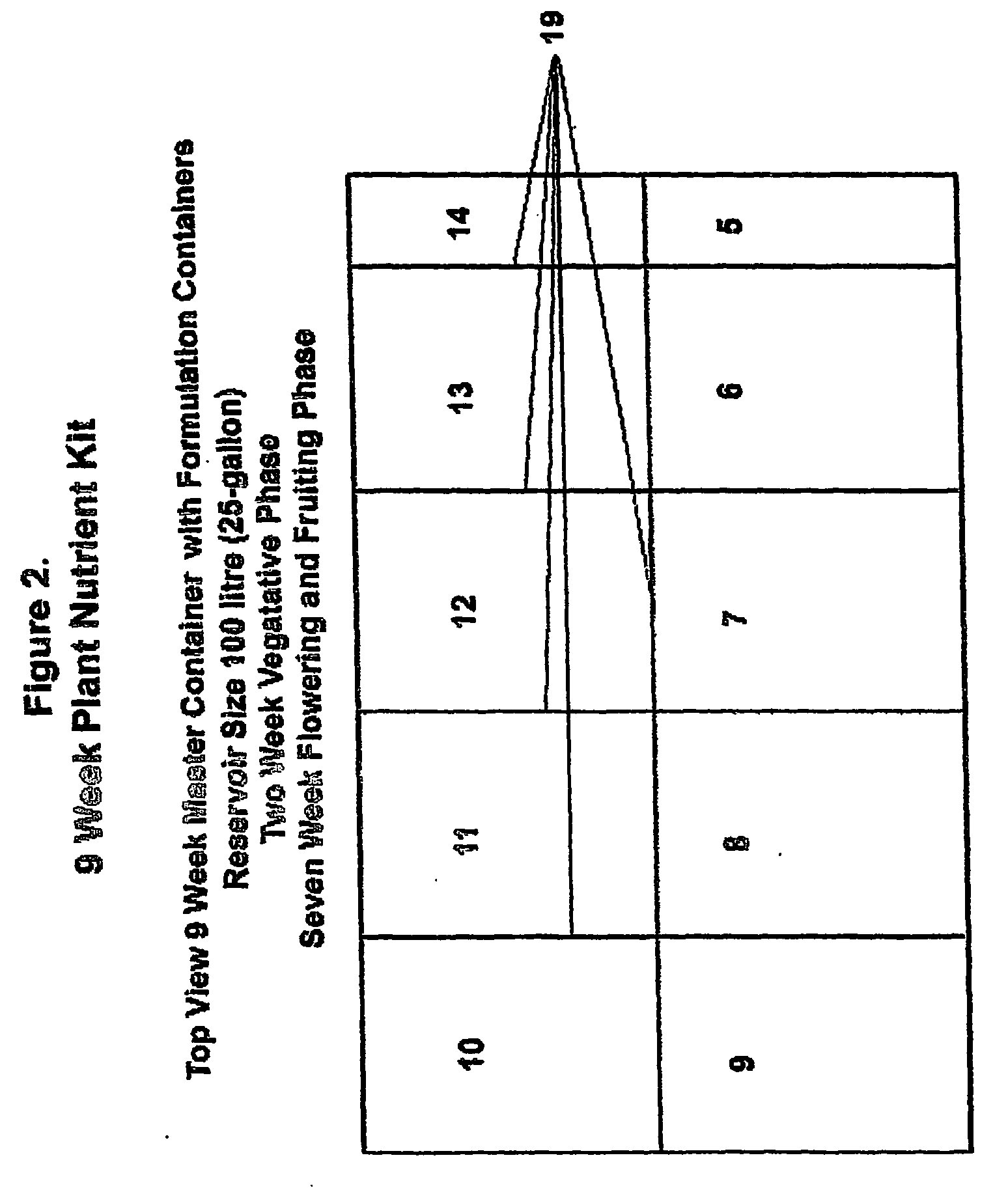

Hydroponic plant nutrient kit and method of use

InactiveUS20060168881A1Extraordinary resultCost-effectiveFertiliser formsCultivating equipmentsFiberDrip irrigation

The present invention provides a complete, safe, cost-effective, simple-to-use, and pH balanced hydroponics nutrient feeding kit for culturing plants indoors, outdoors and in green houses, wherein the hydroponics nutrient feeding kit comprises a set of formulations for making chronologically sequential nutrient solutions to culture a hydroponic crop through an entire growth cycle, wherein each formulation comprises all of the nutrient components required in a batch of nutrient solution. The nutrient components are pre-measured for a specific hydroponic nutrient reservoir size to consistently provide plants with their nutrient requirements for the specific stage of growth through the vegetative phase and the flowering and fruiting phase through to harvest. The hydroponics nutrient feeding system can be used with rock-wool, sphagnum moss, leca, coir, lava rock, soil mixes, aeroponics, drip irrigation, flood and drain, wick, NFT, systems and all other hydroponic growth mediums and systems.

Owner:STRAUMIETIS MICHAEL JAMES

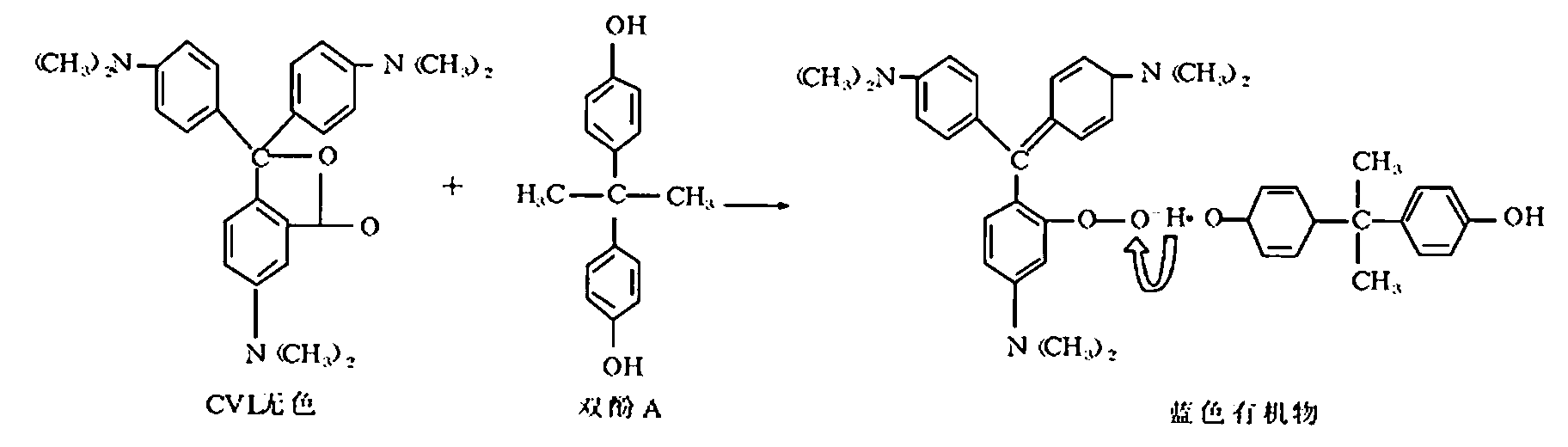

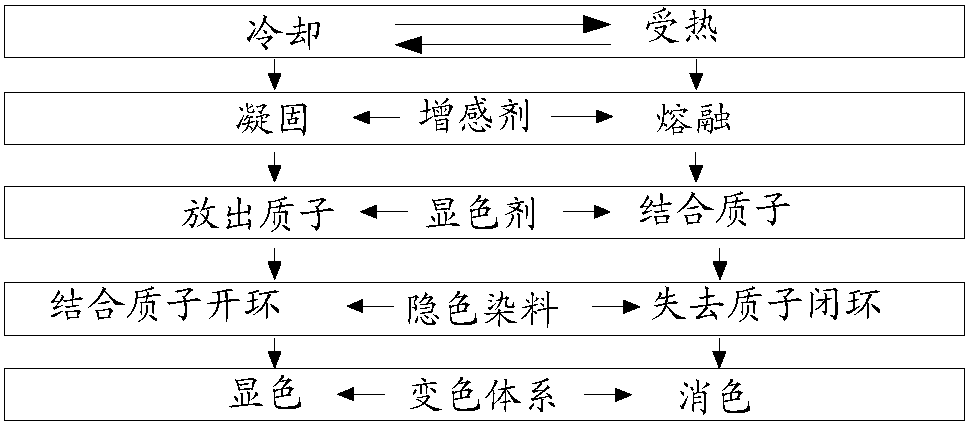

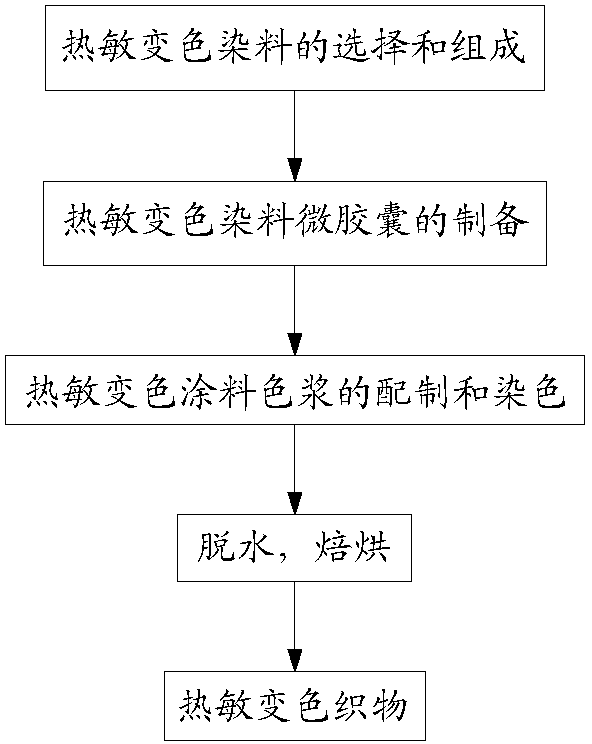

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

Rachael blanket made from Modal cotton

A raschel blanket of modyhr-cotton is prepared form 35-50 wt.% of modyhr, 30-40 wt.% of cotton and 15-30 wt.% of polyester. Its manufacturing process includes warping polyester filament, warping wool yarn blended by modyhr and cotton, weaving for fabric, splitting and opening fine hair, inspecting and sending inspected material to warehouse of semi-finished product.

Owner:上海海欣大津毛织有限公司

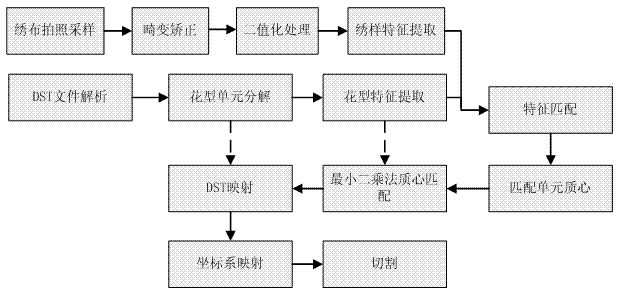

Automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision

InactiveCN102704215AIncrease profitReduce dependencyCharacter and pattern recognitionAutomatic machinesMachine visionLaser cutting

The invention discloses an automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision. In wool toy manufacturing industry, the profile and pattern of the wool toy are processed by adopting an embroidery machine, and the whole embroidery piece is cut one by one by adopting a laser cutter. The method comprises the steps of: firstly parsing a DST file (embroidery file) into an image file, selecting cutting units from the image file, and extracting the information of the cutting units to obtain the inside parameter of the unit; and carrying out correlated processing according to the image of cut sample obtained by camera shooting, matching the obtained cutting unit information with the processed sample, finally determining the cutting line position, generating a PLT file and cutting by a cutter. Different from other laser cutting methods based on machine vision, the method can finish cutting of the whole embroidery sample just by once shooting; and the method has the characteristics of high working efficiency and low unqualified rate, and has very strong cutting capability on the complicated embroidery sample.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com